Patents

Literature

101 results about "Alternative process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The term alternative process refers to any non-traditional or non-commercial photographic printing process. Currently the standard analog photographic printing process is the gelatin silver process, and standard digital processes include the pigment print, and digital laser exposures on traditional color photographic paper.

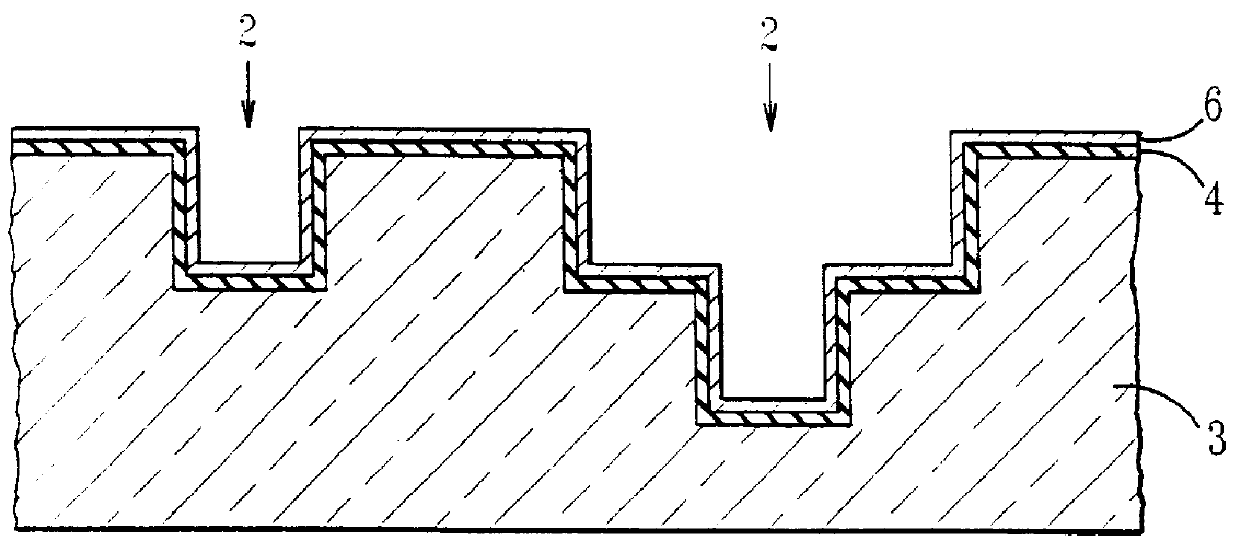

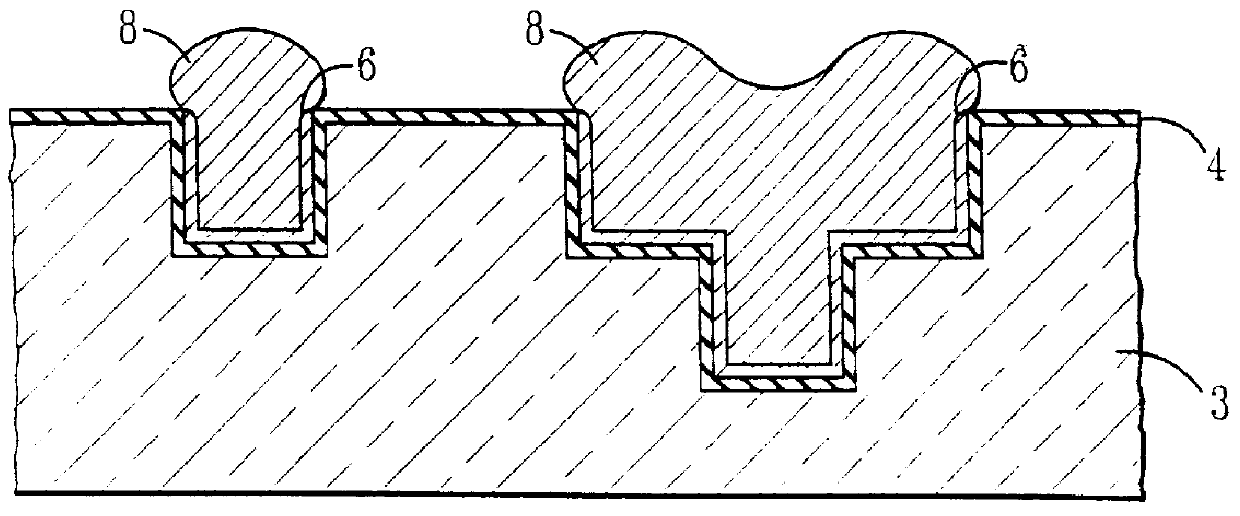

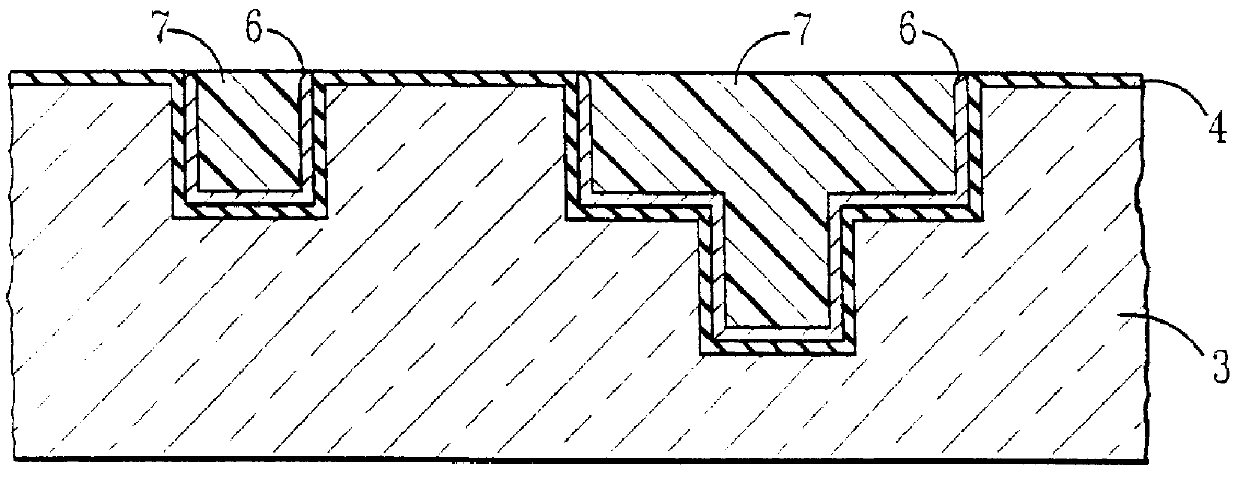

Method to selectively fill recesses with conductive metal

InactiveUS6140234AShorten the timeIncrease productionSolid-state devicesSemiconductor/solid-state device manufacturingResistSemiconductor structure

Recesses in a semiconductor structure are selectively plated by providing electrical insulating layer over the semiconductor substrate and in the recesses followed by forming a conductive barrier over the insulating layer; providing a plating seed layer over the barrier layer; depositing and patterning a photoresist layer over the plating seed layer; planarizing the insulated horizontal portions by removing the horizontal portions of the seed layer between the recesses; removing the photoresist remaining in the recesses; and then electroplating the patterned seed layer with a conductive metal using the barrier layer to carry the current during the electroplating to thereby only plate on the seed layer. In an alternative process, a barrier film is deposited over recesses in an insulator. Then, relatively thick resists are lithographically defined on the field regions, on top of the barrier film over the recesses. A plating base or seedlayer is deposited, so as to be continuous on the horizontal regions of the recesses in the insulator, but discontinuous on their surround wall. The recesses are then plated using the barrier film without seedlayers at the periphery of the substrate wafers for electrical contact. After electroplating, the resist is removed by lift-off process and exposed barrier film is etched by RIE method or by CMP. Also provided is a semiconductor structure obtained by the above processes.

Owner:GLOBALFOUNDRIES INC

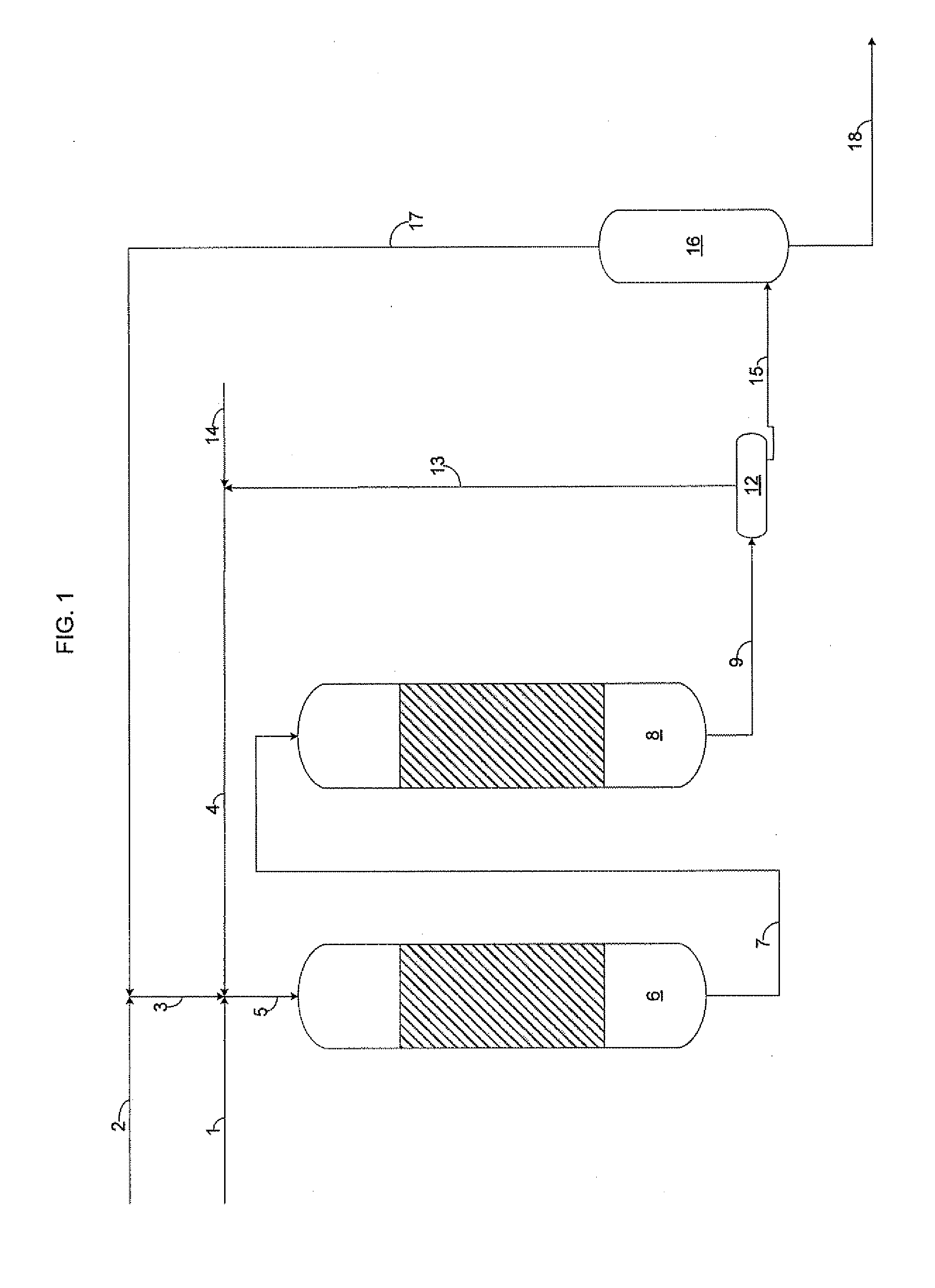

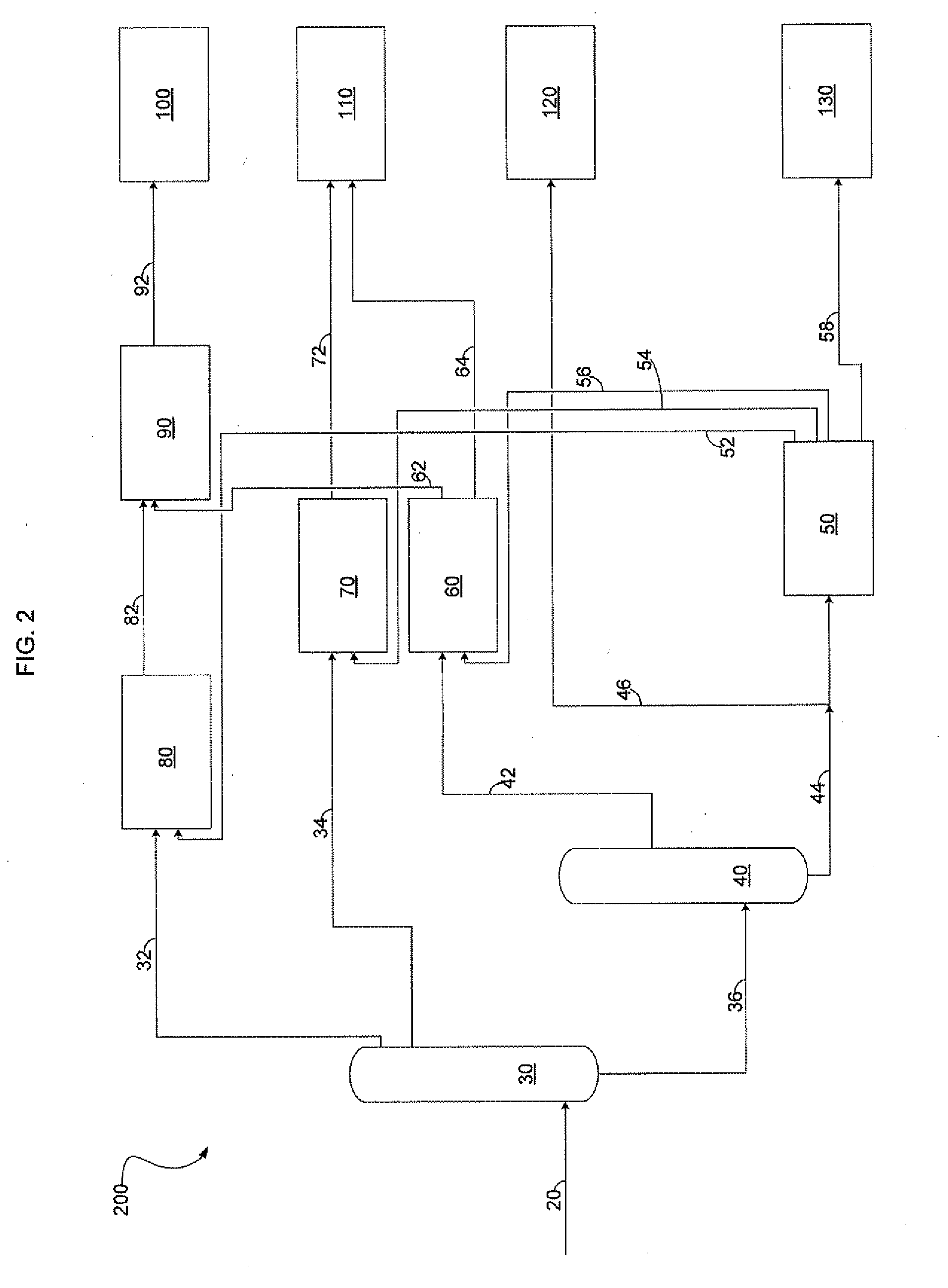

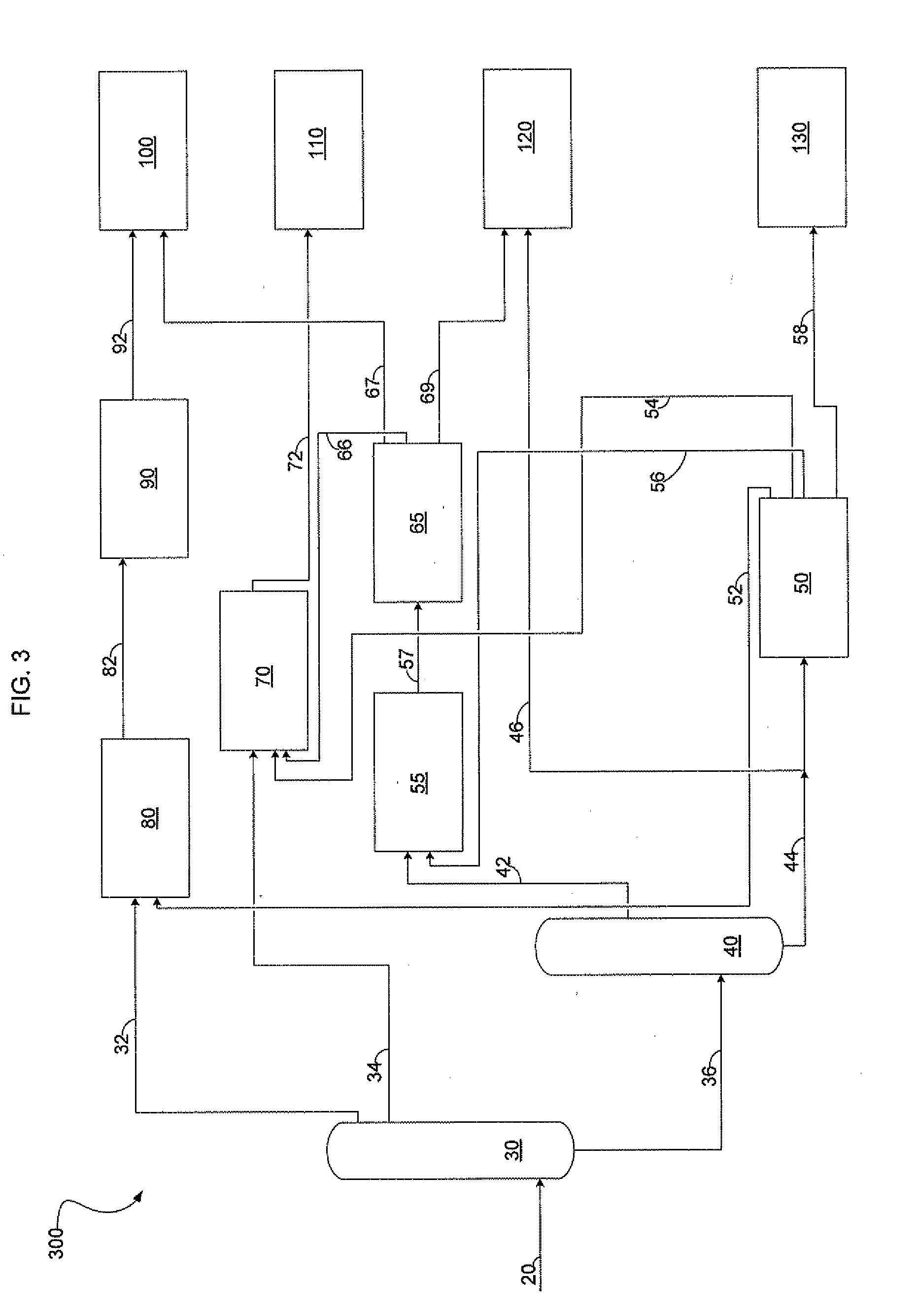

Alternative Process for Treatment of Heavy Crudes in a Coking Refinery

ActiveUS20110083996A1Increasing API gravityReduce the amount of metalThermal non-catalytic crackingRefining with metalsFuel oilPre treatment

The present invention relates to a process for the pretreatment of heavy oils using a catalytic hydrotreating process prior to introduction to a refinery. More specifically, the invention relates to the use of an HDM reactor and an HDS reactor in order to improve the characteristics of the heavy oil, such that when the oil is introduced into the refinery, the refinery can achieve improved throughputs, increased catalysts life, increased life cycles, and a reduction in overall operation costs.

Owner:SAUDI ARABIAN OIL CO

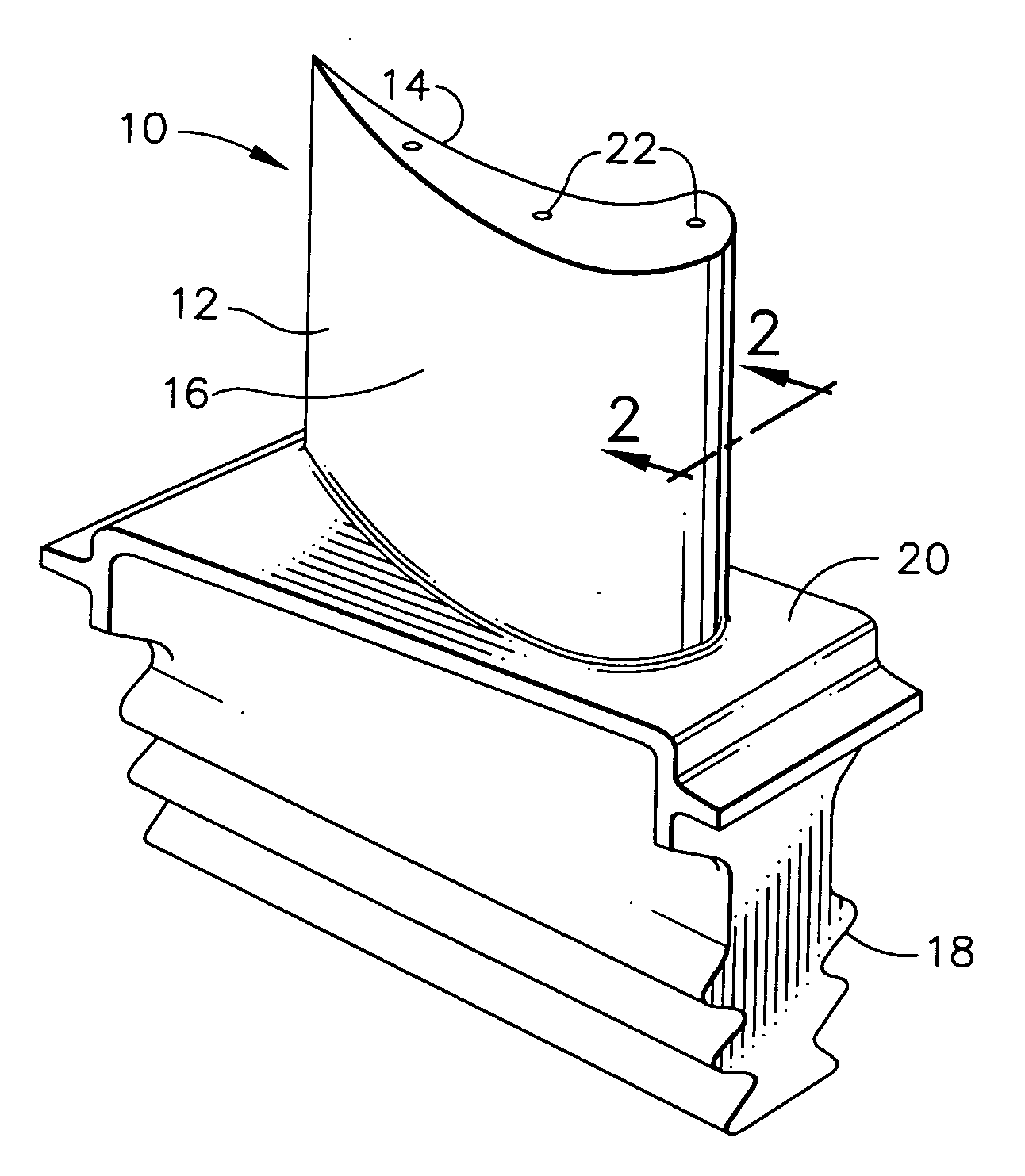

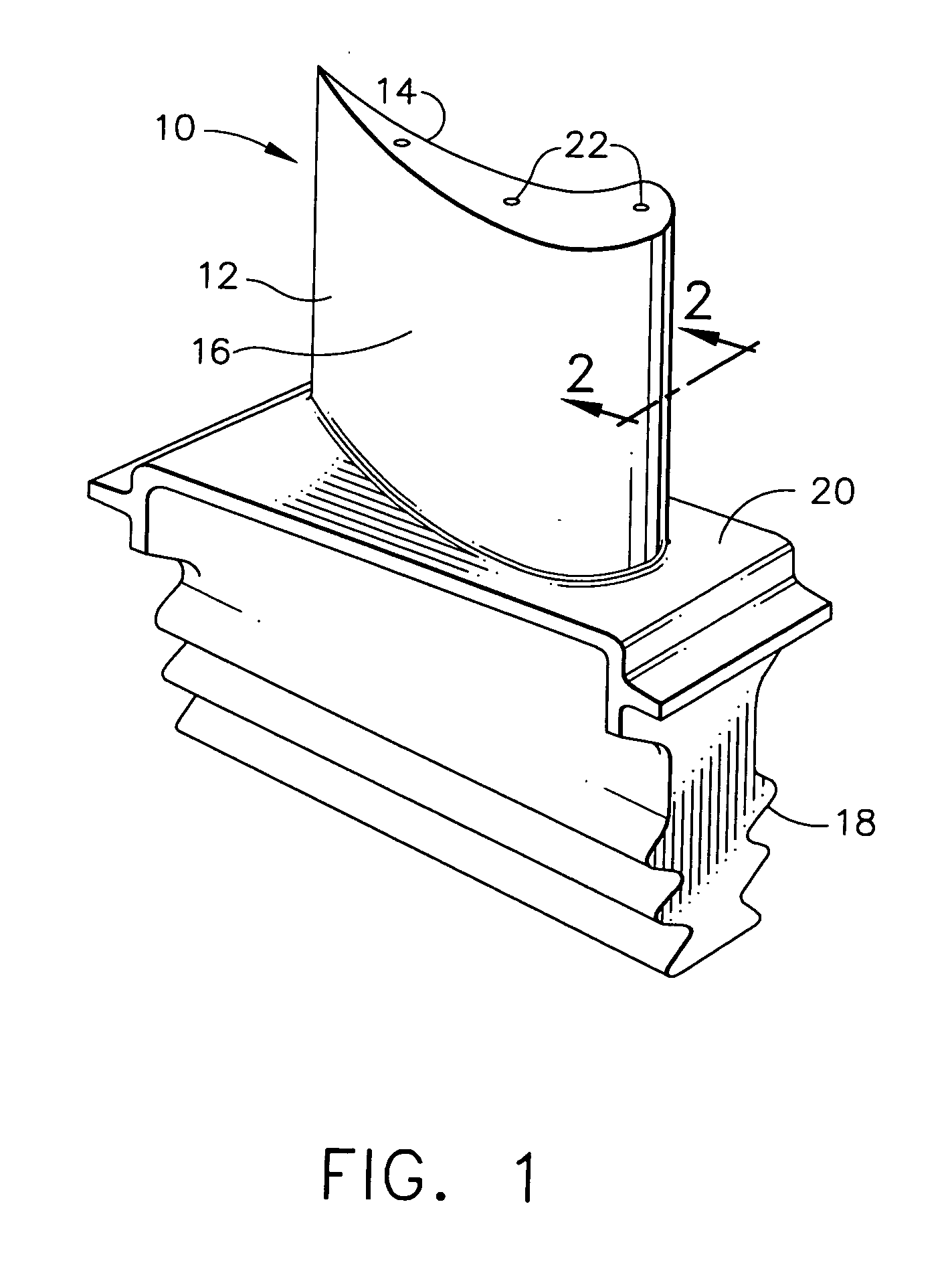

Corrosion resistant sealant for outer EBL of silicon-containing substrate and processes for preparing same

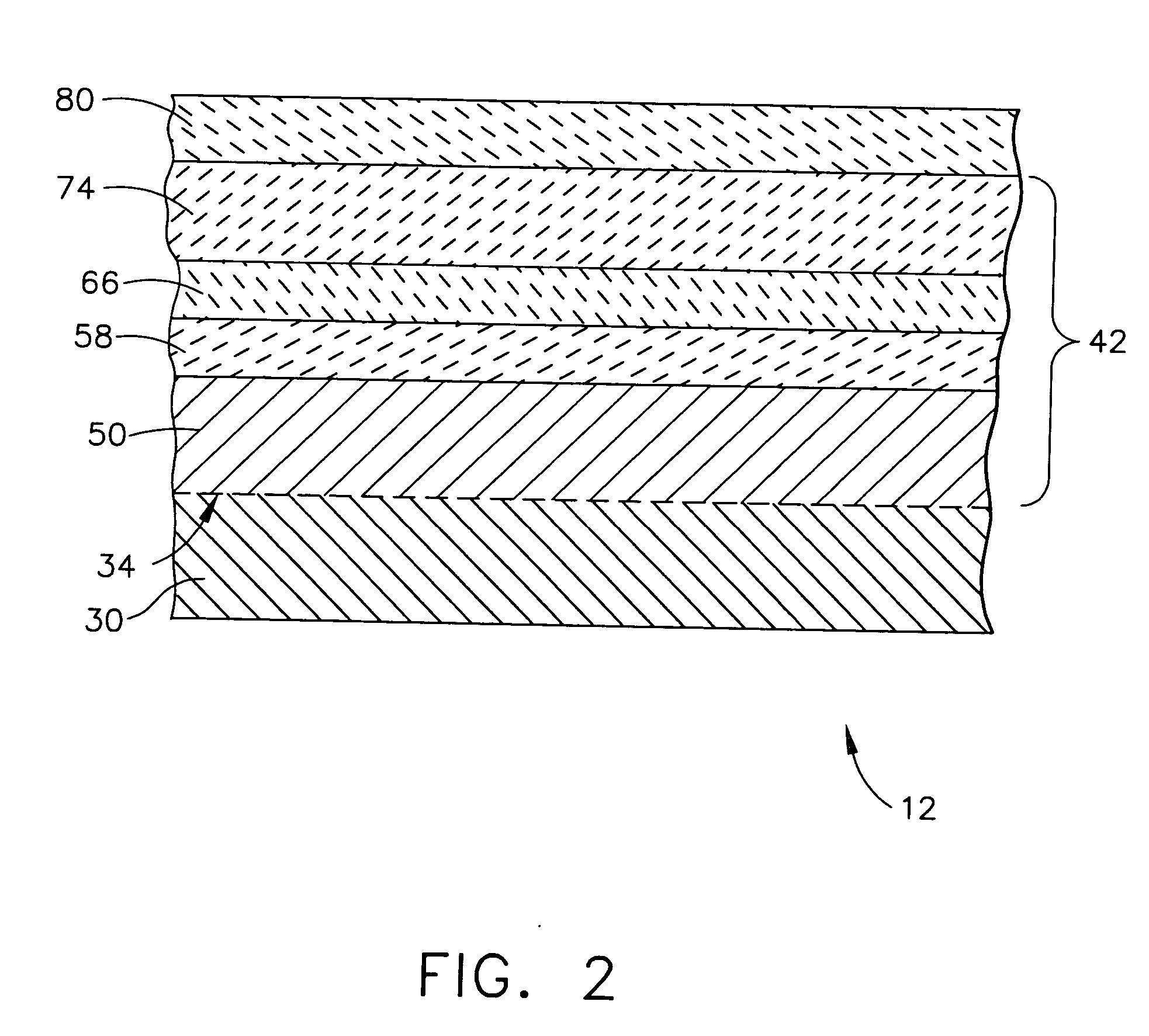

InactiveUS20060280954A1More resistant to environmental attackResist attackMolten spray coatingBlade accessoriesAluminateMetallurgy

An article comprising a silicon-containing substrate, an environmental barrier coating (EBC) overlying the substrate, wherein the EBC comprises a higher metal silicate-containing outer barrier layer; and a corrosion resistant alumina / aluminate sealant for the higher metal silicate-containing outer barrier layer. A process is also provided for forming a corrosion resistant alumina / aluminate sealant layer over the higher metal silicate-containing outer barrier layer. Also provided is an alternative process for treating a porous higher metal silicate-containing outer barrier layer with a liquid composition comprising an corrosion resistant alumina / aluminate sealant precursor to infiltrate the porous higher metal silicate-containing outer barrier layer with the alumina / aluminate sealant precursor in an amount sufficient to provide, when converted to the corrosion resistant alumina / aluminate sealant, protection of the environmental barrier coating against environmental attack; and converting the infiltrated alumina / aluminate sealant precursor within the porous higher metal silicate-containing outer barrier layer to the corrosion resistant alumina / aluminate sealant.

