Patents

Literature

6669results about How to "Reduce heat loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

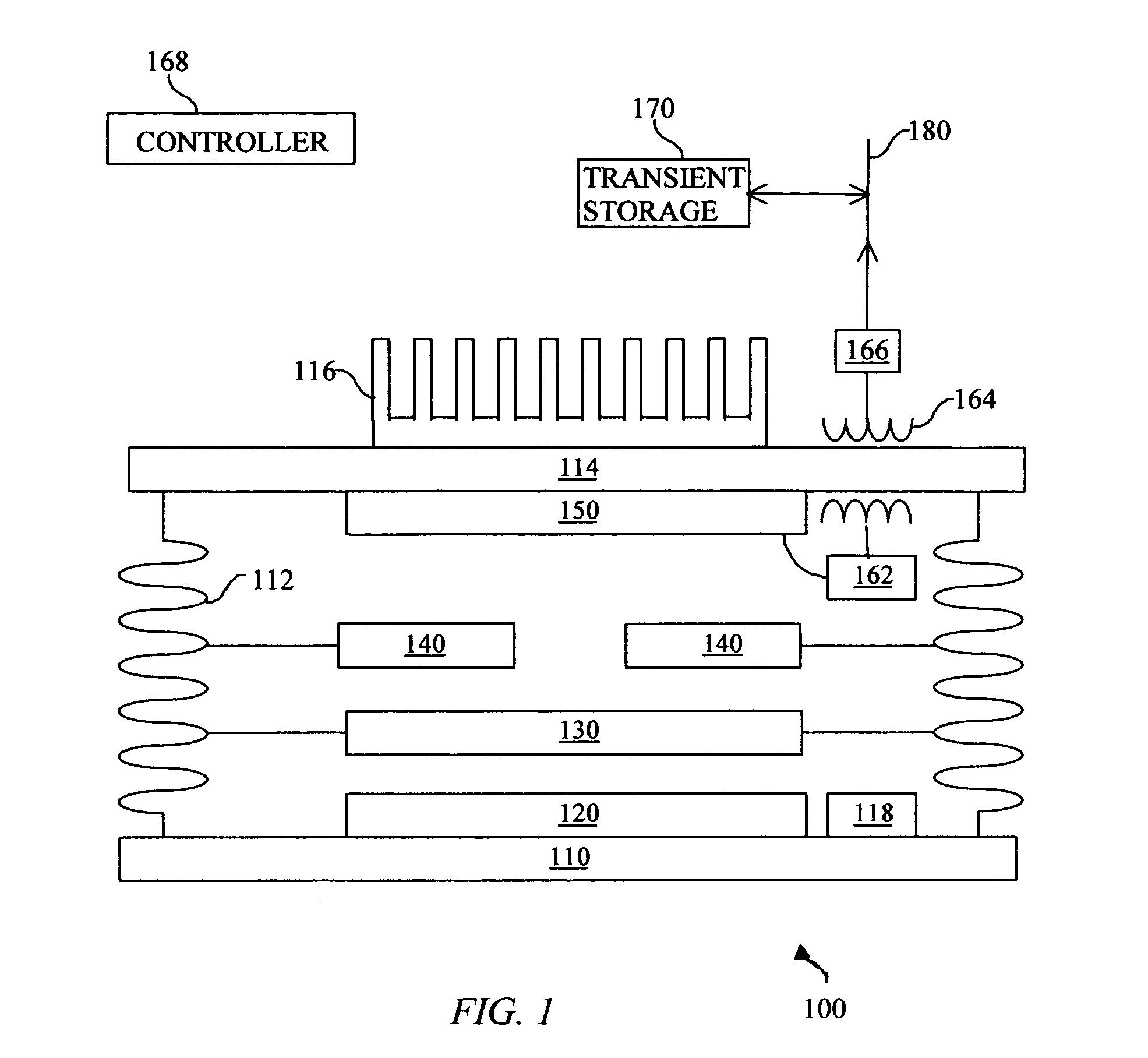

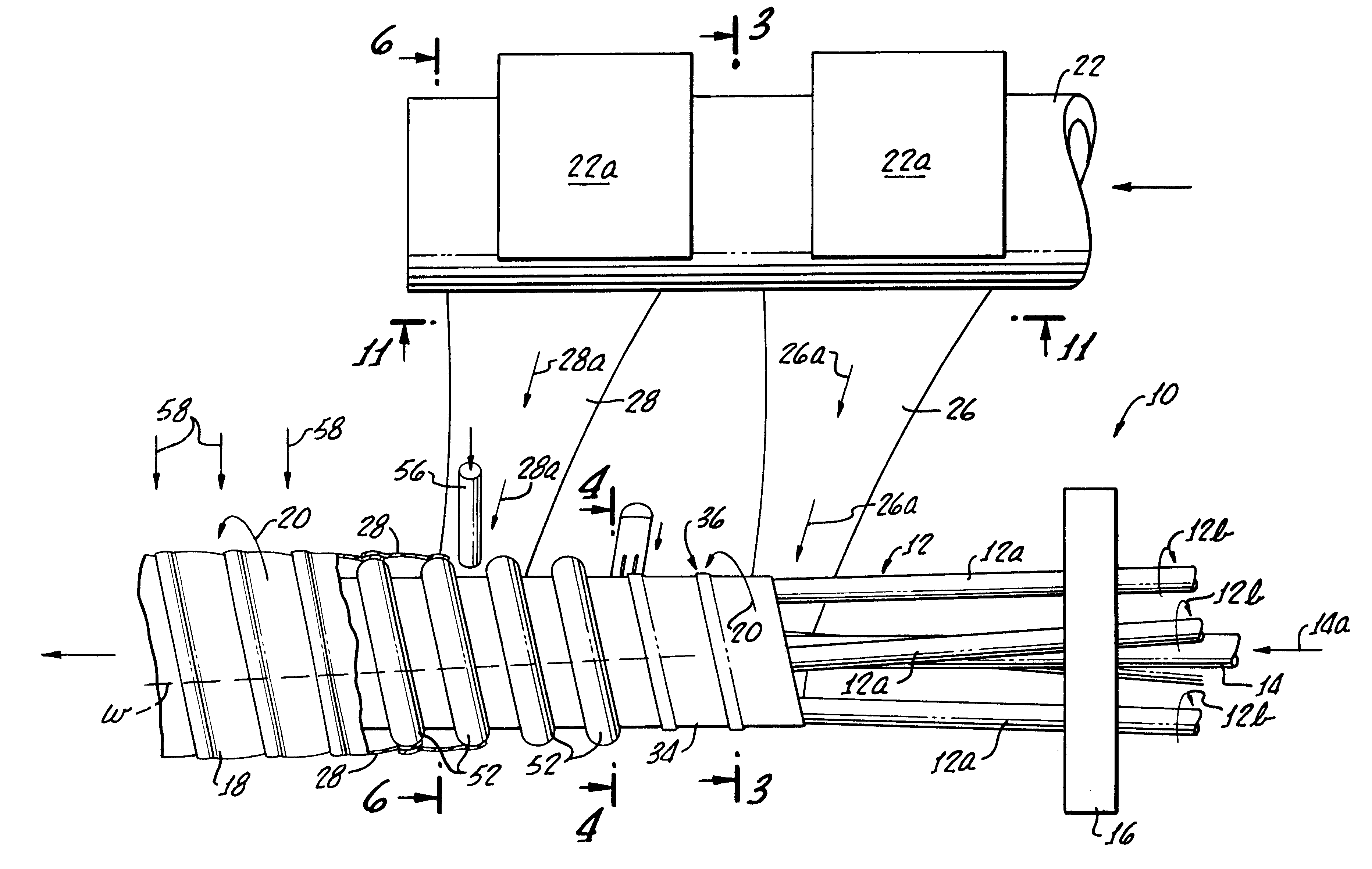

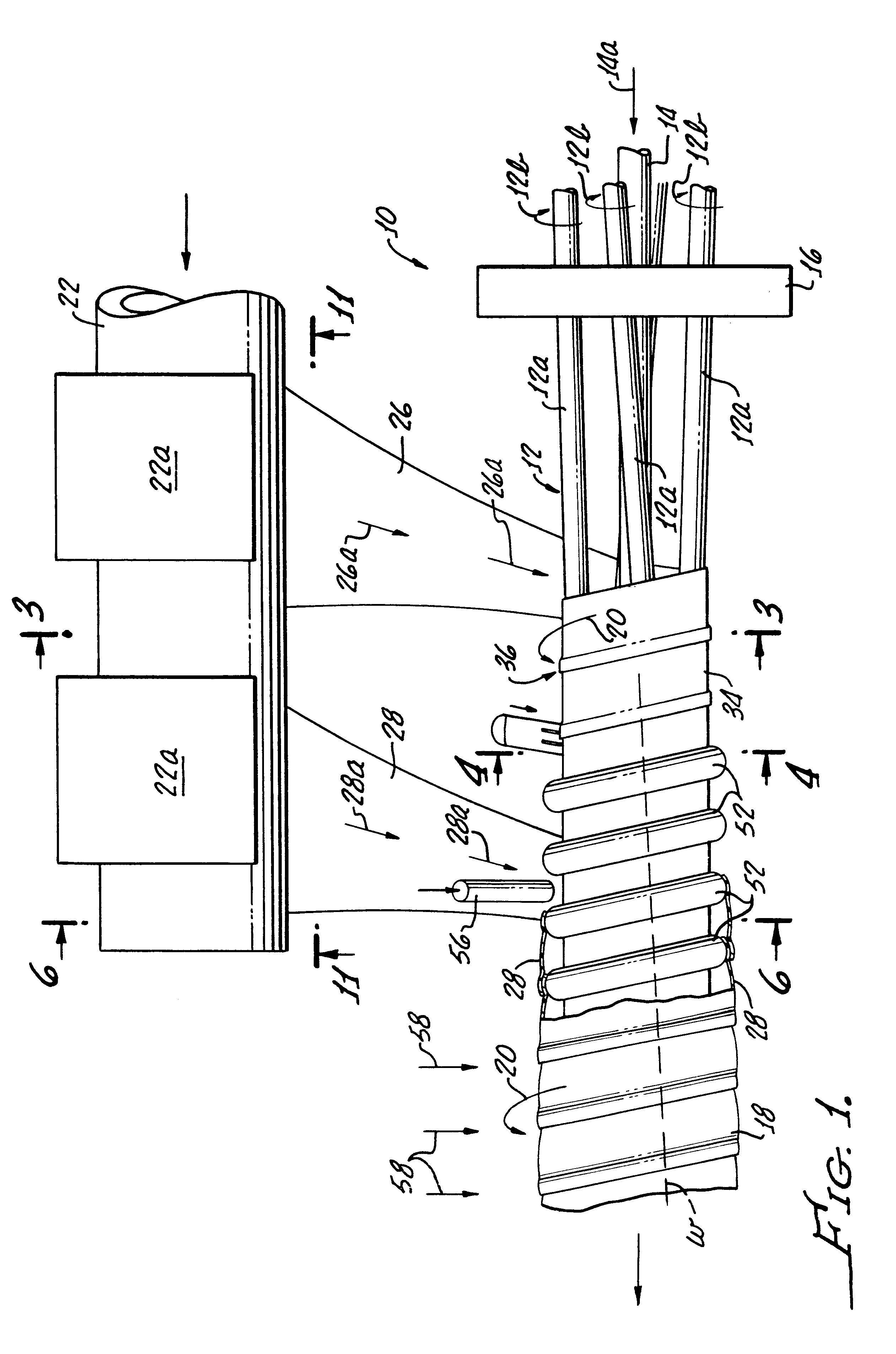

Systems and methods for hydrocarbon recovery

InactiveUS6173775B1Difficult to maintainReduce effectInsulationFluid removalHydrogen compoundsInjector

