Patents

Literature

2769 results about "Caprolactam" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Caprolactam (CPL) is an organic compound with the formula (CH₂)₅C(O)NH. This colourless solid is a lactam (a cyclic amide) of caproic acid. Global demand for this compound is approximately five million tons per year, and the vast majority is used to make Nylon 6 filament, fiber, and plastics.

Nylon 6 polymerization method and direct spinning method of melt of polymer obtained with nylon 6 polymerization method

ActiveCN105669969AIncrease profitReduce manufacturing costFlame-proof filament manufactureHollow filament manufacturePolymer sciencePolyamide

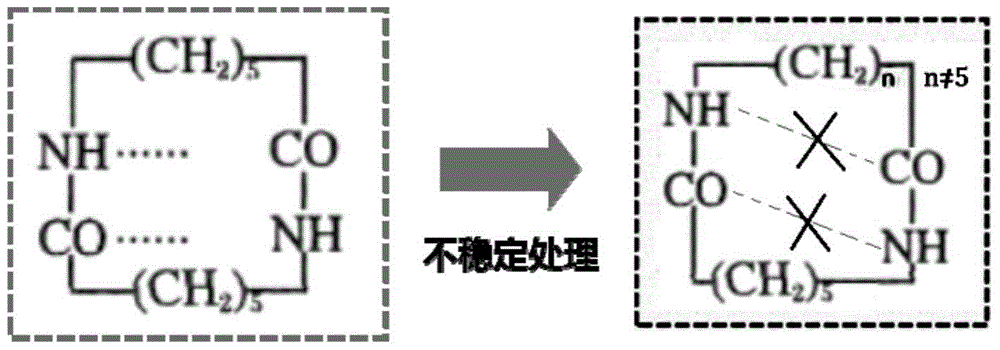

The invention relates a nylon 6 polymerization method and a direct spinning method of a melt of a polymer obtained with the nylon 6 polymerization method. A polyamide 6 prepolymer is prepared at the low temperature, the content of oligomers in the melt is controlled in advance, polymerization is completed before a large quantity of cyclic oligomers are generated with a condensation polymerization dynamic strengthening method, a nylon 6 polymer melt with certain molecular weight is acquired, the content of extracts in the product is smaller than or equal to 1.5 wt%, and the content of cyclic dipolymers is smaller than or equal to 0.2wt%; then, direct melt spinning forming is performed after condensation polymerization dynamic strengthening ends. The process is simple, energy consumption is further reduced while the utilization rate of caprolactam is increased, the obtained melt can be directly used for melt spinning, high-capacity large-scale production is easy to realize, a modifier can be added in the polymerization process, flexible production of nylon 6 is realized, and the nylon 6 can be applied to fibers for clothes, industrial filaments, engineering plastics and other fields.

