Patents

Literature

35649 results about "Corrosion resistant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Corrosion resistance. noun. The definition of corrosion resistance refers to how well a substance (especially a metal) can withstand damage caused by oxidization or other chemical reactions. An example of corrosion resistance is when a boat is treated to prevent rust and is thus able to withstand damage.

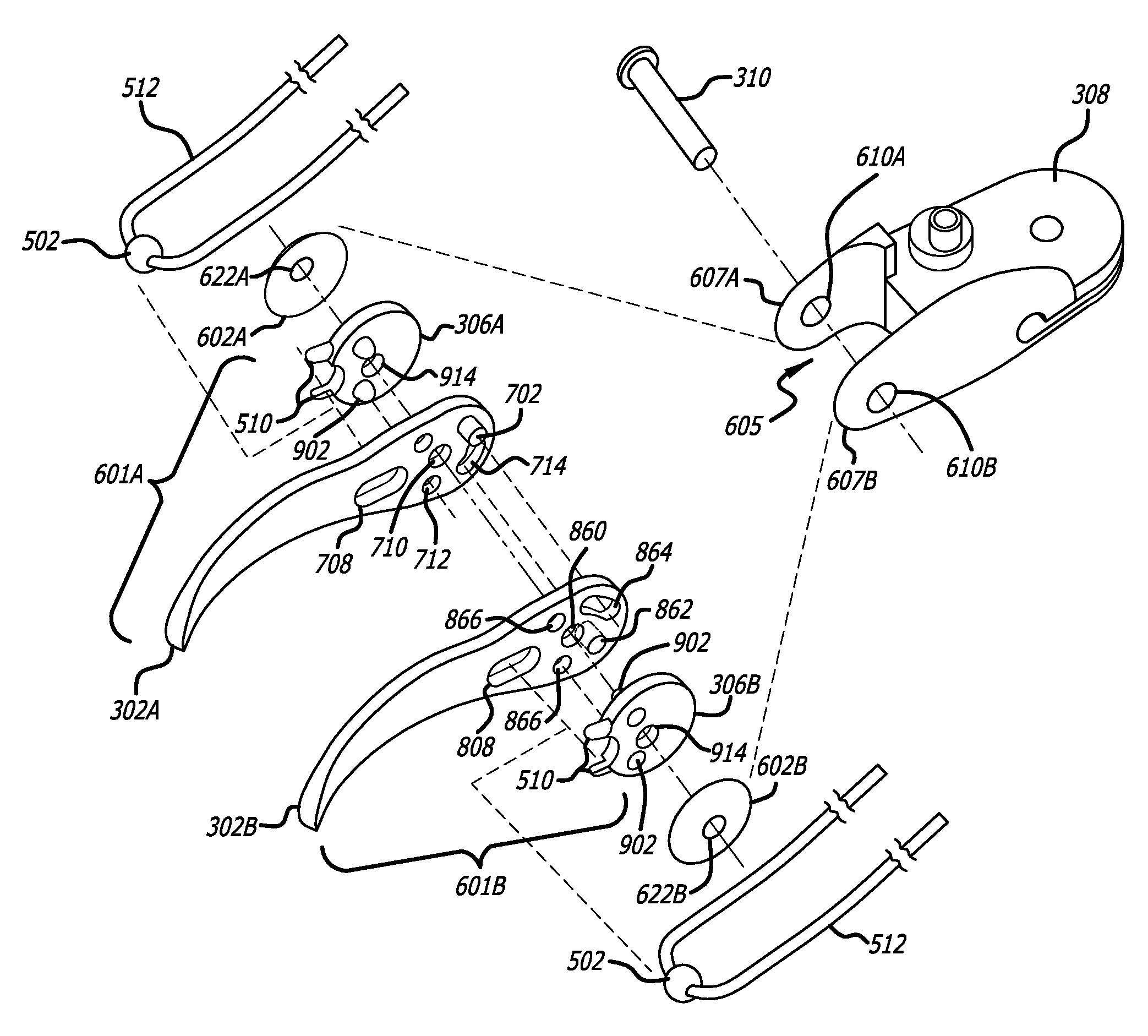

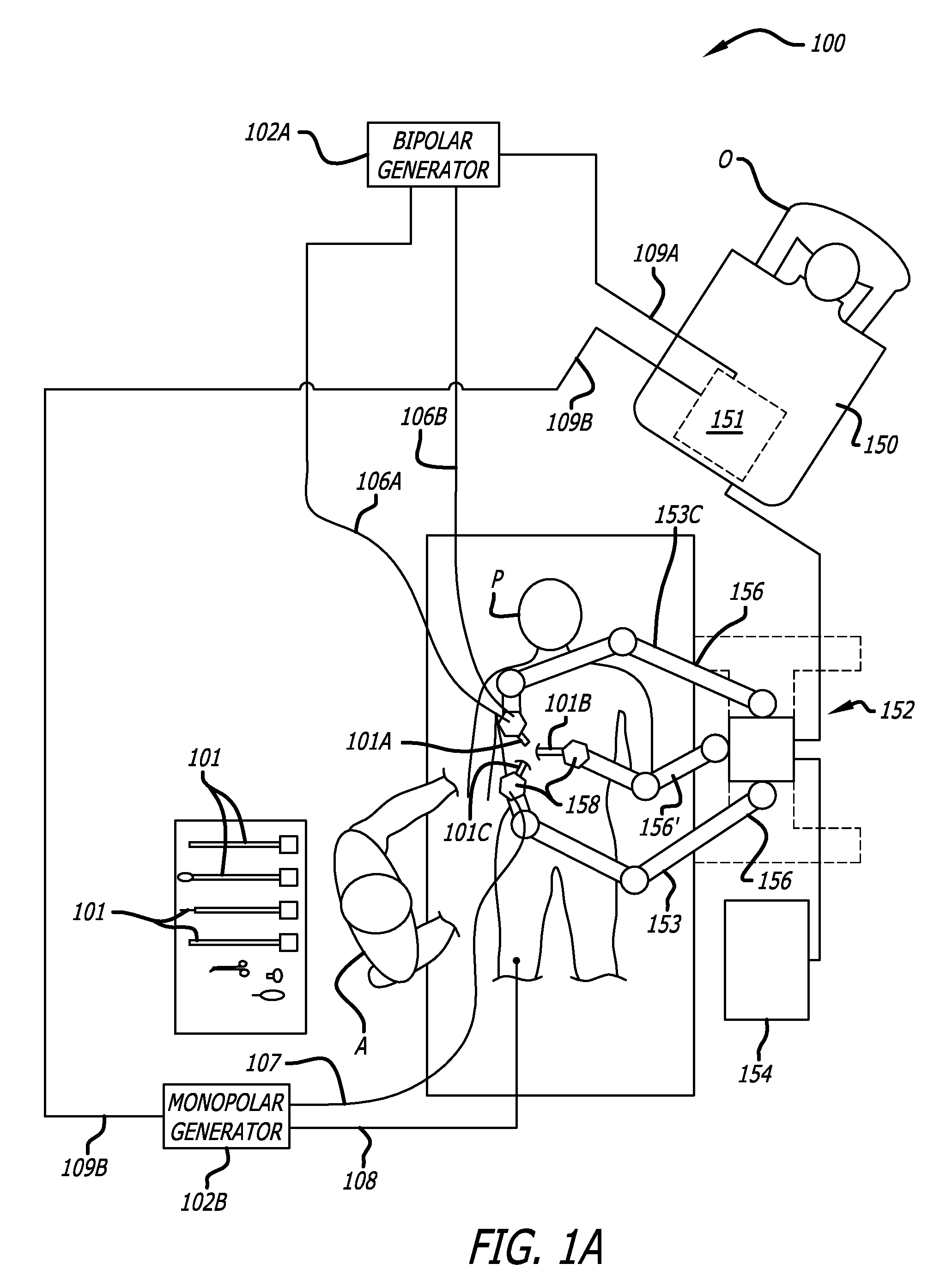

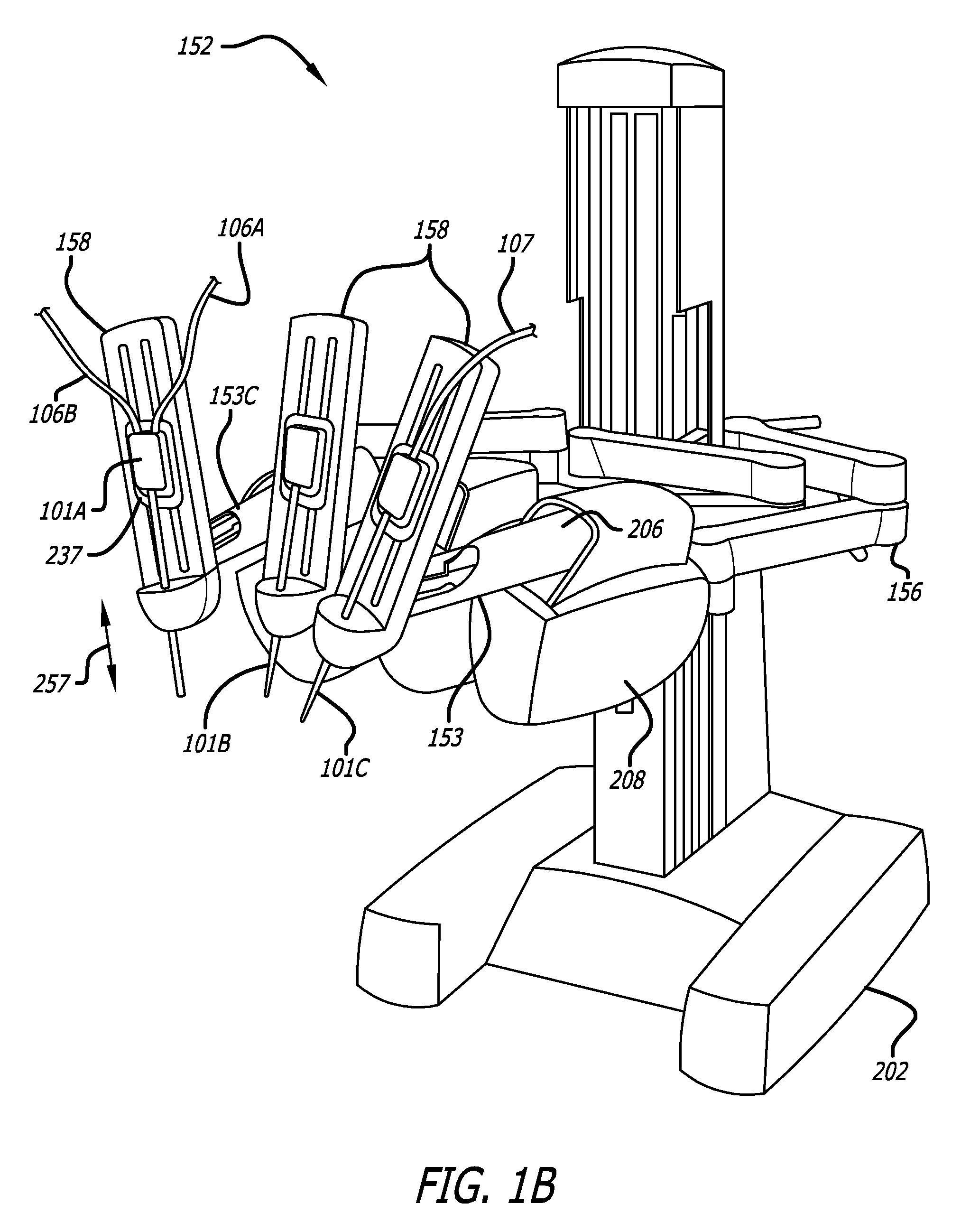

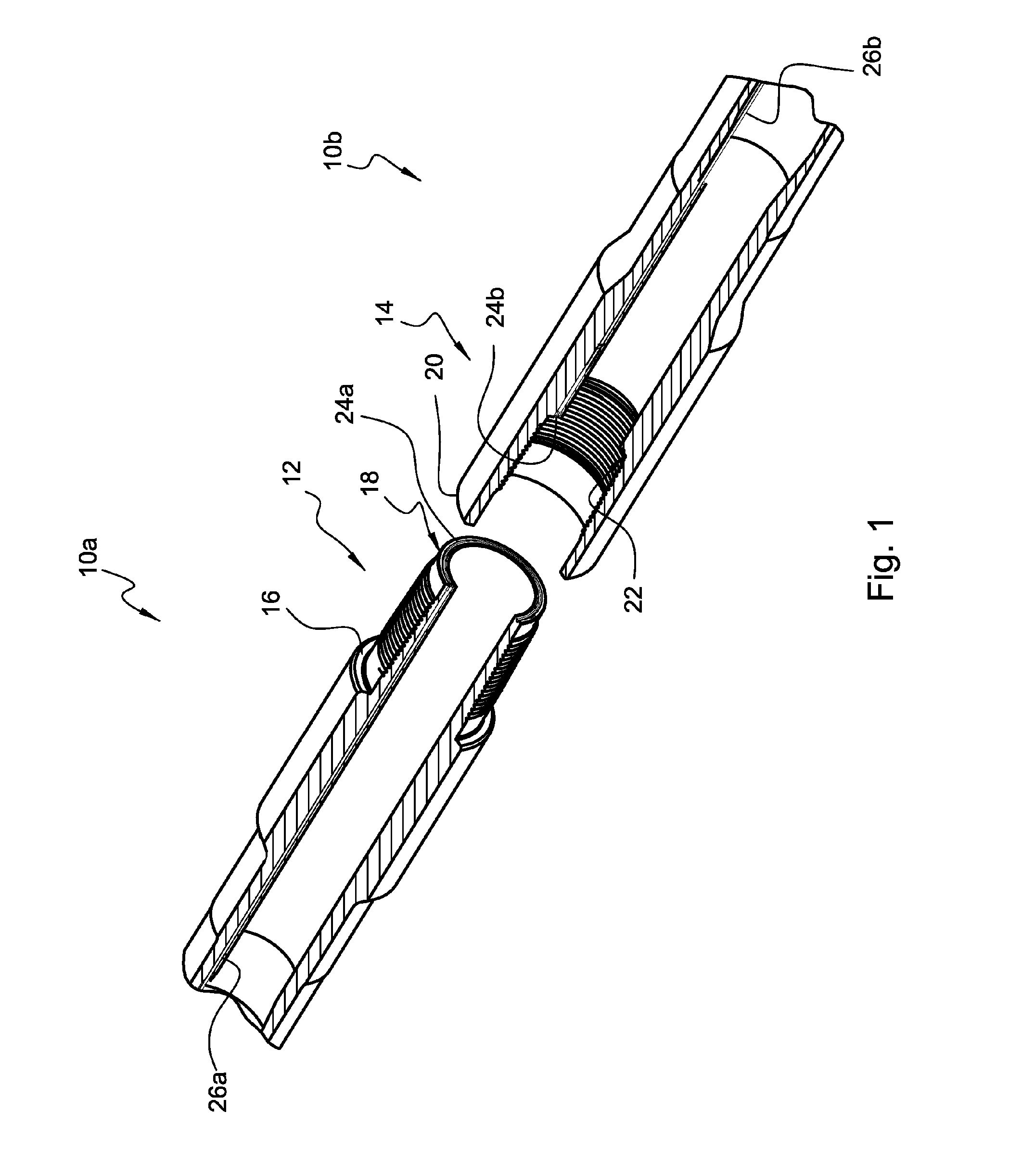

Two-piece end-effectors for robotic surgical tools

In one embodiment of the invention, a robotic surgical tool having opposing jaws, the working element of the robotic surgical tool is made of a different material from the drive element of the robotic surgical tool. The two elements may be manufactured independently and assembled together at a later stage. The material comprising each element may thus have properties more appropriate to the function each element plays in the robotic surgical tool. For example, the metal selected to comprise the blade of a surgical scissor may be corrosion resistant and capable of being sharpened to a high degree.

Owner:INTUITIVE SURGICAL OPERATIONS INC

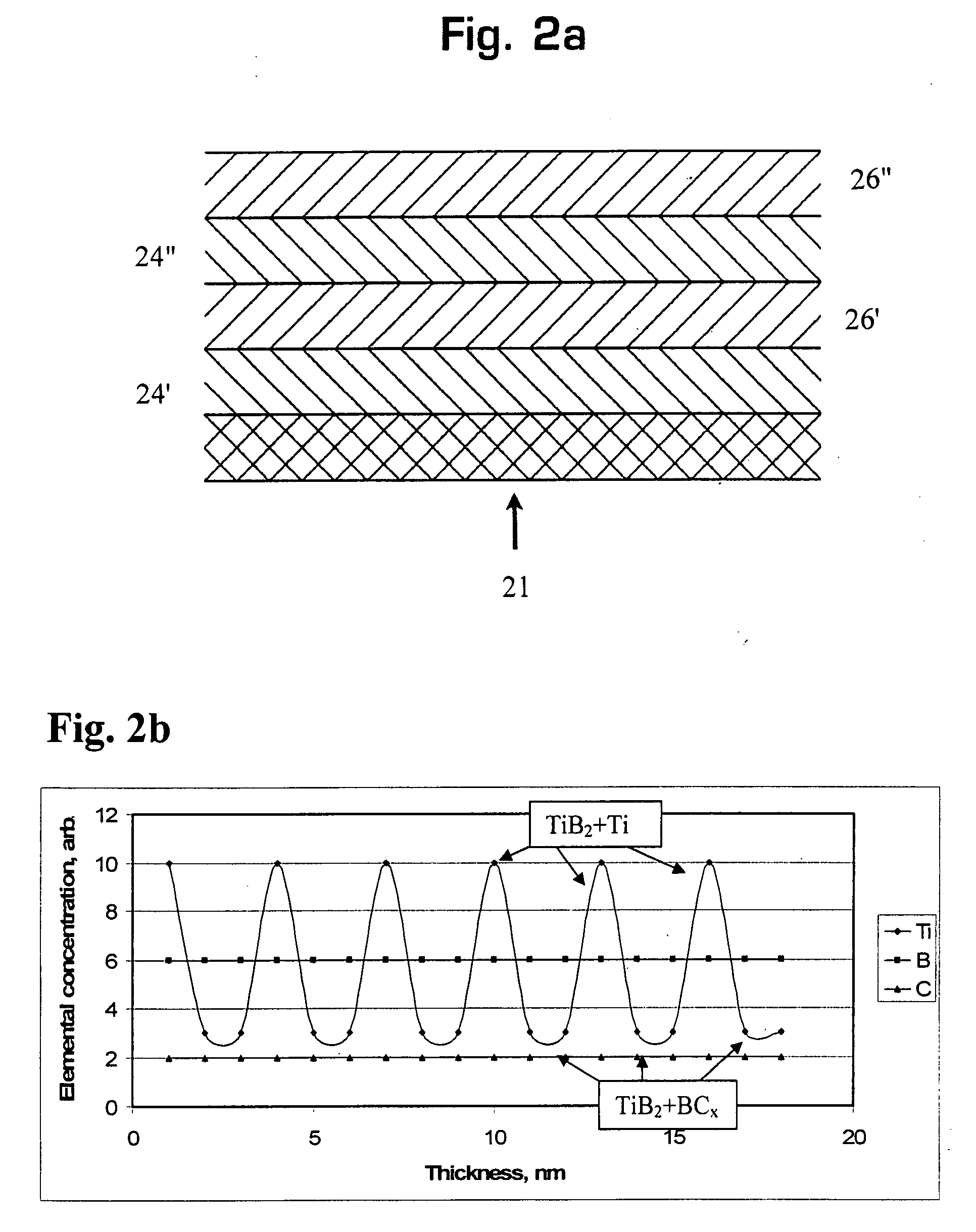

Diamond coatings on reactor wall and method of manufacturing thereof

InactiveUS20020086501A1High purityIncrease resistanceFrom solid stateVacuum evaporation coatingMetallurgySemiconductor

A corrosion resistant component of semiconductor processing equipment such as a plasma chamber includes a diamond containing surface and process for manufacture thereof.

Owner:LAM RES CORP

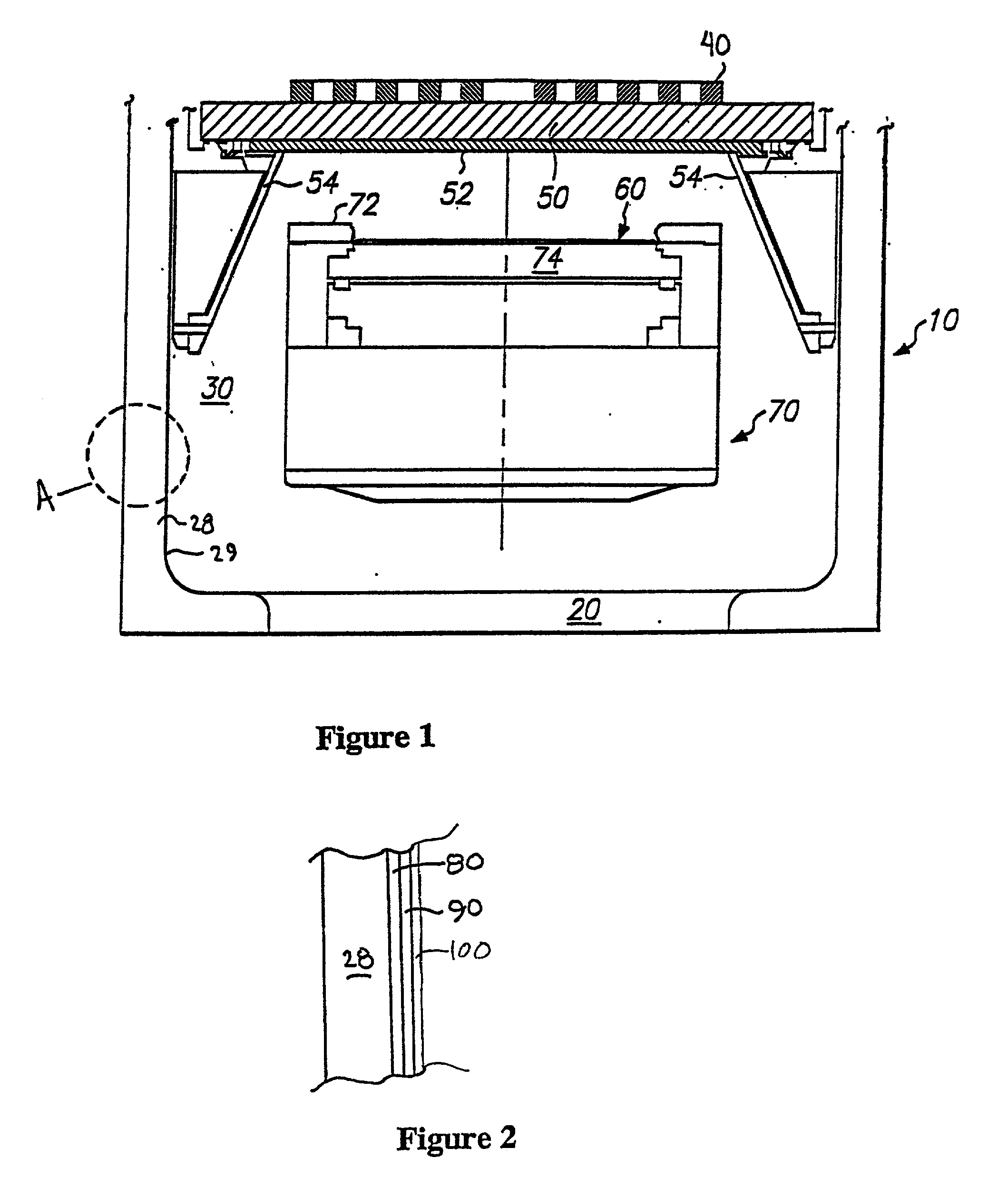

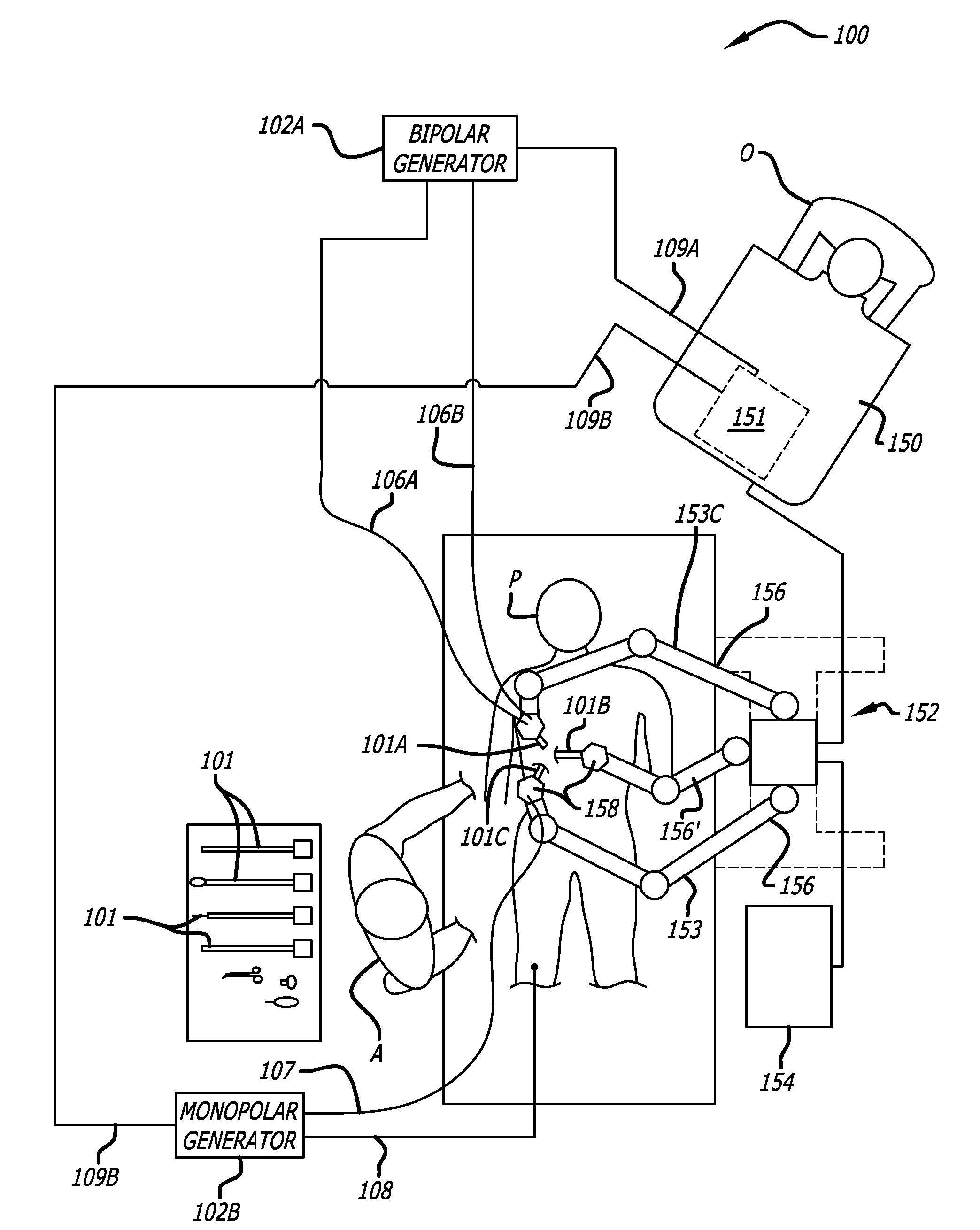

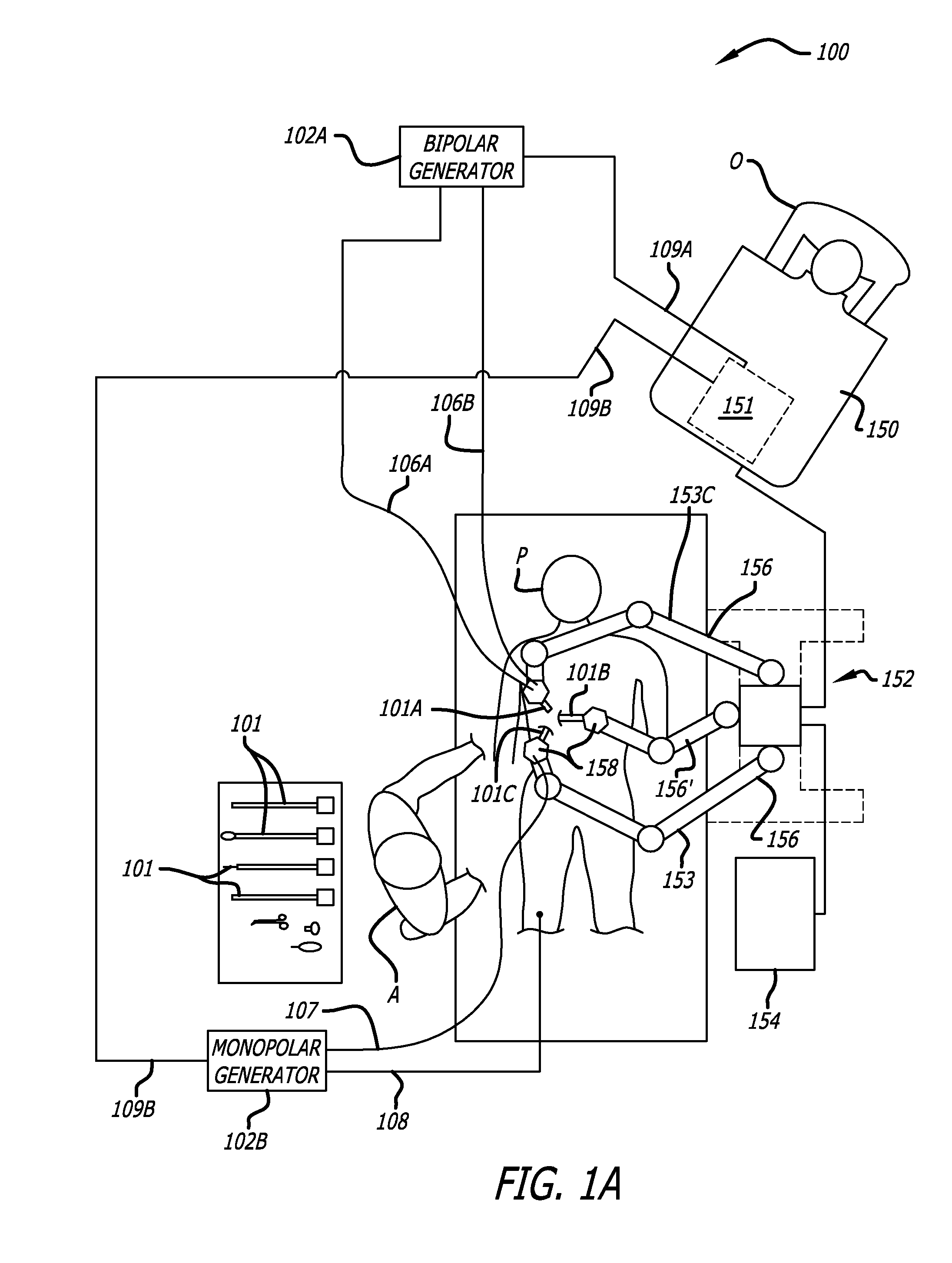

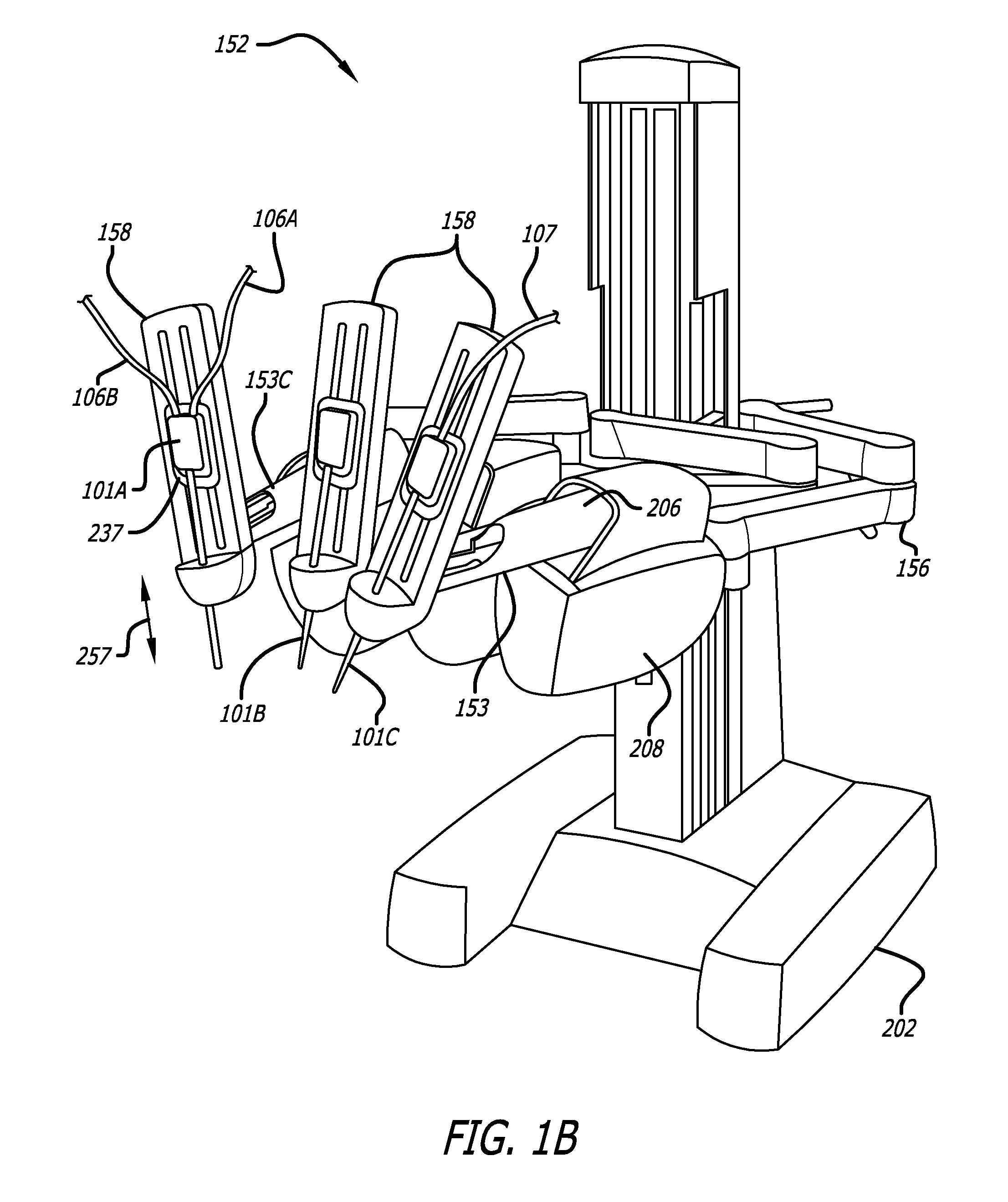

Two-piece end-effectors for robotic surgical tools

In one embodiment of the invention, a robotic surgical tool having opposing jaws, the working element of the robotic surgical tool is made of a different material from the drive element of the robotic surgical tool. The two elements may be manufactured independently and assembled together at a later stage. The material comprising each element may thus have properties more appropriate to the function each element plays in the robotic surgical tool. For example, the metal selected to comprise the blade of a surgical scissor may be corrosion resistant and capable of being sharpened to a high degree.