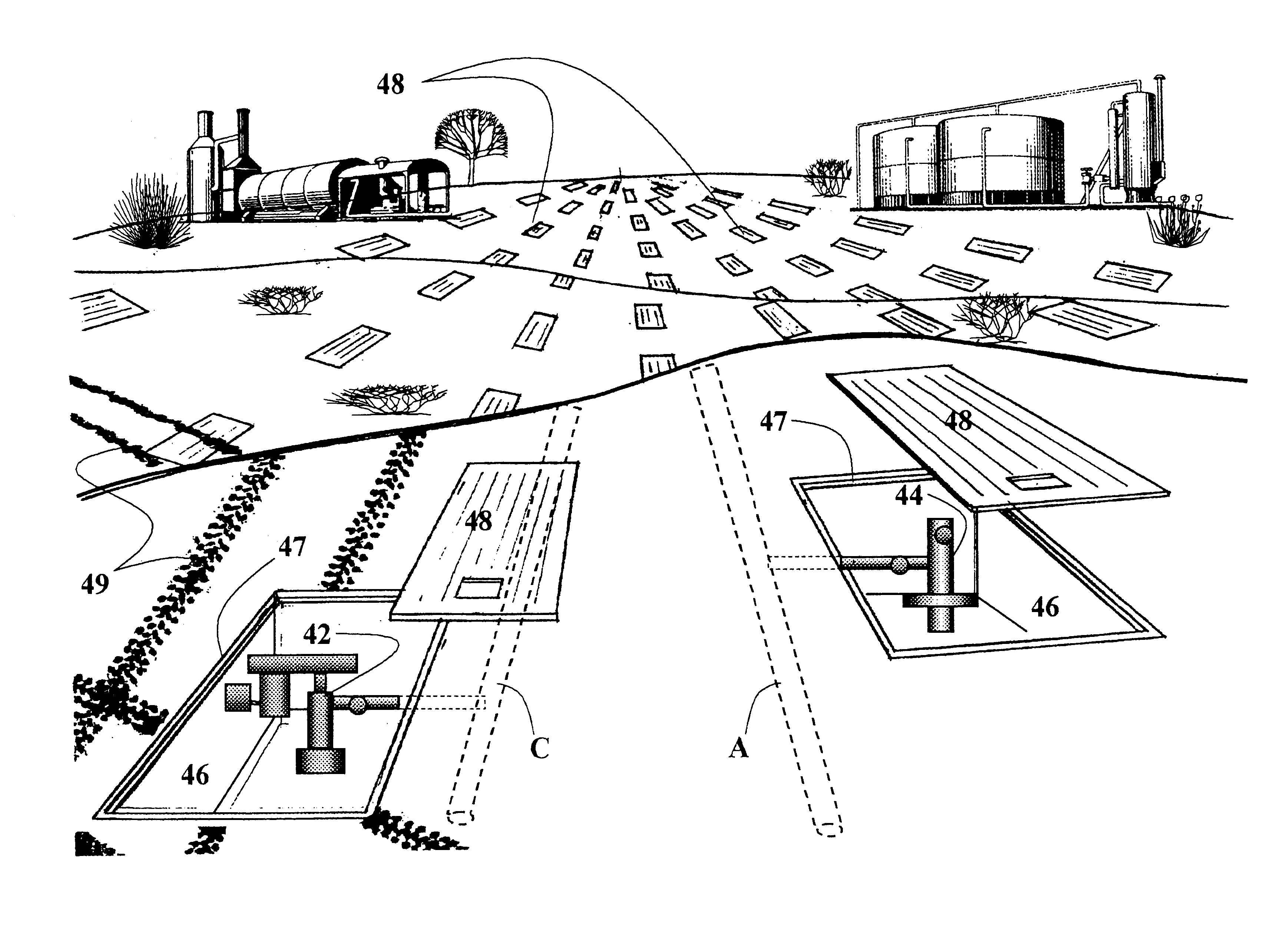

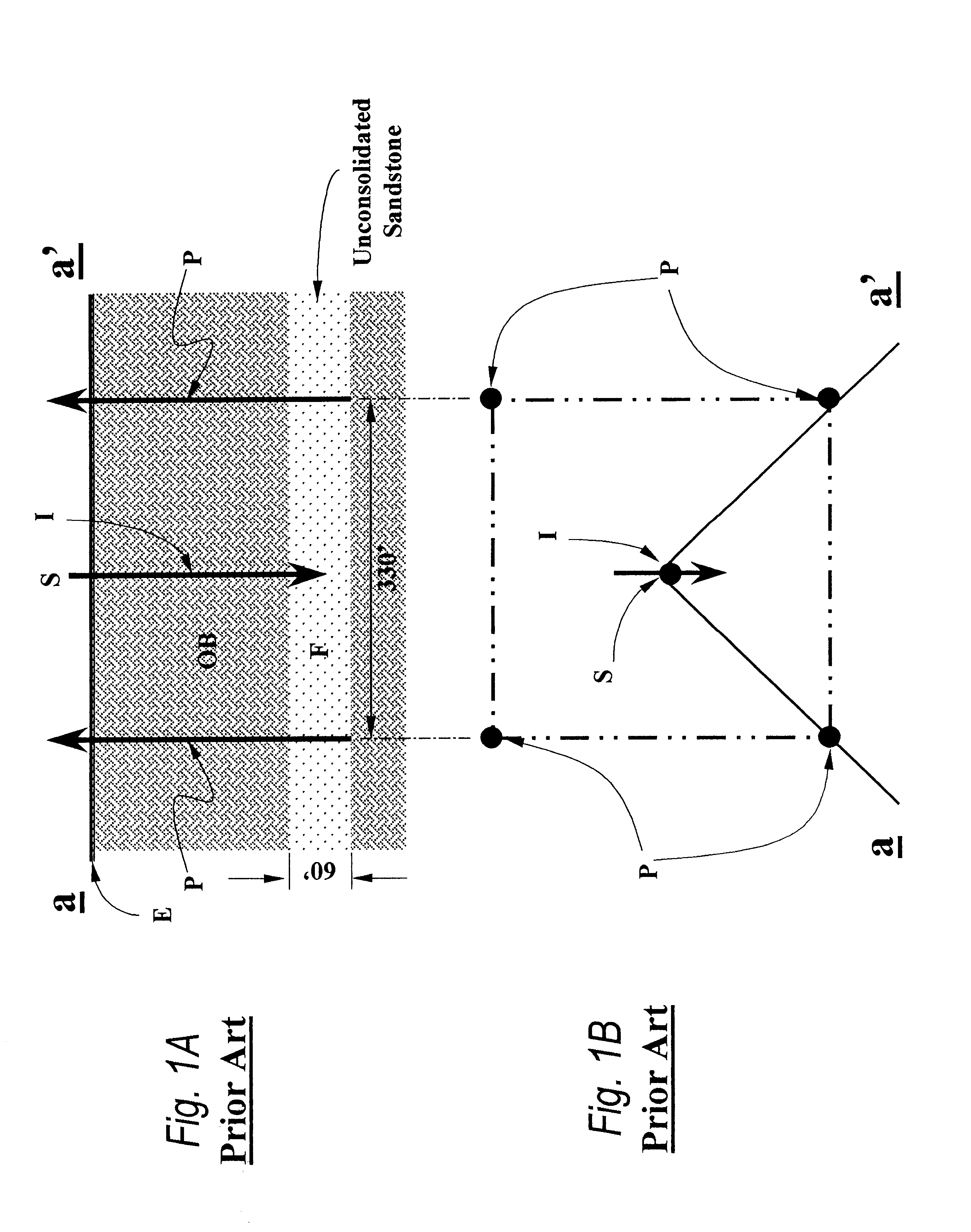

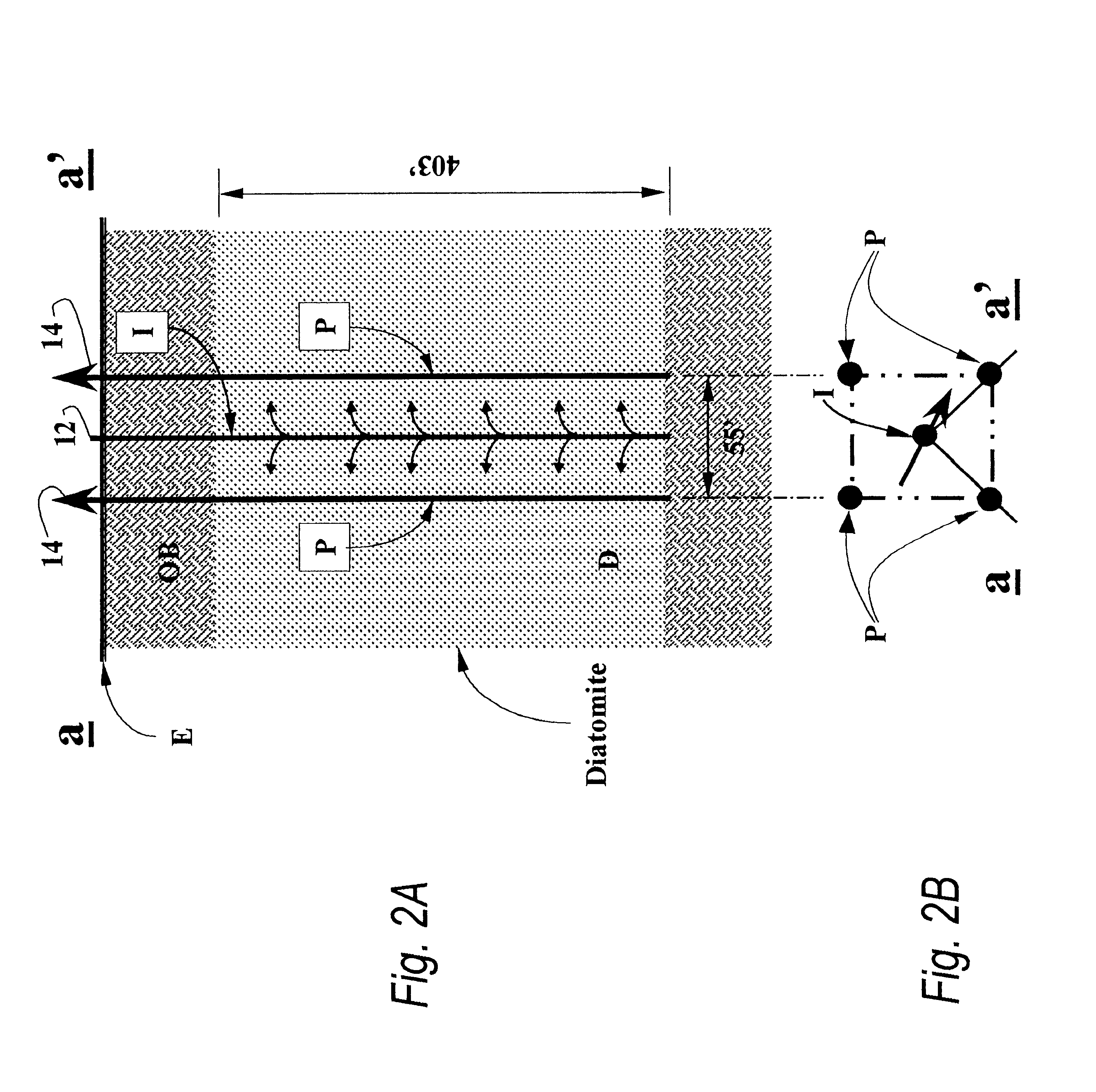

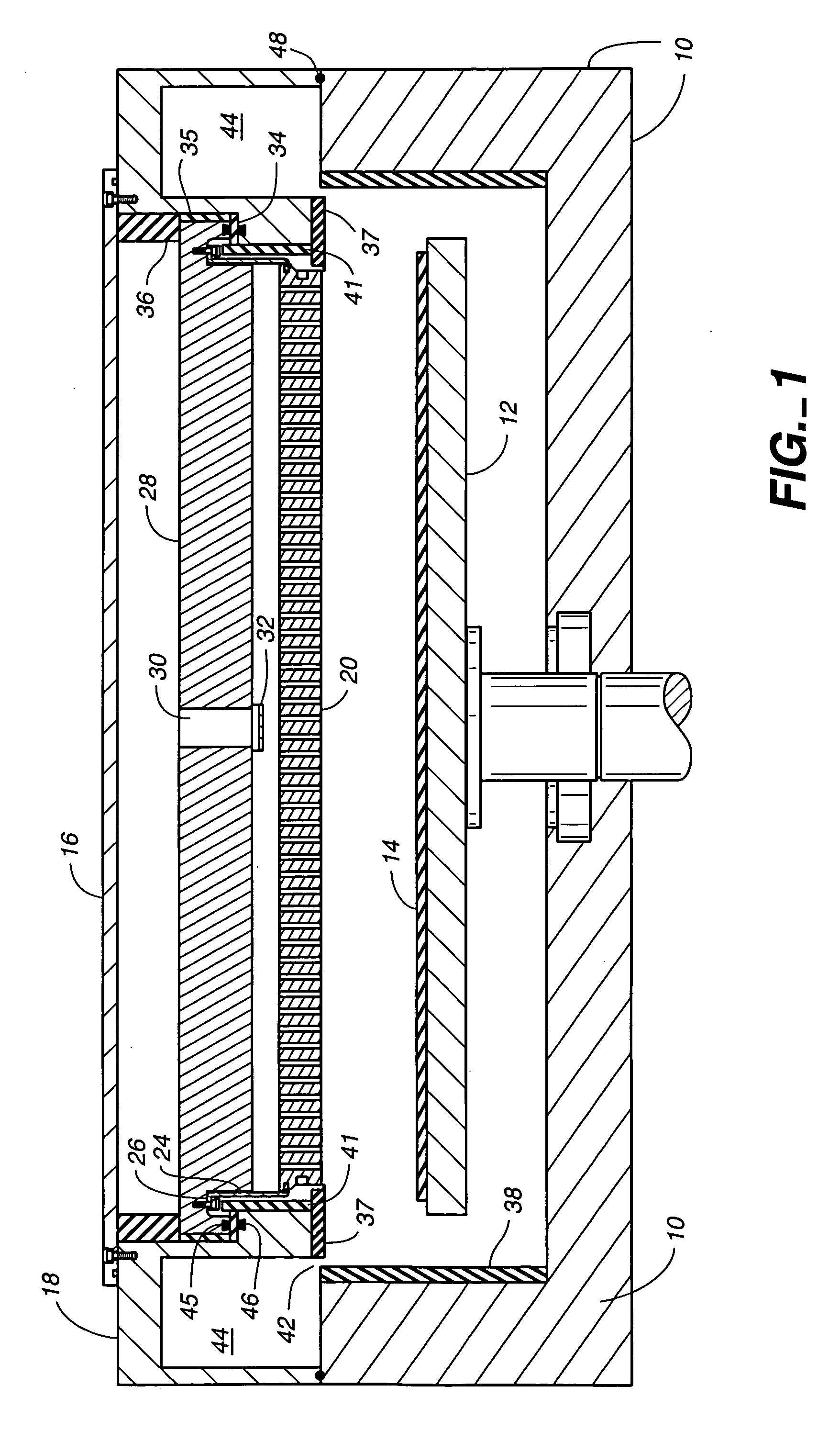

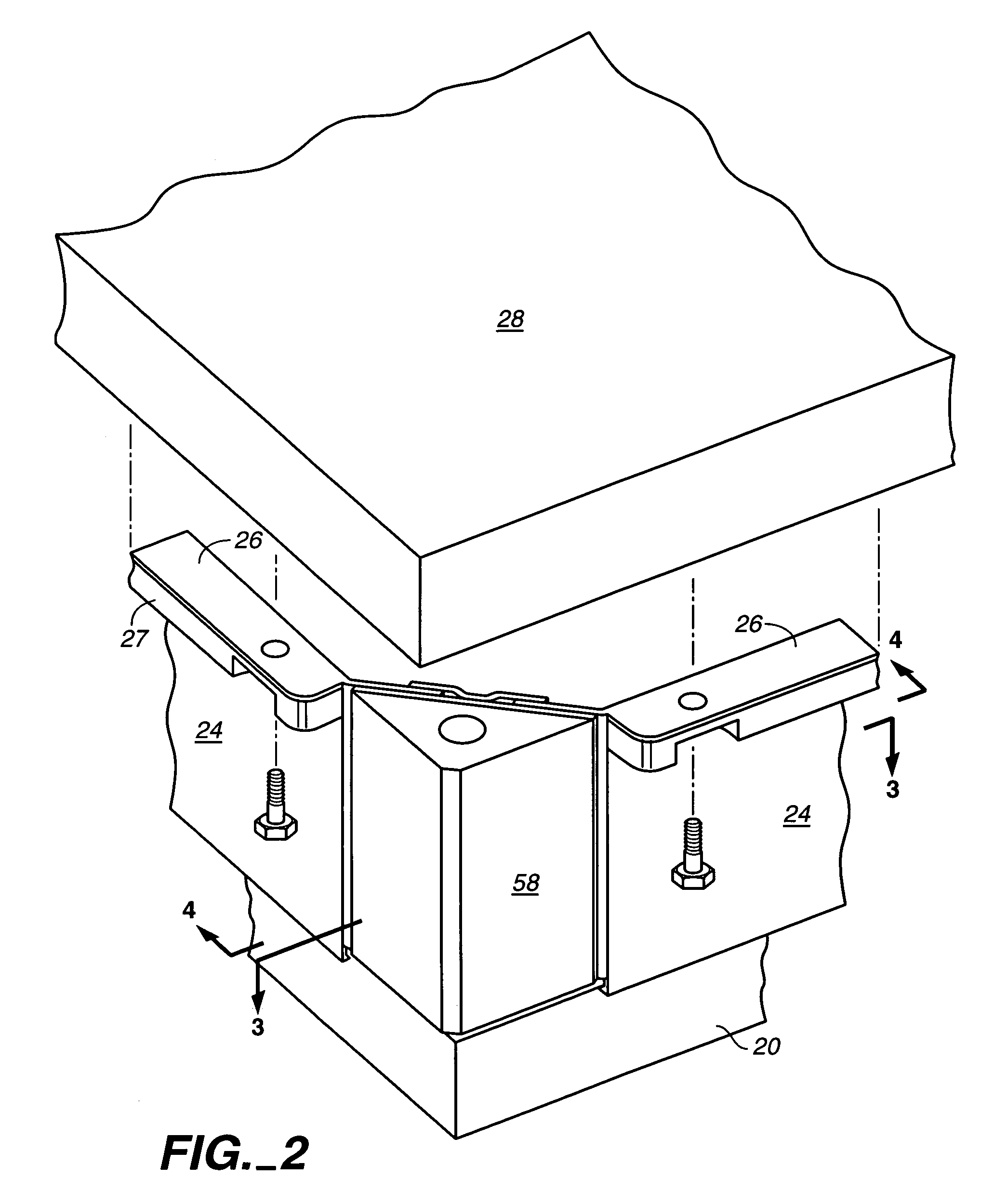

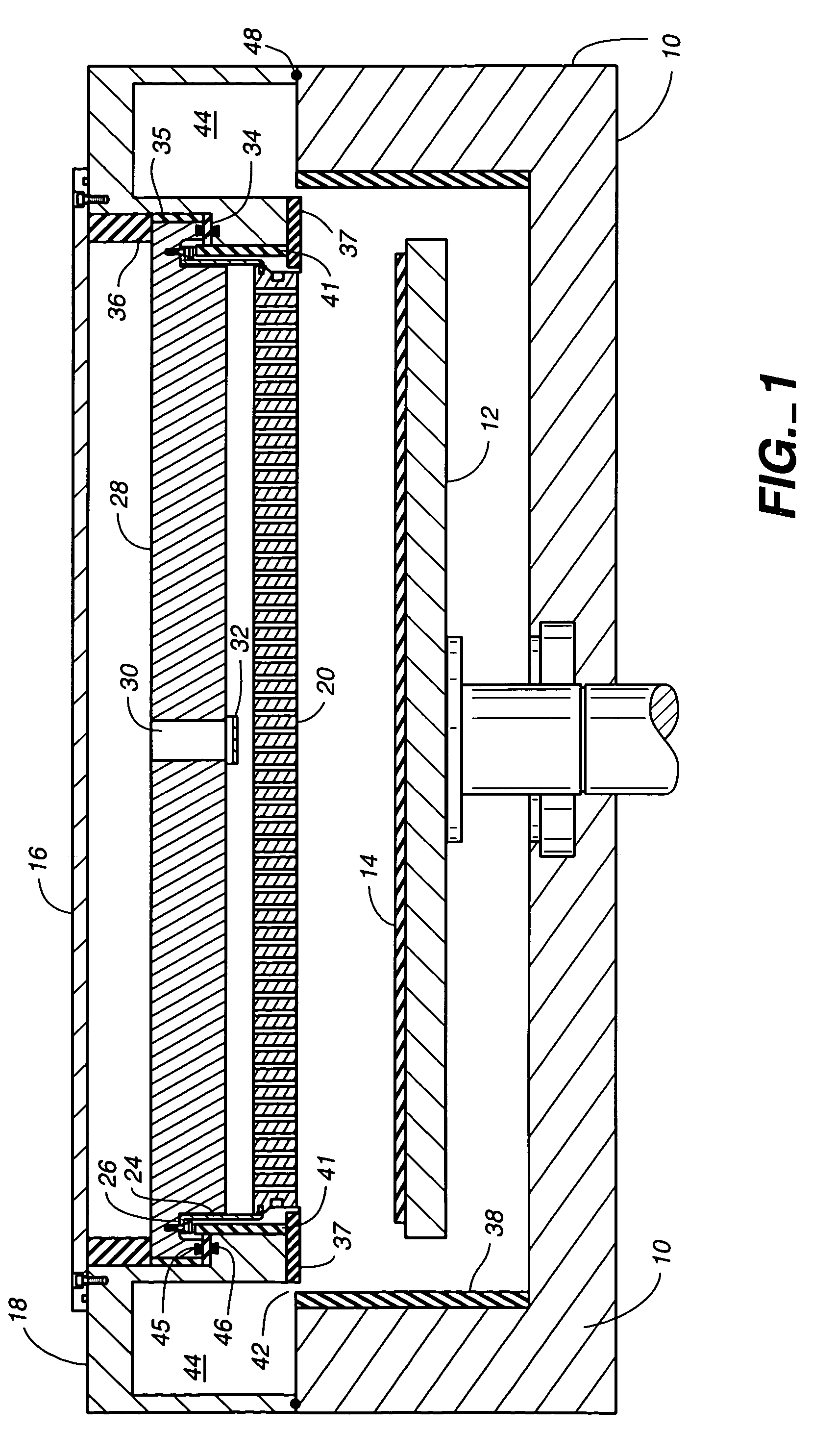

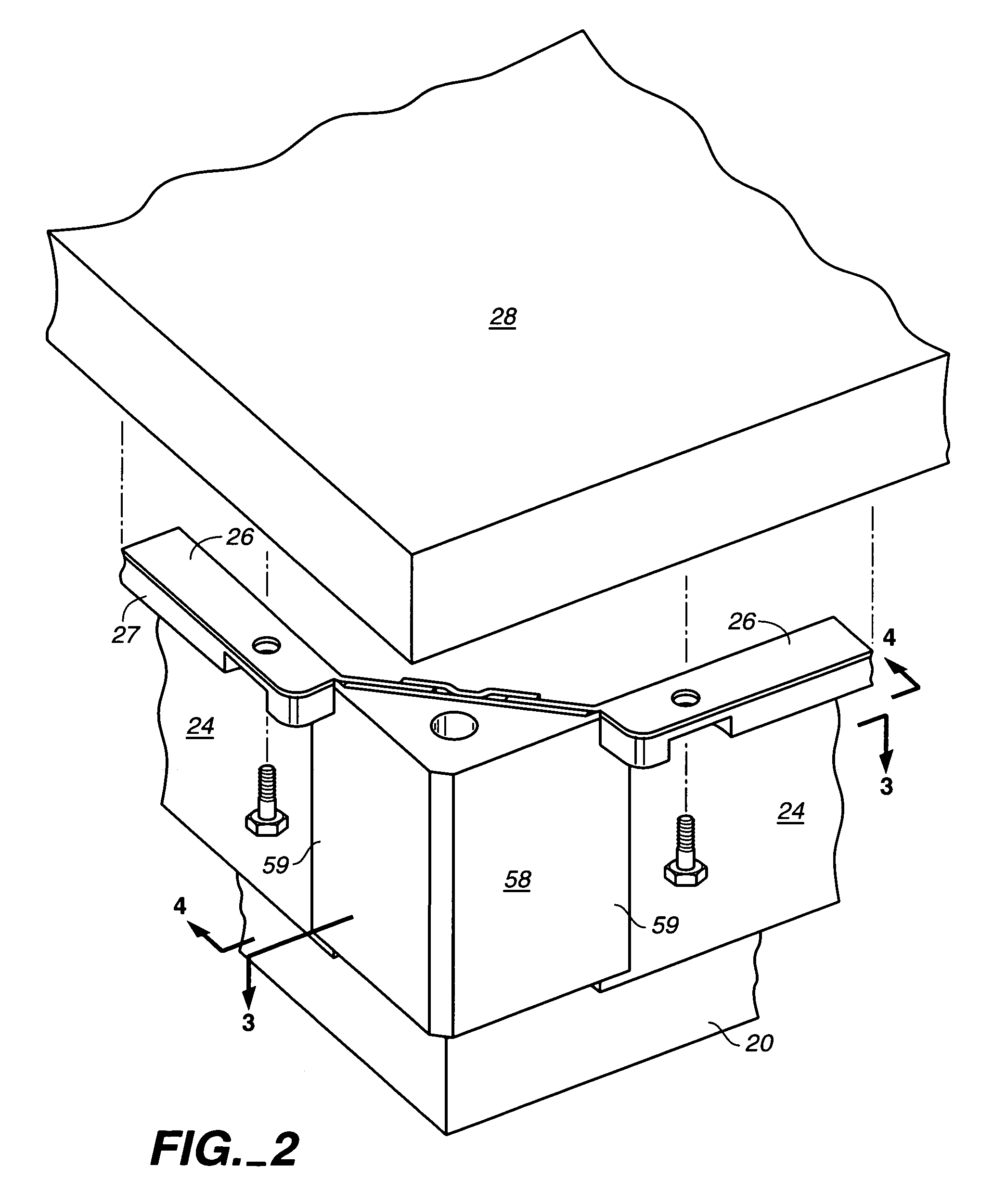

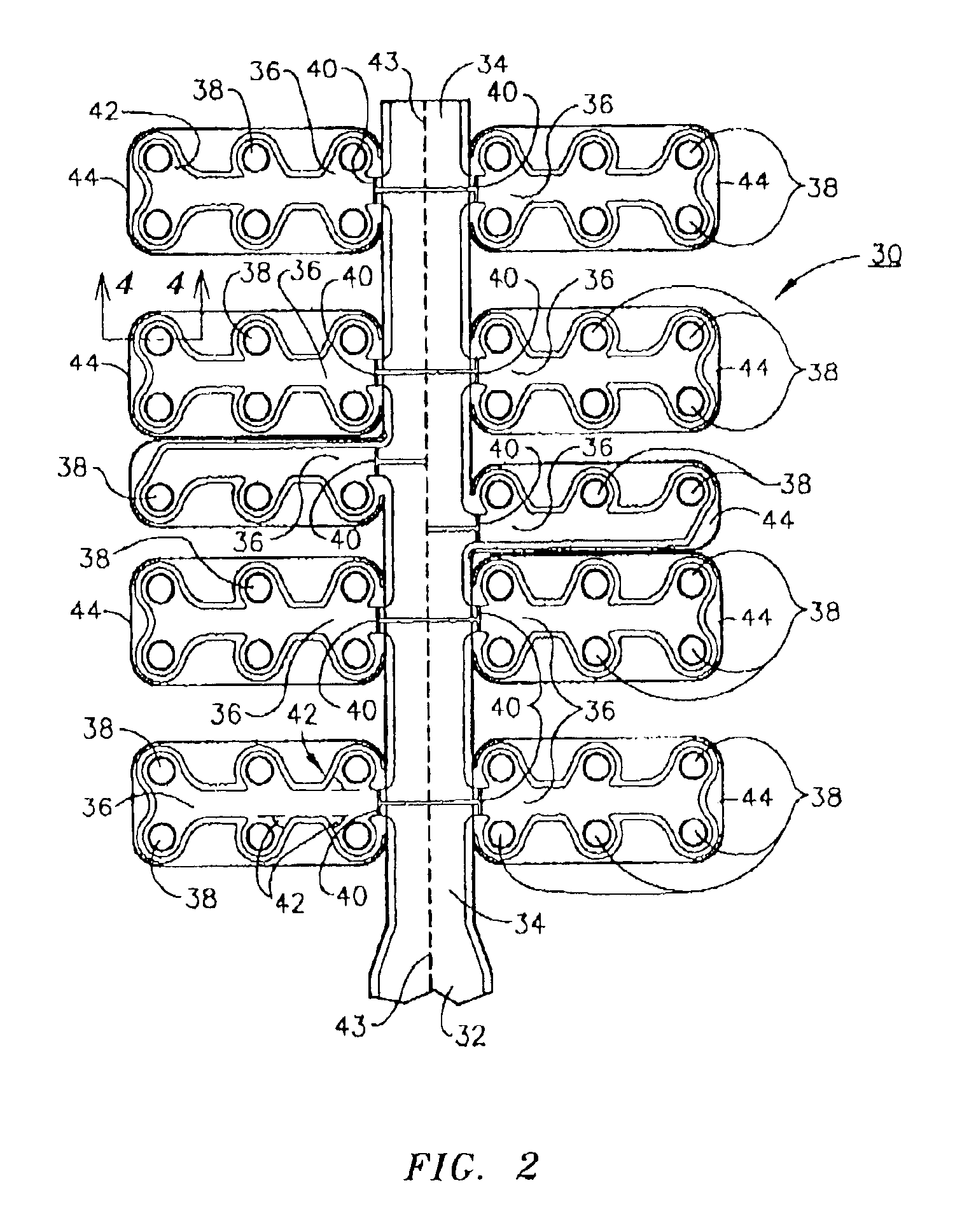

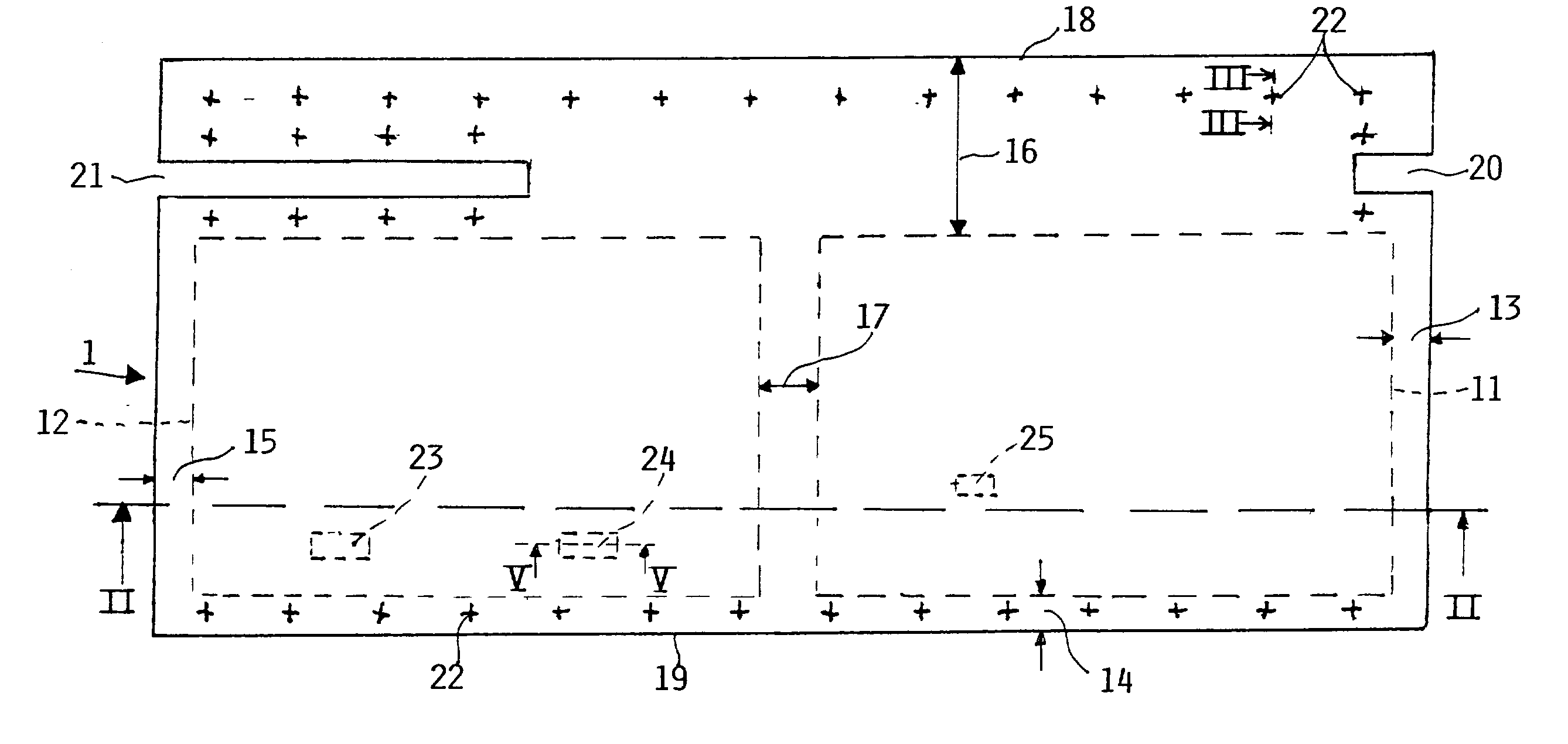

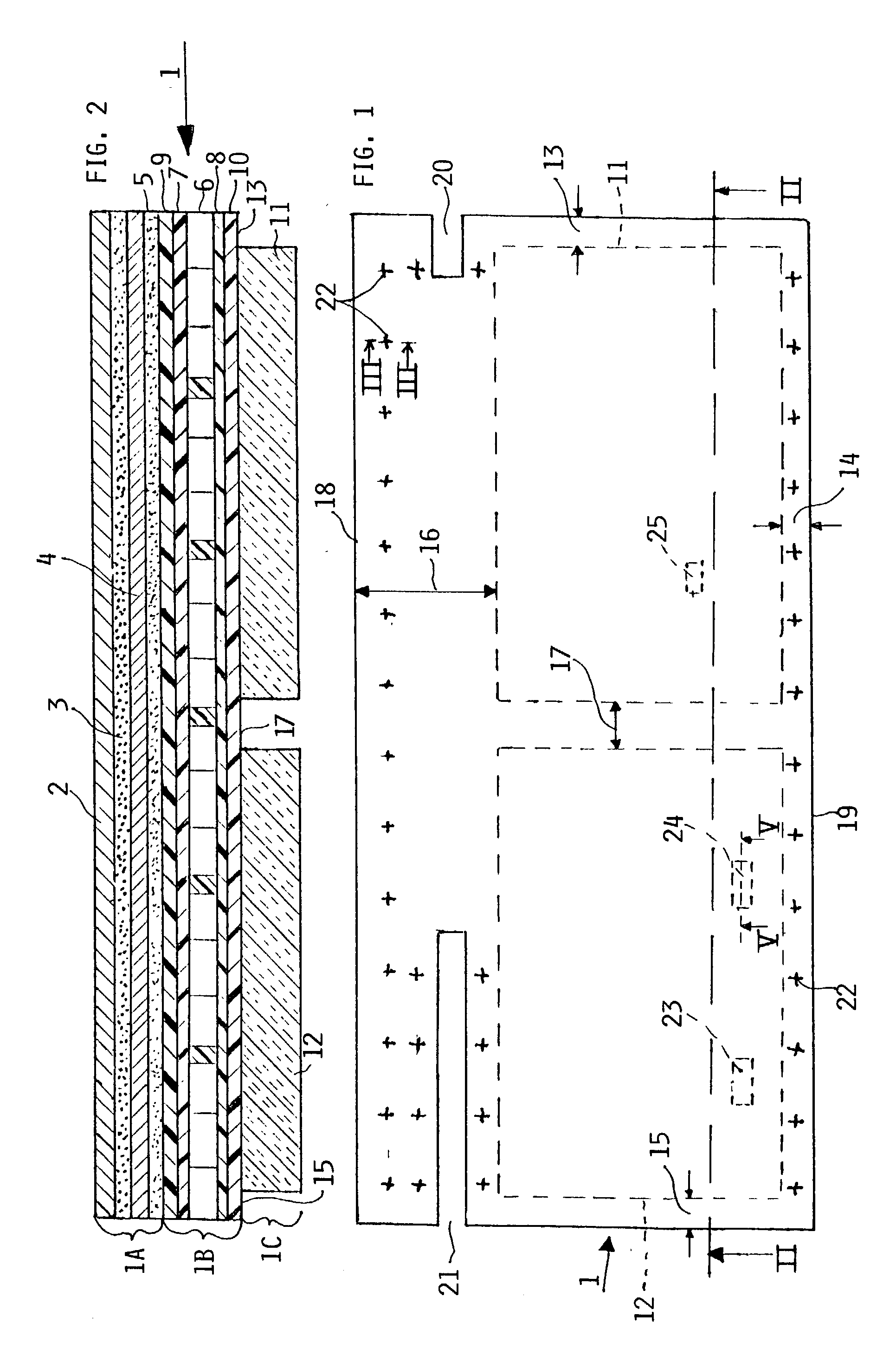

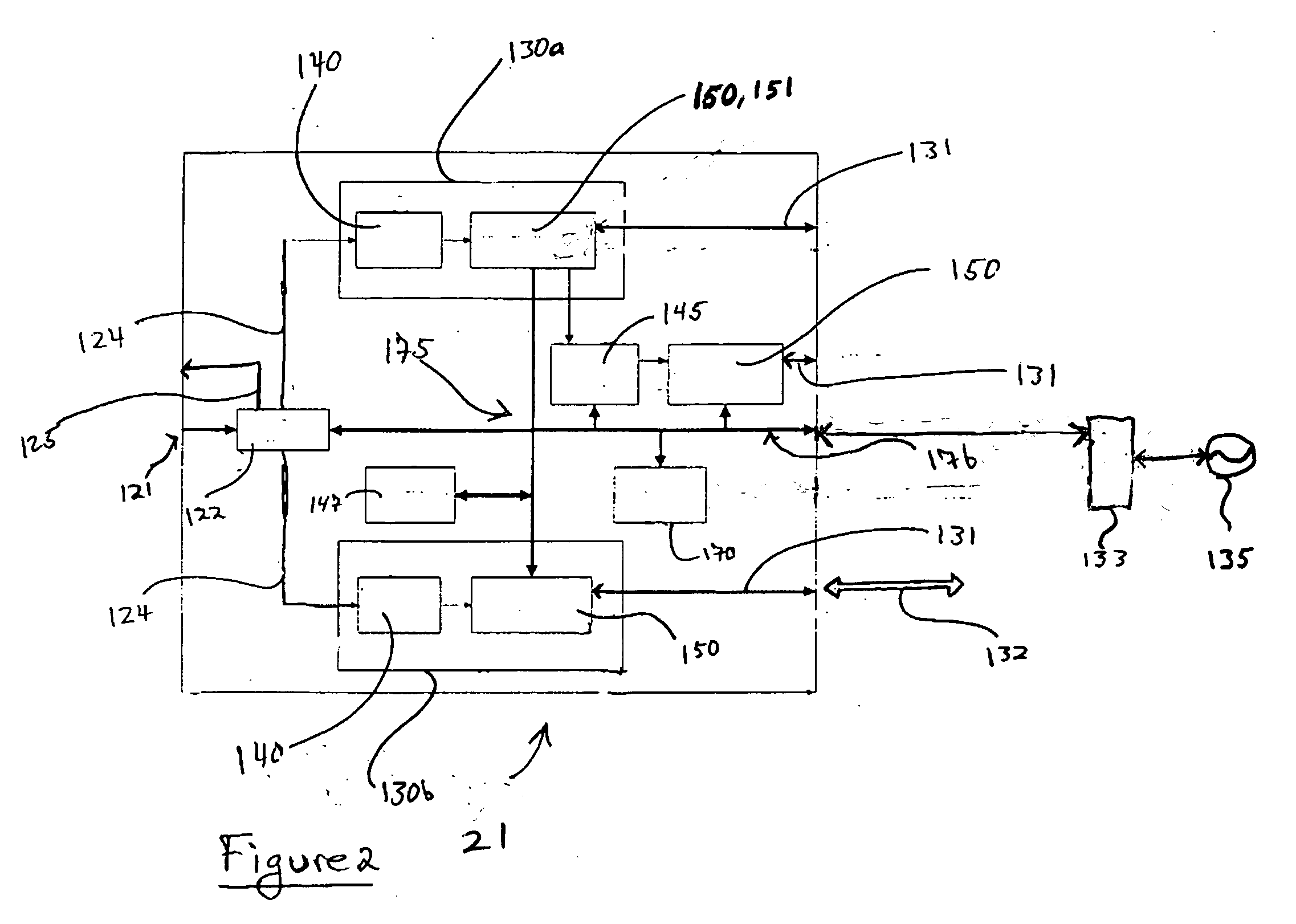

A method has been invented for recovering hydrocarbons from an earth formation containing hydrocarbons, the method including injecting a recovery injectant into the earth formation at a plurality of injection points spaced apart by about 14 to about 208 feet, and producing hydrocarbons from the formation with at least one producer well. In one aspect the method includes injecting steam into an earth formation which contains oil bearing diatomite at a plurality of injection points spaced apart by about 14 to about 208 feet, and producing hydrocarbons from the formation with a one or more producer wells extending into the oil bearing diatomite formation, with a plurality of producer wells spaced apart by a distance ranging between about 14 to about 149 feet, injecting steam into the oil bearing diatomite at an injection rate of between about 10 to about 149 barrels of steam per day per hundred feet thickness of diatomite, and injecting the steam at a pressure between about 10 p.s.i. to about 260 p.s.i. The present invention also discloses a method for treating a hydrocarbon-bearing diatomite formation including applying an artificial overburden over at least a portion of the formation and applying a variable well spacing as needed. A field on an earth formation has been invented for recovering hydrocarbons, the earth formation having an earth surface above it, the field including a plurality of injector well and a plurality of producing wells, the field including at least one injector well per acre of earth surface above the earth formation and at least one producing well per acre. Certain parts of the wells may be in below-grade chambers.

Owner:ELIAS RAMON +2

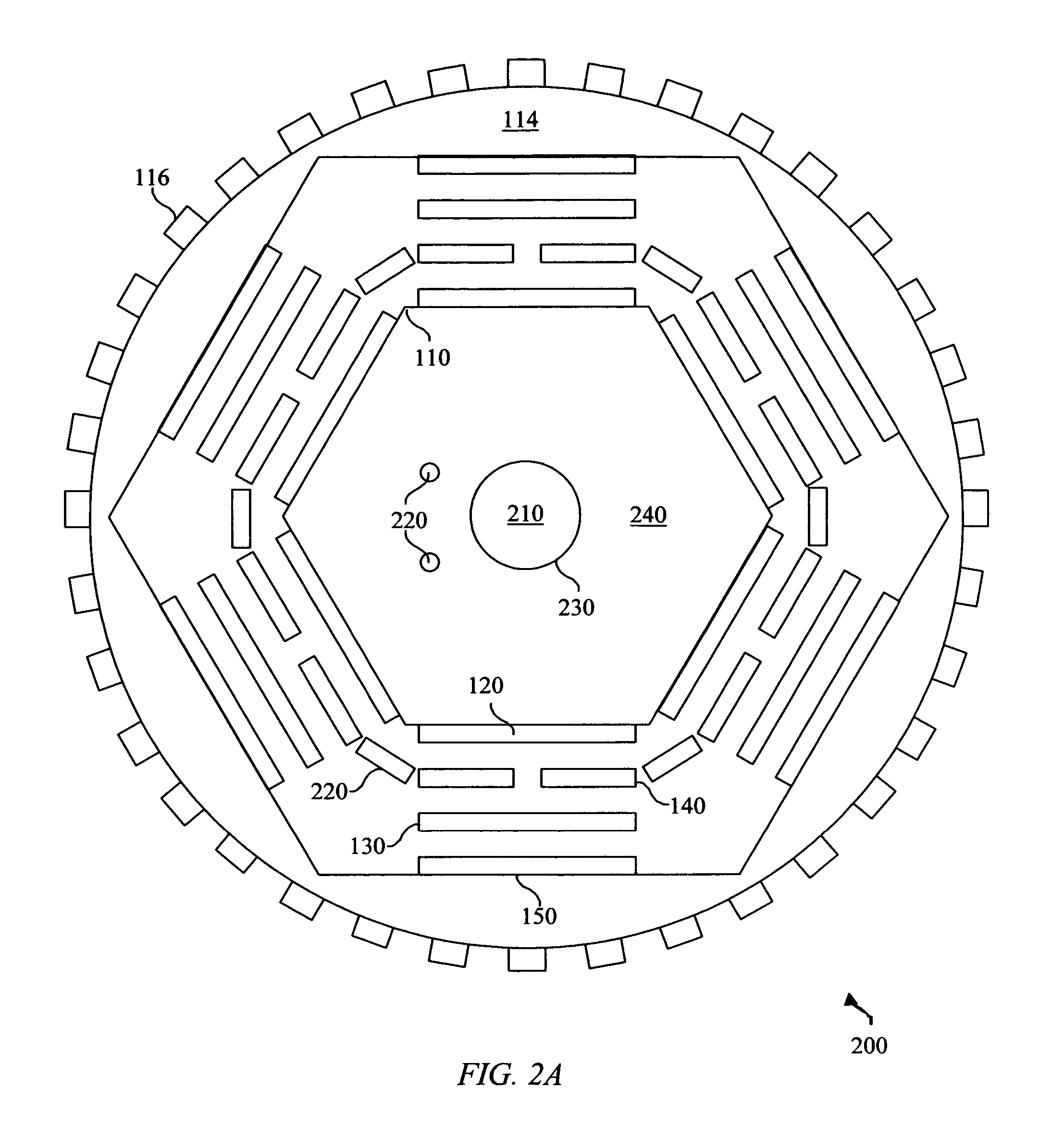

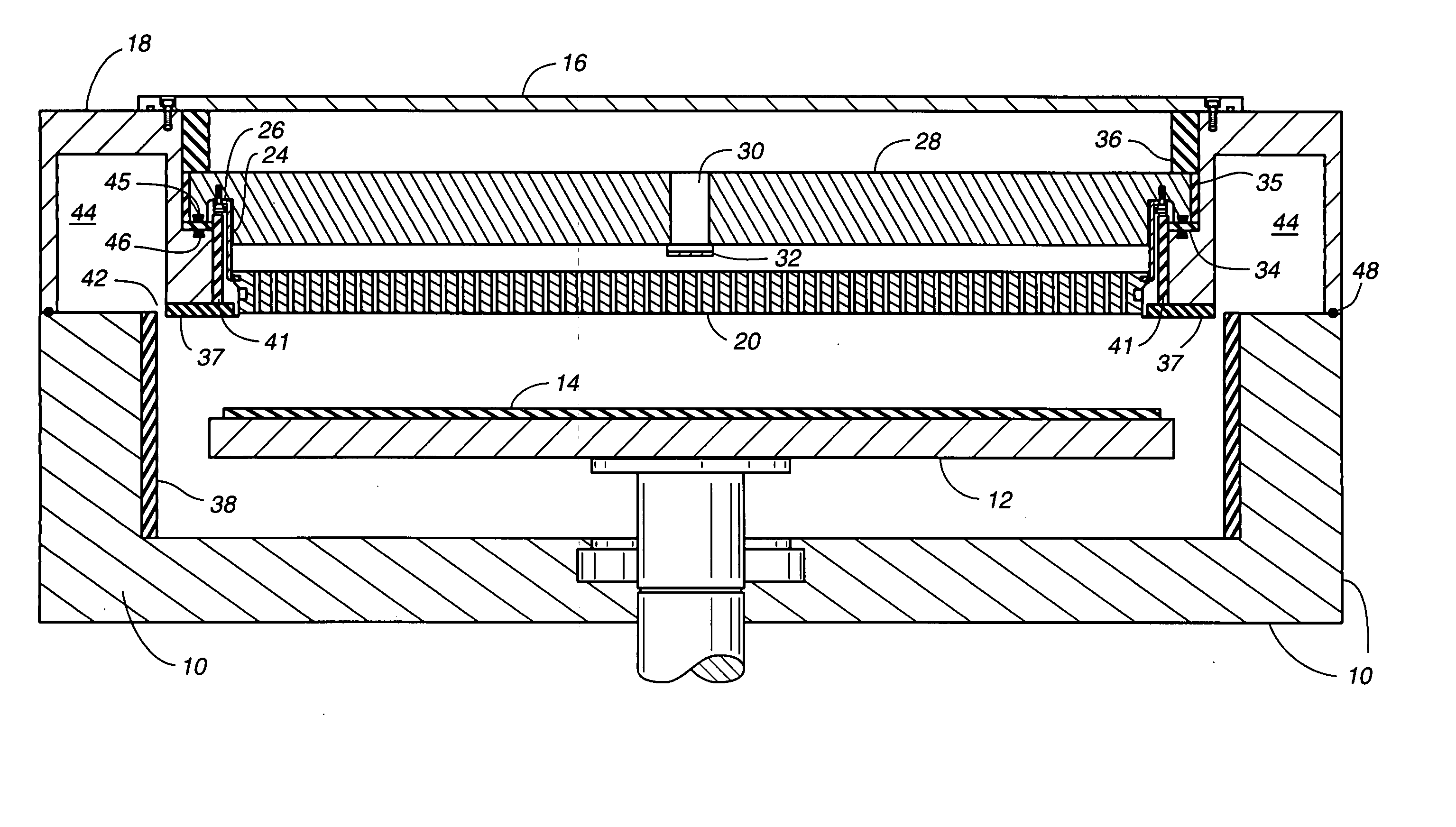

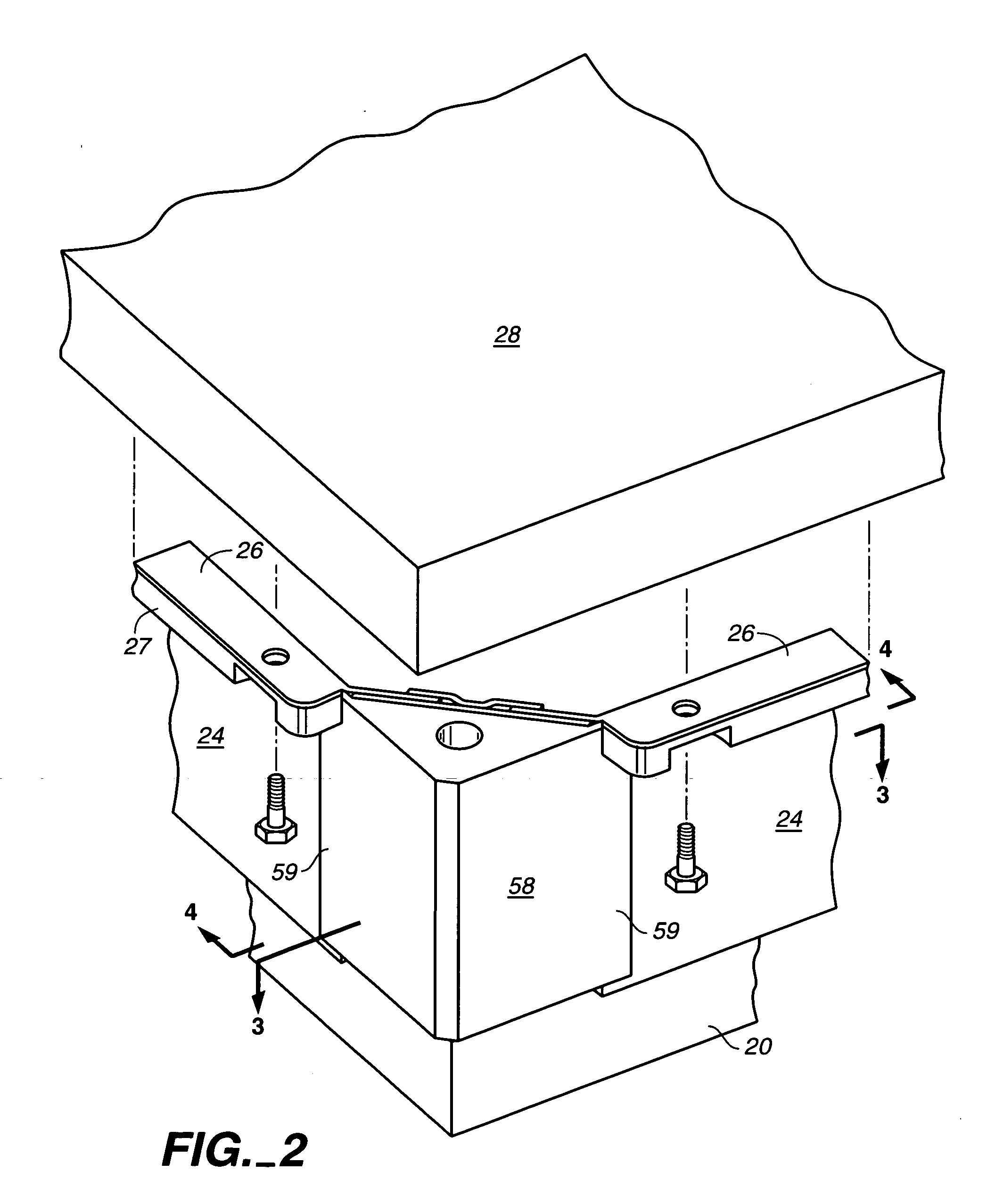

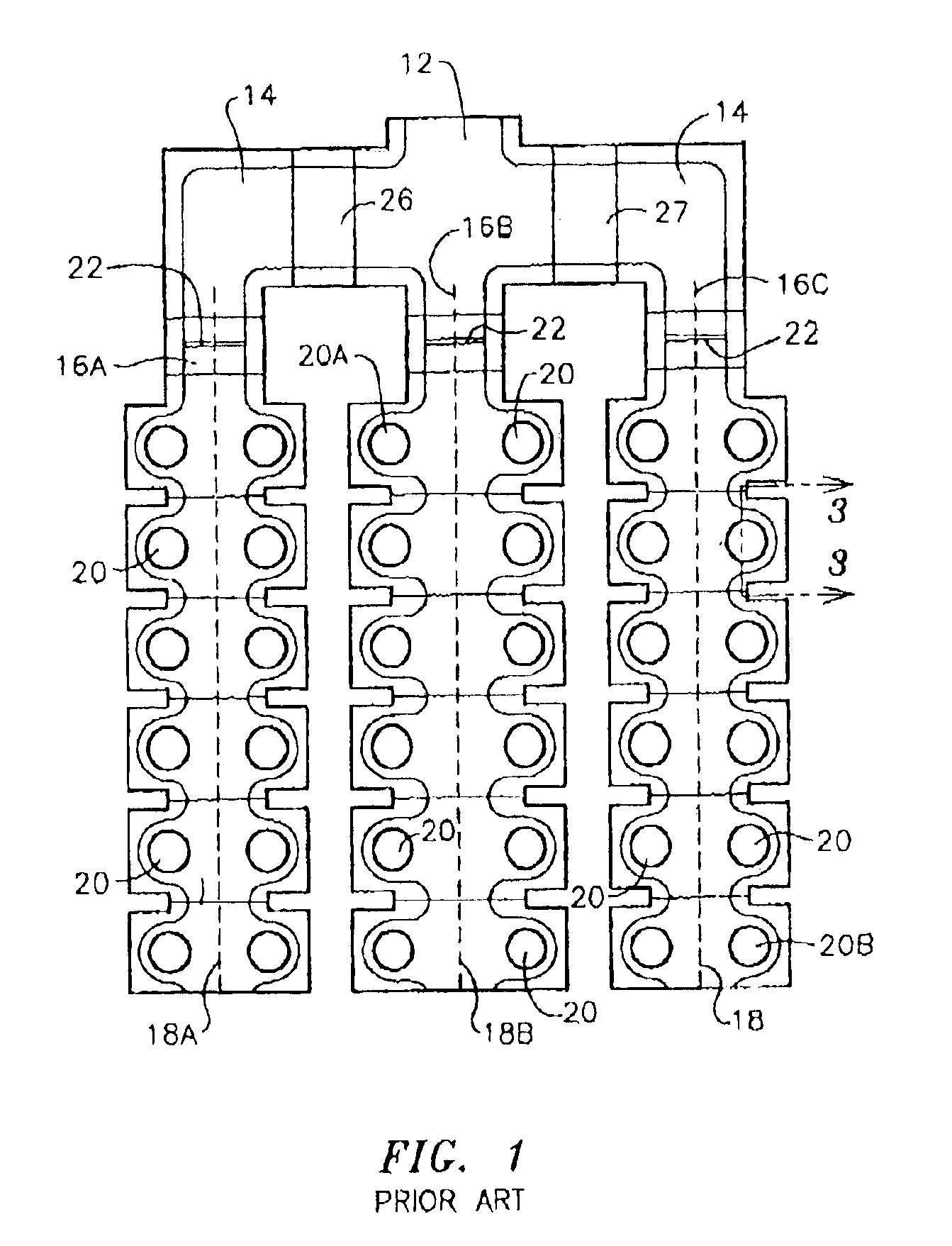

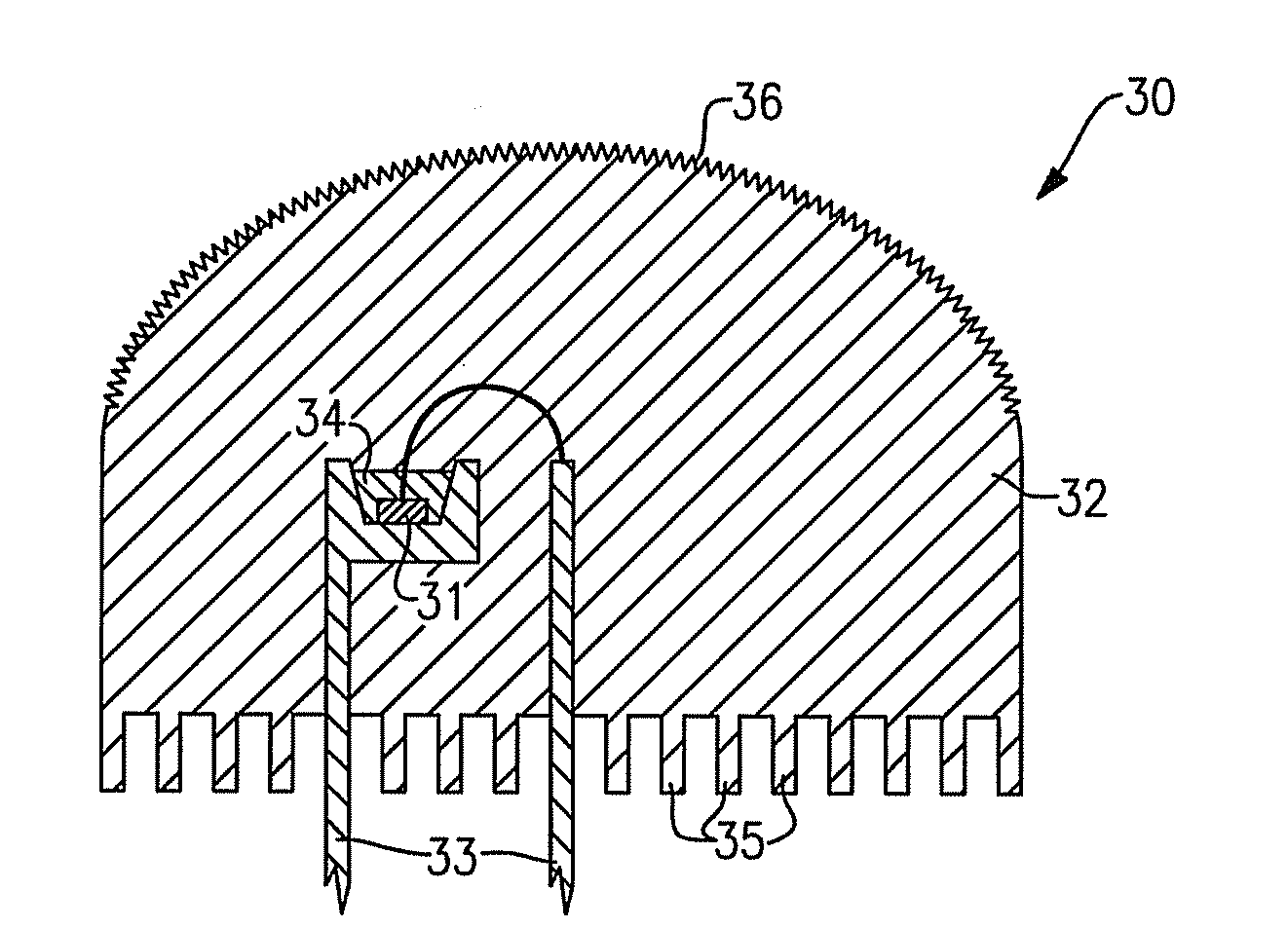

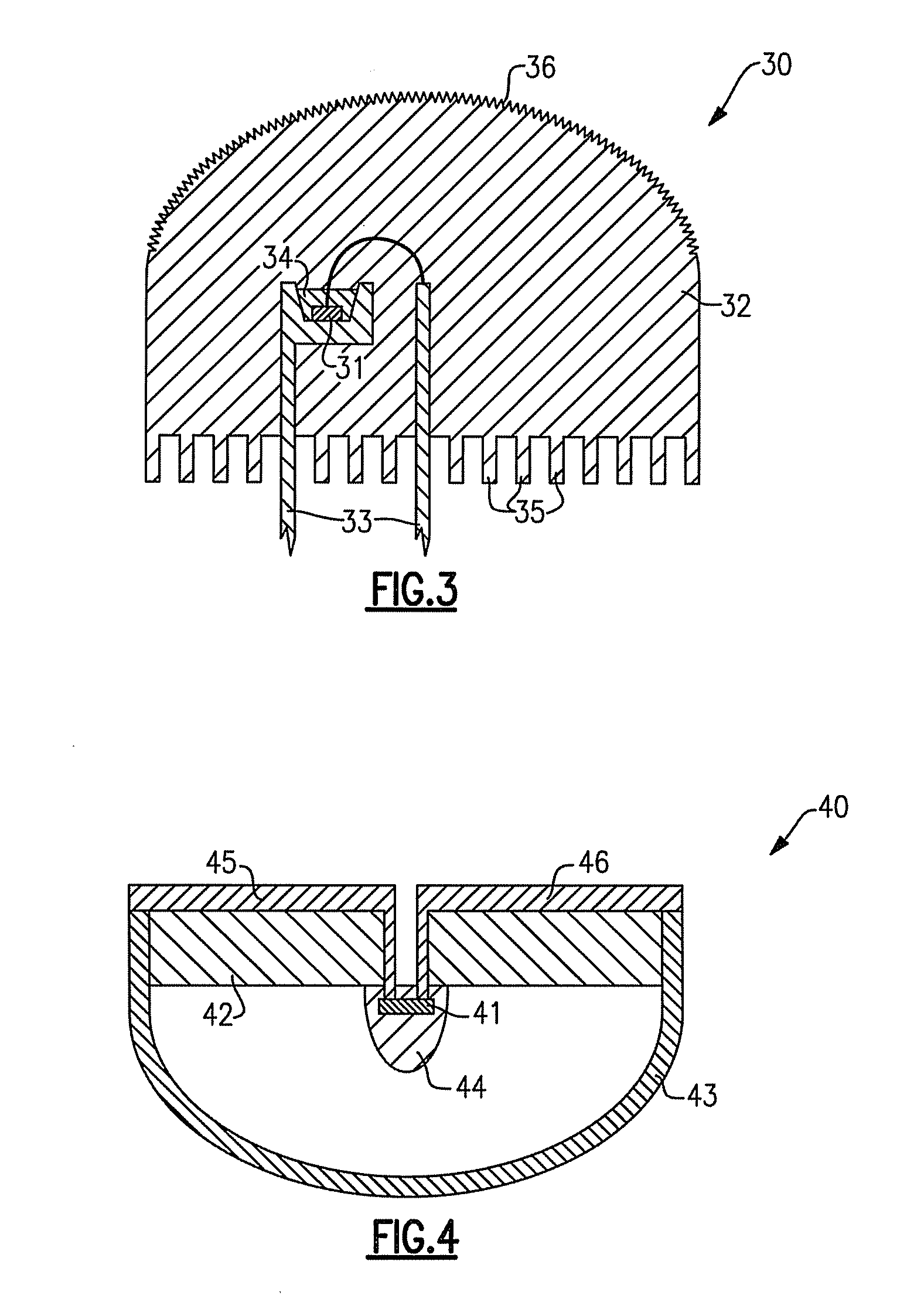

Suspended gas distribution plate

InactiveUS7017269B2Avoid distortionAvoid crackingElectric discharge tubesSemiconductor/solid-state device manufacturingThermal isolationEngineering

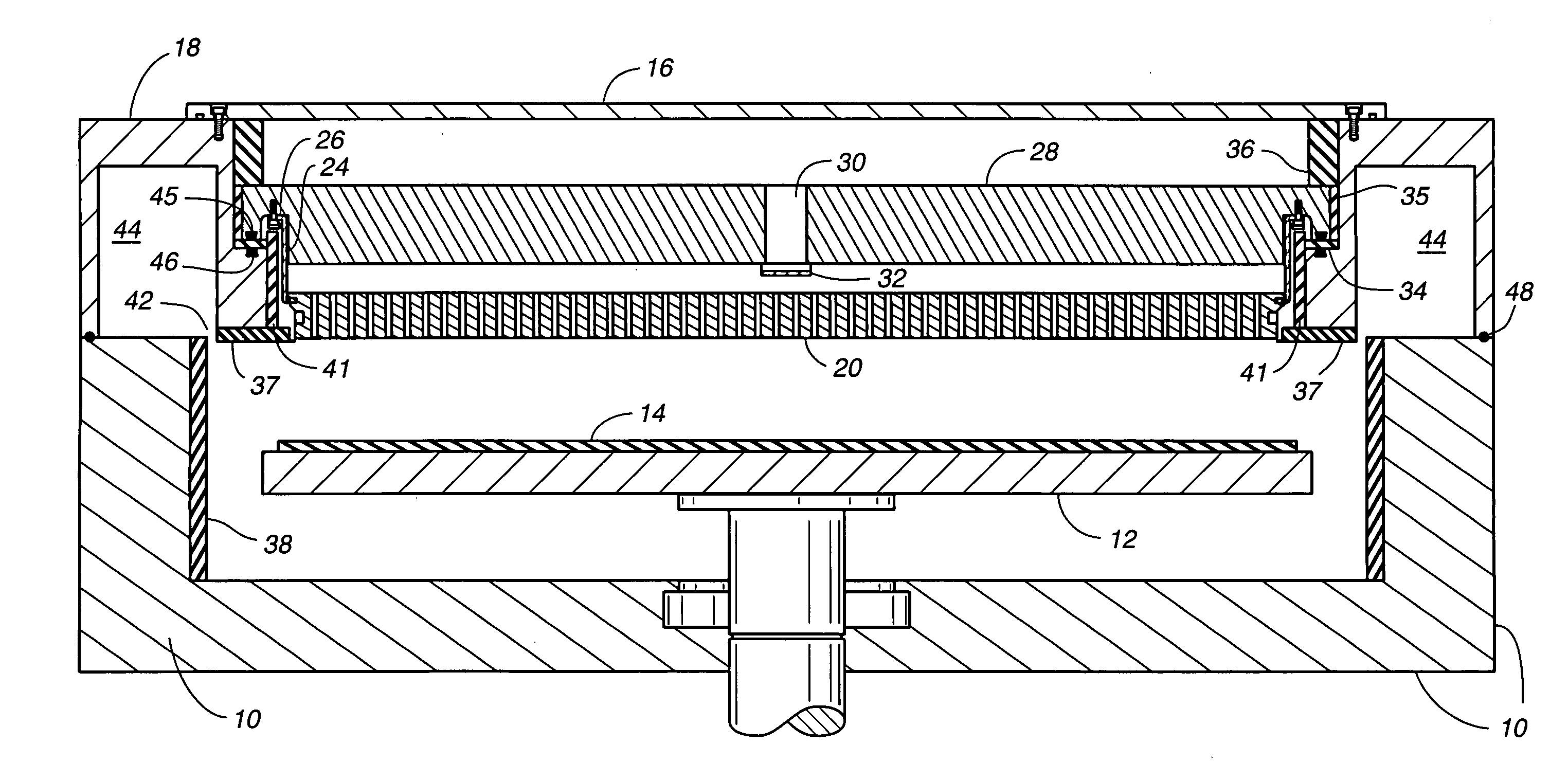

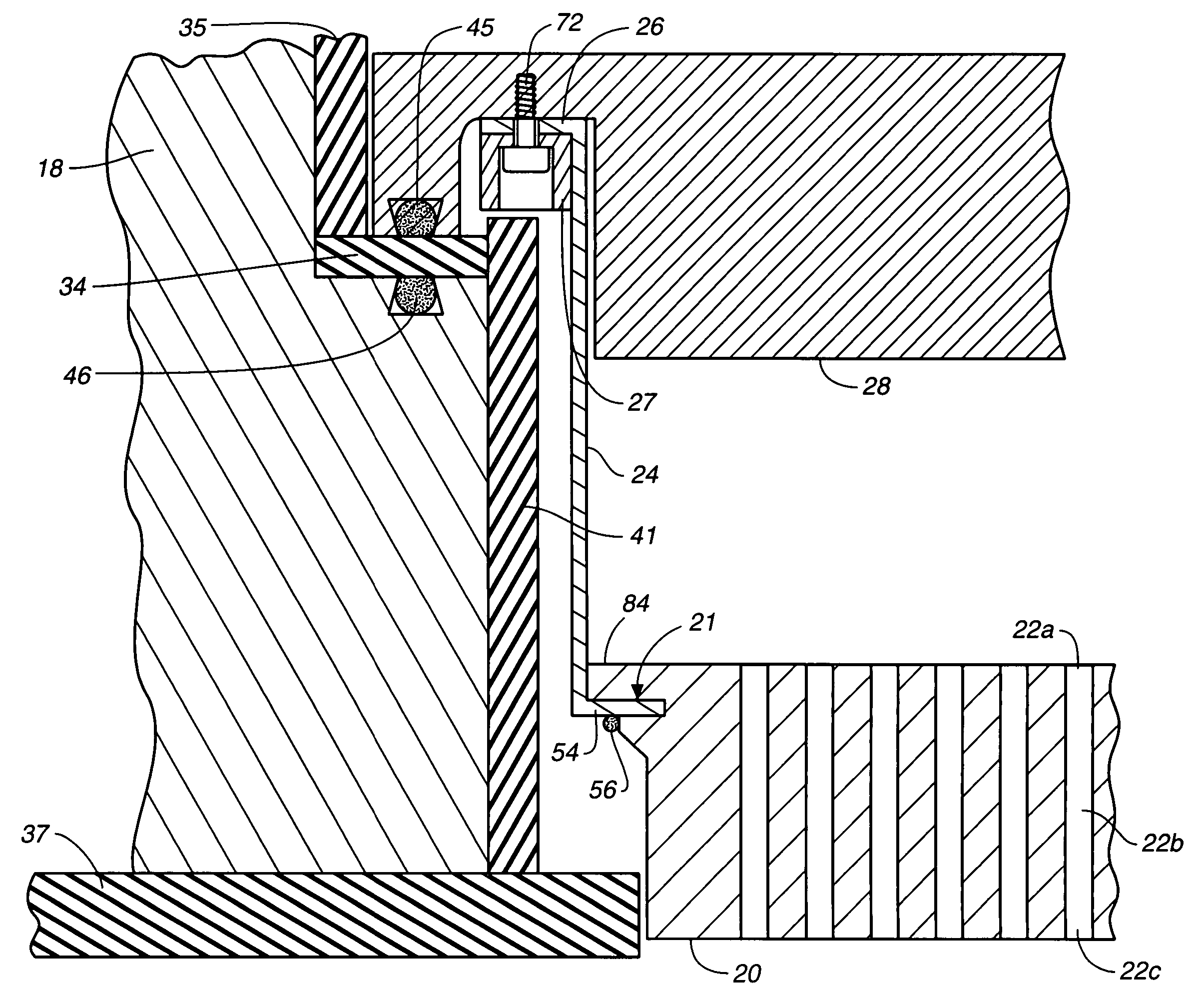

A gas inlet manifold for a plasma chamber having a perforated gas distribution plate suspended by flexible side walls. The flexible suspension minimizes mechanical stress due to thermal expansion of the gas distribution plate. In another aspect, the suspension provides thermal isolation between the gas distribution plate and other components of the chamber.