Owner:ZHEJIANG HENGYI PETROCHEMICAL RES INST CO LTD

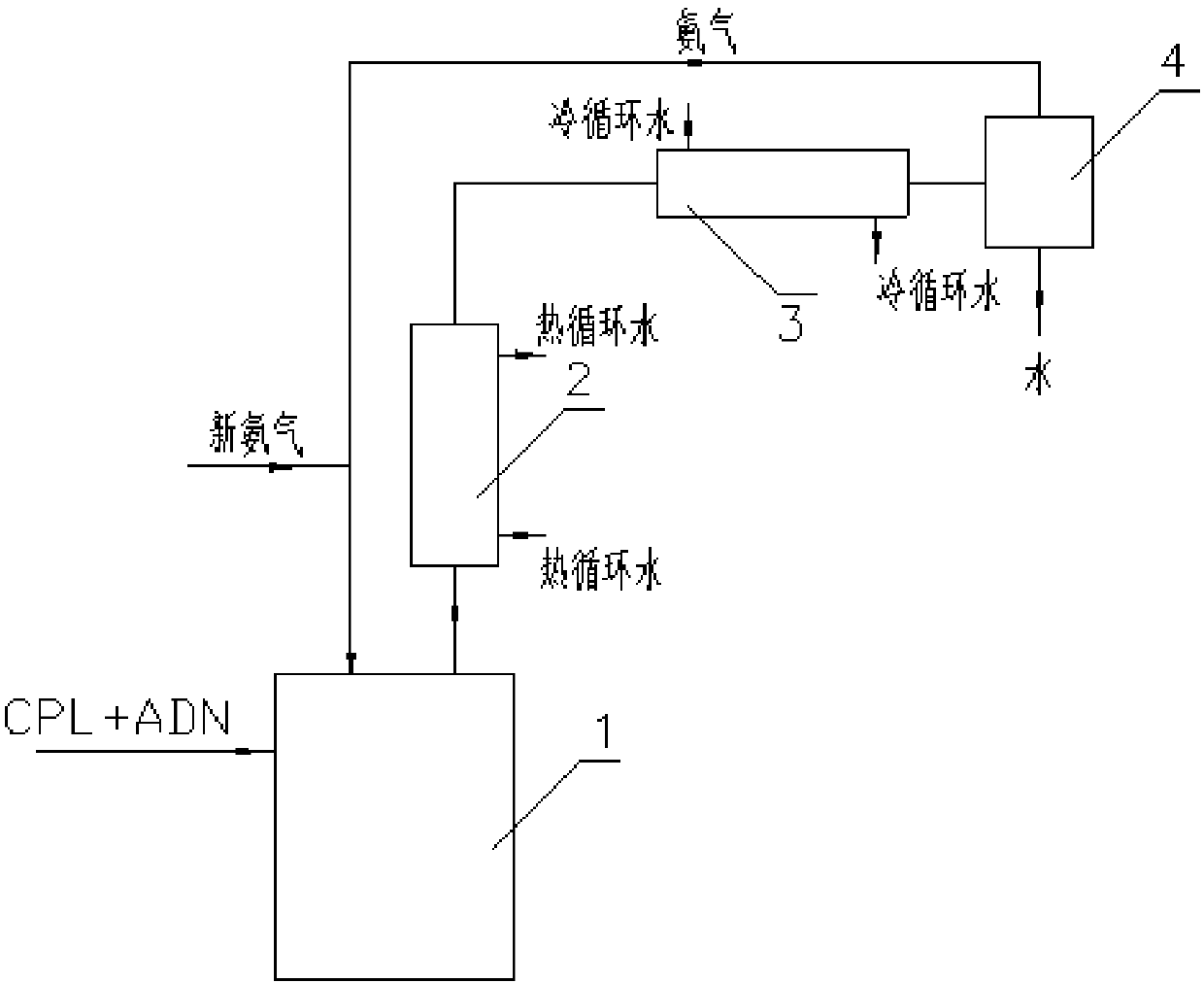

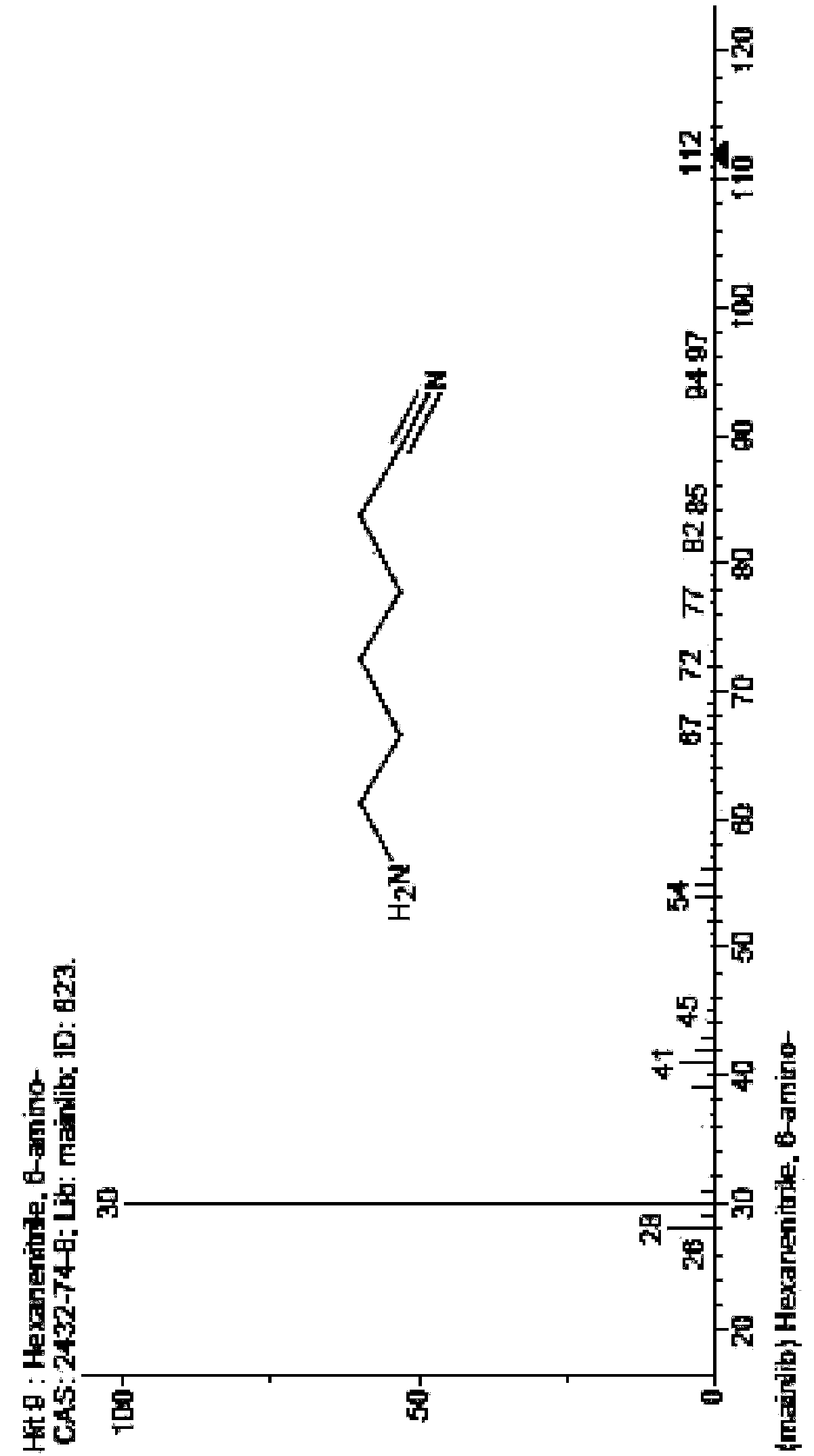

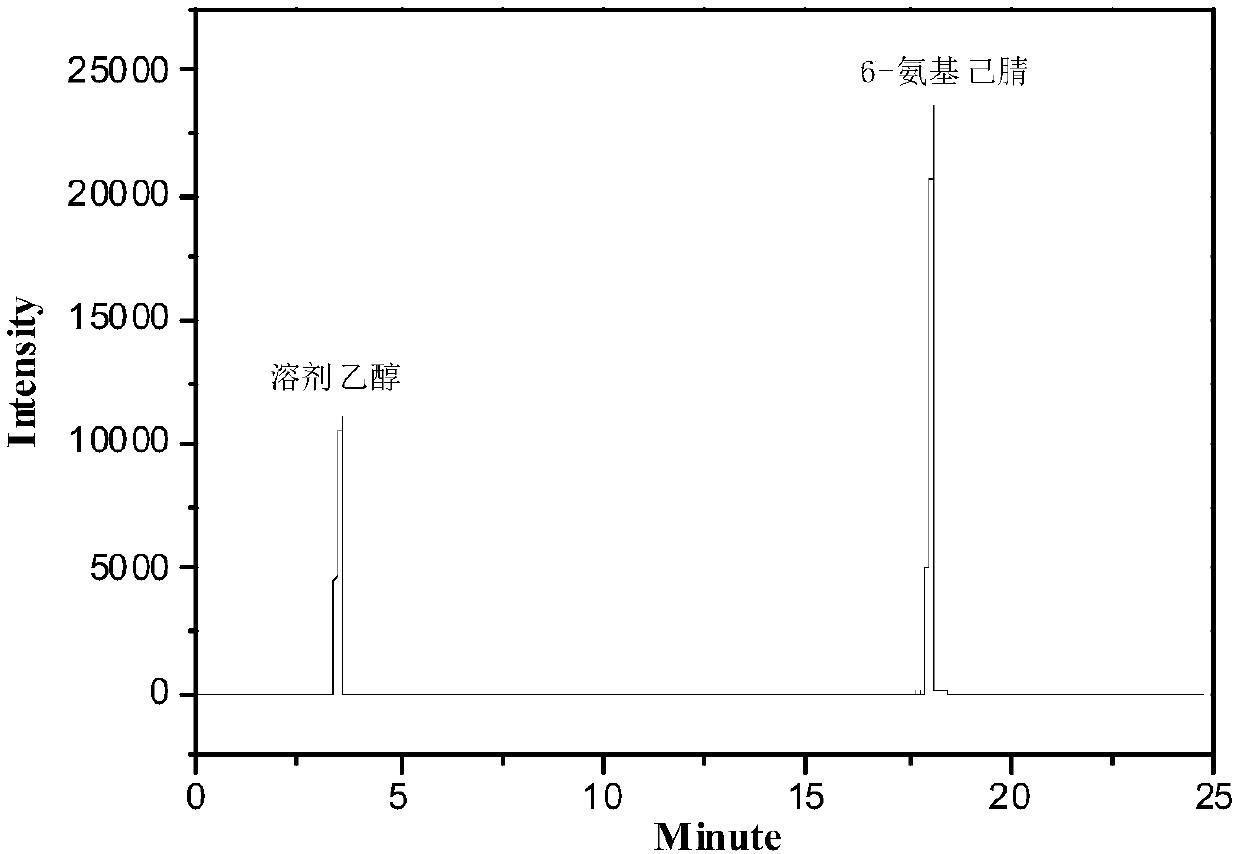

Method and device for preparing 6-amino-capronitrile with caprolactam liquid phase method

InactiveCN107739318AHigh reaction conversion rateGood choicePreparation by carboxylic acid amide dehydrationOrganic solventCaprolactam

