Patents

Literature

1909results about "Electrical/magnetic thickness measurements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Material erosion monitoring system and method

ActiveUS20150276577A1Reduce confusionMultiple EffectsFurnace componentsWeather/light/corrosion resistanceMaterial ErosionMonitoring system

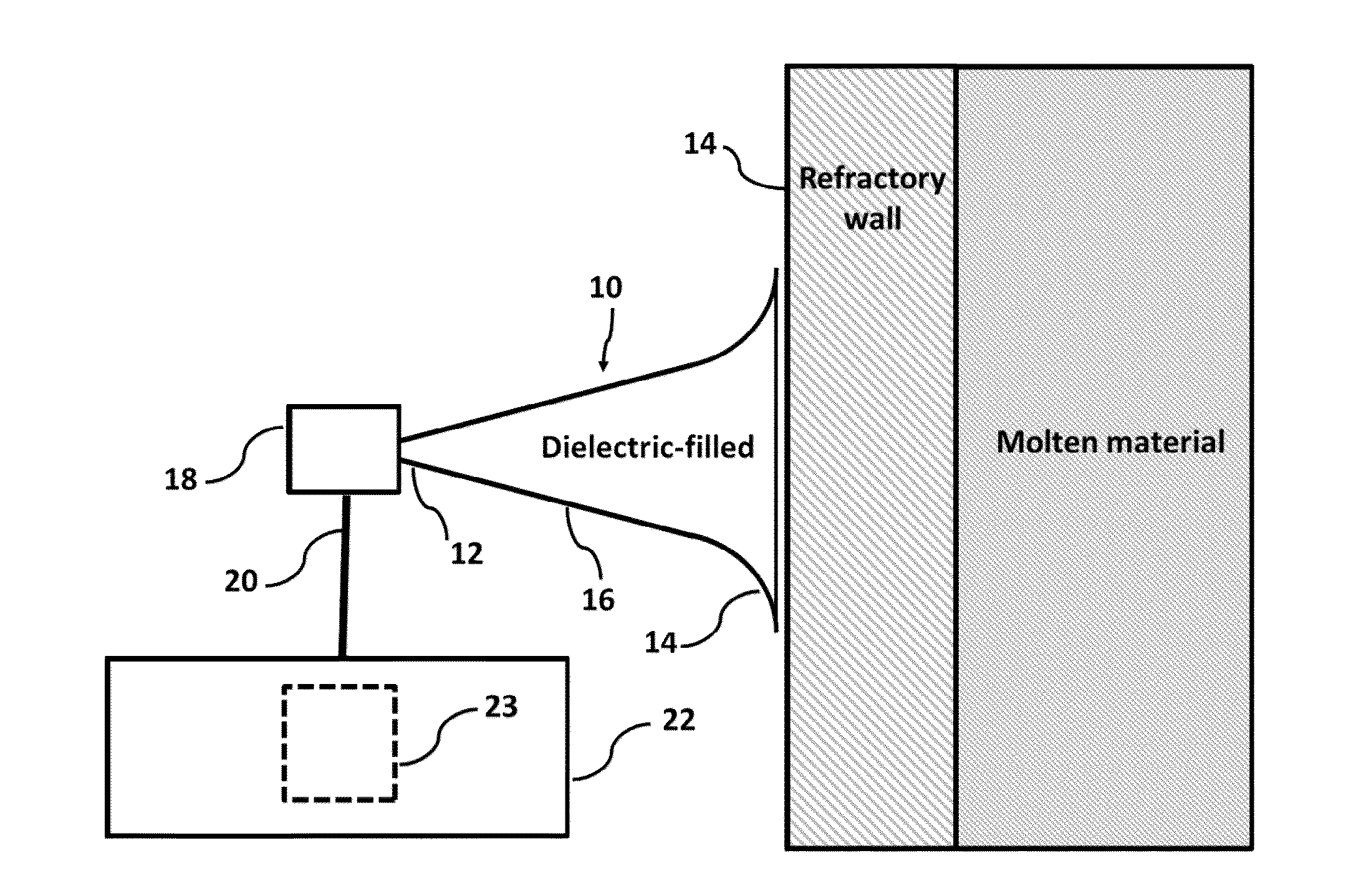

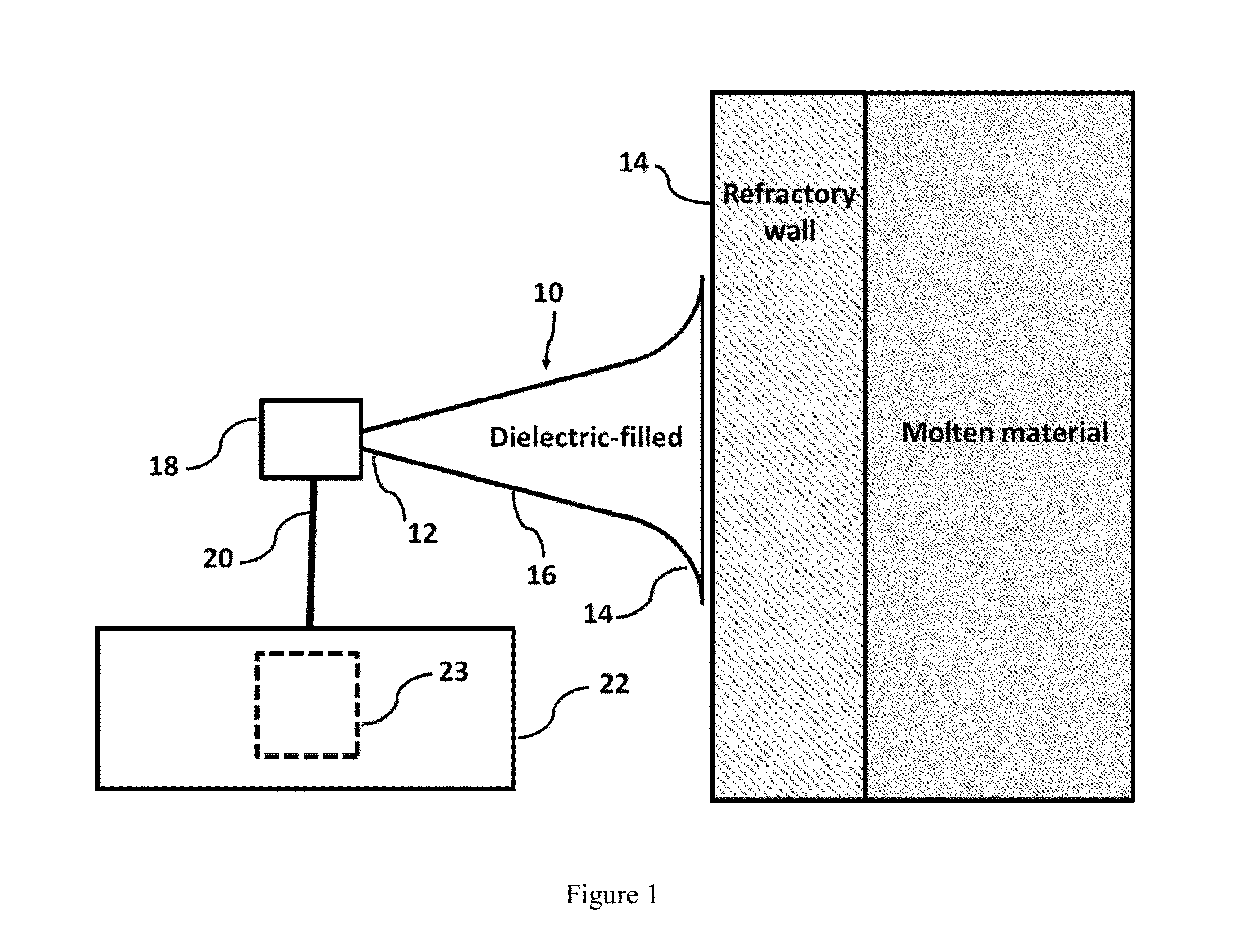

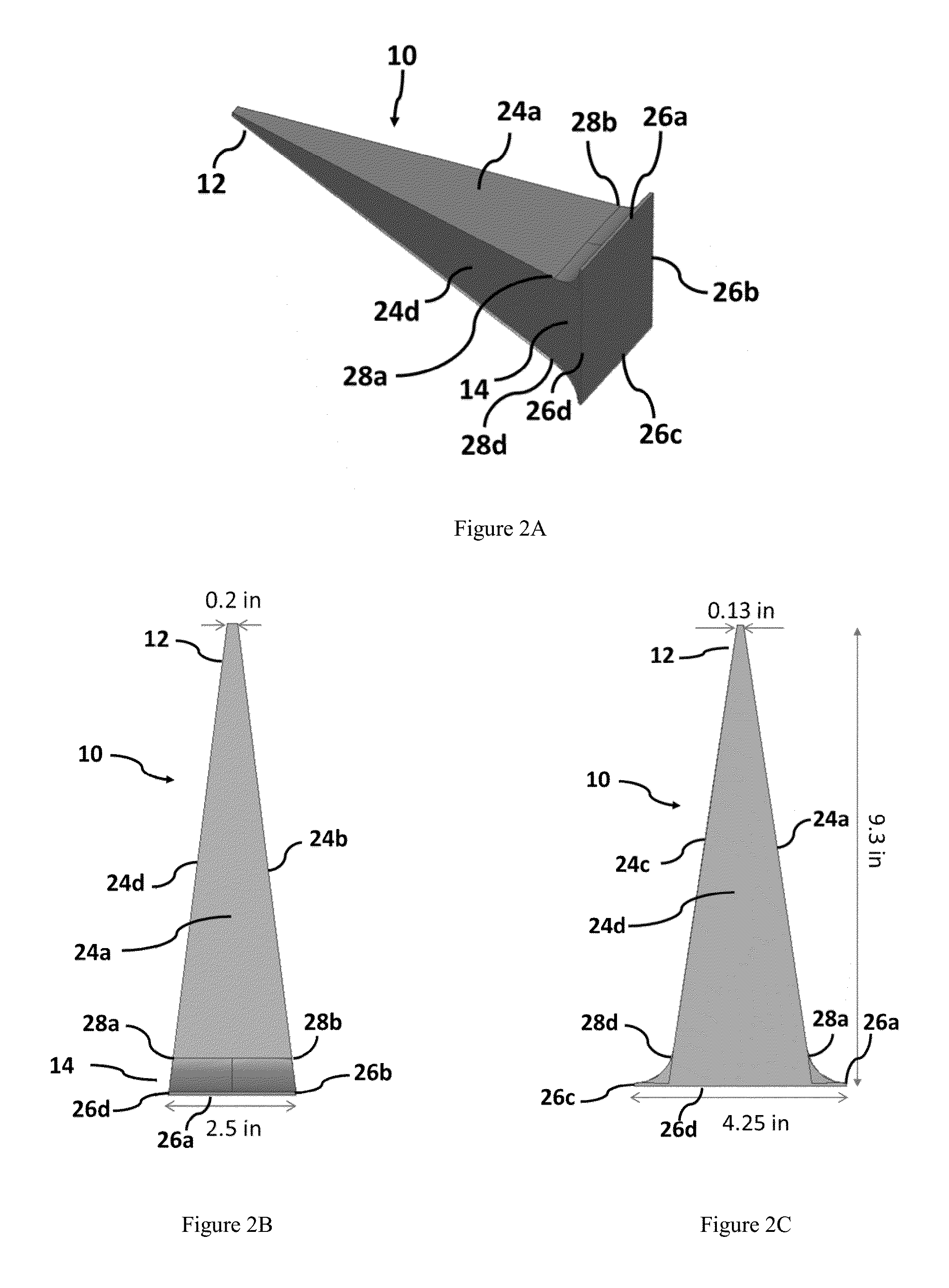

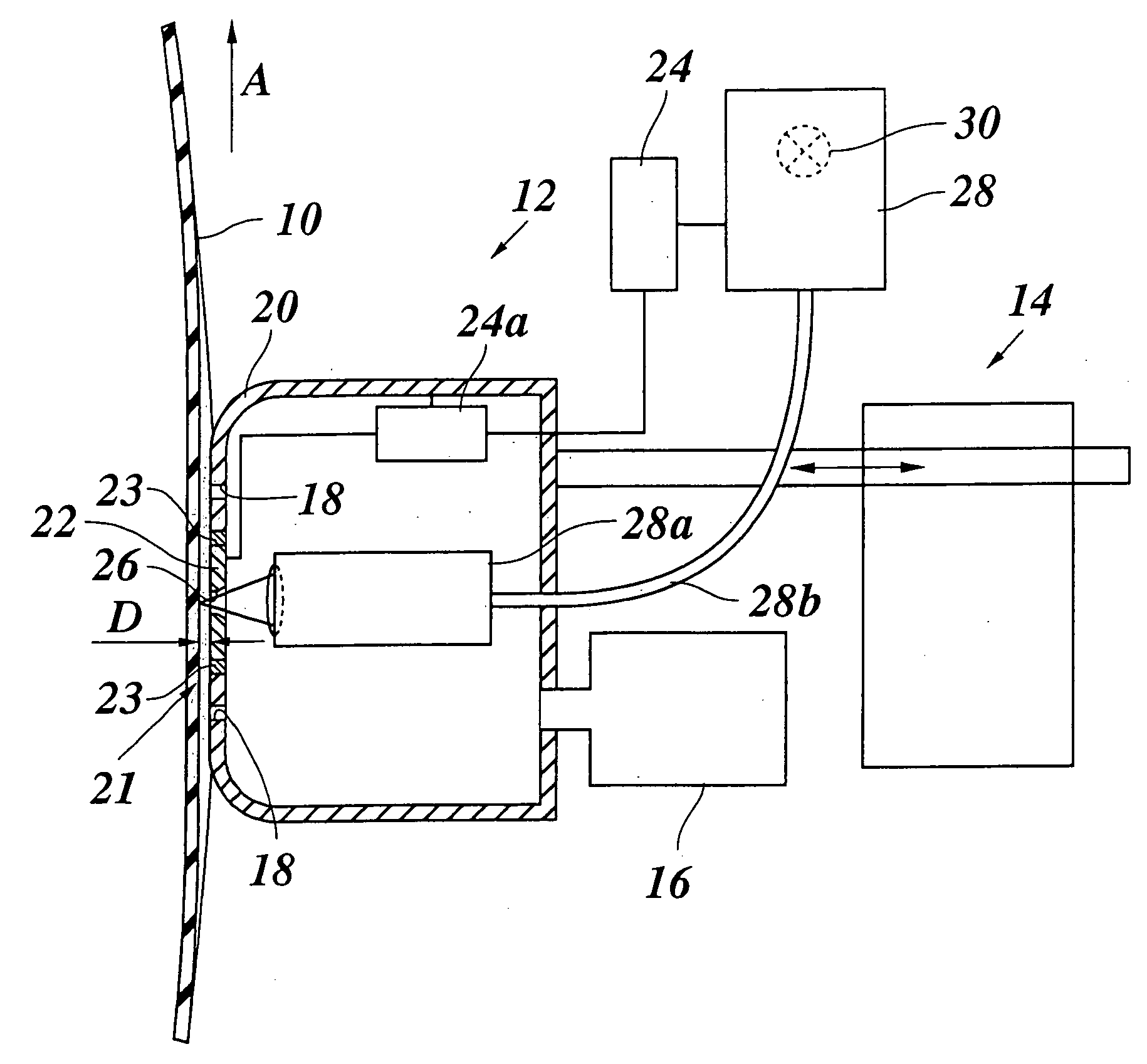

Disclosed is an improved system and method to evaluate the status of a material. The system and method are operative to identify flaws and measure the erosion profile and thickness of different materials, including refractory materials, using electromagnetic waves. The system is designed to reduce a plurality of reflections, associated with the propagation of electromagnetic waves launched into the material under evaluation, by a sufficient extent so as to enable detection of electromagnetic waves of interest reflected from remote discontinuities of the material. Furthermore, the system and method utilize a configuration and signal processing techniques that reduce clutter and enable the isolation of electromagnetic waves of interest. Moreover, the launcher is impedance matched to the material under evaluation, and the feeding mechanism is designed to mitigate multiple reflection effects to further suppress clutter.

