Patents

Literature

2648results about How to "High aspect ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

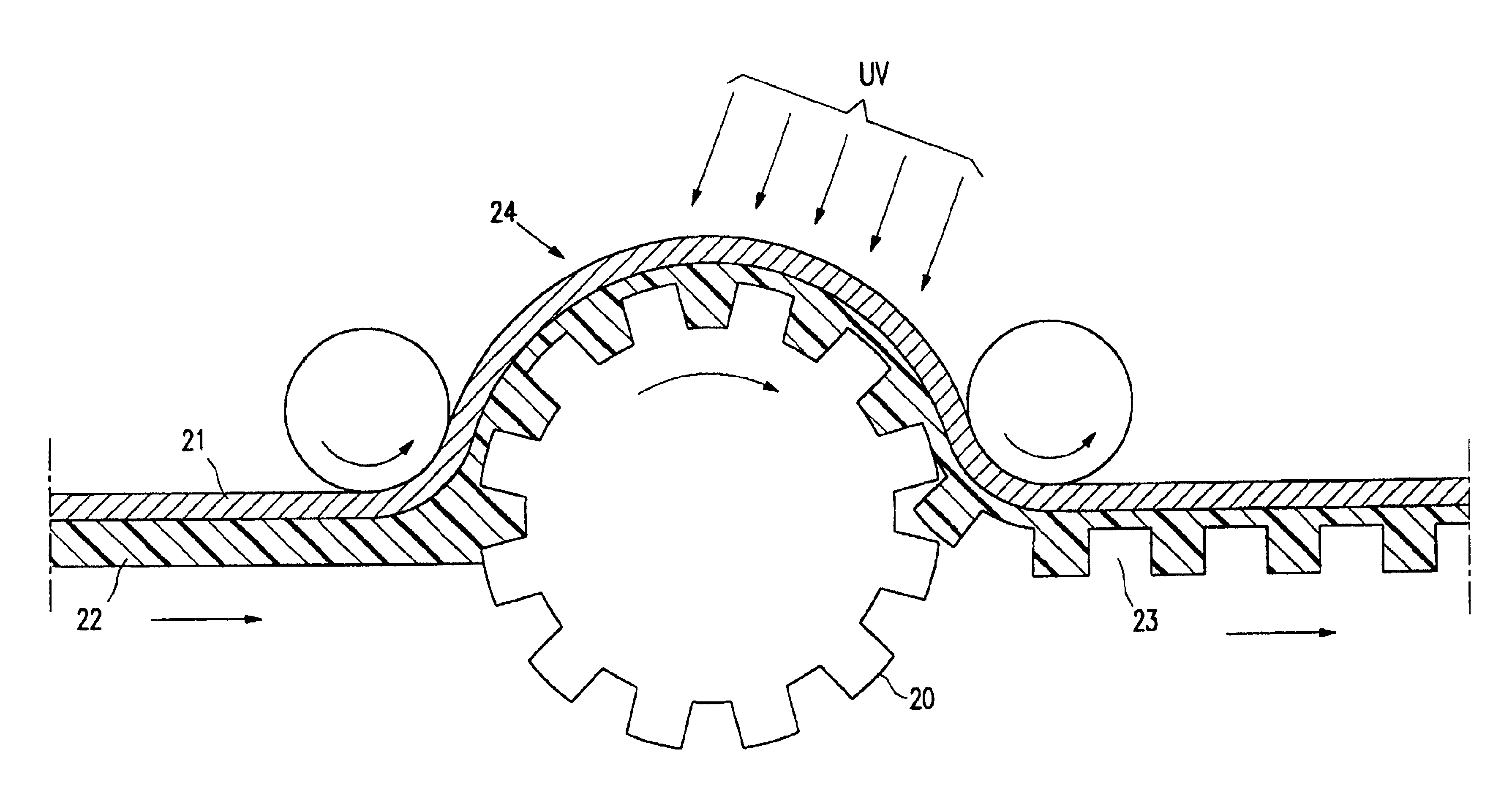

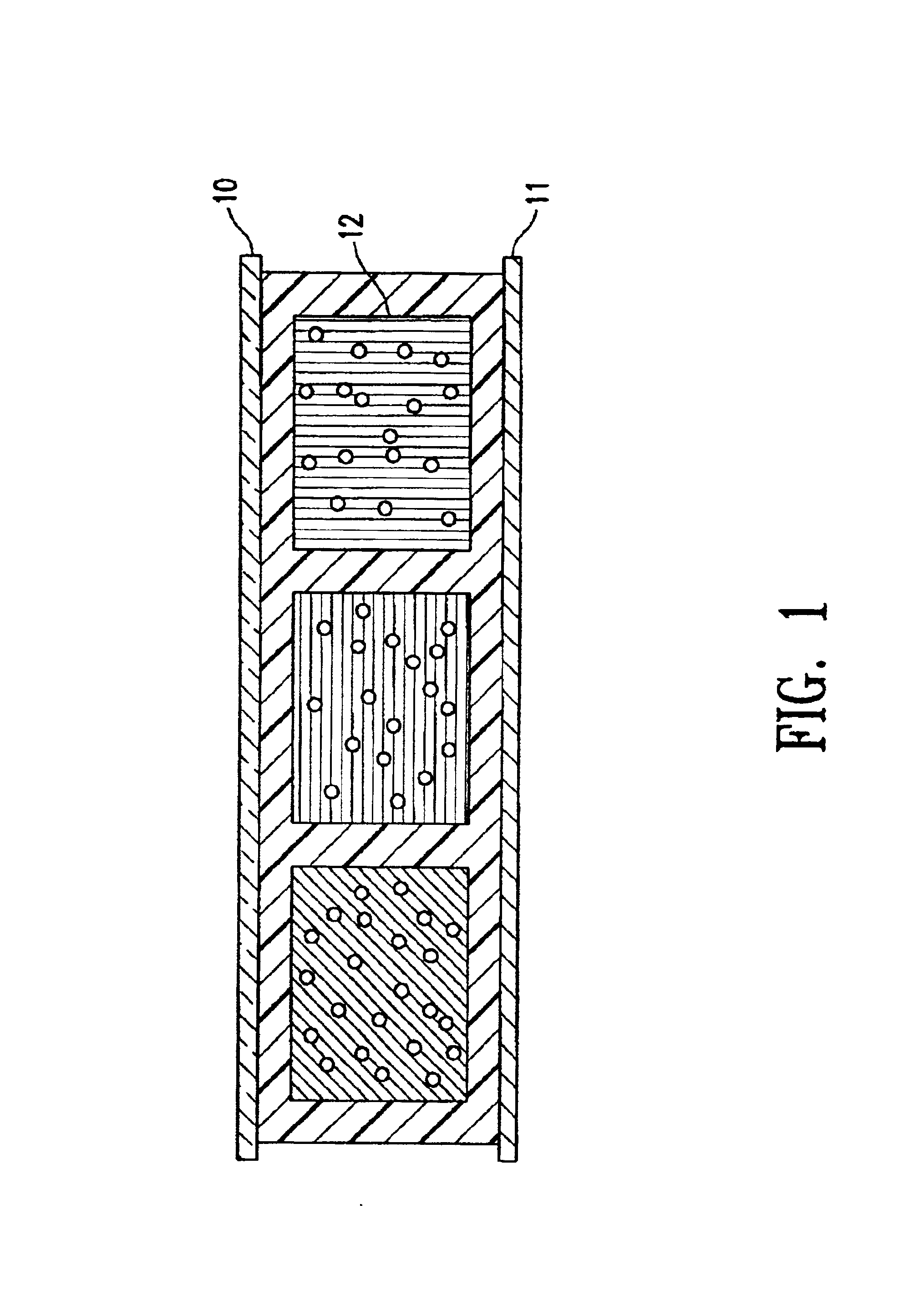

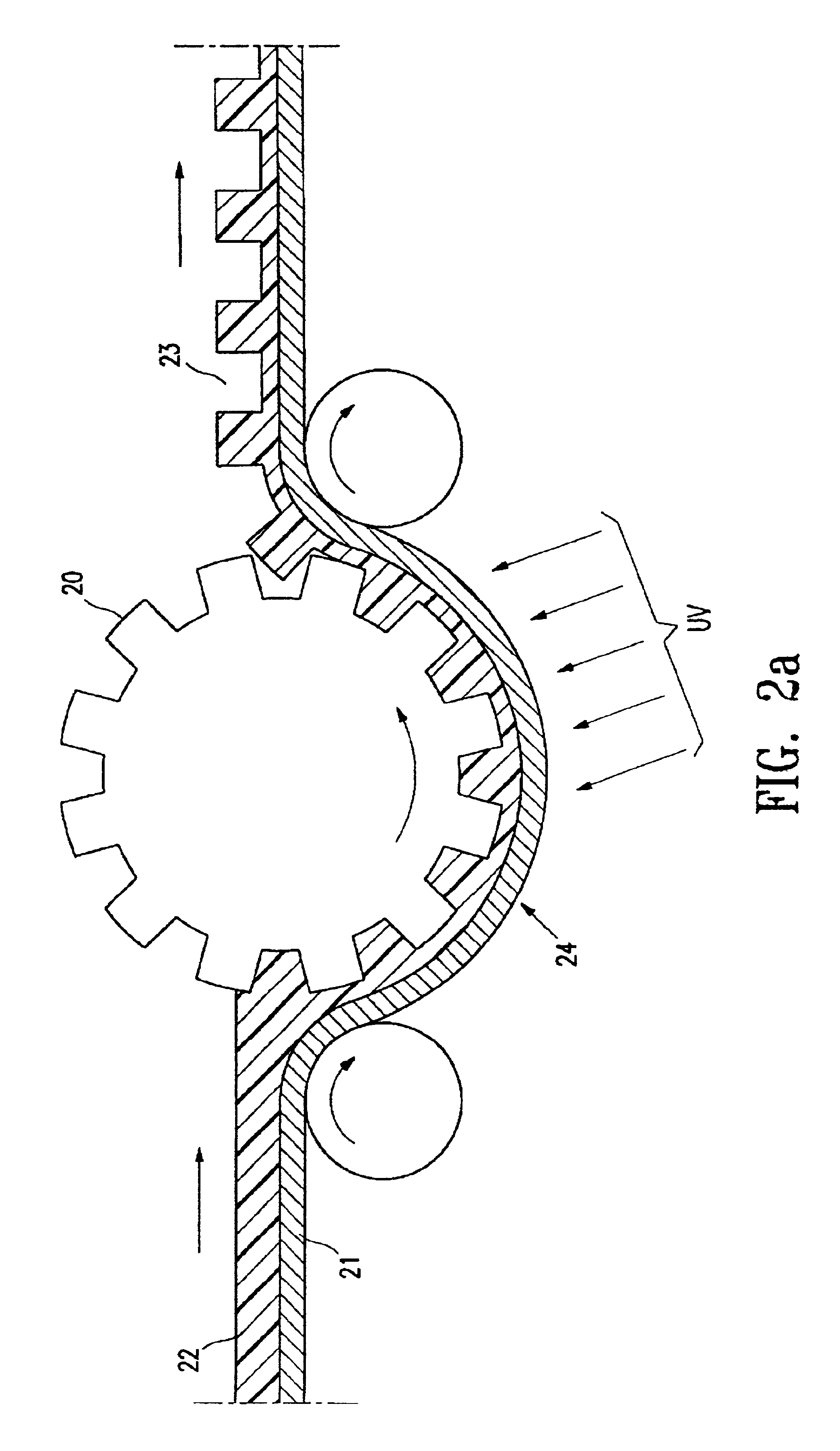

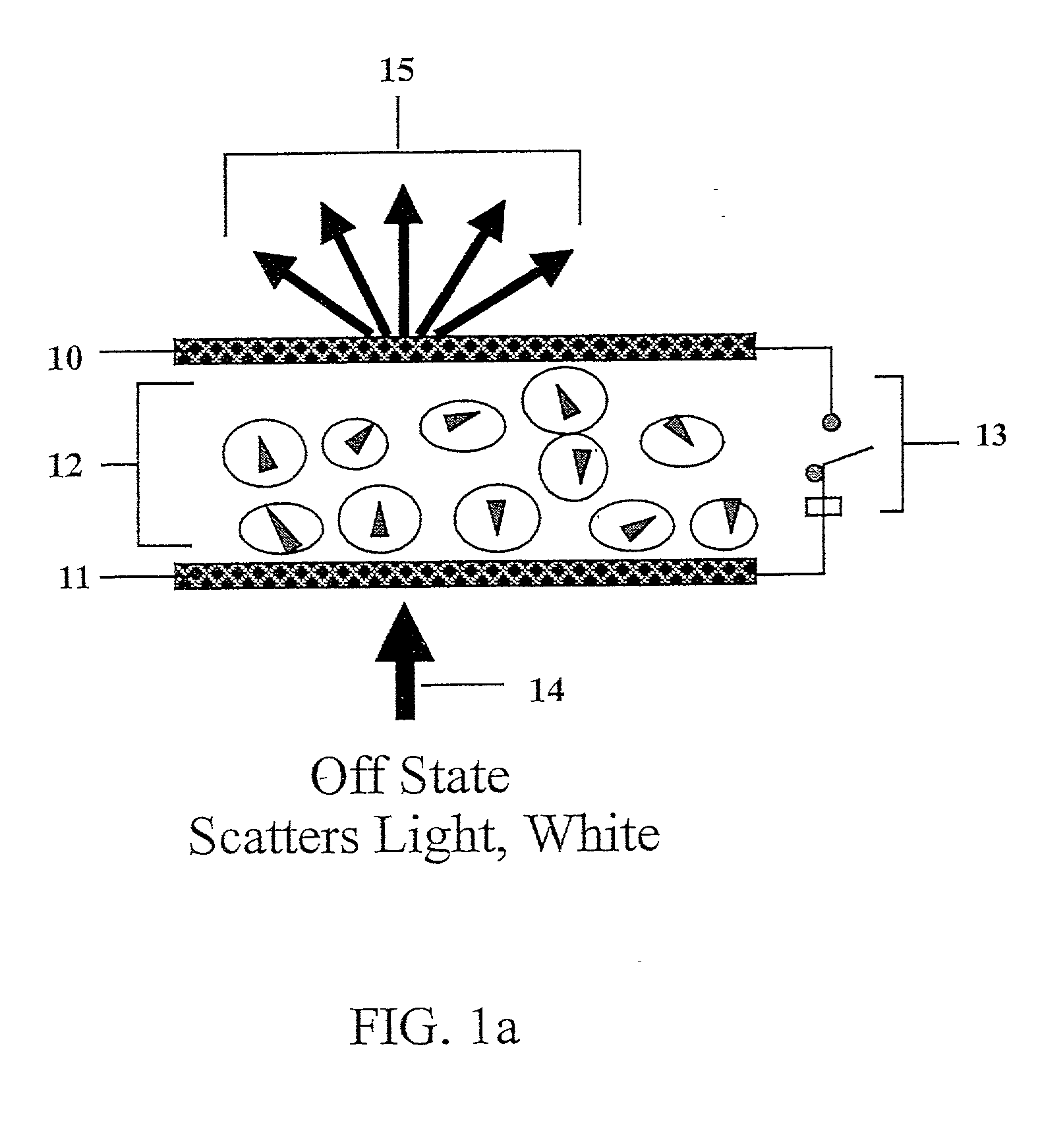

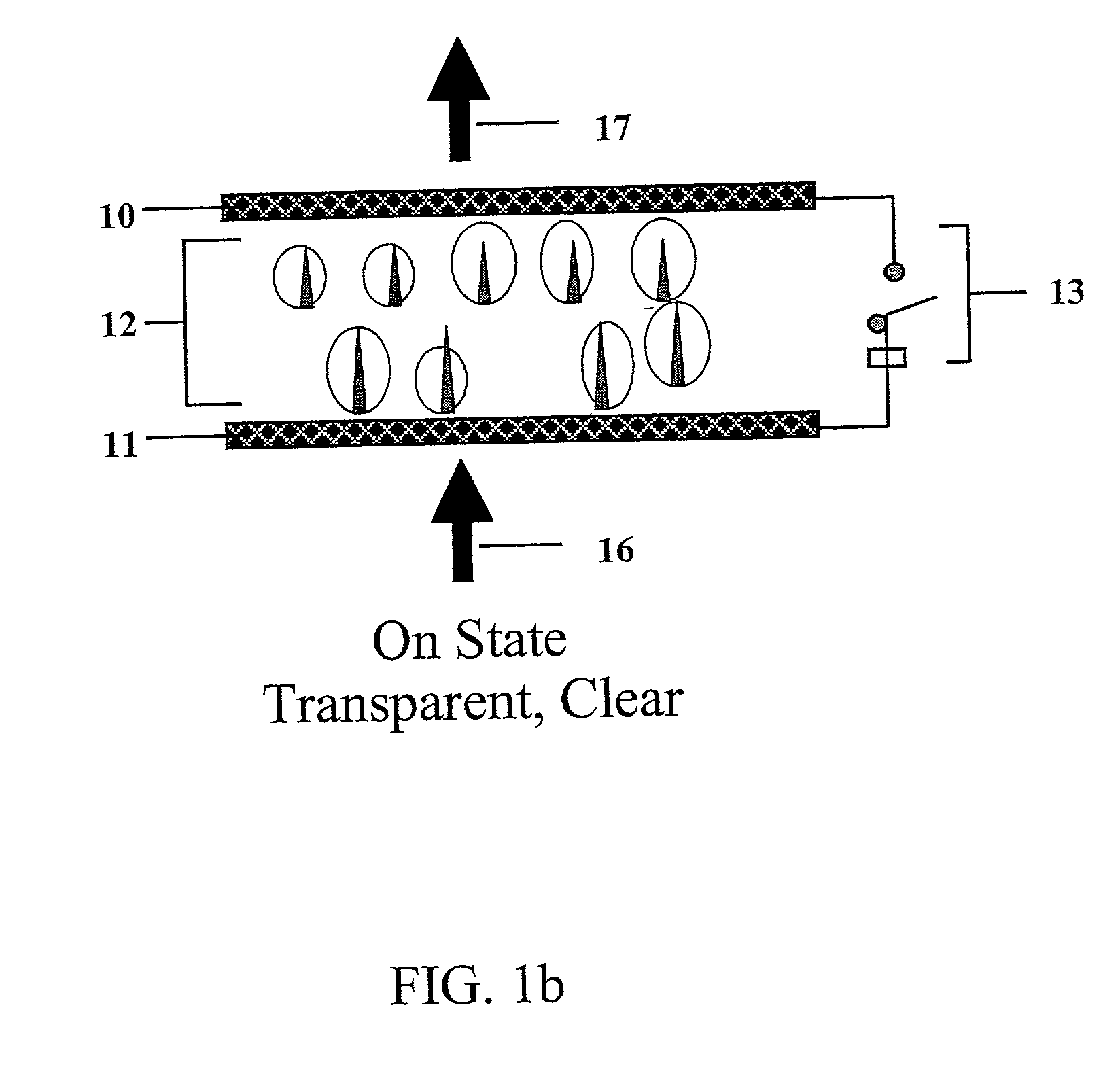

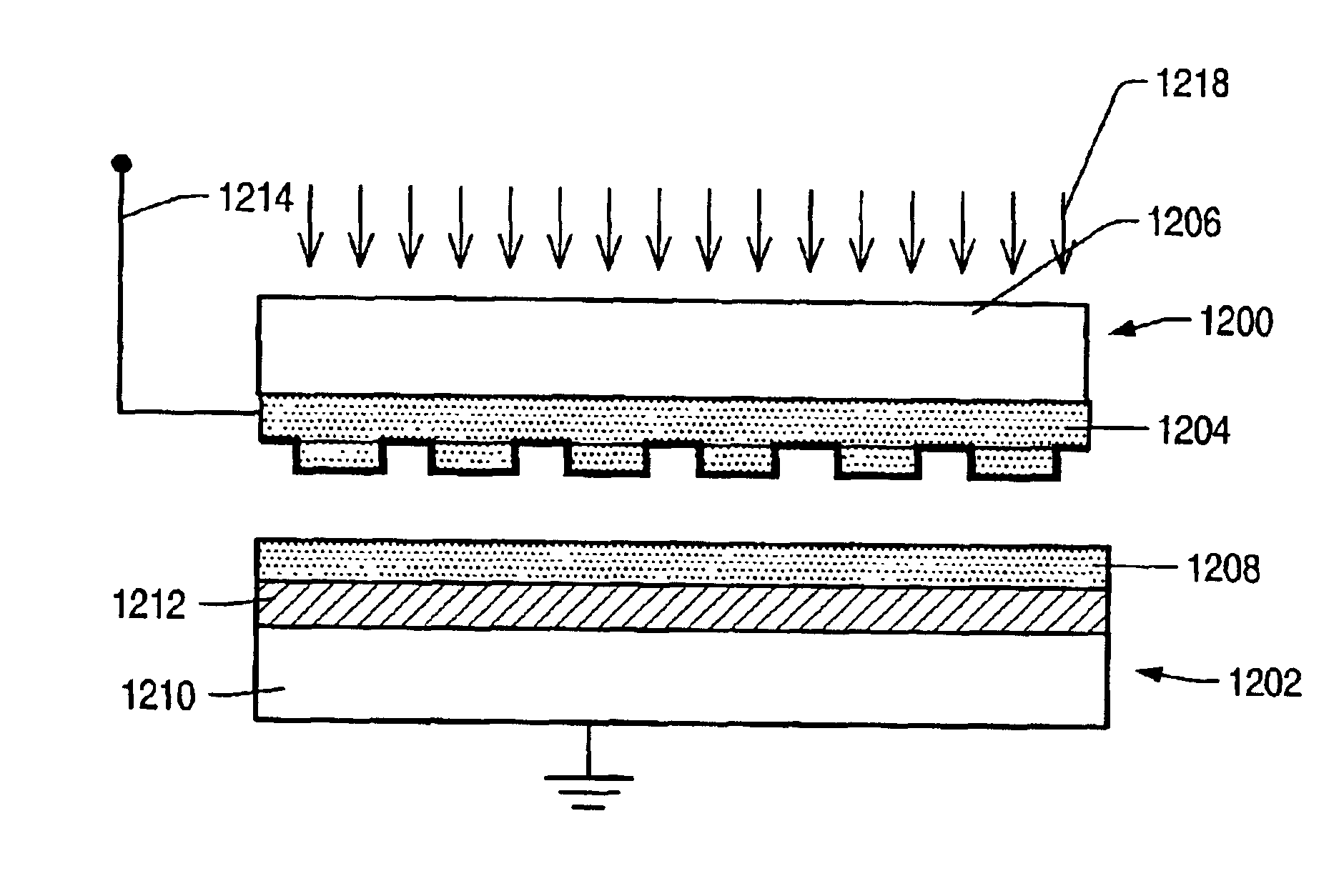

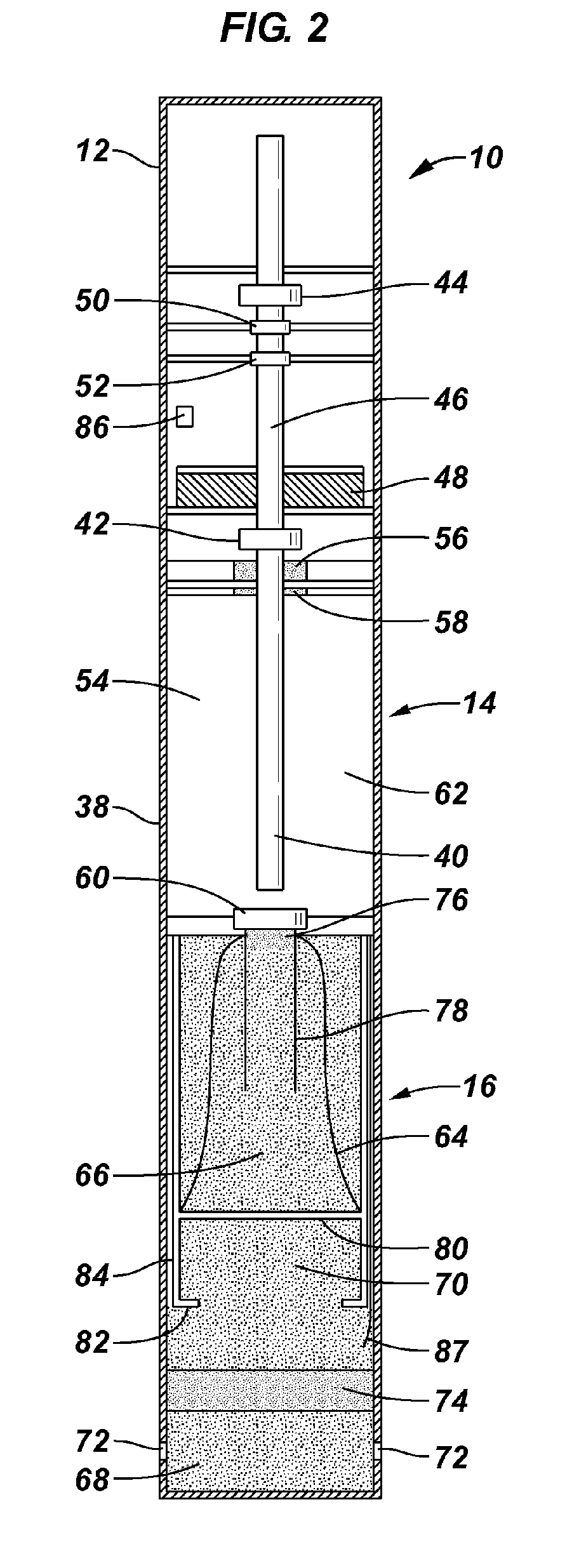

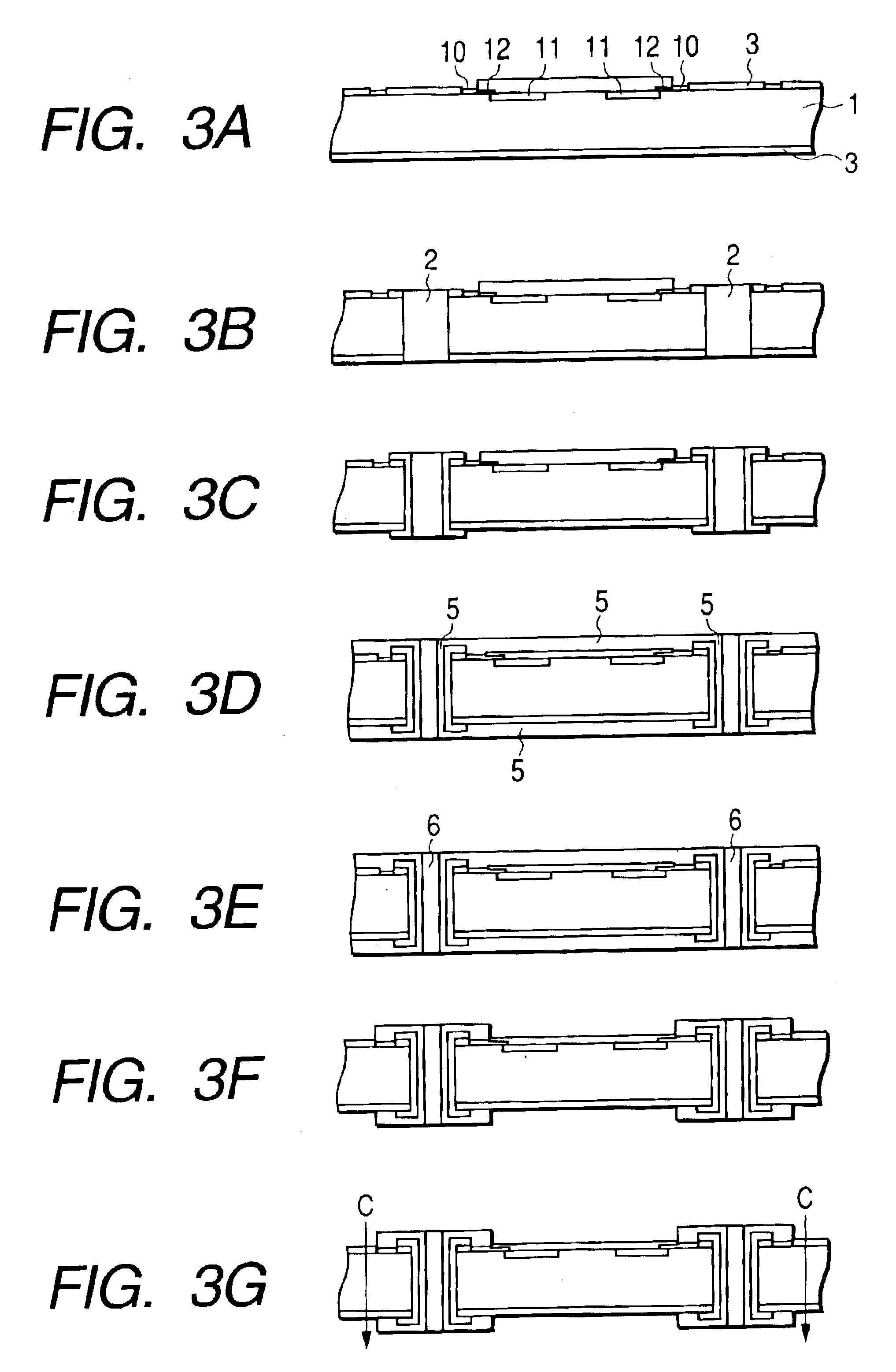

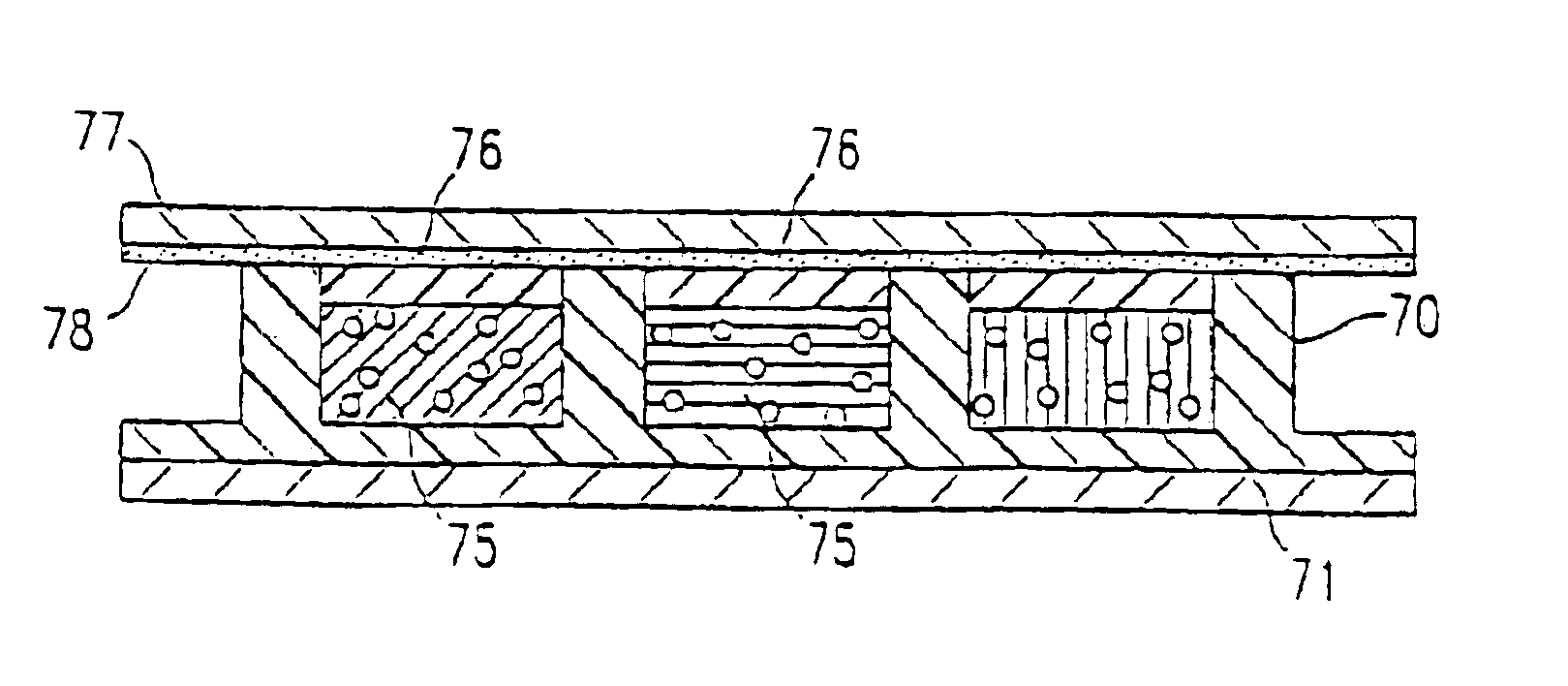

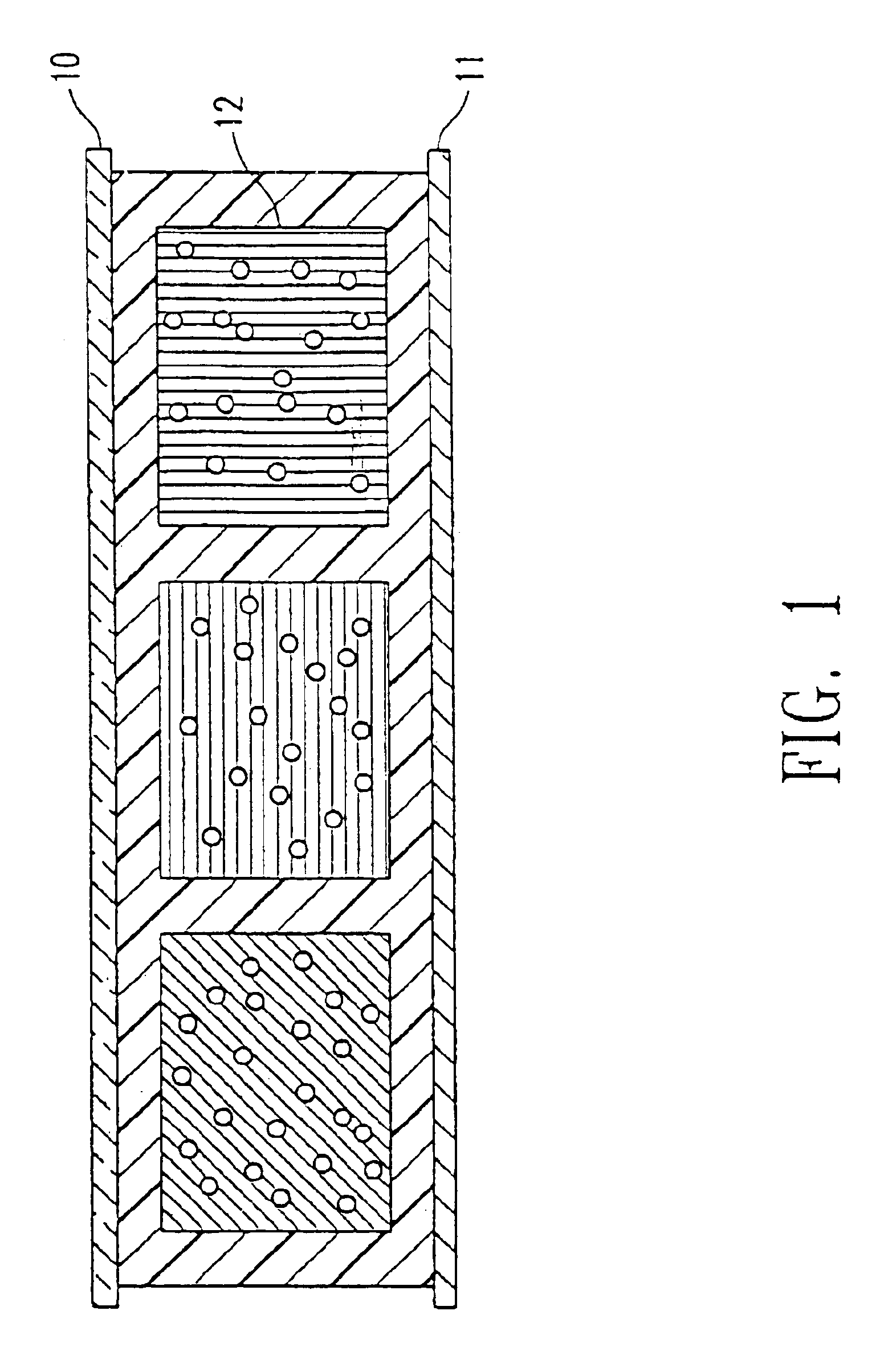

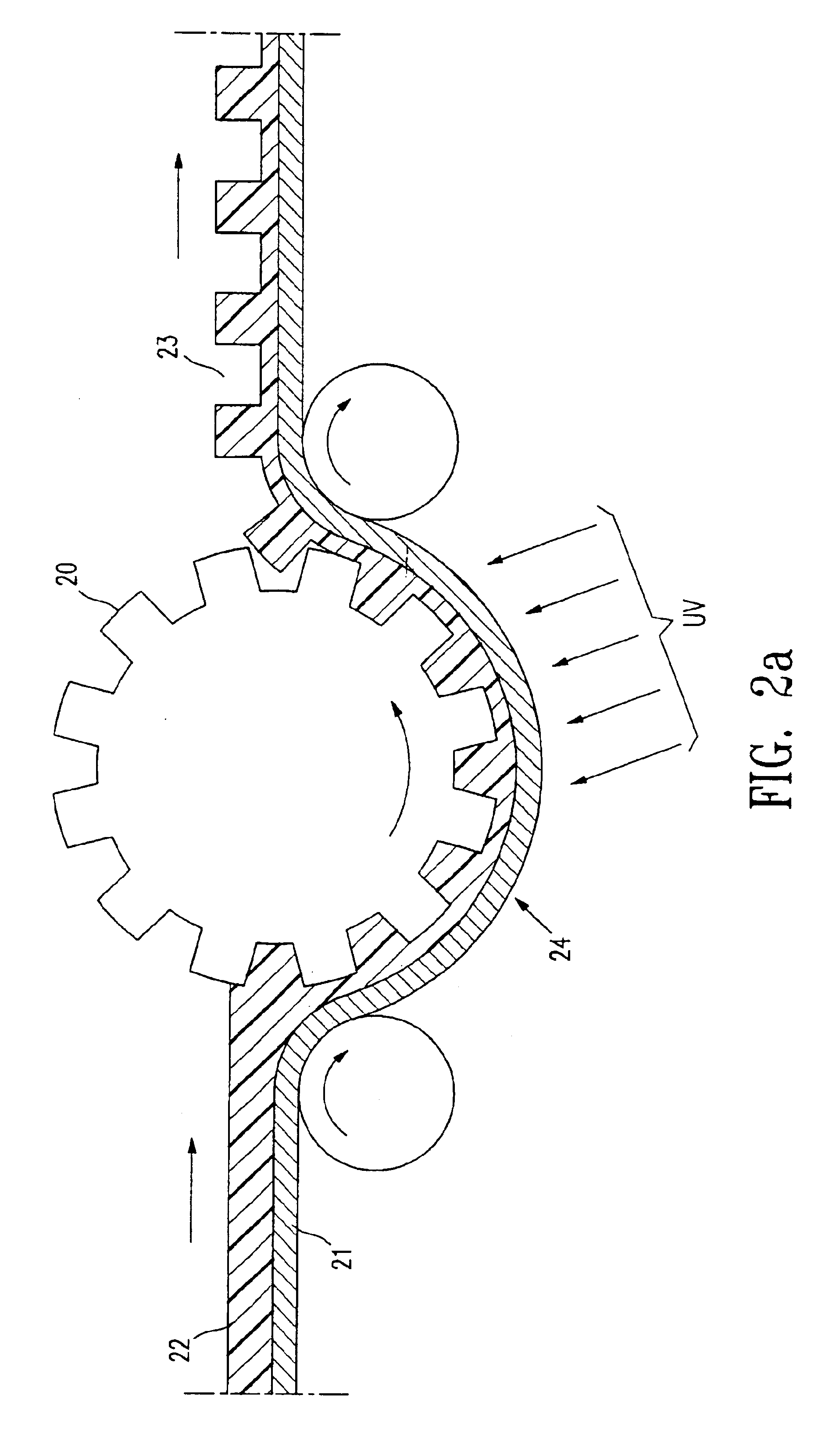

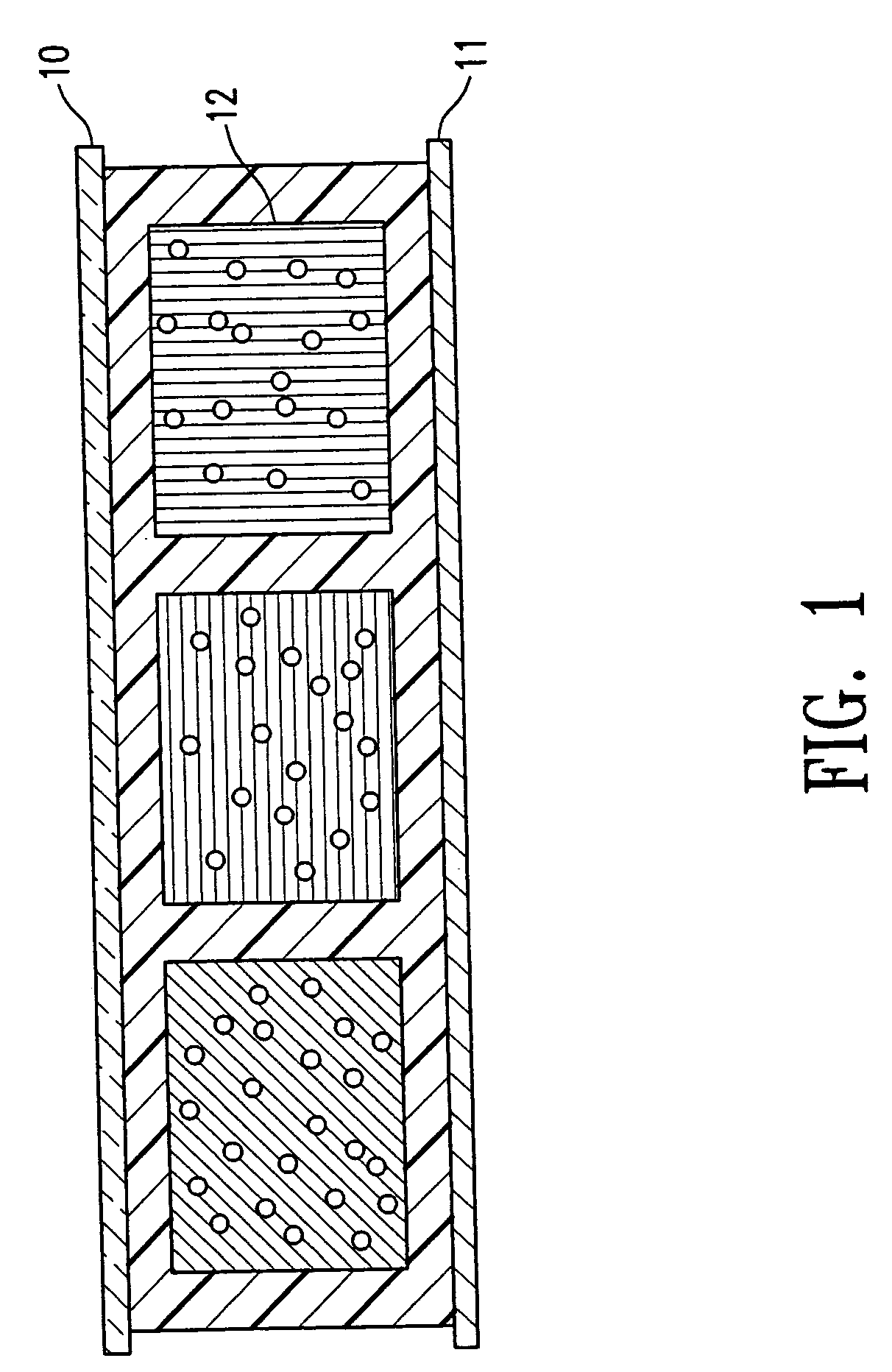

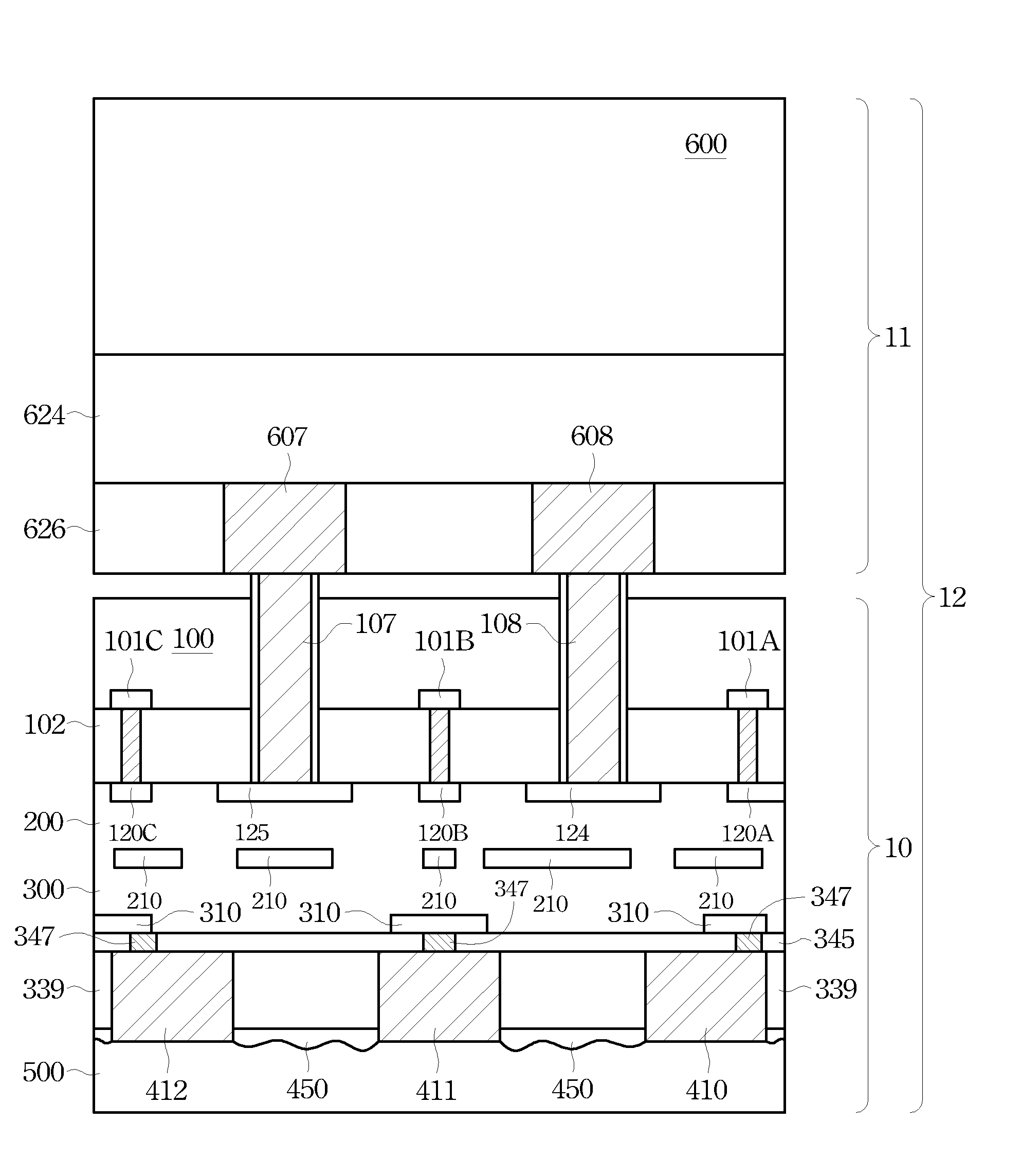

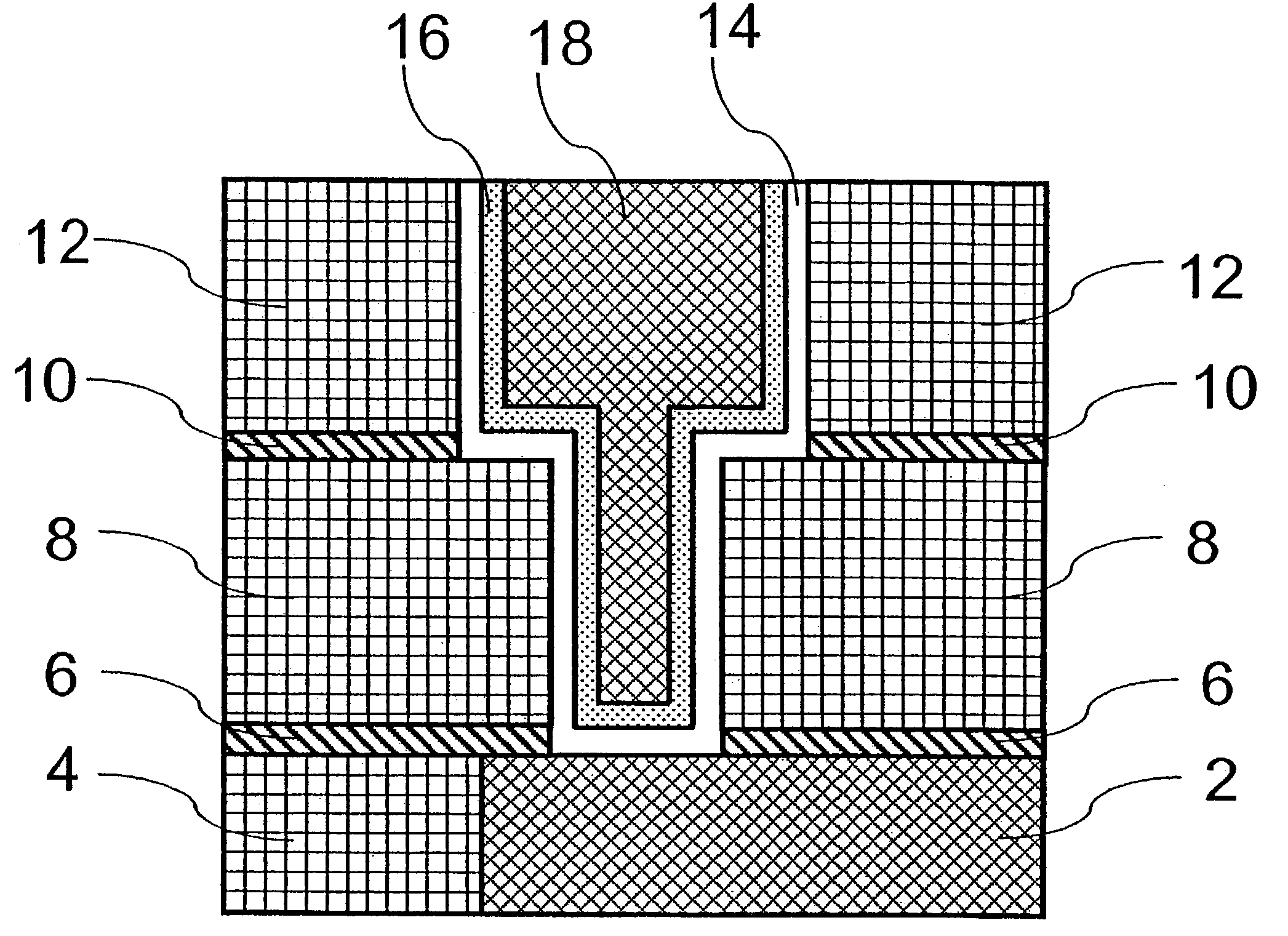

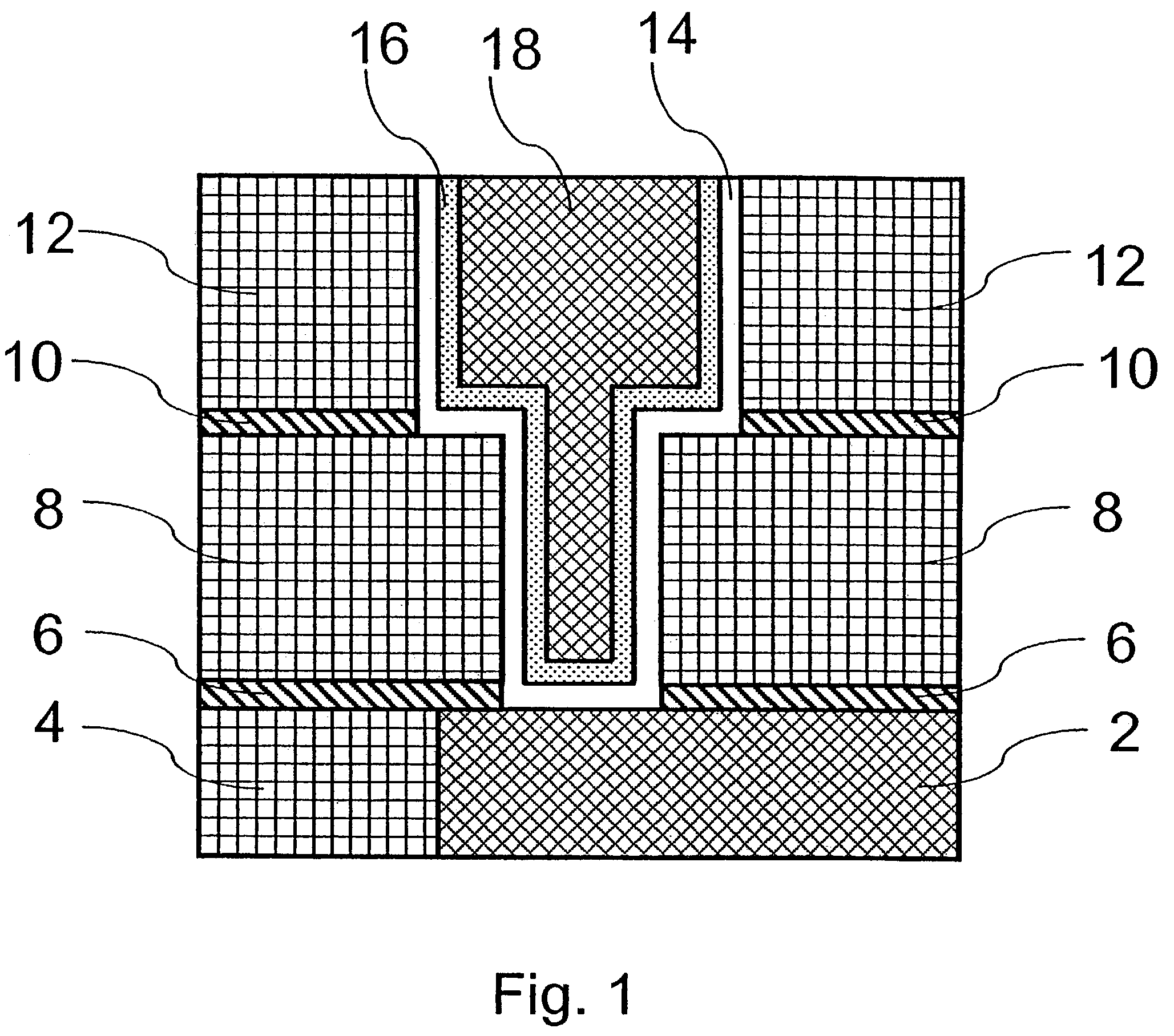

