Patents

Literature

935 results about "Permeability coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

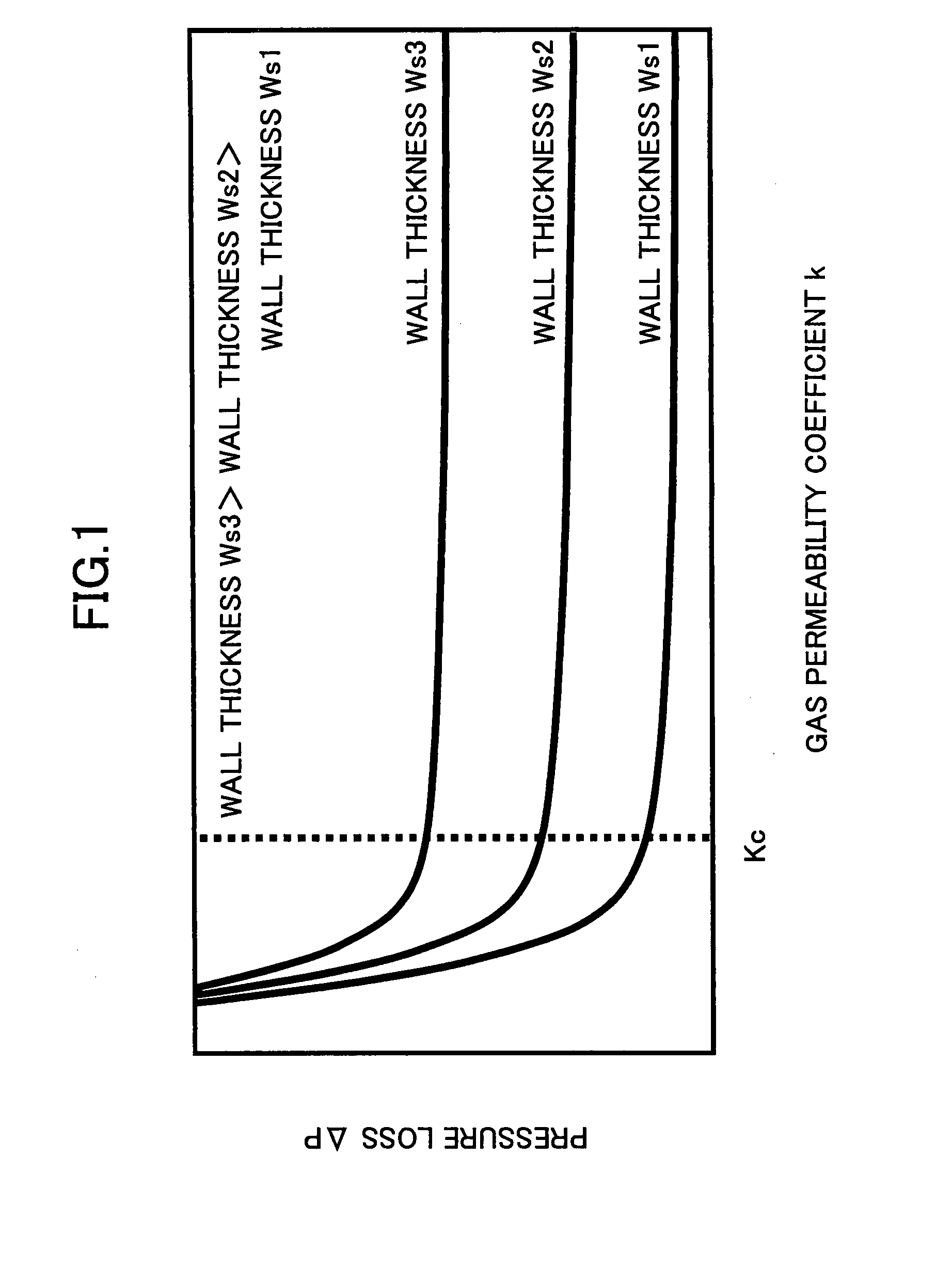

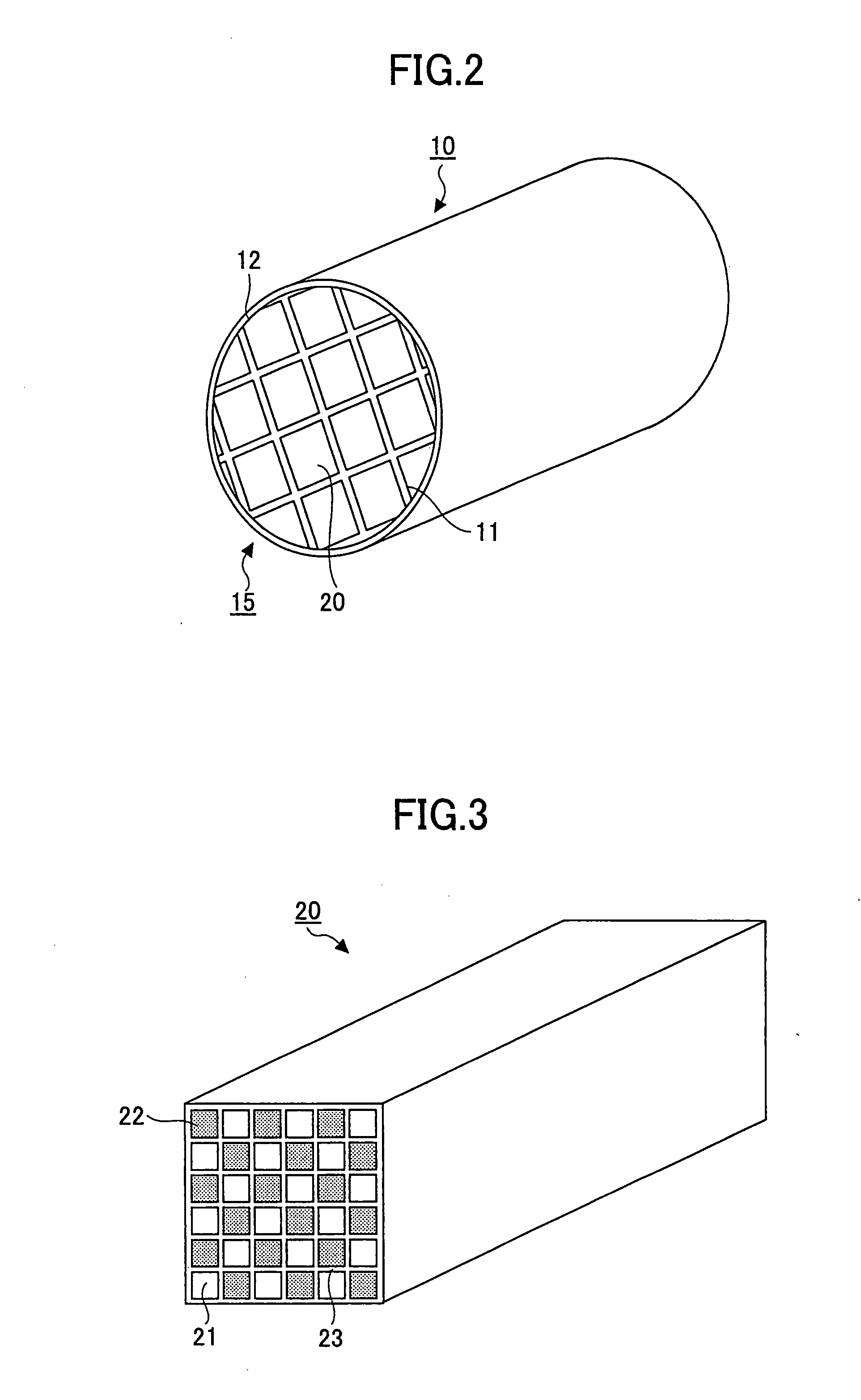

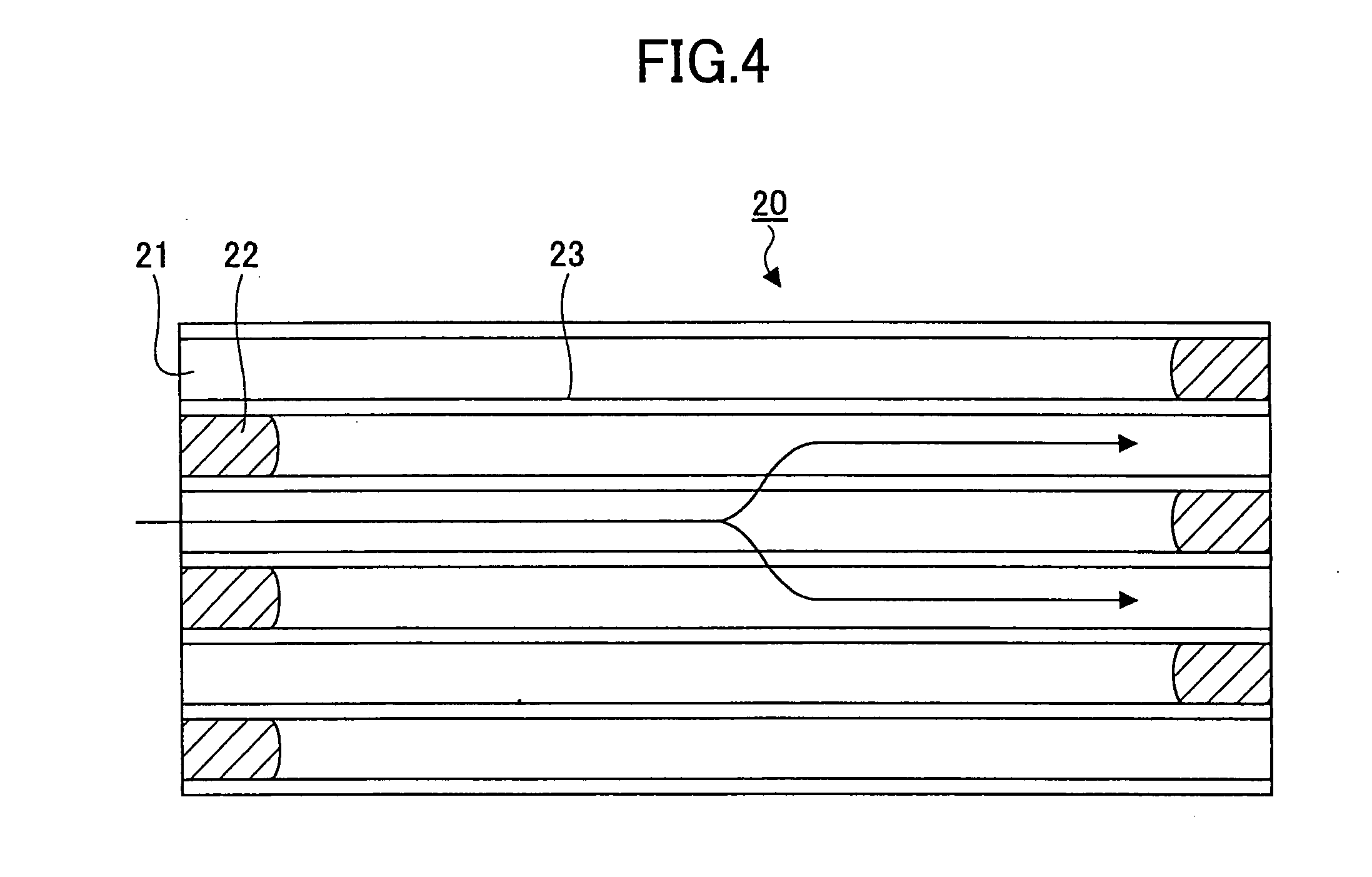

Honeycomb structure and exhaust gas purifying device

ActiveUS20070196620A1Combination devicesInternal combustion piston enginesCell wallPermeability coefficient

Owner:IBIDEN CO LTD

Ceramsite water permeable brick and preparation method thereof

The invention provides a ceramsite water permeable brick, which comprises the following components by weight: 80-100 parts of ceramsite, 10-15 parts of silicon sand, 20-40 parts of cement, a setting accelerator accounting for 2-4% of the weight of the ceramsite, and a water reducing agent accounting for 2-4% of the weight of the ceramsite. According to the invention, silicon sand dust made ceramsite is combined with a small quantity of cement, the setting accelerator, the water reducing agent and a silicon sand fabric to manufacture the ceramsite water permeable brick. One the one hand, the water permeable brick has a beautiful appearance, and on the other hand it combines the lightweight and high strength characteristics of ceramsite. At the same time, ceramsite is round stone rather than polygonal, and usually the gap between round objects is larger than that between polygonal objects, so that the prepared water permeable brick has good permeability effect. The water permeable brick prepared by the method has compressive strength of greater than or equal to 30Mpa and a permeability coefficient of greater than or equal to 0.05cm / s, and the other properties of the brick meet the JCT945-2005 industrial standard.

Owner:RENCHSAND ECO ENVIRONMENT PROTECTION SCI & TECH CO LTD

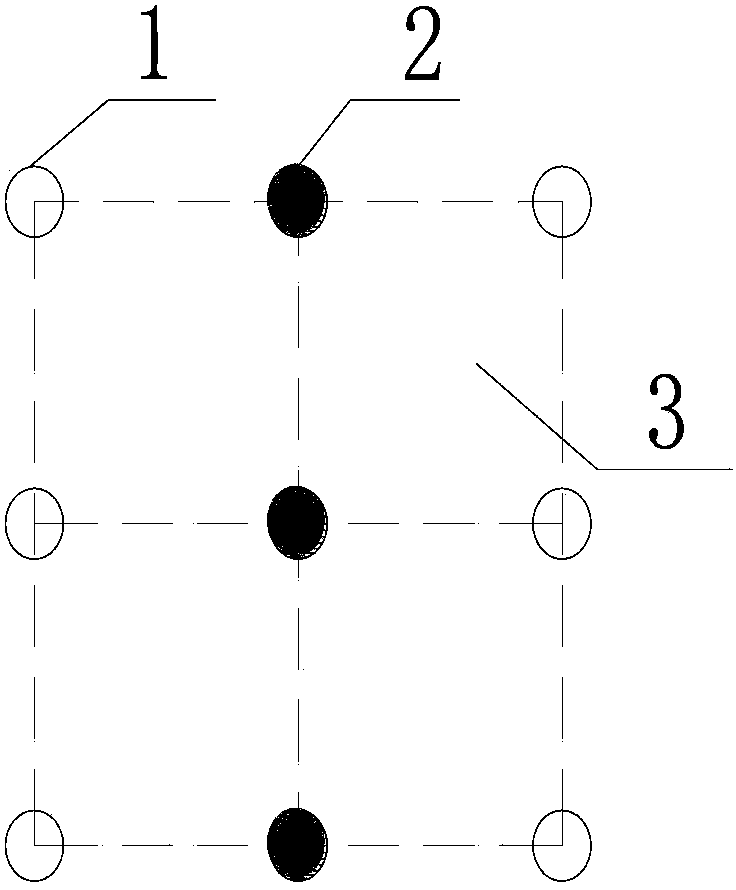

Metal polyporous material with gradient pore structure and preparation thereof

The invention provides a metal porous material with a gradient pore structure, which is formed by at least two porous layers with different pore diameter. The pore diameter of the metal porous material gradually decreases or gradually increases with the thickness direction of the material; a bottom layer of the porous layers is a macropore layer used as a support body; a surface layer of the porous layers is a pore layer used as a filtering precision control layer; the material of the macropore layer is a composite wire gauze, a metal fiber felt or a powder sintered metal porous material; and the material of the pore layer is superfine metal powder or superfine metal fiber. A method for preparing the metal porous material comprises a step of using spraying, dipping or centrifugal coating method to manufacture at least one pore layer on the surface of the support body. Compared with the prior metal porous material in the same grade, the metal porous material with the gradient pore structure has the advantages of obviously raising permeability coefficient, well solving the contradiction between the pore diameter and relative permeability coefficient of the metal porous material and having a simple process.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

High-ductility polymer-rubber powder-honey-combed cement concrete road covering material and construction process thereof

InactiveCN101343162AReduce adverse effectsGood deformabilitySolid waste managementCeramicwarePorosityPolymer modified

Disclosed is a cover material of polymer modification rubber powder porous concrete with high toughness and a making technique thereof. Wherein, in per cubic meter of the concrete, the polymer is 20 to 75 kg, the cement is 200 to 400 kg, and the water to cement ratio is between 0.25 to 0.40 ; in aggregates, the amount of a fine aggregate is less than or equal to 20 percent, and the amount of a coarse aggregate is more than or equal to 80 percent; 0 to 5 kg of plasticizer and / or defoamer are / is added; rubber powder, whose volume fraction is not more than 50 percent, is used to replace the natural aggregate ; or the cement is replaced by mineral admixtures which are not more than 40 percent. The cover material is made by a small machine, a three-roller and an asphalt paver. The main technical parameters of the cover material are as follows: compressive strength is more than or equal to 15 MPa, flexural strength is more than or equal to 5 MPa, anti-skid structure depth is more than or equal to 2.0 mm, porosity is 18 to 22 percent, permeability coefficient is more than or equal to 1.5 mm / s, sound absorption coefficient is more than or equal to 0.30, and noise reduction effect is more than or equal to 5 dB. The cover material can comprehensively utilize the discarded rubber with the advantages of high toughness, sliding resistance and sound absorption and noise reduction. Thus, the cover material is applicable to the covers of the highway, the municipal road and the flat.

Owner:WUHAN UNIV OF TECH

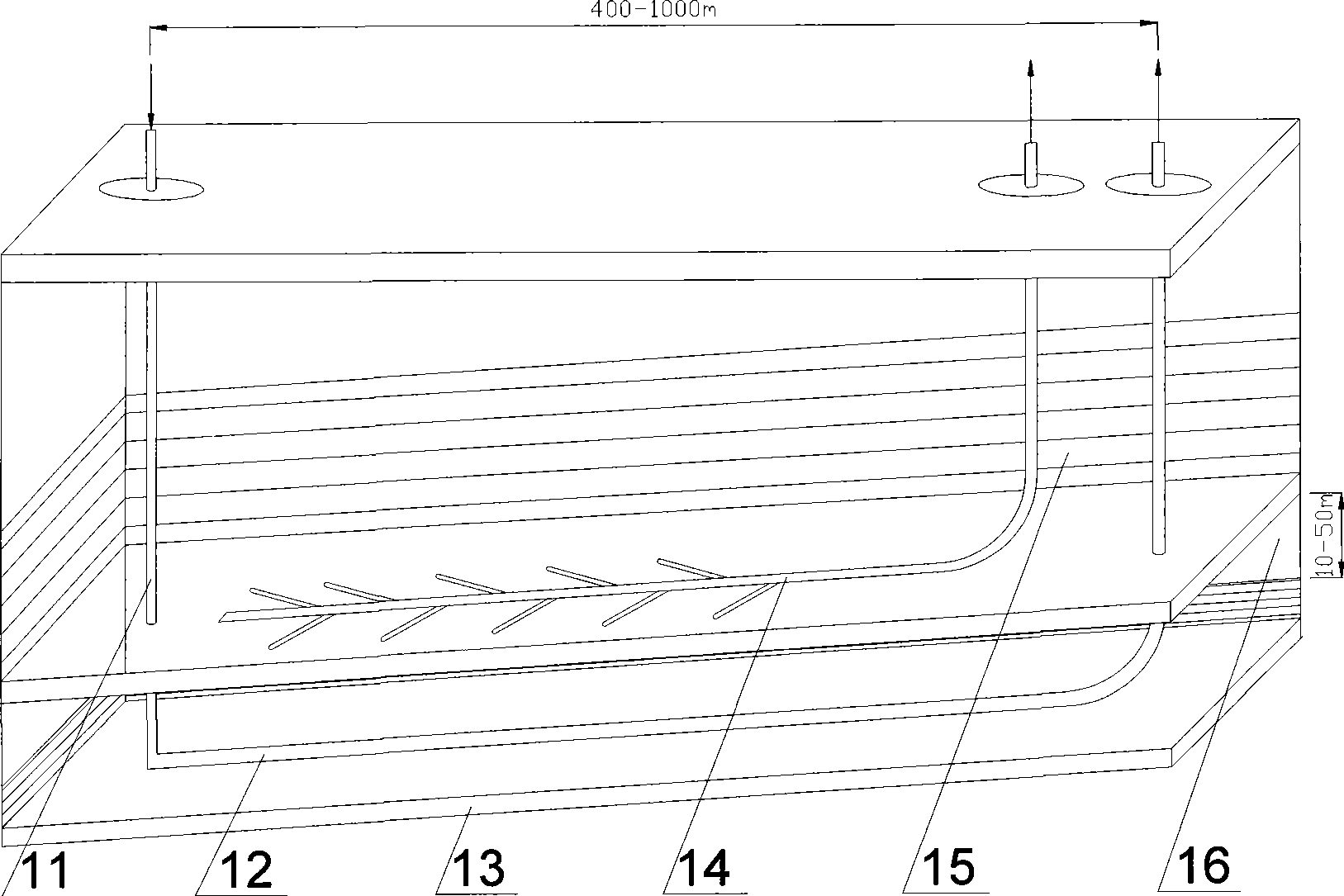

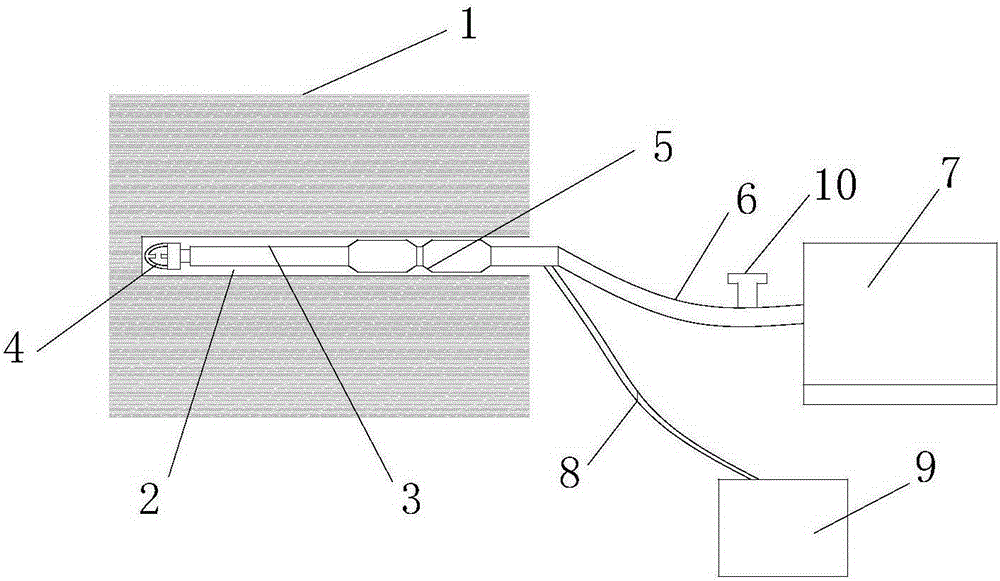

Pressure alternate gas exhausting method by slotting and fracturing coal seams

ActiveCN103362538AExpand the scope of influenceIncrease profitFluid removalGas removalSocial benefitsHigh pressure water

A pressure alternate gas exhausting method by slotting and fracturing coal seams is applicable to the gas control of complex coal seams in a high-gas-content high-ground-stress area, aims to improve the air permeability of coal bodies and the capacity of drilling gas exhausting, and realizes continuous and efficient drilling gas exhausting of the complex coal seams. According to the pressure alternate gas exhausting method, drill holes to-be-slotted and drill holes to-be-fractured are formed by drilling coal seams to a coal floor; pressure-relief annular slots are formed in the bottom area of a coal seam section by virtue of the rotation of high pressure water jets in the drill holes; ground stress around the drill holes is manually discharged, and internal energy of coal seam gas is released; drilling pressure alternate gas exhausting is performed through designed drilling gas exhausting pipes which can shift the functions of gas exhausting and water injection fracturing; the water injection fracturing of the slotted drill holes and the gas exhausting of the fractured drill holes are performed simultaneously (or the water injection fracturing of the fractured drill holes and the gas exhausting of the slotted drill holes are performed simultaneously). Through alternate and repeated operations, the capacity of continuous and efficient drilling gas exhausting is increased; the effective influence range of drilling gas exhausting is increased by 2-4 times; the air permeability coefficient of coal bodies around the drill holes is increased by 200-500 times; the quantity of exhausted gas of drill holes with lengths of 100 m is increased by 2-5 times, so that the pressure alternate gas exhausting method has higher field application value and social benefits.

