Patents

Literature

16886 results about "Electrical contacts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An electrical contact is an electrical circuit component found in electrical switches, relays, connectors and circuit breakers. Each contact is a piece of electrically conductive material, typically metal. When a pair of contacts touch, they can pass an electrical current with a certain contact resistance, dependent on surface structure, surface chemistry and contact time ; when the pair is separated by an insulating gap, then the pair does not pass a current. When the contacts touch, the switch is closed; when the contacts are separated, the switch is open. The gap must be an insulating medium, such as air, vacuum, oil, SF₆. Contacts may be operated by humans in push-buttons and switches, by mechanical pressure in sensors or machine cams, and electromechanically in relays. The surfaces where contacts touch are usually composed of metals such as silver or gold alloys that have high electrical conductivity, wear resistance, oxidation resistance and other properties.

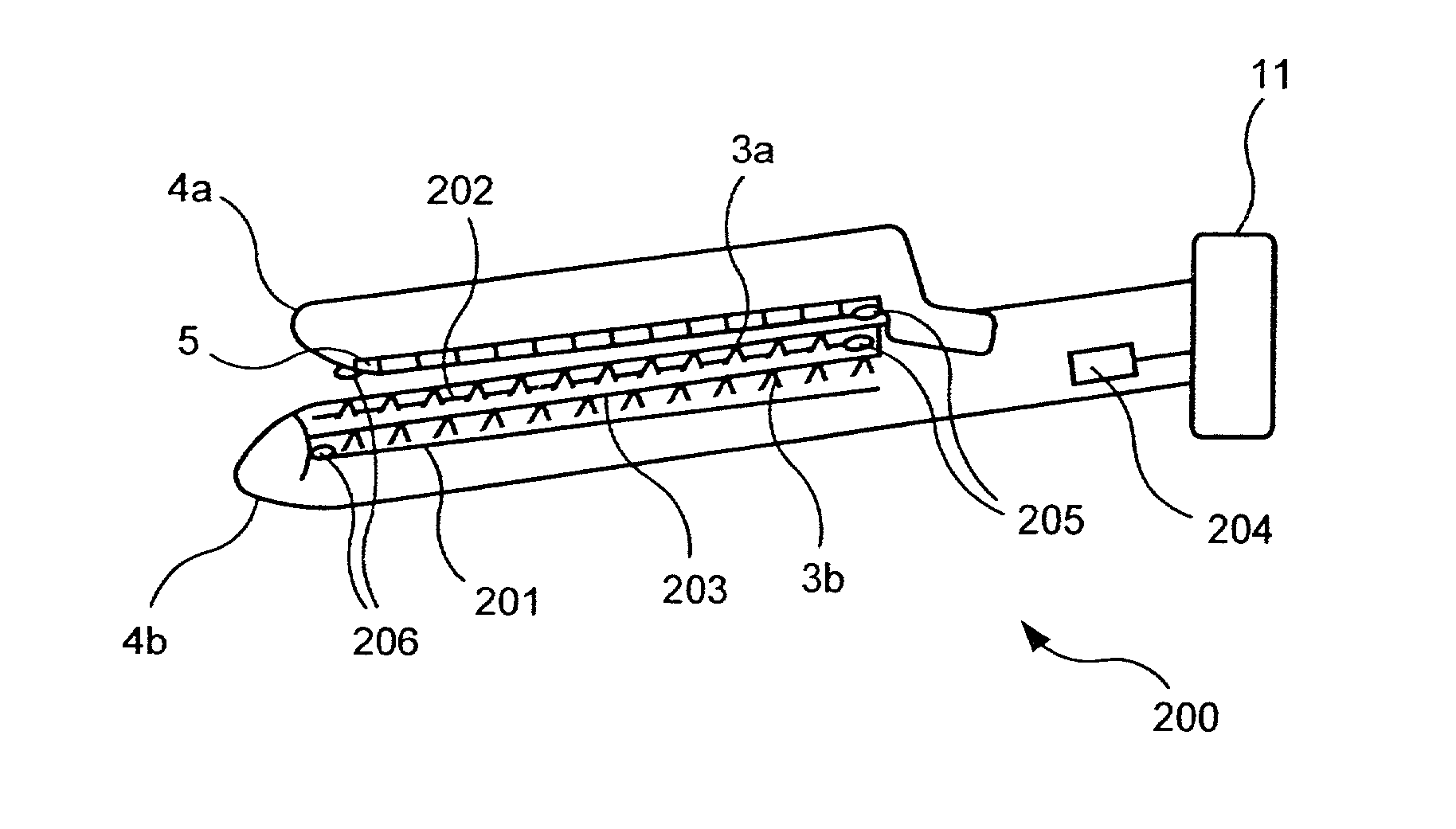

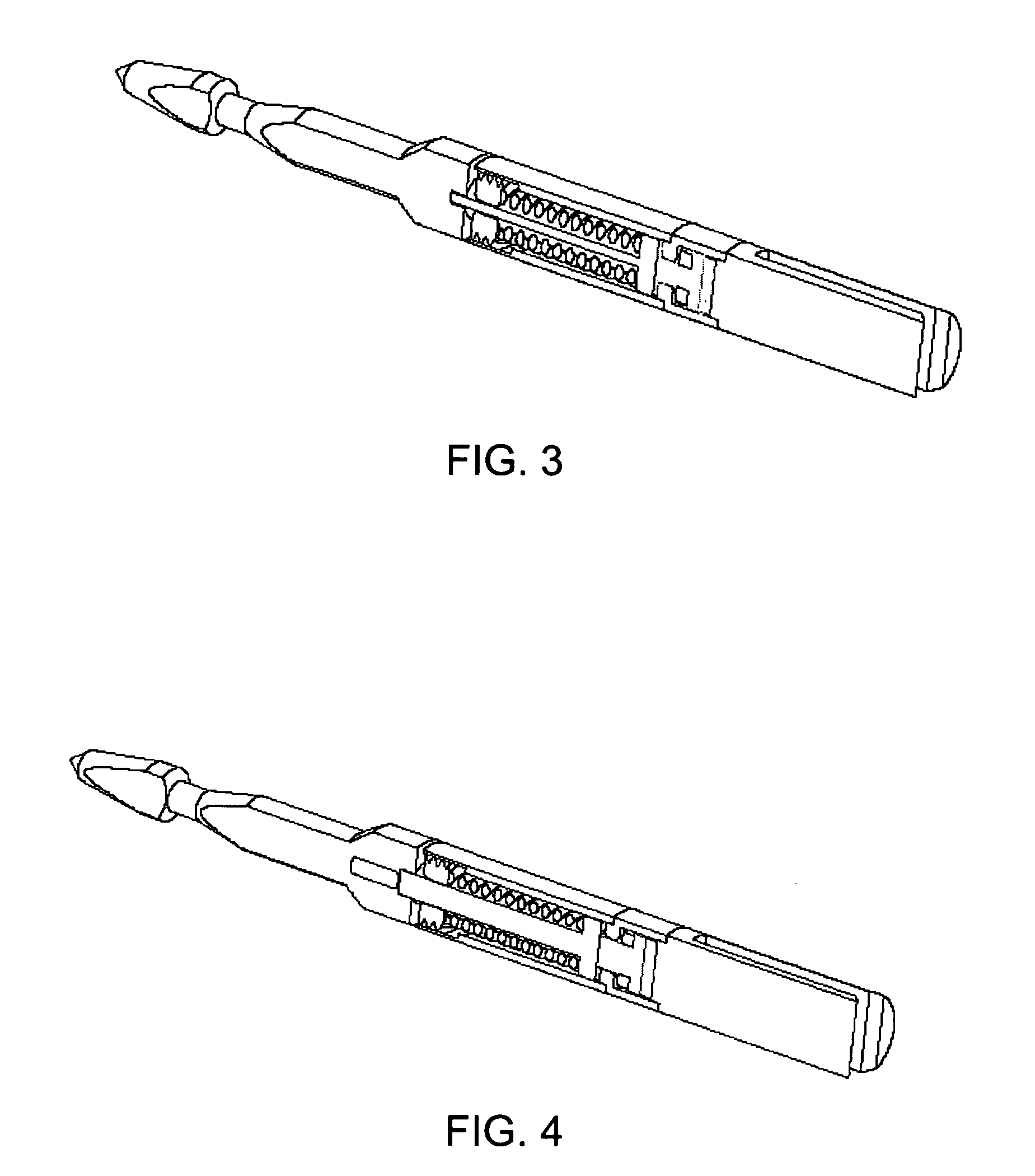

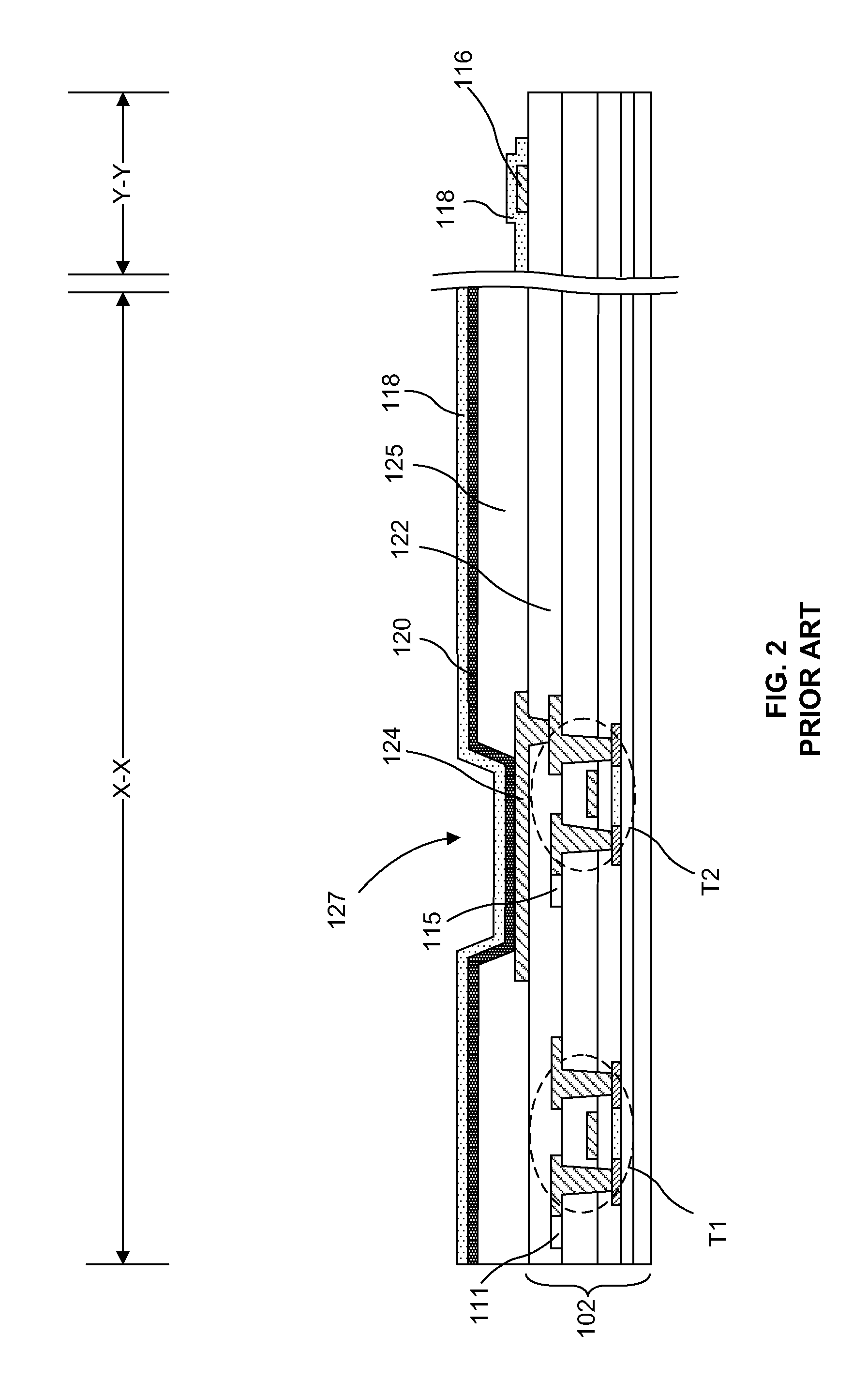

Bipolar or ultrasonic surgical device

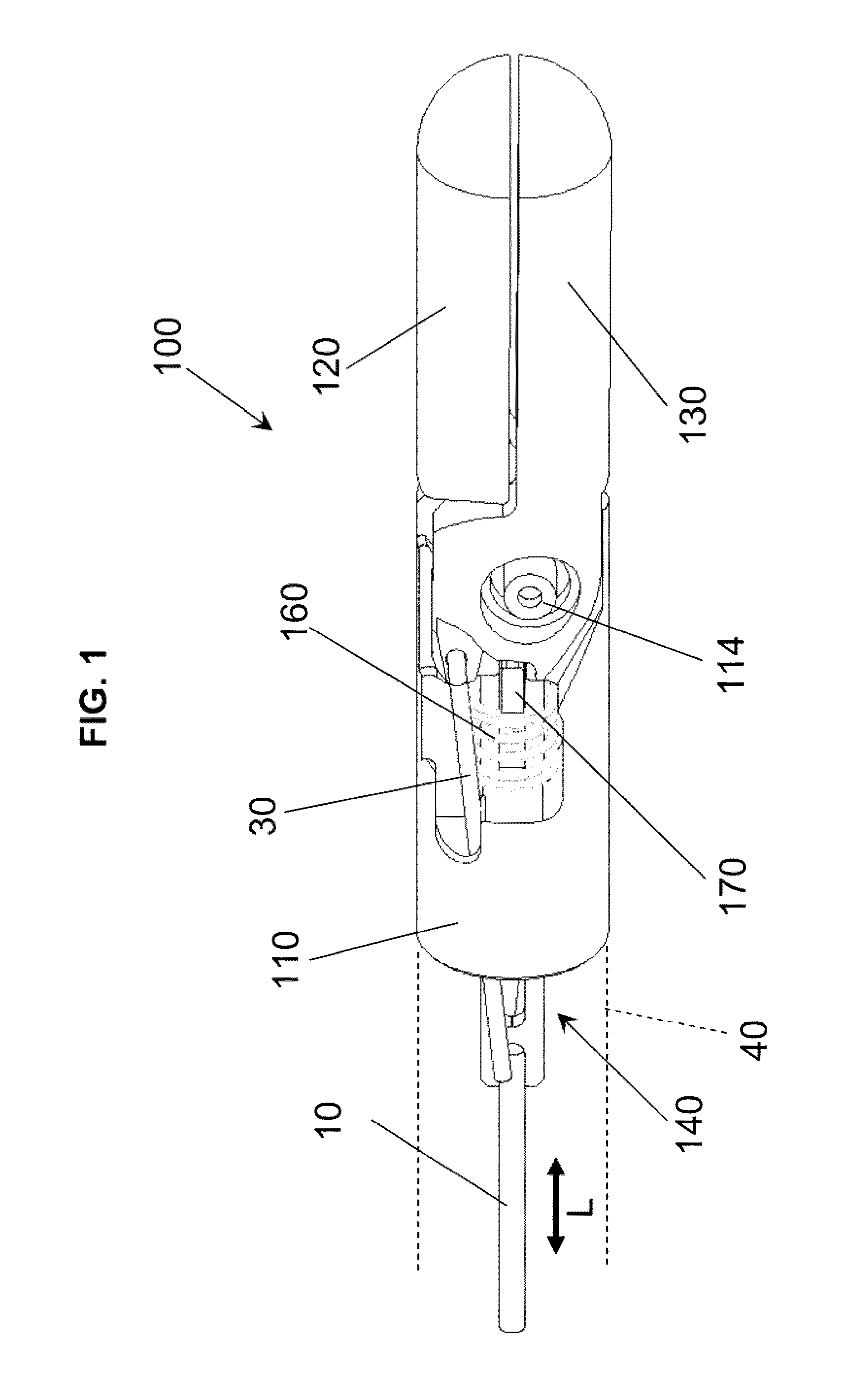

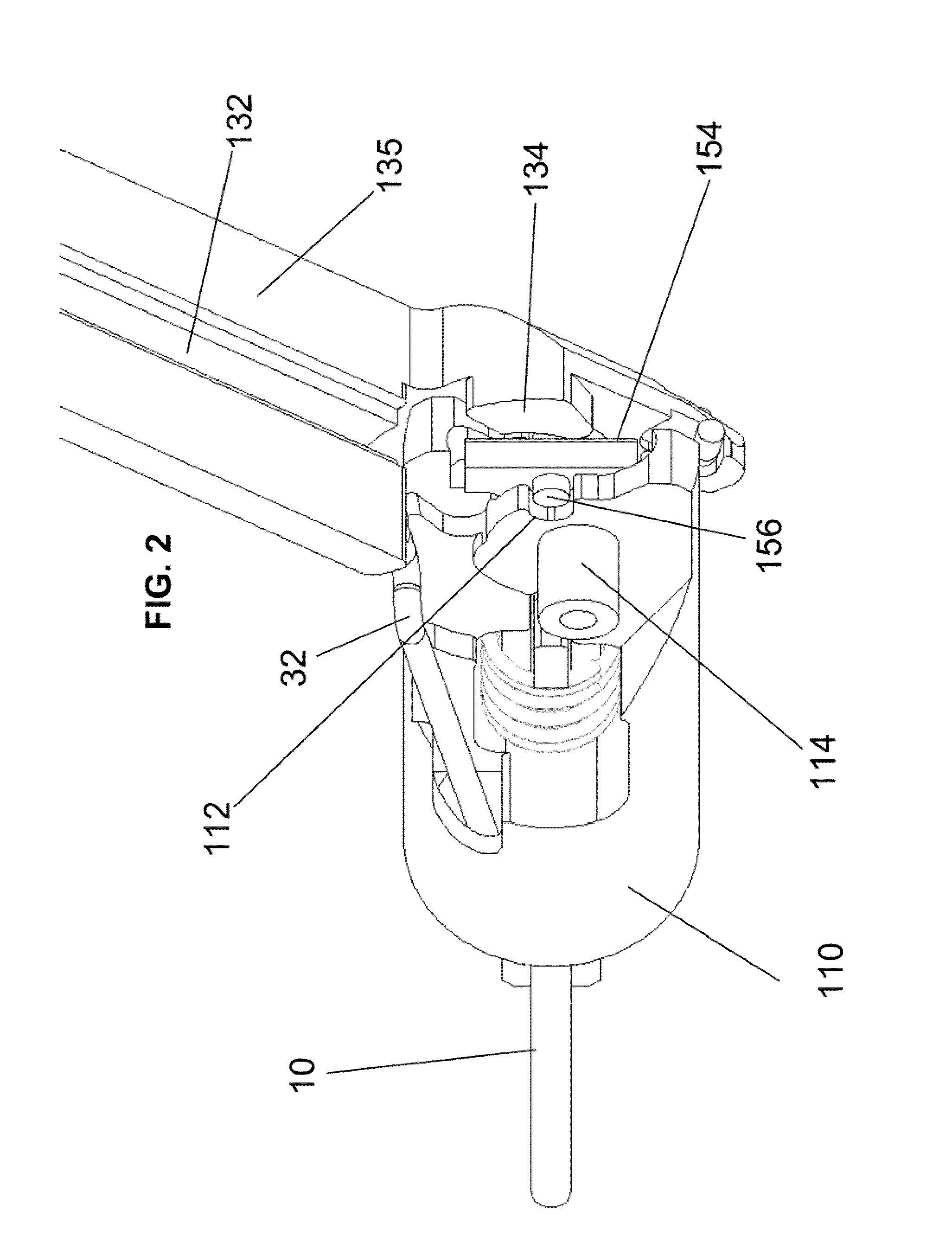

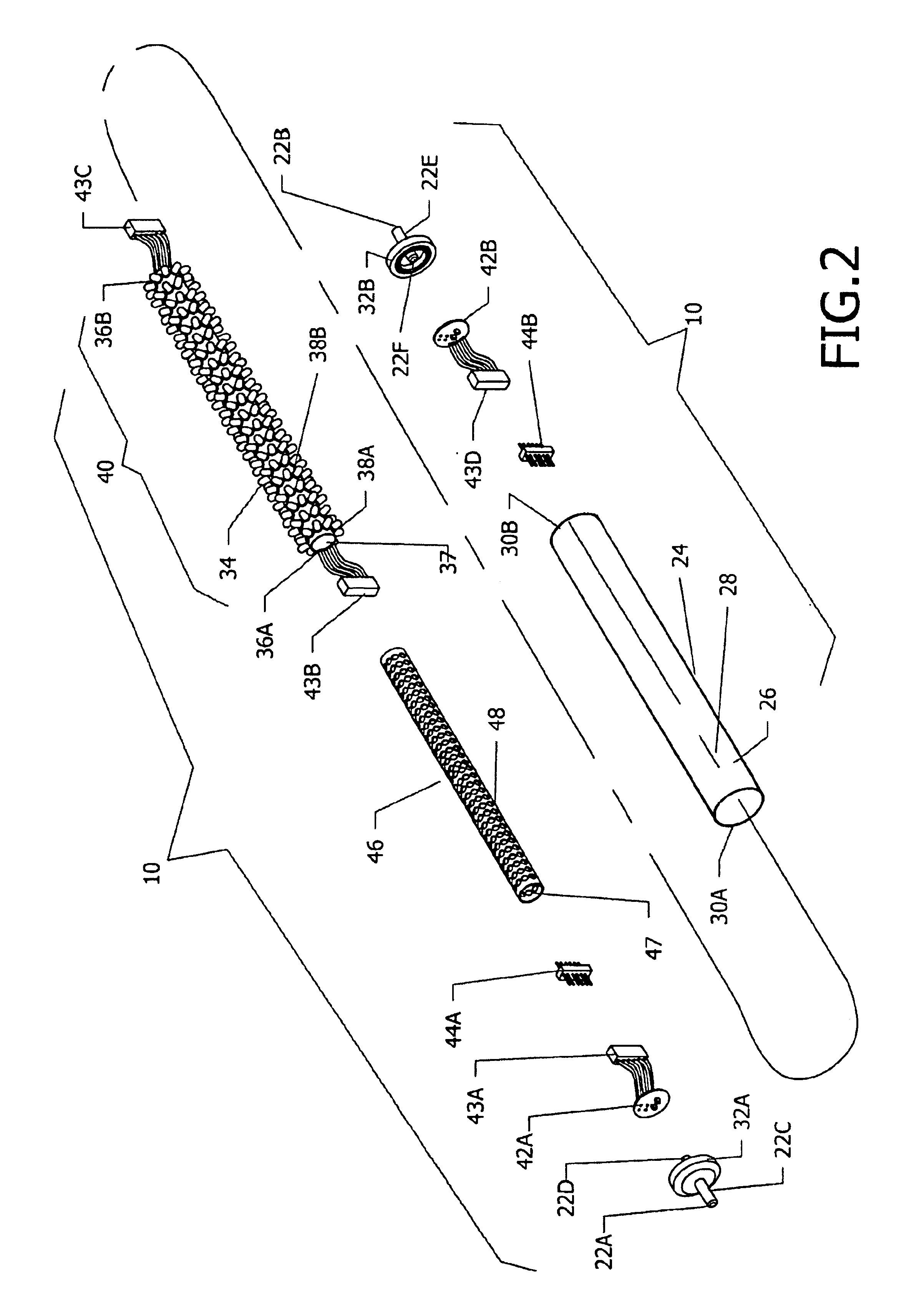

ActiveUS8292888B2Reduce in quantityLess mechanical forceUltrasound therapySurgical needlesAmpullaSurgical device

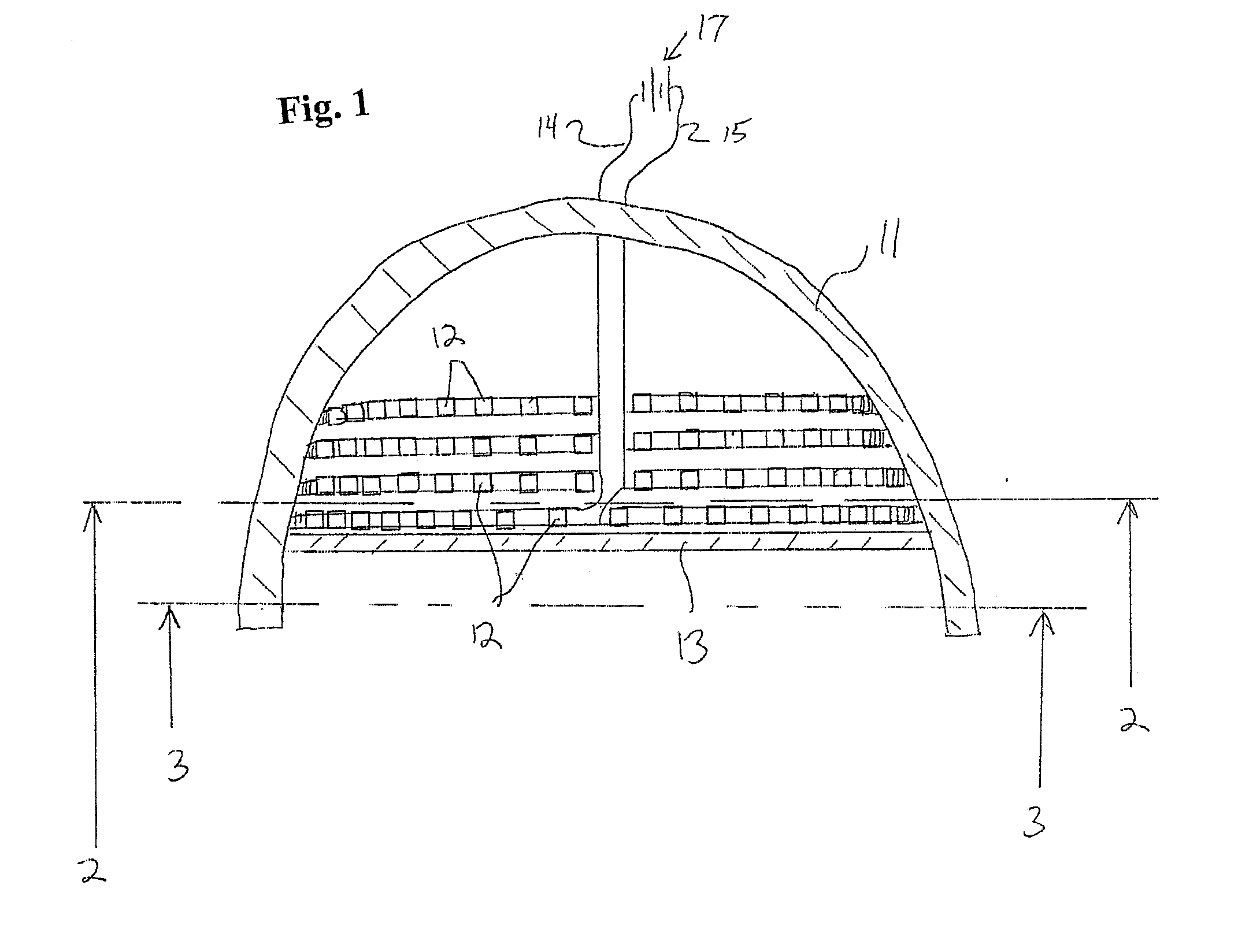

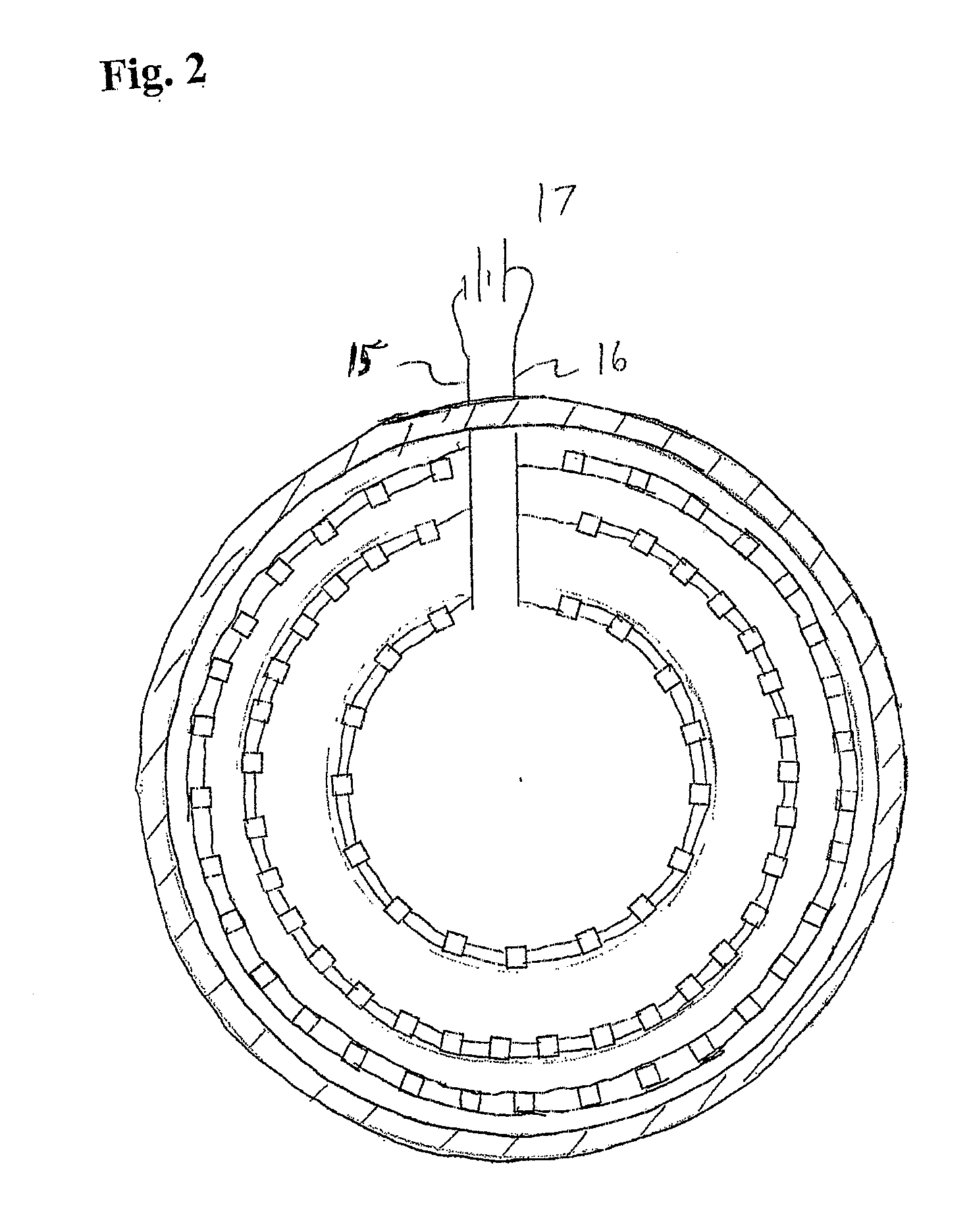

An electro-mechanical surgical device, system and / or method may include a housing, at least two opposing jaw, and at least one electrical contact associated with at least one of the jaws. The electrical contact may include at least one of a bipolar electrical contact and an ultrasonic electrical contact. The electrical contact may be a row of electrodes located on one or all of the jaws. A sensor may also be associated with any tissue located between the jaws to sense and report the temperature of that tissue. A piercable ampulla containing fluid may also be placed on at least one of the jaws so that the fluid is releasable when the jaws are in closed position and the electrode(s) pass through the tissue into the piercable ampulla.

Owner:TYCO HEALTHCARE GRP LP

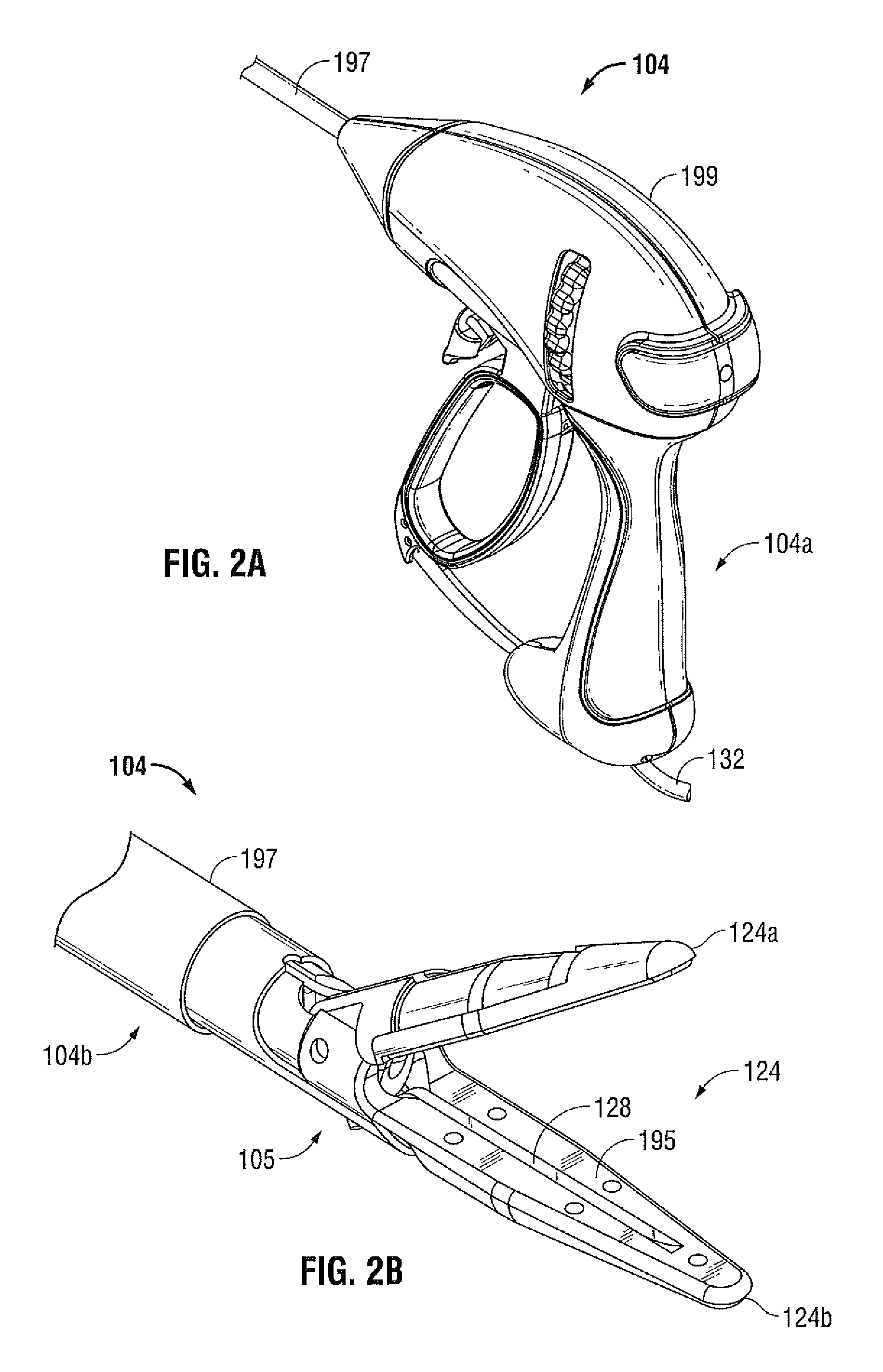

Cordless medical cauterization and cutting device

ActiveUS8328802B2Precise positioningSufficient forceSurgical instruments for heatingSurgical forcepsElectricityRadio frequency signal

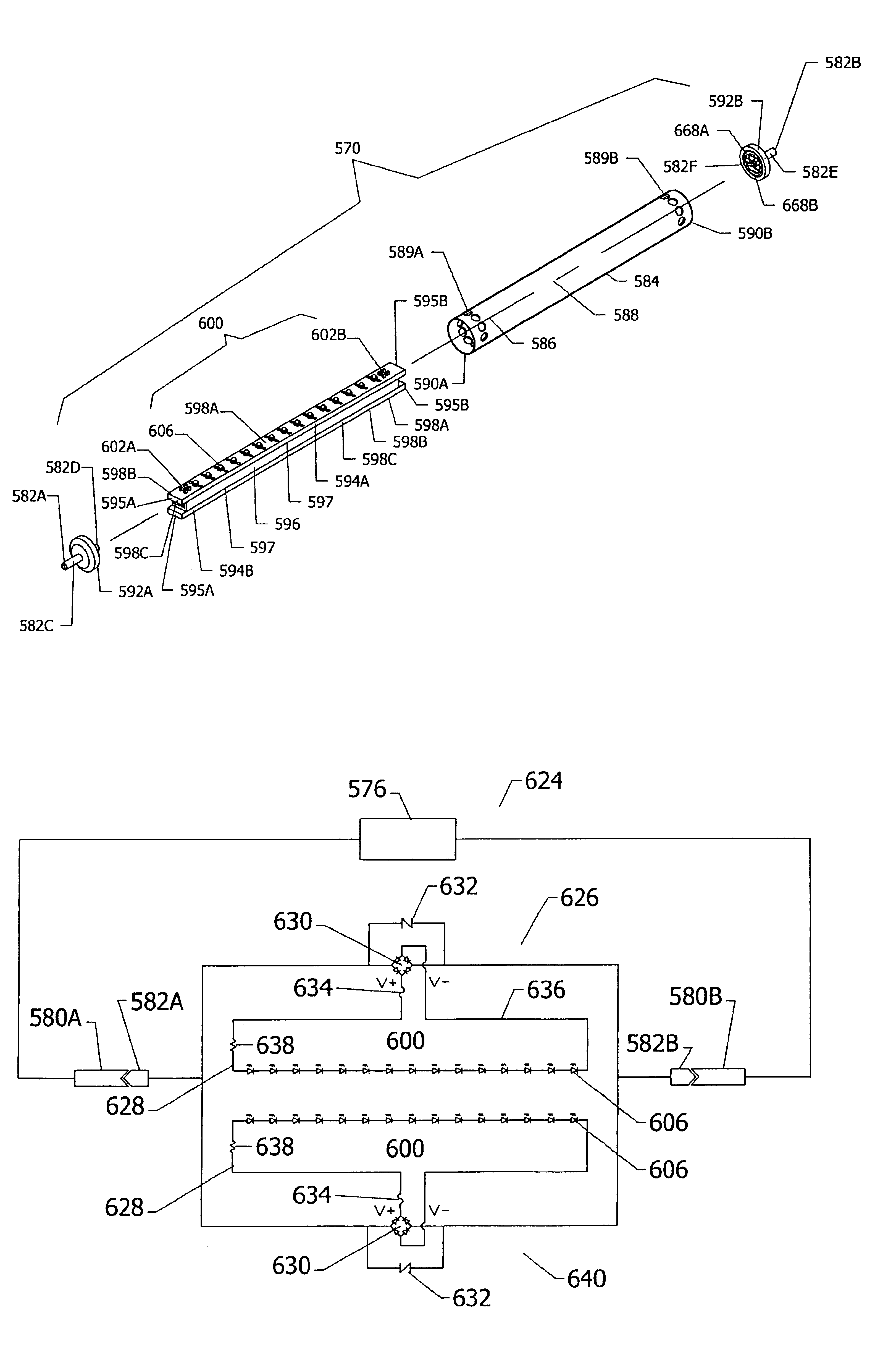

A surgical device includes a radio-frequency-signal-generation assembly including a radio-frequency-signal-generation circuit operable to generate a radio-frequency signal at an output and adapted to couple to a switch-mode power supply and a surgical handle including an end effector having at least one jaw with at least one electrical contact, the end effector including at least one signal input that electrically connects to the output to provide the radio-frequency signal at the at least one electrical contact.