Owner:PANERATECH

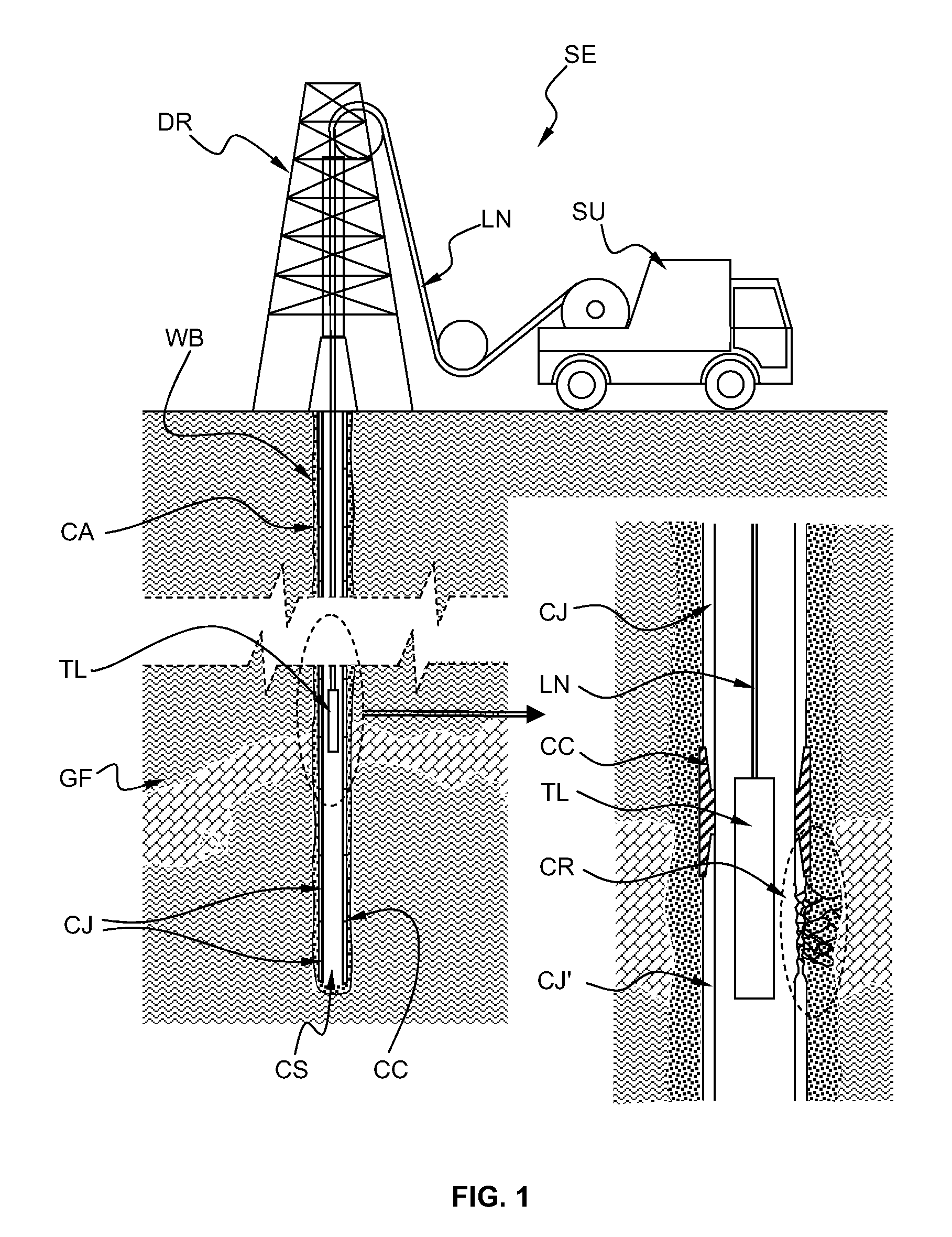

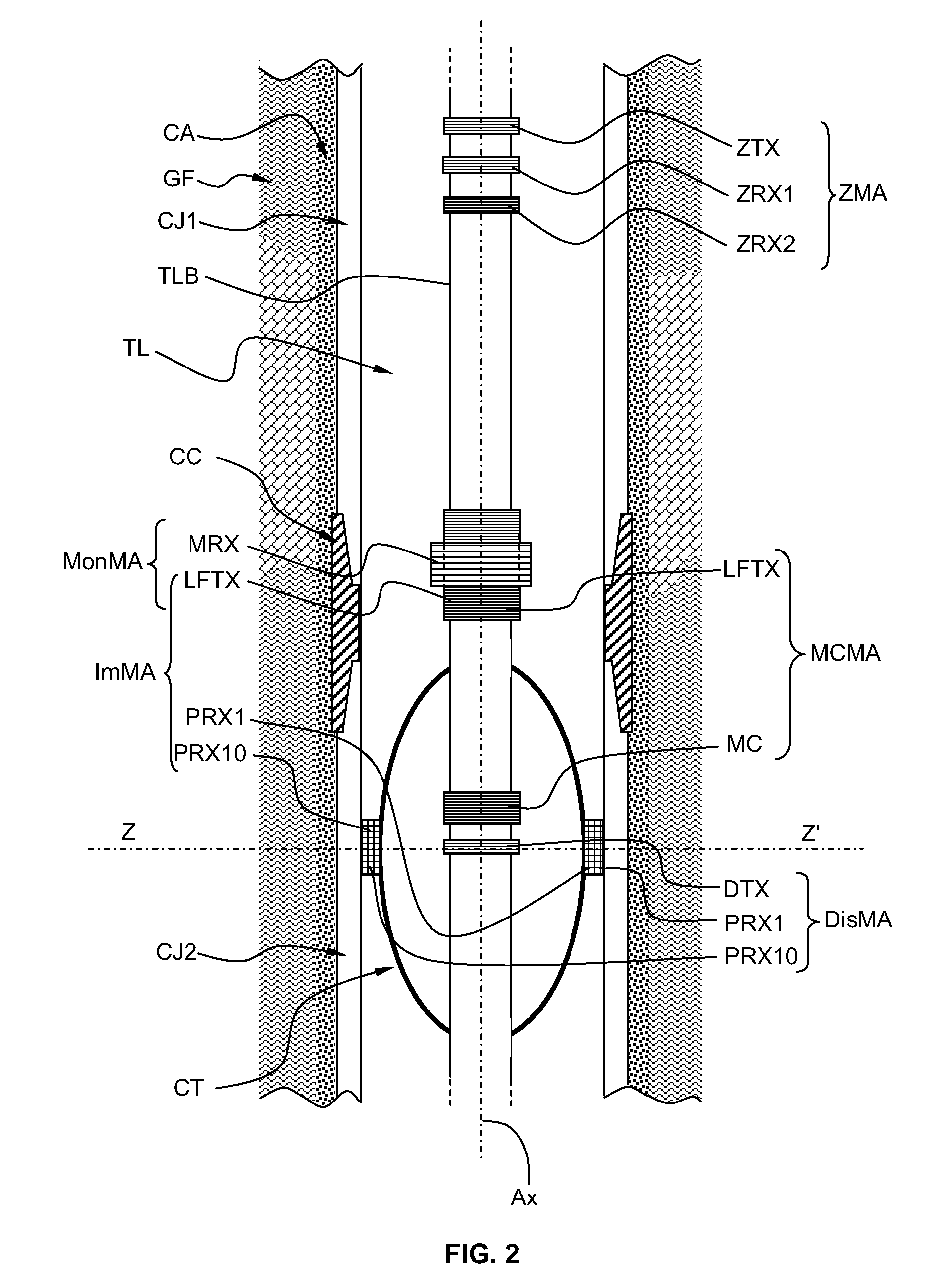

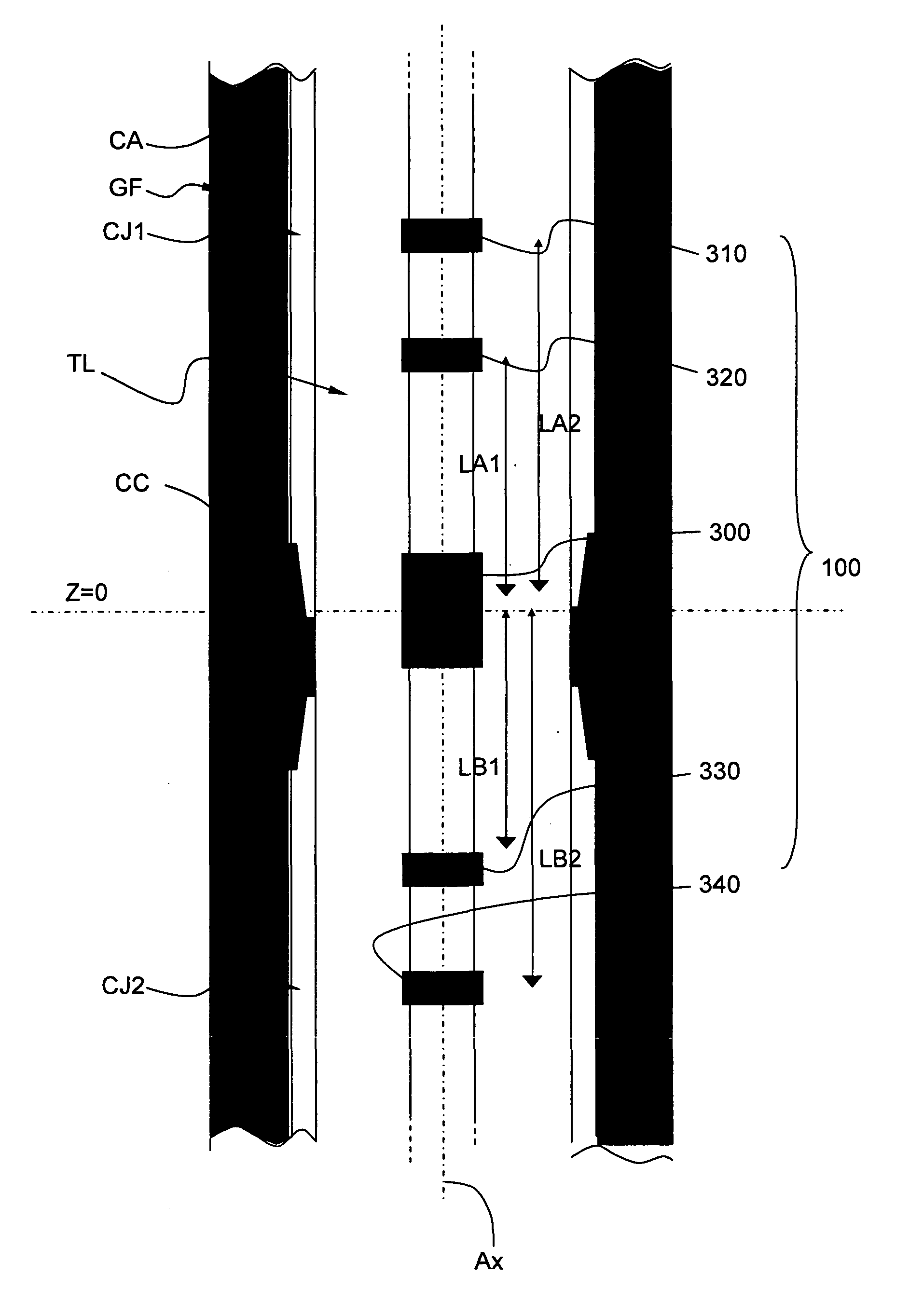

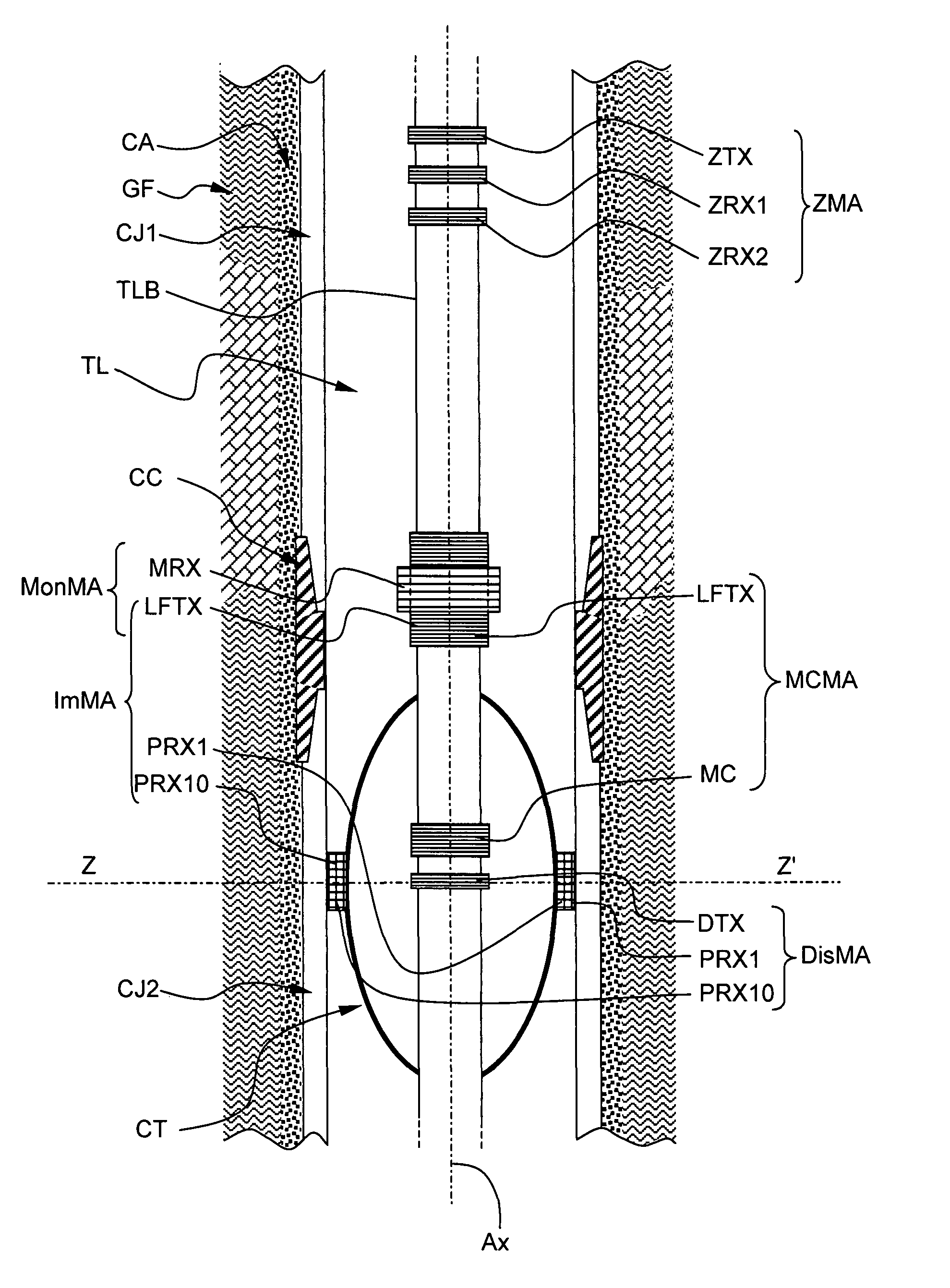

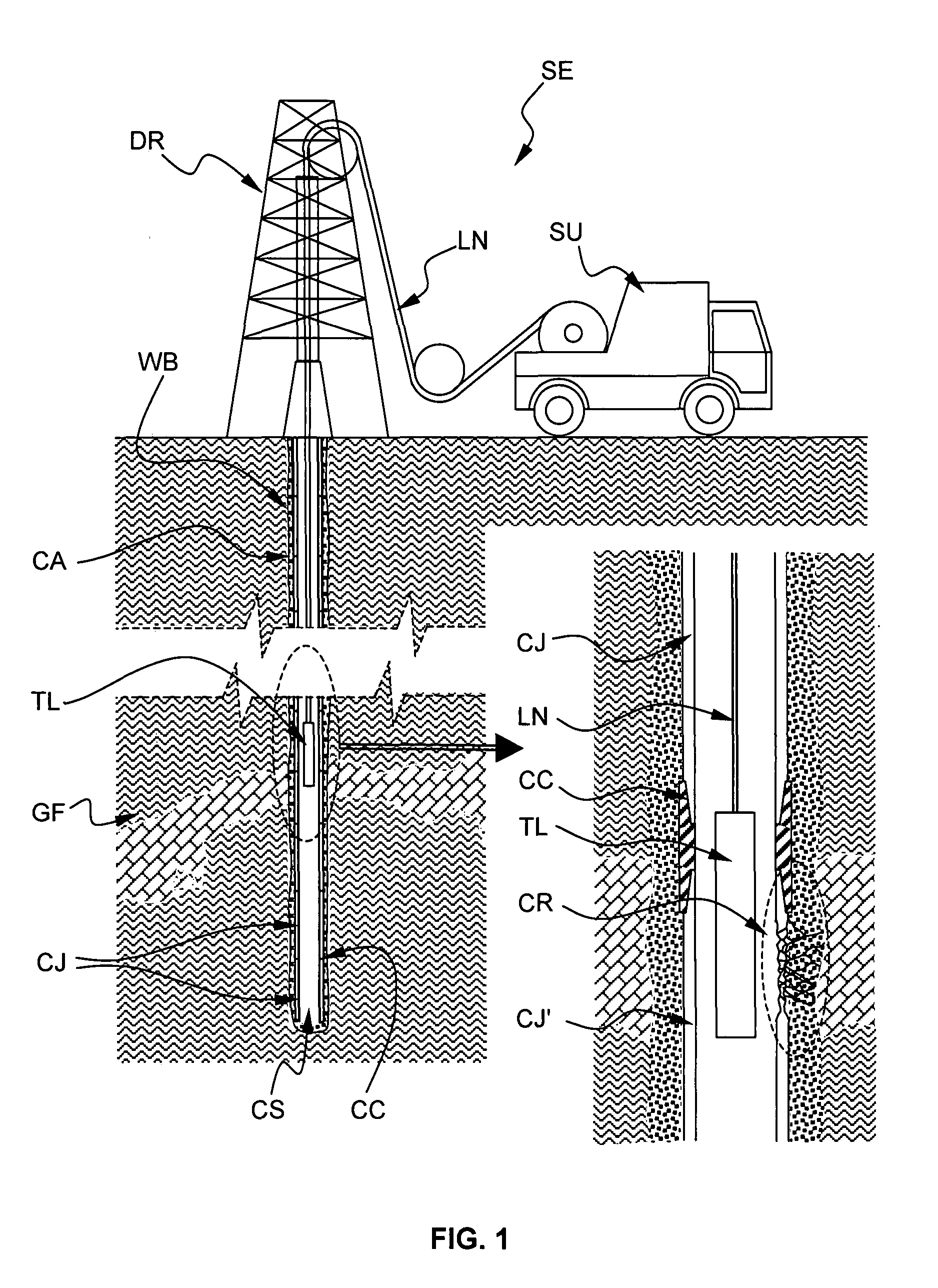

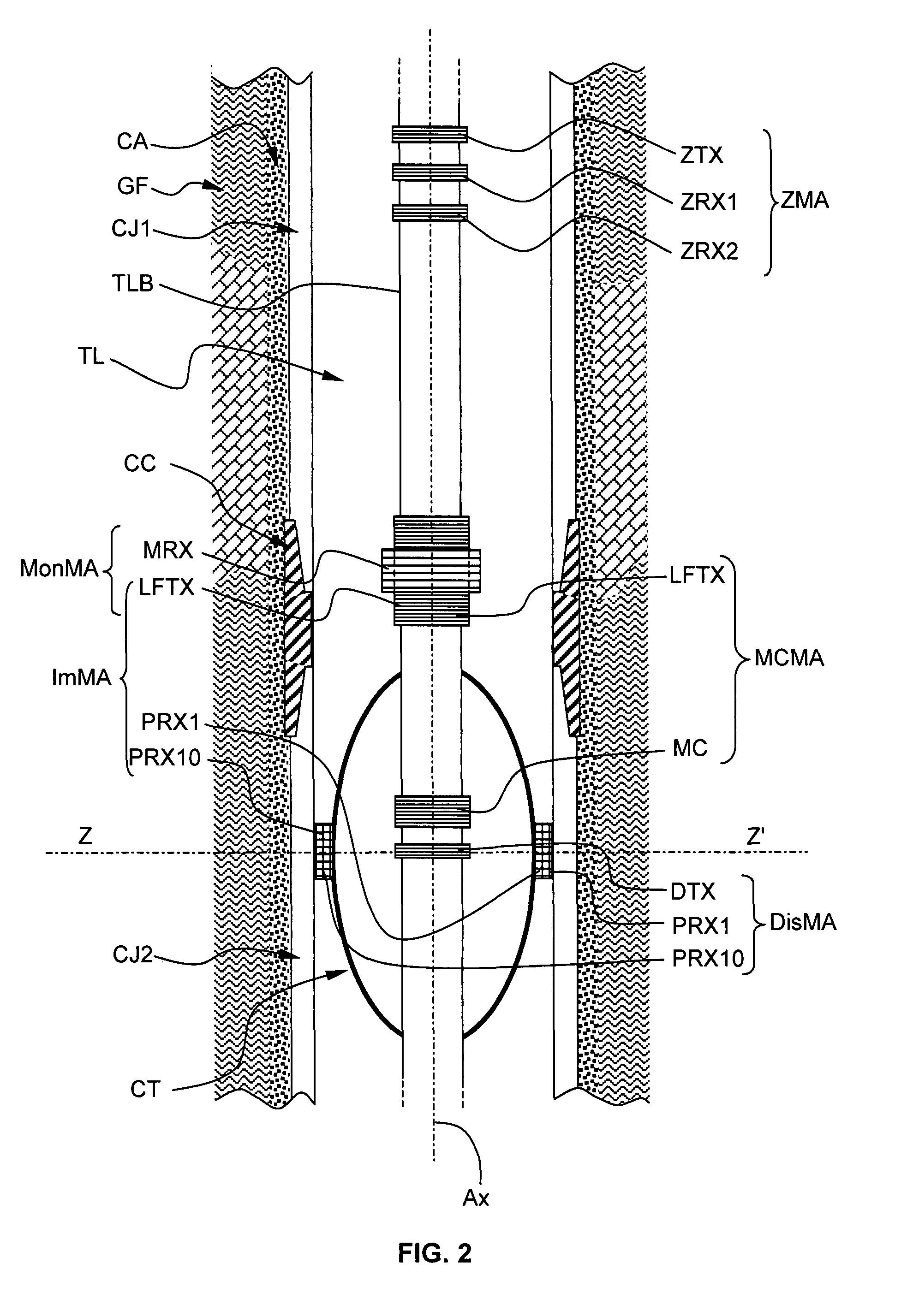

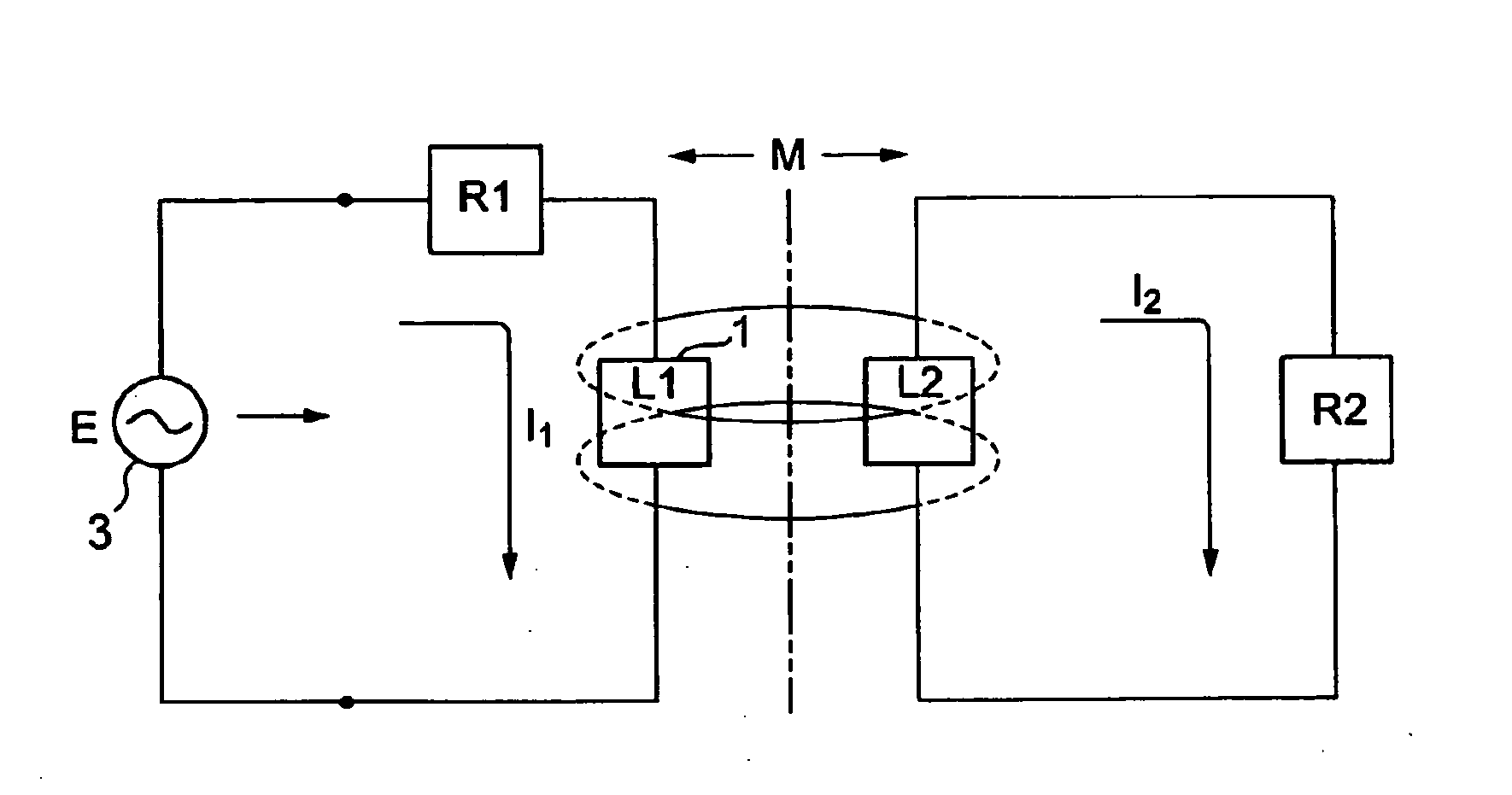

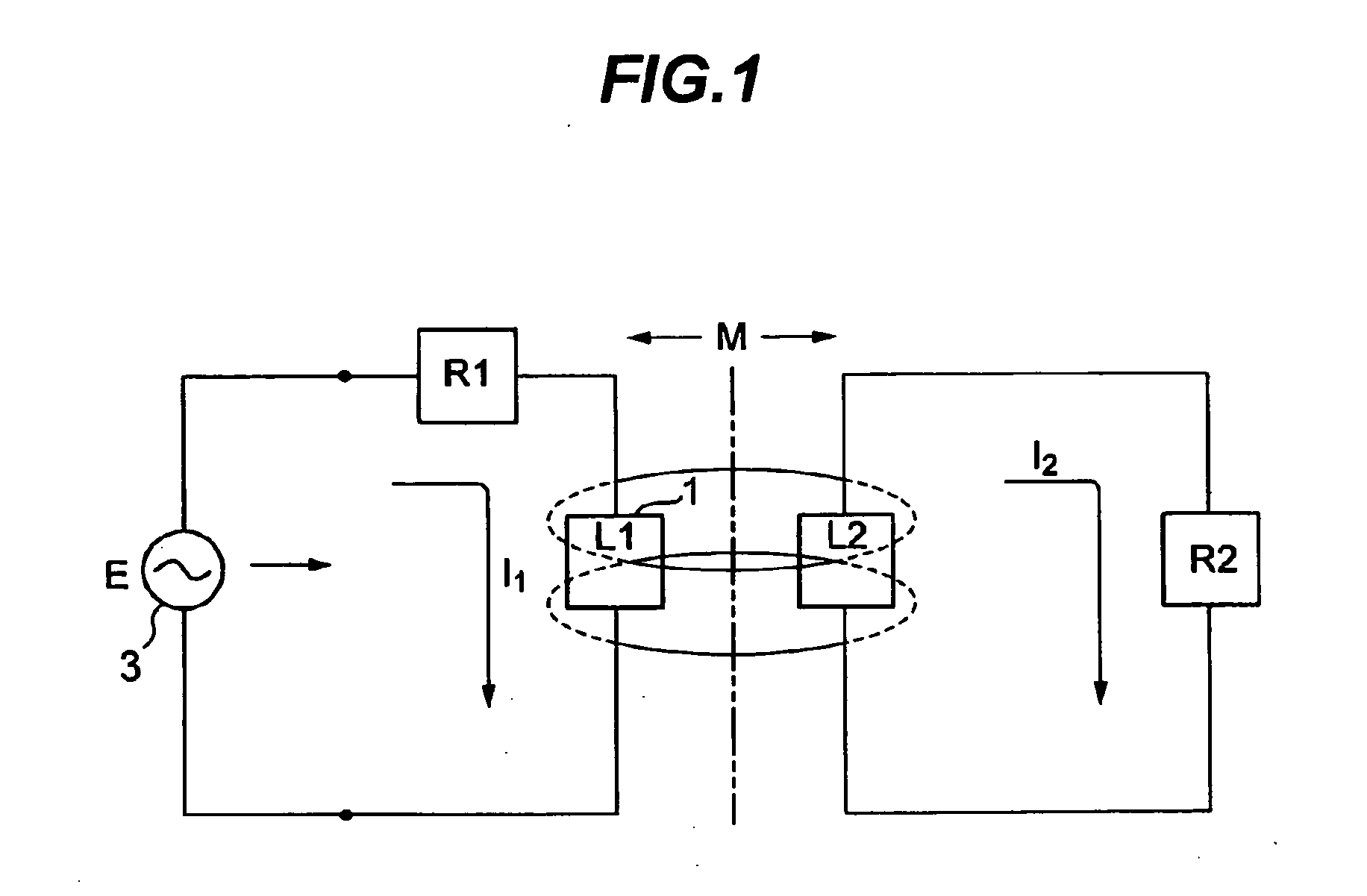

Electromagnetic imaging method and device

InactiveUS20090195244A1Accurate electromagnetic imageImprove accuracyElectric/magnetic detection for well-loggingMagnetic property measurementsTransmitter coilElectrical resistivity and conductivity

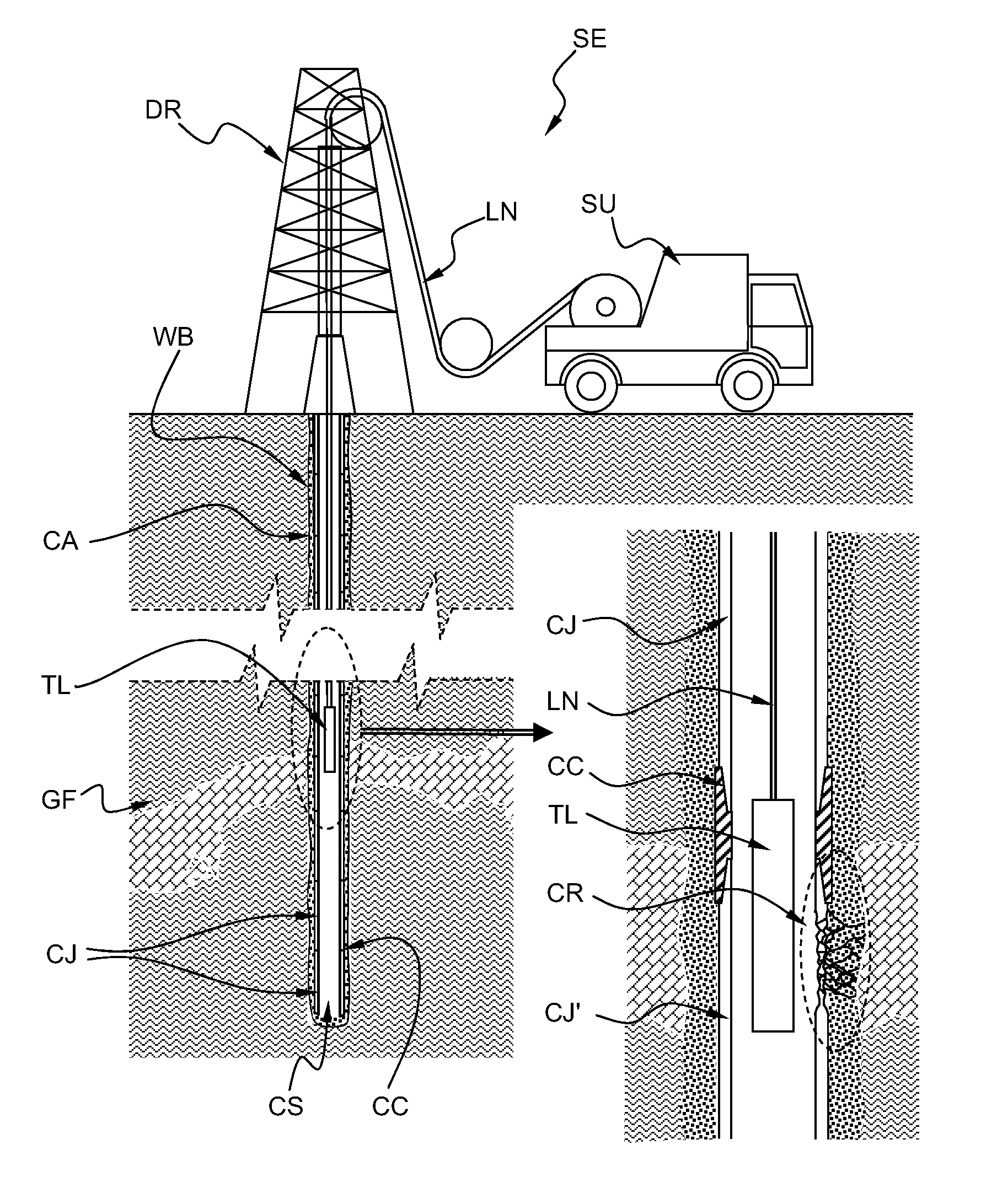

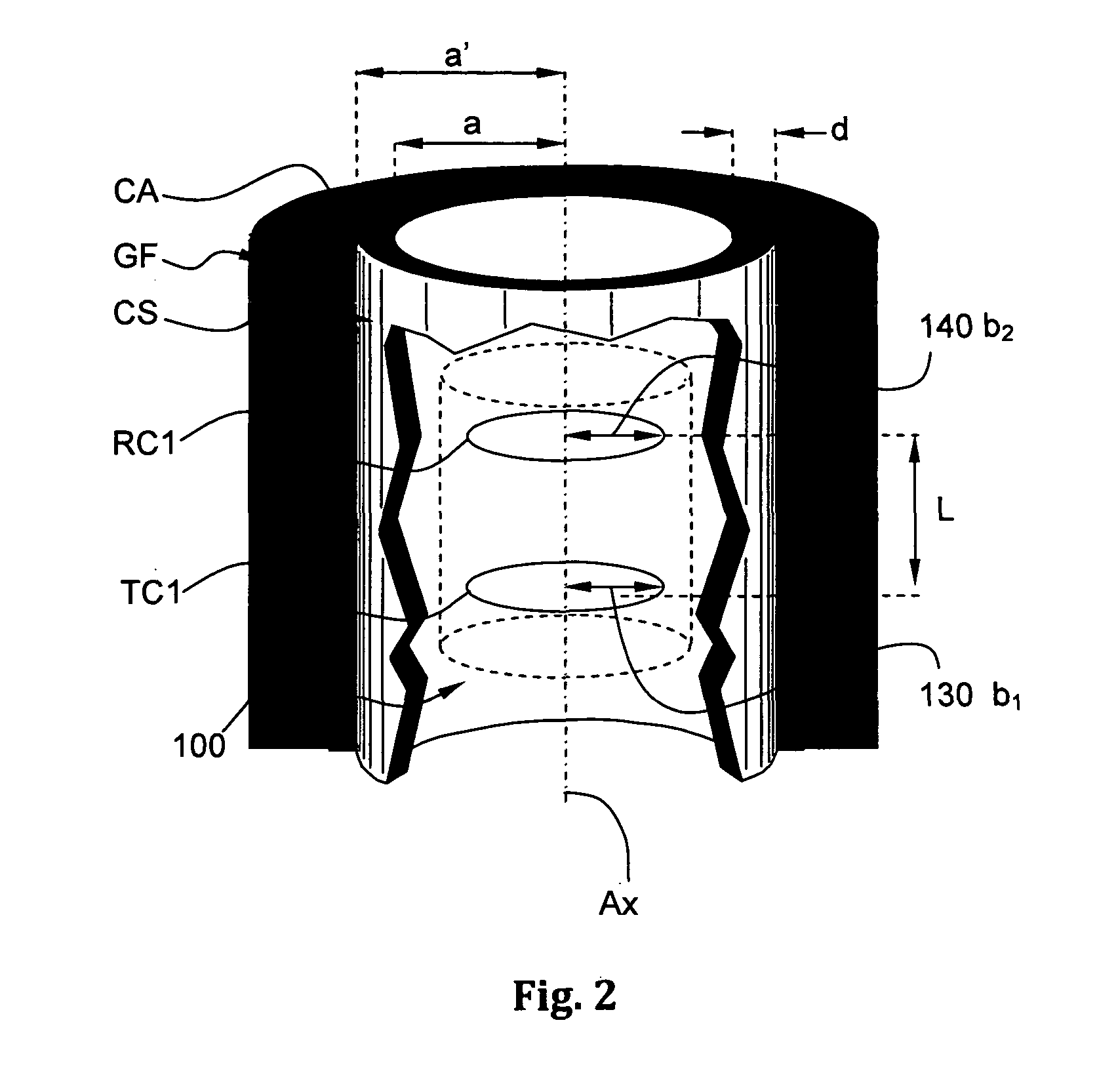

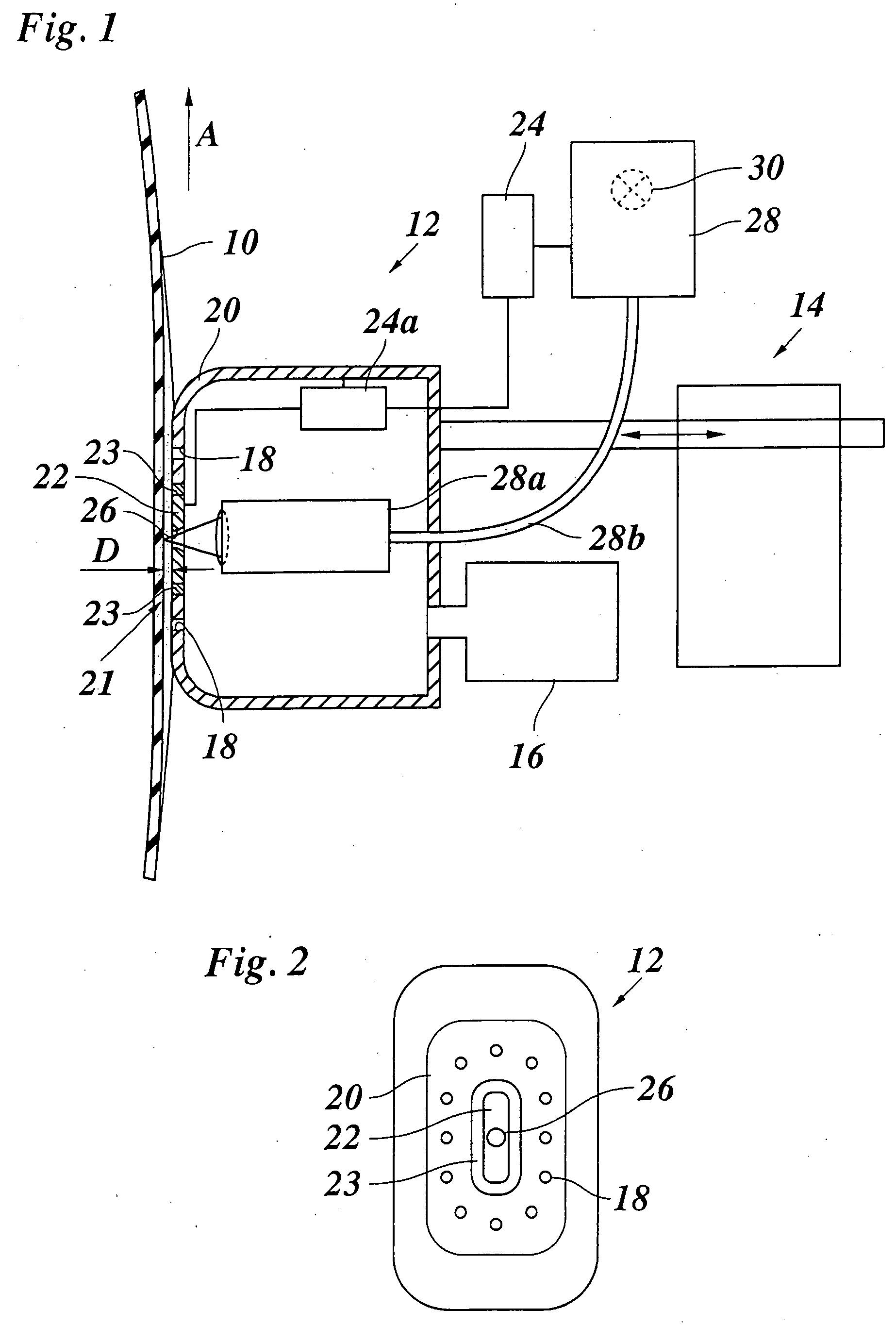

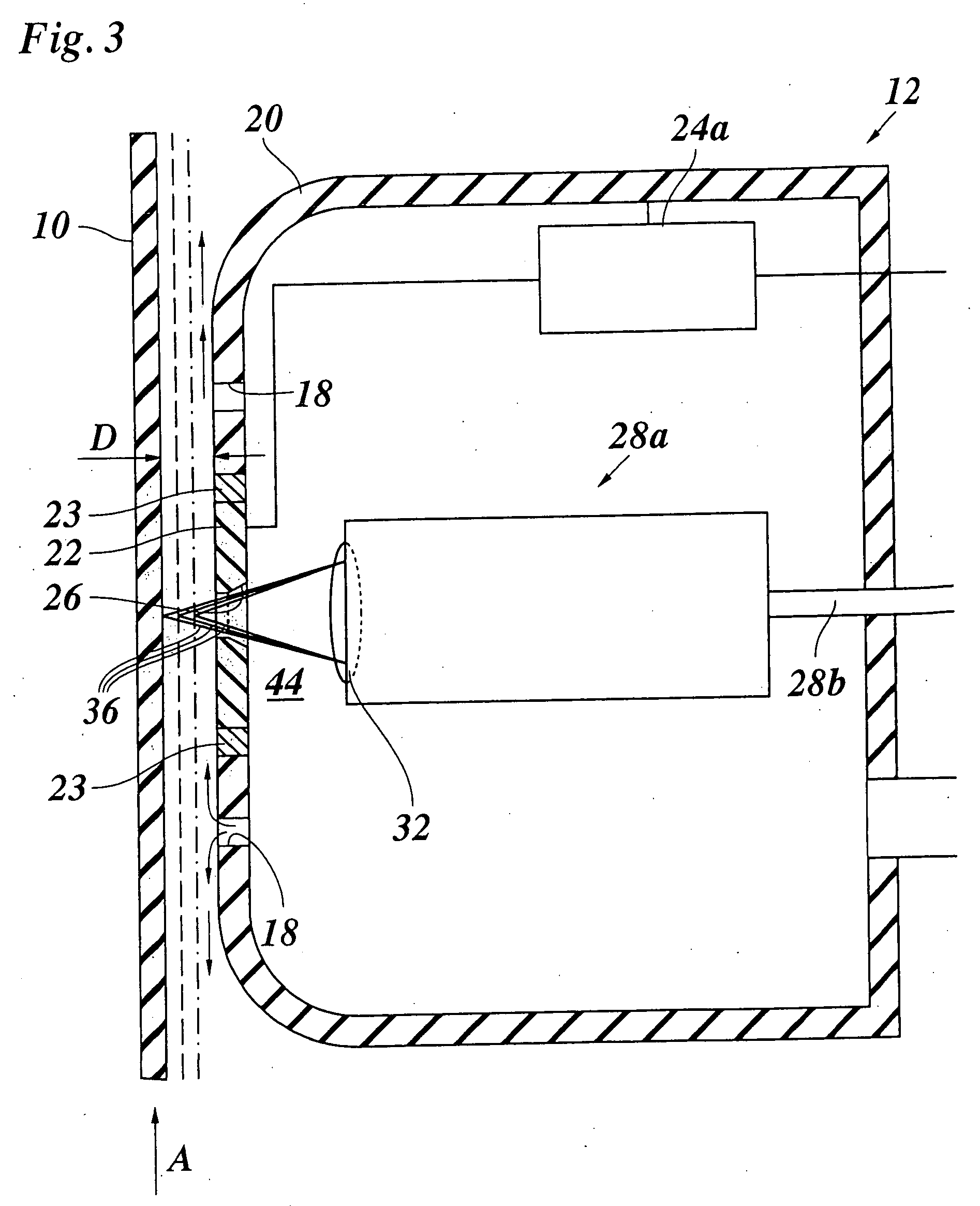

An electromagnetic imaging method for electromagnetically measuring physical parameters of a pipe CJ, CC by means of a plurality of measuring arrangement ZMA, MCMA, MonMa, ImMA comprising a plurality of transmitter coil ZTX, LFTX, DTX and a plurality of receiver coil ZRX1, ZR2, MRX, MC, PRX1, PRX2, PRX3, PRX4, PRX5, PRX6, PRX7, PRX8, PRX9, PRX10, PRX11, PRX12, PRX13, PRX14, PRX15, PRX16, PRX17, PRX18, the transmitter coils and receiver coils being associated so as to form the plurality of measuring arrangement, the plurality of measuring arrangement being adapted to be positioned into the pipe and displaced through the pipe, the physical parameters being measured for a plurality of position along the pipe, the method comprising the steps of:a) determining a first value of an average ratio of magnetic permeability to electrical conductivity and a first value of an average inner diameter of the pipe Z-MES,b) determining an average electromagnetic thickness of the pipe MC-MES,c) determining a second value of the average ratio of magnetic permeability to electrical conductivity and a second value of the average inner diameter of the pipe Mon-MES according to excitation frequencies which are substantially lower than the excitation frequencies used to determine the first values Z-MES,d) determining a first image EMTIM of the pipe electromagnetic thickness and the pipe defects Im-MES,e) discriminating the defects at an inside perimeter of the pipe from the defects at an outside perimeter of the pipe Dis-MES, andf) forming a corrected first image IOFIM of the pipe taking into account a position of the defects.

Owner:SCHLUMBERGER TECH CORP

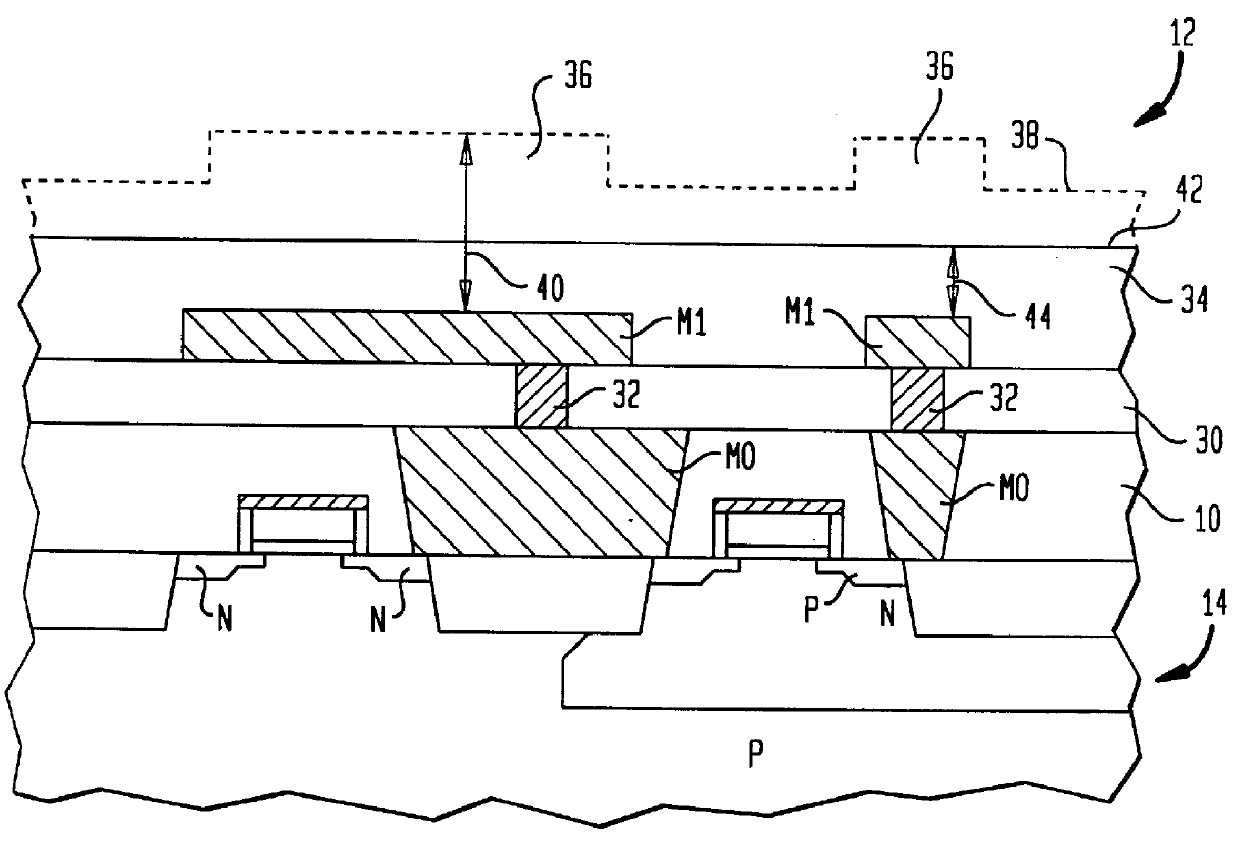

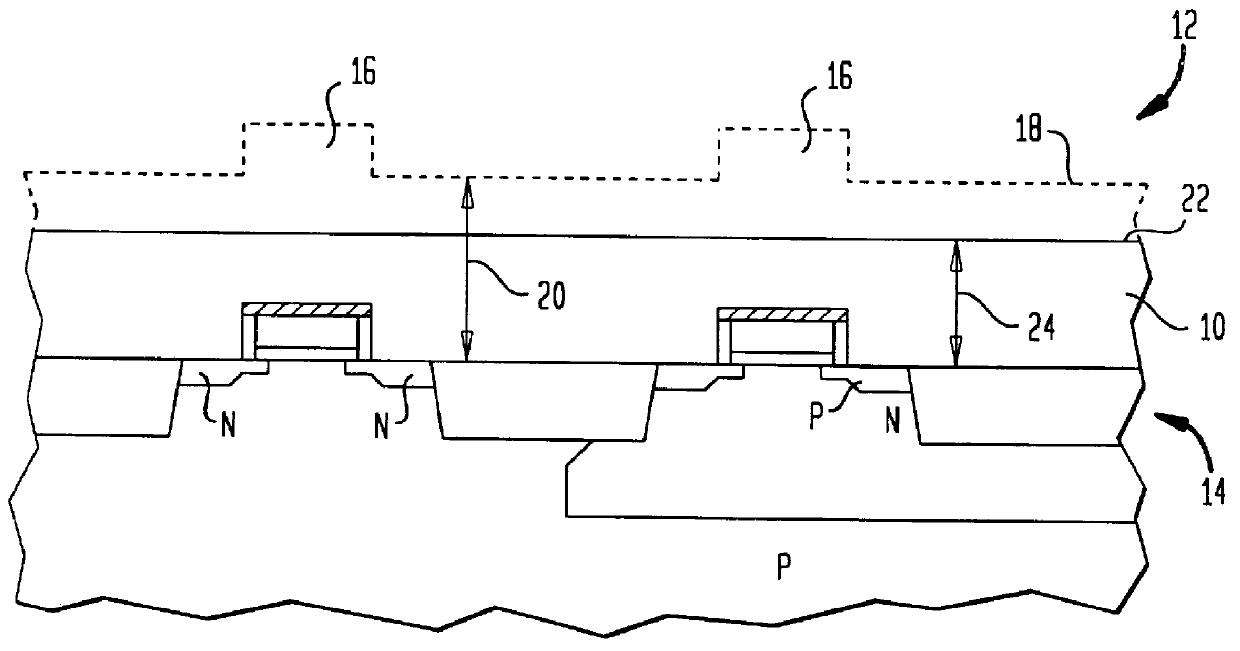

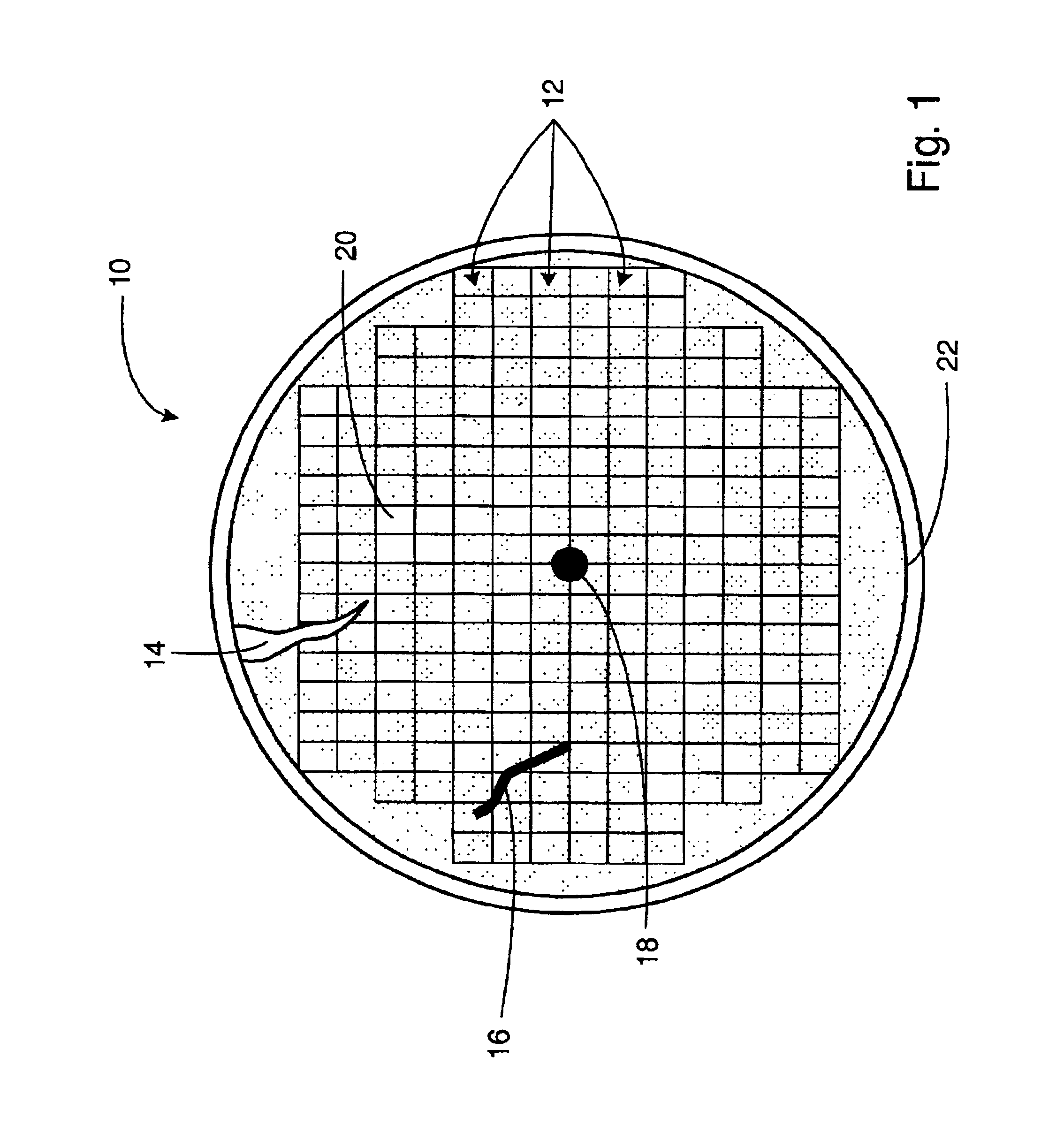

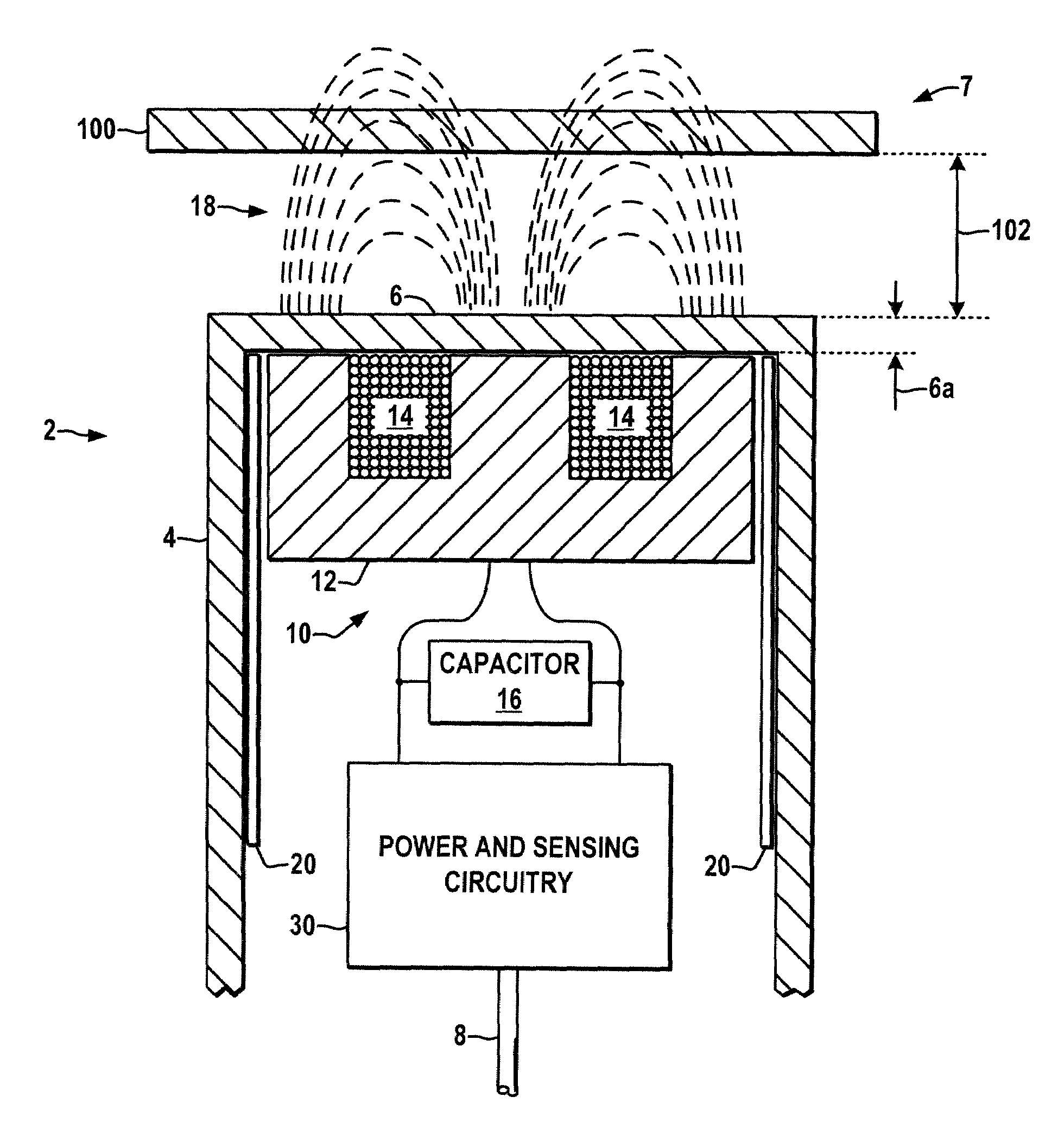

Method and apparatus for in-line oxide thickness determination in chemical-mechanical polishing

InactiveUS6020264ASemiconductor/solid-state device testing/measurementResistance/reactance/impedenceElectrical resistance and conductanceEngineering

In-line thickness measurement of a dielectric film layer on a surface of a workpiece subsequent to a polishing on a chemical-mechanical polishing machine in a polishing slurry is disclosed. The workpiece includes a given level of back-end-of-line (BEOL) structure including junctions. The measurement apparatus includes a platen and an electrode embedded within the platen. A positioning mechanism positions the workpiece above the electrode with the dielectric layer facing in a direction of the electrode. A slurry dam is used for maintaining a prescribed level of a conductive polishing slurry above the electrode, the prescribed level to ensure a desired slurry coverage of the workpiece. A capacitance sensor senses a system capacitance C in accordance with an RC equivalent circuit model, wherein the RC equivalent circuit includes a resistance R representative of the slurry and workpiece resistances and the system capacitance C representative of the dielectric material and junction capacitances. Lastly, a capacitance-to-thickness converter converts the sensed capacitance to a dielectric thickness in accordance with a prescribed system capacitance / optical thickness calibration, wherein the prescribed calibration corresponds to the given level of BEOL structure of the workpiece.

