Patents

Literature

269 results about "Indirect Method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A manipulative technique where the restrictive barrier is disengaged and the dysfunctional body part is moved away from the restrictive barrier until tissue tension is equal in one or all planes and directions.

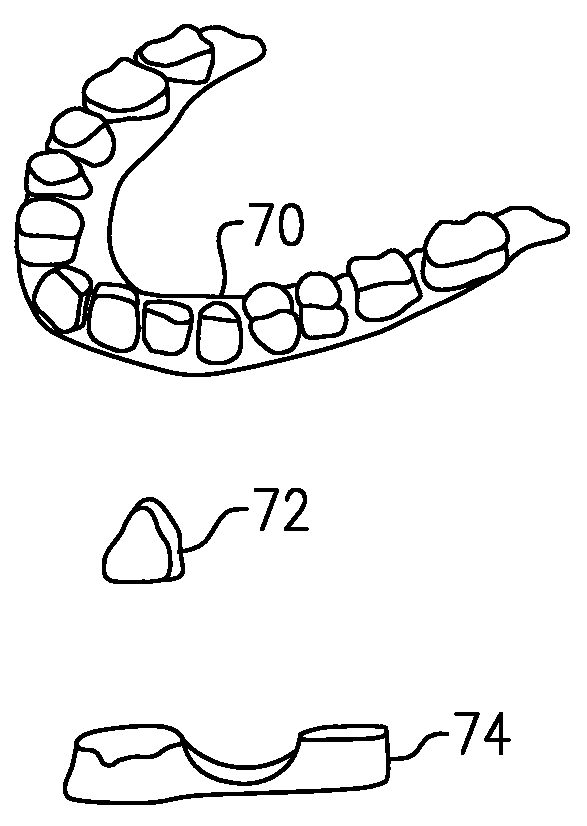

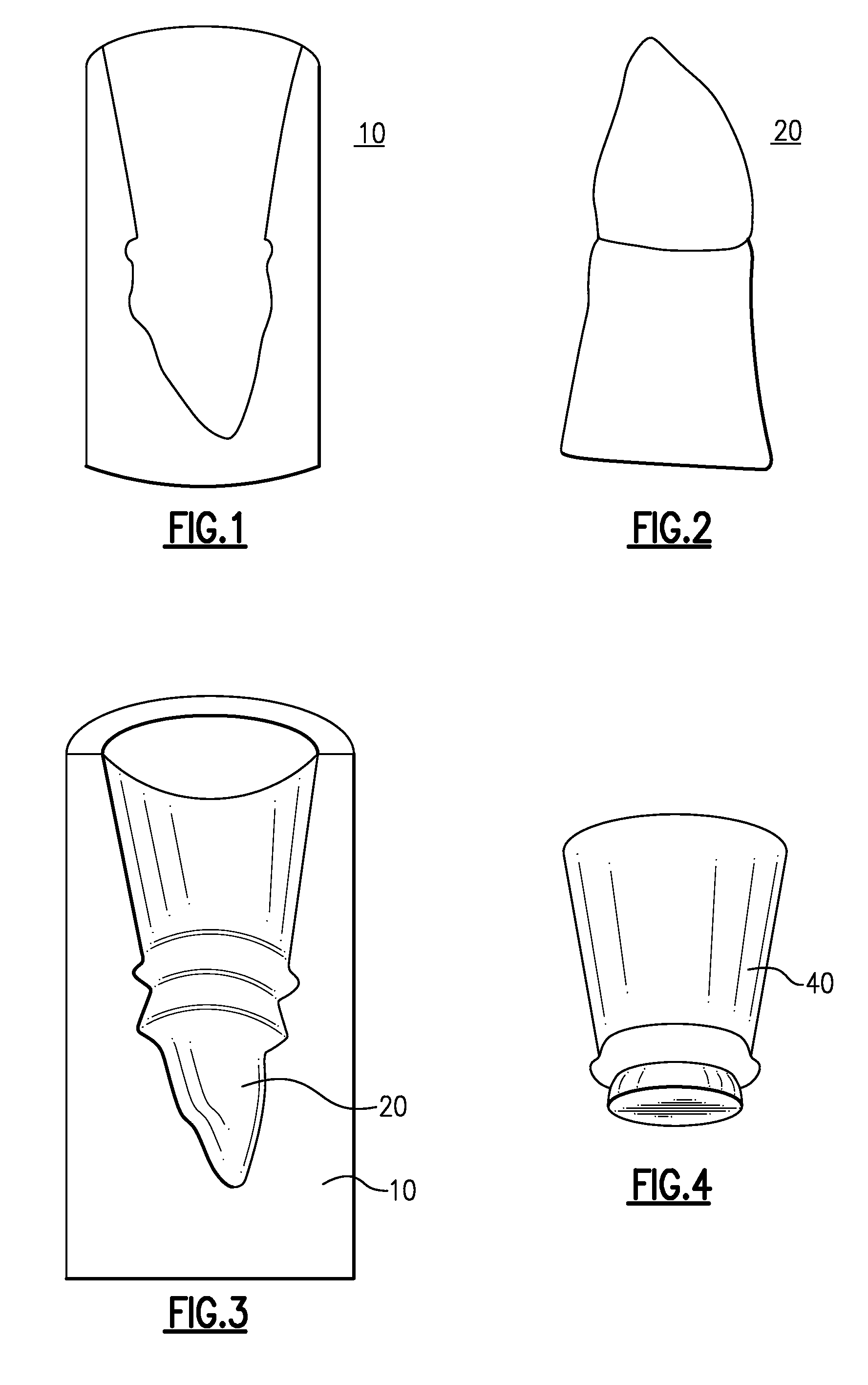

Solid free-form fabrication methods for the production of dental restorations

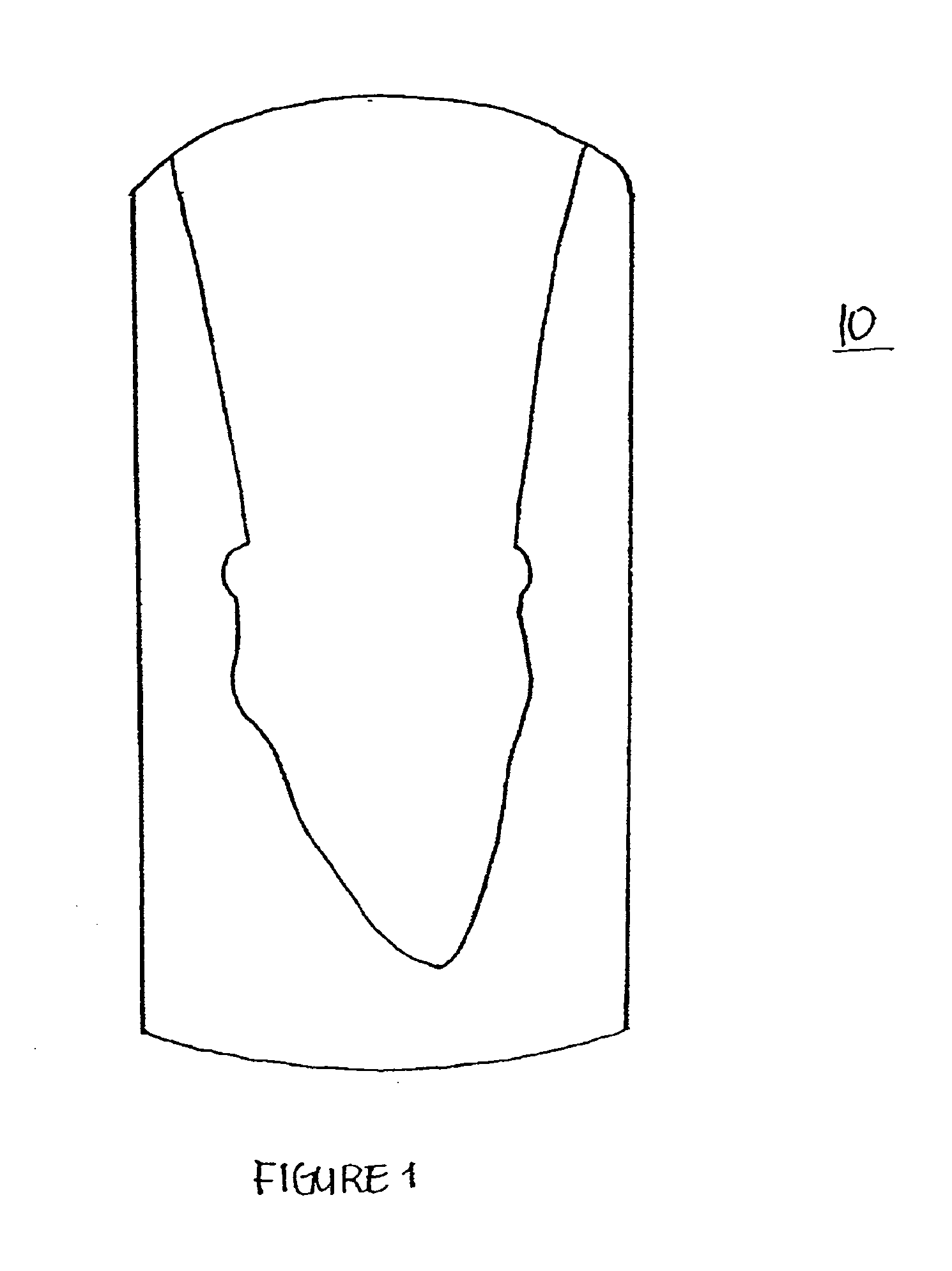

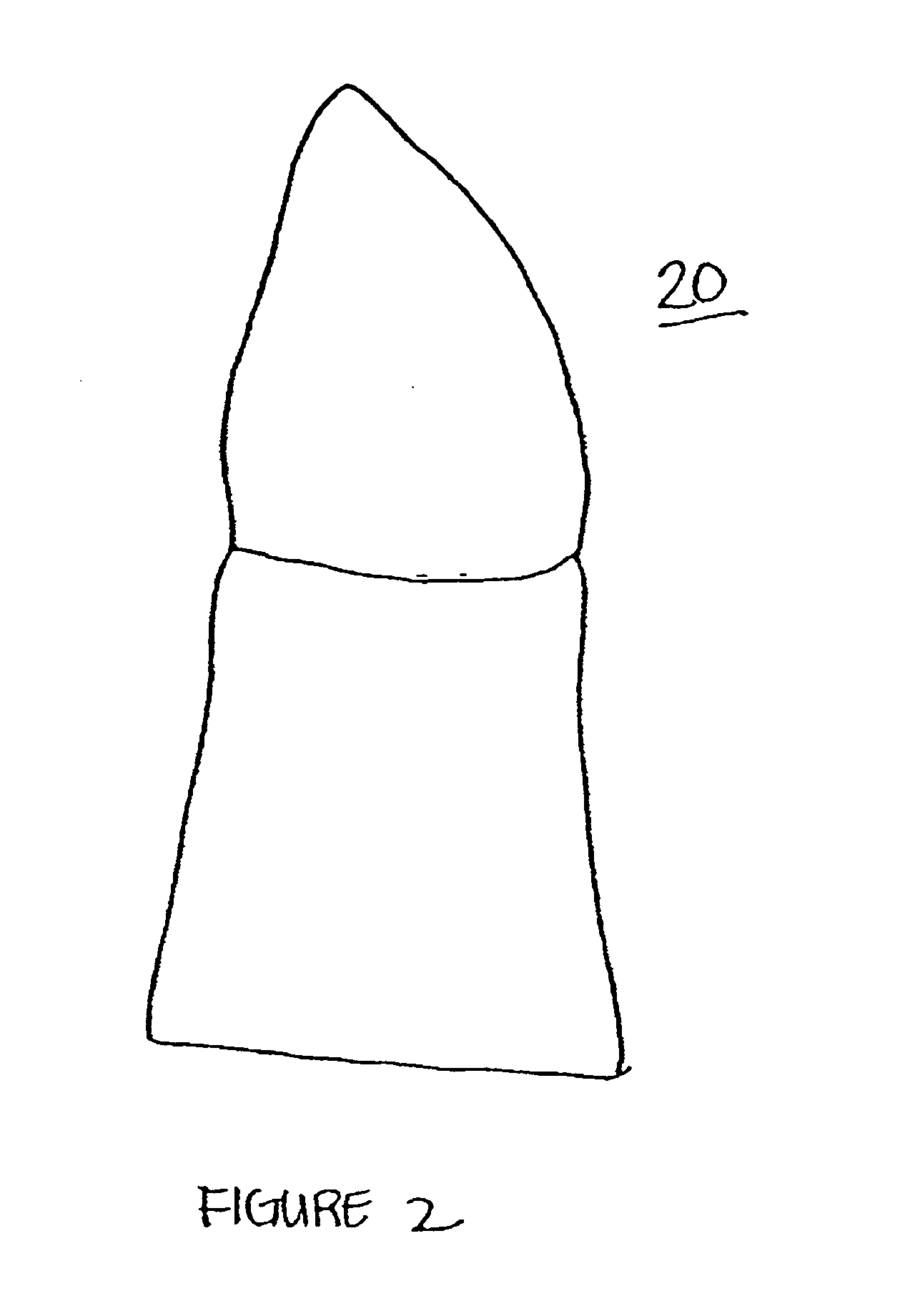

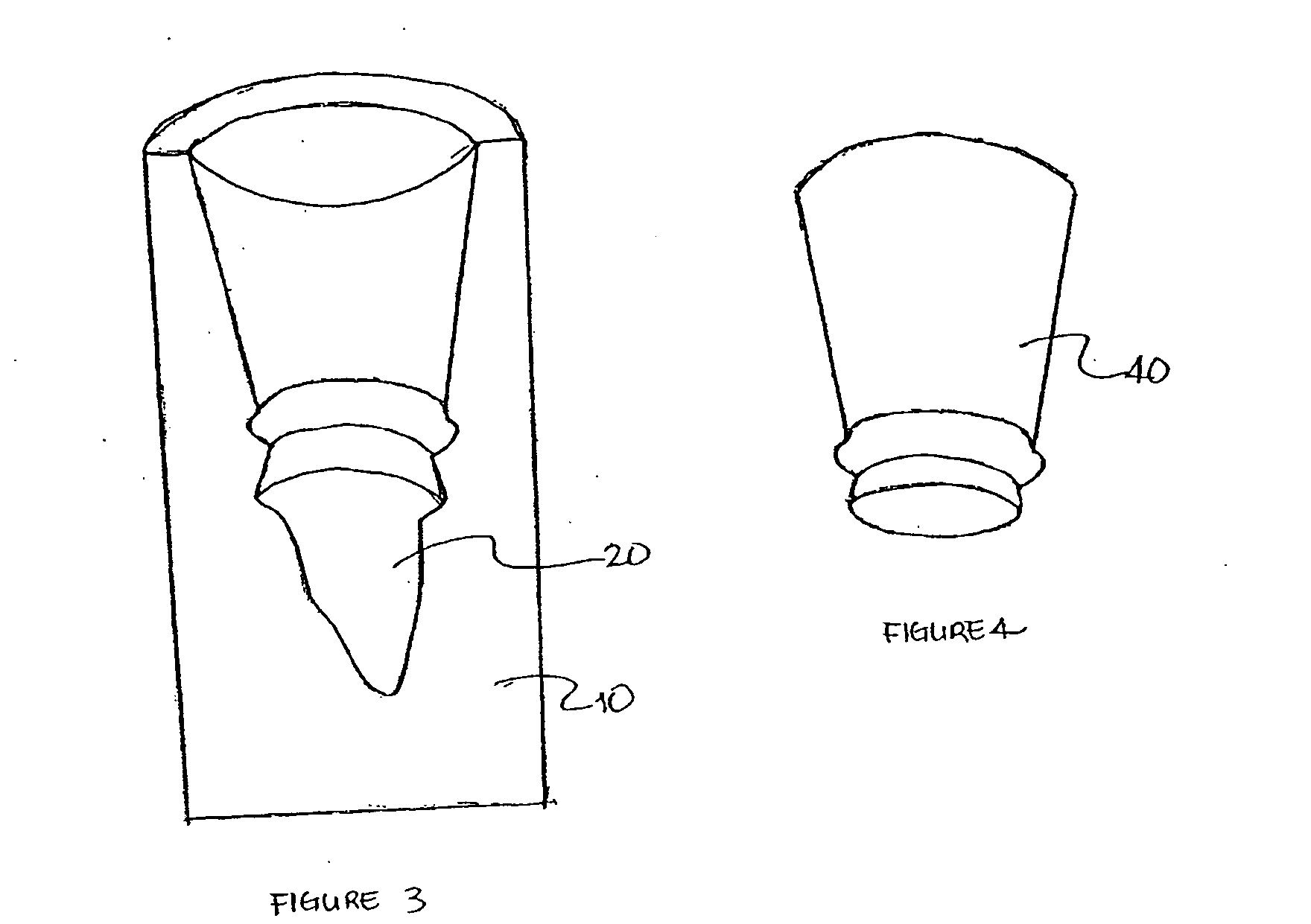

InactiveUS20050023710A1Improve bindingImpression capsCeramic shaping apparatusPolymer scienceFree form

Solid free form fabrication techniques can be utilized indirectly to manufacture substrates, dies, models, near-net shapes, shells, and wax-ups that are then used in the manufacture of dental articles. Digital light processing is the most preferred indirect method for the production of substrates. After the substrates are produced, various coating or deposition techniques such as gel casting, slip casting, slurry casting, pressure infiltration, dipping, colloidal spray deposition or electrophoretic deposition are used to manufacture the dental article.