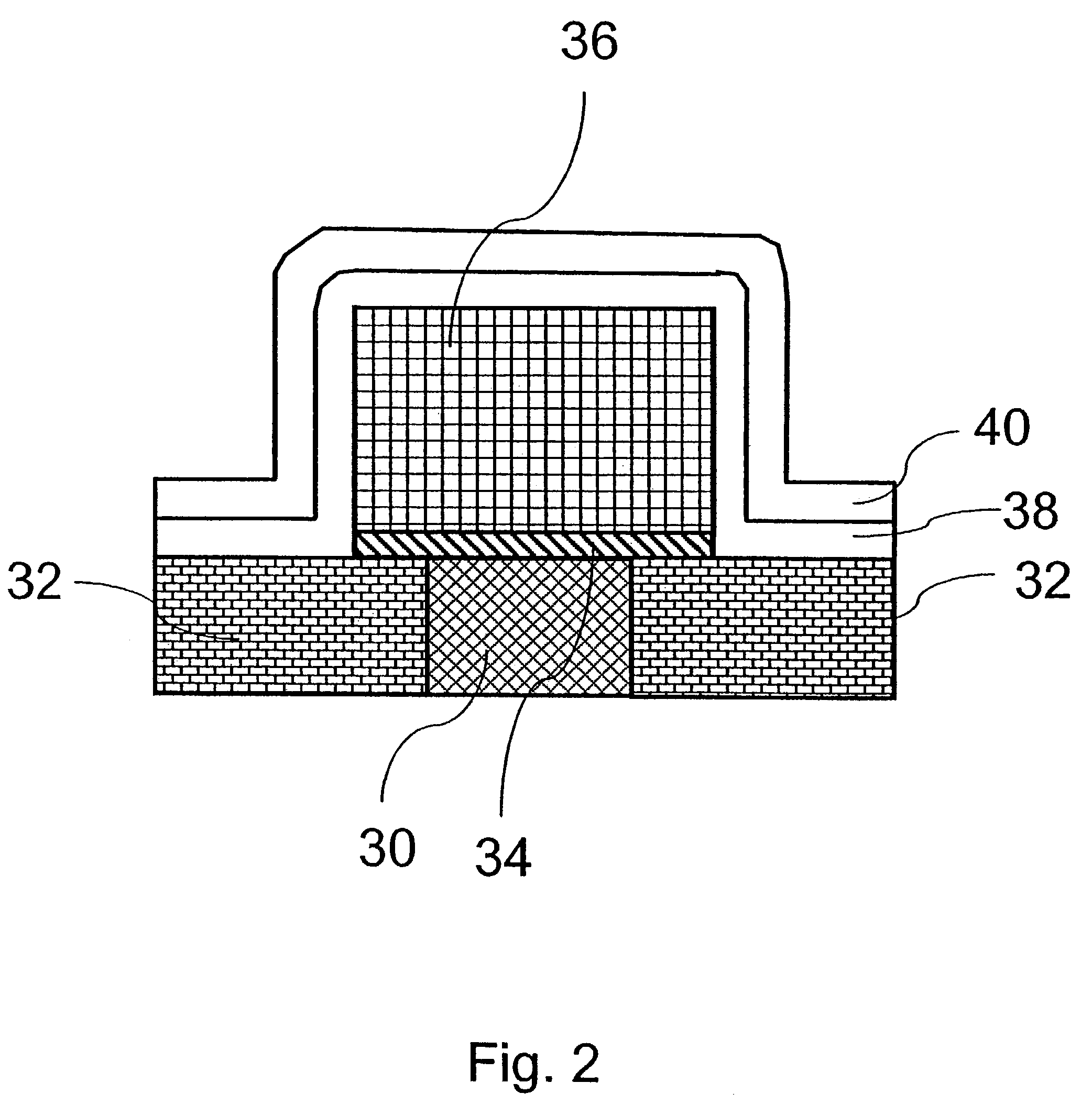

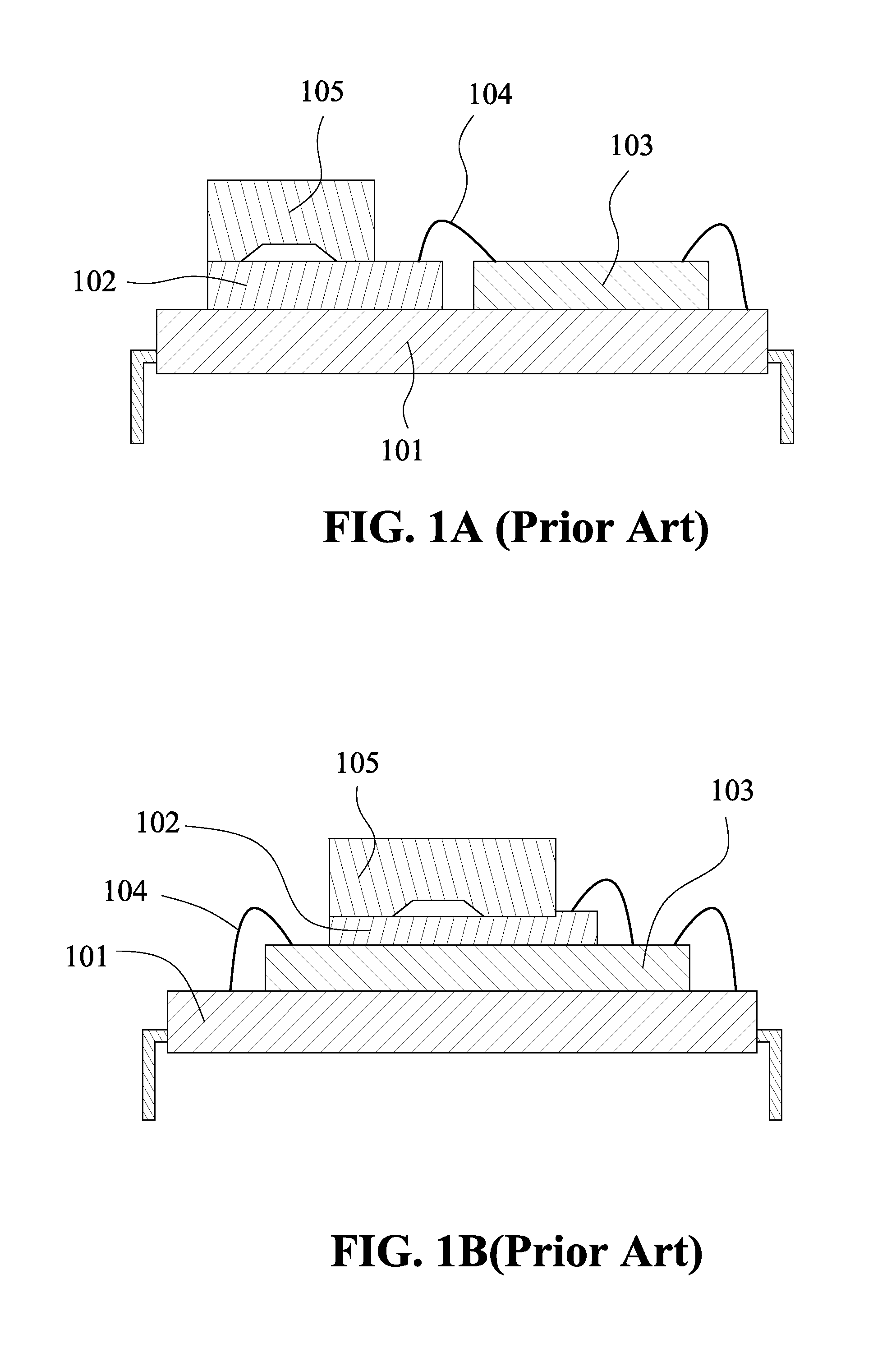

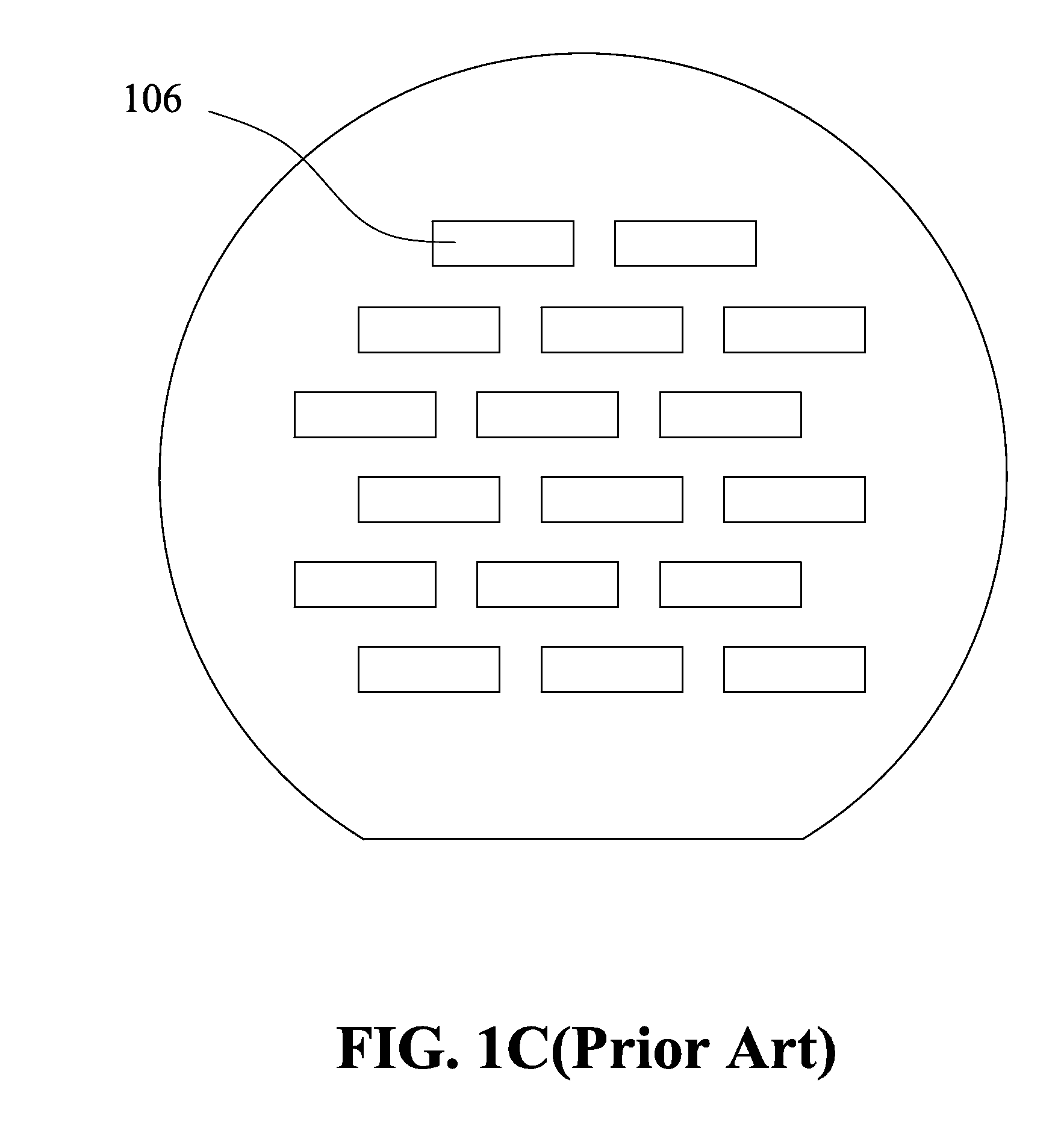

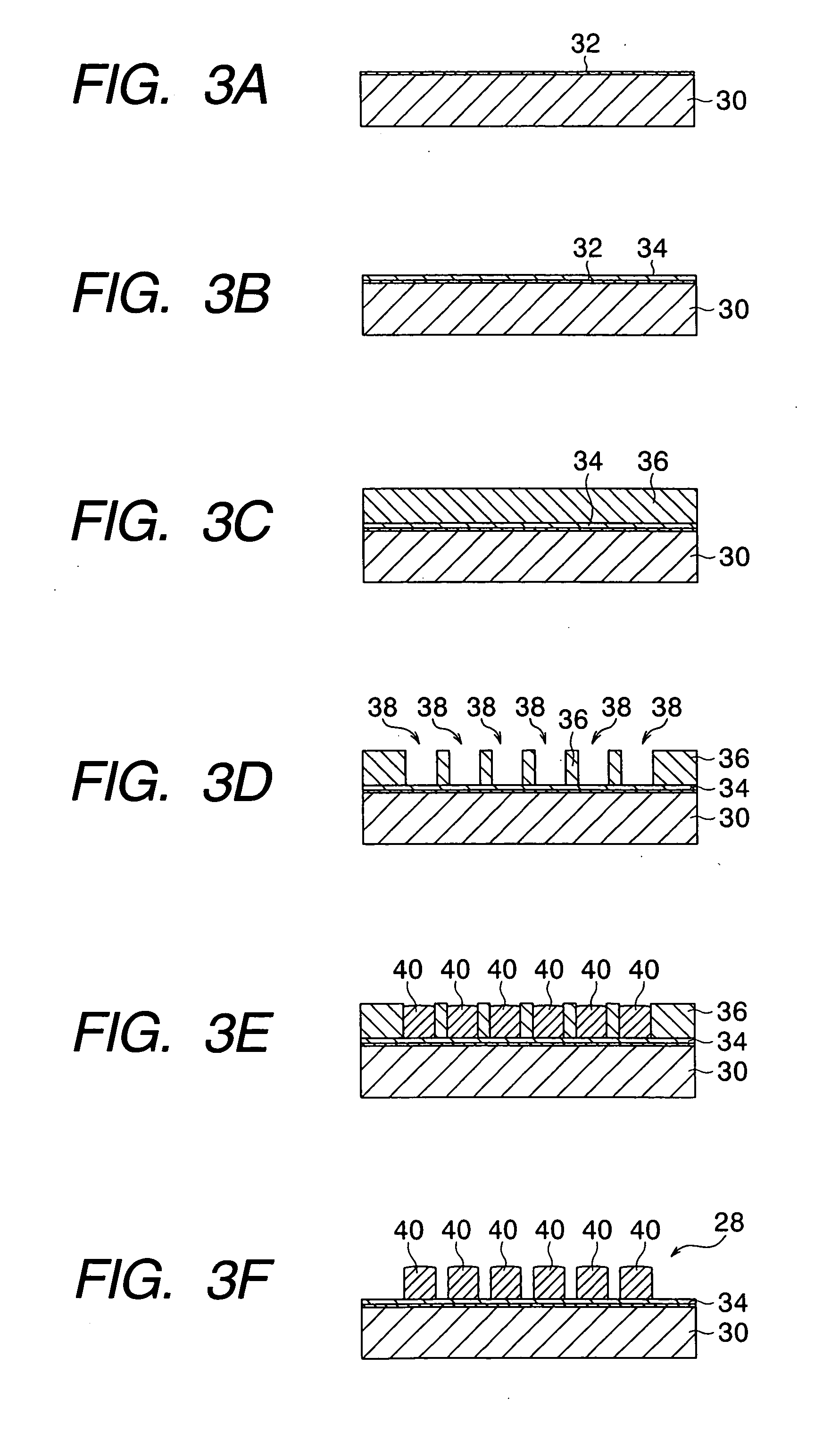

Electrophoretic display and novel process for its manufacture

InactiveUS6930818B1Excellent color addressabilityIncrease contrastStatic indicating devicesMaterial analysis by electric/magnetic meansElectrophoresesDisplay device

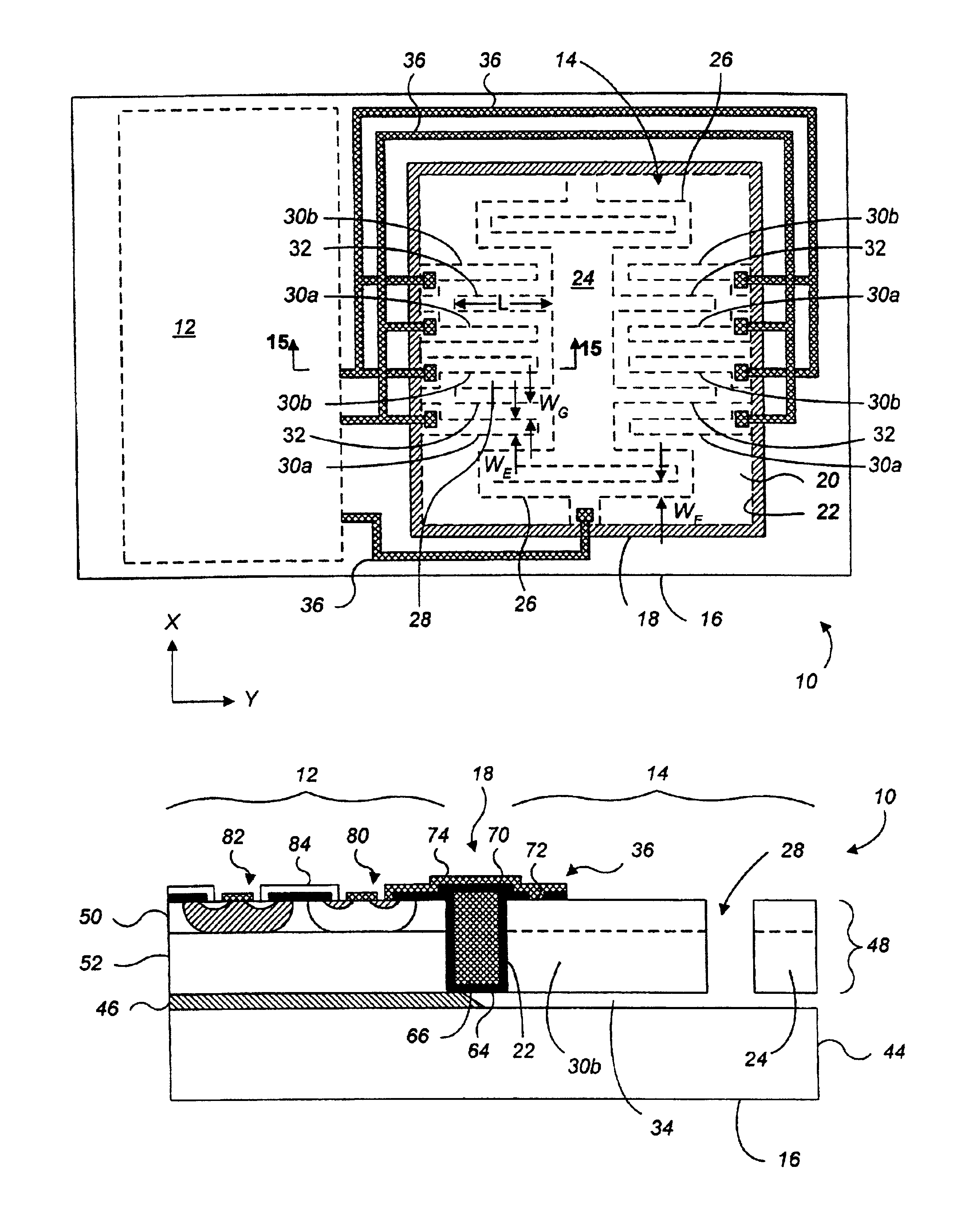

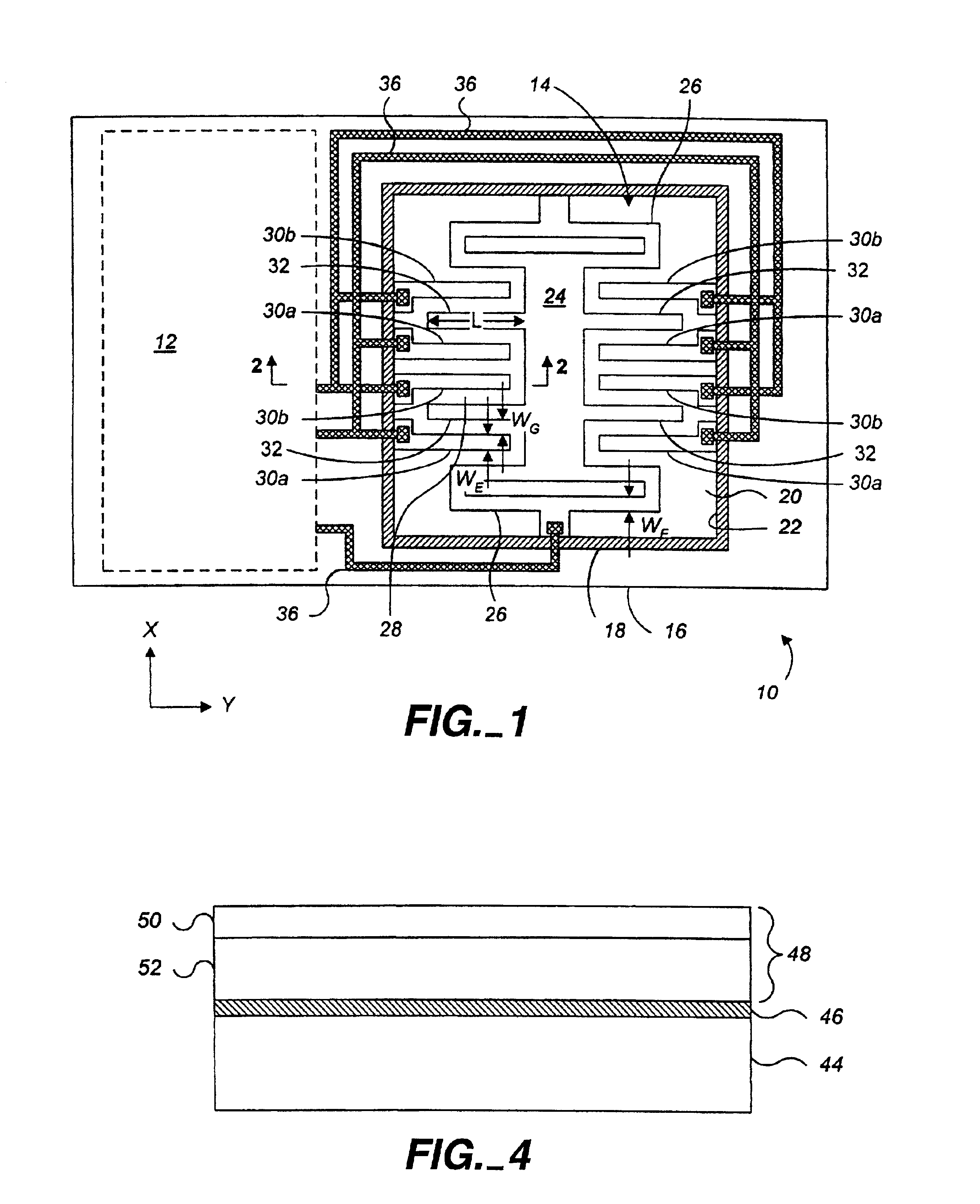

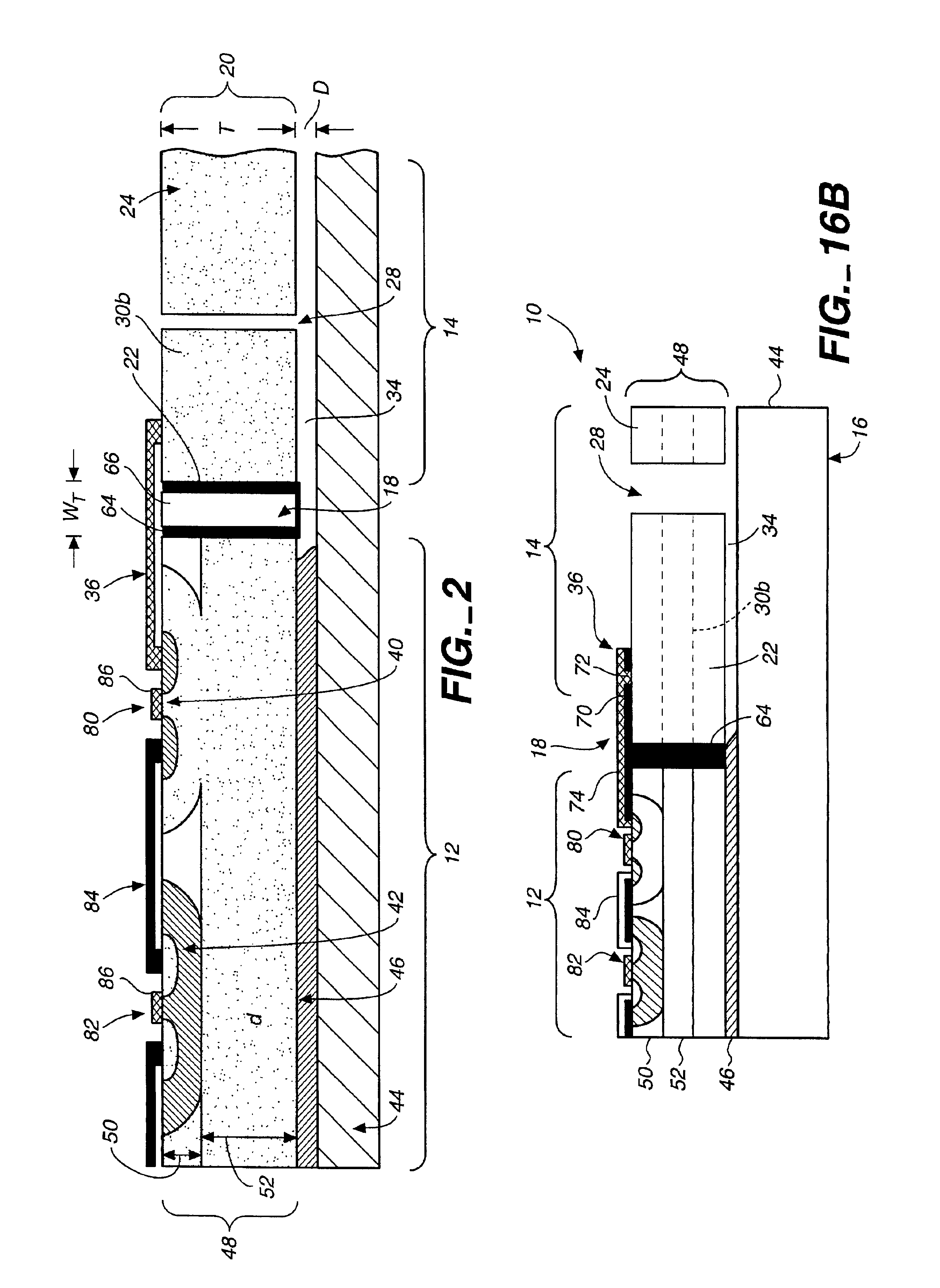

This invention relates to an electrophoretic display comprising cells of well-defined shape, size and aspect ratio which cells are filled with charged pigment particles dispersed in a solvent, and novel processes for its manufacture.

