Patents

Literature

870 results about "Metal fiber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metallic fibers are manufactured fibers composed of metal, metallic alloys, plastic-coated metal, metal-coated plastic, or a core completely covered by metal.

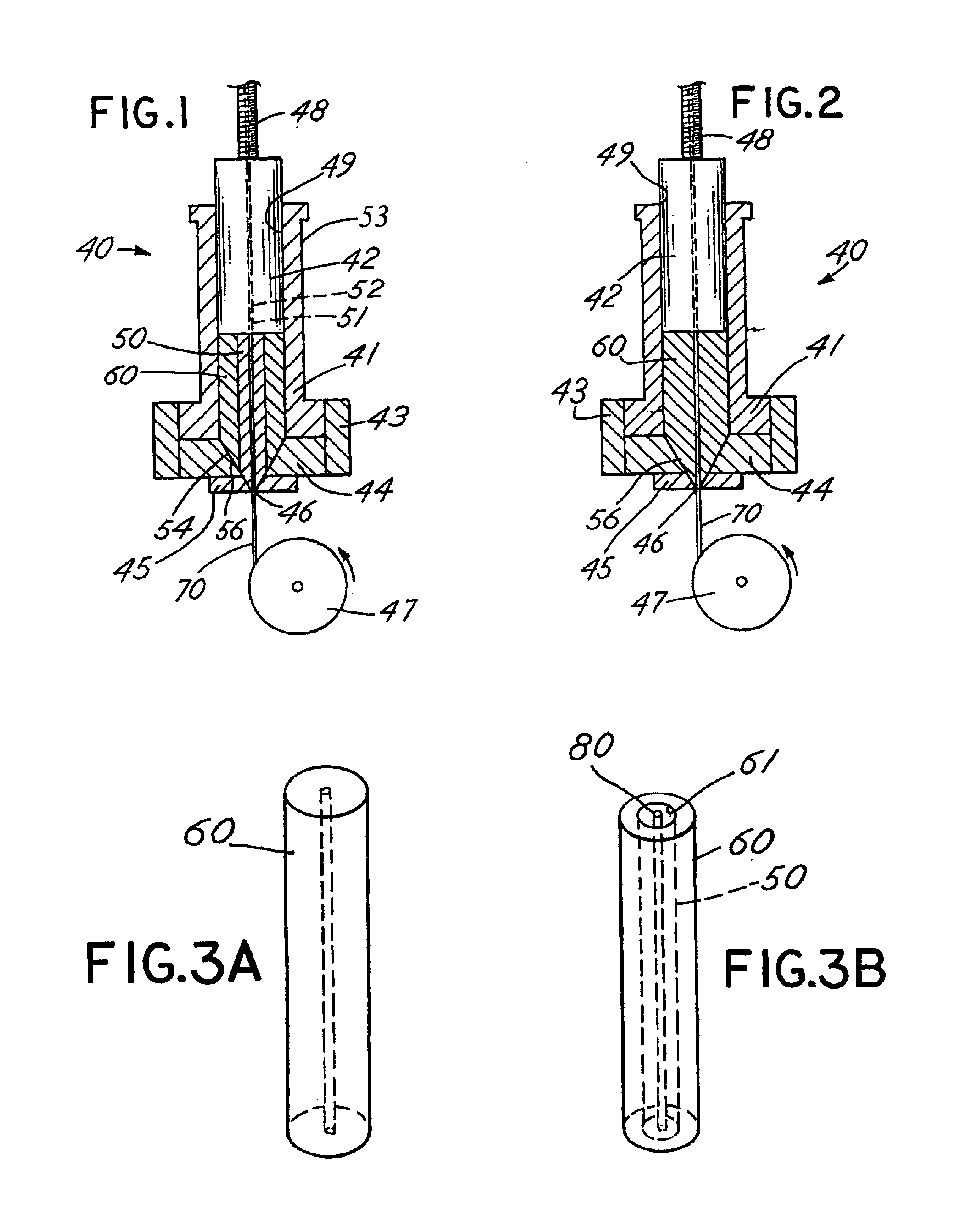

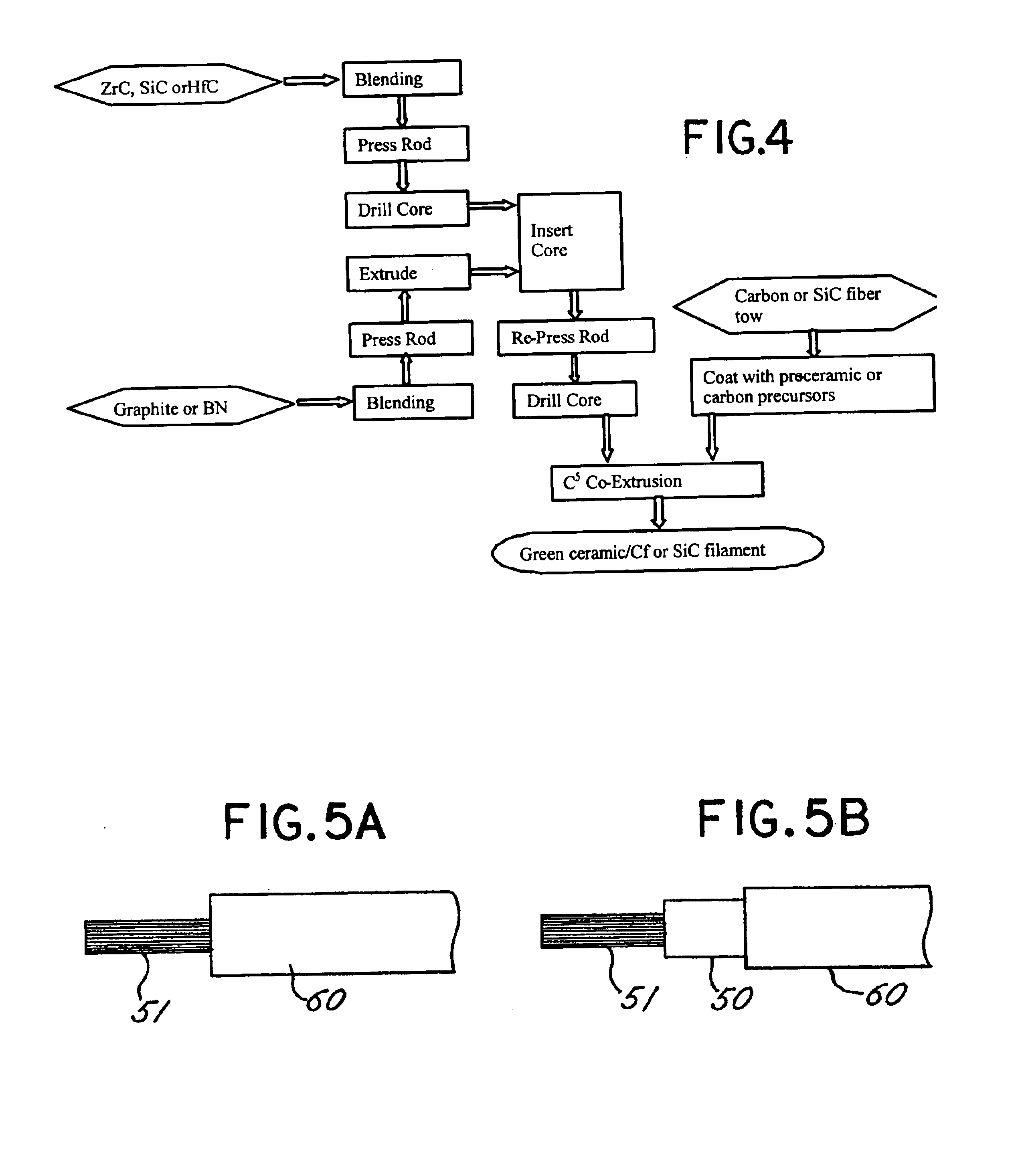

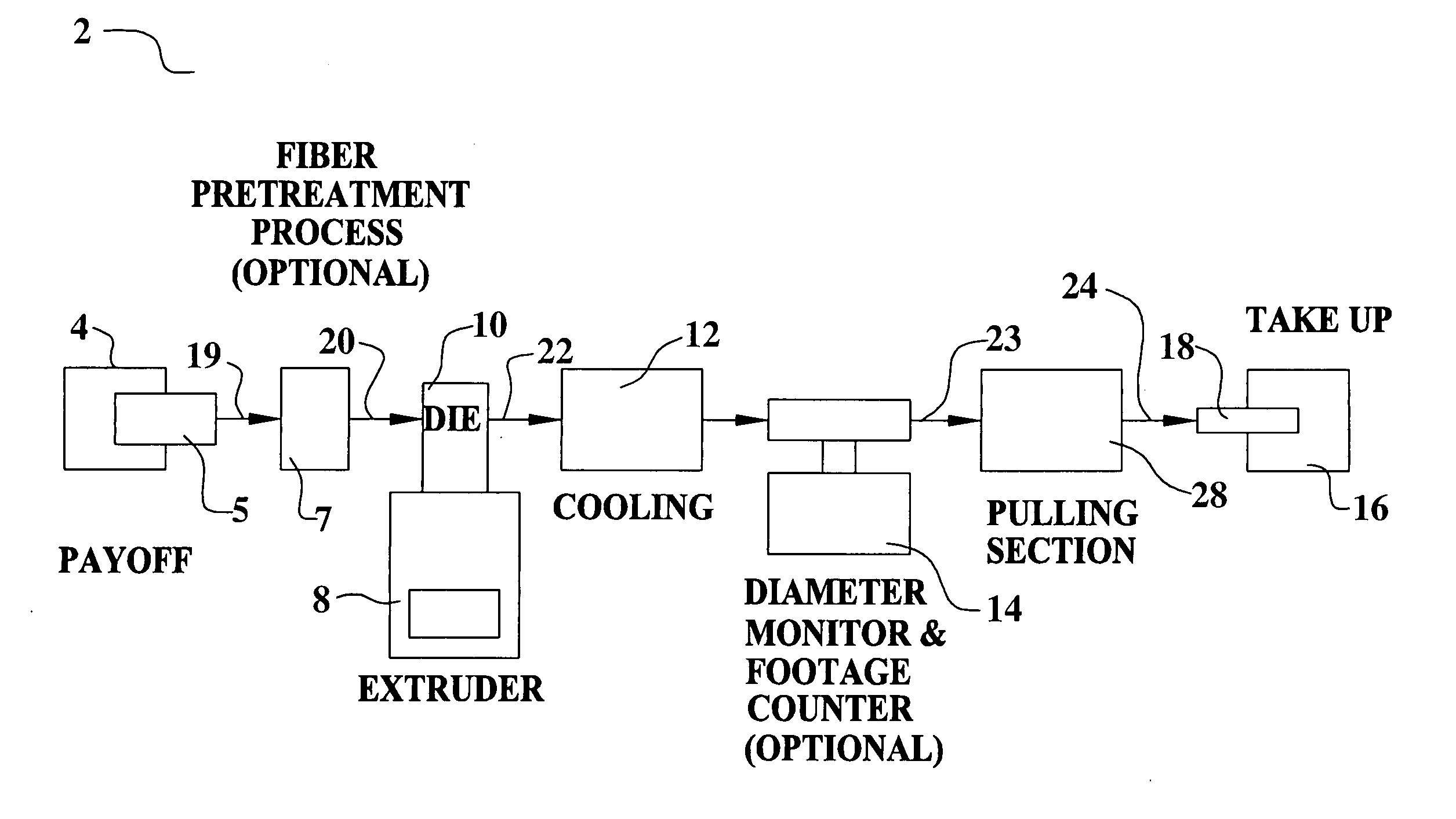

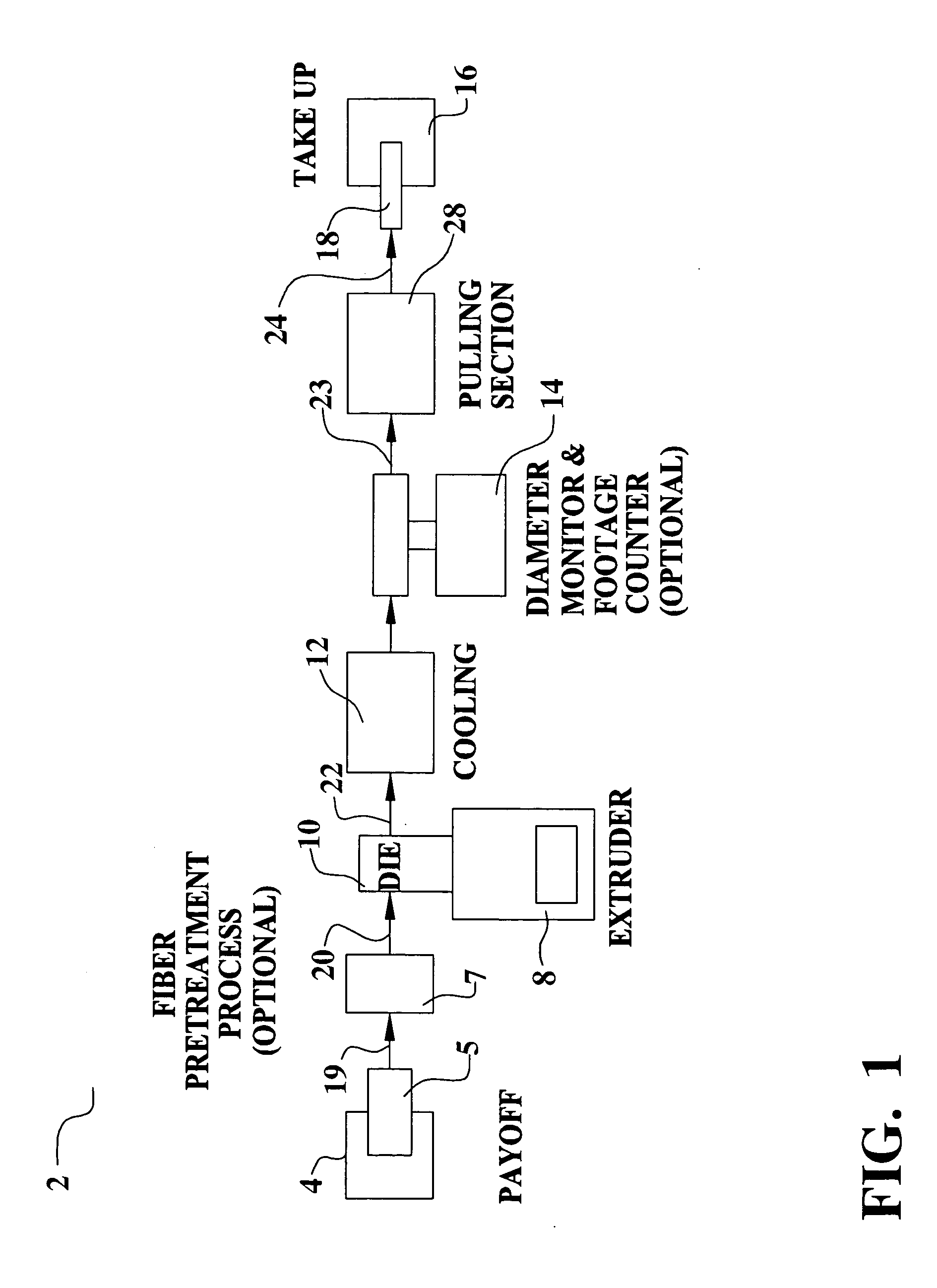

Continuous fiber reinforced composites and methods, apparatuses, and compositions for making the same

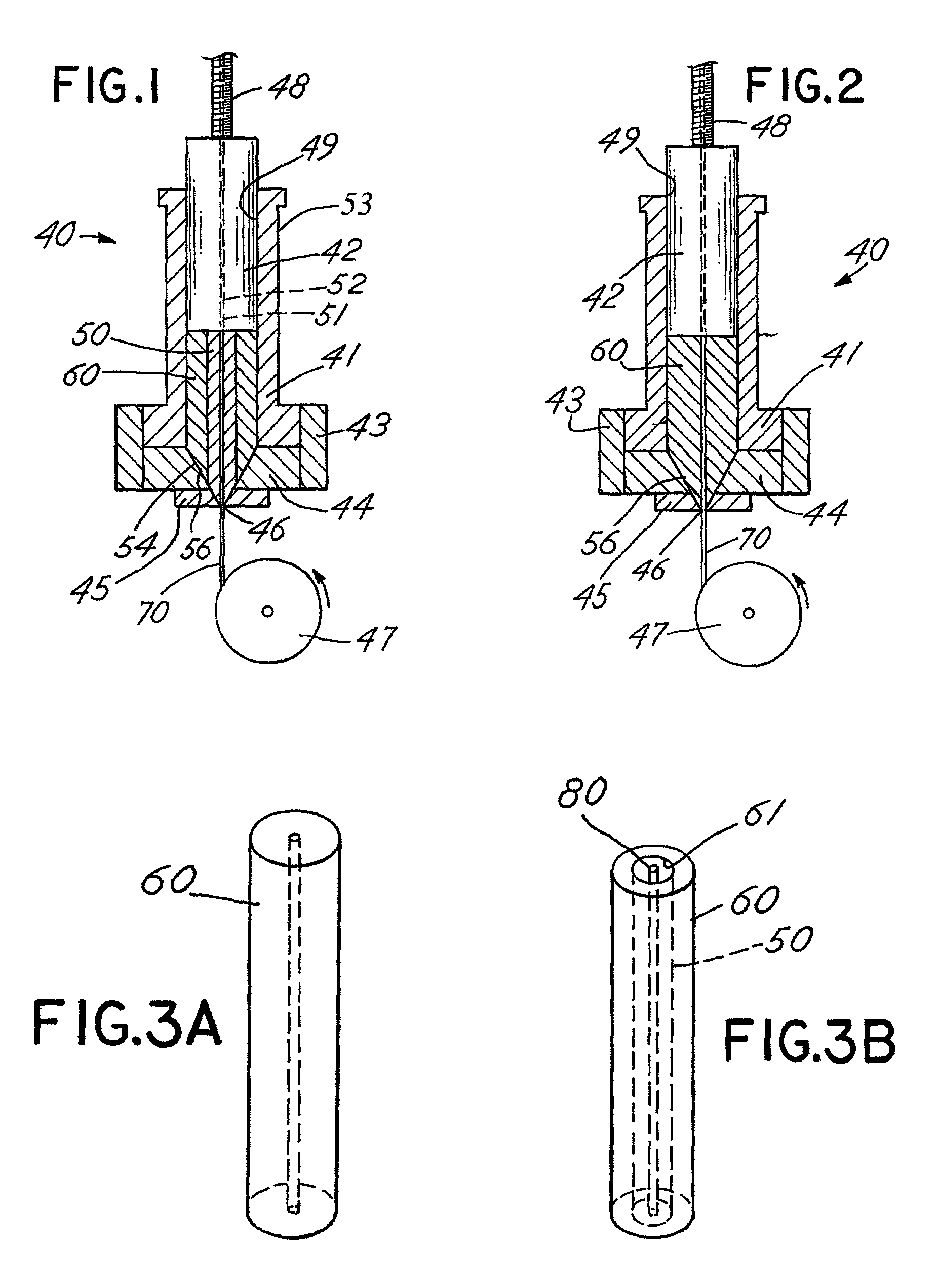

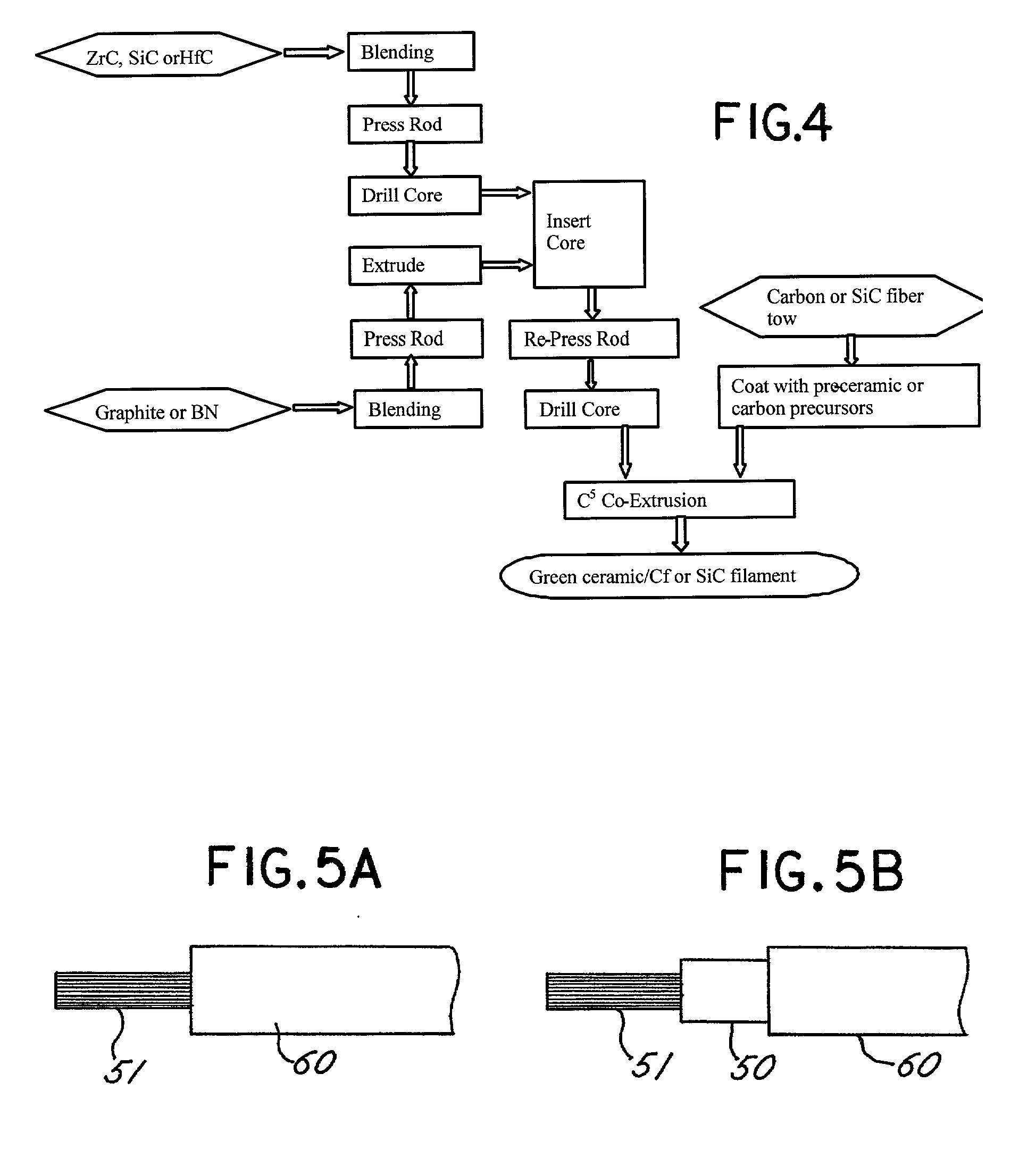

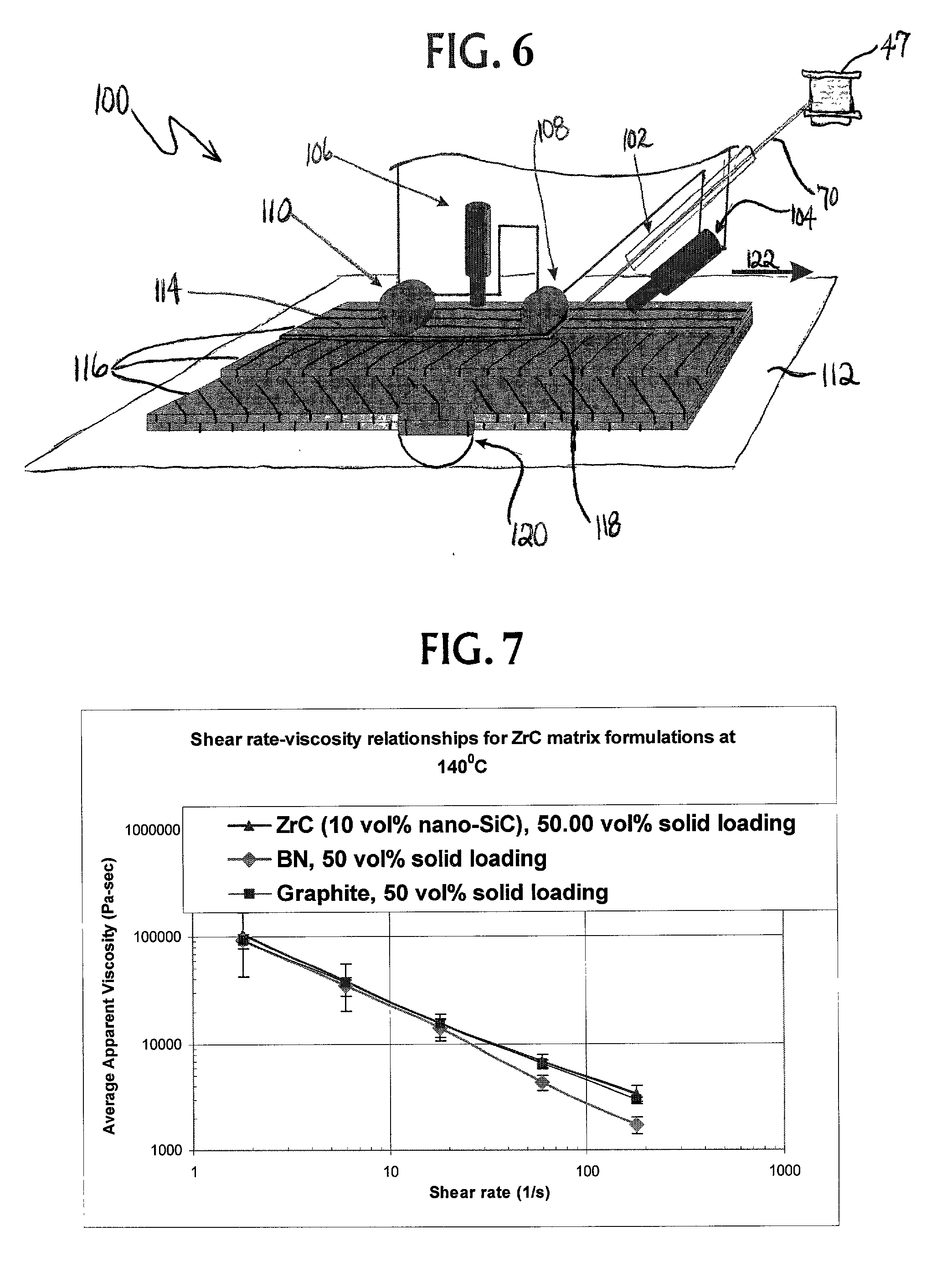

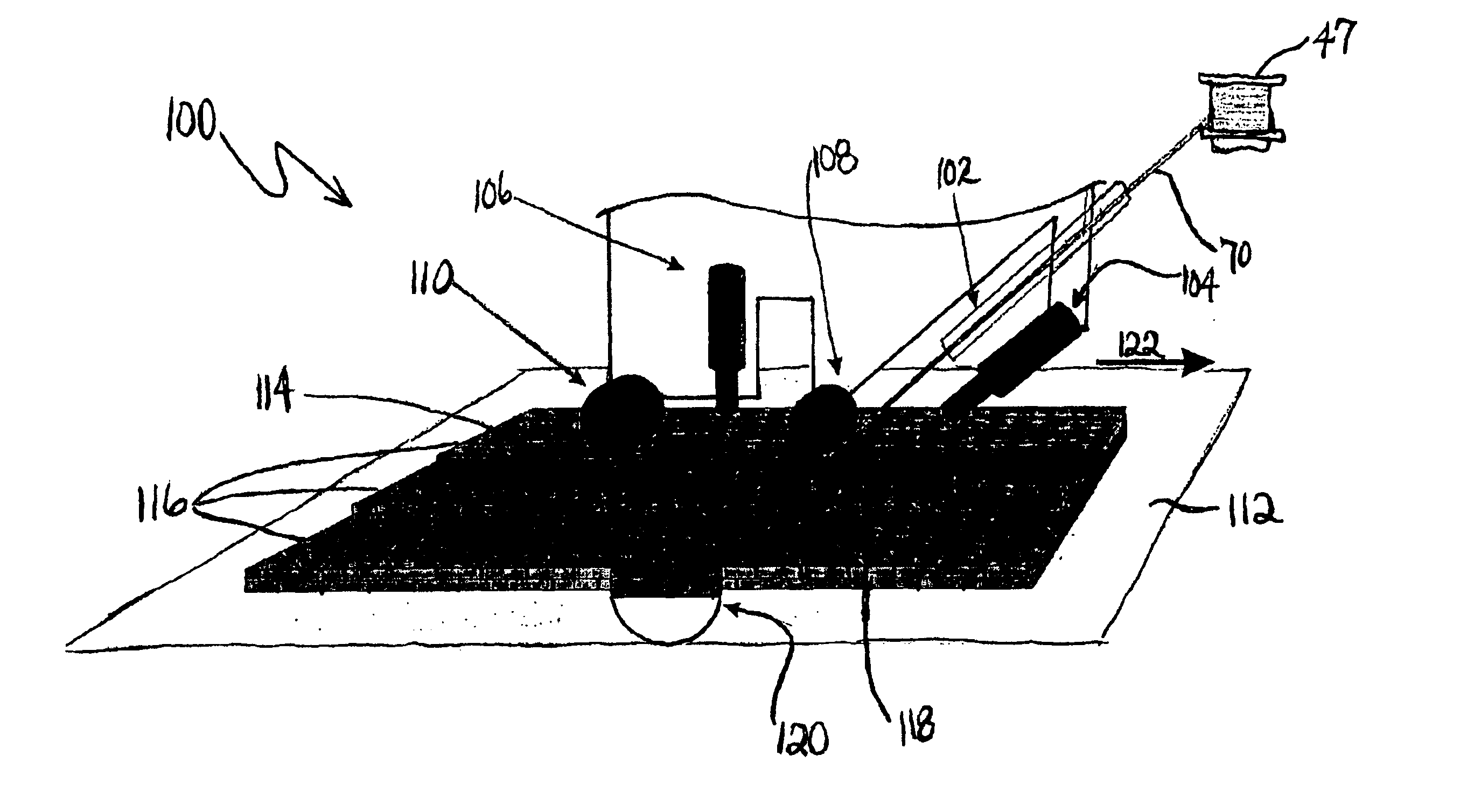

A process for continuous composite coextrusion comprising: (a) forming first a material-laden composition comprising a thermoplastic polymer and at least about 40 volume % of a ceramic or metallic particulate in a manner such that the composition has a substantially cylindrical geometry and thus can be used as a substantially cylindrical feed rod; (b) forming a hole down the symmetrical axis of the feed rod; (c) inserting the start of a continuous spool of ceramic fiber, metal fiber or carbon fiber through the hole in the feed rod; (d) extruding the feed rod and spool simultaneously to form a continuous filament consisting of a green matrix material completely surrounding a dense fiber reinforcement and said filament having an average diameter that is less than the average diameter of the feed rod; and (e) depositing the continuous filament into a desired architecture which preferably is determined from specific loading conditions of the desired object and CAD design of the object to provide a green fiber reinforced composite object.

