Patents

Literature

376 results about "Optical metrology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Model building and analysis engine for combined x-ray and optical metrology

ActiveUS20140019097A1Reduce in quantityReduce correlationMaterial analysis using wave/particle radiationPhotomechanical apparatusX-rayGeometric modeling

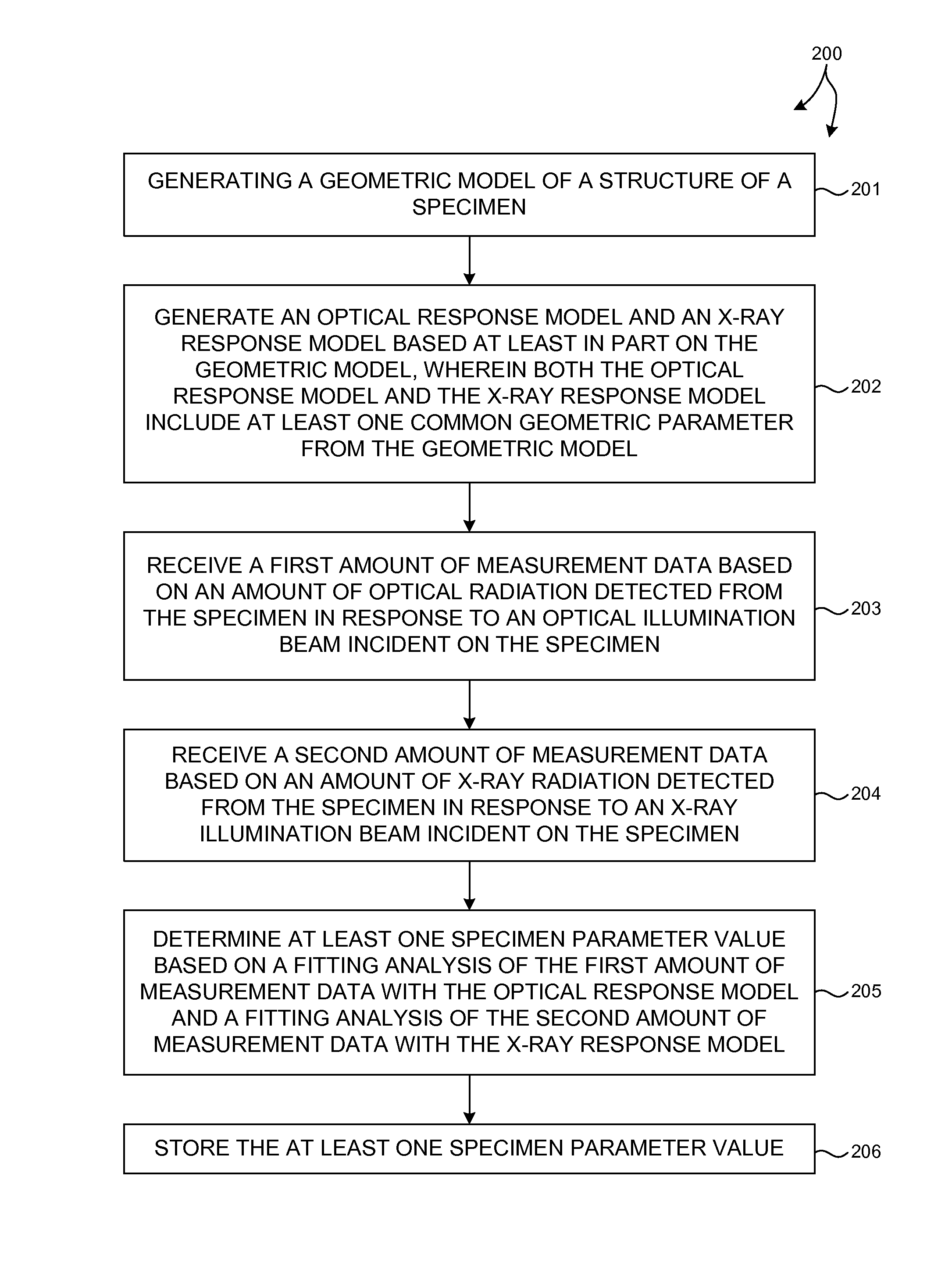

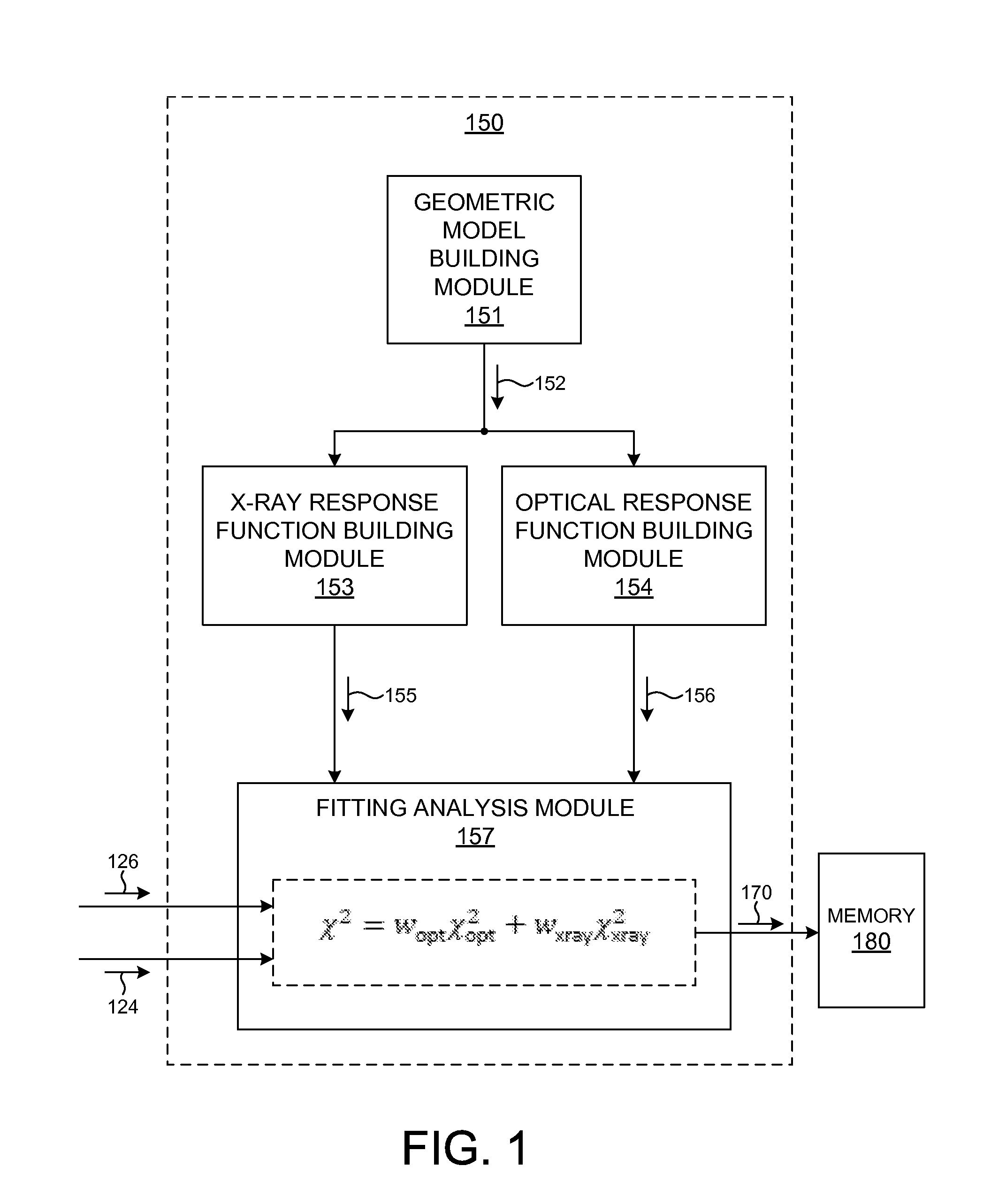

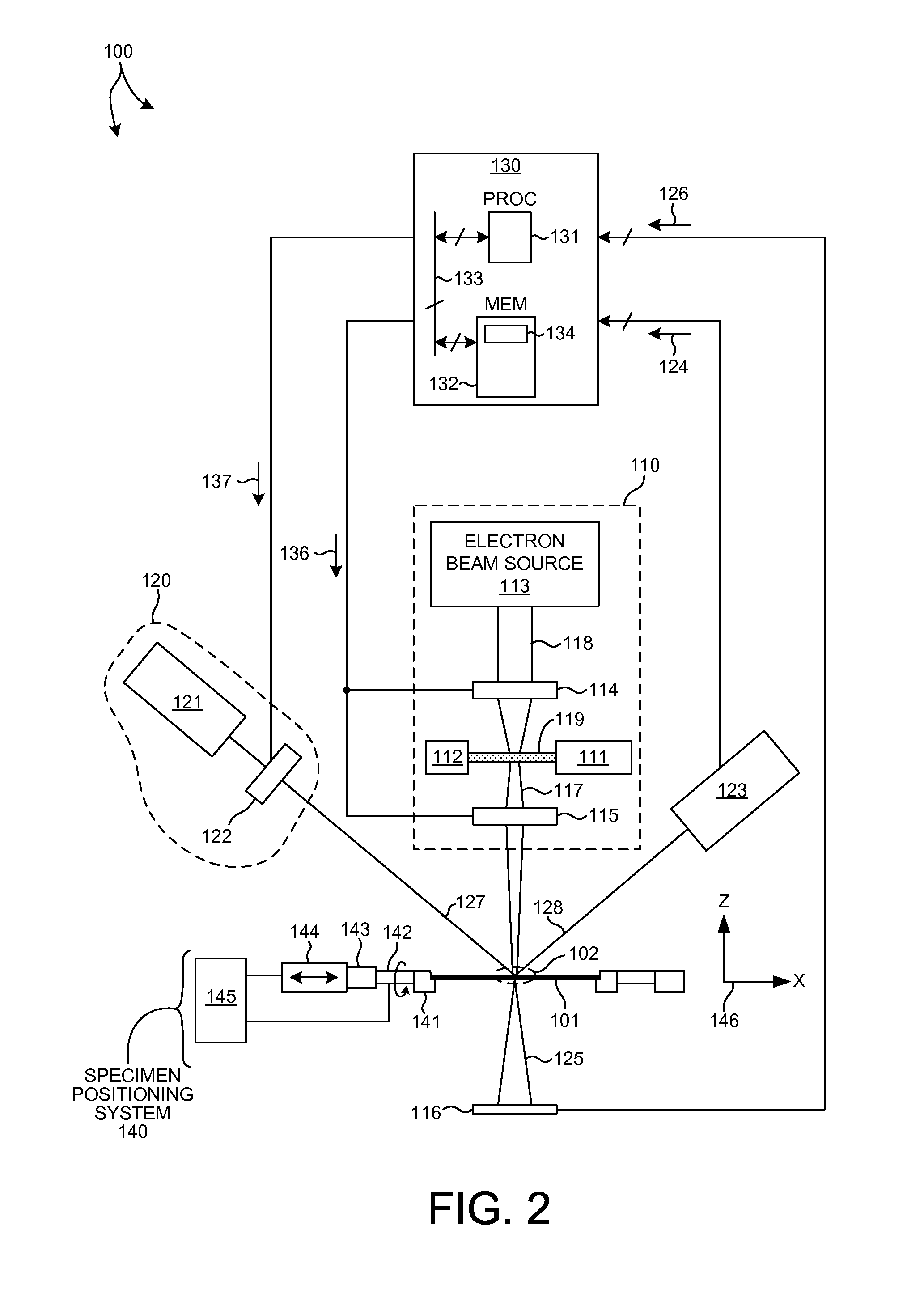

Structural parameters of a specimen are determined by fitting models of the response of the specimen to measurements collected by different measurement techniques in a combined analysis. Models of the response of the specimen to at least two different measurement technologies share at least one common geometric parameter. In some embodiments, a model building and analysis engine performs x-ray and optical analyses wherein at least one common parameter is coupled during the analysis. The fitting of the response models to measured data can be done sequentially, in parallel, or by a combination of sequential and parallel analyses. In a further aspect, the structure of the response models is altered based on the quality of the fit between the models and the corresponding measurement data. For example, a geometric model of the specimen is restructured based on the fit between the response models and corresponding measurement data.

Owner:KLA TENCOR TECH CORP

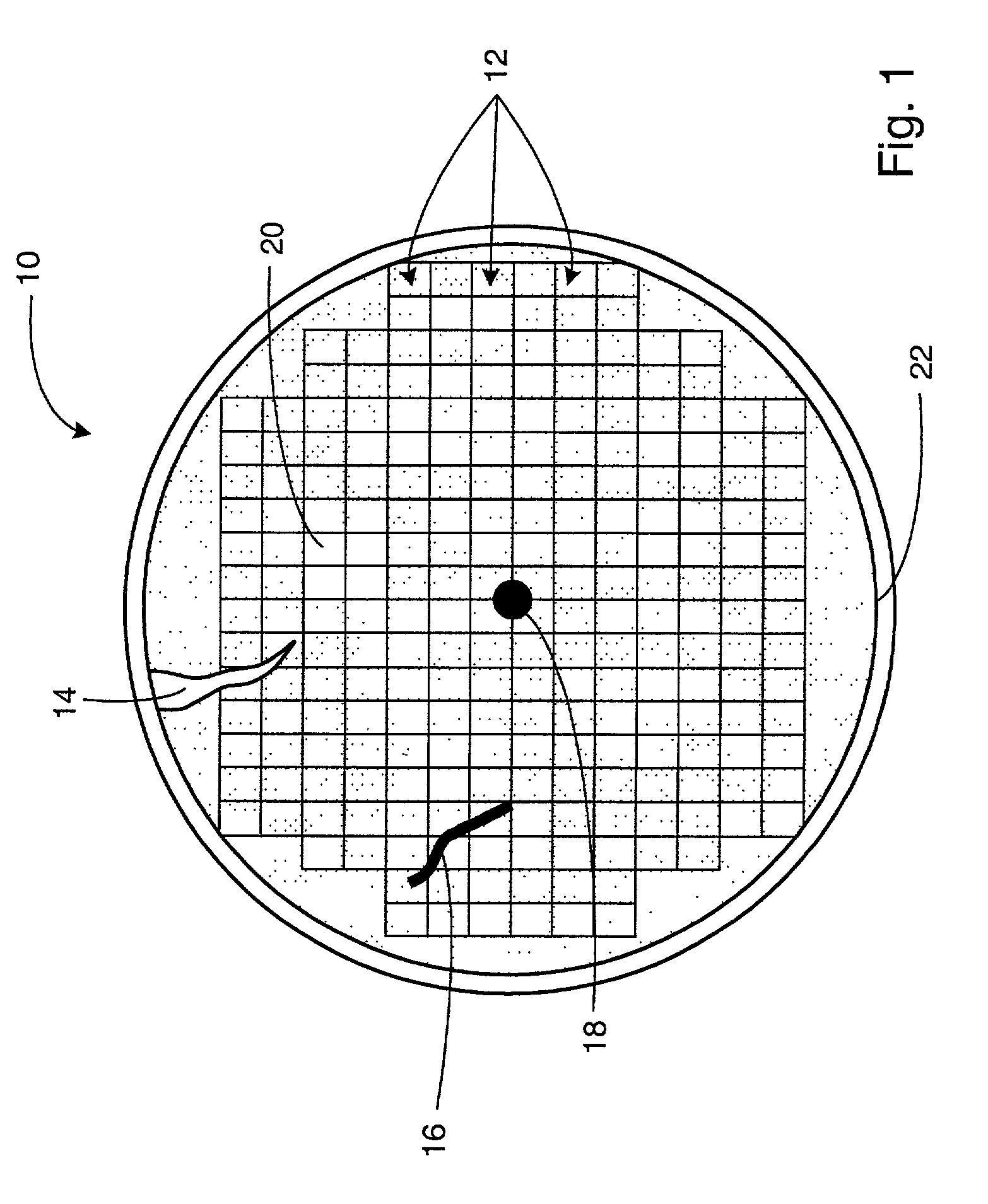

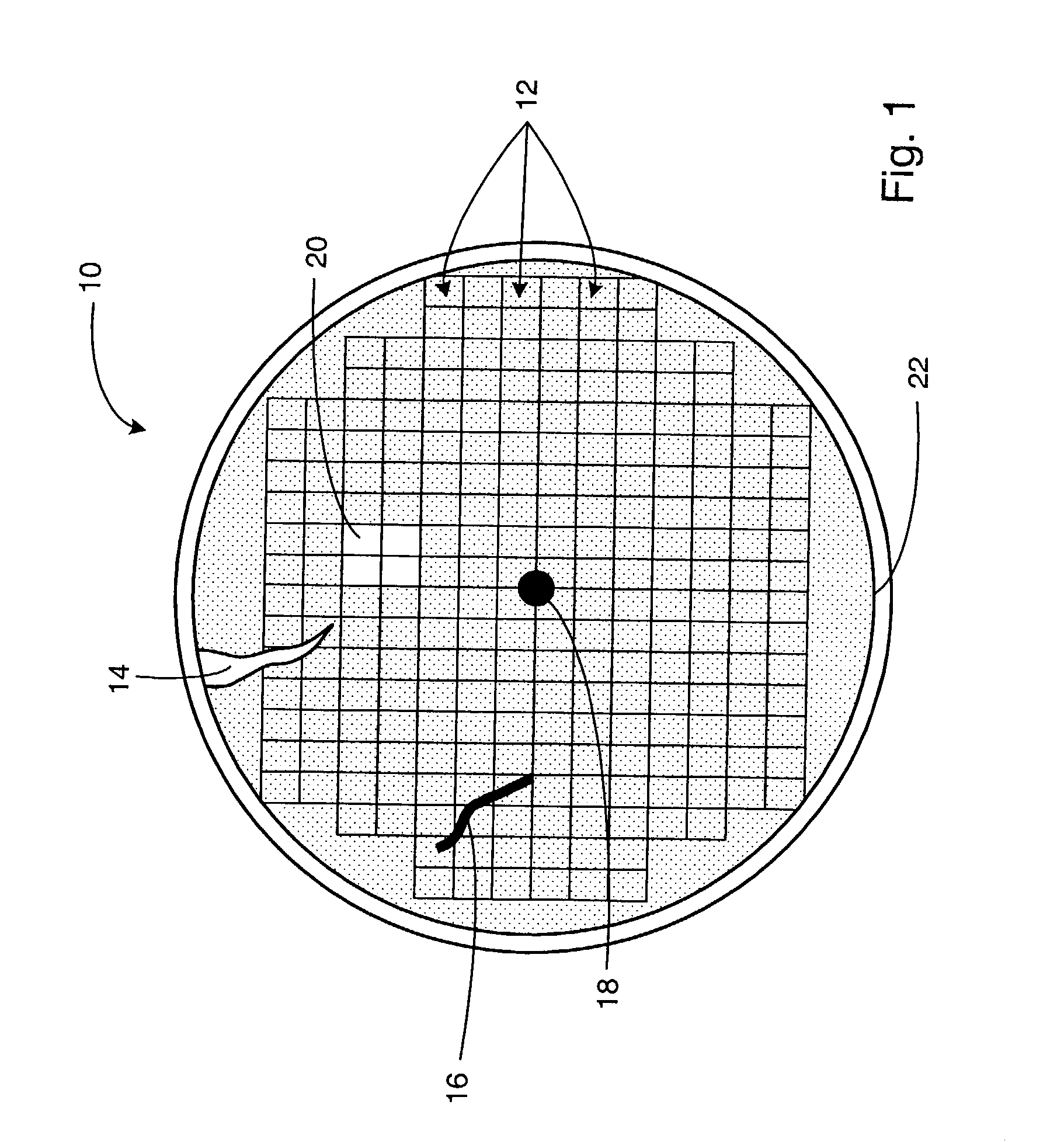

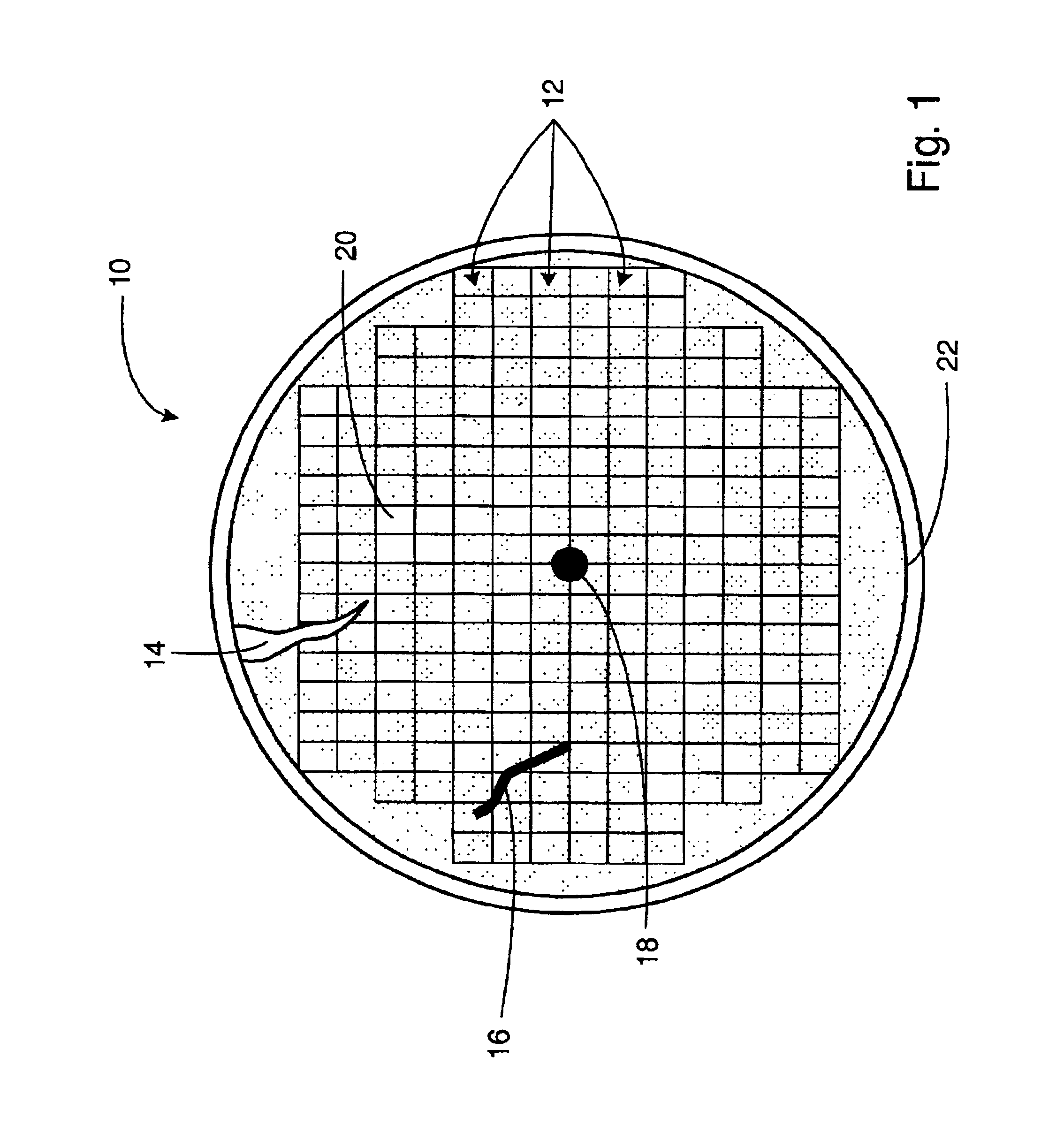

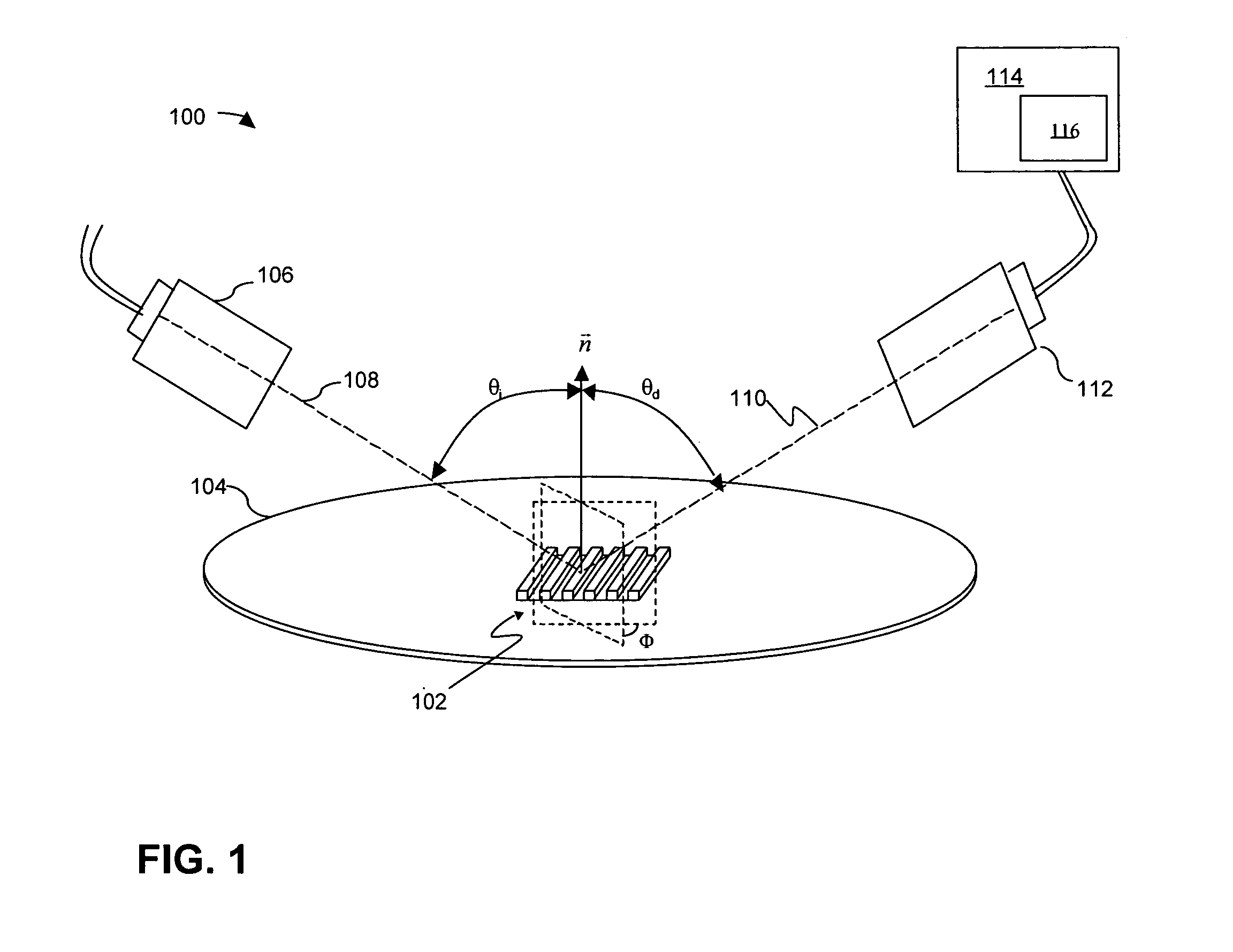

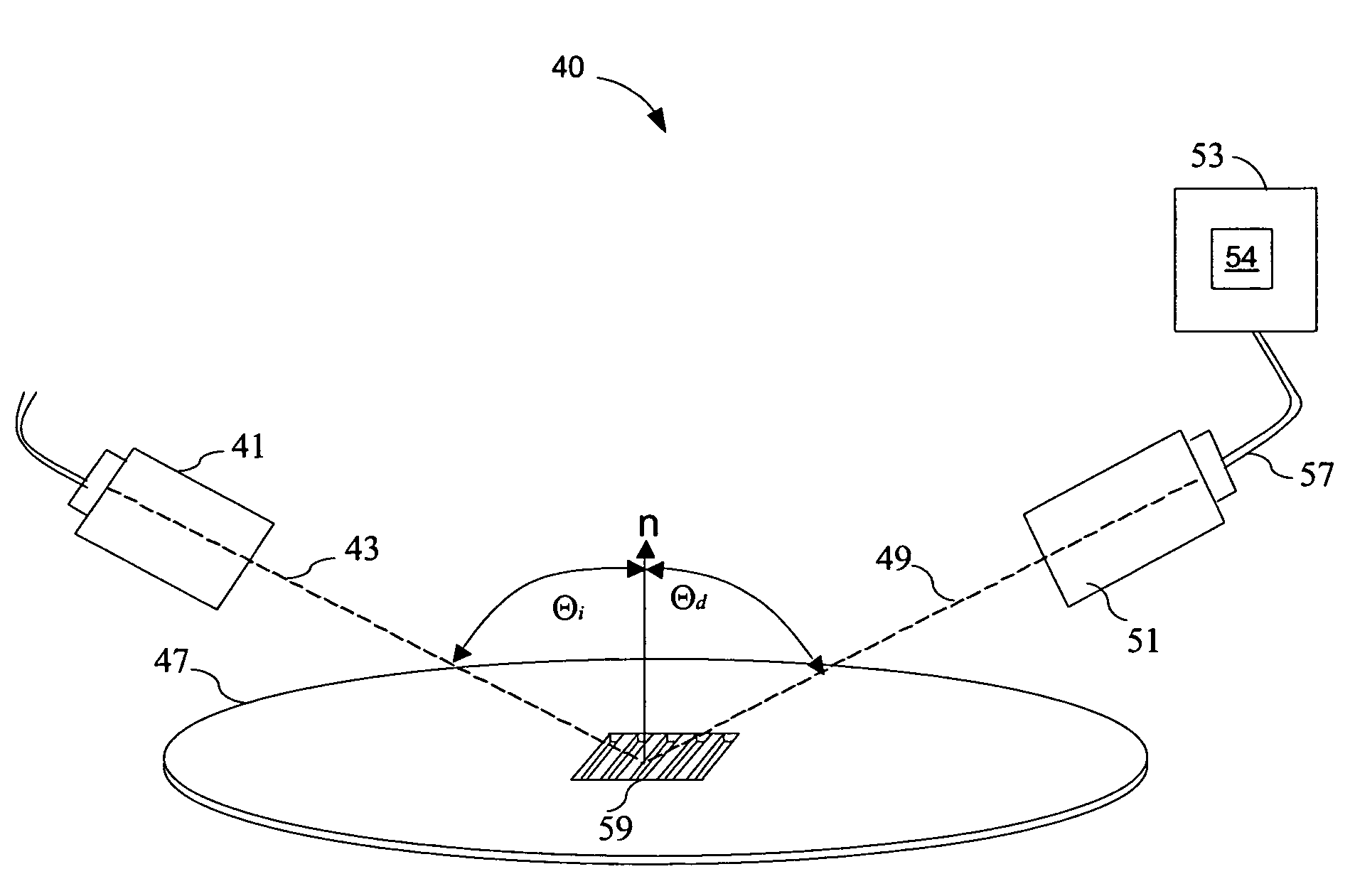

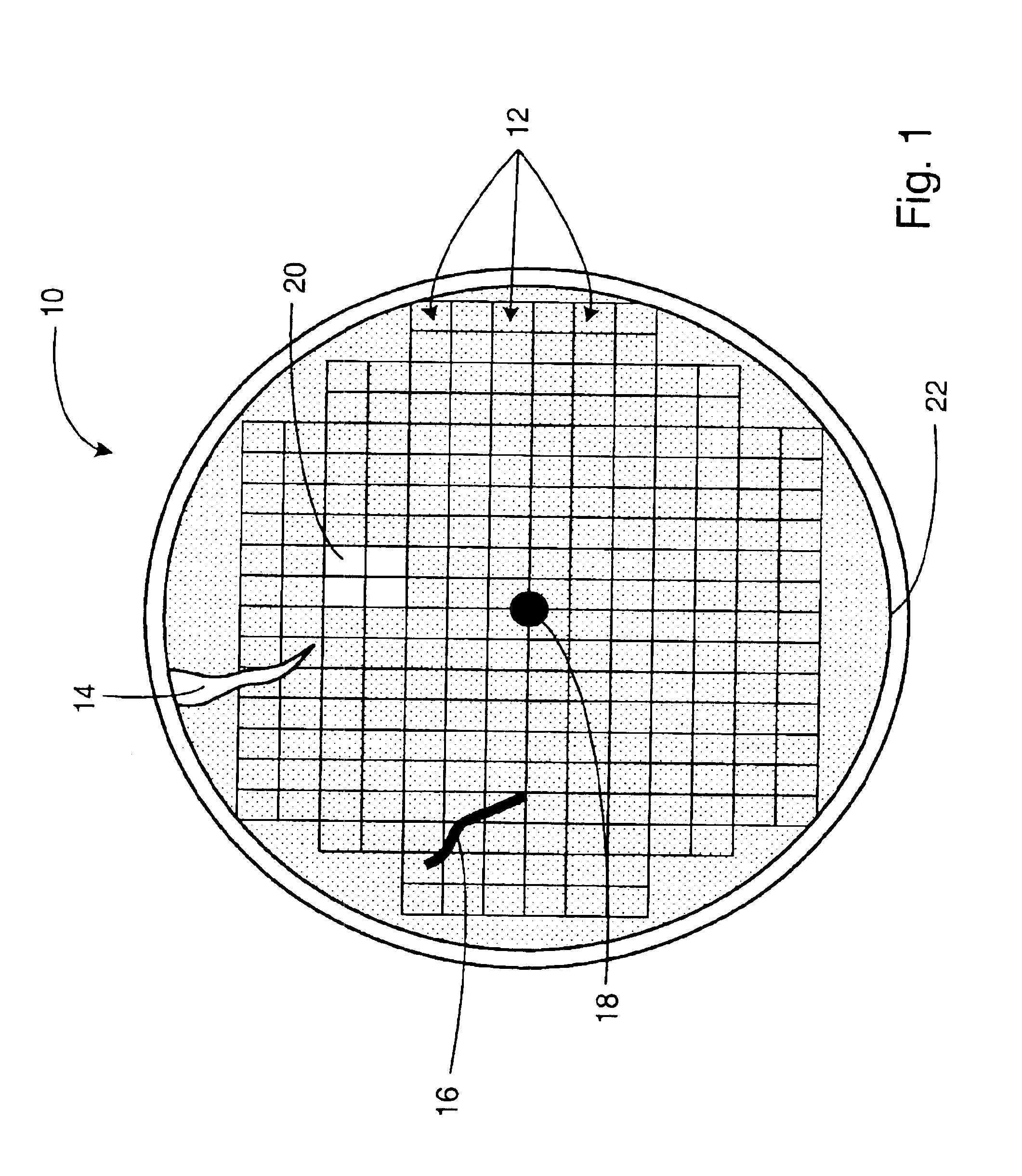

Methods and systems for determining a critical dimension and overlay of a specimen

InactiveUS6891627B1Speed up the processShorten the timeSemiconductor/solid-state device testing/measurementElectric discharge tubesMeasurement deviceEngineering

Methods and systems for monitoring semiconductor fabrication processes are provided. A system may include a stage configured to support a specimen and coupled to a measurement device. The measurement device may include an illumination system and a detection system. The illumination system and the detection system may be configured such that the system may be configured to determine multiple properties of the specimen. For example, the system may be configured to determine multiple properties of a specimen including, but not limited to, critical dimension and overlay misregistration. In this manner, a measurement device may perform multiple optical and / or non-optical metrology and / or inspection techniques.