Owner:GENERAL ELECTRIC CO

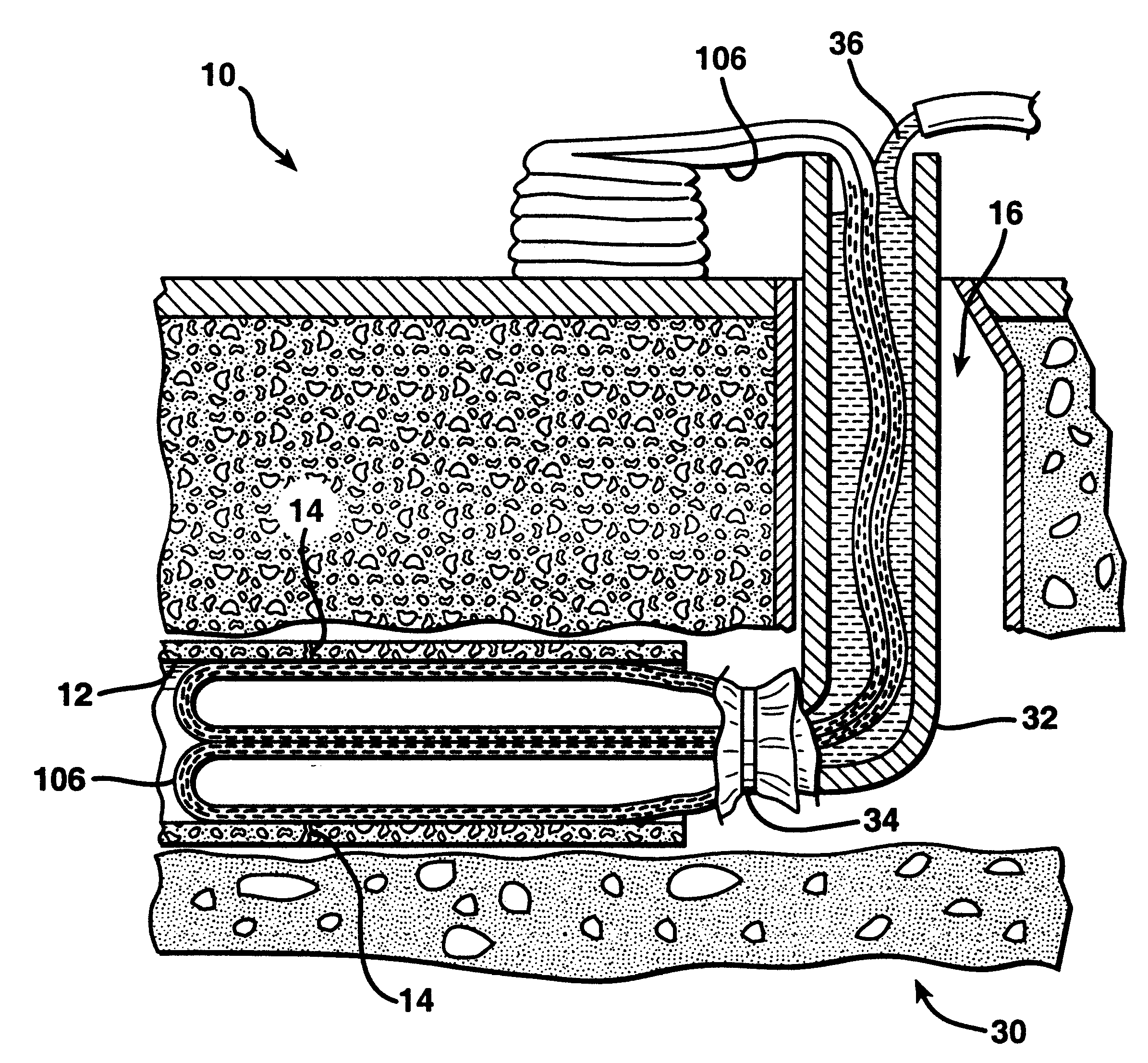

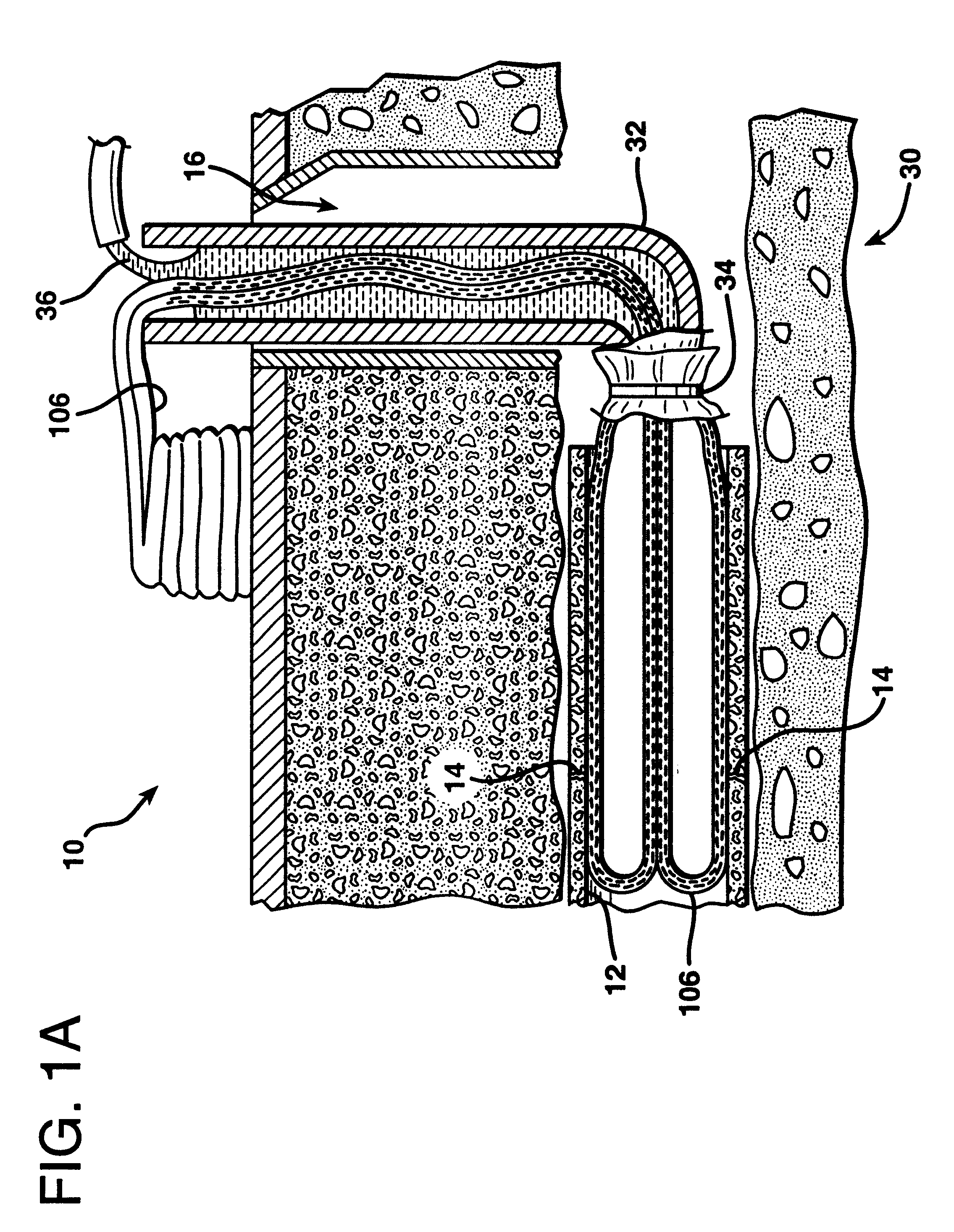

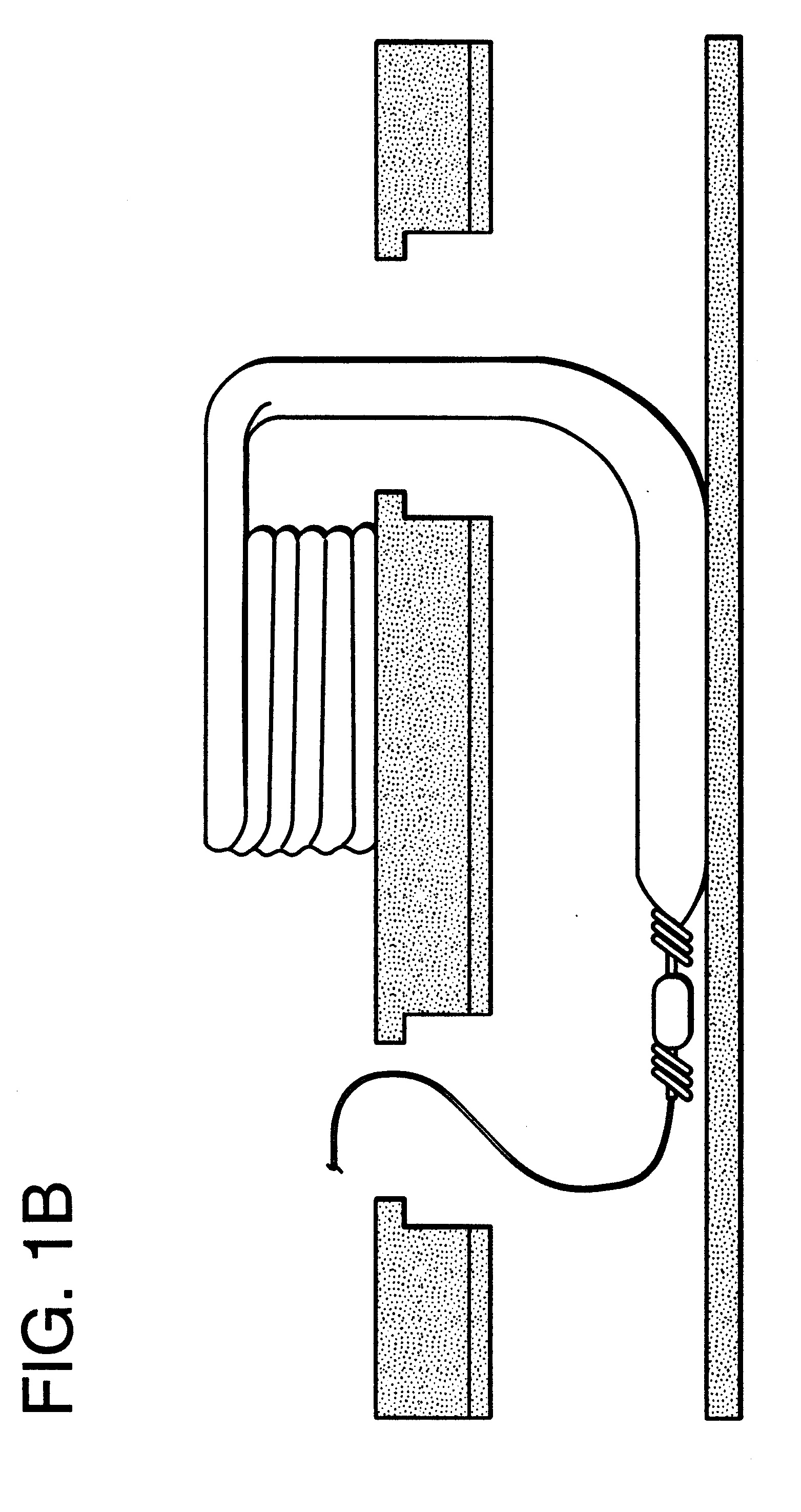

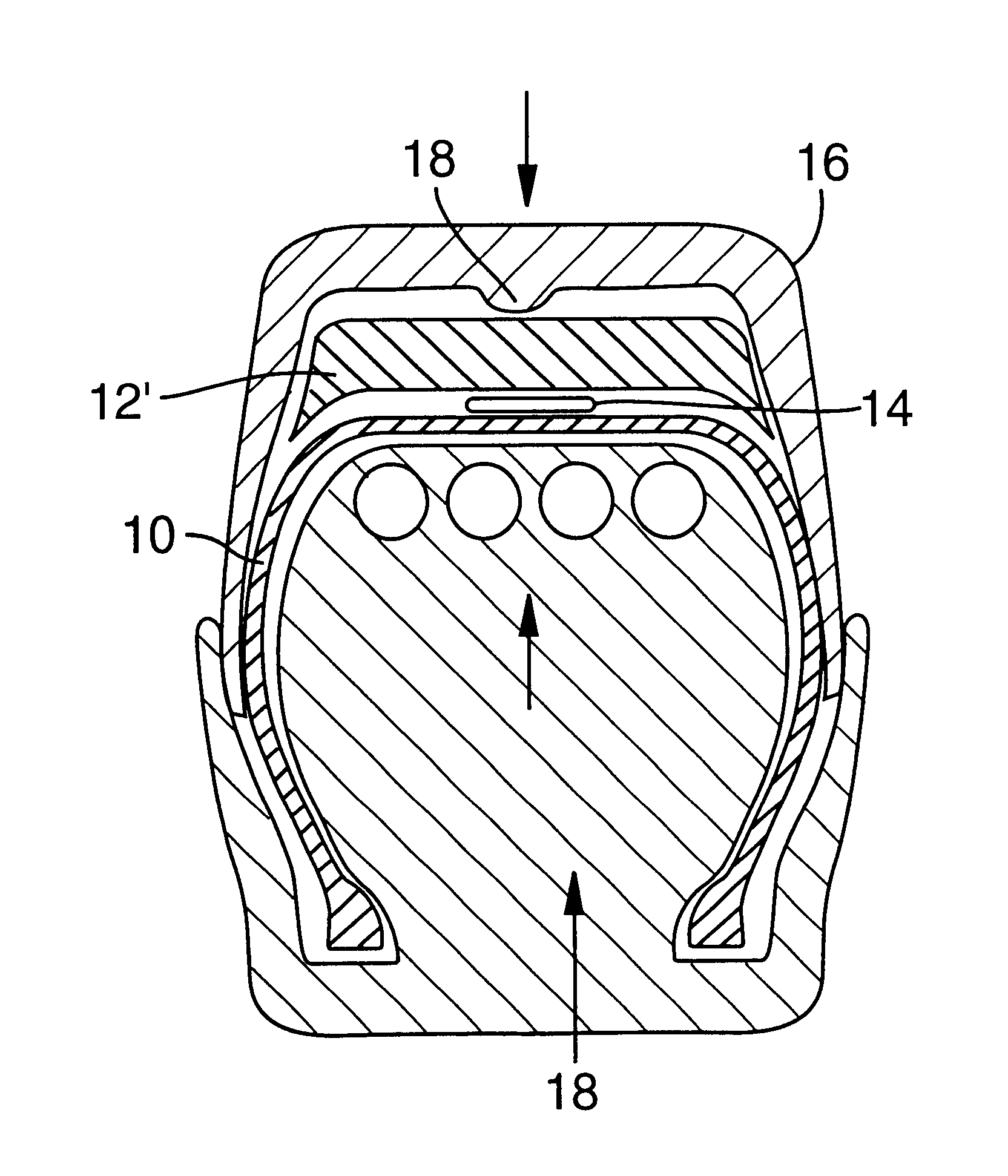

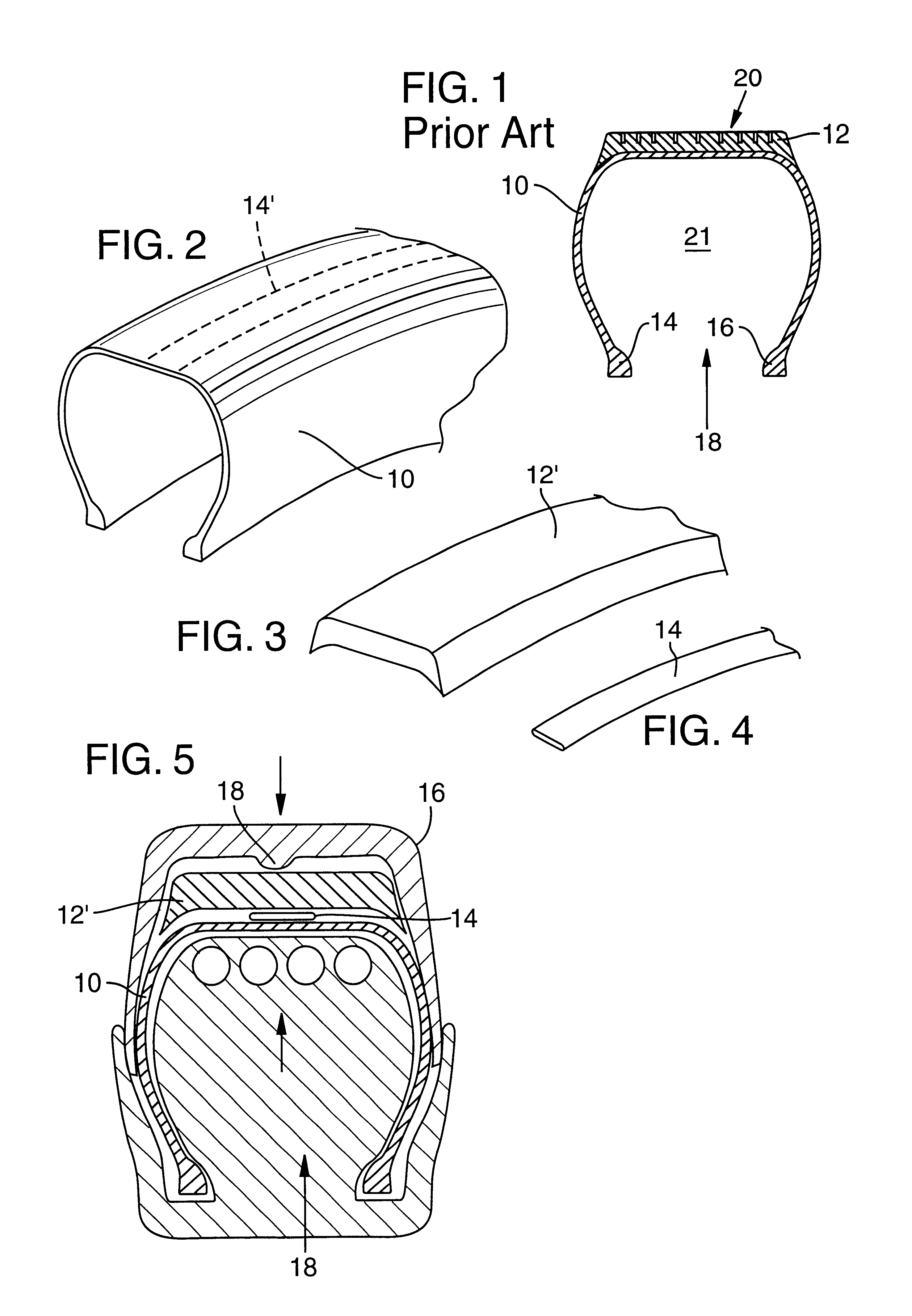

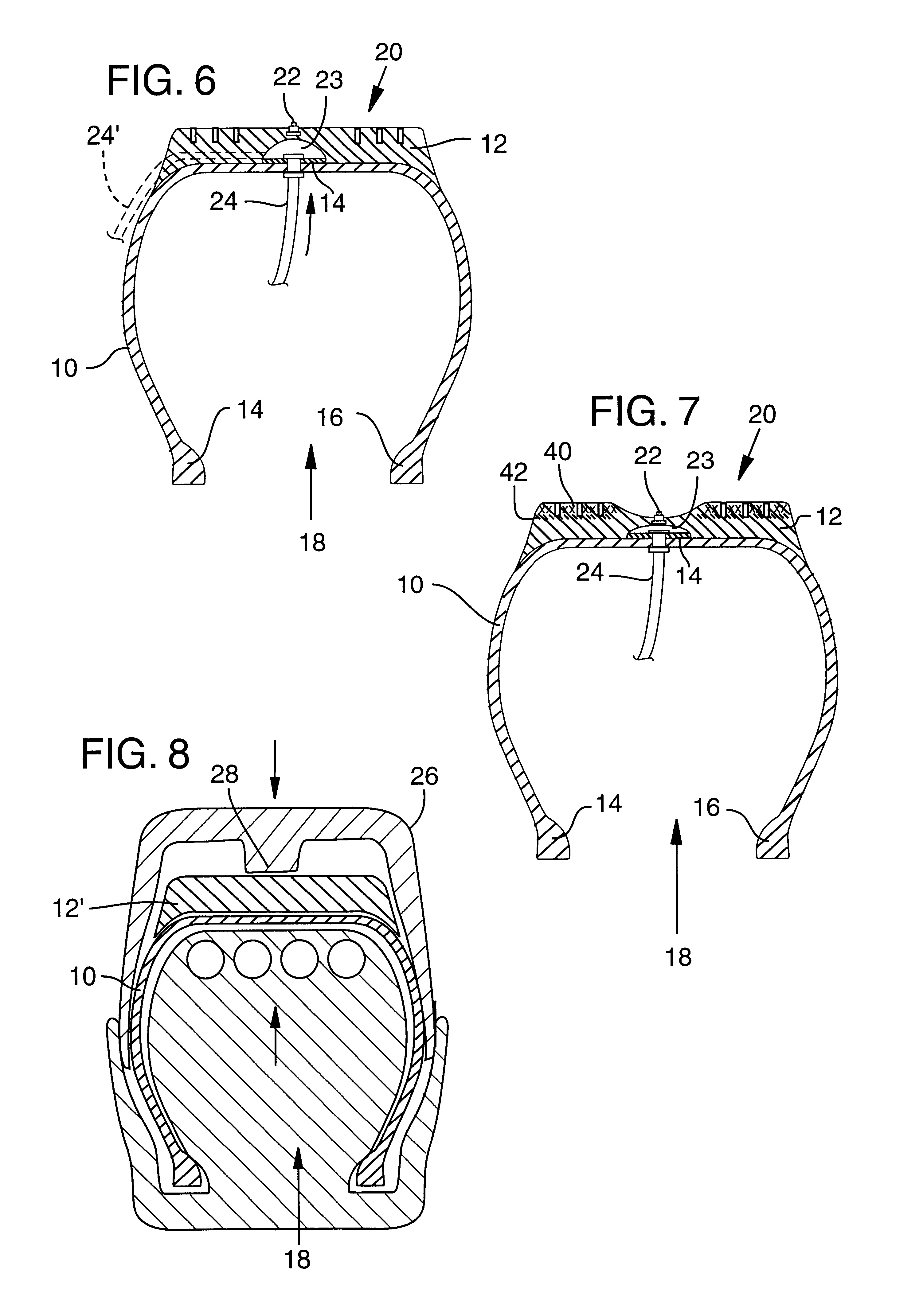

Liner for reinforcing a pipe and method of making the same

A reinforcement liner and methods of manufacturing the liner are disclosed. The liner includes a fabric material having first and second support layers. Each of the layers includes reinforcing fibers. The first and second support layers are oriented in different directions to provide support to the liner in those directions. The liner includes a stitching material that is used to couple the first and second support layers together. The stitching material is preferably an elastic yarn. One of the support layers includes long, chopped strands that are oriented parallel to each other. The long, chopped strands are directed so that they are in the peripheral direction of the finished reinforcement liner. The long, chopped fibers can be distributed continuously or only along portions of the width of the fabric. The disclosed methods of manufacturing a liner include alternative processes by which the liner can be made. The fabric is manufactured in the form of a continuous roll. One method involves winding the roll in a helical pattern about a fixed mandrel. Another method involves mounting several rolls circumferentially about a mandrel. The rolls are mounted so that strips of fabric from each roll overlap a portion of adjacent fabric strips to provide a continuous liner surface on the mandrel.

Owner:OWENS CORNING COMPOSITES SPRL BELGIUM +1

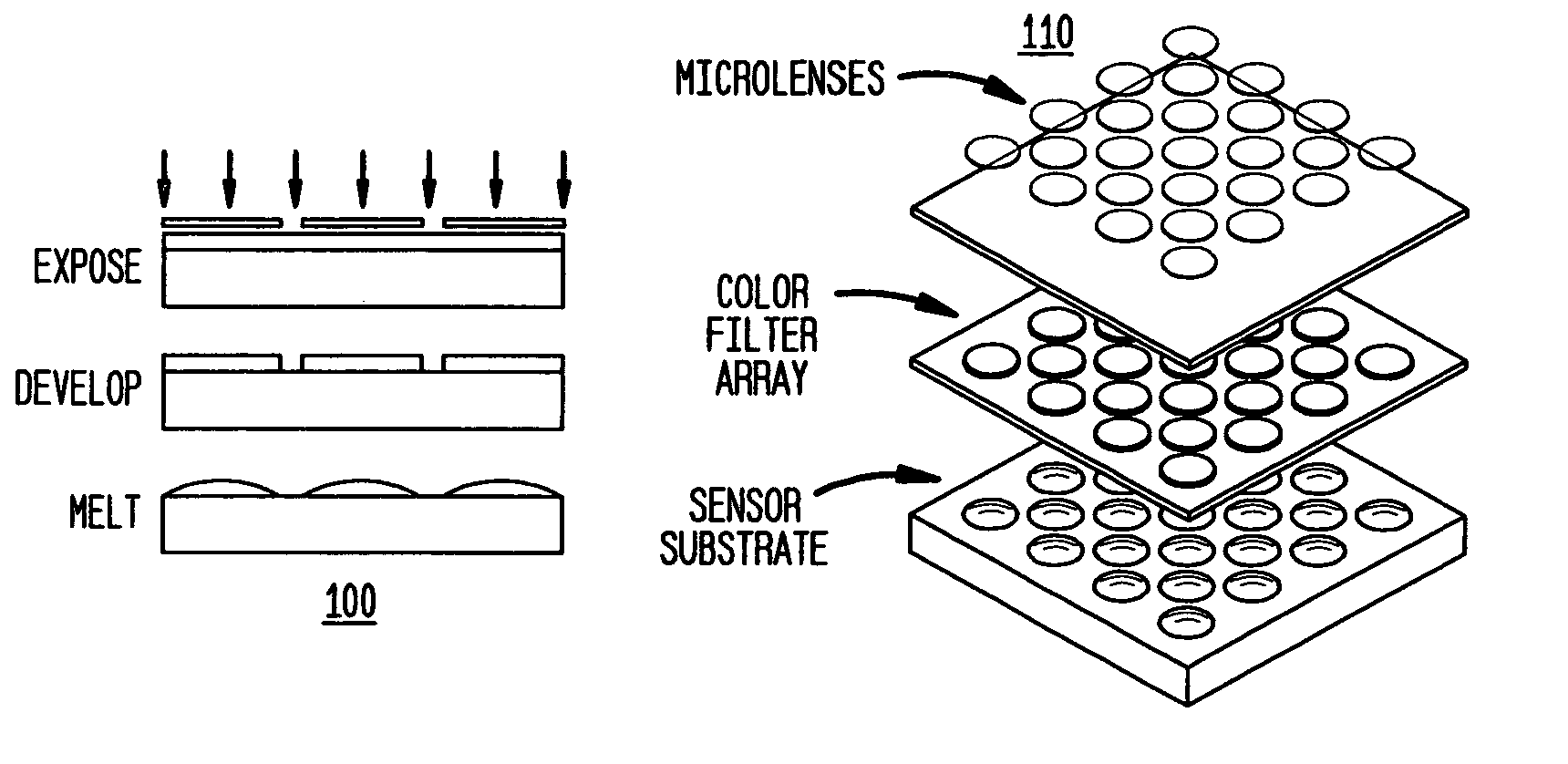

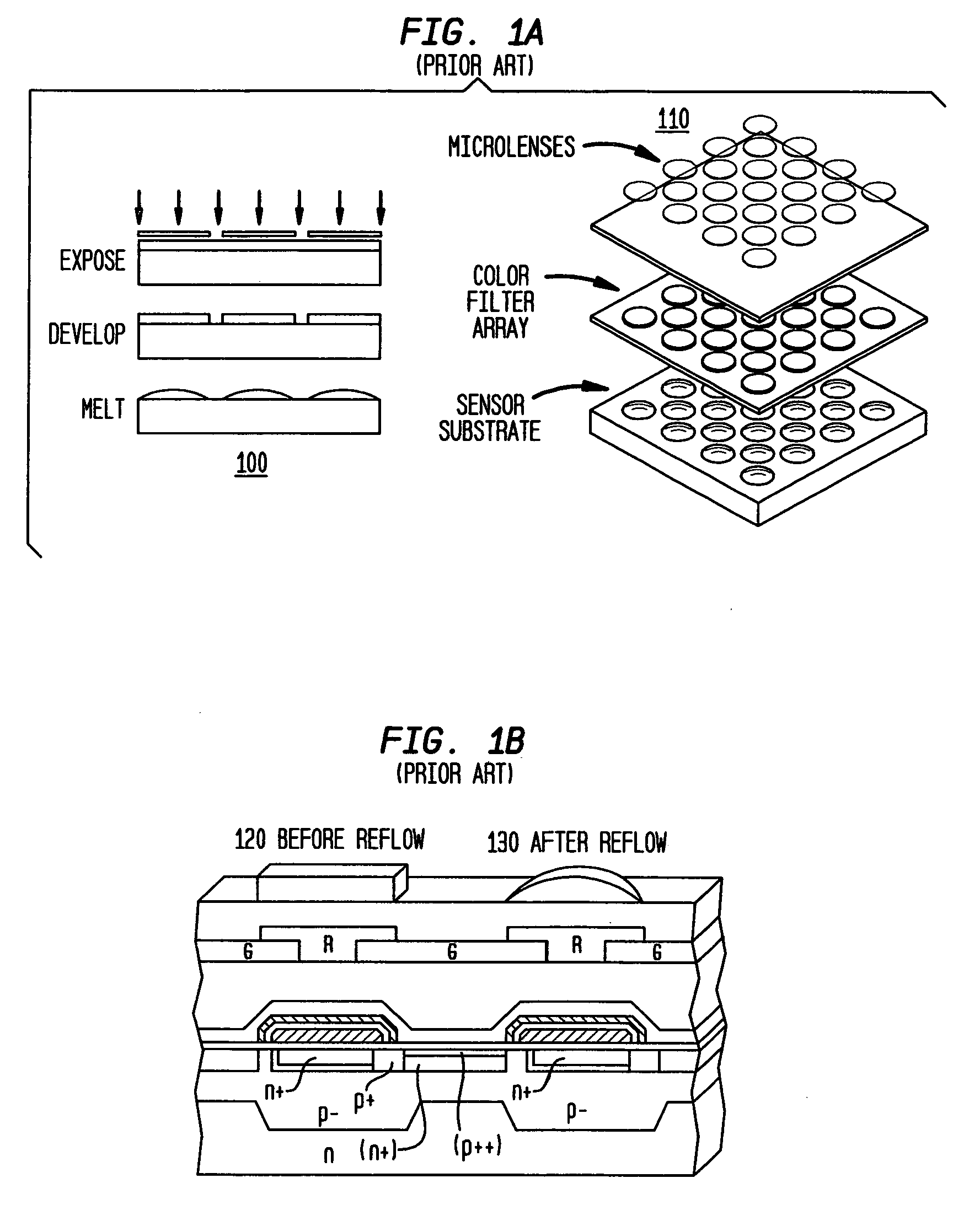

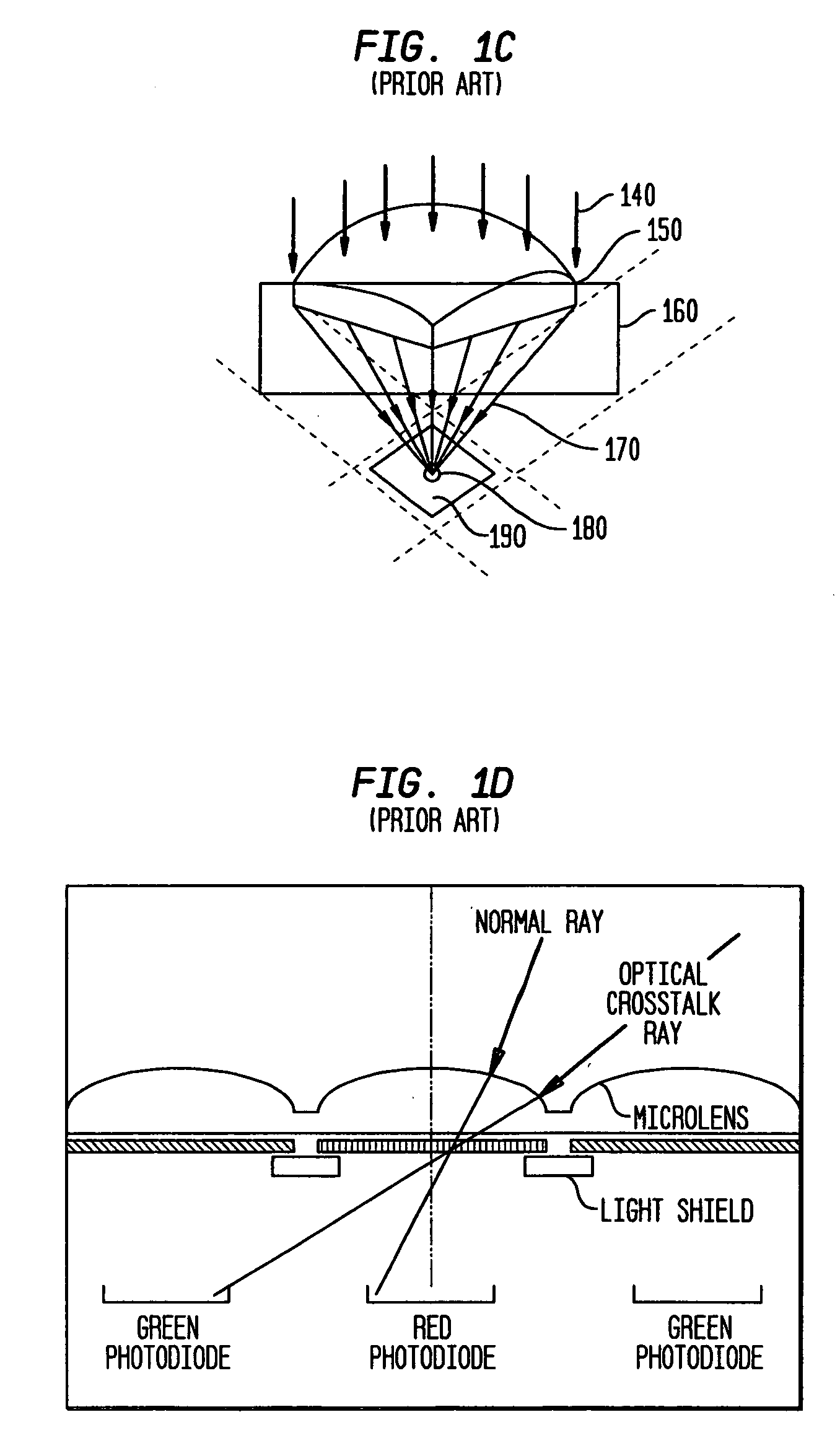

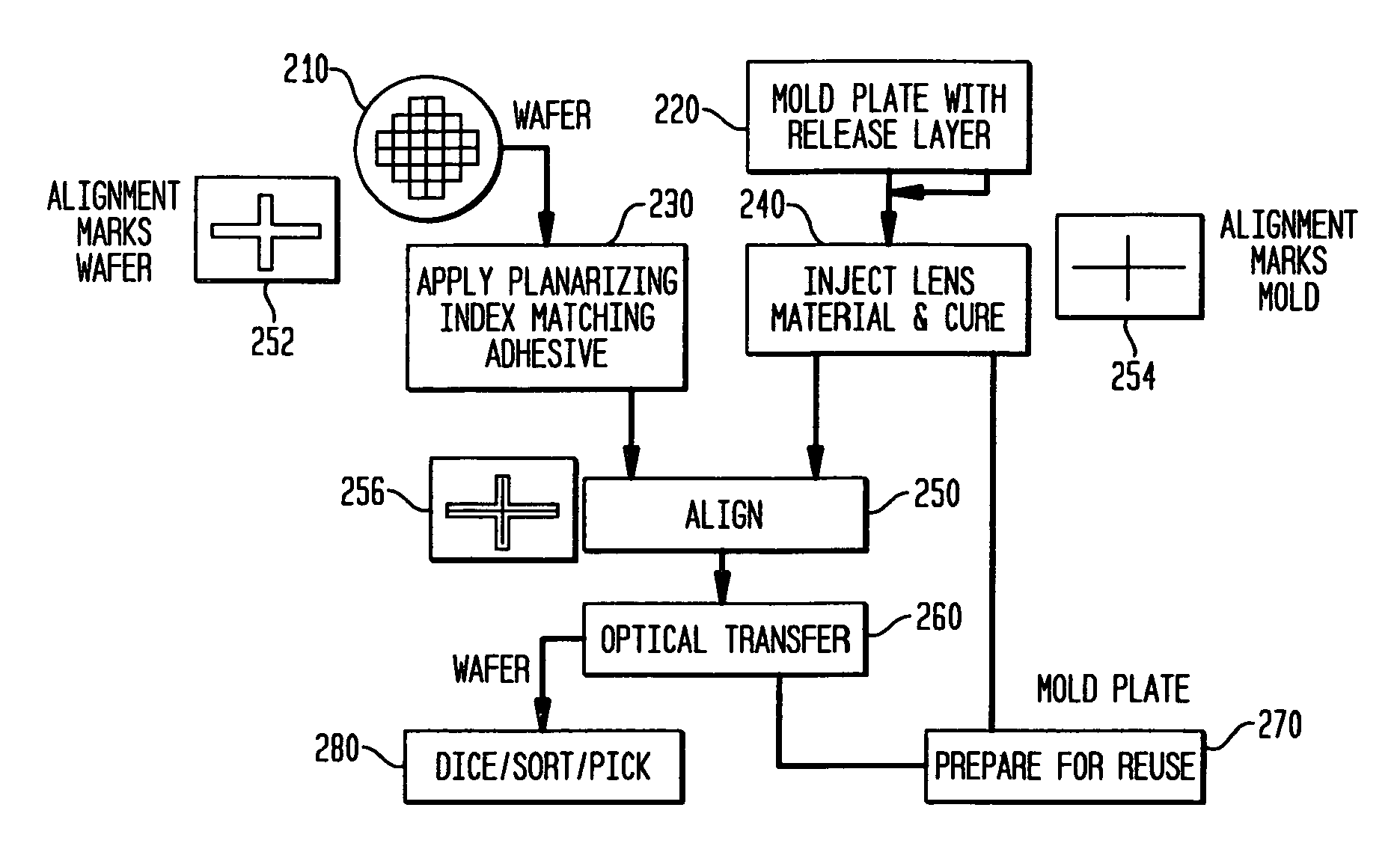

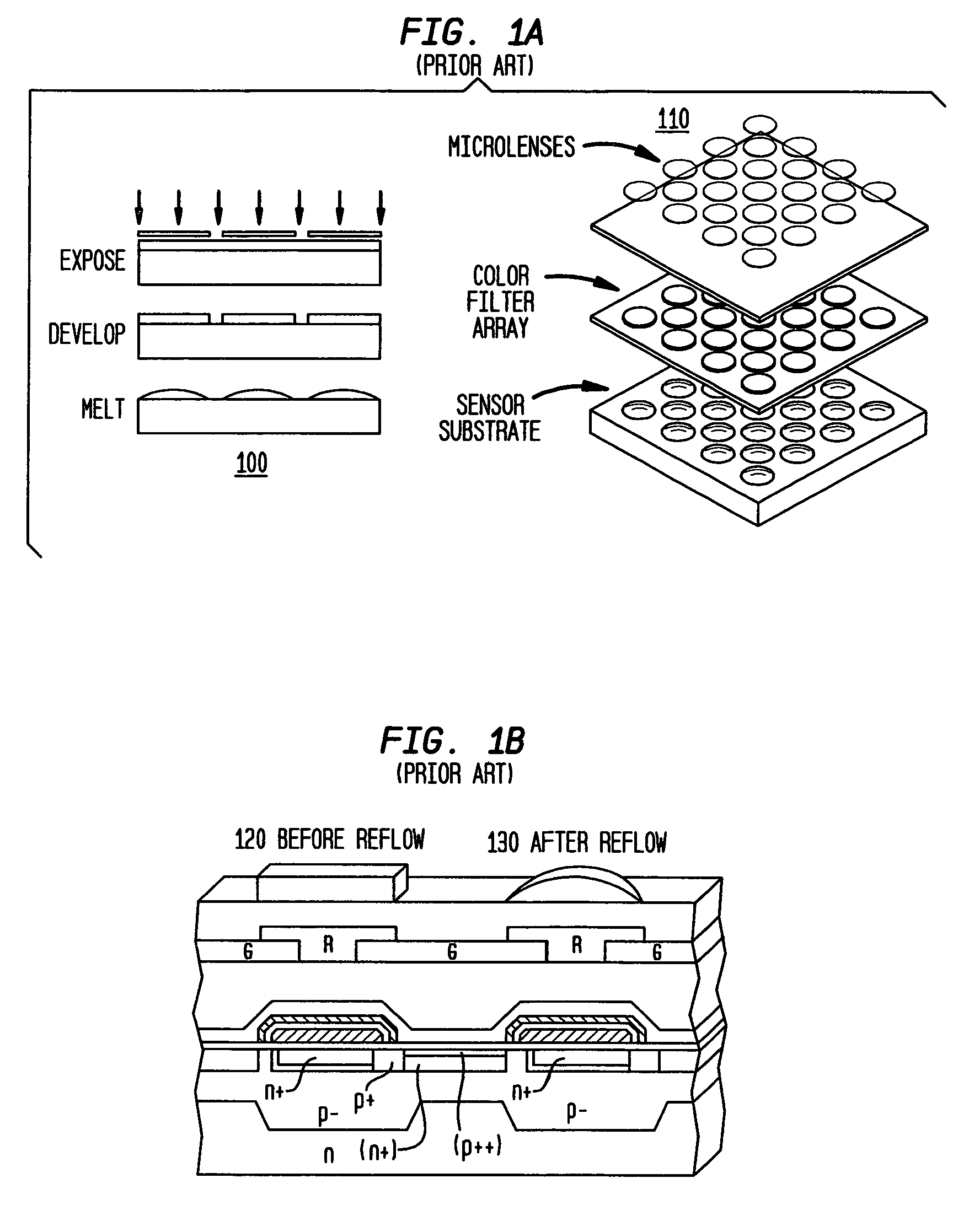

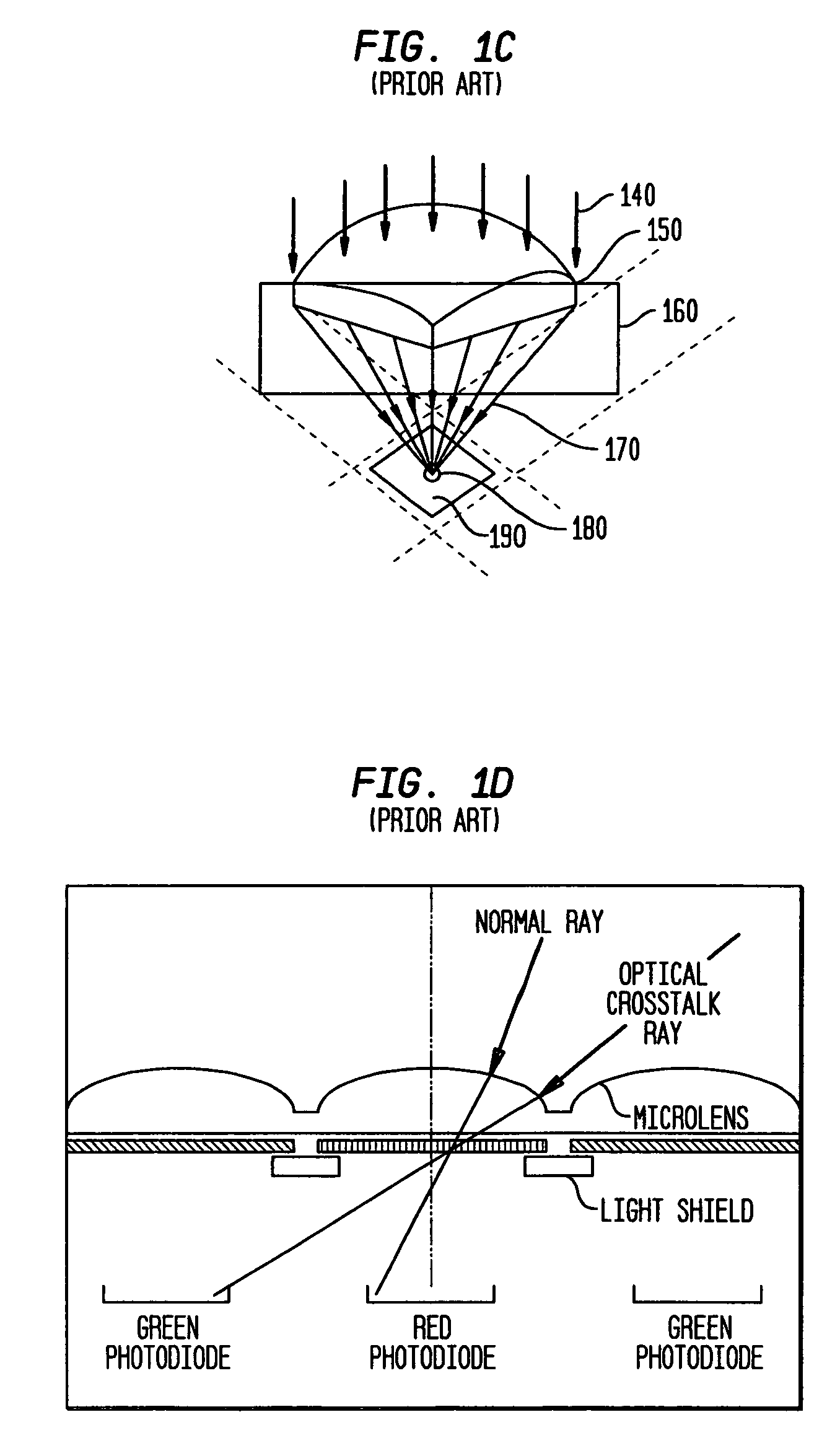

Injection molded microoptics

ActiveUS20070029277A1Minimizes number and task-timesReduces of semiconductor arraysMaterial nanotechnologySolid-state devicesFiberTransformer

A wafer-scale apparatus and method is described for the automation of forming, aligning and attaching two-dimensional arrays of microoptic elements on semiconductor and other image display devices, backplanes, optoelectronic boards, and integrated optical systems. In an ordered fabrication sequence, a mold plate comprised of optically designed cavities is formed by reactive ion etching or alternative processes, optionally coated with a release material layer and filled with optically specified materials by an automated fluid-injection and defect-inspection subsystem. Optical alignment fiducials guide the disclosed transfer and attachment processes to achieve specified tolerances between the microoptic elements and corresponding optoelectronic devices and circuits. The present invention applies to spectral filters, waveguides, fiber-optic mode-transformers, diffraction gratings, refractive lenses, diffractive lens / Fresnel zone plates, reflectors, and to combinations of elements and devices, including microelectromechanical systems (MEMS) and liquid crystal device (LCD) matrices for adaptive, tunable elements. Preparation of interfacial layer properties and attachment process embodiments are taught.