Owner:APPLIED MATERIALS INC

Suspended gas distribution manifold for plasma chamber

InactiveUS7484473B2Avoiding distortion and crackingImprove spatial uniformityElectric discharge tubesSemiconductor/solid-state device manufacturingThermal isolationProduct gas

Owner:APPLIED MATERIALS INC

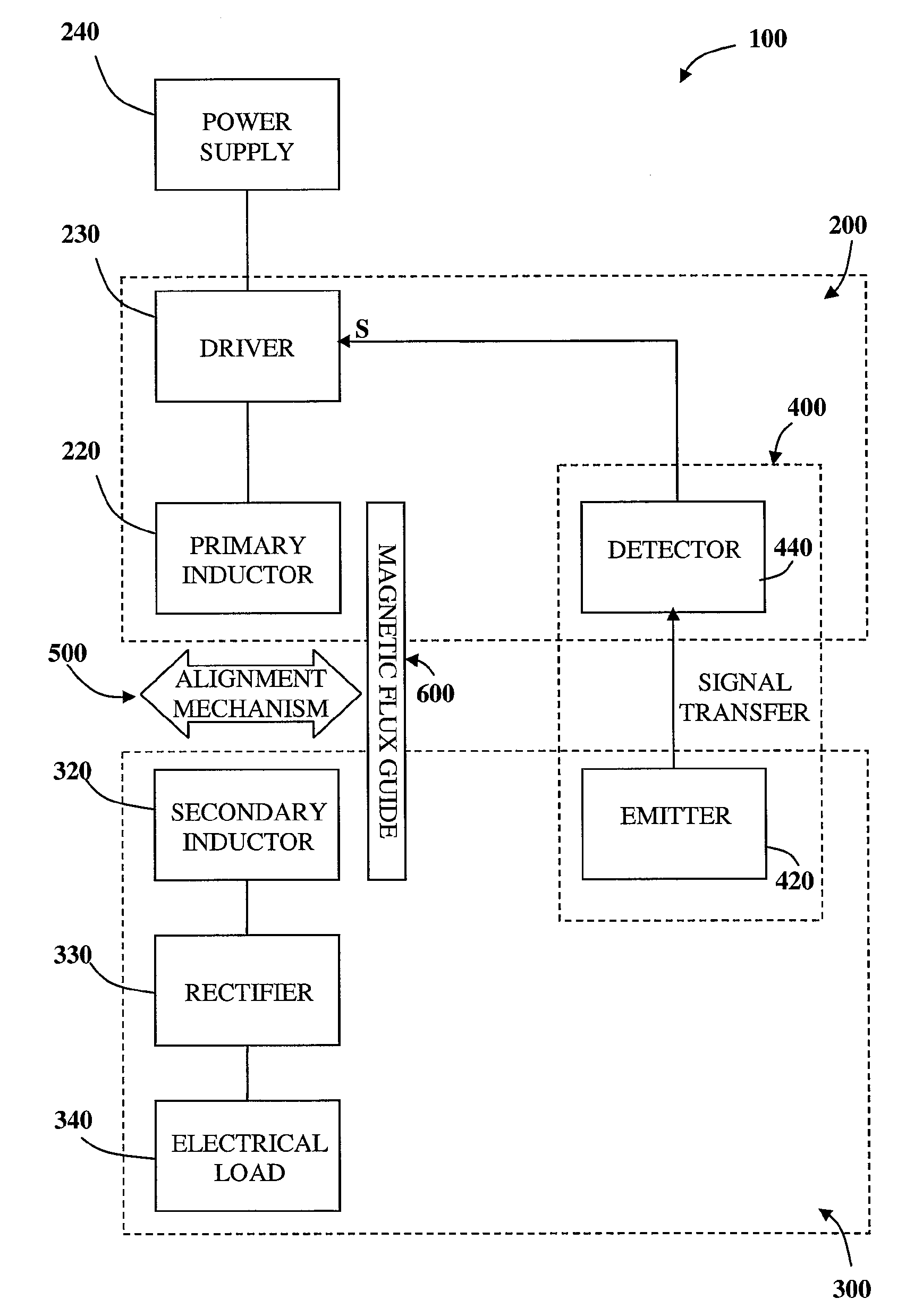

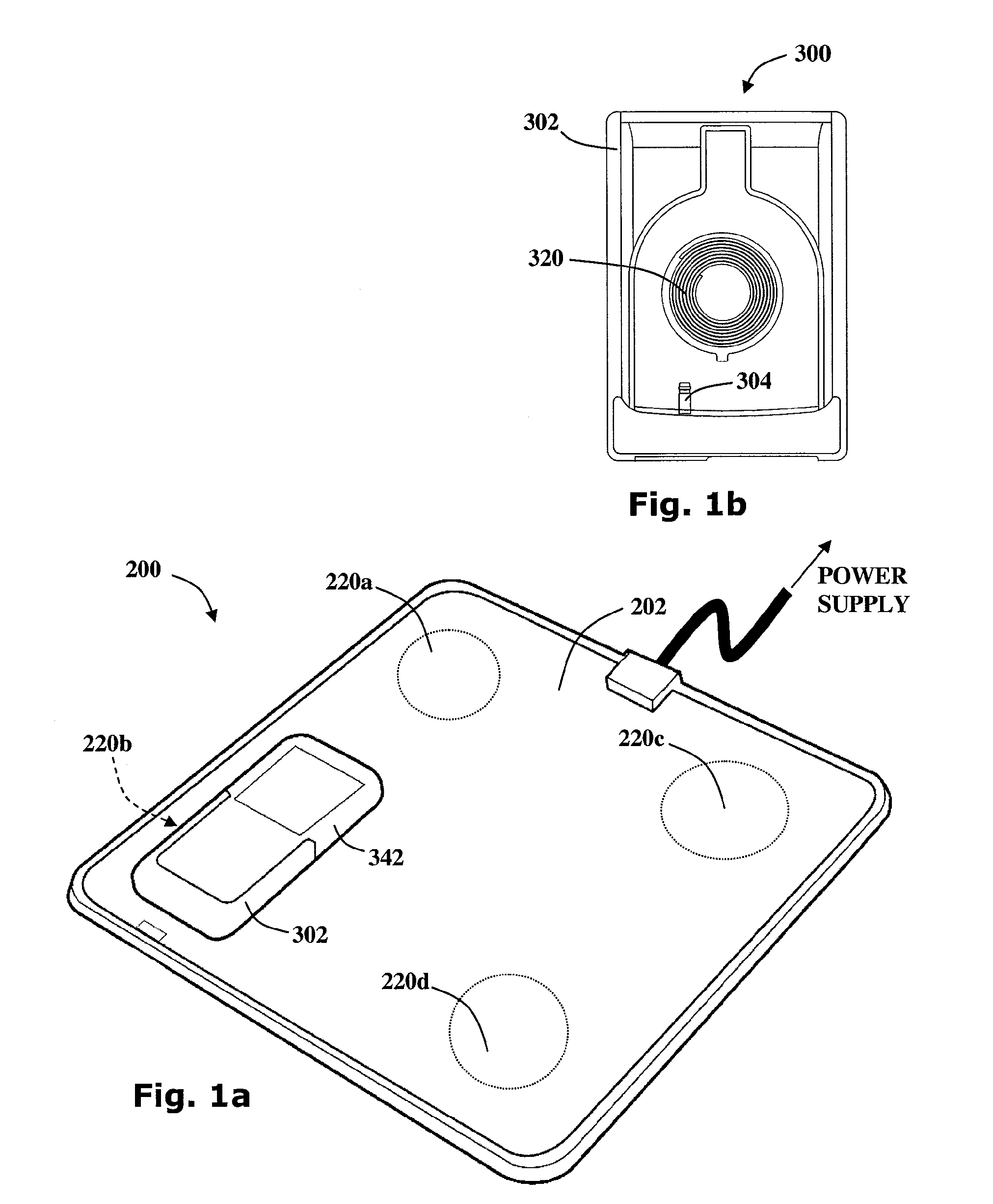

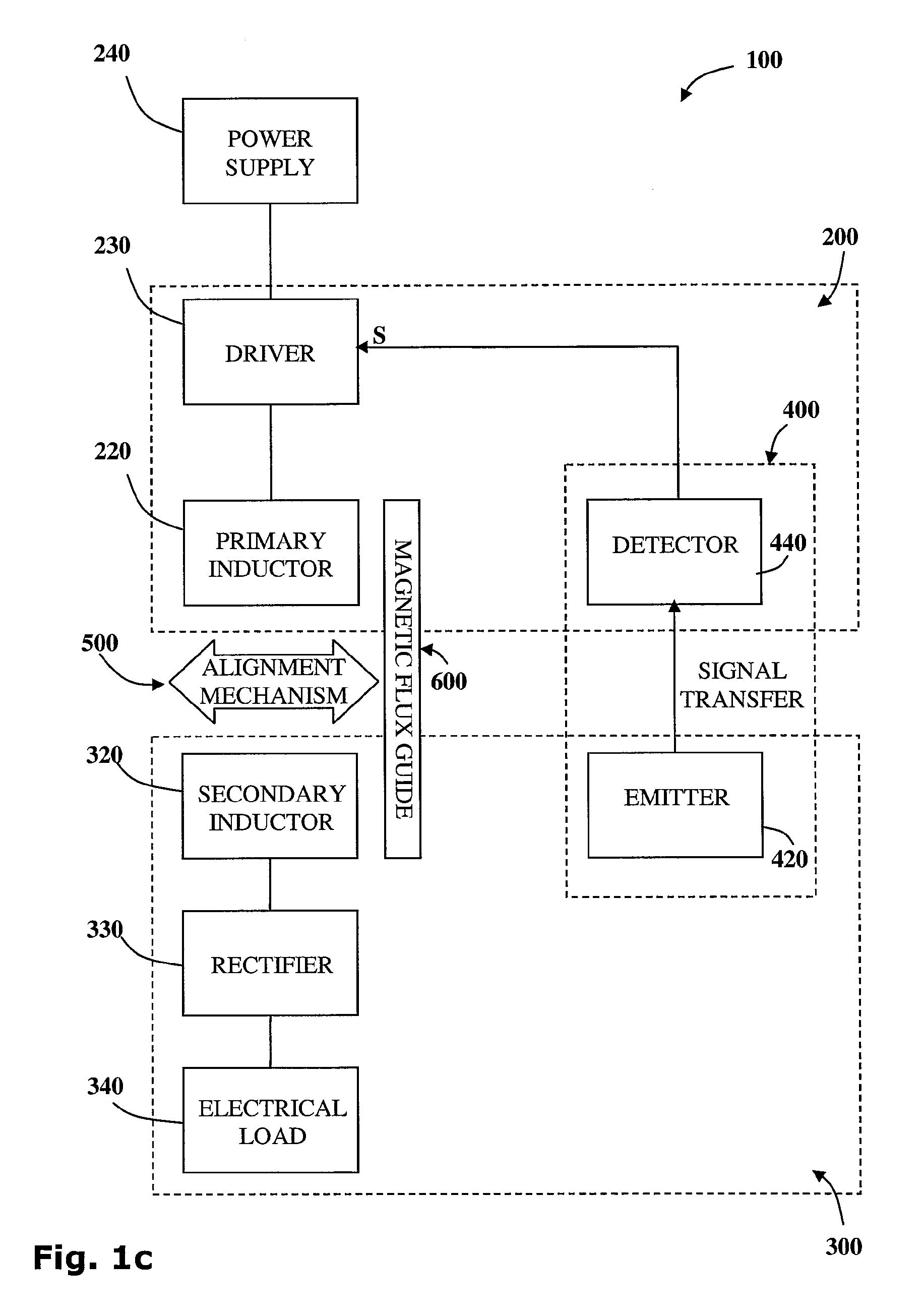

Transmission-guard system and method for an inductive power supply

ActiveUS20110062793A1Avoid connectionReduce heat lossBoards/switchyards circuit arrangementsElectromagnetic wave systemTransmitted powerInductor

A transmission-guard is disclosed for preventing an inductive power outlet from transmitting power in the absence of an inductive power receiver. A transmission lock is associated with an inductive power outlet and a transmission key is associated with an inductive power receiver. The transmission lock is configured to prevent a primary inductor from connecting to the power supply unless triggered by a release signal via the transmission key.

Owner:POWERMAT TECHNOLOGIES

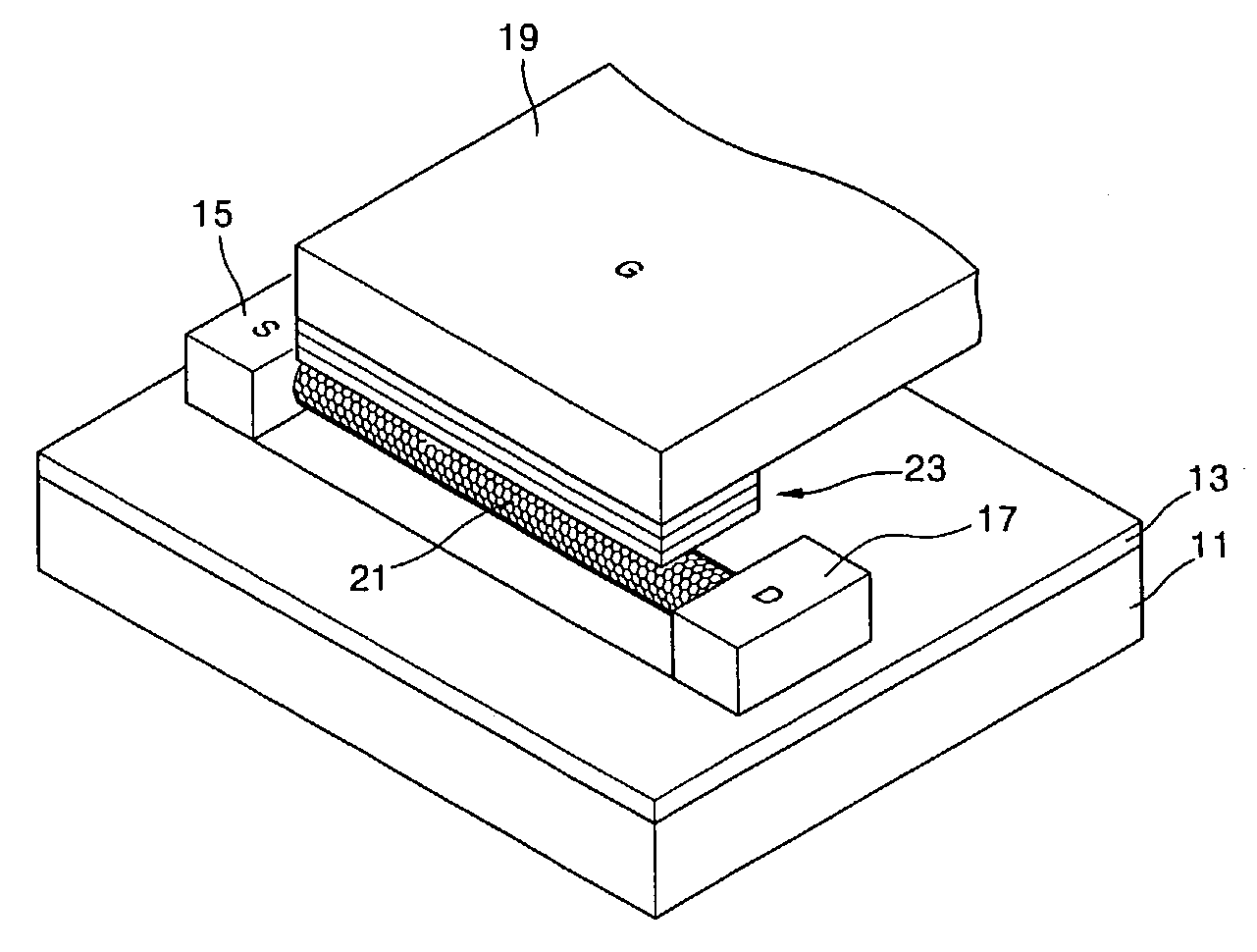

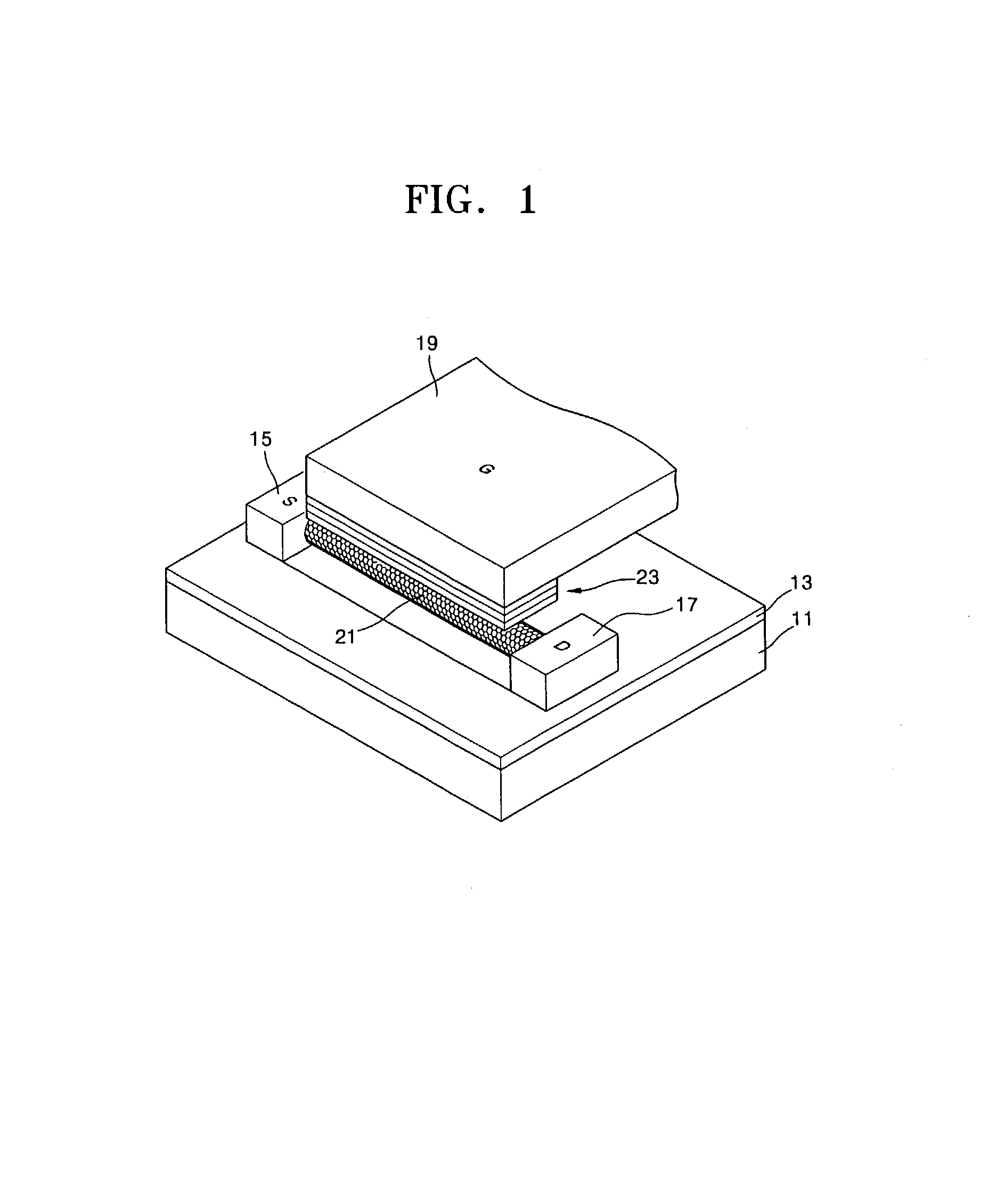

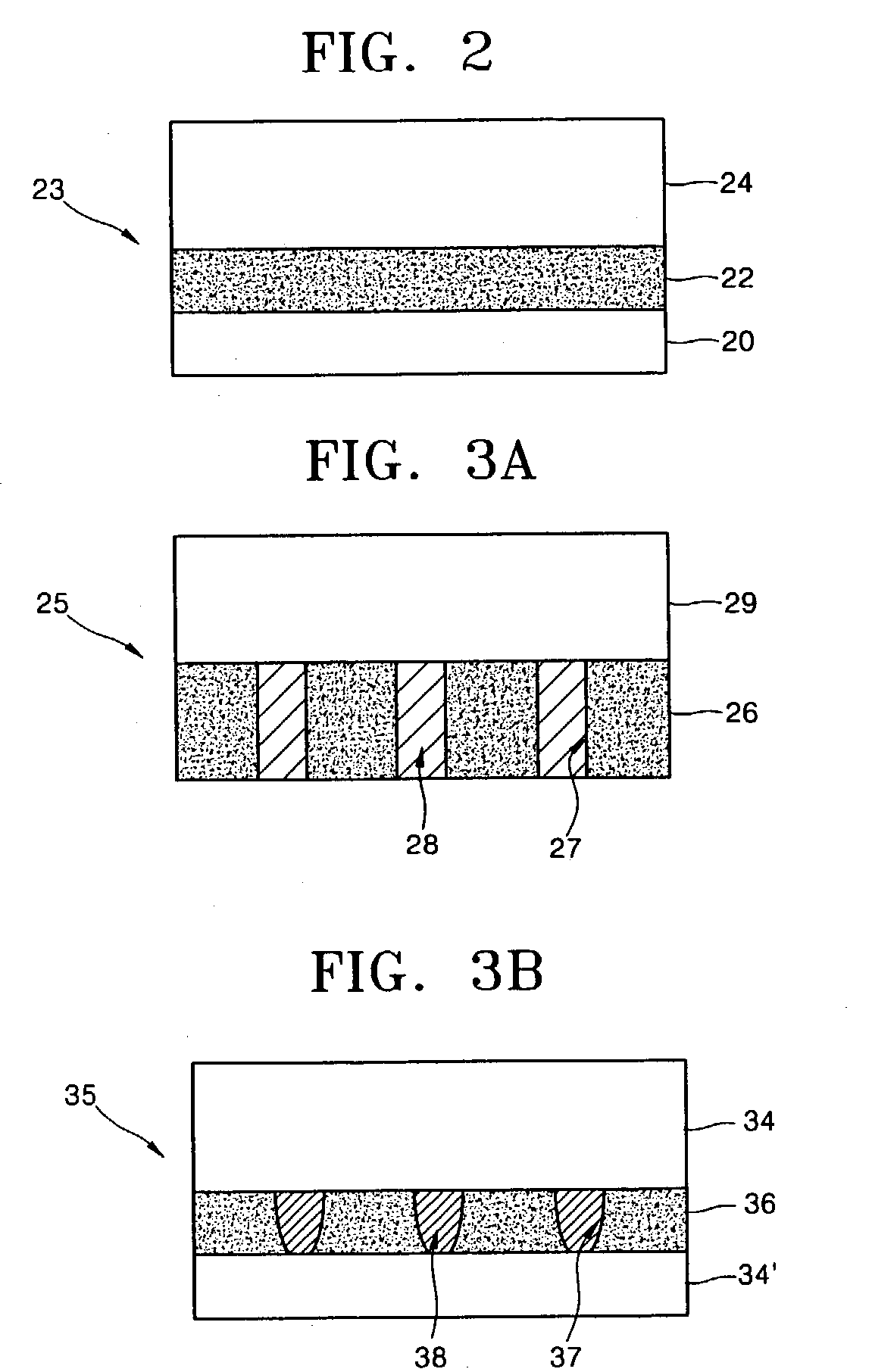

Memory device utilizing carbon nanotubes

InactiveUS7015500B2Increase in malfunctionIncrease resistanceTransistorIndividual molecule manipulationDevice formCarbon nanotube

A fast, reliable, highly integrated memory device formed of a carbon nanotube memory device and a method for forming the same, in which the carbon nanotube memory device includes a substrate, a source electrode, a drain electrode, a carbon nanotube having high electrical and thermal conductivity, a memory cell having excellent charge storage capability, and a gate electrode. The source electrode and drain electrode are arranged with a predetermined interval between them on the substrate and are subjected to a voltage. The carbon nanotube connects the source electrode to the drain electrode and serves as a channel for charge movement. The memory cell is located over the carbon nanotube and stores charges from the carbon nanotube. The gate electrode is formed in contact with the upper surface of the memory cell and controls the amount of charge flowing from the carbon nanotube into the memory cell.

Owner:SAMSUNG ELECTRONICS CO LTD

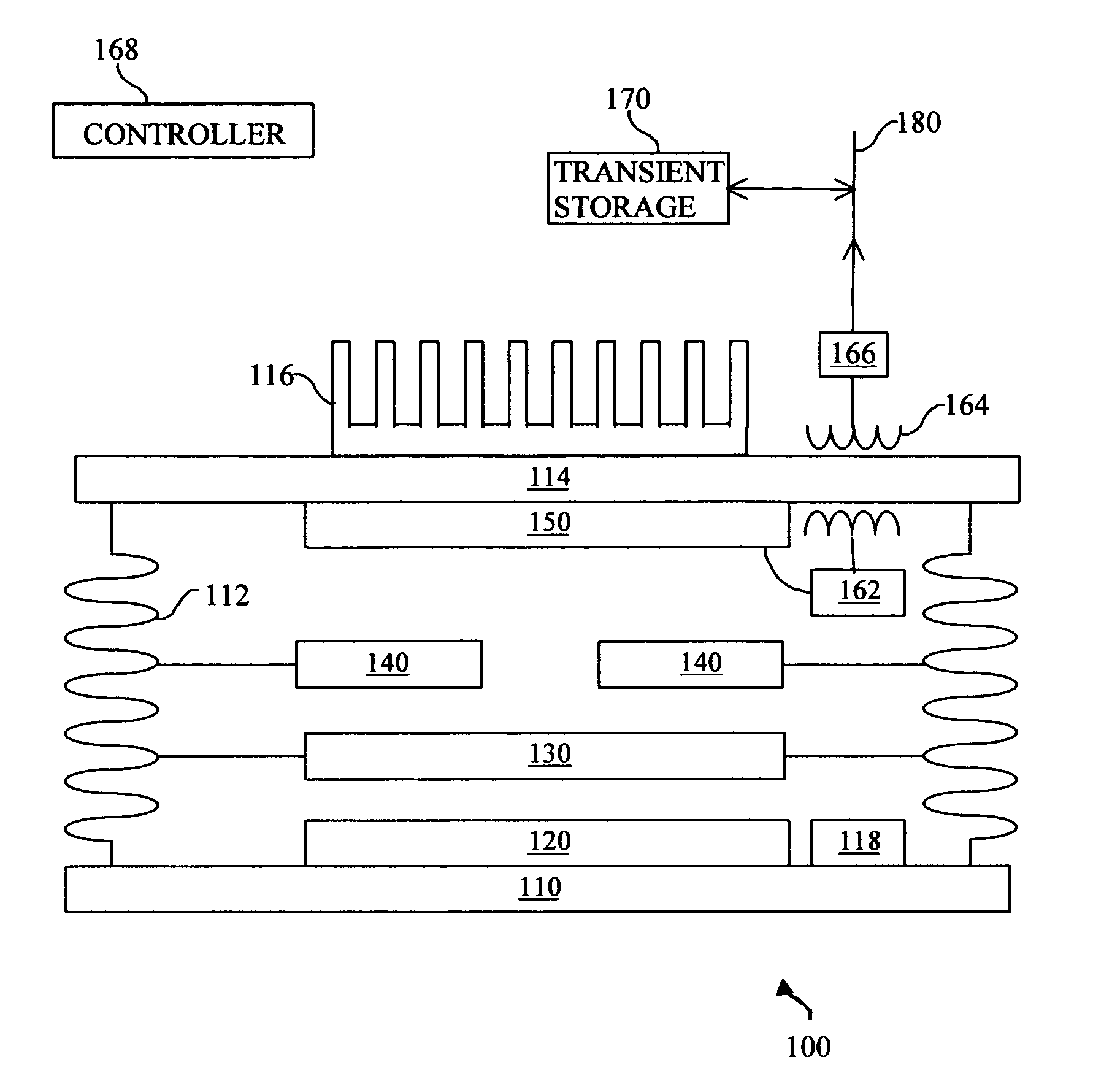

System and method for enhanced thermophotovoltaic generation

InactiveUS20050109386A1Reduce fossil fueled NOx emissionIncreasing burner efficiencyThermoelectric device with peltier/seeback effectPV power plantsThermophotovoltaicDistributed generation

A system and method for lower cost, high efficiency, thermophotovoltaic distributed generation includes: an emitter, a photovoltaic cell, and transient electrical energy storage.

Owner:PRACTICAL TECH

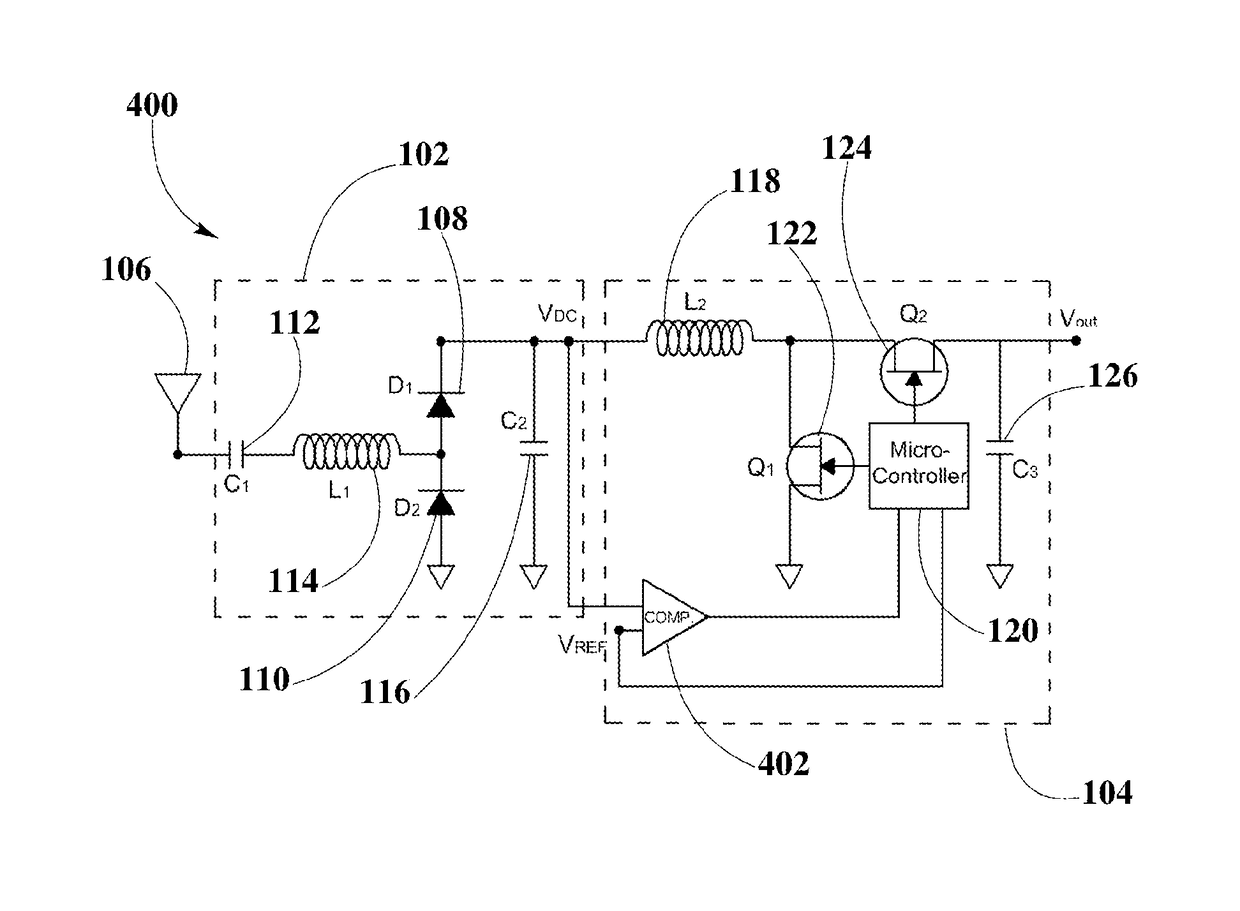

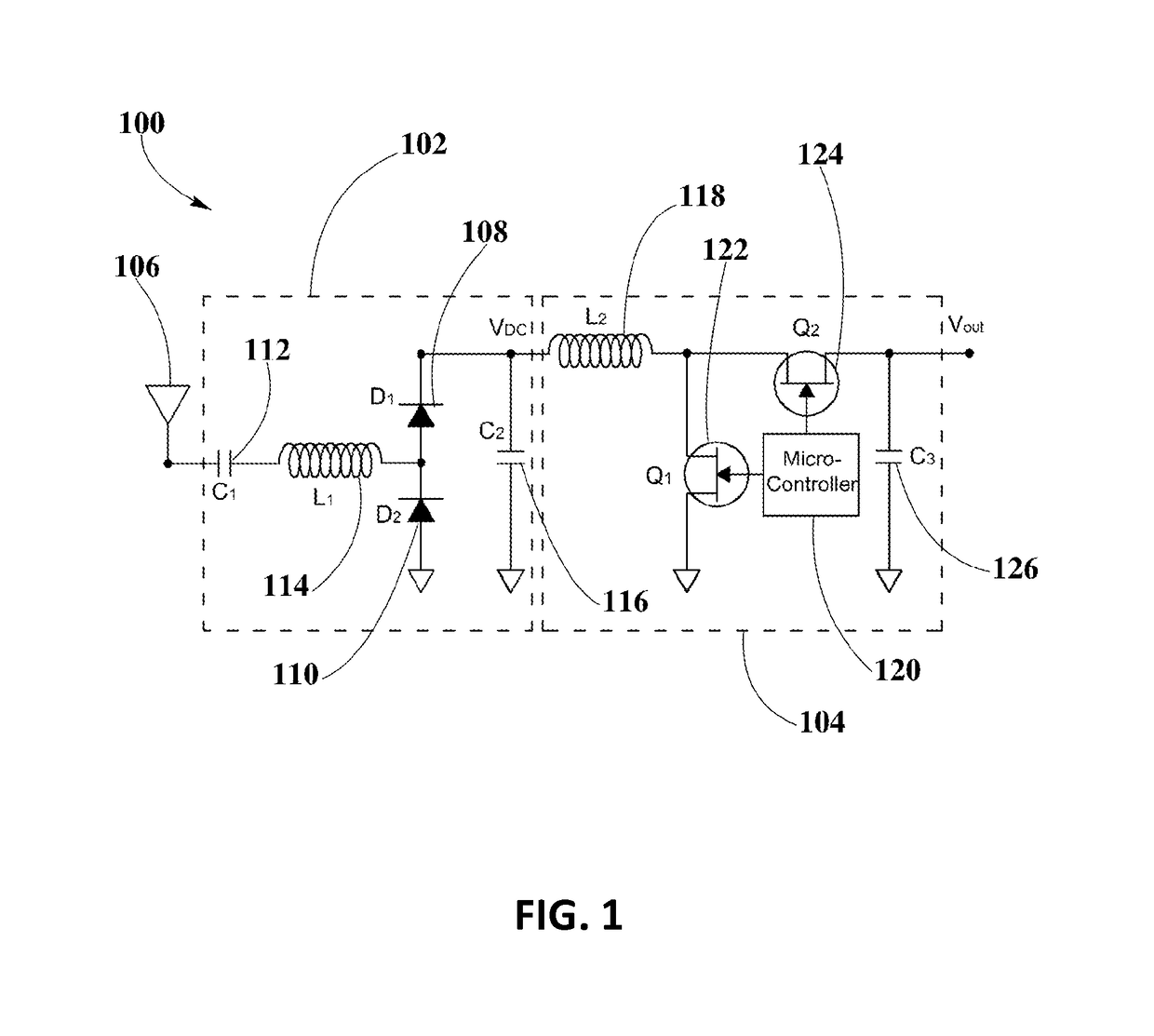

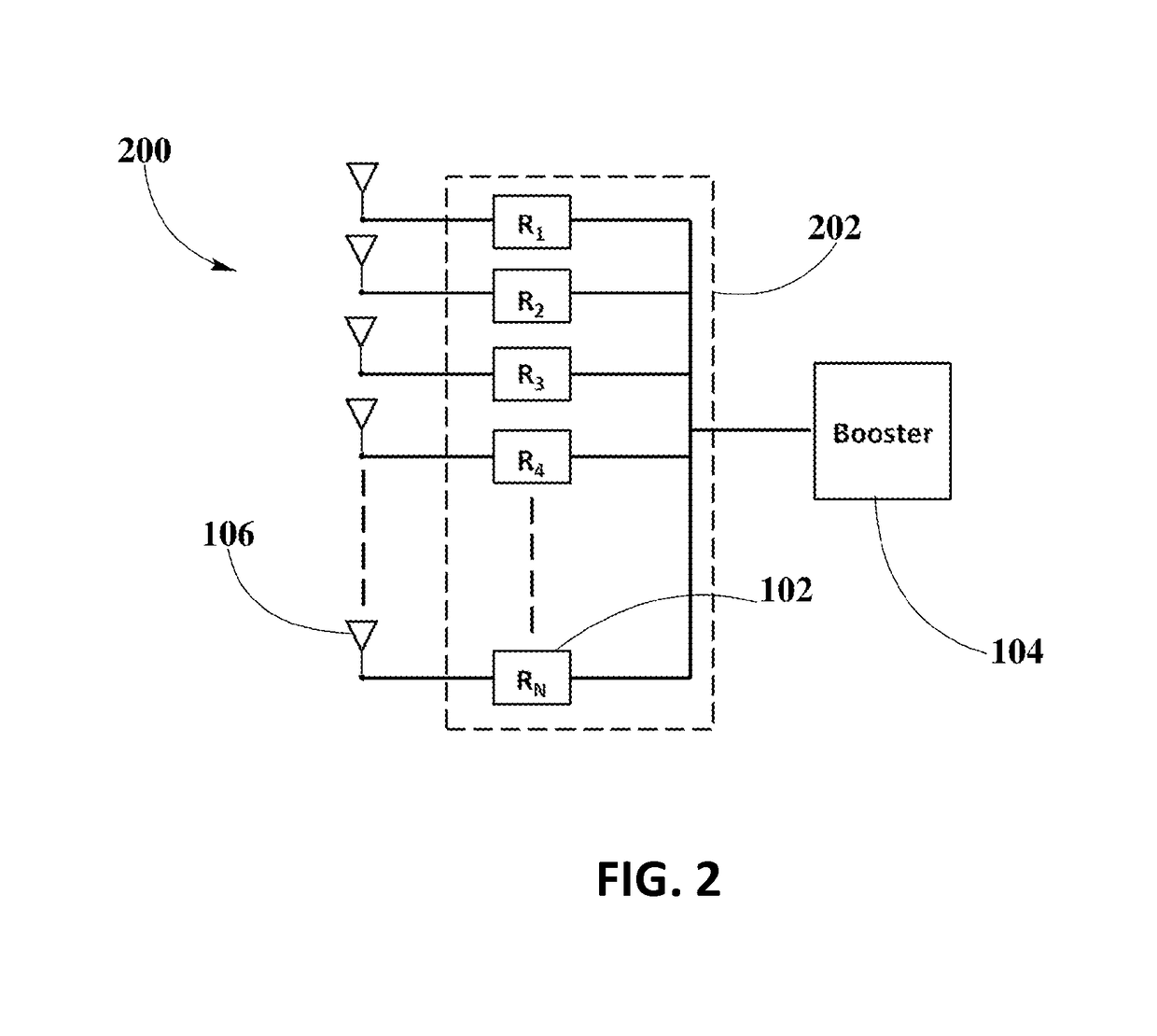

Integrated rectifier and boost converter for wireless power transmission

ActiveUS9806564B2Reduce power consumptionReduce heat lossAc-dc conversion without reversalEfficient power electronics conversionConvertersBoost controller

A novel integrated rectifier and boost converter circuit architecture is disclosed. The rectifier architecture includes a plurality of identical half-bridge rectifiers connected to receiving antennas to convert wireless AC power into DC power. The integrated rectifier may be coupled in series with a charging inductor in a boost converter. The inductor may discharge upon operation of two micro-controller-driven switching transistors using predetermined threshold and timing scheme to turn on / off. The rectifier architecture may provide high power densities, improve efficiency at larger load currents, and may be enabled in an integrated circuit with eight RF signal inputs, eight half-bridge rectifiers, and eight DC outputs ganged together as single feed into the boost converter. The rectifier circuit topology may include a comparator driven by the boost controller with a proprietary algorithm which suits control for a maximum power point tracking functionality, and an external micro-controller for additional control of the boost converter.