Owner:COVIDIEN AG

Force switch

ActiveUS7479608B2Contact surface shape/structureInternal osteosythesisMedical deviceMedical treatment

Owner:ETHICON ENDO SURGERY INC

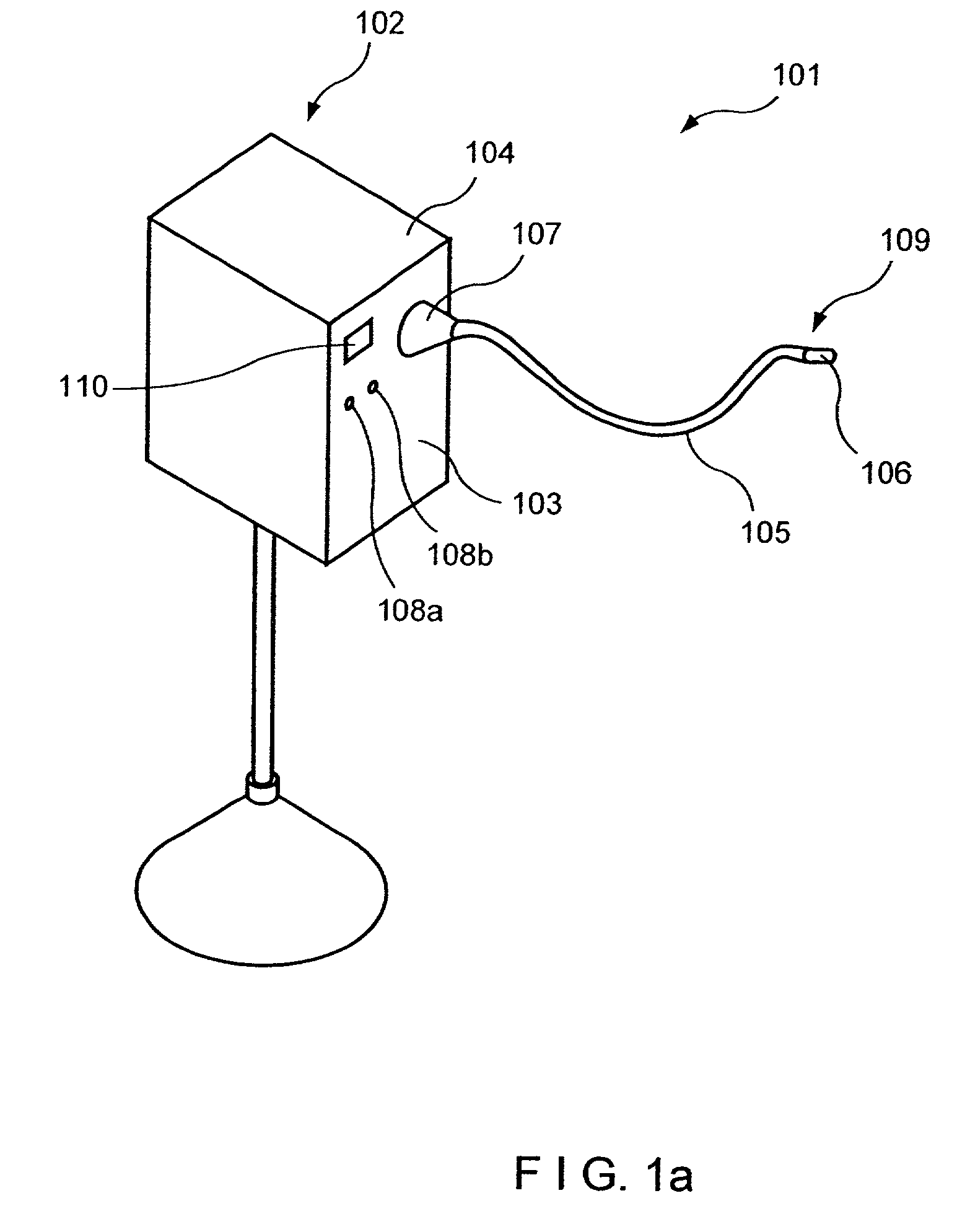

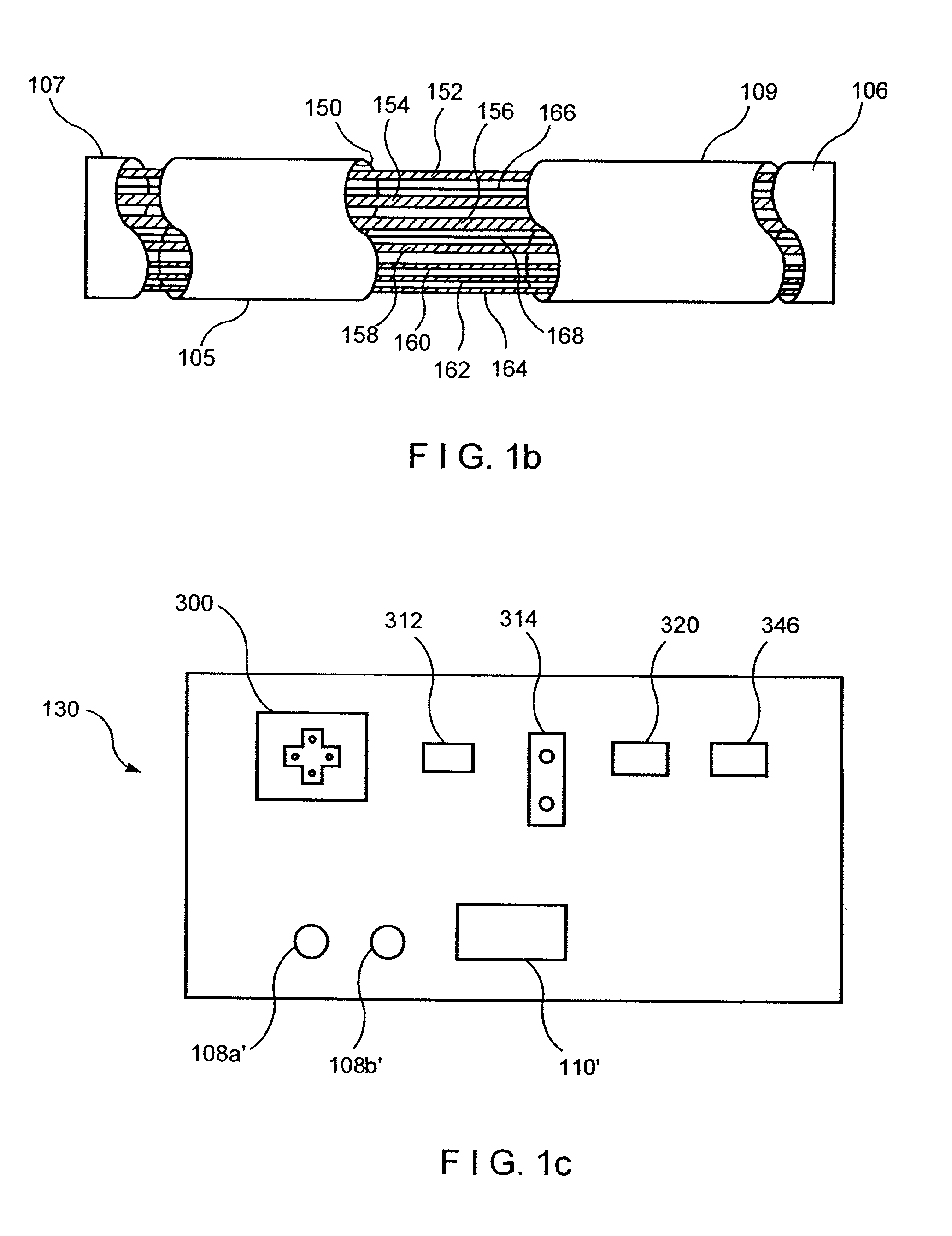

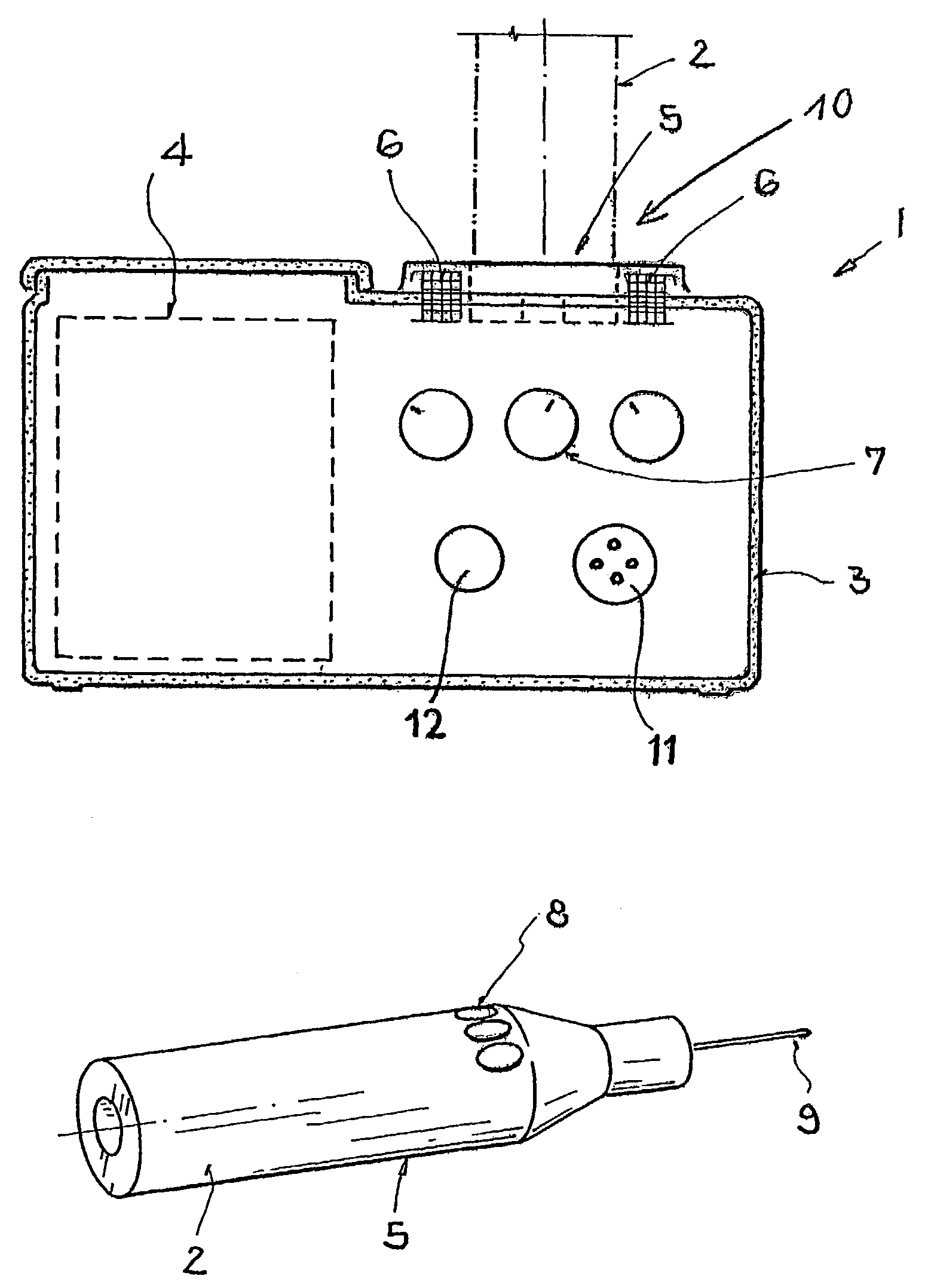

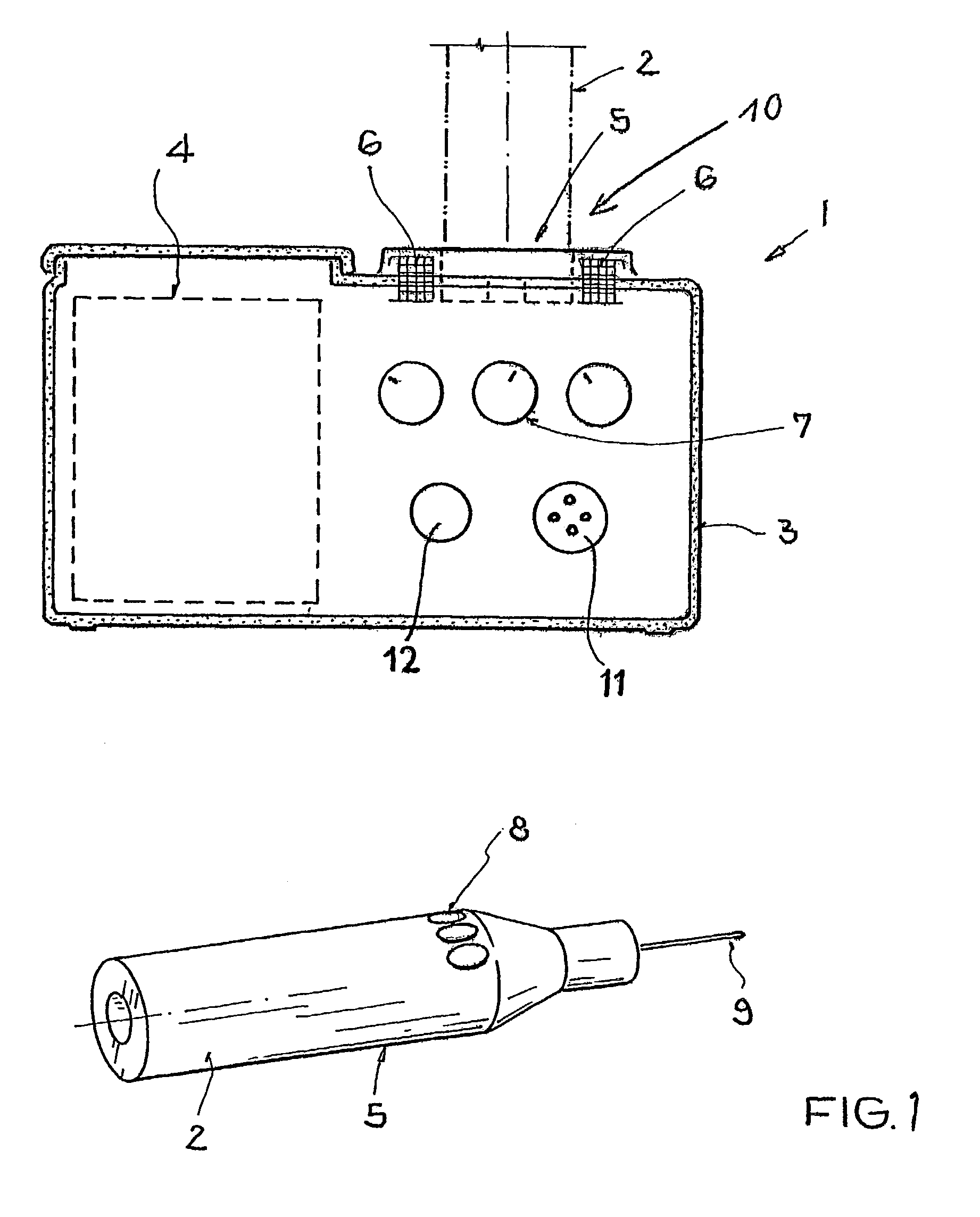

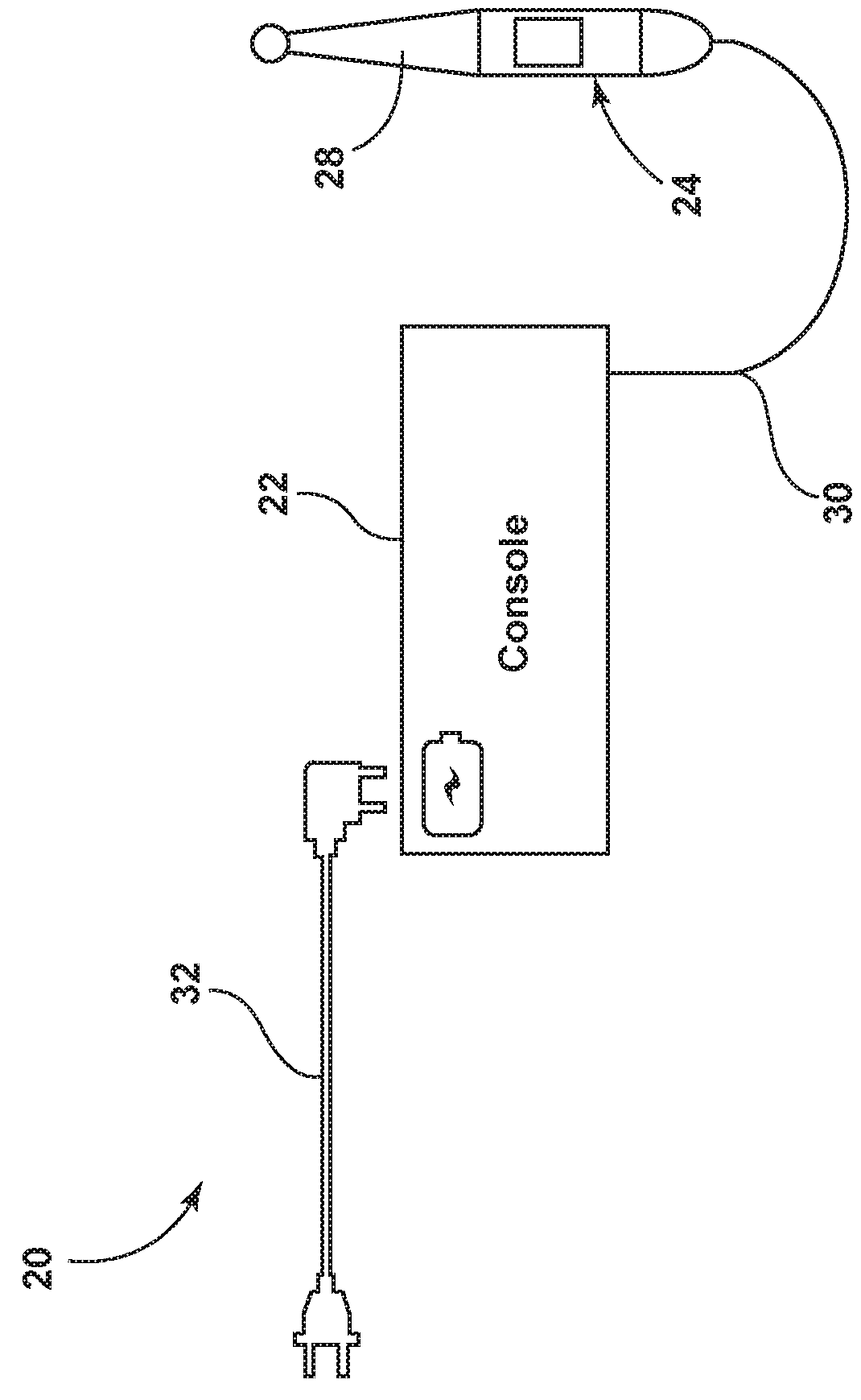

Device for supplying an electro-pen with electrical energy

The invention relates to a device for supplying electrical energy to an electro-pen with an electric drive unit for driving a tool. The device comprises a console with an energy supply unit having an accumulator for supplying the electrical drive unit with electrical energy. The console may be configure to be sterilized by steam having a housing and electrical components that are sealed liquid-tight. The accumulator may include a sterile covering for sterile introduction into the console. A coupling between the console and the electro-pen carries the supply of electrical energy from the console to the electro-pen. The coupling may be an electrical contact in the form of a sterilizable connector or an inductive coupling. The console may be configured to store energy and is thus mobile, or the console may include a connection for connecting to a mains or external power supply for charging the accumulator. The console may include a switch-mode power supply for charging the accumulator. The console may include a holder for receiving and charging the electro-pen. The electro-pen includes an electrical storage device and a coupling for receiving the electrical energy supply from the accumulator. The holder may include an electrical coupling between the console and the electro-pen in which at least two electrical contacts and at least one transformer are disposed about each the holder and the electro-pen. Alternatively, the holder may include an inductive coupling in which at least one transformer having at least one coil is disposed about each the holder and the electro-pen.

Owner:SYNTHES USA

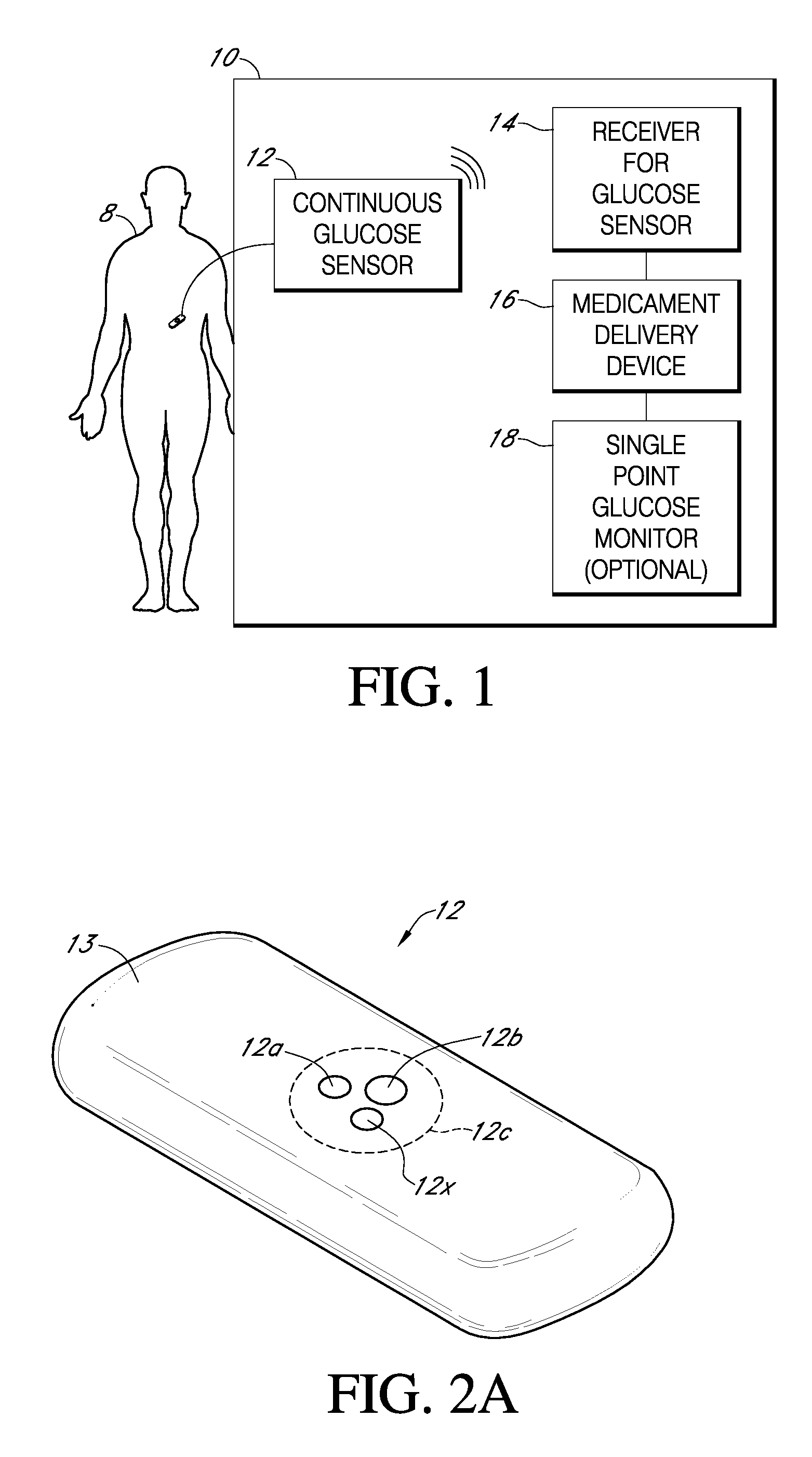

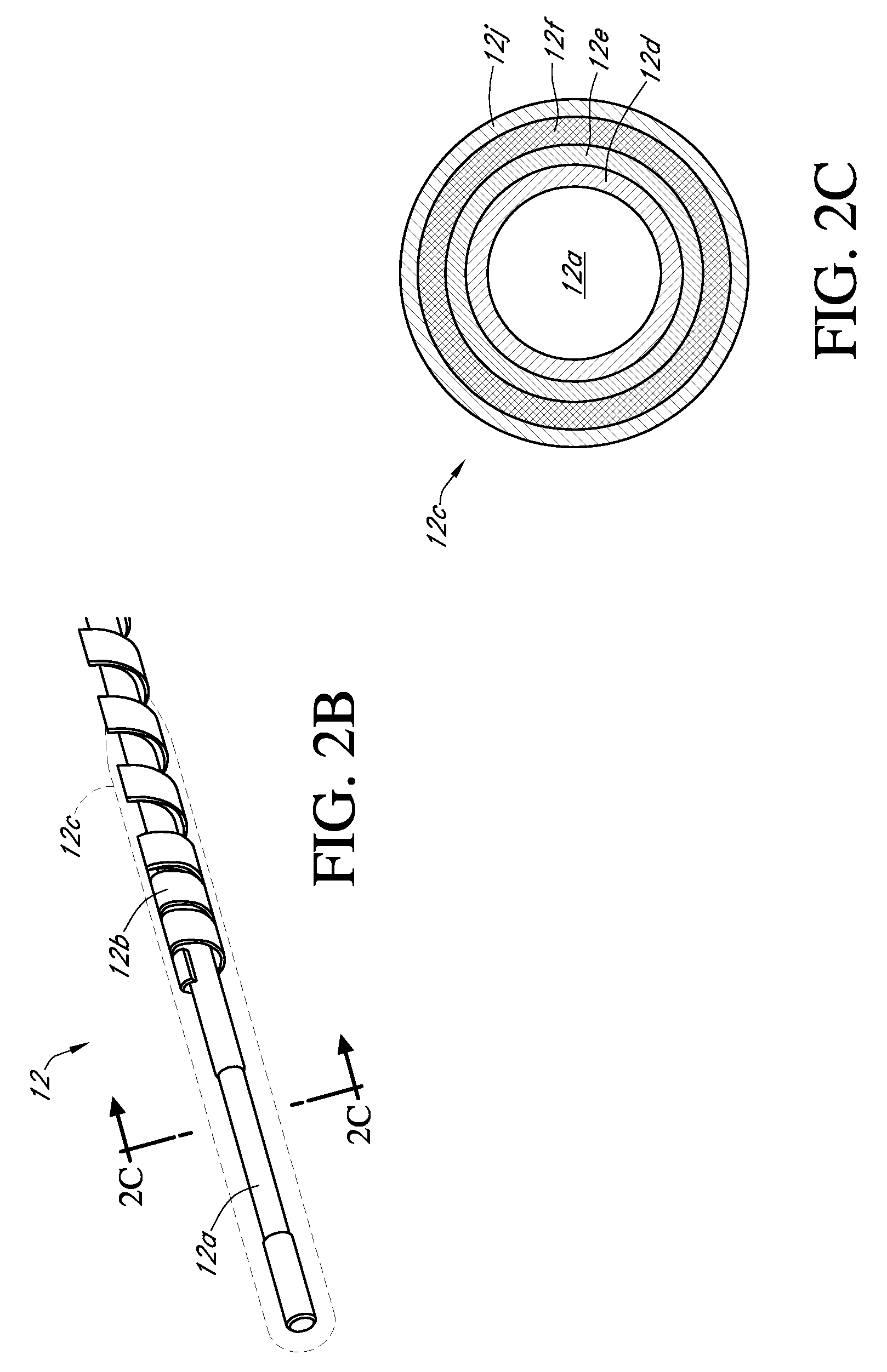

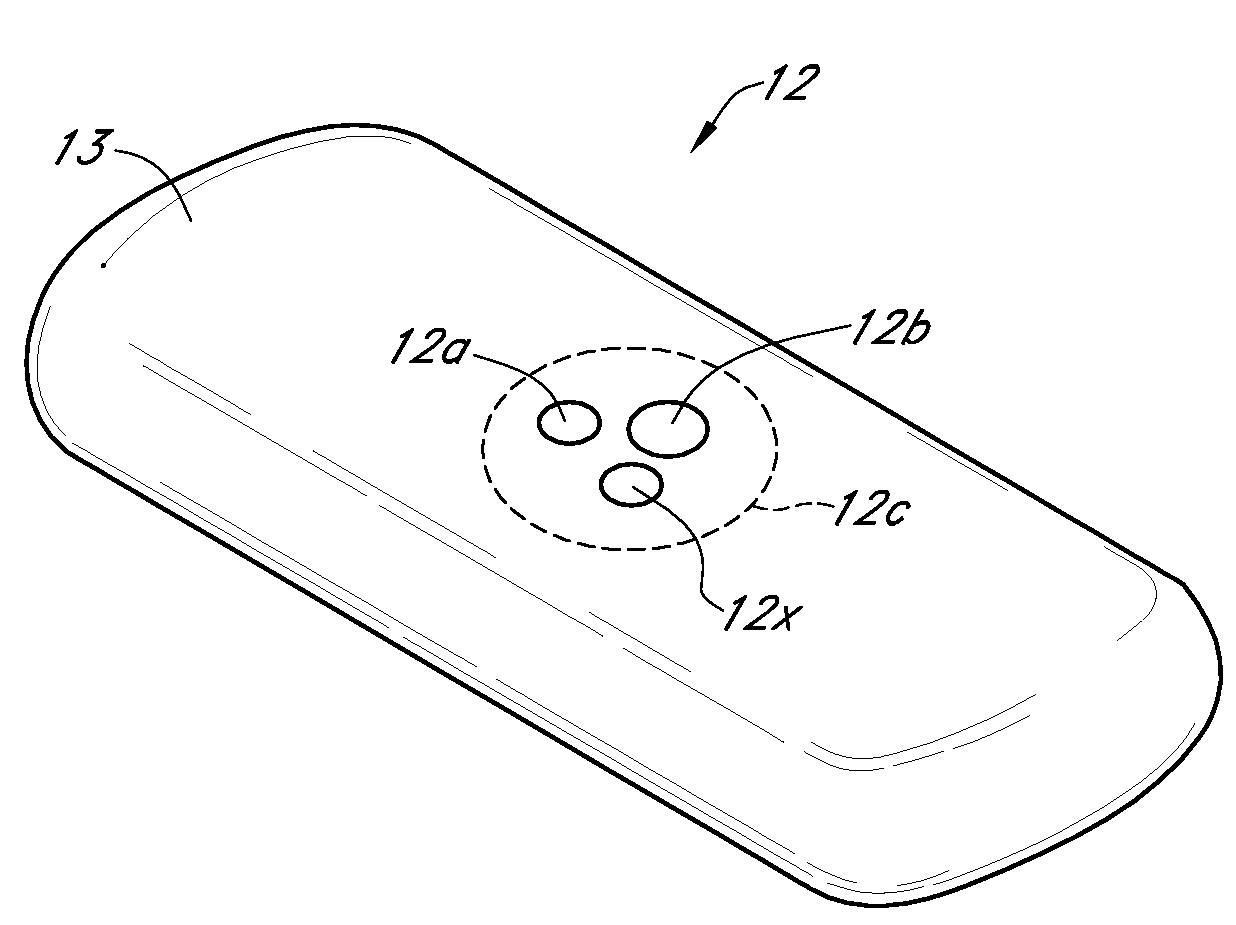

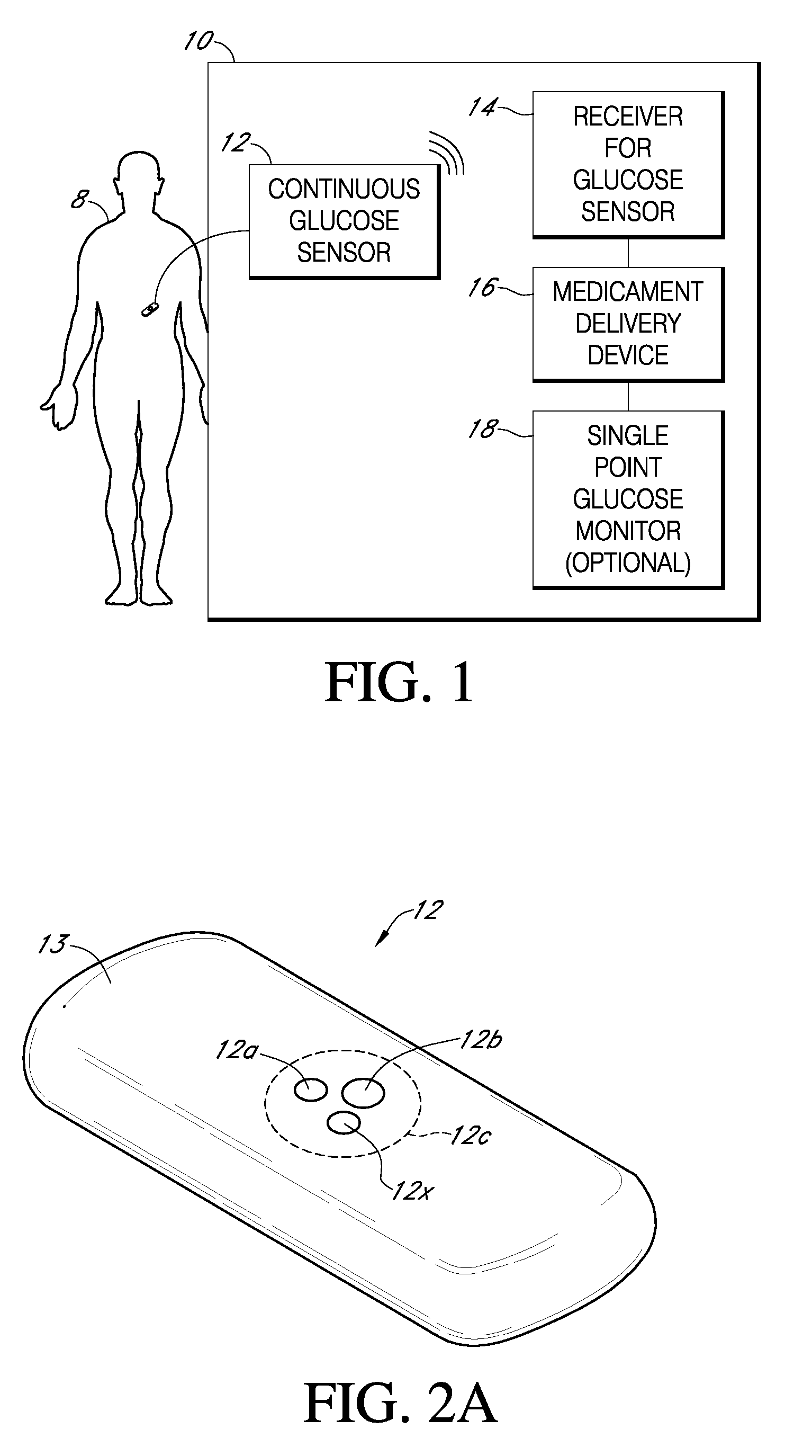

Integrated medicament delivery device for use with continuous analyte sensor

InactiveUS20080306434A1Reduce the burden onSimple processAmpoule syringes2D-image generationDiabetes mellitusMedication injection

An integrated system for the monitoring and treating diabetes is provided, including an integrated receiver / hand-held medicament injection pen, including electronics, for use with a continuous glucose sensor. In some embodiments, the receiver is configured to receive continuous glucose sensor data, to calculate a medicament therapy (e.g., via the integrated system electronics) and to automatically set a bolus dose of the integrated hand-held medicament injection pen, whereby the user can manually inject the bolus dose of medicament into the host. In some embodiments, the integrated receiver and hand-held medicament injection pen are integrally formed, while in other embodiments they are detachably connected and communicated via mutually engaging electrical contacts and / or via wireless communication.

Owner:DEXCOM

Integrated medicament delivery device for use with continuous analyte sensor

ActiveUS20080306435A1Reduce the burden onSimple processAmpoule syringes2D-image generationMedication injectionDiabetes mellitus

An integrated system for the monitoring and treating diabetes is provided, including an integrated receiver / hand-held medicament injection pen, including electronics, for use with a continuous glucose sensor. In some embodiments, the receiver is configured to receive continuous glucose sensor data, to calculate a medicament therapy (e.g., via the integrated system electronics) and to automatically set a bolus dose of the integrated hand-held medicament injection pen, whereby the user can manually inject the bolus dose of medicament into the host. In some embodiments, the integrated receiver and hand-held medicament injection pen are integrally formed, while in other embodiments they are detachably connected and communicated via mutually engaging electrical contacts and / or via wireless communication.