Owner:IBM CORP

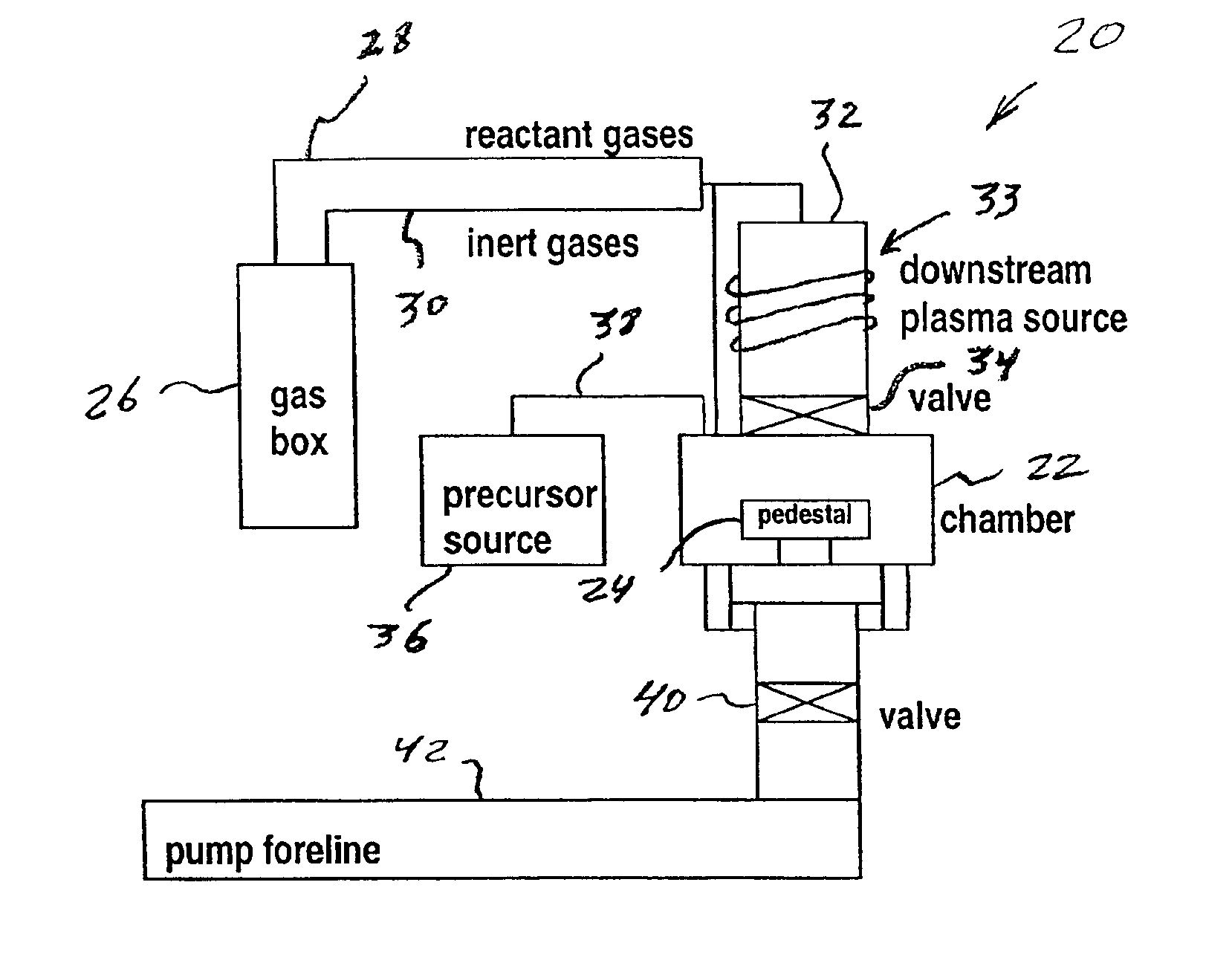

Methods of forming tungsten nucleation layer

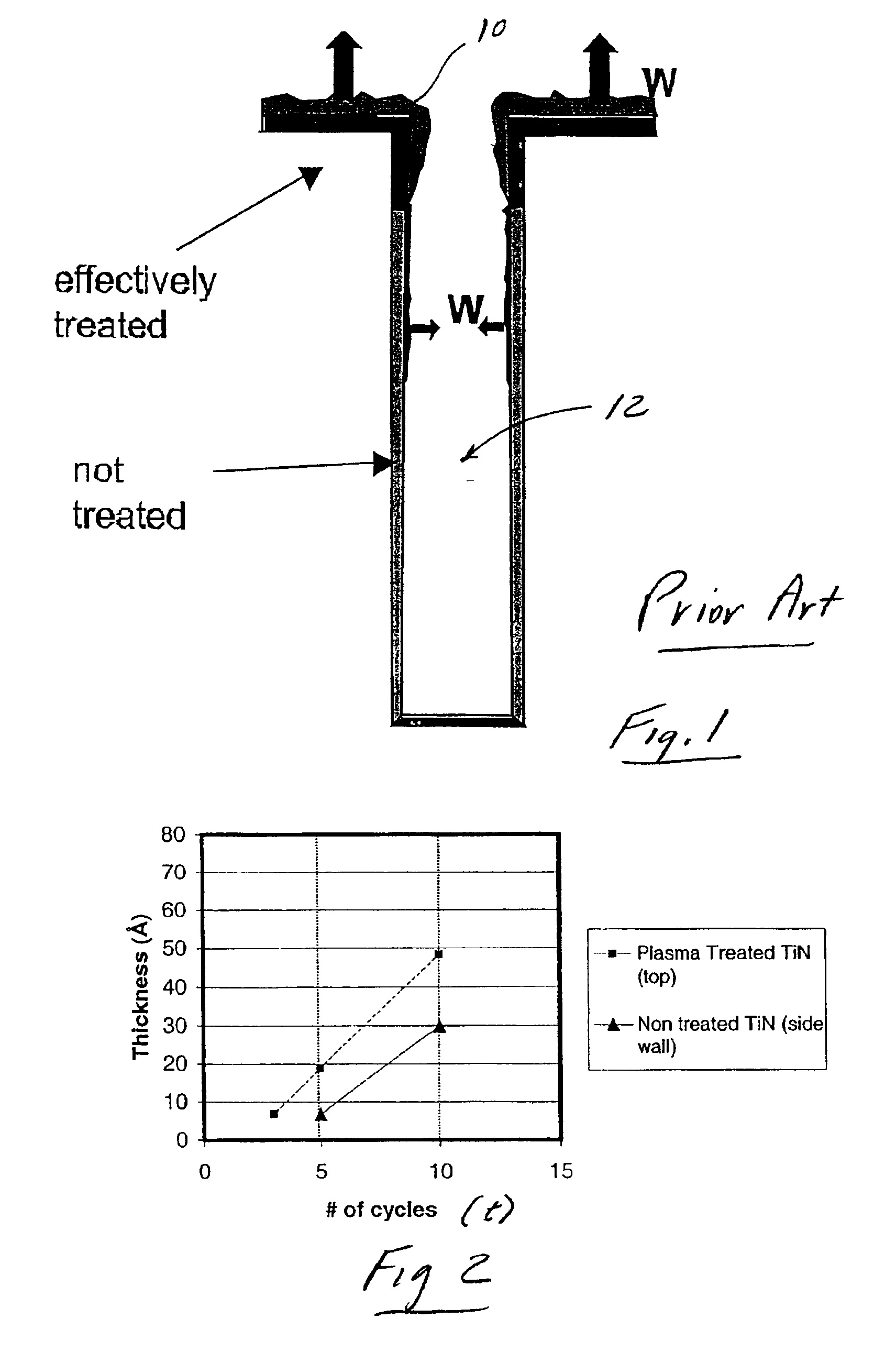

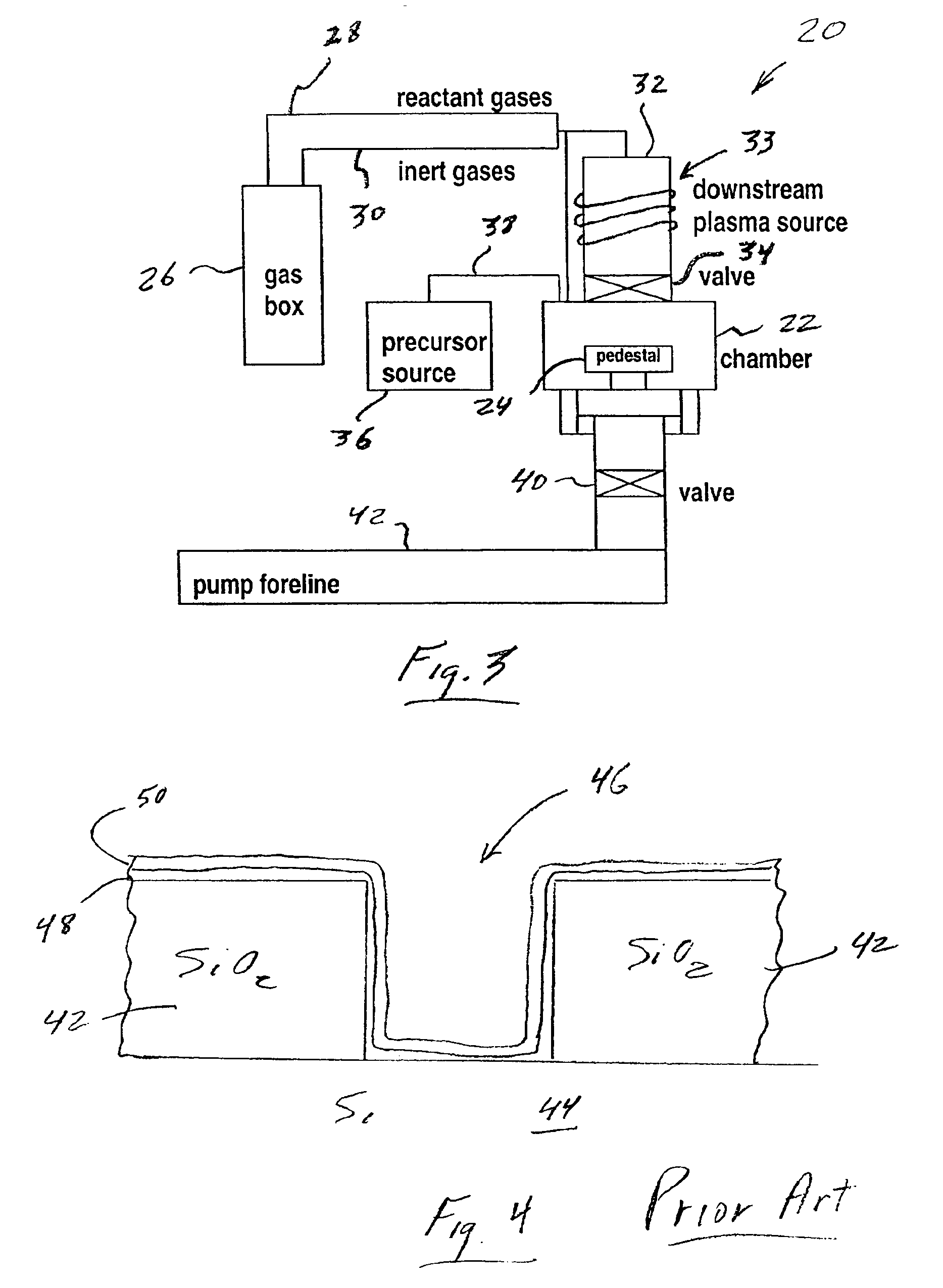

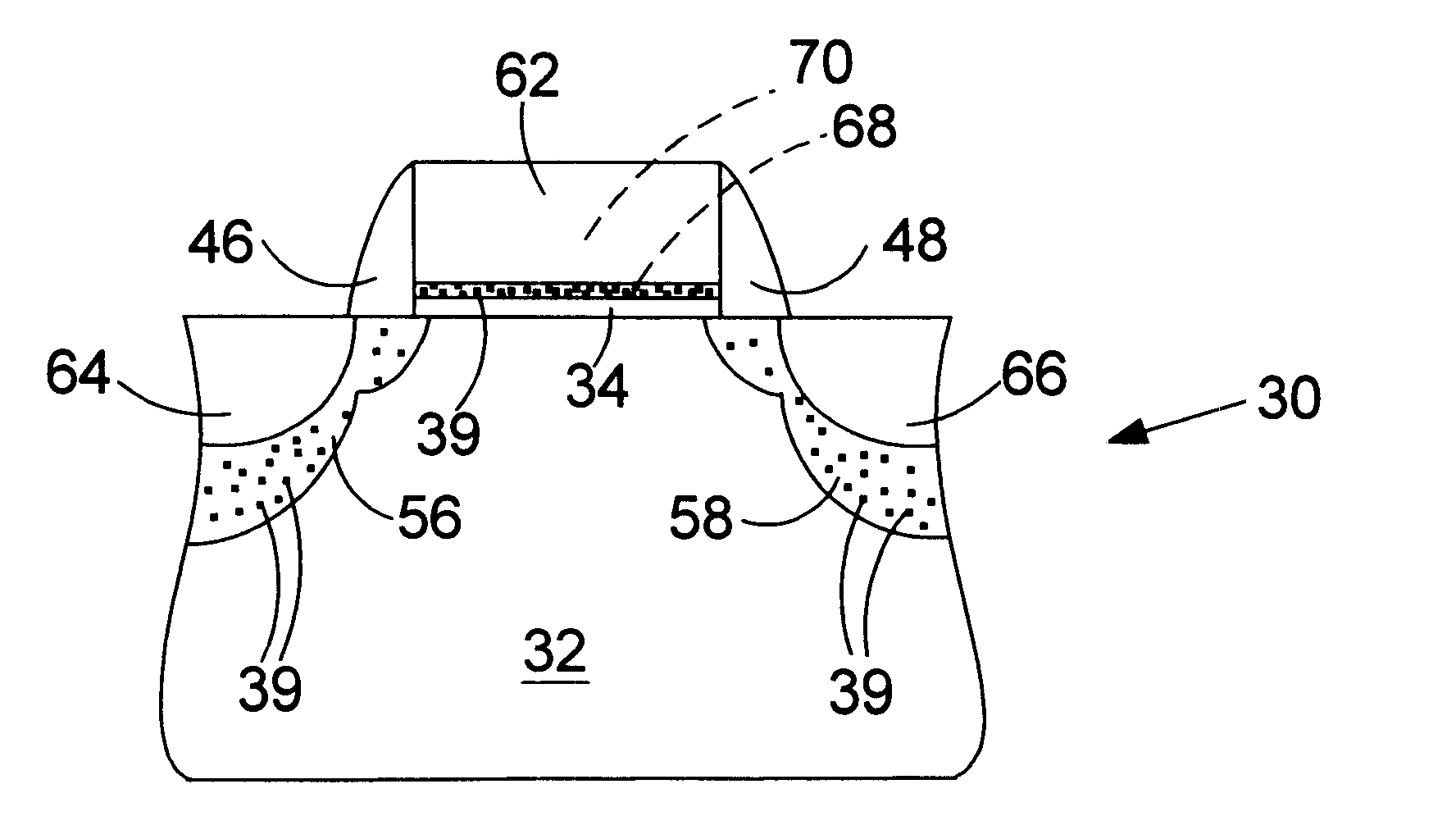

InactiveUS6905543B1Eliminate delaysHighly active andPolycrystalline material growthFrom chemically reactive gasesTitanium nitrideNucleation

The nucleation delay in the formation of a tungsten layer on a substrate is reduced or eliminated by alternative processes. In one process the substrate is exposed to atomic hydrogen before the tungsten nucleation layer is formed. In the other process the substrate is exposed to a boron hydride such as diborane (B2H6) before the nucleation layer is formed. The process works effectively to reduce or eliminate the tungsten nucleation delay on a variety of surfaces, including silicon, silicon dioxide, silicon nitride and titanium nitride.

Owner:NOVELLUS SYSTEMS

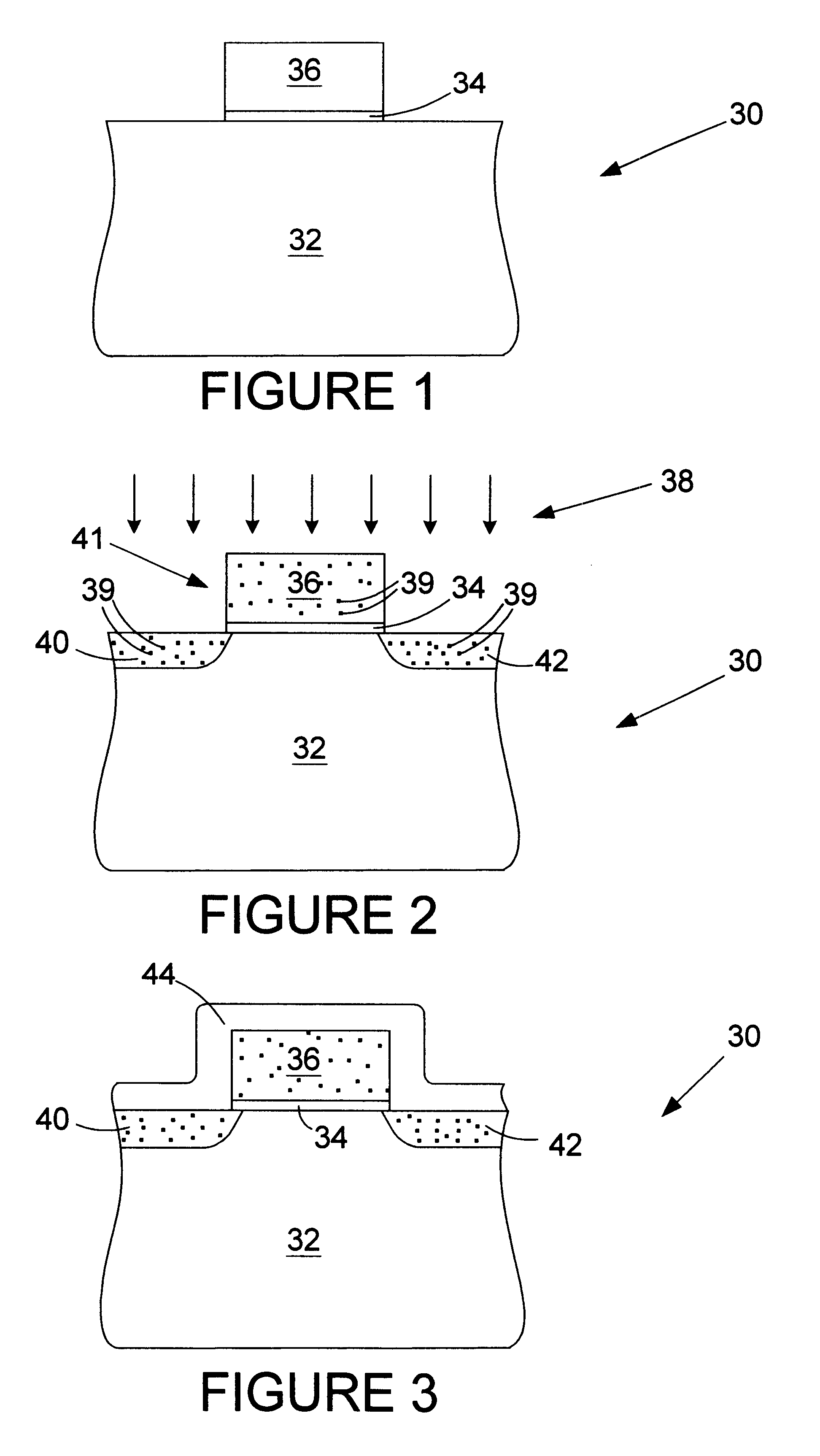

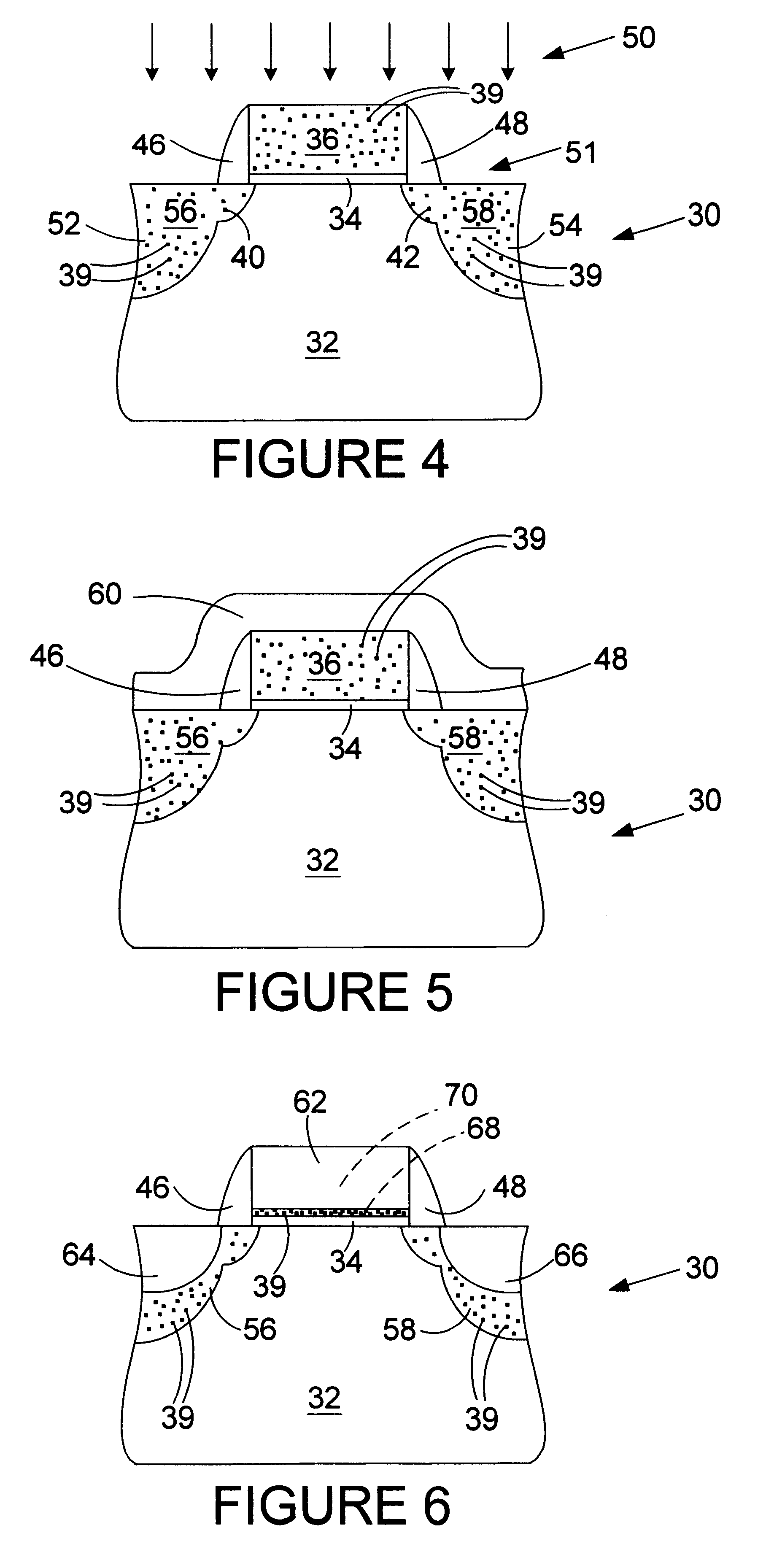

Metal gate electrode using silicidation and method of formation thereof

A semiconductor device is fabricated by providing a substrate, and providing a dielectric layer on the substrate. A polysilicon body is formed on the dielectric layer, and a metal layer is provided on the polysilicon body. A silicidation process is undertaken to silicidize substantially the entire polysilicon body to form a gate on the dielectric. In an alternative process, a cap layer is provided on the polysilicon body, which cap layer is removed prior to the silicidation process. The polysilicon body is doped with a chosen specie prior to the silicidation process, which dopant, during the silicidation process, is driven toward the dielectric layer to form a gate portion having a high concentration thereof adjacent the dielectric, the type and concentration of this specie being instrumental in determining the work function of the formed gate.

Owner:ADVANCED MICRO DEVICES INC

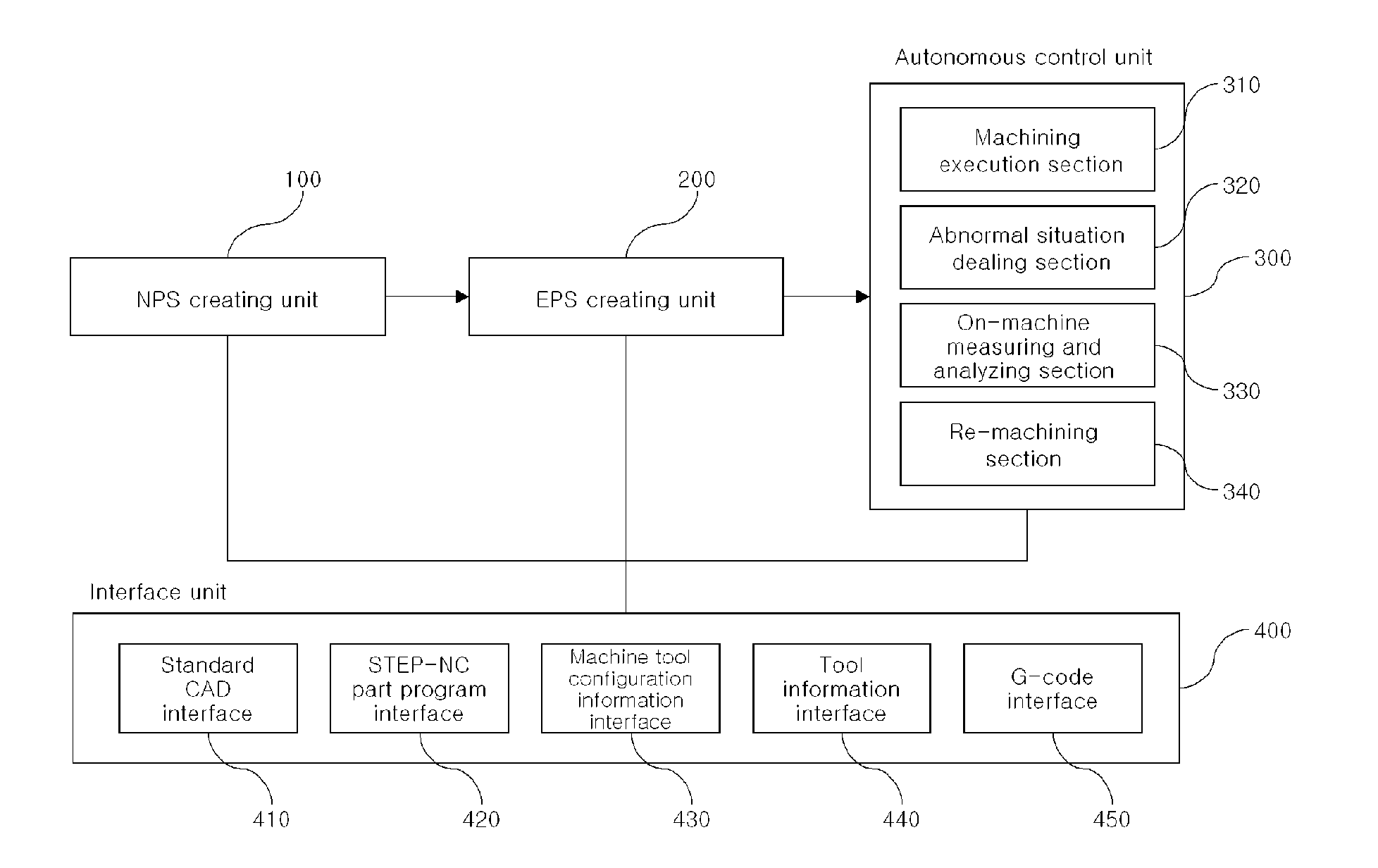

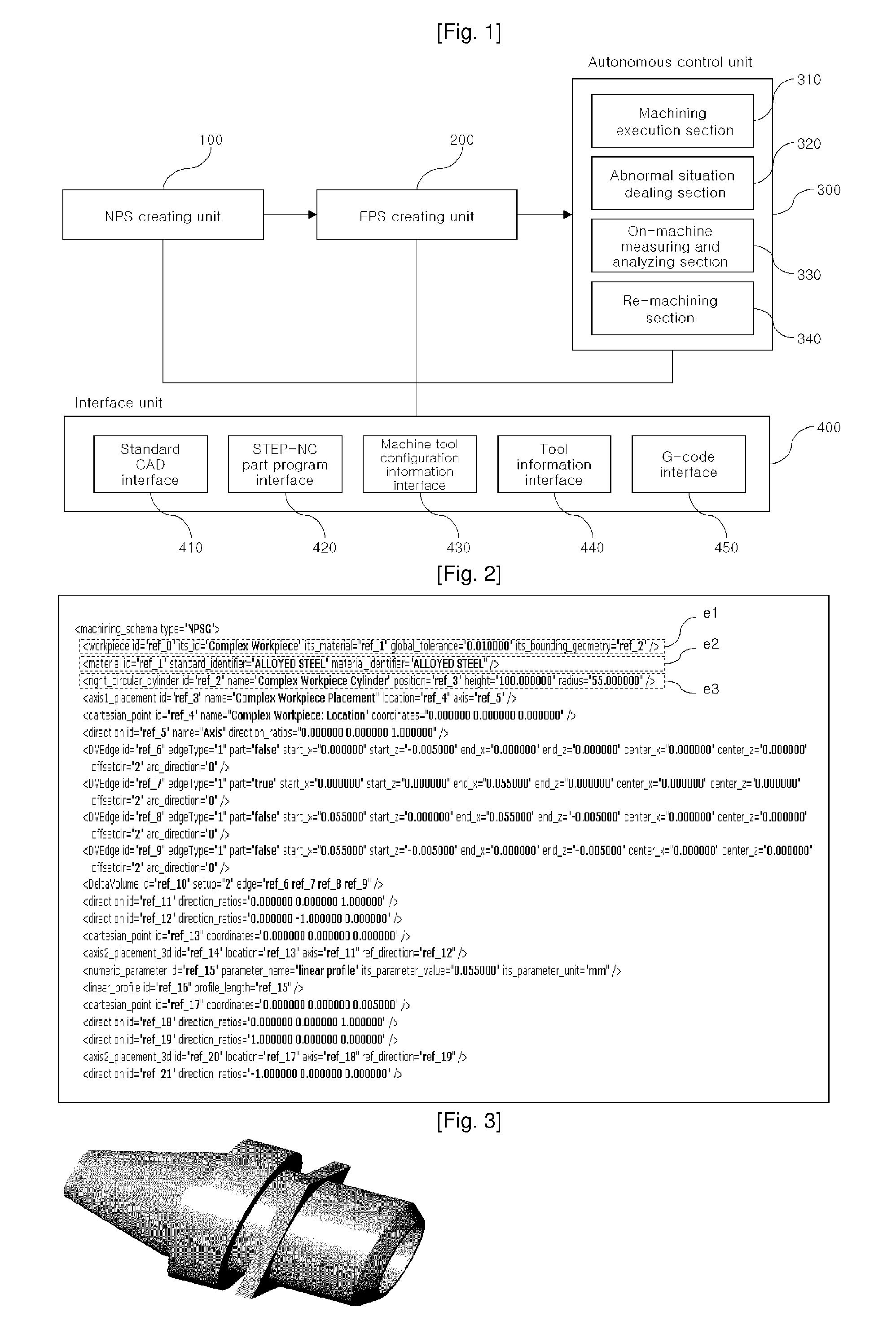

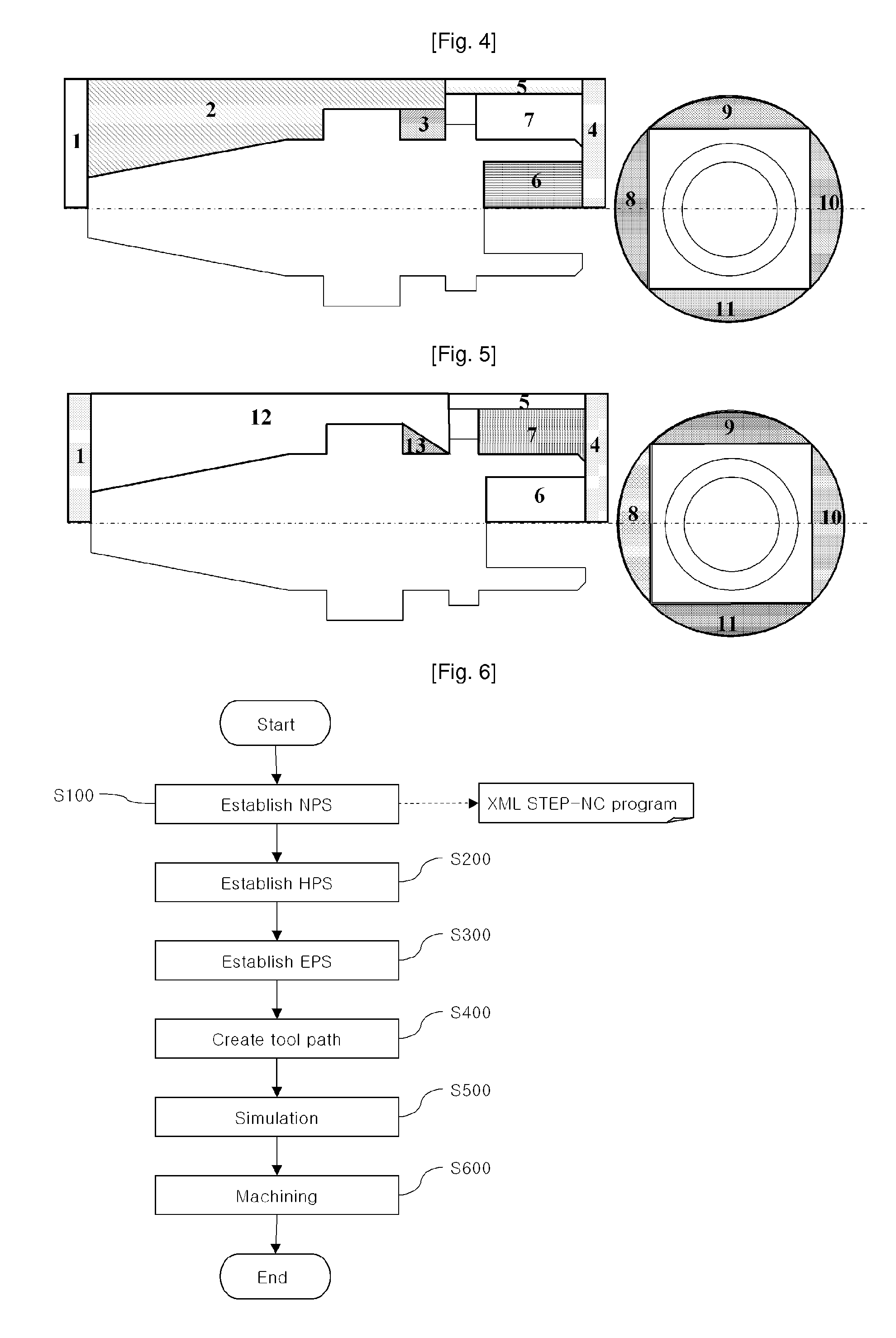

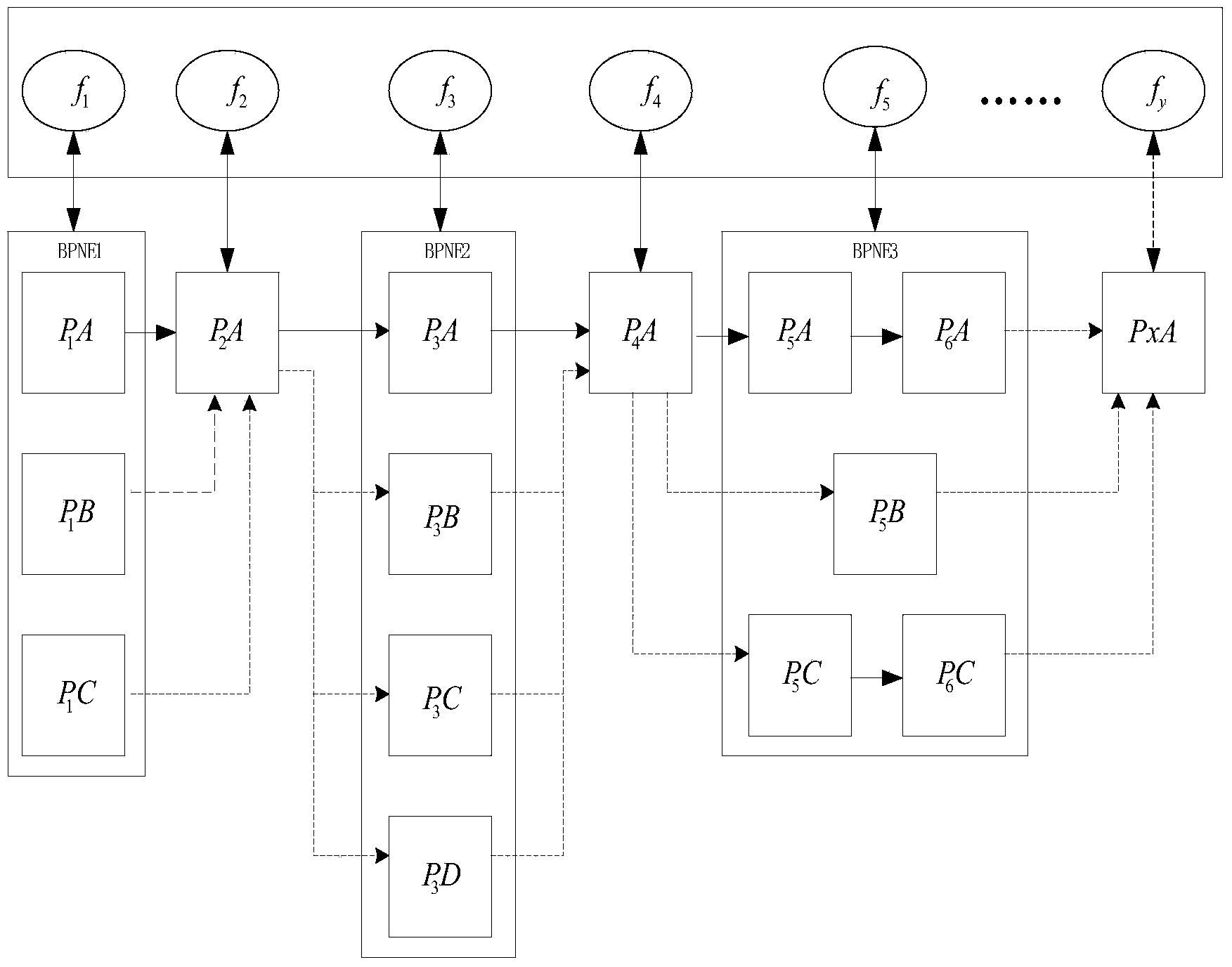

Method of Non-Linear Process Planning and Internet-Based Step-Nc System Using the Same

InactiveUS20080281463A1Decrease productivityEasy constructionProgramme controlSpecial data processing applicationsSTEP-NCAlternative process

The present invention relates to a method of creating a non-linear process plan and an Internet-based STEP-NC system using the same, and more particularly, to a method of creating a non-linear process plan, wherein the non-linear process plan including information on a variety of alternative processes and machining sequences is established in consideration of situations in the field, thereby autonomously dealing with abnormal situations while executing optimal machining, and to an Internet-based STEP-NC system, wherein a STEP-NC part program in an XML format is created based on the established process plan so that process information can be easily exchanged with other systems via the Internet. Since the present invention provide a plurality of machining alternatives to the field, and thus, allow a STEP-NC machine tool to execute machining optimized depending on field situations and to autonomously deal with abnormal situations that may occur during machining.

Owner:POSTECH ACAD IND FOUND

Process for creating expandable tire chamber

InactiveUS6905564B1Improve gripTelevision system scanning detailsAuxillary traction increasing equipmentRoad surfaceEngineering

A process for producing a tire having an expandable chamber utilized for extending and retracting studs provided in the periphery of the tire. In one embodiment, a non-stick film is strategically positioned between the casing and the tread prior to curing the tread onto the casing. The interface at either side of the film forms the sides of an expandable chamber. The tread side of the chamber is inset and studs are affixed thereto. Expansion of the chamber extends the studs out of the inset and into engagement with a road surface. Alternative processes provide a channel in the tread and the expansion chamber formed in the channel.