Owner:INTUITIVE SURGICAL OPERATIONS INC

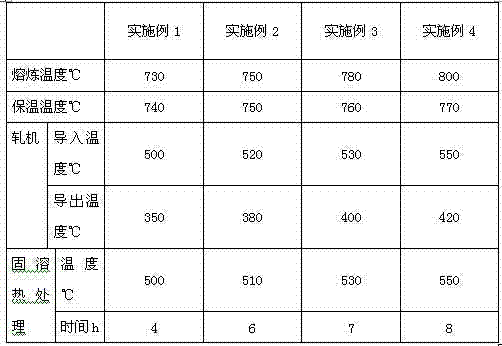

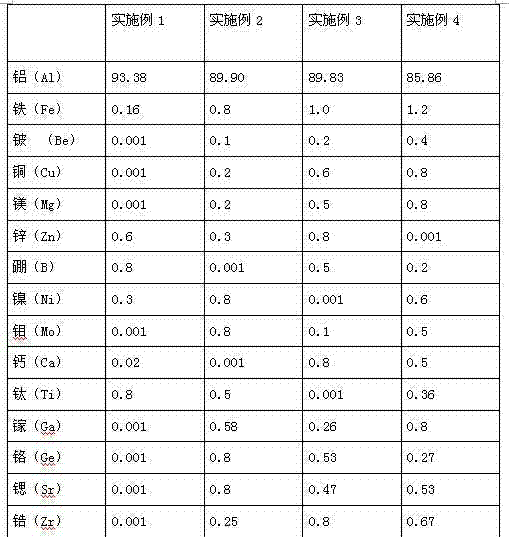

A kind of aluminum alloy material and preparation method thereof

The invention relates to an aluminum alloy material which is characterized in that the aluminum alloy material comprises the following components by weight percent: 0.16-1.2% of Fe, 0.001-0.8% of Cu, 0.001-0.8% of Mg, 0.001-0.8% of Zn, 0.001-0.8% of Ca, 0.001-1.0% of rare-earth elements, a trace amount of strontium, titanium, boron, nickel, chromium, zirconium, vanadium, beryllium, cobalt, lead, tin, bismuth, molybdenum, silver, indium, niobium and barium and the balance of aluminum. The alloy has excellent mechanical strength, processing performance and corrosion resistance and is suitable for the cable armored sheath.

Owner:GUANGDONG XINYI ALUMINUM ALLOY CABLE

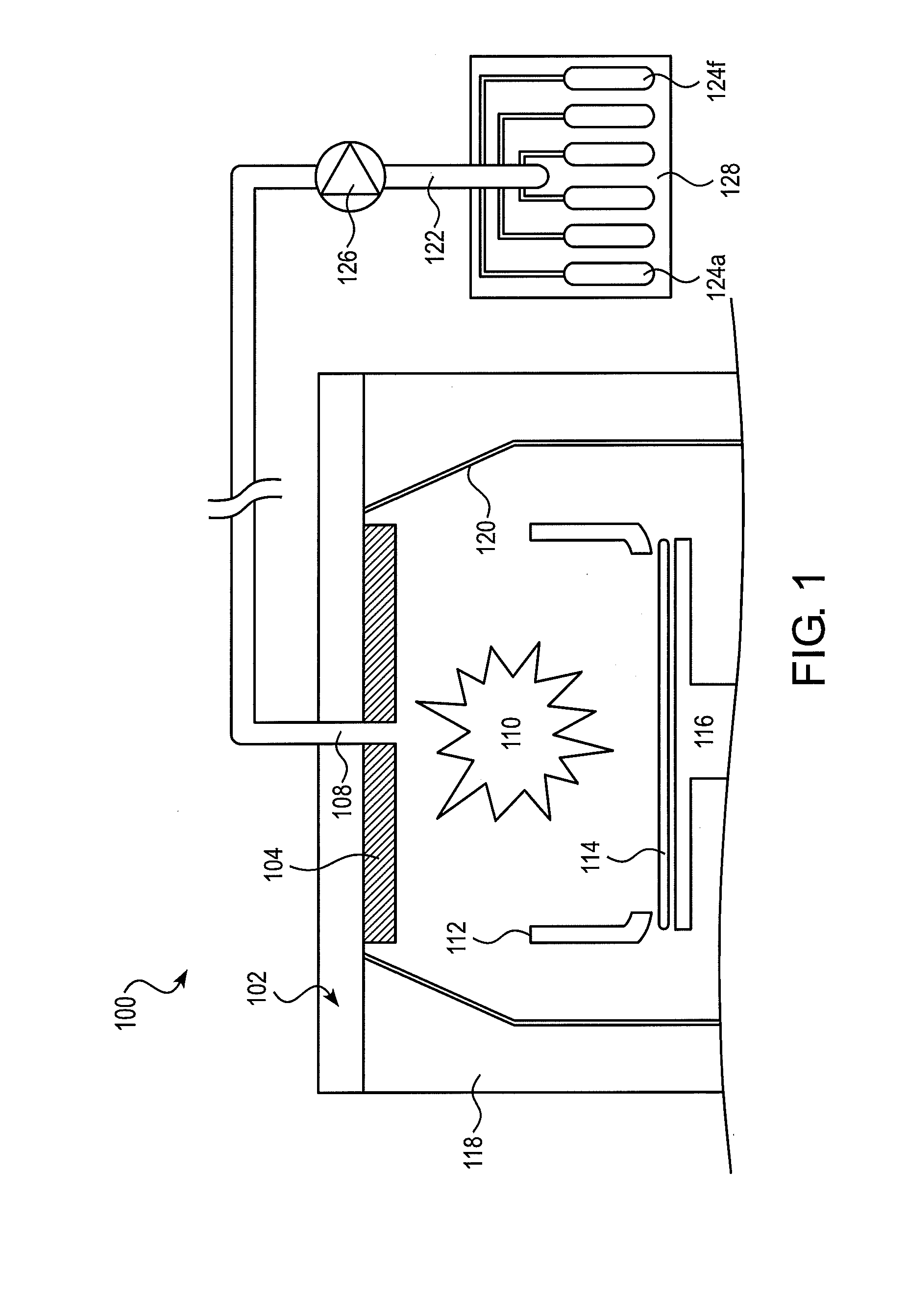

Coating method for gas delivery system

ActiveUS20110259519A1Liquid surface applicatorsElectric discharge tubesProcess systemsDelivery system

A method of coating the inner surfaces of gas passages of a gas delivery system for a plasma process system such as a plasma etching system includes (a) flowing a fluidic precursor of a corrosion-resistant material through the gas passages and depositing a layer of the fluidic precursor to completely coat the inner surfaces of the gas passages; (b) removing excess fluidic precursor from the inner surfaces; (c) curing the deposited layer of the fluidic precursor to form a corrosion-resistant material coating.

Owner:LAM RES CORP

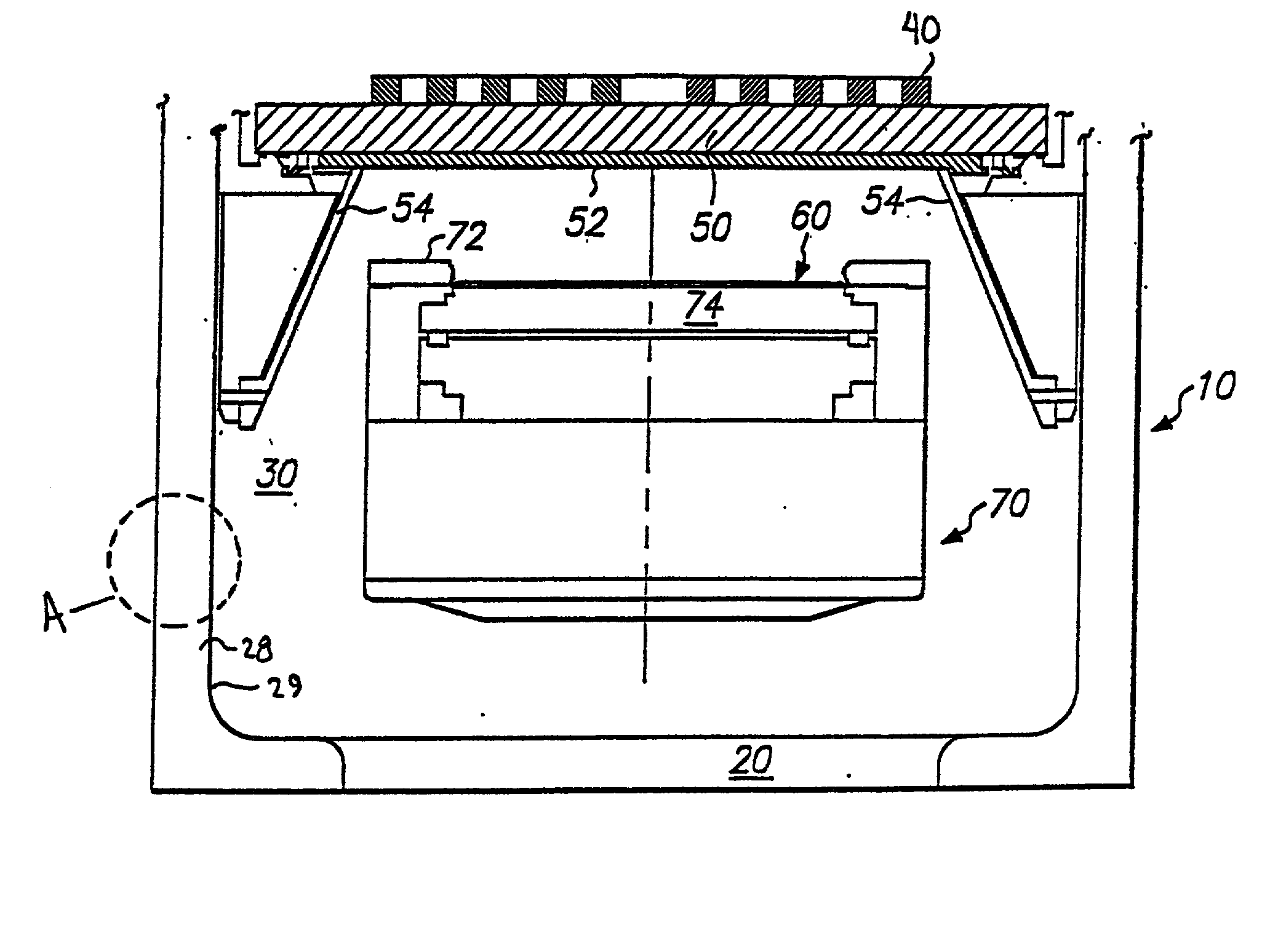

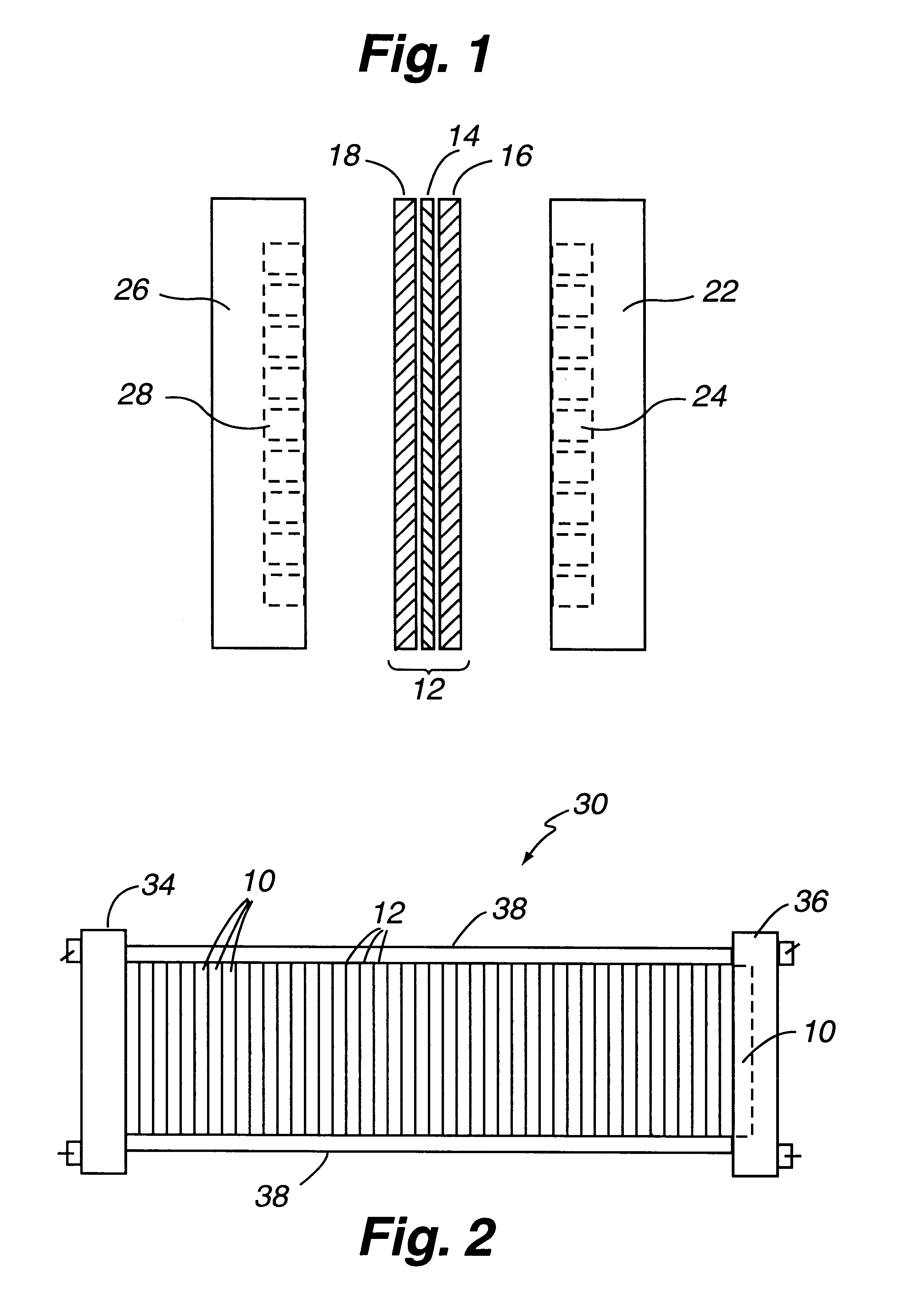

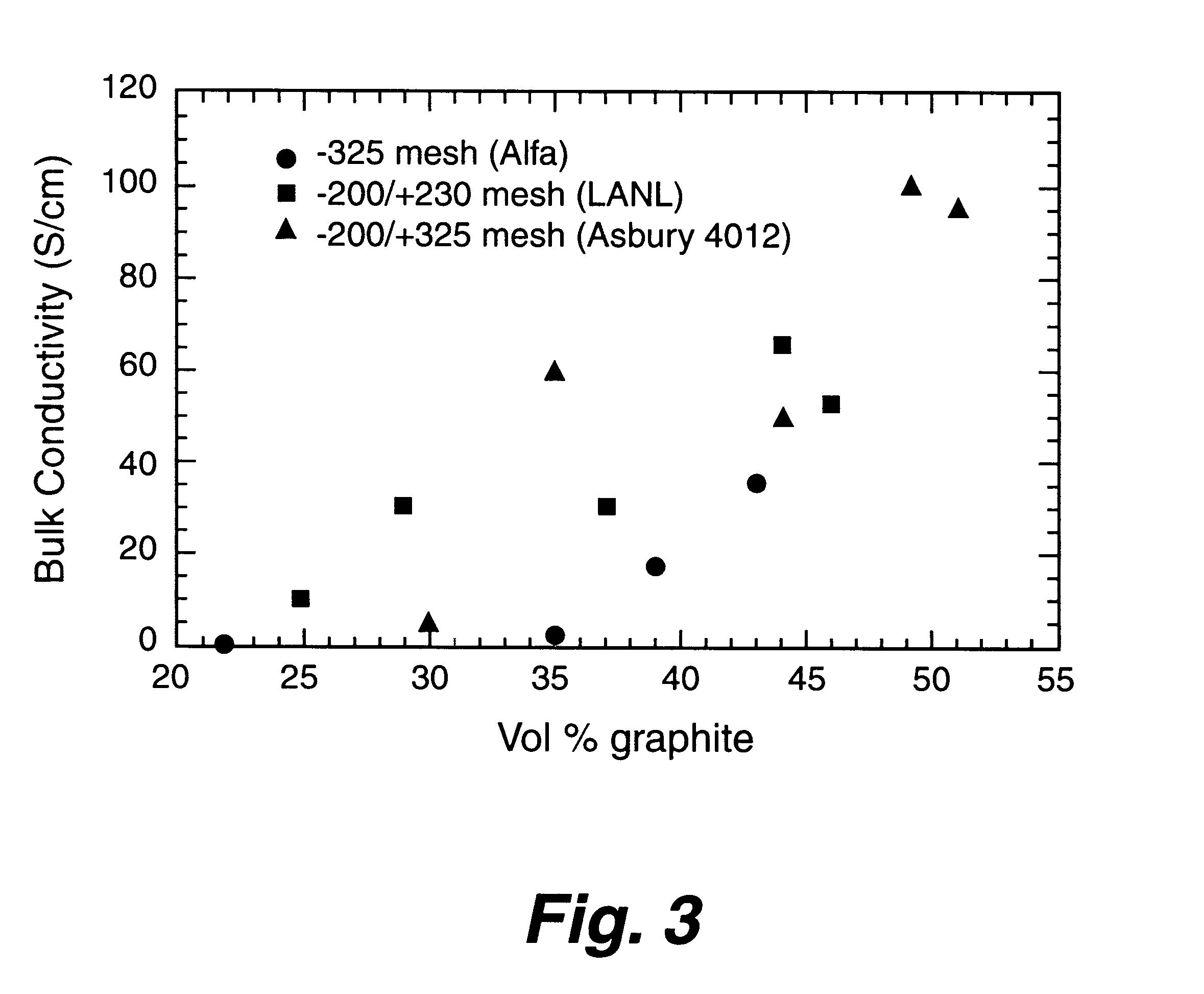

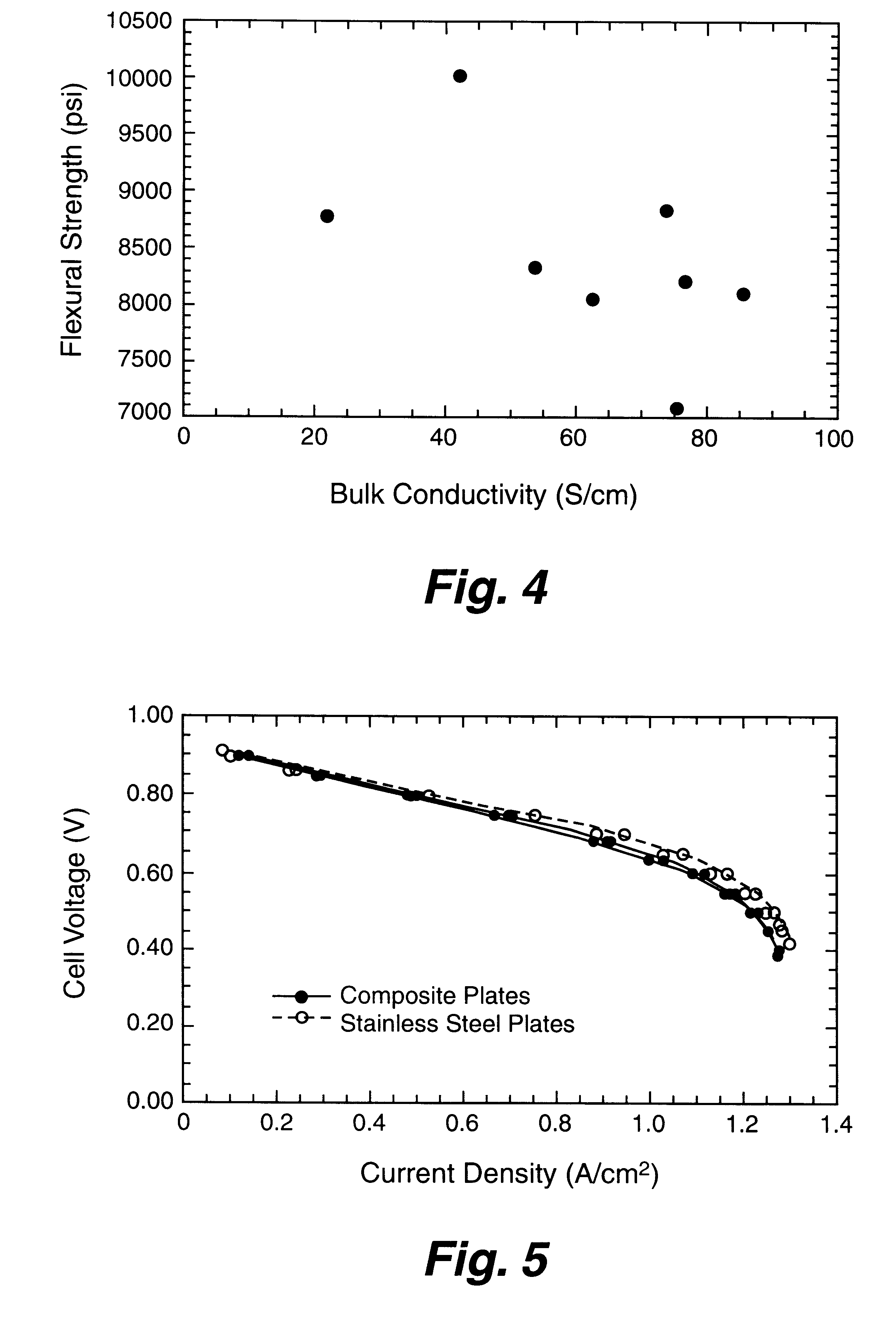

Composite bipolar plate for electrochemical cells

A bipolar separator plate for fuel cells consists of a molded mixture of a vinyl ester resin and graphite powder. The plate serves as a current collector and may contain fluid flow fields for the distribution of reactant gases. The material is inexpensive, electrically conductive, lightweight, strong, corrosion resistant, easily mass produced, and relatively impermeable to hydrogen gas. The addition of certain fiber reinforcements and other additives can improve the properties of the composite material without significantly increasing its overall cost.