Owner:DEXCOM

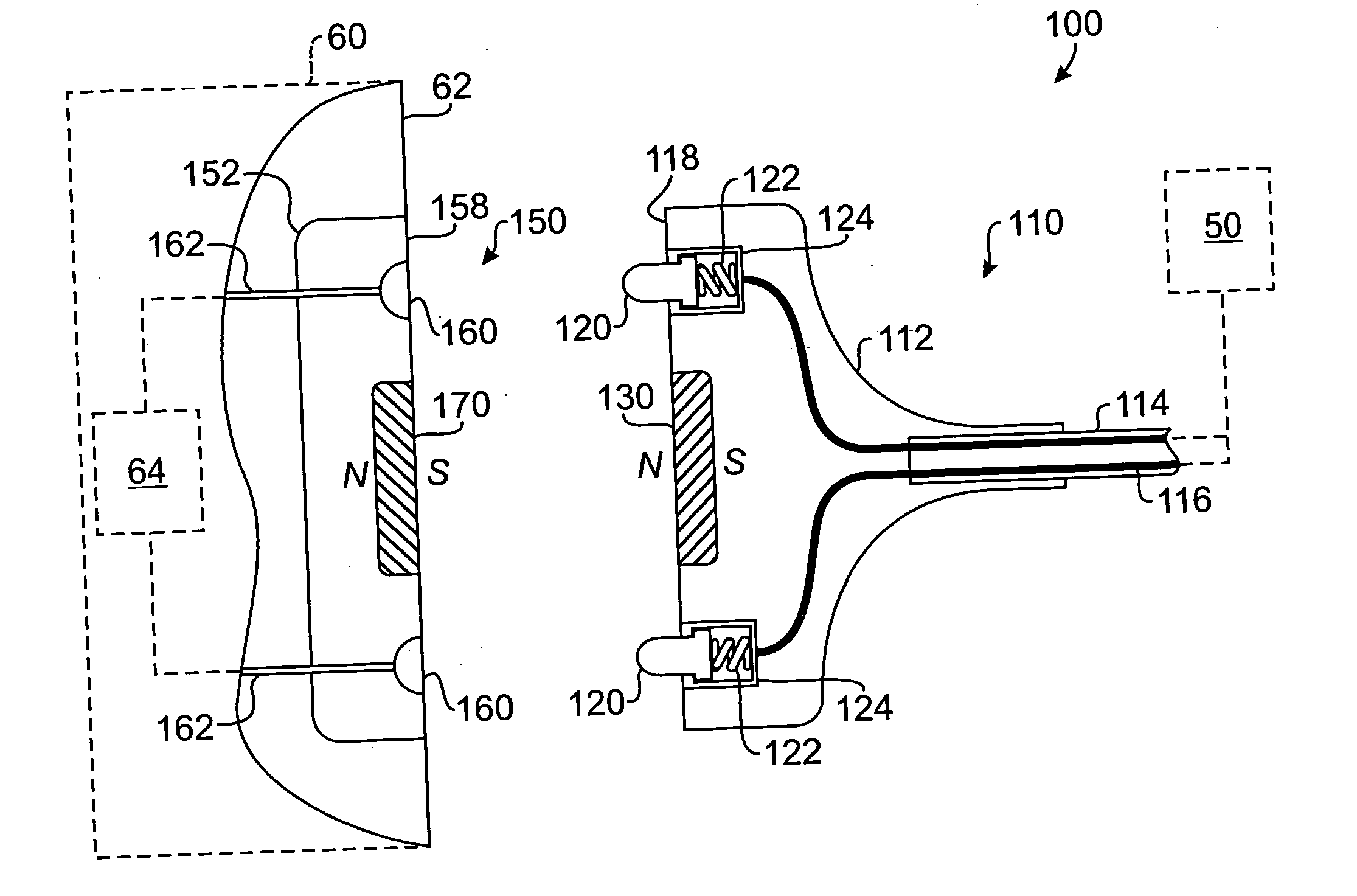

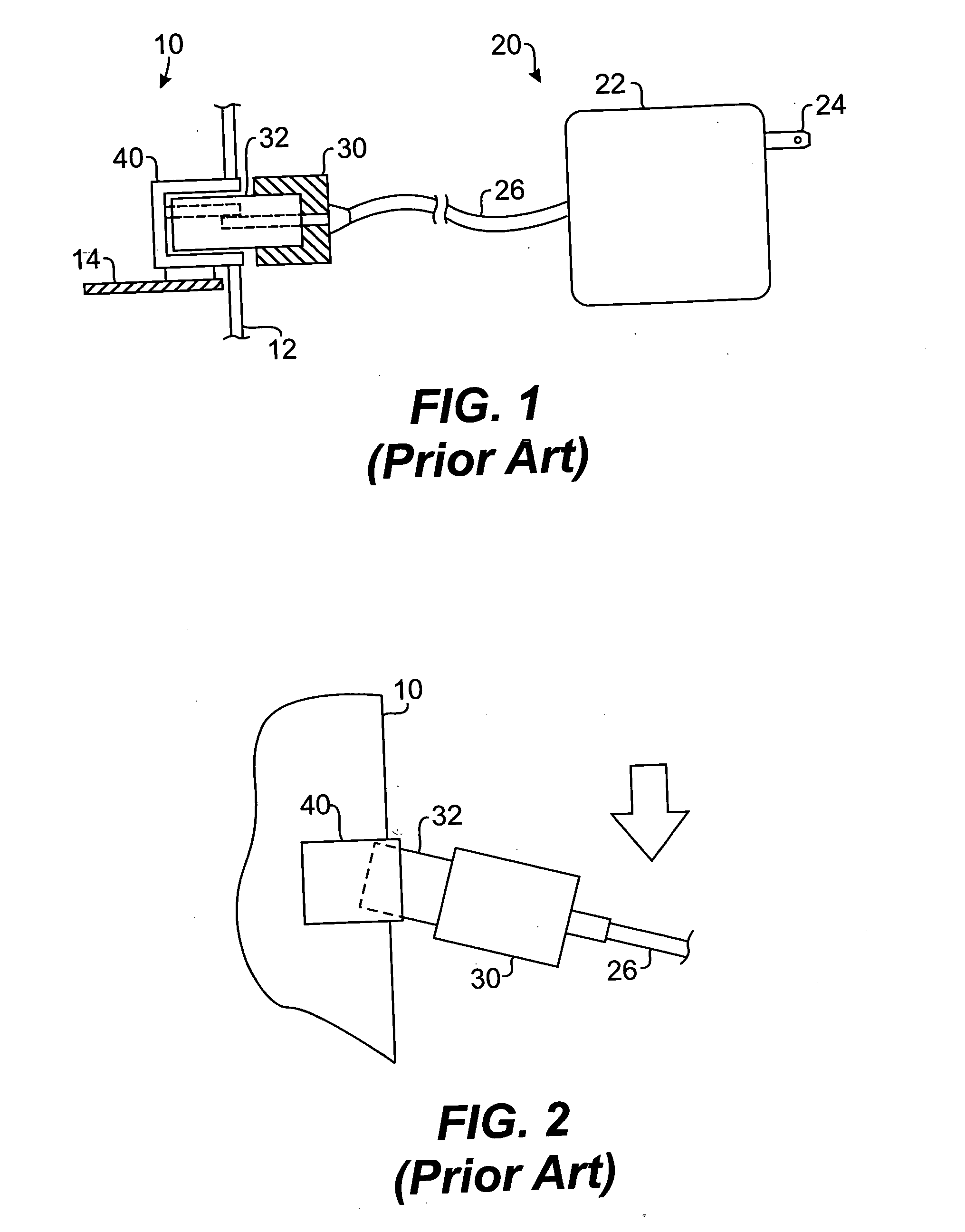

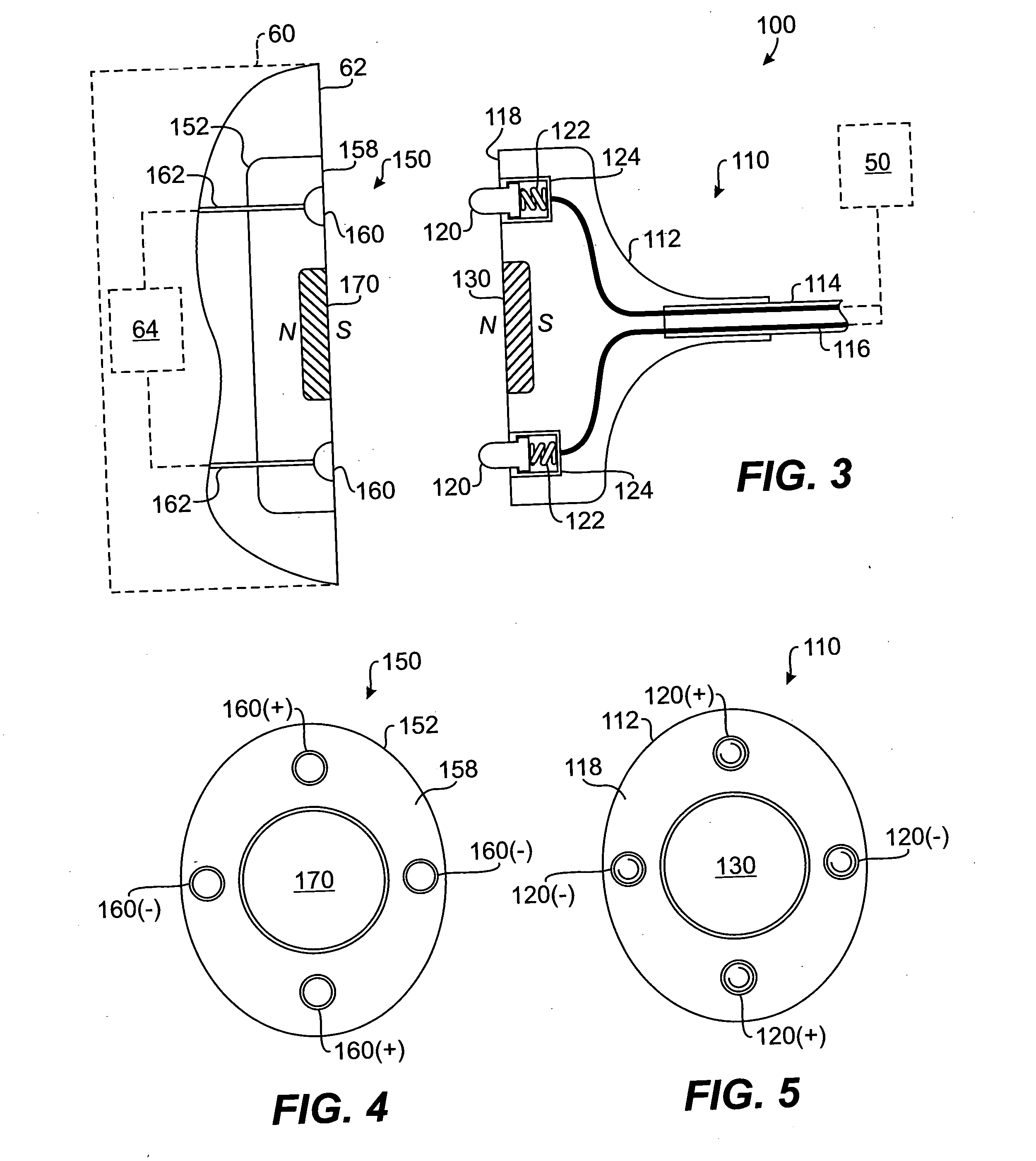

Magnetic connector for electronic device

ActiveUS7311526B2Coupling contact membersElectric connection structural associationsRare-earth magnetElectrical contacts

Owner:APPLE INC

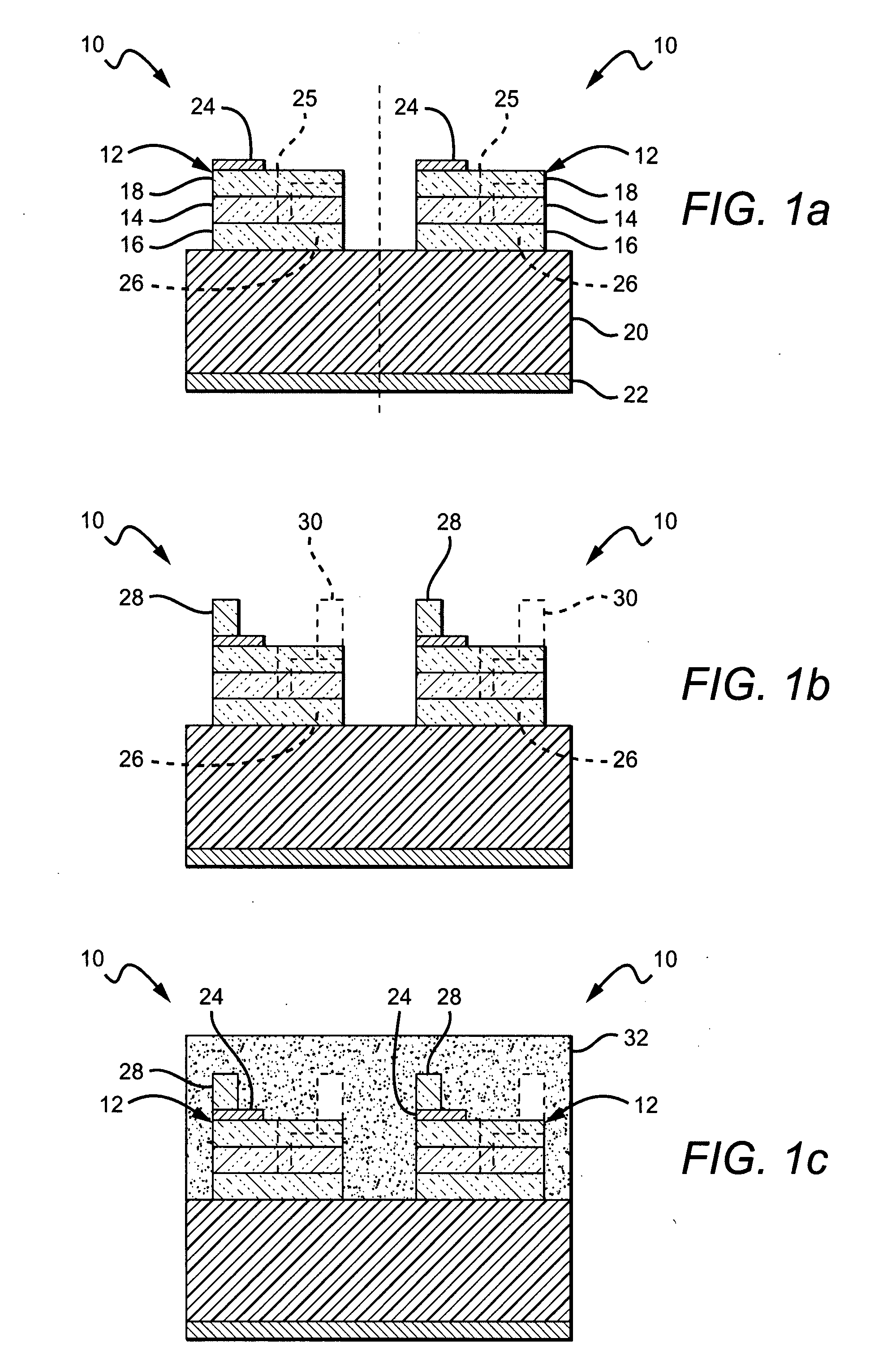

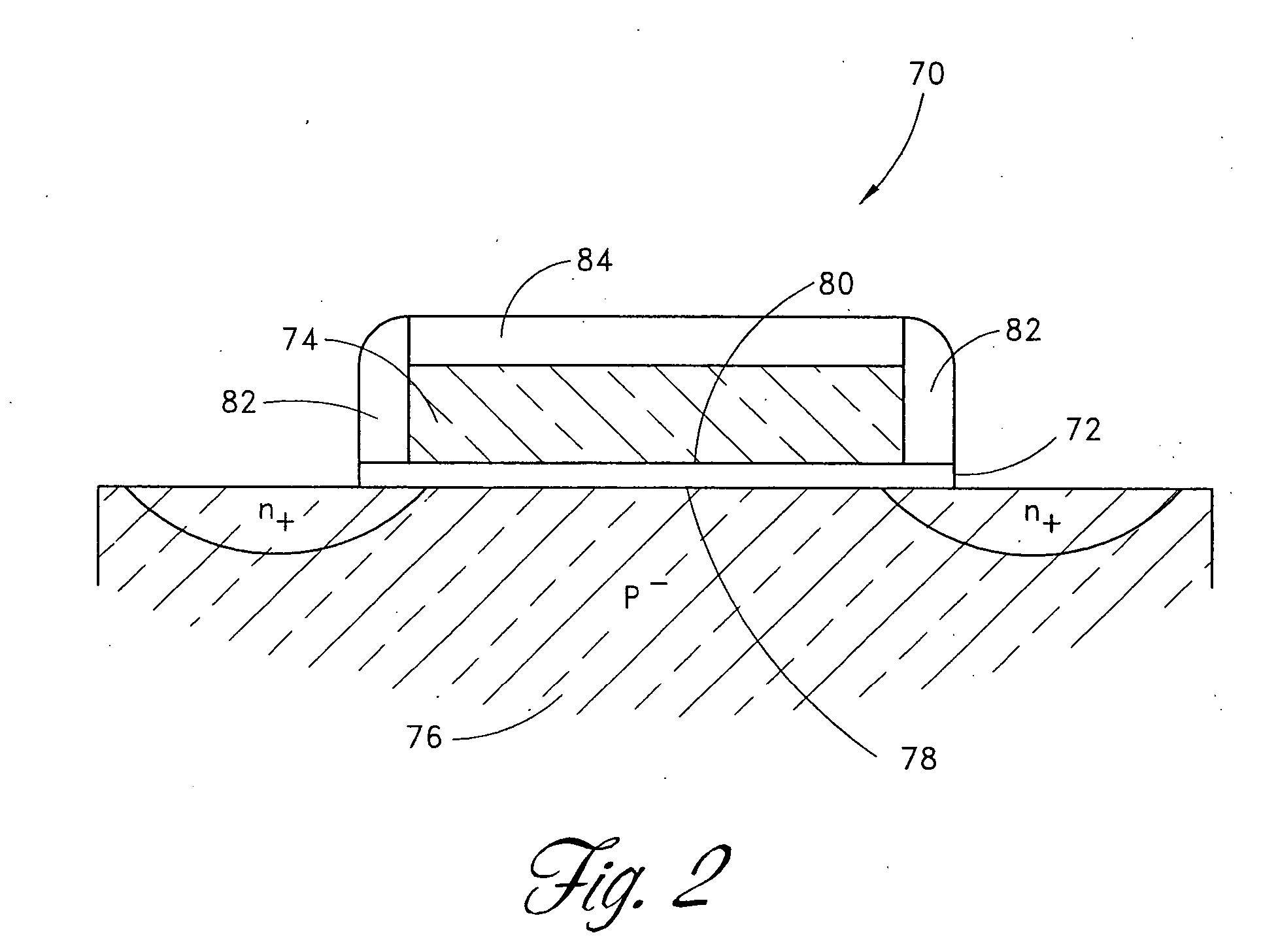

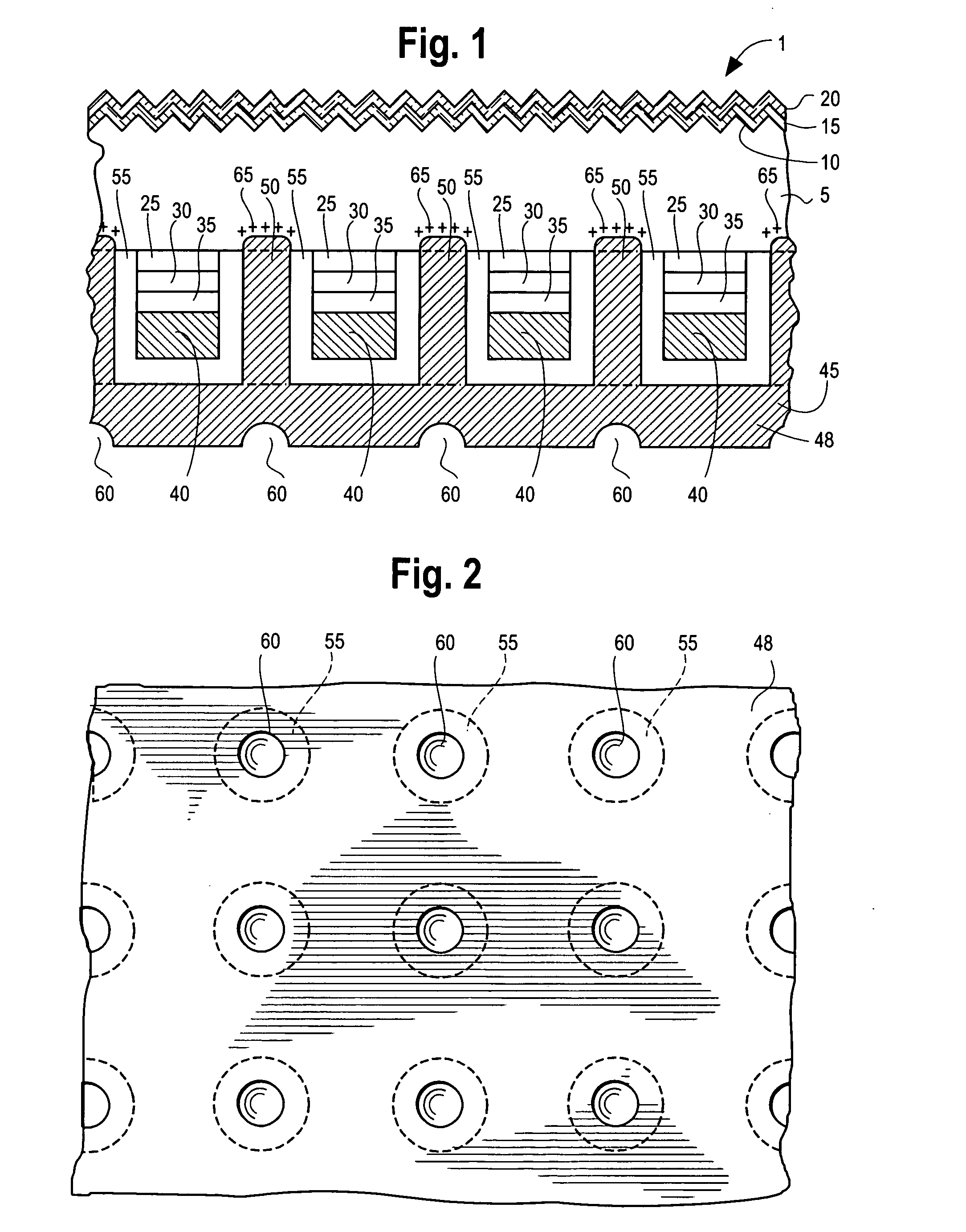

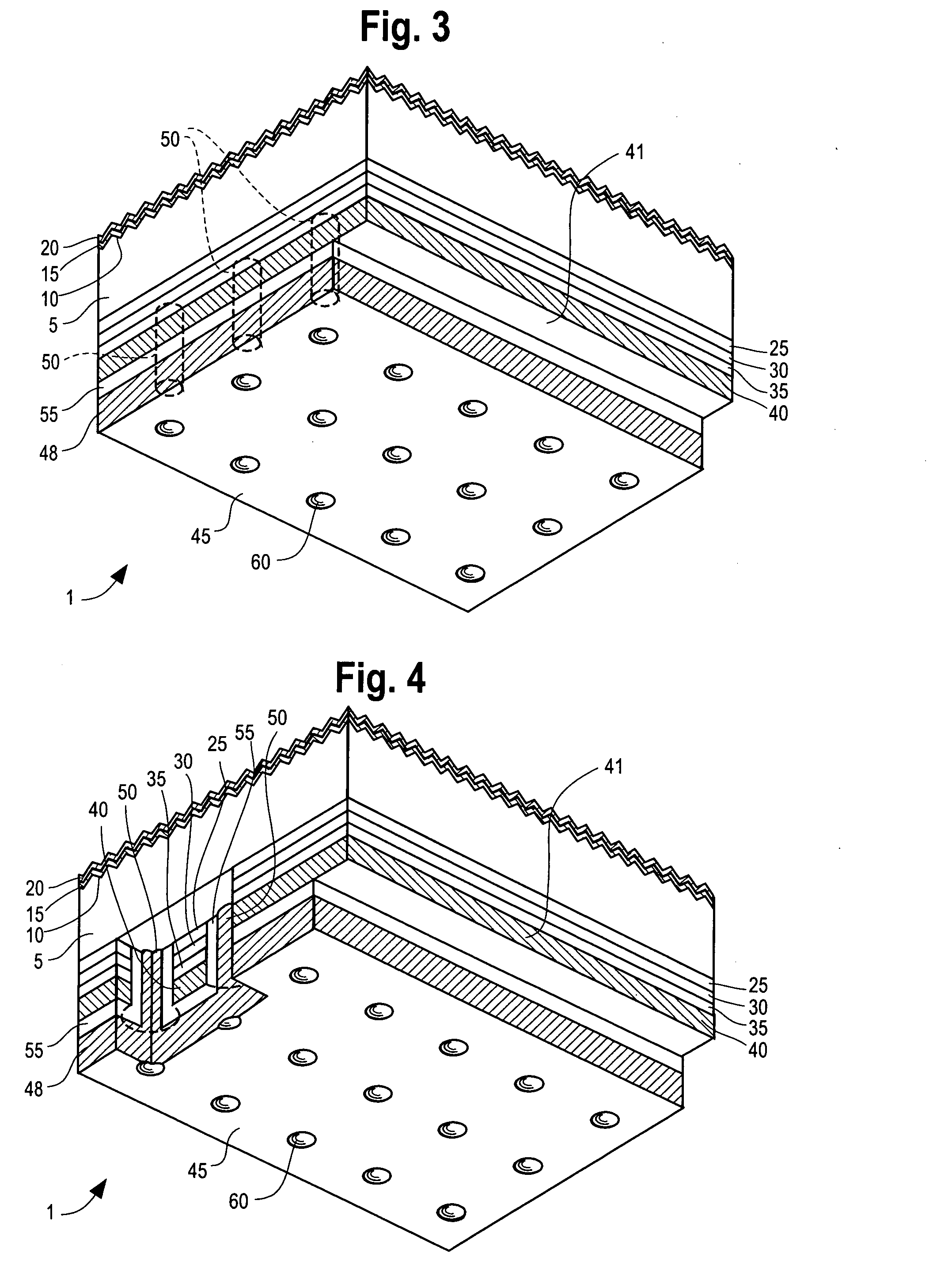

Wafer level phosphor coating method and devices fabricated utilizing method

ActiveUS20080179611A1Solid-state devicesSemiconductor/solid-state device manufacturingPhosphorLight-emitting diode

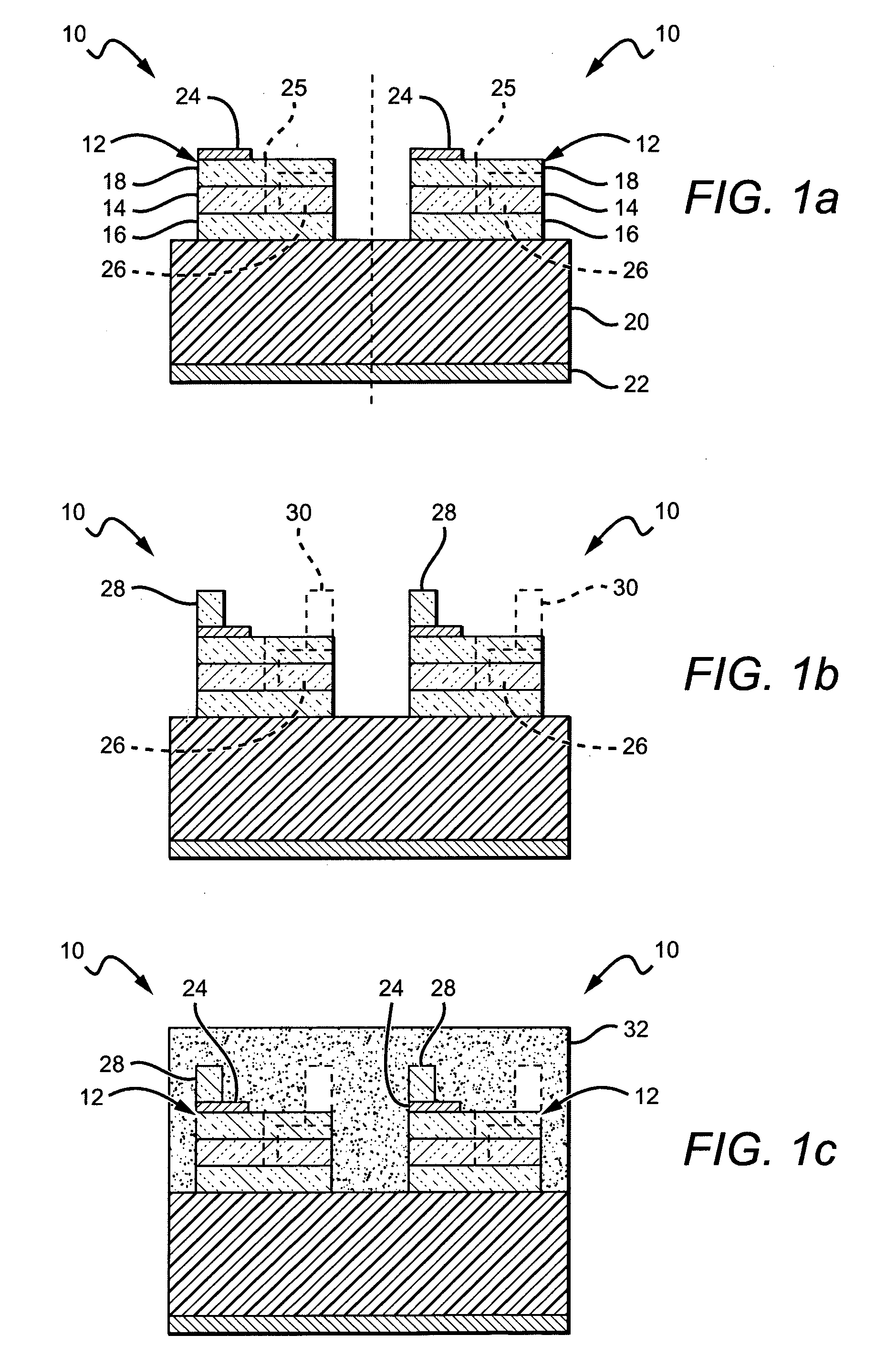

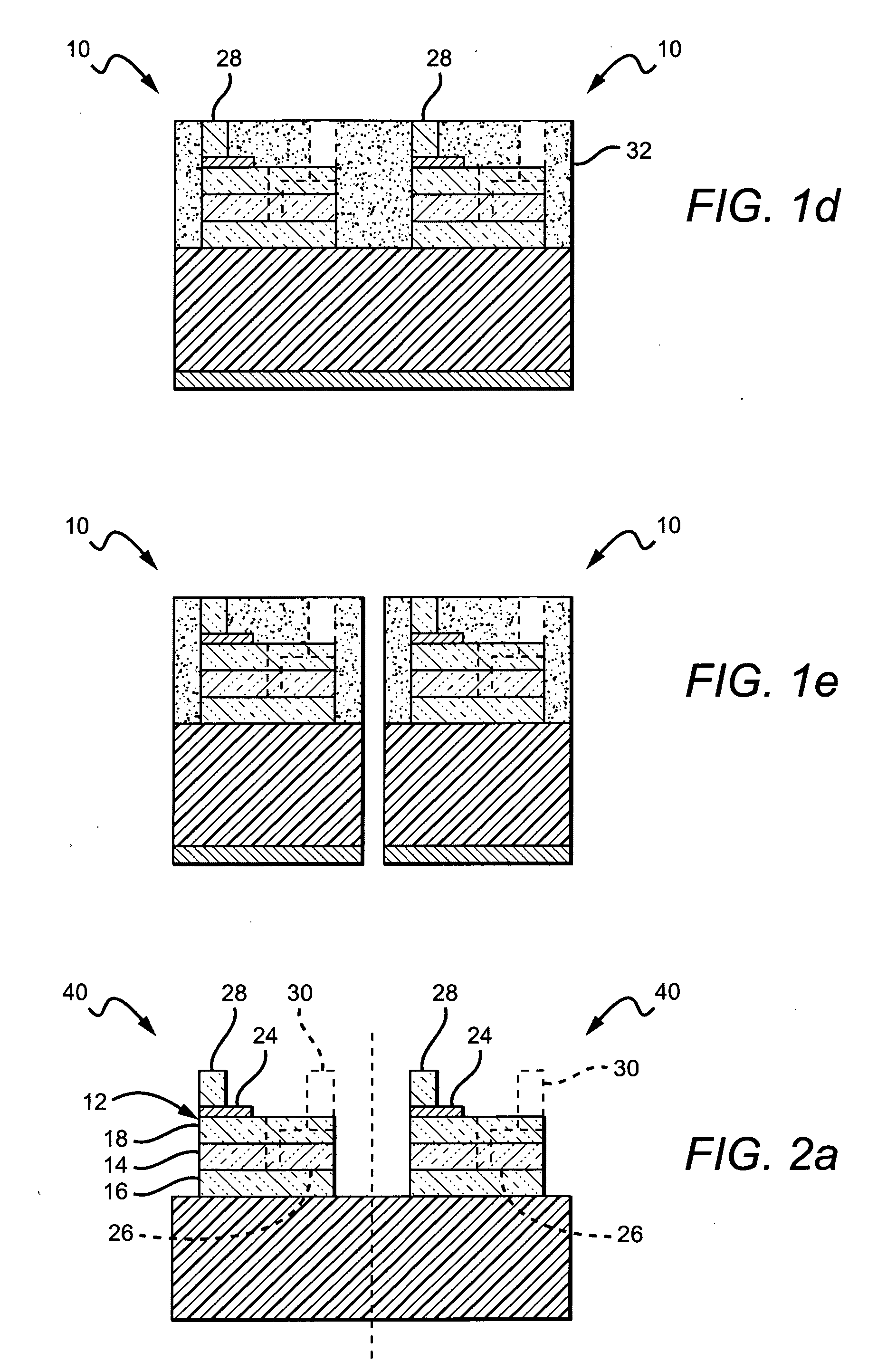

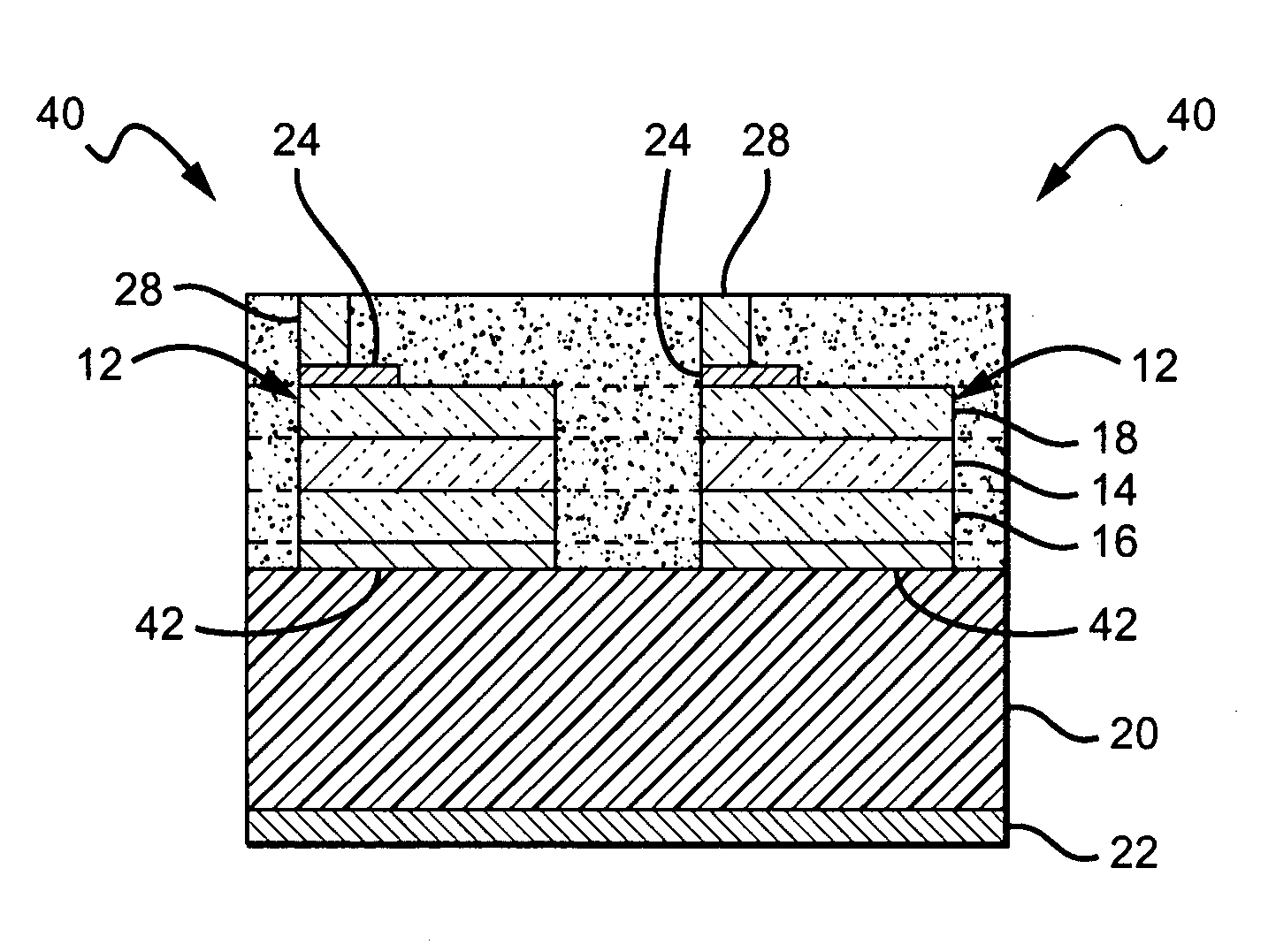

Methods for fabricating light emitting diode (LED) chips comprising providing a plurality of LEDs typically on a substrate. Pedestals are deposited on the LEDs with each of the pedestals in electrical contact with one of the LEDs. A coating is formed over the LEDs with the coating burying at least some of the pedestals. The coating is then planarized to expose at least some of the buried pedestals while leaving at least some of said coating on said LEDs. The exposed pedestals can then be contacted such as by wire bonds. The present invention discloses similar methods used for fabricating LED chips having LEDs that are flip-chip bonded on a carrier substrate and for fabricating other semiconductor devices. LED chip wafers and LED chips are also disclosed that are fabricated using the disclosed methods.

Owner:CREELED INC

Wafer level phosphor coating method and devices fabricated utilizing method

ActiveUS20080173884A1Semiconductor/solid-state device detailsSolid-state devicesPhosphorLight-emitting diode

Methods for fabricating light emitting diode (LED) chips comprising providing a plurality of LEDs typically on a substrate. Pedestals are deposited on the LEDs with each of the pedestals in electrical contact with one of the LEDs. A coating is formed over the LEDs with the coating burying at least some of the pedestals. The coating is then planarized to expose at least some of the buried pedestals while leaving at least some of said coating on said LEDs. The exposed pedestals can then be contacted such as by wire bonds. The present invention discloses similar methods used for fabricating LED chips having LEDs that are flip-chip bonded on a carrier substrate and for fabricating other semiconductor devices. LED chip wafers and LED chips are also disclosed that are fabricated using the disclosed methods.

