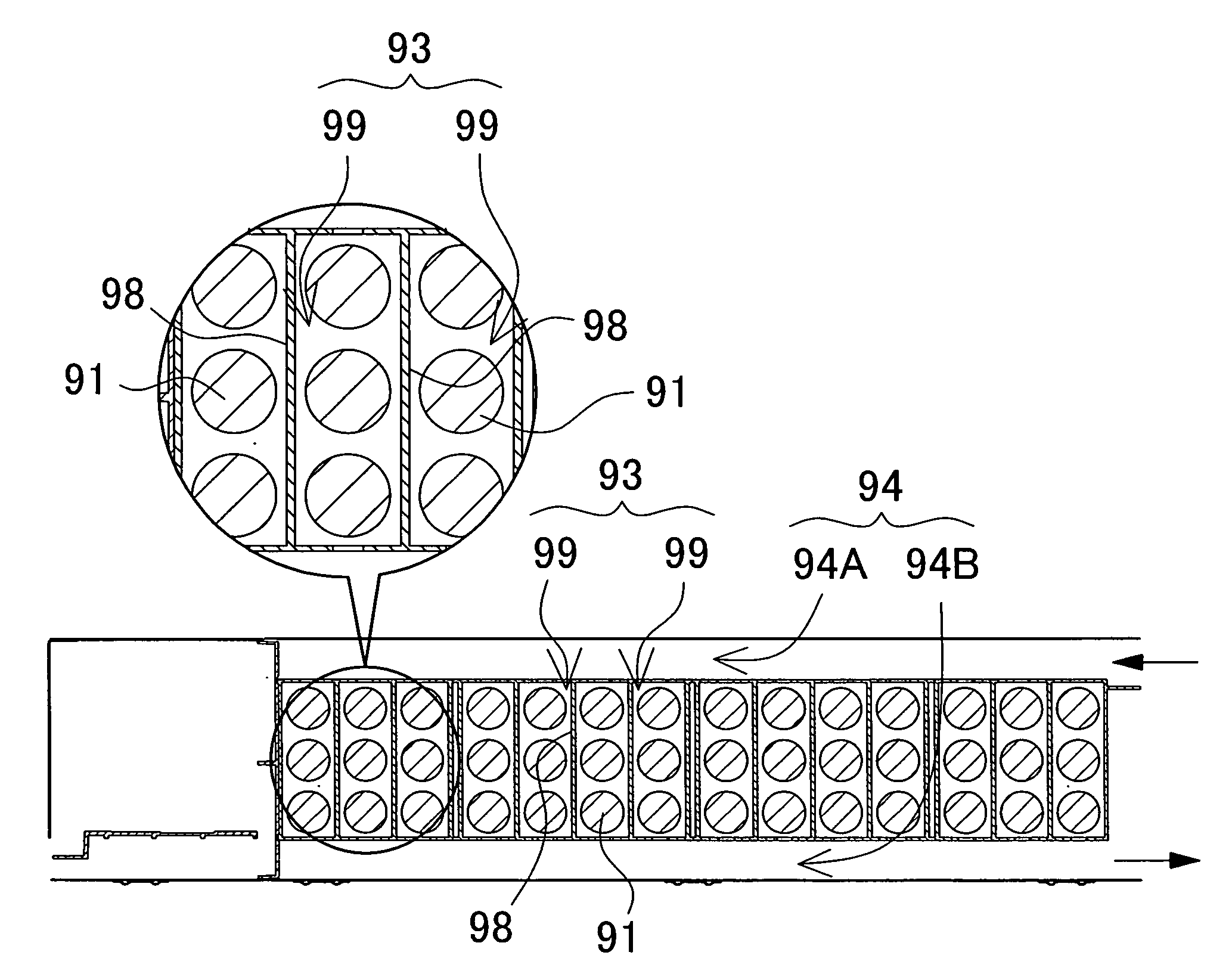

Patents

Literature

92results about How to "Uniform distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flameless heating system

InactiveUS20070259778A1Uniform distributionNon toxicPhysical/chemical process catalystsSolid fuelsHeating systemSolid-state

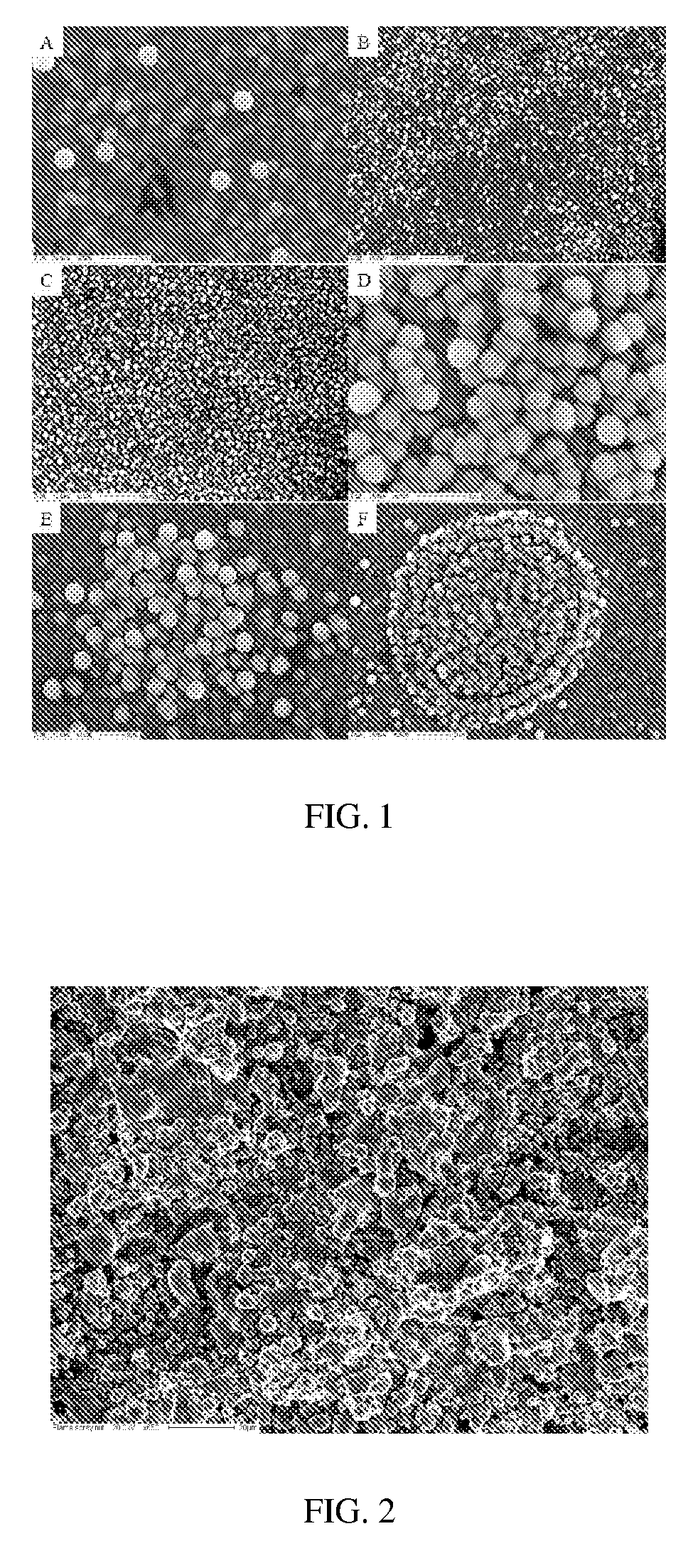

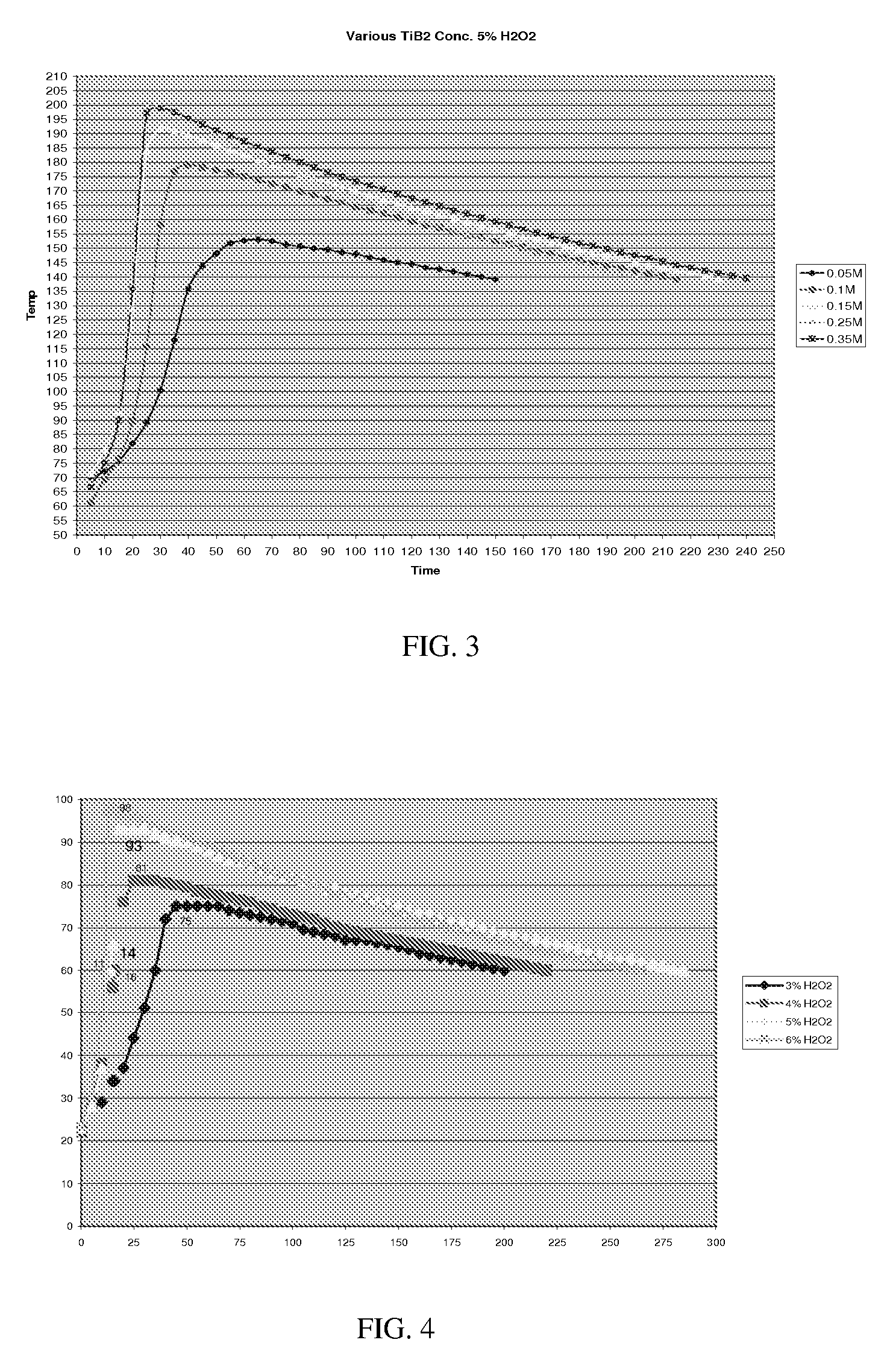

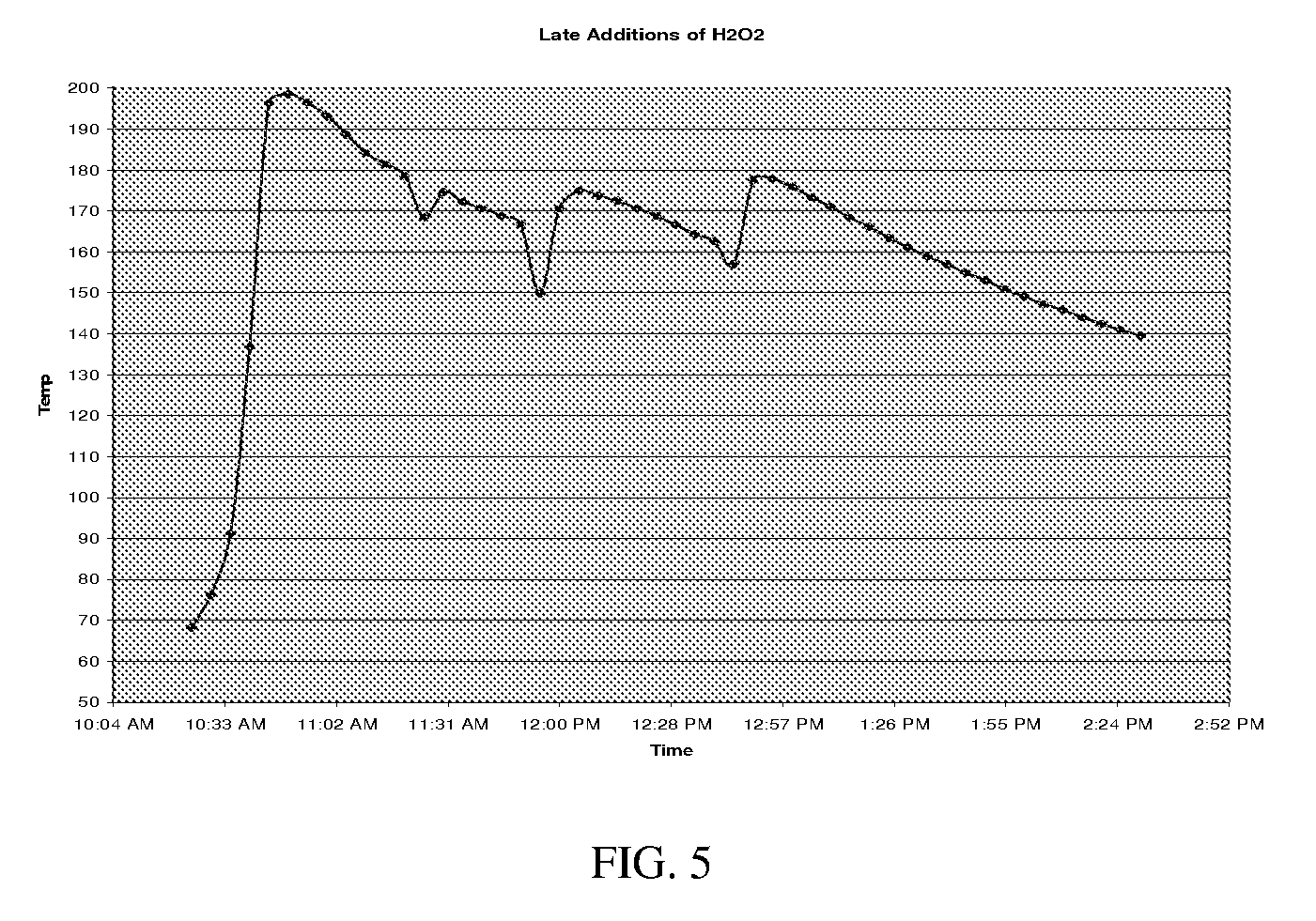

A flameless heating system comprising the mixture of solid state titanium boride materials with a solution of hydrogen peroxide. A small amount of solid titanium boride in the form of a tablet, powder, or thin film is added to an aqueous peroxide solution. After addition of the solid titanium boride to the aqueous peroxide solution, a significant amount of heat is released to the surroundings. As the mixture of solid titanium boride to the aqueous peroxide solution often forms a gel, the mixture provides self-regulated amounts of heat.

Owner:SYRACUSE UNIVERSITY

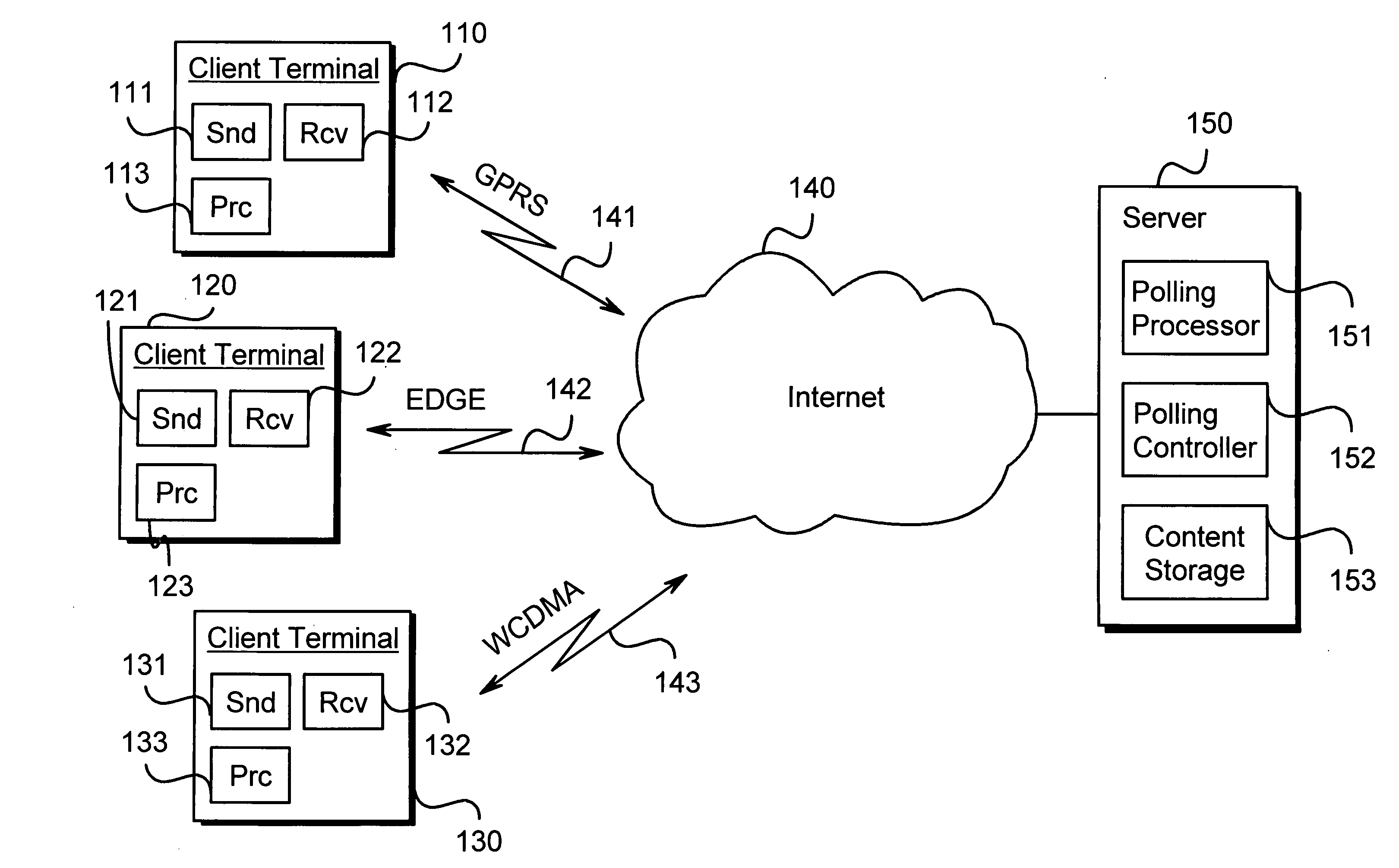

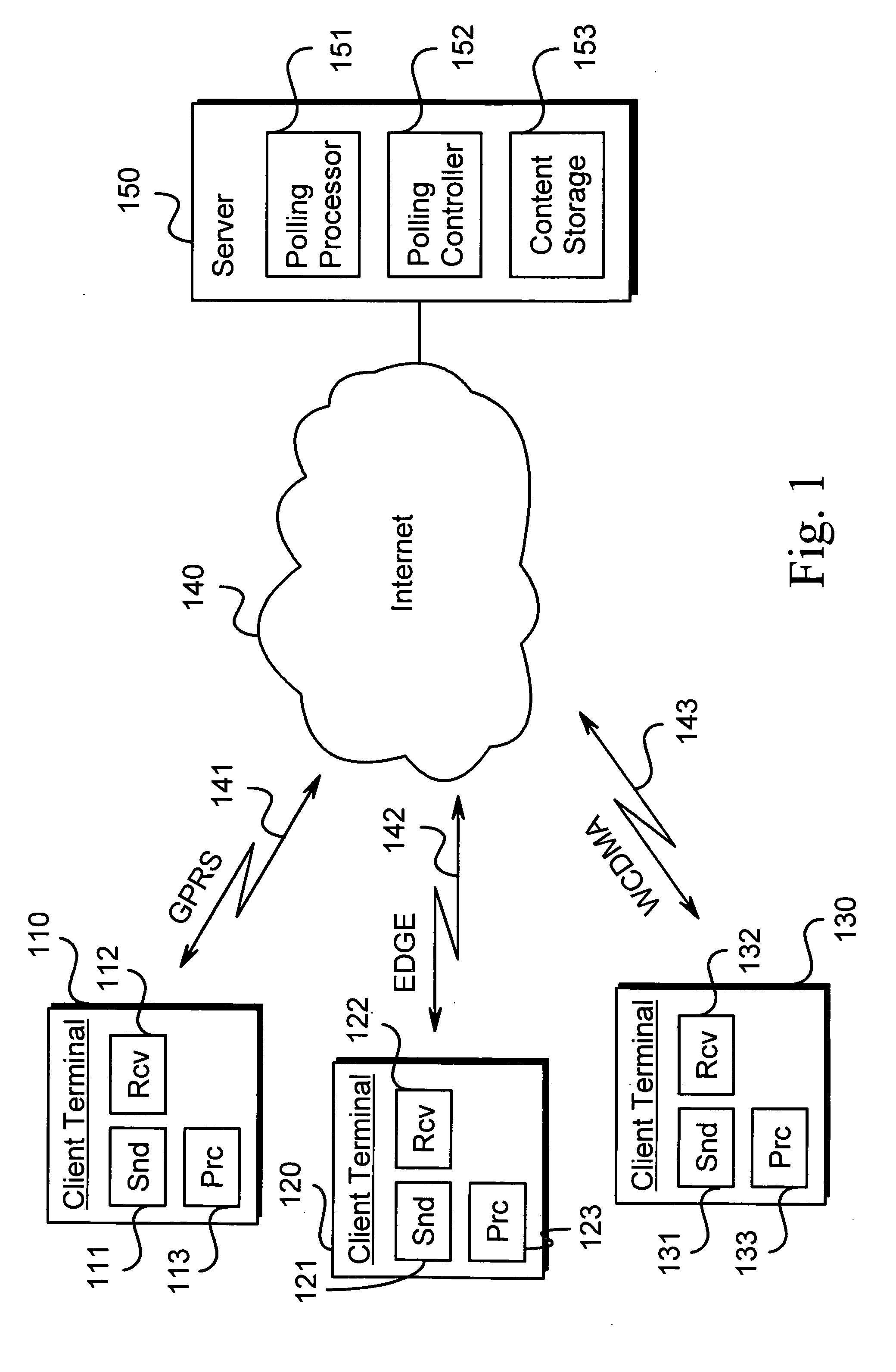

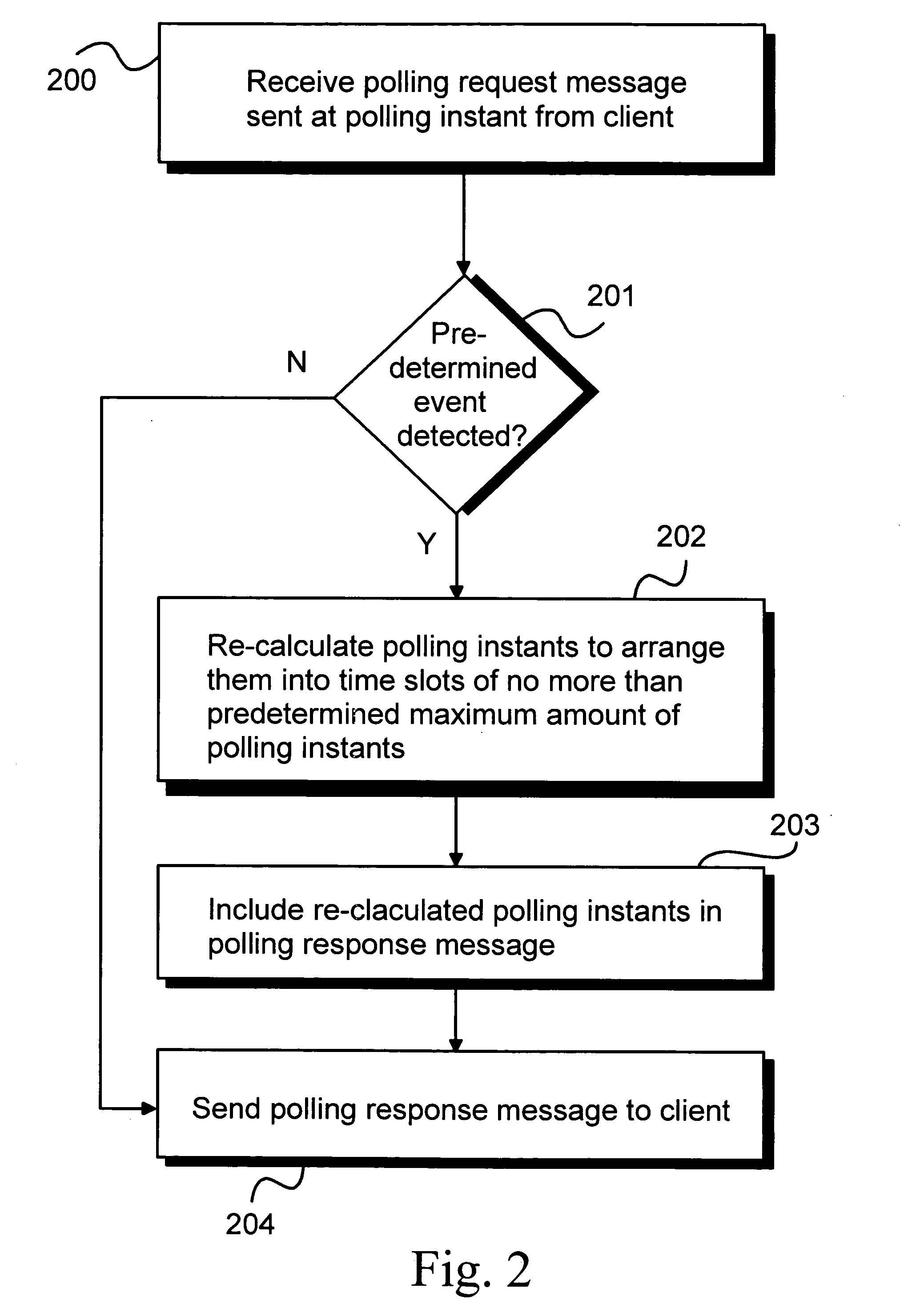

Dynamic polling control for content distribution

ActiveUS20080091773A1Promote stabilityUniform distributionMultiple digital computer combinationsTransmissionClient-sideContent distribution

The invention allows controlling content distribution polling dynamically. A predetermined event is detected. In response, client-specific polling instants are determined in order to arrange the client-specific polling instants into polling time slots, wherein each polling time slot has no more than a predetermined maximum amount of polling instants. The determined client-specific polling instants are then sent to their respective clients.

Owner:NOKIA TECHNOLOGLES OY

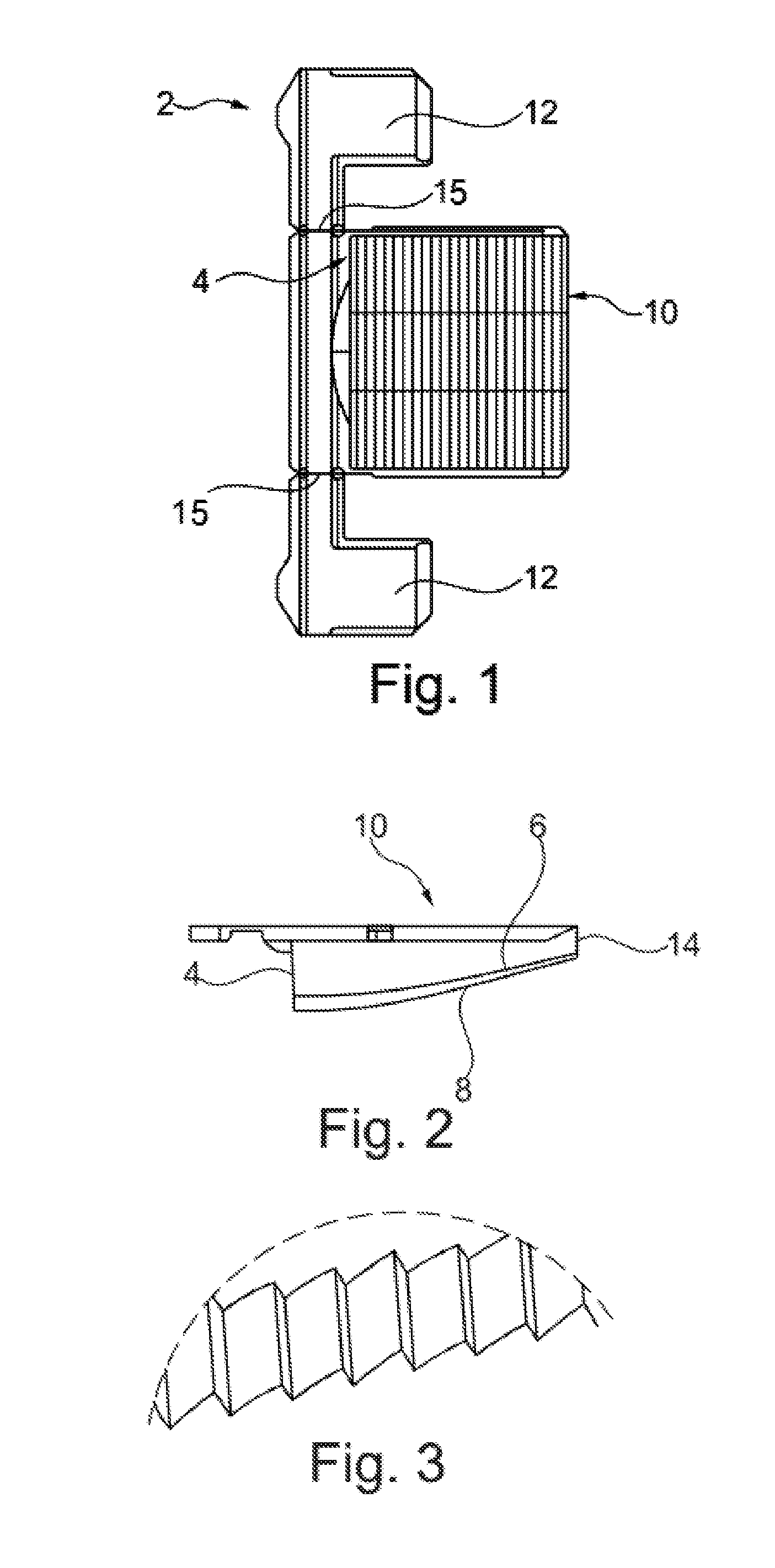

Light Guiding Device

ActiveUS20160341393A1Reduce clearanceUniform distributionOptical signallingVehicle lighting systemsWing mirrorLacquer

A light guiding device for an illumination device, especially for a motor vehicle or an indicator device in a rearview device of a motor vehicle includes a light coupling side for incoupling light from a light source, a reflection side having a reflection layer; and a light outcoupling side, which is disposed generally opposite the reflection side. A clearance between the reflection side and the light outcoupling side generally decreases as the distance from the light incoupling side increases. The reflection side having the reflection layer is configured so that light arriving from the light incoupling side is deflected to the light outcoupling side. The reflection layer may be a paint or lacquer layer that is imprinted or evaporation-coated on the reflection side; and the having a white sheet on or next to the rejection side.