Owner:ADVANCED CERAMICS

Continuous fiber reinforced composites and methods, apparatuses, and compositions for making the same

InactiveUS6899777B2Improved non-brittle failure characteristicFast preparationCeramic shaping apparatusCoatingsMetal fiberPolymer science

A process for continuous composite coextrusion comprising: (a) forming first a material-laden composition comprising a thermoplastic polymer and at least about 40 volume % of a ceramic or metallic particulate in a manner such that the composition has a substantially cylindrical geometry and thus can be used as a substantially cylindrical feed rod; (b) forming a hole down the symmetrical axis of the feed rod; (c) inserting the start of a continuous spool of ceramic fiber, metal fiber or carbon fiber through the hole in the feed rod; (d) extruding the feed rod and spool simultaneously to form a continuous filament consisting of a green matrix material completely surrounding a dense fiber reinforcement and said filament having an average diameter that is less than the average diameter of the feed rod; and (e) depositing the continuous filament into a desired architecture which preferably is determined from specific loading conditions of the desired object and CAD design of the object to provide a green fiber reinforced composite object.

Owner:ADVANCED CERAMICS

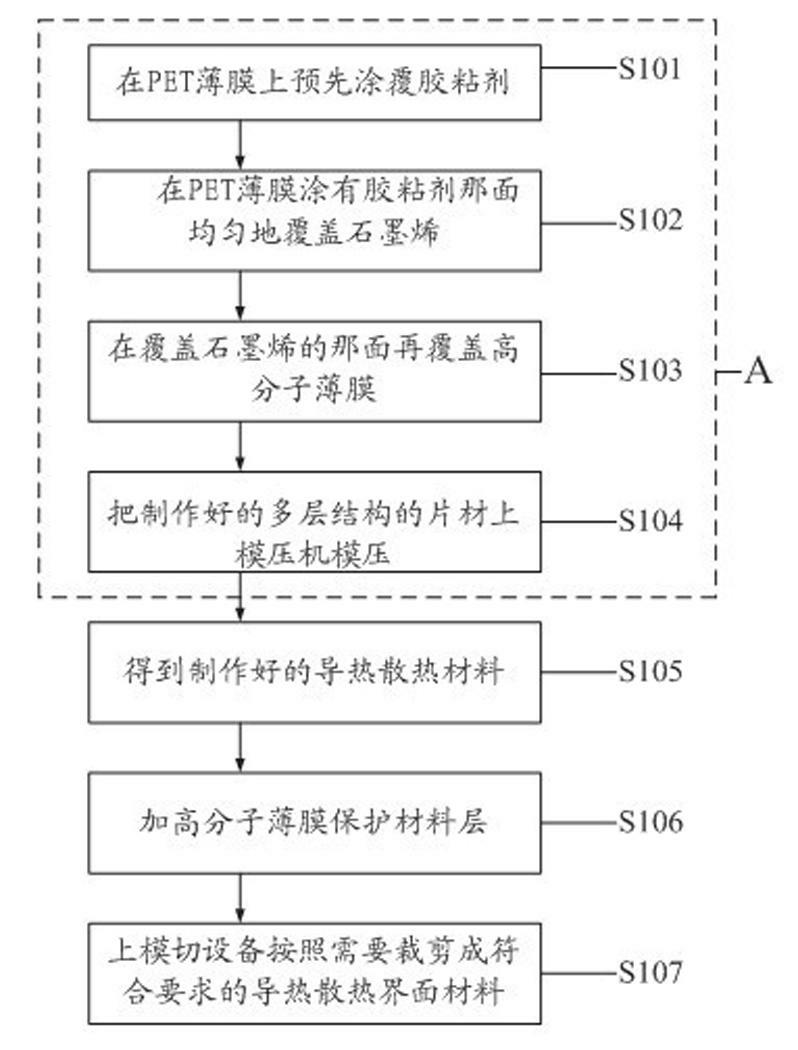

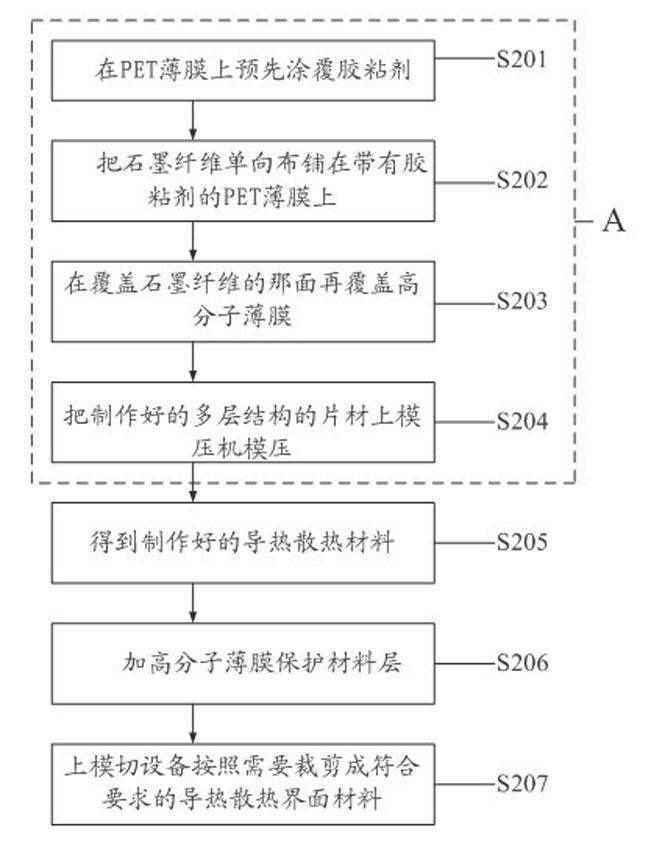

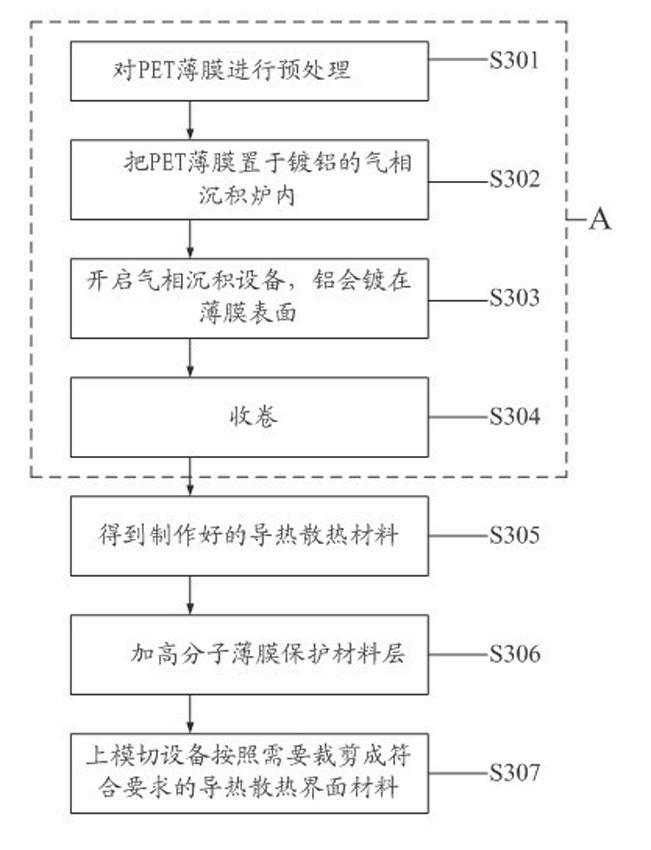

Heat-conduction heat-dissipation interface material and manufacturing method thereof

ActiveCN102651961AReduce volumeThe overall thickness is thinLayered productsCooling/ventilation/heating modificationsMetal fiberCalcium silicate

The invention provides a heat-conduction heat-dissipation interface material and a manufacturing method thereof, wherein the heat-conduction heat-dissipation interface material is applied to the field of heat dissipation of electronic products. The heat-conduction heat-dissipation interface material comprises a heat-conduction heat-dissipation layer and a surface protective material layer, wherein the heat-conduction heat-dissipation layer consists of one or more of graphite, nano graphite, crystalline flake graphite, graphene, pyrolytic carbon, pyrolytic graphite, graphite powder, carbon nano tubes, carbon fibers, graphite fibers, resin, ceramic fibers, quartz fibers, metal fibers, zirconia, boron nitride, silicon nitride, boron carbide, silicon carbide, magnesia powder, metasillicio acid fibers, calcium silicate aluminum fibers, aluminium oxide fibres, copper power, aluminium power, silver power, tungsten power and molybdenum power; and the surface protective material layer is a polymeric membrane. The heat-conduction heat-dissipation interface material manufactured according to the materials and the method provided by the invention has the advantages of effectively improved heat-dissipation performance, small volume, light weight and small thickness, can be used for prolonging the service life of an electronic component, and simultaneously is easy to produce and process.

Owner:SHANGHAI QI JIE CARBON MATERIALS

Method for producing metal fibers

Owner:ATI PROPERTIES

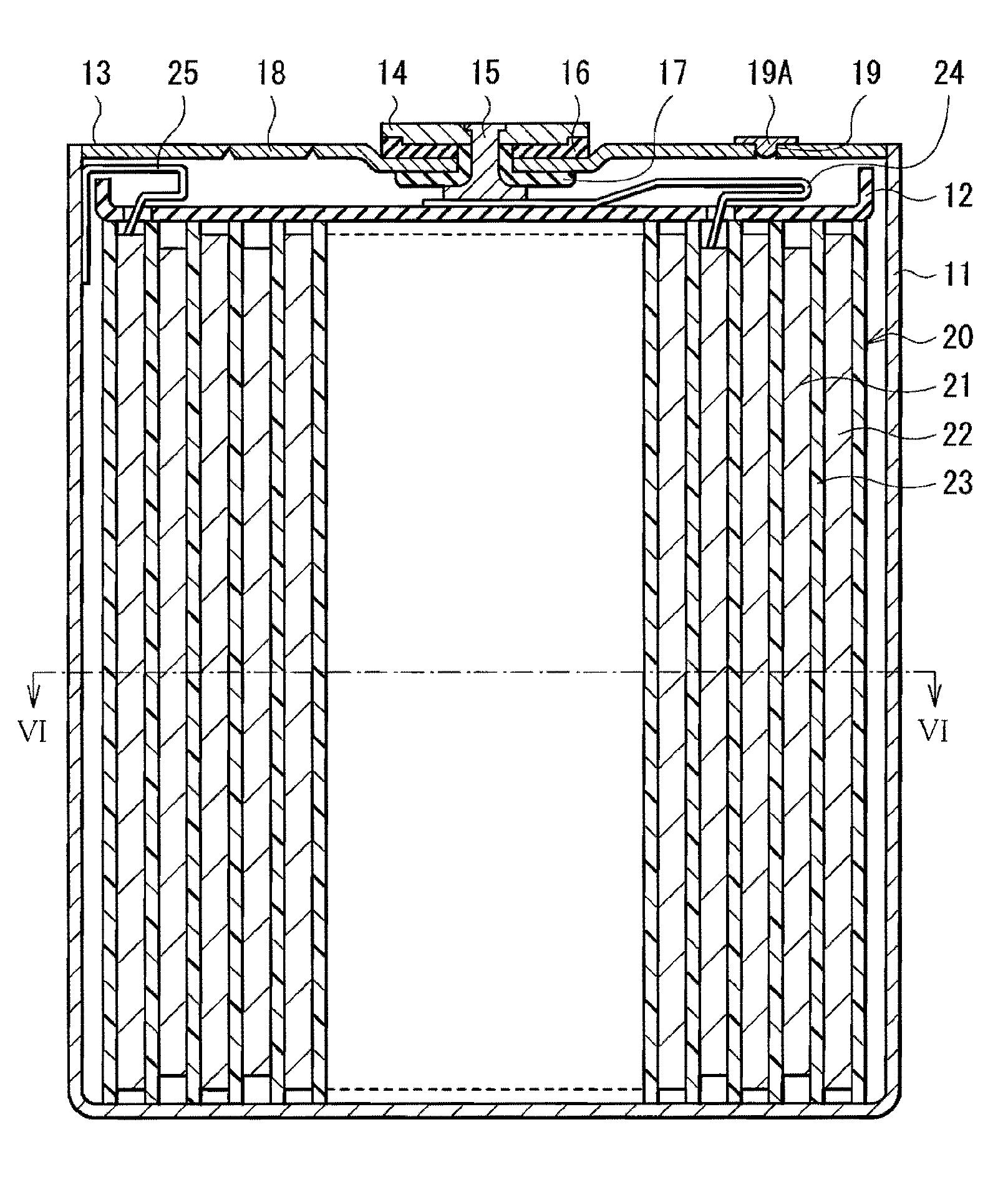

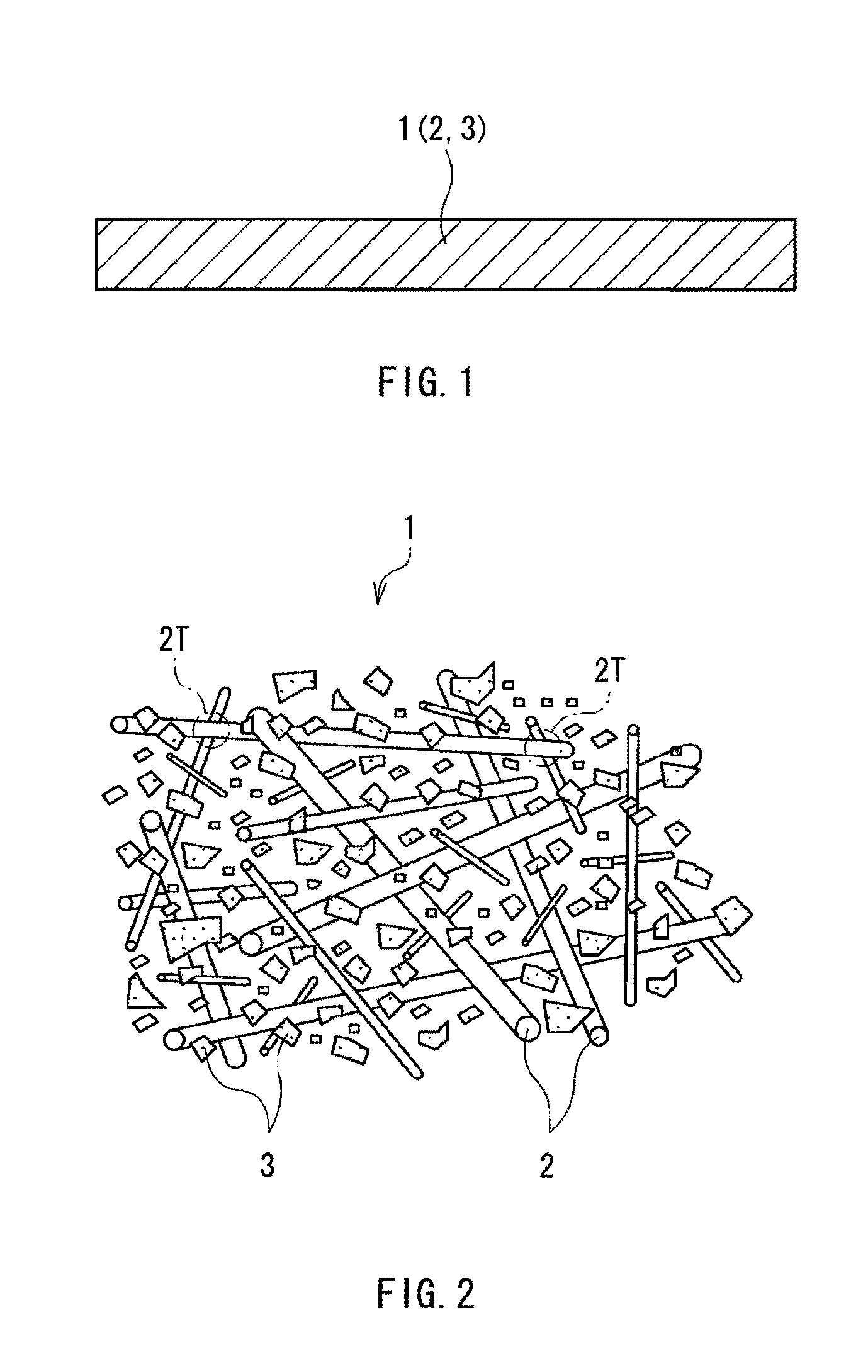

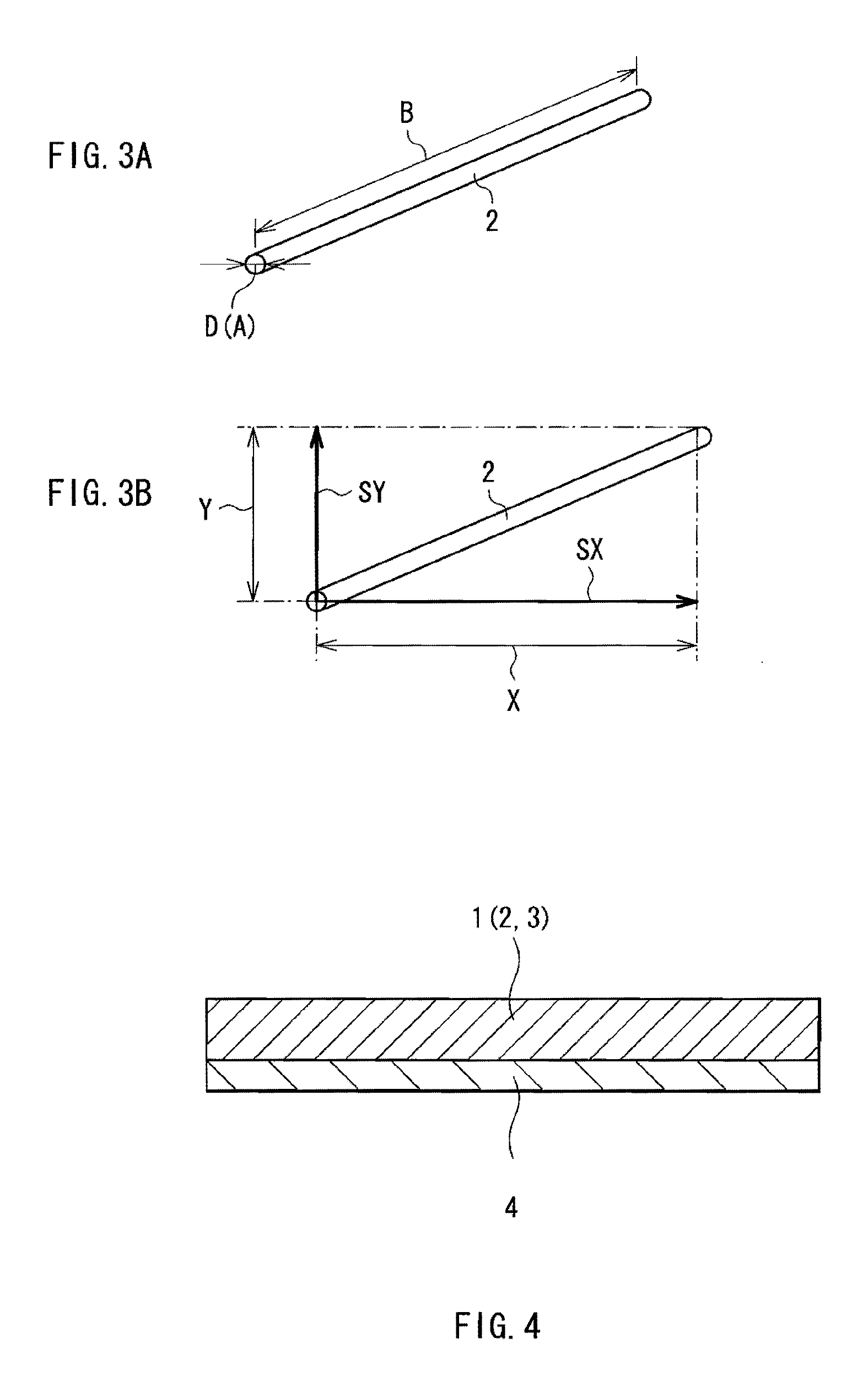

Anode and secondary battery

ActiveUS20090269677A1Improve performanceReduced characteristicsAlkaline accumulatorsFinal product manufactureMetal fiberMetal foil

A secondary battery capable of improving the cycle characteristics is provided. The secondary battery includes a cathode, an anode, and an electrolytic solution. The electrolytic solution is impregnated in a separator provided between the cathode and the anode. The anode has an anode structure on an anode current collector. The anode structure has a structure in which a plurality of anode active material particles having silicon are held by a plurality of metal fibers forming a three-dimensional network structure. Due to the plurality of metal fibers, sufficient conductive paths are obtained among the plurality of anode active material particles. Thus, compared to a general anode in which an active material layer is provided on a current collector made of a metal foil or the like, the current collectivity is improved.

Owner:MURATA MFG CO LTD

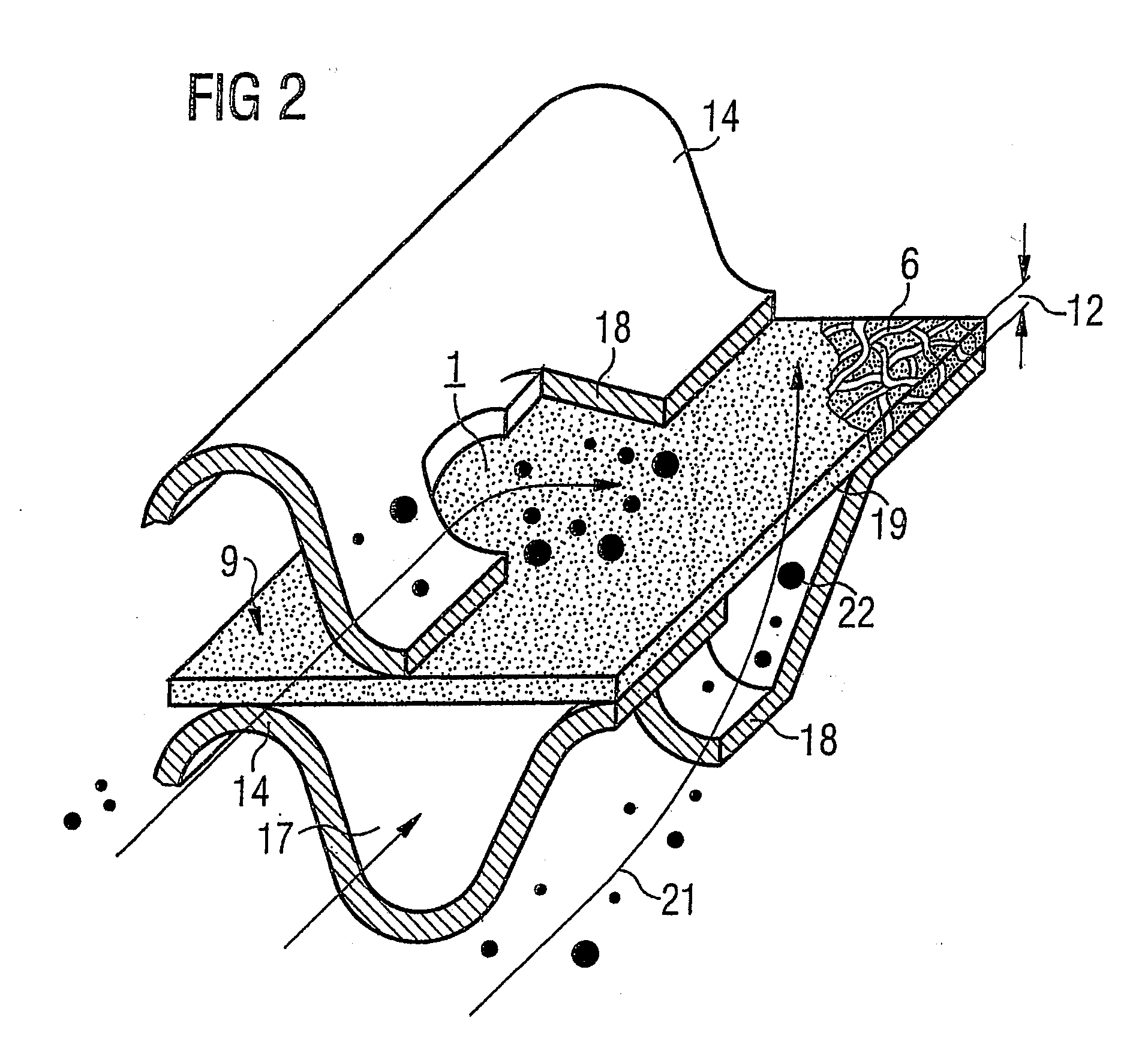

High-temperature-resistant coated fiber layer and particulate trap with the coated fiber layer

InactiveUS20050232830A1Improve efficiencySmall structureCombination devicesInternal combustion piston enginesParticulatesMetal fiber

A high-temperature-resistant fiber layer for an open particulate trap for purifying exhaust gases from mobile internal combustion engines includes metal fibers. At least a section of the fiber layer has a catalytically active and / or adsorbent coating, in particular such as that of an oxidation catalyst and / or a three-way catalyst and / or an SCR catalyst. A longitudinal section, which is substantially perpendicular to a largest outer surface, has openings formed therein with an average size of 0.01 mm to 0.5 mm, in particular 0.05 mm to 0.25 mm. A particulate trap with the coated fiber layer is also provided.

Owner:EMITEC GESELLSCHAFT FUR EMISSIONSTECHNOLOGIE MBH

Flame retardant thermoplastic compositions having EMI shielding

ActiveUS20070105994A1Good physical propertiesConductive materialNon-conductive material with dispersed conductive materialPolysiloxane polycarbonate copolymerMetal fibers

A flame retardant thermoplastic composition having excellent physical properties that includes 20 to 90 wt. % of a polycarbonate resin; from 1 to 35 wt. % of an impact modifier; from 0.5 to 30 wt. % of a polysiloxane-polycarbonate copolymer including from 8 to 30 wt. % polydimethylsiloxane units or the equivalent molar amount of other diorganosiloxane units; from 0.5 to 20 wt. % of a phosphorus-containing flame retardant, and from 3 to 30 wt. % of metal fiber, each based on the total combined weight of the thermoplastic composition, exclusive of any filler. In one embodiment, a molded sample of the thermoplastic composition having a thickness of 3.0 mm (±10%) has an EMI shielding of at least 20 dB. In addition, a molded sample of the thermoplastic composition is capable of achieving UL94 V0 or V1 rating at a thickness of 1.5 mm (±10%). The compositions are useful in forming flame retardant articles having EMI shielding characteristics.