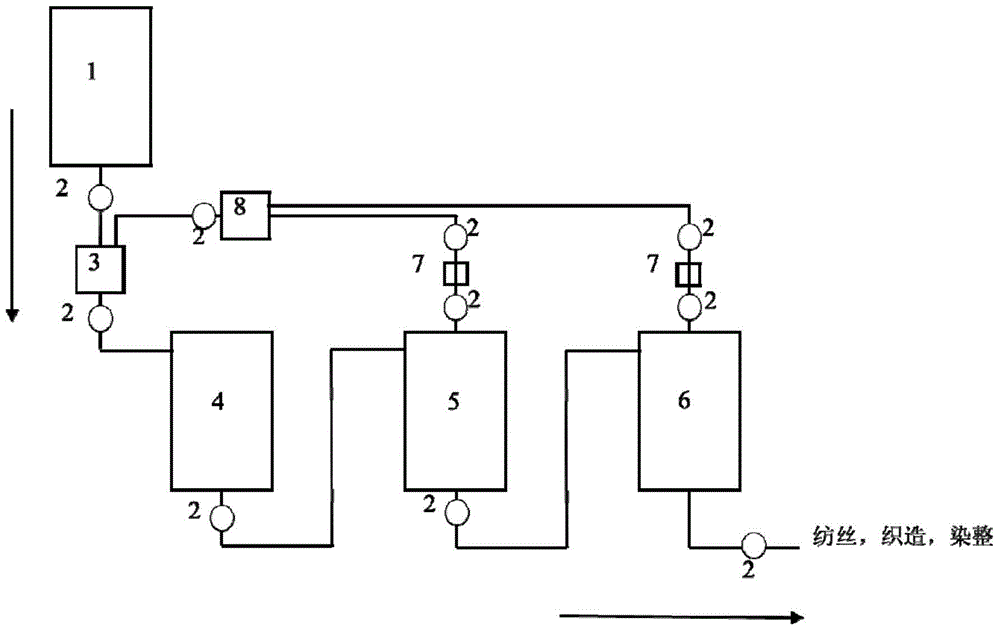

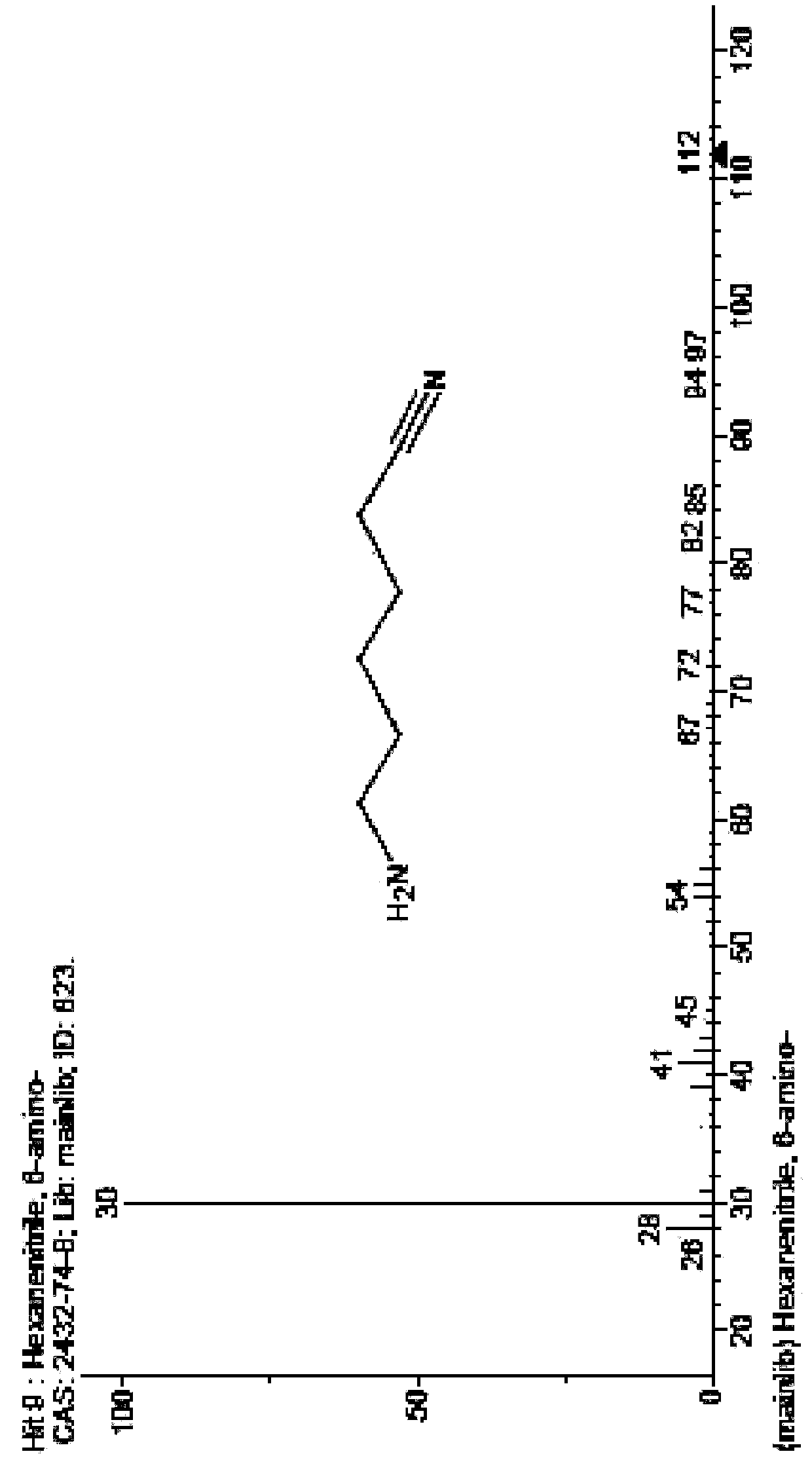

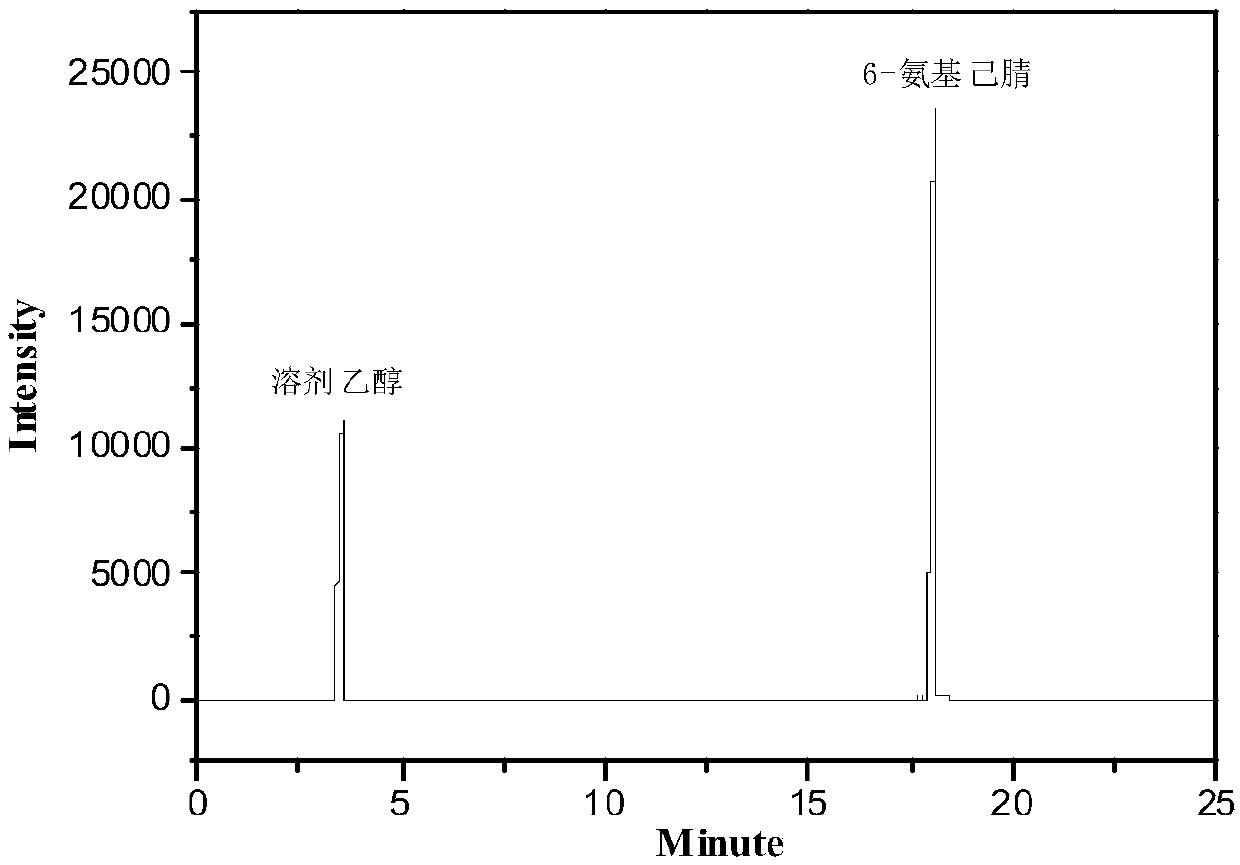

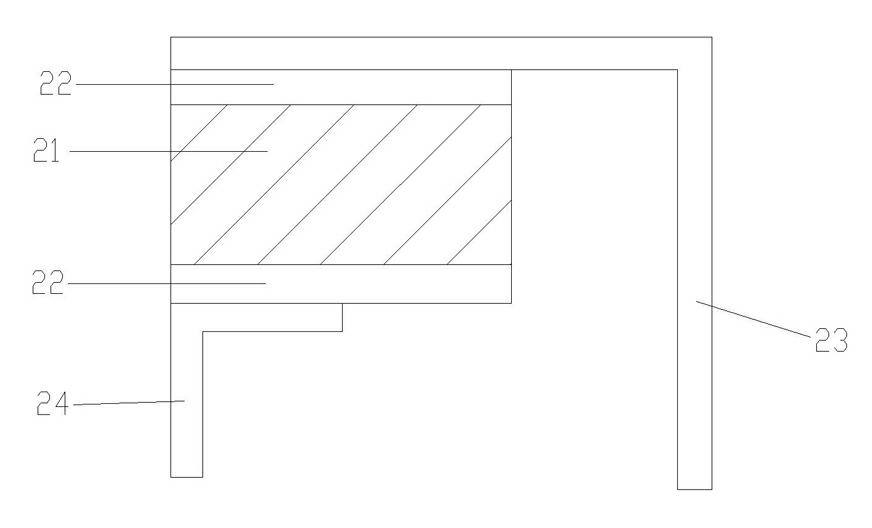

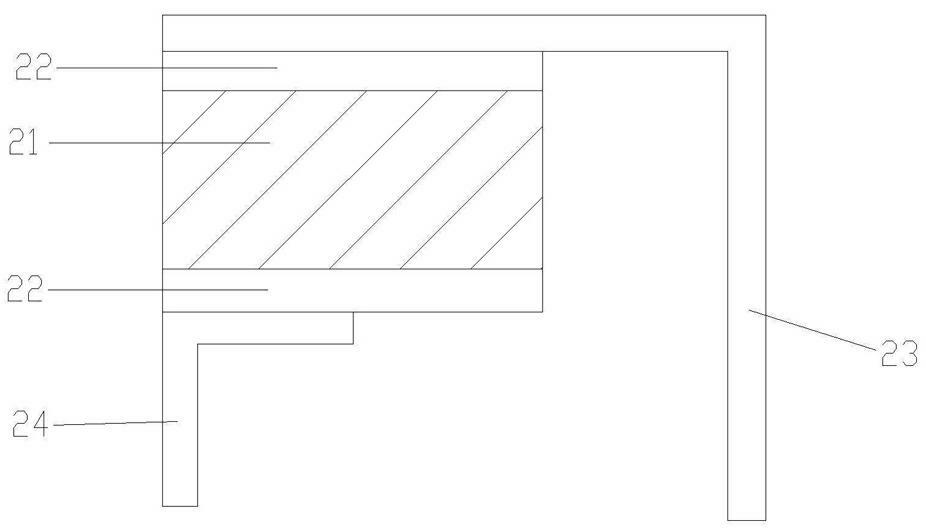

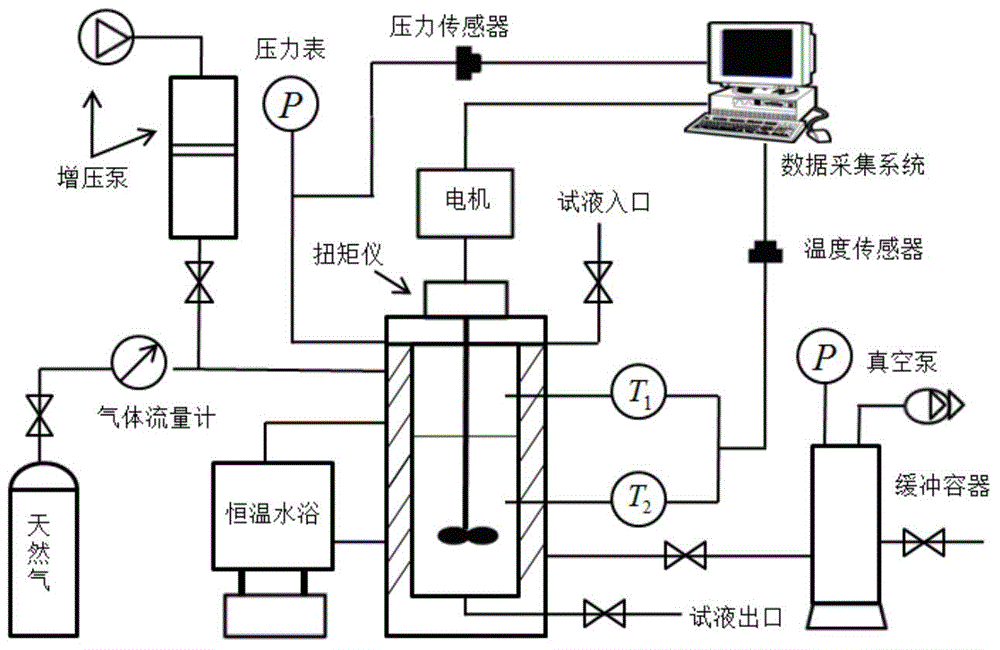

The invention provides a method and device for preparing 6-amino-capronitrile from caprolactam by adopting a liquid phase method. In the method for preparing the 6-amino-capronitrile, the caprolactamis taken as a raw material; the method for preparing the 6-amino-capronitrile comprises the following step: S1: mixing the caprolactam, an organic solvent and a catalyst at a certain mass ratio, so asto obtain a mixed solution, adding the mixed solution into a reaction kettle and stirring and heating the mixed solution; S2: when the mixed solution in step S1 reaches certain temperature, introducing ammonia gas into the mixed solution for a reaction; S3, after the reaction in step S2 is ended, rectifying and purifying a reaction product, so as to obtain pure 6-amino-capronitrile. In the methodfor preparing the 6-amino-capronitrile, the caprolactam is taken as the raw material, the reaction conversion rate is comparatively high, and the preparation process is simple.