Owner:IBM CORP

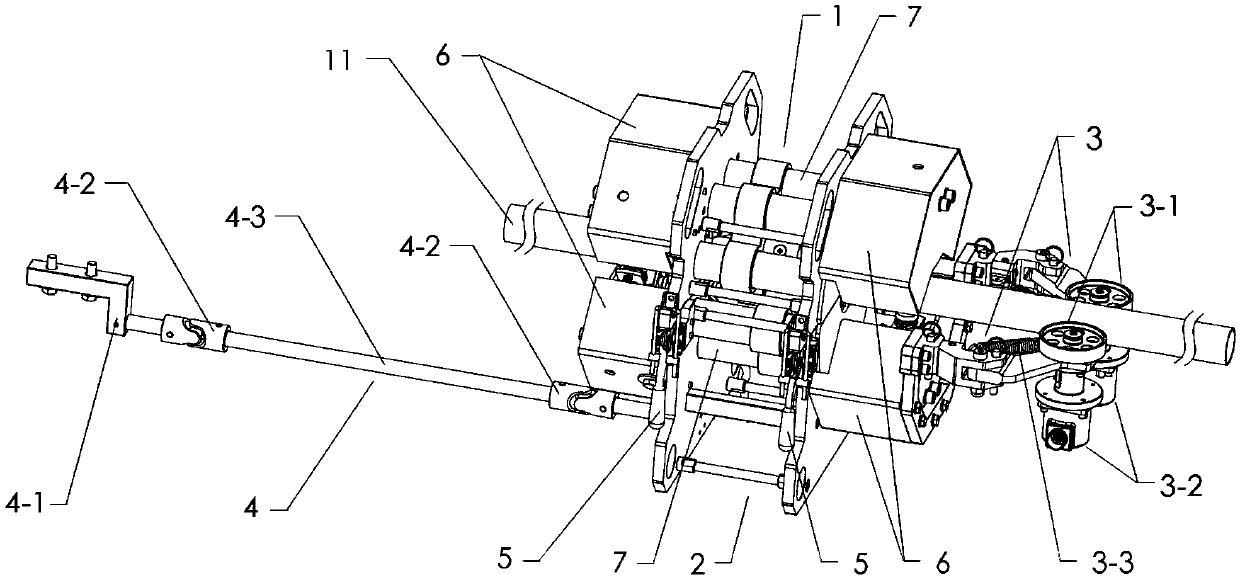

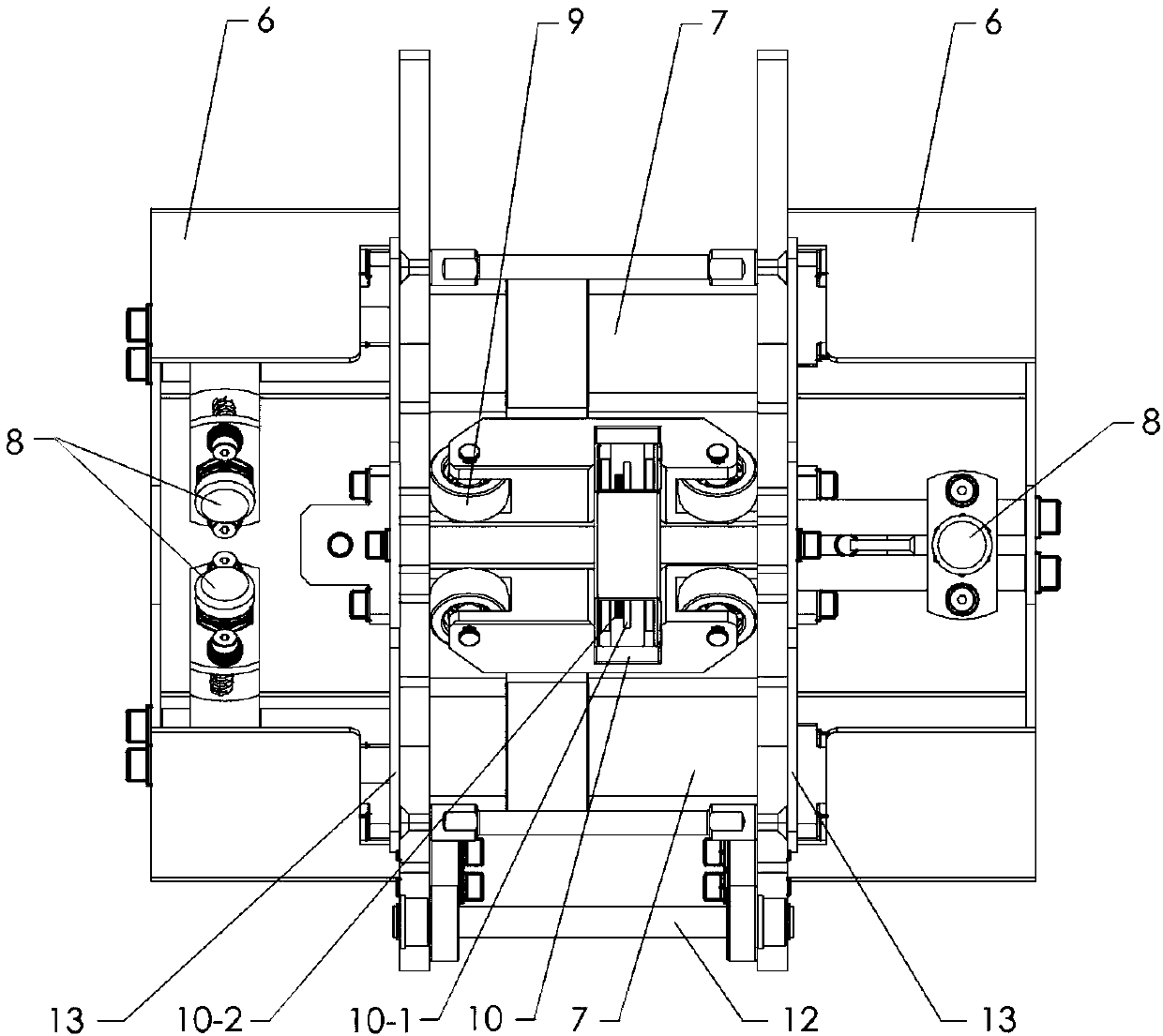

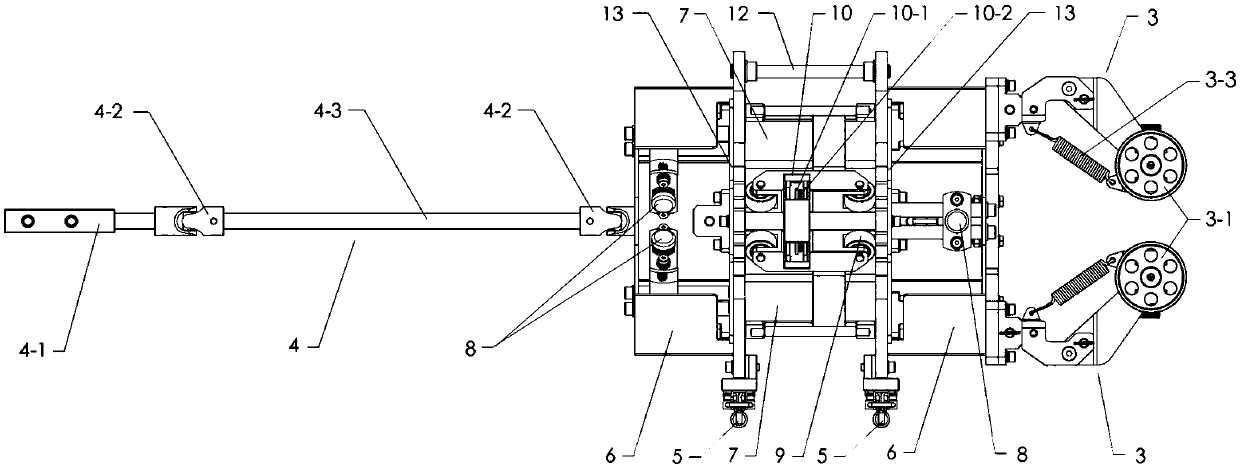

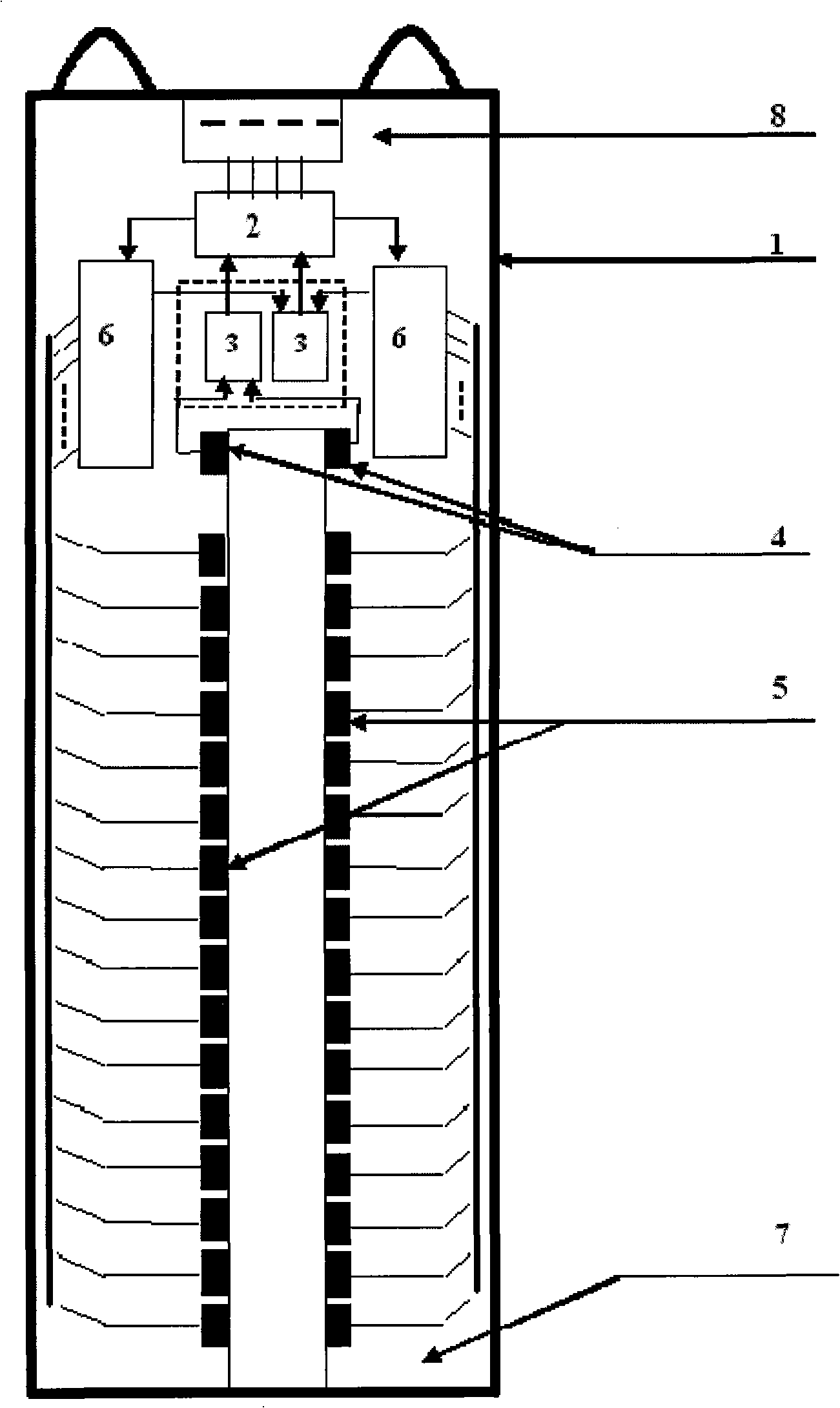

Integrated coiled tubing defect detection device

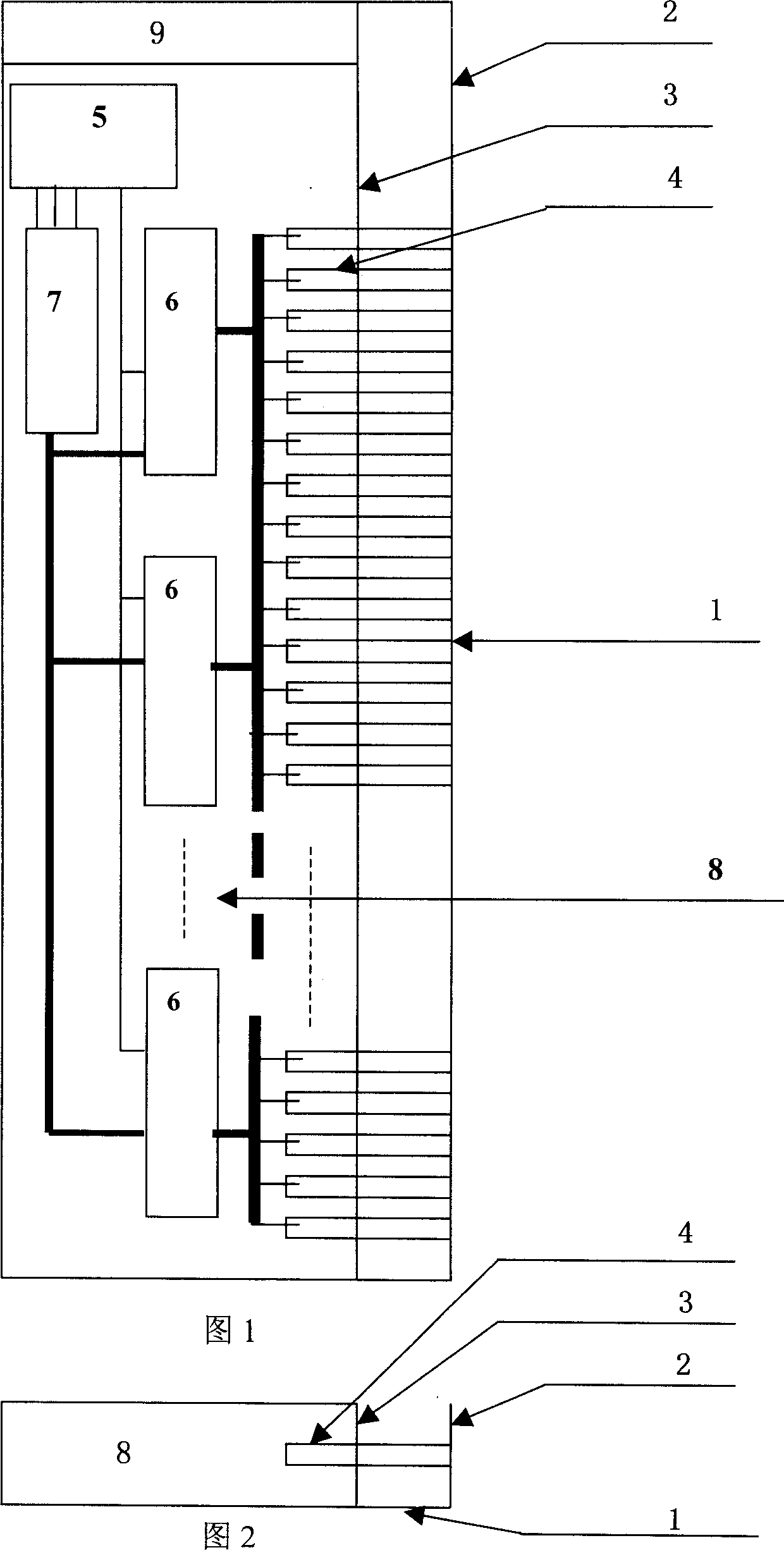

PendingCN109682881AAccurate defect detectionAccurate detection of wall thicknessElectric/magnetic contours/curvatures measurementsUsing electrical meansCoiled tubingEngineering

The invention provides an integrated coiled tubing defect detection device. The coiled tubing defect detection device comprises an upper half detection unit and a lower half detection unit, and a passage for coiled tubing to pass through is formed between the two detection units after the two detection units are matched and assembled with each other, and internally provided with a magnetism generating device, a magnetism leakage detection probe, an ellipticity detection probe and a guide device which are arranged on the two detection units; a measuring arm assembly kit for guiding the two detection units in moving along the coiled tubing is connected to the outsides of the detection units. The device can achieve real-time and precise detection of the wall thickness, outer diameter, ovalityand various physical defects such as corrosion, cracks, mechanical damage and pitting corrosion of coiled tubing columns.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

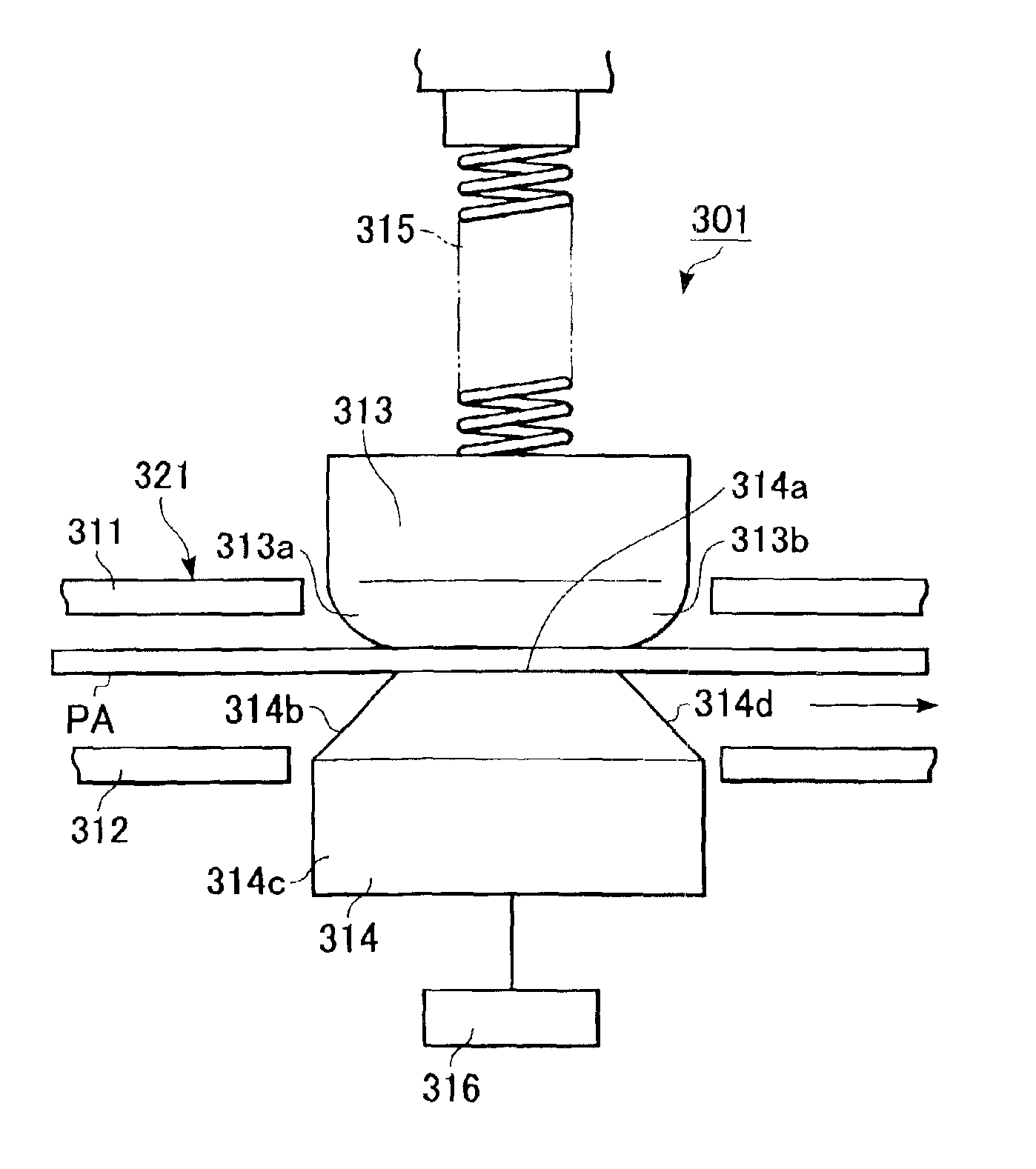

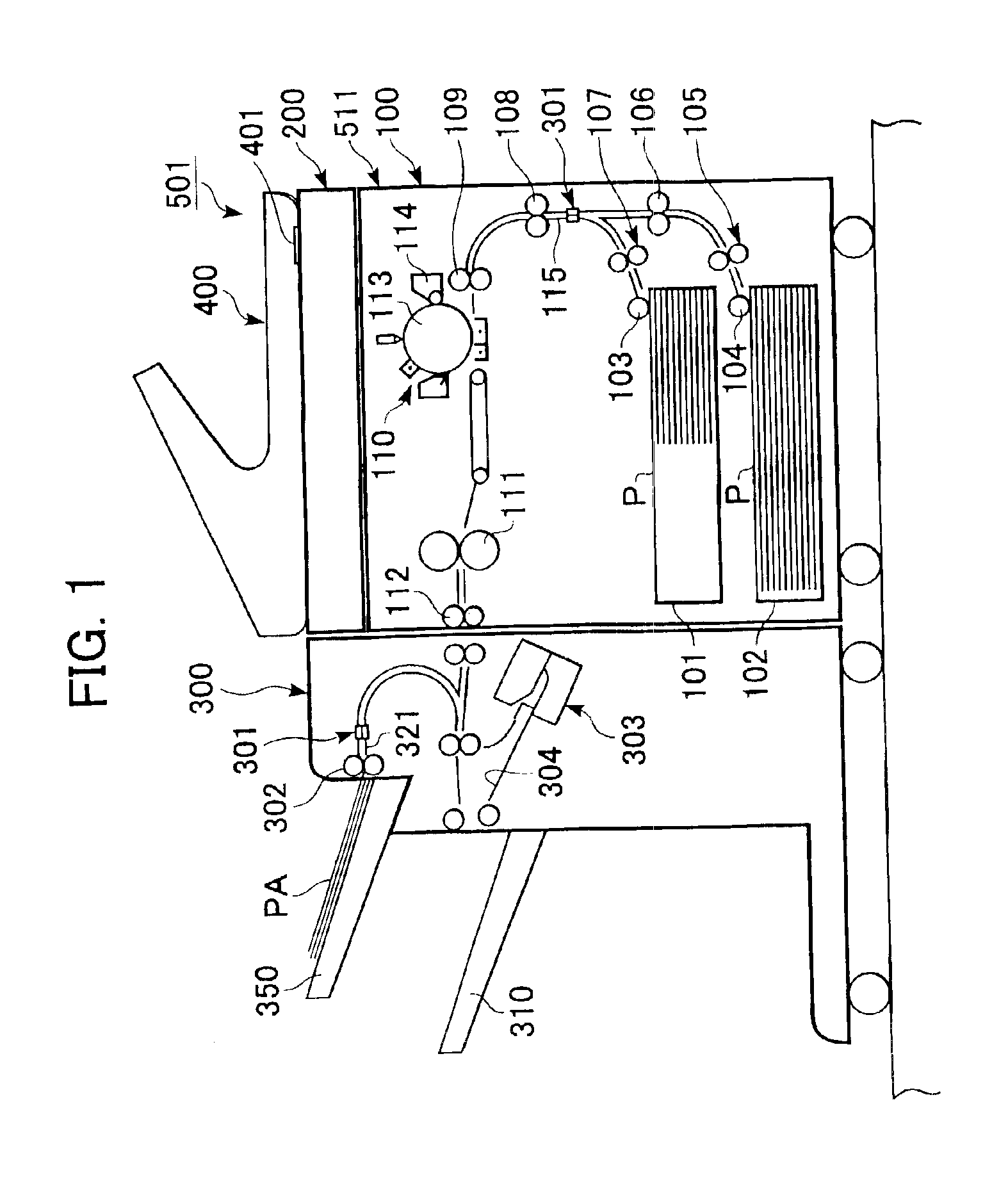

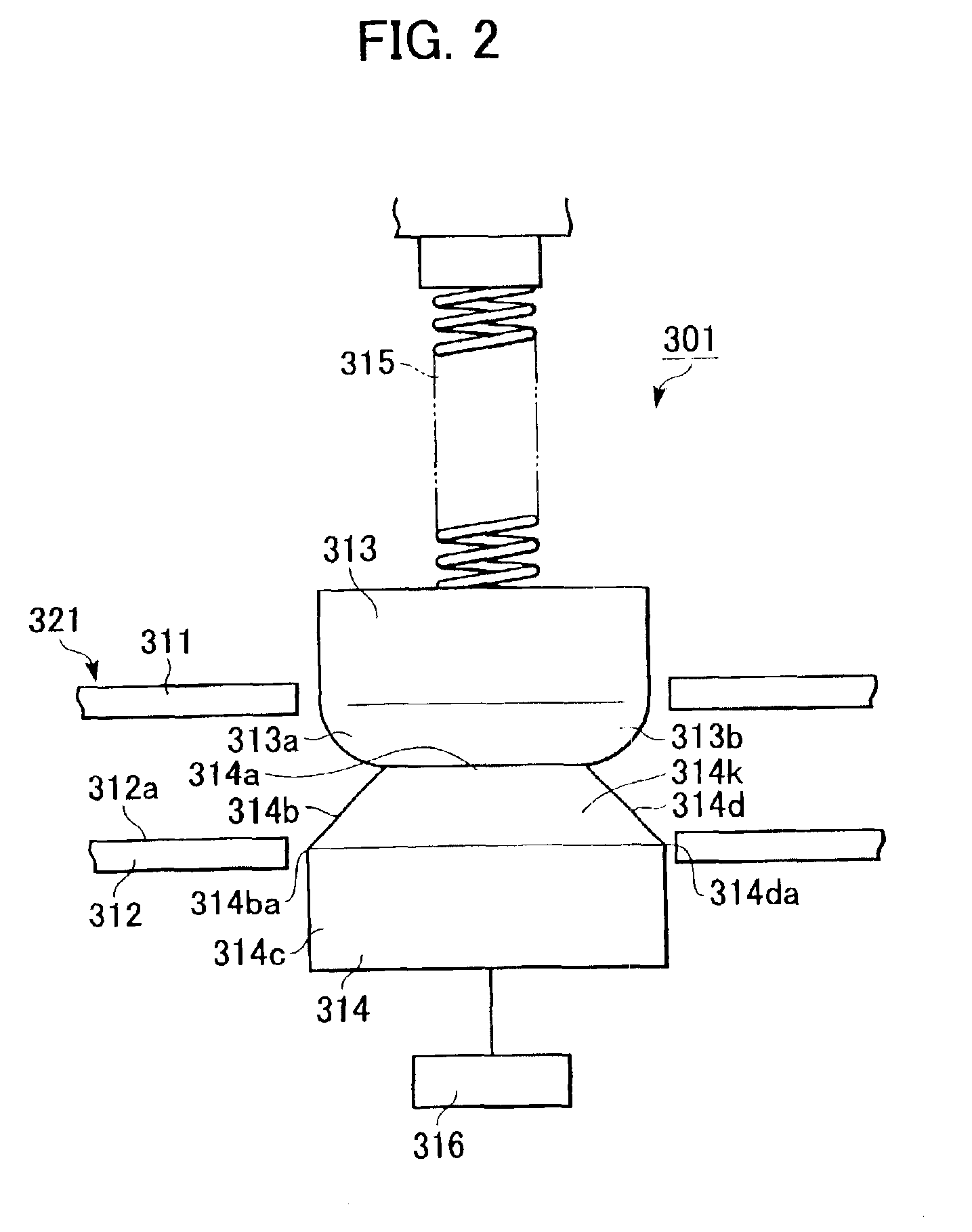

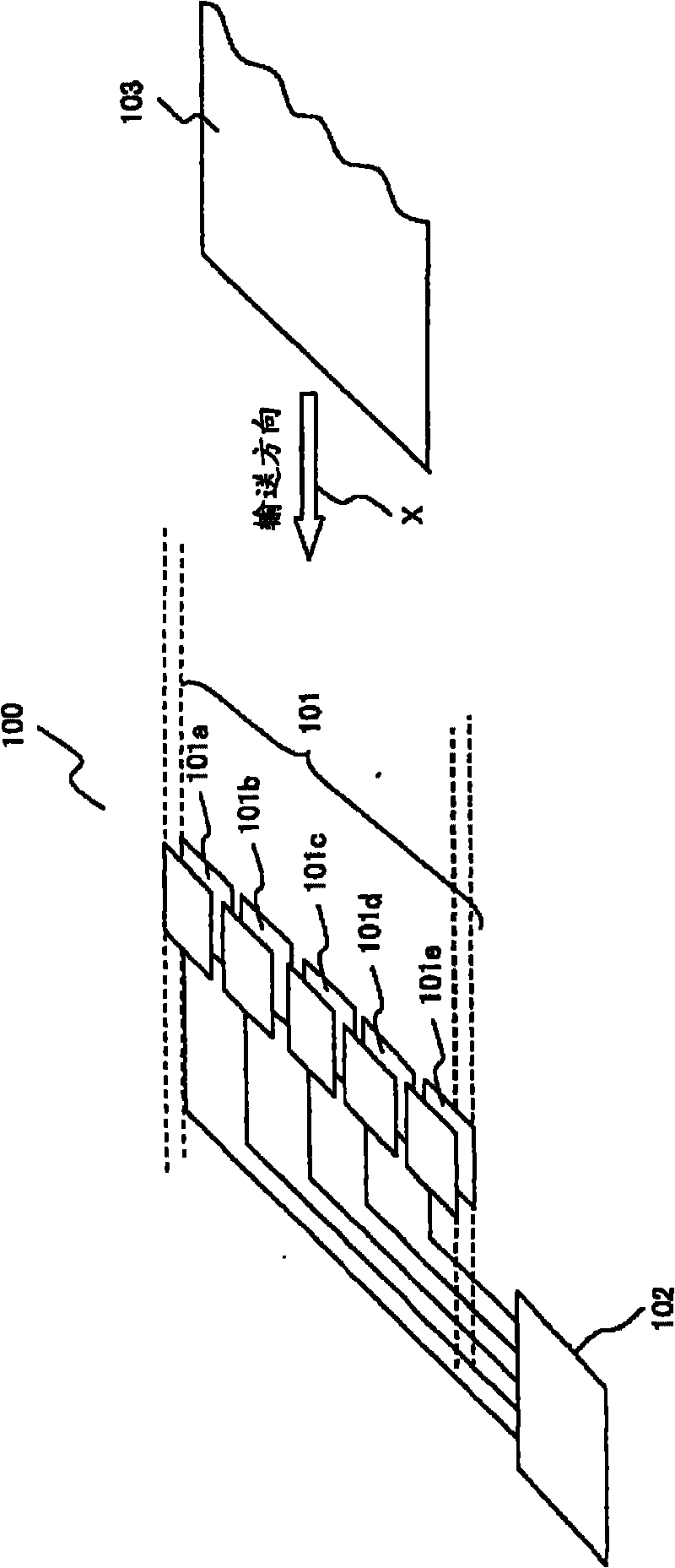

Sheet-thickness detector device and sheet-processing apparatus, image-forming apparatus having the same

A sheet-thickness detector device has a sheet guide with a sheet-guide surface for guiding a sheet between a magnetic field sensor and a magnetic guide element. The magnetic field sensor, having an approach-guide plane disposed upstream in a sheet conveying direction for guiding the sheet to a detection surface, comes into direct contact with the sheet. By the structure mentioned above, the thickness of a sheet is detected so as to determine sheet double feeding and the like without producing sheet jamming.

Owner:CANON KK

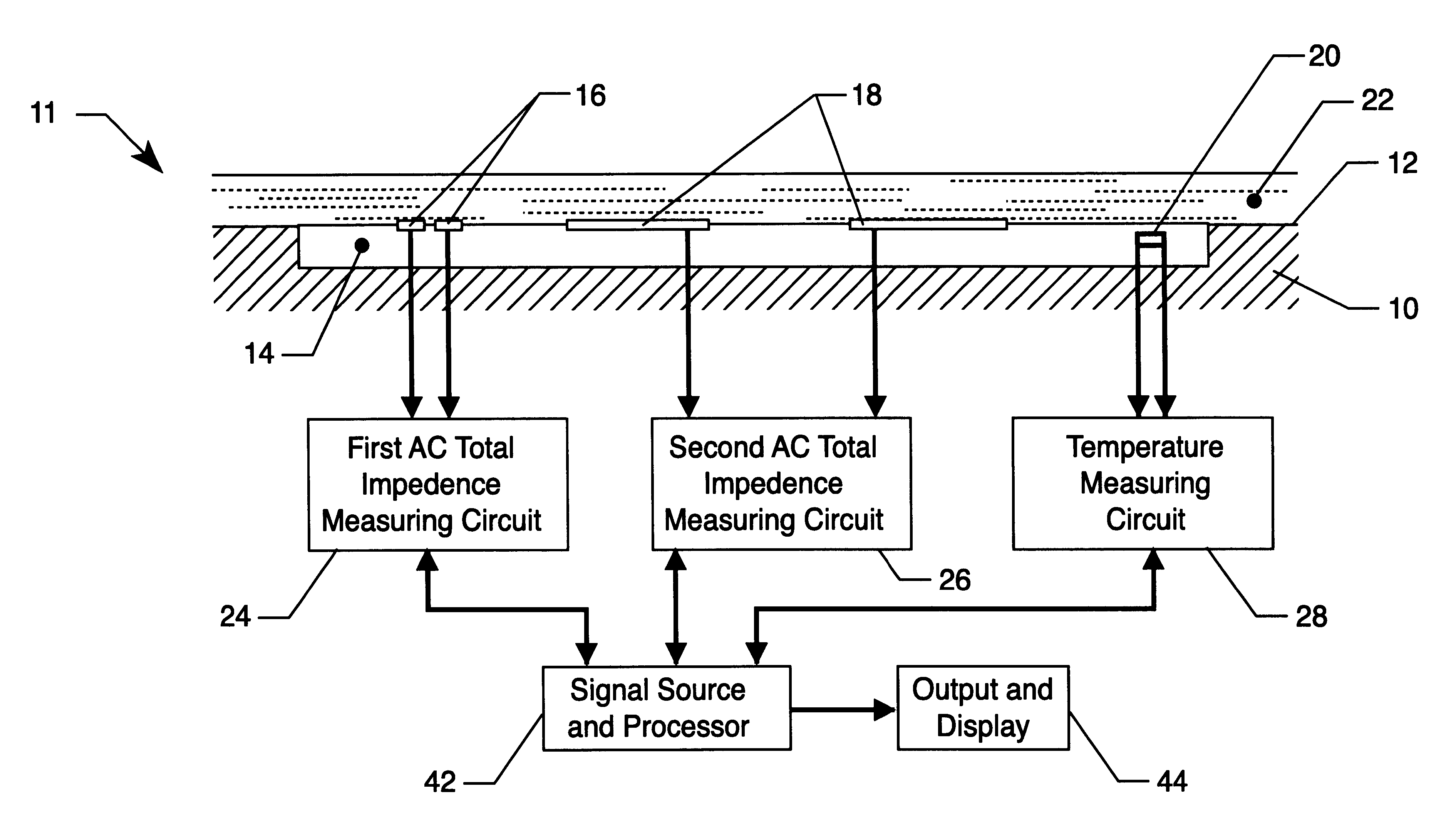

Thickness measurement device for ice, or ice mixed with water or other liquid

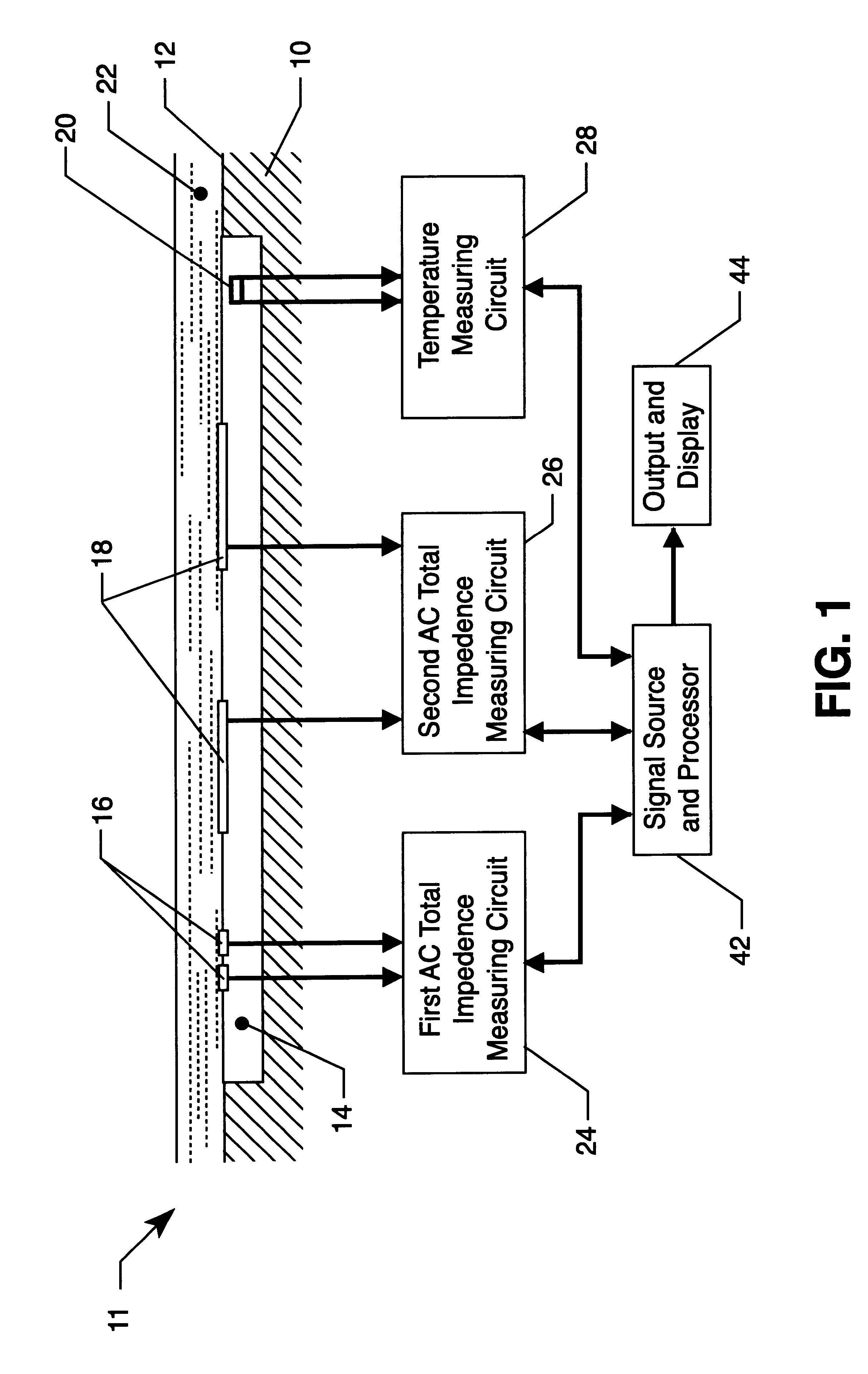

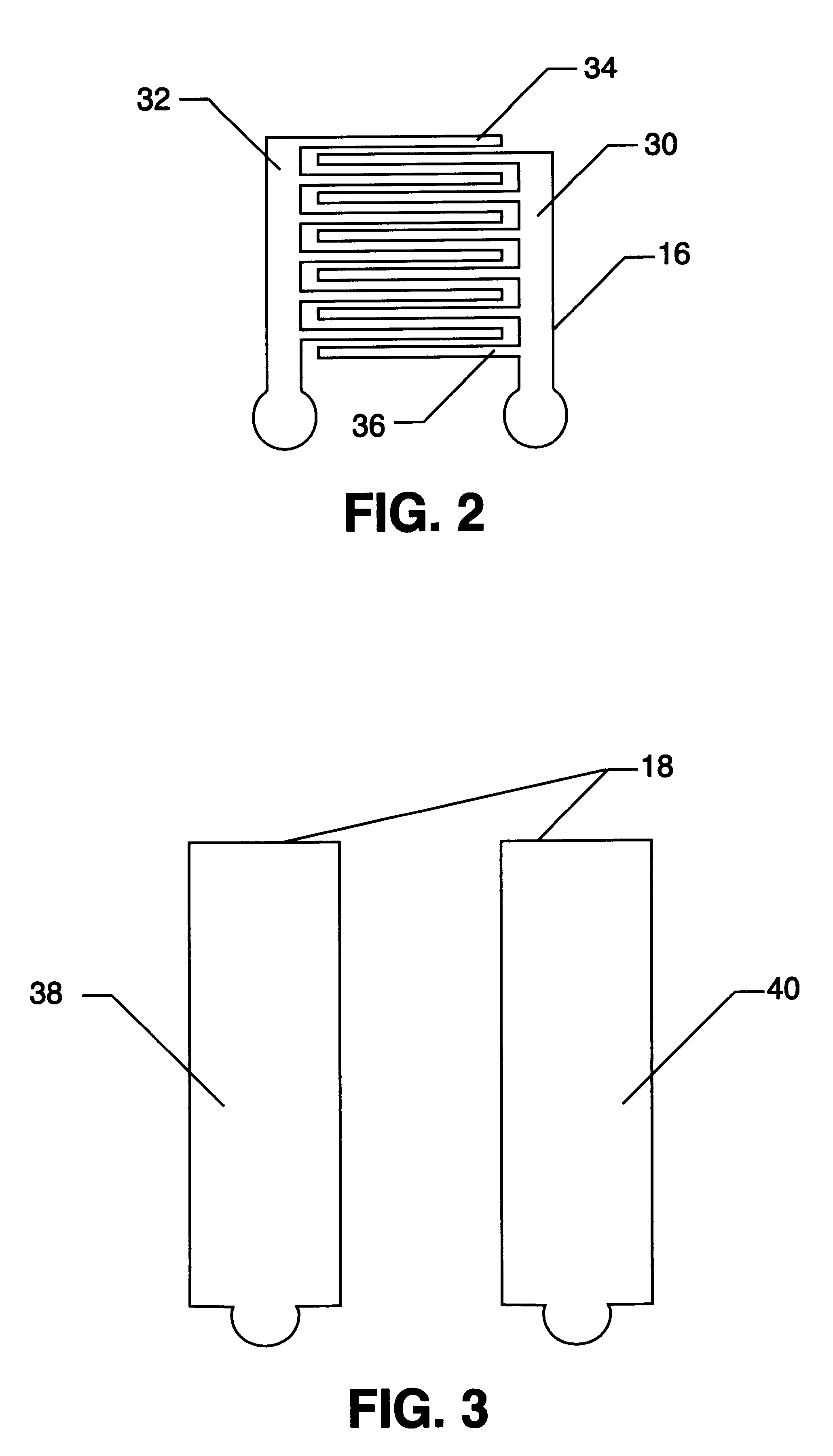

InactiveUS6239601B1Resistance/reactance/impedenceDe-icing equipmentsMeasurement deviceMeasuring output

A device and method are provided for determining the thickness of a layer of solid ice, a mixture of ice and water, or a mixture of ice and other liquid, accumulated on the outer surface of an object. First and second total impedance sensors are operated at first and second frequencies. Corresponding first and second AC total impedance measuring circuits are coupled to the first and second sensors to produce output voltages based on the total impedance changes sensed by the sensors. A processor is coupled to the first and second measuring circuits to generate an output value using the measured output voltages. The output value is indicative of the thickness of the ice or ice and water mixture, or ice and other liquid.