Owner:SHPP GLOBAL TECH BV

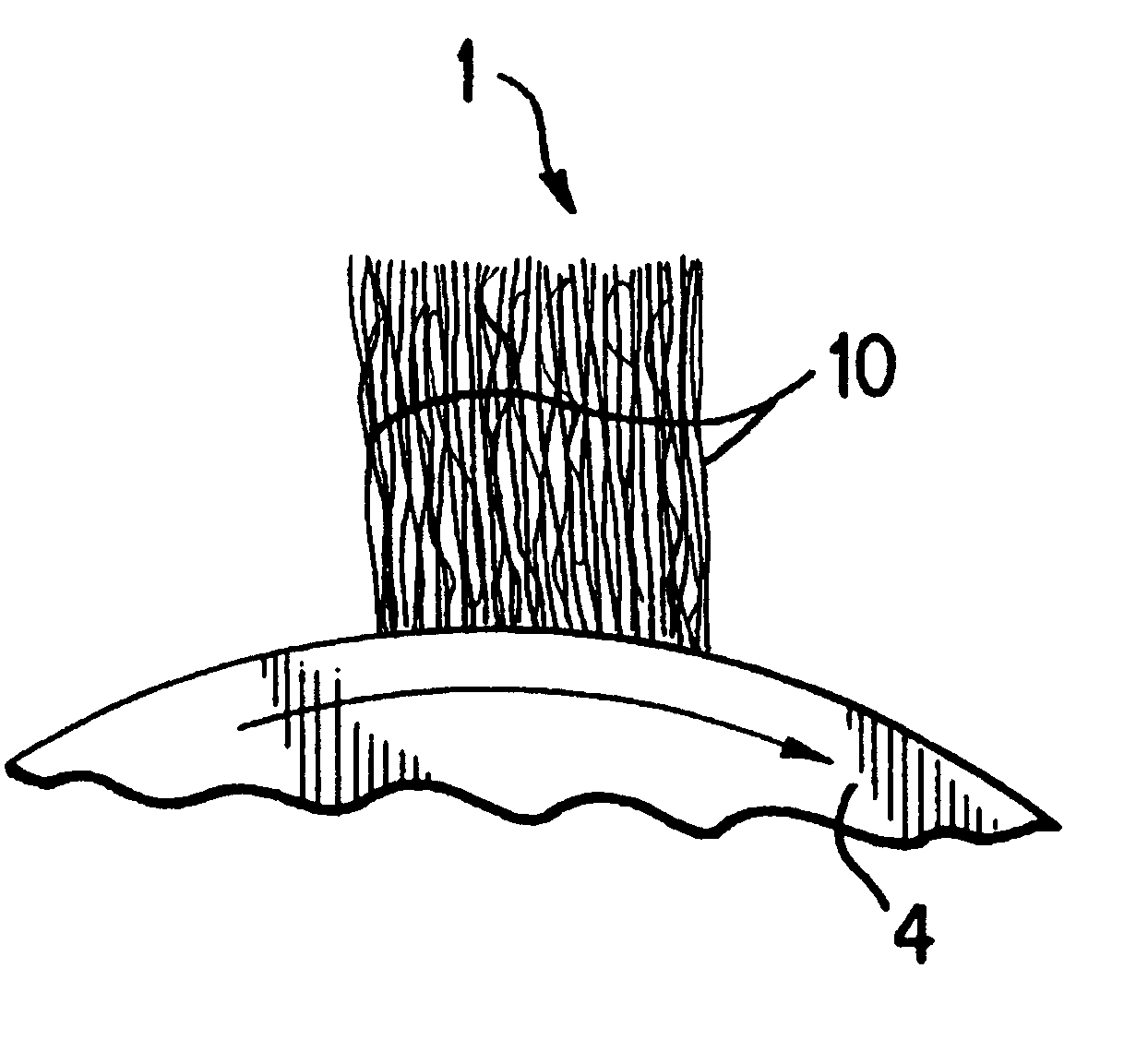

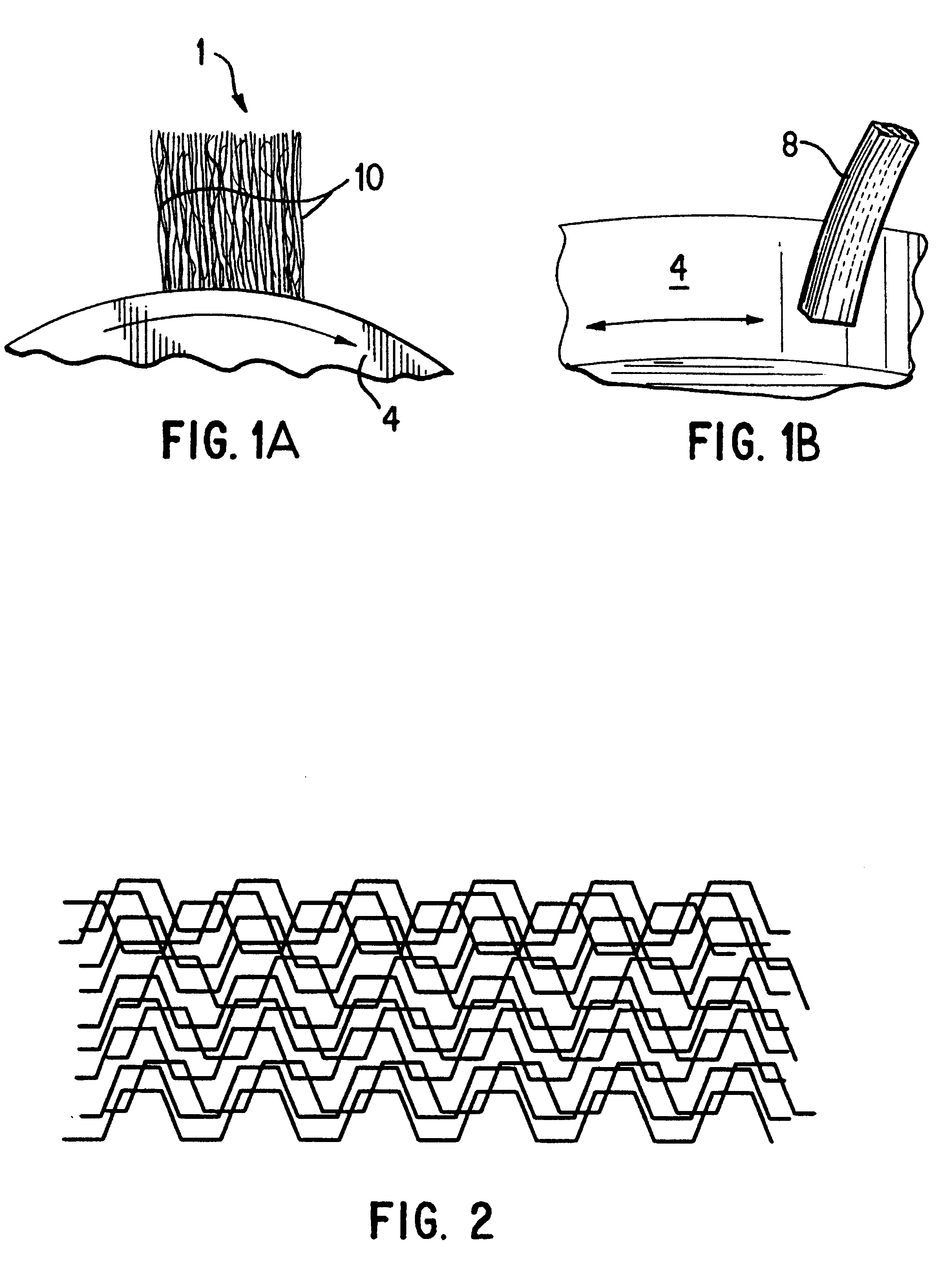

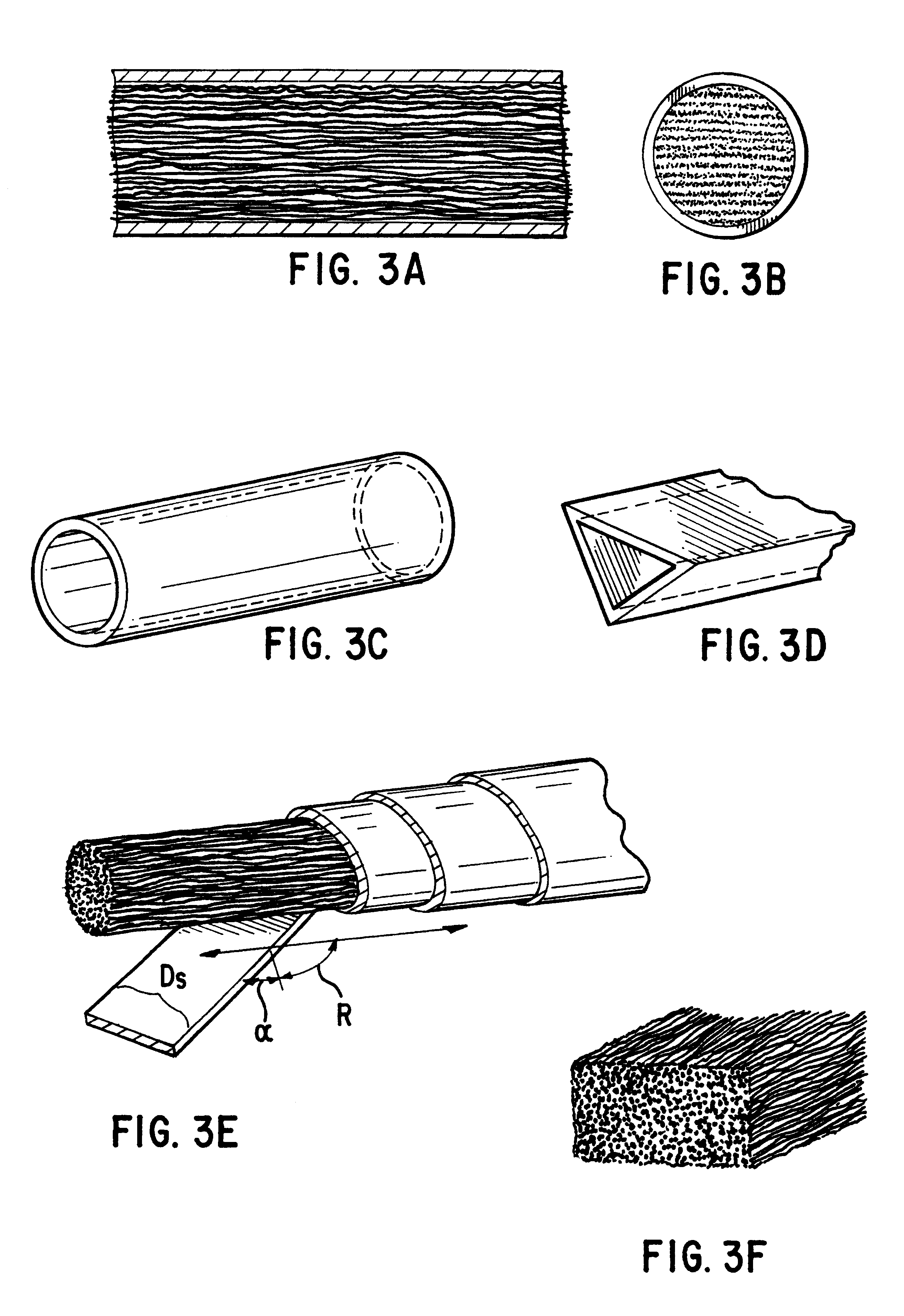

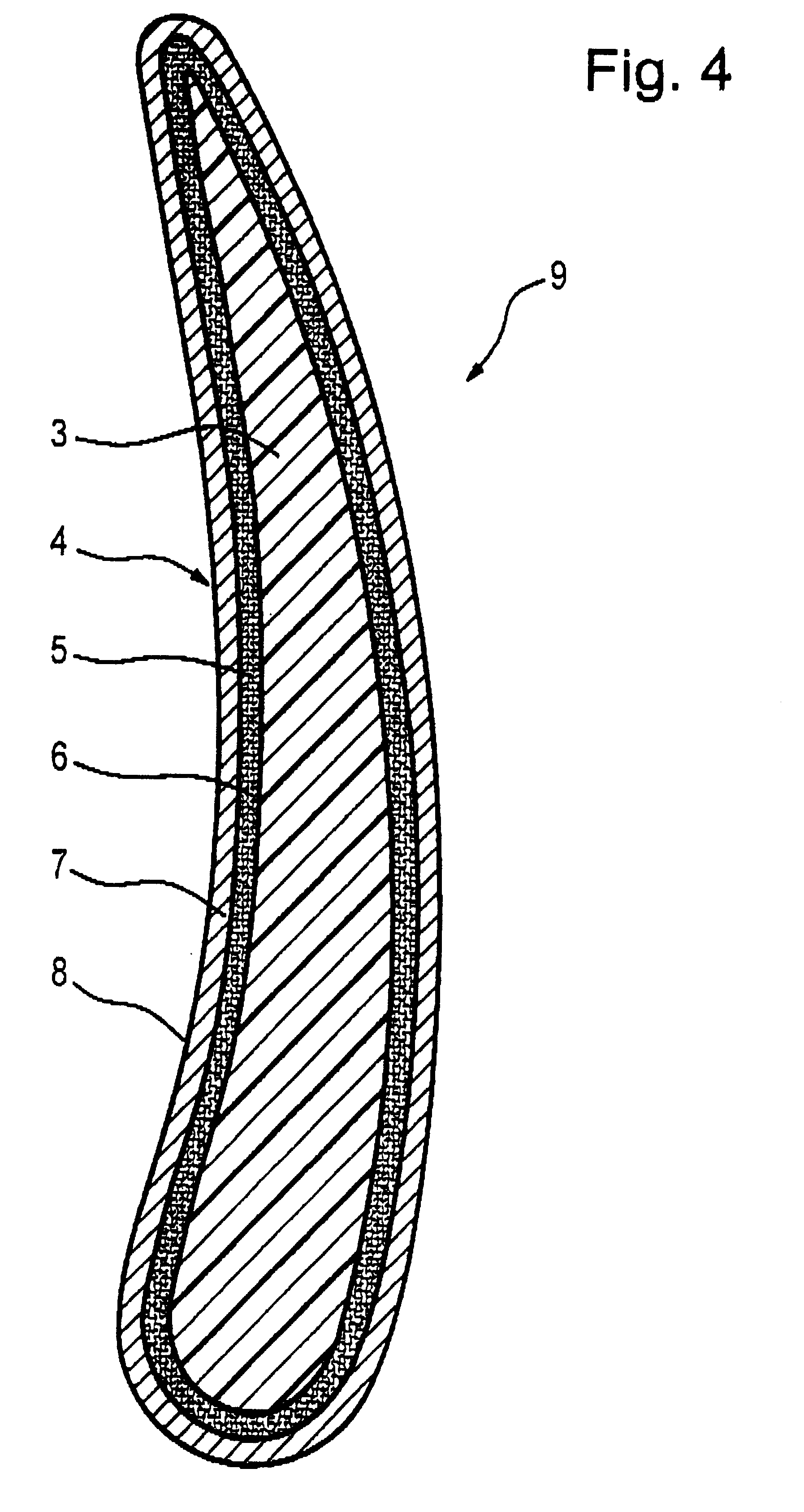

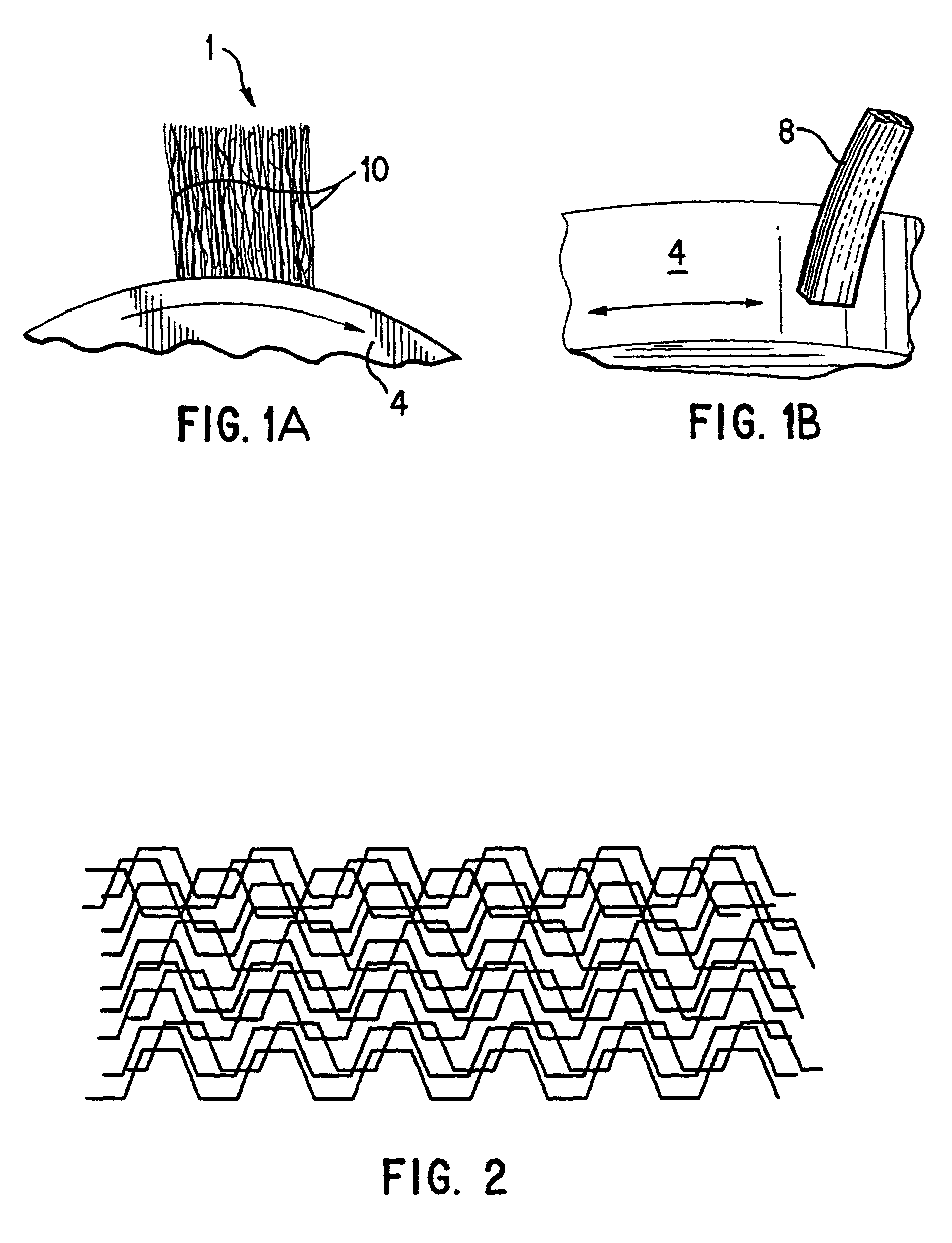

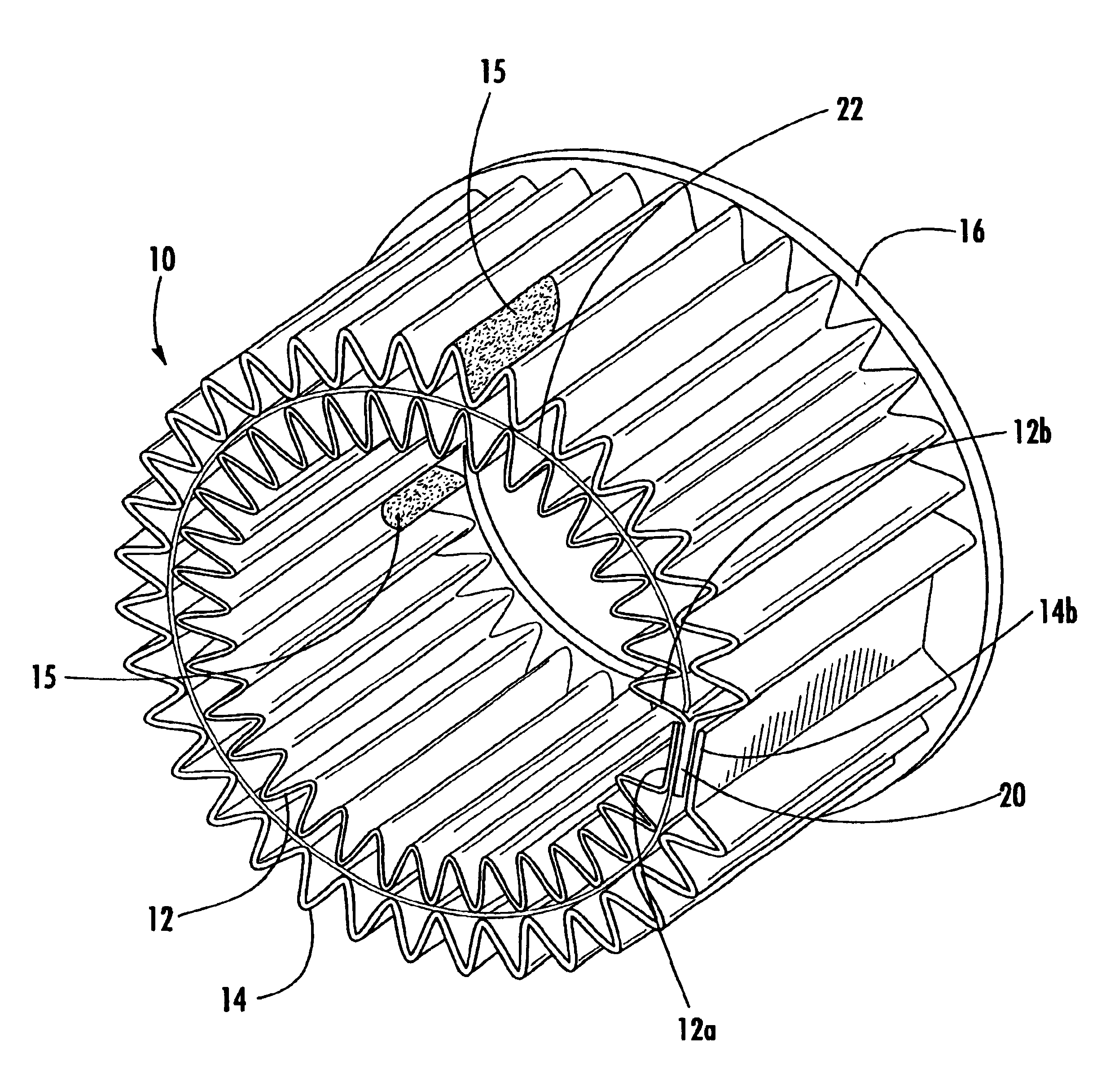

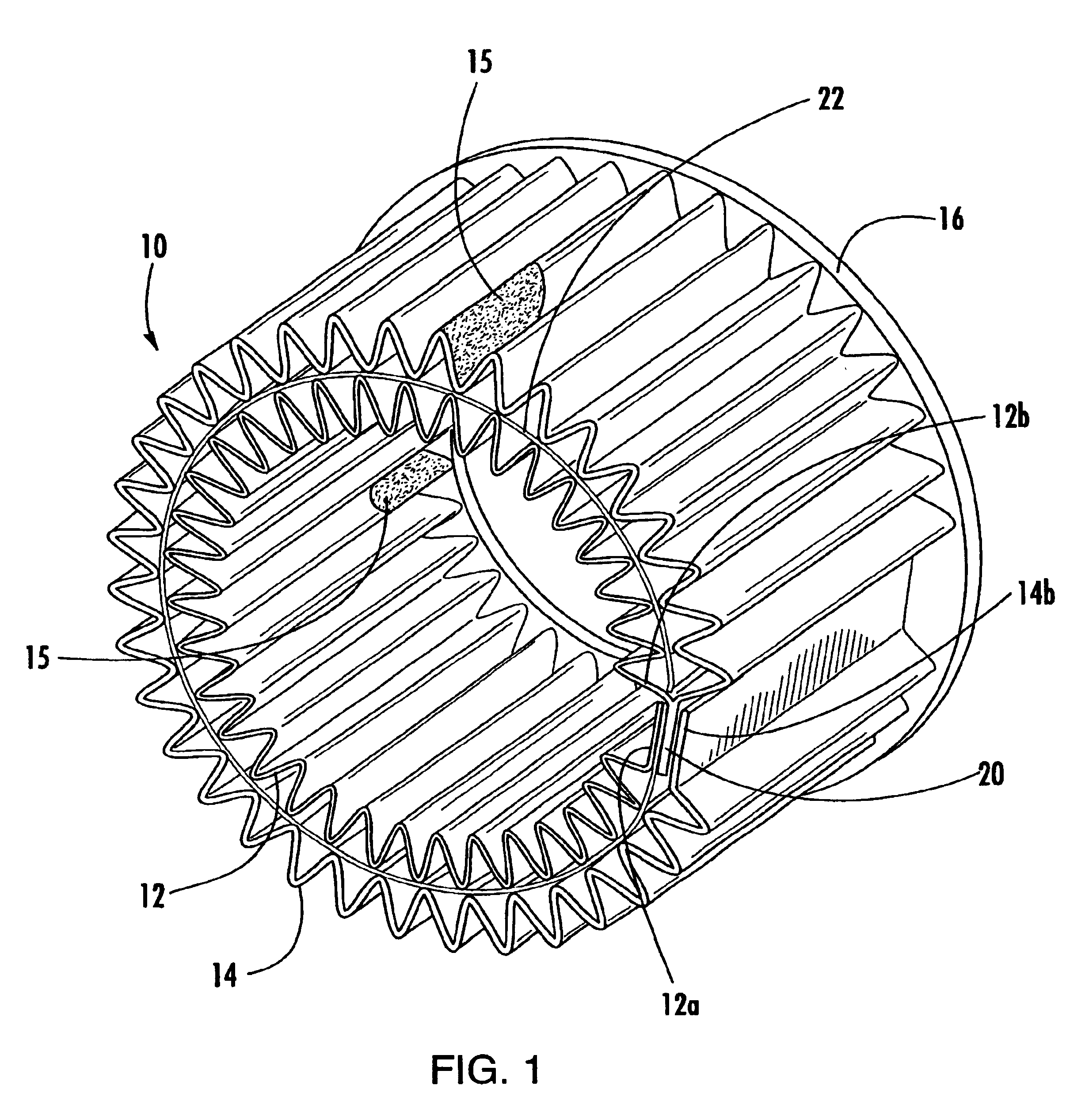

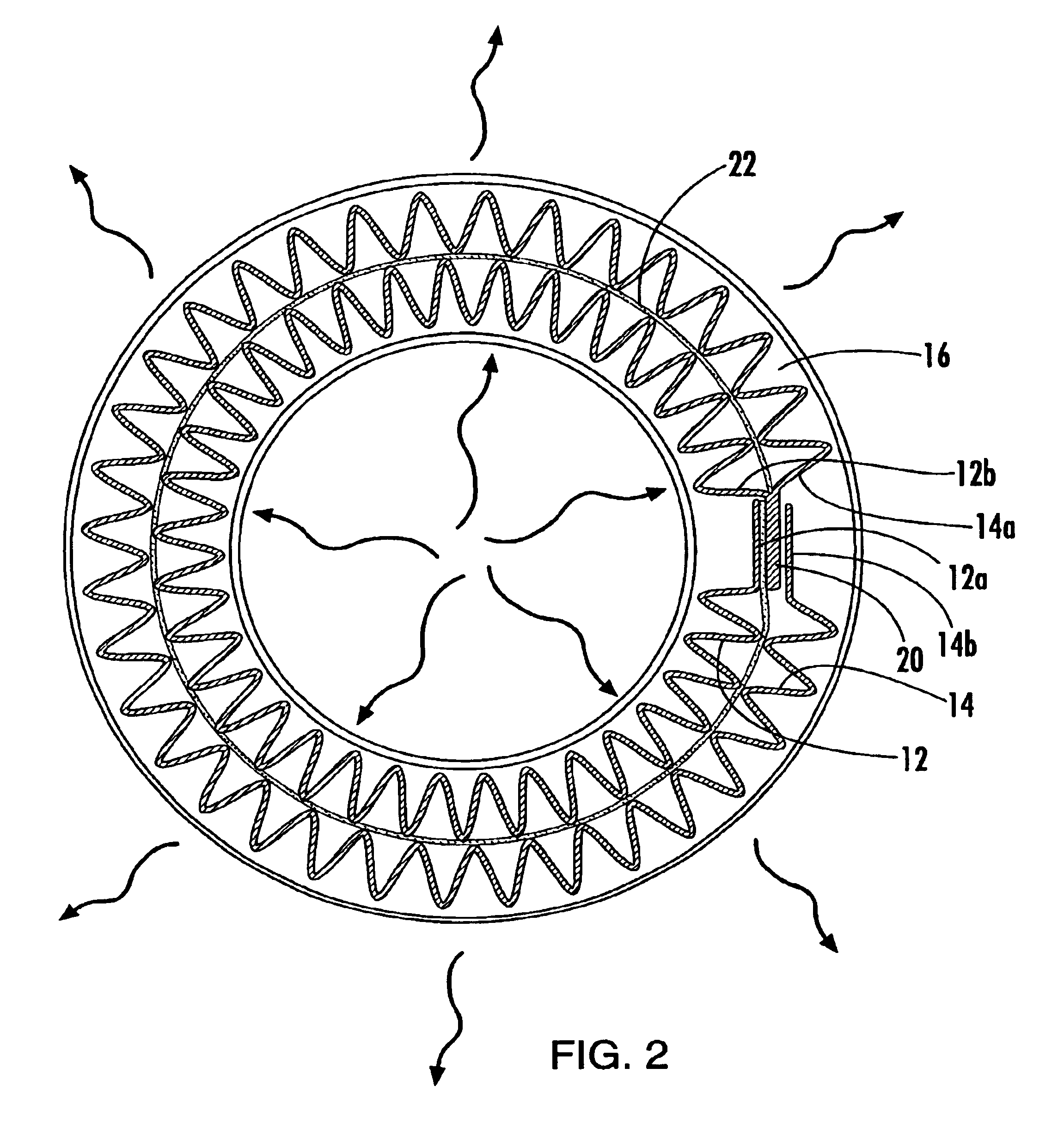

Continuous metal fiber brushes

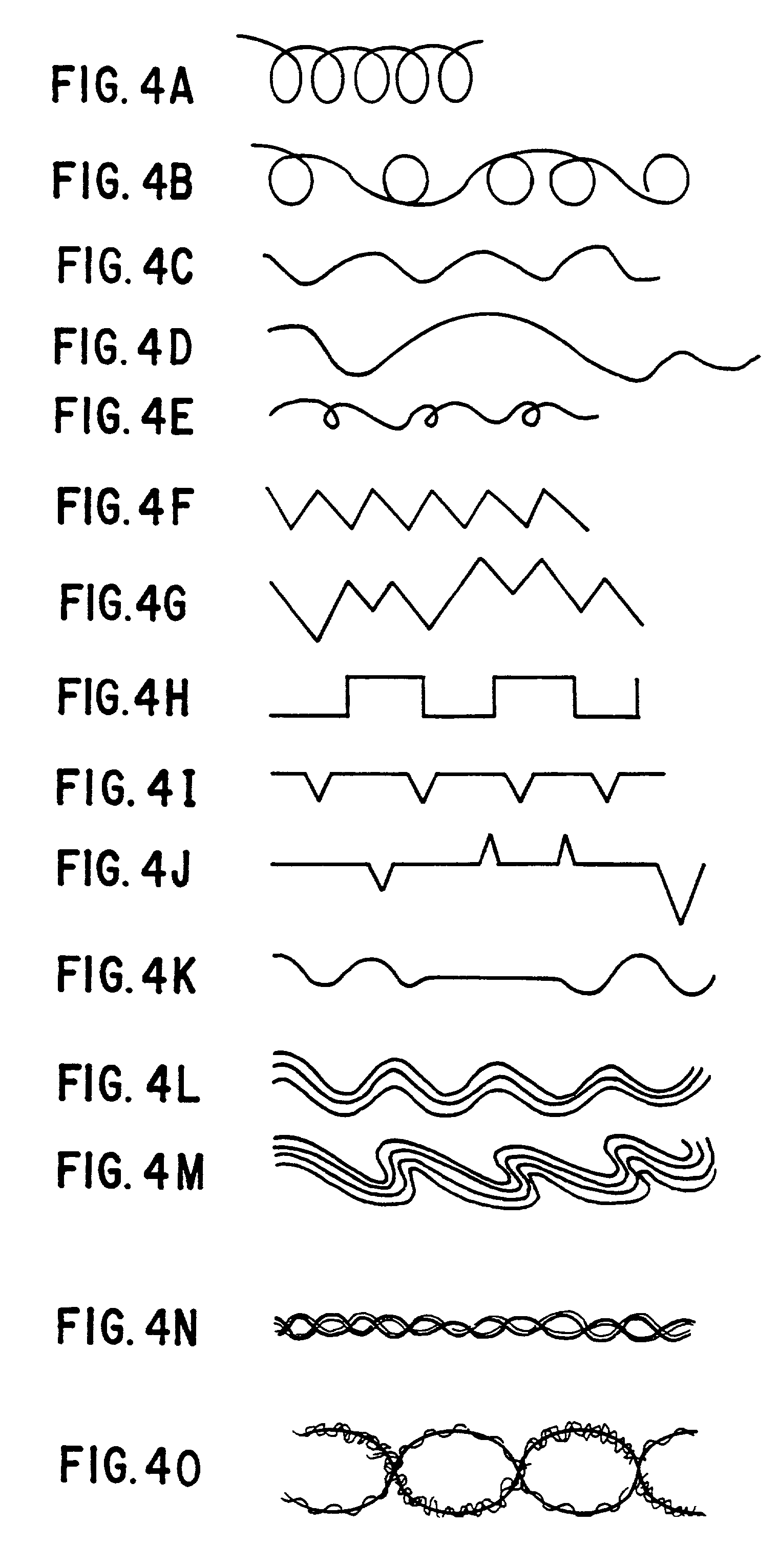

InactiveUS6245440B1Avoid large gapsSuppressing advanceRotary current collectorMagnetic materialsMetal fiberLubrication

A conductive fiber brush including a brush stock composed of plural conductive fibers or strands of fibers at least some of which may have plural bends along the leg of the fibers or strands. The fibers may have a diameter less than 0.2 mm and are arranged in contacting engagement with each other with the touching points among the fibers or strands maintaining elastic tension between the fibers or strands and thereby maintaining voids between the fibers or strands to produce a packing fraction between 1 and 50% and in extreme cases up to 70% but generally between 10-20% depending on the various factors, including the materials used, the current densities to be conducted, and the sliding speeds under operation. The plural bends are implemented by producing fibers or strands having a regular or irregular spiral, wavy, saw-tooth, triangular, and / or rectangular pattern, or other undulating pattern. Optionally, the voids in brush stock may be partially filled with a strengthening, lubricating, abrasive, and / or polishing material, and may be wrapped in an outer sheath, slid into a casing, or provided with an other covering of all or part of the area of the brush stock, be infiltrated or sprayed at the surface with some material, have an increased packing fraction at the surface and / or have some or all of the touching points between the fibers or strands soldered, welded or otherwise thermally joined. Optionally also, the friction among the fibers may be reduced through light lubrication applied by rinsing the brush or brush stock in a lubricant. In one embodiment, the fiber brush is employed in a brush loading device having a hydrostatically controlled brush holder wherein the force exerted on the brush is controlled by a metallic or other conductive hydrostatic fluid which at the same time conducts the current to the brush.