Owner:CHINA TIANCHEN ENG +1

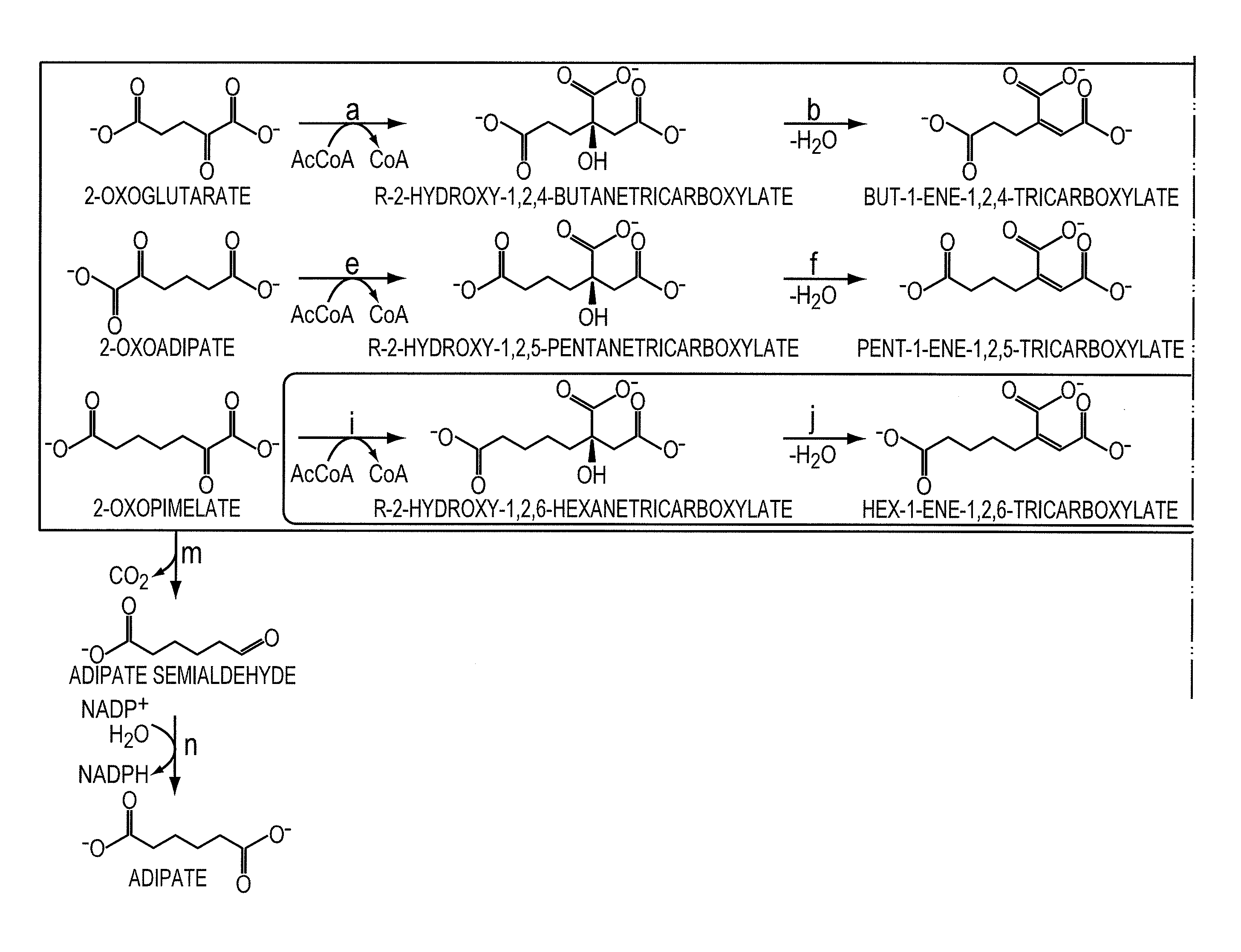

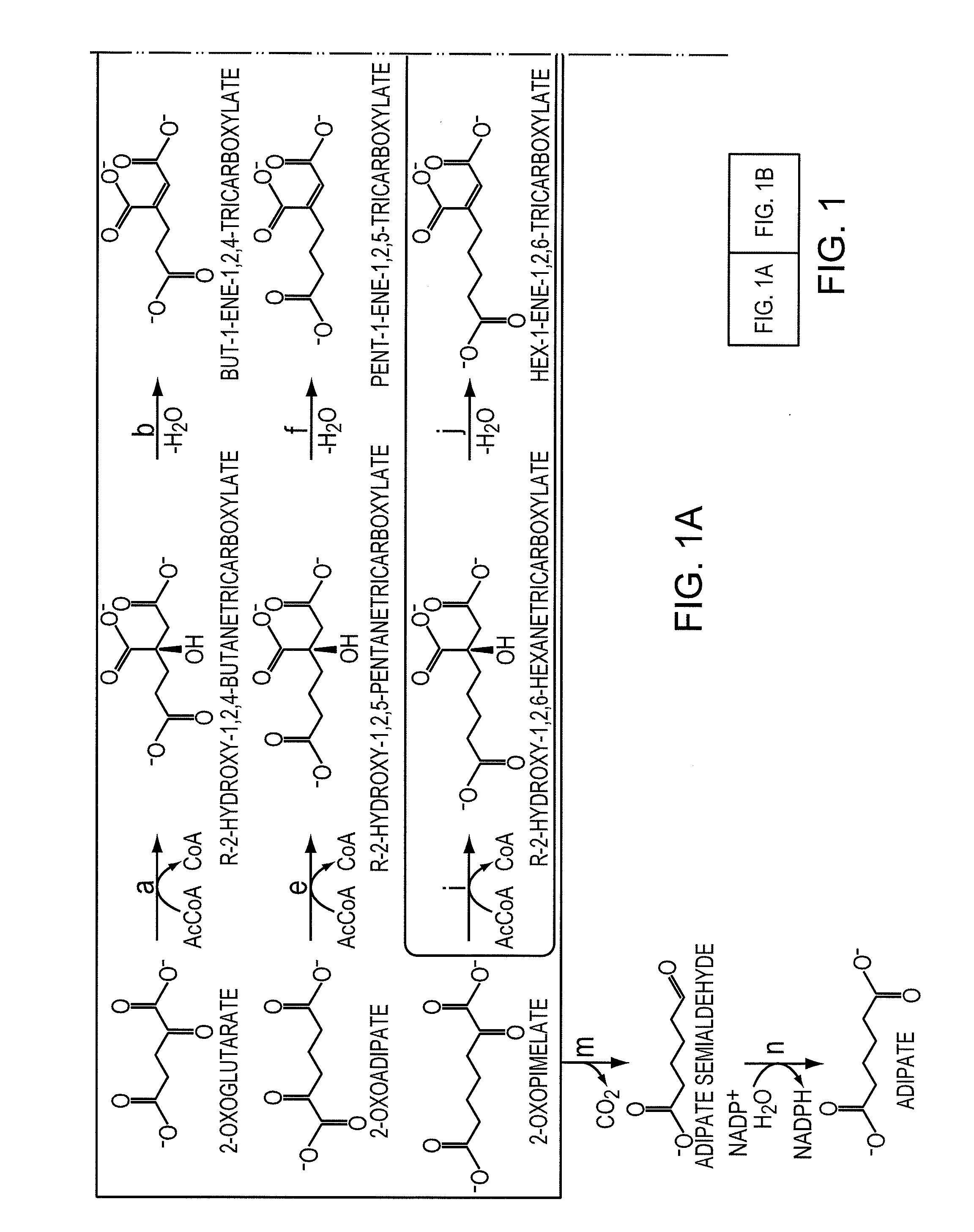

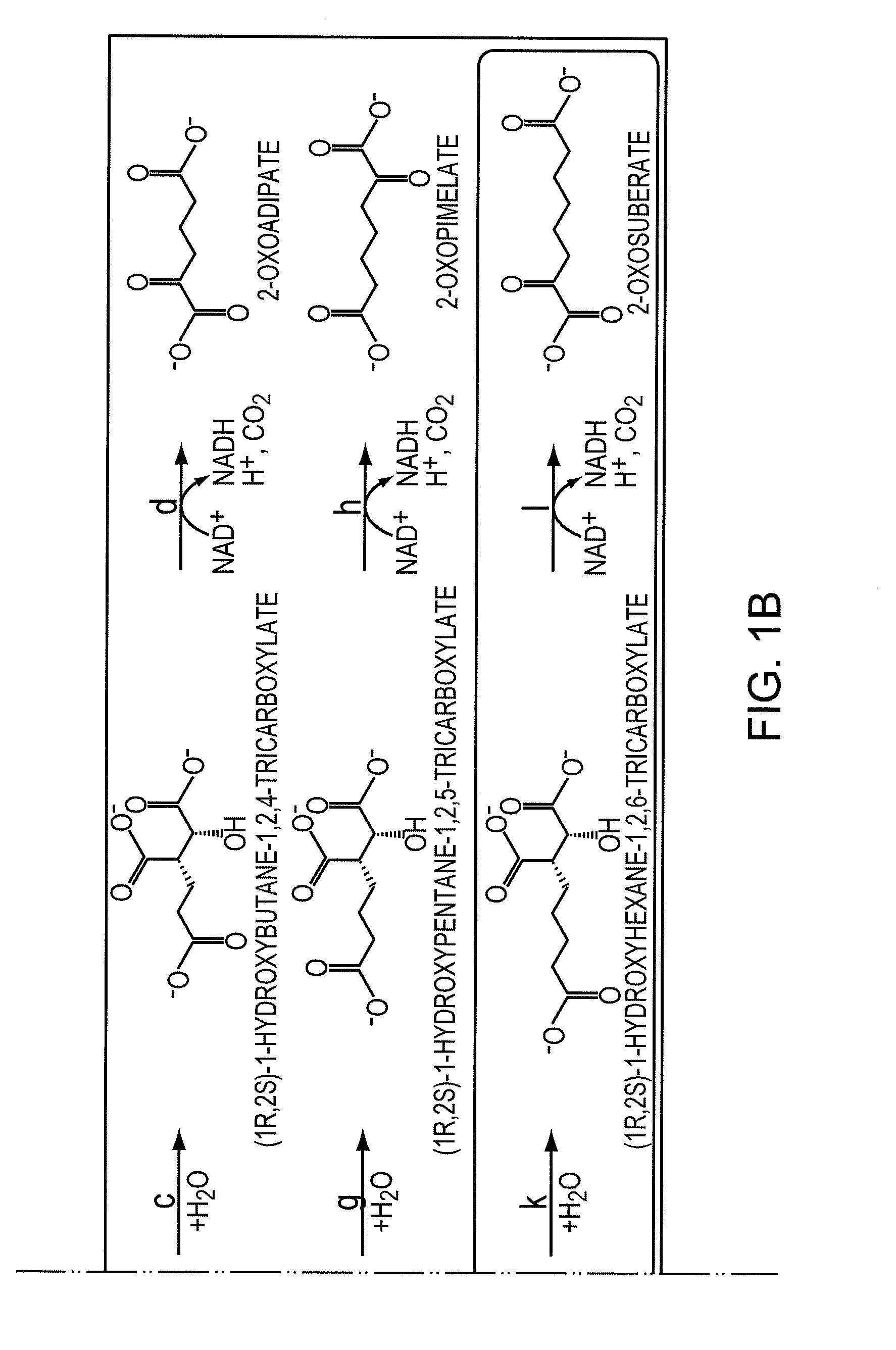

Biological Synthesis of Difunctional Alkanes from Carbohydrate Feedstocks

Aspects of the invention relate to methods for the production of difunctional alkanes in host cells. In particular, aspects of the invention describe components of genes associated with the difunctional alkane production from carbohydrate feedstocks in host cells. More specifically, aspects of the invention describe metabolic pathways for the production of adipic acid, aminocaproic acid, caprolactam, and hexamethylenediamine via 2-ketopimelic acid.

