Patents

Literature

49862results about How to "Evenly distributed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

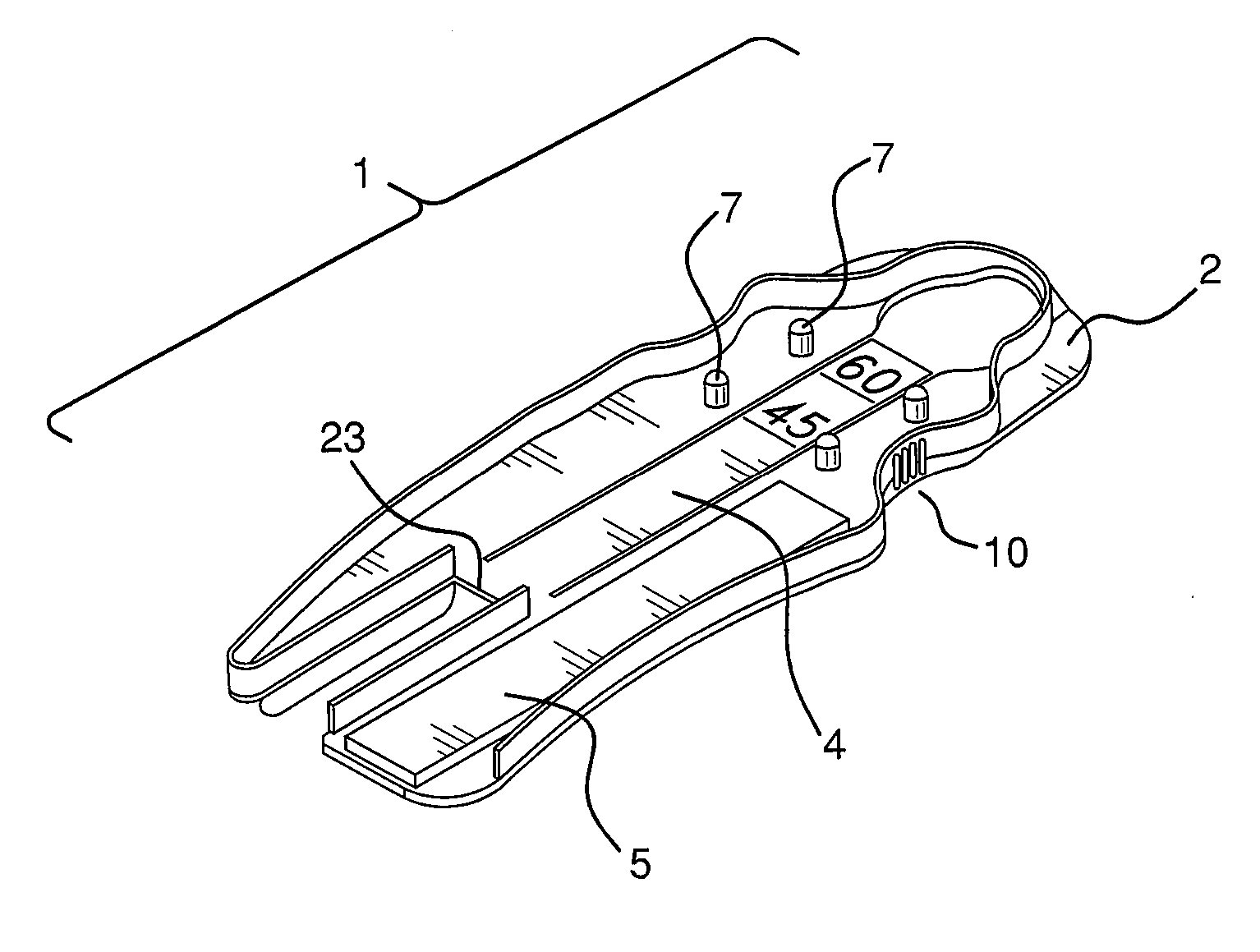

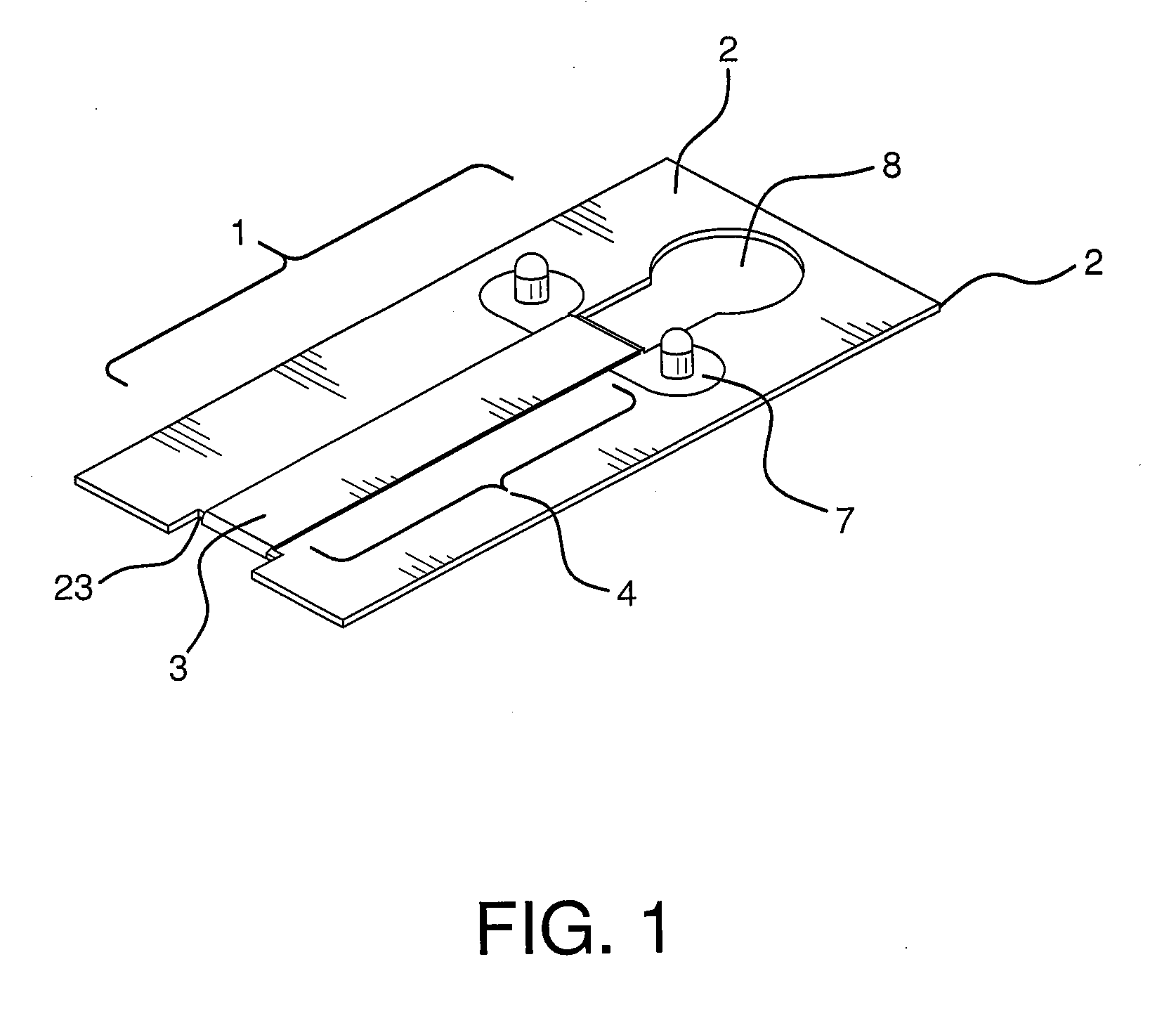

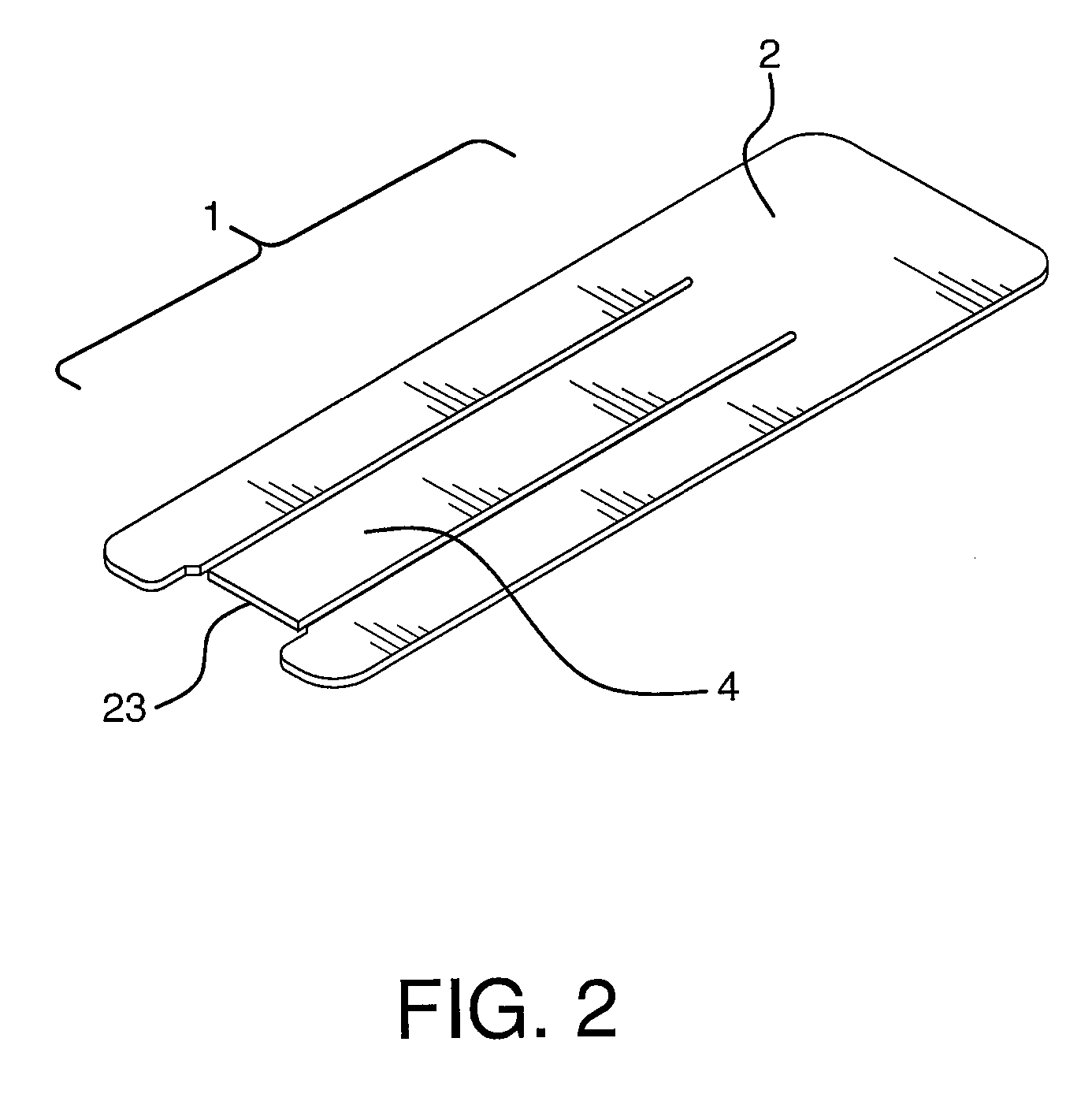

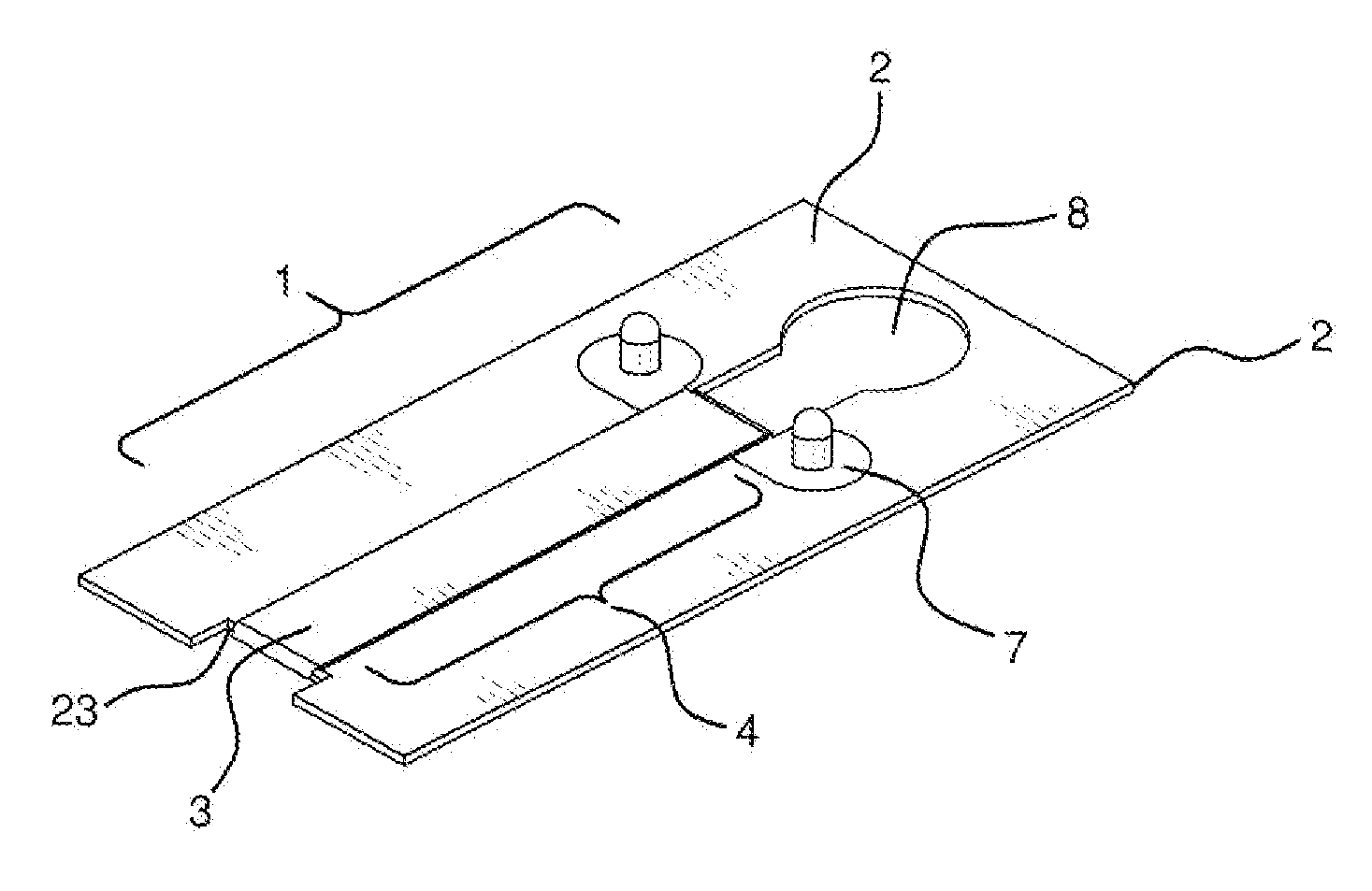

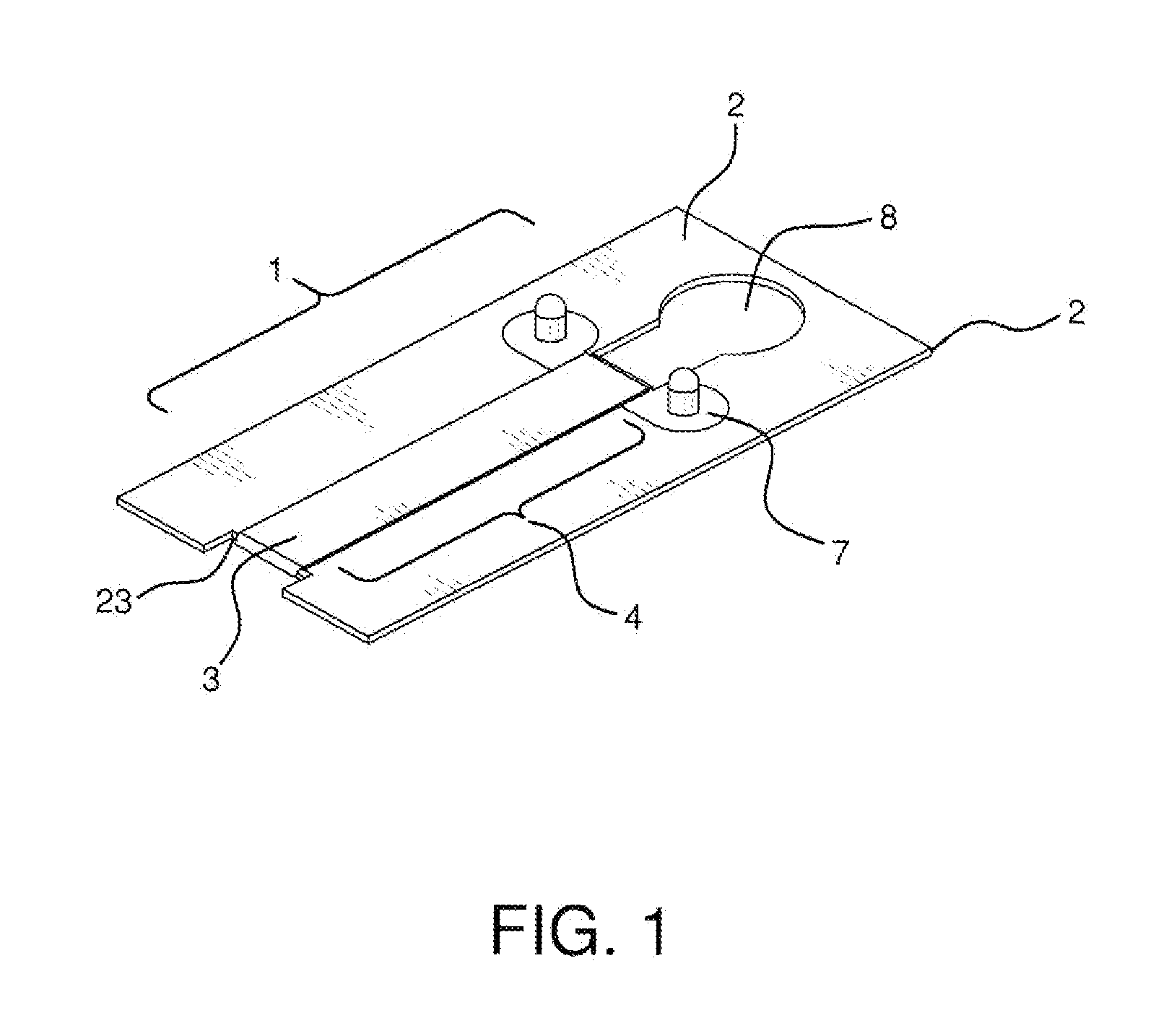

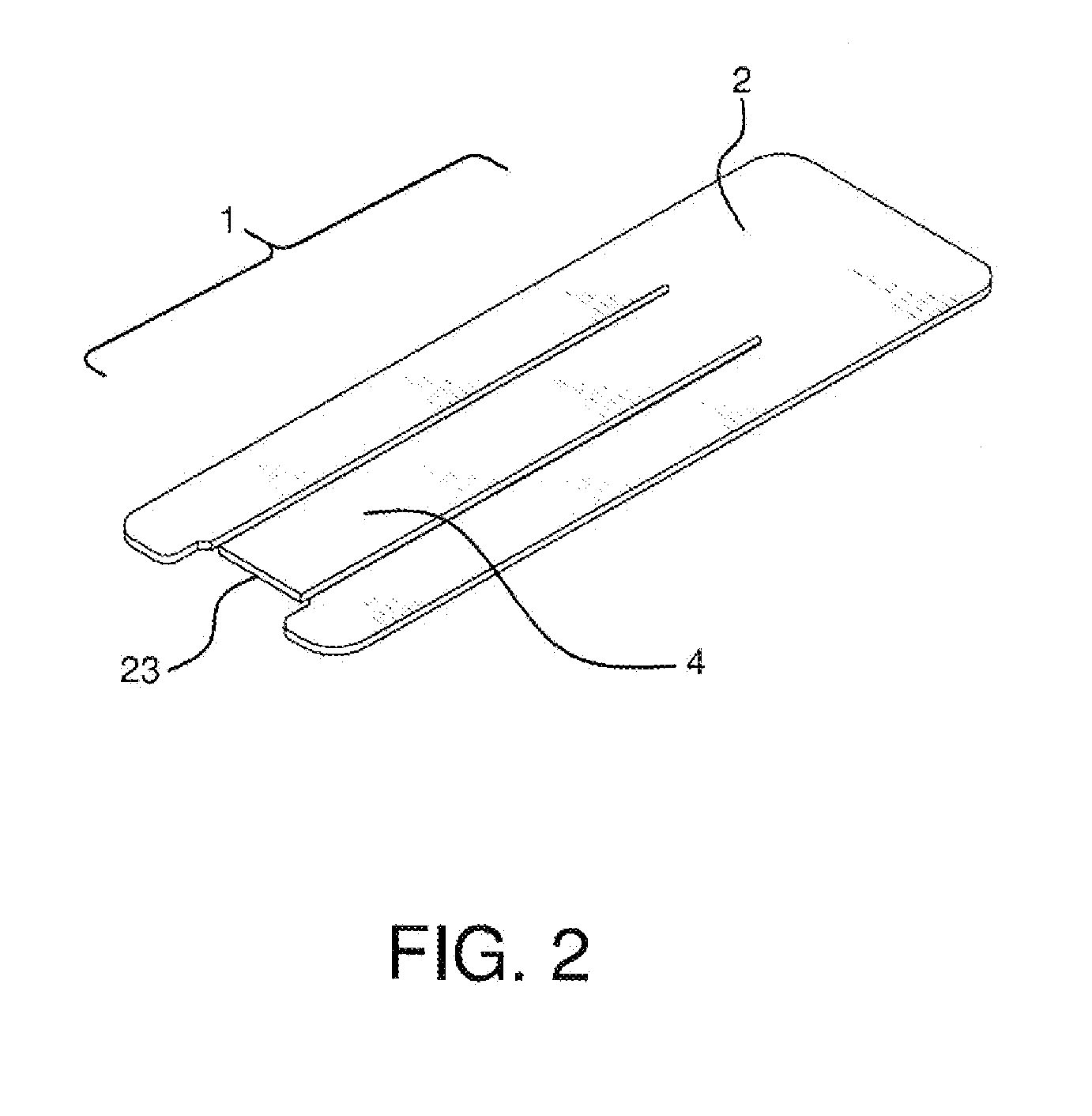

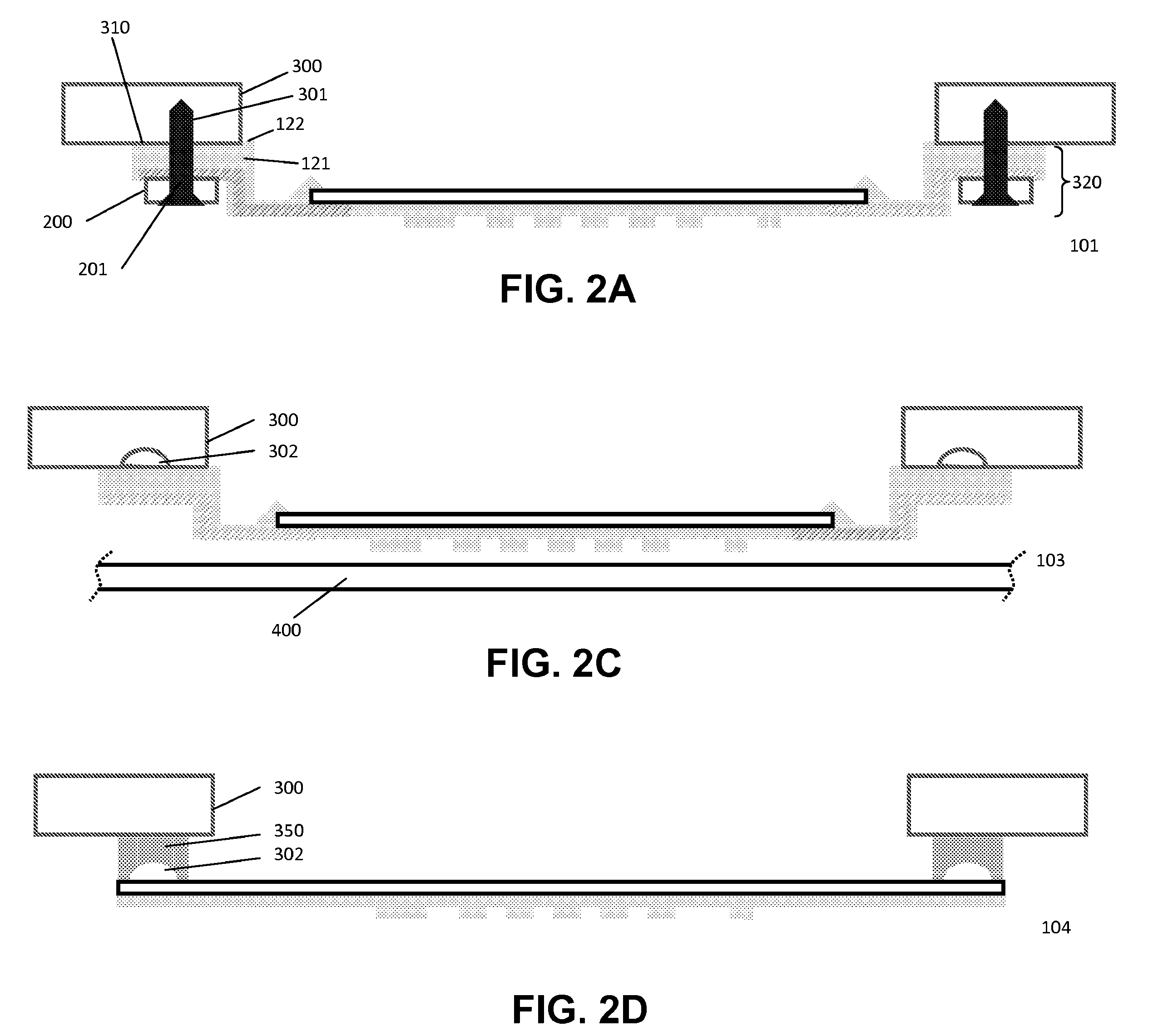

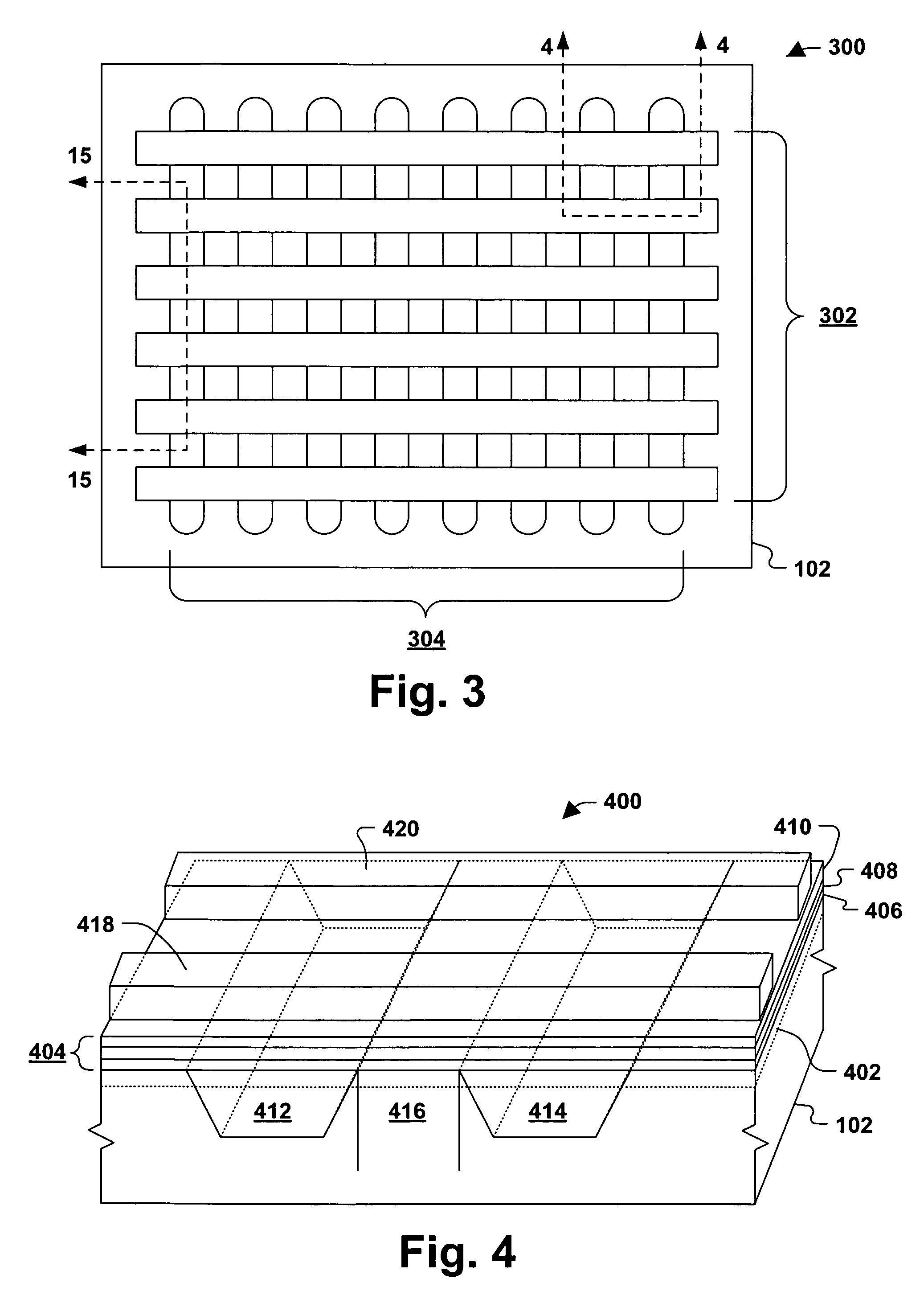

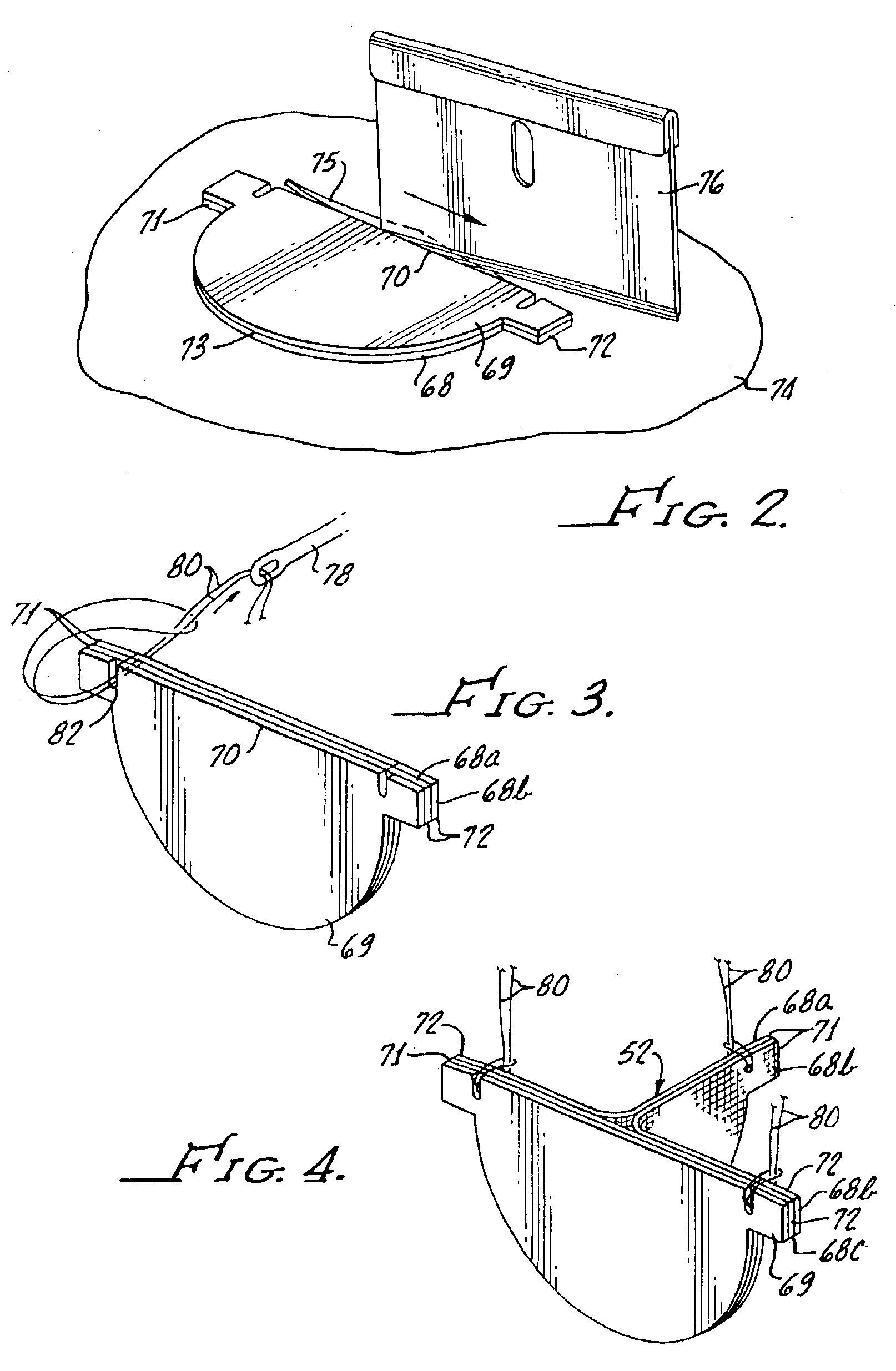

Apparatus for supplying surgical staple line reinforcement

InactiveUS8453904B2Accurately and successfully positionedMaintain strengthSuture equipmentsStapling toolsSurgical stapleBiomedical engineering