Owner:VIRGINIA UNIV PATENT FOUND OF

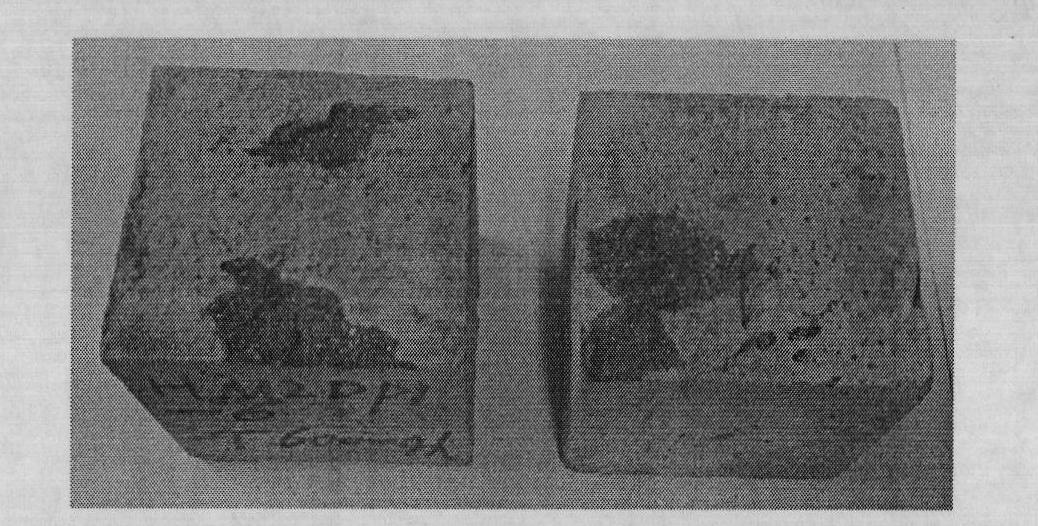

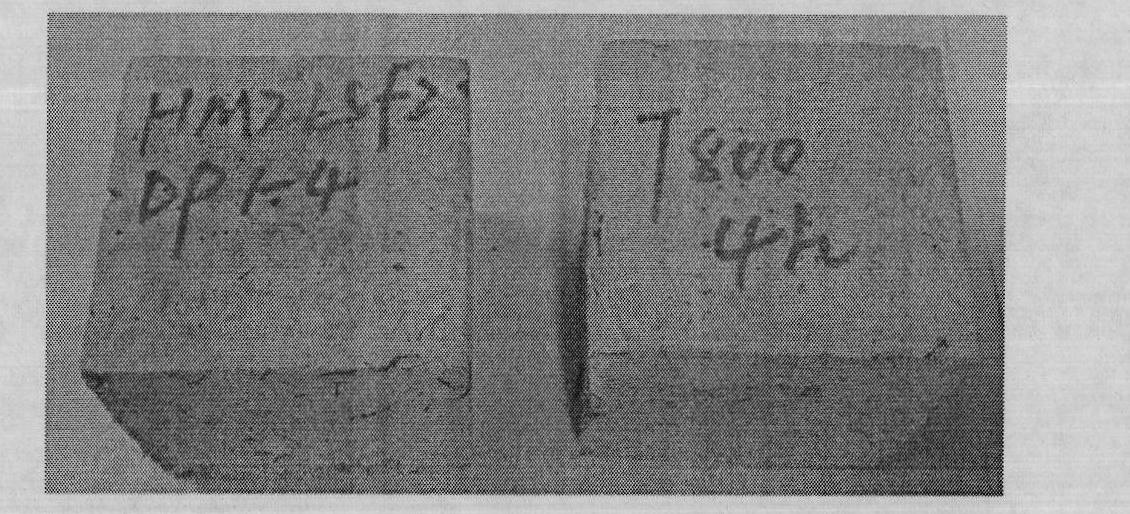

Low carbon magnesia carbon brick and preparation method thereof

The invention relates to the technical field of magnesia carbon brick refractory materials, in particular to a low carbon magnesia carbon brick and a preparation method thereof. The technical proposal comprises the following steps: mixing 58 to 70 weight percent of magnesite grains, 20 to 28 weight percent of magnesite fine powder, 0.5 to 5 weight percent of expansion graphite, 0 to 6 weight percent of crystalline flake graphite, 1 to 5 weight percent of antioxidant, 0.1 to 5 weight percent of metal fibre and 1.5 to 4.5 weight percent of phenolic resin; and molding and drying the mixture to prepare a low carbon magnesia carbon brick of which carbon content is between 2 and 7 percent. The low carbon magnesia carbon brick prepared by the invention has the advantages of low heat expansion rate, good scale resistant performance, good high temperature strengthen, good thermal shock resistant performance, good toughness and corrosion resistance, and the brick is not easy to fracture when using.

Owner:JINAN LUDONG REFRACTORY CO LTD

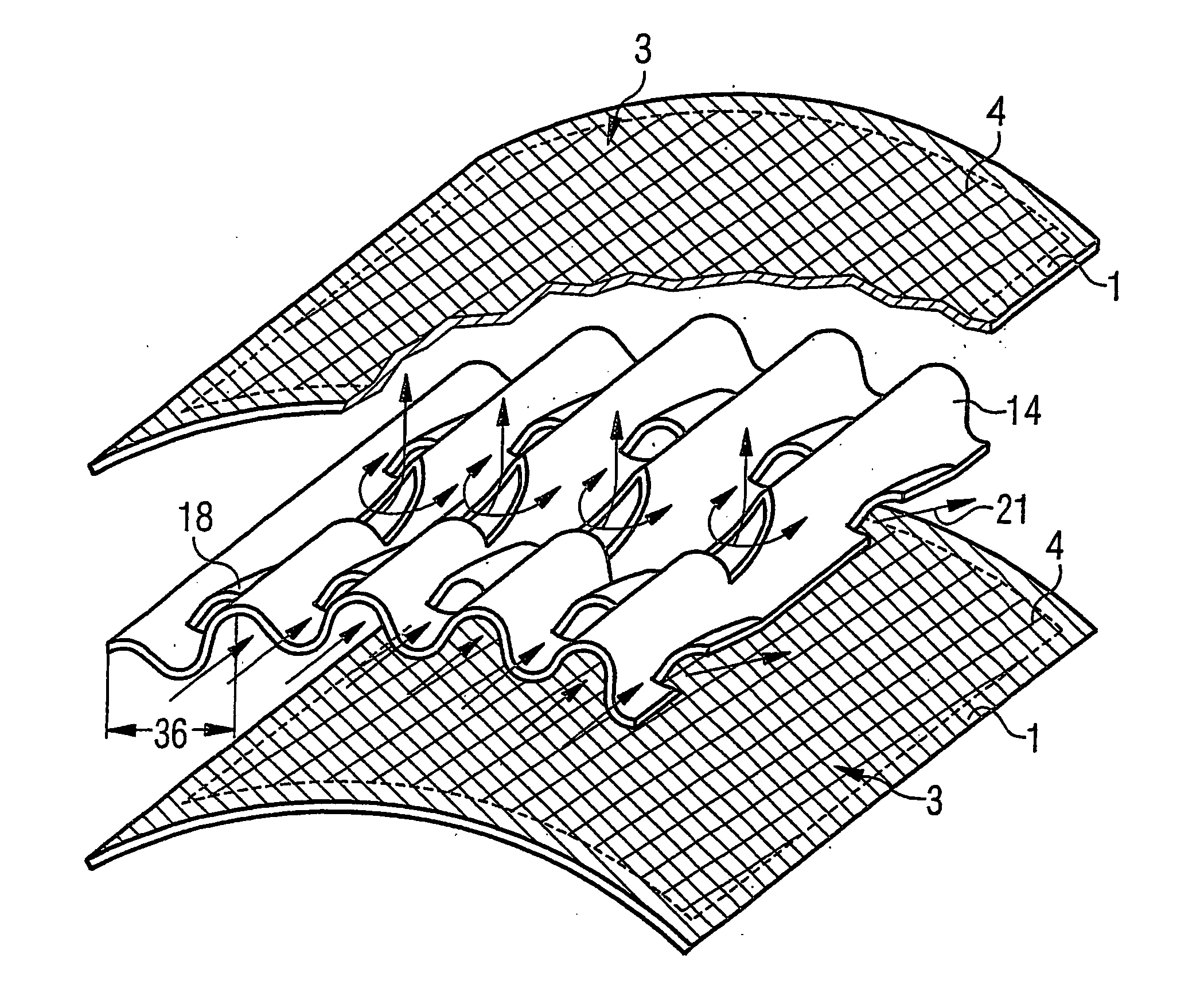

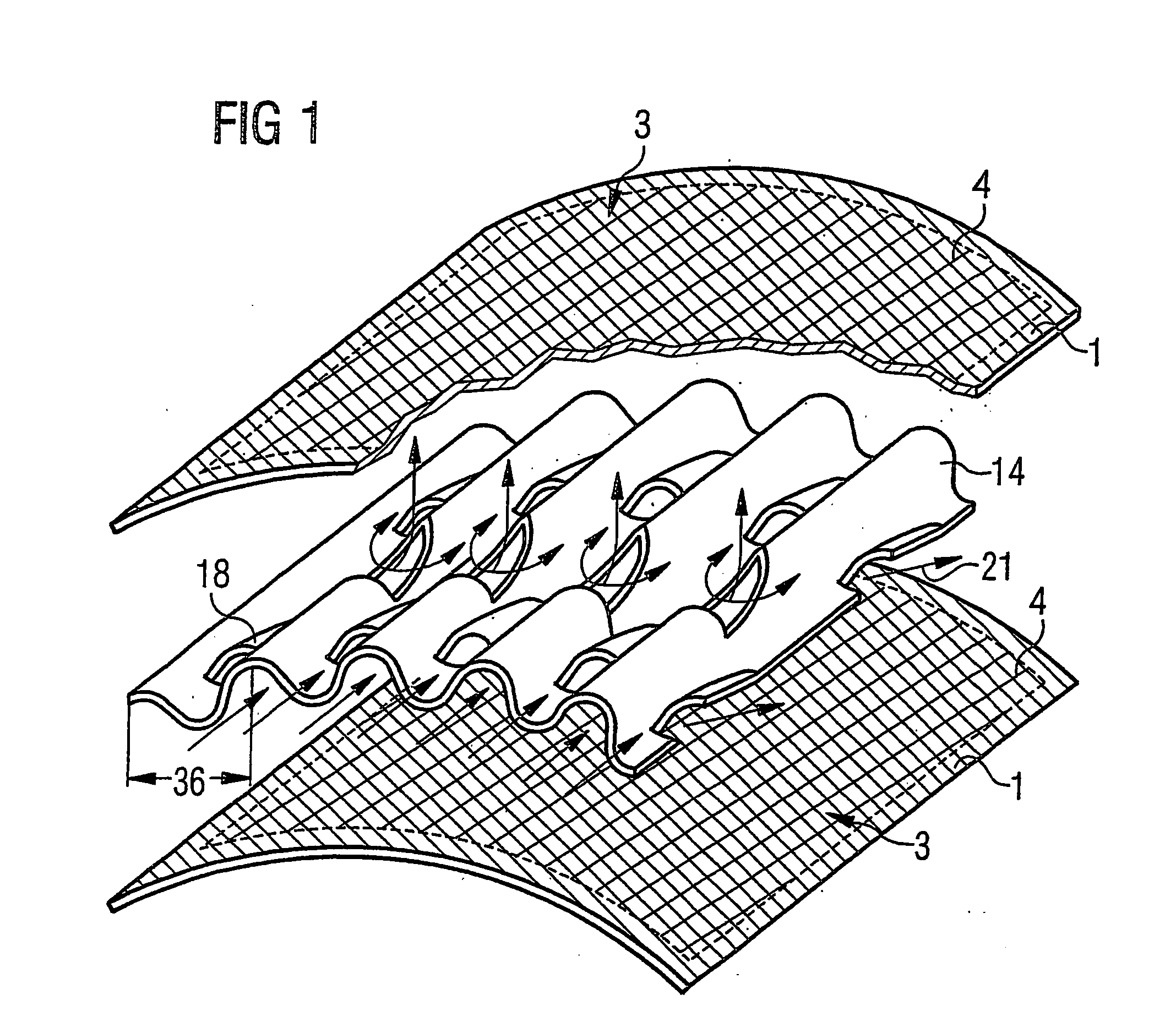

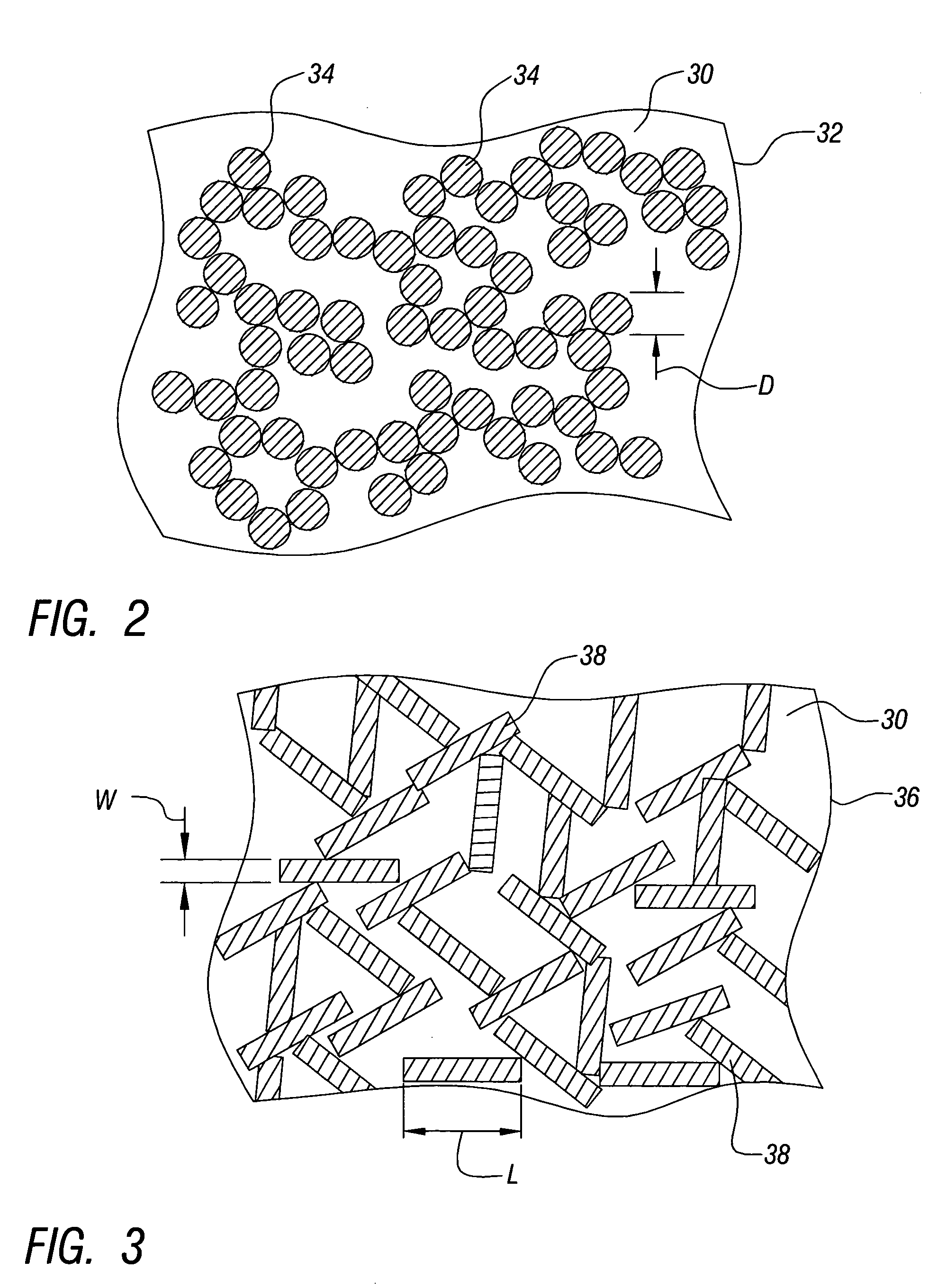

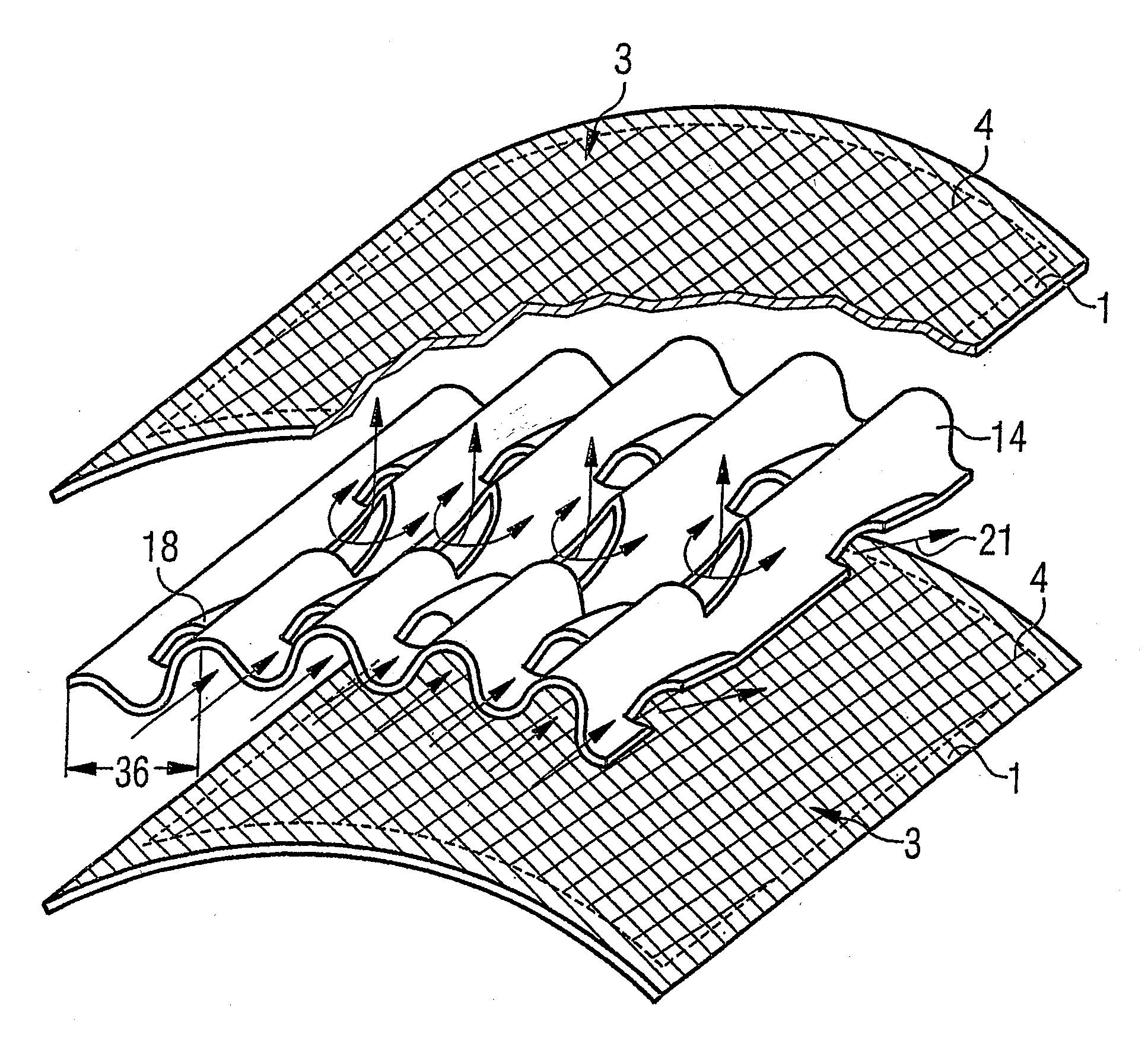

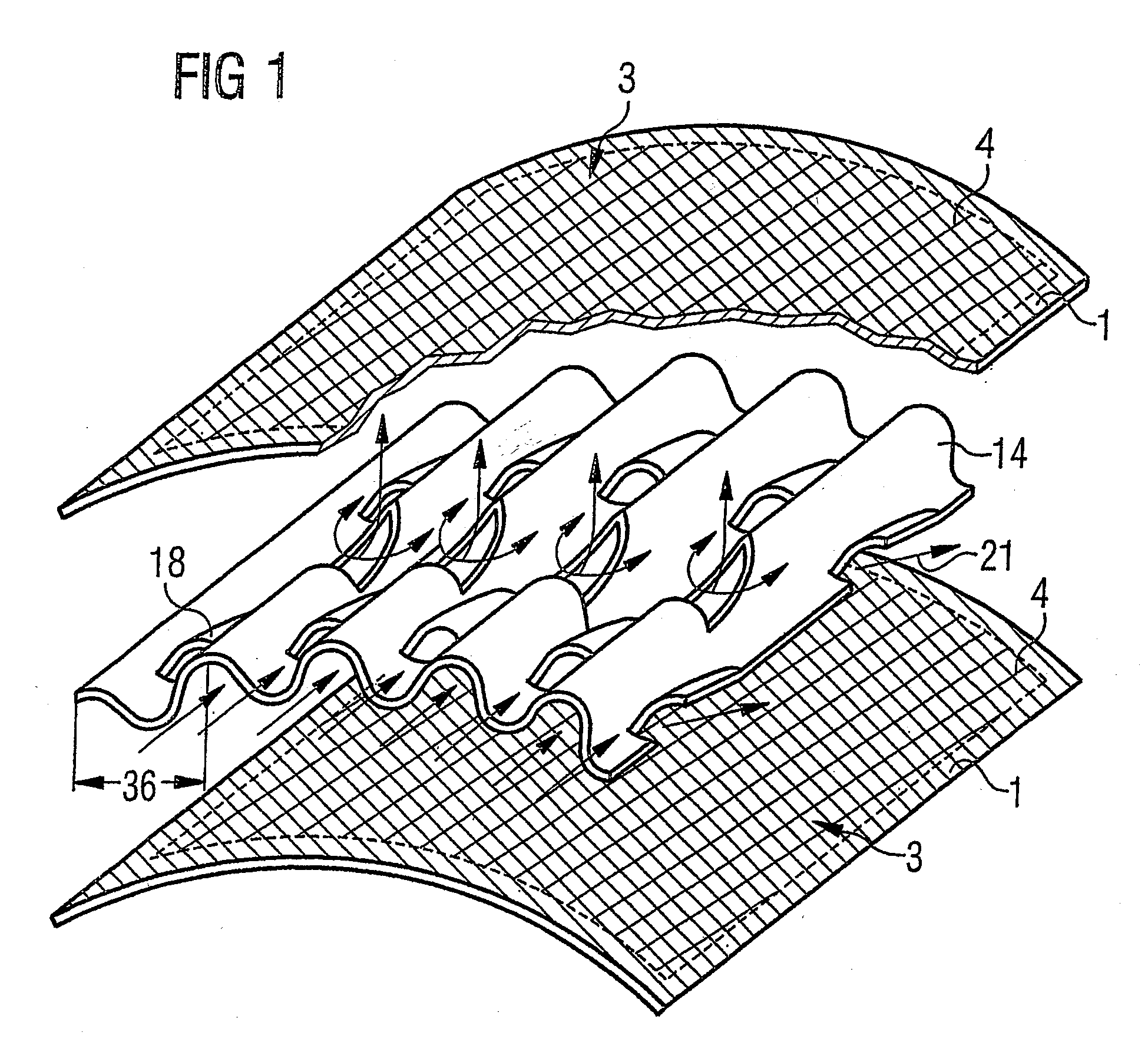

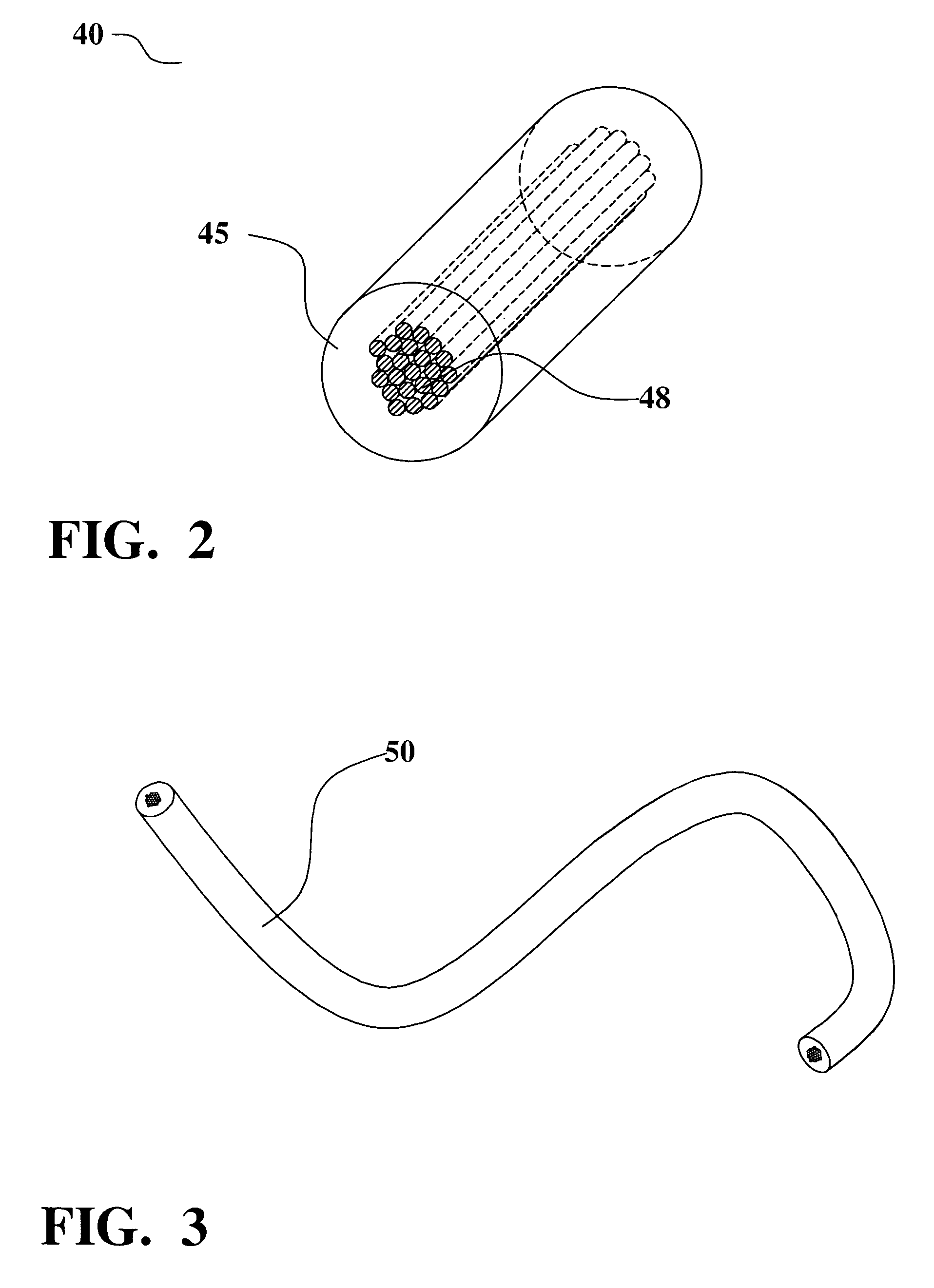

Sandwich material

A sandwich material comprising two metal plates affixed to and separated by a fibrous core, is characterised in that the core comprises a three-dimensional porous network comprising metal fibres, wherein substantially all of the fibres are inclined at an acute angle to the plates. The sandwich material is lightweight, thin and handles like a monolithic sheet. It displays high beam stiffness and is easy to weld. It as therefore particularly useful in the manufacture of aircraft and vehicle parts.