Owner:Q TIRES

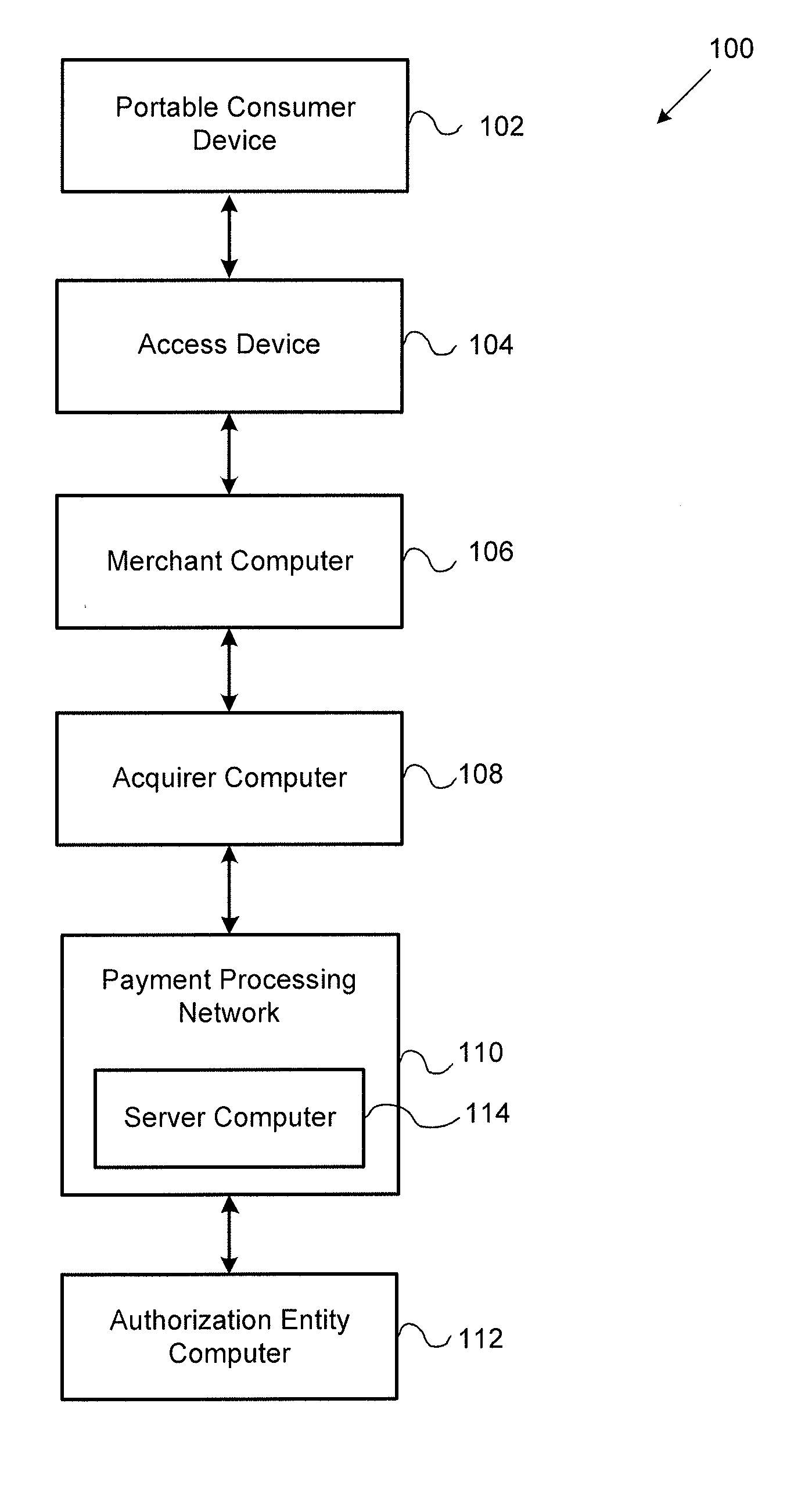

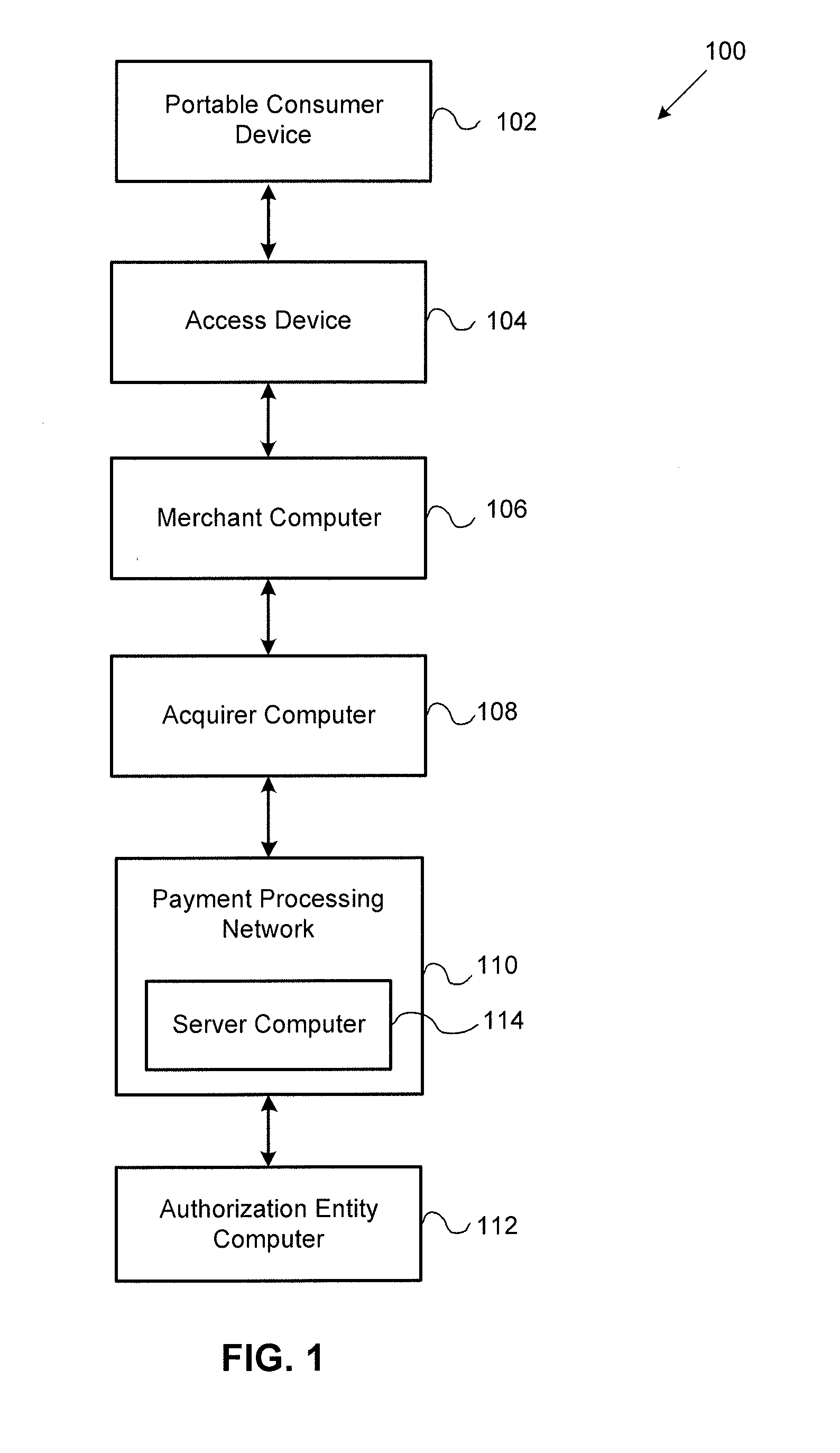

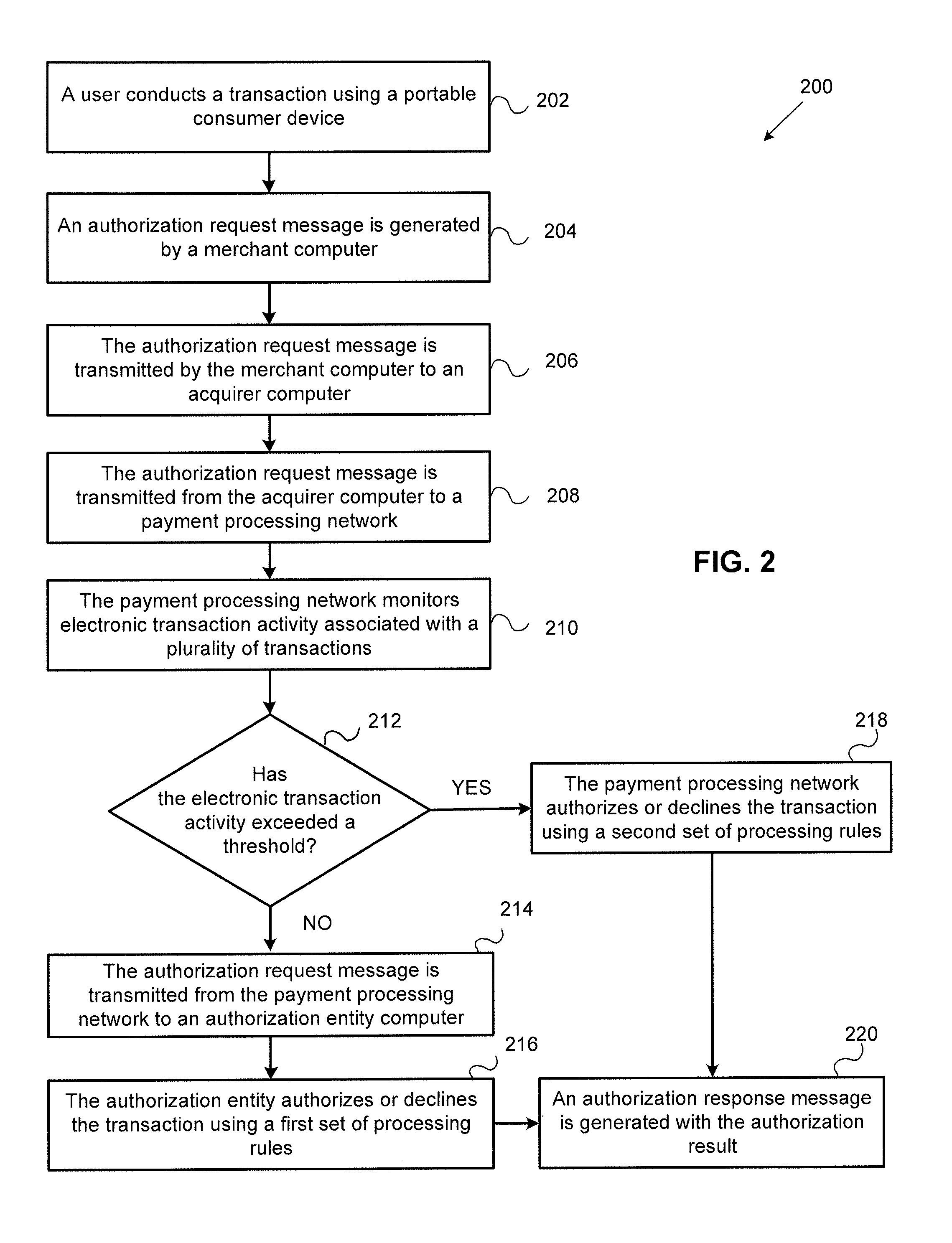

Processor Issuer Detection and User Level Stand-In Authorization

ActiveUS20140304158A1Improved authorization outcomePromote resultsFinanceProtocol authorisationPaymentParallel computing

Embodiments of the invention are directed to systems and methods for stand-in processing using data driven capabilities. Transaction activity of an issuer may be monitored to detect a major incident and to automatically invoke stand-in processing. By modeling each individual account holder's behavior, improved authorization outcomes may be provided by a payment processing network during stand-in processing.

Owner:VISA INT SERVICE ASSOC

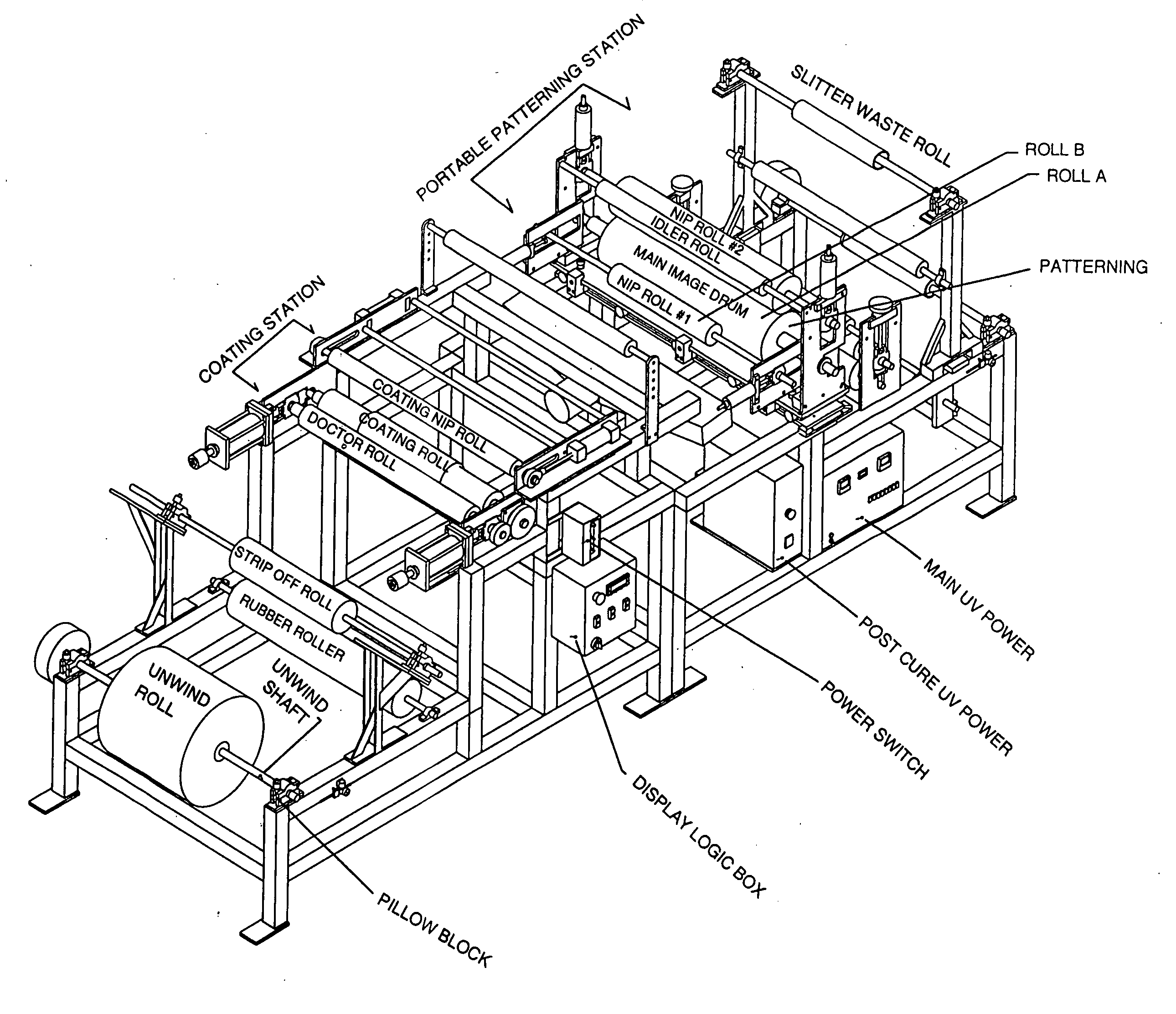

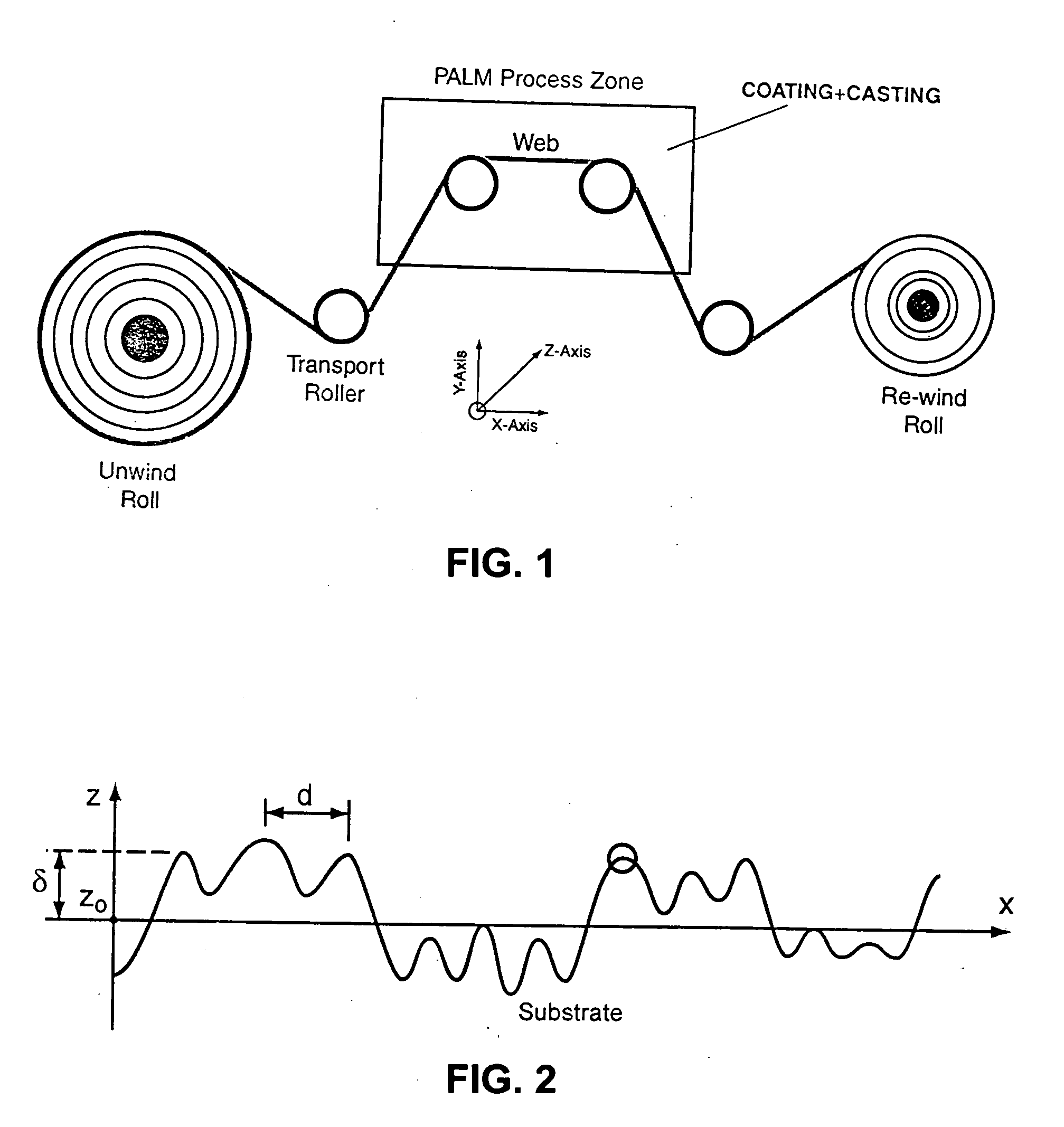

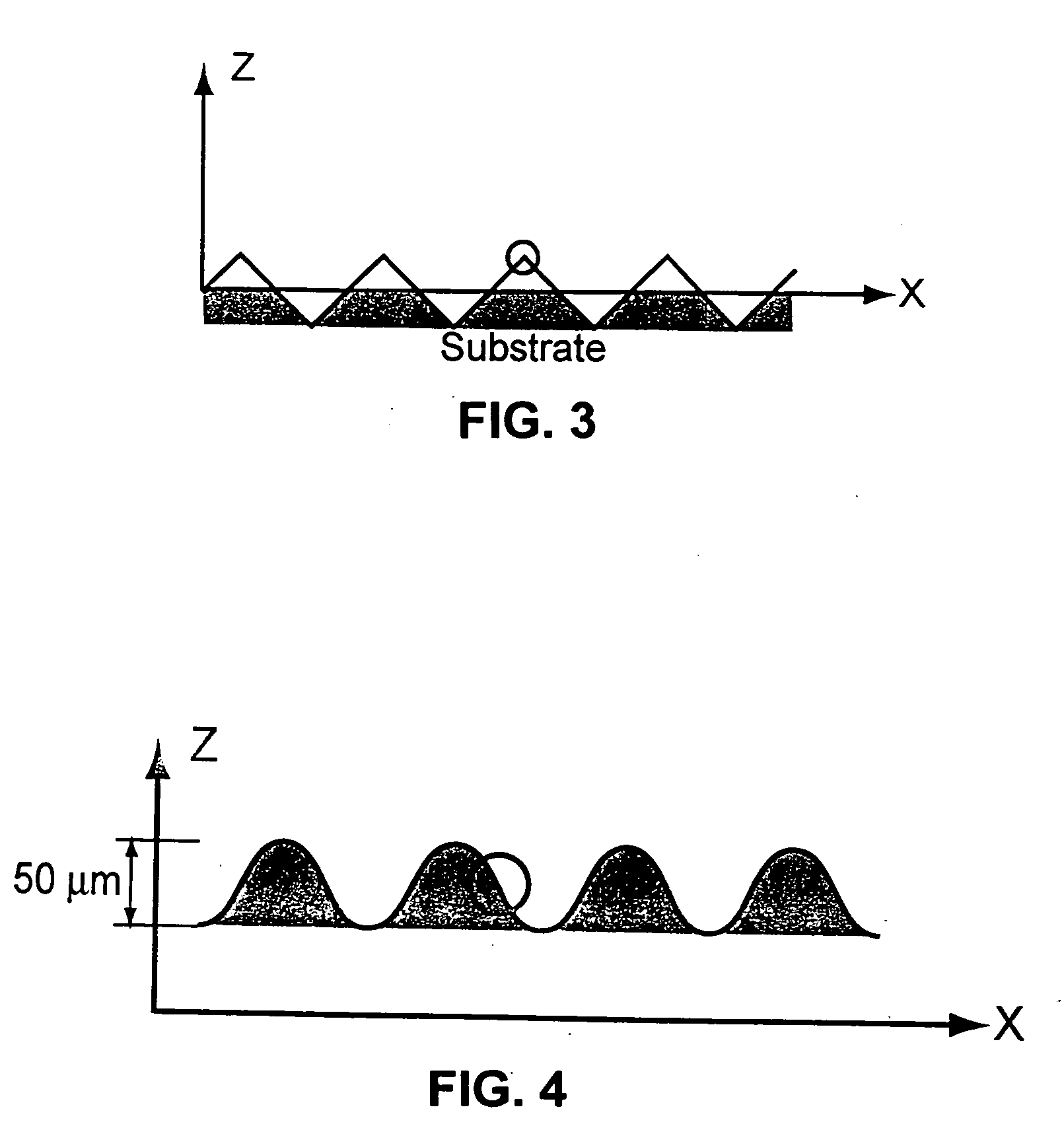

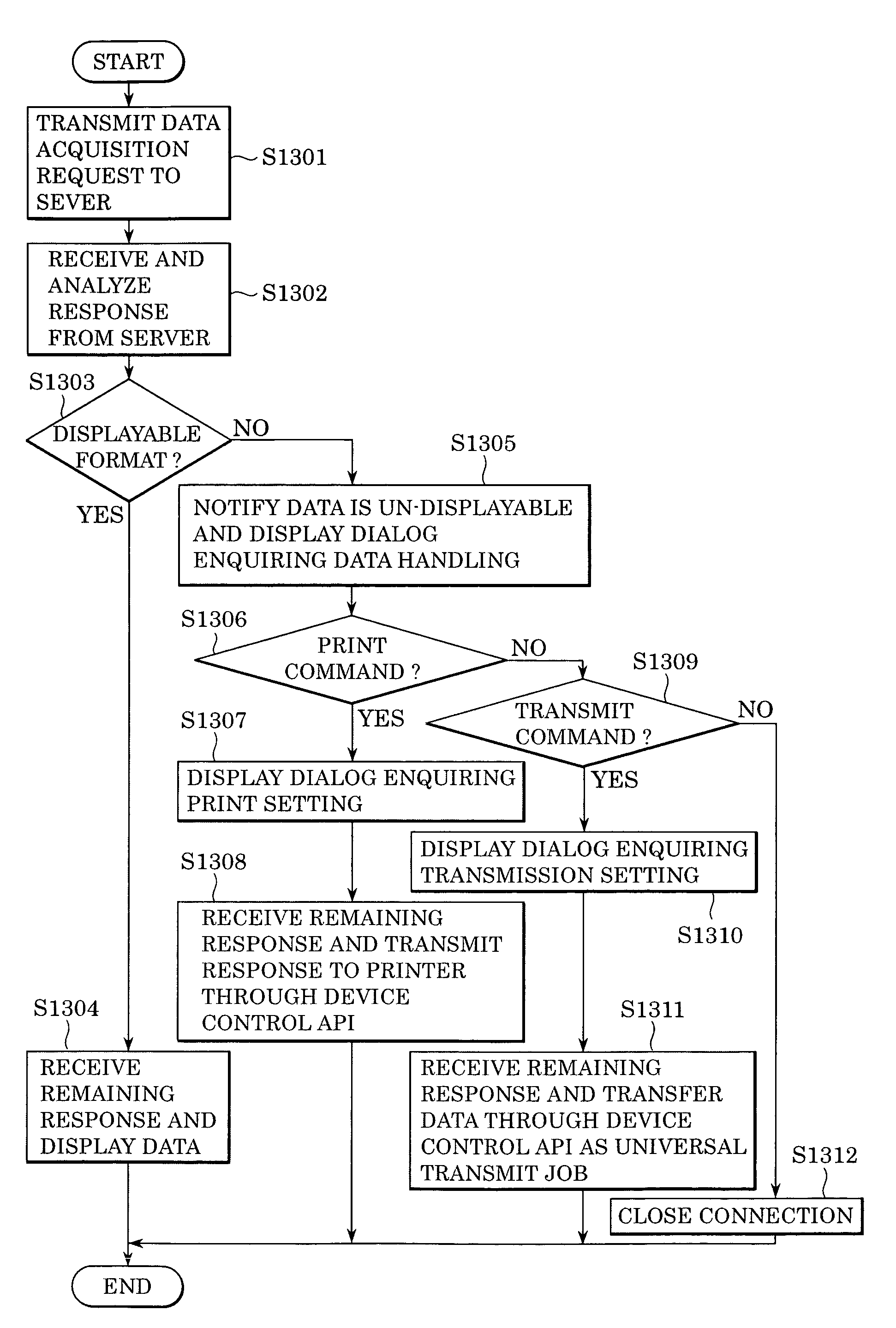

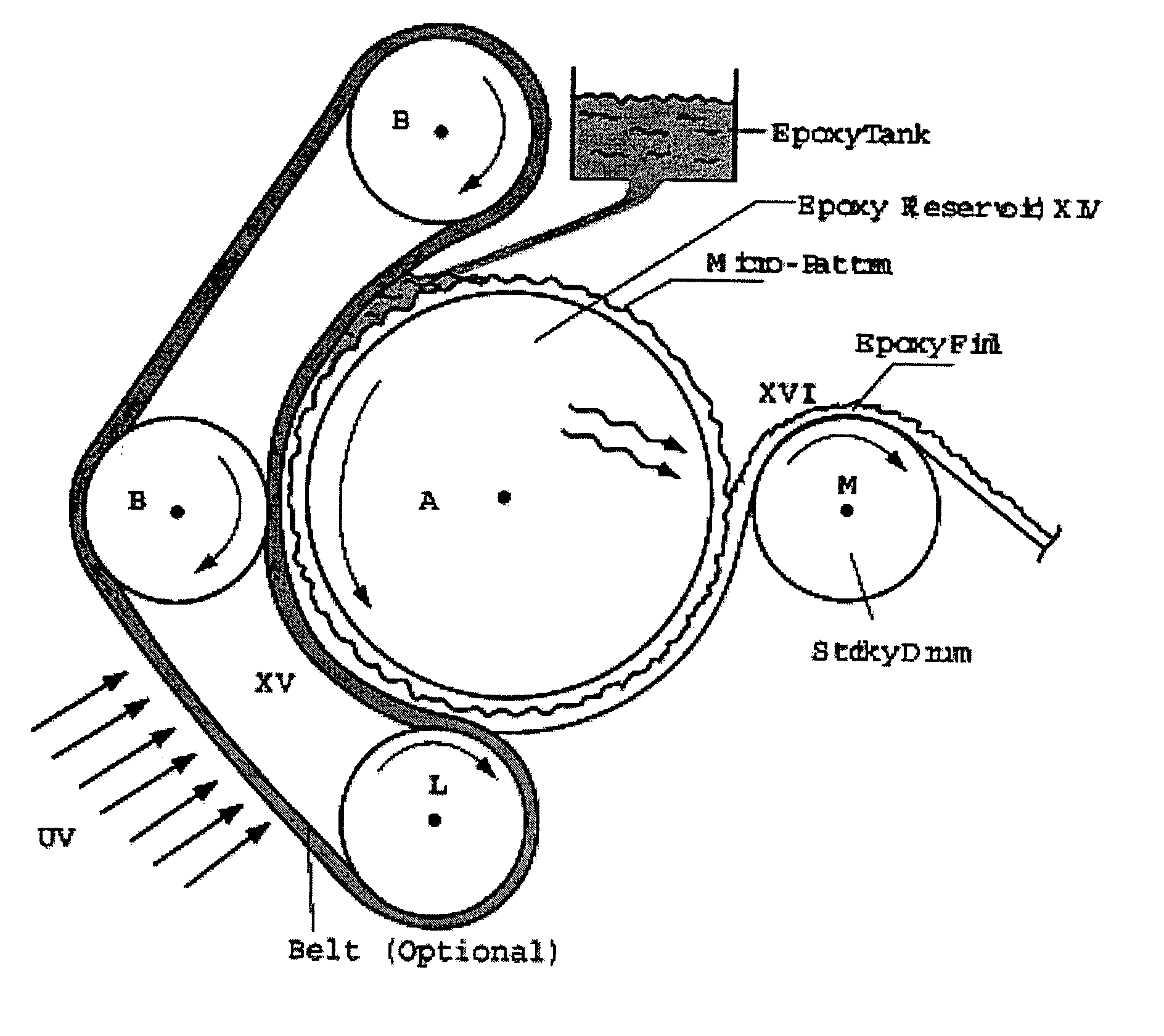

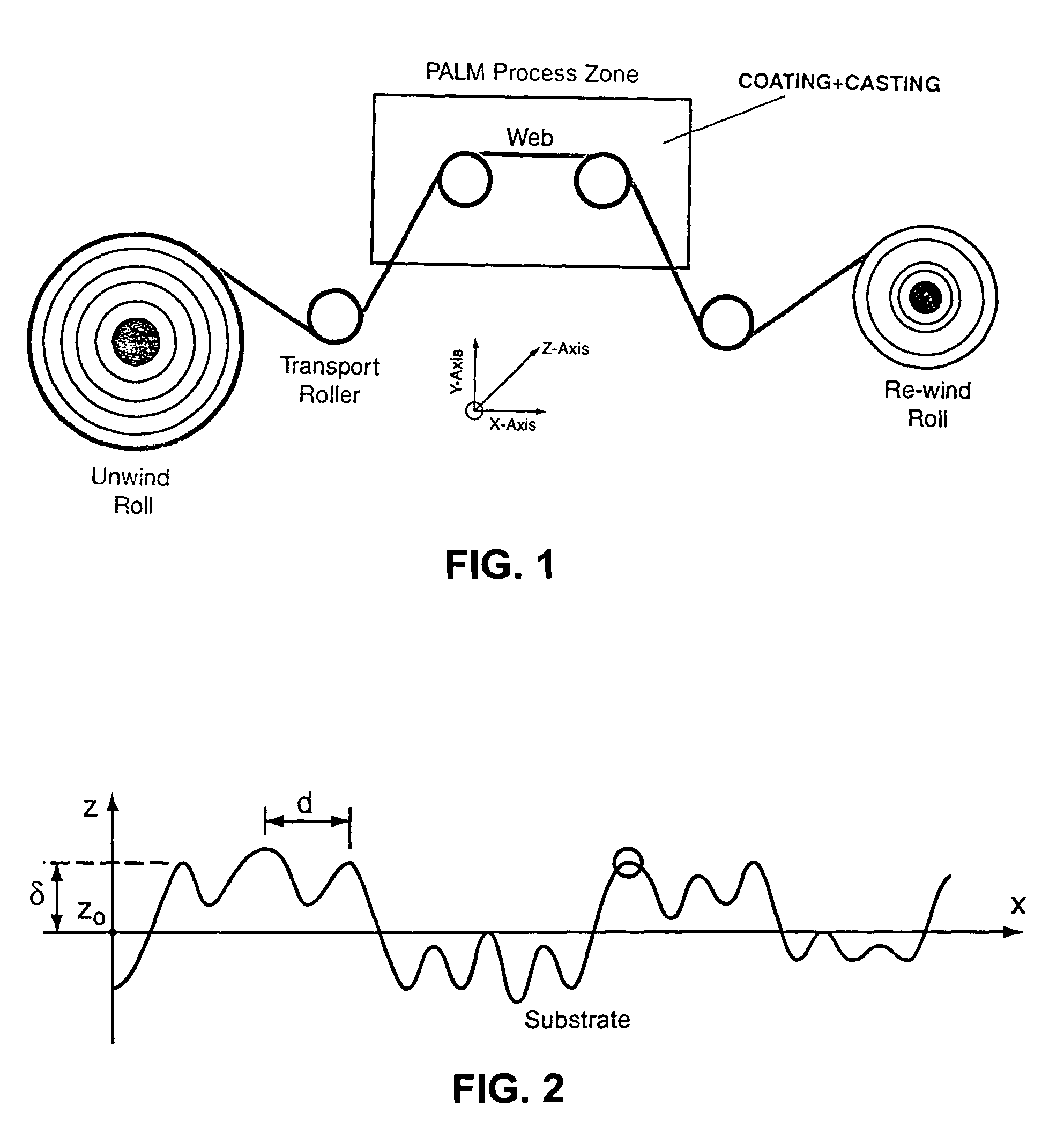

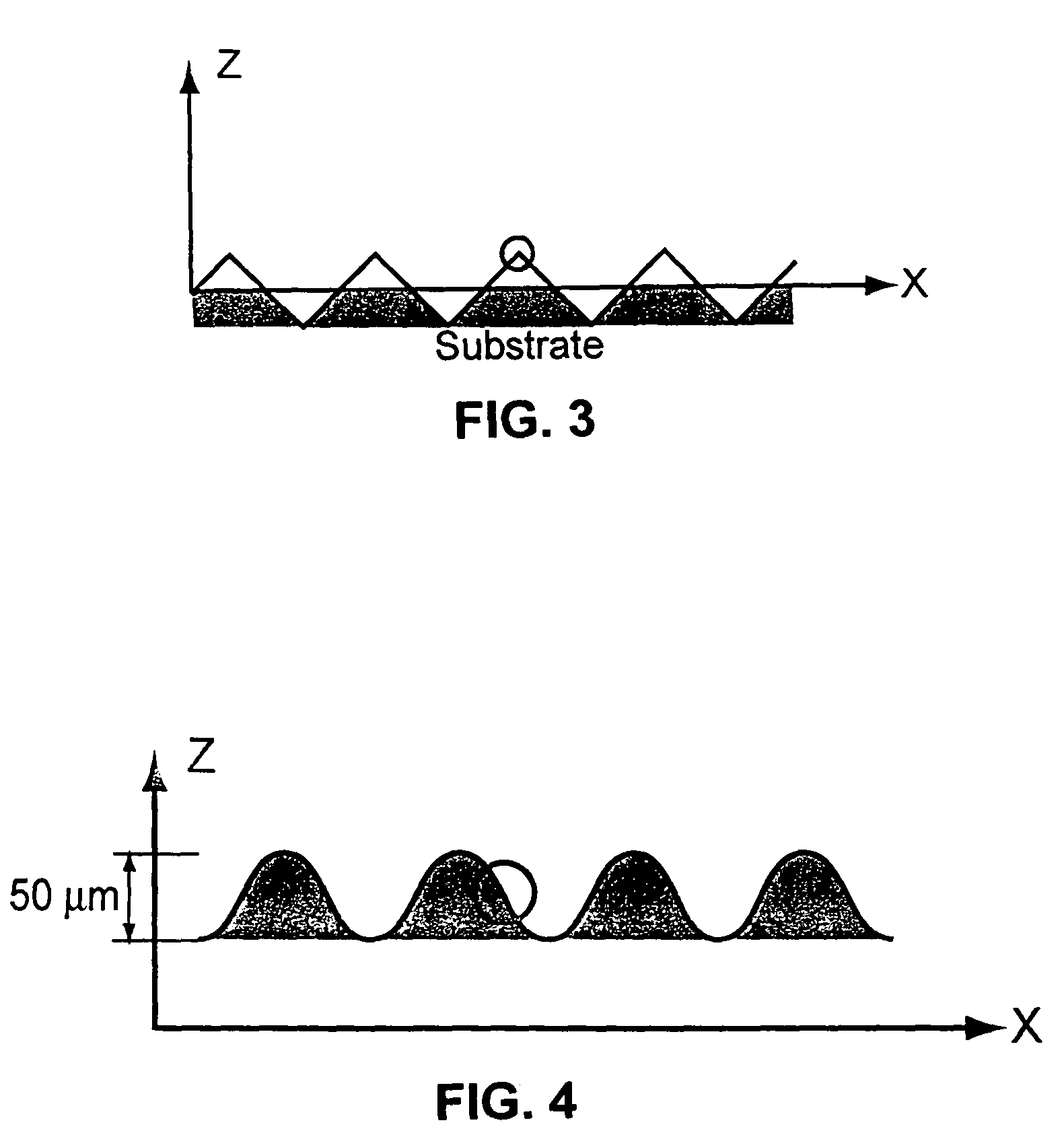

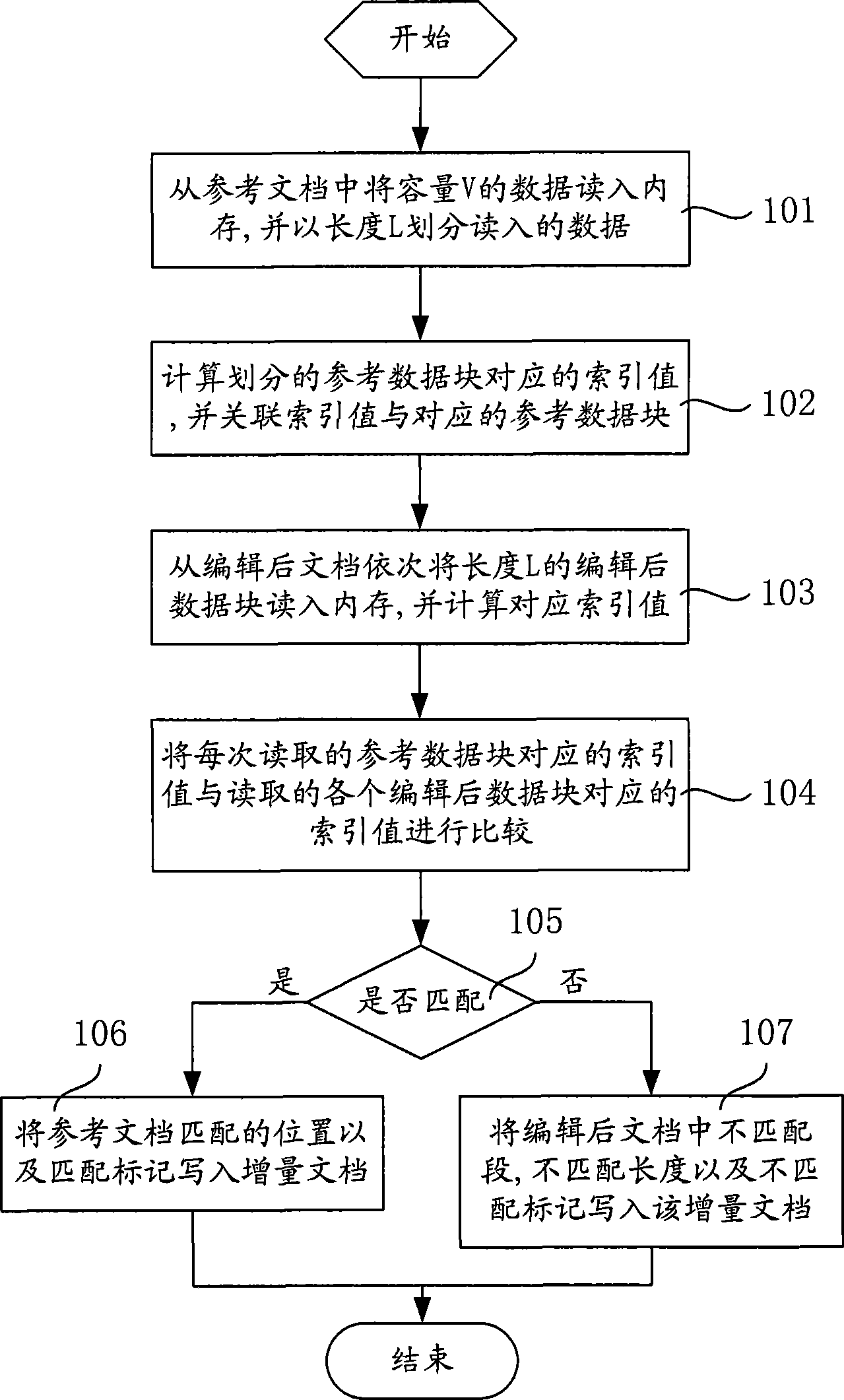

Roll-to-roll method and system for micro-replication of a pattern of large relief three-dimensional microstructures

ActiveUS20080156421A1High viscosityMechanical working/deformationPaper/cardboard wound articlesPolyesterEpoxy

A method and system referred to as PALM (Patterning by Adhesive of Large Relief Three-Dimensional Microstructures) with large reliefs exceeding 1 μm and being as large as 100 μm. The microstructures can be either deterministic (such as microprisms), or random (such as diffusers), the first obtained by copying an original supermaster, and latter obtained by copying a laser speckle pattern. The master process entails copying a supermaster into the form of the microstructure constituting a pattern on the patterning cylinder (called a drum), to be then continuously multiplied in the PALM system, in a continuous roll-to-roll web process. The latter method, together with the related system, is the subject of this invention. The rolls continuously repeat the master pattern, copying by adhesive with large viscosity on acrylic (hybrid) as well as by a monolithic process. The monolithic process can be accomplished using temperature and pressure, or by UV-cured polymerization. Therefore, the invention comprises three alternative processes: one, hybrid (adhesive on acrylic), and two monolithic ones. In the PALM (hybrid) process, an epoxy is wet-coated on film substrates such as polycarbonate (PC), polyester (PET), (PE), or other flexible material. The adhesive, in liquid form, is applied to the substrate by a self-metered coating sub-process. In the present invention, the adhesive is used for forming the microstructure pattern. The microstructure pattern is replicated from a master roll or image drum onto a coating roll.