Owner:CHINA UNIV OF MINING & TECH

Novel coalbed gas thermal recovery process

The invention relates to a new coalbed gas thermal production process which is characterized in that full hot coke is arranged on the lower part of a coalbed gas production well or a gasification well, a gasification agent is pressed in so as to ignite a hole bottom coalbed; and the heat released from the combustion of part of the coalbed can heat up the adjacent coalbed, and improve the analysis capability, permeability coefficient and osmotic pressure of the coalbed, thereby improving the gas yield of the coalbed.

Owner:ENN SCI & TECH DEV

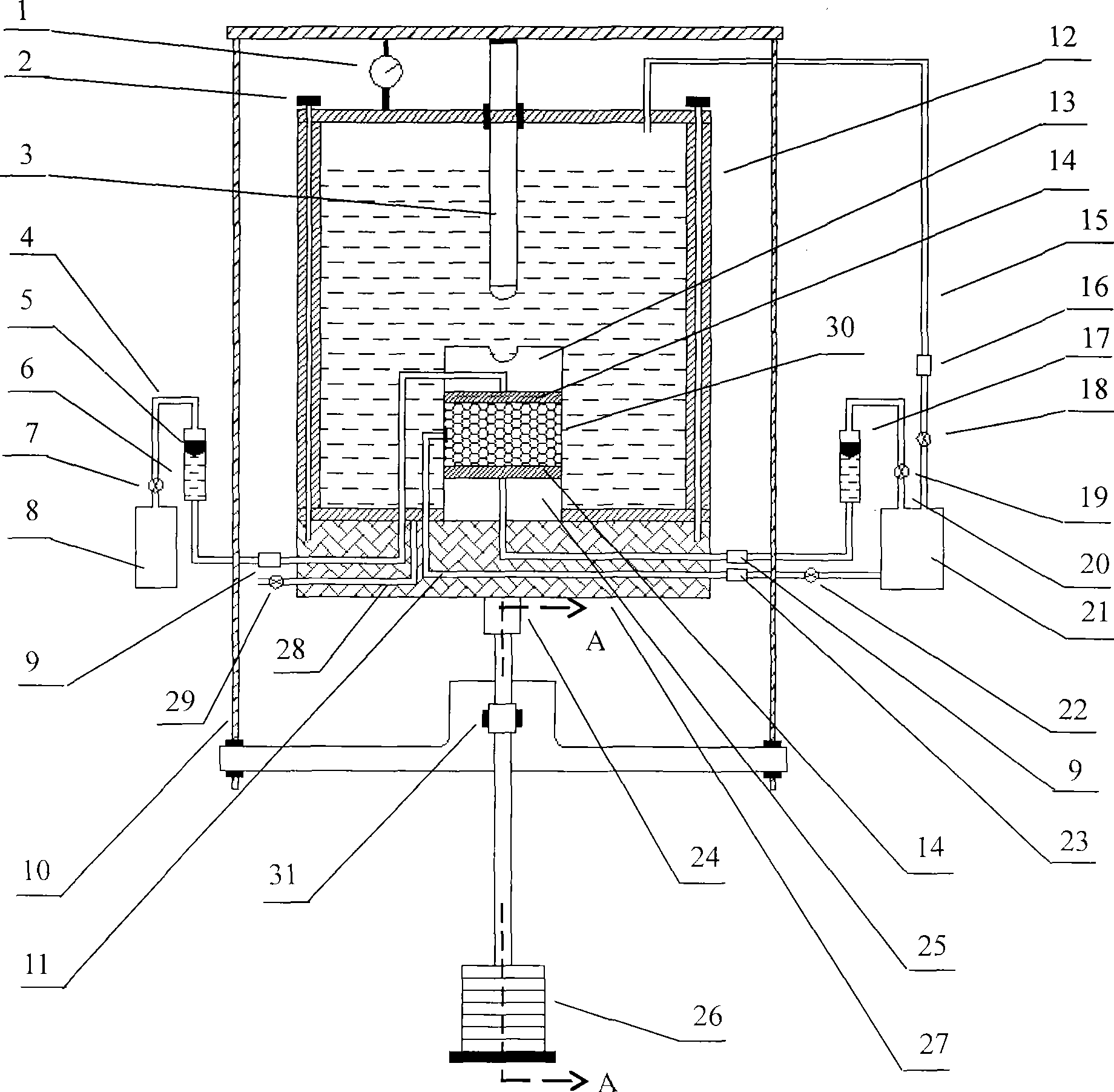

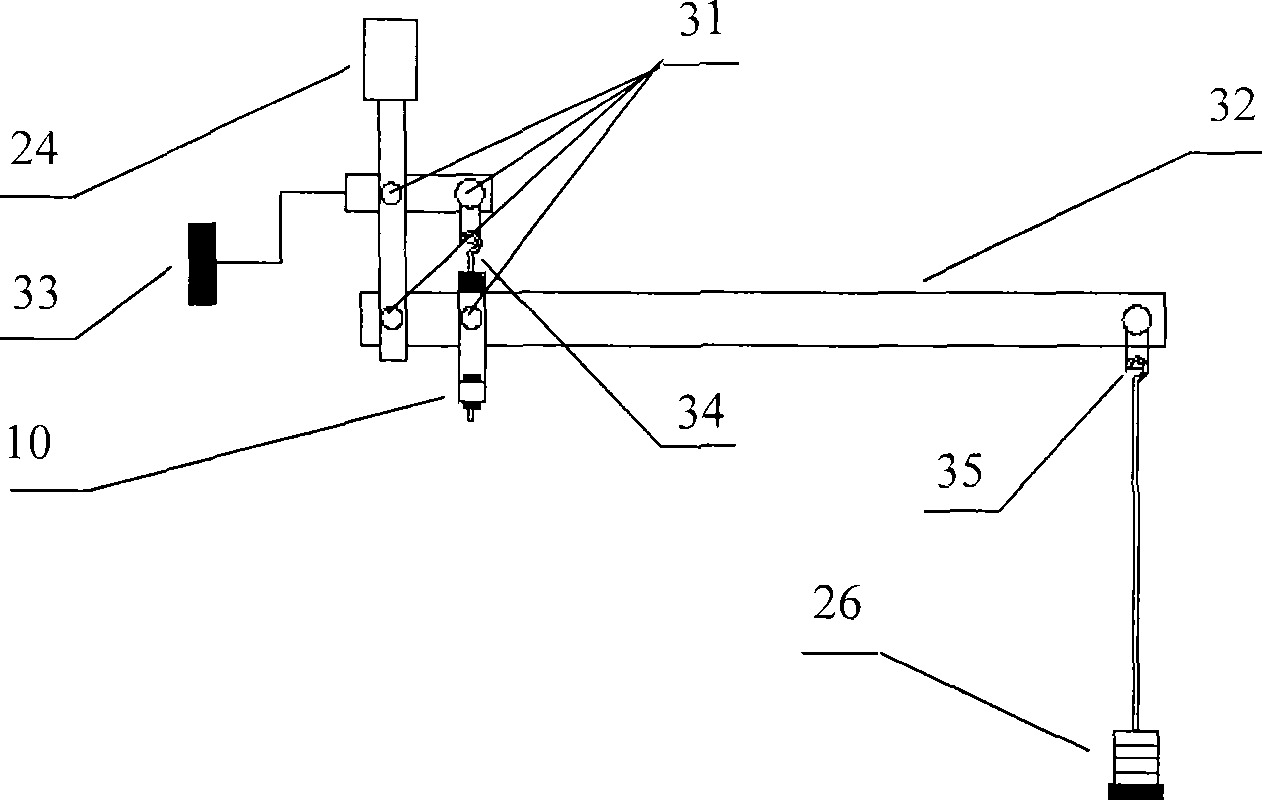

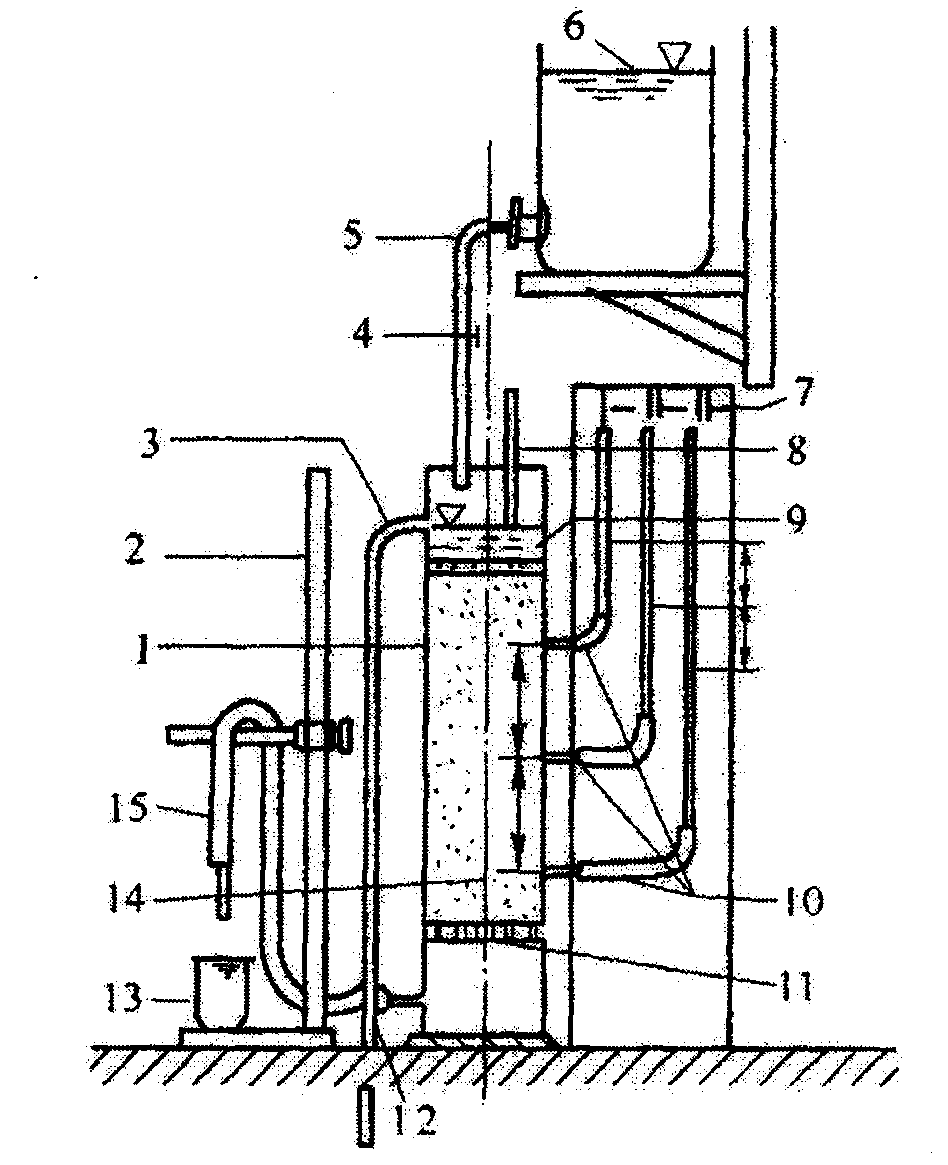

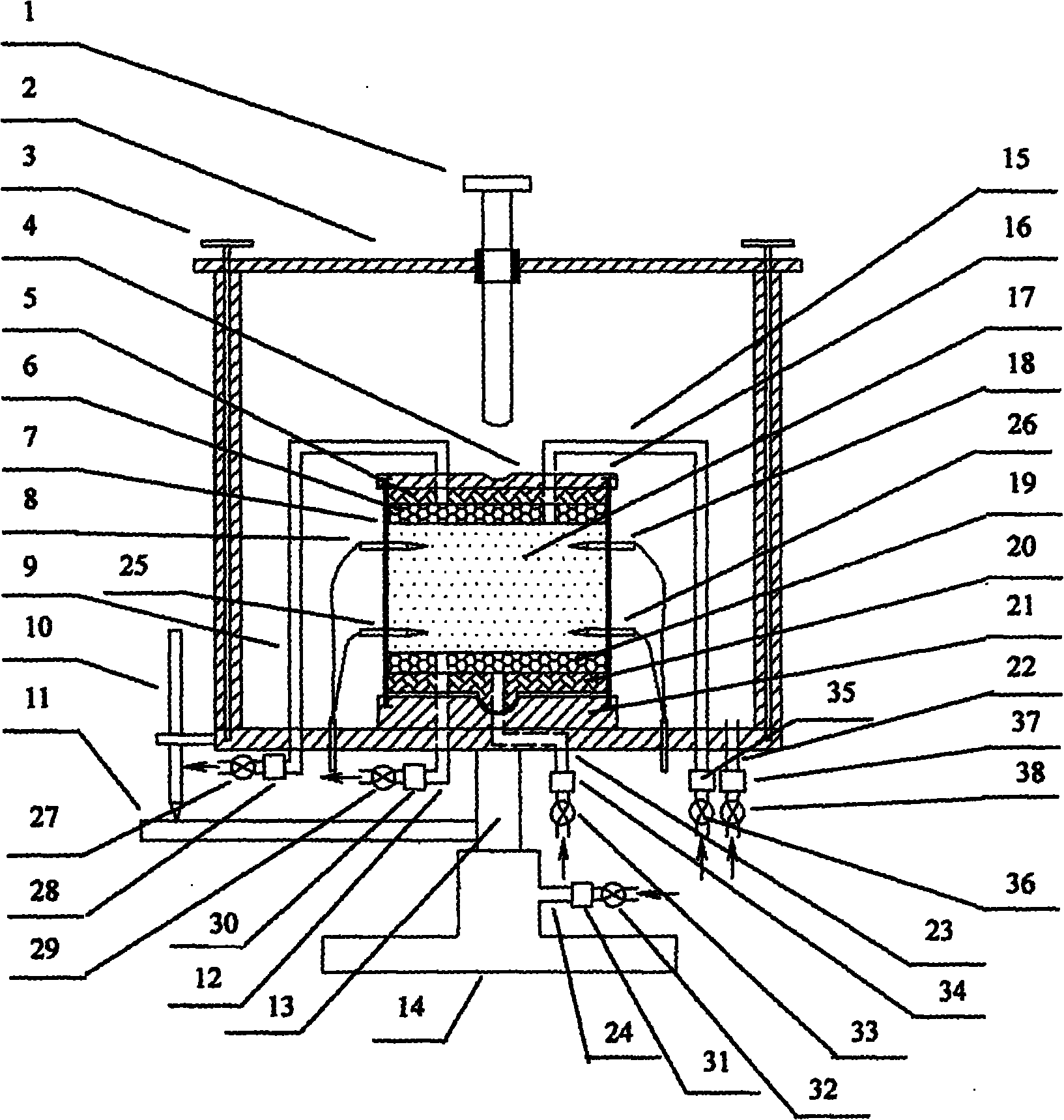

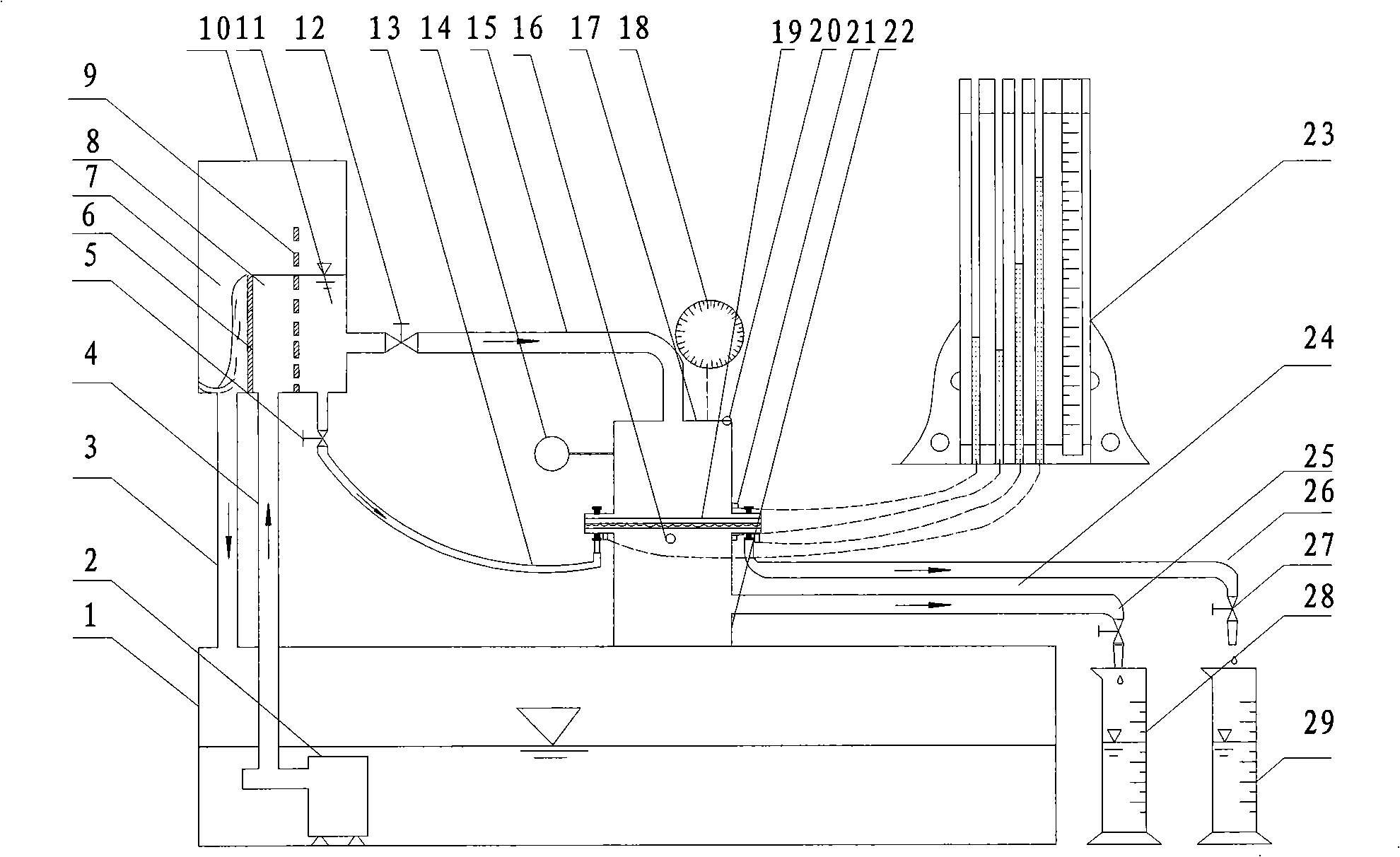

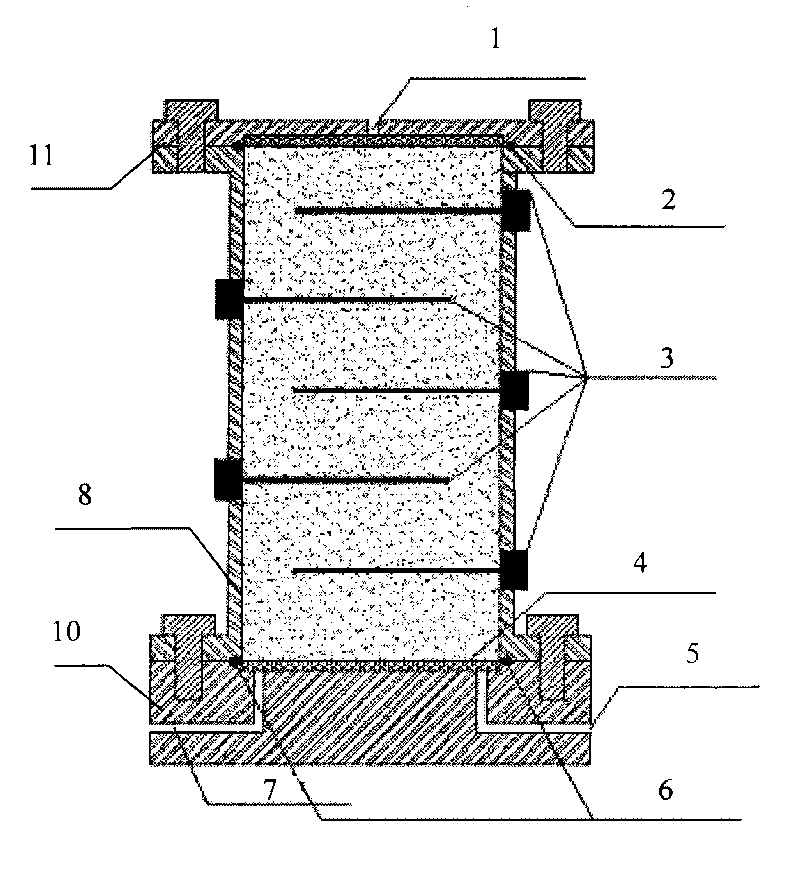

Nonsaturated soil hydraulic parameter measuring device and measuring method

InactiveCN101509865AEasy to manufactureHigh measurement accuracyPermeability/surface area analysisRubber membraneWater volume

The invention relates to an unsaturated soil hydraulic parameter measuring device and a measuring method. The device consists of a pressure chamber 12, a pneumatic pump 21, a vacuum pump 8, a loading frame 10, an appliance base 27, hydraulic pressure pipelines 4 and 20, and pneumatic pipelines 11 and 15. The pneumatic pipelines of the pressure chamber 12 are connected with a pneumatic sensor 16, a pneumatic control valve 18 and the pneumatic pump 21; a water filling pipeline 28 of the appliance base 27 is connected with a control valve 29; the hydraulic pressure pipeline 20 in the center of the sample base is connected with a lower clay plate 14, a hydraulic sensor 9, a water volume measuring pipe 17, a hydraulic pressure control valve 19 and the pneumatic pump 21; a hydraulic pipeline 4 in the center of a top hat is connected with the an upper clay plate 14, the hydraulic sensor 9, a water volume measuring pipe 6, a hydraulic pressure control valve 7 and the vacuum pump 8; a sample 30, a top cap 13, a clay plate 14, a sample 30 and a sample base 25 are arranged between two clay plates 14 and are wrapped by rubber membranes; the sample 30, a pneumatic sensor 23, a pneumatic control valve 22 and the pneumatic pump 21 are connected with the pneumatic pipeline 11 which passes through the rubber membrane from the middle of the sample 30; and the pressure of a weight 26 is added to the sample by the loading frame 10 and a pressurizing shaft 3. The device can be used for measuring soil and water retention curve and unsaturated permeability coefficient of various soils under the condition of three-directional loading.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