Owner:IVOCLAR VIVADENT AG

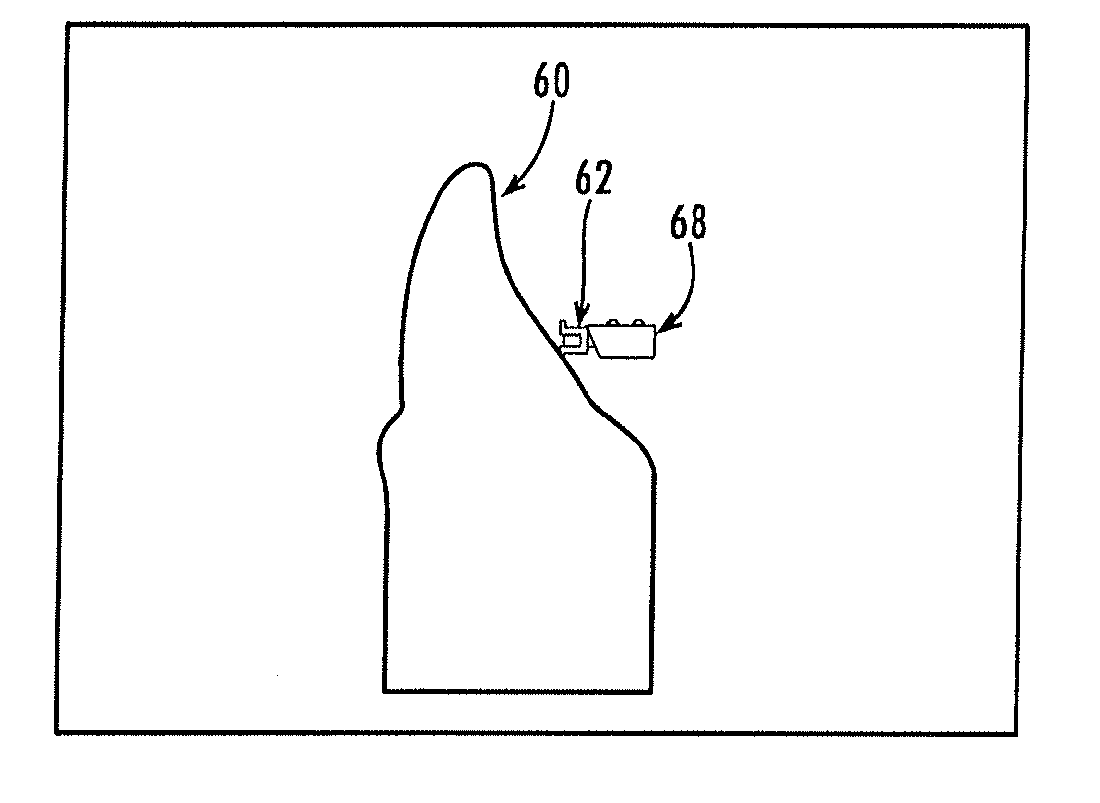

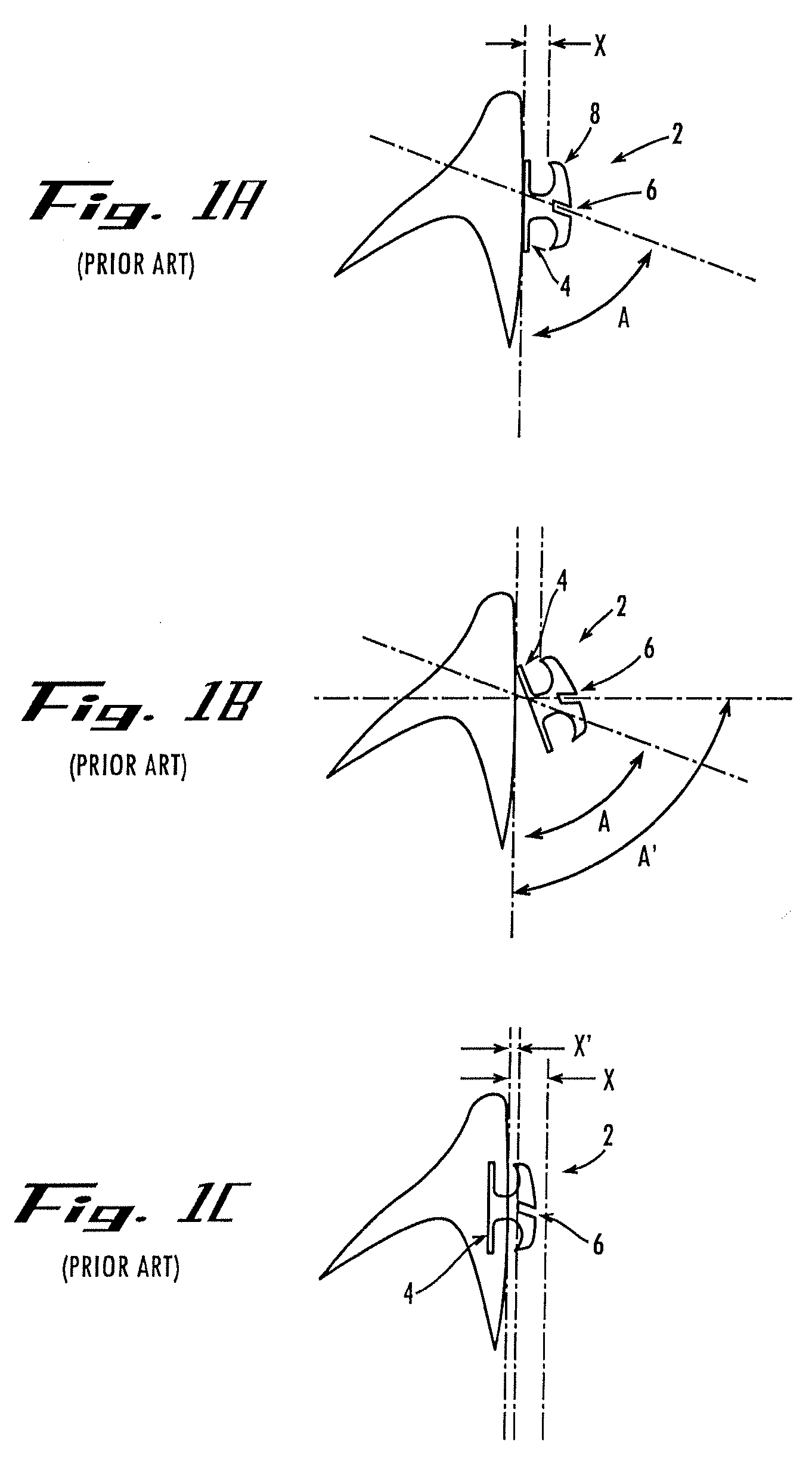

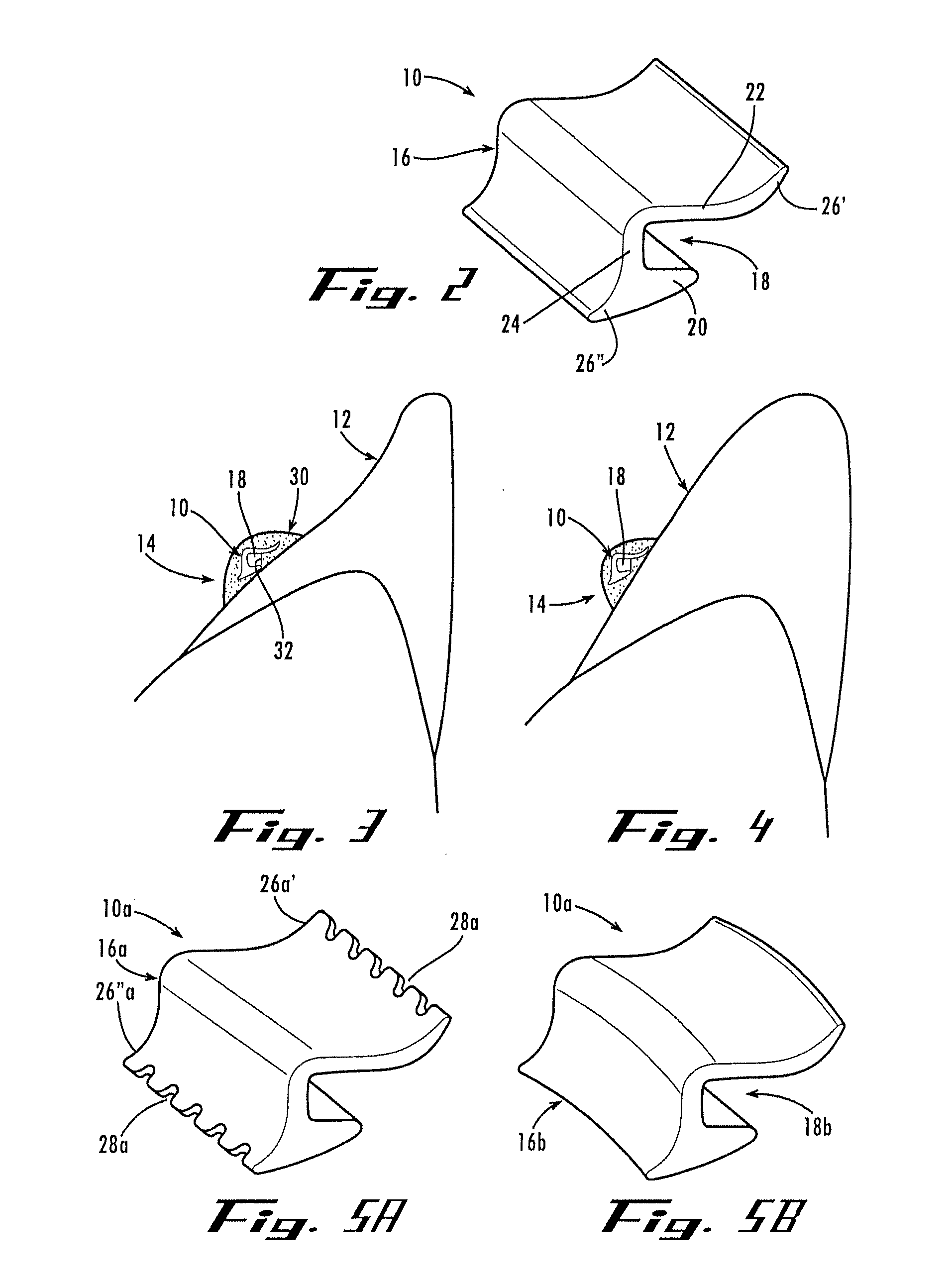

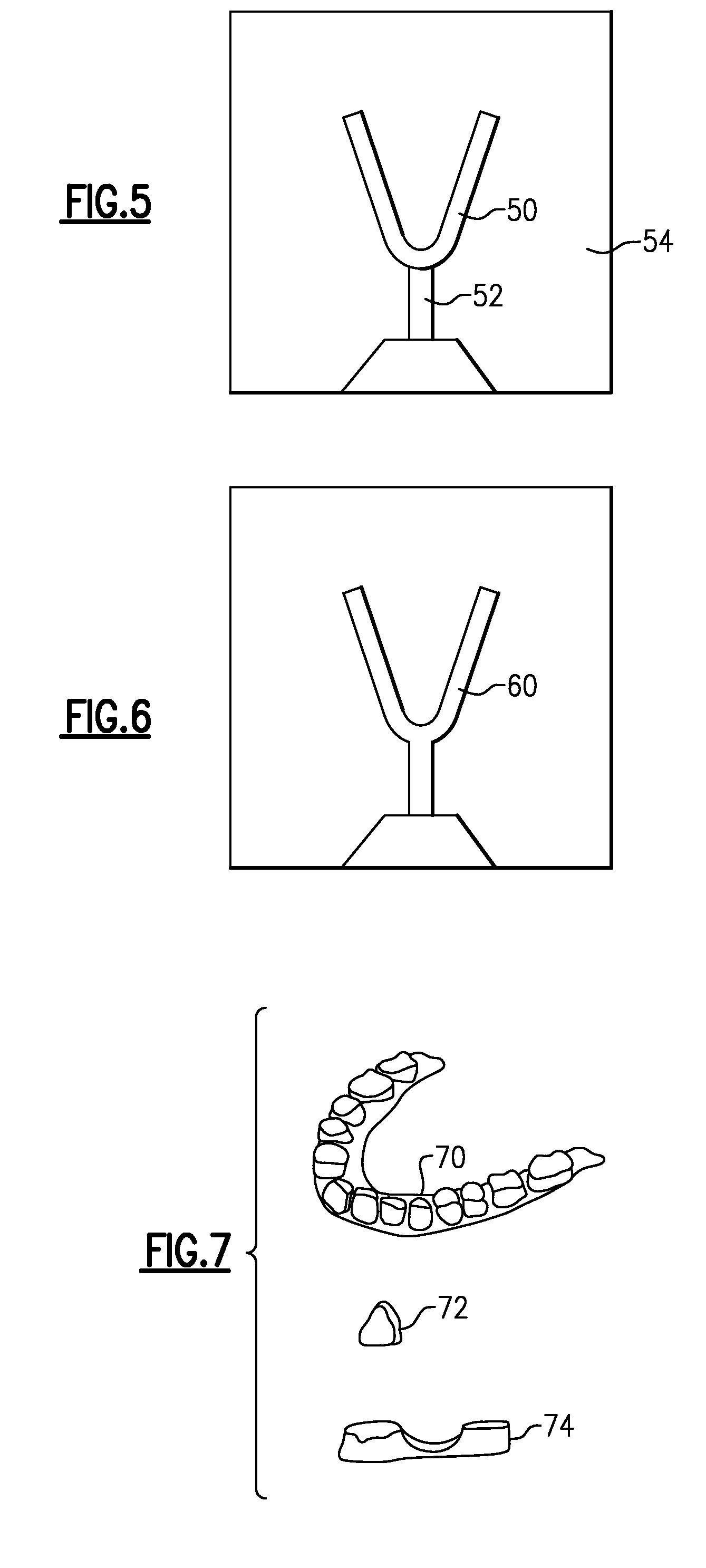

Orthodontic bracket and method of attaching orthodontic brackets to teeth

ActiveUS20070087302A1Minimal size profileEnhance patient comfortAdditive manufacturing apparatusBracketsIndirect MethodPhysical model

An orthodontic bracket having an opening for receiving a wire, but without a base to create a lever arm when the bracket is oriented in free space at a customized angle relative to a tooth surface. The bracket can be embedded into or encapsulated by an adhesive that is bonded to the tooth. A clip is provided for holding the bracket in position and occluding the opening while the adhesive is applied. And indirect methods of attaching the brackets to teeth are provided wherein the brackets can be attached to the lingual side of the teeth in a low-profile arrangement. A first method includes the step of positioning the brackets on a physical model of the teeth by using a positioning machine. A second method includes the step of positioning virtual brackets on a virtual model of the teeth using software, then generating a physical transfer try using rapid prototyping.

Owner:REISING BRIAN C

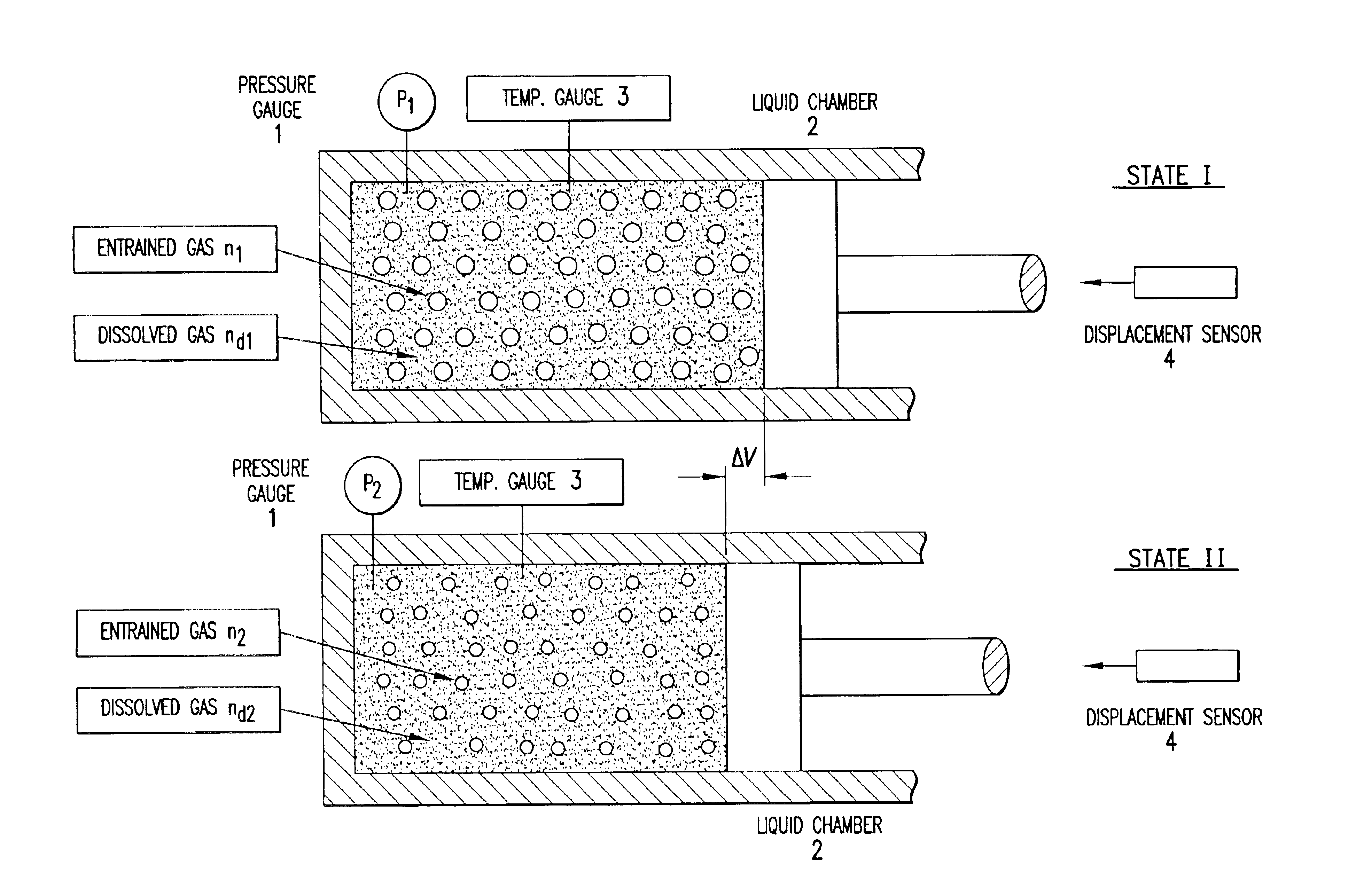

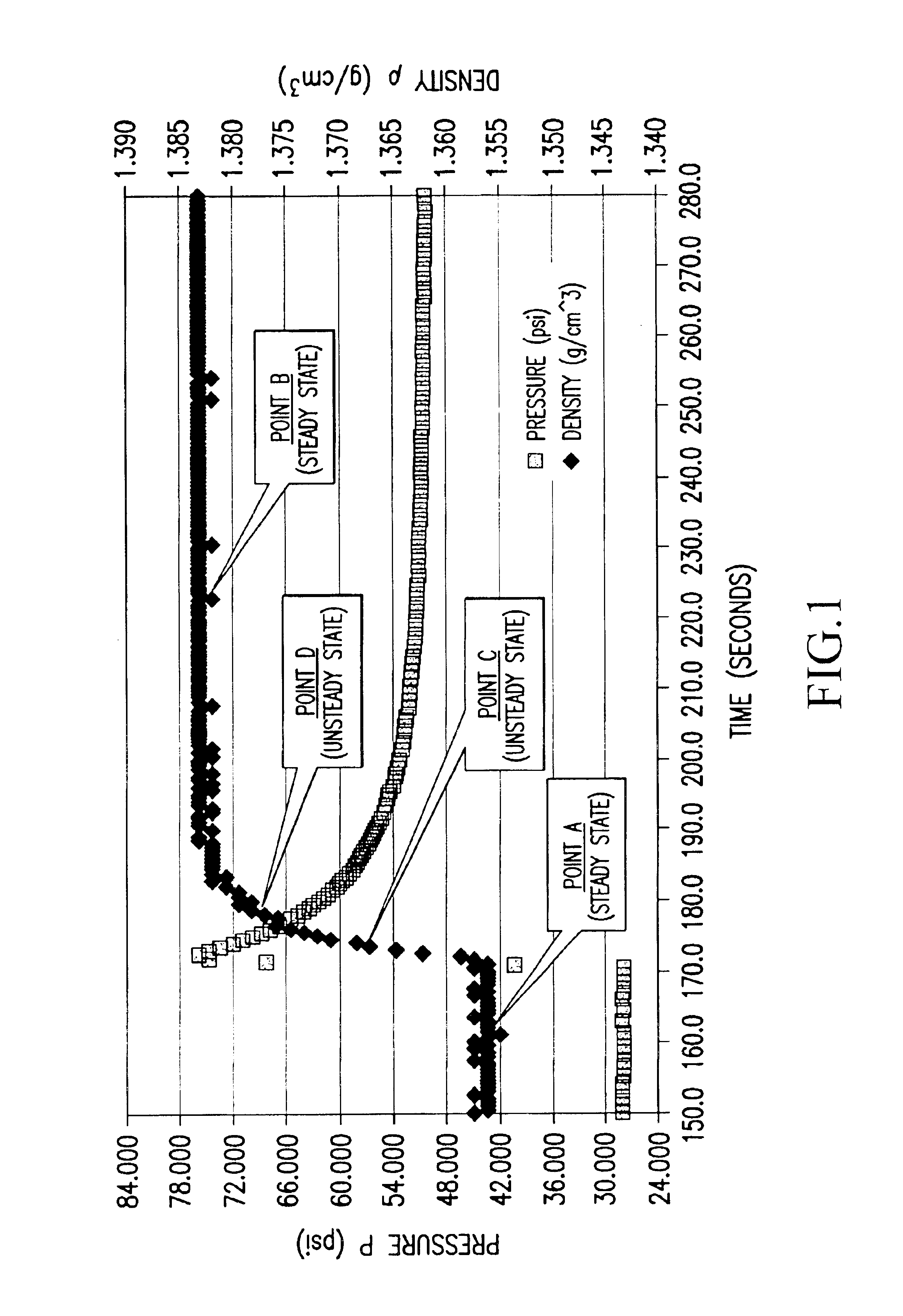

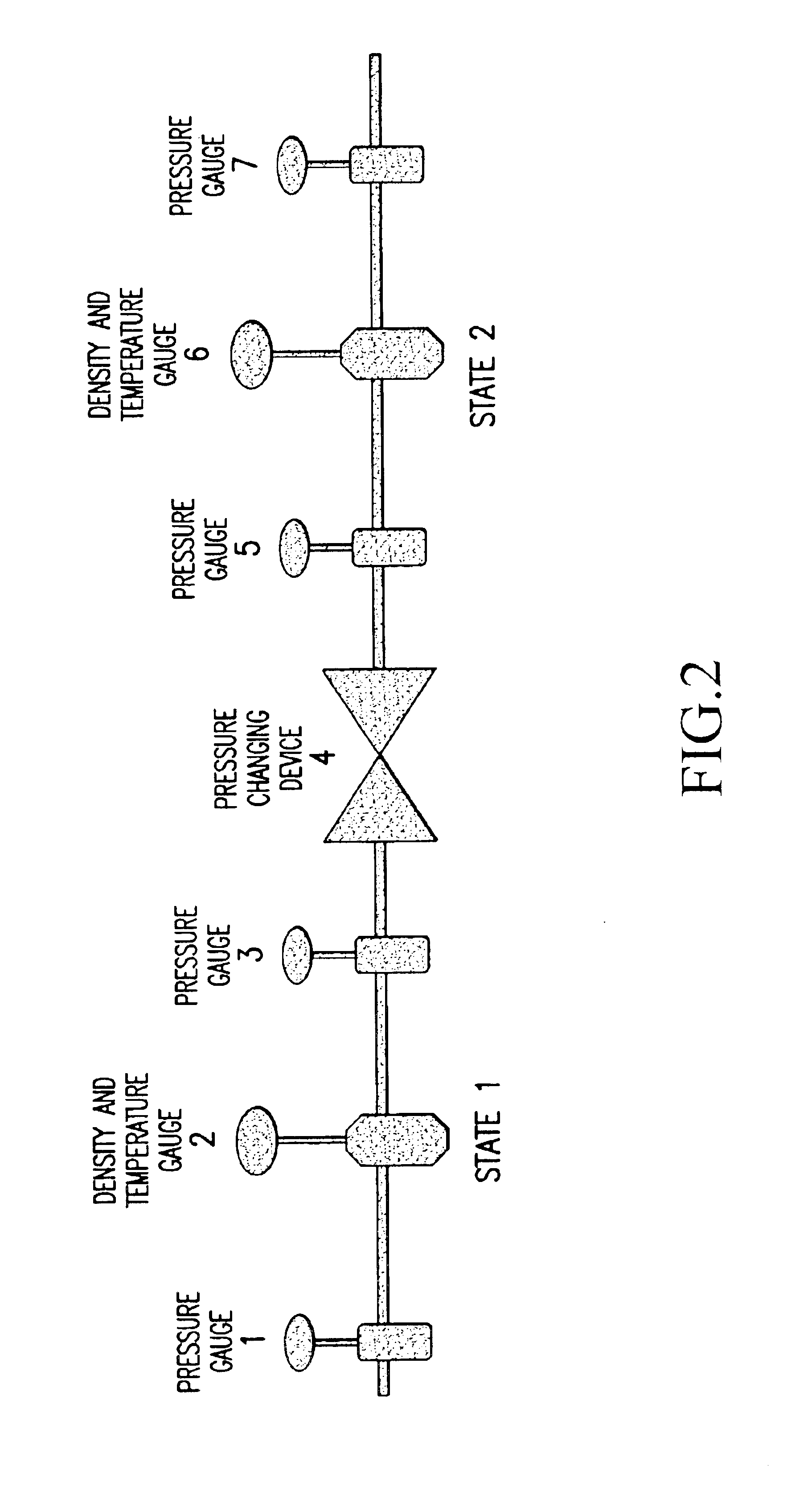

Real time determination of gas solubility and related parameters in manufacturing processes

InactiveUS6847898B1Easy to controlEasy to handleTesting beveragesSpecific gravity by measuring pressure differencesSolubilityApparent density

Methods and apparatuses for determining entrained and / or dissolved gas content of gas-liquid mixtures. Data generated is used to control the True (air-free) or Apparent (air-containing) Density or Entrained Air content of liquids within optimum ranges, e.g. in paper coating processes and in the manufacture of food products, personal care products, pharmaceutical products, paints, petroleum blends, etc. For example, an indirect method of continuously determining the amount of gas entrained in a liquid, by: continuously measuring the temperature, flow rate, and apparent density of the mixture at two different pressure states, and calculating the volume percentage of the gas in the liquid by using equation (28) x%=VsVs+V(28)wherein V is the volume of the gas-free liquid calculated by equation (23) V=1ρ1-[P2P2-P1(1ρ1-1ρ2)-RTP2-P1g(Δ PQa)](23)in which P1 and P2 are two different ambient pressures and ΔP=P2−P1, ρ1 and ρ2 are apparent densities of the liquid sample measured at P1 and P2, respectively, R is the constant of the Ideal Gas Law, T is the liquid temperature, Q is the flow rate, g(ΔP / Qa) is a function for determining the amount of gas being dissolved between P2 and P1, and Vs is determined by equation (27) Vs=TsTP1P2Ps(P2-P1)(1ρ1-1ρ2)-RTsPs(P1P2-P1g(Δ PQa)-g(P1-PsQa)).(27)

Owner:APPVION INC

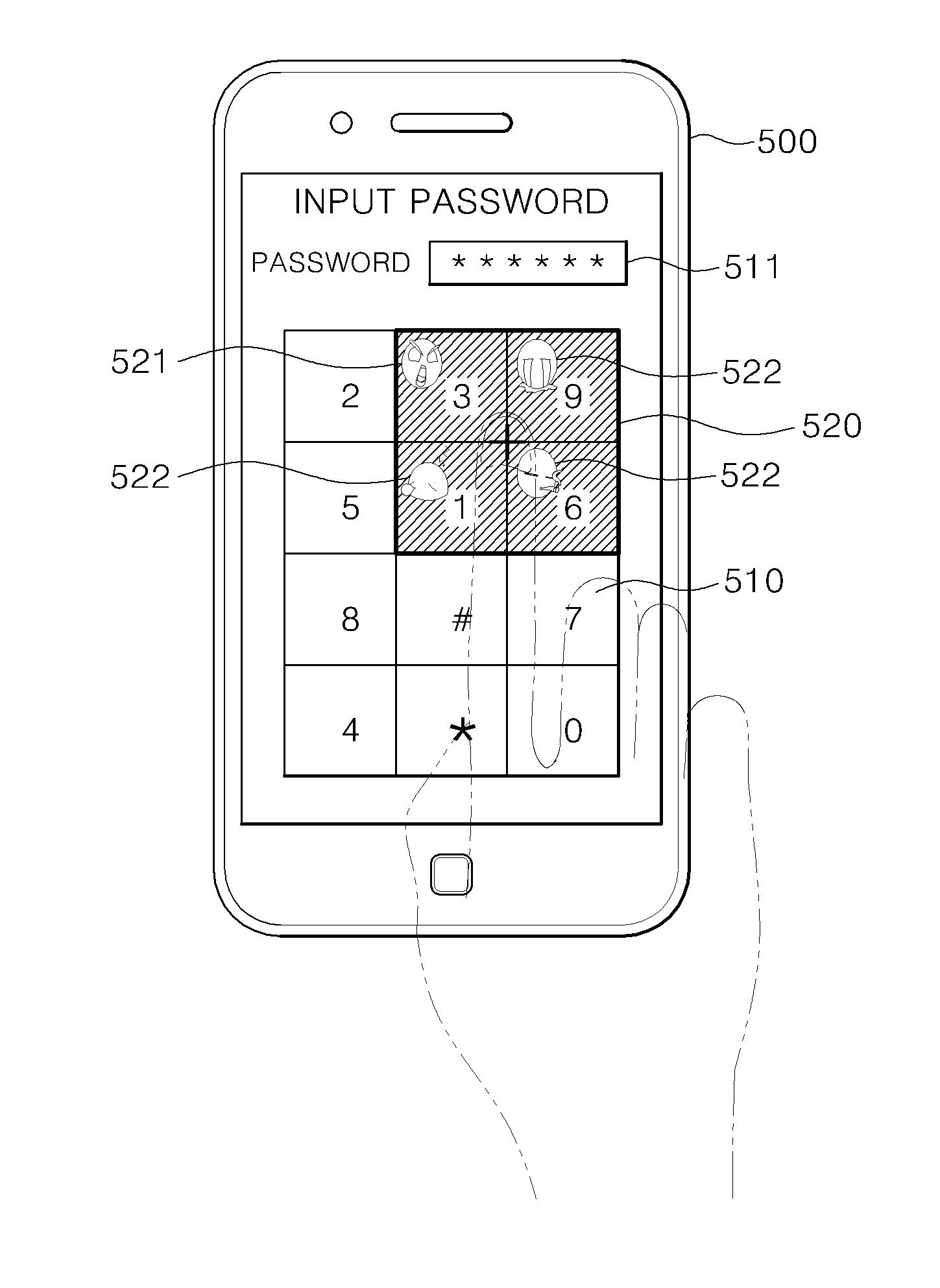

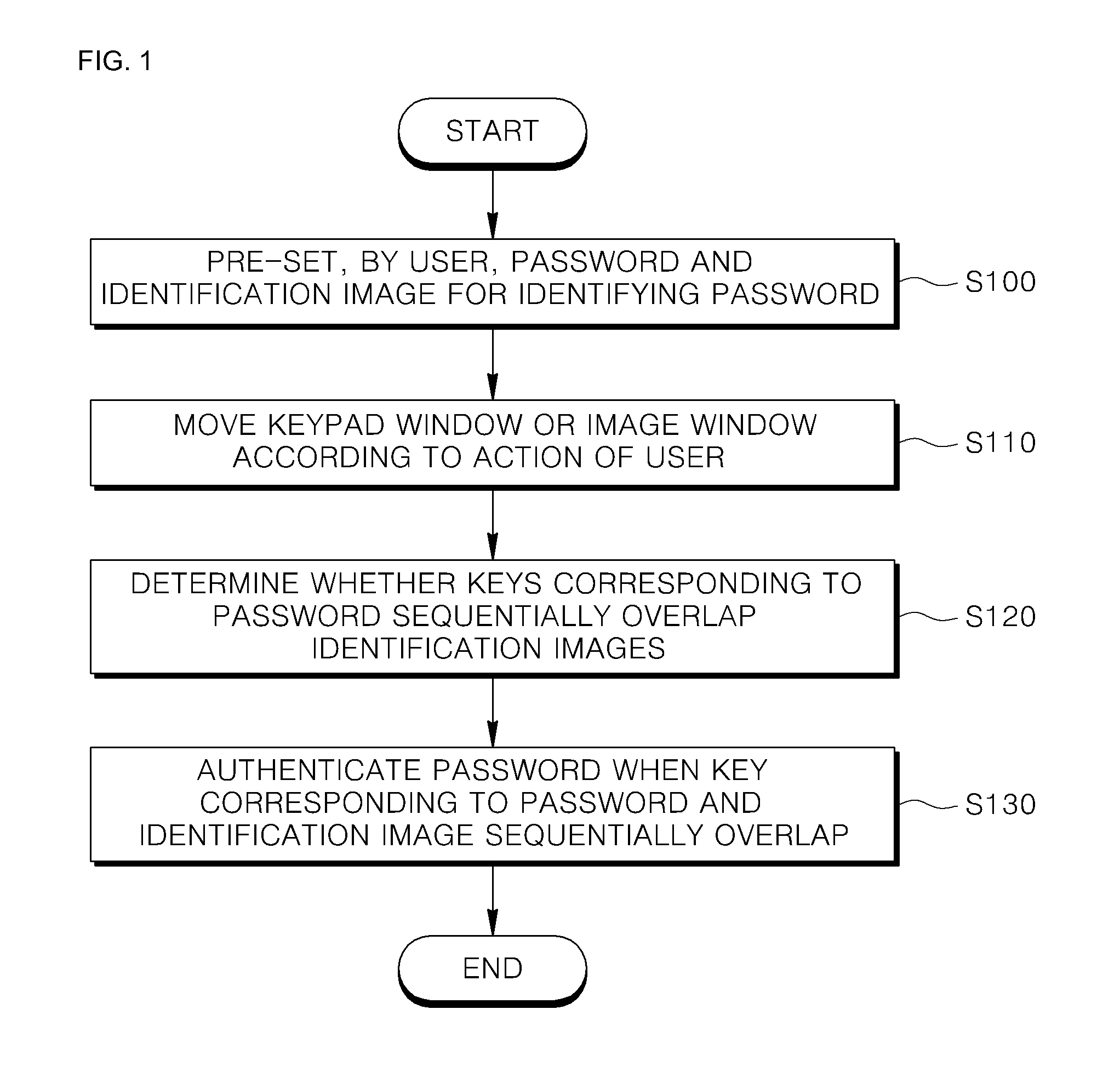

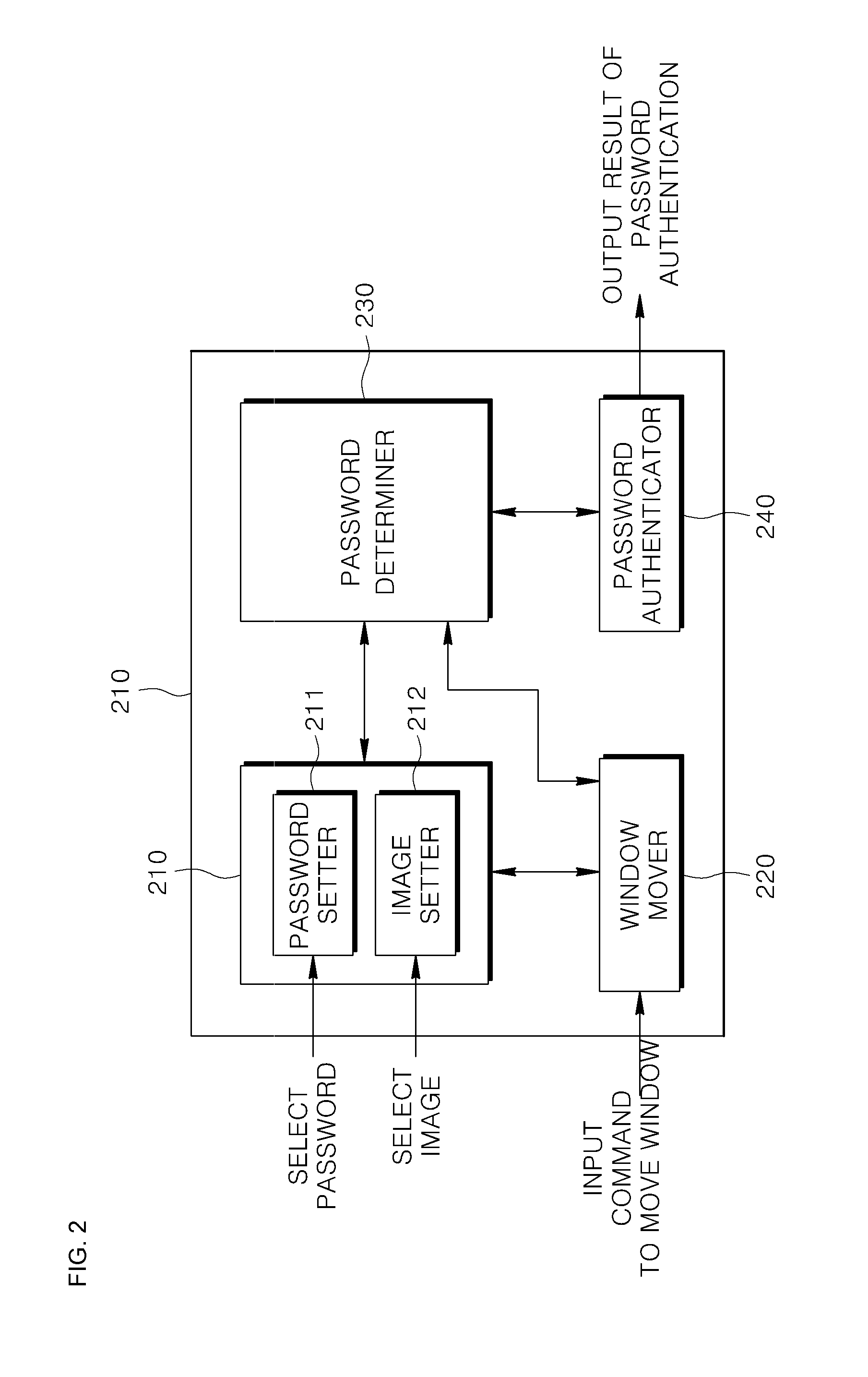

Method and apparatus for authenticating password of user terminal

ActiveUS20140201831A1Digital data processing detailsUser identity/authority verificationIndirect MethodThird person

Provided are method and apparatus for authenticating a password of a user terminal. The method includes: pre-setting, by a user, a password and an identification image for identifying the password; moving a keypad window or an image window realized on a screen of the user terminal according to an action of the user; determining, when a plurality of images included in the image window and a plurality of keys included in the keypad window sequentially overlap with each other, whether a plurality of keys and the identification image corresponding to the password sequentially overlap; and authenticating the password when the plurality of keys and the identification image corresponding to the password sequentially overlap. Accordingly, password information may be protected from a third person observation as the user inputs a pre-set password in an indirect method without having to directly input the pre-set password through an authentication interface.