Owner:KLA CORP

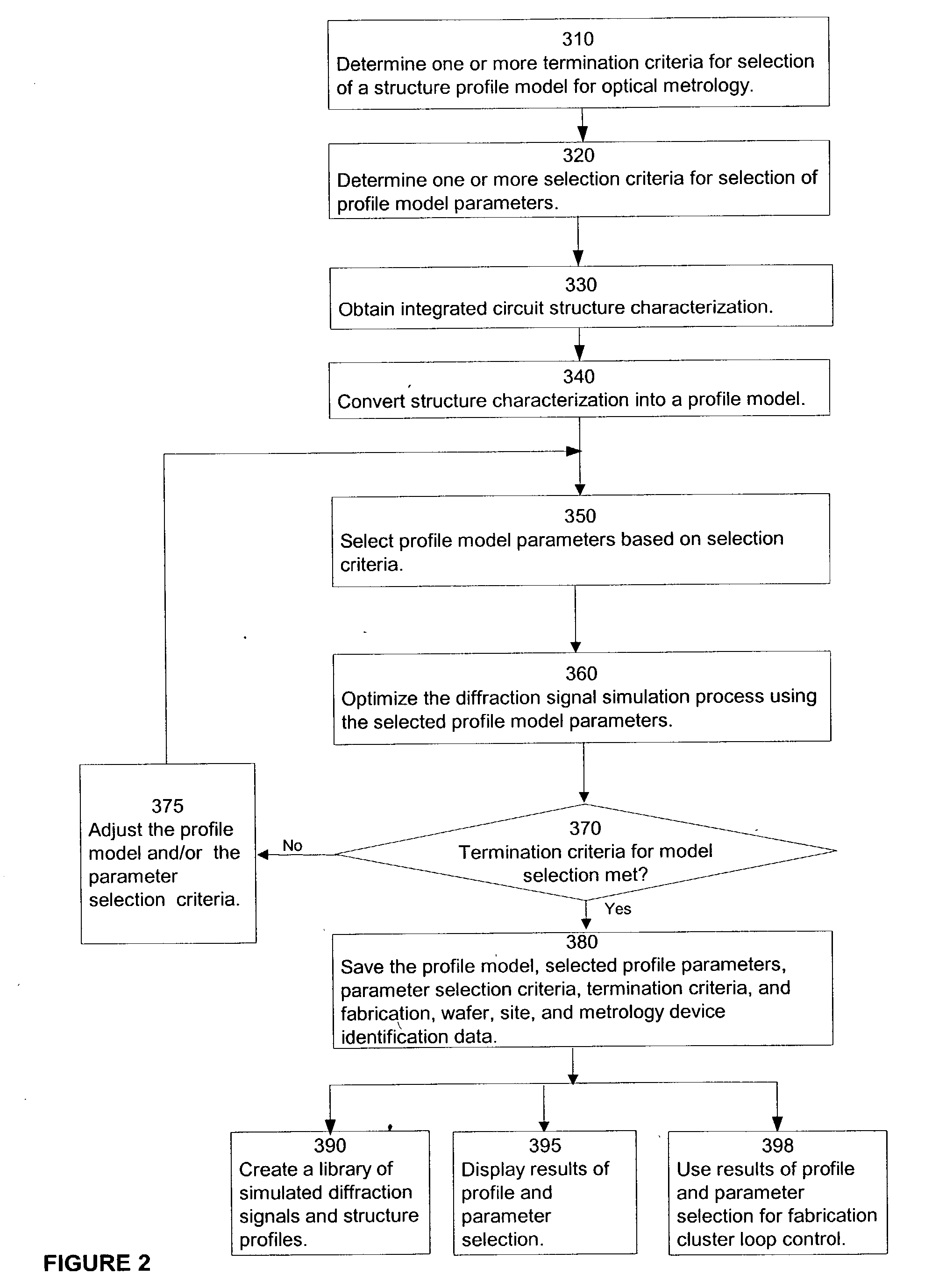

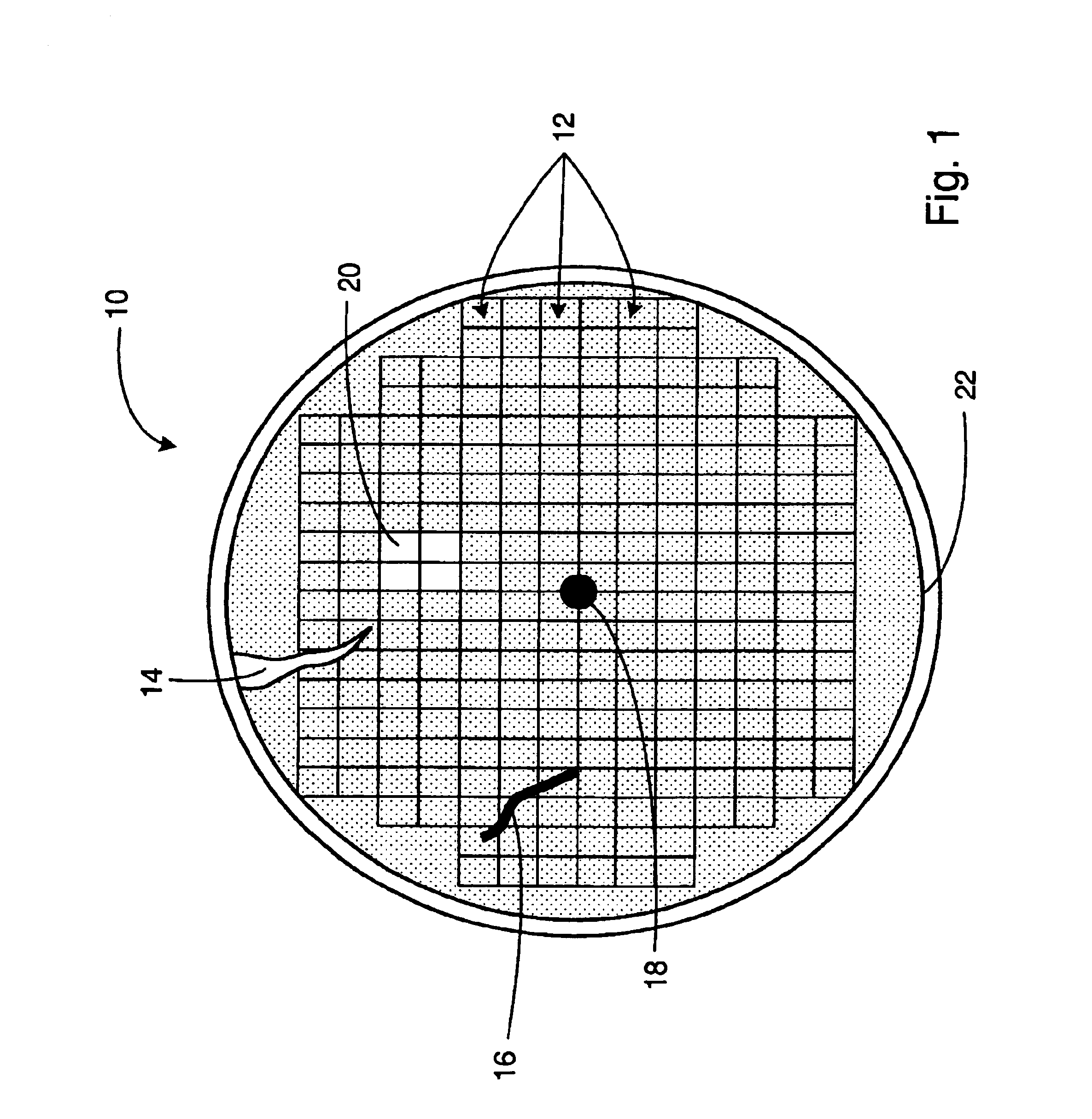

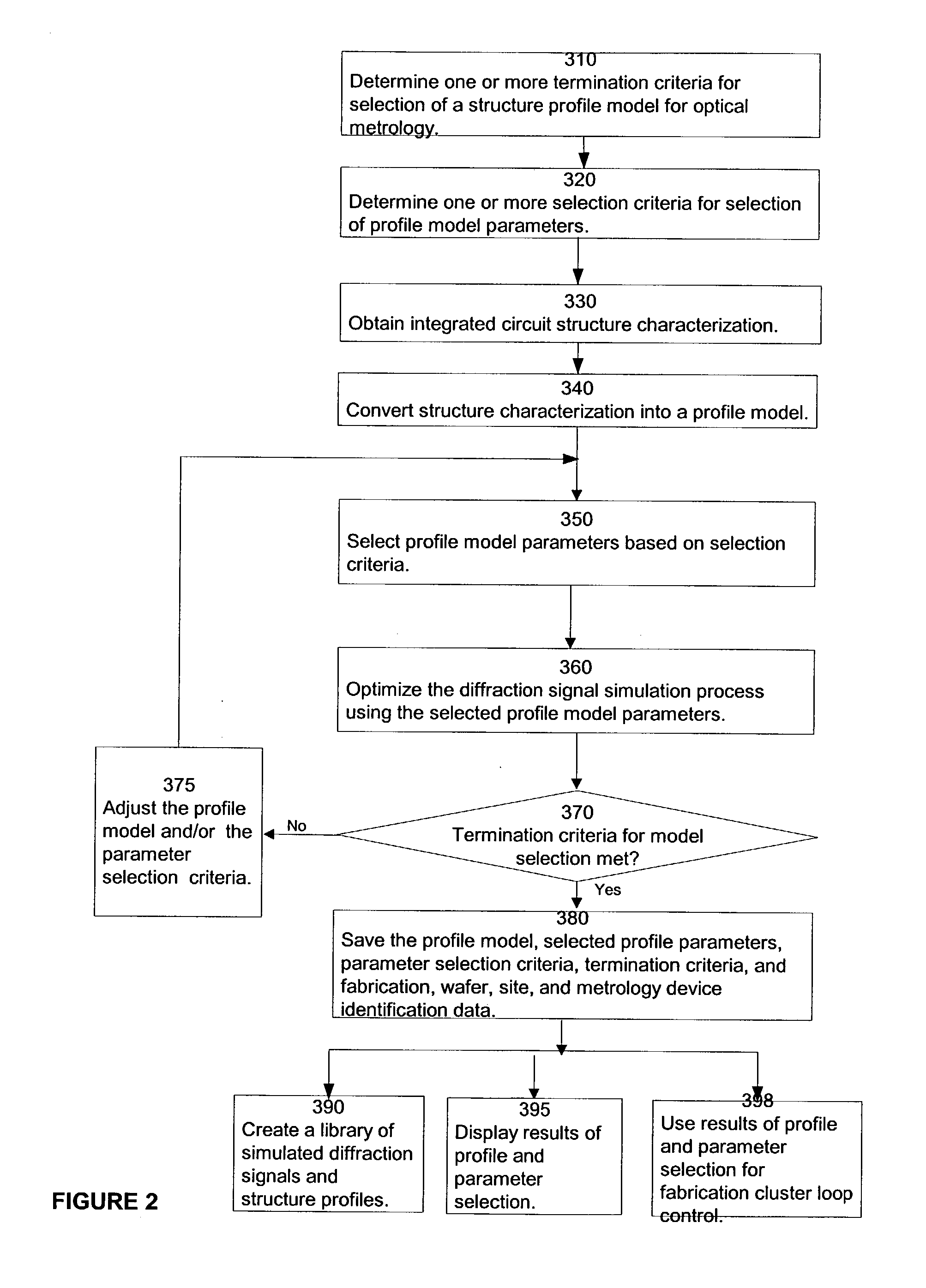

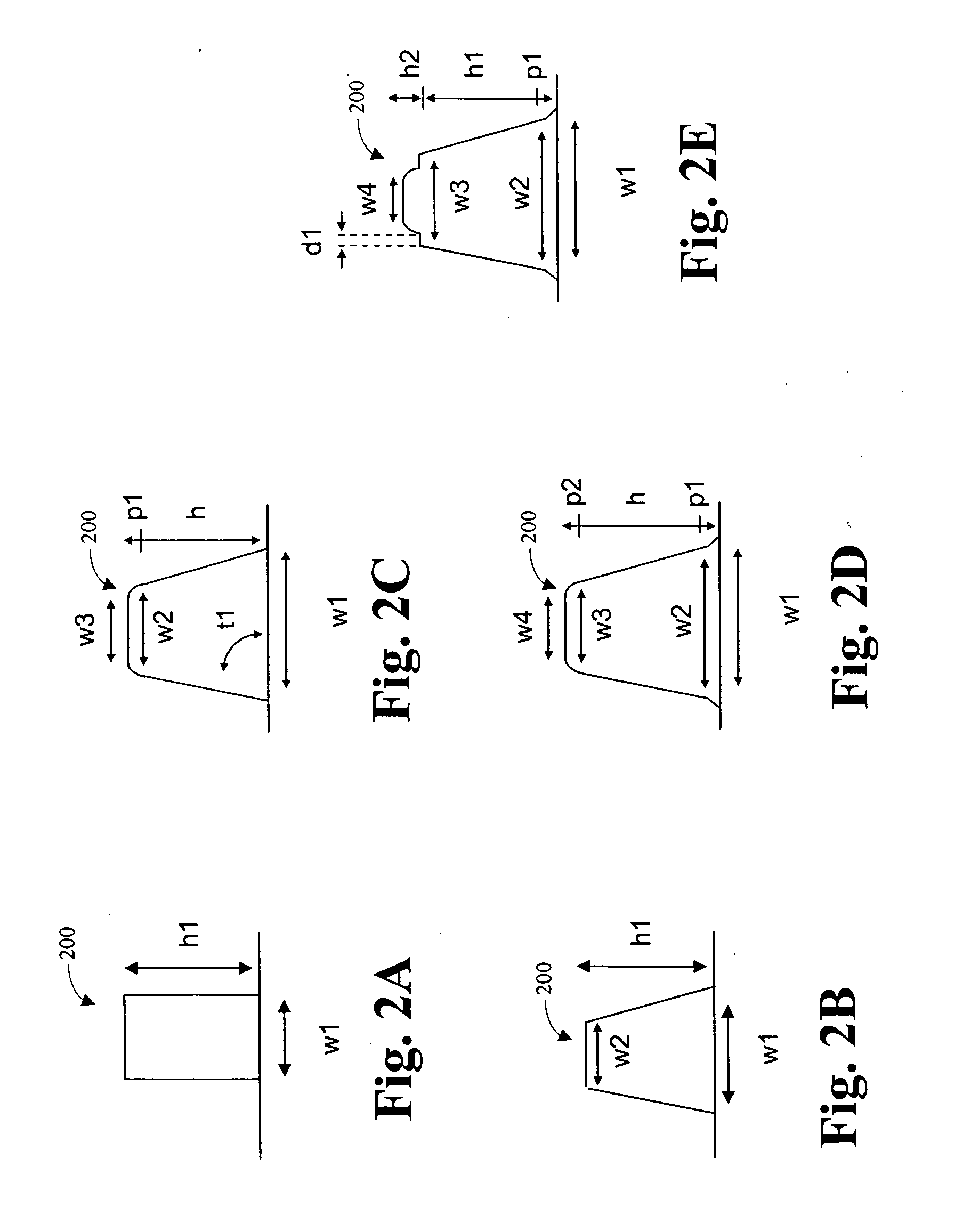

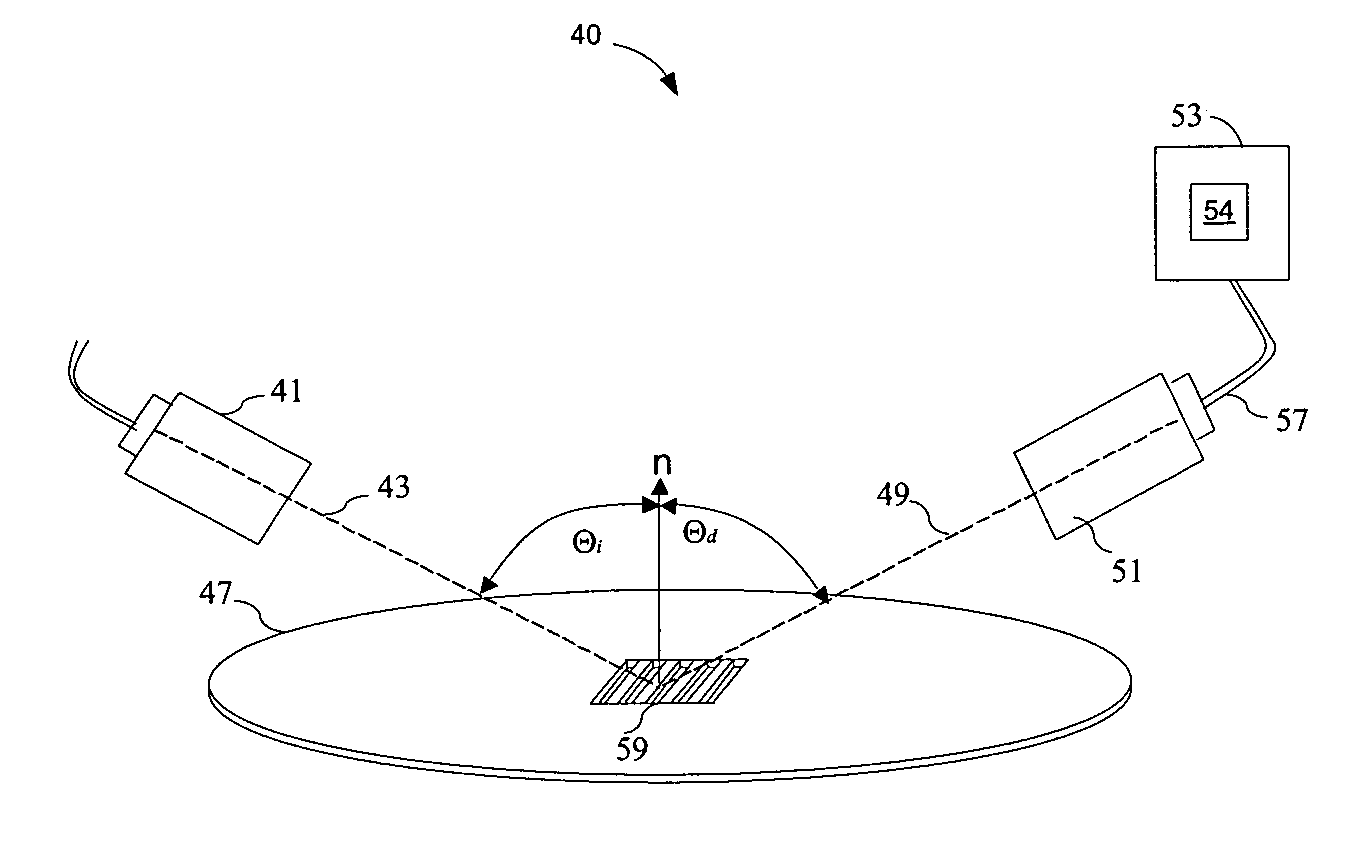

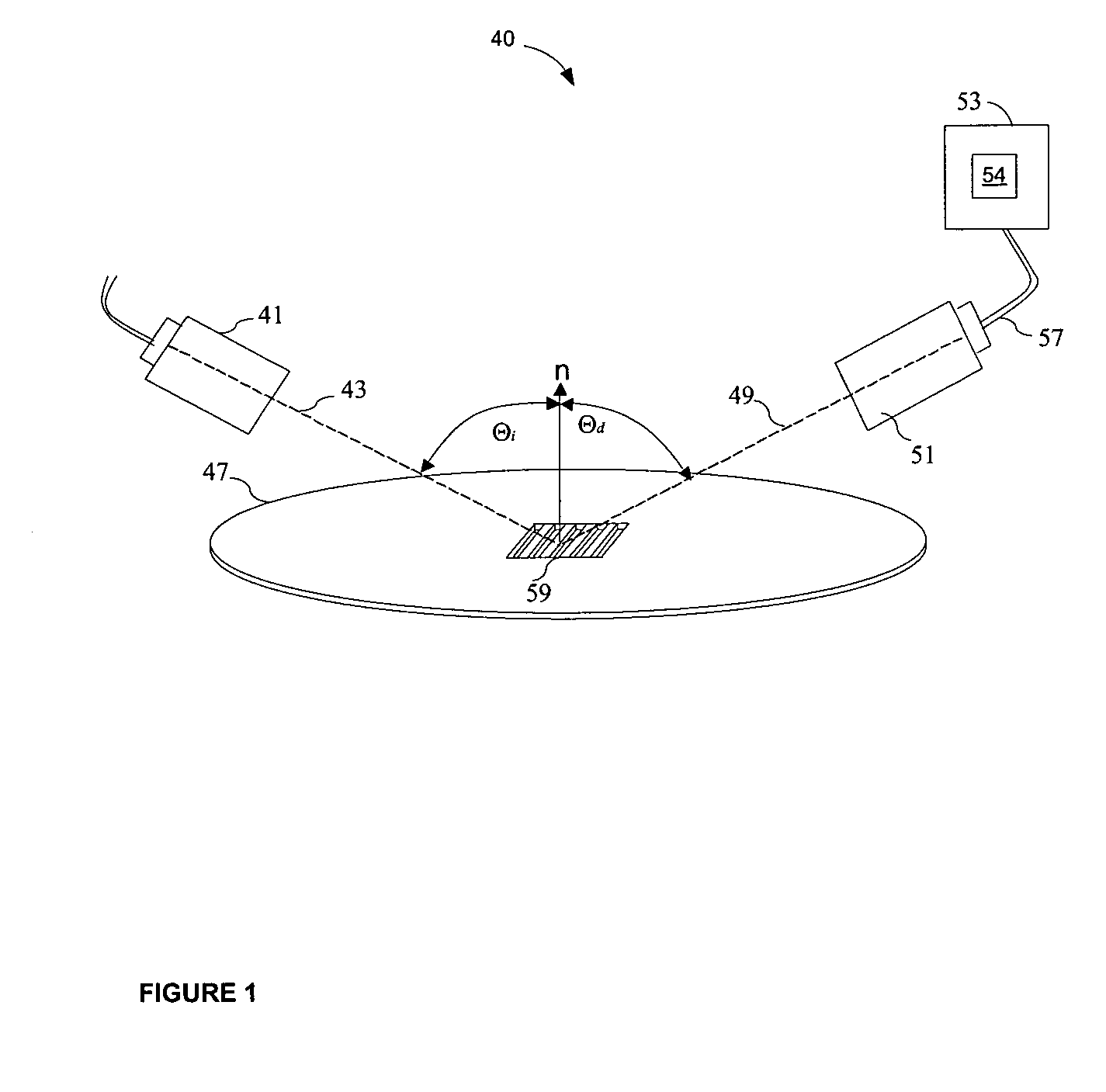

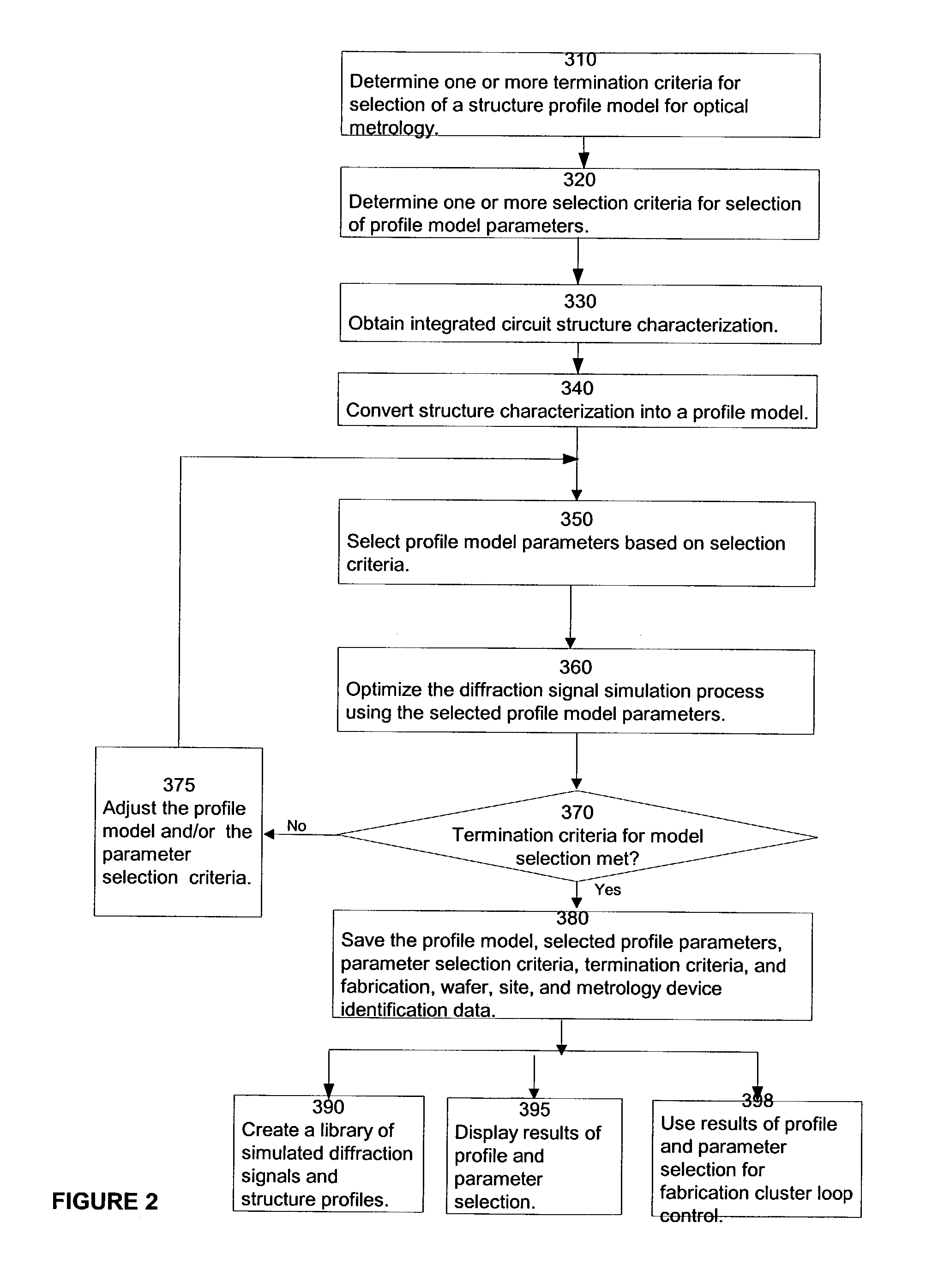

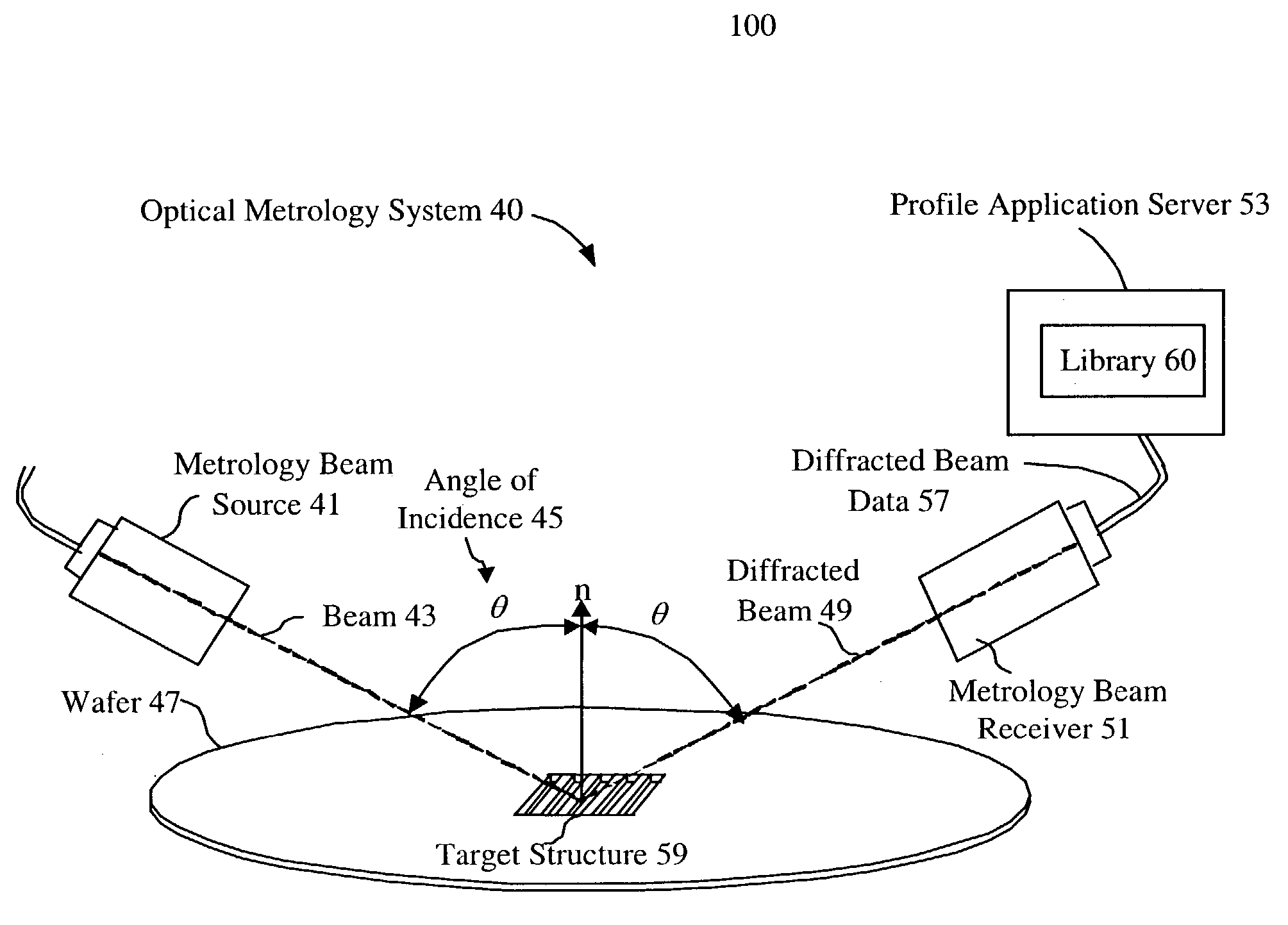

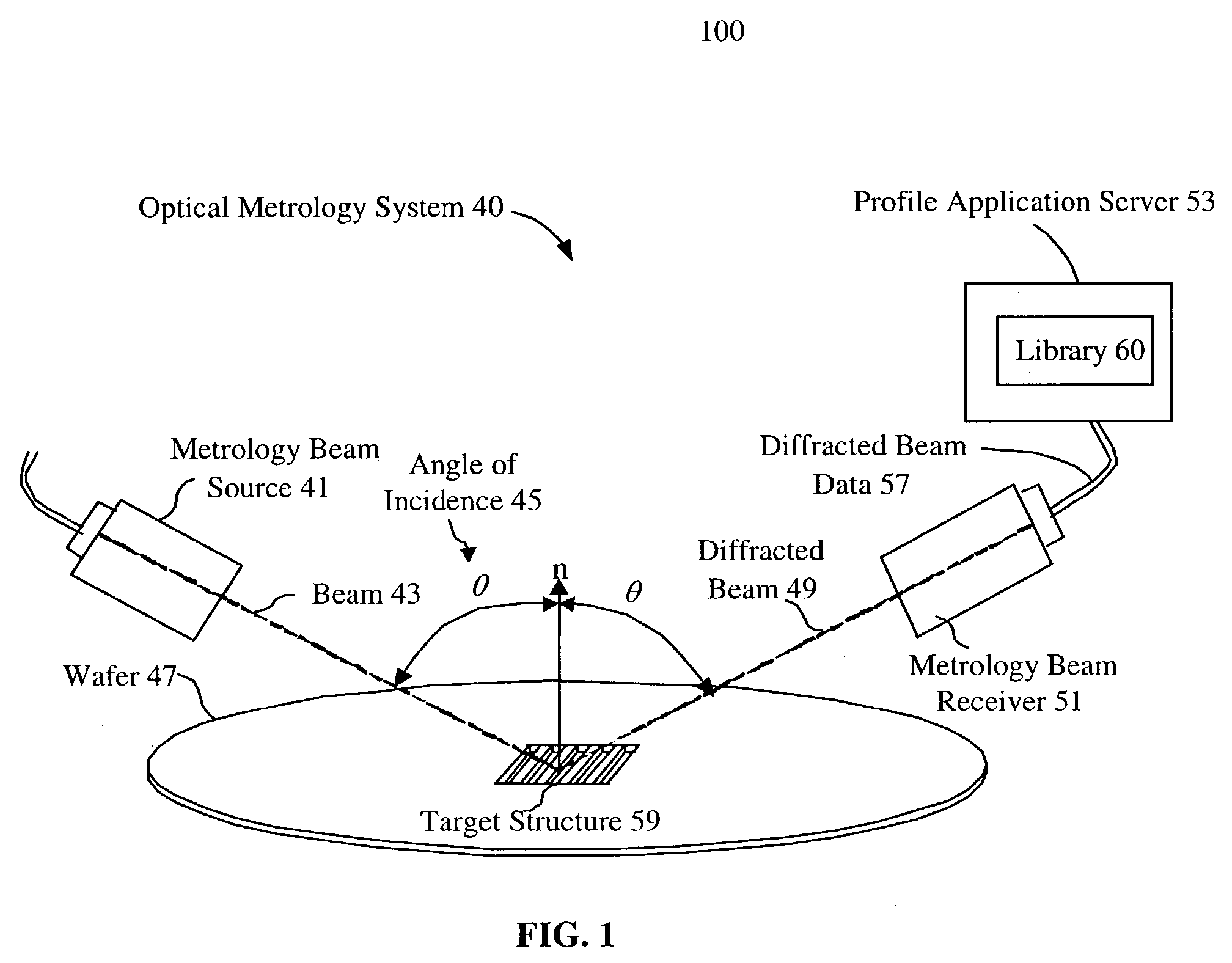

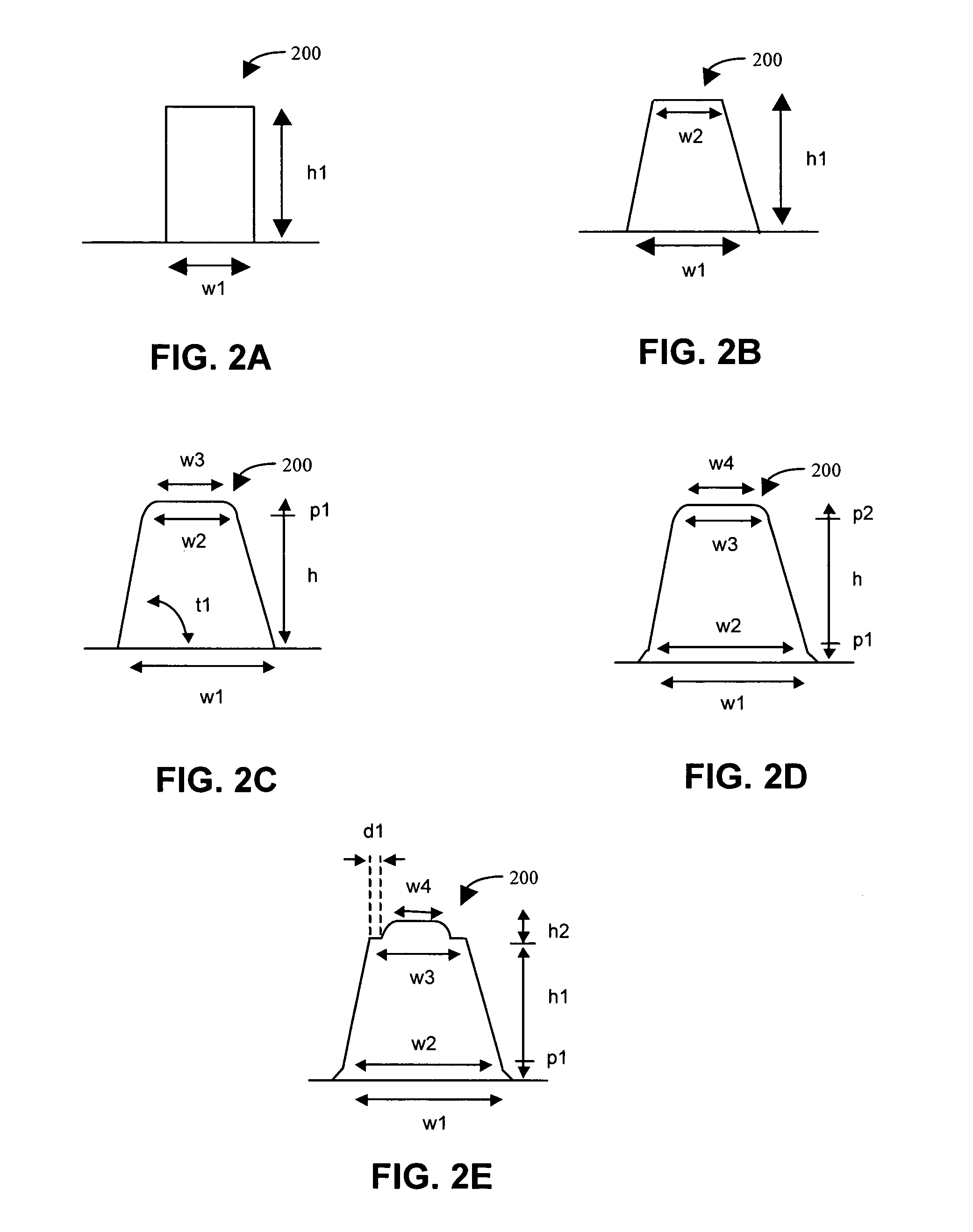

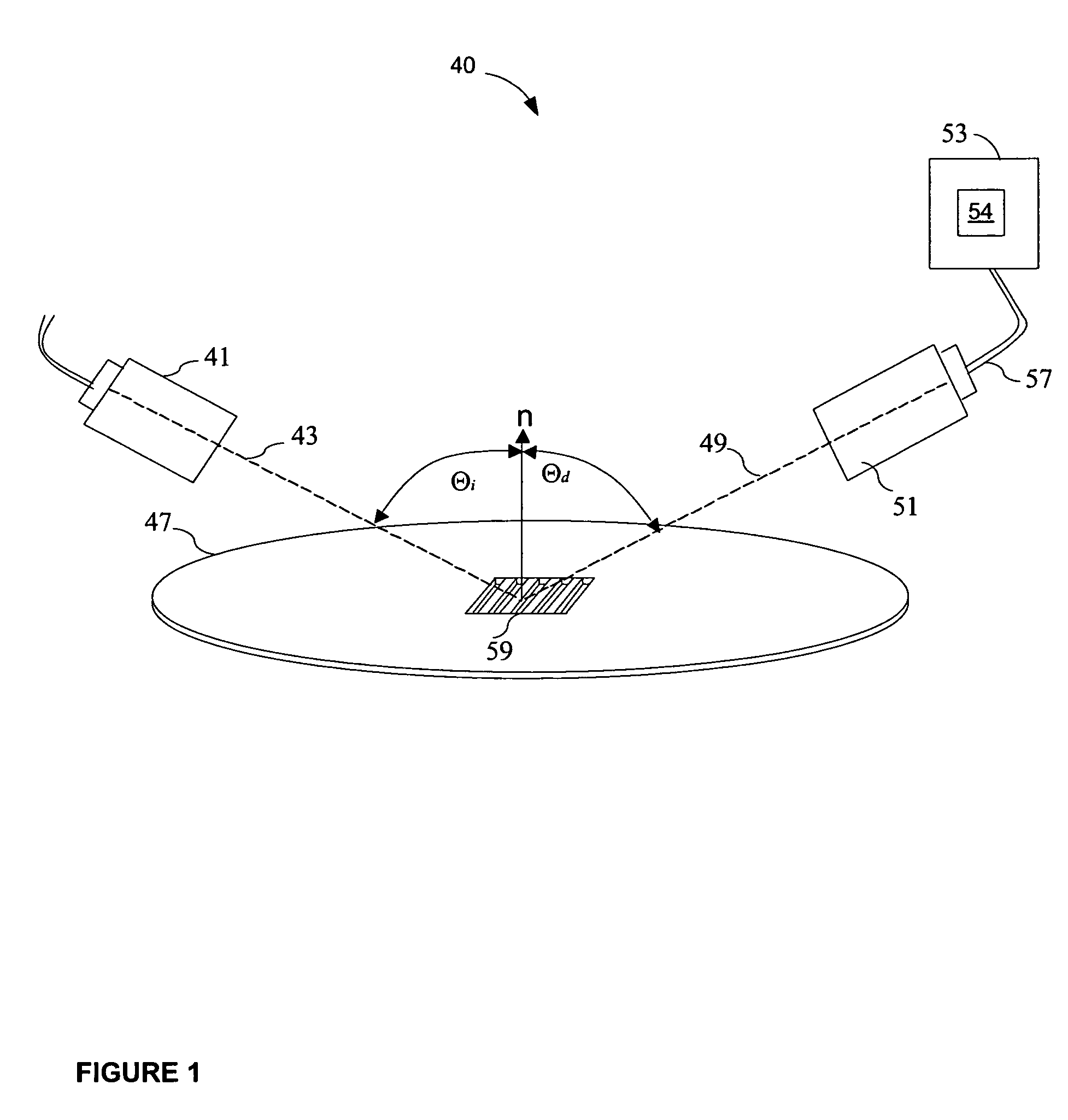

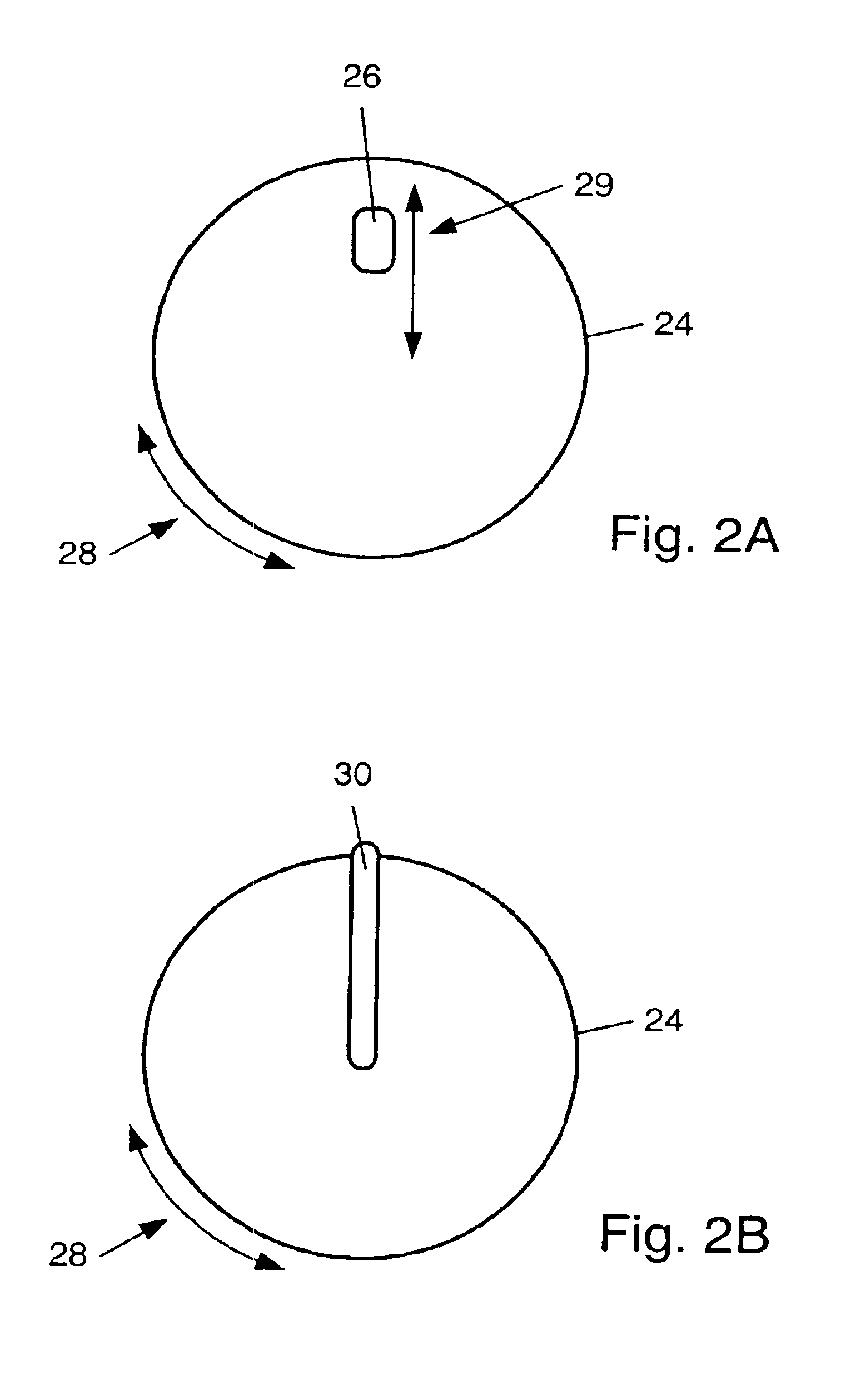

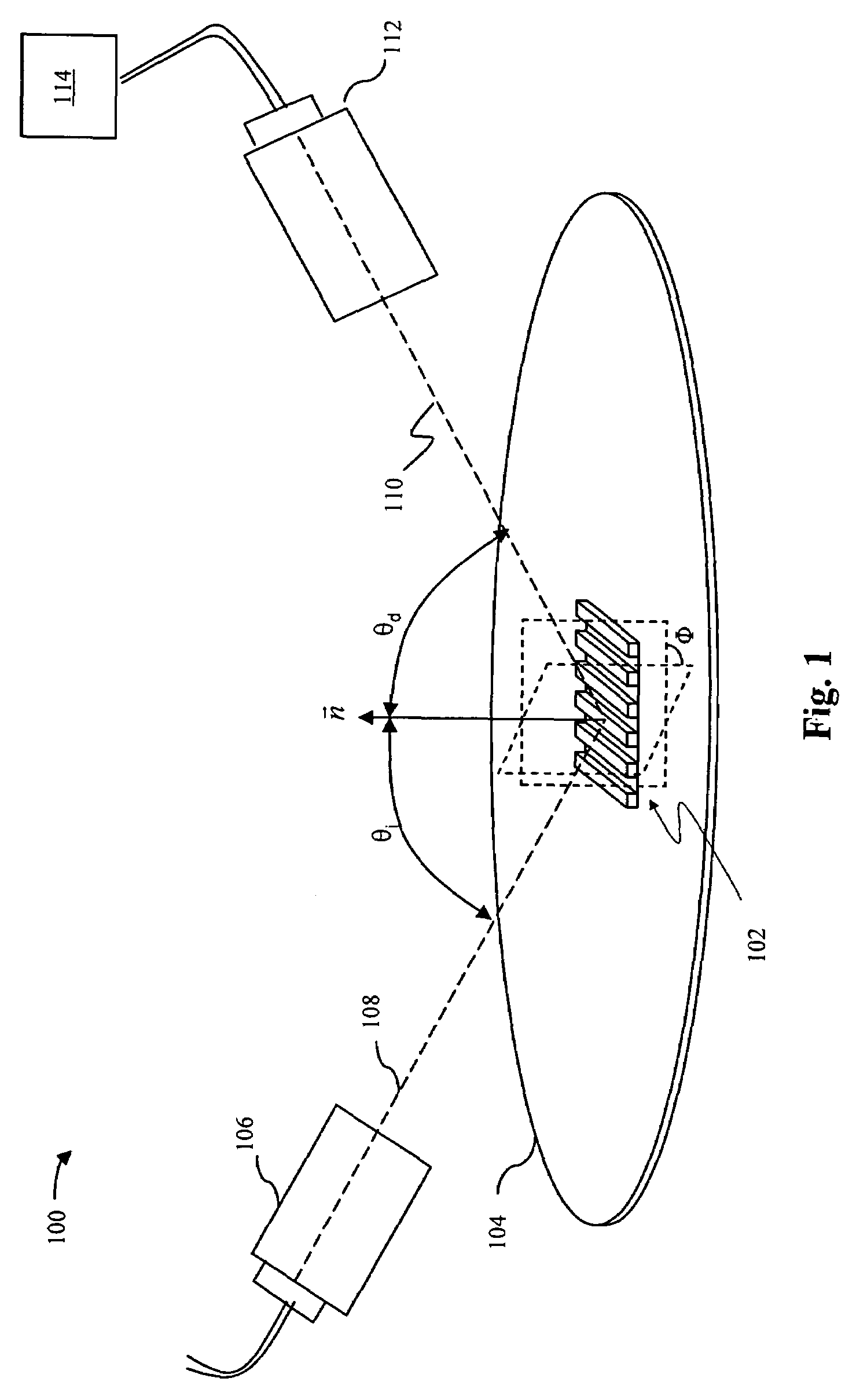

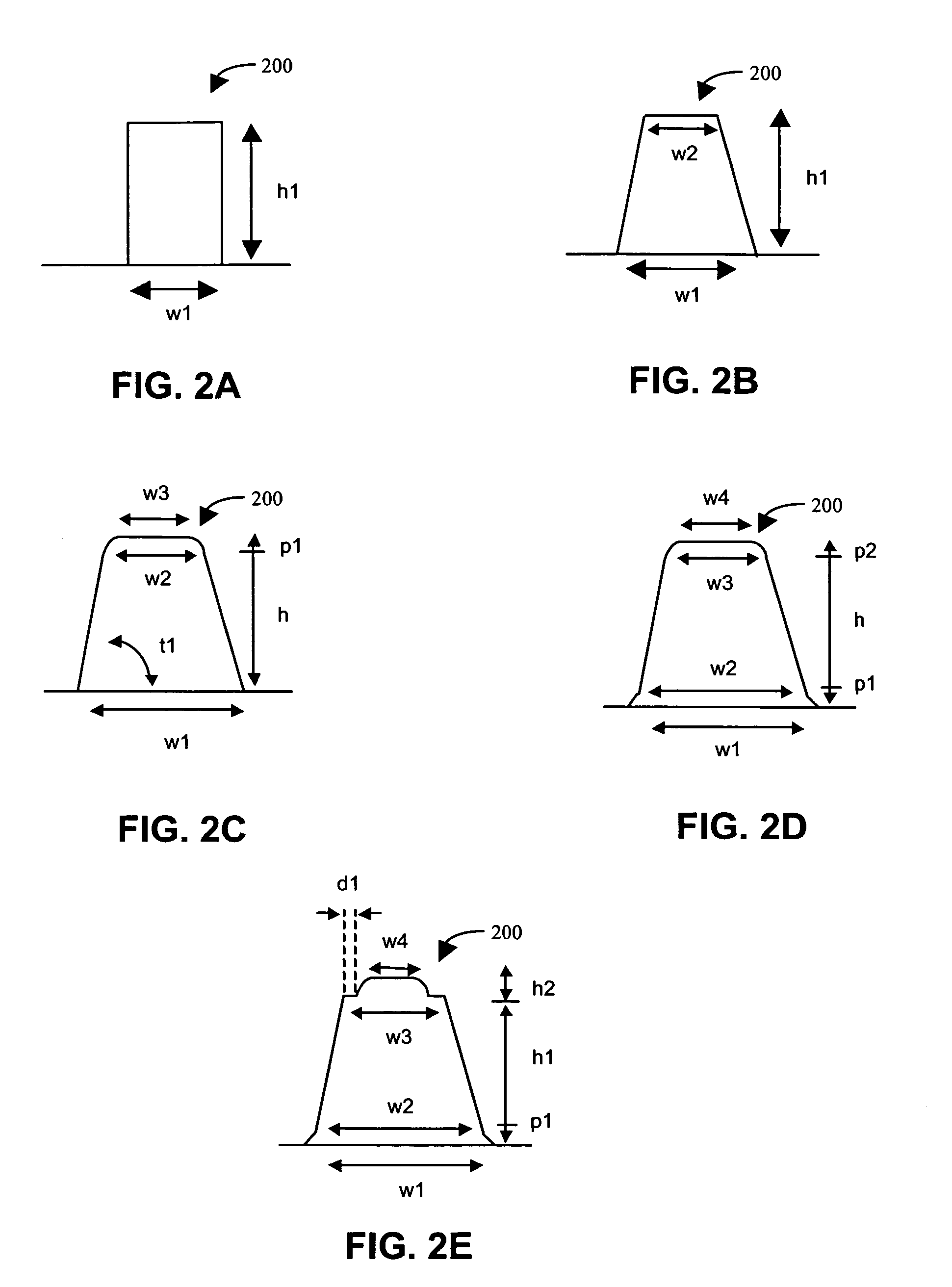

Model and parameter selection for optical metrology

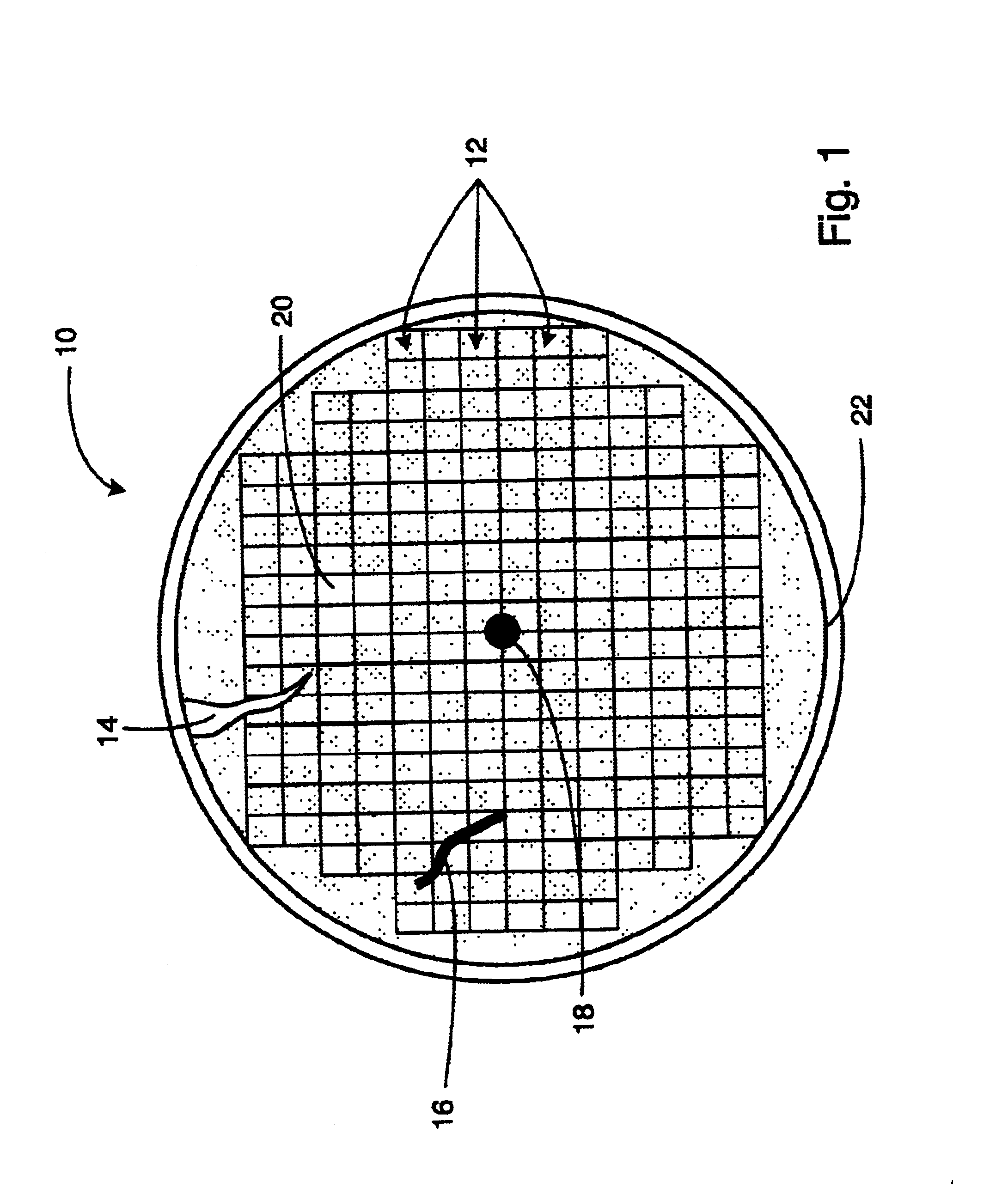

ActiveUS20040017574A1Semiconductor/solid-state device testing/measurementPhase-affecting property measurementsEngineeringSelection criterion