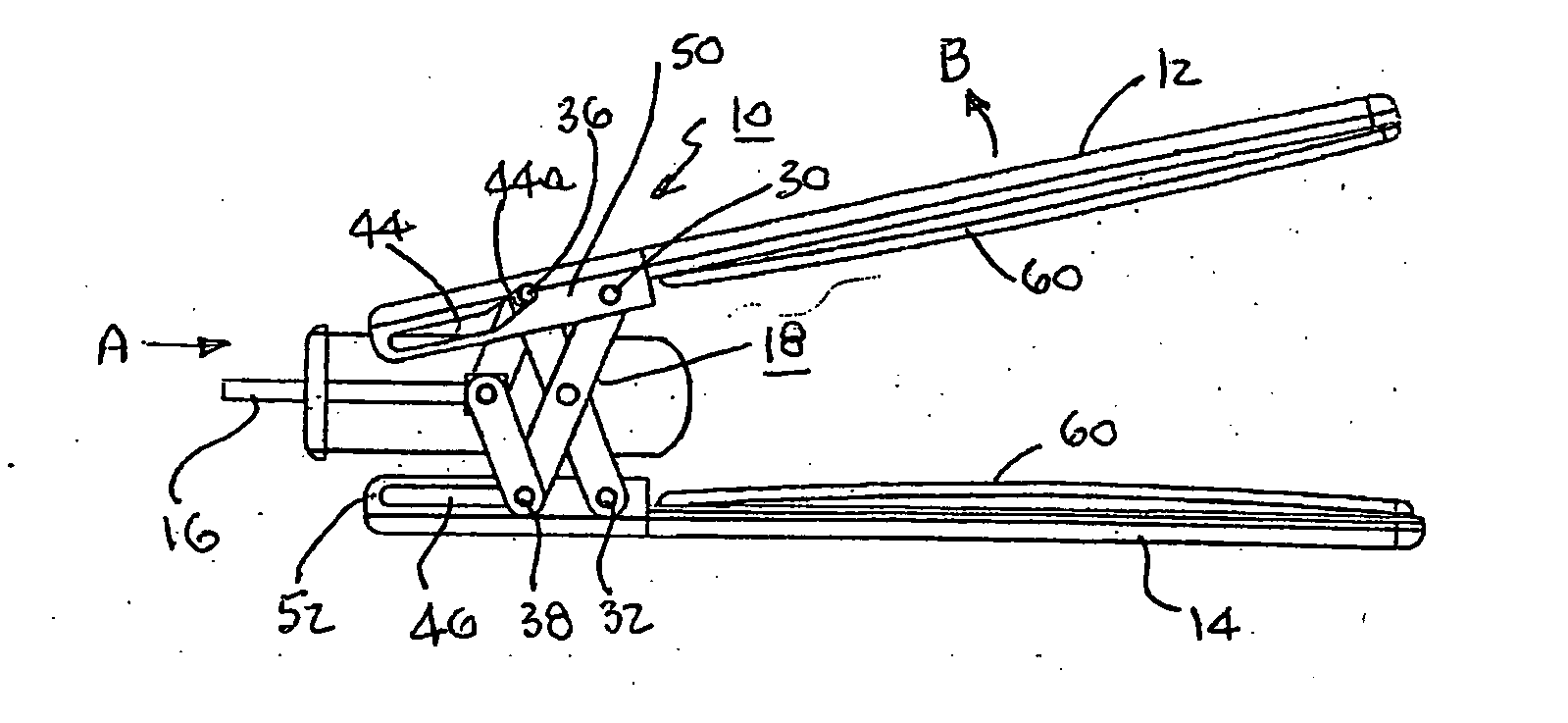

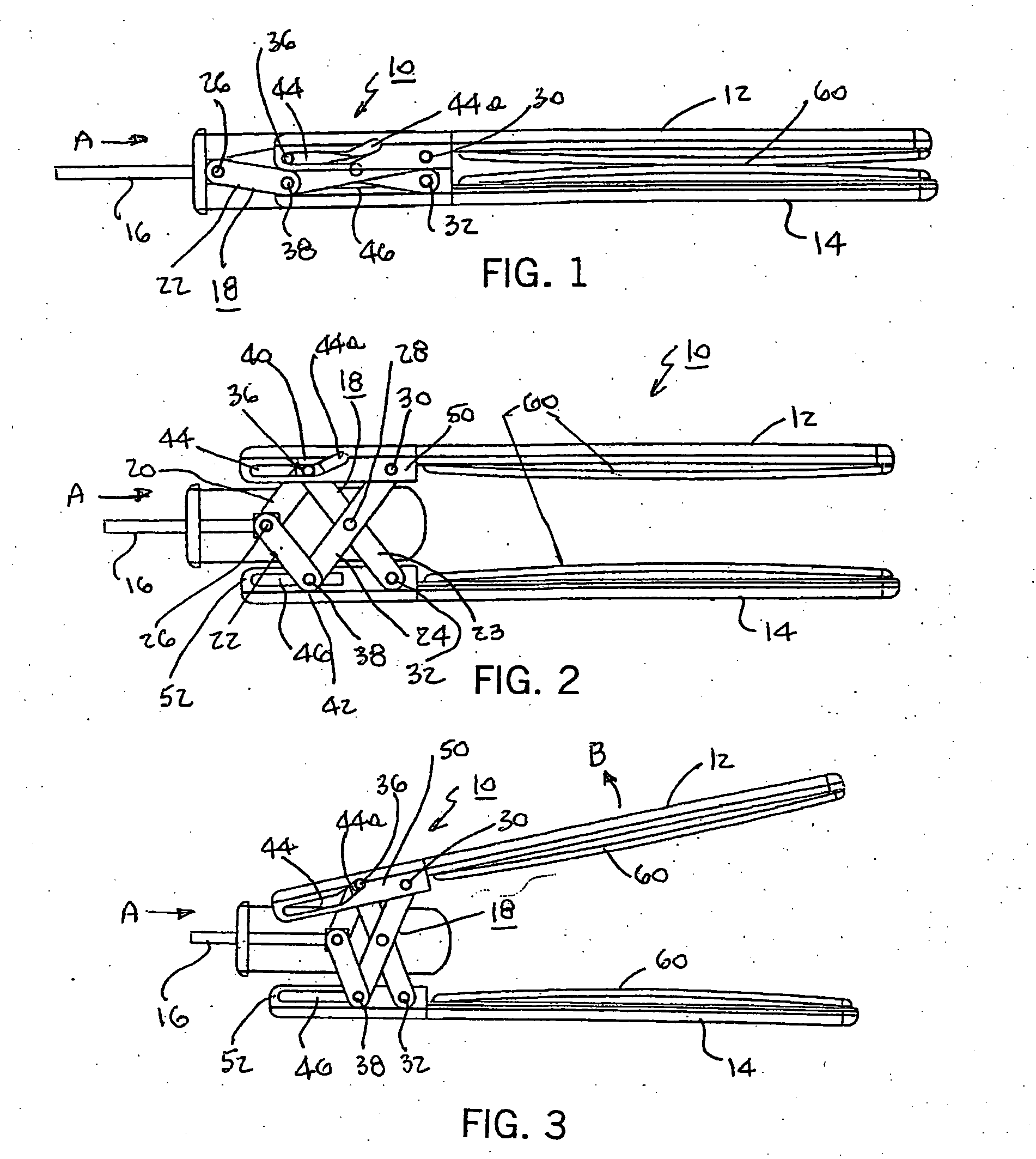

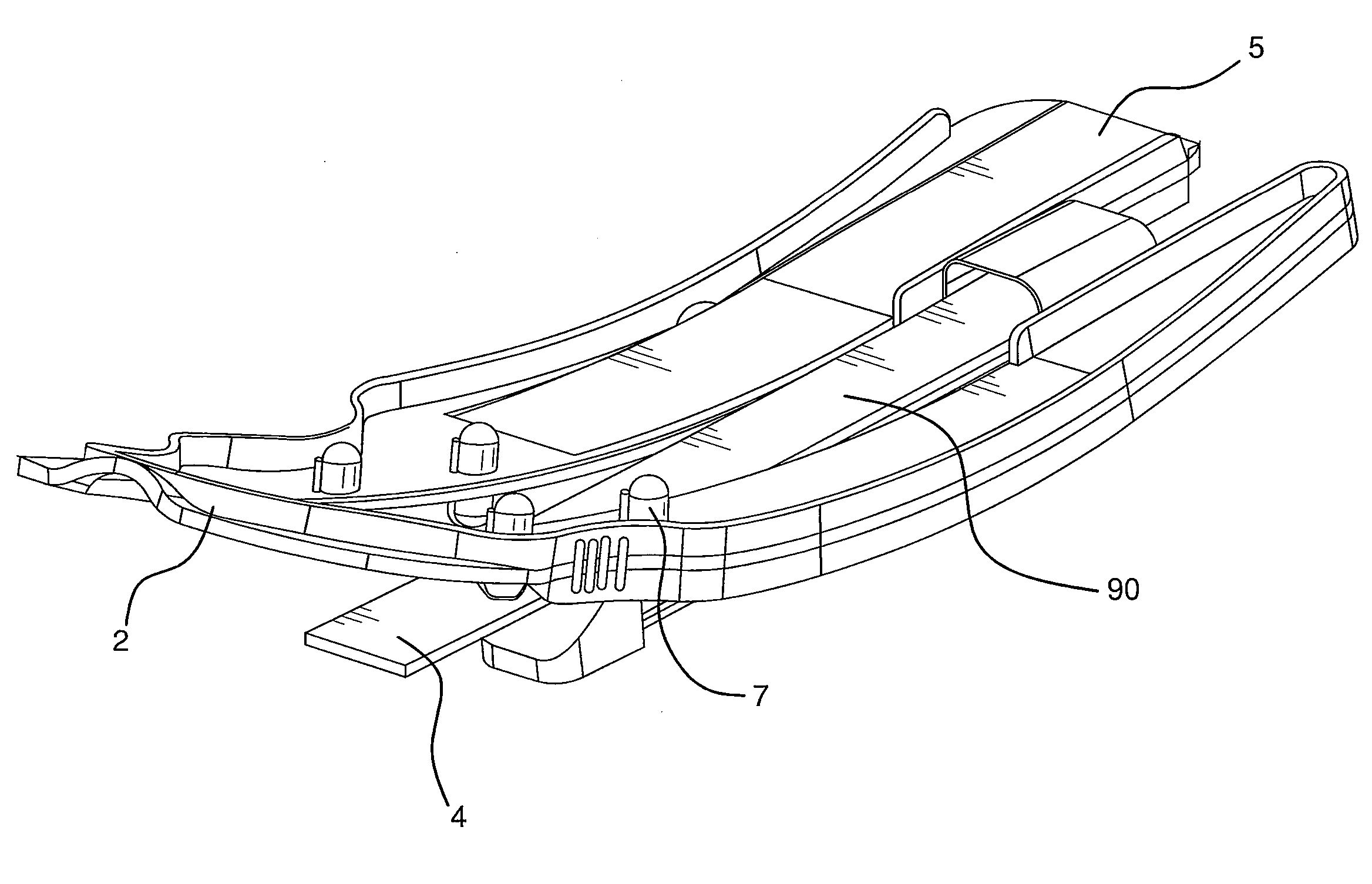

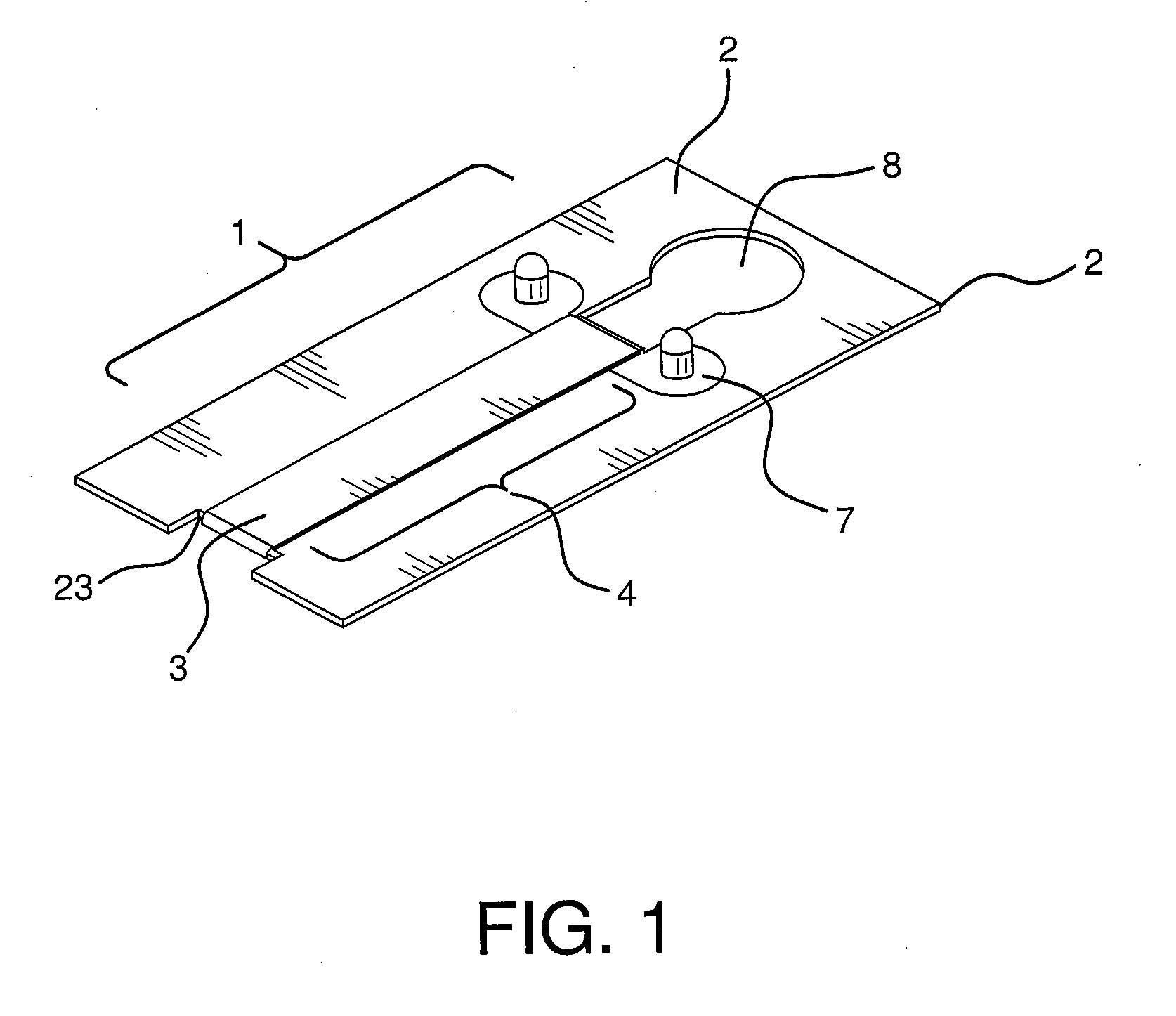

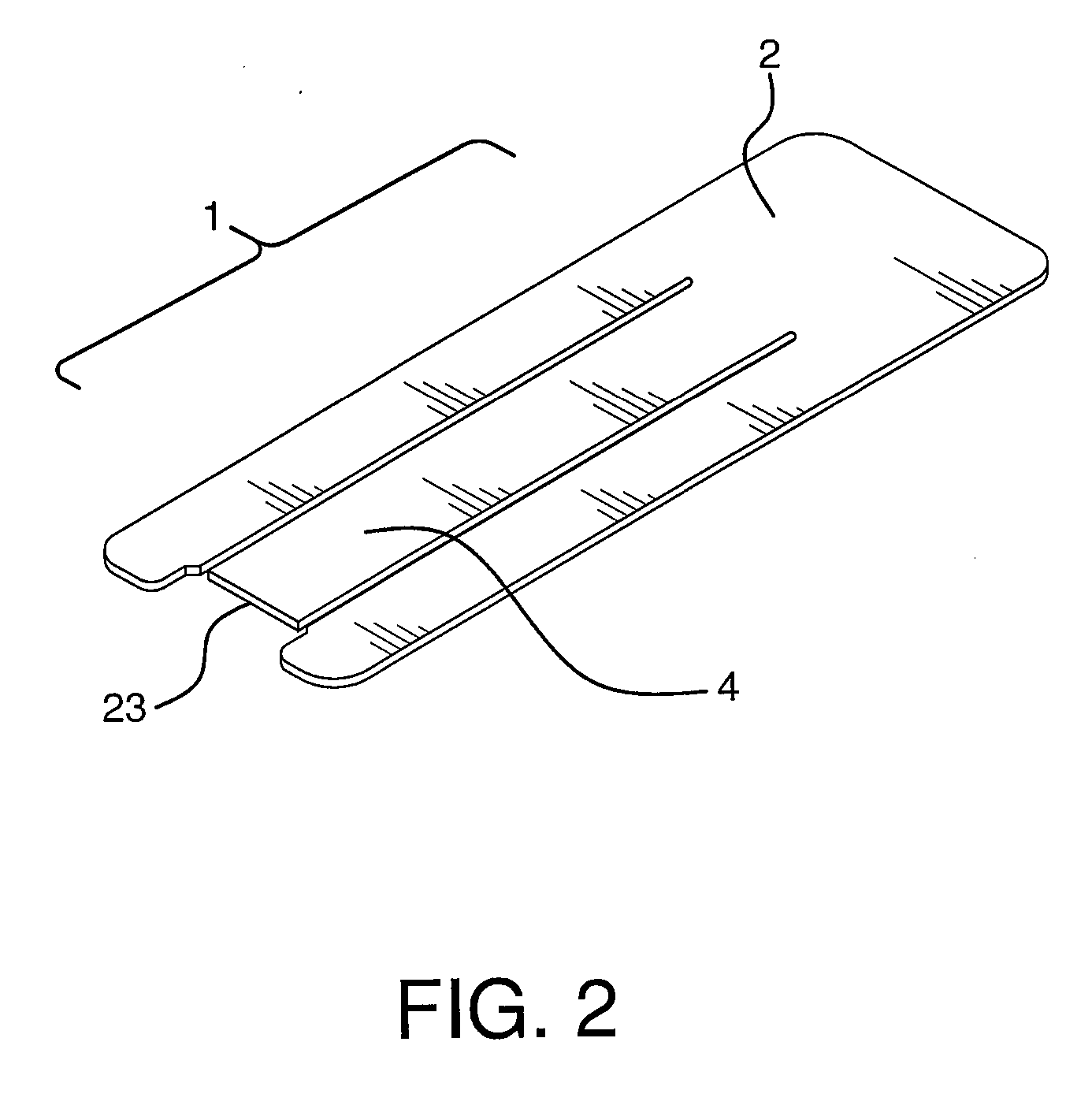

An apparatus for supplying surgical buttress material to a surgical stapler is provided. The apparatus has a pivotable area for attaching surgical buttress material. The apparatus may also have an adhesive and a release liner disposed over the buttress material.

Owner:WL GORE & ASSOC INC

Apparatus for Supplying Surgical Staple Line Reinforcement

InactiveUS20120289979A1Accurately and successfully positionedMaintain strengthSurgical staplesWound clampsSurgical stapleMaterial supply

An apparatus for supplying surgical buttress material to a surgical stapler is provided. The apparatus has a pivotable area for attaching surgical buttress material. The apparatus may also have an adhesive and a release liner disposed over the buttress material.

Owner:WL GORE & ASSOC INC

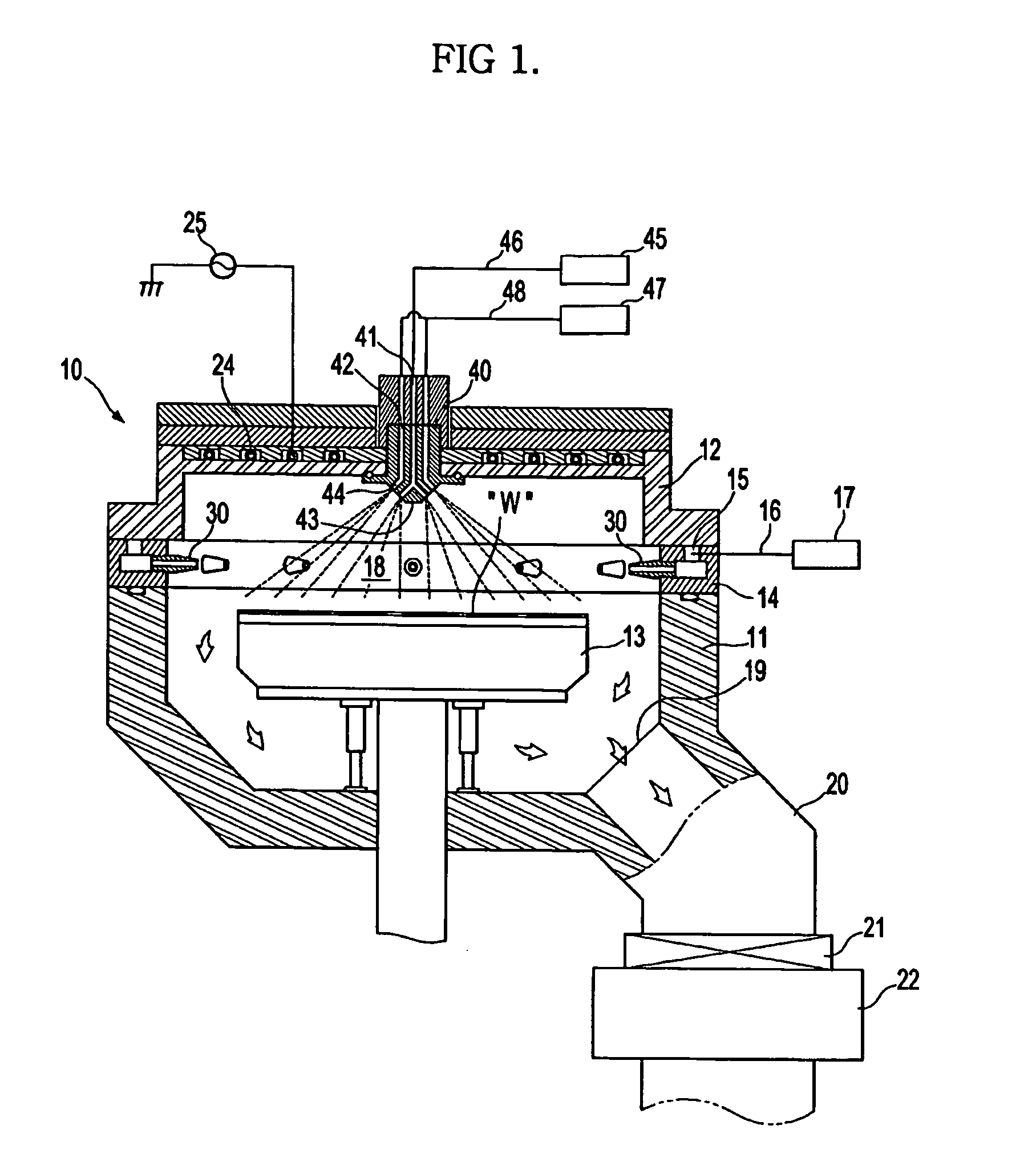

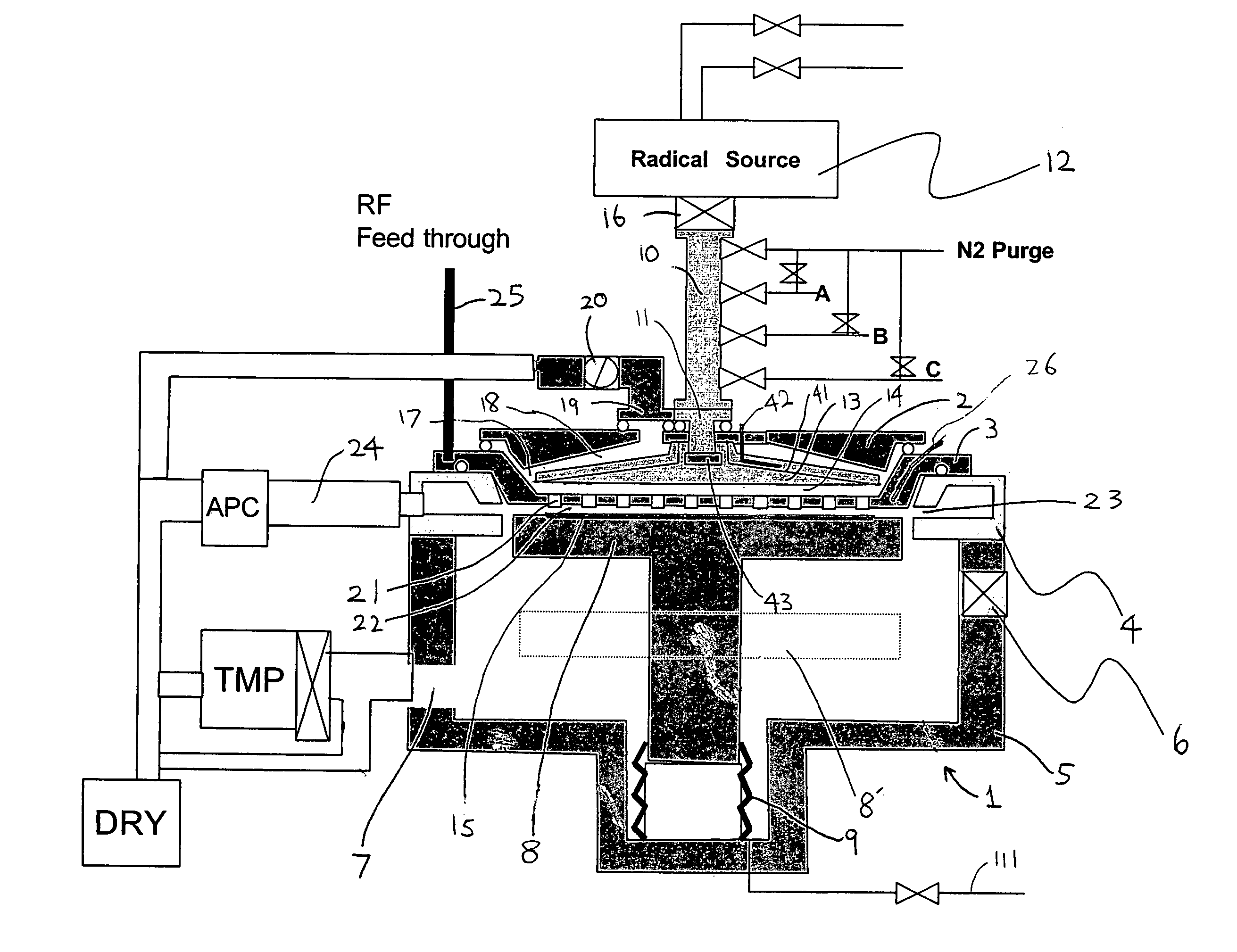

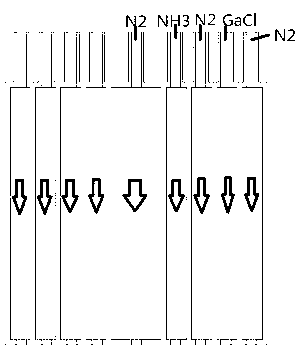

Thin-film deposition apparatus

ActiveUS20050229848A1Hinder reactionAvoid reactionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingProduct gasEngineering

A gas-feeding apparatus configured to be connected to an evacuatable reaction chamber includes a gas-distribution head for introducing gases into the chamber through a head surface. The gas-feeding head includes a first section for discharging a gas through the head surface toward a susceptor and a second section for discharging a gas through the head surface toward the susceptor. The first and the second sections are isolated from each other in the gas-distribution head, at least one of which section is coupled to an exhaust system for purging therefrom a gas present in the corresponding section without passing through the head surface.

Owner:ASM JAPAN

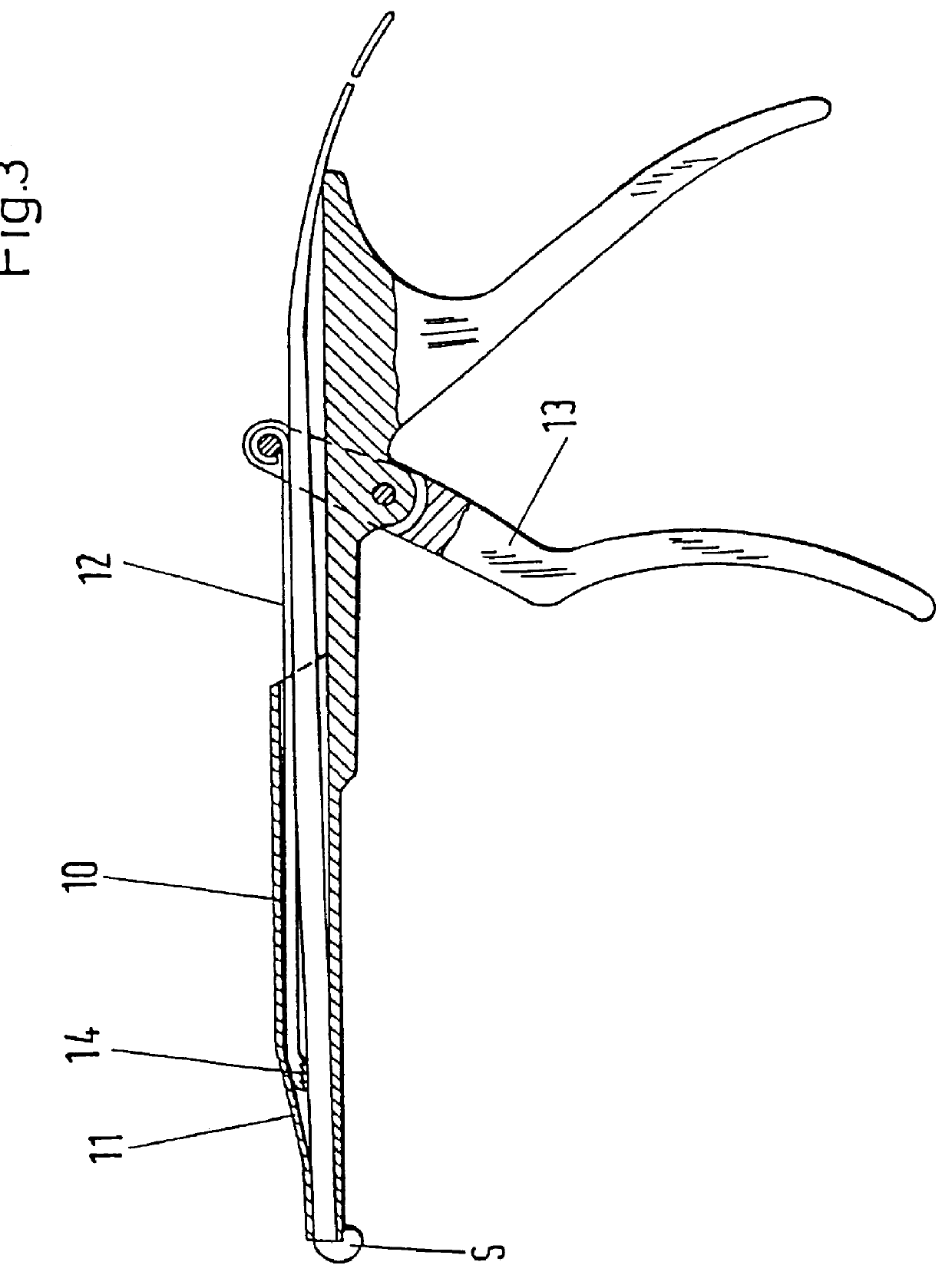

Surgical clamp possessing a combined parallel and scissor style clamp head

InactiveUS20050165429A1Easy constructionLarge openingSurgical forcepsWound clampsSurgical ClampsEngineering