Owner:FOUND OF SOONGSIL UNIV IND COOP

Test method of drill hole gas extraction effective radius

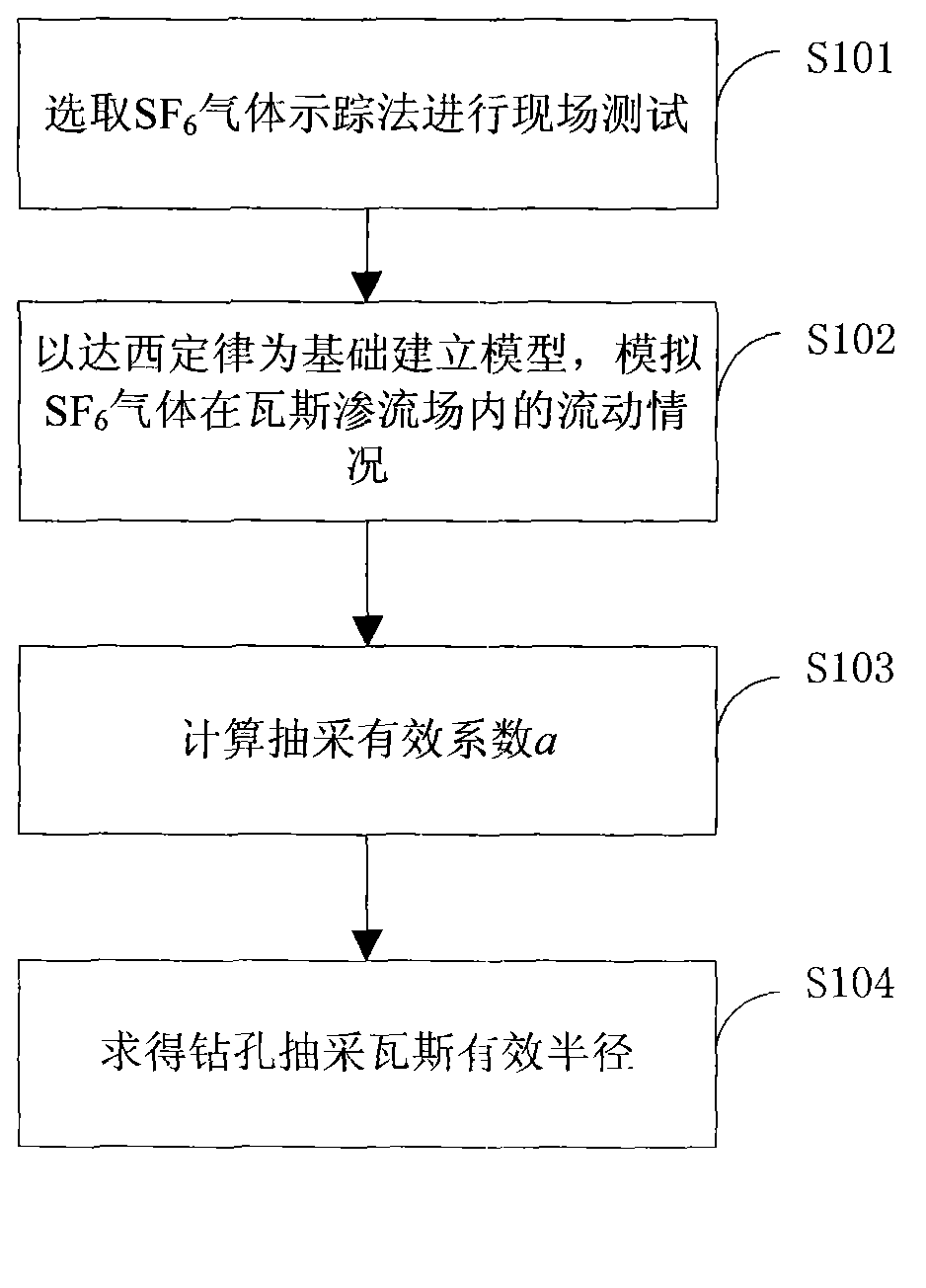

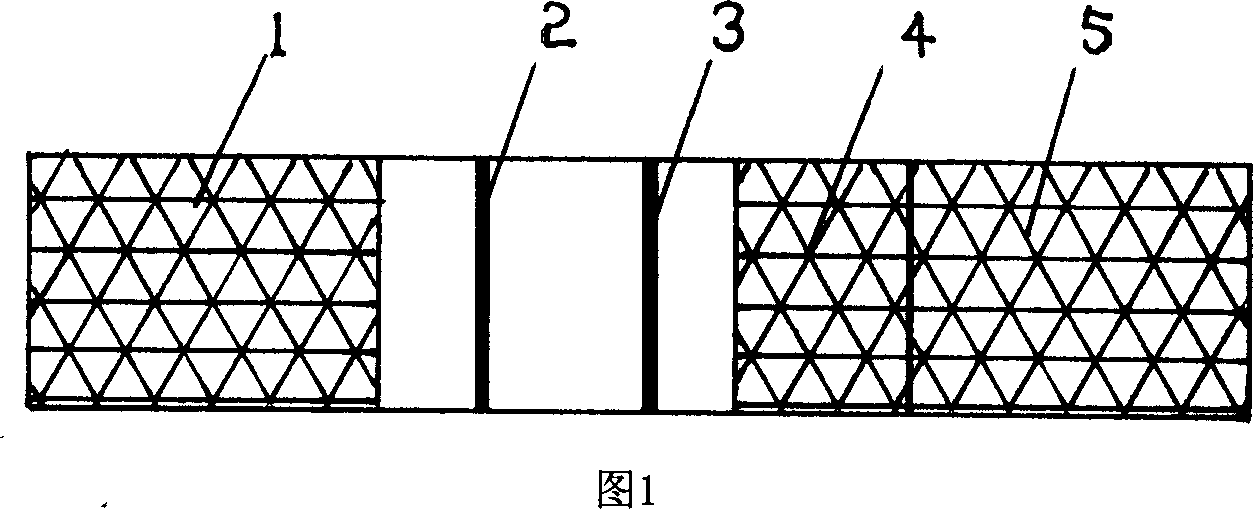

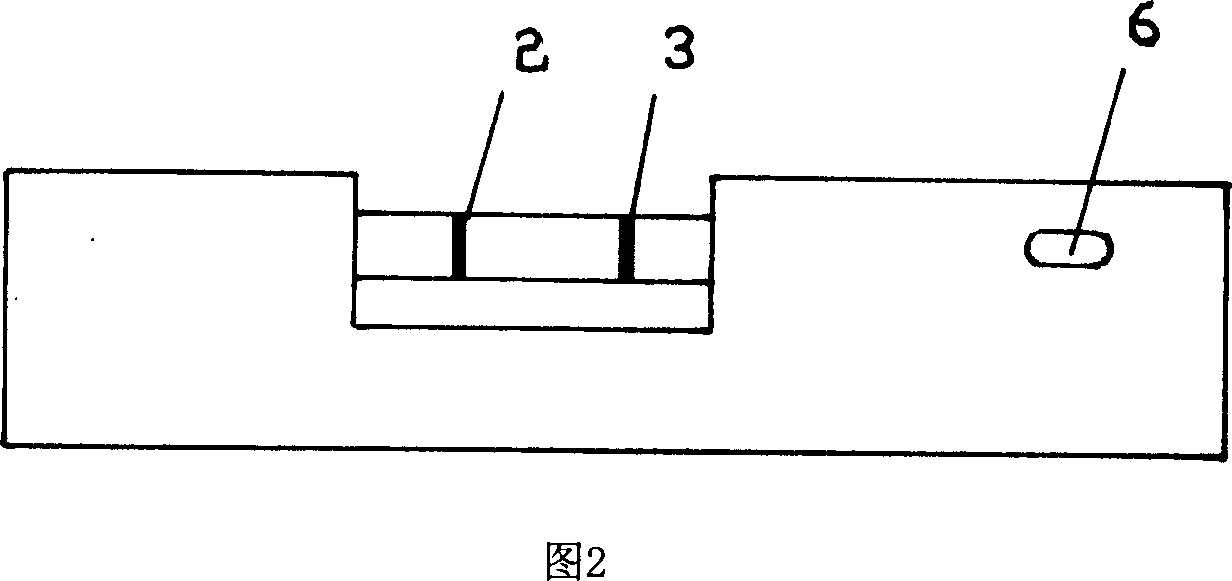

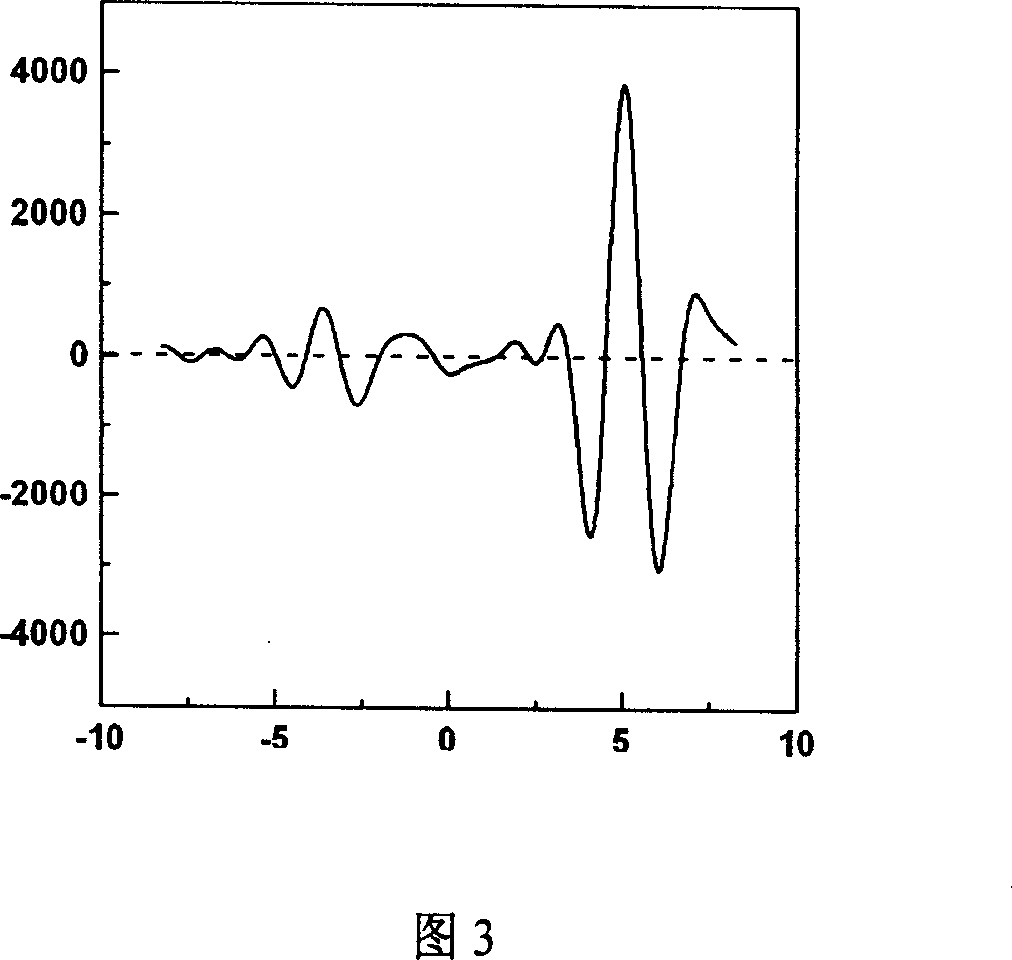

The invention discloses a test method of a drill hole gas extraction effective radius. The test method of the drill hole gas extraction effective radius comprises the following steps: selecting a sulfur hexafluoride (SF6) gas trace method to conduct spot test, under the condition of testing different pitches, sampling and collecting the SF6 gas required time which is detected by a detection hole, establishing a module at the basis of the Darcy law based on the occurrence of coal seam condition of the detecting location, simulating the flowing condition of the SF6 gas in a gas seepage field; calculating and obtaining the required time Ti'of the SF6 gas which moves to a sampling and collecting test hole, calculating a sampling and collecting effective coefficient a; detecting the required time of the SF6 gas based on the sampling and collecting detection hole detected by the SF6 gas trace method, calculating the required time which lowers the relative distance gas pressure below an effective value, and calculating the drill hole gas extraction effective radius based on power function relation between drill hole sampling and collecting gas effective extraction effective radius r (m) and the sampling and collecting time t (d). The test method of the drill hole gas extraction effective radius adopts combination of a direct method and an indirect method, and solves the problems that a plurality of defects exist by using the direct method to detect a drill hole gas extraction radius and extraction effective index is difficult to ascertain.

Owner:HENAN POLYTECHNIC UNIV

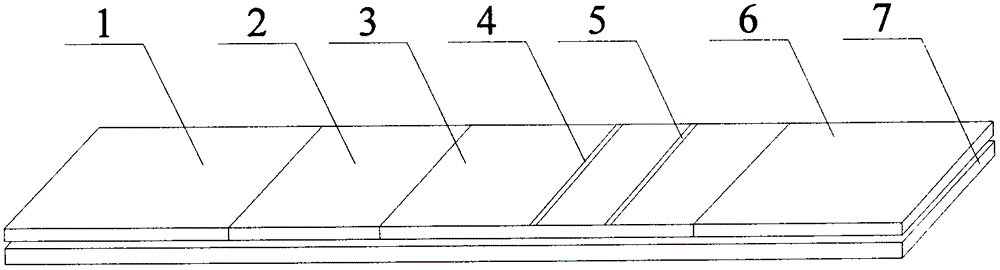

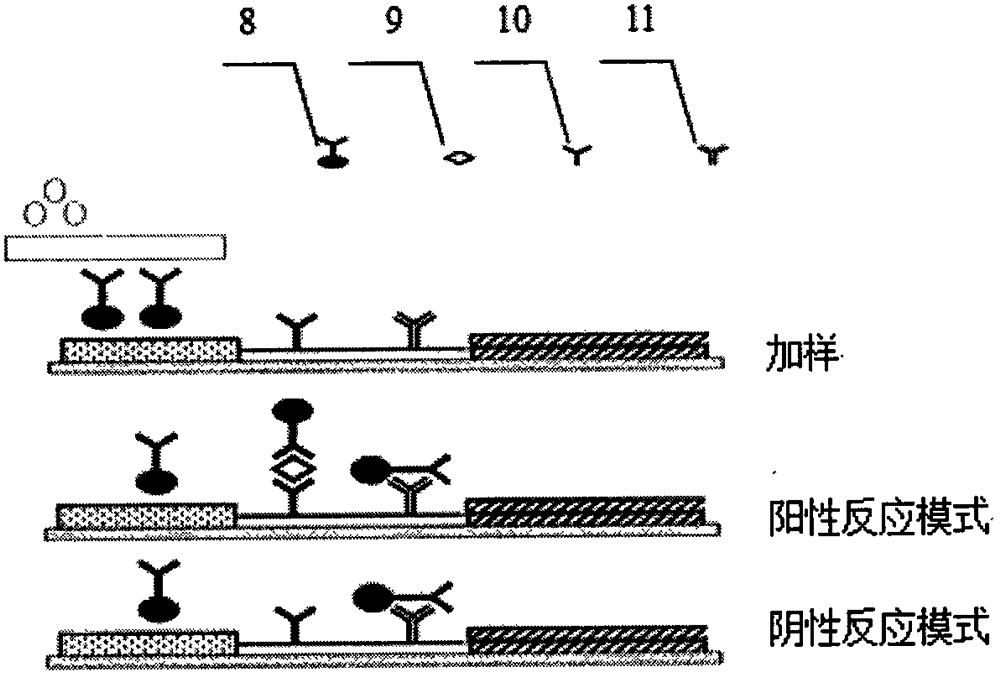

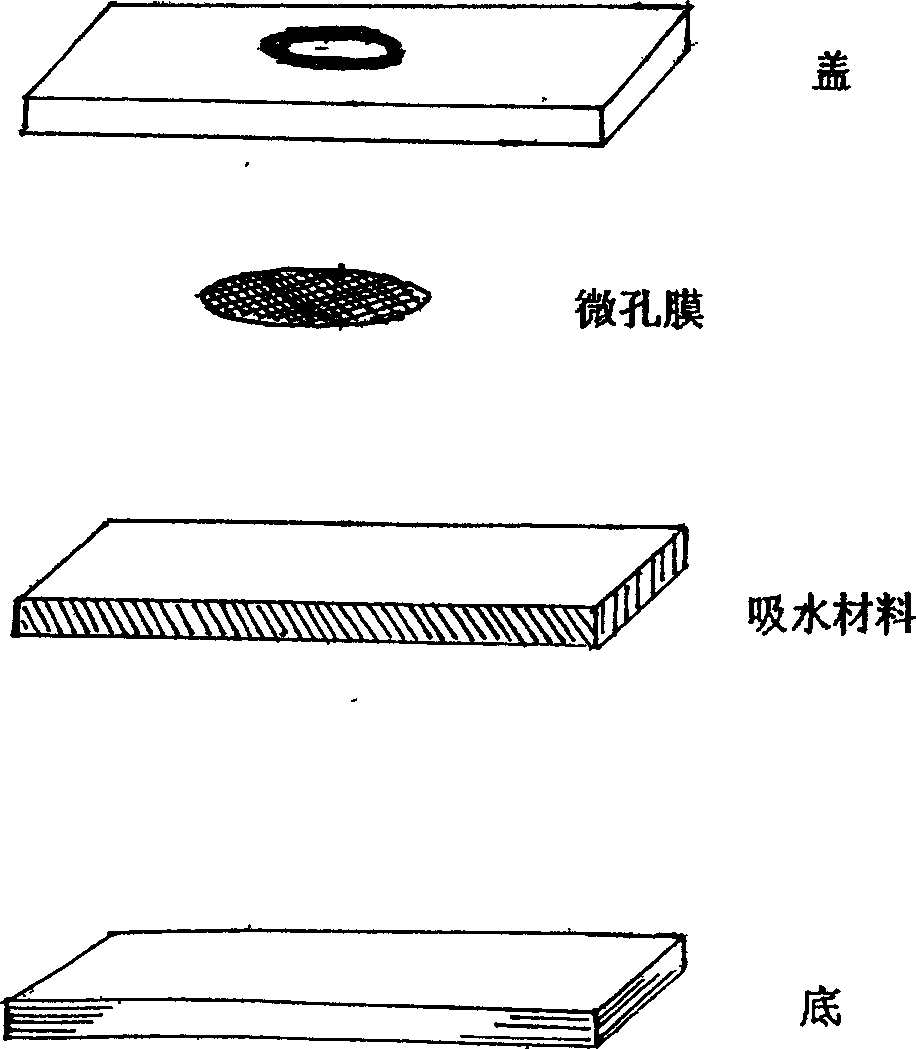

Immuno magnetic bead and producing method, and method and test plate for detection

An immune bead is made up of the magnetic carrier micro ball which combines at least one immune matching base. The micro ball is composed of the magnetic nm particle and the high molecular framework material which the core is the metal particle; the out of the core is high molecular framework, the out layer is the functional layer which can combines functional gene of different immune matching base. The manufacture method includes: the bead pretreatment, the bead activation, manufacture of the coupling antibody, closing the antibody with the confining liquid and purifying the immune bead. The detecting method is to detect the different things by the immunological response sandwich, the competition and the indirect method and set the control system on the testing board. The board is made up of the encrusting test paper, the coupling mat, the sample mat, the water suction mat, the coving film and the testing board outside calipers. It has the high sensitivity and accurate quantity; the regent is simple and cost low.

Owner:YANGTZE DELTA REGION INST OF TSINGHUA UNIV ZHEJIANG

Solid Free-Form Fabrication Methods For The Production of Dental Restorations

Solid free form fabrication techniques can be utilized indirectly to manufacture substrates, dies, models, near-net shapes, shells, and wax-ups that are then used in the manufacture of dental articles. Digital light processing is the most preferred indirect method for the production of substrates. After the substrates are produced, various coating or deposition techniques such as gel casting, slip casting, slurry casting, pressure infiltration, dipping, colloidal spray deposition or electrophoretic deposition are used to manufacture the dental article.

Owner:IVOCLAR VIVADENT AG

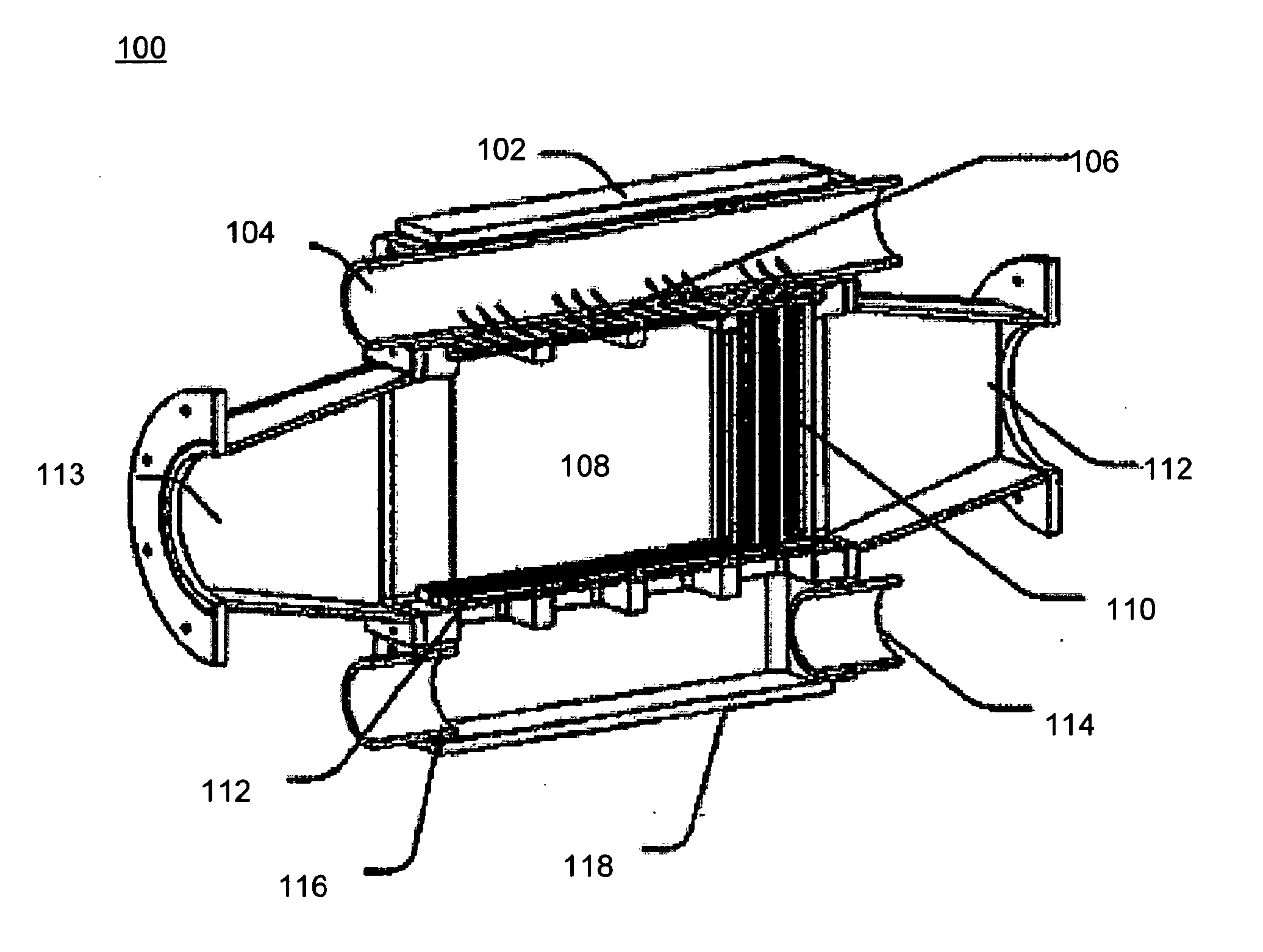

Indirect and direct method of sequestering contaminates

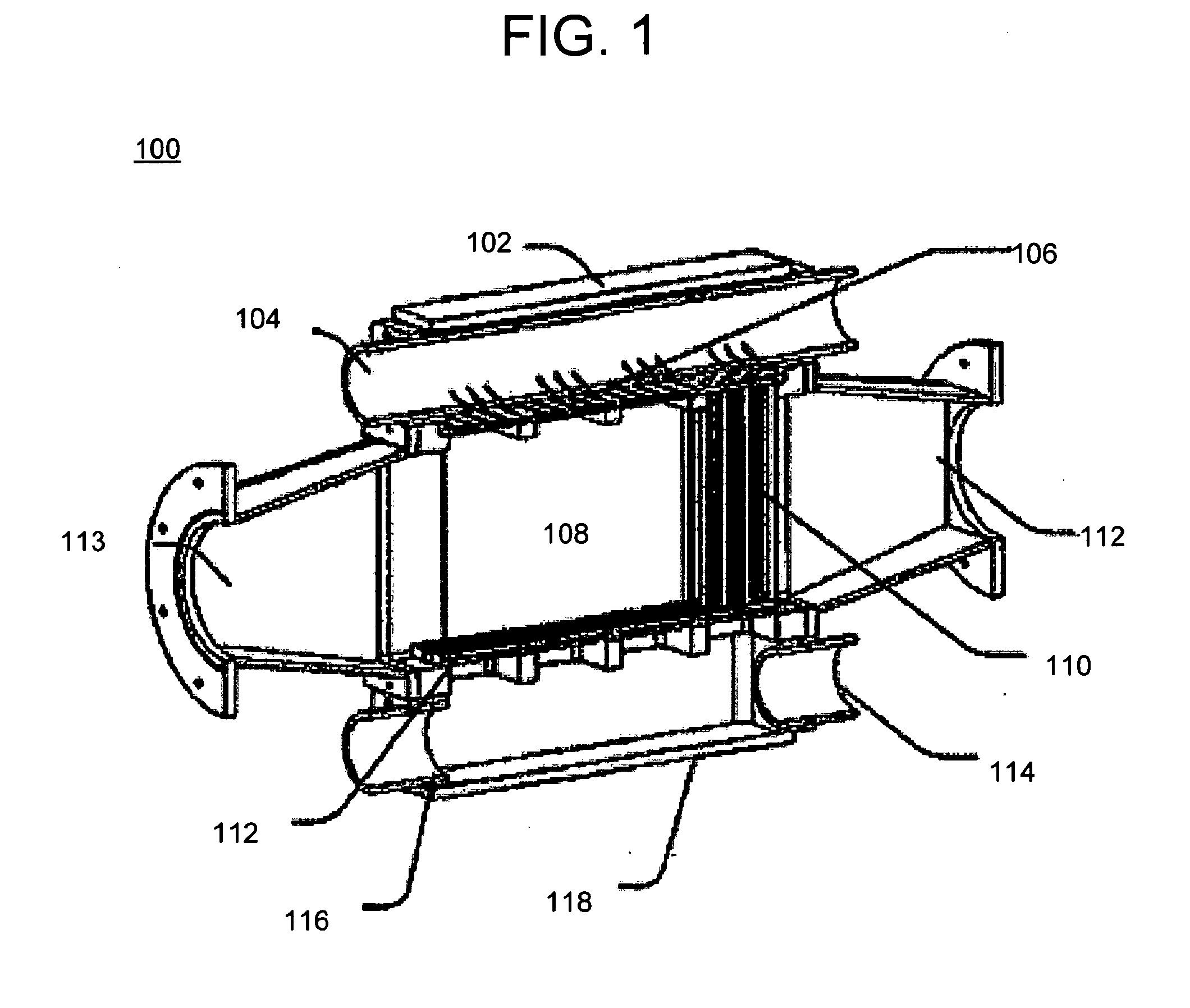

InactiveUS20100092368A1Enhanced mass transferIncrease chanceGas treatmentLaser detailsPerformance enhancementTransfer system

The invention generally relates to a method for sequestration contaminates. More particularly, the invention relates to a significant performance enhancement over existing mineral carbonation processes through the use of a high mass transfer system and an efficient pH swing reaction. More particularly, aspects of the invention are directed to direct and indirect methods of sequestering contaminates.