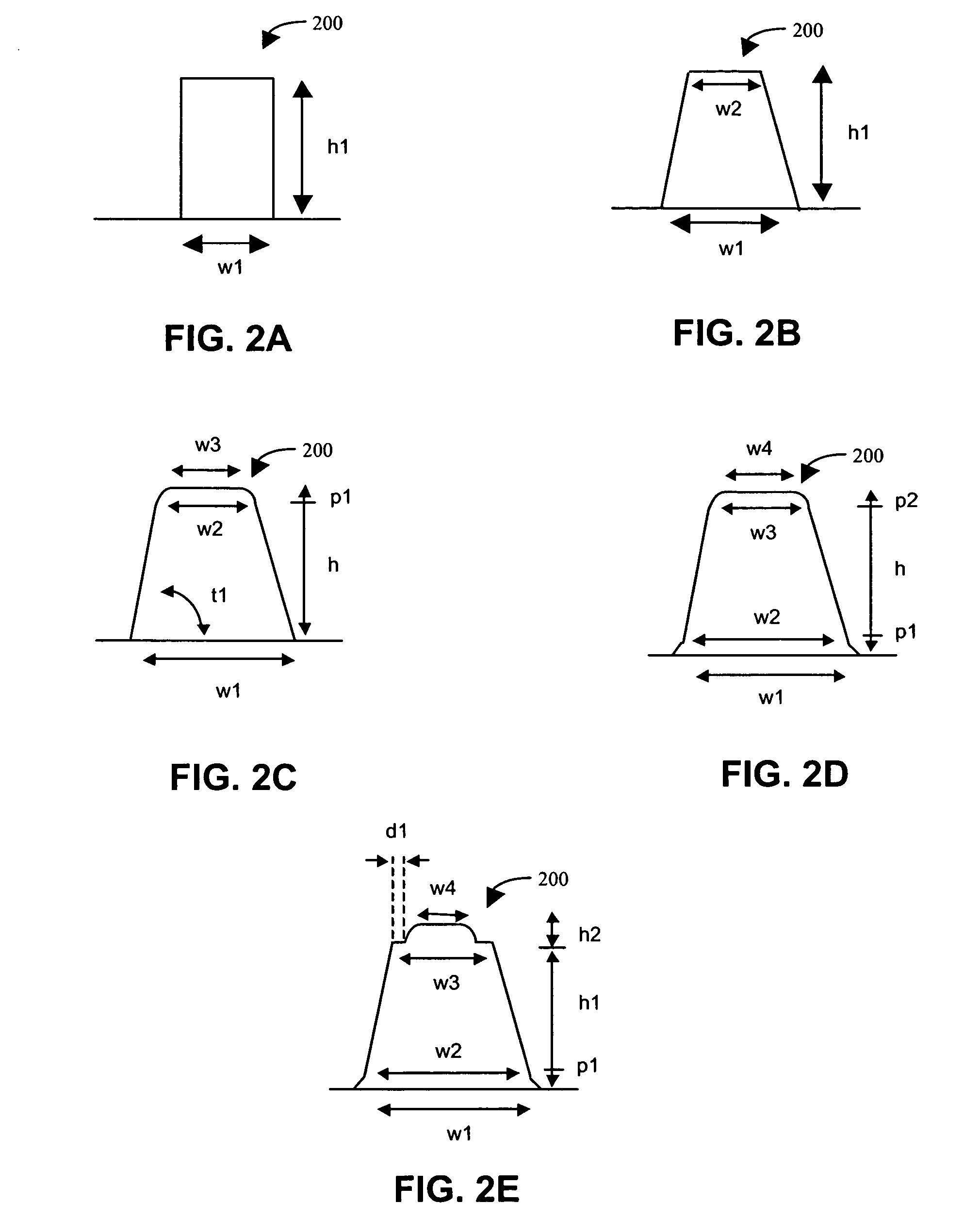

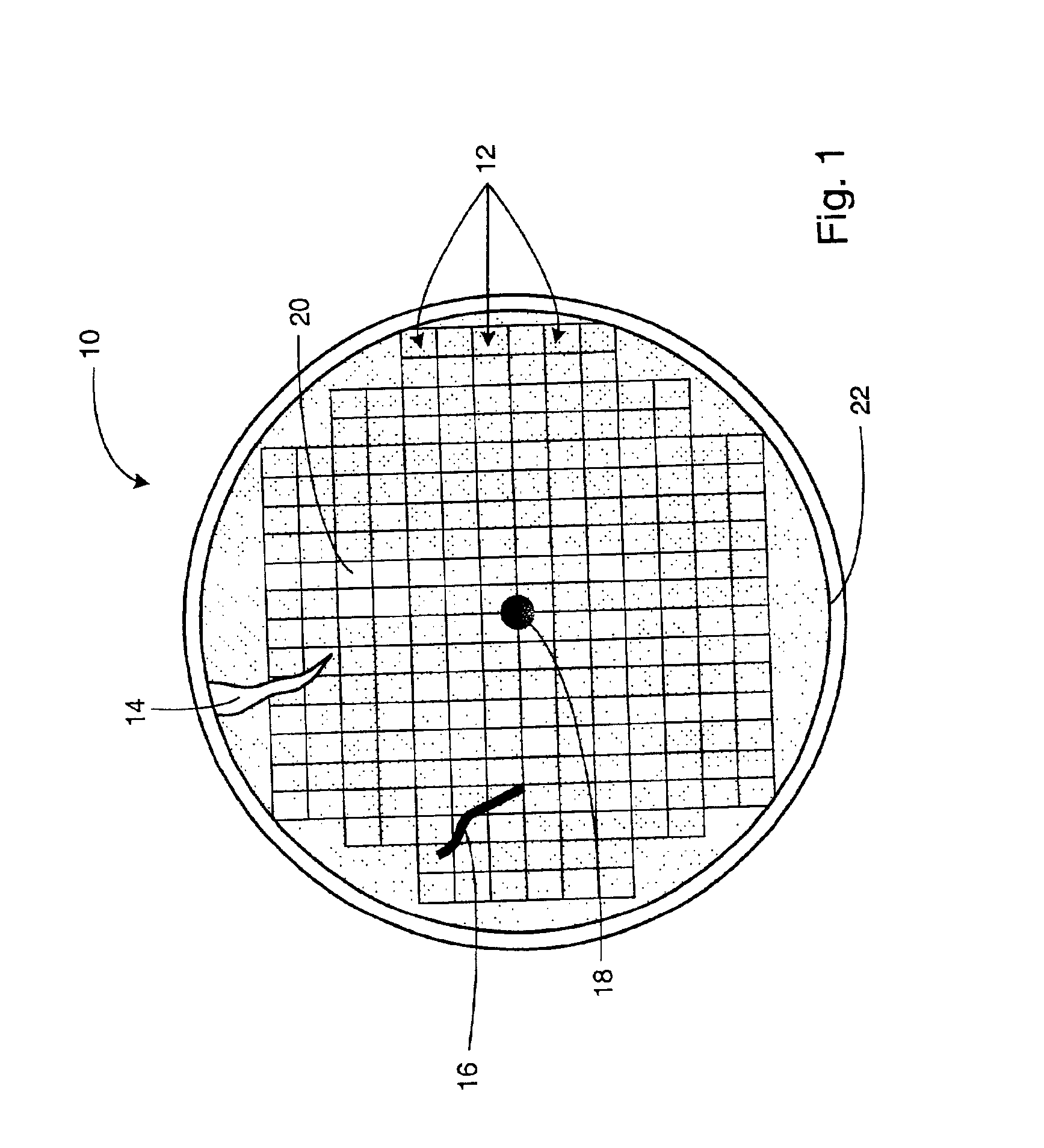

A profile model for use in optical metrology of structures in a wafer is selected, the profile model having a set of geometric parameters associated with the dimensions of the structure. A set of optimization parameters is selected for the profile model using one or more input diffraction signals and one or more parameter selection criteria. The selected profile model and the set of optimization parameters are tested against one or more termination criteria. The process of selecting a profile model, selecting a set of optimization parameters, and testing the selected profile model and set of optimization parameters is performed until the one or more termination criteria are met.

Owner:TOKYO ELECTRON US HOLDINGS INC

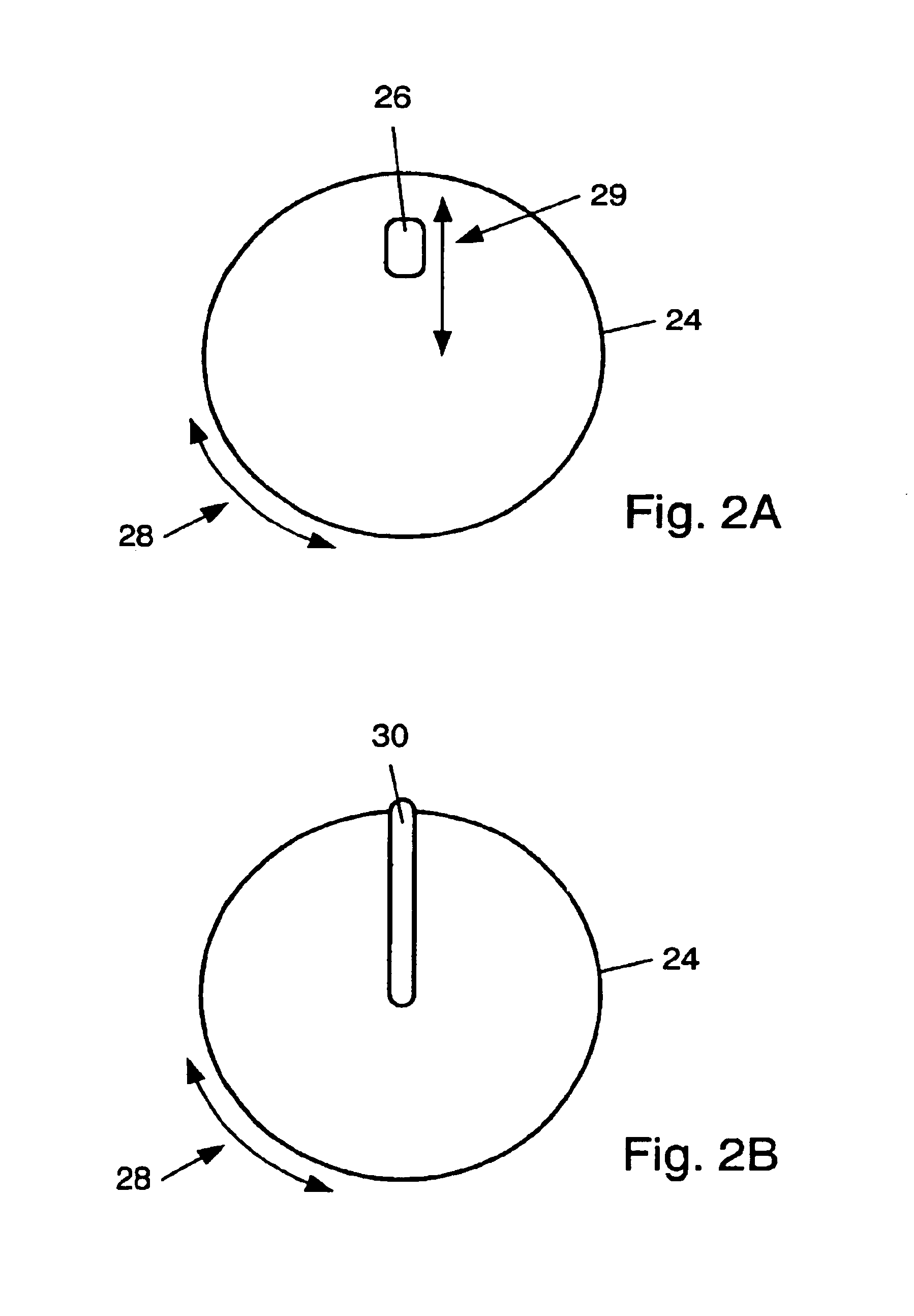

Optical metrology optimization for repetitive structures

InactiveUS20050209816A1Feeler-pin gaugesMechanical counters/curvatures measurementsComputational physicsOptical metrology

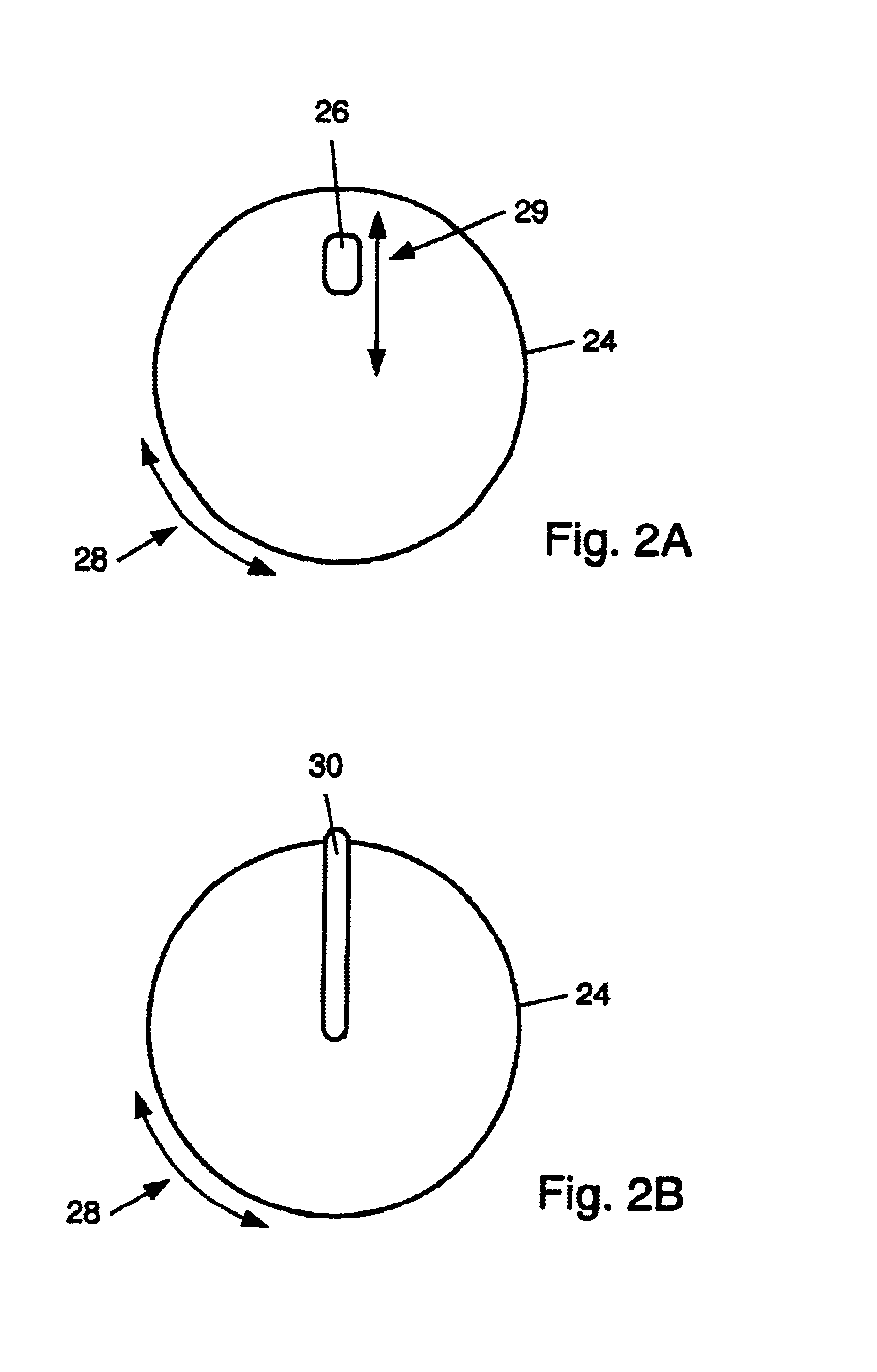

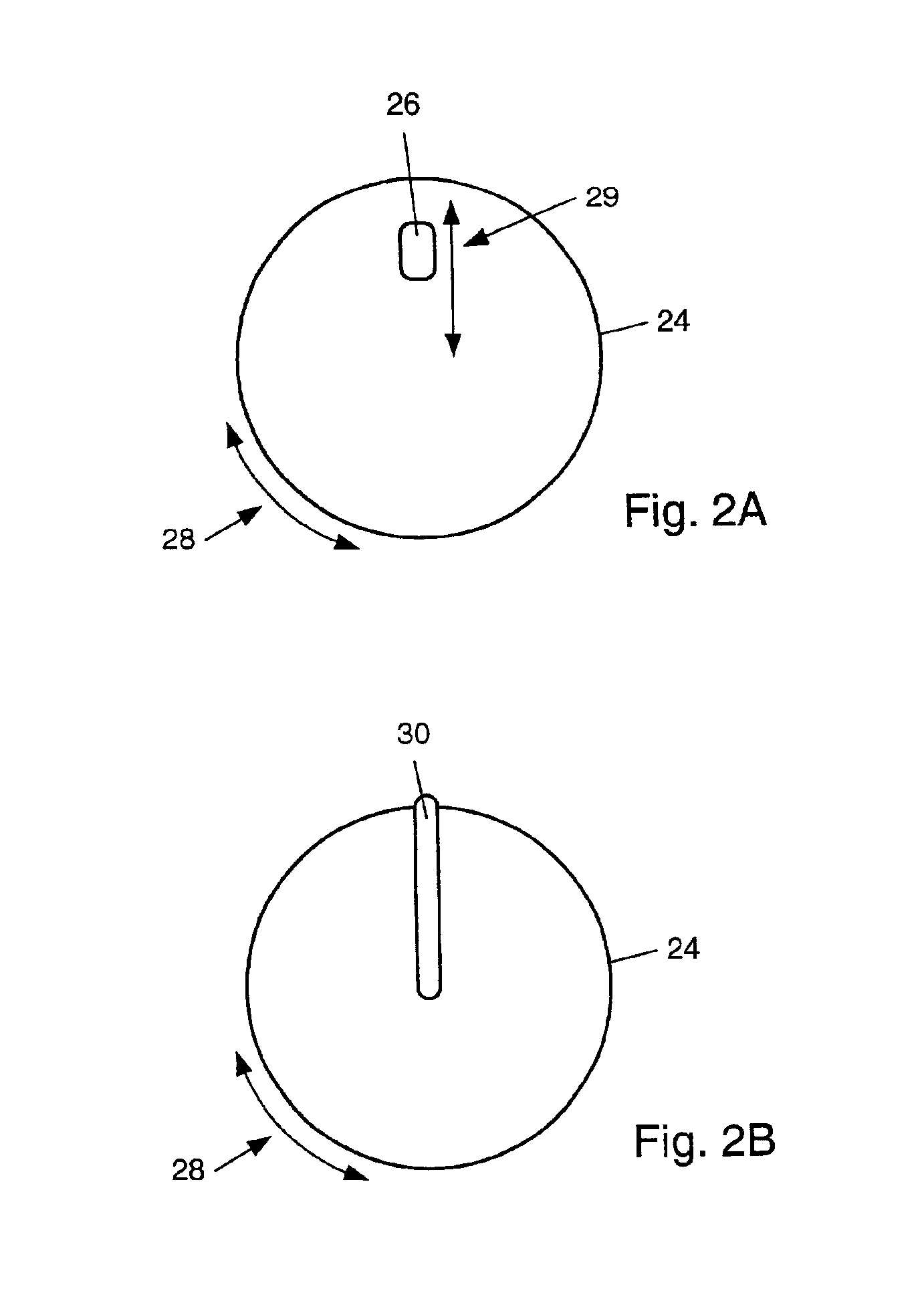

The top-view profiles of repeating structures in a wafer are characterized and parameters to represent variations in the top-view profile of the repeating structures are selected. An optical metrology model is developed that includes the selected top-view profile parameters of the repeating structures. The optimized optical metrology model is used to generate simulated diffraction signals that are compared to measured diffraction signals.

Owner:TOKYO ELECTRON LTD

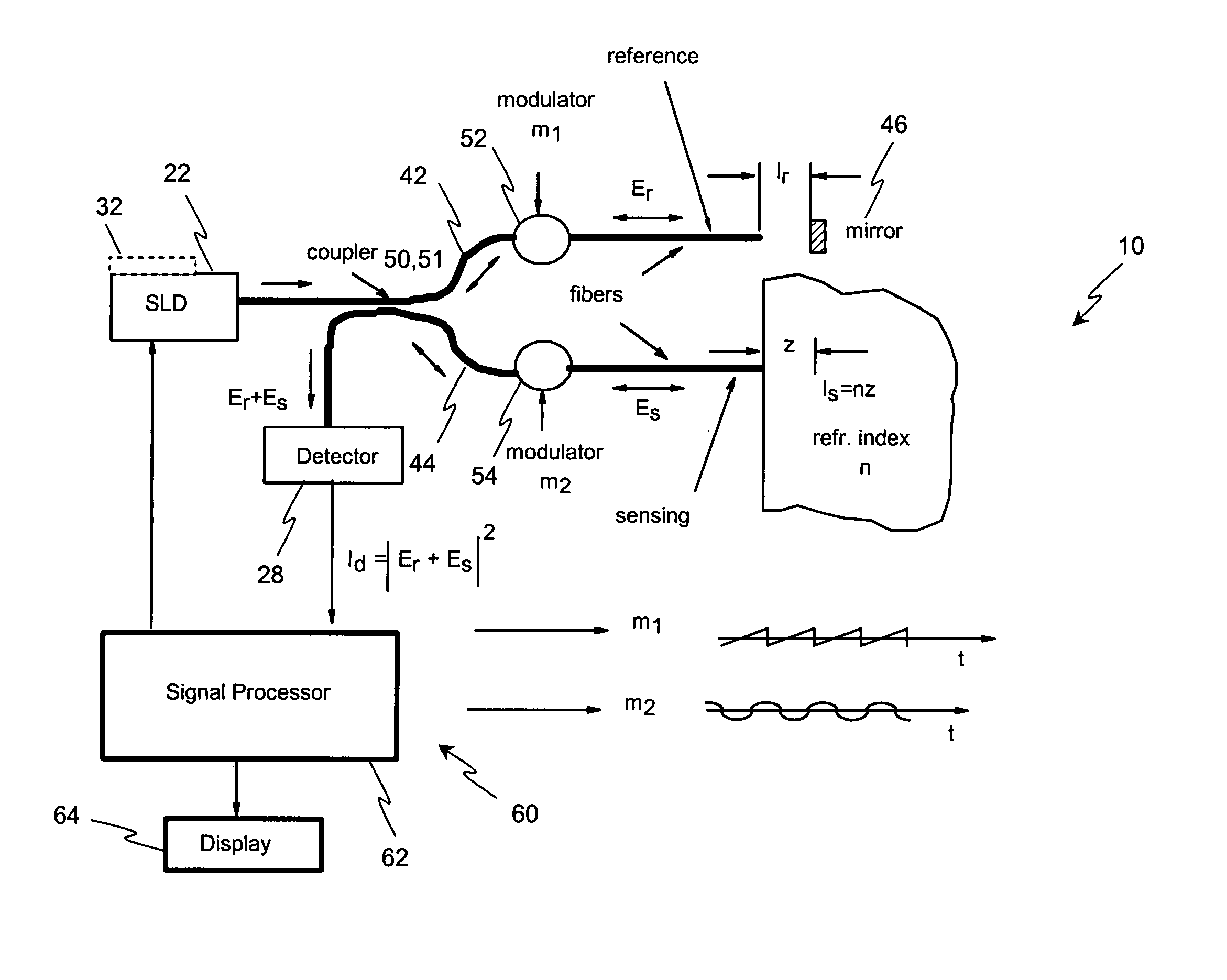

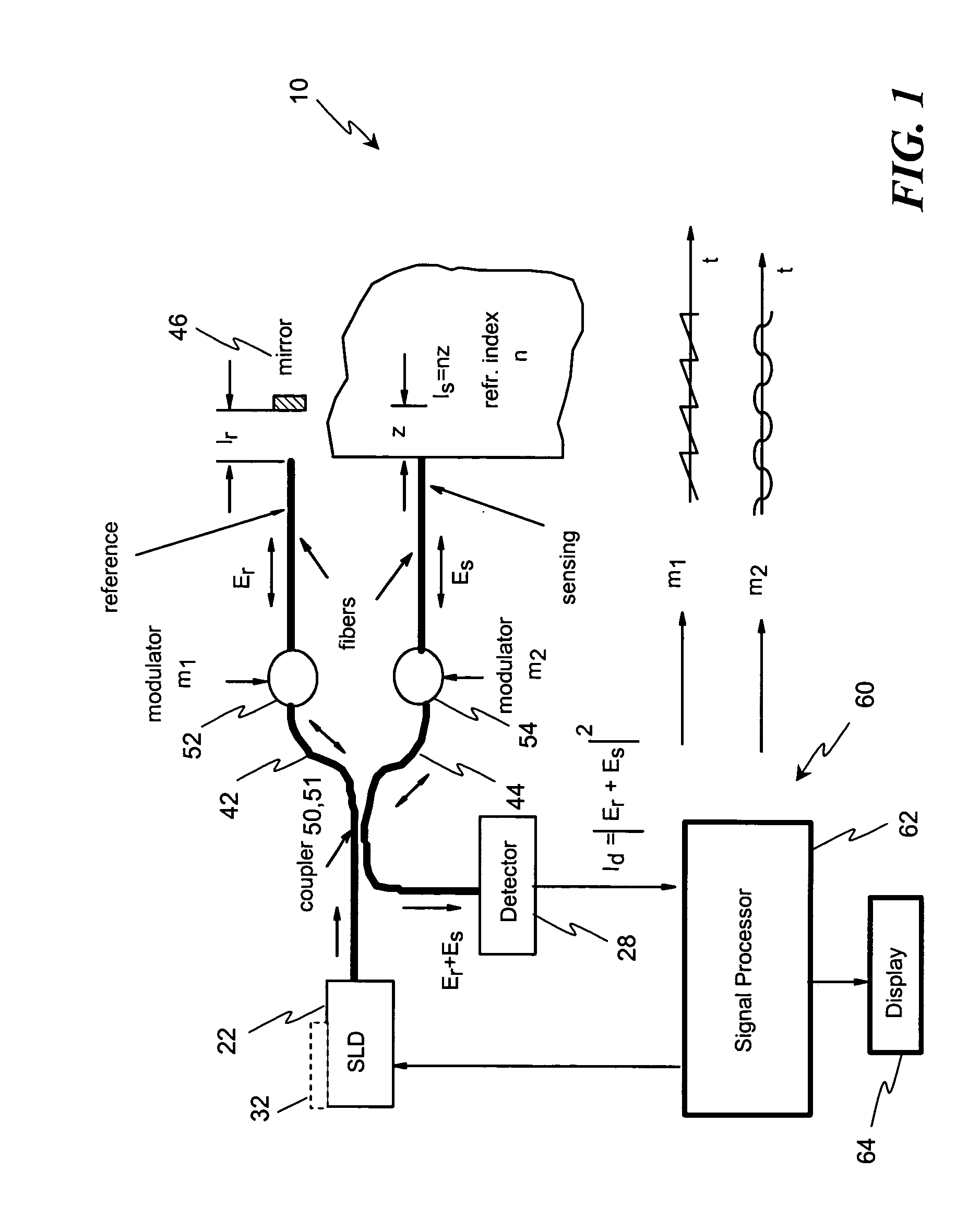

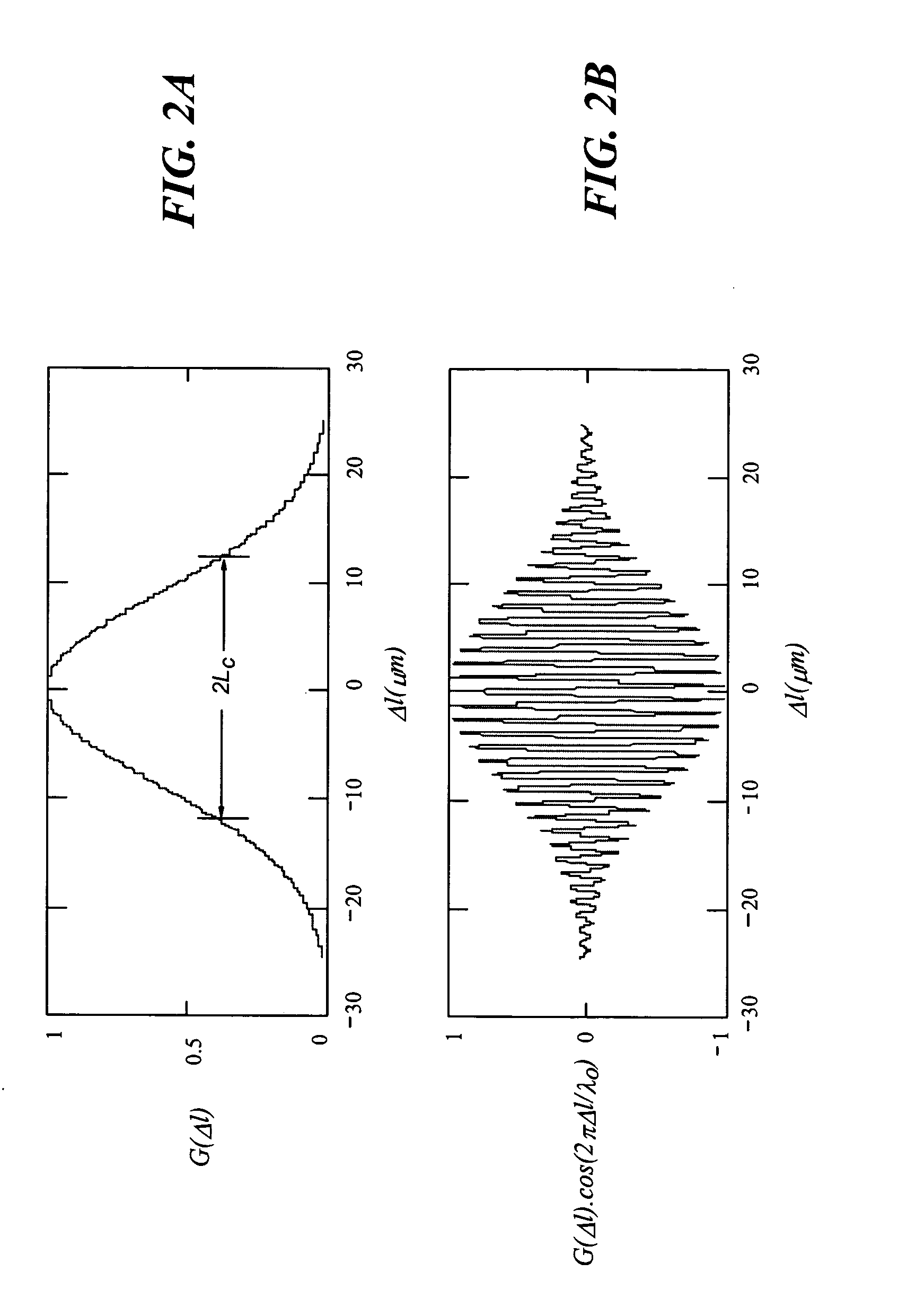

Low coherence interferometric system for optical metrology

InactiveUS20050254059A1Reduce coherenceFacilitate of lightPhase-affecting property measurementsScattering properties measurementsPath lengthOptoelectronics

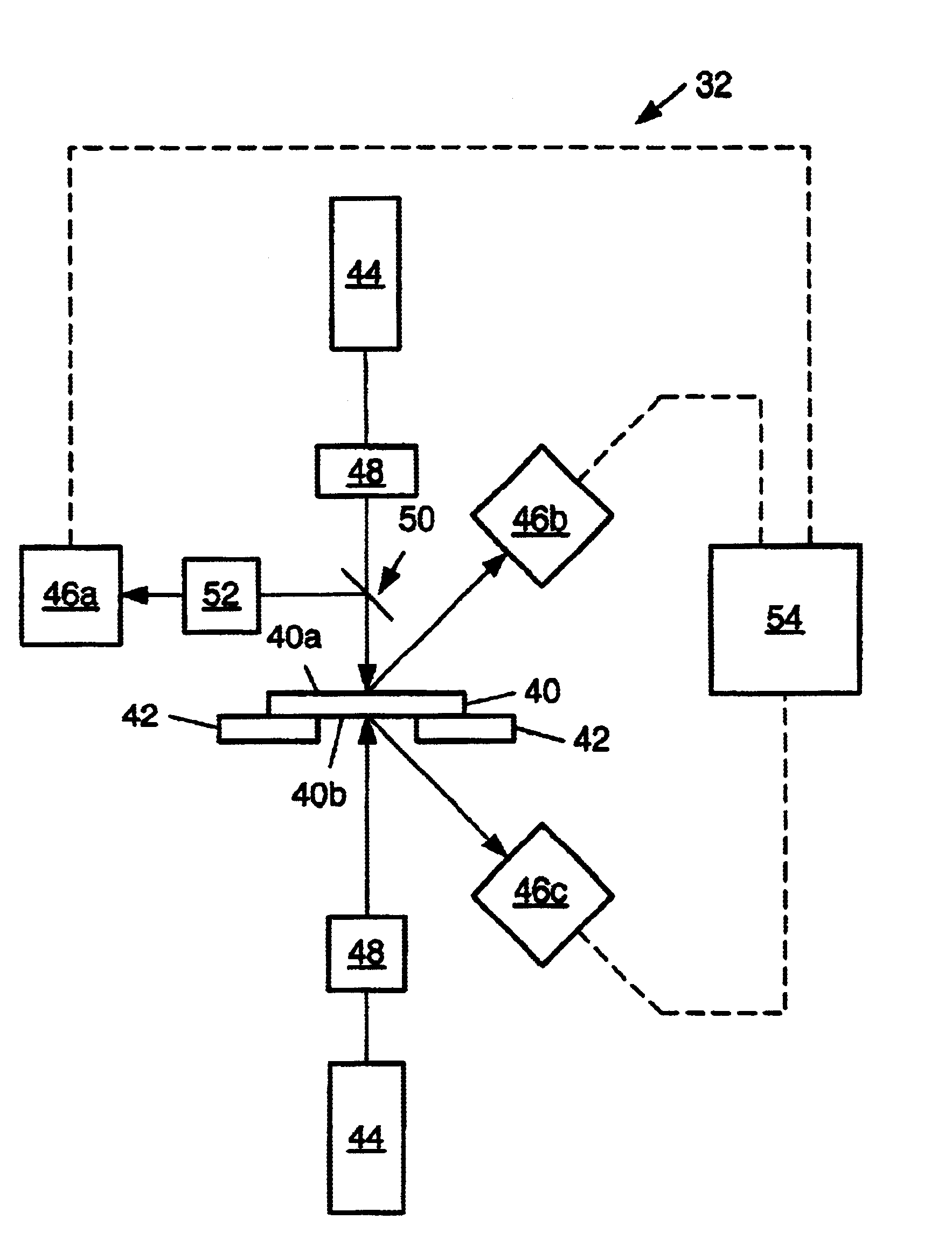

A system for optical metrology of a biological sample comprising: a broadband light source; an optical assembly receptive to the broadband light, the optical assembly configured to facilitate transmission of the broadband light in a first direction and impede transmission of the broadband light a second direction; a sensing light path receptive to the broadband light from the optical assembly; a fixed reflecting device; a reference light path receptive to the broadband light from the optical assembly, the reference light path coupled with the sensing light path, the reference light path having an effective light path length longer than an effective light path length of the sensing light path by a selected length corresponding to about a selected target depth within the biological sample; and a detector receptive the broadband light resulting from interference of the broadband light to provide an electrical interference signal indicative thereof.