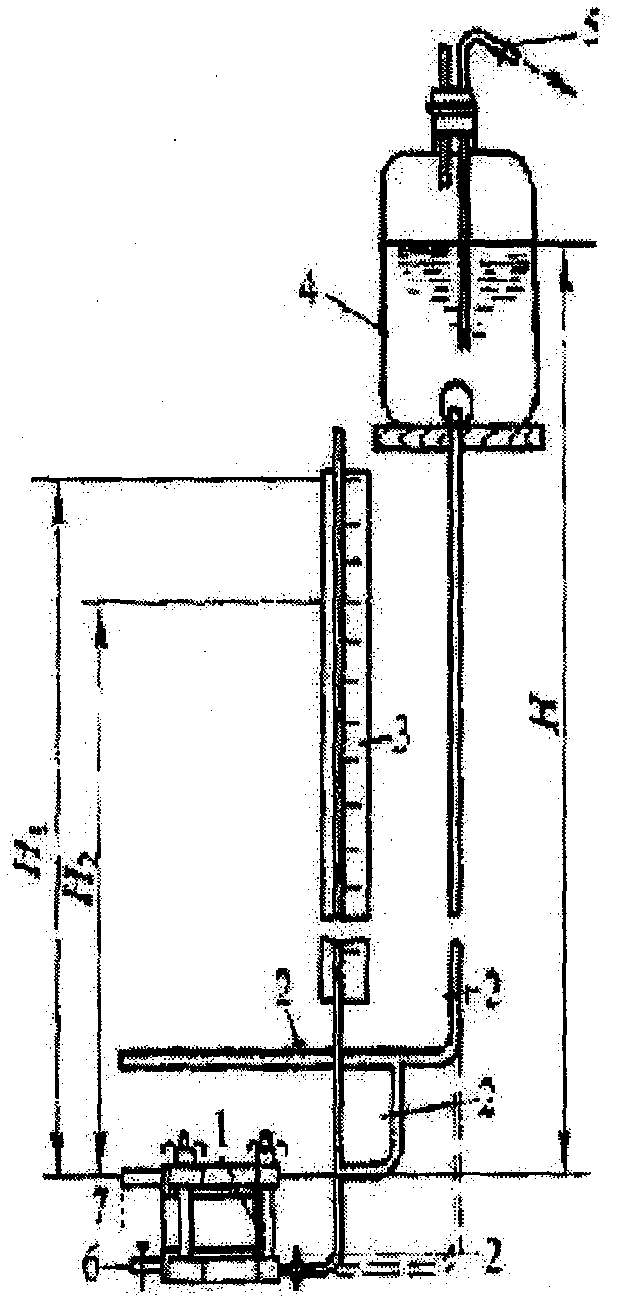

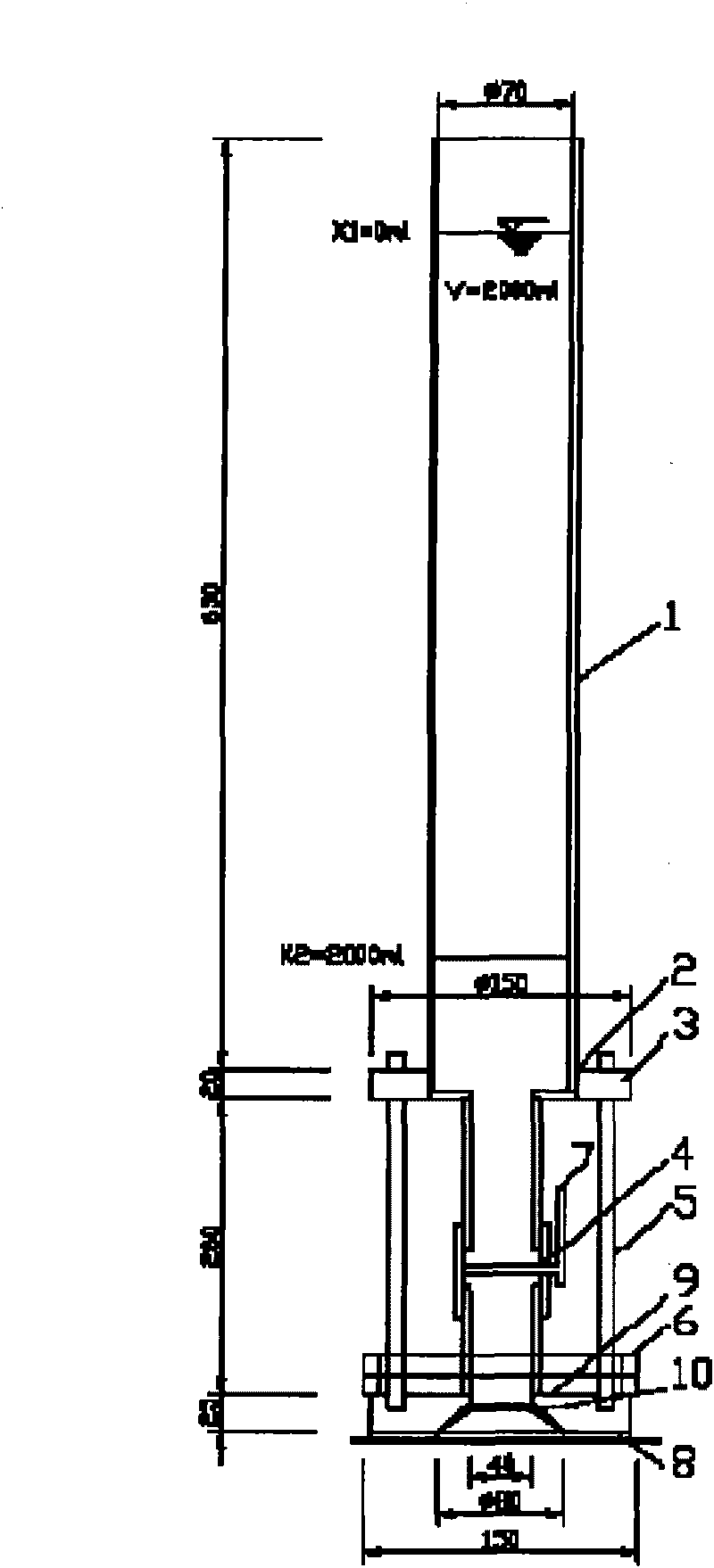

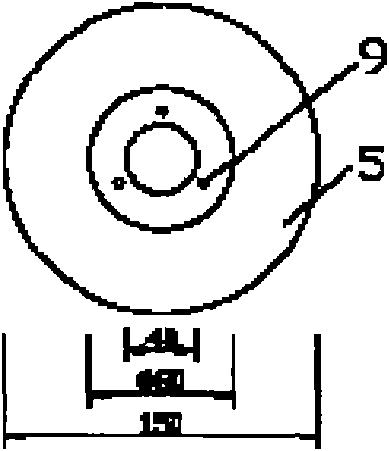

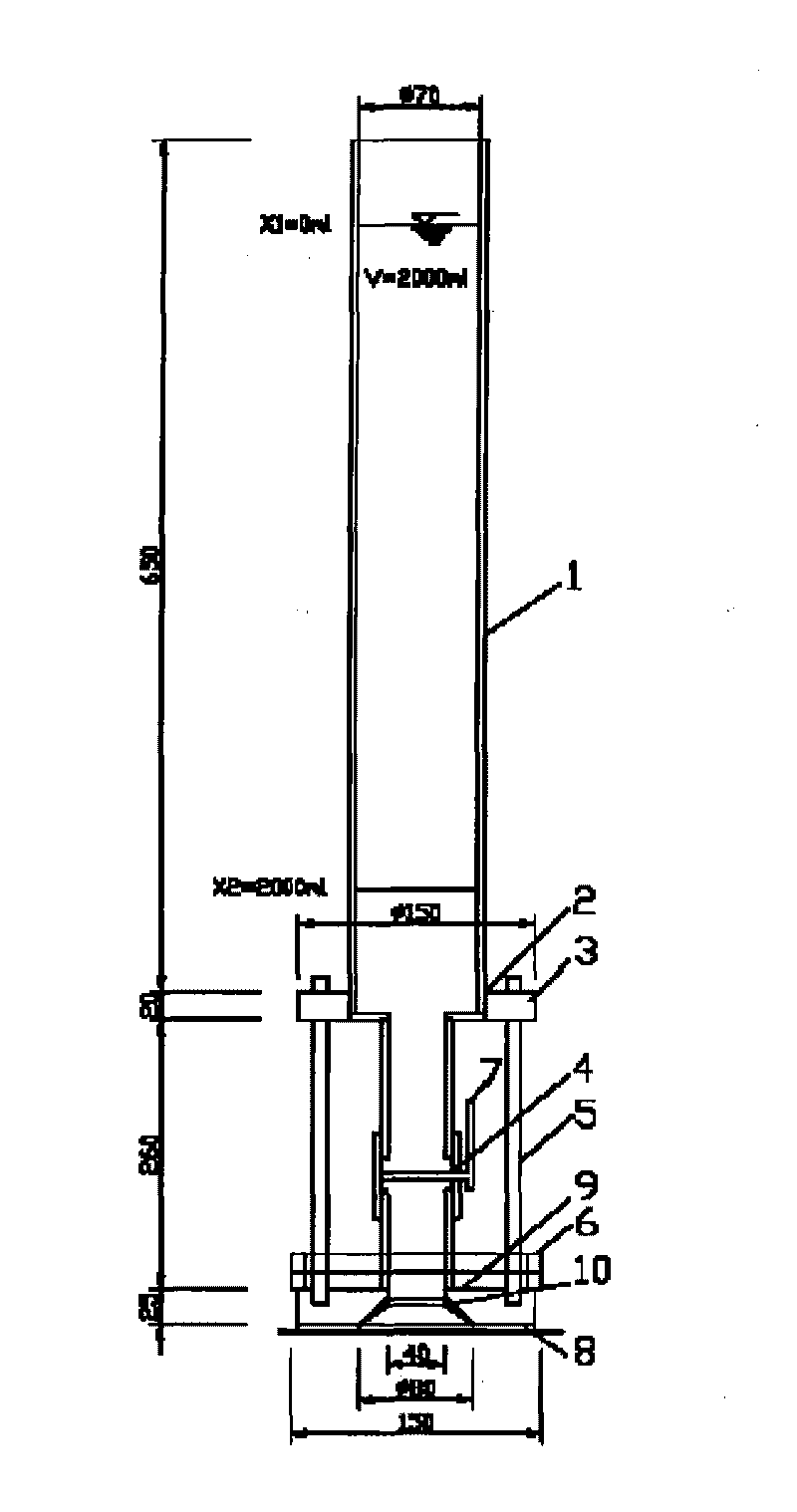

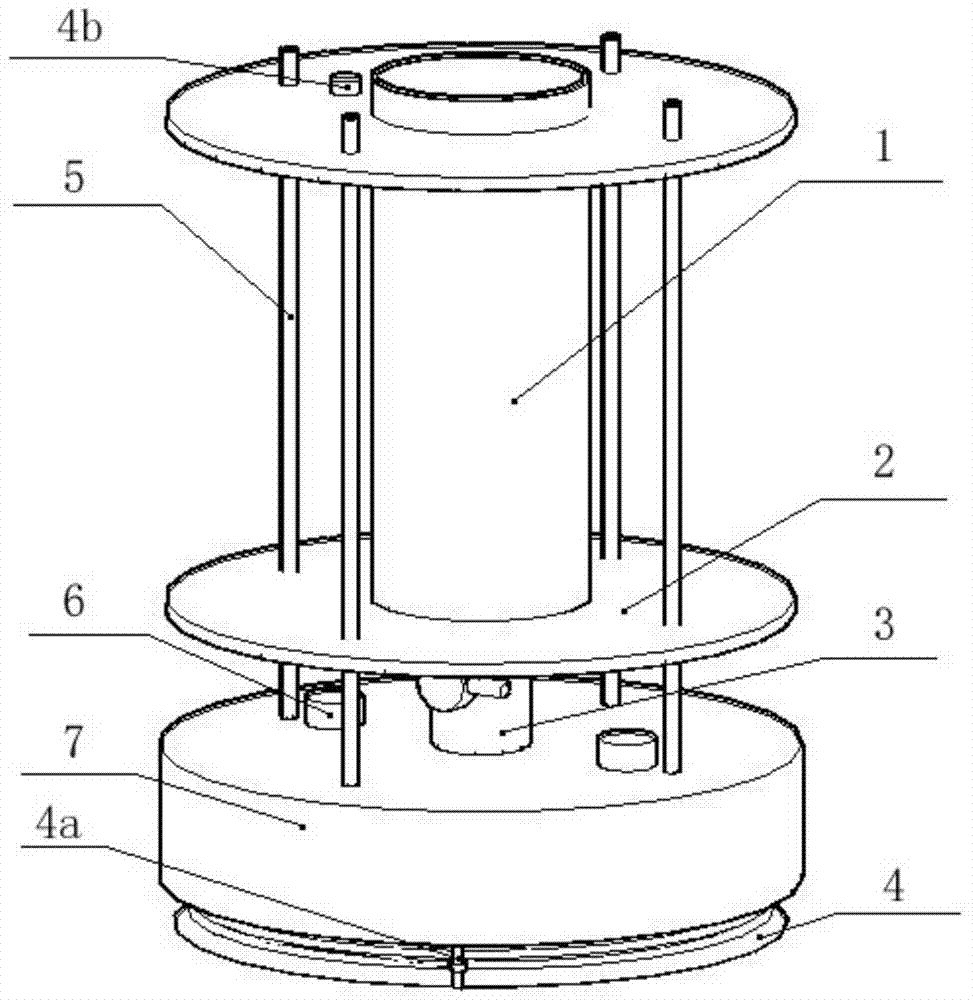

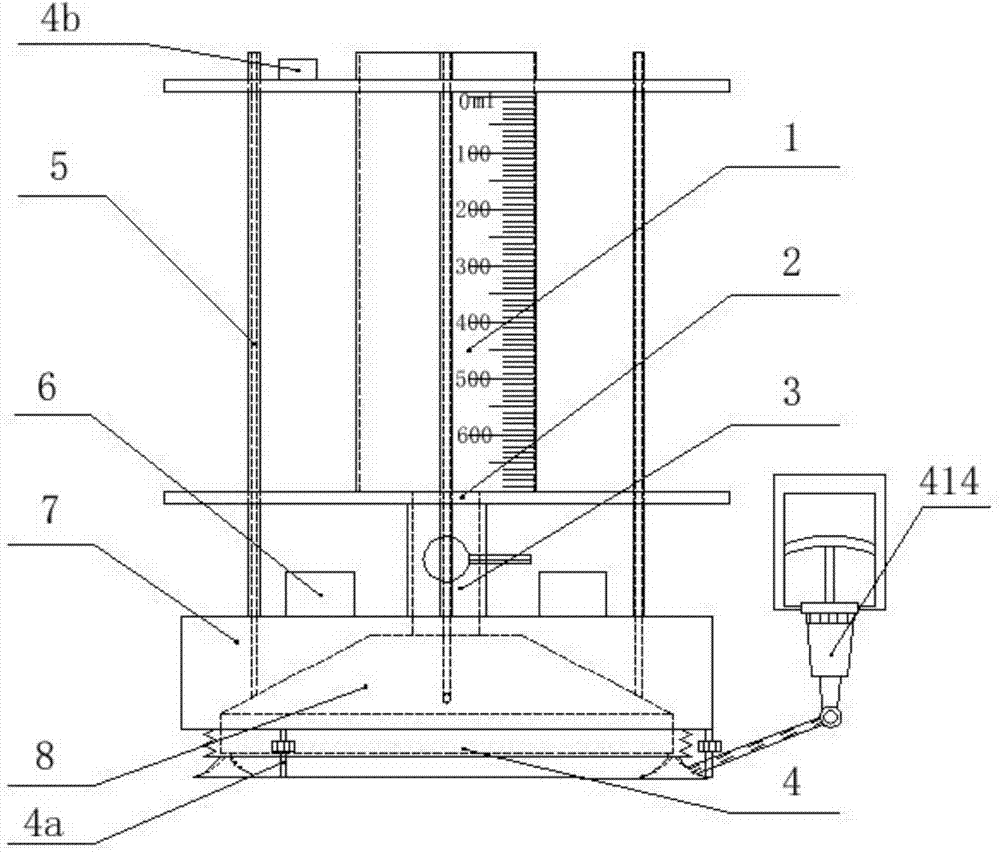

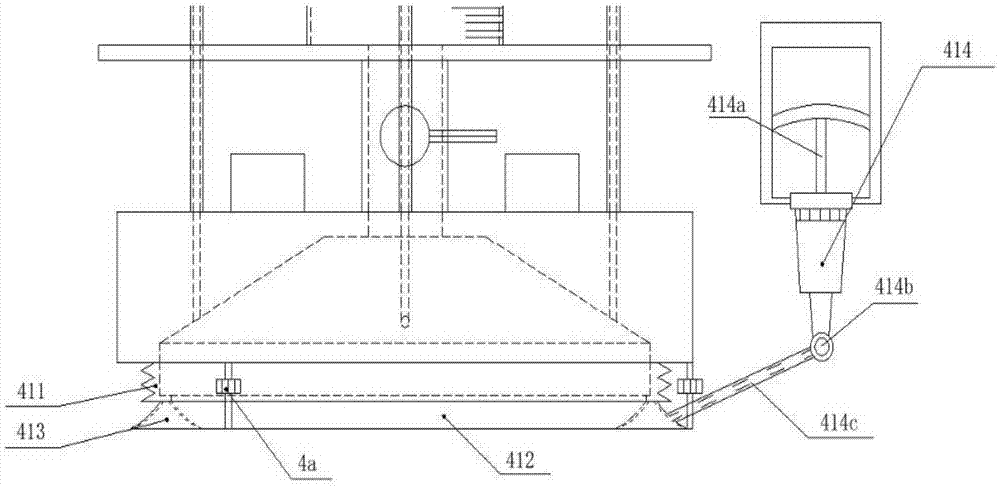

Device for accurately and rapidly determining permeability coefficient of soil

ActiveCN105588796AFast and fully saturatedNovel structurePermeability/surface area analysisSoil sciencePermeability coefficient

The invention discloses a device for accurately and rapidly determining the permeability coefficient of soil, and belongs to technical field of rock and soil analysis equipment. The device comprises a device rack and further comprises a water supply device, a rapid saturation device, a soil sample column, a support and a permeation flow testing device. The soil sample column is fixedly arranged on the support, the water supply device and the rapid saturation device are fixedly arranged above the soil sample column and connected with a cover plate at the upper end of the soil sample column, and the permeation flow testing device is arranged on one side of the support and connected with the lower end of the soil sample column through a testing water guide pipe. The device well solves the problems that soil saturation is not sufficient, and permeation flow reading errors are caused, the testing accuracy of the device is improved, flexible control over the hydraulic gradient is achieved, and the device is convenient to operate, high in precision, low in input cost and wide in application range.

Owner:YANGZHOU UNIV

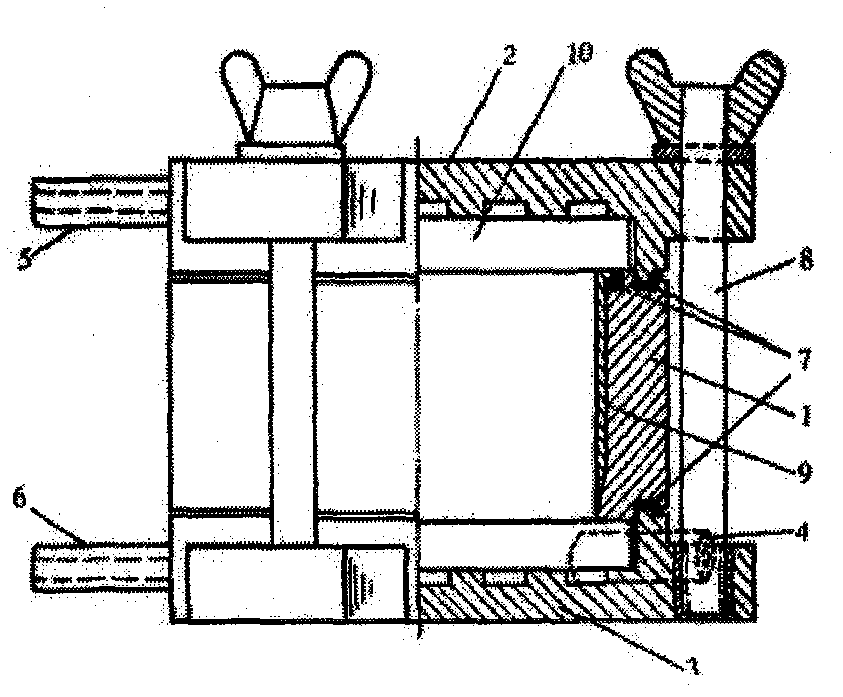

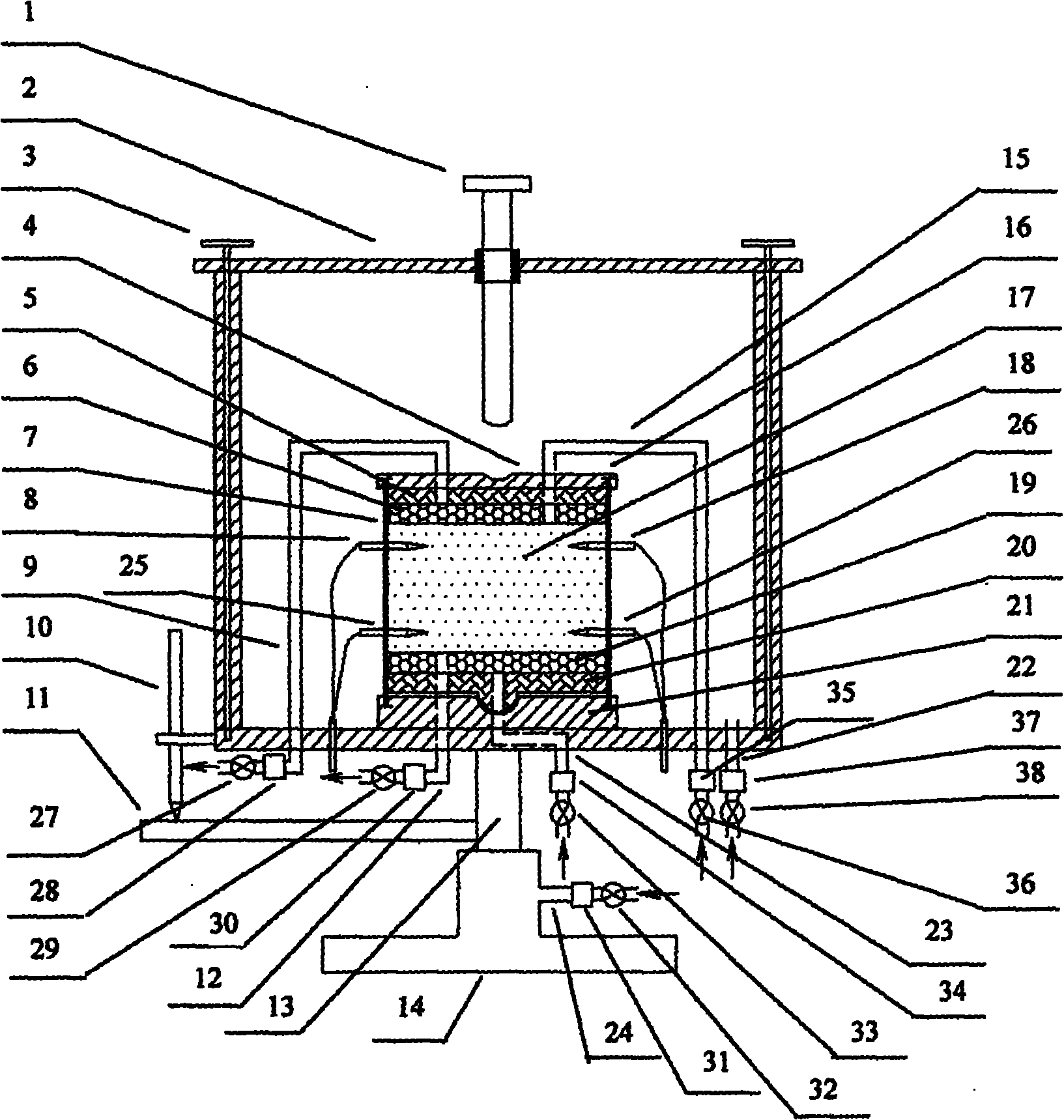

Design manufacturing and application of triaxial penetration tester

InactiveCN102323196ACompact structureReasonable designPermeability/surface area analysisSoil mechanicsEngineering

Design manufacturing and application of a triaxial penetration tester of the invention breaks through the limitation of permeability coefficient testing in Standard for soil test method GB / T50123-1999 and Specification of soil test SL237-014-1999. According to the invention, the tester is designed based on a varying-head principle; with water head with a height of up to 47 m provided by an air compressor, a constant head can be used to process the test results. Coarse grained soil and fine grained soil can be calculated both by a constant head and by a varying head, and the results are of the same order of magnitude and are quite close to each other. The tester of the invention comprises an air compressor, a penetration tester frame, a triaxial penetration pressure chamber, a liquid level sensor, a test data collector and a receiver, a data processing software, and a computer. Data are read on-line, are stored automatically, and samples of 10-9 cm / s or lower can be tested. The tester of the invention can test permeability coefficients of undisturbed soil, disturbed soil, and additive mixtures of soil and cement. The sample preparation method is simple and practical; the test is rapid and convenient, and covers the application fields which require permeability coefficient testing in soil mechanics or materials science.