Owner:SMR PATENTS S A R L

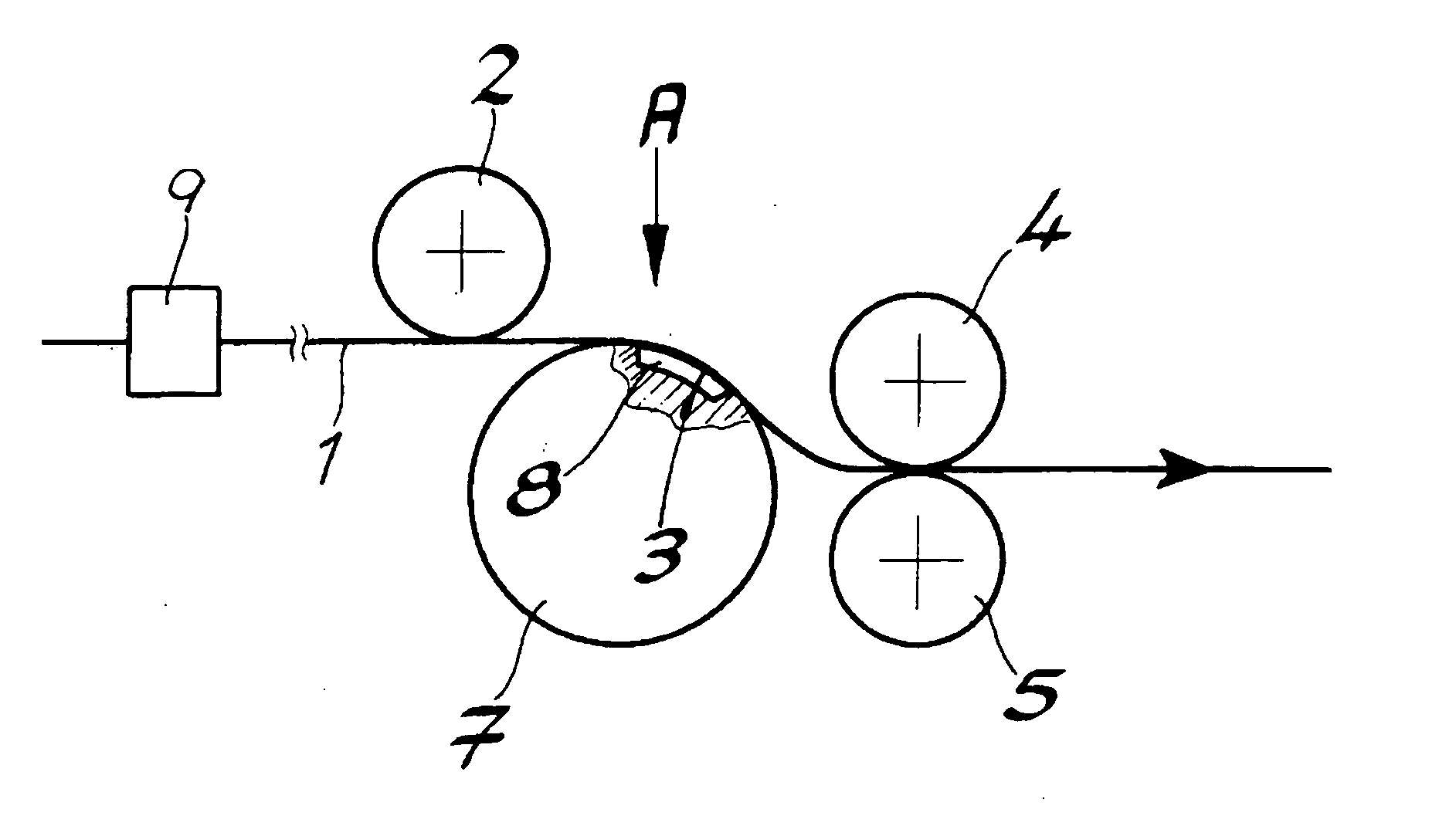

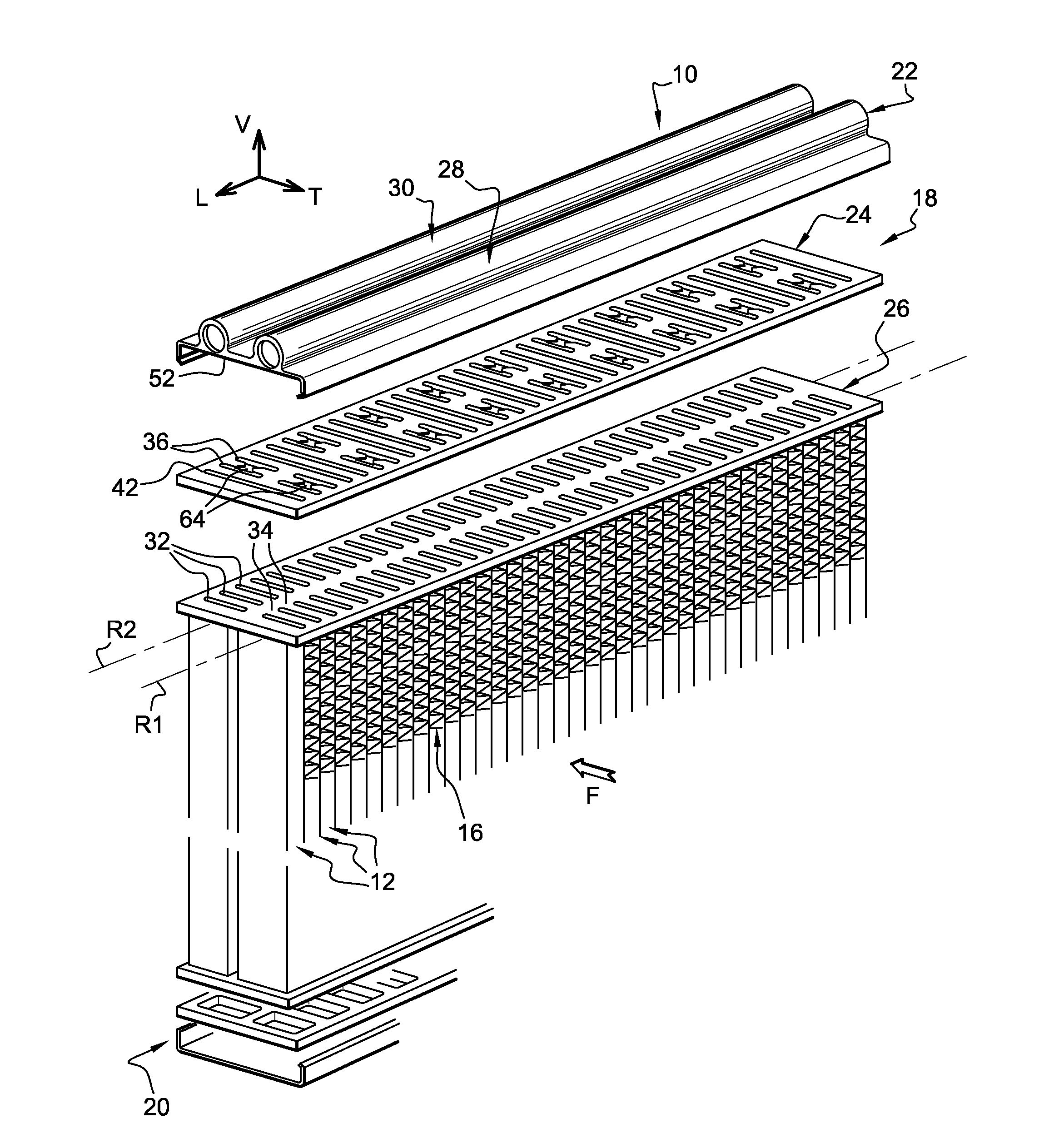

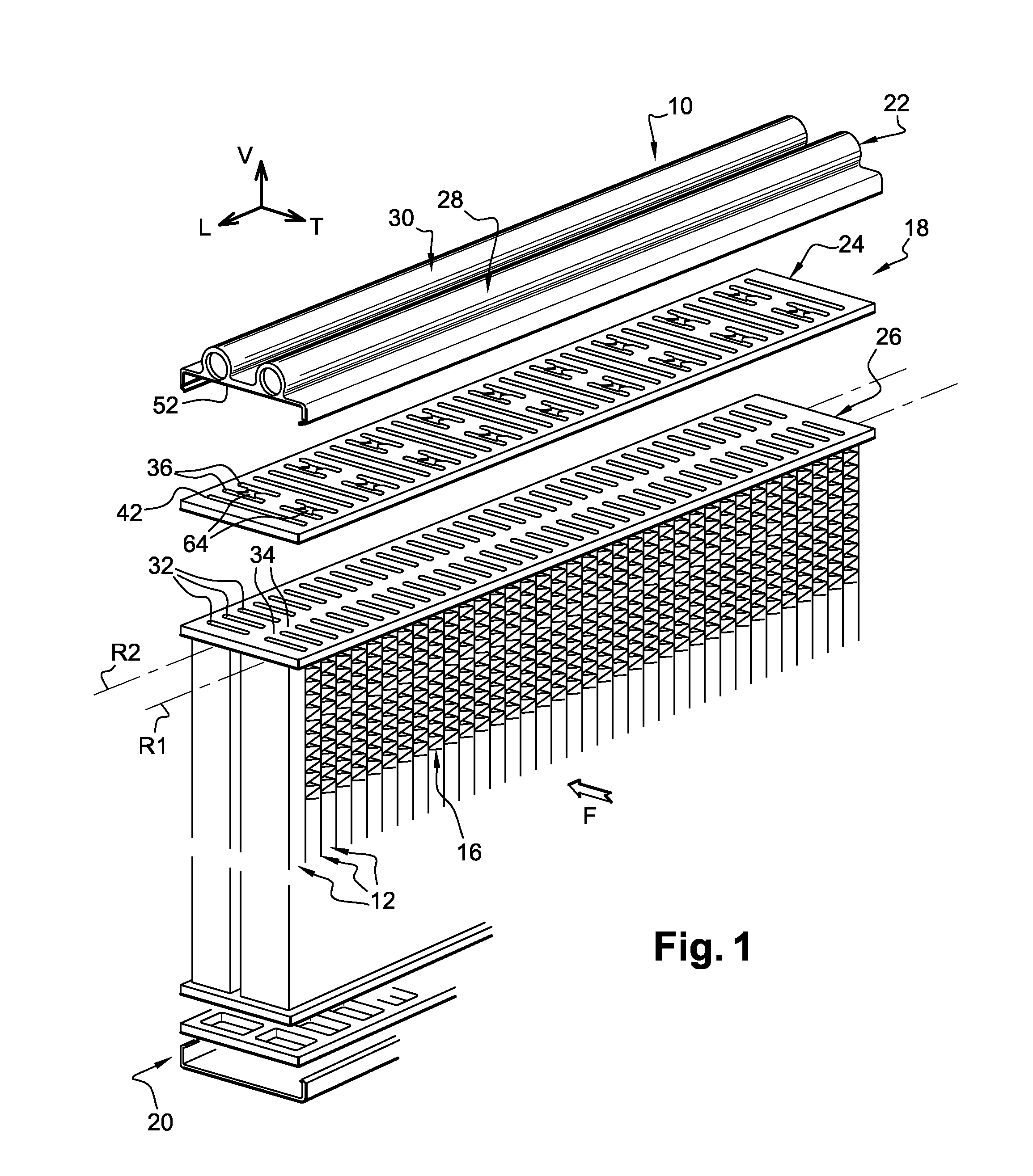

Apparatus and method for applying finishing agents onto a nonwoven web

ActiveUS20050196538A1Uniform distributionPrecise applicationLayered productsPretreated surfacesBiomedical engineeringProcess agent

Owner:REIFENHAUSER GMBH & CO

Hydrogenation method for production of hydrogen peroxide by anthraquinone process

InactiveCN102009960AUniform distributionIncrease contact areaPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesChemical industryHydrogenation process

The invention discloses a hydrogenation method for production of hydrogen peroxide by the anthraquinone process, belonging to the technical field of chemical industry reaction. The method provided by the invention comprises: dispersing the gaseous phase containing hydrogen into the working solution containing the anthraquinone derivatives to obtain the gas-liquid mixing fluid containing micron bubbles, so that the gas-liquid mixing fluid passes through the pipe reactor filled with the hydrogenation catalyst at the space velocity of 3 to 1000h<-1> to finish the hydrogenation process. In the method provided by the invention, the gas-liquid micro-dispersing process and the static bed catalytic hydrogenation process are directly integrated, so that the interphase mass transfer is strengthened, and the contacts between different reactants and between the reactant and the catalyst are more sufficient and more uniform, thereby enhancing the efficiency and the controllability of the hydrogenation process and improving the economical efficiency and the security of the production of the hydrogen peroxide.

Owner:TSINGHUA UNIV

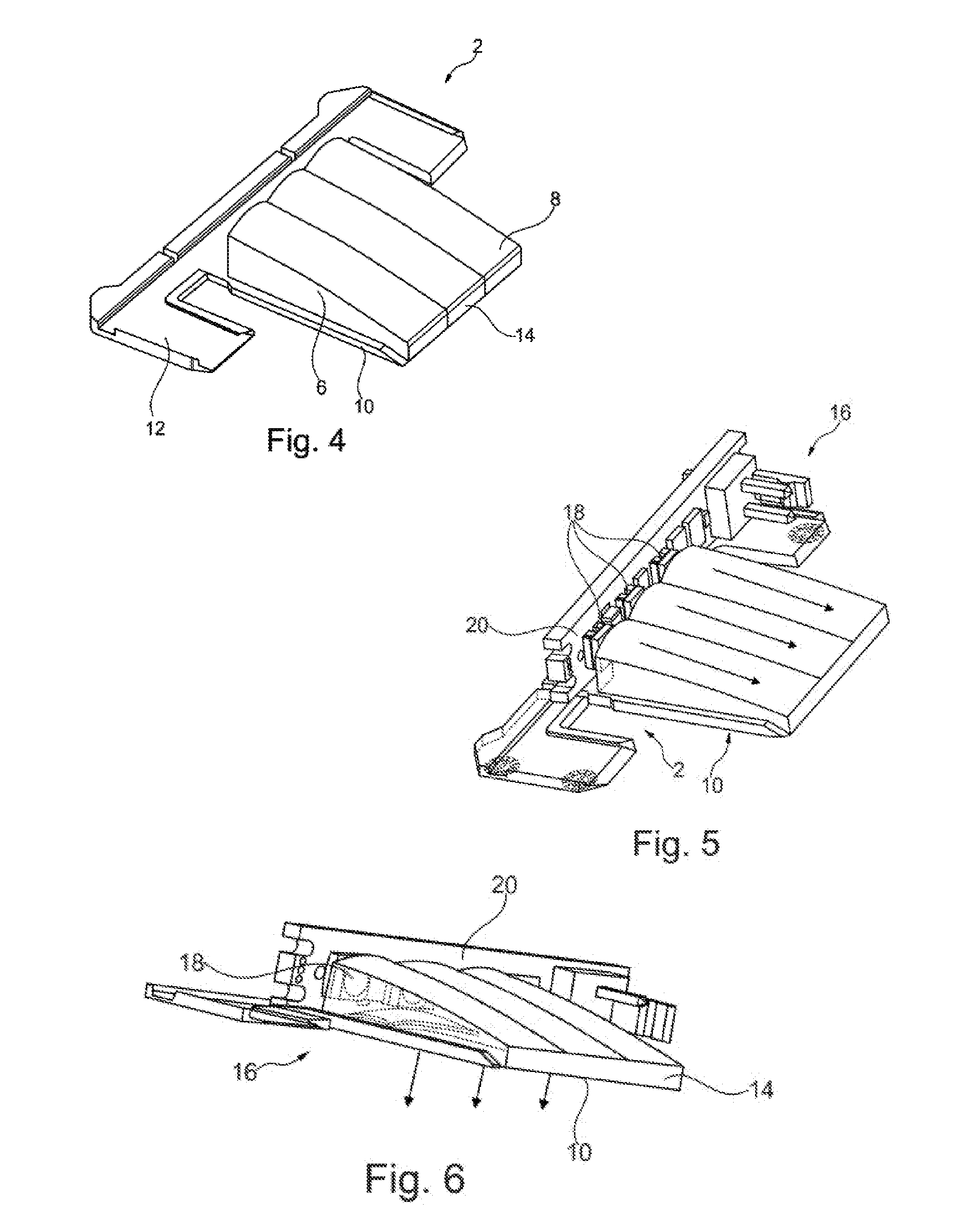

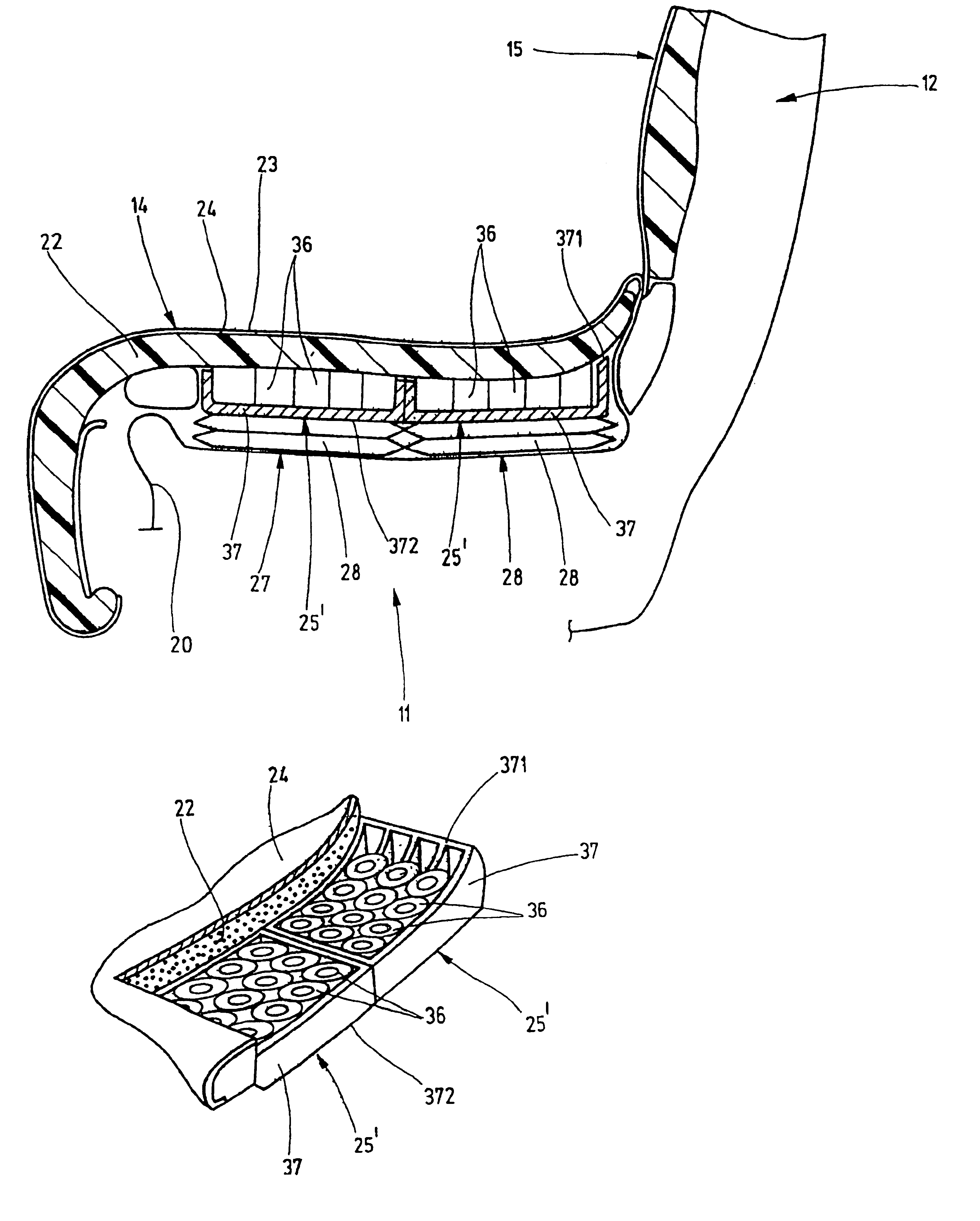

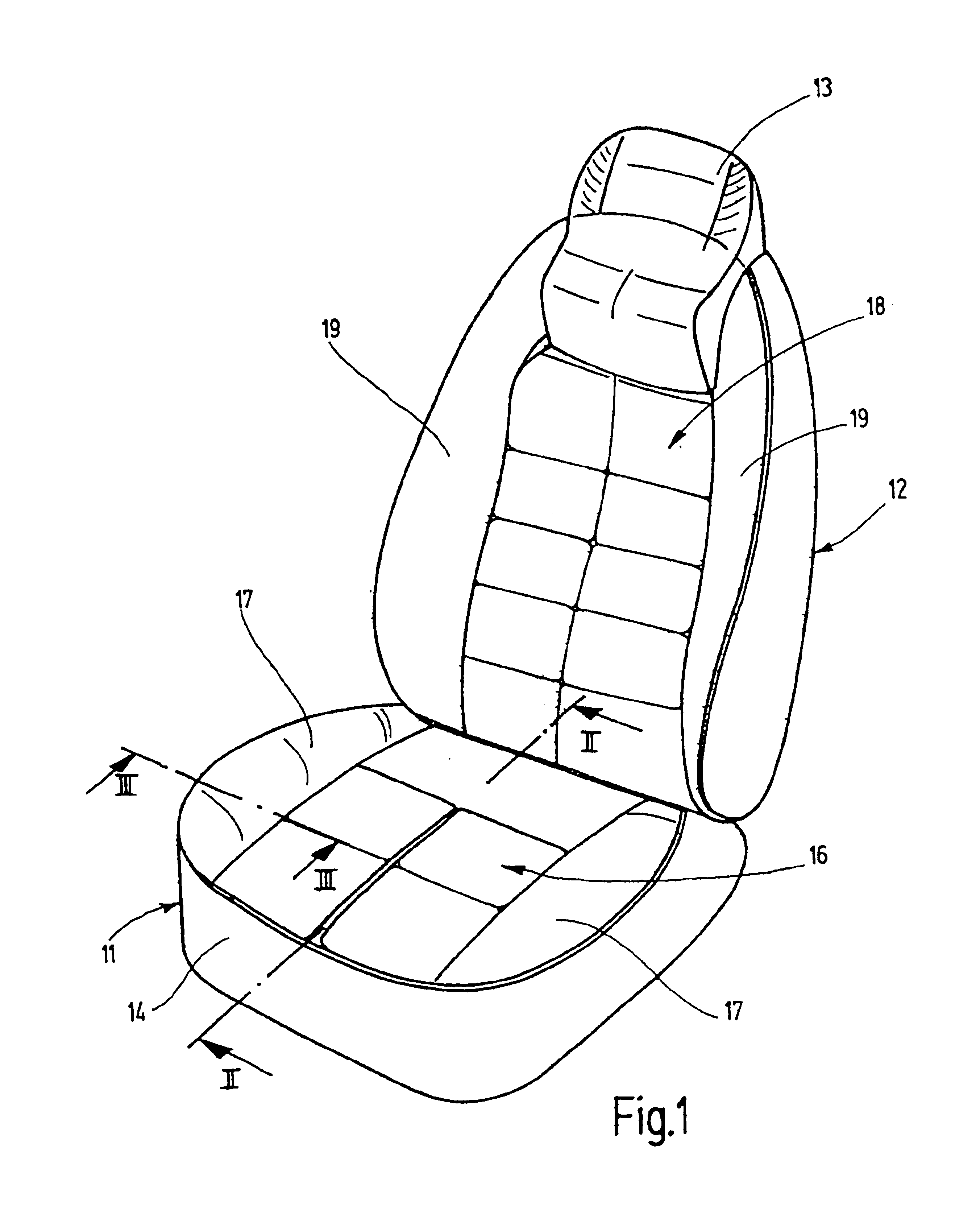

Padding for seats, in particular vehicle seats

InactiveUS6851755B2Uniform distributionIncrease tensionVehicle seatsStuffed mattressesAdverse effectBiomedical engineering

Padding for seats, in particular vehicle seats, has a padded body predetermining the contour of the padded surface, which can be changed. In order to adjust the padded surface contour to support the body of a seated person in an individual and orthopaedically correct manner, avoiding hardening of the padded surface which has an adverse effect on the seat comfort, the padded body is composed, at least in subregions, of a plurality of individual padded segments which are arranged next to one another and can be displaced relative to one another in the direction of the normal of the padded surface. Adjusting elements can displace the padded elements individually.

Owner:BAYERISCHE MOTOREN WERKE AG

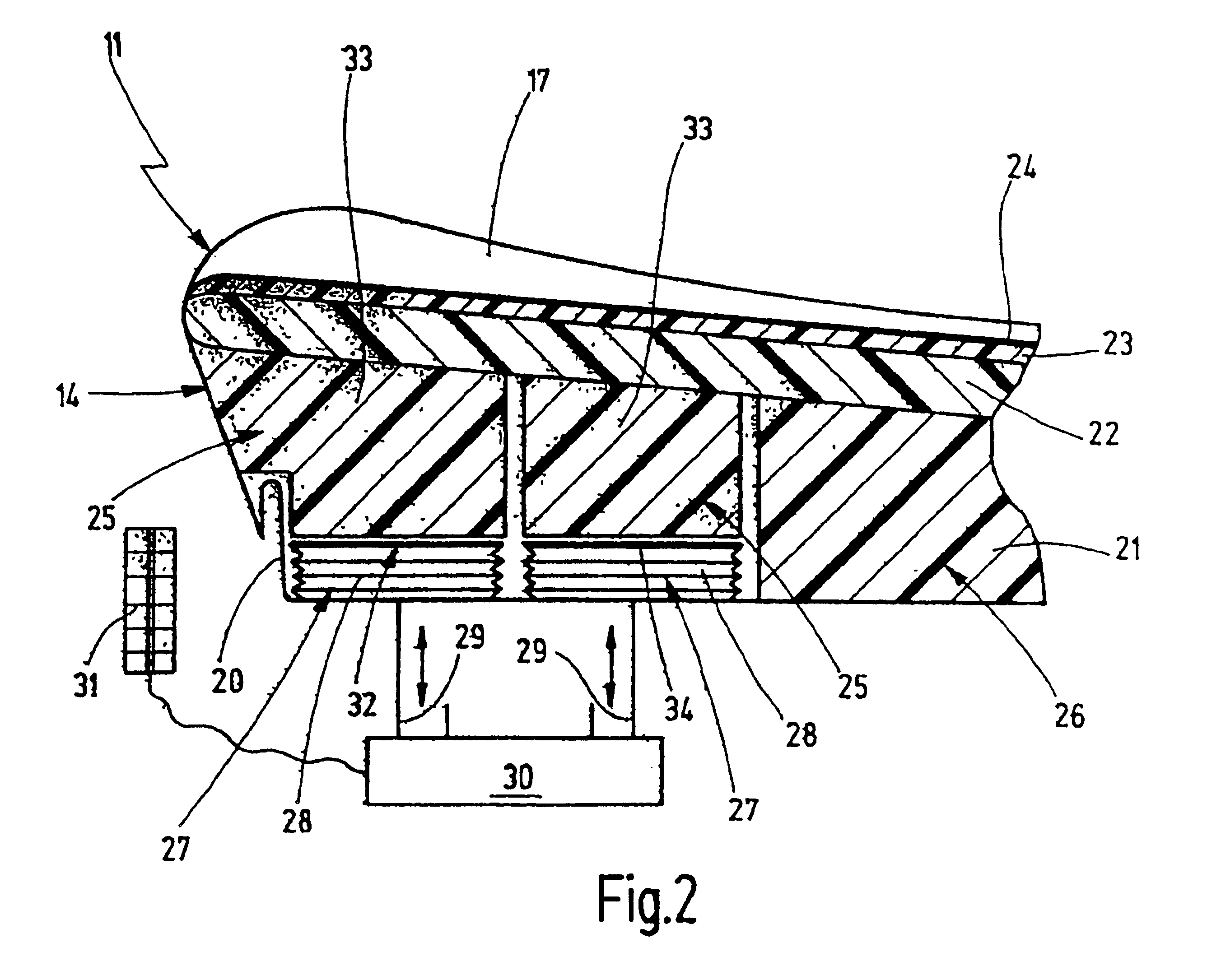

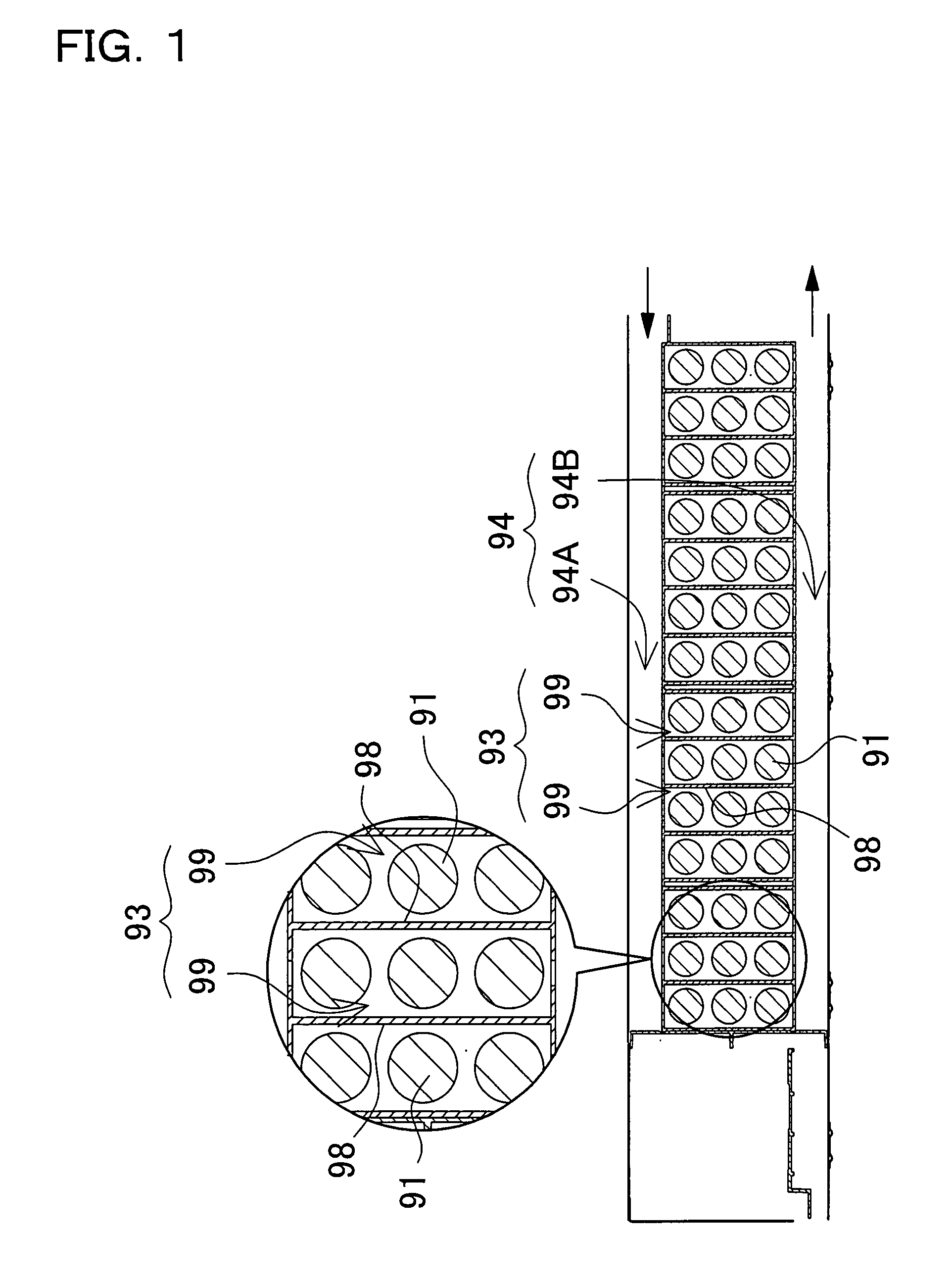

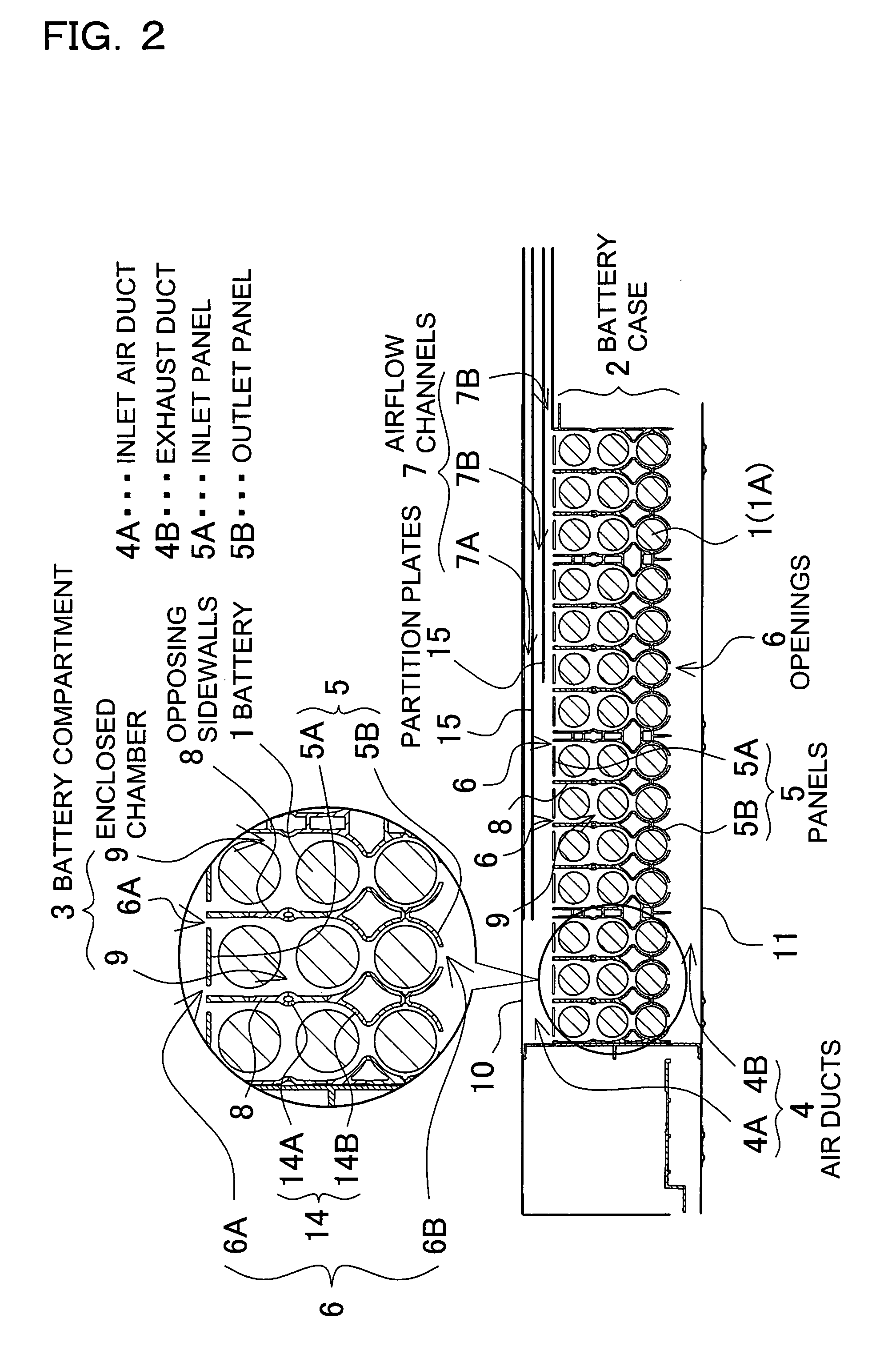

Car power source apparatus

InactiveUS20070202792A1Uniform distributionIncrease airflowAuxillariesCell temperature controlAirflowElectrical and Electronics engineering

The car power source apparatus is provided with a battery case housing a plurality of rechargeable batteries in a battery compartment, and air ducts to carry ventilating air to the battery case and cool the batteries. A plurality of air inlet and outlet openings are provided through panels between the battery compartment and the air ducts. Air inlet and outlet openings are opened in a direction different from the direction of airflow in the ducts. Further, the power source apparatus has a plurality of airflow channels of differing length established inside an air duct in the direction of airflow. This divides ventilating airflow in the air duct into a plurality of airflow channels.

Owner:SANYO ELECTRIC CO LTD

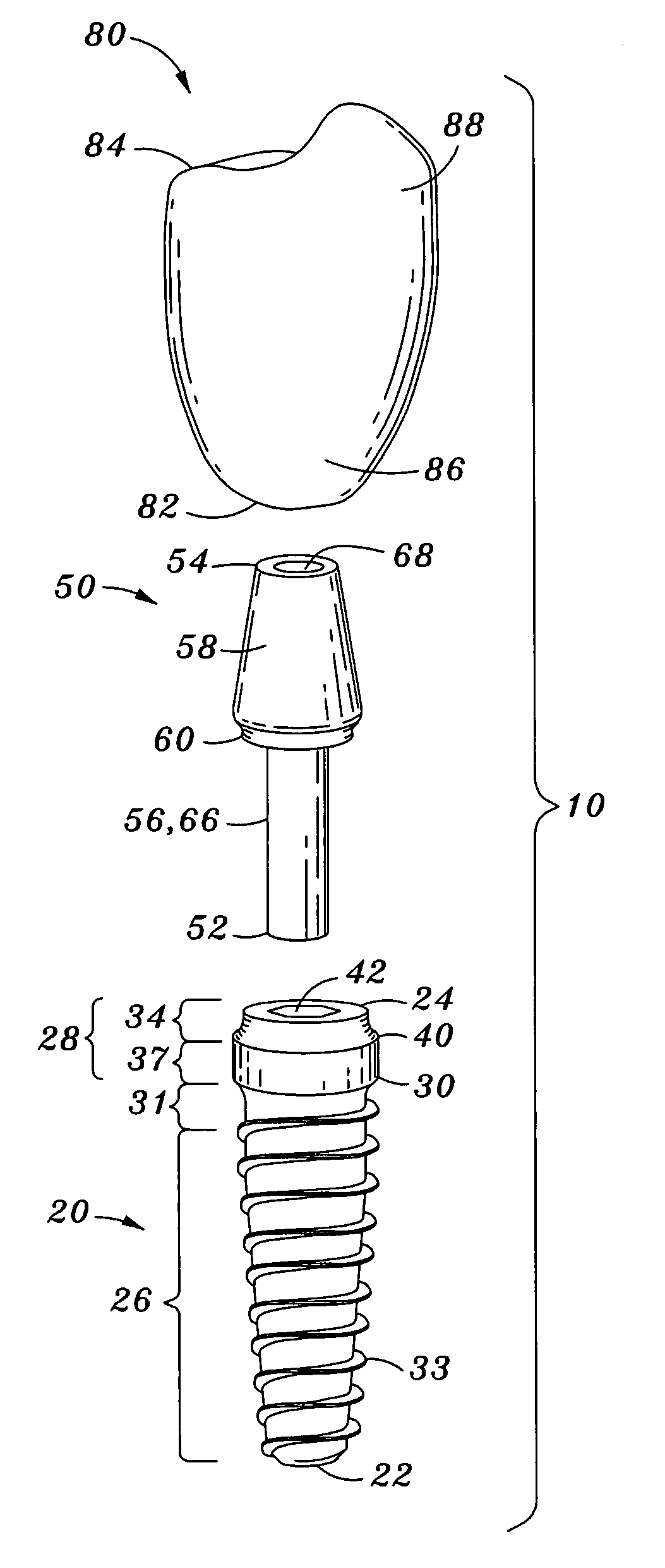

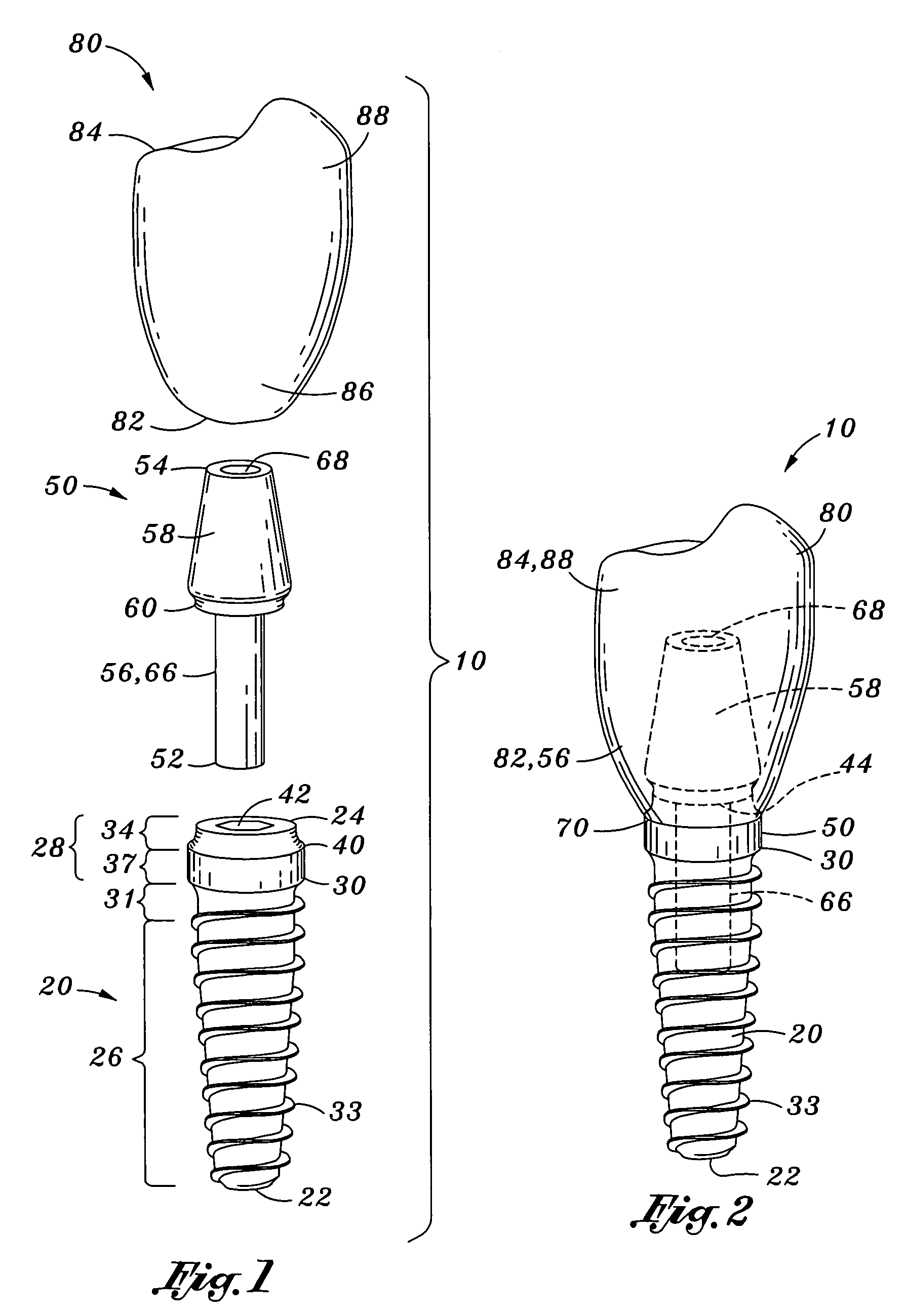

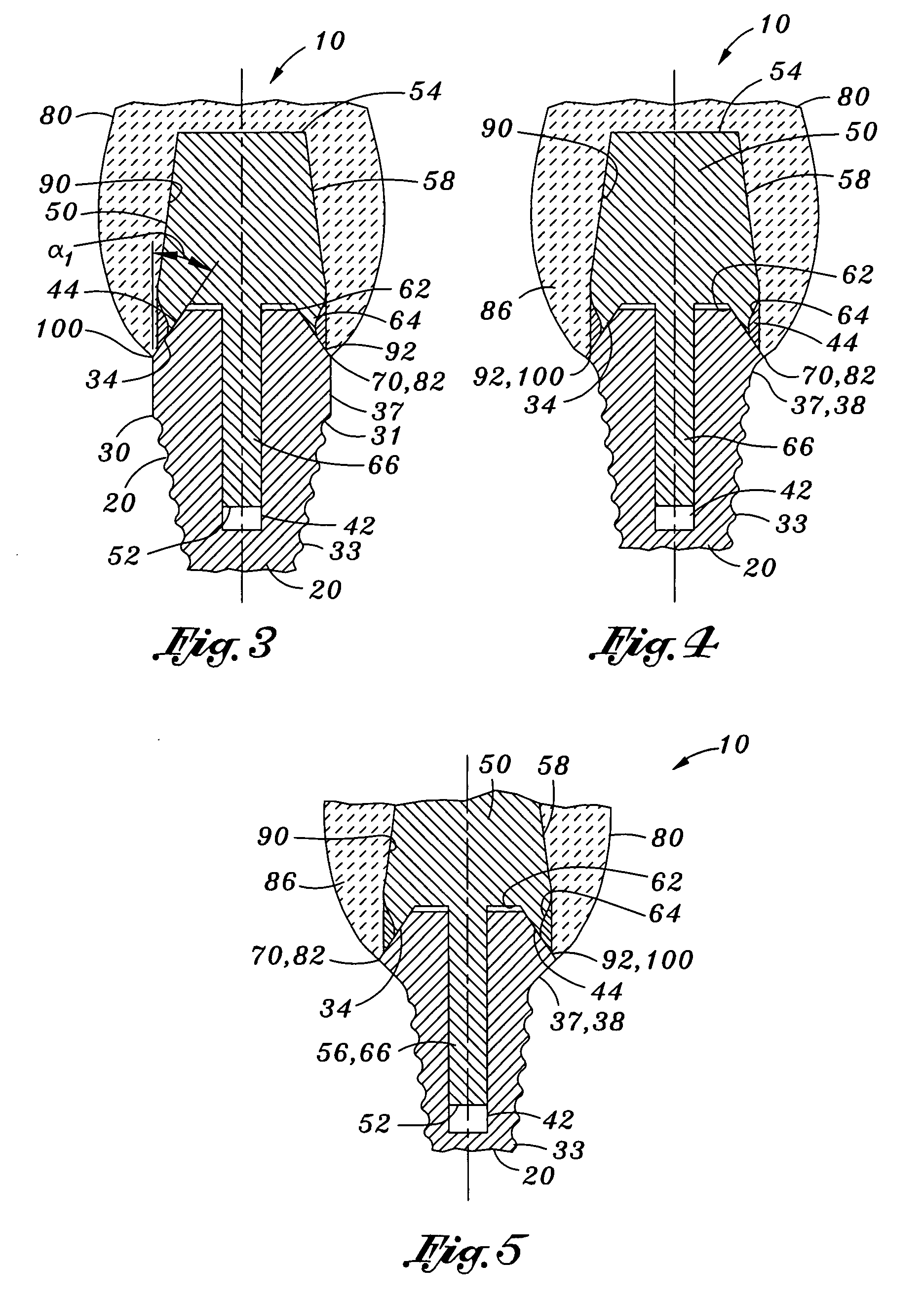

Dental implant

InactiveUS20070254265A1Improve surfaceUniform distributionDental implantsDental implantDental prosthesis

A dental prosthesis comprises an implant, an abutment and a crown. The implant has distal and proximal portions with the implant proximal portion including distal and proximal segments. The implant proximal segment has an outer surface. The abutment has distal and proximal segments and defines an abutment shoulder therebetween. The abutment shoulder is configured to circumferentially engage the outer surface of the implant proximal segment such that an implant abutment joint is defined therebetween. The crown is configured to be positioned over the abutment and the implant such that the crown covers the implant abutment joint. The implant proximal segment has an annular concave cross-section such that the crown distal end has a rounded shape to reduce the potential for stress cracking of the crown.