Owner:TRIAD NAT SECURITY LLC

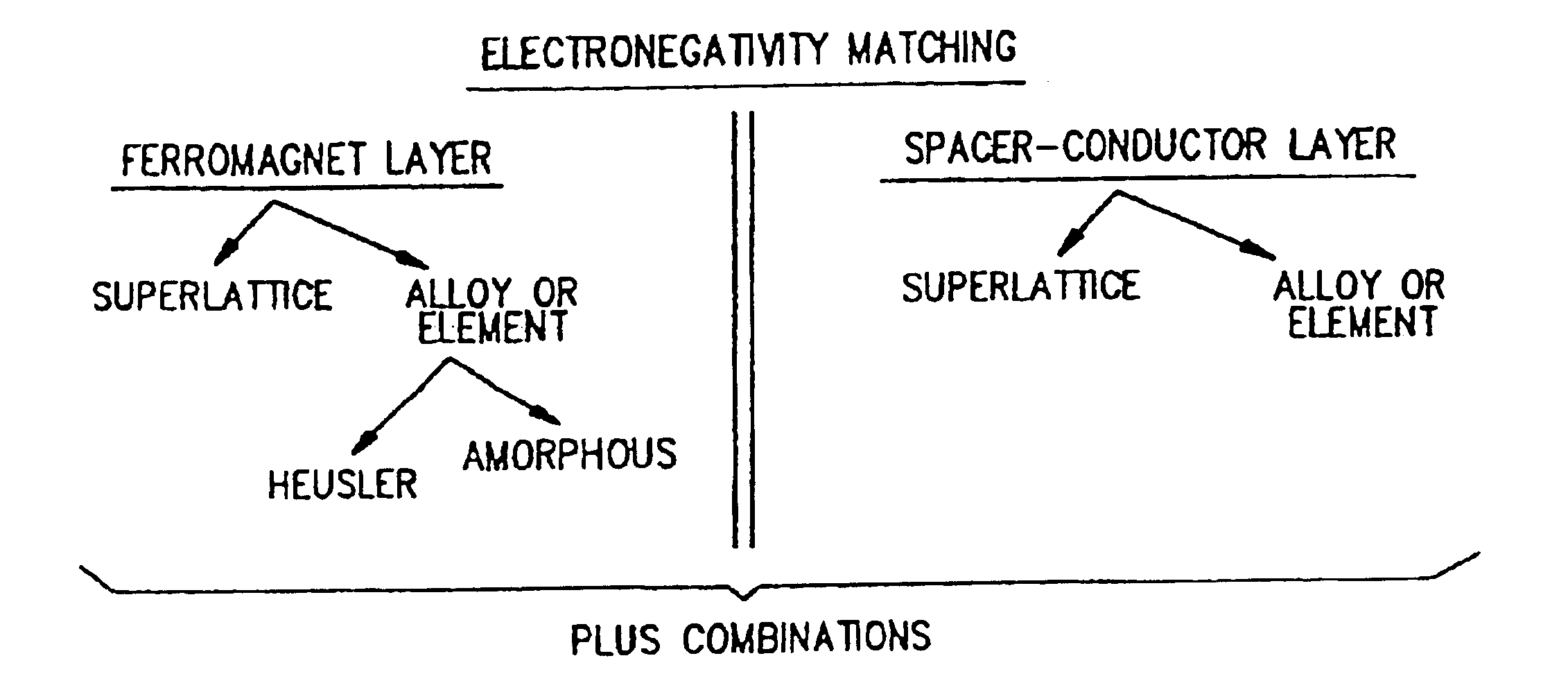

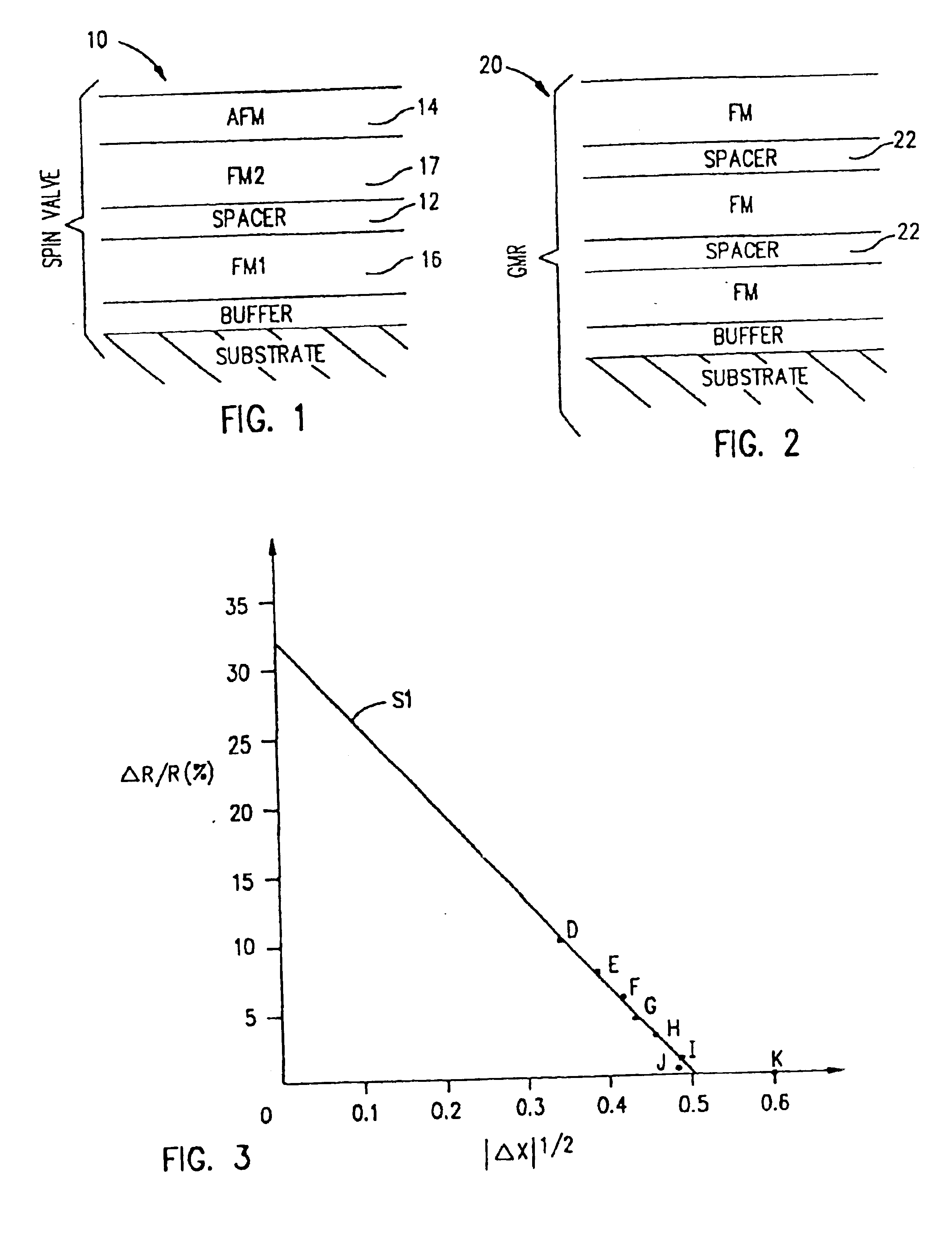

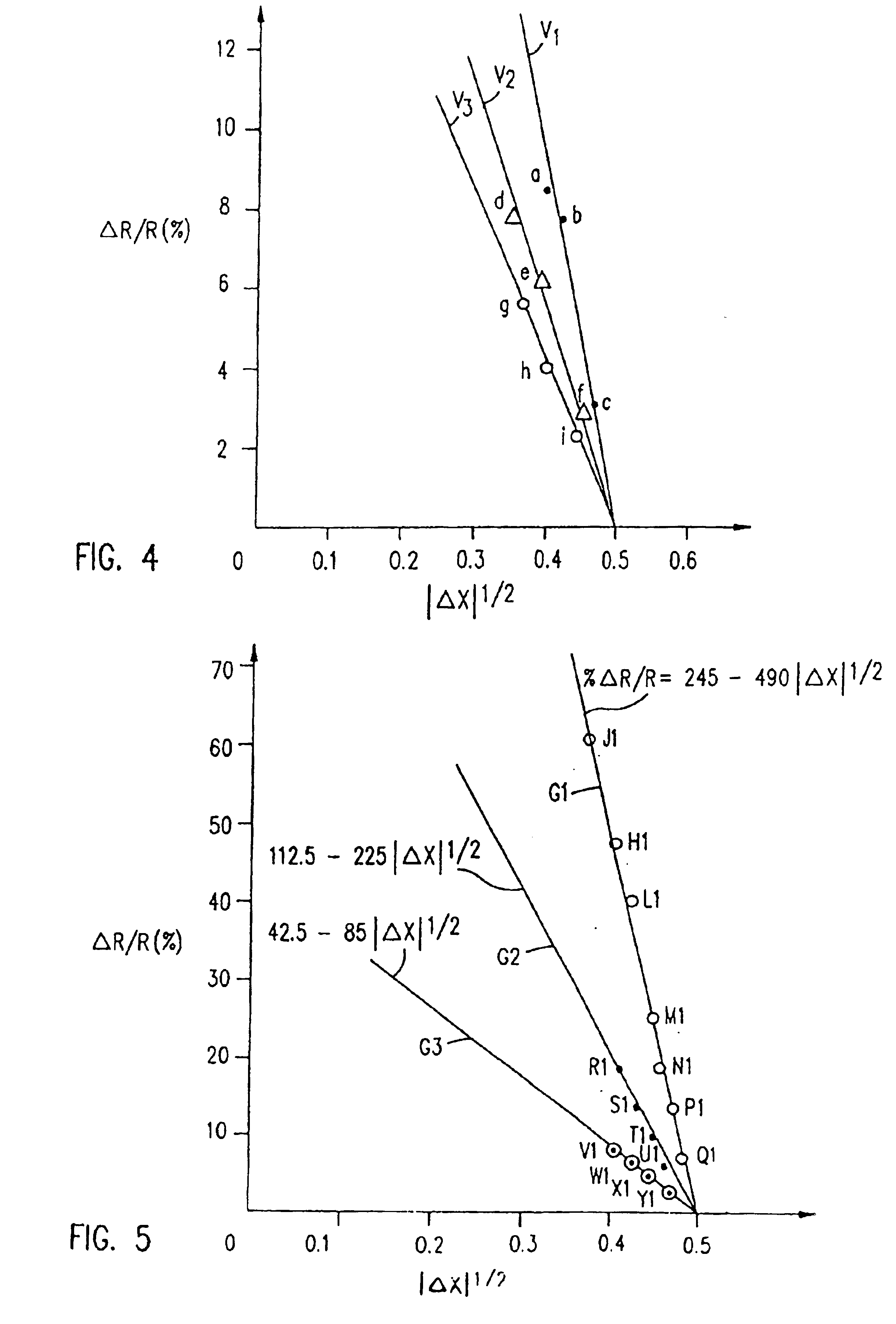

Methods and compositions for optimizing interfacial properties of magnetoresistive sensors

InactiveUS6828897B1Minimize electromigrationExtended service lifeNanomagnetismFixed microstructural devicesMean free pathElectronegativity

A method for maximizing the interfacial properties of magnetoresistive sensors, such as spin valve and GMR sensors used in storage devices, comprises selecting the materials for ferromagnetic layers and for electrically conductive spacers that are interposed between the ferromagnetic layers. The electronegativities of the selected materials are substantially matched so that an absolute value of the differences in electronegativities is minimized. The conductive spacer material provides a relatively low resistivity and a large mean free path. The sensors experience greater chemical and thermal stability, are corrosion resistant, and realize an increased signal output.

Owner:WESTERN DIGITAL TECH INC

Heat and corrosion resistant cast CF8C stainless steel with improved high temperature strength and ductility

A CF8C type stainless steel alloy and articles formed therefrom containing about 18.0 weight percent to about 22.0 weight percent chromium and 11.0 weight percent to about 14.0 weight percent nickel; from about 0.05 weight percent to about 0.15 weight percent carbon; from about 2.0 weight percent to about 10.0 weight percent manganese; and from about 0.3 weight percent to about 1.5 weight percent niobium. The present alloys further include less than 0.15 weight percent sulfur which provides high temperature strength both in the matrix and at the grain boundaries without reducing ductility due to cracking along boundaries with continuous or nearly-continuous carbides. The disclosed alloys also have increased nitrogen solubility thereby enhancing strength at all temperatures because nitride precipitates or nitrogen porosity during casting are not observed. The solubility of nitrogen is dramatically enhanced by the presence of manganese, which also retains or improves the solubility of carbon thereby providing additional solid solution strengthening due to the presence of manganese and nitrogen, and combined carbon.

Owner:UT BATTELLE LLC

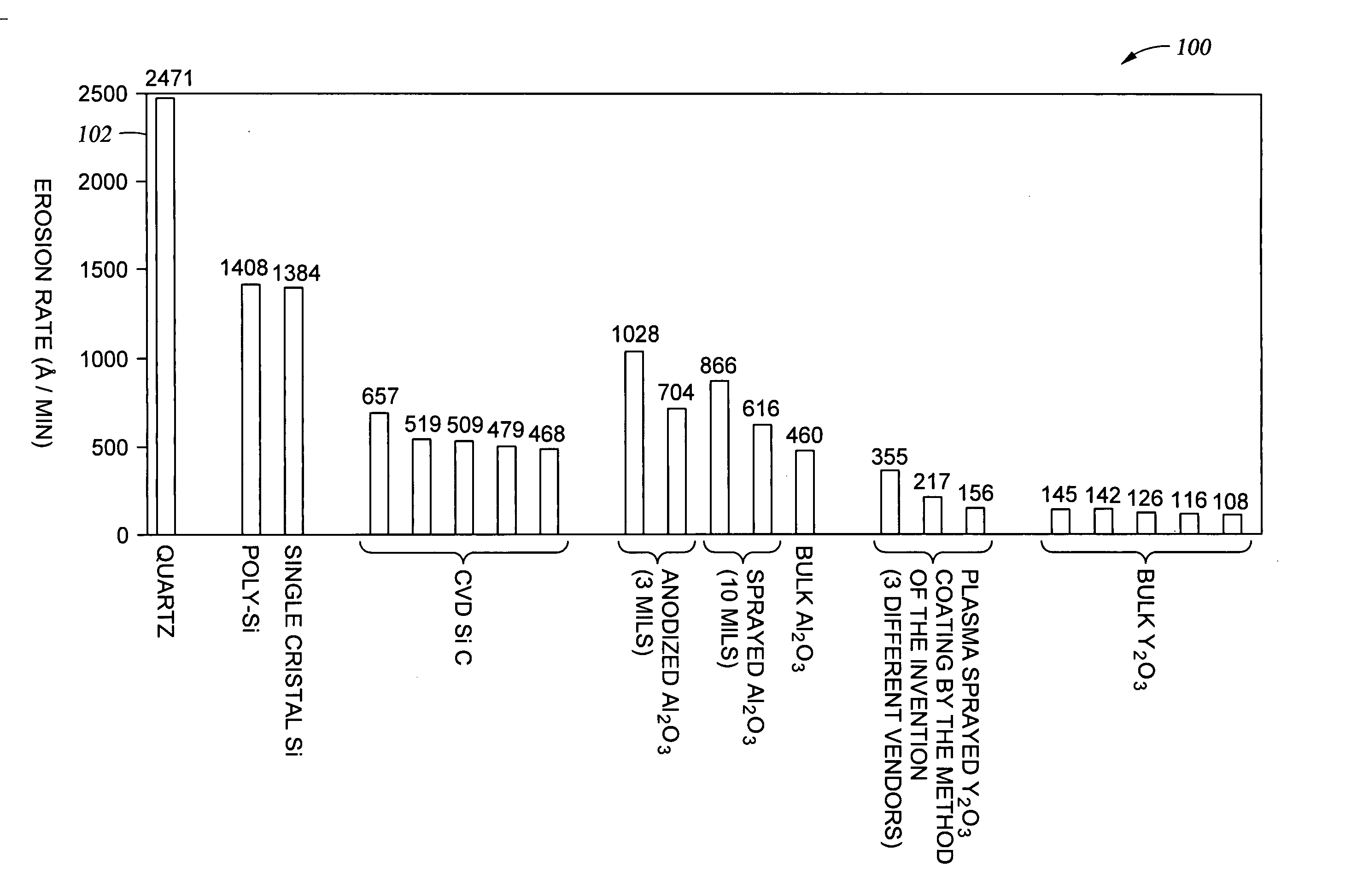

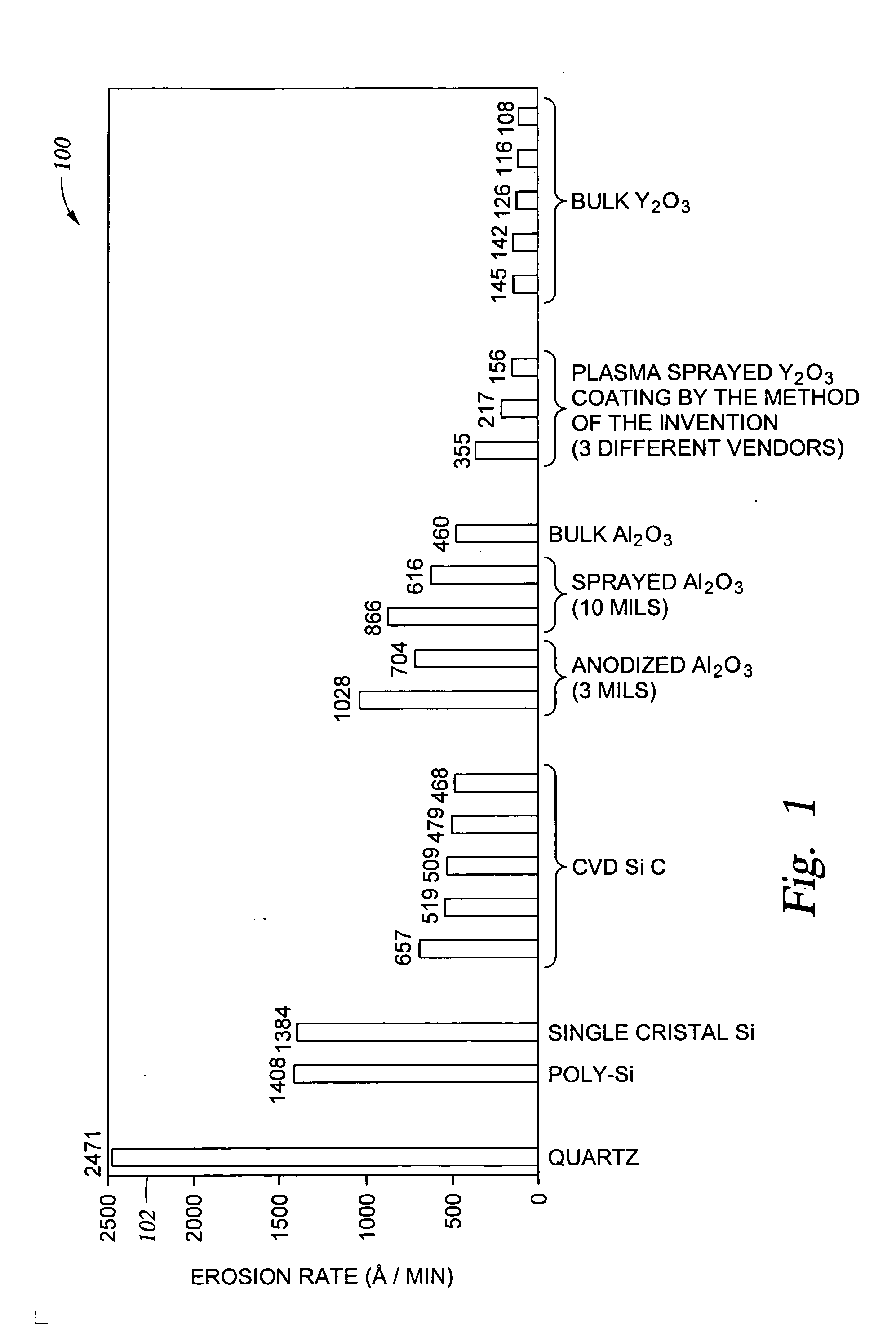

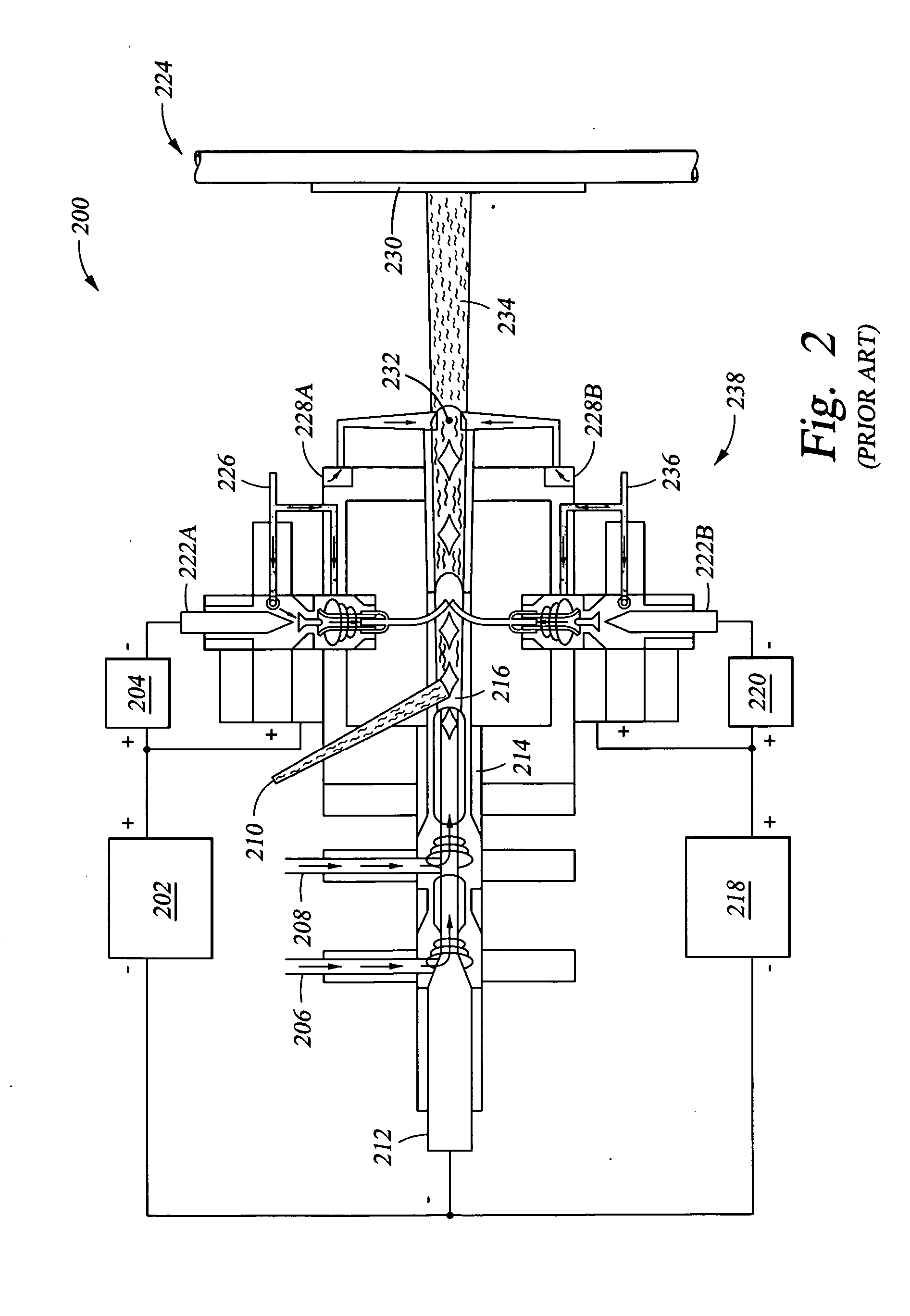

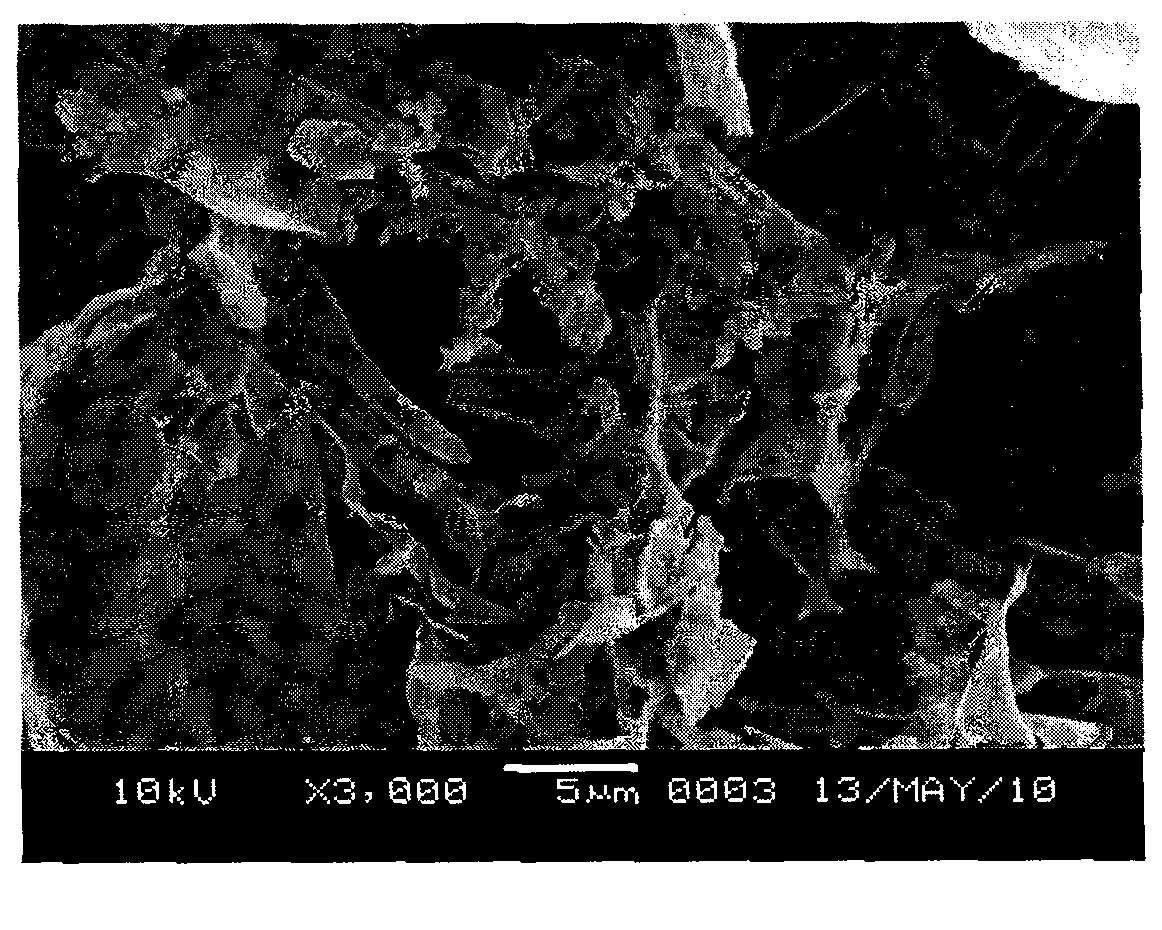

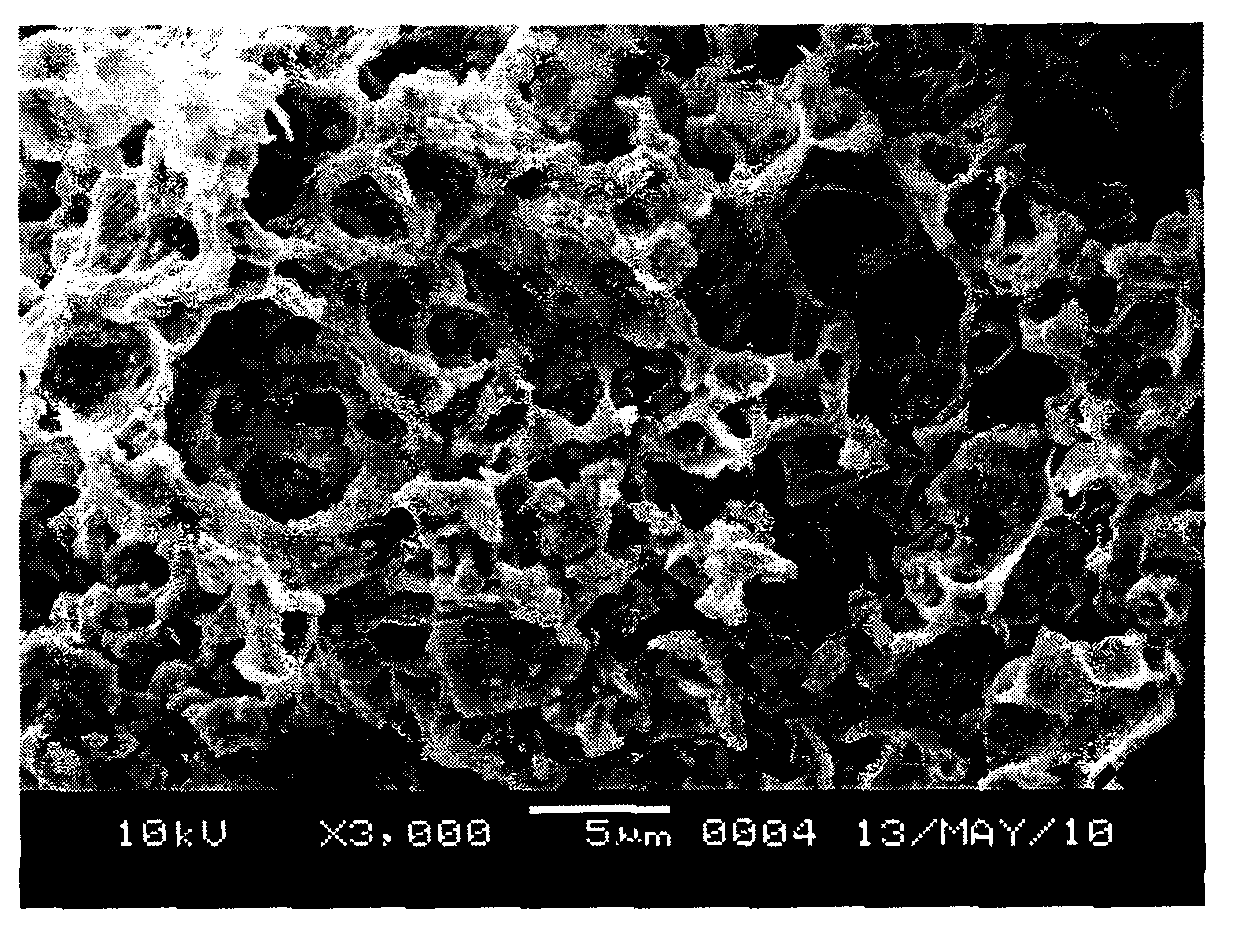

Clean, dense yttrium oxide coating protecting semiconductor processing apparatus

ActiveUS20050037193A1Extended service lifeExcellent plasma corrosion-resistanceLiquid surface applicatorsMolten spray coatingPlasma coatingChemical vapor deposition

Disclosed herein is a method for applying plasma-resistant coatings for use in semiconductor processing apparatus. The coatings are applied over a substrate which typically comprises an aluminum alloy of the 2000 series or the 5000 through 7000 series. The coating typically comprises an oxide or a fluoride of Y, Sc, La, Ce, Eu, Dy, or the like, or yttrium-aluminum-garnet (YAG). The coating may further comprise about 20 volume % or less of Al2O3. The coatings are typically applied to a surface of an aluminum alloy substrate or an anodized aluminum alloy substrate using a technique selected from the group consisting of thermal / flame spraying, plasma spraying, sputtering, and chemical vapor deposition (CVD). To provide the desired corrosion resistance, it is necessary to place the coating in compression. This is accomplished by controlling deposition conditions during application of the coating.

Owner:APPLIED MATERIALS INC

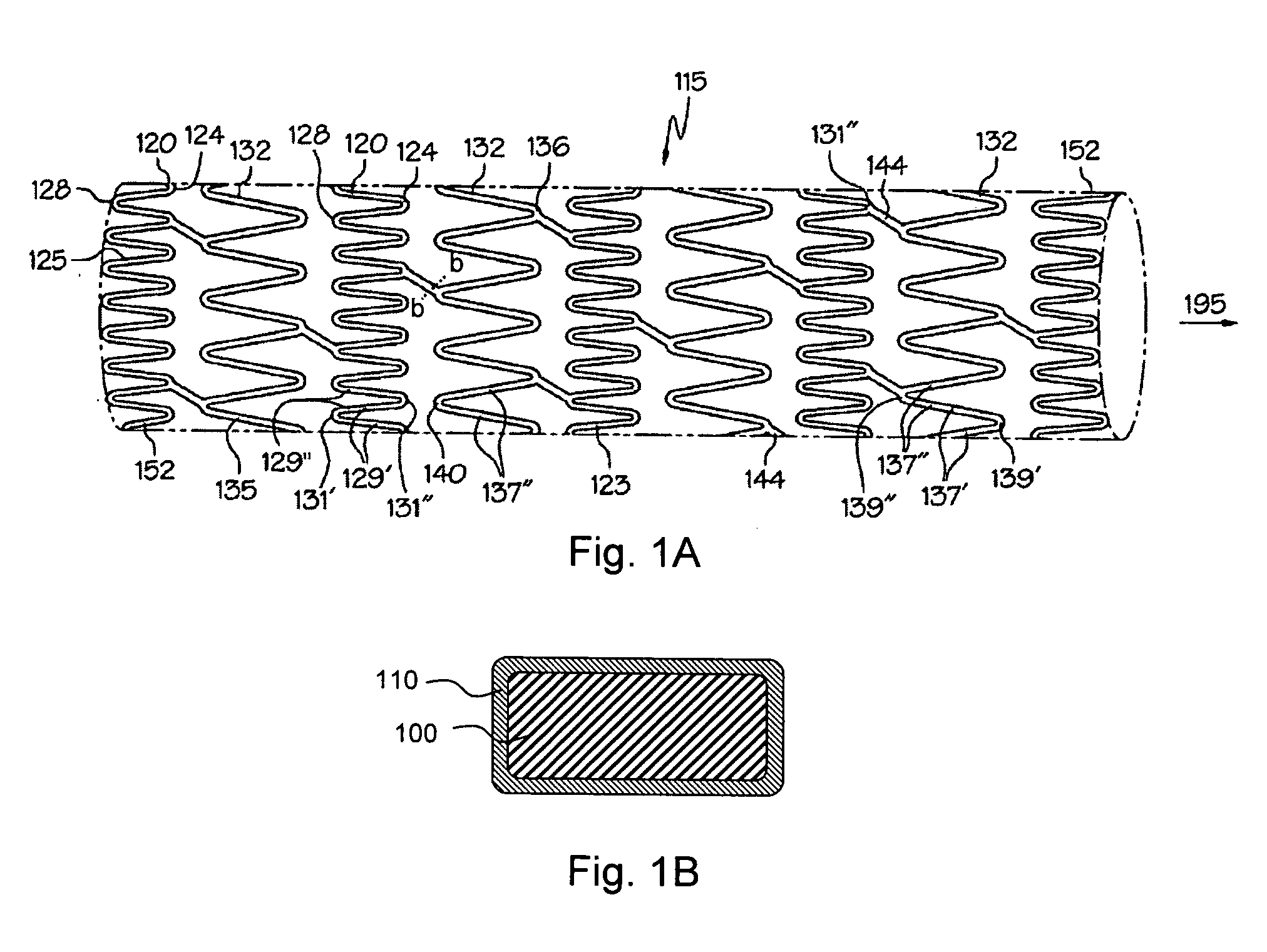

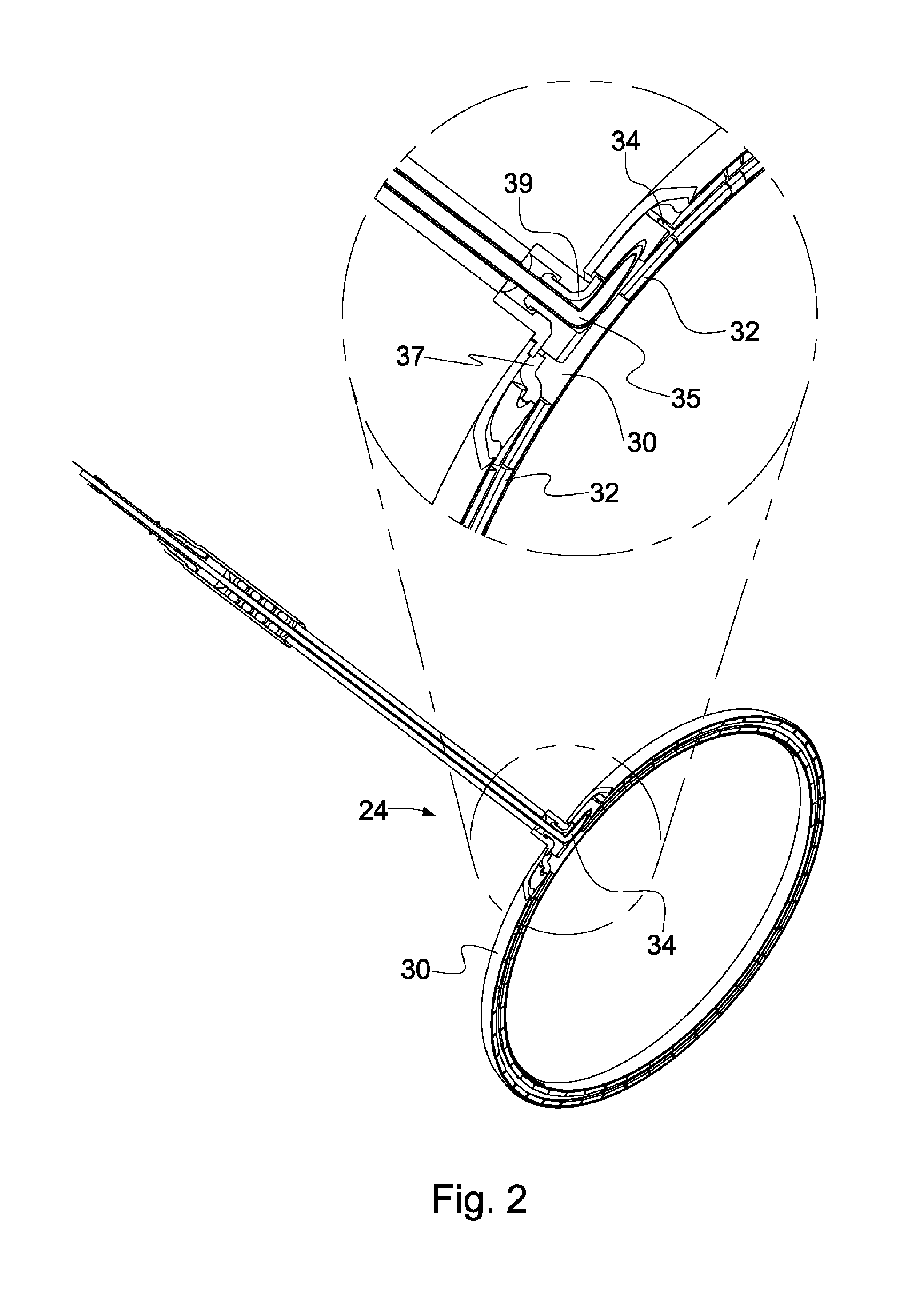

Corrosion resistant coatings for biodegradable metallic implants

InactiveUS20070224244A1Corrosion controlControl corrosion rateSurgeryCoatingsMedical deviceMaterials science

According to an aspect of the invention, implantable medical devices are provided which contain at least one biodegradable metallic region and a polymeric corrosion resistant coating over the biodegradable metallic region. The polymeric corrosion resistant coating slows the rate of corrosion of the biodegradable metallic region upon implantation into a subject.