Owner:ENERGOUS CORPORATION

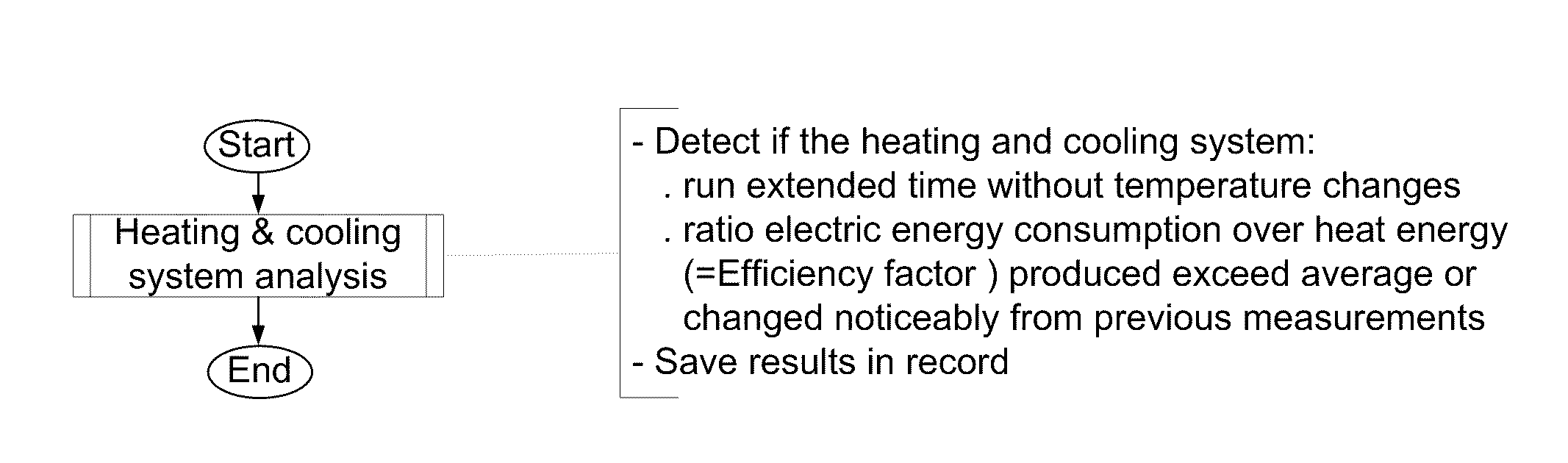

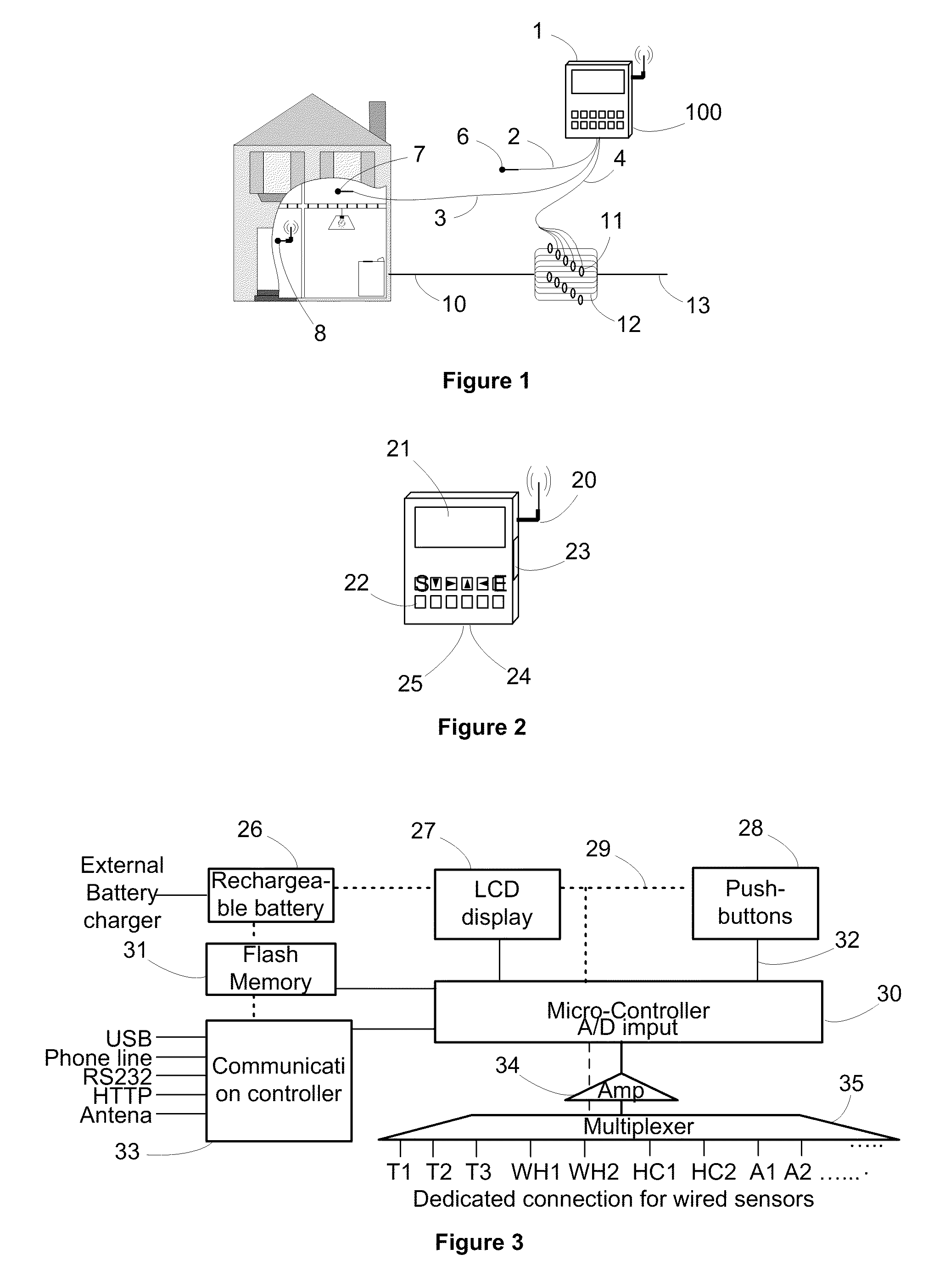

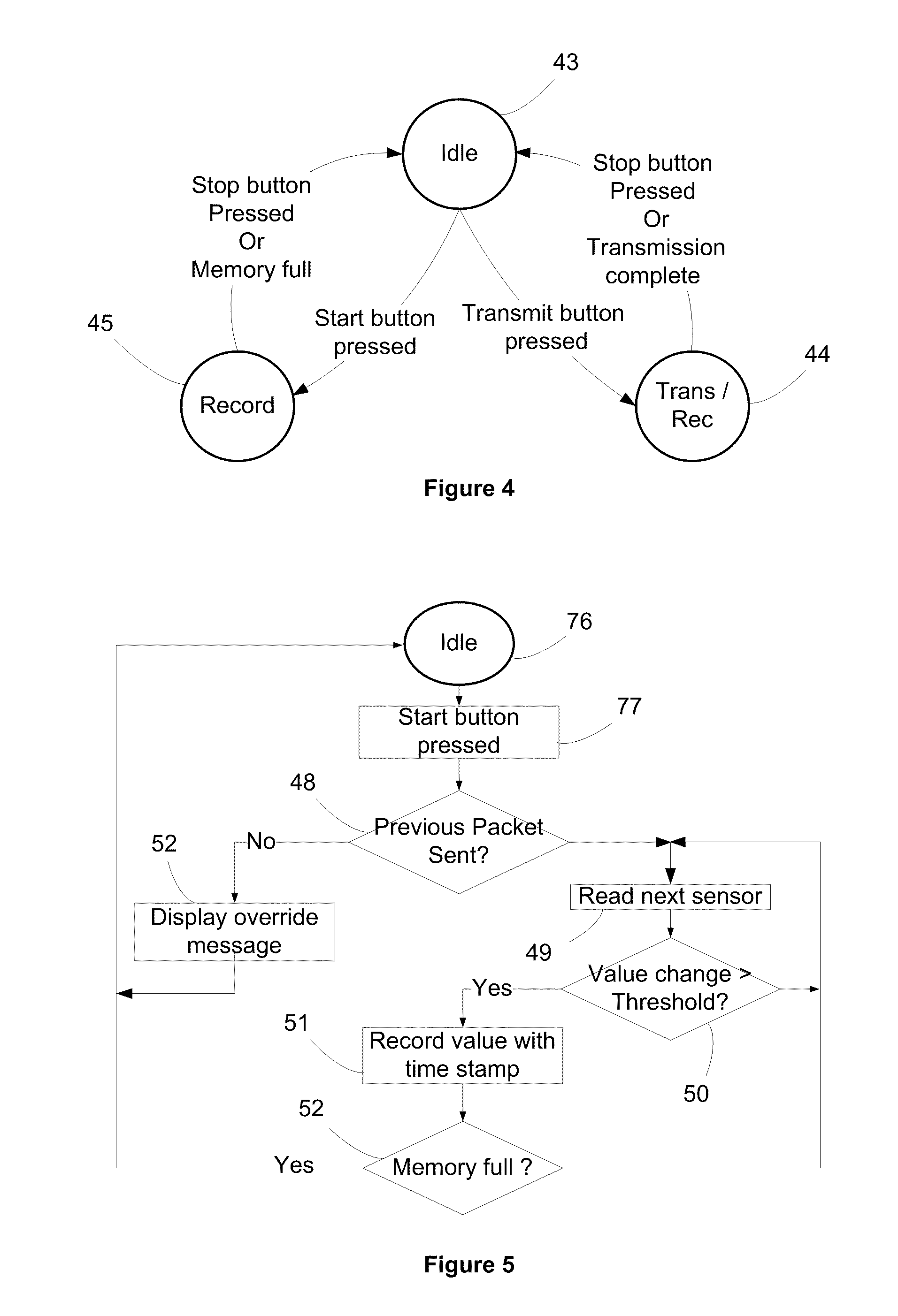

Method and apparatus for comprehensive energy measurement and analysis of a building

InactiveUS20100211222A1Low costReduce heat lossLevel controlSpace heating and ventilationEnergy transferElectricity

An energy monitoring and analysis system for a building includes a logging unit, a processing unit, temperature sensors that read the temperatures inside and outside the building, electric current sensors that read electric currents in all independent electric connections at the main connection panel of the building, and other types of sensors such as those related to natural gas flow. The logging unit periodically collects the data from all the sensors and transmits the data to the processing unit. The processing unit analyzes the data using highly sophisticated algorithms, extracts various parameters, profiles the electric energy usage, identifies potential problems with energy transfer and use, and lists recommendations for corrective actions. The processing unit analyzes data of the building, an HVAC system associated with the building, and consuming devices associated with the building.

Owner:GHOSN MICHEL

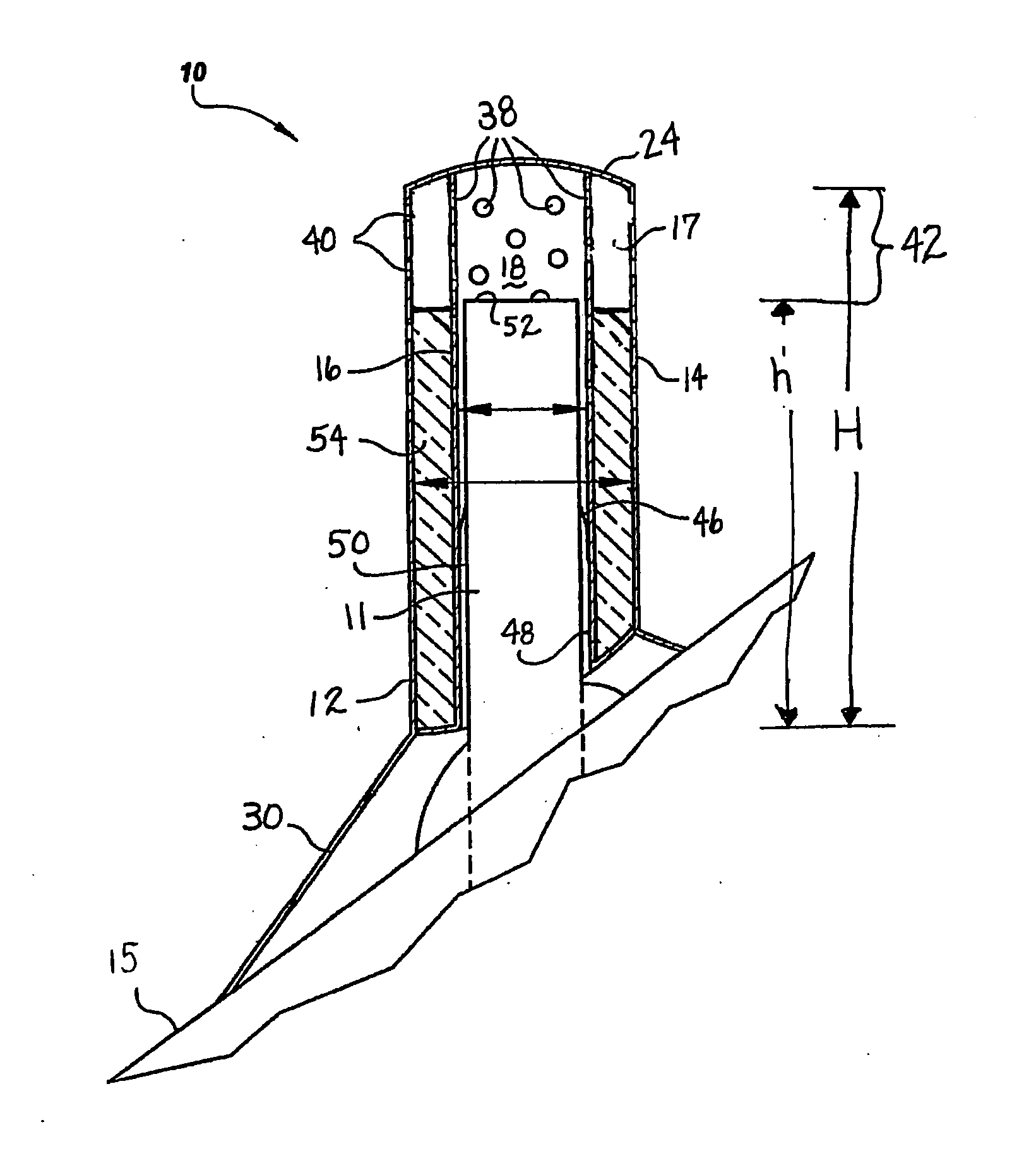

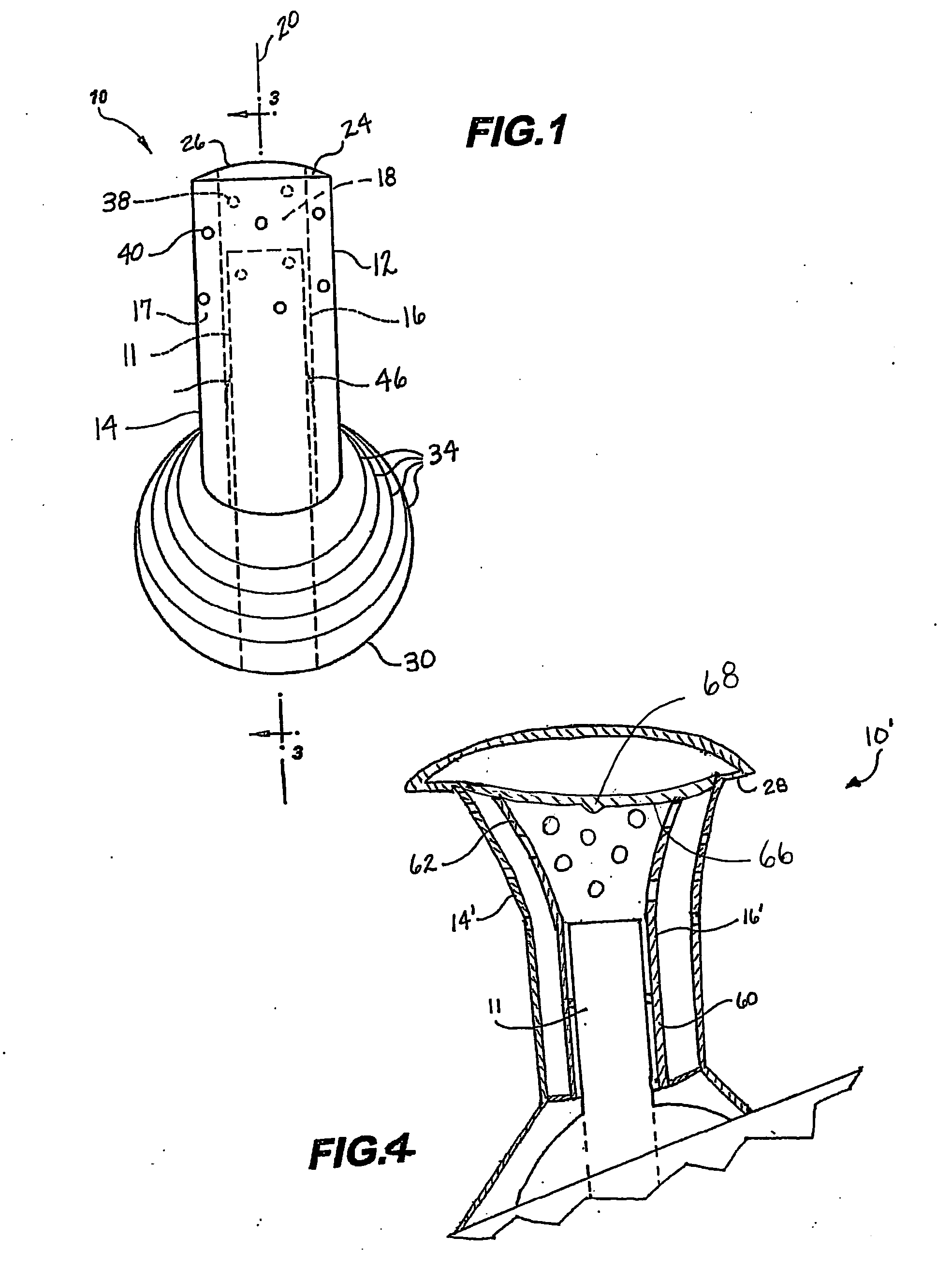

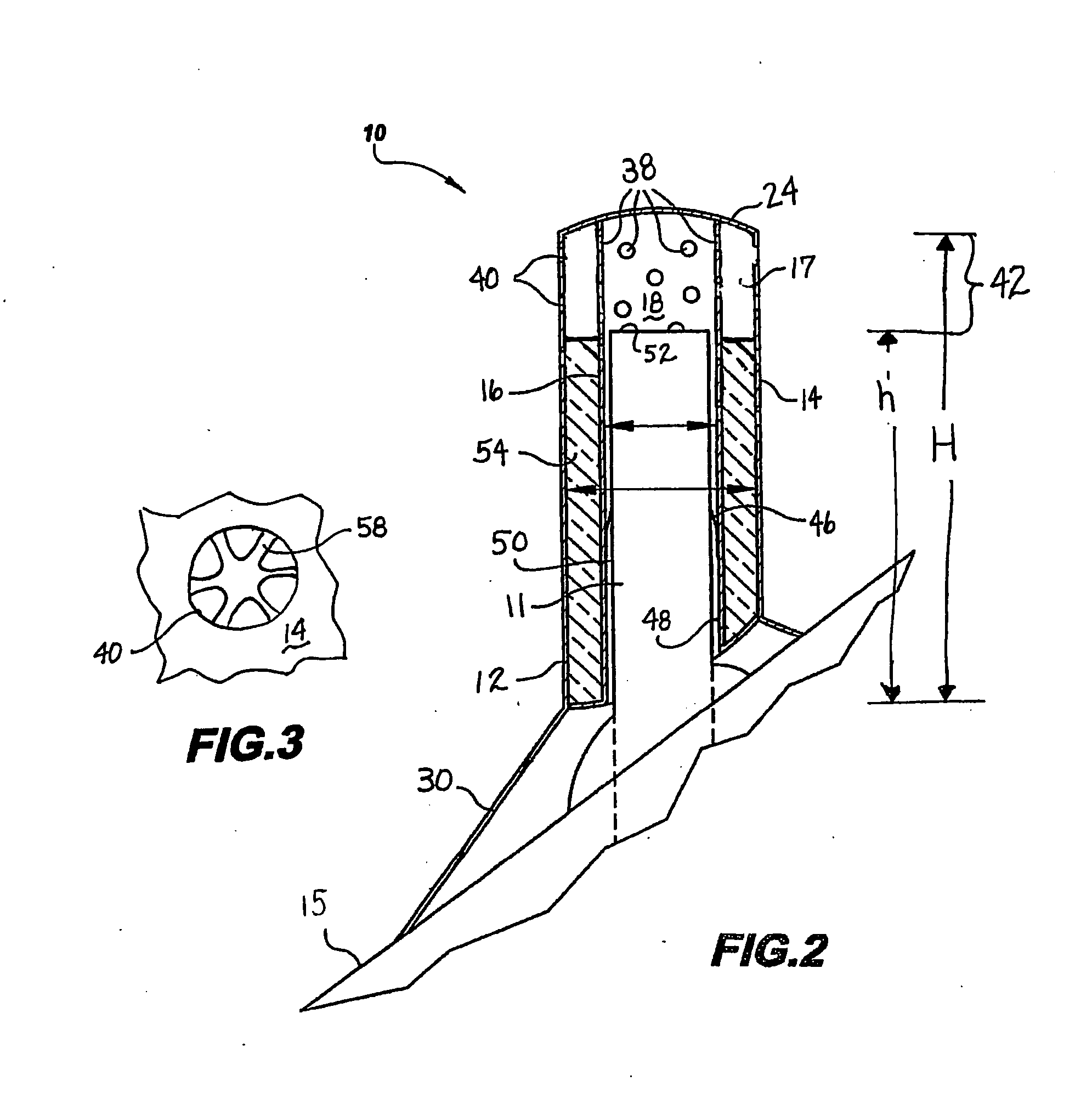

Vent pipe cover

A vent pipe cover having a double walled body for engaging the outermost surface of a vent pipe. The upper end of the body is capped and gas flow passages are provided by first apertures extending through an inner wall and second apertures extending through an outer wall. The apertures are generally formed in at least an upper portion of the body. The body comprises a length sufficient to provide adequate head space for the flow of gasses above the upper edge of the pipe. An insulator may be positioned between the inner and outer walls to reduce heat loss through the pipe. A flared skirt extending from the lower surface of the outer wall includes cutting lines to adapt the vent pipe cover to roofs of differing pitches. One or more deformable clips are used to releaseably engage an inner most surface of the pipe cover with the outermost surface of the vent pipe.

Owner:GRASSMAN MICHAEL D

Suspended gas distribution manifold for plasma chamber

InactiveUS20050000432A1Minimize gas leakagePermit some movementElectric discharge tubesSemiconductor/solid-state device manufacturingThermal dilatationThermal isolation

A gas inlet manifold for a plasma chamber having a perforated gas distribution plate suspended by a side wall comprising one or more sheets. The sheets preferably provide flexibility to alleviate stress in the gas distribution plate due to thermal expansion and contraction. In another aspect, the side wall provides thermal isolation between the gas distribution plate and other components of the chamber.

Owner:APPLIED MATERIALS INC

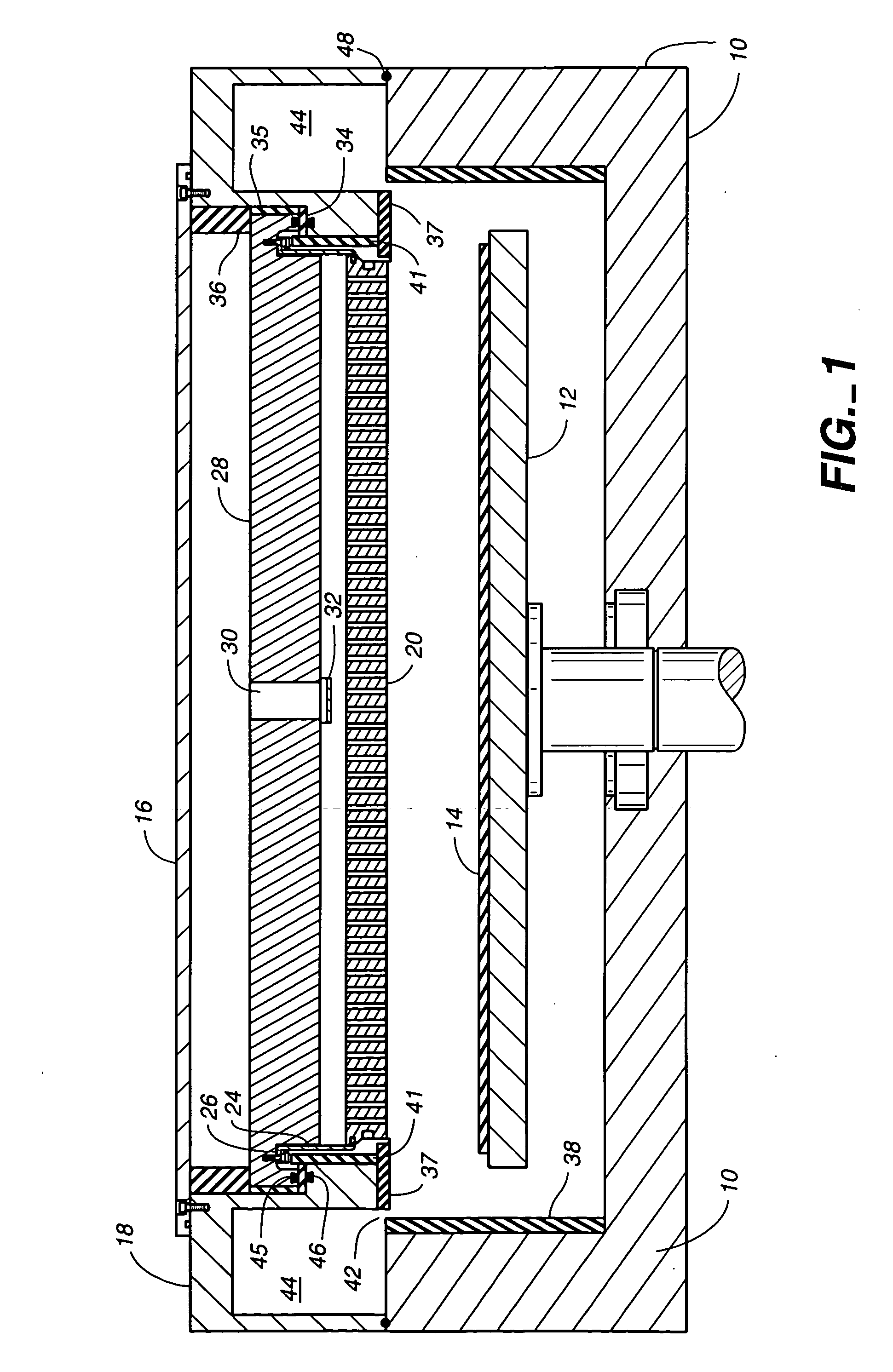

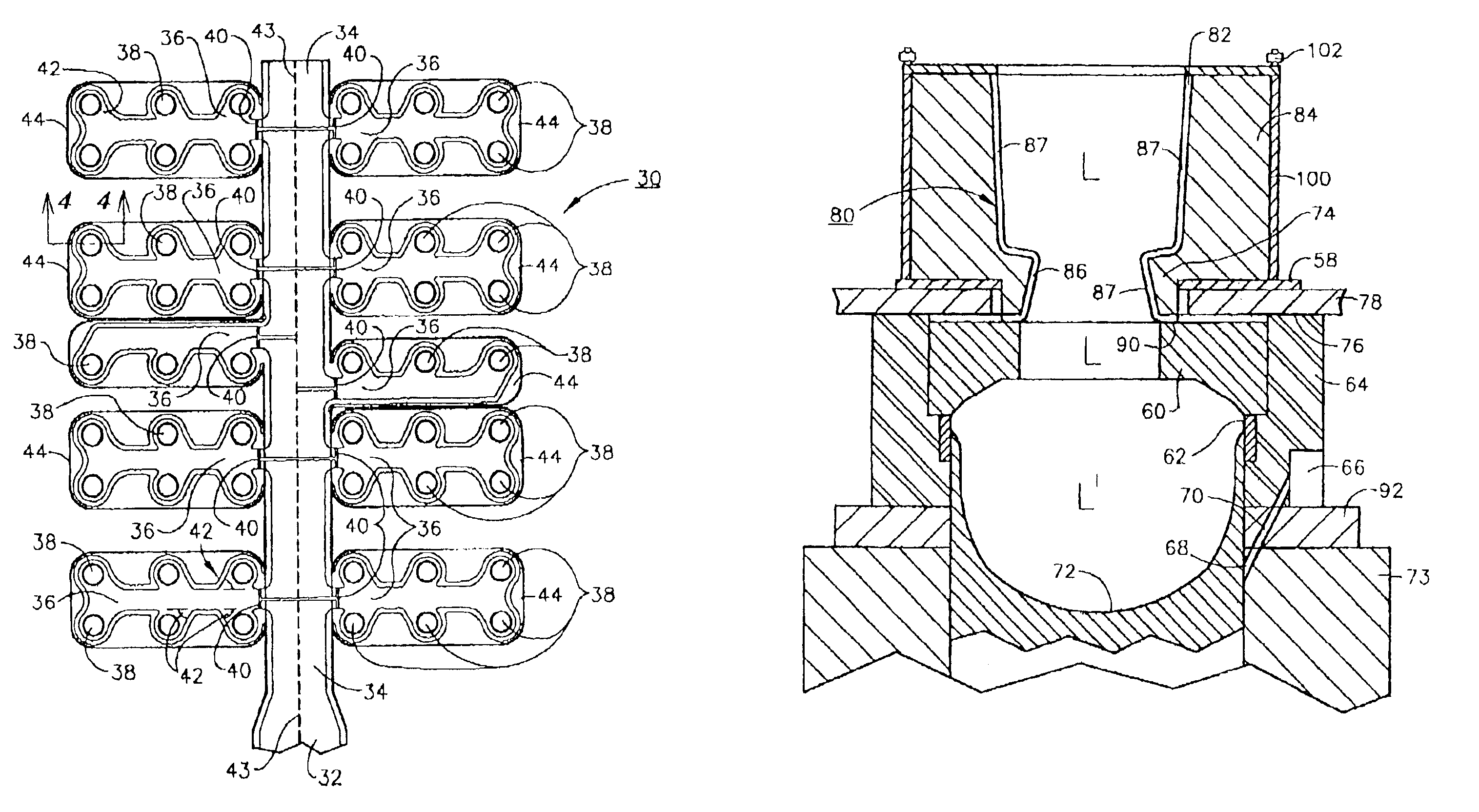

Casting apparatus

A metal distribution system for the simultaneous production of a plurality of logs or round billets from molten metal comprising: 1) a trough for the introduction of molten metal; 2) a plurality of side streams extending from the trough and each of the side streams including a plurality of opposing apertures each of the apertures including a thimble for the shaping of molten metal passing through the trough and the side streams and into the thimbles. A uniform flow of molten metal into the side streams and the individual apertures is provided by the controlled negative angular orientation of the most upstream opposing pair of apertures thereby providing relative uniformity of the temperature of molten metal reaching each of the plurality of apertures. A unique unitized thimble configuration and trough damming arrangement are also described.