Owner:ETHICON INC

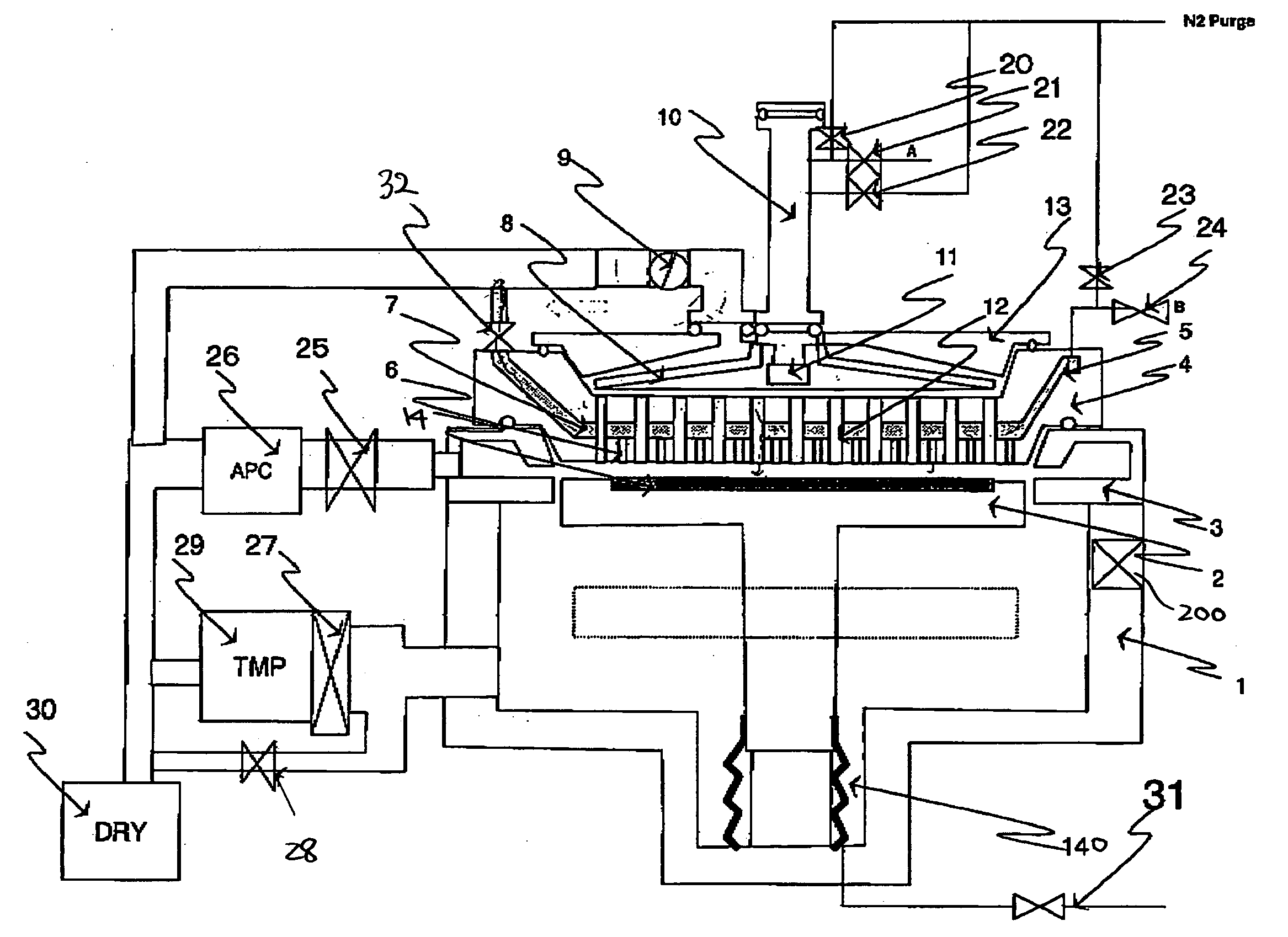

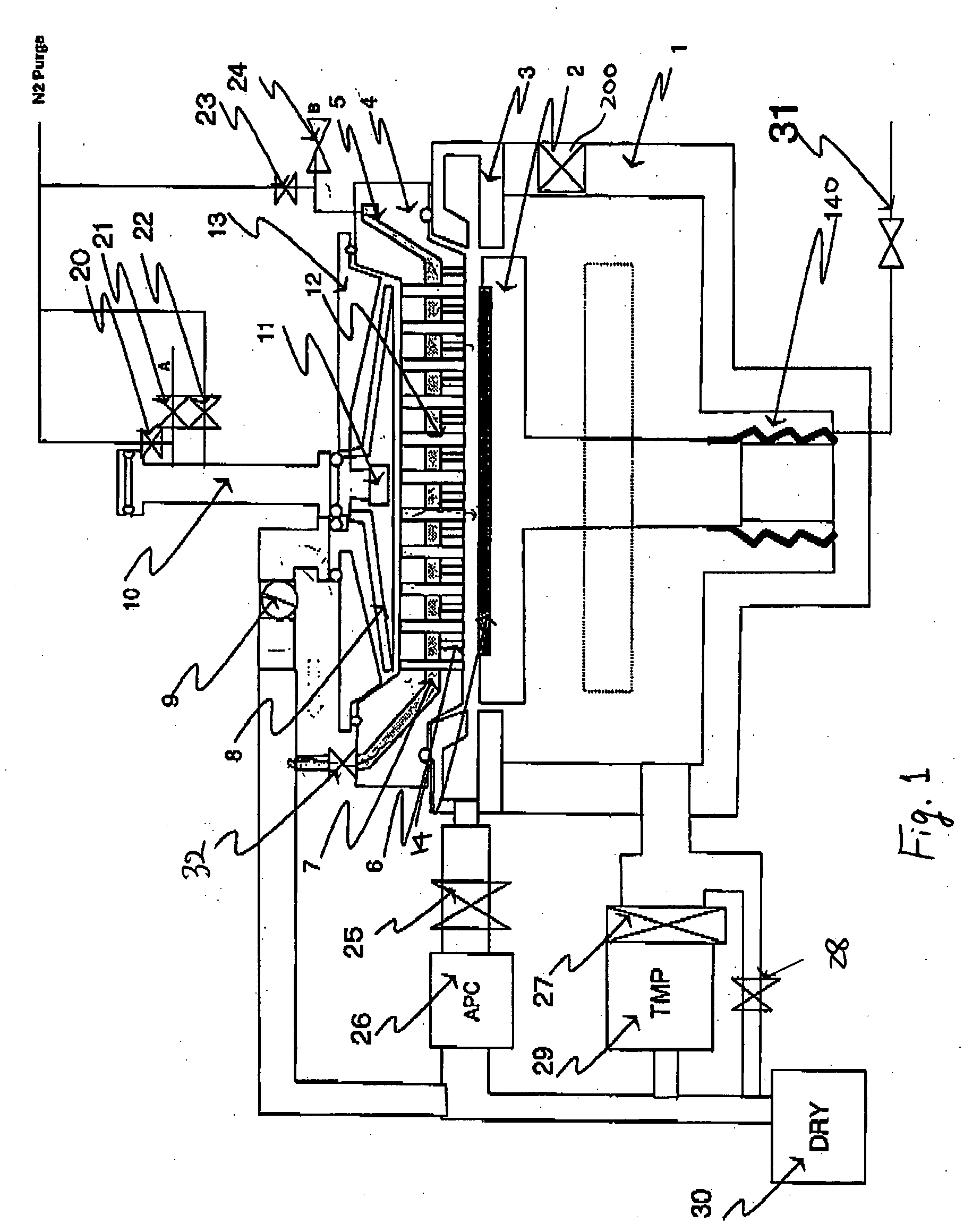

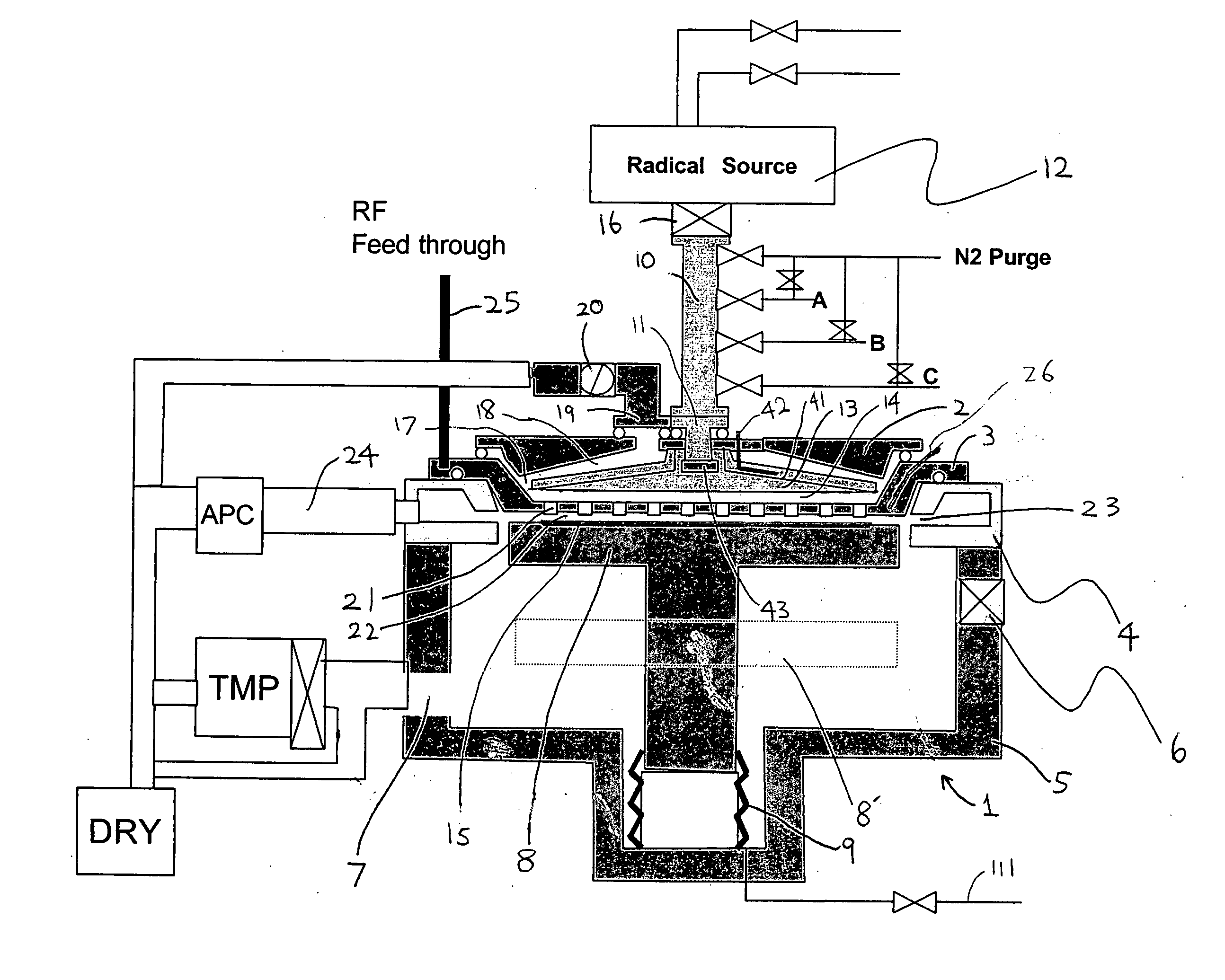

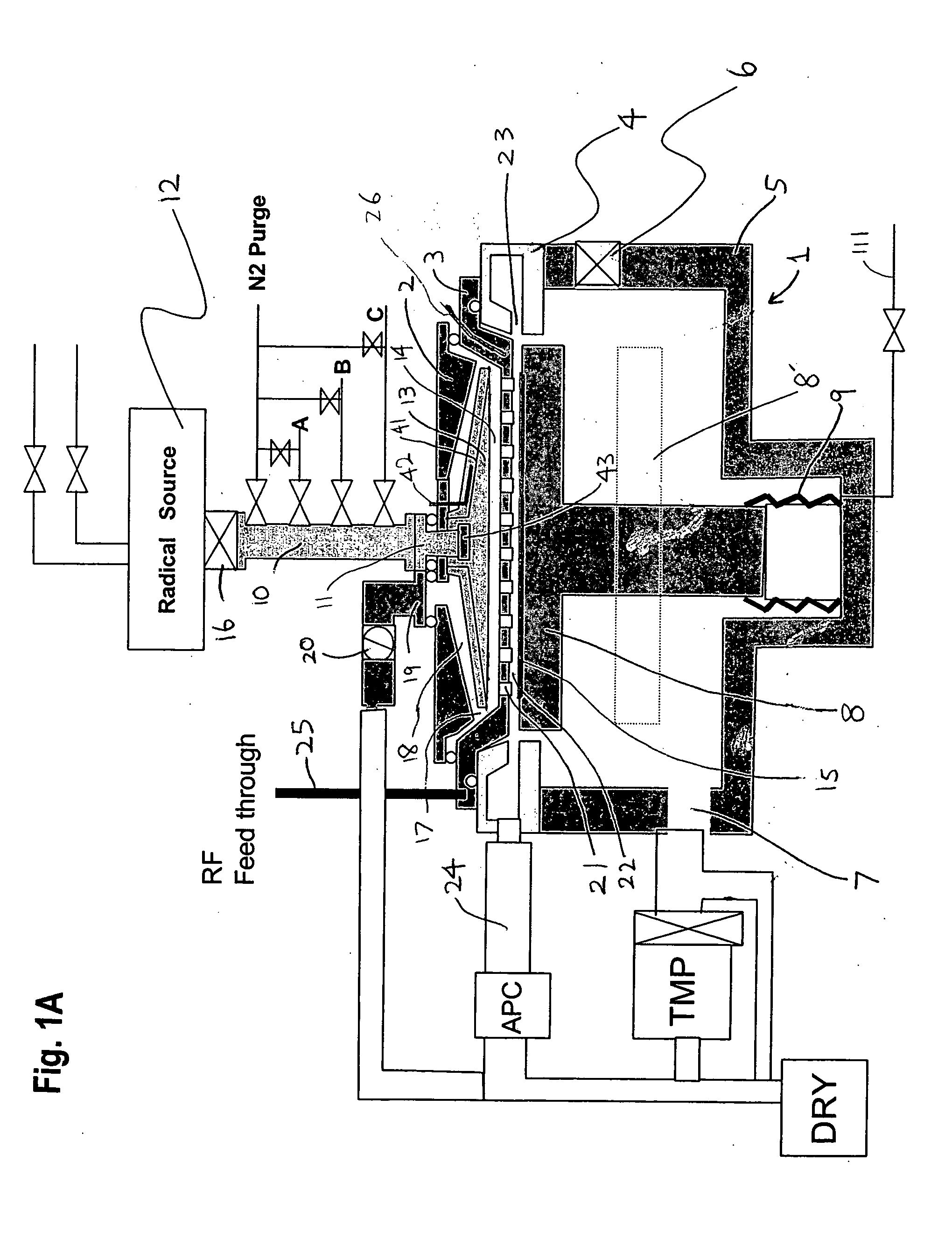

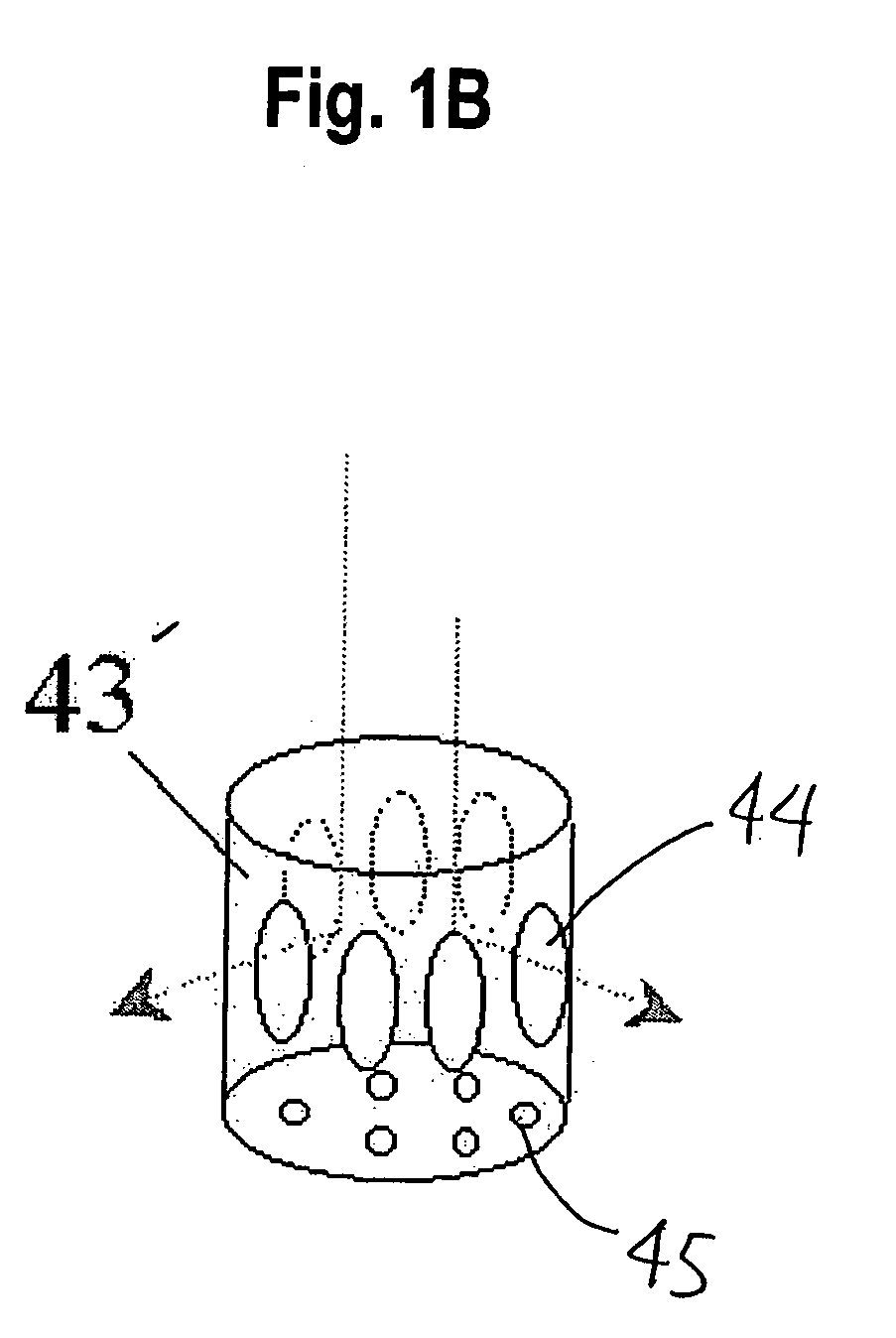

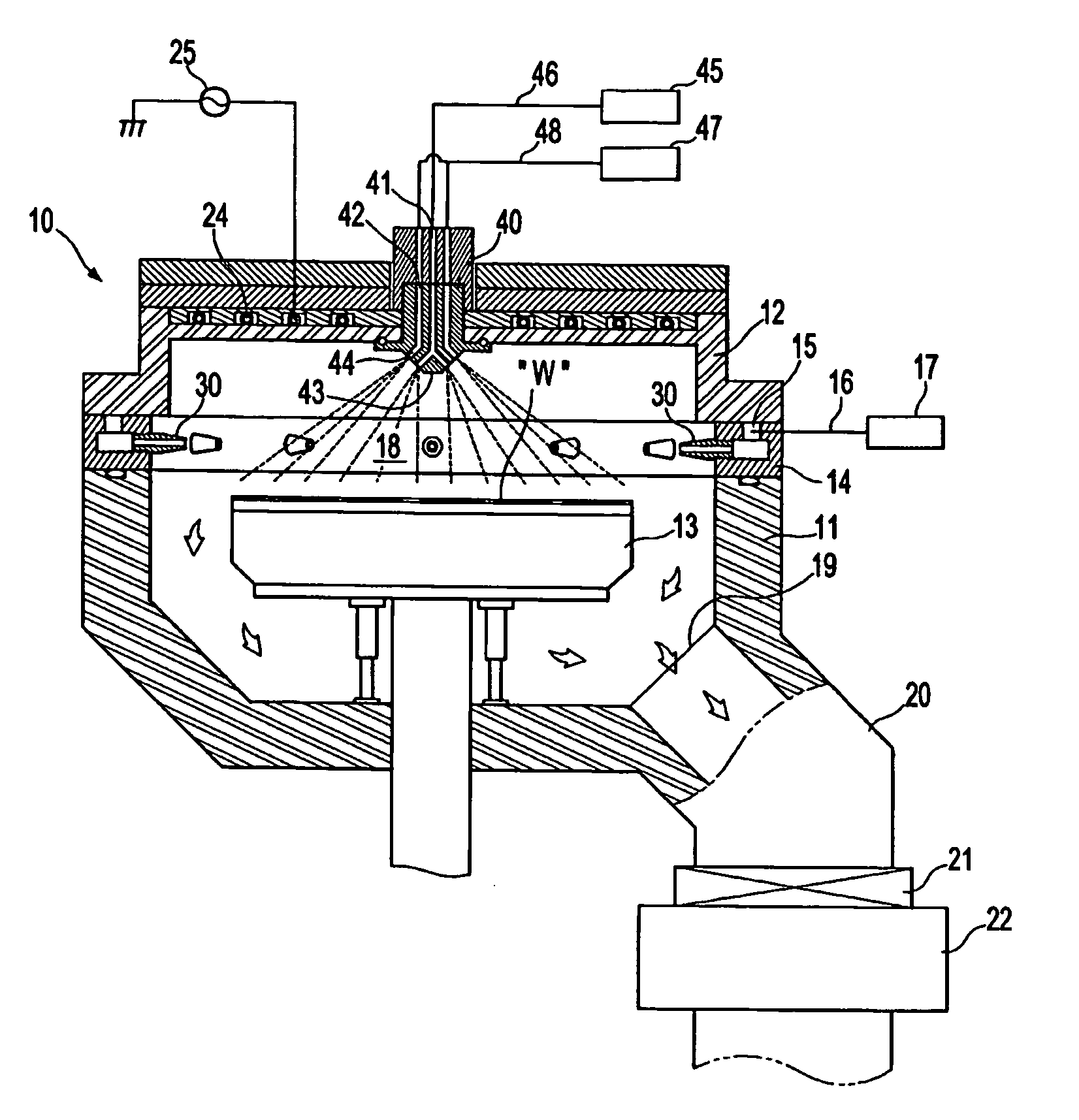

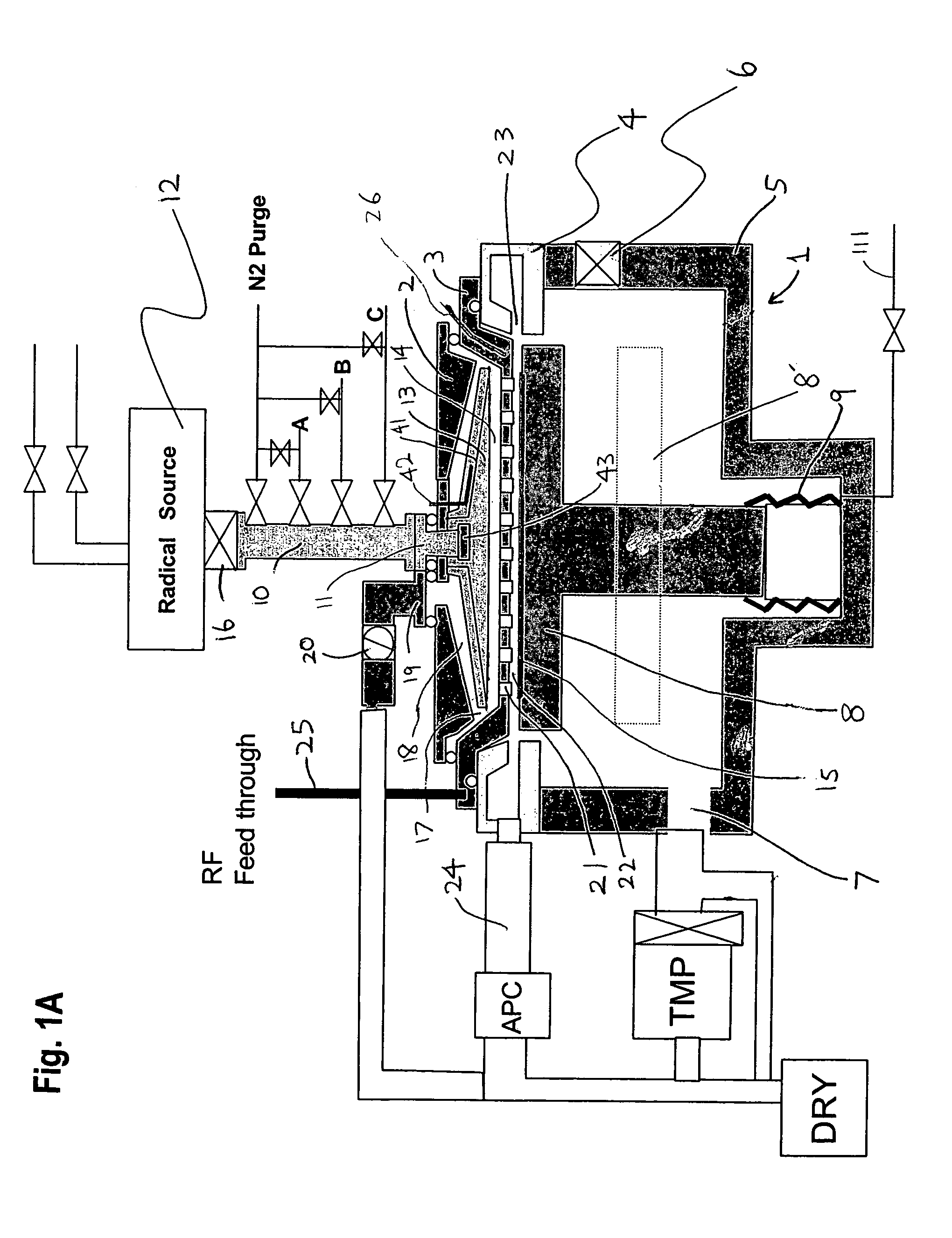

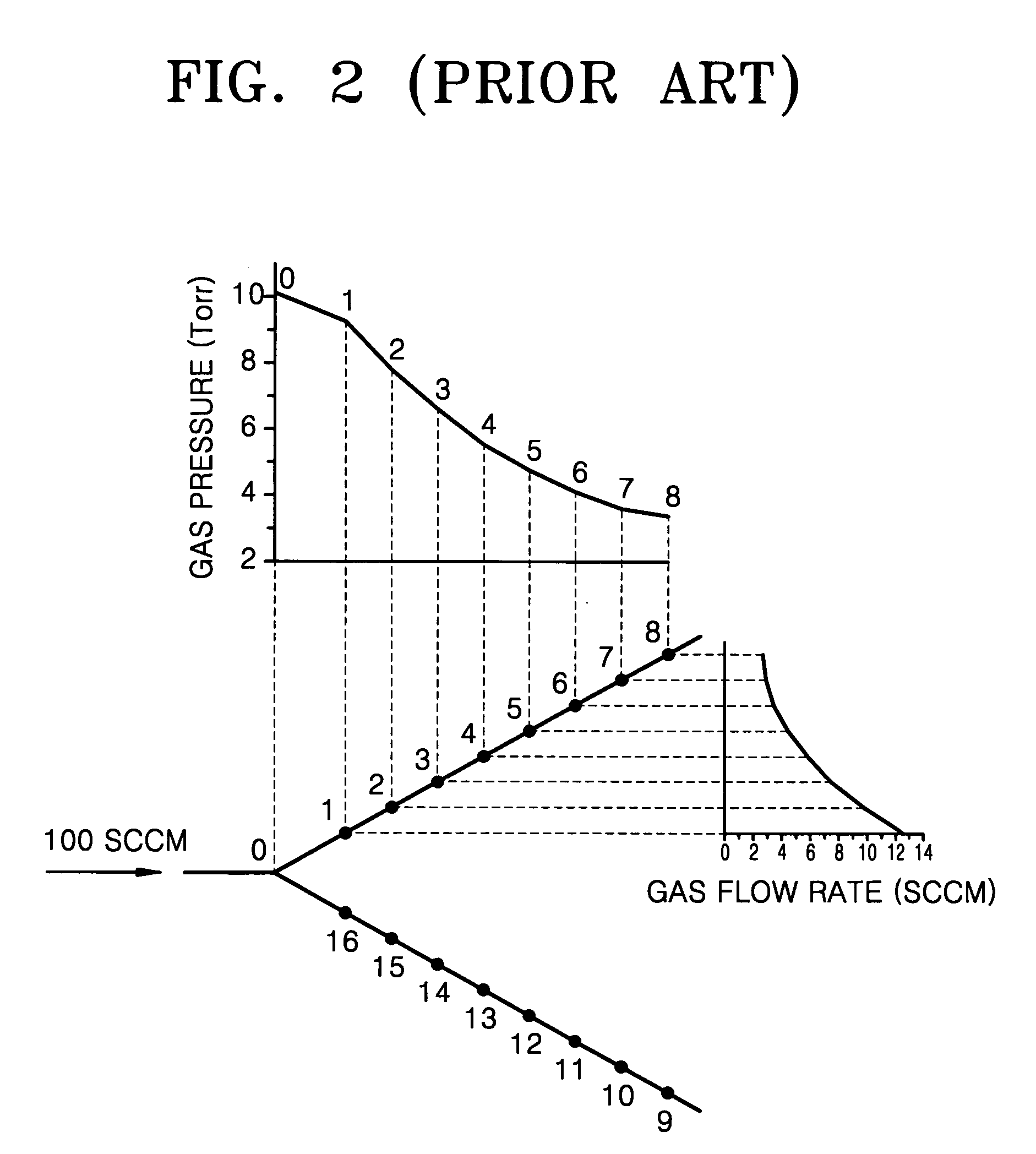

Apparatus and method for forming thin film using upstream and downstream exhaust mechanisms

ActiveUS20050208217A1Improve throughputUniform supplyElectric discharge tubesSemiconductor/solid-state device detailsGas supplySubstrate surface

A thin-film formation apparatus possesses a reaction chamber to be evacuated, a placing portion on which a substrate is placed inside the reaction chamber, a gas-dispersion guide installed over the placing portion for supplying a gas onto a substrate surface, a gas-supply port for introducing the gas into the gas-dispersion guide, a gas-dispersion plate disposed on the side of the substrate of the gas-dispersion guide and having multiple gas-discharge pores, a first exhaust port for exhausting, downstream of the gas-dispersion plate, the gas supplied onto the substrate surface from the gas-dispersion plate, and a second exhaust port for exhausting, upstream of the gas-dispersion plate, a gas inside the gas-dispersion guide via a space between the gas-dispersion guide and the gas-dispersion plate.

Owner:ASM JAPAN

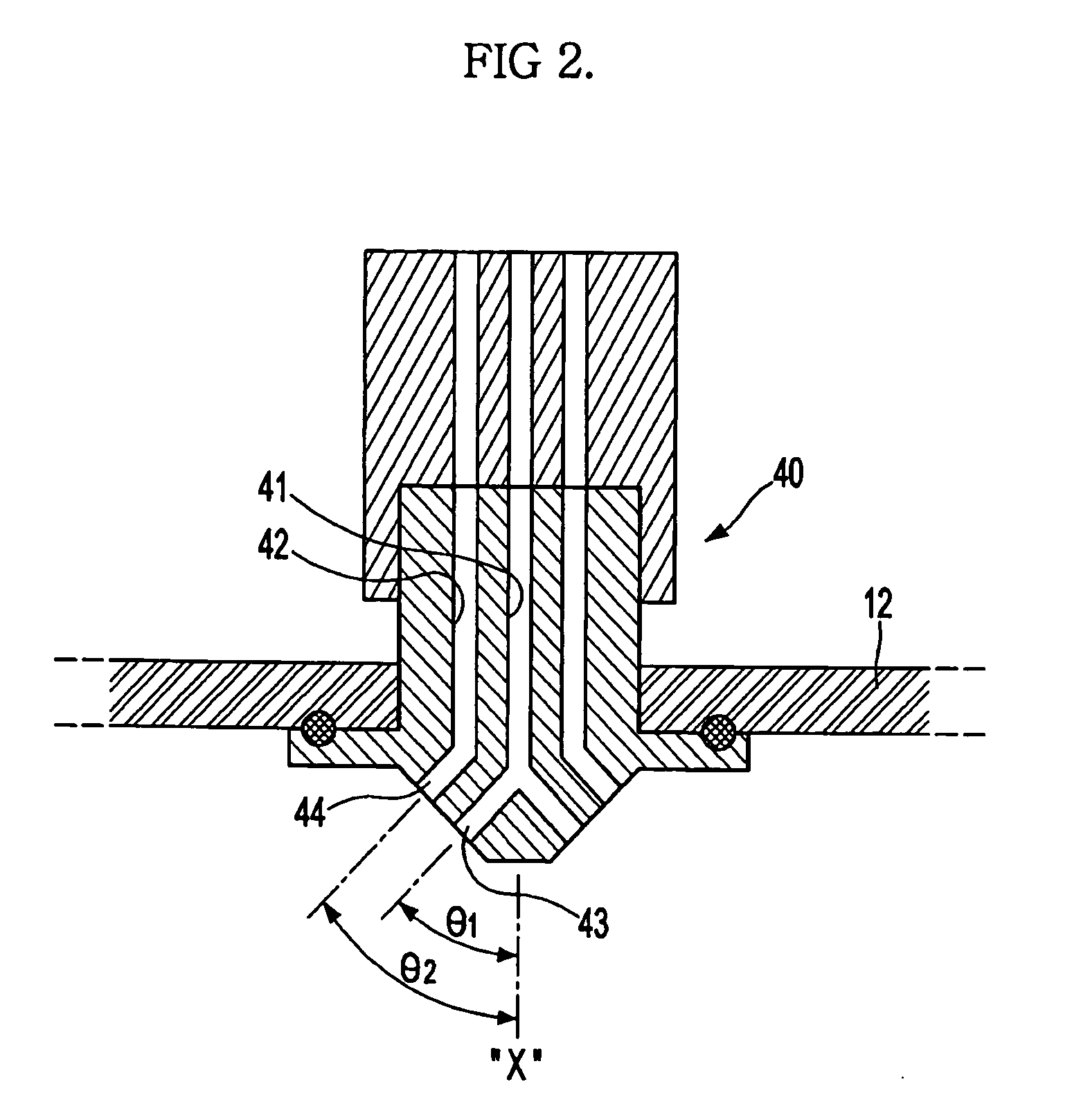

Apparatus to manufacture semiconductor

InactiveUS20060096540A1Expand the scope of diffusionUniformlySemiconductor/solid-state device manufacturingChemical vapor deposition coatingProcess engineeringGas supply

An apparatus to manufacture a semiconductor, in which distribution of process gases supplied to a reaction region in a reaction chamber is uniform, includes a gas supply nozzle to supply process gases to a semiconductor substrate in the reaction chamber, wherein the gas supply nozzle includes a first supply channel formed in a longitudinal direction, and first outlet channels formed at an outlet of the first supply channel such that the first outlet channels are inclined with respect to the direction of the first supply channel at a designated angle to diffuse the process gas supplied through the first supply channel.