Owner:CREELED INC

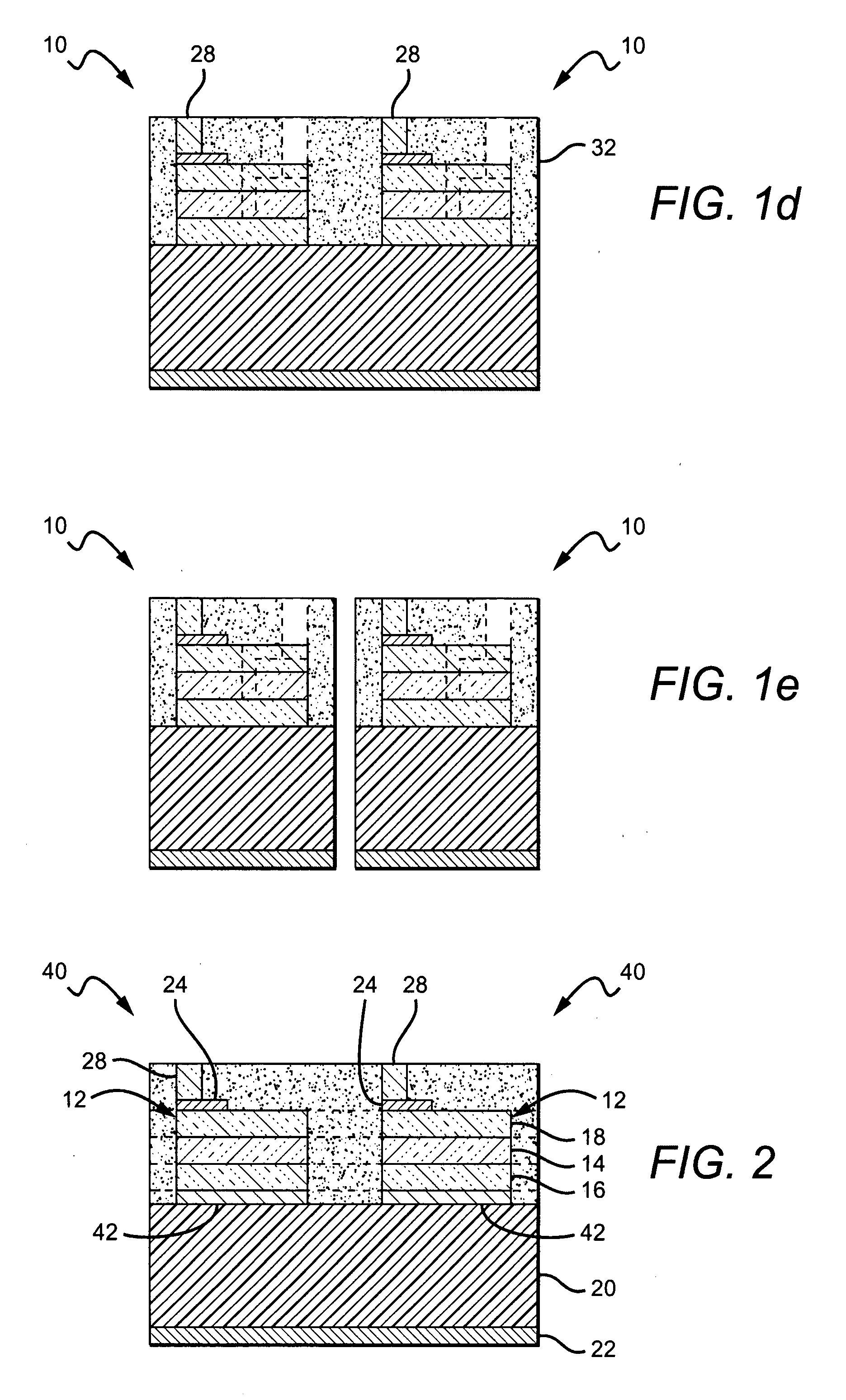

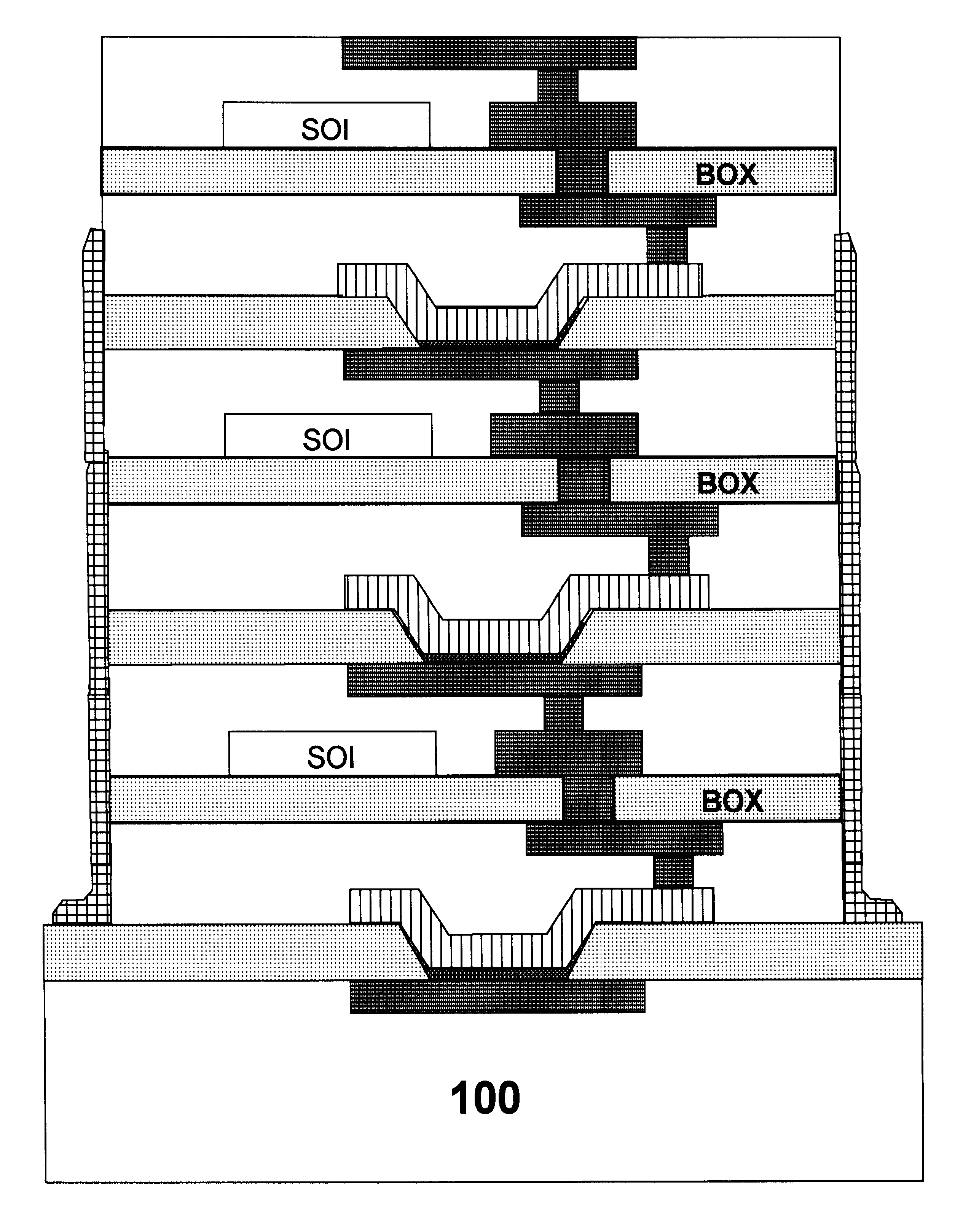

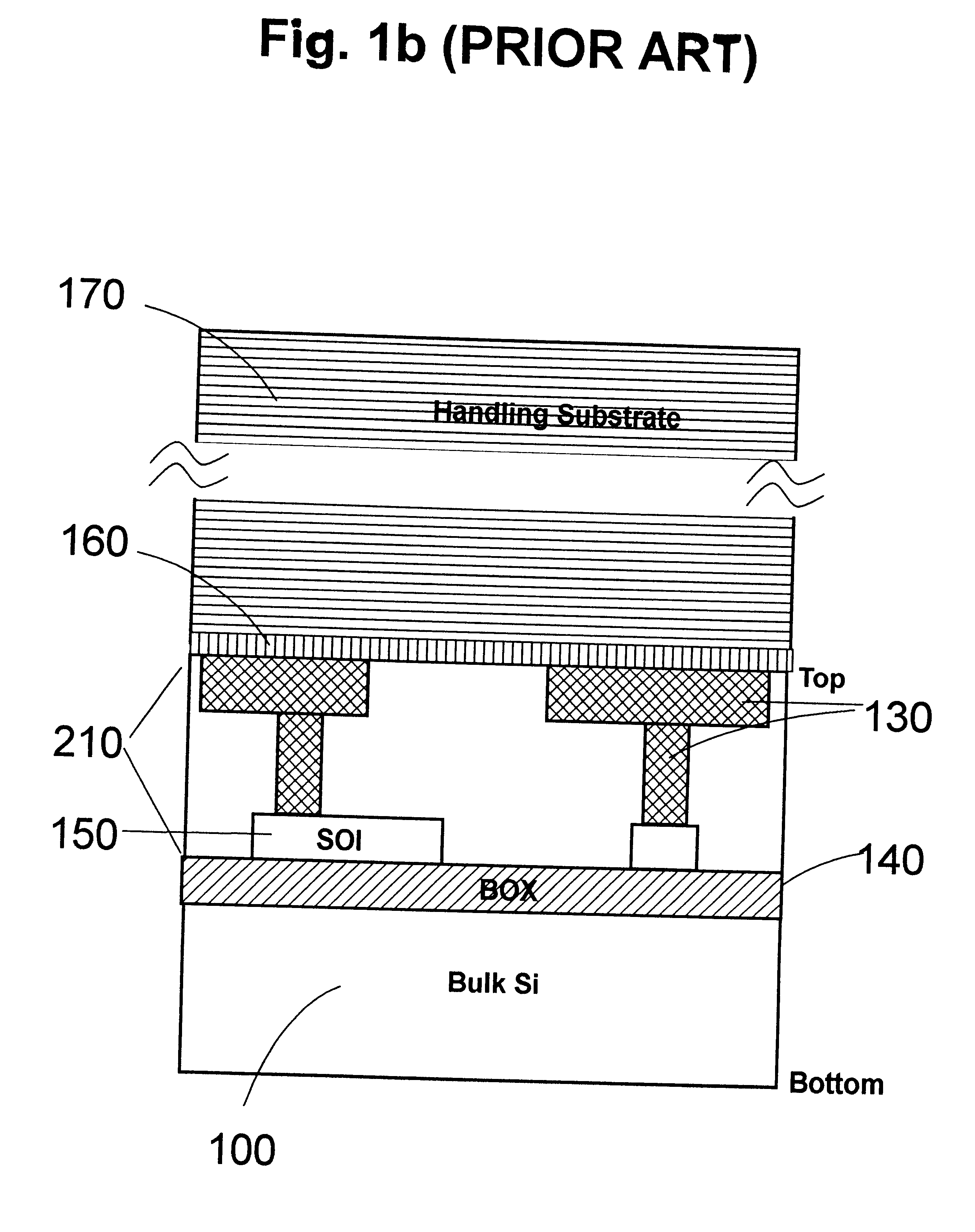

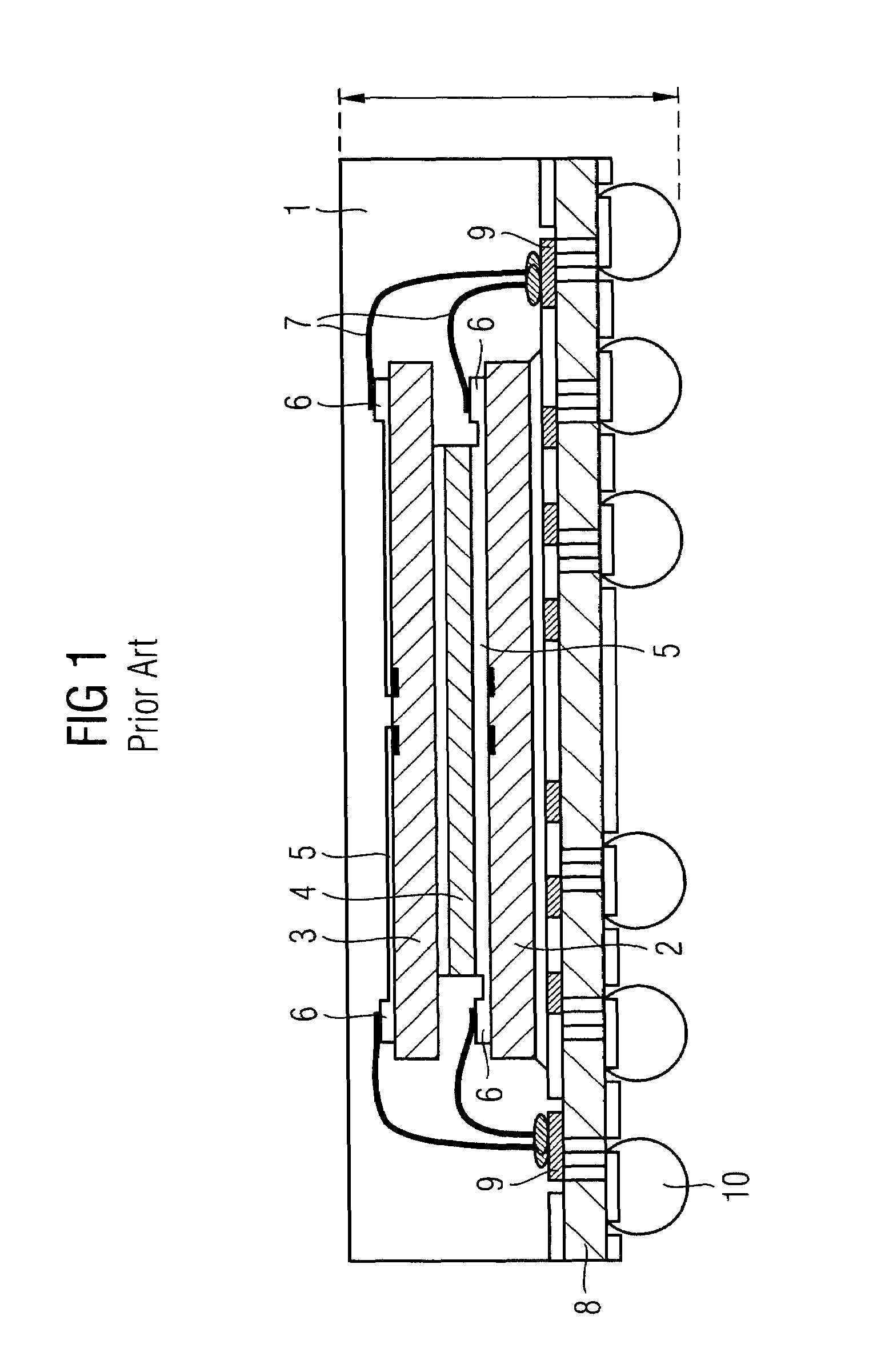

Three-dimensional chip stacking assembly

InactiveUS6355501B1Precise alignmentGood mechanical integritySolid-state devicesSemiconductor/solid-state device manufacturingEngineeringThree-dimensional integrated circuit

An assembly consisting of three dimensional stacked SOI chips, and a method of forming such integrated circuit assembly, each of the SOI chips including a handler making mechanical contact to a first metallization pattern making electrical contact to a semiconductor device. The metalized pattern, in turn, contacts a second metallization pattern positioned on an opposite surface of the semiconductor device. The method of fabricating the three-dimensional IC assembly includes the steps of: a) providing a substrate having a third metalized pattern on a first surface of the substrate; b) aligning one of the SOI chips on the first surface of the substrate, by having the second metallization pattern of the SOI chip make electrical contact with the third metalized pattern of the substrate; c) removing the handler from the SOI chip, exposing the first metallization pattern of the SOI chip; d) aligning a second one of the SOI chips with the first SOI chip, having the second metallization pattern of the second SOI chip make electrical contact to the exposed first metallization pattern of the first SOI chip; and e) repeating steps c) and d) for mounting subsequent SOI chips one on top of the other.

Owner:IBM CORP

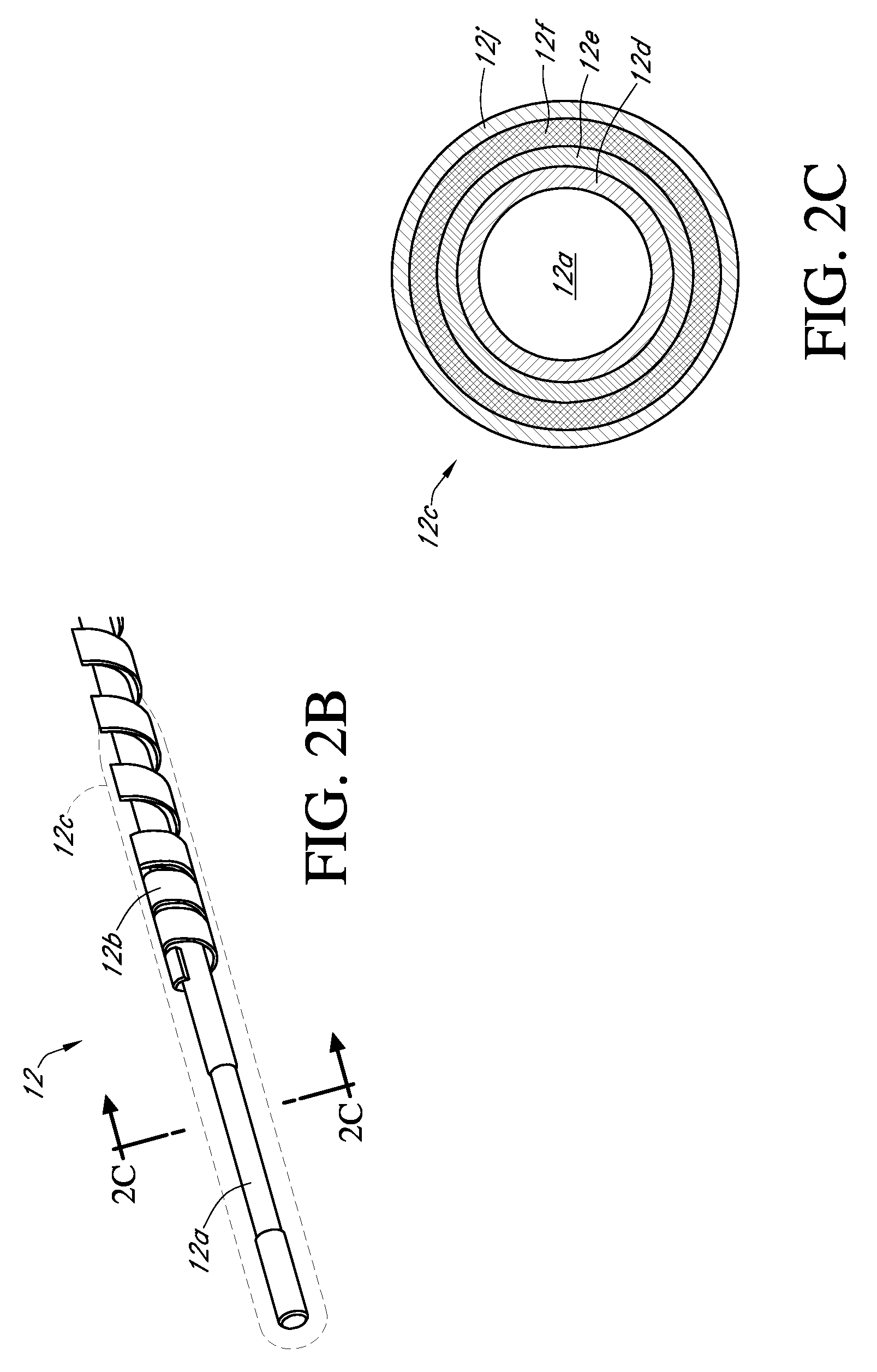

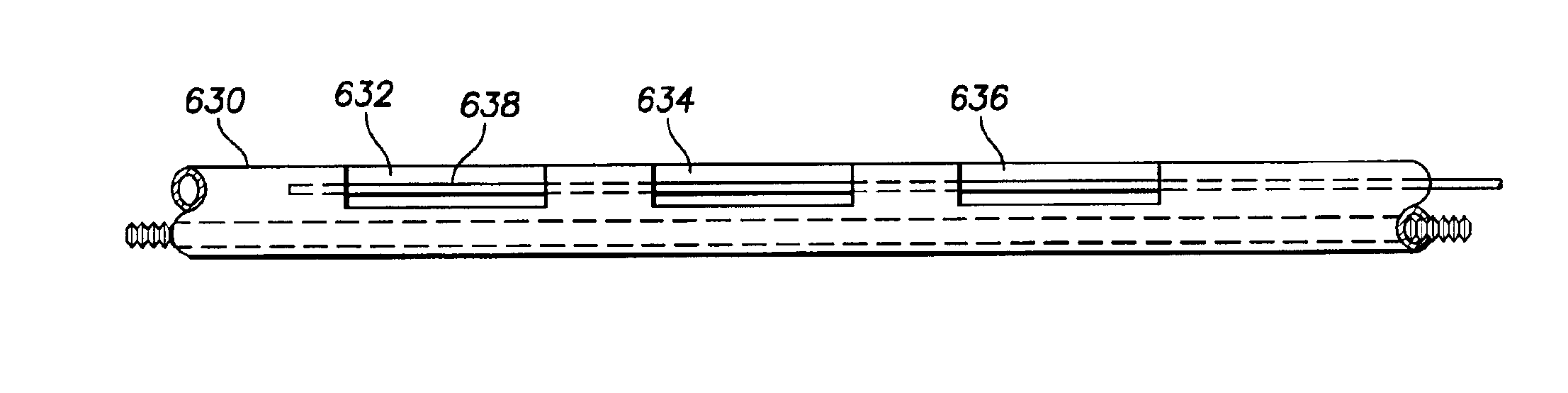

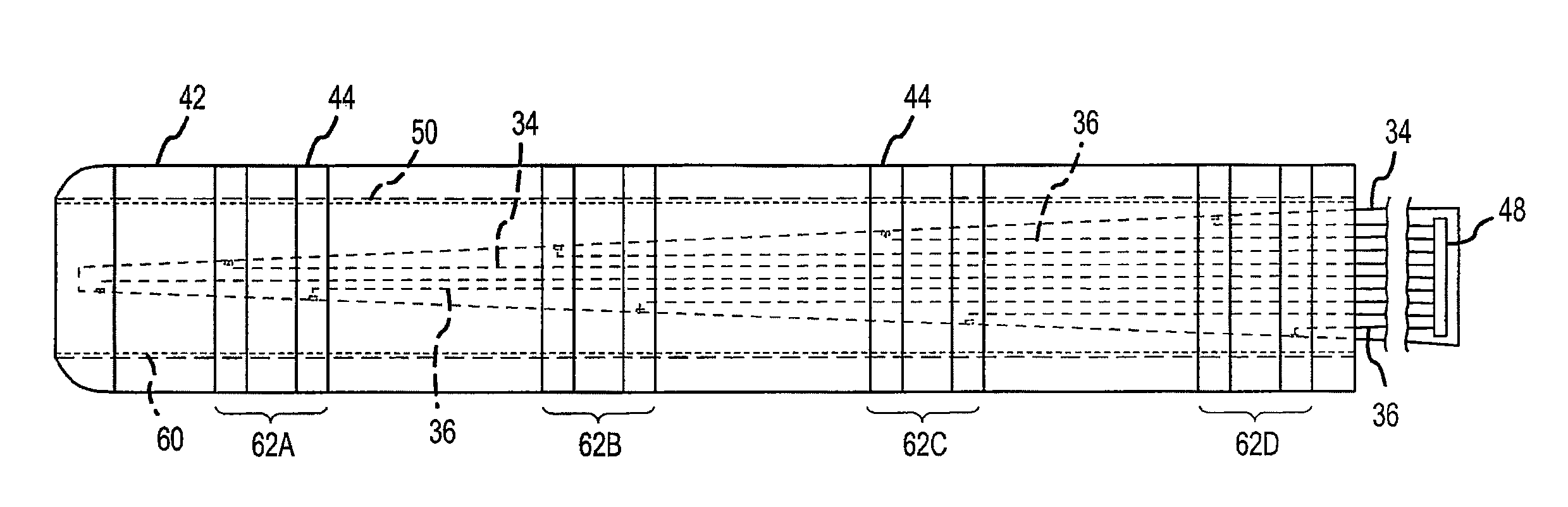

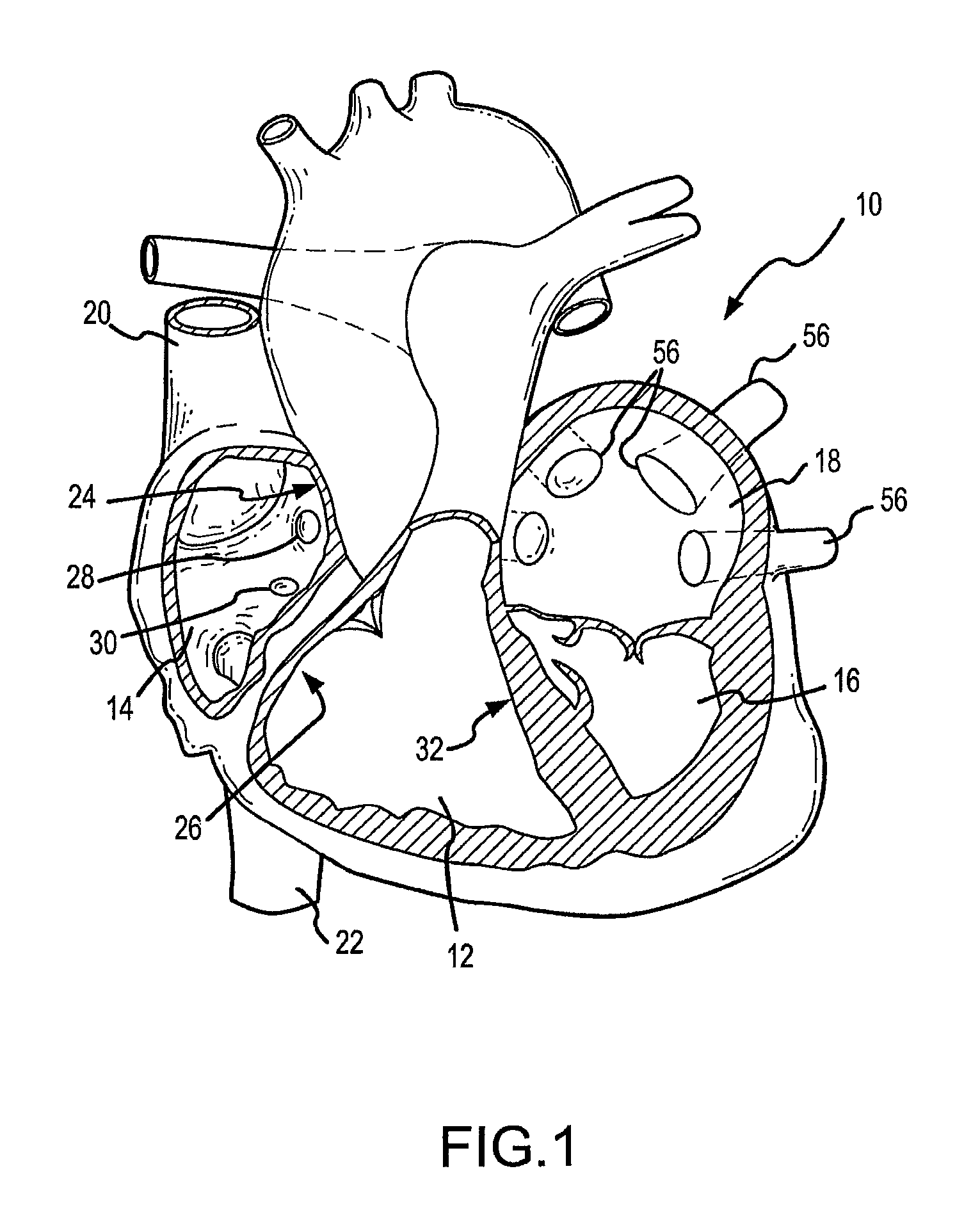

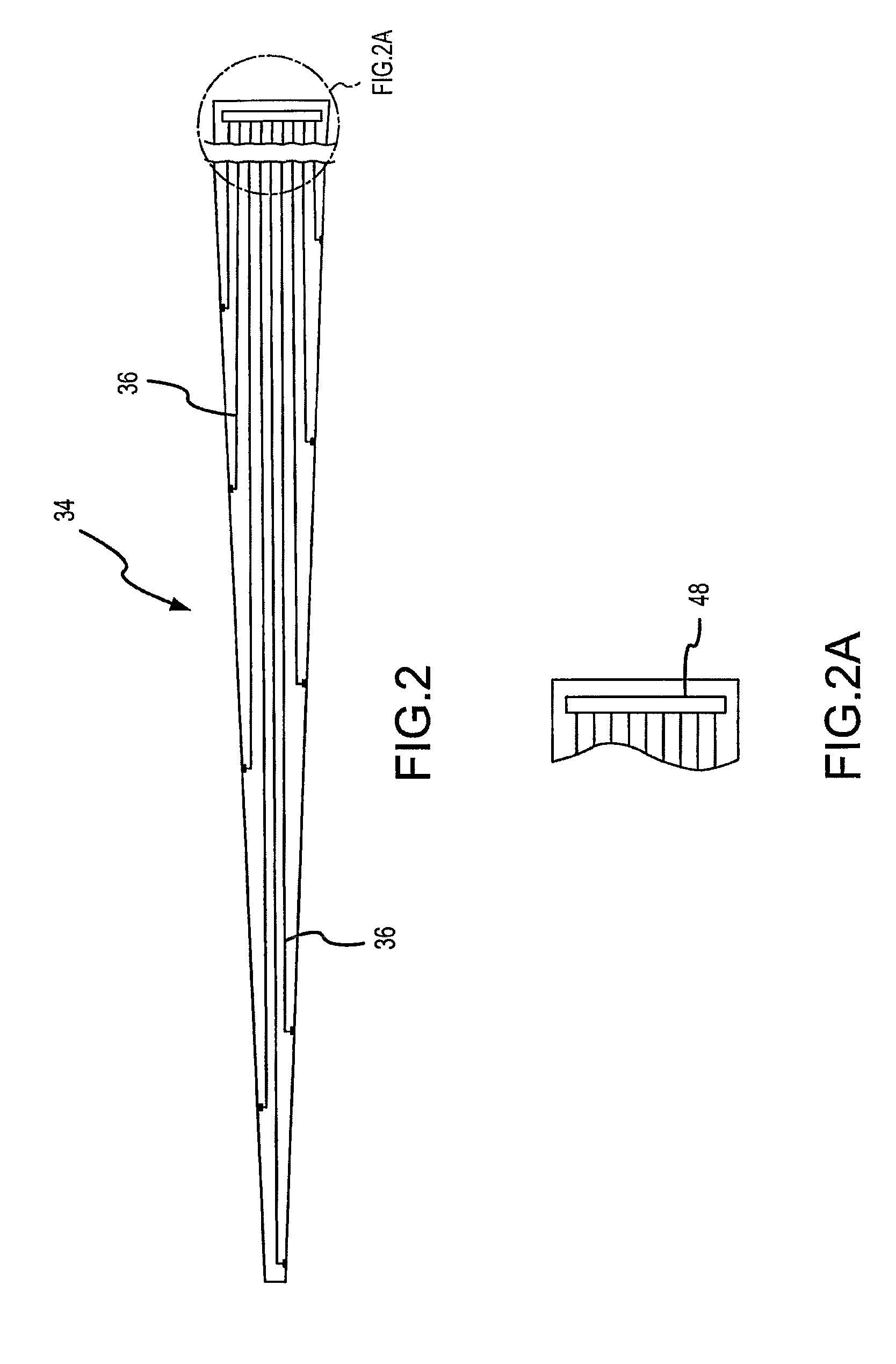

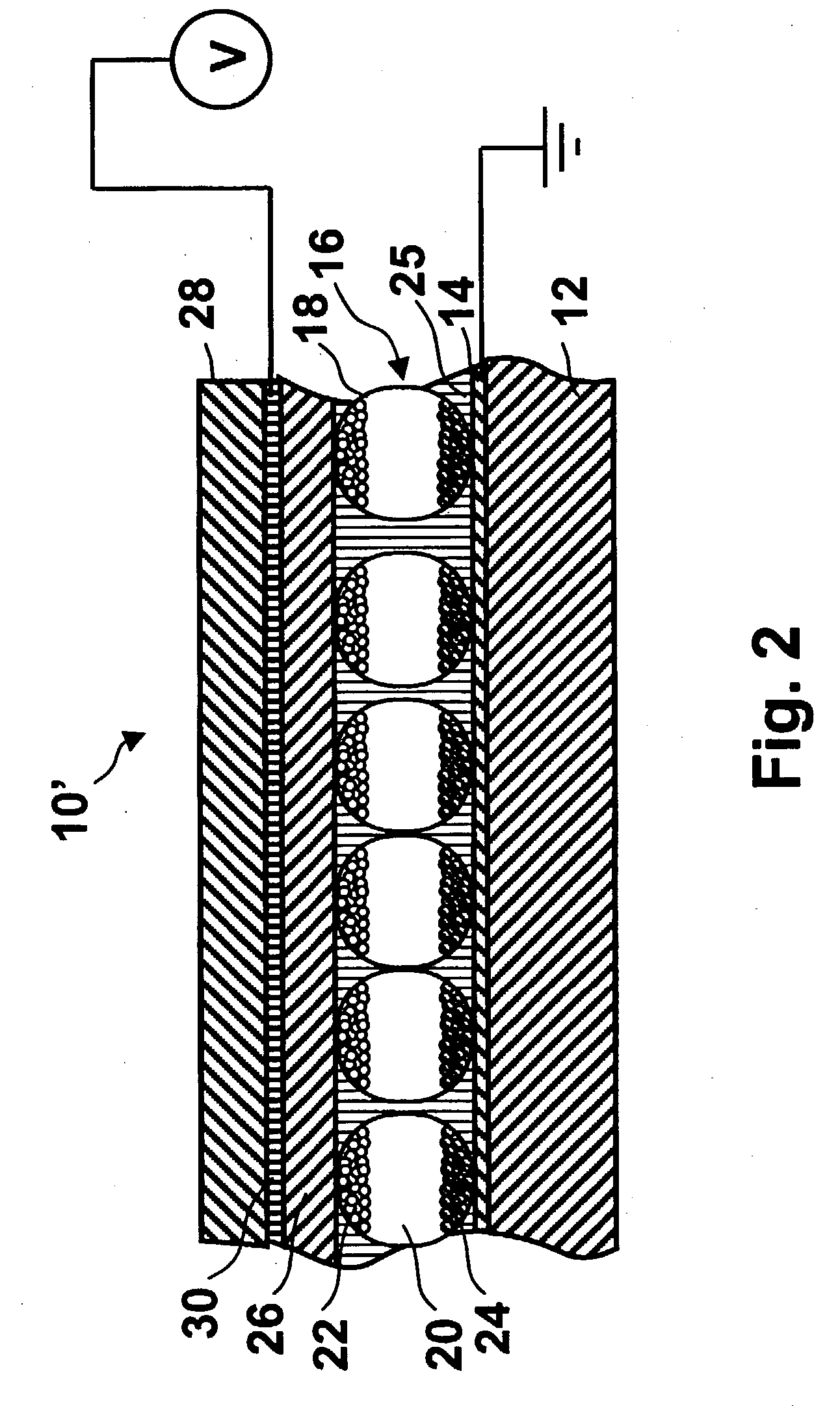

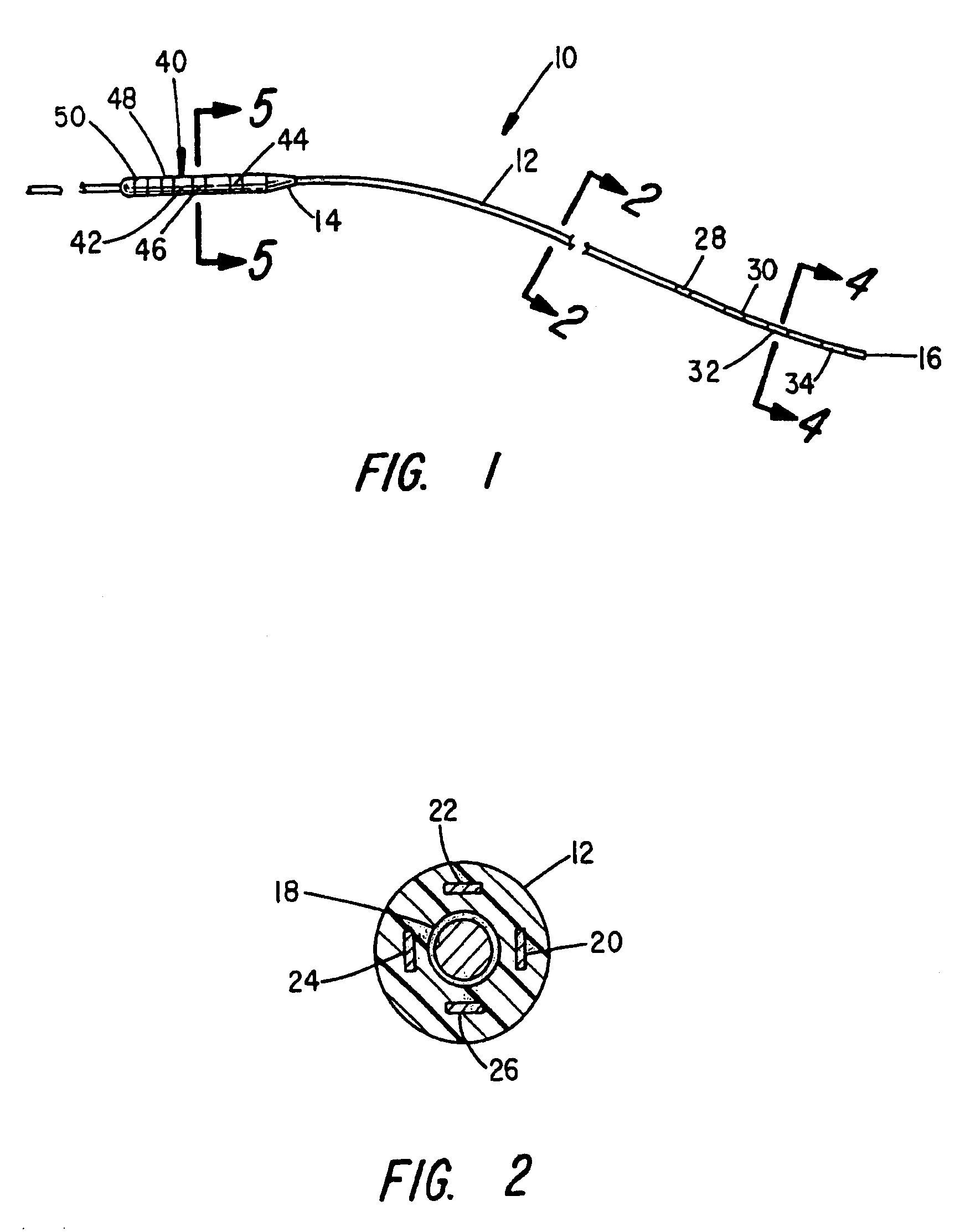

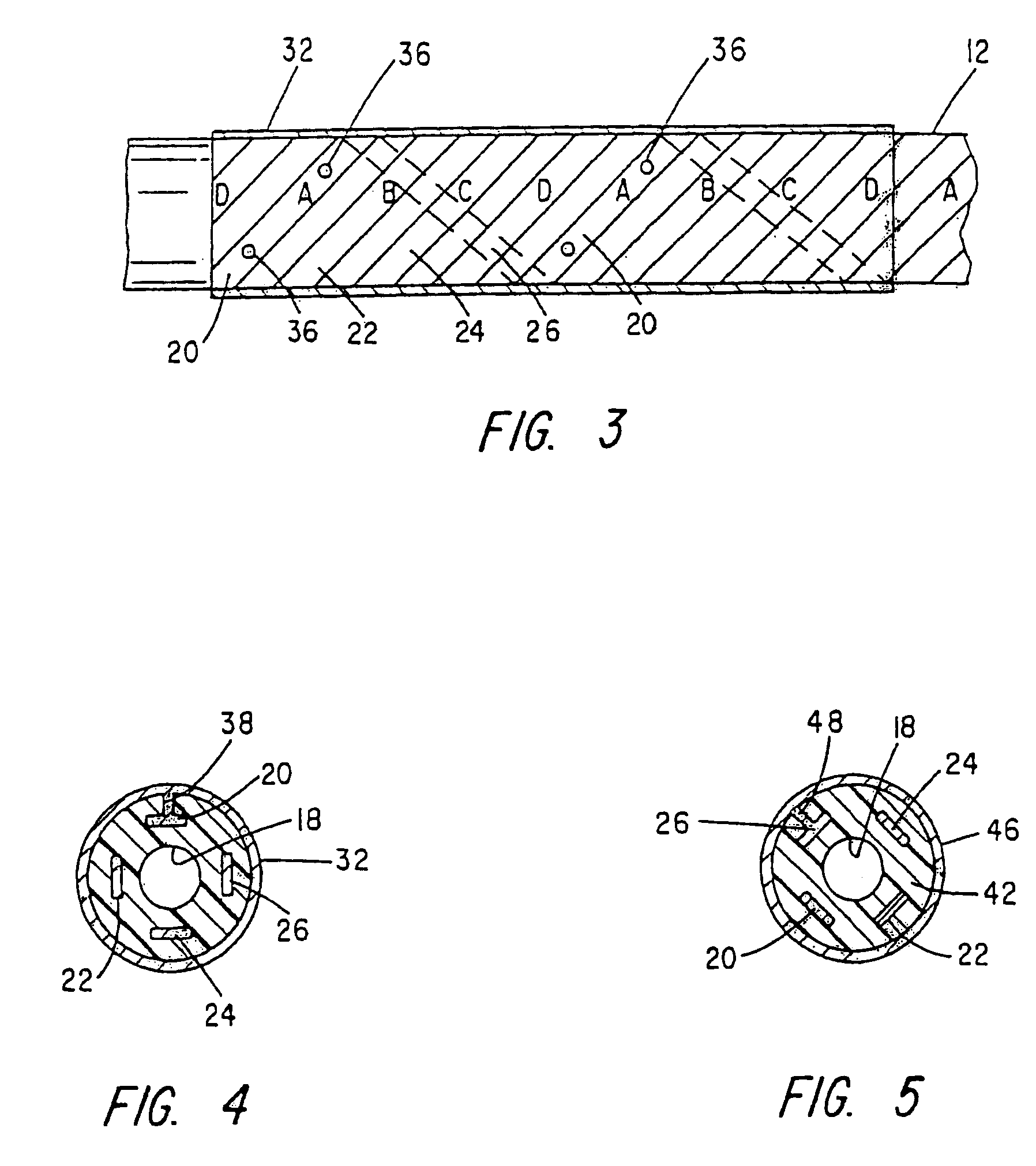

Body implantable lead including one or more conductive polymer electrodes and methods for fabricating same

InactiveUS6999821B2Transvascular endocardial electrodesDiagnostic recording/measuringElectrical conductorCoronary sinus

A body implantable lead comprises a lead body including a conductive polymer electrode disposed along a distal end portion of the lead body for performing one or more of the functions consisting of pacing, sensing, cardioversion and defibrillation. An electrical conductor, preferably in the form of a multistrand cable conductor, couples the conductive polymer electrode with a proximal end of the lead body. The conductive polymer electrode encapsulates the conductor and is in electrical contact therewith along the length, and preferably along substantially the entire length, of the conductive polymer electrode. The lead body may comprise a multilumen polymer housing, the conductor being contained within one of the lumens of the housing. The conductive polymer electrode may be disposed within a window formed in the lead body. Alternatively, the conductive polymer electrode may comprise multiple electrode sections within a corresponding number of windows formed in the lead body and spaced apart along the length thereof. Further, the window and the conductive polymer electrode disposed therein may extend helically about the lead body. Because of its flexibility and because it can have a small diameter, the lead of the invention is particularly advantageous for implantation in the small, tortuous vessels of the coronary sinus region of the heart for left side stimulation and / or sensing.Methods of fabricating lead bodies incorporating conductive polymer electrodes are also disclosed.