Owner:PYROTECK INC

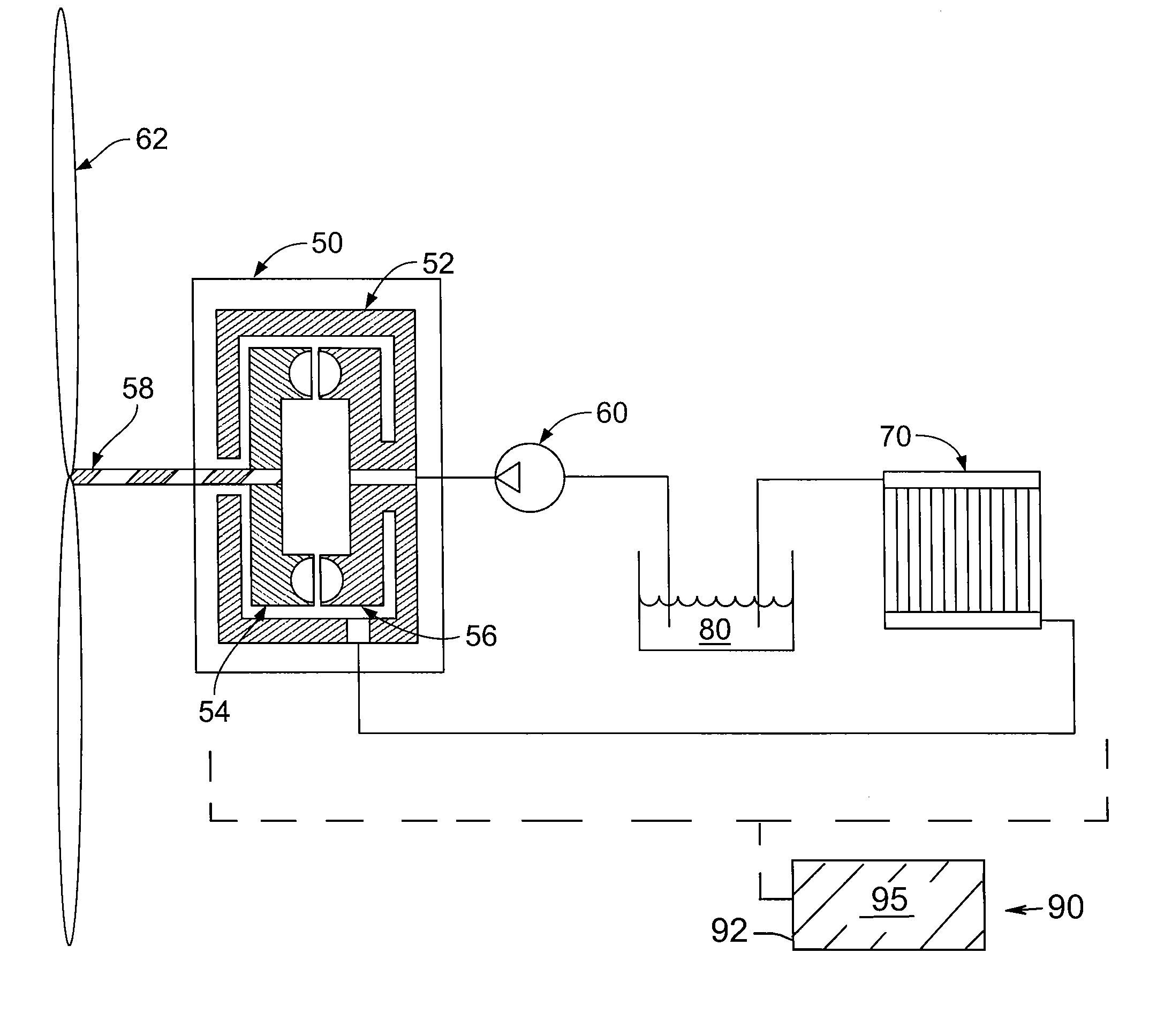

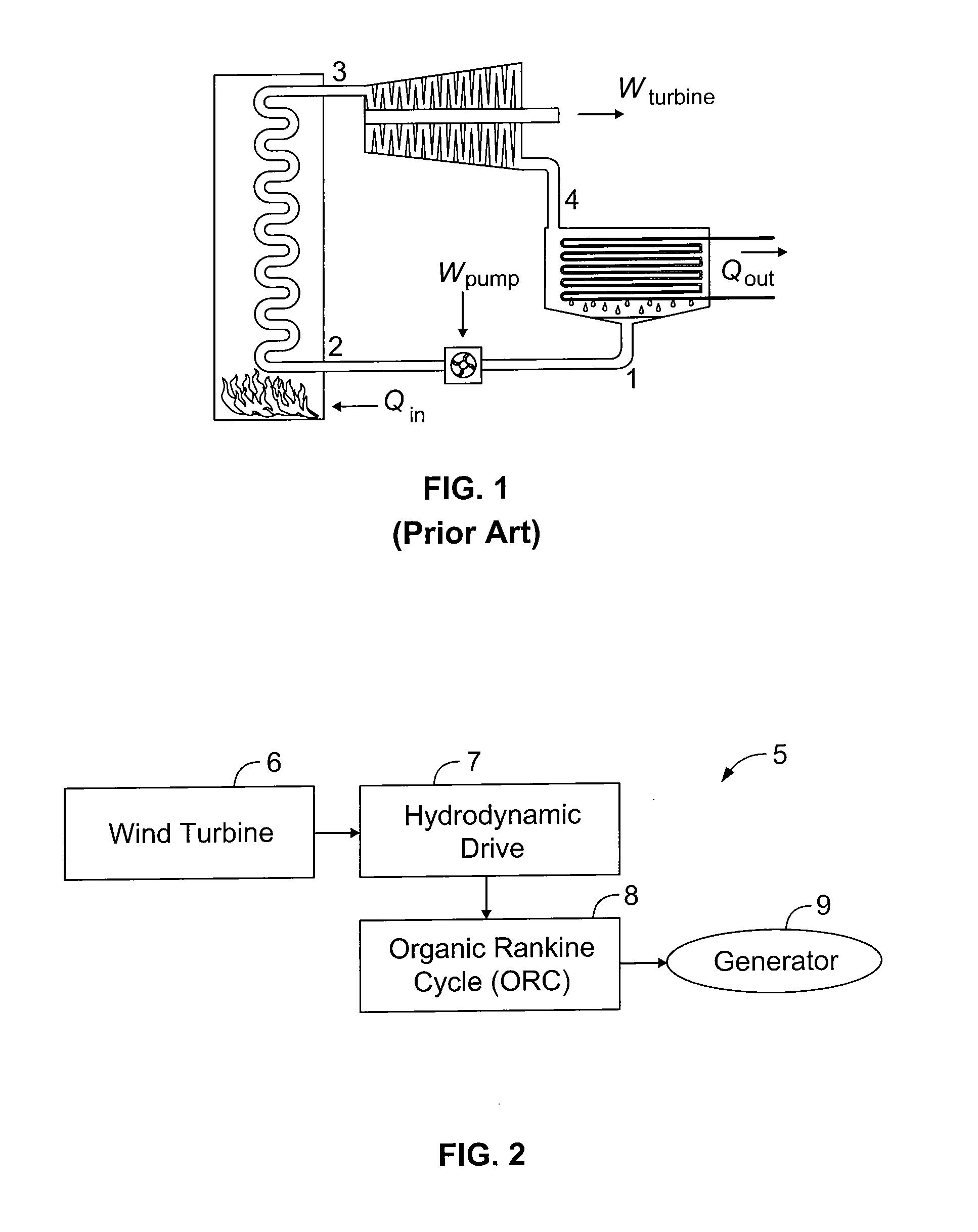

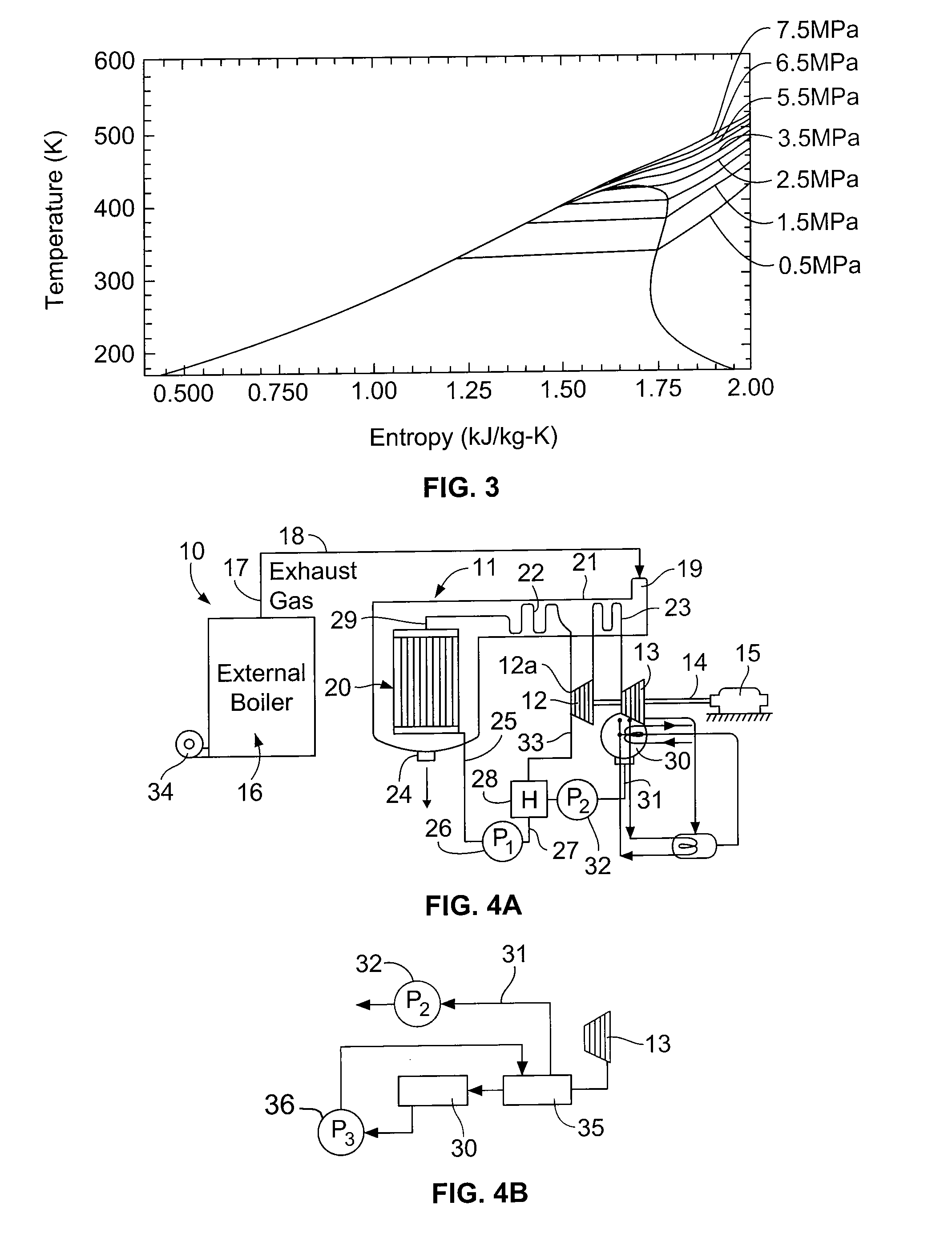

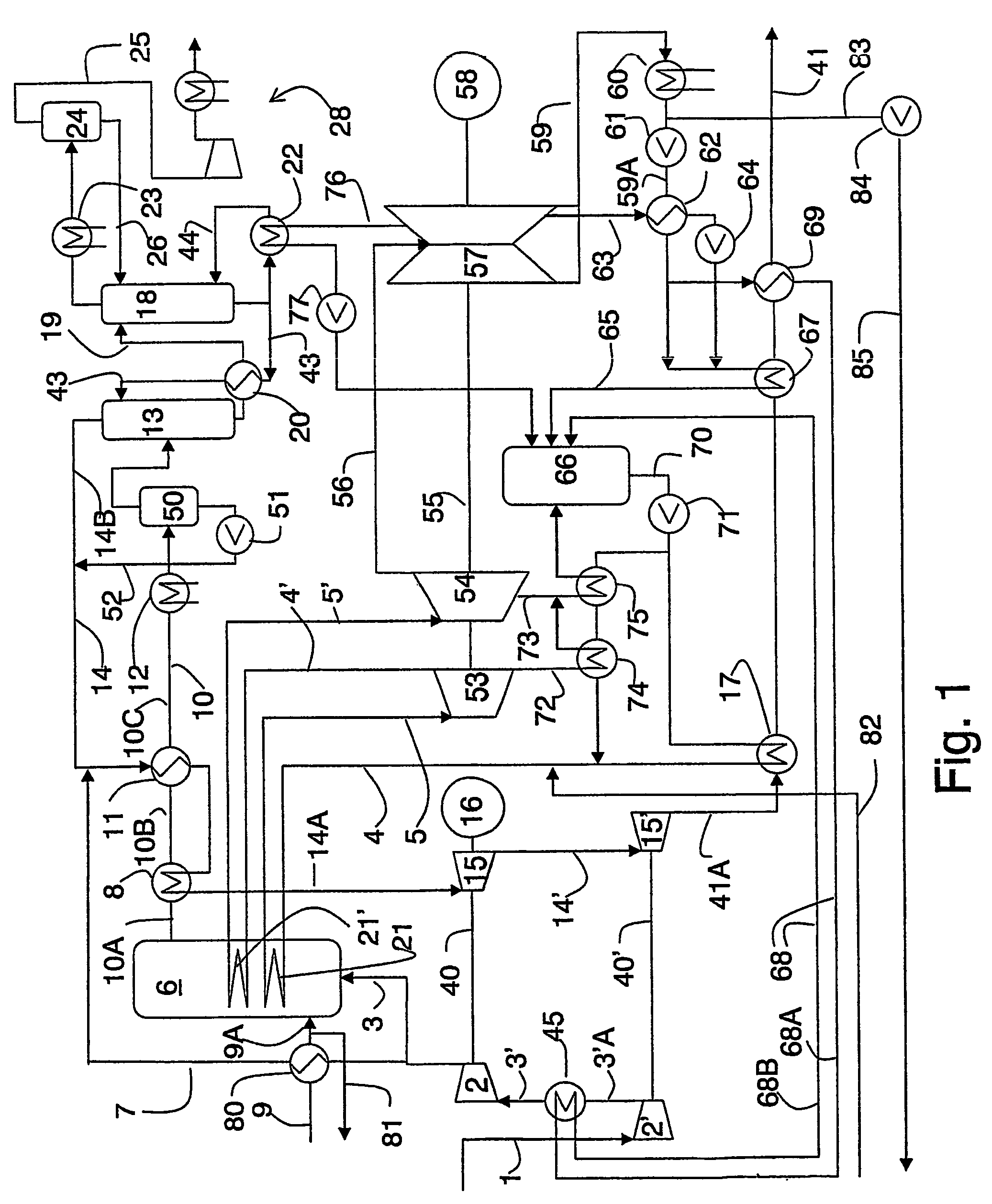

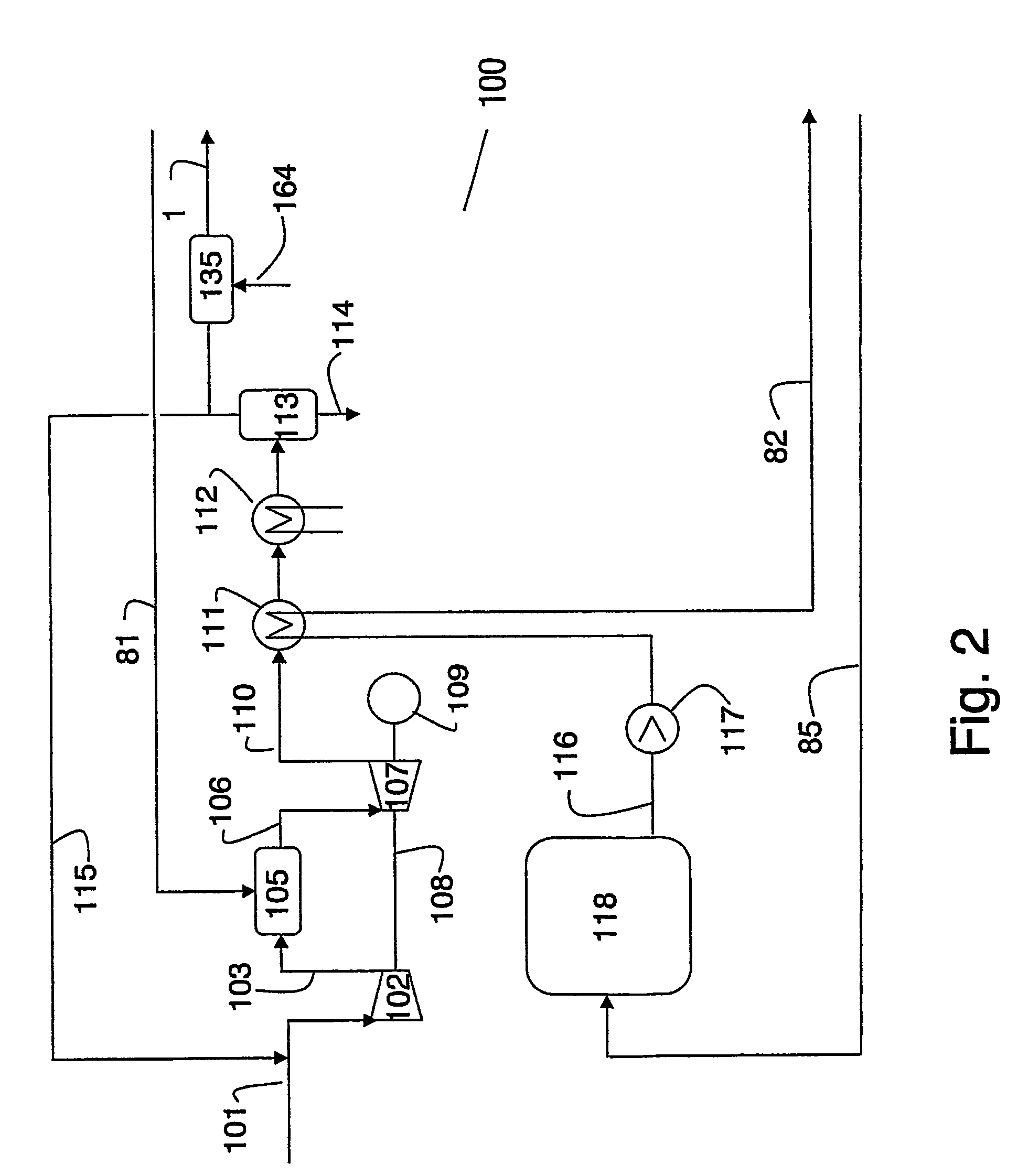

Power generator using a wind turbine, a hydrodynamic retarder and an organic rankine cycle drive

InactiveUS20120001436A1Facilitates easy inspectionEasy maintenanceWind energy with garvitational potential energyEnergy industryElectricityOrganic Rankine cycle

An electric power generating system is provided that uses a wind turbine to generate waste-heat that is utilized in an organic Rankine Cycle drive that converts heat energy into rotation of a generator rotor for generating electricity. A hydrodynamic retarder may be provided that dissipates heat into a hot fluid by directing the flow of the fluid through the hydrodynamic retarder in a manner that resists rotation of blades of the wind turbine. The hot fluid circulating in the hydrodynamic retarder is a thermal heat source for vapor regeneration of organic heat exchange fluid mixture(s) used in the Rankine cycle, expansion of the organic heat exchange fluid being converted into rotation of the generator rotor.

Owner:SAMI SAMUEL DR

Novel method for processing calx sodica sintered alumina by dry method

InactiveCN101434403AReduce heat lossImprove economic efficiencyAluminium oxides/hydroxidesWater contentDecomposer

The invention discloses a processing method for sintering alumina by a novel dry soap lime, which comprises the following steps: (1) raw materials, i.e., broken bauxite, limestone, sodium carbonate and coal are sent to a ball mill to be milled until the oversize product of 100<#> is not lager than 5 percent, and raw meal is made into raw meal balls of 30-50mm; (2) clinker sintering: the raw meal of the step (1) is calcined in a vertical kiln at the temperature of 1150-1250 DEG C to prepare the clinker; (3) clinker leaching: the clinker is leached by the lotion of Bayer process, and then the solution is sent to a desilication groove; (4) decomposition: the desiliconized solution is combined with a Bayer solution, and then the mixture is put into a leaf filter and enters a decomposer to be decomposed by adding seed crystal; and (5) roasting: aluminum hydroxide is roasted into alumina at 950-1200 DEG C. The processing method has the beneficial effect that the water content of the raw meal is reduced to 10-15 percent, thus greatly reducing the specific heat consumption in the sintering process by little change and acquiring higher economic benefits.

Owner:CHONGQING BOSAI MINERALS GROUP

Purification works for thermal power plant

InactiveUS7559977B2Reduce heat lossIncrease energy yieldUsing liquid separation agentCombustion enginesCombustion chamberExhaust fumes

A method for separation of CO2 from the combustion gas from a thermal power plant fired with fossil fuel, wherein the combustion gas from the thermal power plant is used as cooled, compressed and reheated by combustion of natural gas in a combustion chamber to form an exhaust gas, where the exhaust gas is cooled an brought in contact with an absorbent absorbing CO2 from the exhaust gas to form a low CO2 stream and an absorbent with absorbed CO2, and where the low CO2 stream is heated by means of heat exchanges against the hot exhaust gas leaving the combustion chamber before it is expanded in turbines, is described. A plant for performing the method and a combined plant is also described.

Owner:CO2 CAPSOL

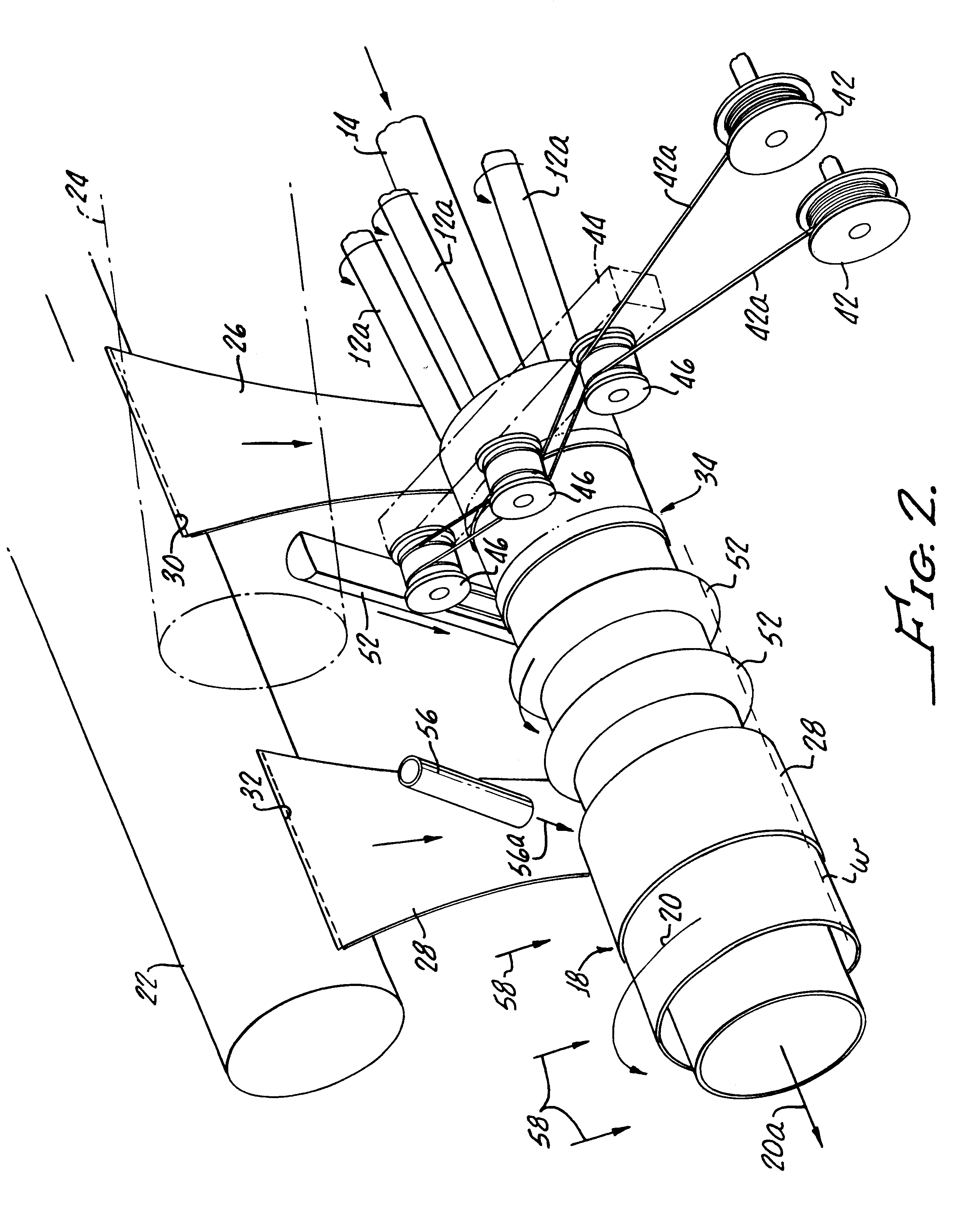

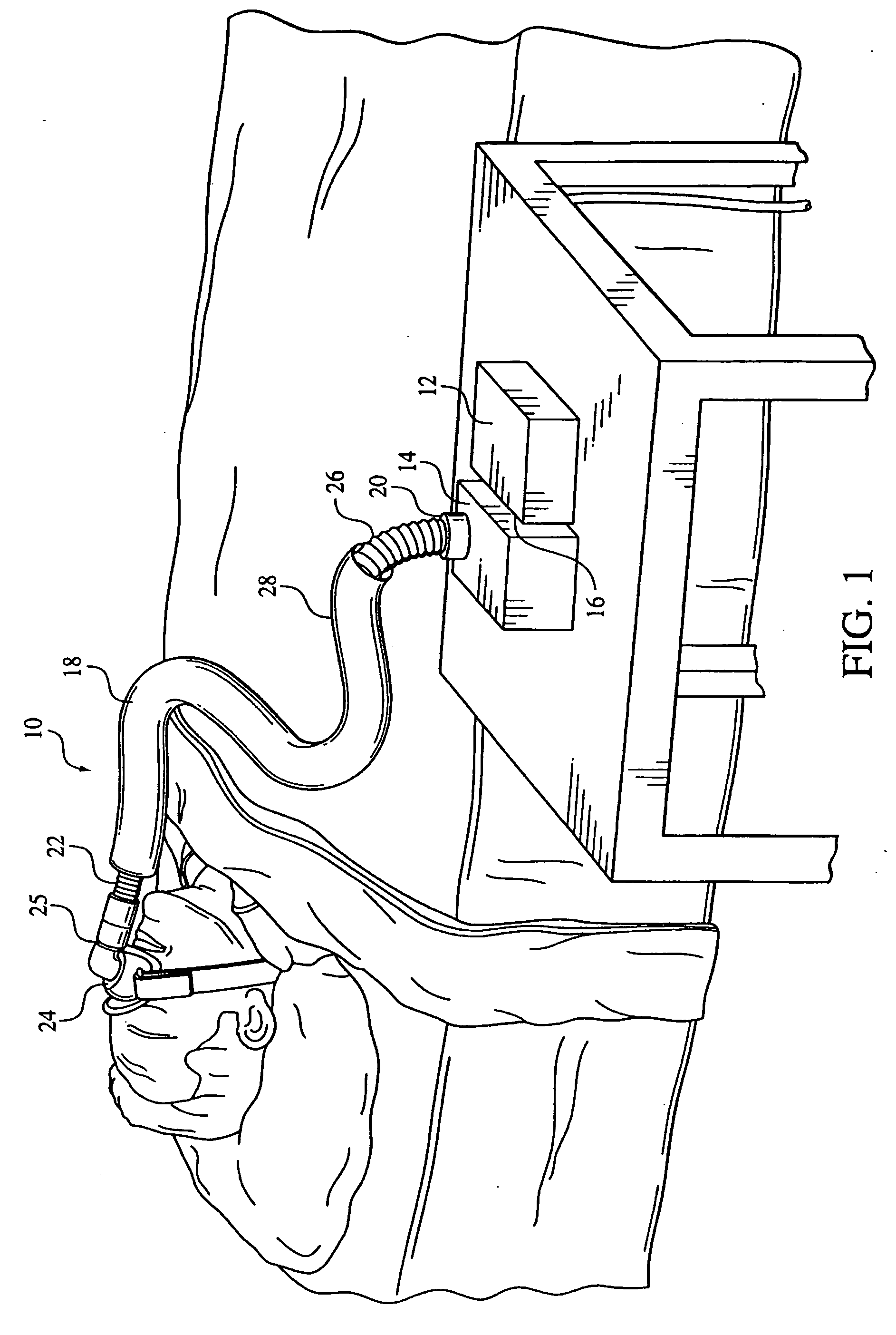

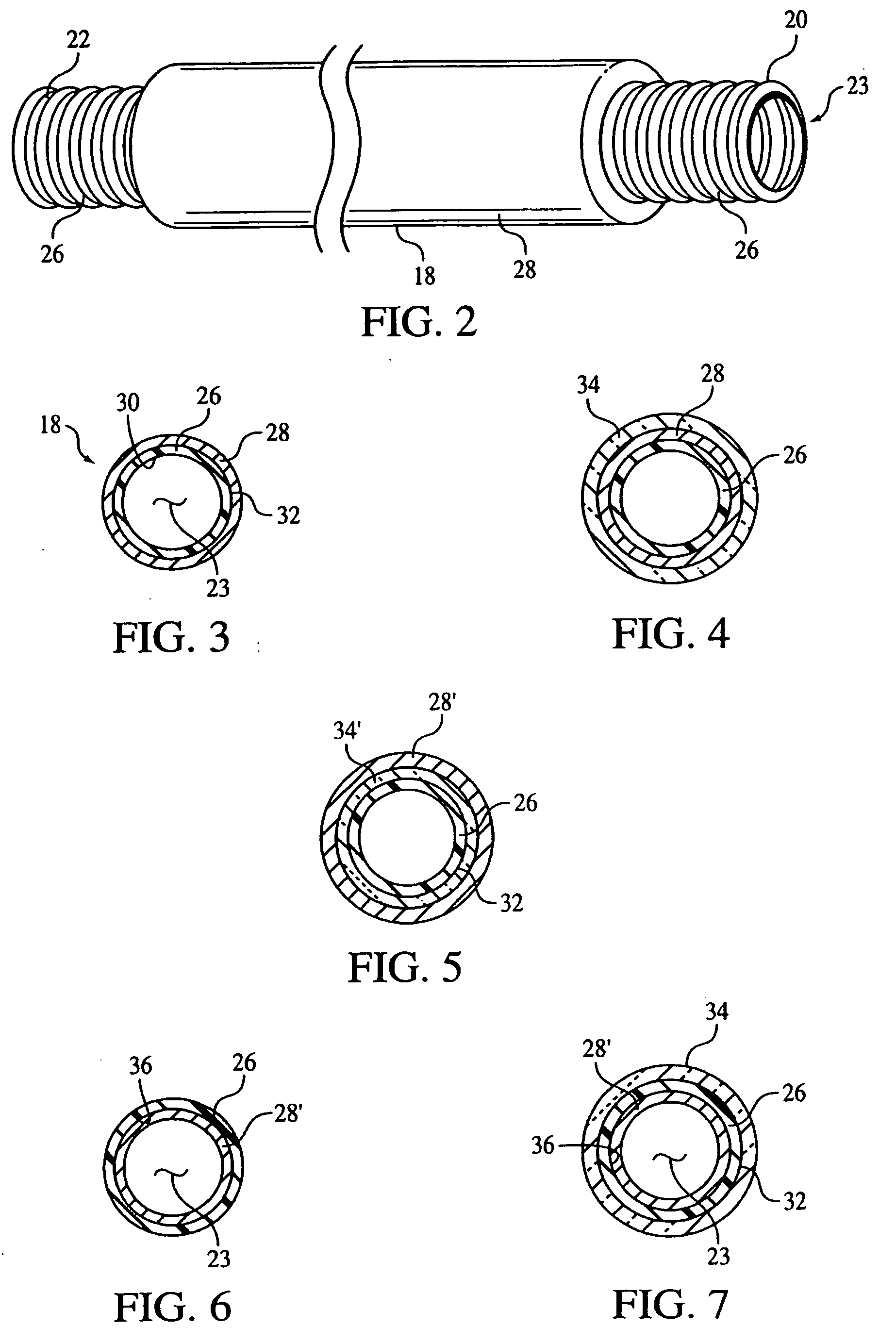

Method of making a double-walled flexible tubing product with helical support bead and heating conductor

InactiveUS6190480B1Increase valueLow and zero temperature lossRespiratorsPaper/cardboard wound articlesBiomedical engineeringDouble walled

A flexible double-walled plastic tubing product includes a helically wound support bead between inner and outer walls, and an helically wrapped electrical resistance heating conductor is disposed adjacent to the inner wall in good heat transfer relation to fluid flow within the tubing product. Fluid flow within the tubing product is insulated against heat loss to ambient by the helical support bead and a trapped "dead-air" space between the walls of the tubing product. Apparatus and method for making the tubing product are disclosed.

Owner:STEWARD PLASTICS INC

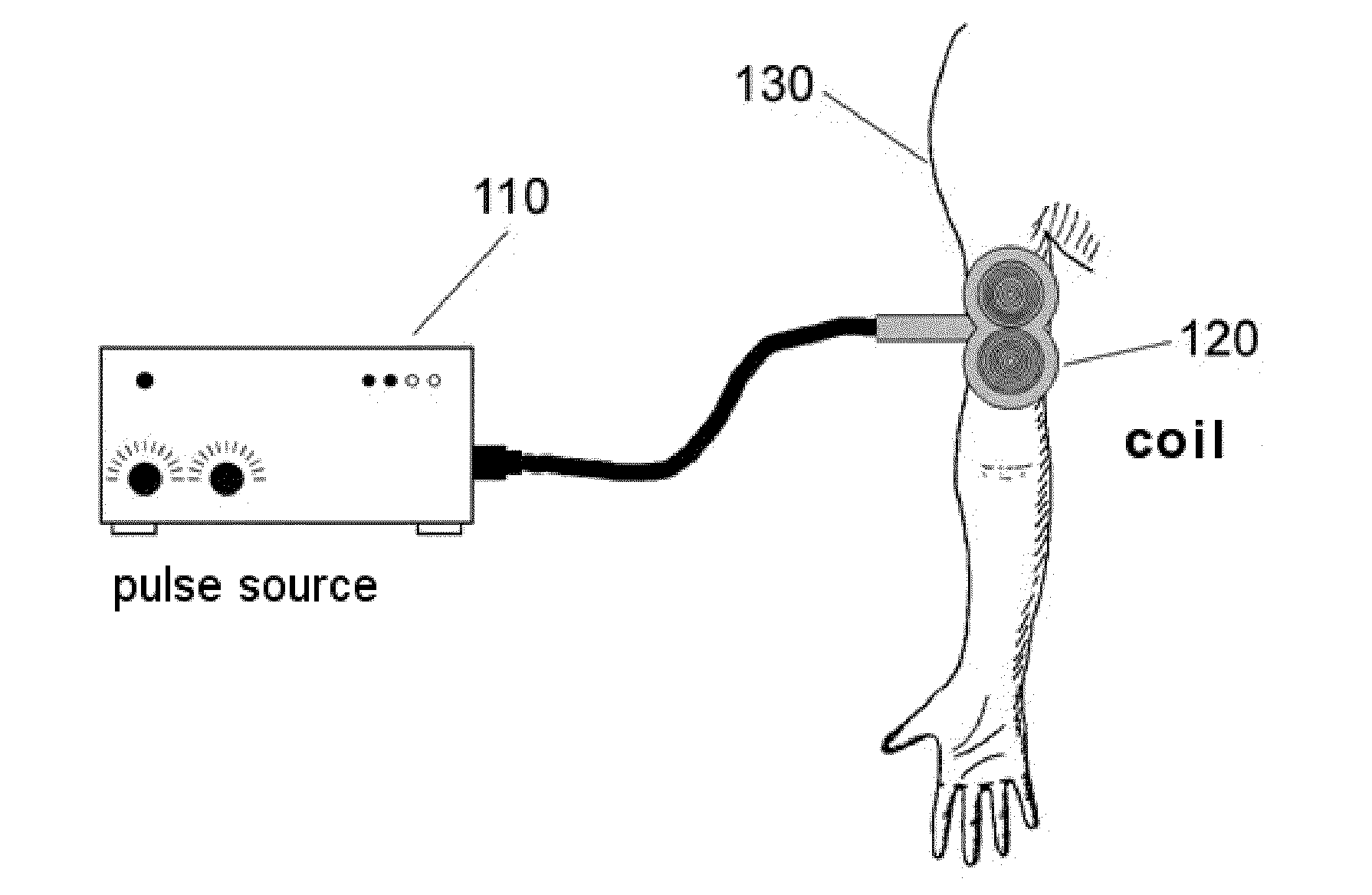

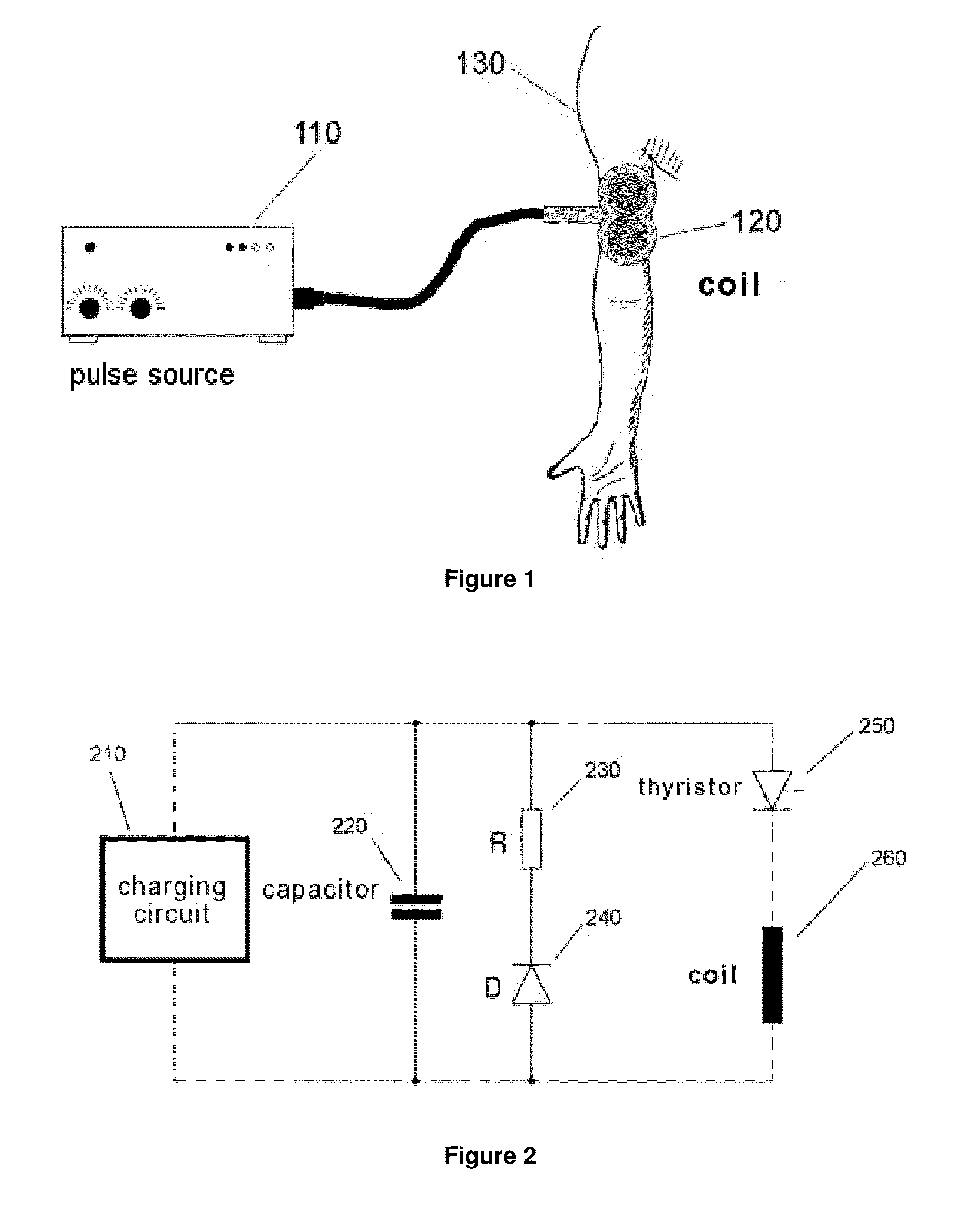

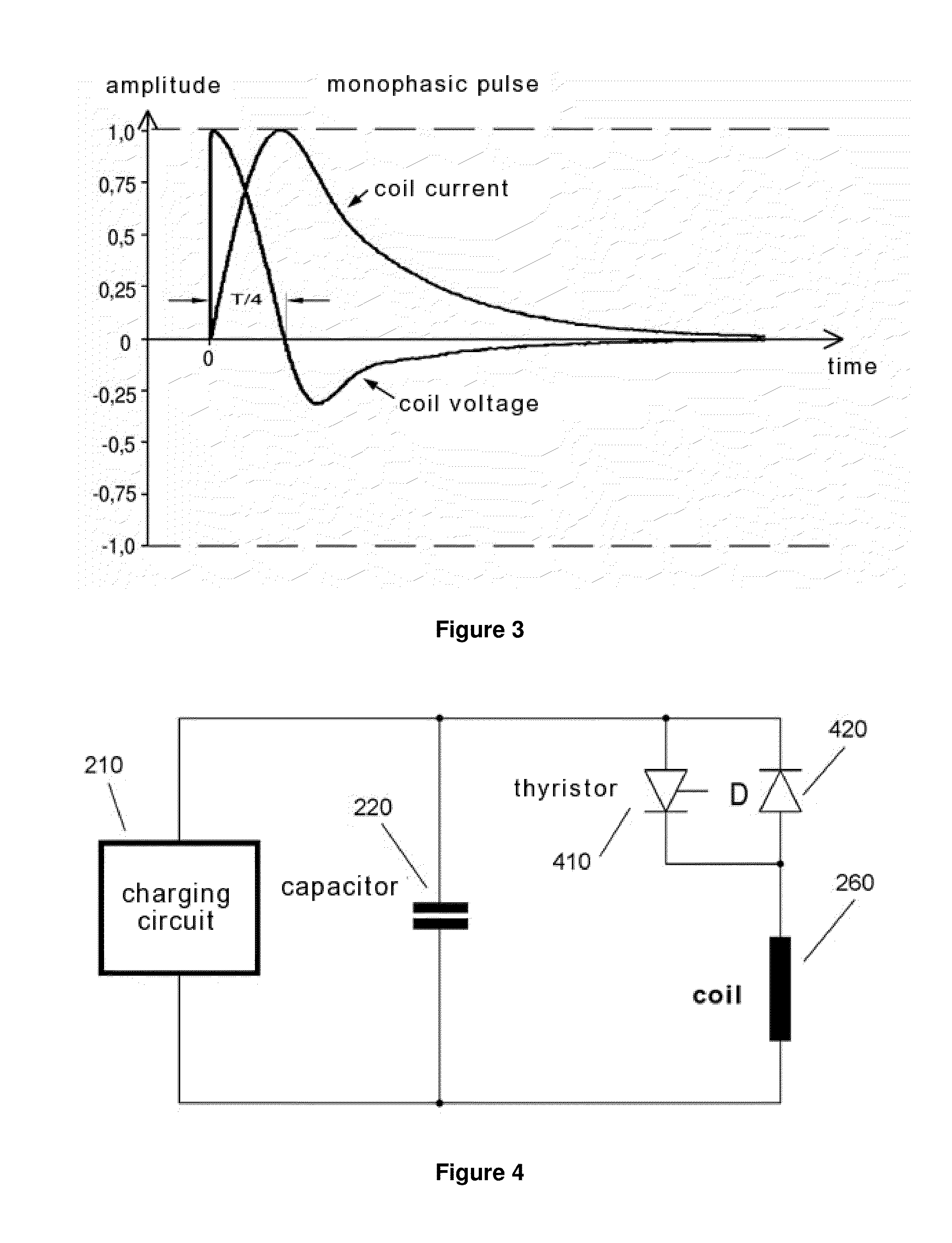

Magnetic stimulation having a freely selectable pulse shape

ActiveUS20130030239A1Low field energyField strengthElectrotherapyThyristorPulse shapingElectromagnetic induction

Device and method for generating brief strong current pulses in a coil for generating magnetic field pulses which according to the electromagnetic induction principle induce stimulation currents in the body tissue triggering an action potential of the nerve and / or muscle cells, where the coil is positionable close to the body tissue to be stimulated so that its magnetic field passes through the body tissue, and where the device comprises a power generating unit that can generate a freely selectable temporal course of the current through the coil during the current pulse. A method for determining an optimized temporal course of a brief strong current pulse through the coil, where the temporal course of the current pulse is calculated using a method which numerically simulates the electrical behavior of nerve and / or muscle cells and the coil and optimizes the course of the current pulse regarding at least one parameter, or which by means of stimulating the nerve and / or muscle cells with predetermined current pulses optimizes the temporal course of the current pulse regarding at least one parameter and therefrom determines essential parameters of nerve and / or muscle cells.

Owner:TECH UNIV MUNCHEN

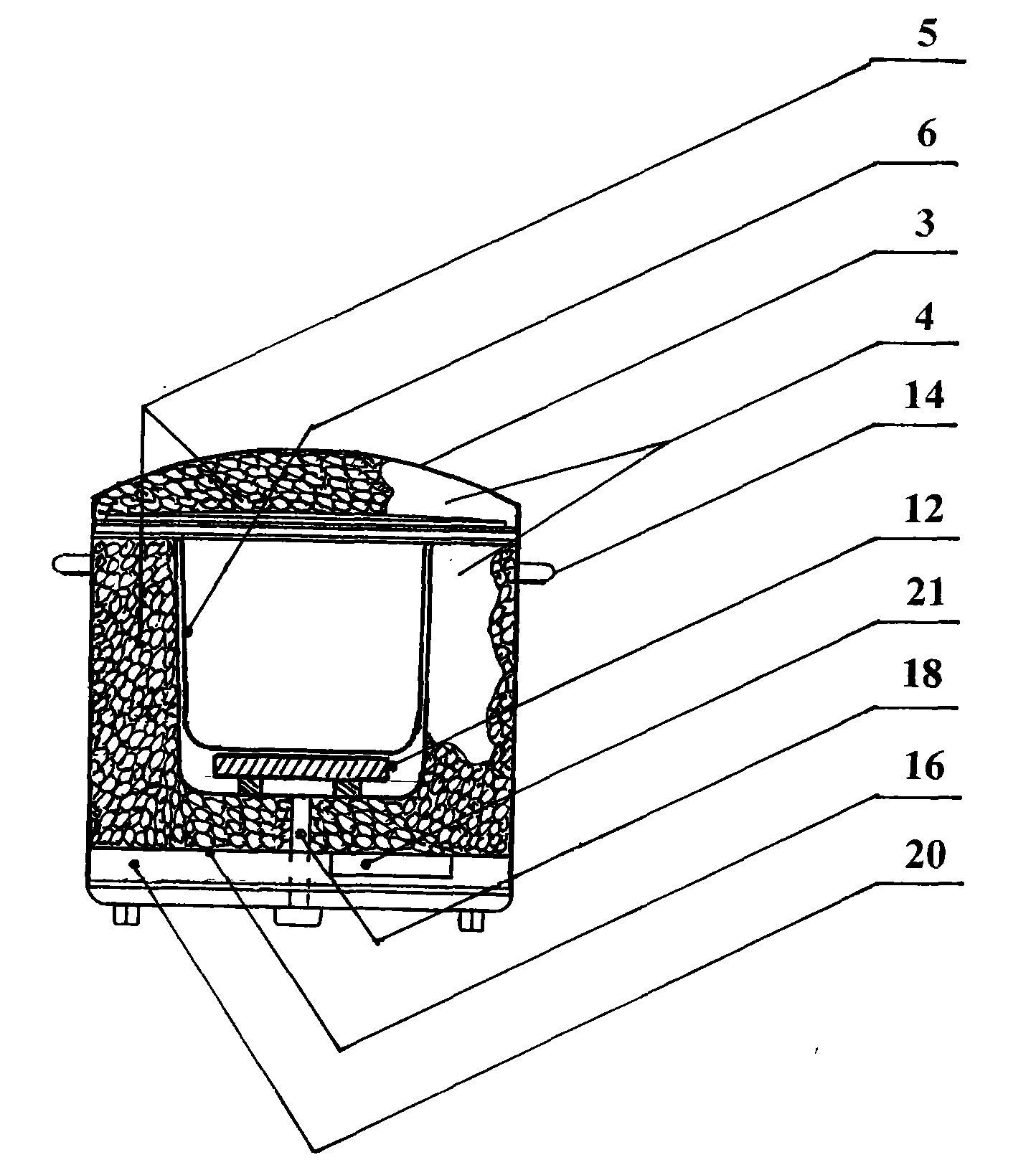

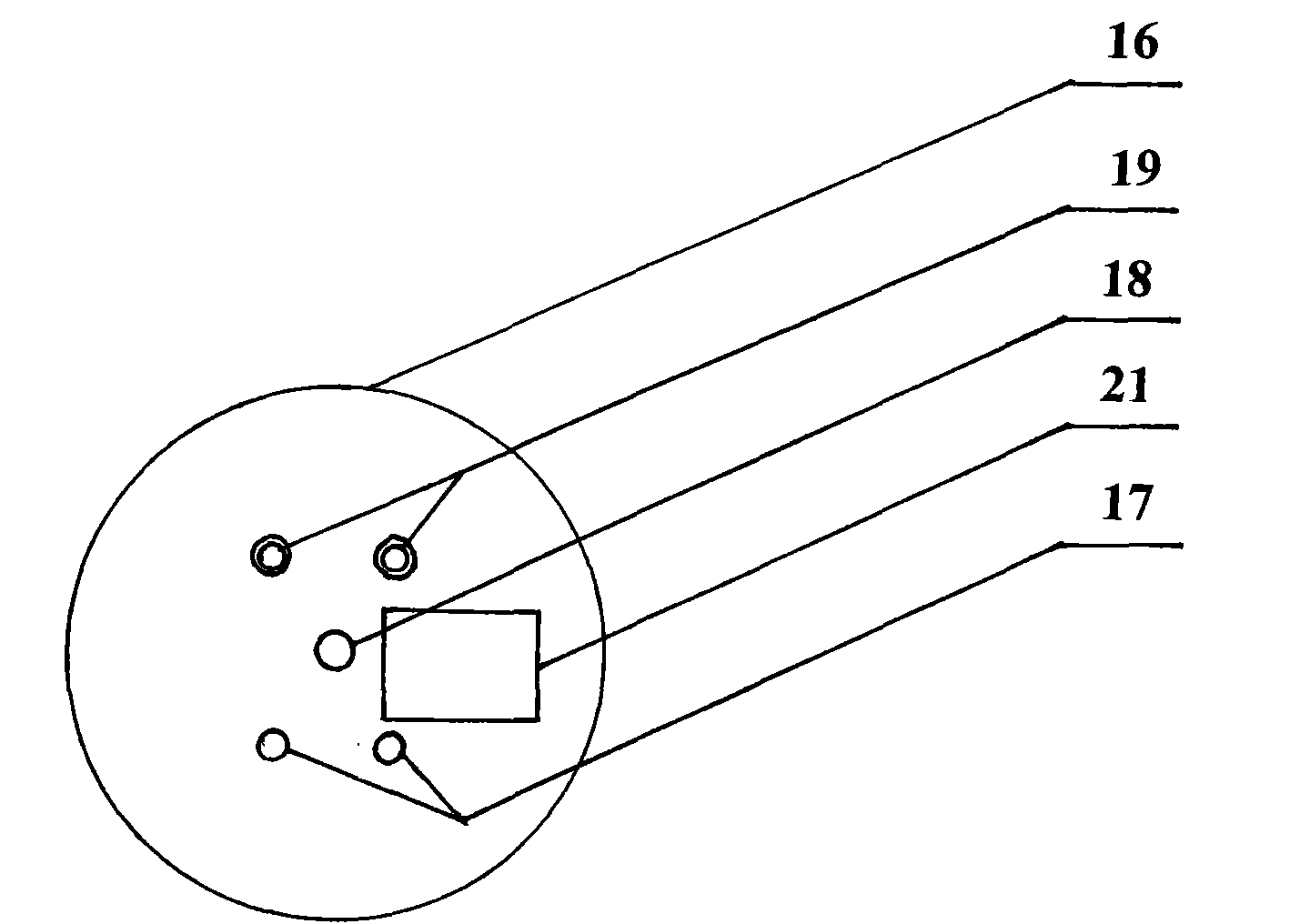

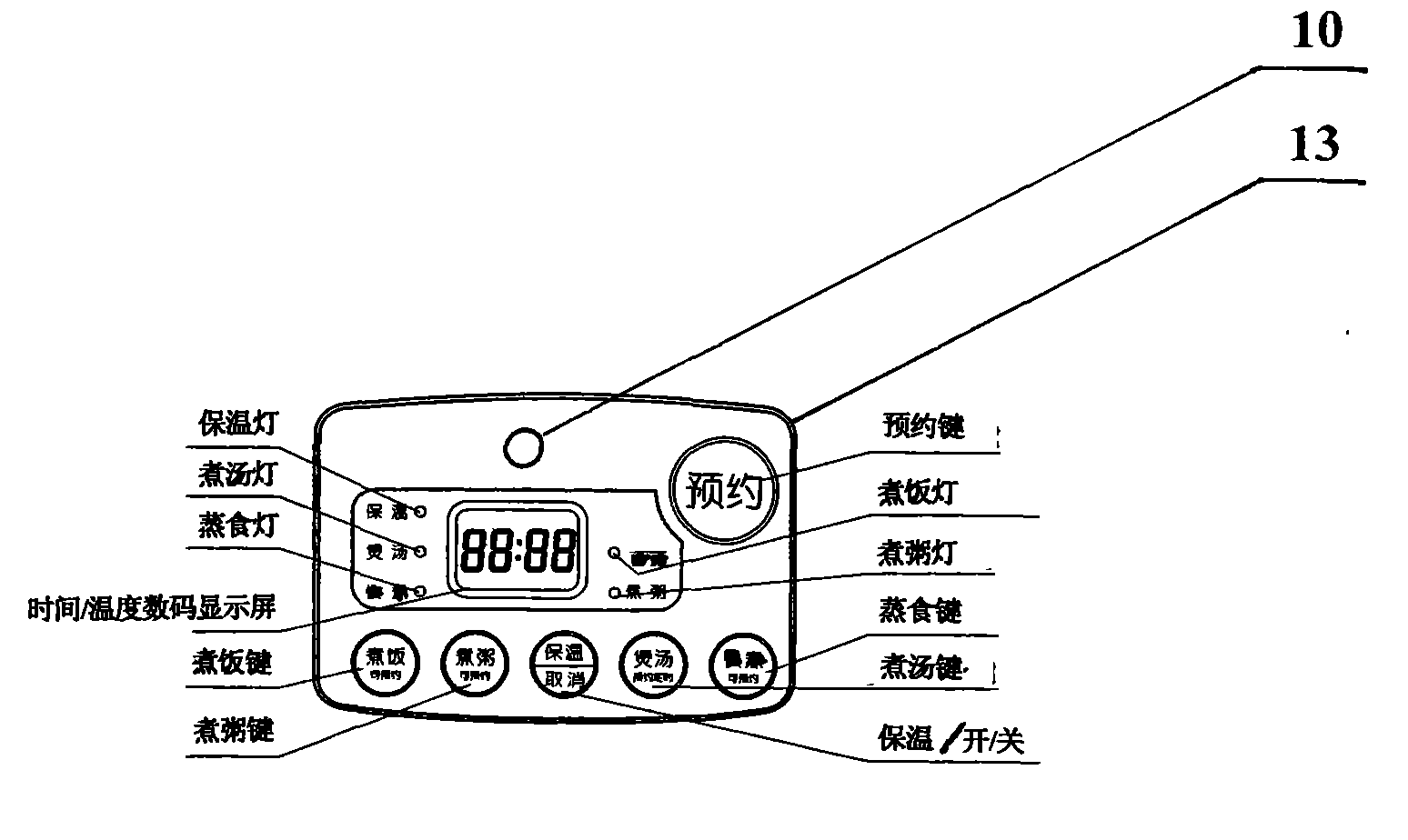

Efficient energy saving electro heating multipurpose cooker and new method of accurate temperature controlling and healthy cooking

InactiveCN101669761APlug the drainSolve technical problems that cannot withstand high temperaturesCooking-vessel lids/coversCooking utensils shields/jacketsElectricityAutomatic control

The invention discloses an efficient energy saving electro heating multipurpose cooker utilizing a new method of accurate temperature controlling and healthy cooking. The technical scheme of the invention is as follows: the outside surface of the cooker body is provided with an ambient temperature sensor; the base of the cooker is provided with an inner pot temperature sensor; the cooker body, thecooker cover and the cooker base are all set to be closed efficient heat insulation interlayers; the closed heat insulation interlayer on the cooker base is arranged between the casing of the cookerbase and the electro heating device; a hallow cavity is arranged between the casing of the cooker base and the closed heat insulation interlayer; and the purposes of energy saving, discharge reducingand healthy cooking can be realized by setting standard control values such as ambient temperature or temperature drop, cooking / steaming temperature and time and the like by an automatic control device and by comparing the ambient real-time temperature or temperature drop with the inner pot real-time temperature to control the power on and power off of the electro heating device. The efficient energy saving electro heating multipurpose cooker can be used for cooking rice, cooking congee, cooking soups and steaming food; compared with various electro rice / congee / soup cooker in the prior art, the invention can save electricity by 30%-50% and can be widely used in families, dining halls and catering enterprises in cities and towns.