Owner:NAT AERONAUTICAS & SPACE ADMINISTATION

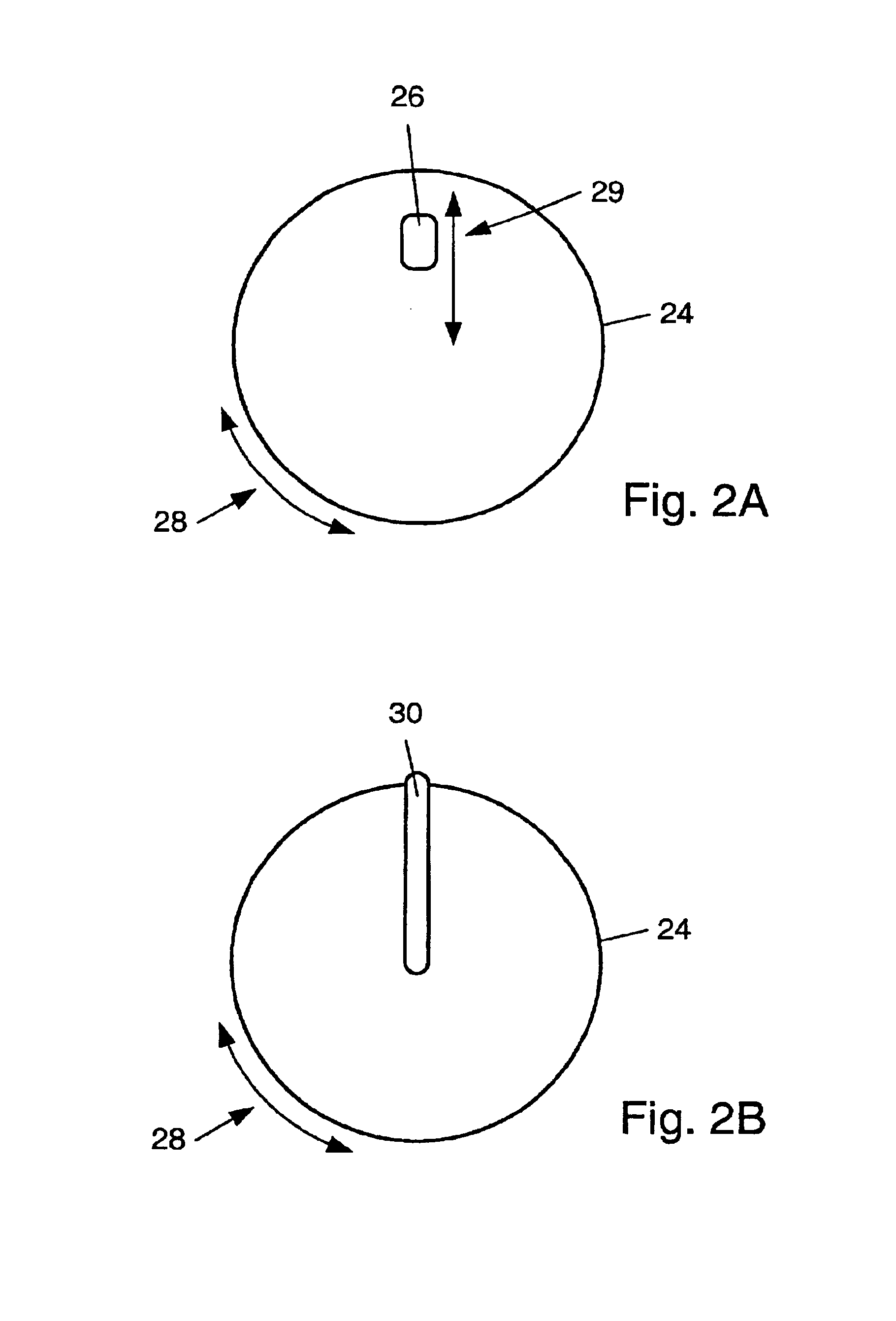

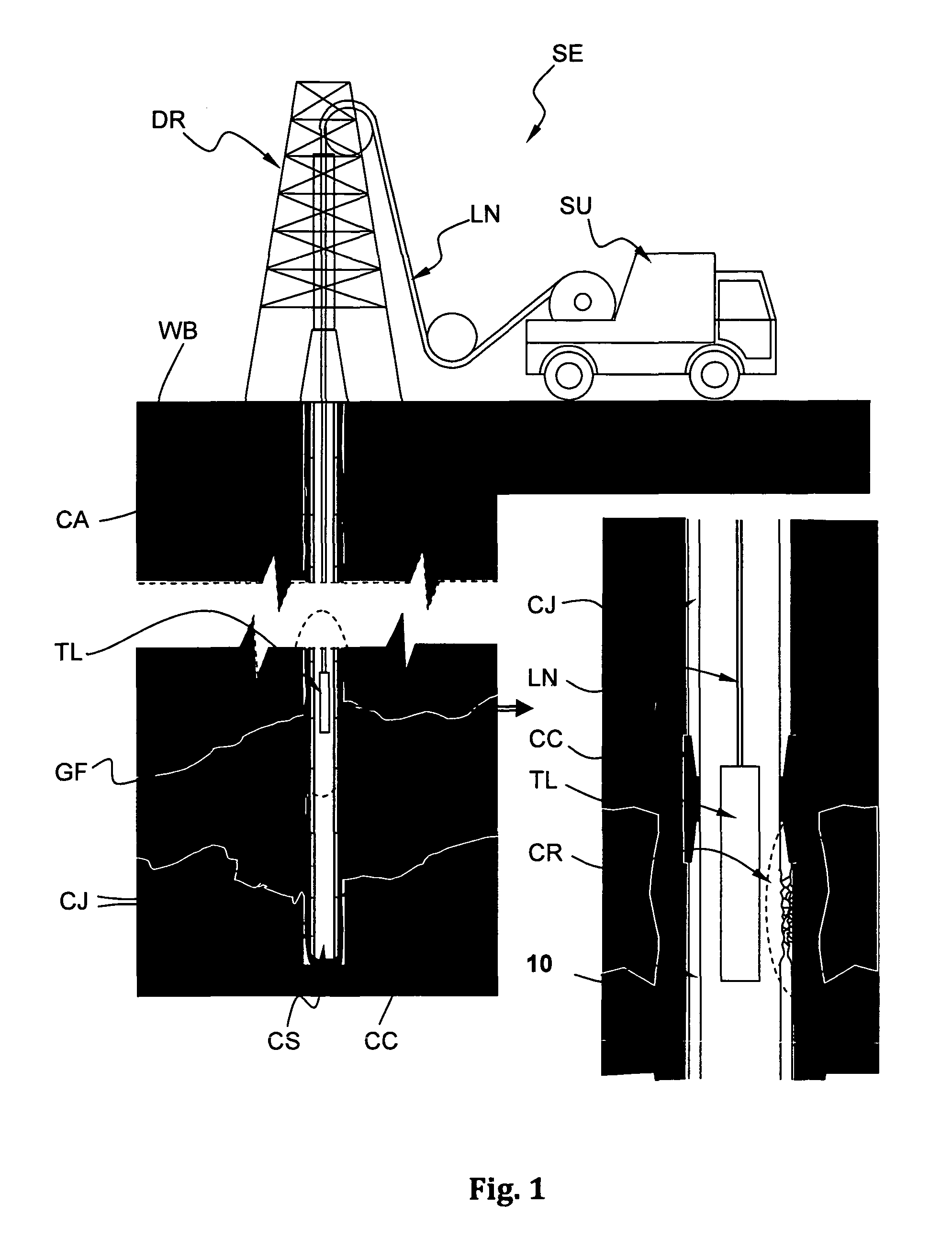

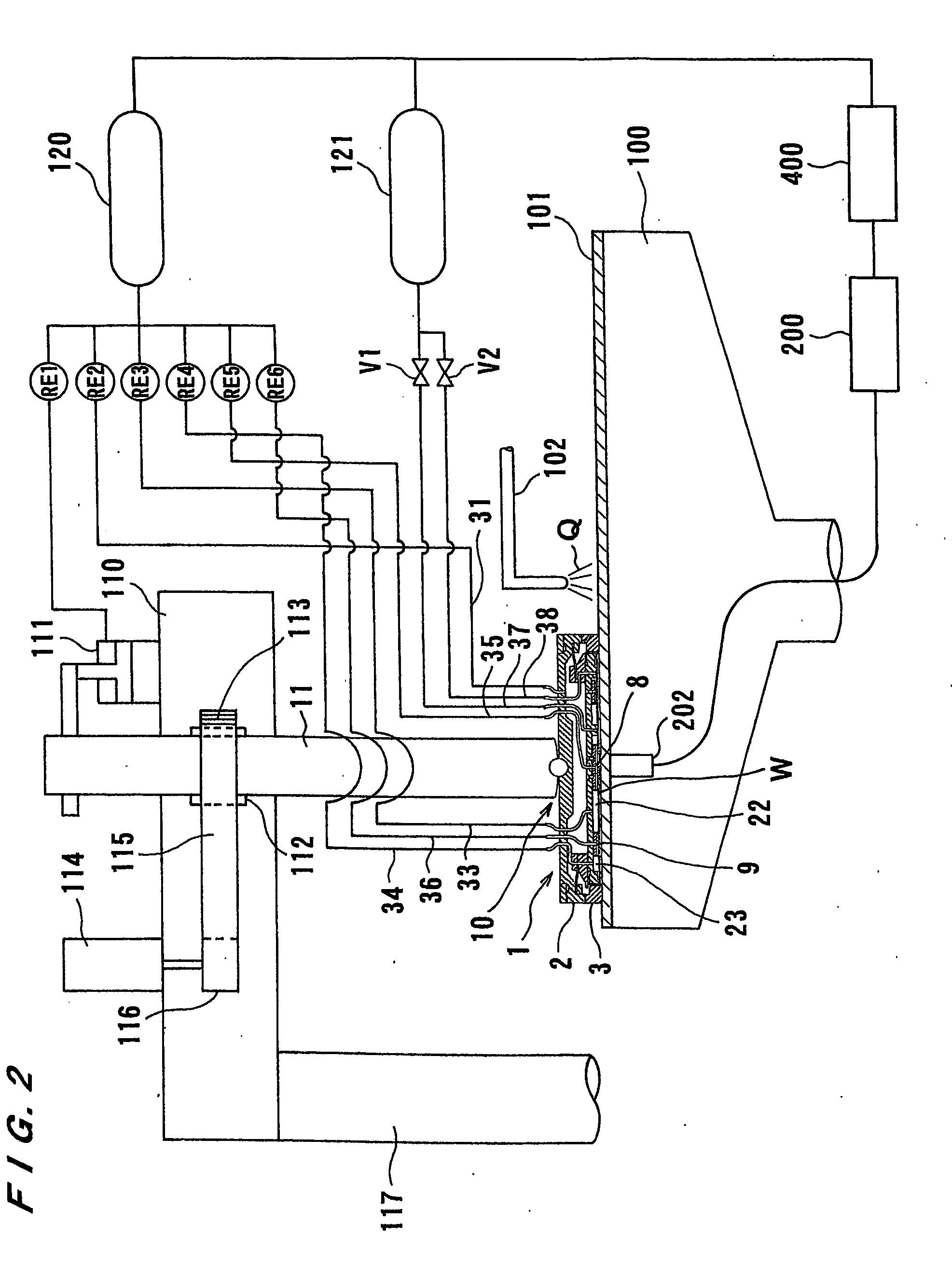

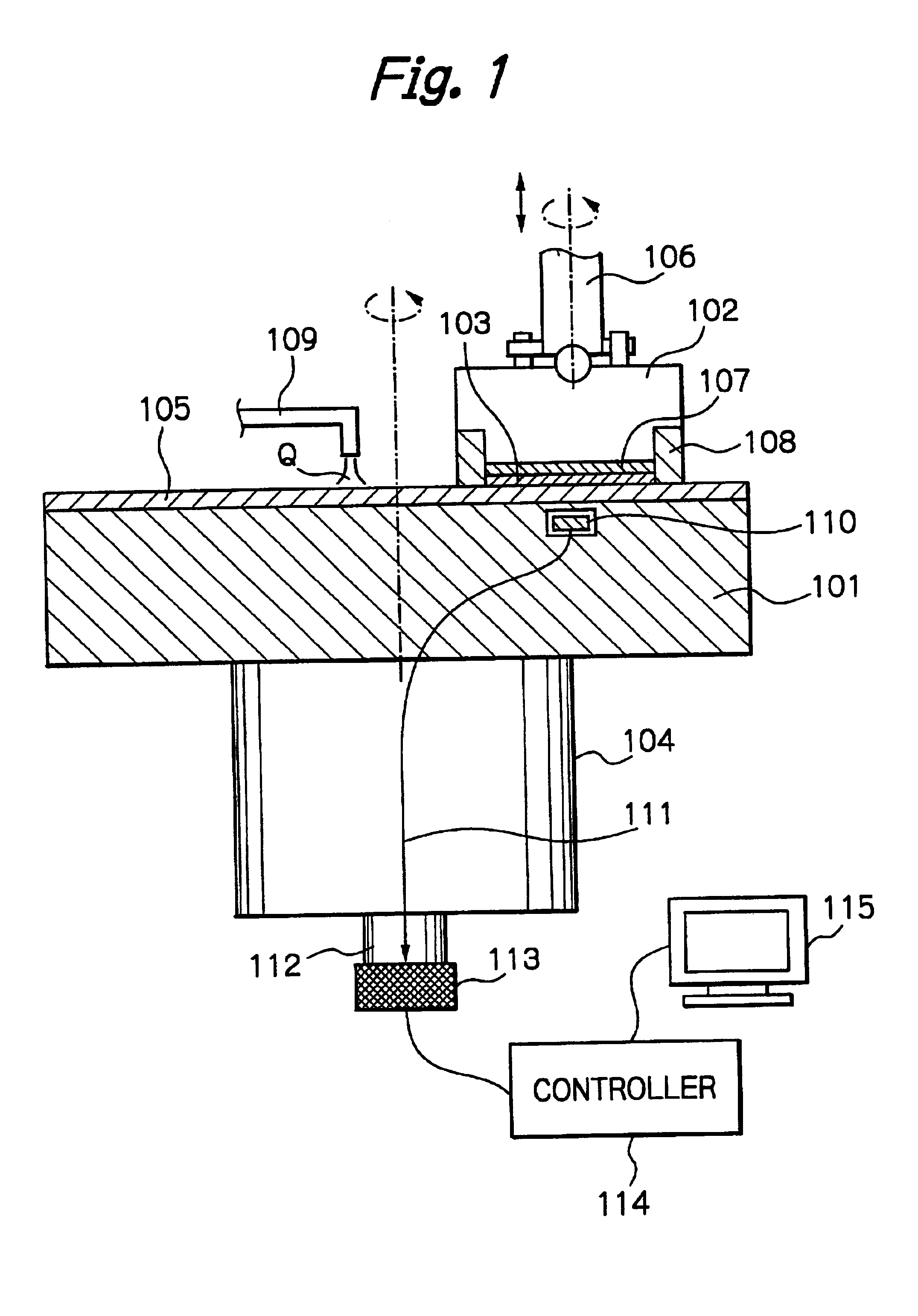

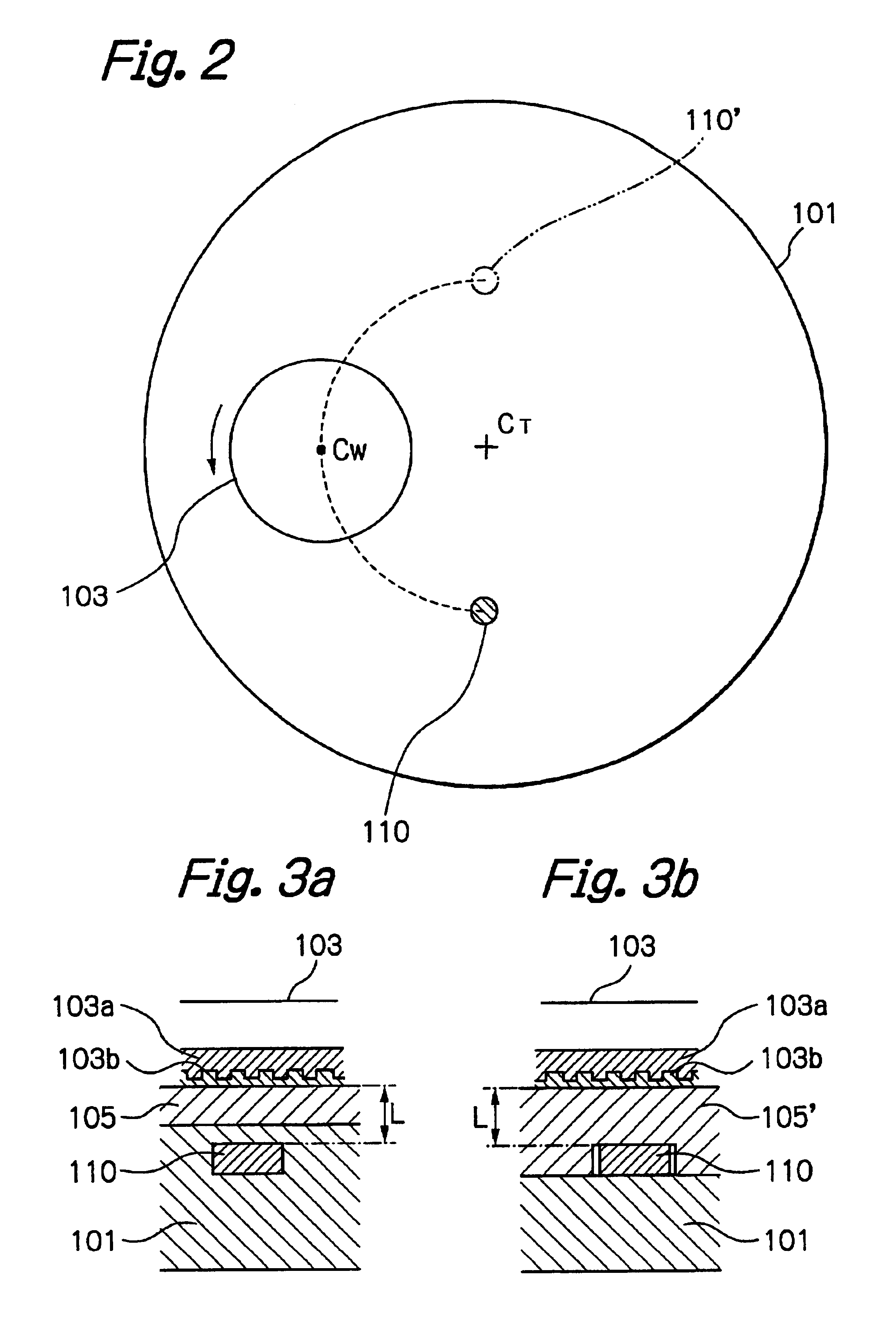

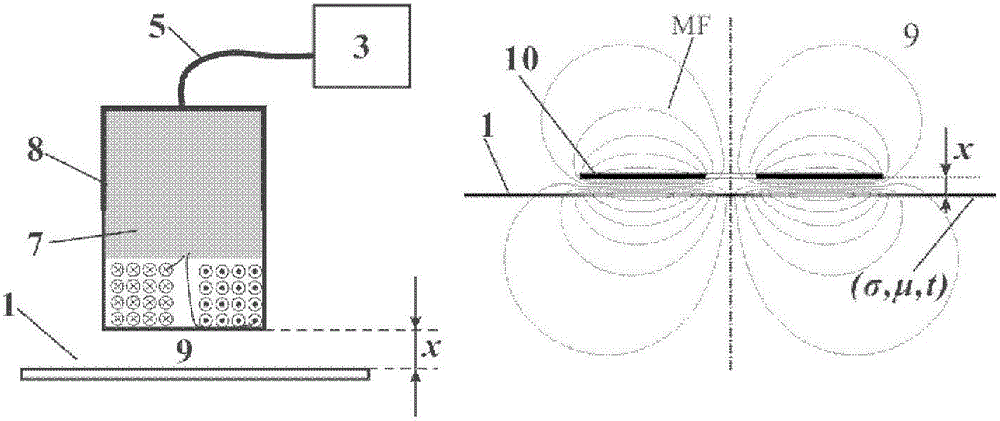

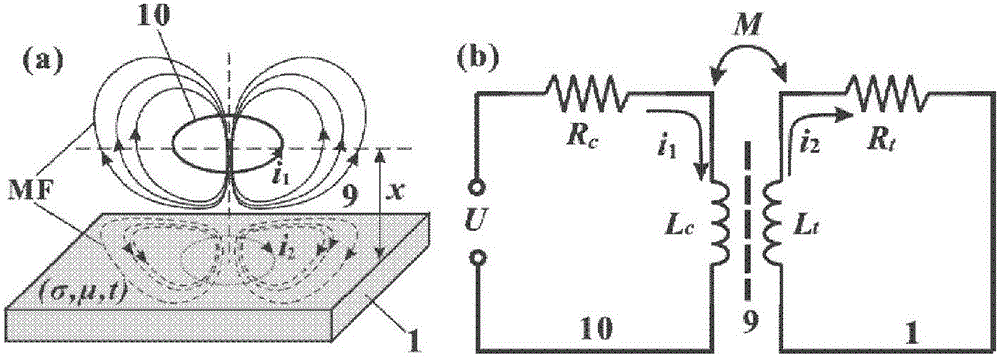

Eddy current sensor

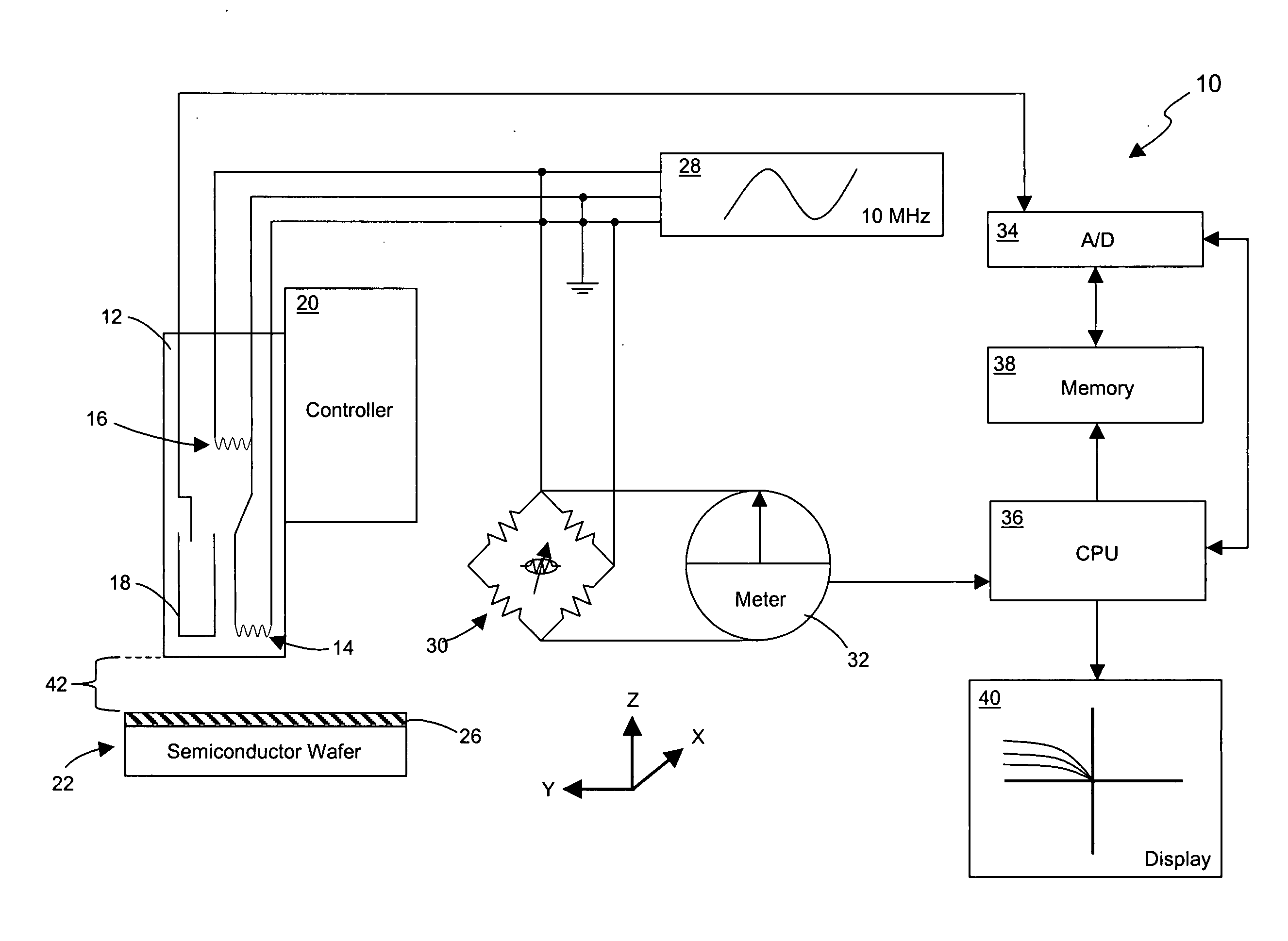

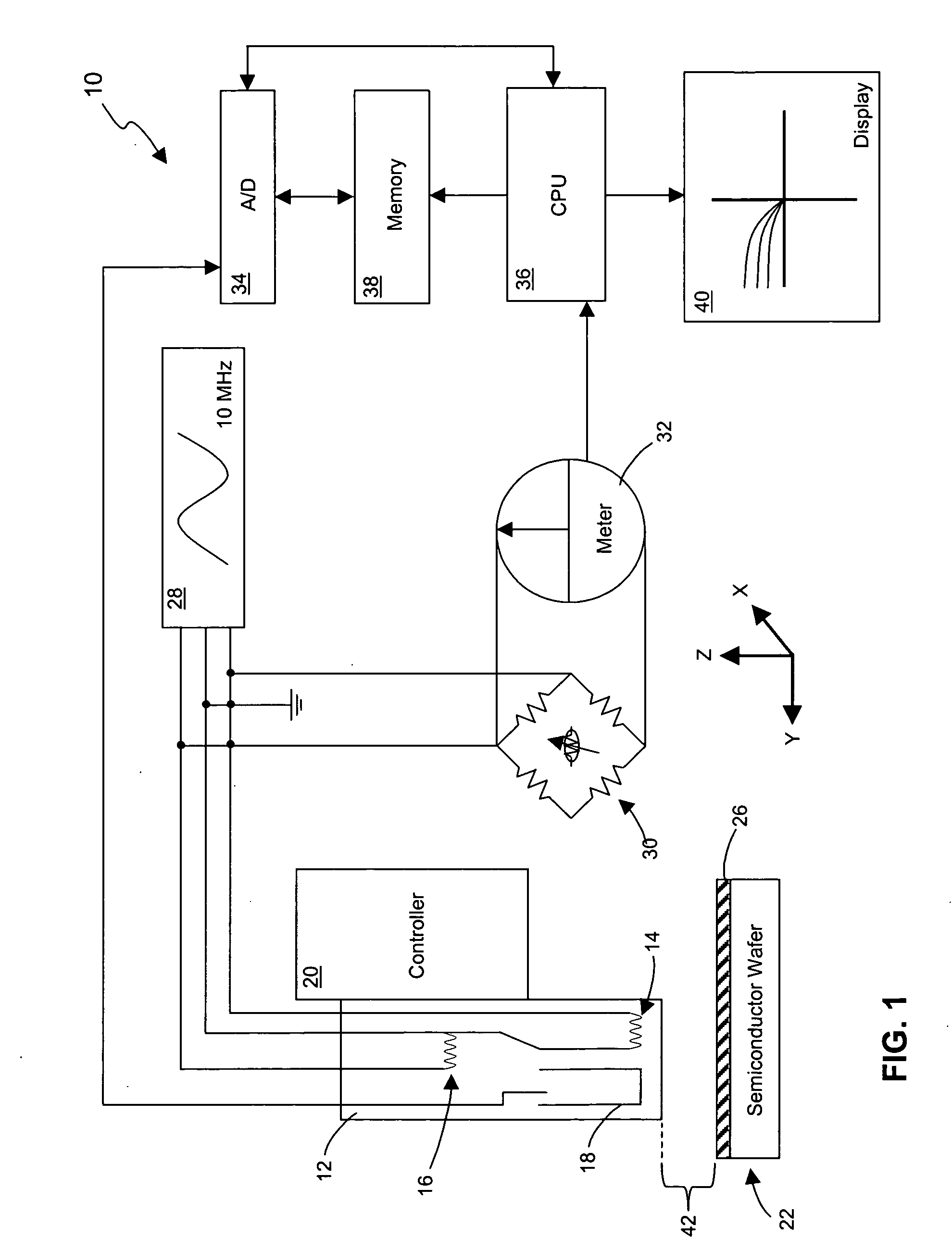

ActiveUS20070103150A1Easy to measureImprove accuracySemiconductor/solid-state device manufacturingMagnetic property measurementsEngineeringMagnetic flux

An eddy current sensor (10) has a sensor coil (100) disposed near a conductive film (6) formed on a semiconductor wafer (W) and a signal source (124) configured to supply an AC signal to the sensor coil (100) to produce an eddy current in the conductive film (6). The eddy current sensor (10) includes a detection circuit operable to detect the eddy current produced in the conductive film (6). The detection circuit is connected to the sensor coil (100). The eddy current sensor (10) also includes a housing (200) made of a material having a high magnetic permeability. The housing (200) accommodates the sensor coil (100) therein. The housing (200) is configured so that the sensor coil (100) forms a path of a magnetic flux (MF) so as to effectively produce an eddy current in the conductive film (6).

Owner:EBARA CORP

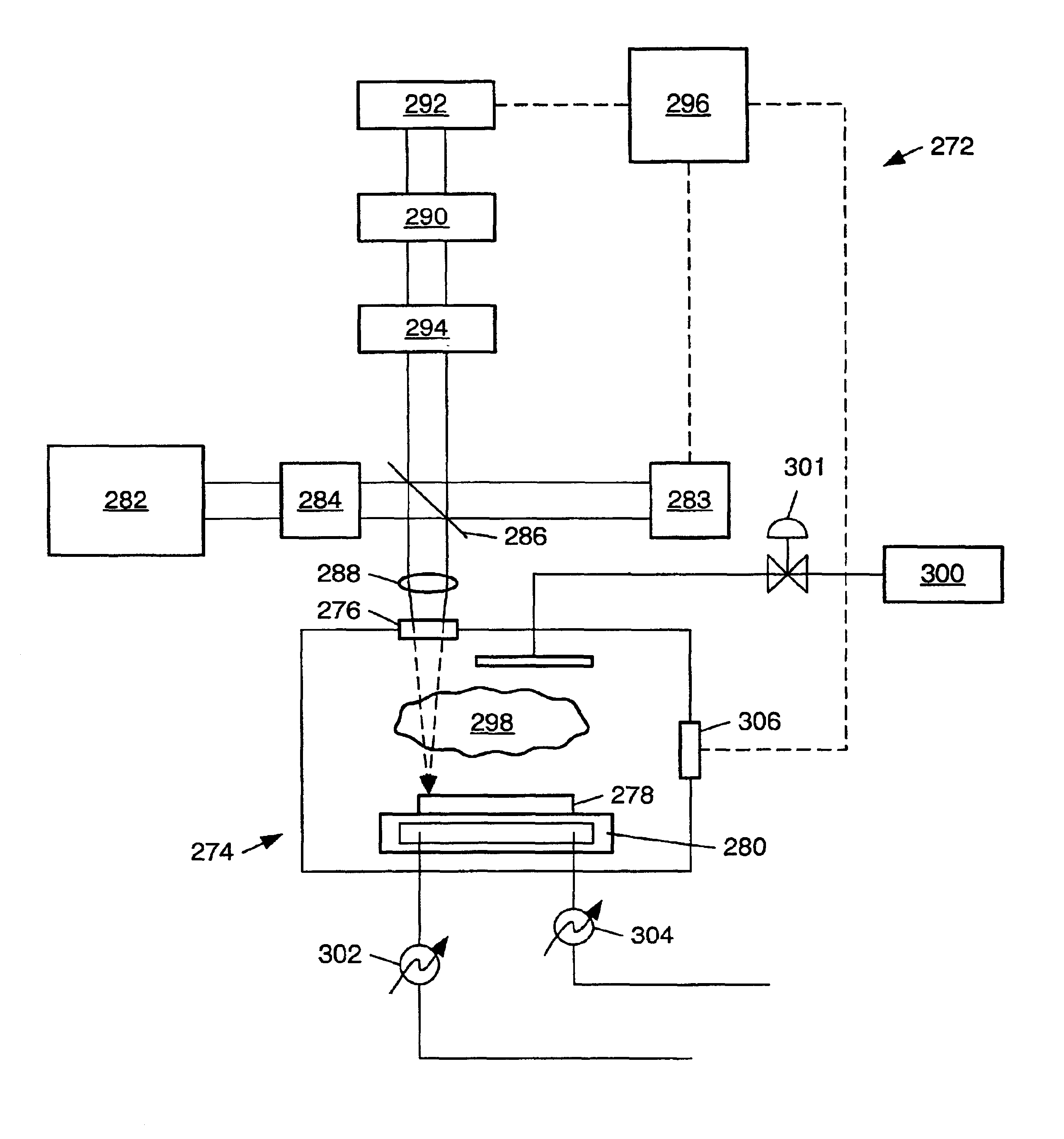

Methods and systems for determining a property of a specimen prior to, during, or subsequent to an etch process

InactiveUS6917433B2Speed up the processShorten the timeSemiconductor/solid-state device testing/measurementPolarisation-affecting propertiesMeasurement deviceEngineering

Methods and systems for monitoring semiconductor fabrication processes are provided. A system may include a stage configured to support a specimen and coupled to a measurement device. The measurement device may include an illumination system and a detection system. The illumination system and the detection system may be configured such that the system may be configured to determine multiple properties of the specimen. For example, the system may be configured to determine multiple properties of a specimen including, but not limited to, a property of a specimen prior to, during, or subsequent to an etch process. In this manner, a measurement device may perform multiple optical and / or non-optical metrology and / or inspection techniques.

Owner:KLA CORP

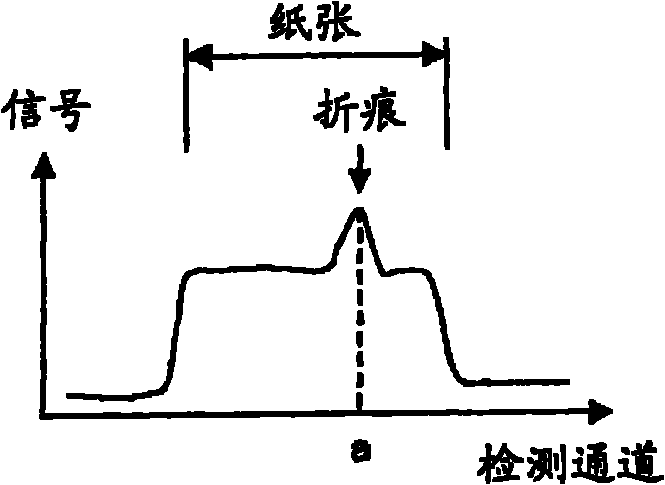

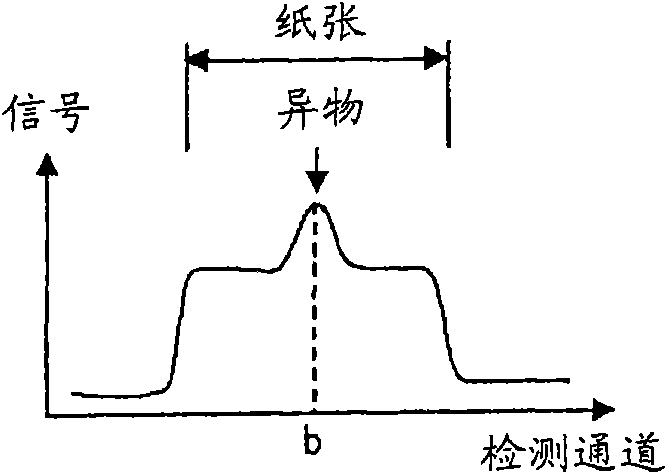

Paper sheet thickness detection device

InactiveCN101754919AReliable detectionPaper-money testing devicesFunction indicatorsCapacitanceForeign matter

A paper sheet thickness detection device which can reliably detect a foreign matter adhering to a paper sheet. A paper sheet thickness detection device (300) comprises a first sensor (301) and a second sensor (302) which detect a change of an electrostatic capacity when a paper sheet (304) such as a bill or a copier paper is inserted, and a thickness detection unit (303) which detects the thickness of the paper sheet (304) by using the signals obtained from the first sensor (301) and the second sensor (302).