Owner:NEUMANN SYST GROUP

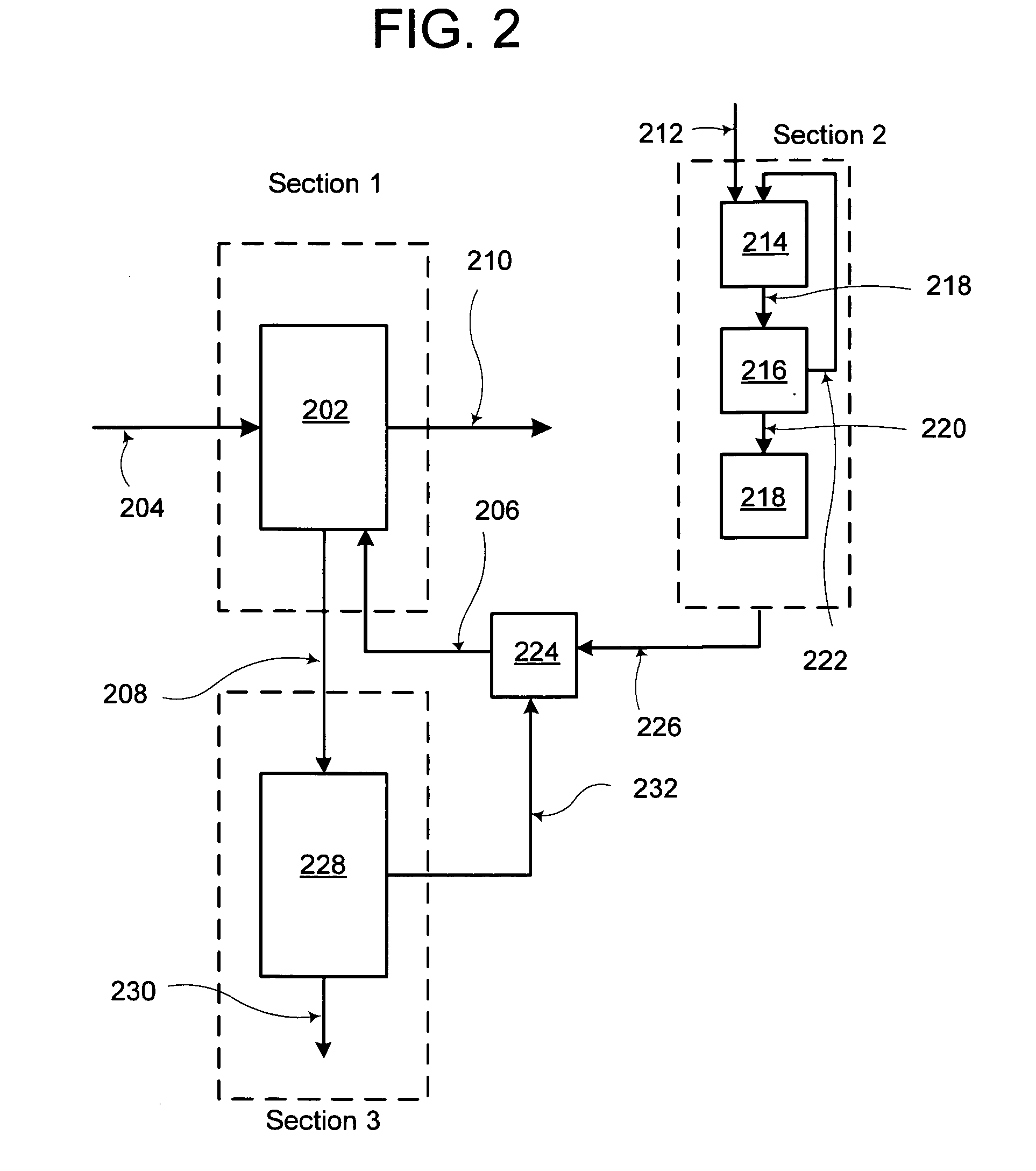

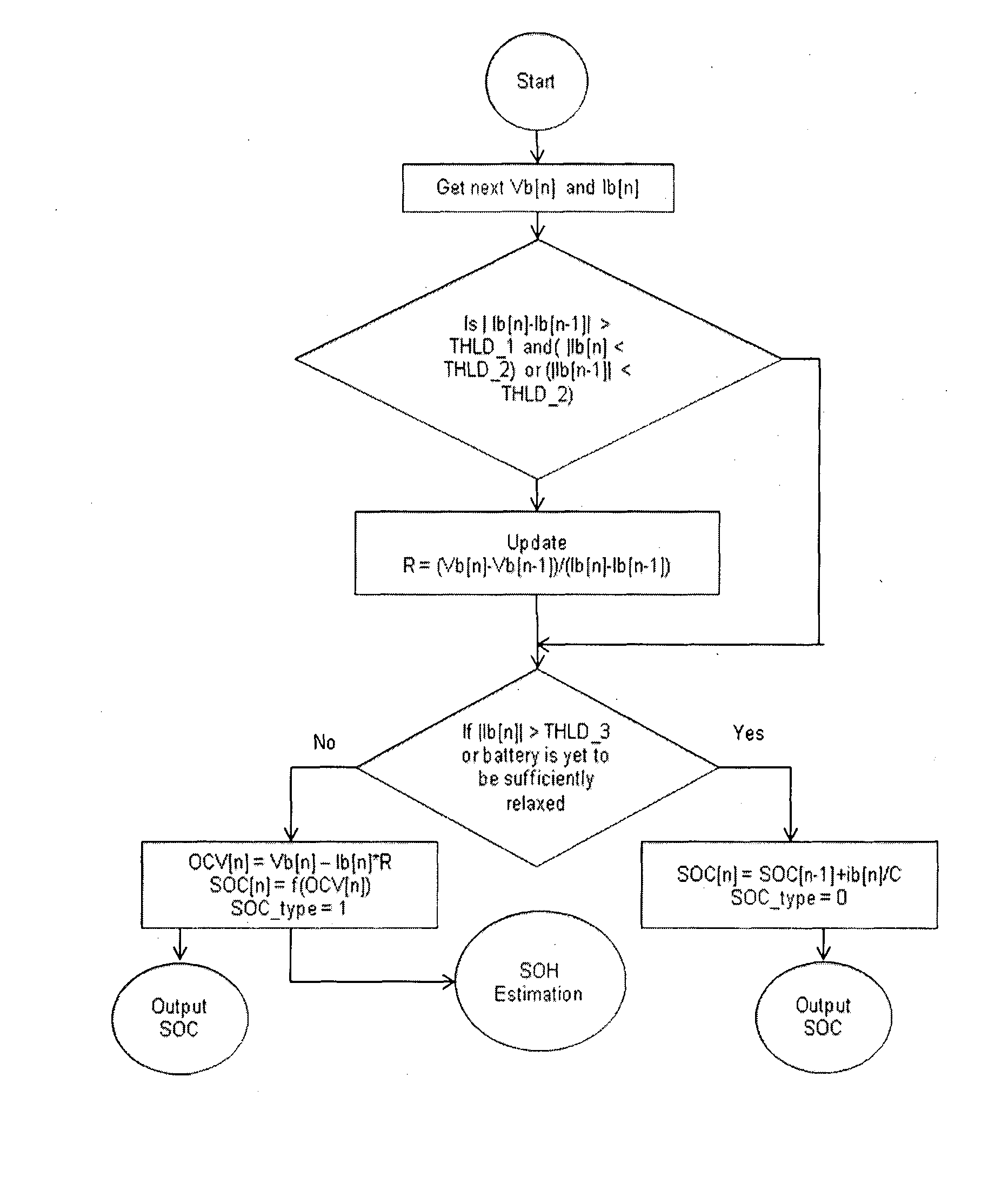

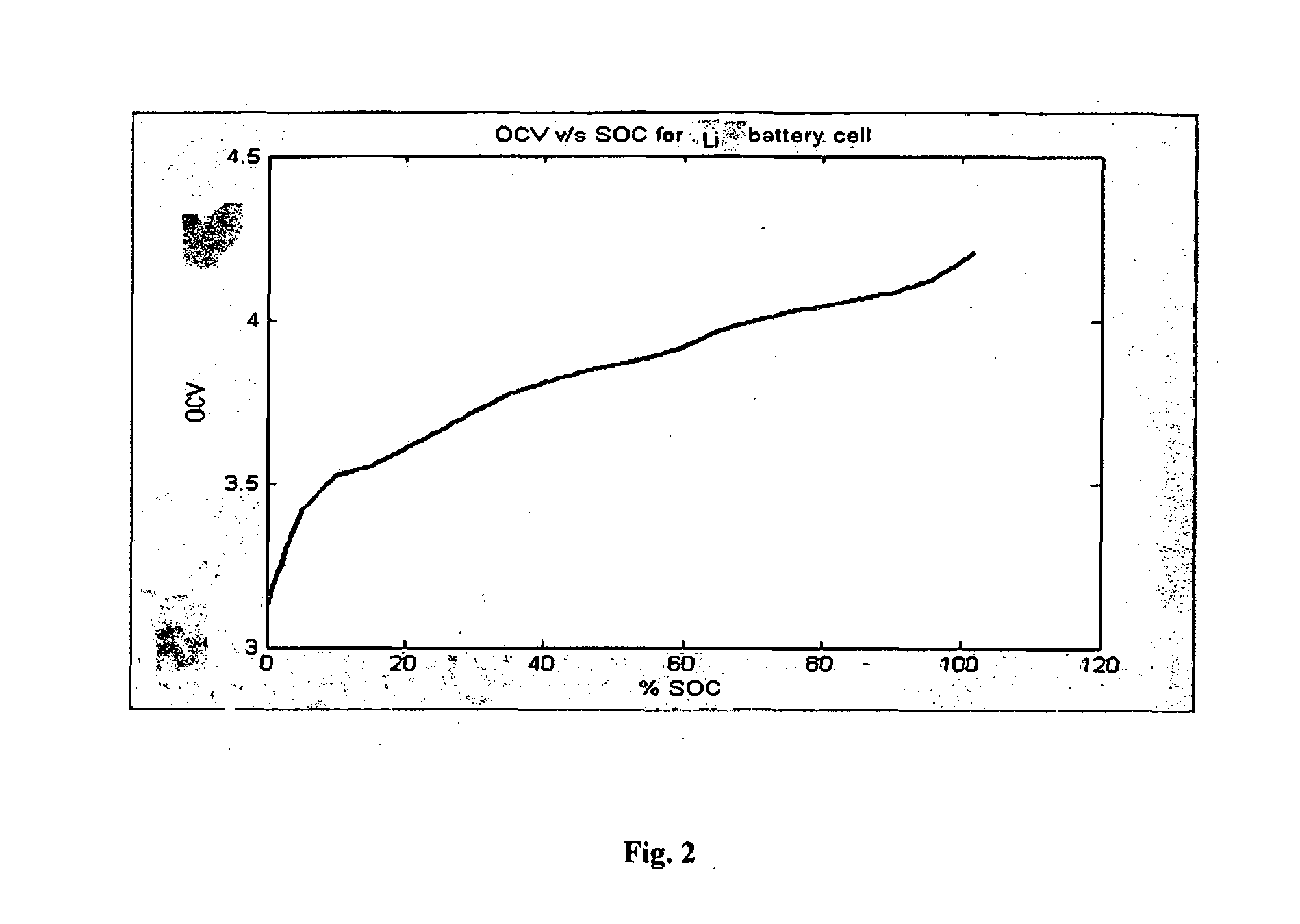

System and method for determining state of charge of a battery

InactiveUS20140236511A1Minimizes requirement of division operationComparable performanceElectrical testingSpecial data processing applicationsCapacitanceBattery state of charge

A novel method and system for determining state of charge of a battery (SOC) is disclosed wherein the direct method and the indirect method are not used at the same time, but alternately as indicated by battery current status. The method of the invention compensates for the exiting modeling errors and parameter estimation errors to provide an accurate SOC estimation. The method of the invention computes the DC offset and the battery capacitance to compensate for the exiting modeling errors and parameter estimation errors.

Owner:KPIT TECH LTD

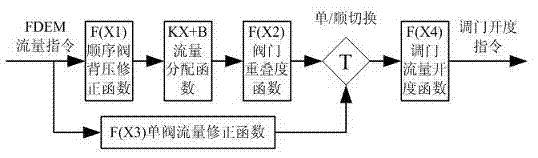

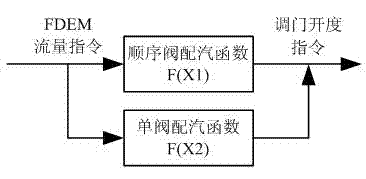

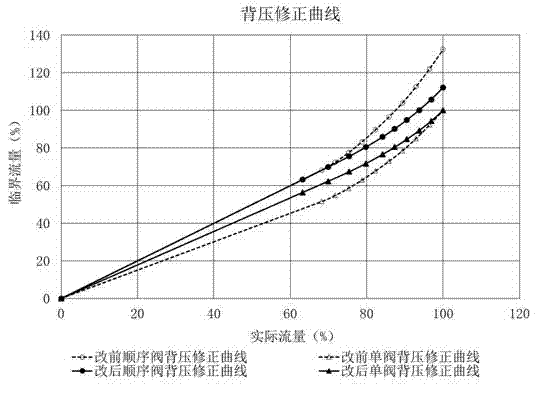

Nozzle governing steam turbine flow characteristic test method

ActiveCN104849052AMeet FM requirementsReduce throttling lossEngine testingSpray nozzleOperation mode

Provided is a nozzle governing steam turbine flow characteristic test method. According to the method, the steam distribution end of a steam turbine is assumed as an equivalent nozzle, the forward pressure, backward pressure and pressure ratio of the equivalent nozzle are taken as variables to perform indirect numerical mapping (direct mapping when the intermediate conversion link 'flow ratio' is removed) on 'actual flow-flow ratio-regulating valve position instruction' of the steam turbine by two different mapping methods, namely, an 'indirect method' and a 'direct method', and regulating valve overlap is finely adjusted by double means of setting 'the regulating valve opening amplitude limit under inlet air flow increase per unit' and numerically quantizing 'the degree of influence of regulating valve throttling loss to the heat consumption of the steam turbine', thereby obtaining a steam distribution function conforming to the actual flow characteristic of the steam turbine and realizing precise control on the inlet air flow of the steam turbine under different valve control modes. The nozzle governing steam turbine flow characteristic test method of the invention is suitable for nozzle governing steam turbine flow characteristic setting and steam turbine steam distribution end operation mode integrated optimizing control research.

Owner:STATE GRID JIANGXI ELECTRIC POWER CO LTD RES INST +1

Method for preparing regenerated cellulose fibers from plant fibrous pulp of reeds and stalks

InactiveCN101736426AHigh strengthGood hygroscopicityArtificial filaments from cellulose solutionsWet spinning methodsPolymer sciencePlant fibre

The invention relates to a method for preparing regenerated cellulose fibers from plant fibrous pulp of reeds and stalks. The method is the solvent method, and comprises the following steps of: preparing 8 to 15 mass percent spinning solution of the regenerated cellulose fibers by adopting the direct method or indirect method; and spinning the obtained spinning solution of the regenerated cellulose fiber. The method has the advantages of simple process, little pollution, and good performance of the fiber prepared by the method. The regenerated cellulose fiber of reeds, stalks and the like, prepared by the method, has the advantages of high strength, softness, smoothness, good moisture absorbing property, convenient dyeing and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