Owner:LUMINIT

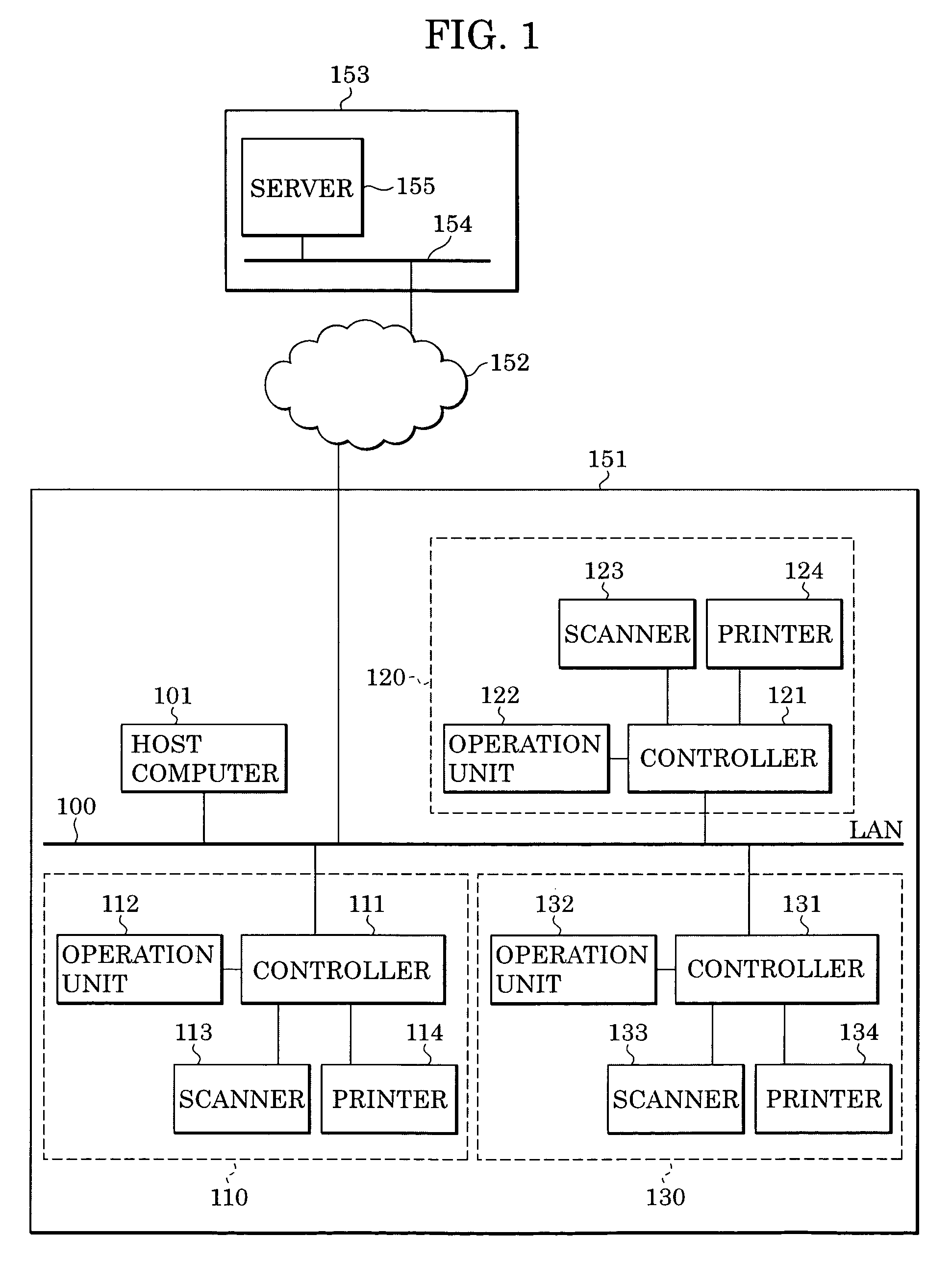

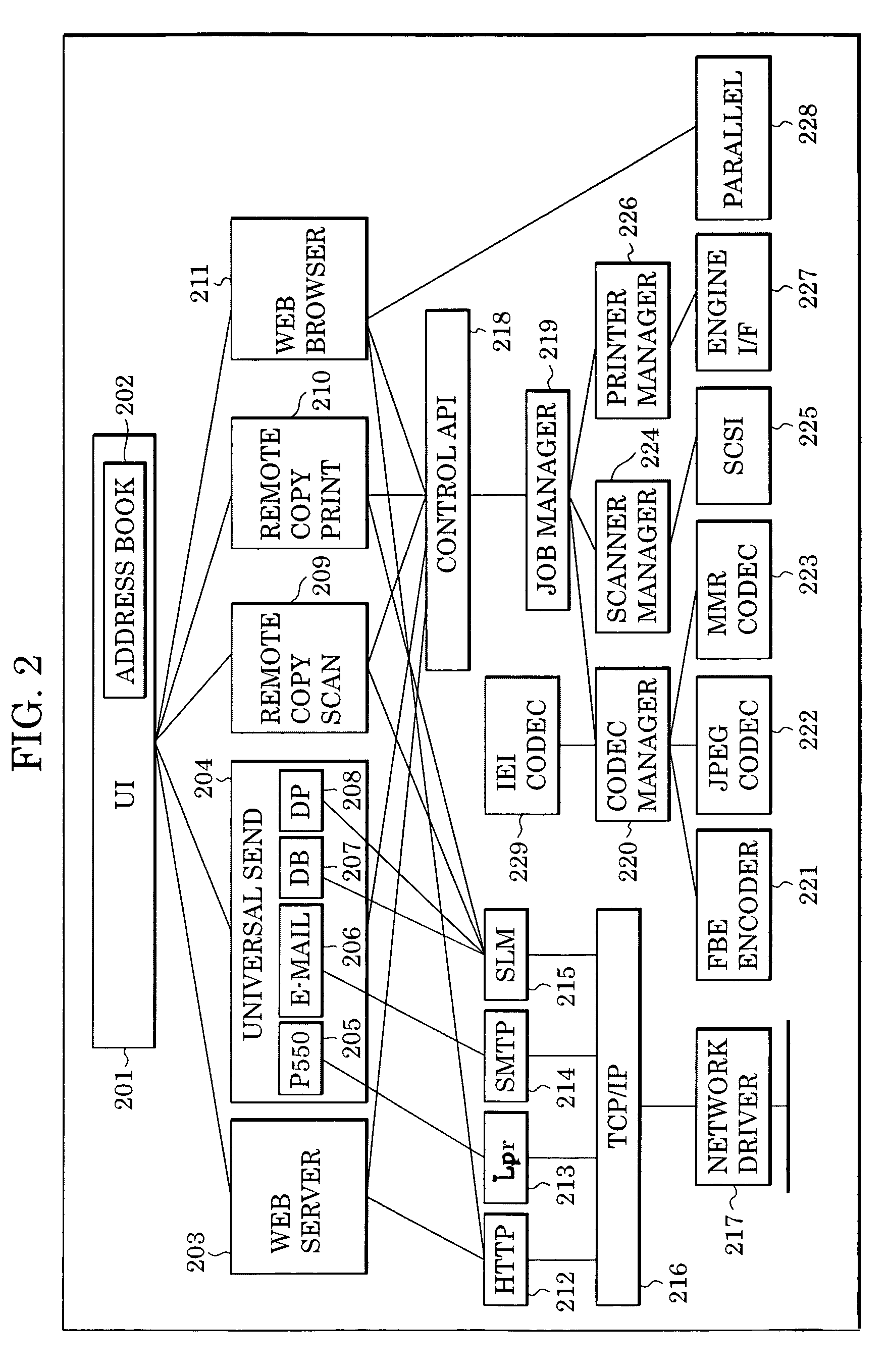

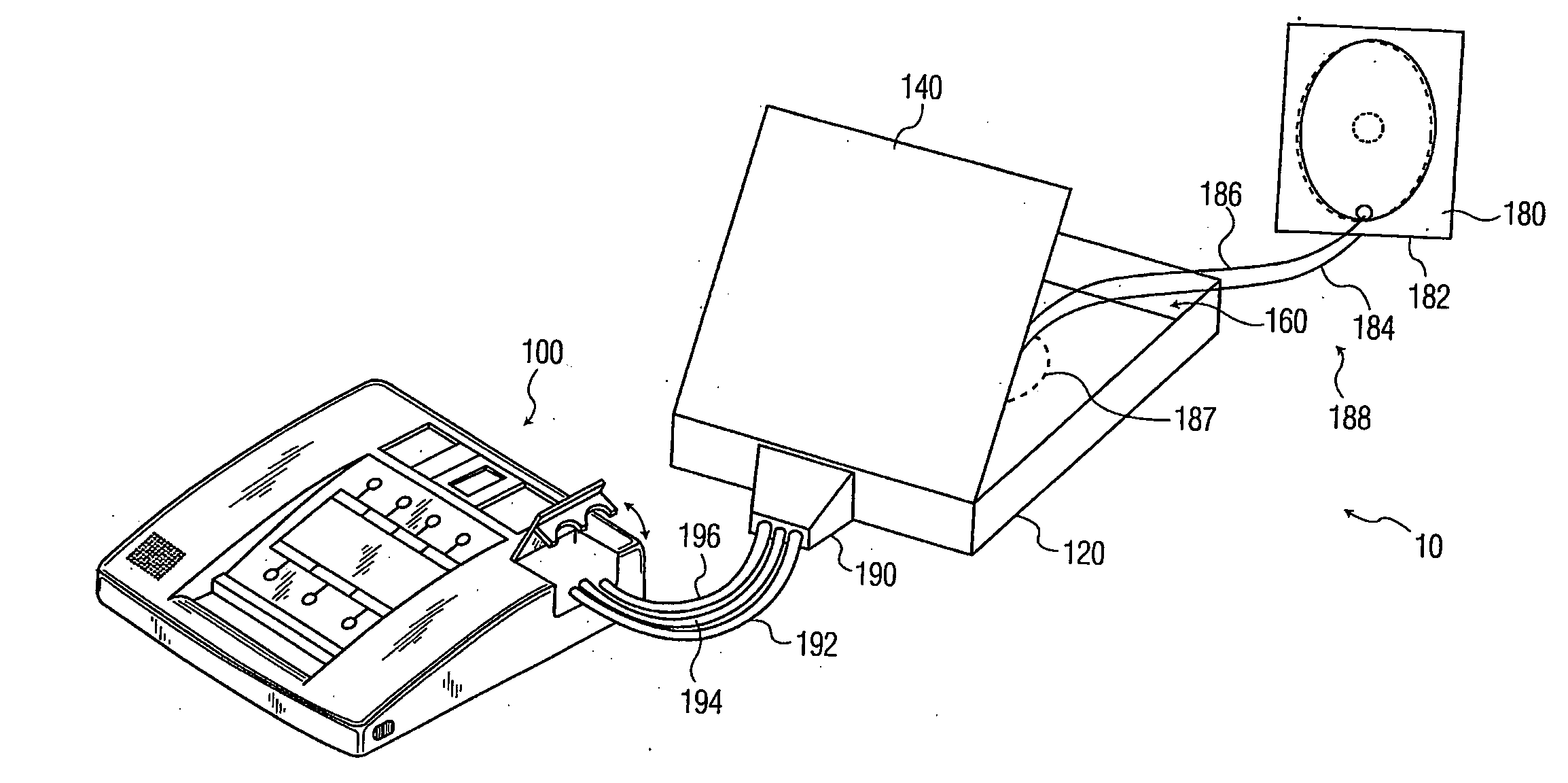

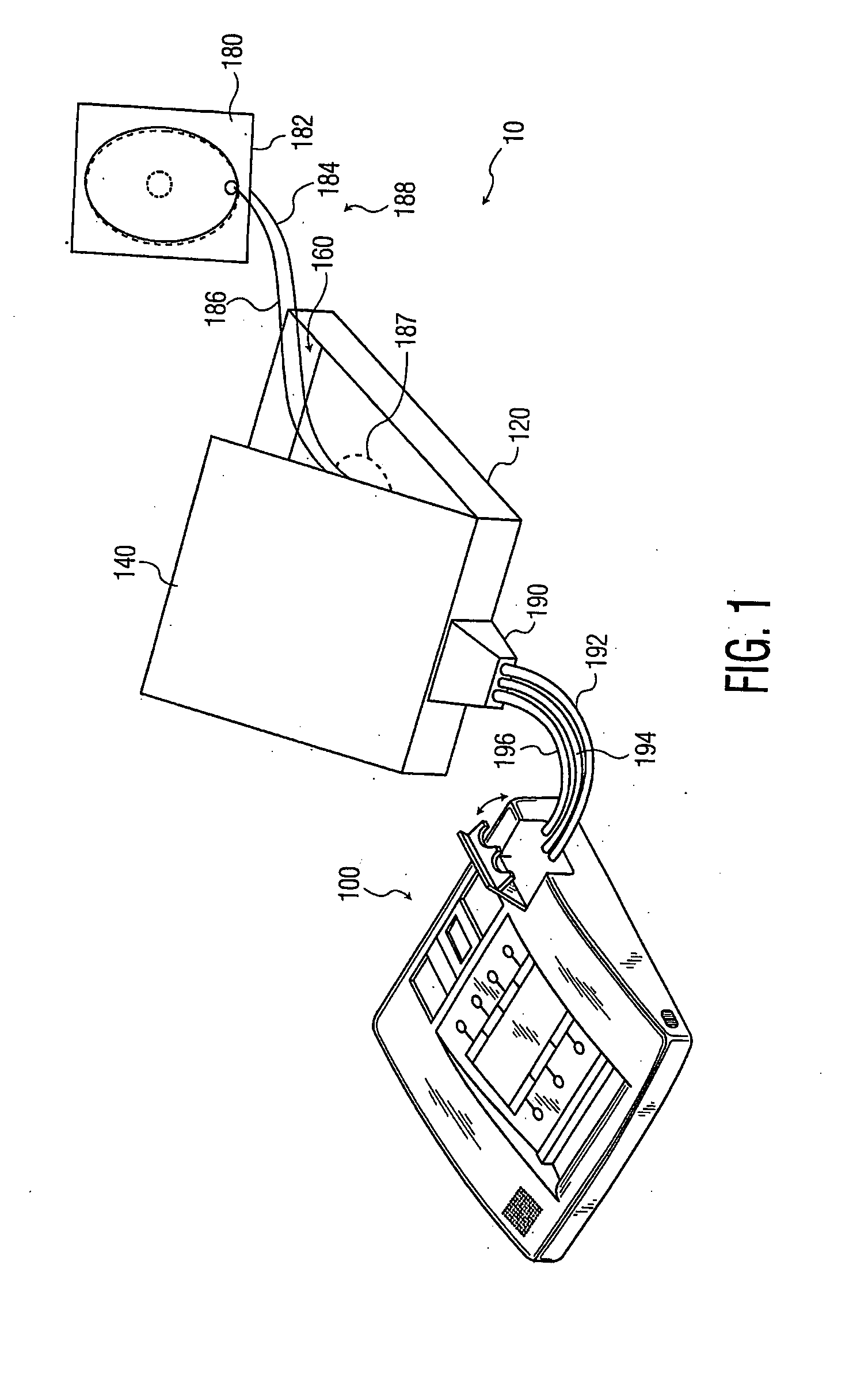

Image processing apparatus, and method for controlling the image processing apparatus to process displayable and non-displayable data received from a server

InactiveUS7464333B2Digitally marking record carriersData processing applicationsInformation processingWeb browser

Owner:CANON KK

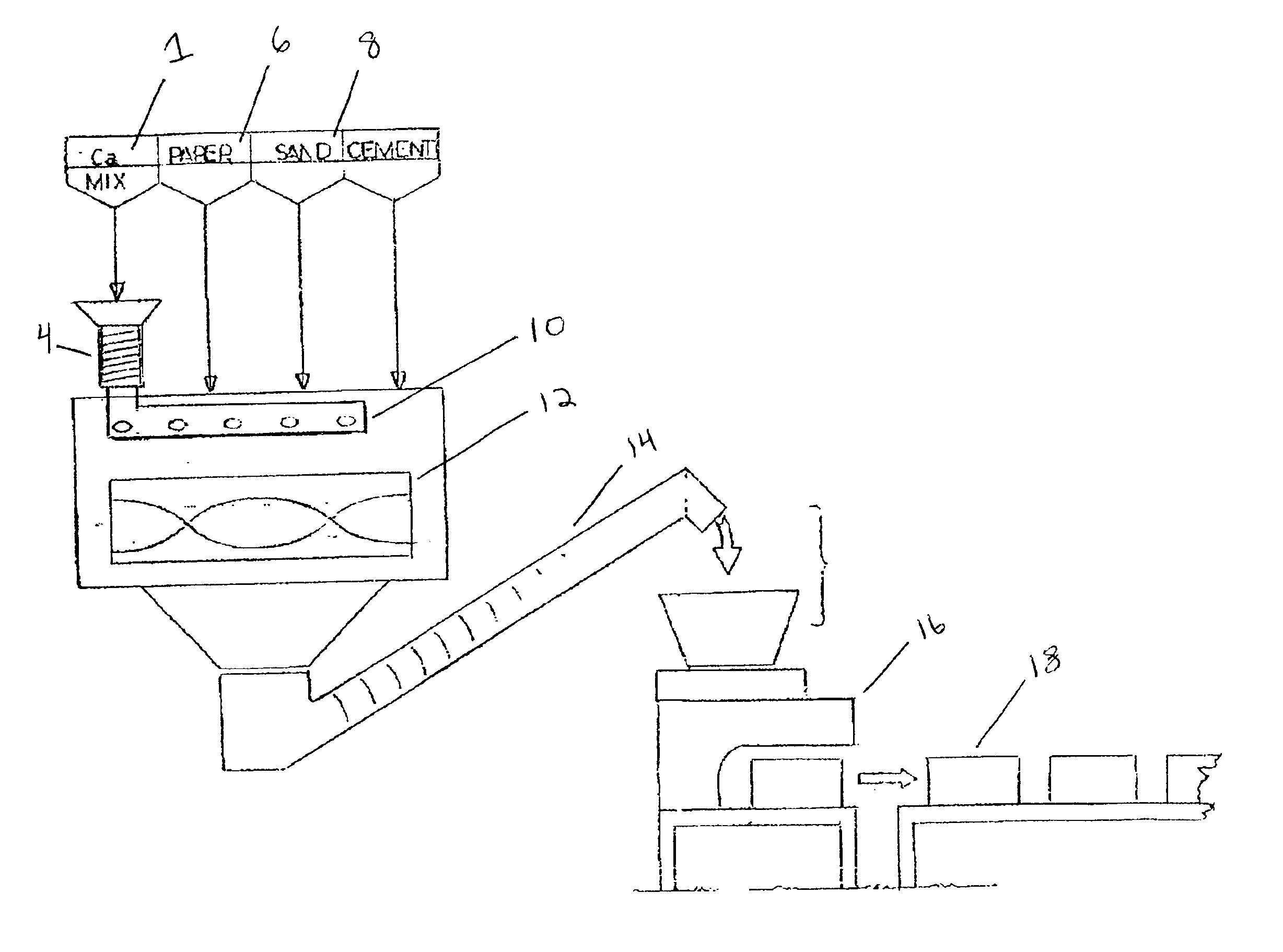

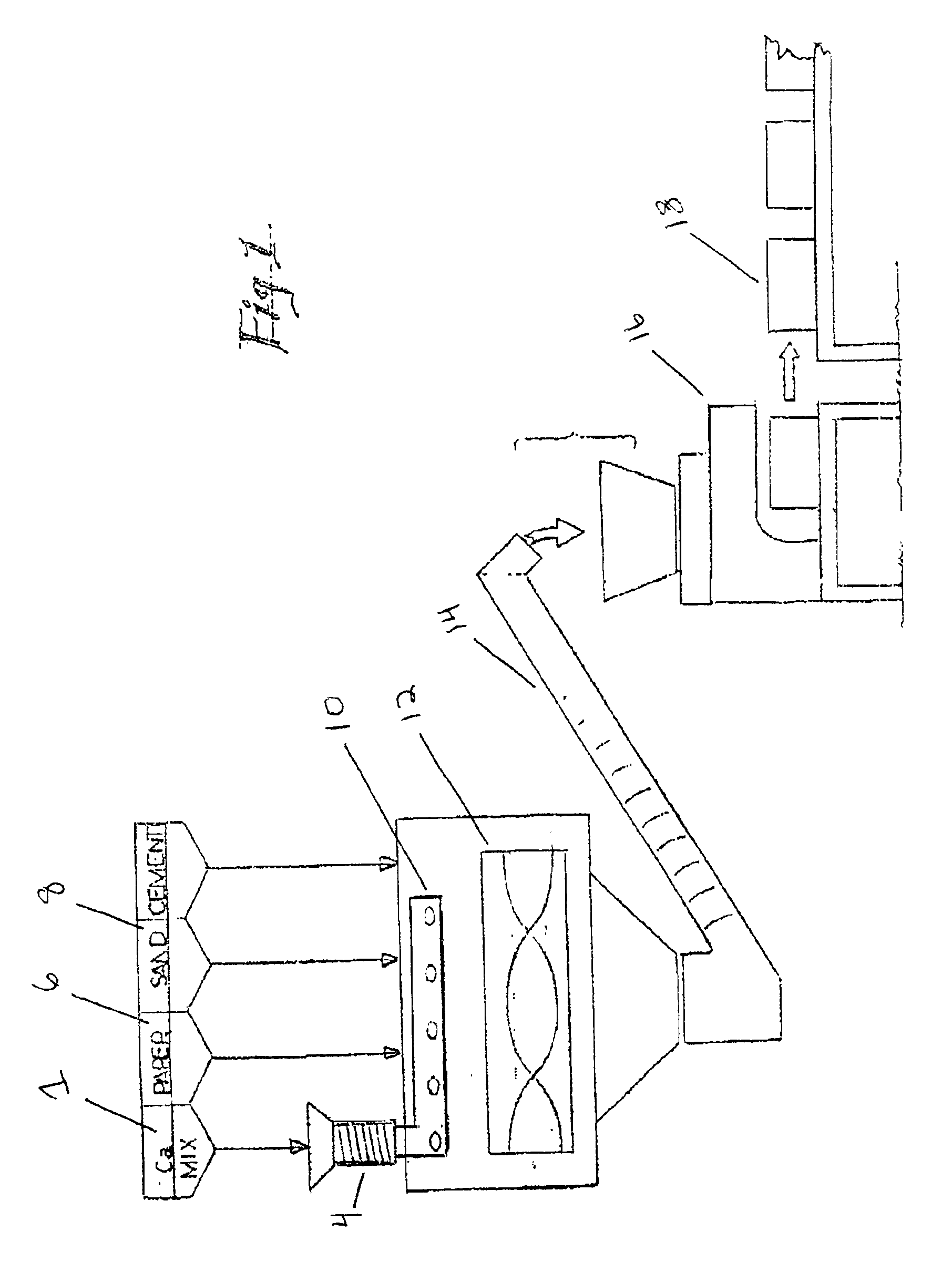

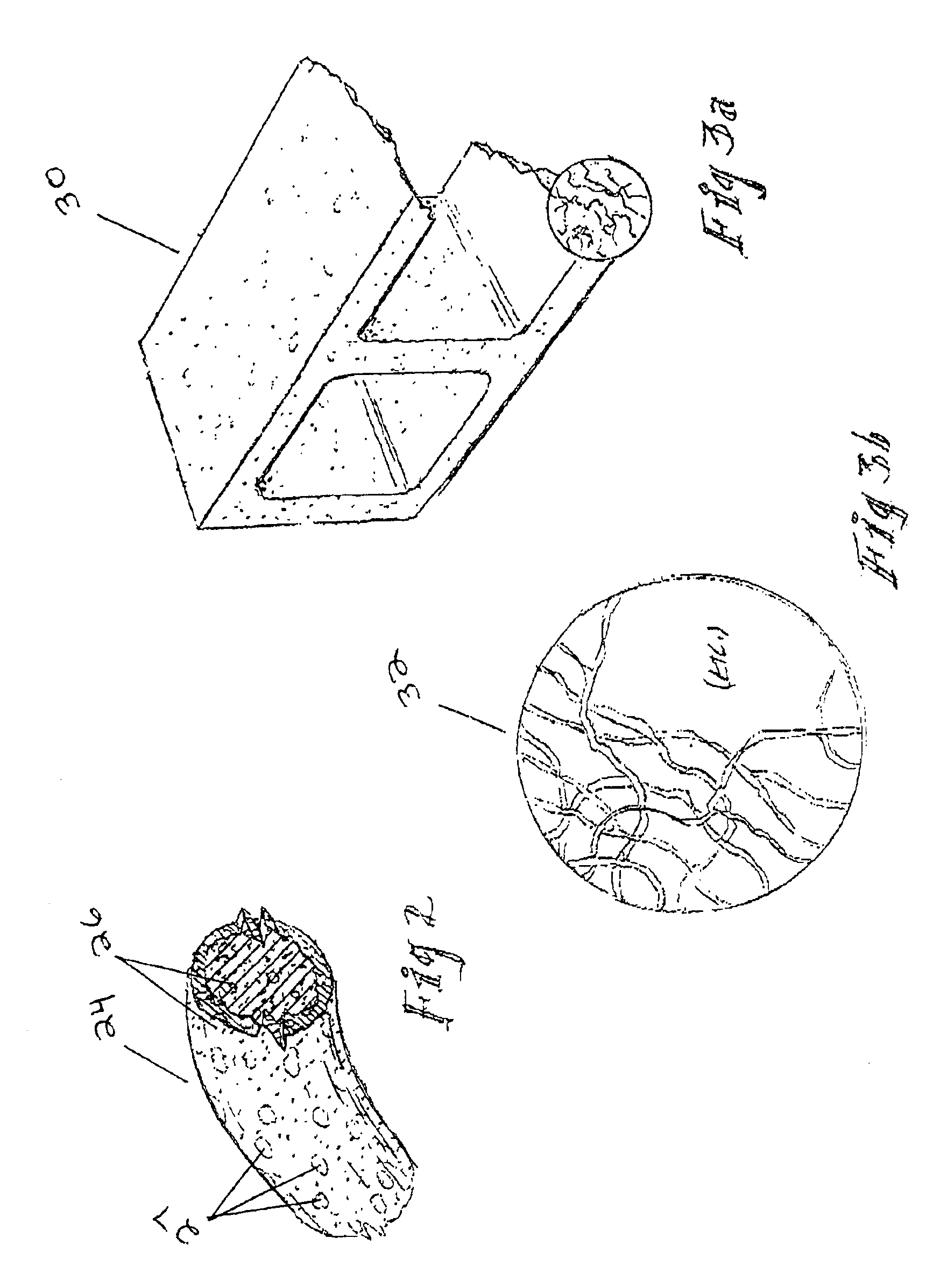

Modified cellulose aggregate material

InactiveUS6843844B1Effectively and efficiently saturatedMinimizes shrinkageSolid waste managementCellulose fiberAlternative methods

A process and method is disclosed for producing a cellulose modified aggregate cement. The process and method advantageously applies a fortifying solution to a dry cellulose material so as to enable substantially complete absorption of the vital components of the solution into and upon the cellulose fibers. The fortifying solution also imparts to and forms a mixture with the fiber so as to provide sufficient water for hydration and cure of cement added thereto, without the need to extract excess water therefrom, thereby preventing the loss of said vital fortifying agents from the aggregate cement formed thereby. Upon admixing cement into the solution treated fibers, a plastic mixture of concrete is formed, well adapted for pouring into press molds for the fabrication of lightweight, high strength construction forms. In an alternative embodiment, a means of forming a raw aggregate material, while simultaneously reclaiming submerged land is disclosed. In the alternative process and method, cellulose waste material is added to submerged land to absorb, and form a wet pile of material there within. The waste material is then allowed to dry. Thereafter the material is treated with anti-mold agents, re-dried and purified / comminuted into cellulose fibers. Thereafter, the material is treated with fortifying agents in a pool. The material is once again allowed to dry and thereafter pressure treated with activating and water proofing materials to yield a raw cellulose modified aggregate.

Owner:THERM O LITE CONSTR PRODS

Injection molded microoptics

ActiveUS7399421B2Minimizes number and task-timesReduces of semiconductor arraysMaterial nanotechnologySolid-state devicesFiberTransformer

A wafer-scale apparatus and method is described for the automation of forming, aligning and attaching two-dimensional arrays of microoptic elements on semiconductor and other image display devices, backplanes, optoelectronic boards, and integrated optical systems. In an ordered fabrication sequence, a mold plate comprised of optically designed cavities is formed by reactive ion etching or alternative processes, optionally coated with a release material layer and filled with optically specified materials by an automated fluid-injection and defect-inspection subsystem. Optical alignment fiducials guide the disclosed transfer and attachment processes to achieve specified tolerances between the microoptic elements and corresponding optoelectronic devices and circuits. The present invention applies to spectral filters, waveguides, fiber-optic mode-transformers, diffraction gratings, refractive lenses, diffractive lens / Fresnel zone plates, reflectors, and to combinations of elements and devices, including microelectromechanical systems (MEMS) and liquid crystal device (LCD) matrices for adaptive, tunable elements. Preparation of interfacial layer properties and attachment process embodiments are taught.

Owner:INT BUSINESS MASCH CORP

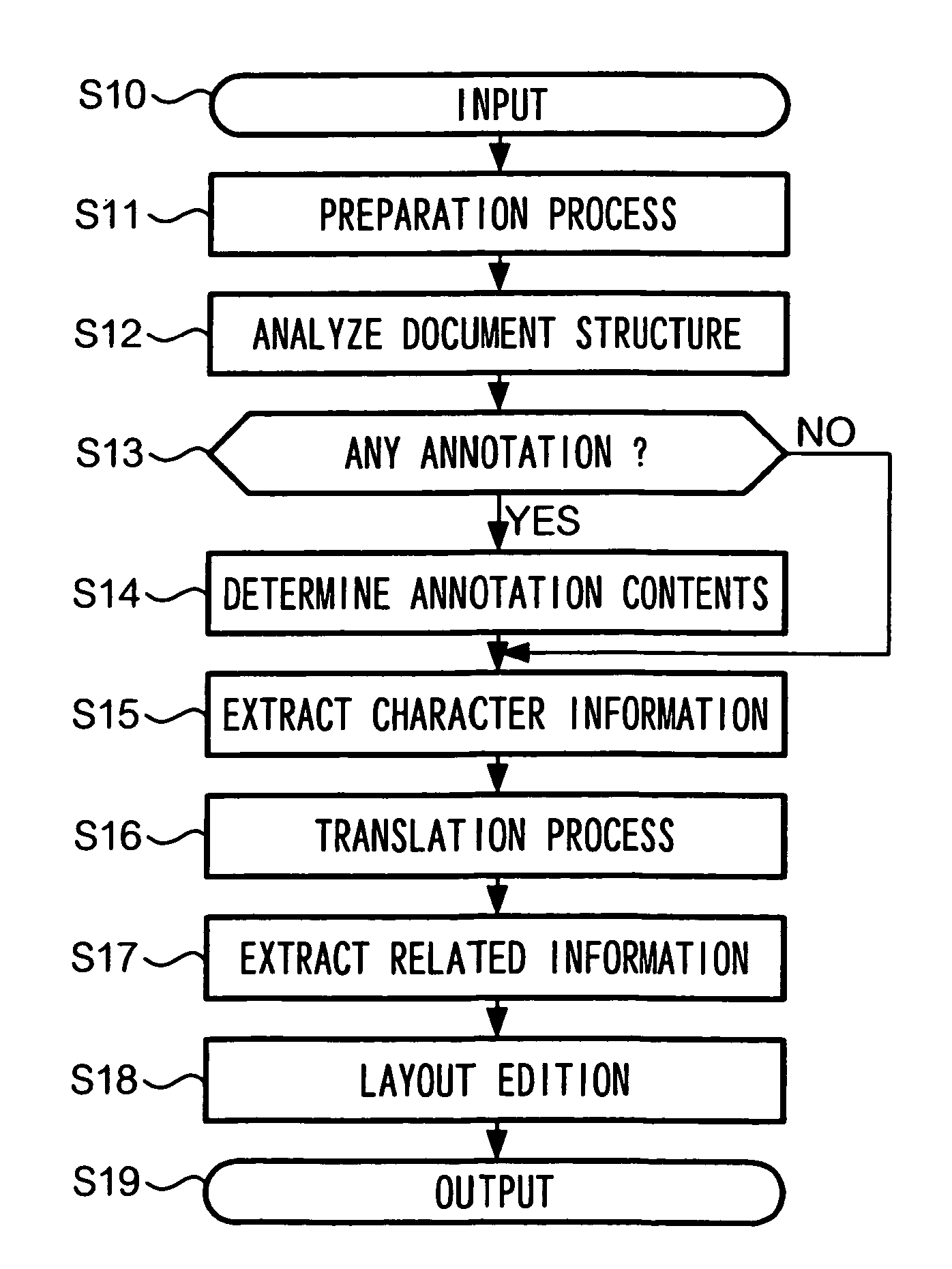

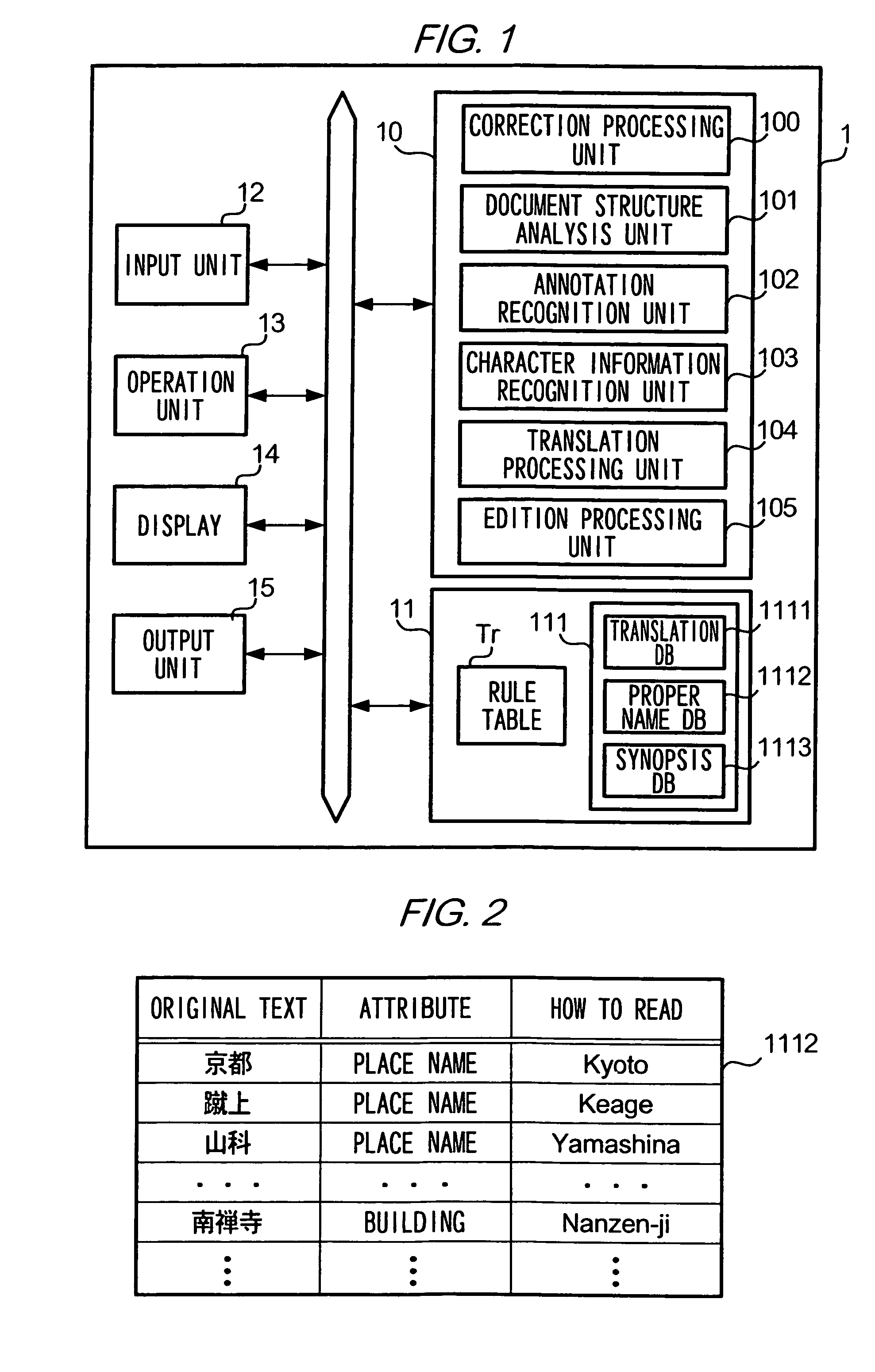

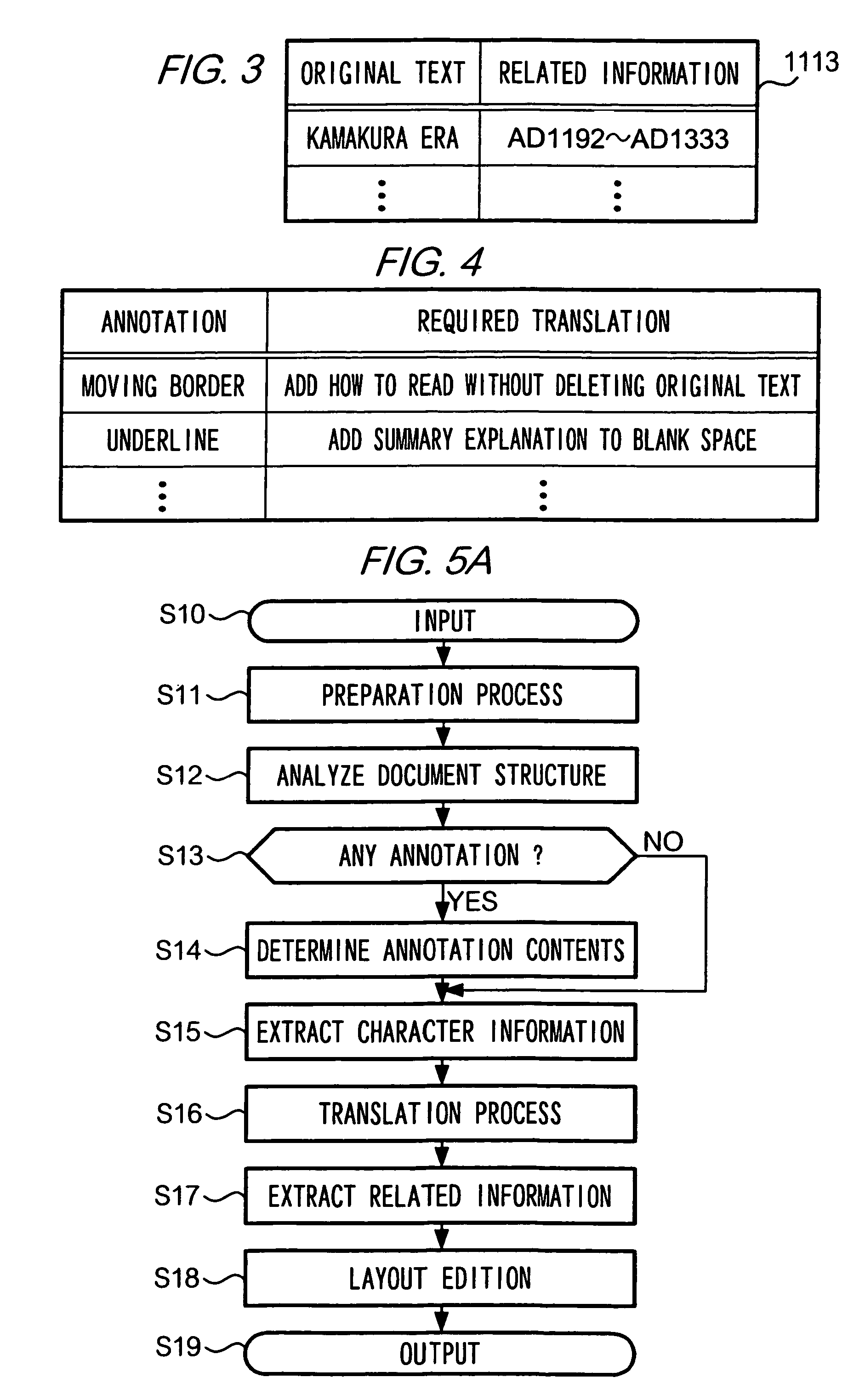

Document translation method and document translation device

InactiveUS7783472B2Placing burdenIncrease speedNatural language translationSpecial data processing applicationsDocument preparationAlternative process