Owner:FUJITSU LTD

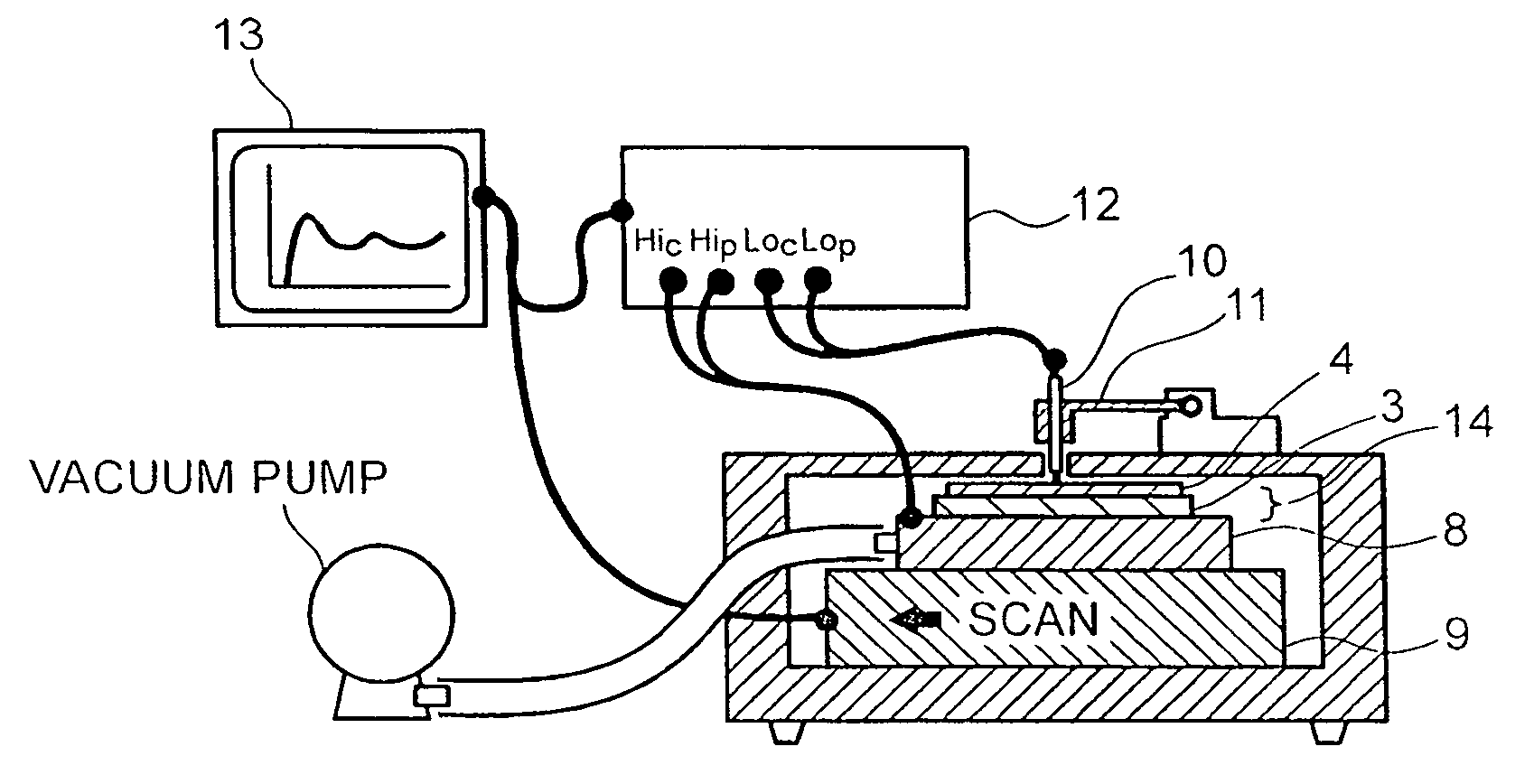

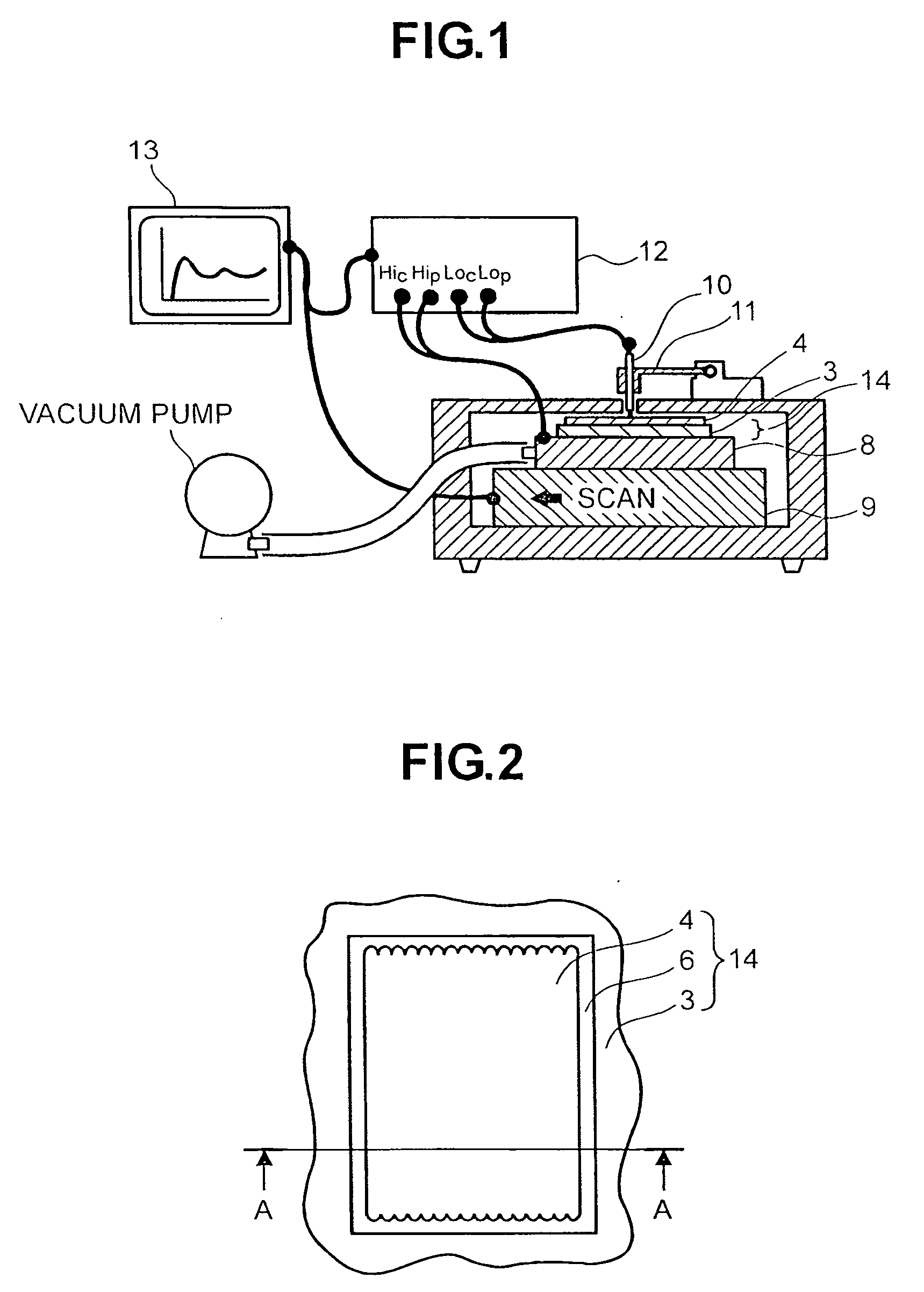

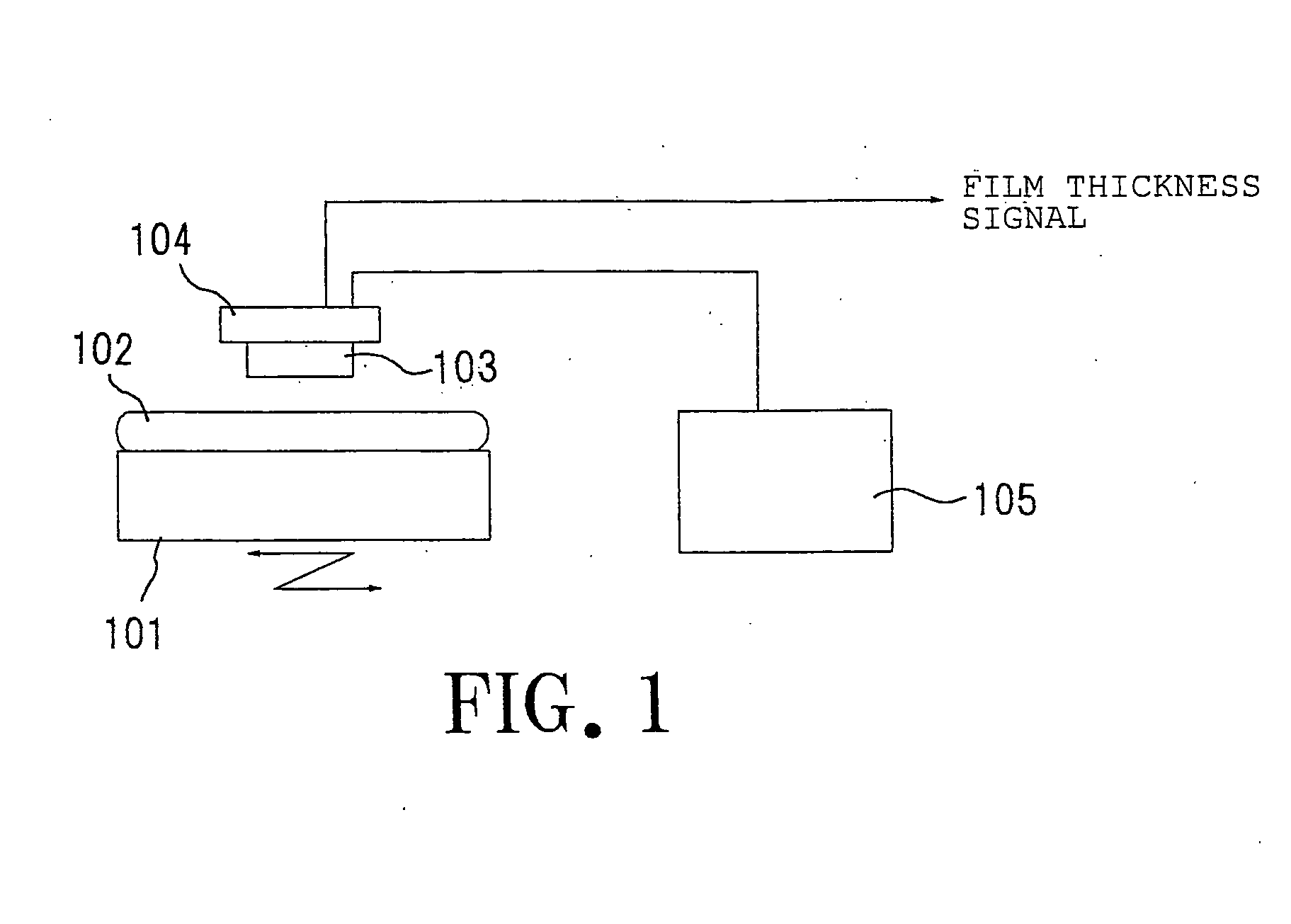

Measuring method and apparatus of thin film thickness

InactiveUS20050073323A1Large scaleCapacitance measurementsSemiconductor/solid-state device testing/measurementCapacitanceElectrical conductor

In an apparatus for measuring thickness of a thin film, which is formed through a conductor, preventing the measurement from an error due to the curve or bend on a substrate surface or a moving surface of a stage, but without necessity of a large-scaled facility, an electric filed is applied between a probe 10 and a stage 8, so as to obtain an electrostatic capacitance of the substrate 3, an electrostatic capacitance of an insulating film, which is formed between the substrate 3, and an electrostatic capacitance defined starting from the substrate 3 to the thin film 4. The electrostatic capacitance between the substrate 3 and the thin film 4 is measured at plural numbers of places covering over the entire surface of the thin film 4. The probe 10 is so supported that the contact load “P” comes to be constant, by the probe 10 onto the thin film 4. A contact area of the probe 10 between the thin film 4 is calculated out through a predetermined equation, assuming the load “P” is constant. From respective electrostatic capacitances and the contact area measured, a distribution of thickness of the thin film 4 over the entire area thereof.

Owner:HITACHI PLANT TECH LTD

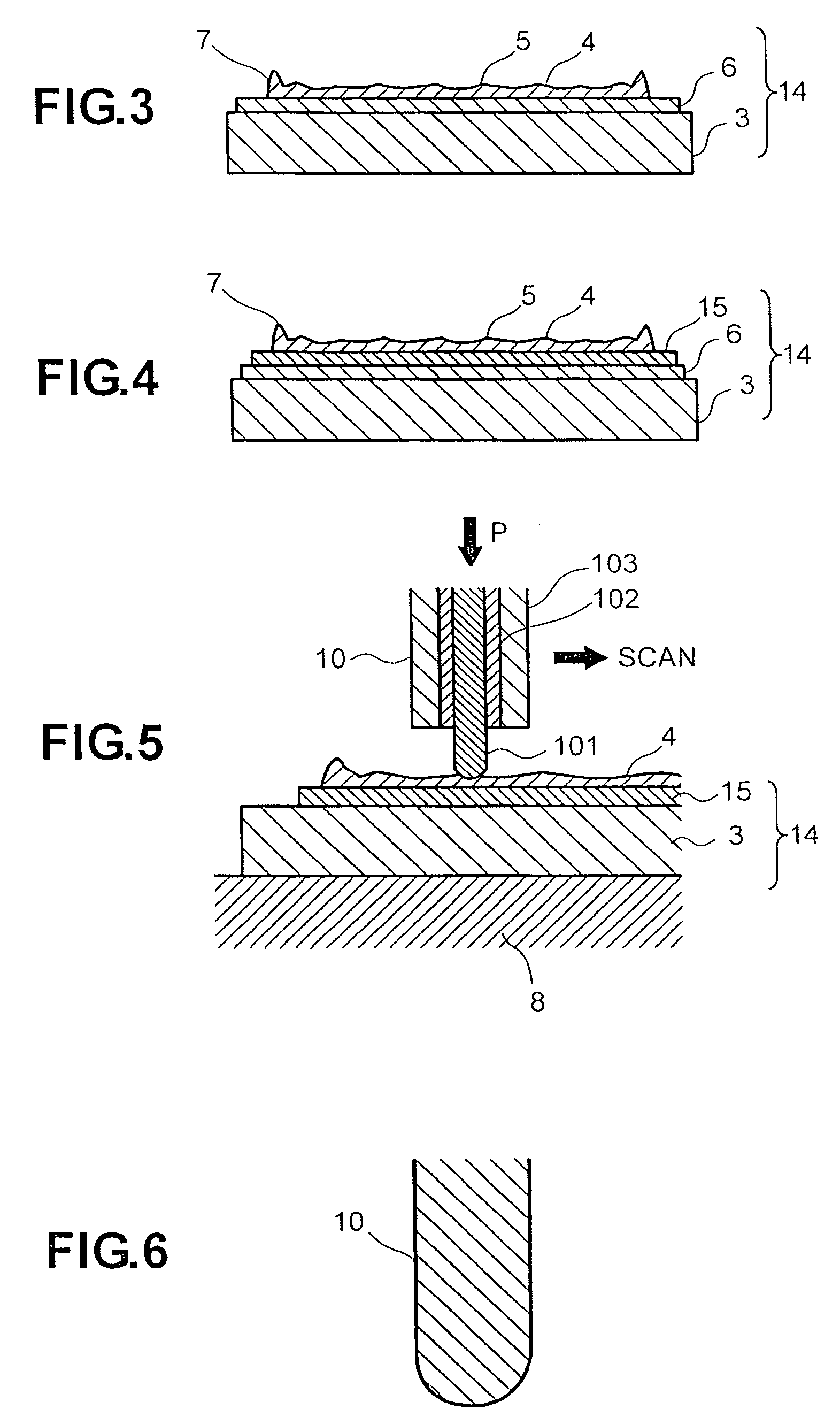

Method and Apparatus for Removal of The Double Indication of Defects in Remote Eddy Current Inspection of Pipes

InactiveUS20120095686A1Reduce signal noiseTaking imageElectric/magnetic detection for well-loggingConstructionsEngineeringEddy current

The apparatus employs the remote field eddy-current (RFEC) inspection technique to electromagnetically measure physical parameters of a metallic pipe. RFEC devices inserted into and displaced along a cylindrical pipes may be used to measure the ratio of pipe thickness to electromagnetic skin-depth and thus allow for the non-invasive detection of flaws or metal loss. Typically these RFEC thickness measurements exhibit a so-called double-indication of flaws, an undesired artifact due to a double-peaked geometrical sensitivity function of the device. The method describes a means by which this double indication artifact may be removed by an appropriate processing of RFEC measurements performed by an apparatus specifically designed for this purpose. The invention is particularly well designed for applications in the oilfield industry.

Owner:SCHLUMBERGER TECH CORP

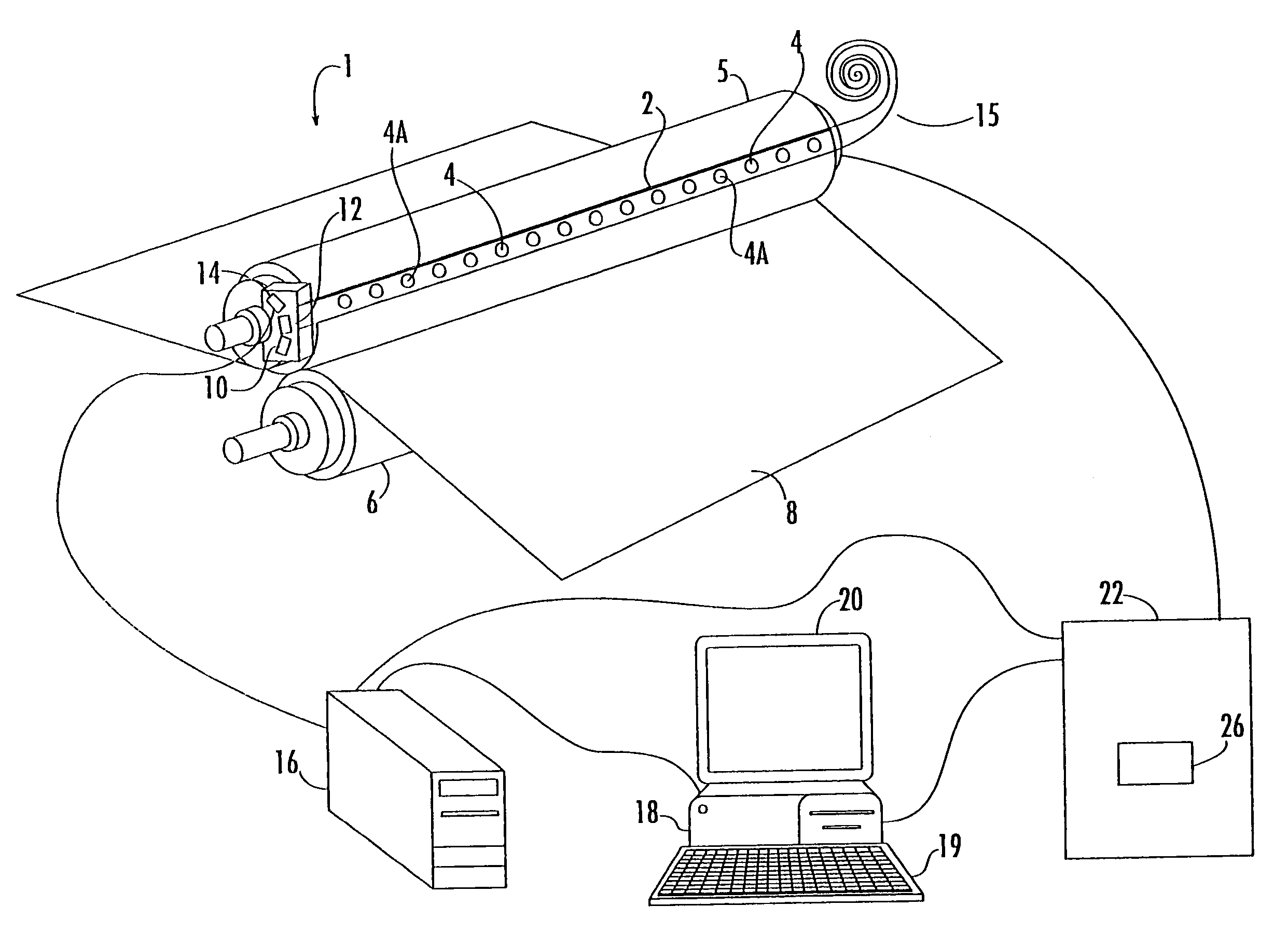

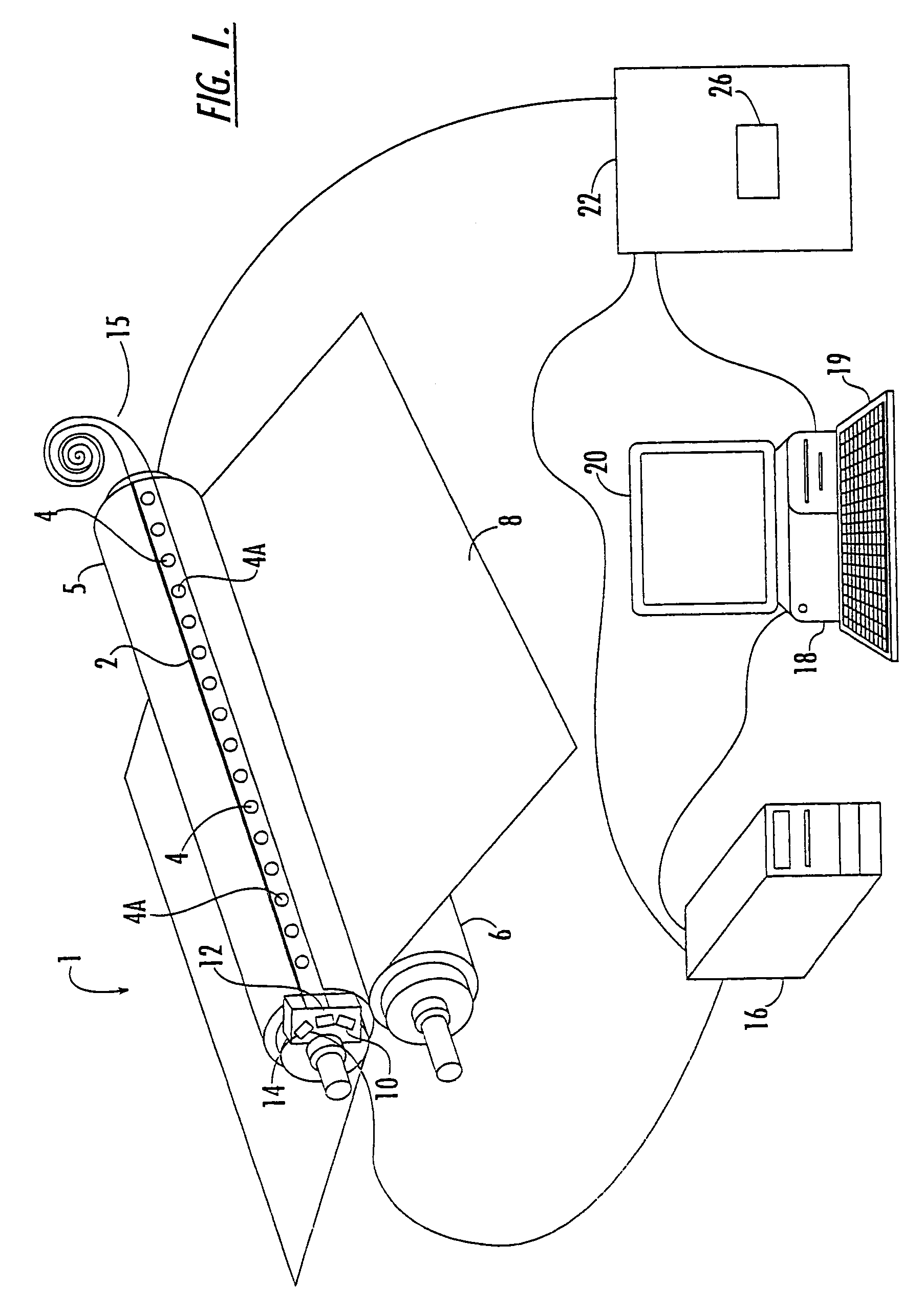

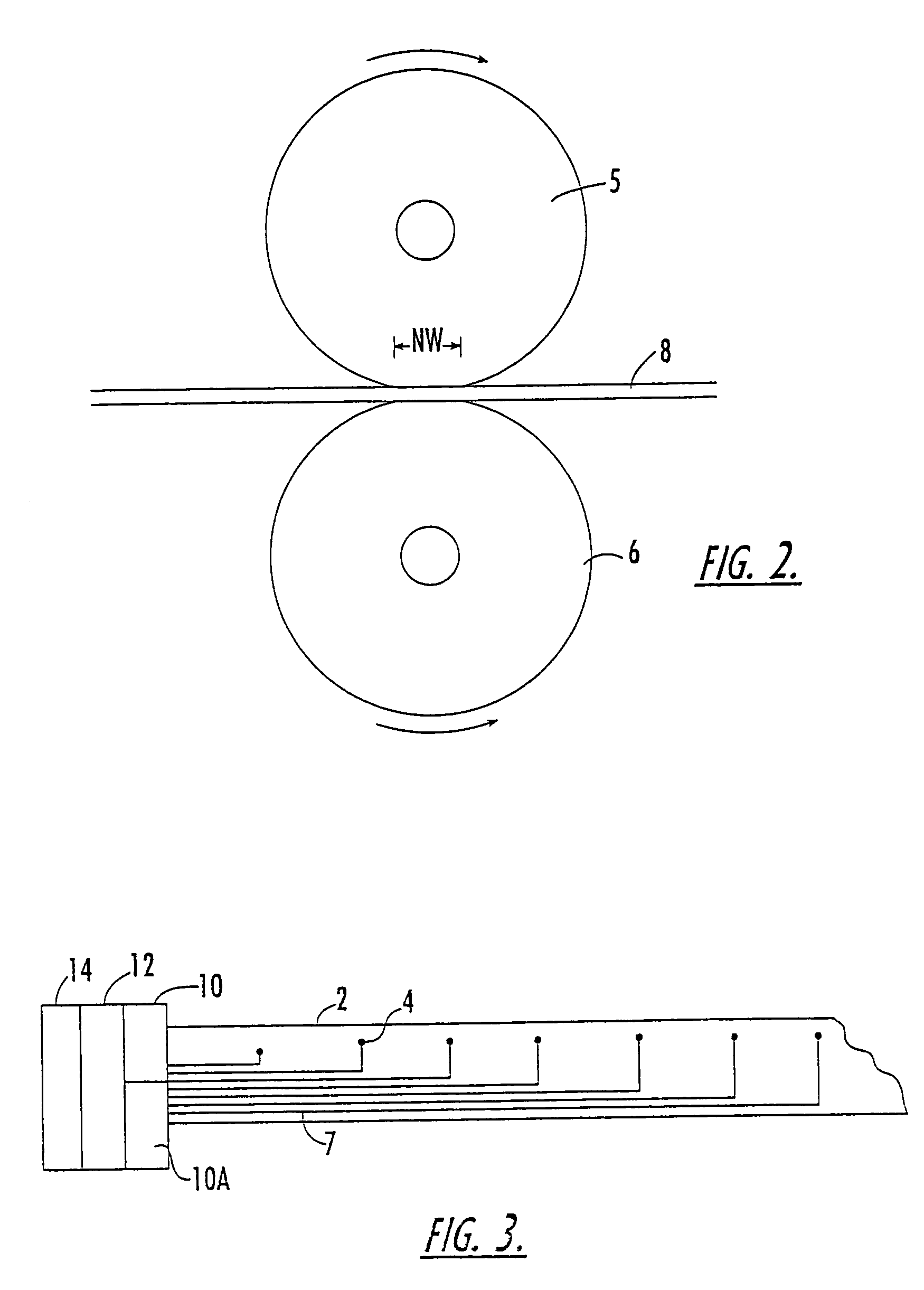

Nip width sensing system and method

InactiveUS7225688B2Force measurementUsing electrical meansElectrical resistance and conductanceResistor

Devices for measuring a nip width between rolls of a press nip include one or more sensors adapted to be placed in the nip while the nip is stationary. The electrical resistance of each sensor corresponds to the size of the nip width, whereby a nip width or a nip width distribution may be determined by measuring the sensor resistance(s). Methods of measuring a nip width distribution include providing a plurality of force sensitive resistor sensors each of which respond to pressure applied thereto to provide a variable sensor resistance as a function of the amount of pressure and the area of the pressure exerted on the sensor.