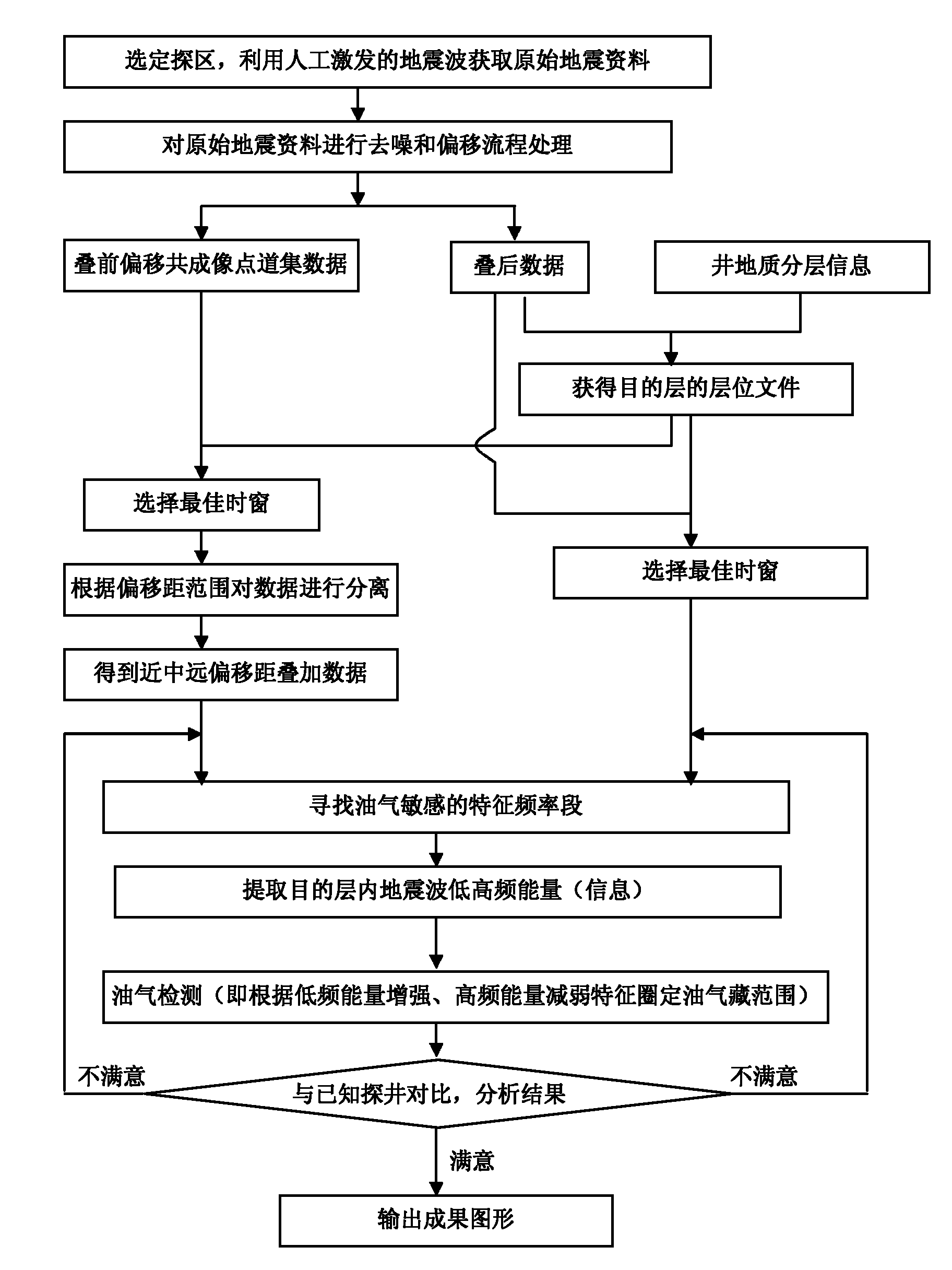

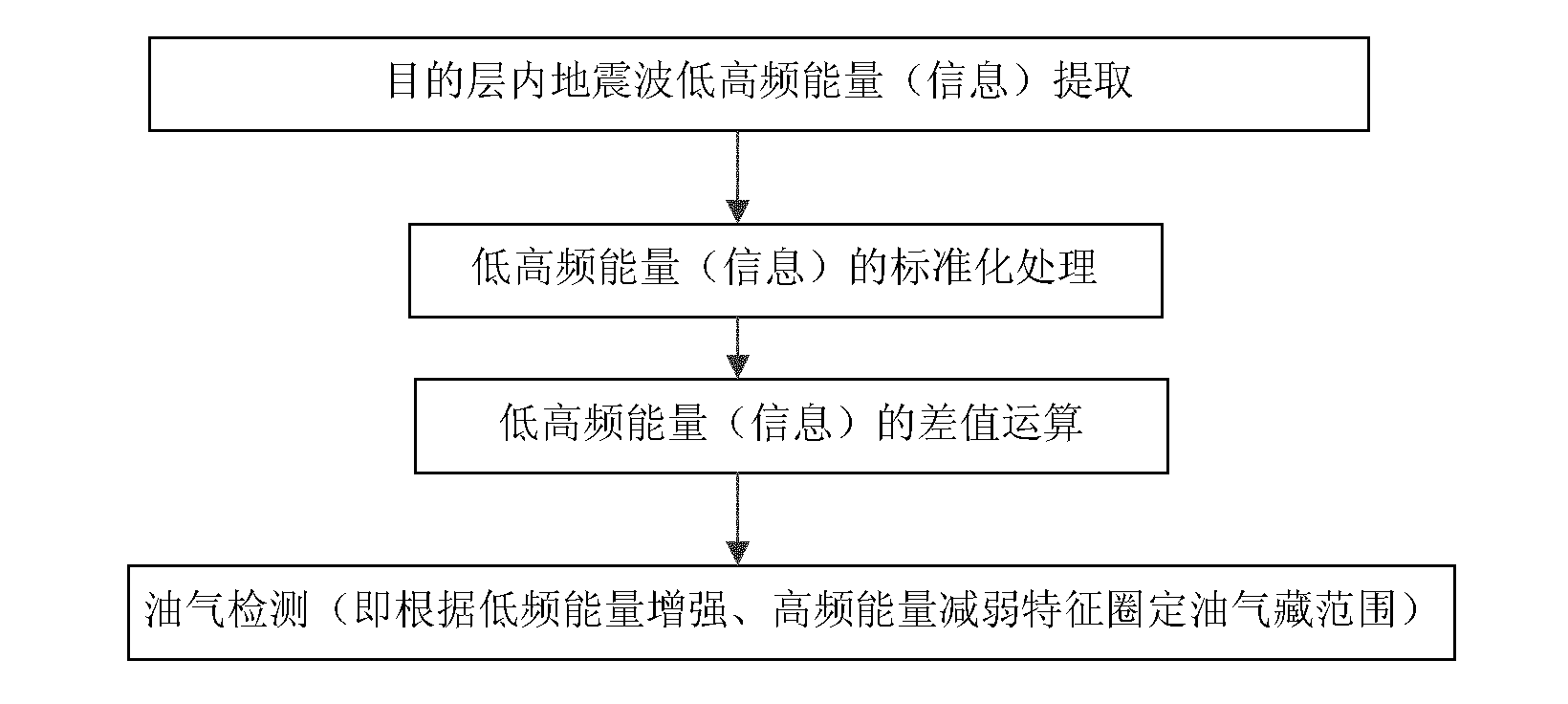

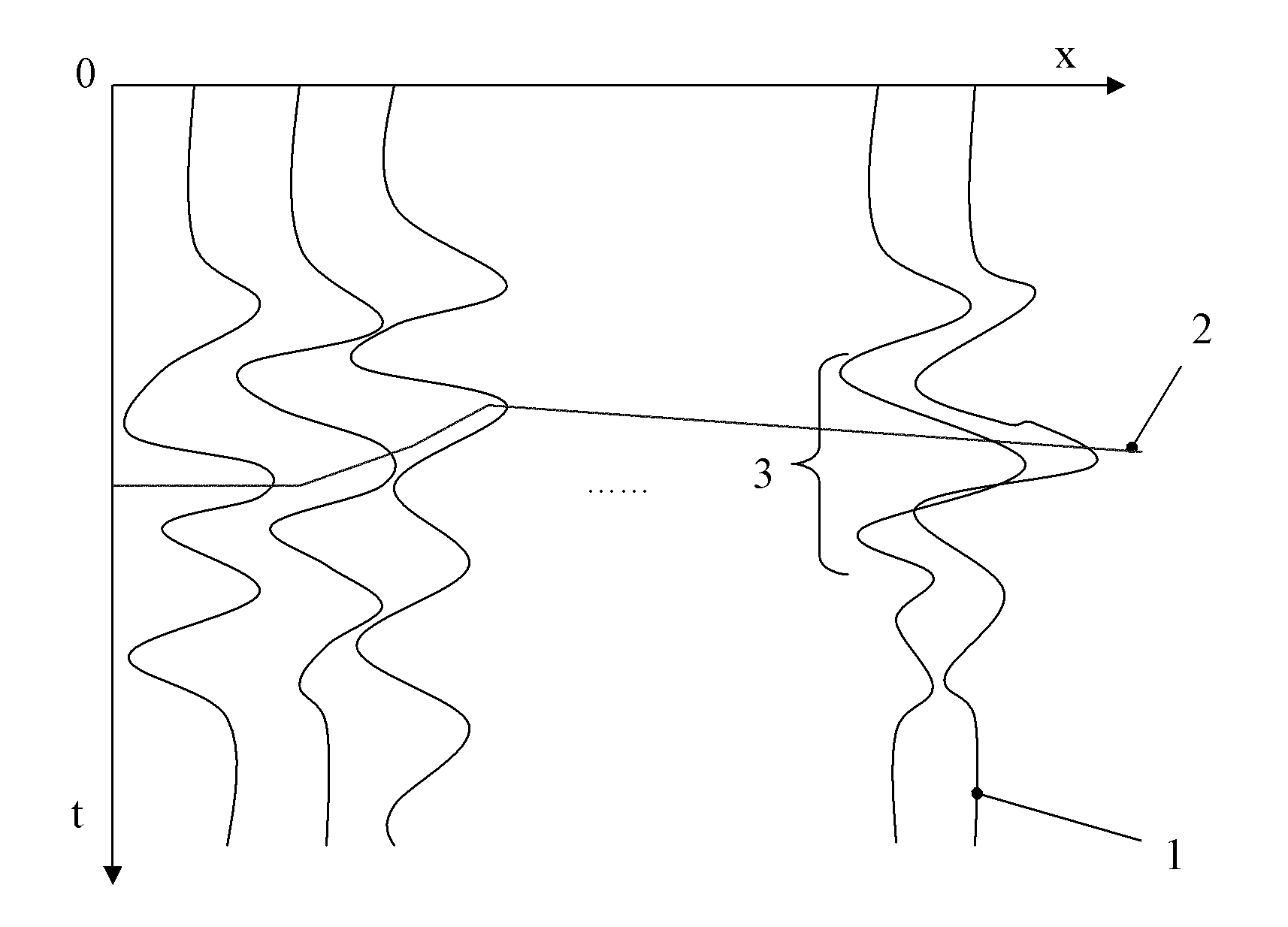

Pre-stack low frequency signal recognition method of complex oil pool

A pre-stack low frequency signal recognition method of complex oil pool comprises the steps of: obtaining the original seismic data by the artificially excited seismic wave, thereby obtaining the geologic horizon file of the target layer; selecting the optimal time window of the geologic horizon file to determine the target layer; separating the near, middle and far offset distance data for the pre-stack seismic data in the target layer; performing spectrum analysis for the data in the target layer range, so as to respectively obtain the oil and gas sensitive optimal frequency ranges of the seismic data before and after the stacking; extracting seismic wave low and high frequency information in the target layer within the oil and gas sensitive optimal frequency ranges by the frequency division technology; detecting whether oil and gas exist or not by the characteristics that the low frequency range energy is enhanced and the high frequency range energy is weakened; and finally comparing with a known exploratory well, and analyzing and outputting the result. In the invention, based on the two-phase medium model much closer to the underground actual situation, the use of the pre-stack low frequency signal with richer information for recognizing the oil and gas reservoir stratums is realized; and compared with traditional indirect method and direct method, the recognition method has the advantages of low cost and high precision.

Owner:OCEAN UNIV OF CHINA

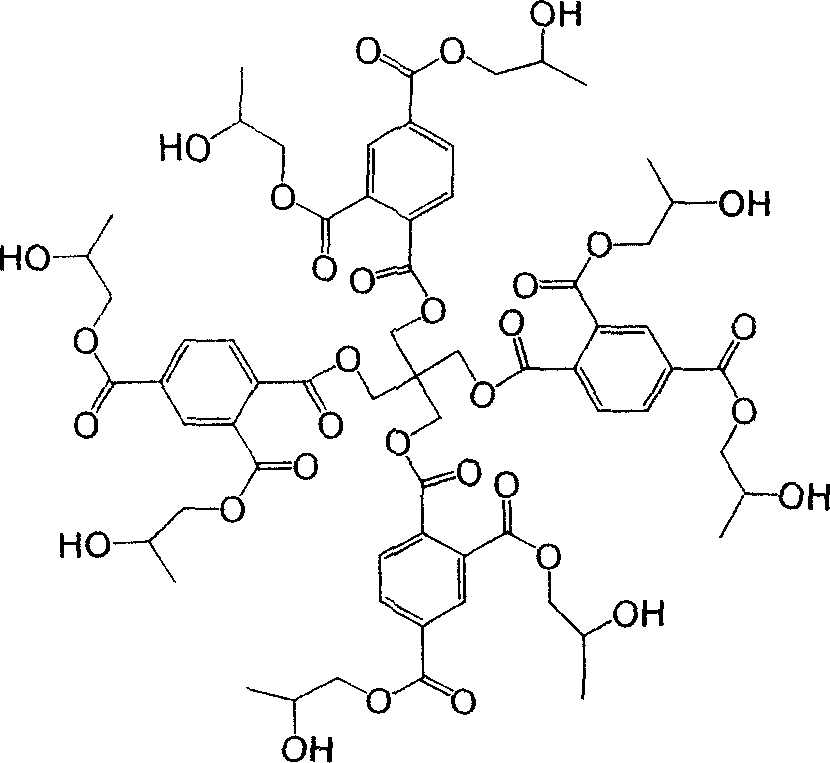

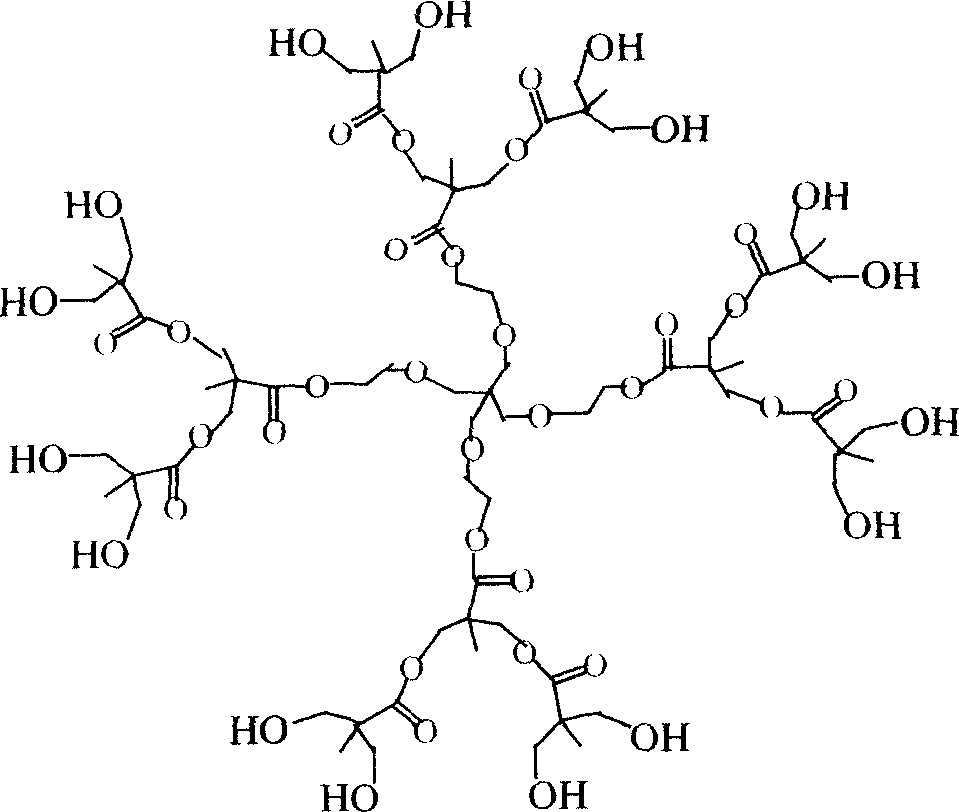

Method for preparing super branched polyacrylate fluorine and application in finishing agent for textile

InactiveCN1687180AWide variety of sourcesNovel preparation methodFibre treatmentPhysical paper treatmentEnd-groupDouble bond

The present invention relates to a fluorine-contained ultrabranched polyacrylate which can be used in water-proofing oil-proofing fabric finishing agent and its preparation method. Said method includes the following steps: using hydroxyterminated ultrabranched polyester as reaction substrate, adopting 'direct method' or 'indirect method' to modifying its hydroxyl end group into polymerizable active double bond, then adding perfluorinated acyl chlroide or esters, and making it and residual hydroxyl end group of said ultrabranched polyester implement esterification reaction; finally making part of its terminal group form into acrylate double bond and making its another part form into perfluoroalkyl so as to obtain the fluorine-contained ultrabranched polyacrylate. Then said fluorine-contanied ultrabranched polyacrylate and hydrocarbon (methyl) acrylate are undergone the process of emulsion copolymerization so as to obtain the water-proofing oil-proofing fluorine-contained fabric finishing agent emulsion.

Owner:上海瀛正科技有限公司

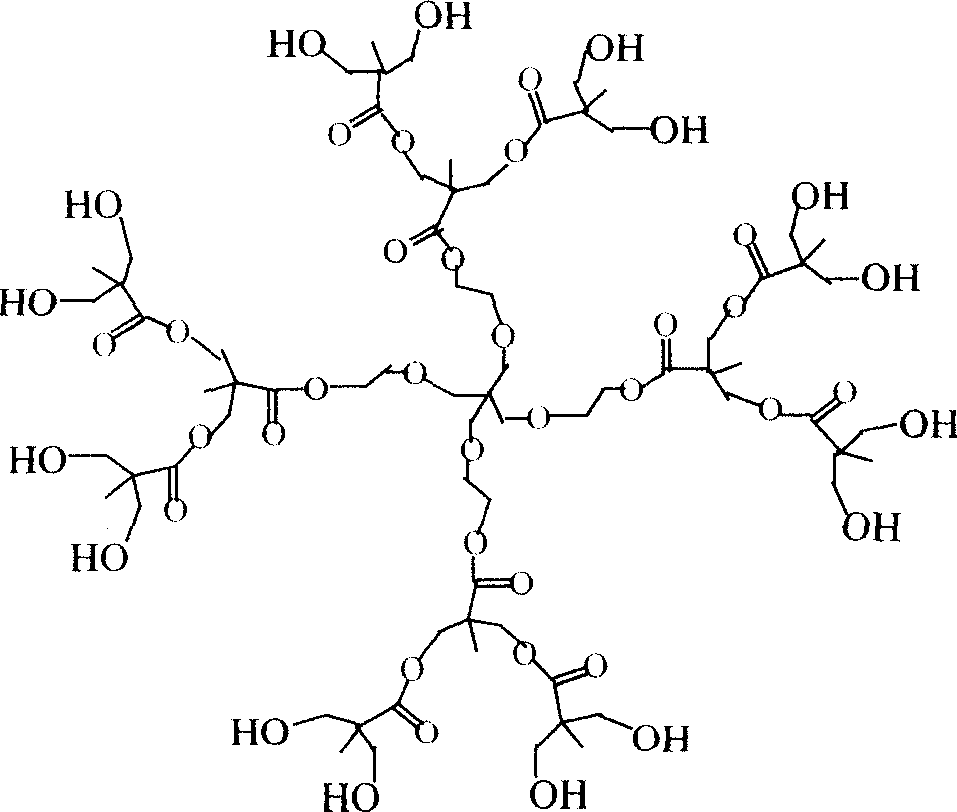

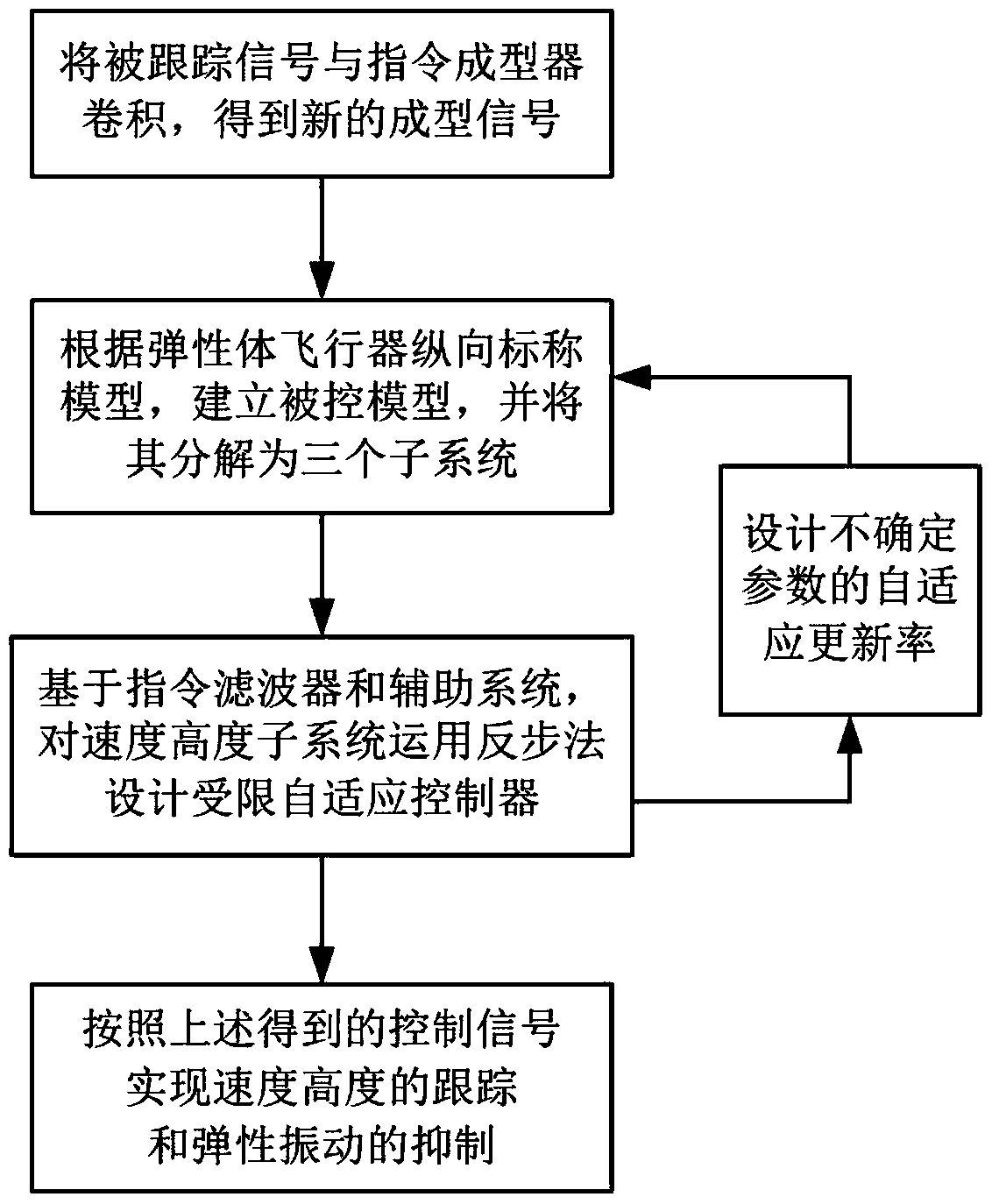

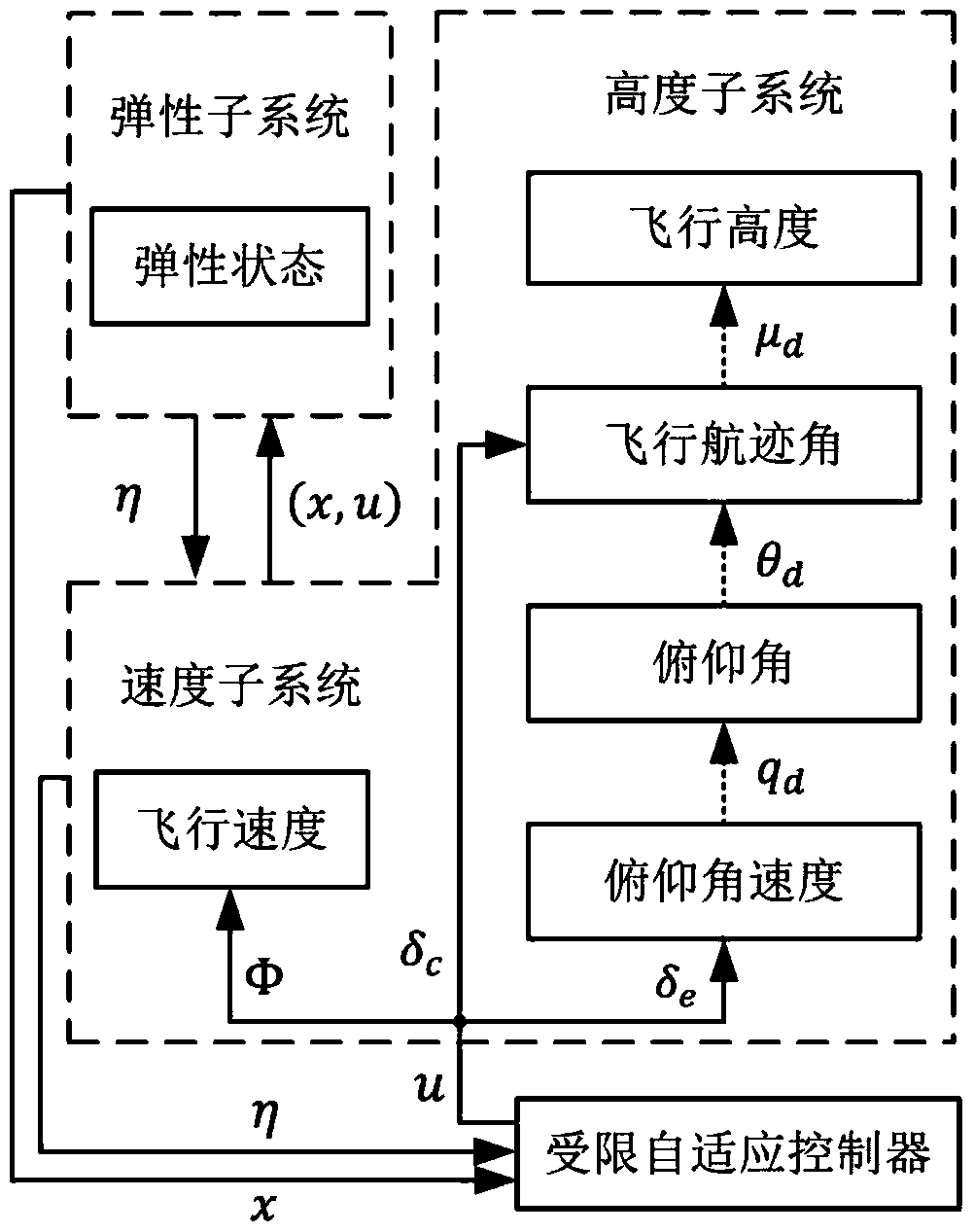

Elastic body aircraft adaptive constrained tracking control indirect method

InactiveCN105182742AReduce residual vibrationDoes not destroy tracking control effectAdaptive controlPosition/course control in three dimensionsElastomerDiagnostic Radiology Modality

The invention discloses an elastic body aircraft adaptive constrained tracking control indirect method. The objective of the invention is to solve the technical problem of low possibility of realizing adaptive tracking of reference instruction signals when an elastic body aircraft has input and state saturation constraints. The method includes the following steps that: a feedforward system is designed based on an instruction former, and tracked signals and the pulses of the former are subjected to convolution, so that new forming signals can be obtained and are adopted as the input of a subsequent feedback system; the design of the feedback system is decomposed into a velocity subsystem, a height subsystem and an elasticity subsystem, and the influence of elastic modality in rigid body dynamic is considered as elastic interference, and uncertain parameters and an external disturbance introduction nominal model are used in combination, and therefore, a controlled system can be obtained; and a saturation constrained adaptive control method can be realized for the controlled system through utilizing an instruction filter and an auxiliary system, and tracking for the forming signals in the feedforward system can be realized, and closed-loop system signals can be uniformly and ultimately bounded, and suppression on elastic modality deformation and vibration can be realized.