Owner:BOSTON SCI SCIMED INC

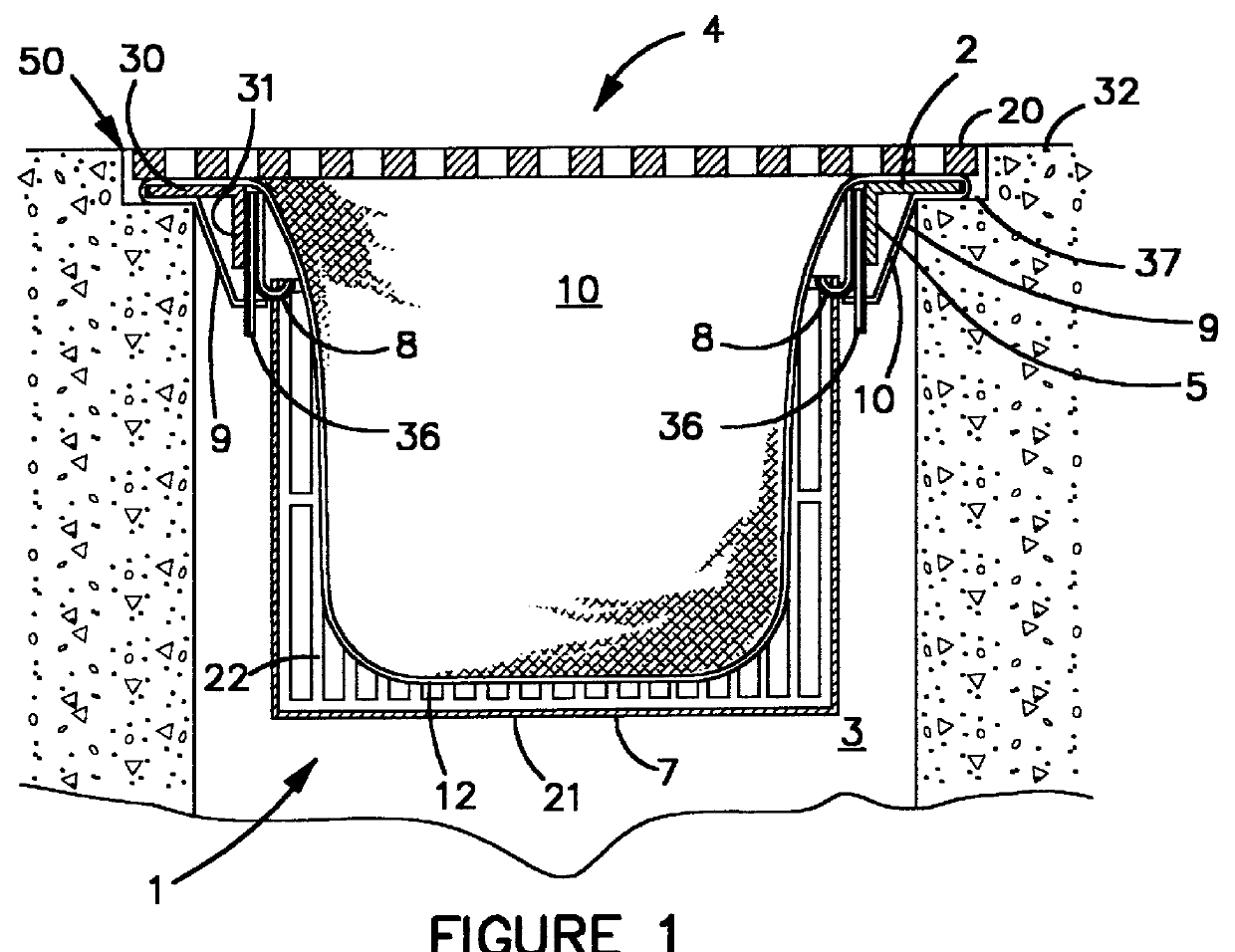

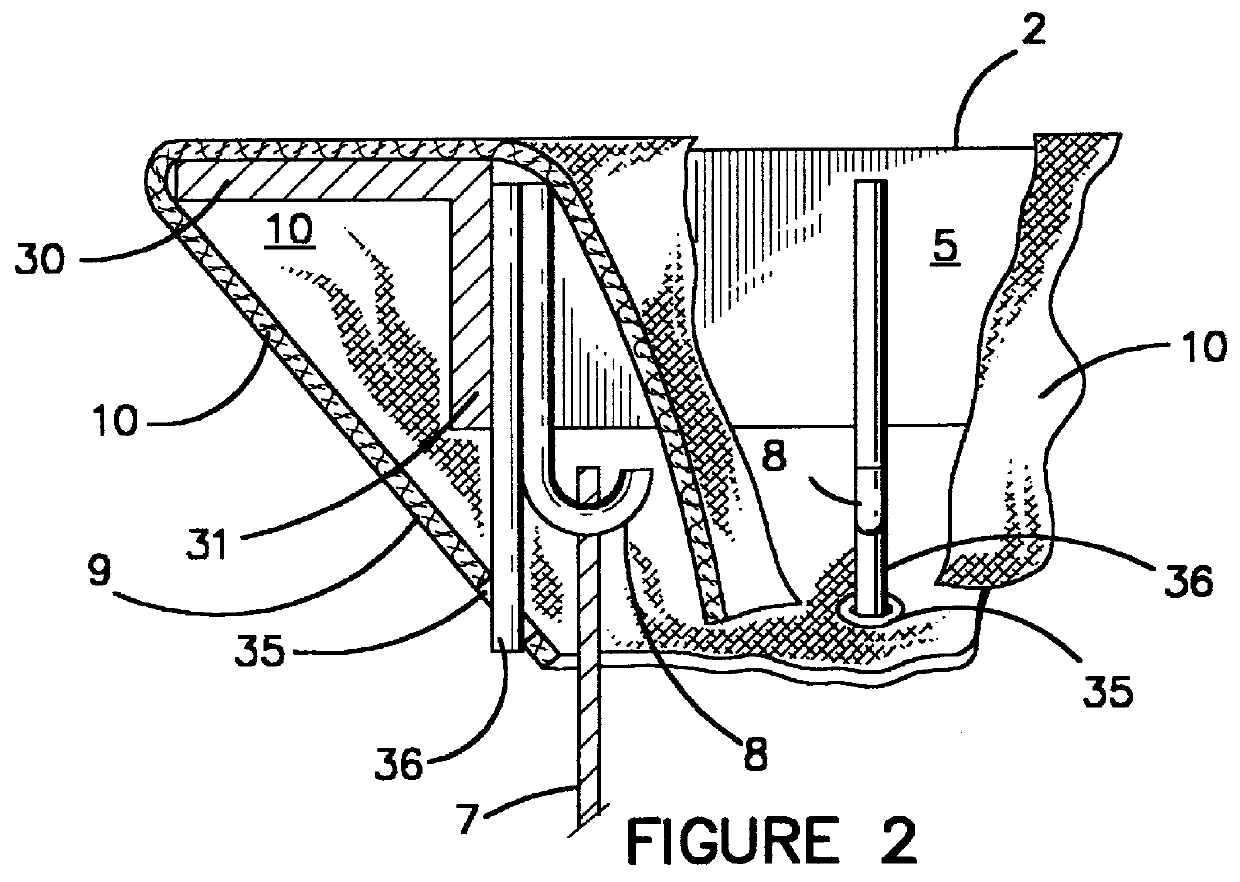

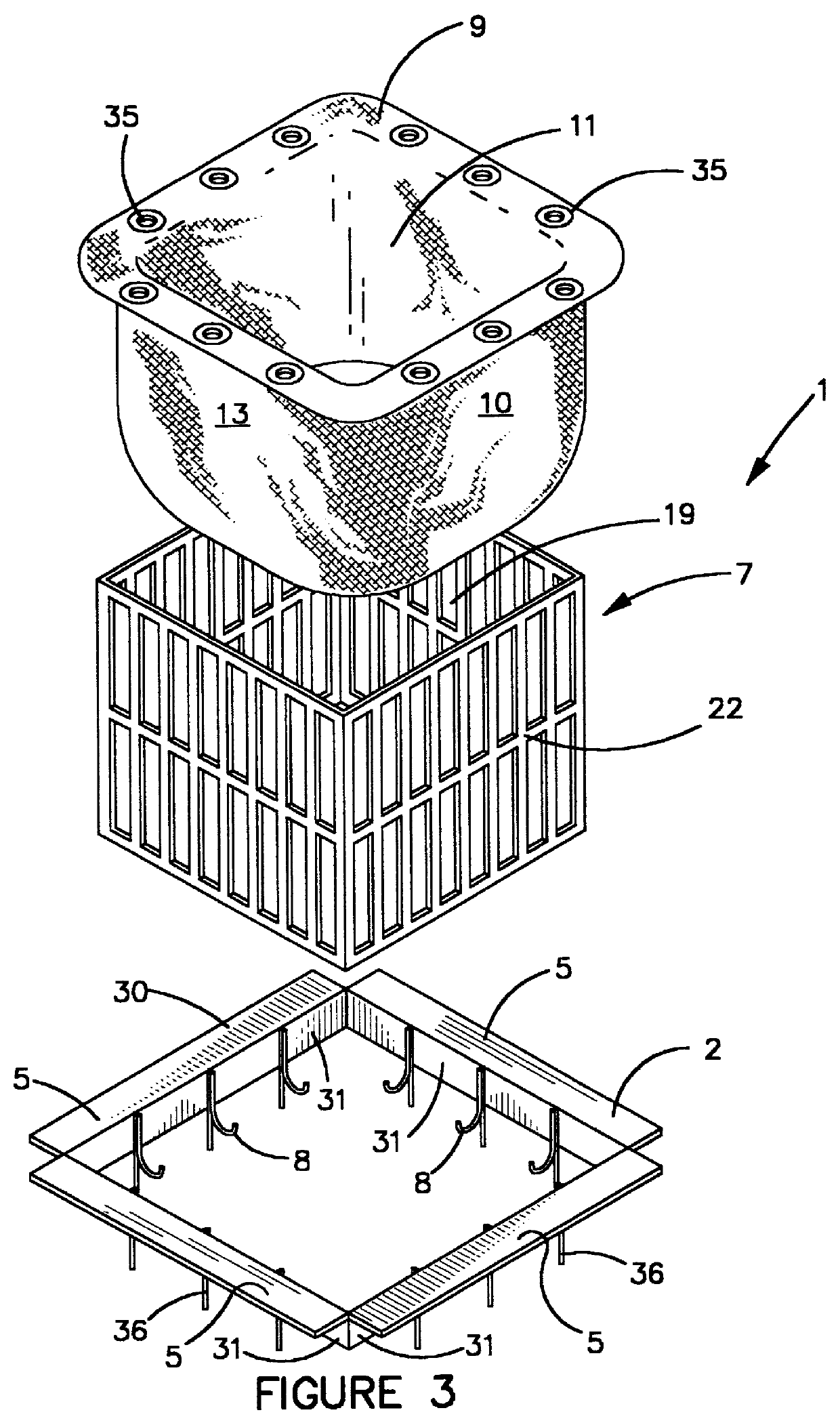

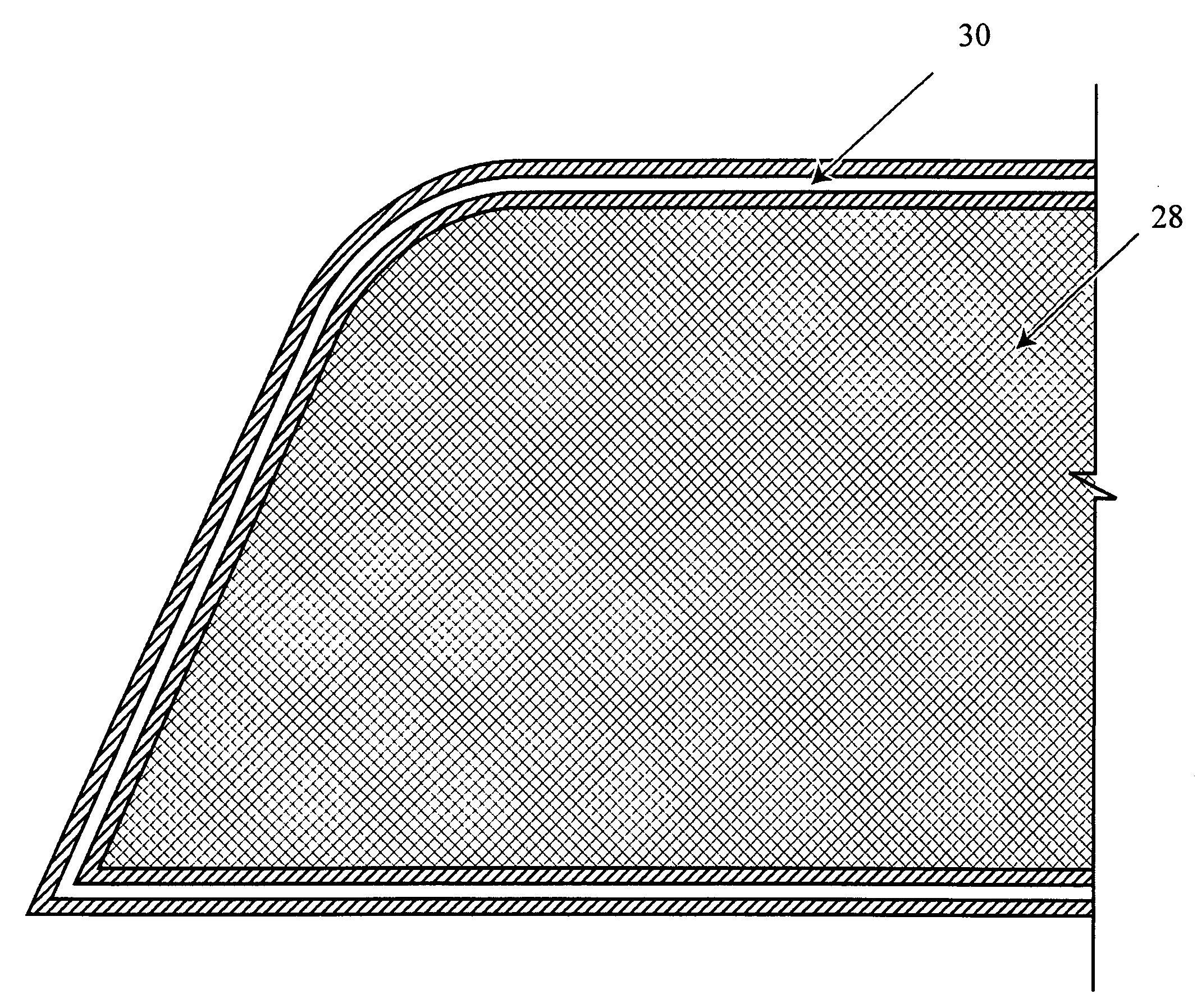

Storm drain liner

InactiveUS6086758AIncrease flow rateFatty/oily/floating substances removal devicesGround-workFilter systemEnvironmental engineering

A drain filtering system is disclosed, comprising a filter placed within a basket which is suspended from frame positioned underneath a drain grate atop the inlet to a storm drain. The filter is constructed from materials which filter out heavy metals and hydrocarbons from the water passing through. The filter also has overflow outlets to prevent back-up of storm water during periods of heavy rain. The basket is constructed from a corrosion resistant material, preferably high density polyethylene which can withstand the extreme pressures exerted by waste and water collected within the filter.

Owner:PACTEC

Corrosion resistant multilayer member

ActiveUS20070111030A1Improve corrosion resistanceRestrains particle contaminationMolten spray coatingElectric discharge tubesPorosityHalogen

A corrosion resistant member to be exposed to a halogen-containing gas atmosphere or a halogen-containing gas plasma atmosphere, comprising a substrate and a plurality of layers deposited thereon including a layer of rare earth fluoride providing the outermost surface and a layer of rare earth oxide having a porosity of less than 5% underlying the rare earth fluoride layer.

Owner:SHIN ETSU CHEM IND CO LTD

Method for producing 700Mpa V-N microalloyed high-strength air corrosion-resistant steel based on sheet bar continuous casting tandem rolling process

InactiveCN1884608AHigh strengthGood formabilityTemperature control deviceMetal rolling arrangementsSheet steelChemical composition

This invention exposed the producing method of V-N microalloyed high strength weathering steel which produced with near net shape con-casting technology. It is smelted in electric furnace or converter, refined, con-casted, casted, then directly sent into roller hearth furnace or soaking pit, hot-rolled, laminar cooled, coiled. The liquid steel's chemical elements are (Wt.%): C: <=0.08%, Si: 0.25- 0.75%, Mn: 0.8-2.0%, P: 0.070-0.150%, S: <=0.040%, Cu: 0.25-0.60 %, Cr: 0.30-1.25 wt%, Ni: <=0.65%, V: 0.05-0.20%, N: 0.015-0.030%. This invention can get the high intensity, formation, weathering, joining character stably. The alloying cost is relatively low. So it can be used to produce container, carriage, and other industry facility.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

Wear resistant vapor deposited coating, method of coating deposition and applications therefor

ActiveUS20070284255A1Stable cutting edgeReduce torsion fatiguePigmenting treatmentSurgeryWear resistantShape-memory alloy

A low friction top coat over a multilayer metal / ceramic bondcoat provides a conductive substrate, such as a rotary tool, with wear resistance and corrosion resistance. The top coat further provides low friction and anti-stickiness as well as high compressive stress. The high compressive stress provided by the top coat protects against degradation of the tool due to abrasion and torsional and cyclic fatigue. Substrate temperature is strictly controlled during the coating process to preserve the bulk properties of the substrate and the coating. The described coating process is particularly useful when applied to shape memory alloys.

Owner:G&H TECH LLC

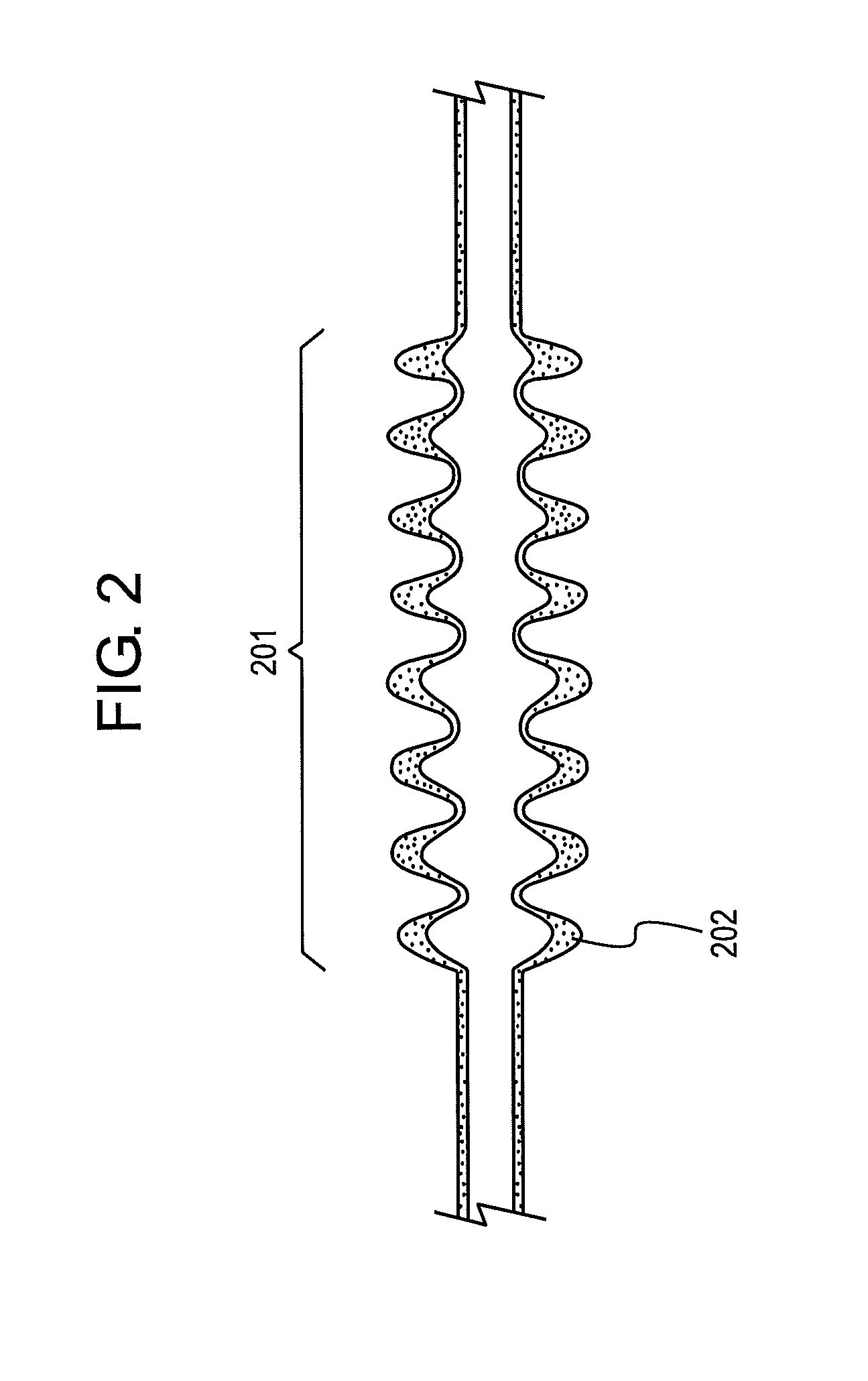

Corrosion-Resistant Downhole Transmission System

An apparatus in accordance with the invention may include a downhole tool and a data transmission path incorporated into the downhole tool. The data transmission path may include one or more contact surfaces providing electrical continuity to the data transmission path. To protect the contact surfaces from corrosion while maintaining electrical conductivity, a coating may be attached to one or more of the contact surfaces. The coating may include any of various materials that increase the corrosion-resistance of the underlying base metal, including but not limited to cobalt, nickel, tin, tin-lead, platinum, palladium, gold, silver, zinc, or combinations thereof.

Owner:INTELLISERV

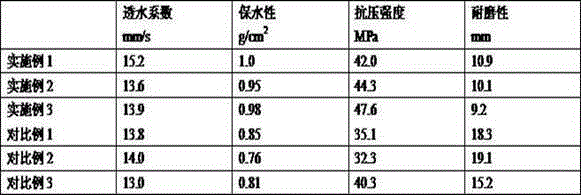

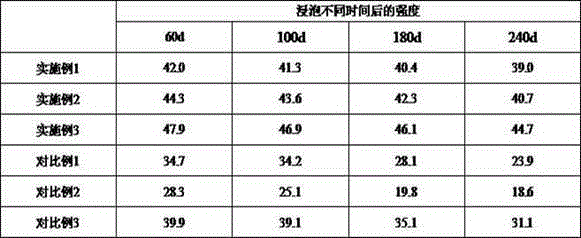

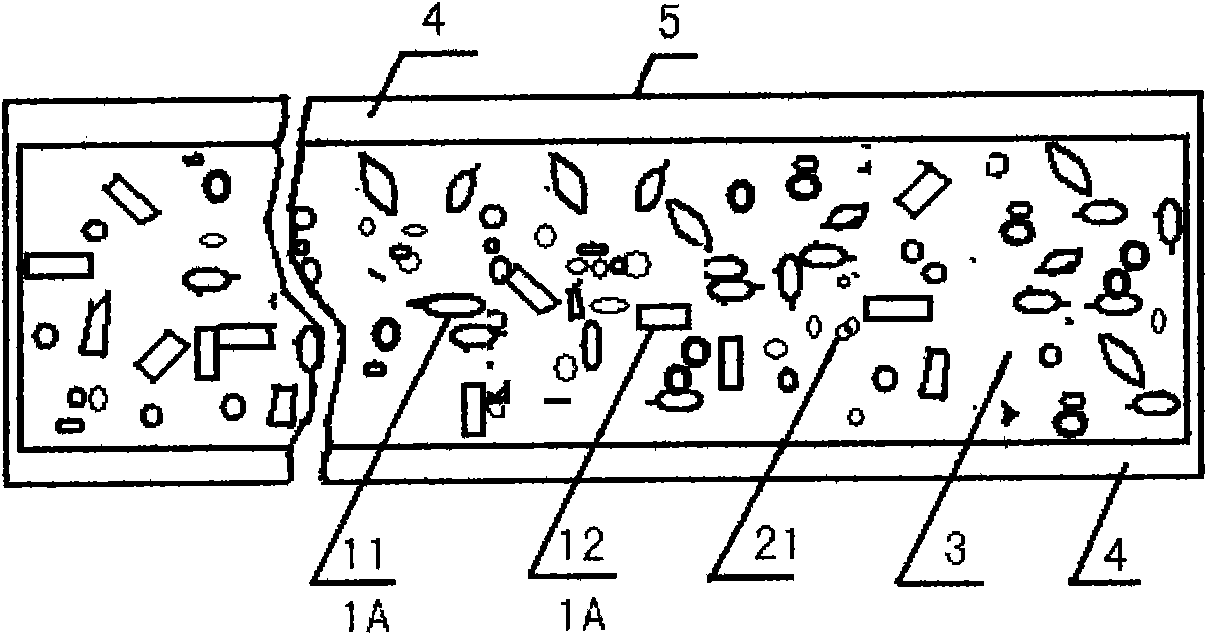

Corrosion resistant water permeable brick

ActiveCN105016765AHigh permeability coefficientHigh compressive strengthCeramicwareCompressive resistanceBrick

The present invention relates to a corrosion resistant water permeable brick, and belongs to the technical field of building materials. The corrosion corrosion resistant water permeable brick comprises 20-25wt% of Portland cement, 1.0-1.2wt% of anhydrite powder, 15.0-20.0wt% of slag pellets, 10-12wt % of cenospheres, 1.5-2.1wt% of admixtures, and the balance of quartz sand. Under the premise that the porosity and water permeability coefficient of the corrosion resistant water permeable brick are significantly higher than that of a water permeable brick, the compressive strength of the corrosion resistant water permeable brick is still higher than that of the conventional water permeable brick, the corrosion resistant water permeable brick has good corrosion resistance, and service life is significantly increased.