Owner:U S BANK NAT ASSOC

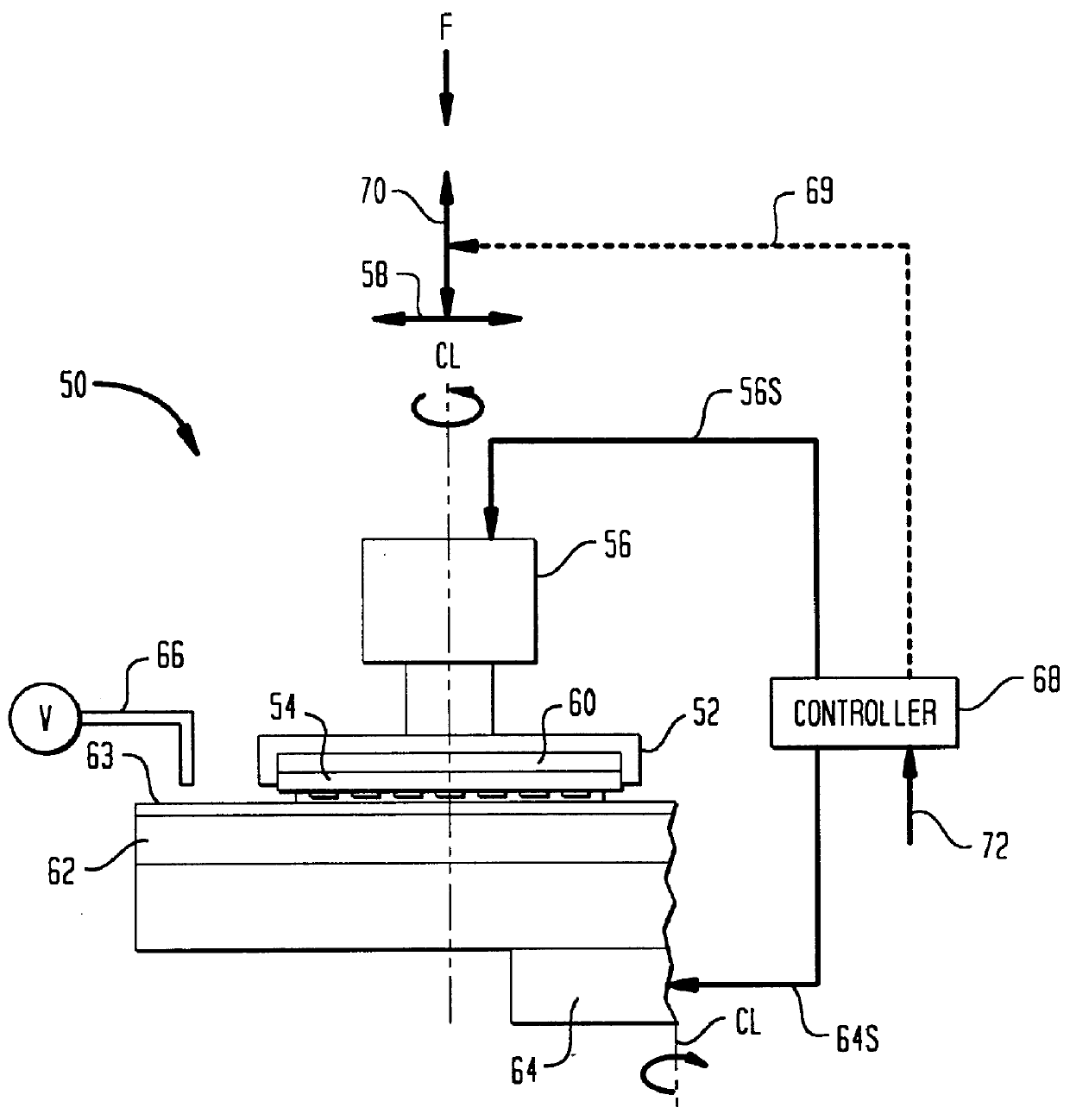

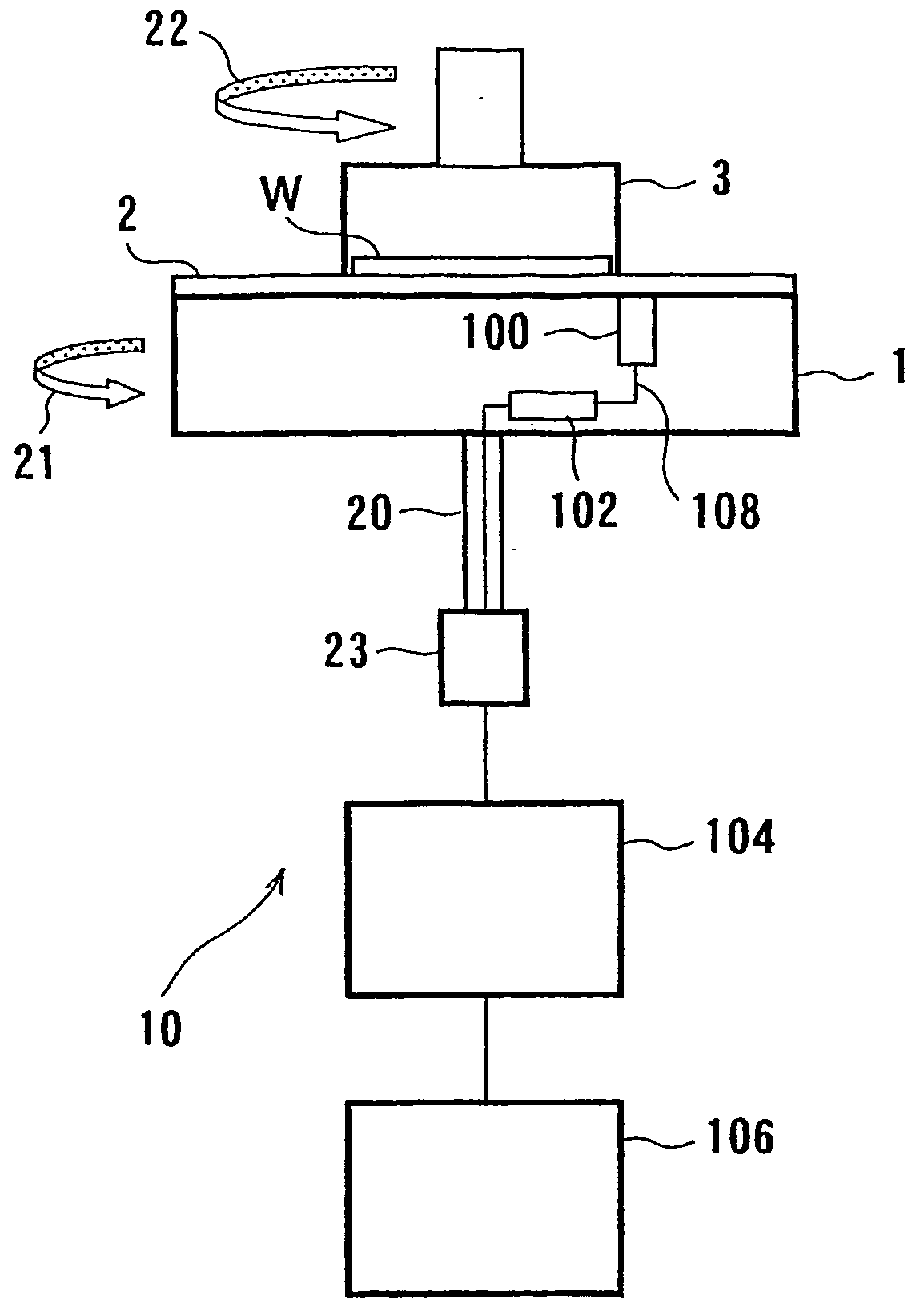

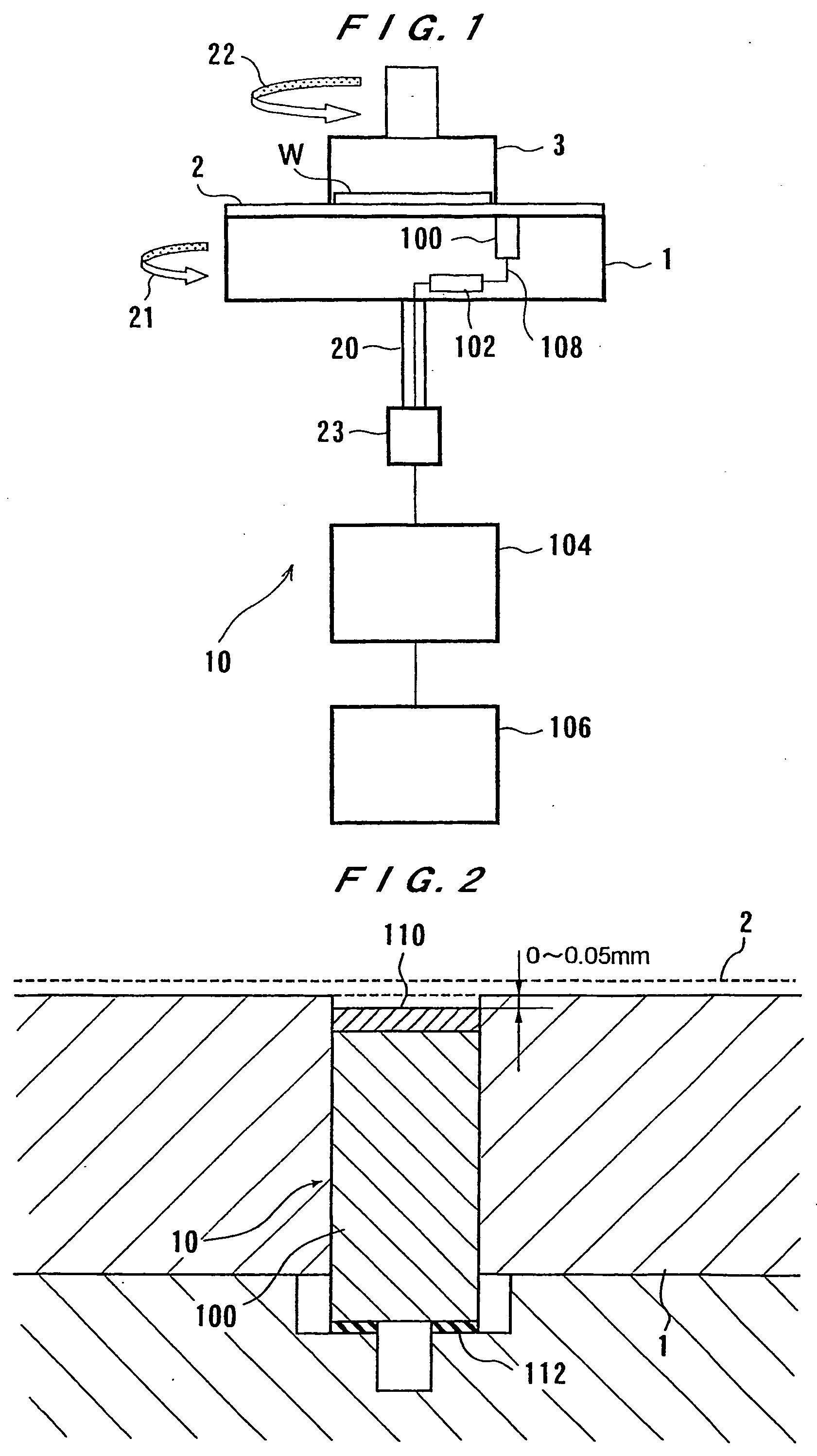

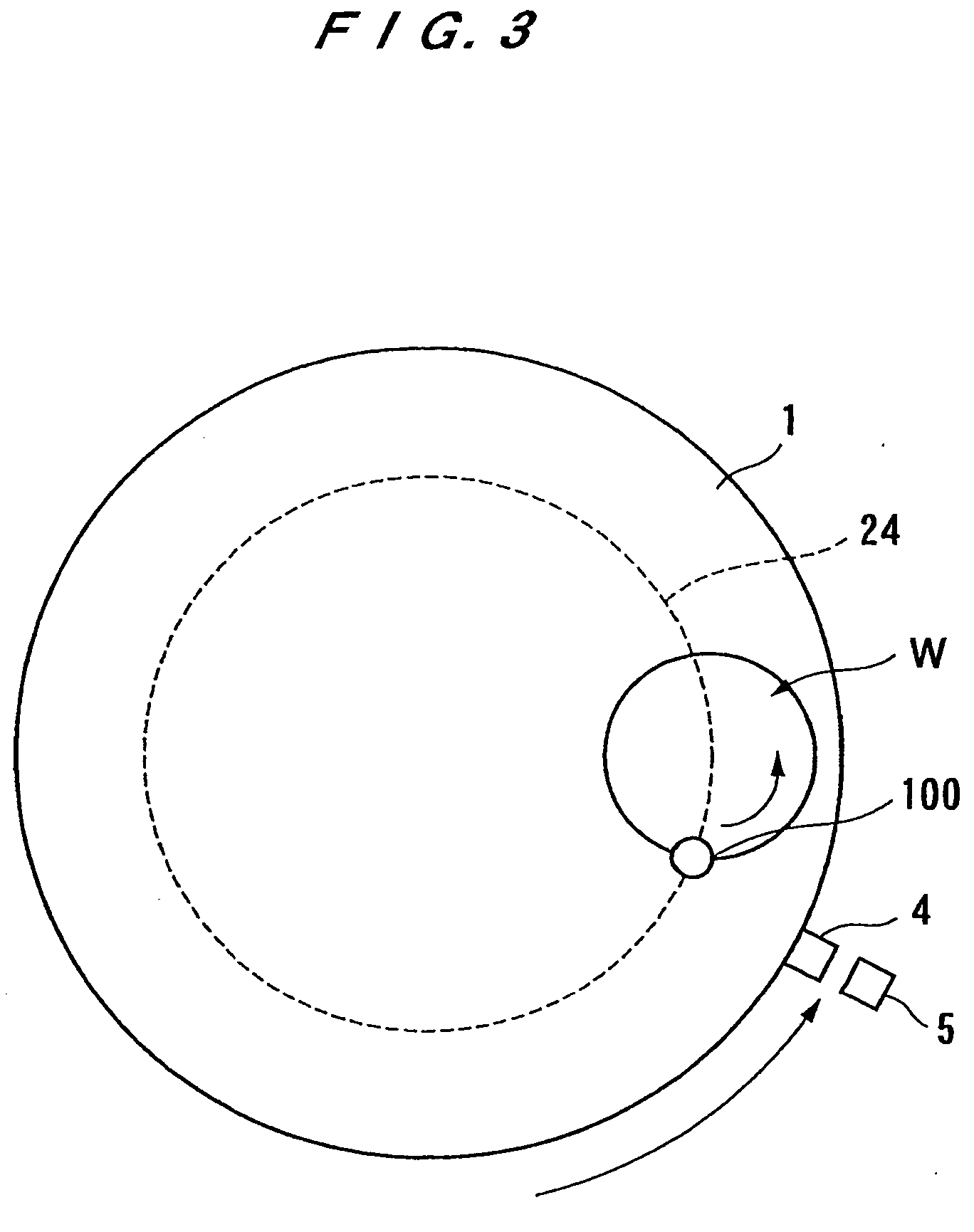

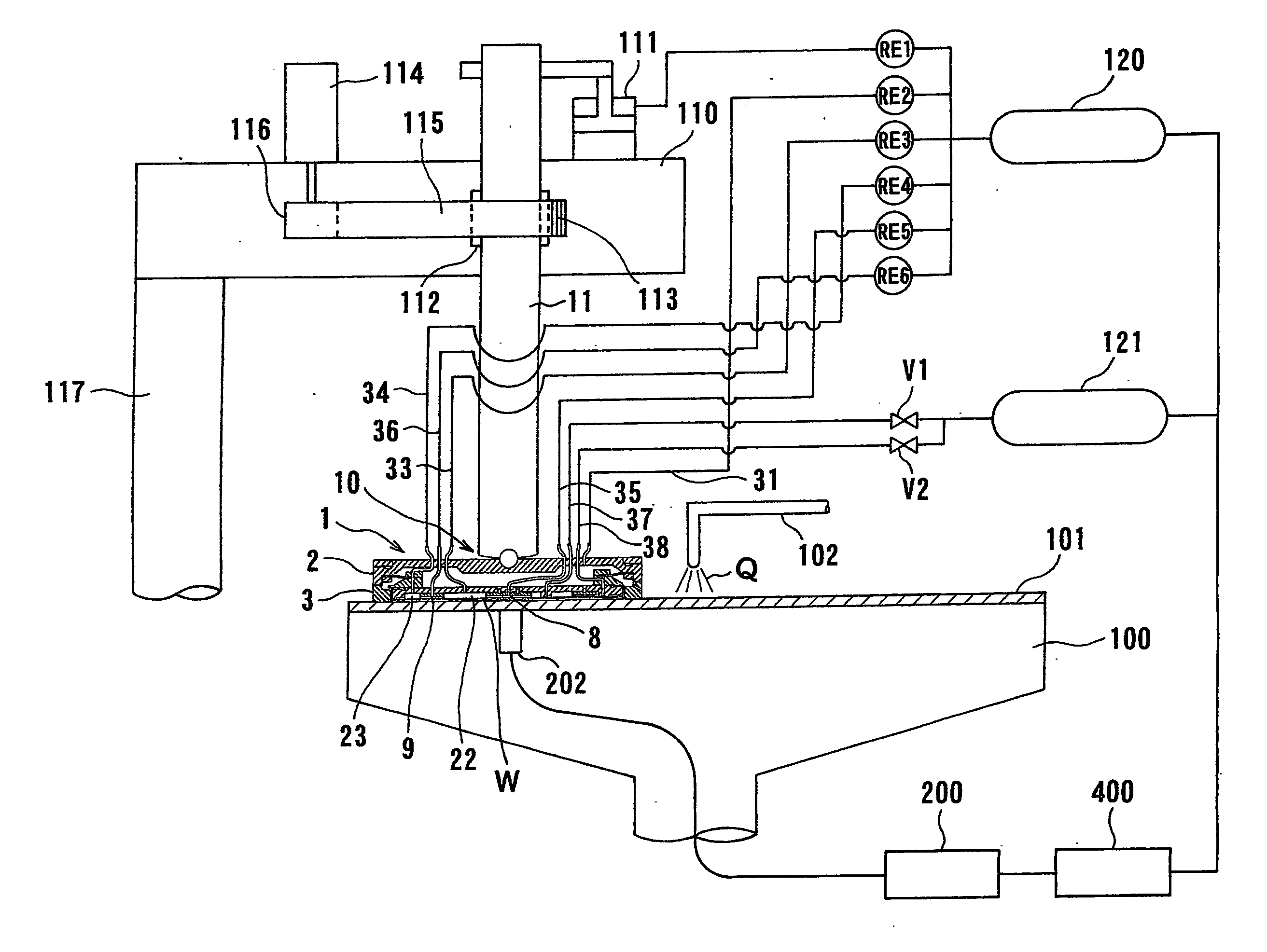

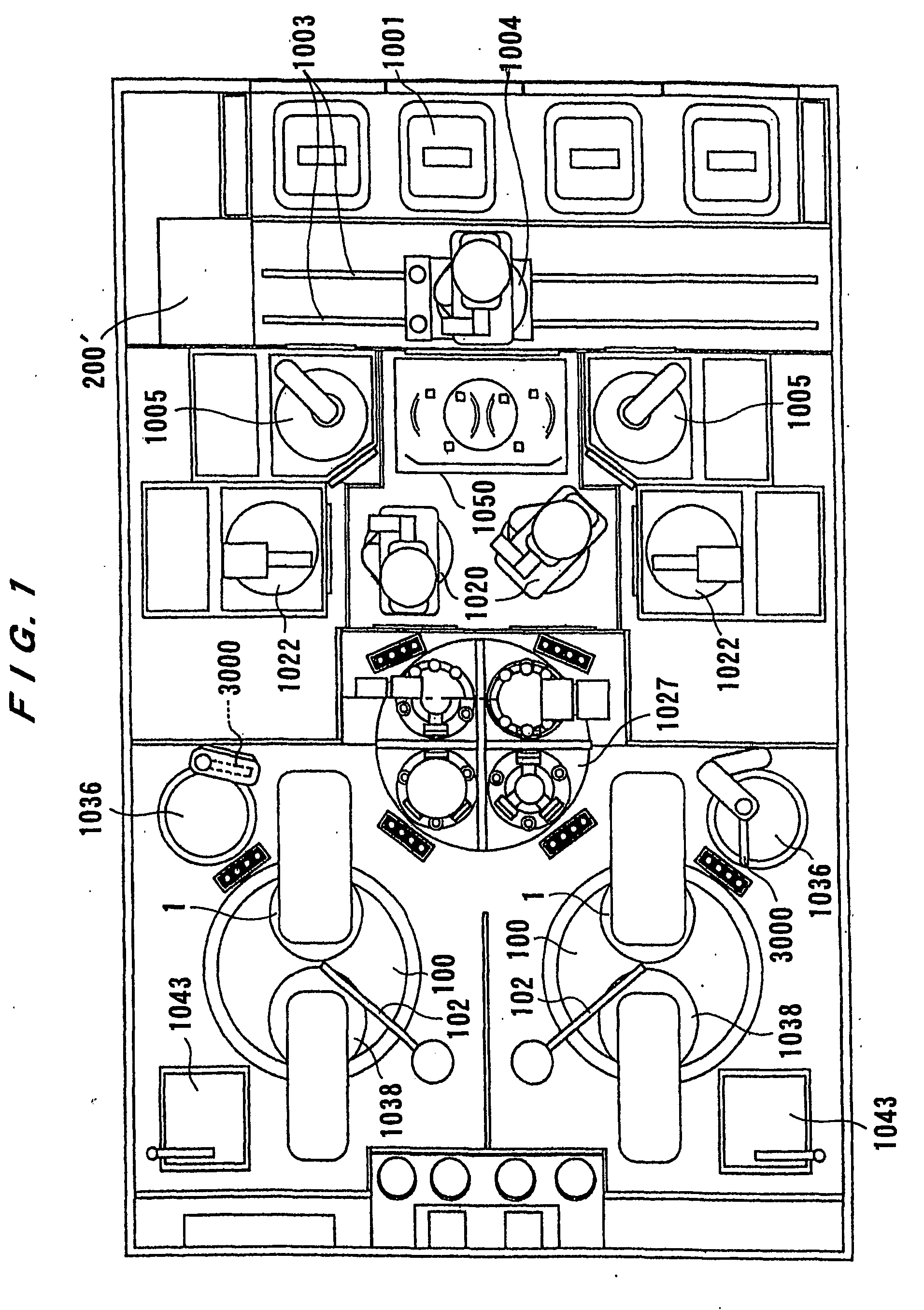

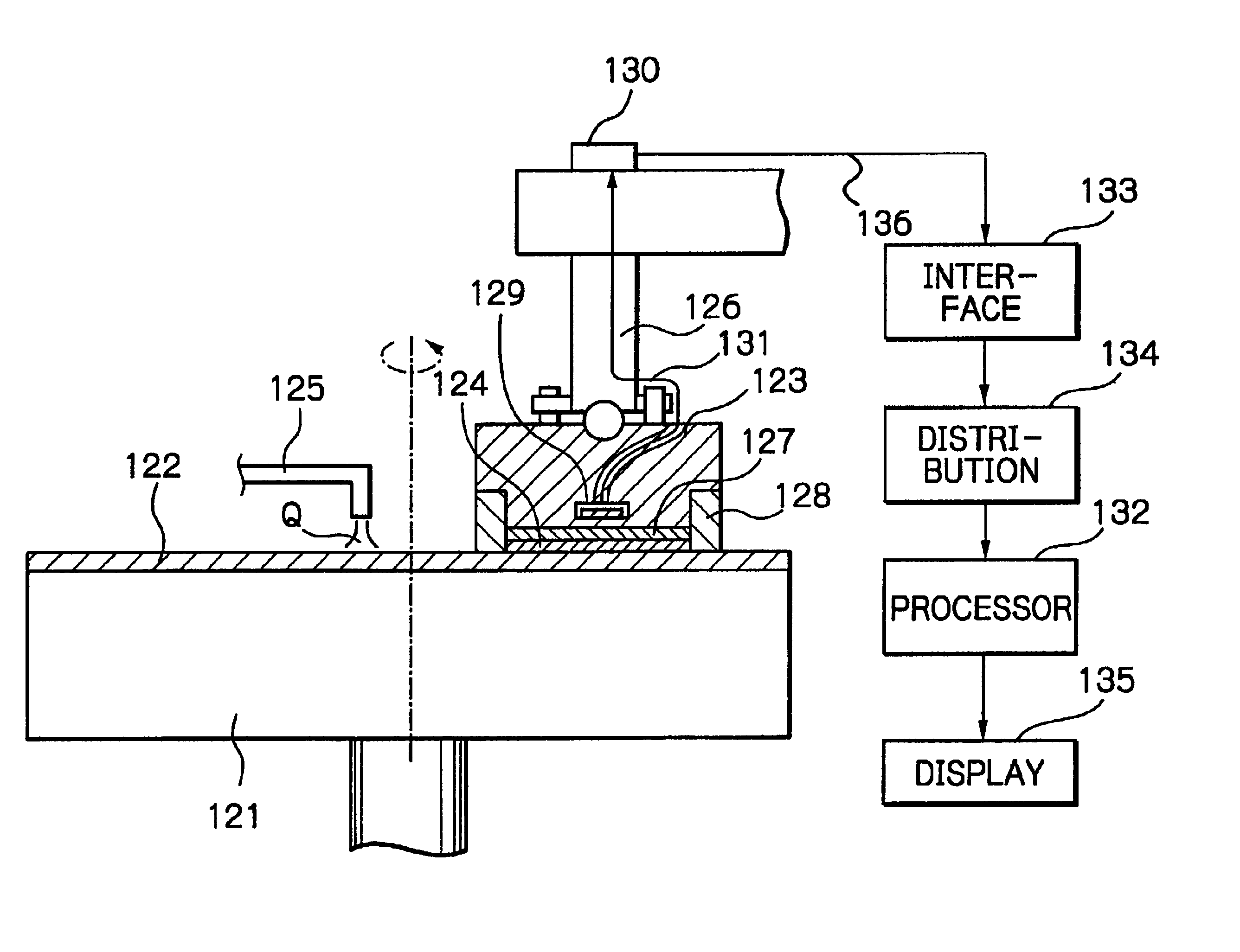

Substrate Polishing Apparatus And Substrate Polishing Method

ActiveUS20080139087A1Uniform film thicknessUniform and stable resultPolishing machinesRevolution surface grinding machinesEngineeringSemiconductor

The present invention relates to a substrate polishing apparatus and a substrate polishing method for polishing a substrate such as a semiconductor wafer to a flat finish. The substrate polishing apparatus includes a polishing table (100) having a polishing surface (101), a substrate holder (1) for holding and pressing a substrate (W) against the polishing surface (101) of the polishing table (100), and a film thickness measuring device (200) for measuring a thickness of a film on the substrate (W). The substrate holder (1) has a plurality of pressure adjustable chambers (22 to 25), and pressures in the respective chambers (22 to 25) are adjusted based on the film thickness measured by the film thickness measuring device (200).

Owner:EBARA CORP

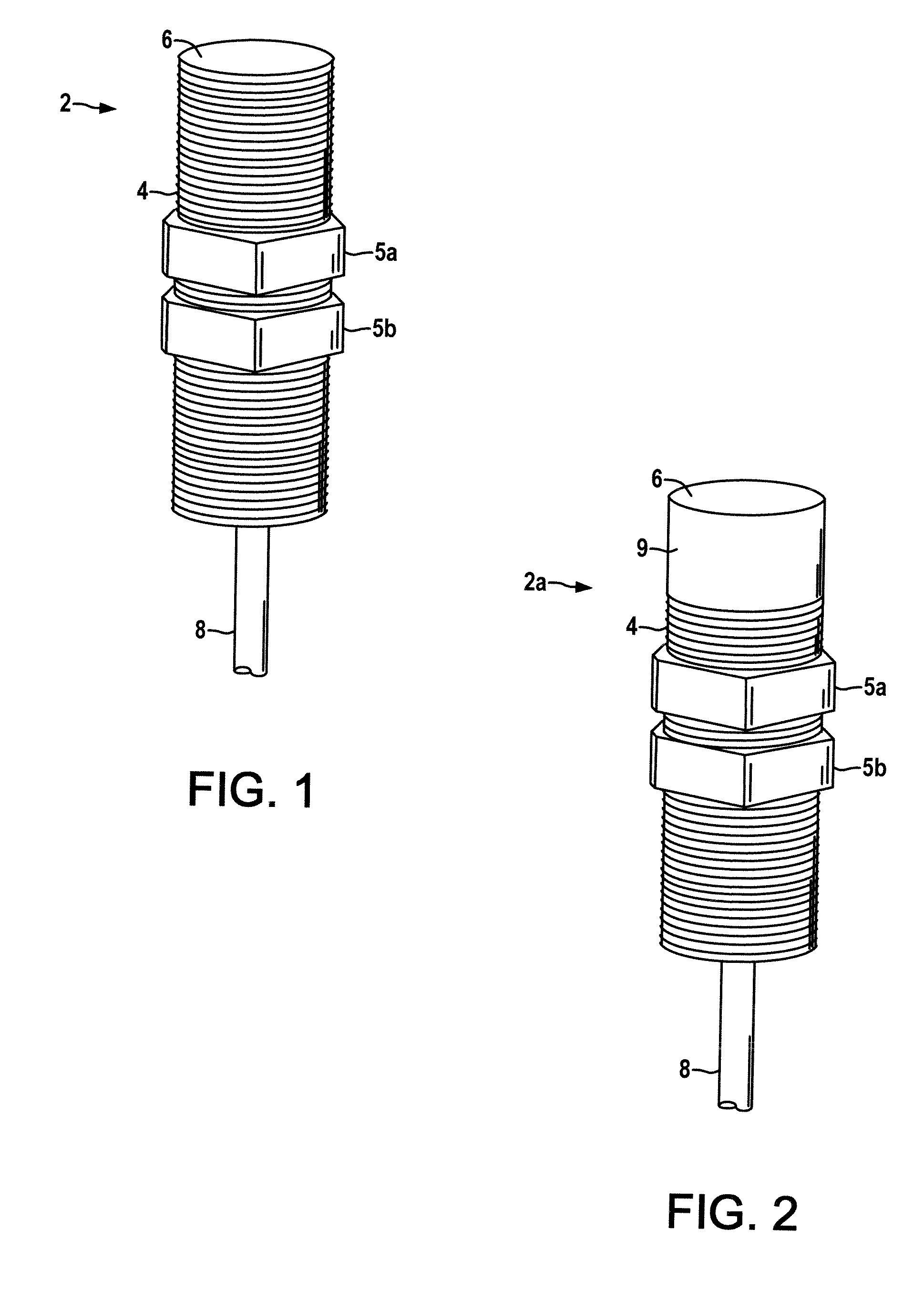

Metal face inductive proximity sensor

ActiveUS20090189600A1To offer comfortReducing amount of field and energy lossMagnetic property measurementsUsing electrical meansProximity sensorEngineering

Metal face inductive proximity sensors and methods are presented for sensing the presence or absence of a target object in a target sensing area in which a coil system is operated to generate a magnetic field extending outward from the sensing face at a frequency in a range that maximizes a relative target effect for the sensing face area, material, and thickness, and a target material from which the target object is made to allow the protective advantages of metal sensing face materials while enhancing sensing distance by optimizing the ratio of the target energy loss to the energy loss in the metal face.

Owner:PEPPERL FUCHS GMBH

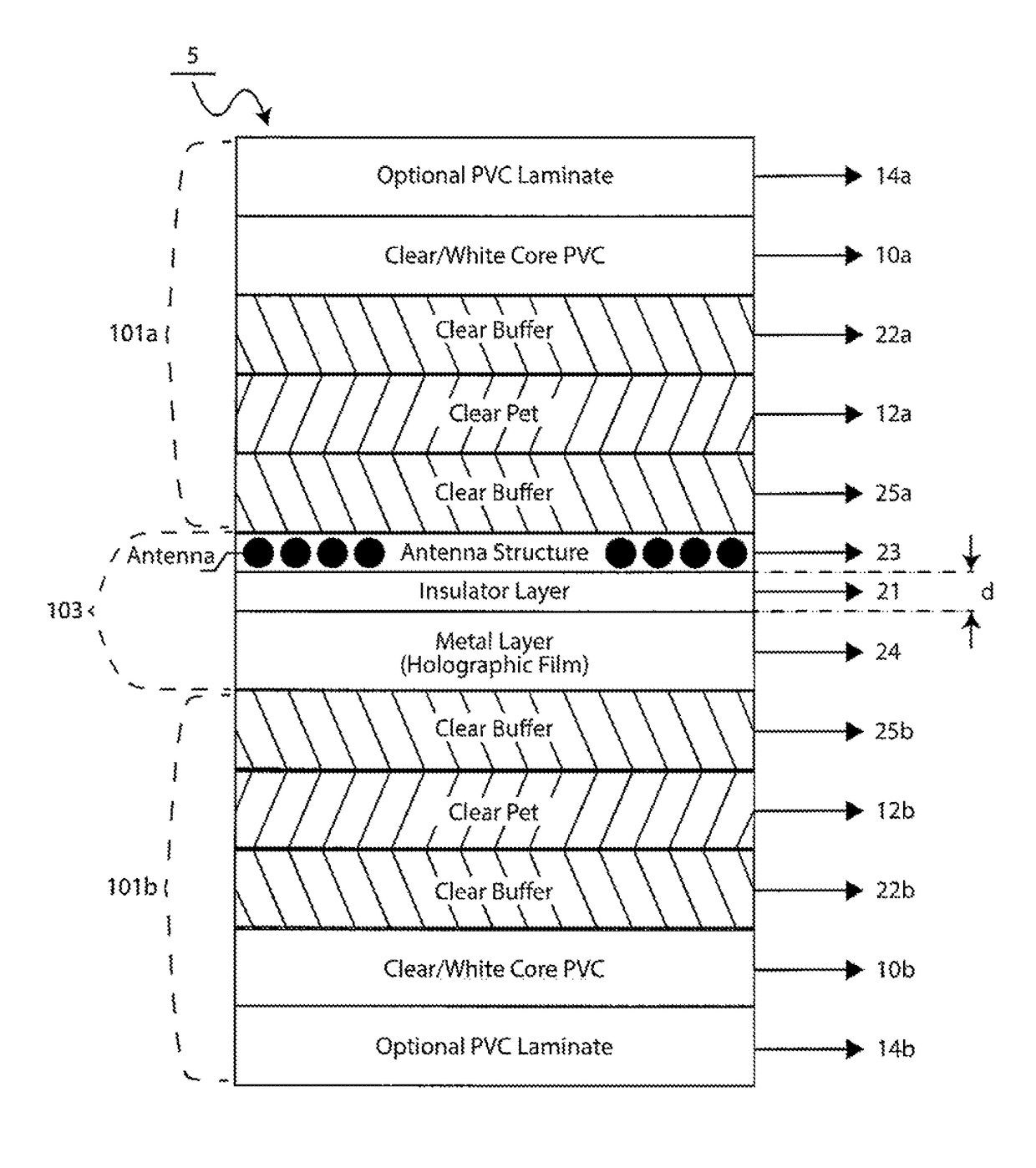

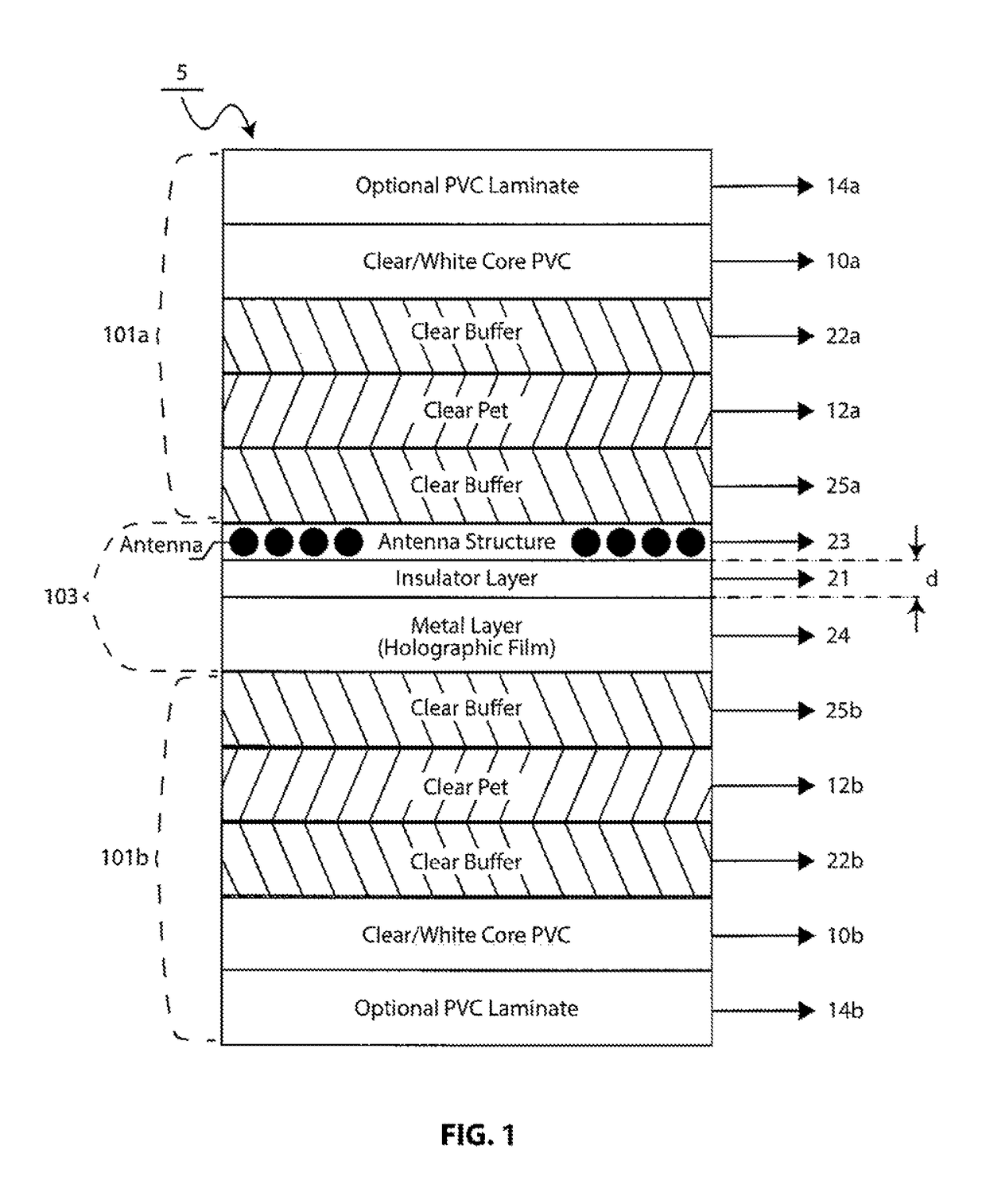

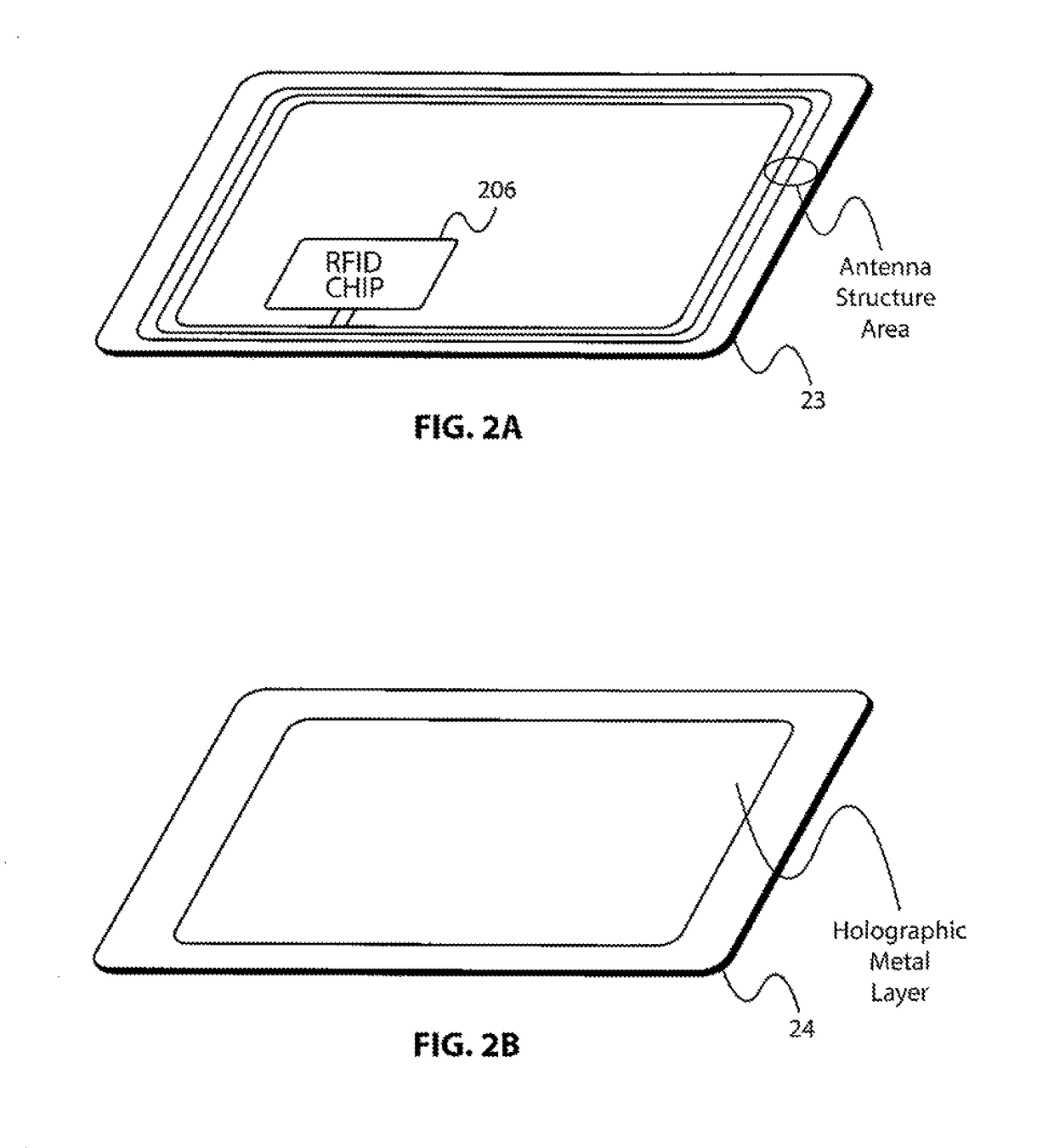

Card with metal layer and an antenna

ActiveUS9721200B2Reliable communicationEnhanced signalAntenna supports/mountingsRadiating elements structural formsCapacitive couplingElectrical and Electronics engineering

In a smart card having an antenna structure and a metal layer, an insulator layer is formed between the antenna structure and the metal layer to compensate for the attenuation due to the metal layer. The thickness of the insulator layer affects the capacitive coupling between the antenna structure and the metal layer and is selected to have a value which optimizes the transmission / reception of signals between the card and a card reader.

Owner:COMPOSECURE LLC

Electromagnetic imaging method and device

InactiveUS7960969B2Accurate electromagnetic imageImprove accuracyElectric/magnetic detection for well-loggingMagnetic property measurementsTransmitter coilEngineering

Owner:SCHLUMBERGER TECH CORP

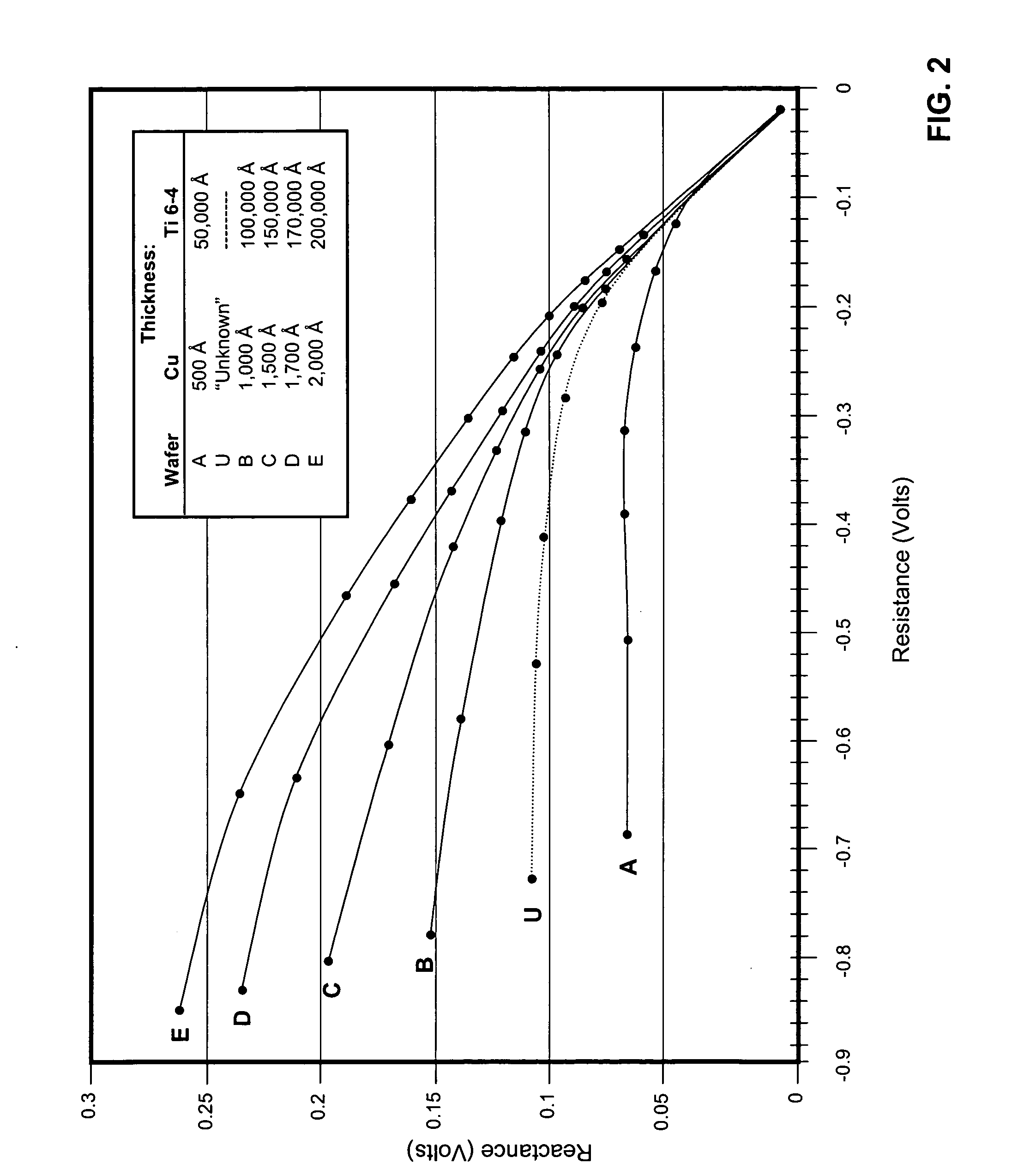

Thickness Estimation Using Conductively Related Calibration Samples

InactiveUS20050017712A1Testing/calibration apparatusMagnetic property measurementsElectrical resistance and conductanceOptics

A method for monitoring an inspection sample includes generating inspection data comprising resistance and reactance measurements that are obtained from an inspection sample having a conductive layer of unknown thickness. Calibration data is used for estimating the thickness of the conductive layer of the inspection sample. This calibration data includes resistance and reactance measurements obtained from one or more calibration samples, each calibration sample having a conductive layer of known thickness. The conductive layers of the inspection sample and the calibration samples comprise different materials having a known conductive relationship.

Owner:LE CUONG DUY

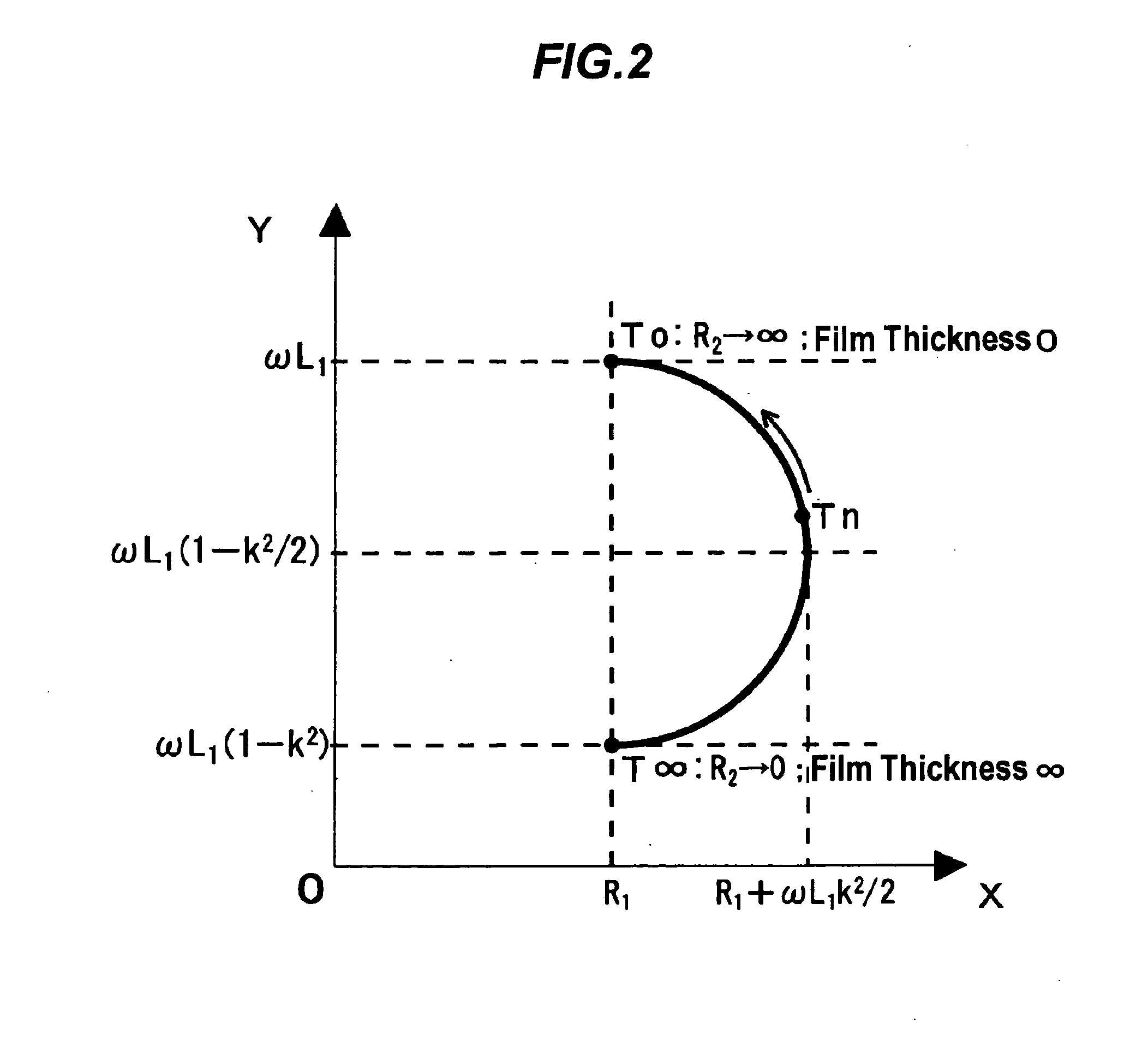

Film thickness measuring apparatus and film thickness measuring method

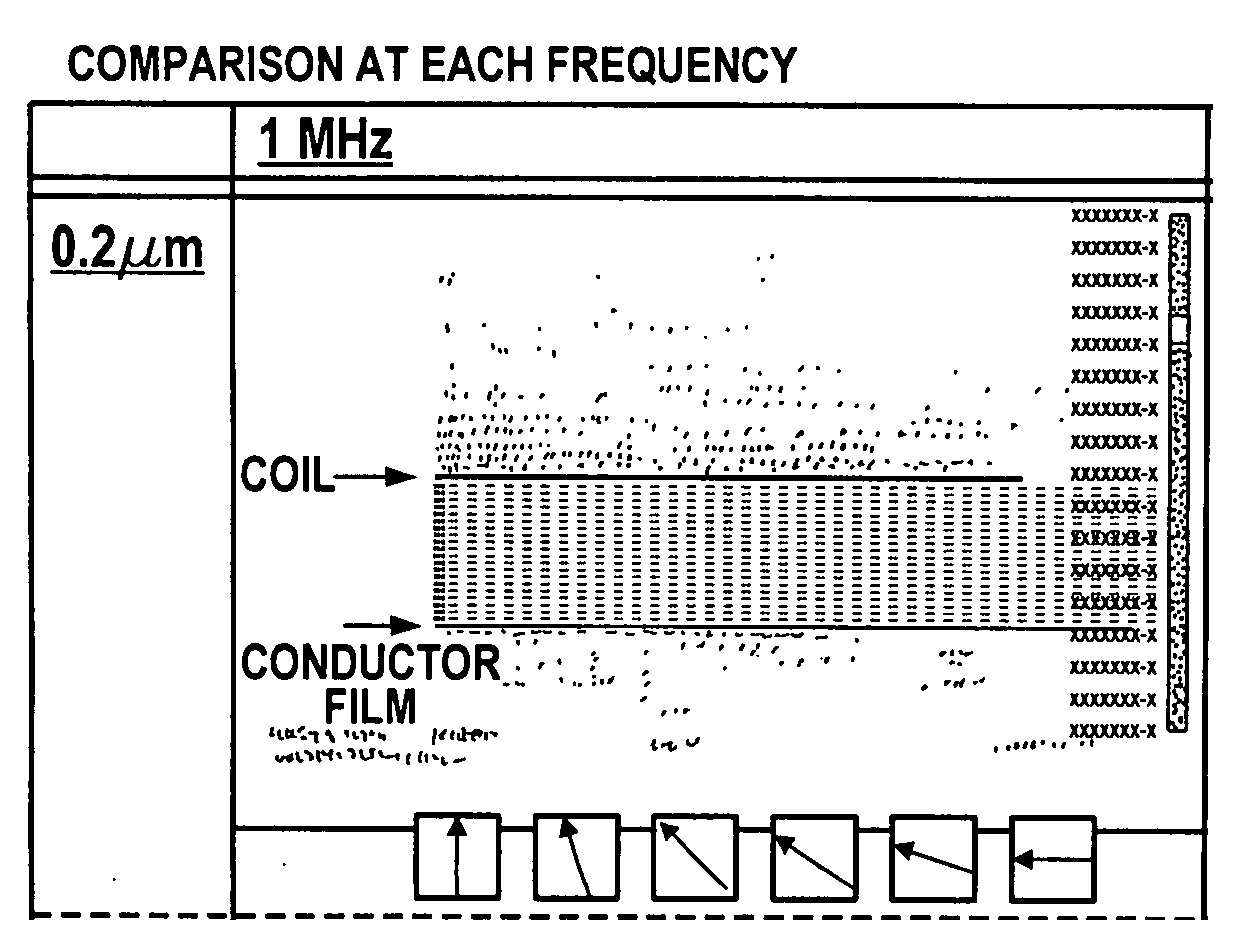

InactiveUS20090256558A1Eliminating infiltration of the magnetic fieldImprove conductivityMagnetic property measurementsUsing electrical meansSkin effectEddy current

Coil is made to be disposed with gap opposed to the surface of wafer, and wafer stage is made to move in X and Y direction and R and θ direction. When supplying an alternating current to coil with the frequency swept by impedance analyzer, the magnetic field made to be induced in coil will operate on the conductive film of wafer. By changing a parameter (a frequency or an angle) influencing the skin effect of the conductive film and giving the parameter to coil, the state where a magnetic field is not made to penetrate relatively the film of wafer and the state where the magnetic field is made to penetrate relatively the film can be formed. From the variation of various values corresponding to the eddy current induced based on the change of state influenced by the skin effect of the conductive film, the film thickness of wafer can be measured with sufficient accuracy.