Owner:申坤 +2

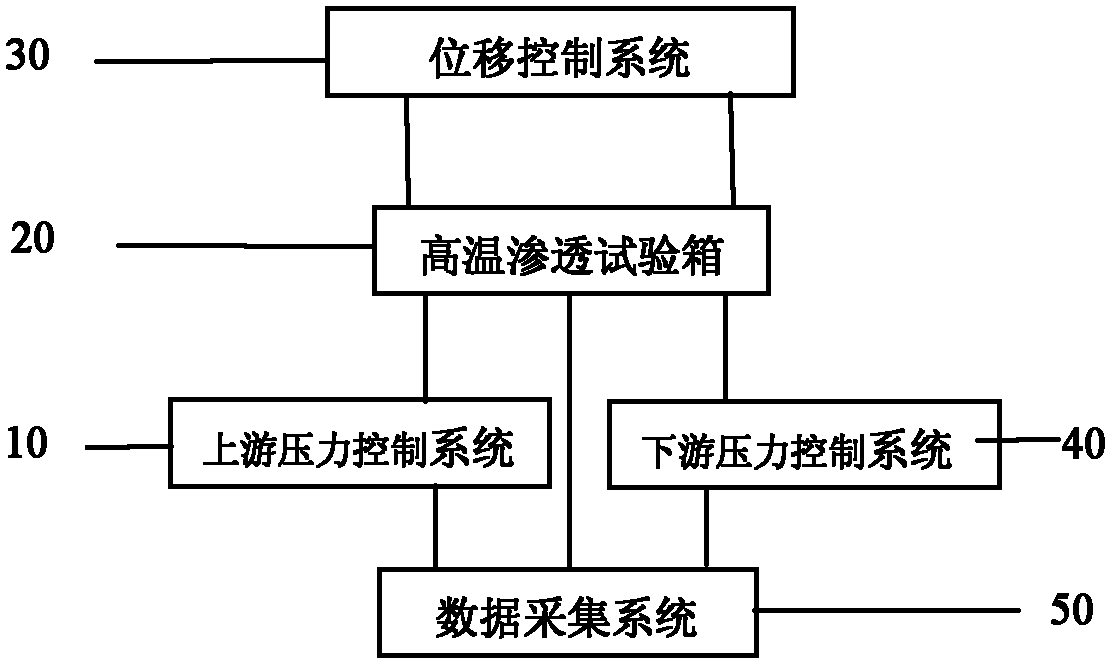

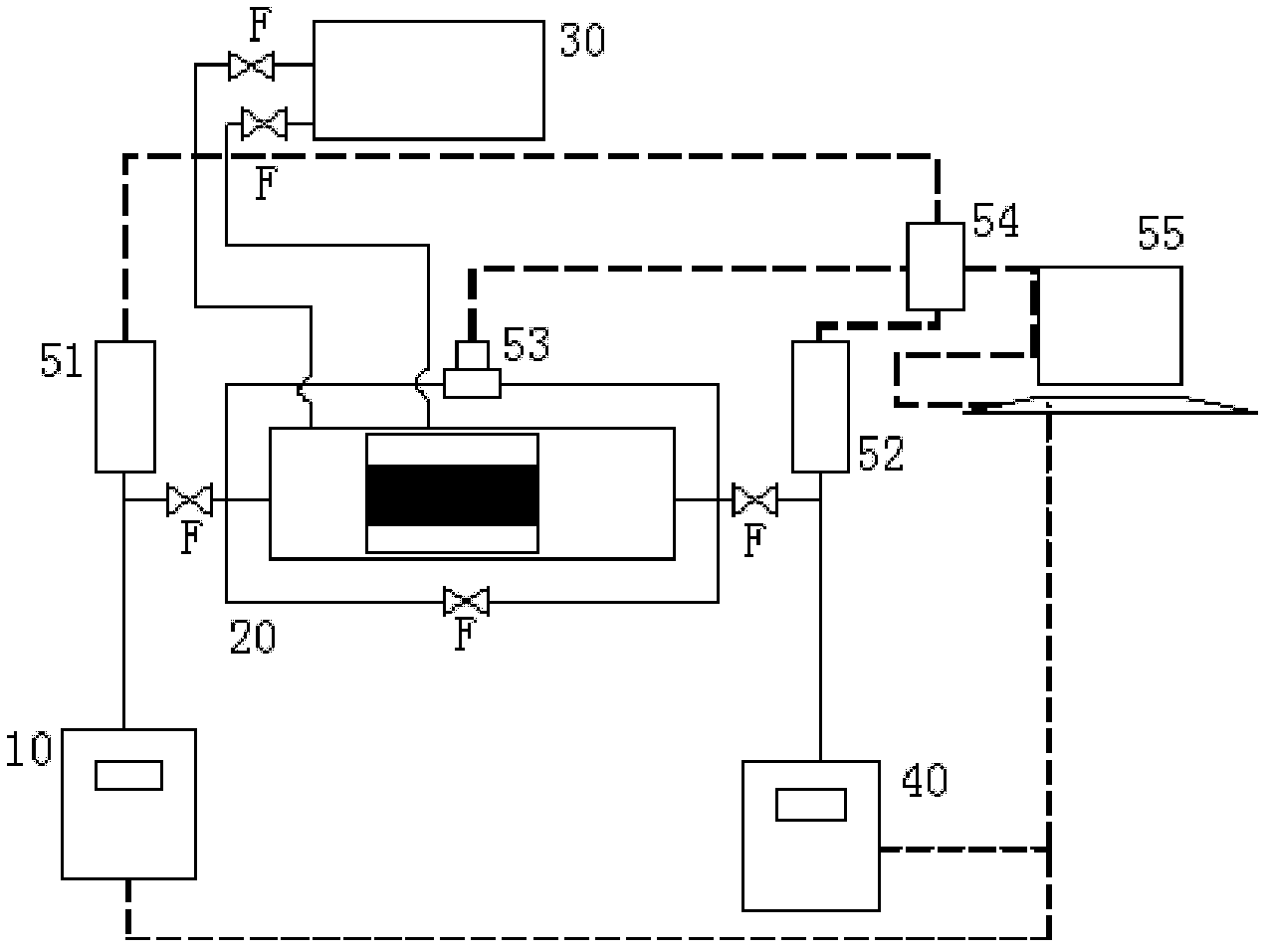

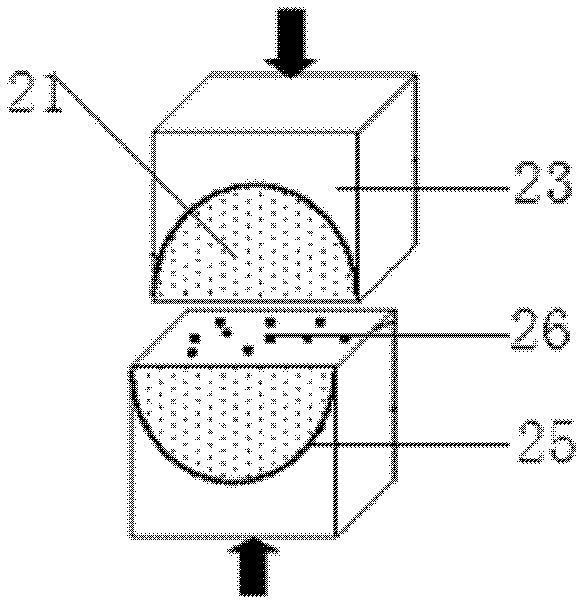

High-temperature fractured rock mass permeation test device and method

InactiveCN102252951ARealize simulationImprove the simulation effectPermeability/surface area analysisControl systemData acquisition

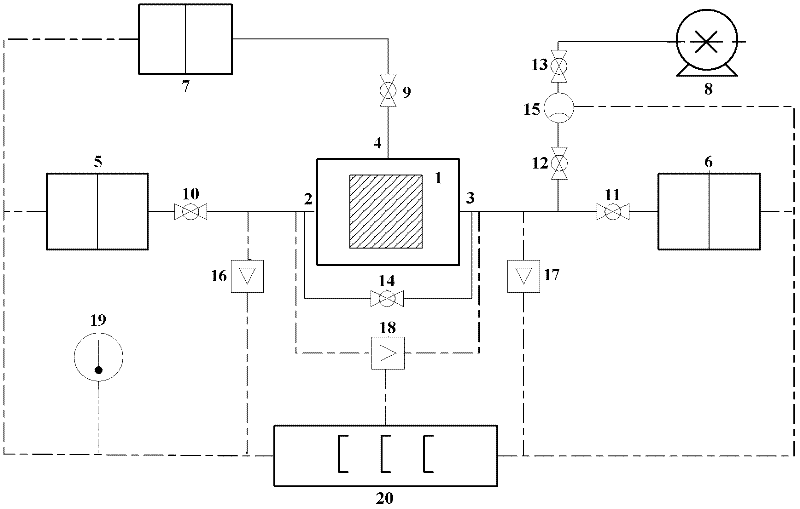

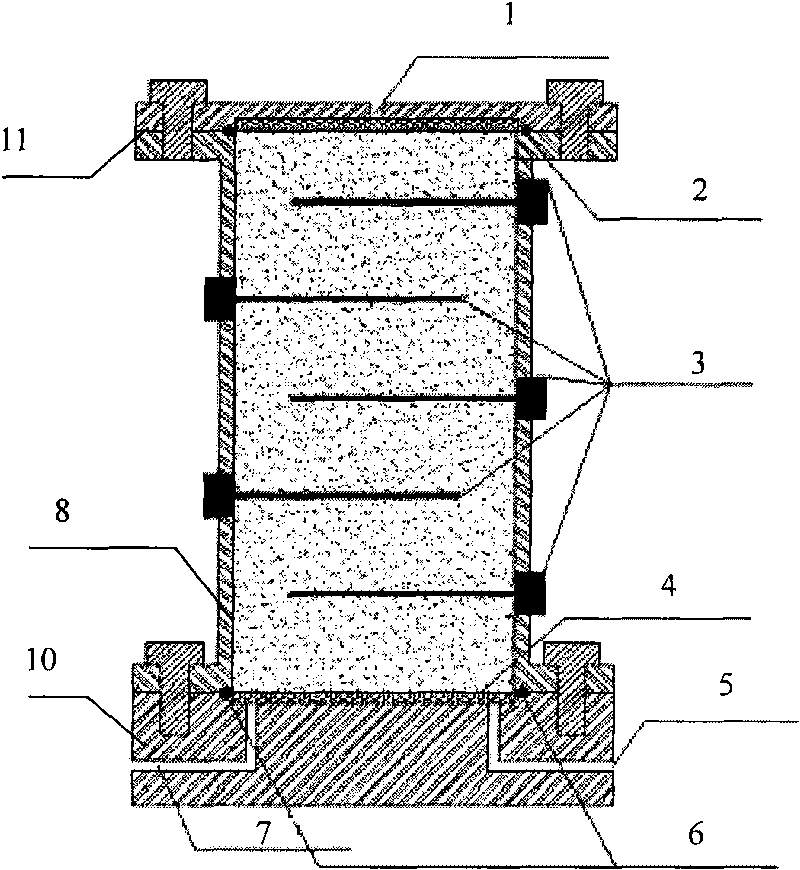

The invention discloses a high-temperature fractured rock mass permeation test device and a high-temperature fractured rock mass permeation test method and relates to a rock mass mechanical test technology. In the device, a displacement control system (30), an upstream pressure control system (10) and a downstream pressure control system (40) are connected with a high-temperature permeation test tank (20) respectively so as to realize control over the high-temperature permeation test tank (20); and the upstream pressure control system (10), the downstream pressure control system (40) and the high-temperature permeation test tank (20) are connected with a data acquisition system (50) respectively to realize date acquisition. The device and the method are suitable for tests of water and airpermeation of various fractured rock masses, and the permeability coefficient of the rock masses can be measured; and the measurement of permeability coefficients of fractures in the fields of hot dry rock geothermal exploitation, deep shale gas exploitation and artificial induction fracture application and the like can be simulated and realized.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

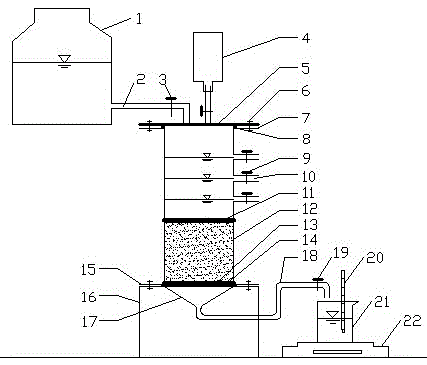

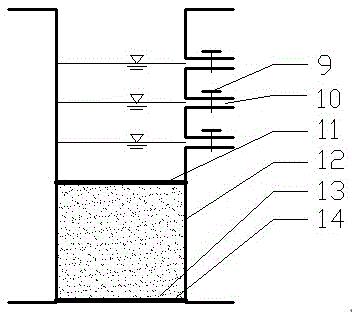

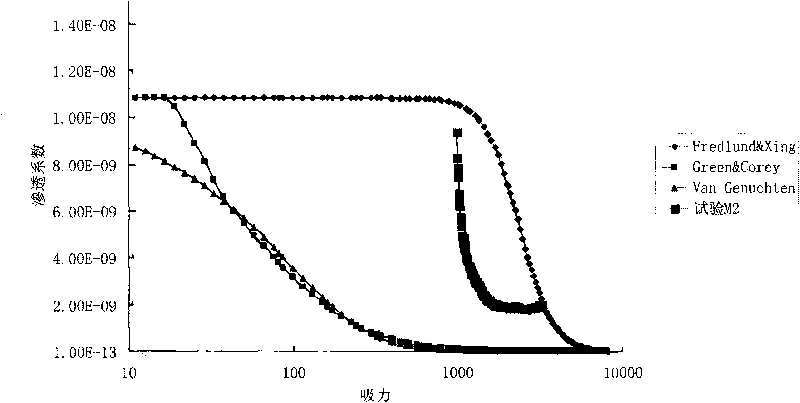

Test method for measuring permeability coefficient of soil body in saturation state or unsaturation state

InactiveCN101813606AHigh measurement accuracyMeet the requirements of one-dimensional vertical stress loadingPermeability/surface area analysisPore water pressurePermeability coefficient

The invention provides a test method for measuring the permeability coefficient of a soil body in a saturation state or an unsaturation state. The test method is characterized by measuring the permeability coefficient of the soil body in the saturation state or the unsaturation state by adopting a testing device, wherein the device consists of a pressure chamber 2, an upper base 5, an upper clay plate 6, a stainless steel side limitation ring 7, a lower clay plate 19, a lower base 20, and a vertical pressure lifting shaft 13; the upper clay plate 6 and the lower clay plate 19 are subjected to air extraction to reach saturation respectively; a sample 17 is placed between the upper clay plate 6 and the lower clay plate 19; and suction balance in the sample 17 is controlled by applying a pore water pressure and a pore air pressure. Due to the adoption of the device, the permeability coefficient of the soil body in the saturation state or the unsaturation state can be precisely measured. The method has the advantages of meeting requirement of loading one-dimensional vertical stress and measuring the permeability coefficient of all kinds of soil bodies in the saturation state or the unsaturation state during civil engineering, along with convenient application and high measurement precision.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

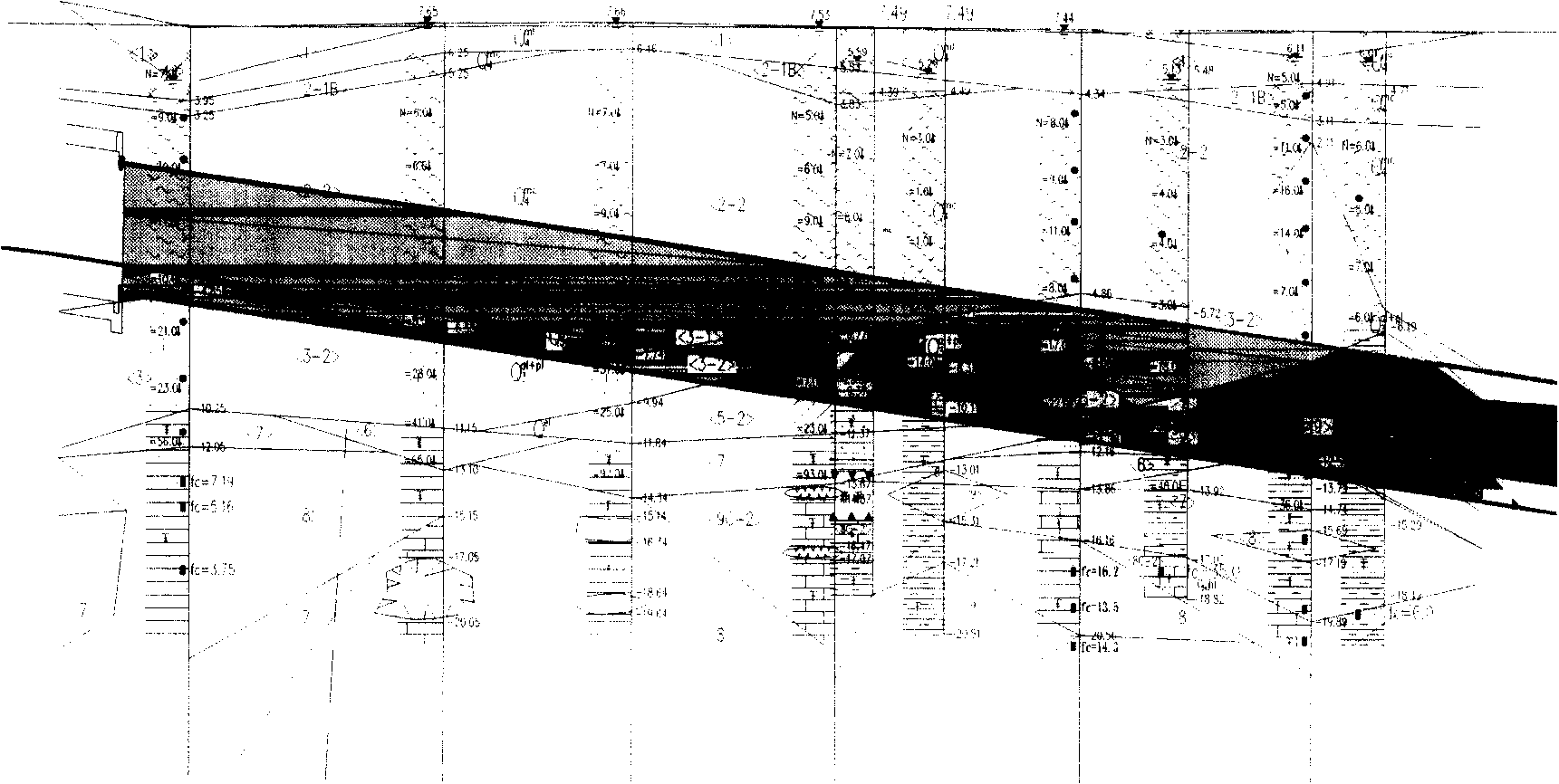

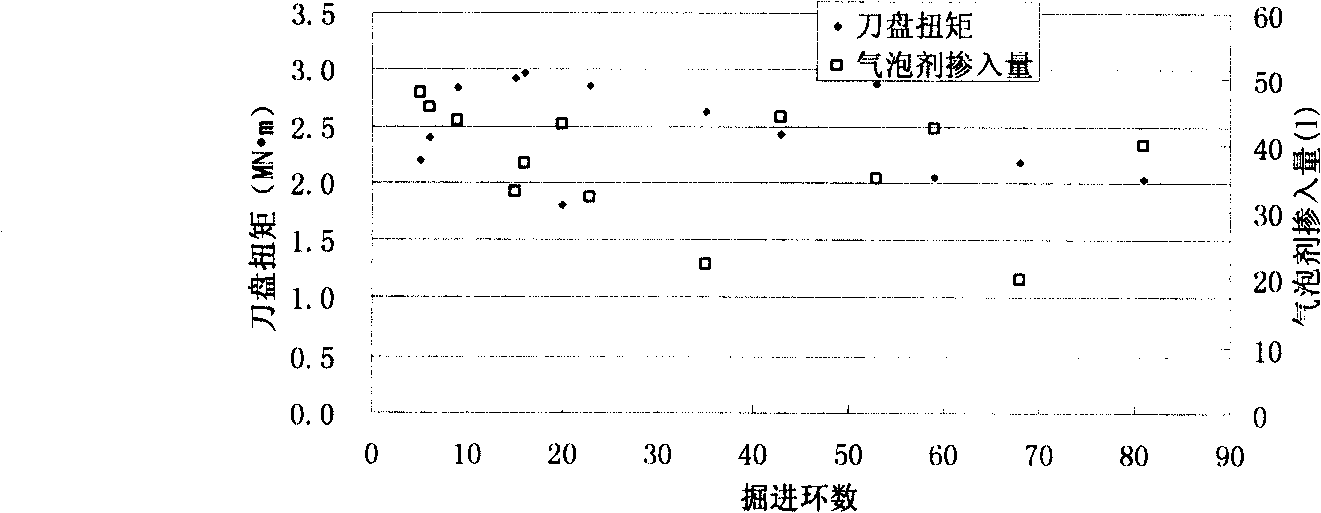

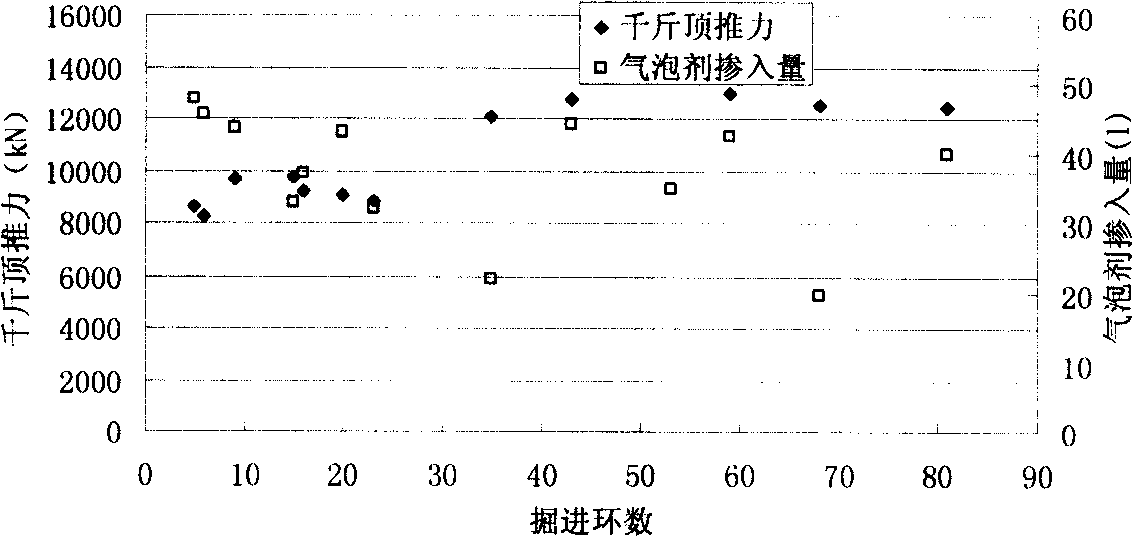

Construction method of composite soil pressure balance tunnel shielding machine for traversing shallow-buried water-rich sand layer

ActiveCN101403307AScientific and reasonable technical solutionsEasy to implementTunnelsEngineeringPressure balance

The invention discloses a construction method that a composite soil pressure balanced shield machine passes through a shallow sand layer rich in water, pertaining to the technical field of tunnel construction. When the composite soil pressure balanced shield machine passes through the shallow sand layer rich in water, an injecting system is arranged at the position of a pressure plate and a cutter head of the shield machine so as to inject a matter-a foaming agent, or bentonite, or a macromoleclar polymer, or the mixture of the three, which has the performances of rapid volume expansion and viscosity increase after absorbing water, into the front shallow sand layer rich in water; the shallow sand layer rich in water is rapidly expanded, soil entering an integral pressure cabin is caused to form plastic flow state, and the soil is caused to reach the permeability coefficient of lower than the magnitude of 10<-5>cm / s which is needed by the construction and the caving degree of 10 to 15cm. The technical proposal is scientific and reasonable, simple and easy to implement, can acquire obvious technique effect, adopts the composite soil pressure balanced shield machine for passing through the shallow sand layer rich in water successfully and acquires satisfactory construction quality as well as guarantees the construction period.