Owner:PERIOSEAL

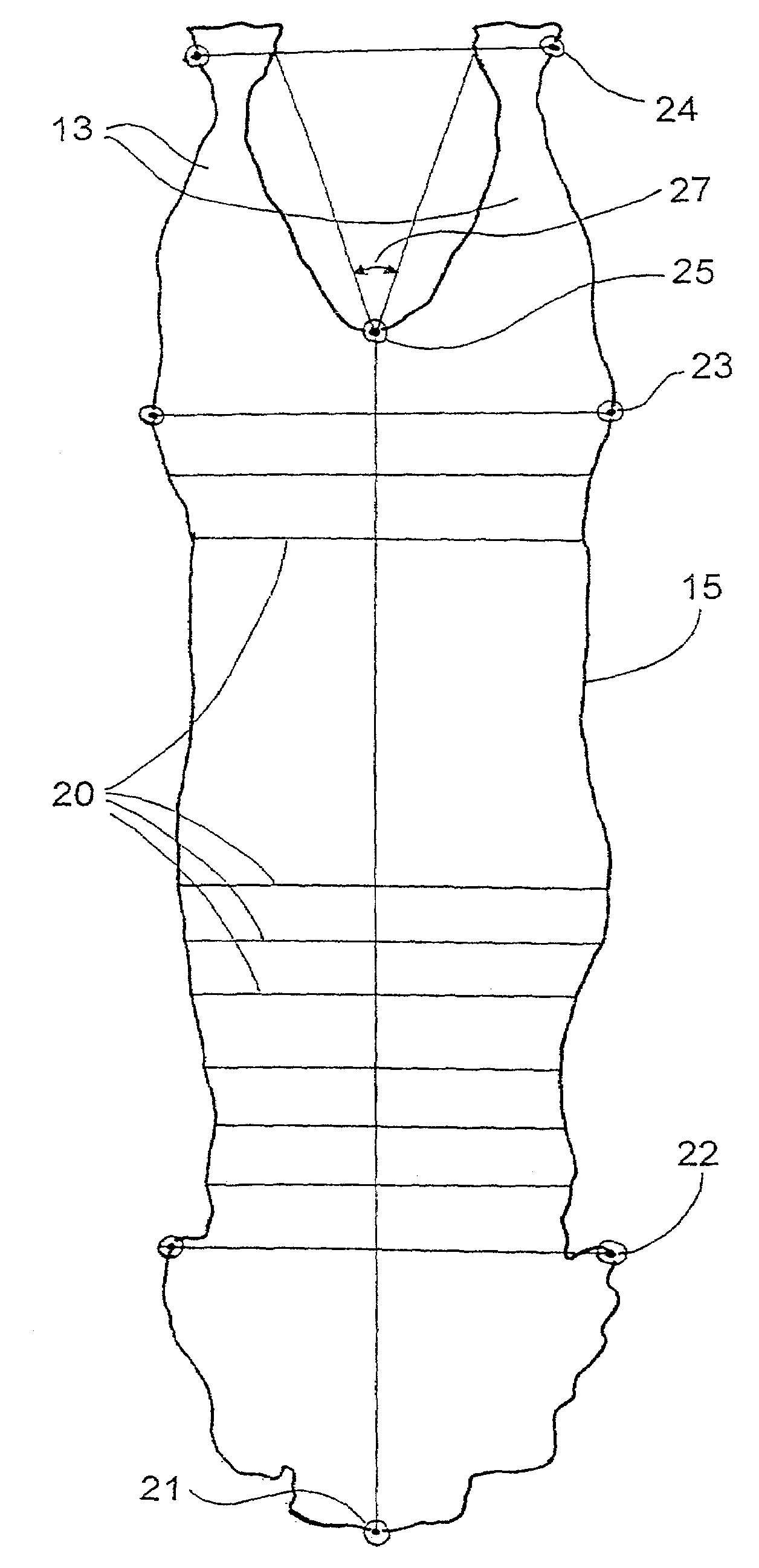

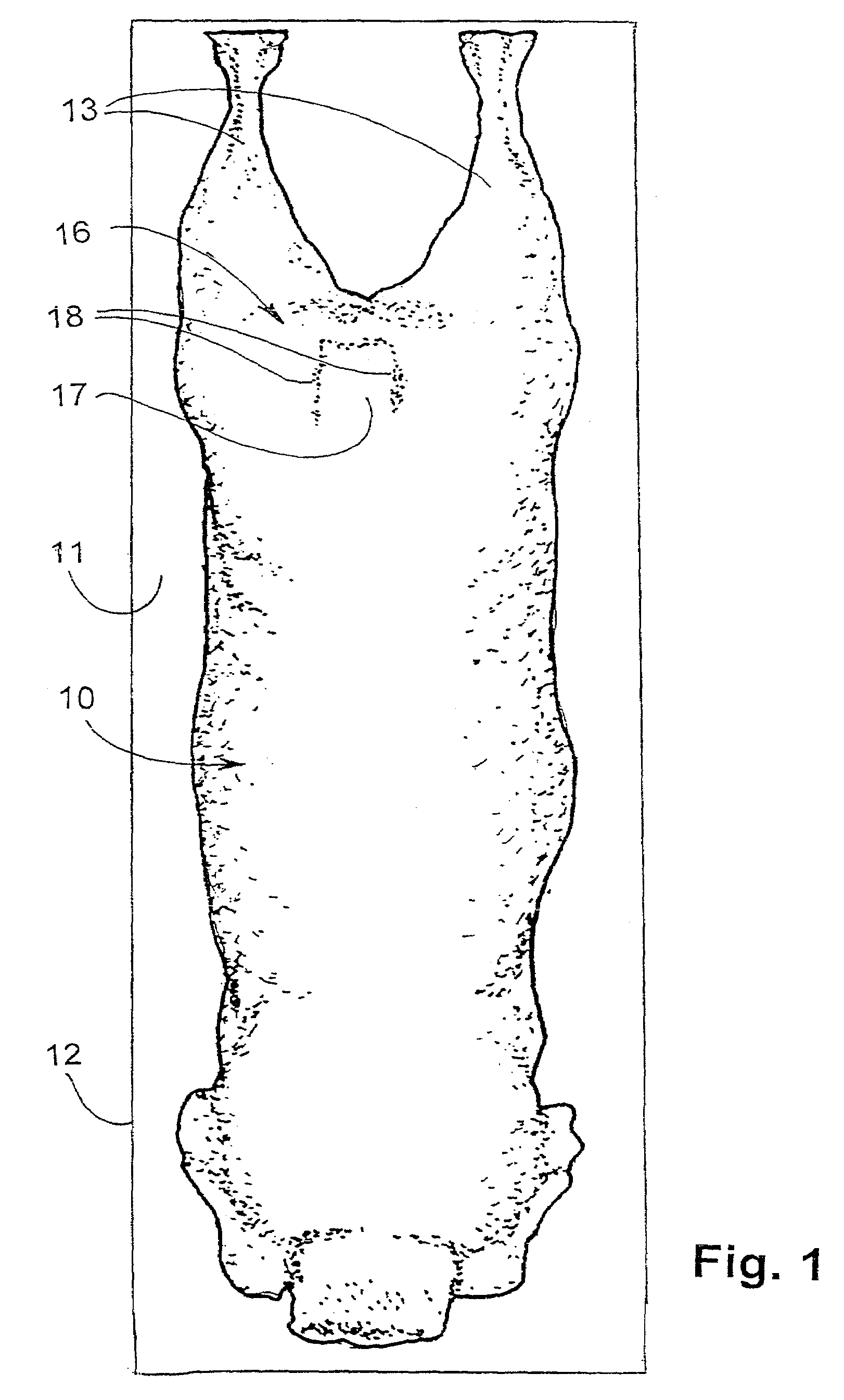

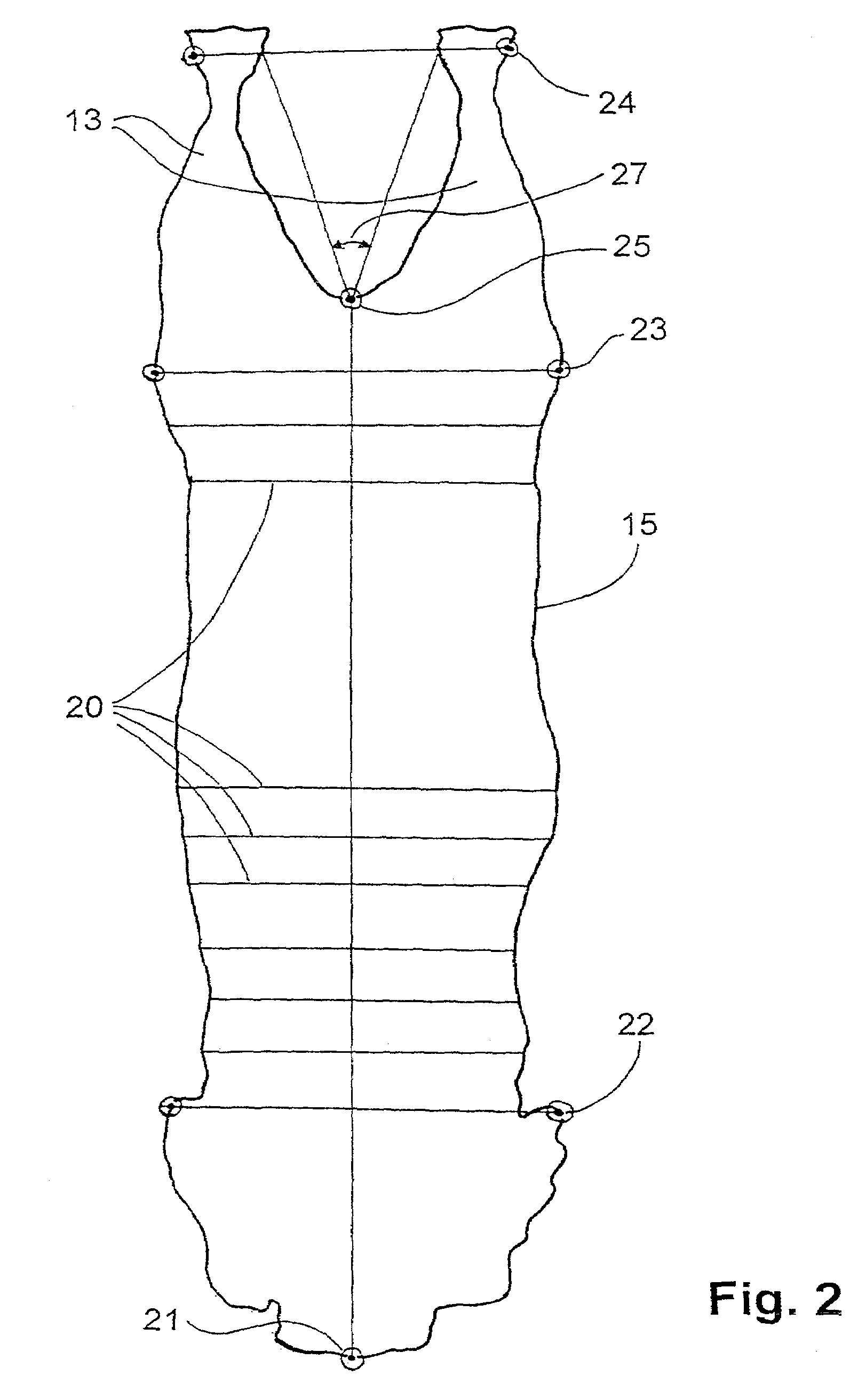

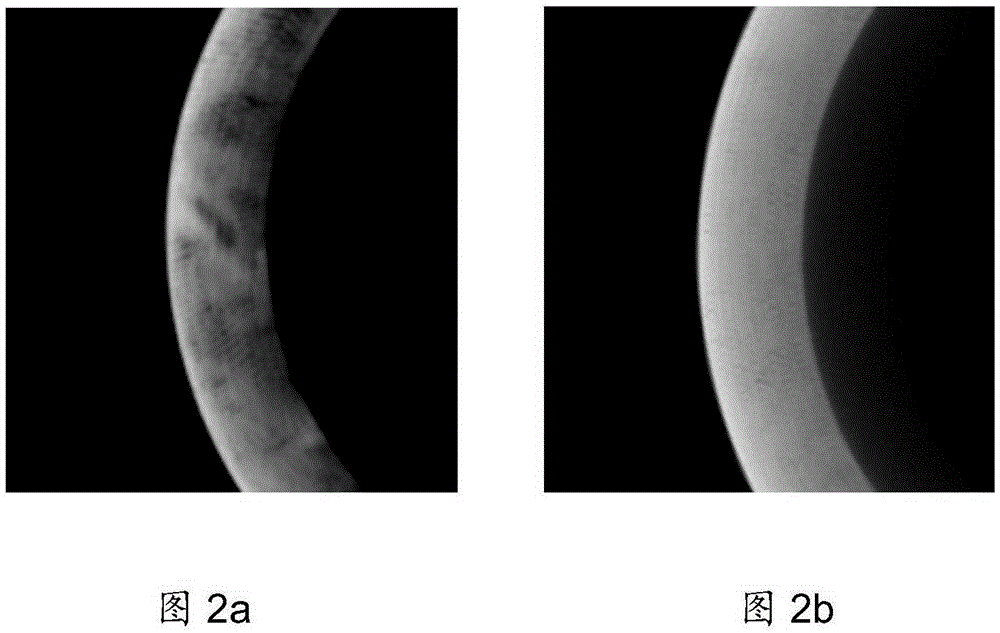

Animal carcase analysis

InactiveUS7110572B1Flatter and more uniform light distributionUniform distributionImage enhancementImage analysisCadaverAnatomical point

The process for analyzing an ovine animal carcase comprises capturing an image of a dorsal view to generate color image data for the carcase (10). Predetermined anatomical points (21–24) of the carcase are identified to then derive dimensional measurements for the carcase. Also characterizing parameters such as yield and fat depth of the carcase are derived by processing color data included in the captured image data in conjunction with the derived dimensional measurements. The color data processed are the color data for predetermined selected surface areas, especially the chump, the loin and the shoulder areas (30–32) of the carcase (10) known or determined to have significant correlation to the characterizing parameter related to fatness. Desirably the tail (17) of the animal carcase is identified and its width determined since this is useful as a variable in a carcase yield predictive equation. The color data comprises average RGB values representing red, green and blue color components which are intensity normalized color values.

Owner:RMS RES MANAGEMENT SYST INC

Led-based flashlight

InactiveUS20050007767A1Uniform distributionPoint-like light sourceWith electric batteriesLight pipeElectronics

A flashlight that utilizes an array of one or more light-emitting diodes (LEDs) as a light source, and a light pipe as a light homogenizer to generate a light beam capable of forming a uniformized light distribution at a given distance from the flashlight is disclosed. The LEDs may be all the same color, or some or all may be different colors. A switch, coupled to switching electronics coupled to the LED array, is used to change the state of the LED array to create a variety of different types of light beams, each of which provides relatively uniform and bright illumination at a given distance from the flashlight, wherein the given distance is selectable by adjusting an adjustable imaging lens.

Owner:OPTICS 1

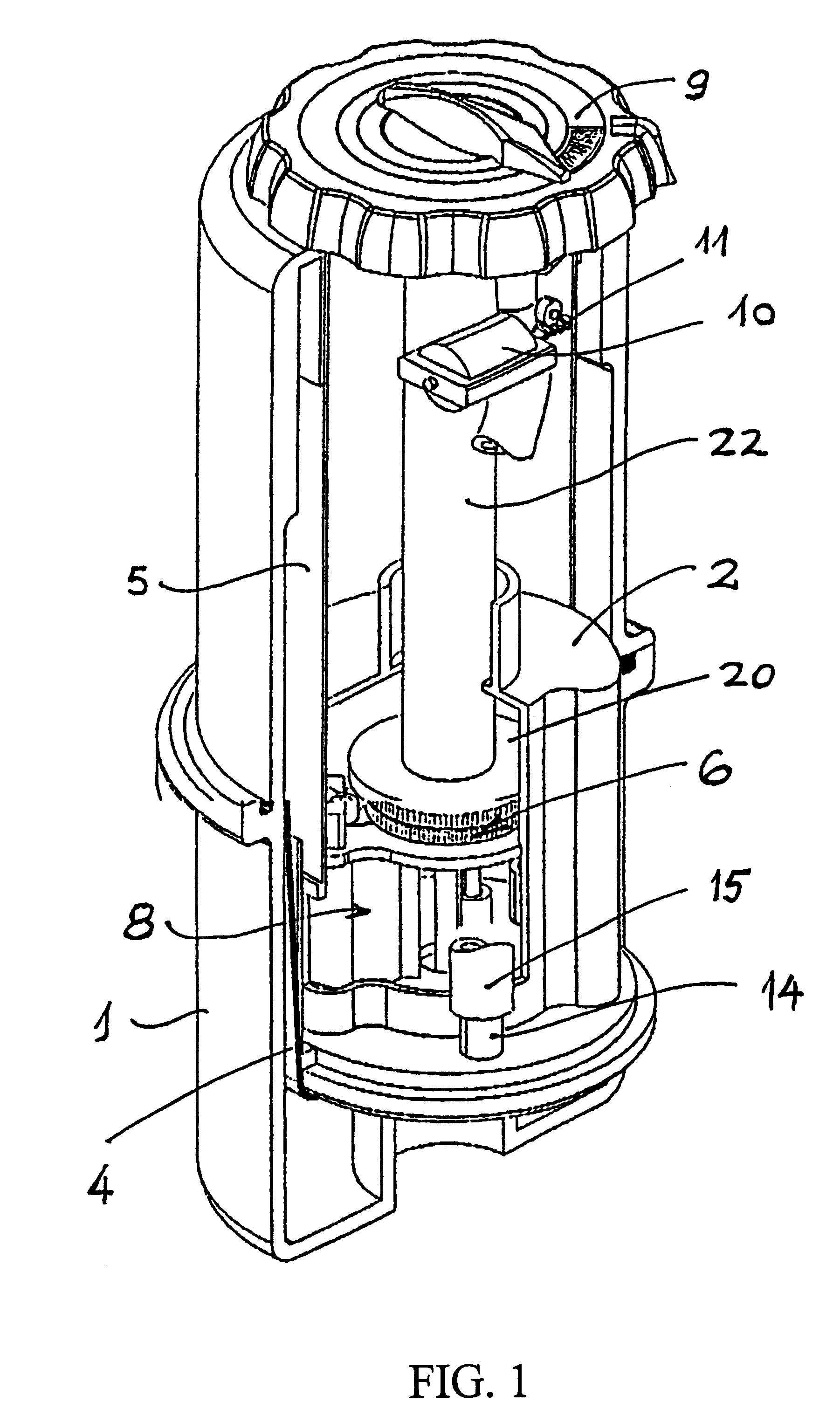

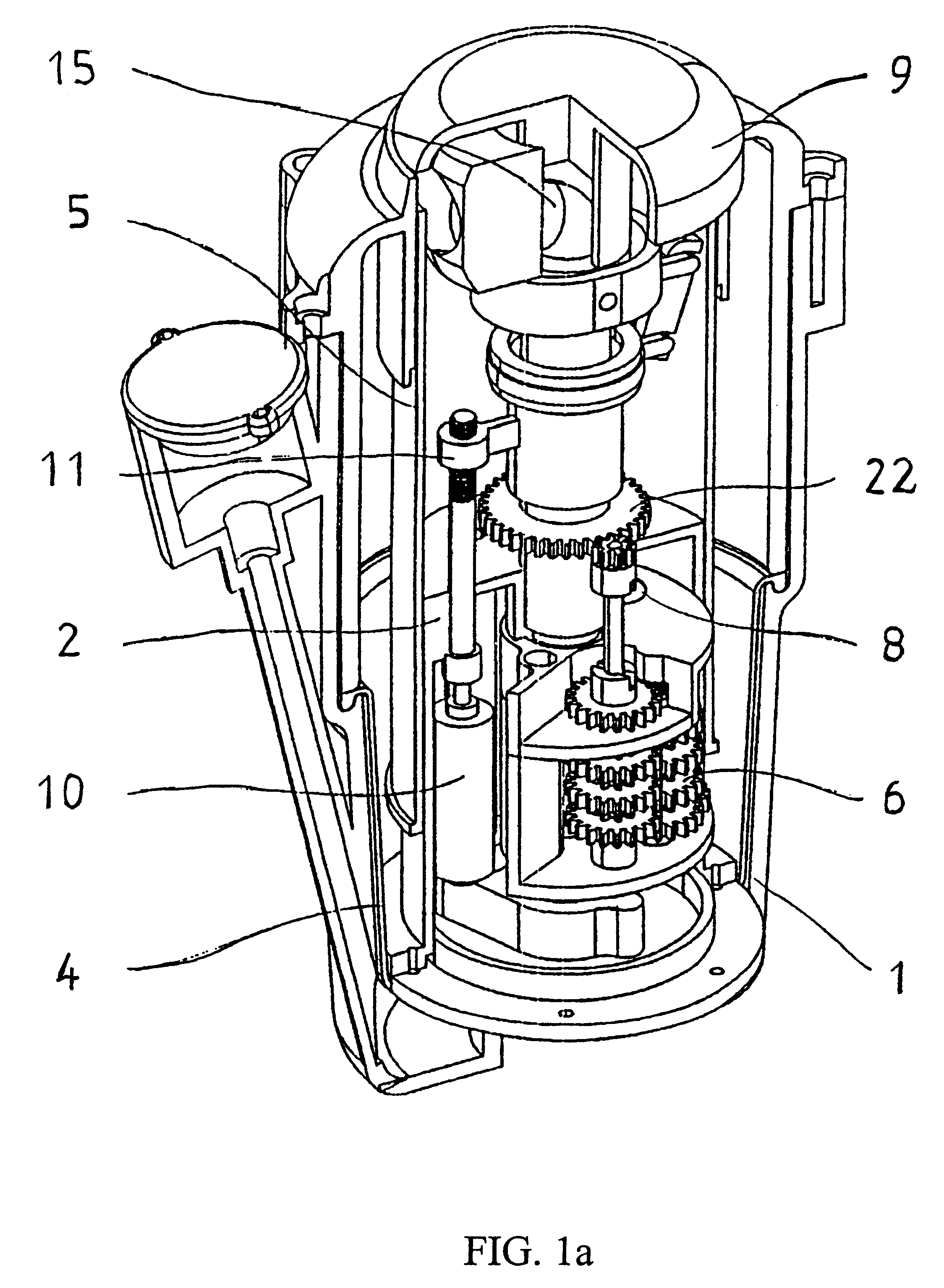

Electrically operated sprinkler

InactiveUS6336596B1Uniform distributionMaintain distributionMovable spraying apparatusEngineeringWater irrigation

A rotary irrigation sprinkler head having a water inlet and a water outlet and a main rotary part. The main rotary part of said sprinkler head is provided with a gear and a plurality of toothed wheels forming a reduction gear, a first low voltage electric motor is provided connected to said reduction gear, the activation of said electric motor would revolve the sprinkler, and a second low voltage electric motor is provided connected to the outlet nozzle of said sprinkler adapted to control the angle of said outlet nozzle.

Owner:DAN MAMTIRIM ISRAELI PARTNERSHIP

Heat exchanger with a mixing chamber

InactiveUS20100319894A1Uniform distributionEvenly distributedEvaporators/condensersMetal-working apparatusEngineeringMixing chamber

A heat exchanger, in particular for a motor vehicle, comprises a collector box and at least one longitudinal row of multi-channel flat tubes through which a first fluid can flow. The collector box is made up of stacked plates including:a header plate with at least one row of mounting slots receiving an end portion of each tube,a distribution plate comprising at least one row of distribution slots,a cover plate comprising at least one row of collecting apertures which connect at least some of the distribution slots to a manifold, at least one collecting aperture being arranged between two adjacent distribution slots.Said collecting aperture is arranged in a main recess provided in the bottom face of the cover plate.

Owner:DELPHI TECH INC

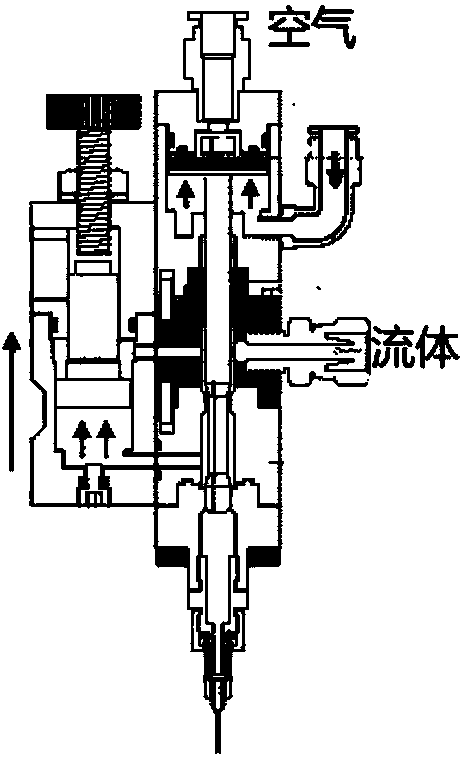

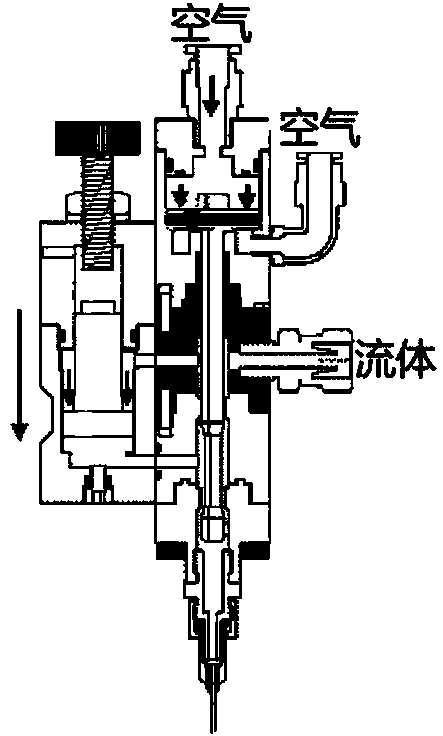

Jetting glue dispensing valve device and jetting glue dispensing method

InactiveCN103464342AAchieve continuous injectionJet realizationLiquid surface applicatorsCoatingsSingle processMechanical engineering

The invention discloses a jetting glue dispensing valve device and a jetting glue dispensing method. The jetting glue dispensing valve device comprises a jetting glue dispensing valve, a glue supply pipeline and a glue supply valve, wherein a turntable capable of being closed / opened quickly is mounted at the bottom of the glue supply valve. During a glue jetting course, the glue supply valve is closed, and a channel allowing a glue solution to flow back to the glue supply valve from the glue supply pipeline is intercepted, so that glue jetting with precise volume is achieved. After a single glue jetting course is finished, the glue supply valve is opened, and the glue supply channel is opened for filling, so that continuous jetting of the glue solution is achieved. When the device and the jetting glue dispensing method are used for glue dispensing, no backflow occurs, so that an effective utilization rate of striker movement is increased, and jetting of a high-viscosity glue solution is facilitated; the device is simple in structure and easy to process; the turntable has the characteristic of periodic rotation, and can stir the glue solution, so that precipitation of fluorescent powder in the glue solution is avoided effectively; the fluid velocity in the jetting glue dispensing valve is distributed more uniformly; and the glue dispensing quality is ensured.