Owner:江苏溧阳建设集团有限公司

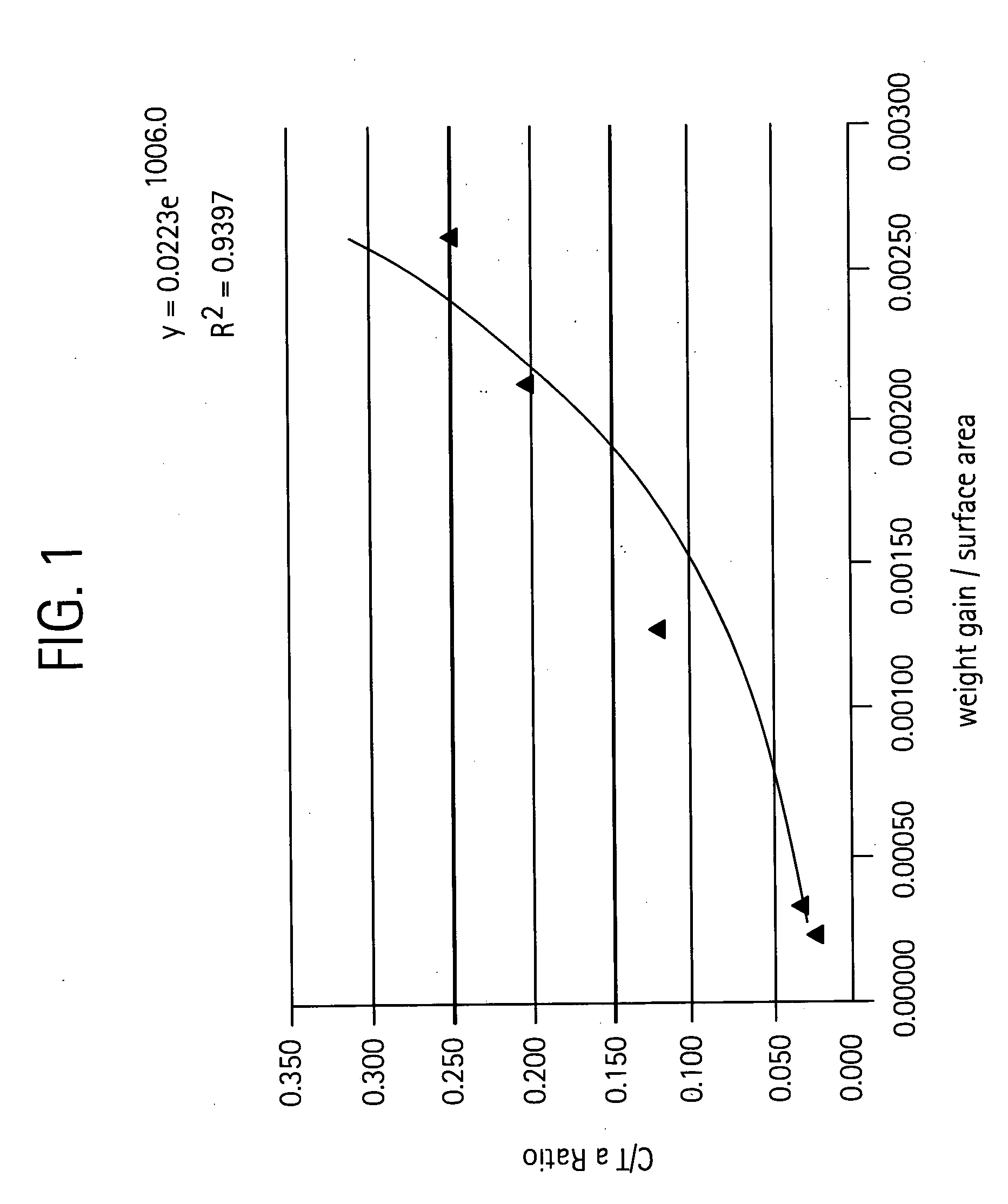

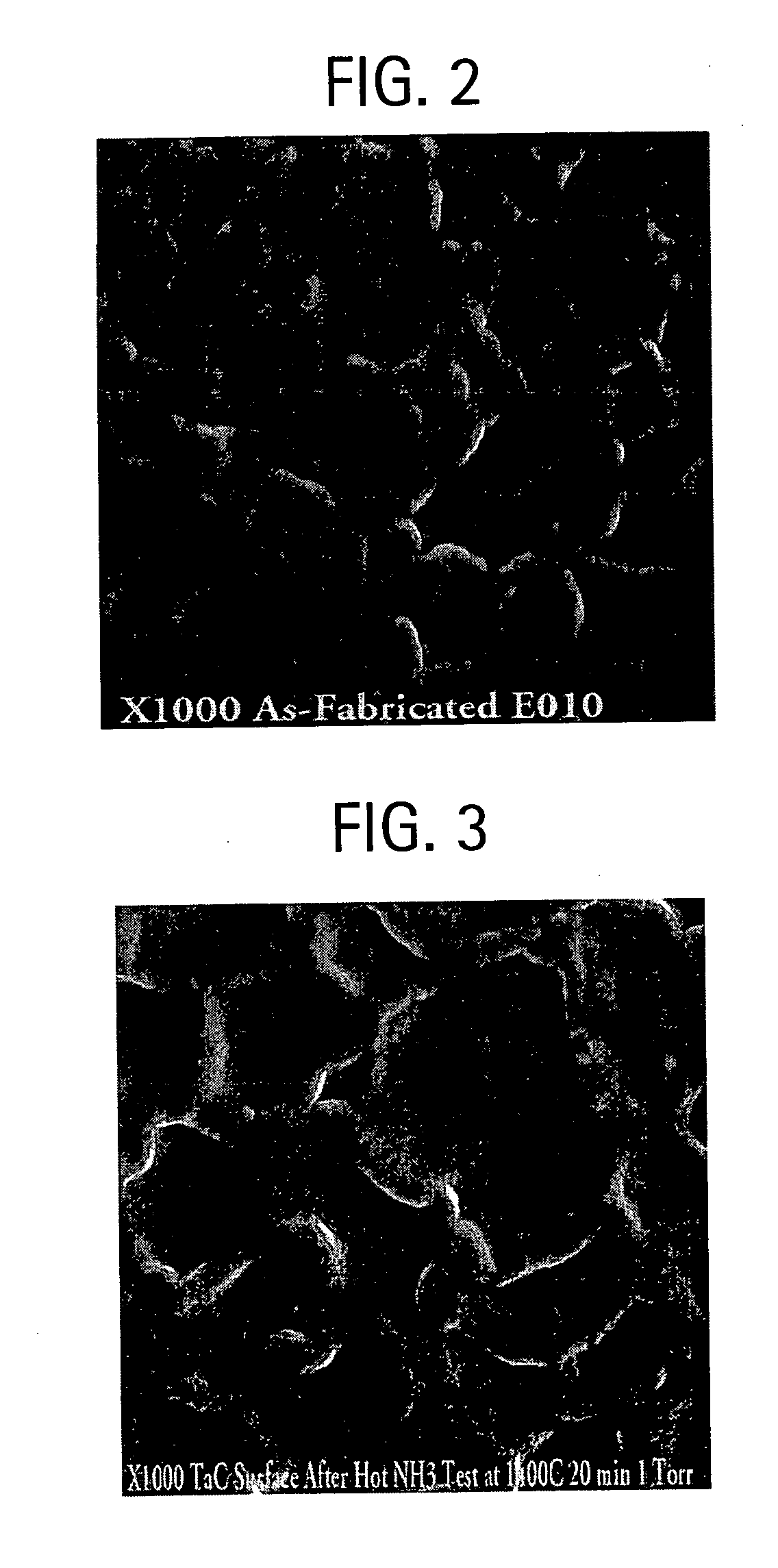

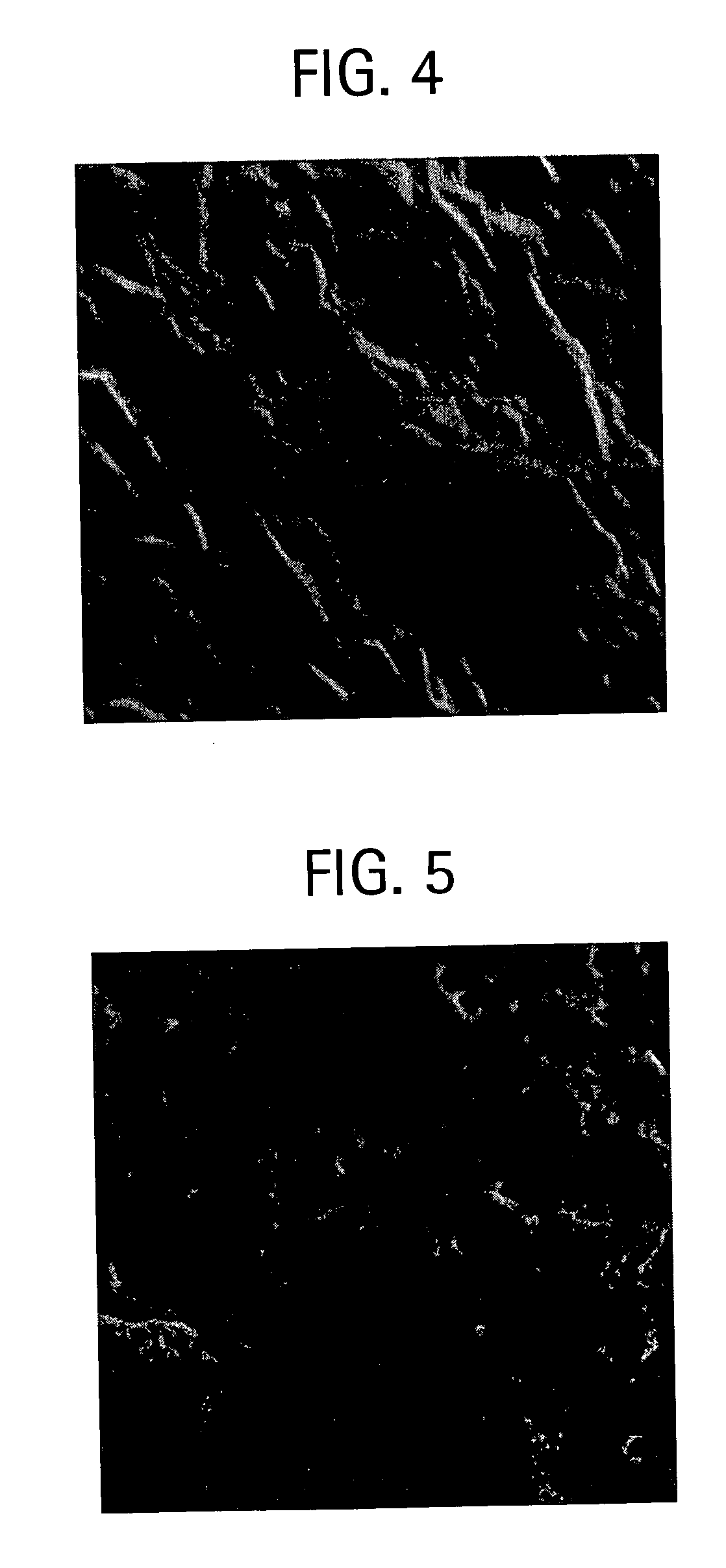

Composite refractory metal carbide coating on a substrate and method for making thereof

InactiveUS20050064247A1Improved corrosion resistance propertyIncreased emissivity insensitivityLiquid surface applicatorsSemiconductor/solid-state device manufacturingBeryllium carbideMagnesium

A composite coating for use on semi-conductor processing components, comprising a refractory metal carbide coating with its surface modified by at least one of: a) a carbon donor source for a stabilized stoichiometry, and b) a layer of nitride, carbonitride or oxynitride of elements selected from a group B, Al, Si, refractory metals, transition metals, rare earth metals which may or may not contain electrically conducting pattern, and wherein the metal carbide is selected from the group consisting of silicon carbide, tantalum carbide, titanium carbide, tungsten carbide, silicon oxycarbide, zirconium carbide, hafnium carbide, lanthanum carbide, vanadium carbide, niobium carbide, magnesium carbide, chromium carbide, molybdenum carbide, beryllium carbide and mixtures thereof. The composite coating is characterized as having an improved corrosion resistance property and little emissivity sensitivity to wavelengths used in optical pyrometry under the normal semi-conductor processing environments.

Owner:GENERAL ELECTRIC CO

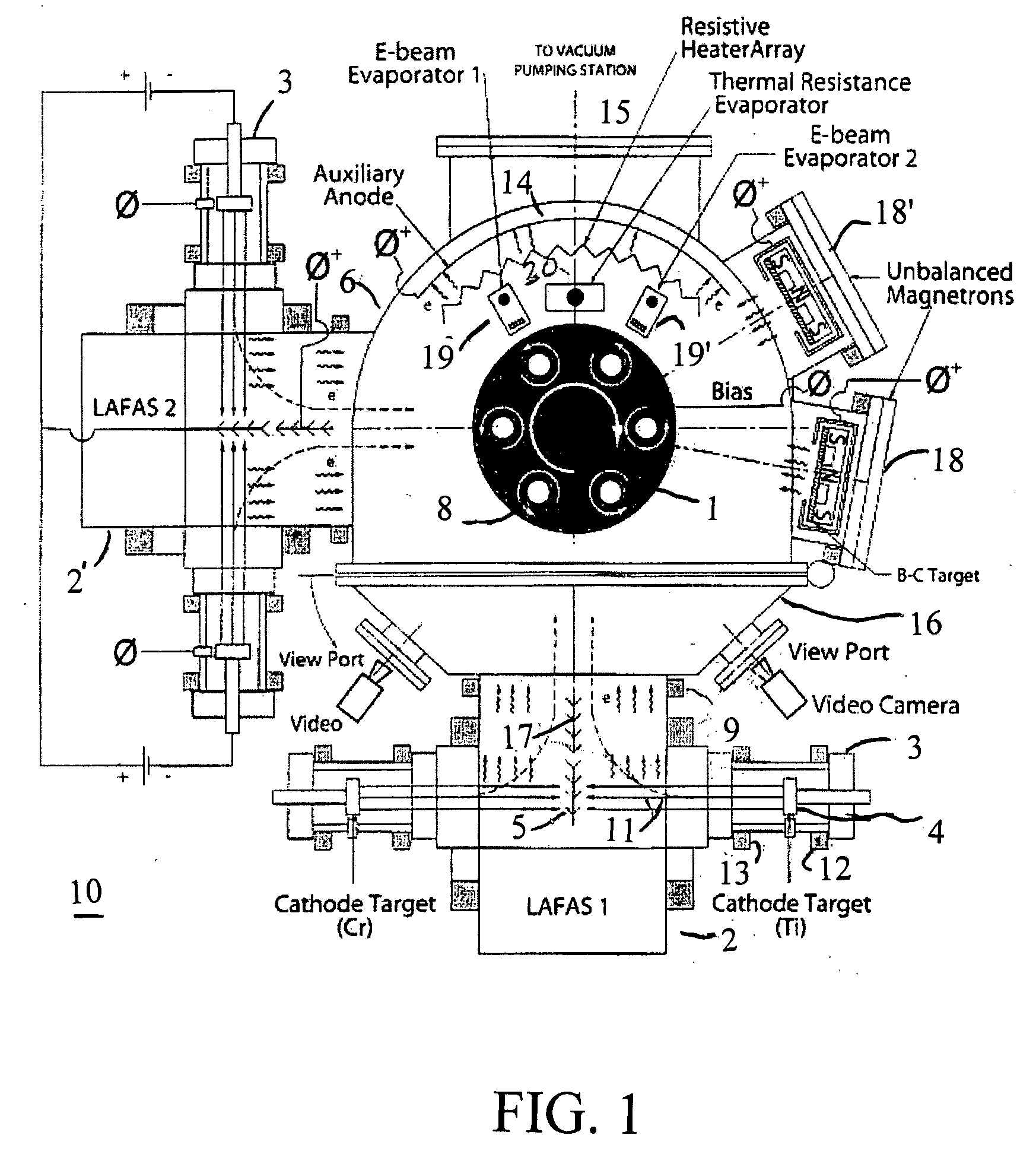

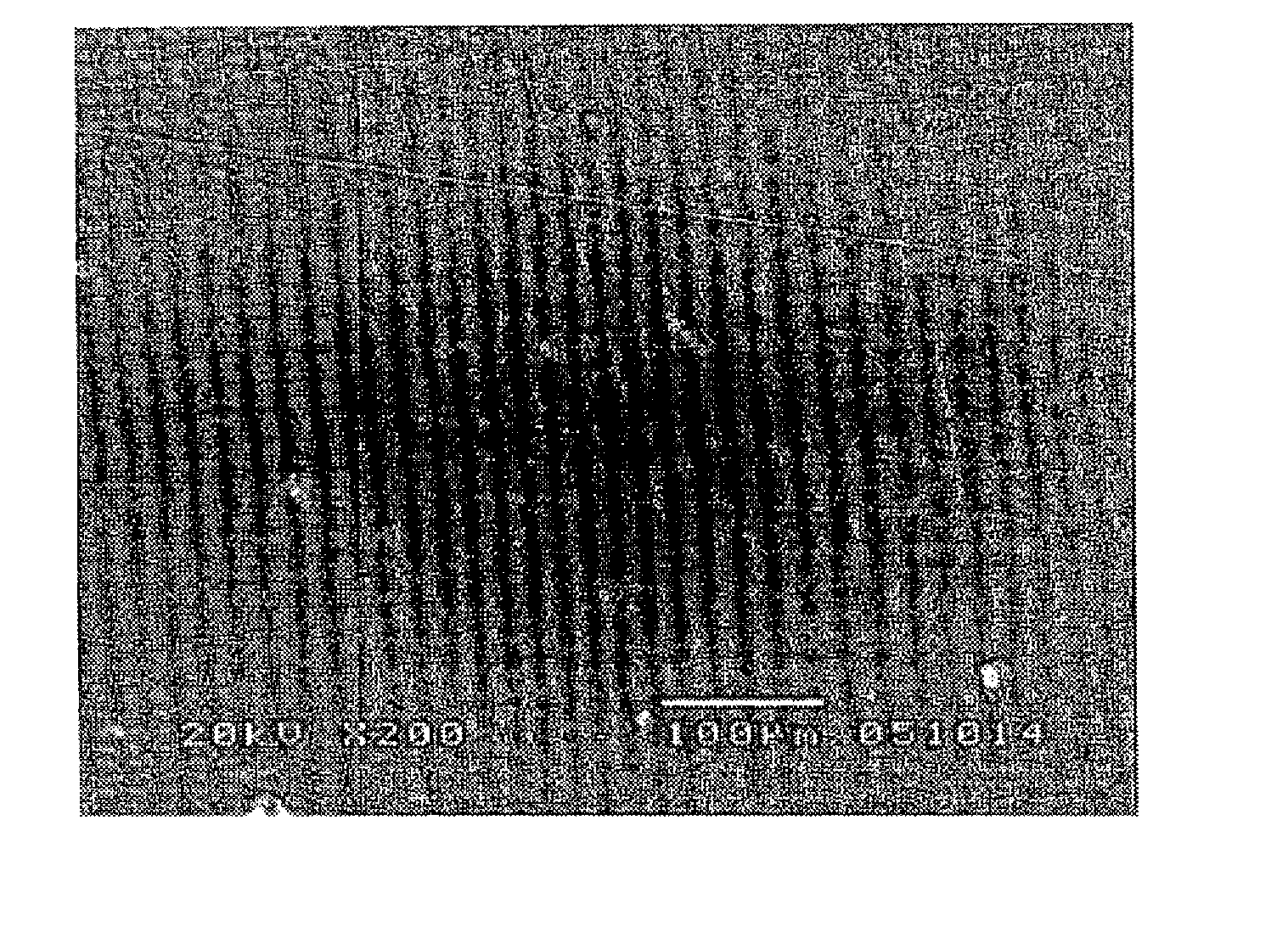

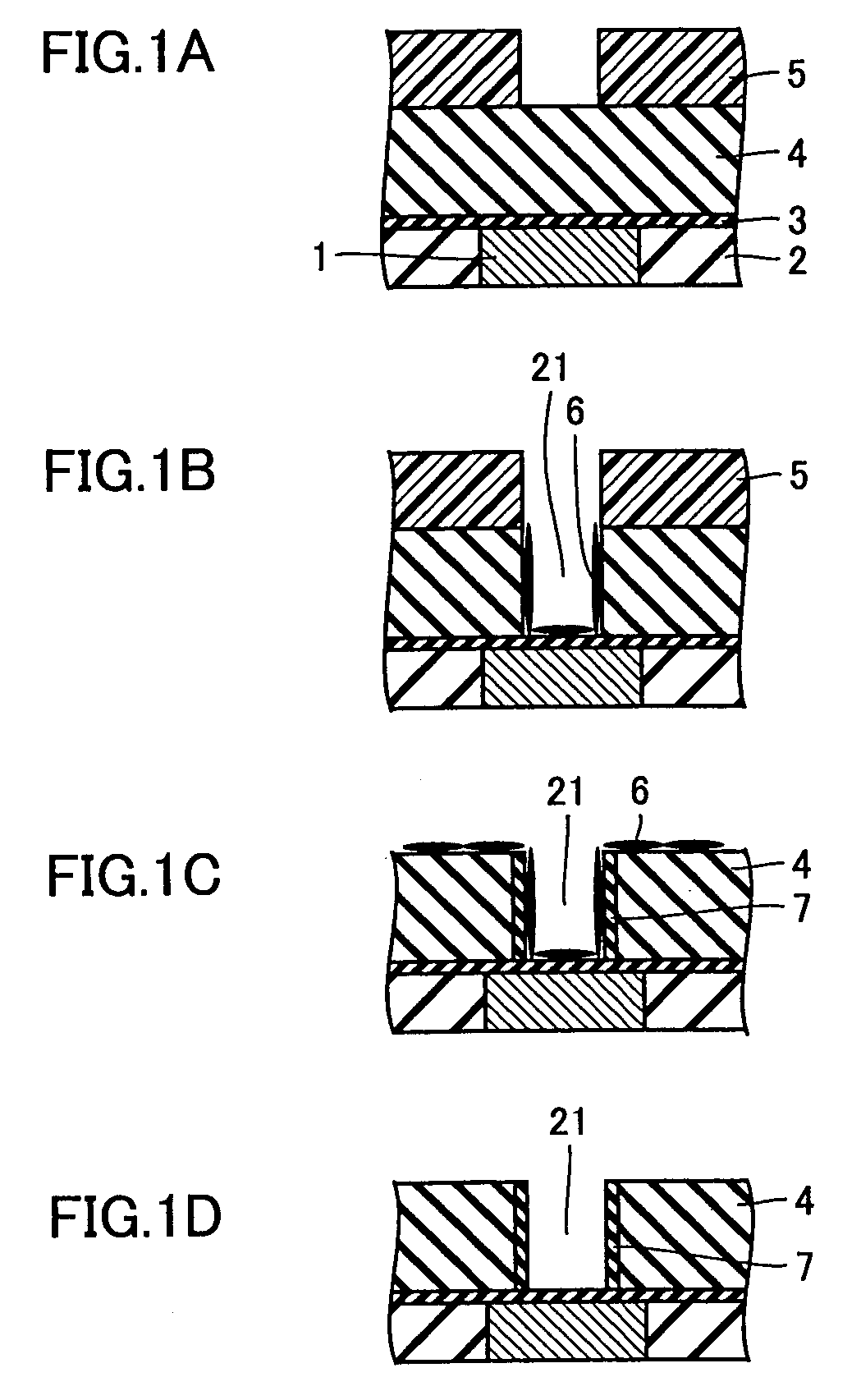

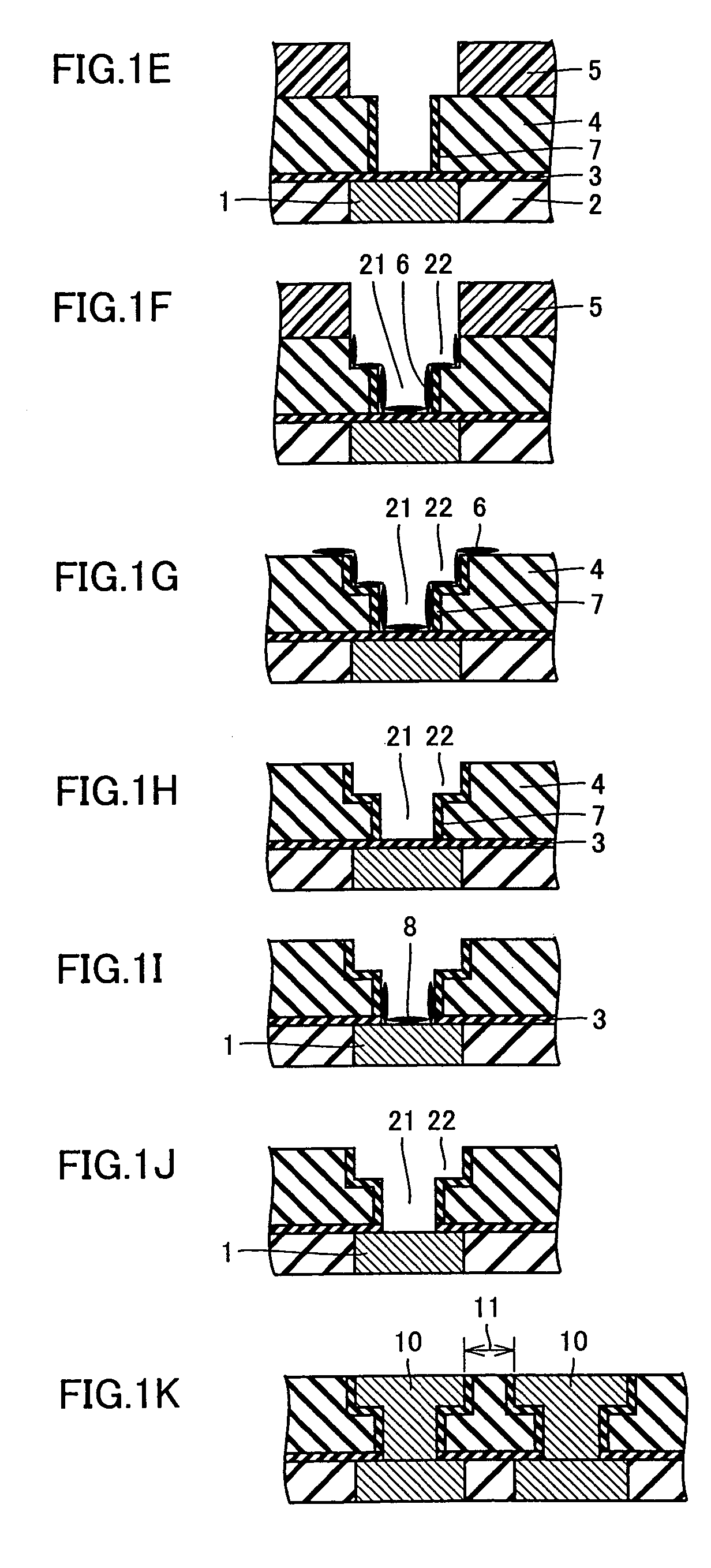

Corrosion resistant component of semiconductor processing equipment and method of manufacturing thereof

A corrosion resistant component of semiconductor processing equipment such as a plasma chamber includes a metal surface such as aluminum or aluminum alloy, stainless steel, or refractory metal coated with a phosphorus nickel plating and an outer ceramic coating such as alumina, silicon carbide, silicon nitride, boron carbide or aluminum nitride. The phosphorus nickel plating can be deposited by electroless plating and the ceramic coating can be deposited by thermal spraying. To promote adhesion of the ceramic coating, the phosphorus nickel plating can be subjected to a surface roughening treatment prior to depositing the ceramic coating.