Owner:VZN CAPITAL

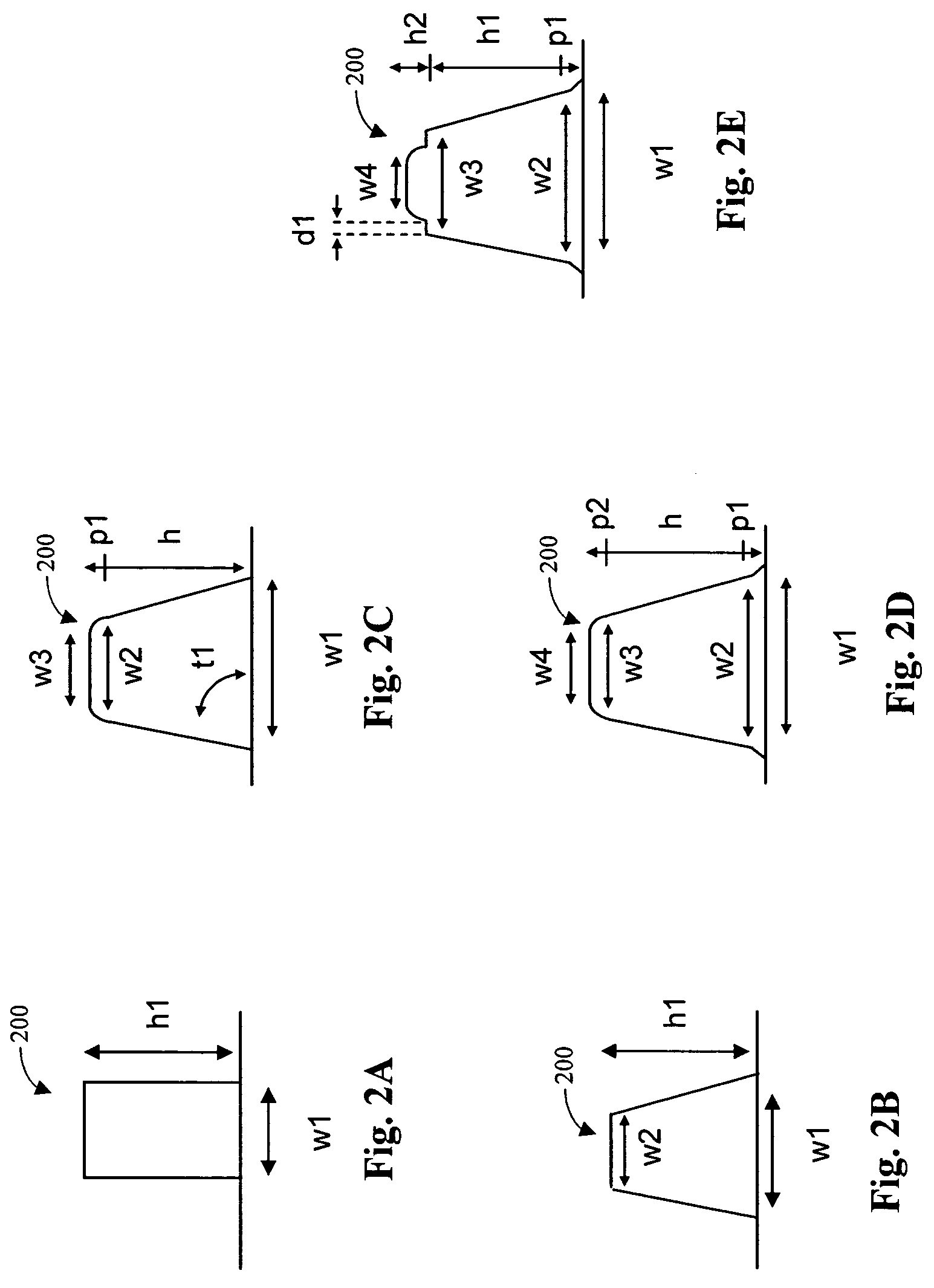

Methods and systems for determining a critical dimension, a presence of defects, and a thin film characteristic of a specimen

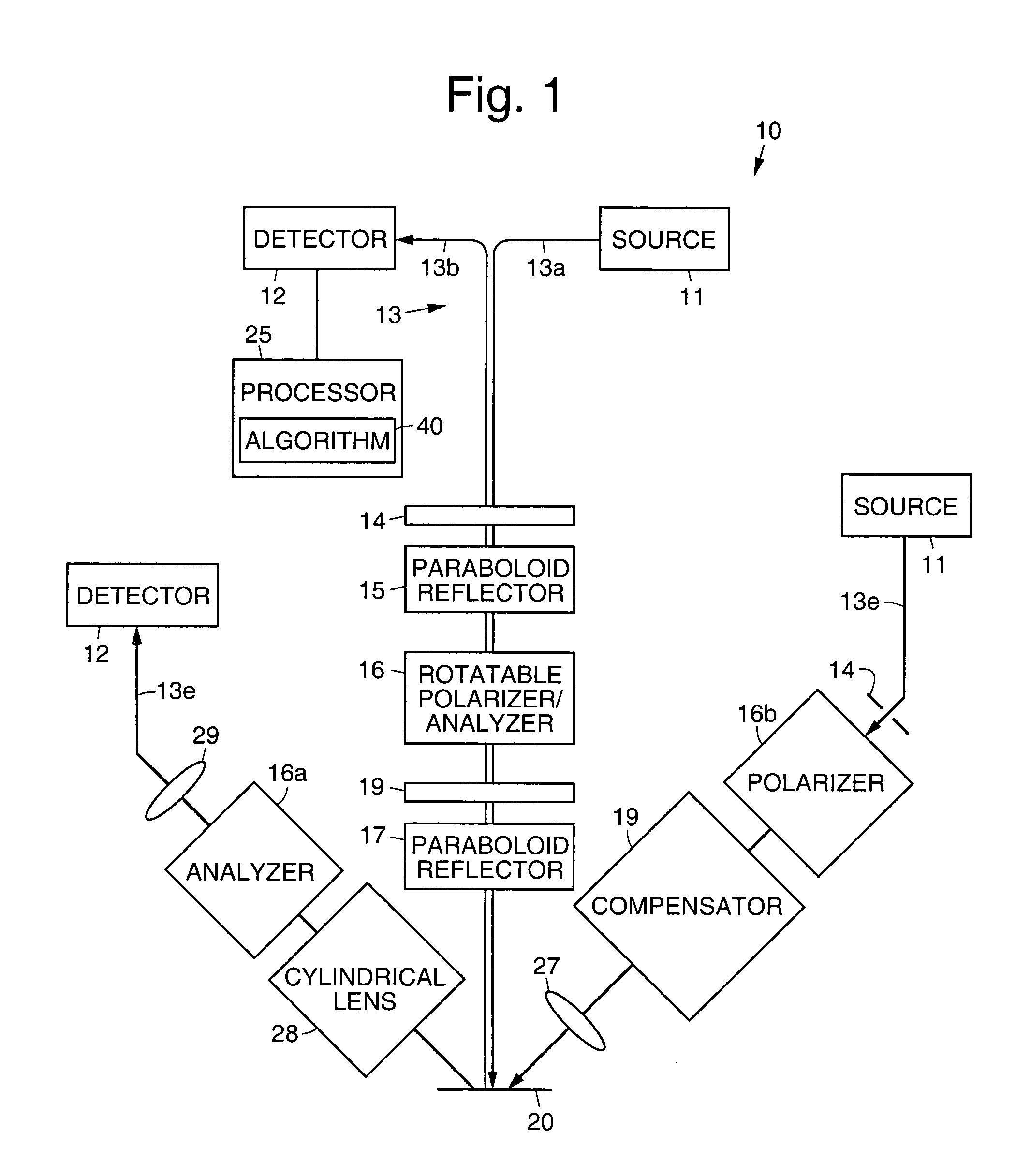

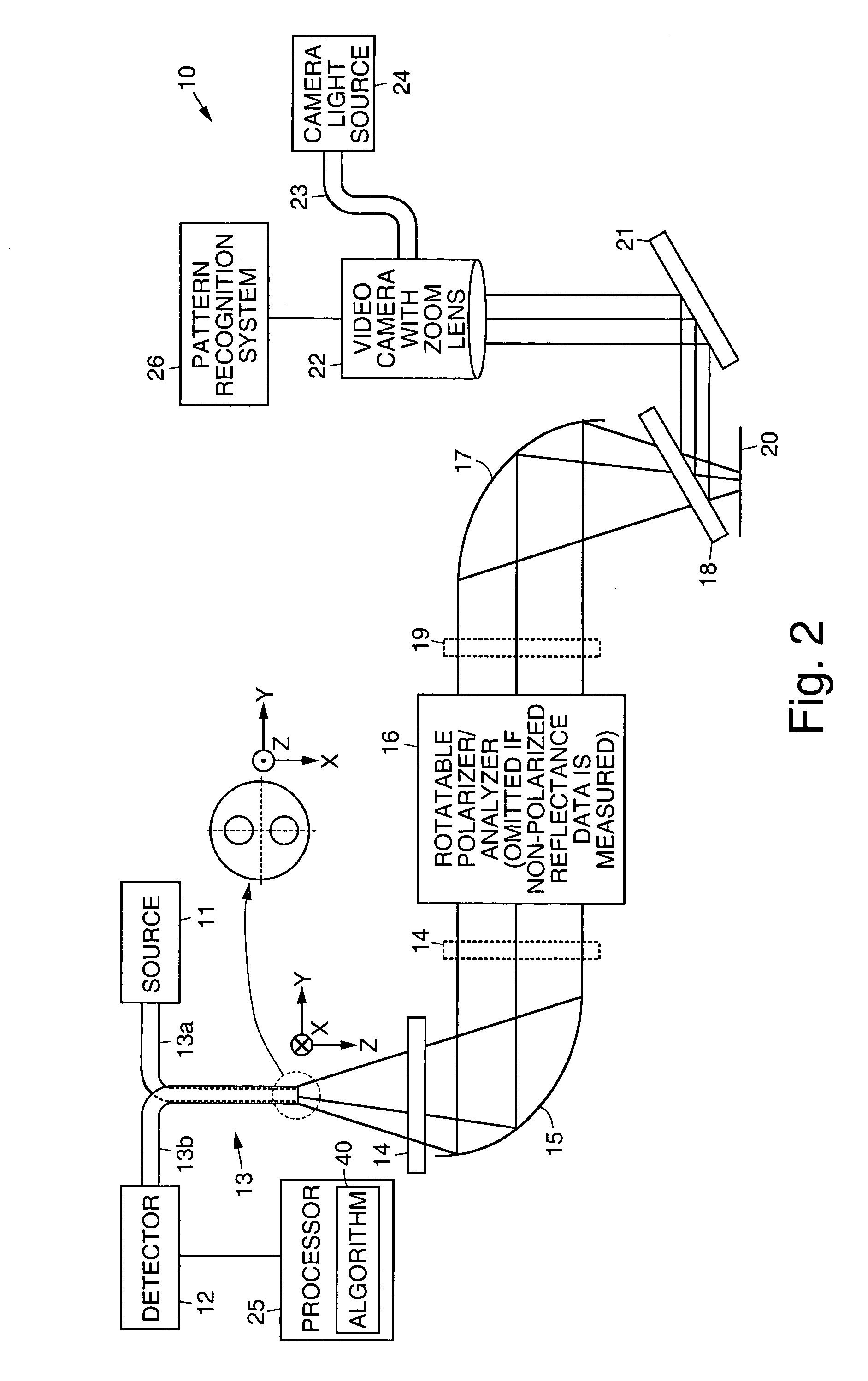

InactiveUS6919957B2Speed up the processShorten the timeSemiconductor/solid-state device testing/measurementPolarisation-affecting propertiesMeasurement deviceEngineering

Methods and systems for monitoring semiconductor fabrication processes are provided. A system may include a stage configured to support a specimen and coupled to a measurement device. The measurement device may include an illumination system and a detection system. The illumination system and the detection system may be configured such that the system may be configured to determine multiple properties of the specimen. For example, the system may be configured to determine multiple properties of a specimen including, but not limited to, critical dimension, a presence of defects, and a thin film characteristic. In this manner, a measurement device may perform multiple optical and / or non-optical metrology and / or inspection techniques.

Owner:KLA TENCOR TECH CORP

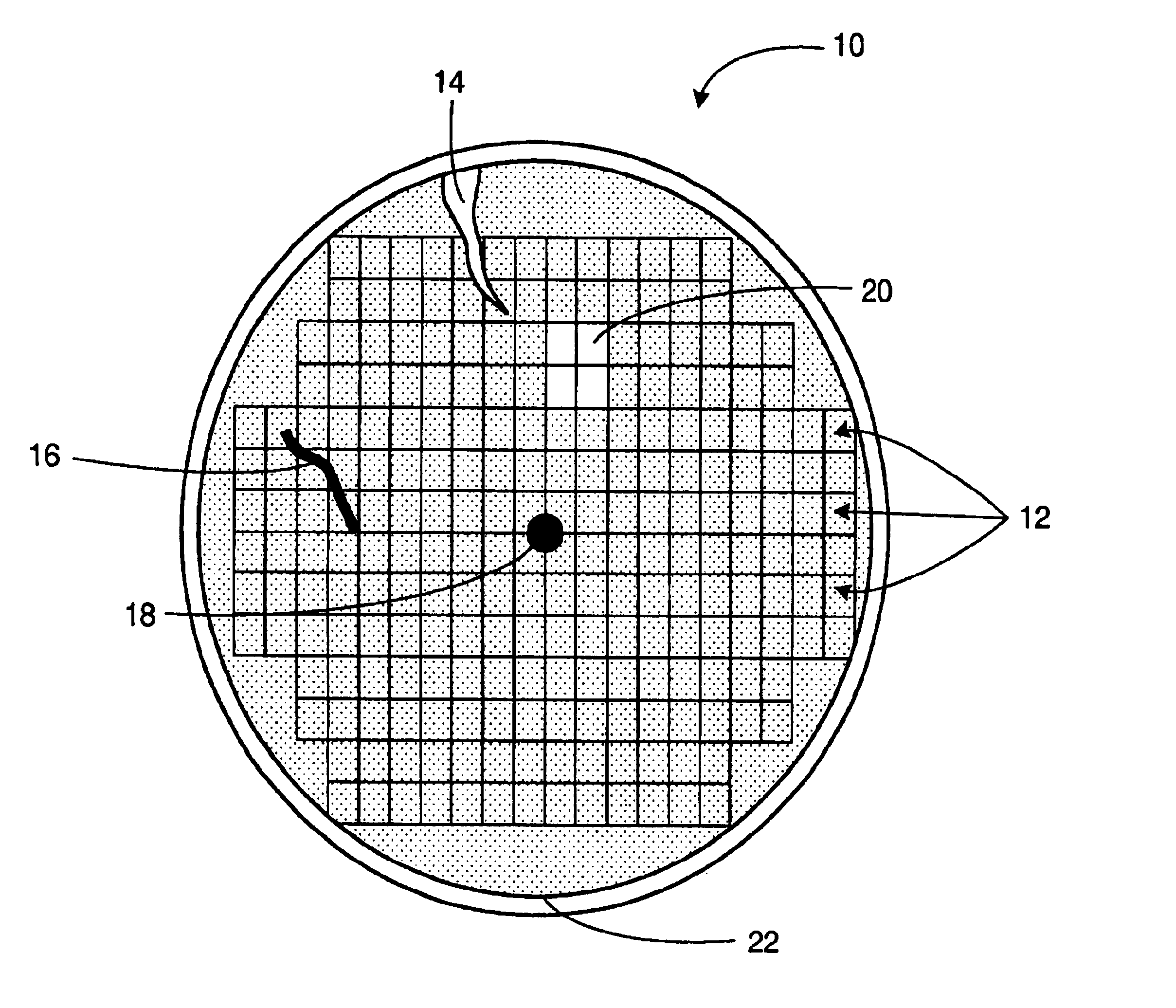

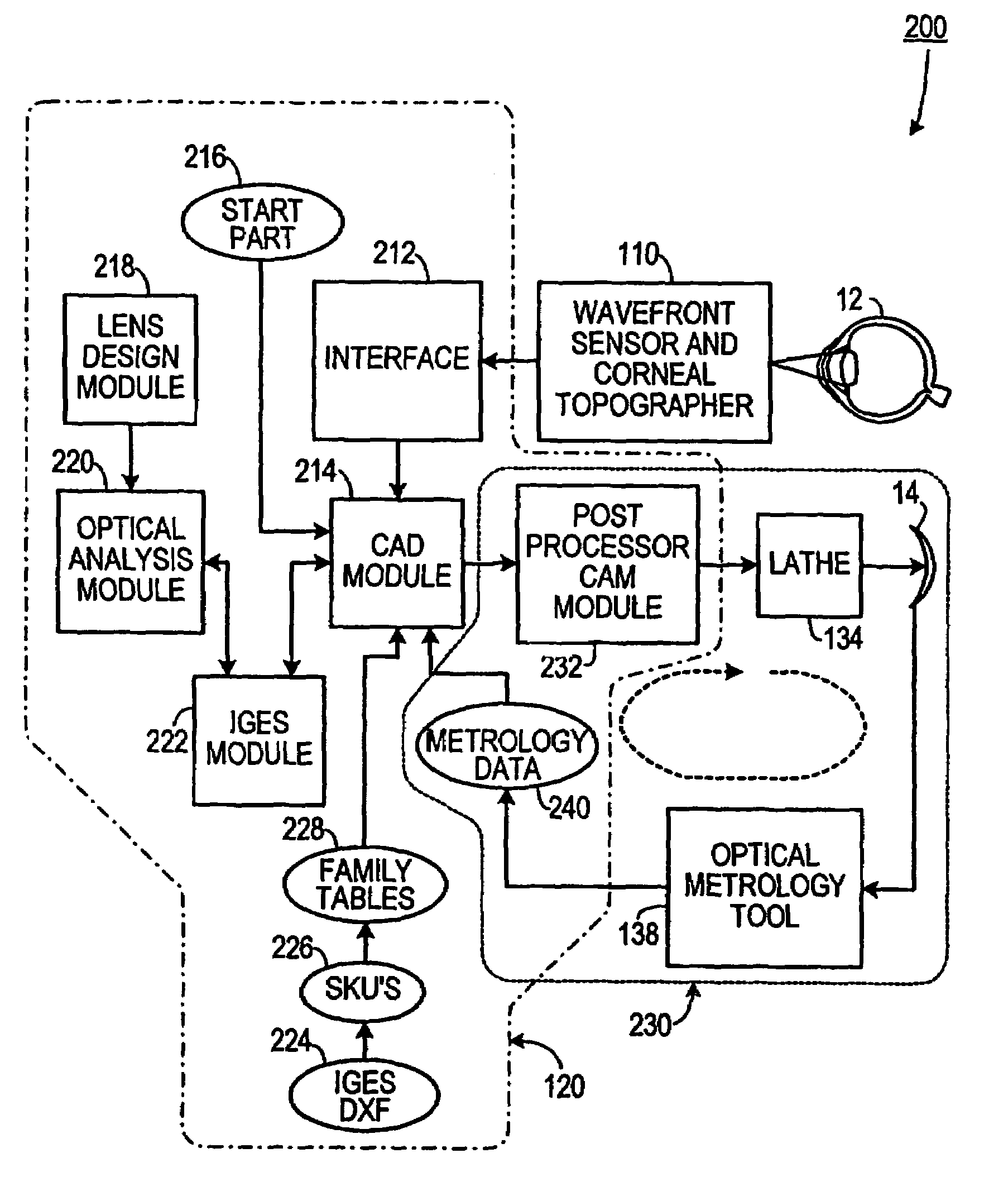

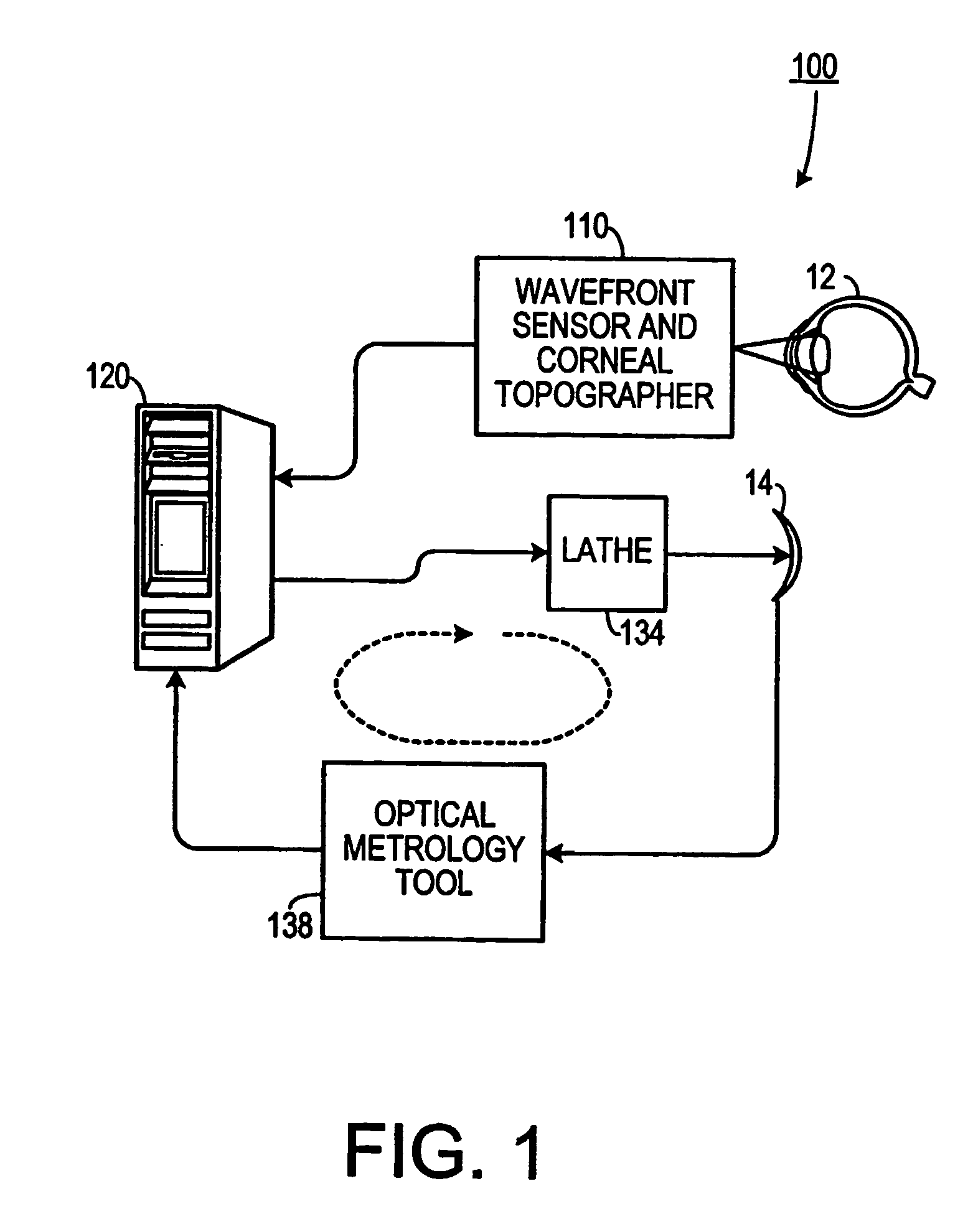

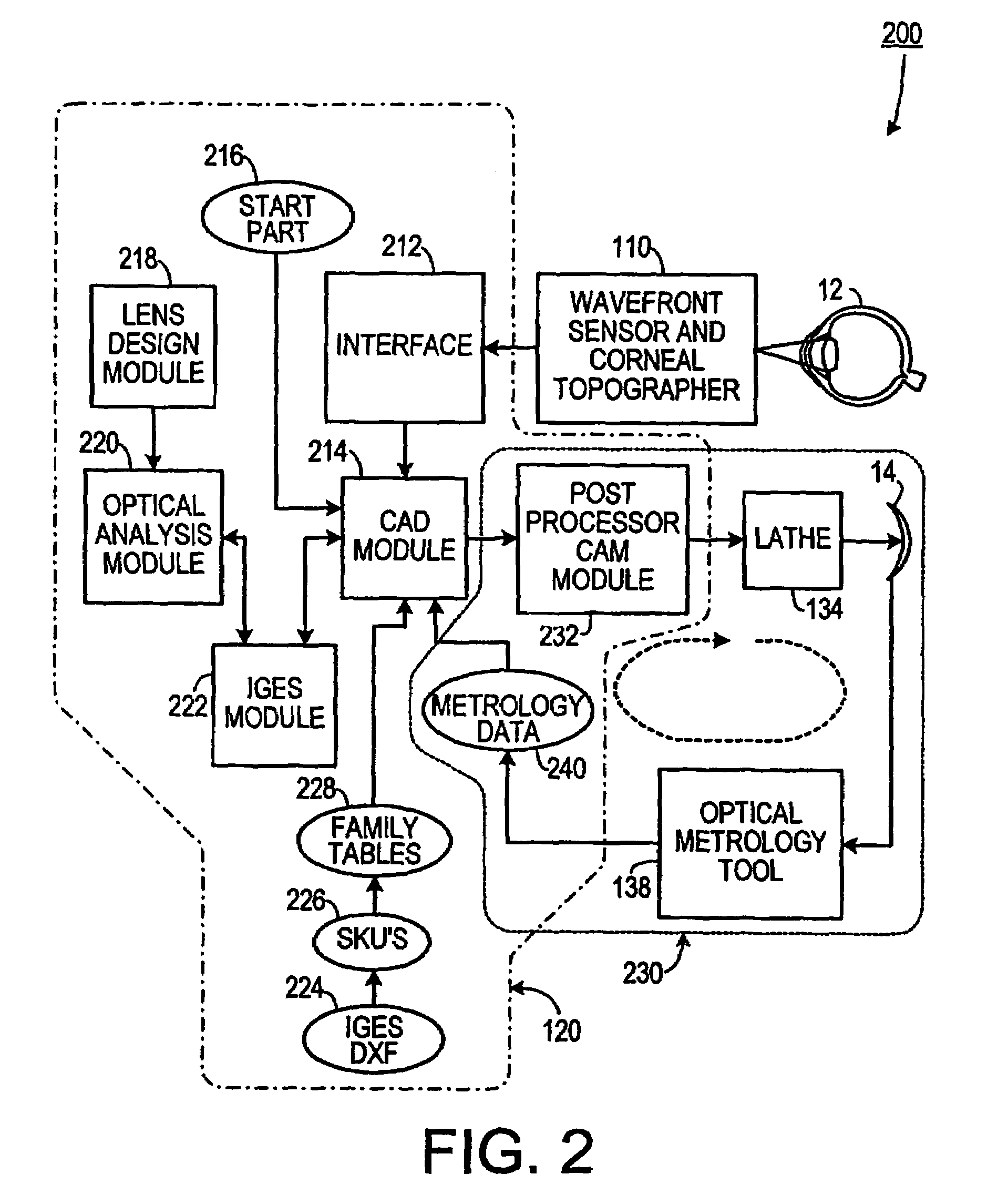

Automatic lens design and manufacturing system

InactiveUS7111938B2Easy to correctAberration correctionSpectales/gogglesEye surgeryCamera lensIntraocular lens

The present invention provides a method for designing and making a customized ophthalmic lens, such as a contact lens or an intraocular lens, capable of correcting high-order aberrations of an eye. The posterior surface of the customized contact lens is designed to accommodate the corneal topography of an eye. The design of the customized ophthalmic lens is evaluated and optimized in an optimizing routine using a computational model eye that reproduces the aberrations and corneal topography of an eye. The present invention also provides a system and method for characterizing the optical metrology of a customized ophthalmic lens that is designed to correct aberrations of an eye. Furthermore, the present invention provides a business model and method for placing an order for a pair of customized ophthalmic lenses.

Owner:ALCON INC

Optimized model and parameter selection for optical metrology

A profile model for use in optical metrology of structures in a wafer is selected based on a template having one or more parameters including characteristics of process and modeling attributes associated with a structure in a wafer. The process includes performing a profile modeling process to generate a profile model of a wafer structure based on a template having one or more parameters including characteristics of process and modeling attributes. The profile model includes a set of geometric parameters associated with the dimensions of the structure. The generated profile model may further be tested against termination criteria and the one or more parameters modified. The process of performing a modeling process to generate a profile model and testing the generated profile model may be repeated until the termination criteria are met.

Owner:TOKYO ELECTRON US HOLDINGS INC

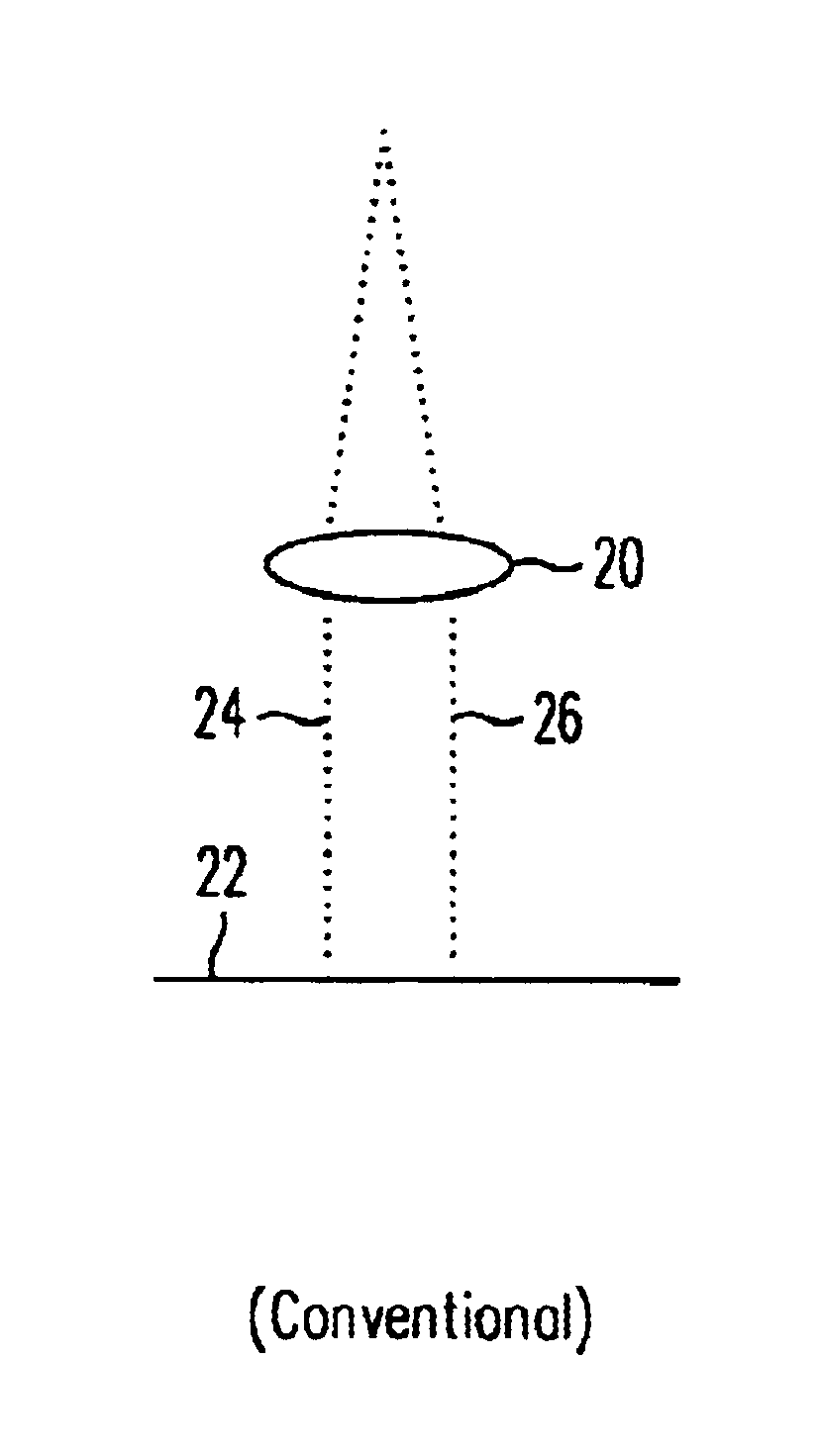

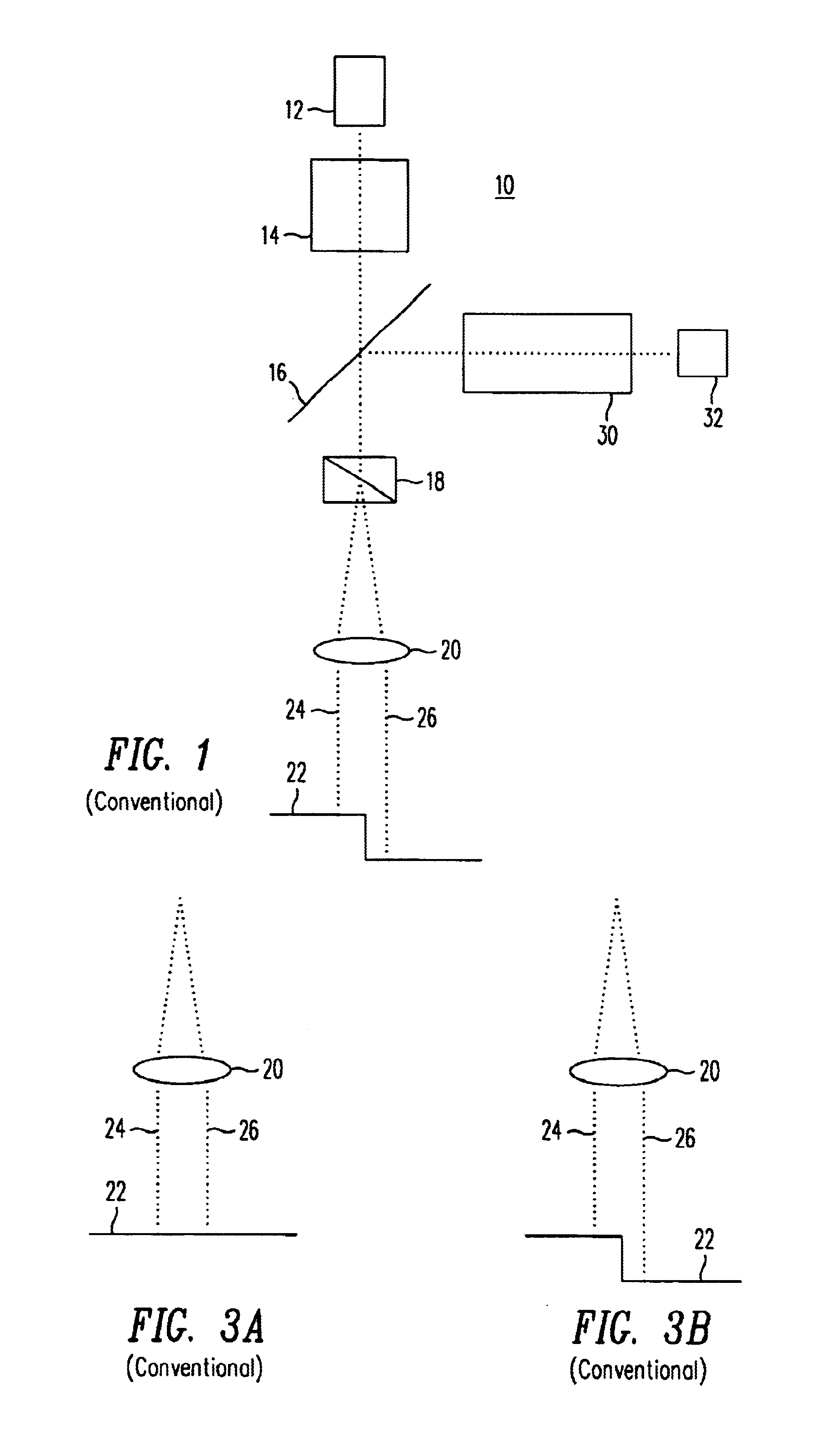

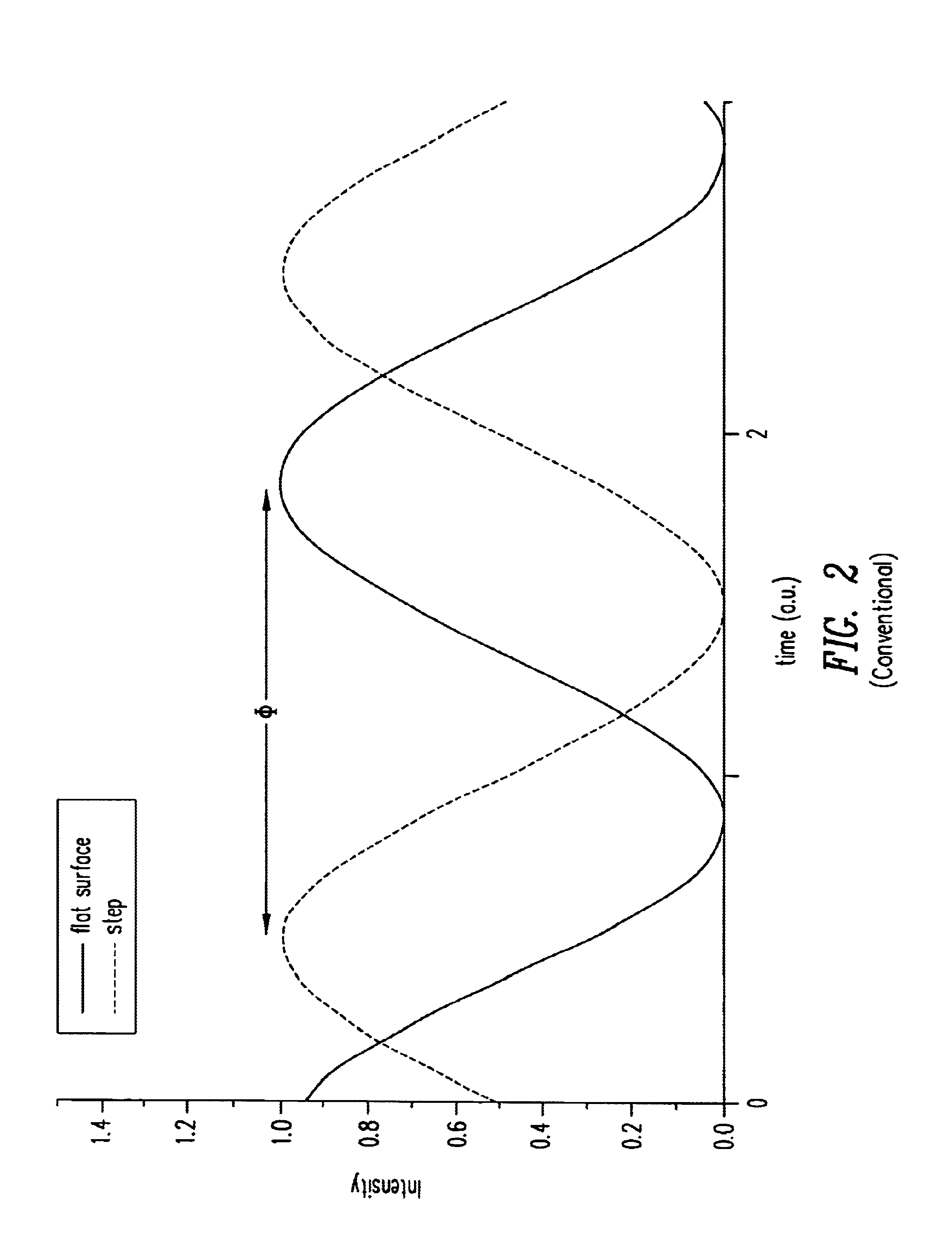

Optical metrology system with combined interferometer and ellipsometer

An interferometer and ellipsometer are combined in a metrology tool to measure the step height of a sample, which may include transparent layers. The metrology tool includes a shared light source that provides a light beam for an interferometer and a light beam for an ellipsometer, interferometer optics which direct the light beam for an interferometer to reflect off of a sample and ellipsometer optics which direct the light beam for an ellipsometer to reflect off a sample, and a detector element for receiving both the reflected light beam for an interferometer and the light beam for an ellipsometer. The light source may produce a single beam that is split into an interferometer and an ellipsometer beam with a beam splitter. In another embodiment, the interferometer and ellipsometer may share at least one of a polarizer, analyzer, or detector element.