Owner:FUJIFILM BUSINESS INNOVATION CORP

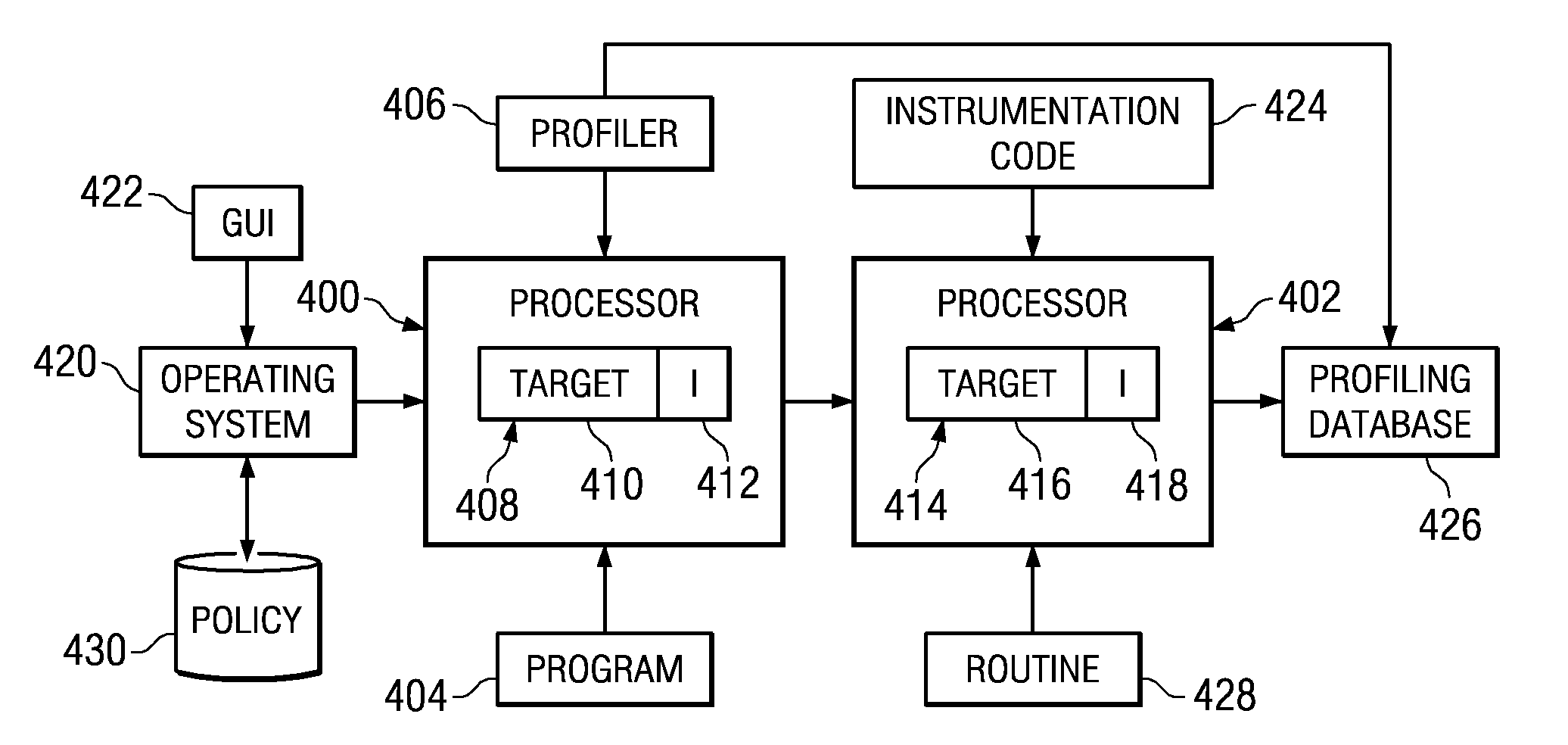

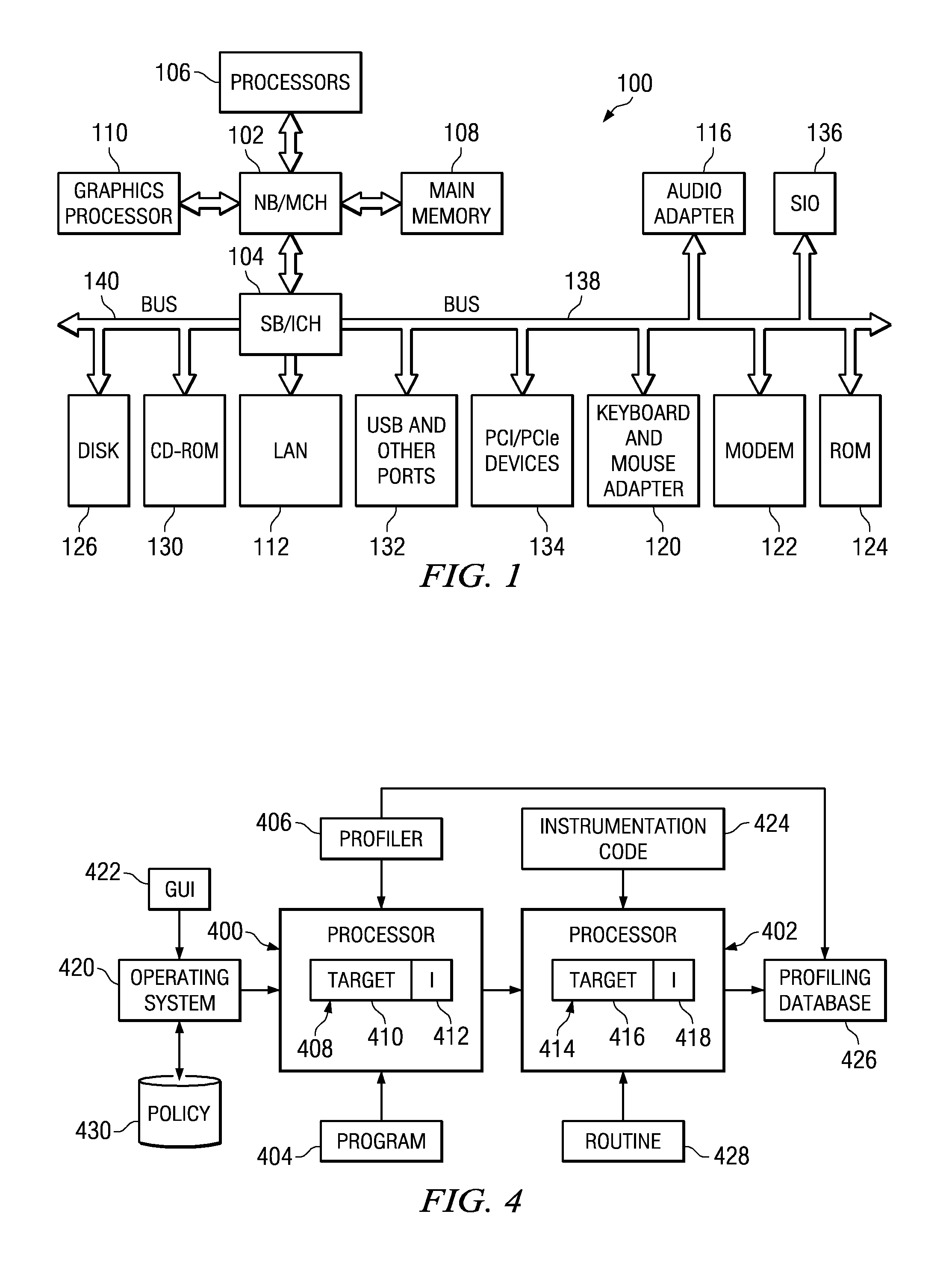

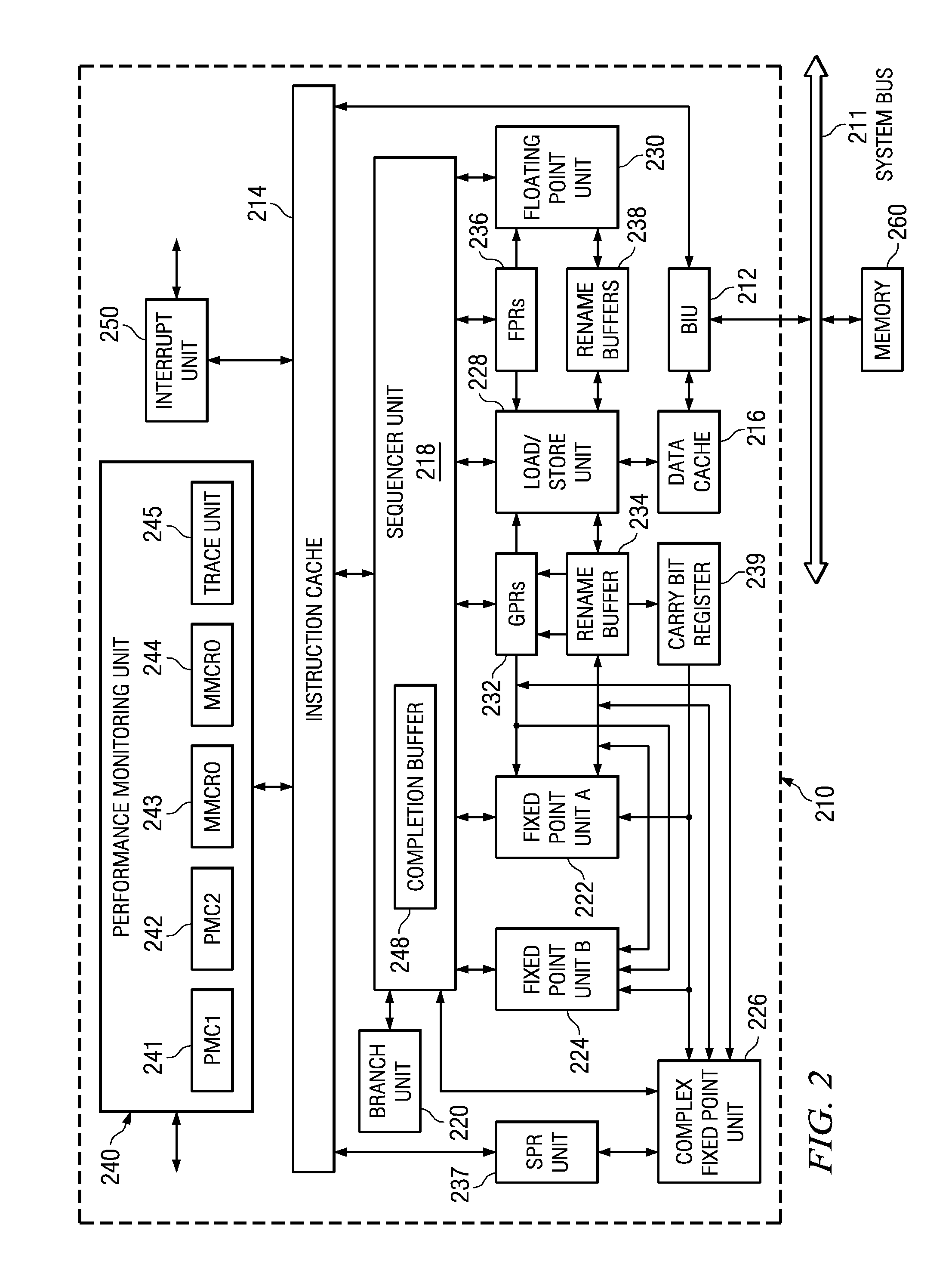

Method and apparatus for executing instrumentation code within alternative processor resources

InactiveUS7865703B2Error detection/correctionGeneral purpose stored program computerParallel computingAlternative process

A computer implemented method, apparatus, and computer program product for executing instructions. A determination is made as to whether a processor executing a plurality of instructions is in an instrumentation mode. The processor has a normal set of resources and an alternate set of resources in which the alternate set of resources is associated with the instrumentation mode. When a determination is made that the processor is in the instrumentation mode, the processor executes instrumentation instructions in the plurality of instructions using the alternate set of resources and executes all other instructions in the plurality of instructions using the normal set of resources.

Owner:INT BUSINESS MASCH CORP

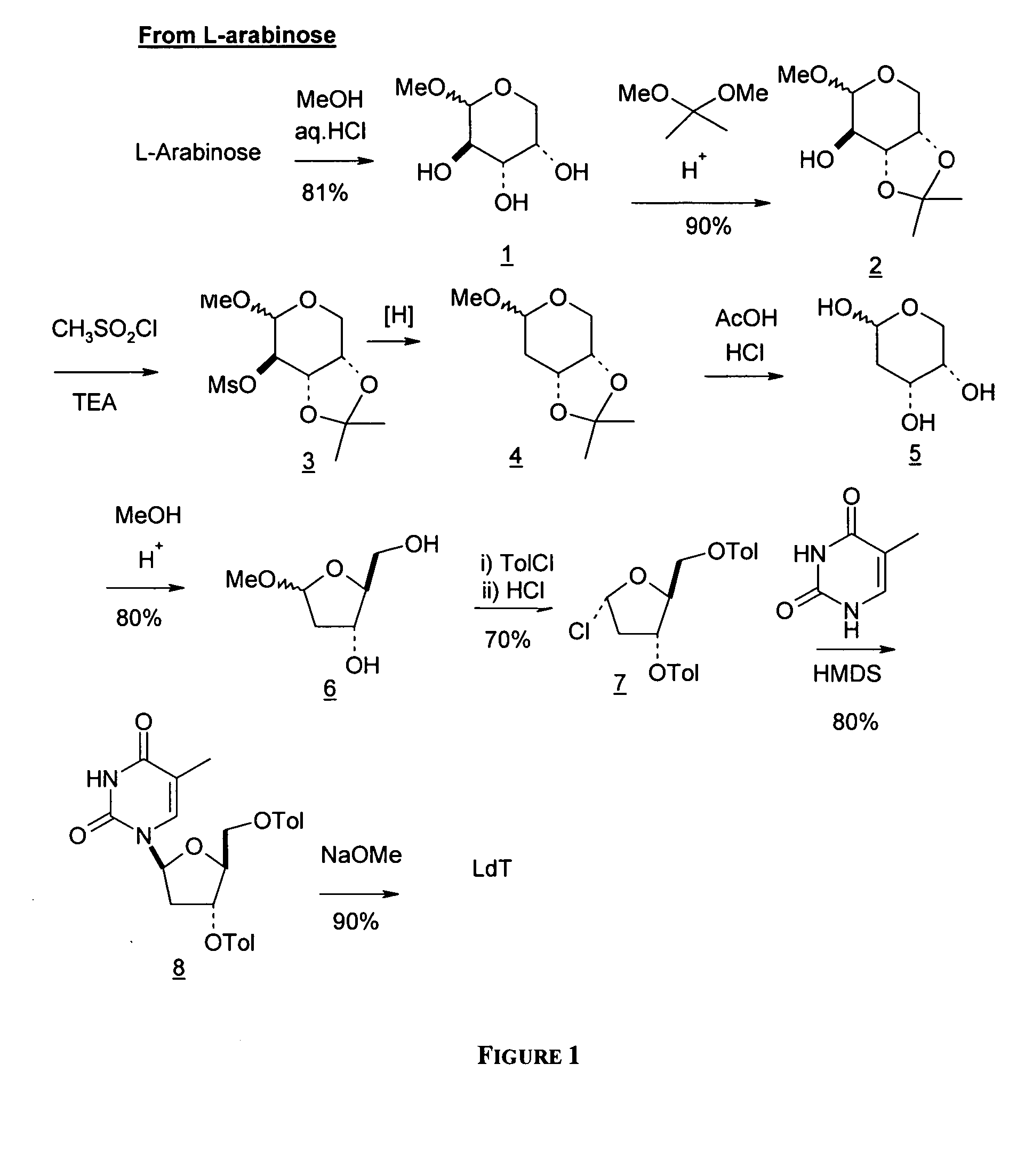

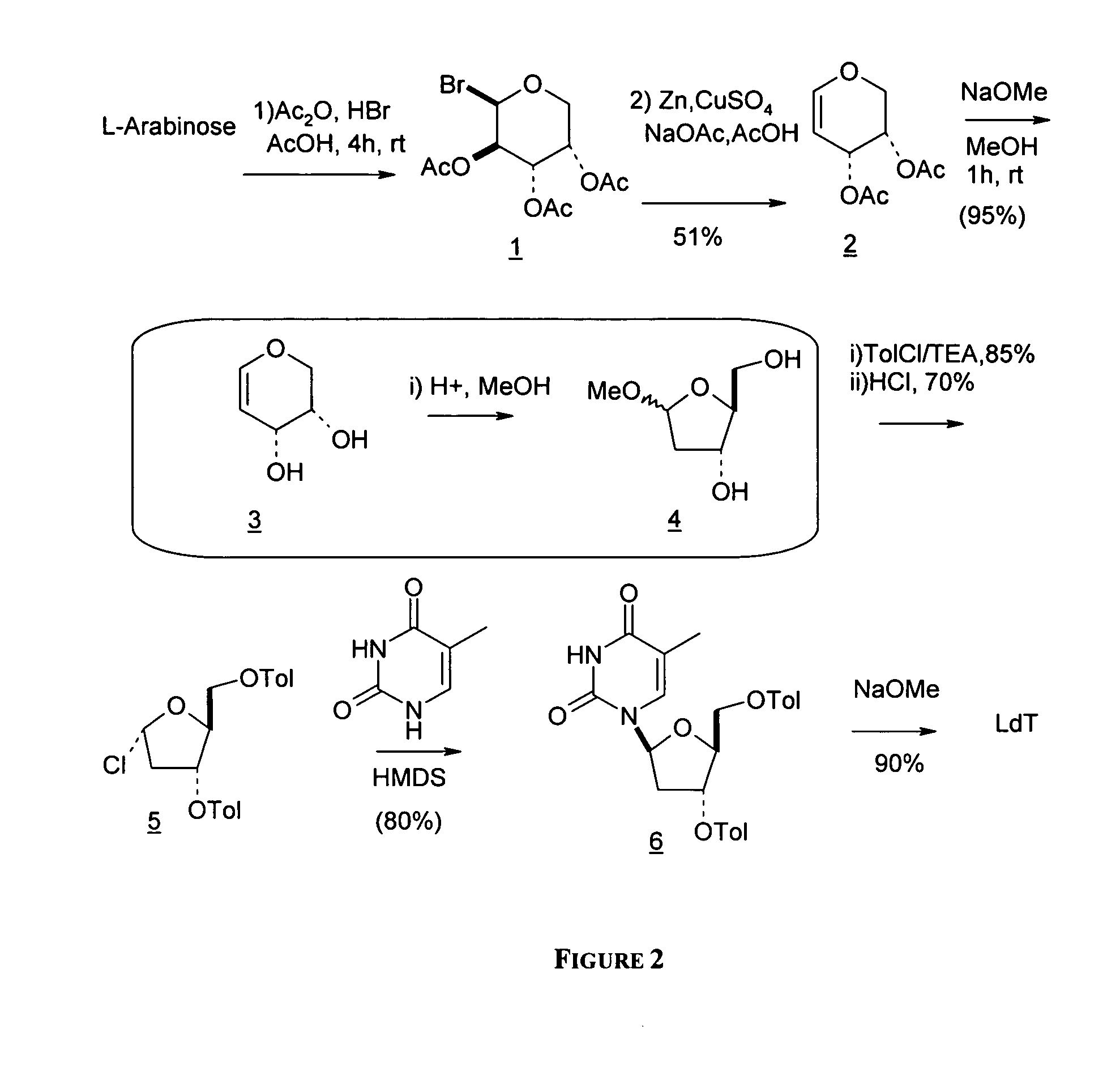

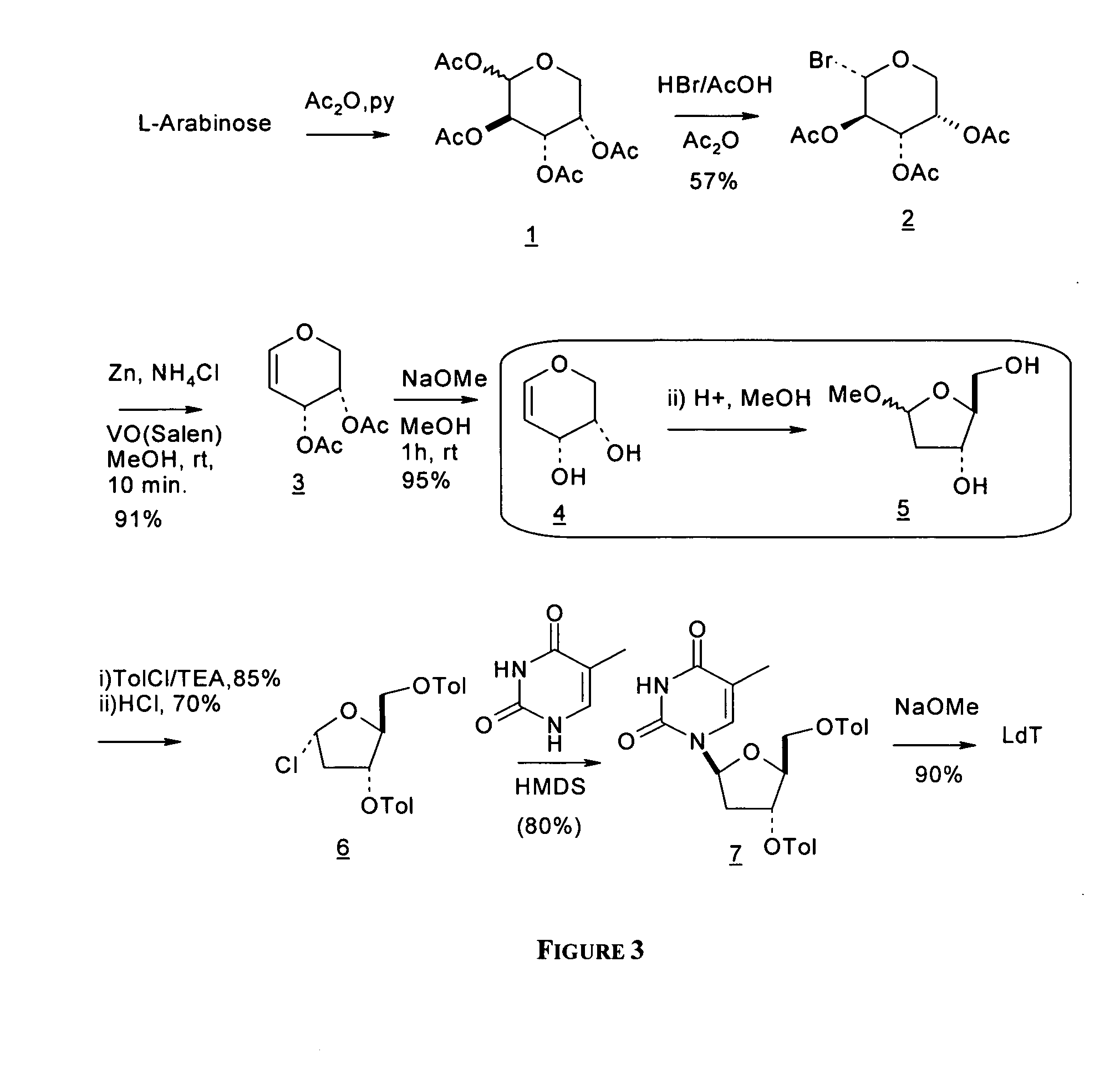

Synthesis of beta-L-2'-deoxy nucleosides

InactiveUS20050059632A1High percent product yieldPercent product yieldEsterified saccharide compoundsBiocideDisplacement reactionsAlternative methods

An improved process for the preparation of 2′-modified nucleosides and 2′-deoxy-nucleosides, such as, β-L-2′-deoxy-thymidine (LdT), is provided. In particular, the improved process is directed to the synthesis of a 2′-deoxynucleoside that may utilize different starting materials but that proceeds via a chloro-sugar intermediate or via a 2,2′-anhydro-1-furanosyl-nucleobase intermediate. Where an 2,2′-anhydro-1-furanosyl base intermediate is utilized, a reducing agent, such as Red-Al, and a sequestering agent, such as 15-crown-5 ether, that cause an intramolecular displacement reaction and formation of the desired nucleoside product in good yields are employed. An alternative process of the present invention utilizes a 2,2′-anhydro-1-furanosyl base intermediate without a sequestering agent to afford 2′-deoxynucleosides in good yields. The compounds made according to the present invention may be used as intermediates in the preparation of other nucleoside analogues, or may be used directly as antiviral and / or antineoplastic agents.

Owner:NOVARTIS AG

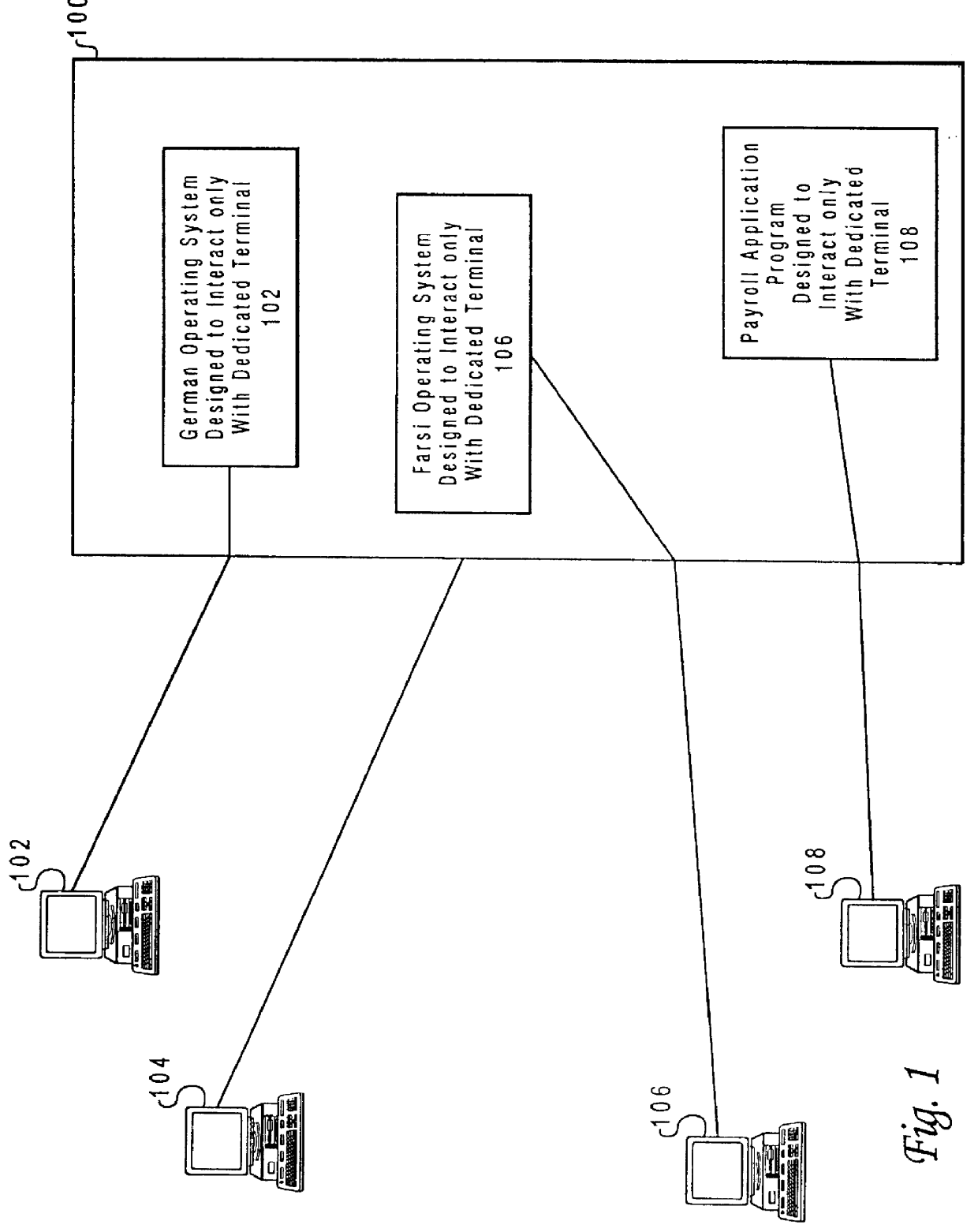

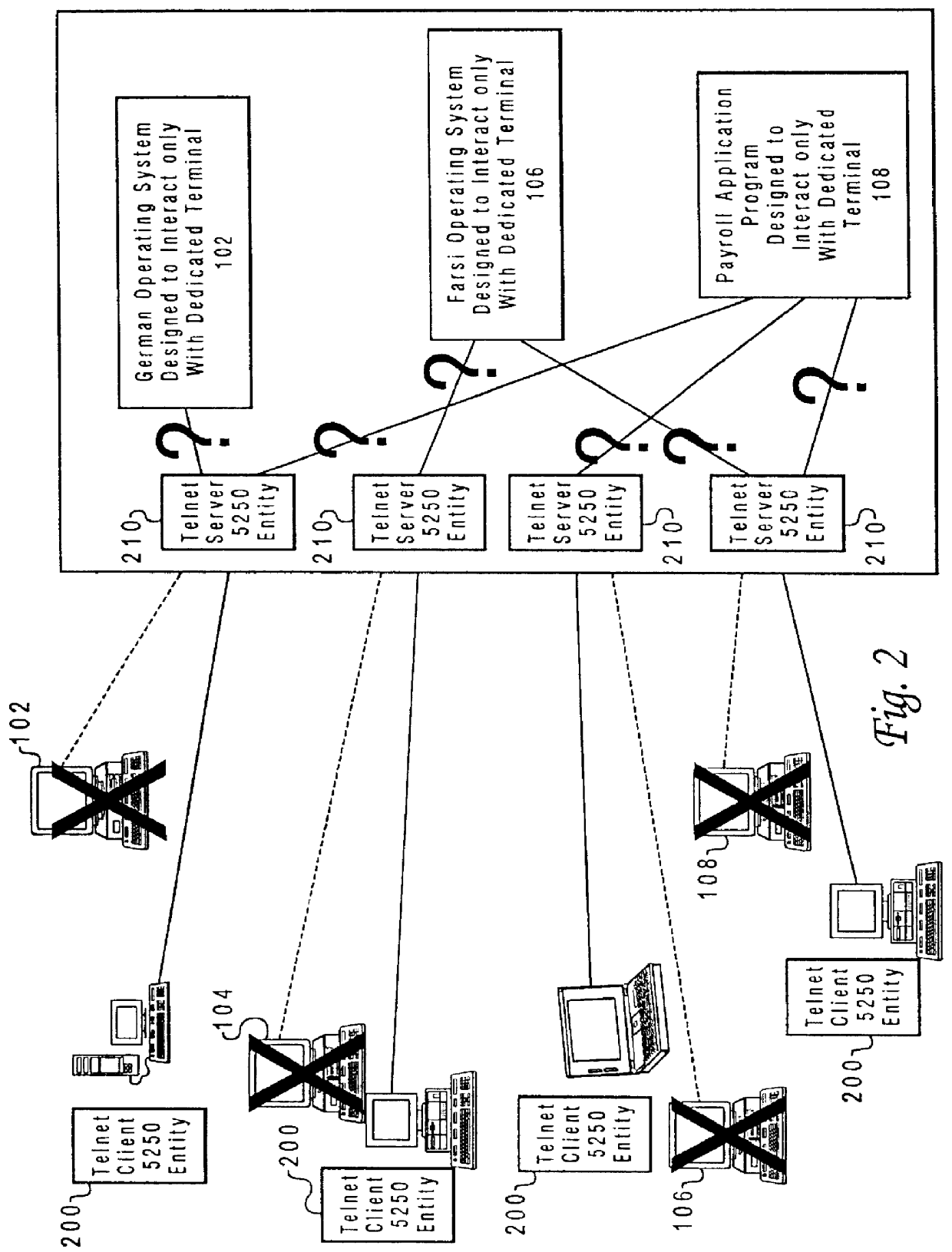

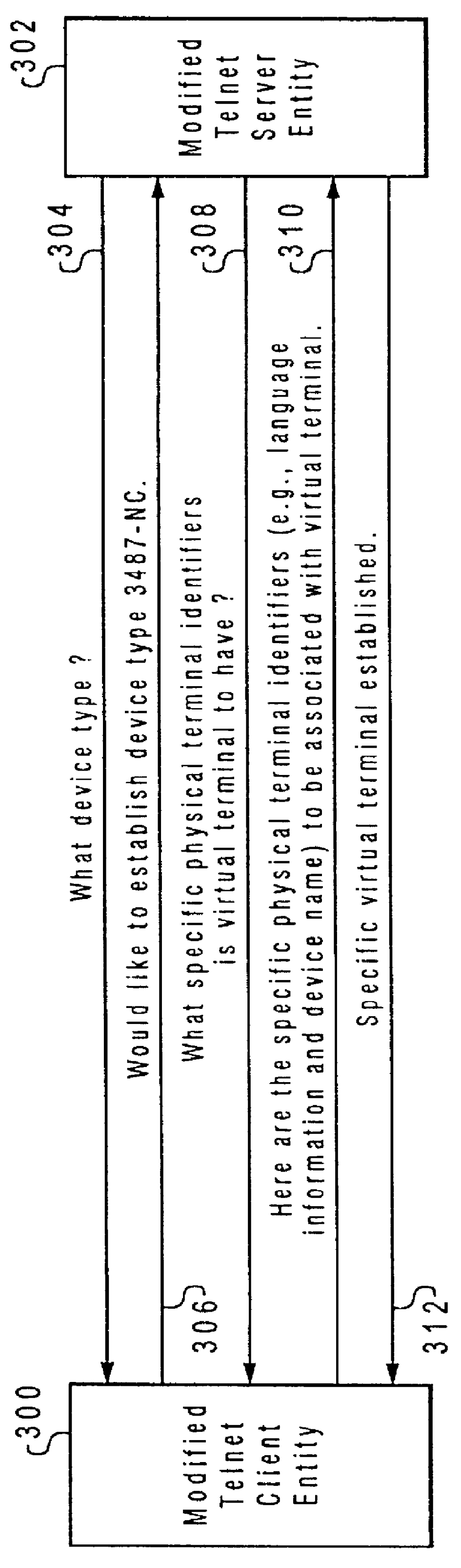

Method and system for replacing physical terminals interacting with hardware specific programs

InactiveUS6011915AMultiple digital computer combinationsProgram loading/initiatingComputer hardwareCommunications software

Provided are a method and system for replacing terminals, linked in a client server relationship with a central server, interacting with hardware specific programs within the central server, and wherein each terminal is identified by hardware specific programs within said central server via specific hardware attributes, and where the specific hardware attributes include at least a port identification and an I / O processor identification associated with the port identification. The method and system achieve the foregoing via the following. A processor is substituted for a selected terminal. Particular hardware attributes of the selected terminal are identified. The identified particular hardware attributes of the selected terminal are emulated using communications software. And, the processor is coupled to the central server via the communications software such that the processor interacts with hardware specific programs within the central server such that the substituted processor interacts with the hardware specific programs in a fashion indistinguishable from the selected terminal.

Owner:IBM CORP

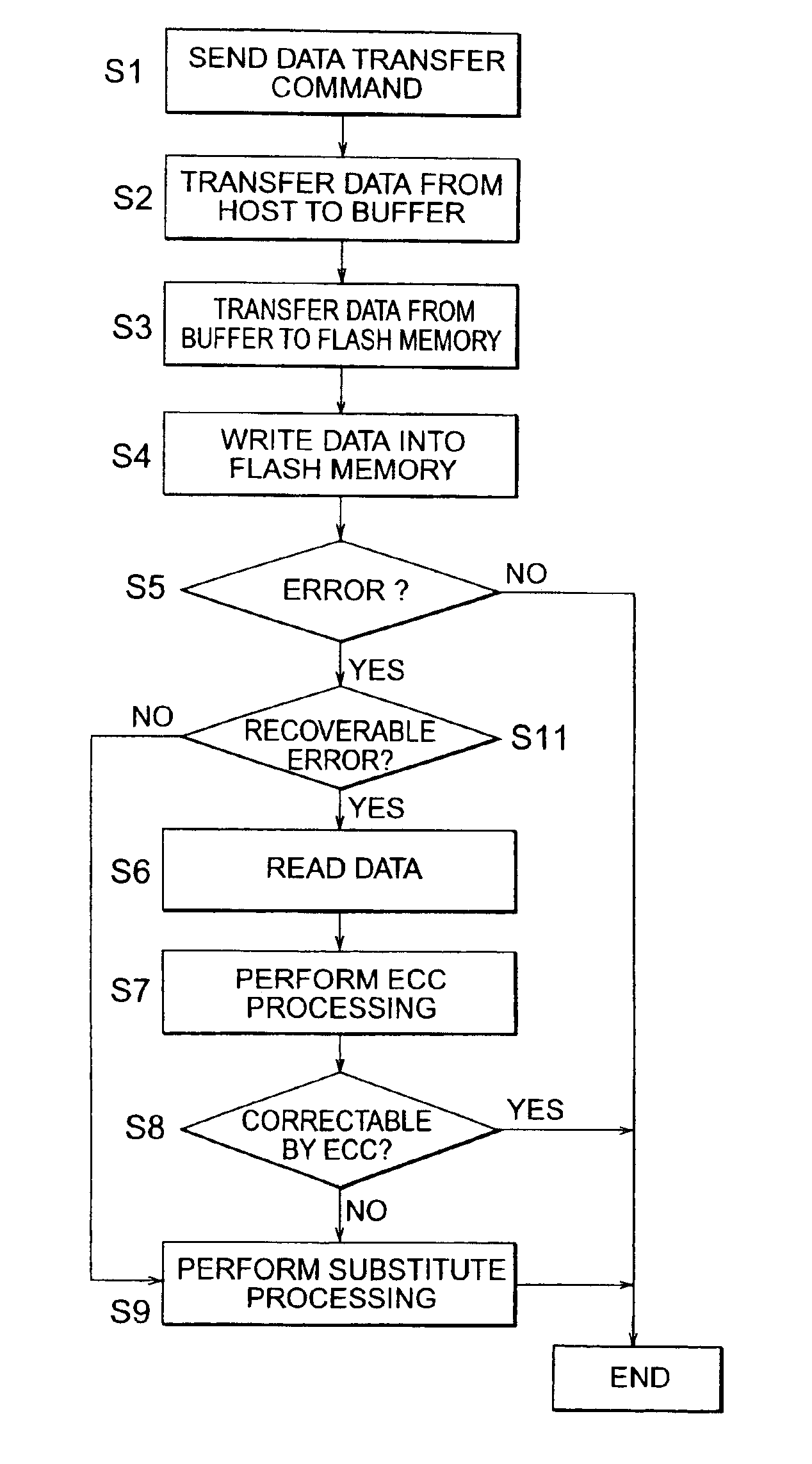

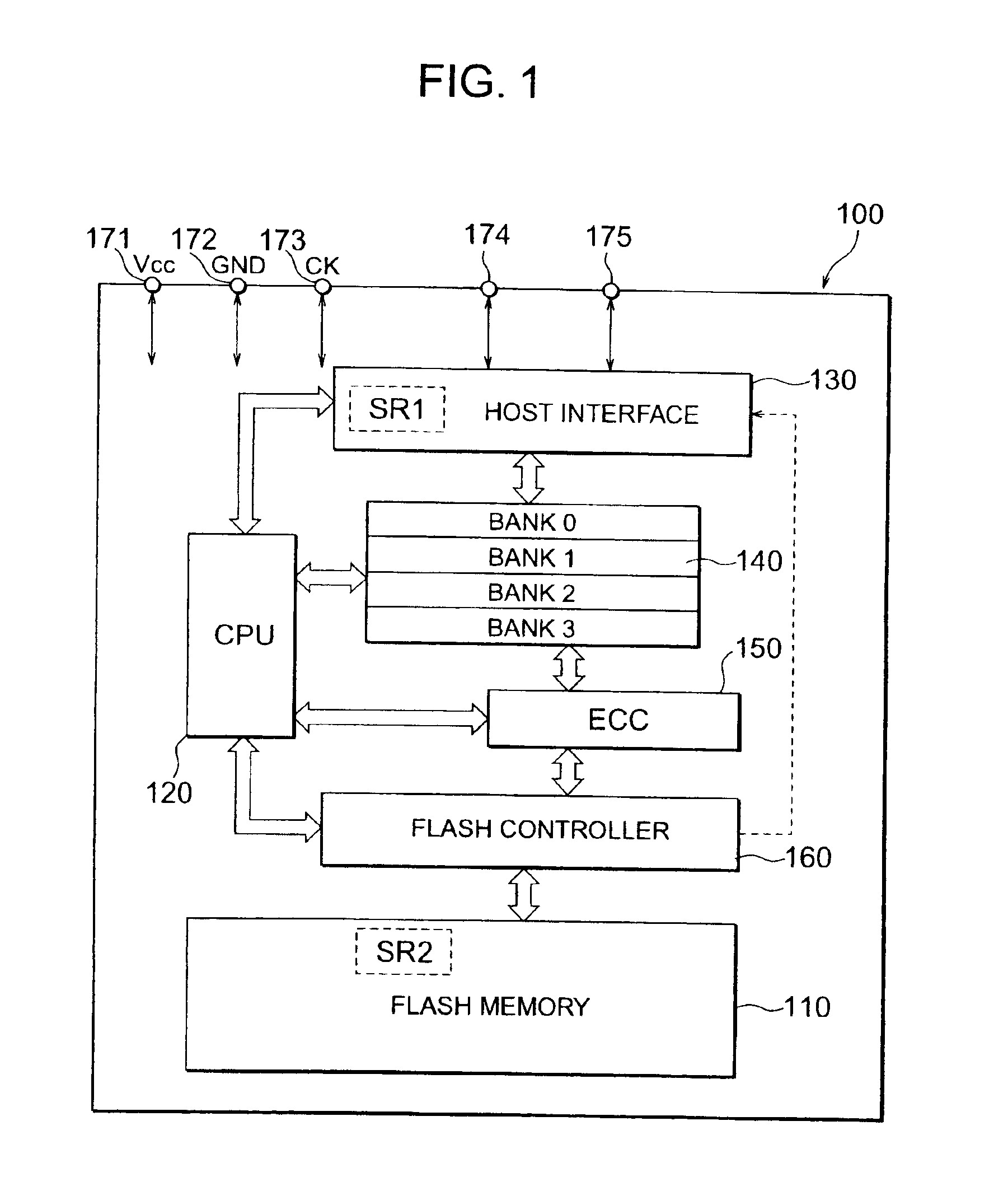

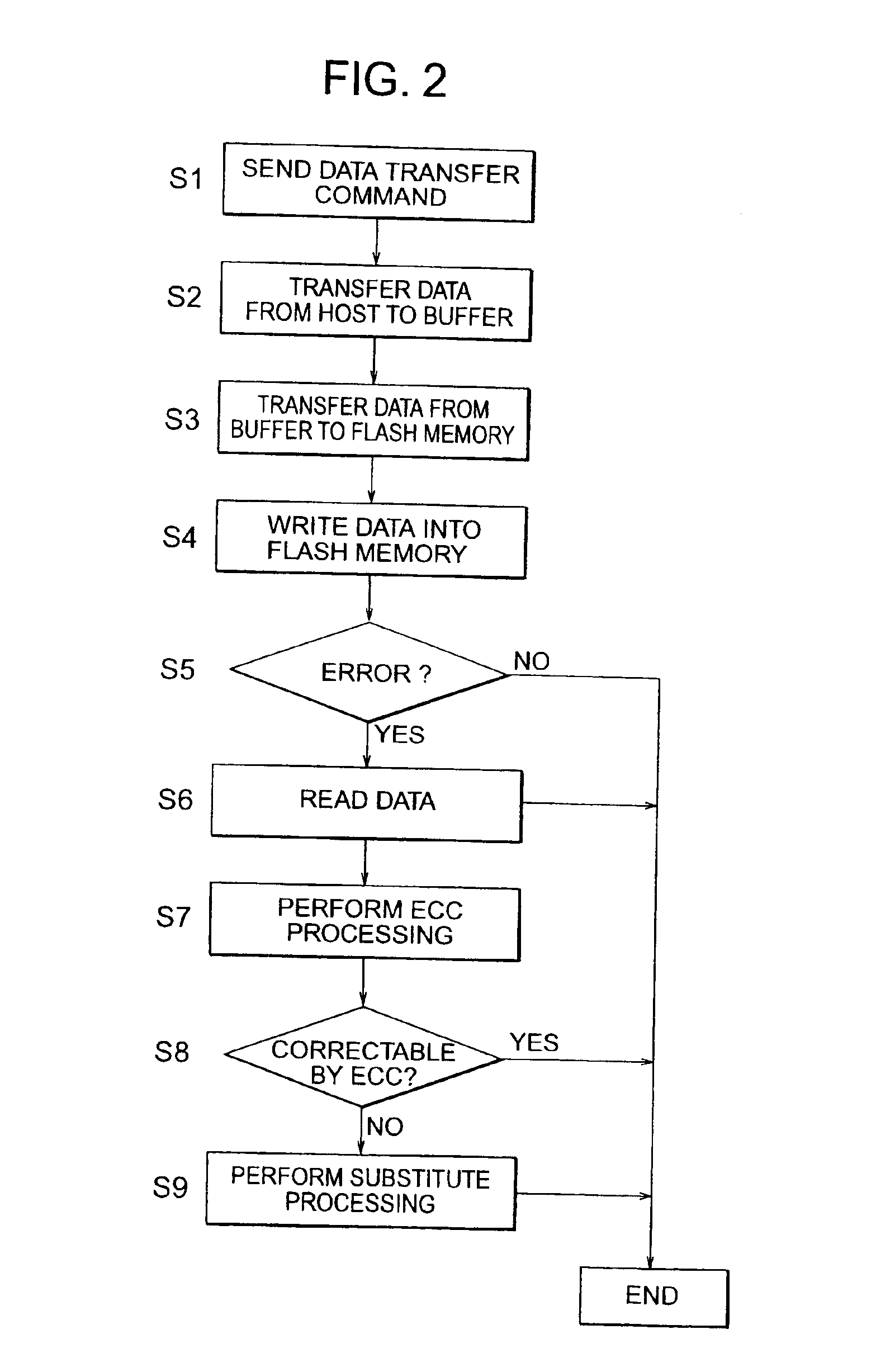

Non-volatile semiconductor memory device

InactiveUS6917547B2Shorten write timePrevent durabilityMemory loss protectionRead-only memoriesAlternative processVolatile memory

When a non-volatile memory write error occurs in a card storage device containing a non-volatile memory and an error correction circuit, write data is read from the non-volatile memory and a check is made if the error can be corrected by the error correction circuit. If the error can be corrected, the write operation is ended. If the error correction circuit cannot correct the error, substitute processing is performed to write data into some other area.