Owner:URBAN MASS TRANSIT ENG CO LTD OF CHINA RAILWAY 11TH BUREAU GRP

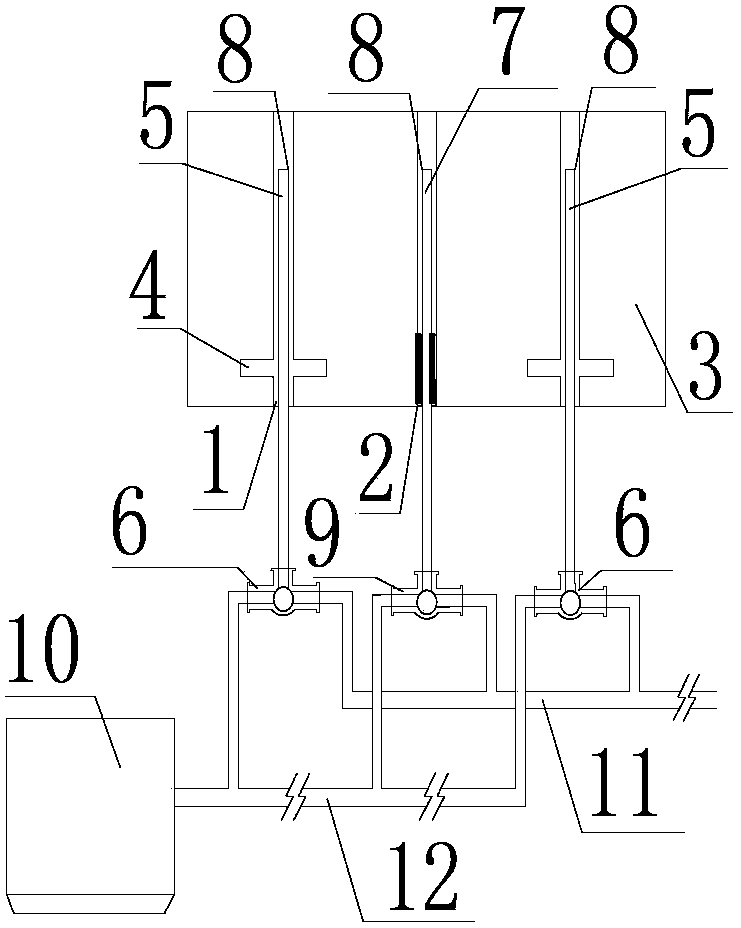

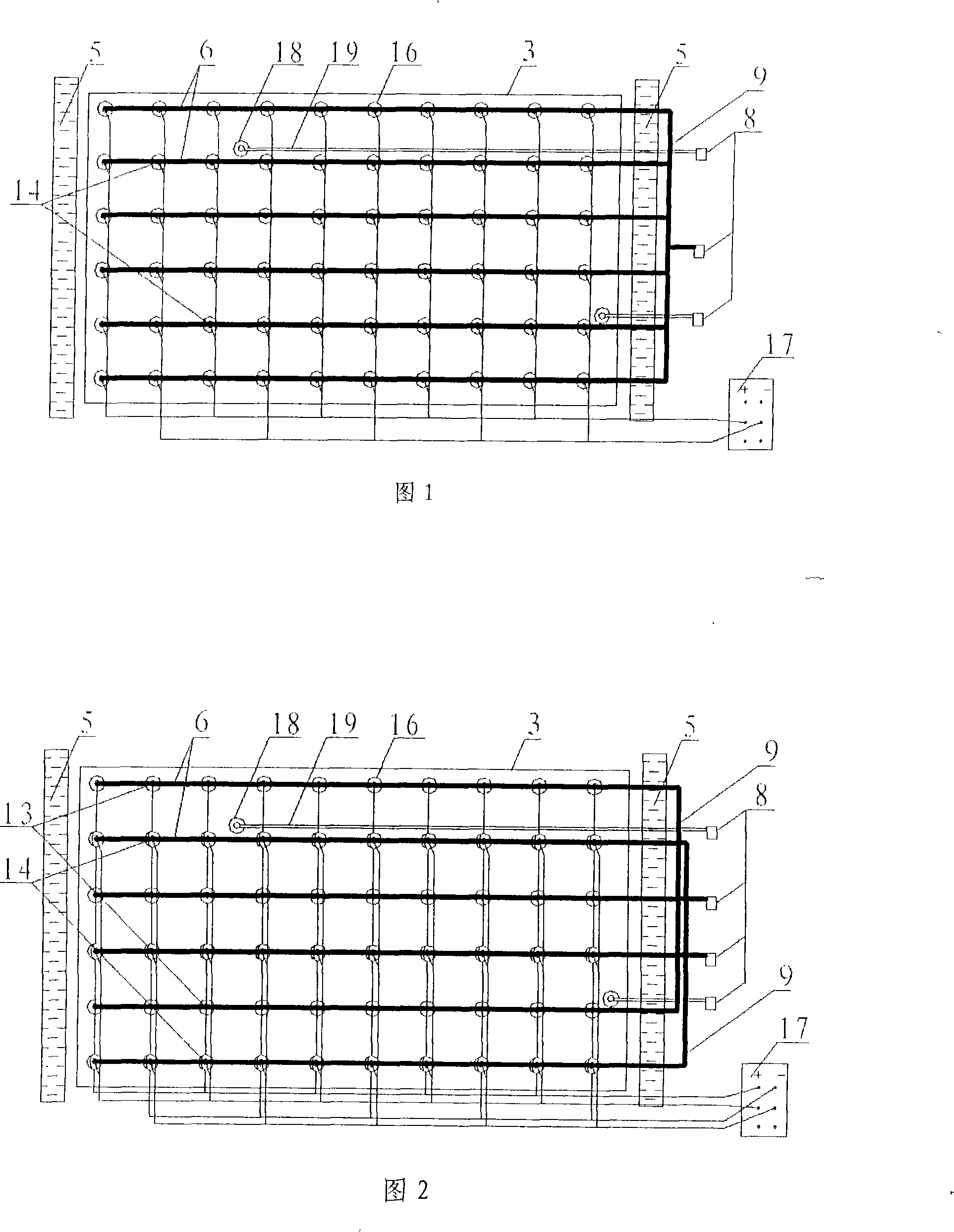

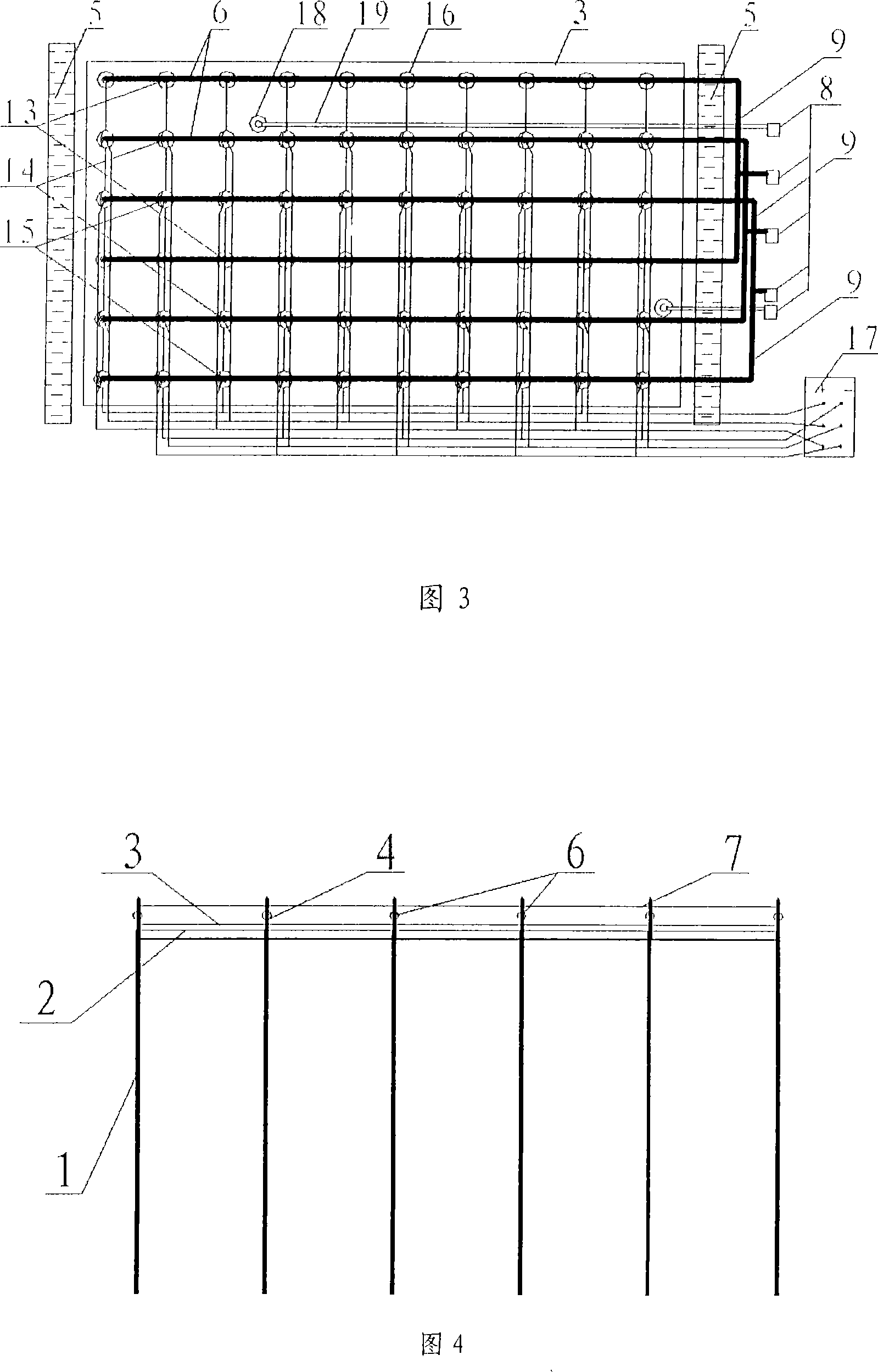

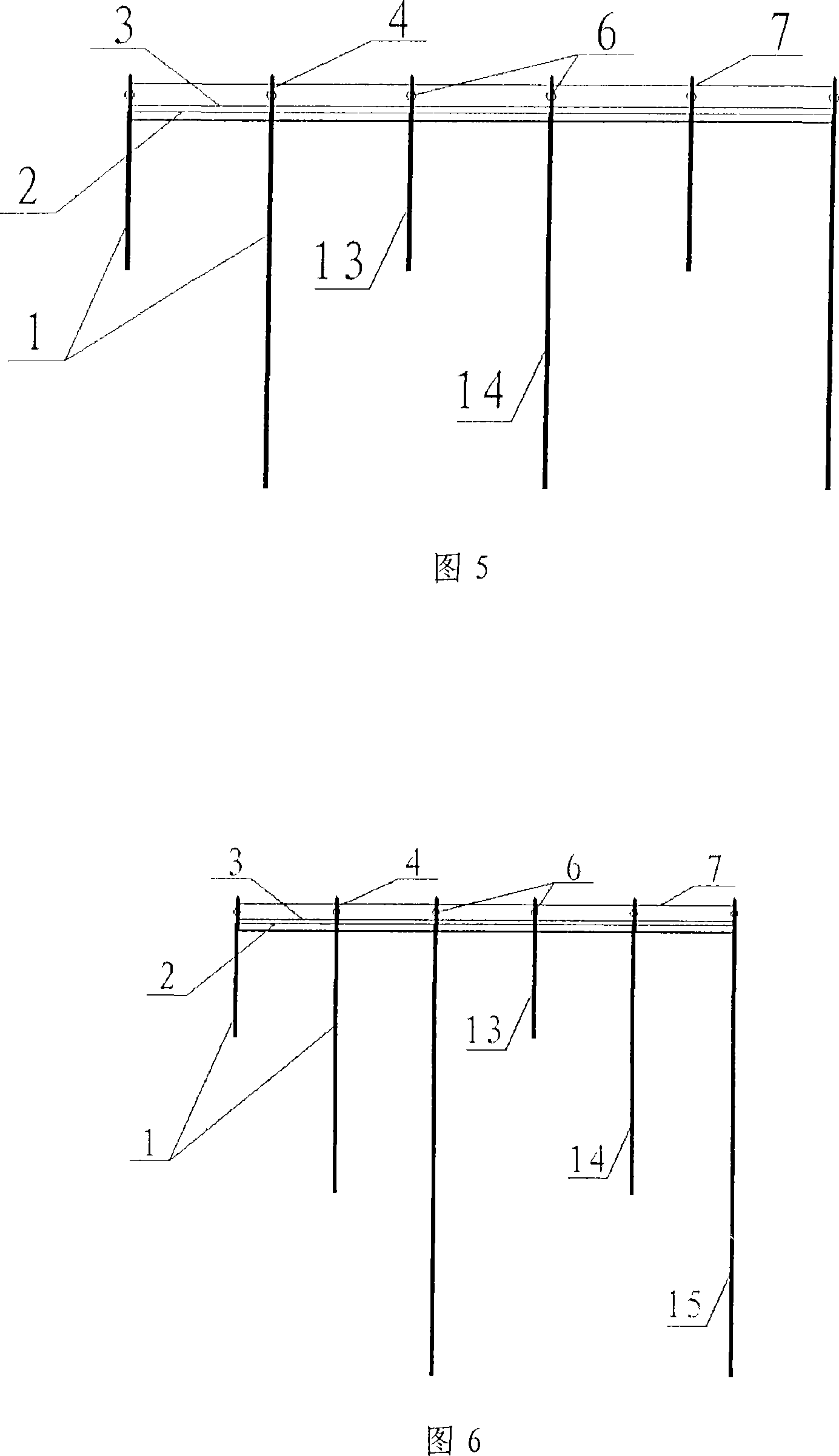

Method of composite electroosmosis, vacuum precipitation and vacuum preload reinforcement foundation and device thereof

ActiveCN101182709AGuaranteed closureExpand the scope of reinforcementSoil preservationEngineeringPermeability coefficient

The invention discloses a method for strengthening the foundation with composite electroosmosis, vacuum dewatering and vacuum preloading, and aims to provide a method for foundation treatment, especially for various types of soil with a permeability coefficient of <10-5cm / s in a large area. Methods of strengthening soft soil foundations. The device used in the method of the present invention adopts a composite pipe and a redundant film with openings or a mesh cap eye film or a mesh cap eye vacuum film with a connector. The method of the invention is a method for reinforcing the foundation that combines electroosmosis, vacuum dewatering and vacuum preloading, and can be implemented in parallel. It has the advantages of balanced treatment, simple and convenient construction, short project time, and high cost performance.

Owner:广西华业建筑工程有限公司

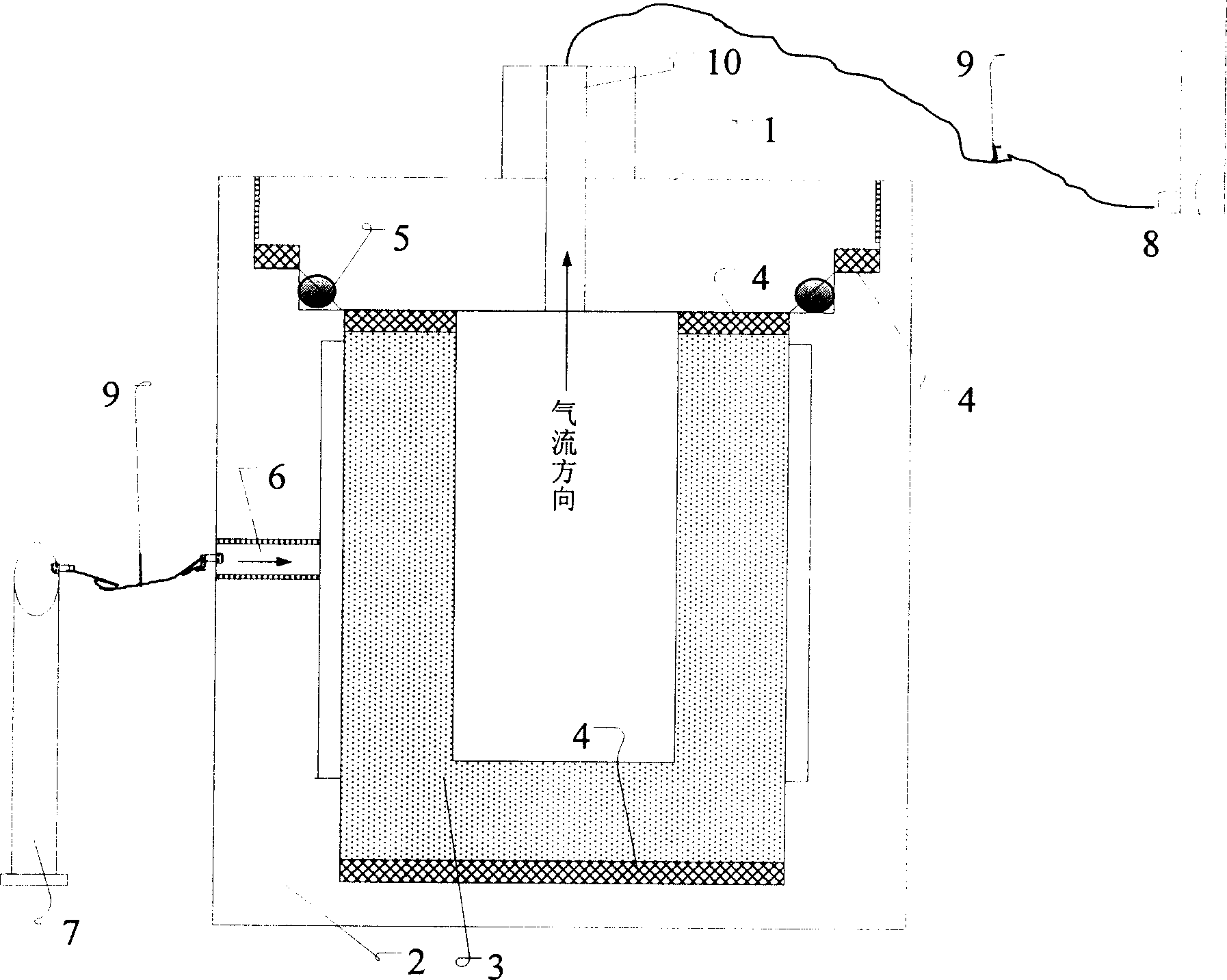

Instrument and method for testing permeability coefficient

ActiveCN101738363AComparableVersatilitySurface/boundary effectPermeability/surface area analysisTester deviceRoad surface

The invention relates to an instrument special for the field test or the nondestructive test of the permeability coefficient for ecological permeable roadways and permeable test blocks and a test method thereof. The instrument for testing the permeability coefficient of the invention comprises a measuring cylinder, a top plate, a base, an upright post bracket, a valve and a timing device, and can intuitively and fast test the permeability coefficient of the permeable roadways and permeable concrete test blocks without sampling drilled cores of the roadways. The instrument and the method for testing the permeability coefficient simulate the calculation of natural rainfall per unit area so that the test and calculation of the permeability coefficient of the permeable roadways are more practical and operable.