Owner:E INK CALIFORNIA

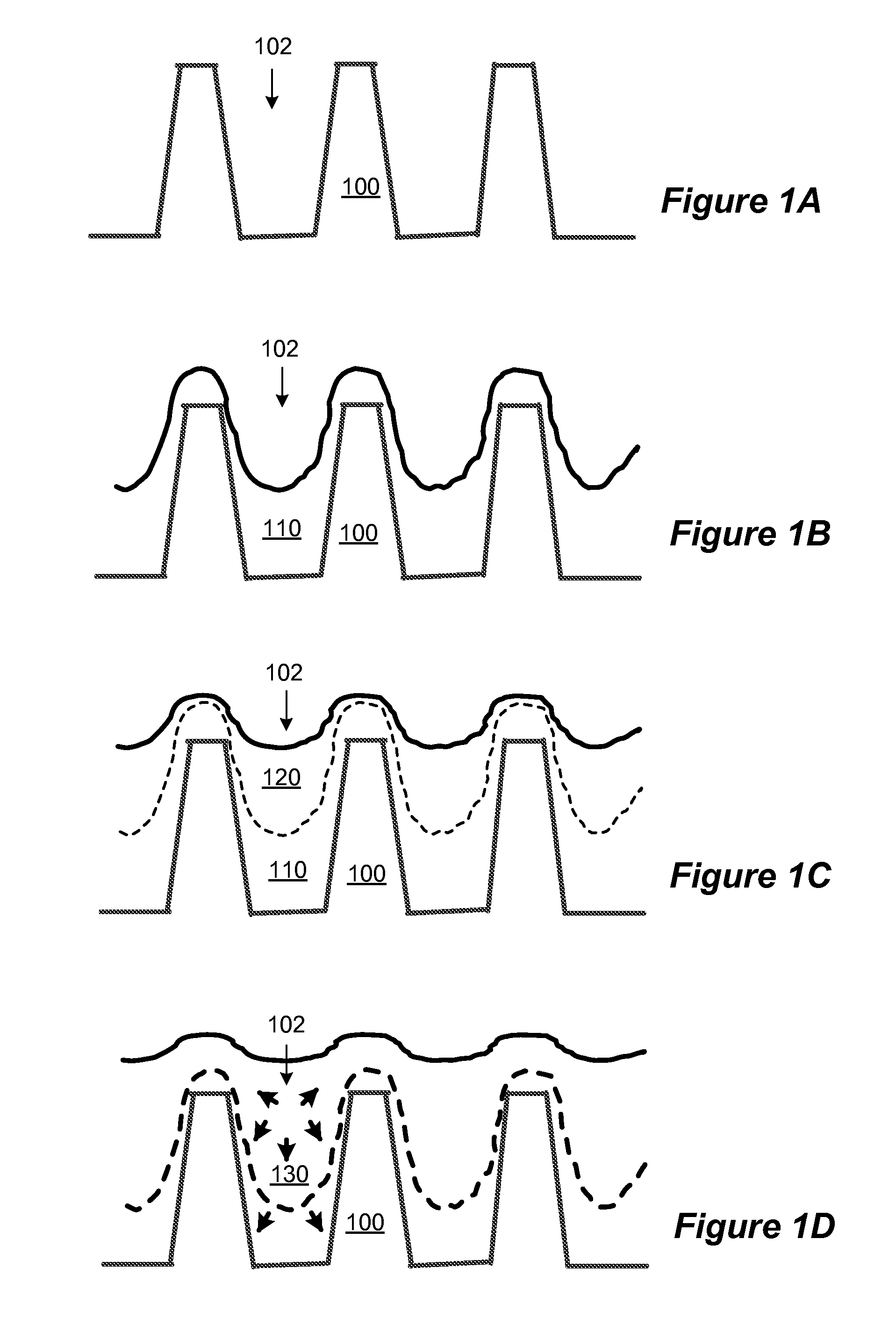

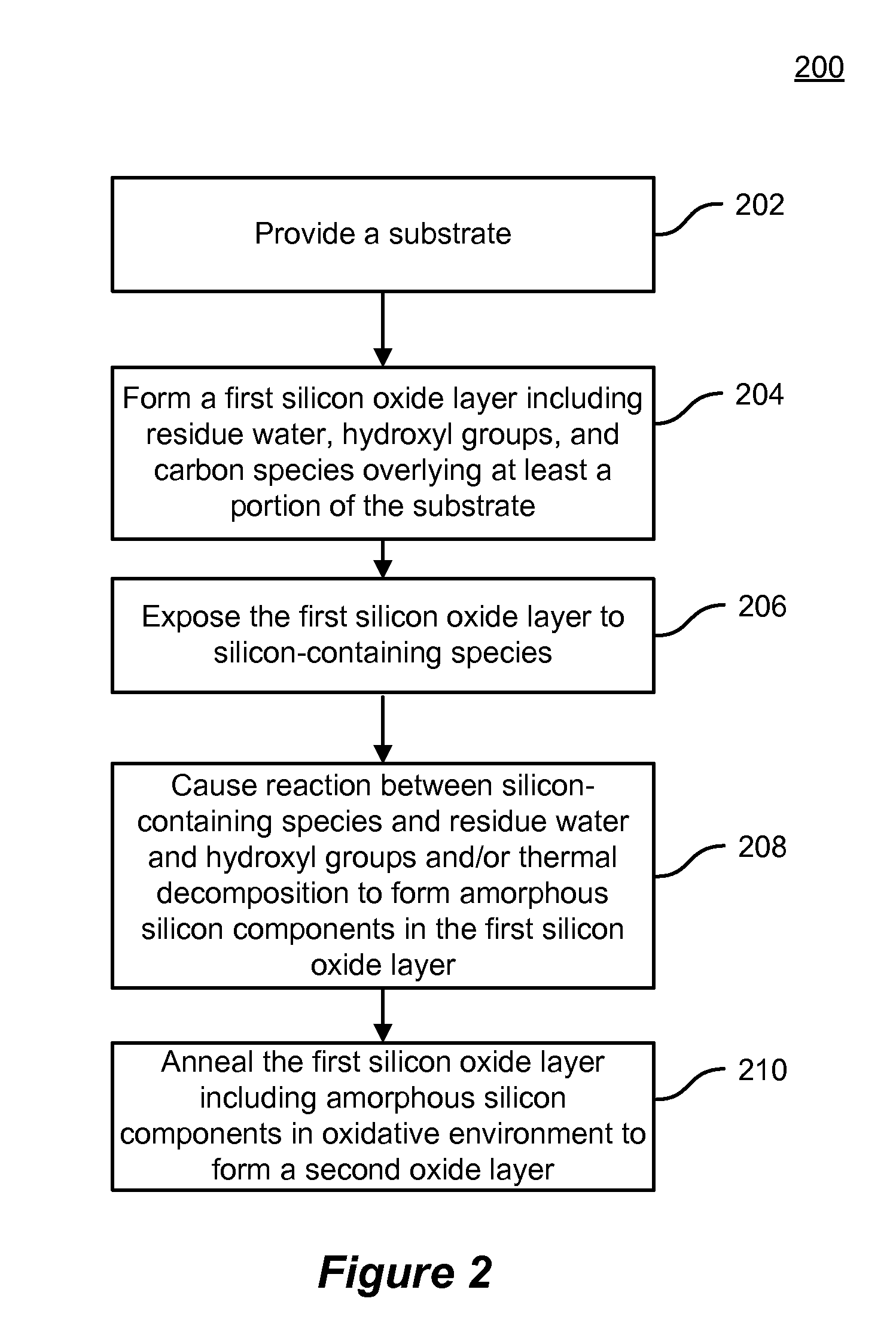

Method and system for improving dielectric film quality for void free gap fill

ActiveUS7541297B2Quality improvementHigh densitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingAmorphous siliconSilicon oxide

Owner:APPLIED MATERIALS INC

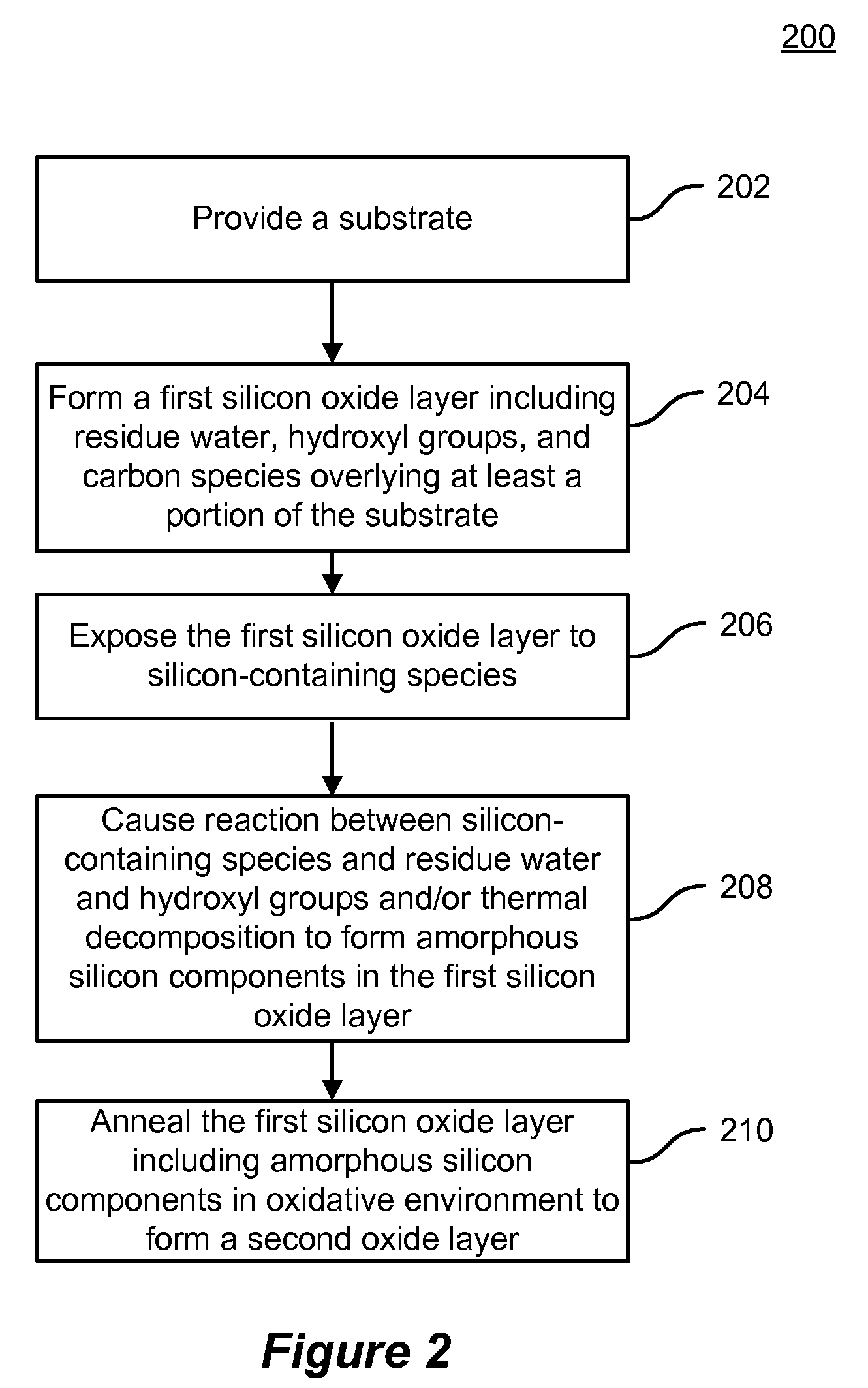

Method and system for improving dielectric film quality for void free gap fill

ActiveUS20090104789A1Quality improvementHigh densitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingSilicon monoxideAmorphous silicon

A method of forming a silicon oxide layer on a substrate. The method includes providing a substrate and forming a first silicon oxide layer overlying at least a portion of the substrate, the first silicon oxide layer including residual water, hydroxyl groups, and carbon species. The method further includes exposing the first silicon oxide layer to a plurality of silicon-containing species to form a plurality of amorphous silicon components being partially intermixed with the first silicon oxide layer. Additionally, the method includes annealing the first silicon oxide layer partially intermixed with the plurality of amorphous silicon components in an oxidative environment to form a second silicon oxide layer on the substrate. At least a portion of amorphous silicon components are oxidized to become part of the second silicon oxide layer and unreacted residual hydroxyl groups and carbon species in the second silicon oxide layer are substantially removed.

Owner:APPLIED MATERIALS INC

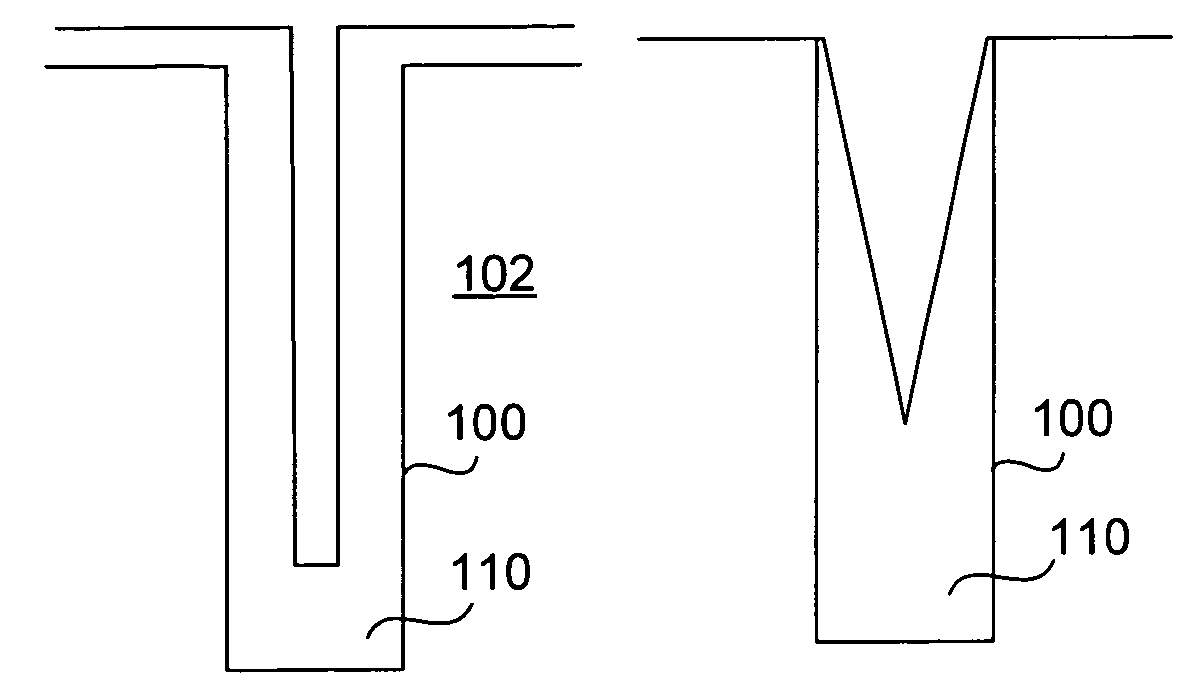

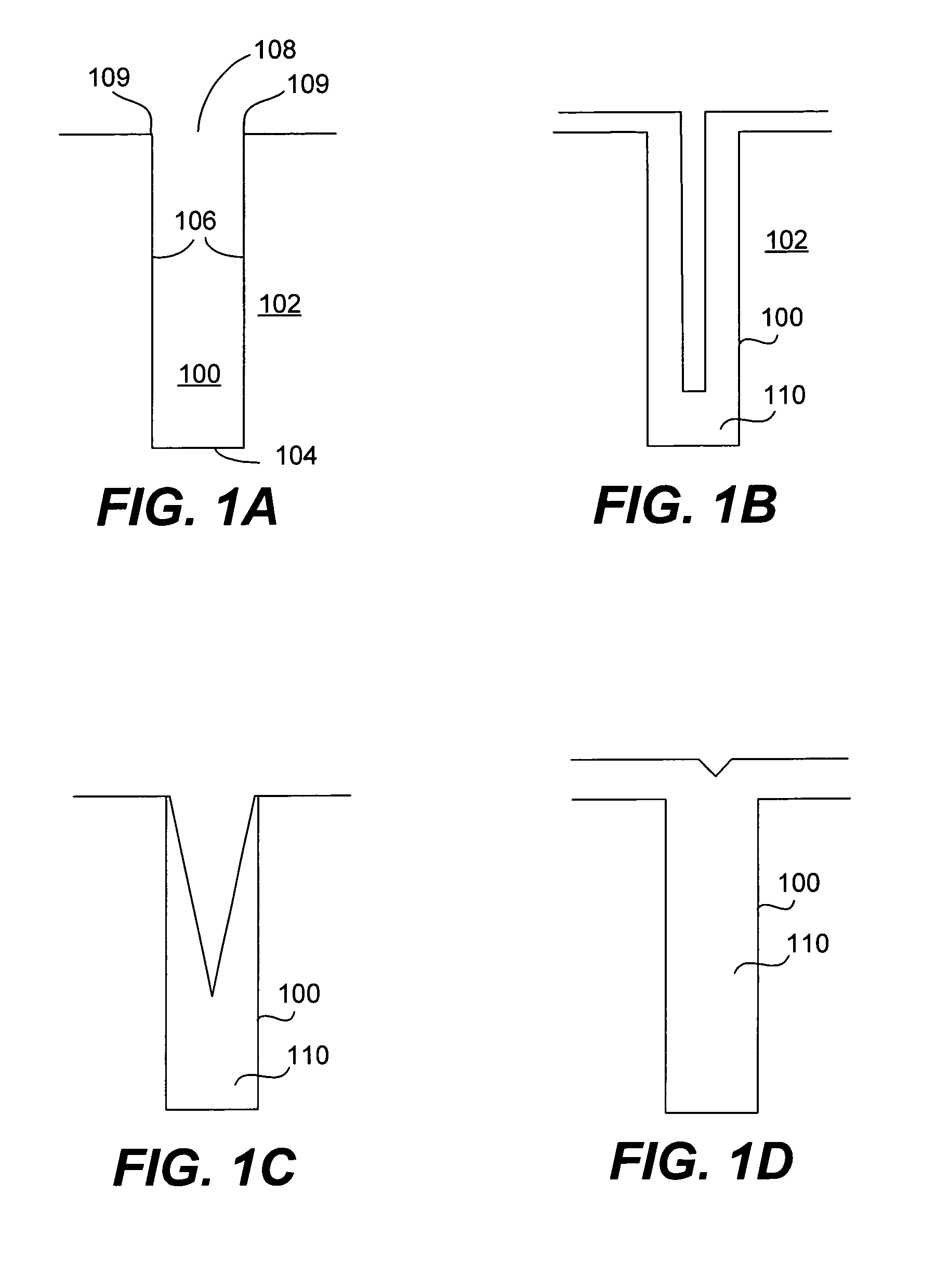

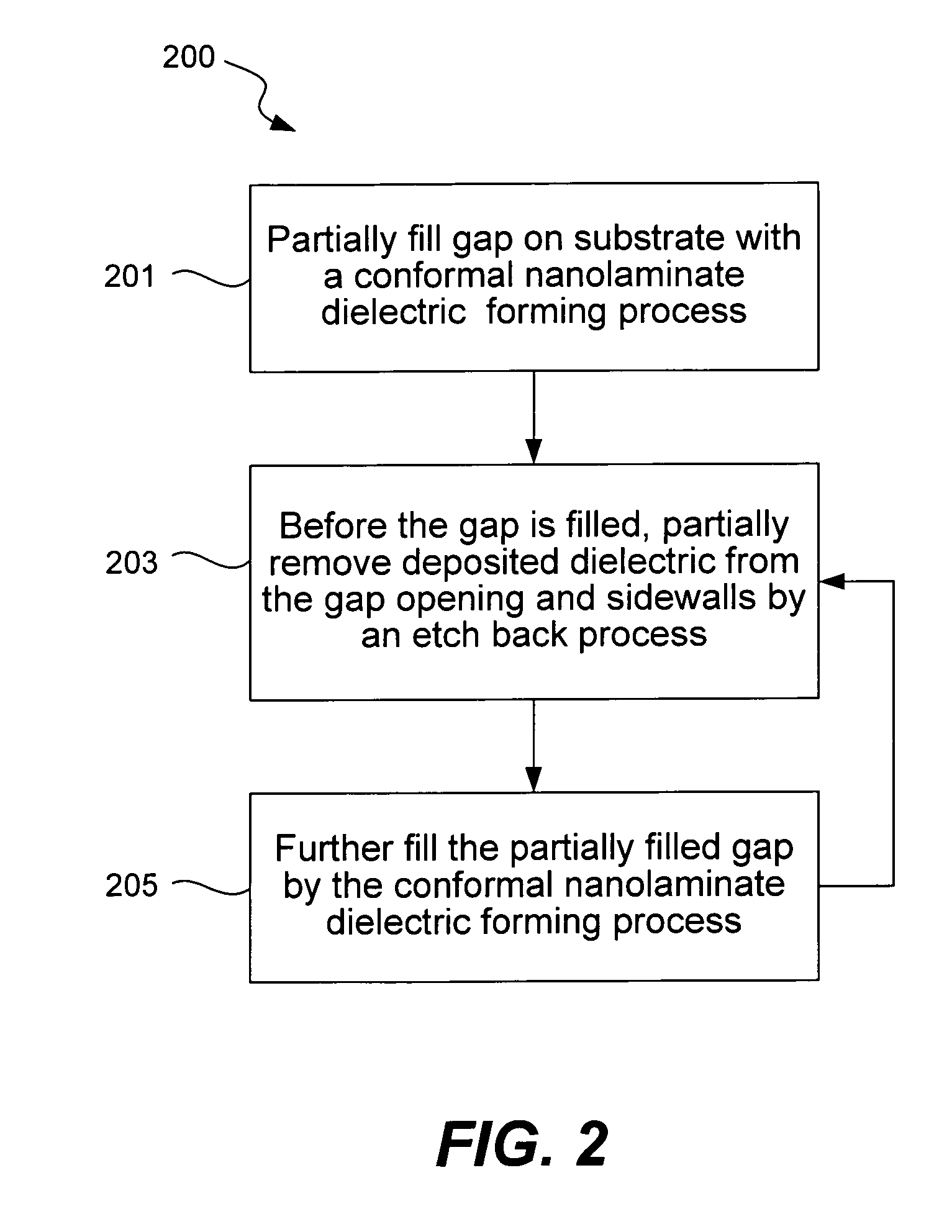

Conformal nanolaminate dielectric deposition and etch back gap fill process

InactiveUS7482247B1Reduce morbidityHigh aspect ratioSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDielectricEngineering

Conformal nanolaminate dielectric deposition and etch back processes that can fill high aspect ratio (typically at least 5:1, for example 6:1), narrow width (typically sub 0.13 micron, for example 0.1 micron or less) gaps with significantly reduced incidence of voids or weak spots involve the use of any suitable confirmal dielectric deposition technique and a dry etch back. The etch back part of the process involves a single step or an integrated multi-step (for example, two-step) procedure including an anisotropic dry etch followed by an isotropic dry etch. The all dry deposition and etch back process in a single tool increases throughput and reduces handling of wafers resulting in more efficient and higher quality nanolaminate dielectric gap fill operations.

Owner:NOVELLUS SYSTEMS

Method for forming insulation film having high density

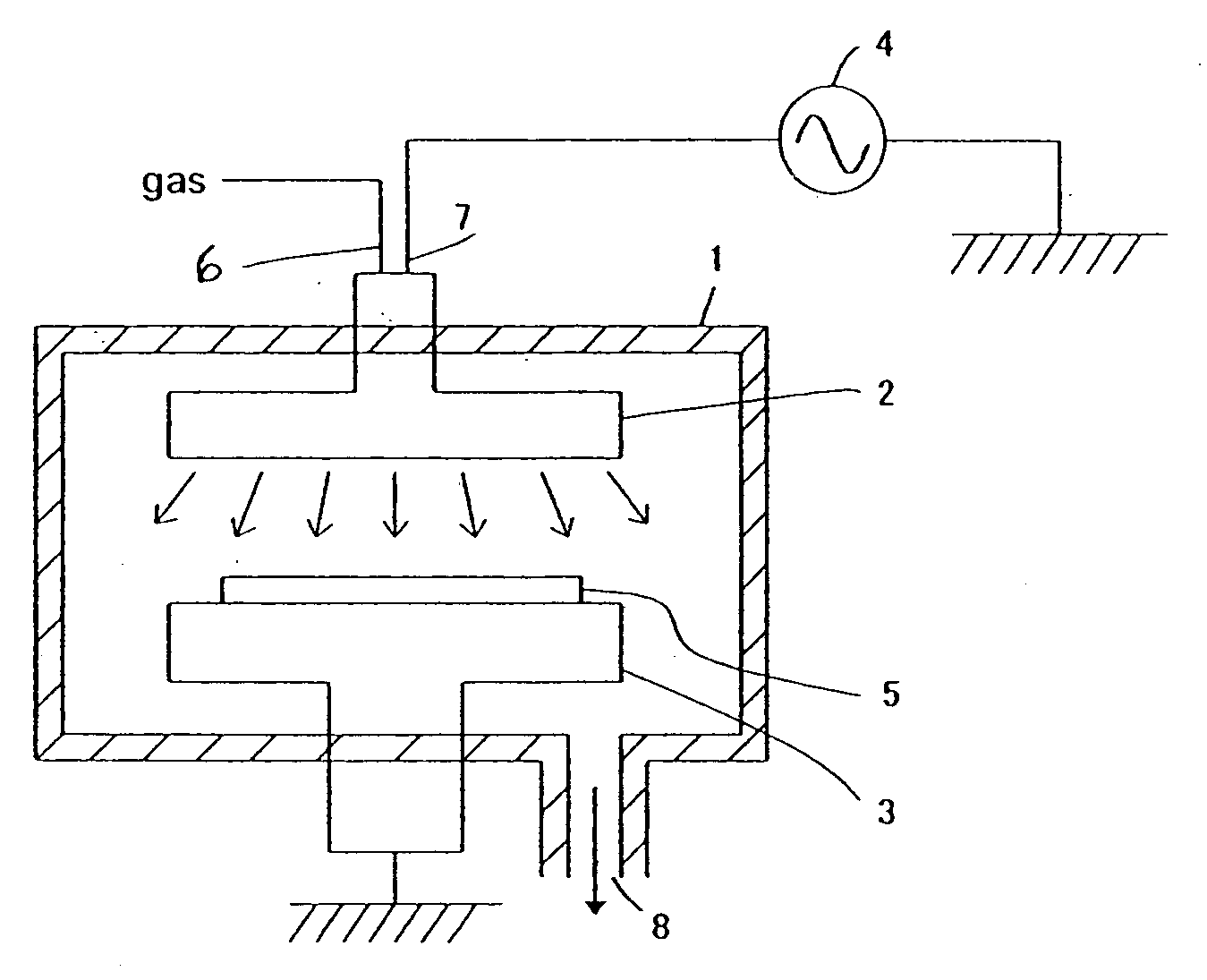

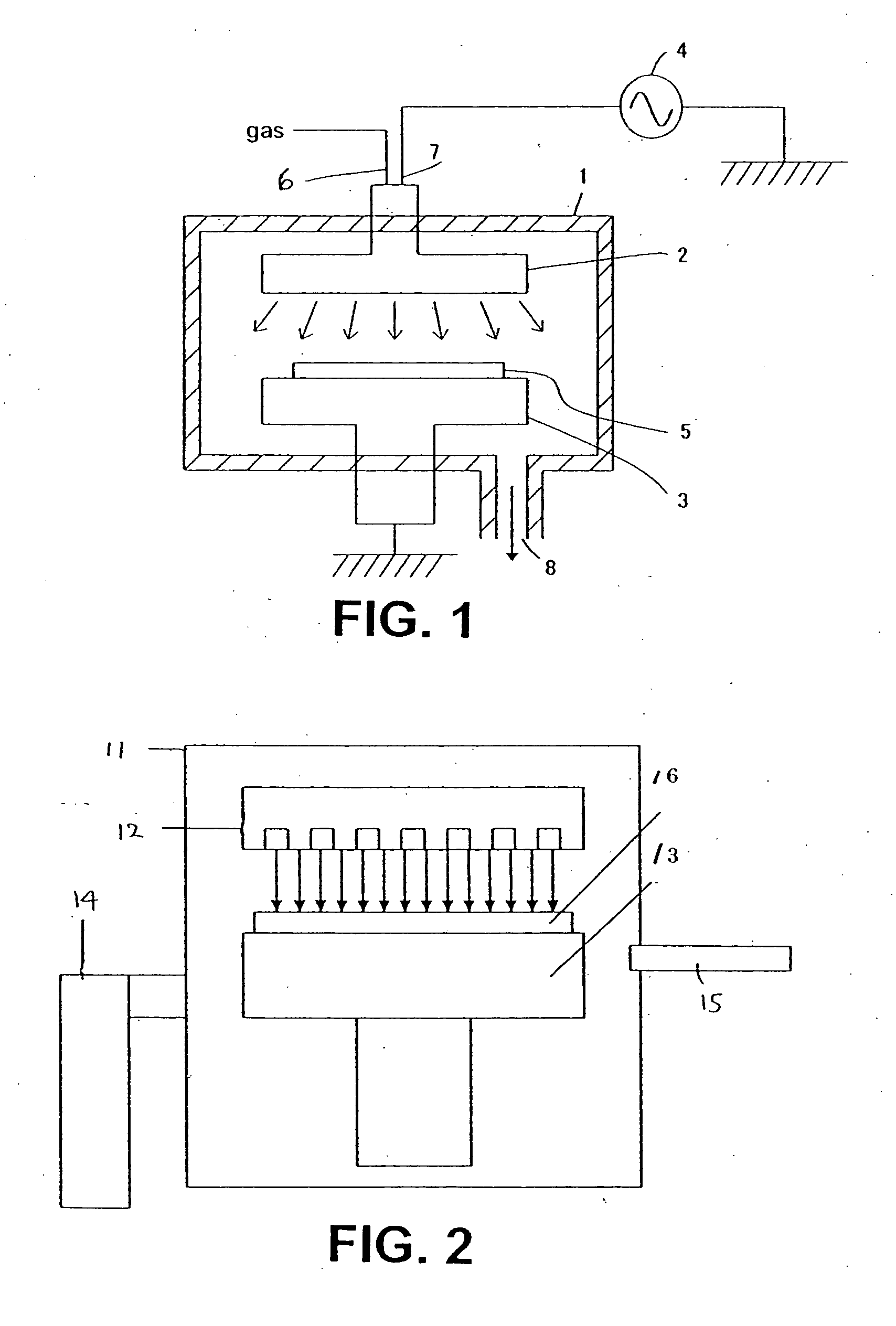

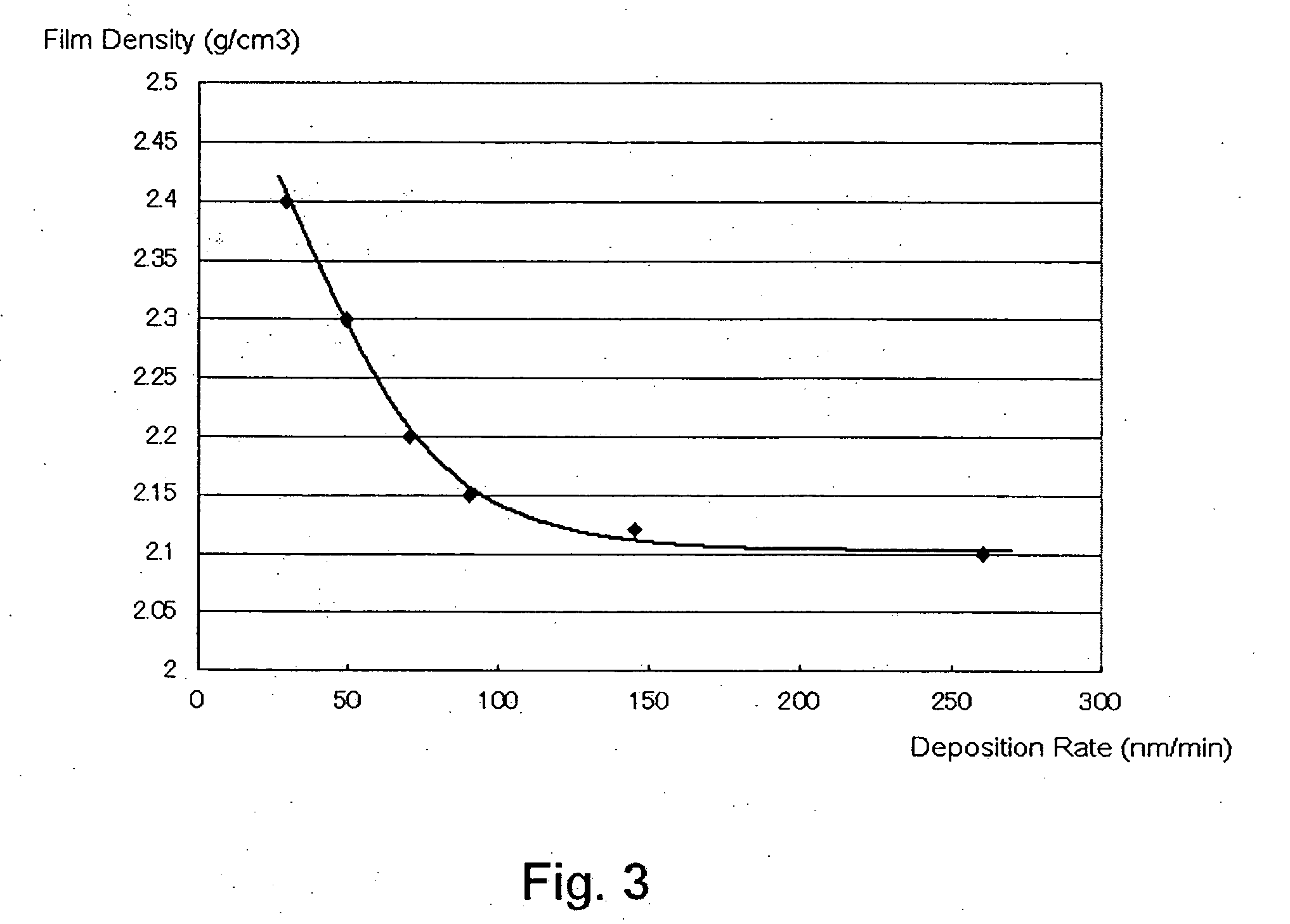

ActiveUS20080076266A1Good filling characteristicHigh aspect ratioSemiconductor/solid-state device manufacturingChemical vapor deposition coatingChemistryPlasma reaction

A method for forming an insulation film on a semiconductor substrate by plasma reaction includes: introducing into a reaction chamber a source gas of a silicon-containing hydrocarbon compound comprising in its molecule at least one Si—O bond and at least one bond selected from the group consisting of a Si—Si bond, Si—N bond, and Si—H bond; introducing into the reaction chamber an additive gas constituted by C, H, and optionally O; controlling a susceptor at a temperature of −50° C. to 50° C.; forming by plasma reaction an insulation film constituted by Si, O, H, and optionally N on an irregular surface of a substrate at a deposition rate of 100 nm / min or less; and heat-treating the substrate with the insulation film, thereby increasing a density of the insulation film to more than 2.1 g / cm3 as a result of the heat treatment.