Owner:CELEXION

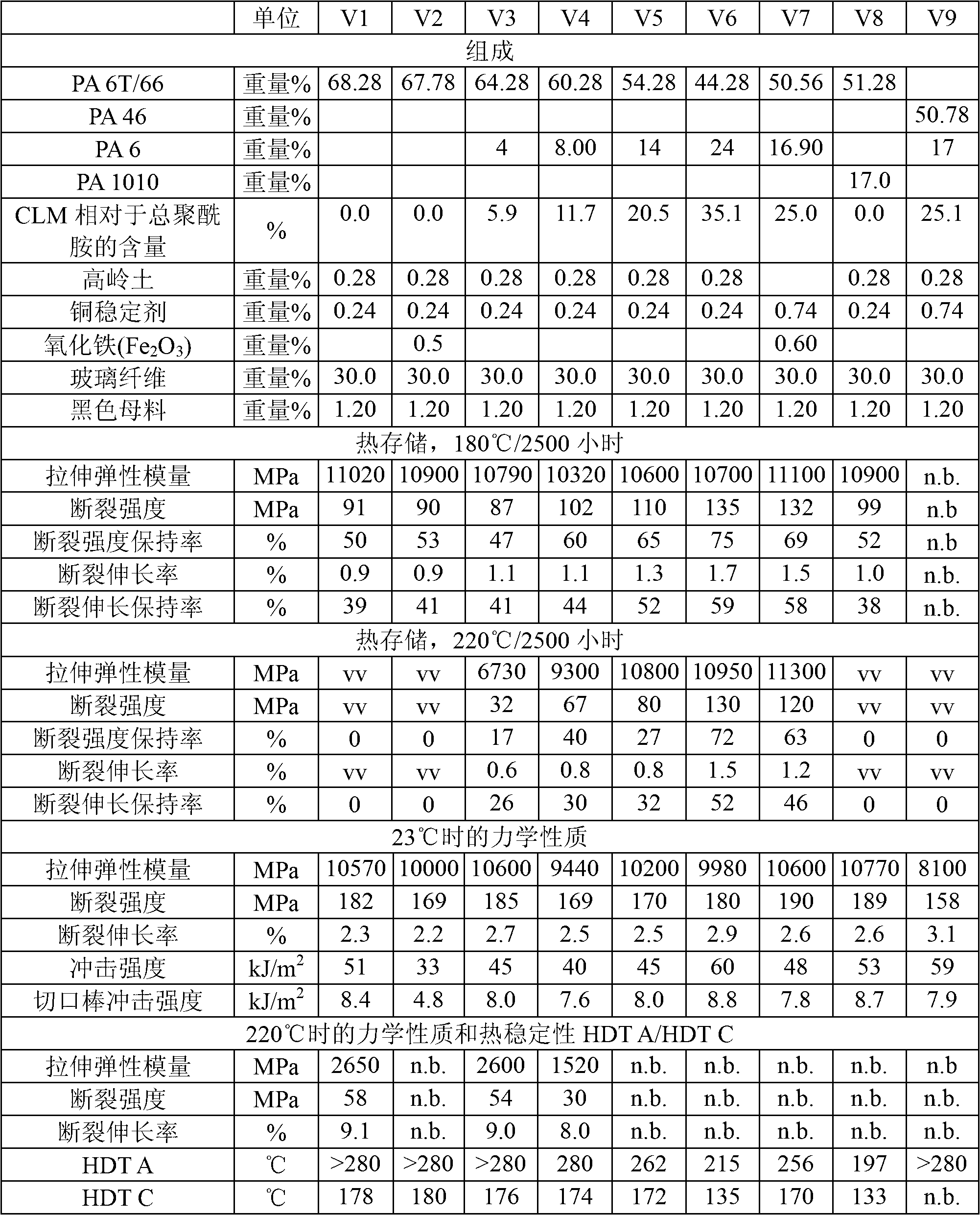

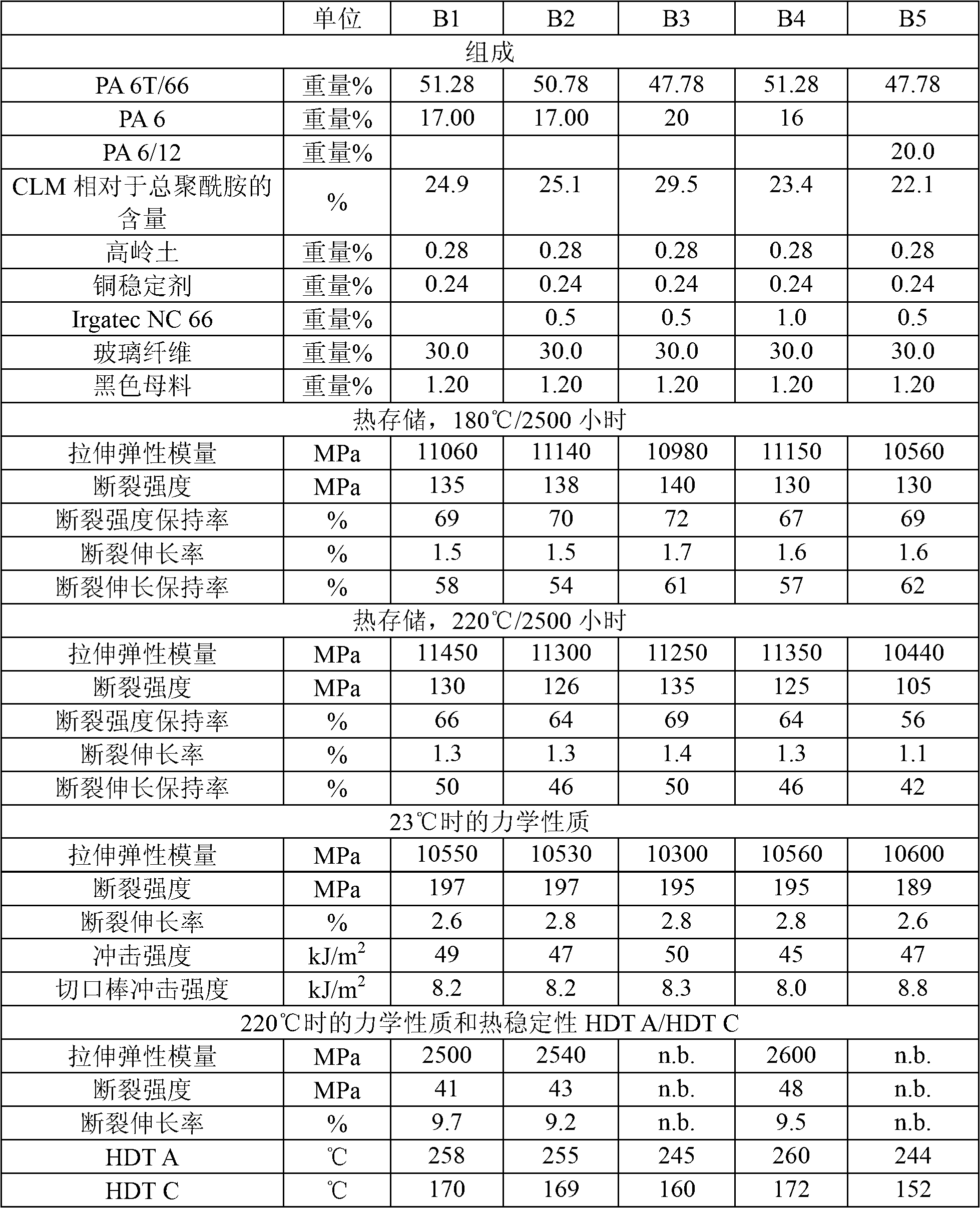

Semiaromatic molding compounds and uses thereof

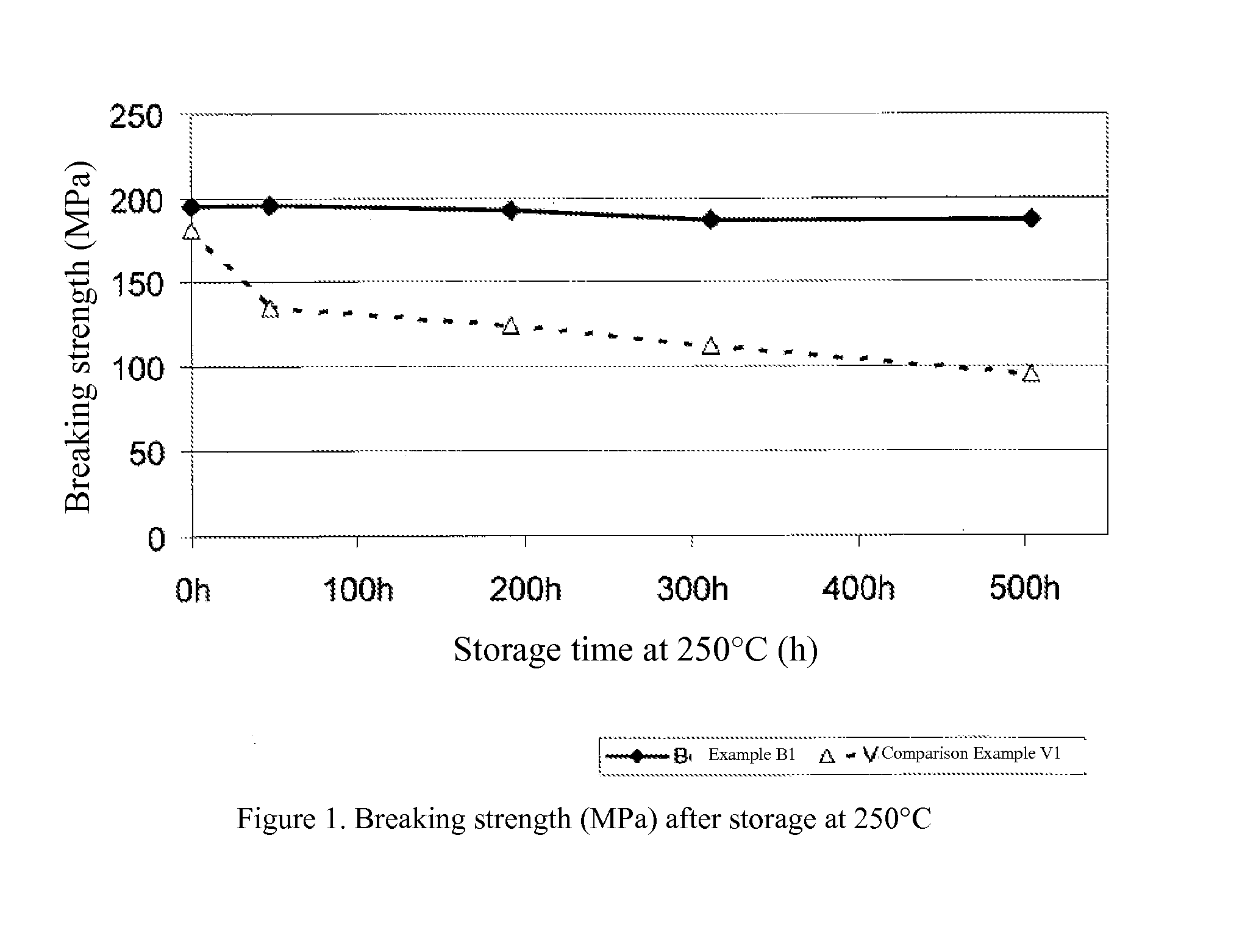

ActiveUS20120321829A1Improve thermal stabilityGood heat aging stabilitySynthetic resin layered productsCeramic shaping apparatusPolyamideCaprolactam

Owner:EMS PATENT AG

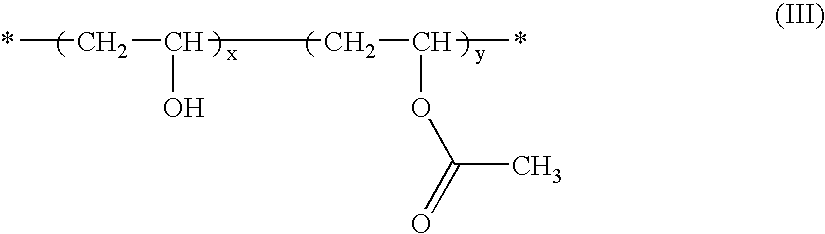

Nanoemulsion containing nonionic polymers, and its uses

These objects and others may be accomplished with the present invention, the first embodiment of which provides an oil-in-water nanoemulsion, which includes:an oily phase dispersed in an aqueous phase;(i) at least one amphiphilic lipid selected from the group including nonionic amphiphilic lipids, anionic amphiphilic lipids, and combinations thereof; and(ii) at least one water-soluble nonionic polymer selected from the group including homopolymers and copolymers of ethylene oxide; polyvinyl alcohols; homopolymers and copolymers of vinylpyrrolidone; homopolymers and copolymers of vinylcaprolactam; homopolymers and copolymers of polyvinyl methyl ether; neutral acrylic homopolymers and copolymers; C1–C2 alkyl celluloses and their derivatives; C1–C3 alkyl guar; C1–C3 hydroxyalkyl guar; and combinations thereof;wherein a ratio of the weight of the oily phase to the weight of the amphiphilic lipid (i) ranges from 1.2 to 10;and wherein the oily phase includes oil globules having a number-average size of less than 100 nm. The nanoemulsion obtained is preferably transparent and stable on storage. It may form a composition for topical, preferably cosmetic or dermatological compositions, pharmaceutical compositions and ophthalmological compositions.