Owner:上海砼仁环保技术发展有限公司

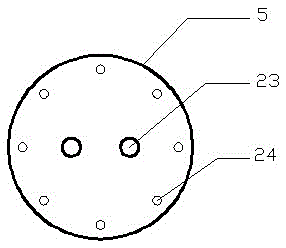

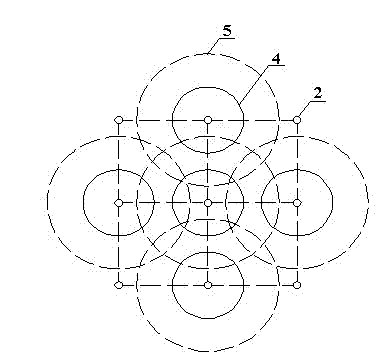

Integral permeability testing machine for self circulation measuring for perpendicular and horizontal permeability coefficient

InactiveCN101285754AFast deliveryPrecise deliveryTextile testingPermeability/surface area analysisGraduated cylinderPermeability coefficient

The invention discloses a comprehensive permeability testing machine for measuring vertical permeability coefficient and horizontal permeability coefficient. The invention comprises a constant-pressure water tank which is communicated with two water supply pipes, wherein, one water supply pipe is communicated with an upper pressure chamber; the top of the upper pressure chamber is provided with a barometer and an air-bleed hole and the side face of the upper pressure chamber is provided with an inflating device; the upper pressure chamber is communicated with a lower pressure chamber through an assembly member; the upper part of the lower pressure chamber is provided with a bubble exhaust hole and the lower part of the lower pressure chamber is communicated with a graduated flask through an exhaust pipe and a metered valve; the other water supply pipe is connected to the left of the assembly member; and the assembly member is communicated with the graduated flask through the exhaust pipe and the metered valve and consists of an impervious membrane, silicon rubber, a V-shaped slot board and a pressurized plastic membrane. The comprehensive permeability testing machine has the advantages that: firstly, the pressurized plastic membrane can quickly, precisely and uniformly transfer normal pressure to a sample, and the impervious membrane can prevent leakage of the sidewall; secondly, water flow is uniformly infiltrated into the V-shaped slot; thirdly, due to arrangement of the silicon rubber, the border effect is reduced; fourthly, the whole machine realizes measurement of the vertical permeability coefficient and the horizontal permeability coefficient, and is precise, simple and clean, highly efficient, practical and convenient to operate.

Owner:ZHEJIANG UNIV

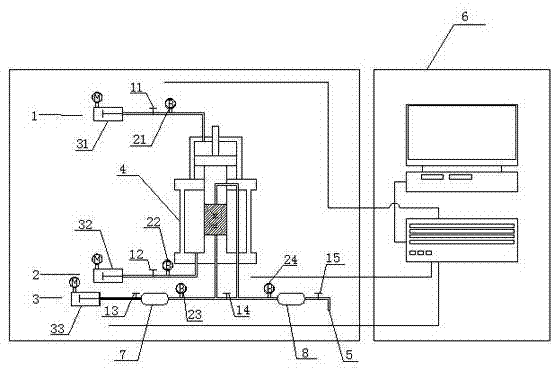

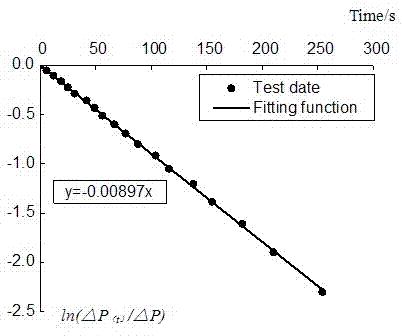

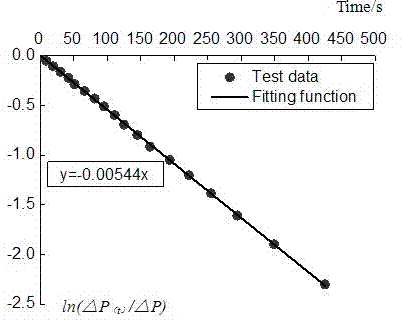

Device and method for simultaneously measuring permeability coefficient, compressibility coefficient and porosity of rock

InactiveCN102507407AQuick measurementAccurate measurementPermeability/surface area analysisPorosityDifferential pressure

The invention relates to a device and method for simultaneously measuring permeability coefficient, compressibility coefficient and porosity of rock. The device is composed of a pressure chamber, an upstream inlet, a downstream inlet, a peripheral pressure inlet, an upstream pump, a downstream pump, a peripheral pressure pump, a vacuum pump, a peripheral pressure valve, an upstream needle valve, a downstream needle valve, a vacuum needle valve, a vacuum valve, a separating valve, a vacuum gauge, an upstream pressure gauge, a downstream pressure gauge, a differential pressure gauge, a thermometer and a console. The device is reliable in principle and simple and convenient to operate, is suitable for dynamic measurement of seepage characteristic parameters and change characteristics thereofof rock under complex stress change conditions. By adopting the device, the permeability coefficient, compressibility coefficient and porosity of the rock under the stress coupling action can be simultaneously measured, experiment basis is provided for design, construction and safety evaluation of seepage associated engineering as well as qualitative and quantitative analysis of permeation changecharacteristics and rules of the rock under the complex stress change conditions, and actual engineering requirements are satisfied.

Owner:SOUTHWEST PETROLEUM UNIV +1

Time domain reflection unsaturated permeameter and method for measuring unsaturated permeability coefficient

InactiveCN101738360APreparing sample for investigationPermeability/surface area analysisRubber ringTime domain

The invention relates to a time domain reflection unsaturated permeameter. The center of a barrel cap (11) is provided with an air outlet (1); the joint of the barrel cap (11) and a barrel wall (8) is sealed by a first rubber ring (2), and the joint of a base (10) and the barrel wall (8) is sealed by a second rubber ring (6); and 5 buried waveguides (3) are arranged at equal intervals in the barrel wall (8), a soil sample in the barrel wall (8) is isolated from the base (10) by porous stones (4), and the positions on the base, corresponding to the porous stones, are respectively provided with a water inlet (7) and a water outlet (5). The invention also provides a method for measuring the unsaturated permeability coefficient of a soil body. The method uses a time domain reflection probe to measure the water content of the soil body in the fixed positions and solves the unsaturated permeability coefficient of the measured medium by making use of the beforehand-measured soil-water characteristic curve of the measured soil body and finally using the instant section method. The invention can be used for measuring the unsaturated permeability coefficient of different soil samples (undisturbed or remolded) and improves the accuracy.

Owner:TONGJI UNIV

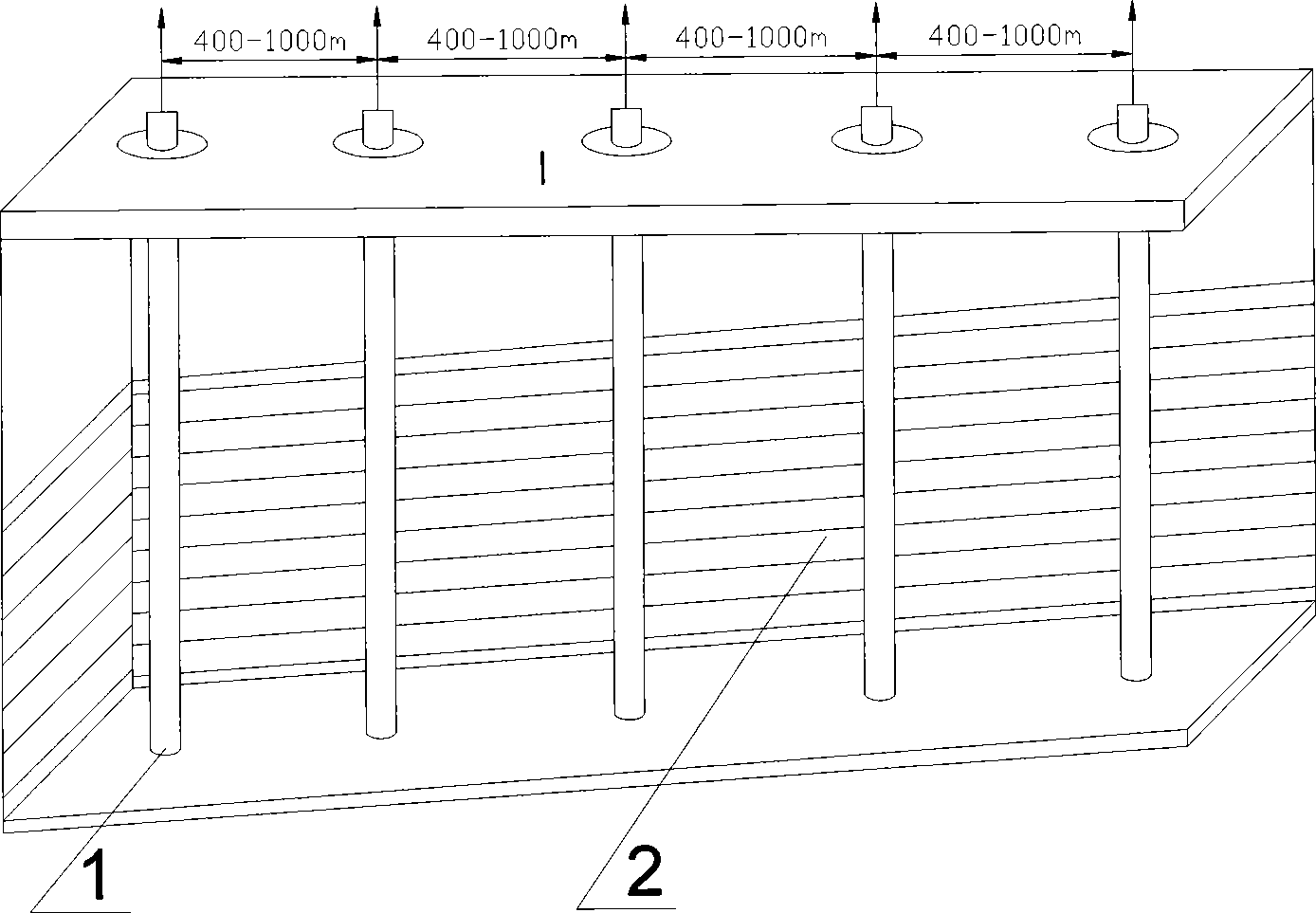

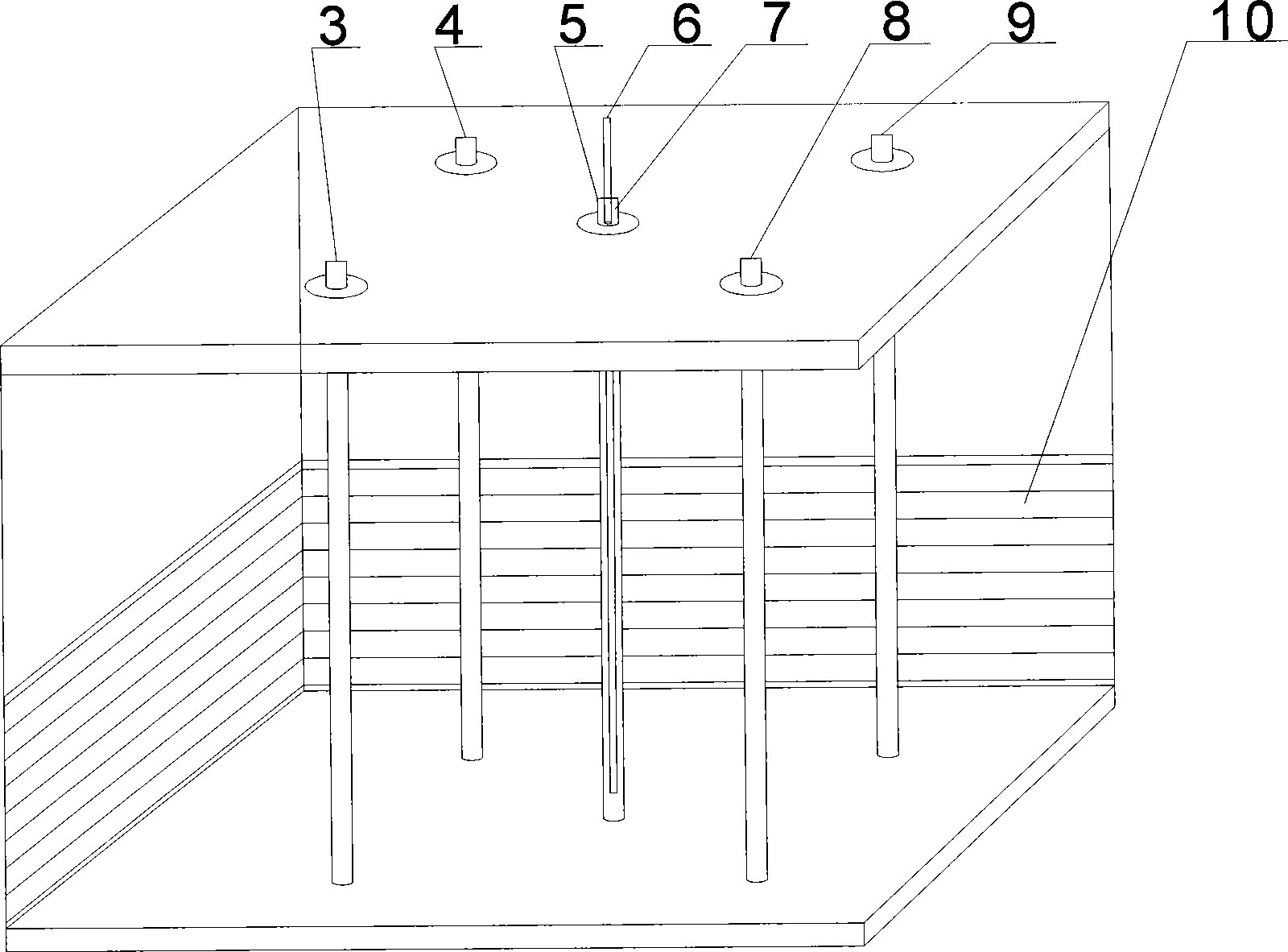

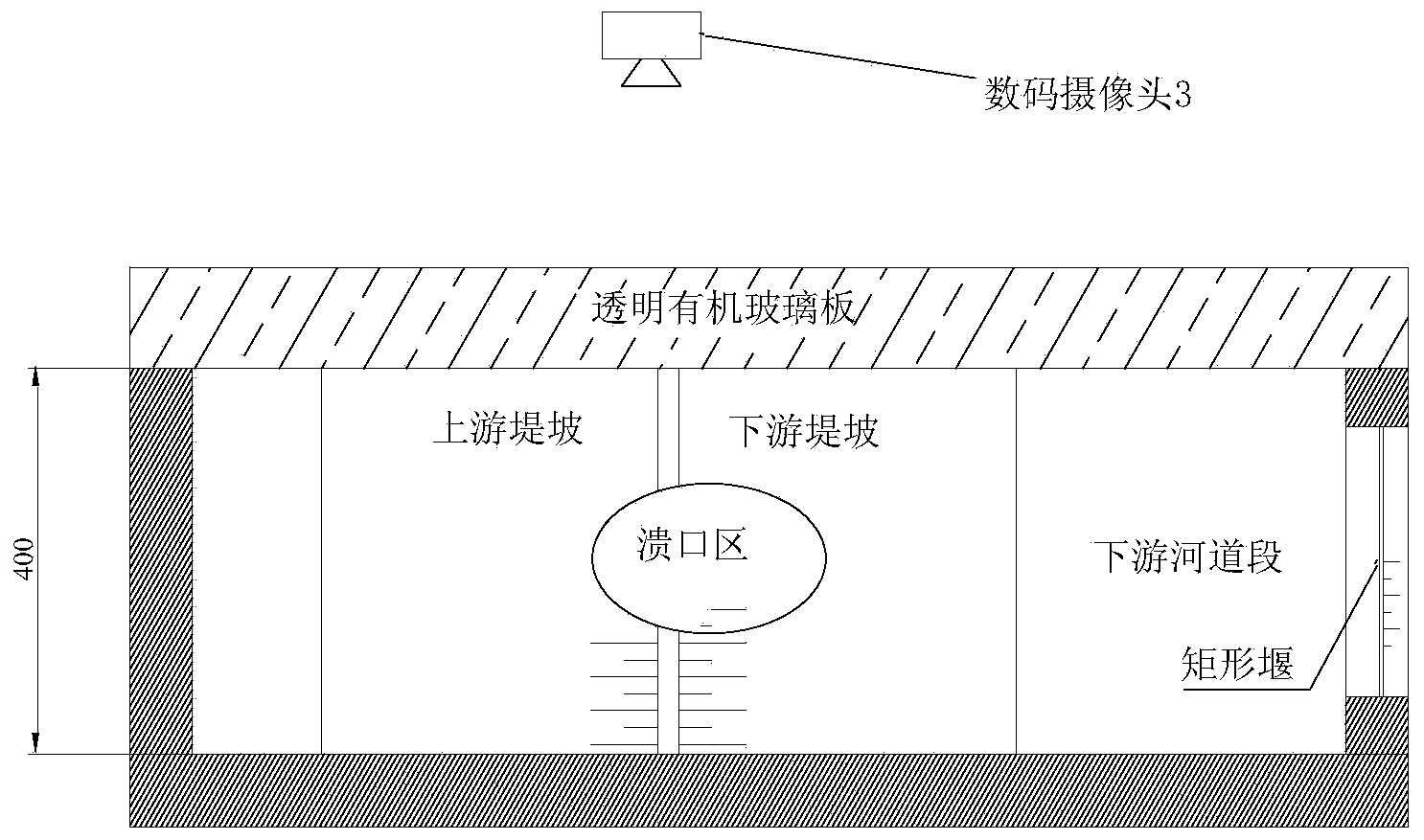

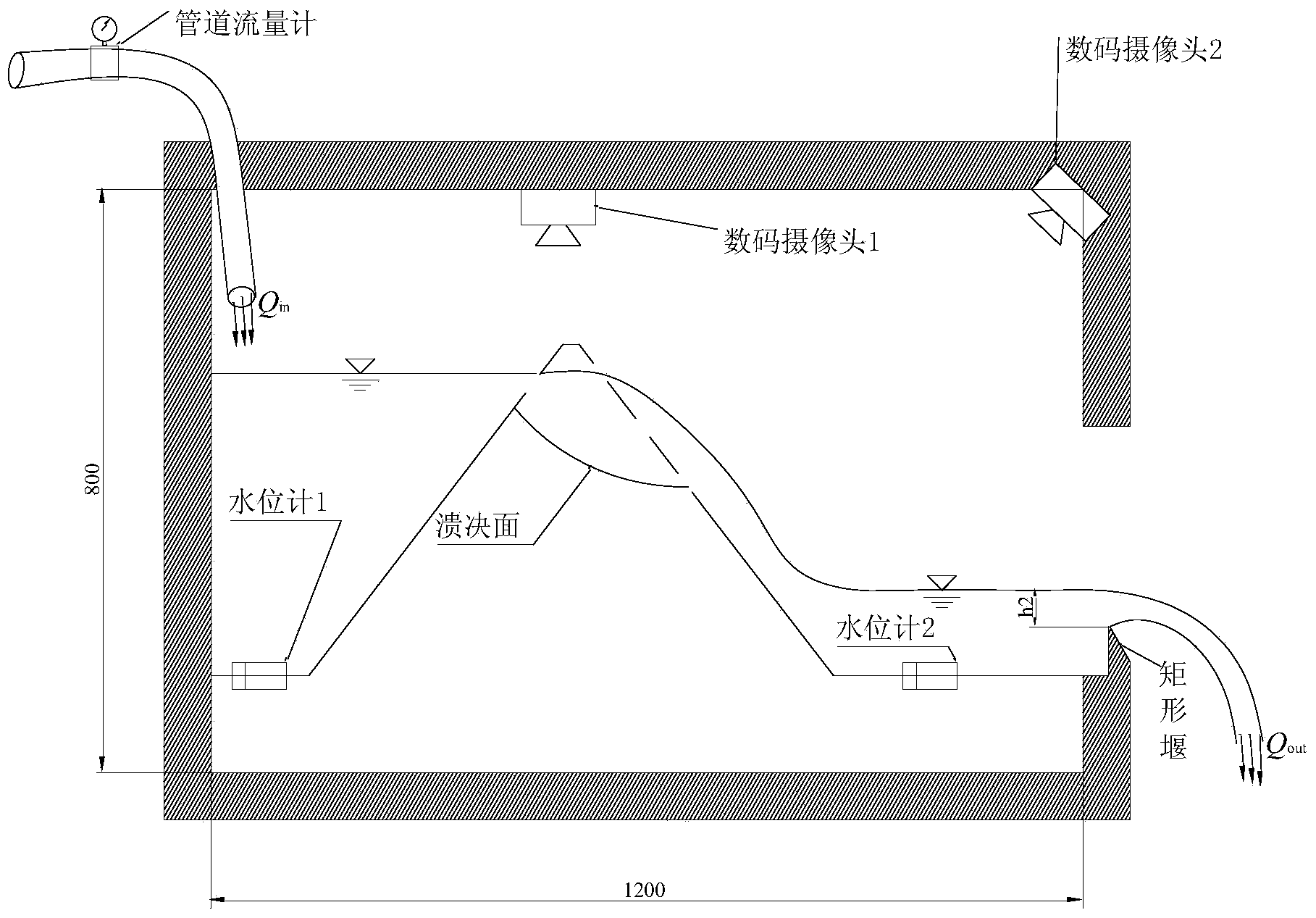

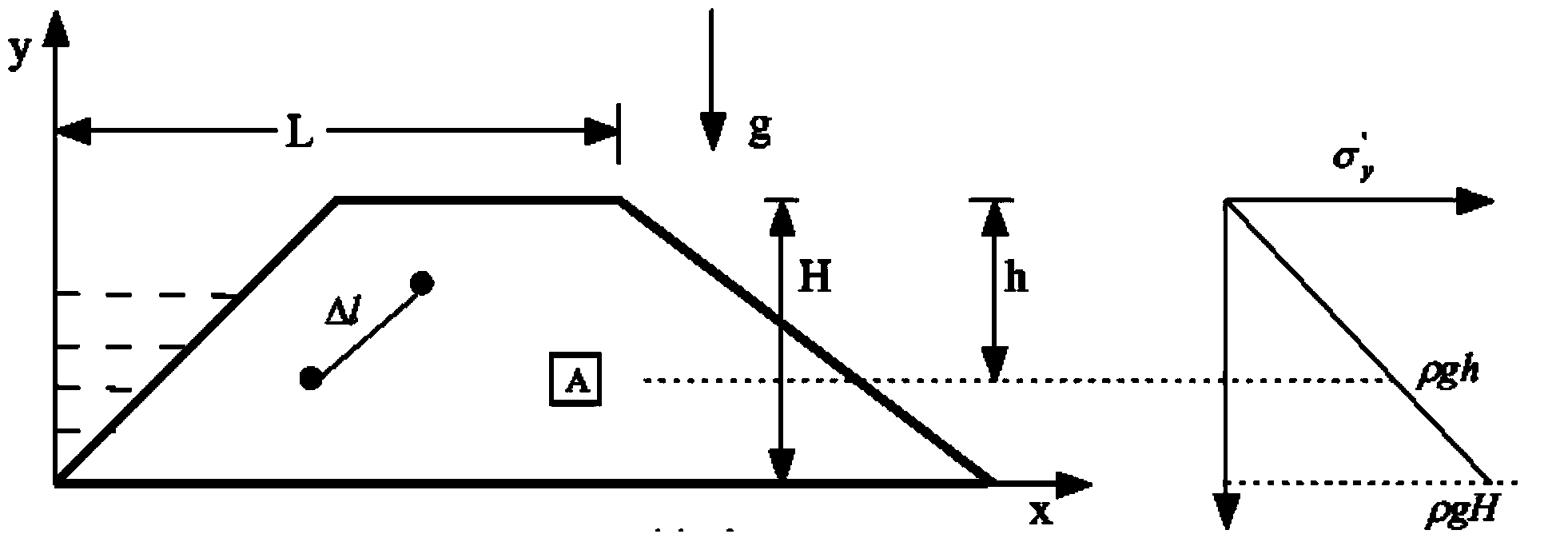

Earth-rock dam break centrifugal model test analysis method

ActiveCN103726475AThe test analysis method is reliable and reasonableMeet the actual needs of the projectHydraulic modelsEngineeringSize ratio

An earth-rock dam break centrifugal model test analysis method is characterized by comprising the following steps that (1) an earth-rock dam break test special model box is arranged; (2) the working principle and the stress similarity criterion of a centrifugal machine are used, an earth-rock dam prototype and a 1 / N-contraction-scale centrifugal test model are obtained, under the Ng centrifugal acceleration condition, the linear size ratio of the model and the prototype is 1 / N, and the earthing stress of the model and the prototype is the same; (3) according to the seepage similarity criterion, the obtained permeability coefficient of centrifugal model earth is N times of the permeability coefficient of prototype earth; (4) according to the shearing strength similarity criterion, the particle diameter of model cohesiveless earth-rock materials is reduced by N times; and (5) according to the water flow similarity criterion, the similarity criterion of commonly-used physical quantity in an earth-rock dam break centrifugal model test is obtained. The method is not limited or restricted by fields, a large amount of earth and a large number of water resources are of no need during testing, and the method has the advantages of being low in cost and short in time.