Owner:ASM JAPAN

Method of forming barrier film

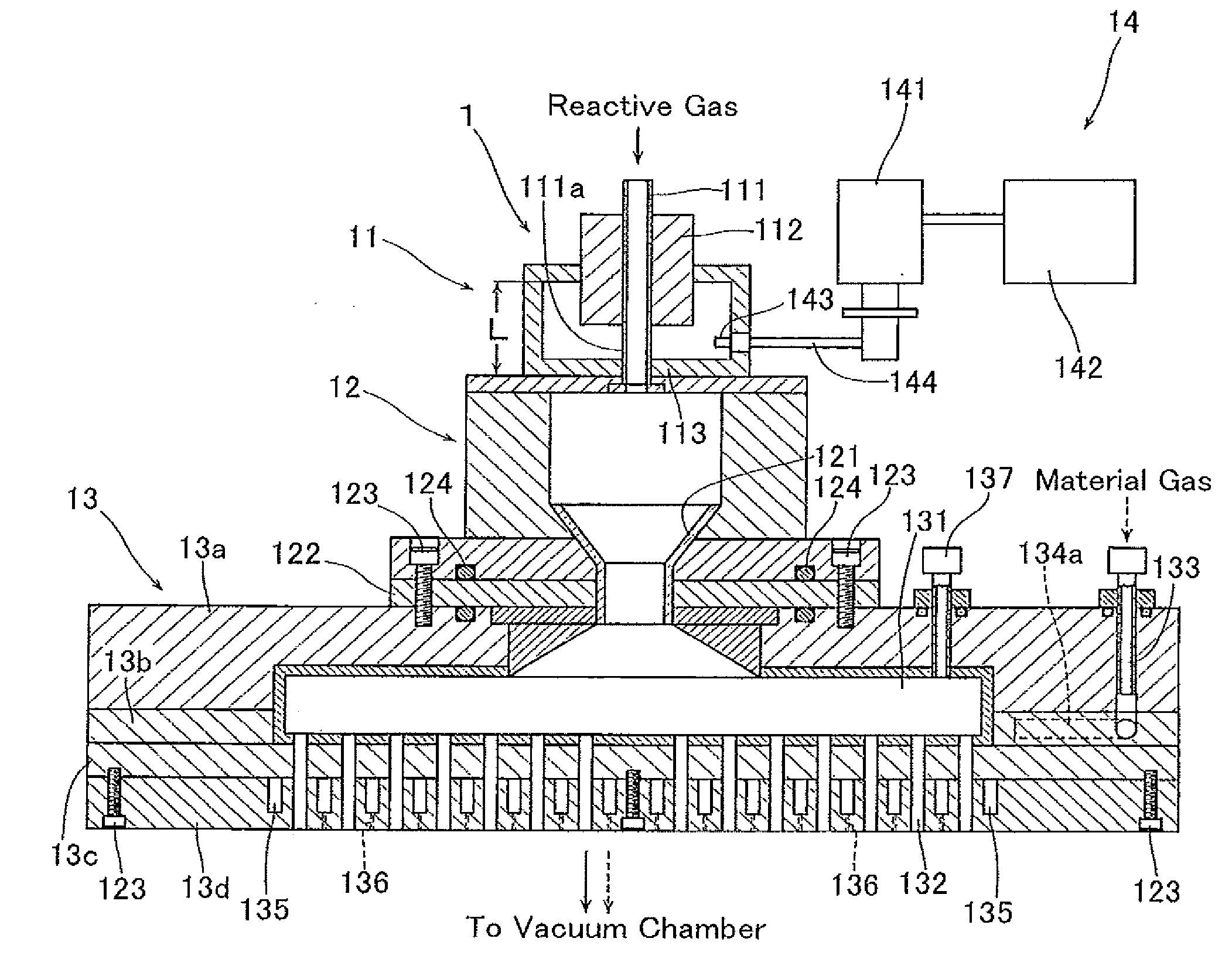

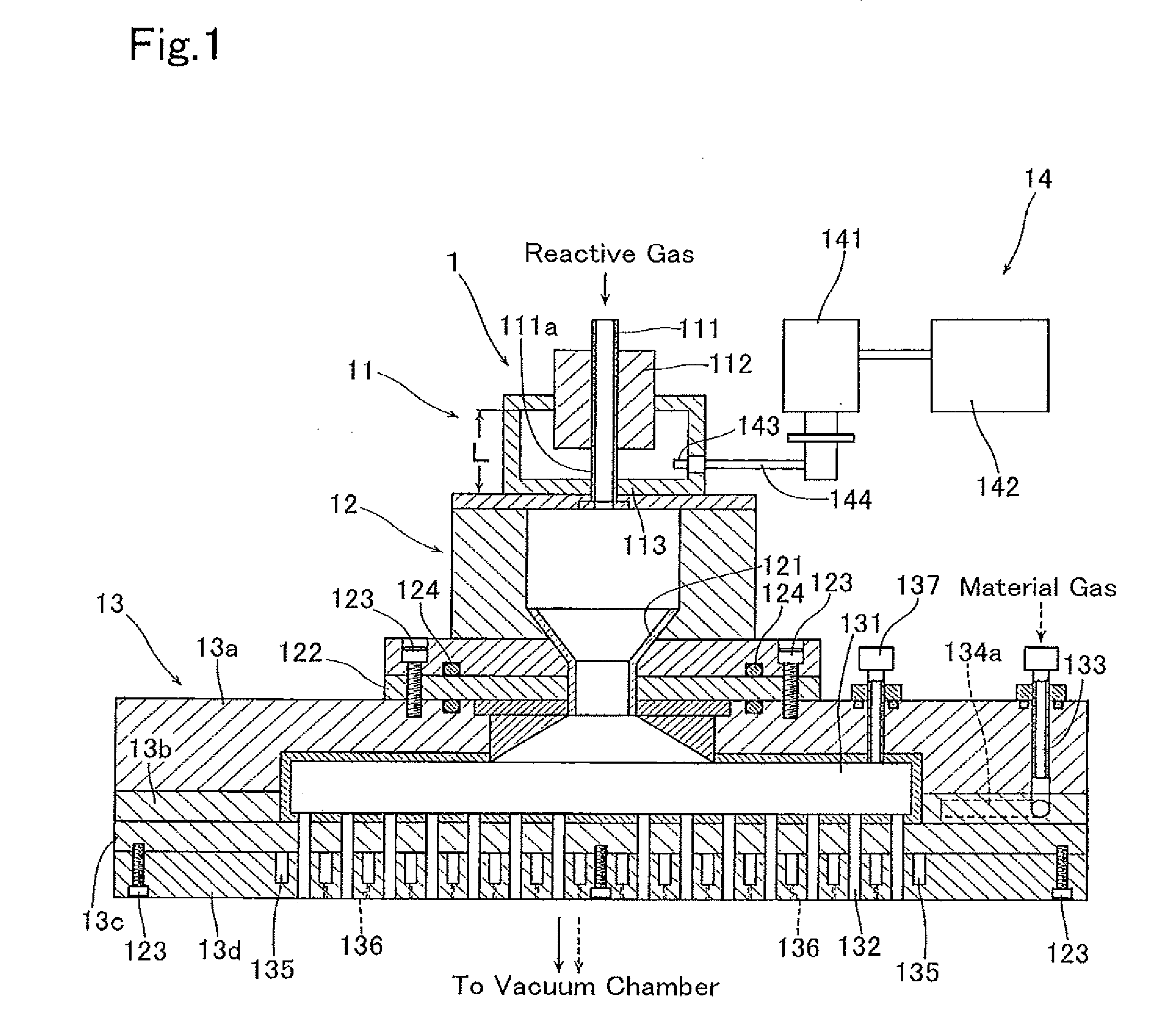

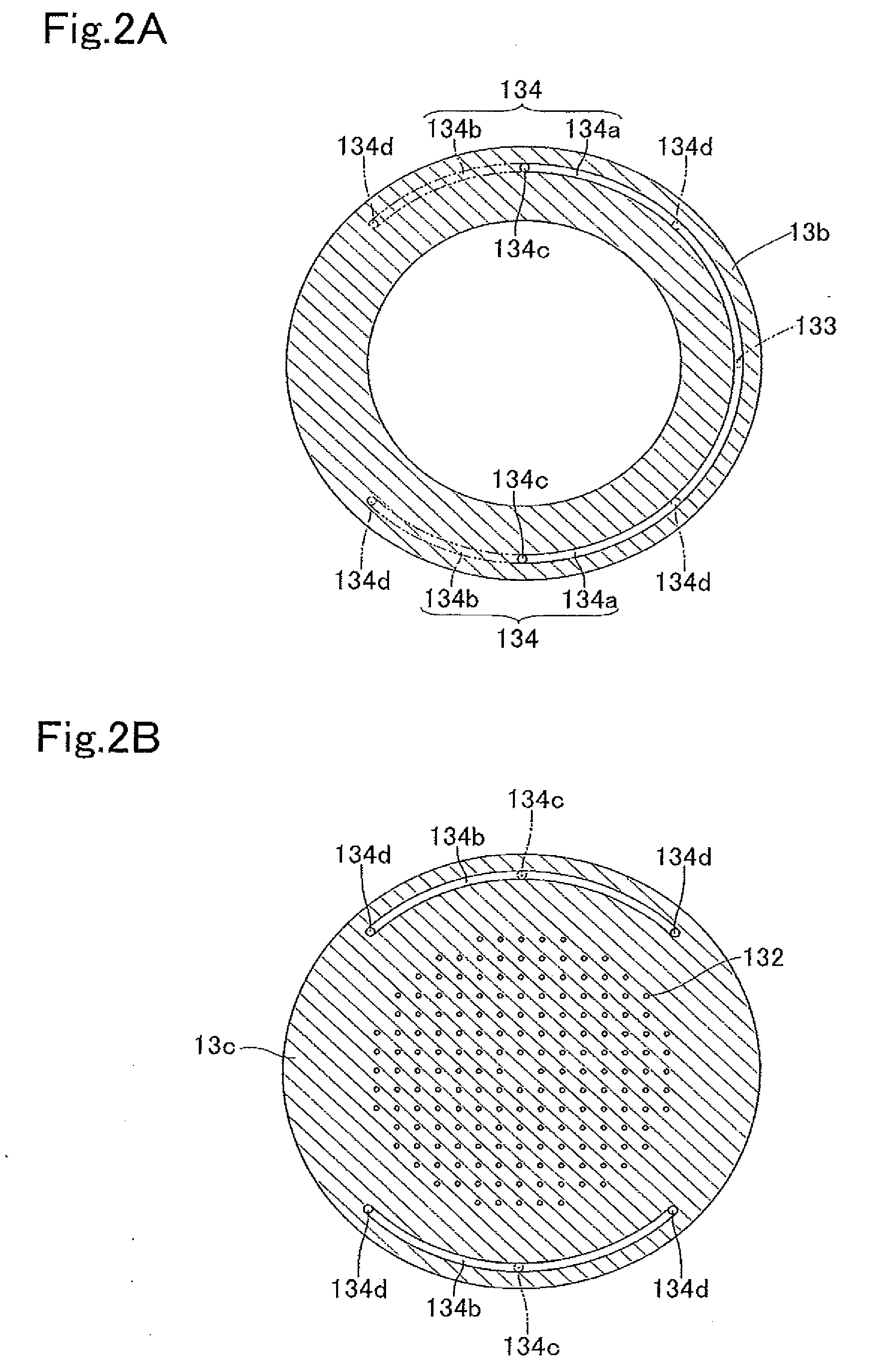

ActiveUS20100068891A1High aspect ratioReduce particleSemiconductor/solid-state device manufacturingChemical vapor deposition coatingResonant cavityMicrowave

A barrier film made of a ZrB2 film is formed by use of a coating apparatus provided with plasma generation means including a coaxial resonant cavity and a microwave supply circuit for exciting the coaxial resonant cavity, the coaxial resonant cavity including spaced apart conductors provided around the periphery of a nonmetallic pipe for reactive gas introduction, the coaxial resonant cavity having an inner height equal to an integer multiple of one-half of the exciting wavelength, the plasma generation means being constructed such that a gas injected from one end of the nonmetallic pipe is excited into a plasma state by a microwave when the gas is in a region of the nonmetallic pipe which is not covered with the conductors and such that the gas in the plasma state is discharged from the other end of the nonmetallic pipe.

Owner:ULVAC INC

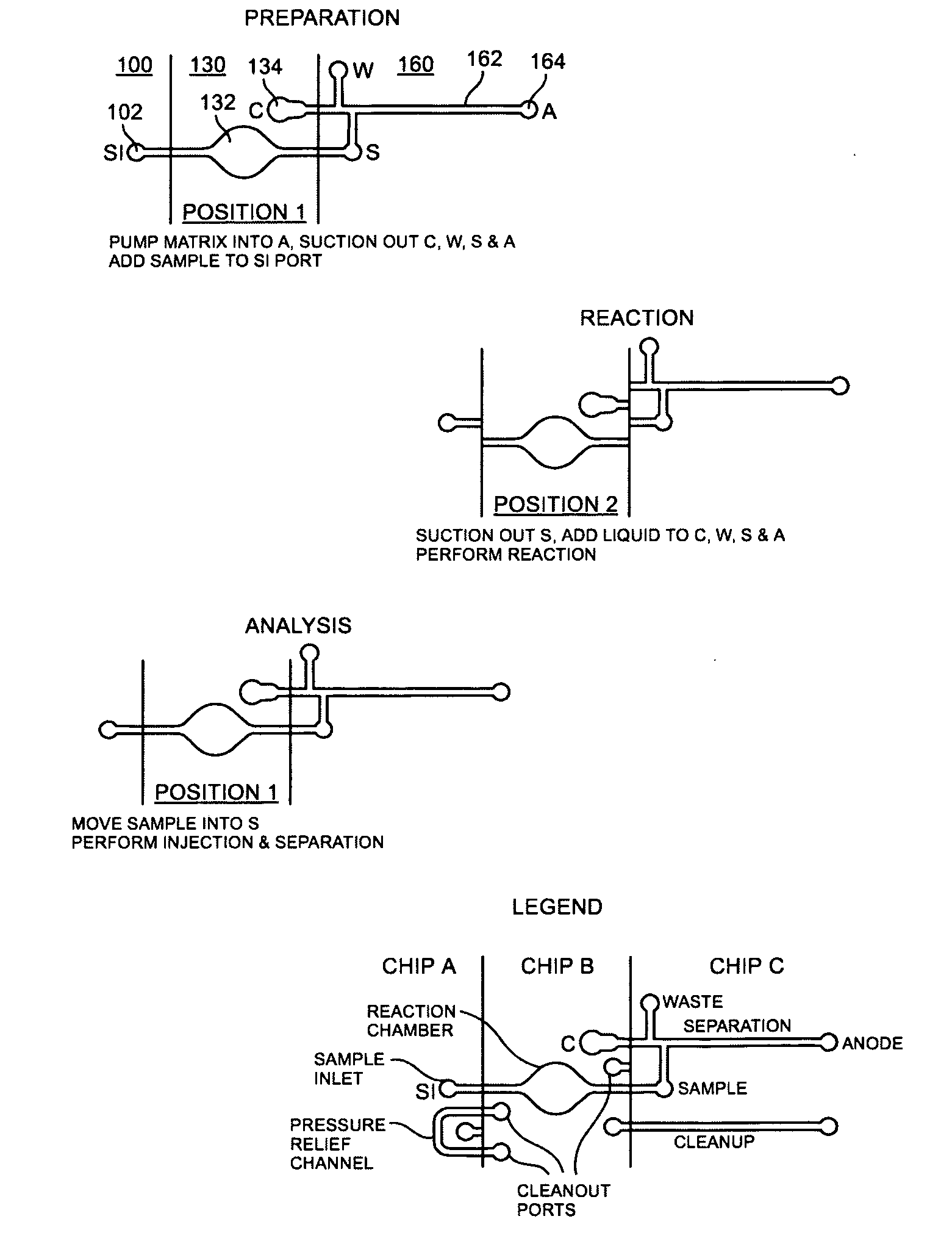

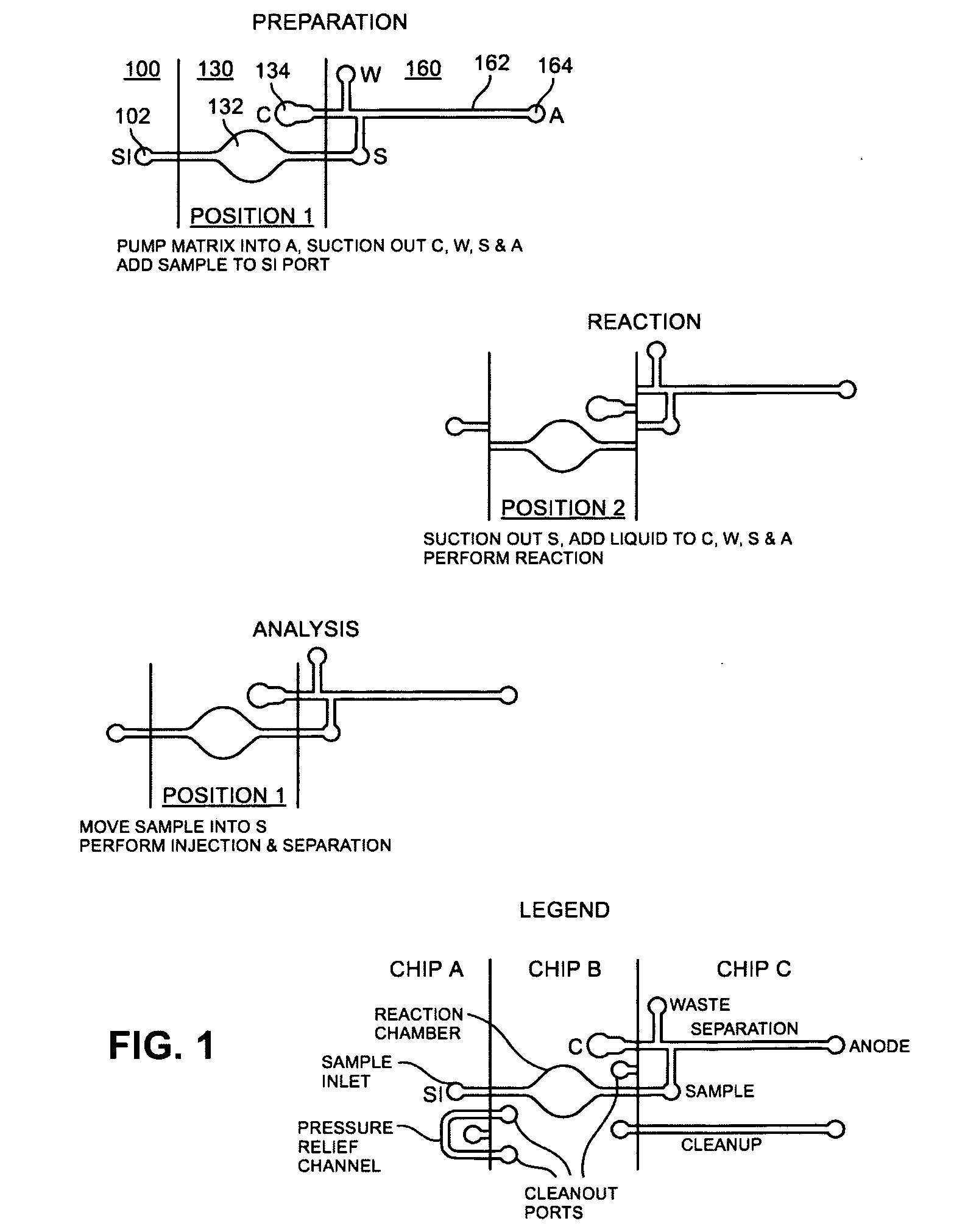

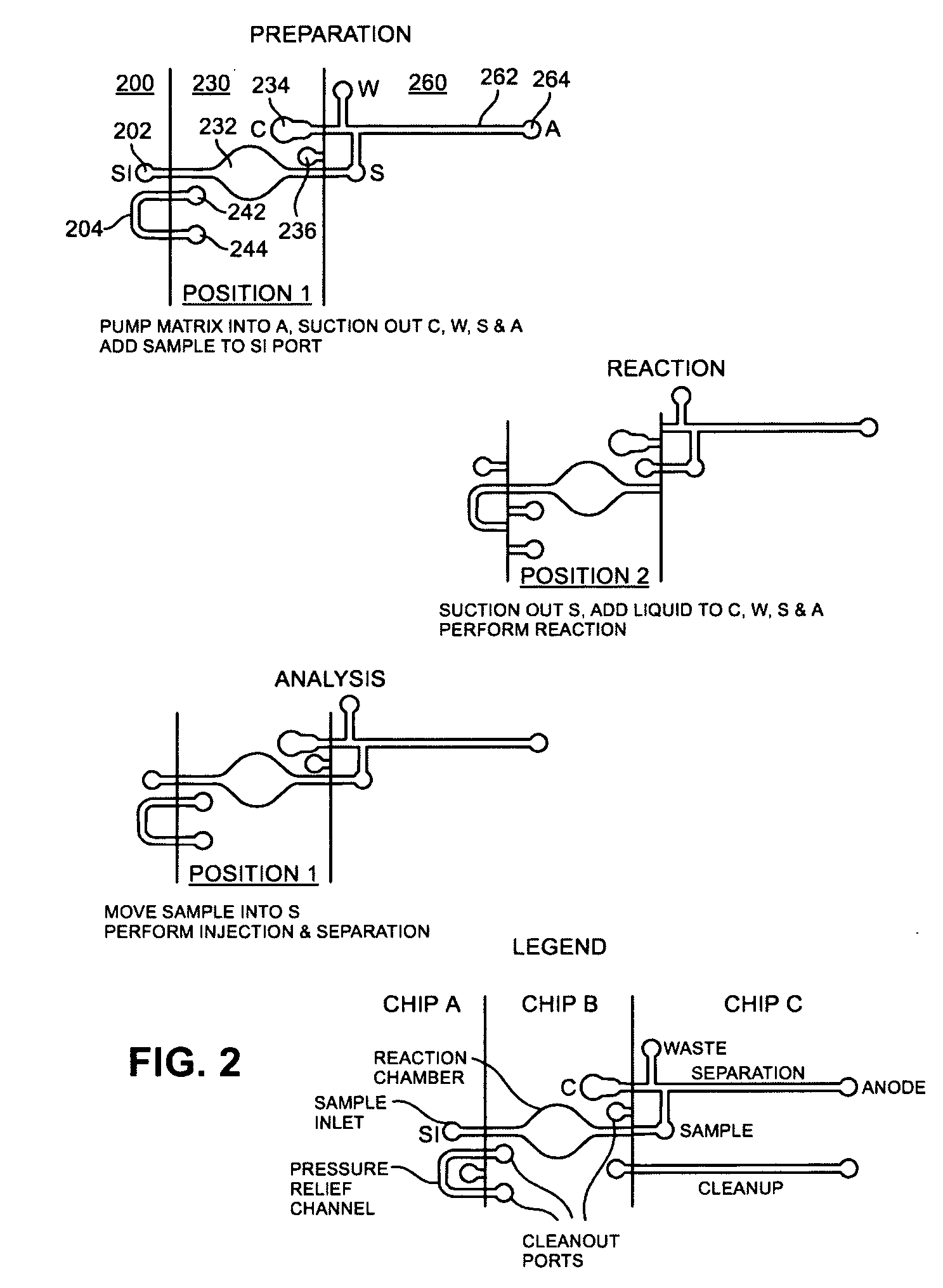

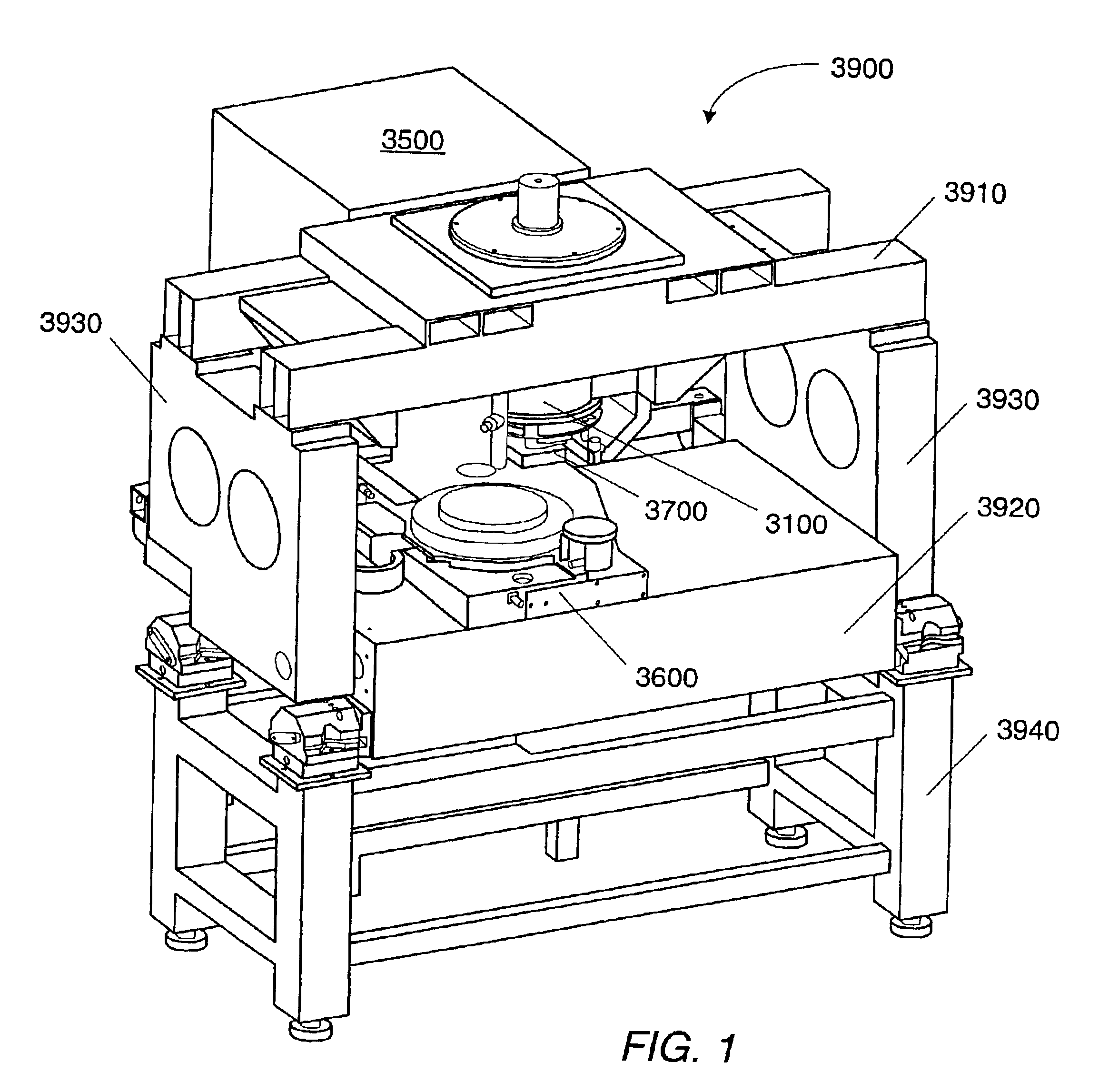

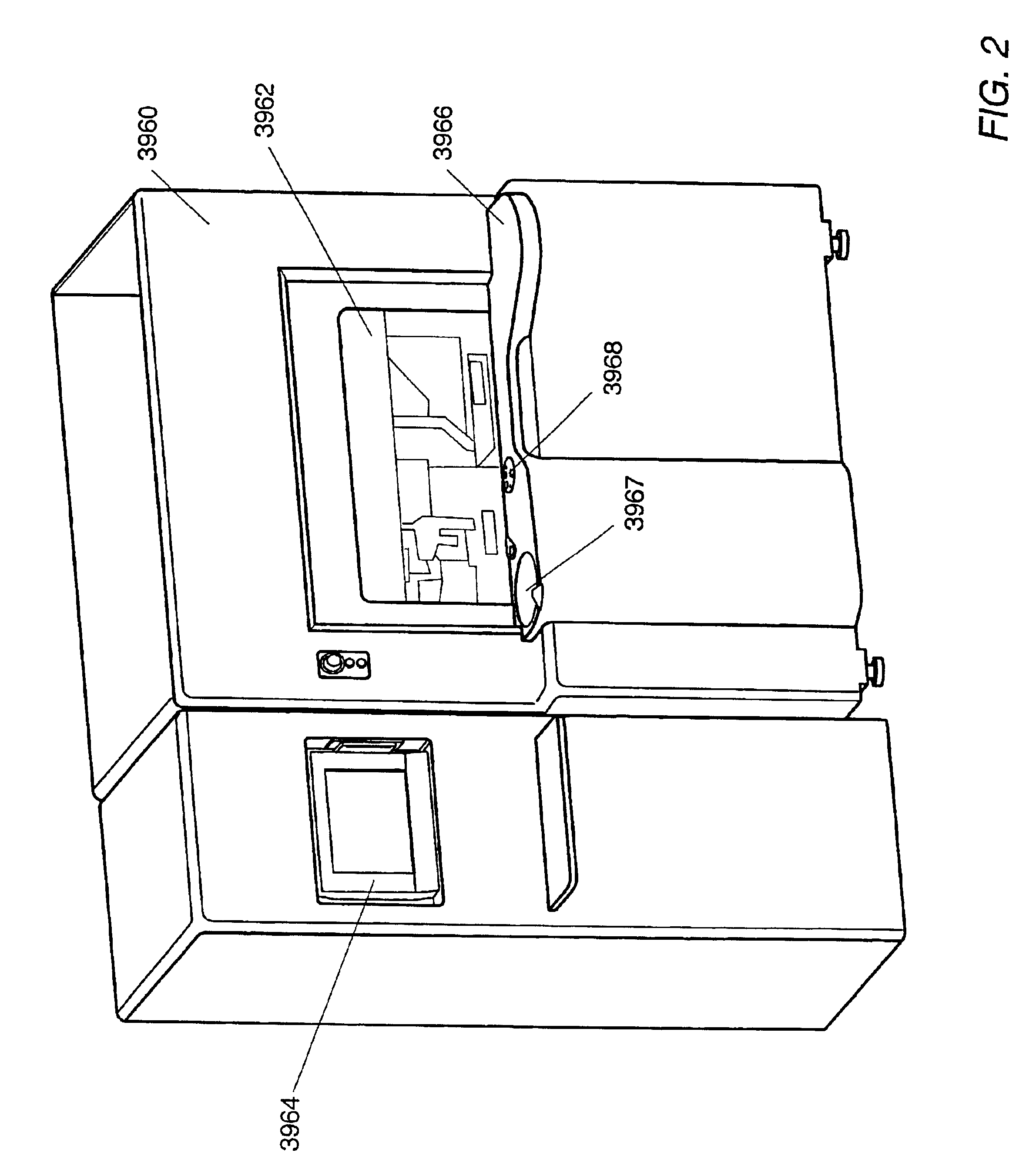

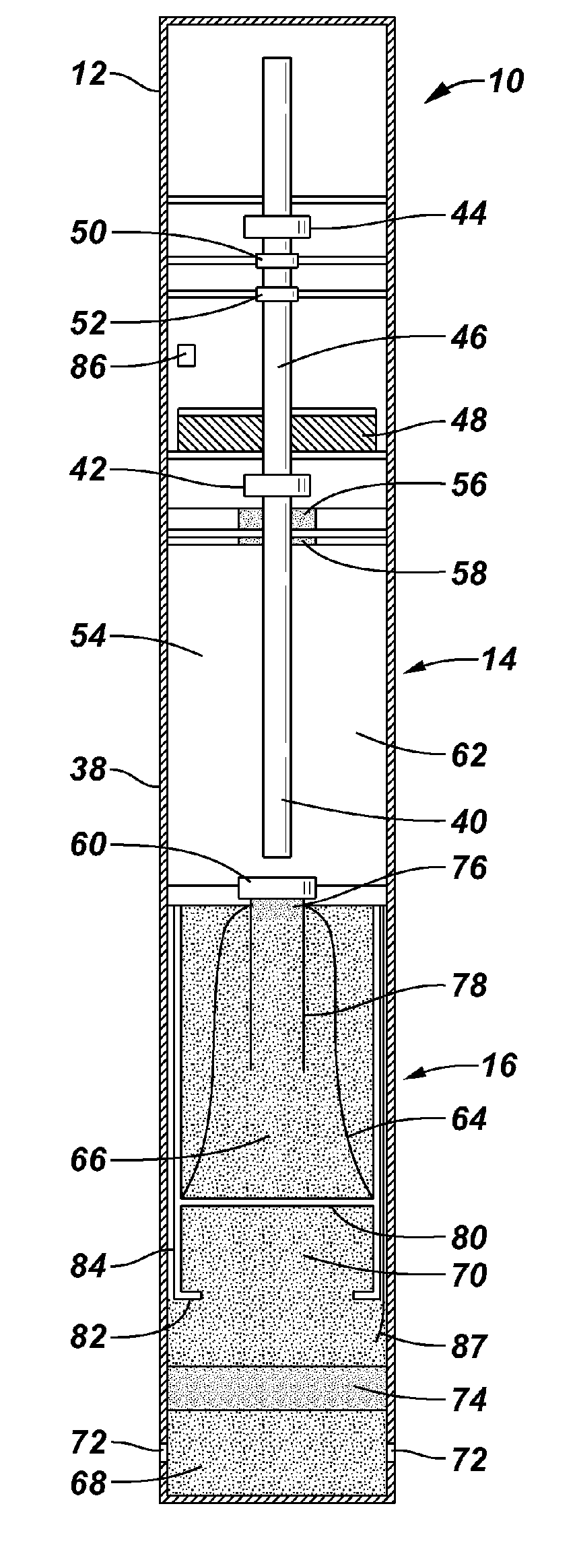

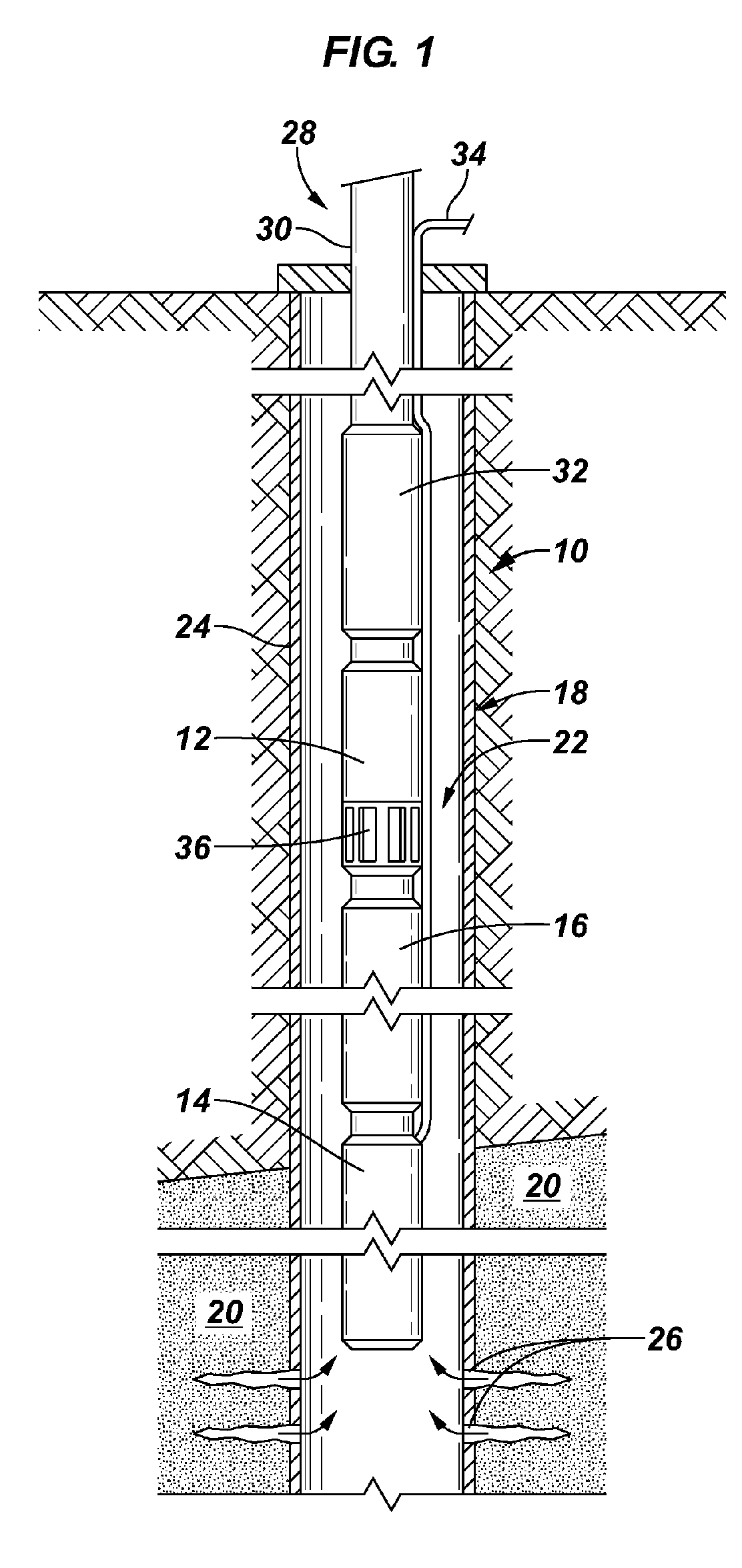

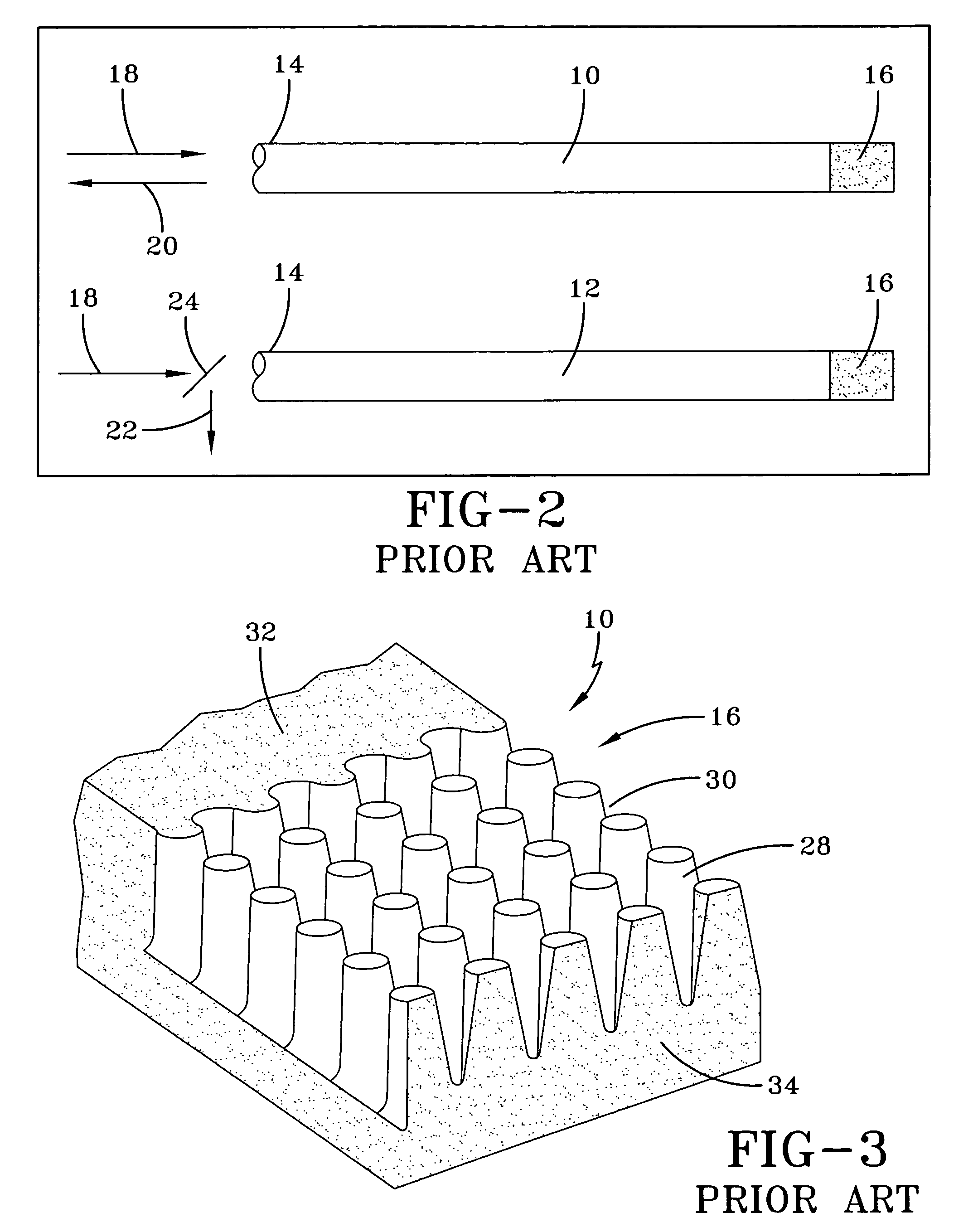

Integrated system with modular microfluidic components

ActiveUS20050161669A1Reduce wearEasy to useElectrolysis componentsSemiconductor/solid-state device detailsModularityEngineering