Owner:LAM RES CORP

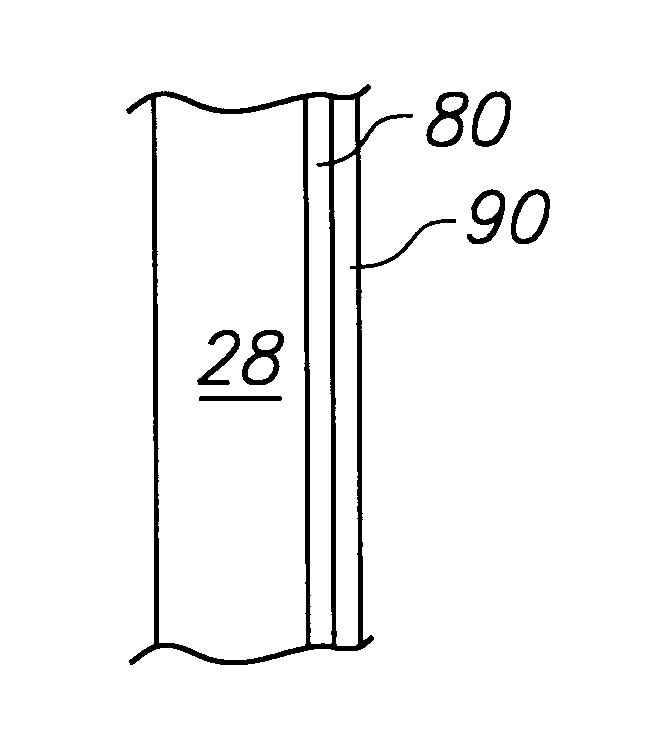

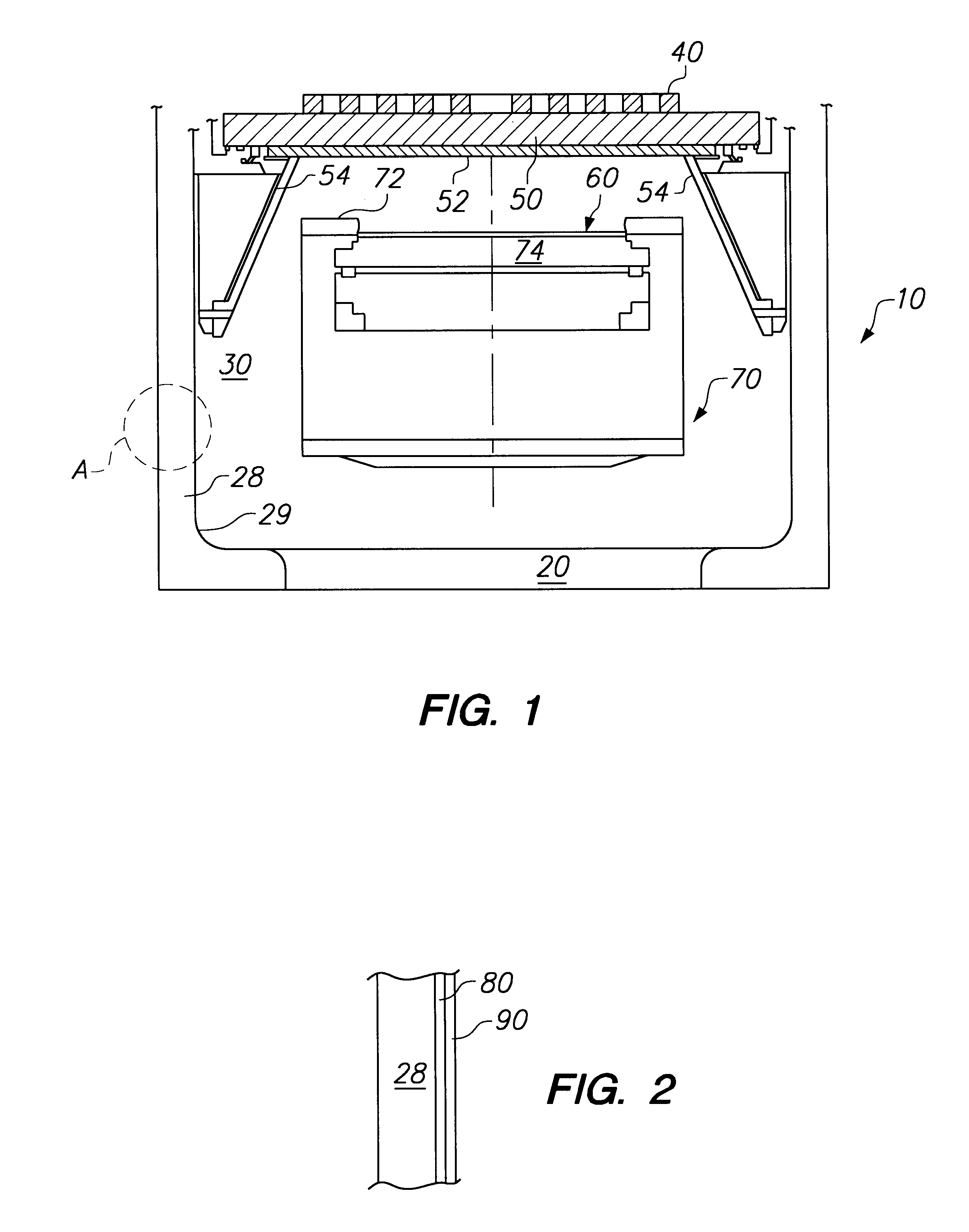

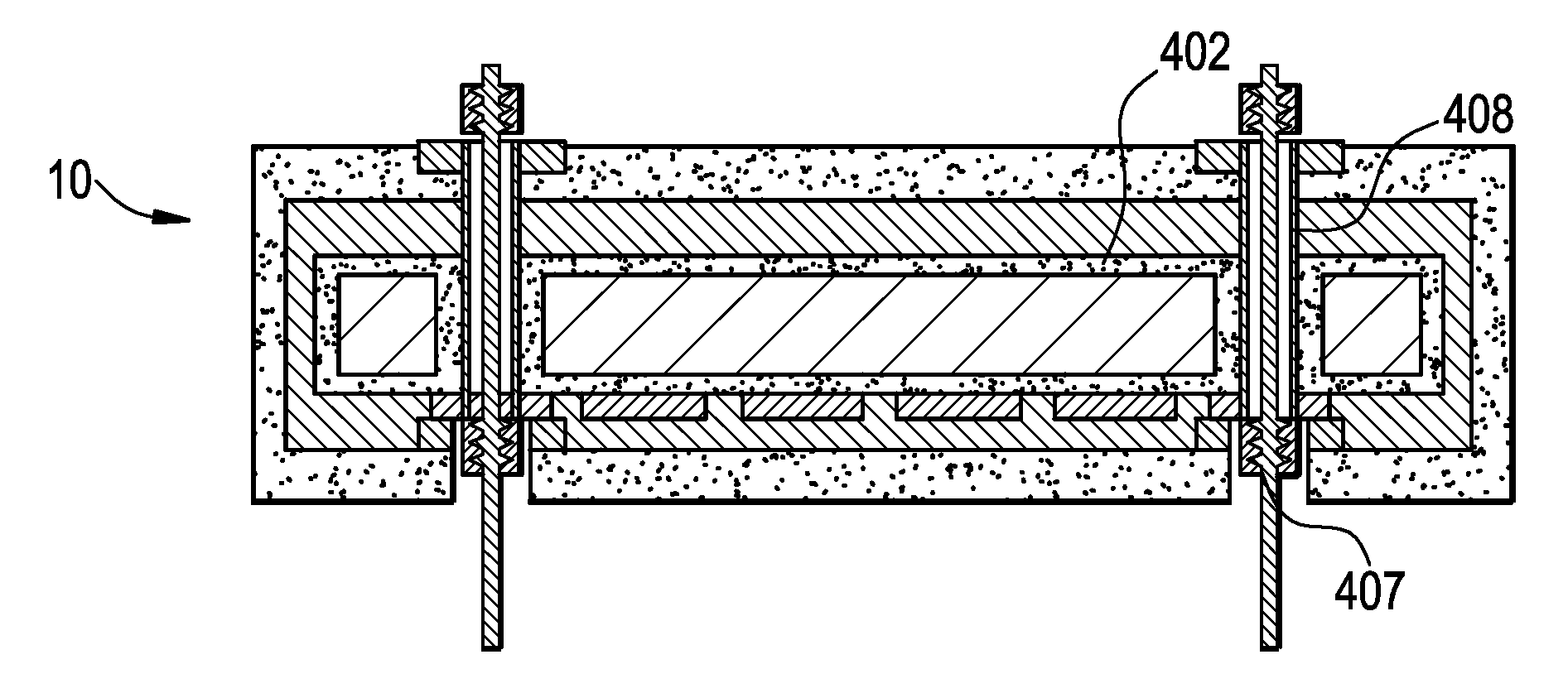

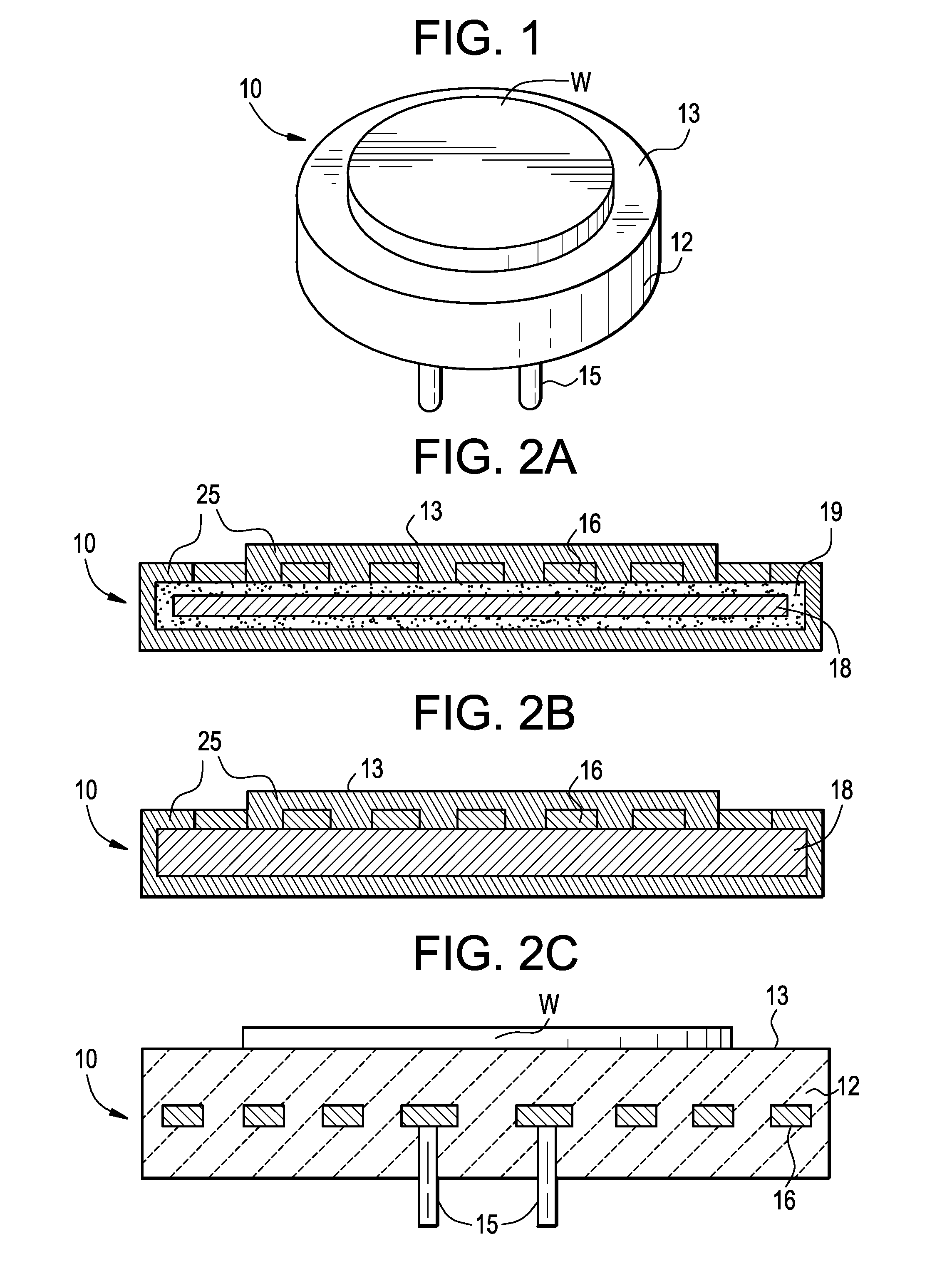

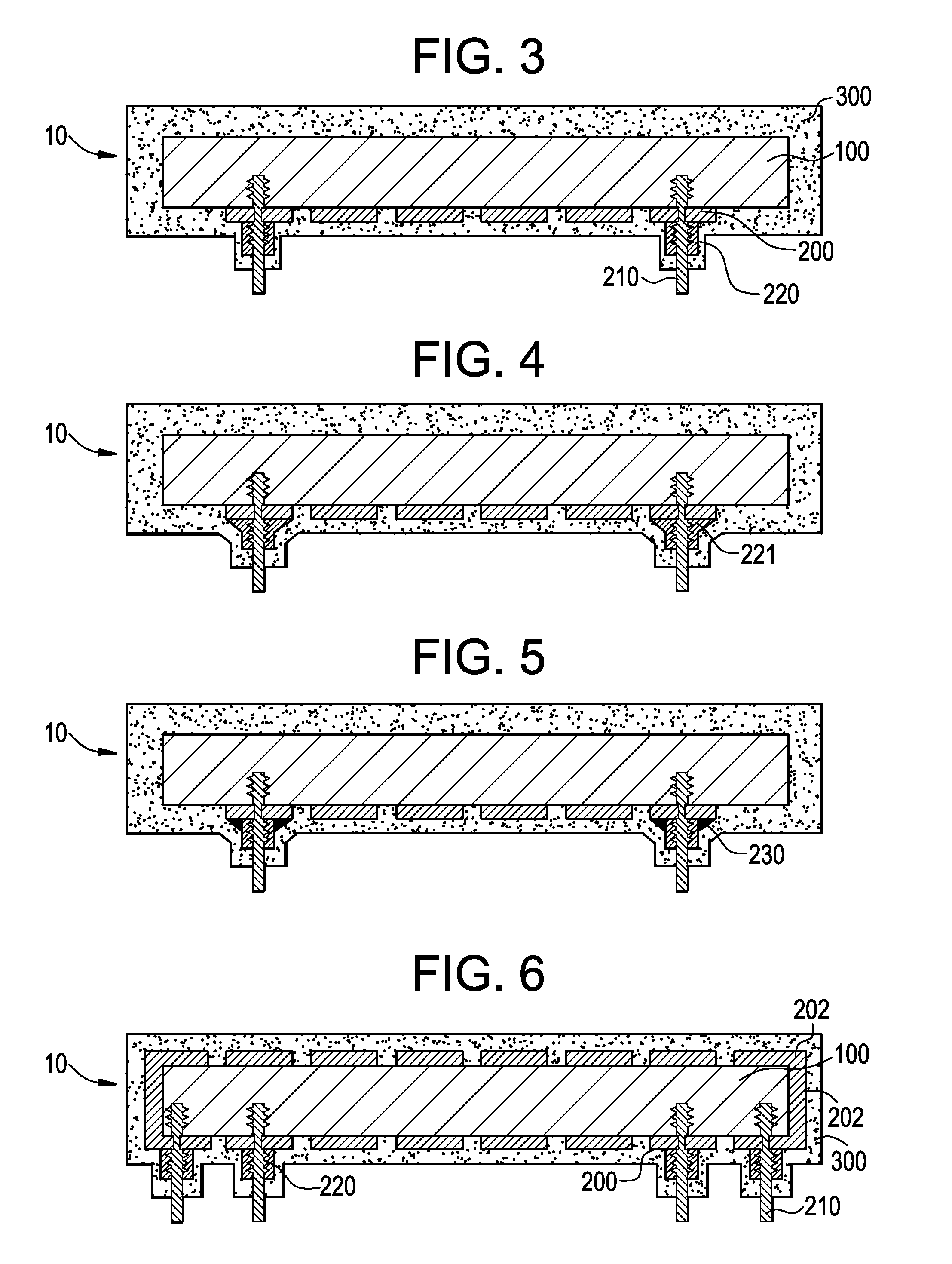

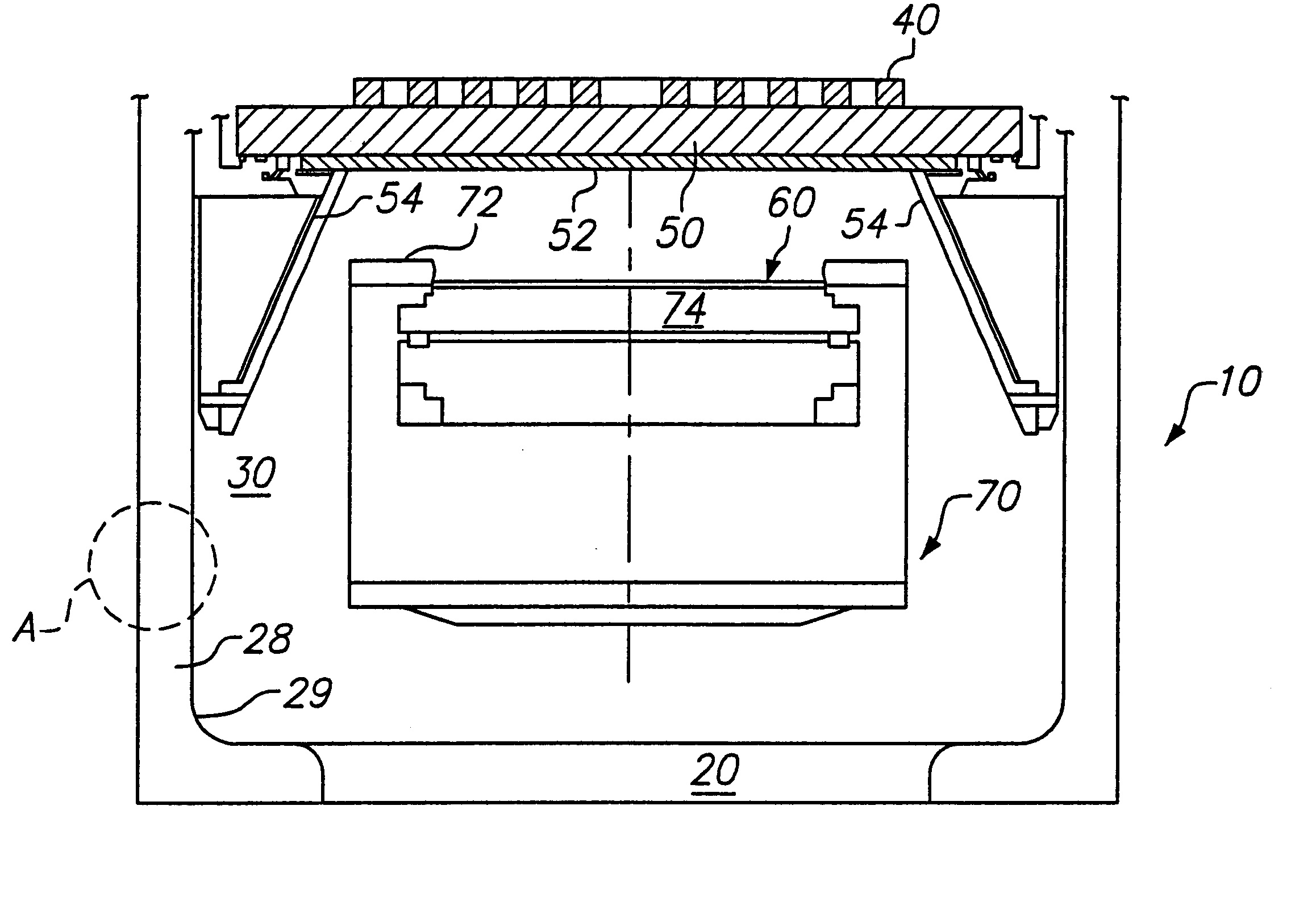

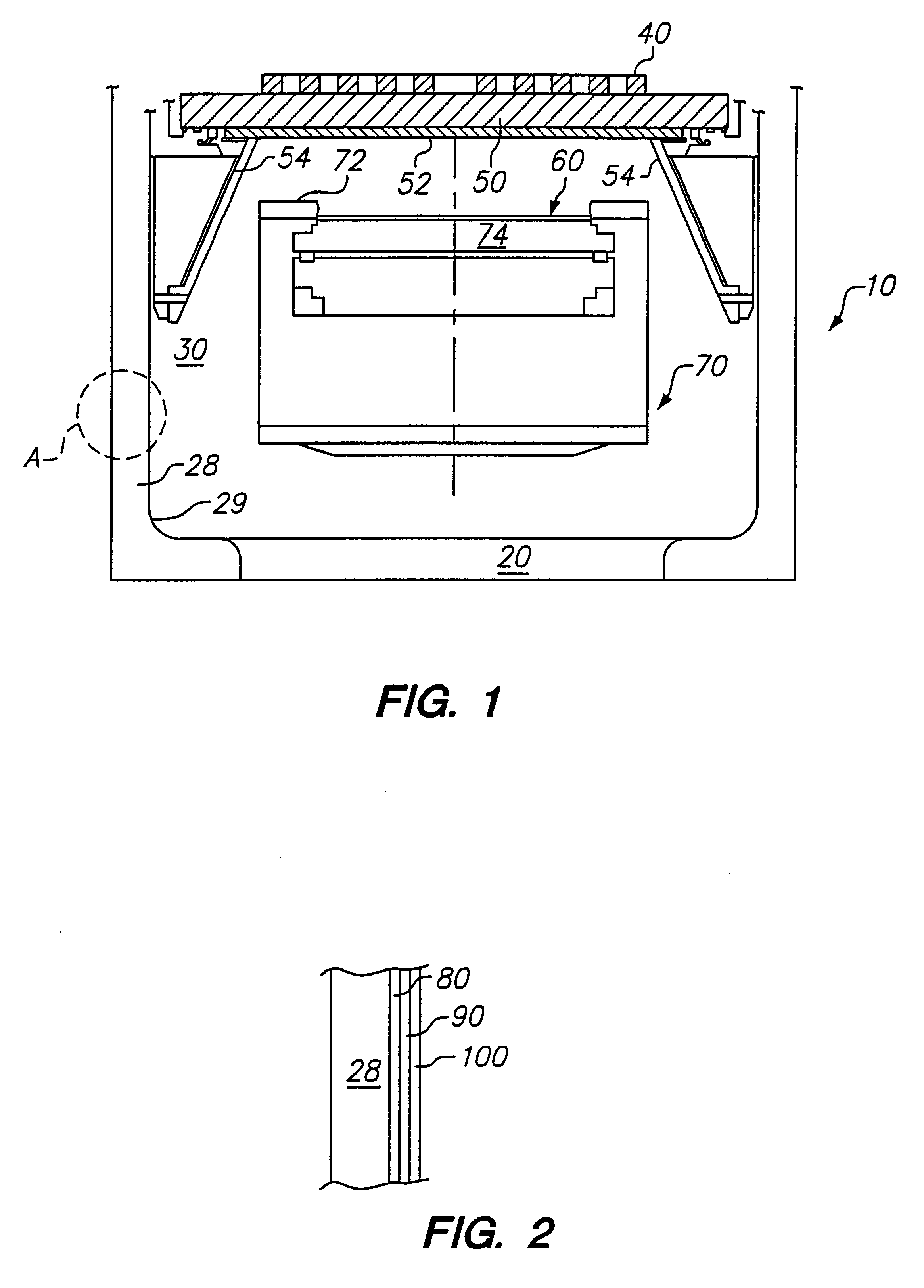

Corrosion resistant wafer processing apparatus and method for making thereof

InactiveUS20080016684A1Line/current collector detailsSemiconductor/solid-state device manufacturingElectrical connectionWadding

A wafer processing apparatus characterized by having corrosion resistant connections for its electrical connections, gas feed-through channels, recessed areas, raised areas, MESA, through-holes such as lift-pin holes, threaded bolt holes, blind holes, and the like, with the special configurations employing connectors and fillers having excellent chemical resistant properties and optimized CTEs, i.e., having a coefficient of thermal expansion (CTE) that closely matches the CTE of the base substrate layer, the electrode(s), as well as the CTE of coating layer. In one embodiment, a nickel plated molybdenum insert is employed.

Owner:GENERAL ELECTRIC CO

Diamond coatings on reactor wall and method of manufacturing thereof

InactiveUS6537429B2High purityIncrease resistanceVacuum evaporation coatingSemiconductor/solid-state device manufacturingSemiconductorPlasma chamber

A corrosion resistant component of semiconductor processing equipment such as a plasma chamber includes a diamond containing surface and process for manufacture thereof.

Owner:LAM RES CORP

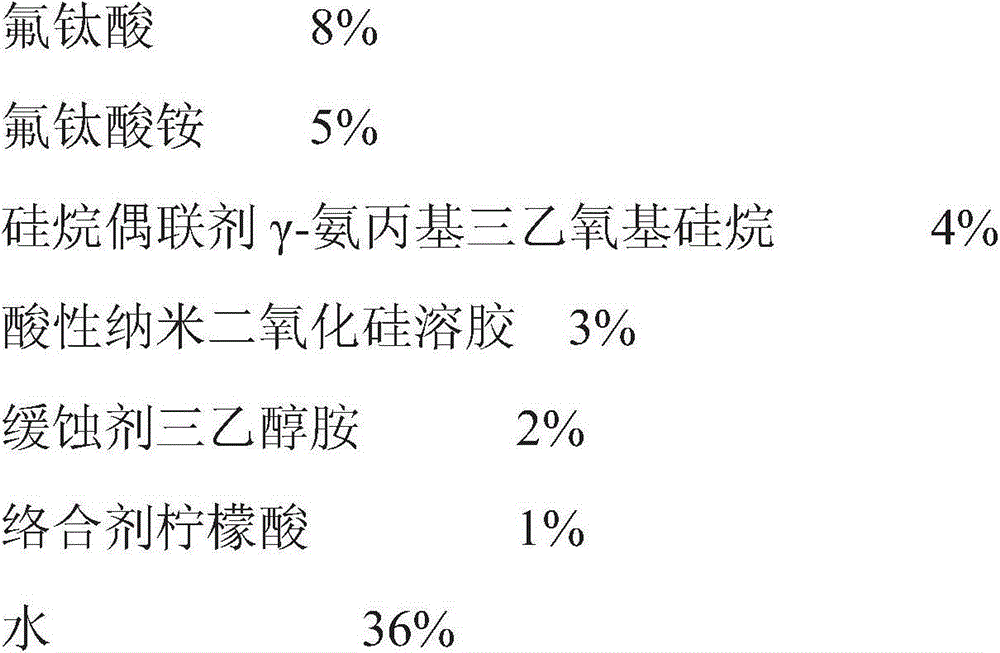

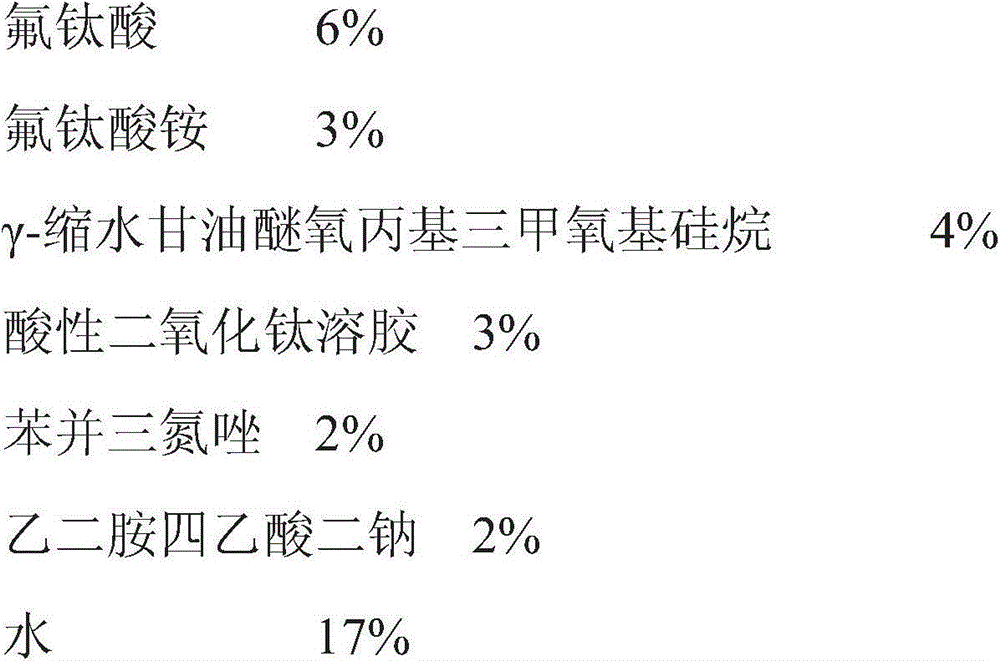

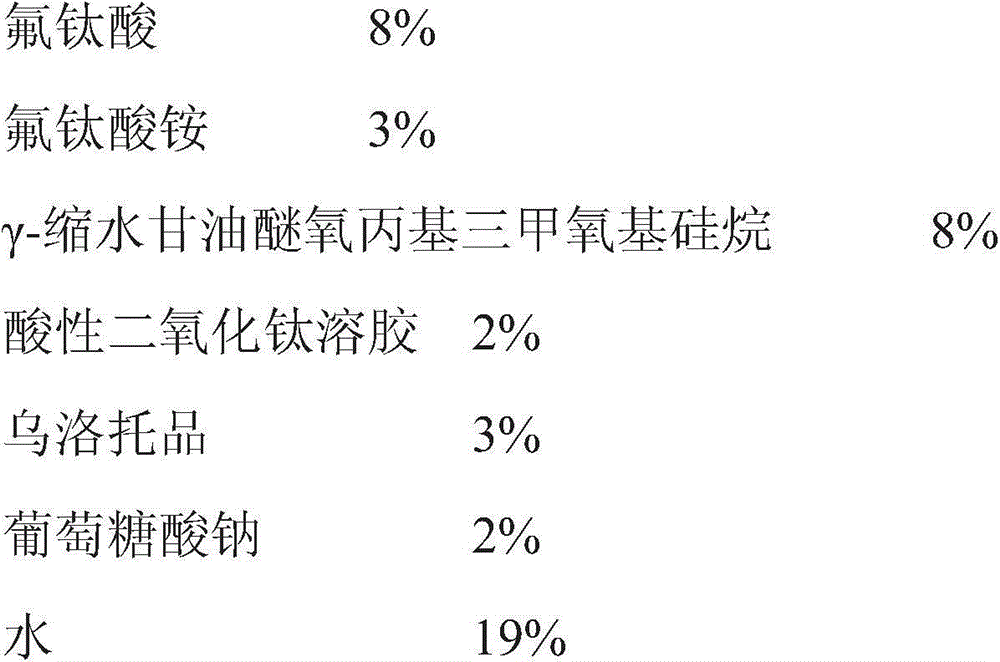

Corrosion-resistant magnesium aluminum alloy chromium-free passivation solution

InactiveCN104561970AHigh hardnessImprove stain resistanceMetallic material coating processesWater basedChromium free

The invention discloses a corrosion-resistant magnesium aluminum alloy chromium-free passivation solution, which comprises the following components: 10-40 parts of water-base resin, 1-10 parts of nanoparticle sol, 1-10 parts of fluoric-containing acid, 1-5 parts of fluoric acid-containing salt, 1-5 parts of a rare earth catalyst, 1-10 parts of a silane coupling agent, 1-5 parts of a corrosion inhibitor, 1-2 parts of a complexing agent and 40-70% of water. The corrosion-resistant magnesium aluminum alloy chromium-free passivation solution does not contain chromium and other toxic and harmful substances, meets the ROHS environmental protection law of the European Union, and meanwhile, can form an organic and inorganic composite passivation film and a thin film on the surface of a magnesium aluminum layer, and the formed composite passivation film has an excellent physical property and corrosion resistance, and has higher corrosion resistance and long salt fog time, so that the corrosion resistance of a magnesium aluminum alloy plate is better improved.

Owner:苏州禾川化学技术服务有限公司

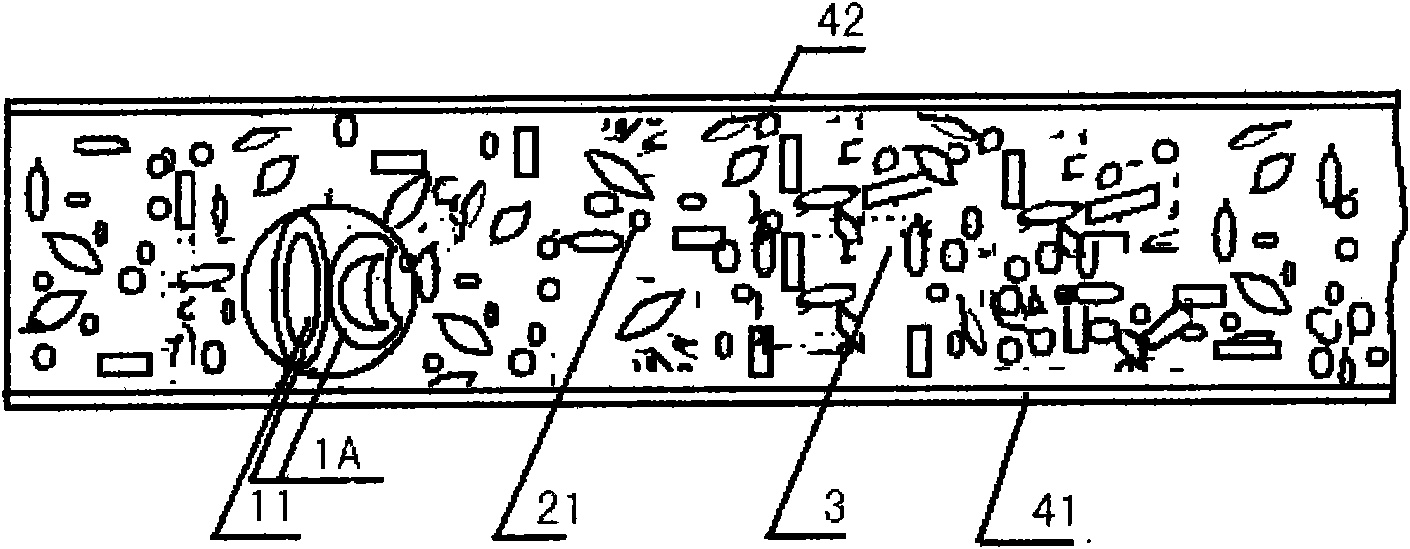

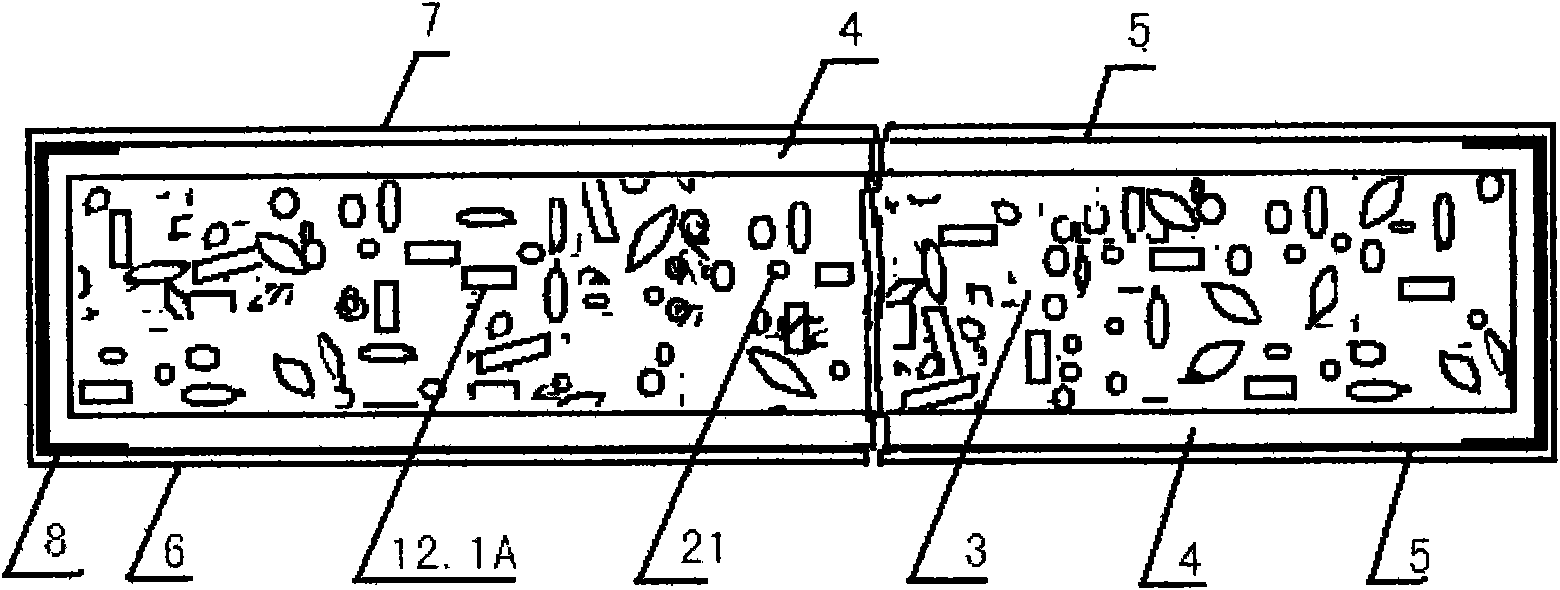

Environment-friendly light heat-insulating material and manufacturing method thereof

The invention relates to an environment-friendly light heat-insulating material for fireproof doors and buildings, and a manufacturing method thereof. The manufacturing method is characterized by comprising the following steps of: pretreating plant hollow core bodies and / or flexible porous fillers by using a water glass adhesive; mixing with inorganic fire-resistant hollow particles; and performing mould pressing, shaping and drying to obtain the environment-friendly light heat-insulating material. The hollow core bodies and the flexible porous fillers are arranged multidirectionally; one layer of water glass adhesive is arranged at least on the surfaces of the hollow core bodies and the flexible porous fillers; and discontinuous holes are reserved between the hollow core bodies and / or the flexible porous fillers and the inorganic fire-resistant hollow particles. Preferably, the hollow core bodies are rice husks and straw sections; and the flexible porous fillers are foam and fibers. Renewable plant resources and recovered foam and fiber waste are adopted, so the environment-friendly light heat-insulating material is energy-saving and environment-friendly; and a large number of sealed holes are formed among the material particles through the penetration and coating of the modified water glass adhesive, and a heat-insulating hydrophobic corrosion-resistant multi-effect protective layer is provided, so the environment-friendly light heat-insulating material has good fireproof, heat-insulating and heat-preserving effects, high weather resistance, combined rigidity and toughness, low density and low cost.