Owner:NANJING HYDRAULIC RES INST

Permeability measurement device and measurement method in rock rheological process

The invention relates to a novel measurement method for permeability coefficients in a rock rheological process. A shaft pressure loading system is connected with a shaft pressure room of a three-shaft pressure room; a confining pressure loading system is connected with a confining pressure room of the three-shaft pressure room; a seepage control system is connected with a liquid emission system; samples are in parallel connection with the seepage control system and the liquid emission system; a computer data acquisition system is connected with the shaft pressure loading system, the confining pressure loading system and the seepage control system respectively; the device further comprises an upper water storage tank and a lower water storage tank; and the upper water storage tank and the lower water storage tank are connected between the seepage control system and the liquid emission system respectively. The measurement method can measure the permeability coefficients in all phases of the rock rheological process under different confining pressures and different deviatoric stress levels. According to the comparison between experimental results of the permeability coefficients in various phases of the rock rheological process and other conventional test methods, the reliability and the effectiveness of the method can be estimated. Compared with the traditional measurement method, the method overcomes the defects of long test process and complex test operation, and has the advantages of short test process, simplicity and convenience in operation and the like.

Owner:HOHAI UNIV

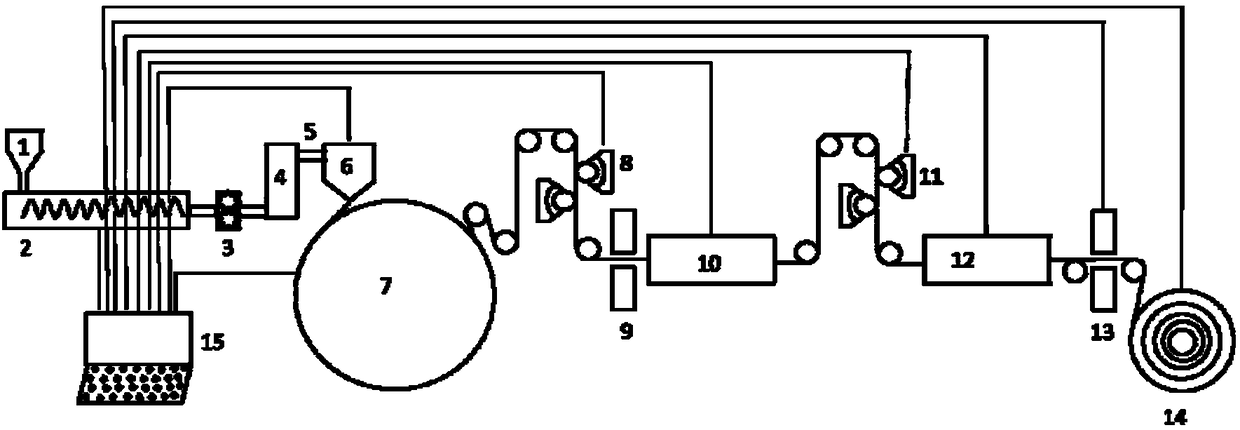

Coal mine underground high-power electric knock assisted hydraulic fracturing permeability enhancement method

ActiveCN105275443AIncrease the number of cracksIncrease the lengthFluid removalGas removalShock waveHigh energy

The invention relates to a coal mine underground high-power electric knock assisted hydraulic fracturing permeability enhancement method suitable for increasing extraction radius and total extraction amount of gas extraction drilling. The method comprises the following steps that: a borehole extends from one side of a laneway to a coal seam is constructed; a high-voltage pulse discharger which is installed at the front end of a fracturing steel pipe is sent to the bottom of the borehole; a hole packer, which is separated from the orifice of the borehole by 2 to 3m, is installed on the borehole; the outer end of the fracturing steel pipe is connected with a high-pressure pump station through a high-pressure rubber hose; and the high-voltage pulse discharger is connected with a high-voltage electric pulse generator through a cable; after water with a certain pressure is injected into the borehole, the high-voltage electric pulse generator is started so as to apply high-power electric knock assisted hydraulic fracturing to the coal seam; after the high-power electric knock assisted hydraulic fracturing, the high-voltage pulse discharger and the fracturing steel pipe are quitted; and a gas extraction pipeline is connected into the borehole. According to the method of the invention, high energy released by high-voltage electric pulses is utilized to form shock waves in the water, and therefore, a large number of cracks can be formed in the coal seam, and primary cracks are extended. With the method adopted, the permeability coefficient of a coal body can be increased by 100 to 300 times, and single-hole gas extraction efficiency can be effectively improved.

Owner:CHINA UNIV OF MINING & TECH

Composite polypropylene microporous membrane, and preparation method and application thereof

InactiveCN109422890ASimple production processImprove performanceCell component detailsCoatingsPolymer scienceCoating system

The invention discloses a composite polypropylene microporous membrane, and a preparation method and application thereof, and provides a device for preparing the composite polypropylene microporous membrane. According to the preparation method, a coating layer is introduced to the surface of one side or both sides of a membrane slice by a coating system during preparation of a biaxially oriented polypropylene microporous membrane, and the coating layer is stretched in both longitudinal and transverse directions or only in the transverse direction to achieve the preparation of the composite polypropylene microporous membrane. The method simplifies the production process of the composite polypropylene microporous membrane and improves the performance of the polypropylene microporous membrane. The composite polypropylene microporous membrane is used in a lithium battery, and since the coating layer is a polymer or a composition capable of forming a gel with an electrolyte, the cycle and safety performance of the lithium battery can be improved. The composite polypropylene microporous membrane is used for gas separation, and separation and enrichment of different gases can be achieveddue to different permeability coefficients of the coating layer to different gases.

Owner:BEIJING NORMAL UNIVERSITY

Polyvinylidene fluoride hollow fiber ultrafiltration membrane with permanent hydrophilcity and preparation method thereof

The invention discloses a polyvinylidene fluoride hollow fiber ultrafiltration membrane with permanent hydrophilcity and a preparation method thereof. The preparation method comprises the following steps of: sequentially adding 13 wt% to 25 wt% of polyvinylidene fluoride, 8 wt% to 16 wt% of additives and 0.02 wt% to 3.0 wt% of surface active agents and solvents in a dissolving tank, and then stirring for dissolving for 2 to 16 hours at 15 to 90 DEG C to the fully uniform state to prepare that initial membrane casting liquid; sequentially adding initiating agents accounting for 0.1 wt% to 3.5 wt% of polar monomers and the polar monomers accounting for 0.1 wt% to 5.0 wt% of the membrane casting liquid in the membrane casting liquid, and reacting for 1 to 12 hours at 15 to 90 DEG C to prepare hydrophilic membrane casting liquid; and preparing the hydrophilic hollow fiber ultrafiltration membrane by adopting the traditional dry-wet spinning technology. For the hydrophilic polyvinylidene fluoride hollow fiber ultrafiltration membrane prepared in the preparation method, the pure water permeability coefficient is greater than 230 L / m2*hr*0.1MPa, the retention rate of bovine serum albumin (67000MW) is greater than 95.0%, the breaking elongation rate of fibers is greater than 200%, and the fracture pressure is greater than 0.55 MPa. The polyvinylidene fluoride hollow fiber ultrafiltration membrane with permanent hydrophilcity is especially suitable for deep treatment and recycling of waste water, clarification and separation in the fields of biochemical engineering and medicament, and the like.

Owner:UNIV OF JINAN

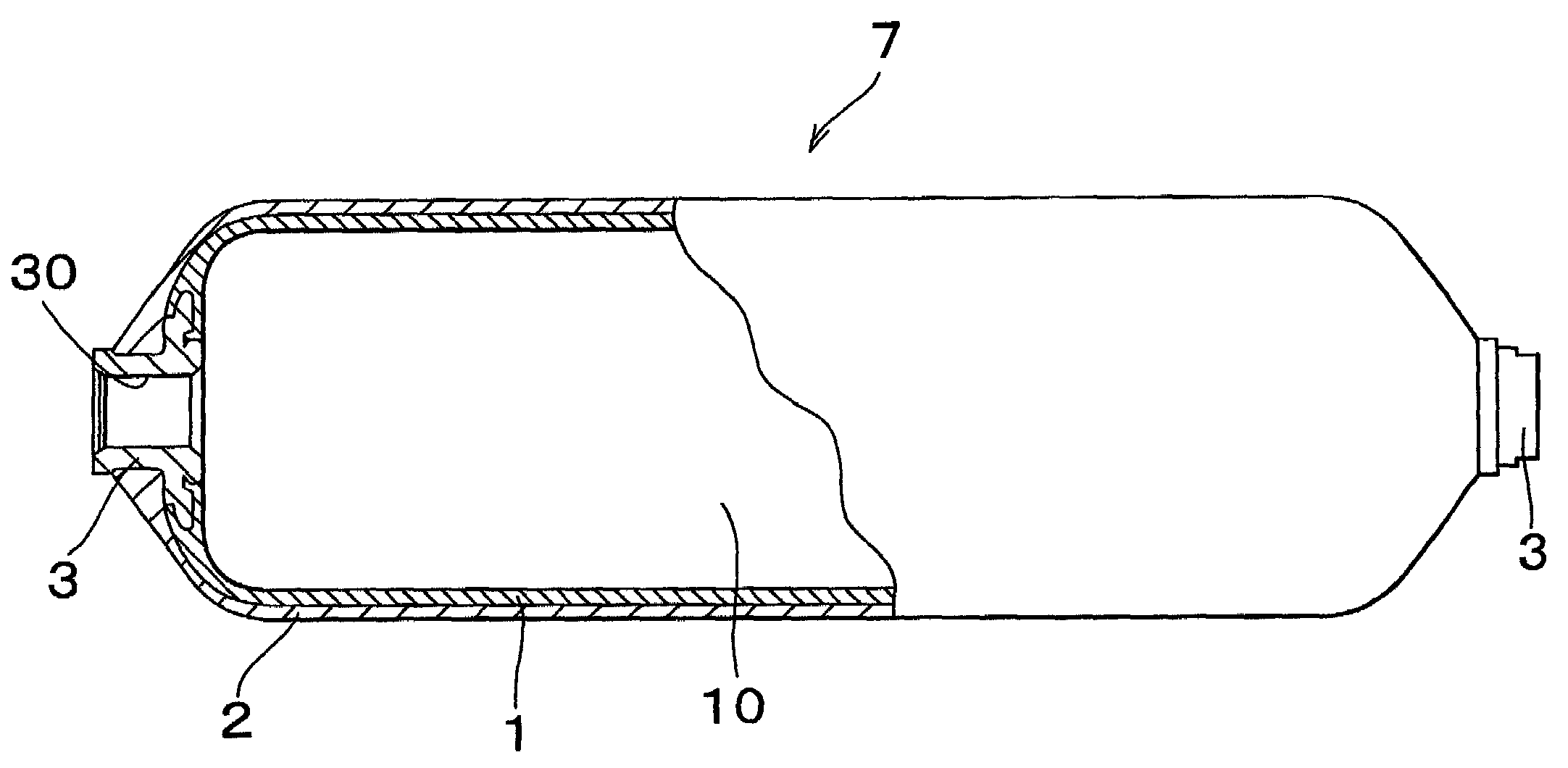

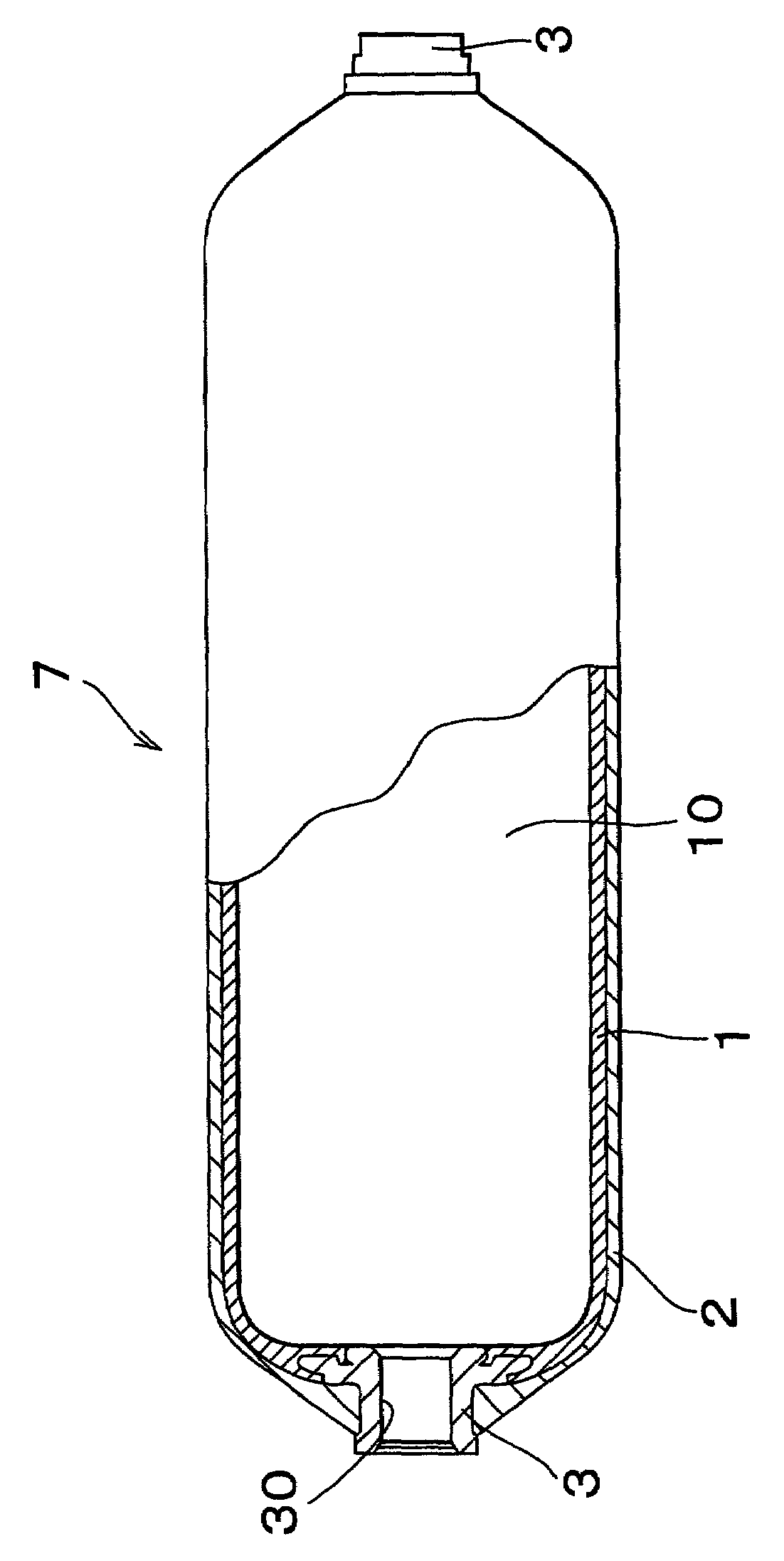

Liner for high pressure gas container and high pressure gas container

InactiveUS7208207B2Improved gas impermeabilityImprove pressure resistanceEnvelopes/bags making machineryGlass/slag layered productsProduct gasHigh pressure

A liner for a high pressure gas container includes a resin composition containing a polyphenylene sulfide resin and an olefin based resin. The resin composition has a methane gas permeability coefficient of 1.7×10−16 mol·m / m2·s·Pa or smaller at 40° C., and tensile elongation of 50% or greater after fracture at 23° C. A high pressure gas container having such a liner is also provided.

Owner:TOYODA GOSEI CO LTD +1

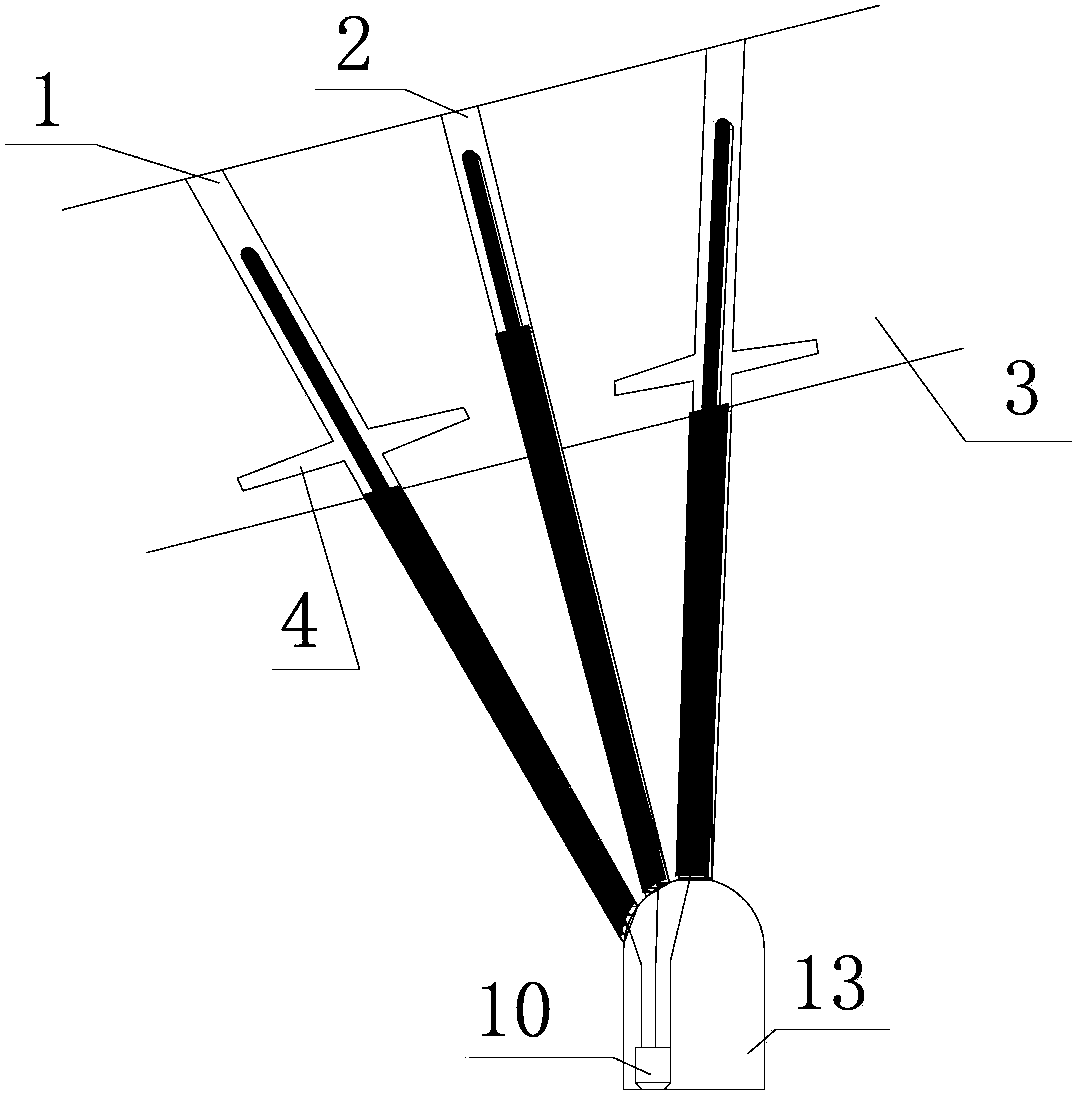

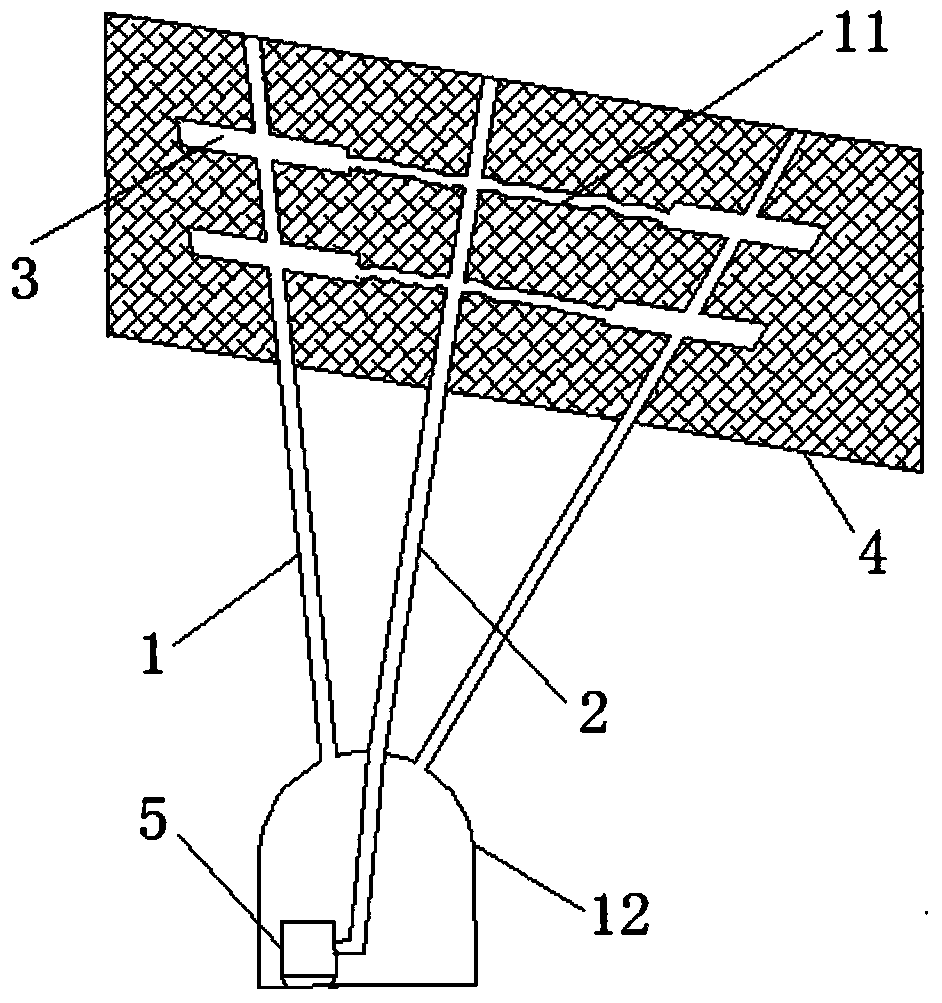

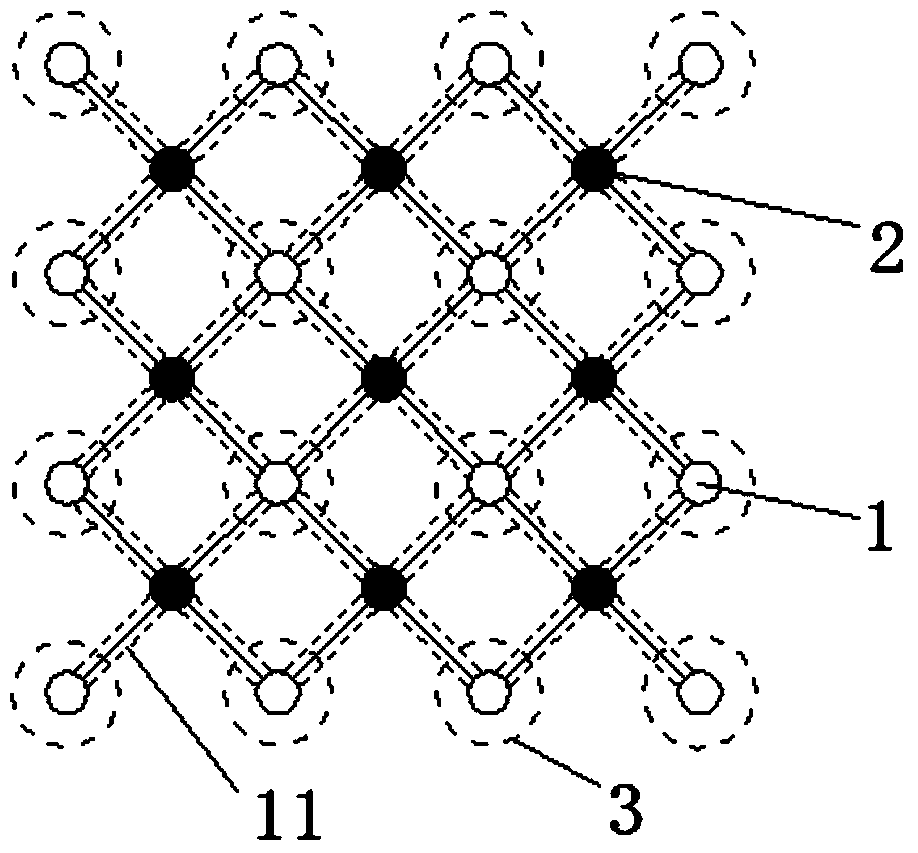

Slotting and fracturing cooperation networking permeability increasing method for low-permeability coal seam