Owner:CENT SOUTH UNIV

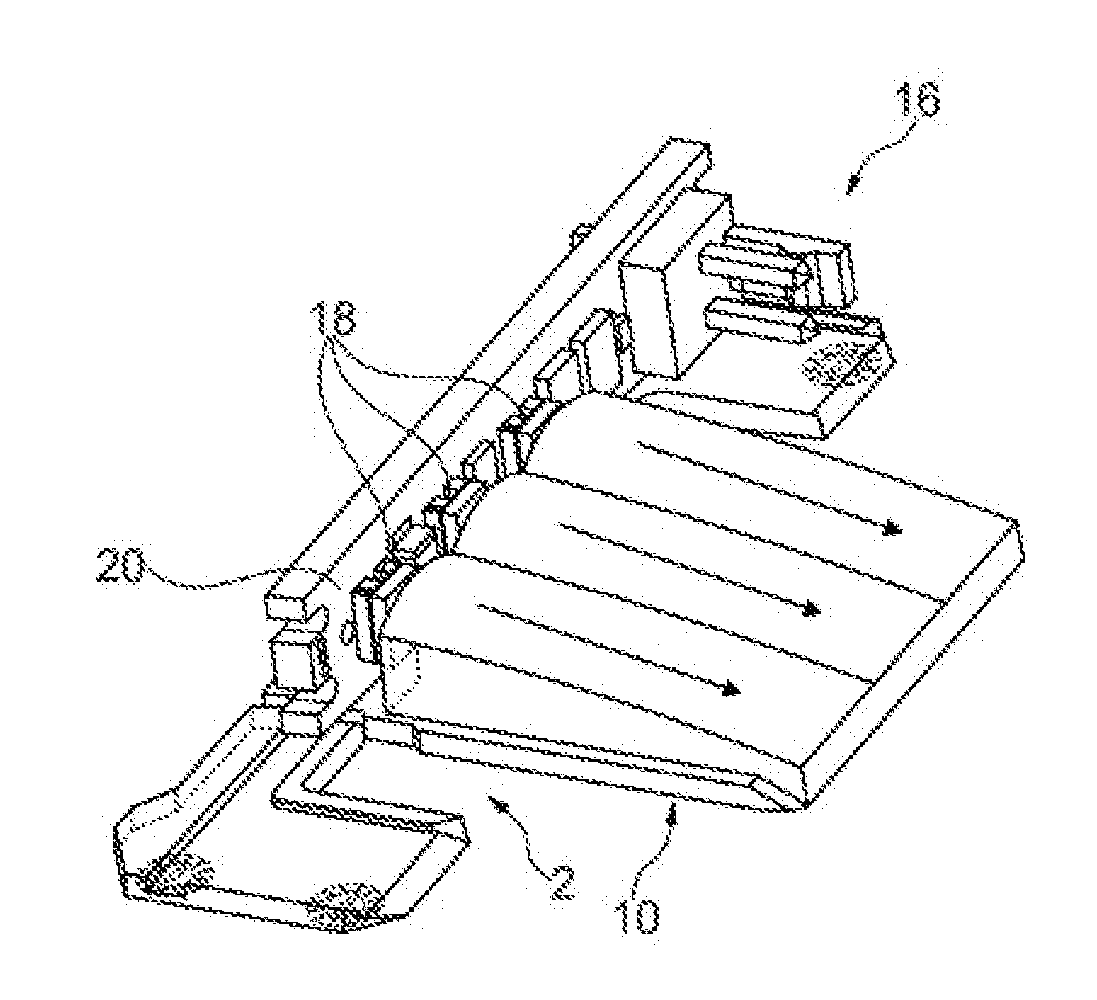

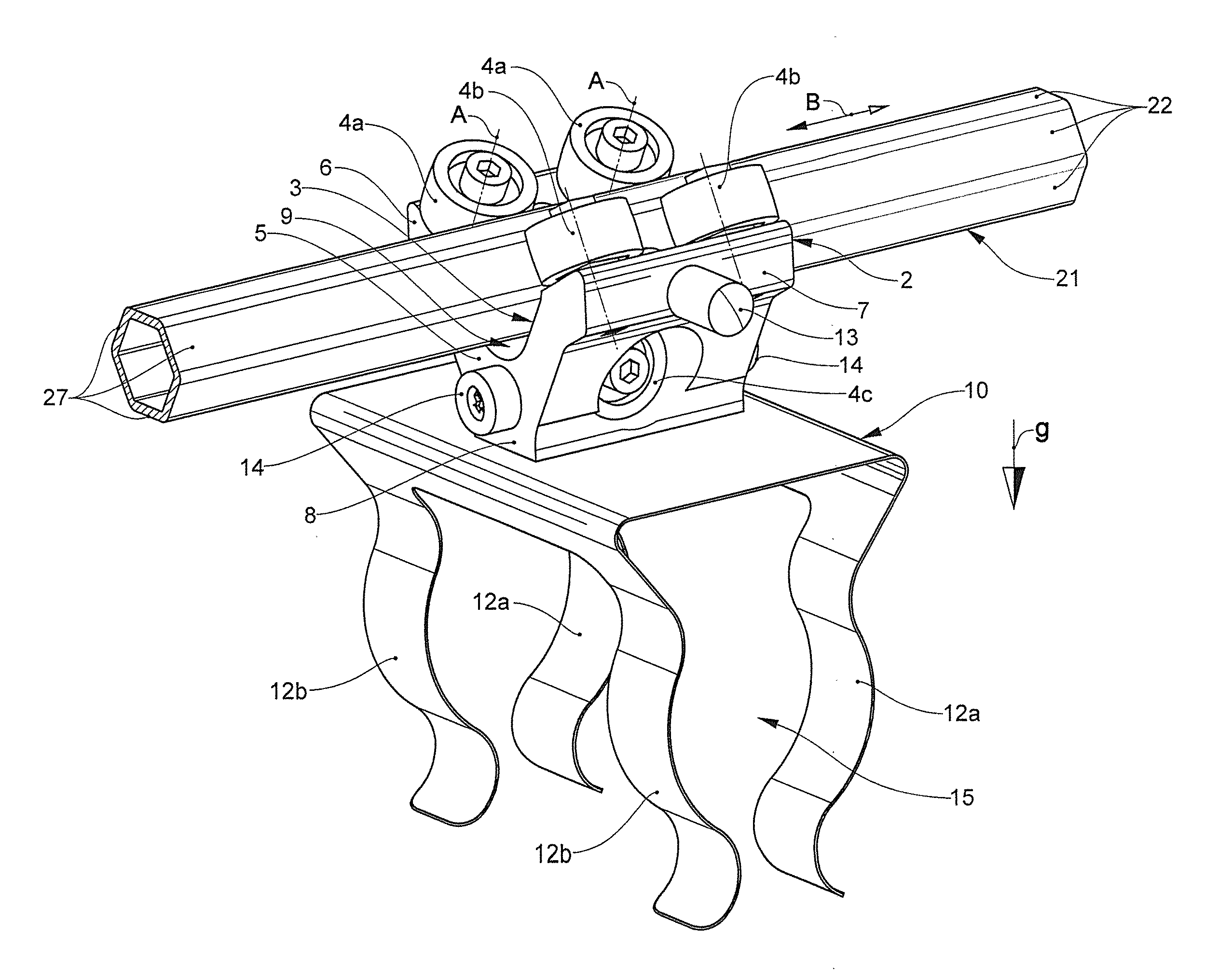

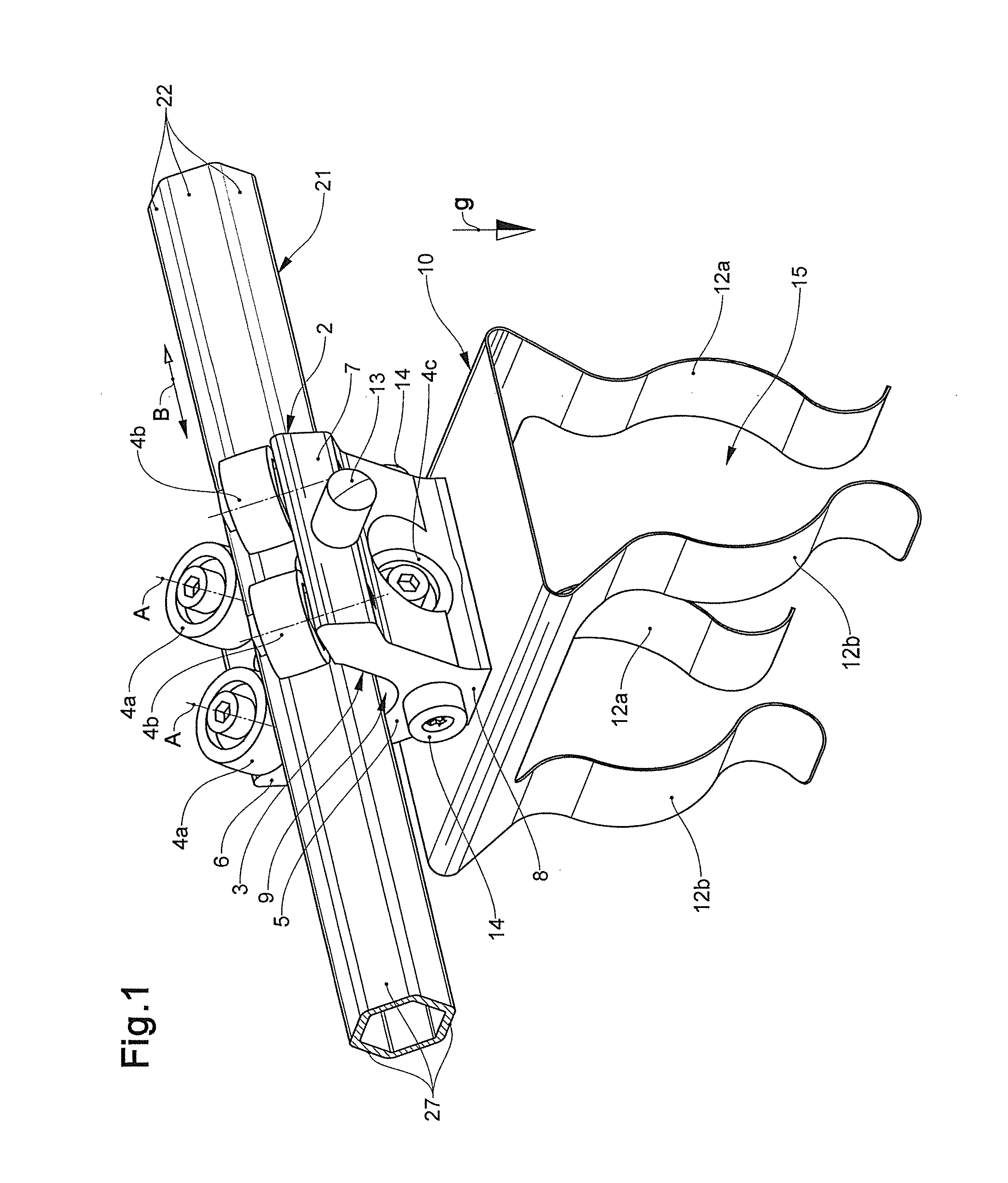

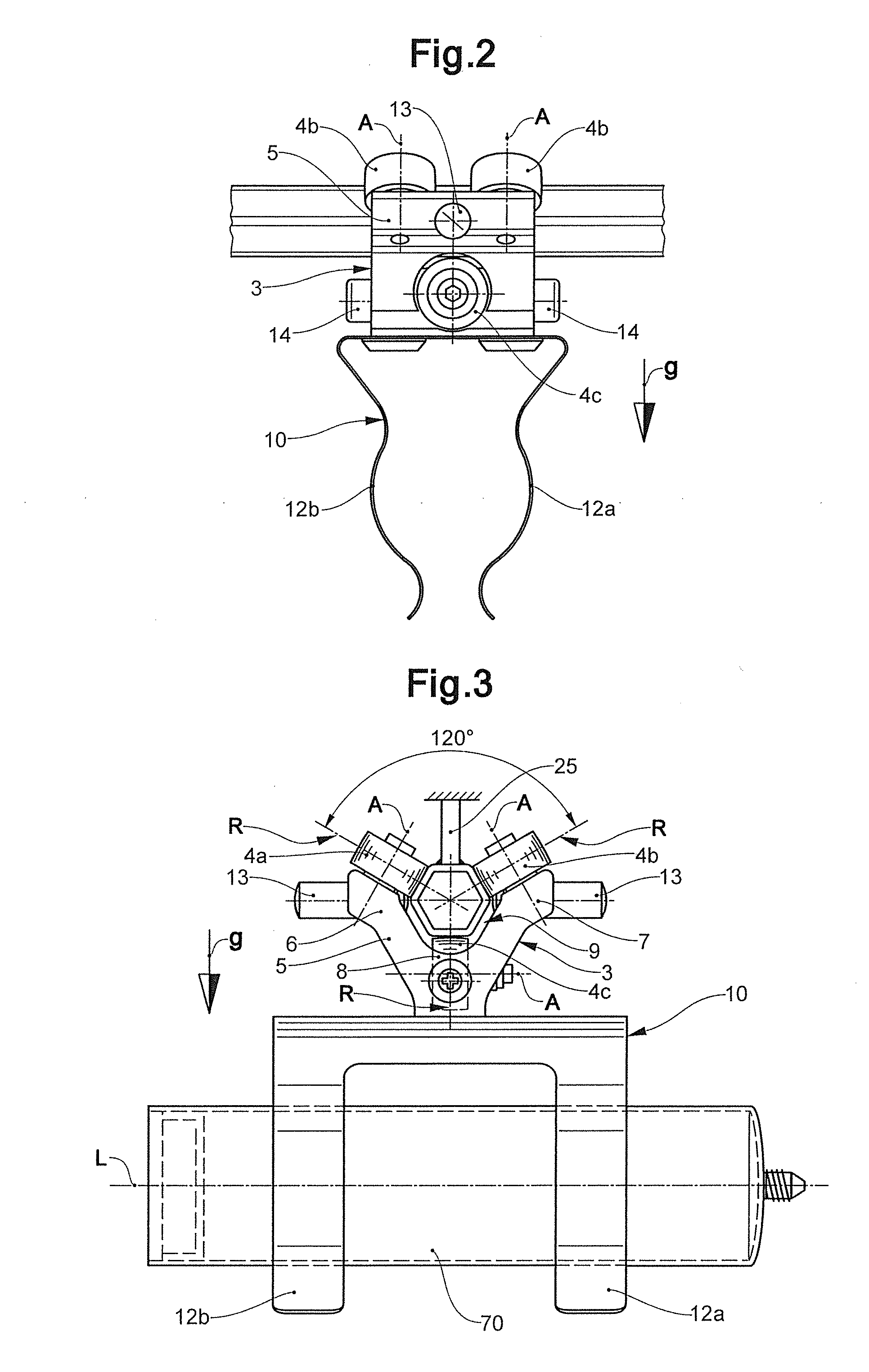

Method and device for the transfer of piece goods to a conveying installation

InactiveUS20140291124A1Overcome disadvantagesUniform distributionConveyorsManual conveyance devicesMechanical engineeringEngineering

The device for the transfer of piece goods (70) to a conveying installation (1) comprises at least one goods piece receiver (51) for positioning a goods piece (70) in a transfer zone (Z) of the conveying installation (1). The conveying installation (1) comprises a plurality of conveying elements (10) which are moveable along a conveying path and are for conveying the taken-over piece goods (70). The device moreover comprises a slide mechanism (52) with a slide element (53), by way of which a goods piece (70) can be moved in a push movement out of the goods piece receiver (51) to the conveying element (10) and can be transferred to the conveying element (10).

Owner:FERAG AG

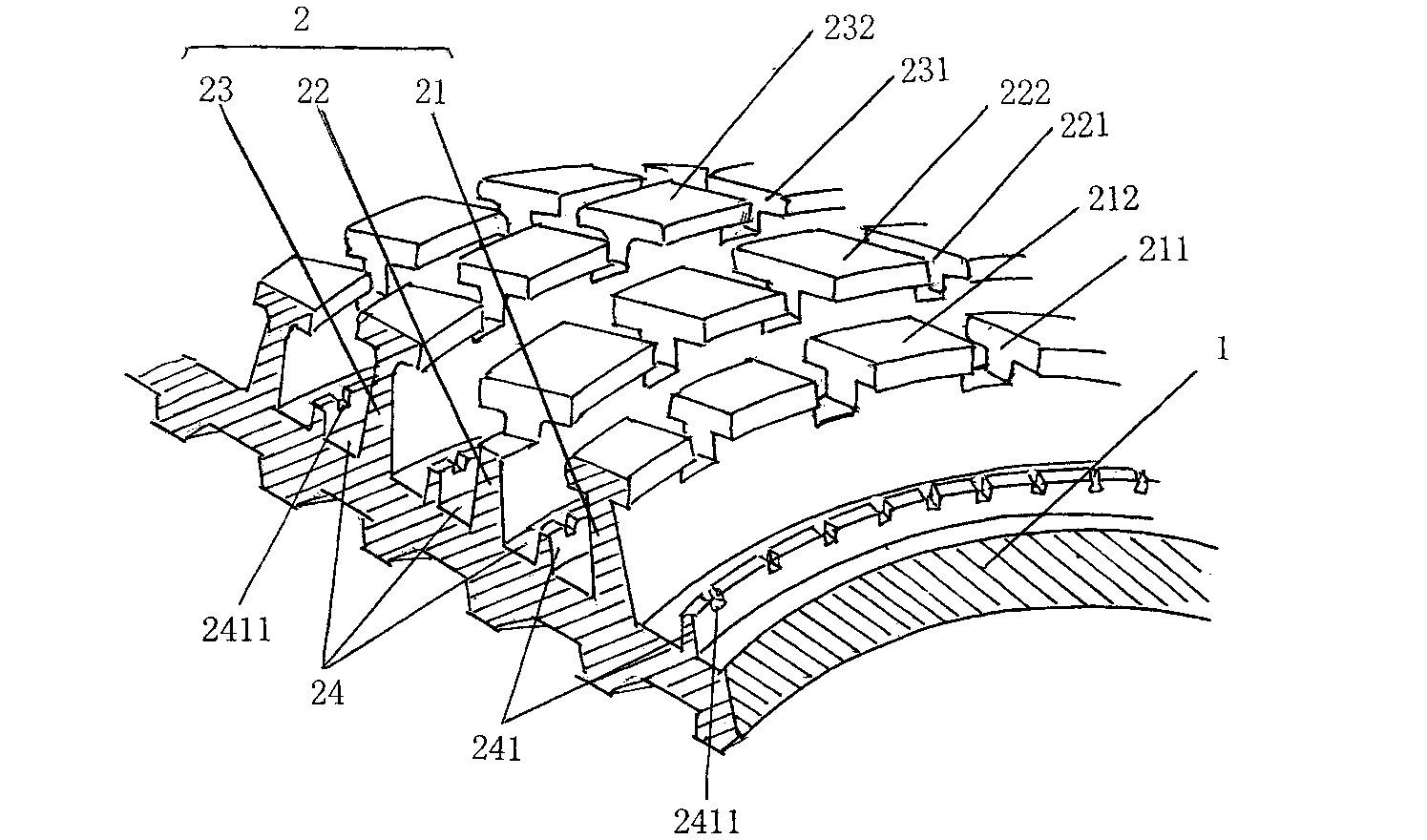

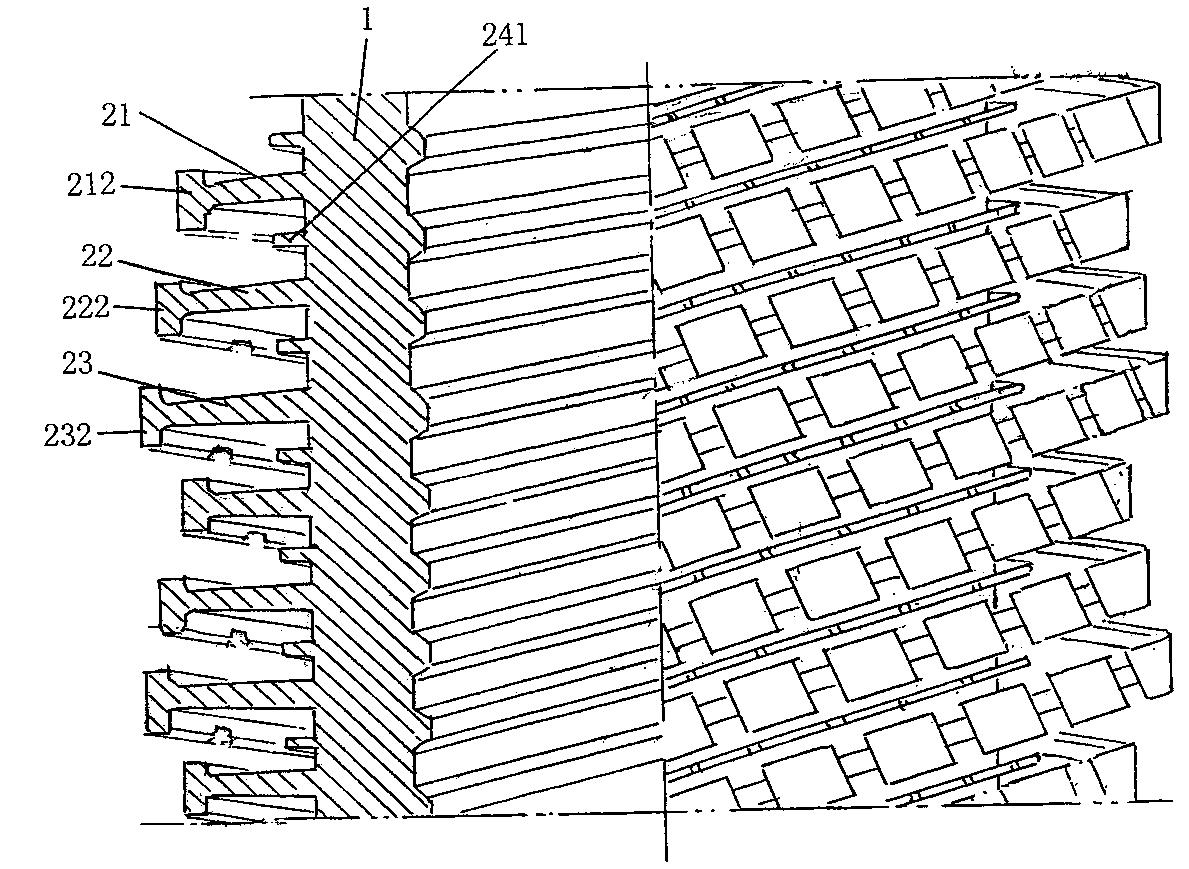

Heat-exchange tube

InactiveCN103063072AEasy to break awayUniform distributionTubular elementsEngineeringMechanical engineering

The invention discloses a heat-exchange tube and belongs to the field of heat enhancement of heat transfer and energy saving. The heat-exchange tube comprises a tube body and a helical fin group, wherein the helical fin is formed by a first helical fin, a second helical fin and a third helical fin, first grooves are formed on the upper portion of the first helical fin, helical fin top portions among the first grooves form first T-shaped fin platforms; second grooves are formed on the upper portion of the second helical fin, helical fin top portions among the second grooves form second T-shaped fin platforms; third grooves are formed on the upper portion of the third helical fin, and helical fin top portions among the third grooves form third T-shaped fin platforms. The heat-exchange tube is characterized a first distance between the top surfaces of the first T-shaped fin platforms and a fin root portion of the first helical fin is smaller than a second distance between the top surfaces of the second T-shaped fin platforms and a fin root portion of the second helical fin, the second distance is smaller than a third distance between the top surfaces of the third T-shaped fin platforms and a fin root portion of the third helical fin, and find grooves are formed in the spaces between the first helical fin and the second helical fin, the second helical fin and the third helical fin, and between the third helical fin and the first helical fin. By the aid of the heat-exchange tube, heat exchange efficiency for falling film evaporation is improved.

Owner:JIANGSU CUILONG PRECISION COPPER TUBE CORP

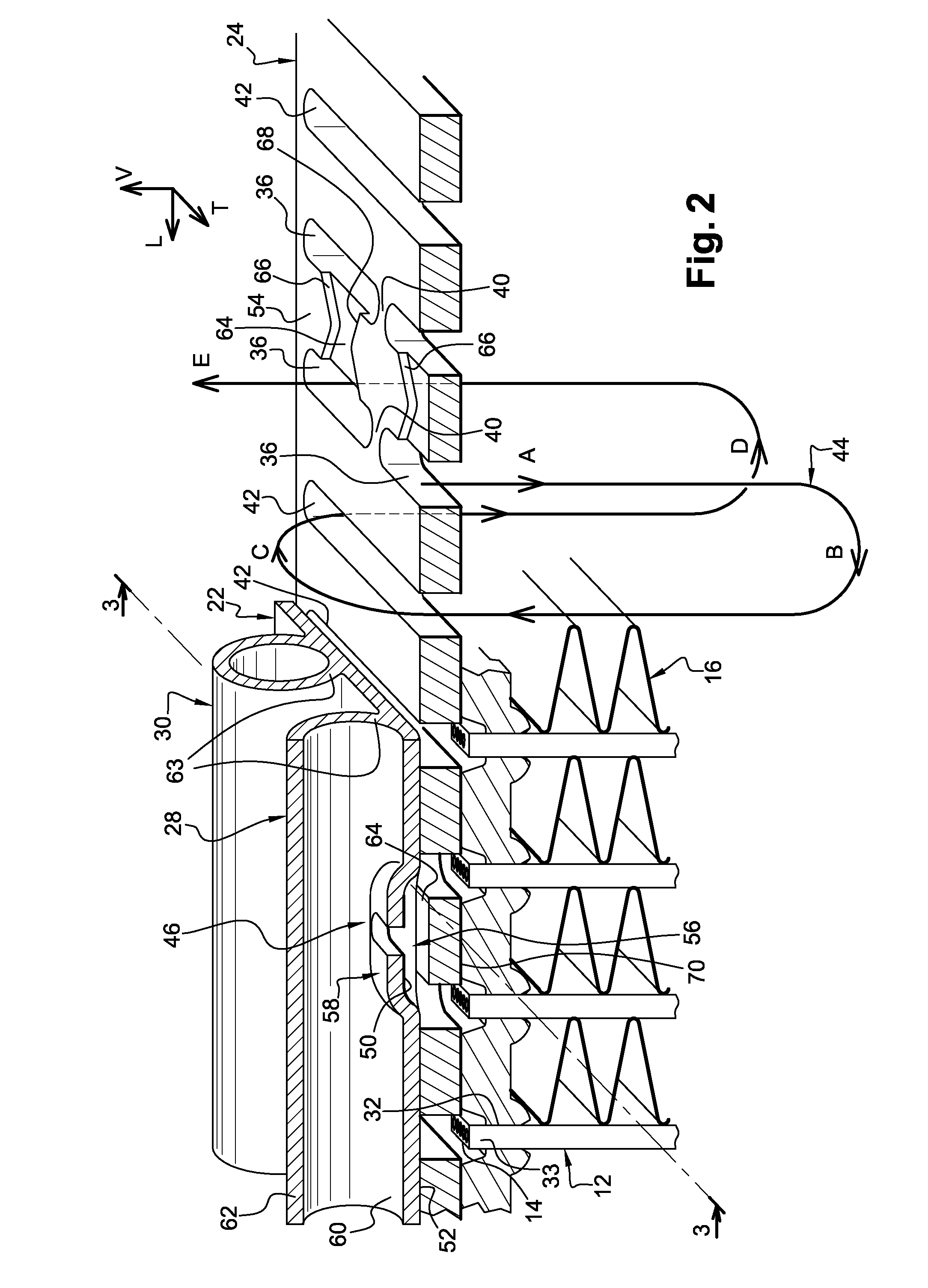

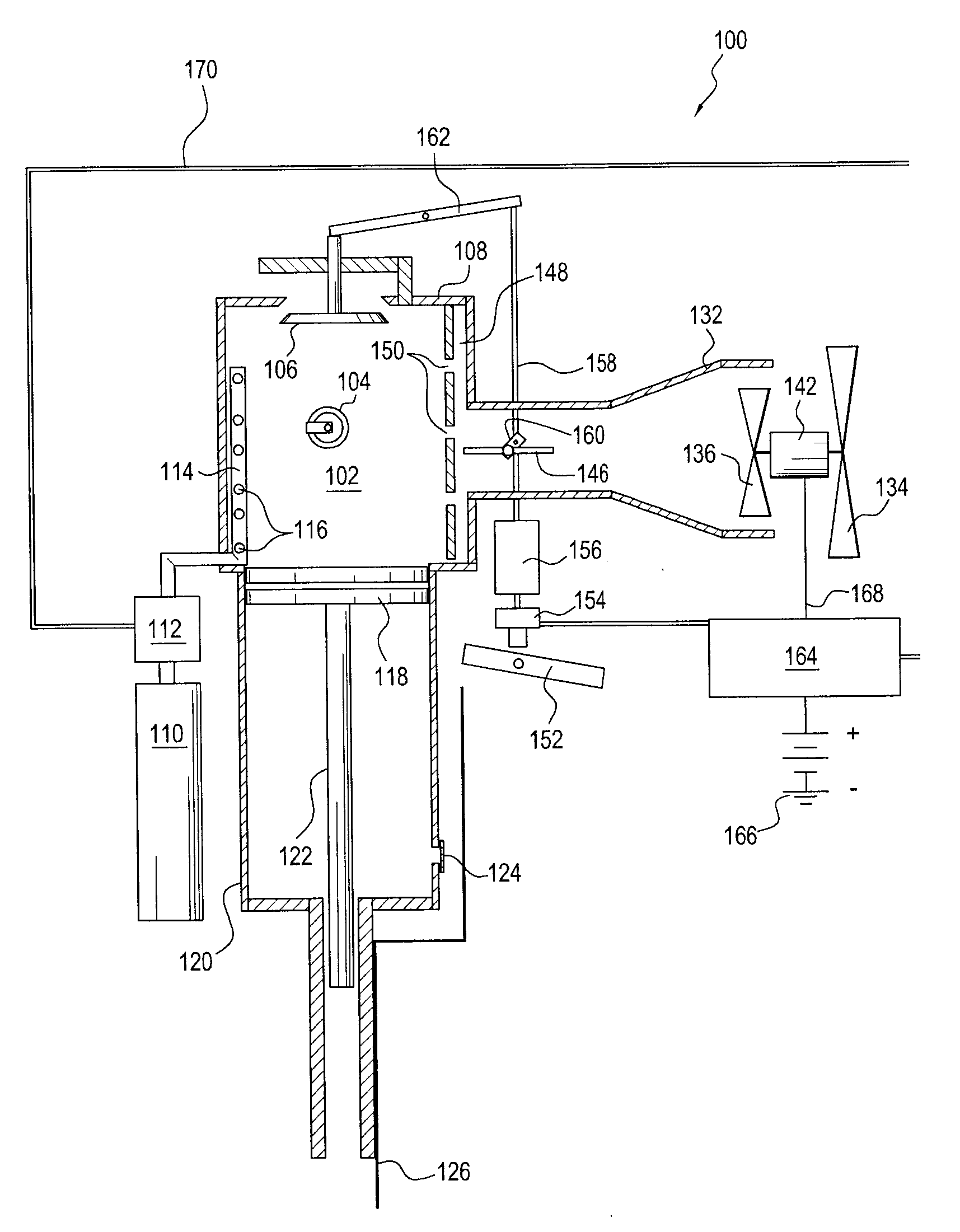

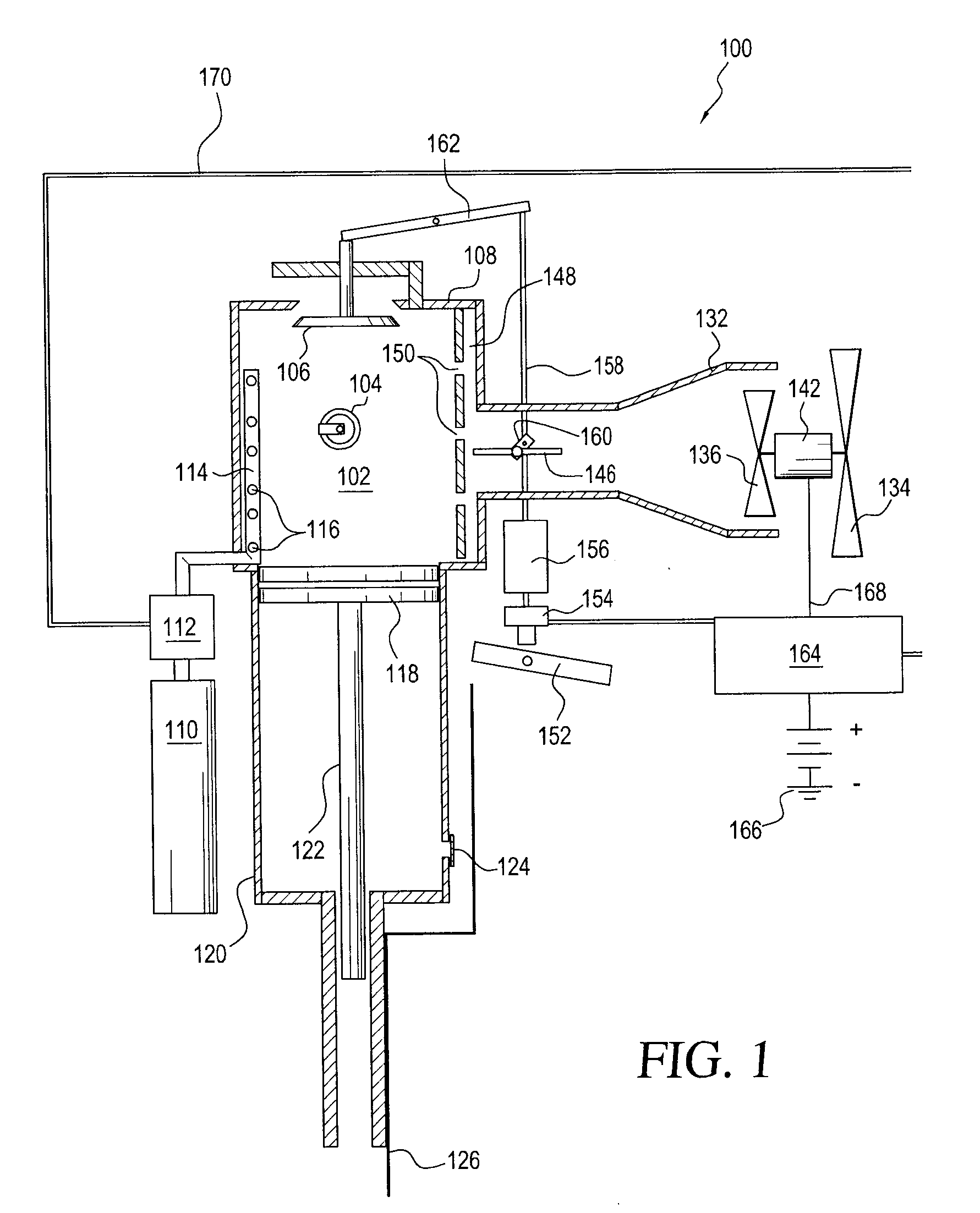

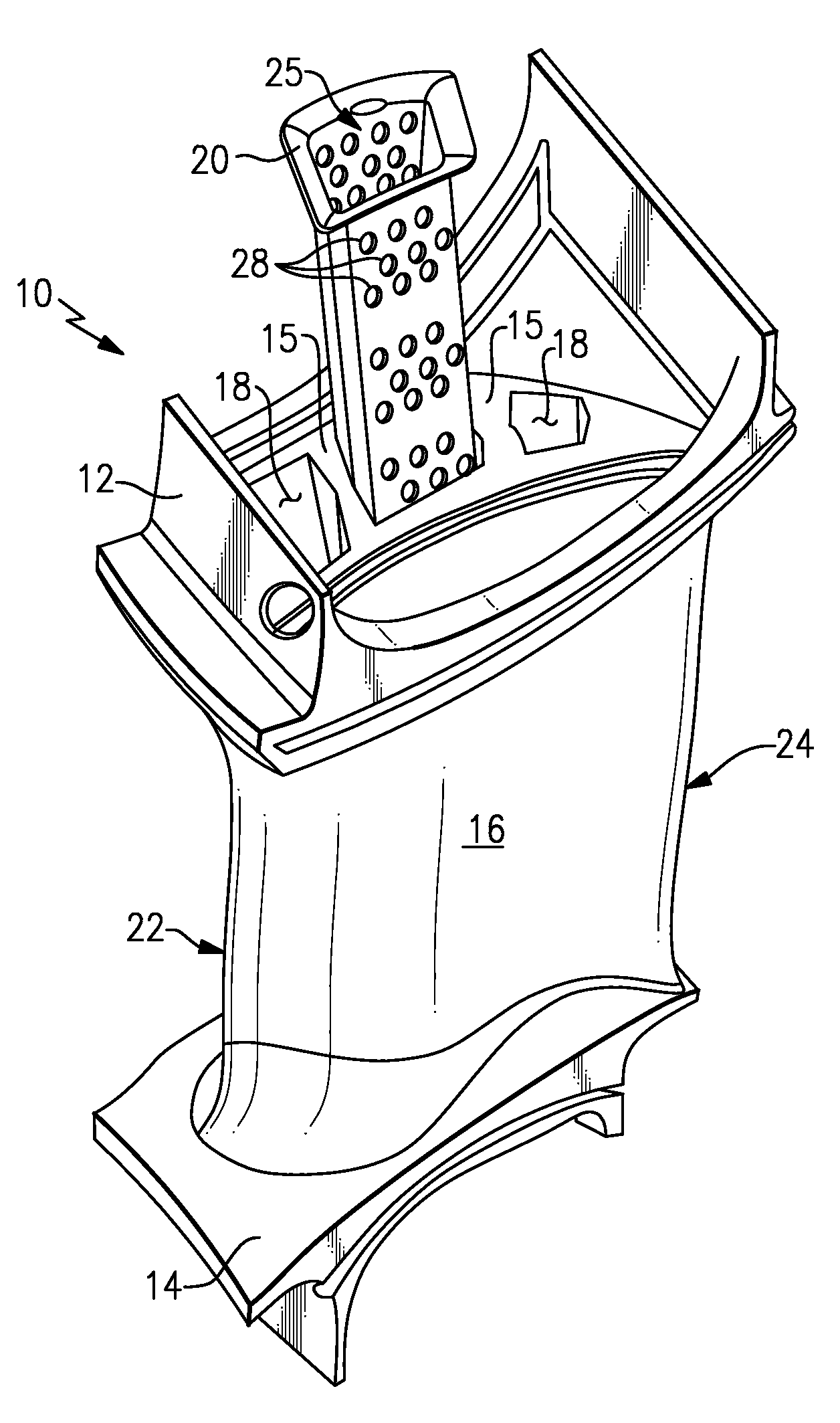

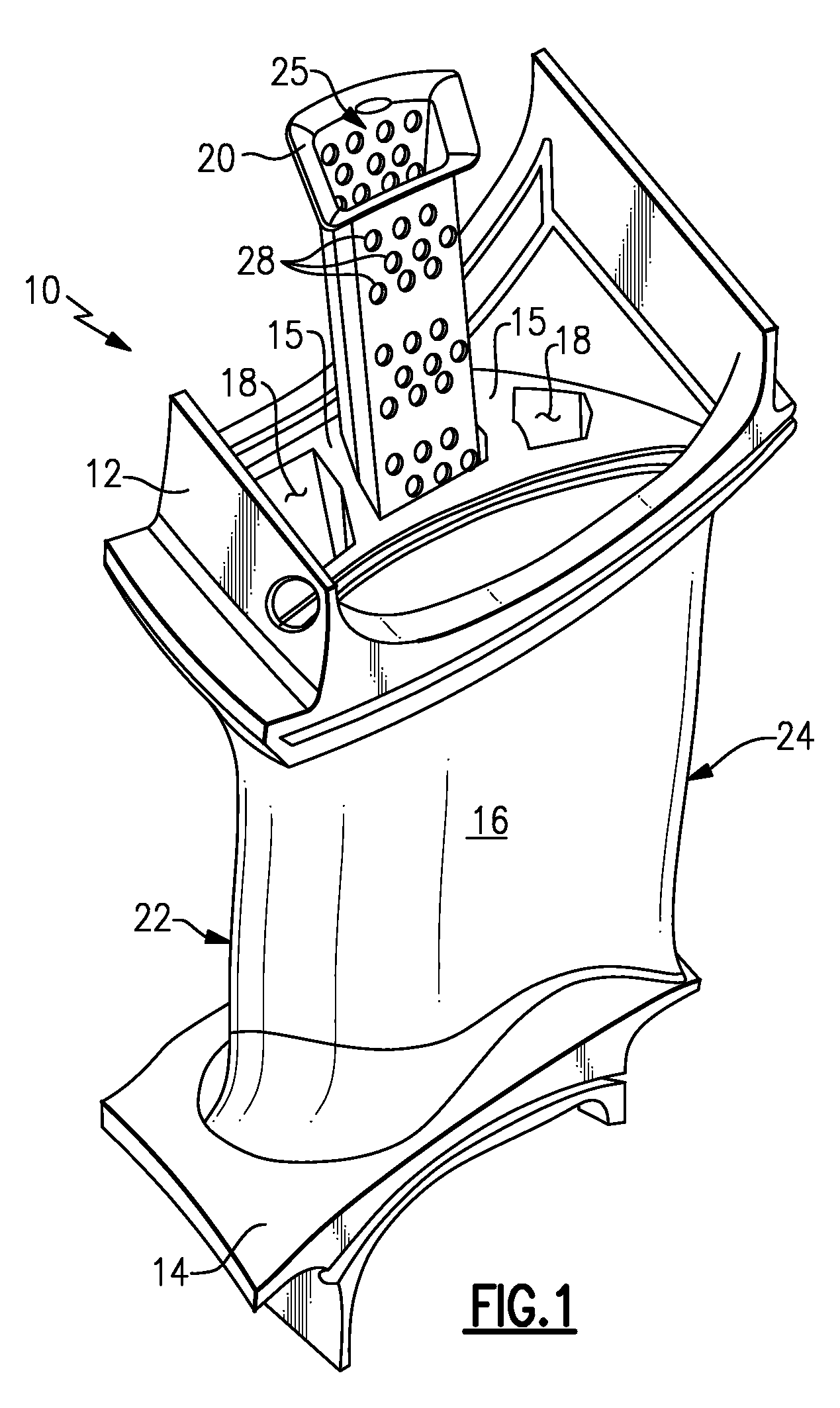

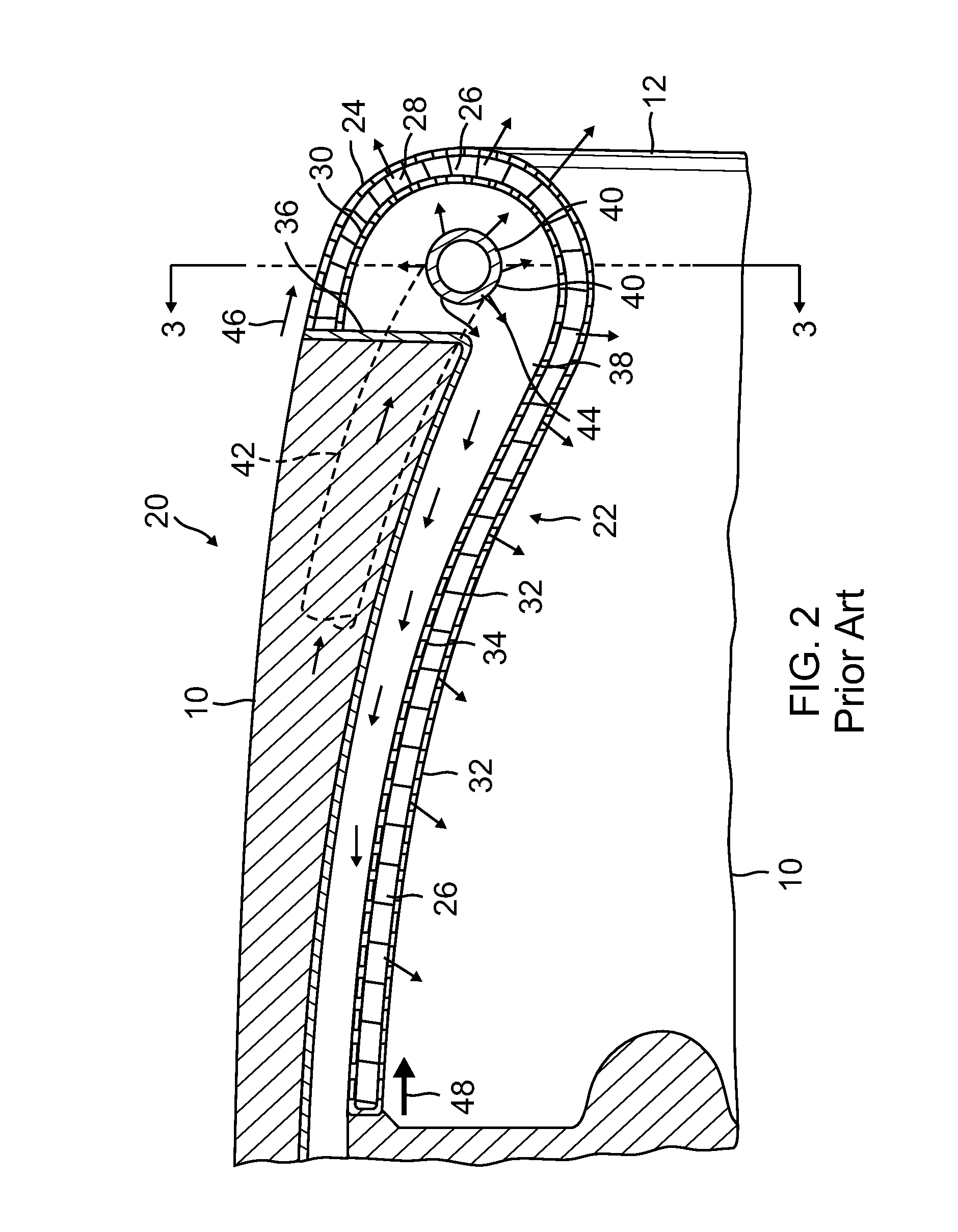

Combustion chamber and cooling system for fastener-driving tools

A new and improved combustion chamber and cooling system for a fastener-driving tool wherein a new and improved tangentially oriented, vortex induced fuel-injection system is operatively associated with the tool's combustion chamber. In addition, a new and improved trigger-controlled valve actuating system, such as, for example, a switch-operated, solenoid-actuated valve-controlling system, is incorporated within the tool so as to ensure the rapid operation of the intake and outlet valve structures. Still further, a sealed, liquid evaporative or liquid recirculating cooling system is integrally incorporated within the tool housing.