Owner:RENESAS ELECTRONICS CORP

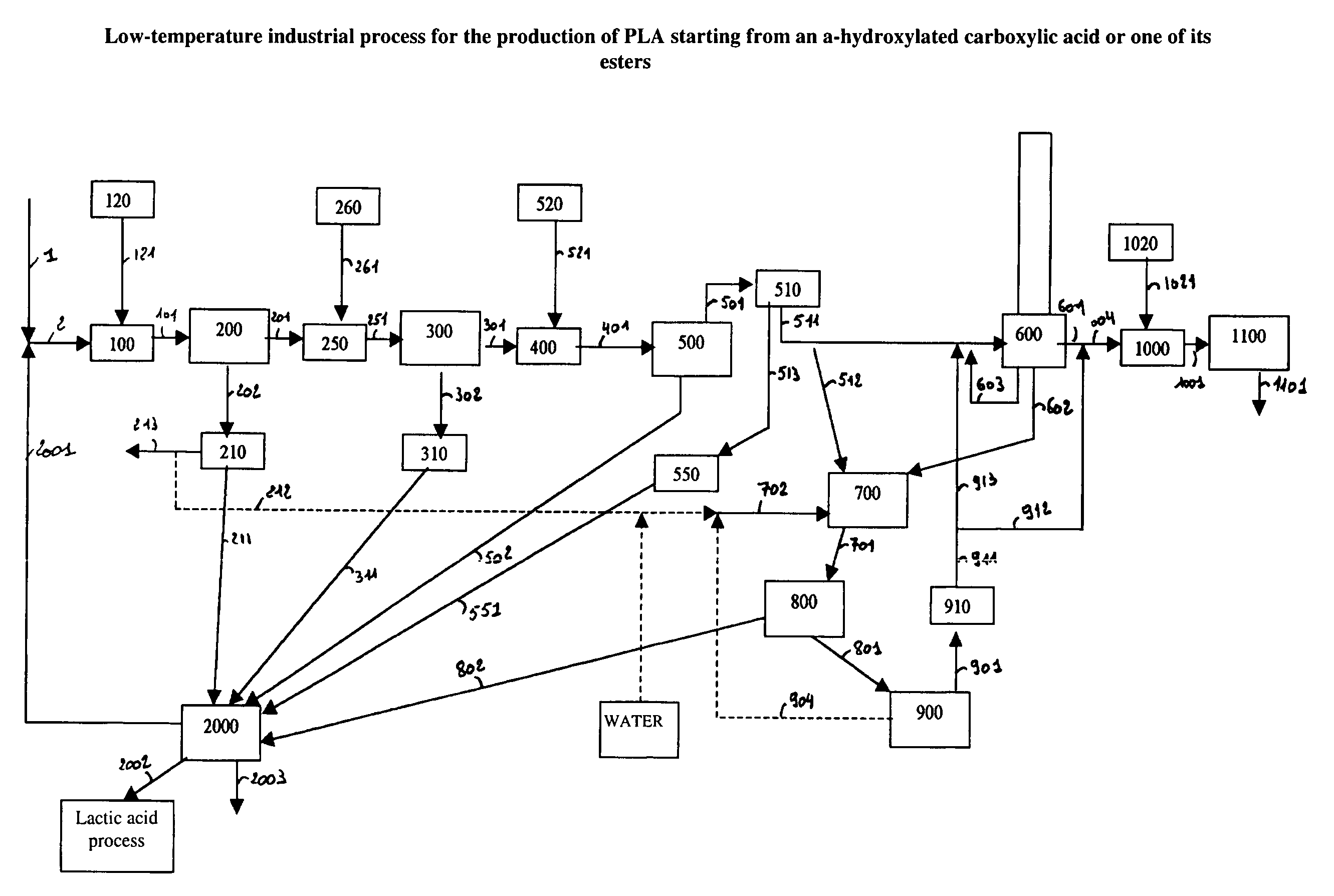

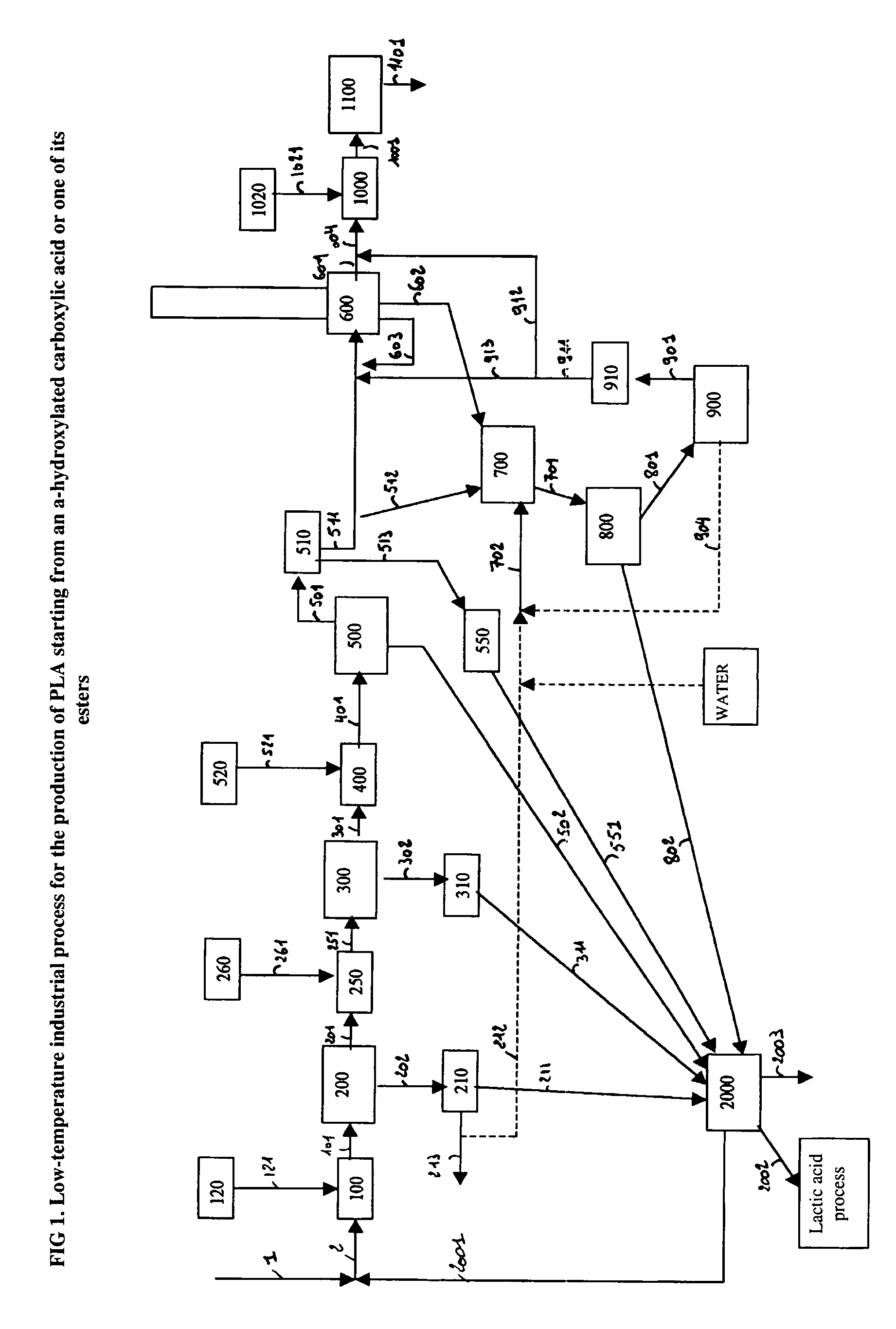

Method for the production of polyactide from a solution of lactic acid or one of the derivatives thereof

A process for the production of polylactide, the stages of which for the production and purification of lactide, starting from an aqueous solution of lactic acid or of its derivatives, includes evaporation of water with formation of oligomers, depolymerization to give lactide, condensation and then crystallization of the crude lactide product to give purified lactide, aqueous treatment of the residual fractions from the crystallization and polymerization of purified and / or prepurified lactide to give polylactide in an extruder and in the presence of catalysts. An alternative process includes carrying out the aqueous treatment before the crystallization.

Owner:BRUSSELS BIOTECH

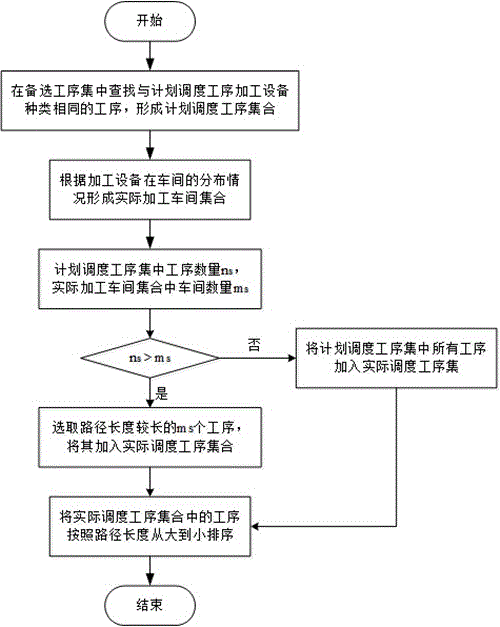

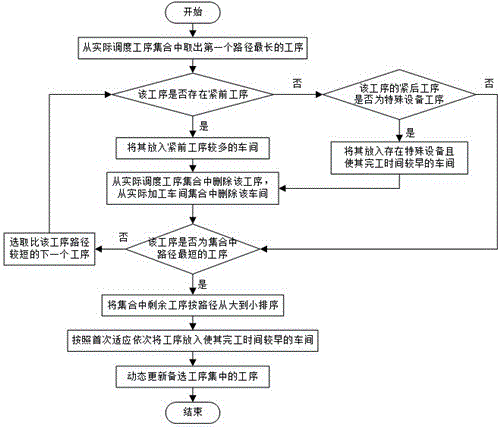

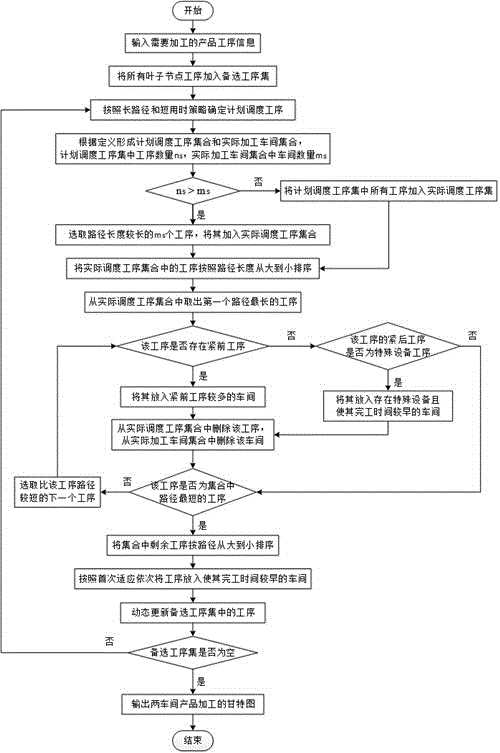

Asymmetric multi-workshop integrated dispatching method with consideration of same-kind-of-equipment process

PendingCN106651139ALoad balancingImprove parallelismResourcesTotal factory controlPath lengthAlternative process

The invention relates to an asymmetric multi-workshop integrated dispatching method with consideration of a same-kind-of-equipment process. The method comprises: all leaf nodes are added to an alternative process set; a planned dispatching process is determined from the alternative process set according to a method of selecting a long-path process and a short-time process preferably; a processing equipment type of the planned dispatching process is determined; a process identical with the processing equipment of the planned dispatching process is searched in the alternative process set; a planned dispatching process set is formed by a same-equipment process; a practical dispatching process set is determined based on a method of same-kind-of-equipment process long-path optimization method; and then according to a multi-workshop process group dispatching balancing method, processes in the practical dispatching process set are distributed to proper processing workshops, the processes in the practical dispatching process set are dispatched successively according to a descending path length order, and the process is placed into a workshop enabling a transferring frequency to be reduced preferably, so that the workshop parallelism and balancing can be improved. Therefore, the method can be applied to integrated asymmetric multi-workshop dispatching of single complex products.

Owner:HARBIN UNIV OF SCI & TECH

Substitutive treatment agent for metal surface phosphating and preparation method thereof

The invention discloses a substitutive treatment agent for metal surface phosphating and a preparation method thereof, and relates to the metal surface treatment technology. The substitutive treatment agent for phosphating consists of the following components of: gamma-APS, anhydrous alcohol, fluozirconate and de-ionized water, wherein the substitutive treatment agent for phosphating consisting of the components is a silane and nanoceramic composite film; the preparation method for the silane and nanoceramic composite film which consists of the components and is used for pre-treating the metal surface comprises the following steps of: rinsing with hot water; degreasing in advance; rinsing for the first time; rinsing for the second time; rinsing for the third time; performing phosphate-free conversion; rinsing a straight bar; rinsing for the fourth time; rinsing for the fifth time; and finishing the preparation. The substitutive treatment agent and the preparation method have the advantages that: the silane and nanoceramic composite film does not rust in 48 hours after being formed on the metal surface of a cold rolled steel sheet and the like and naturally cooled so as to meet the requirement on corrosion resistance in the production process; and meanwhile, the composite silane film has high bonding force with polyester coating layers, the cross-cut test for the adhesion reaches the first grade, the comprehensive impact resistance reaches 50cm / kg, the bending resistance is less than 1mm, and the salt spray test is more than or equal to 500 hours.

Owner:ANHUI WEILAI SURFACE TECH

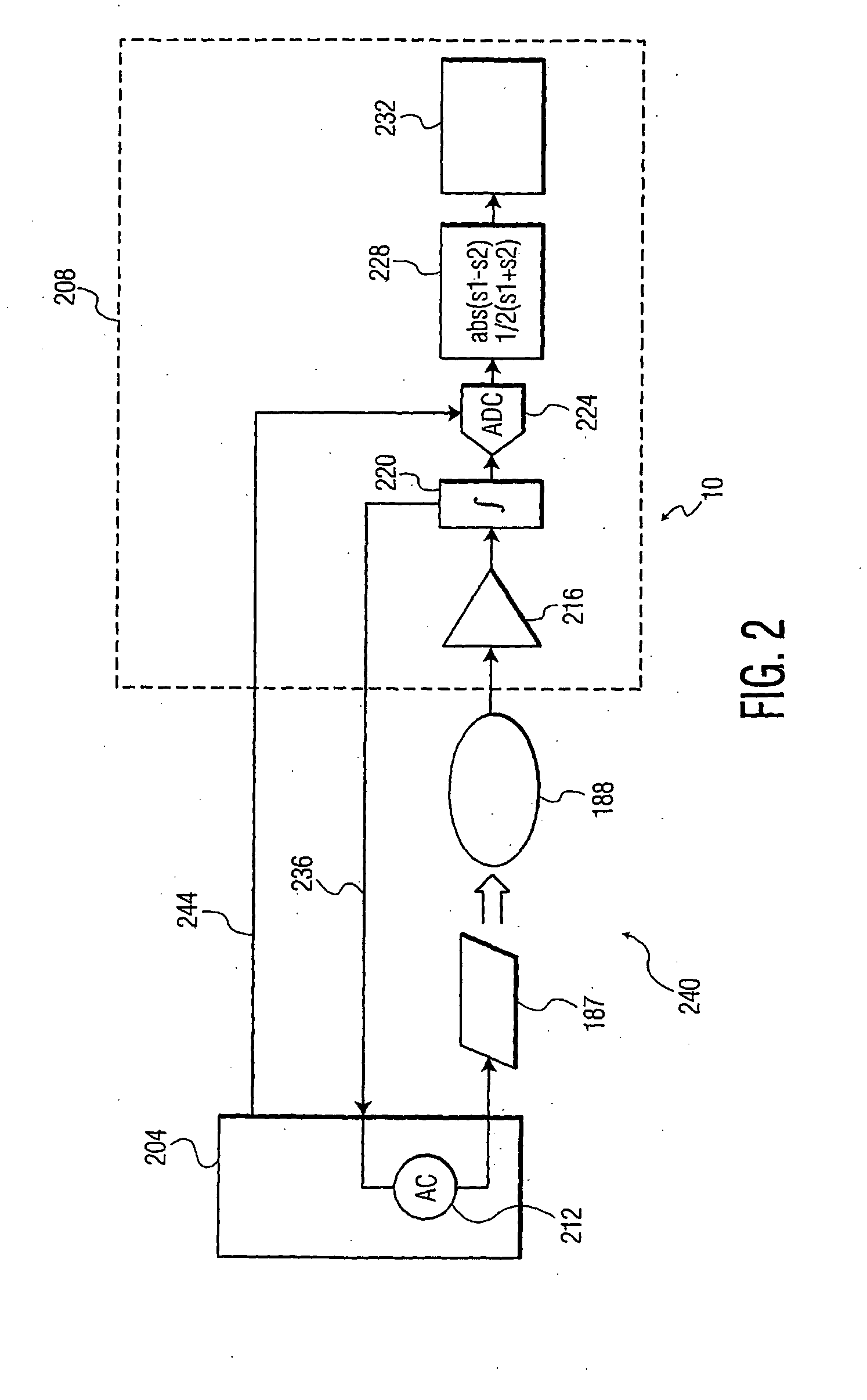

Electric- or Magnetic-Field Based Detection of when Electrode Pads have been Handled or Removed from their Package

ActiveUS20080140171A1Accurately advancedEfficient workHeart defibrillatorsExternal electrodesCapacitanceAlternative process

Handling or removal of a pair of defibrillator electrode pads from their package is detected in order to effectively time the issuance of prompts to guide the user. One plate of a capacitor is embedded in the package, the electrode pads and lead wires serving as the other plate. Impedance across the capacitor in an alternating current circuit is monitored to detect an increase in the distance between the pads and the package. The impedance level is determined, in a low-cost hardware solution, by rectifying and then integrating an output voltage of the capacitor to produce a voltage signal whose magnitude attenuates as the pads arc handled or removed. In one embodiment, the above methodology is time-division multiplexed with an alternative process that identifies handling or removal based on pad-to-pad impedance. In a further embodiment, the capacitive configuration is replaced with an inductive one.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

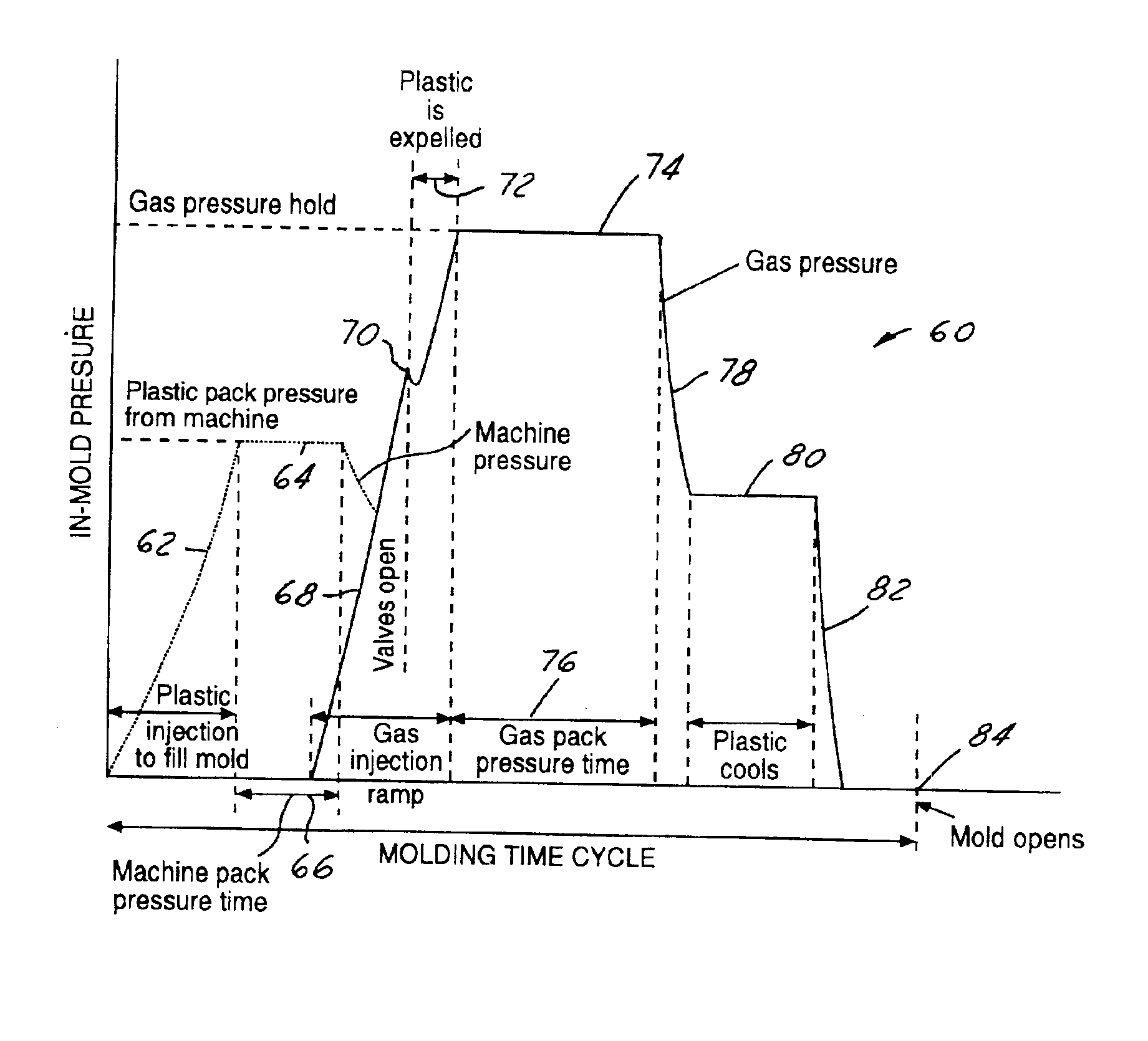

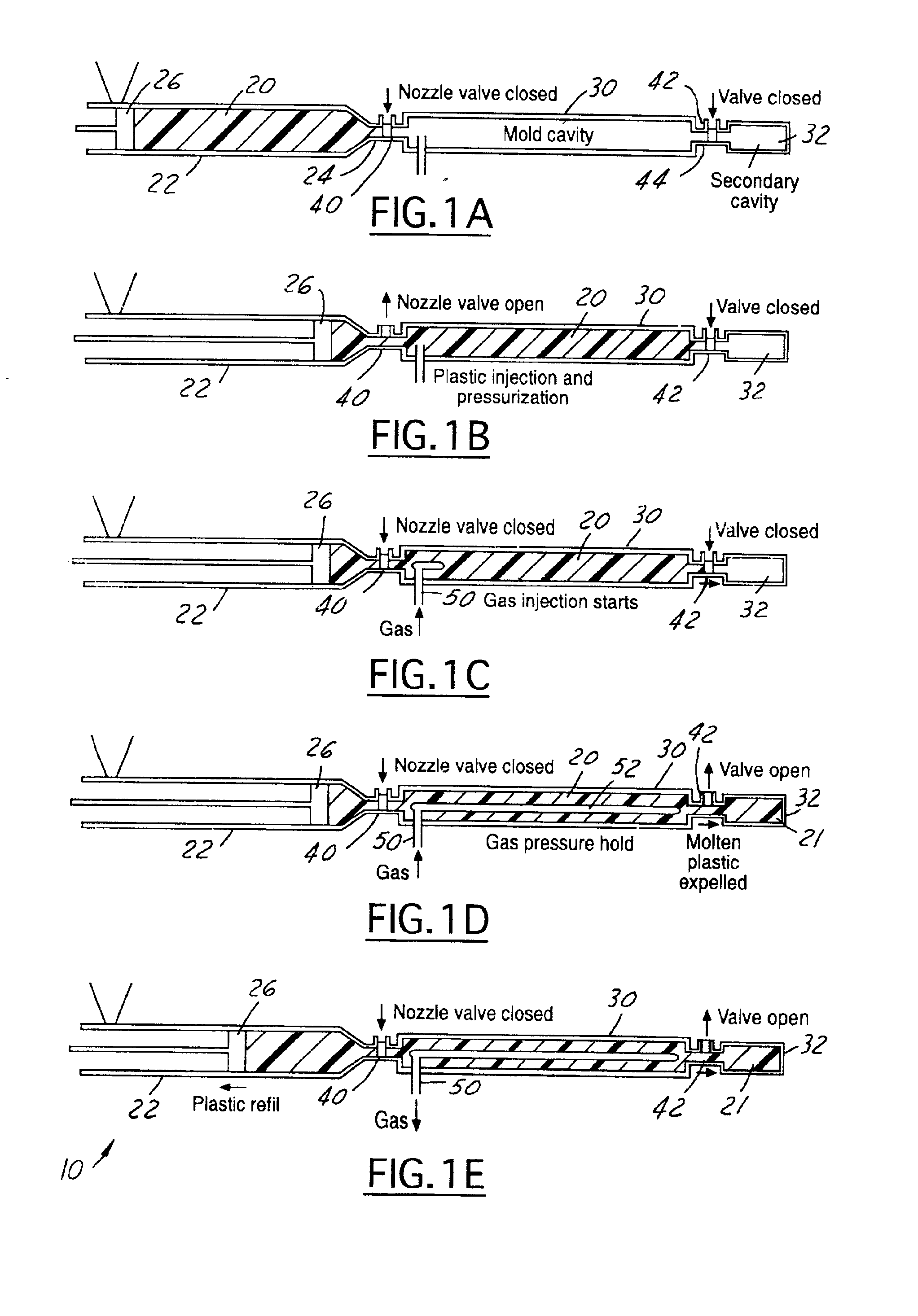

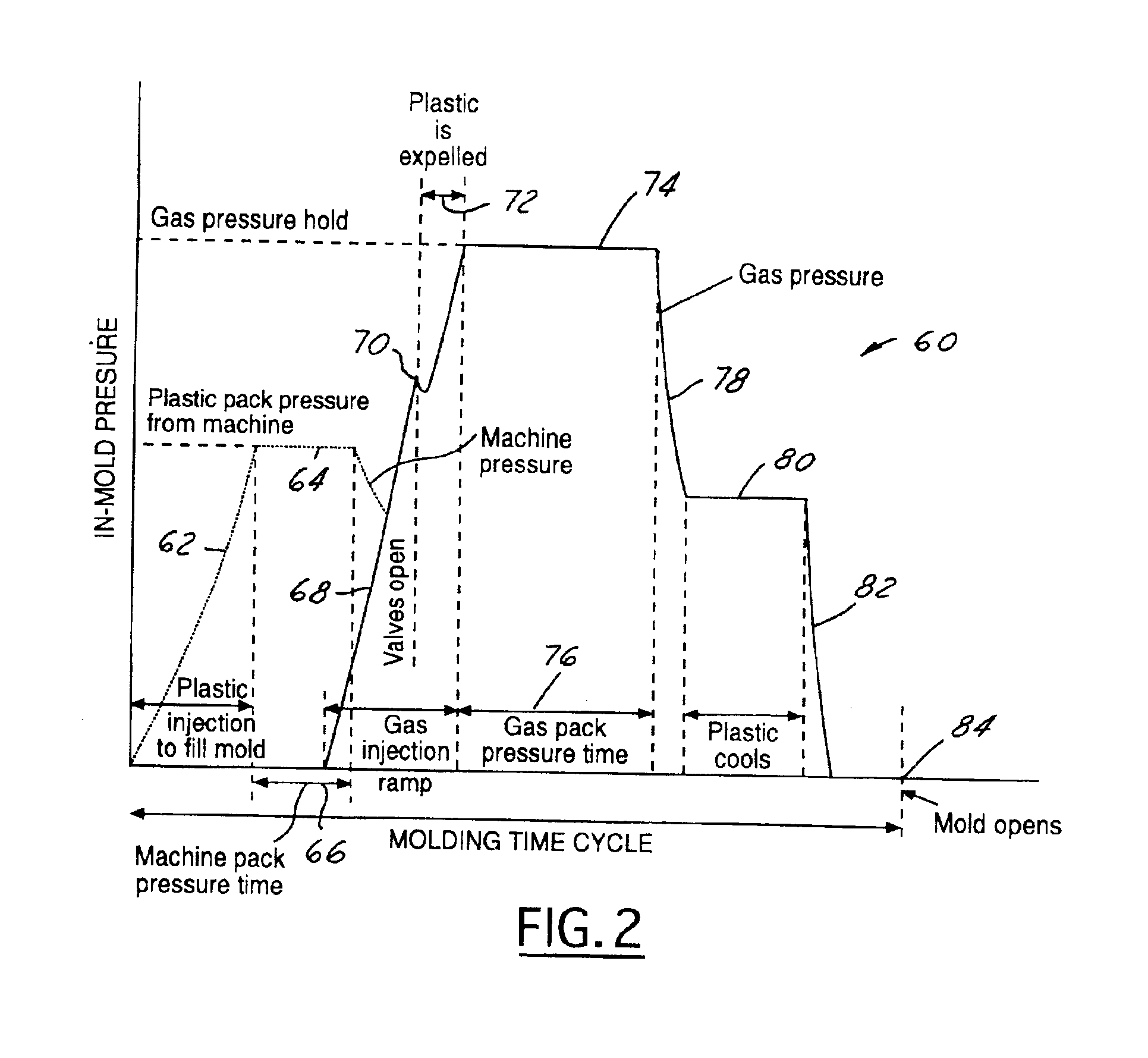

Plastic expulsion process for forming hollow tubular products

InactiveUS6953546B2Easy to controlGood reproducibilityHollow articlesPlastic injection moldingPlastic materials

A system and process for gas assisted plastic injection molding, particularly of hollow tubular components. The plastic material is injected into the mold cavity through an apex of a cone-shaped inlet configuration. After the molding pressure is held for a period of time, gas is injected into the plastic material and pressure is again held for a period of time, a valve member is opened allowing plastic to be expelled into a secondary cavity. The flow of the plastic and gas are controlled in an axial direction in order to prevent turbulence. The gas flow axially along the center of the tubular member allows the expulsion of plastic from the center uniformly along the length of the tube. In an alternative process, the gas is displaced axially into the barrel of the injection molding machine.

Owner:CINPRES

Image forming apparatus, control method therefor, and storage medium storing program for the same

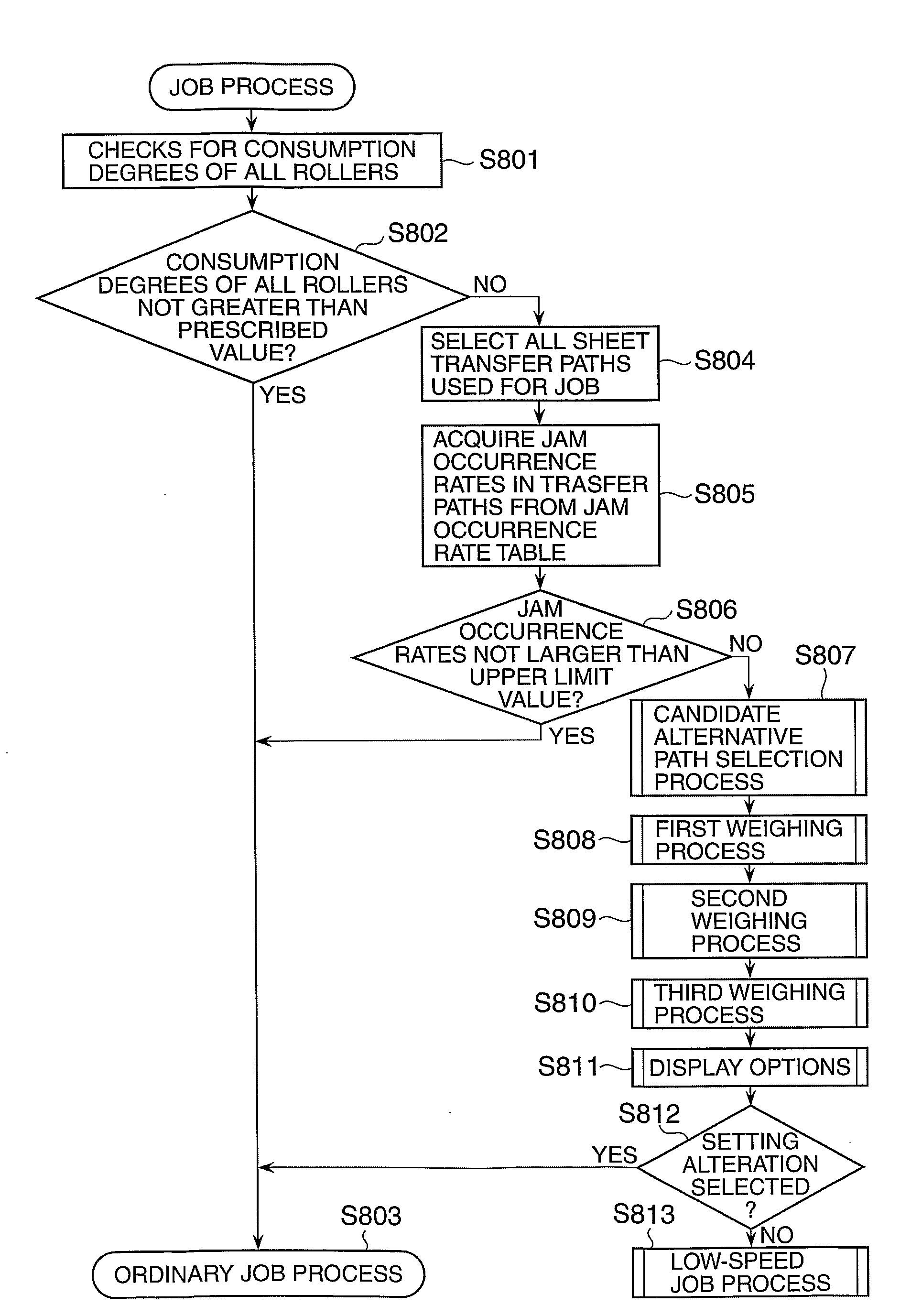

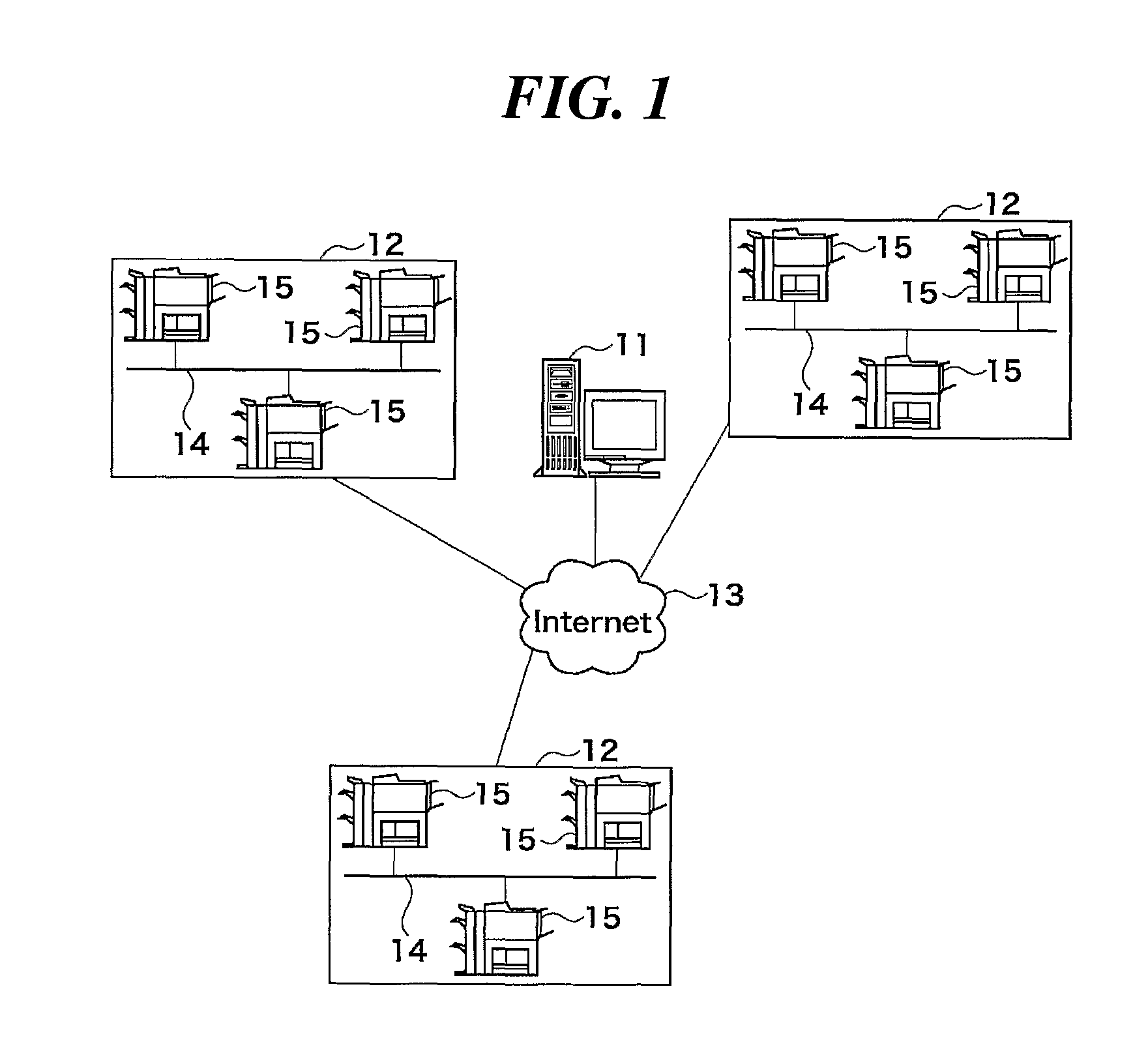

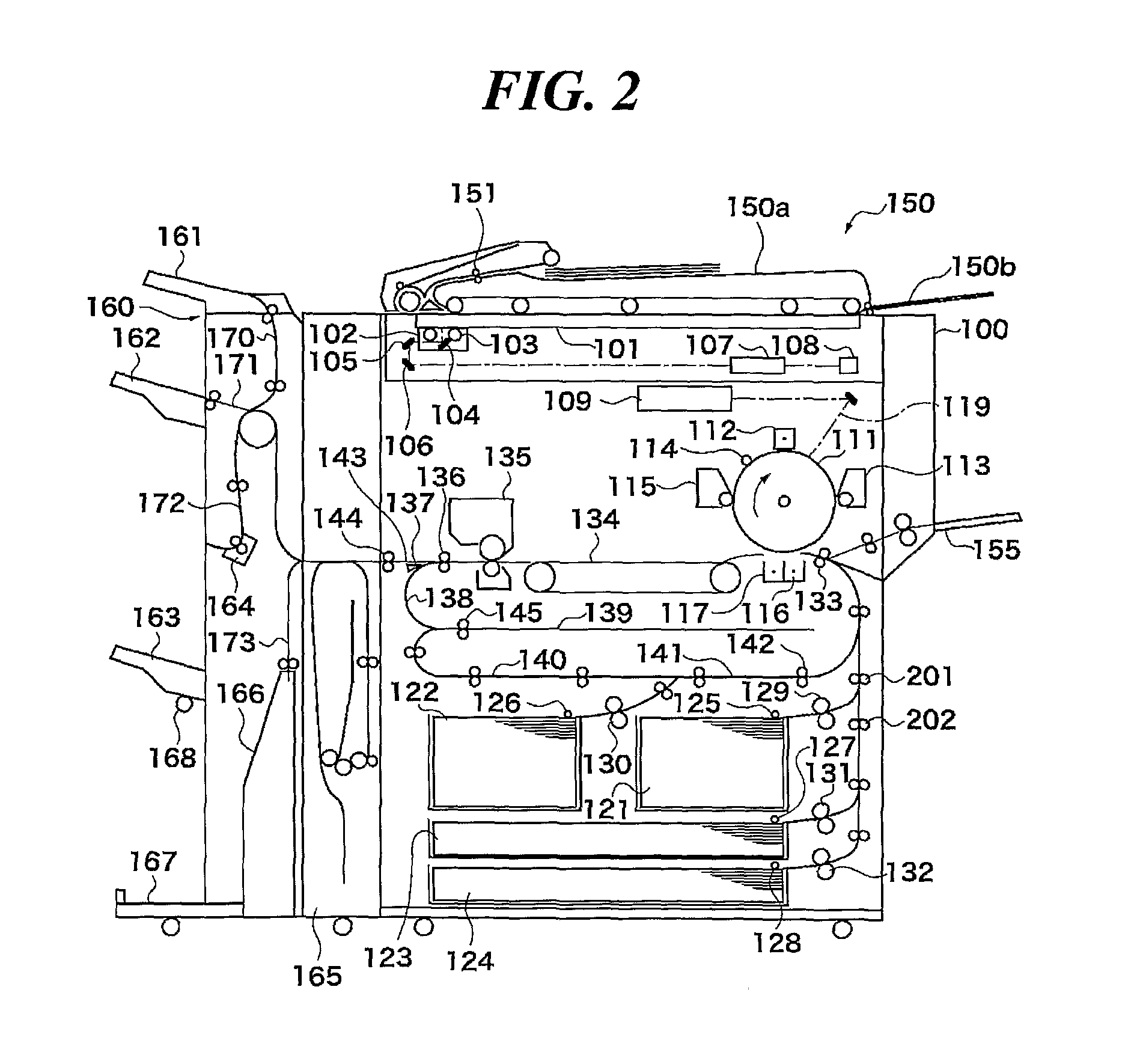

An image forming apparatus capable of being used for a longest possible time period without the need for a user to determine the necessity of part replacement. In a case that a conveyance roller or other part whose consumption degree exceeds a prescribed value is used for a job set by the user, an MFP displays to the user candidates for alternative process using an alternative path in which the conveyance roller or other part is not used and a candidate for alternative process to perform a low-speed process (S702 to S704). The candidates for alternative paths are selected based on weight information set in such a manner that alternative paths are selected in an ascending order of jam occurrence rate acquired from a monitoring server.