Owner:PACESETTER INC

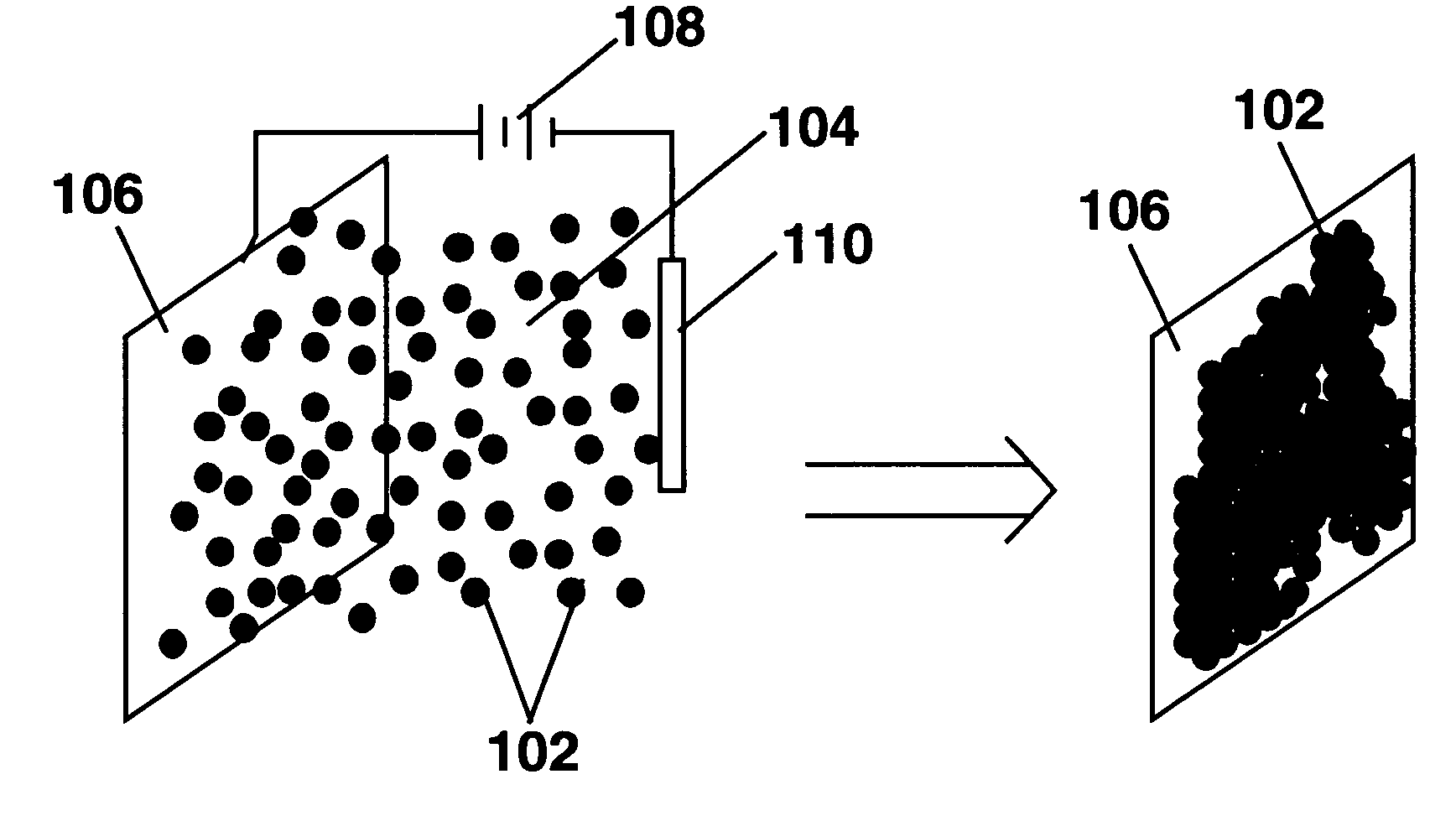

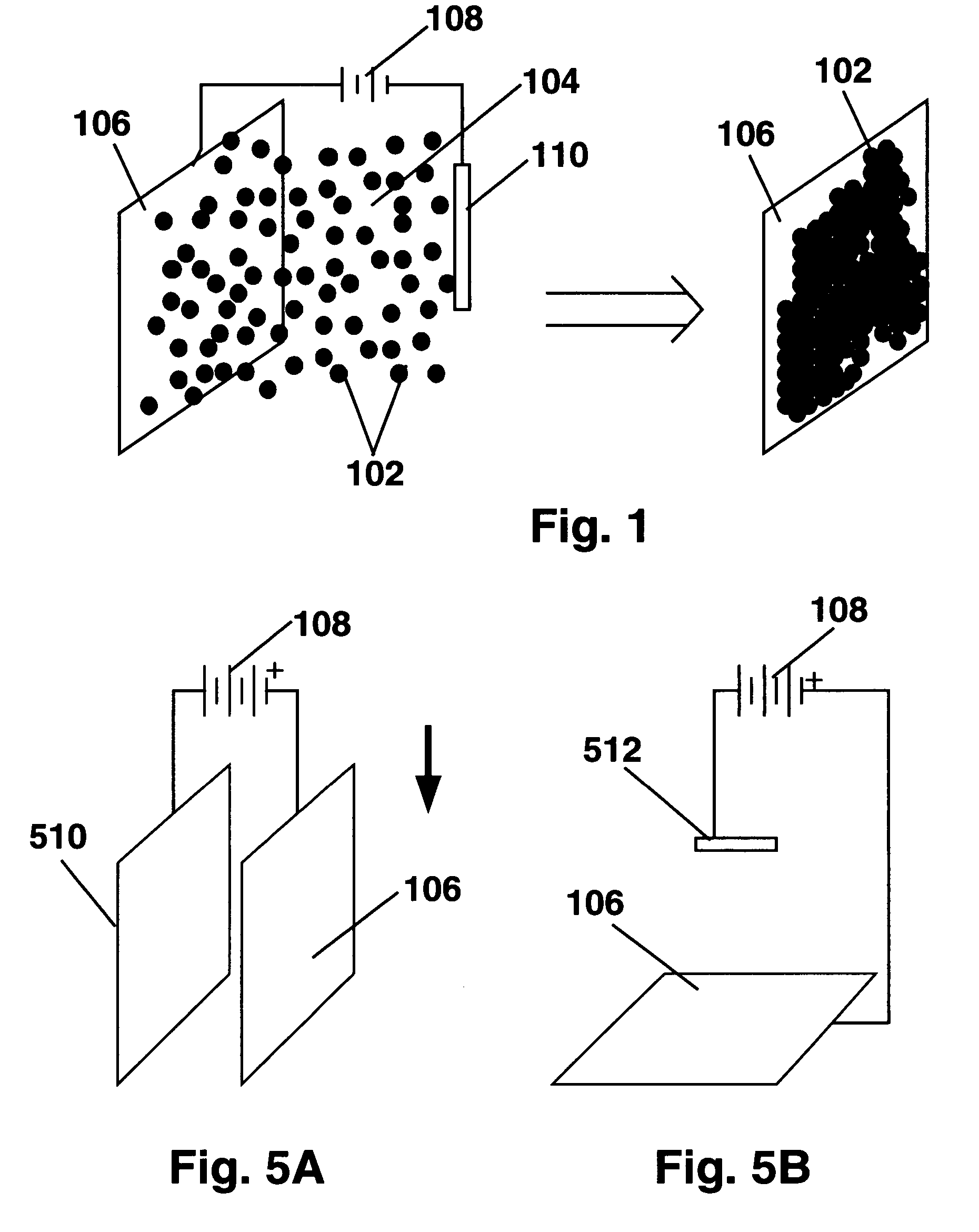

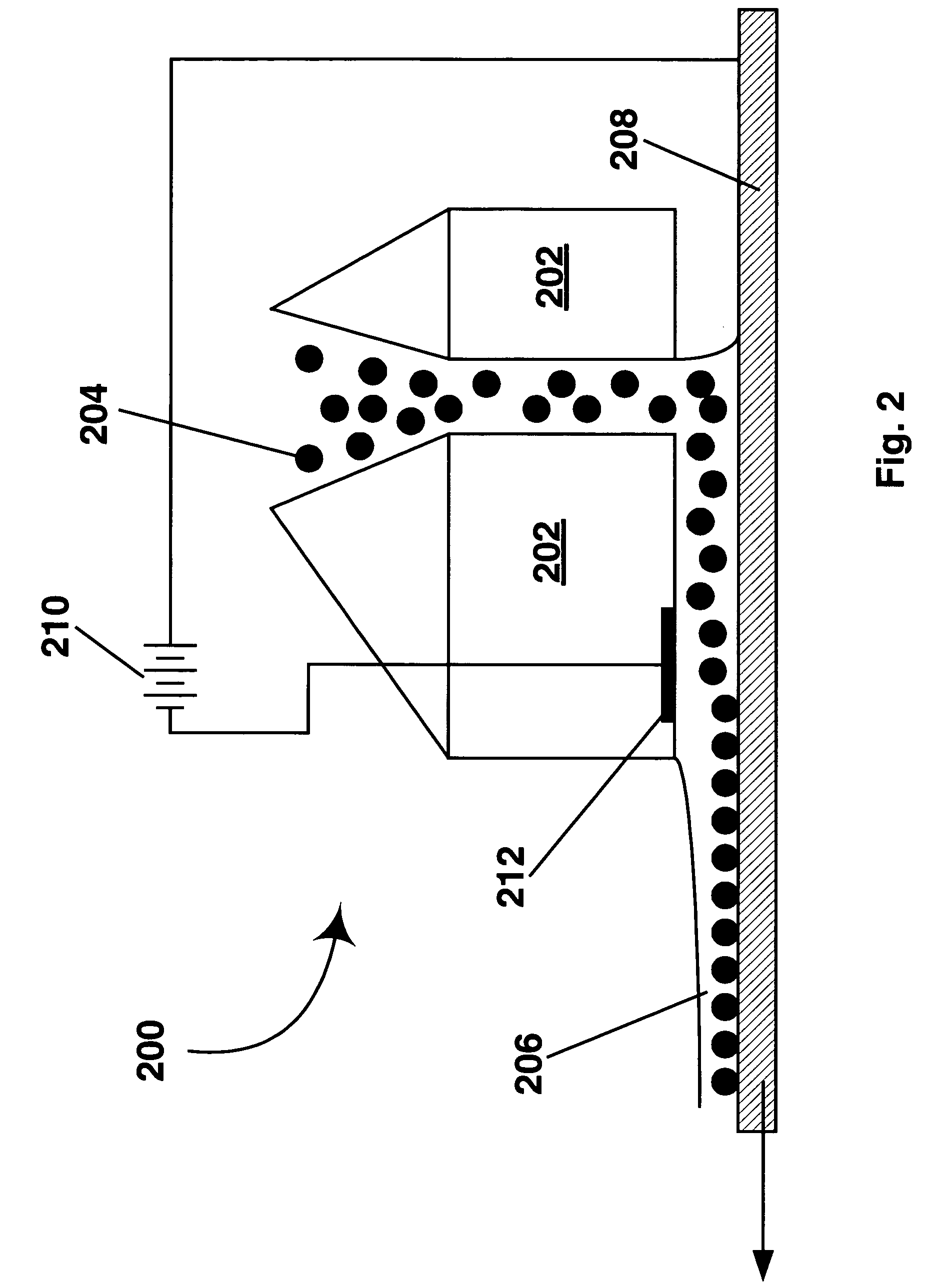

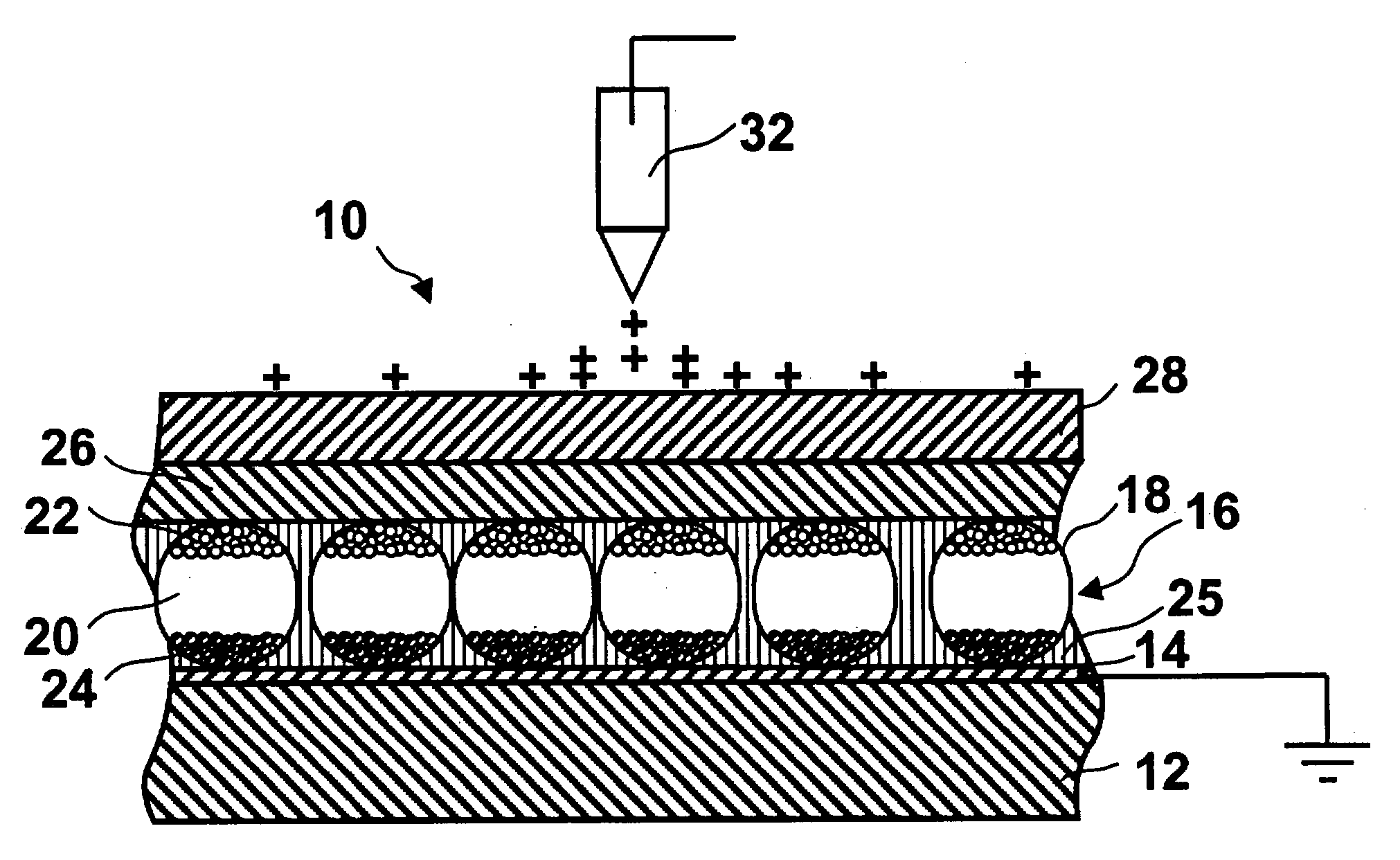

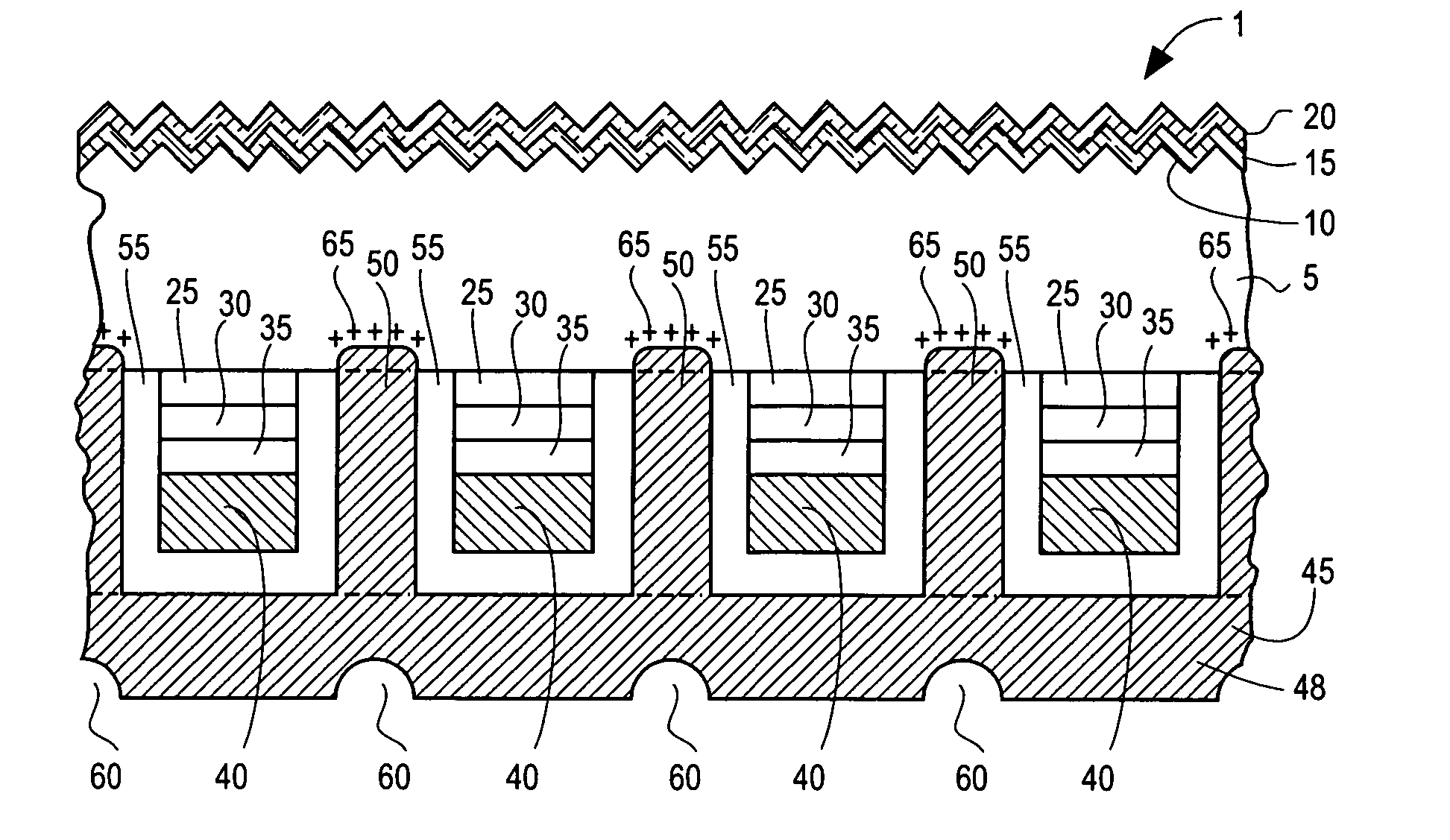

Processes for the production of electrophoretic displays

ActiveUS7339715B2Electric shock equipmentsElectrophoretic coatingsElectrophoresisPotential difference

A coating of an encapsulated electrophoretic medium is formed on a substrate (106) by dispersing in a fluid (104) a plurality of electrophoretic capsules (102), contacting at least a portion of a substrate (106) with the fluid (104); and applying a potential difference between at least a part of the portion of the substrate (106) contacting the fluid (104) and a counter-electrode (110) in electrical contact with the fluid (104), thereby causing capsules (102) to be deposited upon at least part of the portion of the substrate (106) contacting the fluid (102). Patterned coatings of capsules containing different colors may be deposited in registration with electrodes using multiple capsule deposition steps. Alternatively, a patterned coating may be deposited upon a substrate containing a conductive layer by varying the conductivity of the conductive layer by radiation exposure or by coating portions of the conductive layer with an insulating layer, typically a photoresist.

Owner:E INK CORPORATION

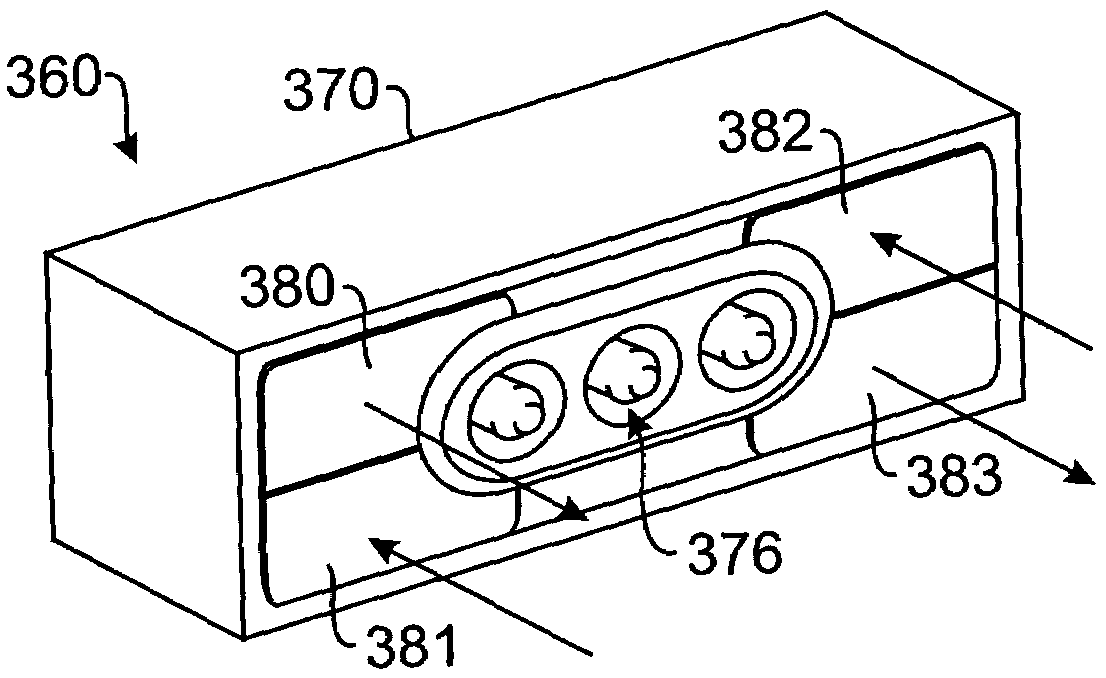

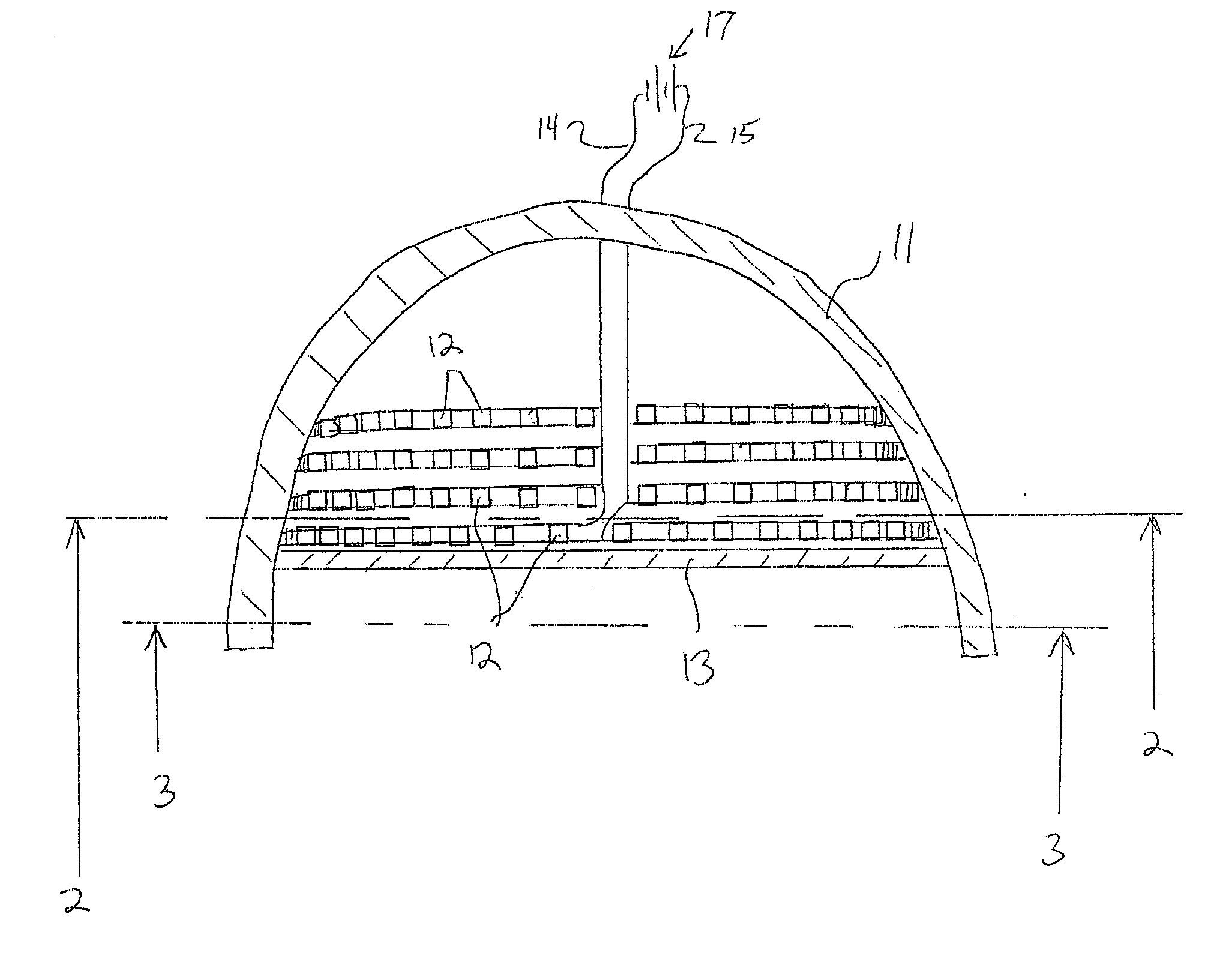

Lighting device

ActiveUS20070139923A1Eliminates thermal interfaceReduce the temperatureCoupling device connectionsPoint-like light sourceElectricityEffect light

A lighting device comprises, or consists essentially of, a housing, a solid state light emitter and conductive tracks. The conductive tracks are positioned on the housing and are coupleable with a power supply. The conductive tracks comprise a positive conductive track and a negative conductive track. Each of the solid state light emitters is in electrical contact with a positive conductive track and a negative conductive track. Another lighting device comprises a fixture and a solid state light emitter in which the fixture comprises conductive elements which are coupleable to at least one power supply and the solid state light emitter is mounted on the fixture. There is also provided a lighting device which provides light of an intensity which is at least 50 percent of its initial intensity after 50,000 hours of illumination.

Owner:IDEAL IND LIGHTING LLC

LED retrofit lamp

InactiveUS6853151B2Reduce materialReduce power consumptionPoint-like light sourceElongate light sourcesElectrical connectionLED lamp

An LED lamp for mounting to an existing fluorescent lamp fixture having a ballast assembly including ballast opposed electrical contacts, comprising a tubular wall generally circular in cross-section and having tubular wall ends with one or more LEDs positioned within the tubular wall between the tubular wall ends. An electrical circuit provides electrical power from the ballast assembly to the LED(s). The electrical circuit includes at least one metal substrate circuit board and means for electrically connecting the electrical circuit with the ballast assembly. The electrical circuit includes an LED electrical circuit including opposed electrical contacts. Each metal substrate circuit board supports and holds the one or more LEDs and the LED electrical circuit. Each metal substrate circuit board is positioned within the tubular wall between the tubular wall ends. At least one electrical string is positioned within the tubular wall and generally extends between the tubular wall ends. One or more LEDs are in electrical connection with at least one electrical string and are positioned to emit light through the tubular wall. Means for suppressing ballast voltage is included. The metal substrate circuit board includes opposed means for connecting the metal substrate circuit board to the tubular wall ends, which include means for mounting the means for connecting, and the one or more metal substrate circuit boards.

Owner:SIGNIFY HLDG BV

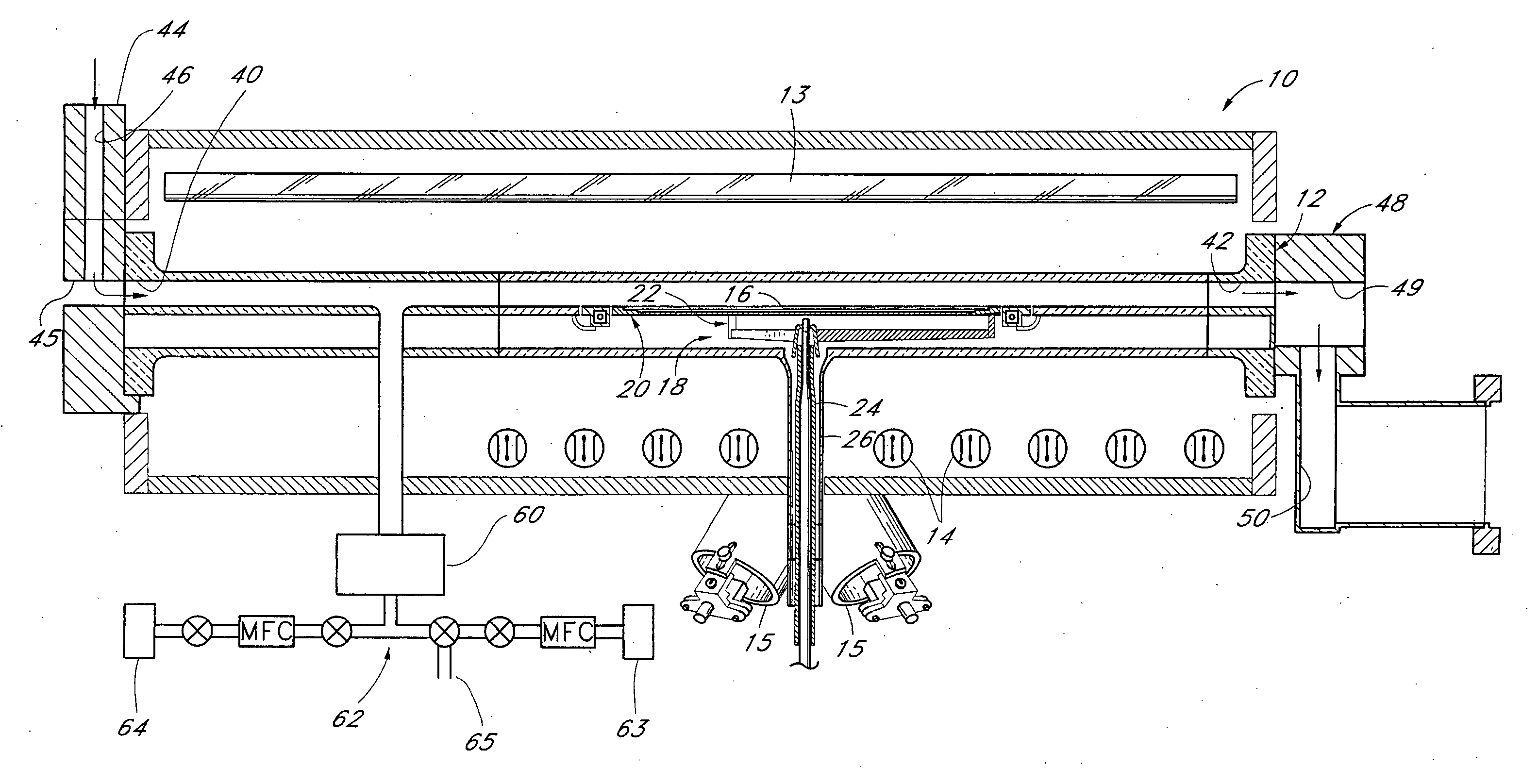

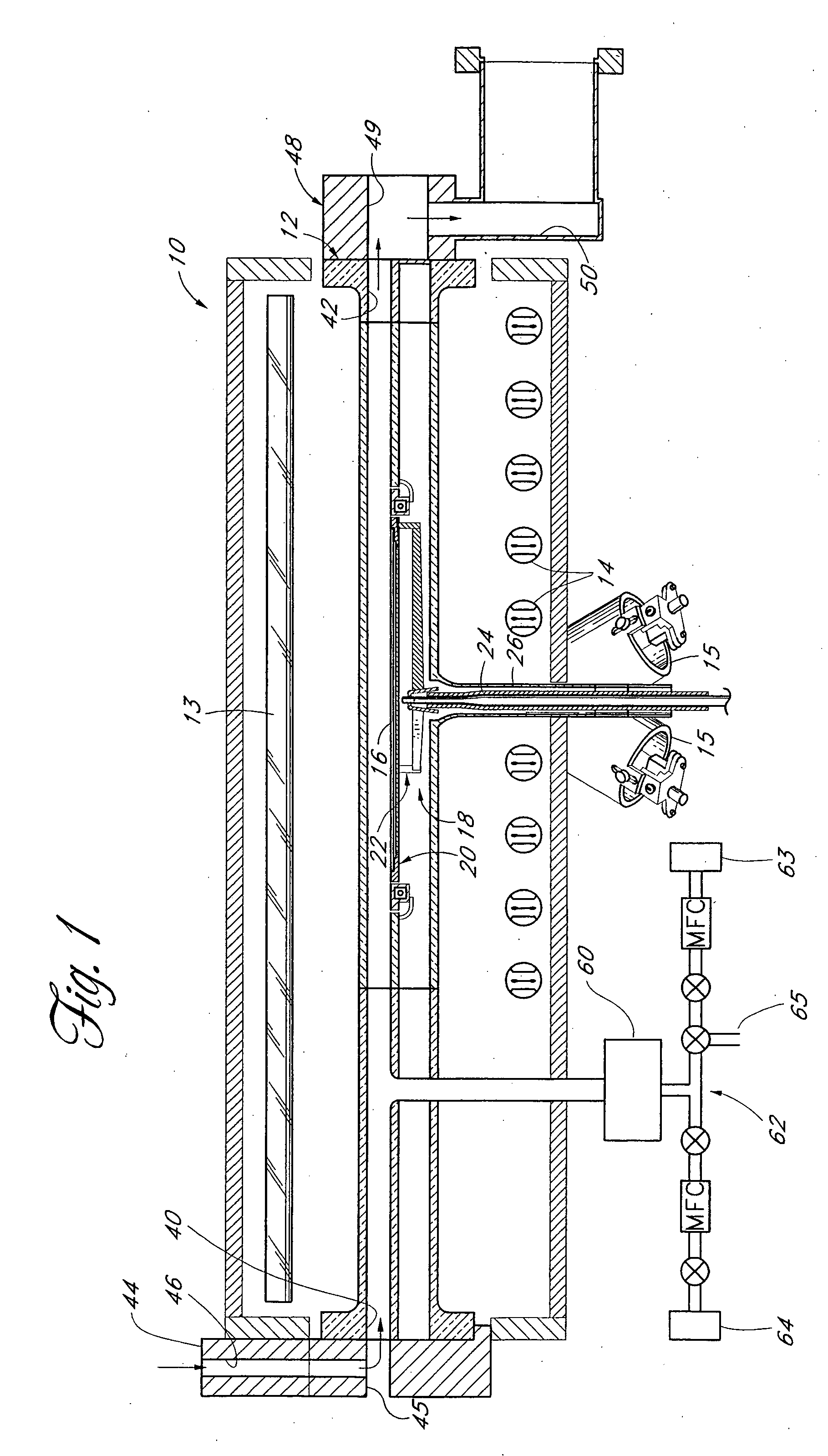

Thin films

InactiveUS20050181555A1Quality improvementHigh dielectric constantSolid-state devicesSemiconductor/solid-state device manufacturingGate dielectricSilicon oxide

Thin films are formed by formed by atomic layer deposition, whereby the composition of the film can be varied from monolayer to monolayer during cycles including alternating pulses of self-limiting chemistries. In the illustrated embodiments, varying amounts of impurity sources are introduced during the cyclical process. A graded gate dielectric is thereby provided, even for extremely thin layers. The gate dielectric as thin as 2 nm can be varied from pure silicon oxide to oxynitride to silicon nitride. Similarly, the gate dielectric can be varied from aluminum oxide to mixtures of aluminum oxide and a higher dielectric material (e.g., ZrO2) to pure high k material and back to aluminum oxide. In another embodiment, metal nitride (e.g., WN) is first formed as a barrier for lining dual damascene trenches and vias. During the alternating deposition process, copper can be introduced, e.g., in separate pulses, and the copper source pulses can gradually increase in frequency, forming a transition region, until pure copper is formed at the upper surface. Advantageously, graded compositions in these and a variety of other contexts help to avoid such problems as etch rate control, electromigration and non-ohmic electrical contact that can occur at sharp material interfaces. In some embodiments additional seed layers or additional transition layers are provided.

Owner:ASM INTERNATIONAL

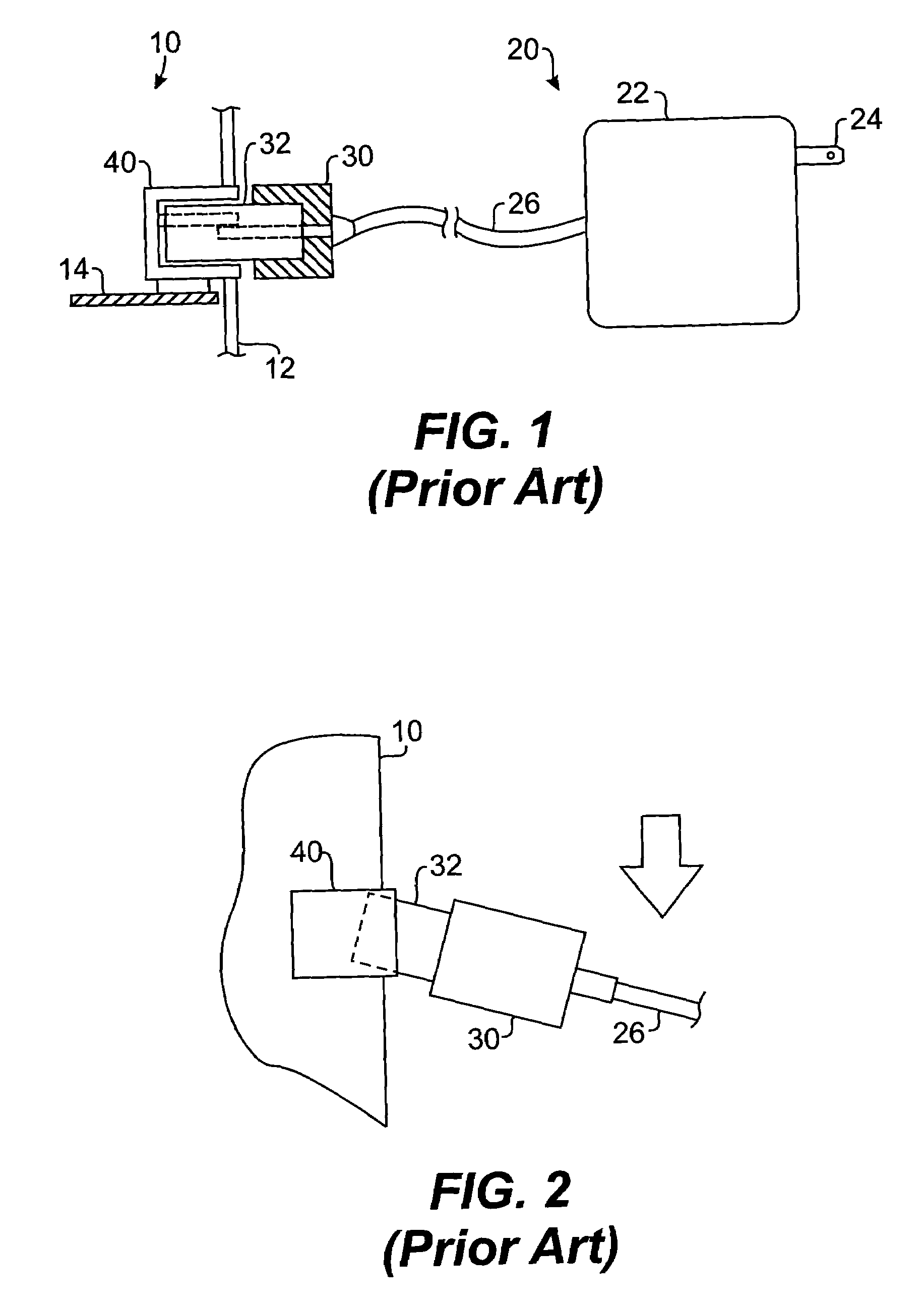

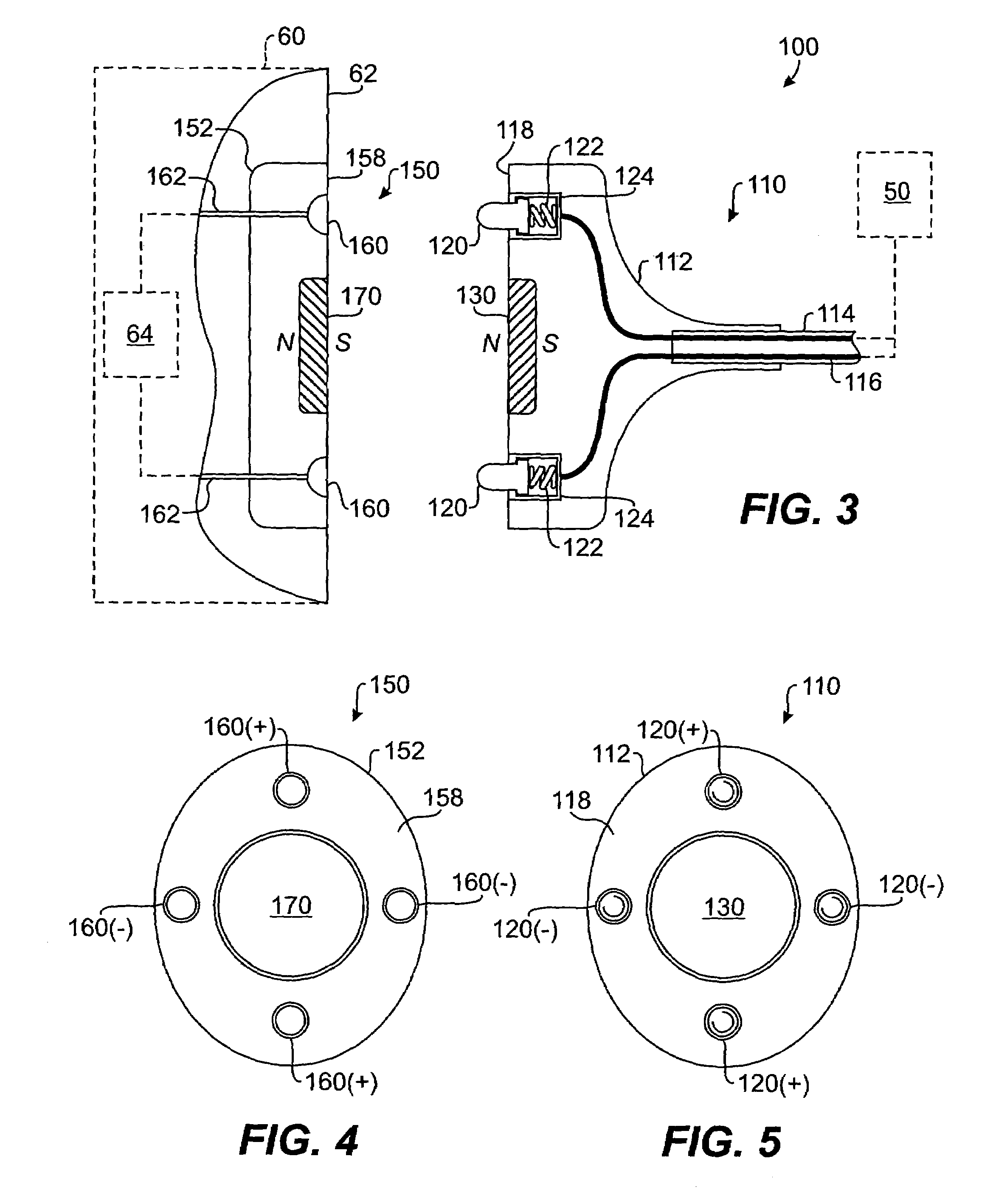

Magnetic connector for electronic device

ActiveUS20070072443A1Coupling contact membersElectric connection structural associationsEngineeringRare-earth magnet

An electrical plug and receptacle relying on magnetic force to maintain contact are disclosed. The plug and receptacle can be used as part of a power adapter for connecting an electronic device, such as a laptop computer, to a power supply. The plug includes electrical contacts, which are preferably biased toward corresponding contacts on the receptacle. The plug and receptacle each have a magnetic element. The magnetic element on one or both of the plug and receptacle can be a magnet, which is preferably a permanent rare earth magnet although electromagnets may also be used. The magnetic element on the plug or receptacle that does not include a magnet is composed of ferromagnetic material. When the plug and receptacle are brought into proximity, the magnetic attraction between the magnet and its complement, whether another magnet or a ferromagnetic material, maintains the contacts in an electrically conductive relationship.