ActiveCN104389631AImprove breathabilityIncreased air permeability coefficientFluid removalGas removalHigh pressure waterHigh pressure

The invention provides a slotting and fracturing cooperation networking permeability increasing method for a low-permeability coal seam, which is applicable to regional gas control for high-gas-content low-permeability coal seams. The permeability increasing method comprises the following steps that: firstly, hole positions of slotting drill holes and fracturing drill holes are arranged alternately at a floor suction roadway in a networking arrangement mode; each slotting drill hole is subjected to high-pressure water jet flow slotting to form an annular slotted hole; and then, each fracturing drill hole is subjected to segmented fracturing, and a fracture net is formed in the coal seam. The slotting drill holes and the fracturing drill holes are in cooperative arrangement; the slotted holes formed by slotting are used for controlling the expanding direction of fracturing cracks; the number of cracks in the coal seam can be effectively increased through segmented fracturing multiple times; and good conditions are created for the drill hole gas extraction and the gas flowing in the coal seam. After the fracturing cracks are communicated with the slotted holes, a crack network is formed in the coal seam; the permeability coefficient of a coal body around the drill holes can be improved by 150 to 400 times; the single-drill-hole gas extraction effective influence range can be expanded by 2 to 4 times; the drill hole gas extraction quantity can be increased by 3 to 6 times; and the gas pre-extraction time in the high-gas outburst coal seam can be effectively shortened.

Owner:CHINA UNIV OF MINING & TECH

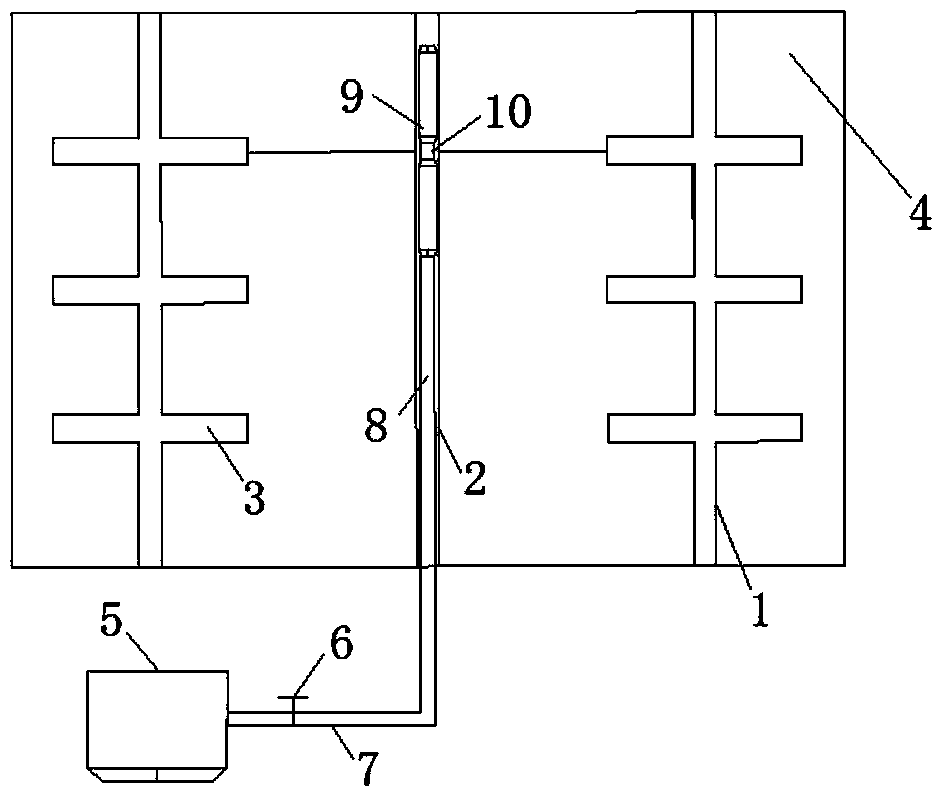

Device and method for measuring water permeability coefficient of asphalt pavement

ActiveCN104849196AExhaust smoothly and fullyExhaust without dead endsPermeability/surface area analysisRoad surfaceEngineering

The invention discloses a device and a method for measuring the water permeability coefficient of an asphalt pavement. The device is characterized in that a measuring cylinder is vertically arranged in the center of the top of a base provided with a hollow cavity; a quick-opening valve is arranged at the bottom of the measuring cylinder; the measuring cylinder is communicated with the hollow cavity of the base by the opened quick-opening valve; four graduated exhaust pipes which have equal diameters are vertically and evenly distributed at the periphery of the measuring cylinder; the bottom ends of the exhaust pipes pass through the top surface of the base and are communicated with the hollow cavity of the base; the pipe orifices on the tops of the exhaust pipes are higher than the liquid level of the top of the measuring cylinder; the bottom of the base is provided with a sealing leveling ring which is sealed with the ground and is capable of adjusting the base to be horizontal. The device and the method are used for measuring a water permeating system of the asphalt pavement; after the device and the method are used, the test process is simplified, the test accuracy is improved, and the consistency of test data is guaranteed.

Owner:HEFEI UNIV OF TECH

Annular detecting instrument for concrete gas seepage coefficient and detecting method

ActiveCN1815174ASimplified calculation modelHigh precisionSurface/boundary effectMaterial testing goodsTest sampleTester device

Owner:SHANGHAI TONGJI CONSTR QUALITY INSPECTION STATION

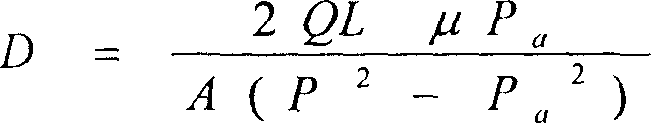

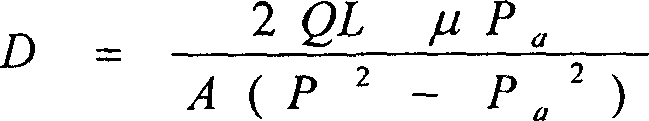

Hollow fiber compound film, preparation and application

InactiveCN101259381AEasy to makeImprove controllabilitySemi-permeable membranesSeparation factorFiber

The invention relates to a preparation method and application of a hollow fibre compound membrane; PVA, EDTMPA and PS are taken as raw materials; the mass ratio of the EDTMPA to the PVA is 1 to 50 : 50 to 99; a PS hollow fibre is used as a supporting layer; the preparation method includes that: the PVA is dissolved into water to be prepared into a solution with a mass concentration of 4 to 7 percent; the EDTMPA is added into the PVA water solution, the mixture is subject to stirring and filtering for impurity removal so as to obtain a casting solution which stands for defoaming, then the PS hollow fibre supporting layer is dipped into the foam-free casting solution and is dried. The invention has simple preparation, strong controllability, high separating property, abundant raw materials and low price; when the invention is used for removing the water in propylene, the permeability coefficient can reach 2851GPU and the separation factor is 302000.

Owner:TIANJIN UNIV

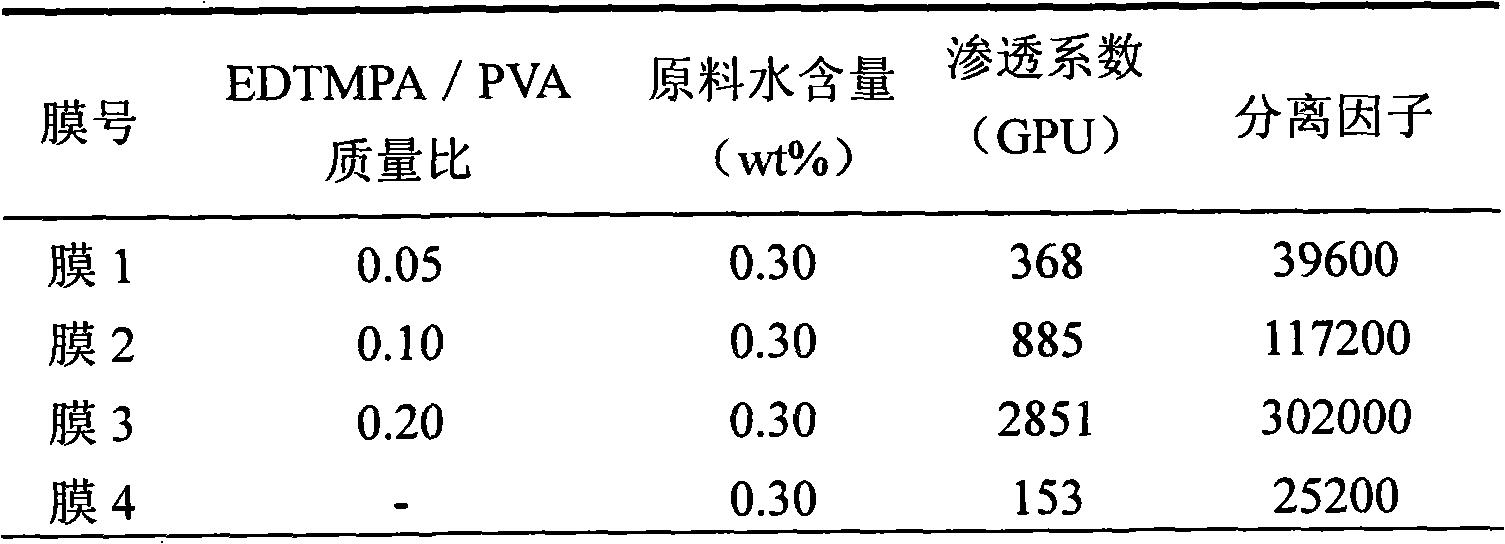

Silica sand composition, formed body and preparation method for formed body

The invention provides a silica sand composition which comprises silica sand having a polymer coating and a first binder, wherein, the polymer coating is a cured second binder, and the first binder and the second binder are respectively one or more selected from the group consisting of an acrylic acid resin adhesive, an epoxy resin adhesive and a polyurethane adhesive. The invention also provides a preparation method for a formed body and the formed body prepared by using the method. The method comprises the steps of mixing of all the components of the silica sand composition, molding and curing of the first binder. The formed body prepared from the composition by using the method has good water permeability, high strength and an excellent strength retention rate, and has a compressive strength of 45 to 70 MPa when in a dry state, a compressive strength of 28 to 55 MPa when in a wet state, a cyclic strength of 20 to 45.5 MPa after 5 cycles, a strength loss rate of only 27 to 60% and a permeability coefficient of 3 to 7 cm / s.

Owner:RENCHSAND ECO ENVIRONMENT PROTECTION SCI & TECH CO LTD

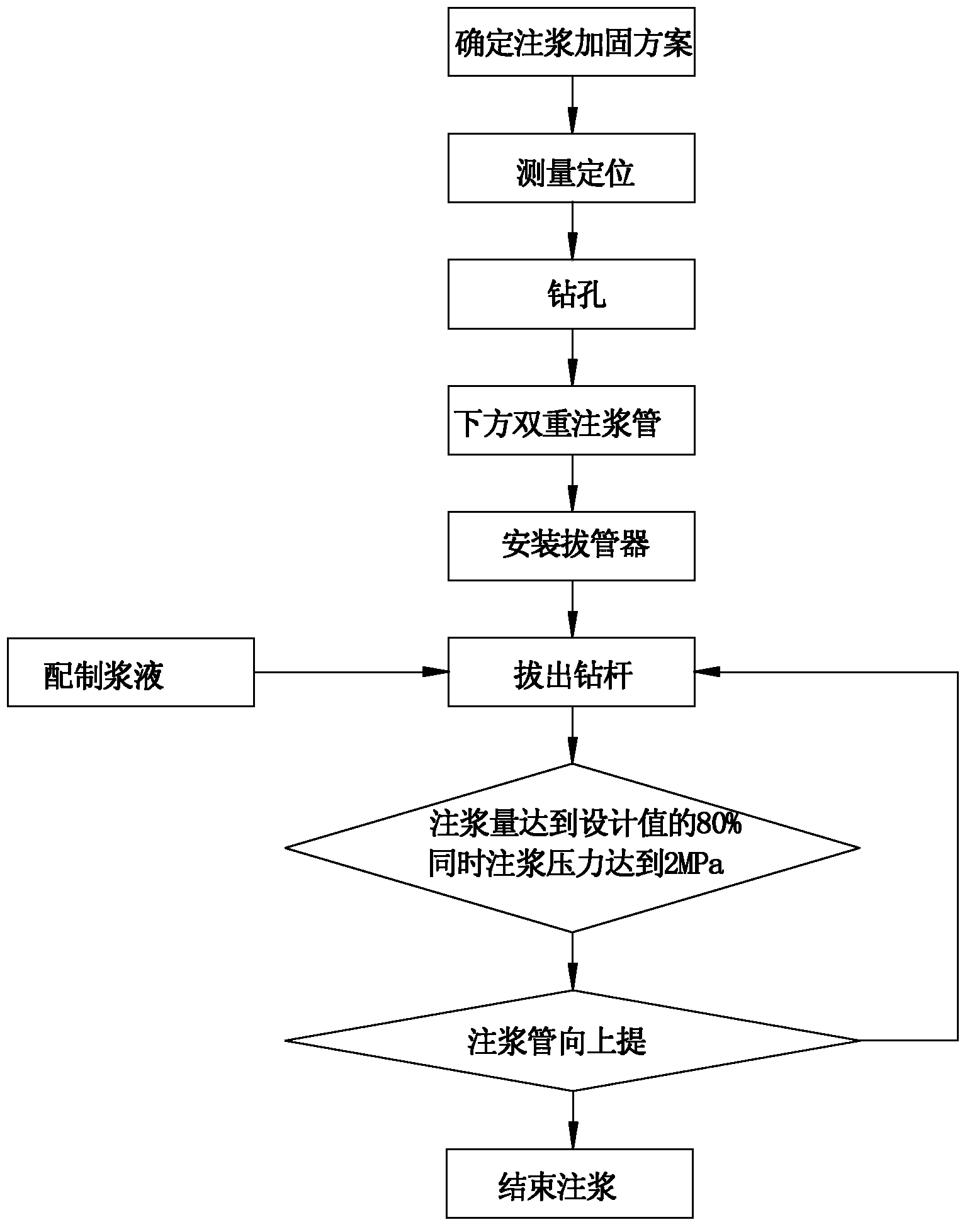

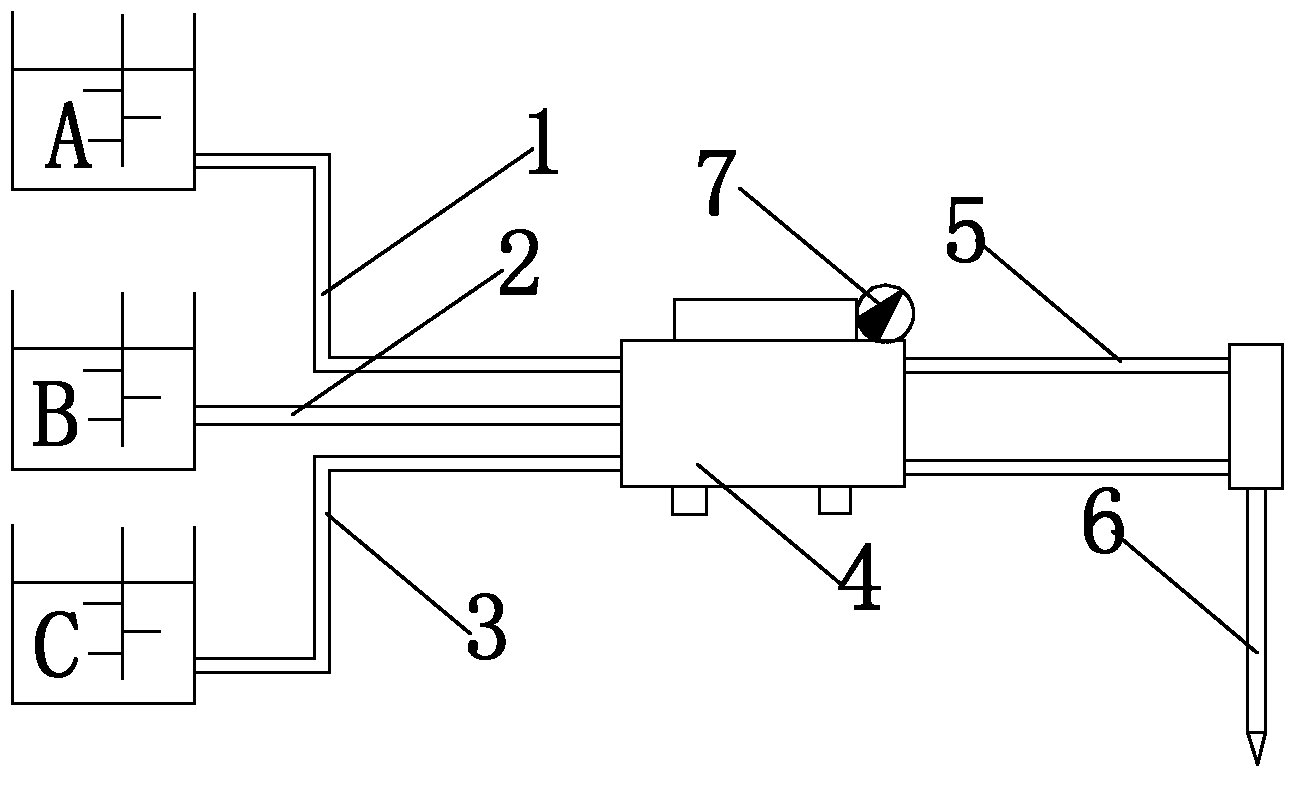

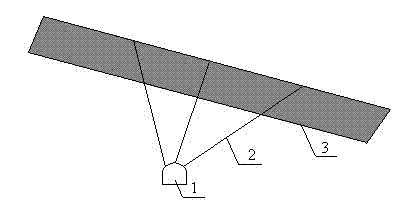

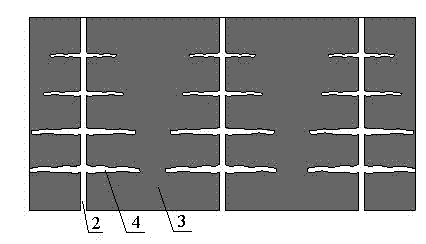

Sublevel retreating type two-fluid composite grouting construction method for deep foundation pit of sandy gravel stratum

ActiveCN103266614AWith hydraulic fully automatic operationLarge operating torqueExcavationsSlurryPermeability coefficient

The invention discloses a sublevel retreating type two-fluid composite grouting construction method for a deep foundation pit of a sandy gravel stratum. The method comprises the steps of determining a grouting reinforcement scheme; conducting field measuring and setting-out; drilling holes, placing double grouting pipes downwards after the holes are formed, then installing pipe pulling devices, and pulling out drill pipes; preparing grouting fluids; conducting grouting in every other hole, conducting two-fluid composite grouting of the cement-water glass grouting fluid and the modified water glass grouting fluid, and comprehensively considering conversion of the grouting fluids according to changes of the grouting pressure, the flow and grouting positions, wherein the grouting pressure reaches 2MPa or exceeds 3MPa at the same time when the grouting quantity exceeds 80% of the designed value; and after the double pipes are lifted, repeating the grouting process till grouting is finished. The method has the advantages that the phenomenon that the grouting pipes can not be installed due to hole collapse can be avoided; advantages of the two grouting fluids are integrated by composite grouting of the two grouting fluids, waterproof curtains are achieved, meanwhile, the permeability coefficient is low, and the setting strength is high; and the problem that the pipes are pulled difficultly due to grouting fluid backflow is solved.

Owner:BEIJING MUNICIPAL CONSTR +2

Slotting induced-flow pressure-relief anti-reflection method for complicated seam

ActiveCN102966372AAchieving safe miningImprove extraction efficiencyFluid removalGas removalSocial benefitsDesorption

A slotting induced-flow pressure-relief anti-reflection method for a complicated seam is suitable for gas control of high-gas high-ground-stress complicated seam regions, can improve the gas permeability and gas desorption rate of coal, solves the difficult problems of low exhausting and mining efficiencies of coal-bed gas, high drilling construction load and the like, and realizes efficient gas exhausting and mining as well as fast outburst elimination of the complicated seam. High-pressure water is jetted into drilled holes to cut and destroy the coal in a rotary manner, and the coal in the radial direction of the drilled holes is destroyed and disturbed, so that buckling failures of the coal are induced and the coal and the gas are enabled to be spouted out of the drilled holes, as a result, the gas expansion energy of the coal is released, coal cracks are expanded and the exposure surface area of the coal is increased. therefore, the gas exhausting and mining efficiencies of coal are improved, coal and gas burst risks are eliminated, the effective influence range of drilling gas exhausting and mining is improved by 1-3 times, the air permeability coefficient of coal around the drilled holes is improved by 100-200 times, the drilling methane gas exhausting and mining quantity is improved by 2-5 times within hundreds of meters, and the outburst elimination time of the coal bed is shortened by 30-50 percent. The slotting induced-flow pressure-relief anti-reflection method for the complicated seam has very good field application value and social benefits.

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com