Owner:CAMBRIDGE ENTERPRISE LTD

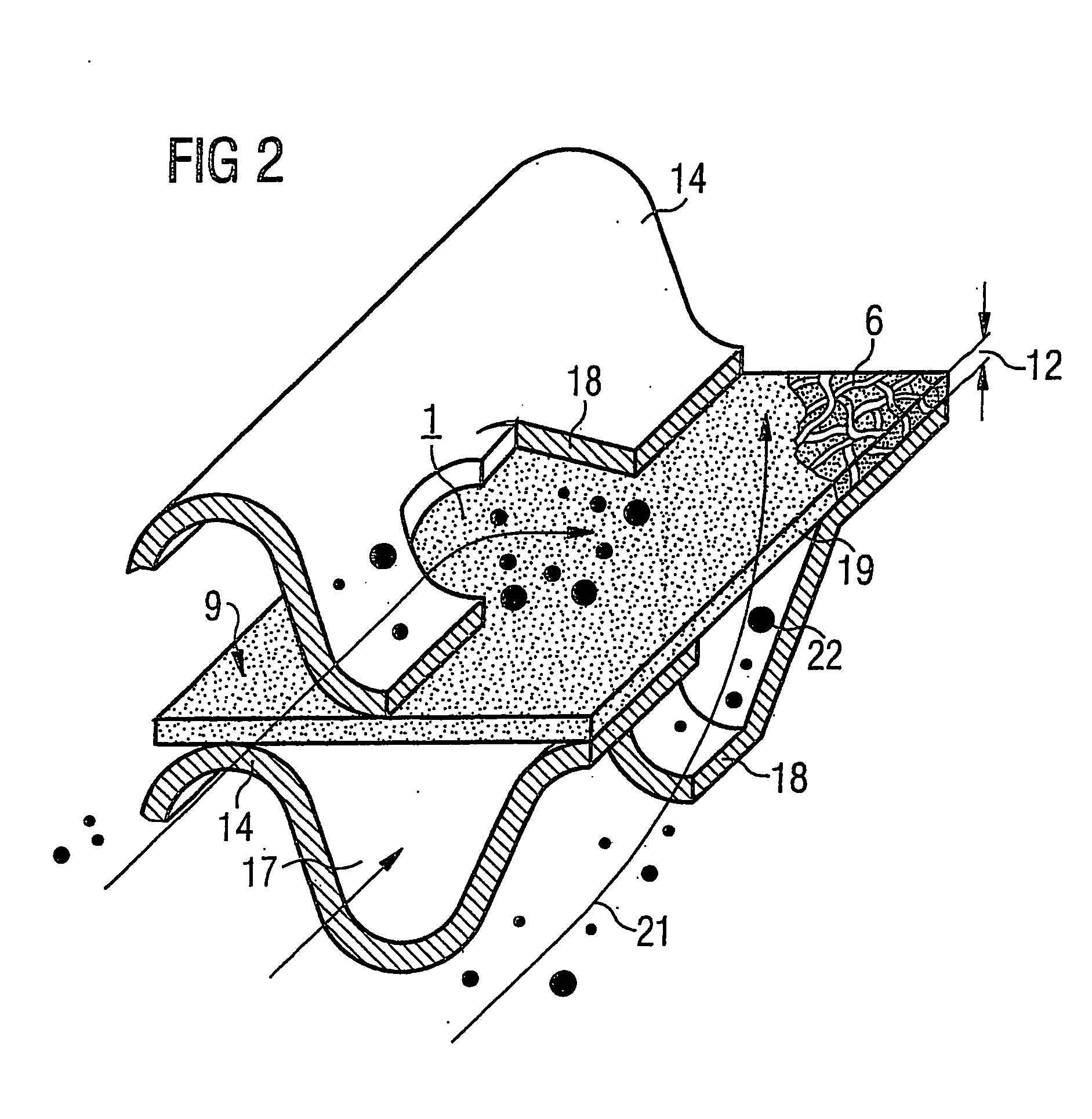

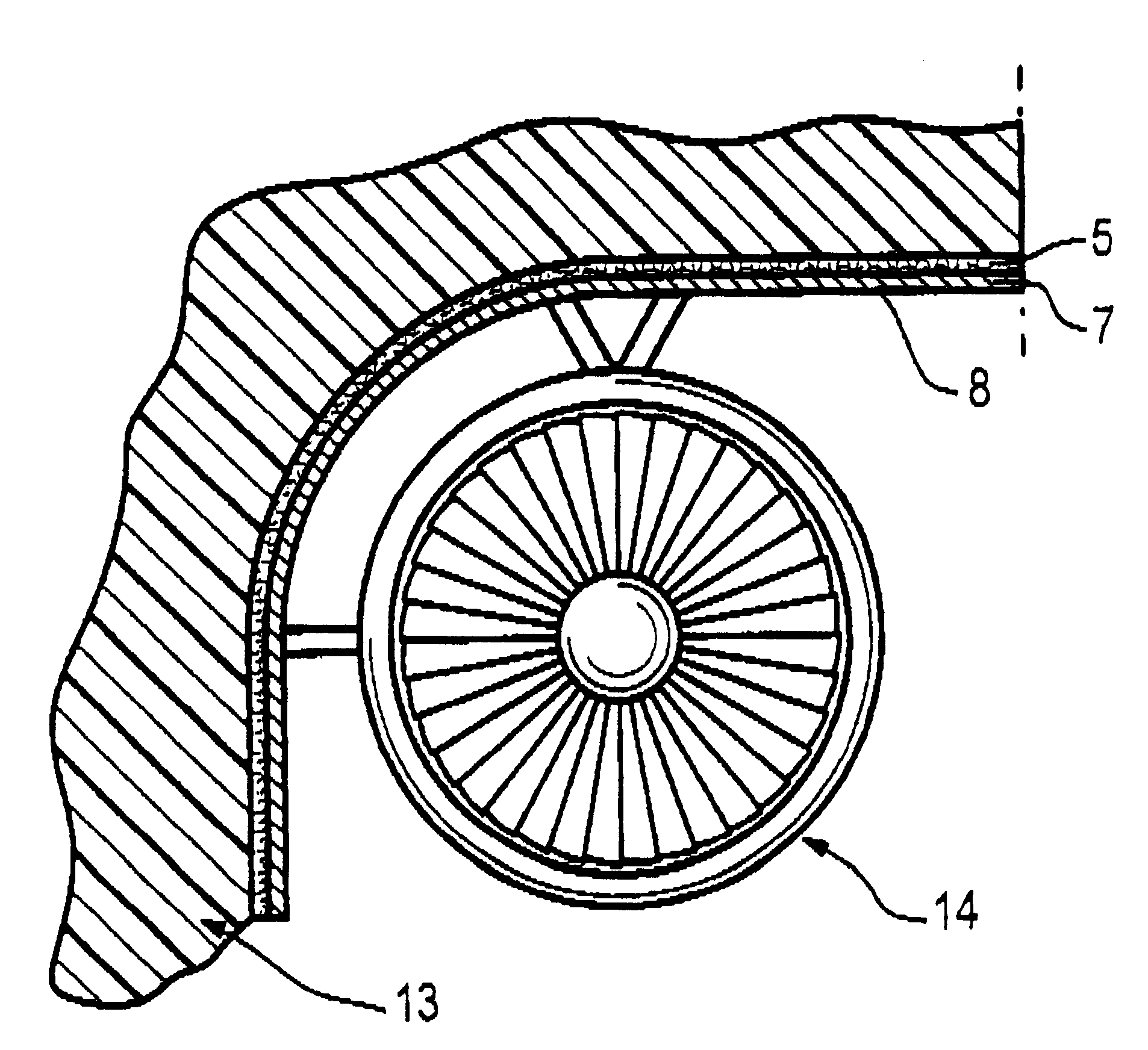

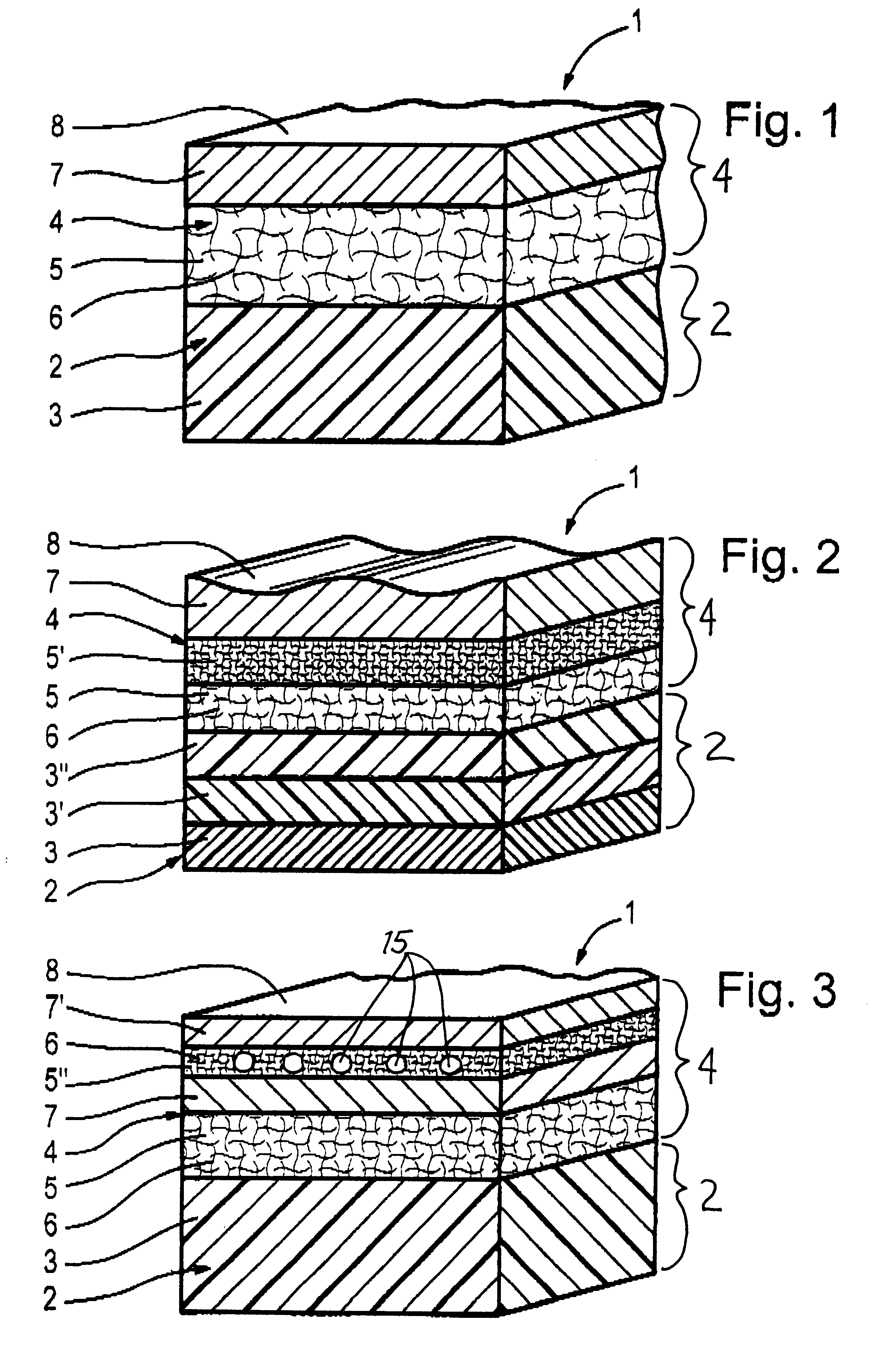

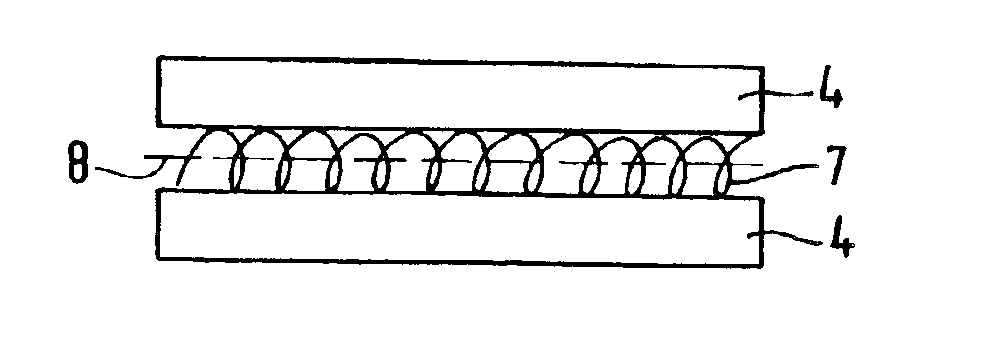

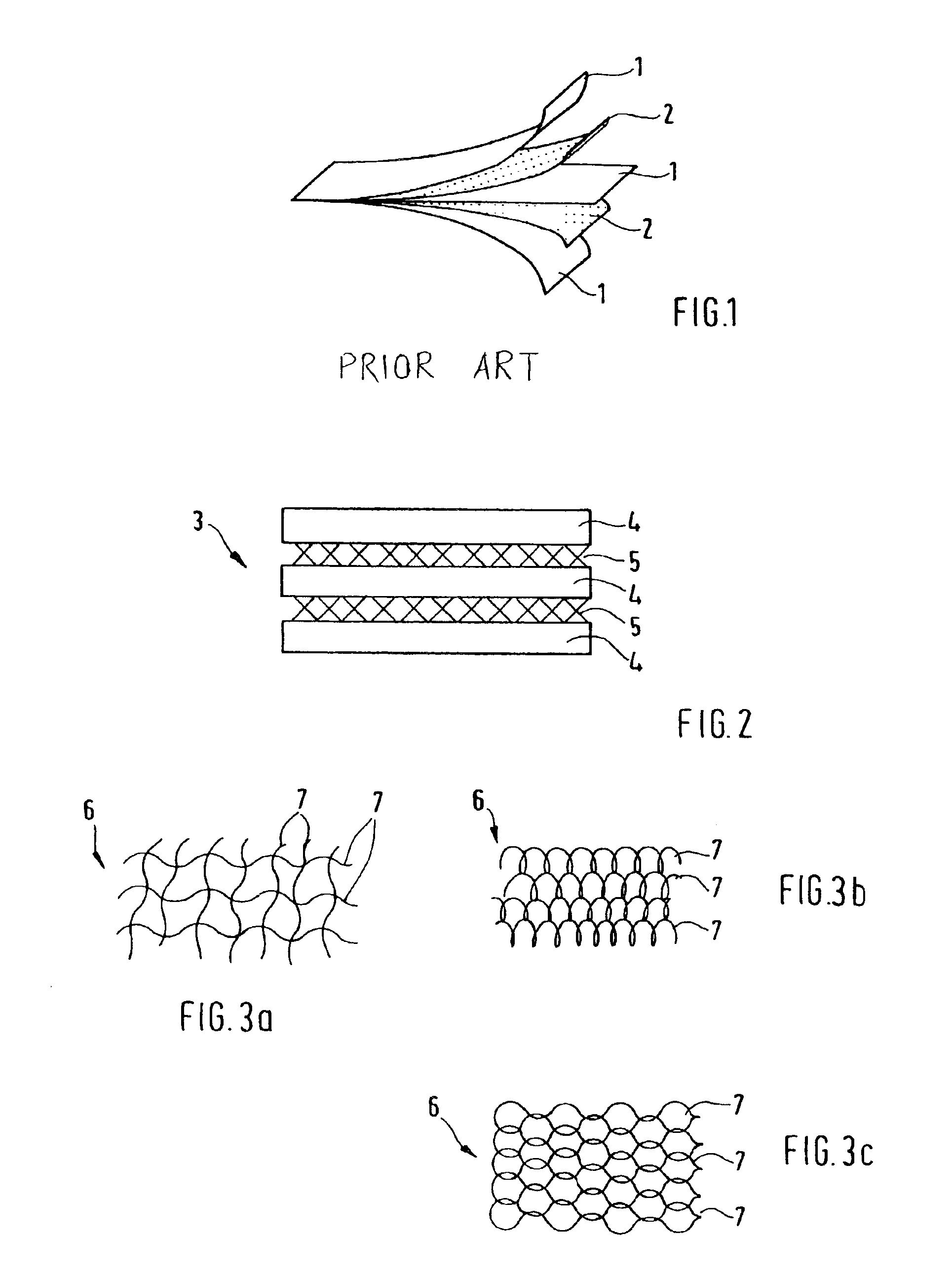

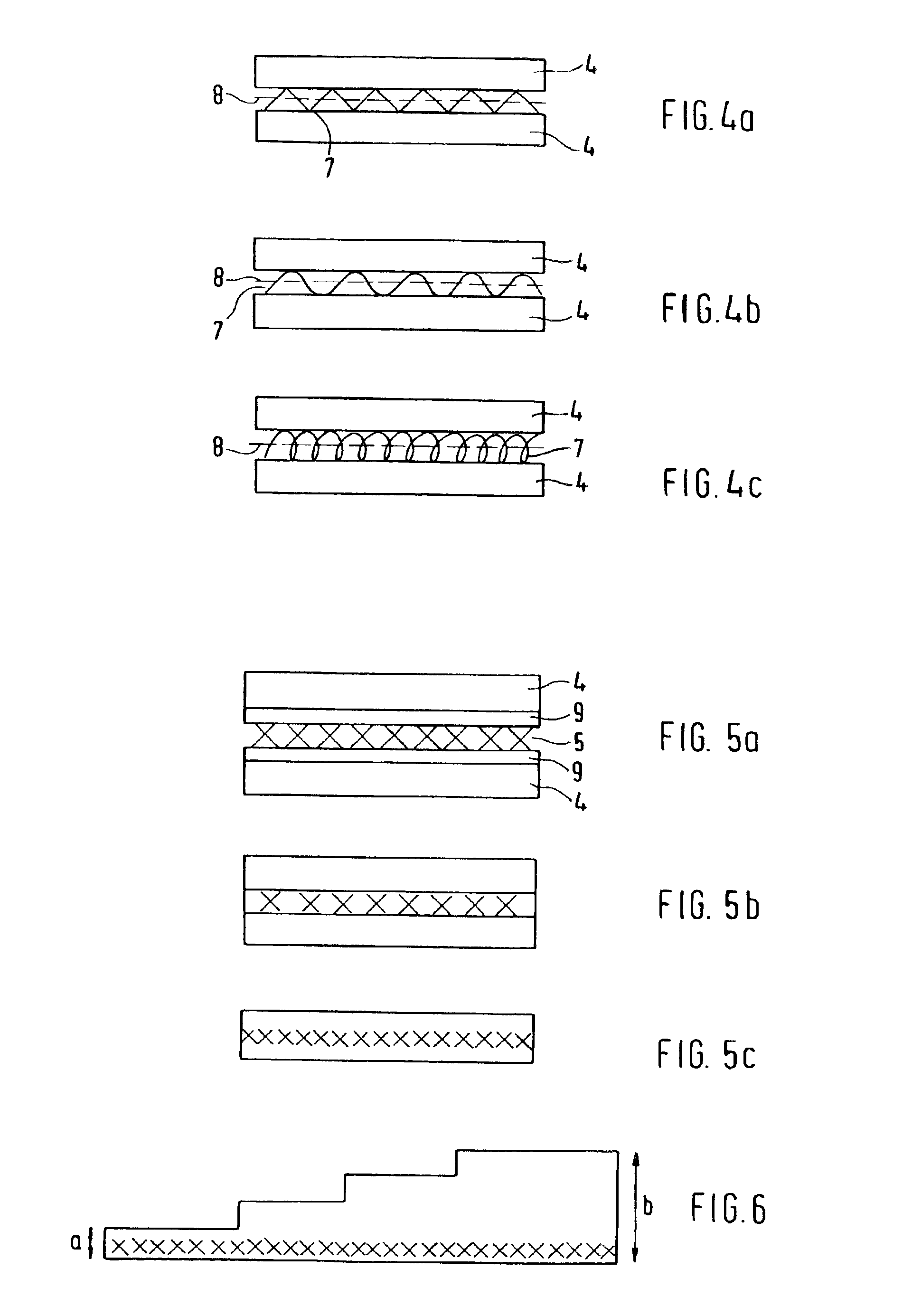

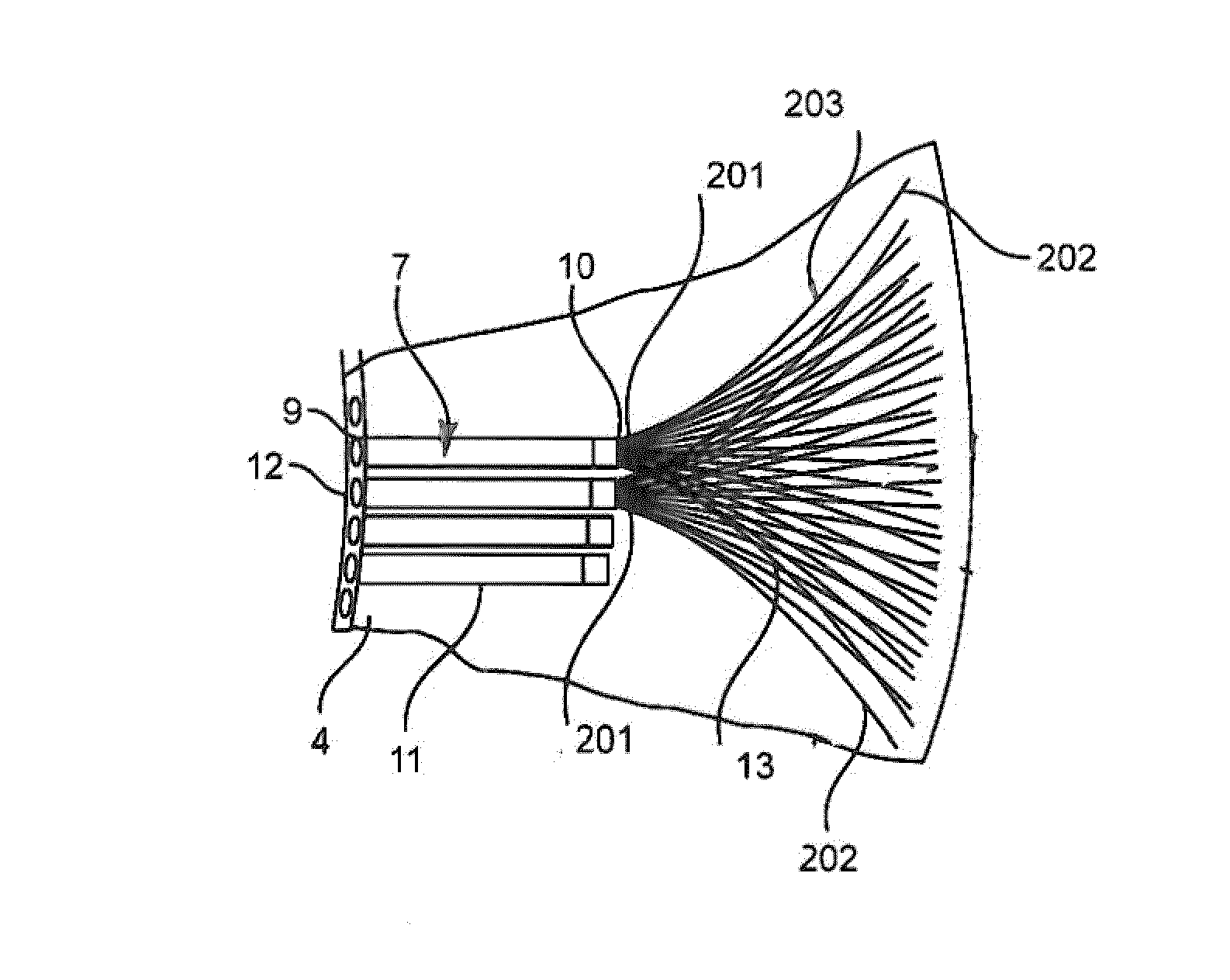

Layer structure including metallic cover layer and fiber-reinforced composite substrate, and a method of making the same

InactiveUS6521331B1Improve adhesionImprove permeabilityFilm/foil adhesivesSynthetic resin layered productsPorosityMetal fiber

A composite laminate or layer structure includes a substrate (2) and a cover layer (4) bonded thereon. The substrate is made up of at least one layer (3) of fiber-reinforced synthetic material. The cover layer includes at least one layer (5) of metal fibers and / or threads (6), and a metal sheet (7) forming the outer surface skin (8) of the layer structure. The metal sheet is bonded by soldering or sintering onto the metal fibers and / or threads (6), while the layer of metal fibers and / or threads in turn is bonded to the underlying fiber-reinforced synthetic material (3) by being mutually and integrally permeated by a synthetic resin matrix and bonding material. Also, the metal fibers and / or threads (6) may be intermeshed with the fibers of the synthetic material (3). To provide improved bonding at both opposite sides thereof, the layer (5) of metal fibers and / or threads (6) has a lower porosity on the side adjoining the metal sheet, and a higher porosity on the side adjoining the fiber-reinforced synthetic material (3) of the substrate.

Owner:MTU AERO ENGINES GMBH

Continuous metal fiber brushes

InactiveUS20010024735A1Improve the immunityMore rigidRotary current collectorMagnetic materialsMetal fiberLubrication

A conductive fiber brush including a brush stock composed of plural conductive fibers or strands of fibers at least some of which may have plural bends along the length of the fibers or strands. The fibers may have a diameter less than 0.2 mm and are arranged in contacting engagement with each other with the touching points among the fibers or strands maintaining elastic tension between the fibers or strands and thereby maintaining voids between the fibers or strands to produce a packing fraction between 1 and 50% and in extreme cases up to 70% but generally between 10-20% depending on the various factors, including the materials used, the current densities to be conducted, and the sliding speeds under operation. The plural bends are implemented by producing fibers or strands having a regular or irregular spiral, wavy, saw-tooth, triangular, and / or rectangular pattern, or other undulating pattern. Optionally, the voids in brush stock may be partially filled with a strengthening, lubricating, abrasive, and / or polishing material, and may be wrapped in an outer sheath, slid into a casing, or provided with an other covering of all or part of the area of the brush stock, be infiltrated or sprayed at the surface with some material, have an increased packing fraction at the surface and / or have some or all of the touching points between the fibers or strands soldered, welded or otherwise thermally joined. Optionally also, the friction among the fibers may be reduced through light lubrication applied by rinsing the brush or brush stock in a lubricant. In one embodiment, the fiber brush is employed in a brush loading device having a hydrostatically controlled brush holder wherein the force exerted on the brush is controlled by a metallic or other conductive hydrostatic fluid which at the same time conducts the current to the brush.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

Electrically conductive thermoplastic polymer composition

InactiveUS6936191B2Improve conductivityReduce the amount requiredNon-insulated conductorsConductive materialMetal fibersThermosetting polymer

Disclosed is an electrically conductive thermoplastic polymer composition comprising a thermoplastic polymer and a synergistic combination of metal fibers and metal-coated fibers, structures made therefrom, and a process to make said compositions and structures.