Owner:APPLE INC

Electrochromic rearview mirror incorporating a third surface metal reflector

InactiveUS6064508AEconomical and reliableLow costMirrorsSolid-state devicesEpoxyElectrical conductor

An electrochromic variable reflectance mirror for a vehicle includes a reflector / electrode on the third surface of the mirror. This reflector / electrode forms an integral electrode in contact with the electrochromic media, and may be a single layer of a highly reflective material or may comprise a series of coatings. When a series of coatings is used for the reflector / electrode, there should be a base coating which bonds to the glass surface and resists any adverse interaction, e.g., corrosive action, with the constituents comprising the electrochromic media, an optional intermediate layer (or layers) which bonds well to the base coating and resists any adverse interaction with the electrochromic media, and at least one highly reflective layer which directly contacts the electrochromic media and which is chosen primarily for its high reflectance, stable behavior as an electrode, resistance to adverse interaction with the materials of the electrochromic media, resistance to atmospheric corrosion, resistance to electrical contact corrosion, the ability to adhere to the base or intermediate layer(s) (if present) and to the epoxy seal, and ease of cleaning. If a base layer is deposited it preferably covers the entire third surface; however, when this is done the highly reflective layer may optionally only coat the central portion of the third surface and not the perimeter edge portion. The third surface reflector / electrode provides of improved electrical interconnection techniques used to impart a voltage drive potential to a transparent conductor on the mirror's second surface.

Owner:GENTEX CORP

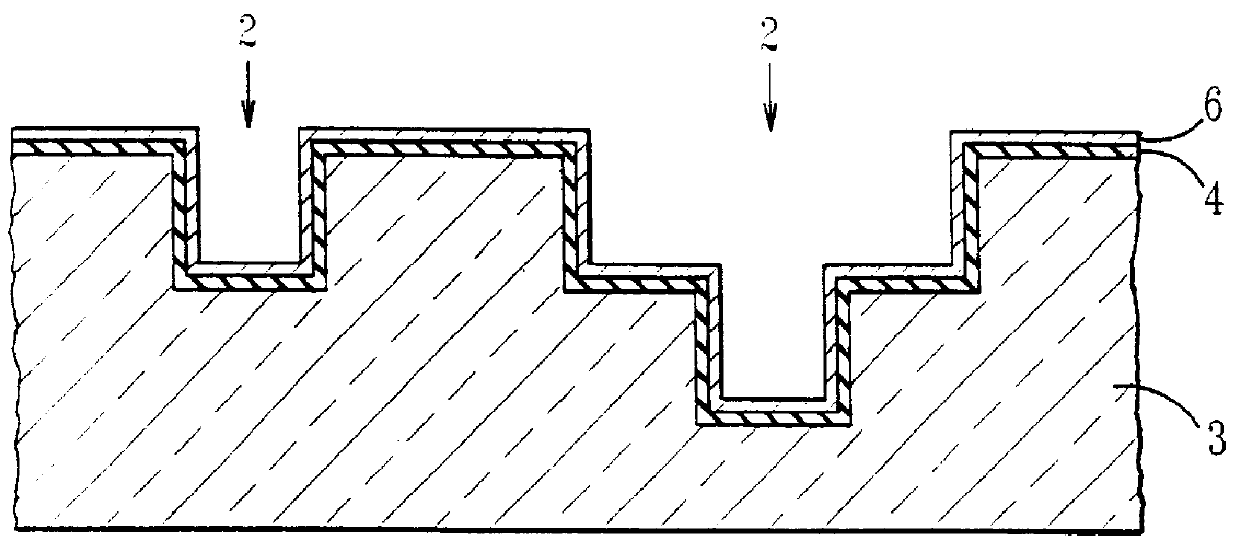

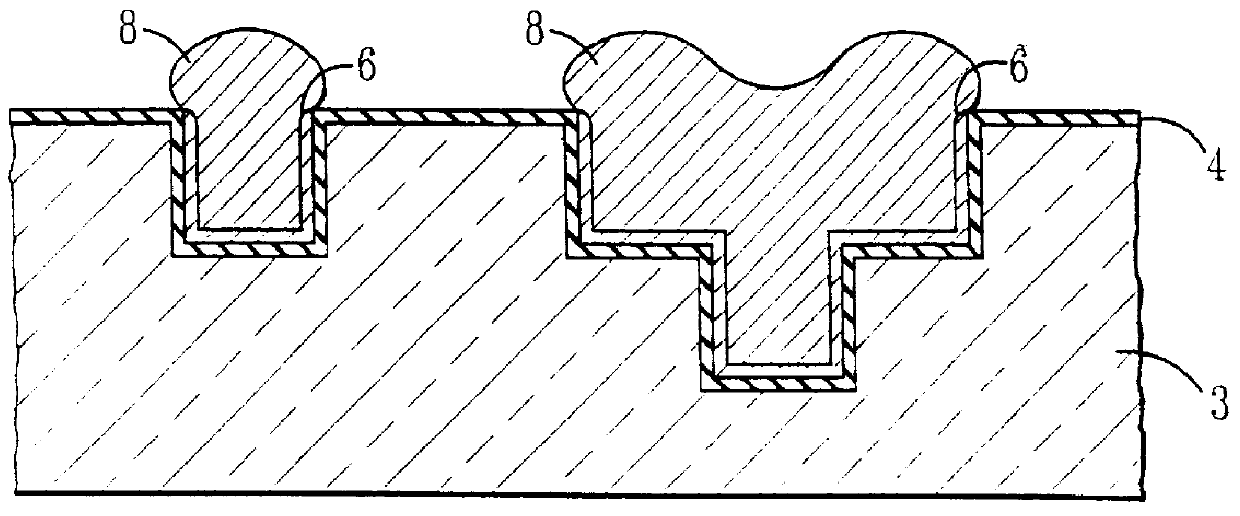

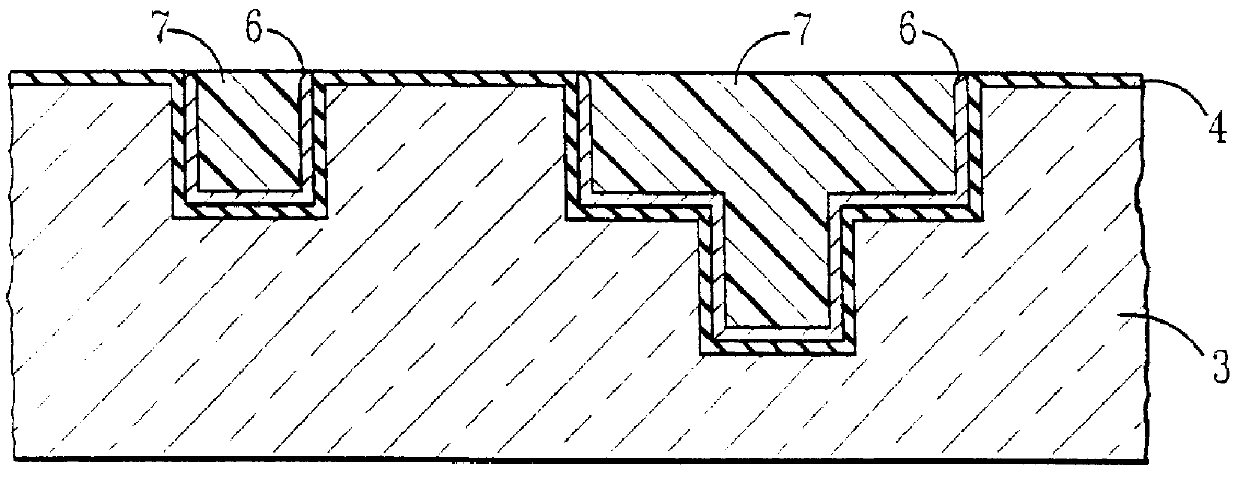

Method to selectively fill recesses with conductive metal

InactiveUS6140234AShorten the timeIncrease productionSolid-state devicesSemiconductor/solid-state device manufacturingResistSemiconductor structure

Recesses in a semiconductor structure are selectively plated by providing electrical insulating layer over the semiconductor substrate and in the recesses followed by forming a conductive barrier over the insulating layer; providing a plating seed layer over the barrier layer; depositing and patterning a photoresist layer over the plating seed layer; planarizing the insulated horizontal portions by removing the horizontal portions of the seed layer between the recesses; removing the photoresist remaining in the recesses; and then electroplating the patterned seed layer with a conductive metal using the barrier layer to carry the current during the electroplating to thereby only plate on the seed layer. In an alternative process, a barrier film is deposited over recesses in an insulator. Then, relatively thick resists are lithographically defined on the field regions, on top of the barrier film over the recesses. A plating base or seedlayer is deposited, so as to be continuous on the horizontal regions of the recesses in the insulator, but discontinuous on their surround wall. The recesses are then plated using the barrier film without seedlayers at the periphery of the substrate wafers for electrical contact. After electroplating, the resist is removed by lift-off process and exposed barrier film is etched by RIE method or by CMP. Also provided is a semiconductor structure obtained by the above processes.