Owner:ILLINOIS TOOL WORKS INC

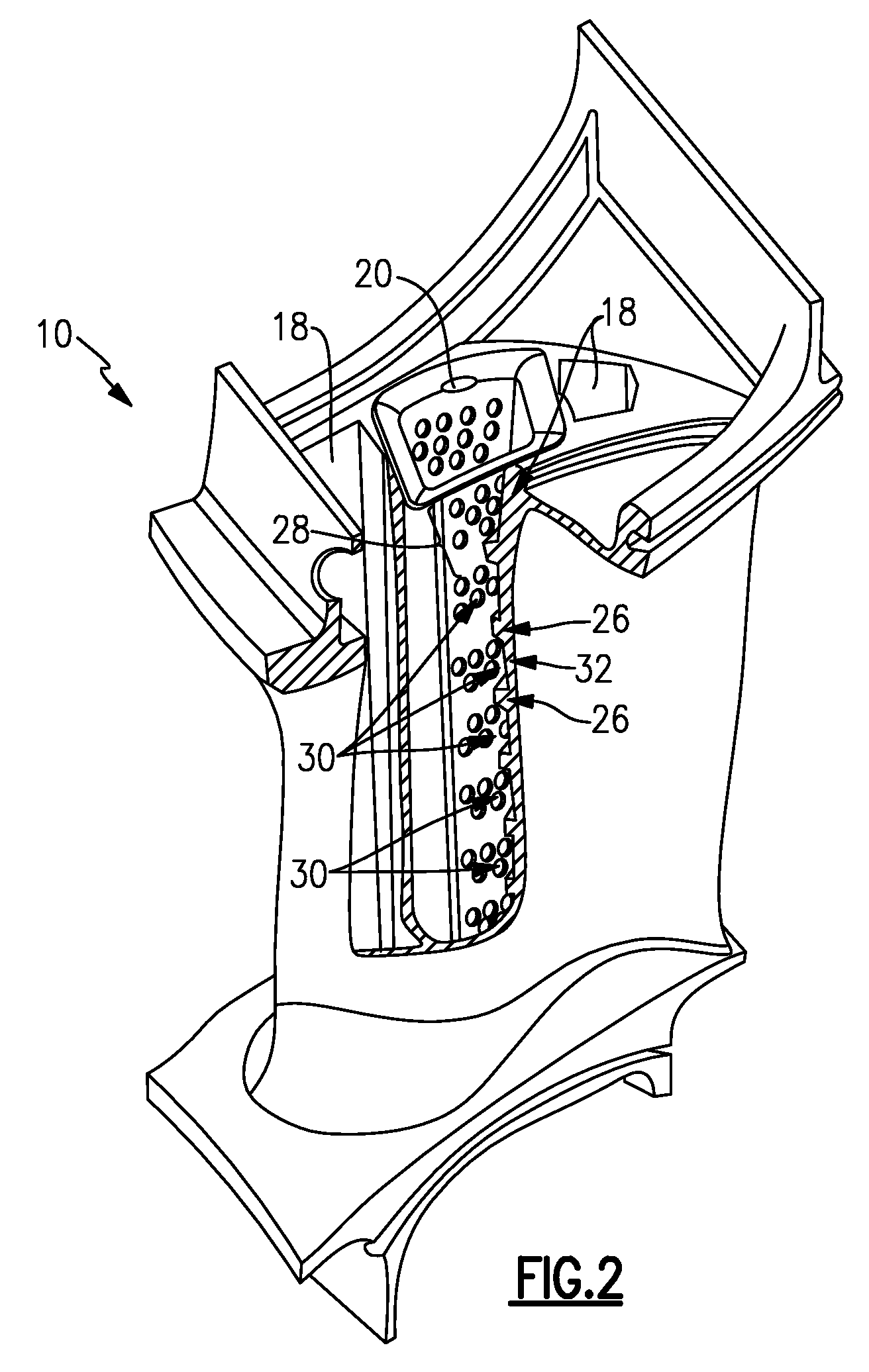

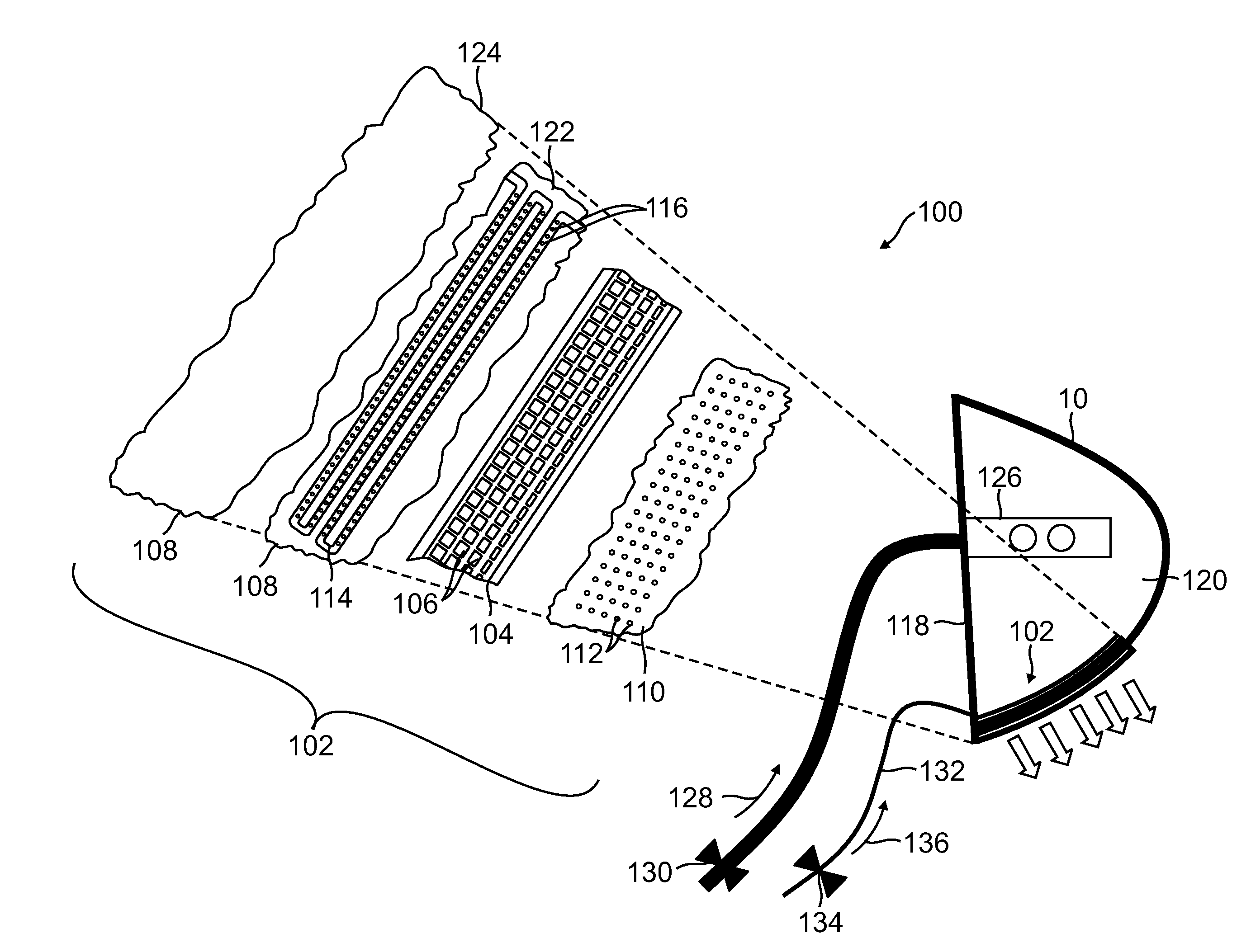

Chambered airfoil cooling

An airfoil assembly includes an airfoil with at least one cavity that is in communication with a source of cooling air. A baffle is disposed within that cavity and includes a plurality of openings for directing cooling air against the hot wall. A plurality of dividers extends between the baffle walls and the internal cavity to direct cooling air toward one of a leading edge chamber and a trailing edge chamber.

Owner:RAYTHEON TECH CORP

Preparation method of pressed active carbon and pressed active carbon

ActiveCN103769047AClog or hinder generationEvenly distributedOther chemical processesAlkali metal oxides/hydroxidesActivated carbonFreeze-drying

The invention provides a preparation method of pressed active carbon. According to the invention, a wet-process forming method is used for preparing the pressed active carbon, namely, an active carbon disperse pulp containing active carbon, a bonder and water is obtained firstly, then the pulp is injected into a corresponding mold according to required shape, then the freeze-drying is carried out on the mold and the active carbon disperse slurry contained in the mold, so as to obtain the pressed active carbon, wherein the pressed active carbon is formed by a plurality of active carbon sheets via laminating, each active carbon sheet is formed by a plurality of active carbon particles through bonding, a hole I formed among active carbon sheets is bigger than a hole II formed among the active carbon particles. Due to the adoption of the method, the operation difficulty is low, the evenness and adsorbing property of the pressed active carbon can be improved, the pressed active carbons in optional shapes can be prepared, and furthermore, the application scope is wide.

Owner:DONGFENG COMML VEHICLE CO LTD

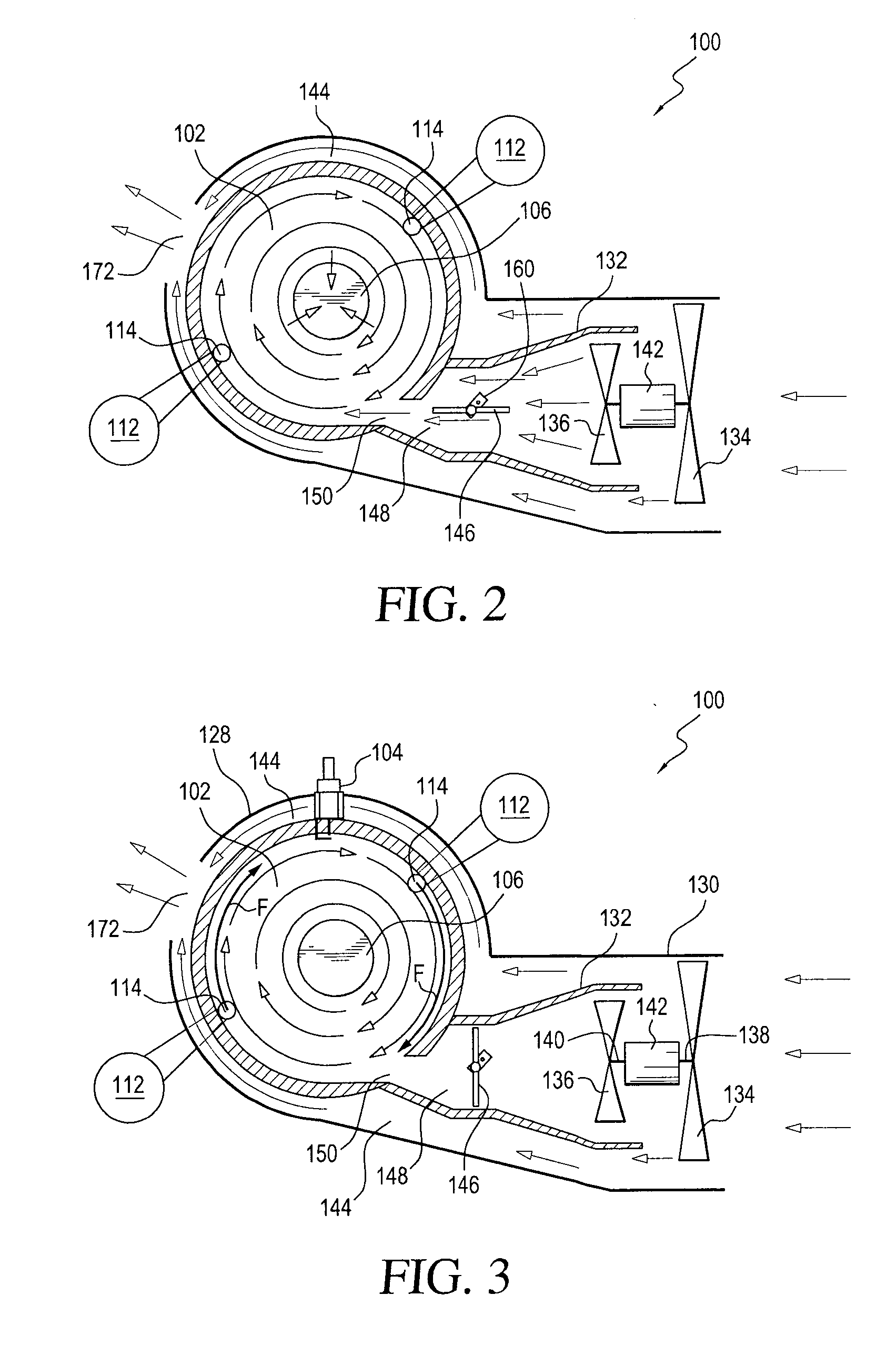

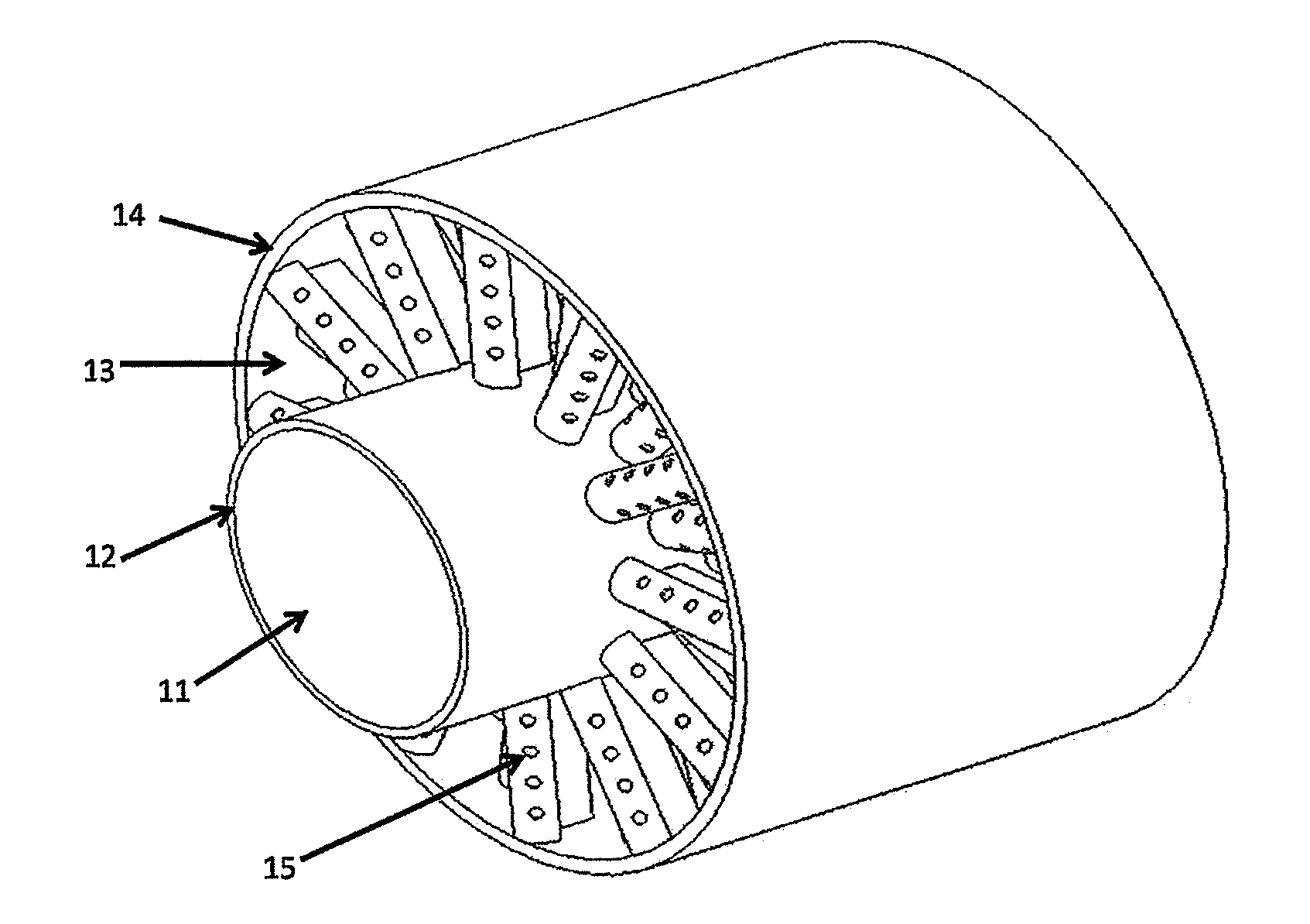

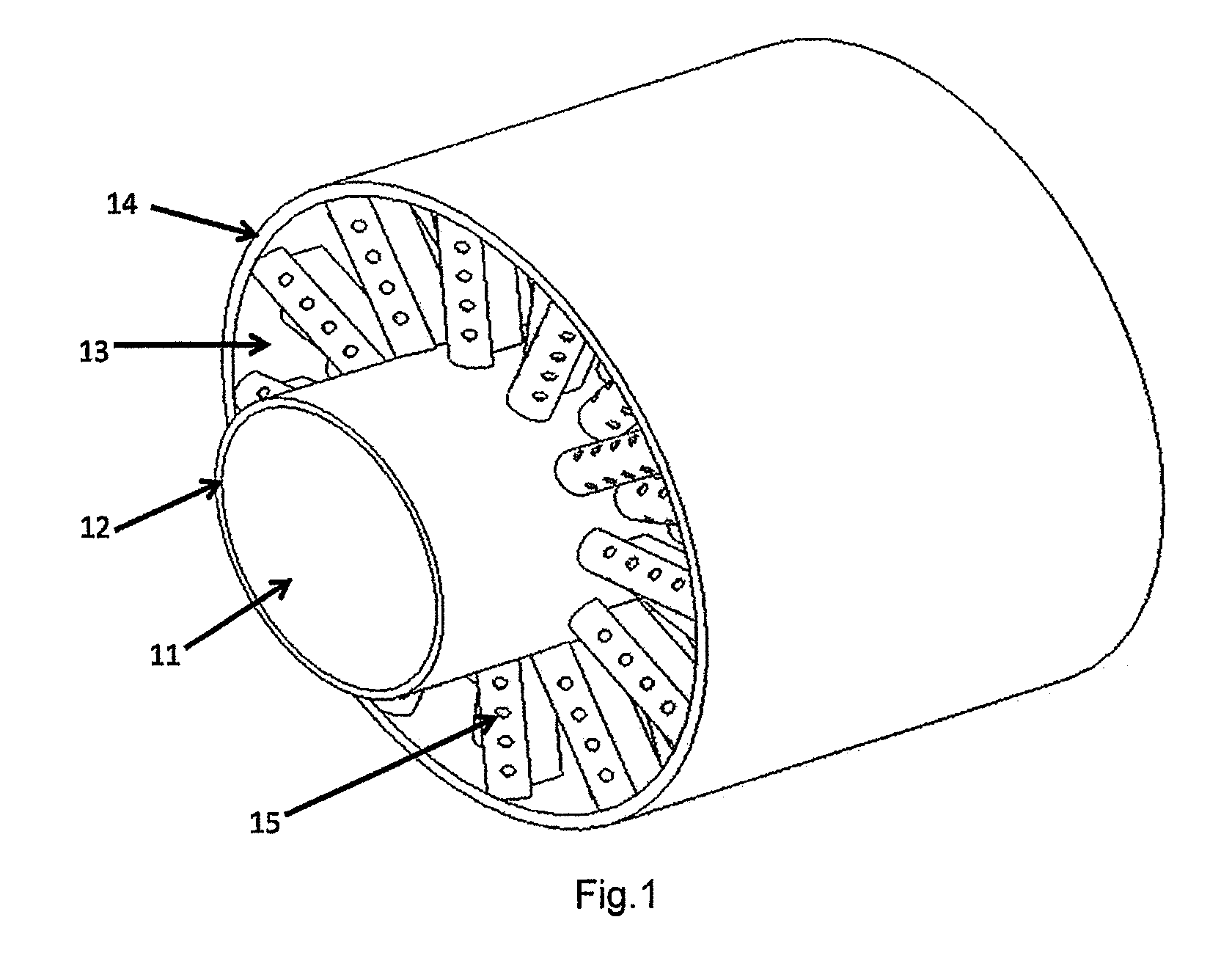

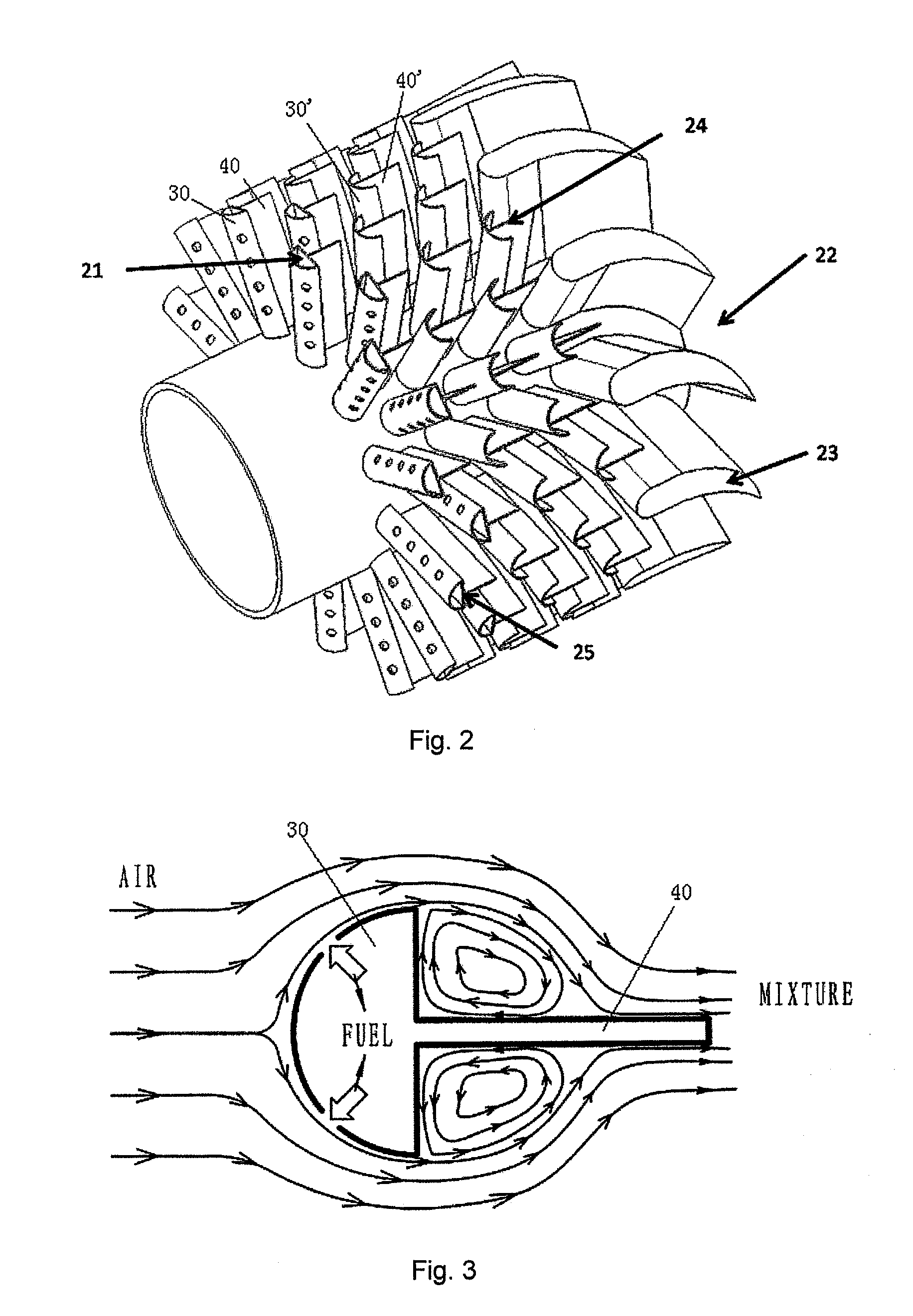

Air fuel premixer having arrayed mixing vanes for gas turbine combustor

ActiveUS20130133329A1Uniform distributionLarge scaleContinuous combustion chamberEngine fuctionsGas turbinesAirflow

A fuel-air premixer for use in a combustor of a gas turbine includes an air inlet, a fuel inlet, a shroud, a central body and a cascade of vanes. The premixer mixes fuel and air in the annular mixing passage into a uniform mixture for injecting into a combustor reaction zone. The air from a compressor is injected into the mixer through an air inlet. The fuel is introduced into air stream via fuel injection holes that pass through the walls of the vanes which contain internal fuel flow passages. The flow field inside the premixer is broken up by the arrayed vanes into a series of small regions each containing a well designed small size mixing eddy which is steadily attached to the surface of the vanes.

Owner:INNER MONGOLIA ZHONGKE PUSHI GAS TURBINE CO LTD

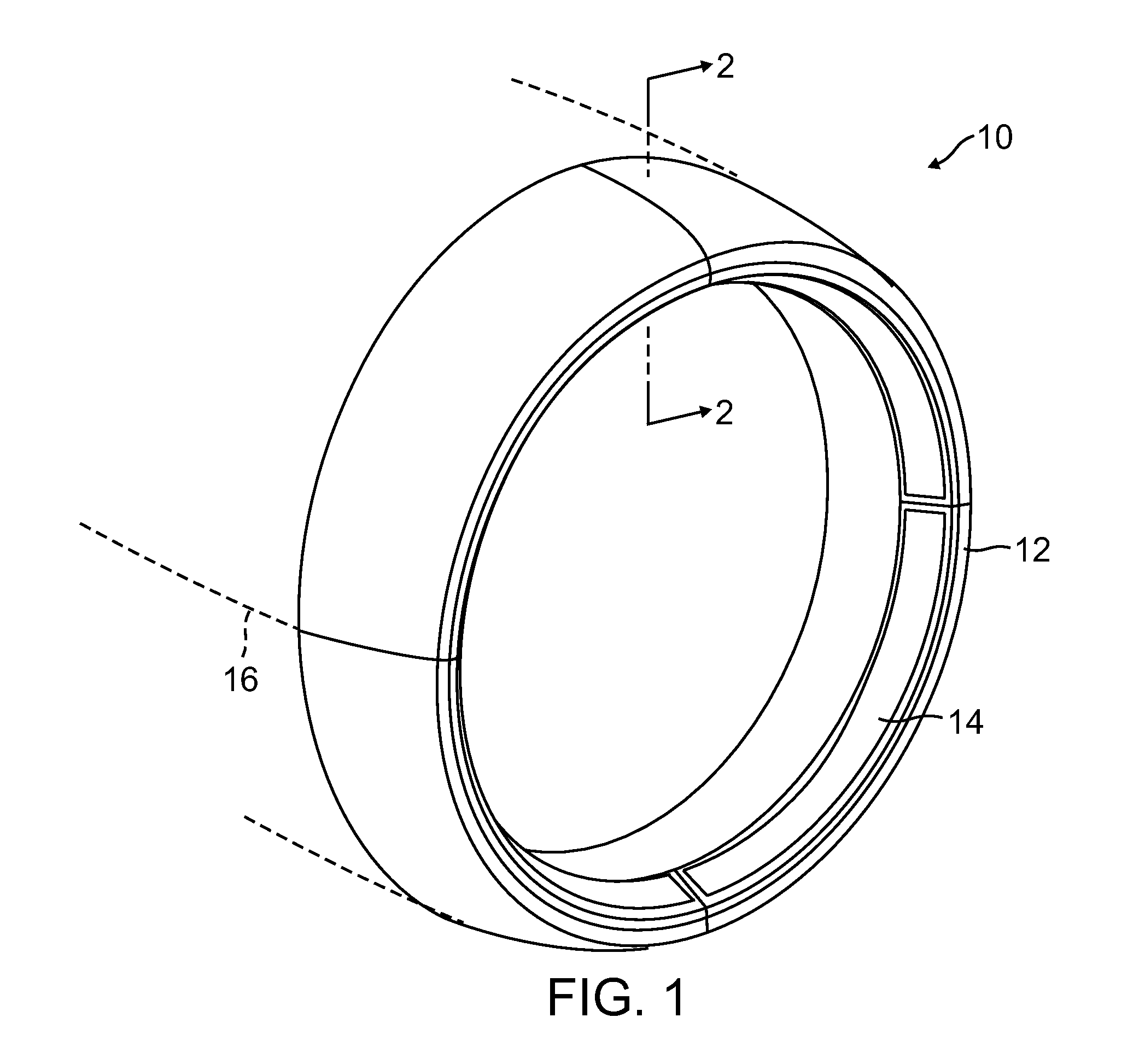

Jet engine Anti-icing and noise-attenuating air inlets

ActiveUS20170008635A1Uniform distributionPrevent separationEngine manufactureEngine fuctionsRigid frameMesh grid

An embodiment of a jet engine air inlet providing anti-icing, and optionally, engine noise reduction, includes a rigid frame defining a gridwork of contiguous cells. A cap skin has an outer surface sealingly attached to an inner surface of the frame. An outer skin has an inner surface sealingly attached to an outer surface of the frame and contains a plurality of openings therein.Each of the openings is disposed in fluid communication with a corresponding one of the cells, each of which can comprise a Helmholtz resonator. A serpentine manifold extends adjacent to an inner end of each of the cells and contains a plurality of apertures in a sidewall thereof, each of which is disposed in fluid communication with a corresponding one of the cells.