Owner:TOKYO SEIMITSU

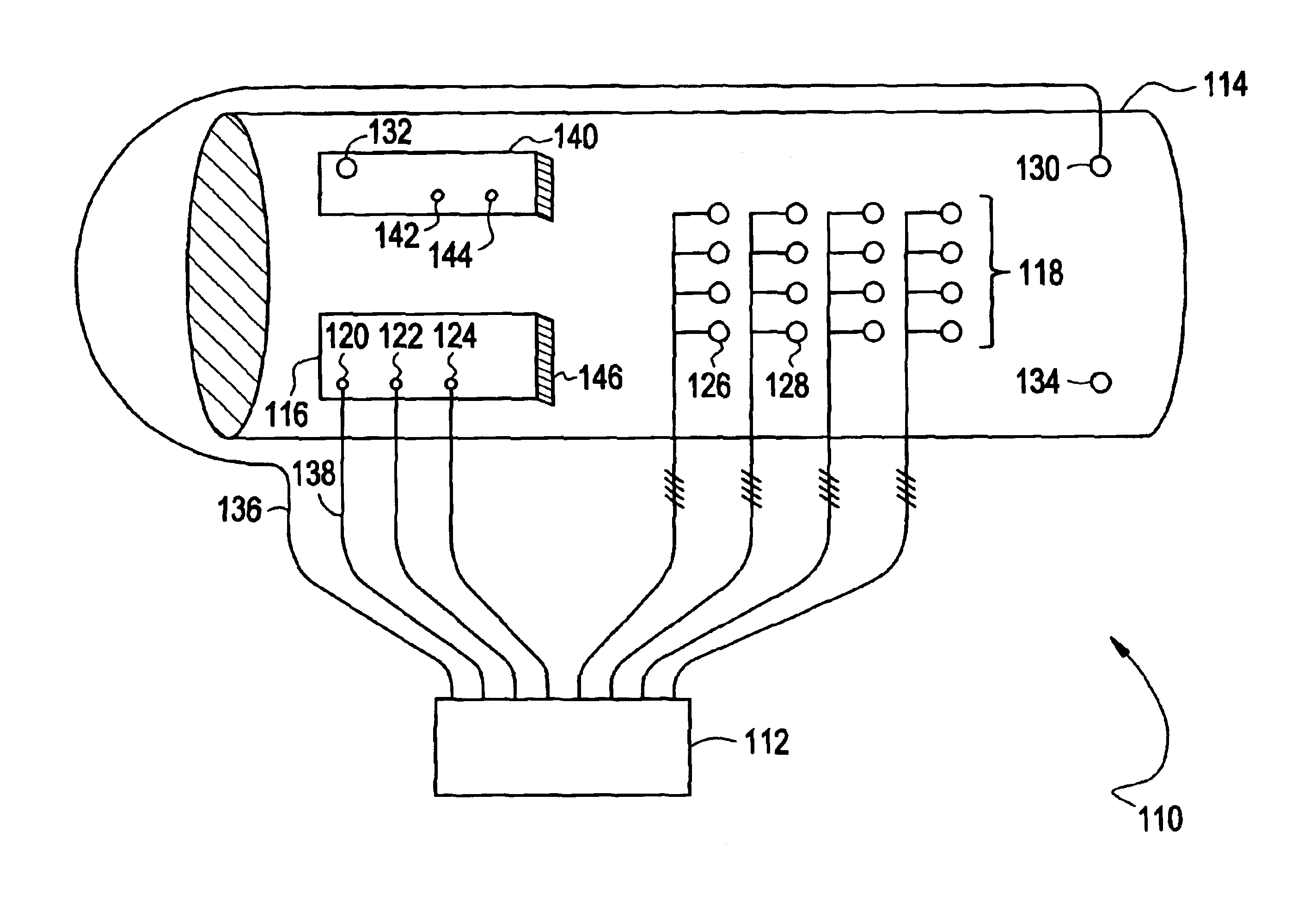

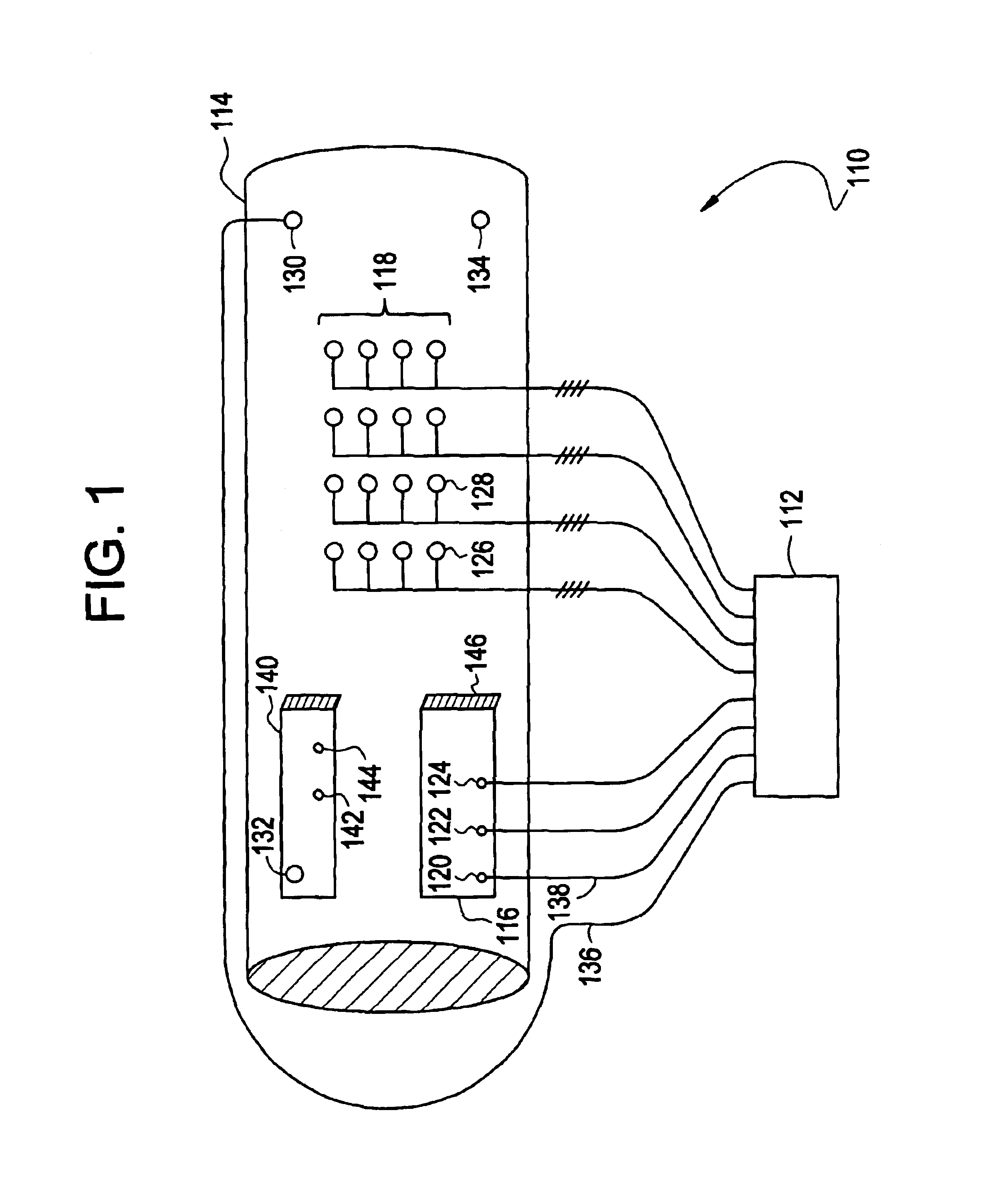

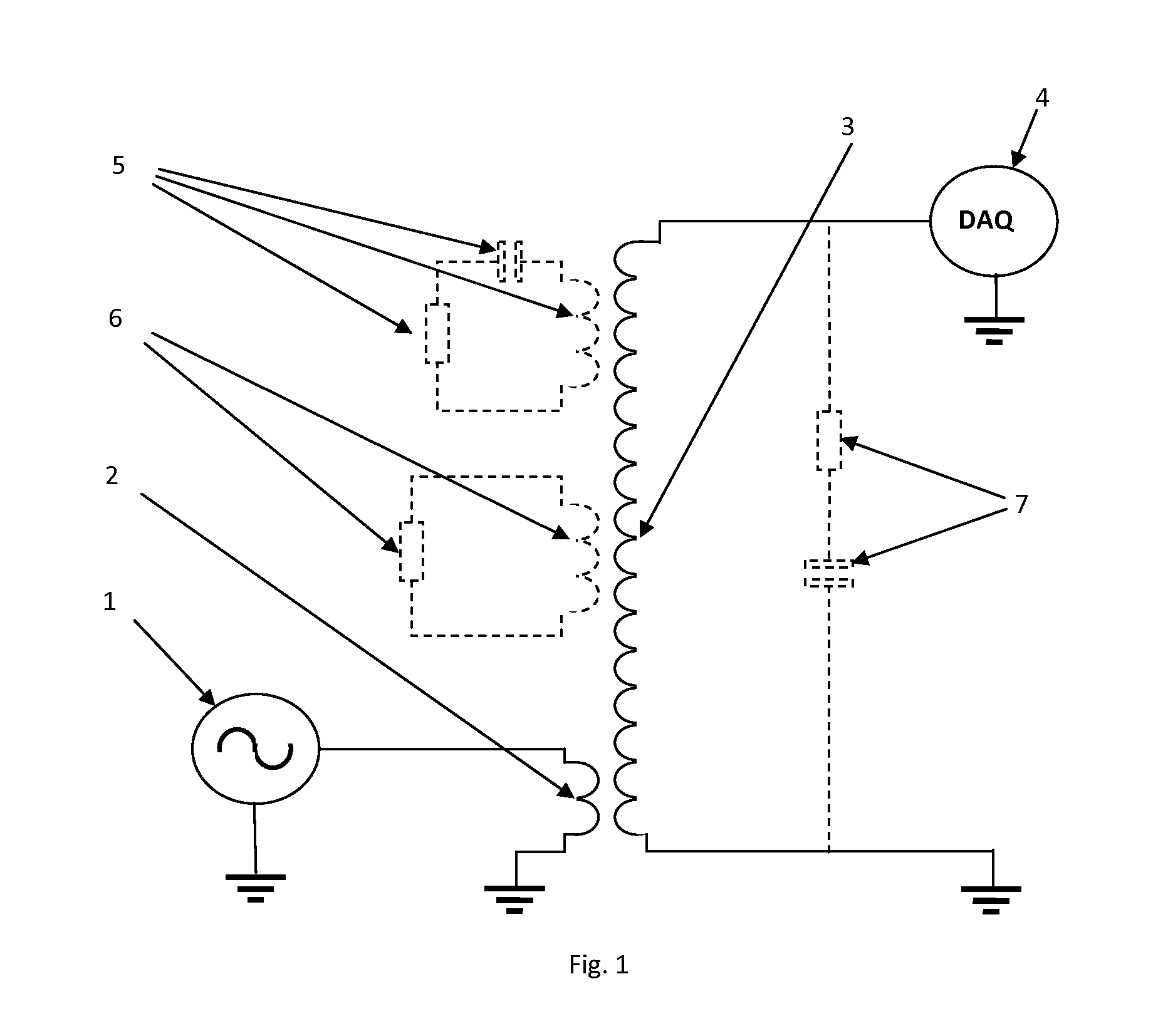

System and method for monitoring defects in structures

InactiveUS6922641B2Improve the immunityGreater potential dropElectric/magnetic contours/curvatures measurementsUsing electrical meansEngineeringElectric current

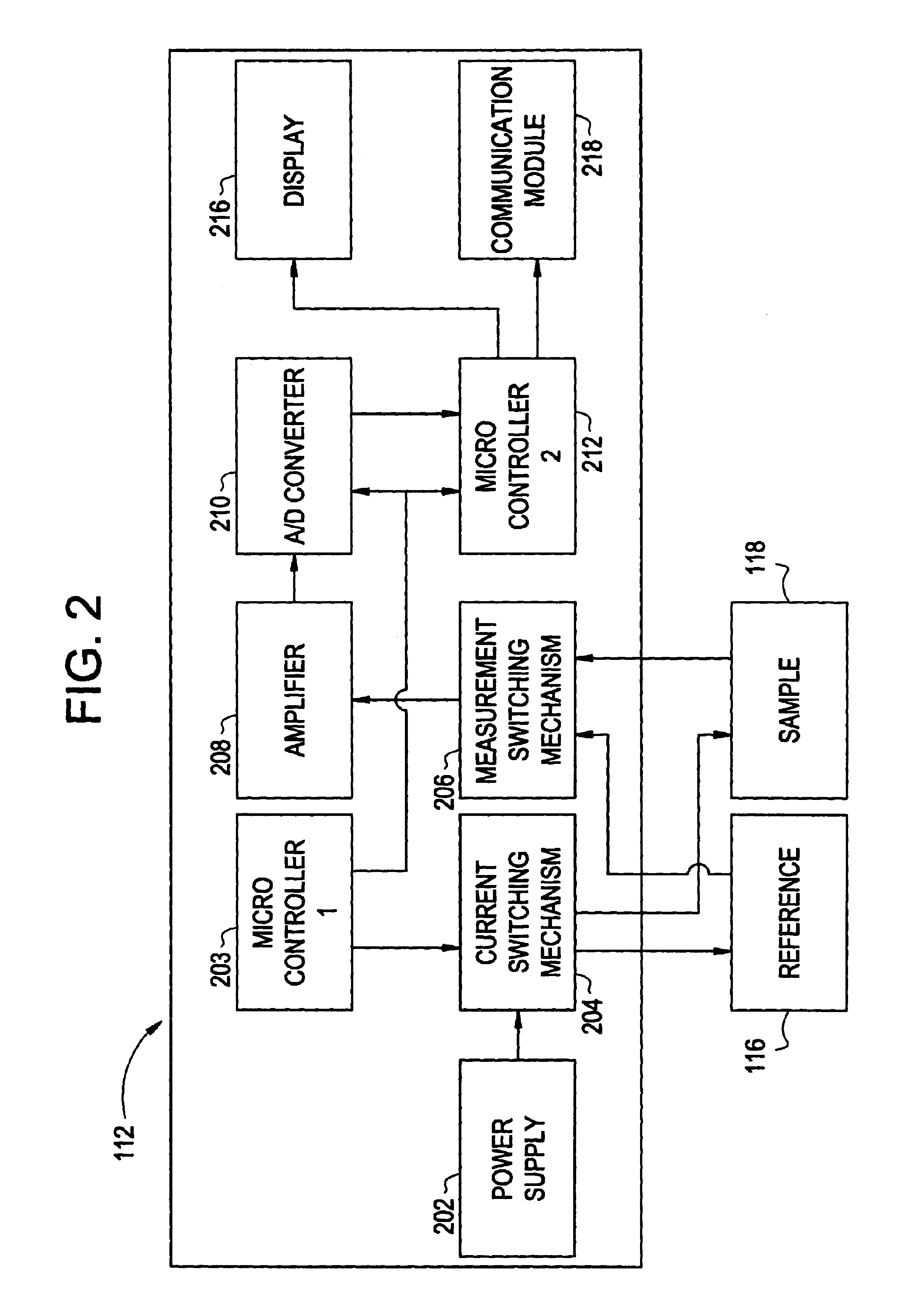

A system and method for monitoring defects in a structure are provided. The system includes a power supply for supplying an electric current to a monitoring area of the structure and a reference; a measurement circuit for measuring a potential drop across at least two contact points of the monitoring area and at least two contact points of the reference; and a processor adapted to determine a ratio of the monitoring area potential drop to the reference potential drop indicative of a percentage change in a thickness of the structure. The method includes the steps of supplying the current to the monitoring area and the reference; measuring a first potential drop across the monitoring area and the reference; and determining the ratio indicative of the percentage change in the thickness of the structure.

Owner:GENERAL ELECTRIC CO

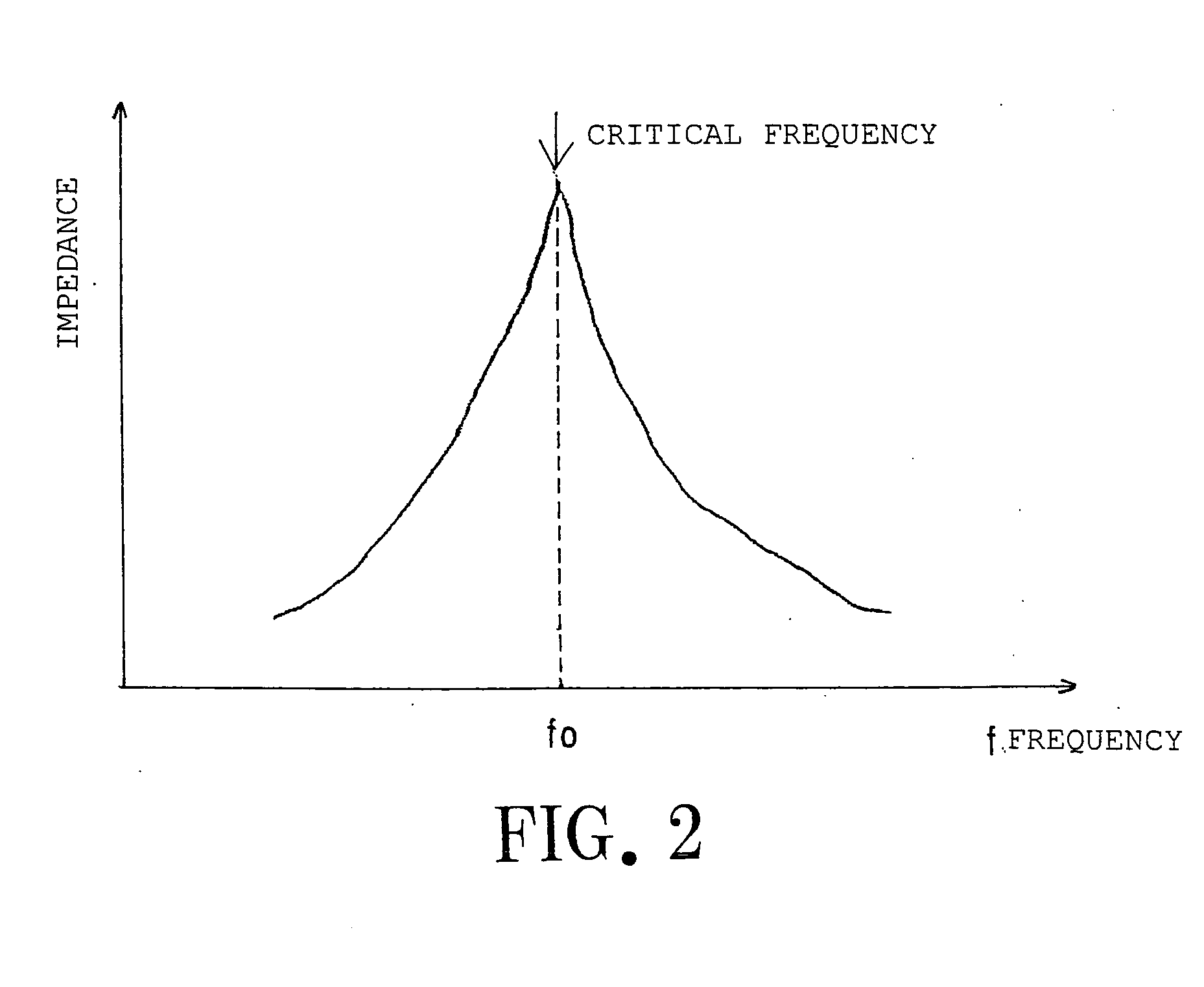

Frequency measuring device, polishing device using the same and eddy current sensor

InactiveUS7046001B2Improve accuracyShort time intervalSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingFrequency measurementsCurrent sensor

A frequency measuring device capable of accurately detecting an end point of polishing a semiconductor wafer by obtaining a frequency measurement result highly accurately in a short period of time. A device FC, which measures the frequency of a measured signal comprises a counting section including a plurality of n-nary counters, a time reference circuit which outputs a time reference signal for every predetermined time interval, and a plurality of gate circuits whose outputs are connected to the inputs of the n-nary counters. The gate circuits receive the measured signal at a first input and receive the time reference signal at the predetermined time intervals at a second input. With this structure, the counting section supplies the frequency measured result of the measured signal every predetermined time interval.

Owner:SCI MED LIFE SYST +1

Capacitance ratio type ice-covering thickness sensor and its detection method

InactiveCN101285673AAccurate measurementRealize continuous automatic detectionElectrical/magnetic thickness measurementsCapacitanceParallel plate

The invention relates to a capacitance ratio type icing thickness sensor and a detection method thereof. The sensor is characterized in that: a relative capacitance value detection loop is formed by a single chip microcomputer inside a sensor, a double-channel capacitance digital converter, detected media icing or air spreading between pole plates, a group of parallel pole plate detection capacitors which have an geometric structure the same with a reference parallel plate pole plate detection capacitor and are arranged according to fixed ruler scale spacing positions, as well as a double-channel programmable control scale gating circuit; under the control of the single chip microcomputer, the capacitance value obtained by each relative capacitance value detection loop is compared with the reference capacitance value obtained by a reference capacitance value detection loop which is formed by the single chip microcomputer inside the sensor, the double-channel capacitance digital converter and the reference parallel plate pole plate detection capacitor, and the measurement on the surface icing thickness of the sensor is realized by analyzing and judging a ratio result. Under the condition of ice rain or freezing, the sensor can continuously and automatically detect the icing thickness of suspended power transmission lines, pylons, buildings, equipment surfaces, branches, etc.

Owner:TAIYUAN UNIV OF TECH

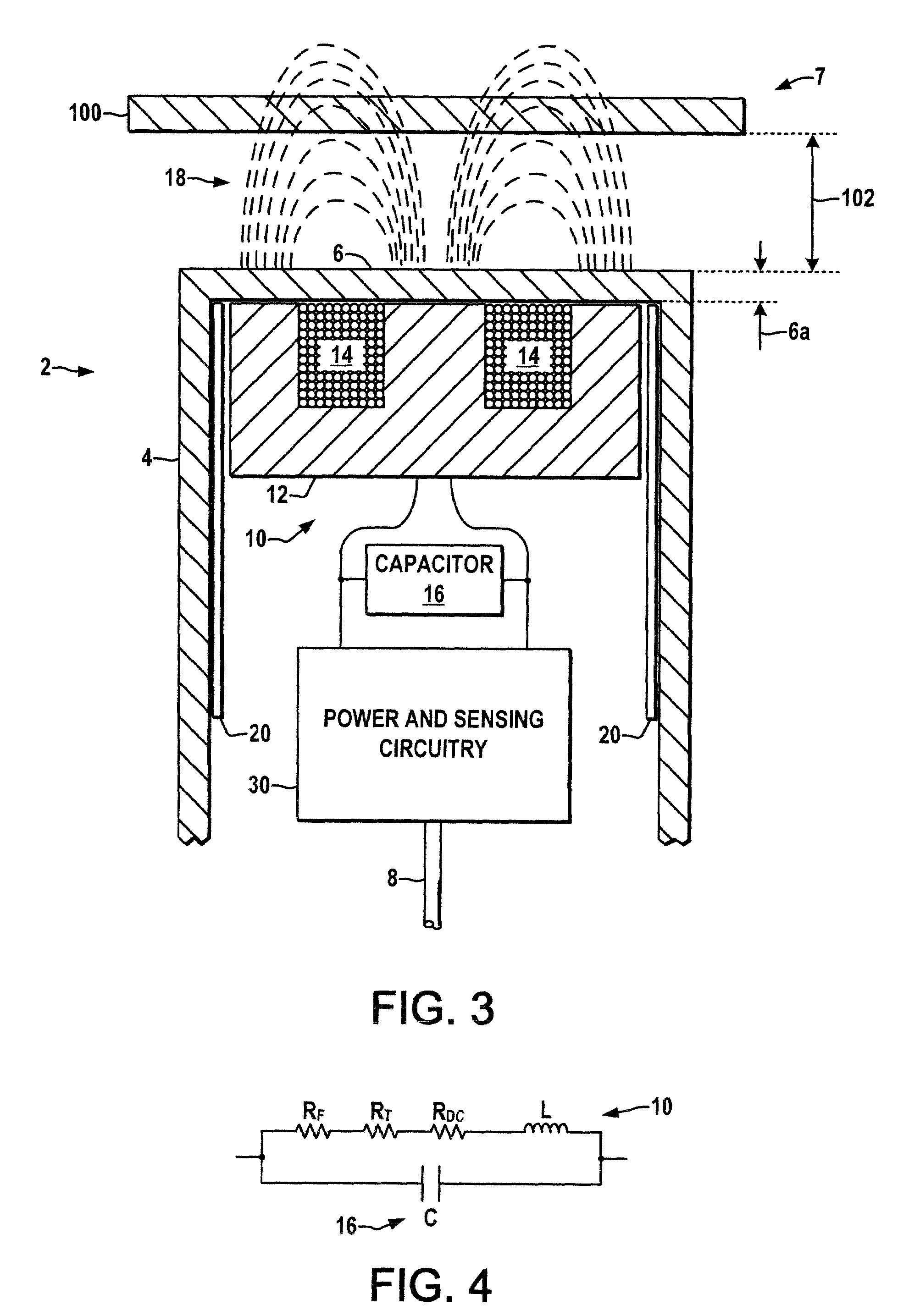

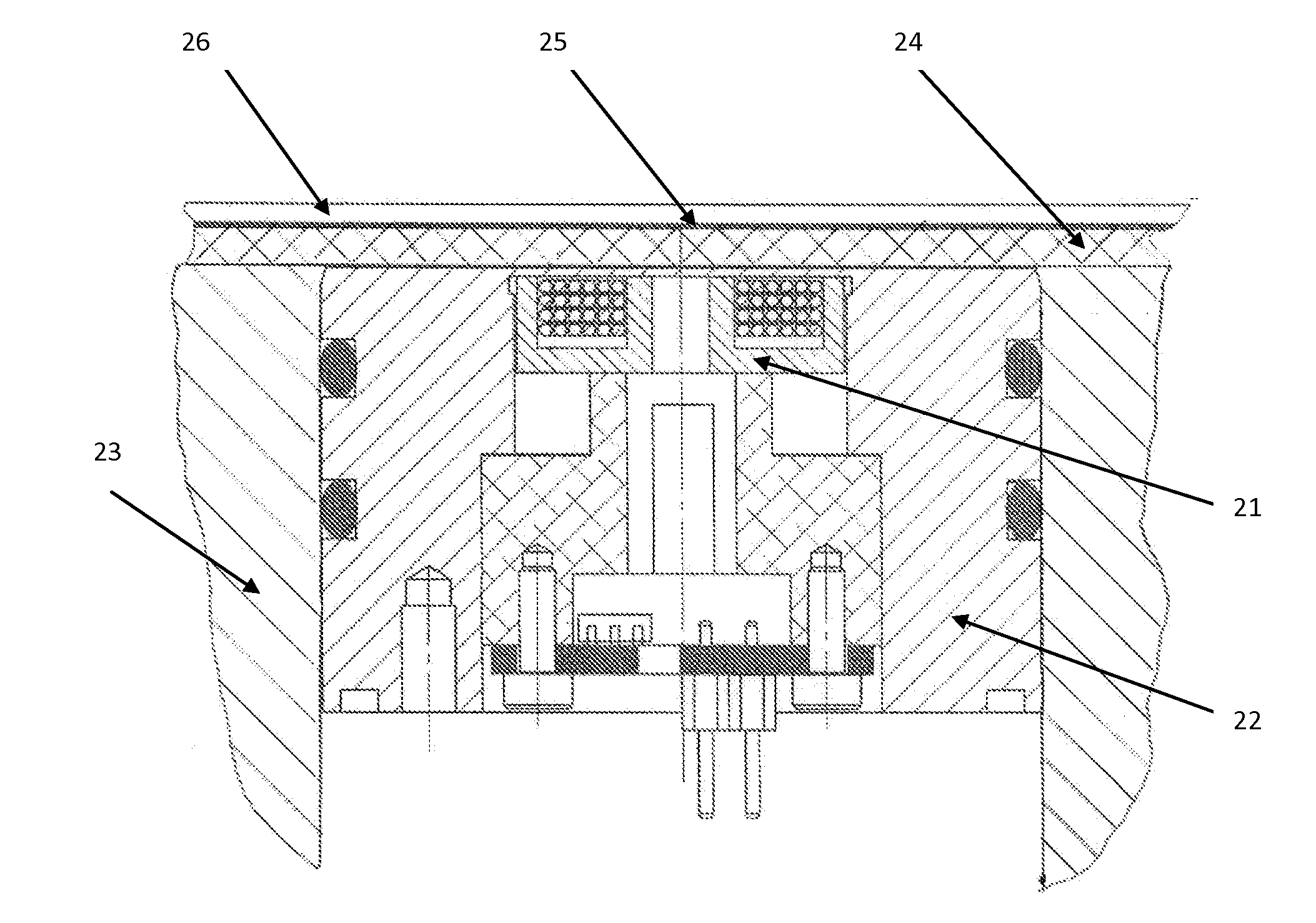

Apparatus and method of using impedance resonance sensor for thickness measurement

An apparatus for, and methods of use for, measuring film thickness on an underlying body are provided. The apparatus may include at least one Impedance Resonance (IR) sensor, which may include at least one sensing head. The at least one sensing head may include an inductor having at least one excitation coil and at least one sensing coil. The excitation coil may propagate energy to the sensing coil so that the sensing coil may generate a probing electromagnetic field. The apparatus may also include at least one power supply, at least one RF sweep generator electrically connected to the excitation coil; at least one data acquisition block electrically connected to the sensing coil; at least one calculation block; and at least one communication block. Methods of monitoring conductive, semiconductive or non-conductive film thickness, and various tools for Chemical Mechanical Polishing / Planarization (CMP), etching, deposition and stand-alone metrology are also provided.