Owner:BEIHANG UNIV

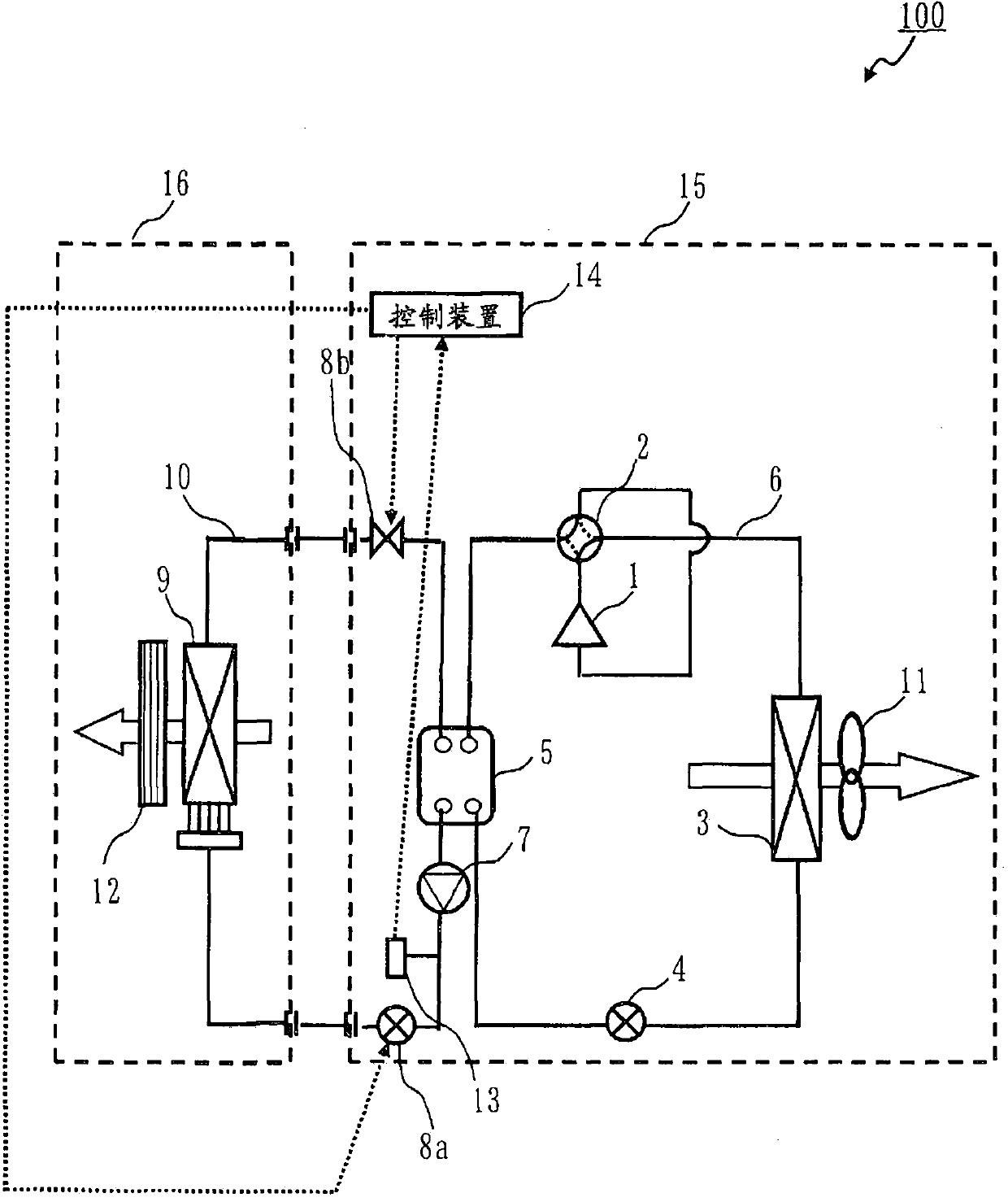

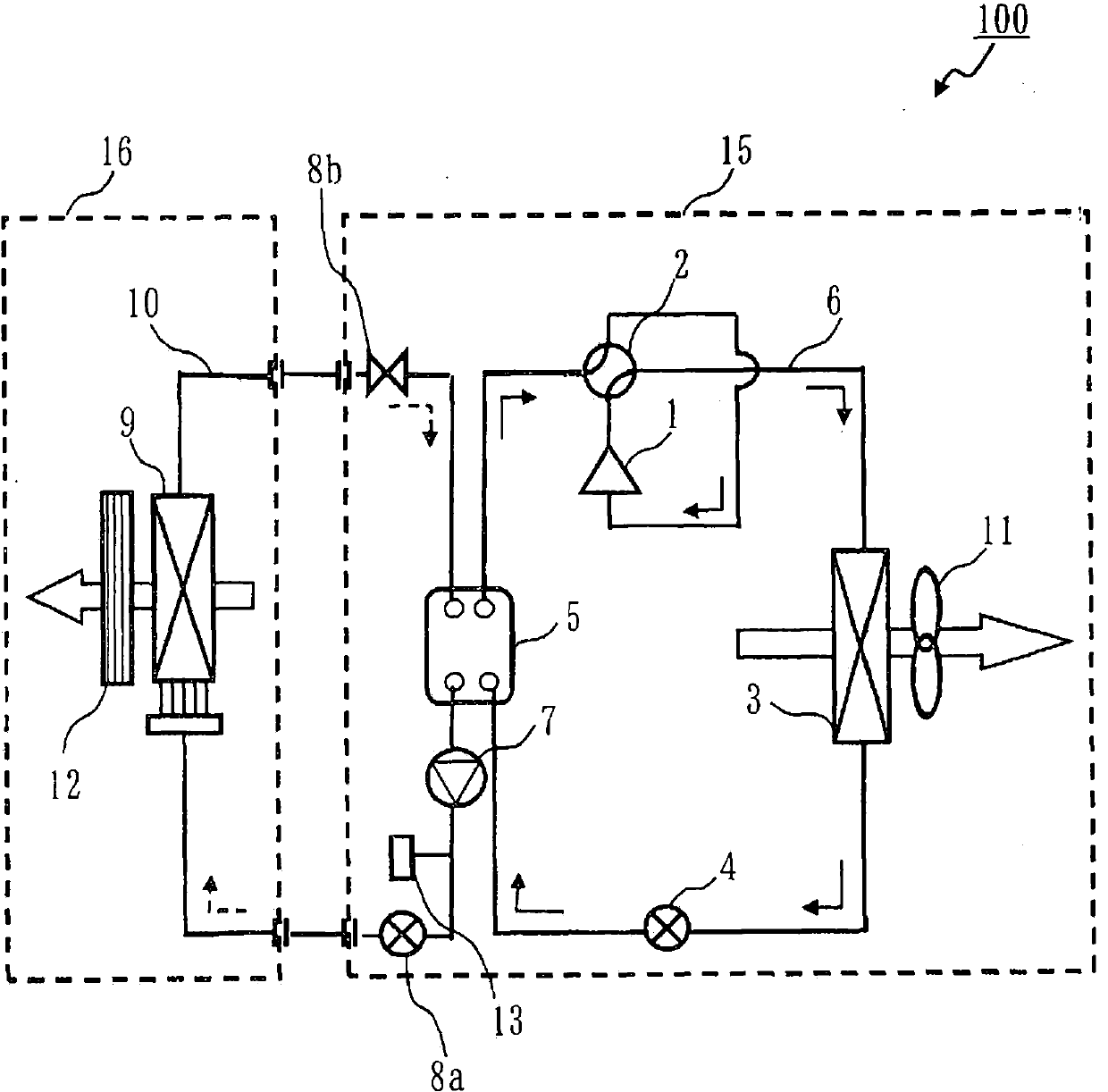

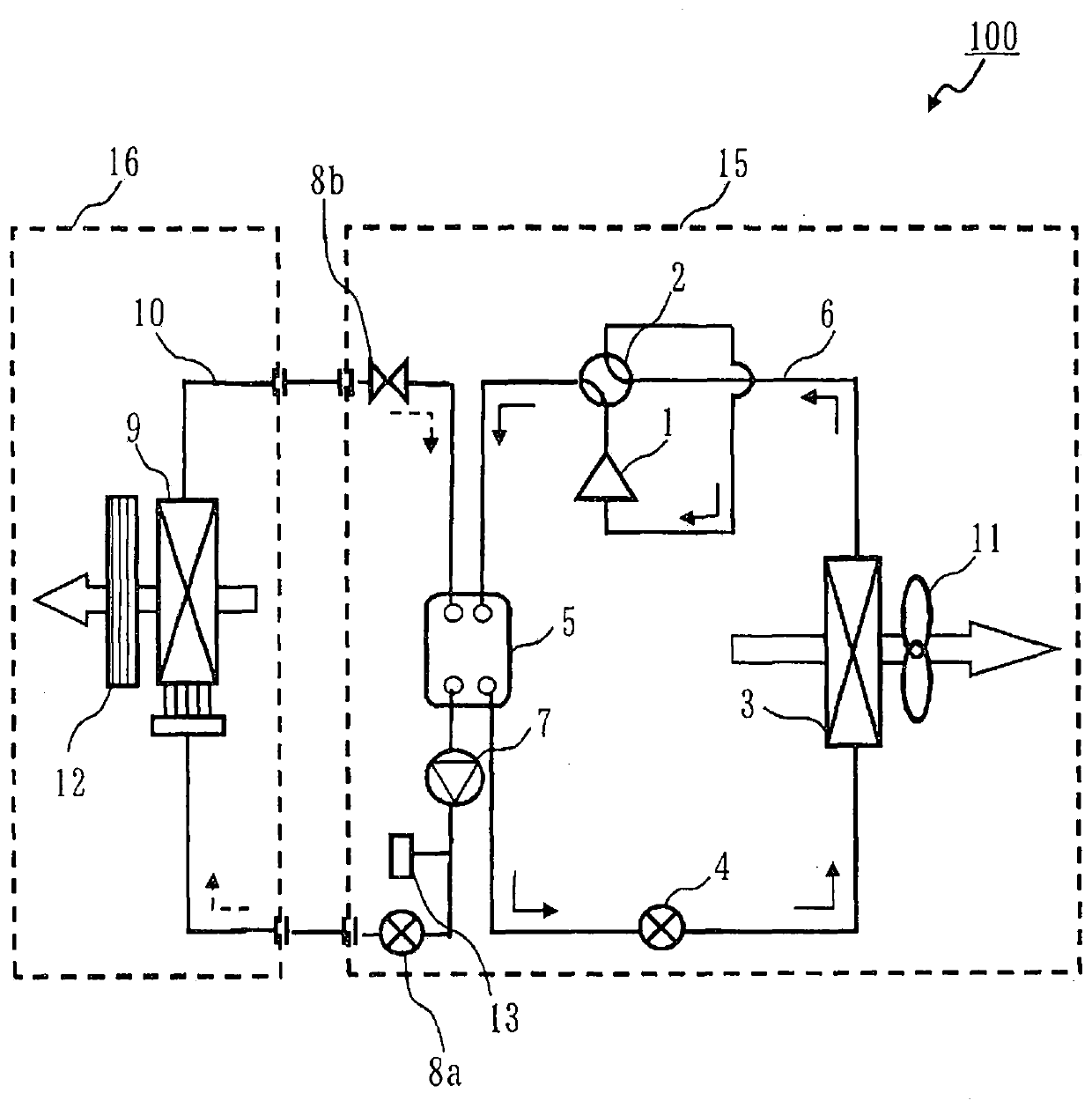

Heat pump device and method for controlling heat pump device

ActiveCN103797317APrevent flow throughPrevent leakageMechanical apparatusSpace heating and ventilation safety systemsIntermediate heat exchangerWater flow

In order to prevent the refrigerant in the primary-side circuit from leaking via the secondary-side circuit in a heat pump device that is equipped with a primary-side circuit on the heat source side and a secondary-side circuit on the load side and employs an indirect method, an air conditioner (100) is equipped with: a leakage detection device (13) that detects the leakage of refrigerant circulating in a refrigerant circuit (6), which is the primary-side circuit, from an intermediate heat exchanger (5) to a water circuit (10), which is the secondary-side circuit; and a control device (14) that, when the leakage detection device (13) detects leakage, closes valves (8a, 8b) provided on either side of the intermediate heat exchanger (5) in the water circuit (10), preventing the water in which refrigerant is mixed from flowing past the valves (8a, 8b).

Owner:MITSUBISHI ELECTRIC CORP

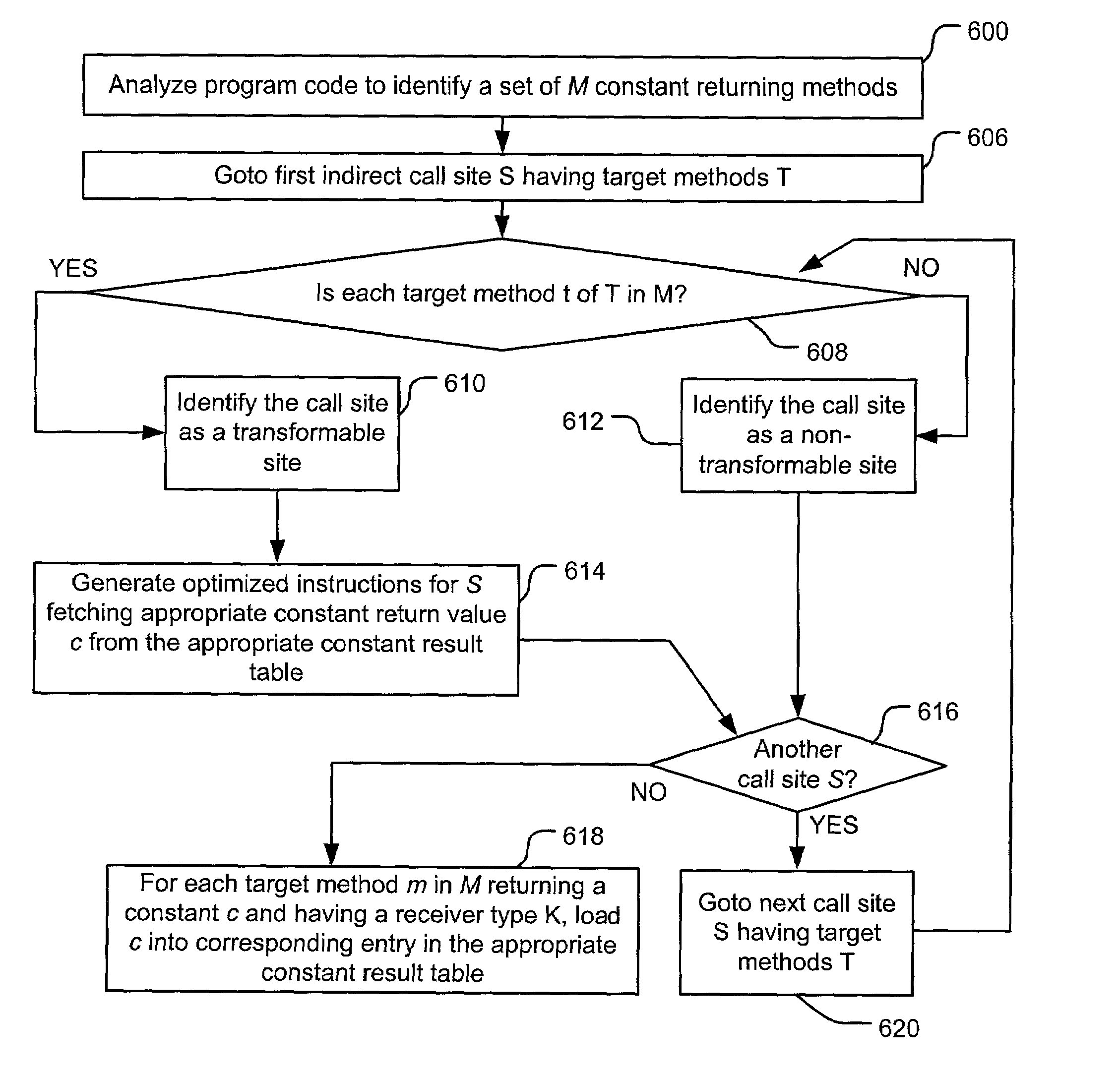

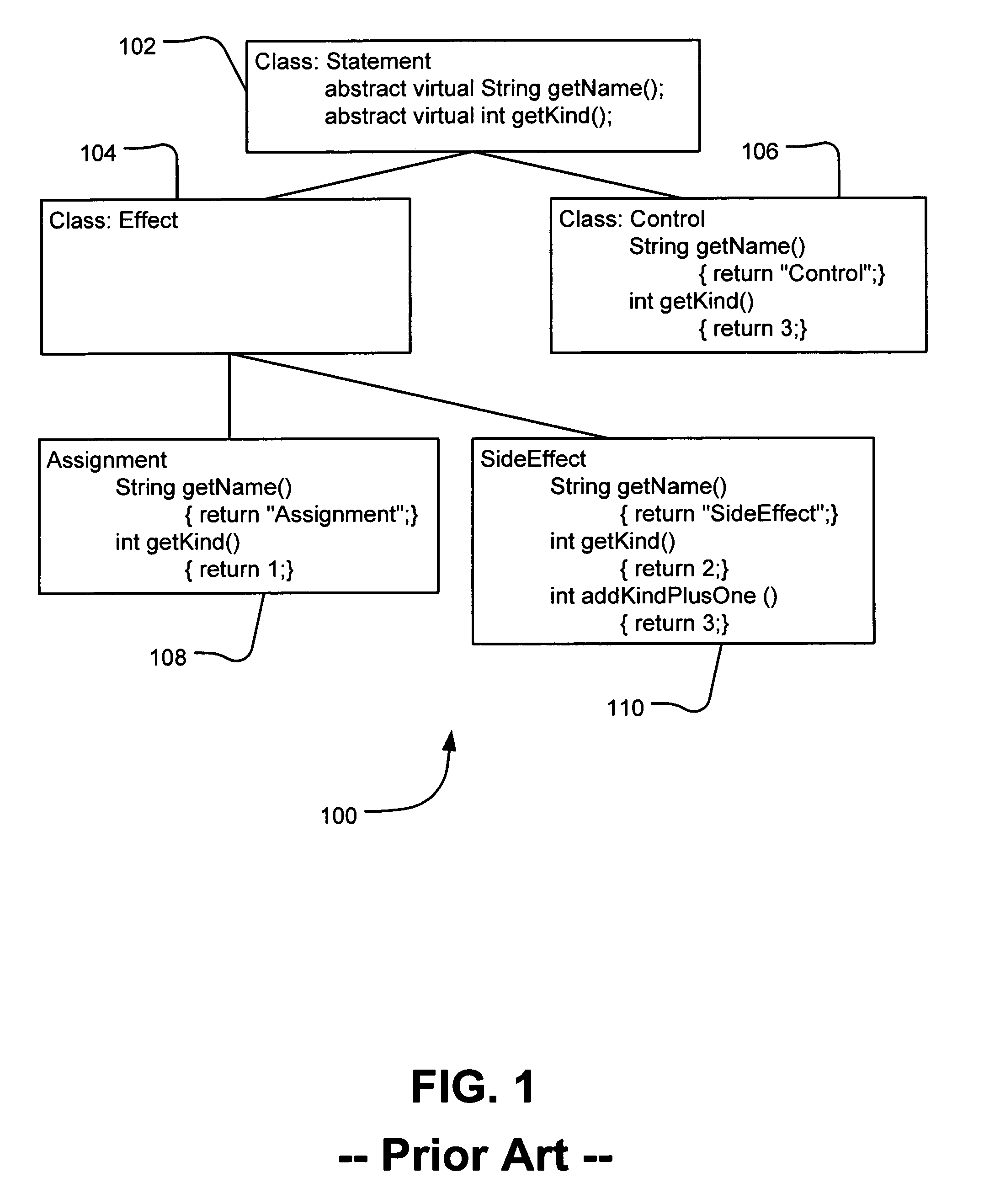

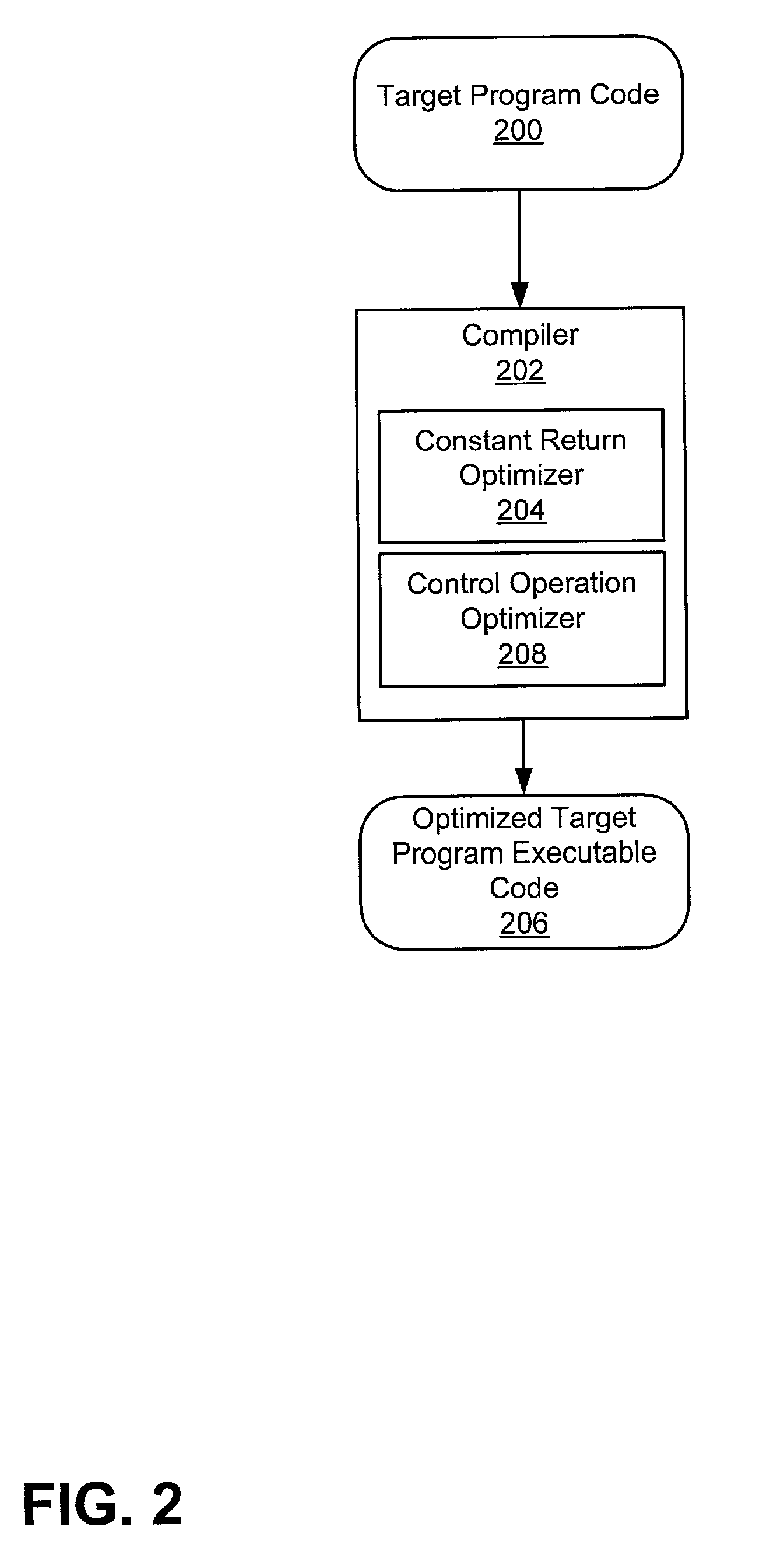

Constant return optimization transforming indirect calls to data fetches

InactiveUS7028293B2No side effectSimple methodSoftware engineeringSpecific program execution arrangementsData ingestionCall site

Indirect method invocation of methods that only return constant values is optimized using fetching operations and return constant tables. Such method calls can be optimized if all possible method calls via the call site instruction return a constant value and have no side effects. Each constant return value is loaded from a return constant table, and method invocation is eliminated. If all possible target methods in a program result in a constant return value and have no side effects, an associated virtual function dispatch table (vtable) may be used as the return constant table. Furthermore, control operation optimization may be applied to identify type constraints, based on one or more possible type-dependent constant return values from an indirect method invocation. An optimizer identifies and maps between a restricted set of values and an associated restricted set of types on which execution code may operate relative to a given control operation. The type constraints are used to optimize the associated execution code by filtering propagation of runtime type approximations for optimization.

Owner:MICROSOFT TECH LICENSING LLC

Immunofluorescence test strip based on phosphorescent technology, and preparation method and application thereof

InactiveCN102866251ARealize quantitative detectionQuick QualificationBiological testingImmunofluorescencePorphyrin

The invention provides an immunofluorescence test strip based on a phosphorescent technology, and a preparation method and application thereof. A phosphorescent material, namely pt-porphyrin / pd-porphyrin, is used as a biomarker of the test strip, a result is shown in a mode of infrared light signals under illumination of green light, and can be identified by an instrument, so that quantitative detection for a detected object is realized. The test strip comprises a sample pad, a conjugate pad, an analyzing membrane, a water-sucking pad and a liner. A phosphorescent material marker is fixed on the conjugate pad, and a detecting line and a quality control line are fixed on the analyzing membrane. The invention also discloses a preparation method for the test strip and application of the test strip in quantitative detection of biological samples. According to difference of immunoreaction modes of an object to be detected, the test strip includes a sandwich method mode, a competition method mode, an indirect method mode and a capture method mode; and according to difference of properties of the detected object, different objects to be detected in the sample can be quickly and sensitively detected and analyzed qualitatively and quantitatively by using different detection modes.

Owner:SHENZHEN AIRUI BIO TECH

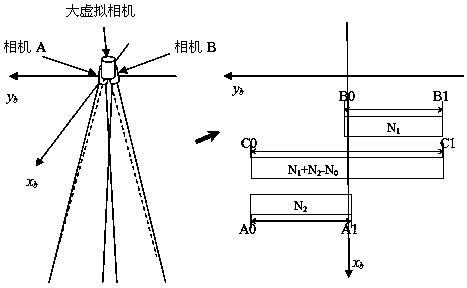

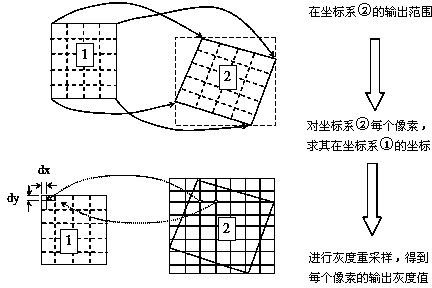

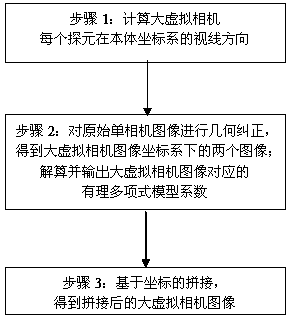

Narrow-view-field double-camera image fusion method based on large virtual camera

InactiveCN103697864ARealize splicingNo human intervention requiredGeometric image transformationPicture interpretationCamera imageBack calculation

The invention discloses a narrow-view-field double-camera image fusion method based on a large virtual camera. The narrow-view-field double-camera image fusion method comprises the steps of constructing the large virtual camera according to two single cameras, and constructing geometric imaging parameters of the large virtual camera according to geometric imaging parameters of the two single cameras; constructing corresponding geometric imaging models according to the geometric imaging parameters of the two cameras and the large virtual cameras; calculating and outputting a rational polynomial model coefficient corresponding to the large virtual camera; respectively performing indirect-method geometric correction on images of the two single cameras according to a coordinate forward calculation process and a coordinate back calculation process based on the geometric imaging models to obtain two images under an image coordinate system of the large virtual camera, and obtaining a fused image of the large virtual camera. According to the narrow-view-field double-camera image fusion method based on the large virtual camera, the concept of the large virtual camera is ingeniously used; high-precision fusion of the images of the two cameras in a narrow view field is realized, and the rational polynomial model coefficient corresponding to the large virtual camera is supplied; furthermore, the processing procedure is fully automatic, and manual intervention is not needed; the narrow-view-field double-camera image fusion method is applicable to a ground preprocessing procedure.

Owner:WUHAN UNIV

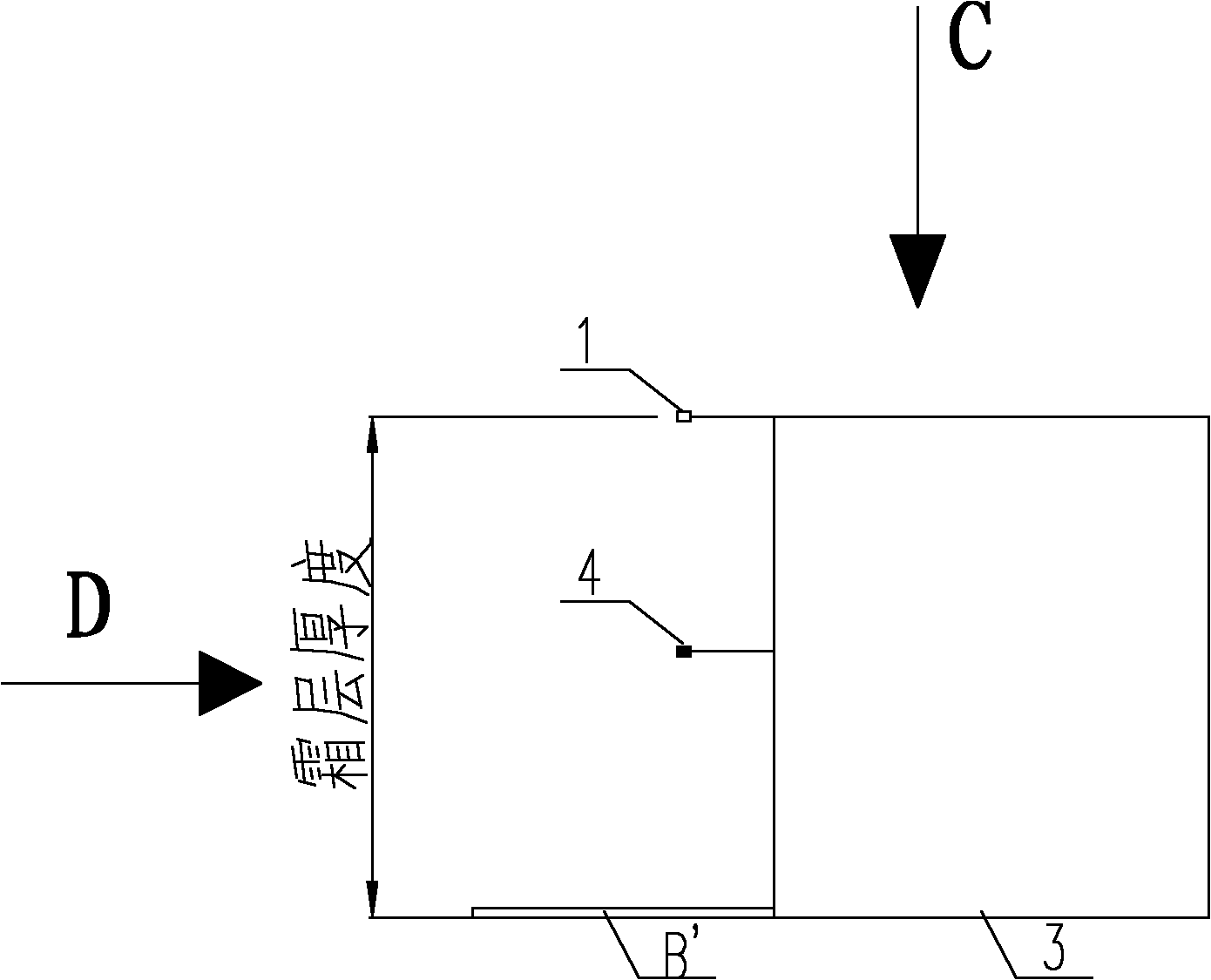

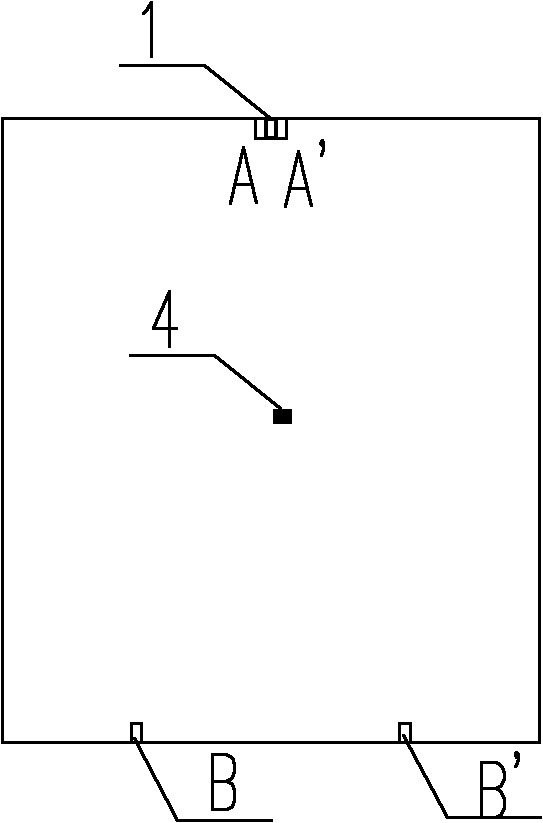

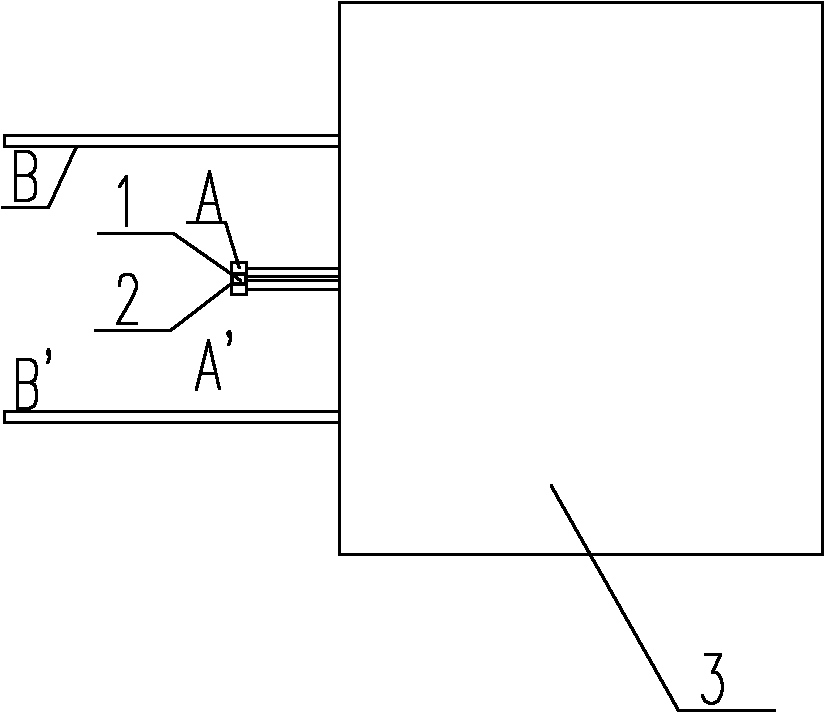

Defrosting detector and defrosting control method based on frost layer thickness

InactiveCN102095295ASave materialLow costCorrosion preventionElectrical/magnetic thickness measurementsFrostEngineering

The invention discloses a defrosting detector and a defrosting control method based on the frost layer thickness, belonging to the field of air source heat pump control, and aiming at solving the problems of the inaccurate judgement of defrosting by adopting an indirect method for the existing air source heat pump and over high cost. According to the invention, an insulative layer is coated at the outer surface of a heating resistor, and first electrode pairs A-A' are arranged at the left and right of the heating resistor. The defrosting control method is as follows: in non-working state of the defrosting detector: disconnecting all switches; in the starting up state of the defrosting detector: starting the defrosting detector at the temperature of minus 12 DEG C- 1 DEG C the switching off, intermittently the switching on and off; in the starting state of defrosting: heating the resistor to work, conducting the first electrolde pairs A-A' by a frost melting water film, and outputting defrosting signals; in the defrosting state of the air source heat pump: conducting a second electrode pair B-B' by the frost melting at the surface of the fin; and in the defrosting suspending state of the defrosting detector: determining that the defrosting is finished when the output voltage signal is zero.