Owner:THE BOEING CO

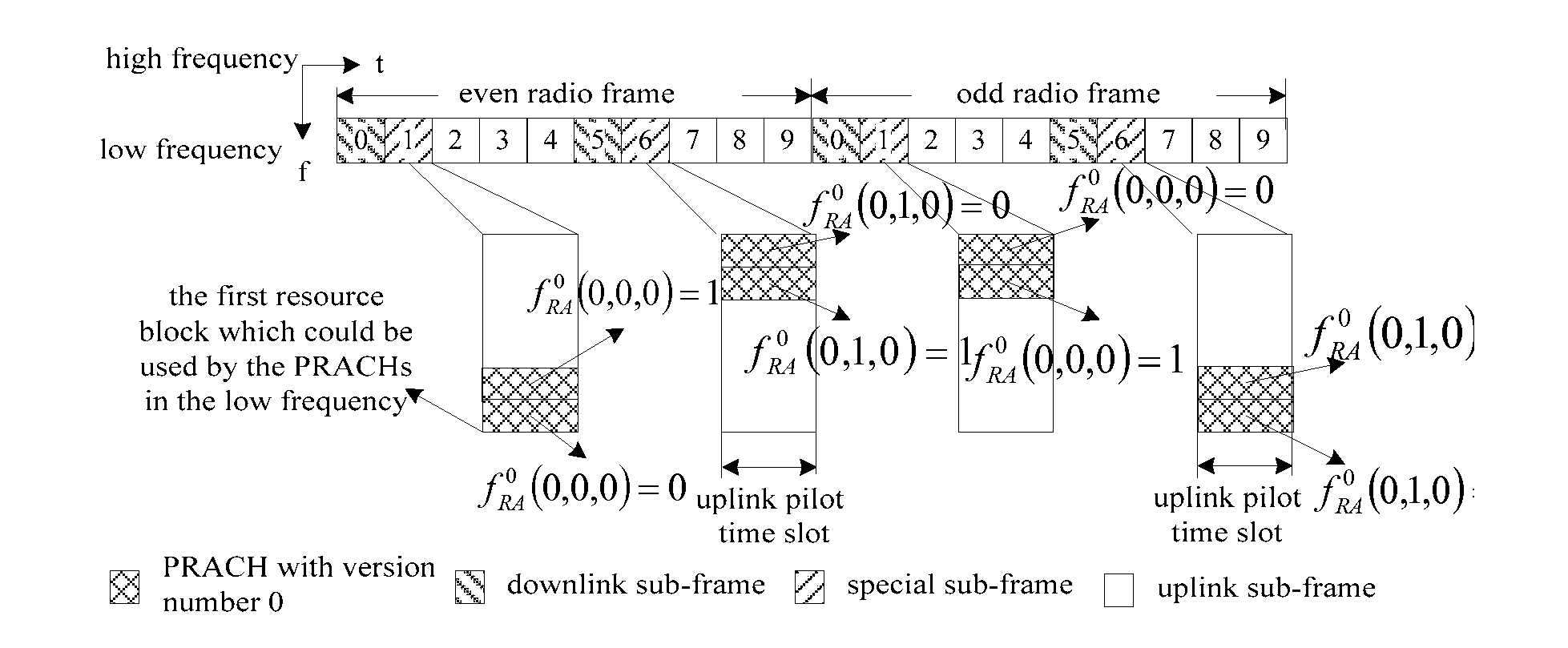

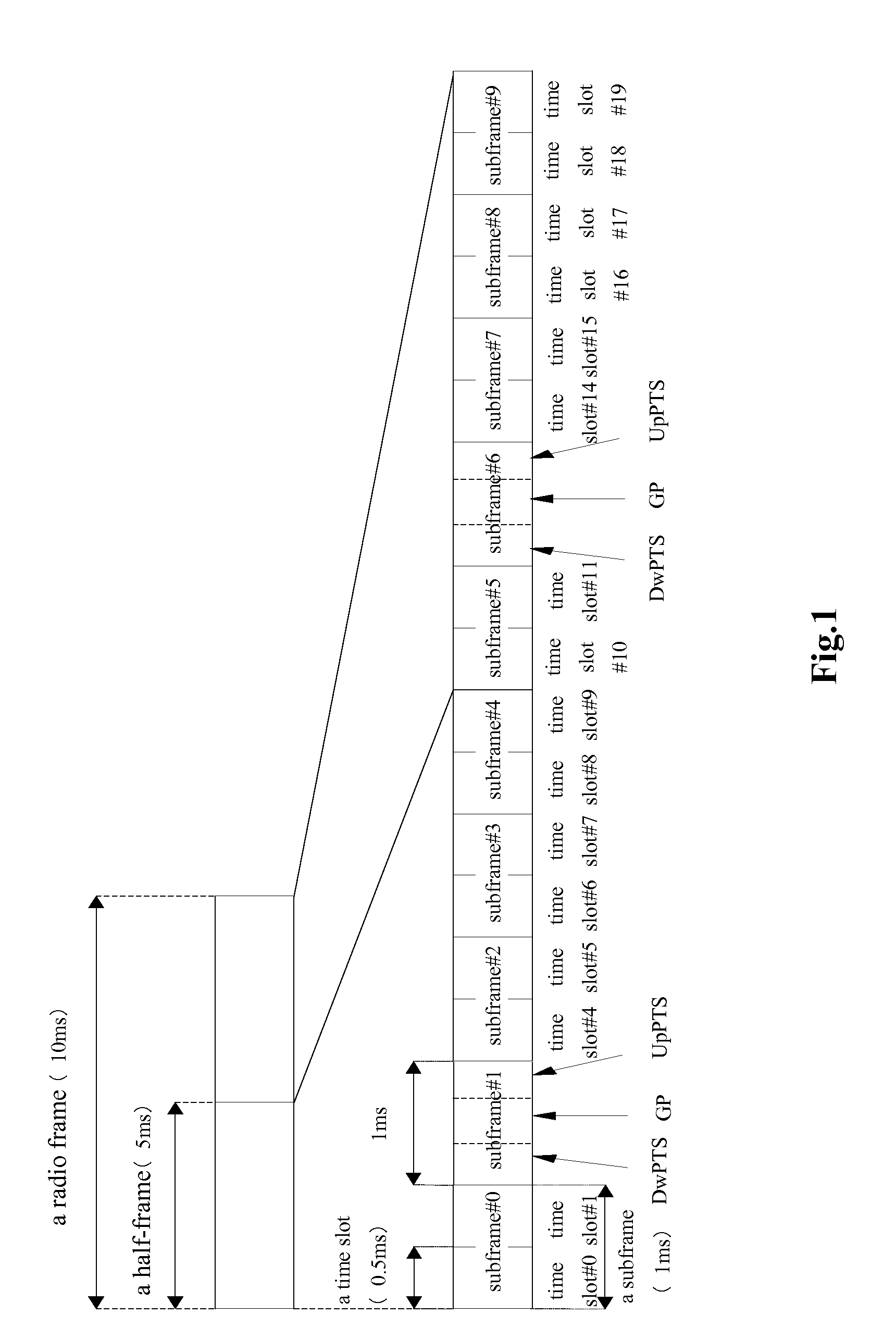

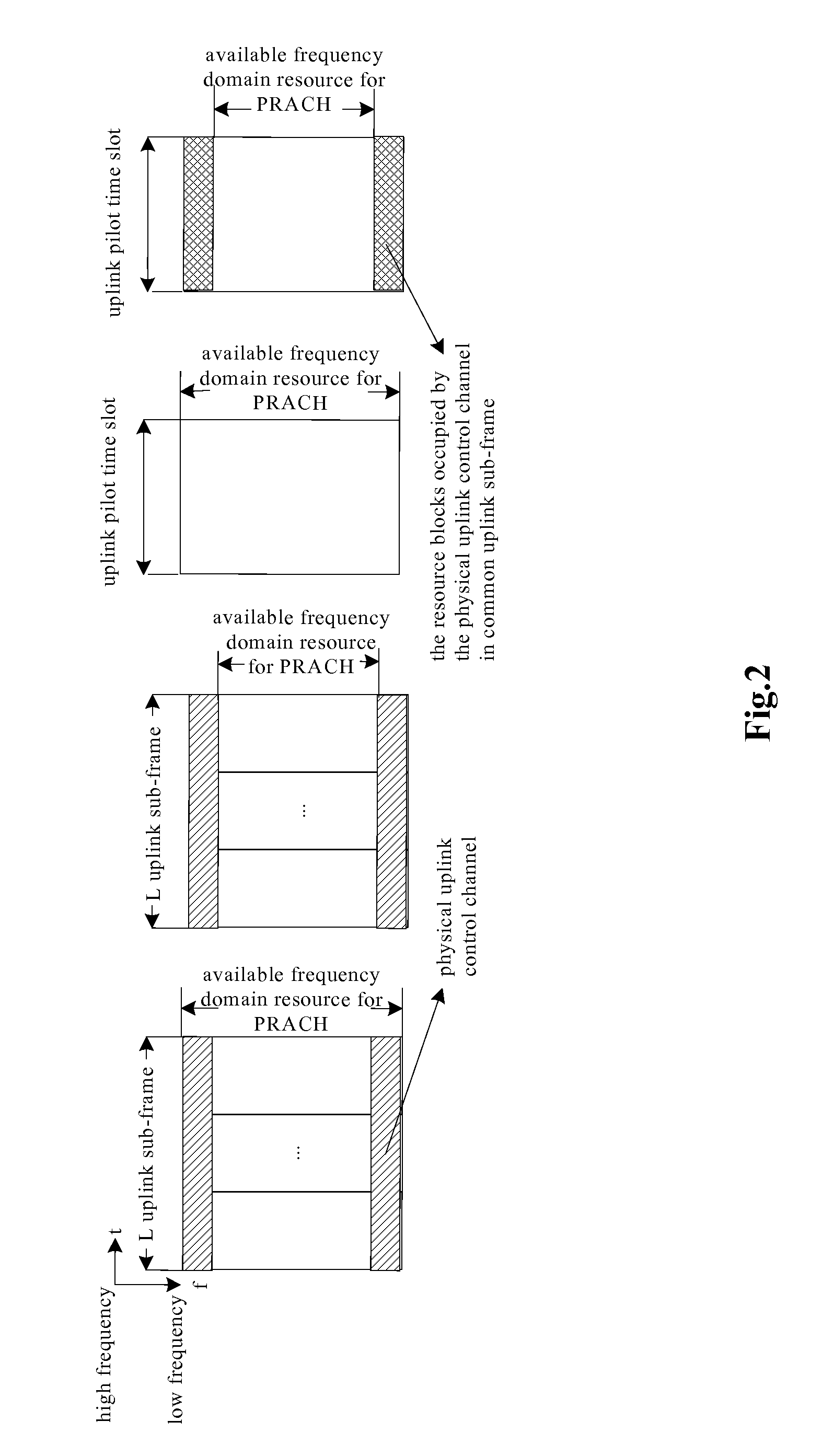

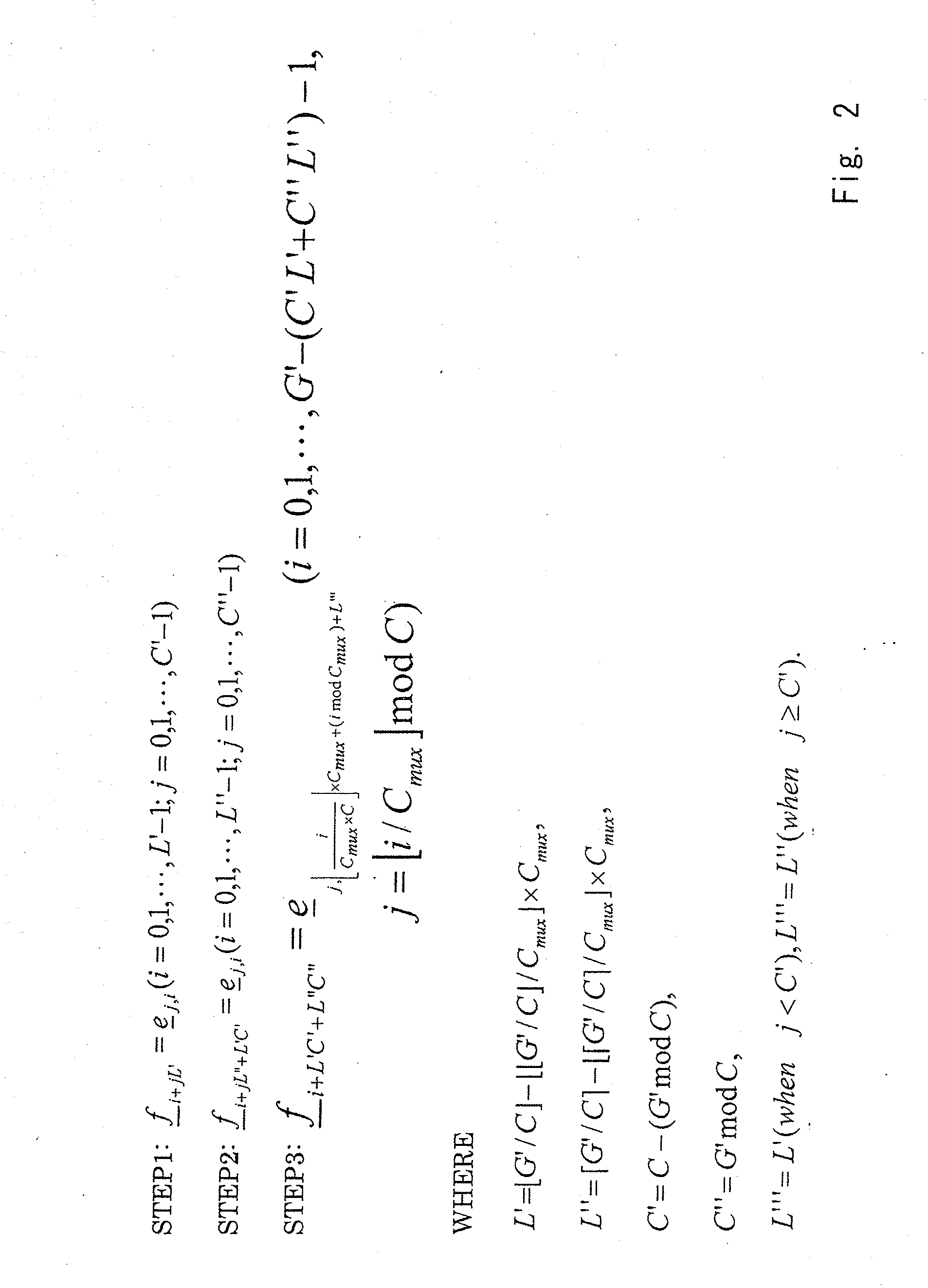

Method for Mapping Physical Random Access Channels

ActiveUS20110090863A1Reduce inter-cell interferenceUniform distributionTransmission path divisionCriteria allocationFrequency bandFrequency domain

The present invention discloses a method for mapping physical random access channels, which comprises the following steps: the PRACHs in the same time domain location are mapped from low frequency to high frequency, or from high frequency to low frequency in usable frequency resource, wherein one PRACH occupies 6 resource blocks, and the frequency bands occupied by two adjacent PRACHs in the frequency domain do not overlap; or the PRACHs in the same time domain location are mapped from two sides to the middle in usable frequency resource, wherein one PRACH occupies 6 resource blocks, and the frequency bands occupied by two adjacent PRACHs in the frequency domain do not overlap. The present invention enables uniformly distributing the PRACHs which require to be processed by the same base station in the time domain, and decreasing the inter-cell interference of the second type PRACH to the utmost extent at the same time.

Owner:ZTE CORP

Curcumin micelle nasal solution and preparation method thereof

ActiveCN104997727AImprove solubilityImprove stabilitySenses disorderNervous disorderPolymer sciencePolyethylene glycol

The invention discloses a curcumin micelle nasal solution which contains curcumin used as a main drug, a preservative and an isoosmotic adjusting agent. The curcumin micelle nasal solution is characterized by comprising a poly(N-vinylcaprolactam)-polyvinyl acetate-polyethylene glycol copolymer, a medicinal polyethylene glycol auxiliary material and RGD peptide which are used as medicinal excipients. The mass ratio of the main drug curcumin to the poly(N-vinylcaprolactam)-polyvinyl acetate-polyethylene glycol copolymer medicinal excipient is 1:12-1:20. The mass ratio of the medicinal polyethylene glycol auxiliary material to the poly(N-vinylcaprolactam)-polyvinyl acetate-polyethylene glycol copolymer medicinal excipient is 1:20-1:40. The mass ratio of RGD peptide to the medicinal polyethylene glycol auxiliary material is 1:2-1:4. According to the prepared curcumin micelle nasal solution, curcumin has good solubility in an aqueous solution. By a preparation method of the curcumin micelle nasal solution, water solubility of curcumin is solved, and molecular stability of curcumin is raised. Meanwhile, particle size of the micelle is adjusted to an appropriate particle size range (150-220 nm), and stability of the micelle aqueous solution is enhanced.

Owner:SHANDONG EYE INST

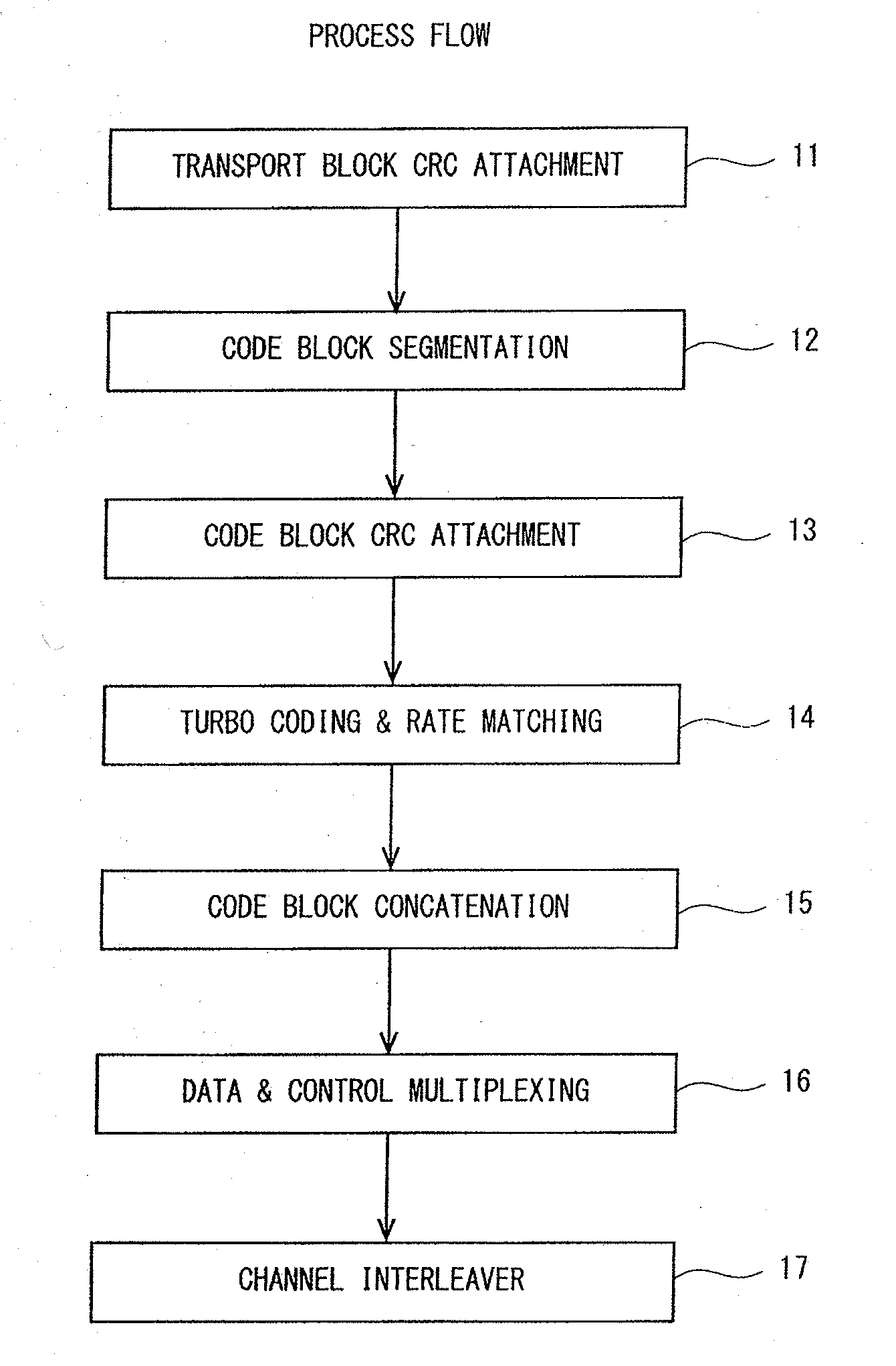

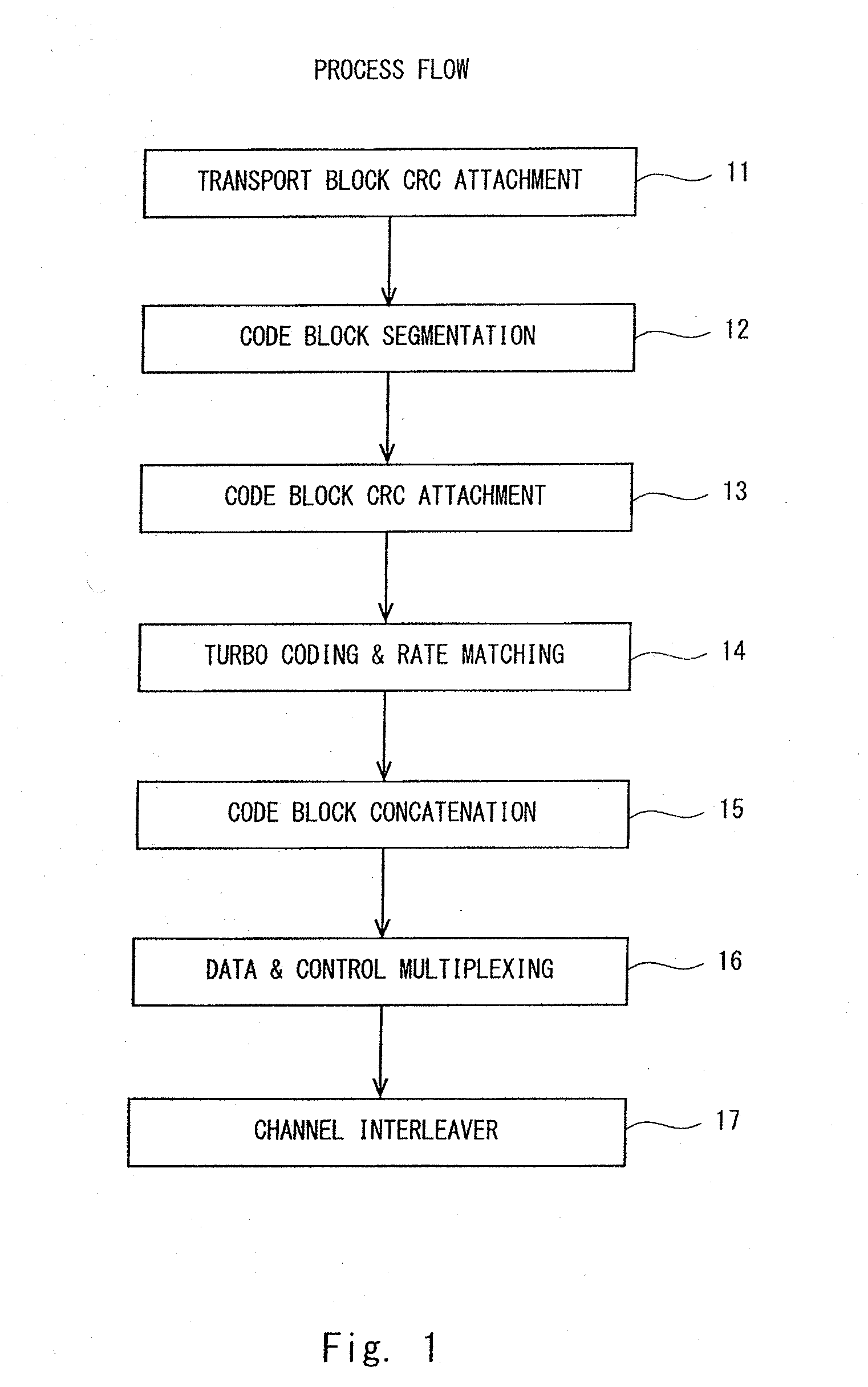

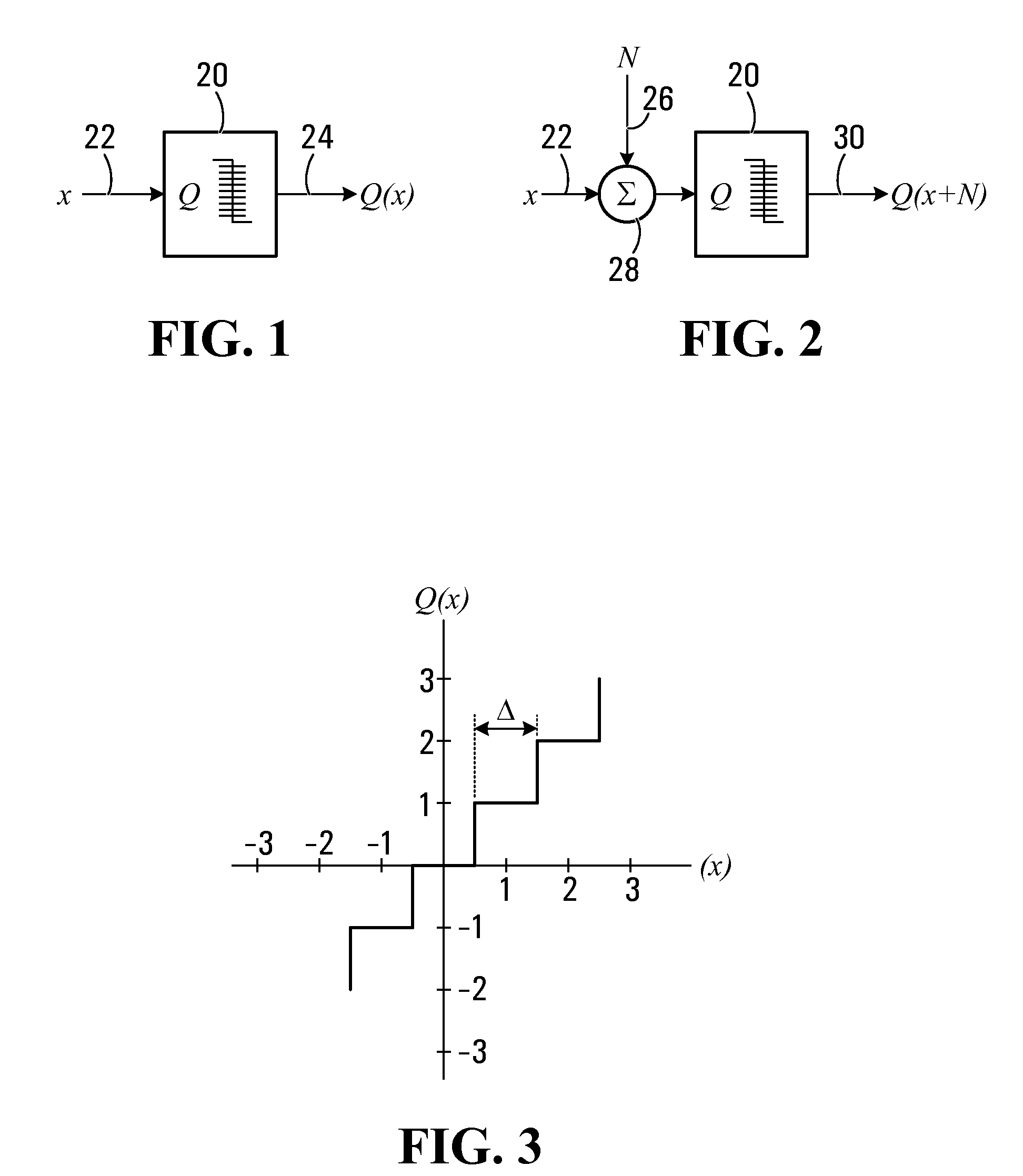

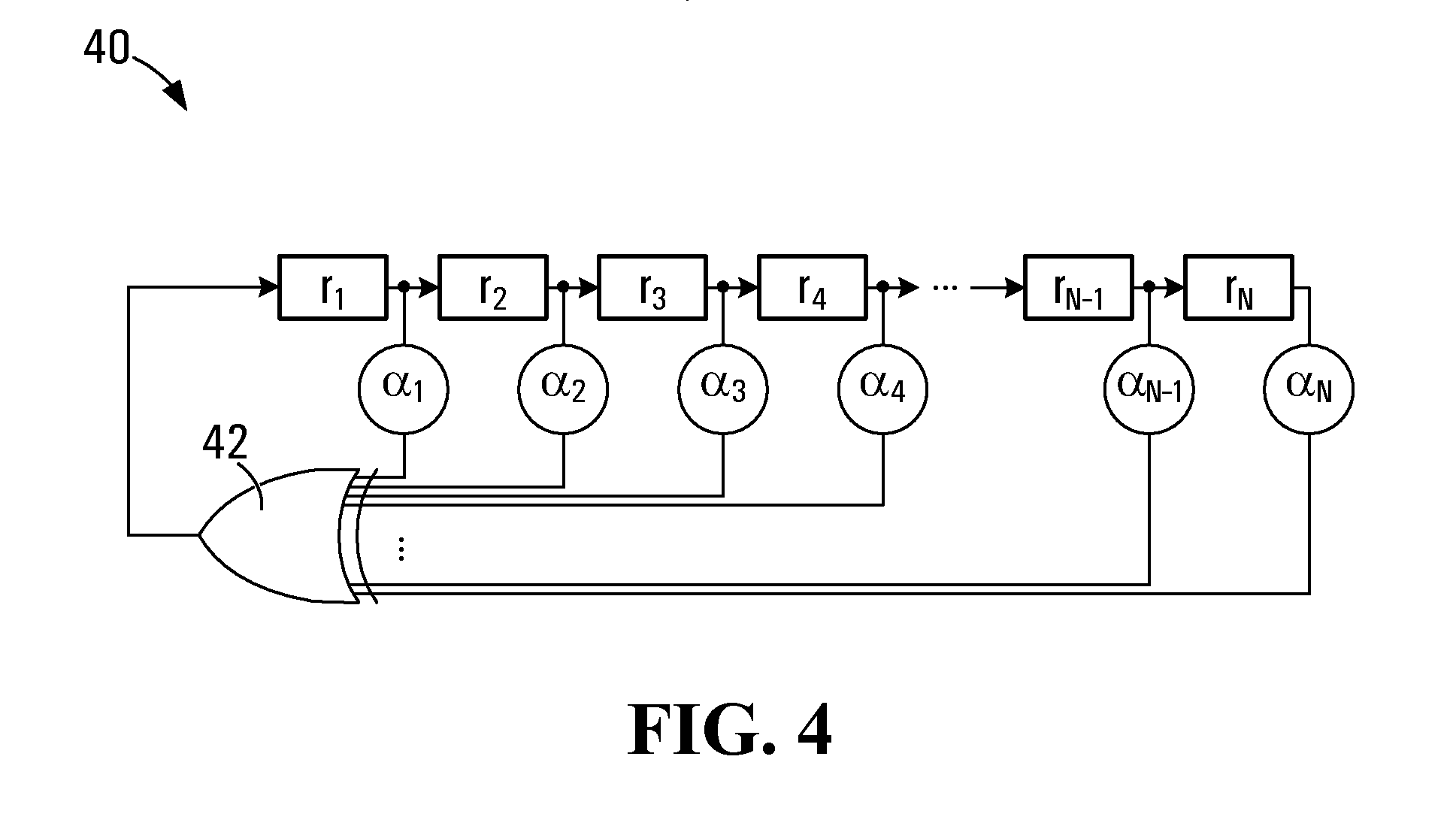

Radio transmitting/receiving device, communication system, and channel coding processing method used thereby

ActiveUS20140136922A1Uniform distributionNo unevenness occurs in error resilienceBurst error correctionCode conversionChannel codeUser Error

A radio transmitting / receiving device uses a channel interleaver with turbo codes serving as error-correcting codes to convert burst errors into random errors. The radio transmitting / receiving device, in Code Block Concatenation (15), when dividing a Transport Block into a plurality of Code Blocks, performs channel coding so that burst errors that occur during transmission are distributed to all the Code Blocks. Therefore, when burst errors occur, the errors can be uniformly distributed to all Code Blocks in a Transport Block so that no unevenness occurs in error resilience between the Code Blocks.

Owner:NEC CORP

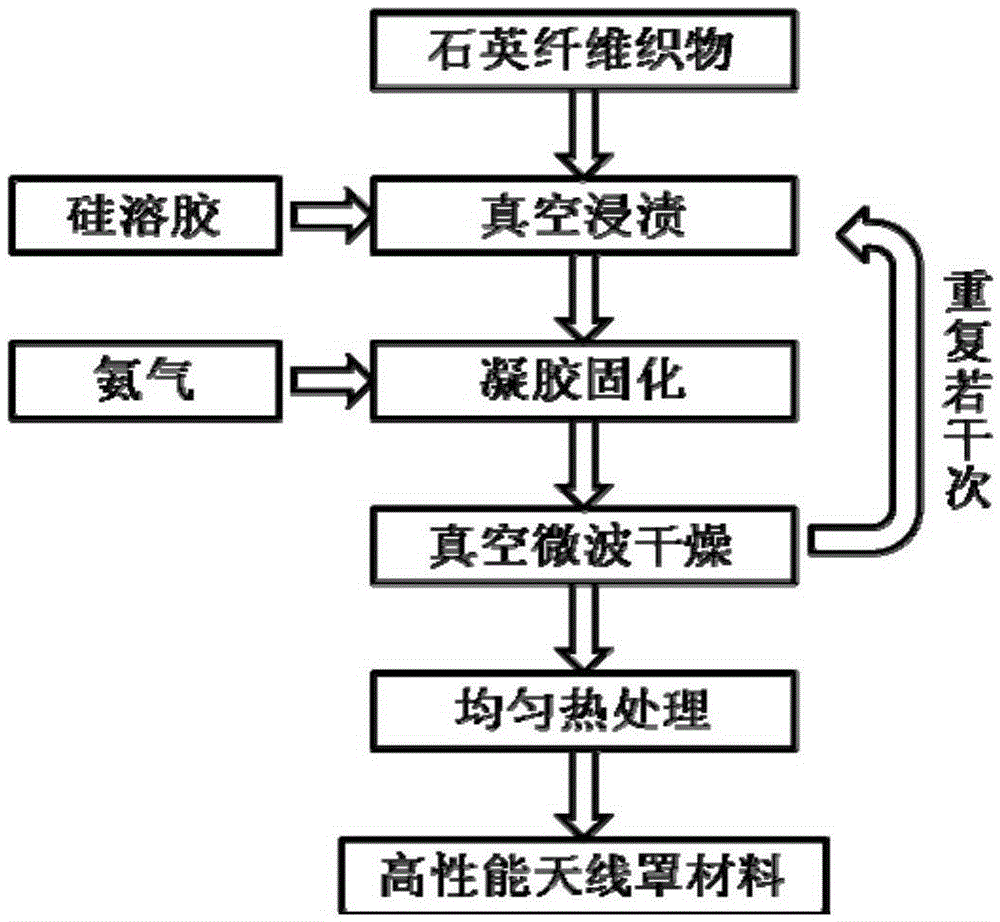

Uniform compaction method of silicon oxide based antenna housing composite

The invention relates to a uniform compaction method of a silicon oxide based antenna housing composite. According to the method, after fiber fabric is steeped, silicasol gel is changed into solid, so that overflow and loss of silicasol in subsequent procedures are avoided; quick drying is carried out by using a vacuum microwave drying technology subsequently; the above process is circulated for several times; finally, after uniform heat treatment, namely heating during rotation, the relatively compact composite with uniform density is obtained; the method significantly improves density uniformity of the material via a whole gel technology and a uniform heat treatment technology; the drying efficiency is improved via microwave drying based on the silicasol gel; time consumed by a drying procedure is shortened; and a material preparation period is shortened.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