Owner:SAMSUNG ELECTRONICS CO LTD

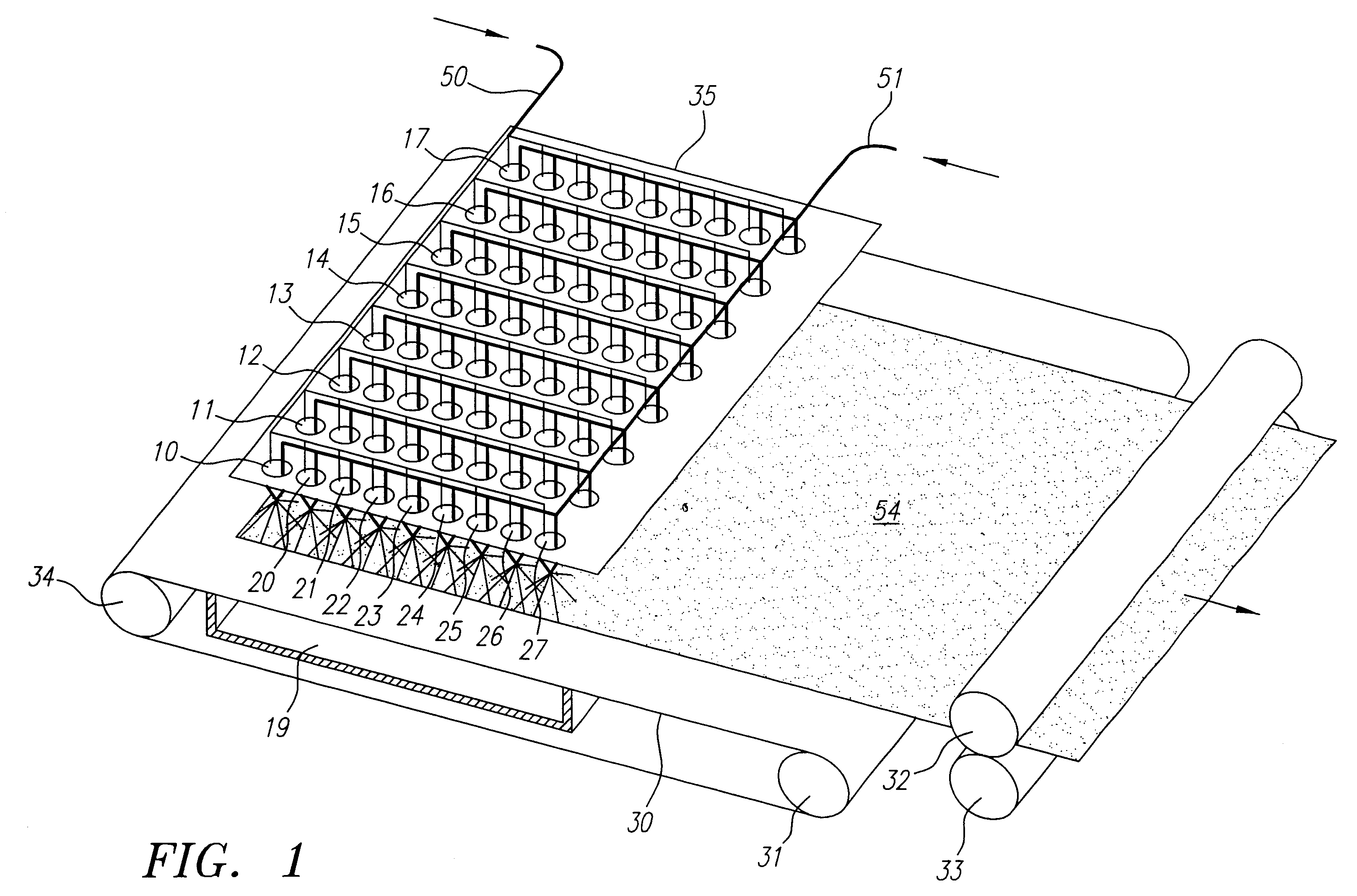

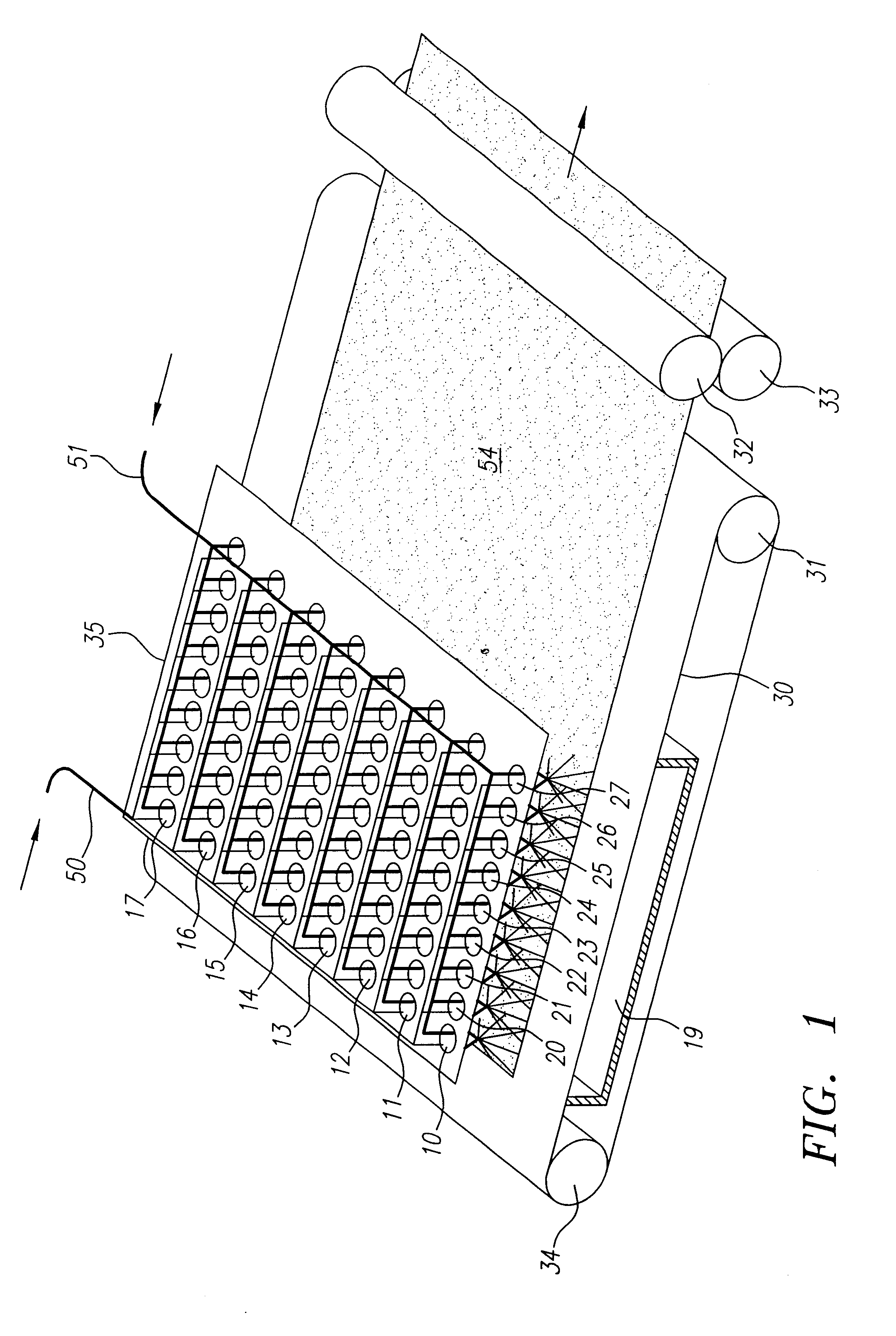

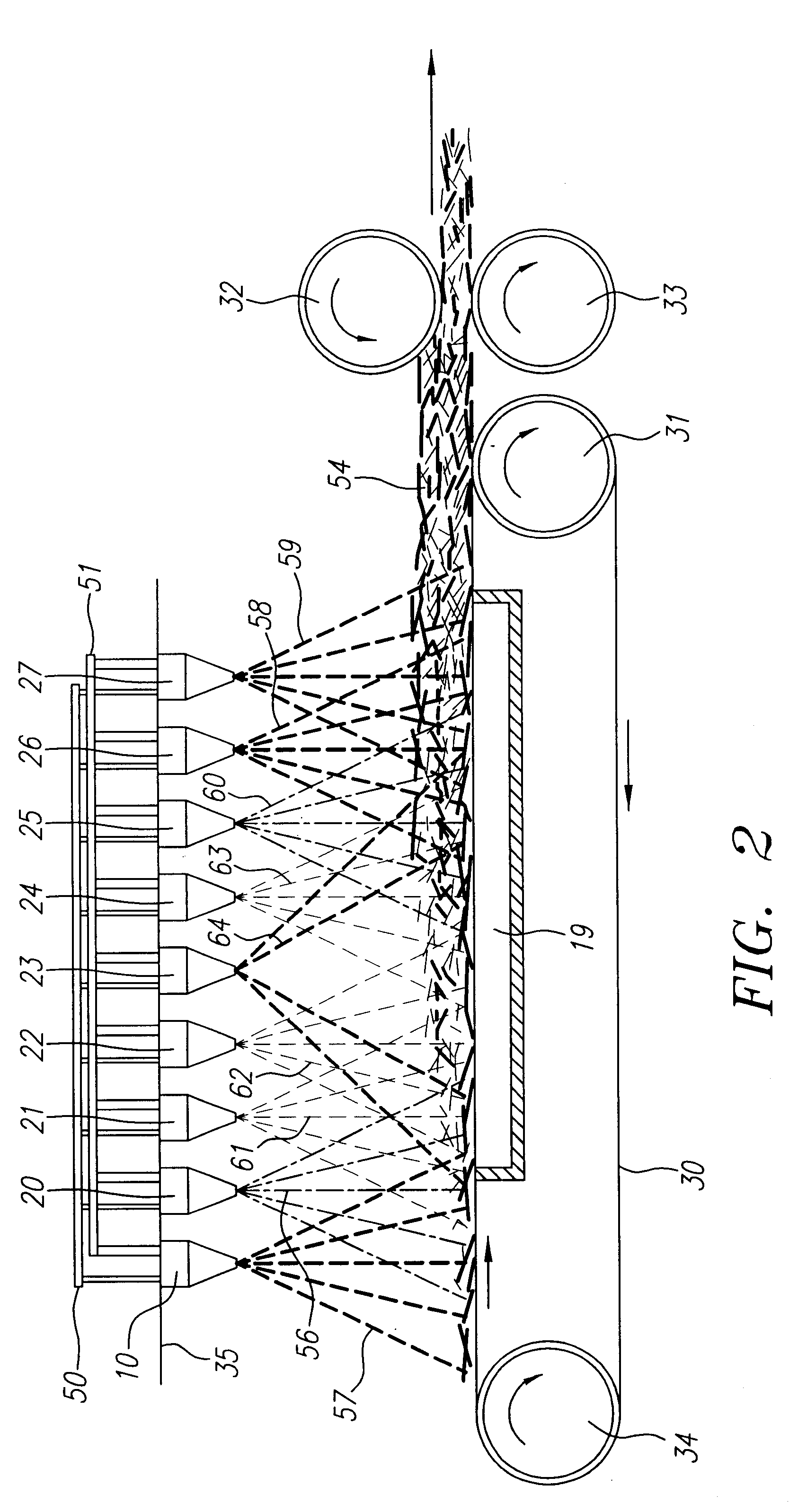

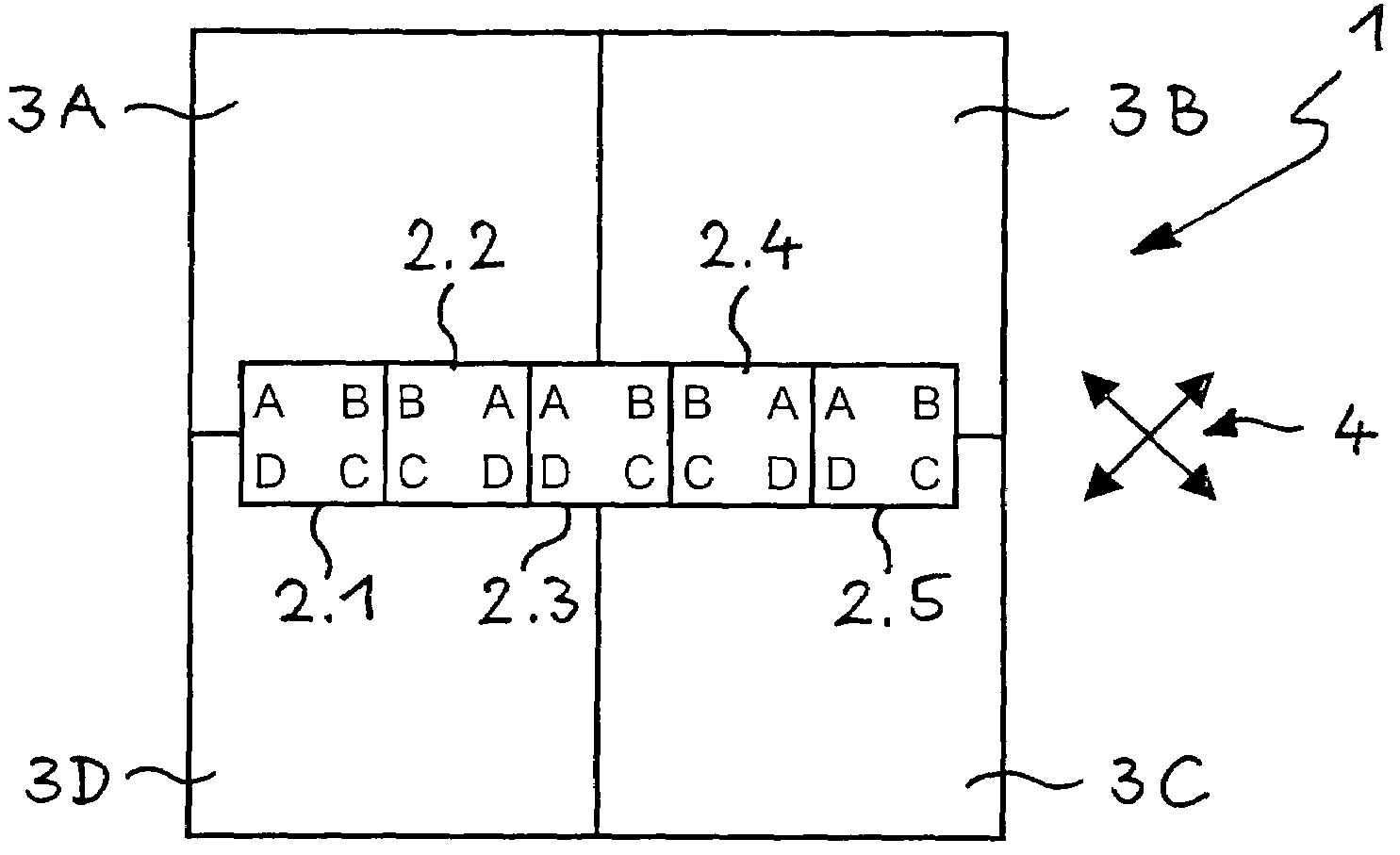

Method and apparatus for producing high efficiency fibrous media incorporating discontinuous sub-micron diameter fibers, and web media formed thereby

InactiveUS6315806B1Increase distanceReduce resistanceFilament/thread formingLoose filtering material filtersMean diameterFiber

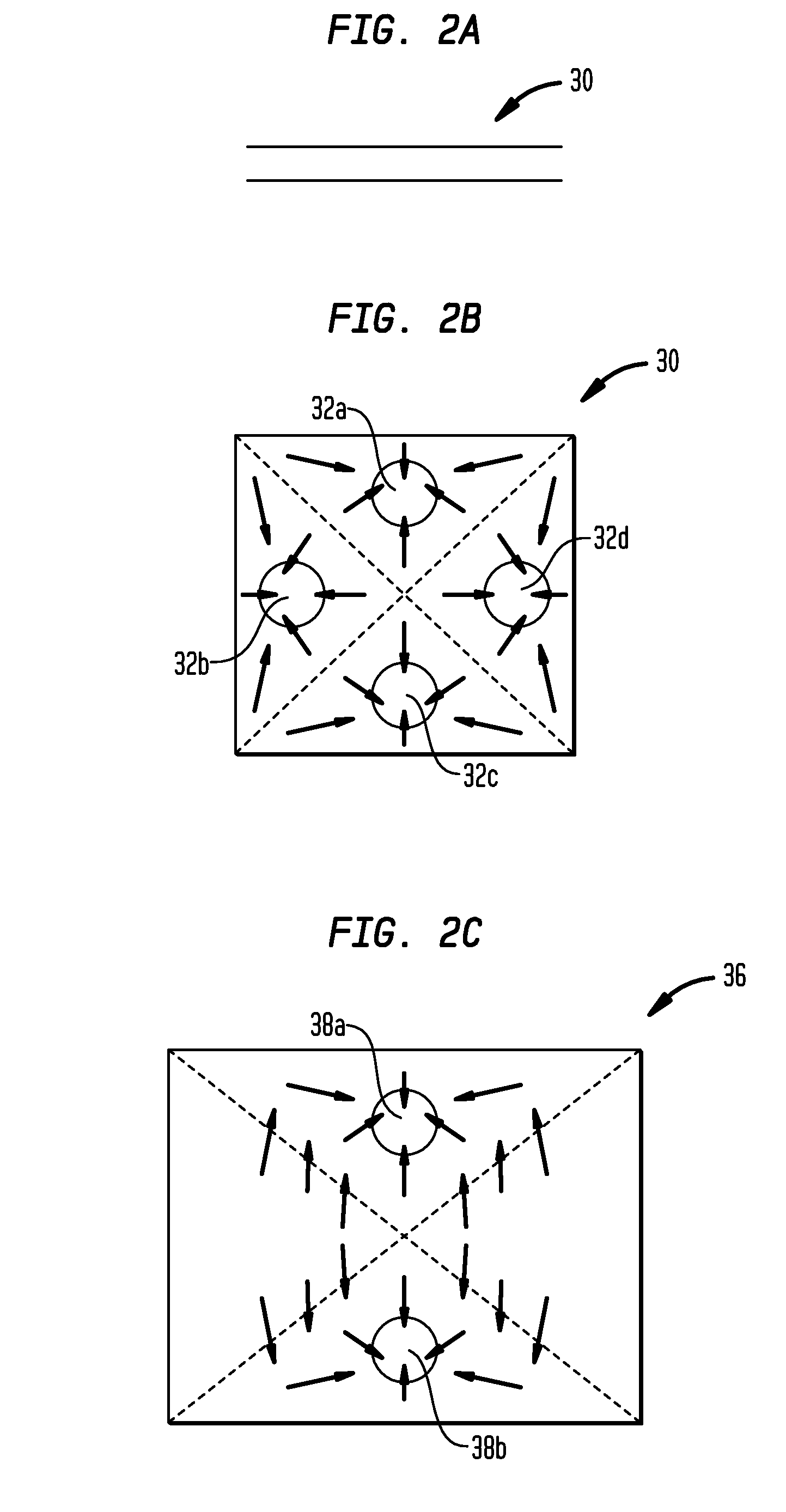

A composite filtration medium web of fibers containing a controlled dispersion of a mixture of sub-micron and greater than sub-micron diameter polymeric fibers is described. The filtration medium is made by a two dimensional array of cells, each of which produces a single high velocity two-phase solids-gas jet of discontinuous fibers entrained in air. The cells are arranged so that the individual jets are induced to collide in flight with neighboring jets in their region of fiber formation, to cause the individual nascent fibers of adjacent jets to deform and become entangled with and partially wrap around each other at high velocity and in a localized fine scale manner before they have had an opportunity to cool to a relatively rigid state. The cells are individually adjusted to control the mean diameters, lengths and trajectories of the fibers they produce. Certain cells are adjusted to generate a significant percentage of fibers having diameters less than one micron diameter, and which are relatively shorter in length and certain other cells are adjusted to generate a significant percentage of structure-forming reinforcing fibers having diameters greater than one micron diameter which are relatively longer in length. By employing appropriate close positioning and orientation of the cells in the array, the sub-micron fibers are caused to promptly entangle with and partially wrap around the larger reinforcing fibers. The larger fibers thereby trap and immobilize the sub-micron diameter fibers in the region of formation, to minimize the tendency of sub-micron diameter fibers to clump, agglomerate, or rope together in flight. Also, the larger fibers in flight are made to form a protective curtain to prevent the sub-micron fibers from being carried off by stray air currents.

Owner:THE PROCTER & GAMBLE COMPANY

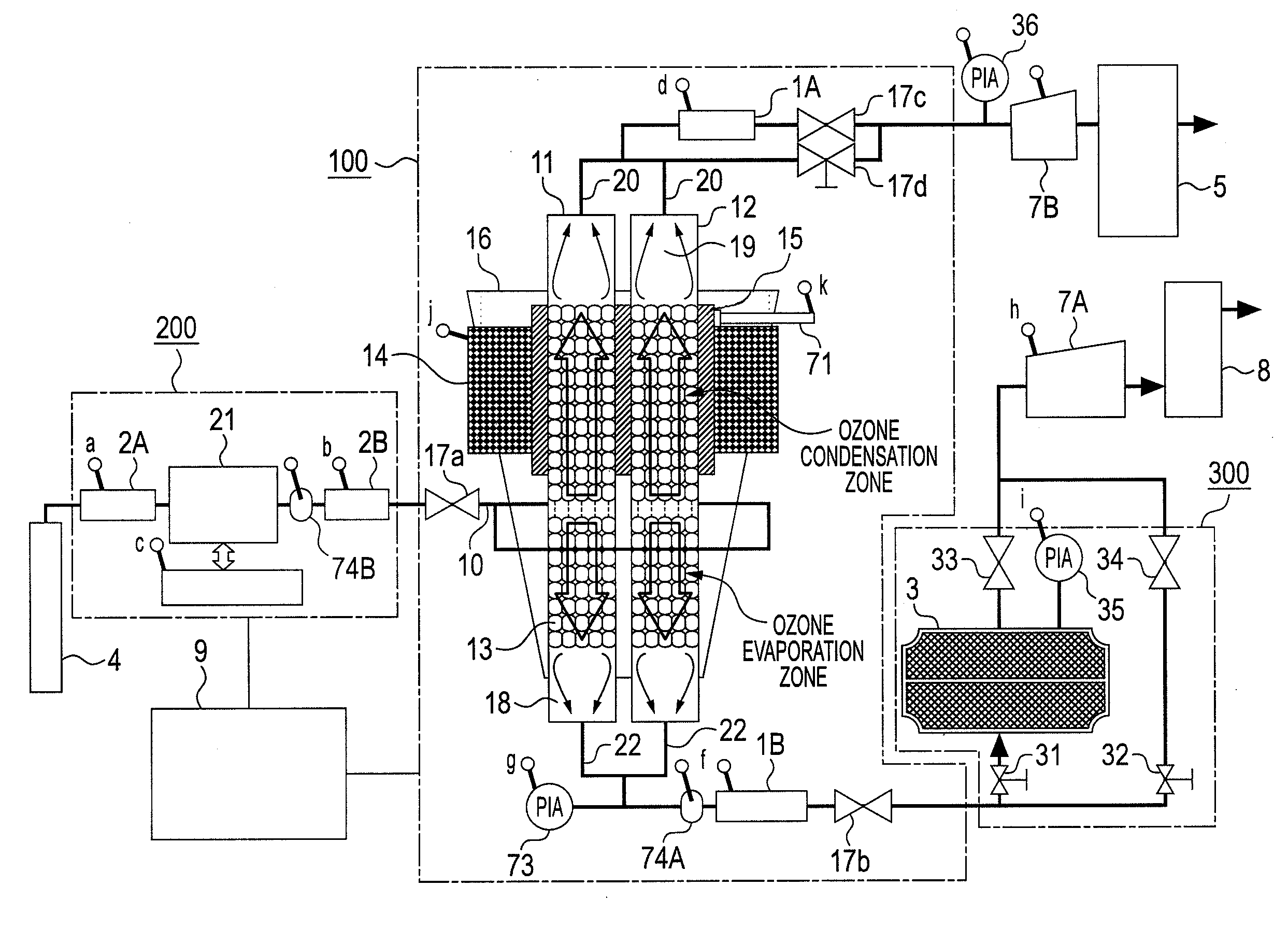

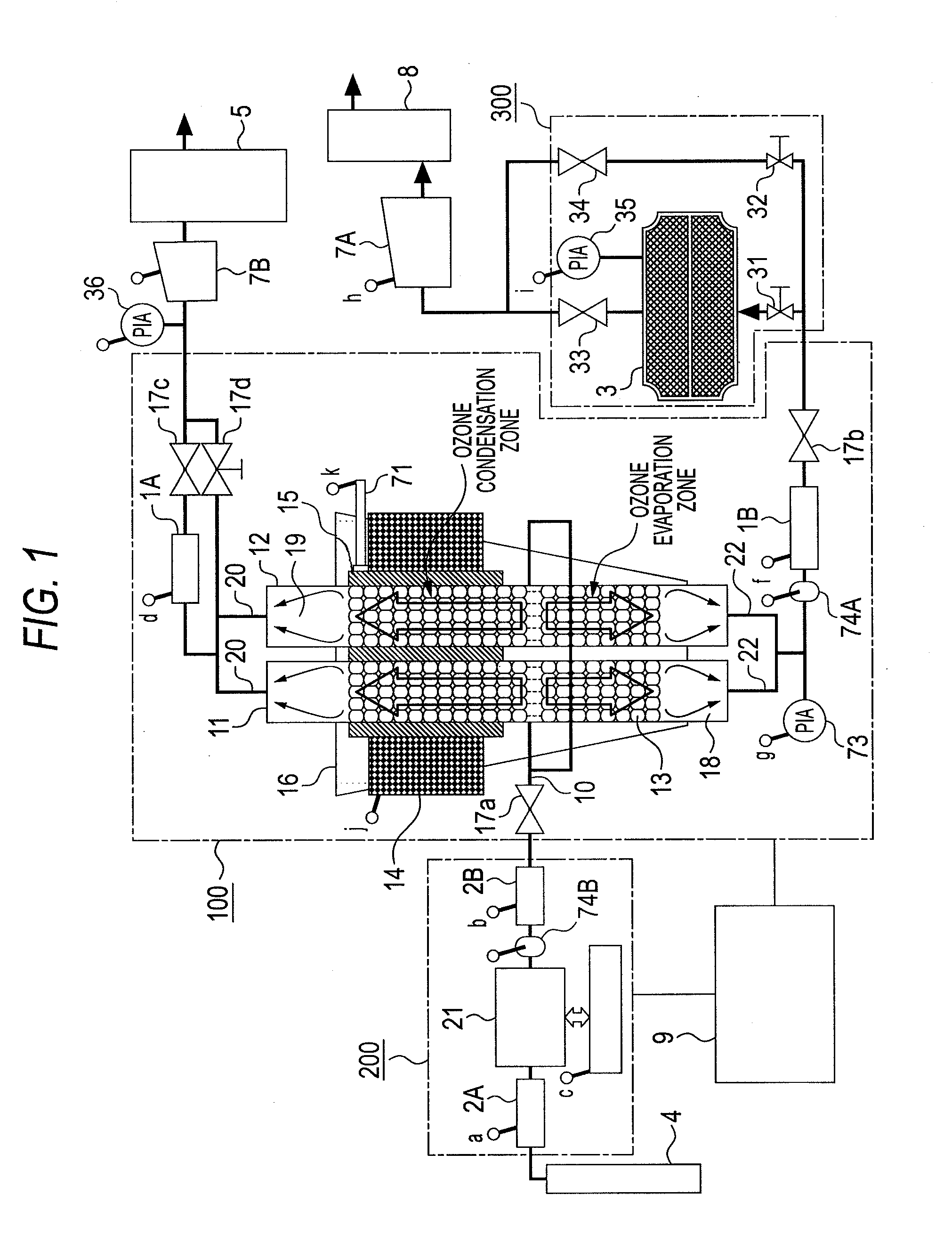

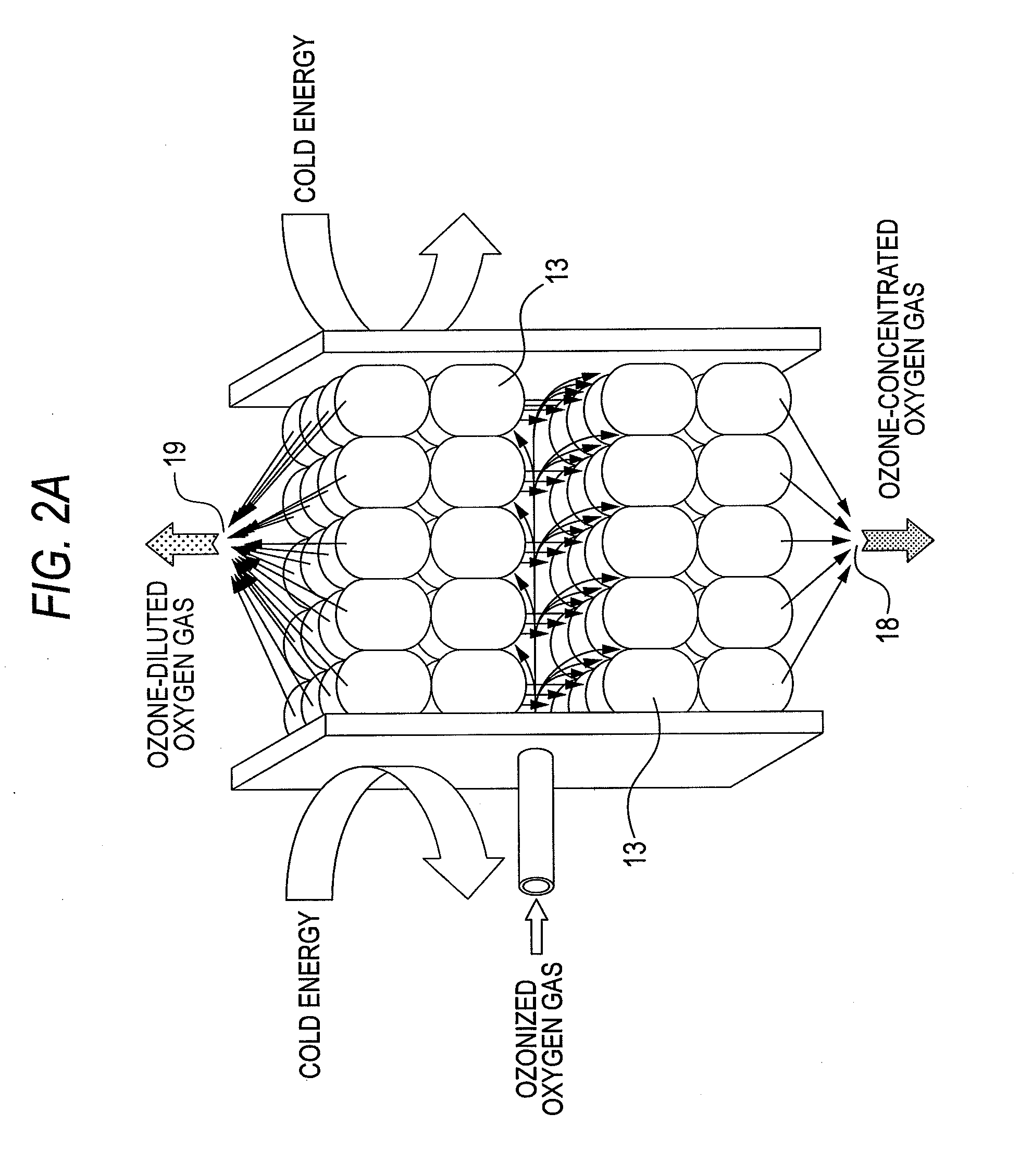

Apparatus for concentrating and diluting specific gas and method for concentrating and diluting specific gas

ActiveUS20100162752A1Improve processing efficiencySmall sizeSolidificationGas treatmentSpherical shapedVaporization

One ozone concentrating chamber is provided therein with a part of a cooling temperature range where ozone can be selectively condensed or an oxygen gas can be selectively removed by transmission from an ozonized oxygen gas, and a part of a temperature range where condensed ozone can be vaporized, and condensed ozone is vaporized by moving condensed ozone with flow of a fluid or by gravitation to the part where condensed ozone can be vaporized, whereby the ozonized oxygen gas can be increased in concentration. Such a constitution is provided that a particle material 13 for condensation and vaporization filled in the ozone concentrating chambers 11 and 12 has a spherical shape of a special shape with multifaceted planes on side surfaces, or an oxygen transmission membrane 130 capable of selectively transmitting an oxygen gas in an ozone gas is provided.

Owner:TOSHIBA MITSUBISHI-ELECTRIC IND SYST CORP

Method of preparing catalyst for manufacturing carbon nanotubes

InactiveUS20070020167A1Improve uniformityMinimize agglomerationMaterial nanotechnologyNanostructure manufactureFreeze-dryingCarbon nanotube

A novel method of forming catalyst particles, on which carbon nanotubes grow based, on a substrate with increased uniformity, and a method of synthesizing carbon nanotubes having improved uniformity are provided. A catalytic metal precursor solution is applied to a substrate. The applied catalytic metal precursor solution is freeze-dried, and then reduced to catalytic metal. The method of forming catalyst particles can minimize agglomeration and / or recrystallization of catalyst particles when forming the catalyst particles by freeze-drying the catalyst metal precursor solution. The catalyst particles formed by the method has a very uniform particle size and are very uniformly distributed on the substrate.

Owner:SAMSUNG SDI CO LTD

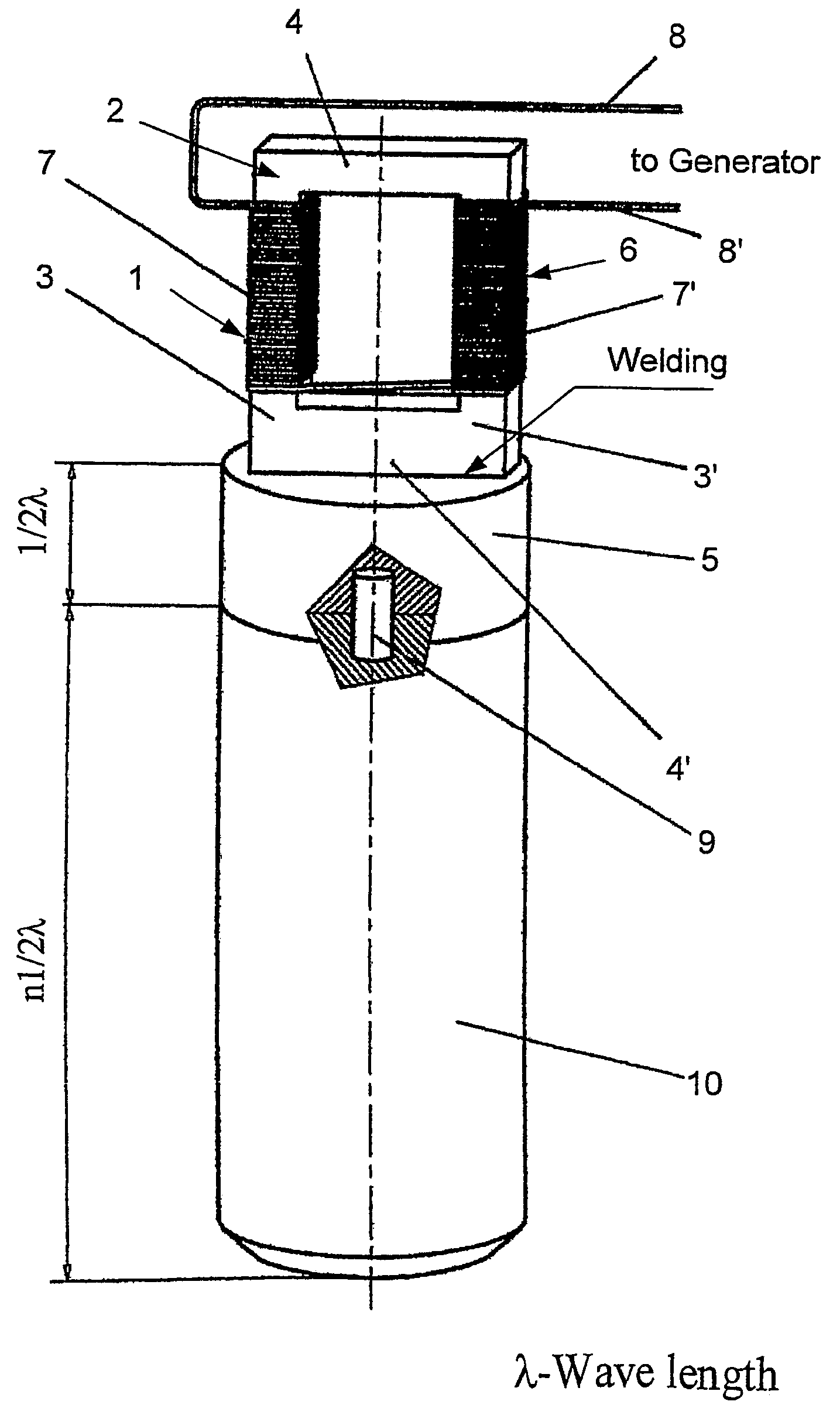

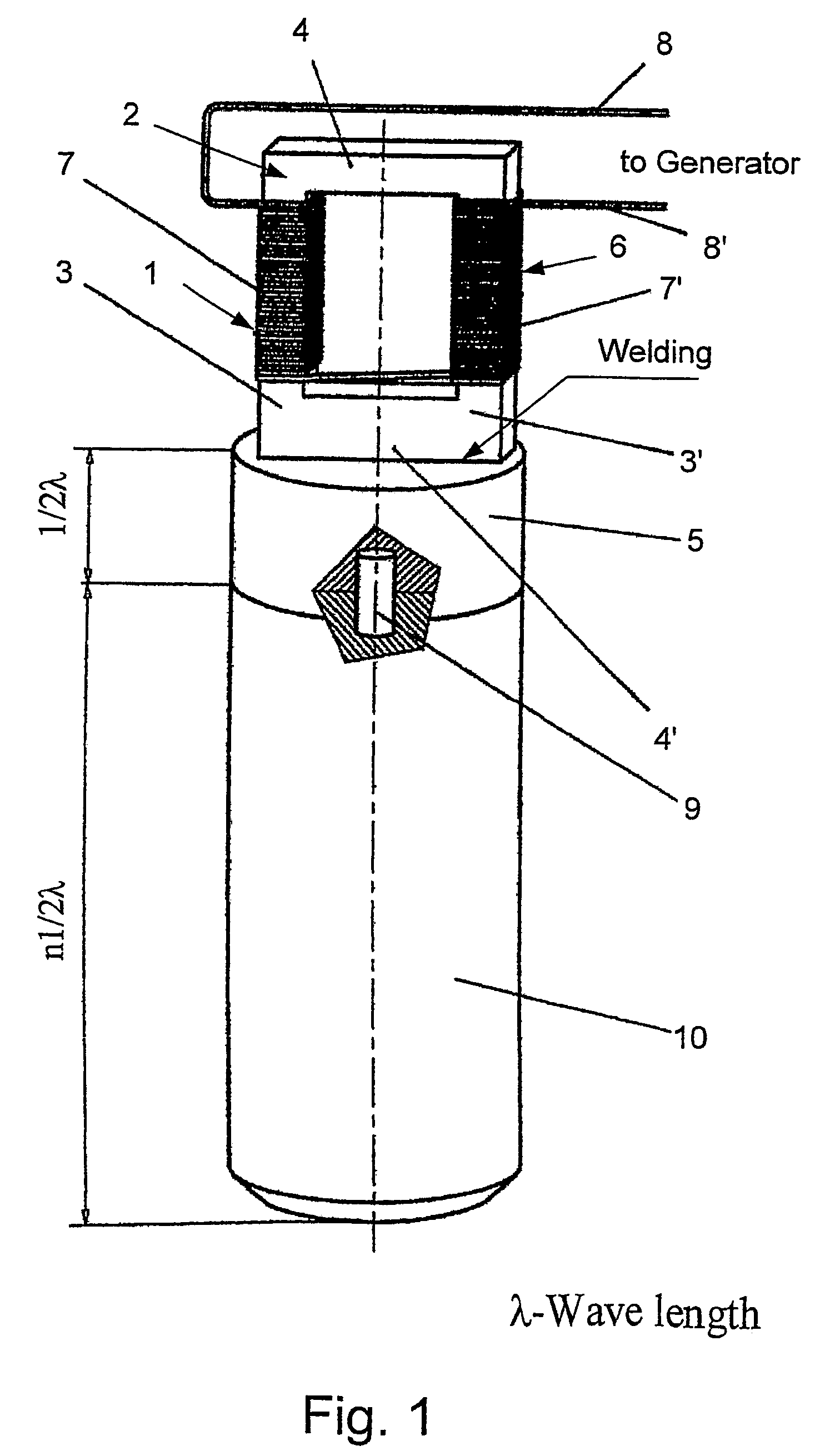

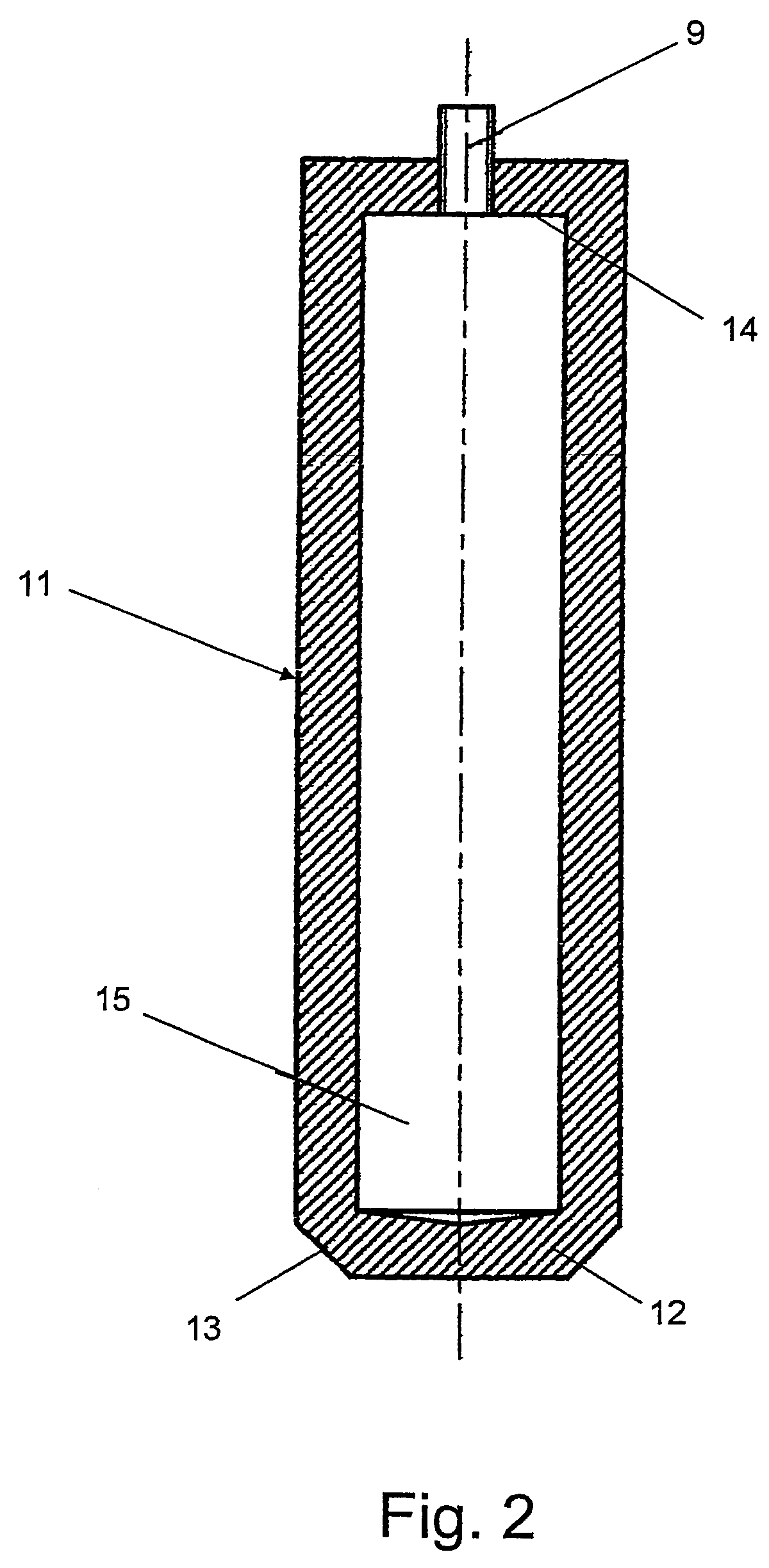

High power ultrasonic reactor for sonochemical applications

InactiveUS7157058B2Homogeneous distributionReduce thicknessMaterial nanotechnologyPigmenting treatmentEngineeringMagnetostrictive transducers

Ultrasound device having a reaction chamber, which includes a magnetostrictive transducer and a horn transmitting ultrasound radiation substantially uniformly throughout the reaction chamber. The horn is hollow and is constituted by a cylinder having an empty inner chamber at its core defining a resonance chamber, which may be cylindrical and may comprise a plurality of sections of cylindrical shape or a central section of larger diameter and two terminal sections of smaller diameter.