Owner:HARBIN INST OF TECH

Method for preparing acetic acid esterified modified dextrin and crosslinking acetic acid esterified composite modified dextrin

InactiveCN102206288AImprove polarity characteristicsReduce the number of hydrogen bondsFermentationAcetic acidFreezing thawing

The invention relates to a method for preparing acetic acid esterified modified dextrin and crosslinking acetic acid esterified composite modified dextrin, which comprises two methods, i.e., a direct method and an indirect method. The direct method comprises the steps of directly taking malto dextrin or pyrolyzed dextrin as the raw material and carrying out chemical modification, i.e., acetic acid esterification or crosslinking acetic acid esterification; and the indirect method comprises the steps of taking starch as the raw material, carrying out the chemical modification, i.e., the acetic acid esterification or the crosslinking acetic acid esterification, to obtain corresponding starch derivatives firstly, and then dextrinizing after enzymolysis or pyrolysis to obtain a final product. The method for preparing the crosslinking acetic acid esterified composite modified dextrin further comprises two modification sequences, i.e., crosslinking is carried out before esterification, or the esterification is carried out before the crosslinking. The acetic ester or crosslinking acetic ester dextrin derivatives have the characteristics of good stability, high transparence, strong thickening performance, low hygroscopicity, low retrogradation, freeze-thaw stability, excellent emulsibility and the like.

Owner:SOUTH CHINA UNIV OF TECH

PLA2R antibody quantitative detection test strip and manufacturing and detection methods

InactiveCN104849452AImprove stabilityQuantitative detection safetyDisease diagnosisFluorescence/phosphorescenceFluorescenceQuantum dot

The invention relates to the technical field of biology, in particular to a PLA2R antibody quantitative detection test strip and manufacturing and detection methods. The test strip uses a principle of detecting an antibody with an indirect method and comprises the steps of coating PLA2R on a nitrocellulose membrane respectively; spraying a quantum dot-coupled anti-human IgG antibody on a conjugate mat, then overlapping a sample mat, the conjugate mat, the nitrocellulose membrane and water absorption paper on an adhesive PVC bottom plate in sequence, cutting into test strips of certain width and assembling into a detection card, wherein an antibody concentration value can be detected by a fluorescence analyzer, and is used for quantitatively detecting the PLA2R antibody in the sample. By using a quantum dot immunochromatographic method, the content of the PLA2R antibody in serum, plasma and whole blood can be safely, precisely and fast detected in a non-invasive, low-risk and low-price manner, and an auxiliary action can be provided for preliminary screening and illness monitoring of idiopathic membranous nephropathy.

Owner:SHENZHEN BLOT BIOTECH

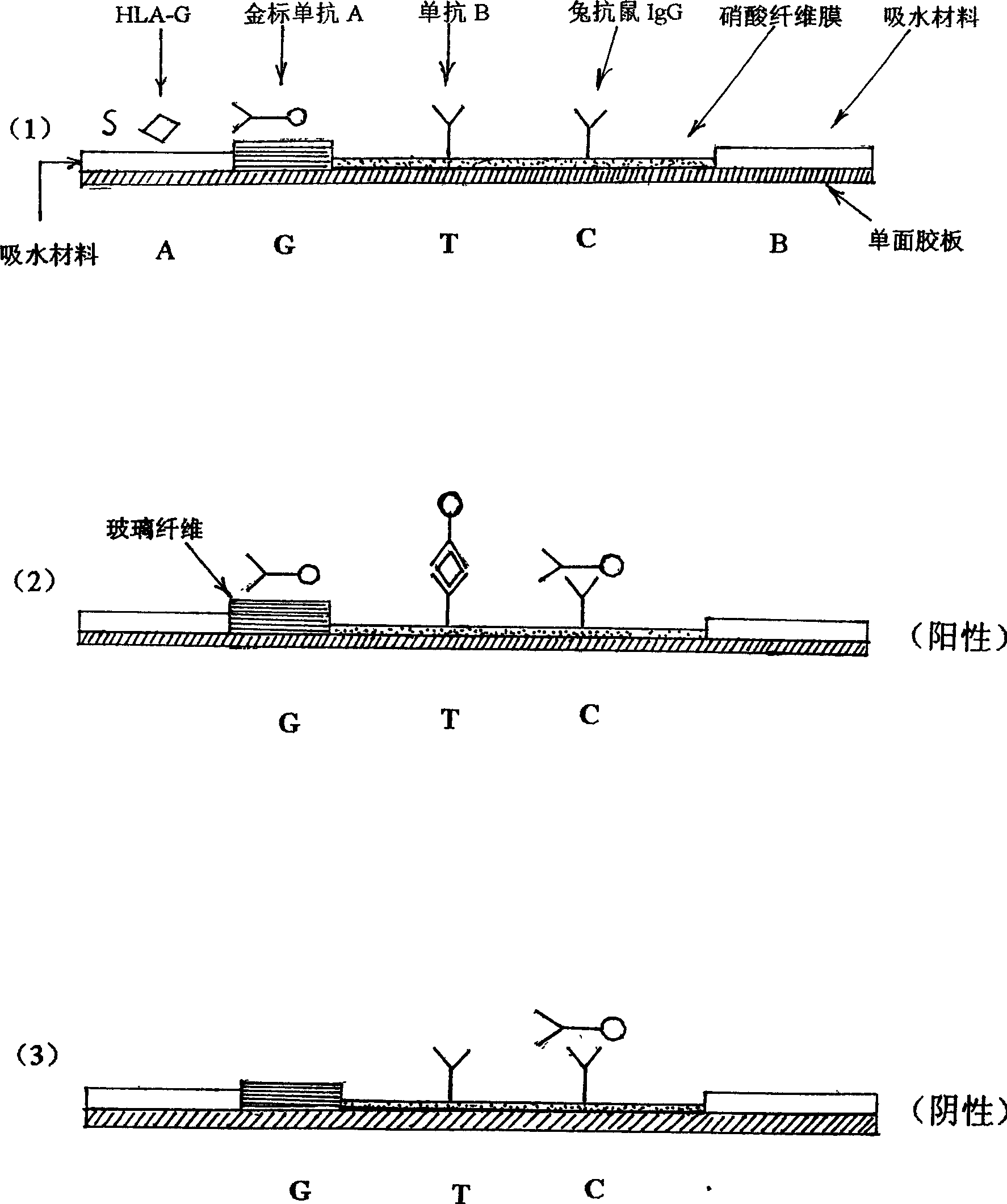

Simple method for detecting HLA-G and antibody thereof by gold-labeled immunoassay

The invention discloses a simple method for detecting HLA-G and antibody thereof by gold-labeled immunoassay. The invention uses the monoclonal antibody of HLA-G and an HLA-G antigen fragment and / or HLA-G for successfully developing a gold-labeled immunity percolation analysis kit, and a gold-labeled immunochromatography sandwich method and competition method kit, which are used for the public to easily, rapidly and cheaply self-check and self-test the HLA-G in body fluid such as blood, saliva, urine, and the like so as to diagnose the early malignant tumor. In order to diagnose the earlier malignant tumor, a kit for detecting the HLA-G antibody by a gold-labeled immunochromatography indirect method is also developed and used for diagnosing the earlier malignant tumor. The kits are all called as 'broad-spectrum tumor diagnostic kit'. The invention aims at developing an easy, rapid and cheap 'broad-spectrum tumor diagnostic kit' for the self-check and self-test of the public so as to realize primary tumor screening and achieve the goal of finding and curing the tumor early, save the lives of the tumor patients, and reduce the tumor mortality.

Owner:天津东亚生物技术有限公司

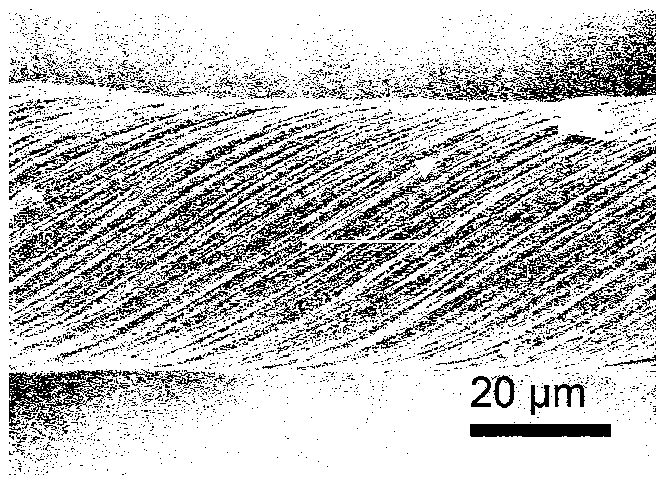

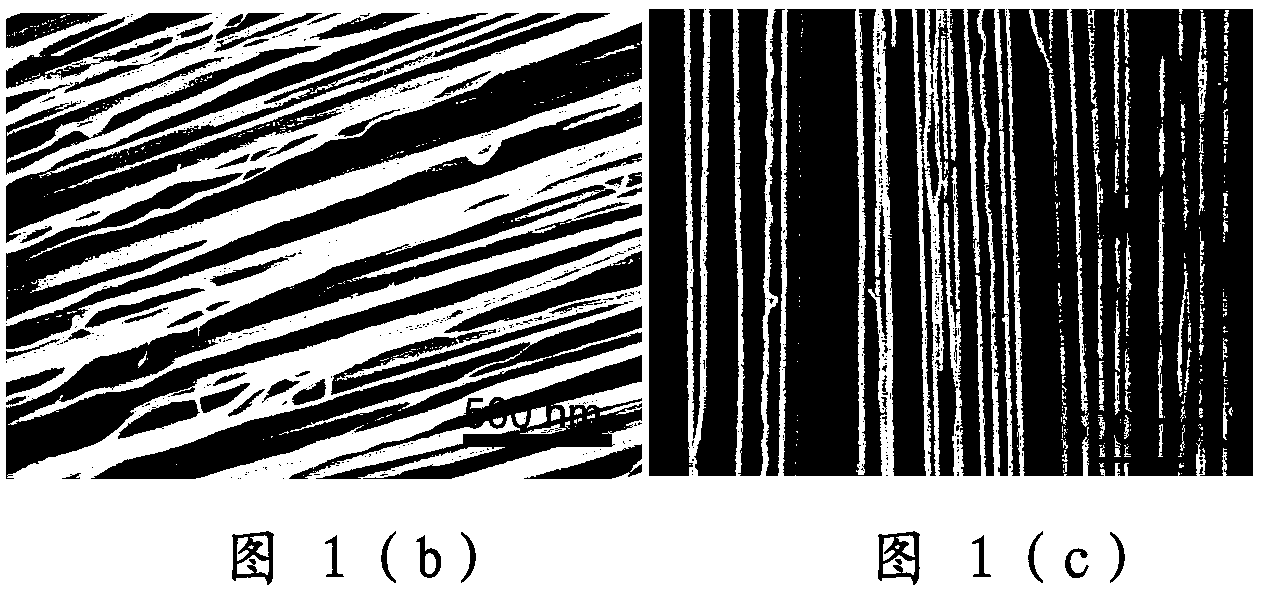

Horizontal directional carbon nanotube array and preparation method thereof

ActiveCN103303898ASimple methodEfficient preparation processMaterial nanotechnologyCarbon compoundsCarbon nanotubeBCN nanotube

The invention discloses a horizontal directional carbon nanotube array and a preparation method thereof. The preparation method comprises the following steps of: applying a stretching force to a combination body comprising carbon nanotubes, and forming a directional carbon nanotube array in at least partial region of the surface of the combination body under the action of the stretching force; placing the combination body on a base, enabling the directional carbon nanotube array to be directly contacted with the base, applying a pressure to the combination body towards the base, and enabling at least one part of the directional carbon nanotube array to be adhered onto the base under the action of the pressure; removing the combination body from the base to obtain the horizontal directional carbon nanotube array on the base. Compared with the method for preparing the horizontal directional carbon nanotube array by adopting a direct method or an indirect method in the prior art, the method is simple, easy to popularize, quick and efficient in preparation process, and high in finished product rate.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

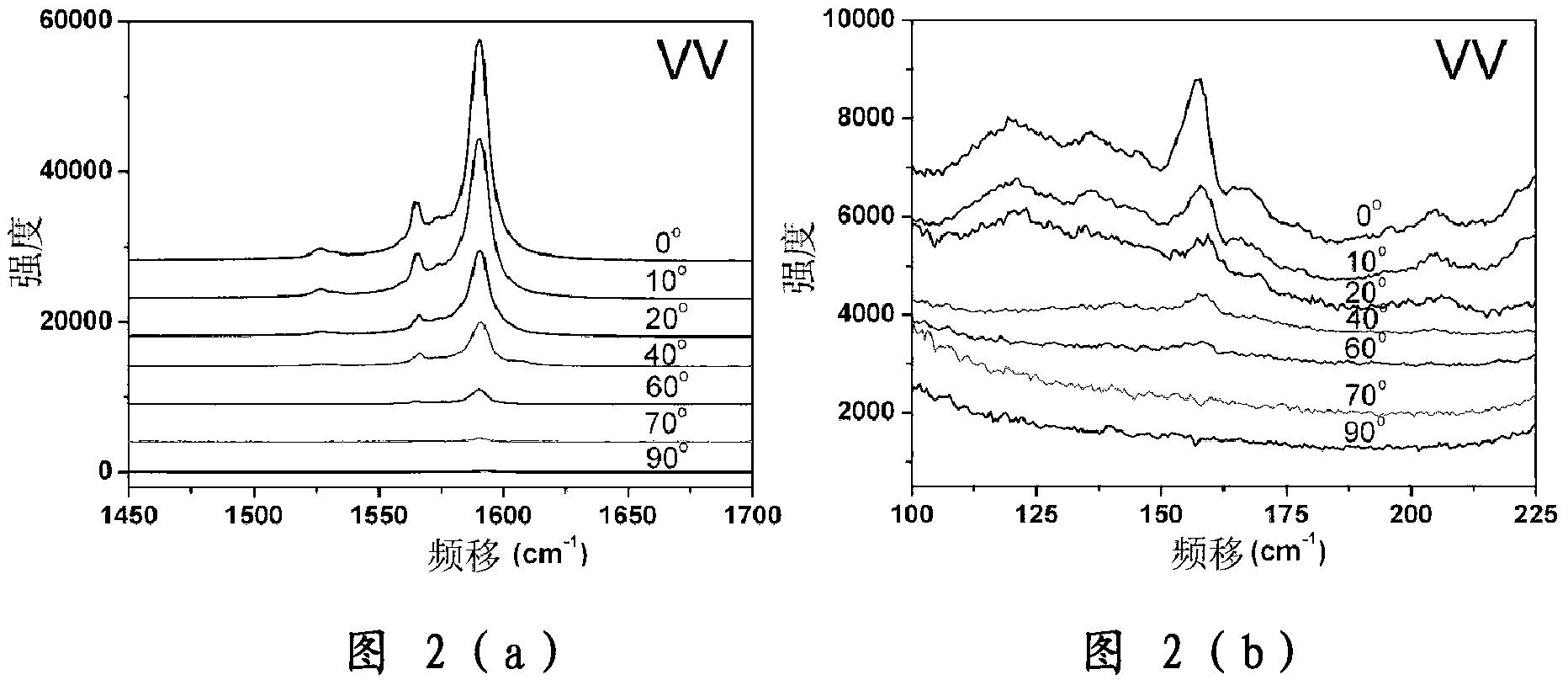

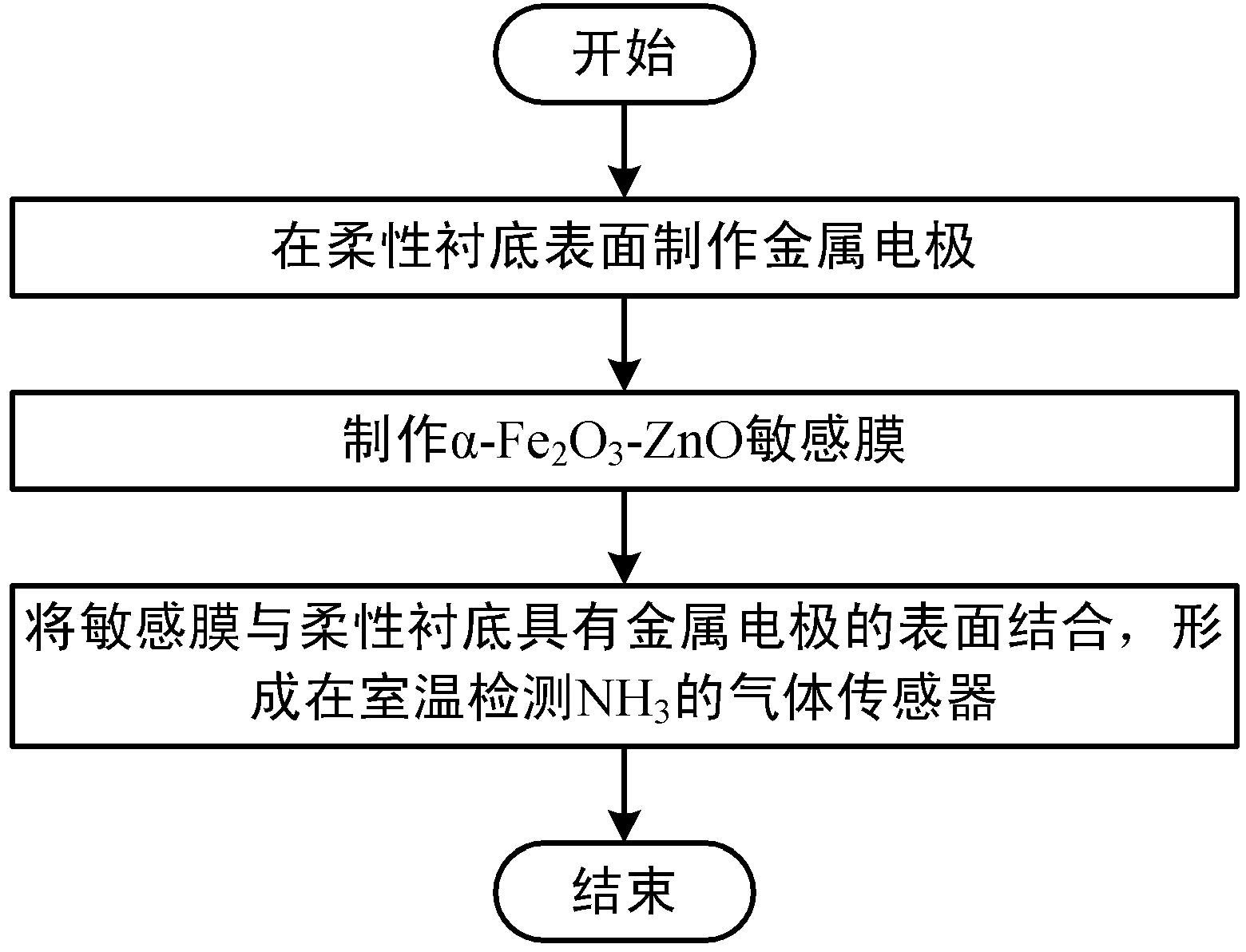

Method for manufacturing gas sensor for detecting NH3 at room temperature

InactiveCN103308560AAvoid high temperature operationMaterial analysis by electric/magnetic meansSilver pasteRoom temperature

The invention discloses a method for manufacturing a gas sensor for detecting NH3 at room temperature. The method comprises the following steps of: manufacturing a metal electrode on the surface of a flexible substrate; manufacturing a sensitive membrane Alpha-Fe2O3-ZnO; and combining the sensitive membrane Alpha-Fe2O3-ZnO and the surface, which is provided with the metal electrode, of the flexible substrate to form the gas sensor for detecting the NH3 at the room temperature. According to the method, the sensitive membrane material is combined with the flexible substrate by an indirect method, so that high-temperature operation on the flexible substrate in a sensitive membrane preparation process is avoided; the sensitive membrane Alpha-Fe2O3-ZnO is coated on the SiO2 substrate; then the lower SiO2 is etched off by HF acid, and the sensitive membrane is separated from the substrate; and finally a layer of conductive silver paste is coated on the electrode surface of the flexible substrate, so that the sensitive membrane can be combined with the flexible substrate.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

High temperature resistant and flame retardant nitrile rubber cable material

InactiveCN103554572AImprove performanceWith high temperature resistanceRubber insulatorsLow-density polyethylenePolymer science

The invention relates to a cable material, and specifically relates to a high temperature resistant and flame retardant nitrile rubber cable material. The cable material comprises the following raw materials in parts by weight: 45-50 parts of nitrile rubber (3445), 14-17 parts of ethylene propylene terpolymer, 4-5 parts of polytetrafluoroethylene, 23-26 parts of low density polyethylene, 1-2 parts of sulphur, 4-6 parts of zinc stearate, 24-28 parts of N339 carbon black, 4-5 parts of soybean oil, 12-15 parts of sepiolite powder, 4-5 parts of antimonous oxide, 18-22 parts of vermiculite powder, 3-5 parts of zinc oxide by an indirect method, 3-5 parts of zinc stearate, 2-4 parts of potassium citrate, 1-2 parts of decabromodiphenylethane, 1-2 parts of acrylonitrile and 4-5 parts of an assistant. The cable material combines the advantages of nitrile rubber, ethylene propylene terpolymer, low density polyethylene and other assistant raw materials, and enhances performance of conventional nitrile rubber cable materials, so that the high temperature resistant and flame retardant nitrile rubber cable material has the advantages of high temperature resistance, flame retardance, aging resistance, storage resistance and the like, can satisfy the using demand of special occasions, and is harmless to the environment and human body and broad in application prospect.