Owner:CANON KK

Roll-to-roll method and system for micro-replication of a pattern of large relief three-dimensional microstructures

A method and system referred to as PALM (Patterning by Adhesive of Large Relief Three-Dimensional Microstructures) with large reliefs exceeding 1 μm and being as large as 100 μm. The microstructures can be either deterministic (such as microprisms), or random (such as diffusers), the first obtained by copying an original supermaster, and latter obtained by copying a laser speckle pattern. The master process entails copying a supermaster into the form of the microstructure constituting a pattern on the patterning cylinder (called a drum), to be then continuously multiplied in the PALM system, in a continuous roll-to-roll web process. The latter method, together with the related system, is the subject of this invention. The rolls continuously repeat the master pattern, copying by adhesive with large viscosity on acrylic (hybrid) as well as by a monolithic process. The monolithic process can be accomplished using temperature and pressure, or by UV-cured polymerization. Therefore, the invention comprises three alternative processes: one, hybrid (adhesive on acrylic), and two monolithic ones. In the PALM (hybrid) process, an epoxy is wet-coated on film substrates such as polycarbonate (PC), polyester (PET), (PE), or other flexible material. The adhesive, in liquid form, is applied to the substrate by a self-metered coating sub-process. In the present invention, the adhesive is used for forming the microstructure pattern. The microstructure pattern is replicated from a master roll or image drum onto a coating roll.

Owner:LUMINIT

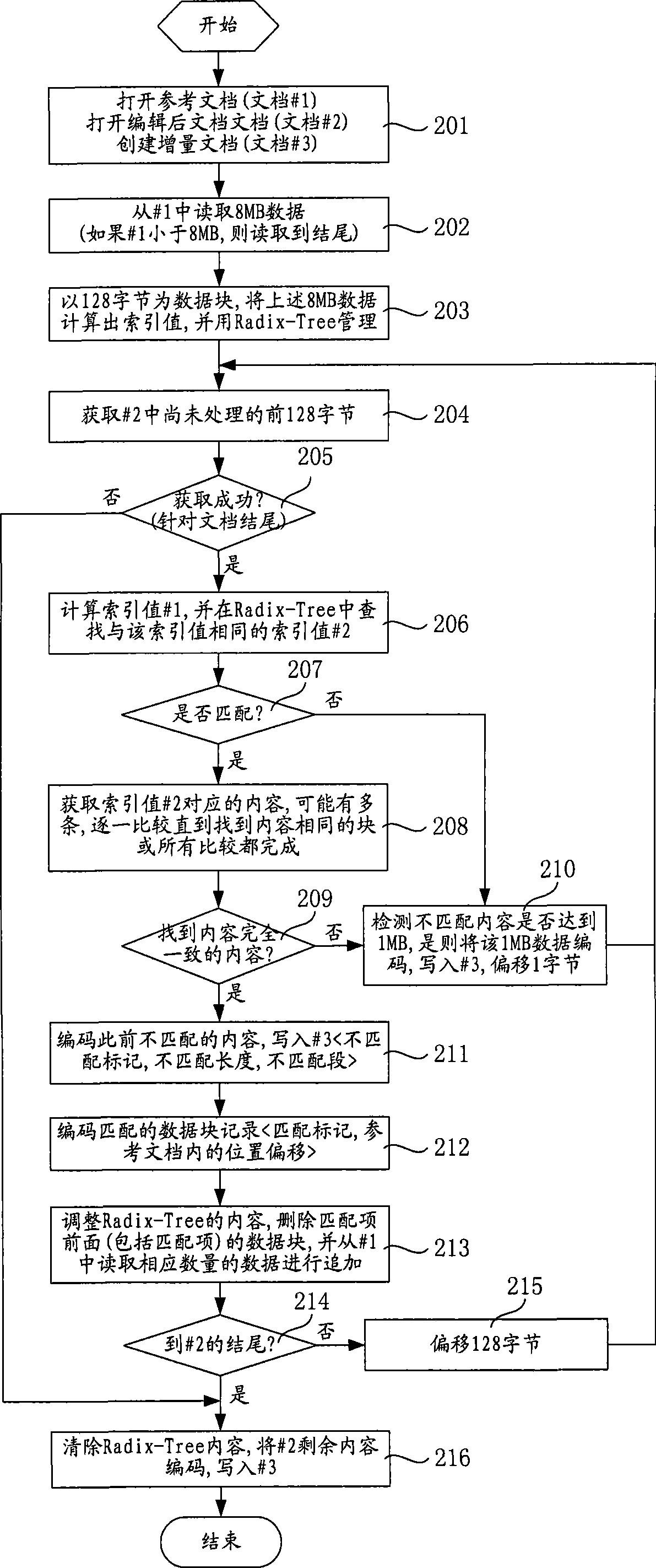

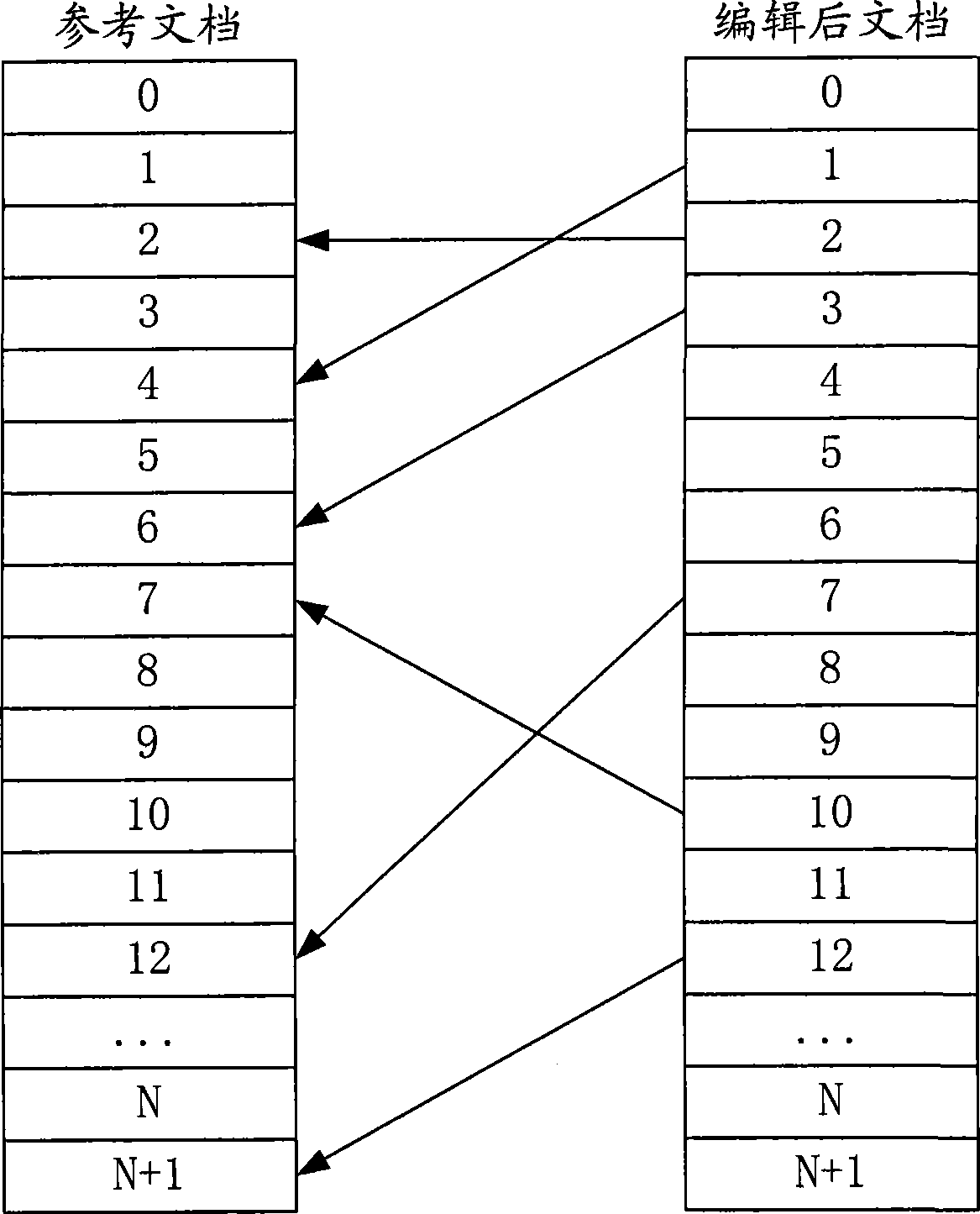

Electronic document increment memory processing method

ActiveCN101482839AReduce the burden onRedundant operation error correctionSpecial data processing applicationsInternal memoryMemory processing

The present invention relates to a method for generating incremental document after edition of electronic document, wherein the method comprises the following steps: reading the data from a reference document into an internal memory and dividing; calculating the index value corresponding with the divided reference data block and relating; sequentially reading the edited data block into the internal memory and calculating the corresponding index value; comparing the index value corresponding with the reference data block with the index value corresponding with the data block after editing, if the two index value are matching with each other, writing the matching position of reference document and matching mark into the incremental document, and otherwise writing the unmatched segment in the document after editing, the unmatched length and the unmatched mark into the incremental document. The invention also relates to a method for recovering the document after editing according to incremental document. The invention generates the incremental document through establishing a mapping relationship between two documents before and after editing and according to the recorded mapping relationship. The incremental document only requires processing for substituting the document after editing in the aspects of data storing, filing, backup, etc. for further reducing the storing burden or network transmission burden.

Owner:BEIJING 21VIANET DATA CENT

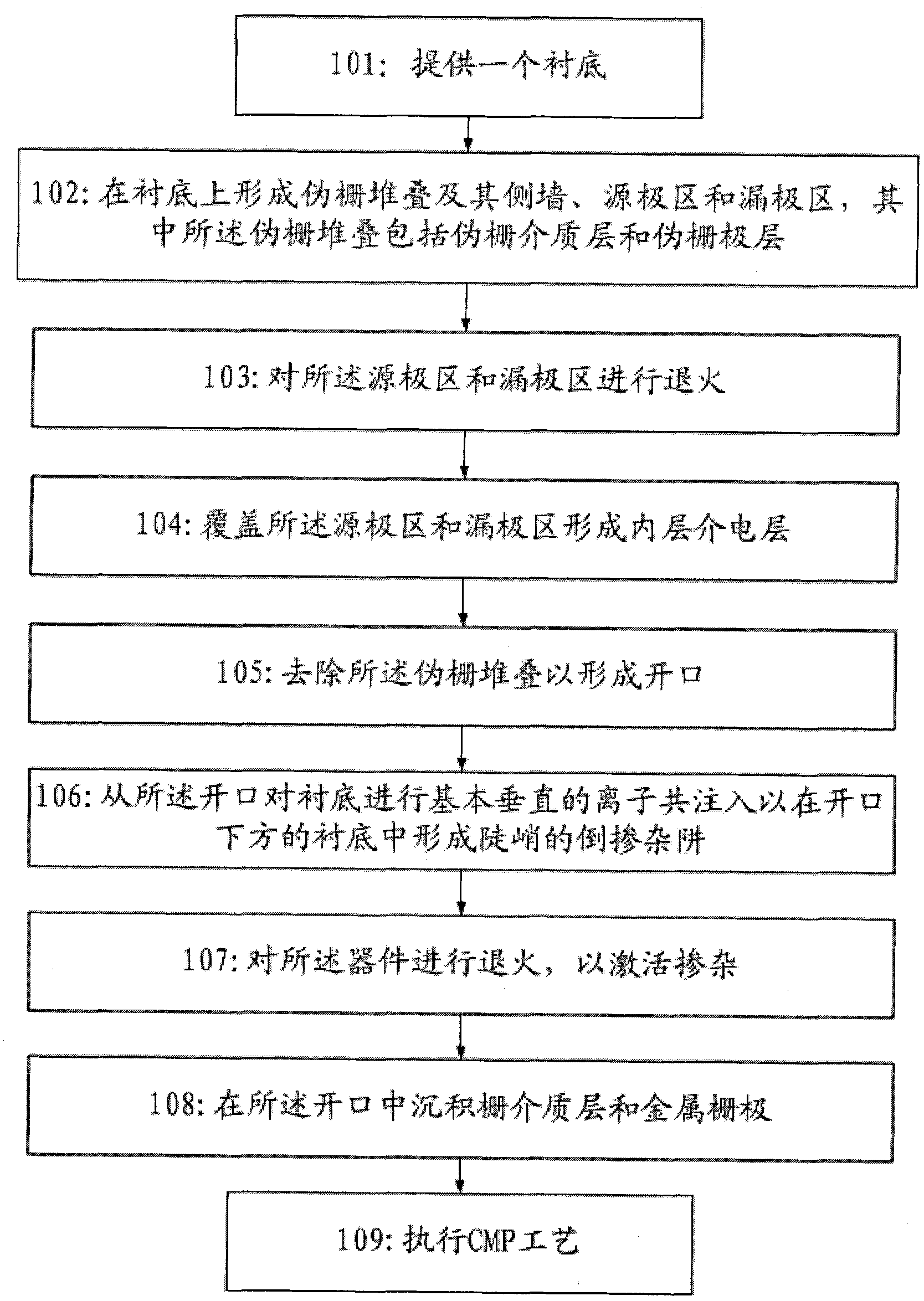

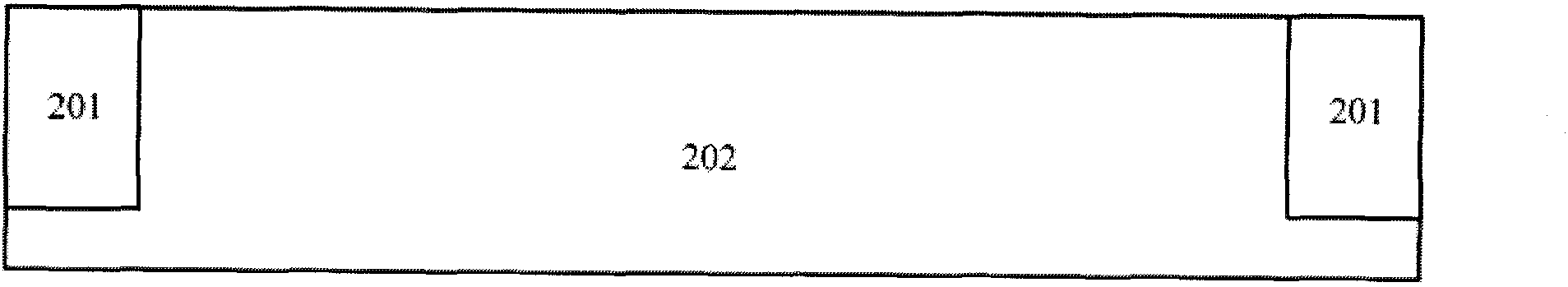

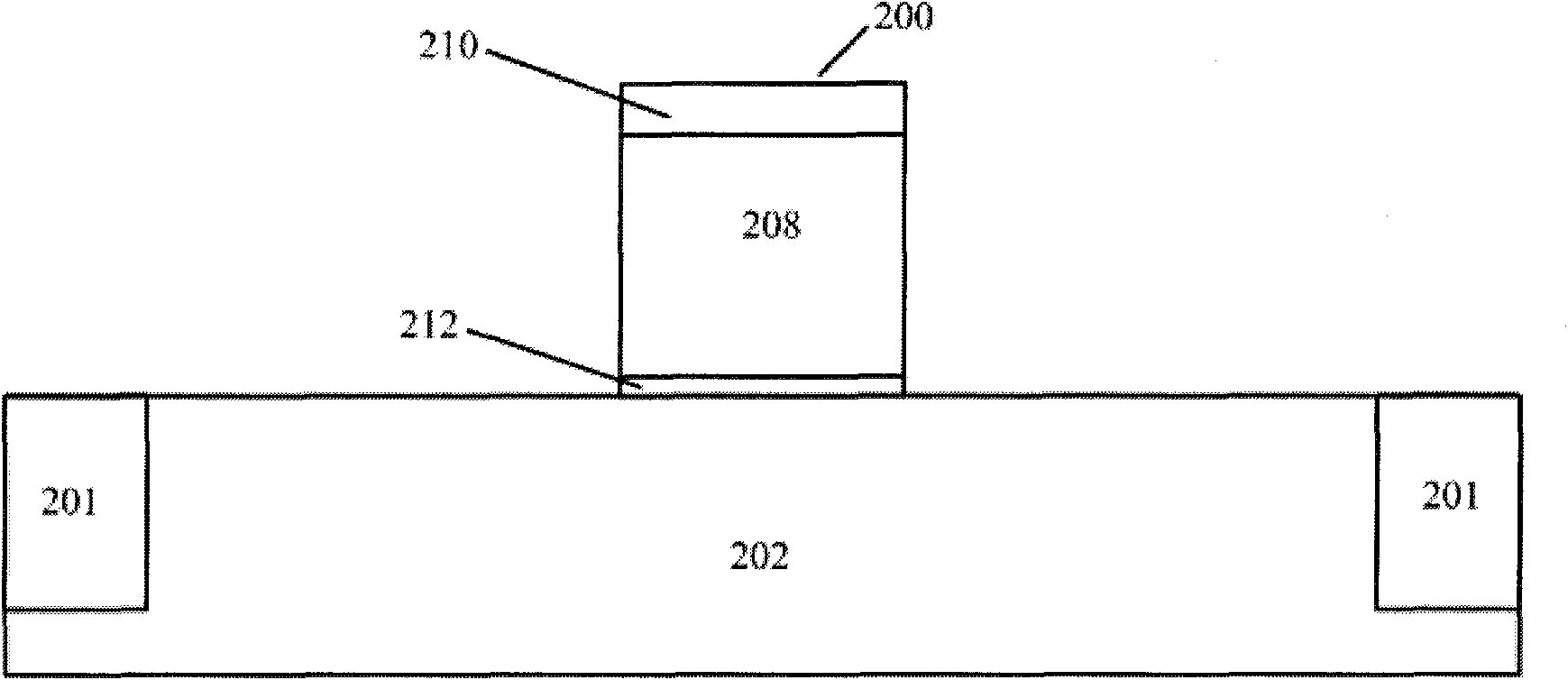

High-performance semiconductor device and manufacturing method thereof

ActiveCN102157379ASemiconductor/solid-state device manufacturingSemiconductor devicesCapacitanceMOSFET

The invention provides a method for manufacturing a semiconductor device, comprising the following steps of: firstly forming a false gate stack and a side wall thereof, a source electrode region and a drain electrode region by utilizing a gate alternative process; annealing the source electrode region and the drain electrode region, and then removing the false gate stack; carrying out basically vertical ion co-implantation and / or slant ion co-implantation on a substrate to form a steep inverted dopant well in the substrate positioned below an opening and / or respectively form ion implantation regions near the source electrode region and the drain electrode region by utilizing the opening formed by removing the false gate stack, and then annealing the semiconductor device to activate doping; and depositing a gate dielectric layer and a metal gate electrode in the opening. Thus, the increase of tape-to-tape leakage currents and source drain junction capacitances of an MOSFET (Metal-Oxide-Semiconductor Field Effect Transistor) device are inhibited and the breakdown of a source electrode and a drain electrode is prevented, thereby the performance of the semiconductor device is improved.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

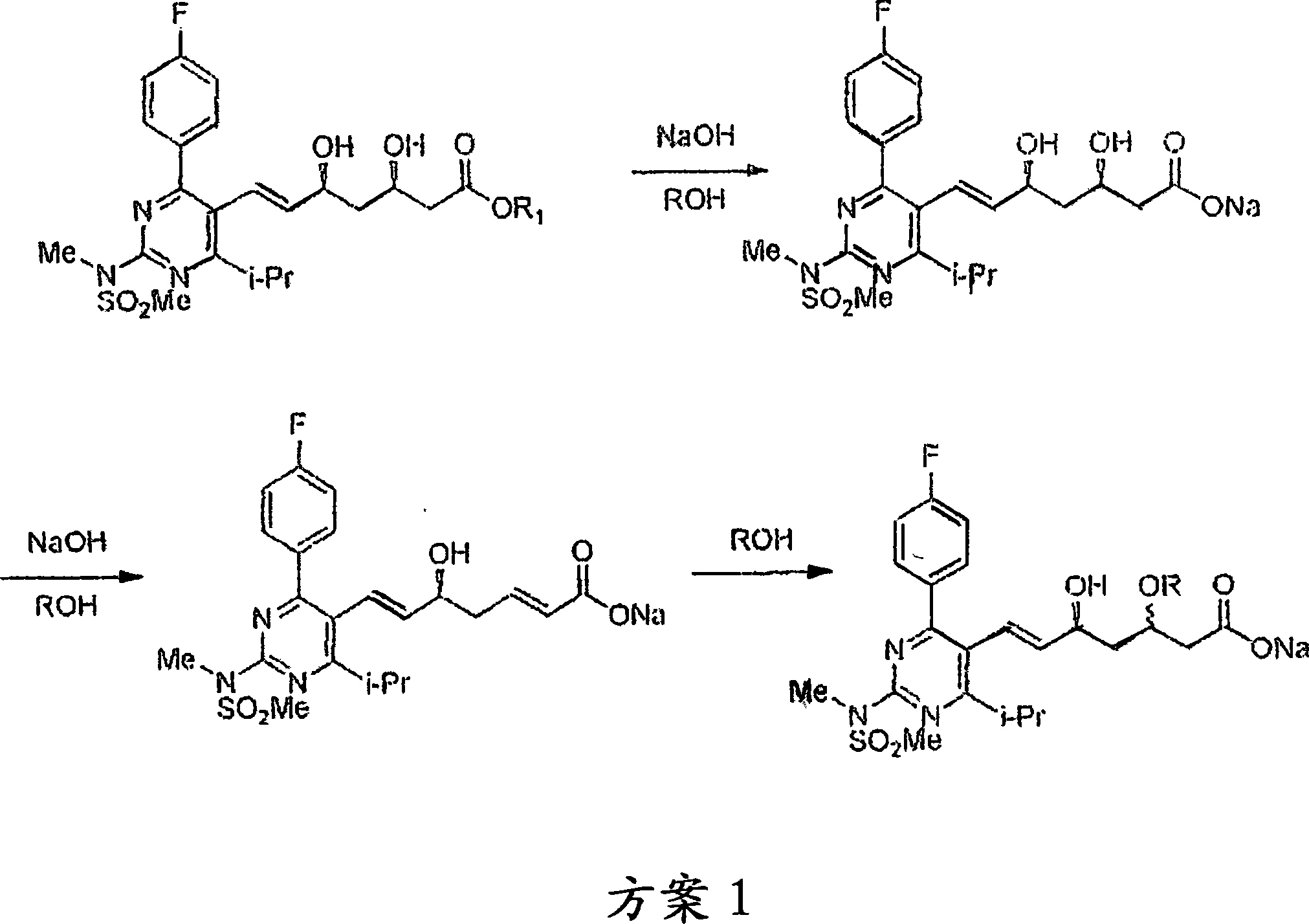

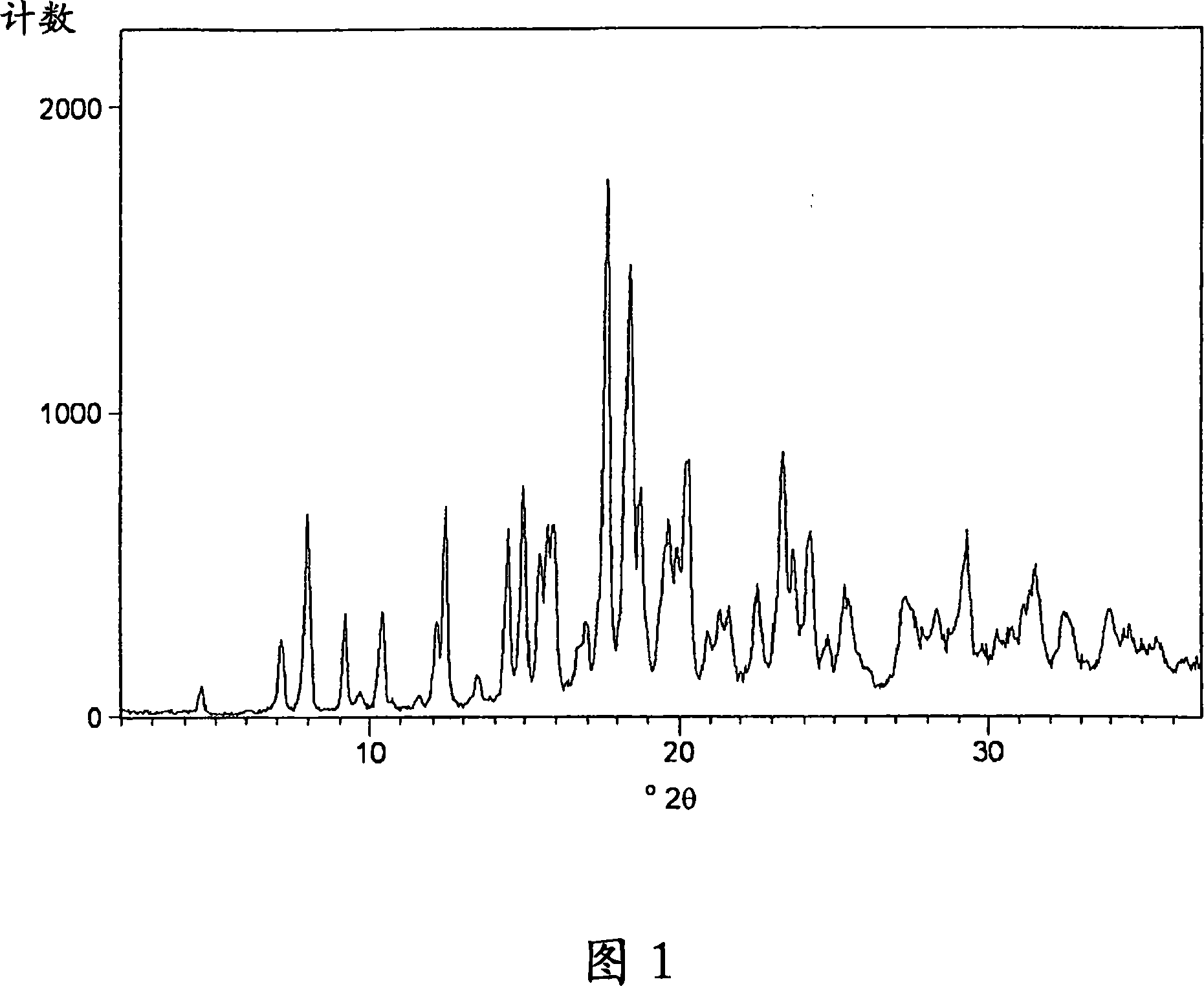

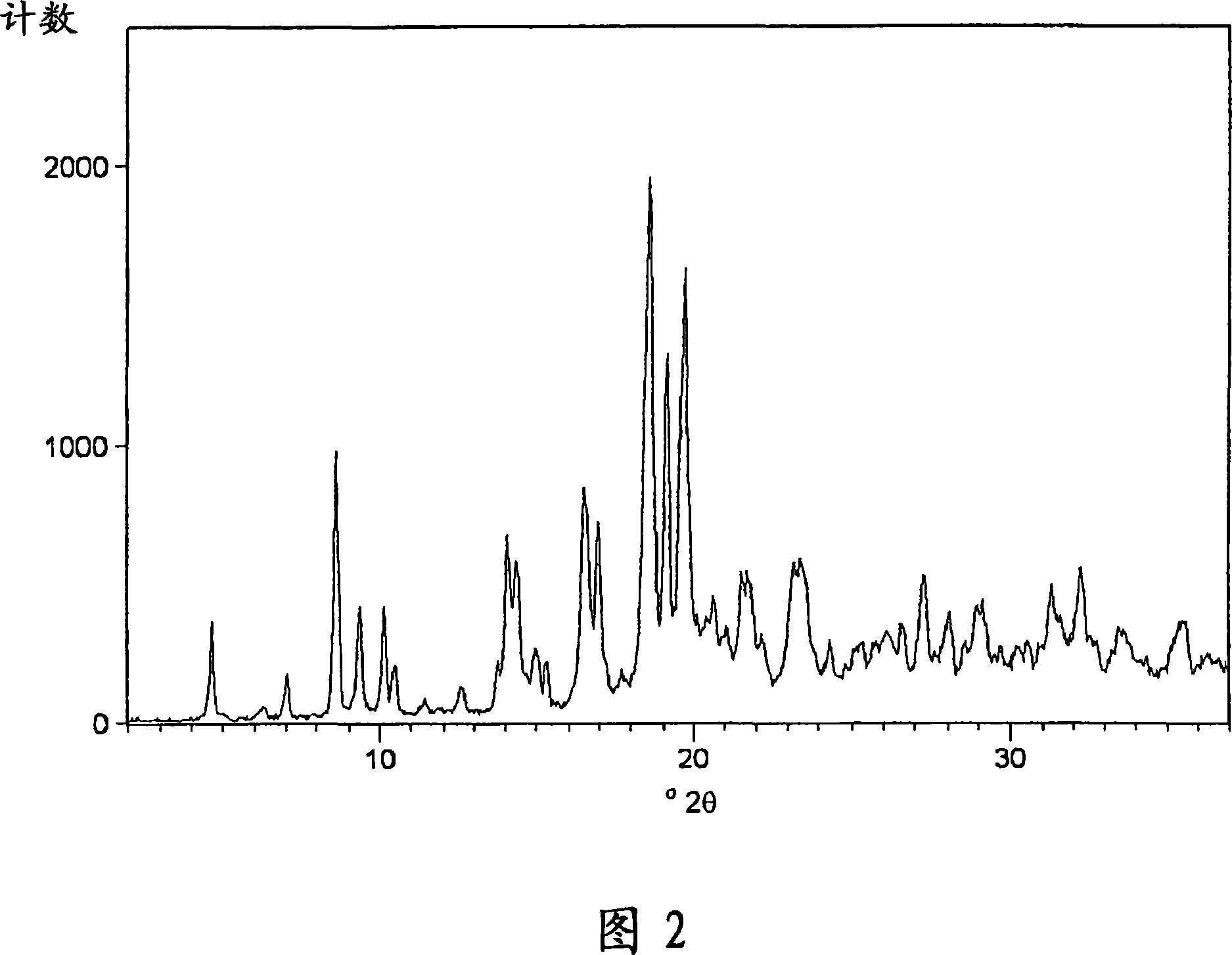

Process for preparing amorphous rosuvastatin calcium free of impurities

InactiveCN101208307AOrganic active ingredientsOrganic chemistryHMG-CoA reductaseRosuvastatin Calcium

A pure amorphous form of rosuvastatin calcium having purity of more than 99.5%, preferably a purity of more than 99.8%, more preferably a purity of more than 99.9% as determined by HPLC area percentage, and free from any traces of alkali metal impurities is disclosed. A process of preparing said pure amorphous form of rosuvastatin calcium is disclosed, which comprises hydrolysis of C1-C5 alkyl esters of rosuvastatin, preferably terf-butyl ester of rosuvastatin, with an organic nitrogen base, e.g. guanidines, amidines, amines and quaternary ammonium hydroxides, in the presence of water, optionally containing aprotic solvent, following the conversion of thus obtained rosuvastain salt with a source of calcium to desired rosuvastatin calcium, which is then isolated. An alternative process is disclosed, which comprises the conversion of numerous novel ammonium salts of rosuvastatin, preferably tert-octylammonium salt of rosuvastatin, with the source of calcium to desired commercial rosuvastatin calcium. Rosuvastatin calcium is HMG CoA reductase, useful in the treatment of hyperlipidemia, hypercholesterolemia and atherosclerosis.

Owner:LEK PHARMA D D

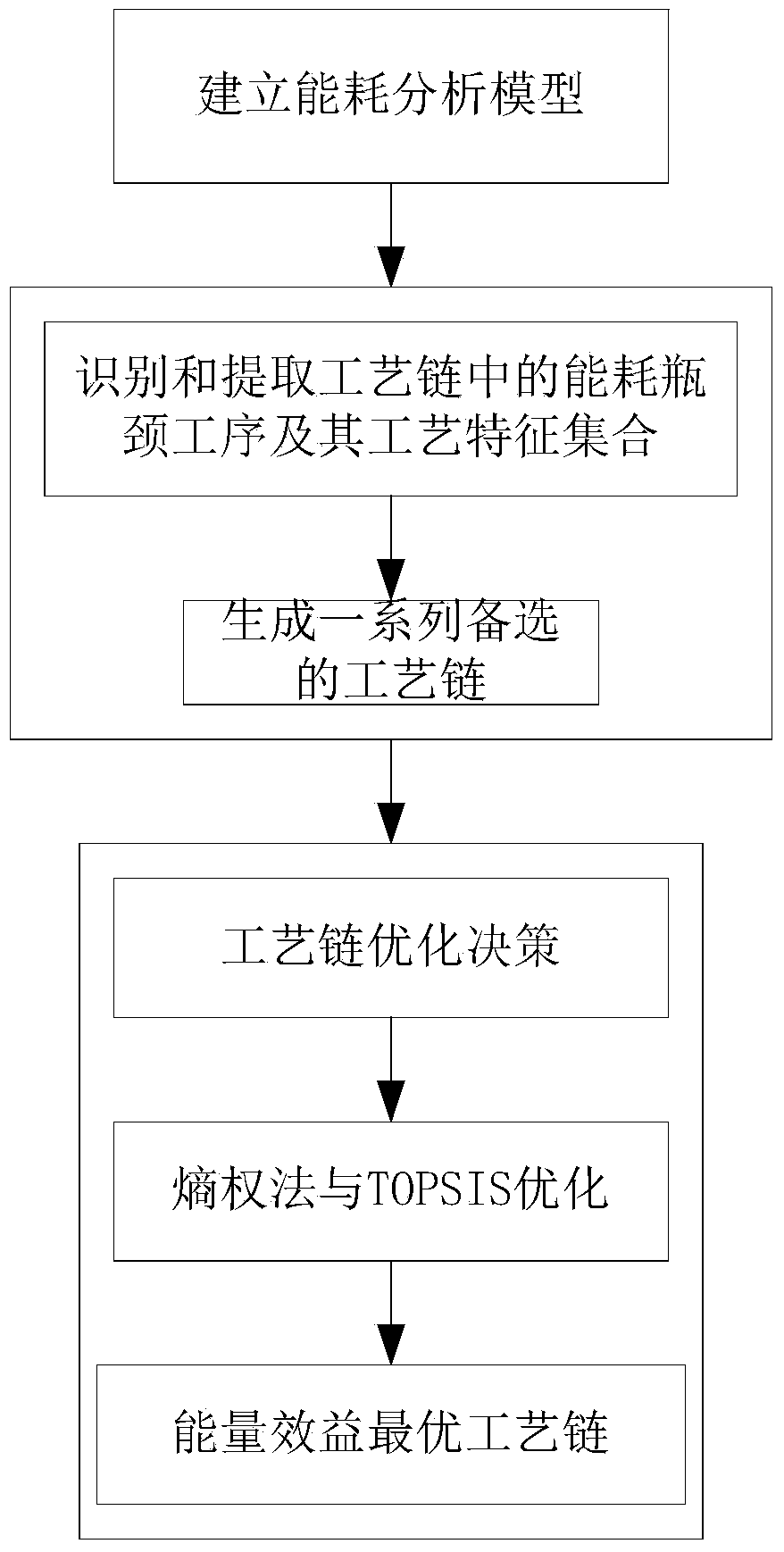

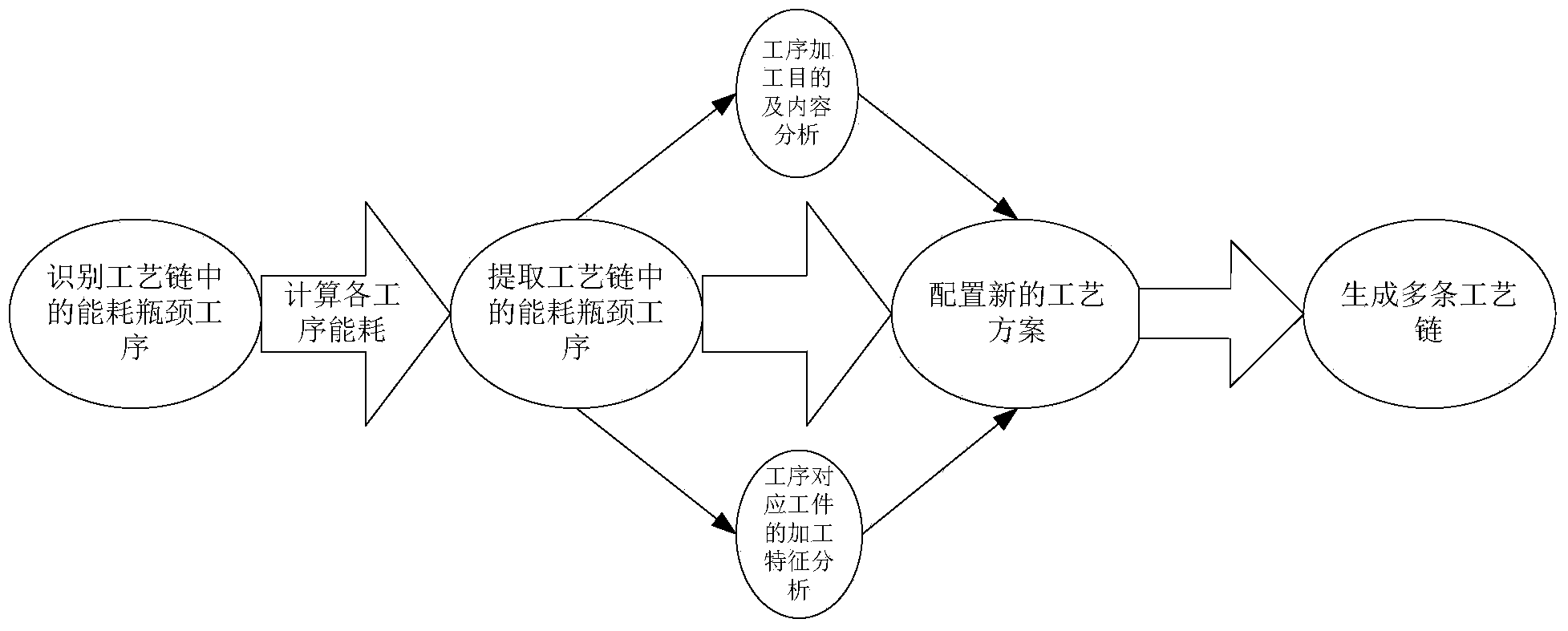

Machining process chain optimization method for energy efficiency improvement

InactiveCN103839115AEnergy Efficiency ImprovementFully consider the characteristicsEnergy industryForecastingFeature setEntropy weight method

The invention discloses a machining process chain optimization method for energy efficiency improvement. The method includes the steps that an energy consumption analysis model is established, on the basis of the model, energy consumption bottleneck processes are recognized from all processes forming process chains, and then machining process feature sets corresponding to the energy consumption bottleneck processes are determined respectively; replaceable machining process features are found out and configured to be the machining processes which are relatively lower in energy consumption, and therefore a series of alternative process chains are generated; optimization processing is conducted on the alternative process chains by the adoption of the entropy weight method and the multi-attribute decision method, the process chain with the optimal energy efficiency is selected to serve as an optimization result, and therefore the whole optimization process of the machining process chain is completed. According to the method, the machining process chain with optimal energy efficiency performance can be obtained, meanwhile the machining efficiency is greatly improved, the workpiece machining period is shortened, the product cost is lowered, and therefore the method is particularly suitable for the occasions of precision machining or industrial machining of various workpieces.

Owner:WUHAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com