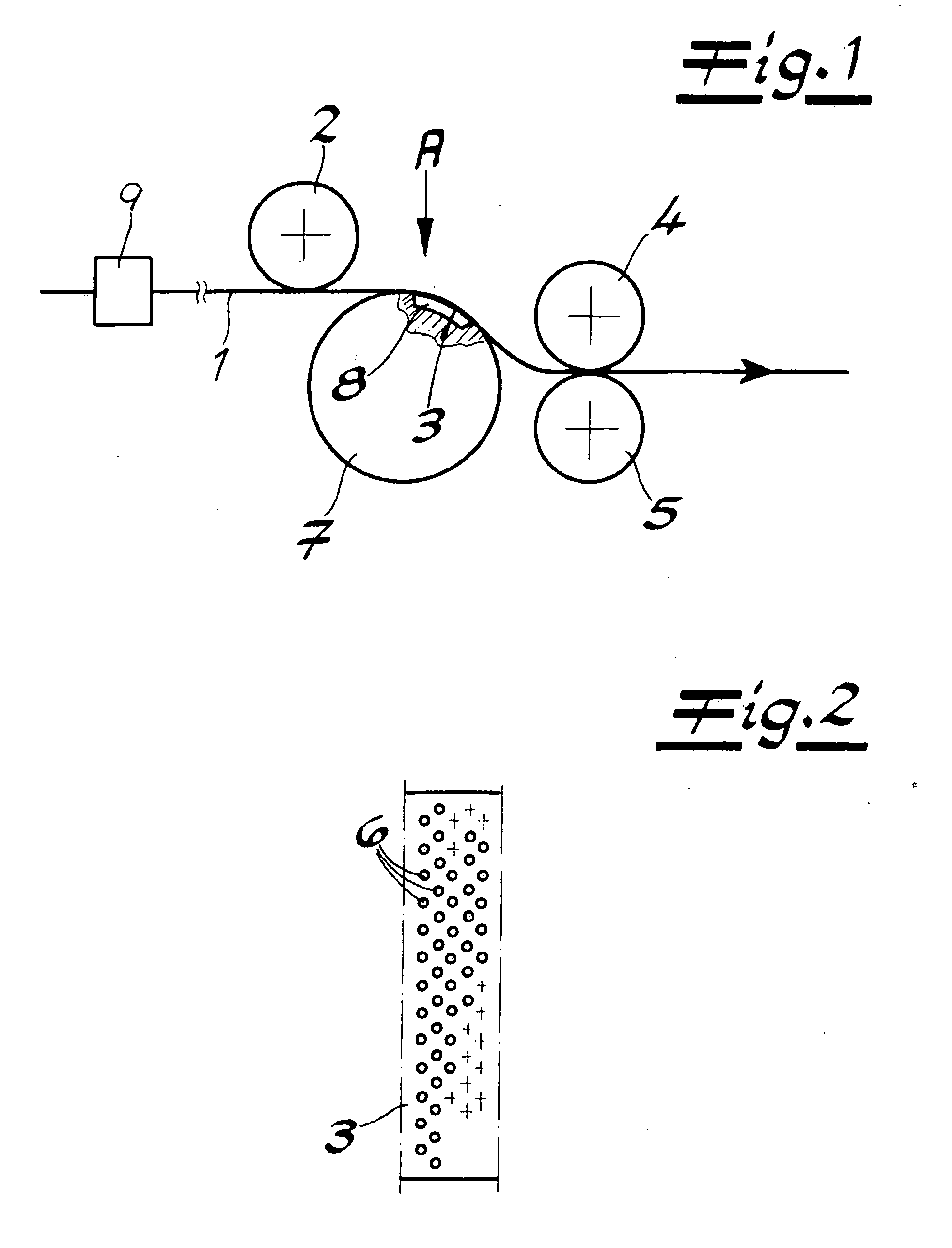

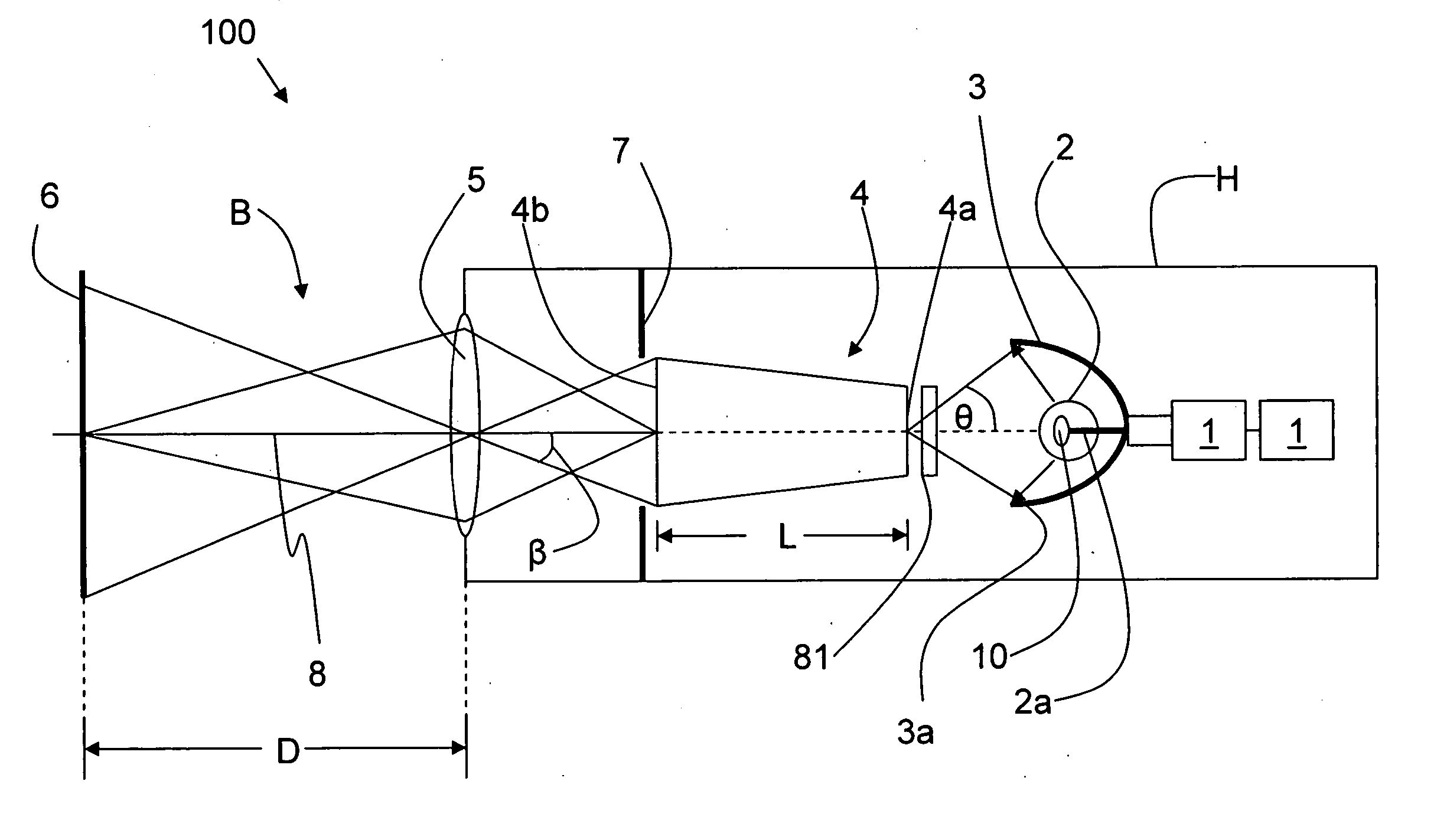

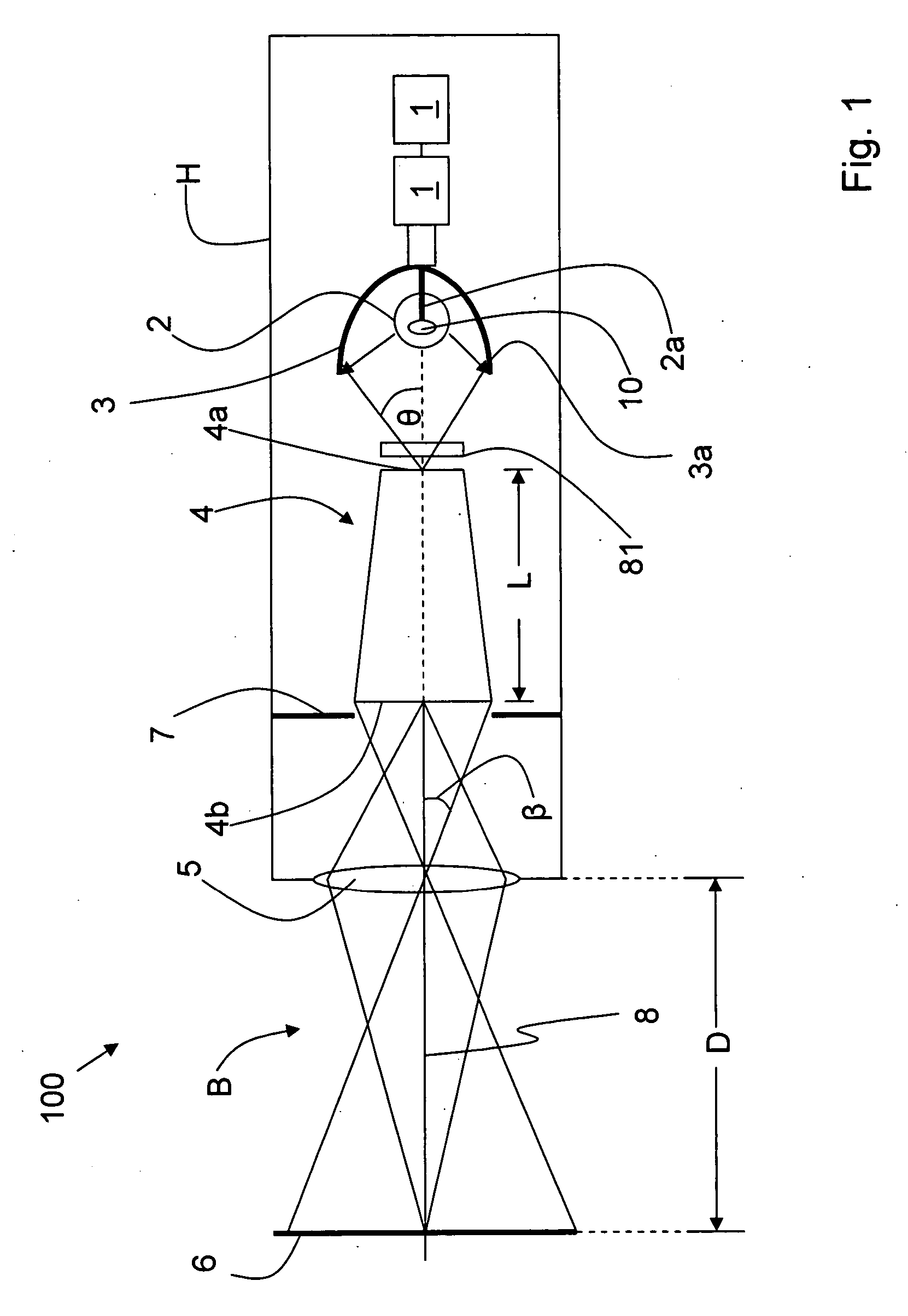

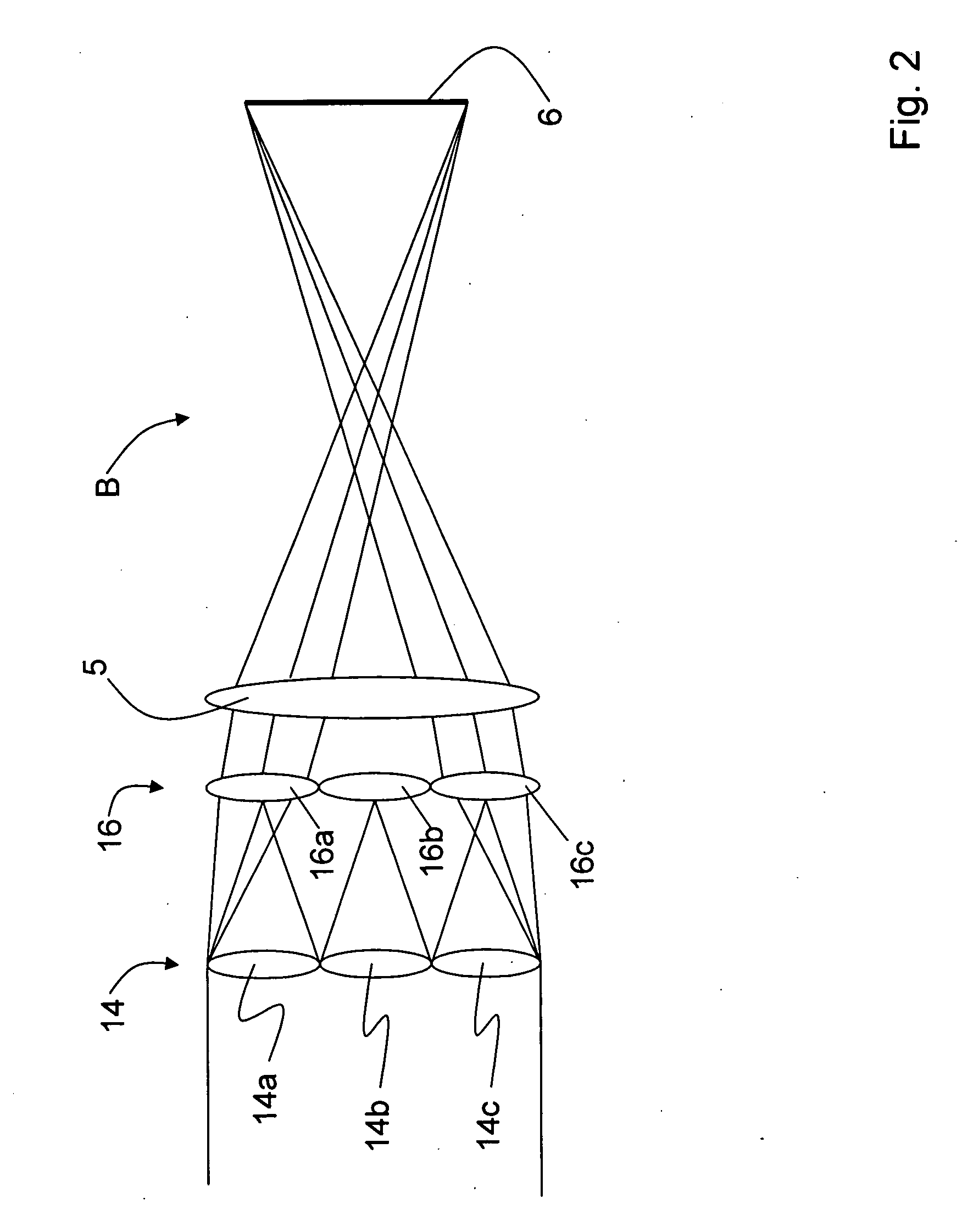

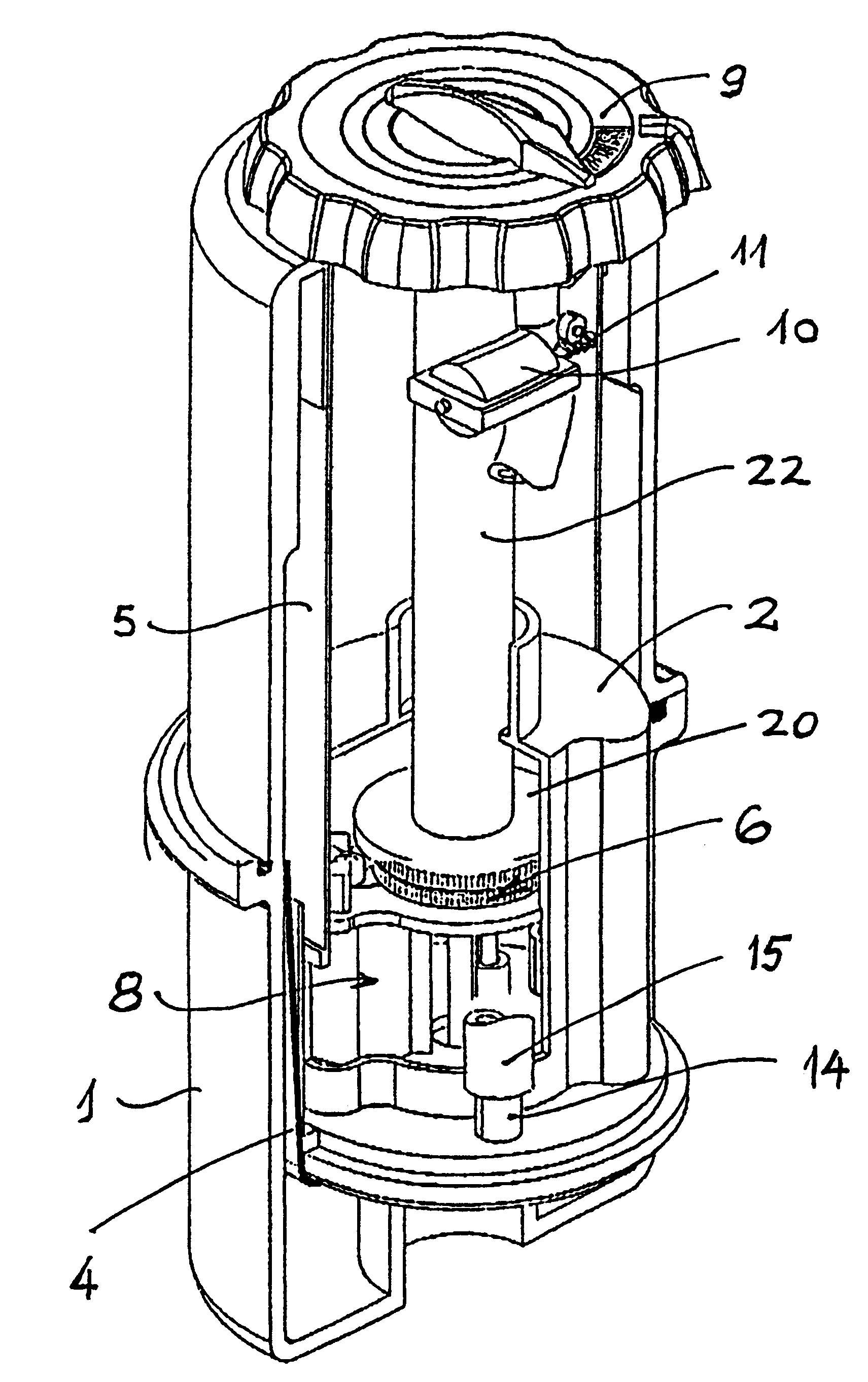

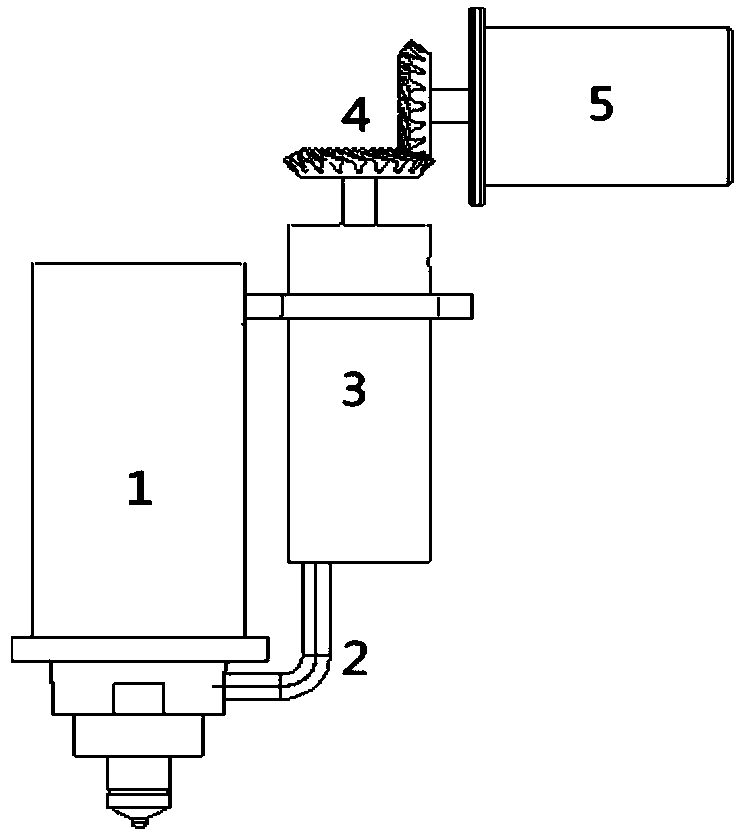

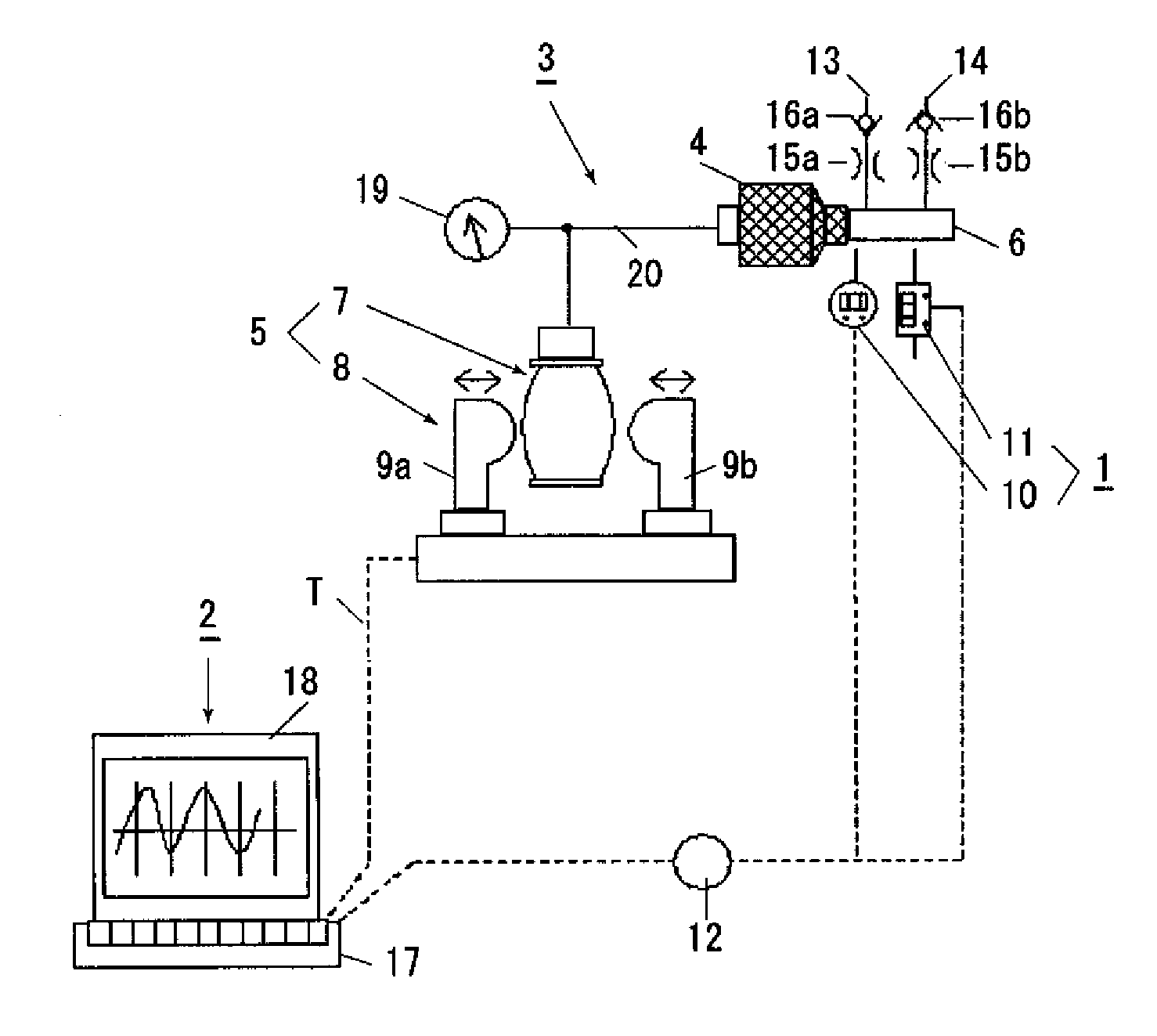

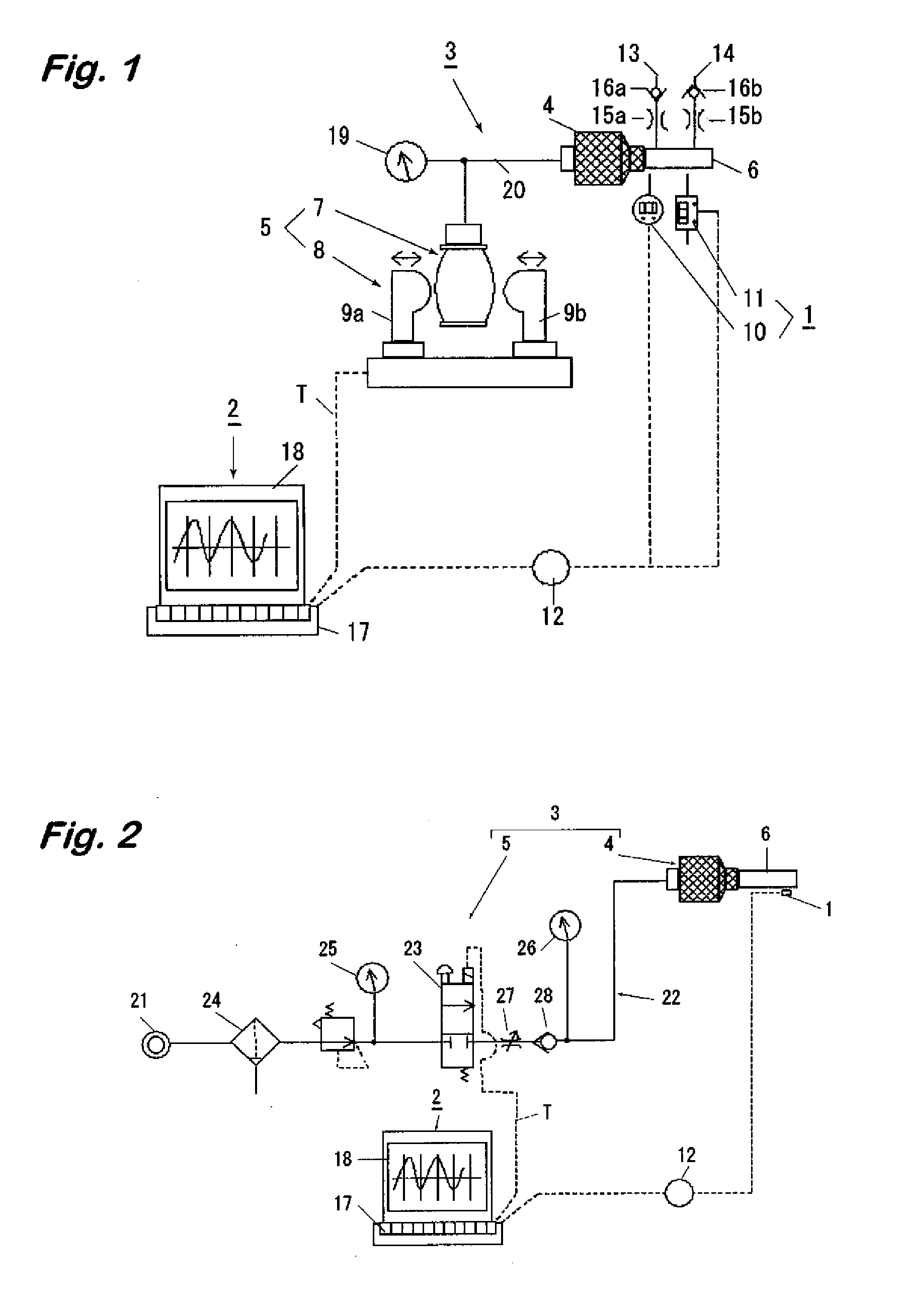

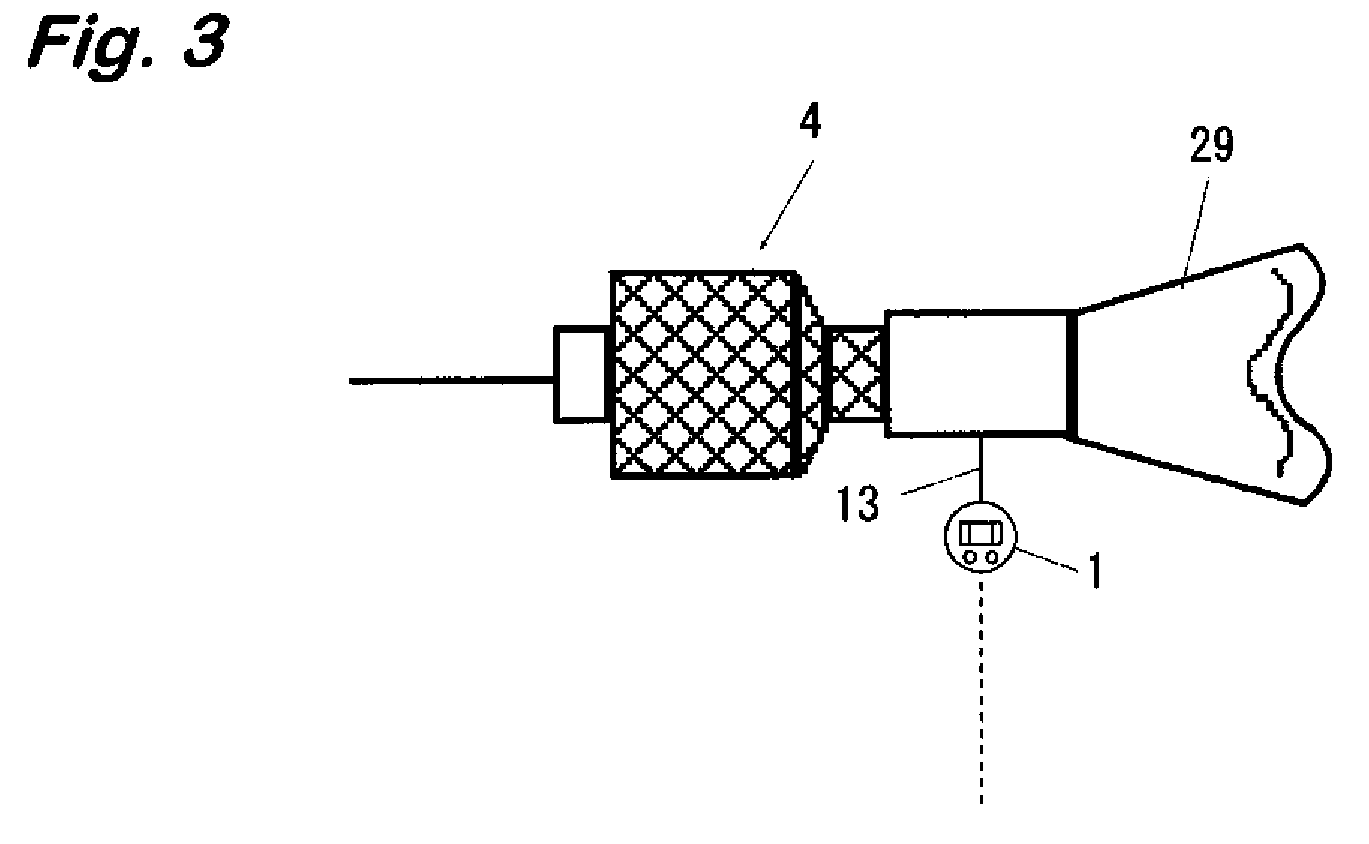

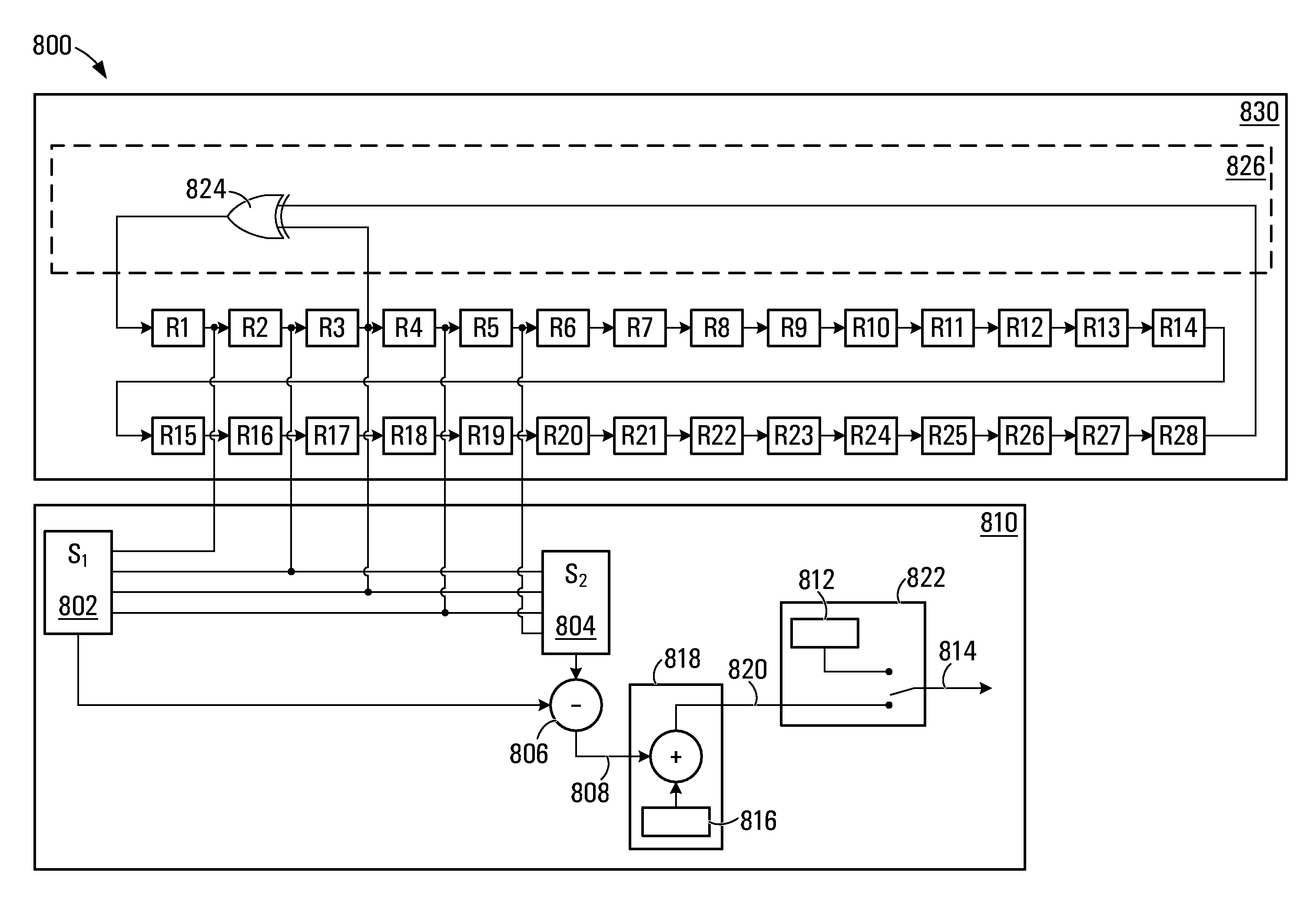

Test substance administration system for animal experiment

ActiveUS20100263666A1Reliably inhaledUniform distributionRespiratorsMedical devicesPhases of clinical researchExperimental animal

[Subject]A test substance application system for animal experiment capable of administering a required amount of a test substance uniformly and reliably from a nose or a mouth into a nasal cavity or into a lung of an experimental animal is provided.[Means for Solution]The system includes a respiration monitoring device 2 that monitors a respiration state of an experimental animal detected by a respiration pick-up device 1 to thereby measure a timing upon switching from an expiratory phase to an inhalatory phase and outputs a trigger signal T at that timing, and an application device 3 that sprays a predetermined amount of a test substance into a nasal cavity or an oral cavity of the experimental animal when the trigger signal T is outputted from the device 2.

Owner:SHIN NIPPON BIOMEDICAL LAB

High-pass dither generator and method

InactiveUS20080055651A1Uniform distributionImage enhancementElectric signal transmission systemsHigh-pass filterNormal density

A method and circuit for generating an M-bit digital dither signal with a substantially uniform probability density function and high-pass spectrum are disclosed. The circuit includes a linear feedback shift register (LFSR) with N storage elements where N>M, and a high-pass filter. The method involves sampling at least M storage elements of the LFSR with each clock cycle to form an M-bit LFSR output and high-pass filtering and the M-bit LFSR output to provide the M-bit dither signal.