Owner:NANOMETRICS

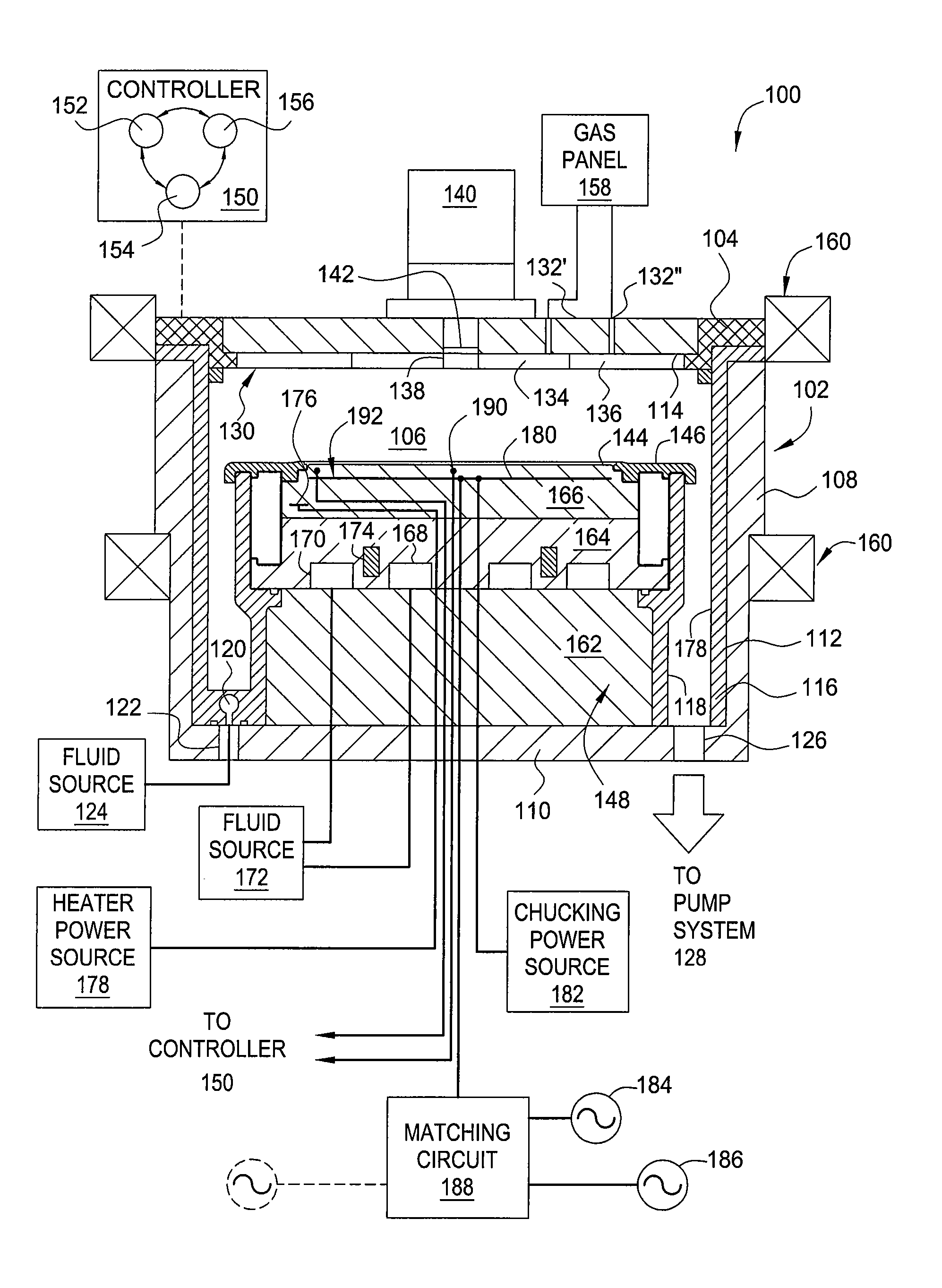

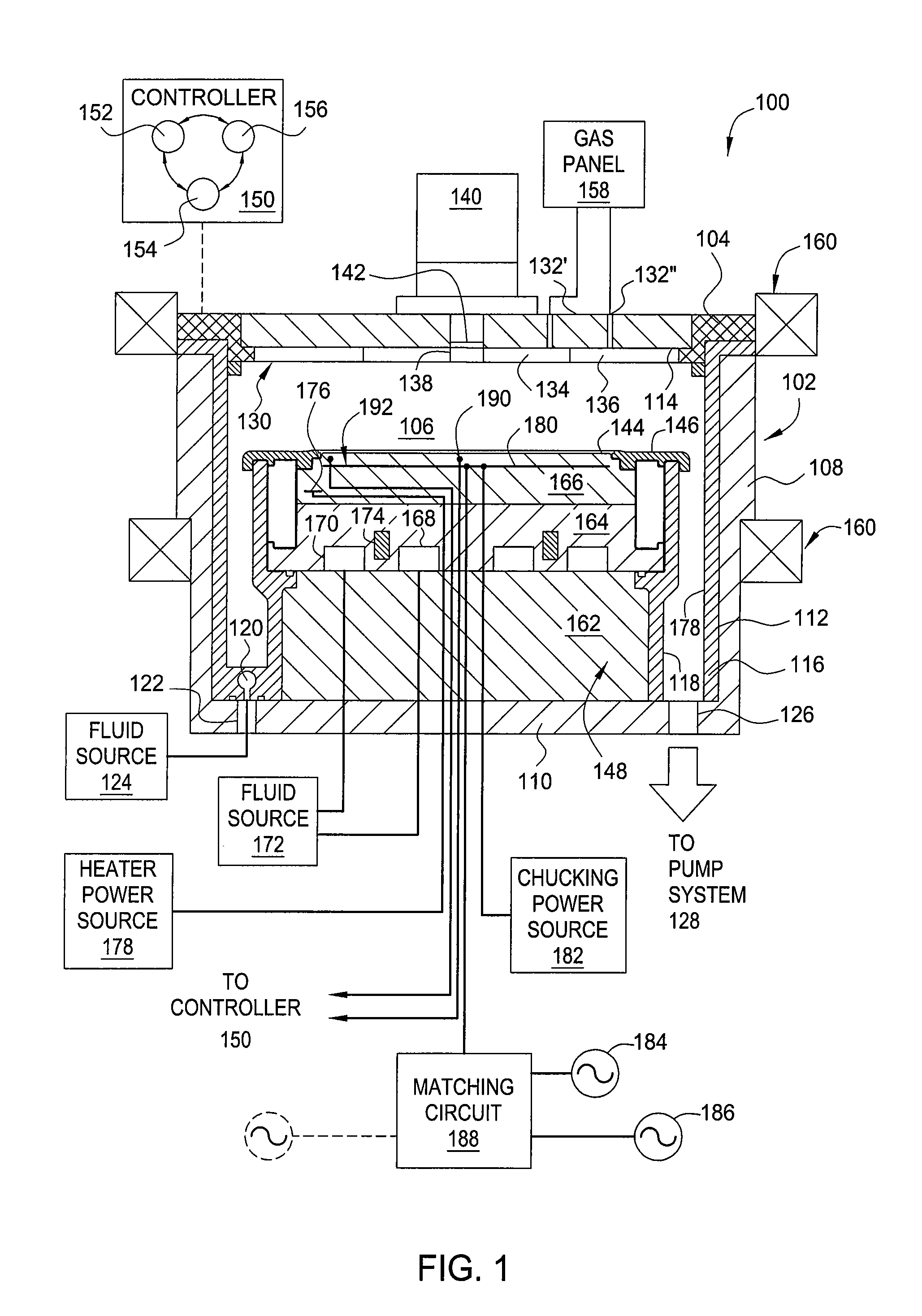

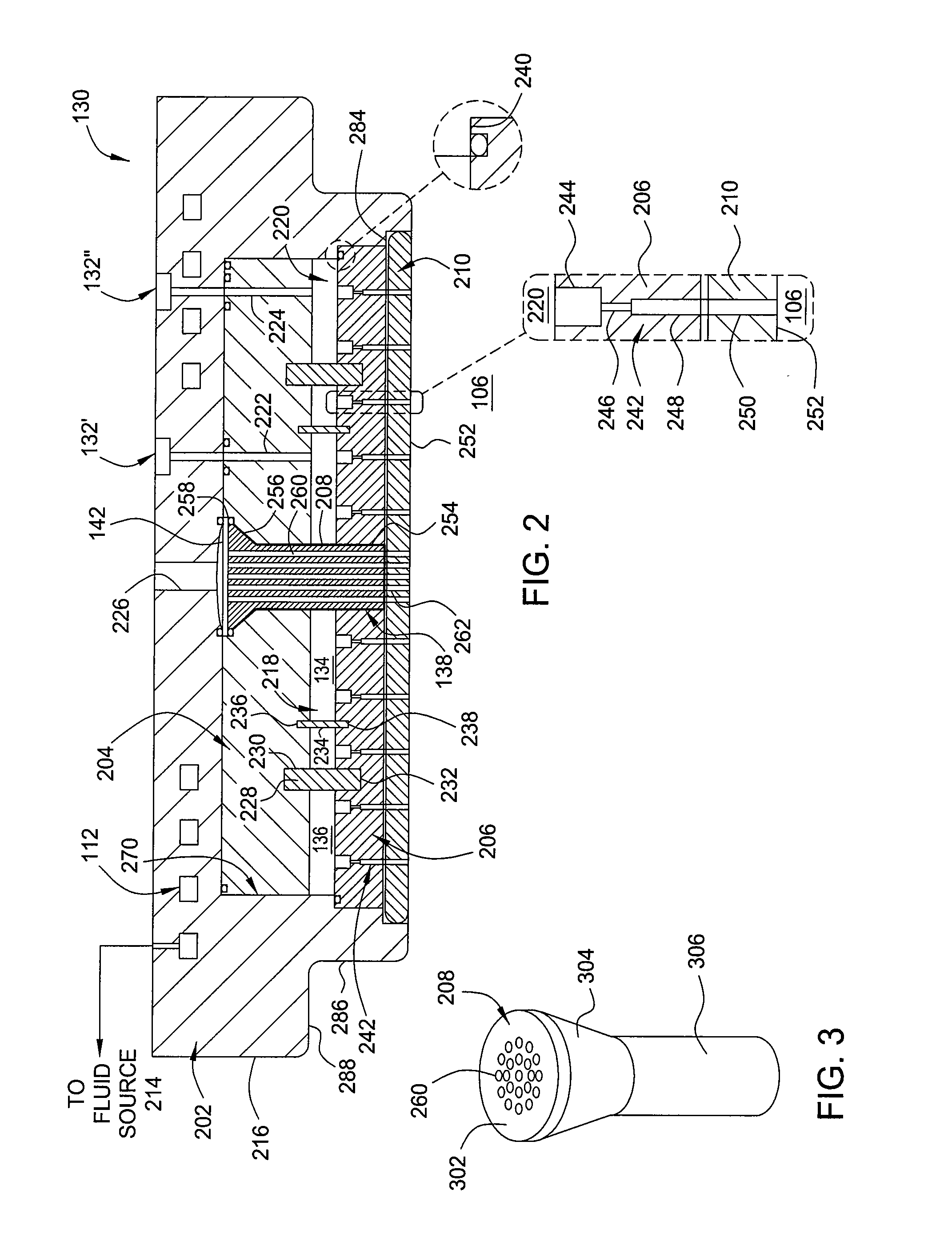

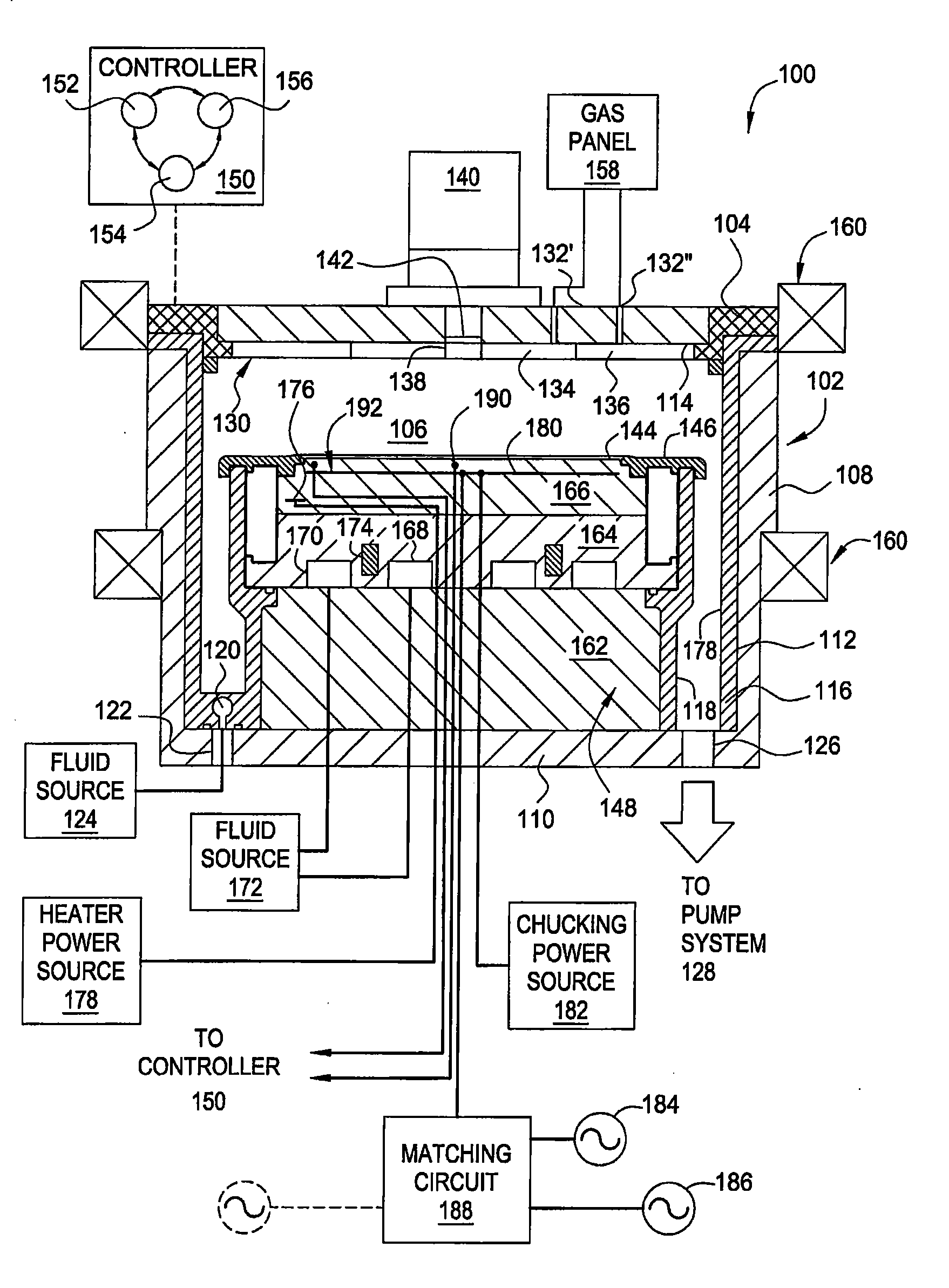

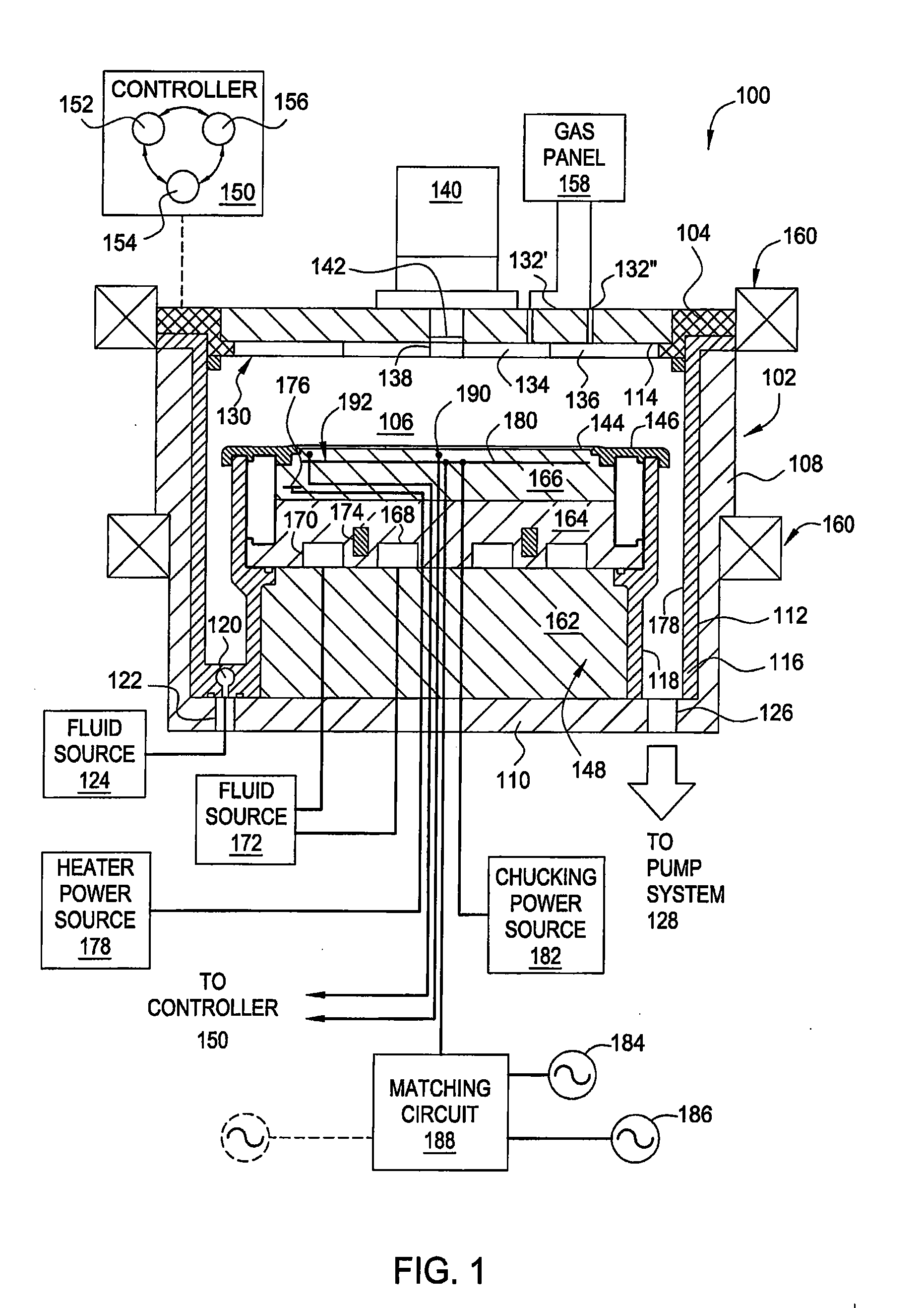

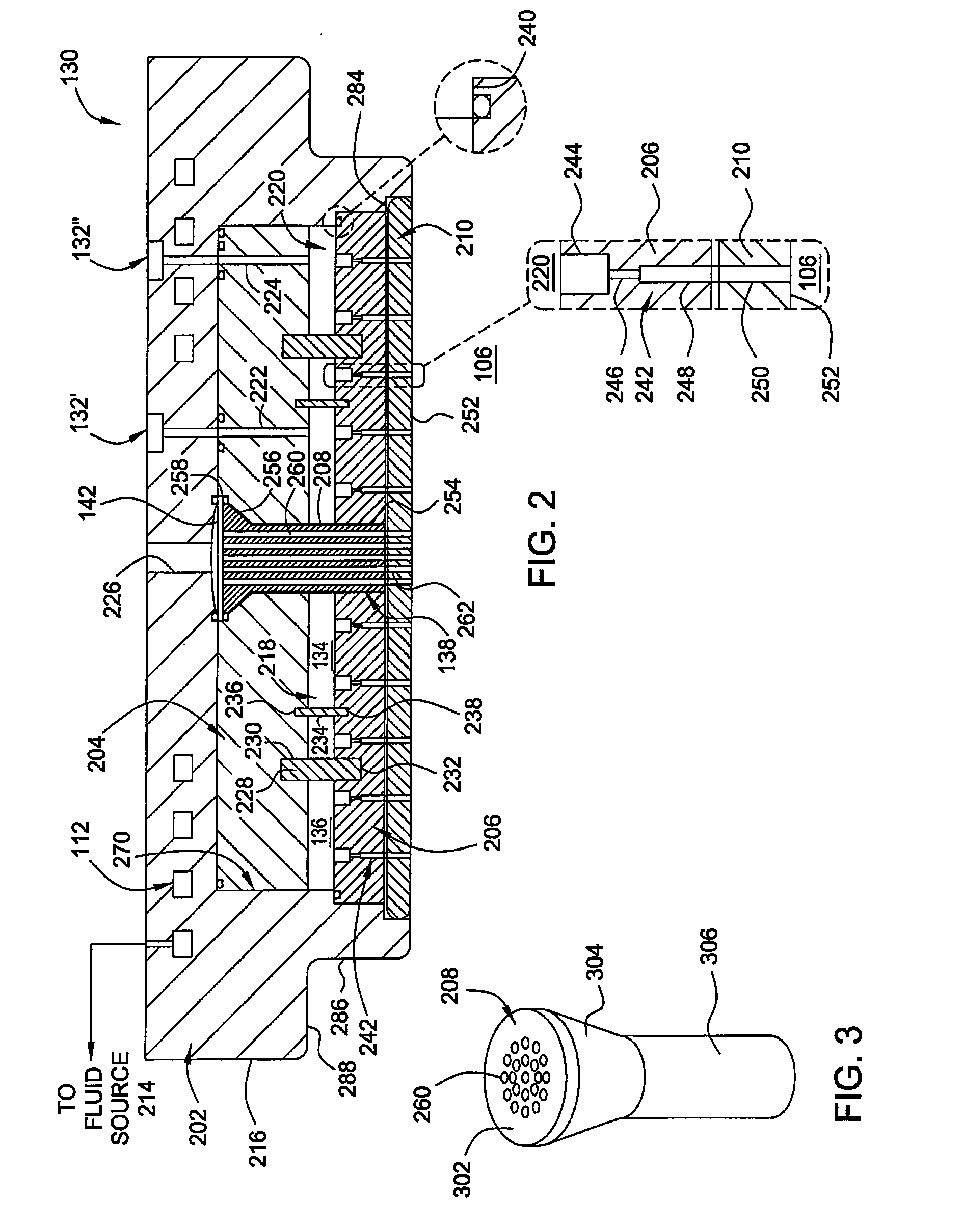

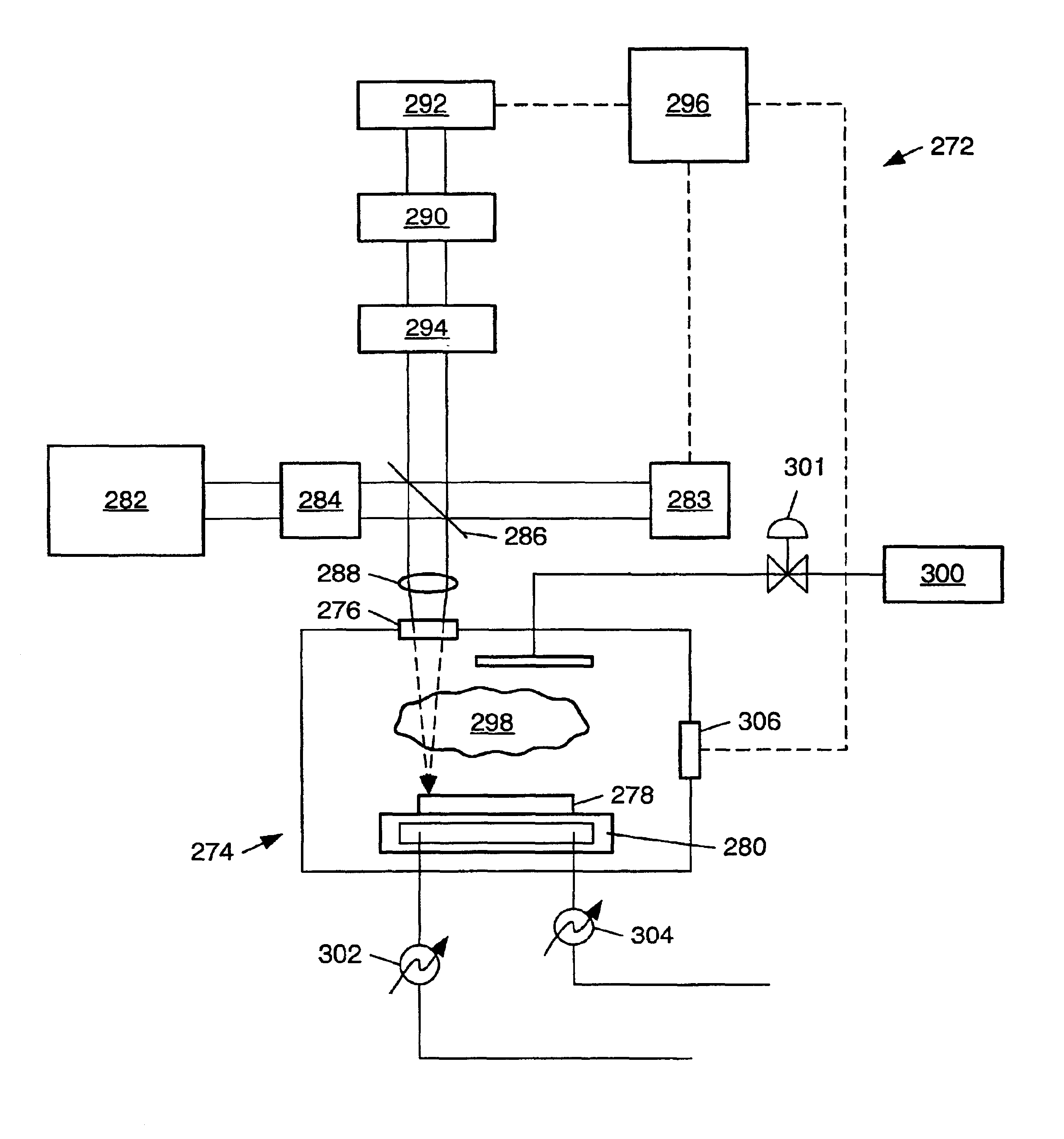

Apparatus for etching high aspect ratio features

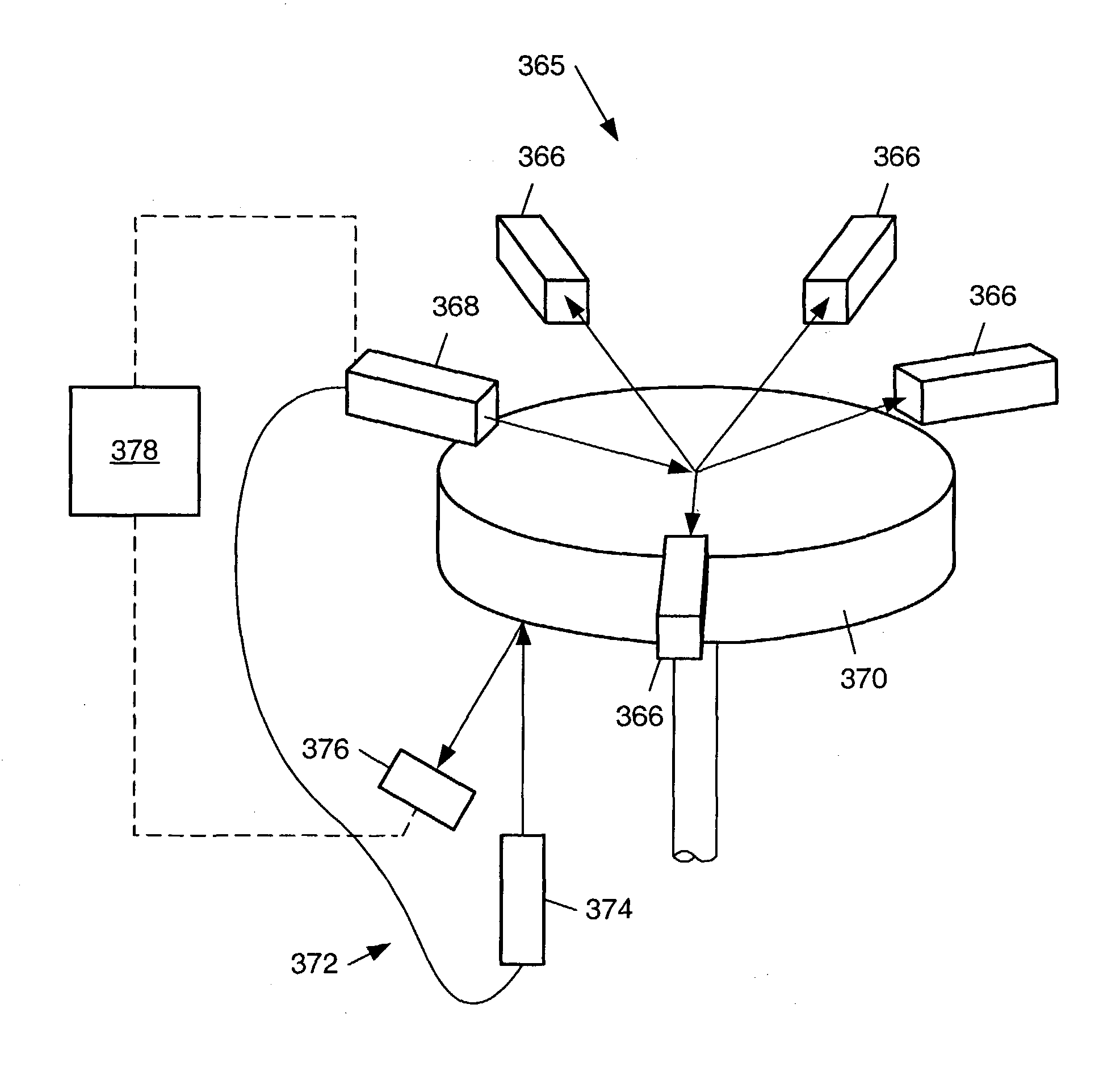

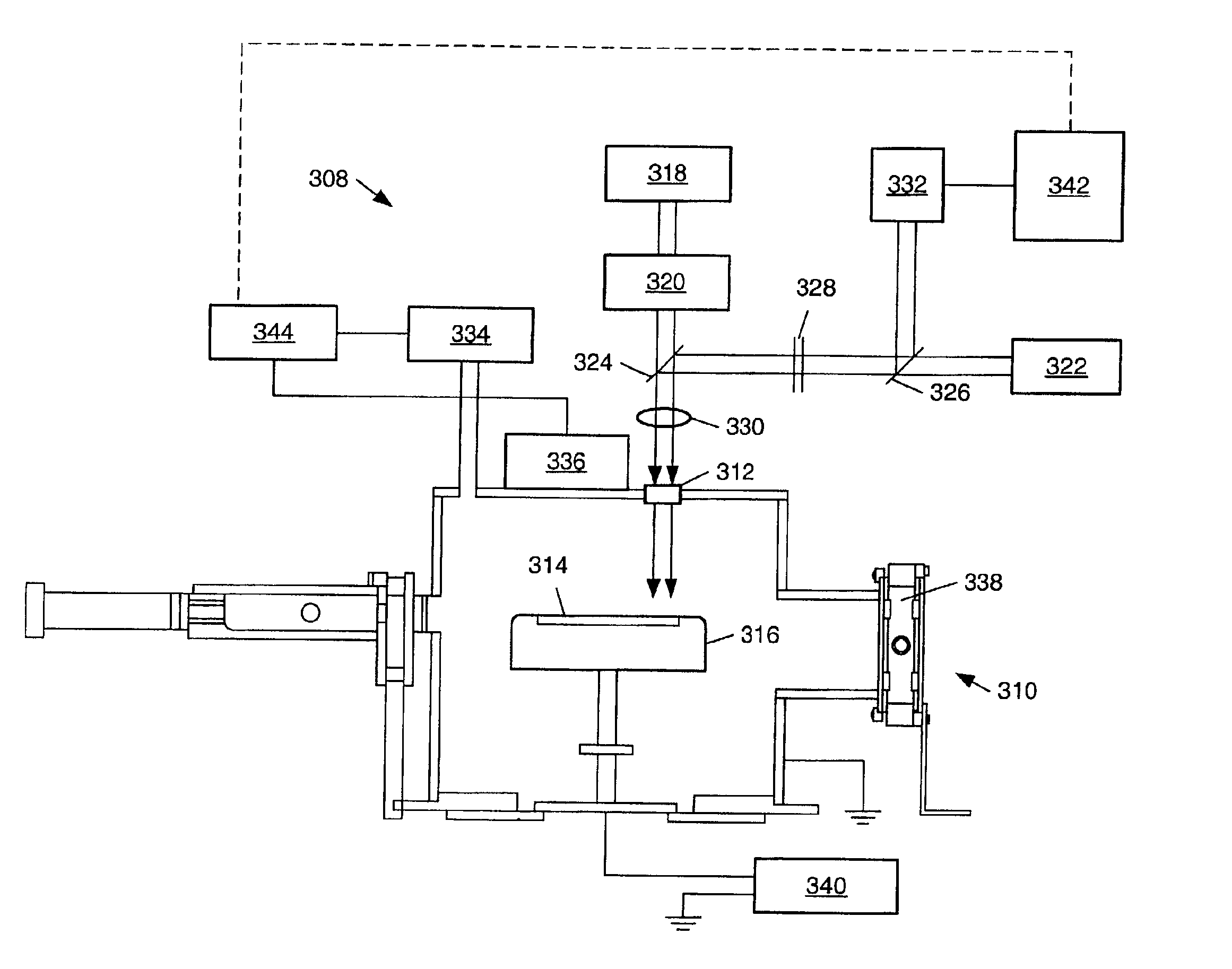

InactiveUS20070256785A1Improve performanceHigh aspect ratioElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringOptical metrology

Embodiments of the invention provide a method and apparatus, such as a processing chamber, suitable for etching high aspect ratio features. Other embodiments include a showerhead assembly for use in the processing chamber. In one embodiment, a processing chamber includes a chamber body having a showerhead assembly and substrate support disposed therein. The showerhead assembly includes at least two fluidly isolated plenums, a region transmissive to an optical metrology signal, and a plurality of gas passages formed through the showerhead assembly fluidly coupling the plenums to the interior volume of the chamber body.

Owner:APPLIED MATERIALS INC

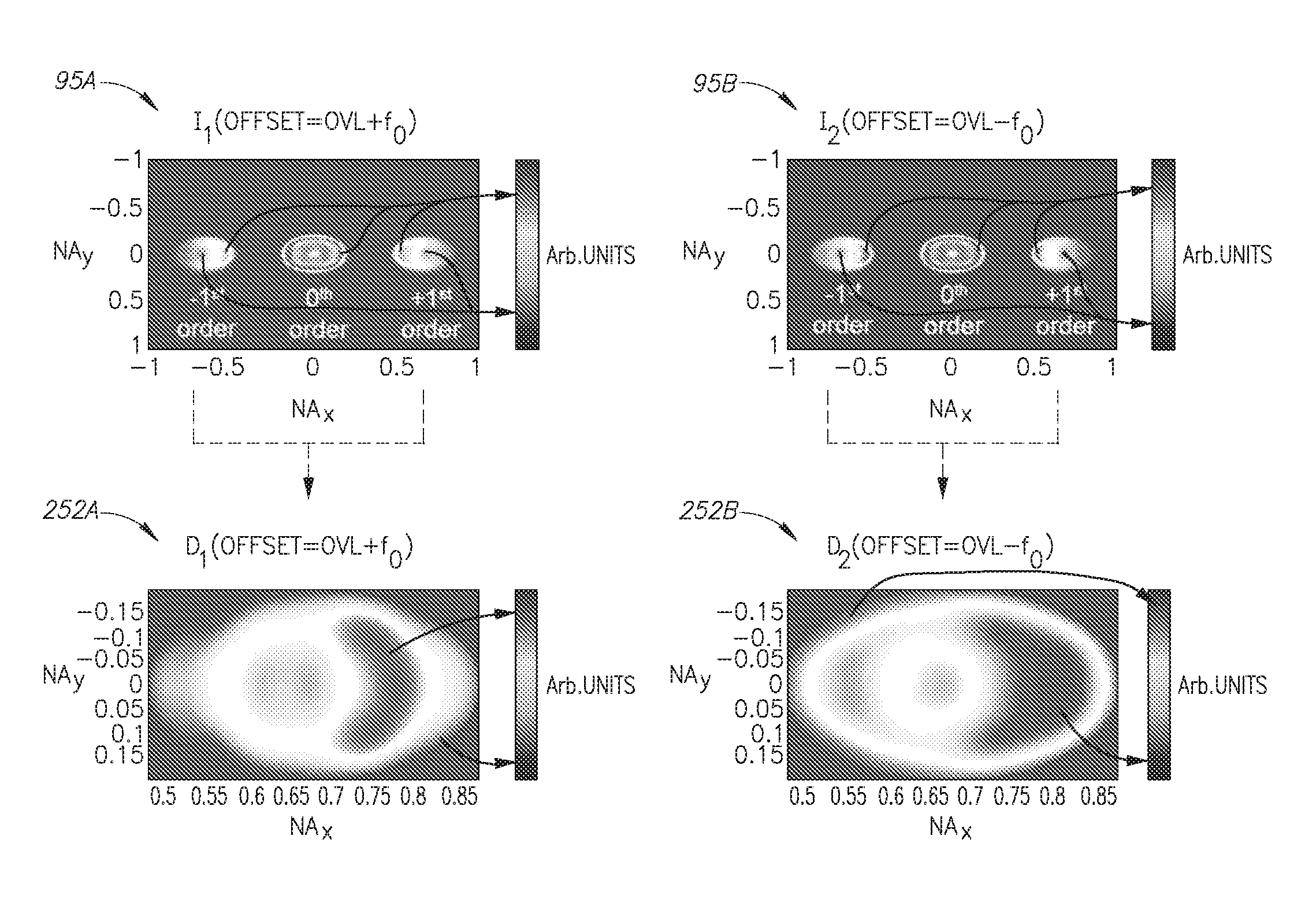

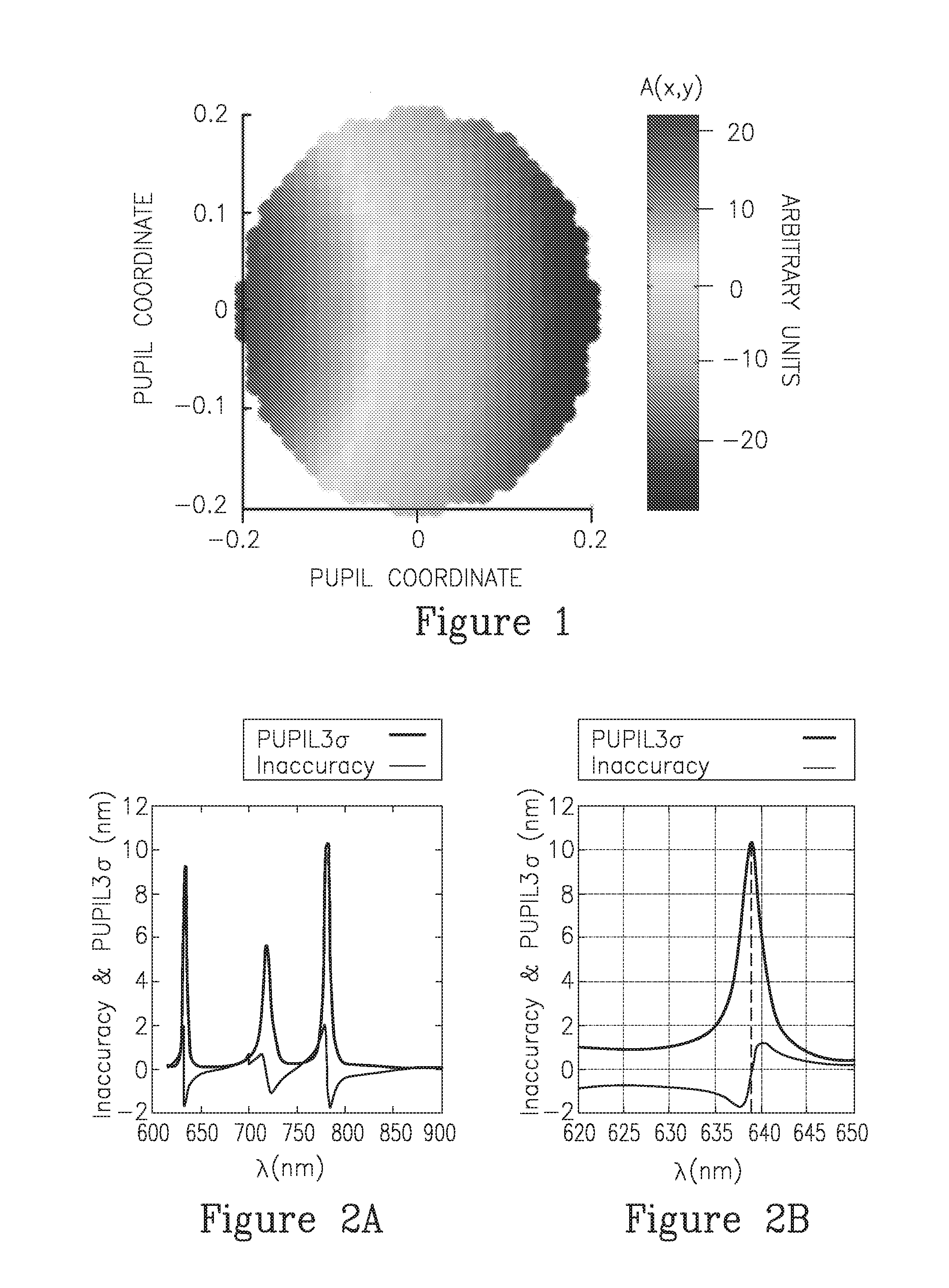

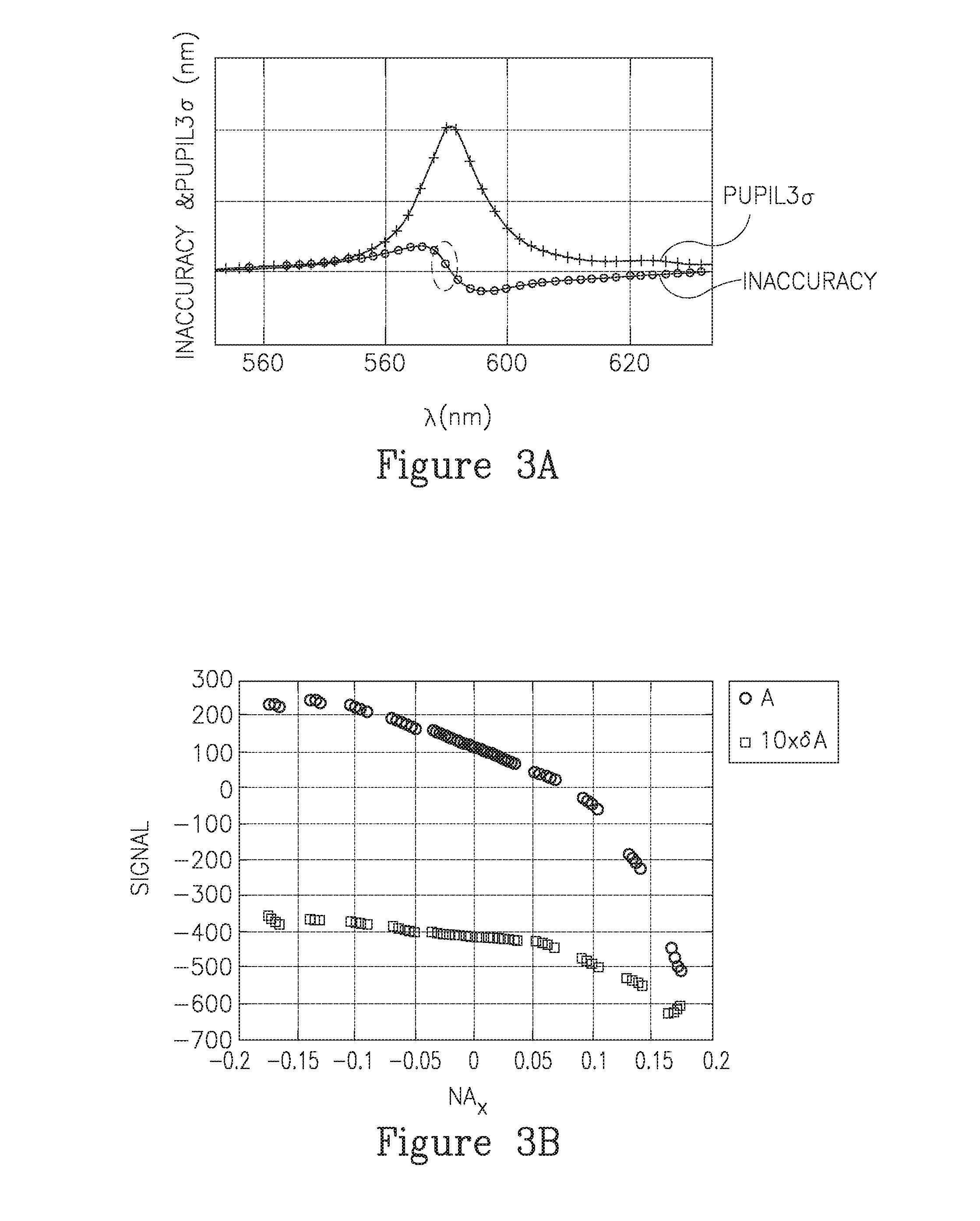

Methods of analyzing and utilizing landscapes to reduce or eliminate inaccuracy in overlay optical metrology

ActiveUS20160313658A1Limit scopeSemiconductor/solid-state device testing/measurementPhotomechanical apparatusOptical metrologyMeasurement precision

Methods are provided for deriving a partially continuous dependency of metrology metric(s) on recipe parameter(s), analyzing the derived dependency, determining a metrology recipe according to the analysis, and conducting metrology measurement(s) according to the determined recipe. The dependency may be analyzed in form of a landscape such as a sensitivity landscape in which regions of low sensitivity and / or points or contours of low or zero inaccuracy are detected, analytically, numerically or experimentally, and used to configure parameters of measurement, hardware and targets to achieve high measurement accuracy. Process variation is analyzed in terms of its effects on the sensitivity landscape, and these effects are used to characterize the process variation further, to optimize the measurements and make the metrology both more robust to inaccuracy sources and more flexible with respect to different targets on the wafer and available measurement conditions.

Owner:KLA TENCOR TECH CORP

Selecting a profile model for use in optical metrology using a machine learining system

InactiveUS20050192914A1Photomechanical apparatusDigital computer detailsEngineeringOptical metrology

A profile model can be selected for use in examining a structure formed on a semiconductor wafer using optical metrology by obtaining an initial profile model having a set of profile parameters. A machine learning system is trained using the initial profile model. A simulated diffraction signal is generated for an optimized profile model using the trained machine learning system, where the optimized profile model has a set of profile parameters with the same or fewer profile parameters than the initial profile model. A determination is made as to whether the one or more termination criteria are met. If the one or more termination criteria are met, the optimized profile model is modified and another simulated diffraction signal is generated using the same trained machine learning system.

Owner:TOKYO ELECTRON LTD

Optimized model and parameter selection for optical metrology

A profile model for use in optical metrology of structures in a wafer is selected based on a template having one or more parameters including characteristics of process and modeling attributes associated with a structure in a wafer. The process includes performing a profile modeling process to generate a profile model of a wafer structure based on a template having one or more parameters including characteristics of process and modeling attributes. The profile model includes a set of geometric parameters associated with the dimensions of the structure. The generated profile model may further be tested against termination criteria and the one or more parameters modified. The process of performing a modeling process to generate a profile model and testing the generated profile model may be repeated until the termination criteria are met.

Owner:TOKYO ELECTRON US HOLDINGS INC

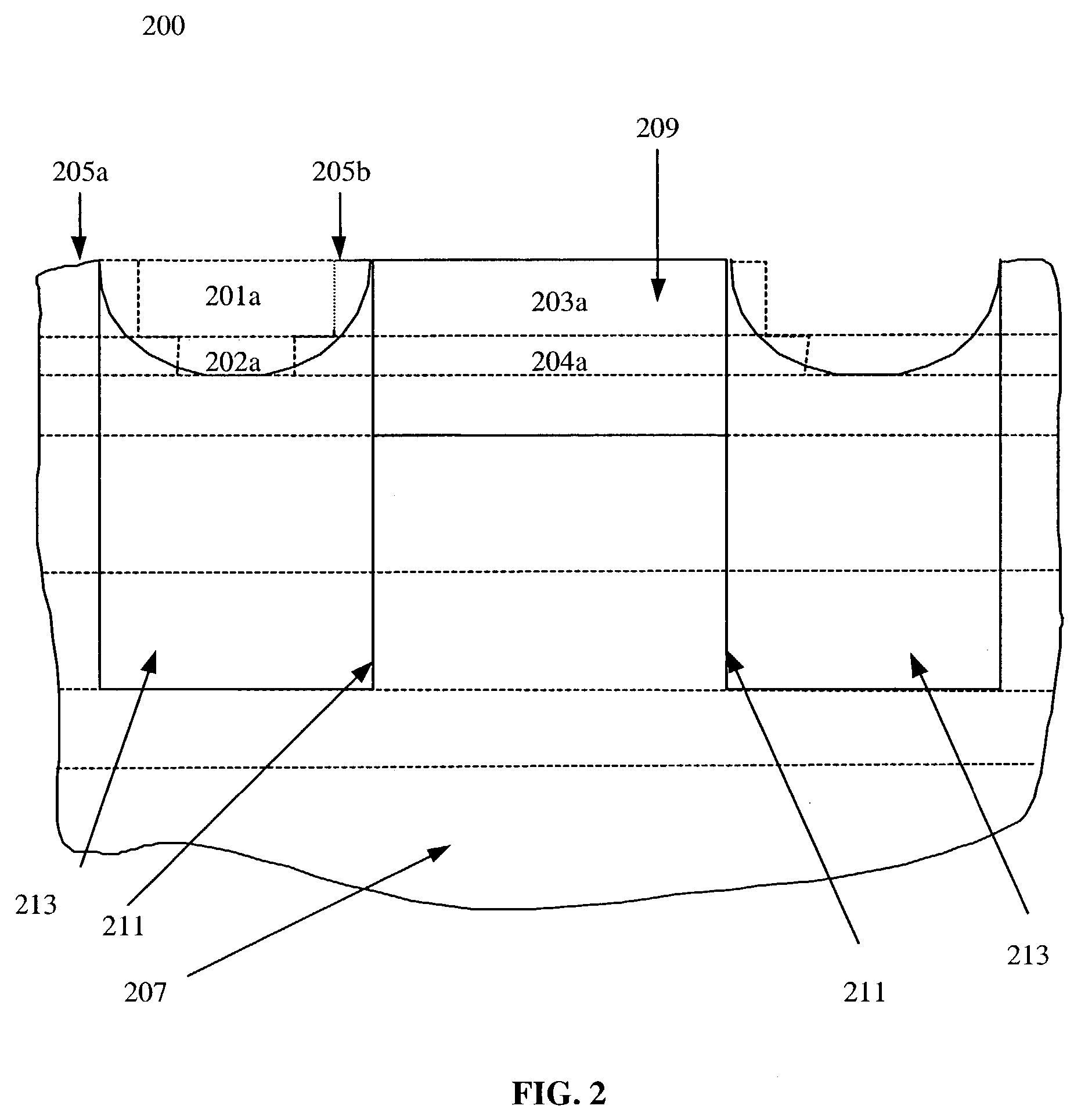

Model optimization for structures with additional materials

ActiveUS7072049B2Scattering properties measurementsOptically investigating flaws/contaminationMulti materialEngineering

A wafer structure profile is modeled by determining one or more termination criteria. A determination is made as to whether a wafer structure includes at least one layer having three or more materials alone a line within the at least one layer. An optical metrology model for the wafer structure is created, where three or more materials are incorporated in the model for the at least one layer having three or more materials. A set of diffraction signals is simulated using the optical metrology model. The set of simulated diffraction signals and a set of diffraction signals measured off of the wafer structure are used to determine if the one or more termination criteria are met. The optical metrology model is modified until the one or more termination criteria are met.