Owner:NANO SIZE

Highly sensitive, fast pixel for use in an image sensor

ActiveUS7560701B2Overcomes speed limitationReasonable sensitivitySolid-state devicesMaterial analysis by optical meansElectric signalDemodulation

Owner:AMS SENSORS SINGAPORE PTE LTD

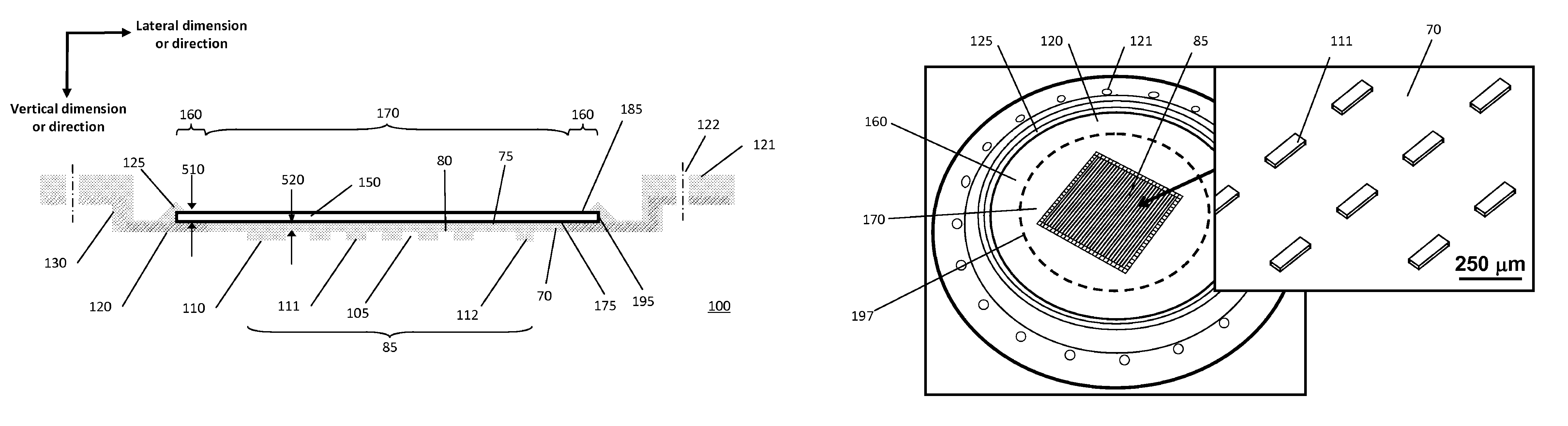

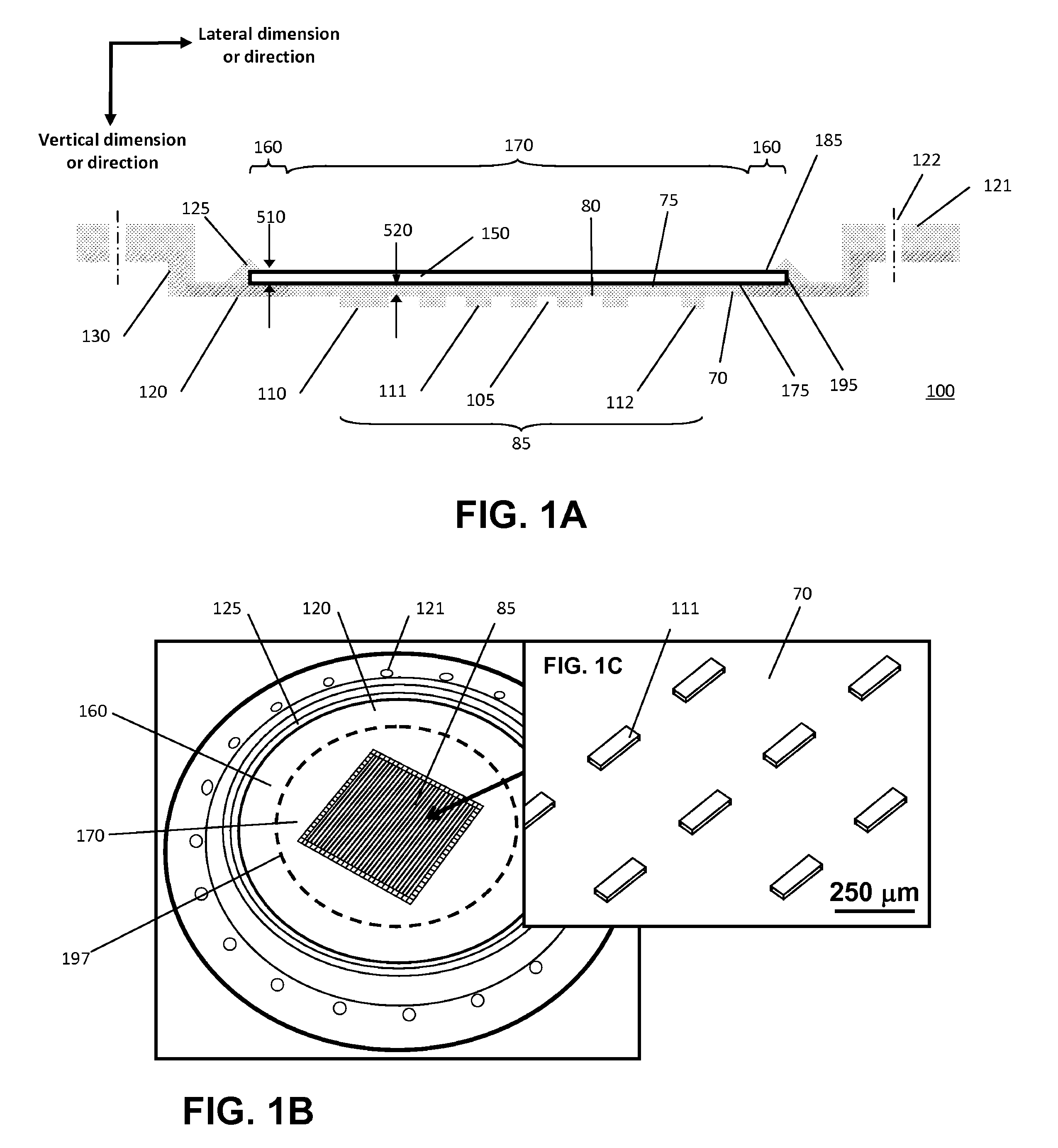

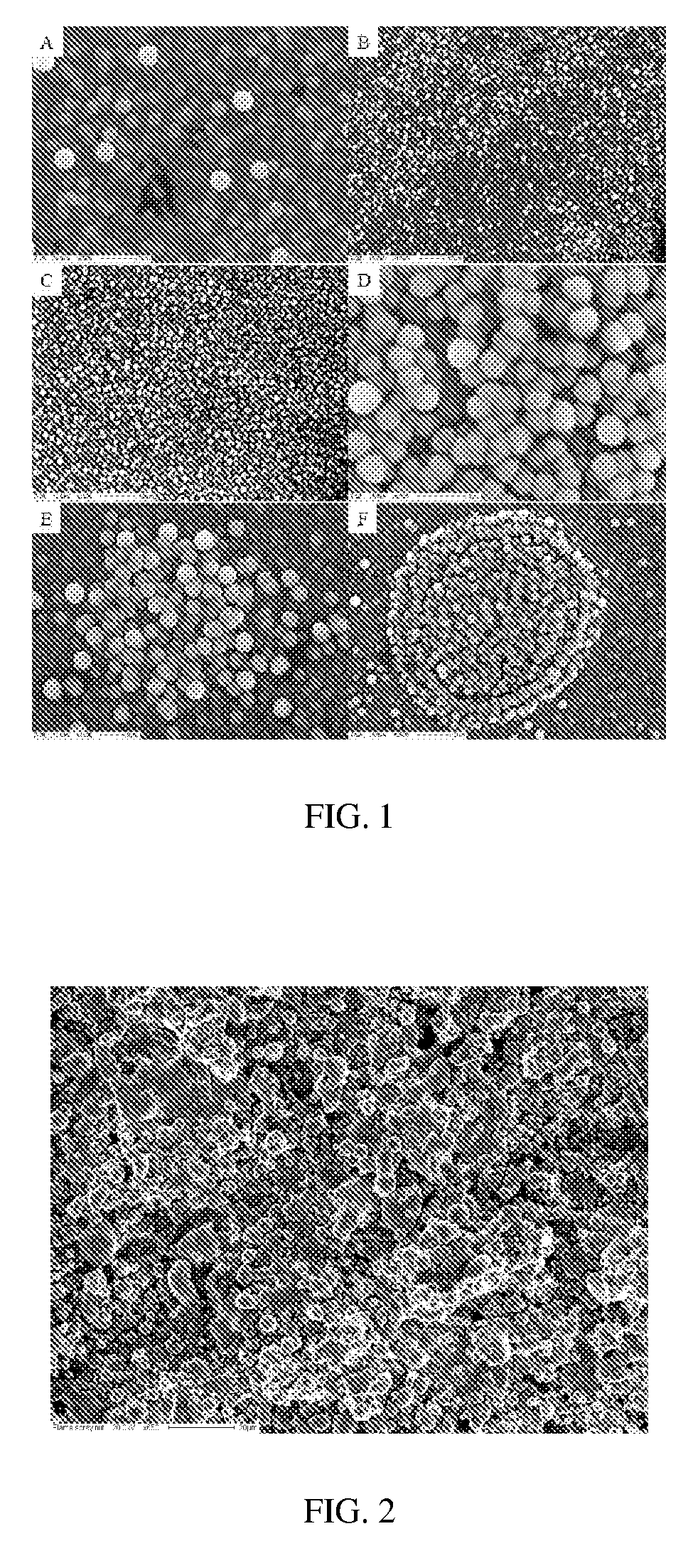

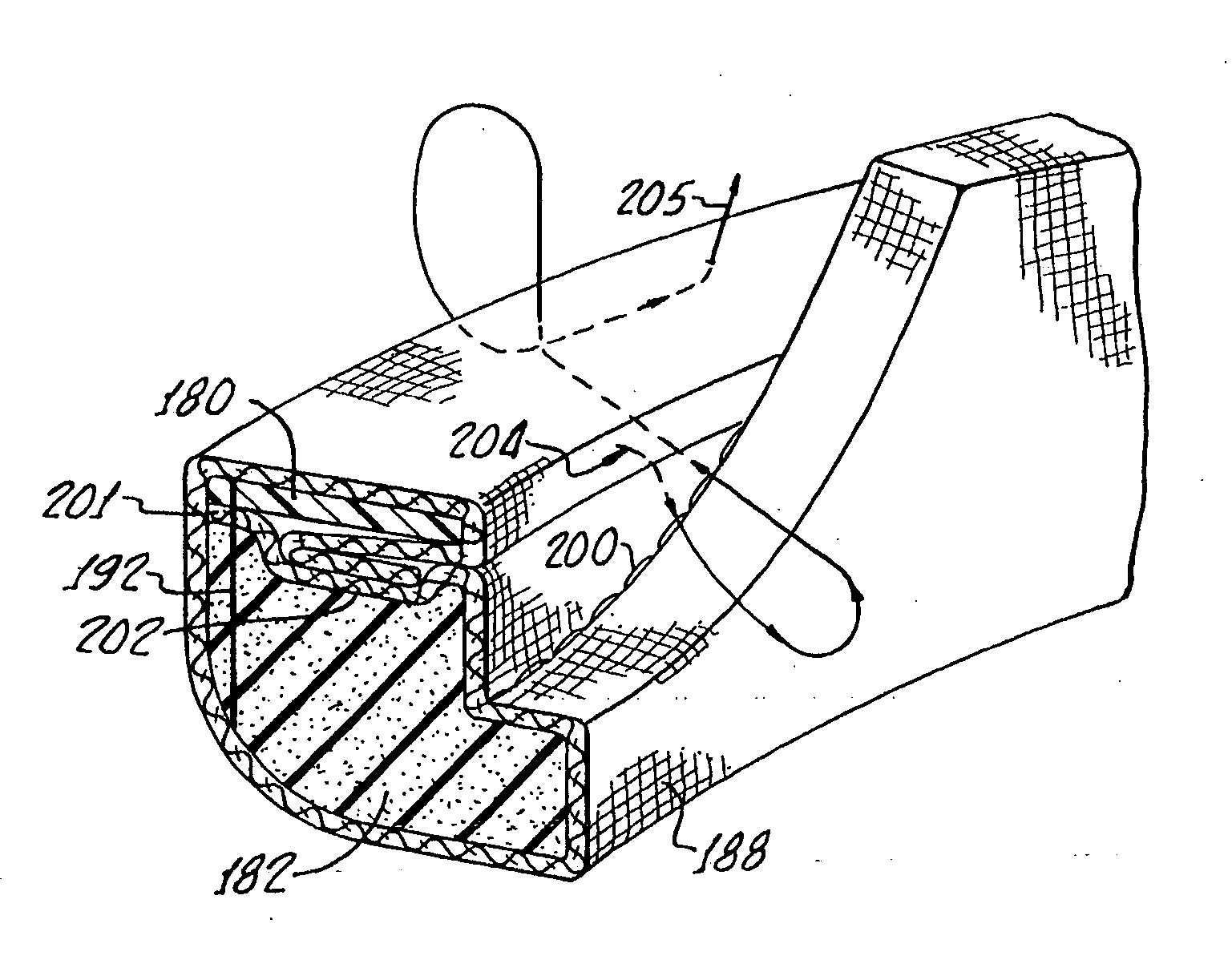

Reinforced composite stamp for dry transfer printing of semiconductor elements

ActiveUS7927976B2Easy to controlPrecise and repeatable vertical motionTurning machine accessoriesMouldsSemiconductor structureContact force

Provided are reinforced composite stamps, devices and methods of making the reinforced composite stamps disclosed herein. Reinforced composite stamps of certain aspects of the present invention have a composition and architecture optimized for use in printing systems for dry transfer printing of semiconductor structures, and impart excellent control over relative spatial placement accuracy of the semiconductor structures being transferred. In some embodiments, for example, reinforced composite stamps of the present invention allow for precise and repeatable vertical motion of the patterned surface of the printing apparatus with self-leveling of the stamp to the surface of a contacted substrate. Reinforced composite stamps of certain aspect of the present invention achieve a uniform distribution of contact forces between the printing apparatus patterned surface and the top surface of a substrate being contacted by the reinforced composite stamp of the printing apparatus.

Owner:X DISPLAY CO TECH LTD

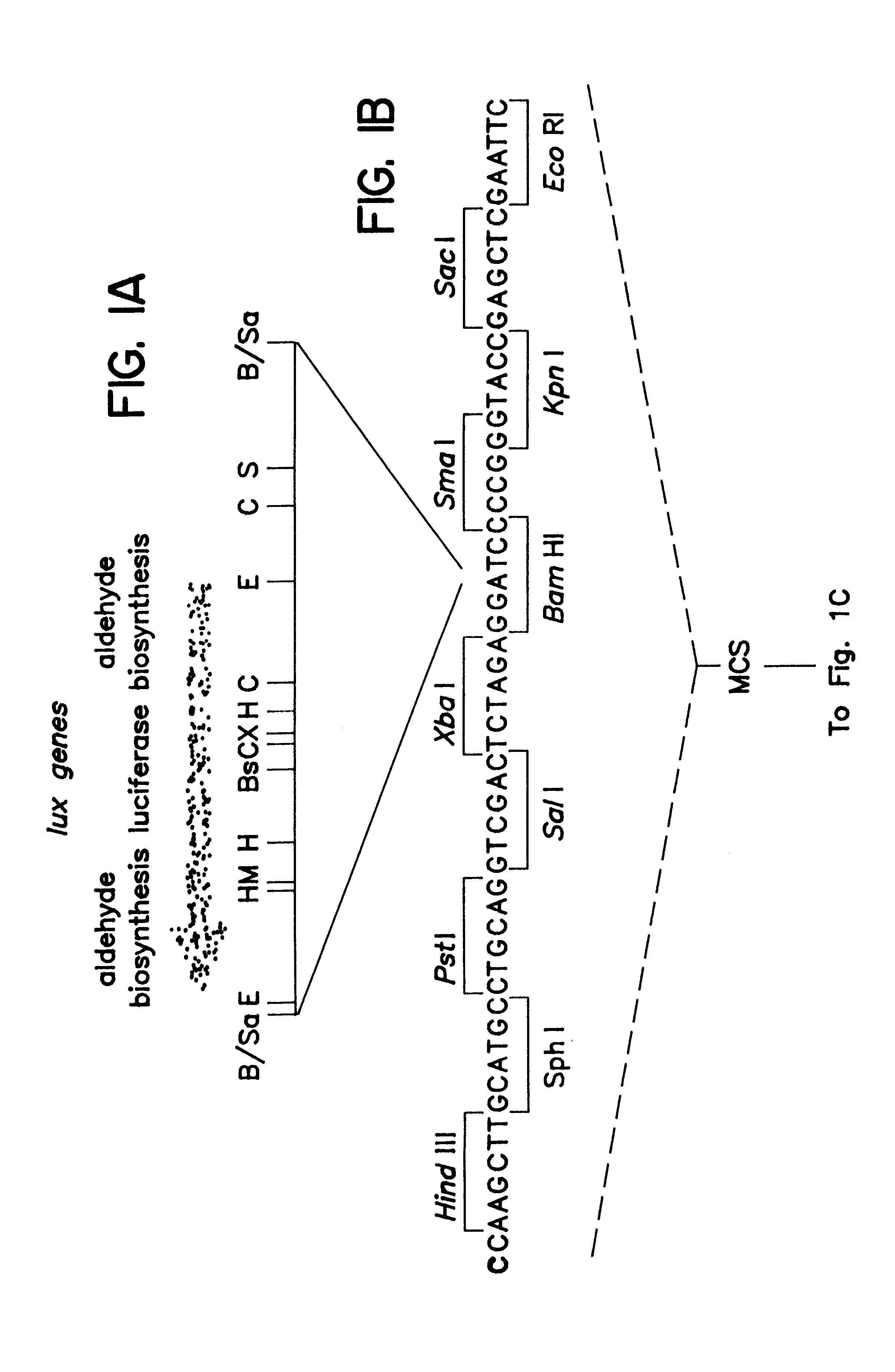

Non-invasive localization of a light-emitting conjugate in a mammal

InactiveUS6217847B1Accurate measurementEvenly distributedUltrasonic/sonic/infrasonic diagnosticsBacteriaMammalNon invasive

Methods and compositions for detecting and localizing light originating from a mammal are disclosed. Also disclosed are methods for tracking light emission to selected regions, as well as for tracking entities within the mammal. In addition, animal models for disease states are disclosed, as are methods for localizing and tracking the progression of disease or a pathogen within the animal, and for screening putative therapeutic compounds effective to inhibit the disease or pathogen.

Owner:LELAND STANFORD JUNIOR UNIV OF THE BOARD OF TRUSTEES THE

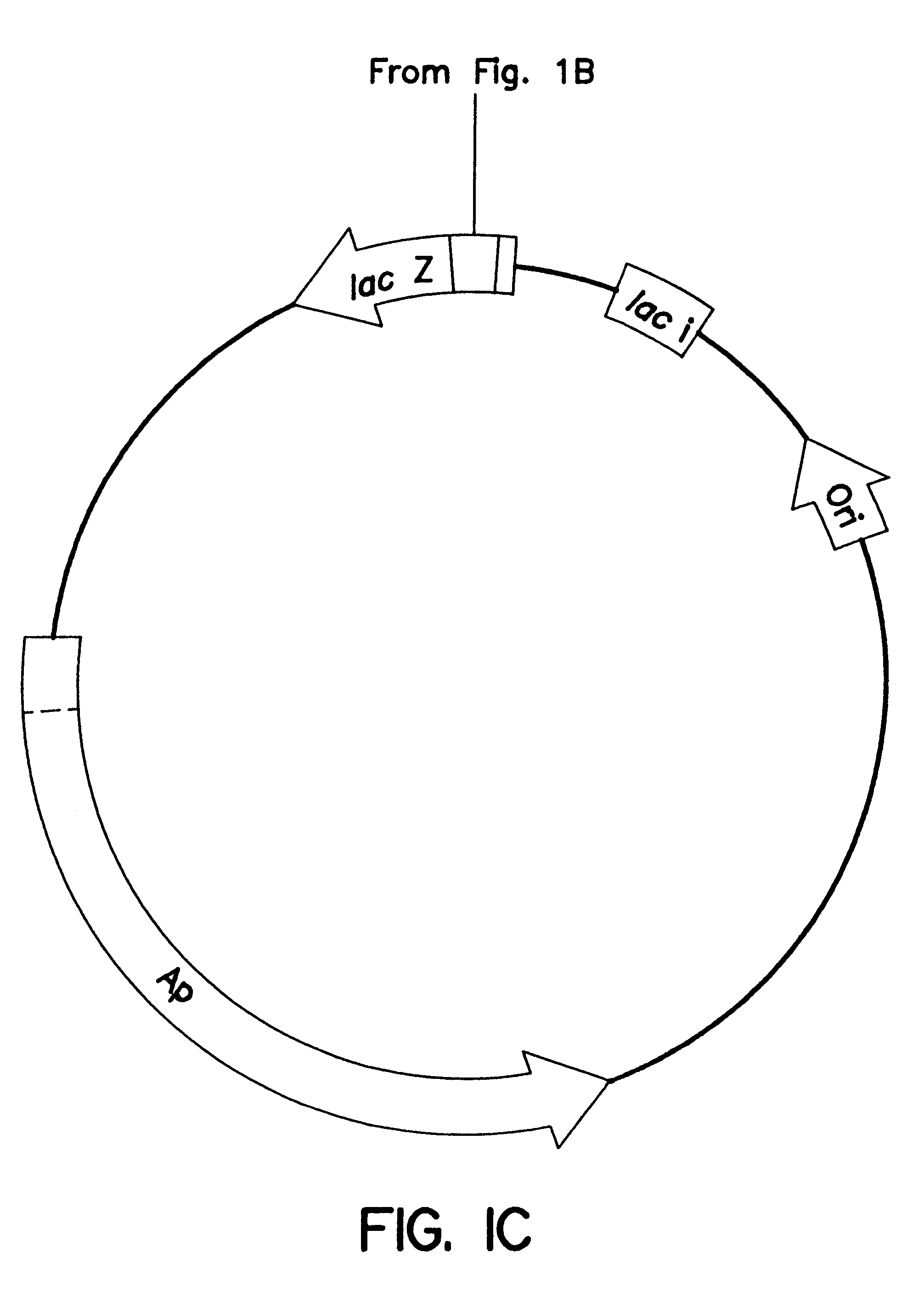

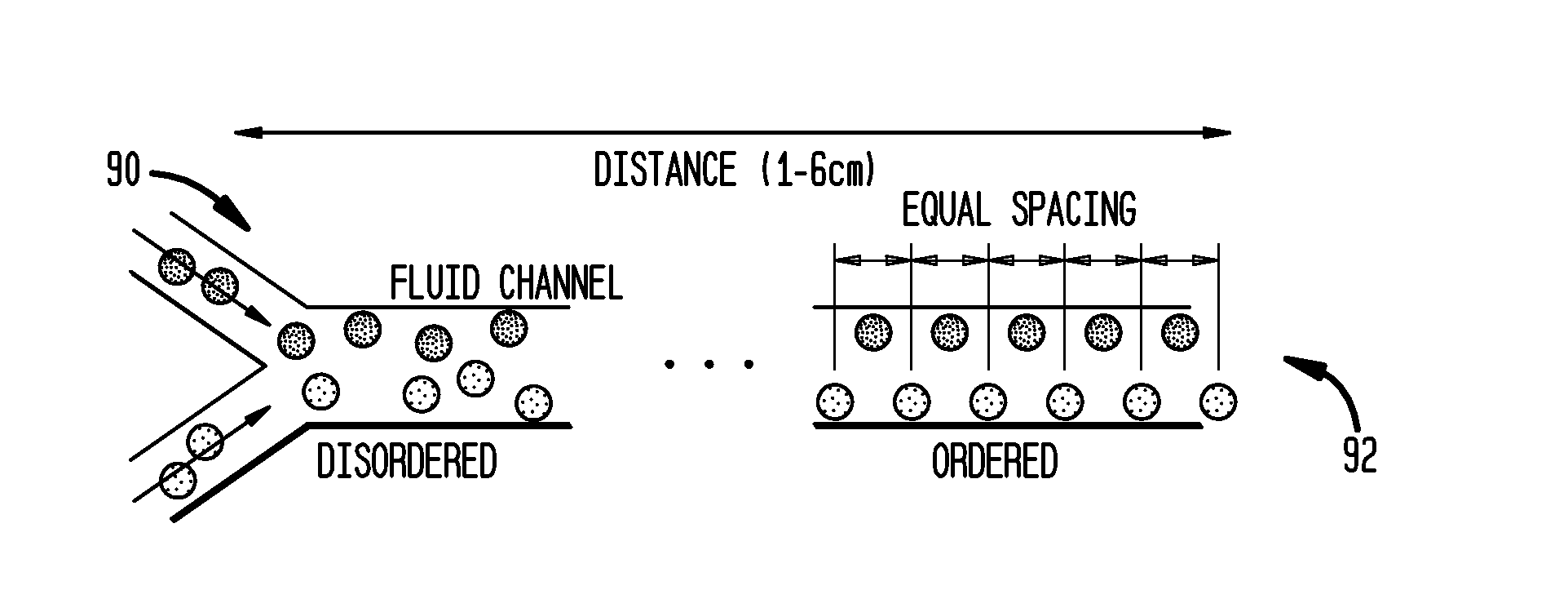

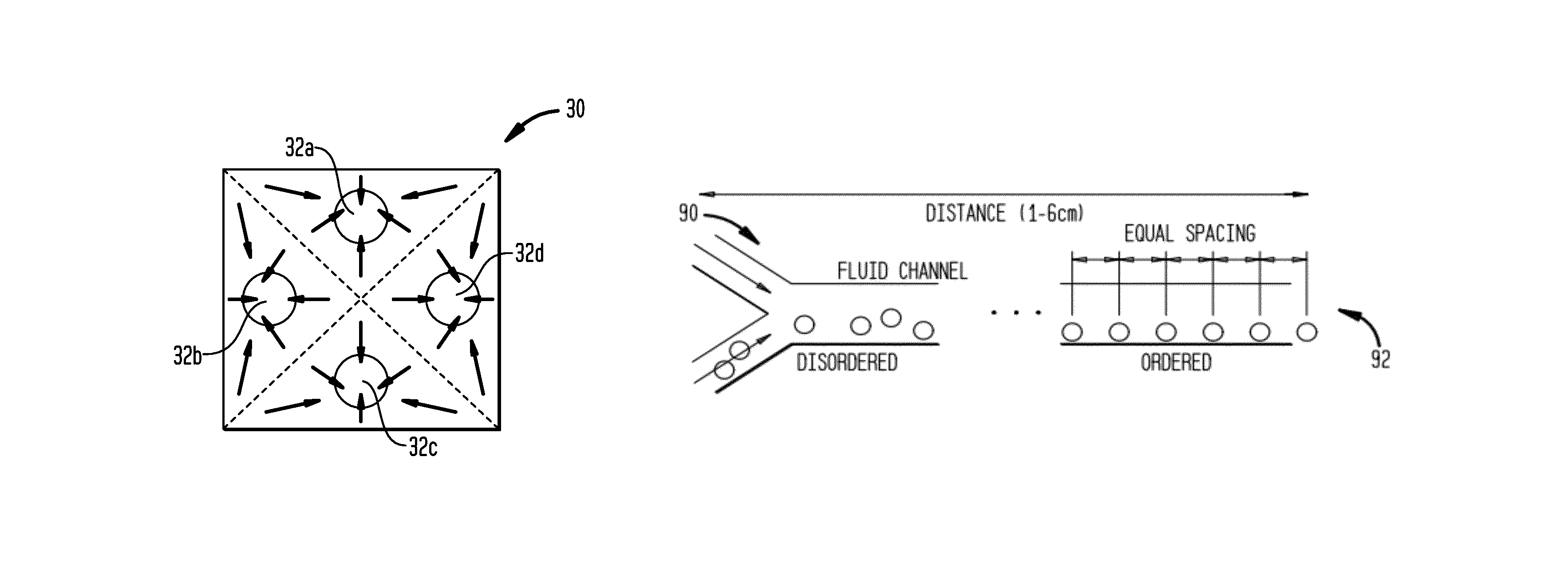

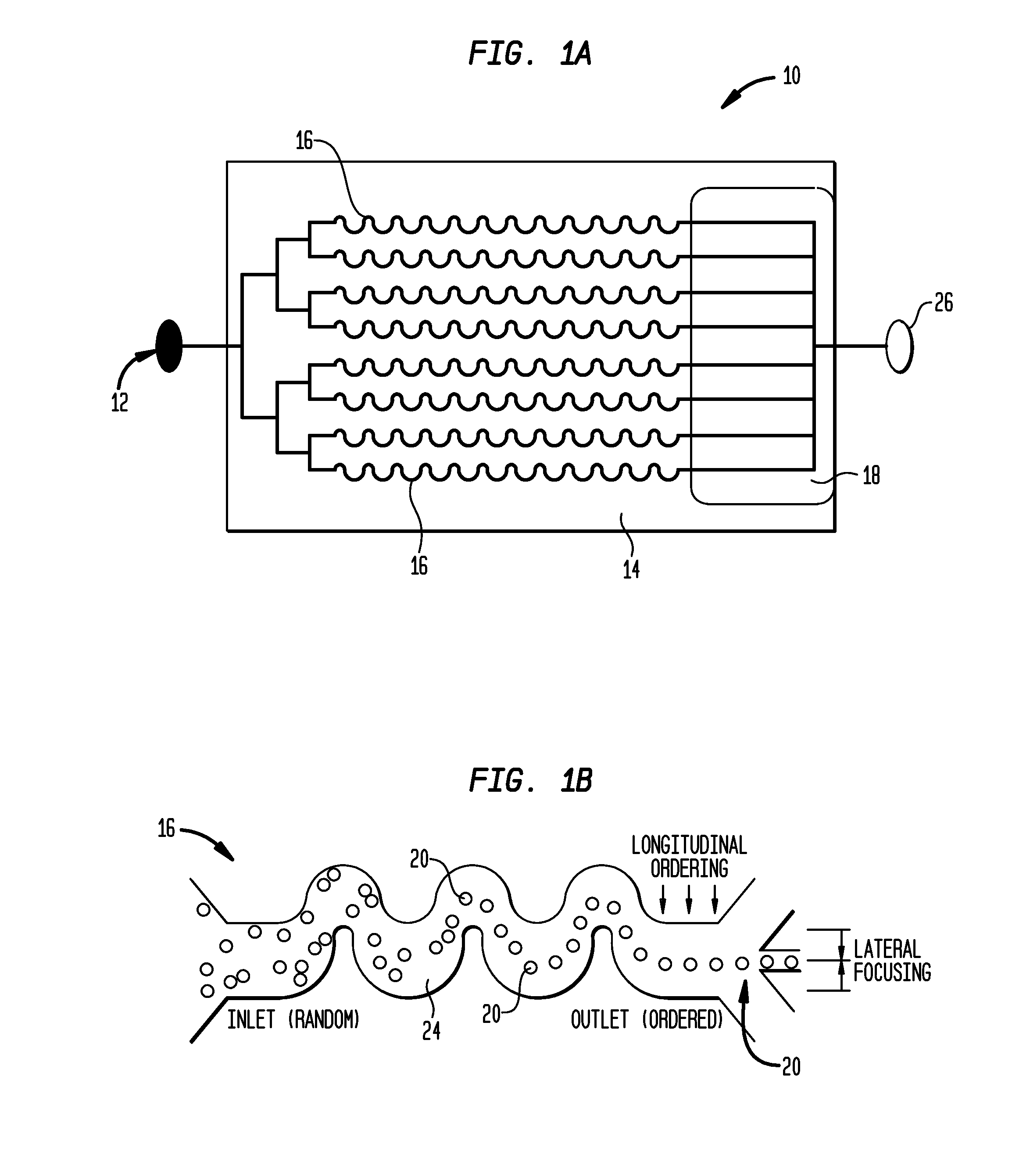

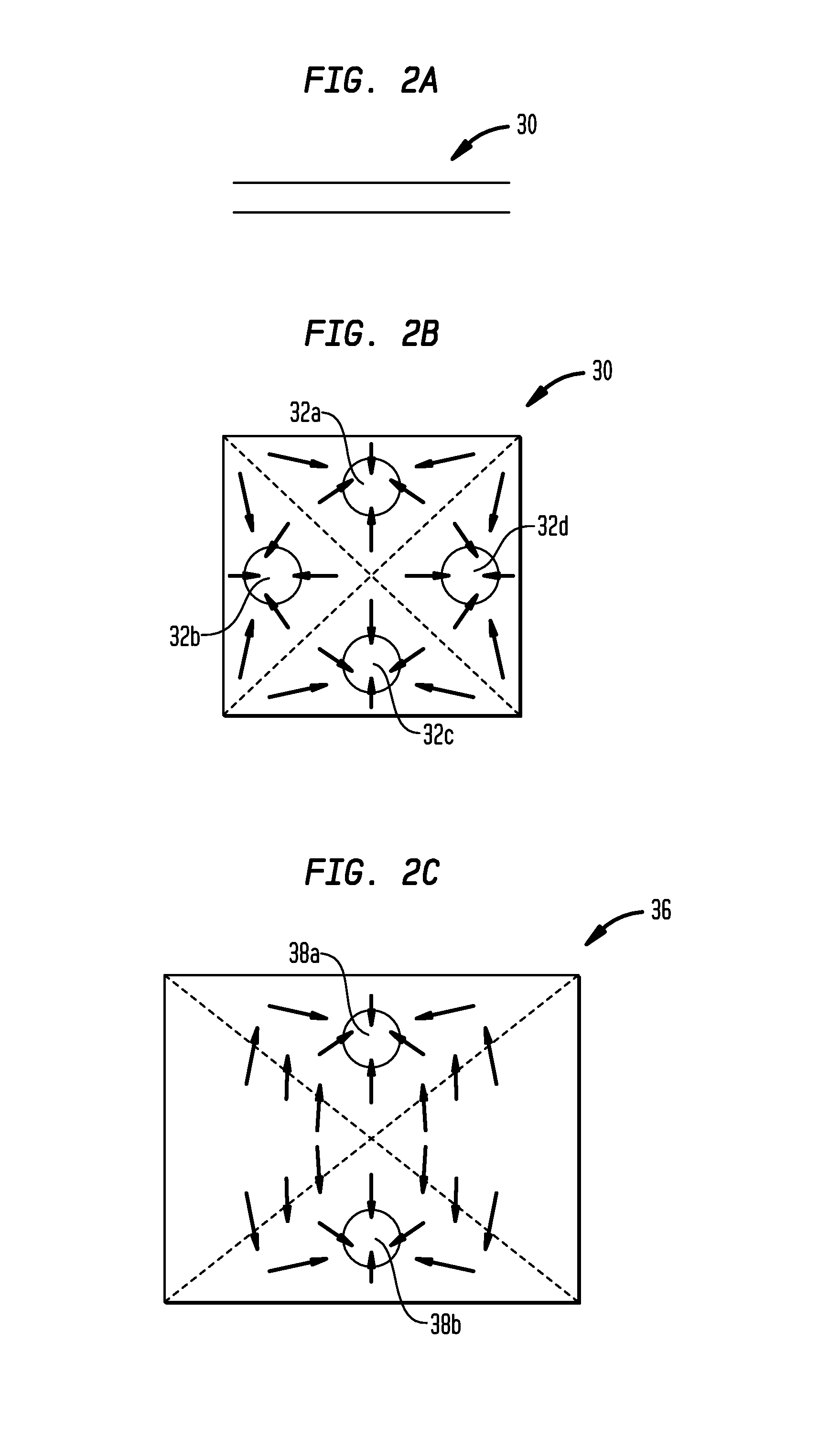

Systems and methods for particle focusing in microchannels

ActiveUS20090014360A1Increase in sizeImprove concentrationImmobilised enzymesSolvent extractionEngineeringSuspended particles

Various systems, methods, and devices are provided for focusing particles suspended within a moving fluid into one or more localized stream lines. The system can include a substrate and at least one channel provided on the substrate having an inlet and an outlet. The system can further include a fluid moving along the channel in a laminar flow having suspended particles and a pumping element driving the laminar flow of the fluid. The fluid, the channel, and the pumping element can be configured to cause inertial forces to act on the particles and to focus the particles into one or more stream lines.