Owner:ATI TECH INC

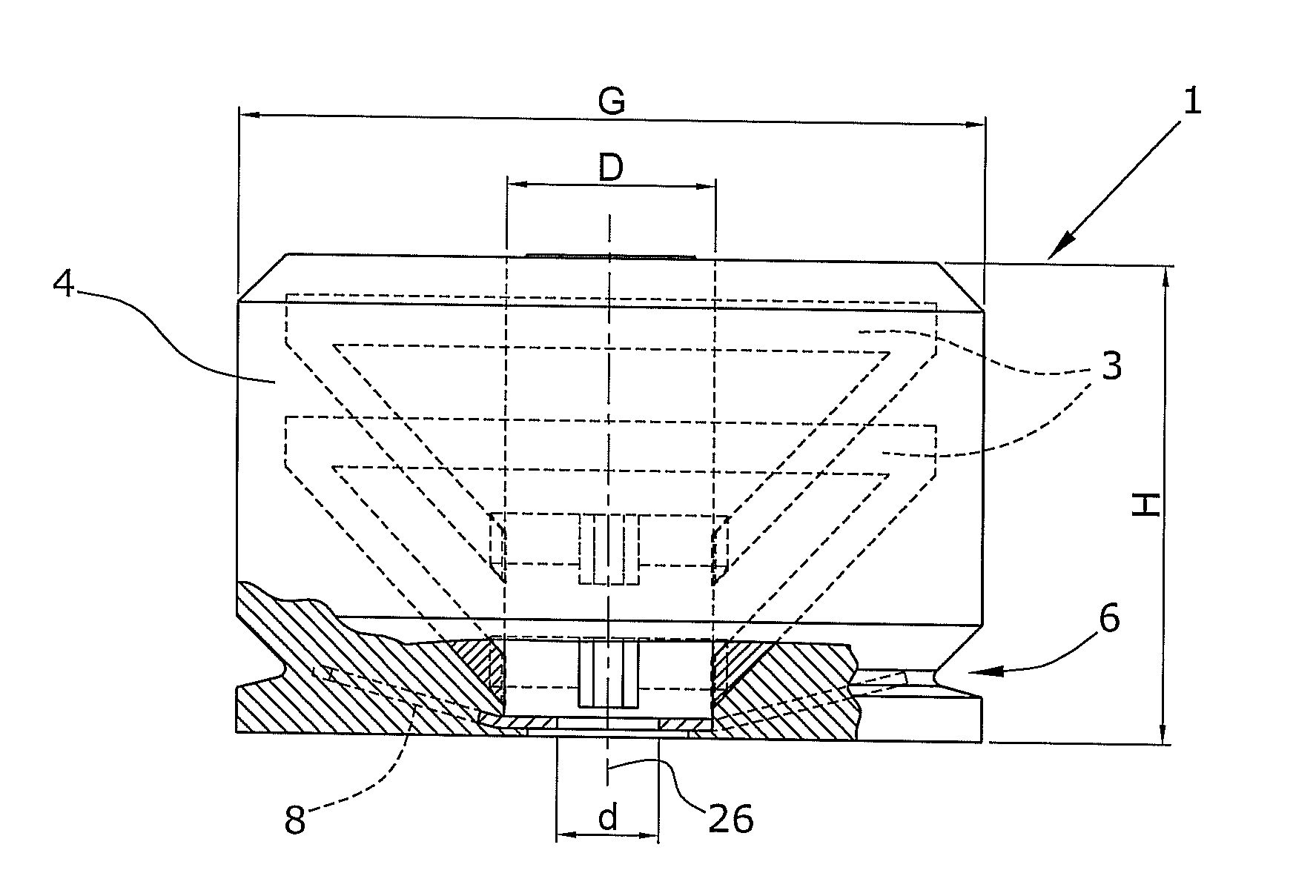

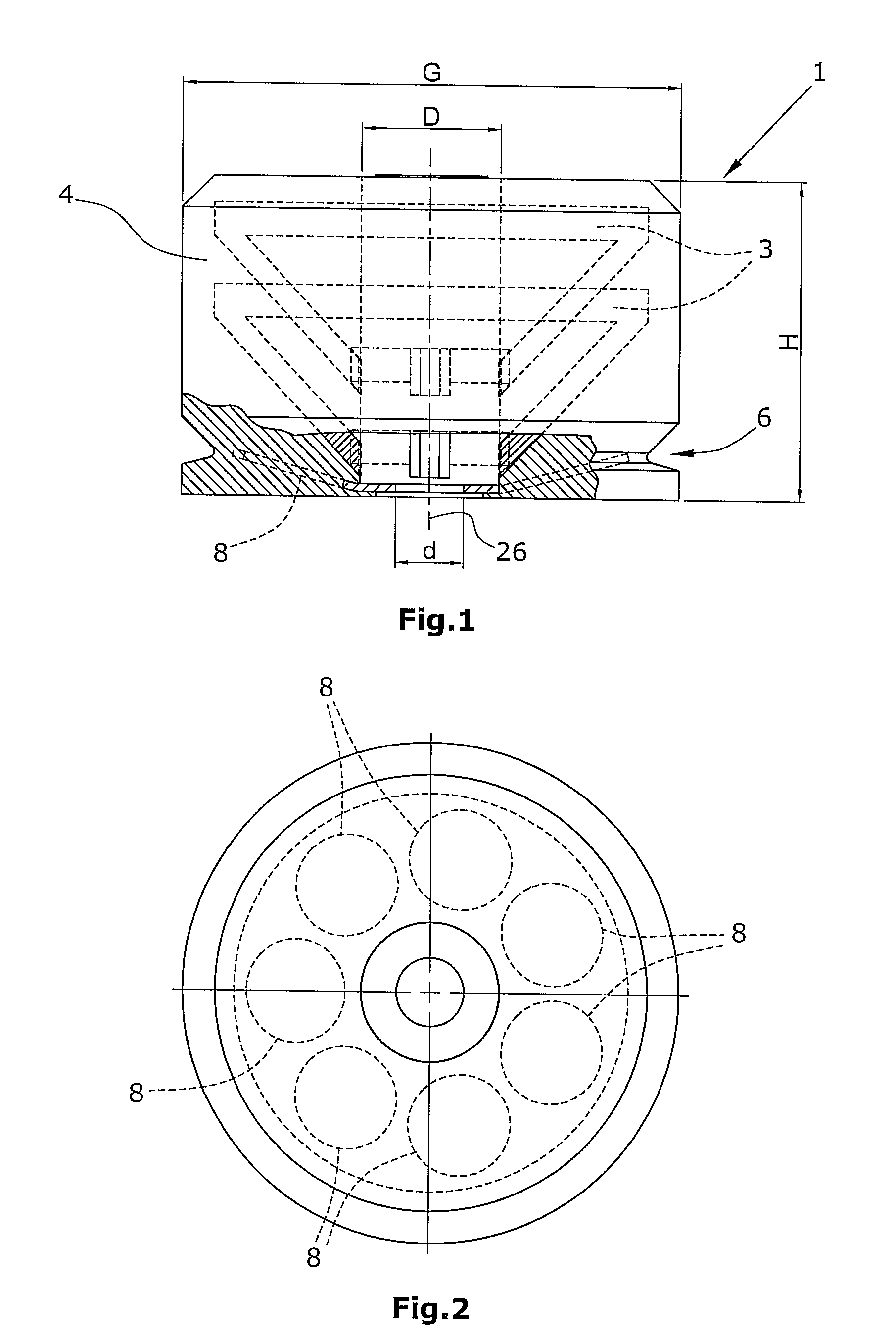

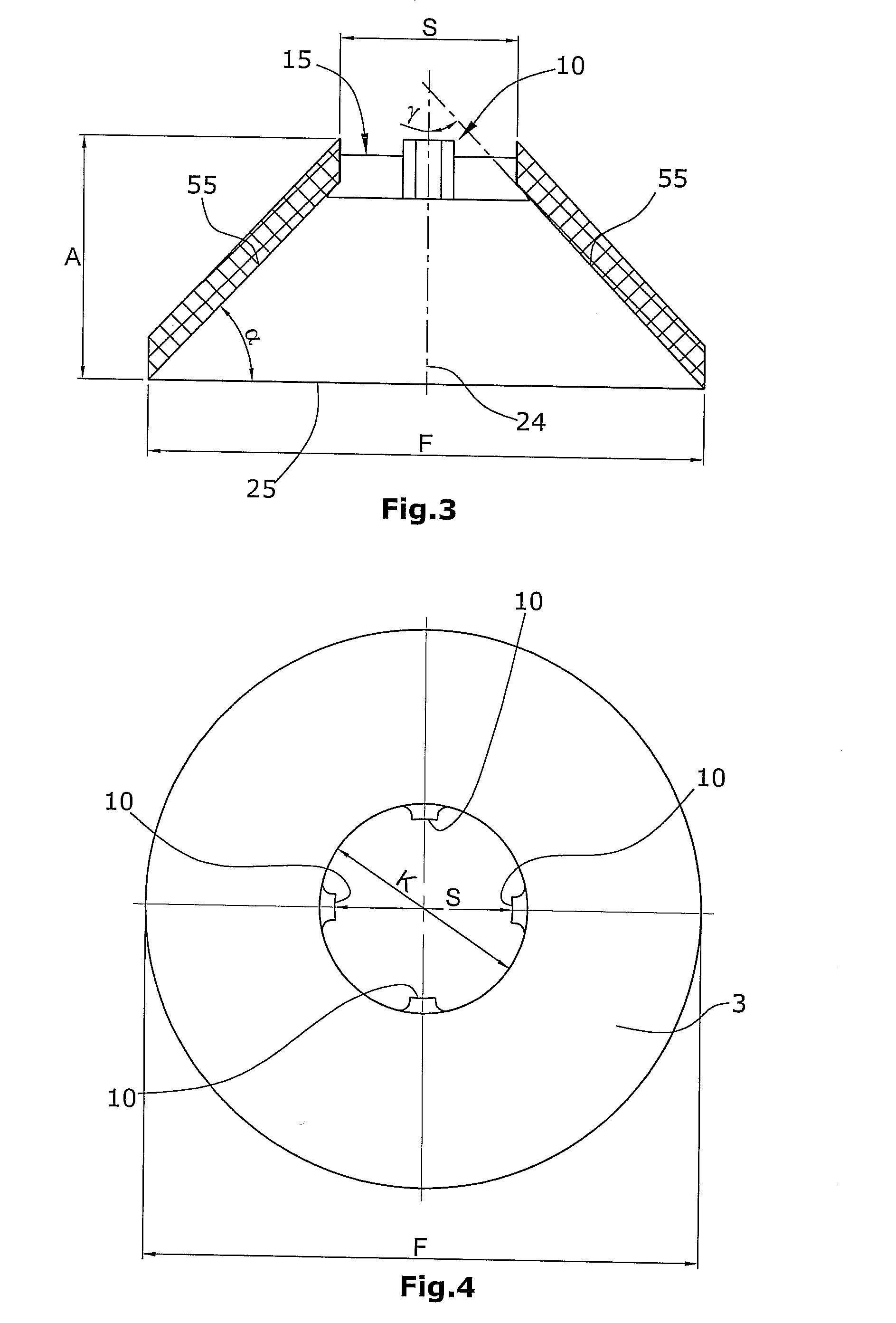

Buffer for absorbing impacts

ActiveUS20110227264A1Reduce construction heightUniform distributionPortable framesMultiple spring combinationsEngineering

Owner:ACLA WERKE

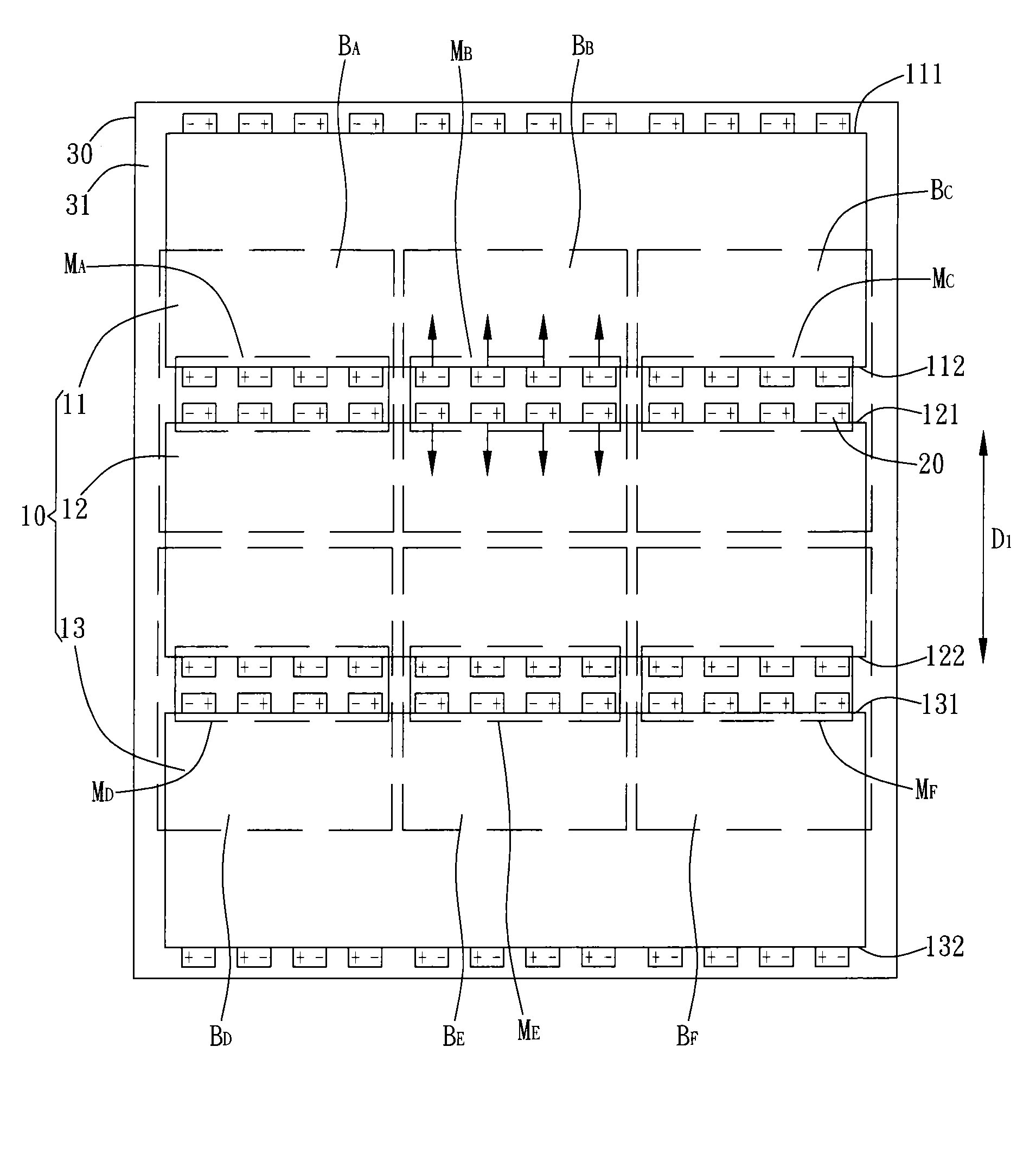

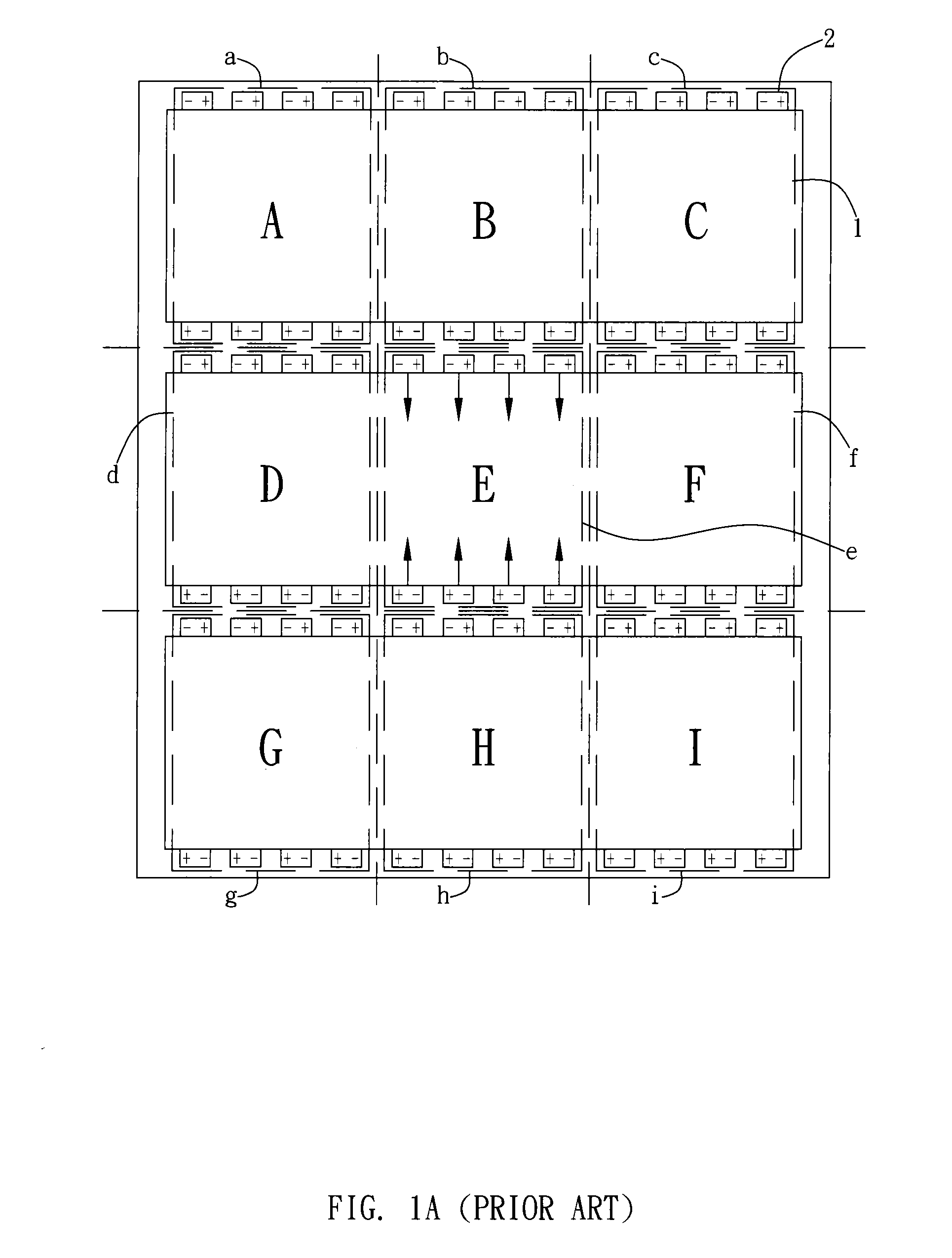

Backlight Module with Localized Light Source Control

InactiveUS20110157917A1Uniform distributionEvenly distributedMechanical apparatusLight guides for lighting systemsOptoelectronicsLight guide

A backlight module with localized light source control is provided. The backlight module includes a first light guide plate, a second light guide plate, and a plurality of luminous elements. The first light guide plate includes a first side. The second light guide plate includes a second side. The first and second light guide plates are disposed along a first direction, so that the first side of the first light guide and the second side of the second light guide face to each other. The luminous elements are respectively disposed along the first side and the second side and emit lights thereto, wherein at least a portion of the luminous elements disposed along the first side and the second side form a light source module so as to act simultaneously.

Owner:AU OPTRONICS CORP

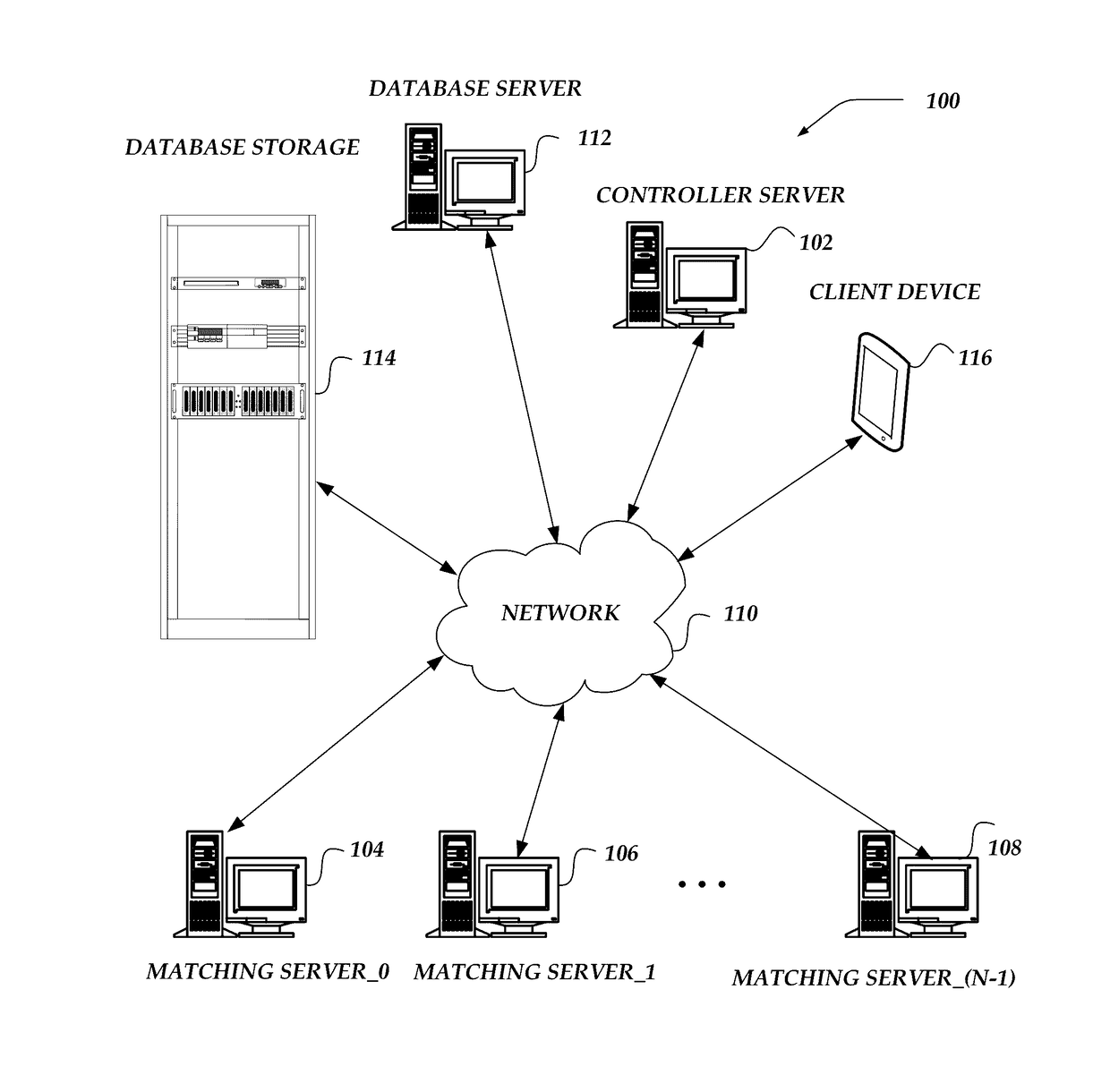

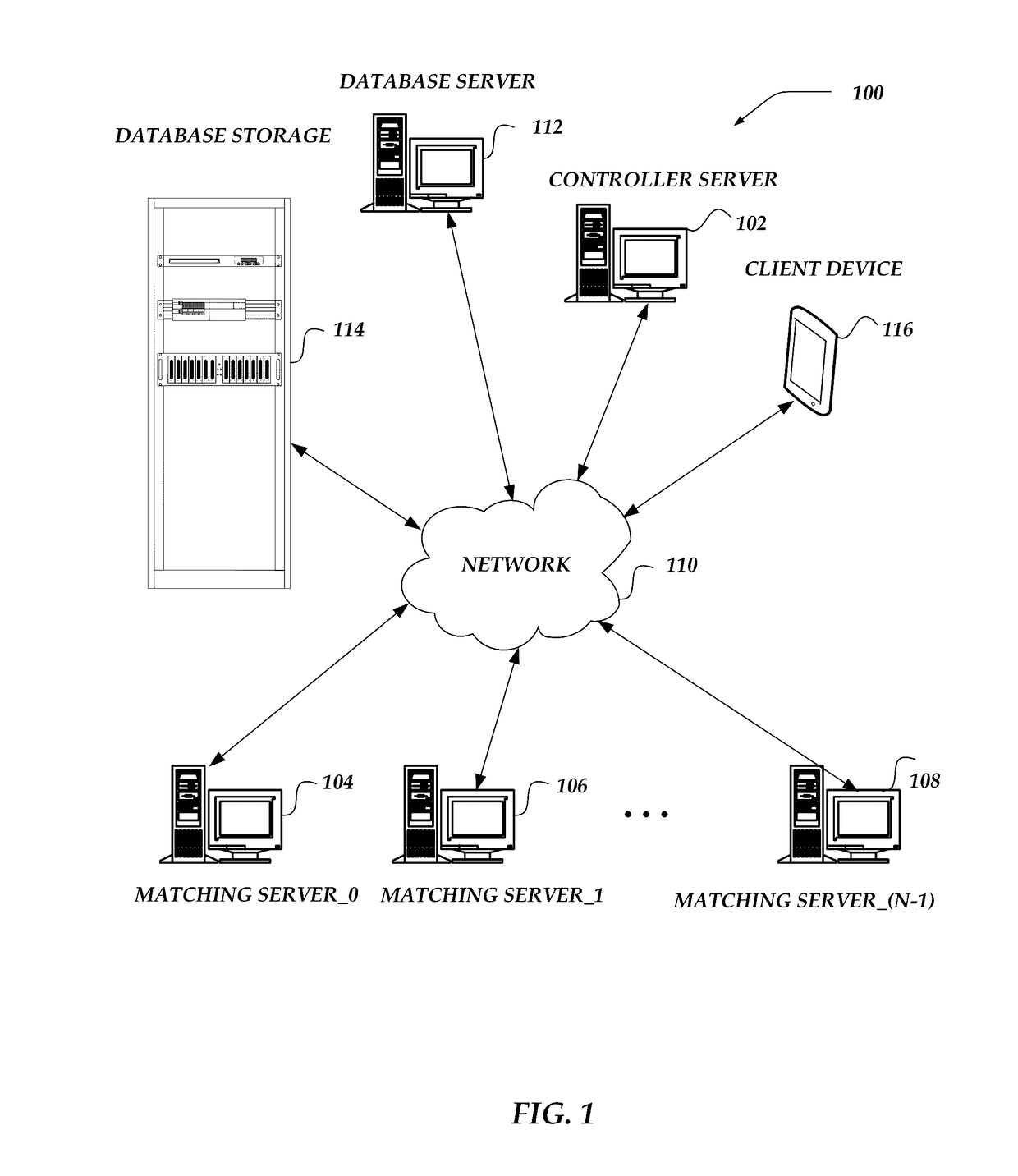

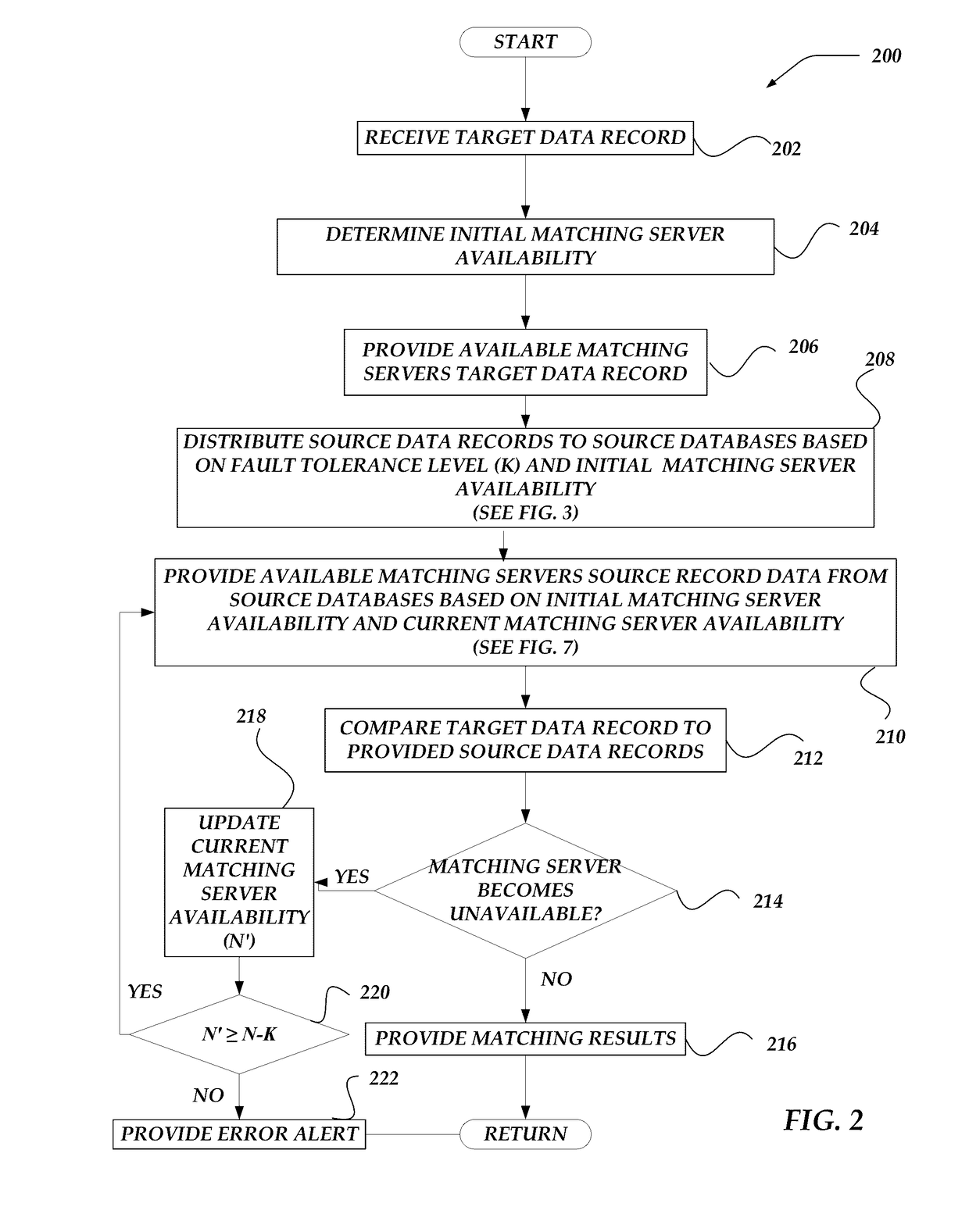

Fault-tolerant methods, systems and architectures for data storage, retrieval and distribution

ActiveUS20170083415A1Uniform distributionRedundant operation error correctionSpecial data processing applicationsSequential accessData records

The disclosure is directed towards fault-tolerant methods, systems and architectures for data distribution. One method includes generating fault distribution tables. The table entries correspond to a copy of data records. The entry and copy are associated with a fault status, a node, and a group that are based on a position of the entry within the distribution table. The method also includes storing the copy of the data record that corresponds to the entry in a database that is included in a plurality of databases. In response to determining an unavailable node included in the plurality of nodes, the method determines a fault status, a node, and a group. The method provides an available node sequential access to data records that are stored in a particular database that is stored locally on the available node in a tree structure.

Owner:TIGERIT AMERICAS LLC

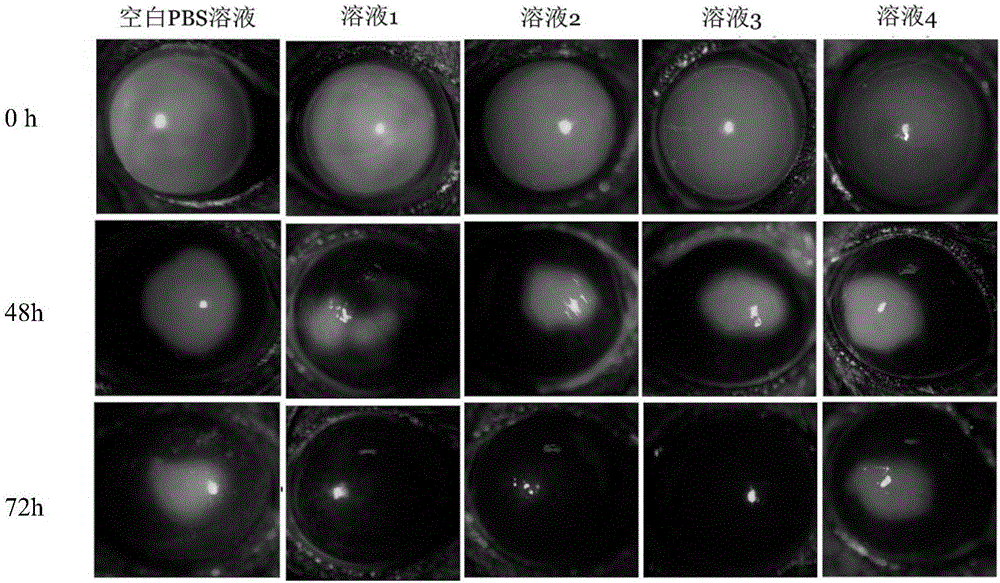

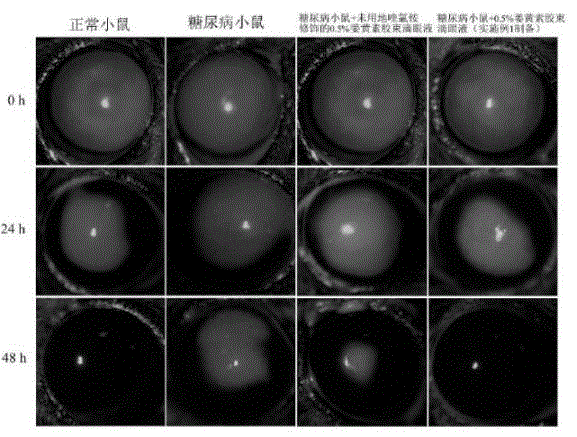

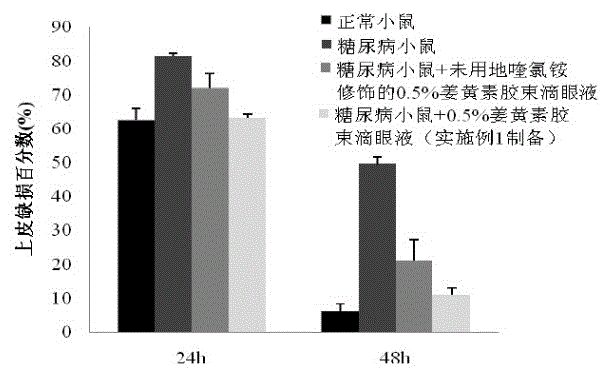

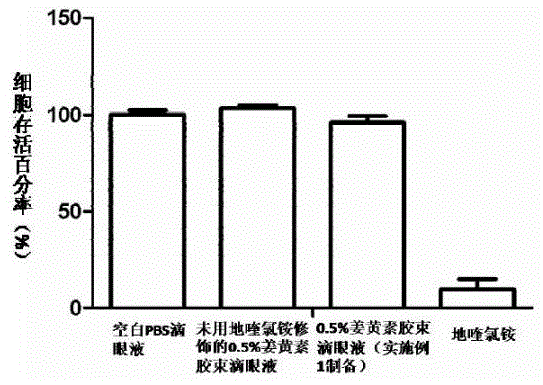

Curcumin micelle eye drop and preparation method thereof

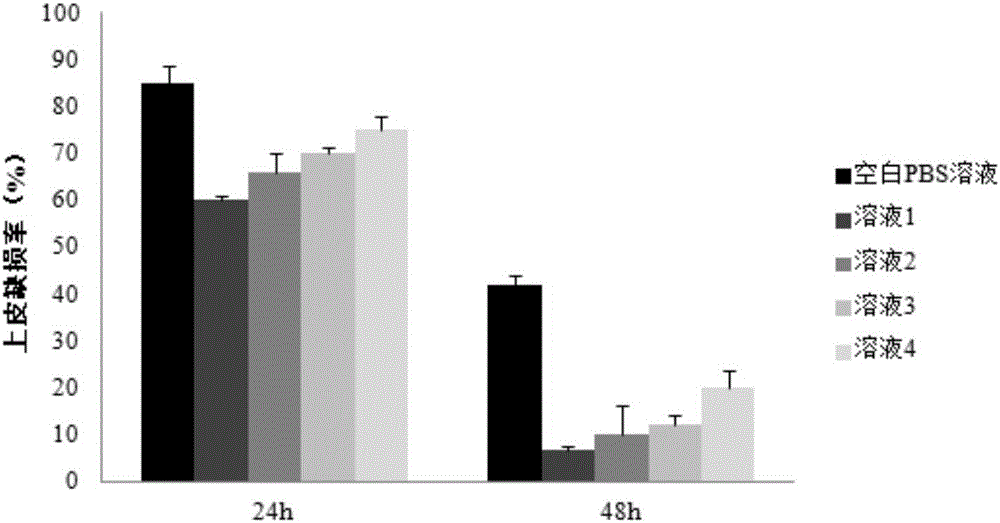

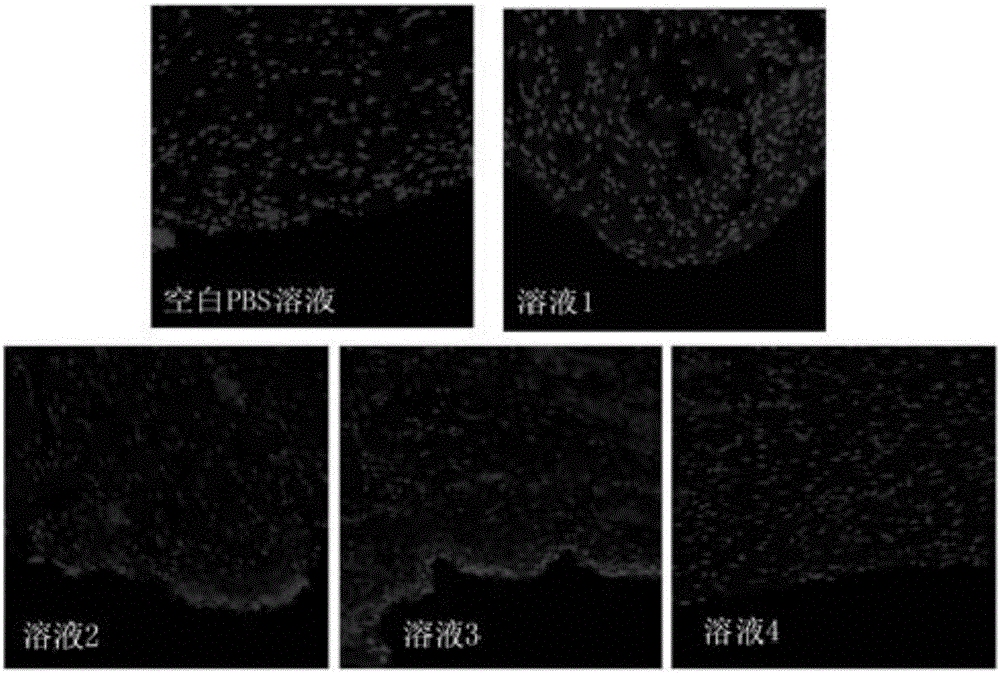

ActiveCN105030669AImprove solubilitySmall particle sizeSenses disorderMetabolism disorderPolythylene glycolPharmaceutical Aids

The invention discloses a curcumin micelle eye drop. The eye drop comprises curcumin as a main drug, an antiseptic, an isotonic regulator, and also comprises a polyethylene caprolactam-polyvinyl acetate-polyethylene glycol copolymer as a drug adjuvant, and dequalinium chloride as a mitochondrial targeting modifier and a stabilizer, a mass ratio of the curcumin main drug to the polyethylene caprolactam-polyvinyl acetate-polyethylene glycol block copolymer drug adjuvant is 1:12-1:20, and a mass ratio of dequalinium chloride to the polyethylene caprolactam-polyvinyl acetate-polyethylene glycol copolymer drug adjuvant is 1:20-1:40. The administration concentration of the curcumin micelle eye drop prepared in the invention can reach 5mg / ml, and the eye drop has the advantages of small micelle particle size, uniform distribution range, good drug stability, reduction of the administration irritation, improvement of the drug absorption of cornea, reduction of the administration concentration, prolongation of the action time of the drug, reduction of the administration frequency, improvement of the patient compliance, and very good economy.

Owner:SHANDONG EYE INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com