Owner:DOW GLOBAL TECH LLC

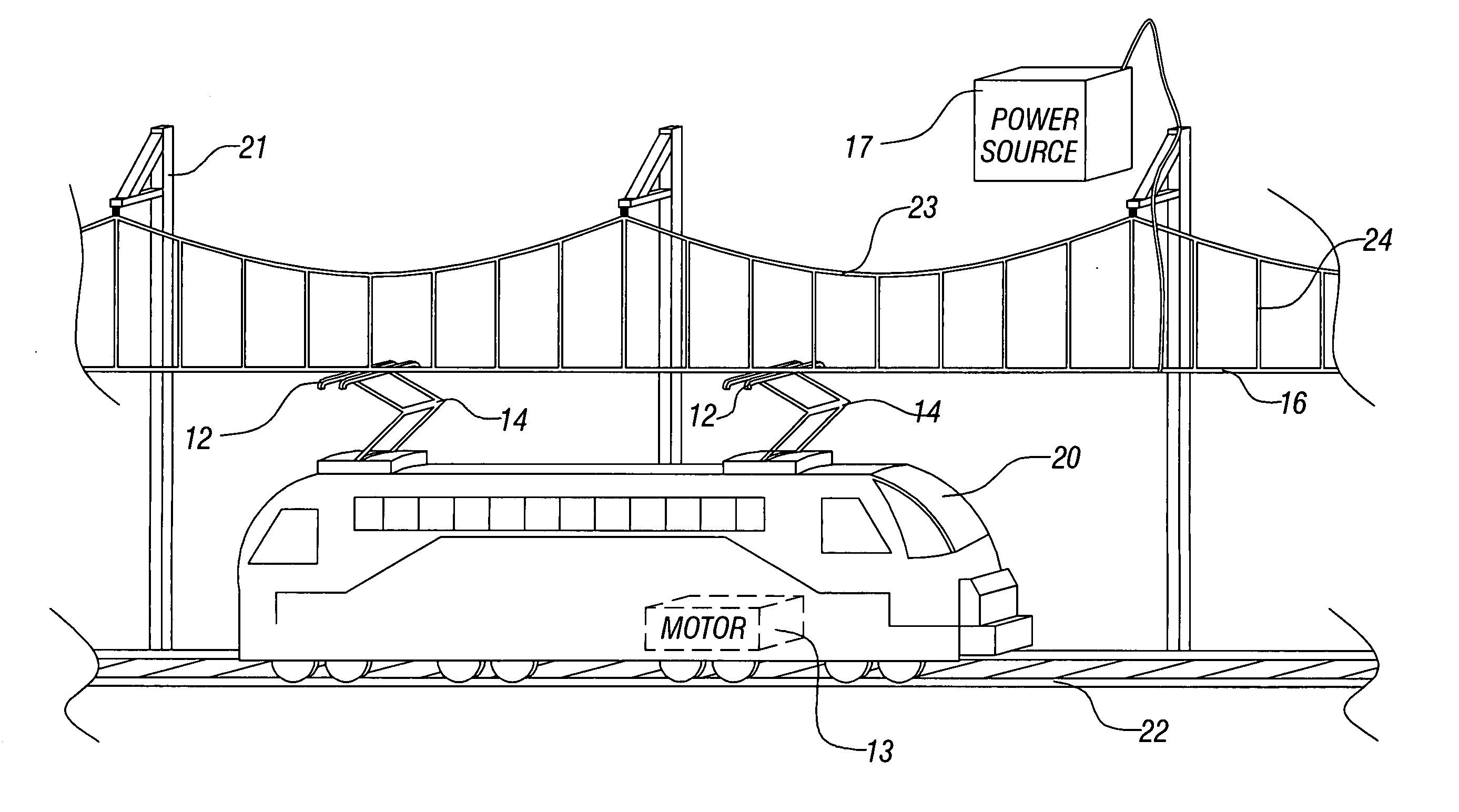

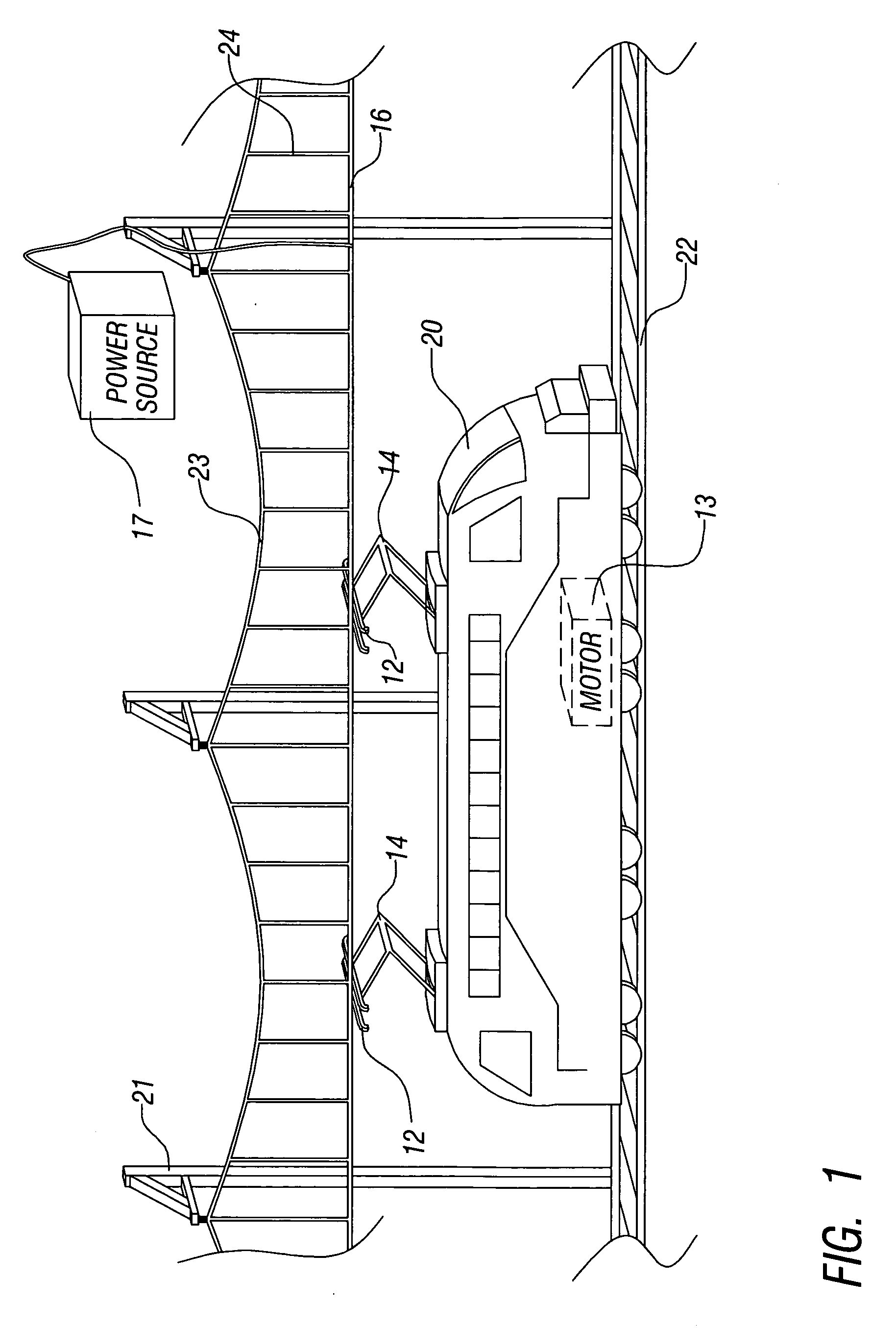

Low cost electrical power connectivity for railway systems manufactured from conductive loaded resin-based materials

InactiveUS20060071862A1Non-insulated conductorsNon-conductive material with dispersed conductive materialMetal fiberElectrical conductor

Electrical connectivity devices for railway systems are formed of a conductive loaded resin-based material. The conductive loaded resin-based material comprises micron conductive powder(s), conductive fiber(s), or a combination of conductive powder and conductive fibers in a base resin host. The percentage by weight of the conductive powder(s), conductive fiber(s), or a combination thereof is between about 20% and 50% of the weight of the conductive loaded resin-based material. The micron conductive powders are metals or conductive non-metals or metal plated non-metals. The micron conductive fibers may be metal fiber or metal plated fiber. Further, the metal plated fiber may be formed by plating metal onto a metal fiber or by plating metal onto a non-metal fiber. Any platable fiber may be used as the core for a non-metal fiber. Superconductor metals may also be used as micron conductive fibers and / or as metal plating onto fibers in the present invention.

Owner:INTEGRAL TECHNOLOGY INC

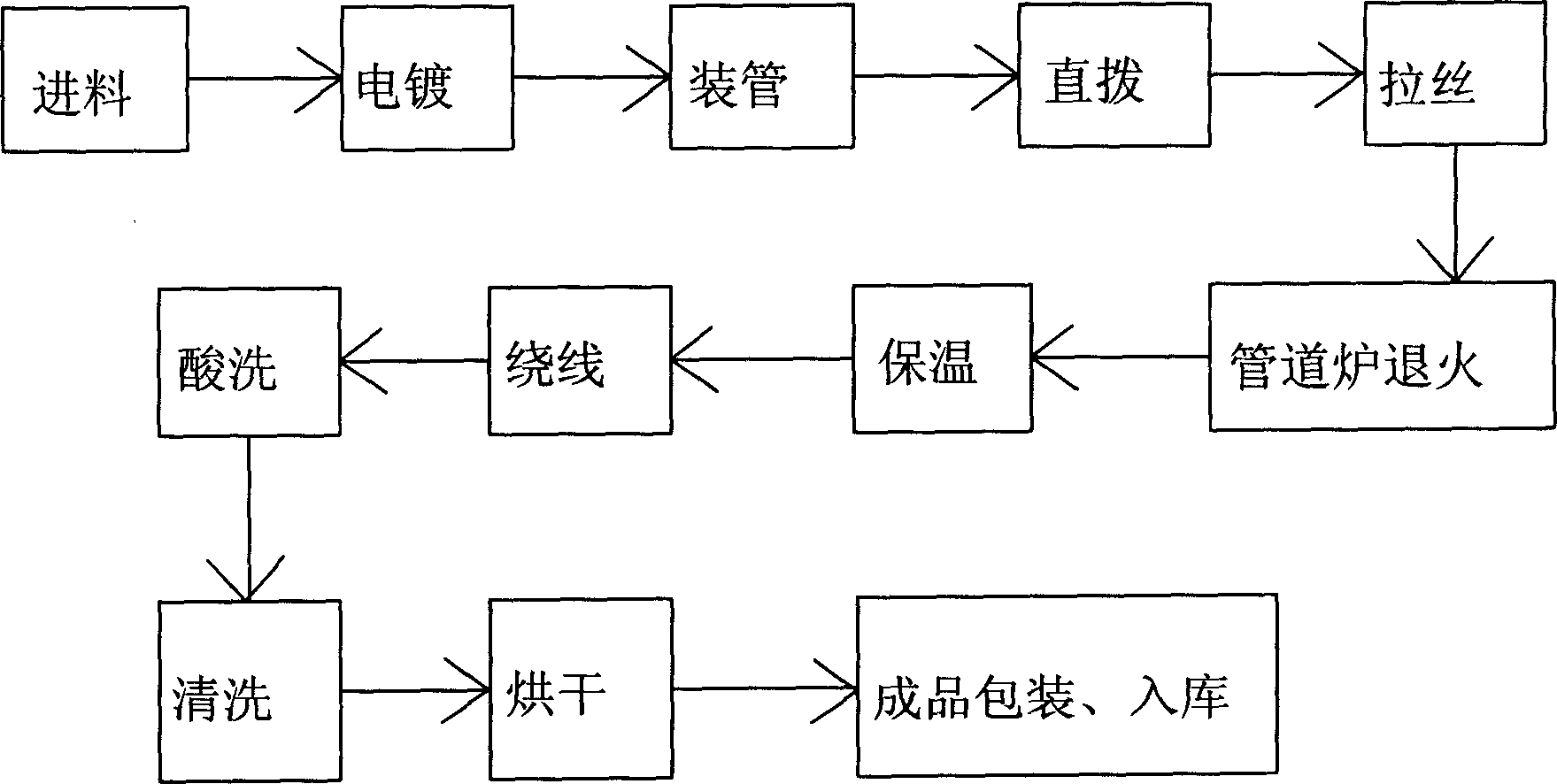

Metal fiber wire and its producing process

InactiveCN1900345AOvercome the pullOvercome the disadvantages of changing chemical elementsMetal fiberManganese

The present invention belongs to the field of metal processing technology, and is especially one kind of metal fiber wire and its production process. The metal fiber wire is made with the material comprising C 0.03-0.08 wt%, Mn 0.20-0.46 wt%, Si 0.40-0.63 wt%, Ce or La 0.02-0.10 wt%, Al 4.8-5.9 wt%, Cr 15-26 wt%, Cu 0.05-2 wt%, S 0.03-0.04 wt%, P 0.04-0.05 wt% and Fe 66-81 wt%. The making process includes the steps of: feeding material, electroplating, tubing, straightening, drawing, annealing, maintaining temperature, winding, acid pickling, washing, stoving, etc. The metal fiber wire has single fiber diameter up to 6 micron, strength higher than 16 N / sq cm, elongation of 1.40 %, and high comprehensive performance.

Owner:周建华

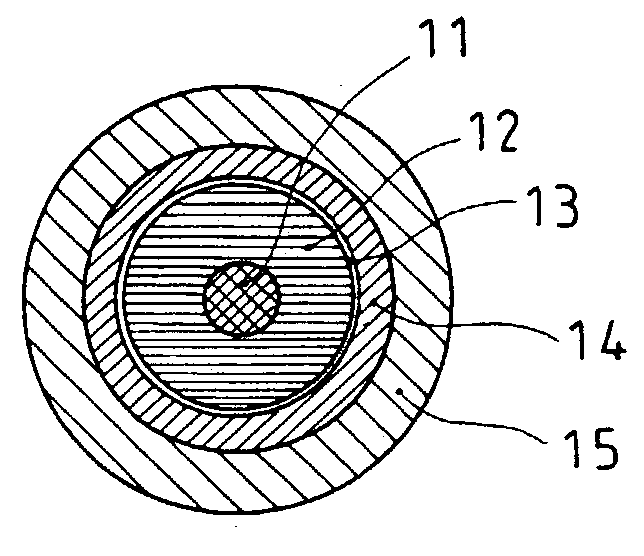

Structure of a cable

InactiveUS20050011664A1Reduced isolationImprove shielding effectConductive materialPower cables with screens/conductive layersMetal fiberInsulation layer

An improved structure of a cable featuring an enhanced shield layer, with the arrangement comprised of a conductor, an insulation layer, a metal braid layer, an outer jacket, and an enhanced shield layer disposed between the insulation layer and the metal braid layer. The enhanced shield layer can be conductive plastic, conductive carbon black, conductive colorant, conductive coating, conductive metallic powder, or metal fiber, any of which eliminates electrostatic noise generated by a variety of causes in audio / video cables and thereby solves the problem of electrostatic discharge

Owner:RICH ELECTRIC WIRE & CABLE

Sandwich material

A sandwich material comprising two metal plates affixed to and separated by a fibrous core, is characterised in that the core comprises a three-dimensional porous network comprising metal fibres, wherein substantially all of the fibres are inclined at an acute angle to the plates. The sandwich material is lightweight, thin and handles like a monolithic sheet. It displays high beam stiffness and is easy to weld. It as therefore particularly useful in the manufacture of aircraft and vehicle parts.

Owner:CAMBRIDGE ENTERPRISE LTD

Particulate Trap with Coated Fiber Layer and Exhaust System Having the Particulate Trap

InactiveUS20080250775A1Small structureImprove efficiencyInternal combustion piston enginesExhaust apparatusMetal fiberParticulates

An open particulate trap for purifying exhaust gases from mobile internal combustion engines includes at least one at least partially structured metal foil and at least one high-temperature-resistant fiber layer having metal fibers defining the open particulate trap for purifying exhaust gases from mobile internal combustion engines. The fiber layer has a section and, at least in the section, a catalytically active coating being an SCR catalyst. An exhaust system of an automobile internal combustion engine includes an exhaust pipe defining a flow direction and at least the following components disposed in succession in the flow direction: a reducing-agent feed for supplying liquid urea and the particulate trap.

Owner:EMITEC GESELLSCHAFT FUR EMISSIONSTECHNOLOGIE MBH

Filter element

InactiveUS6991673B2Small movementReduce convective heat lossCombination devicesAuxillary pretreatmentMetal fiberAdhesive

A filter element comprises a pleated metal fiber fleece being pleated according to pleating lines providing an edge with pleat openings to be closed in order to make gas flowing through the metal fiber fleece. The filter element further comprises at least two flanks, each of these flanks comprising a stiff material layer. The stiff material layer and the metal fiber fleece are connected using a layer of ceramic adhesive, which prevents direct contact of the metal fiber fleece over the length of the edge of the metal fiber fleece with the flank. Meanwhile the flanks, being essentially perpendicular to the pleating lines, closing the pleat openings in order to prevent bypasses.