Owner:SILICON VALLEY SCI

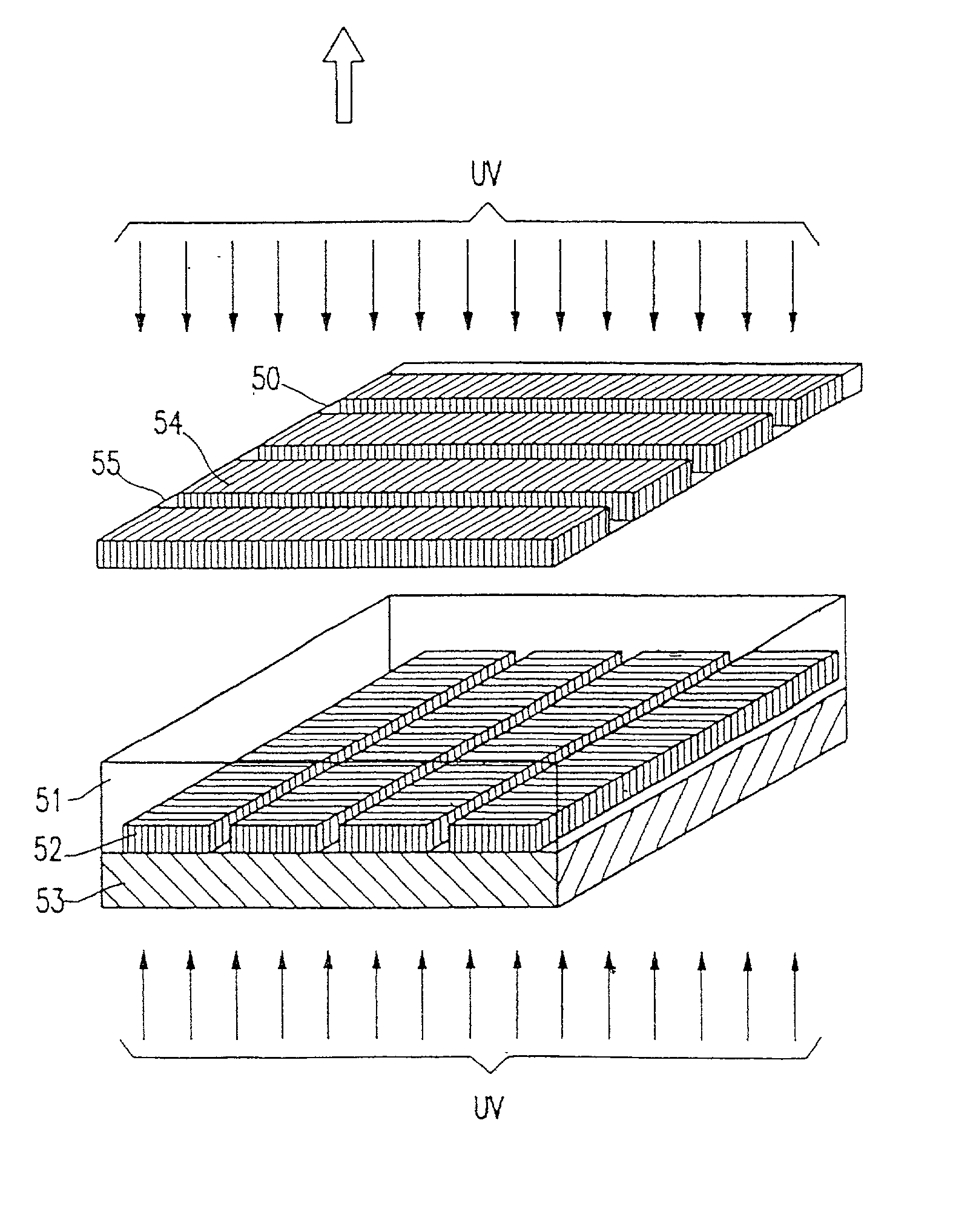

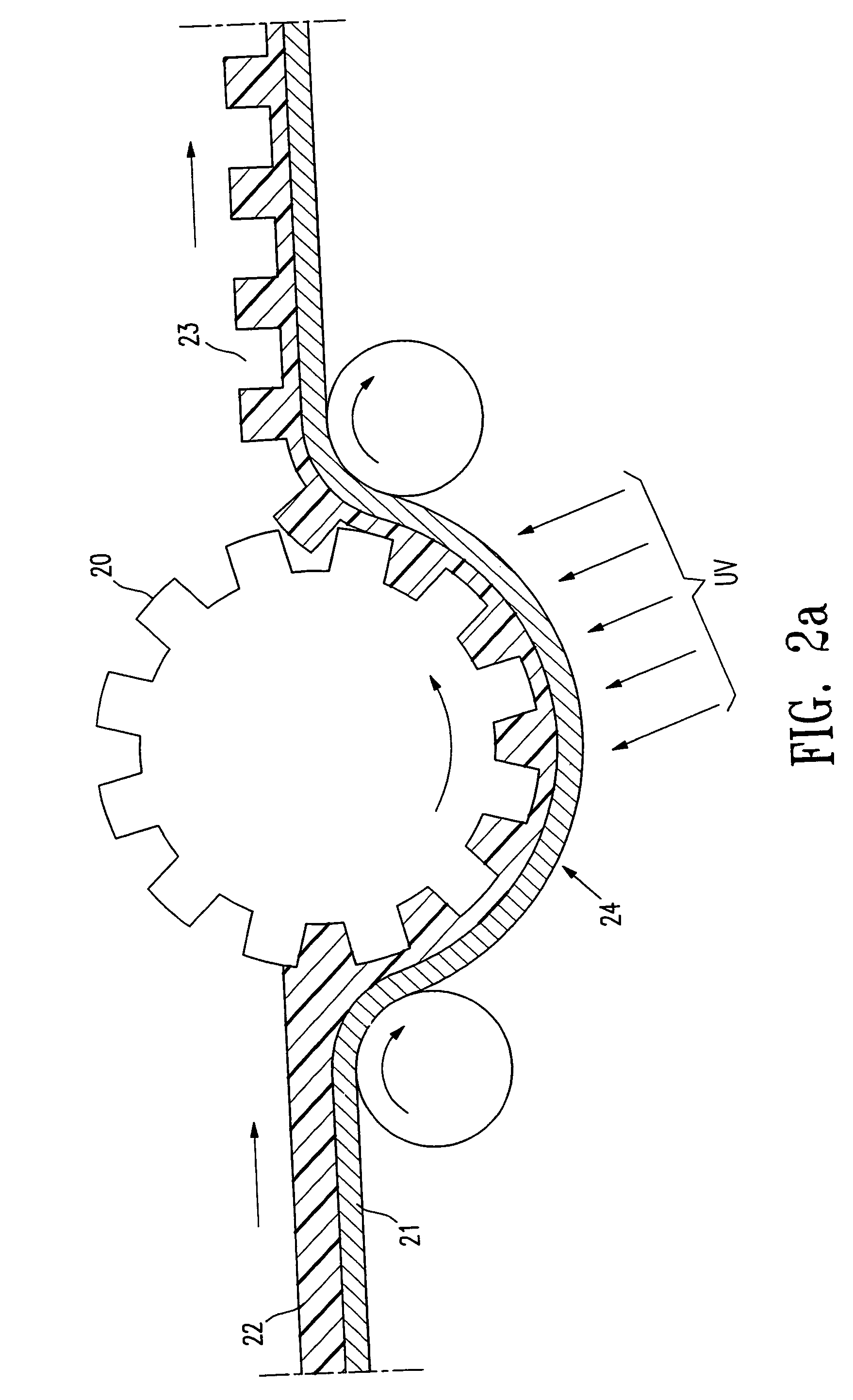

Transmissive or reflective liquid crystal display and novel process for its manufacture

InactiveUS20020126249A1Improve contrast ratioImprove color saturationLiquid crystal compositionsNon-linear opticsCrystallographyLiquid-crystal display

This invention relates to liquid crystal (LC) displays comprising cells of well-defined shape, size and aspect ratio which cells are filled with a liquid crystal composition preferably containing dichroic dye(s), and novel processes for their manufacture.

Owner:E INK CALIFORNIA

Method for imprint lithography using an electric field

InactiveUS6908861B2High aspect ratioDecorative surface effectsNanoinformaticsLithographic artistLithography process

A lithography process for creating patterns in an activating light curable liquid using electric fields followed by curing of the activating light curable liquid is described. The process involves the use of a template that is formed of non-conductive and electrically conductive portions. The template is brought into close proximity to the activating light curable liquid on the substrate. An external electric field is applied to the template-substrate interface while maintaining a uniform, carefully controlled gap between the template and substrate. This causes the activating light curable liquid to be attracted to the raised portions of the template. Activating light is applied to the curable liquid while an electric field is applied to the template to create a patterned layer on the substrate.

Owner:CANON KK

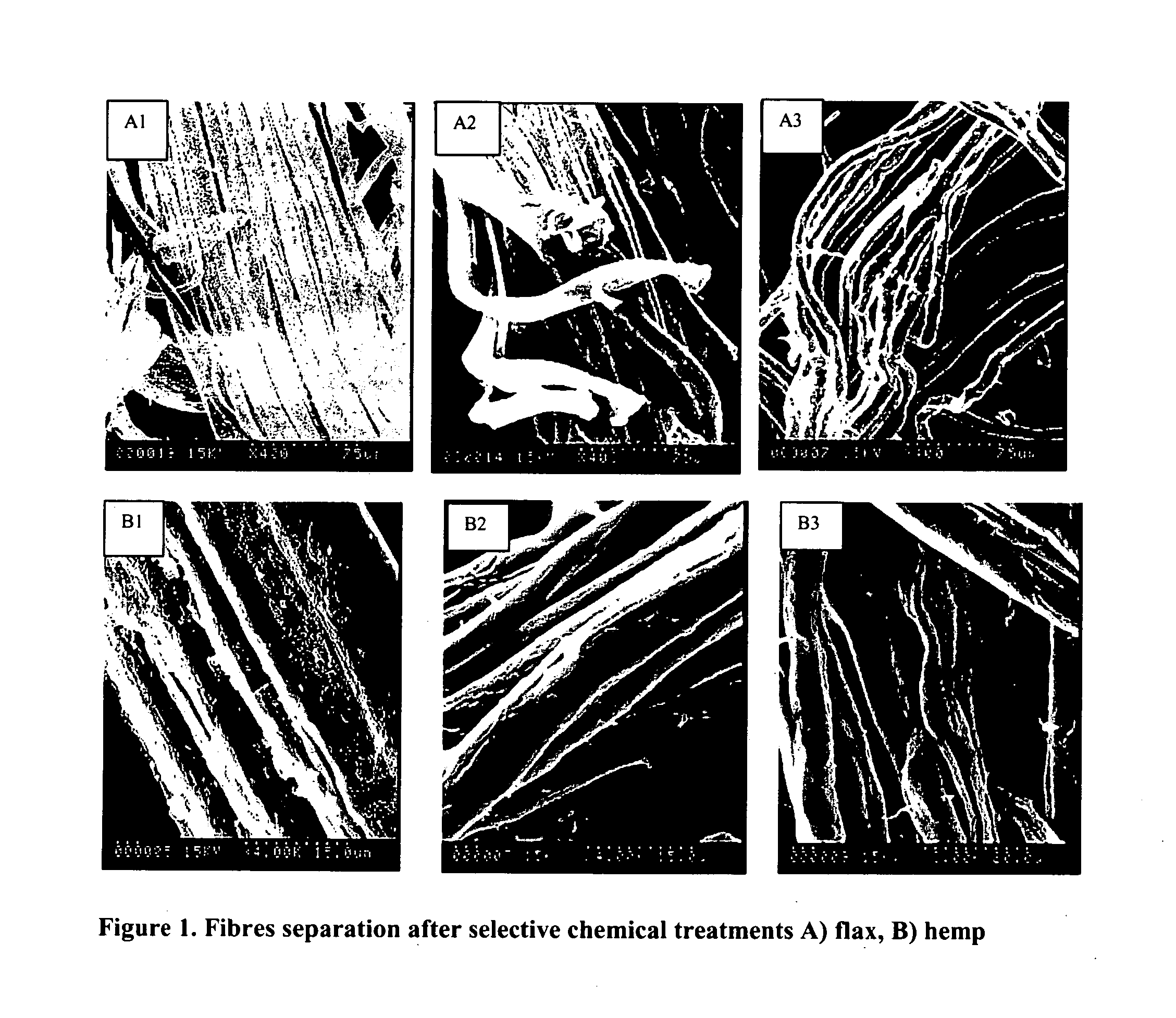

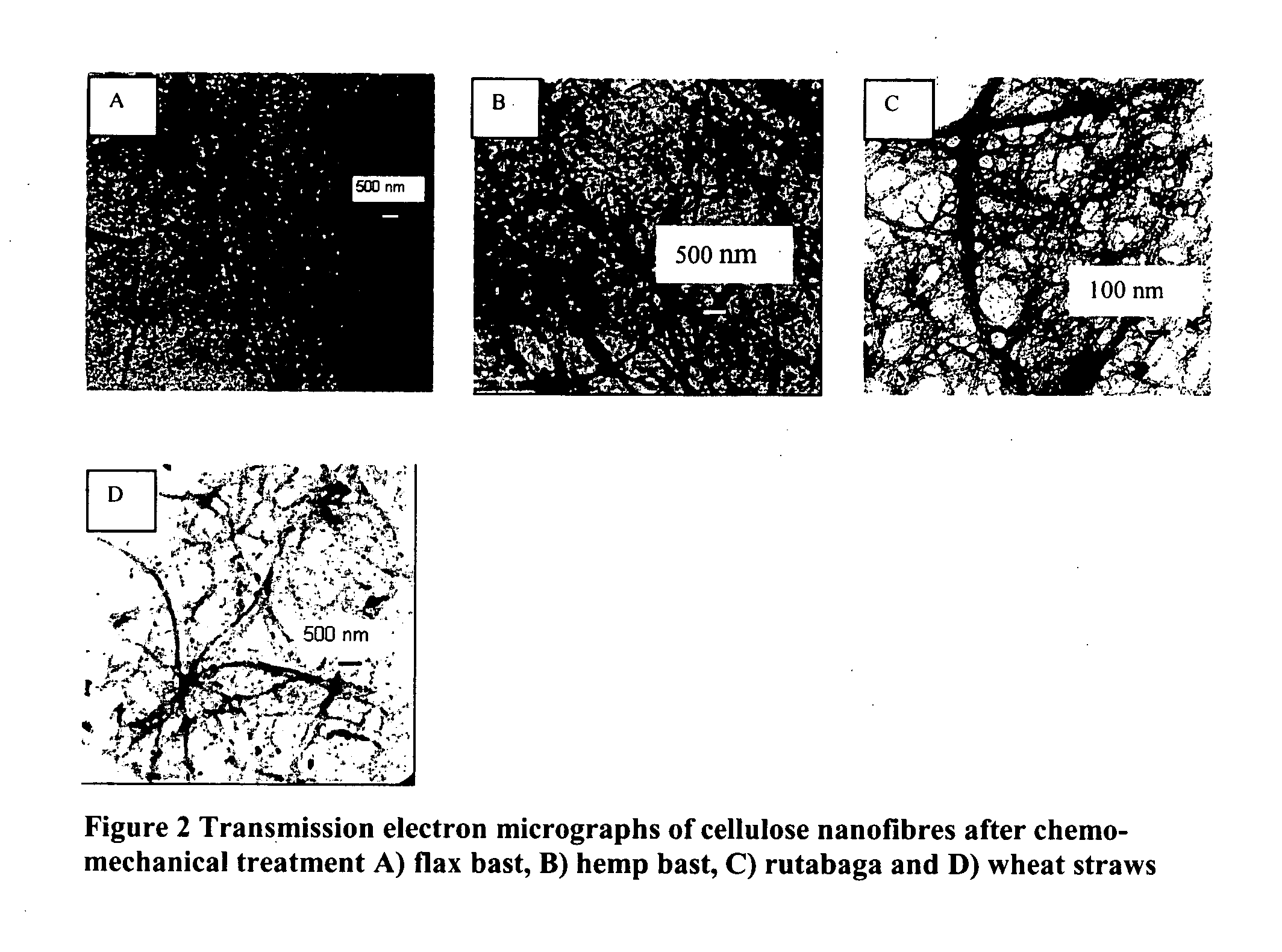

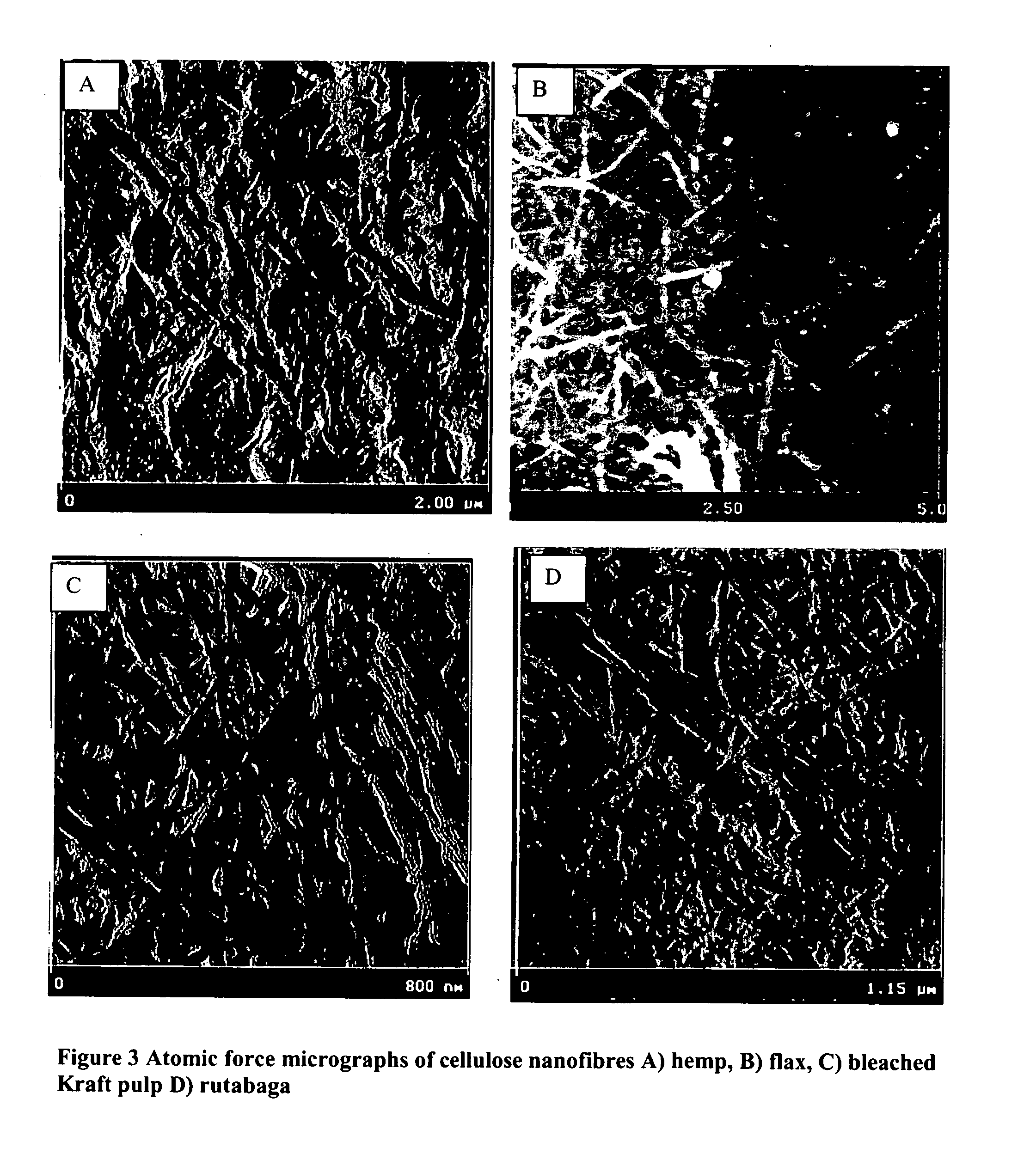

Manufacturing process of cellulose nanofibers from renewable feed stocks

InactiveUS20080146701A1High aspect ratioRaise the potentialMaterial nanotechnologyFats/resins/pitch/waxes removal in pulpCelluloseNatural fiber

Cellulose nanofibers have been processed from renewable feedstock in particularly from natural fibers, root crops and agro fibers, wherein the pulp was hydrolysed at a moderate temperature of 50 to 90 degree C., one extraction was performed using dilute acid and one extraction using alkali of concentration less than 10%; and residue was cryocrushed using liquid nitrogen, followed by individualization of the cellulose nanofibers using mechanical shear force. The nanofibers manufactured with this technique have diameters in the range of 20-60 nm and much higher aspect ratios than long fibers. Due to its lightweight and high strength its potential applications will be in aerospace industry and due to their biodegradable potential with tremendous stiffness and strength, they find application in the medical field such as blood bags, cardiac devices, valves as a reinforcing biomaterial.

Owner:SAIN MOHINI M +1

Polymeric Composites, Oilfield Elements Comprising Same, and Methods of Using Same in Oilfield Applications

InactiveUS20070142547A1Improve barrier propertiesImprove mechanical propertiesNon-metal conductorsLayered productsSubject matterEngineering

Oilfield elements and assemblies are described comprising a polymeric matrix formed into an oilfield element, and a plurality of expanded graphitic nanoflakes and / or nanoplatelets dispersed in the polymeric matrix. Methods of using the oilfield elements and assemblies including same in oilfield operations are also described. This abstract allows a searcher or other reader to quickly ascertain the subject matter of the disclosure. It will not be used to interpret or limit the scope or meaning of the claims. 37 CFR 1.72(b).

Owner:SCHLUMBERGER TECH CORP

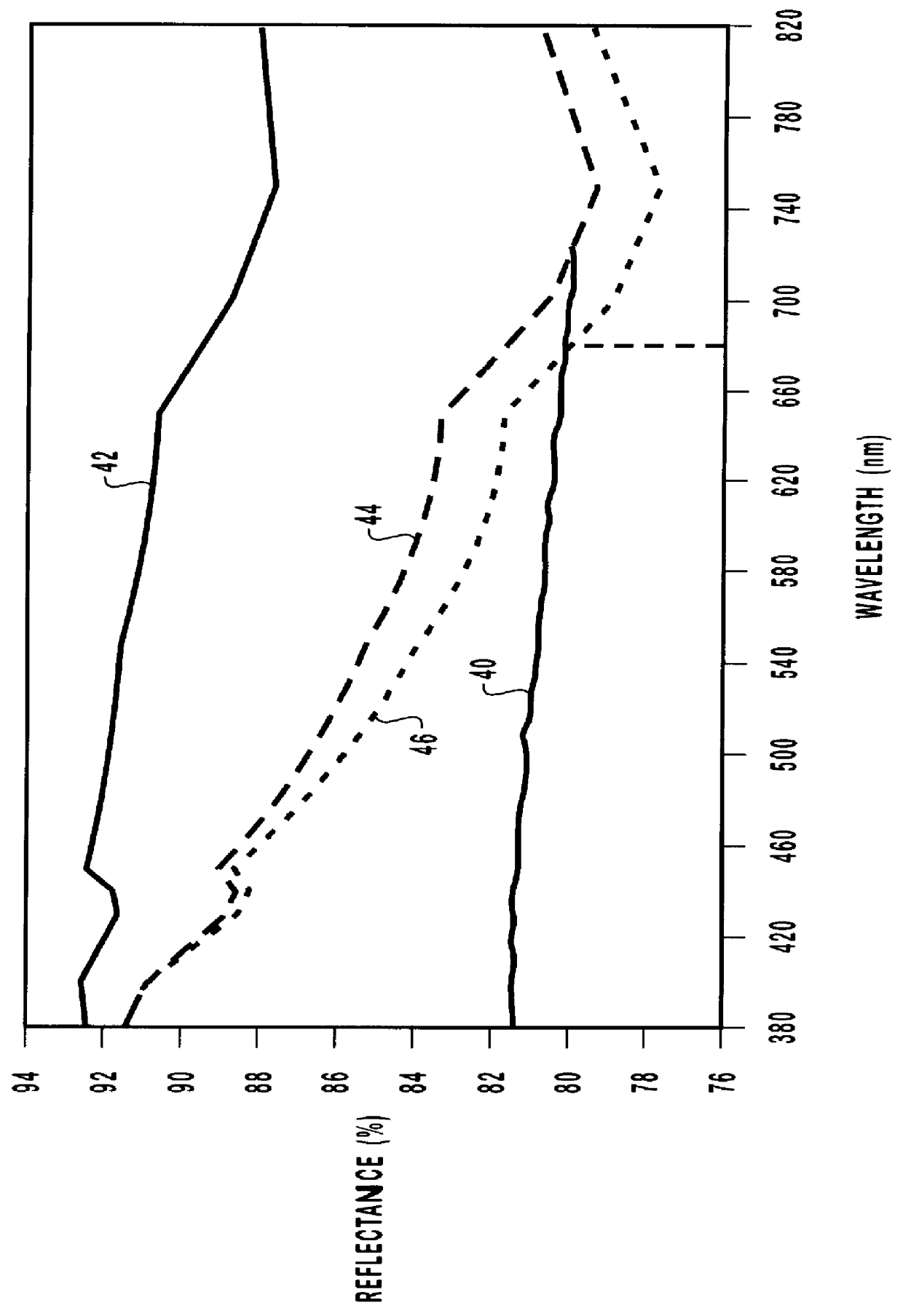

Bright metal flake

InactiveUS6013370AGood specular reflectance characteristicHigh aspect ratioPigmenting treatmentRecord information storageSilicon dioxideReflectivity

A rigid and brittle bright metal flake is formed of a central layer of a reflective material supported on both sides by dielectric layers. In a preferred embodiment, the metal layer is aluminum having a thickness of about 100 nm and the dielectrics are either silicon dioxide or magnesium fluoride, each having a thickness of about 100 nm. The result is a very thin three-layered metal flake about 300 nm thick that exhibits a uniaxial compressive strength of about 8 times a corresponding uniaxial tensile strength. As a result, the metal flake is then afforded the benefits of rigidity and brittle fracture during the manufacturing and applicational processes which ultimately provides favorable planar and specular reflectance characteristics in the visible wavelength range.

Owner:JDS UNIPHASE CORP

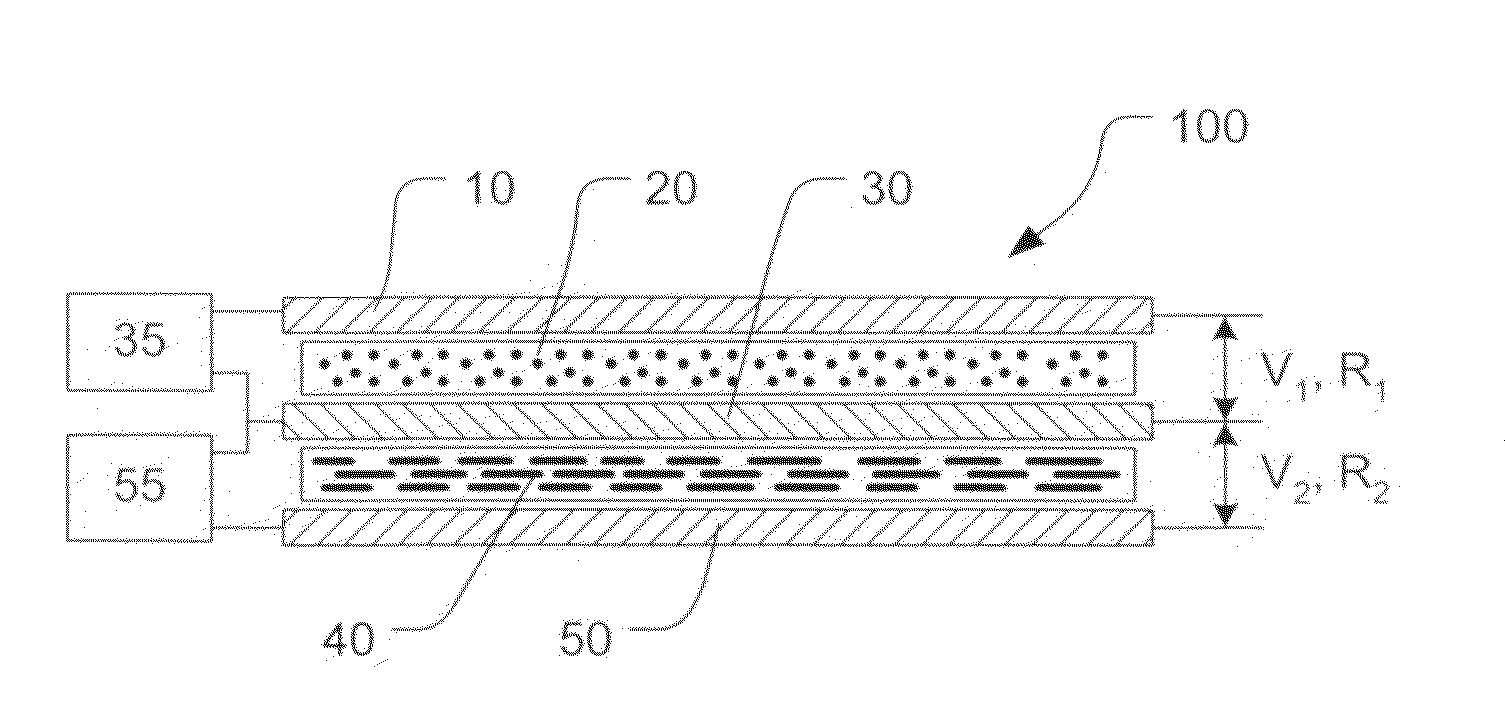

Flexural deformation sensing device and a user interface using the same

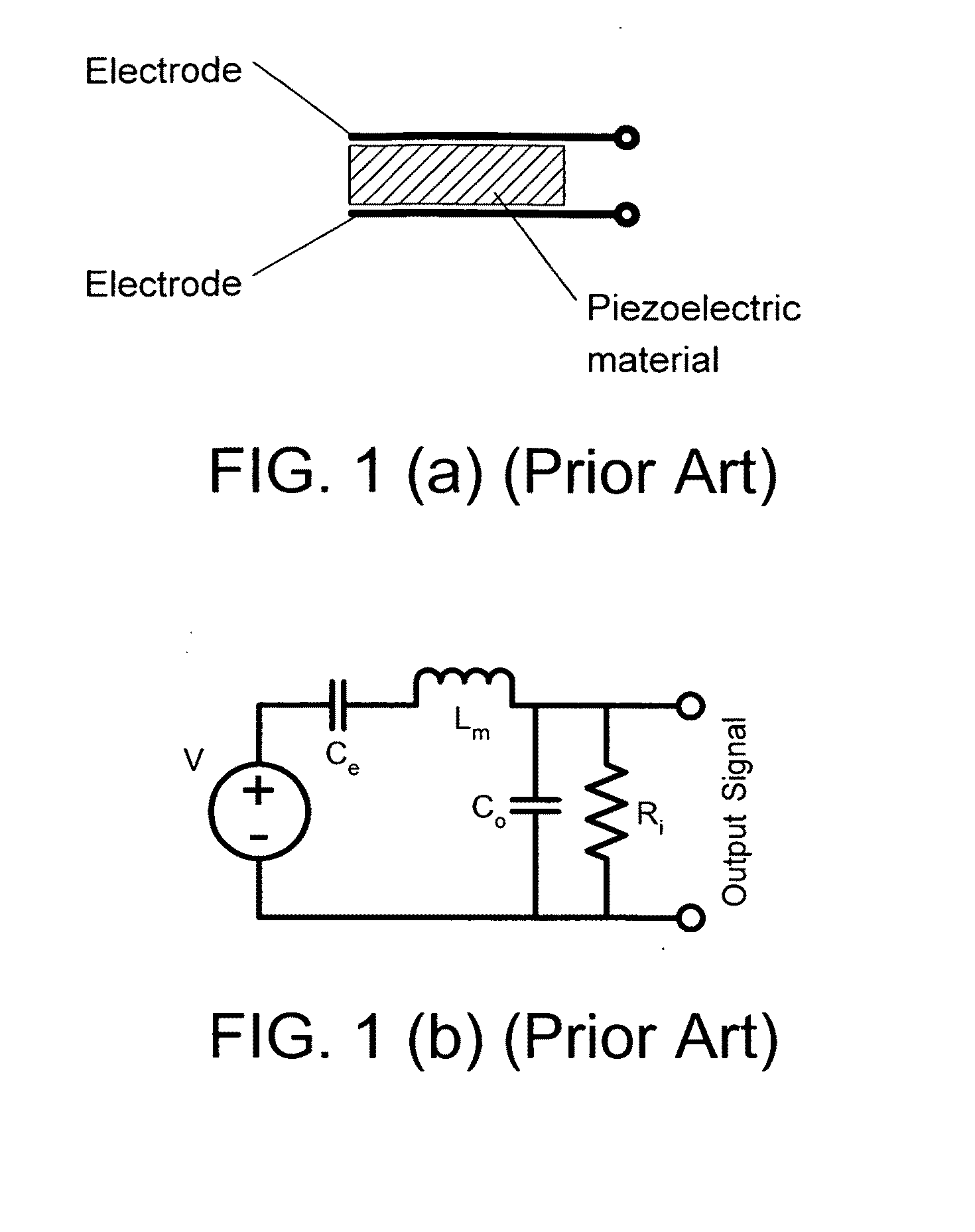

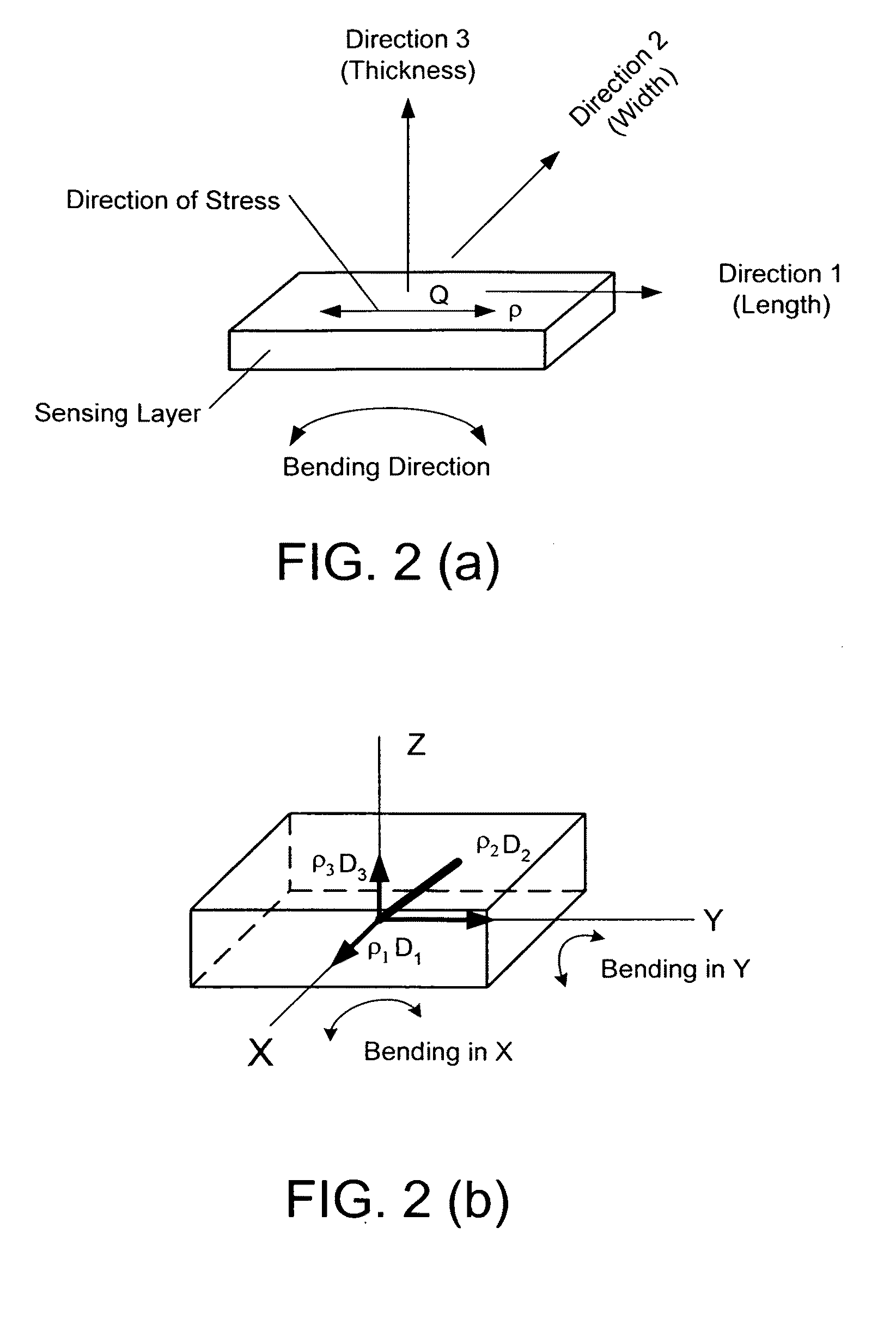

ActiveUS20090293631A1High aspect ratioForce measurement using piezo-electric devicesUsing electrical meansElectrical batteryElectricity

A sensing device is provided for measuring flexural deformations of a surface. Such a sensing device may be used as a user interface in portable electronic devices. The sensing device comprises at least one cell. The cell comprises a first electrode, a central electrode, a second electrode, a first piezoelectric sensing layer placed between the first electrode and the central electrode, a second piezoelectric sensing layer placed between the central electrode and the second electrode, and a circuit connected to the first, second and the central electrodes. The circuit is configured to measure a first electrical signal between the first electrode and the central electrode, and a second electrical signal between the second electrode and the central electrode. At least one of the first electrical signal and the second electrical signal is responsive to an external stress applied on the sensing device.