Owner:TOKYO ELECTRON LTD

Methods and systems for determining a presence of defects and a thin film characteristic of a specimen

InactiveUS7106425B1Speed up the processShorten the timeScattering properties measurementsOptically investigating flaws/contaminationMeasurement deviceEngineering

Owner:KLA TENCOR TECH CORP

Methods and systems for determining a critical dimension and overlay of a specimen

InactiveUS7751046B2Speed up the processShorten the timeSemiconductor/solid-state device testing/measurementPolarisation-affecting propertiesMeasurement deviceEngineering

Methods and systems for monitoring semiconductor fabrication processes are provided. A system may include a stage configured to support a specimen and coupled to a measurement device. The measurement device may include an illumination system and a detection system. The illumination system and the detection system may be configured such that the system may be configured to determine multiple properties of the specimen. For example, the system may be configured to determine multiple properties of a specimen including, but not limited to, critical dimension and overlay misregistration. In this manner, a measurement device may perform multiple optical and / or non-optical metrology and / or inspection techniques.

Owner:KLA TENCOR TECH CORP

Apparatus for etching high aspect ratio features

ActiveUS20070256786A1High aspect ratio featureElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringOptical metrology

Embodiments of the invention provide a method and apparatus, such as a processing chamber, suitable for etching high aspect ratio features. Other embodiments include a showerhead assembly for use in the processing chamber. In one embodiment, a processing chamber includes a chamber body having a showerhead assembly and substrate support disposed therein. The showerhead assembly includes at least two fluidly isolated plenums, a region transmissive to an optical metrology signal, and a plurality of gas passages formed through the showerhead assembly fluidly coupling the plenums to the interior volume of the chamber body.