Owner:安徽文峰电子科技集团有限公司

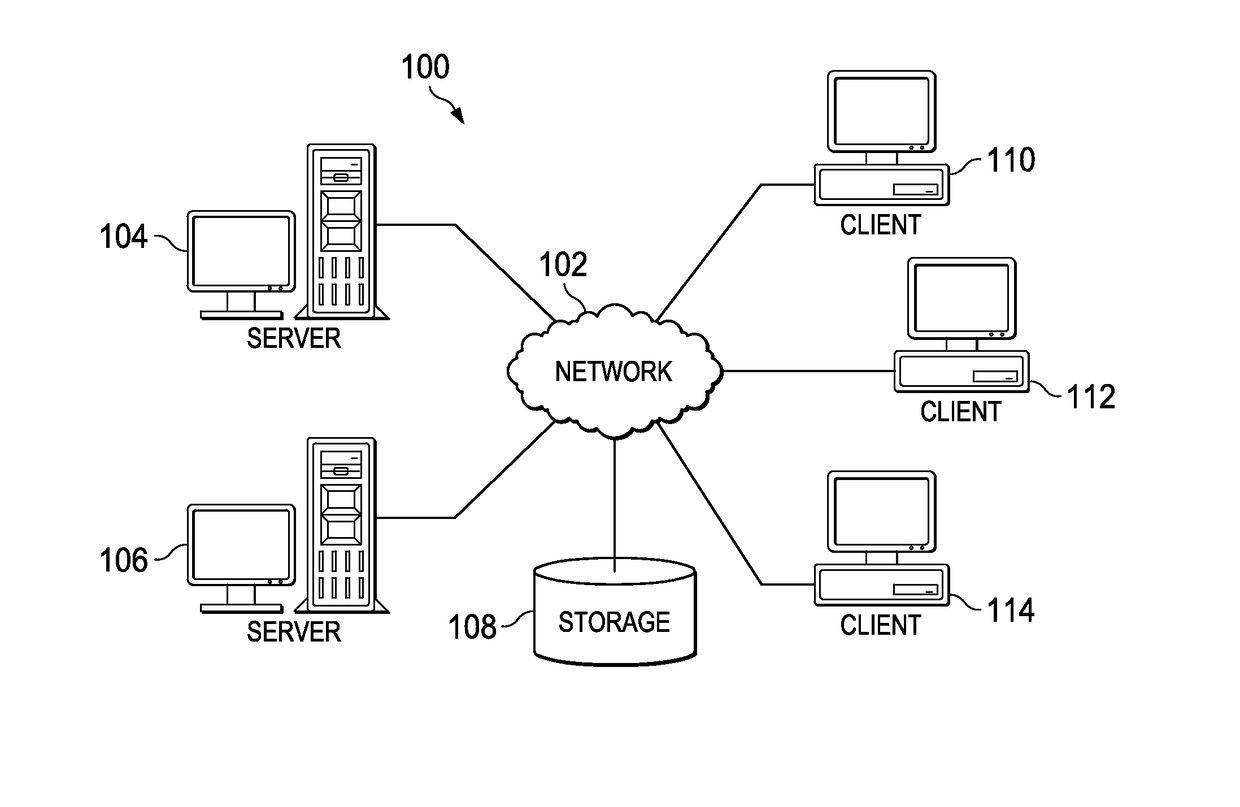

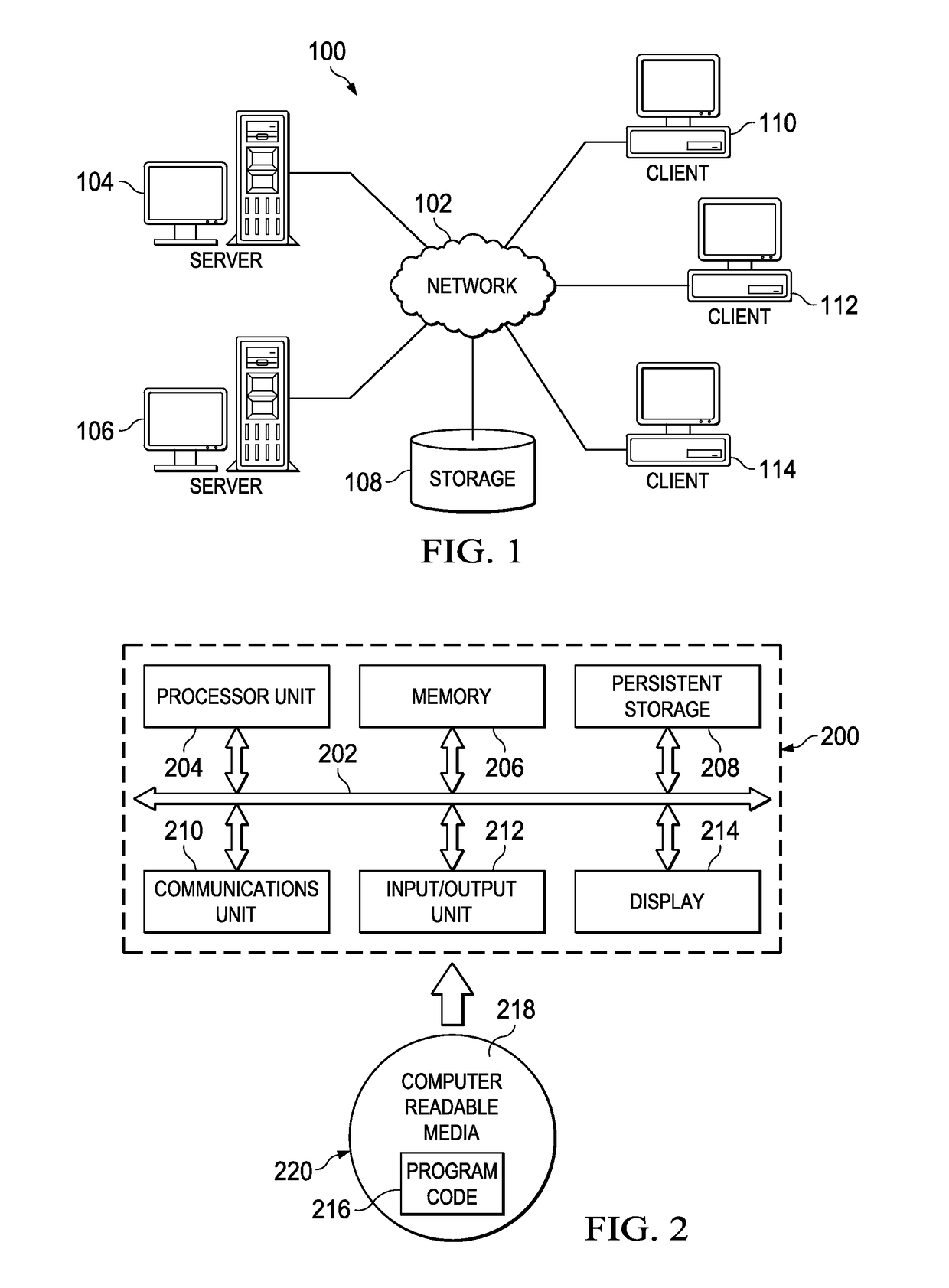

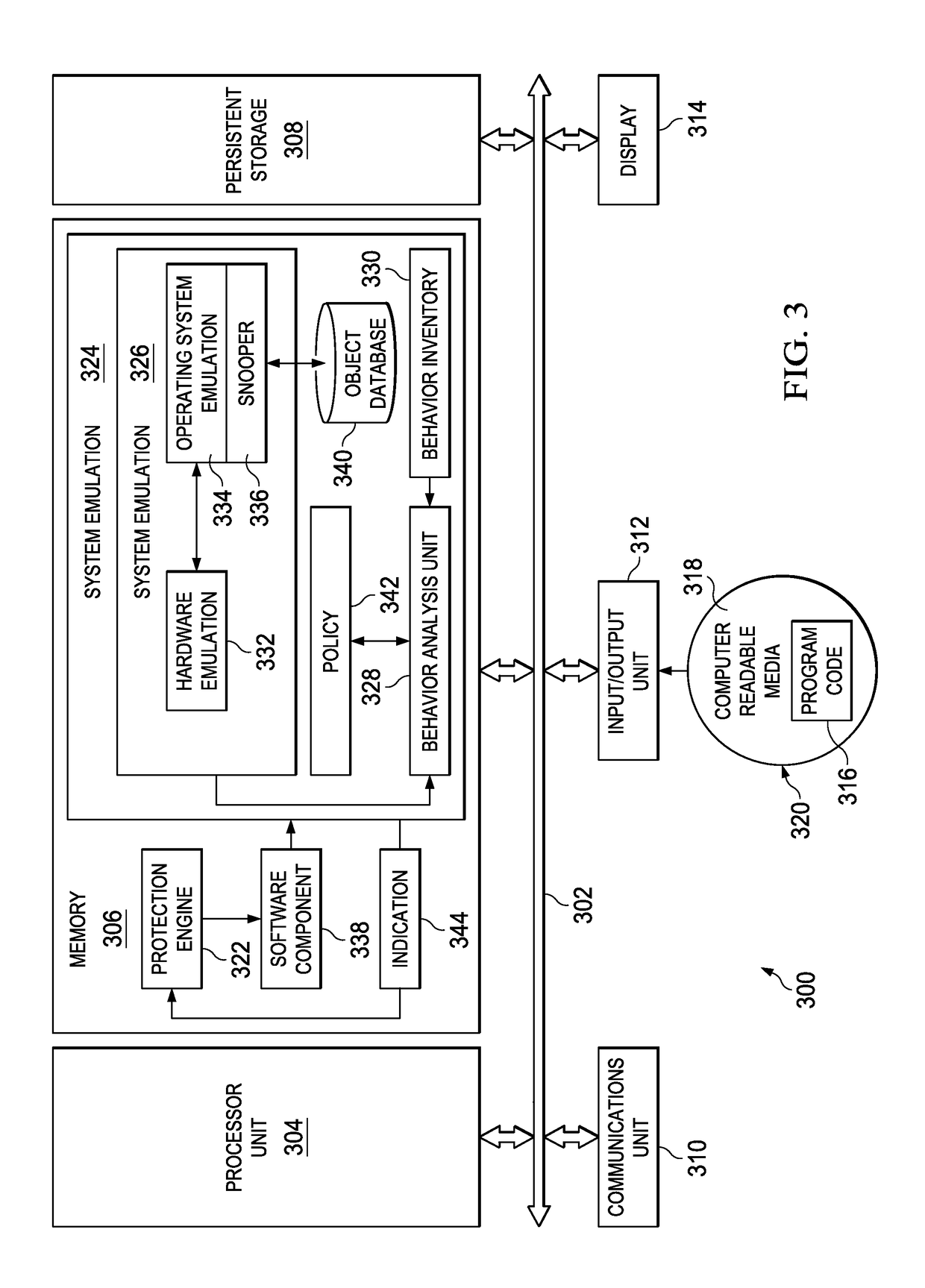

Autonomic exclusion in a tiered delivery network

ActiveUS20170093888A1Platform integrity maintainanceData switching networksIntrusion prevention systemClient-side

An edge device is dynamically reconfigured to block undesired traffic using control information that originates in a core network. The control information is delivered to the device indirectly and, in particular, by a core appliance (e.g., an intrusion prevention system) setting and returning an HTTP cookie to a requesting client. The edge device is pre-configured to respond to HTTP cookies that have (or that are) control information. When the receiving client later returns that cookie to the edge device to obtain subsequent service, the control information that originated at the core is used by the device to deny that service. This indirect method of communicating the control information (from the core to the requesting client and then back to the device) enables the device to be reconfigured dynamically as needed to address network exploits or other threats.

Owner:IBM CORP

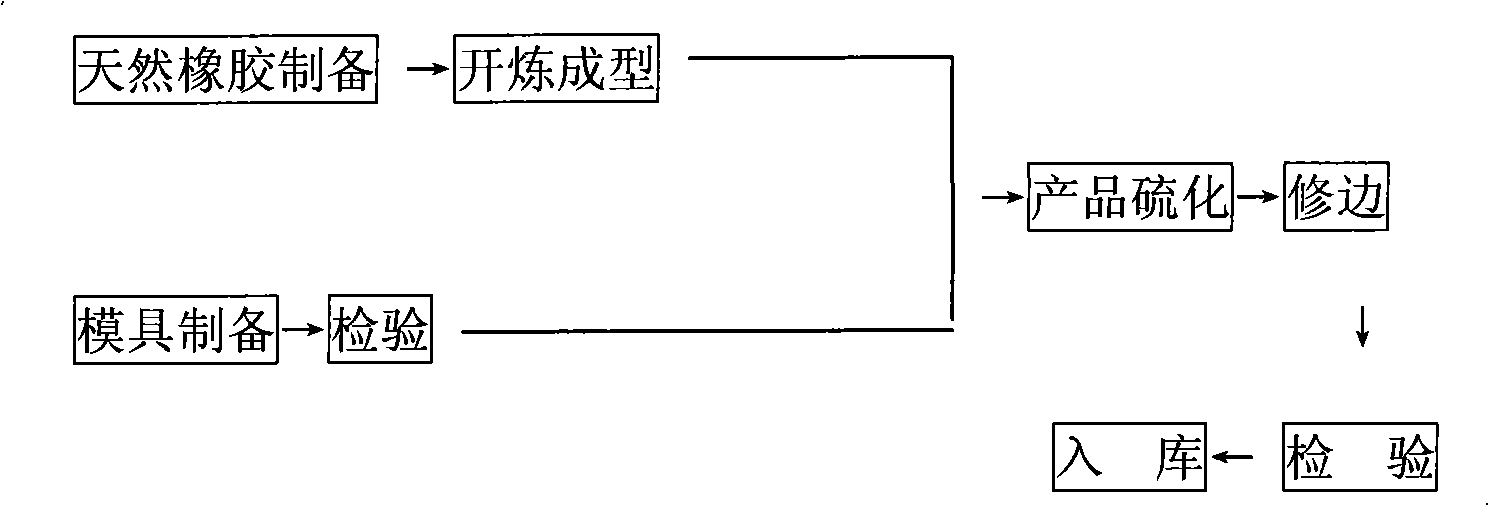

Shock absorption loop for automotive transmission and manufacturing process thereof

InactiveCN101402749AHigh bonding strengthIncrease elasticityRubber-like material springsLow internal friction springsVulcanizationMetal framework

The invention discloses a shock absorption ring used in an automobile transmission system, which is vulcanized by the adoption of a metal framework and rubber. A production technology is as follows: firstly, 80 portions to 120 portions of natural rubber NR, 35 portions to 50 portions of carbon black, 3 potions to 10 portions of high aromatic oil, 3 portions to 5 portions of an anti-aging agent, 1 portion to 2 portions of stearic acid, 4 portions to 6 portions of zinc oxide (indirect method), 1.8 portions to 2.8 portions of sulfur, 1.2 portions to 2.0 portions of an accelerant and 0.2 portion to 0.4 portion of an anti-scorching agent are mixed and kneaded into gross rubber by a Banbury mixer; and the qualified gross rubber after tests is milled and molded, and then put into a mould in a vulcanizer for vulcanization treatment. During the treatment process, the pressurization is carried out till 120 Kgf / cm2 to 160Kgf / cm2 and the temperature rises to 170 DEG C to 180 DEG C. And the treatment lasts for 6min to 8min and finally the obtained shock absorption ring is trimmed, verified and put in storage. The obtained shock absorption ring is characterized by high bonding strength, good elasticity, high damping, stable inherent frequency, good endurance quality and the like, and can improve the comfortability of the automobile and realize vibration absorption and noise reduction.

Owner:ANHUI ZHONGDING SEALING PARTS +1

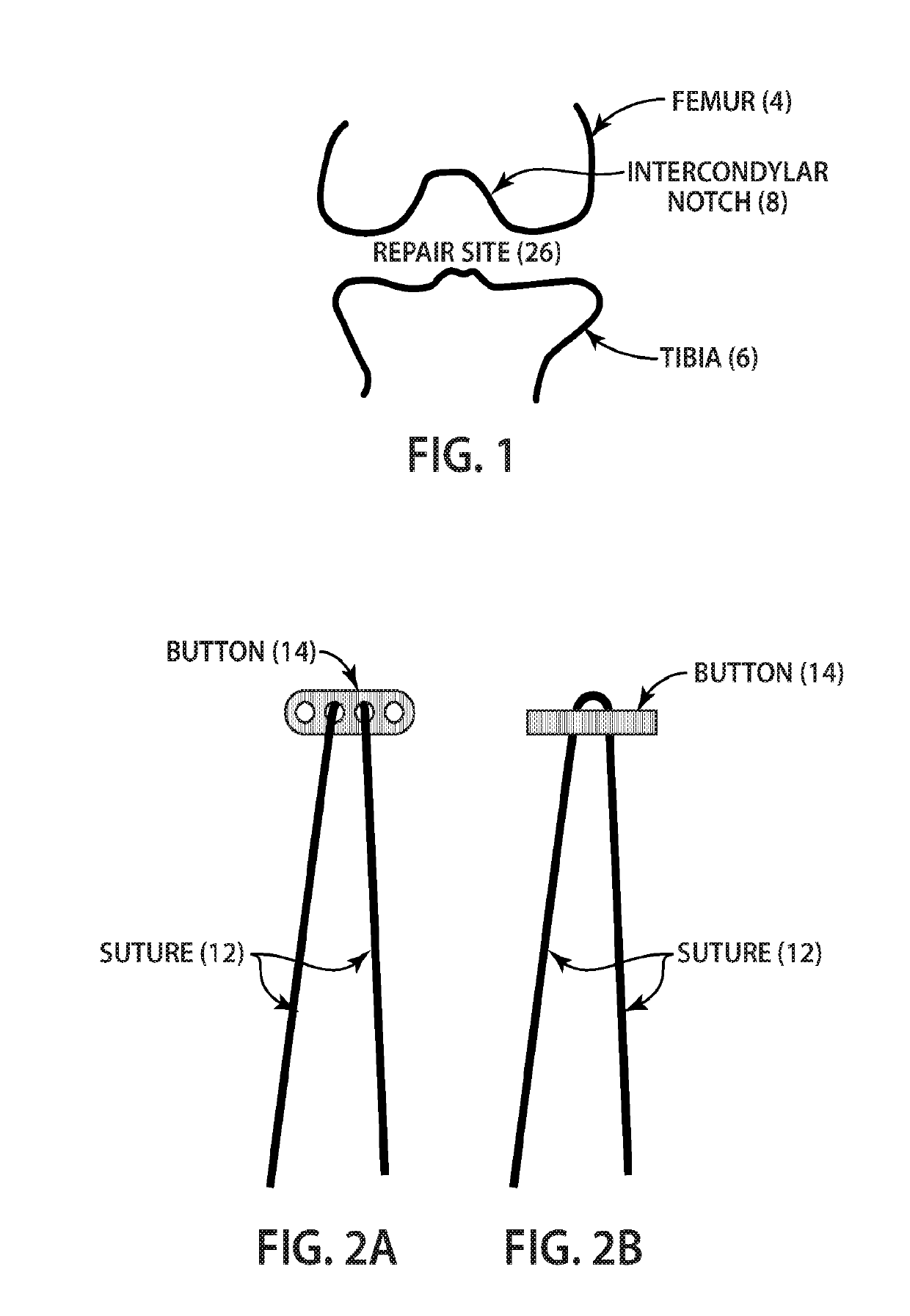

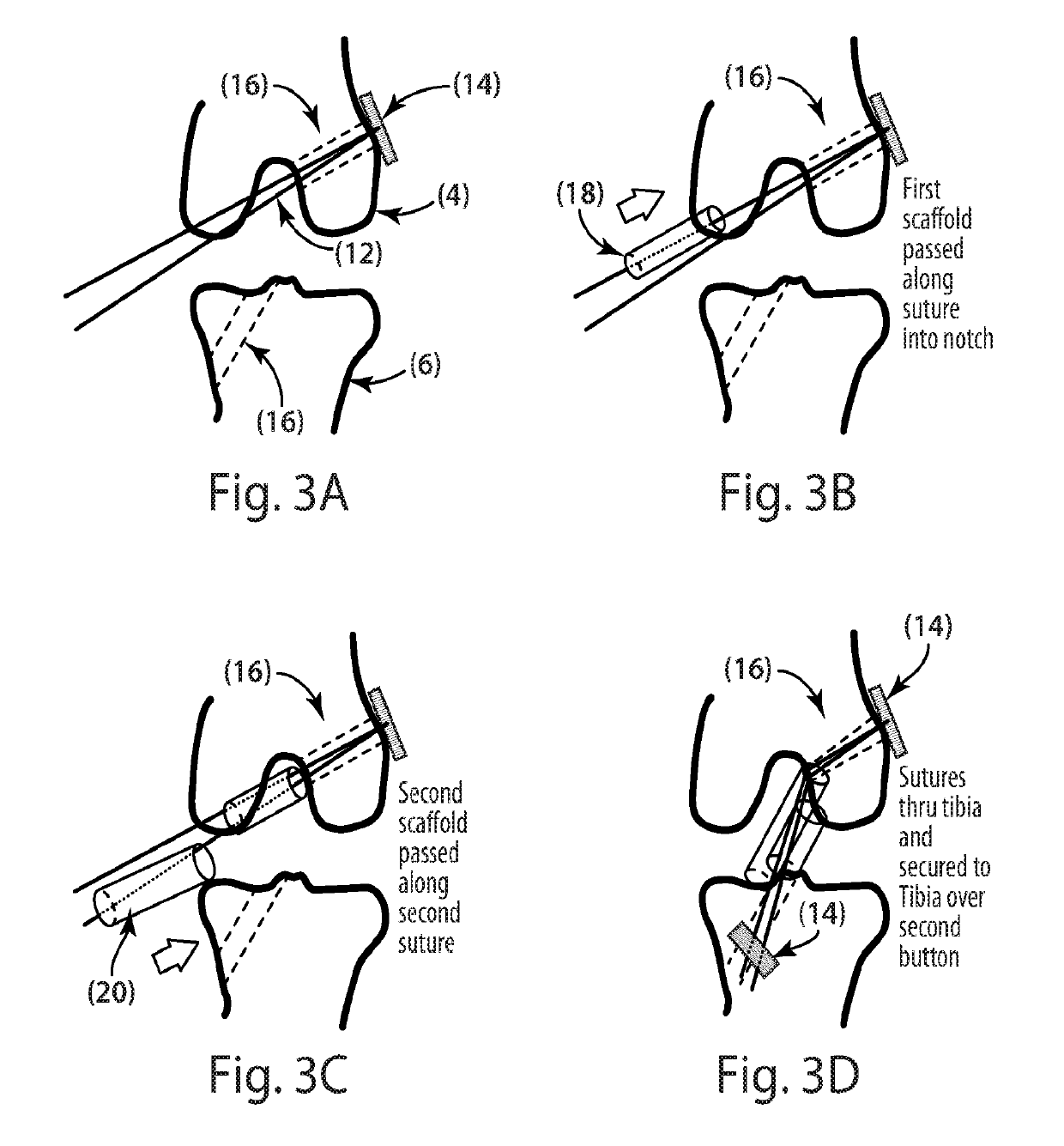

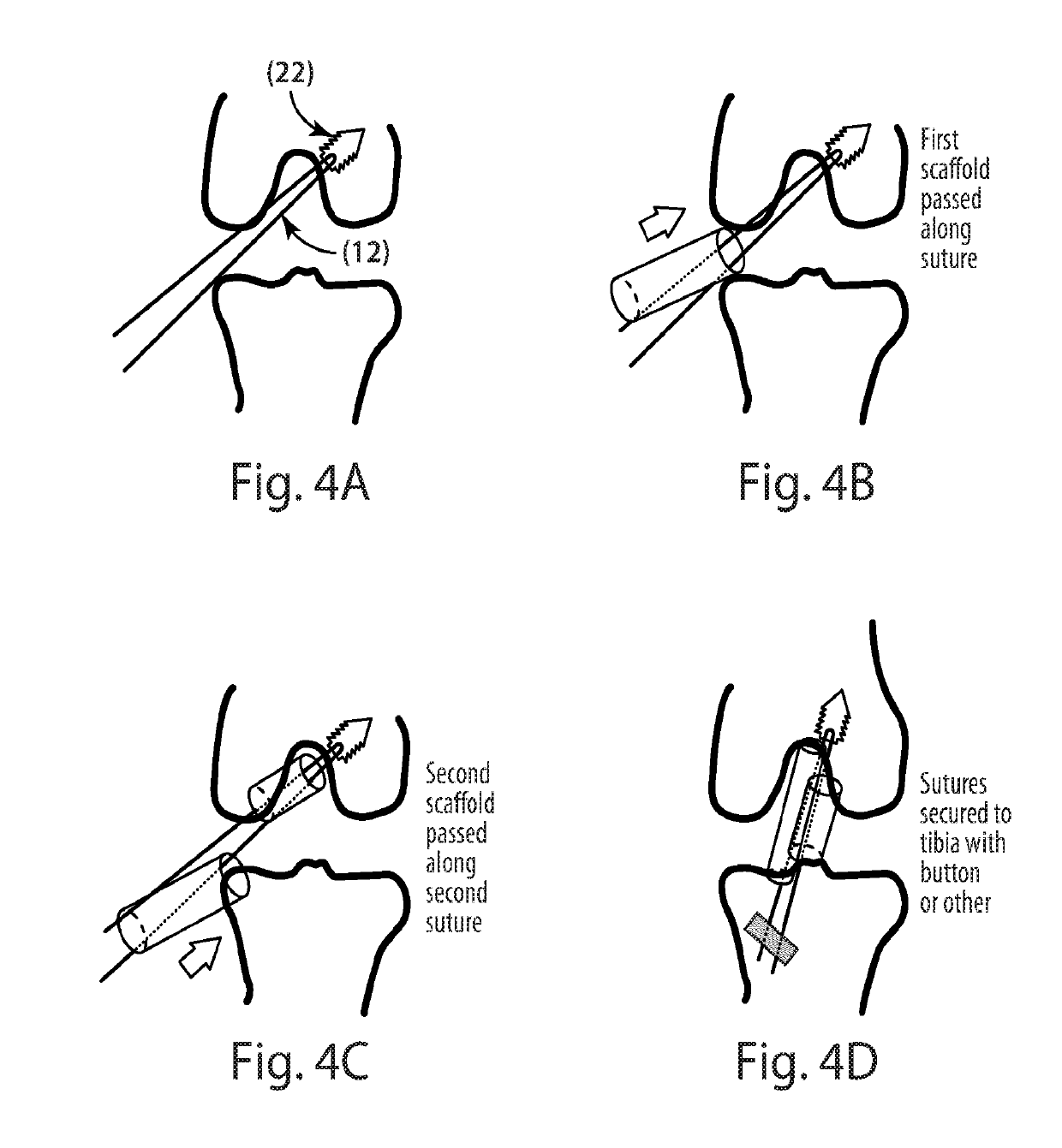

Indirect method of articular tissue repair

Methods and devices for the repair of a torn or injured ligament or tendon are provided. The methods include the use of multiple scaffolds, e.g., beads. The multiple scaffolds may be positioned along a suture or other device such that they are moveable with respect to one another or the injured tissue.

Owner:CHILDRENS MEDICAL CENT CORP +1

Kit for in vitro detection of anti-cyclic citrullinated peptide (CCP) antibody and preparation method thereof

InactiveCN102323402ANo biological toxicitySignificant technological progressMaterial analysisAnti ccp antibodiesImmunosorbents

The invention belongs to the field of biological engineering, and provides a kit for in vitro detection of an anti-cyclic citrullinated peptide (CCP) antibody, which comprises a detection plate, a CCP antigen, a colloidal gold-labeled recombinant gold staphylococcus aureus A protein conjugate, a confining liquid, a washing liquid, a positive reference product and a negative reference product. The invention also provides a preparation method of the kit for the in vitro detection of the anti-CCP antibody. The kit adopts an indirect method immunosorbent assay principle to detect the anti-CCP antibody in a human serum, the CCP antigen is coated on a nitrocellulose membrane to be made into a solid-phase antigen for capturing the anti-CCP antibody in the human serum, and then colloidal gold is labeled on staphylococcus aureus A protein (SPA) to form the colloidal gold conjugate as a tracer; and if the detected human serum contains the anti-CCP antibody, then a solid phase antigen-anti-CCP antibody-colloid gold conjugate is formed and has red spots. The invention can be applied to the auxiliary diagnosis of rheumatoid arthritis.

Owner:上海精臻生物科技有限公司

Electric insulating rubber and fabrication method thereof

ActiveCN103254518ASimplified Recipe StructureMeet production needsRubber insulatorsRubber materialEthylene-propylene-diene-monomer

The invention belongs to the technical field of rubber, discloses electric insulating rubber and a fabrication method thereof, and aims at providing electric insulating rubber which is good in insulativity and simple in fabrication method. The electric insulating rubber adopts the technical scheme that the electric insulating rubber comprises the following components in parts by weight: 100 parts of EPDM (Ethylene-Propylene-Diene Monomer), 20-30 parts of calcined kaolin, 0.1-0.3 parts of thiofide PZ, 1-2 parts of stearic acid, 30-40 parts of paraffin oil, 5-8 parts of indirect-method zinc oxide, 0.3-0.5 parts of rubber accelerator CZ, 5 parts of liquid EPDM, 15-25 parts of fumed silica, 0.5-1.5 parts of silane coupling agent, 1-2 parts of sulfur and 1-2 parts of rubber accelerator DM. The fabrication method of the electric insulating rubber comprises the following steps of 1) weighing the components, 2) conducting internal mixing by sections, 3) adding sulfur to an open mill for mixing, and outputting sheet rubber, and 4) placing for 4-8h to allow rubber materials to be more uniform.

Owner:武汉科能电气有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com