Owner:郭卫康

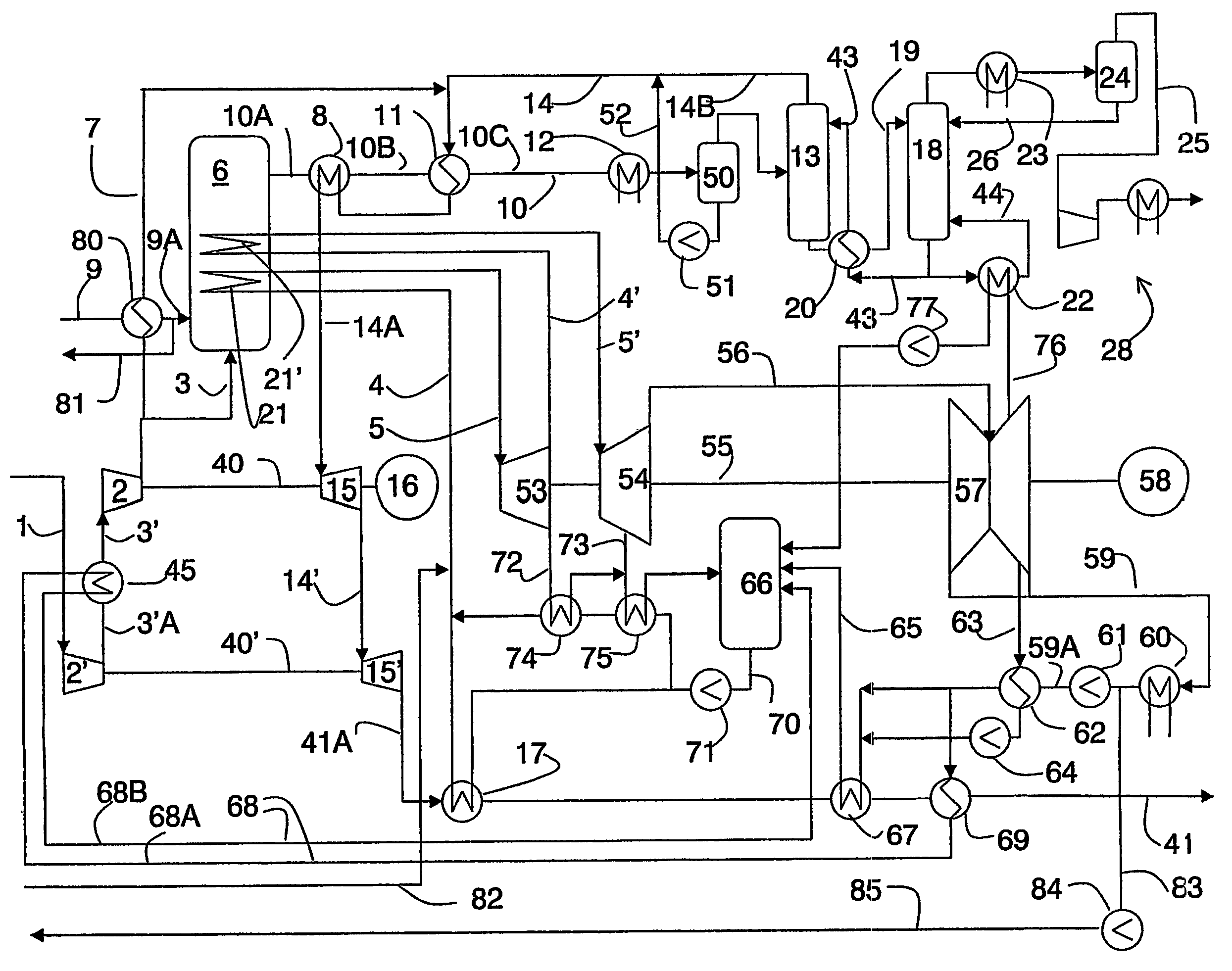

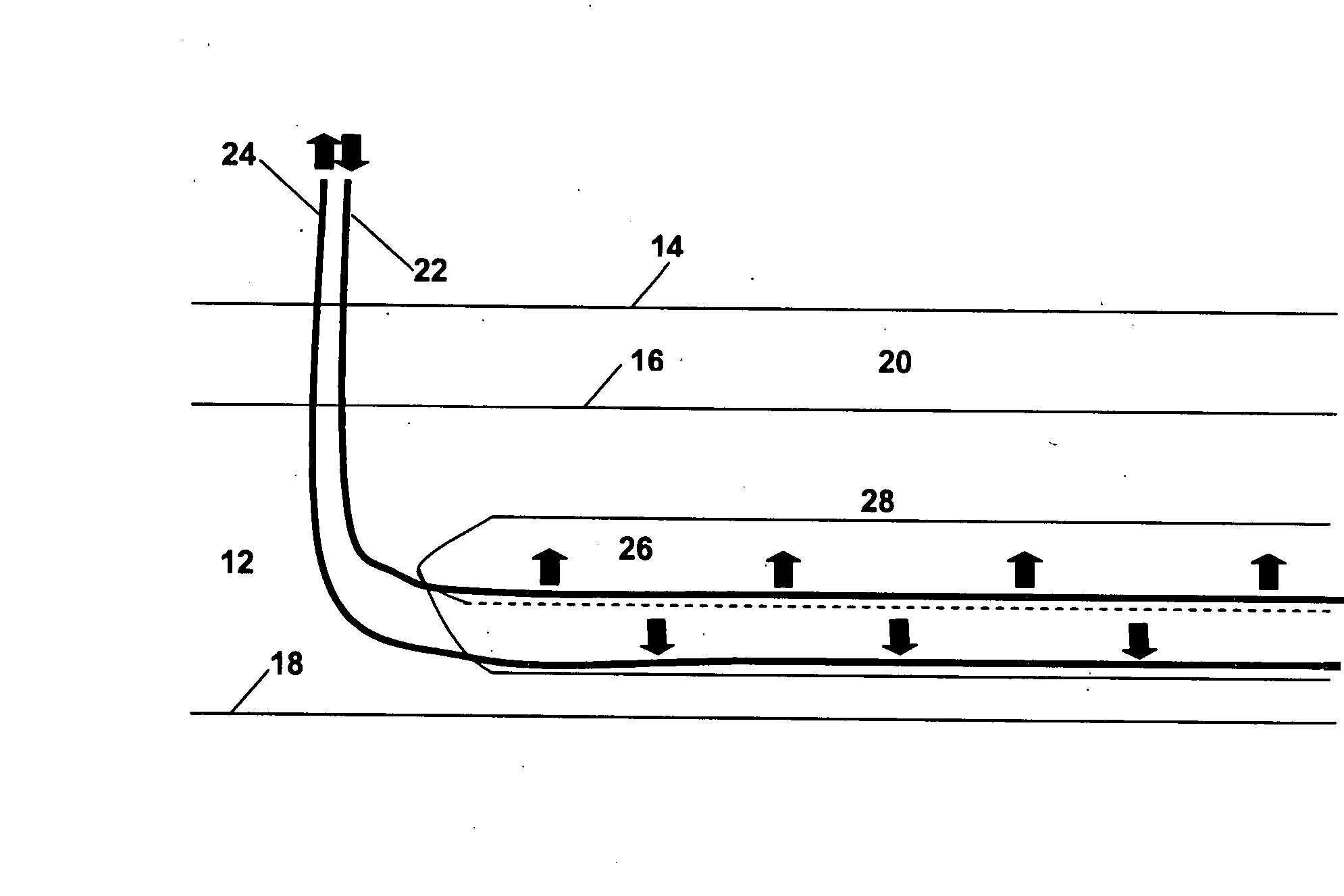

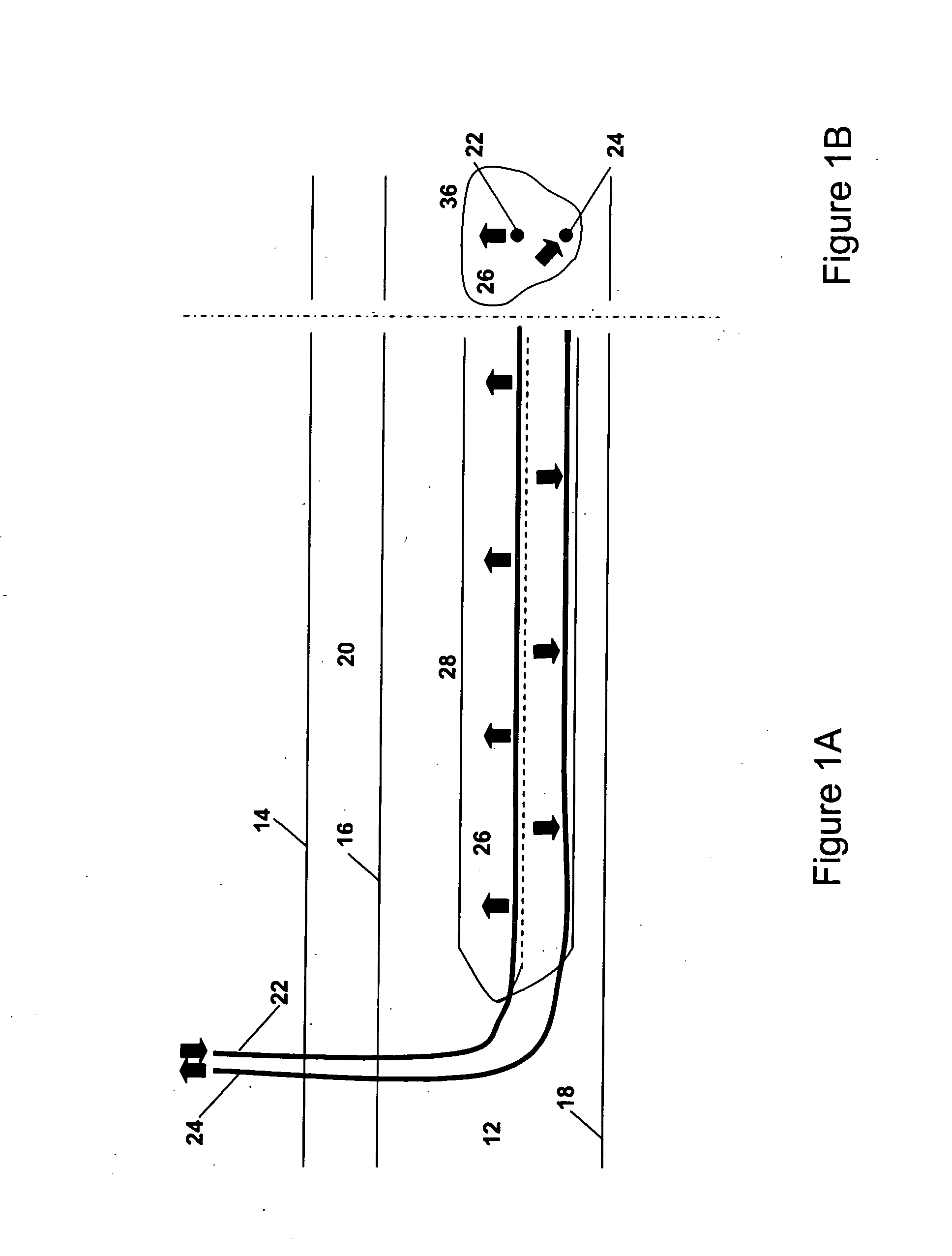

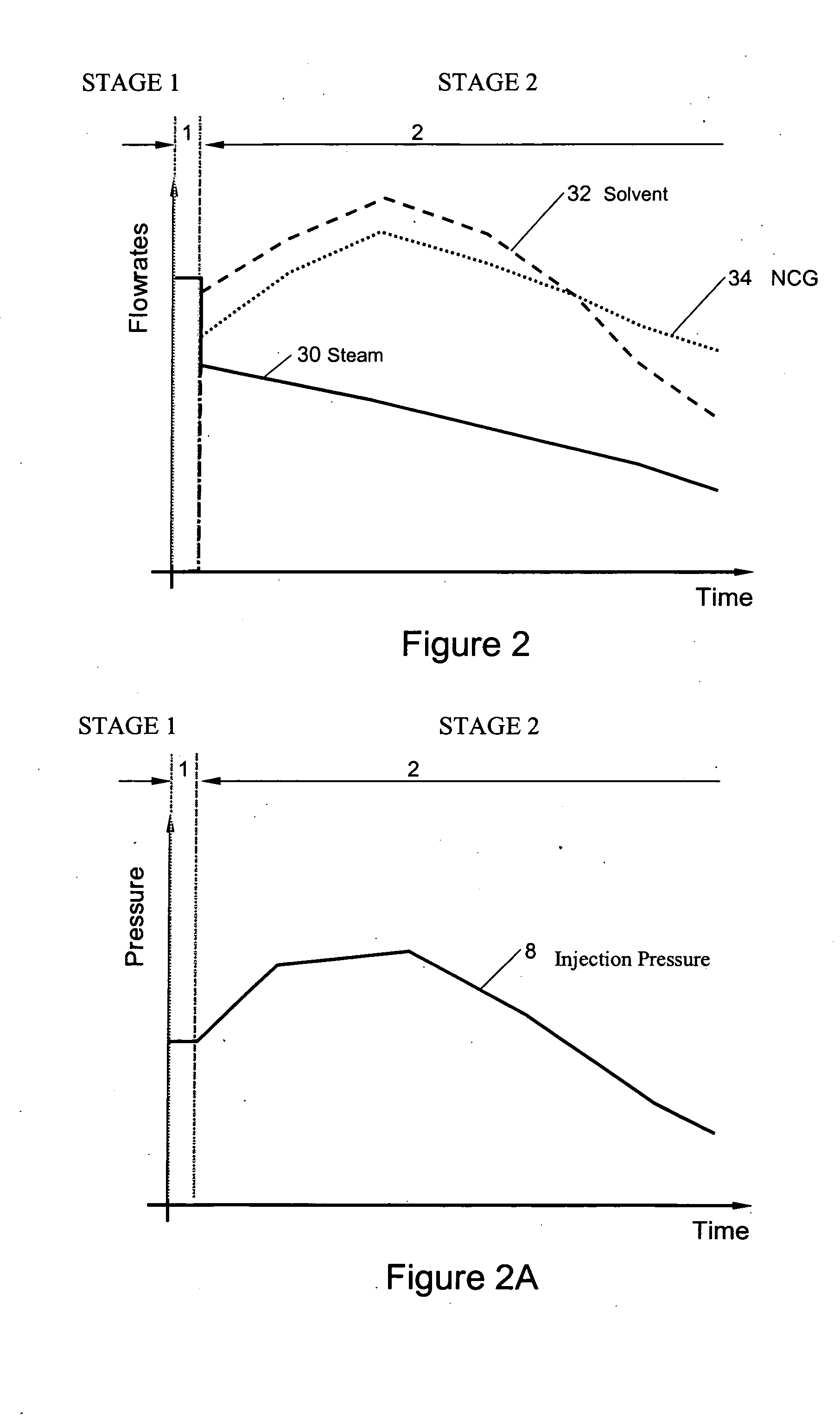

In situ process to recover heavy oil and bitumen

InactiveUS20080017372A1Maximize actionLow viscositySurveyFluid removalHydrocarbon solventsFluid viscosity

An in situ reservoir recovery process consisting of a horizontal injection well and a horizontal production well to extract bitumen or heavy oil from a reservoir. The process consists of a first phase operated at high-pressure in which steam, hydrocarbon solvent and non-condensable gases are injected into the reservoir and a second phase in which the injected fluids are transitioned to a high content of solvent and non-condensable gas and a reduced amount of steam to maintain a warm zone in the neighbourhood of the injection and production wells. The steam injection is sufficient to promote vapor transport of the solvent into the vapor depletion chamber and maintain the process at elevated temperatures in order to maintain low fluid viscosities in the production wellbore and to achieve preferred phase behaviour of the solvent hydrocarbon and the heavy oil or bitumen. The operating pressure of the process is controlled to prevent losses of the solvent hydrocarbon to the formation and to aid in solvent production to the production well in order for future re-cycling.

Owner:PARAMOUNT RESOURCES LTD

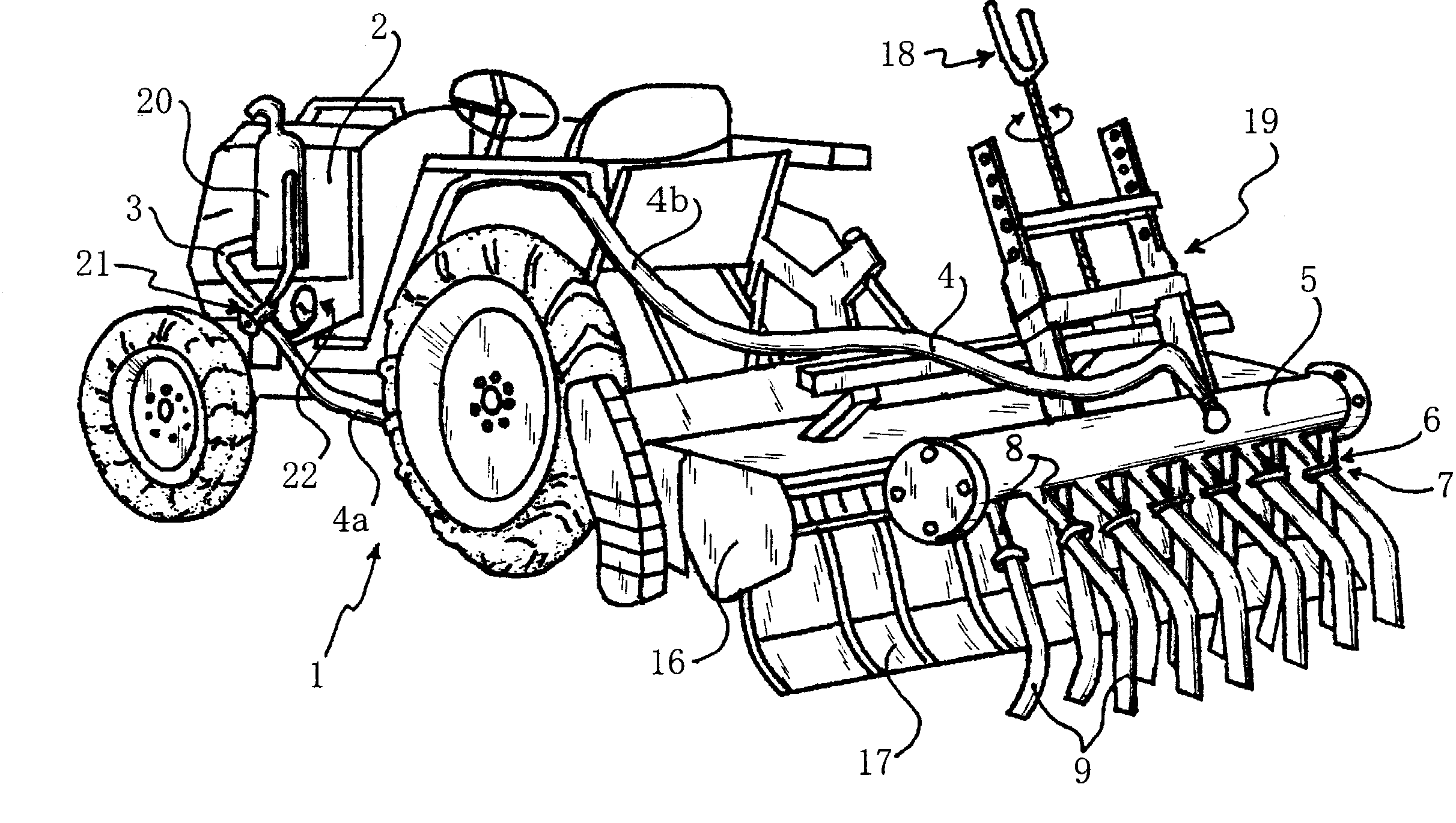

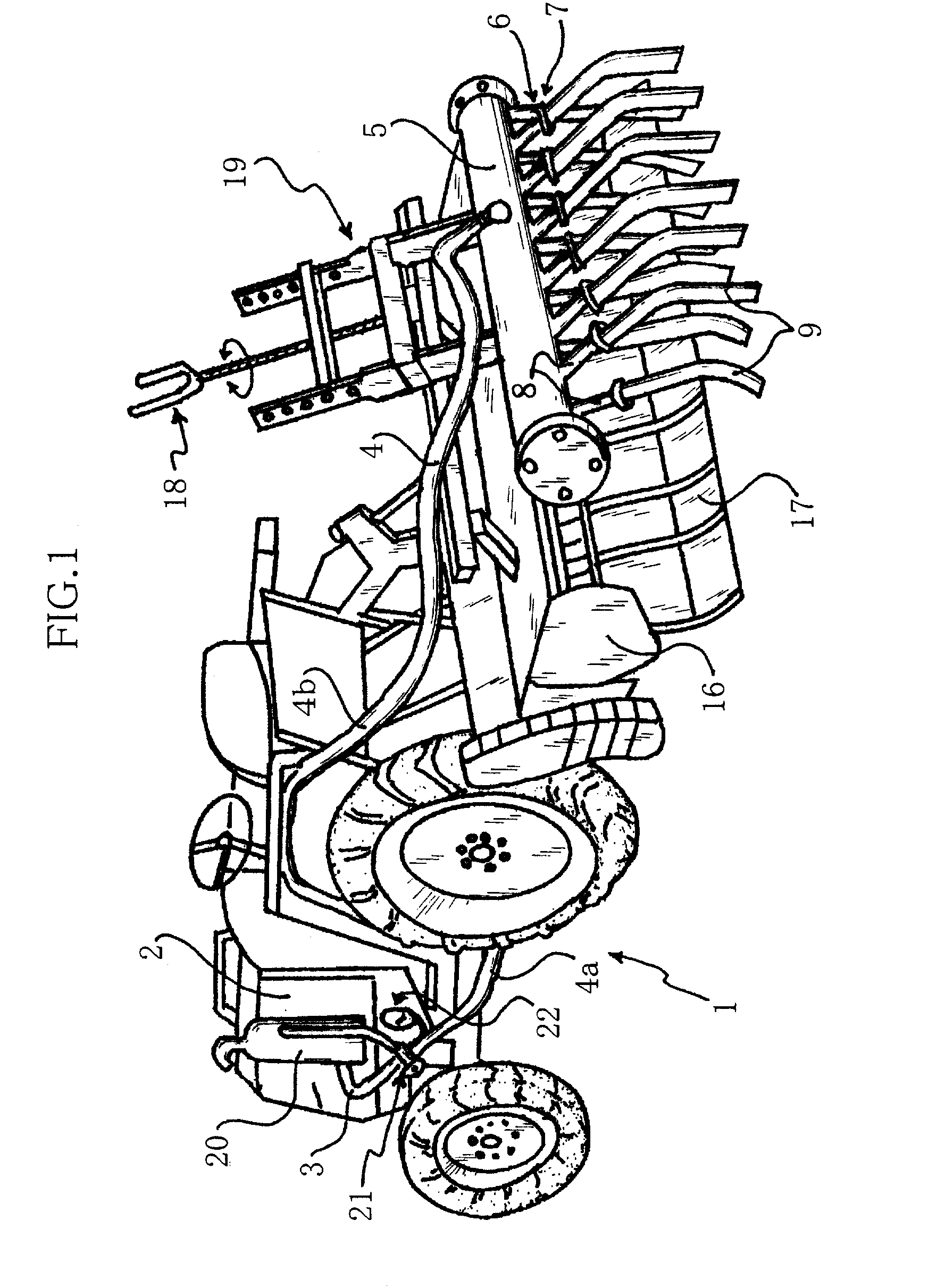

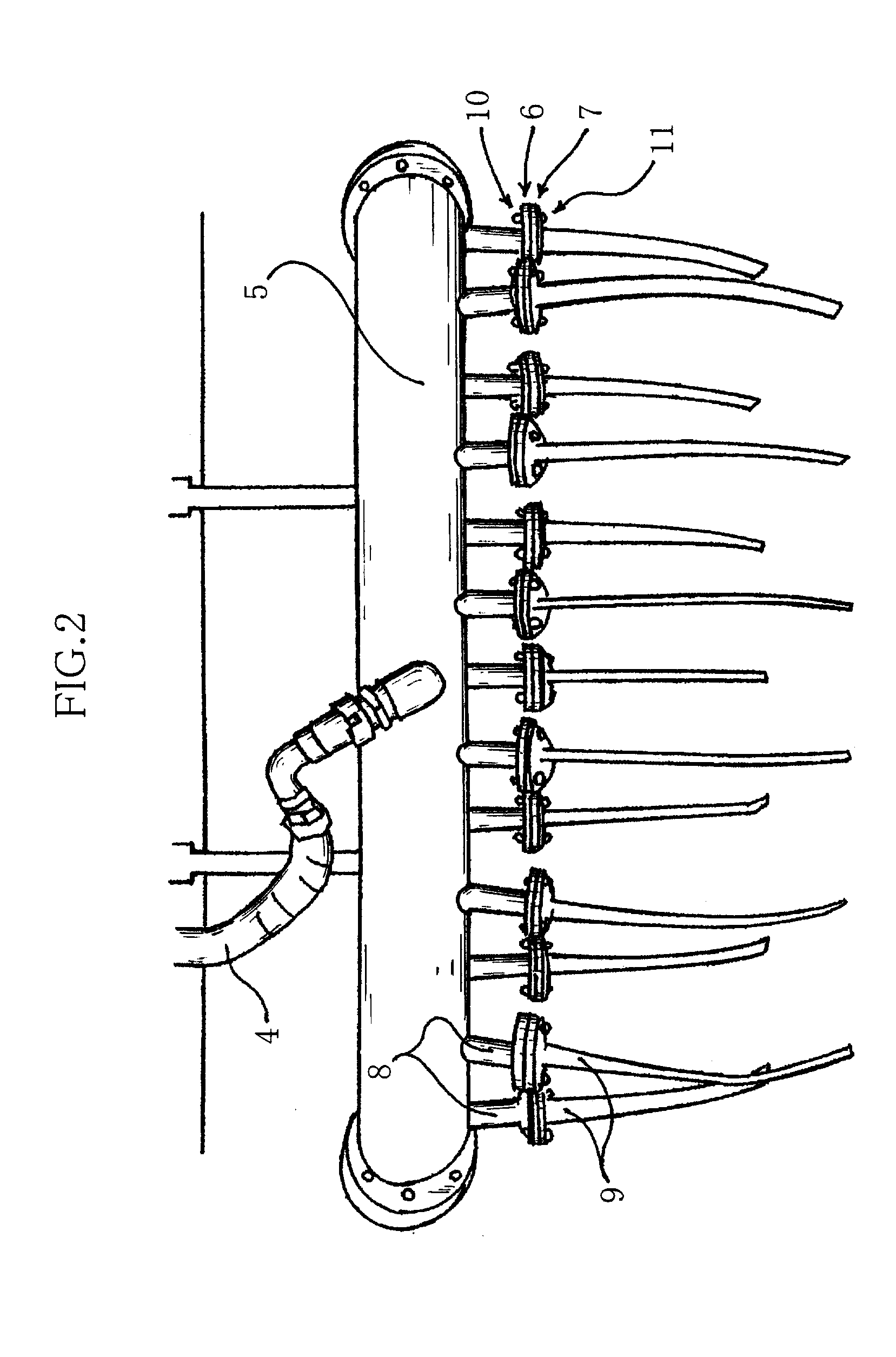

Soil pasteurizing apparatus and method using exhaust gas

InactiveUS20090290938A1High costEasy to assembleContaminated soil reclamationSteam soil sterilisationCarbon dioxideAgriculture

In agriculture, one of the most important issues is the extent to which the yield of high quality crops can be increased while saving labor and reducing costs. However, there are many problems in that so-called injuries of crops due to continuous cropping and other causes seriously reduce productivity. The present invention provides an apparatus and a method that can pasteurize soil using gases emitted from the engine of a tractor, while at the same time, carbon dioxide, sulfur oxides, and other acidic fumes in exhaust gas are fixed as calcium salts with slaked lime that has been applied in advance on the soil to be pasteurized, and these gaseous components can, as much as possible, be prevented from escaping into the atmosphere.

Owner:ASAOKA HISATOSHI +1

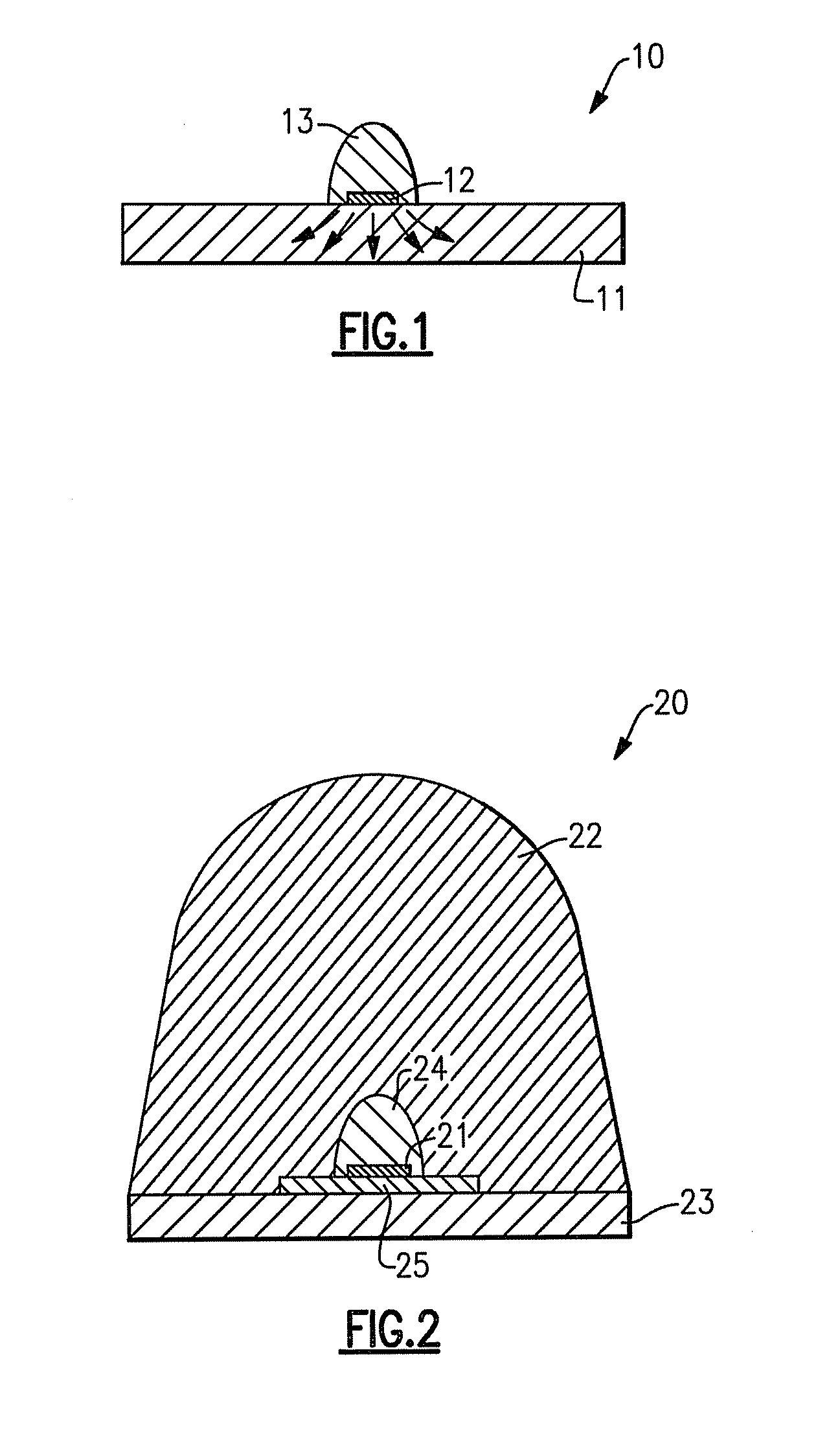

Lighting device which includes one or more solid state light emitting device

ActiveUS20100102697A1Reduce heat lossAvoid lostDischarge tube luminescnet screensElectric discharge tubesEffect lightLight emitting device

There is provided a lighting device which comprises at least one solid state light emitter and a substantially transparent heat sink. The heat sink and the solid state light emitter are positioned and oriented relative to one another such that if the solid state light emitter is illuminated, light emitted by the solid state light emitter which exits the lighting device passes through at least a portion of the heat sink. Also, there is provided a lighting device which comprises at least one solid state light emitter and means for extracting heat from the solid state light emitter.

Owner:IDEAL IND LIGHTING LLC

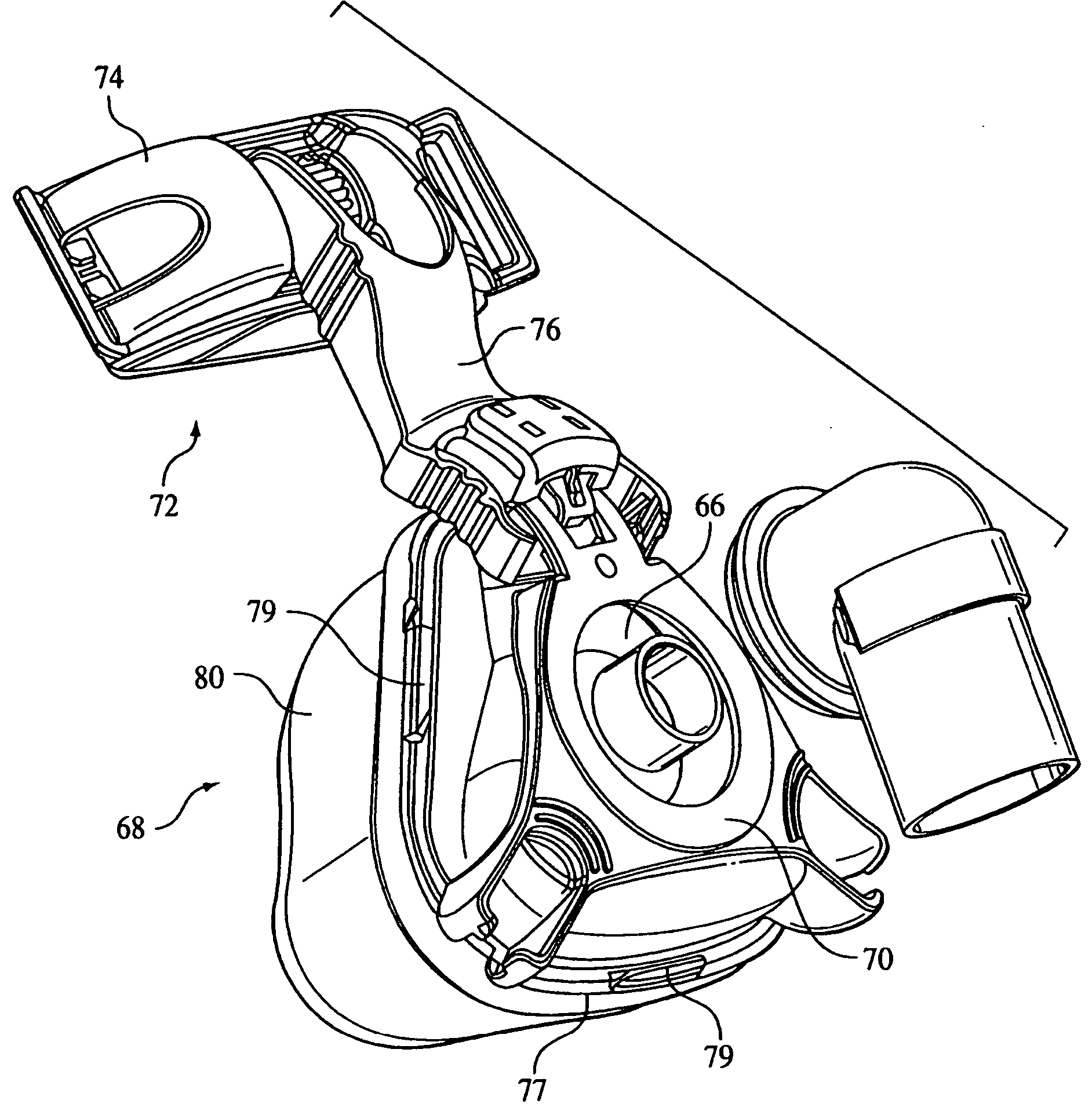

Condensation reduction and management systems in a gas flow delivery system

InactiveUS20060144399A1Controlling and reducing condensationControlling and reducing in and interfaceBreathing filtersRespiratory masksMedicineWater trap

Condensation management techniques for a gas flow delivery system. The techniques include providing a radiant barrier associated with patient circuit and / or a patient interface, providing a water trap and / or an absorbent insert in the patient interface device, or a combination of these techniques. The radiant barrier prevents condensation from forming in the patient circuit and / or the patient interface. The water trap and absorbent insert in the patient interface control condensation that reaches or forms in the interior of the patient interface to prevent it from interfering the user of the gas delivery system.