Owner:GLOBALFOUNDRIES INC

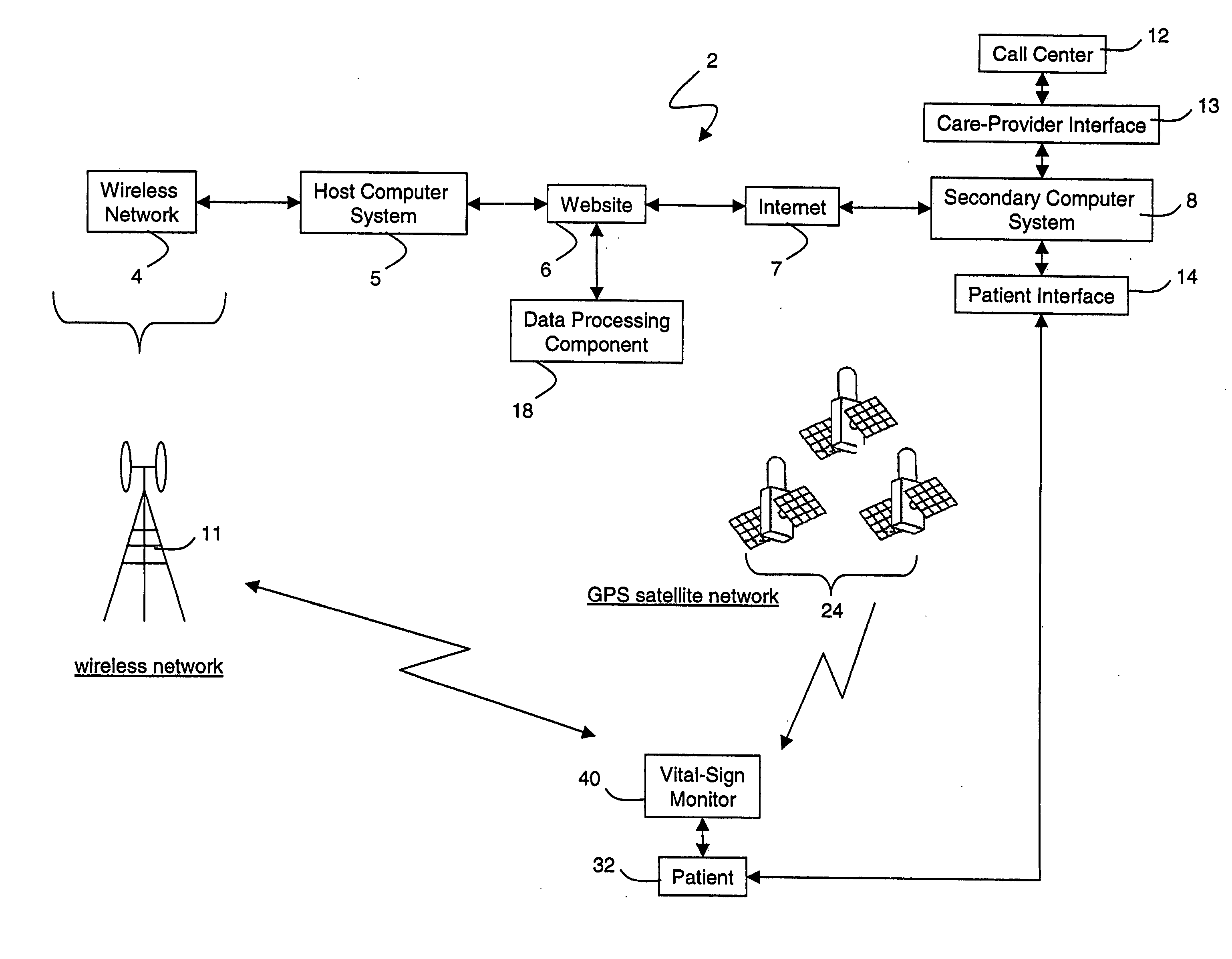

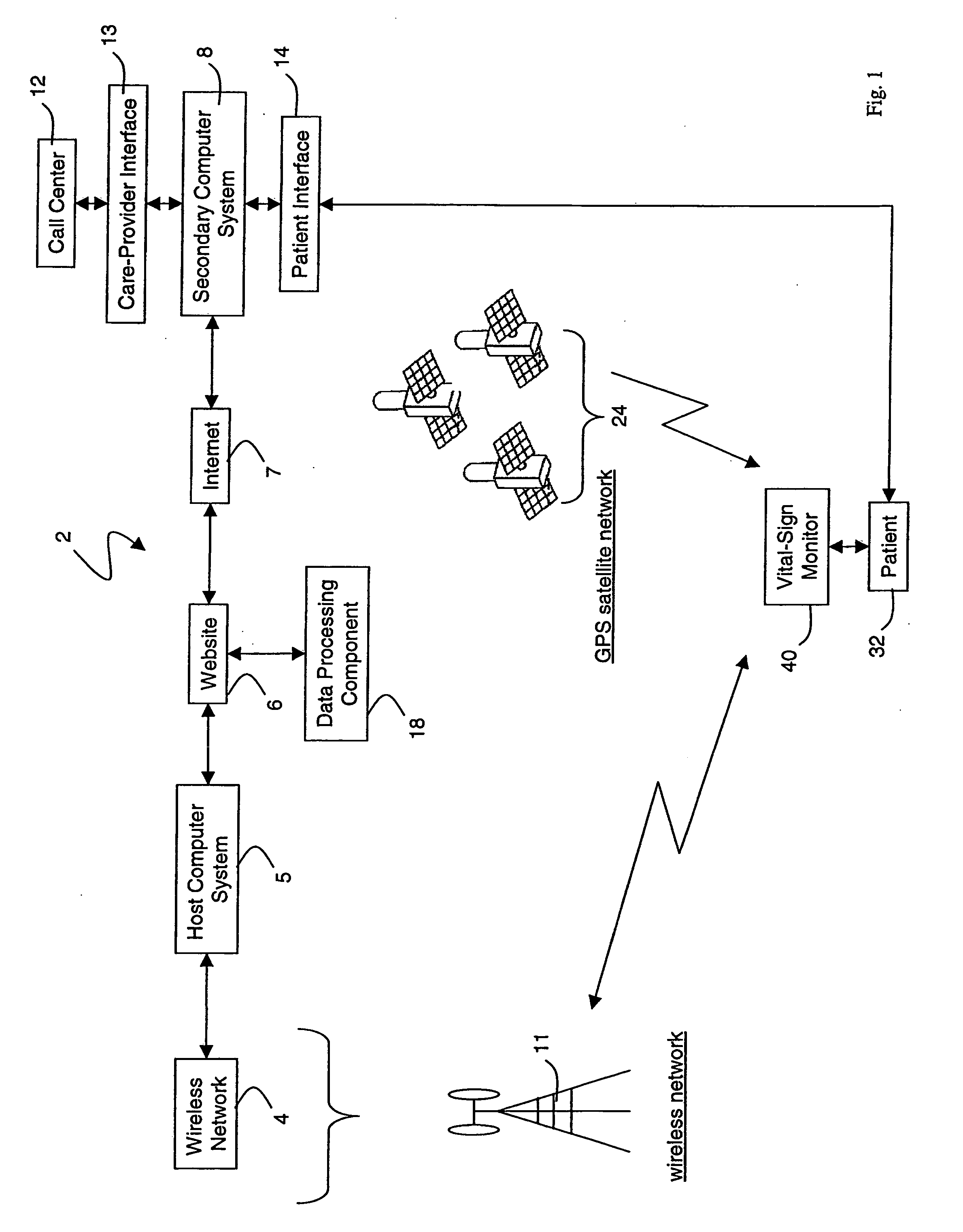

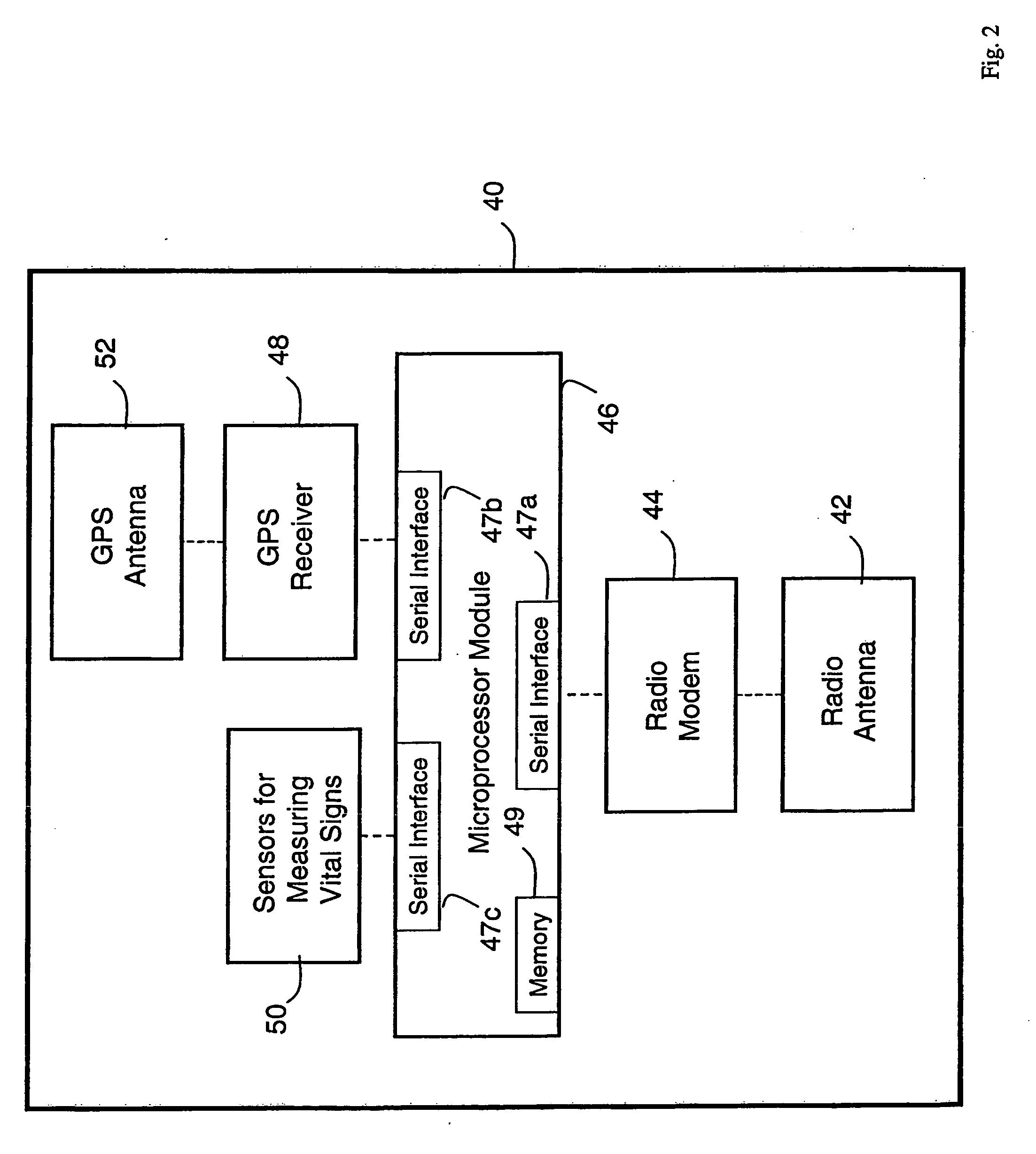

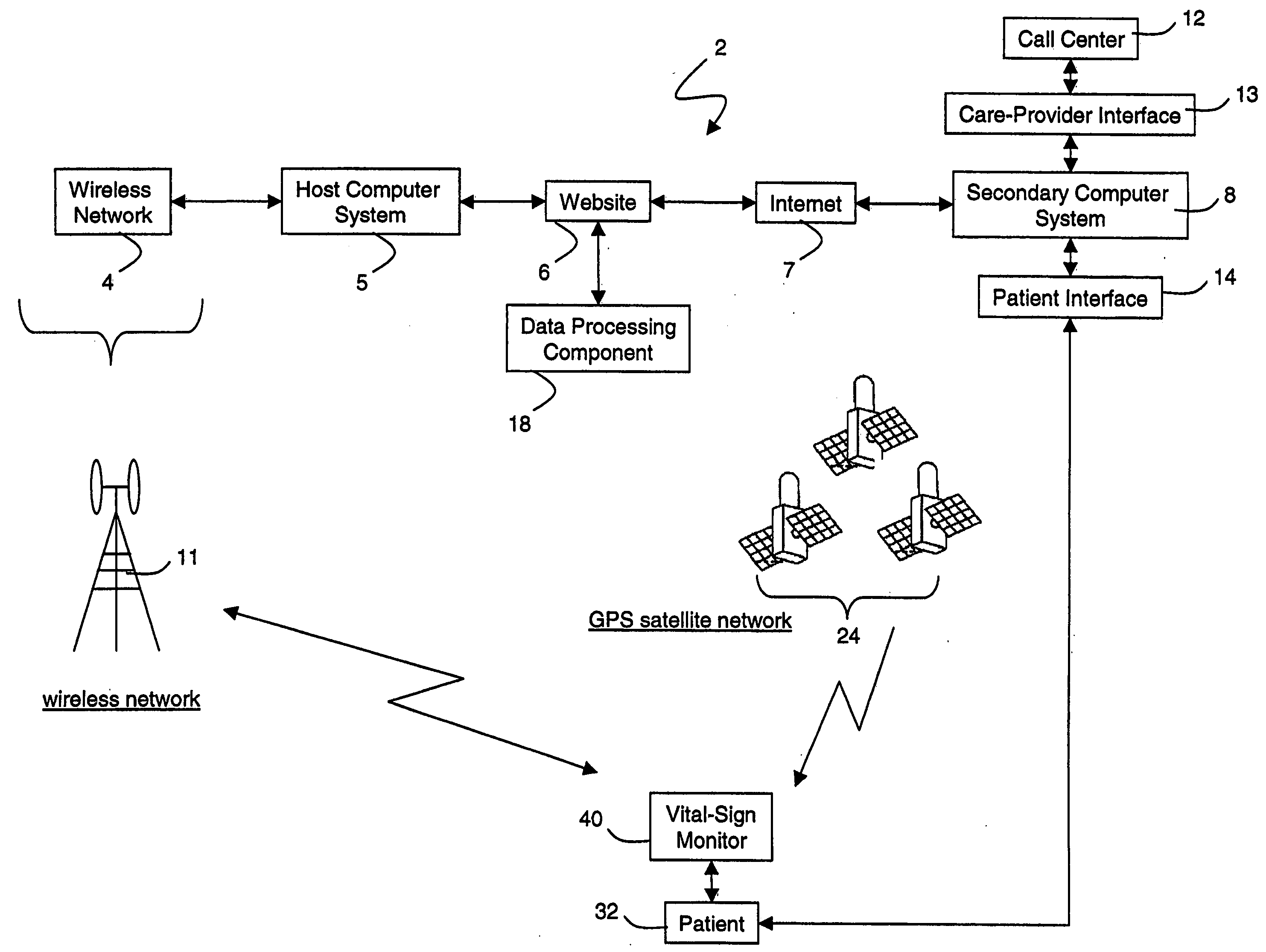

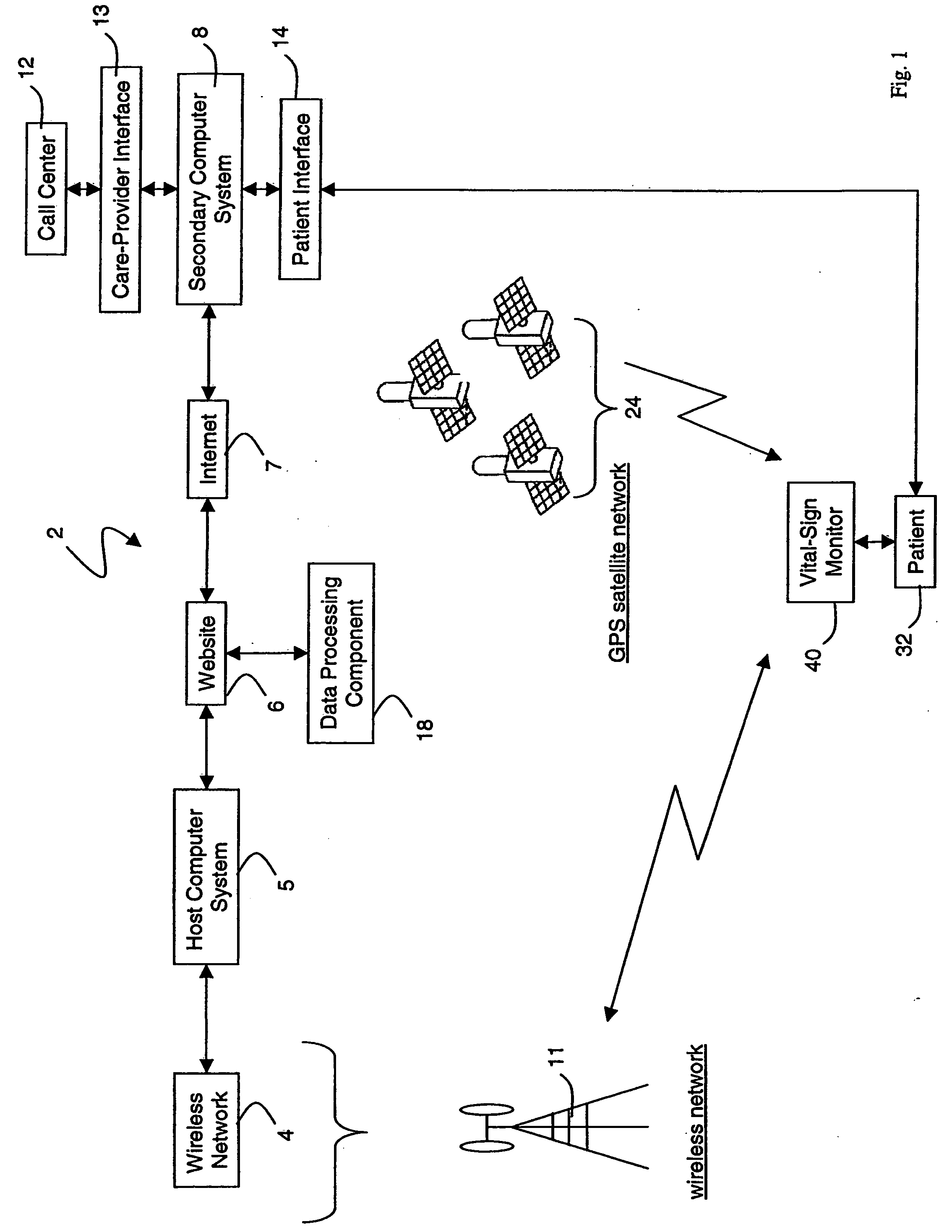

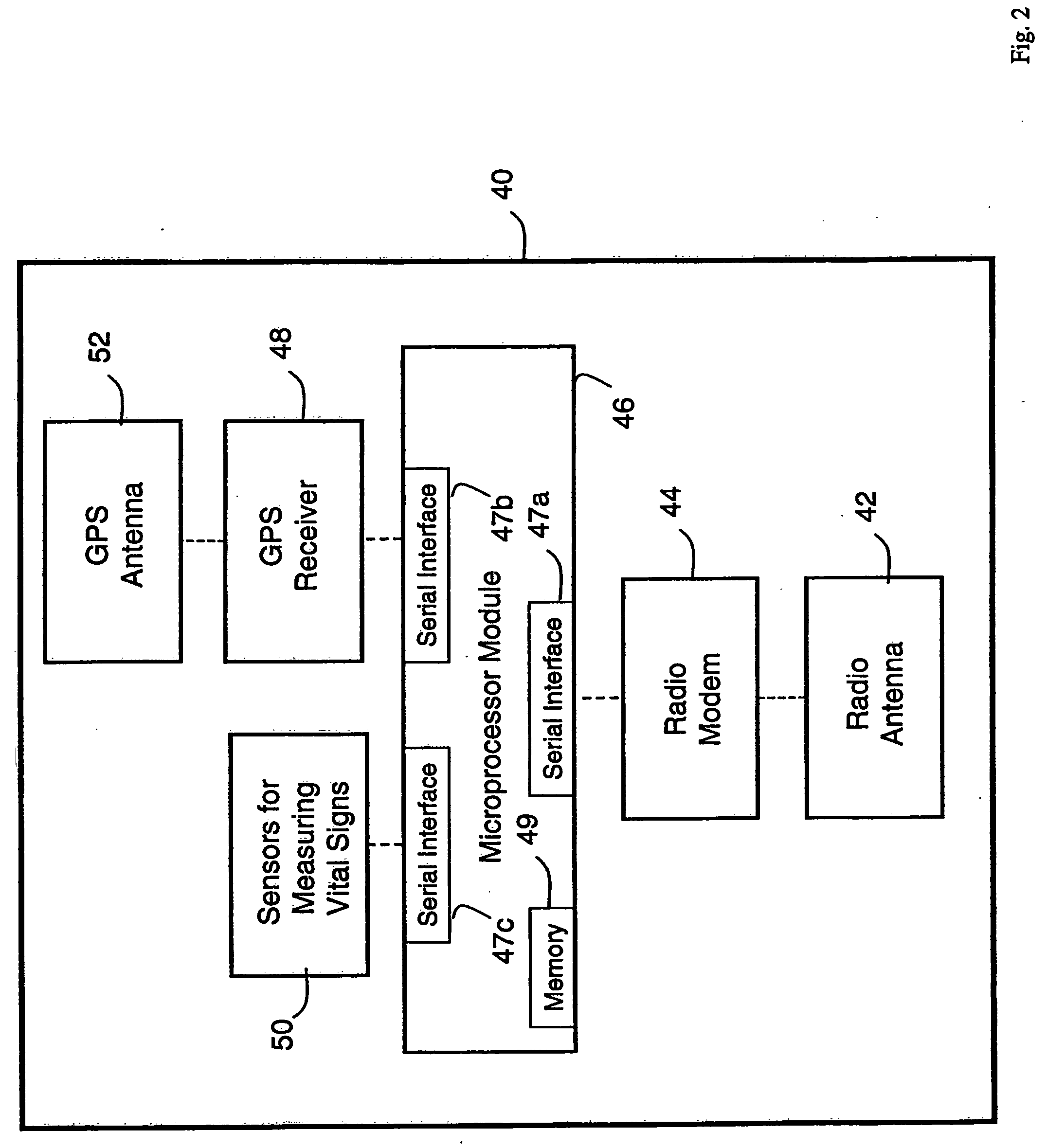

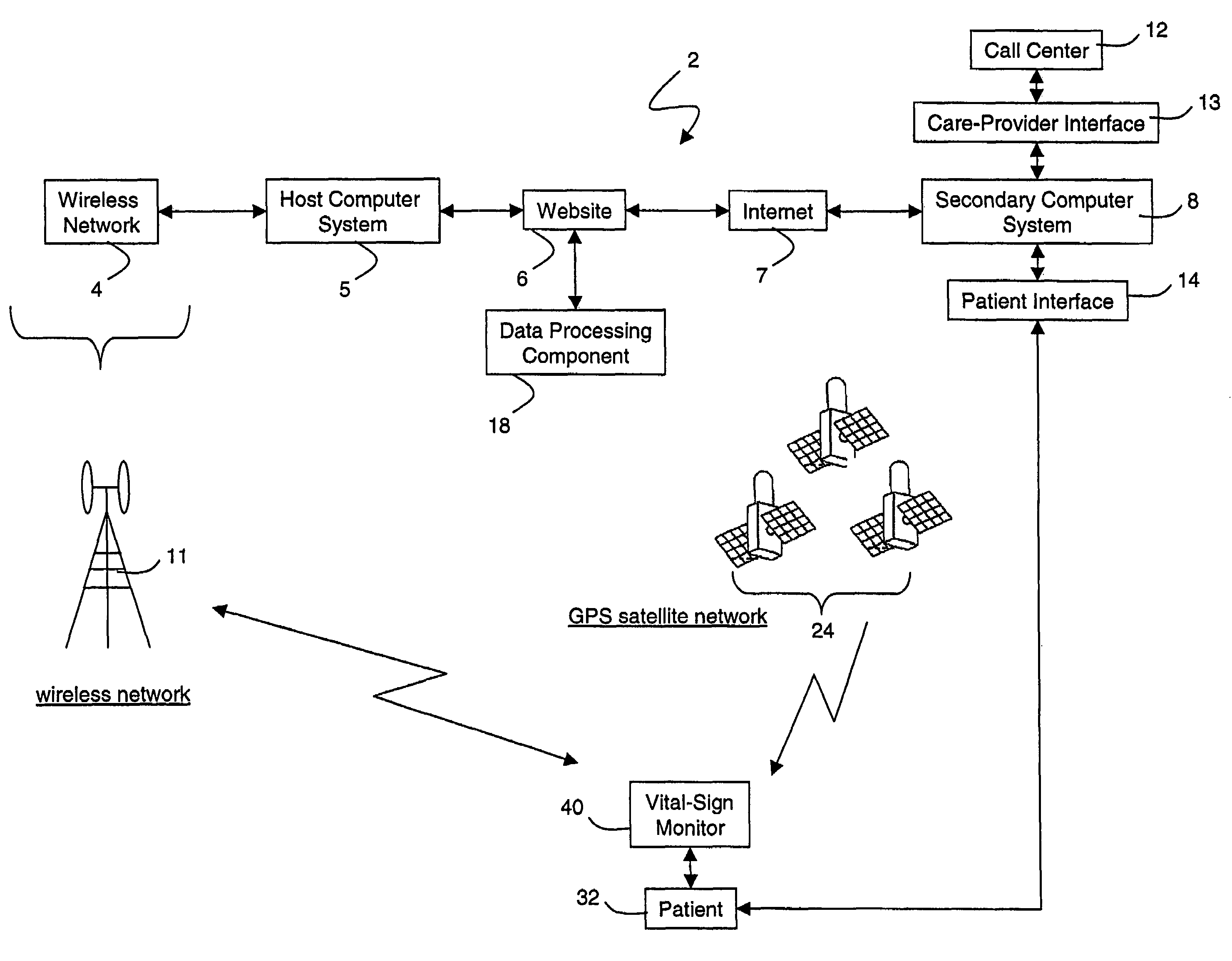

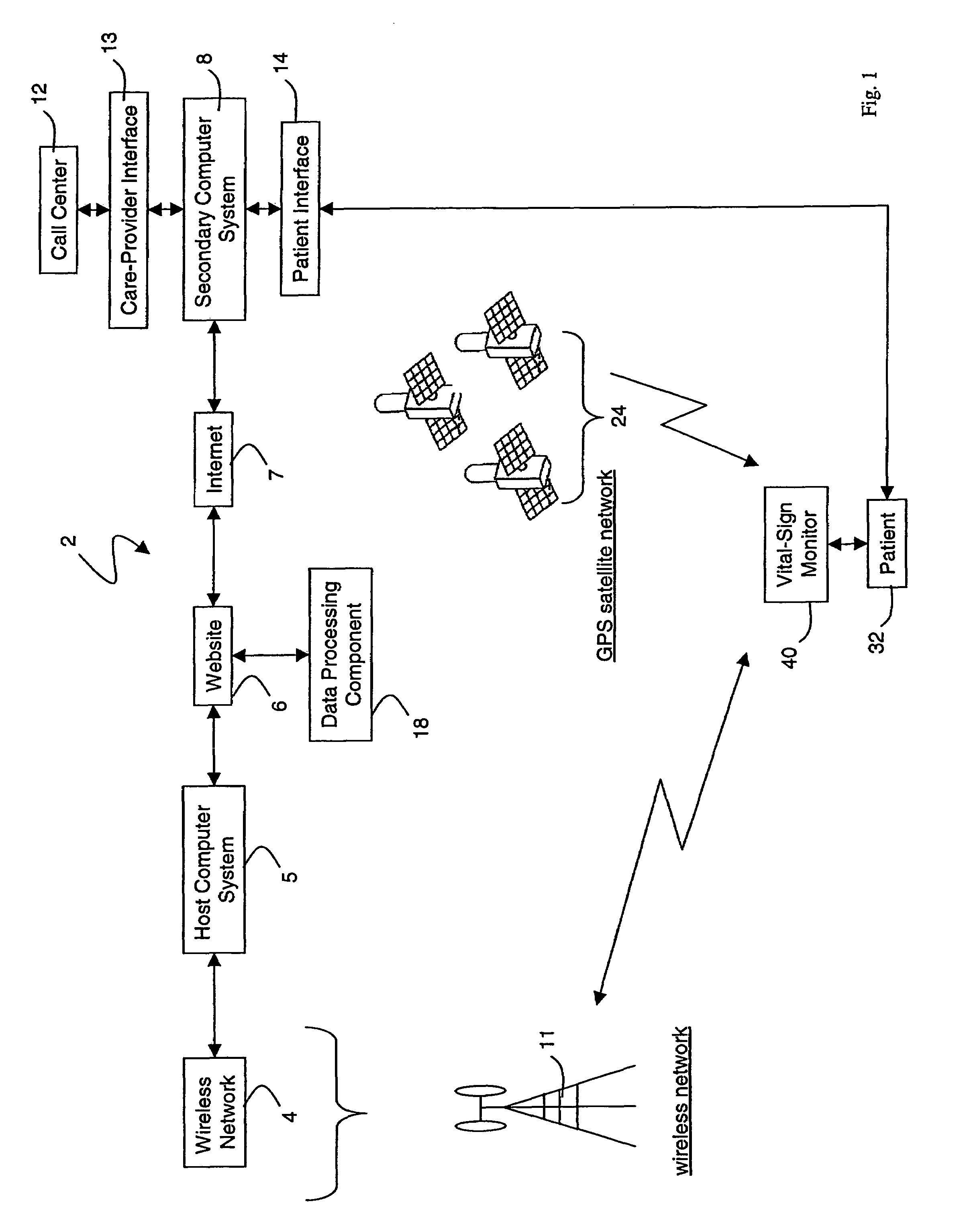

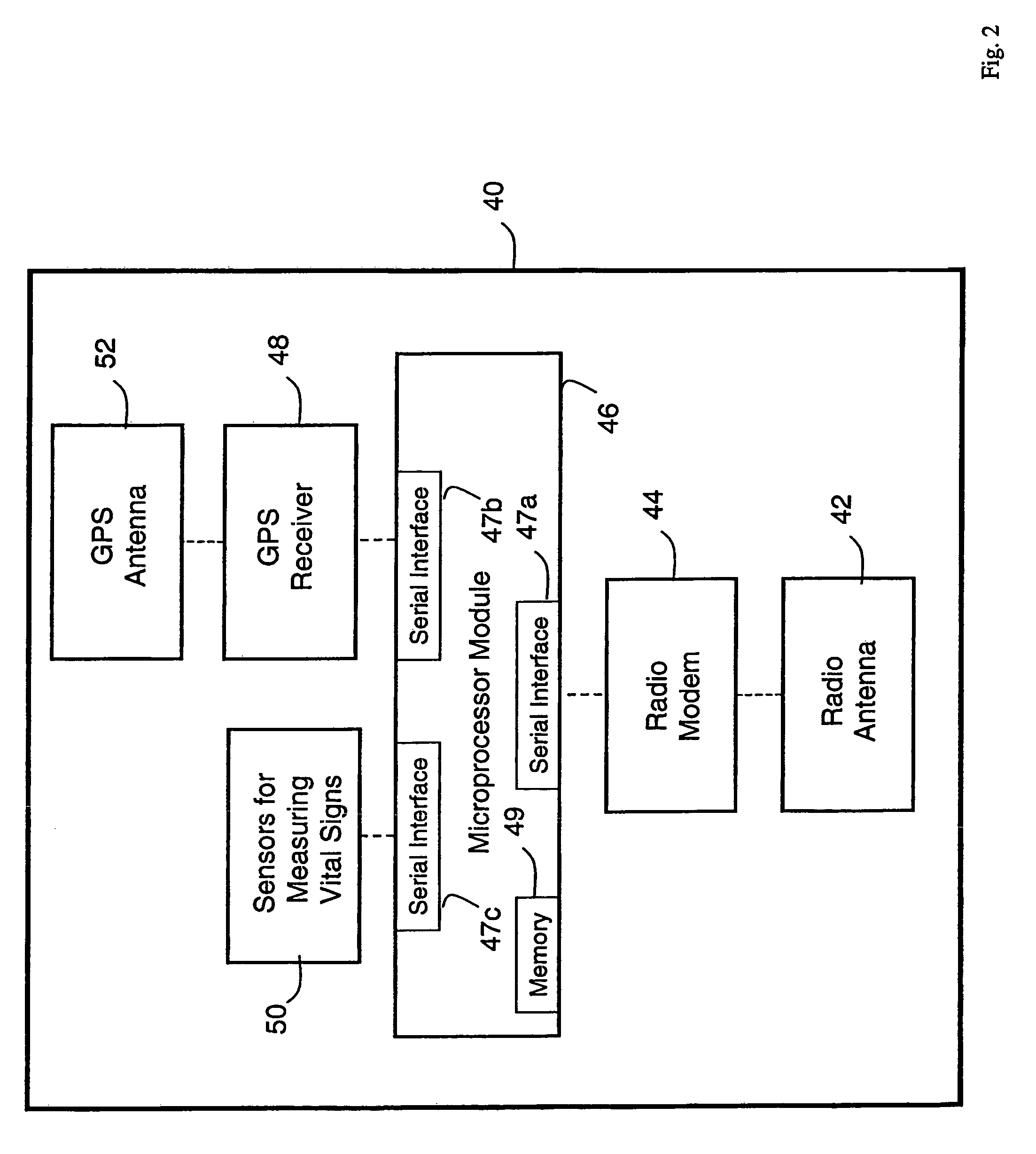

Wireless, internet-based medical-diagnostic system

ActiveUS20050010087A1Accurate diagnosisMinimize impactSurgeryCatheterGlobal Positioning SystemUser interface

A system for monitoring a patient's vital signs that features a vital-sign monitor including sensors for measuring from the patient at least one of the following vital-sign data: O2 saturation, blood pressure, electro-cardiogram, respirator rate, and blood glucose level. The system also includes a global positioning system that determines location-based data. A wireless transmitter, in electrical contact with the vital-sign monitor and global positioning system, receives the vital-sign and location-based data and wirelessly transmits these data through a conventional wireless network. A gateway software piece receives and processes the data from the wireless network and stores these data in a computer memory associated with a database software piece. The system also includes an Internet-based user interface that displays the vital sign data for both individual patients and care-providers.

Owner:SOTERA WIRELESS

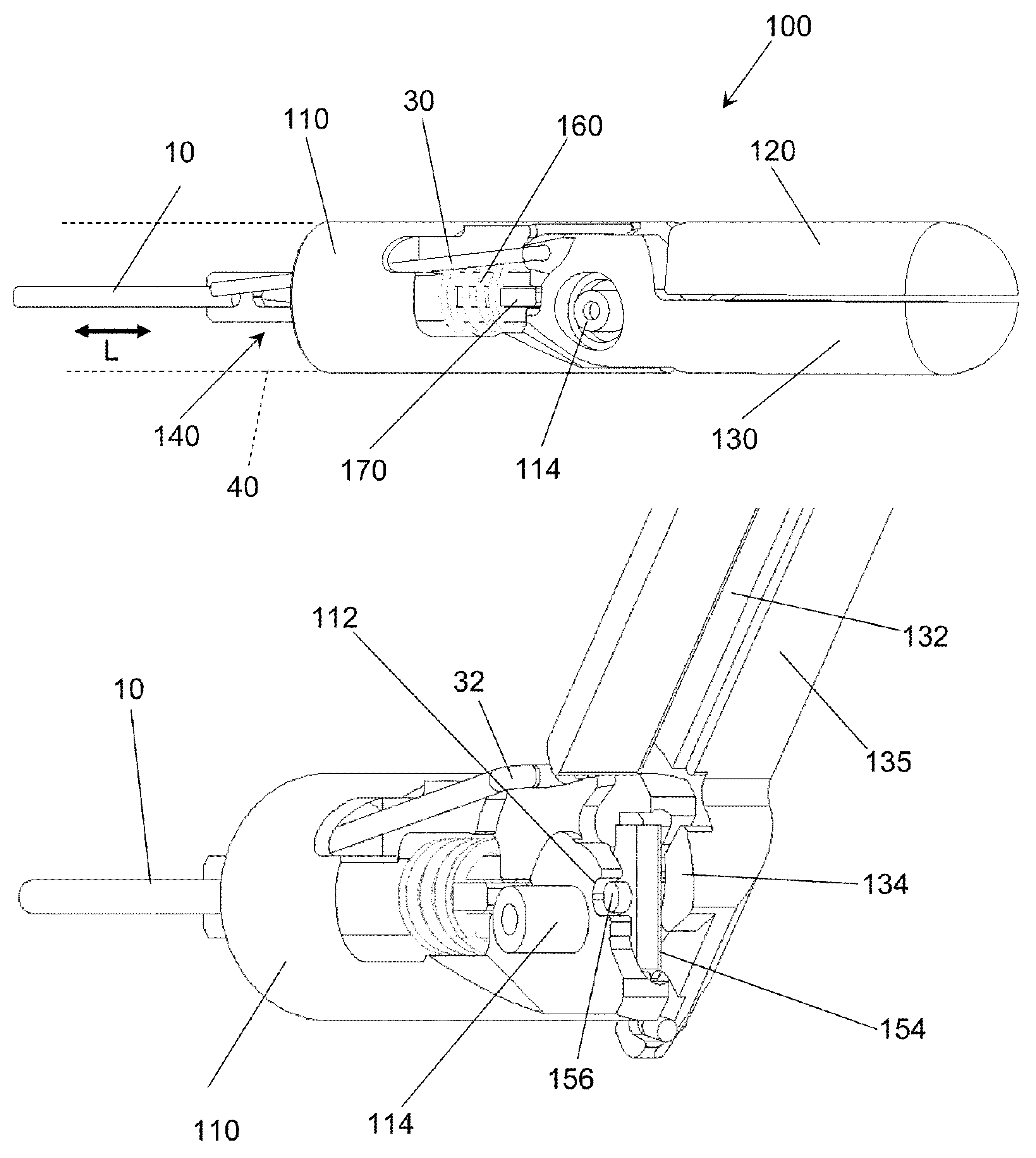

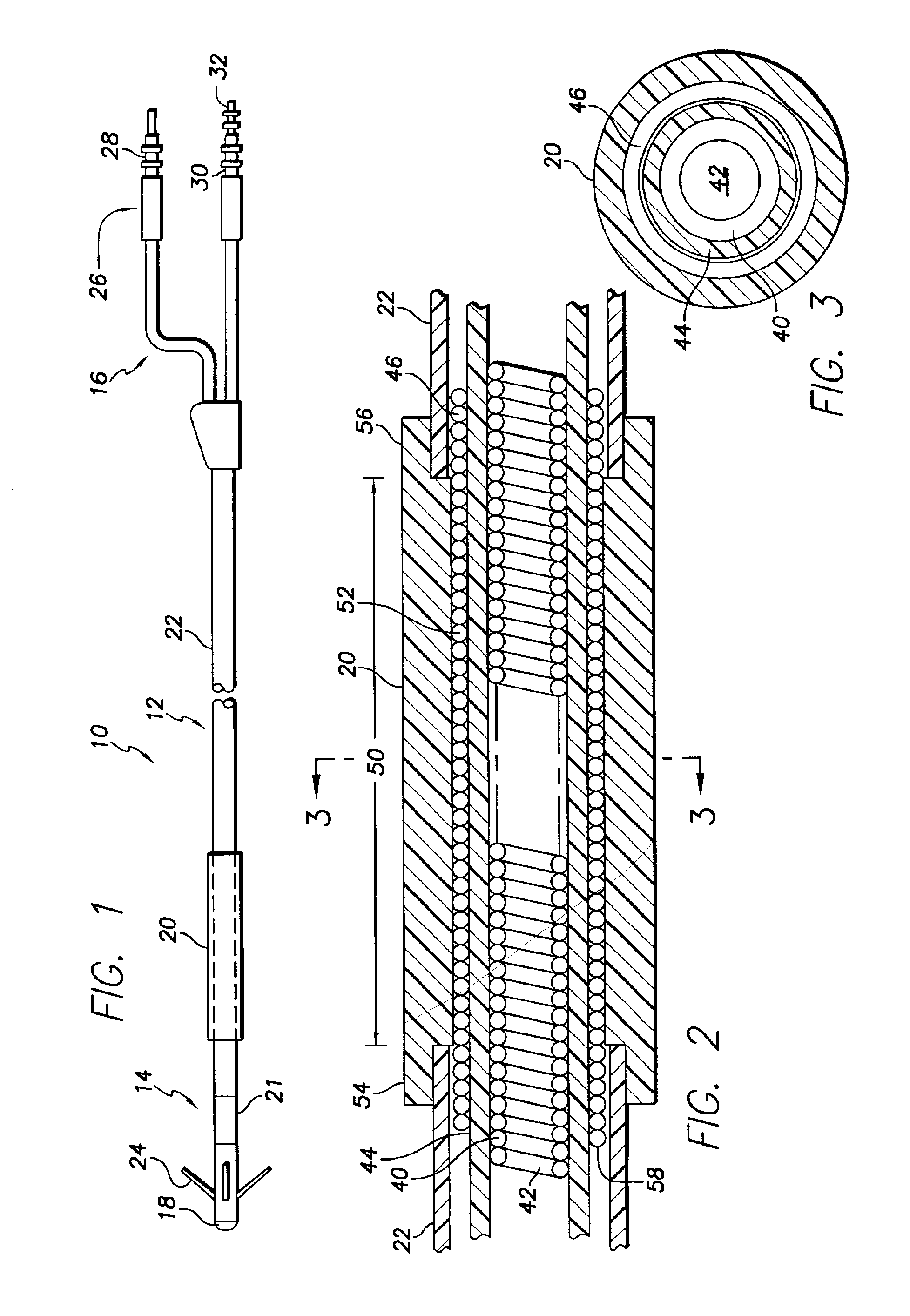

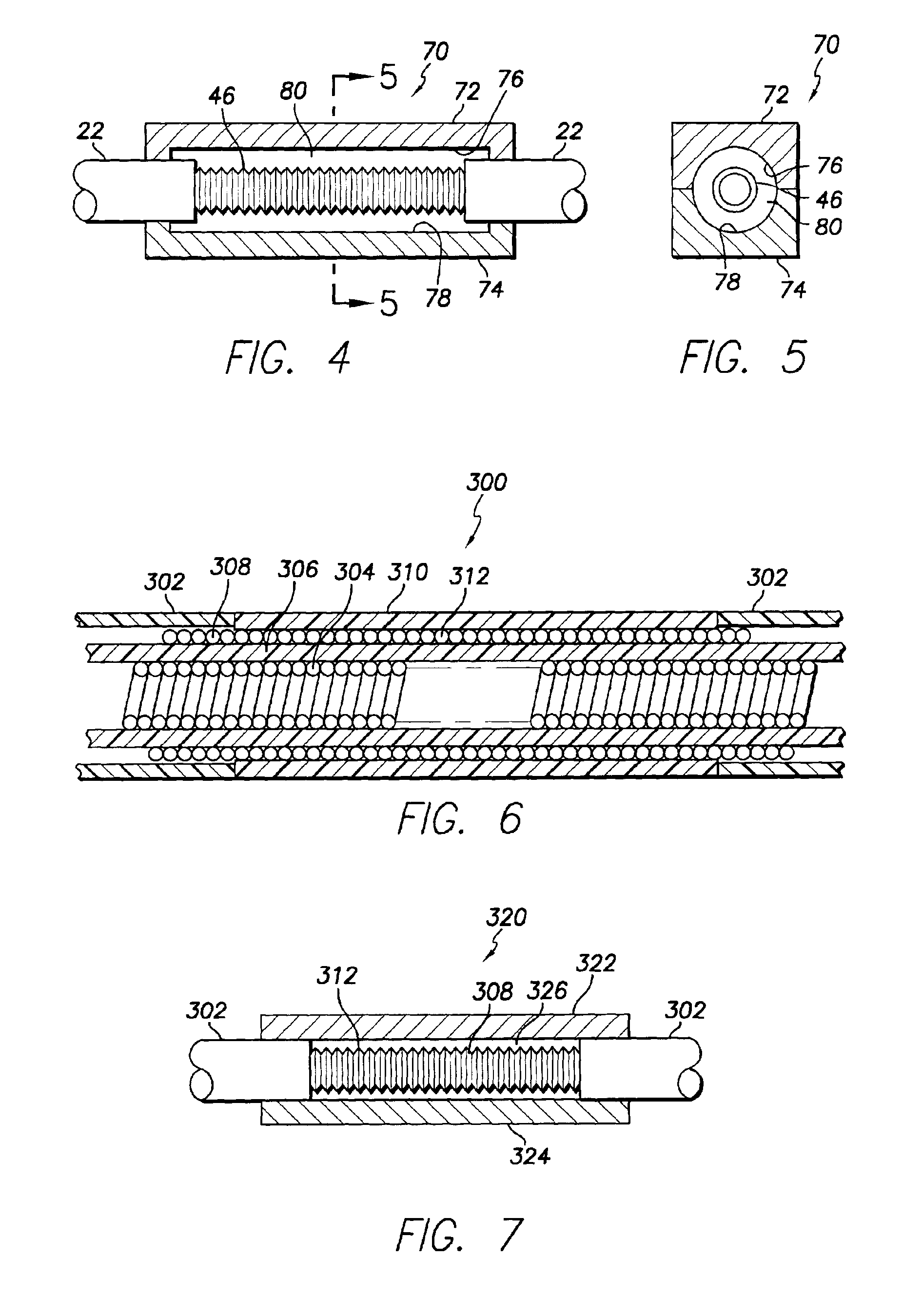

Medical device with flexible printed circuit

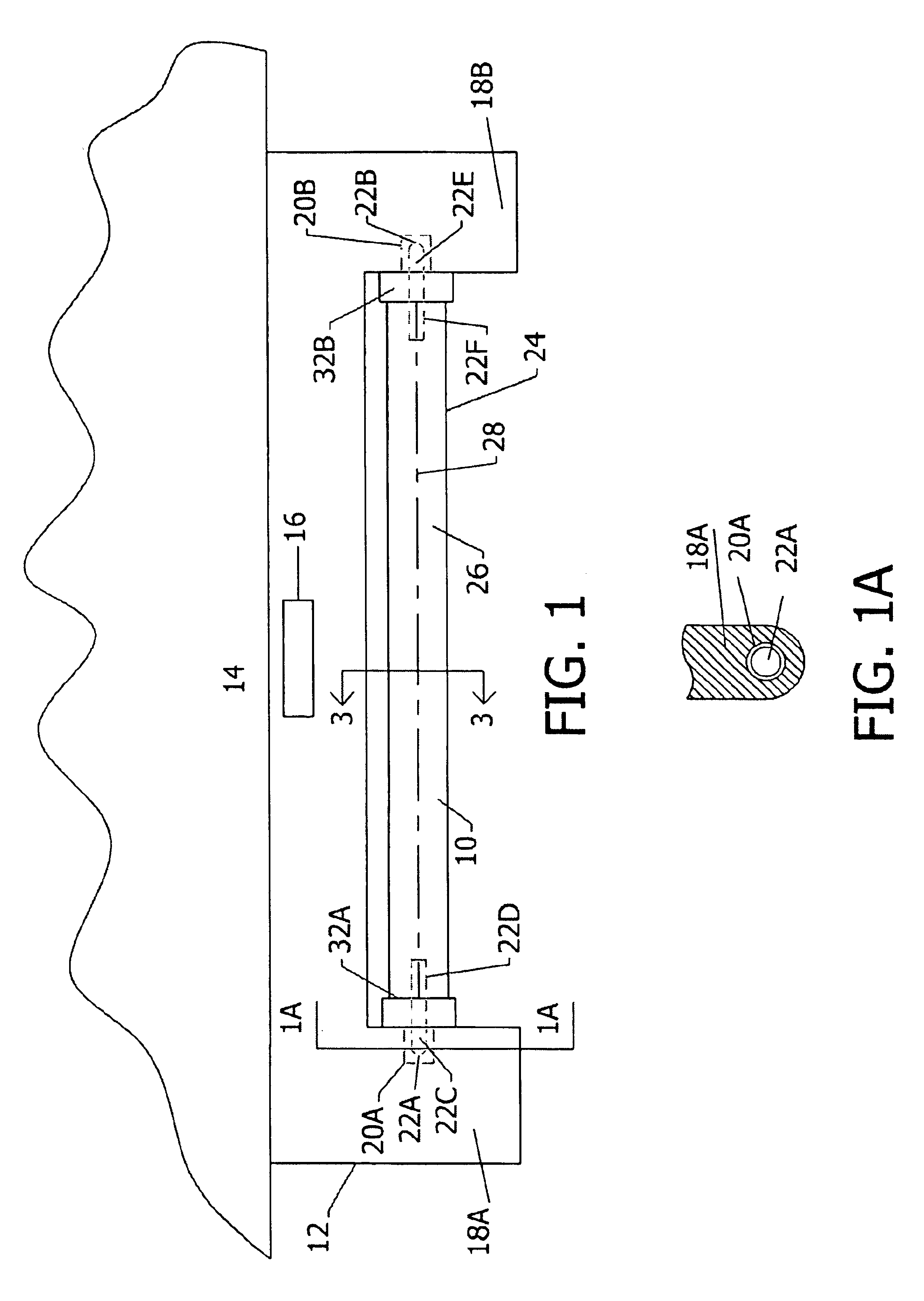

A catheter or lead having a flexible printed circuit for conveying signals and / or energy. Each trace may be in electrical connection with one or more external electrical contacts. More specifically, each trace is typically electrically connected to a single contact. The traces and contacts may assist in diagnosis and / or detection of bio-electrical signals emitted by organs, and may transmit such signals to a connector or diagnostic device affixed to the catheter. The external electrical contacts may detect bioelectric energy or may deliver electrical or thermal energy to a target site.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

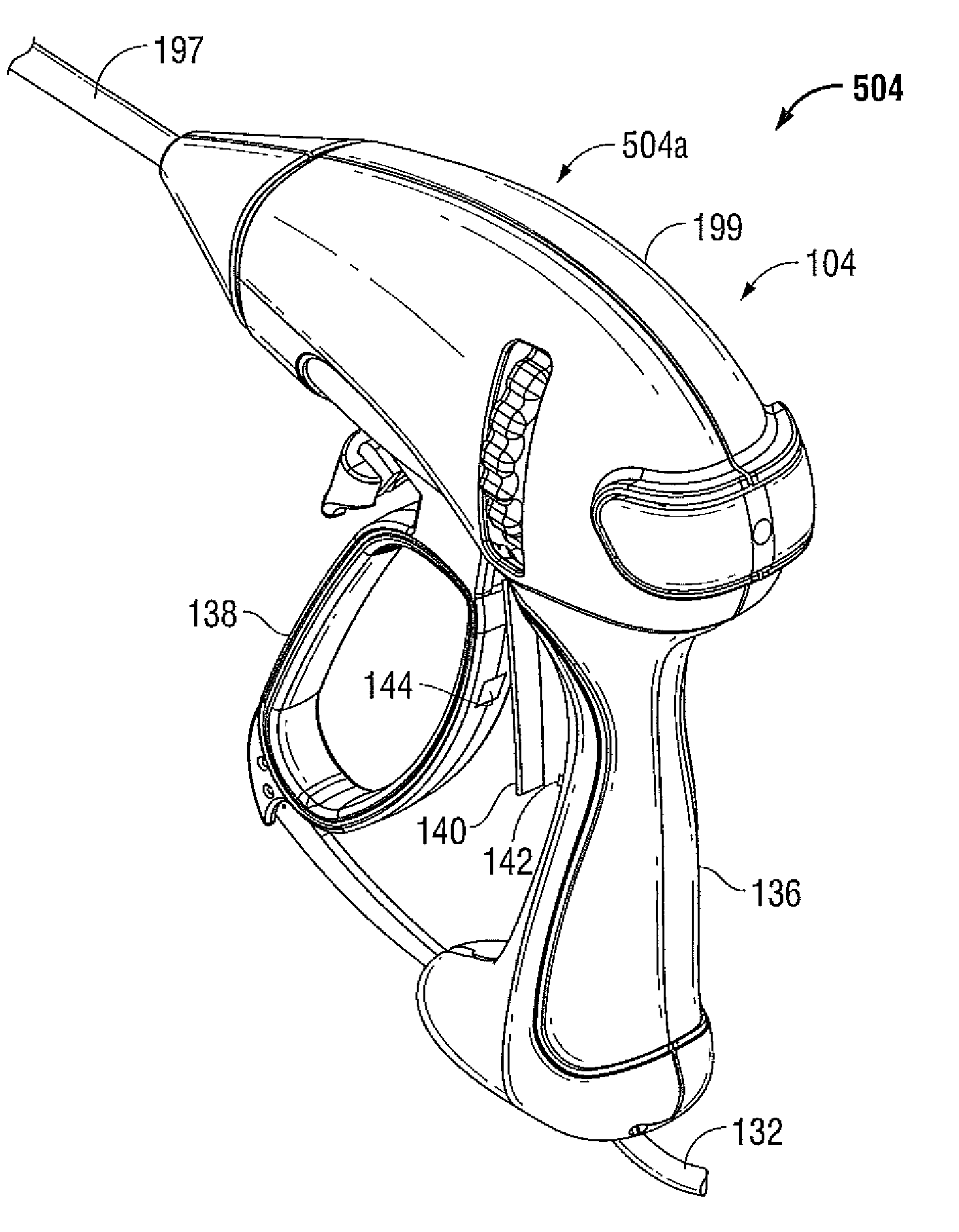

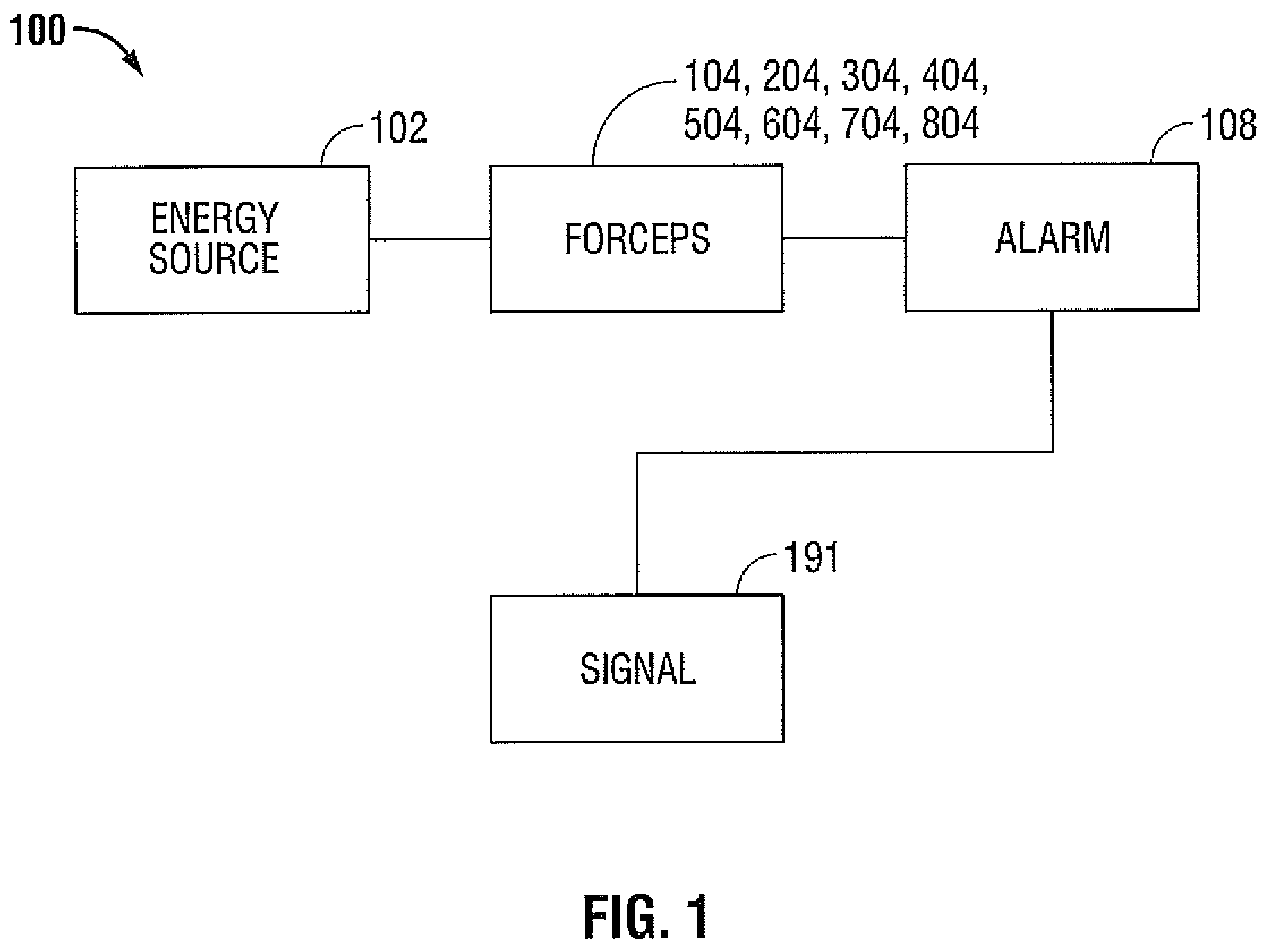

Vessel sealer and divider with blade deployment alarm

ActiveUS8251994B2DiagnosticsSurgical instruments for heatingElectrical resistance and conductanceElectricity

An electrosurgical forceps includes a selectively advanceable knife and a knife deployment alarm configured to emit a signal under predetermined conditions. An alarm is configured to emit a signal when the cutting blade moves relative to the blade channel. A series of resistances are arranged so that a shorting of each resistor is indicative of a predetermined operating condition triggering the alarm to emit a signal. Pressure sensors, optical measurement devices, and electrical contacts are envisioned for determining blade or trigger actuation or translation.

Owner:TYCO HEALTHCARE GRP LP

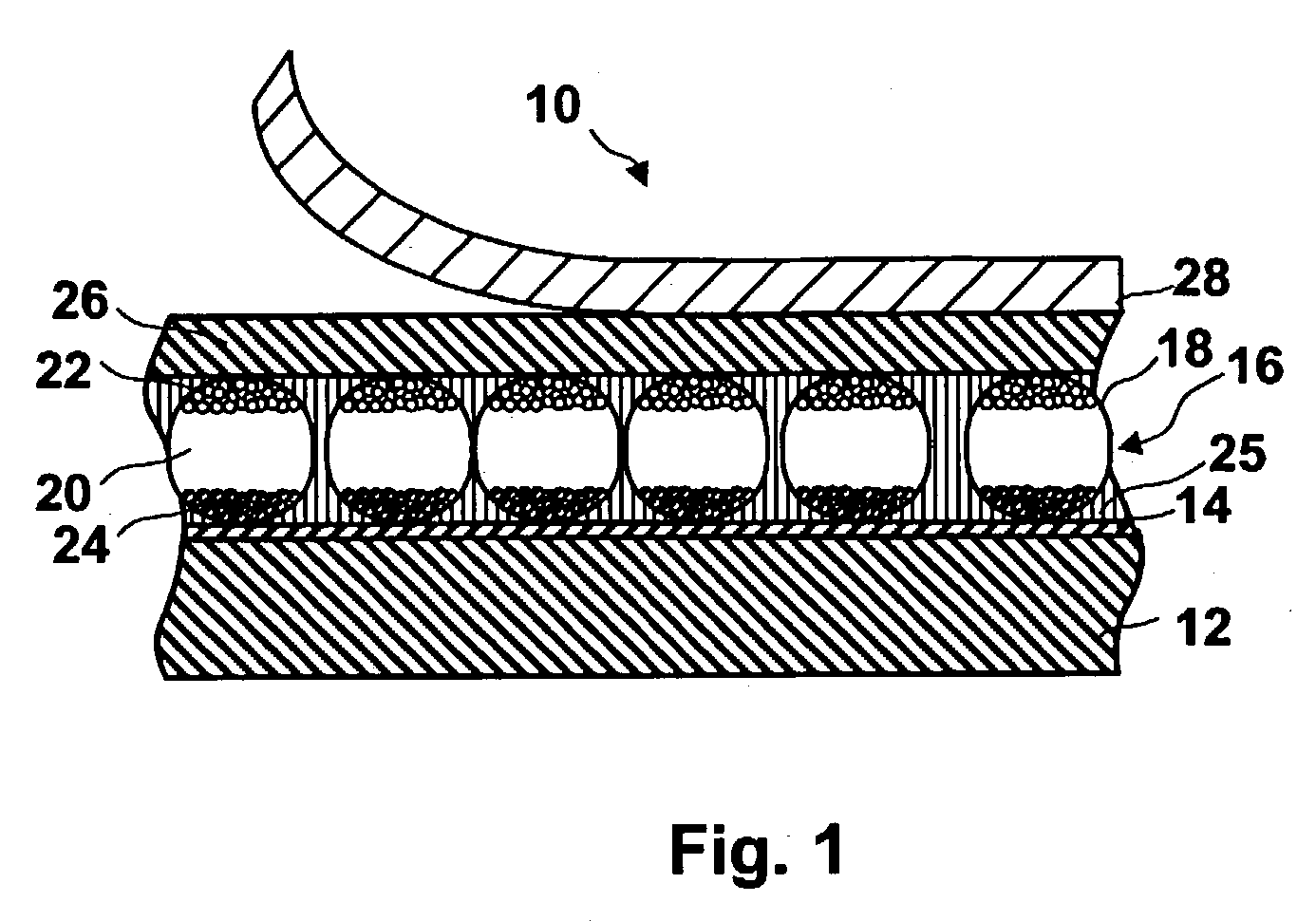

Components and methods for use in electro-optic displays

ActiveUS20040027327A1Avoid problemsLiquid surface applicatorsStatic indicating devicesElectricityDisplay device

A front plane laminate useful in the manufacture of electro-optic displays comprises, in order, a light-transmissive electrically-conductive layer, a layer of an electro-optic medium in electrical contact with the electrically-conductive layer, an adhesive layer and a release sheet. This front plane laminate can be prepared as a continuous web, cut to size, the release sheet removed and the laminate laminated to a backplane to form a display. Methods for providing conductive vias through the electro-optic medium and for testing the front plane laminate are also described.

Owner:E INK CORPORATION

Back-contact photovoltaic cells

A photovoltaic cell comprising a wafer comprising a semiconductor material of a first conductivity type, the wafer comprising a first light receiving surface and a second surface opposite the first surface; a first passivation layer positioned over the first surface of the wafer; a first electrical contact positioned over the second surface of the wafer; a second electrical contact positioned over the second surface of the wafer and separated electrically from the first electrical contact; a second passivation layer positioned over the second surface of the wafer in the region on the wafer that is at least between the first electrical contact and the second surface of the wafer; and a layer comprising a semiconductor material of a conductivity opposite the conductivity of the wafer and positioned in the region between the second passivation layer and the first contact.

Owner:BP CORP NORTH AMERICA INC

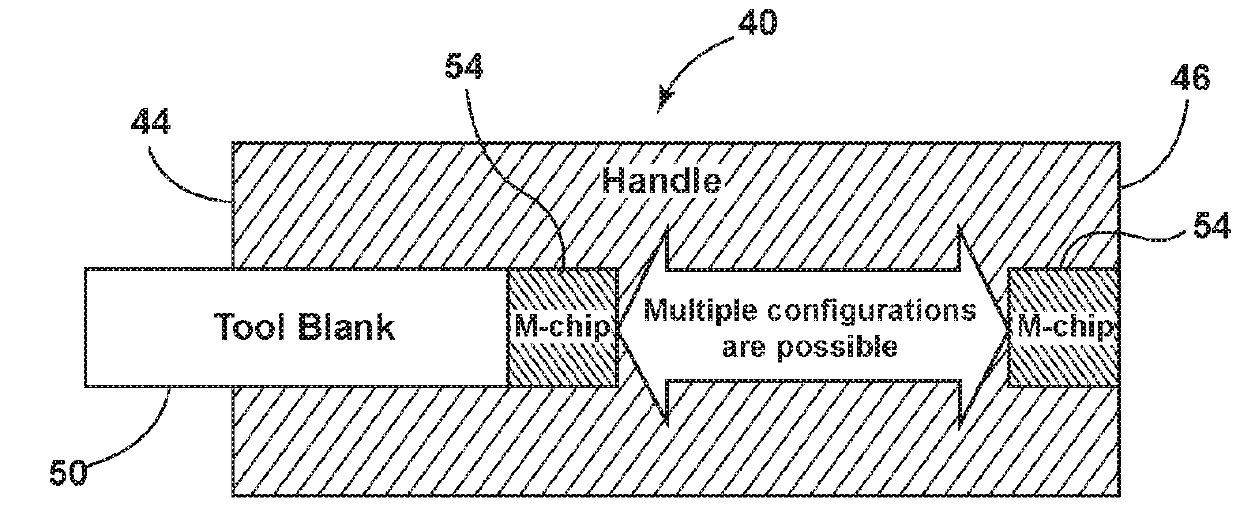

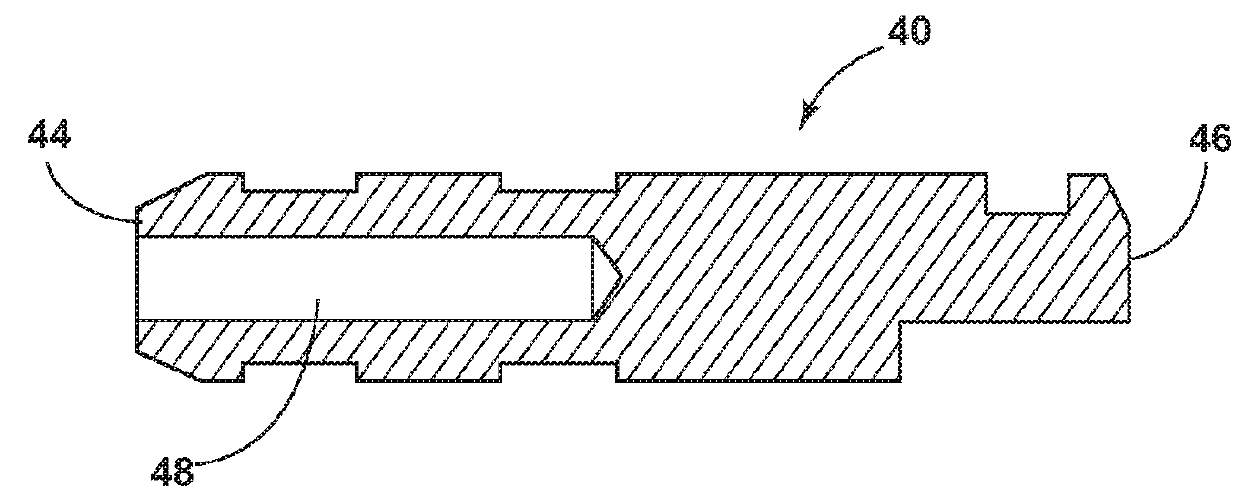

Electronic tool recognition system for dental devices

A tool for use with an electronic tool recognition system includes a tool blank with a distal tip configured for performing a procedure and a proximal handle encasing, fixedly, a proximal end of the tool blank. A tool-identifying apparatus including a mechanical resonator is embedded in a proximal end of the tool blank to provide a tool identifier. A conductive wire in electrical contact with the resonator provides the identifier to a processor. In another arrangement, conductive brushes in contact with slip rings provide the identifier to a processor. In another arrangement, a dental tool handle includes an insulating portion defining a recess in a proximal end of the handle configured to receive either a sensor or an information-managing chip.