Owner:RYPOS

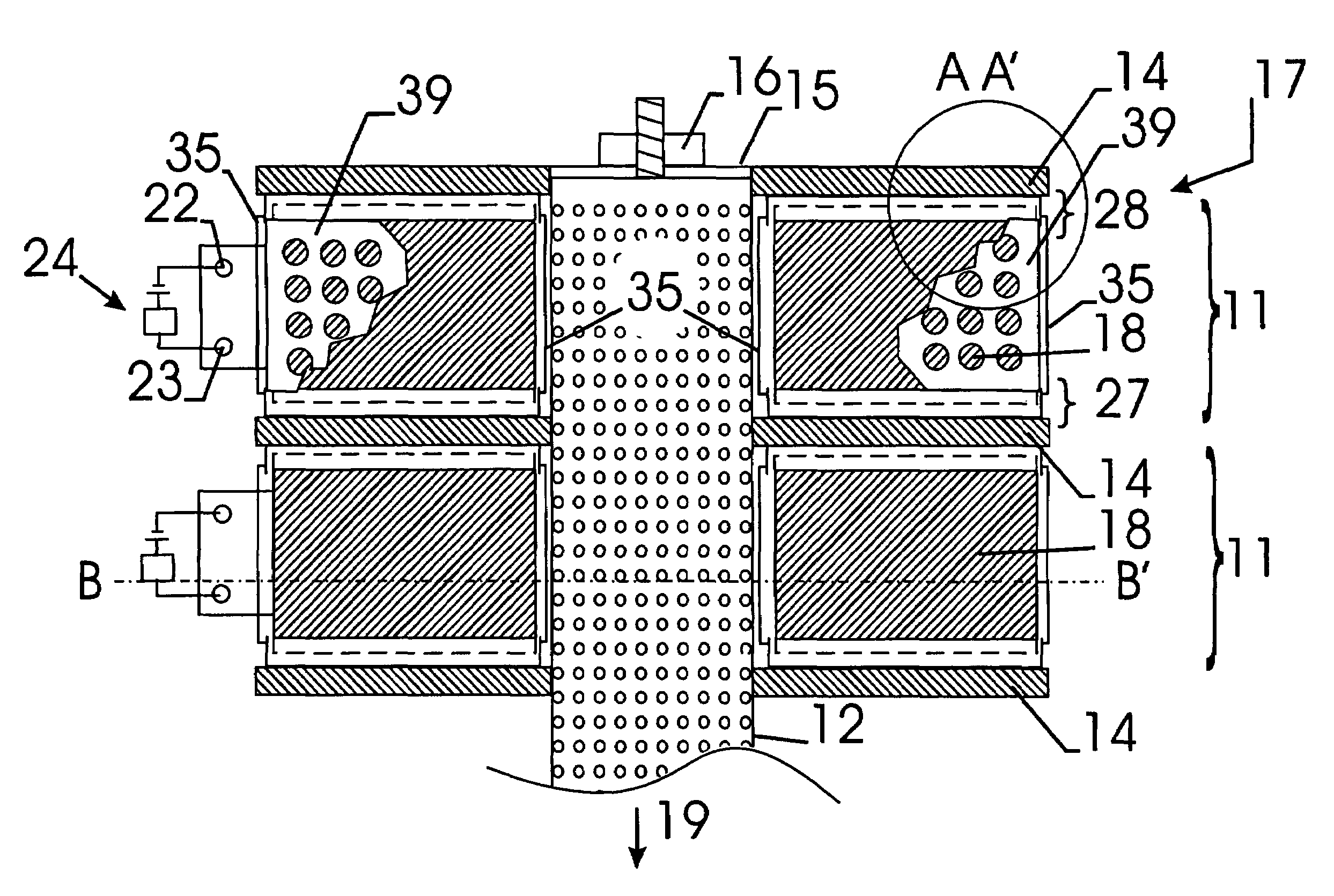

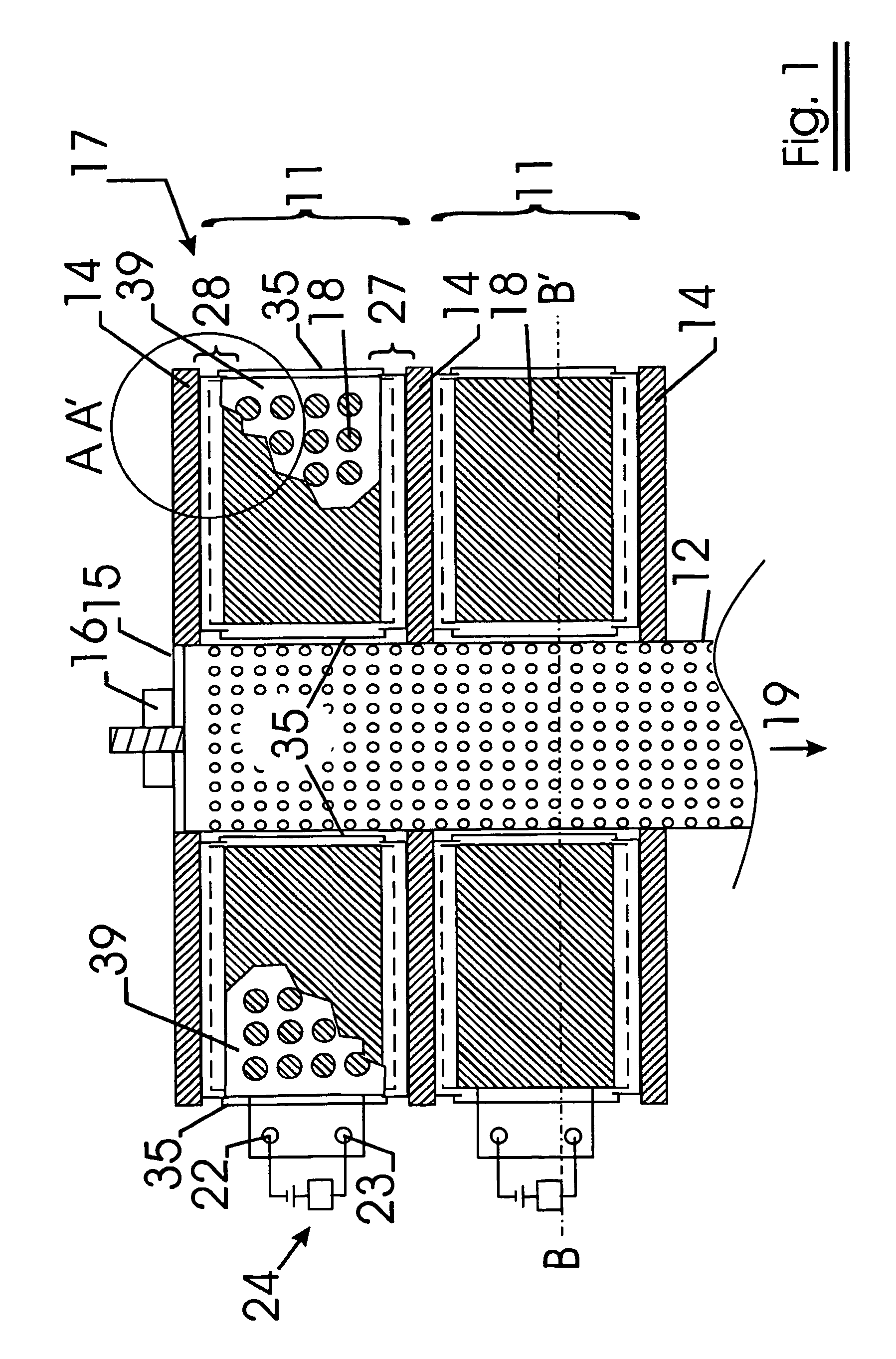

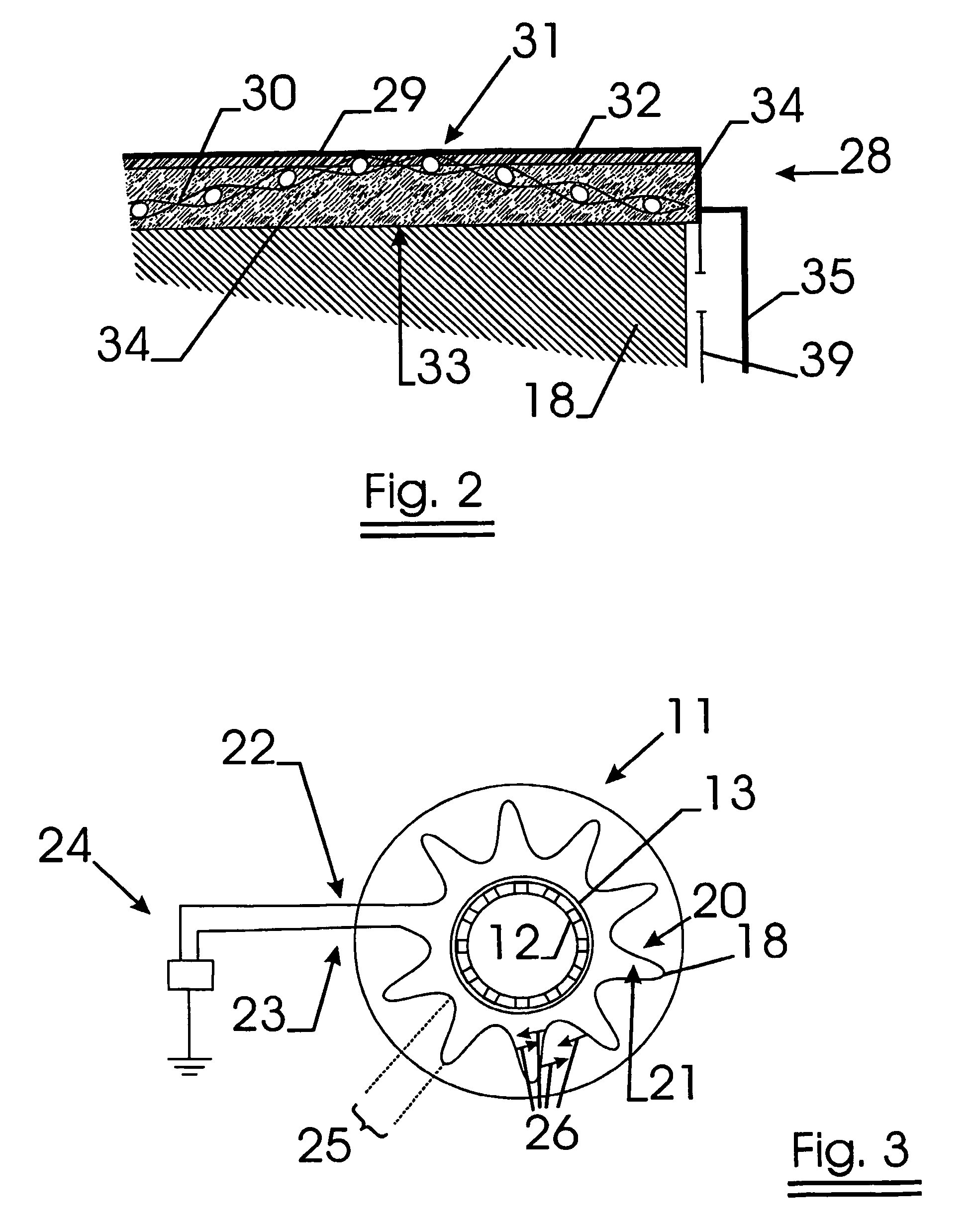

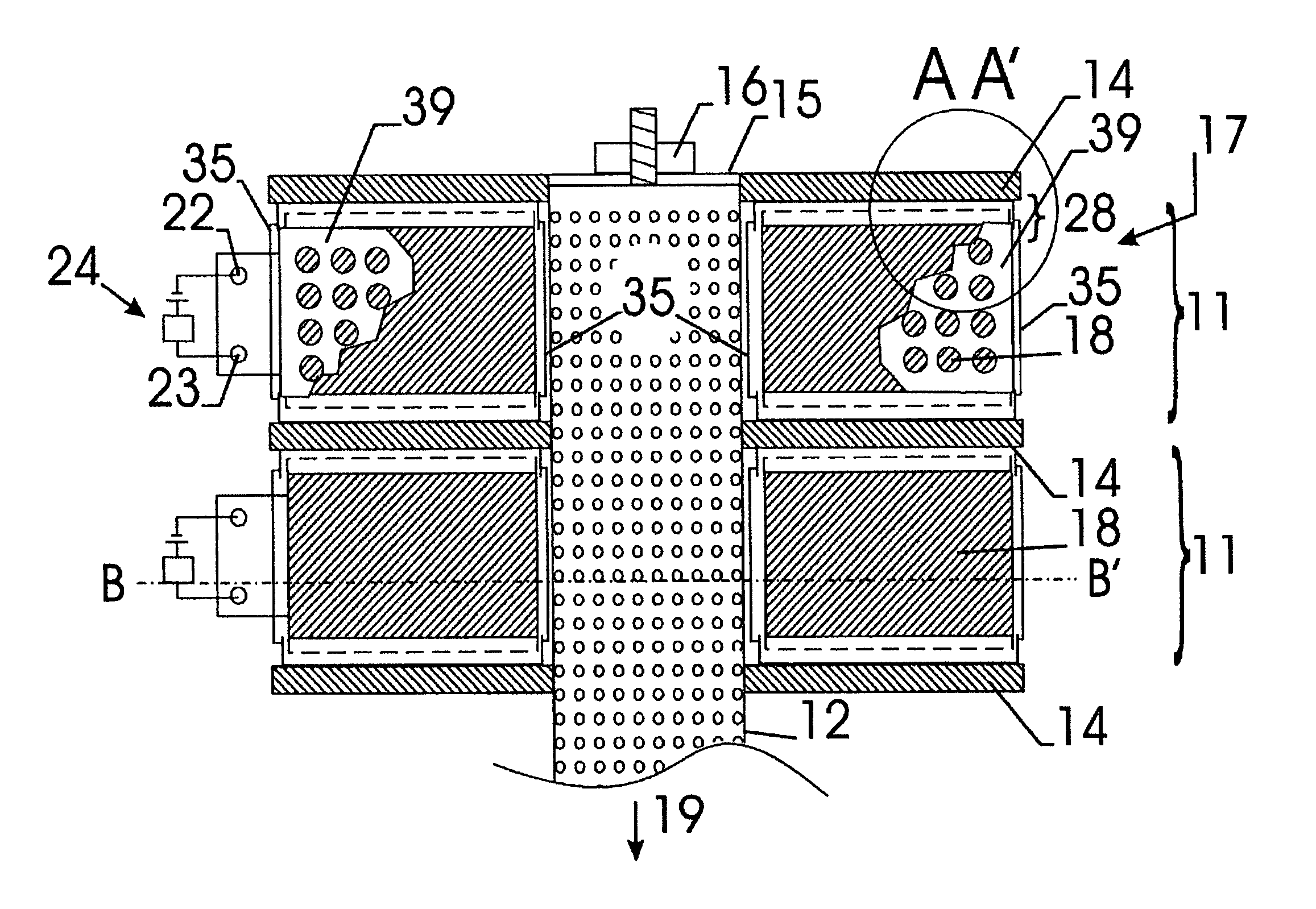

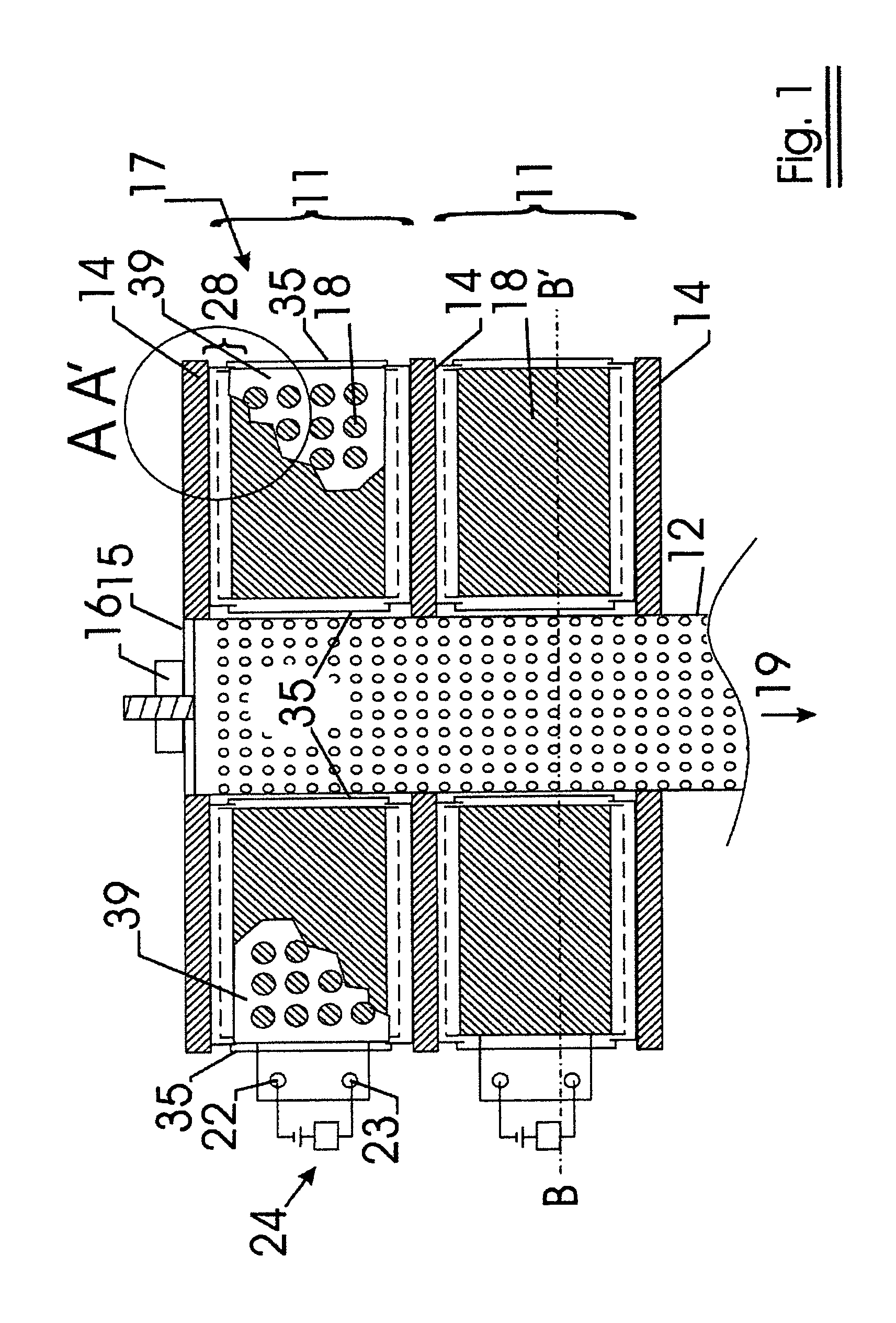

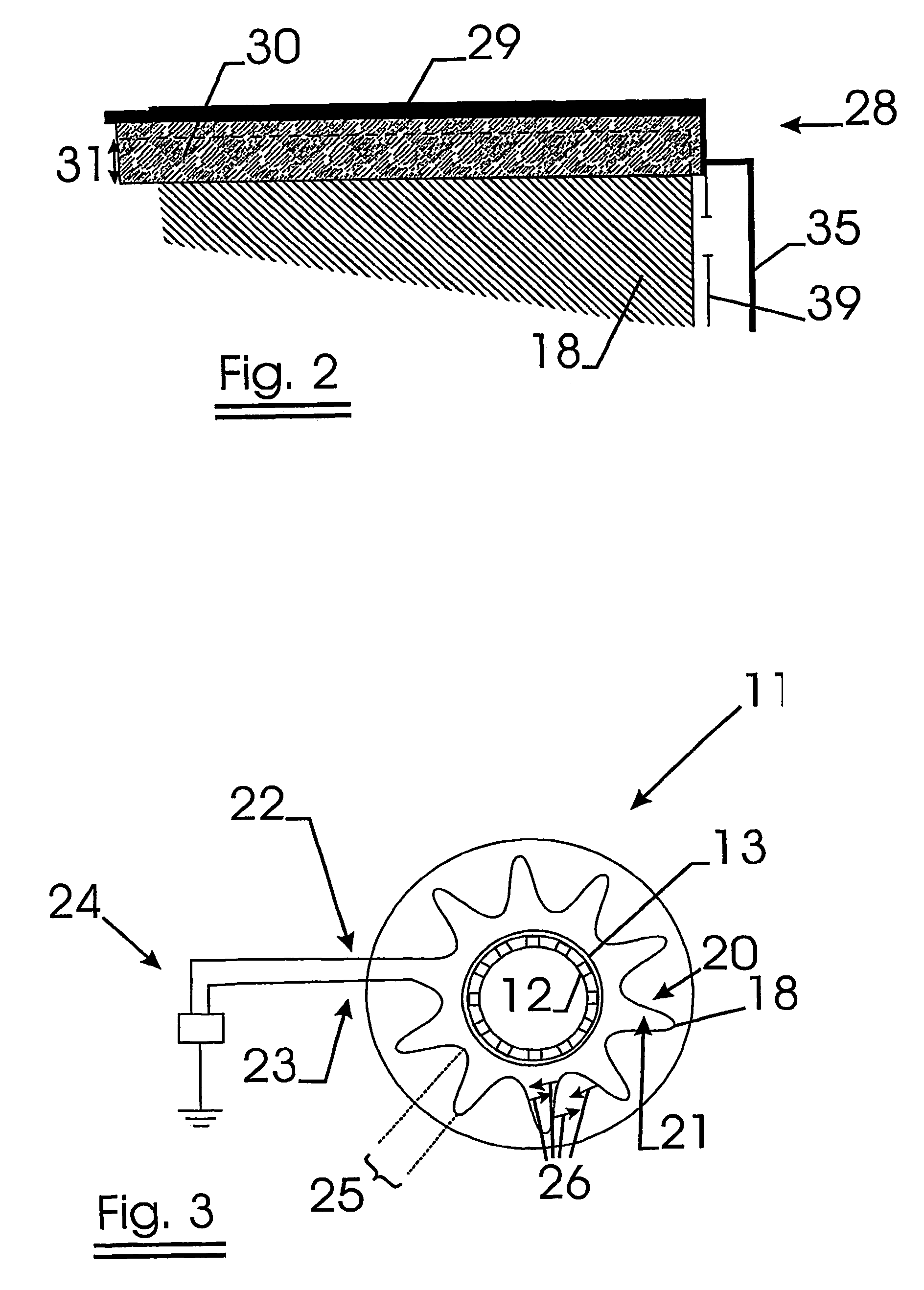

Bifilar diesel exhaust filter construction using sintered metal fibers

InactiveUS6942708B2Overcome disadvantagesCombination devicesAuxillary pretreatmentElectrical resistance and conductanceMetal fiber

A diesel particulate filter construction, for filtering particulate from a flow of exhaust, includes a first layer of electrically resistive metal filter material in line with the flow of exhaust with particulate therein and a second layer of electrically resistive filter material which is also in line with the flow of exhaust with particulate therein. The layers are pleated cylinders concentrically positioned relative to one another. Current from a power supply is routed through the first layer and the second layer, which are electrically connected in series to one another. The layers are positioned so that exhaust flows through both the layers. Sufficient heat is generated by the flow of current through the layers to generate heat to, in turn, burn off entrapped particulate. The layers may be made of made of different materials of different fiber sizes or coated with different catalysts to generate different amounts of heat from one another to improve the filtration characteristics of the particulate filter construction.

Owner:RYPOS

Super-hydrophobic/super-oleophilic oil-water separating net

Super hydrophobic / super oleophylic oil-water separation net has meshes 300-1500 covered thin perfluoroalkyl siloxane copolymer membrane with thickness 20~50nm, which can be metal fiber fabric of stainless steel or cupper, or fabric or terylene and nylon. Its preparation method is: 1. degrease, clean with acid and bath to the fabric net and dry; 2. for the weight share, mix the liquid with perfluoroalkyl siloxane 0.1-5%, water 1-10%, hydrochloric acid or 1N 0.1-2% and other is alcohol for 30-120 minutes, form gel-sol; 3. dip the net into gel-sol for 3-30 seconds, take out, dry naturally, repeat for 2-8 times; 4. take hot curing for the fabric net at 80-250Deg for 10-120 minutes, obtain the membrane and oil-water separation net.

Owner:NANJING UNIV

Resin-coated micron conductive fiber wiring

InactiveUS20060289189A1Low costHighly effectiveInsulated cablesHeating element shapesMetal fiberElectrical conductor

A resin-coated, micron conductive fiber wiring material, a method of fabricating, and applications are achieved. The micron conductive fibers may be metal fiber or metal plated fiber. Further, the metal plated fiber may be formed by plating metal onto a metal fiber or by plating metal onto a non-metal fiber. Any platable fiber may be used as the core for a non-metal fiber. Superconductor metals may also be used as micron conductive fibers and / or as metal plating onto fibers in the present invention.

Owner:AISENBREY THOMAS

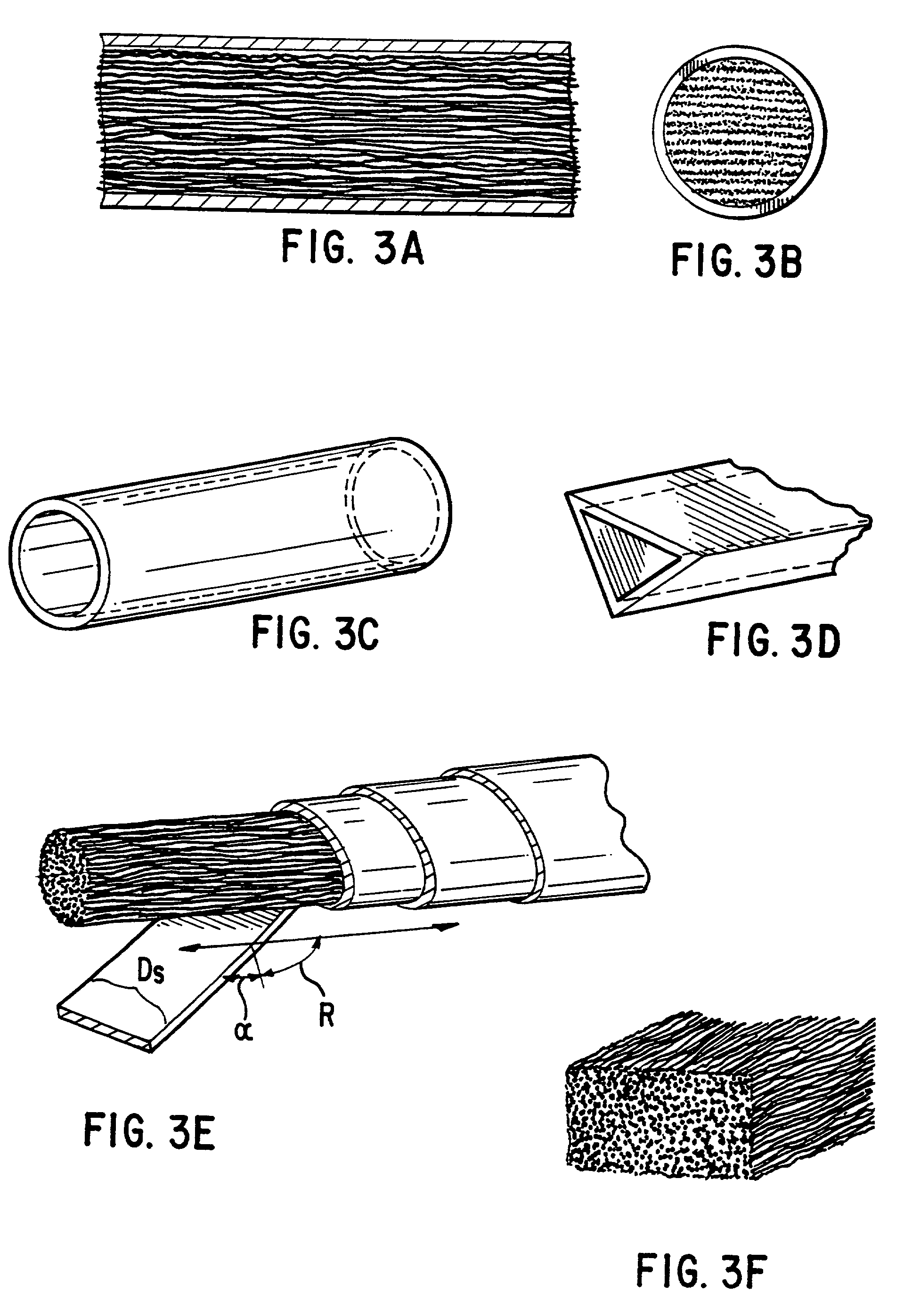

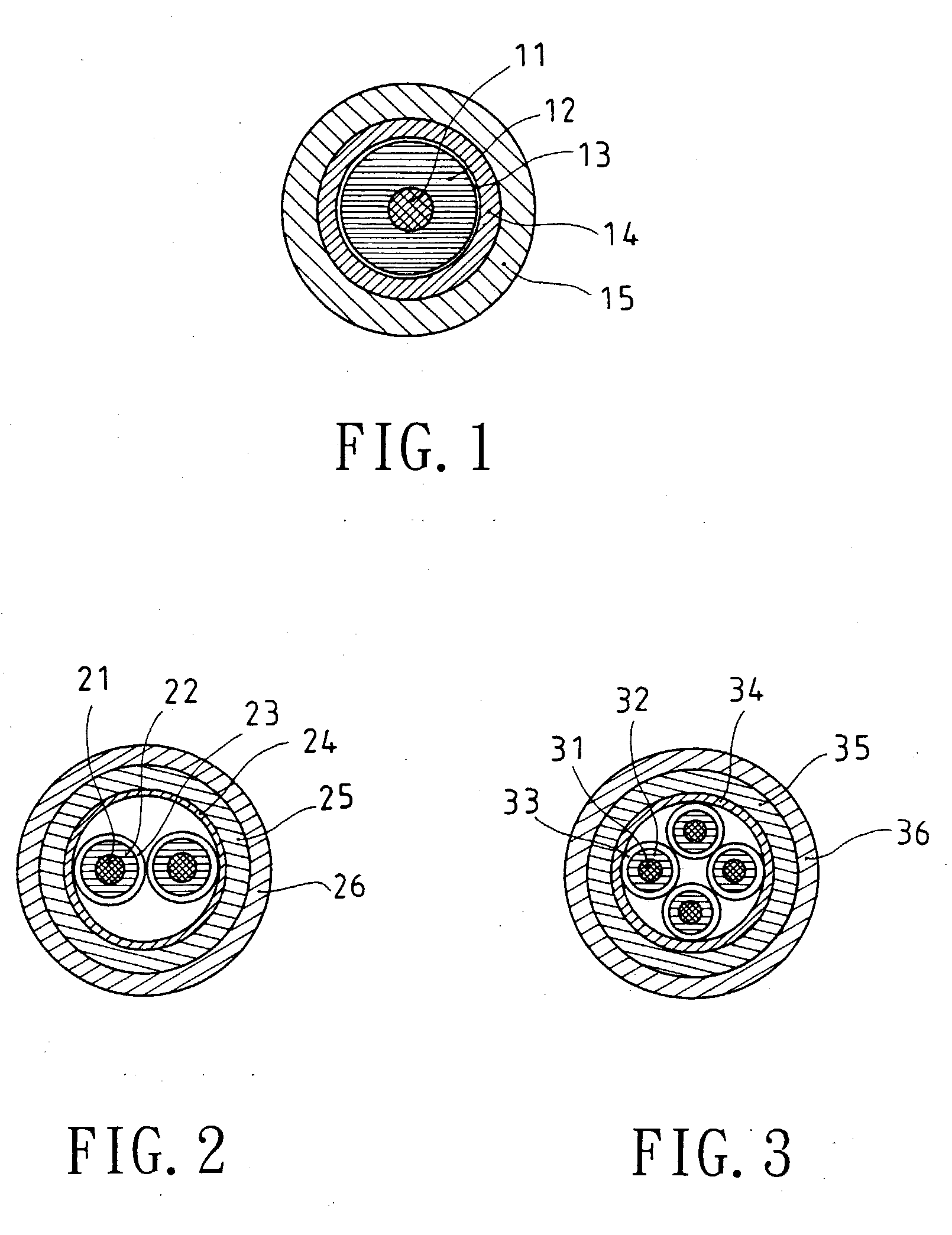

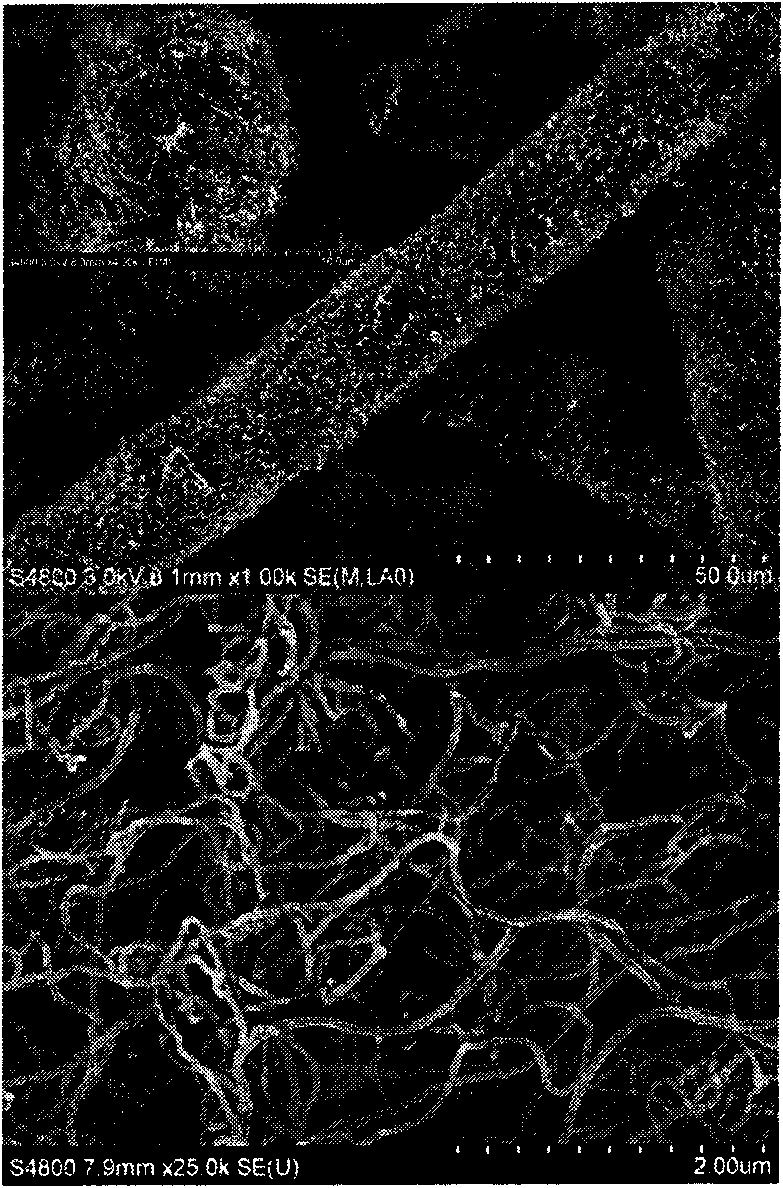

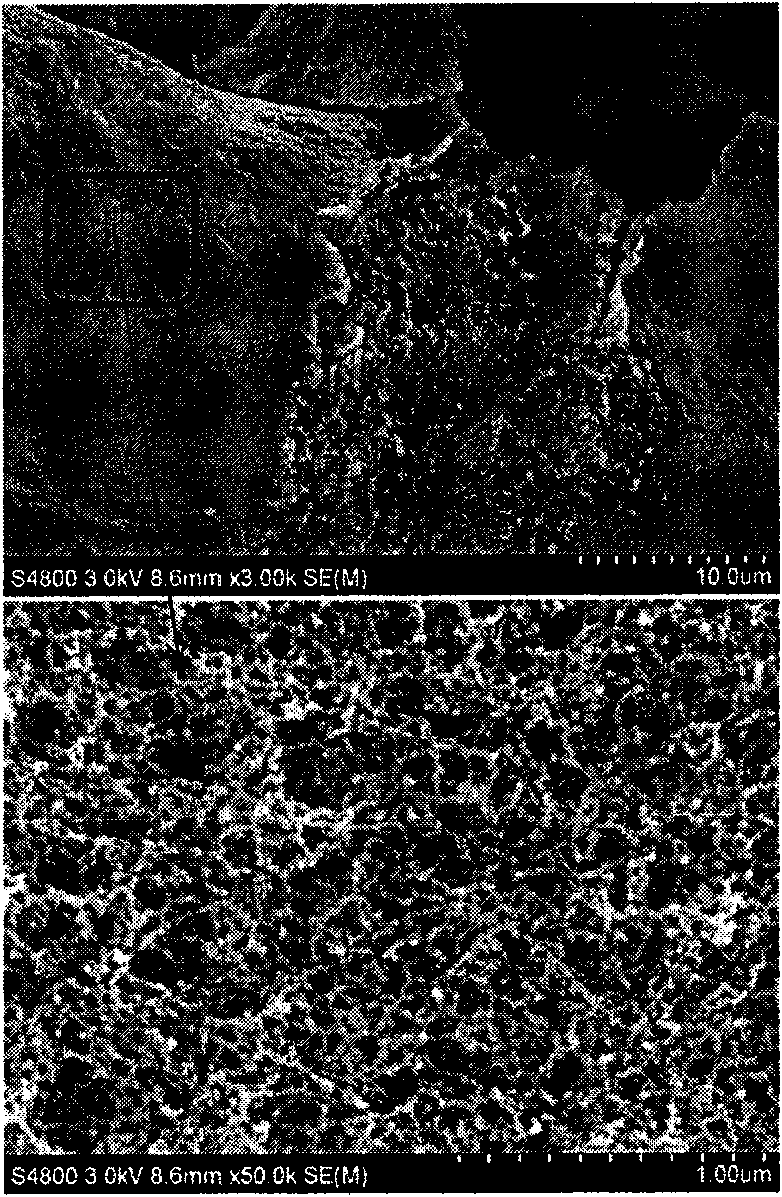

Metal fiber-reinforced composite material as well as a method for its production

InactiveUS6861156B2Simple procedureEasy to useArmour platesThin material handlingMetal fiberMetallic materials

A metal fiber-reinforced composite material can be produced by providing metal layers and reinforcing layers disposed alternately into a sandwich structure, the reinforcing layers containing fibers of a high-strength metallic material, which are disposed in the form of a loose structure between the metal layers, in order to create a material excess of fibers in the reinforcing layers, the sandwich structure being bonded by a thermomechanical process in such a manner, that the fibers are lengthened because of the excess of material, the sandwich structure being bonded.

Owner:AIRBUS OPERATIONS GMBH

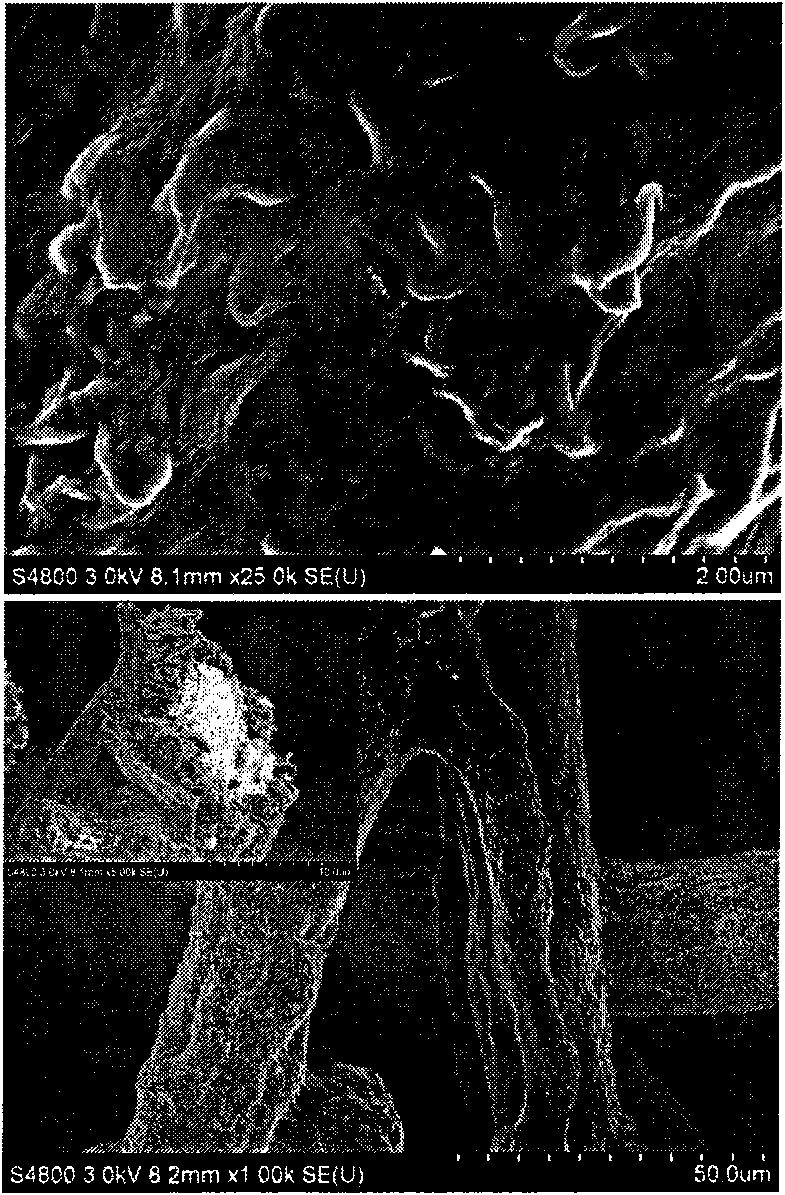

Metal fiber-nanometer carbon fiber-carbon aerogel composite material and preparation method and use thereof

InactiveCN101661839ASelf-supportingGood for electrolyte storageElectrode manufacturing processesHybrid capacitor electrodesMetal fiberInternal resistance

The invention discloses a metal fiber-nanometer carbon fiber-carbon aerogel composite material and a preparation method and a use thereof, wherein, the material contains metal fiber, nanometer carbonfiber and carbon aerogel; a binding point of the metal fiber is sintered on a tri-dimensional net structure, the nanometer carbon fiber grows on the metal fiber, and the carbon aerogel is coated on the nanometer carbon fiber. The preparation method comprises the following steps: sintering the metal fiber net structure in a large area on a selected thin layer; allowing the nanometer carbon fiber togrow by catalyzing a selected chemical vapor phase deposition method of a carbon-containing compound under a specified condition; then coating a selected organic polymer on the nanometer carbon fiber, and carbonizing the polymer at a certain temperature to obtain the metal fiber-nanometer carbon fiber-carbon aerogel composite material. The material can be taken as an electrode material of a novelchemical power supply; and the material has a self-supporting integral structure without an organic polymer macromolecular binding agent, has a tri-dimensional layered hole structure which is beneficial to ion transmission and storage, and has high electrical conductivity, small internal resistance and good chemical energy storage performance.