Owner:重庆恒宏致嘉全过程建设项目管理有限公司

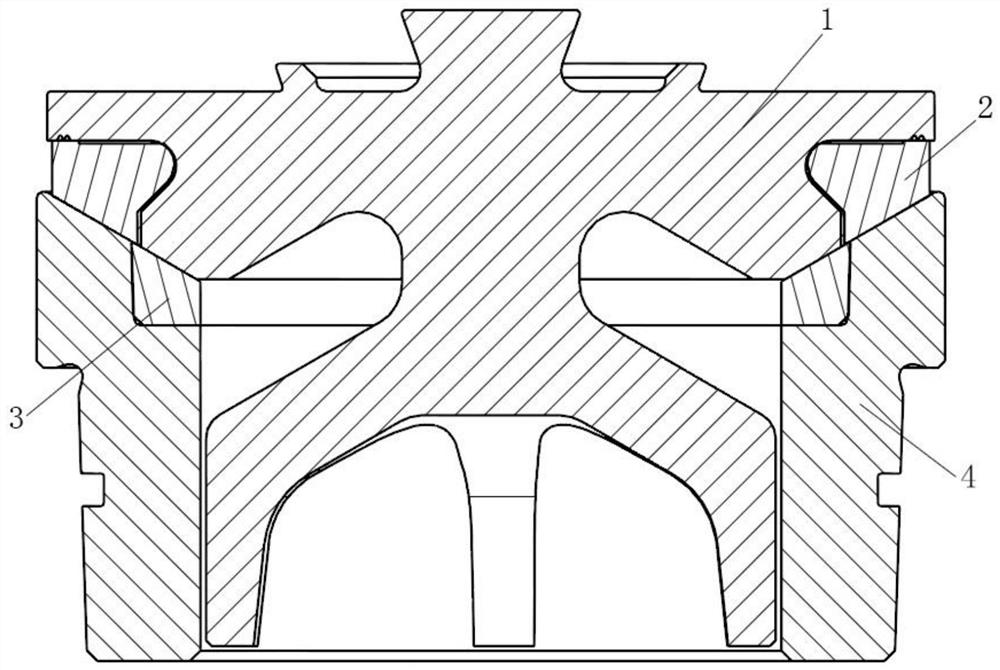

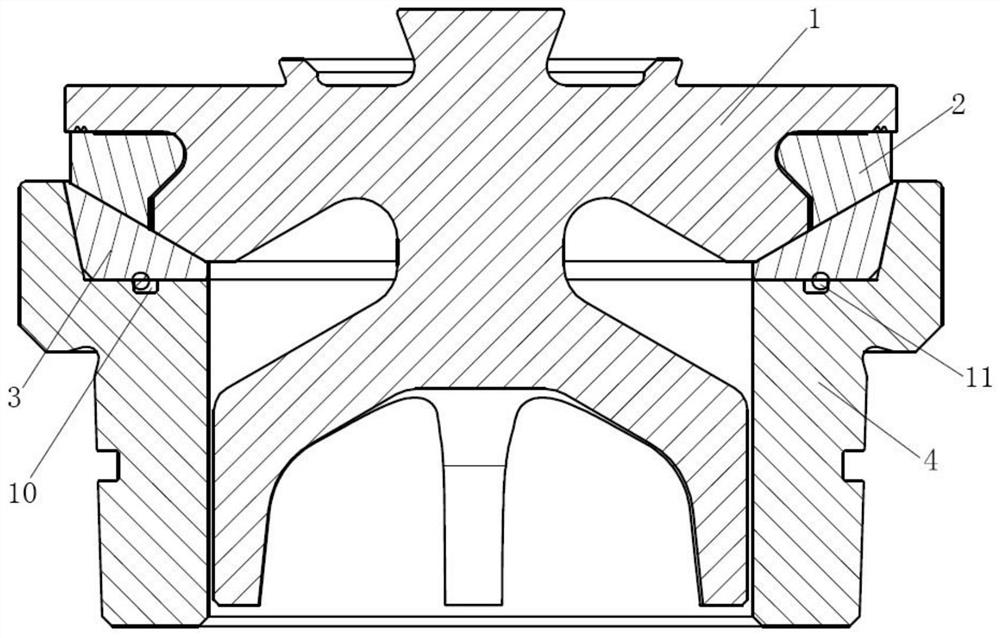

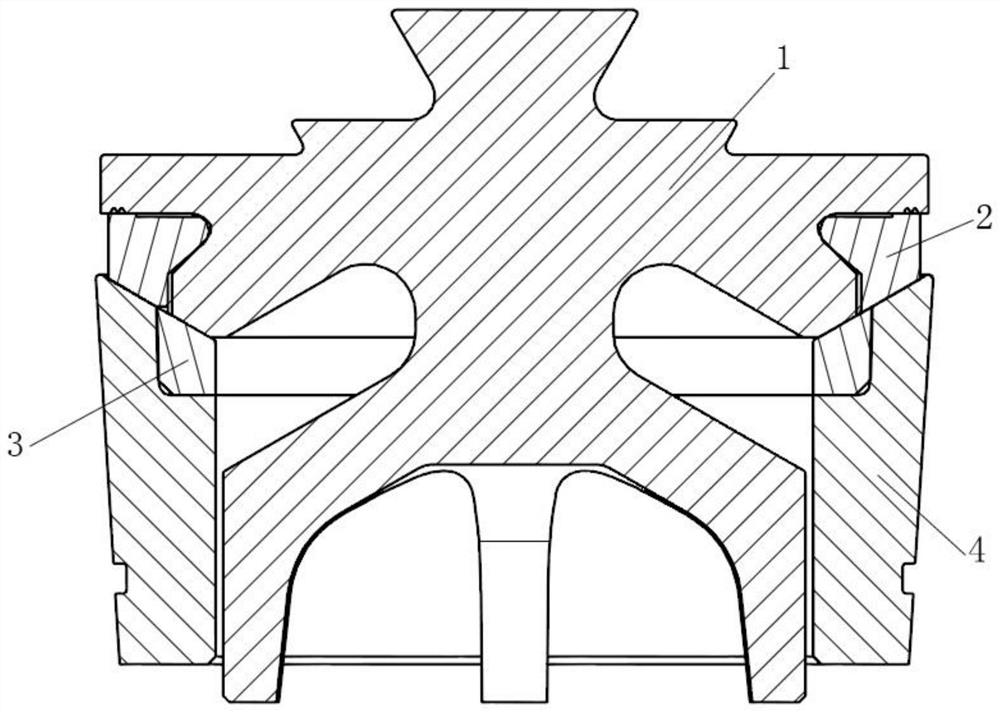

Long-service-life split type valve seat

PendingCN111664087AExtended service lifeHigh hardnessPositive displacement pump componentsLiquid fuel engine componentsWorking pressureStructural engineering

The invention discloses a long-service-life split type valve seat. The long-service-life split type valve seat comprises linings and bases. The linings are embedded into the outlet ends of the bases.The linings are matched with a valve body for use. Each lining is a tungsten carbide alloy. The long-service-life split type valve seat has the beneficial effects that the valve seat is composed of the linings and the bases, the linings are made of a hard alloy material, the hardness, the strength, the wear resistance and the corrosion resistance of the linings are improved, and the service life of the valve seat is greatly prolonged; the valve seat is of a split structure, once abrasion occurs, only the linings or the bases need to be replaced, integral replacement is not needed, maintenanceis convenient, the time and labor are saved, and meanwhile the production cost of an oil and gas field is reduced; the appropriate diameter sizes of the linings can be selected according to the working pressure, the conveying medium, the degree of abrasion of the valve body to the valve seat and the like in actual working conditions, and the application range is wide; the linings and the bases arein various shapes and can be combined according to actual working condition requirements, and the applicability is high.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

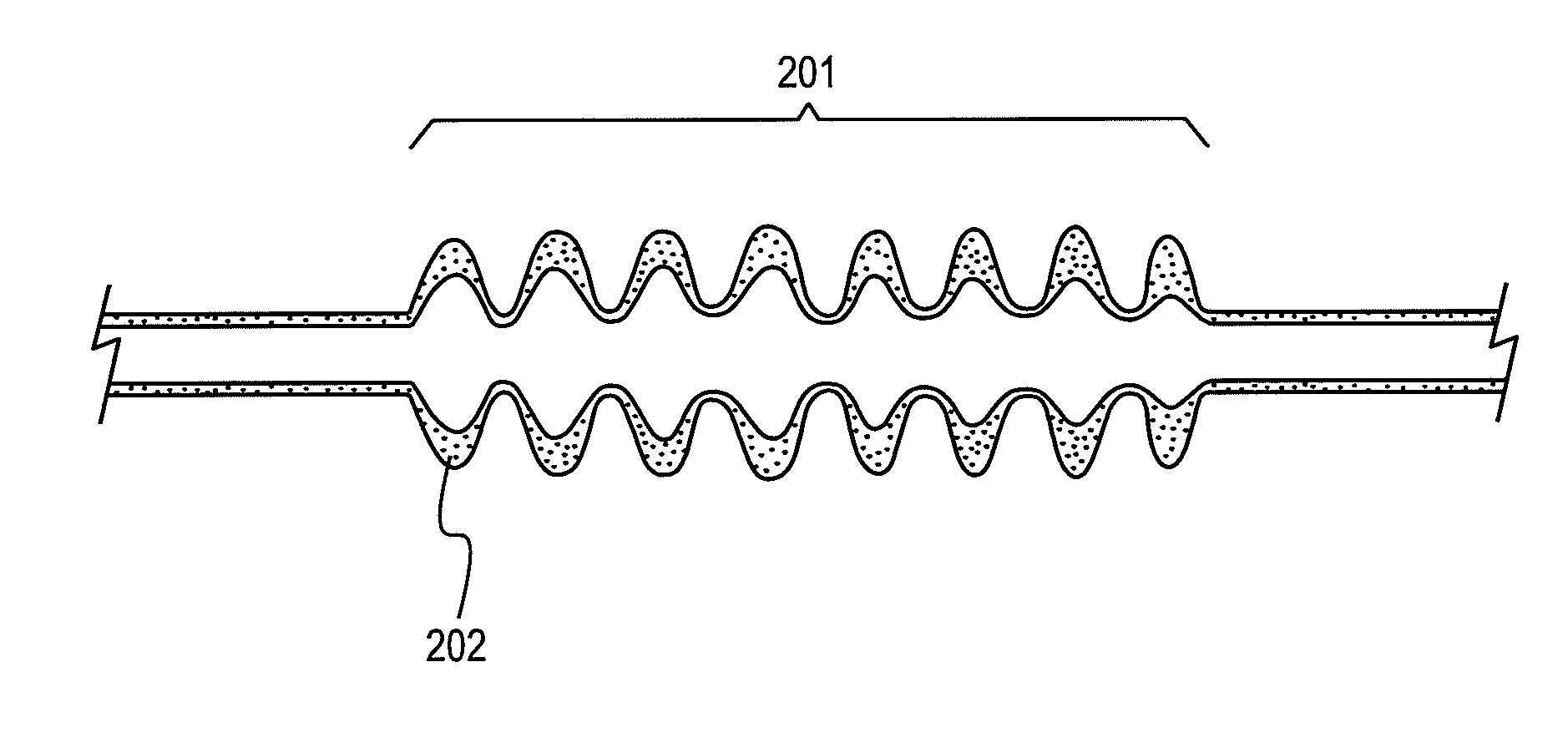

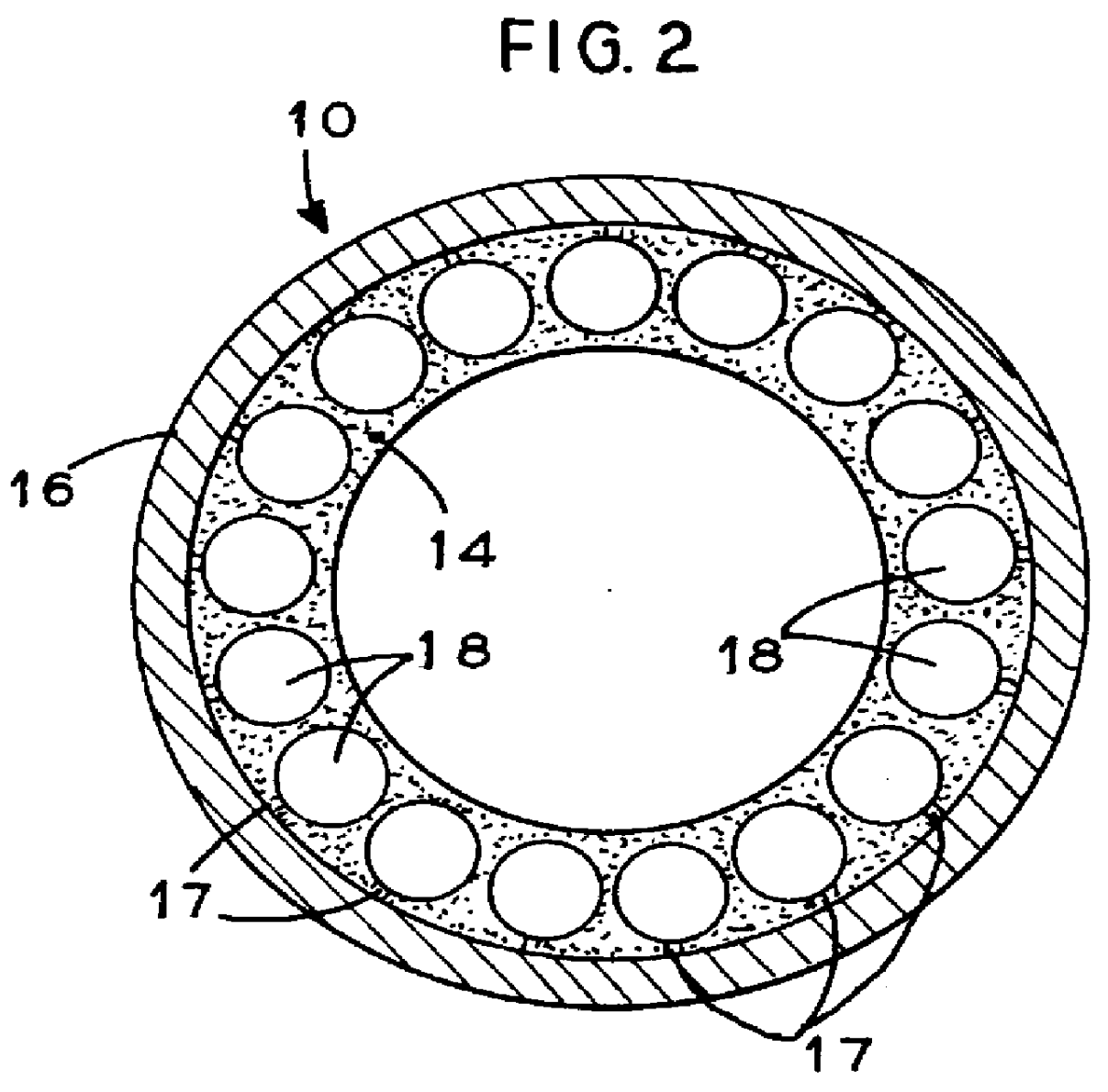

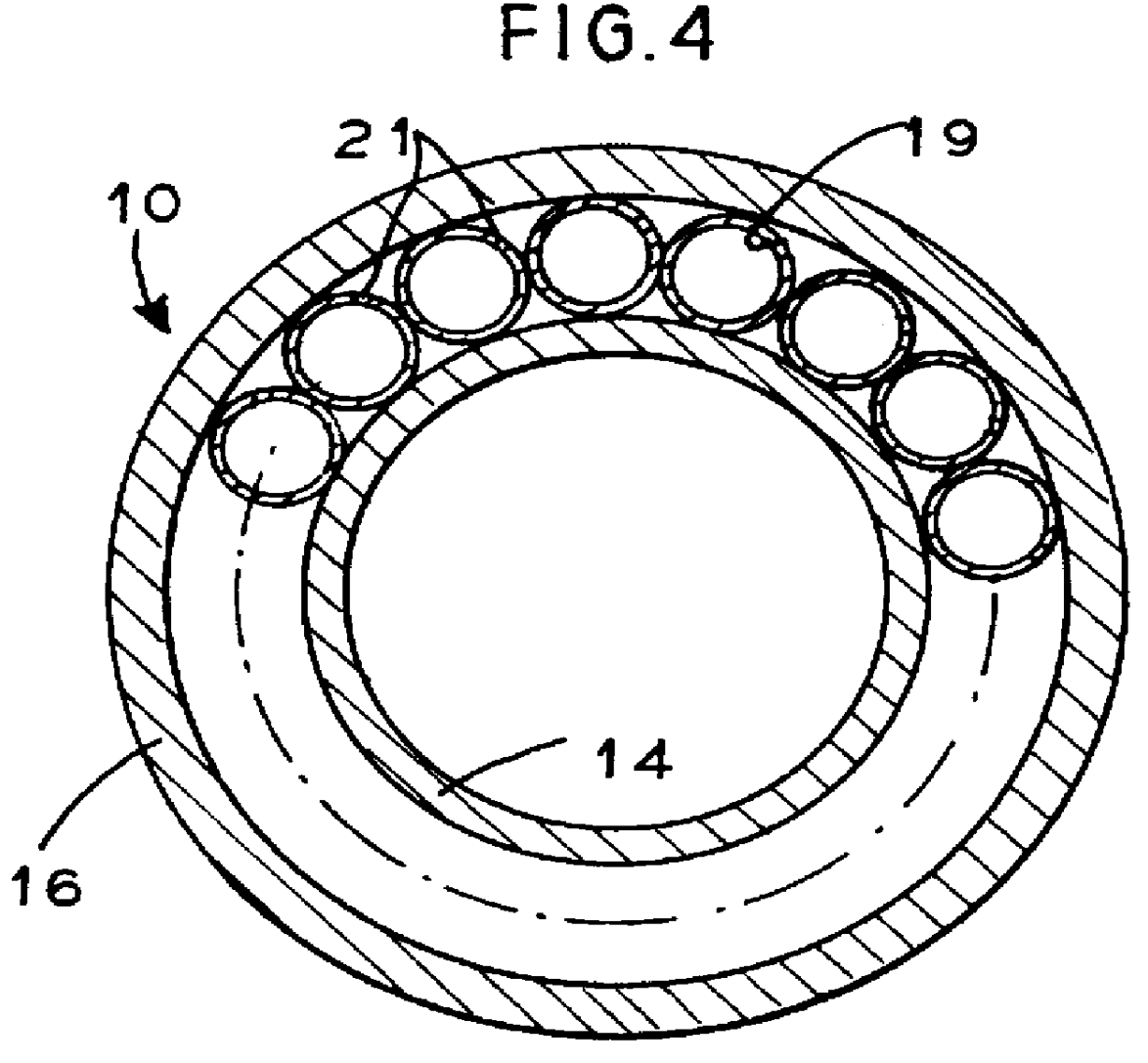

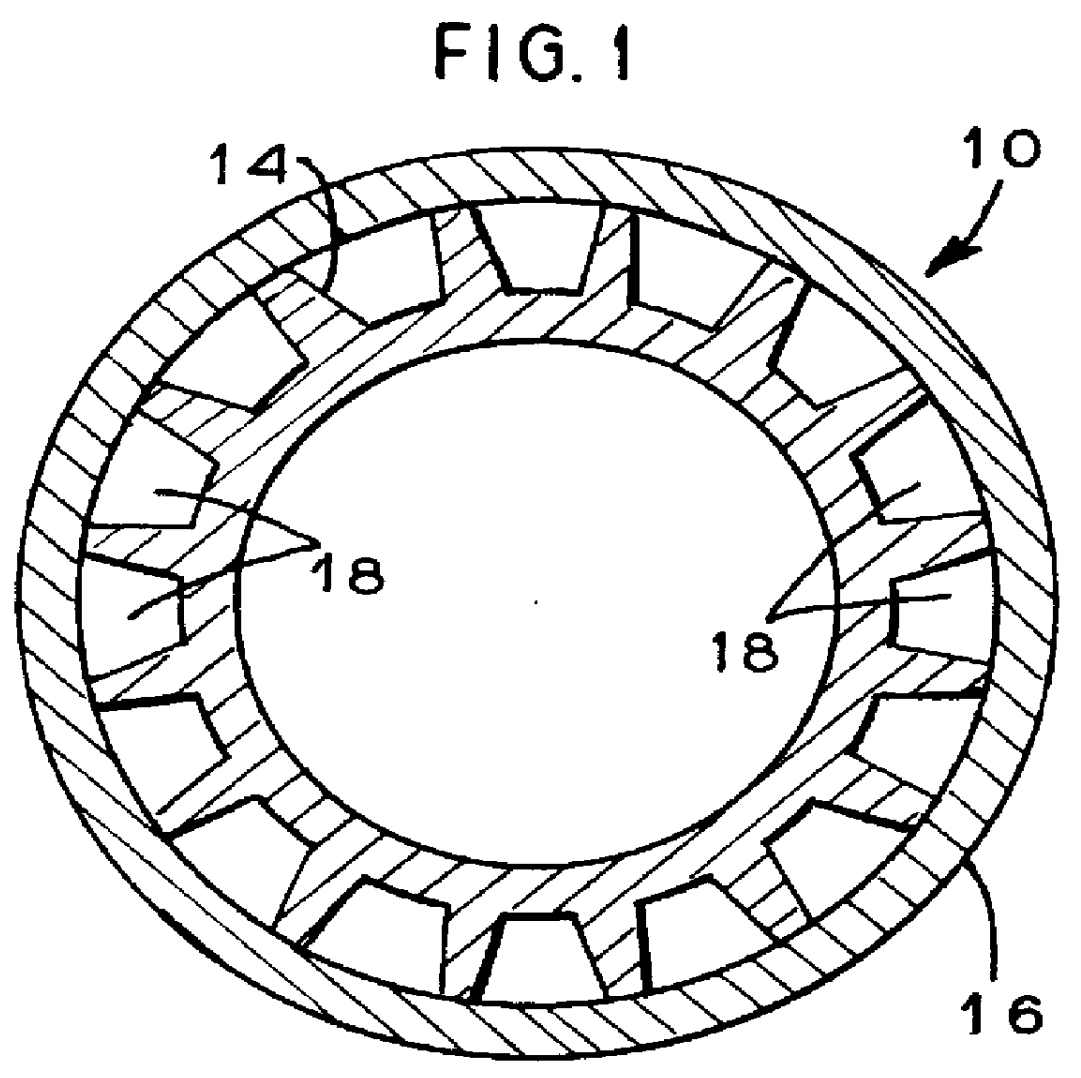

Internally insulated, corrosion resistant pipeline

An internally insulated, corrosion resistant pipeline. An inner fluid barrier is formed preferably by a polymer liner. The outer pipe may be a steel pipe. The liner is provided with a plurality of passages or an open annulus. The passages in the liner or annulus between the pipe and liner are filled with an insulation material.

Owner:J RAY MCCDERMOTT SA

Corrosion resistant member

InactiveUS20070092696A1Loss of corrosion resistant capabilityUseful displayMolten spray coatingVacuum evaporation coatingCorrosion resistantCorrosive substance

When a corrosion resistant member is exposed to a chlorine-containing gas or plasma thereof and then to the ambient atmosphere, the member surface does not absorb moisture. The surface of the member to be exposed to a chlorine-containing gas or a plasma thereof does not form chloride particles of substrate material. After washing of the member with water, the wash water exhibits no corrosive nature to the substrate. The member is free of damages to the substrate and of a loss of corrosion resistant capability.

Owner:SHIN ETSU CHEM IND CO LTD

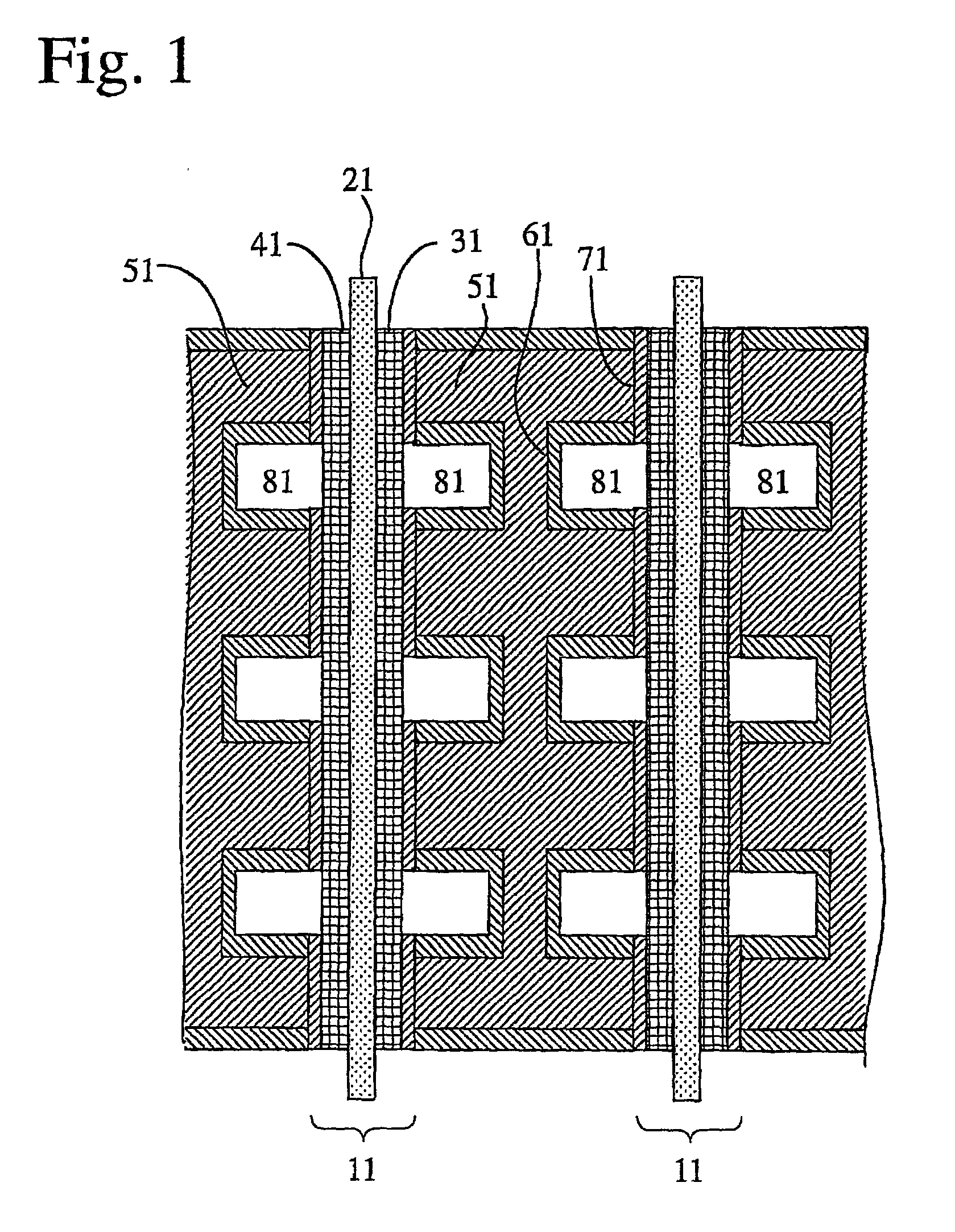

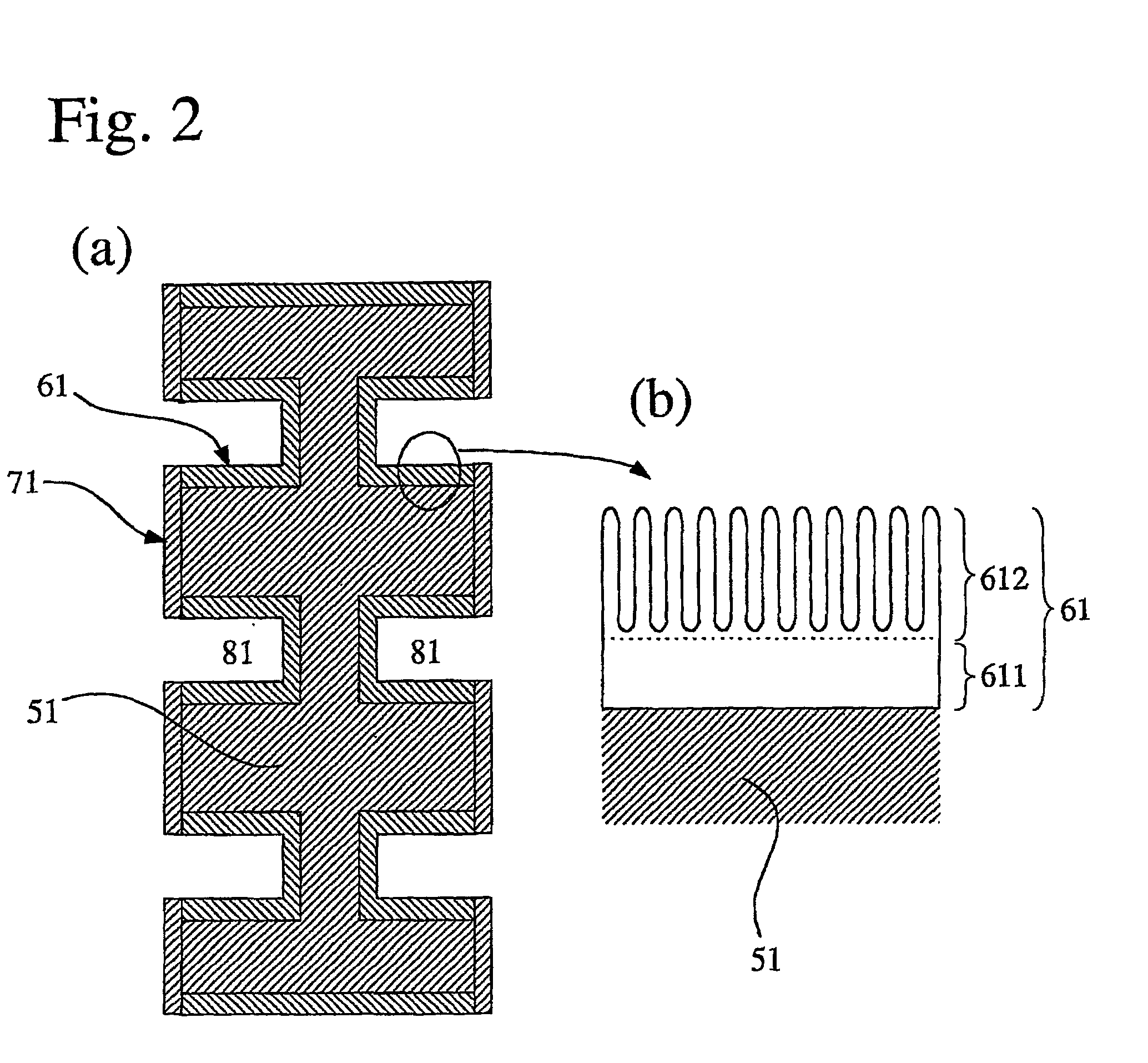

Embossed current collector separator for electrochemical fuel cell

InactiveUS20020009630A1Improve conductivityImprove corrosion resistanceElectrode carriers/collectorsSpecial surfacesFuel cellsEngineering

A bipolar current collector separator for a fuel cell composed of a metal plate having flow channels and contact faces that come into contact with electrodes or collectors, wherein a corrosion-resistant layer such as an anodized aluminum layer and a heat-resistant polymer layer is disposed on each of the flow channels.