Owner:THE GENERAL HOSPITAL CORP

Apparatus for supplying surgical staple line reinforcement

InactiveUS20090095791A1Thinner materialAccurately and successfully positionedSuture equipmentsStapling toolsBiomedical engineeringMaterial supply

An apparatus for supplying surgical buttress material to a surgical stapler is provided. The apparatus has a pivotable area for attaching surgical buttress material. The apparatus may also have an adhesive and a release liner disposed over the buttress material.

Owner:WL GORE & ASSOC INC

Apparatus and method for forming thin film using upstream and downstream exhaust mechanisms

ActiveUS7408225B2Reduce impactEvenly distributedElectric discharge tubesSemiconductor/solid-state device detailsGas supplySubstrate surface

A thin-film formation apparatus possesses a reaction chamber to be evacuated, a placing portion on which a substrate is placed inside the reaction chamber, a gas-dispersion guide installed over the placing portion for supplying a gas onto a substrate surface, a gas-supply port for introducing the gas into the gas-dispersion guide, a gas-dispersion plate disposed on the side of the substrate of the gas-dispersion guide and having multiple gas-discharge pores, a first exhaust port for exhausting, downstream of the gas-dispersion plate, the gas supplied onto the substrate surface from the gas-dispersion plate, and a second exhaust port for exhausting, upstream of the gas-dispersion plate, a gas inside the gas-dispersion guide via a space between the gas-dispersion guide and the gas-dispersion plate.

Owner:ASM JAPAN

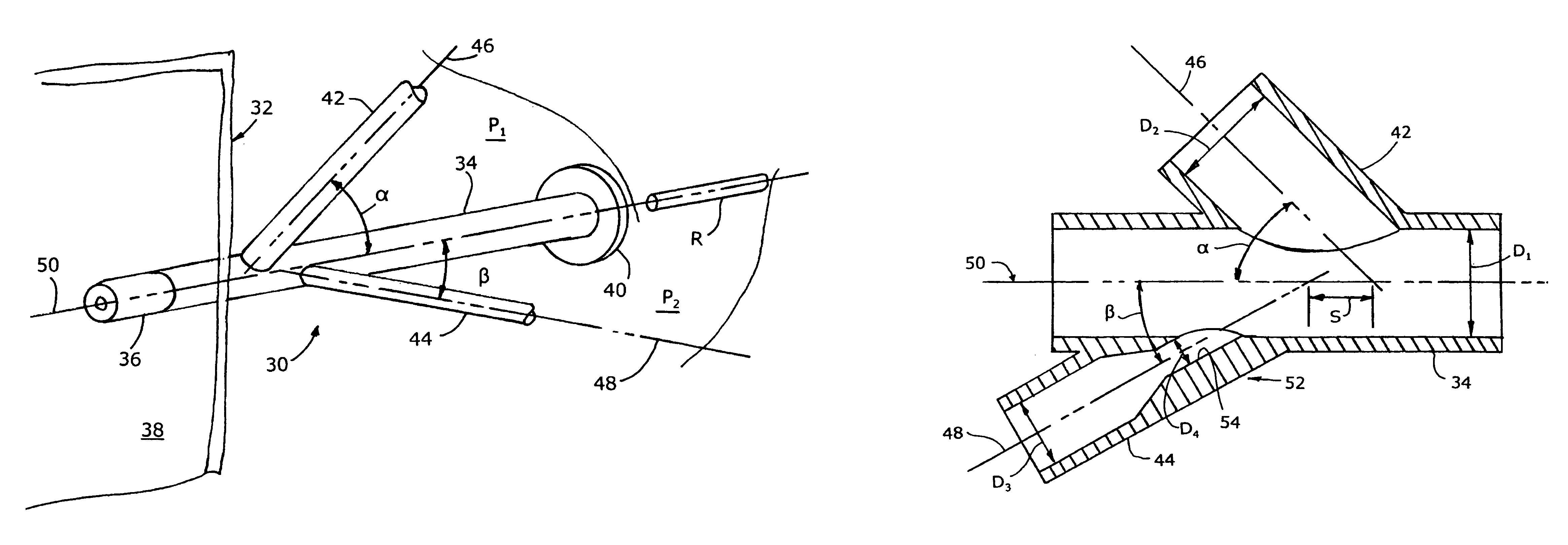

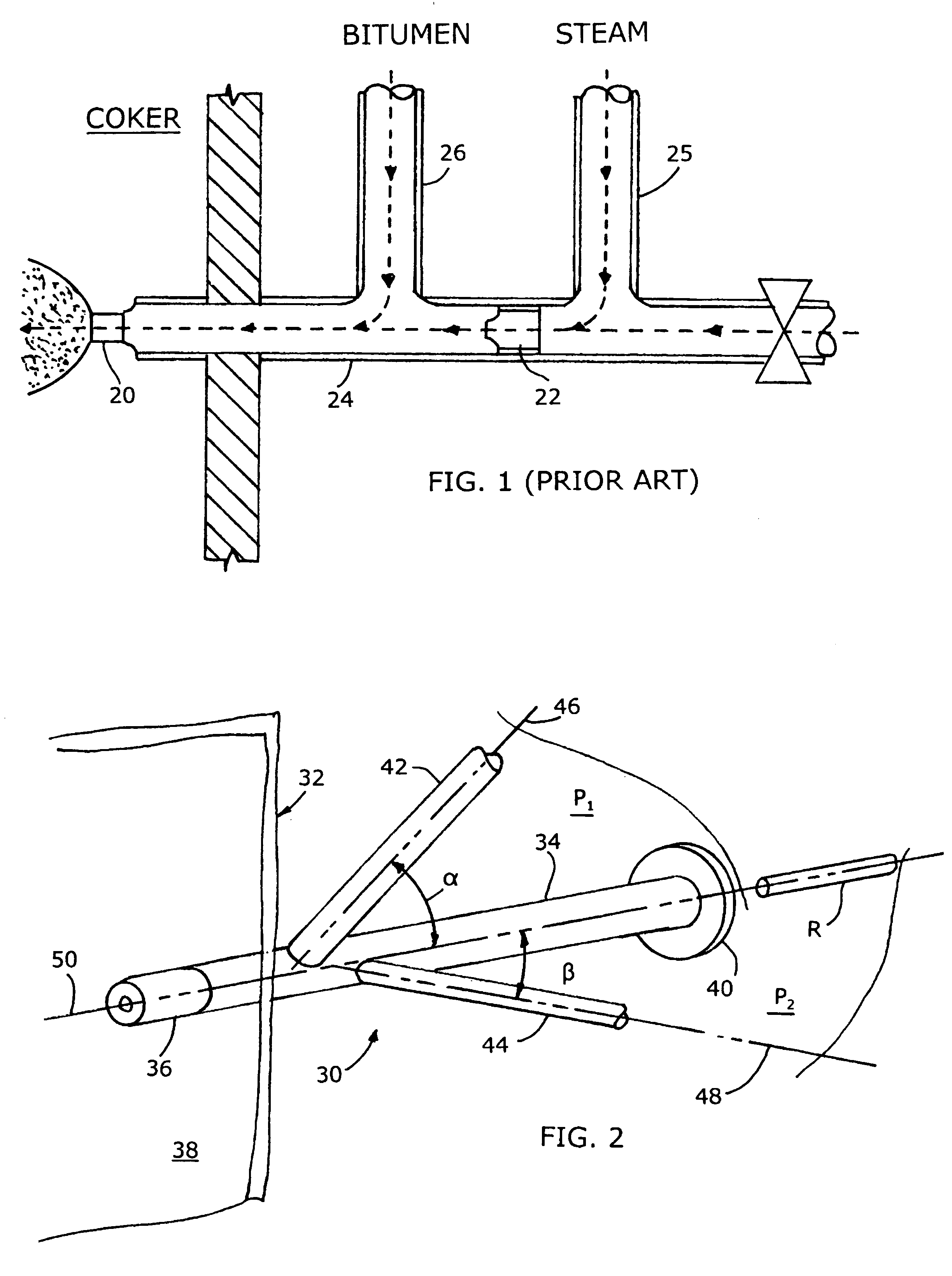

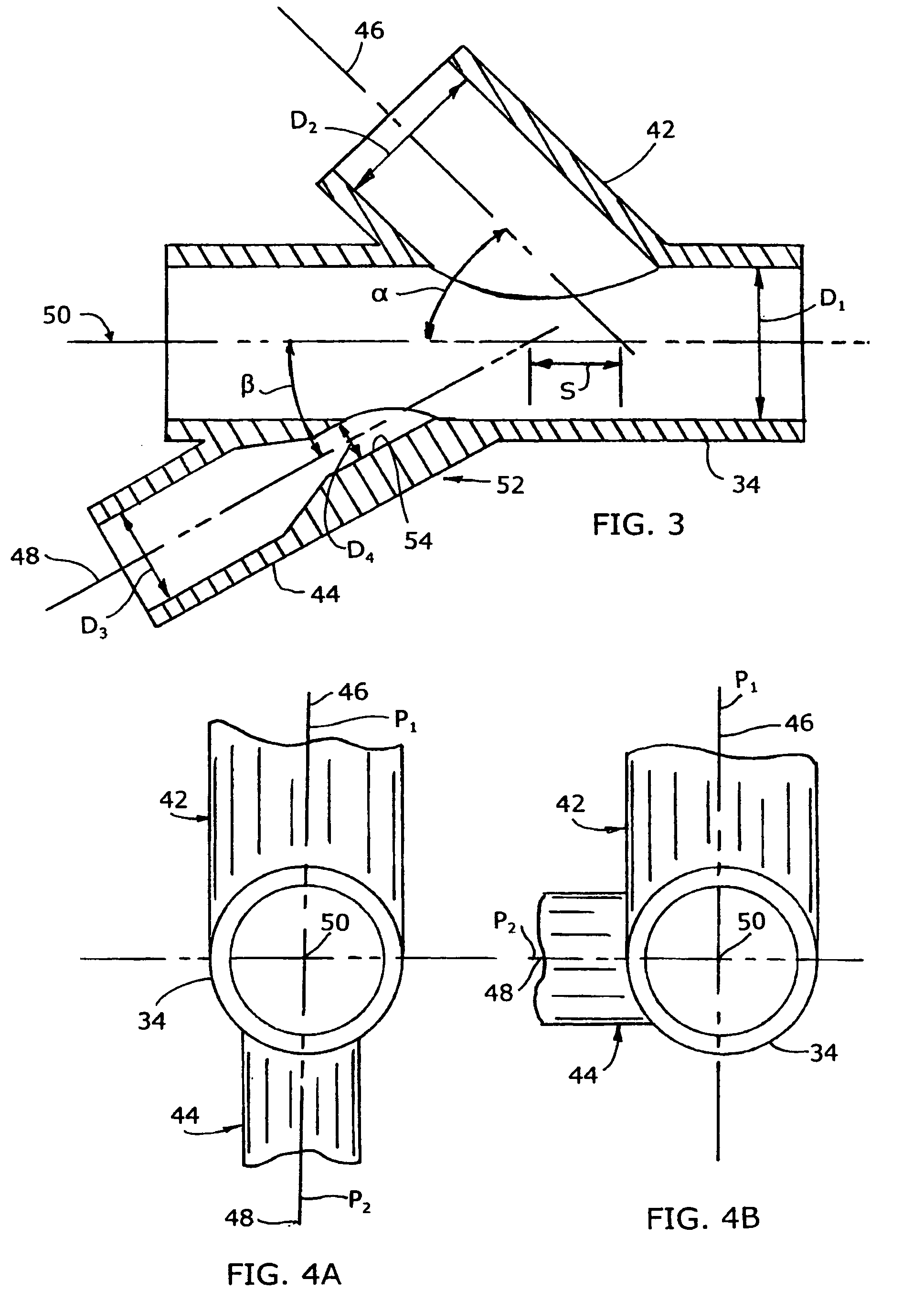

Mixing arrangement for atomizing nozzle in multi-phase flow

ActiveUS7140558B2Smooth transitionEasy to processCharging-discharging device combinationsFlow mixersAcute angleShortest distance

The invention relates to an improved mixing arrangement for, primarily, moving bitumen in steam from sources of such bitumen and steam to a reactor or coker for further processing of the bitumen into petroleum products. The invention provides a main conduit connected to an atomizing nozzle mounted in a wall of the reactor and first and second conduits for flowing bitumen and steam respectively into the main conduit. The first conduit is angled relative to the main conduit at an acute angle of about 45° and the second conduit is angled relative to the main conduit at an acute angle of about 30°. The second conduit is positioned upstream of the first conduit by a short distance of about 23 mm and may be angled radially relative to the first conduit by any angle, although a 90° angle is preferred. A flow accelerating nozzle is located in the second conduit adjacent the entrance therefrom into the main conduit The arrangement of the invention improves the flow characteristics of 2-phase material flowing to the atomizing nozzle, reducing pulsations in the main conduit and improving the resulting atomization of the bitumen in the reactor.

Owner:NAT RES COUNCIL OF CANADA +1

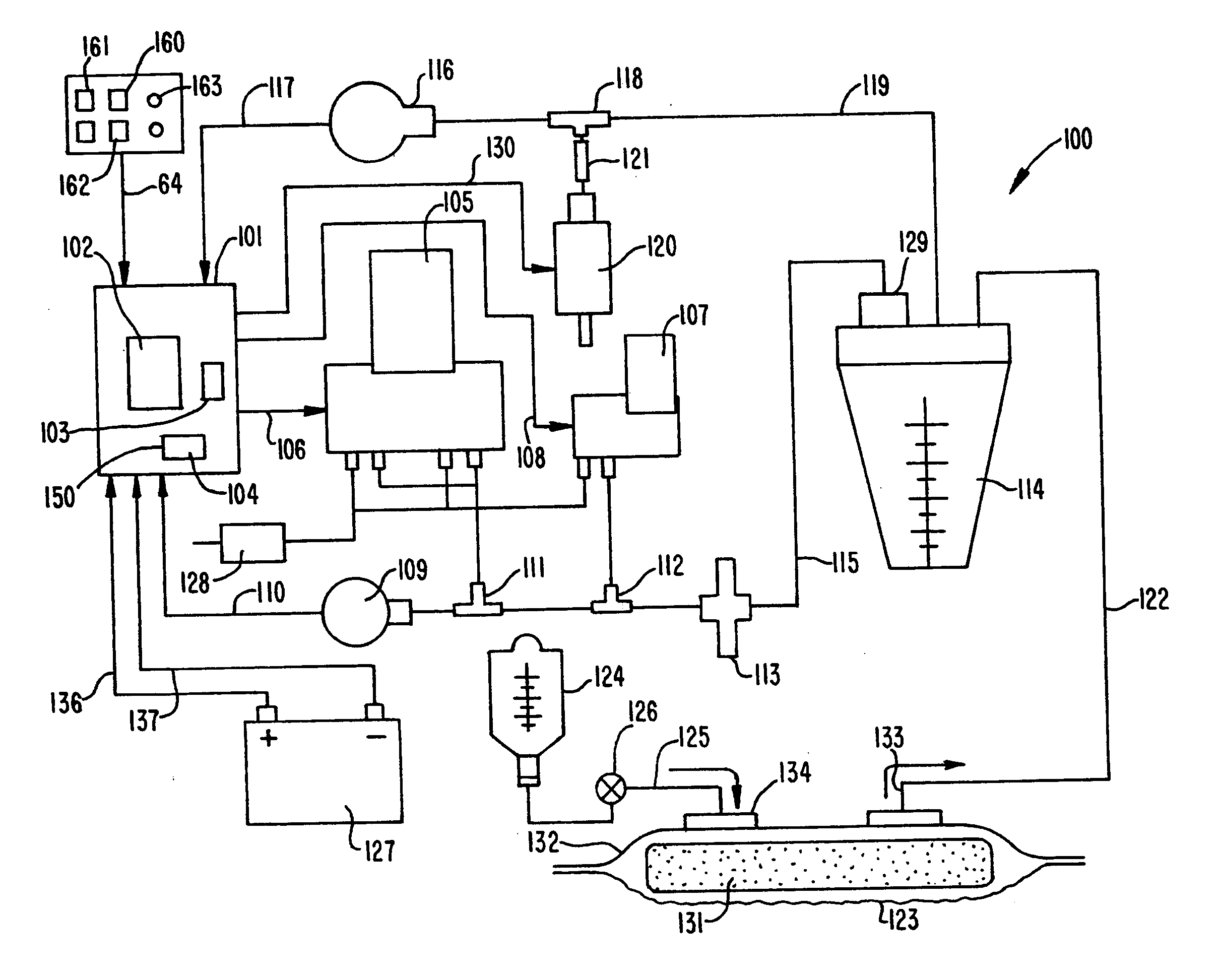

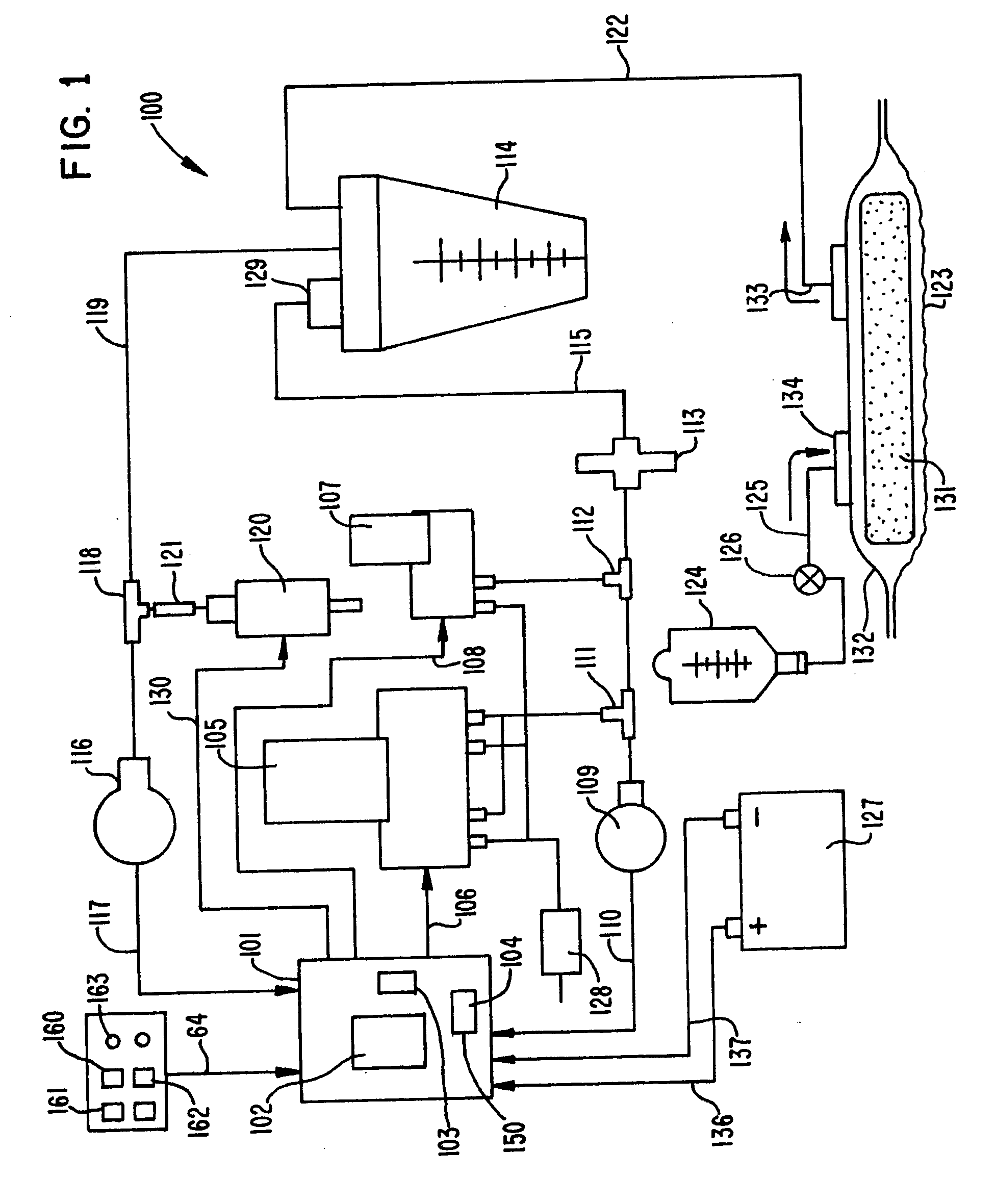

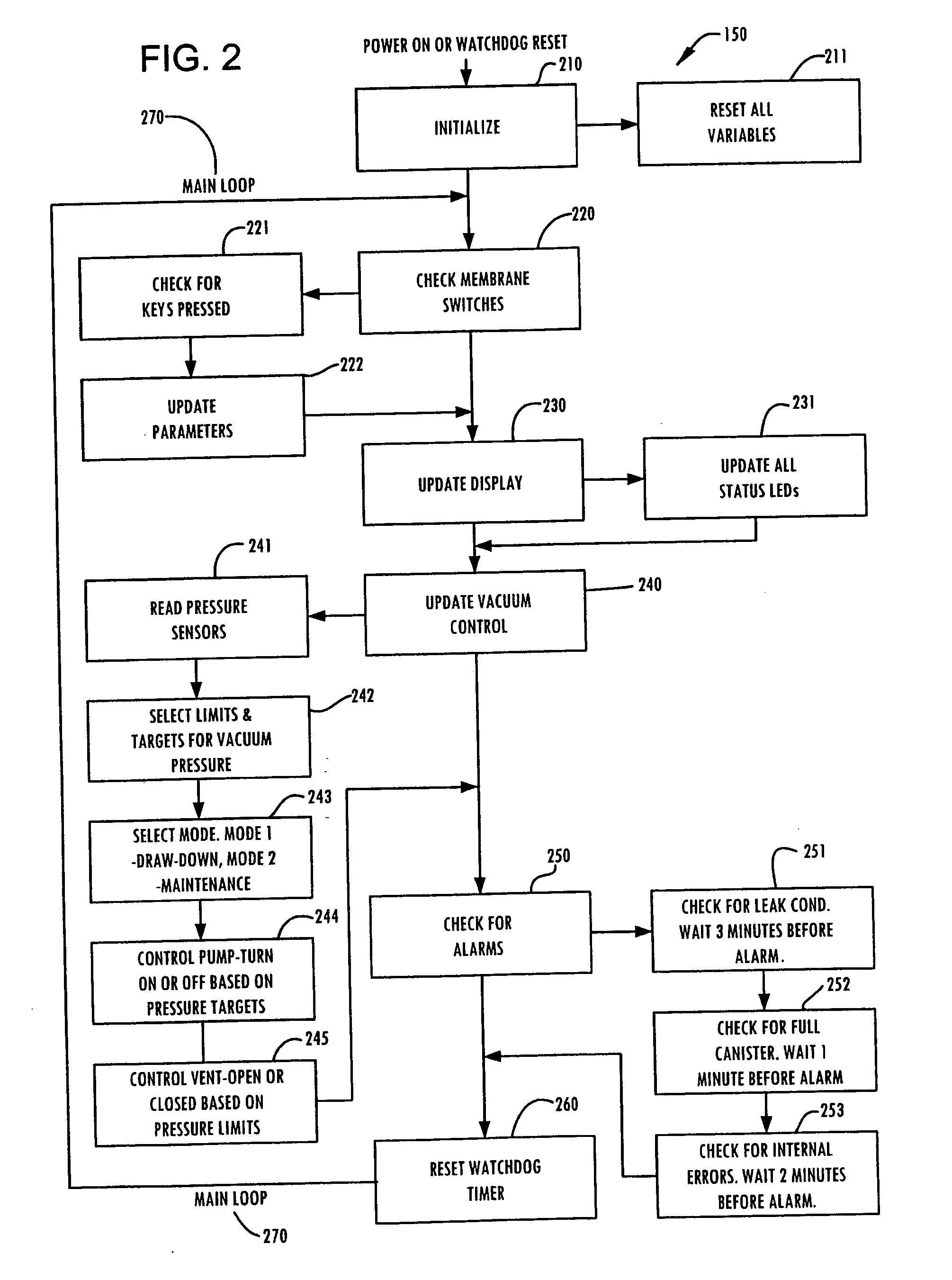

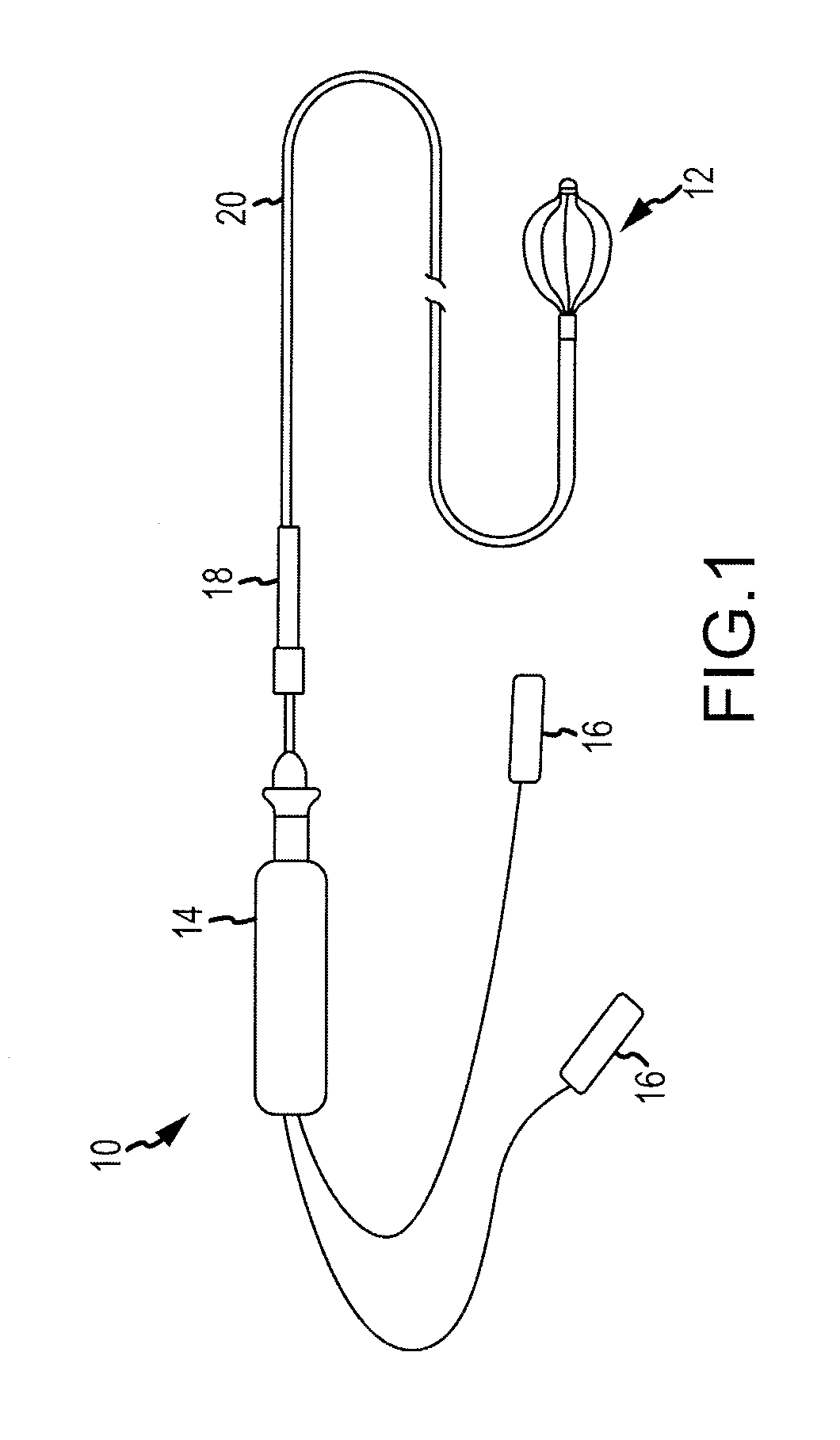

Wound irrigation device

ActiveUS20070032762A1Easy to disassembleHighly efficaciousWound drainsPlastersBiomedical engineeringMembrane configuration