Owner:APPLIED MATERIALS INC

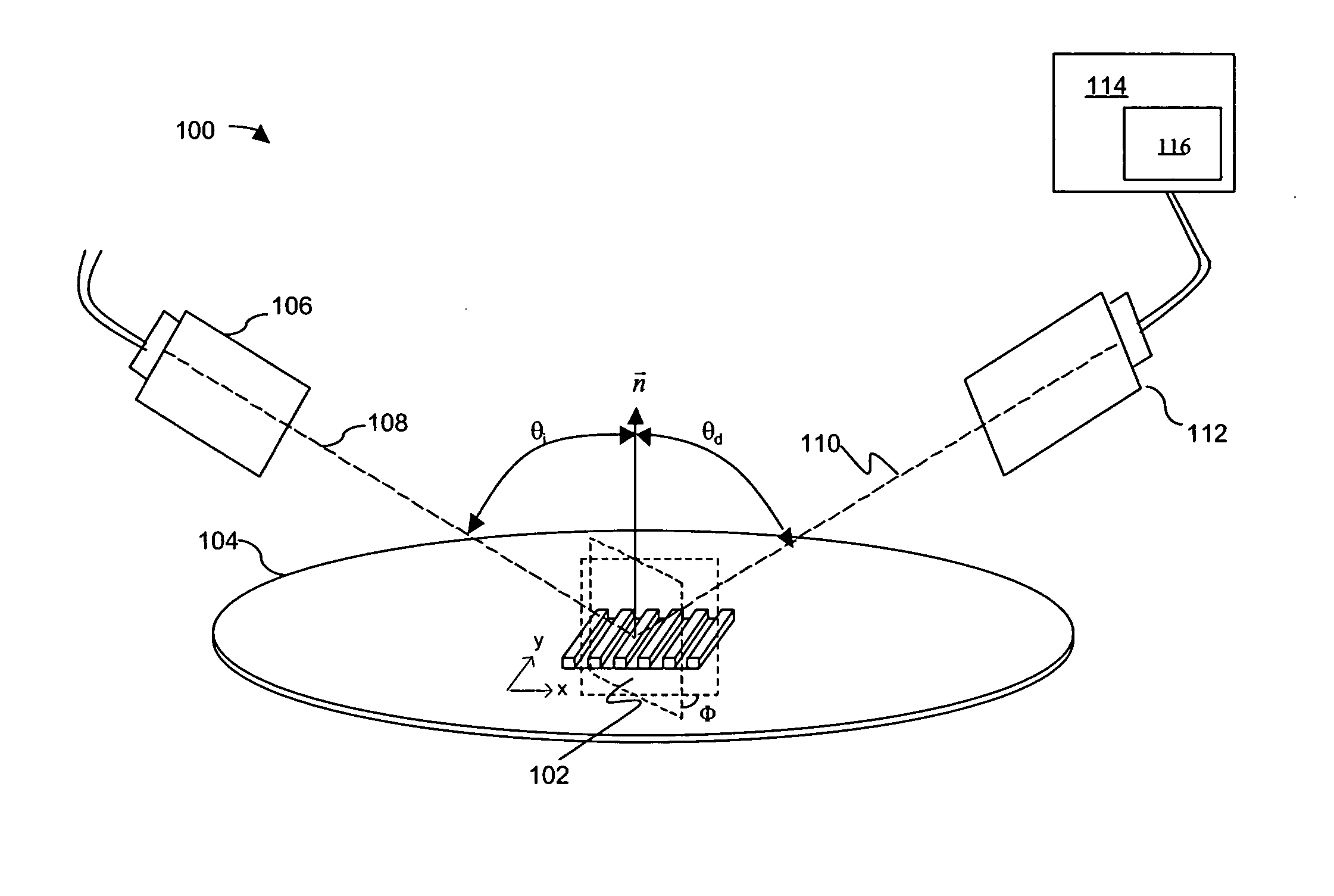

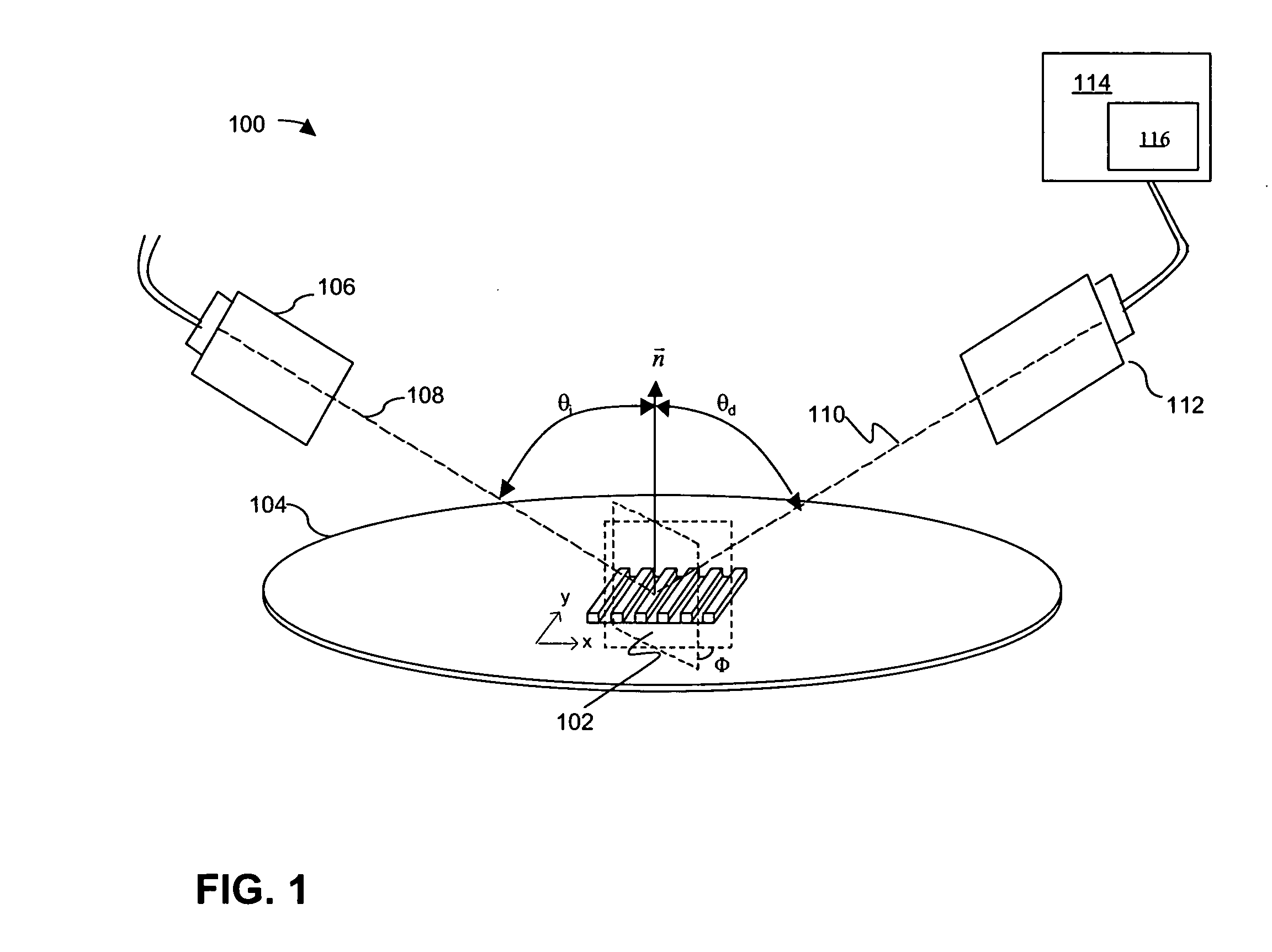

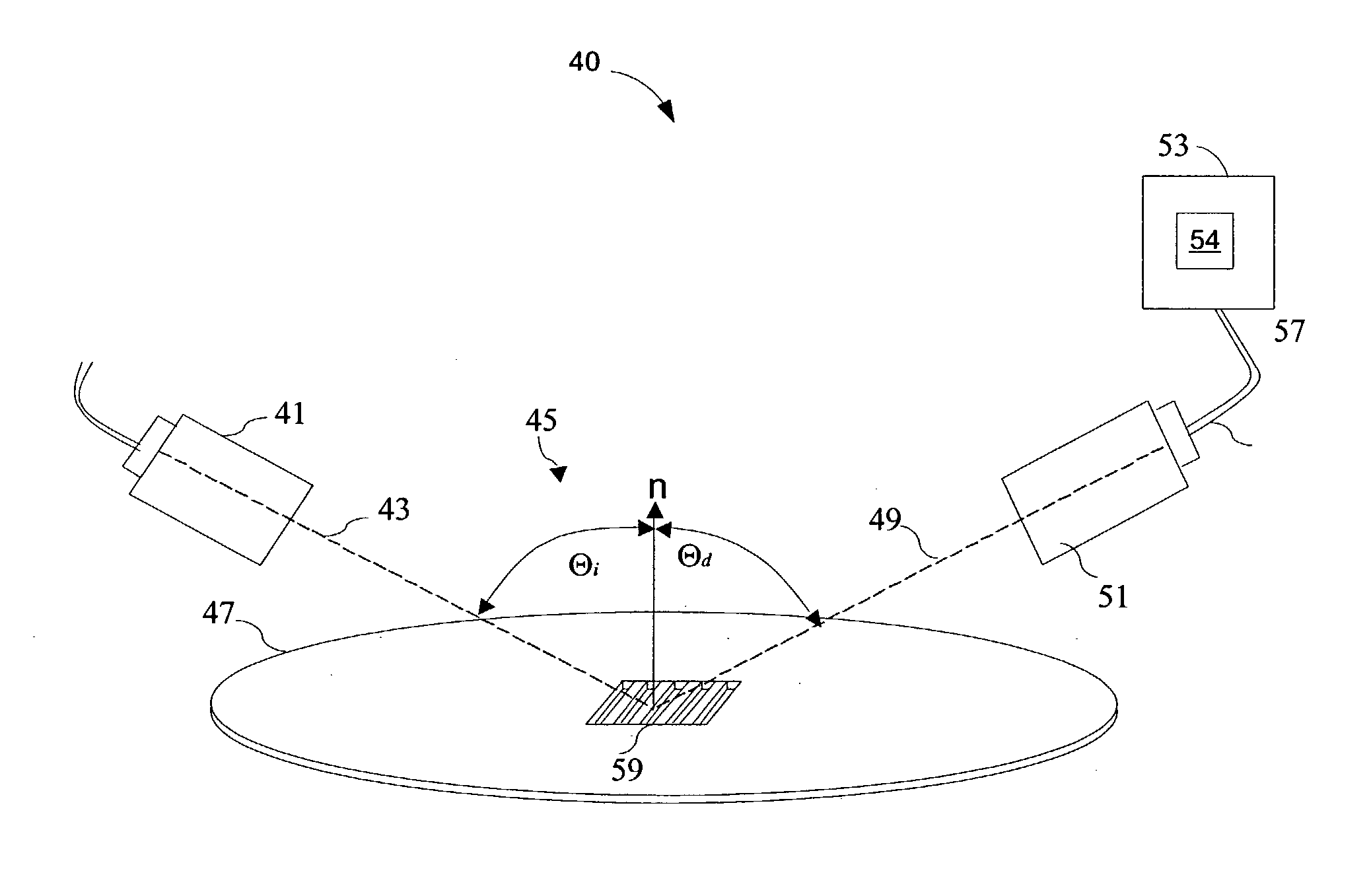

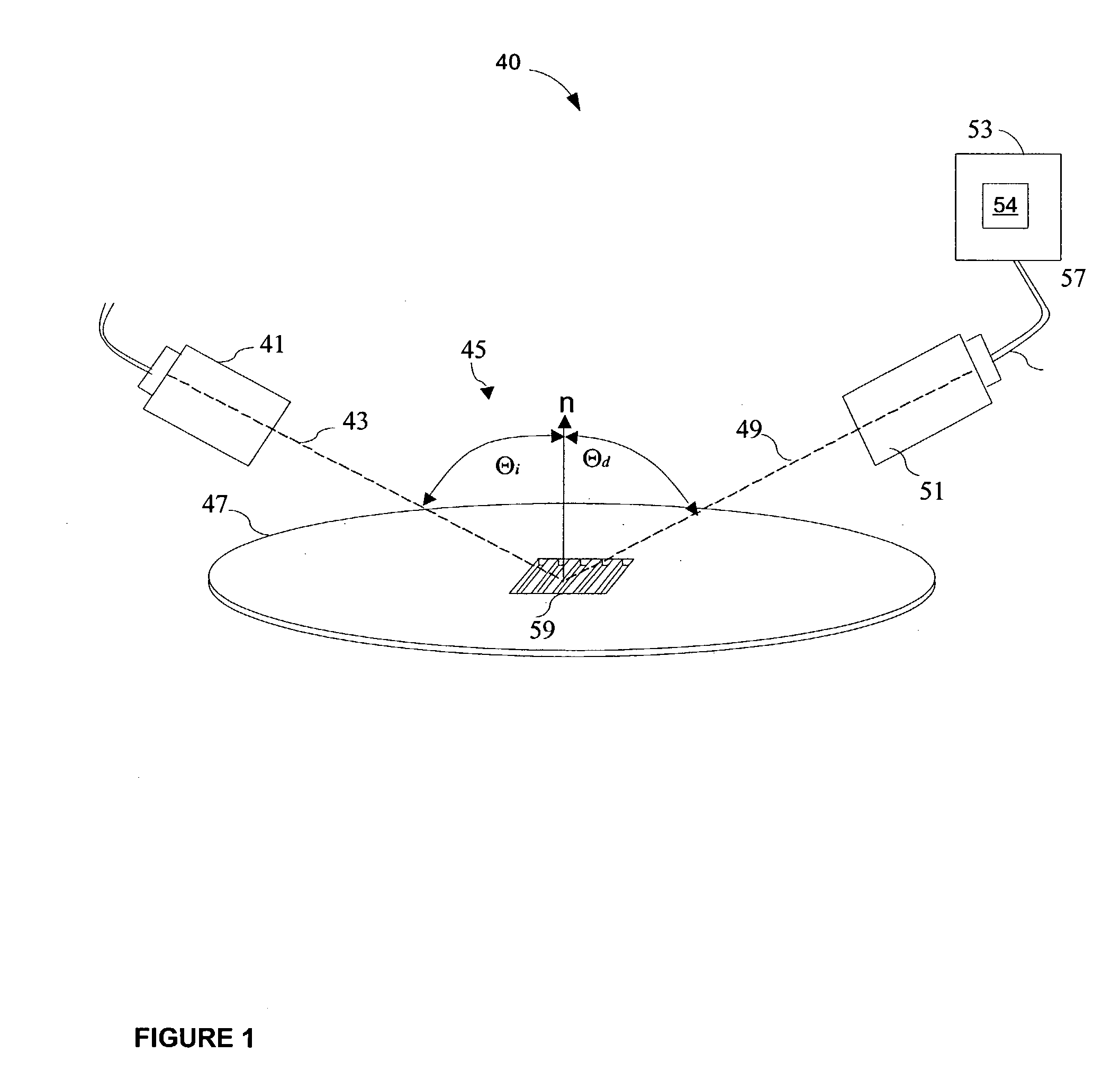

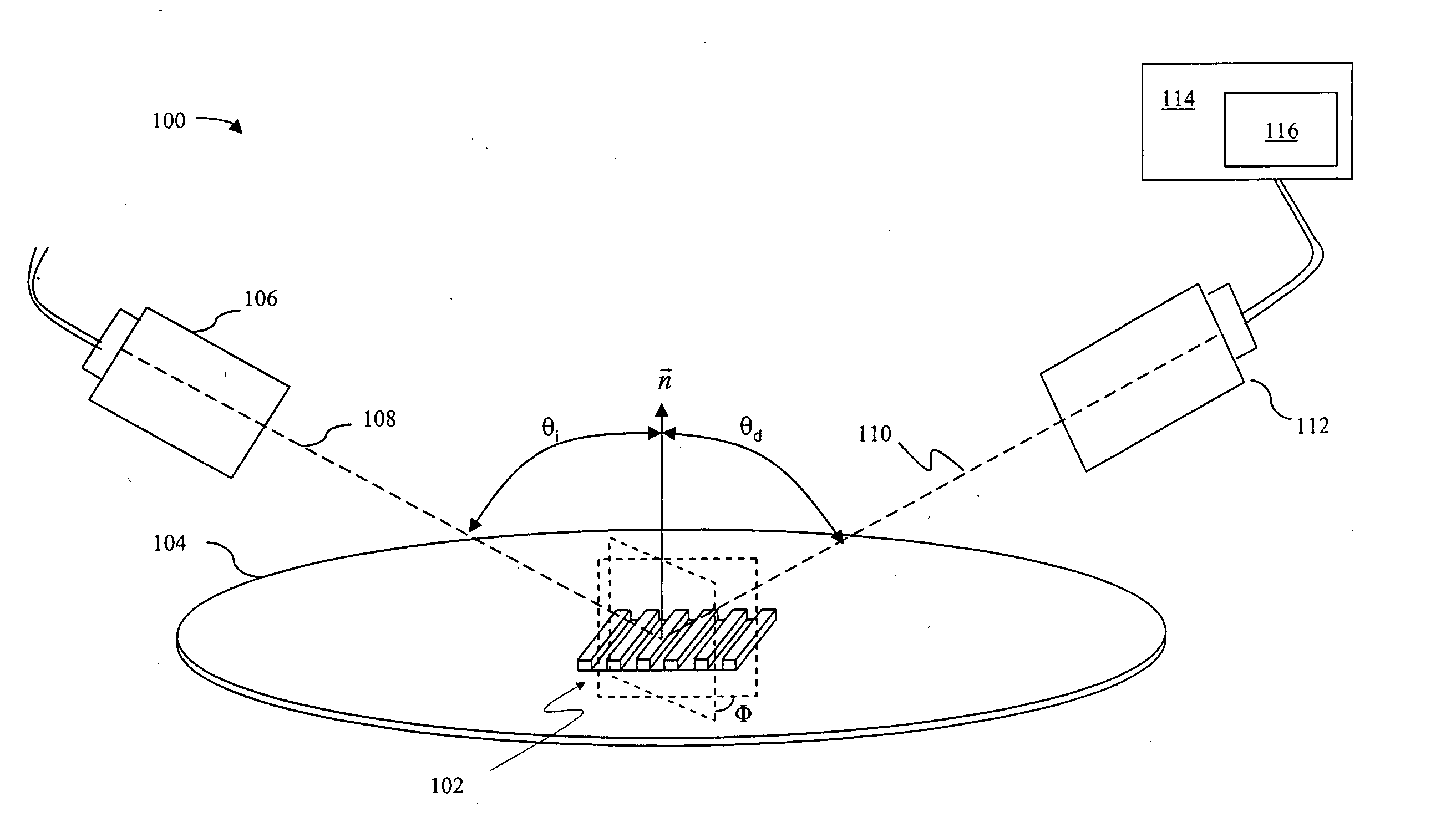

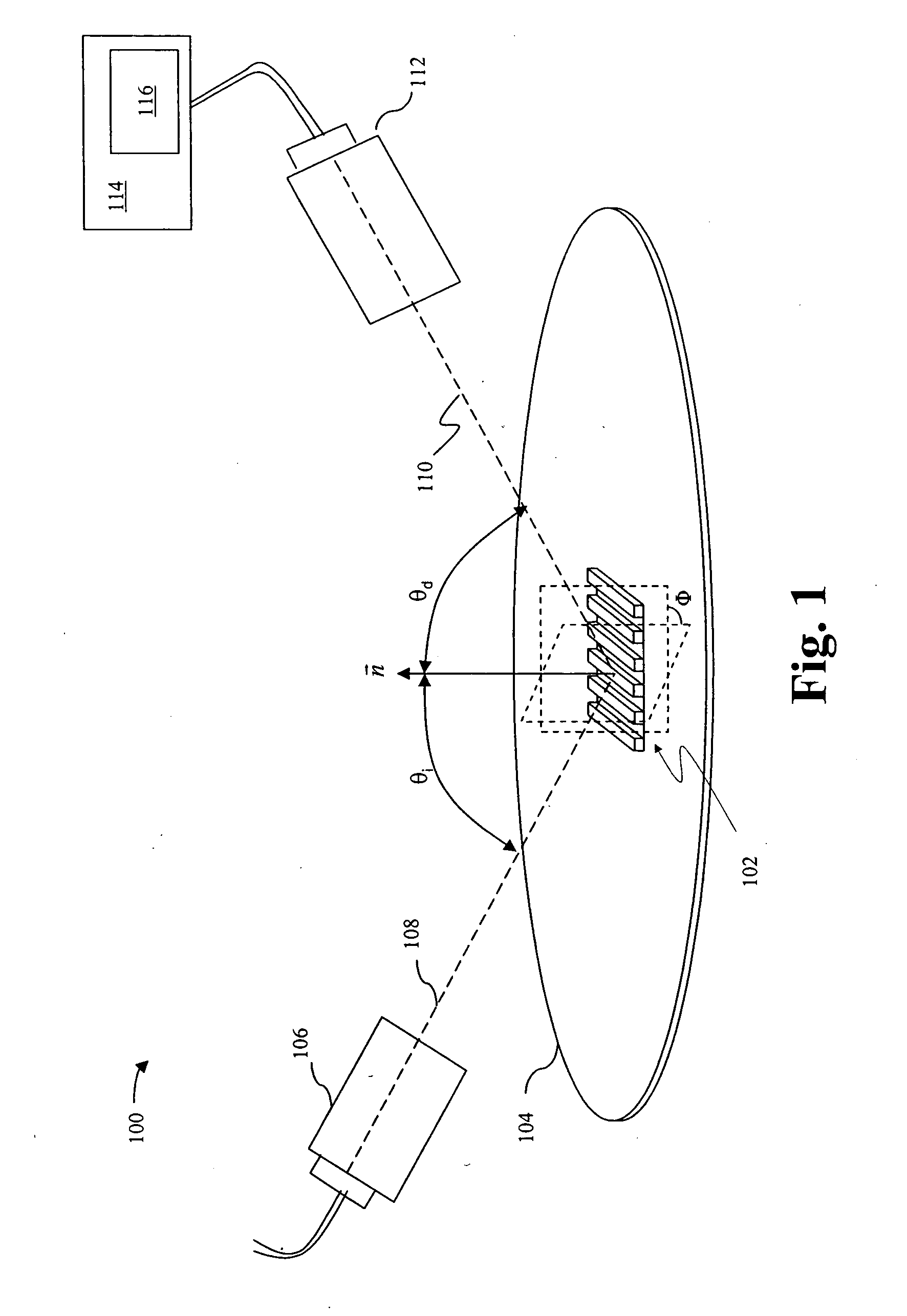

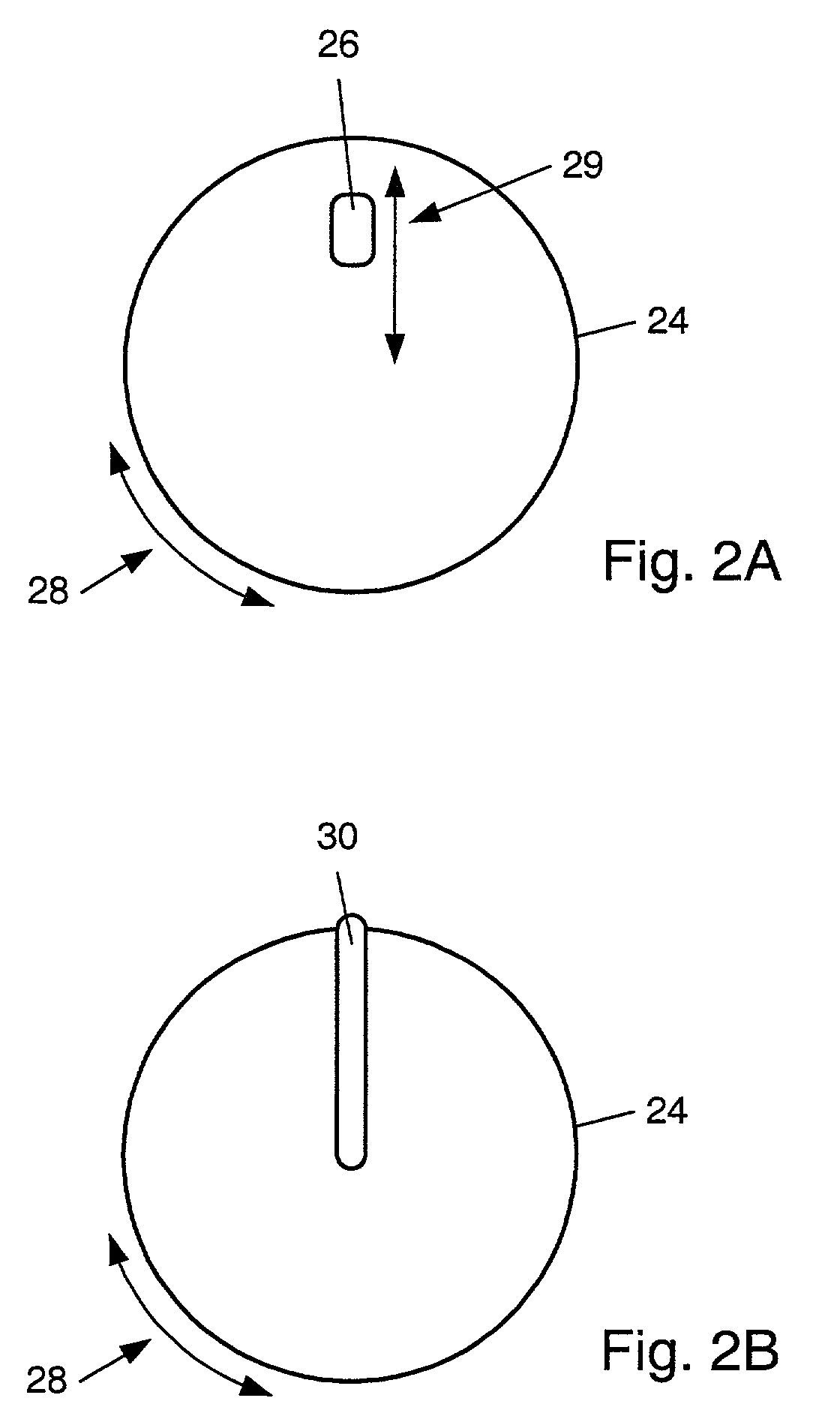

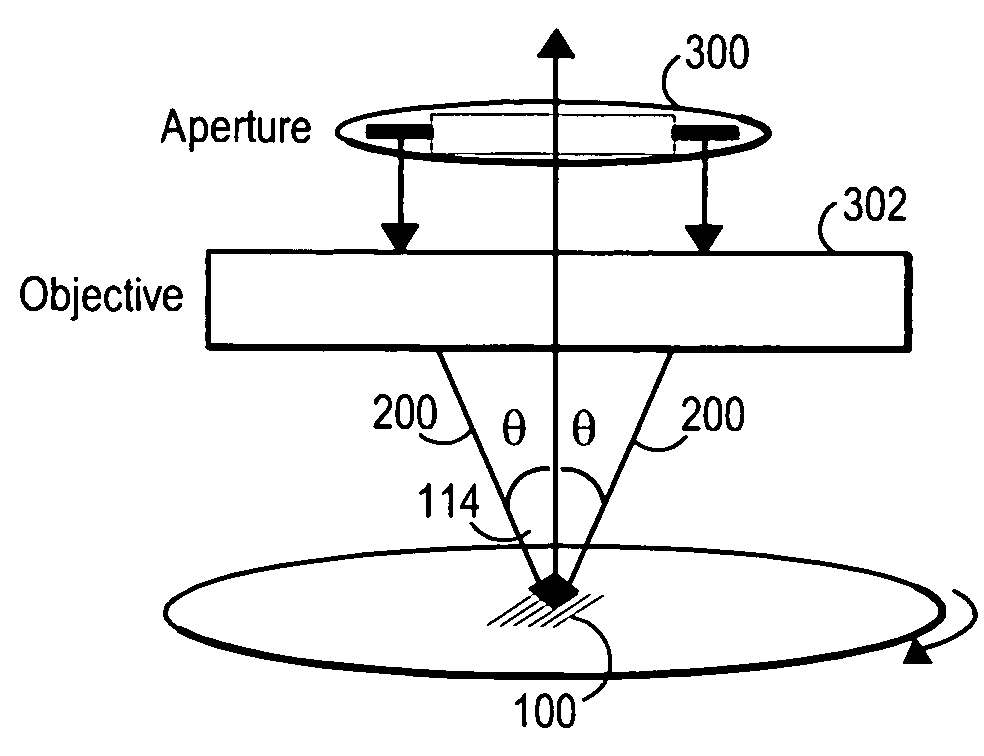

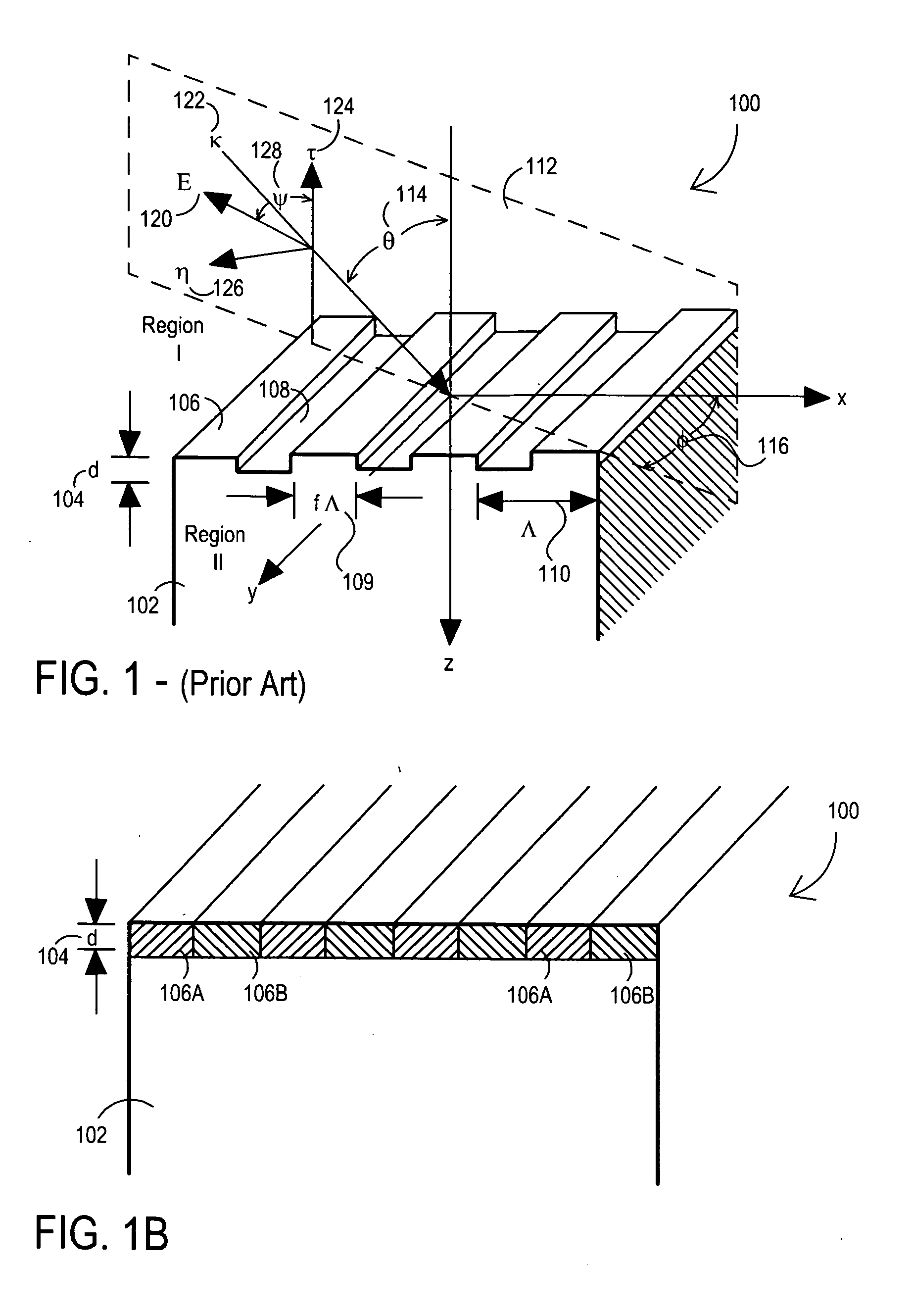

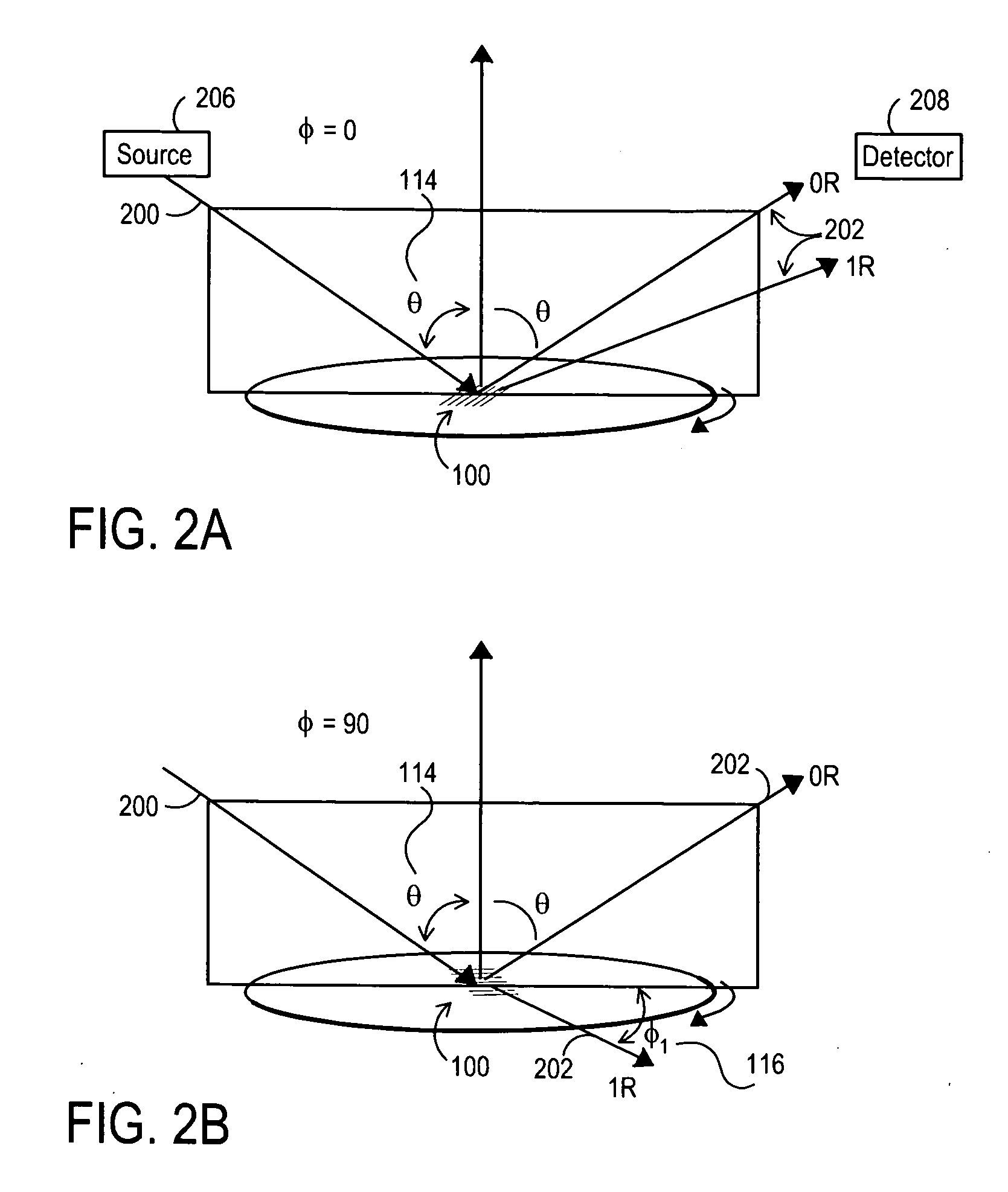

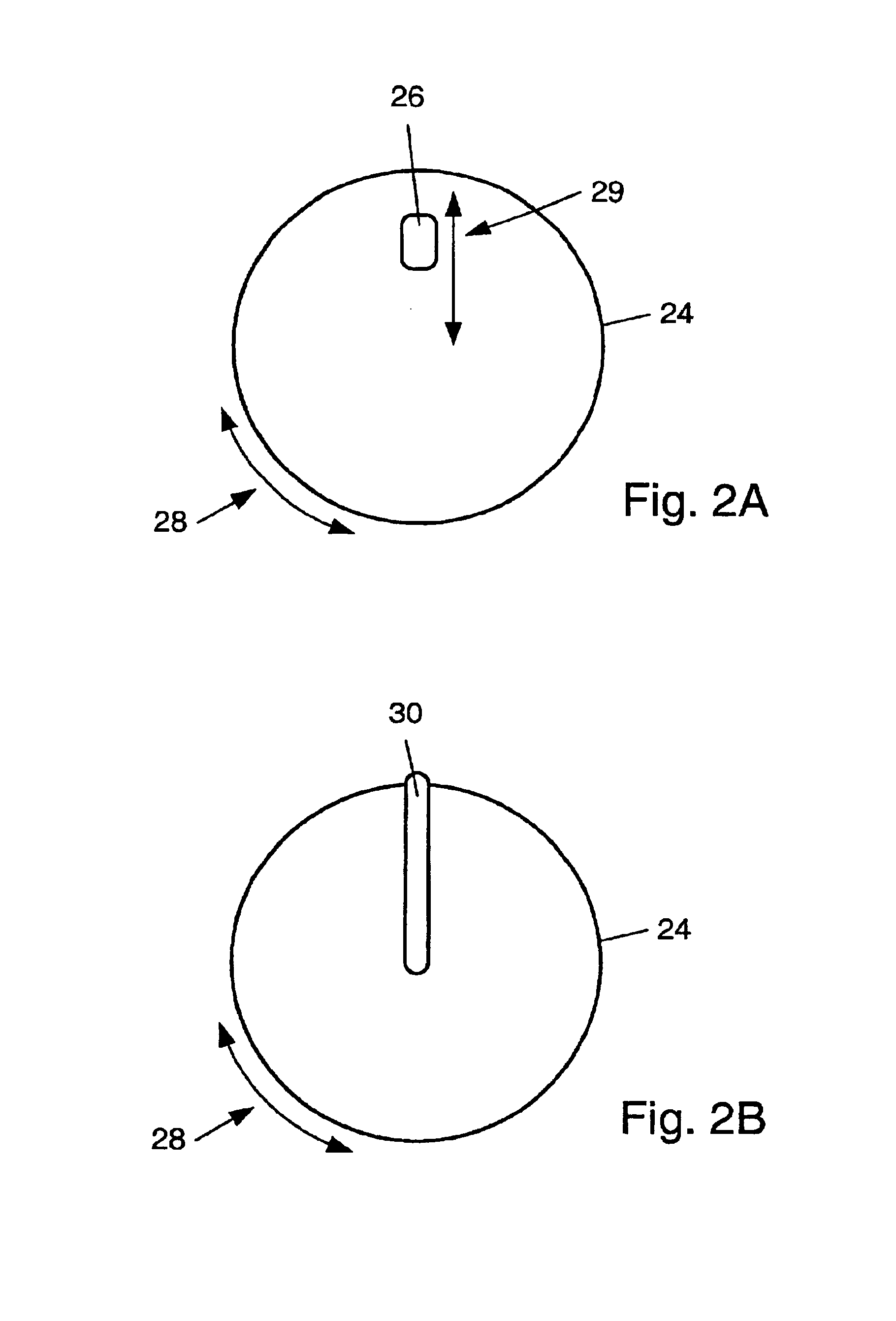

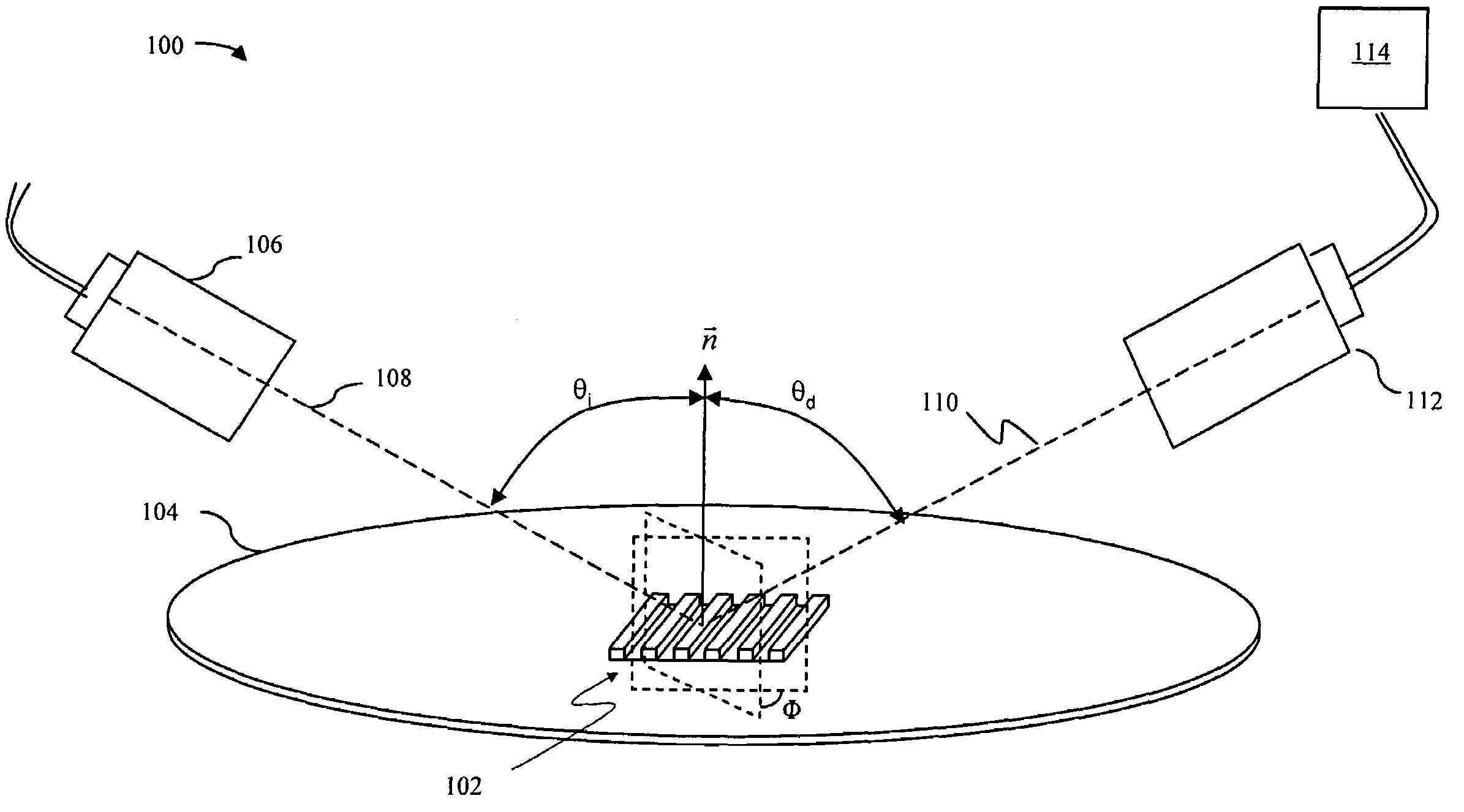

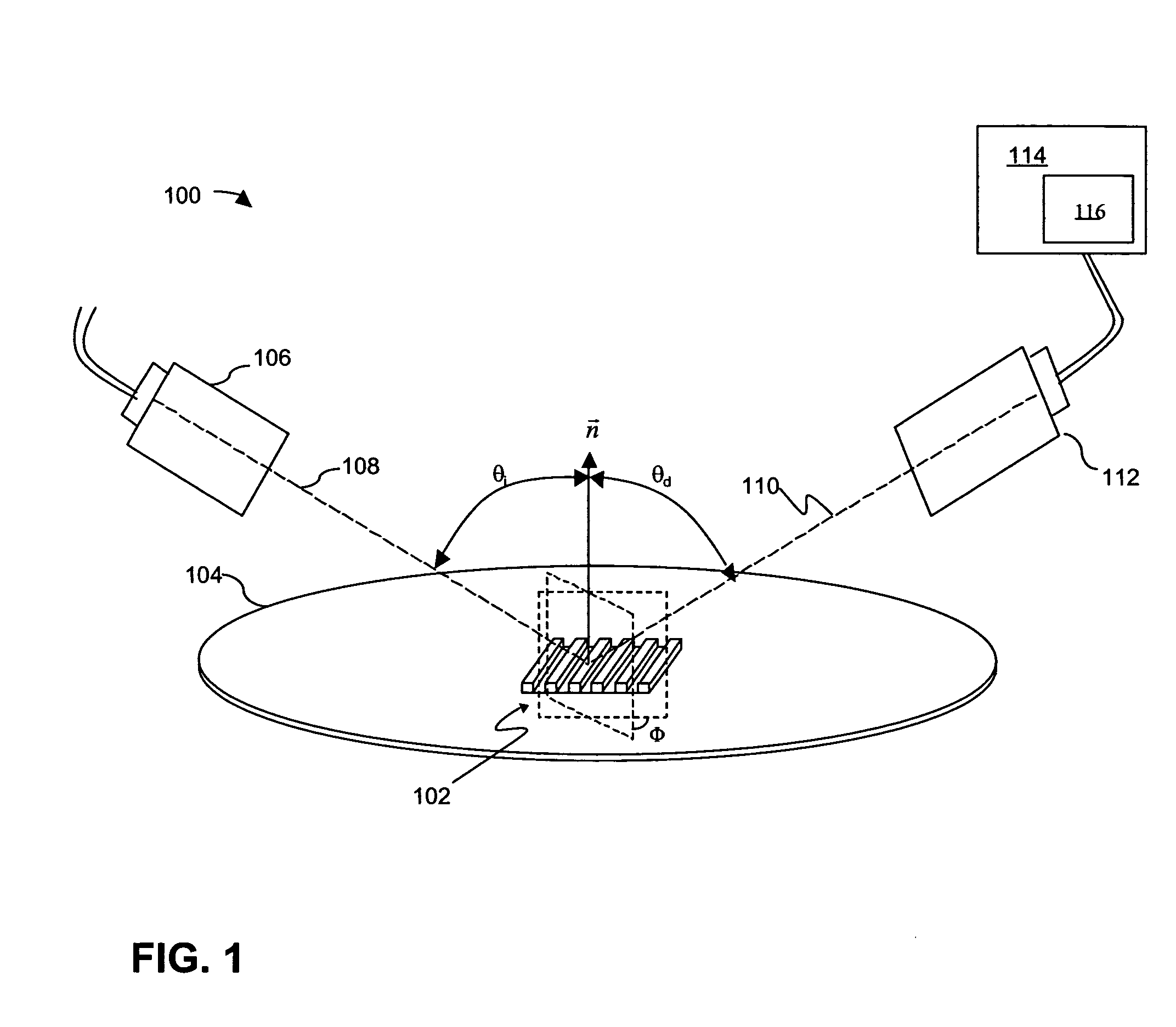

Method and apparatus for optically measuring periodic structures using orthogonal azimuthal sample orientations

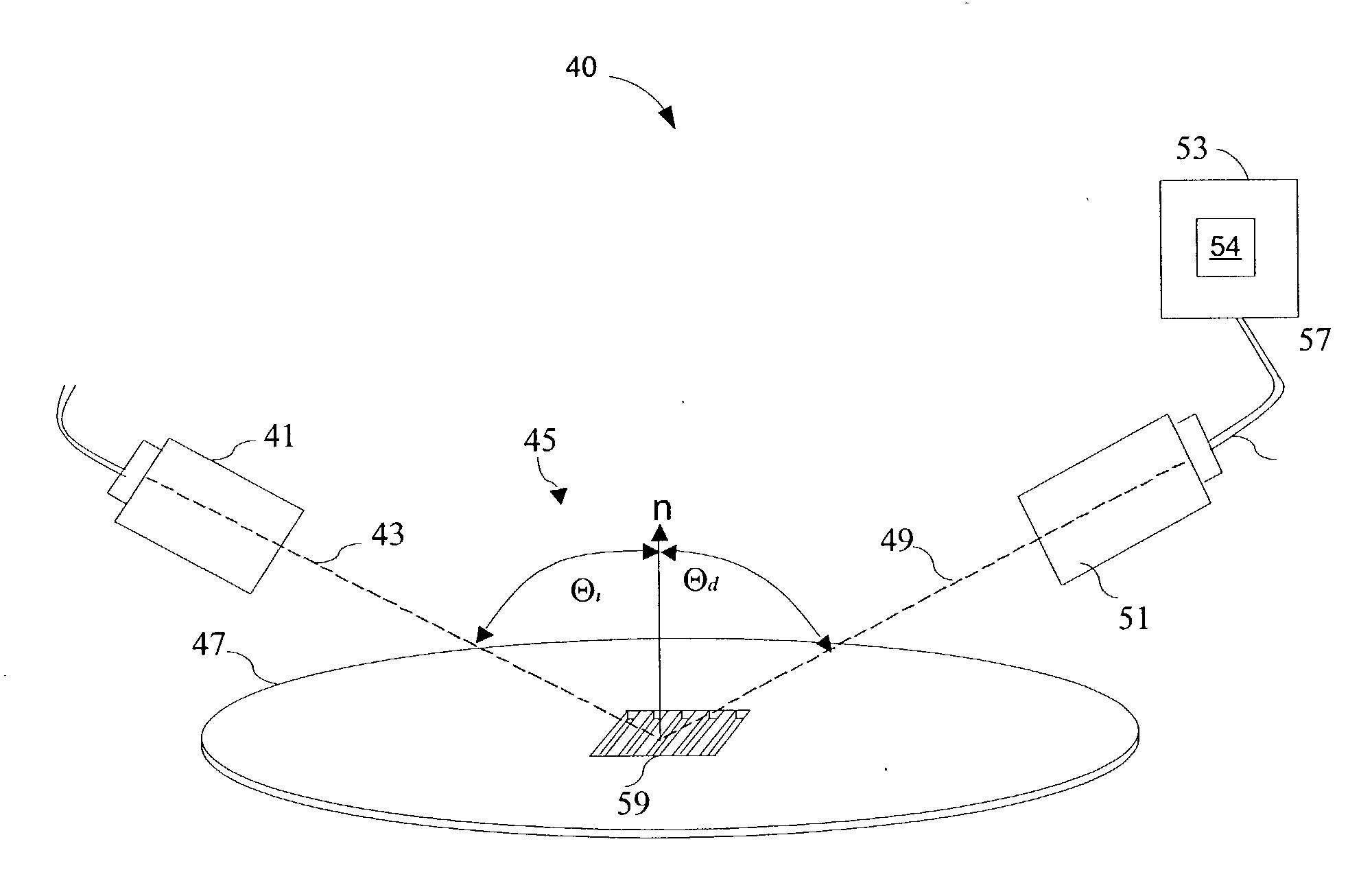

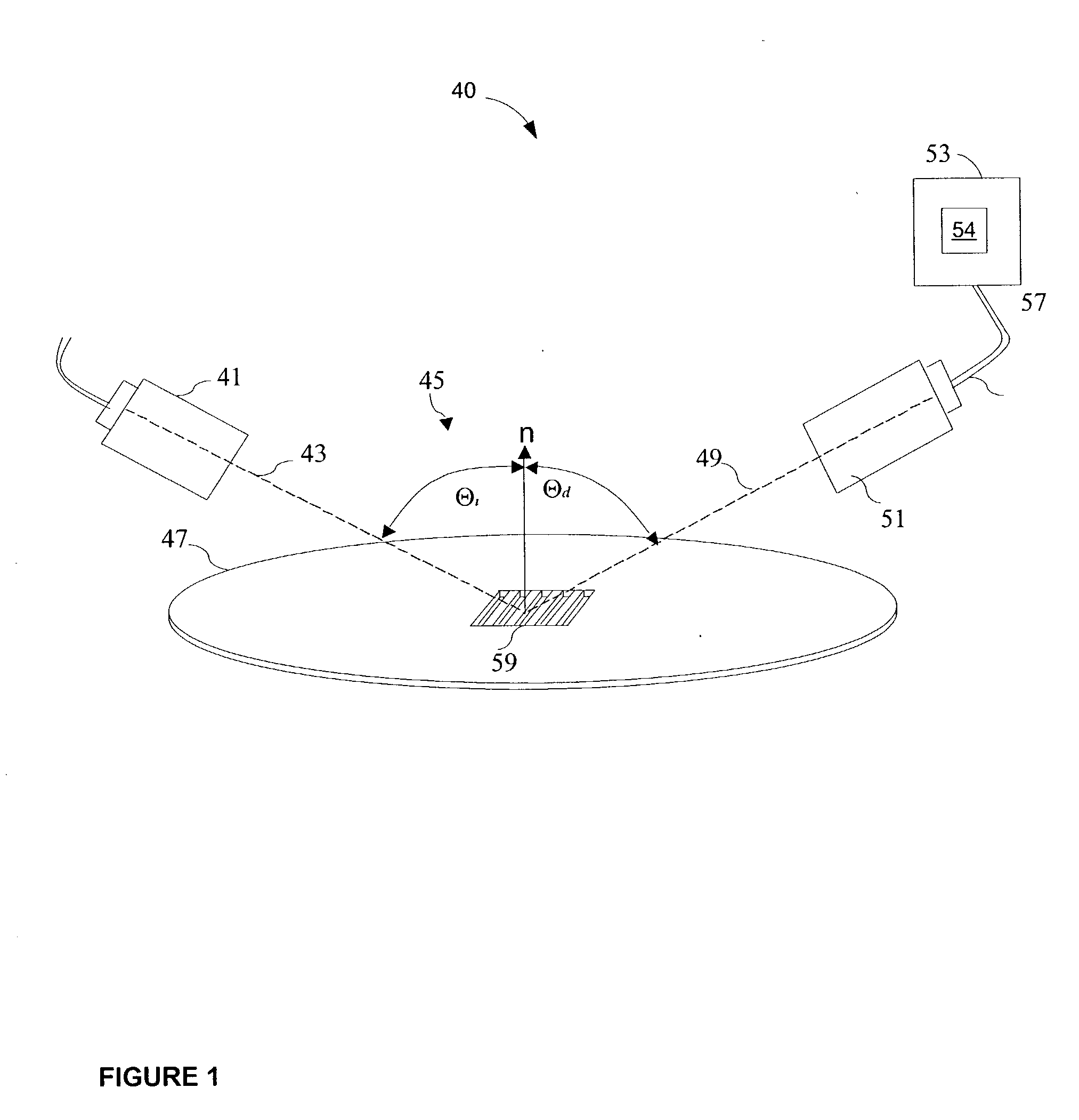

InactiveUS20080129986A1Increase computing speedReduce computing timeAngle measurementRadiation pyrometryGratingAngle of incidence

An optical metrology apparatus for measuring periodic structures using multiple incident azimuthal (phi) and polar (theta) incident angles is described. One embodiment provides the enhanced calculation speed for the special case of phi=90 incidence for 1-D (line and space) structures, which has the incident plane parallel to the grating lines, as opposed to the phi=0 classical mounting, which has incident plane perpendicular to the grating lines. The enhancement reduces the computation time of the phi=90 case to the same order as the corresponding phi=0 case, and in some cases the phi=90 case can be significantly faster. One advantageous configuration consists of two measurements for each sample structure, one perpendicular to the grating lines and one parallel. This provides additional information about the structure, equivalent to two simultaneous angles of incidence, without excessive increase in computation time. Alternately, in cases where the computation for phi=90 is faster than the corresponding phi=0 incidence, it may be advantageous to measure parallel to the grating lines only. In the case where two sets of incident angles are used, the incident light can be polarized to provide a total of four sets of data—Rs0, Rp0, Rs90, Rp90—for each incident polar angle, all from the same structure.

Owner:JORDAN VALLEY SEMICON

Methods and systems for determining a property of a specimen prior to, during, or subsequent to an etch process

InactiveUS6917433B2Speed up the processShorten the timeSemiconductor/solid-state device testing/measurementPolarisation-affecting propertiesMeasurement deviceEngineering

Methods and systems for monitoring semiconductor fabrication processes are provided. A system may include a stage configured to support a specimen and coupled to a measurement device. The measurement device may include an illumination system and a detection system. The illumination system and the detection system may be configured such that the system may be configured to determine multiple properties of the specimen. For example, the system may be configured to determine multiple properties of a specimen including, but not limited to, a property of a specimen prior to, during, or subsequent to an etch process. In this manner, a measurement device may perform multiple optical and / or non-optical metrology and / or inspection techniques.

Owner:KLA CORP

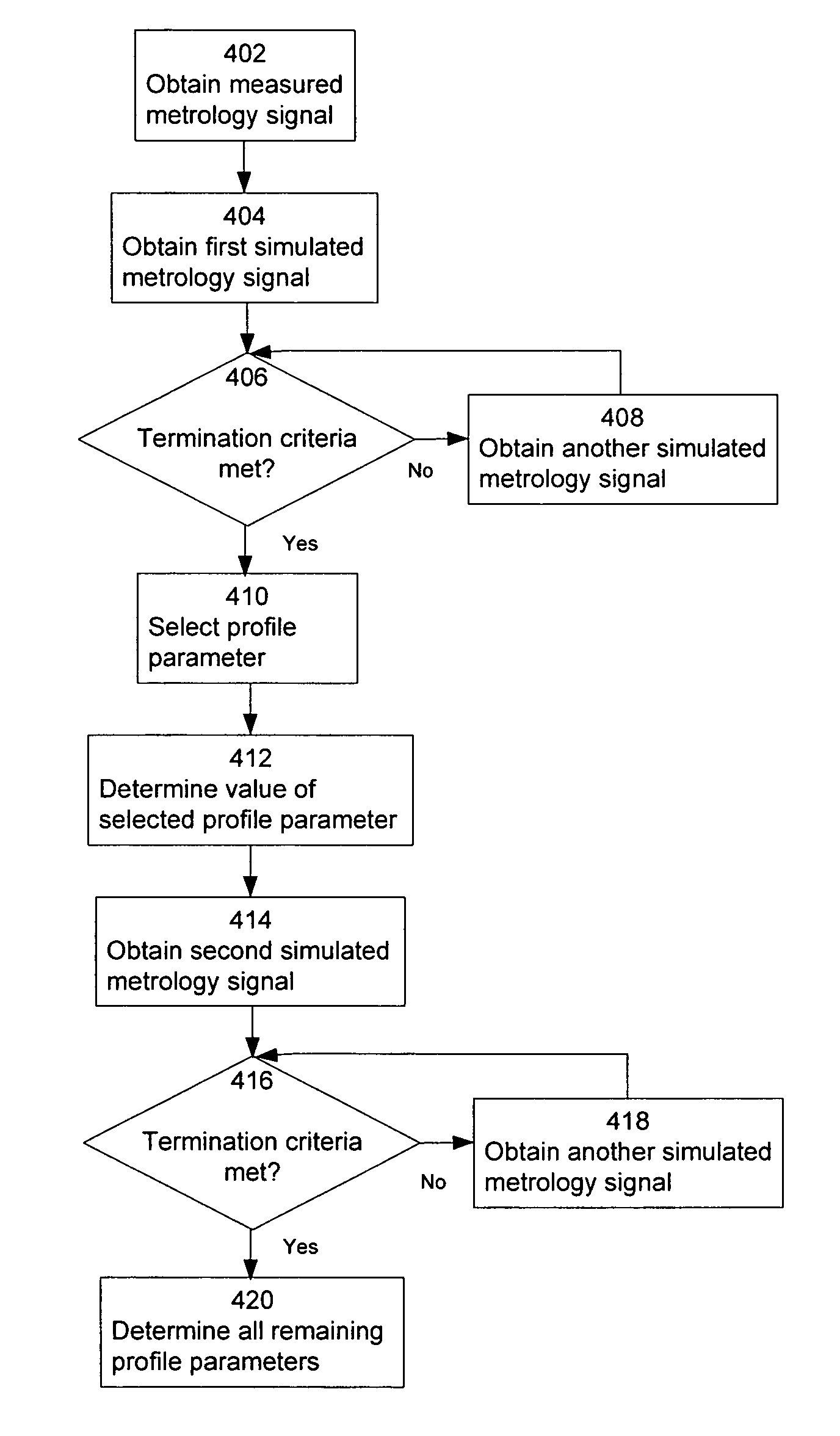

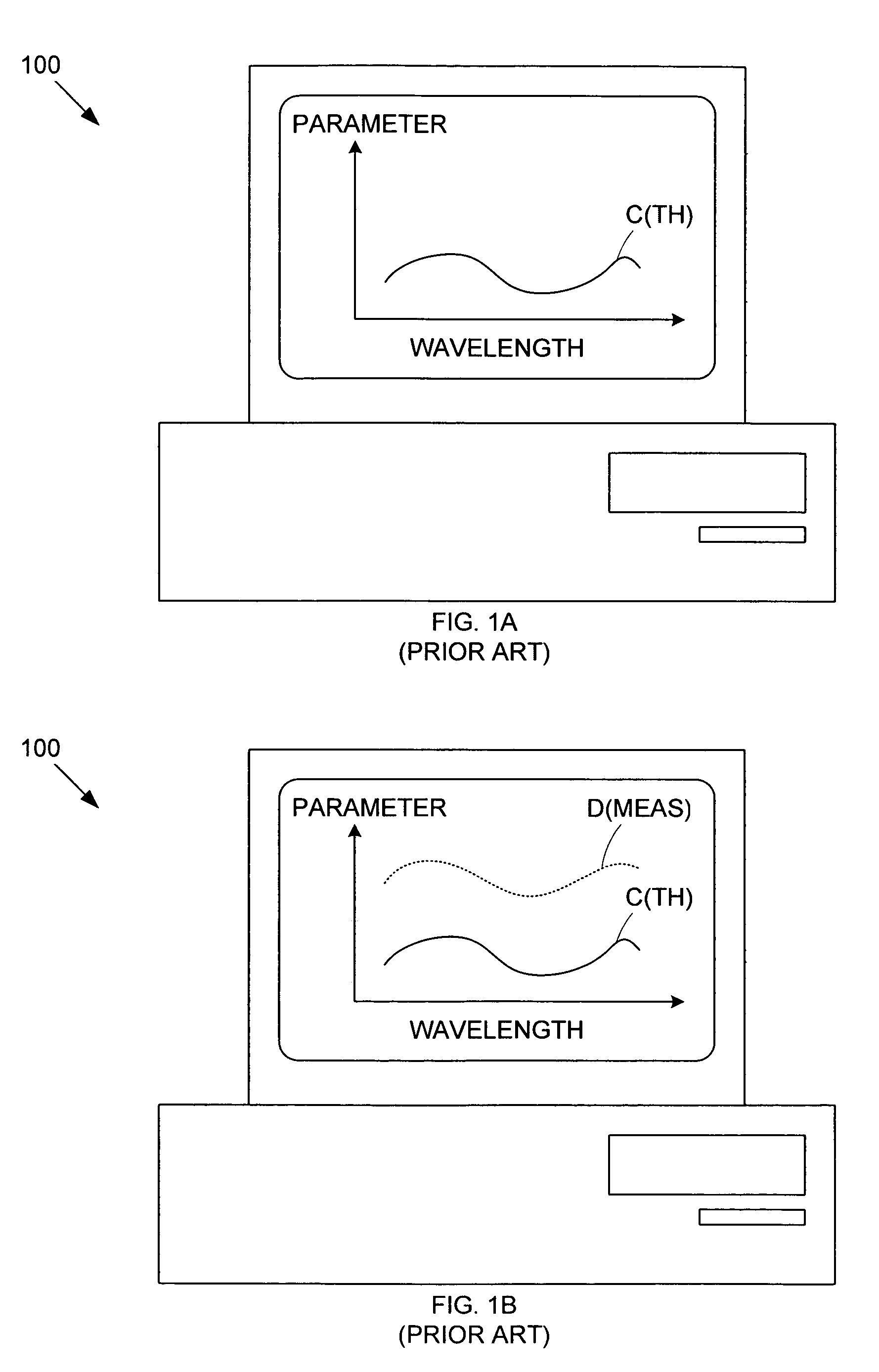

Parametric optimization of optical metrology model

InactiveUS7126700B2Semiconductor/solid-state device testing/measurementAmplifier modifications to reduce noise influenceSignal correlationOptical metrology

The profile of an integrated circuit structure is determined by obtaining a measured metrology signal and a first simulated metrology signal, which has an associated profile model of the structure defined by a set of profile parameters. When the two signals match within a first termination criterion, at least one profile parameter is selected from the set of profile parameters. A value for the selected profile parameter is determined. A second simulated metrology signal having an associated profile model of the structure defined by a set of profile parameters with at least one profile parameter equal or close to the determined value for the selected profile parameter is obtained. When the measured and the second simulated metrology signals match within a second termination criterion, values for one or more remaining profile parameters are determined from the set of profile parameters associated with the second simulated metrology signal.

Owner:TOKYO ELECTRON LTD

Model and parameter selection for optical metrology

ActiveUS7330279B2Semiconductor/solid-state device testing/measurementPhase-affecting property measurementsEngineeringSelection criterion

A profile model for use in optical metrology of structures in a wafer is selected, the profile model having a set of geometric parameters associated with the dimensions of the structure. A set of optimization parameters is selected for the profile model using one or more input diffraction signals and one or more parameter selection criteria. The selected profile model and the set of optimization parameters are tested against one or more termination criteria. The process of selecting a profile model, selecting a set of optimization parameters, and testing the selected profile model and set of optimization parameters is performed until the one or more termination criteria are met.

Owner:TOKYO ELECTRON US HOLDINGS INC

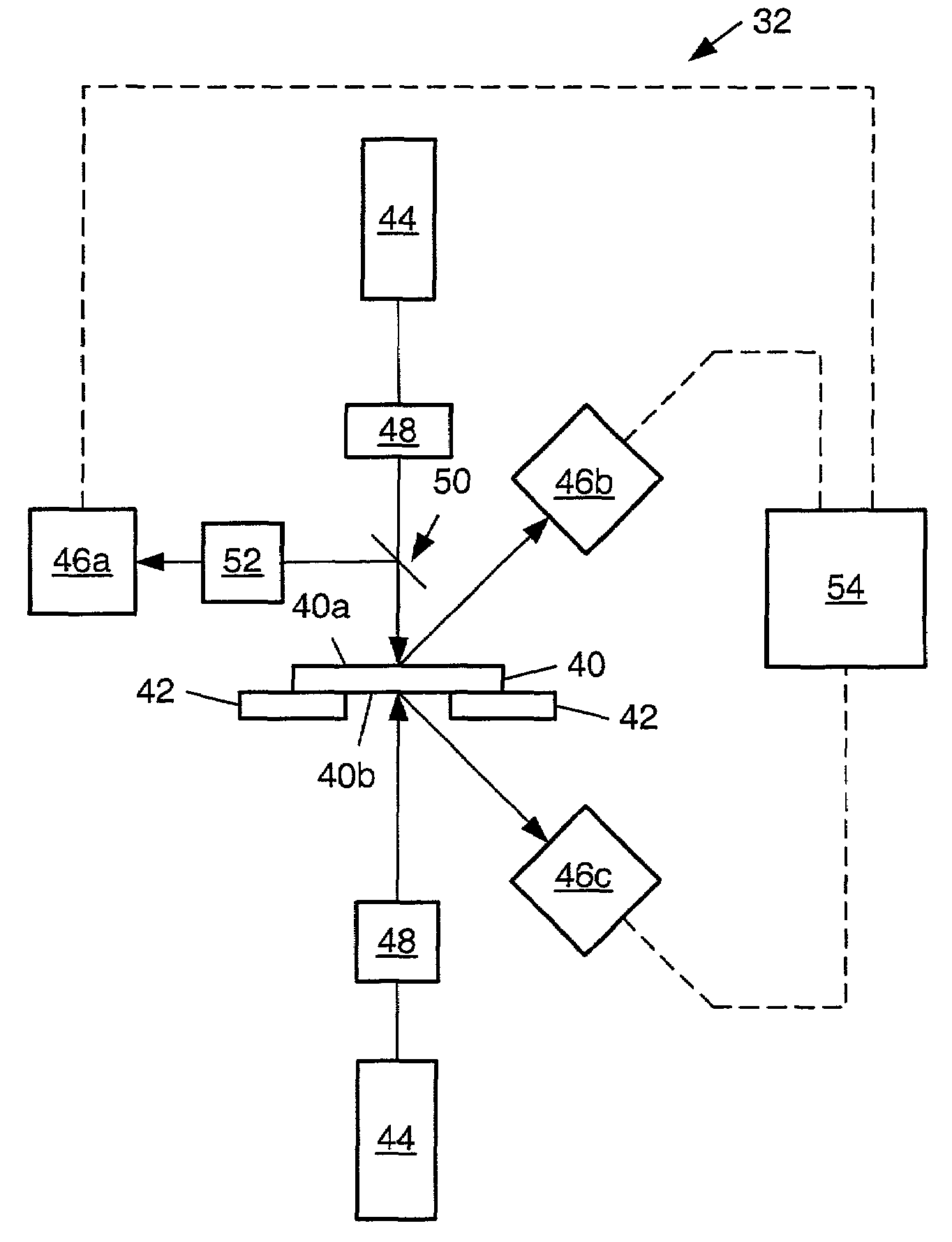

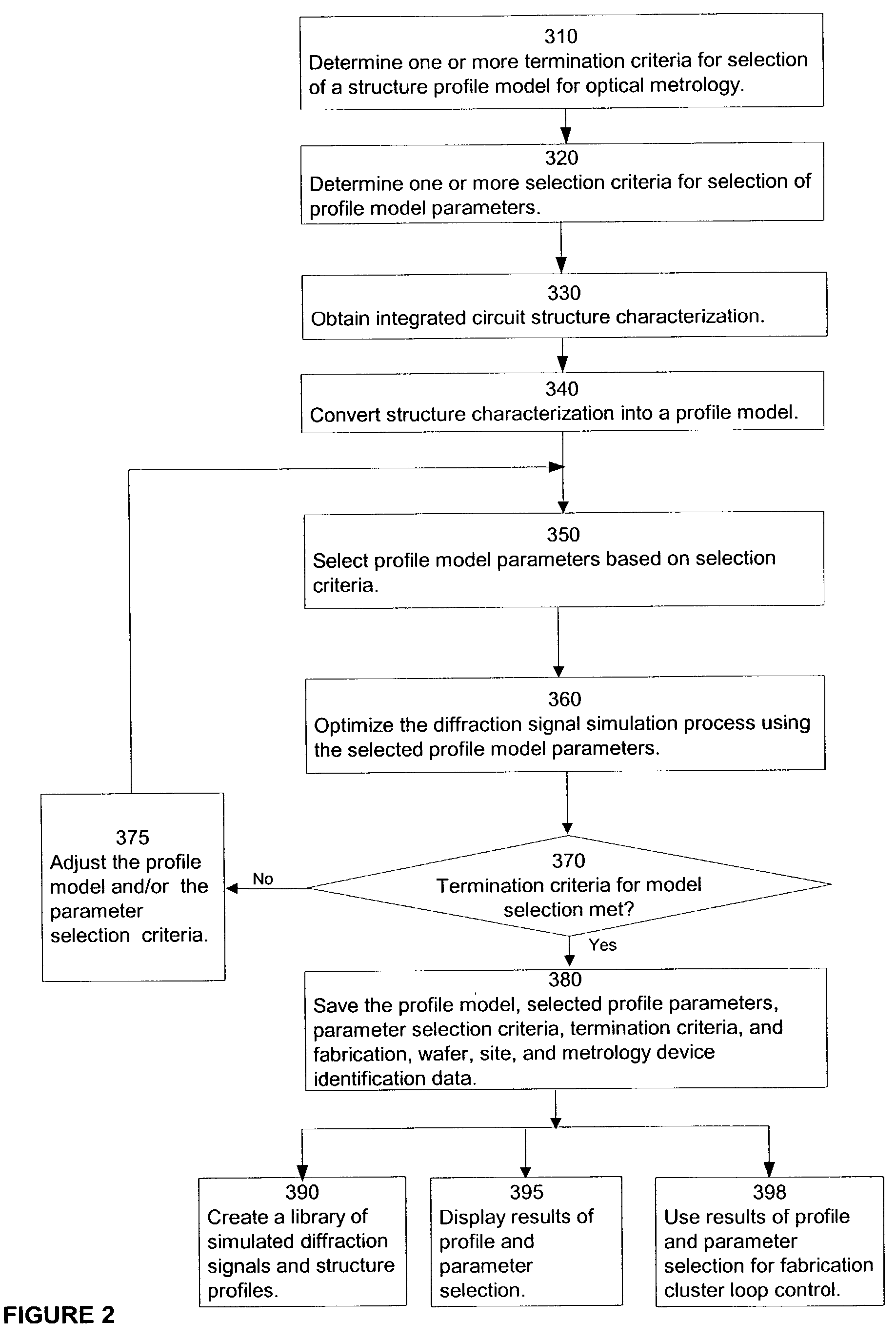

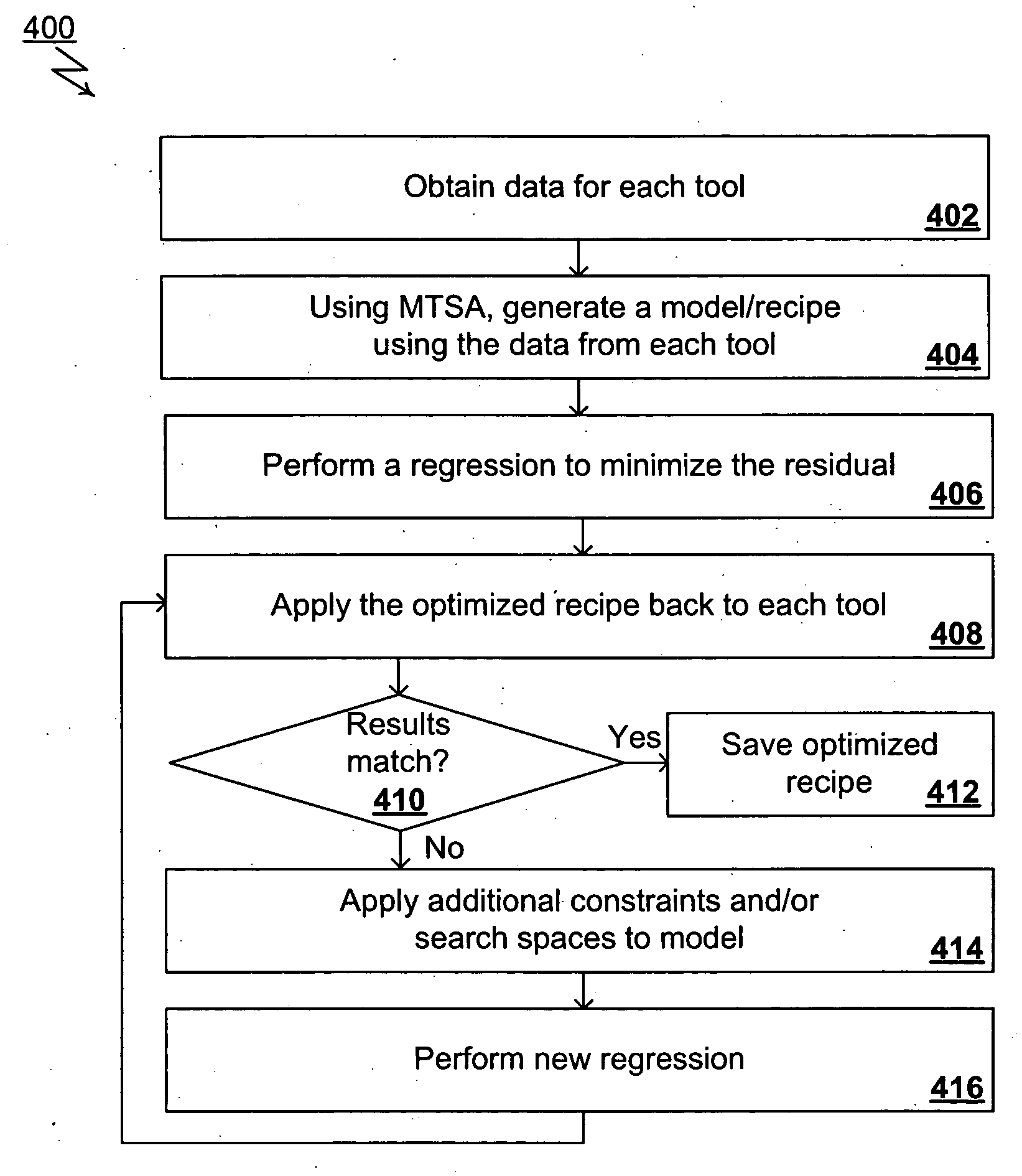

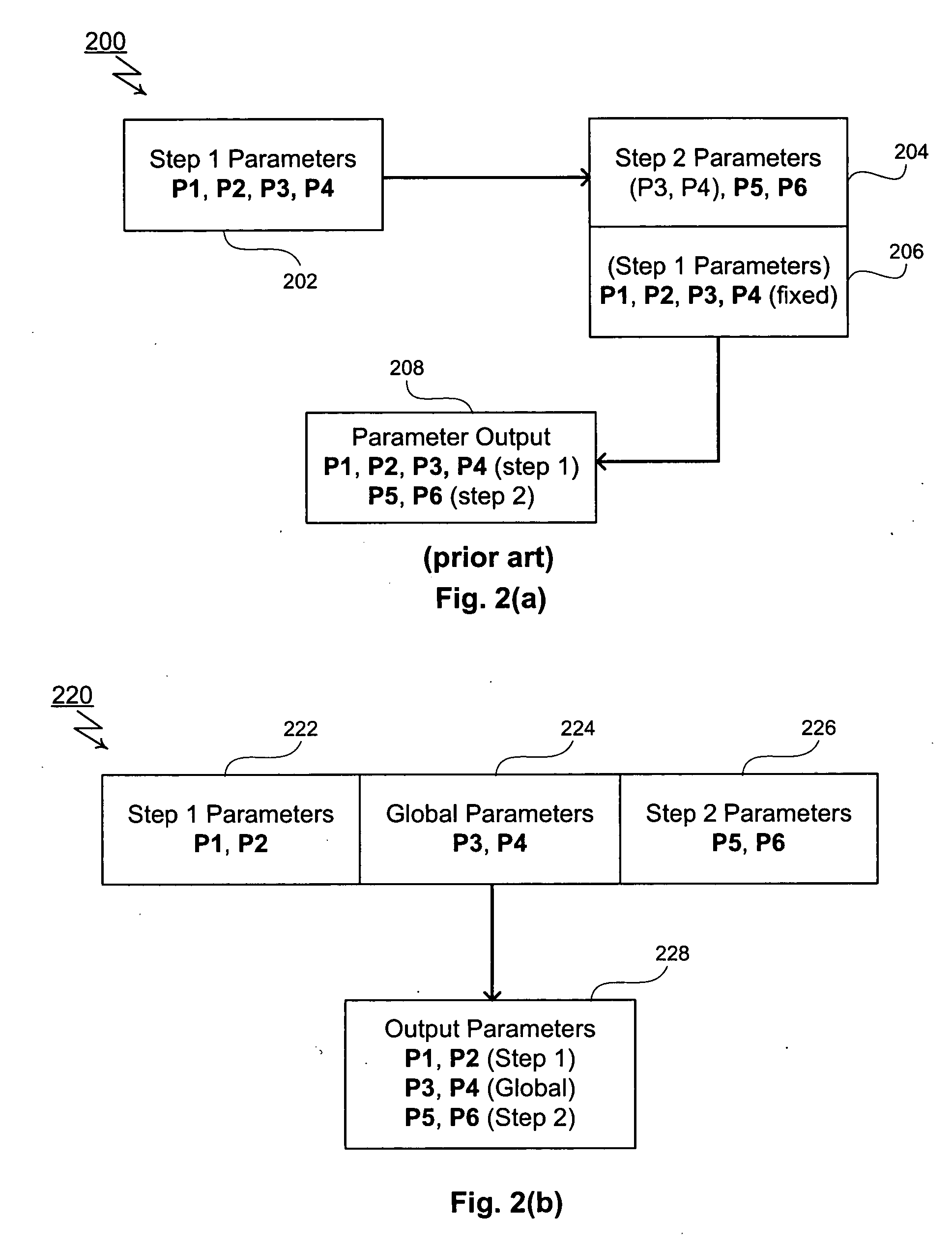

Multiple tool and structure analysis

ActiveUS20060167651A1Amplifier modifications to reduce noise influenceComputer controlData setStructure analysis

Measurement data sets for optical metrology systems can be processed in parallel using Multiple Tool and Structure Analysis (MTSA). In an MTSA procedure, at least one parameter that is common to the data sets can be coupled as a global parameter. Setting this parameter as global allows a regression on each data set to contain fewer fitting parameters, making the process is less complex, requiring less processing capacity, and providing more accurate results. MTSA can analyze multiple structures measured on a single tool, or a single structure measured on separate tools. For a multiple tool recipe, a minimized regression solution can be applied back to each tool to determine whether the recipe is optimized. If the recipe does not provide accurate results for each tool, search parameters and / or spaces can be modified in an iterative manner until an optimized solution is obtained that provides acceptable solutions on each tool.