Owner:RIKEN CO LTD

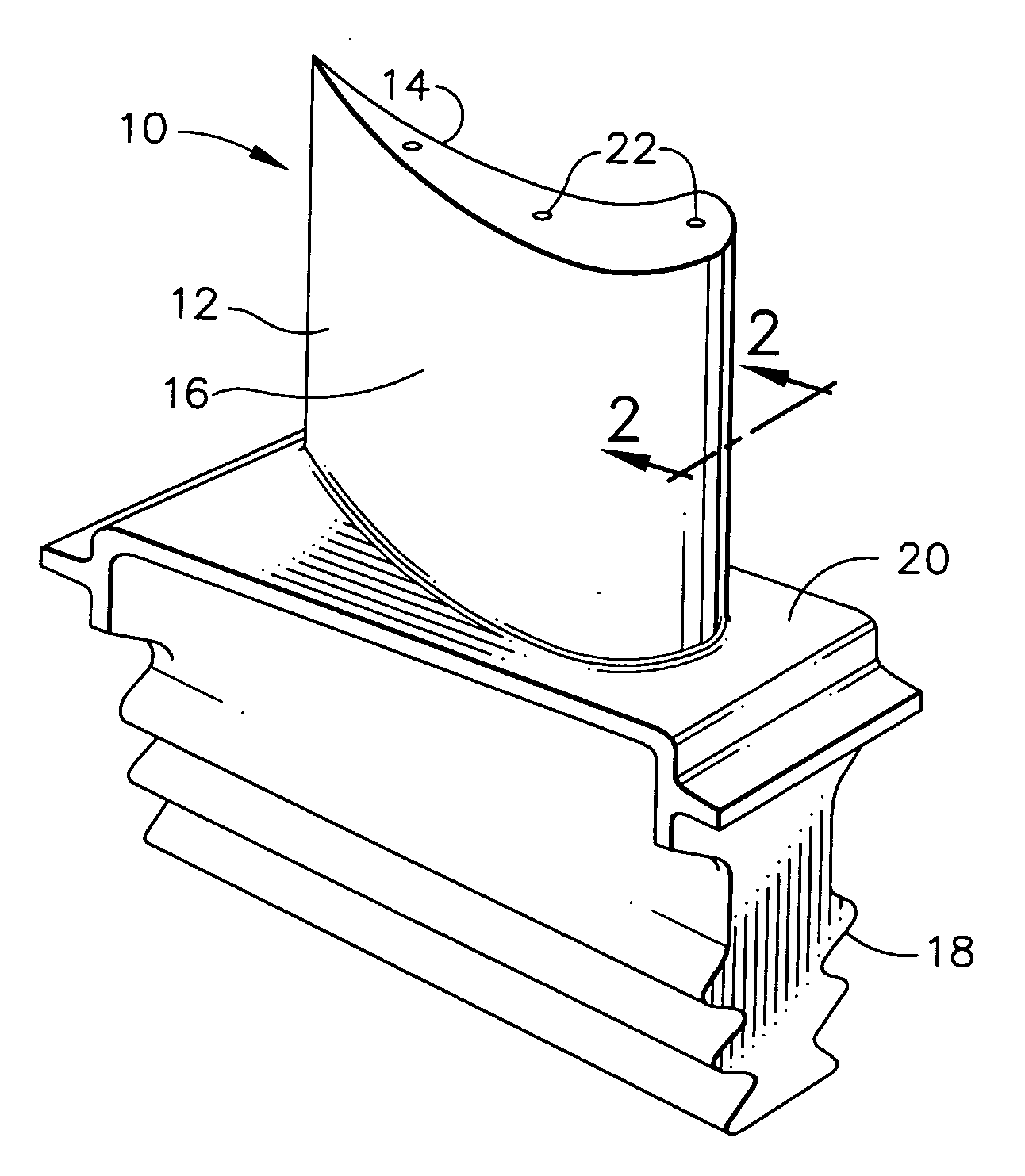

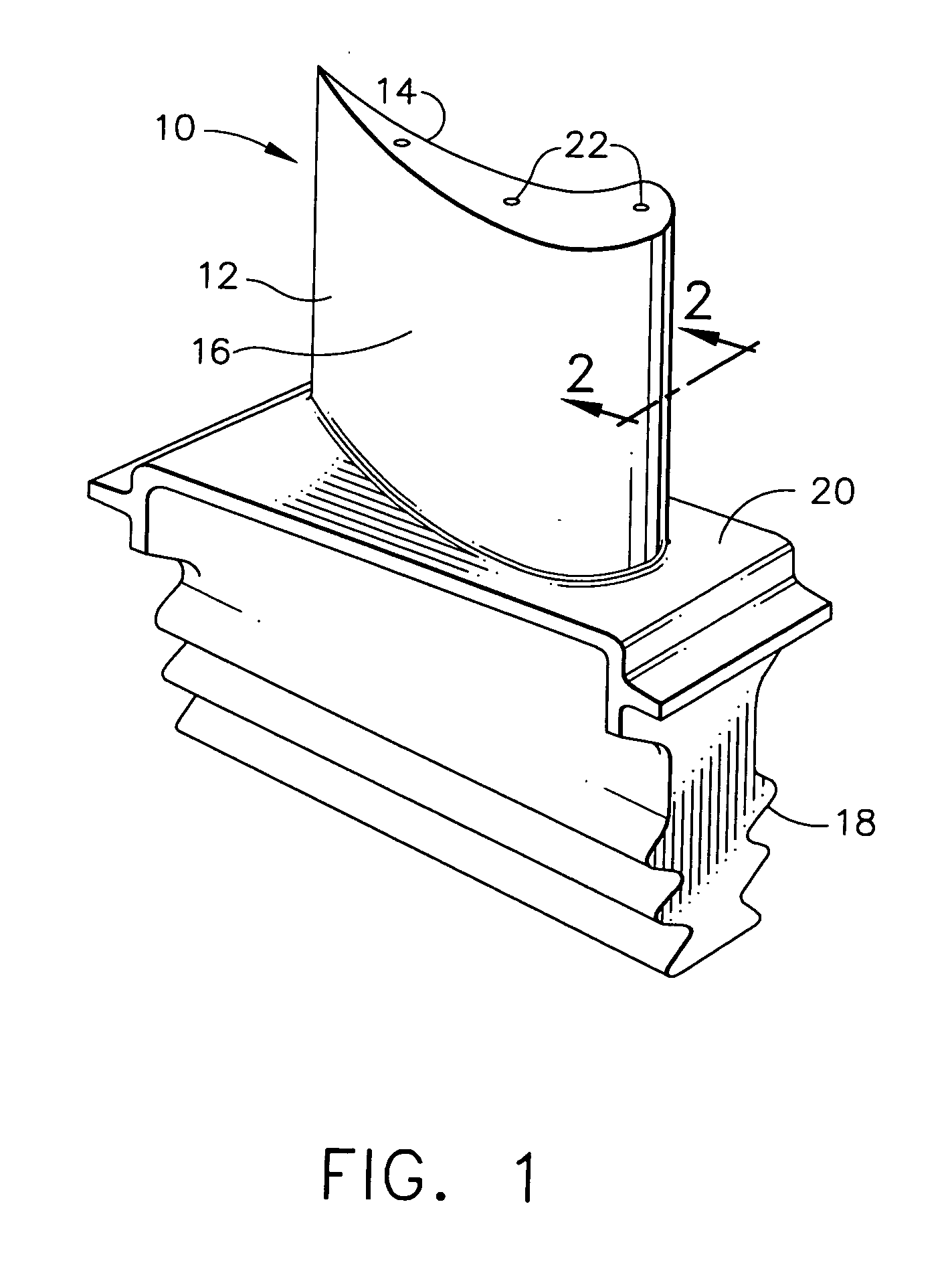

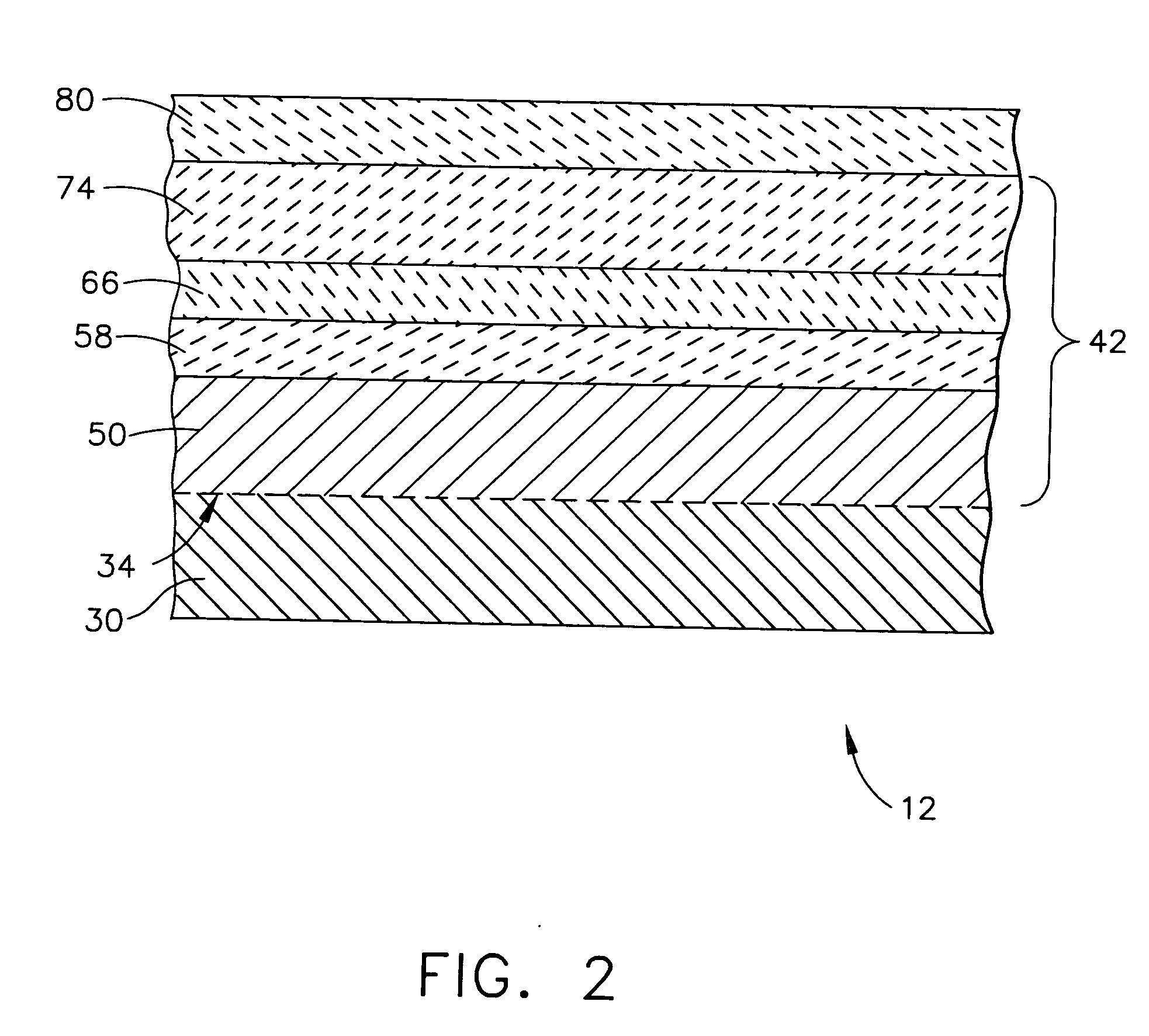

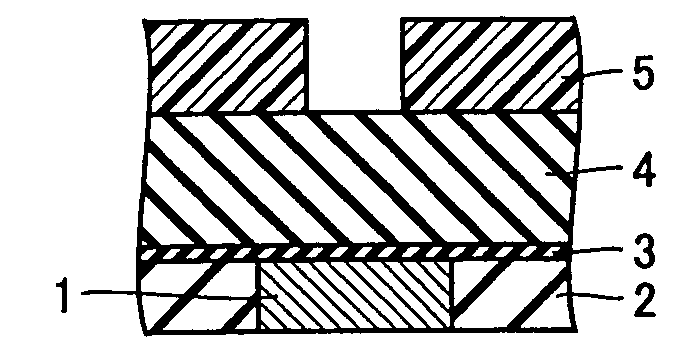

Corrosion resistant sealant for outer EBL of silicon-containing substrate and processes for preparing same

InactiveUS20060280954A1More resistant to environmental attackResist attackMolten spray coatingBlade accessoriesAluminateMetallurgy

An article comprising a silicon-containing substrate, an environmental barrier coating (EBC) overlying the substrate, wherein the EBC comprises a higher metal silicate-containing outer barrier layer; and a corrosion resistant alumina / aluminate sealant for the higher metal silicate-containing outer barrier layer. A process is also provided for forming a corrosion resistant alumina / aluminate sealant layer over the higher metal silicate-containing outer barrier layer. Also provided is an alternative process for treating a porous higher metal silicate-containing outer barrier layer with a liquid composition comprising an corrosion resistant alumina / aluminate sealant precursor to infiltrate the porous higher metal silicate-containing outer barrier layer with the alumina / aluminate sealant precursor in an amount sufficient to provide, when converted to the corrosion resistant alumina / aluminate sealant, protection of the environmental barrier coating against environmental attack; and converting the infiltrated alumina / aluminate sealant precursor within the porous higher metal silicate-containing outer barrier layer to the corrosion resistant alumina / aluminate sealant.

Owner:GENERAL ELECTRIC CO

Cleaning composition for removing resists and method of manufacturing semiconductor device

InactiveUS7250391B2Good removal effectInhibitionSemiconductor/solid-state device manufacturingNon-surface-active detergent solventsResistCopper interconnect

The cleaning composition for removing resists includes a salt of hydrofluoric acid and a base not containing a metal (A component), a water-soluble organic solvent (B1 component), at least one organic acid or inorganic acid (C component), water (D component), and, optionally, an ammonium salt (E1 component), and having a pH 4-8. Thus, in manufacturing a semiconductor device, such as a copper interconnecting process, efficiency of removing resist residue and other etching residue after etching or ashing is improved, and corrosion resistance of a copper and an insulating film is also improved.

Owner:PANASONIC CORP +2

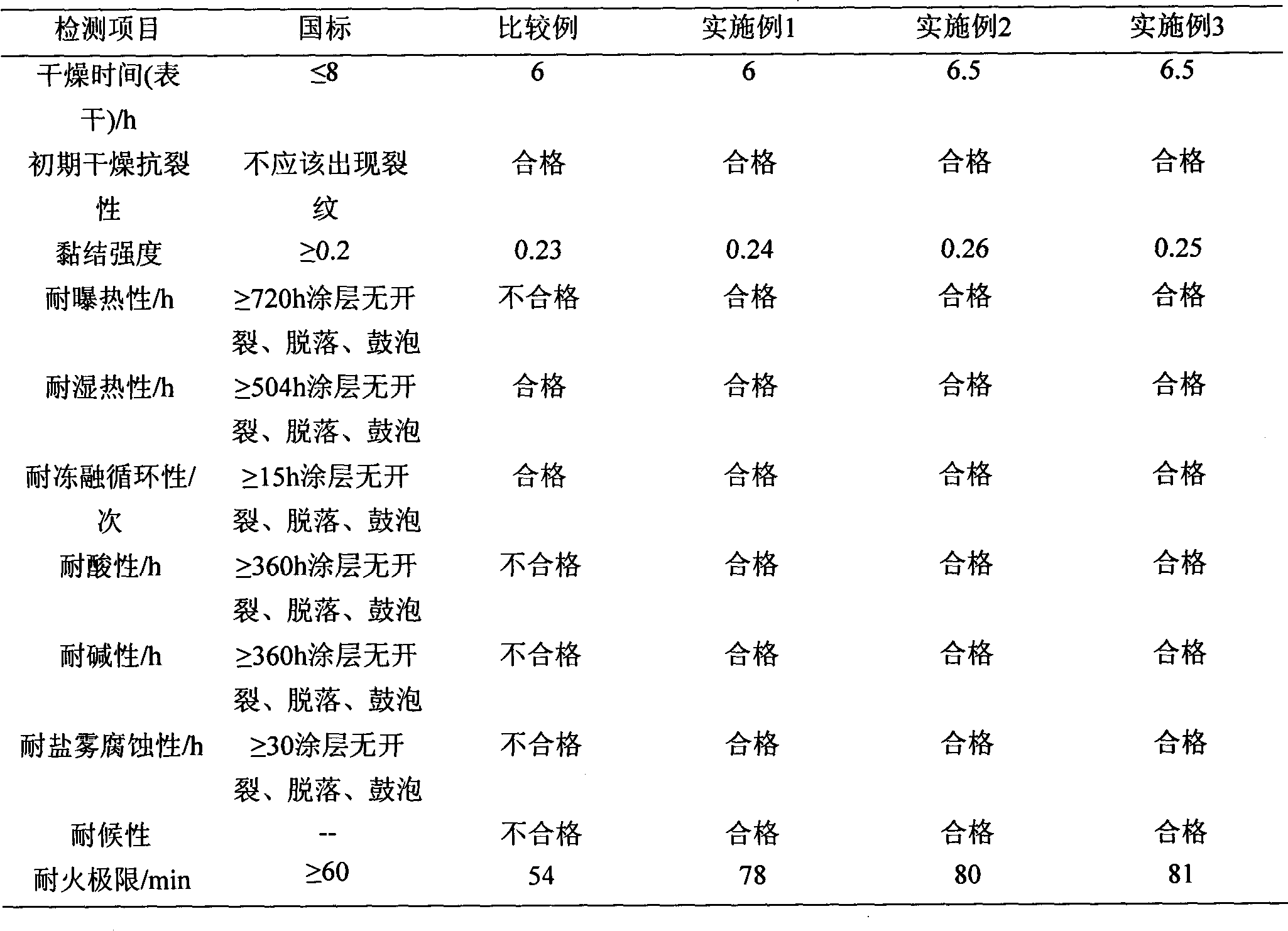

Aqueous ultra-thin expansion type steel structure fire-proof anti-corrosive paint and preparation method thereof

InactiveCN101857760AGuaranteed expansion heightHas anti-rustFireproof paintsAnti-corrosive paintsAcrylic resinRust

The invention relates to an aqueous ultra-thin expansion type steel structure fire-proof anti-corrosive paint and a preparation method thereof. The fire-proof anti-corrosive paint is prepared by adding ammonium polyphosphate, pentaerythritol, melamine, titanium white, expandable graphite, a preservative, a ceramic filler, an antifoaming agent, a dispersing agent, a plasticizer and the like into organic silicon-modified acrylic resin emulsion serving as a film forming base material. The paint has the advantages of high fire-proof performance, anti-corrosion and anti-rust function, and high water resistance, acid-alkali resistance and corrosion resistance, capability of meeting the requirements of various steel structures on the fire-proof and anti-corrosion performance, environmental friendliness, low cost, and readily available raw materials, so the paint can be widely applied to fire-proof protection of various steel structures.

Owner:EAST CHINA UNIV OF SCI & TECH

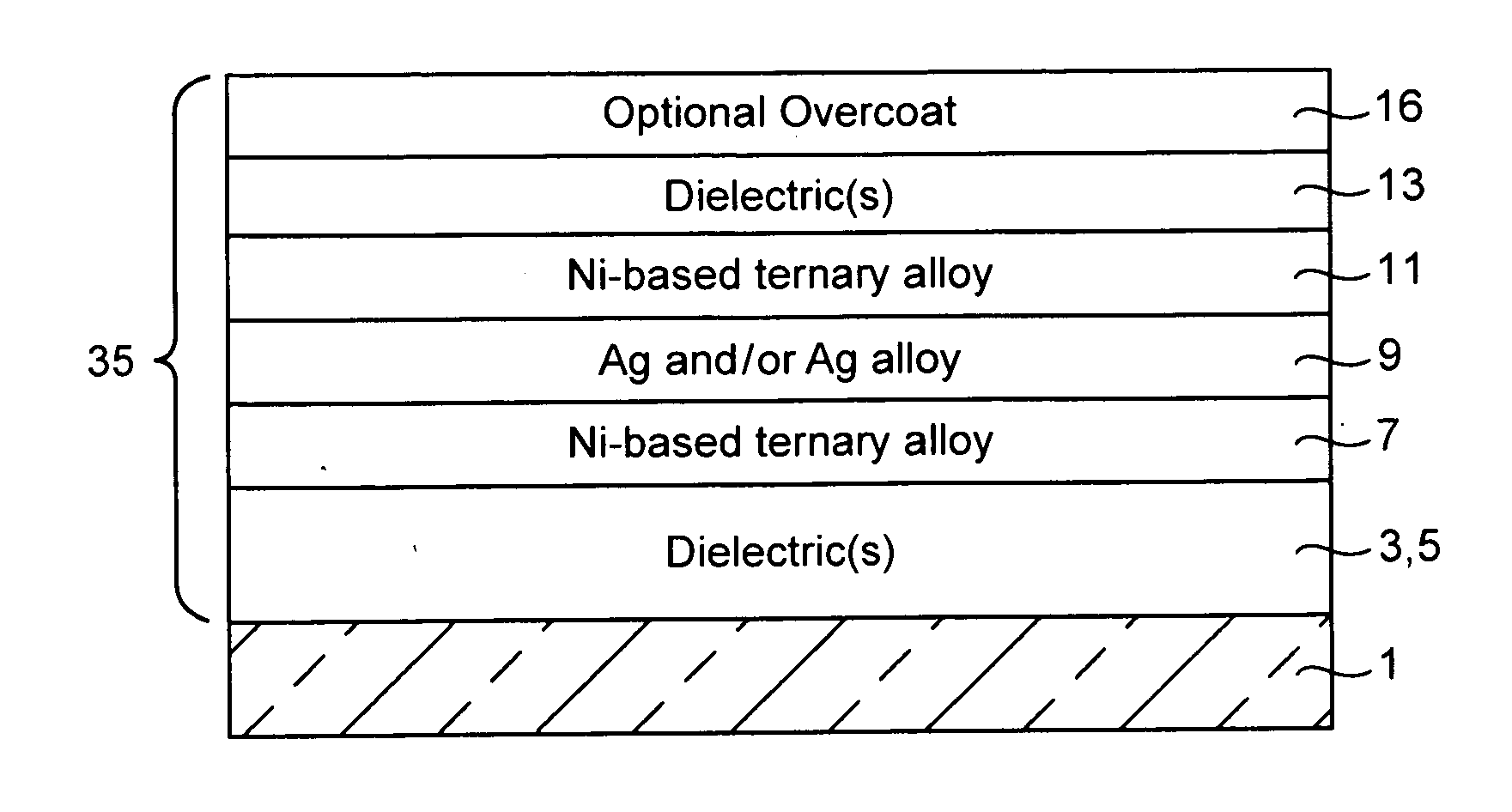

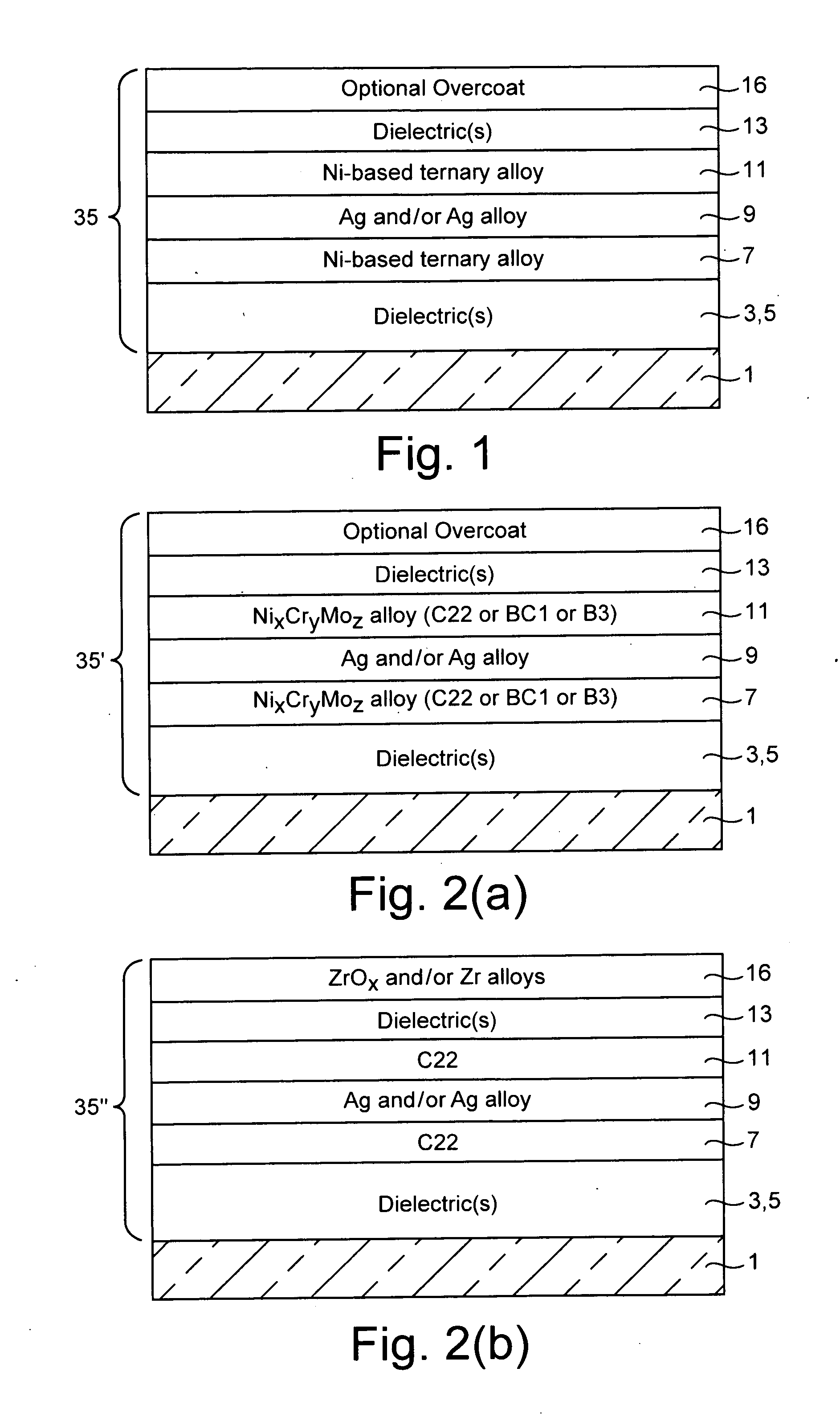

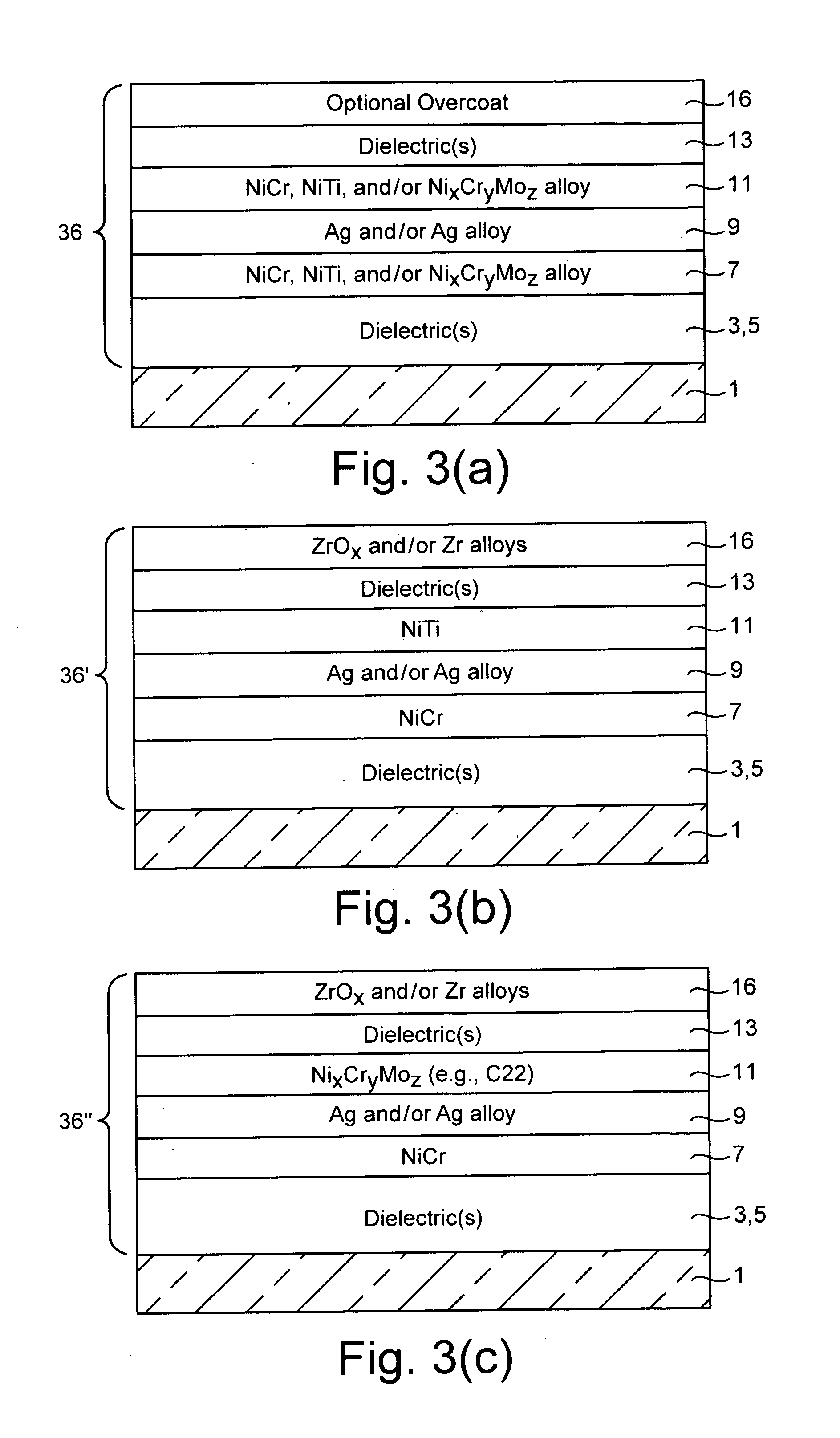

Barrier layers comprising Ni-inclusive ternary alloys, coated articles including barrier layers, and methods of making the same

ActiveUS20120225317A1Reduce sheet resistanceImprove transmittanceVacuum evaporation coatingSputtering coatingMaterials scienceChromium

Certain example embodiments relate to Ni-inclusive ternary alloy being provided as a barrier layer for protecting an IR reflecting layer comprising silver or the like. The provision of a barrier layer comprising nickel, chromium, and / or molybdenum and / or oxides thereof may improve corrosion resistance, as well as chemical and mechanical durability. In certain examples, more than one barrier layer may be used on at least one side of the layer comprising silver. In still further examples, a NixCryMoz-based layer may be used as the functional layer, rather than or in addition to as a barrier layer, in a coating.

Owner:GUARDIAN GLASS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com