Owner:INNOVATIVE THERAPIES LLC

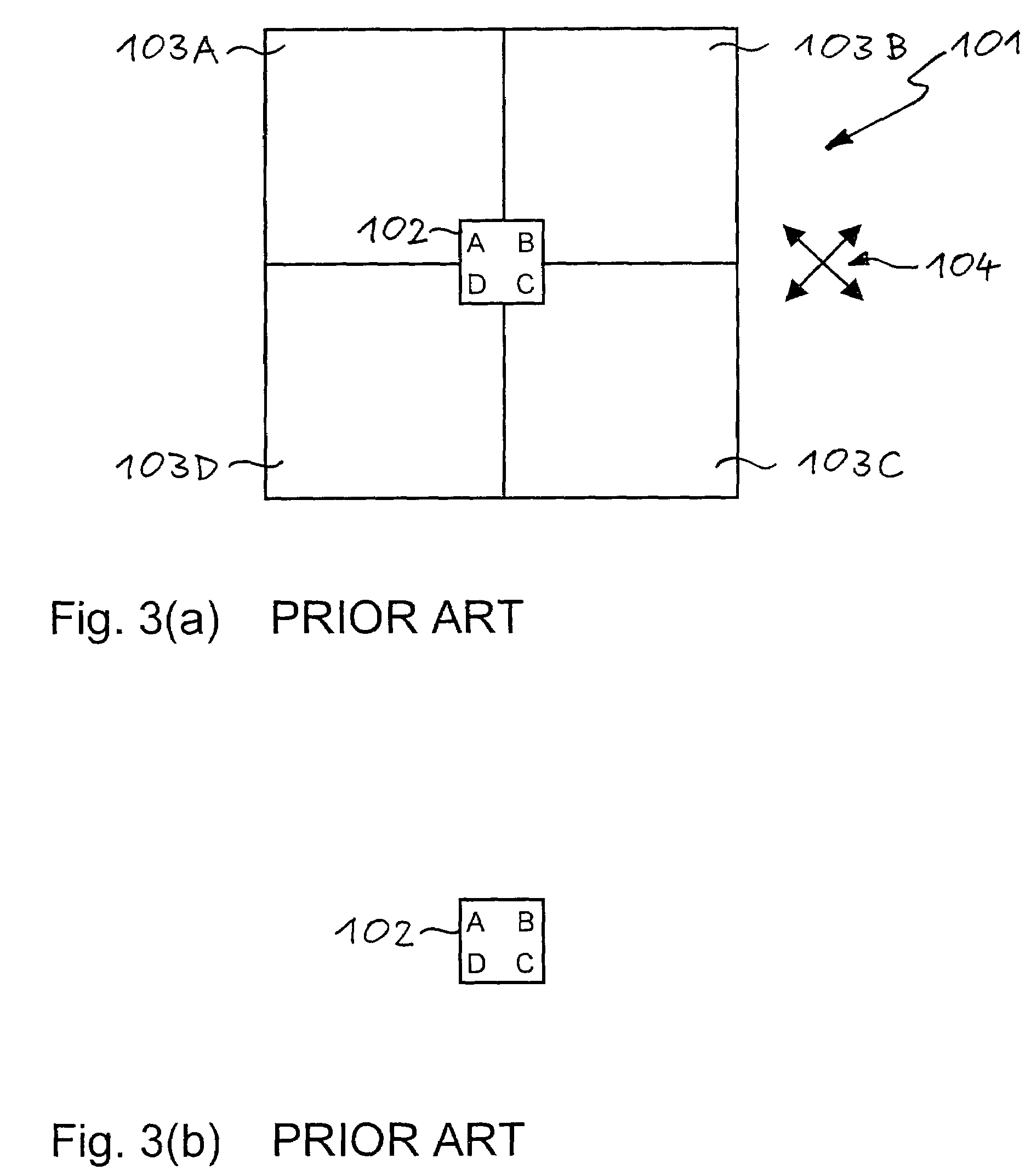

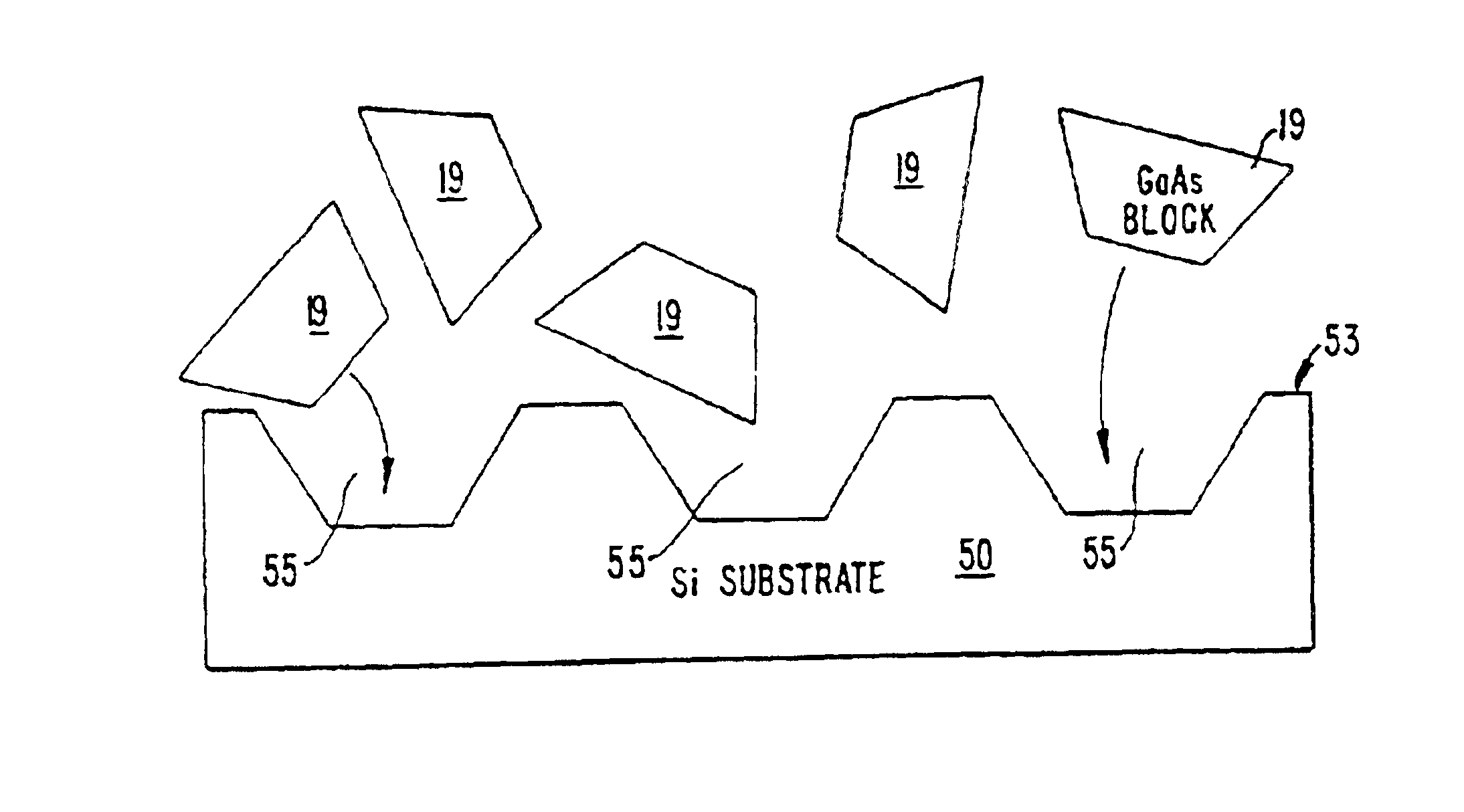

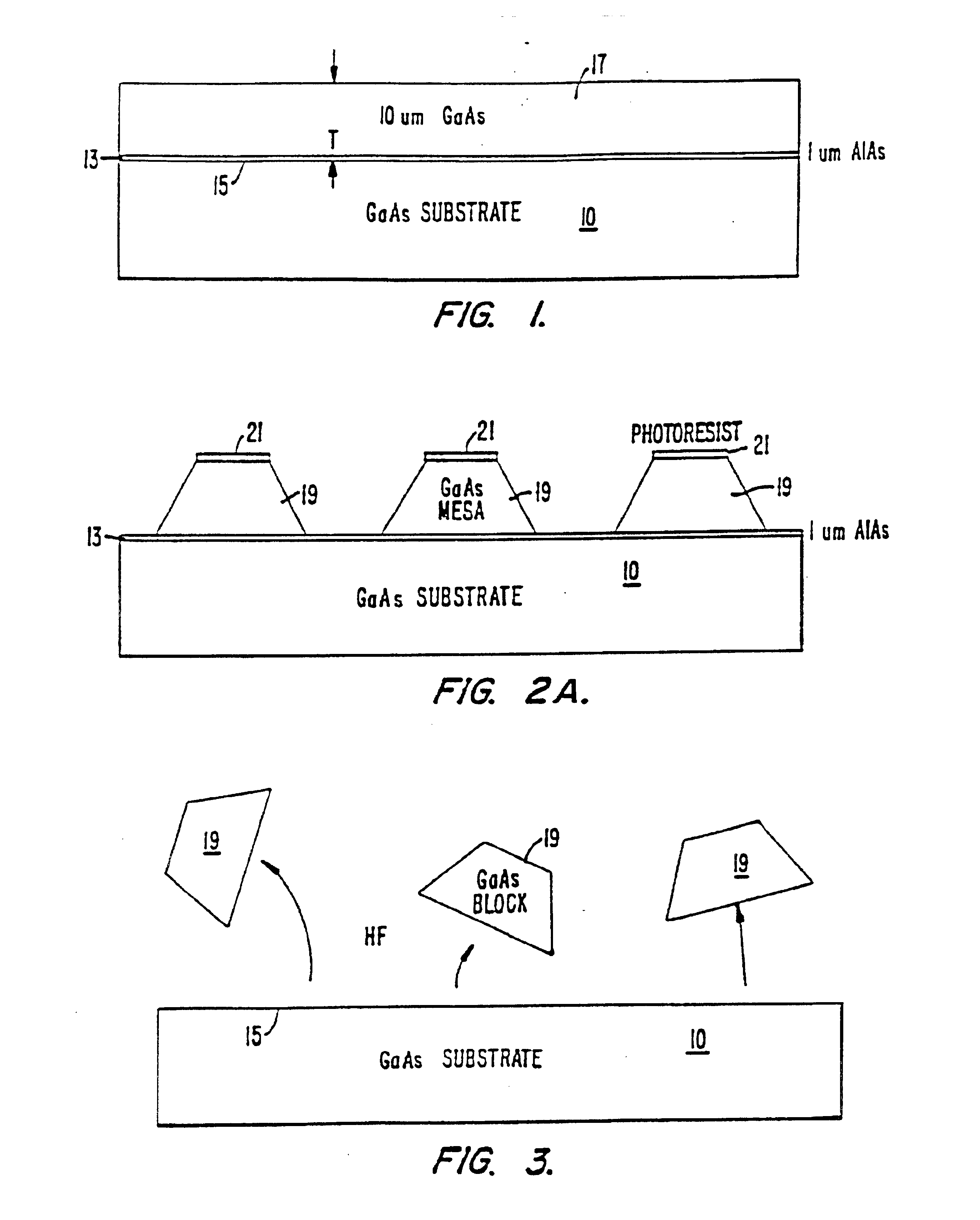

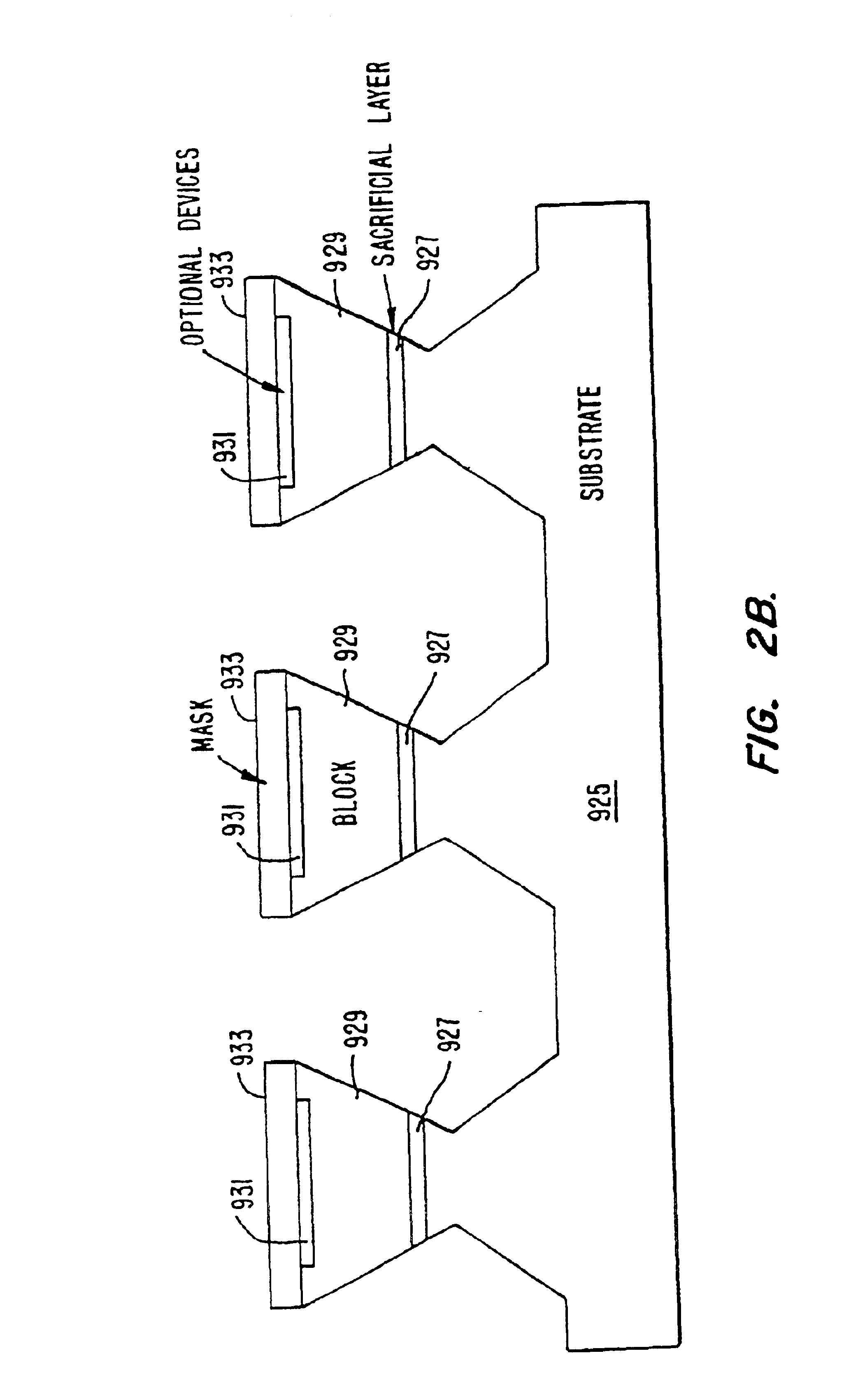

Method and apparatus for fabricating self-assembling microstructures

InactiveUS6864570B2Promote circulationEvenly distributedTransistorSemiconductor laser arrangementsFluid transportSelf assemble

A method and apparatus for assembling microstructures onto a substrate through fluid transport. The microstructures being shaped blocks self-align into recessed regions located on a substrate such that the microstructure becomes integral with the substrate. The improved method includes a step of transferring the shaped blocks into a fluid to create a slurry. Such slurry is then dispensed evenly or circulated over the top surface of a substrate having recessed regions thereon. The microstructure via the shape and fluid tumbles onto the surface of the substrate, self-aligns, and engages into a recessed region.

Owner:RGT UNIV OF CALIFORNIA

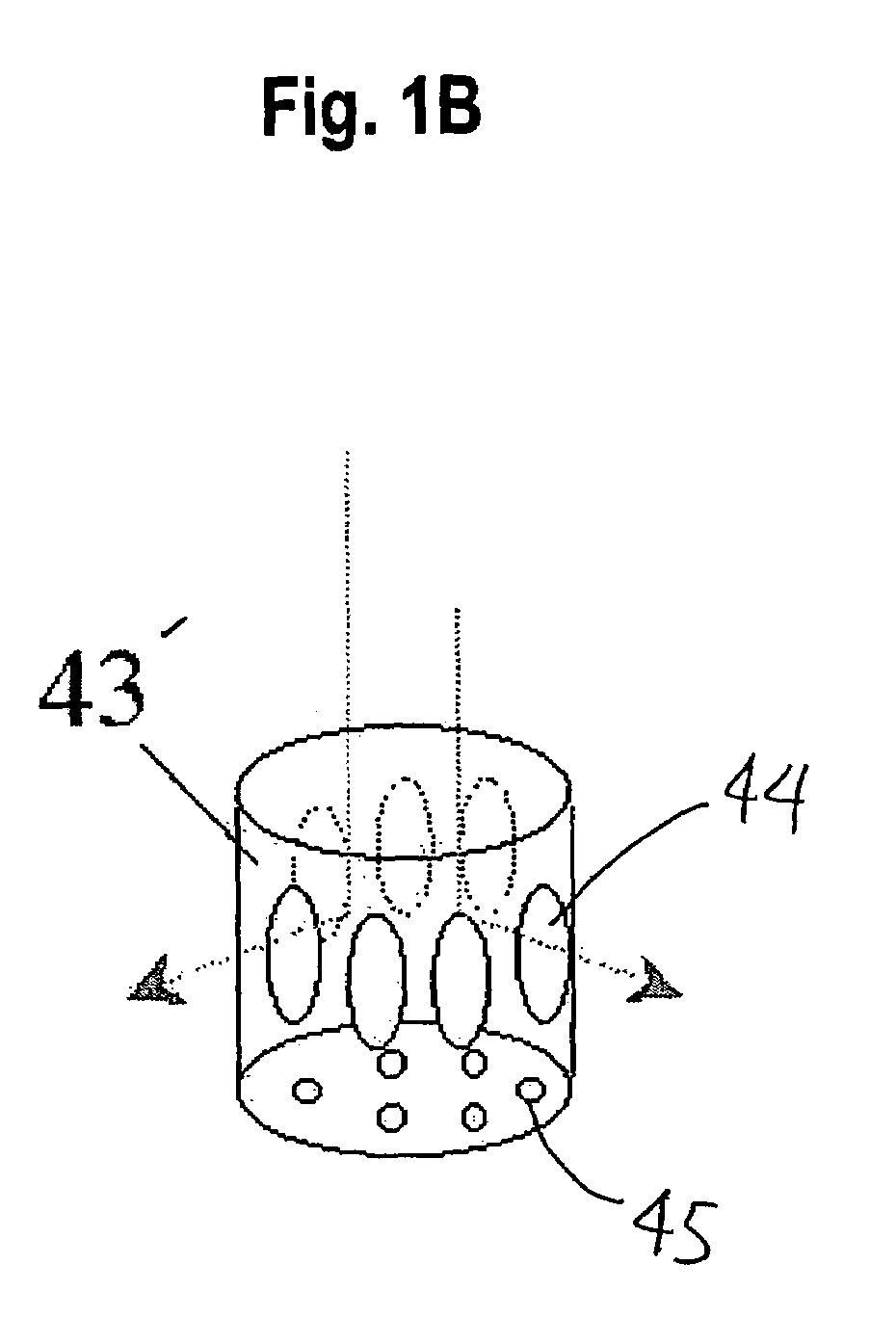

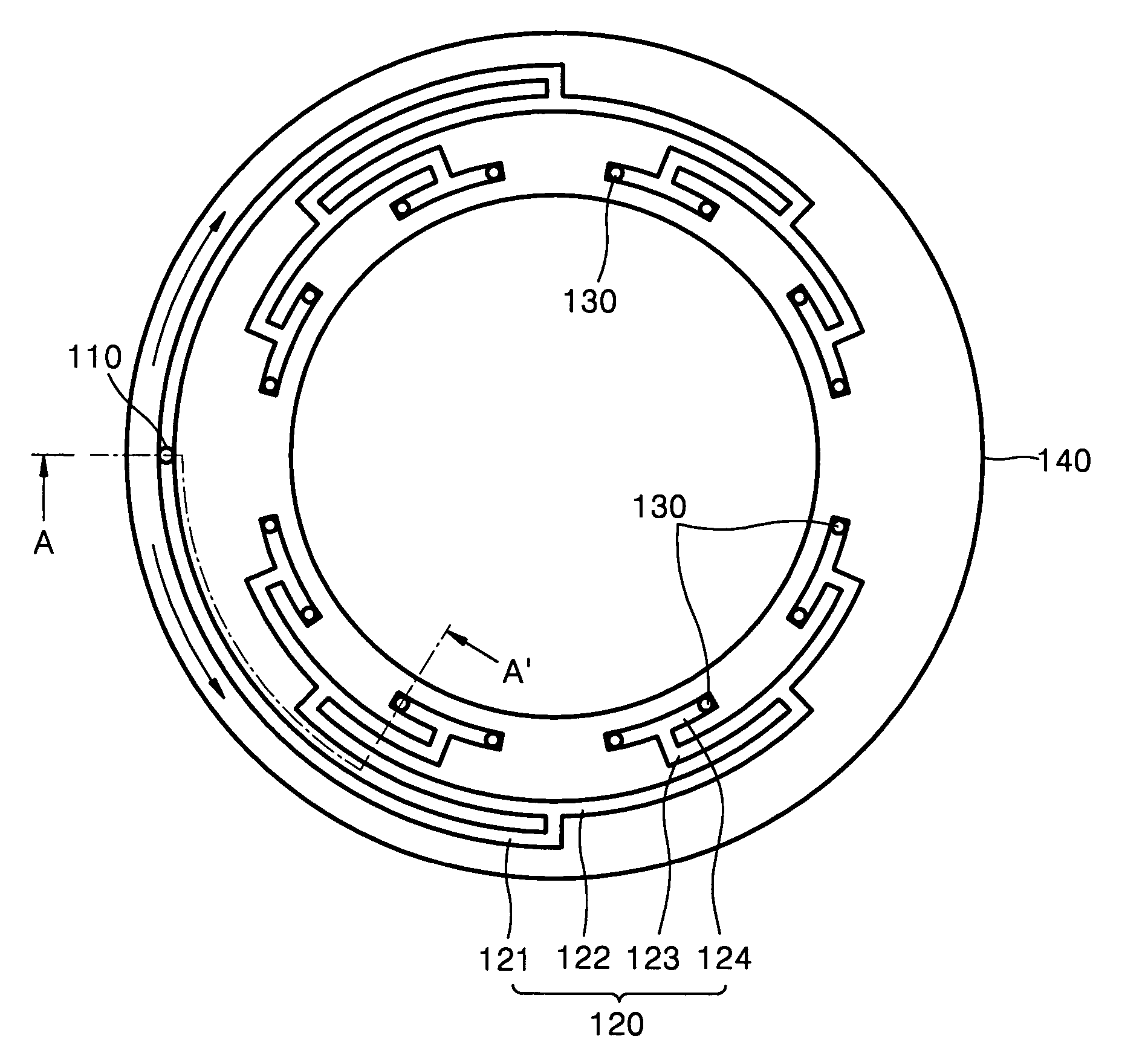

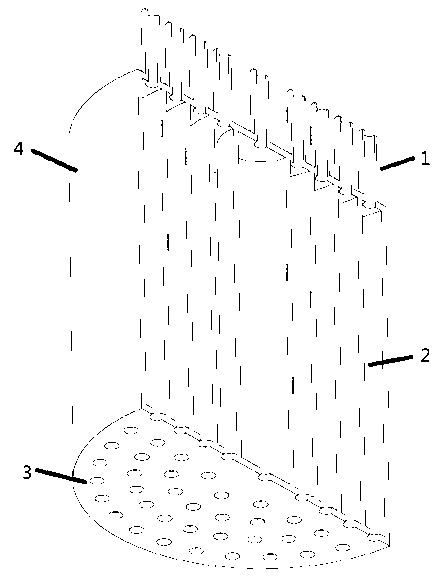

Gas injection apparatus for semiconductor processing system

InactiveUS7252716B2Improve uniformityEvenly distributedVacuum evaporation coatingSemiconductor/solid-state device manufacturingReactive gasGas passing

A gas injection apparatus for injecting a reactive gas into a reaction chamber of a semiconductor processing system includes an injector in contact with an inner surface of a wall of the reaction chamber. The injector has a plurality of nozzles through which the reactive gas is injected into the reaction chamber. A gas inlet penetrates the wall of the reaction chamber. A manifold is disposed between the wall of the reaction chamber and the injector, and supplies the reactive gas flowing through the gas inlet to the nozzles. Gas channels in the manifold are arranged on a plurality of levels to equalize the lengths of gas paths connecting the gas inlet to each of the plurality of nozzles. This configuration makes the flow rate of reactive gas supplied through each of the plurality of nozzles to the reaction chamber uniform.

Owner:SAMSUNG ELECTRONICS CO LTD

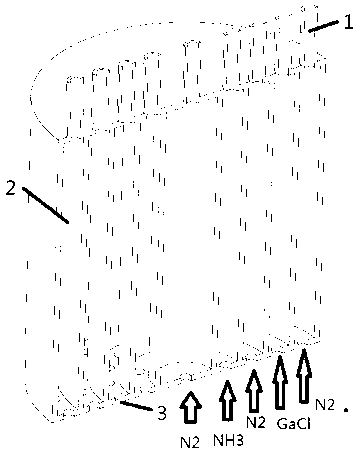

Concentric-ring sprayer structure for material vapor phase epitaxy

InactiveCN103014846ANo effect on growthGrowth impactFrom chemically reactive gasesVapour phase epitaxySprayer

The invention discloses a concentric-ring sprayer structure for material vapor phase epitaxy, which solves the problem that the large-area deposition region provides a uniform flow field of a precursor gas mixture in a large-substrate or multi-substrate crystal growth process. The sprayer structure comprises more than one independent air inlet pipeline, wherein each air inlet pipeline is provided with a controller for monitoring and regulating inlet gas flow speed and flow rate; the bottom of the sprayer is provided with an air outlet baffle; more than one concentric ring is arranged in the sprayer; independent cavities are formed among the concentric rings and are mutually separated; the top end of each concentric ring is connected with one independent air inlet pipeline; and the air outlet baffle at the bottom end of each concentric ring is provided with one or more air outlets. The air sources are mutually separated and independently controlled; and the multi-sprayer integrated use mode obviously improves the quality of the large-area deposited grown crystal, and greatly enhances the production efficiency.

Owner:SINO NITRIDE SEMICON +1

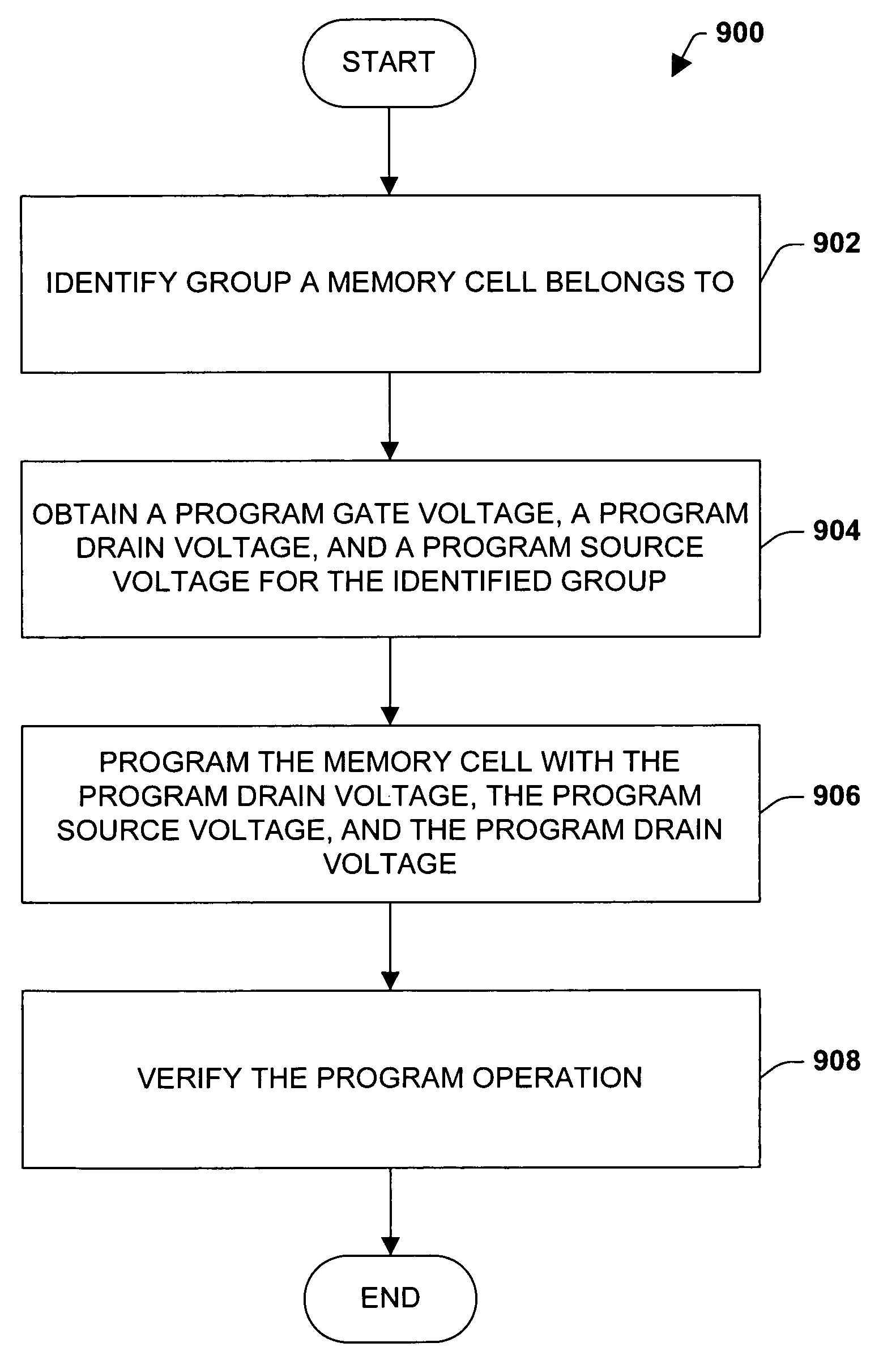

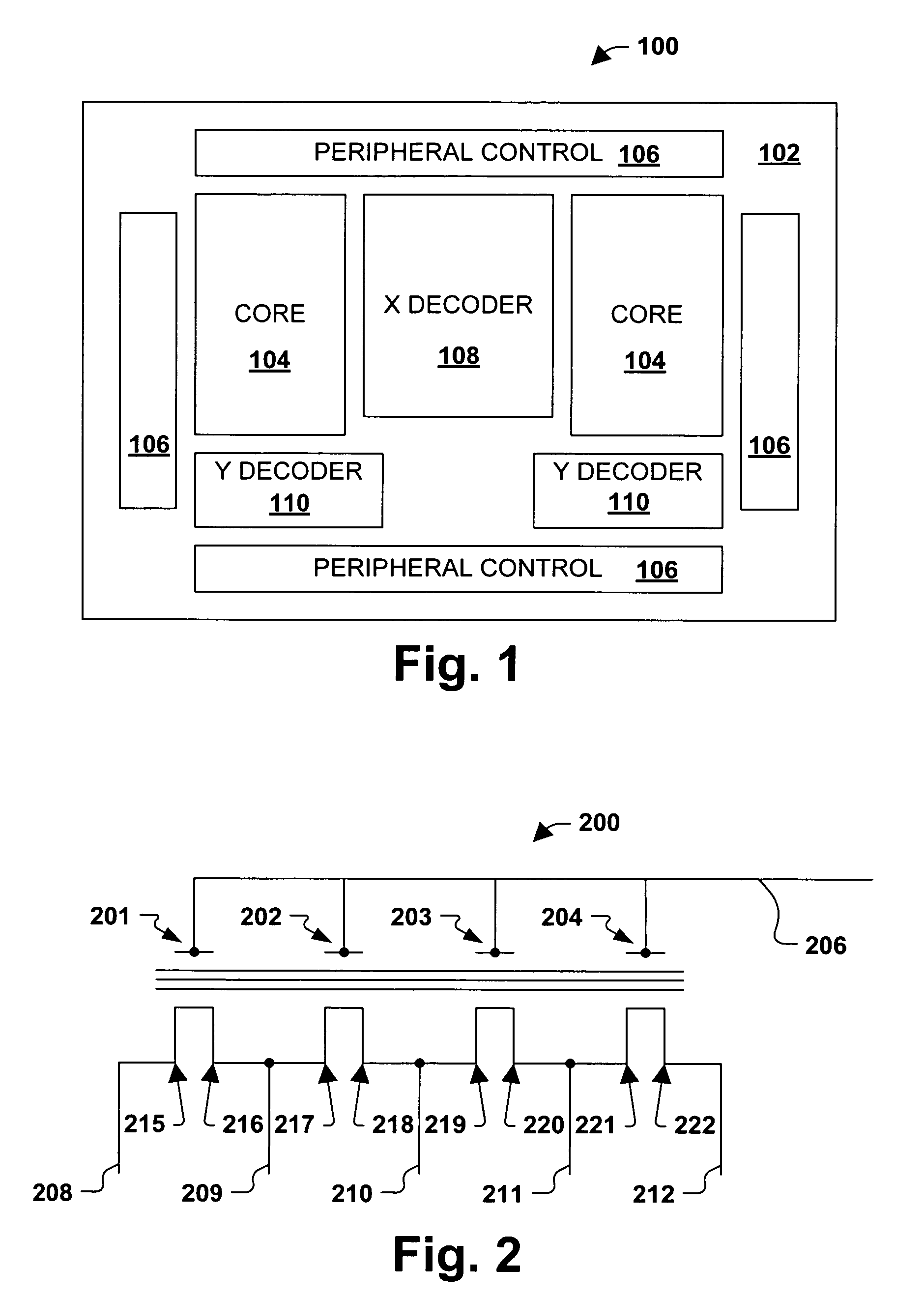

Method of determining voltage compensation for flash memory devices

ActiveUS7440333B2Better programmingEvenly distributedRead-only memoriesDigital storageParallel computingVoltage compensation

Owner:INFINEON TECH LLC +1

Gas-scrubbed hollow fiber membrane module

InactiveUS6156200AAvoid enteringEvenly distributedUltrafiltrationWater/sewage treatment bu osmosis/dialysisPorous membraneHollow fibre membrane

A method and apparatus for removing fouling materials from the surface of a plurality of porous membranes (9) arranged in a membrane module (4) by providing, from within the module, by means (10) other than gas passing through the pores of said membranes, gas bubbles in a uniform distribution relative to the porous membrane array such that the bubbles move past the surfaces of the membranes (9) to dislodge fouling materials therefrom. The membranes (9) are arranged in close proximity to one another and mounted to prevent excessive movement therebetween. The bubbles also produce vibration and rubbing together of the membranes to further assist removal of fouling materials.

Owner:EVOQUA WATER TECH

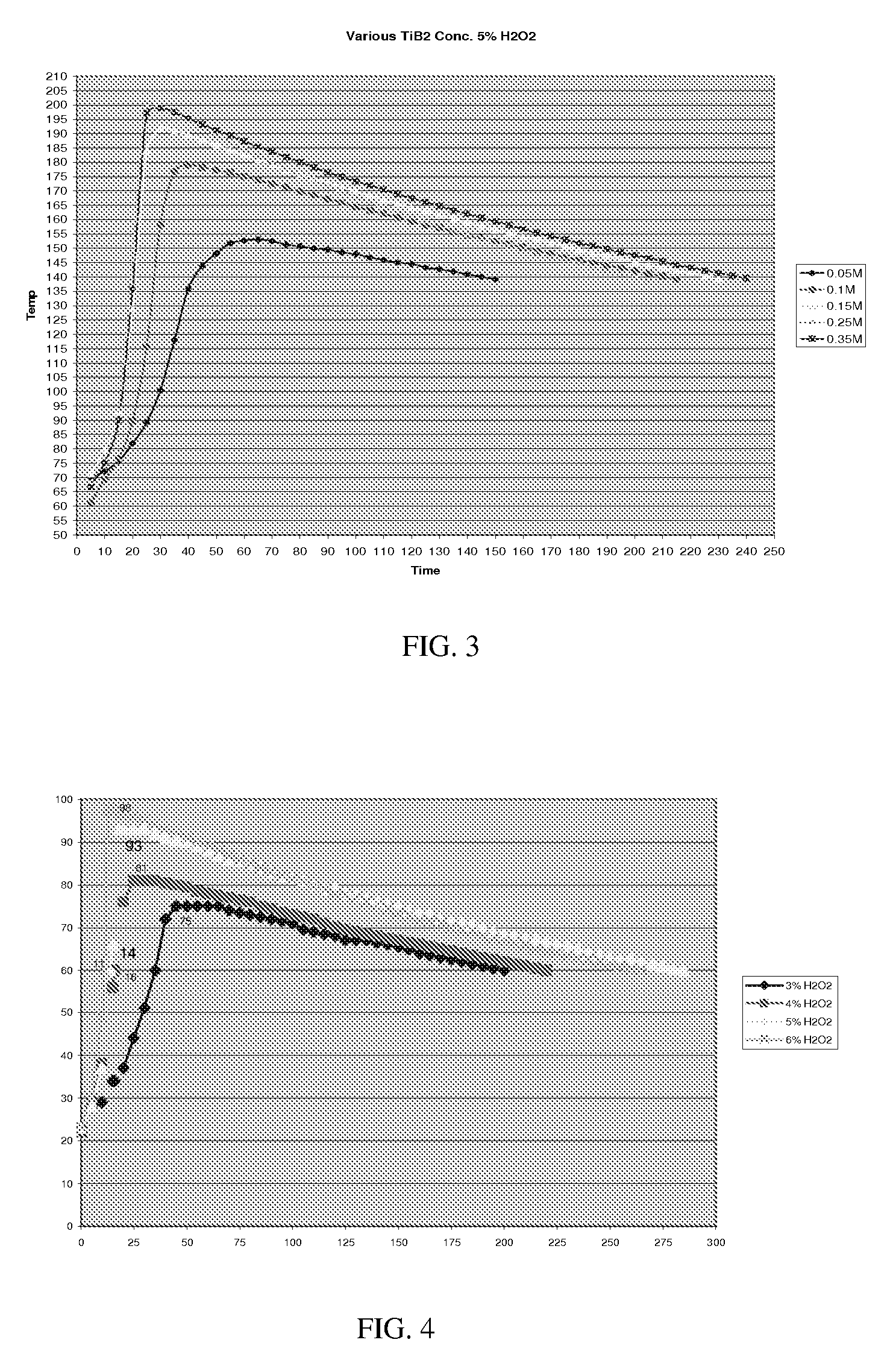

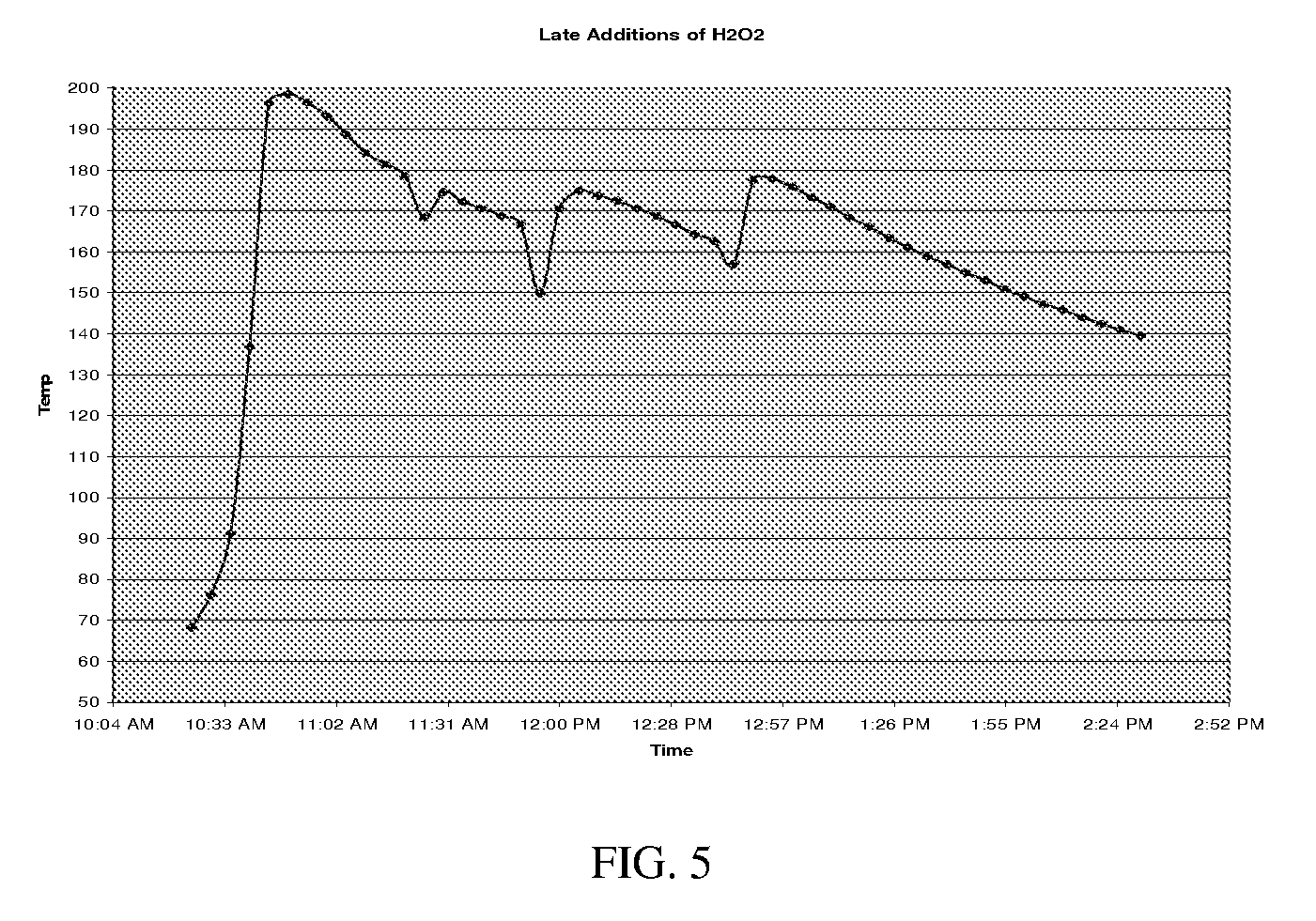

Flameless heating system

InactiveUS20070259778A1Uniform distributionNon toxicPhysical/chemical process catalystsSolid fuelsHeating systemSolid-state

A flameless heating system comprising the mixture of solid state titanium boride materials with a solution of hydrogen peroxide. A small amount of solid titanium boride in the form of a tablet, powder, or thin film is added to an aqueous peroxide solution. After addition of the solid titanium boride to the aqueous peroxide solution, a significant amount of heat is released to the surroundings. As the mixture of solid titanium boride to the aqueous peroxide solution often forms a gel, the mixture provides self-regulated amounts of heat.