Owner:THERMA WAVE INC

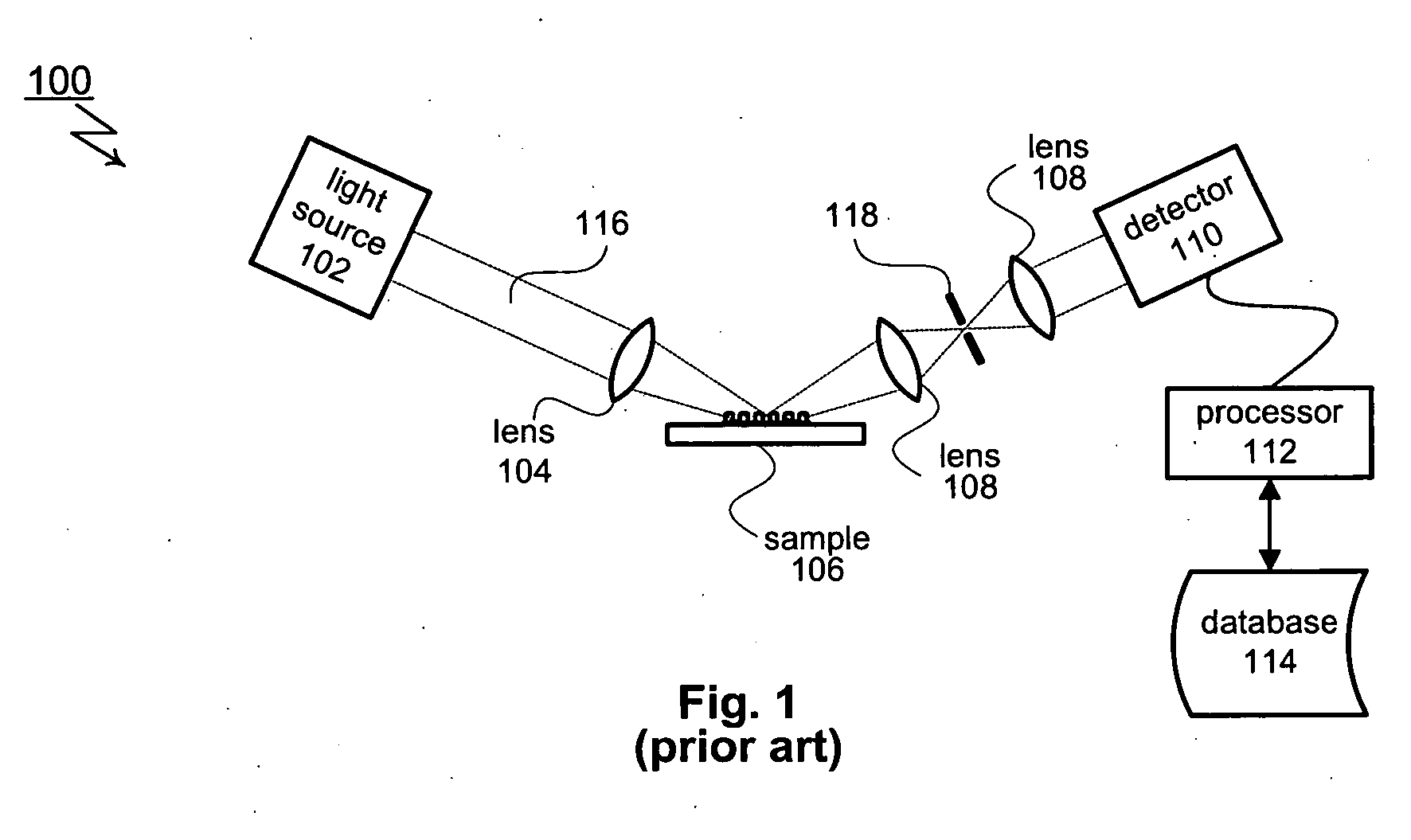

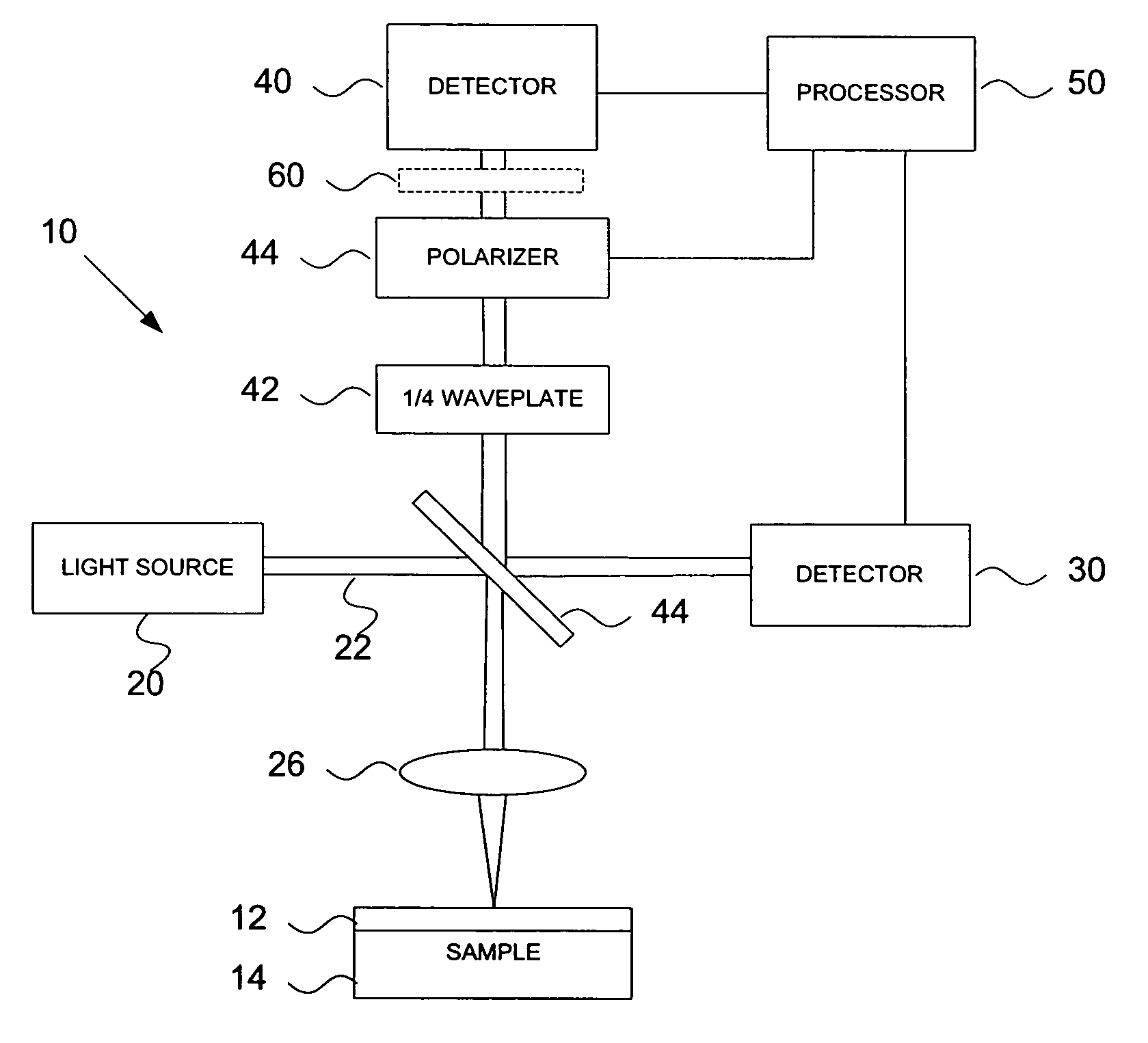

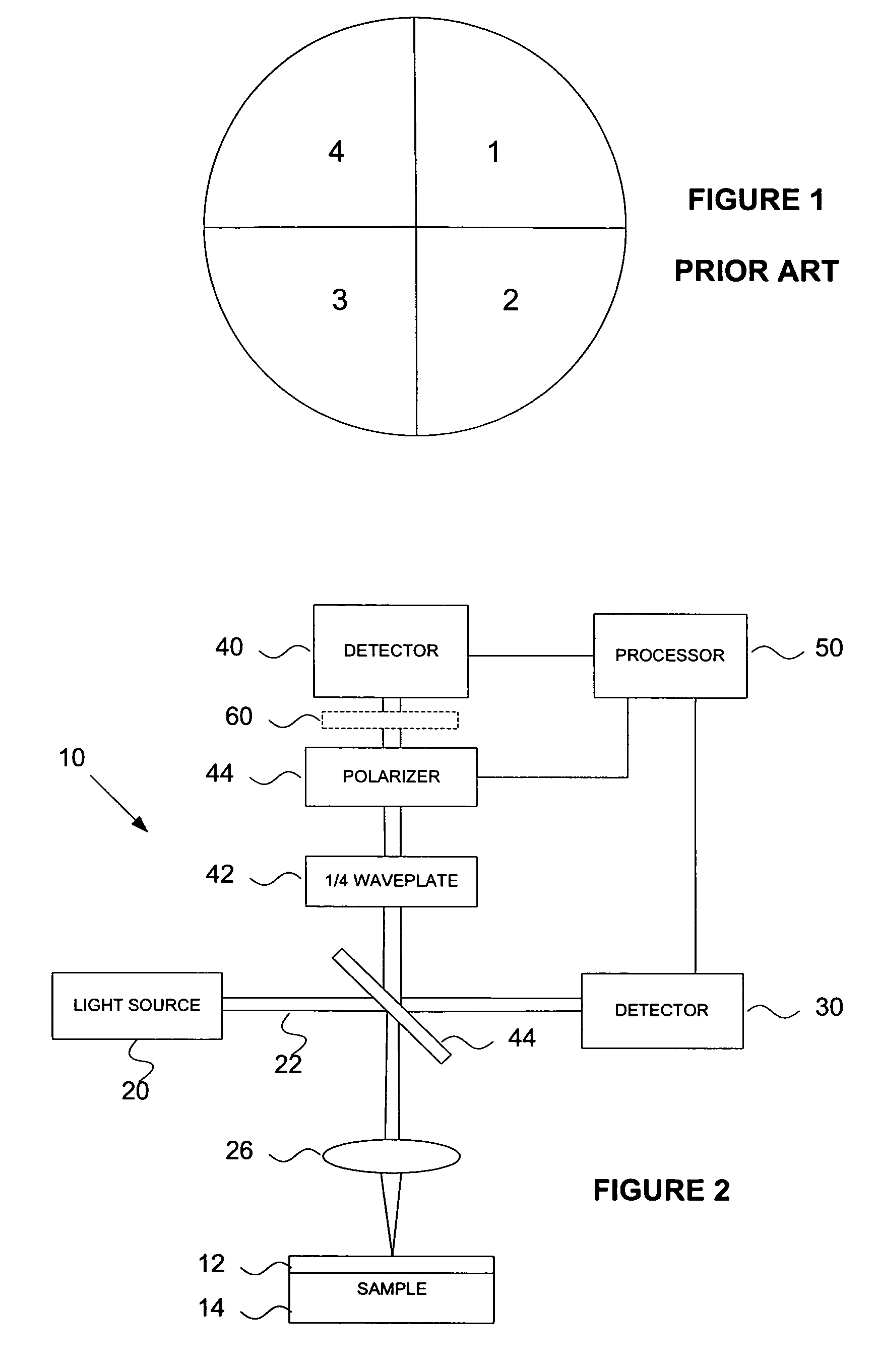

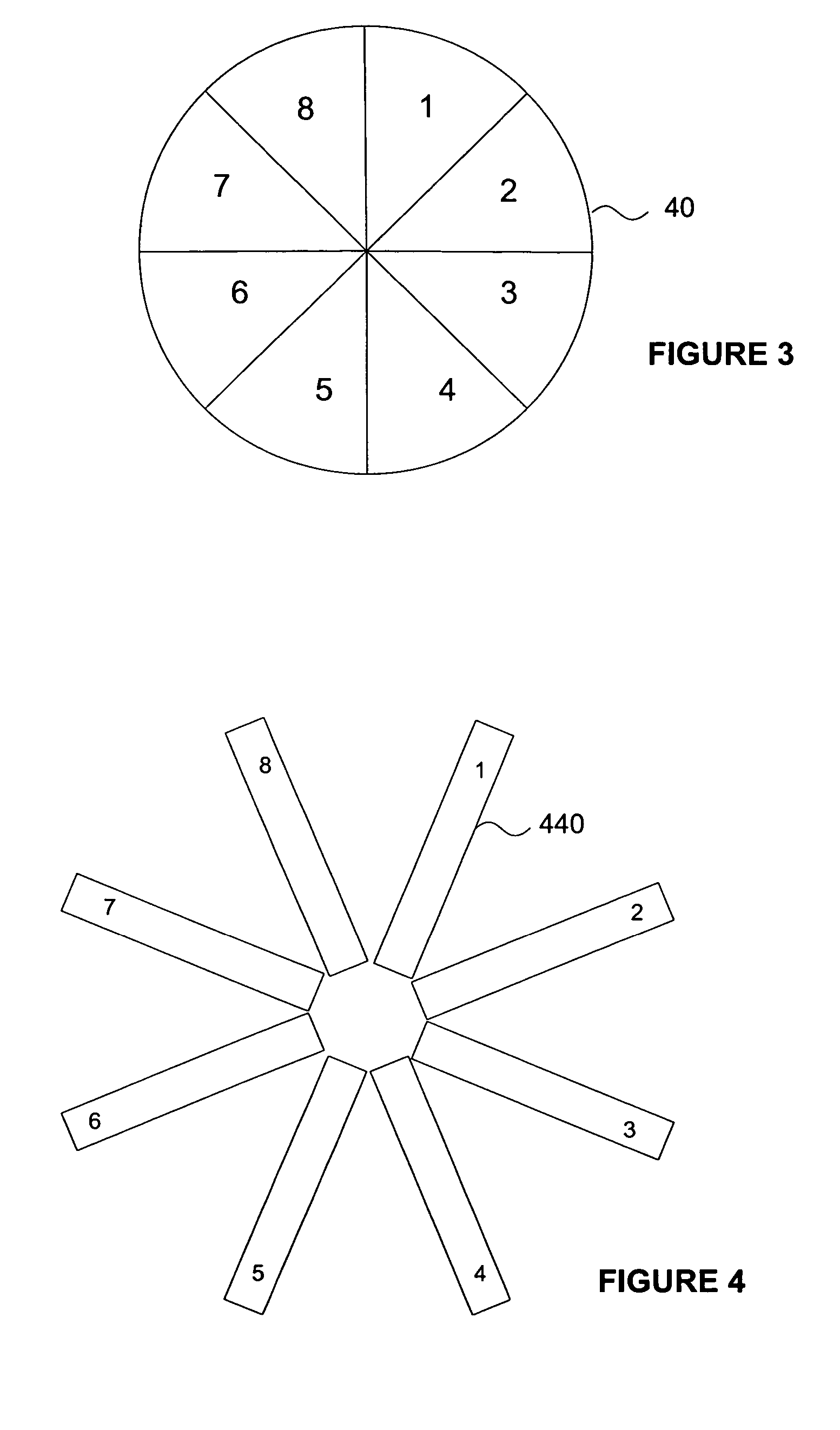

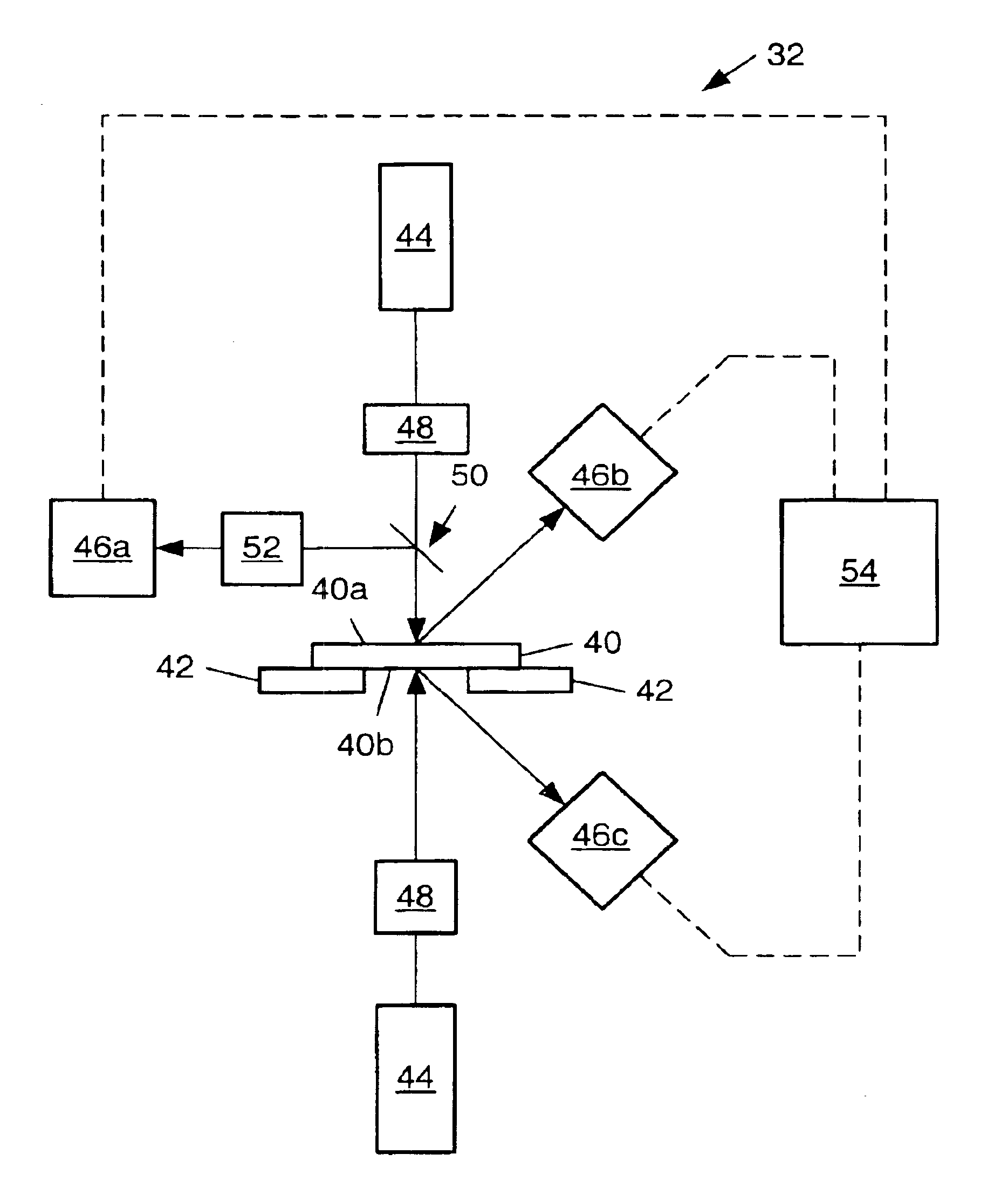

Detector configurations for optical metrology

InactiveUS6995842B2Phase delayAccurate assessmentMaterial analysis by optical meansUsing optical meansAngle of incidenceEllipse

An apparatus is disclosed for obtaining ellipsometric measurements from a sample. A probe beam is focused onto the sample to create a spread of angles of incidence. The beam is passed through a quarter waveplate retarder and a polarizer. The reflected beam is measured by a detector. In one preferred embodiment, the detector includes eight radially arranged segments, each segment generating an output which represents an integration of multiple angle of incidence. A processor manipulates the output from the various segments to derive ellipsometric information.

Owner:KLA CORP

Methods and systems for determining flatness, a presence of defects, and a thin film characteristic of a specimen

InactiveUS6917419B2Speed up the processShorten the timeSemiconductor/solid-state device testing/measurementPolarisation-affecting propertiesMeasurement deviceEngineering

Methods and systems for monitoring semiconductor fabrication processes are provided. A system may include a stage configured to support a specimen and coupled to a measurement device. The measurement device may include an illumination system and a detection system. The illumination system and the detection system may be configured such that the system may be configured to determine multiple properties of the specimen. For example, the system may be configured to determine multiple properties of a specimen including, but not limited to, flatness, a presence of defects, and a thin film characteristic. In this manner, a measurement device may perform multiple optical and / or non-optical metrology and / or inspection techniques.

Owner:KLA CORP

Examining a structure formed on a semiconductor wafer using machine learning systems

Owner:TOKYO ELECTRON LTD

Optical metrology systems and methods

ActiveUS7505133B1Minimises levelAvoid disadvantagesMaterial analysis by optical meansUsing optical meansAngle of incidenceRefractive index

Metrology systems and methods that measure thin film thickness and or index of refraction of semiconductor wafers with at least one deposited or grown thin film layer. The present invention measures near normal incidence and grazing angle of incidence reflection (using reflected broadband UV, visible, and near infrared electromagnetic radiation) from a small region on a sample. Embodiments of the system selectively comprise a near-normal incidence spectrometer / ellipsometer, a high angle of incidence spectrometer / ellipsometer, or a combination of the two.

Owner:BRUKER NANO INC

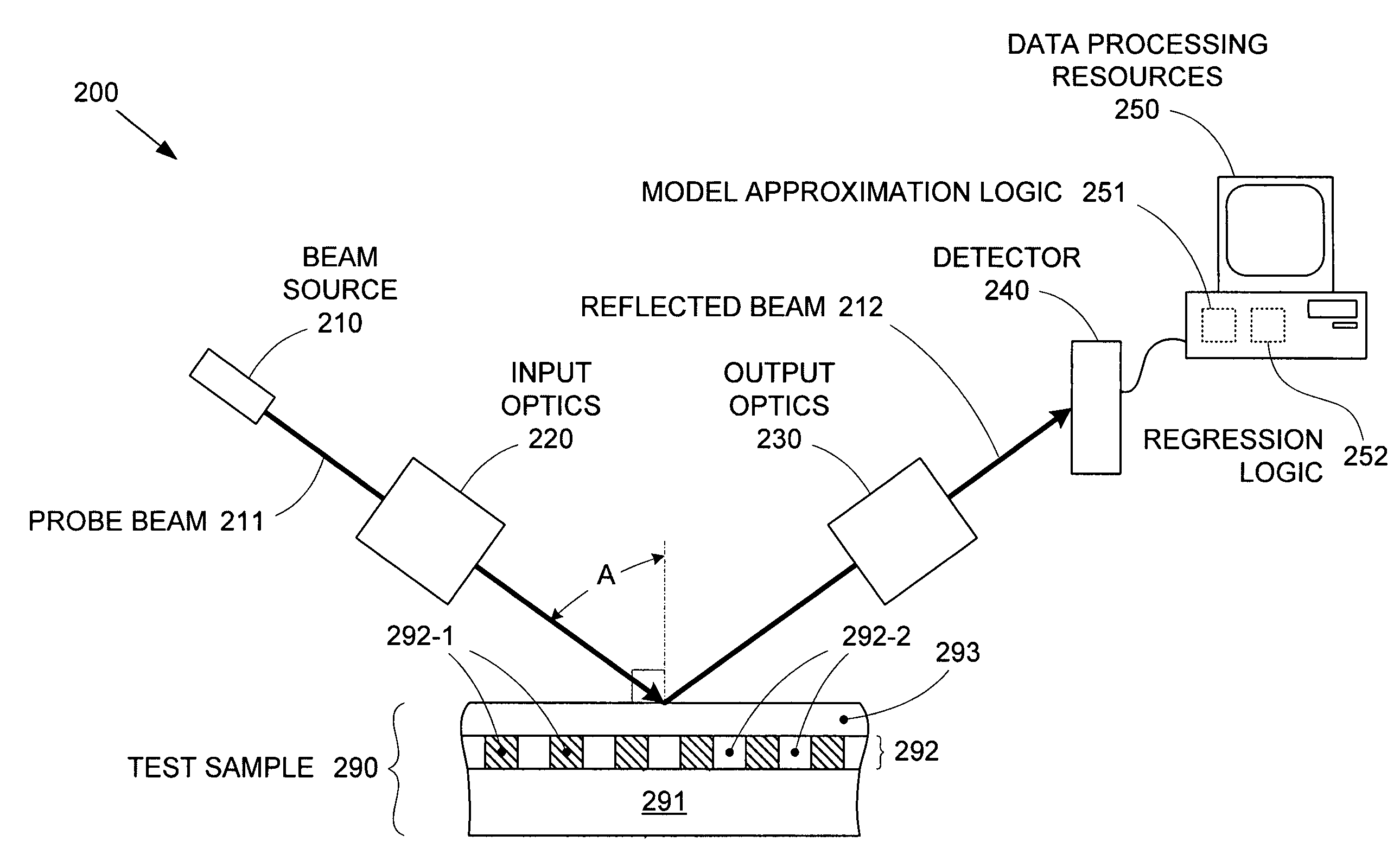

Optical metrology on patterned samples

ActiveUS7321426B1Accurately measuring attributeEliminates computationMaterial analysis by optical meansUsing optical meansGratingModel selection

An optical metrology system includes model approximation logic for generating an optical model based on experimental data. By eliminating theoretical model generation, in which the fundamental equations of a test sample must be solved, the model approximation logic significantly reduces the computational requirements of the metrology system when measuring films formed on patterned base layers. The experimental model can be created by selecting an expected mathematical form for the final model, gathering experimental data, and compiling a lookup model. The lookup model can include the actual measurement data sorted by output (attribute) value, or can include “grating factors” that represent compensation factors that, when applied to standard monolithic model equations, compensate for the optical effects of grating layers.

Owner:KLA TENCOR TECH CORP

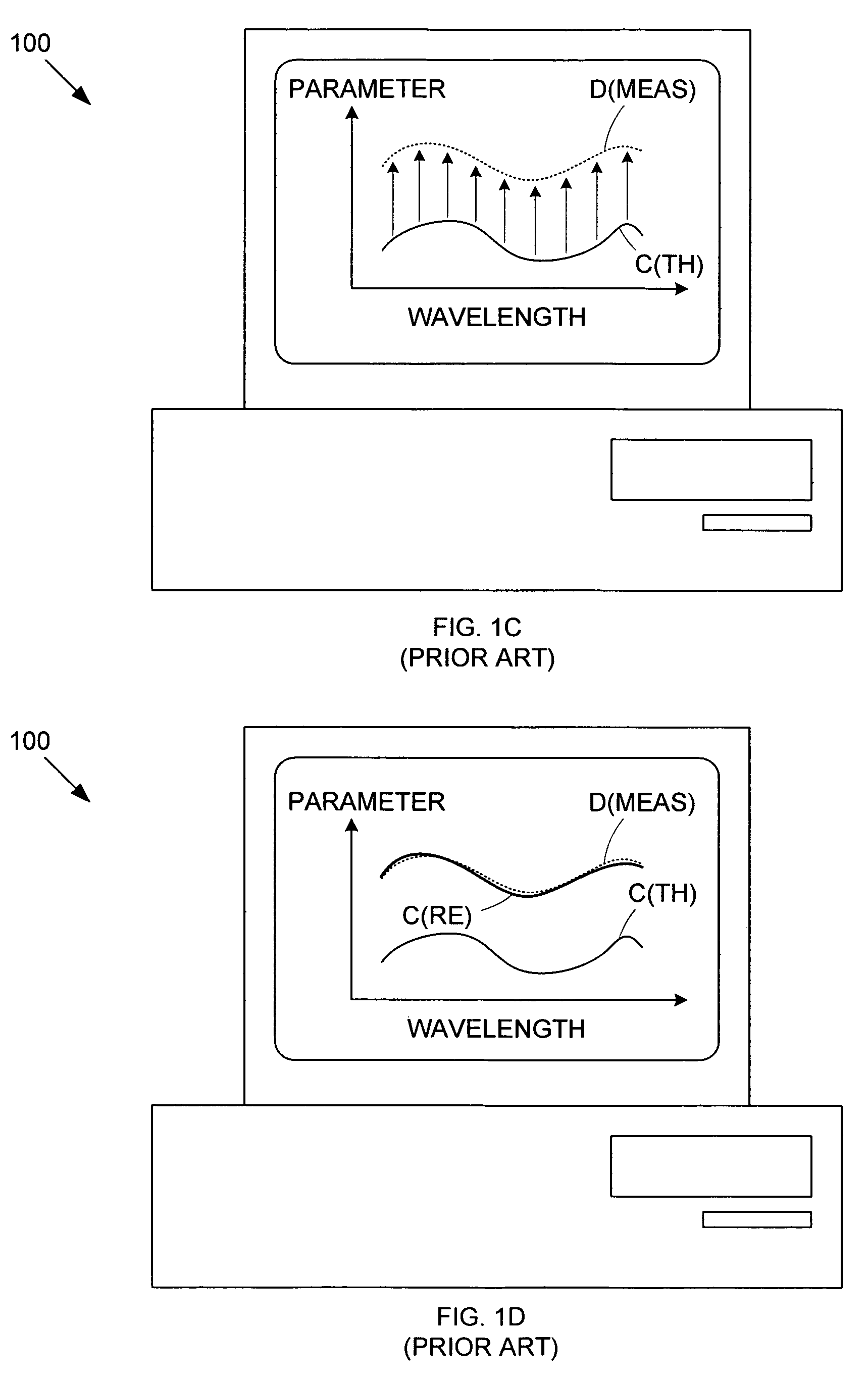

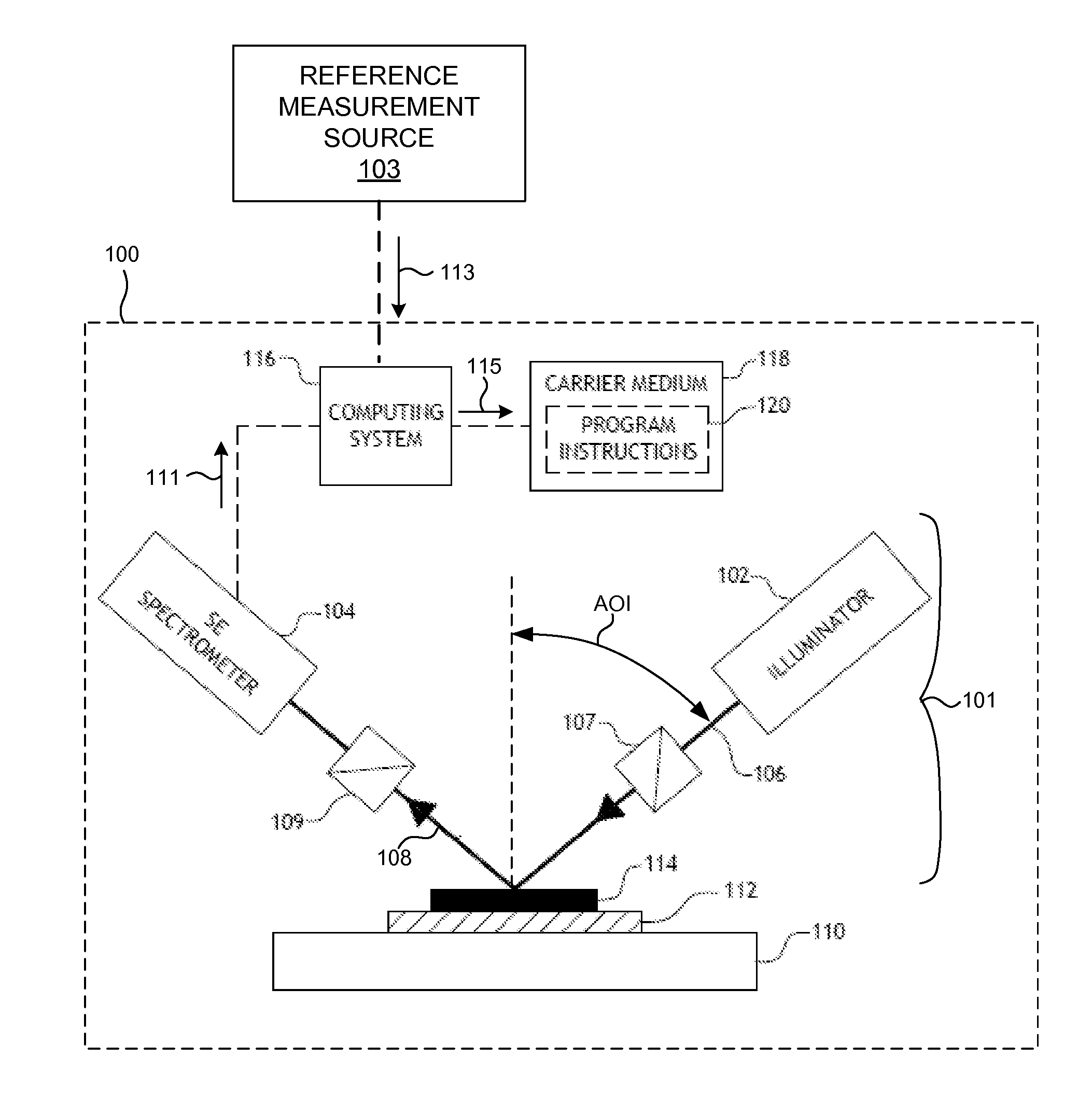

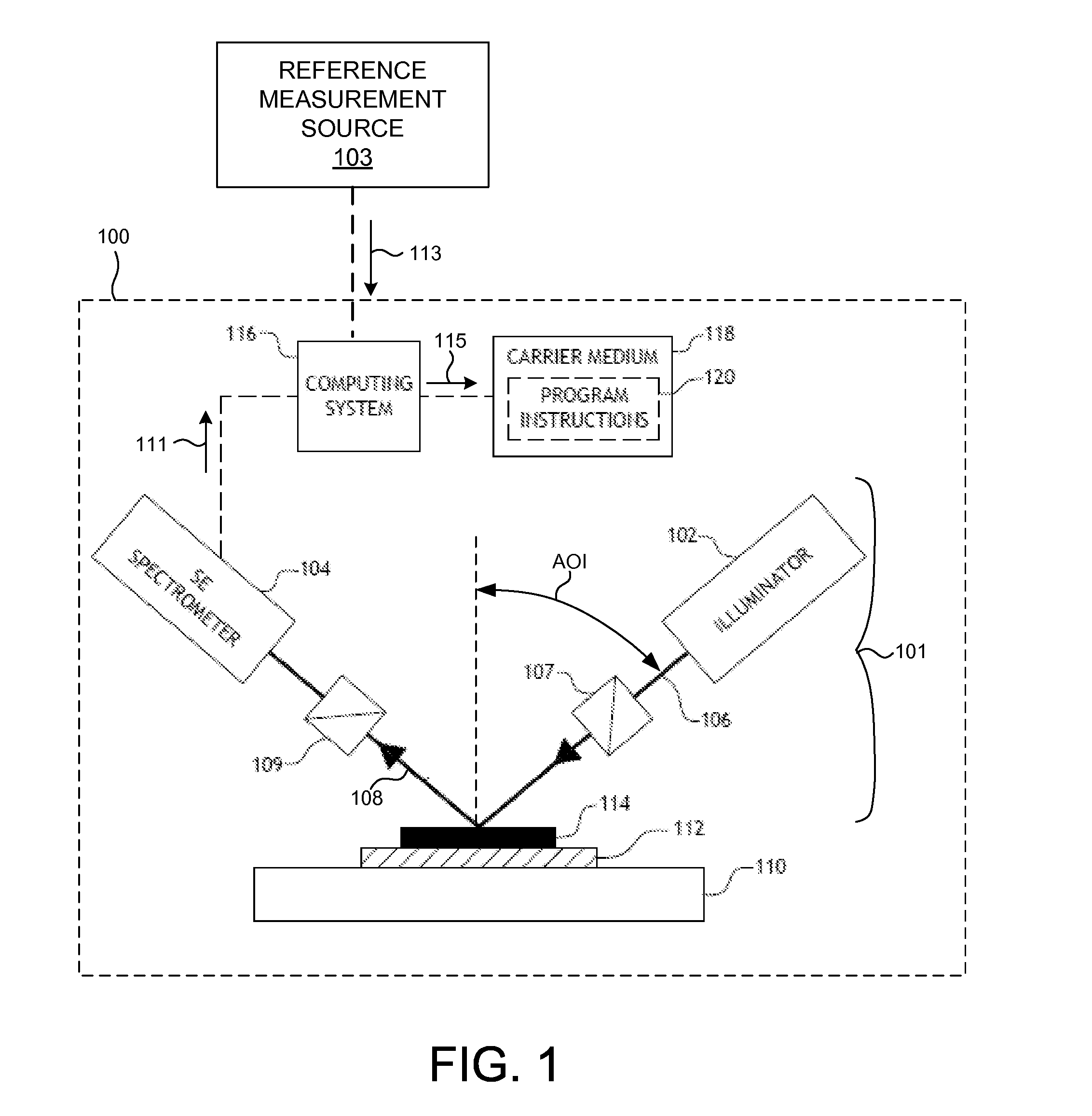

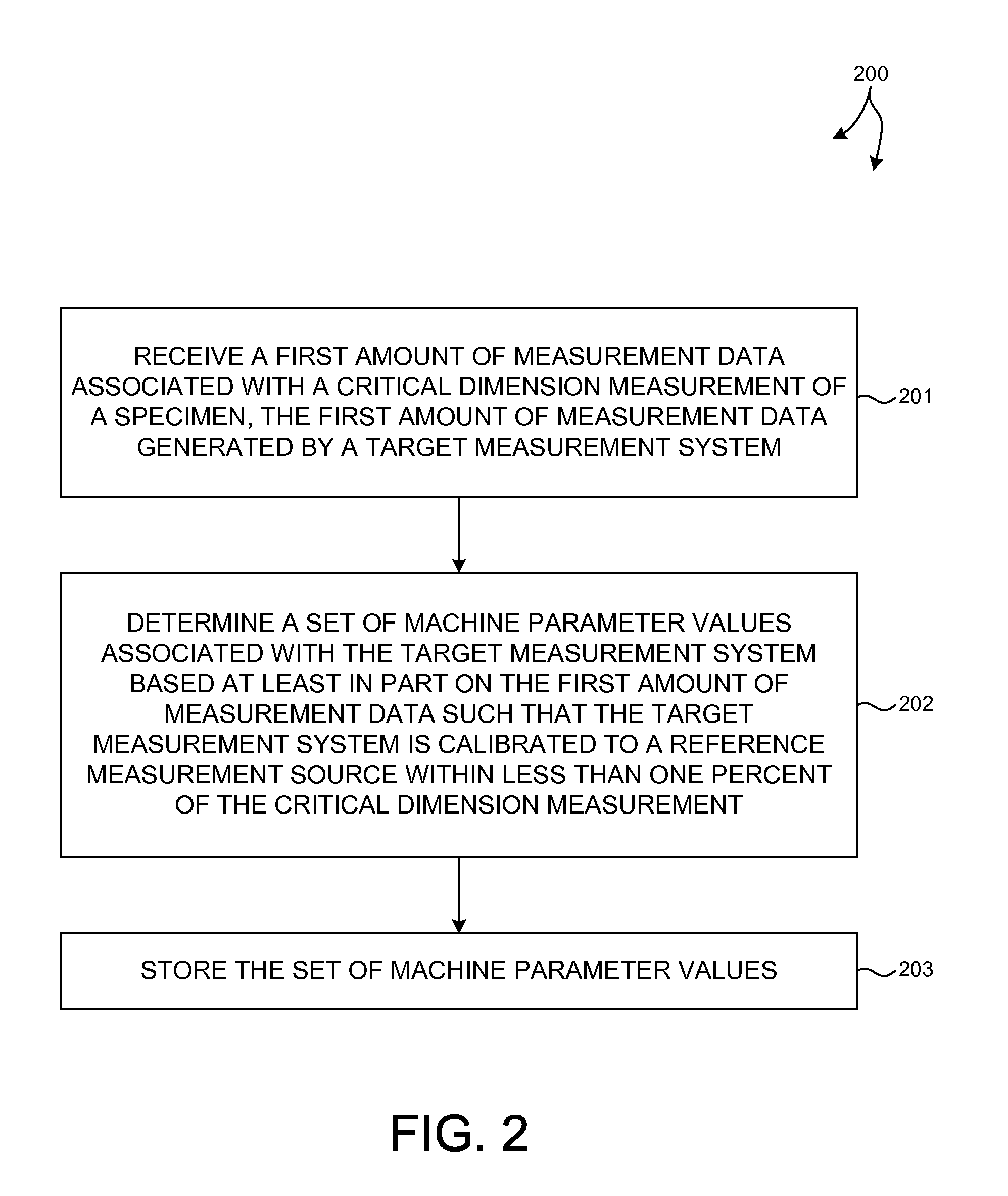

Calibration Of An Optical Metrology System For Critical Dimension Application Matching

InactiveUS20130245985A1Broaden applicationEnhance tool-to-tool matchingTesting/monitoring control systemsPhotomechanical apparatusOptical metrologyData calibration

Methods and systems for matching critical dimension measurement applications at high precision across multiple optical metrology systems are presented. In one aspect, machine parameter values of a metrology system are calibrated based on critical dimension measurement data. In one further aspect, calibration of the machine parameter values is based on critical dimension measurement data collected by a target measurement system from a specimen with assigned critical dimension parameter values obtained from a reference measurement source. In another further aspect, the calibration of the machine parameter values of a target measurement system is based on measurement data without knowledge of critical dimension parameter values. In some examples, the measurement data includes critical dimension measurement data and thin film measurement data. Calibration of machine parameter values based on critical dimension data enhances application and tool-to-tool matching among systems for measurement of critical dimensions, film thickness, film composition, and overlay.

Owner:KLA TENCOR TECH CORP

Methods and systems for determining an implant characteristic and a presence of defects on a specimen

InactiveUS6891610B2Speed up the processShorten the timeSemiconductor/solid-state device testing/measurementPolarisation-affecting propertiesMeasurement deviceEngineering

Methods and systems for monitoring semiconductor fabrication processes are provided. A system may include a stage configured to support a specimen and coupled to a measurement device. The measurement device may include an illumination system and a detection system. The illumination system and the detection system may be configured such that the system may be configured to determine multiple properties of the specimen. For example, the system may be configured to determine multiple properties of a specimen including, but not limited to, an implant characteristic and a presence of defects. In this manner, a measurement device may perform multiple optical and / or non-optical metrology and / or inspection techniques.

Owner:KLA TENCOR CORP

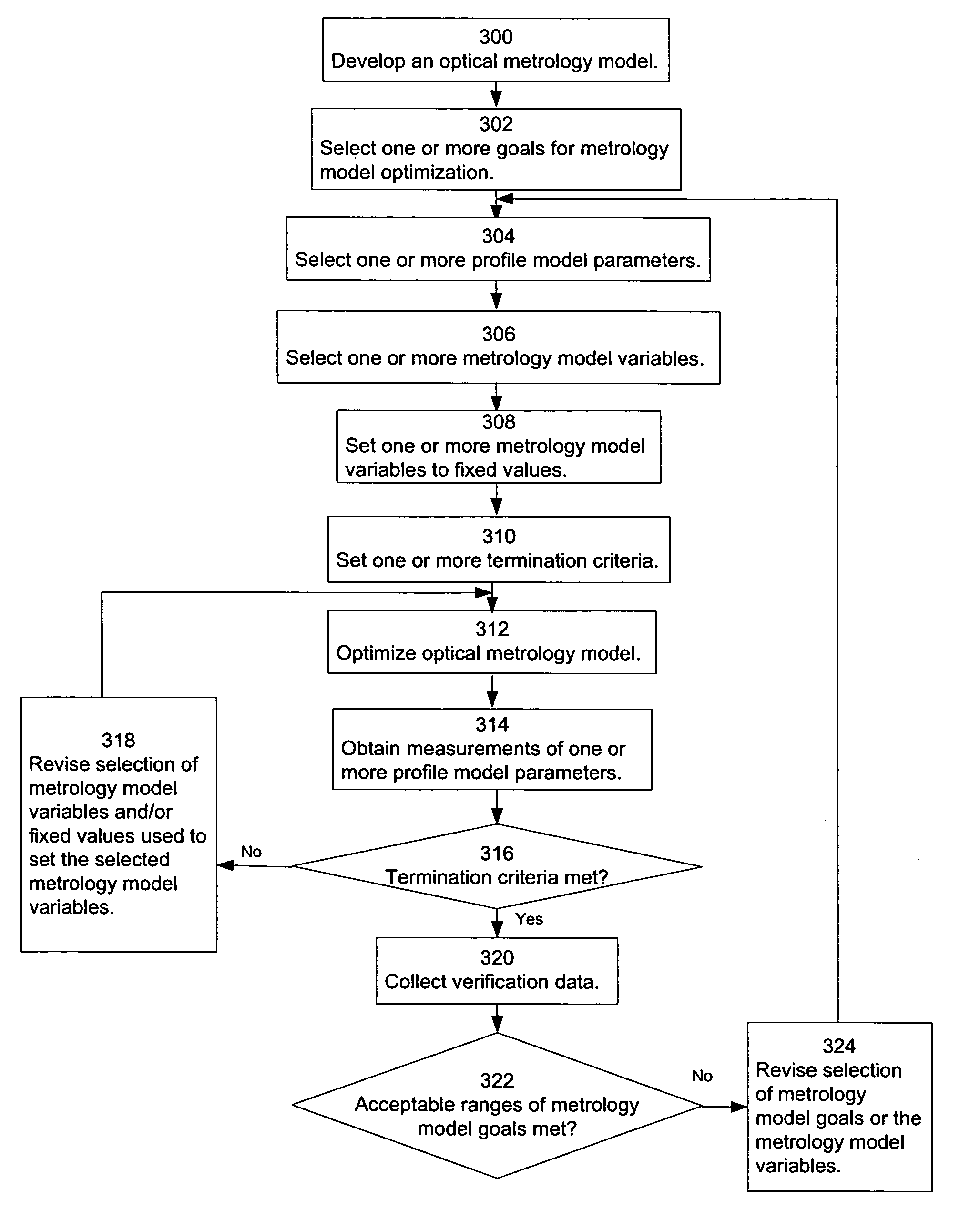

Optical metrology model optimization based on goals

ActiveUS7171284B2Semiconductor/solid-state device testing/measurementPhotomechanical apparatusEngineeringModel parameters

The optimization of an optical metrology model for use in measuring a wafer structure is evaluated. An optical metrology model having metrology model variables, which includes profile model parameters of a profile model, is developed. One or more goals for metrology model optimization are selected. One or more profile model parameters to be used in evaluating the one or more selected goals are selected. One or more metrology model variables to be set to fixed values are selected. One or more selected metrology model variables are set to fixed values. One or more termination criteria for the one or more selected goals are set. The optical metrology model is optimized using the fixed values for the one or more selected metrology model variables. Measurements for the one or more selected profile model parameters are obtained using the optimized optical metrology model. A determination is then made as to whether the one or more termination criteria are met by the obtained measurements.

Owner:TOKYO ELECTRON LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com