Owner:NEOVISION

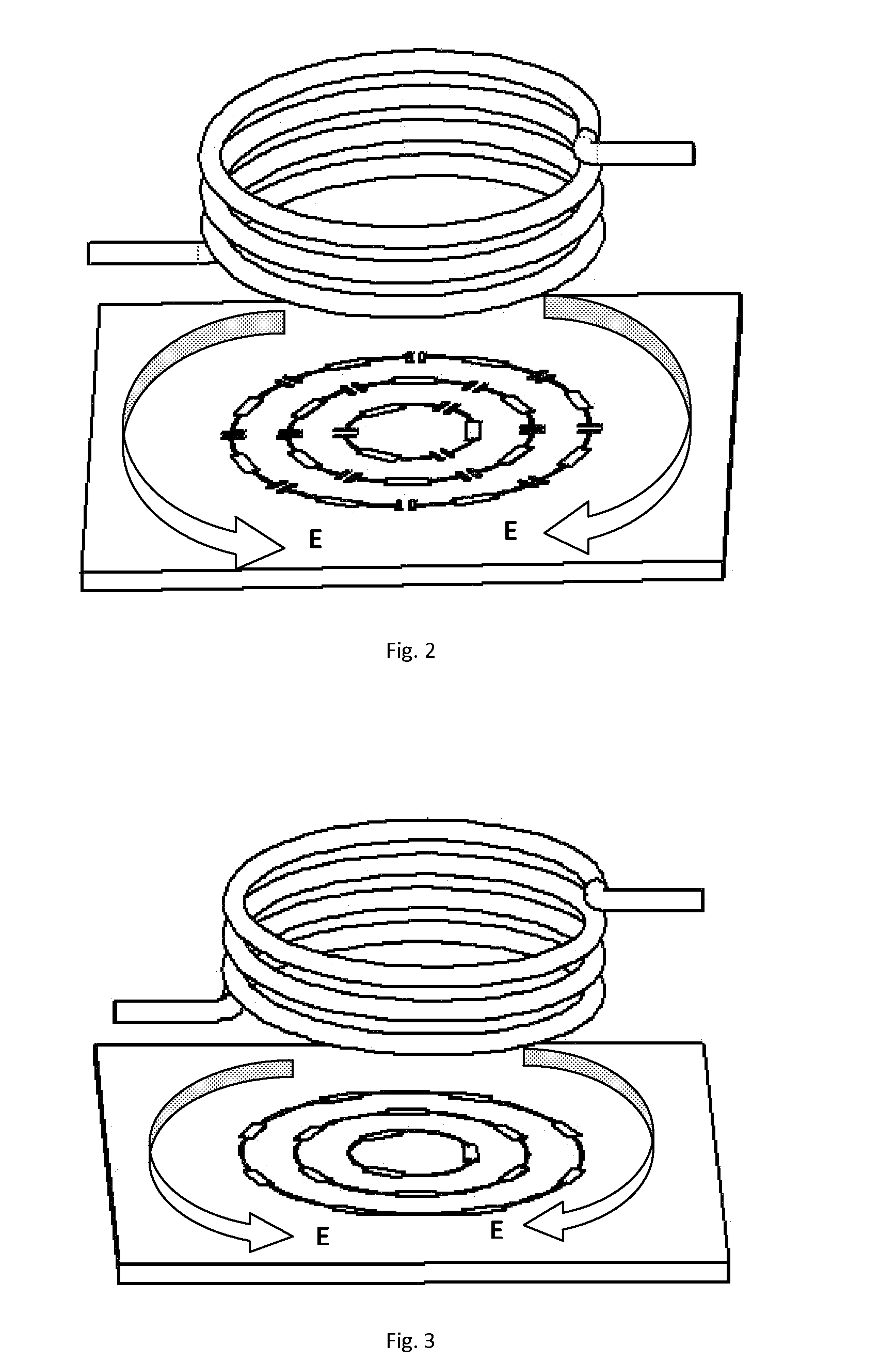

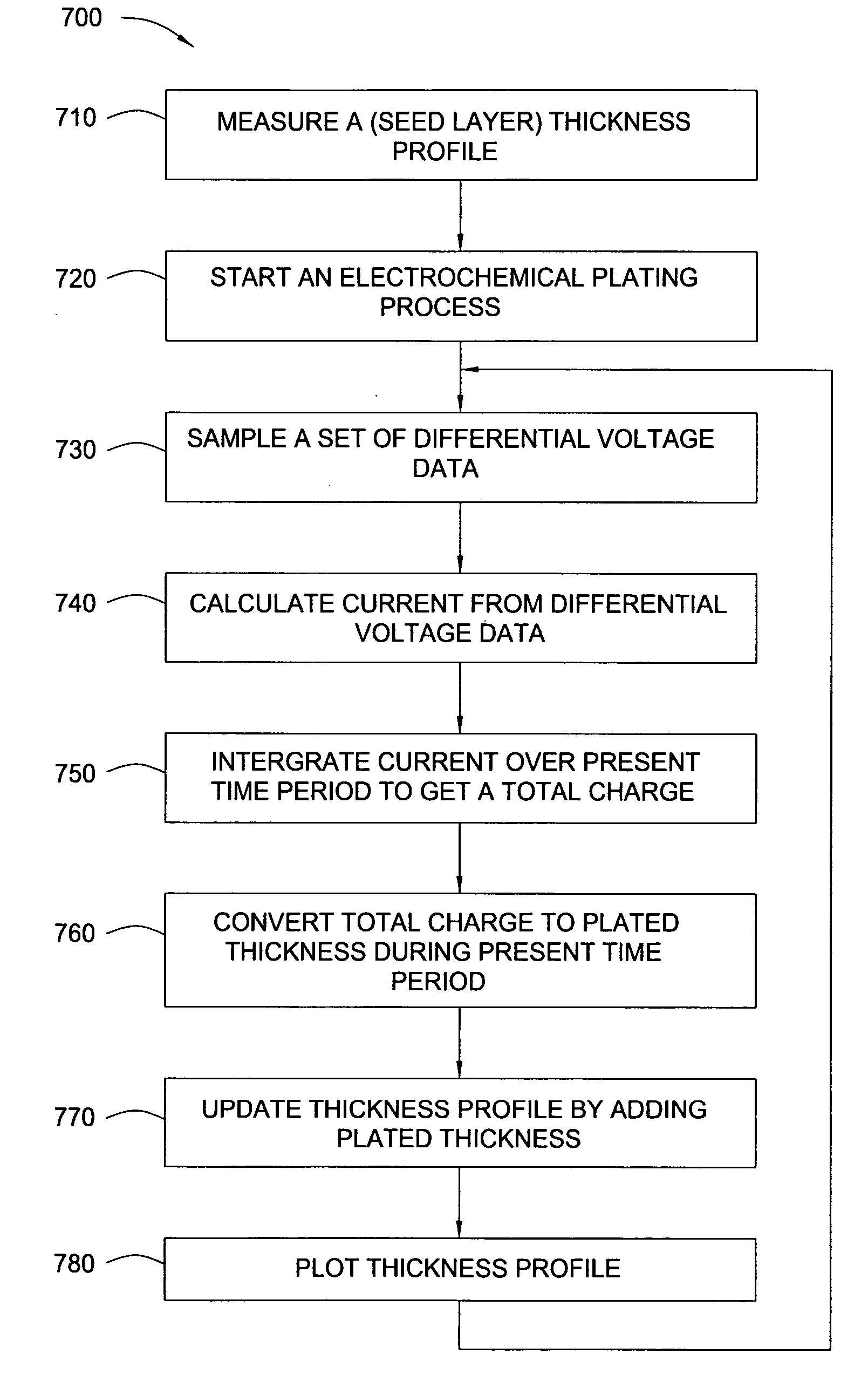

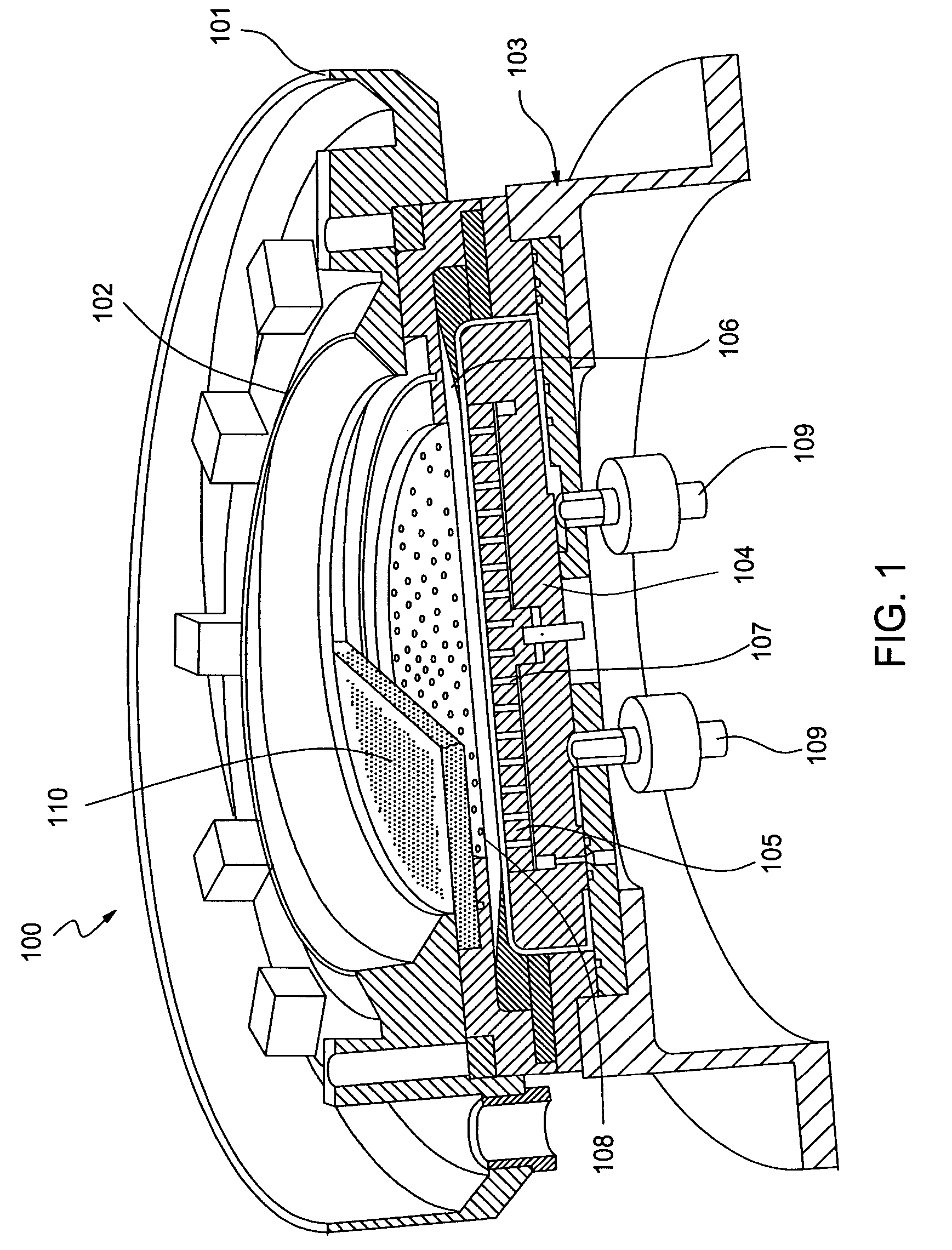

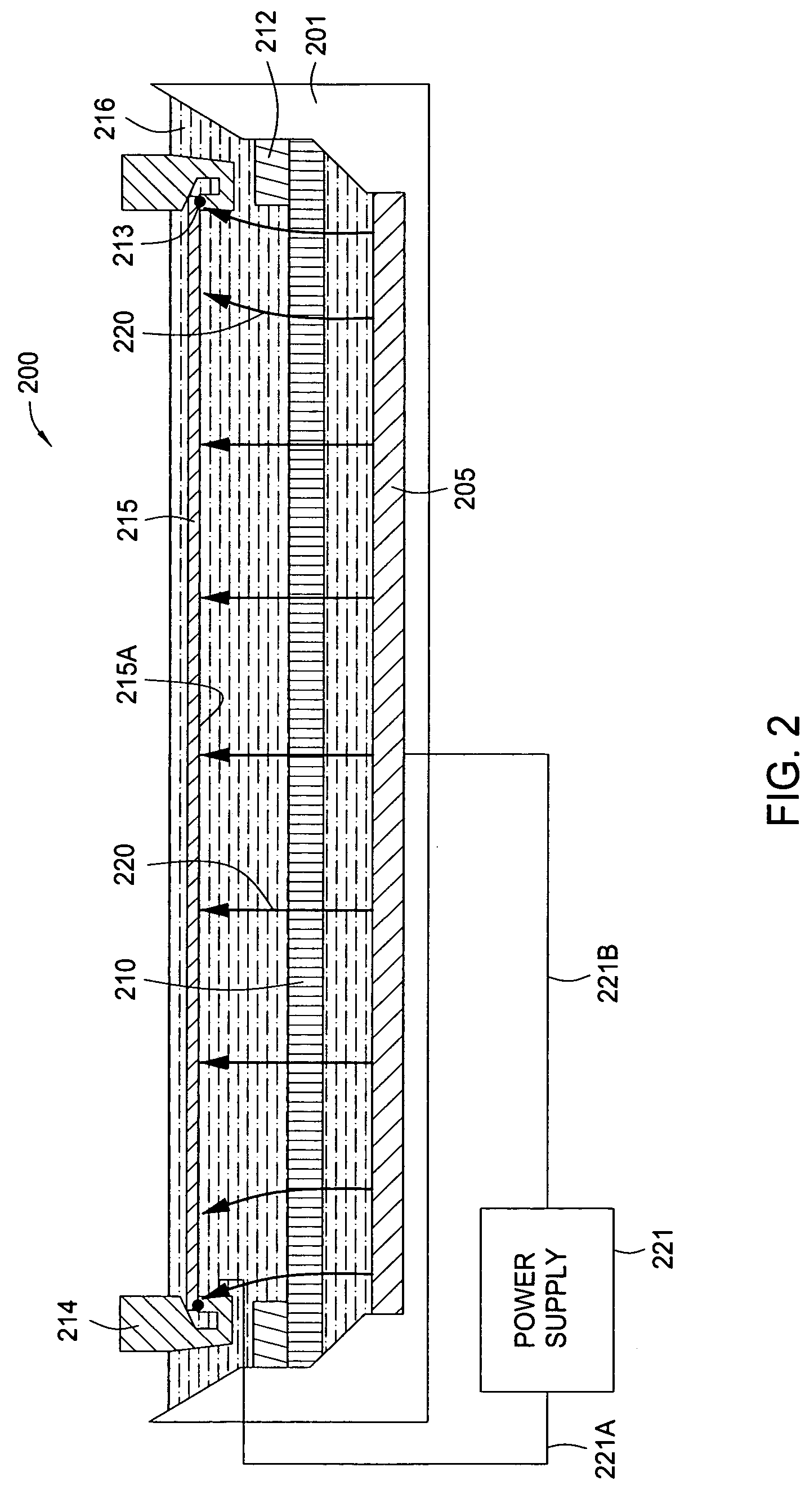

In-situ profile measurement in an electroplating process

InactiveUS20060266653A1CellsSemiconductor/solid-state device manufacturingElectrochemistryElectroplating

A method and apparatus for measuring differential voltages in an electrolyte of an electrochemical plating cell. Current densities are calculated from the measured differential voltages and correlated to thickness values of plated materials. A real time thickness profile may be generated from the thickness values.

Owner:APPLIED MATERIALS INC

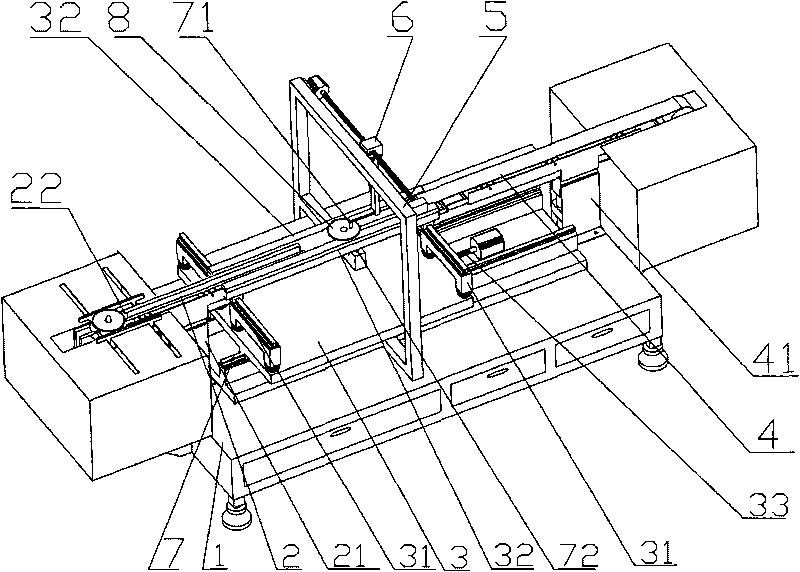

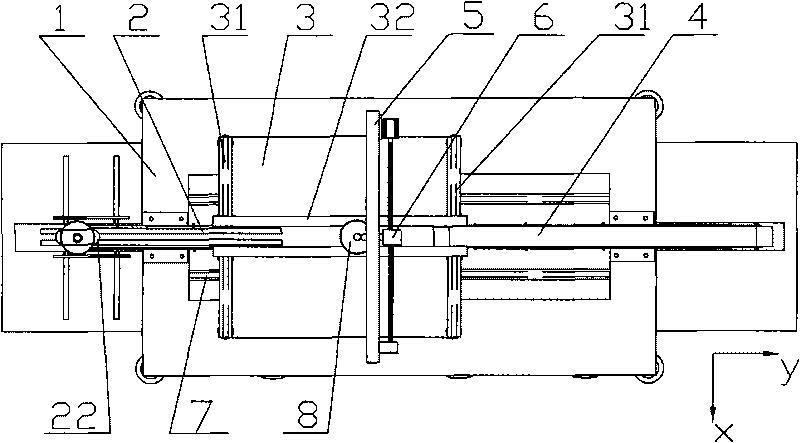

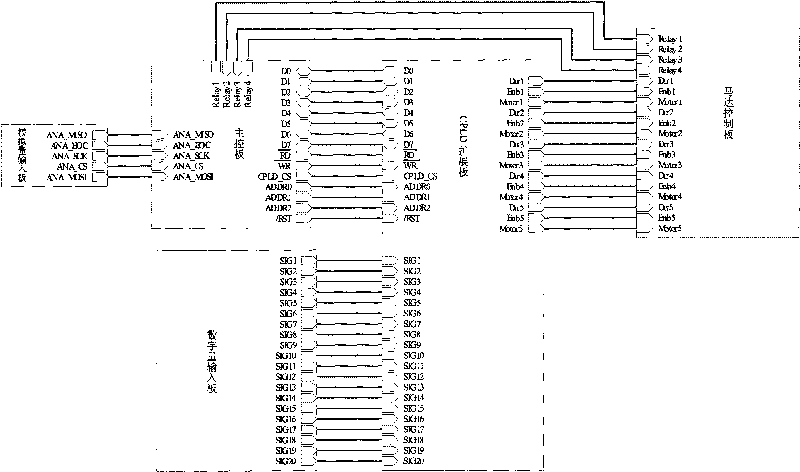

Automatic test device of flatness and thickness of metal sheet

InactiveCN101726243AGuaranteed correctnessRealize coordinated and continuous operationElectric/magnetic roughness/irregularity measurementsElectrical/magnetic thickness measurementsTest efficiencyAutomatic test equipment

The invention relates to an automatic test device of the flatness and thickness of a metal sheet, which comprises a machine frame, a feeding mechanism, a test platform and a discharging mechanism. The machine frame and the test platform are connected through a Y-directional track. The test platform comprises a test frame, guide rails, a test cross beam, a cantilever fixing frame, a cantilever, an upper test probe, a lower test probe, a Y-directional ball screw mechanism and a measuring circuit. The automatic test device has the following beneficial effects that: the test is accurate; the test efficiency and the test precision are improved because the probes always cover the effective test range of a saw blade; mechanical and electrical integration technology is fully used, the structure is simple, the operation and maintenance are convenient, and the application in the field of the test of the flatness and thickness of other metals can be realized with a little improvement, and the promotion and use are easy; and an eddy induction principle is used to realize the test of the flatness and the thickness of the metal sheet, the interference of water and other non-metal impurities on the saw blade is eliminated effectively, precise positioning of the saw blade is not required in test, the price is low, and the operation is simple.

Owner:WUHAN TEXTILE UNIV

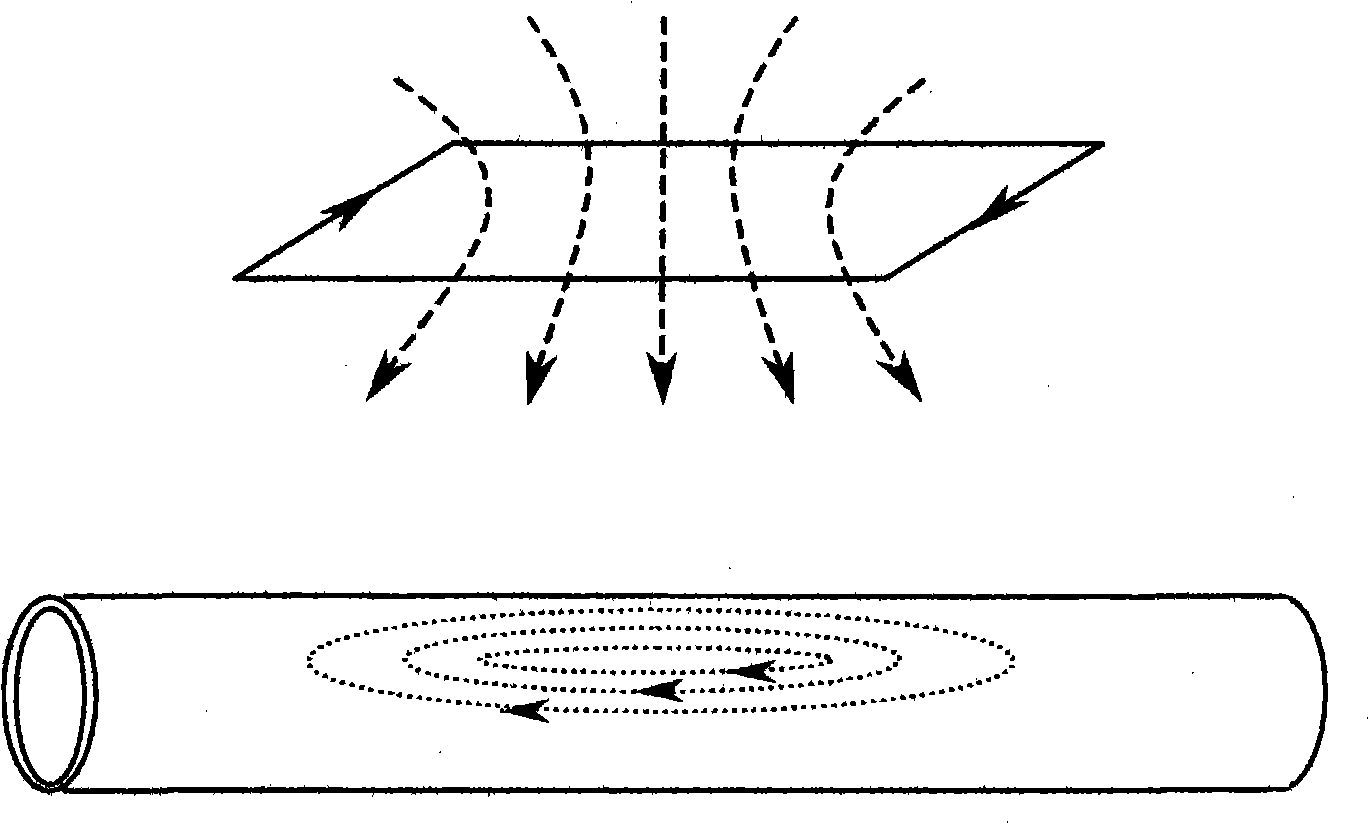

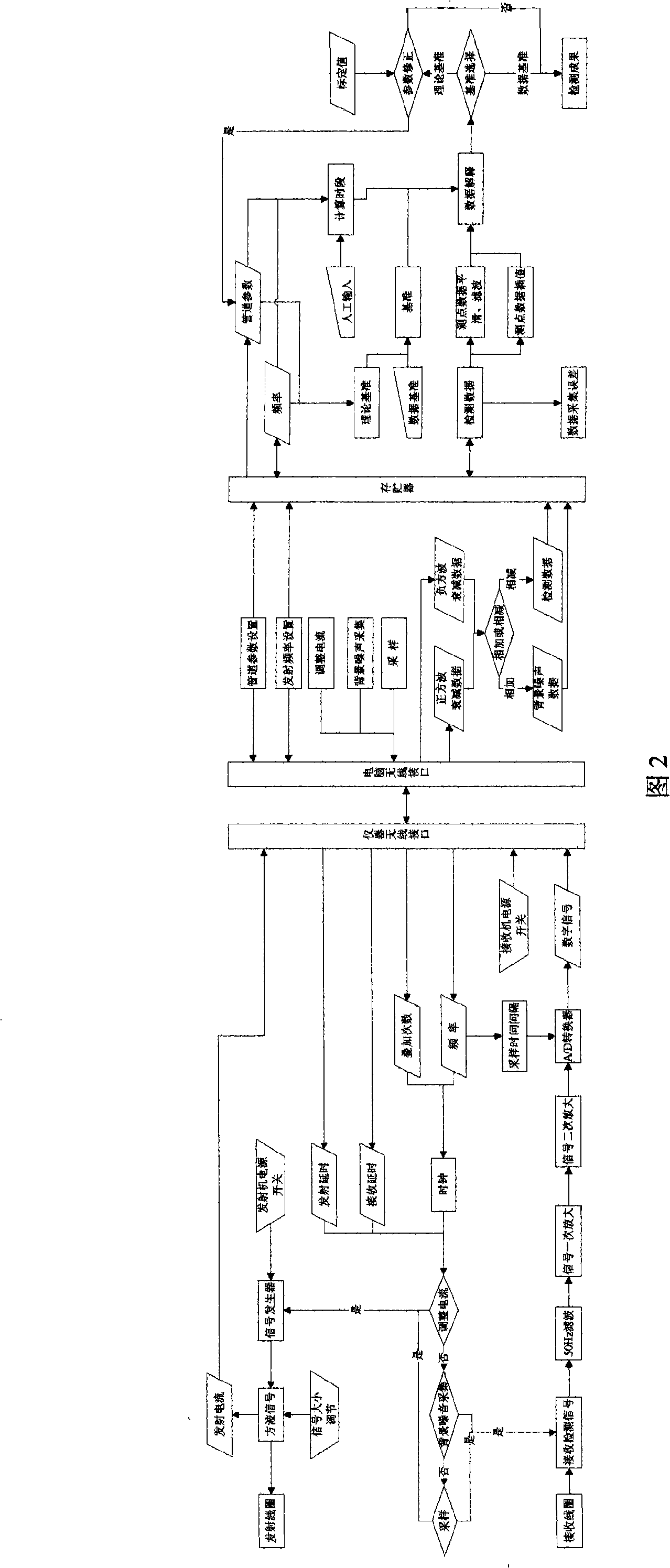

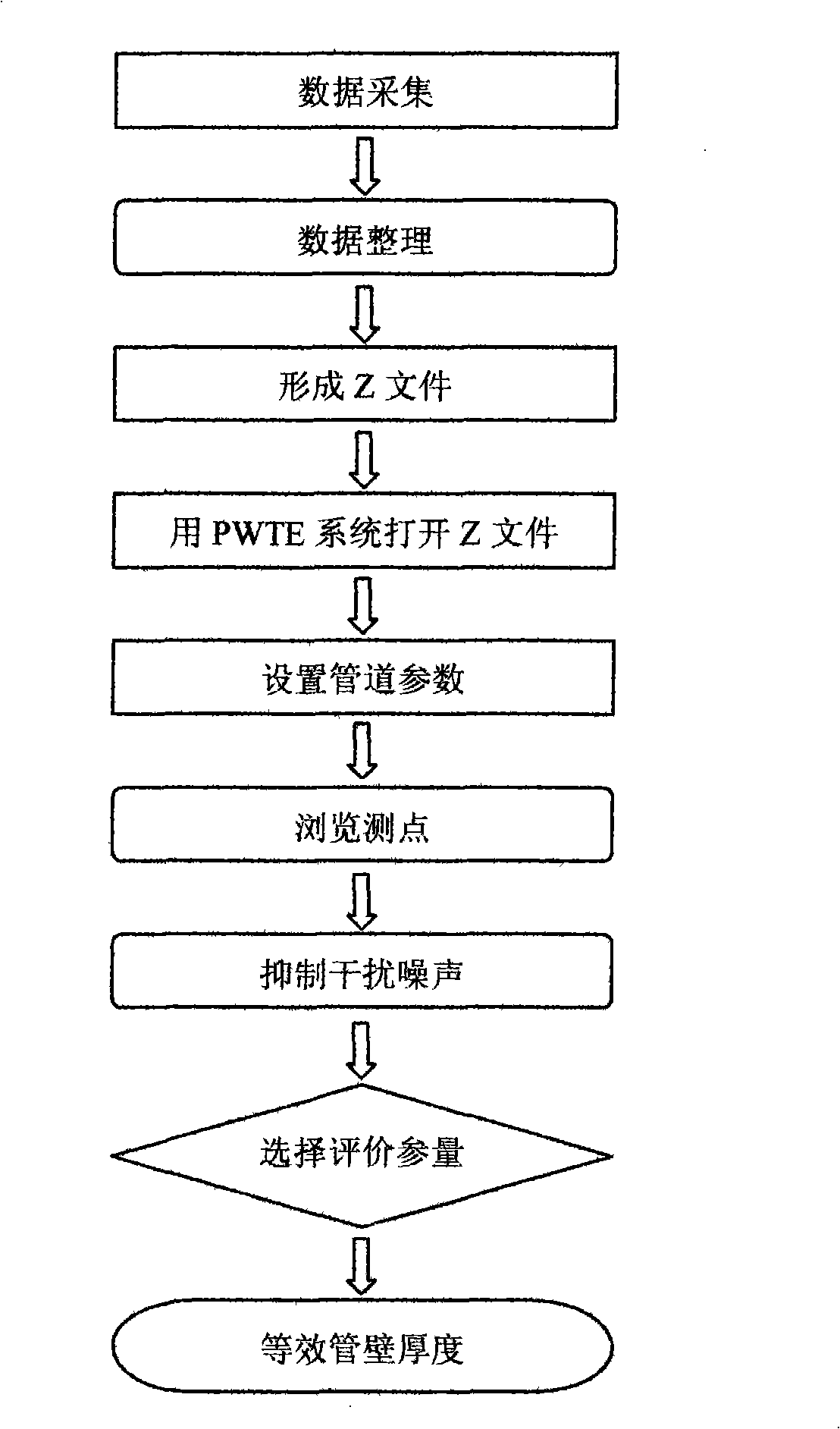

TEM detecting method for pipe wall thickness and intelligent detector for GBH pipe corrosion

ActiveCN101358827APipeline systemsElectrical/magnetic thickness measurementsPetrochemicalElectric power

The present invention relates to a corrosion examination and non-destructive examination method for a metal pipeline. The instant electromagnetic technology (TEM) is used to examine the average thickness of the wall of the pipeline under the condition that no dig is performed, no corrosion-prevention layer is damaged and the normal running of the pipeline is not influenced. The method is characterized in that when other conditions are the same, the metal pipeline with different wall thicknesses can have obvious time divisibility on a normalized pulse instant-changing responding curved line. The wall thickness of the measured section of the pipe can be obtained by the indication of the known wall thickness and the method of inversing modeling. The present invention also relates to a corrosion examination and non-destructive examination systematic device for the metal pipeline. A virtual instrument is designed and produced with the TEM examination method for the wall thickness of the metal pipeline; a data collector adopts the instant-changing electromagnetic instrument; the control of the instruments, the data processing and the results expression are realized by the software of the computer, so that the expansion property of the instrument is strengthened, and the renewing speed is accelerated, and the complicate data processing analysis can be performed instantly. The device can be widely used for examining the corrosion of the anti-corrosion heat-preservation pipeline in the industries such as the petroleum industry, the petrochemical industry, the fuel gas industry, the electric power industry, the water supply industry, and the like.

Owner:BAODING CHICHENGQIANLI SCI & TECH

Polishing monitoring method and polishing apparatus

ActiveUS20090104847A1Accurate monitoringReduced availabilitySemiconductor/solid-state device manufacturingMagnetic property measurementsCurrent sensorEngineering

The present invention provides a method of monitoring a change in film thickness during polishing using an eddy current sensor. This method includes acquiring an output signal of the eddy current sensor as a correction signal value during water-polishing of a substrate, during dressing of the polishing pad, or during replacement of the polishing pad, calculating a correcting amount from a difference between the correction signal value and a predetermined correction reference value, calculating an actual measurement signal value by subtracting the correction amount from the output signal of the eddy current sensor when polishing a substrate having a conductive film, and monitoring a change in thickness of the conductive film during polishing by monitoring a change in the actual measurement signal value.

Owner:EBARA CORP

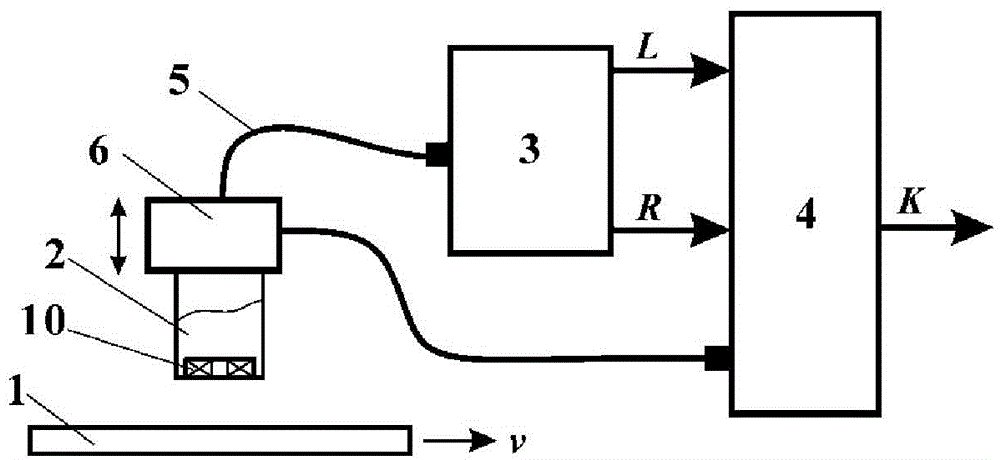

Conductive film thickness measurement system based on eddy current sensor and method thereof

ActiveCN104154852AEasy to handleSimple and clearElectrical/magnetic thickness measurementsElectrical resistance and conductanceMicro actuator

The invention provides a conductive film thickness measurement system based on an eddy current sensor and a corresponding measurement method. The thickness measurement is realized by using the relation between the slope of an LOC line formed by the corresponding points of the impedance of an eddy current sensor detection coil in a resistance-inductance plane in different detection distances and the thickness of a measured conductive film. The conductive film thickness measurement system comprises an eddy current sensor probe with the detection coil, an impedance measurement circuit, a micro actuator for realizing the vertical movement of the probe, and a controller which controls the measurement process and thickness result output. The method is simple and efficient, the thickness of a conductive film can be accurately measured without contact, the measurement result is nearly not affected by a detection distance, a thickness measurement range is in a range from tens of nanometers to several millimeters, and the method can be widely applied to the semiconductor metal film detection, a metal film online measurement system in an industrial production line and the quality monitoring or detection of various film coating processes.

Owner:UNIV OF SCI & TECH OF CHINA

Apparatus and method for capacitive measurement of materials

InactiveUS20060152231A1Improve thickness measurement accuracyAccurate thickness measurementResistance/reactance/impedenceMaterial analysis by optical meansCapacitive measurementDistance measurement

Method for measuring thicknesses of a film, a foil or a material layer with a measuring head which is spaced away from the film and with which a capacitive thickness measurement is performed, in which an optical distance measurement is performed with a distance measuring device and a distance determined by the optical distance measurement is used in determining the film thickness in the capacitive thickness measurement.

Owner:PLAST CONTROL GMBH

Condenser type ice layer thickness sensor and detecting method thereof

InactiveCN1737490AAccurate measurementRealize fixed-point continuous automatic detectionElectrical/magnetic thickness measurementsMicrocontrollerMachine control

This invention relates to capacitor thickness sensor and its test method in the field of automatic testing technique, which is characterized by the following: forming testing circuit by the capacitor measurement circuit and single machine control circuit and the sensor inside scale code switch circuit through one set of metal capacitor test pole slice and metal capacitor testing pole slice space; generating scale code switch control signals along certain order by the senor inside single machine control to connect metal capacitor test pole slices adjacent two metal capacitor test pole slices to test the capacitor value and to determine the ice layer thickness sensor.

Owner:TAIYUAN UNIV OF TECH

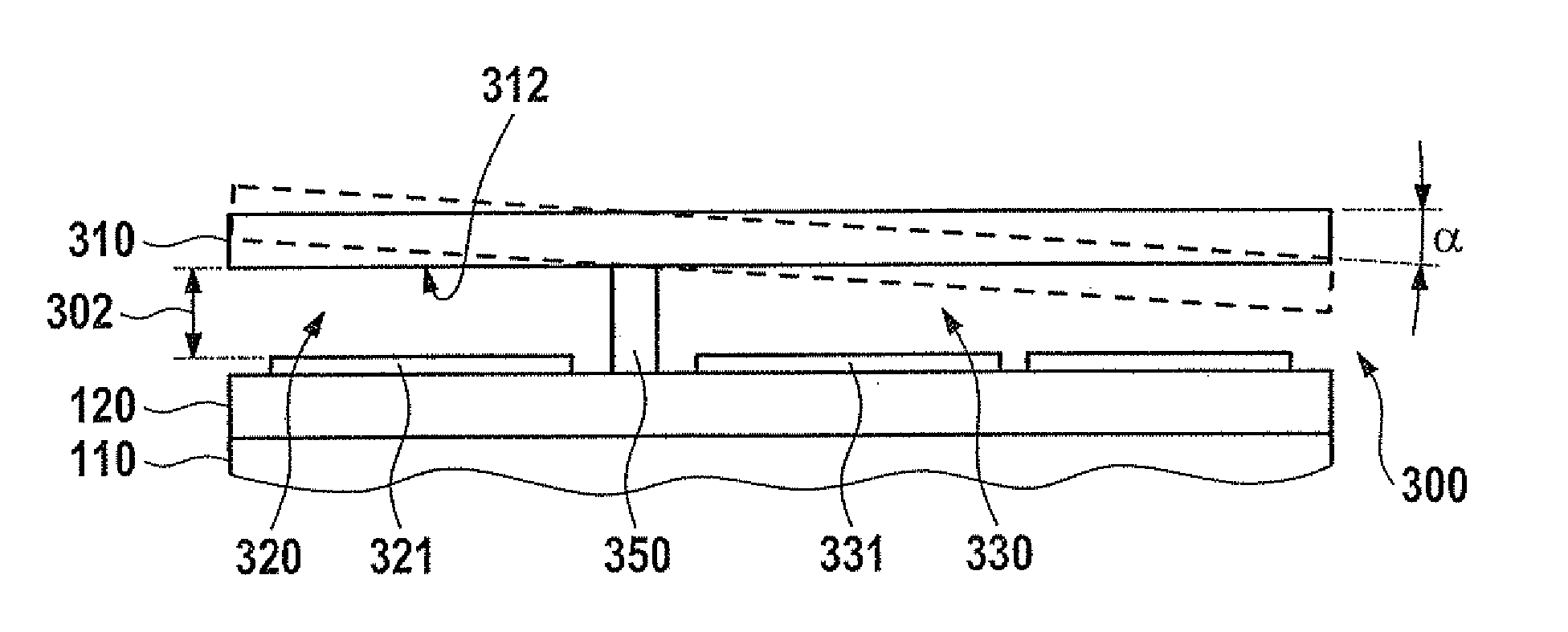

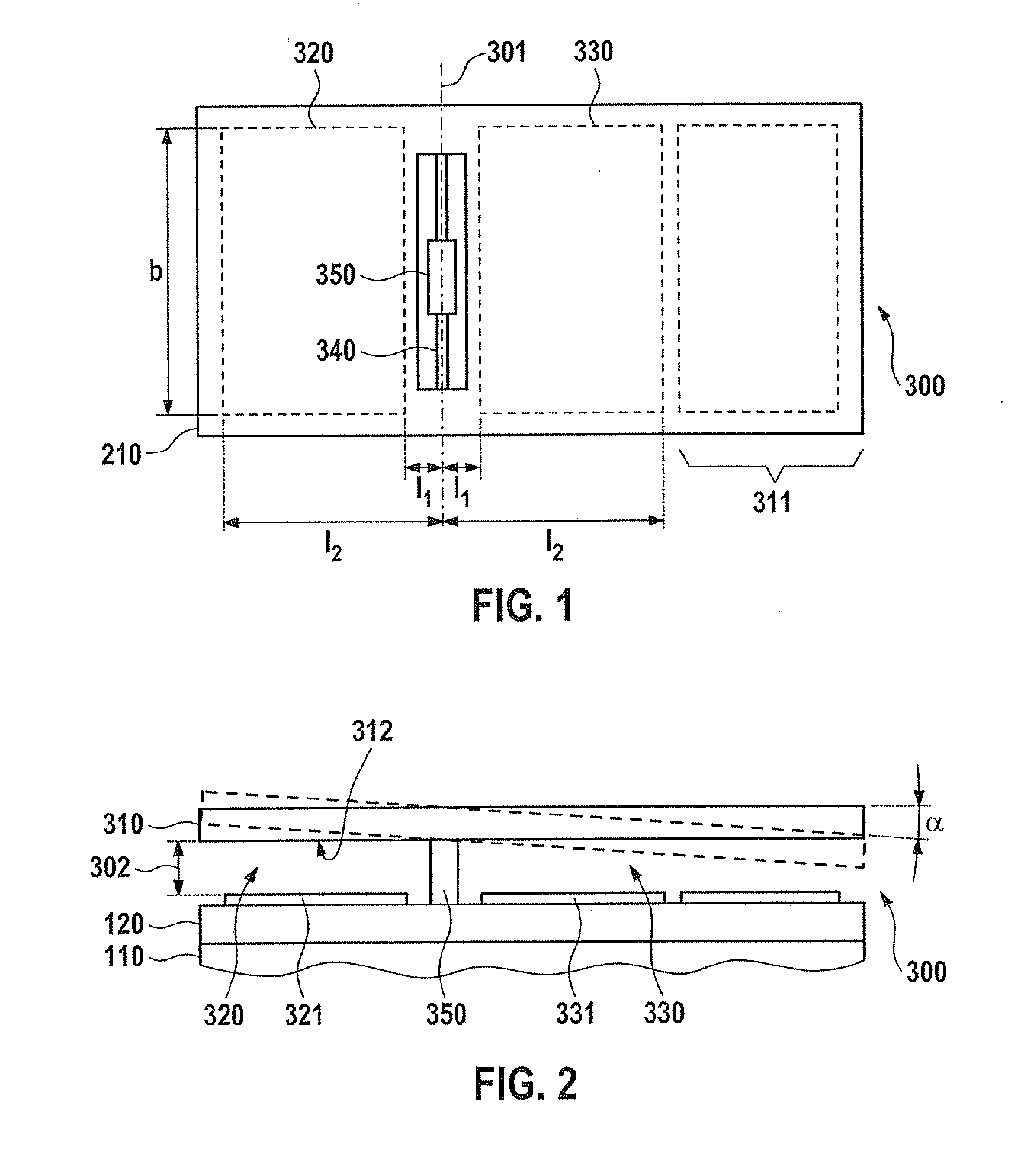

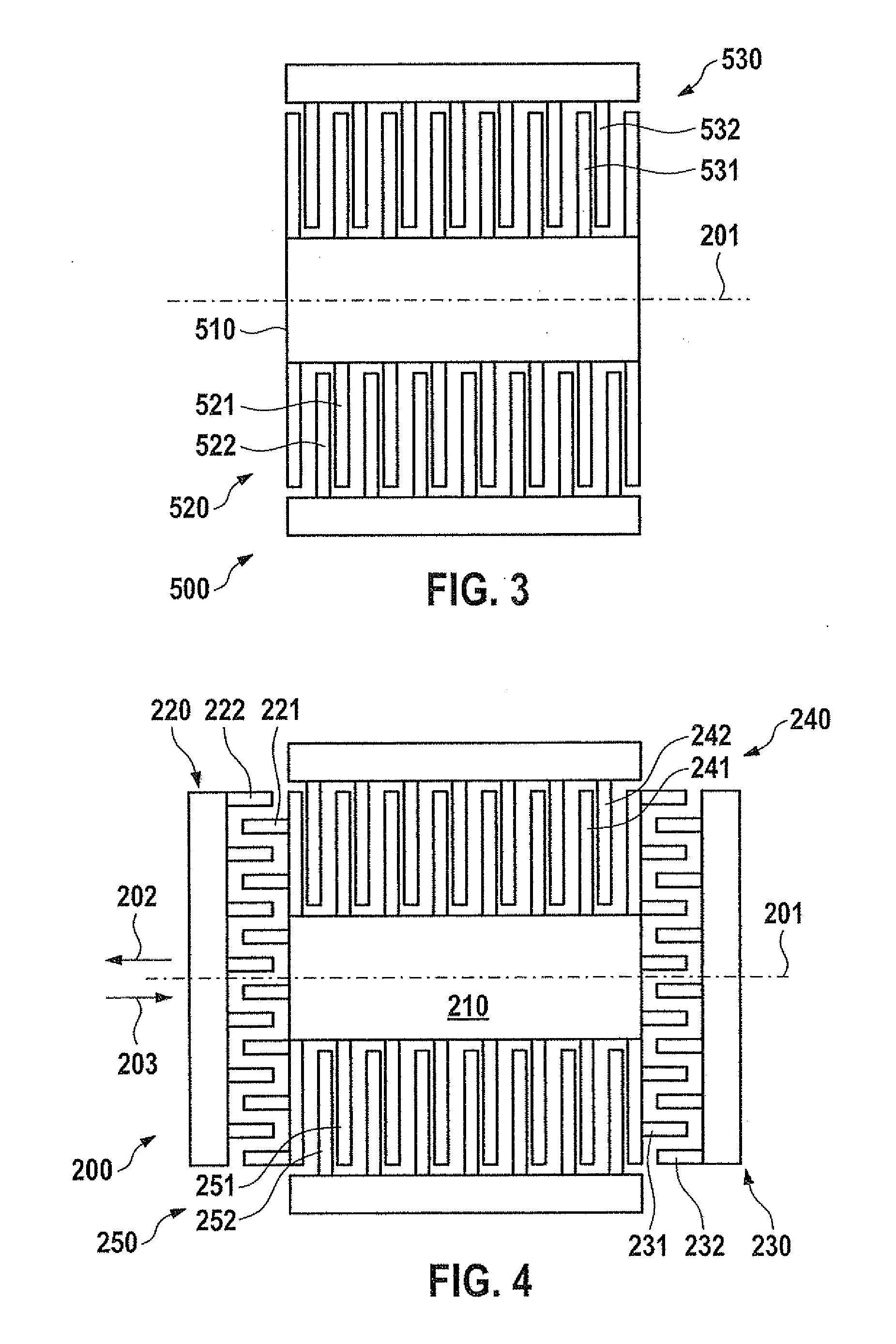

Micromechanical component having a test structure for determining the layer thickness of a spacer layer and method for manufacturing such a test structure

ActiveUS20110296917A1Reduce manufacturing costSimplified determinationResistance/reactance/impedenceAcceleration measurementSeismic massSlice thickness

A micromechanical component is described including a substrate having a spacer layer and a test structure for ascertaining the thickness of the spacer layer. The test structure includes a seismic mass, which is elastically deflectable along a measuring axis parallel to the substrate, a first electrode system and a second electrode system for deflecting the seismic mass along the measuring axis, having a mass electrode, which is produced by a part of the seismic mass, and a substrate electrode, which is situated on the substrate in each case, the first electrode system being designed to be thicker than the second electrode system by the layer thickness of the spacer layer.

Owner:ROBERT BOSCH GMBH

Popular searches

Material analysis by electric/magnetic means Using wave/particle radiation means Flaw detection using microwaves Radio wave reradiation/reflection Material magnetic variables Lapping machines Grinding feed control Material capacitance Electrical/magnetic diameter measurements Electrographic process apparatus

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com