Owner:RIC INVESTMENTS LLC

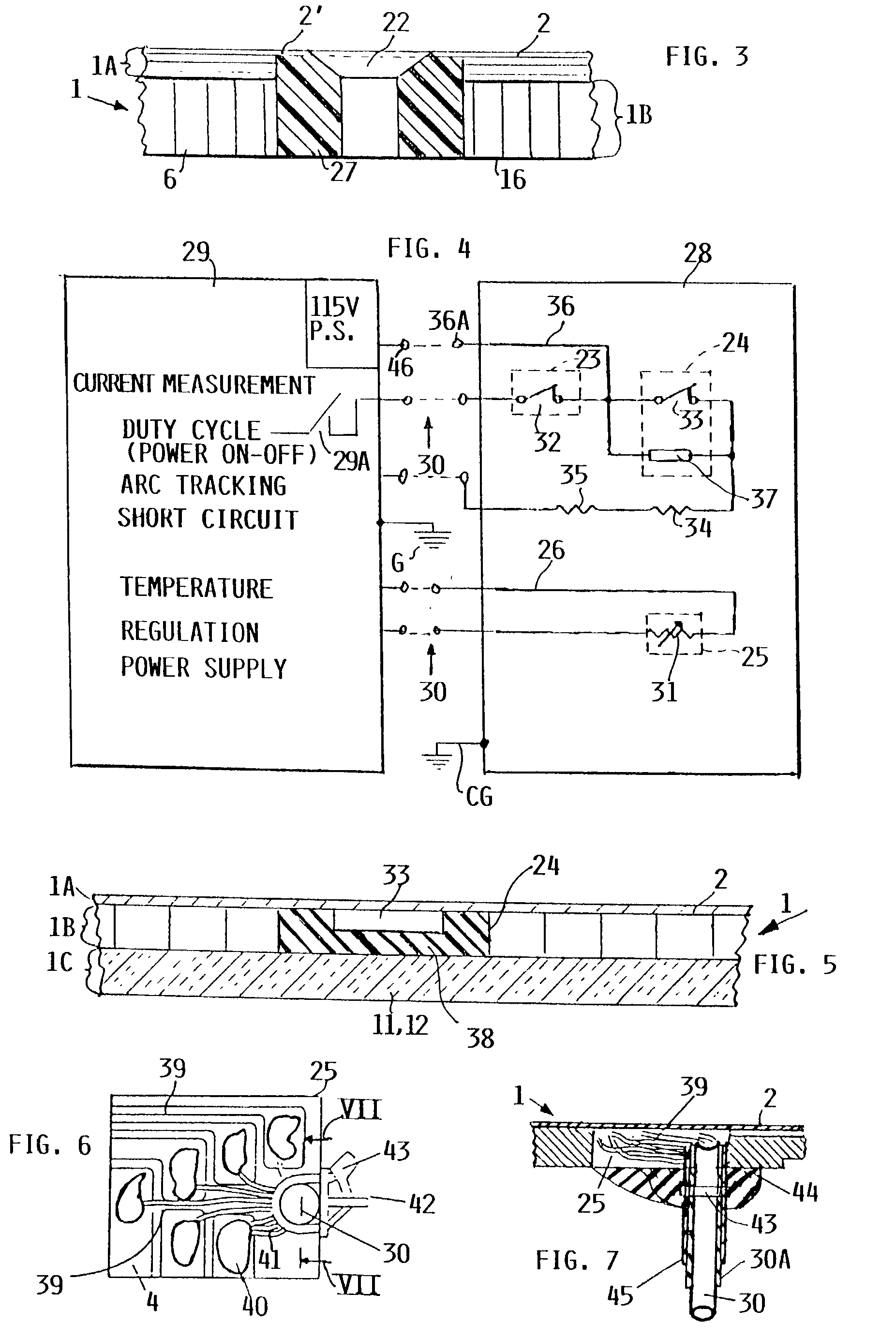

Electrically heated aircraft composite floor panel

InactiveUS20020168184A1Avoid temperature riseReduce consumptionFluid heatersElectric heating systemGlass fiberFiber-reinforced composite

An aircraft floor heating panel is constructed for mechanical strength and to meet special heating requirements next to a door in an aircraft. The panel has a lightweight core. Each surface of the core is first covered with at least one carbon-fiber reinforced composite layer for protection against deterioration. Each carbon fiber layer in turn is covered by a glass fiber reinforced composite layer for mechanical strength. A foil heater is arranged inside the composite panel coextensive with at least a portion of the panel area. A heat distributing metal plate covers the panel as an upper step-on surface. A heat insulating layer is bonded to the panel opposite the heat distributing metal plate. A triple heat control is provided for an increased safety against fire hazards.

Owner:AIRBUS OPERATIONS GMBH

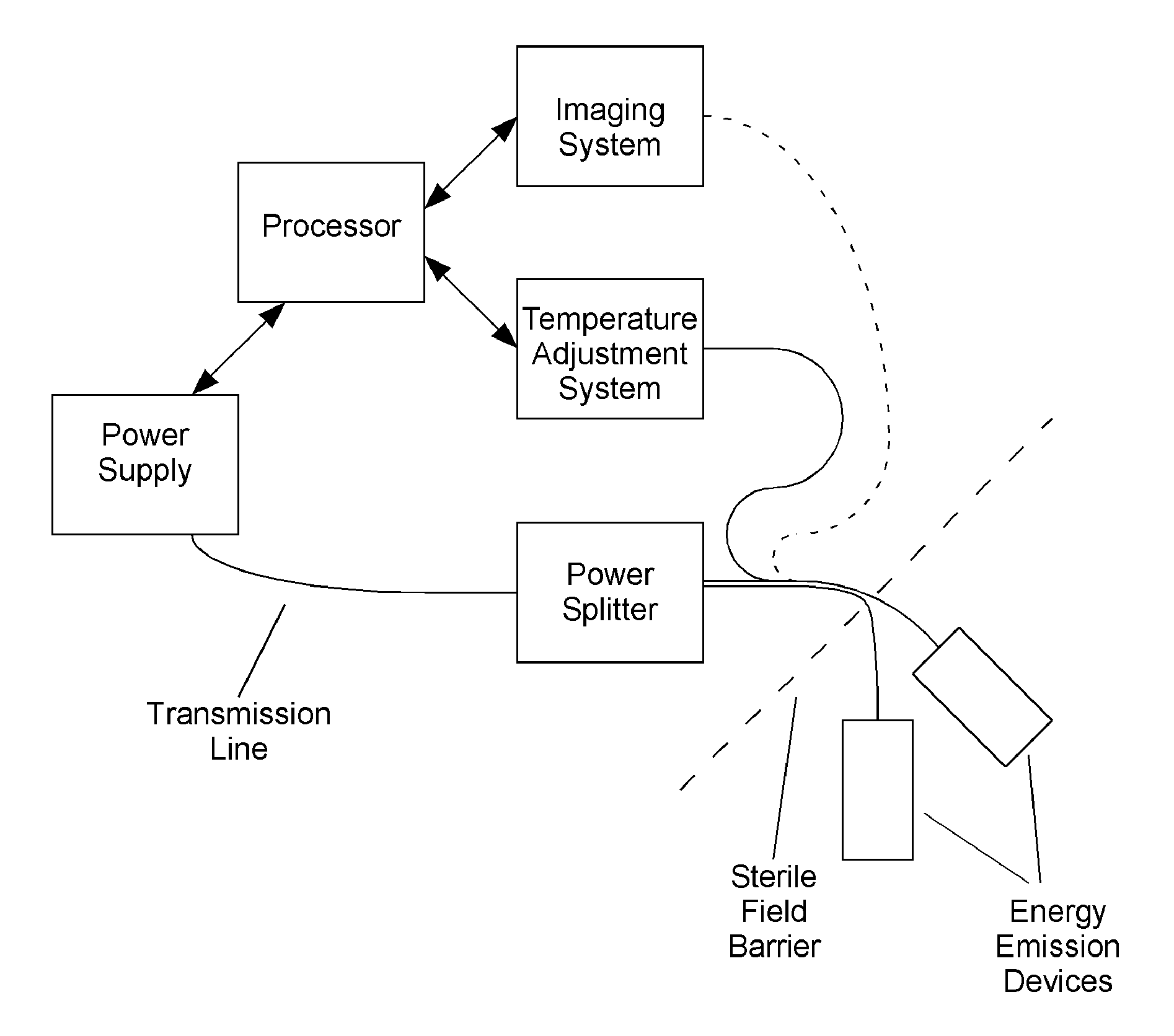

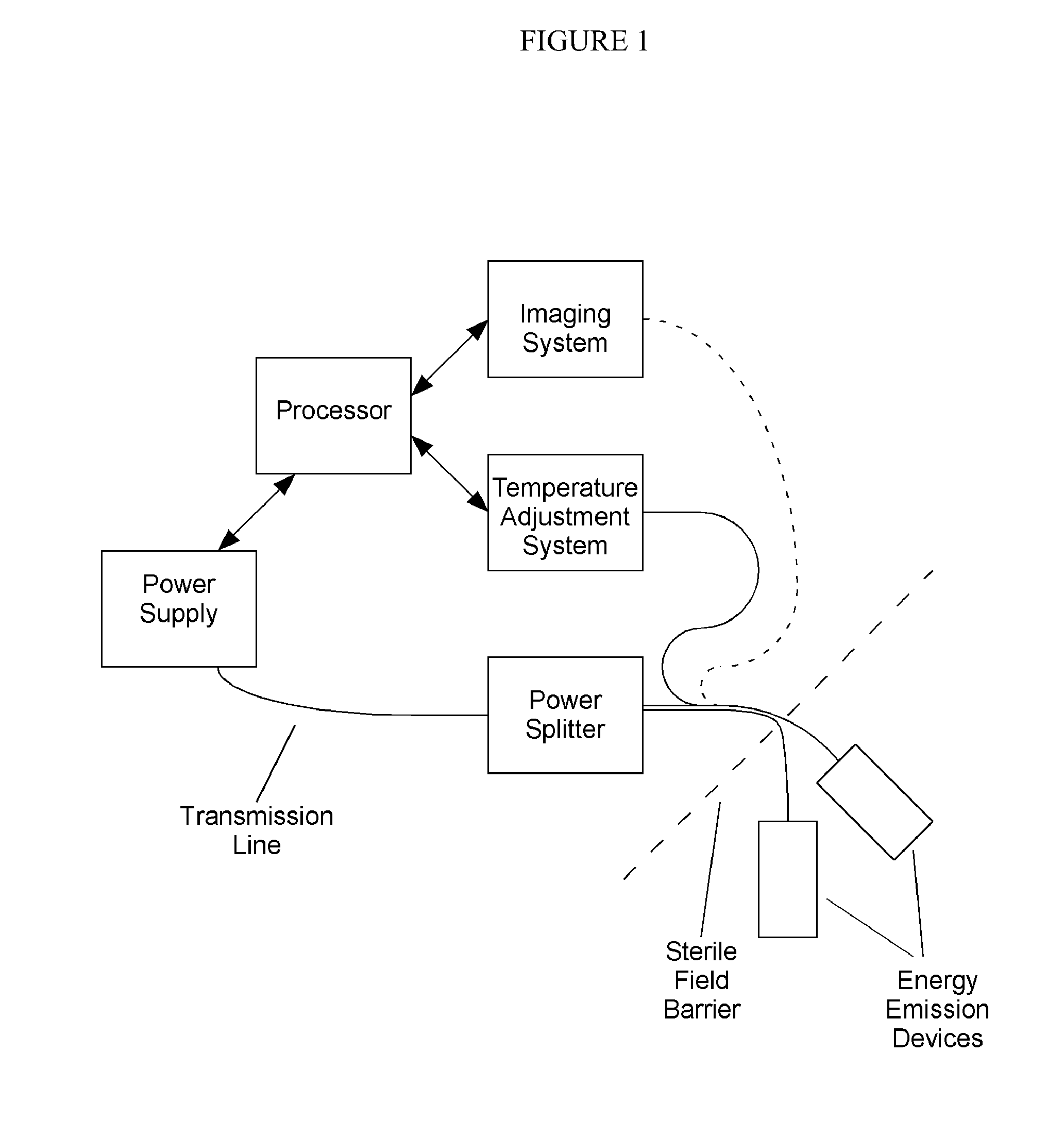

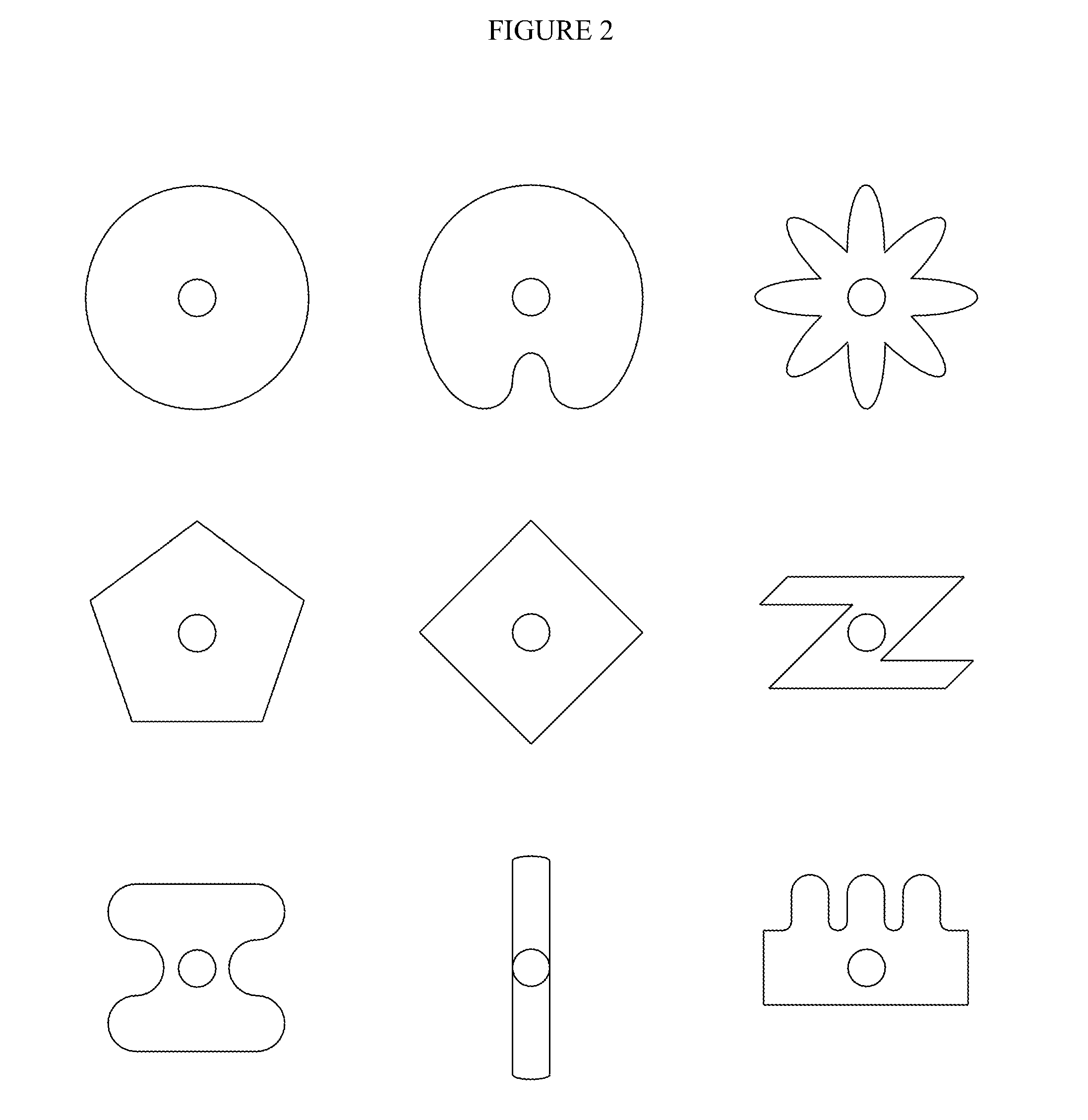

Energy delivery systems and uses thereof

ActiveUS20130116679A1Reduced flexibilityAvoiding undesiredGuide needlesSurgical instruments for heatingThrombusDelivery system

The present invention relates to comprehensive systems, devices and methods for delivering energy to tissue for a wide variety of applications, including medical procedures (e.g., tissue ablation, resection, cautery, vascular thrombosis, treatment of cardiac arrhythmias and dysrhythmias, electrosurgery, tissue harvest, etc.). In certain embodiments, systems, devices, and methods are provided for delivering energy to difficult to access tissue regions (e.g. peripheral lung tissues), and / or reducing the amount of undesired heat given off during energy delivery.

Owner:NEUWAVE MEDICAL

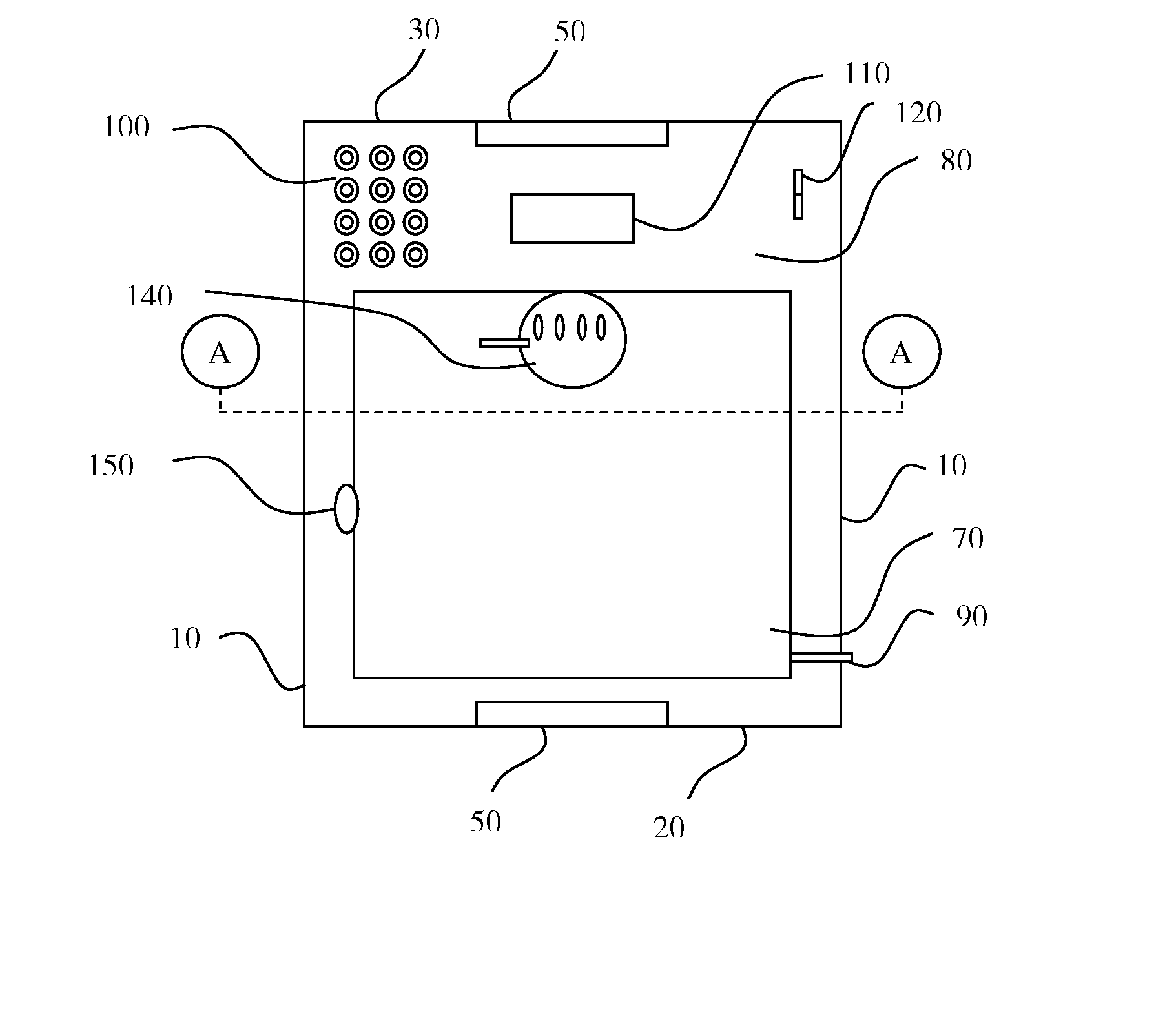

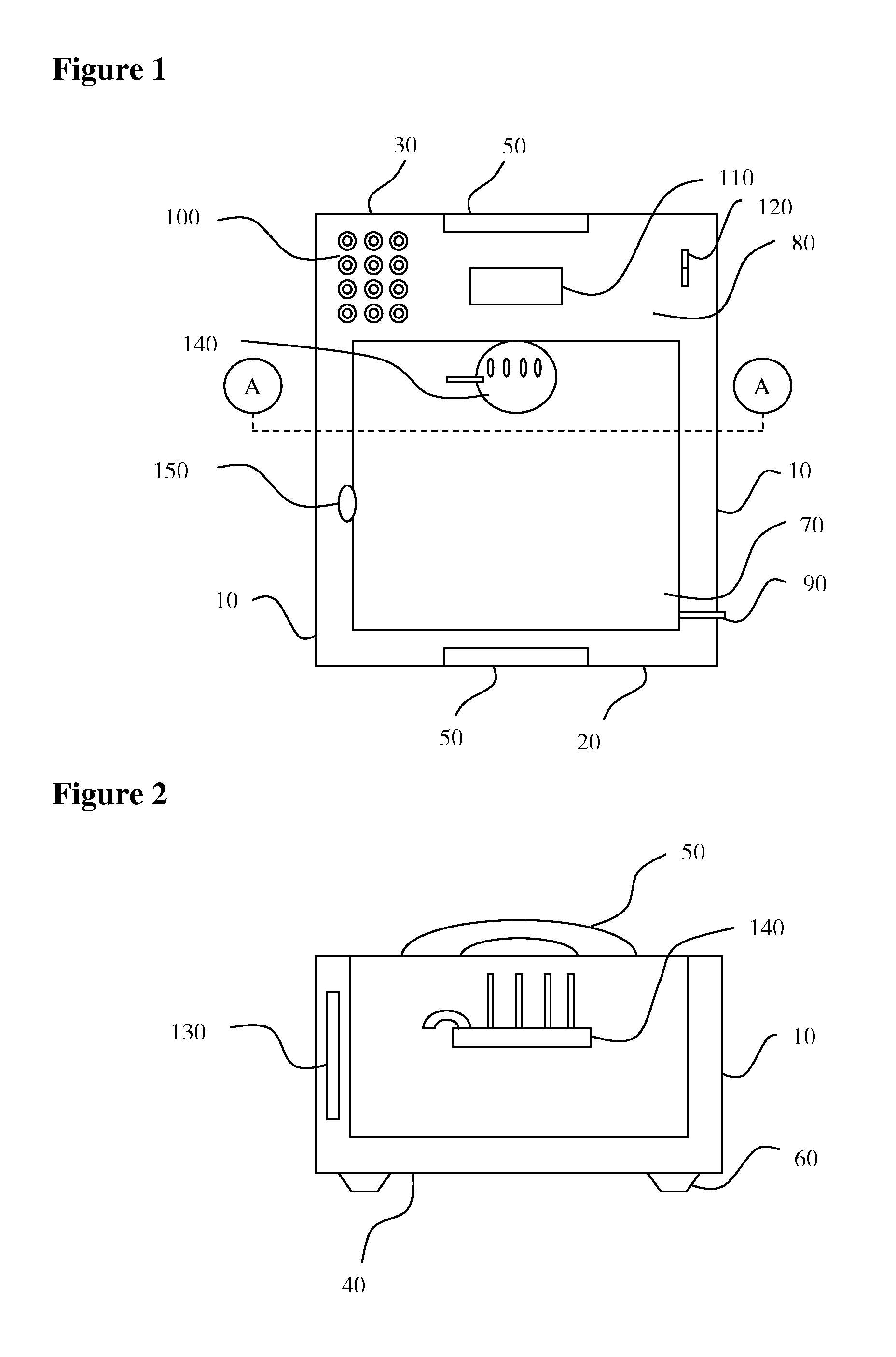

Sous vide cooker with integrated immersion circulator

InactiveUS20080066624A1Reduce heat lossMaintain heating abilityMilk preservationBoiling over preventionVacuum packEngineering

A sous vide cooking appliance which holds the cooking liquid and vacuum packed food, circulates the liquid, heats the liquid, and regulates the temperature of the liquid.

Owner:TAYLOR ALEX +1

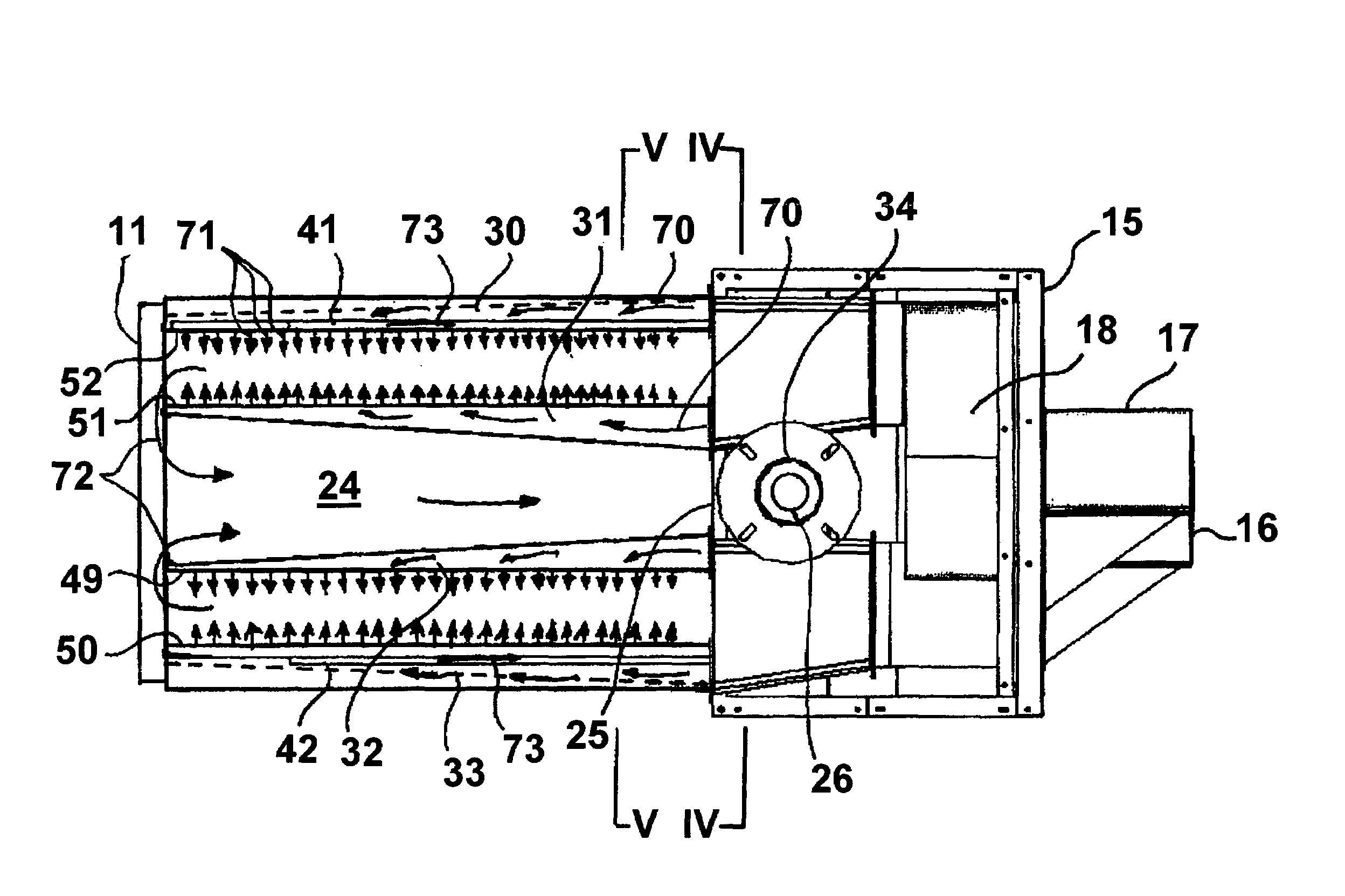

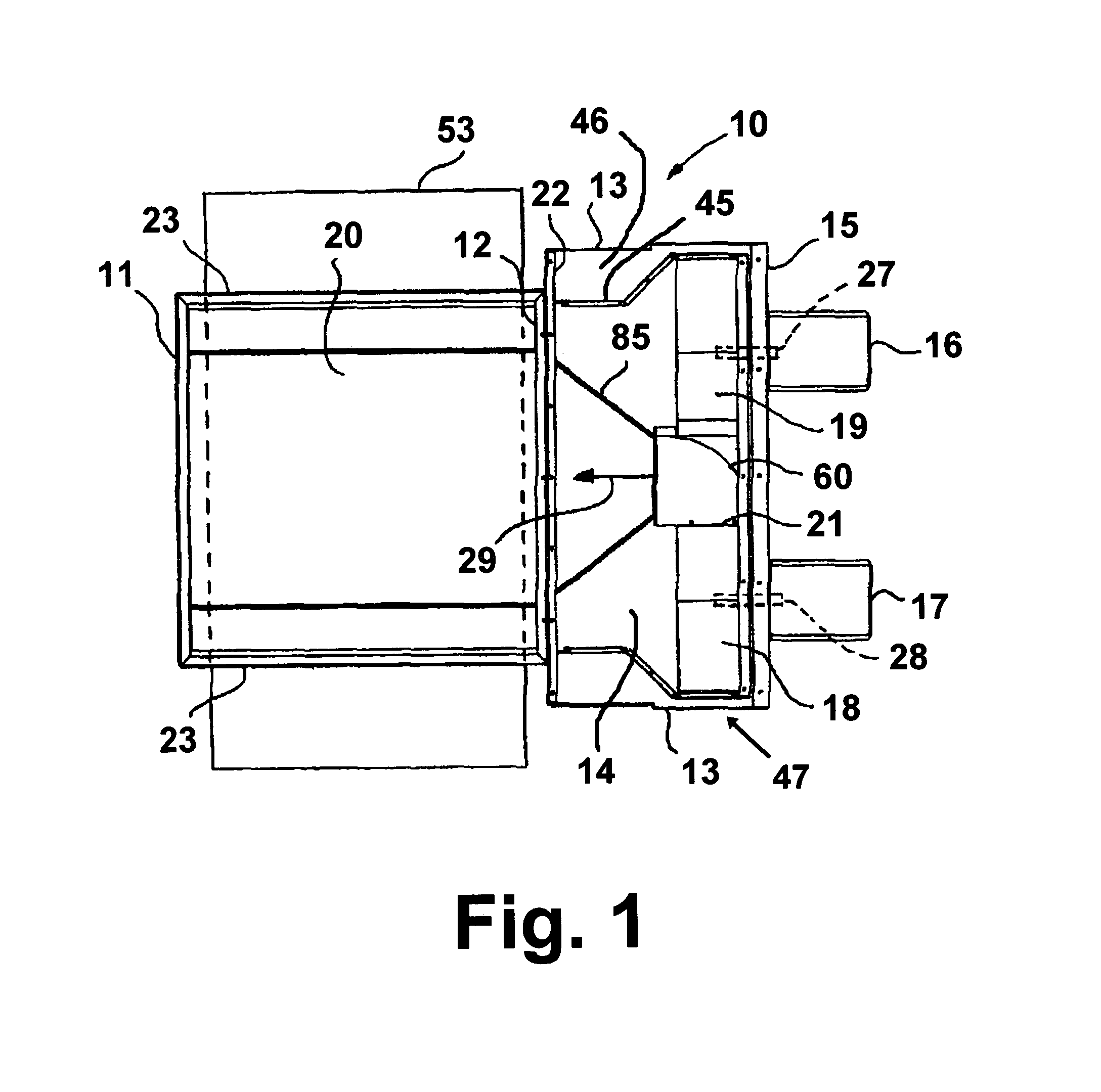

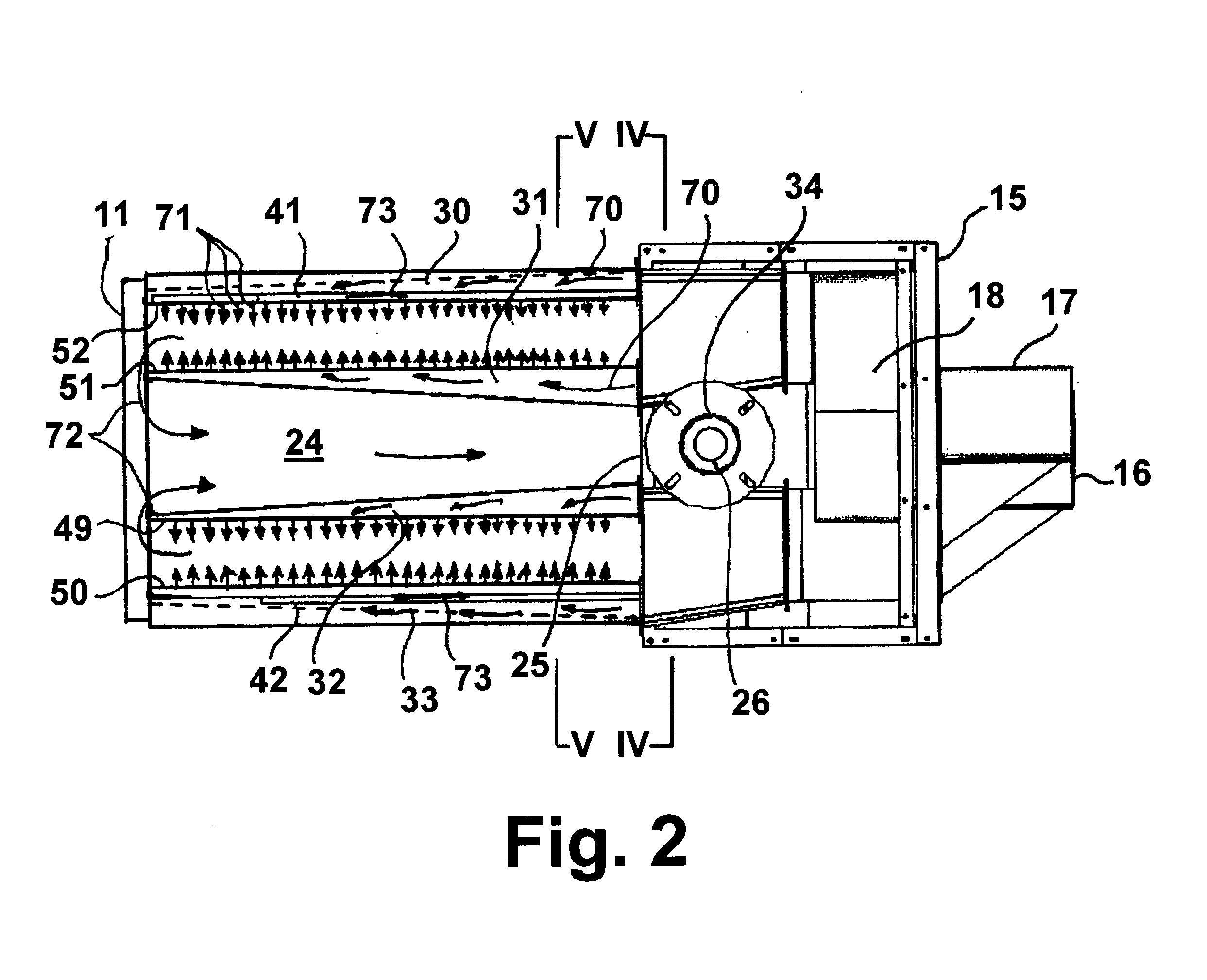

Dual conveyor jet impingement oven

InactiveUS6880545B2Reduce heat lossHigh speedDomestic stoves or rangesCooking fumes removalEngineering

Owner:GAS TECH INST

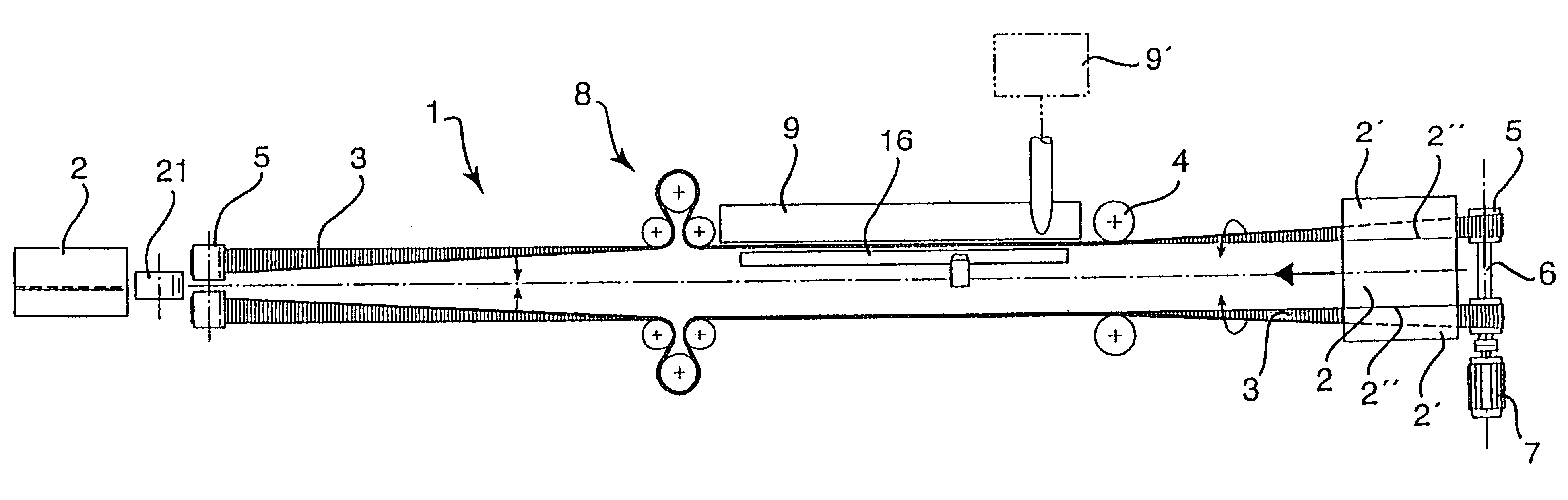

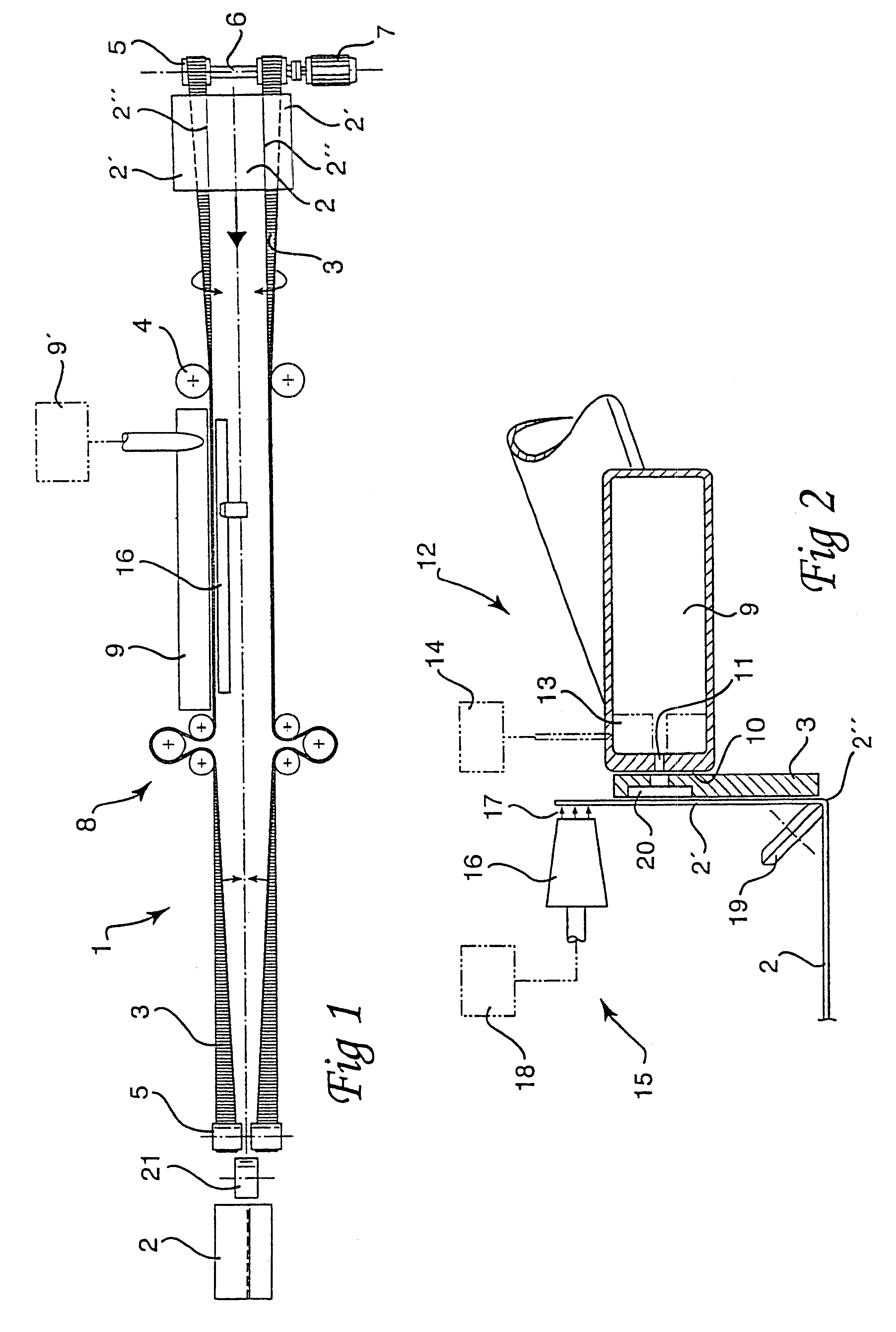

Apparatus for conveying and folding flexible packaging material

InactiveUS6637583B1High precisionReduce heatEnvelopes/bags making machineryBoxes/cartons making machineryEngineeringMechanical engineering

The disclosure relates to an apparatus for conveying and folding flexible packaging material, comprising a conveyor (1) with a conveyor belt (3) which is provided with through-going holes and which, for a part of its length, extends substantially rectilinearly and with constant orientation along a suction box (9). By connecting the suction box (9) to a source of partial vacuum, a partial vacuum is created at the side of the belt facing towards the packaging material, which ensures that the packaging material is well-fixed and can thereby pass closely adjacent and be heated by a heating device (15) extending along the belt. The apparatus makes for concentrated, energy-efficient and well-defined heating of an edge region of the packaging material intended for thermosealing.