Owner:RPX CORP

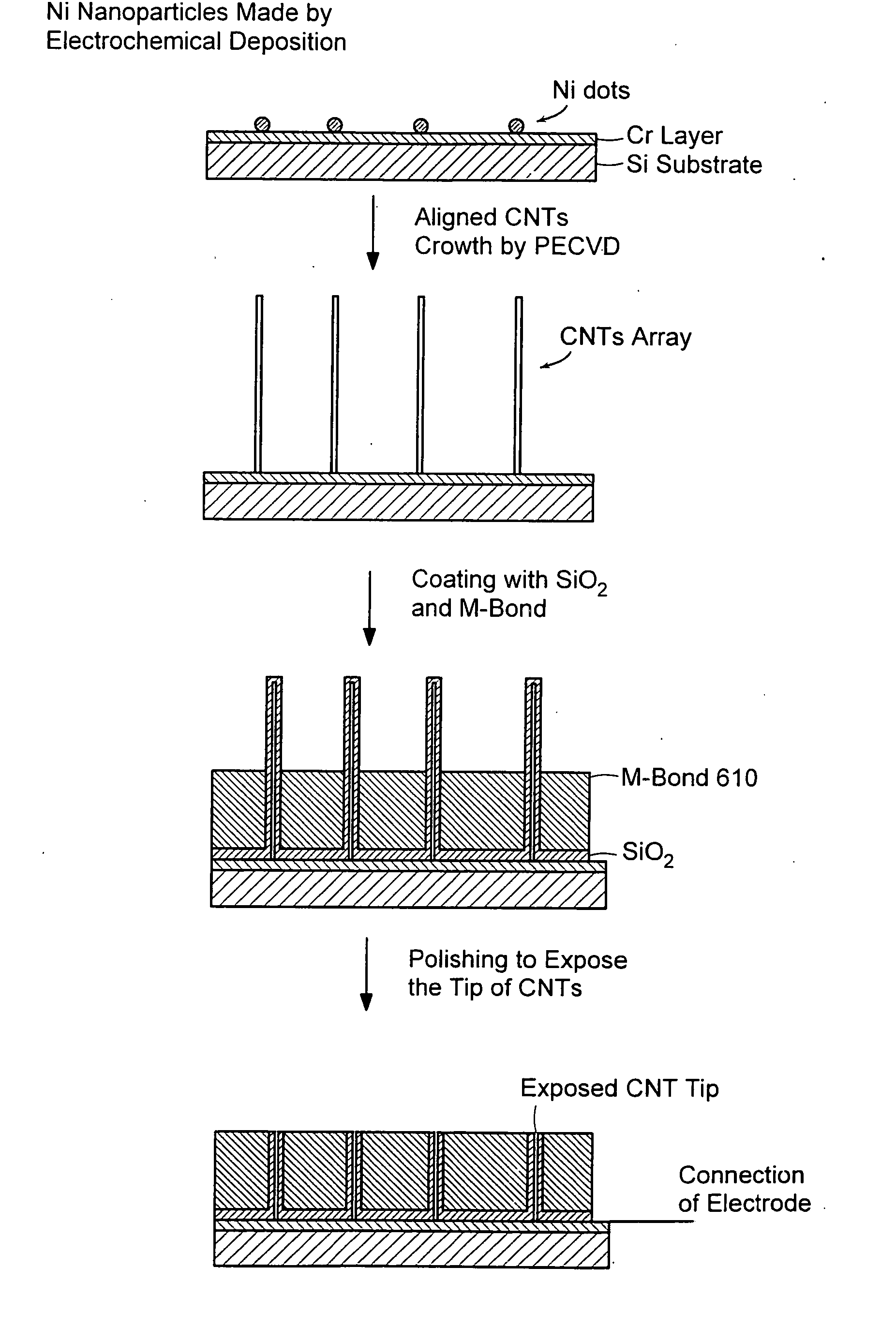

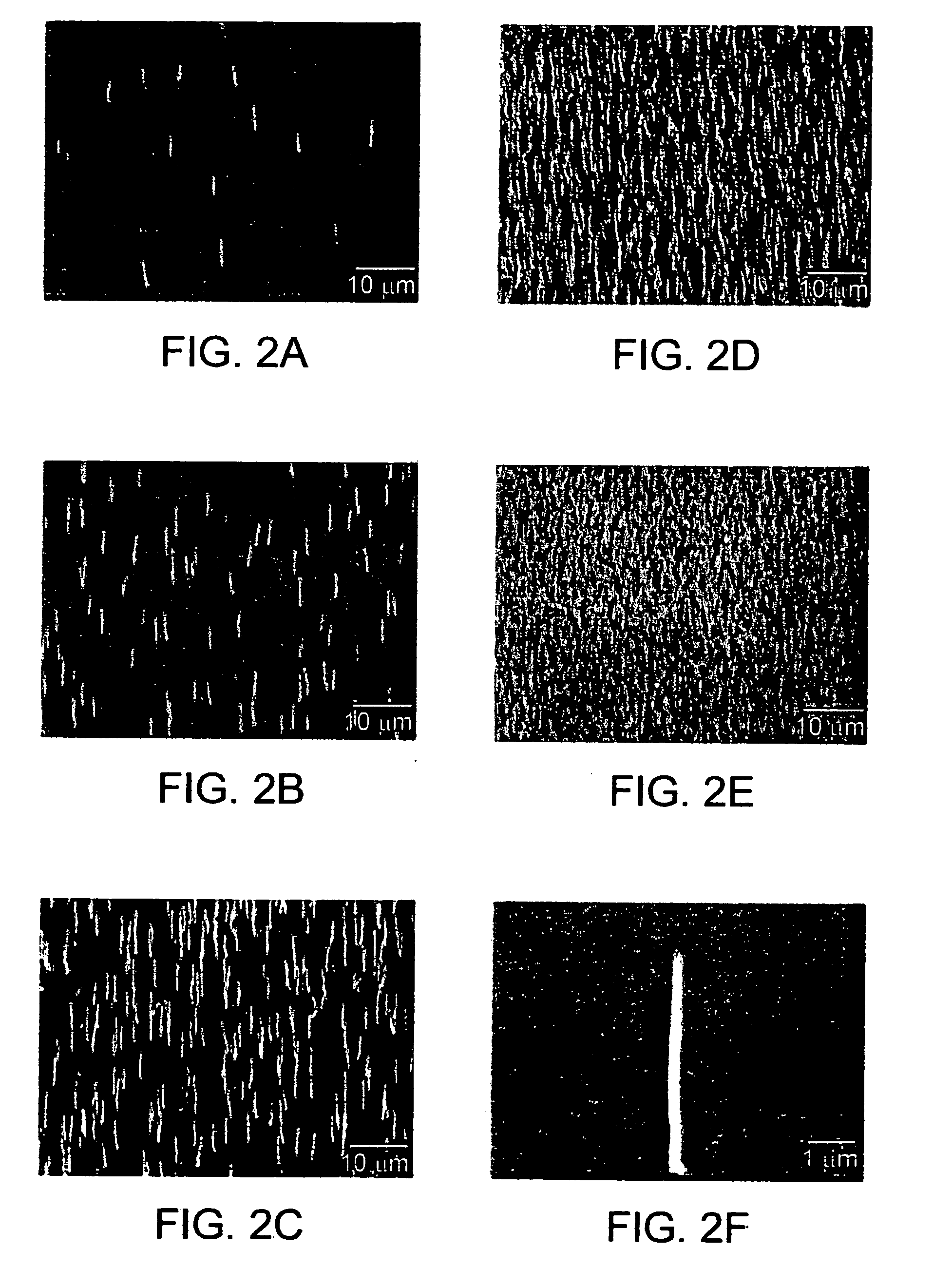

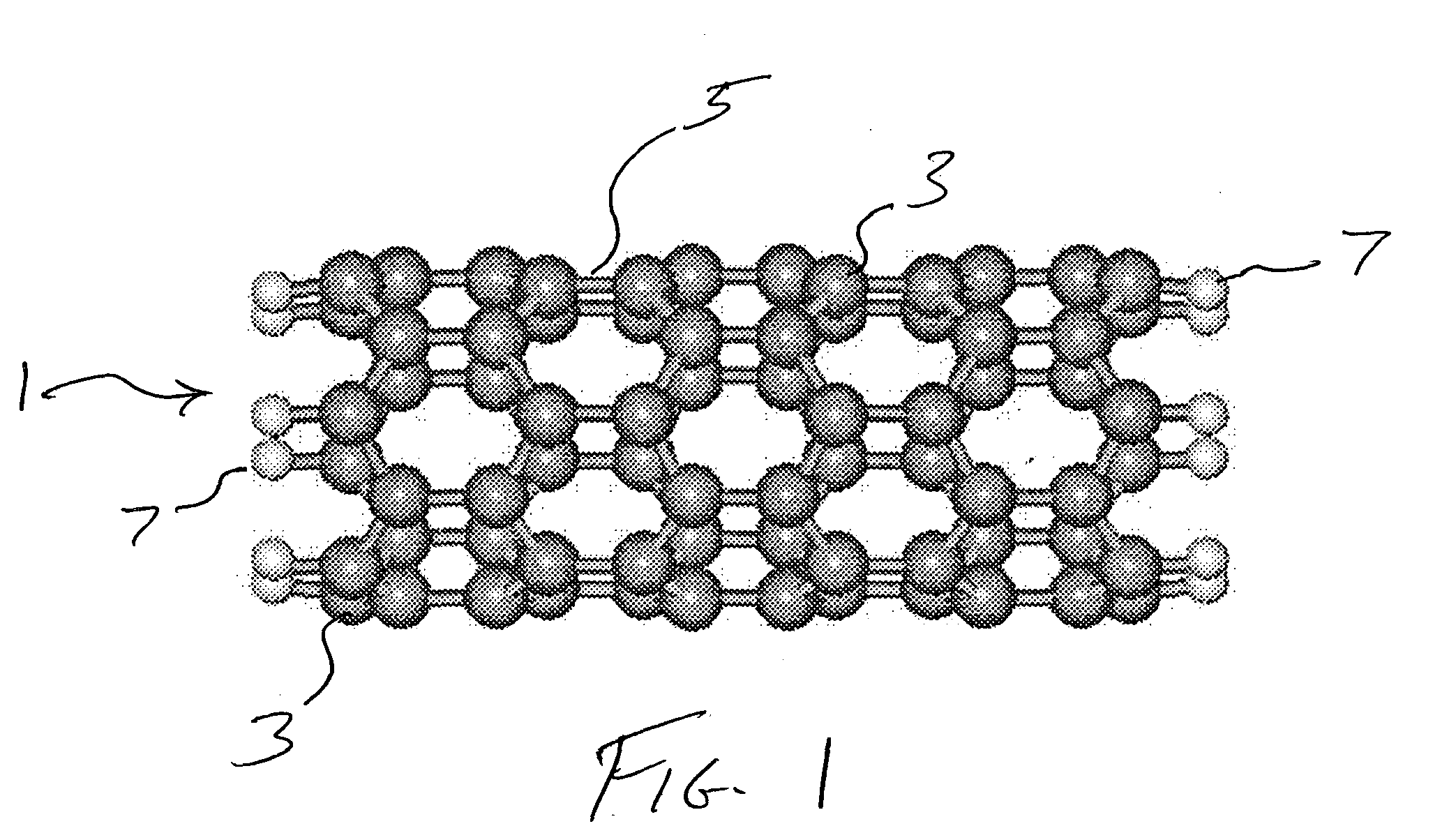

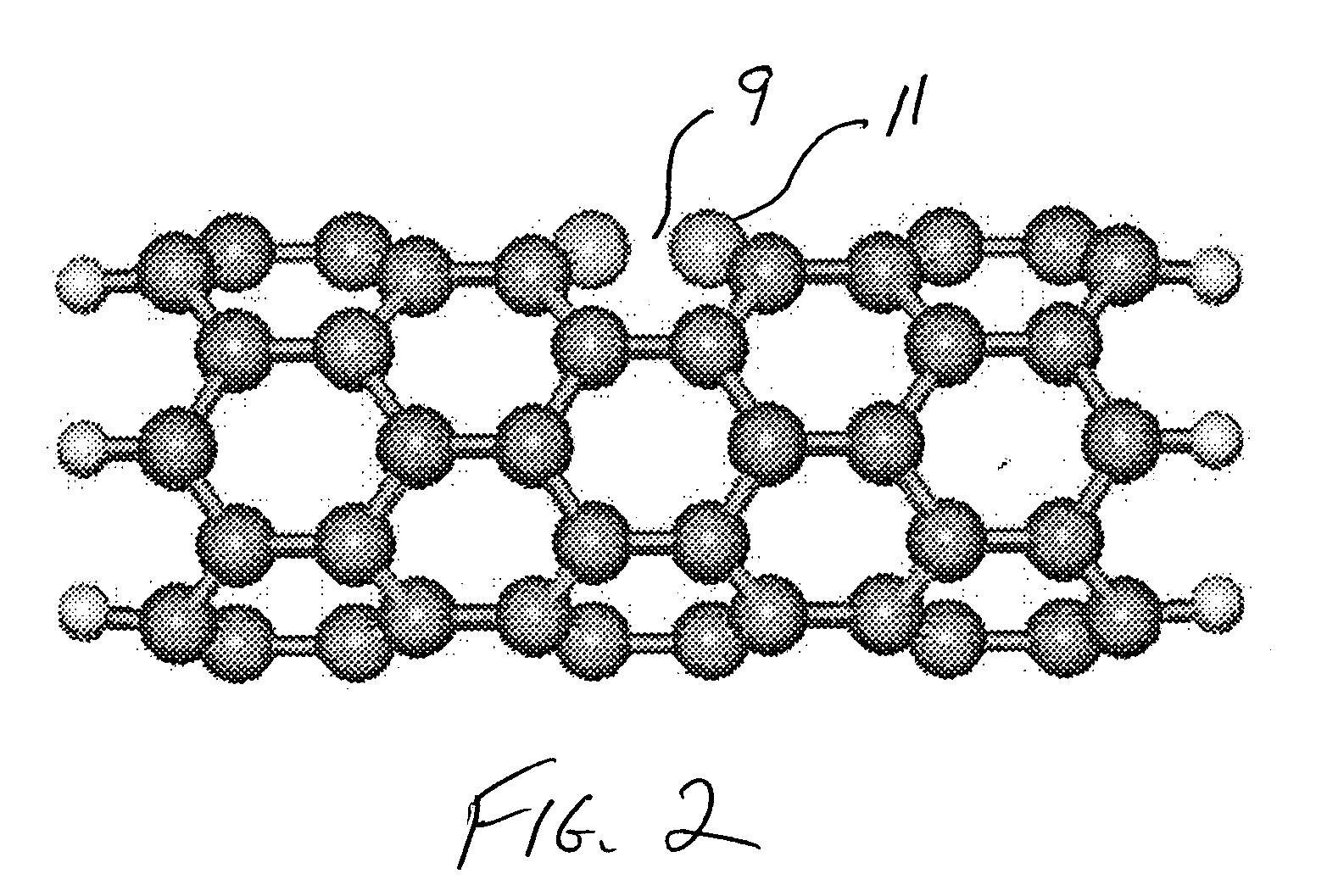

Carbon nanotube nanoelectrode arrays

InactiveUS20050230270A1Increase spacingIncrease the lengthImmobilised enzymesBioreactor/fermenter combinationsAdhesiveCarbon nanotube

The present invention relates to microelectode arrays (MEAs), and more particularly to carbon nanotube nanoelectrode arrays (CNT-NEAs) for chemical and biological sensing, and methods of use. A nanoelectrode array includes a carbon nanotube material comprising an array of substantially linear carbon nanotubes each having a proximal end and a distal end, the proximal end of the carbon nanotubes are attached to a catalyst substrate material so as to form the array with a pre-determined site density, wherein the carbon nanotubes are aligned with respect to one another within the array; an electrically insulating layer on the surface of the carbon nanotube material, whereby the distal end of the carbon nanotubes extend beyond the electrically insulating layer; a second adhesive electrically insulating layer on the surface of the electrically insulating layer, whereby the distal end of the carbon nanotubes extend beyond the second adhesive electrically insulating layer; and a metal wire attached to the catalyst substrate material.

Owner:BOSTON COLLEGE +1

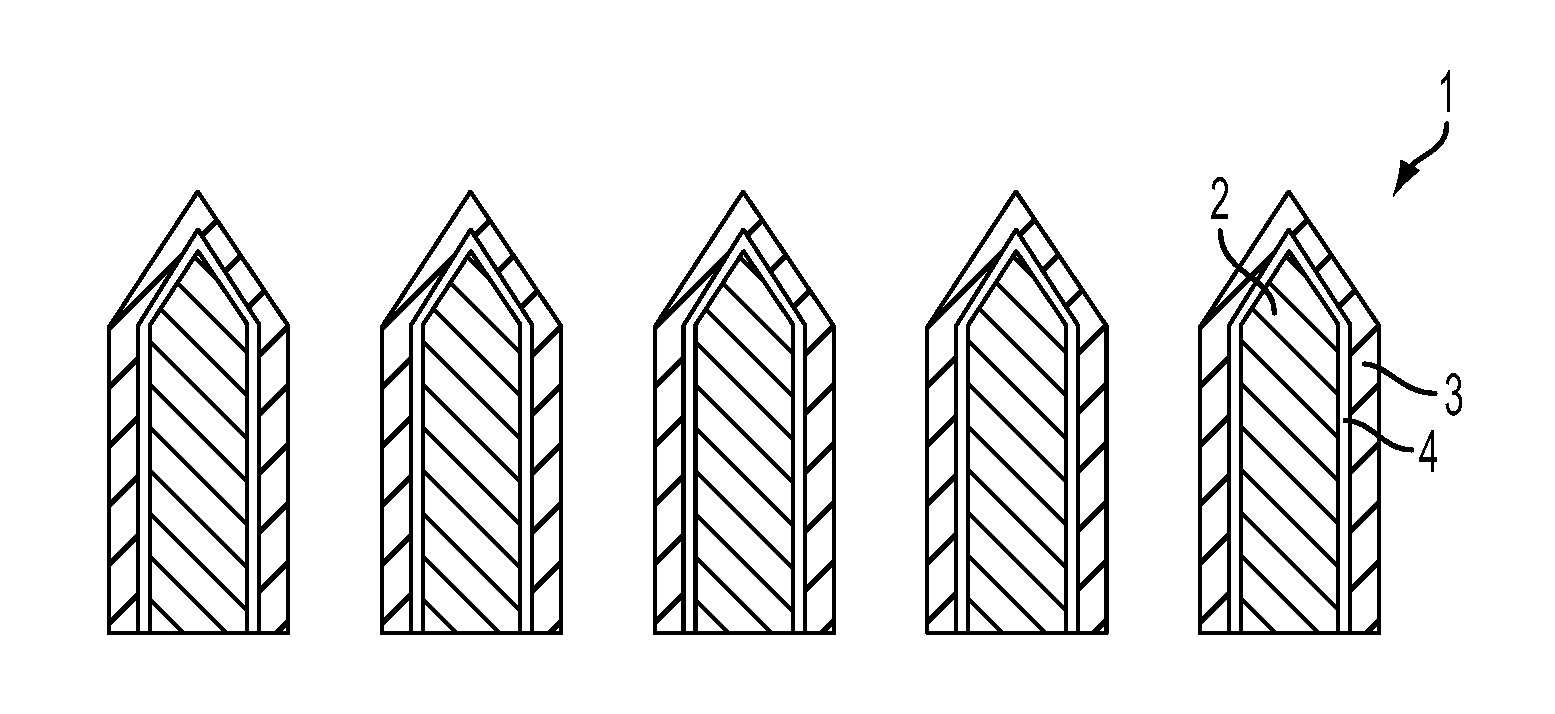

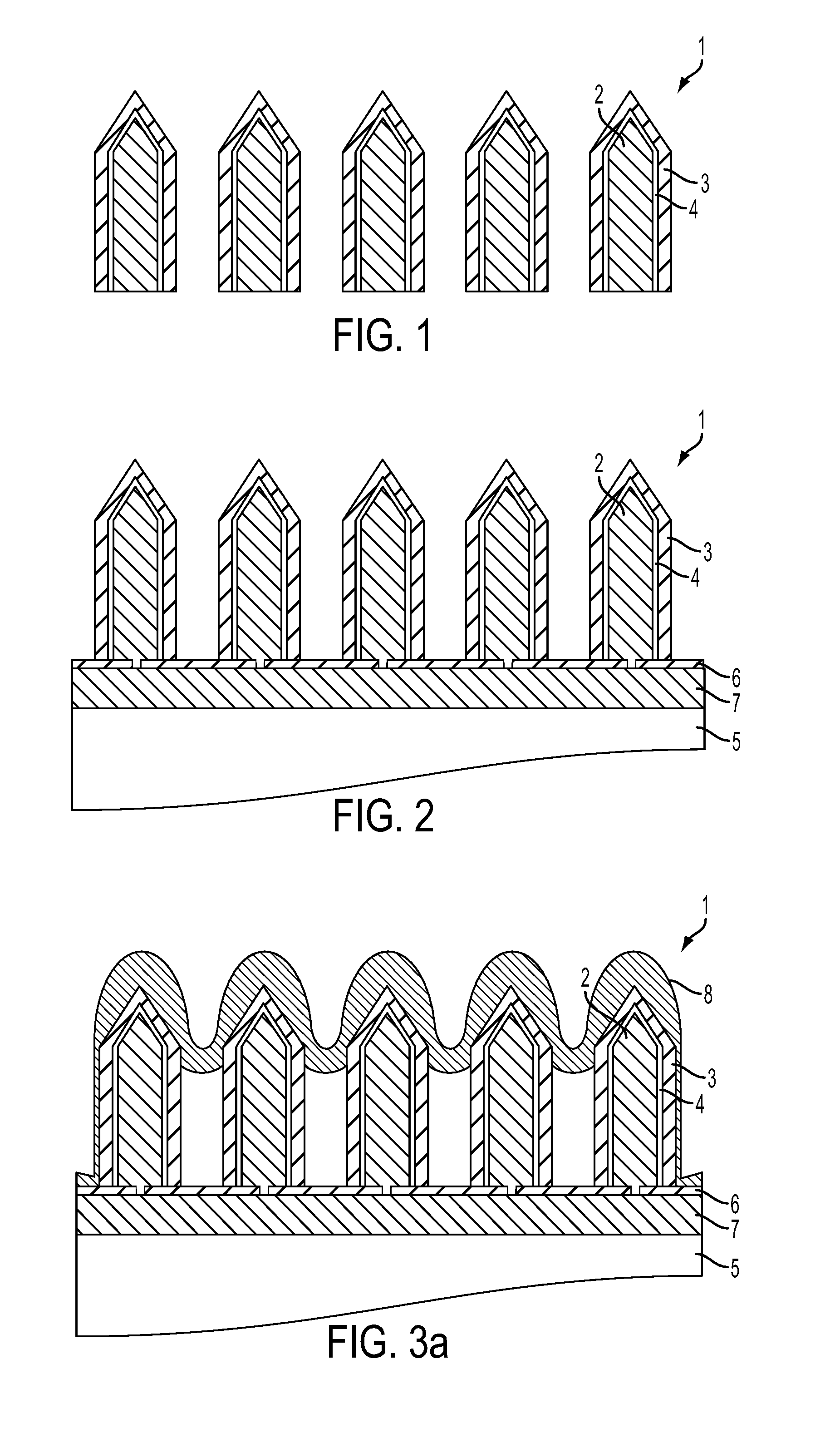

Nanowire LED structure and method for manufacturing the same

ActiveUS20110309382A1Discontinuity is reduced and eliminatedEasy to spreadSolid-state devicesSemiconductor/solid-state device manufacturingElectricityAir bridge

A light emitting diode (LED) structure includes a plurality of devices arranged side by side on a support layer. Each device includes a first conductivity type semiconductor nanowire core and an enclosing second conductivity type semiconductor shell for forming a pn or pin junction that in operation provides an active region for light generation. A first electrode layer extends over the plurality of devices and is in electrical contact with at least a top portion of the devices to connect to the shell. The first electrode layer is at least partly air-bridged between the devices.

Owner:NANOSYS INC

Method of growing electrical conductors

ActiveUS7067407B2Quality improvementGood step coverageSemiconductor/solid-state device manufacturingCapacitorsElectrical conductorAtomic layer deposition

Owner:ASM INTERNATIONAL

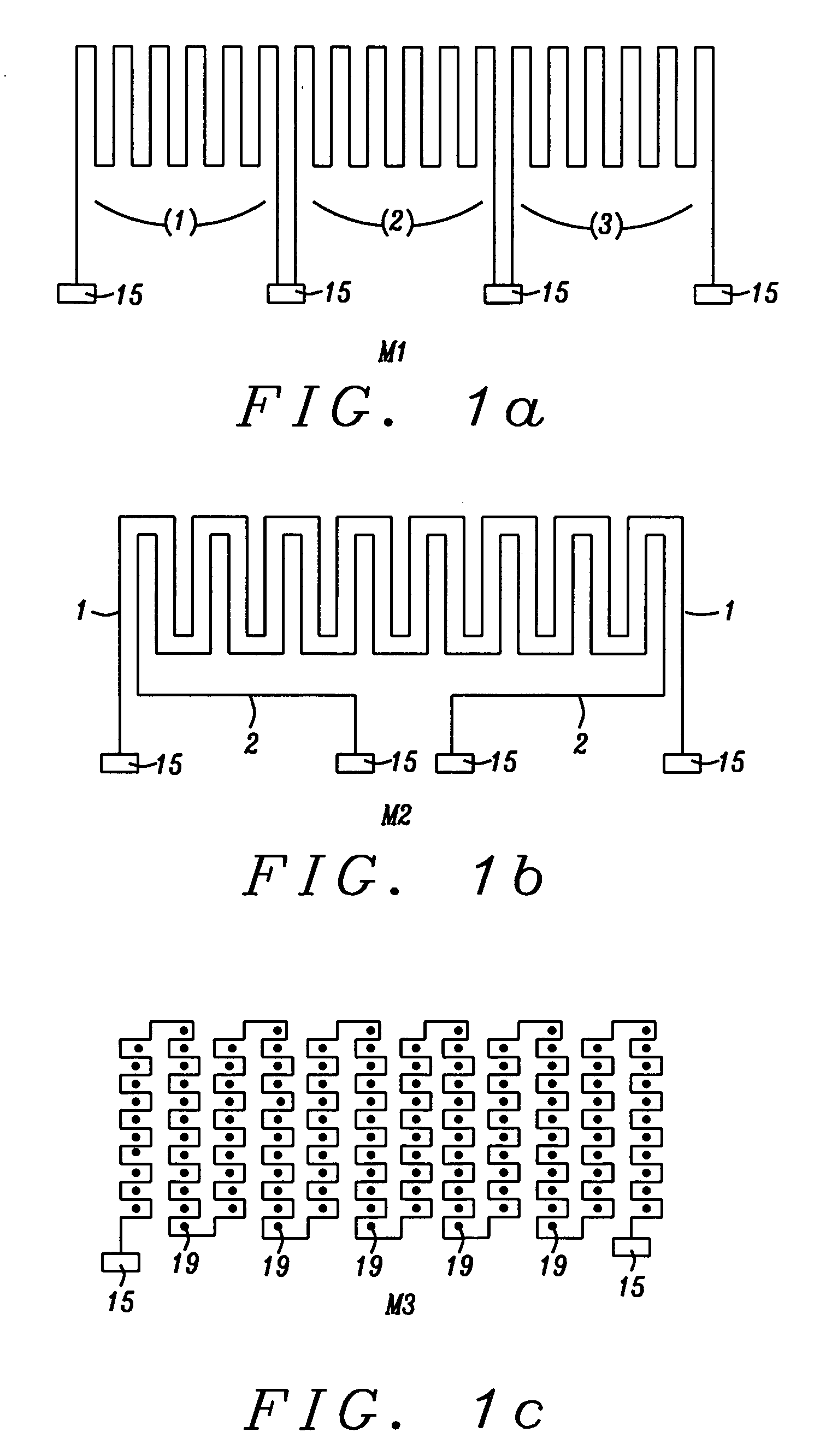

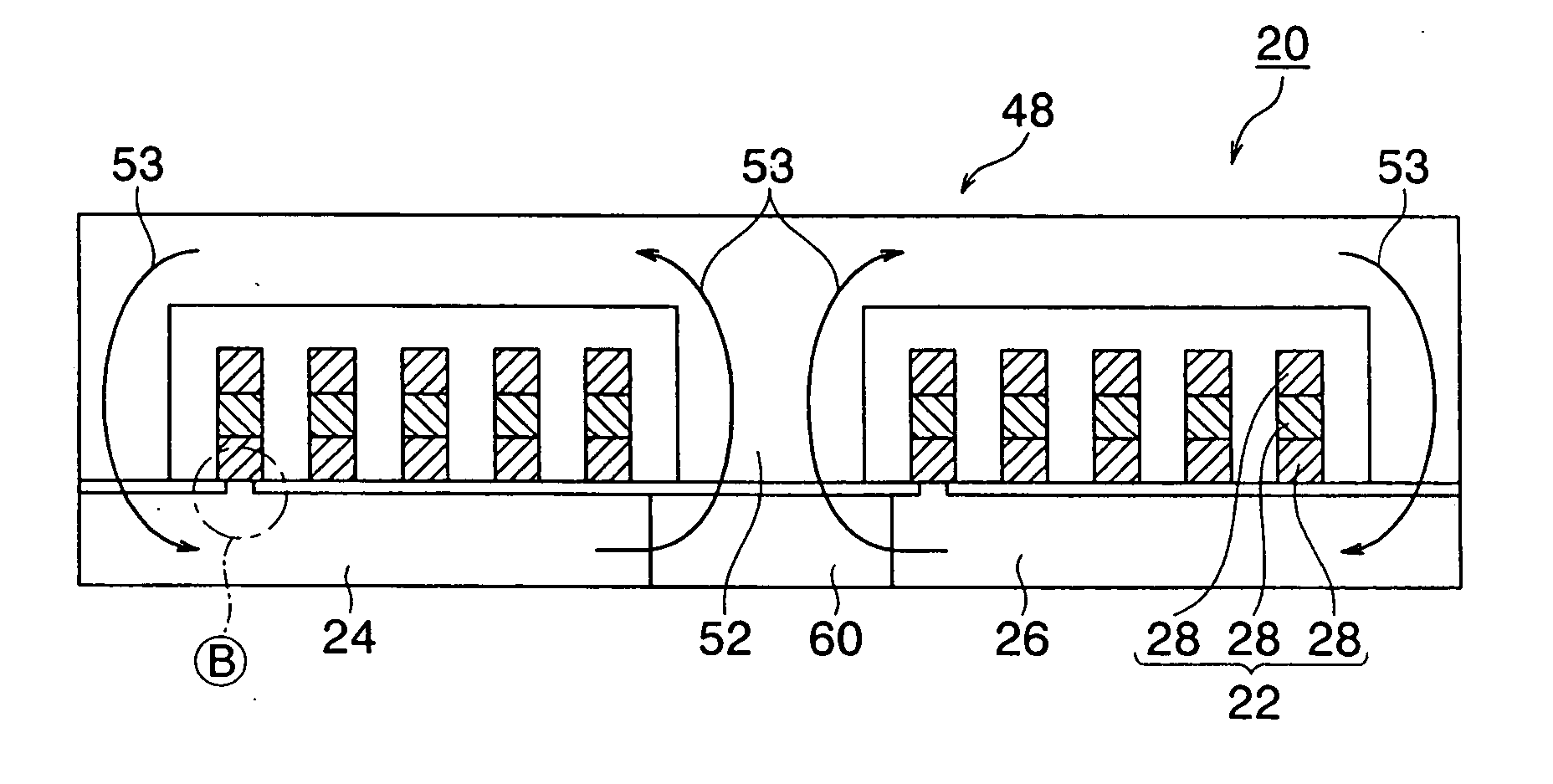

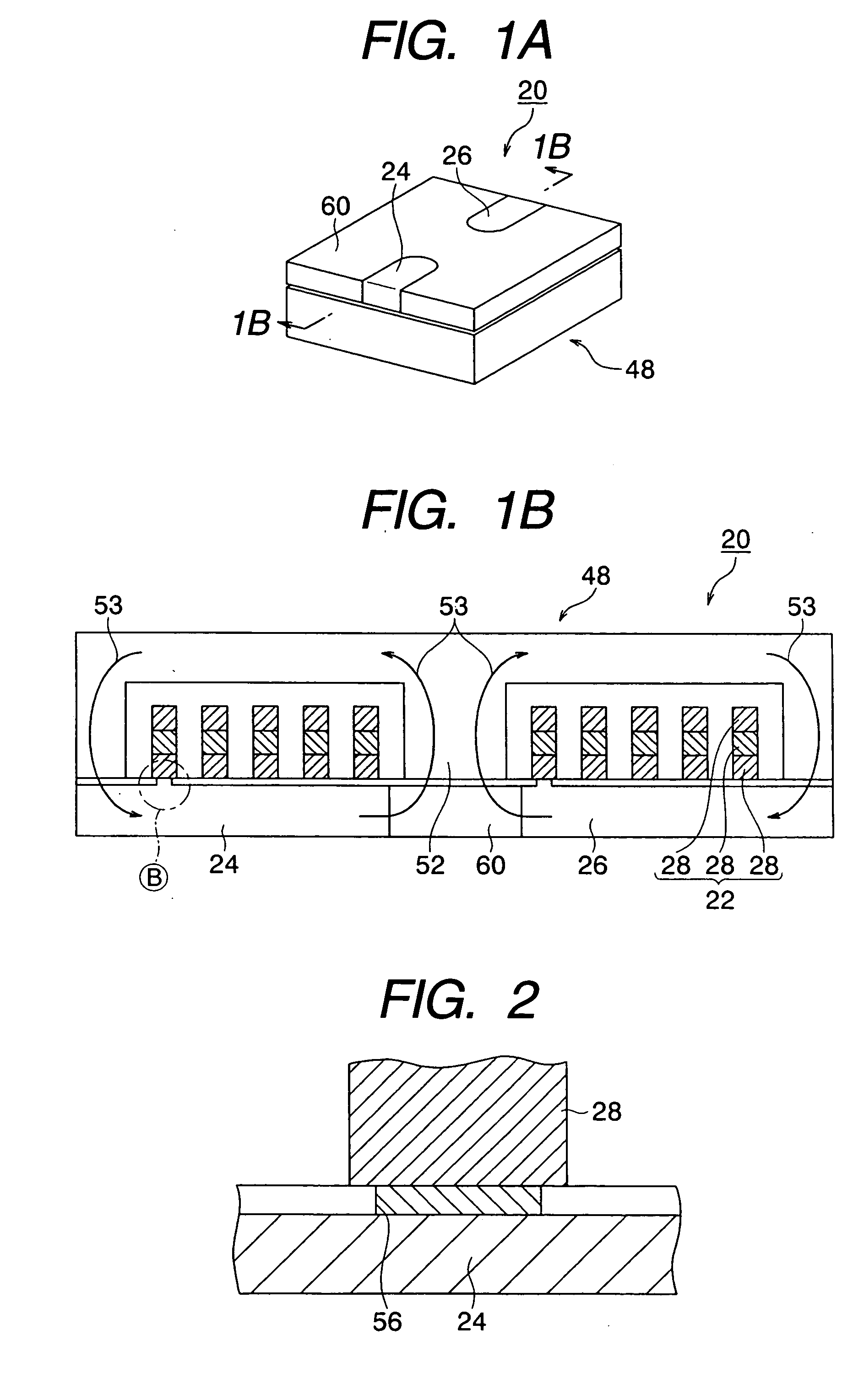

Microfabricated system for magnetic field generation and focusing

InactiveUS20050275497A1Easily of circuitryWell formedTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesDielectricMicro coil

A method of forming, in or on a Si substrate, planar micro-coils with coil windings of high aspect ratio (>3) and a wide variety of geometric shapes. The micro-coils may be formed on a Si substrate and be embedded in a dielectric, or they may be formed in trenches within a Si substrate. The micro-coils may have field enhancing ferromagnetic pillars rising above the micro-coil plane, formed at positions of maximum magnetic field strength and the micro-coils may also include magnetic layers formed beneath the substrate and contacting the pillars to form a substantially closed pathway for the magnetic flux. The substrate may be thinned to membrane proportions. These micro-coils produce strong magnetic fields with strong field gradients and can be used in a wide variety of processes that involve the exertion of strong magnetic forces at small distances or the creation of magnetic wells for trapping and manipulating small particles.

Owner:AGENCY FOR SCI TECH & RES +1

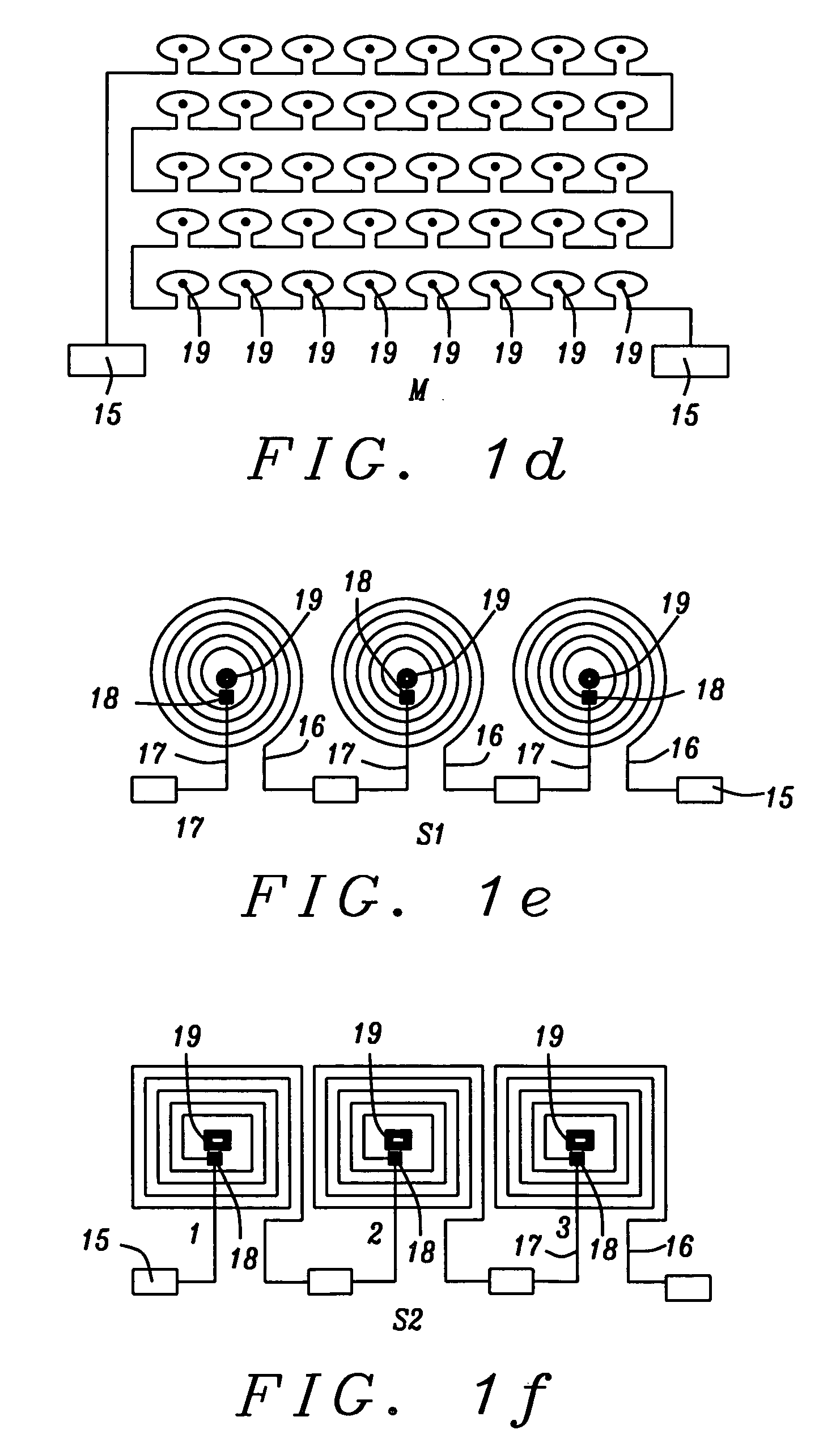

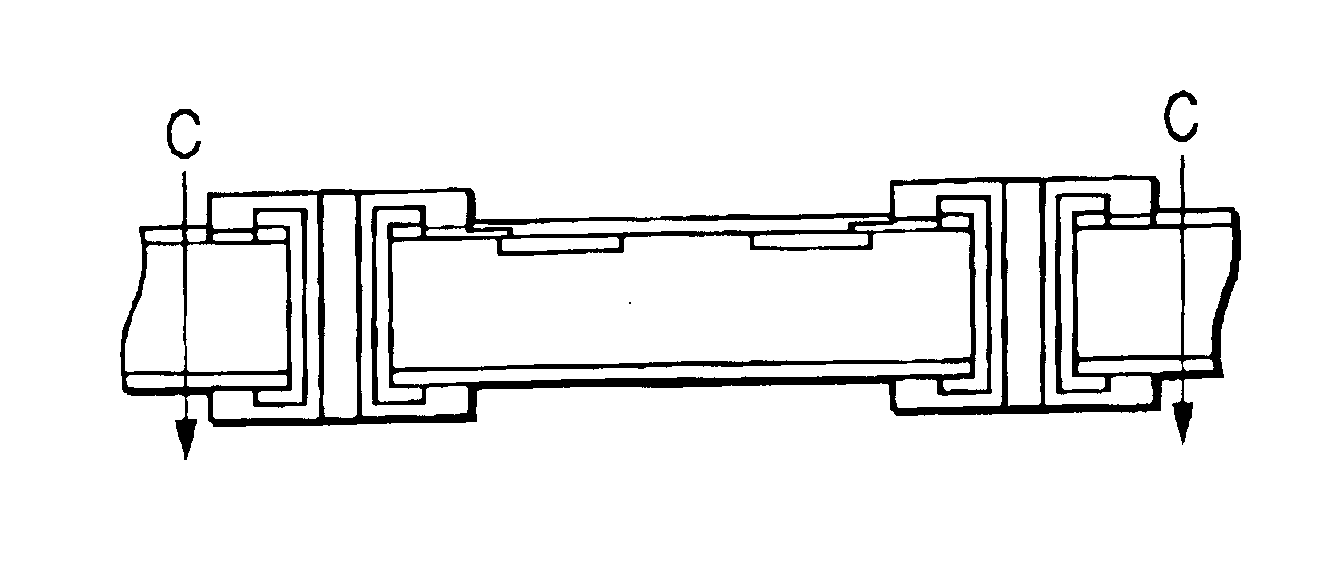

Semiconductor device and method of manufacturing semiconductor device

InactiveUS6856023B2Low costConductive and reliableSemiconductor/solid-state device detailsSolid-state devicesElectrical connectionSemiconductor

The semiconductor device of the present invention comprises a substrate; at least one through hole formed through the substrate between front and back surfaces of the substrate; an electrical connection portion formed by a semiconductor process on at least one surface of the front and back surfaces of the substrate in a vicinity of an end opening of the through hole; an insulating layer formed of an organic material on an inside surface of the through hole; and an electroconductive layer formed on an inside surface of the insulating layer, wherein the electrical connection portion is electrically connected to the electroconductive layer to be electrically connected to a side of the other surface of the substrate.