Owner:THE KERR

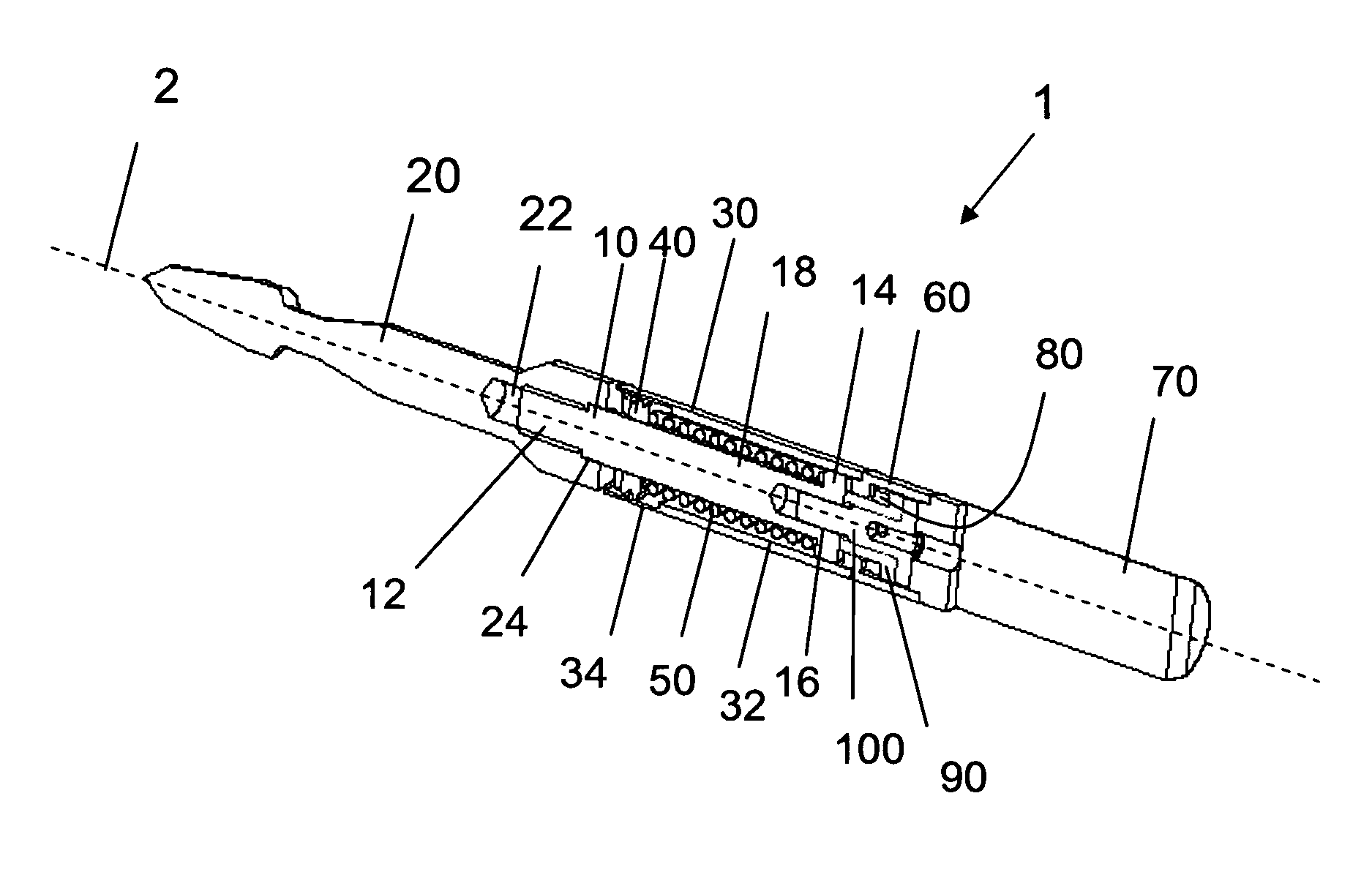

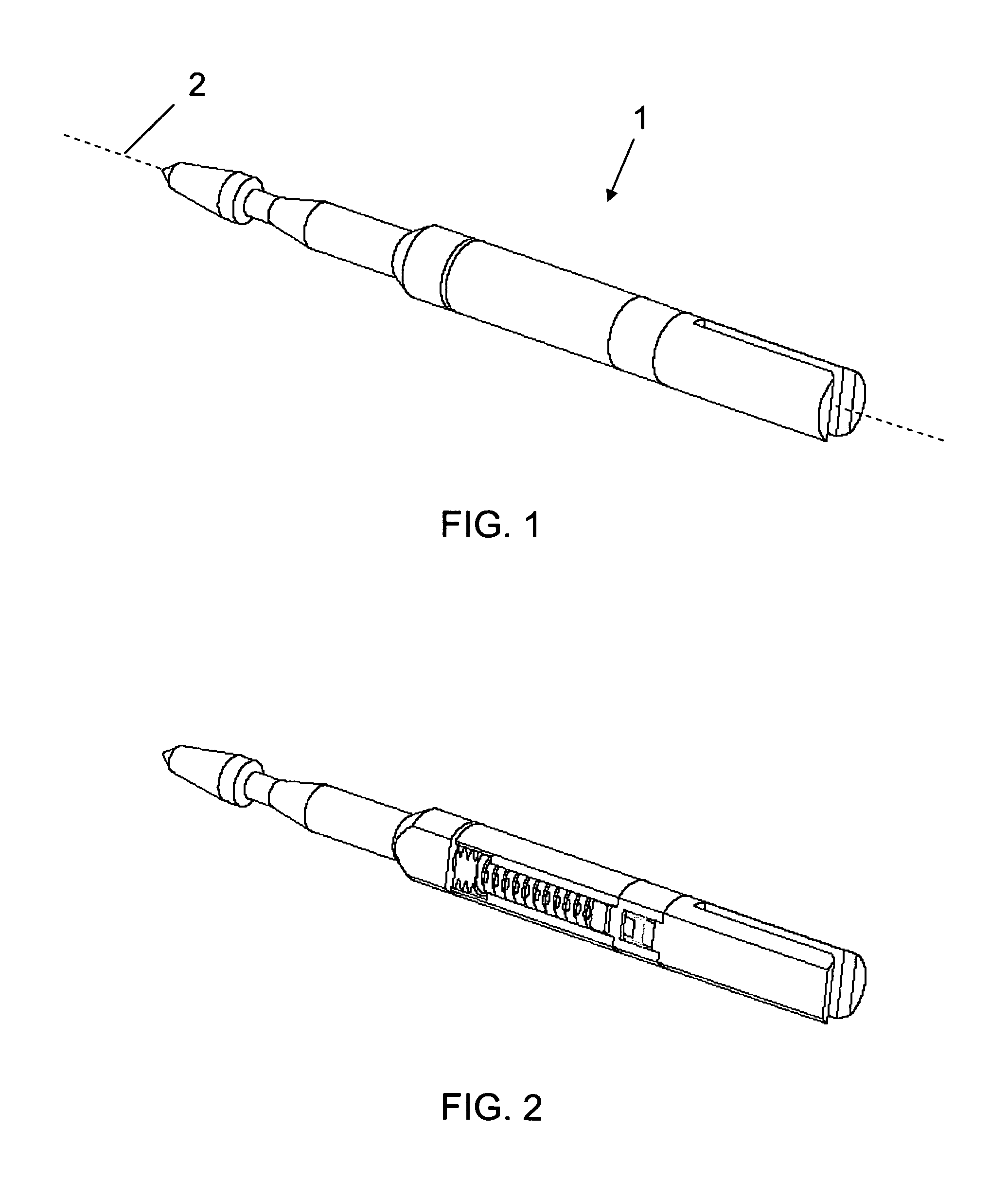

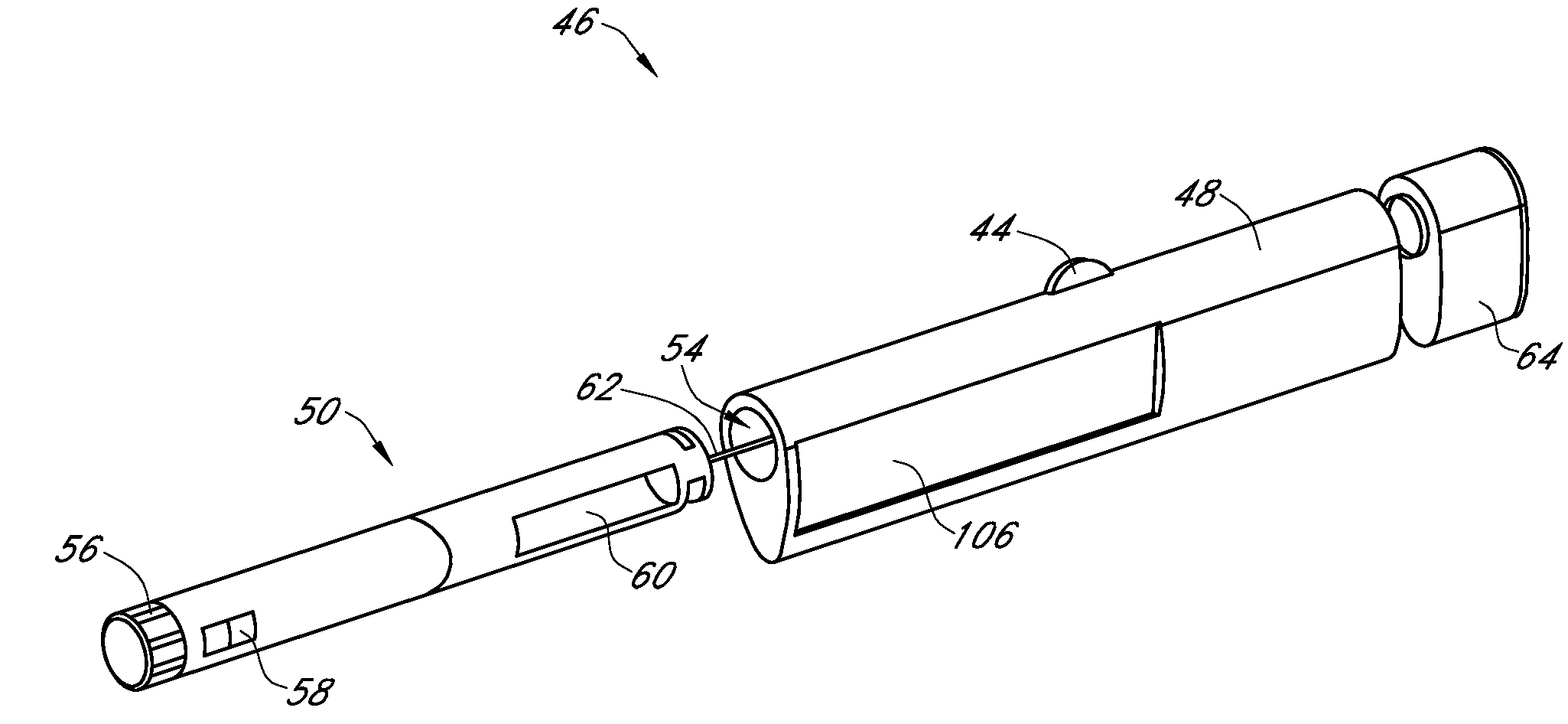

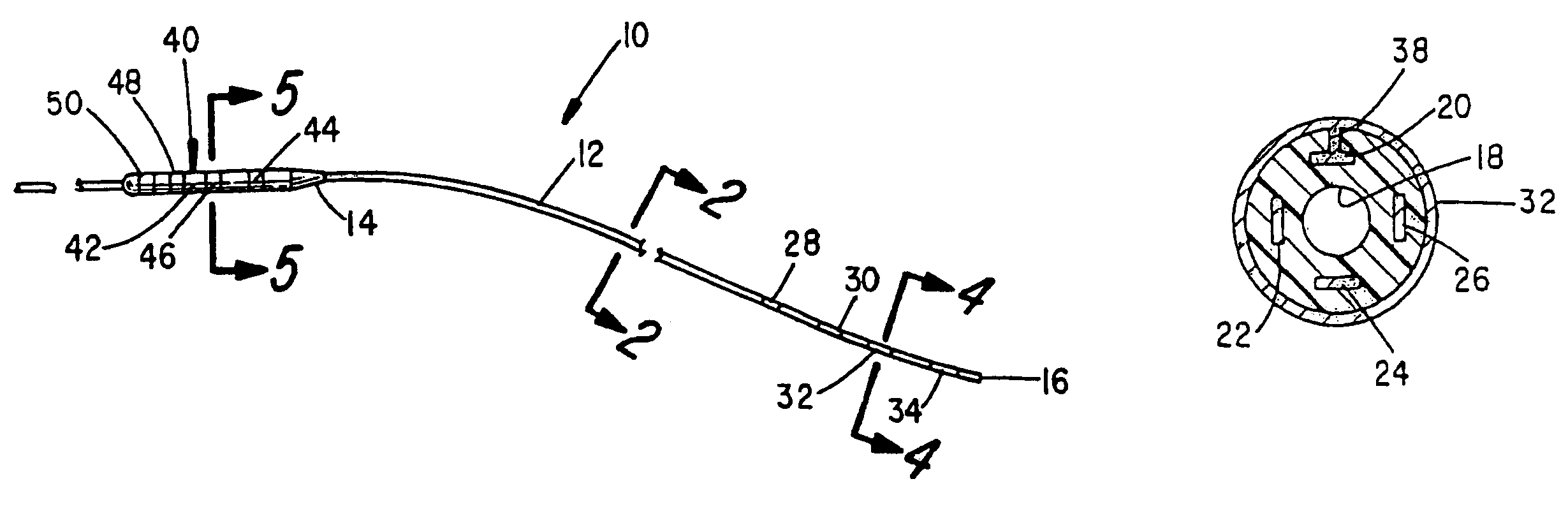

Neurostimulating lead

A neurostimulating lead is provided for use in stimulating the spinal chord, spinal nerves, or peripheral nerves or for use in deep brain stimulation that comprises an elongated, flexible lead having improved steerability properties. The lead includes a plurality of thin-film metal electrodes connected by conductors embedded within the wall of the lead to electrical contacts at the proximal end of the lead. The lead is further designed to include an internal lumen for use with a guidewire in an over-the-wire lead placement.

Owner:ADVANCED NEUROMODULATION SYST INC

Wireless, internet-based, medical diagnostic system

InactiveUS20060142648A1Accurate diagnosisMinimize impactRespiratory organ evaluationSensorsEmergency medicineGlobal Positioning System

A system for monitoring a patient's vital signs that features a vital-sign monitor including sensors for measuring from the patient at least one of the following vital-sign data: O2 saturation, blood pressure, electrocardiogram, respirator rate, and blood glucose level. The system also includes a global positioning system that determines location-based data. A wireless transmitter, in electrical contact with the vital-sign monitor and global positioning system, receives the vital-sign and location-based data and wirelessly transmits these data through a conventional wireless network. A gateway software piece receives and processes the data from the wireless network and stores these data in a computer memory associated with a database software piece. The system also includes an Internet-based user interface that displays the vital sign data for both individual patients and care-providers.

Owner:TRIAGE DATA NETWORKS

Wireless, internet-based medical-diagnostic system

ActiveUS7396330B2Accurate diagnosisMinimize impactSurgeryCatheterGlobal Positioning SystemUser interface

A system for monitoring a patient's vital signs that features a vital-sign monitor including sensors for measuring from the patient at least one of the following vital-sign data: O2 saturation, blood pressure, electro-cardiogram, respirator rate, and blood glucose level. The system also includes a global positioning system that determines location-based data. A wireless transmitter, in electrical contact with the vital-sign monitor and global positioning system, receives the vital-sign and location-based data and wirelessly transmits these data through a conventional wireless network. A gateway software piece receives and processes the data from the wireless network and stores these data in a computer memory associated with a database software piece. The system also includes an Internet-based user interface that displays the vital sign data for both individual patients and care-providers.

Owner:SOTERA WIRELESS

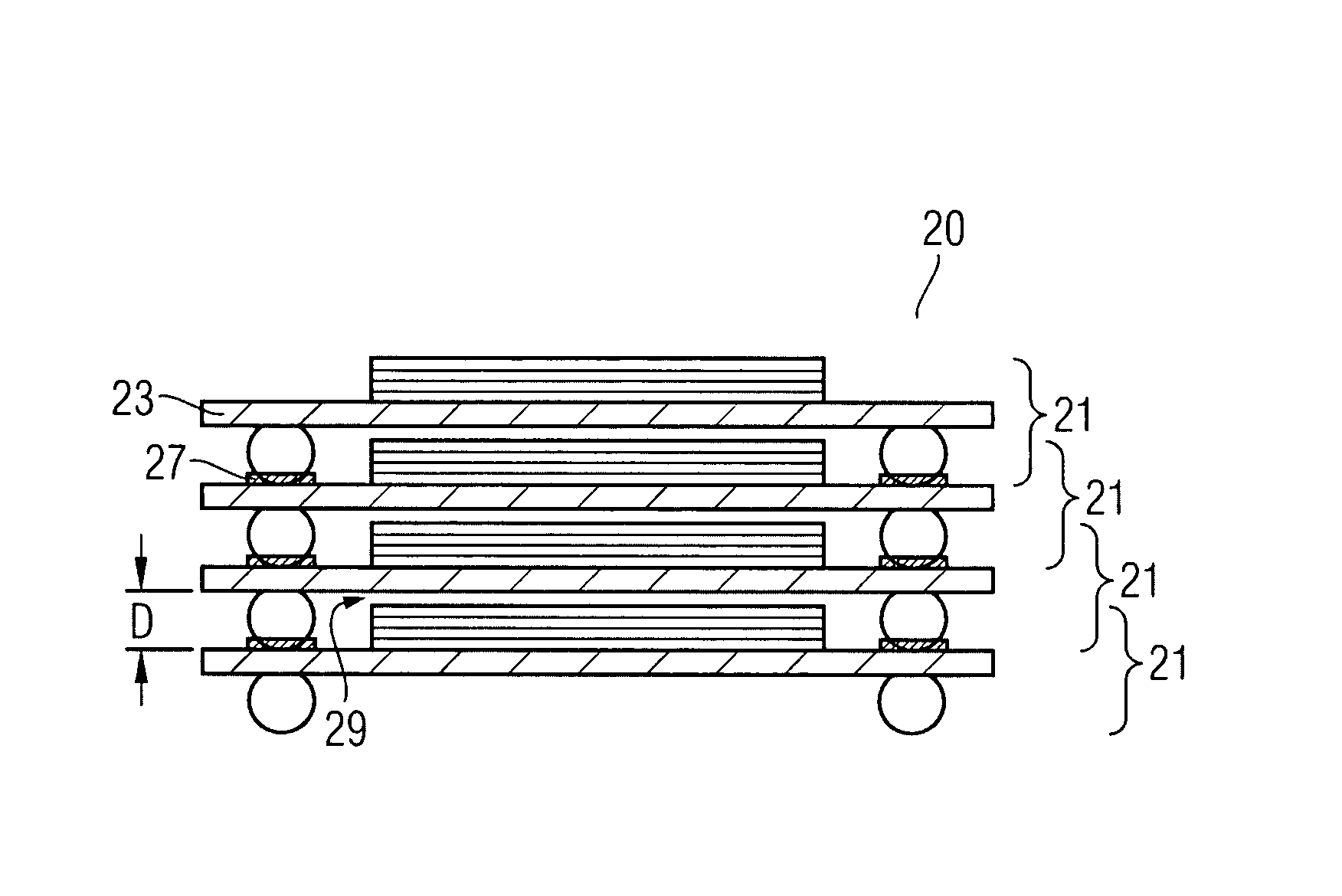

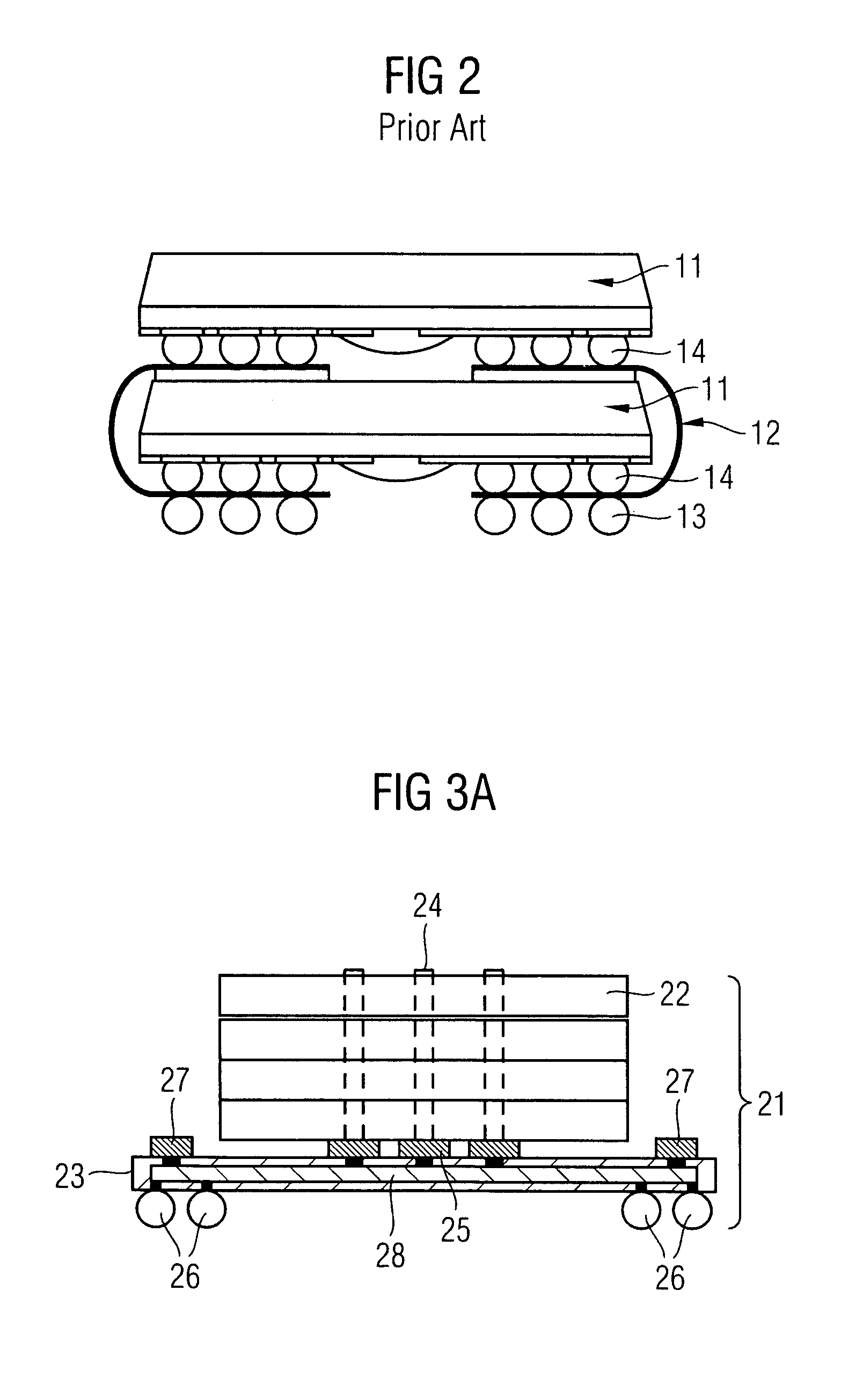

Multi-chip device and method for producing a multi-chip device

InactiveUS7297574B2Increase productionIncrease memory capacitySemiconductor/solid-state device detailsSolid-state devicesEngineeringContact element

The present invention relates to a multi-chip device comprising a plurality of chip stacks each including a plurality of single chips stacked on each other, wherein the stacked single chips are electrically interconnected by one or more through-chip-connection extending through at least one of the single chips and a substrate providing one or more first contact elements each of which is in contact with one of the through-chip-connections and providing one or more second contact elements being in electrical contact with the first contact elements, wherein the plurality of chip stacks are stacked onto each other and wherein the second contact elements of one of the chip stacks each being arranged to be in contact to one or more third contact elements of an adjacent one of the chip stacks.

Owner:POLARIS INNOVATIONS LTD

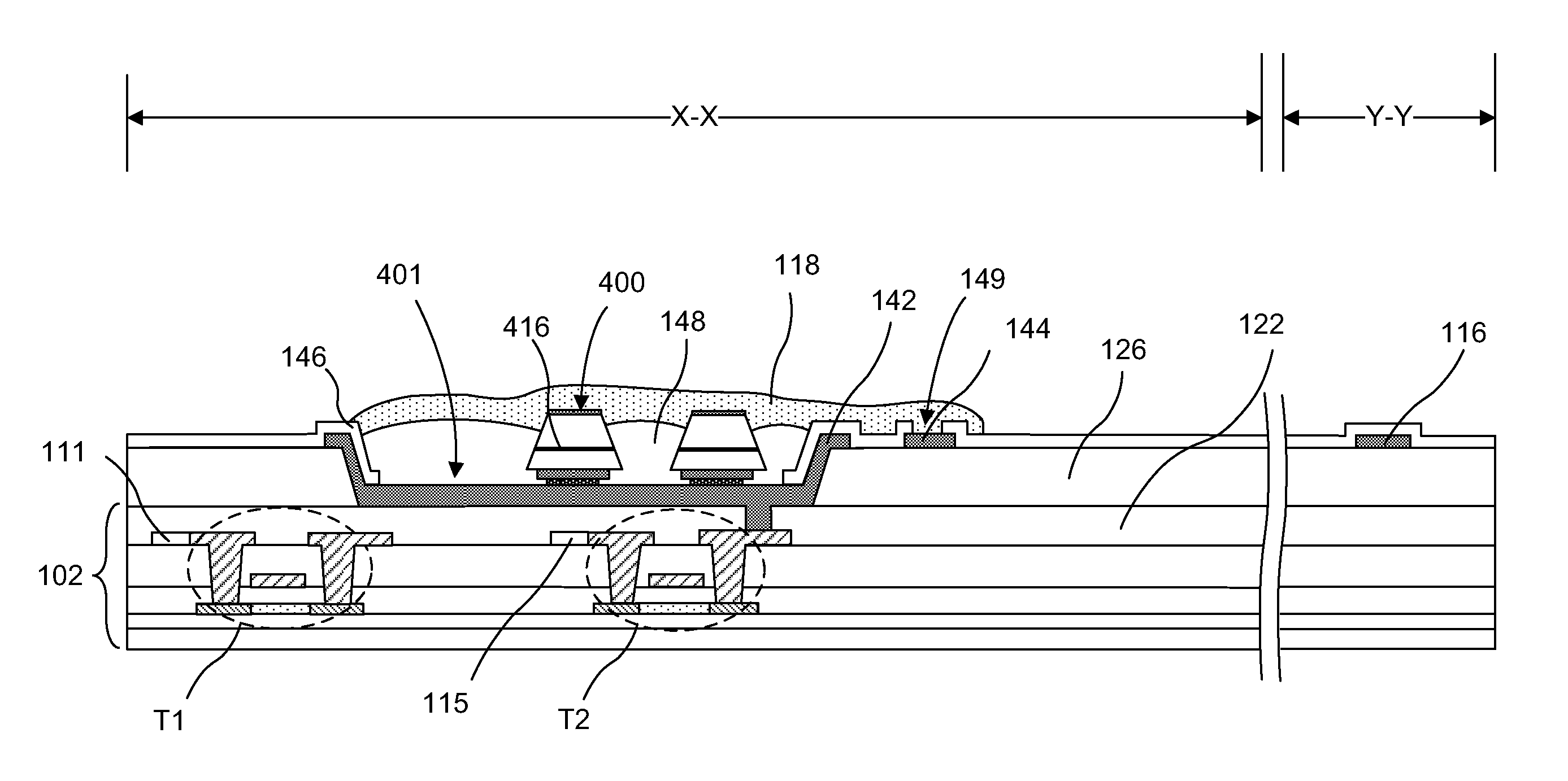

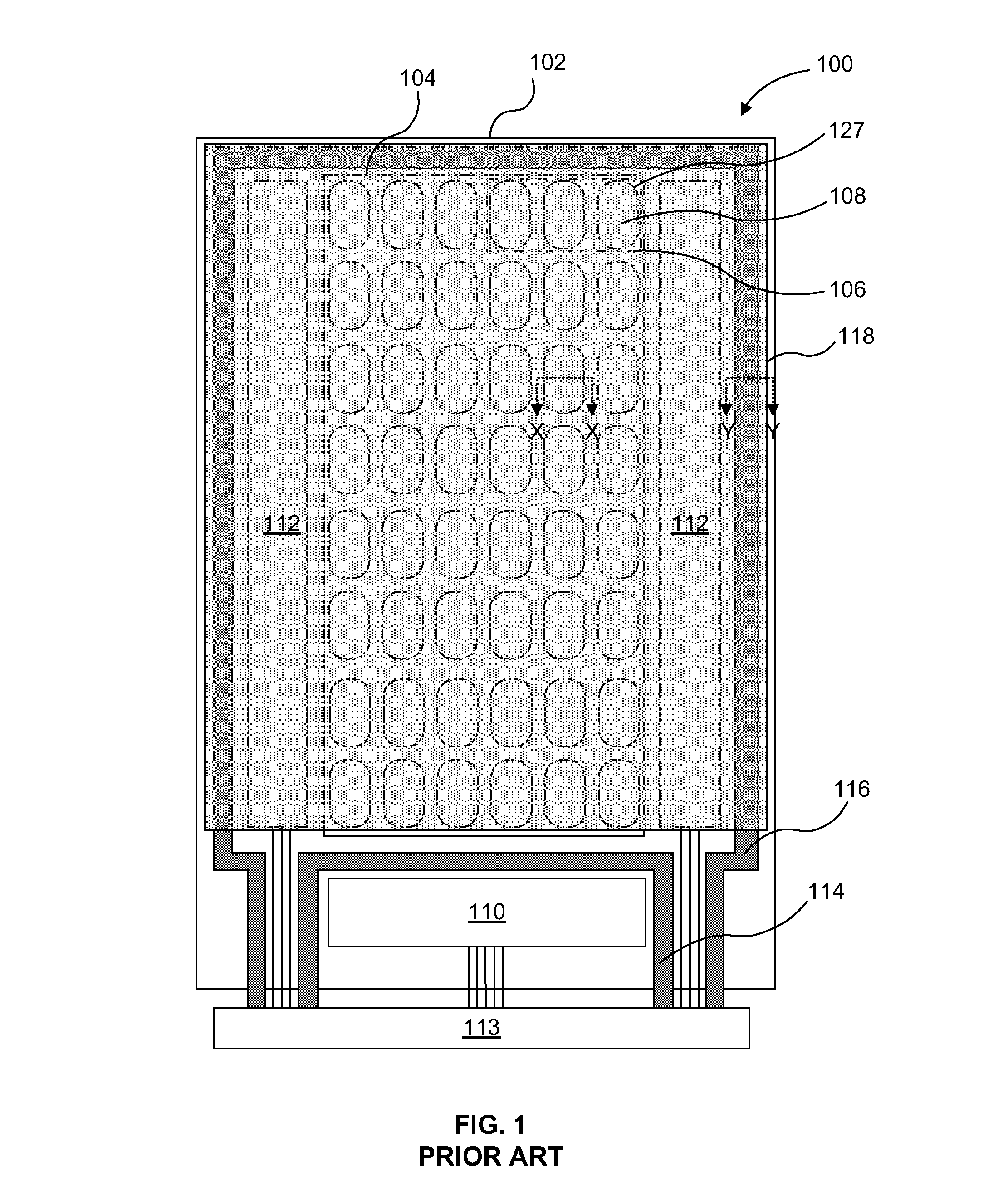

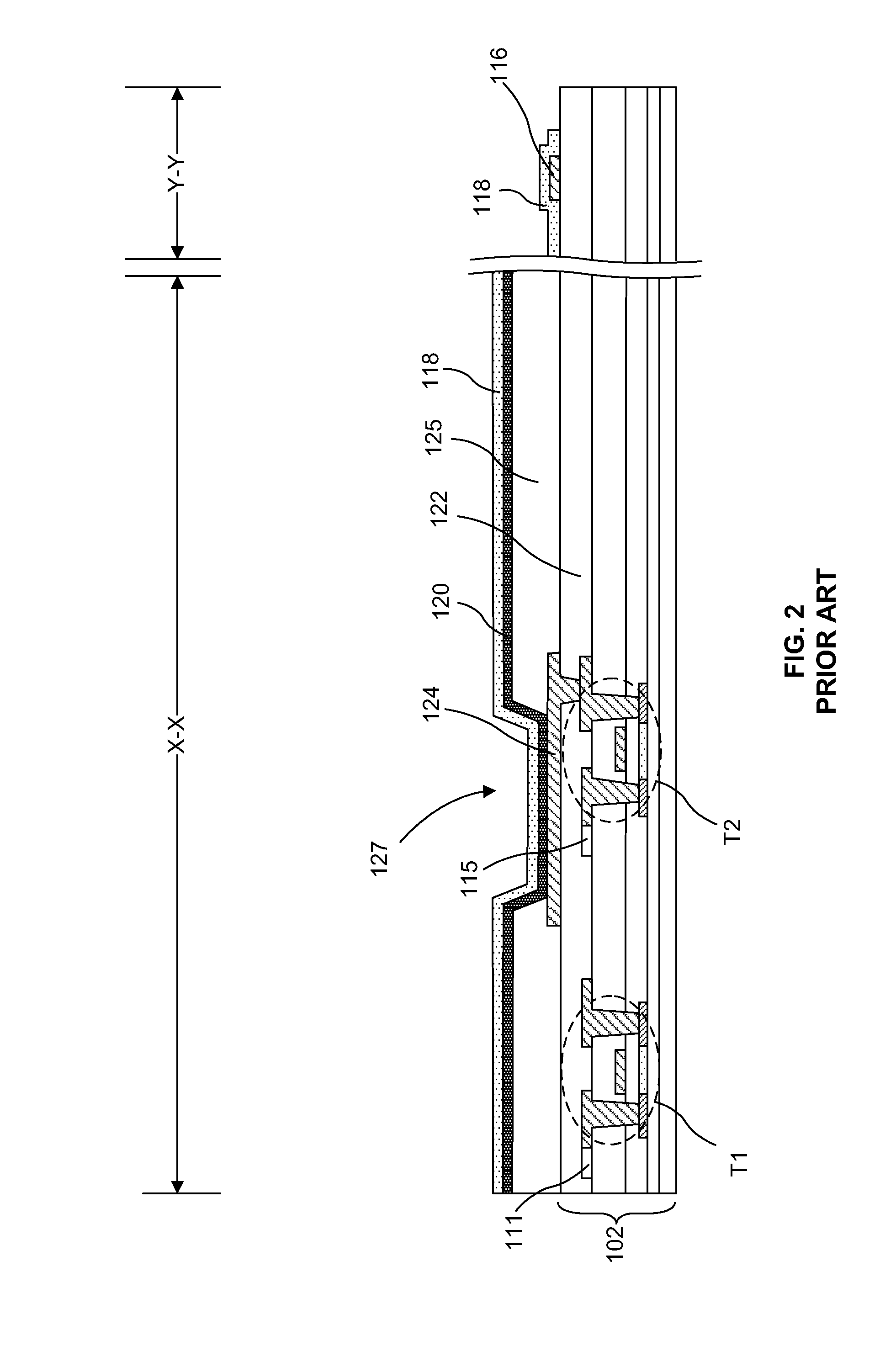

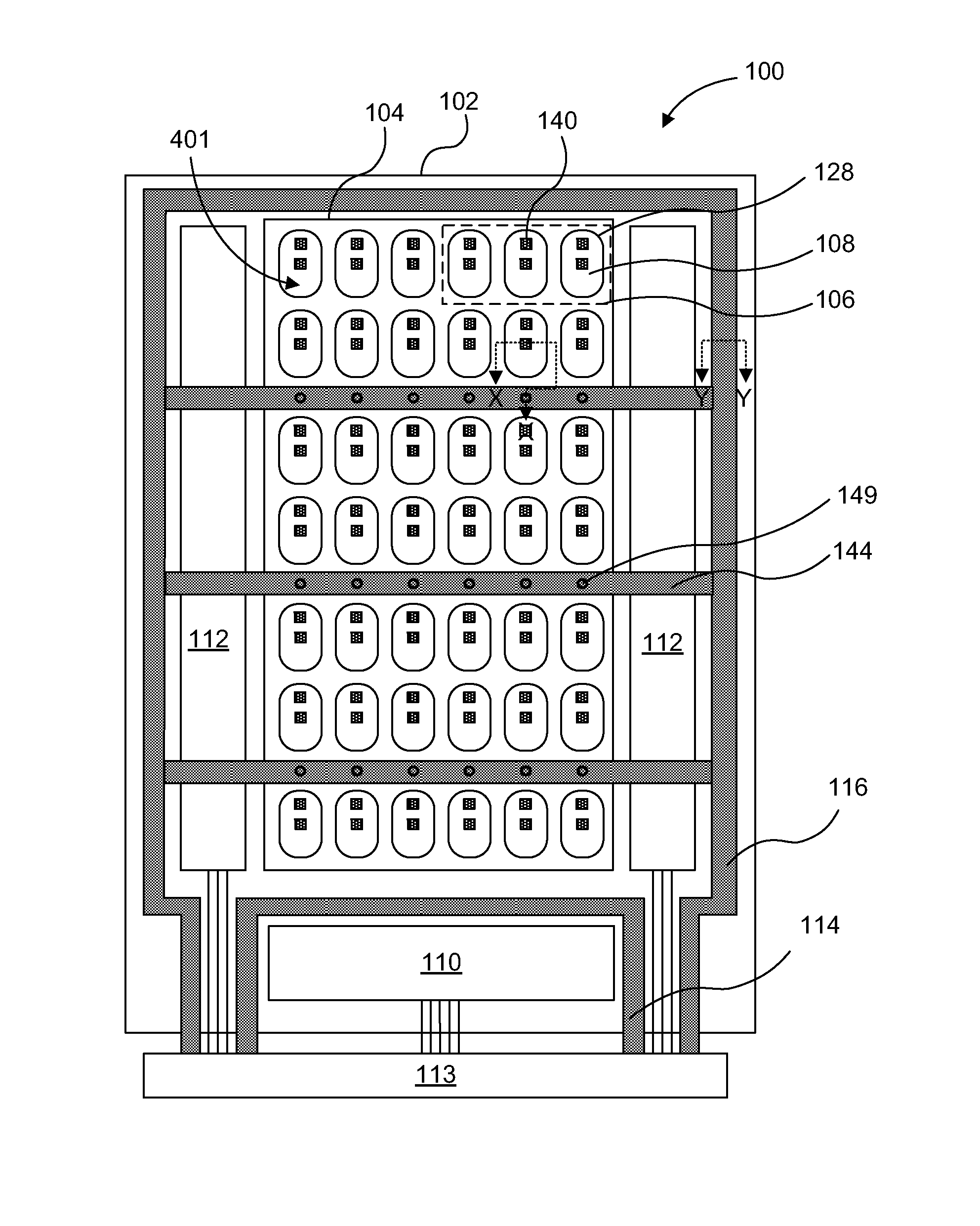

Light emitting diode display with redundancy scheme

ActiveUS8791474B1Reduce probabilityStatic indicating devicesSolid-state devicesLED displayDisplay device

A display panel and method of manufacture are described. In an embodiment, a display substrate includes a pixel area and a non-pixel area. An array of subpixels and corresponding array of bottom electrodes are in the pixel area. An array of micro LED devices are bonded to the array of bottom electrodes. One or more top electrode layers are formed in electrical contact with the array of micro LED devices. In one embodiment a redundant pair of micro LED devices are bonded to the array of bottom electrodes. In one embodiment, the array of micro LED devices are imaged to detect irregularities.

Owner:APPLE INC

Method of fabricating a light emitting diode display with integrated defect detection test

ActiveUS20140267683A1Reduce probabilityImage analysisStatic indicating devicesLED displayDisplay device

A display panel and method of manufacture are described. In an embodiment, a display substrate includes a pixel area and a non-pixel area. An array of subpixels and corresponding array of bottom electrodes are in the pixel area. An array of micro LED devices are bonded to the array of bottom electrodes. One or more top electrode layers are formed in electrical contact with the array of micro LED devices. In one embodiment a redundant pair of micro LED devices are bonded to the array of bottom electrodes. In one embodiment, the array of micro LED devices are imaged to detect irregularities.

Owner:APPLE INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com