Owner:EAST CHINA NORMAL UNIV

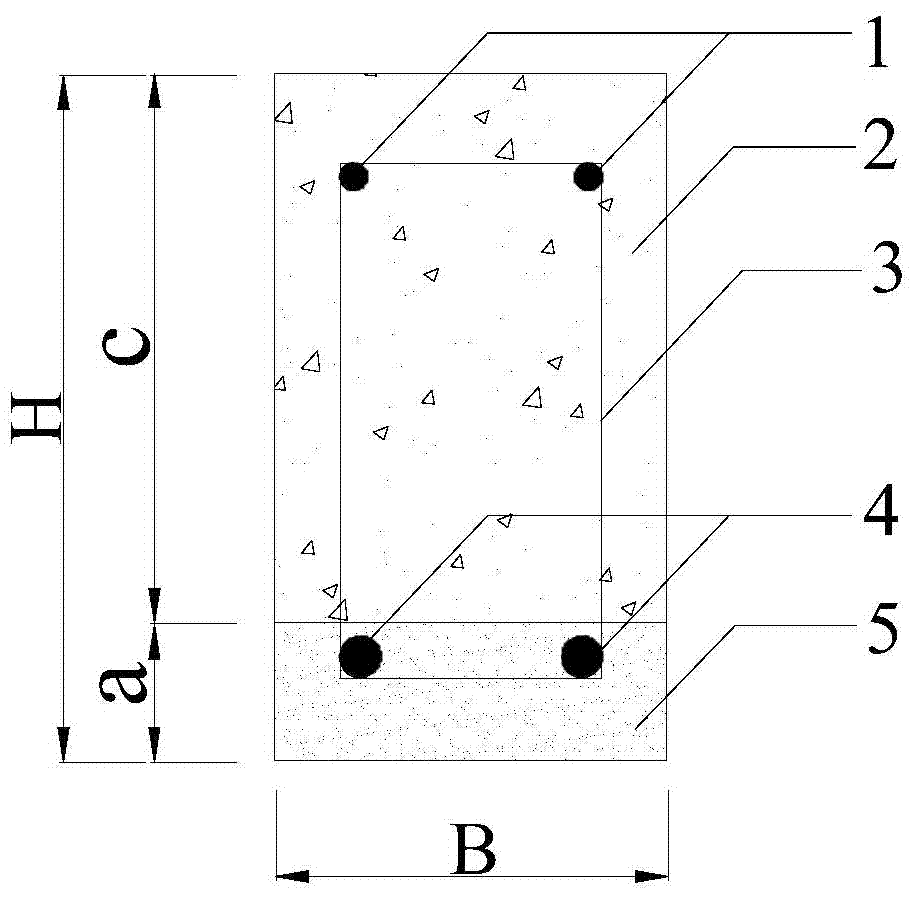

Cement-based composite material with high-temperature resistance and superhigh performance and preparation method thereof

InactiveCN102092996AReduce burstImprove compactnessSolid waste managementMetal fiberAggregate (composite)

The invention discloses a cement-based composite material with high-temperature resistance and superhigh performance and a preparation method thereof. The cement-based composite material comprises the raw materials of a gelled material, an aggregate, fibers, a water reducing agent and water, wherein the gelled material is a mixture of cement and active mineral admixture, the aggregate is yellow sand or a mixture of yellow sand and pebbles, and the fibers are organic fibers or mixtures of organic fibers and metal fibers. The cement-based composite material is produced through improvement on the basis of common concrete manufacturing, has the properties of superhigh mechanical property and high-temperature resistance, is applicable to high-temperature resistant engineering structures, and is favorable for preventing the collapse and the destruction of the construction structures in a fire disaster.

Owner:NANJING UNIV OF SCI & TECH

Filter element comprising pleated metal fiber fleece

InactiveUS6991672B2Avoid heat lossReduce heat lossCombination devicesAuxillary pretreatmentMetal fiberEngineering

A filter element comprising a pleated metal fiber fleece is pleated according to pleating lines, providing an edge with pleat openings to be closed to make gas flowing through the metal fiber fleece. The filter element comprising at least two flanks, each of these flanks comprises a thermally and electrically insulating fabric and a stiff material layer. The thermally and electrically insulating fabric is present at one side of the stiff material layer, providing a thermally and electrically insulated side to the flank. The metal fiber fleece is mounted between the thermally and electrically insulated sides of both flanks, which exercise a clamping force on the edges of the metal fiber fleece in a direction essentially parallel to the pleating lines, while the flanks closing said pleat openings.

Owner:RYPOS

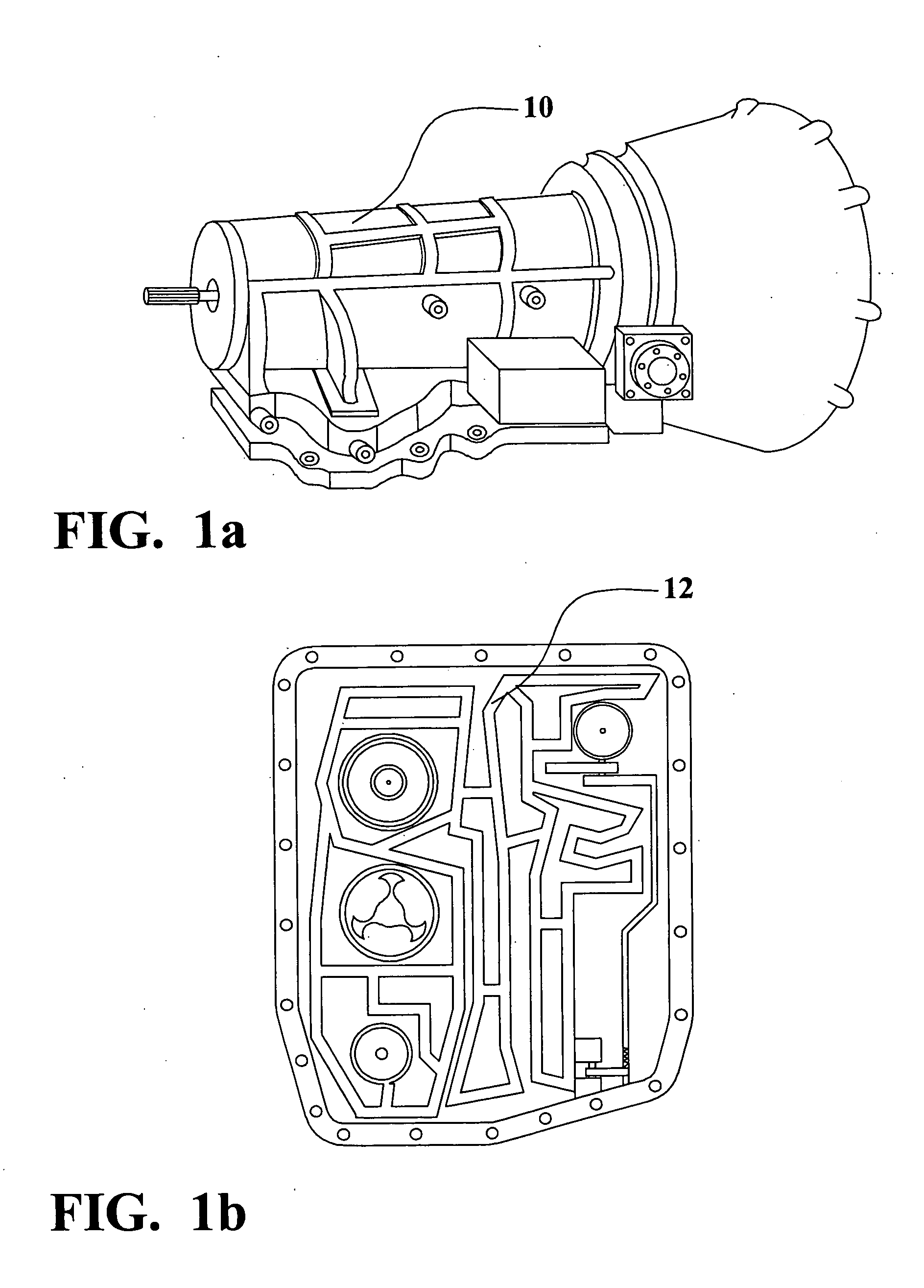

Low cost housings for vehicle mechanical devices and systems manufactured from conductive loaded resin-based materials

InactiveUS20050212162A1Reduce weightImprove conductivityPrinted circuit aspectsRadiating elements structural formsMetal fiberElectrical conductor

Automotive housings are formed of a conductive loaded resin-based material. The conductive loaded resin-based material comprises micron conductive powder(s), conductive fiber(s), or a combination of conductive powder and conductive fibers in a base resin host. The percentage by weight of the conductive powder(s), conductive fiber(s), or a combination thereof is between about 20% and 50% of the weight of the conductive loaded resin-based material. The micron conductive powders are metals or conductive non-metals or metal plated non-metals. The micron conductive fibers may be metal fiber or metal plated fiber. Further, the metal plated fiber may be formed by plating metal onto a metal fiber or by plating metal onto a non-metal fiber. Any platable fiber may be used as the core for a non-metal fiber. Superconductor metals may also be used as micron conductive fibers and / or as metal plating onto fibers in the present invention.

Owner:INTEGRAL TECHNOLOGY INC

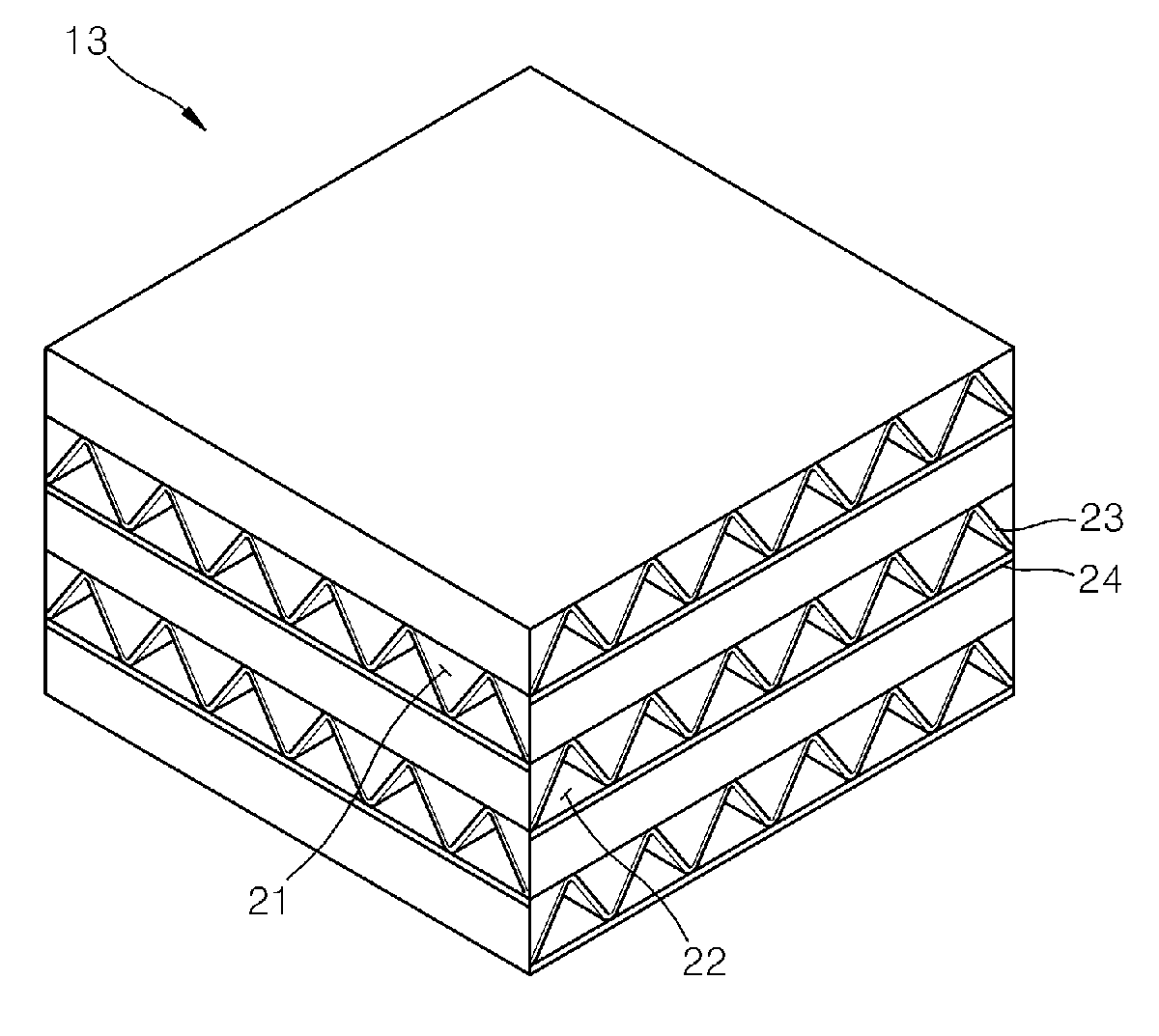

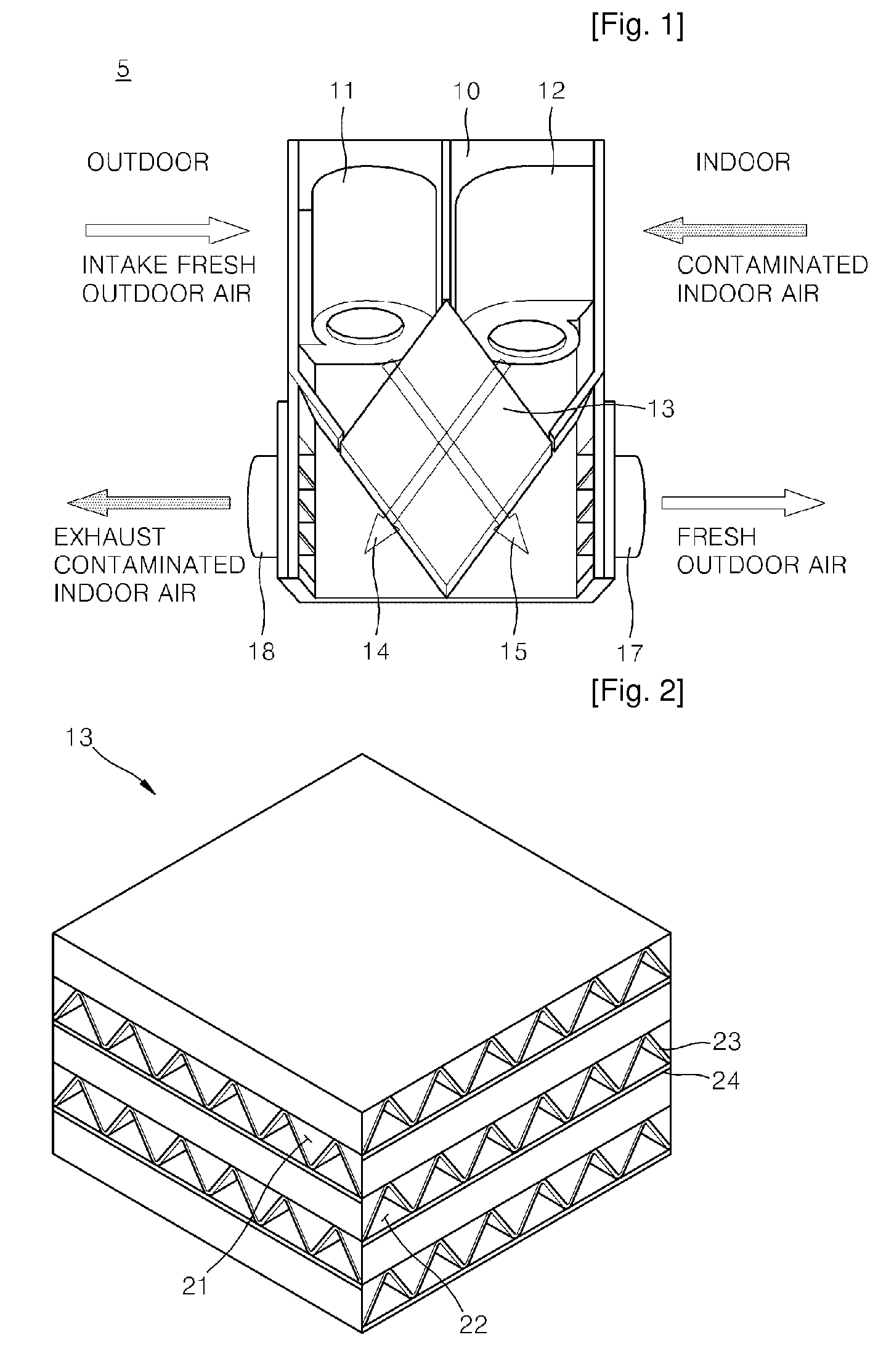

Heat conduction unit with improved laminar

InactiveUS20100032145A1Increase heatImproving moisture exchange performanceEnergy recovery in ventilation and heatingHeat recovery systemsMetal fiberCarbon nanotube

A heat conduction unit having an improved laminar is provided. The heat conduction unit of the present invention includes a pair of exhaust and intake layers crossing each other for exchanging heat between exhaust and intake airflows; and a laminar interposed between the exhaust and intake layers and having a having a fiber synthetic fabric layer with a high water absorbancy and heat conductivity. The fiber synthetic fabric layer is made by densely weaving a microfiber in the form of a fabric, the fabric being weaved by adding micro metal fiber, by adding microfiber plated with metal, or by adding at least ones of micro copper molecules, aluminum molecules, carbon black molecules, carbon nano tube molecules, titanium dioxide (TiO2) molecules, and nano-silver molecules, to a raw material resin of the microfiber.

Owner:LEE CHAN BONG

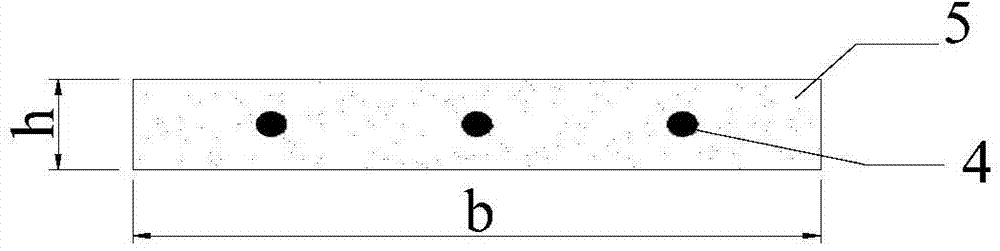

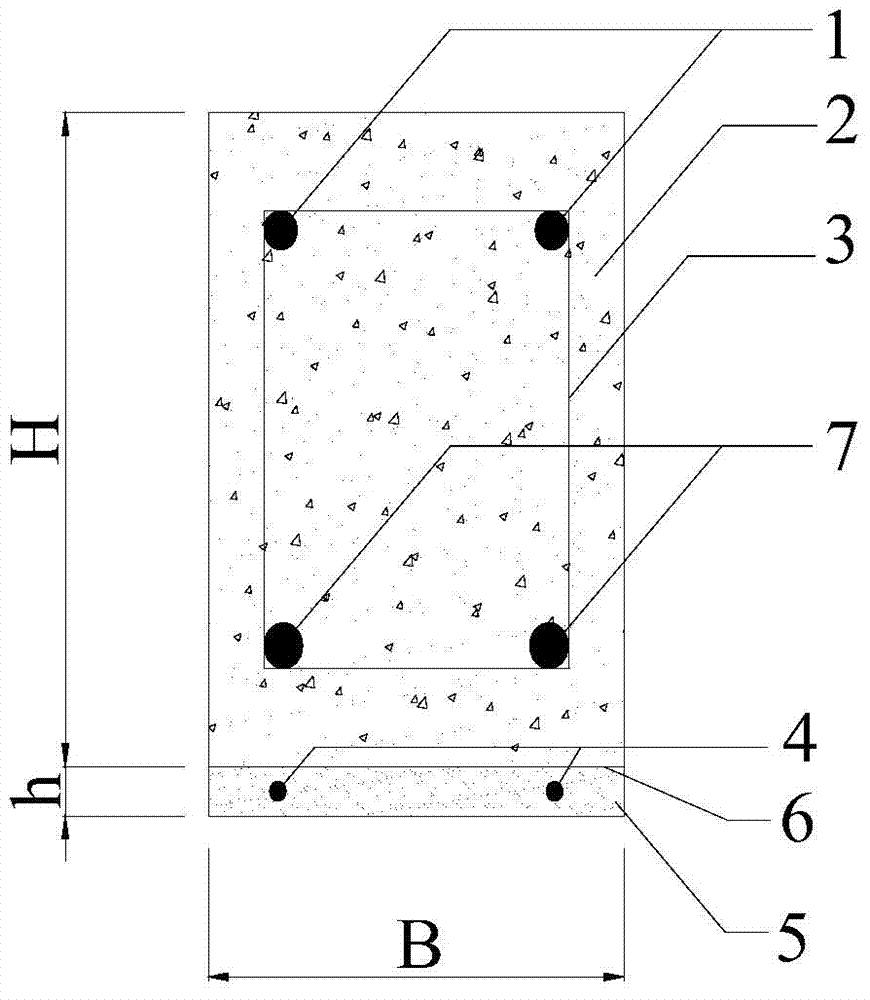

High toughness cement-based material-nonmetal fiber rib composite structure as well as application and application method thereof

InactiveCN103938803AImprove carrying capacityIncreased durabilityBuilding repairsGirdersCarbon fibersPolyvinyl alcohol

The invention discloses a high toughness cement-based material-nonmetal fiber rib composite structure. According to the structure, a high toughness cement-based material is adopted as a base material, nonmetal fiber rib is adopted as directional reinforcing rib; the high toughness cement-based material comprises the following components in percentage by weight: 35% of cement, 45-55% of fly ash, 5-10 % of silicon ash and 5-10% of metakaolin; high-strength short fiber is one or more out of polyvinyl alcohol fiber, polyethylene fiber, carbon fiber and aramid fiber; the nonmetal fiber rib is carbon fiber reinforced plastic rib, aramid fiber reinforced plastic rib, glass fiber reinforced plastic rib or basalt fiber reinforced plastic rib. The invention further discloses applications and an application method of the high toughness cement-based material-nonmetal fiber rib composite structure. The high toughness cement-based material and the nonmetal fiber rib are utilized to reinforce the reinforced concrete structure, so that the bearing capacity and the durability of the structure are increased and the aging speed of the structure is reduced.

Owner:ZHEJIANG UNIV +1

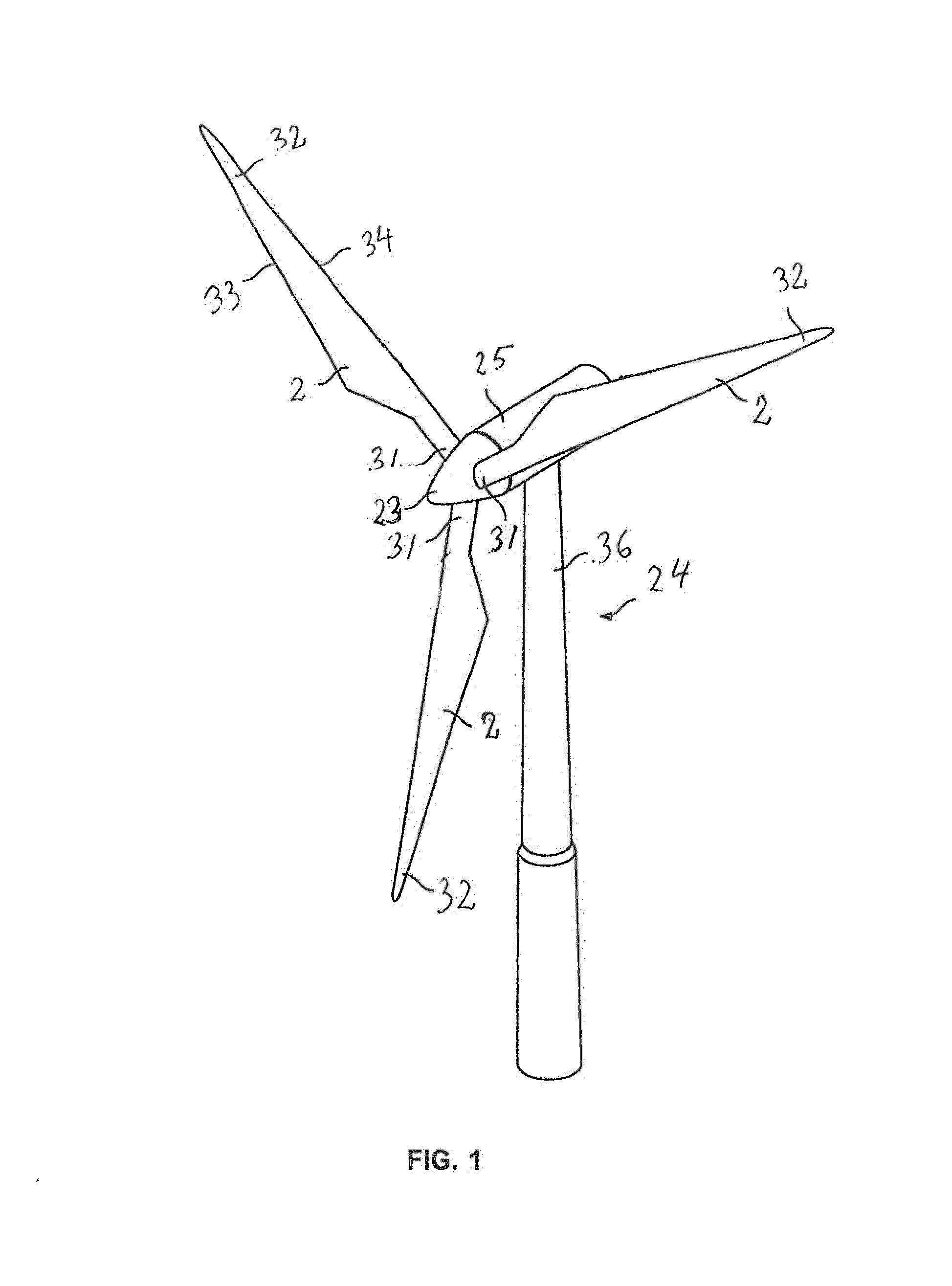

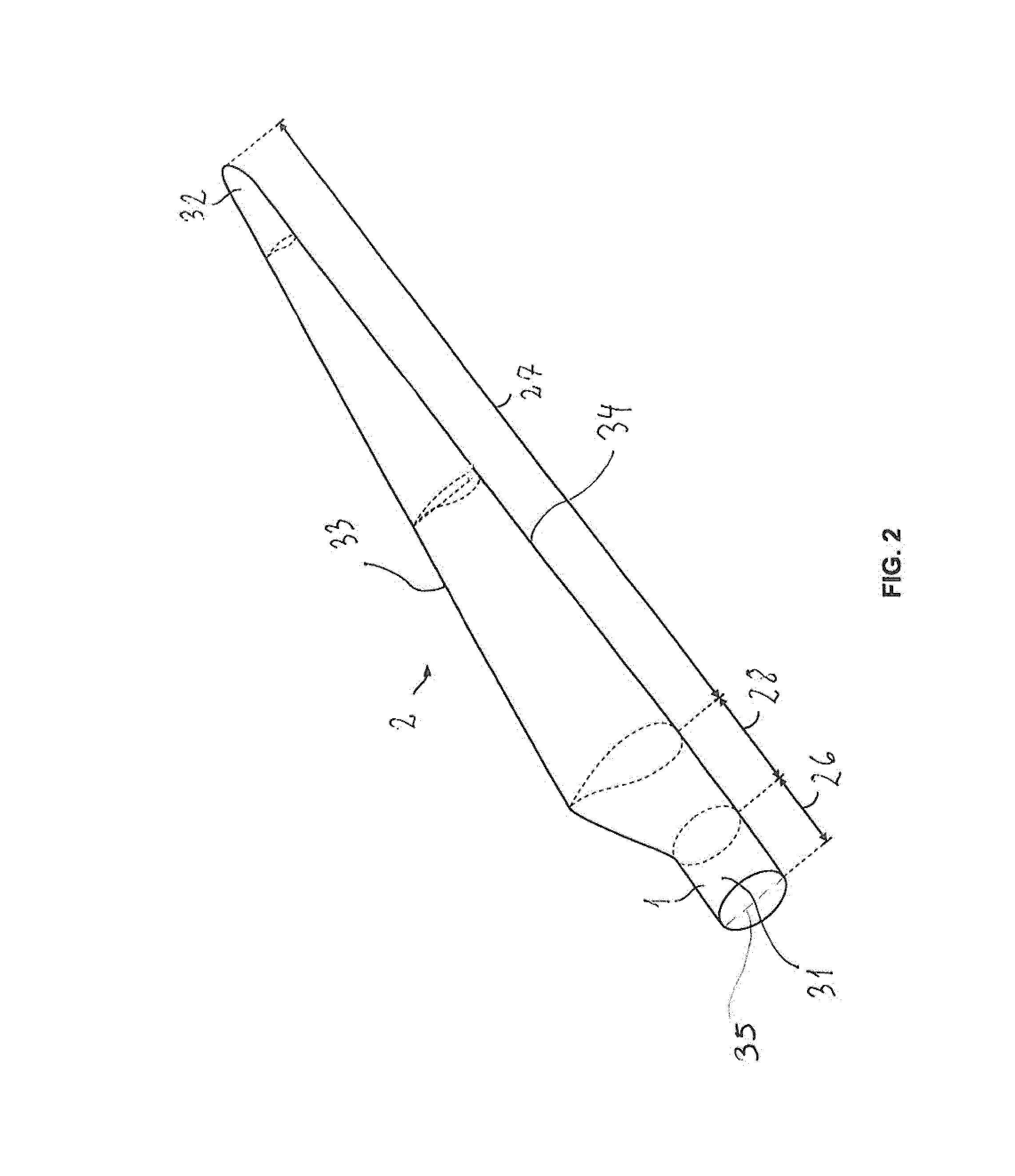

Wind turbine blade having a root region with elongated fastening members provided with metal fibres

ActiveUS20140030094A1High retention rateReduce the overall diameterPropellersEngine manufactureTurbine bladeFiber-reinforced composite

A wind turbine blade for a wind turbine is a shell structure of a fibre-reinforced composite and comprises a root region and an airfoil region. The root region has ring-shaped cross section and comprises a plurality of elongated bushings 7 with an inner thread 22 and embedded interspaced in the fibre-reinforced polymer so as to substantially follow the circumference of the root region and allow access from the outside to the inner threads. Each fastening member 7 is provided with a notch 60′ in the periphery 11 thereof. A rod-shaped locking element 61 passes through the notch 60′ in engagement therewith. The locking element 61 is fixedly and tightly fitting arranged in a through-going circular bore 65 extending through the wall of the root region.

Owner:LM WP PATENT HLDG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com