Owner:CANON KK

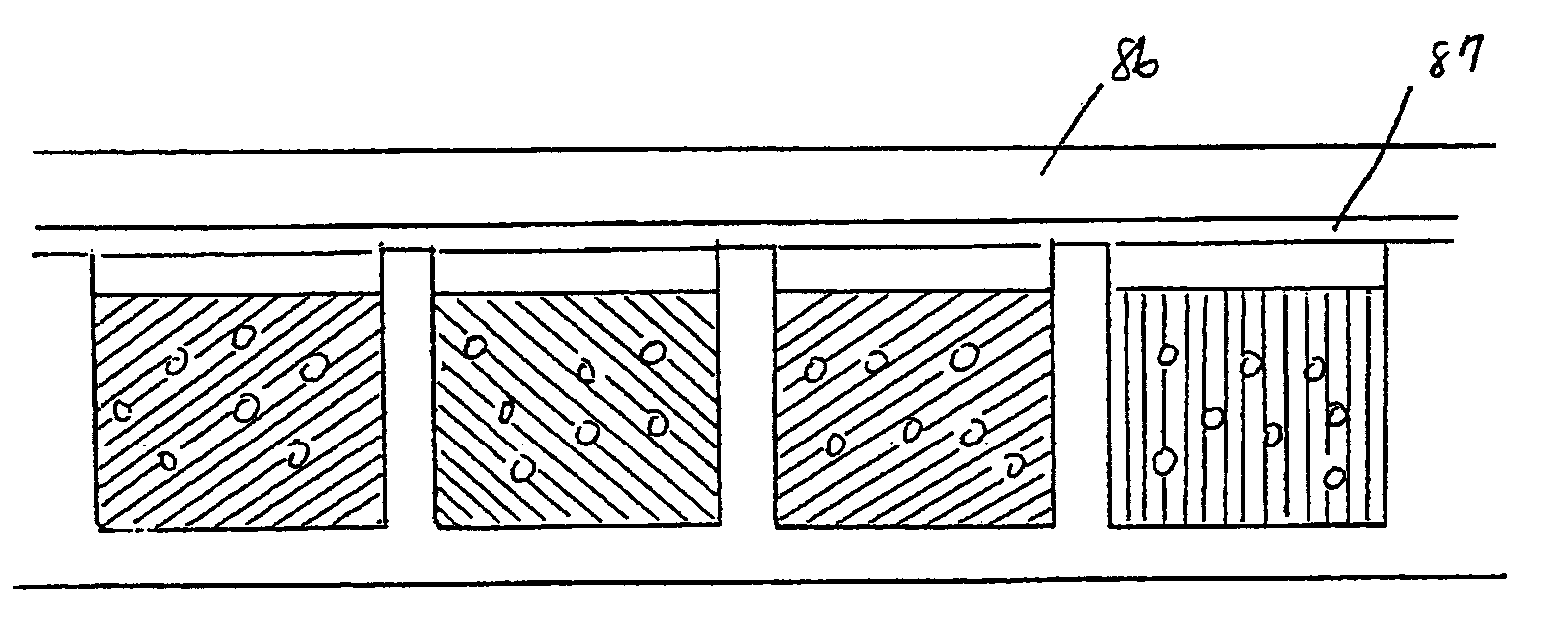

Electrophoretic display and novel process for its manufacture

InactiveUS6859302B2Excellent color addressabilityIncrease volumeSludge treatmentStatic indicating devicesElectrical batteryElectrophoresis

This invention relates to an electrophoretic display comprising cells of well-defined shape, size and aspect ratio which cells are filled with charged pigment particles dispersed in a solvent, and novel processes for its manufacture.

Owner:E INK CALIFORNIA

Electrophoretic display and process for its manufacture

InactiveUS7052571B2Excellent color addressabilityIncrease contrastFurnace componentsLamination ancillary operationsElectrophoresisDisplay device

This invention relates to an electrophoretic display comprising cells of well-defined shape, size and aspect ratio, which cells are filled with charged pigment particles dispersed in a solvent, and novel processes for its manufacture.

Owner:E INK CORPORATION

Method of forming stacked dies

ActiveUS8158456B2High aspect ratioReduce riskSolid-state devicesSemiconductor/solid-state device manufacturingWafer backgrindingSilicon

The formation of through silicon vias (TSVs) in an integrated circuit (IC) die or wafer is described in which the TSV is formed in the integration process prior to metallization processing. TSVs may be fabricated with increased aspect ratio, extending deeper in a wafer substrate. The method generally reduces the risk of overly-thinning a wafer substrate in a wafer back-side grinding process typically used to expose and make electrical contacts to the TSVs. By providing deeper TSVs and bonding pads, individual wafers and dies may be bonded directly between the TSVs and bonding pads on an additional wafer.

Owner:TAIWAN SEMICON MFG CO LTD

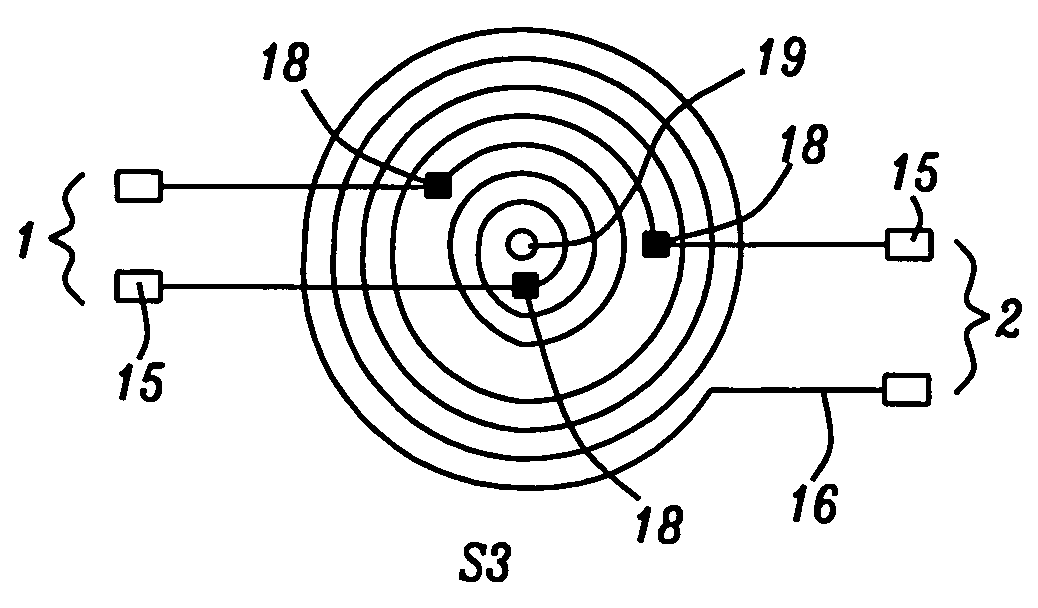

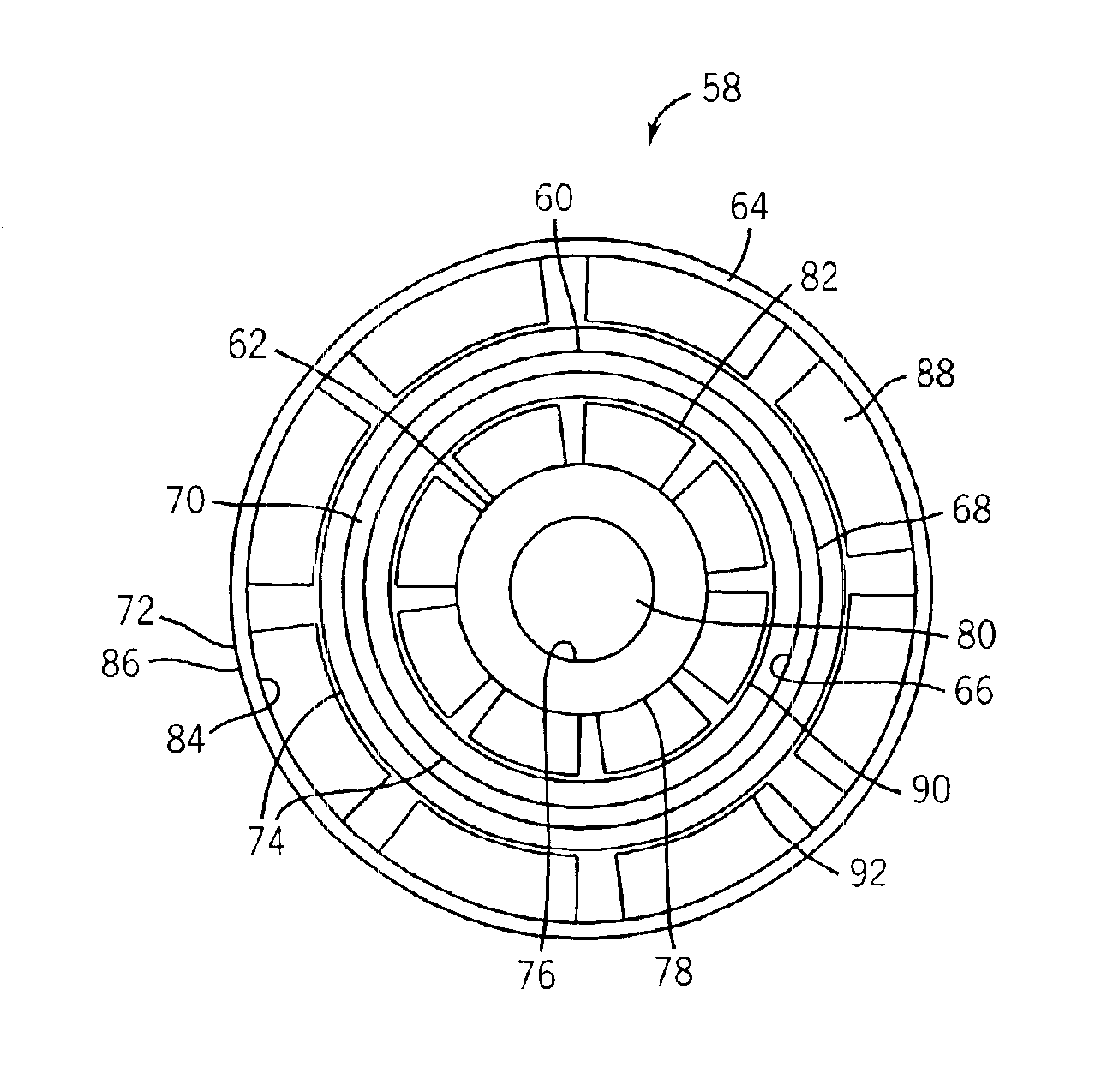

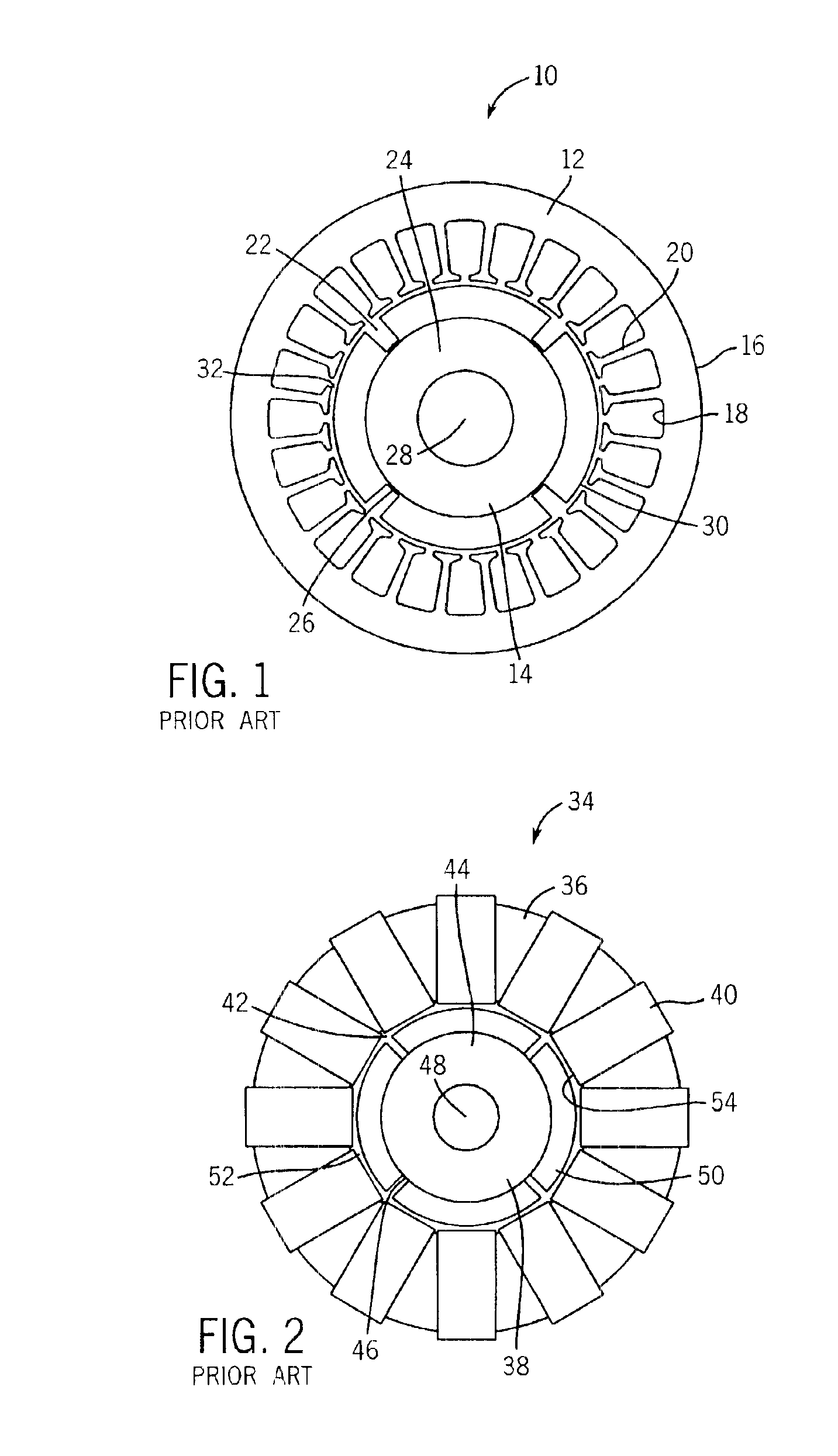

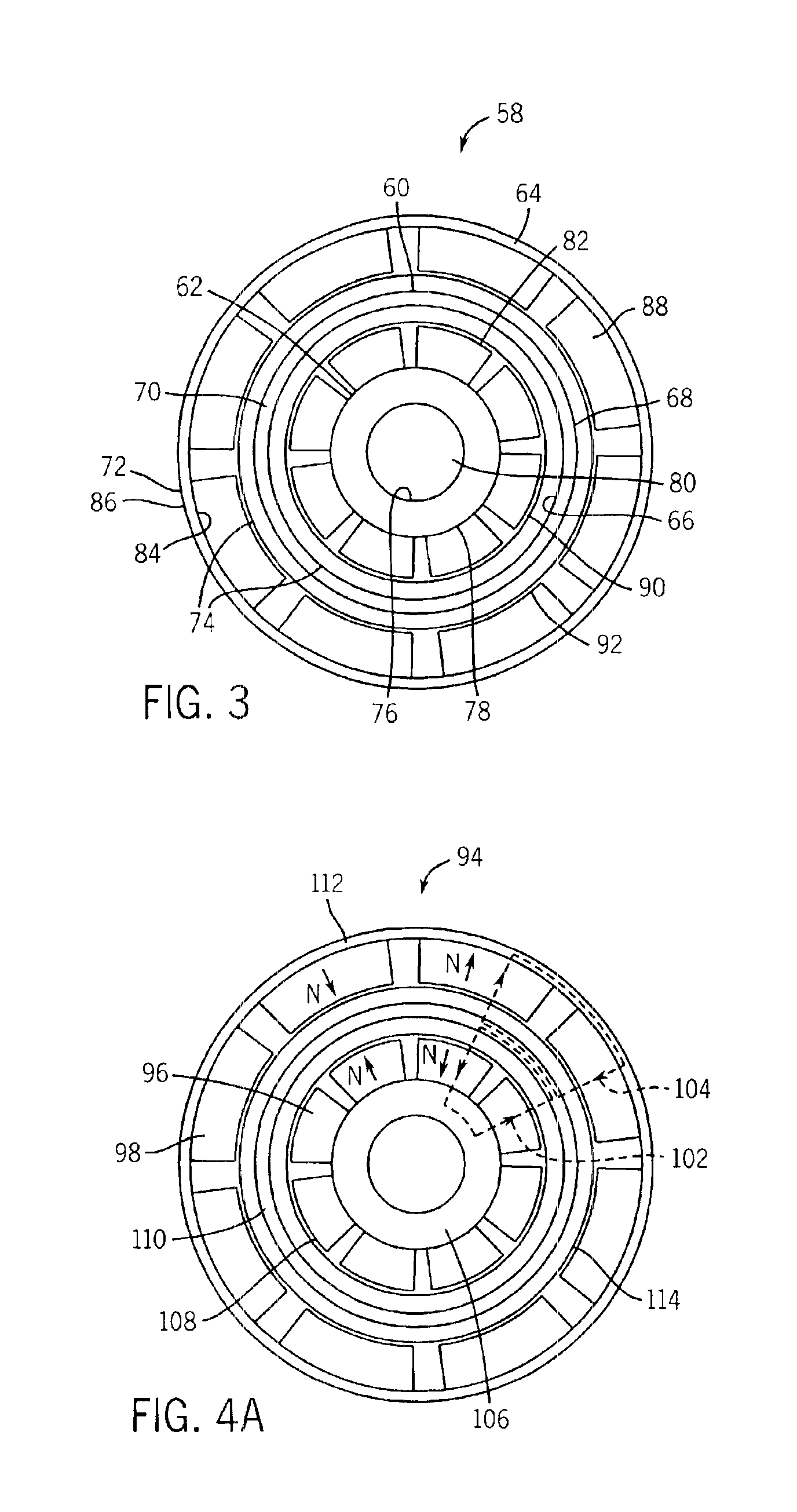

Dual-rotor, radial-flux, toroidally-wound, permanent-magnet machine

InactiveUS6924574B2Increased torque densityReduce the cost of the whole machineSynchronous generatorsMagnetic circuit rotating partsSurface mountingElectric machine

The present invention provides a novel dual-rotor, radial-flux, toroidally-wound, permanent-magnet machine. The present invention improves electrical machine torque density and efficiency. At least one concentric surface-mounted permanent magnet dual-rotor is located inside and outside of a torus-shaped stator with back-to-back windings, respectively. The machine substantially improves machine efficiency by reducing the end windings and boosts the torque density by at least doubling the air gap and optimizing the machine aspect ratio.

Owner:WISCONSIN ALUMNI RES FOUND

Method of growing electrical conductors

InactiveUS7494927B2Quality improvementGood step coverageSemiconductor/solid-state device manufacturingChemical vapor deposition coatingElectrical conductorOptoelectronics

A method for forming a conductive thin film includes depositing a metal oxide thin film on a substrate by an atomic layer deposition (ALD) process. The method further includes at least partially reducing the metal oxide thin film by exposing the metal oxide thin film to a reducing agent, thereby forming a seed layer. In one arrangement, the reducing agent comprises one or more organic compounds that contain at least one functional group selected from the group consisting of —OH, —CHO, and —COOH. In another arrangement, the reducing agent comprises an electric current.

Owner:ASM INTERNATIONAL

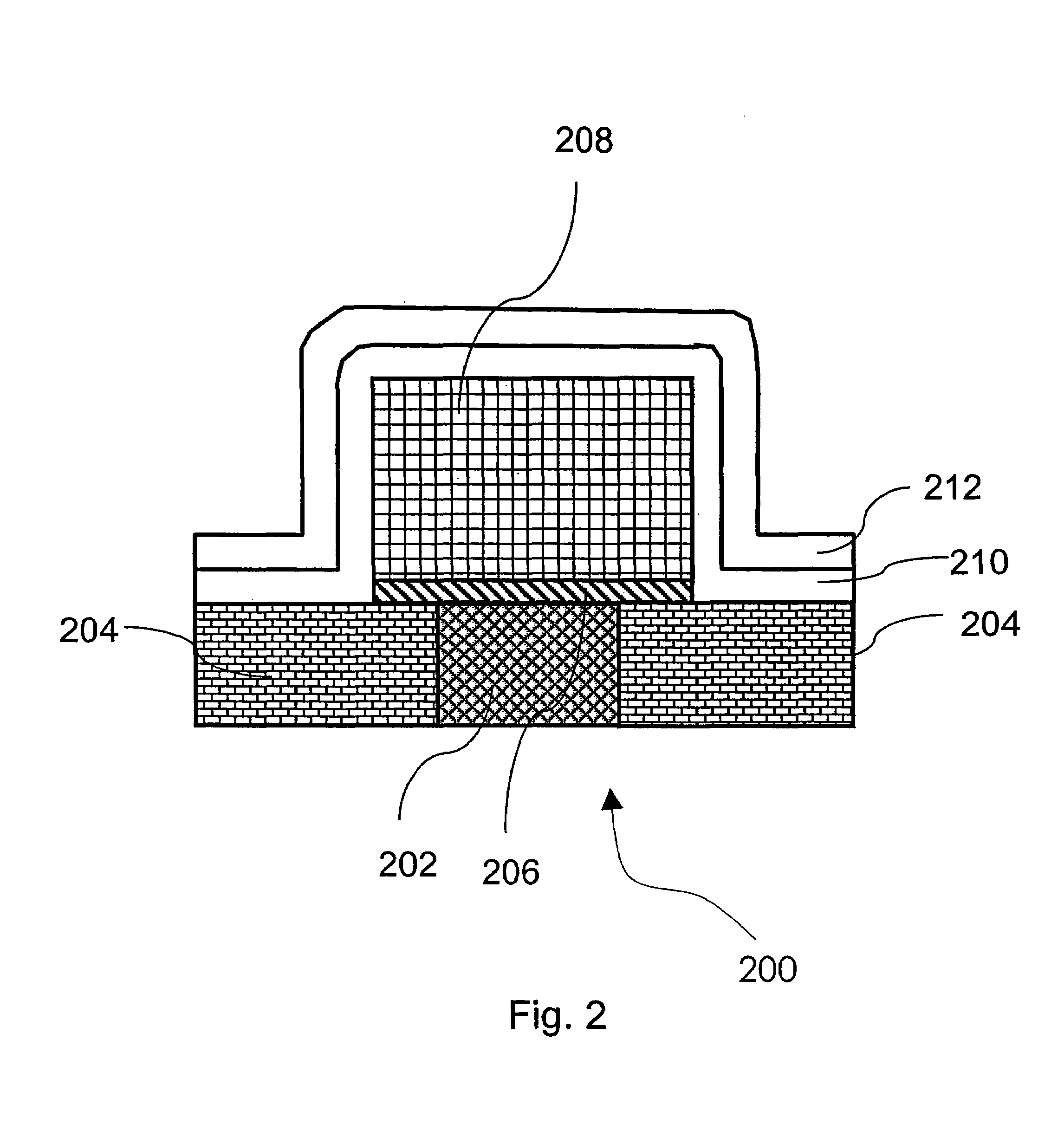

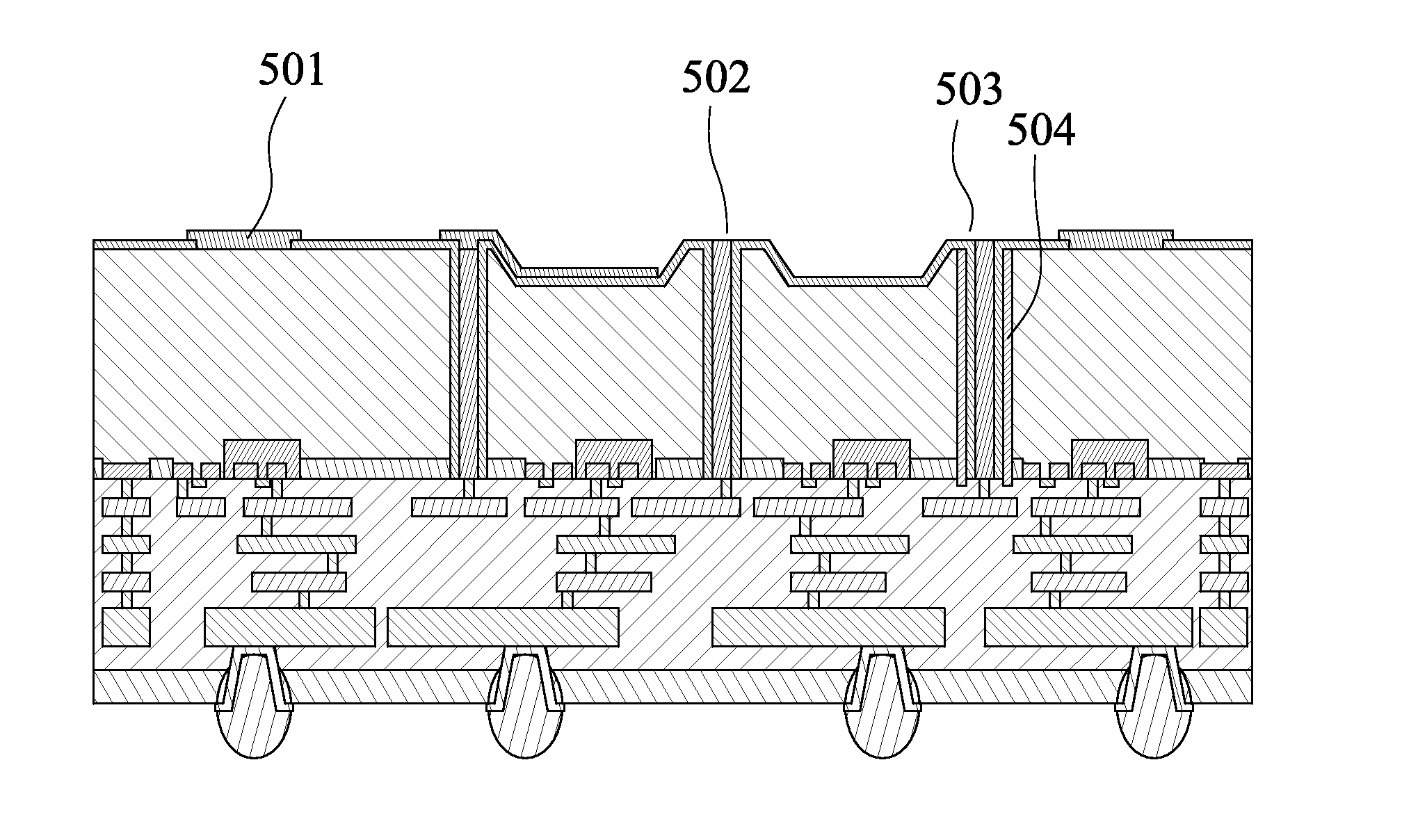

Integrated compact MEMS device with deep trench contacts

InactiveUS20130168740A1High aspect ratioIncrease contactSolid-state devicesSpeed/acceleration/shock instrument detailsCMOSSolder ball

A compact MEMS motion sensor device is provided, including a CMOS substrate layer, with plural anchor posts having an isolation oxide layer surrounding a conductive layer. On one side of CMOS substrate layer, the device further includes a field oxide (FOX) layer, a first set and a second set of implant doped silicon areas, a first polysilicon layer, an oxide layer embedded with plural metal layers interleaved with via hole layers, a Nitride deposition layer, an under bump metal (UBM) layer and a plurality of solder spheres. On the other side of CMOS substrate layer, the present invention further includes a backside interconnect isolation oxide layer, a first MEMS bonding layer, a first metal compound layer, a second MEMS bonding layer, a MEMS layer, a first MEMS eutectic bonding layer, a second metal compound layer, a second MEMS eutectic bonding layer, and a MEMS cap layer.

Owner:WINDTOP TECH CORP

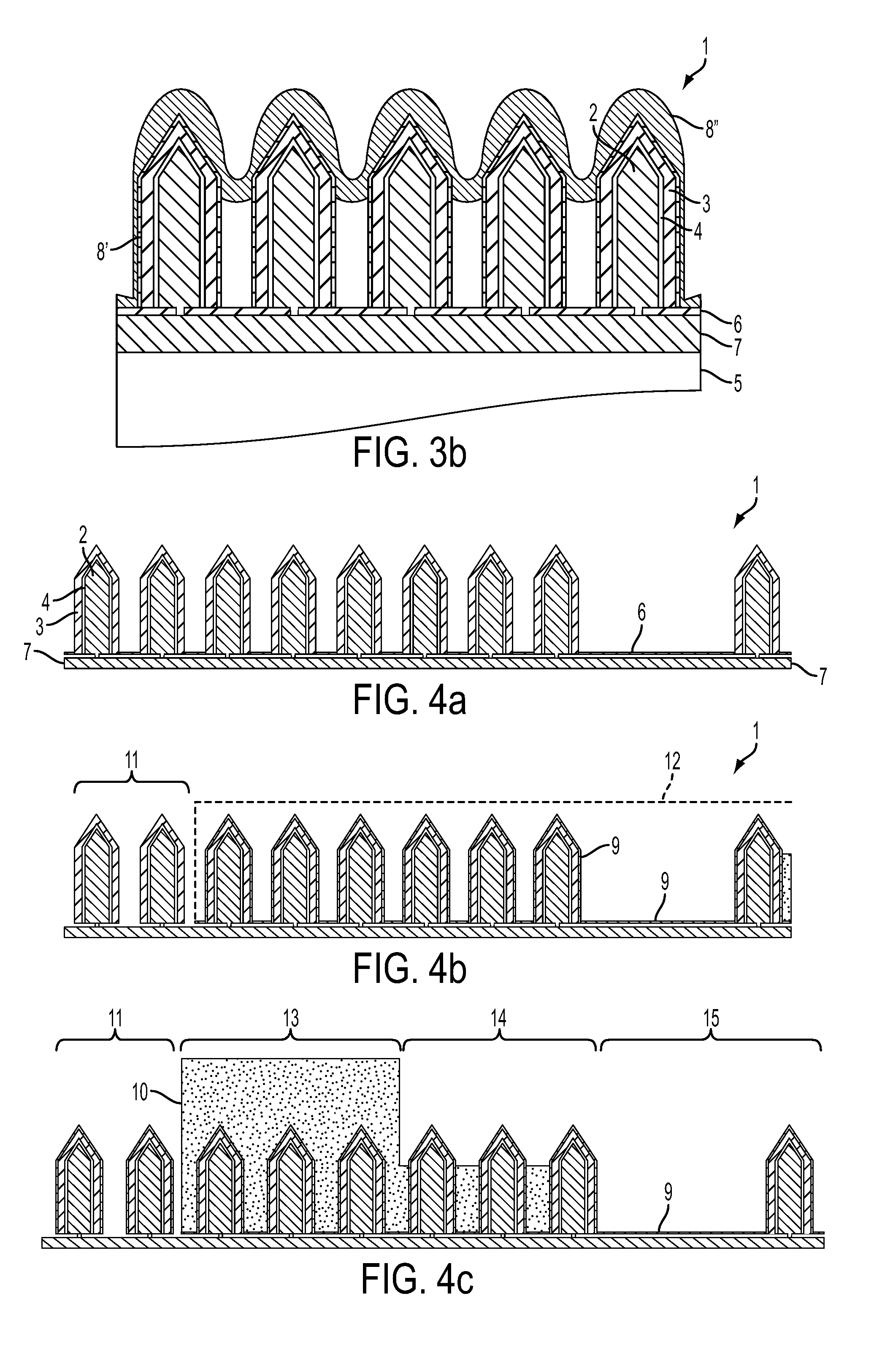

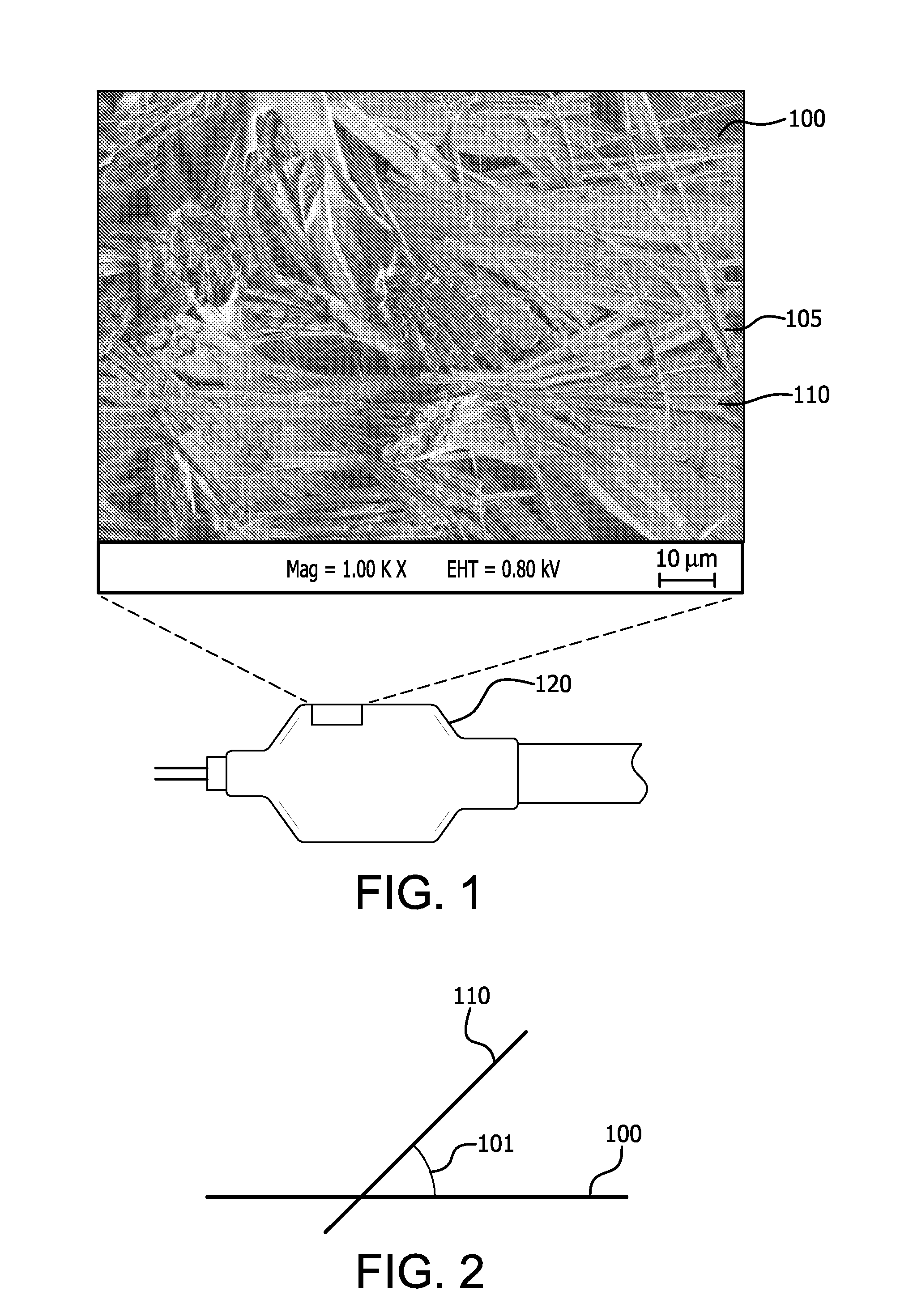

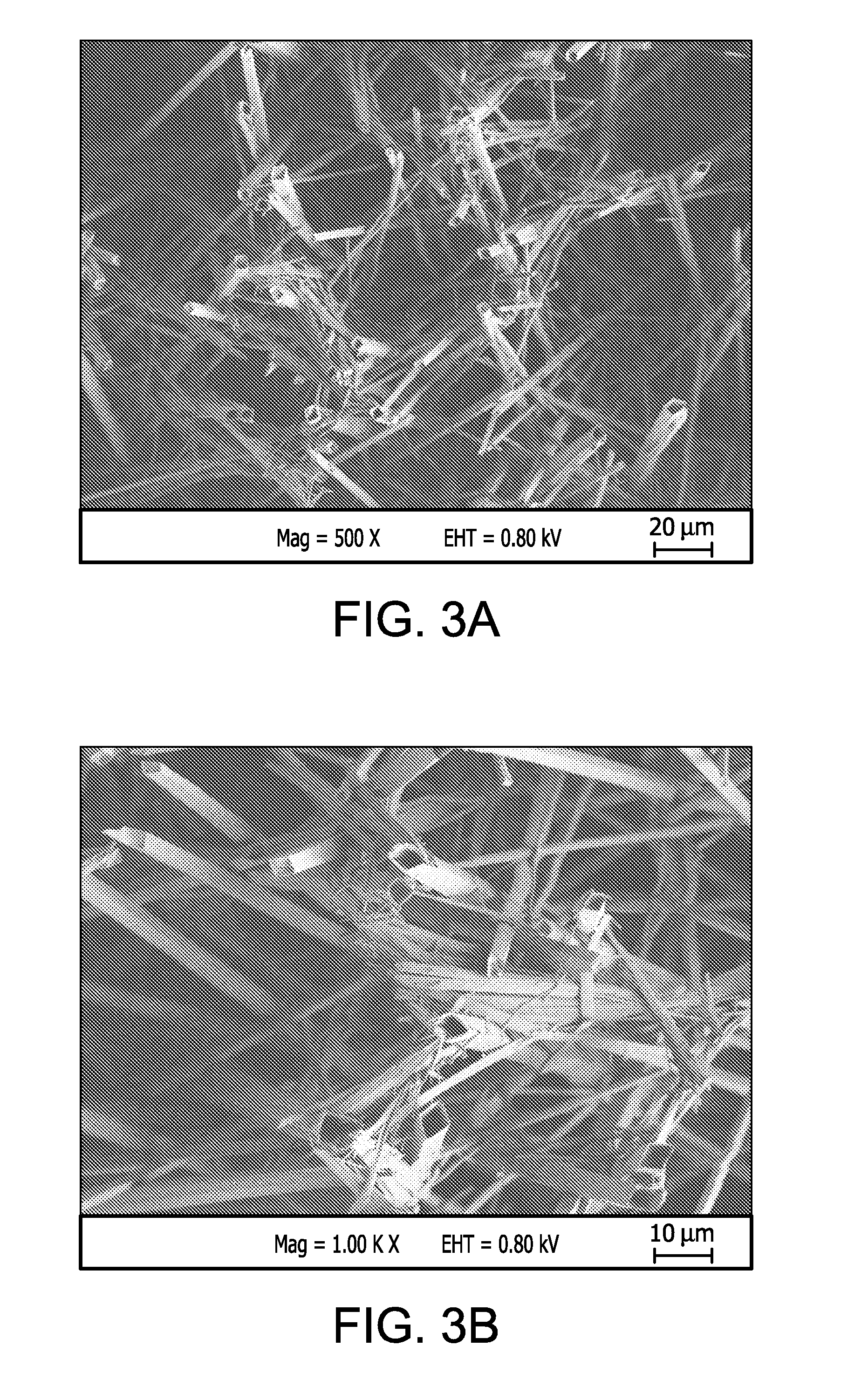

Porous composites with high-aspect ratio crystals

ActiveUS20140271775A1Easy to attachHigh aspect ratioOrganic active ingredientsBiocideVascular diseaseMedicine

The present disclosure is directed toward composite materials comprising high aspect ratio habits of drug crystals which can be partially or fully extending into a substrate, and additionally, can be projecting from a substrate at an angle of about 20° to about 90°. The present disclosure is directed toward medical devices, such as medical balloons, comprising said composite and methods of using and making the same. The described composite can be used for the local treatment of vascular disease. The present disclosure is also directed toward paclitaxel crystals with a hollow acicular habit.