Owner:LOREAL SA

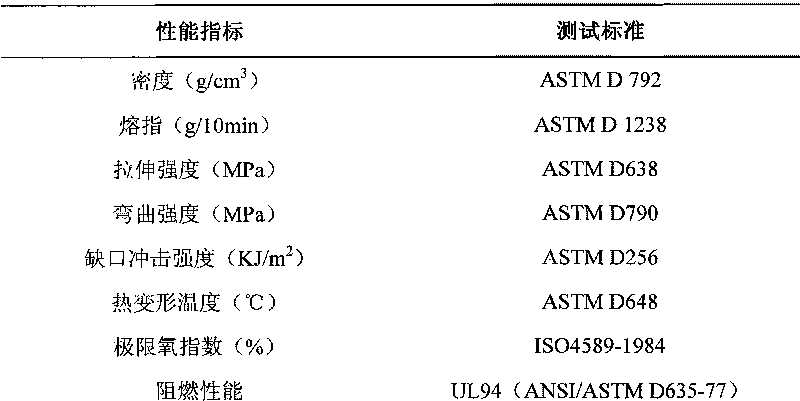

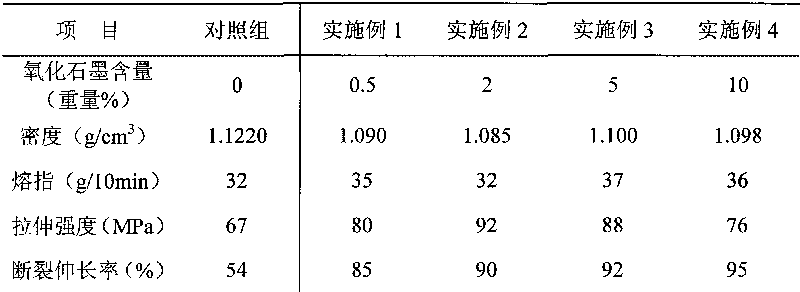

Carbon-based nano cast nylon composite material and in-situ polymerization preparation method thereof

InactiveCN101928457AEvenly dispersedQuality improvementOther chemical processesNon-conductive material with dispersed conductive materialIn situ polymerizationNanoparticle

The invention discloses a carbon-based nano cast nylon composite material and an in-situ polymerization preparation method thereof. The method is characterized by comprising the following steps of: heating a caprolactam raw material to between 70 and 120 DEG C for melting, adding carbon-based nano particles into the caprolactam melt in a weight ratio of the carbon-based nano particles to the caprolactam monomer of 0.1-5: 100, namely uniformly dispersing carbon-based nano particle graphite oxide or graphene into the caprolactam melt by using ultrasonic wave or in a grinding mode, heating the mixture to between 110 and 150 DEG C, dehydrating the mixture for 5 to 30 minutes under the vacuum of 0.05 to 0.098MPa, adding 0.1 to 1 weight part of catalyst and 0.1 to 1 weight part of cocatalyst into the mixture, casting the uniform mixture into a die preheated to between 150 and 180 DEG C, keeping the temperature for 30 to 60 minutes, and cooling the mixture to obtain the carbon-based nano cast nylon composite material. Compared with the carbon-based nano-free cast nylon material, the mechanical properties of the carbon-based nano cast nylon composite material such as tensile strength, tensile modulus, bending strength, elongation at break and the like are improved by 5 to 20 percent, and the abrasion resistance of the cast nylon composite material is improved.

Owner:泸州市科华工程塑料有限公司 +1

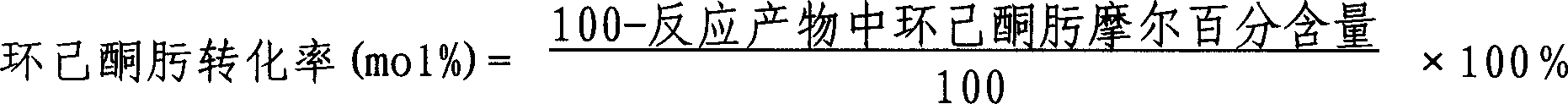

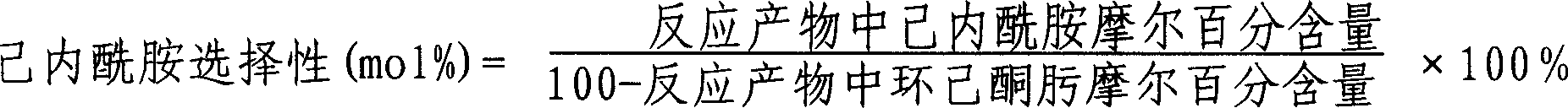

Method for preparing catalyst of containing MFI structured molecular sieve

ActiveCN1600428APromote regenerationImprove conversion rateLactams preparationMolecular sieve catalystsBeckmann rearrangementMolecular sieve

A MFI-molecular sieve catalyst for preparing caprolactam from cyclohexanone oxime by gas-phase Beckmann rearrangement is prepared through proportionally mixing MFI-molecular sieve with alkaline silica gel, shaping, drying and calcining. It has high conversion rate and selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