Owner:SYRACUSE UNIVERSITY

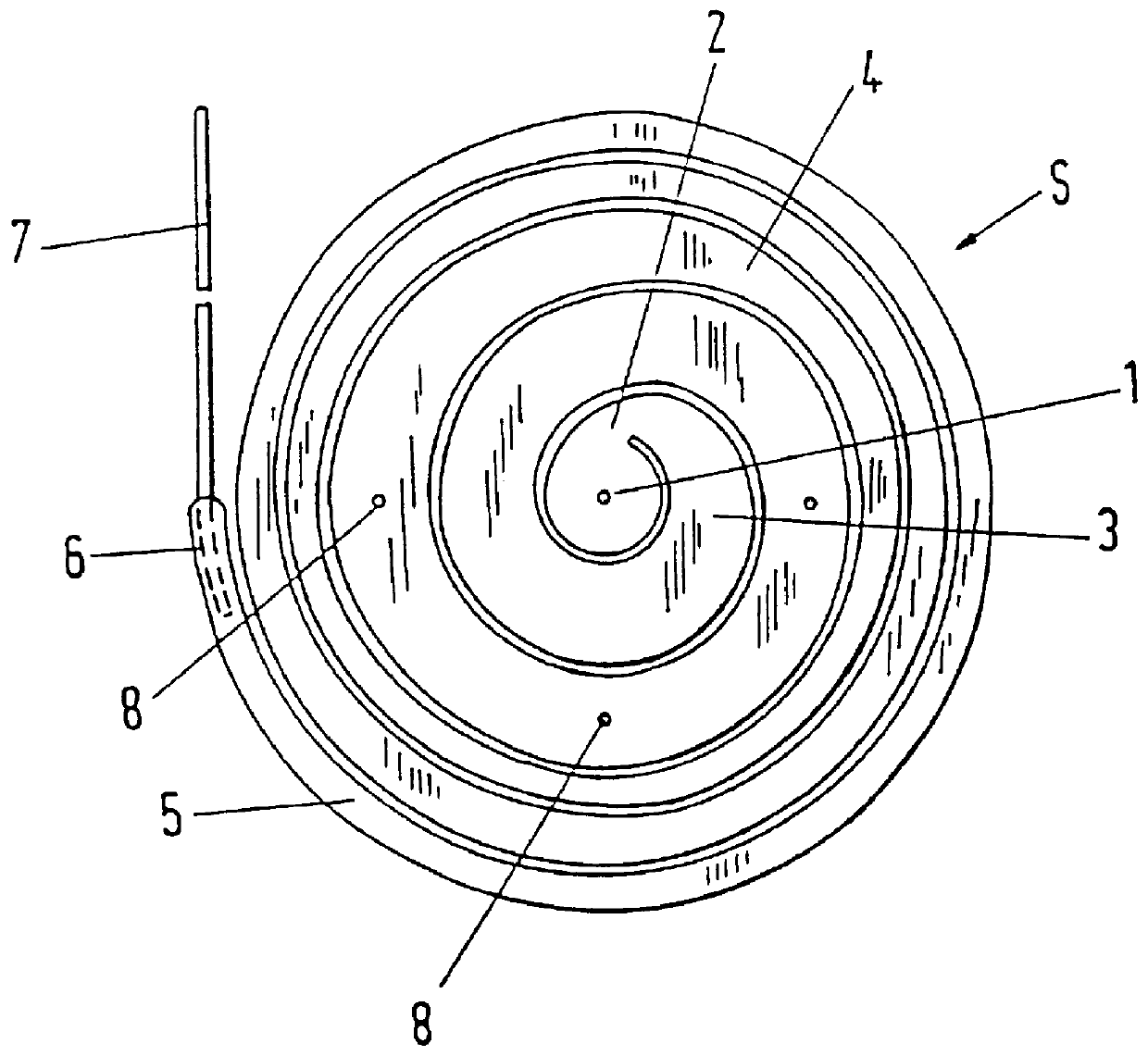

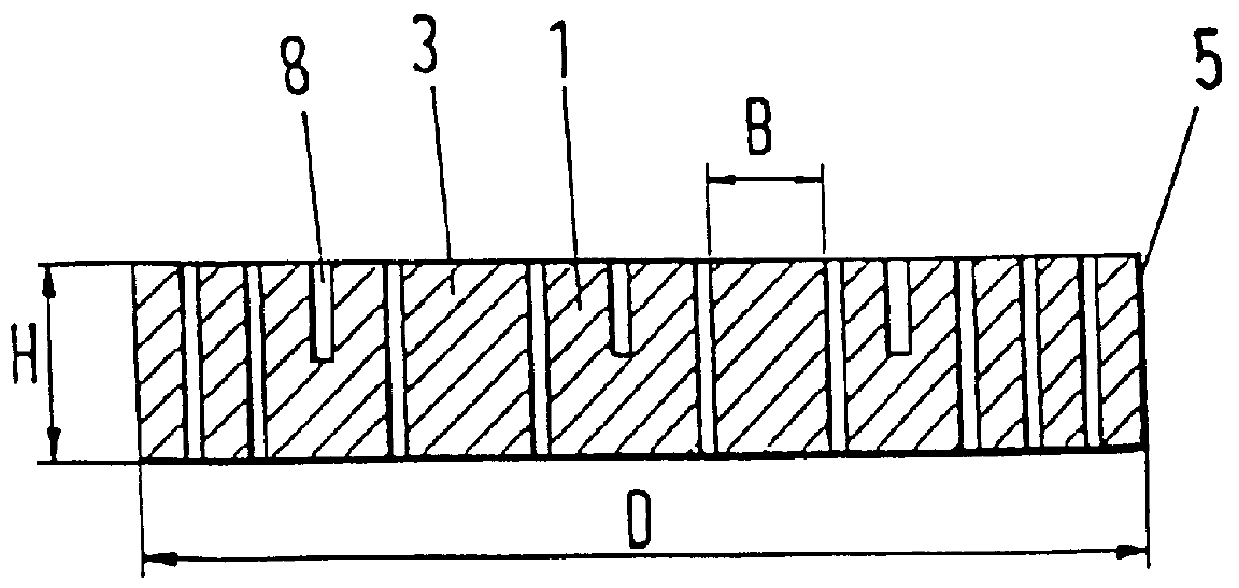

Intervertebral prosthesis

InactiveUS6165218AEvenly distributedCanting of the elastic body is preventedSurgical scissorsJoint implantsInterior spaceIntervertebral disc

An implant, in particular an intervertebral prosthesis, which consists of an elongated elastic body which is form-elastic and takes on the form of a spiral S in the force free state. The spiral can be drawn by a reverse winding up into an insertion instrument which is only insubstantially larger in the insertion region than the cross-section of the elongated elastic body in order to reach the inner space of an intervertebral disc through a small opening in the annulus fibrosus and to push in and sever off the self winding spiral when the interior is filled. This has the advantage that inner spaces of differing sizes can be filled with the same spiral.

Owner:ZIMMER GMBH

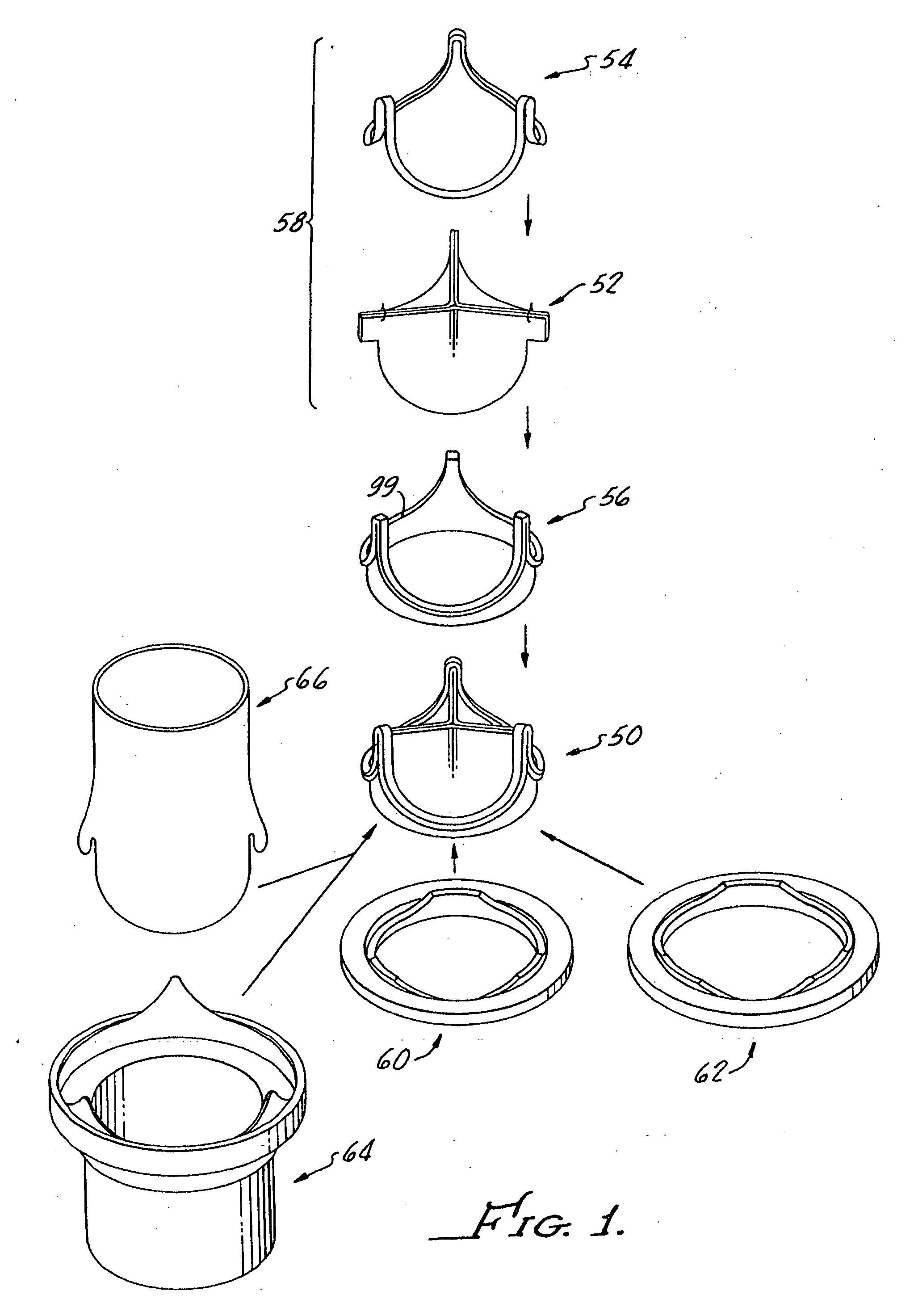

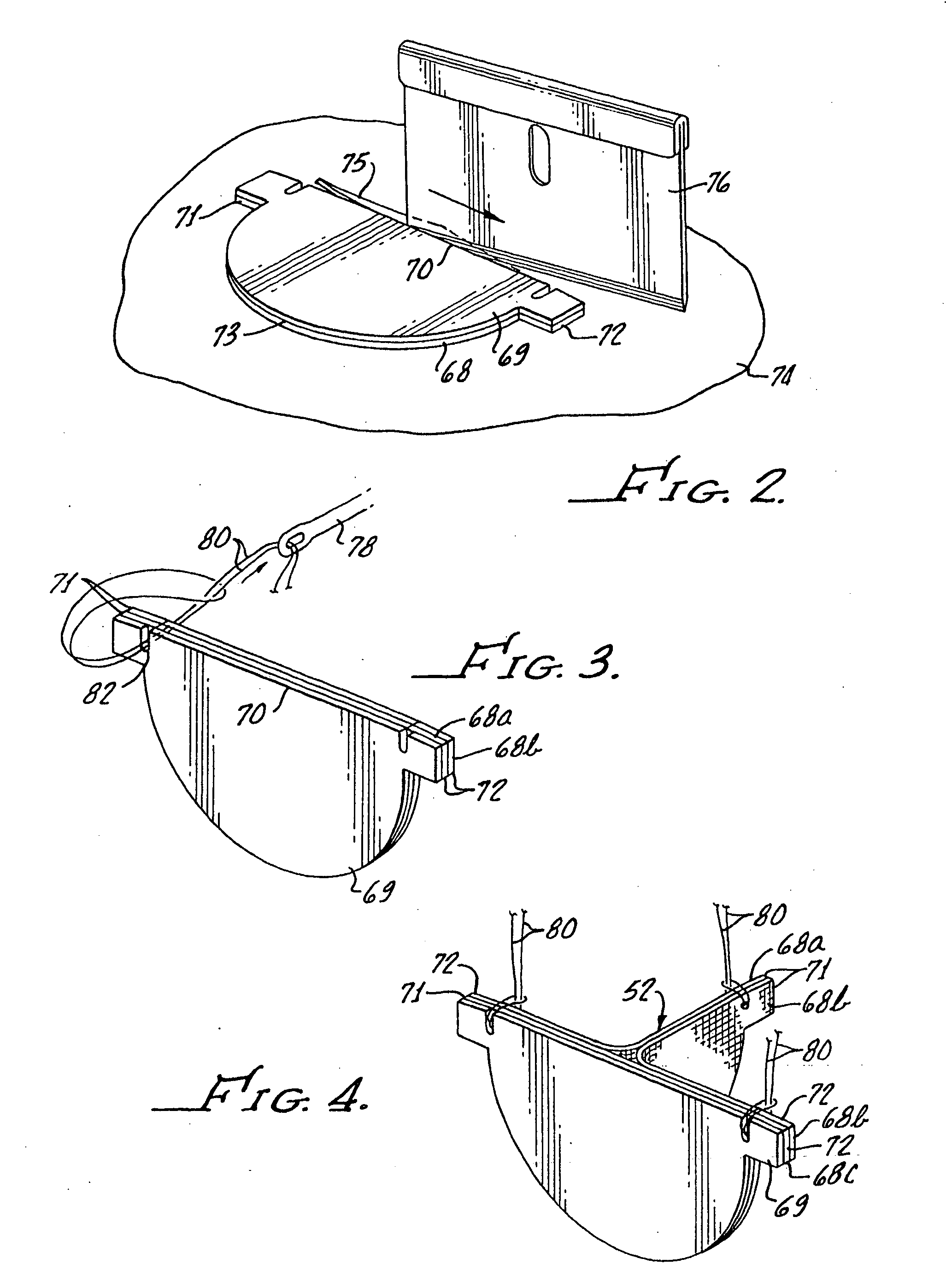

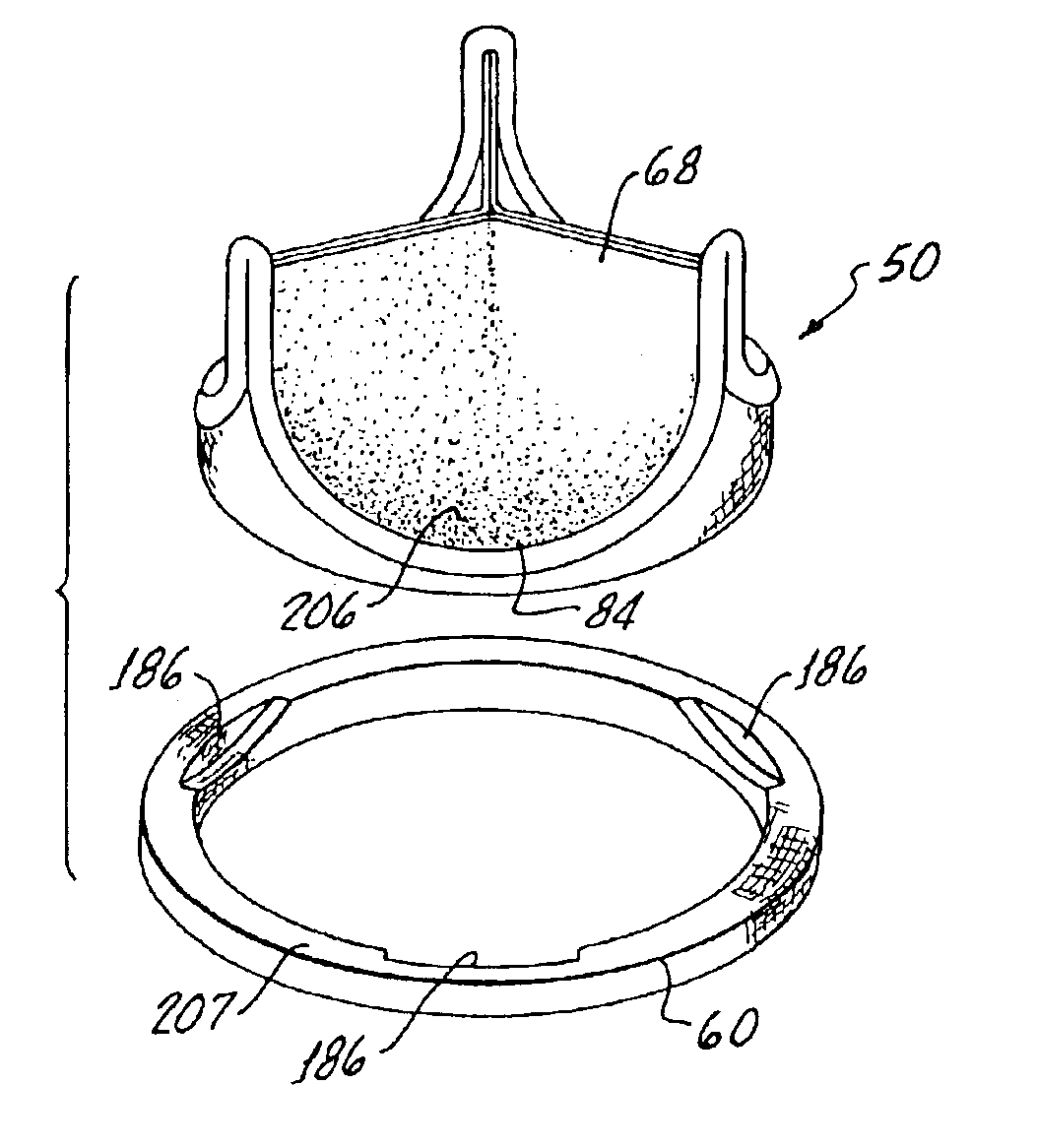

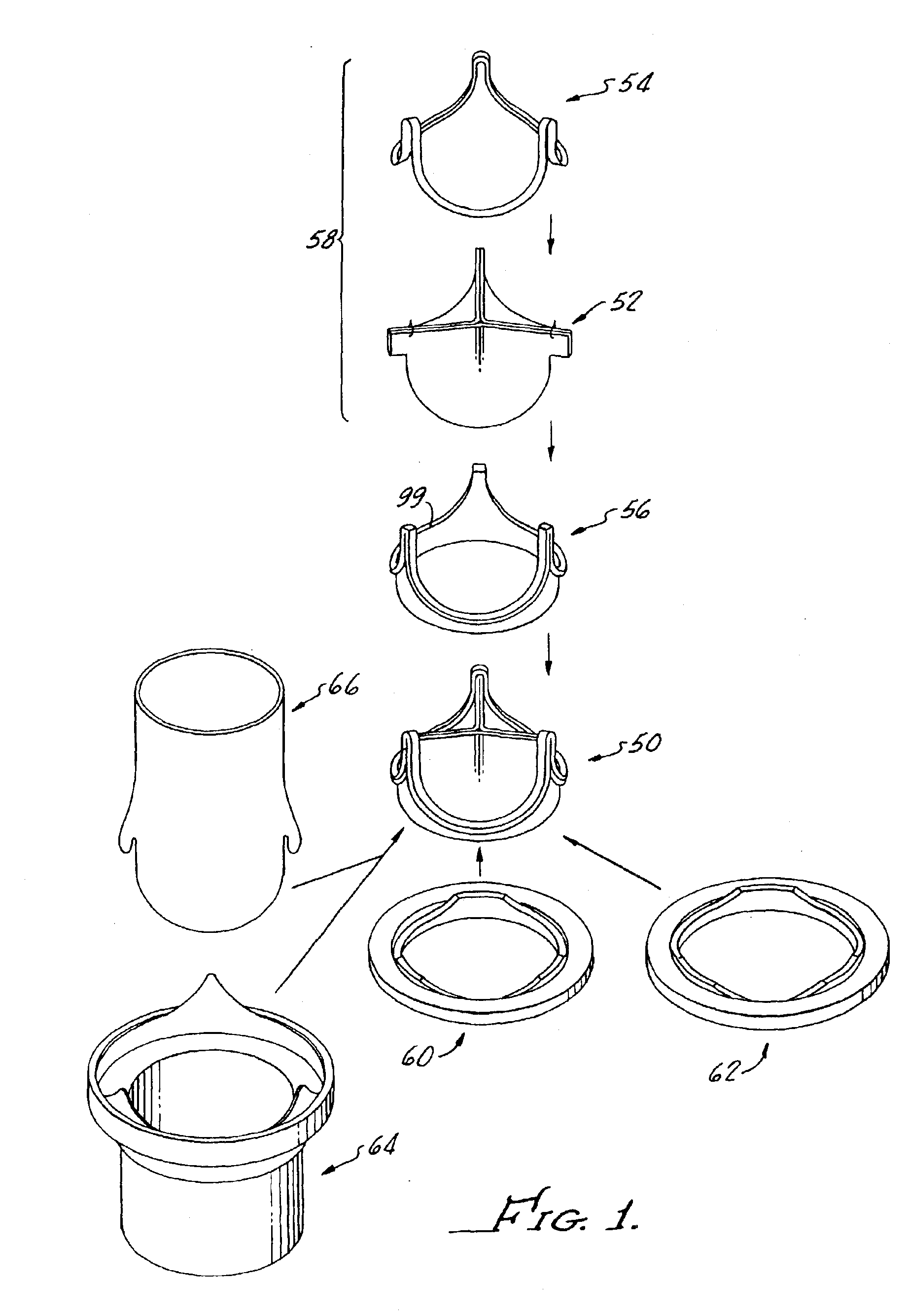

Contoured heart valve suture rings

InactiveUS20060009842A1Improving long-term functionalityReduce pointsHeart valvesInsertion stentCatheter

Improved, adaptable tissue-type heart valves and methods for their manufacture are disclosed wherein a dimensionally stable, pre-aligned tissue leaflet subassembly is formed and its peripheral edge clamped between and attached to an upper shaped wireform and a lower support stent. A variety of adaptable structural interfaces including suture rings, flanges, and conduits may be attached to the support stent with or without an outlet conduit disposed about the wireform to provide a tissue-type heart valve adaptable for use in either a natural heart or in mechanical pumping devices. The methods include forming individual leaflets with a template and using the template to attach the leaflets together to form a tissue leaflet subassembly. The template and leaflets include a straight edge terminating in oppositely directed tabs, and a curvilinear cusp edge extending opposite the straight edge. The template may include a guide slot in its straight edge and the assembly includes aligning two leaflet tabs with the template and passing sutures through the guide slot and through the leaflet tabs. The leaflet subassembly is mated to a wireform with the tabs extending through commissure posts of the wireform. A support stent having an upper surface matching the lower surface of the wireform sandwiches the edges of the leaflet subassembly therebetween. Separated tabs on the leaflet subassembly are passed through the wireform commissures and attached to adjacent stent commissures so as to induce clamping of the leaflet tabs between the stent commissures and wireform commissures upon a radially inward force being applied to the leaflets.

Owner:EDWARDS LIFESCIENCES CORP

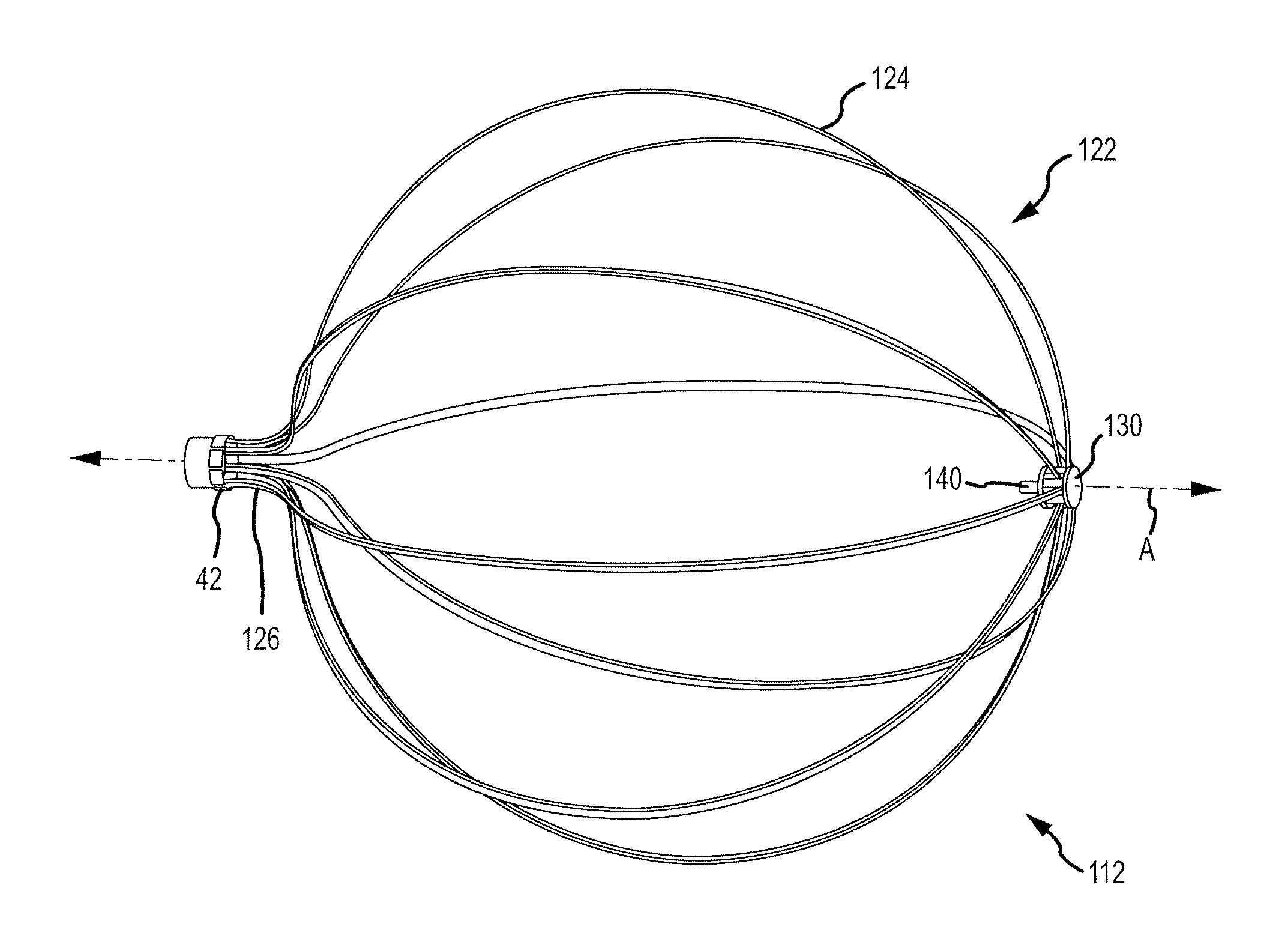

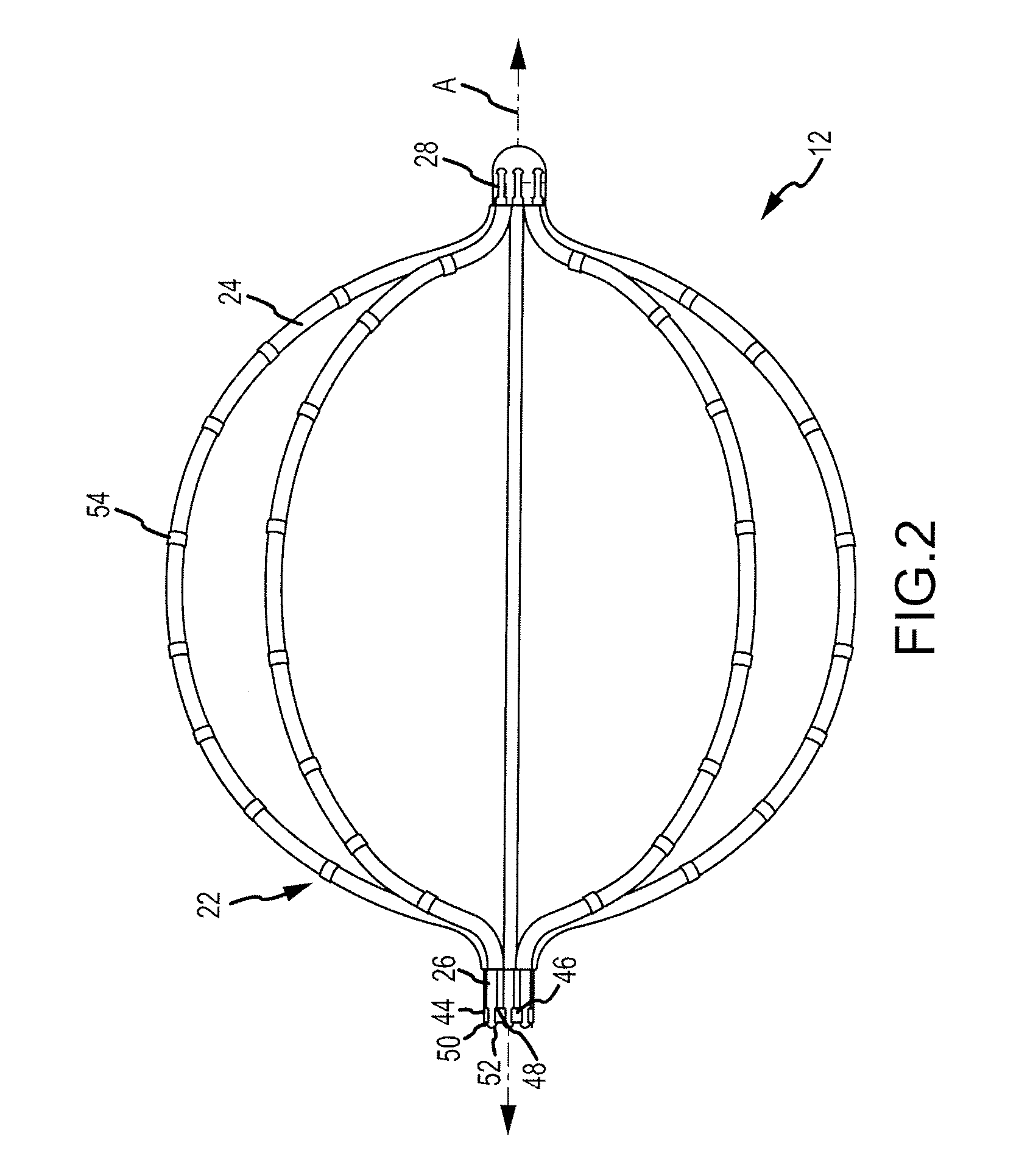

Electrode support structure assemblies

ActiveUS20130172715A1Stress minimizationEvenly distributedElectrocardiographyCatheterEngineeringElectrode

An electrode support structure assembly is provided comprising an electrode support structure including a plurality of splines. Each of the plurality of splines can have a proximal end portion and a distal end portion. The assembly further comprises a first element defining an axis and comprising an outer surface. The outer surface comprises a plurality of slots configured to receive the distal end portion of each of the plurality of splines. The first element is configured such that the distal end portion of each of the plurality of splines may move with respect to each slot. In accordance with some embodiments, the distal end portion of each of the plurality of splines comprises a section configured for engagement with the first element, wherein the section comprises a shoulder.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

Foam carrier containing amphiphilic copolymeric gelling agent

InactiveUS20050069566A1Broaden applicationEvenly distributedAntibacterial agentsCosmetic preparationsAlcohol freeWater soluble

The invention relates to an alcohol-free cosmetic or pharmaceutical foam carrier including water, a hydrophobic solvent, a surface-active agent and a gelling agent. The cosmetic or pharmaceutical foam carrier does not contain aliphatic alcohols, making it non-irritating and non-drying. The alcohol-free foam carrier is suitable for inclusion of both water-soluble and oil soluble pharmaceutical and cosmetic agents.

Owner:FOAMIX PHARMACEUTICALS LIMITED

Heart valves and suture rings therefor

InactiveUS6945997B2Reduce stress pointImproving long-term functionalityHeart valvesInsertion stentTissues types

Improved, adaptable tissue-type heart valves and methods for their manufacture are disclosed wherein a dimensionally stable, pre-aligned tissue leaflet subassembly is formed and its peripheral edge clamped between and attached to an upper shaped wireform and a lower support stent. A variety of adaptable structural interfaces including suture rings, flanges, and conduits may be attached to the support stent with or without an outlet conduit disposed about the wireform to provide a tissue-type heart valve adaptable for use in either a natural heart or in mechanical pumping devices. The methods include forming individual leaflets with a template and using the template to attach the leaflets together to form a tissue leaflet subassembly. The template and leaflets include a straight edge terminating in oppositely directed tabs, and a curvilinear cusp edge extending opposite the straight edge. The template may include a guide slot in its straight edge and the assembly includes aligning two leaflet tabs with the template and passing sutures through the guide slot and through the leaflet tabs. The leaflet subassembly is mated to a wireform with the tabs extending through commissure posts of the wireform. A support stent having an upper surface matching the lower surface of the wireform sandwiches the edges of the leaflet subassembly therebetween. Separated tabs on the leaflet subassembly are passed through the wireform commissures and attached to adjacent stent commissures so as to induce clamping of the leaflet tabs between the stent commissures and wireform commissures upon a radially inward force being applied to the leaflets.

Owner:EDWARDS LIFESCIENCES CORP

Systems and methods for particle focusing in microchannels

ActiveUS8186913B2Improve concentrationEvenly distributedImmobilised enzymesSolvent extractionSuspended particlesEngineering

Various systems, methods, and devices are provided for focusing particles suspended within a moving fluid into one or more localized stream lines. The system can include a substrate and at least one channel provided on the substrate having an inlet and an outlet. The system can further include a fluid moving along the channel in a laminar flow having suspended particles and a pumping element driving the laminar flow of the fluid. The fluid, the channel, and the pumping element can be configured to cause inertial forces to act on the particles and to focus the particles into one or more stream lines.

Owner:THE GENERAL HOSPITAL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com