Owner:WL GORE & ASSOC INC

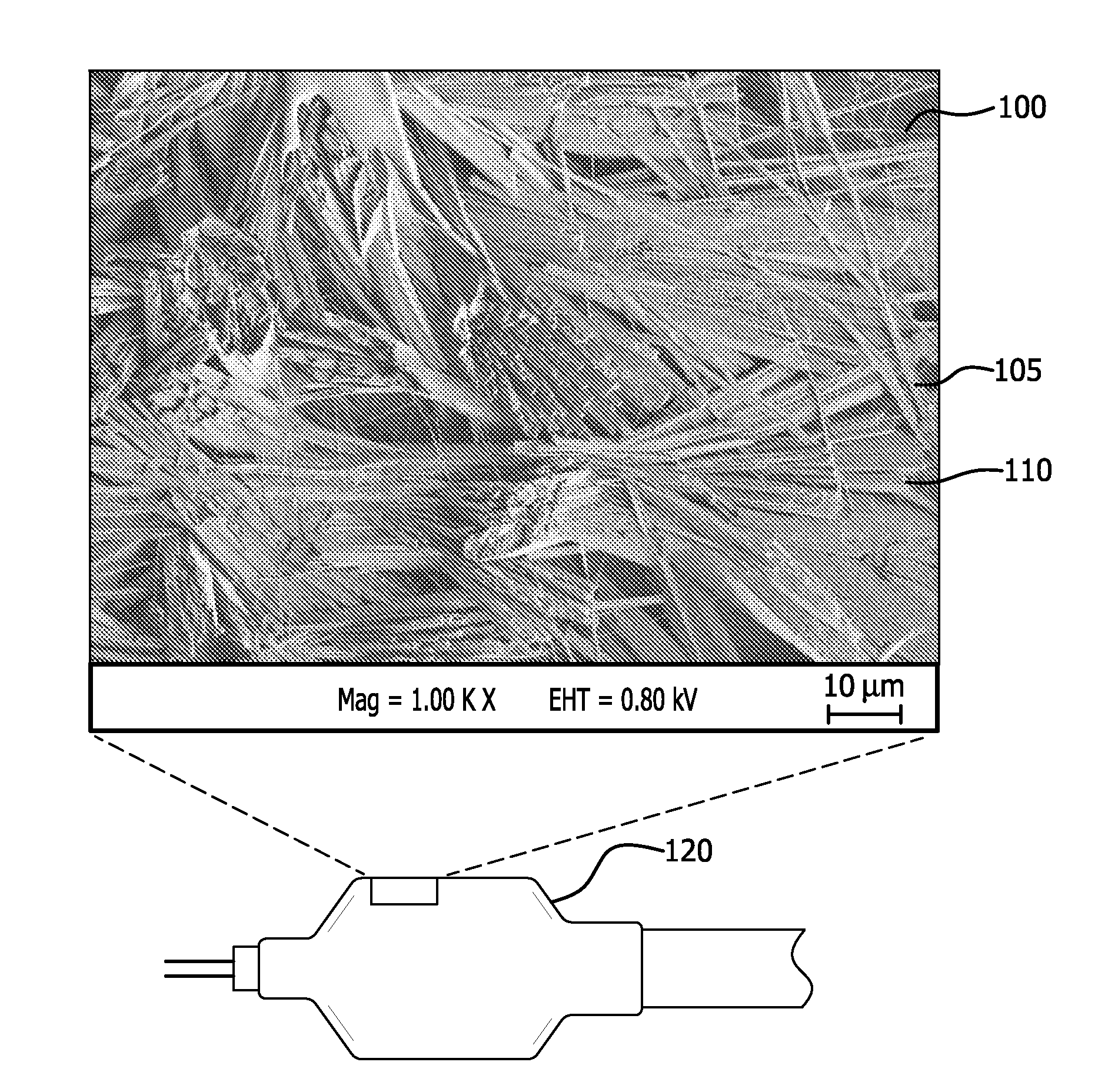

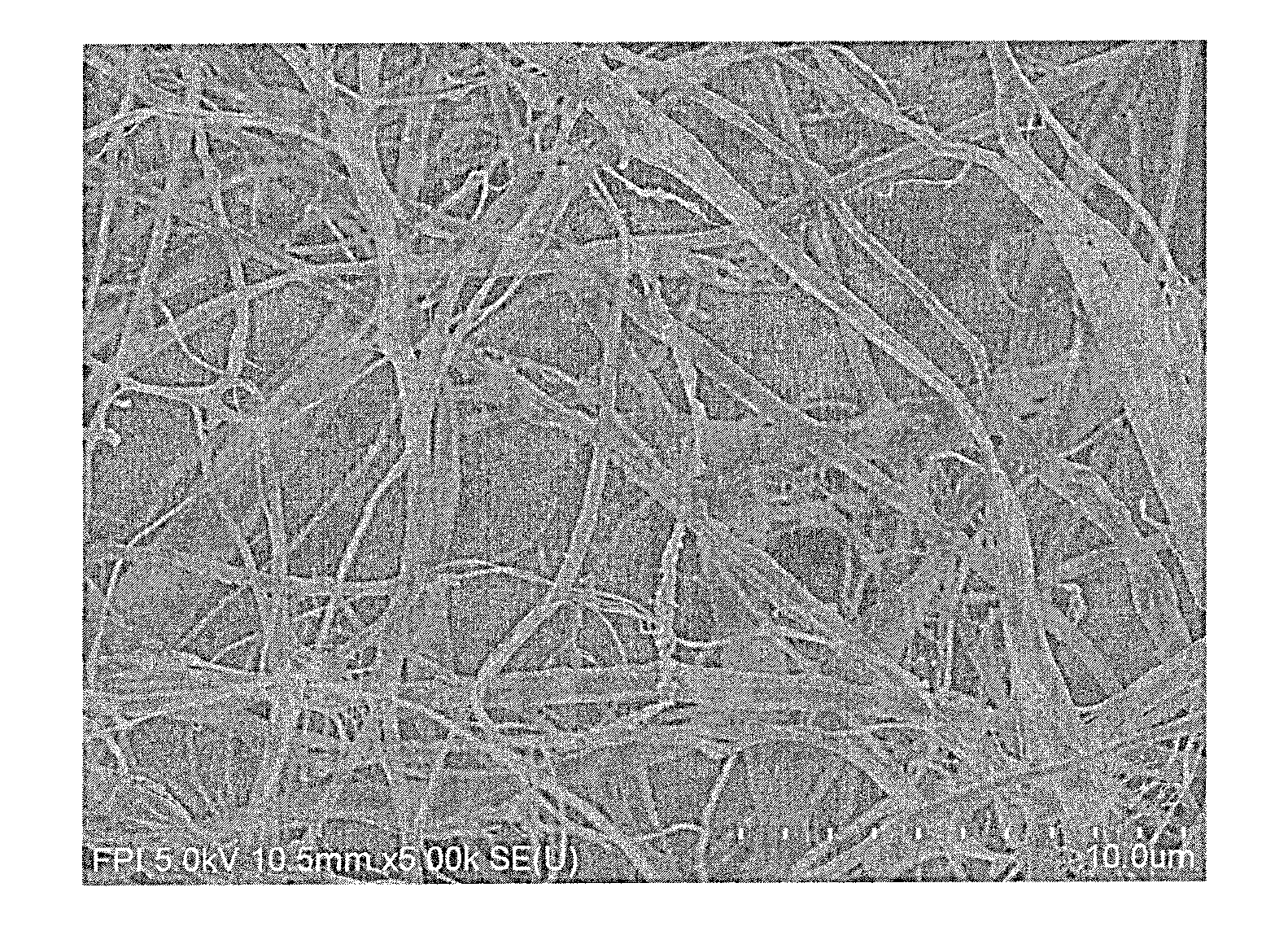

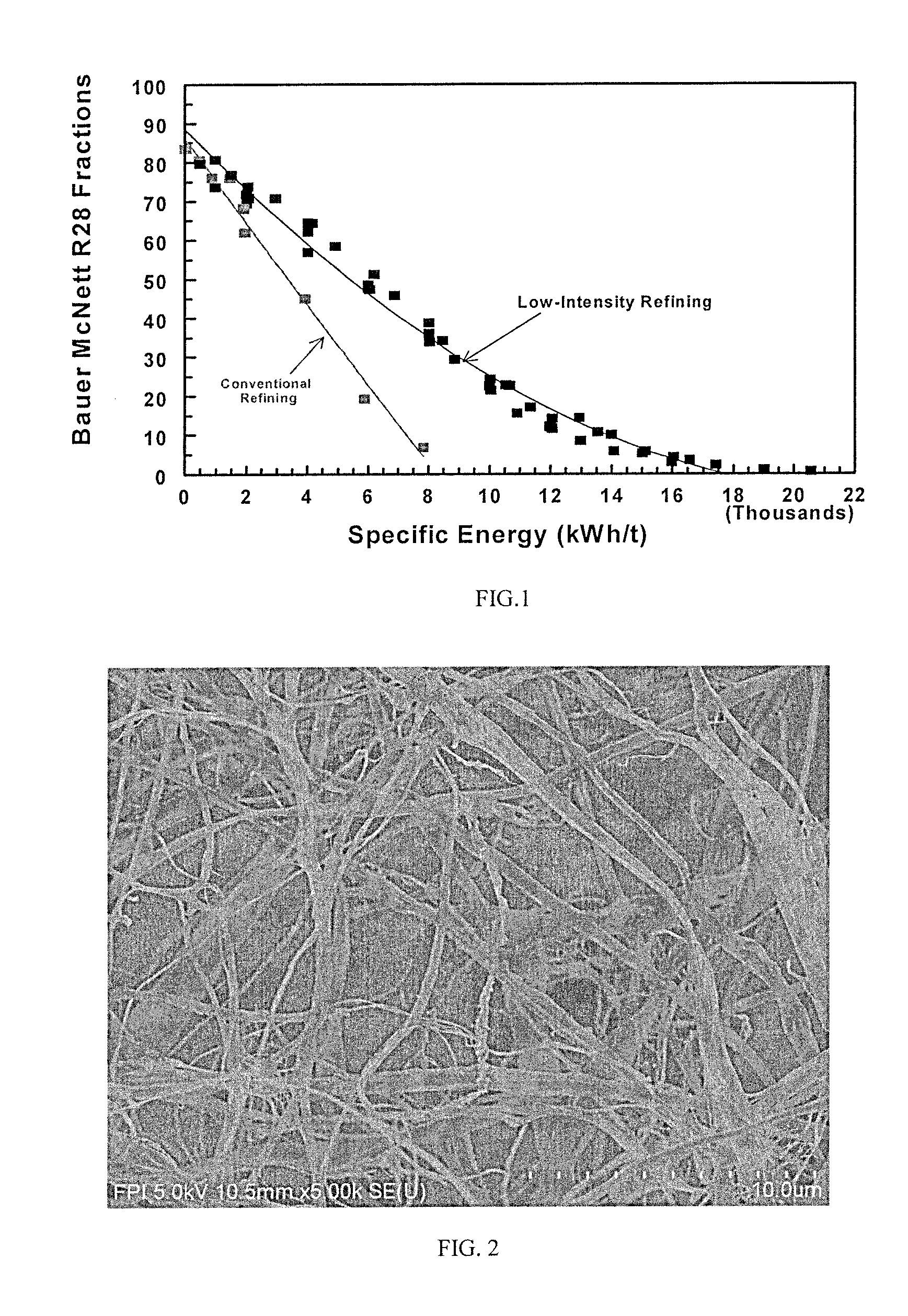

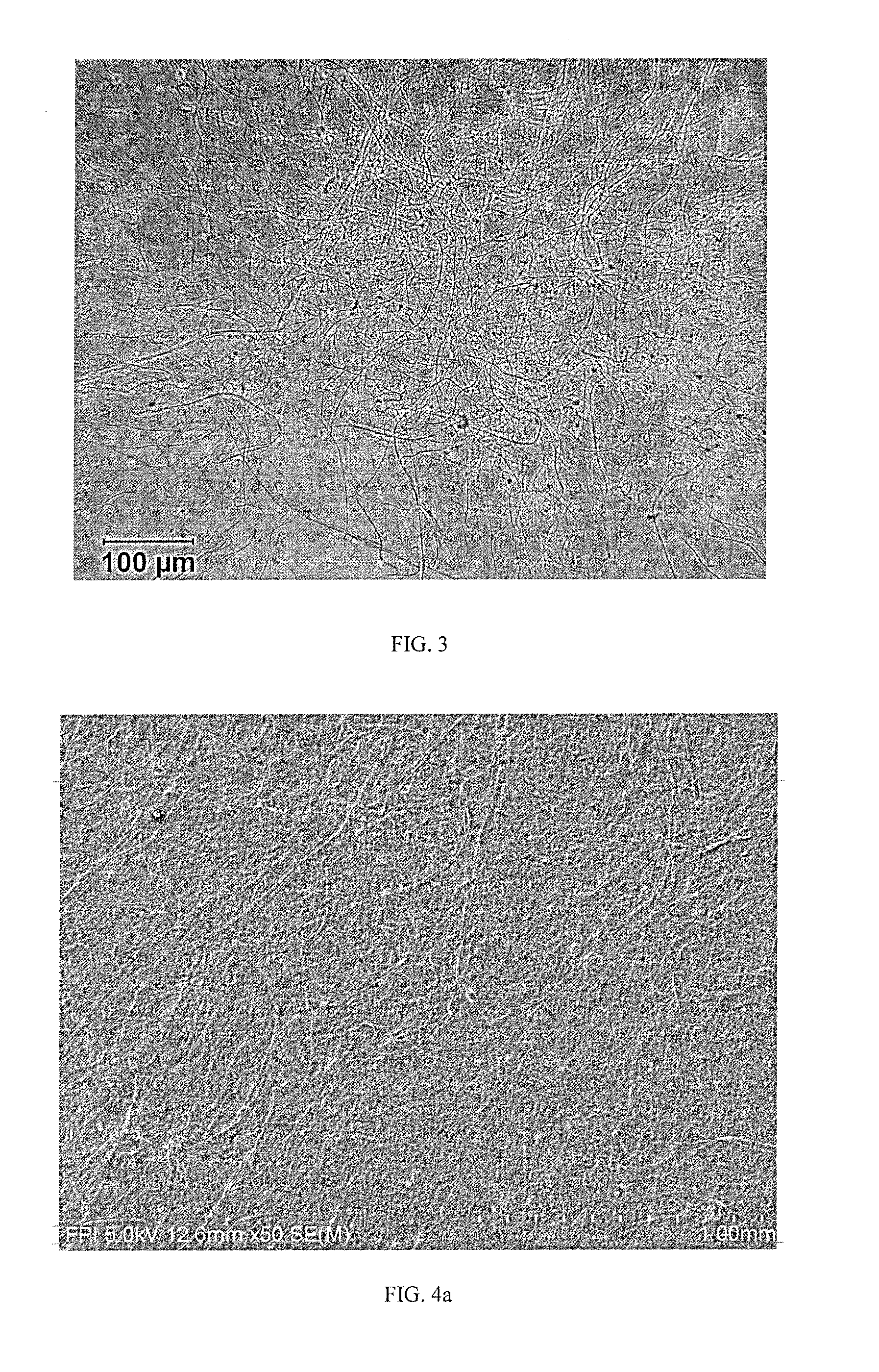

High aspect ratio cellulose nanofilaments and method for their production

ActiveUS20130017394A1High consistency refiningIncrease surface areaMaterial nanotechnologyFinely-divided cellulose conservationMicrometerPaperboard

A method to produce on a commercial scale, high aspect ratio cellulose nanofilaments (CNF) from natural lignocellulosic fibers comprises a multi-pass high consistency refining (HCR) of chemical or mechanical fibers using combinations of refining intensity and specific energy. The CNF produced represents a mixture of fine filaments with widths in the submicron and lengths from tens of micrometers to few millimeters. The product has a population of free filaments and filaments bound to the fiber core from which they were produced. The proportion of free and bound filaments is governed in large part by total specific energy applied to the pulp in the refiner, and differs from other cellulose fibrillar materials by their higher aspect ratio and the preserved degree of polymerization (DP) of cellulose, and are excellent additives for the reinforcement of paper, tissue, paperboard and the like. They display exceptional strengthening power for never-dried paper webs.

Owner:FPINNOVATIONS INC

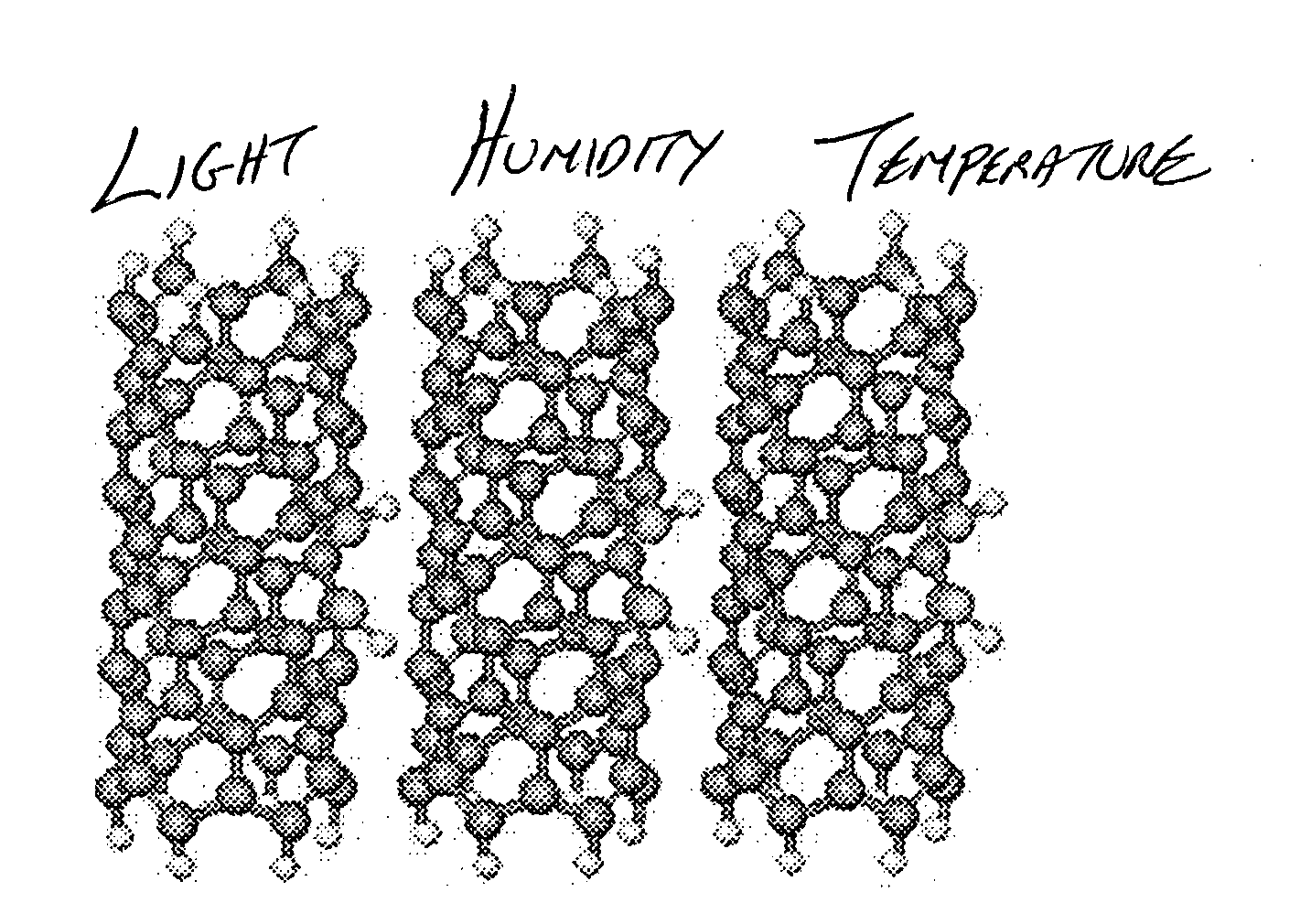

Defect controlled nanotube sensor and method of production

InactiveUS20050036905A1Avoid contactImprove defect densityMaterial nanotechnologyAnalysis using chemical indicatorsEngineeringMethods of production

Sensor for detecting a physical or chemical quantity, comprising a defect controlled nanotube. The sensor can be produced by post treating a nanotube with sufficient energy to modify at least one of density and type of defects in the nanotube, and associating the nanotube with a circuit capable of providing an output signal based upon change of electrical characteristic of the nanotube in response to stimulus of the nanotube.

Owner:MATSUSHITA ELECTRIC WORKS LTD

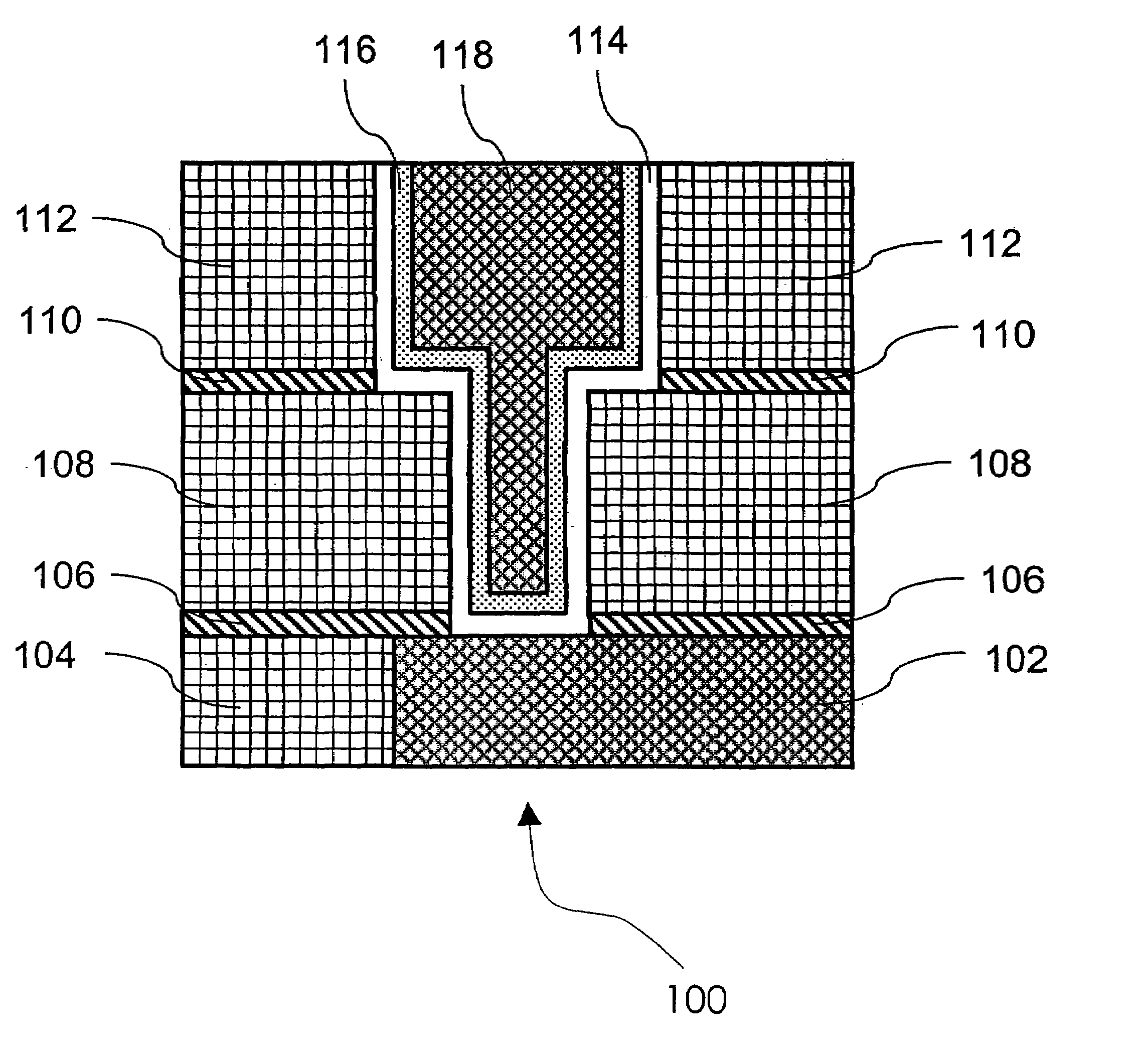

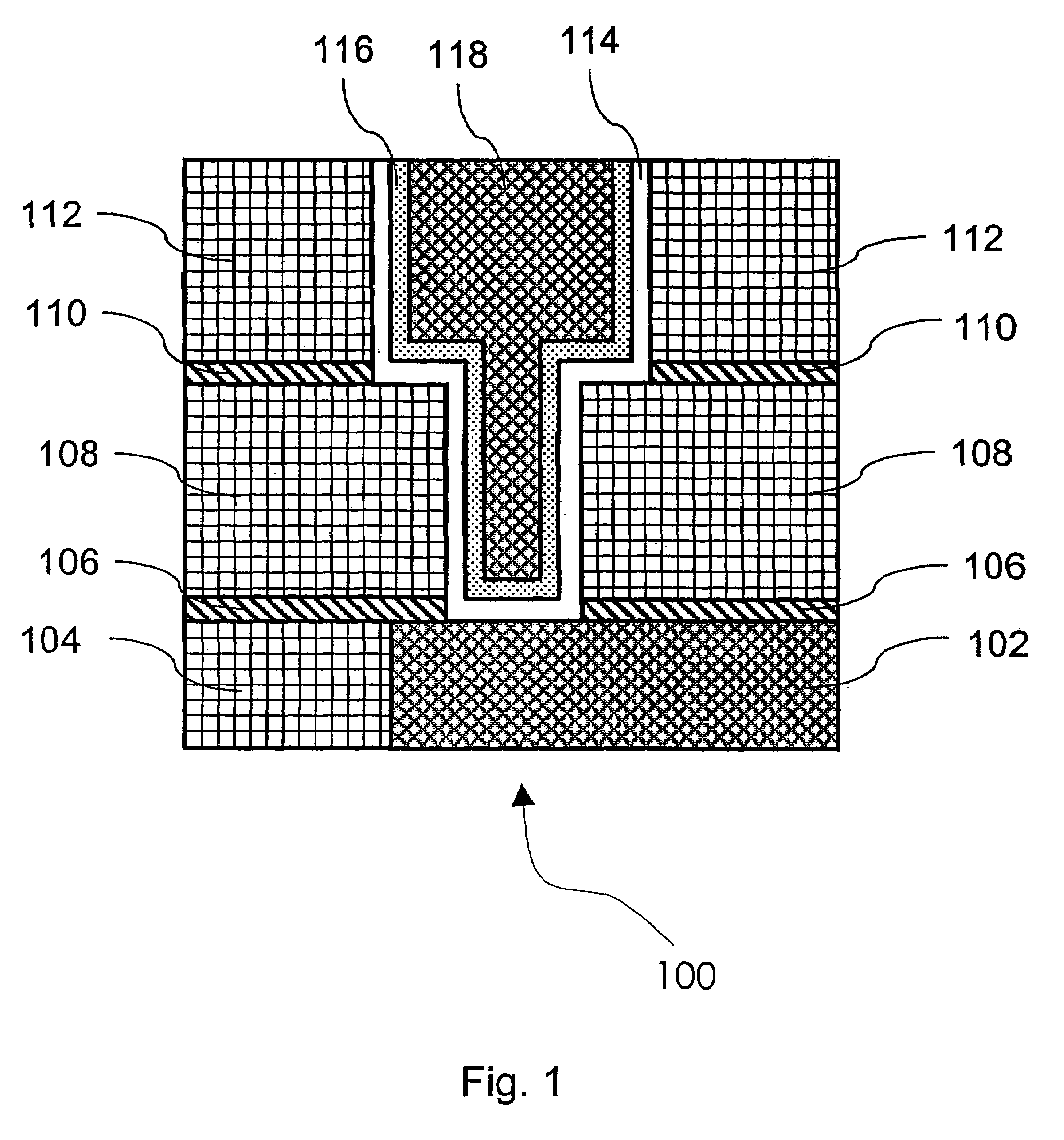

Method of fabricating a microfabricated high aspect ratio device with electrical isolation

InactiveUS6960488B2High aspect ratioLarge sense capacitanceTelevision system detailsAcceleration measurement using interia forcesInterconnectionMicrostructure

A microfabricated device having a high vertical aspect ratio and electrical isolation between a structure region and a circuit region. The device may be fabricated on a single substrate and may include electrical interconnections between the structure region and the circuit region. The device includes a substrate and an isolation trench surrounding a structure region in the substrate. The isolation trench includes a lining of a dielectric insulative material. A plurality of microstructure elements are located in the structure region and are laterally anchored to the isolation trench.

Owner:RGT UNIV OF CALIFORNIA

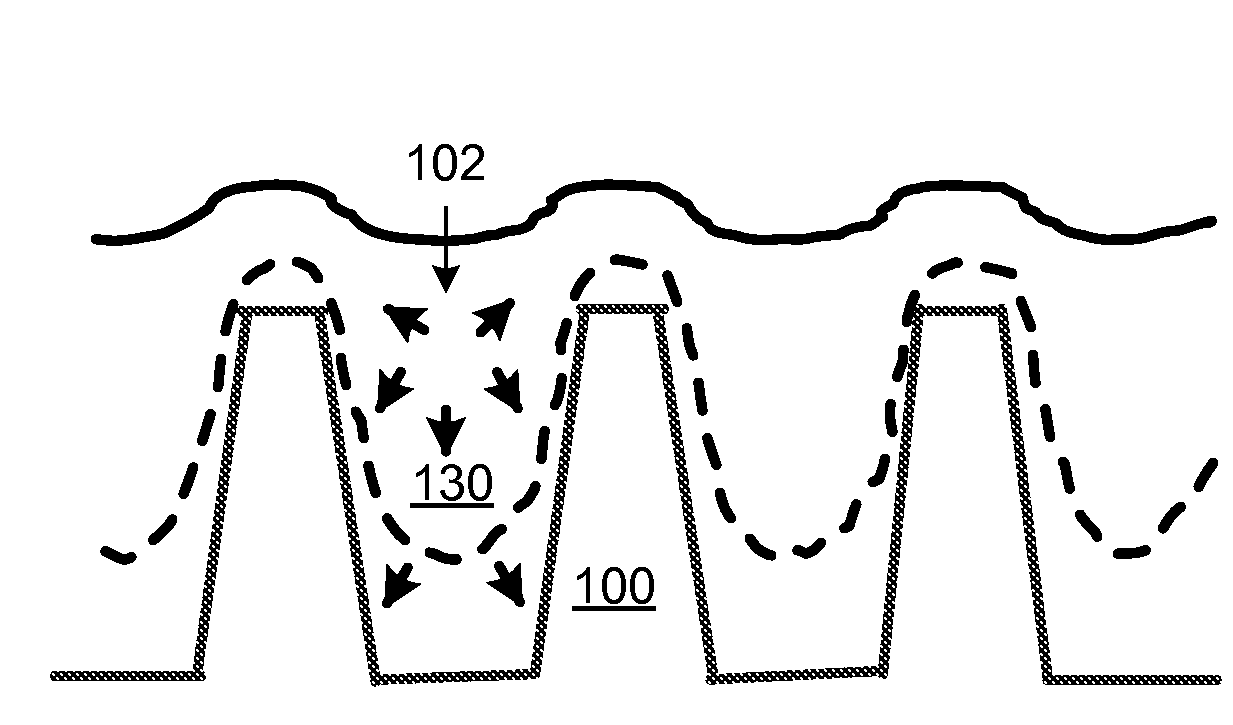

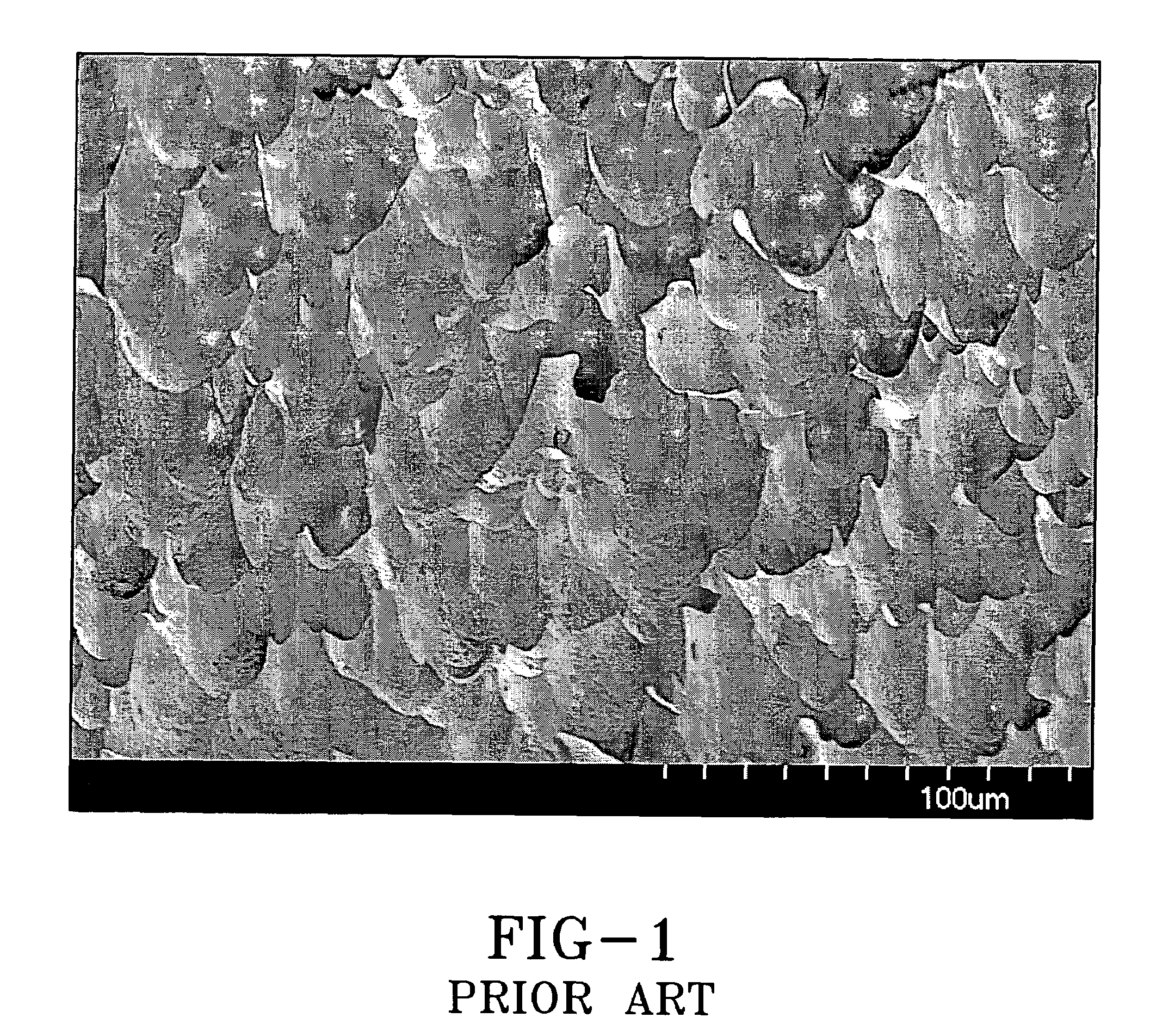

Method for texturing surfaces of optical fiber sensors used for blood glucose monitoring

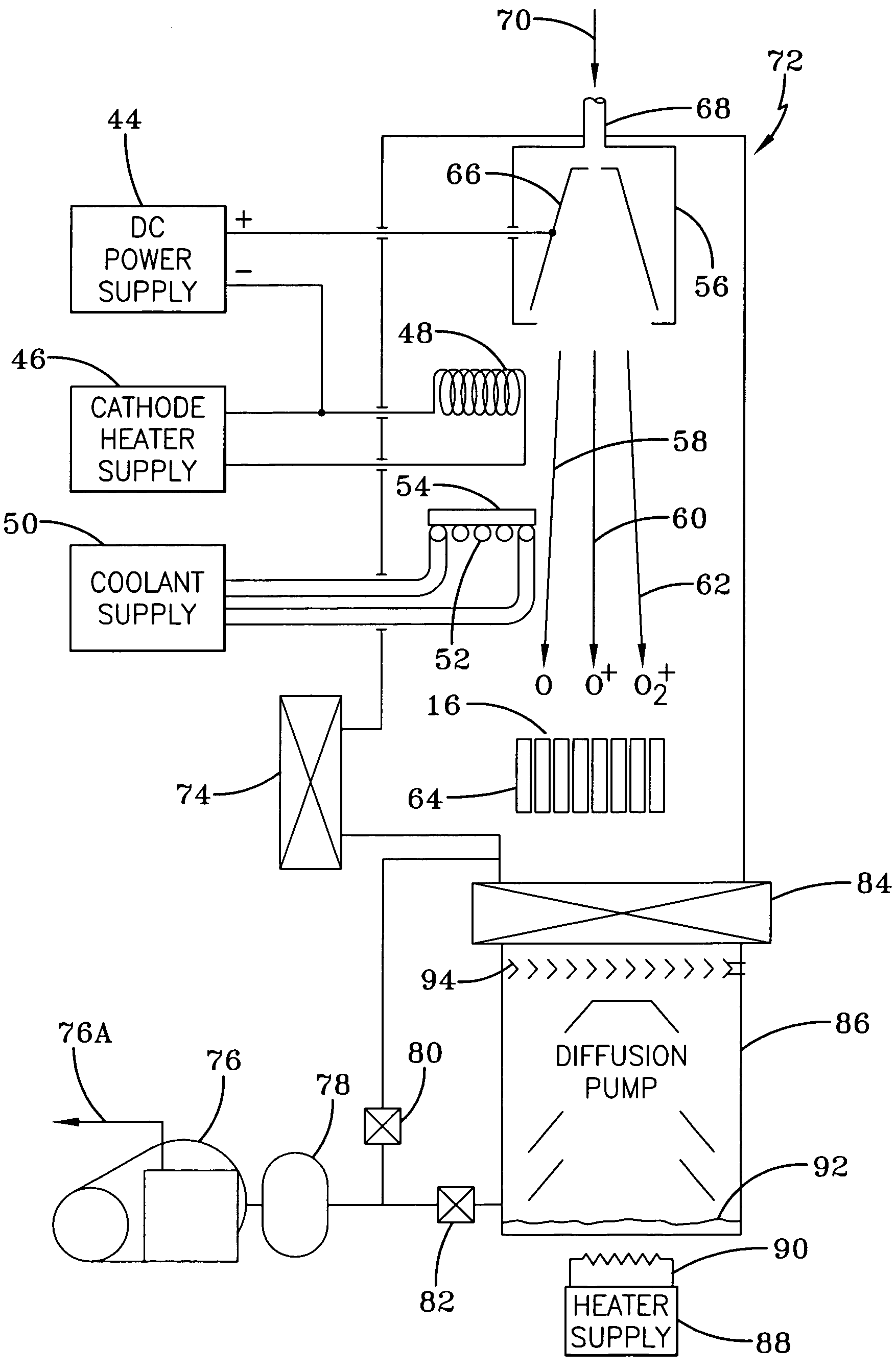

InactiveUS7308164B1High aspect ratioMaterial analysis by optical meansCoupling light guidesCellular componentBlood sugar monitoring

Disclosed is a method and the resulting product thereof comprising a solid light-conducting fiber with a point of attachment and having a textured surface site consisting a textured distal end prepared by being placed in a vacuum and then subjected to directed hyperthermal beams comprising oxygen ions or atoms. The textured distal end comprises cones or pillars that are spaced upon from each other by less than 1 micron and are extremely suitable to prevent cellular components of blood from entering the valleys between the cones or pillars so as to effectively separate the cellular components in the blood from interfering with optical sensing of the glucose concentration for diabetic patients.

Owner:UNITED STATES OF AMERICA AS REPRESENTED BY THE ADMINISTRATOR NAT AERONAUTICS & SPACE ADMINISTRATION

High density inductor and method for producing same

InactiveUS20040164835A1Reduce core sizeAccurate shapeTransformers/inductances coils/windings/connectionsSolid-state devicesHigh densityInductor

A method for producing a high density inductor includes the steps of forming a coil having a spiral shape, sealing the coil in the interior of a core member, and forming a terminal electrode for allowing electric conduction to said coil on the outside of said core member. In this method, the coil is formed by repeating a process of forming a wire layer by means of a thin film forming process and a process of forming an additional wire layer on top of the wire layer by means of the thin film forming process to pile up the wire layers. With this production method, it is possible to form a coil with a high aspect ratio. In addition, the inductor is designed in such a way that the core member envelopes only the coil. With that design, it is possible to make the inductor compact.

Owner:TDK CORPARATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com