Owner:TETRA LAVAL HLDG & FINANCE SA

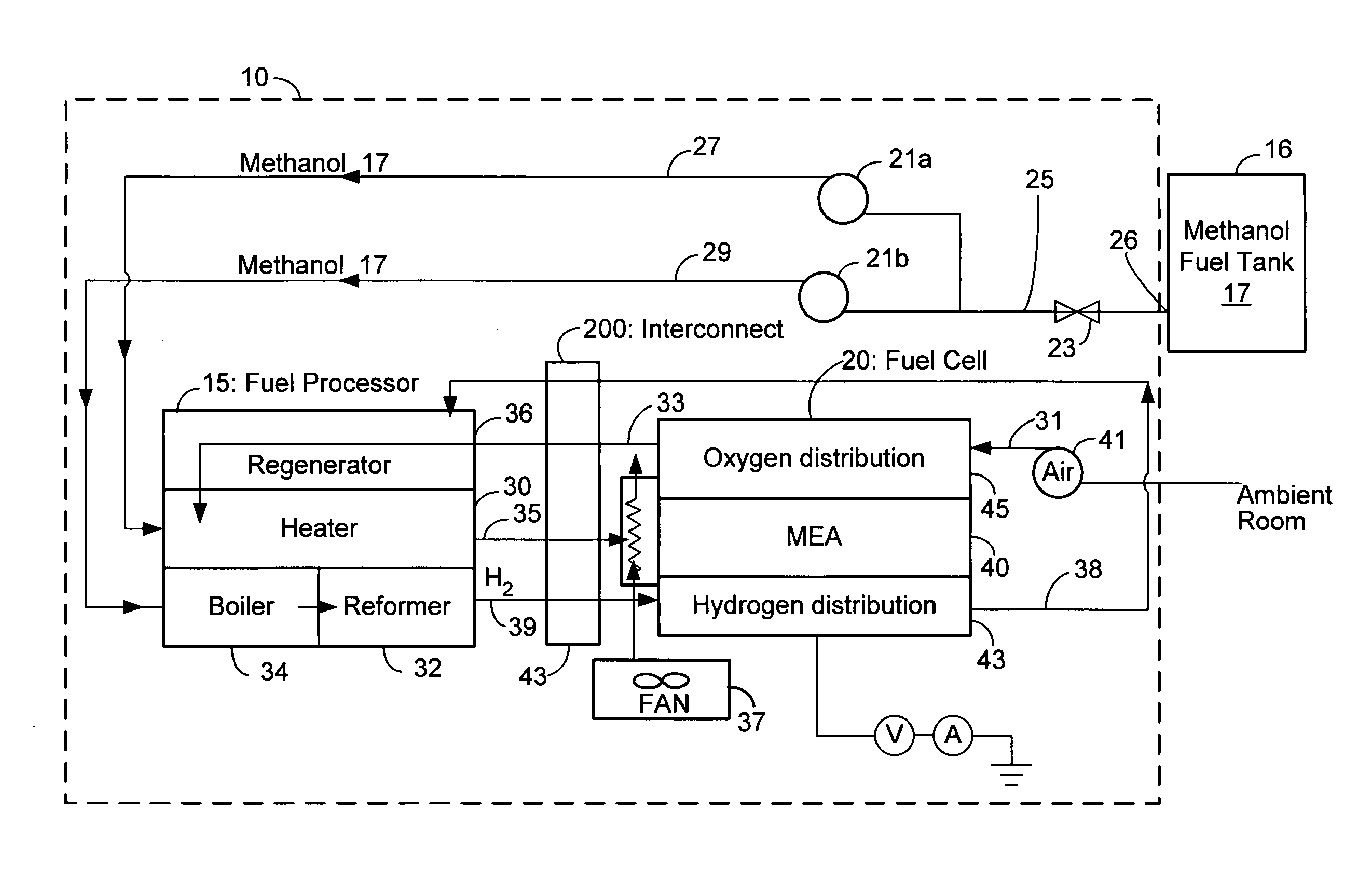

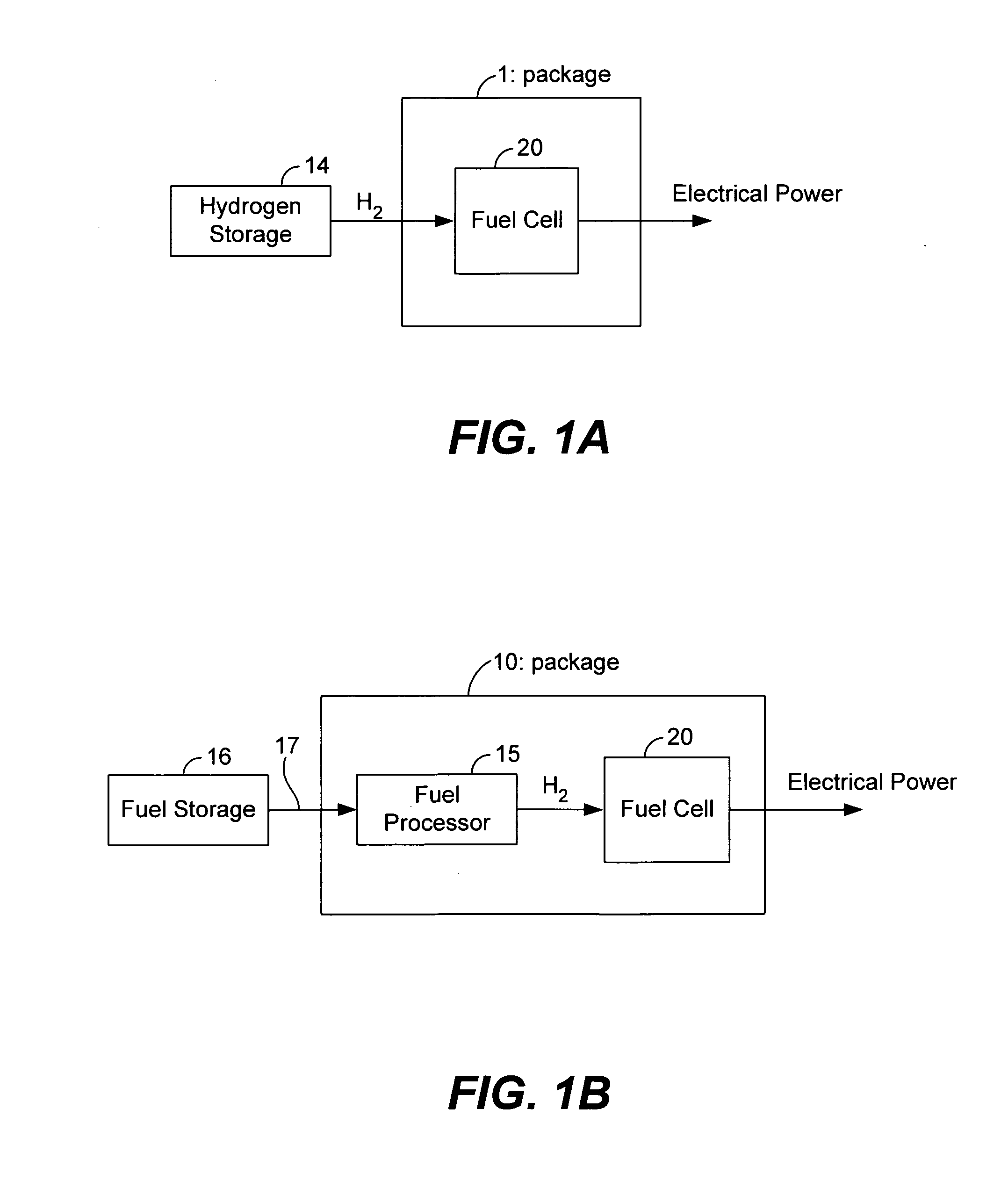

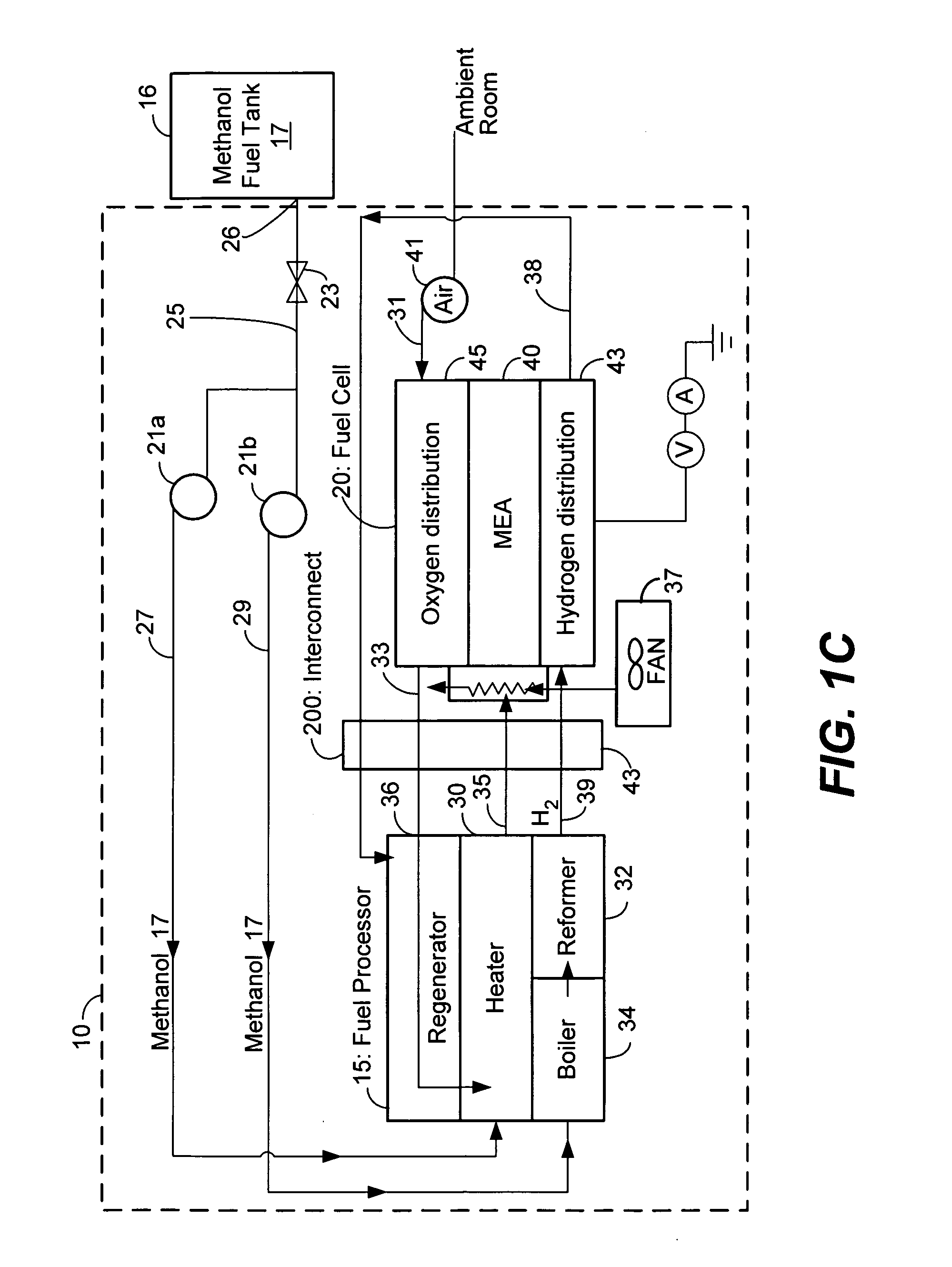

Compact fuel cell package

ActiveUS20060134470A1Decrease heat lossIncrease thermal efficiencyReactant parameters controlFuel cells groupingElectric energyUnit volume

The invention relates to a compact and portable fuel cell package. The package includes a fuel cell that generates electrical energy. Some packages also include a fuel processor that produces hydrogen from a fuel source. Fuel cell packages described herein provide power densities (power per unit volume or mass) at levels not yet seen. One package employs an interconnect disposed at least partially between a fuel cell and a fuel processor. The interconnect forms a structural and plumbing intermediary between the two. Given the portable size of fuel cell packages described herein, the invention is well suited to power portable electronics devices. One portable fuel cell package includes a tether, which allows electrical and detachable coupling to an electronics device.

Owner:ADVENT TECH LLC

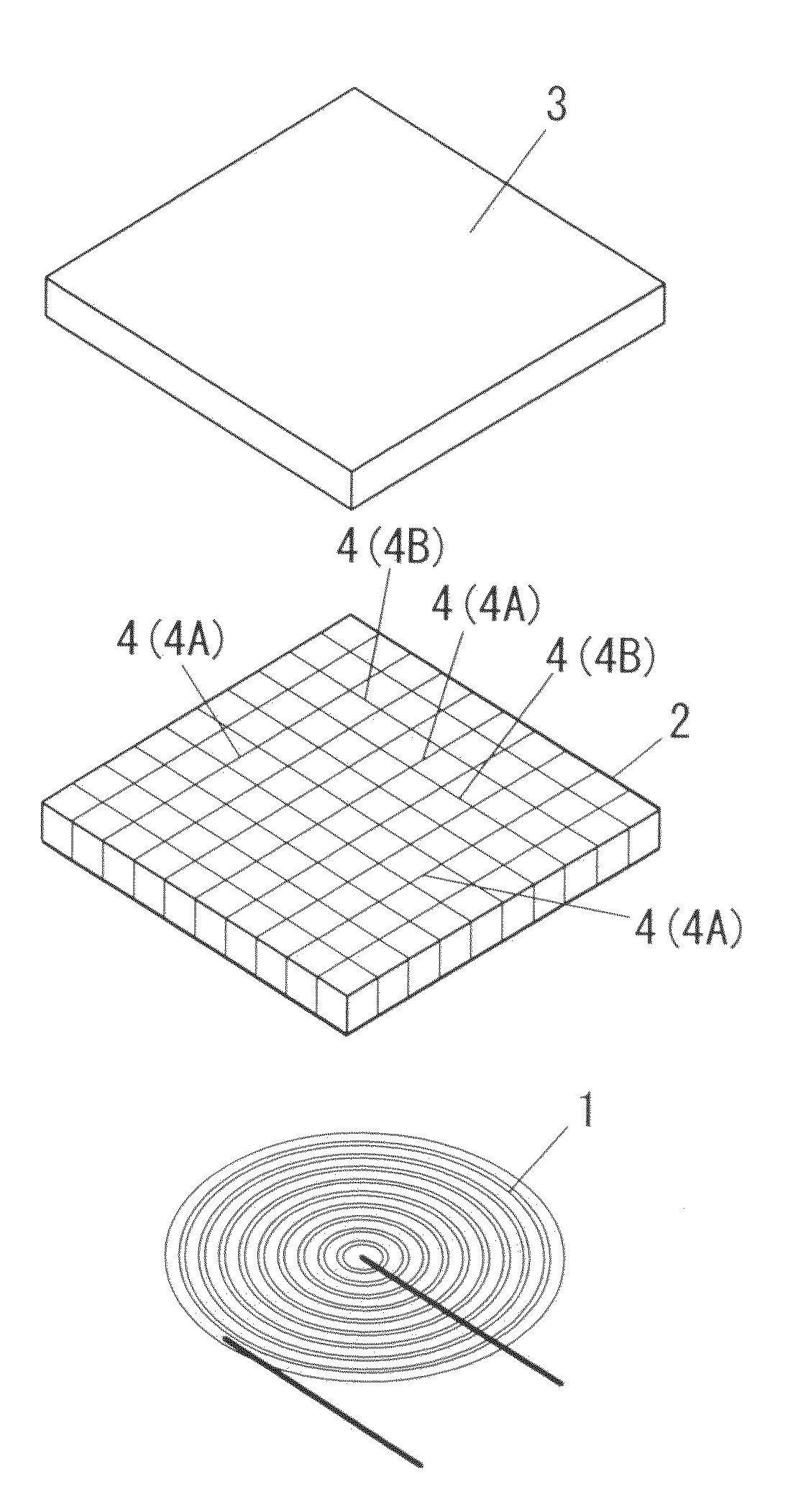

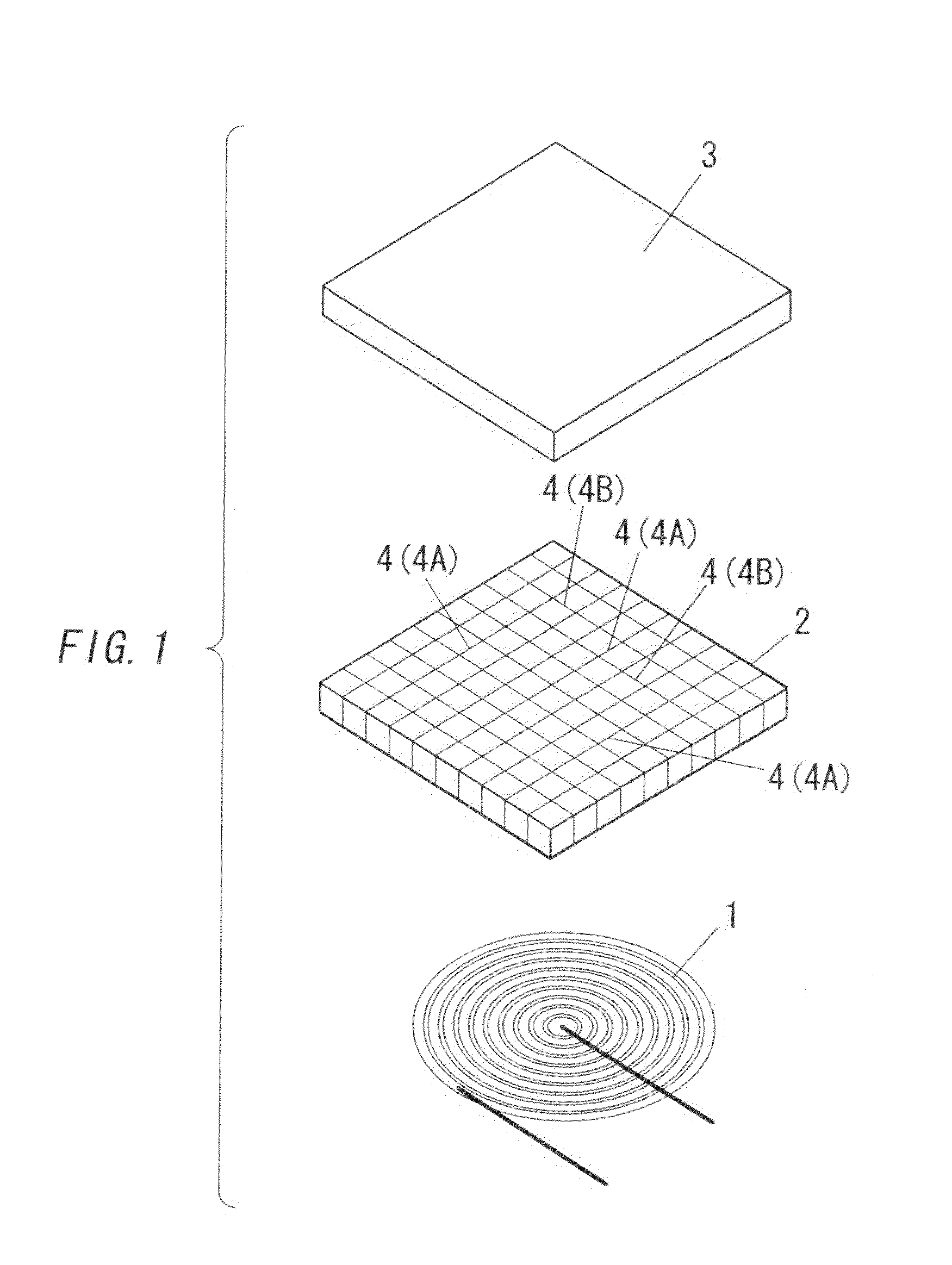

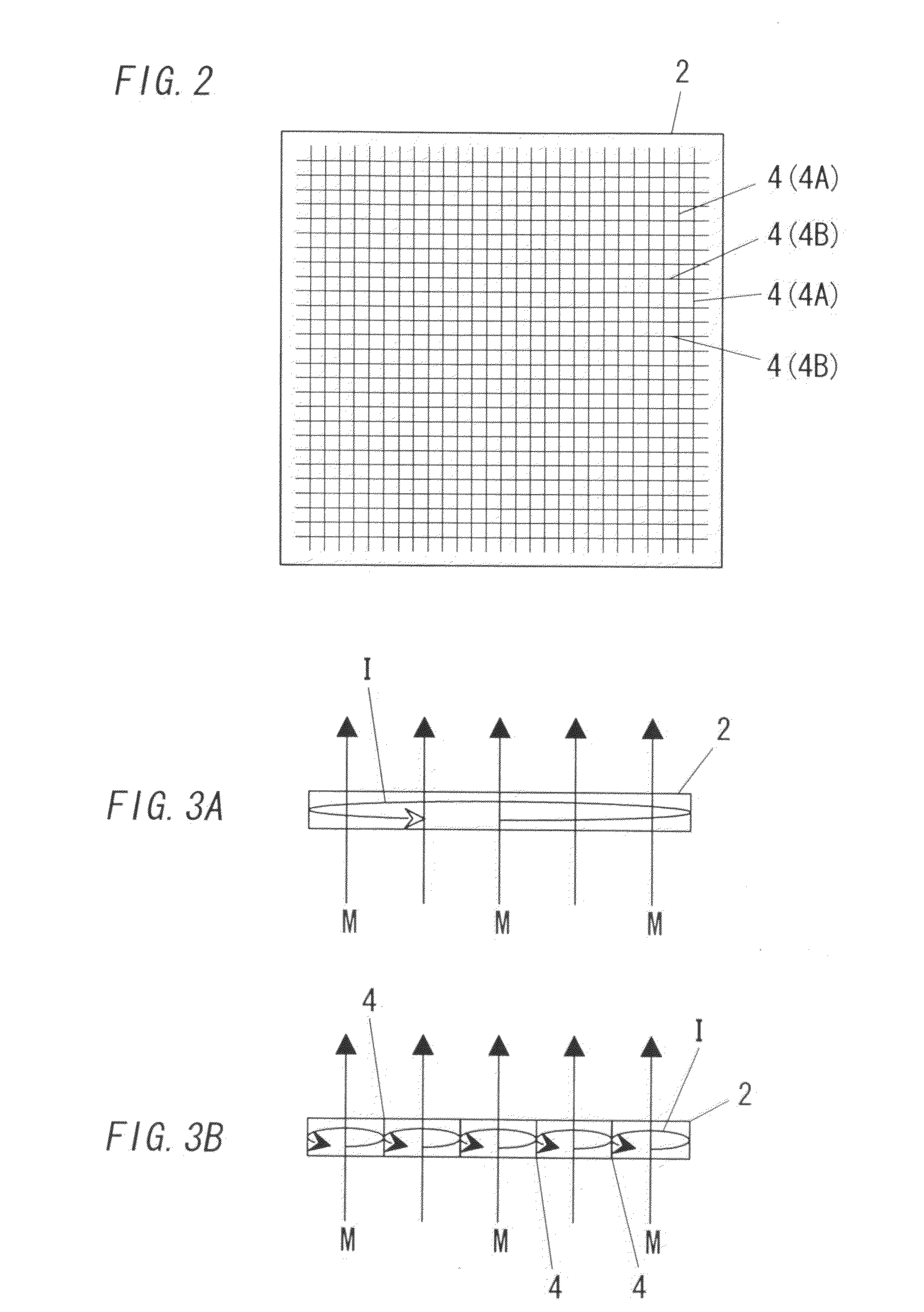

Power reception coil unit

InactiveUS20100320843A1Inhibit temperature riseImprove transmission efficiencyElectromagnetic wave systemTransformersElectricityElectric power transmission

A power reception coil unit includes a power reception coil configured to be magnetically coupled to a power supply coil during a power transmission and a magnetic plate made of a magnetic material having electrical conductivity. The power reception coil is a planar coil. The magnetic plate has its surface opposed to the power reception coil and is parallel to the power reception coil. The magnetic plate is provided with a plurality of slits in the surface.

Owner:PANASONIC CORP

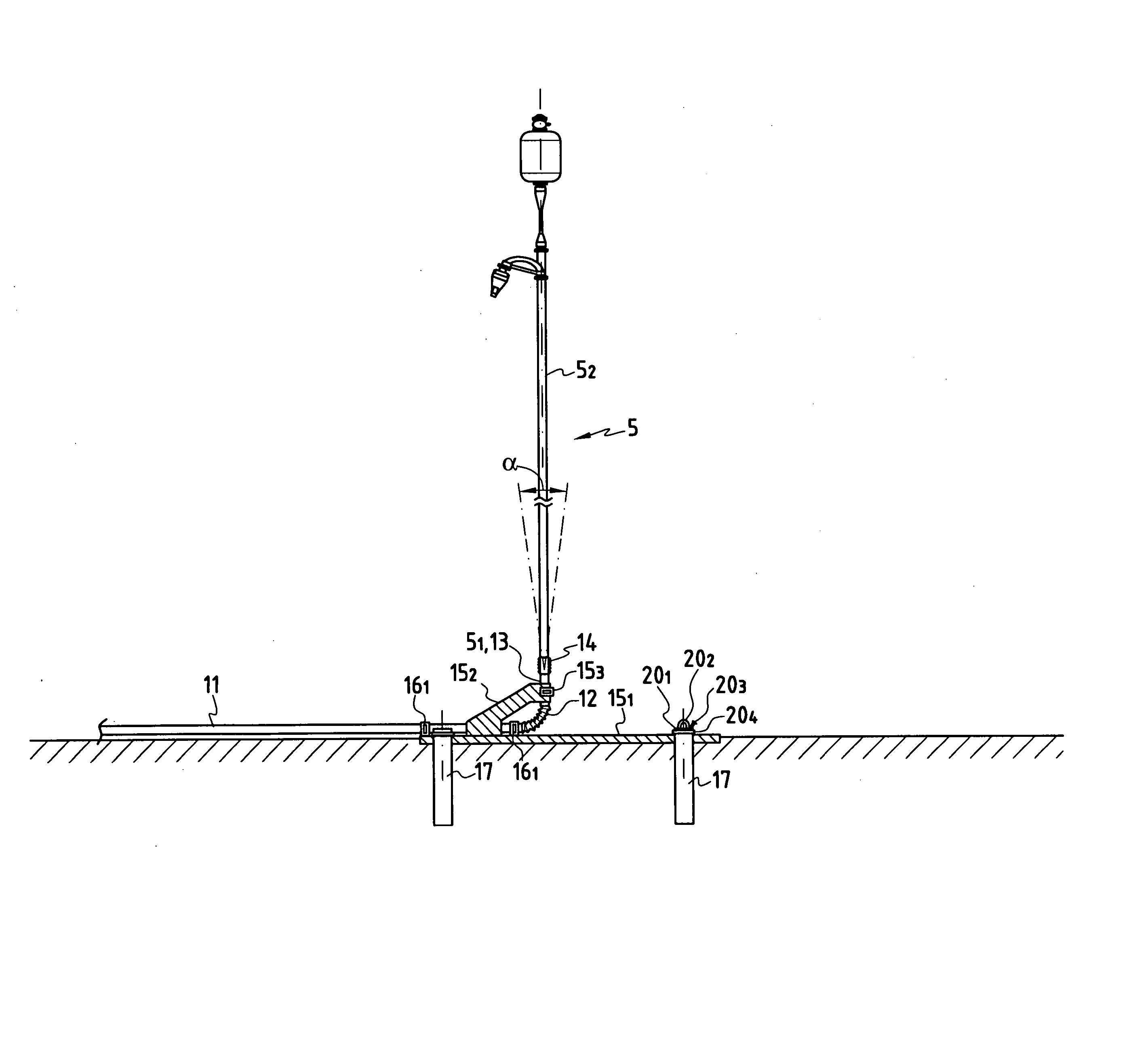

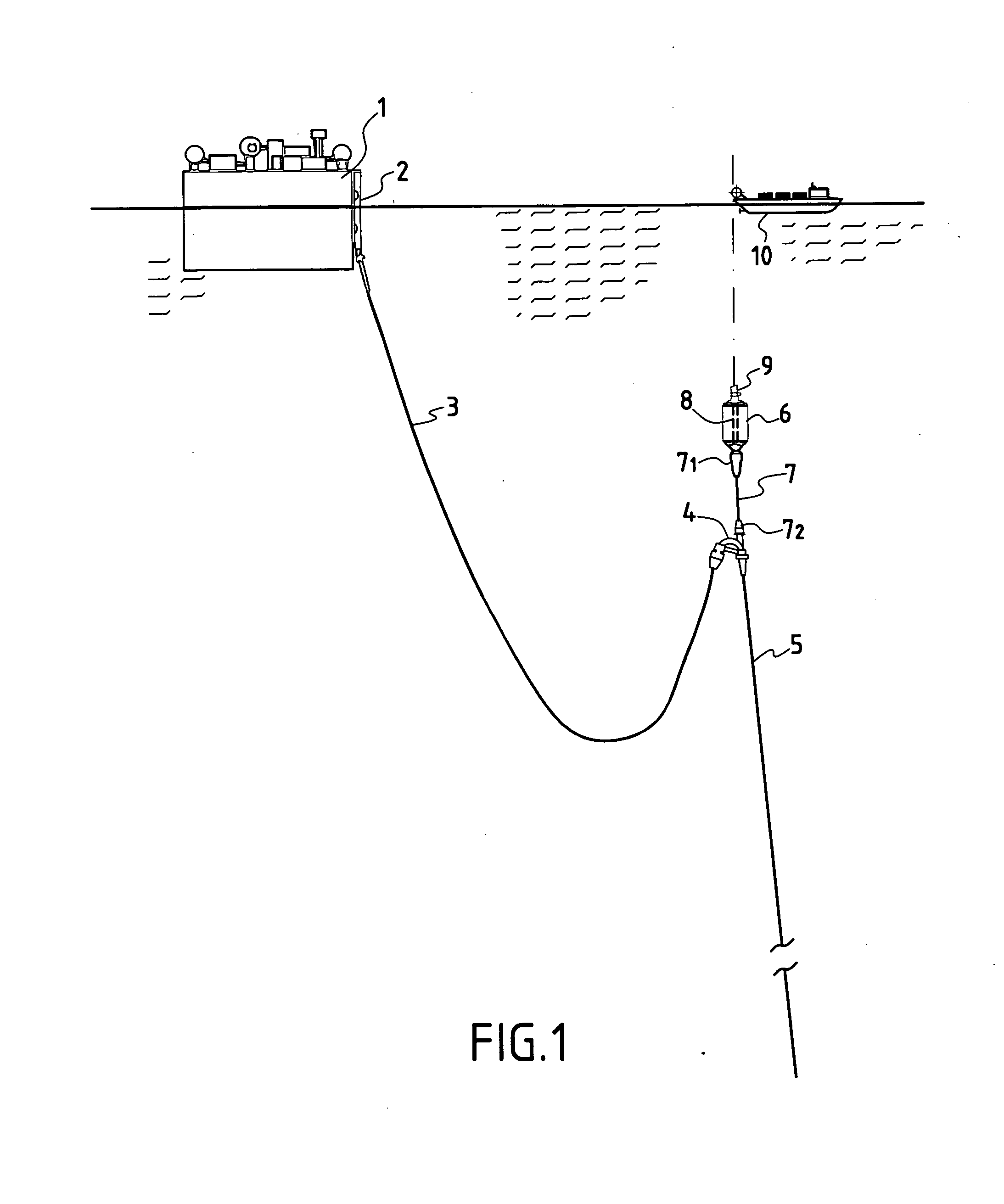

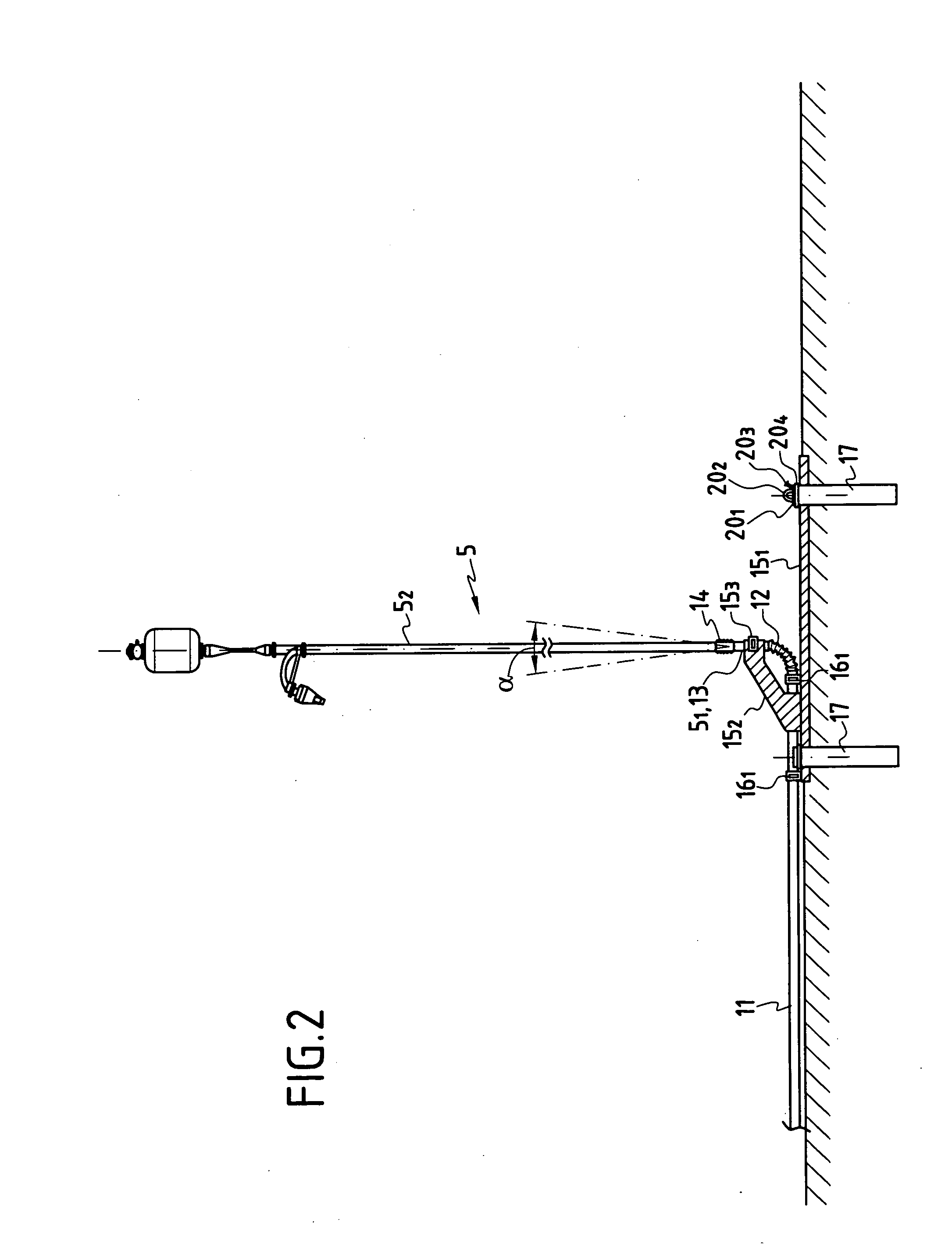

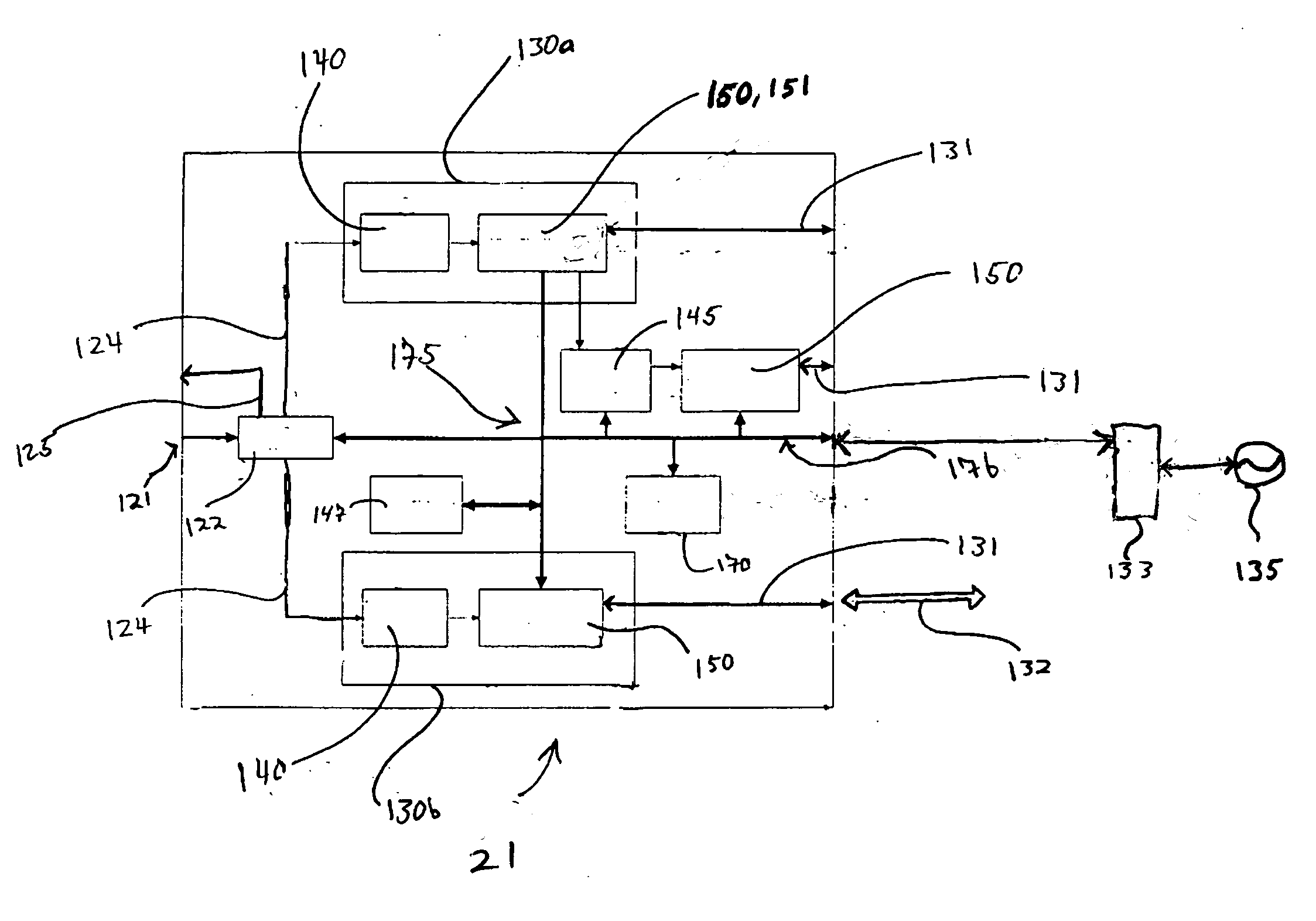

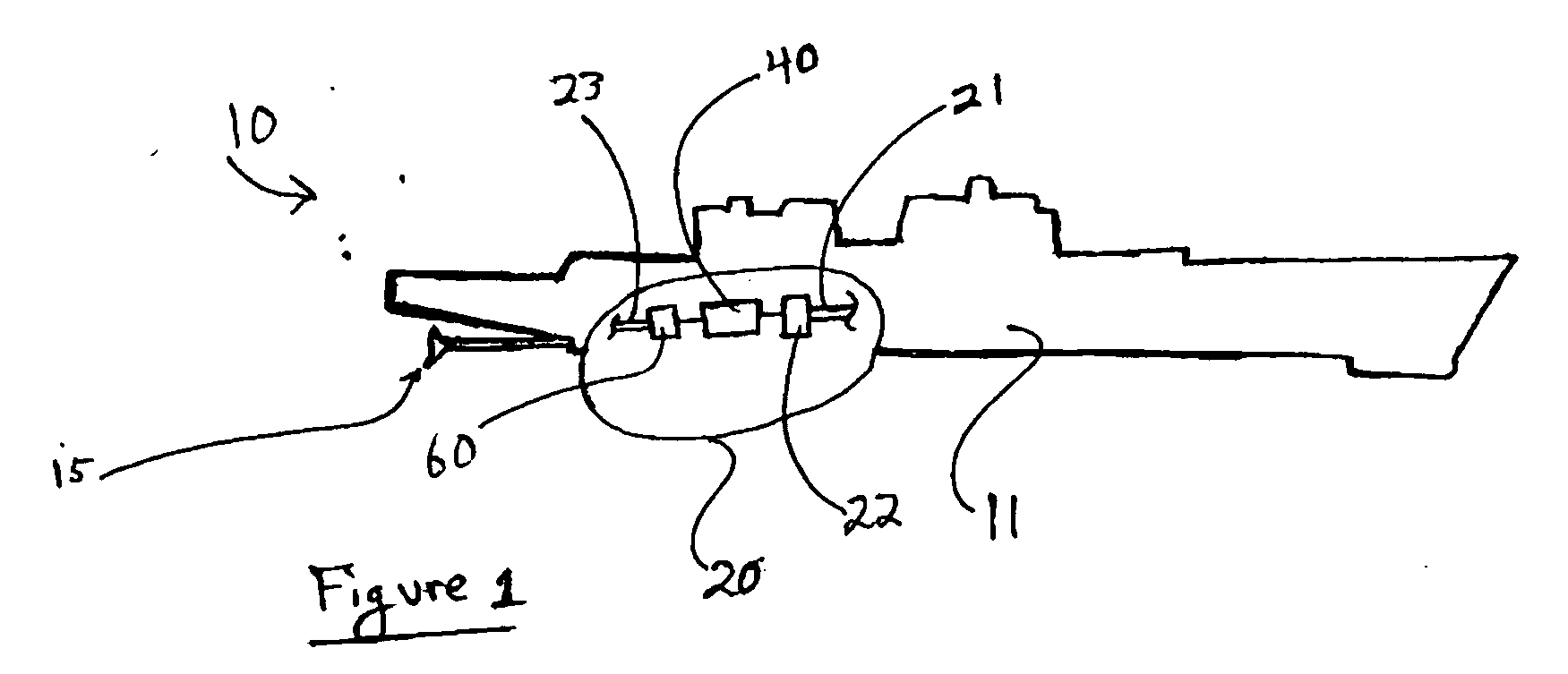

Underwater pipeline connection joined to a riser

InactiveUS20040156684A1Reduce heat lossAvoid disadvantagesPipe laying and repairDrilling rodsTowerSeabed

The invention relates to a bed to surface connection for an underwater pipeline (11), resting on the seabed, in particular at great depth, of the hybrid tower type, comprising a static base (151-152) resting on the bed. According to the invention said pipeline (11), resting on the seabed is connected by means of a flexible pipeline element (12) with an elbow bend, to a vertical riser (5), the bottom end of which is fixed with relation to said base.

Owner:SAIPEM SA

Power generation system

InactiveUS20060266043A1Efficient mannerEfficient and practicableInternal combustion piston enginesHeat recovery systemsThermal energyPlasma generator

A thermal plasma generator may be used in conjunction with at least one thermal to electric converter, such as a solid state thermal to electric energy to electric converter. A micropipe heat pump extracts heat from the at least one thermal to electric energy device, which in turn may convert the heat into electrical power. The power generation system may be disposed within a vehicle, and provide electrical power for propelling the vehicle.

Owner:JEROME ALLAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com