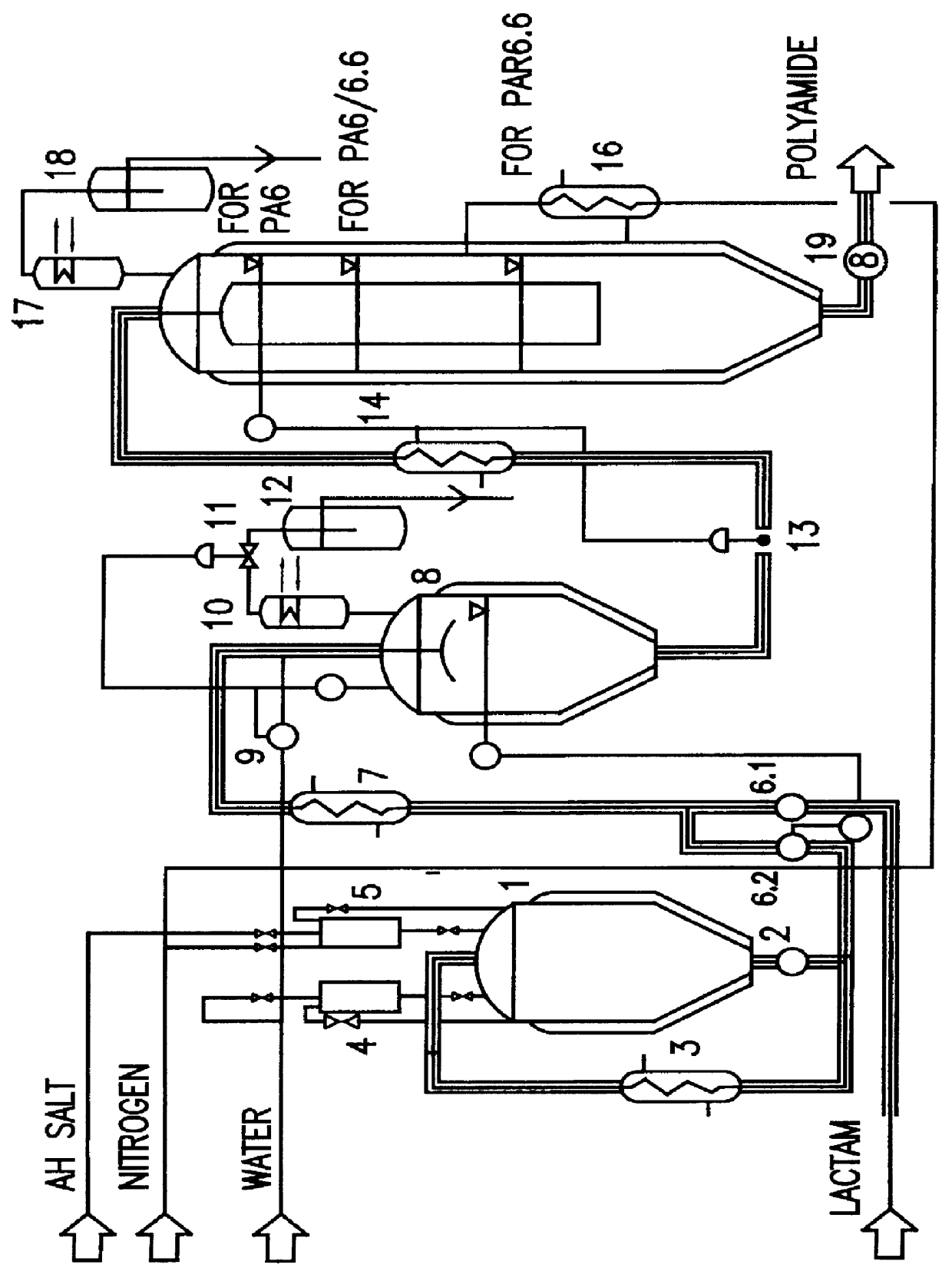

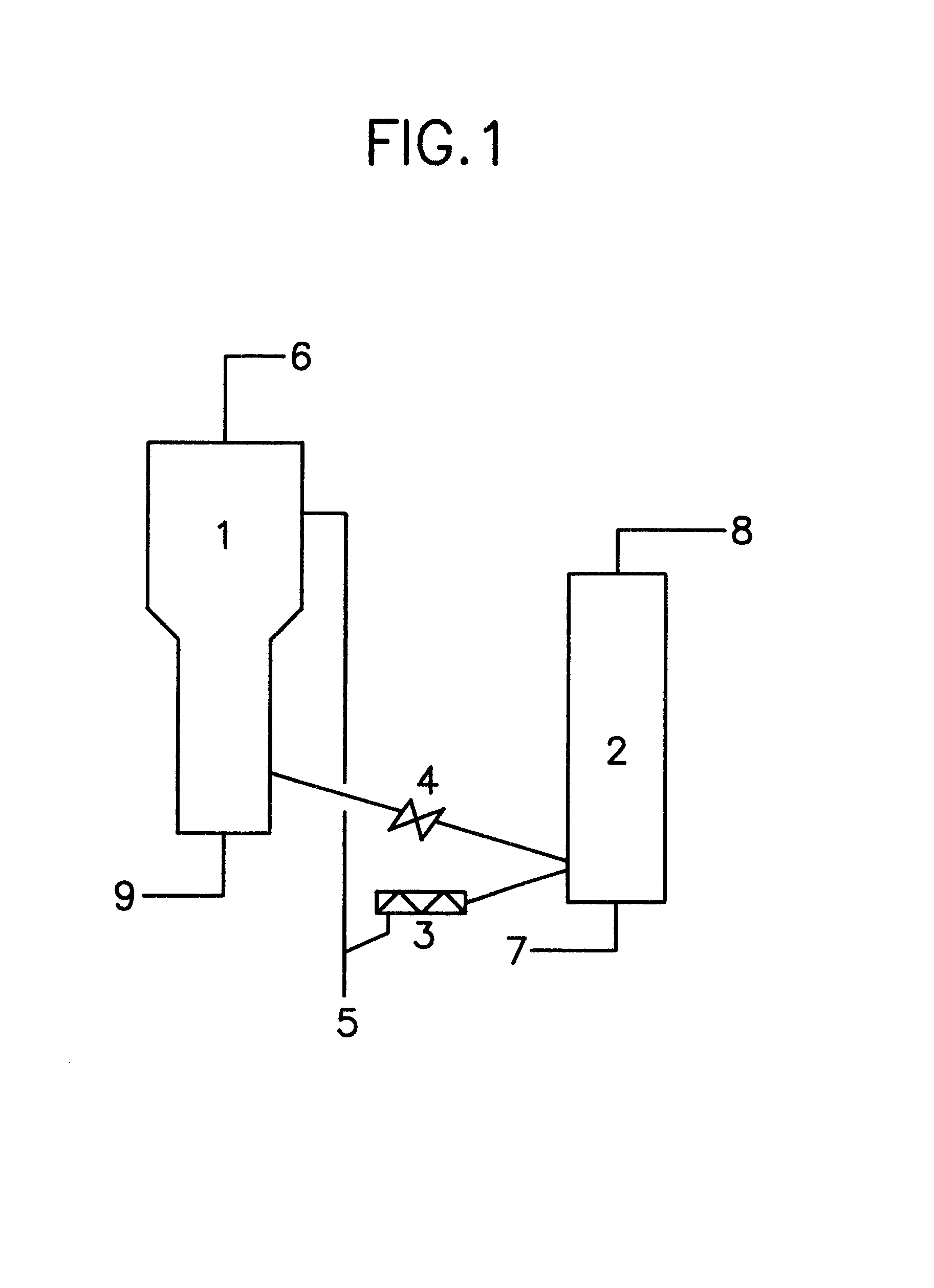

Process and device for the standardized continuous production of polyamides

InactiveUS6136947AHigh viscosityOvercome disadvantagesChemical recyclingHexamethyldiamineHexamethylenediamine

PCT No. PCT / EP96 / 05514 Sec. 371 Date Nov. 13, 1998 Sec. 102(e) Date Nov. 13, 1998 PCT Filed Dec. 10, 1996 PCT Pub. No. WO90 / 21758 PCT Pub. Date Jun. 19, 1997A process and device for the standardised continuous production of polyamide 6, polyamide 6.6 and / or copolyamides from e-caprolactam and / or adipic acidic hexamethylenediamine or adipic acid and hexamethylenediamine uses a combination of known specific processes to design a polymerisation reactor in which product with sufficiently high quality can be produced with the most efficient possible use of the energy applied and in such a way that the initial substances can be used alternately in the individual processing stages: pre-heating of the initial products using a common heat exchanger to 190-300 DEG C.; polymerisation of the initial products in a pressure stage with or without elimination of water and product recycling at 150-280 DEG C. and a pressure of <20 bar, dewatering of the polymer melt in a one to five turn coil under slow pressure reduction; and final condensation of the melt in at least one common vertical reactor at temperatures of between 210 and 285 DEG C.

Owner:POLYMER ENG

Method for preparing 6-aminocapronitrile by gas phase method

InactiveCN107602416AEasy to makeHigh reaction conversion ratePreparation by carboxylic acid amide dehydrationGas phasePhase method

The invention provides a method for preparing 6-aminocapronitrile by a gas phase method. The method uses caprolactam as a raw material, and comprises the following steps of S1, mixing caprolactam vapor with an hot ammonia gas according to a certain mass ratio; S2, subjecting a mixture of the caprolactam vapor and the hot ammonia gas, which is obtained in the step S1, to ammoniation and dehydrationreaction in a condition that a catalyst exists, so as to obtain ammoniated efflux; S3, separating and purifying the ammoniated efflux obtained in the step S2, so as to obtain the pure 6-aminocapronitrile. The method for preparing the 6-aminocapronitrile by the gas phase method, which is provided by the invention, is relatively high in reaction conversion ratio which can be up to 96 percent or above, and is simple in preparation process.

Owner:CHINA TIANCHEN ENG +1

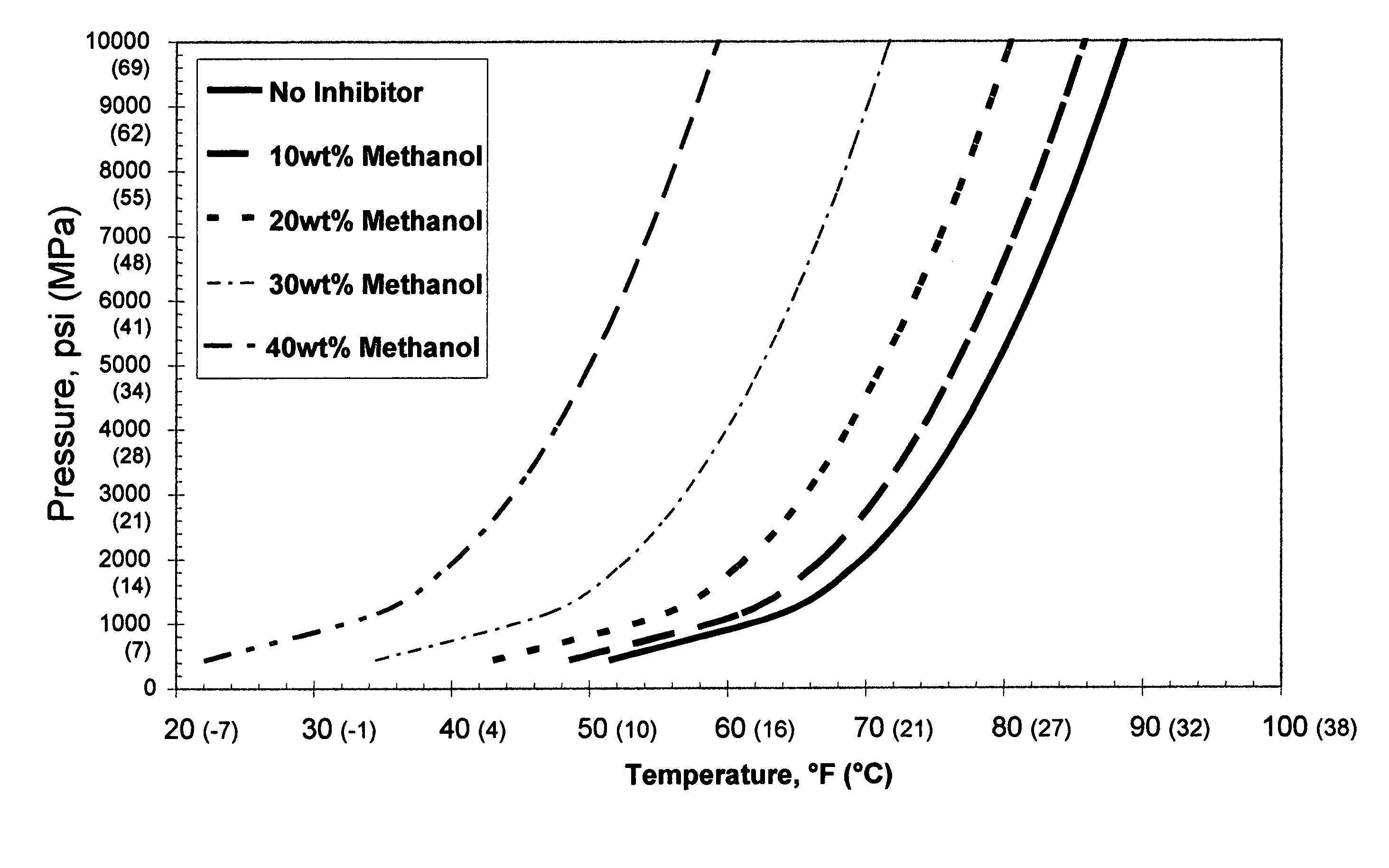

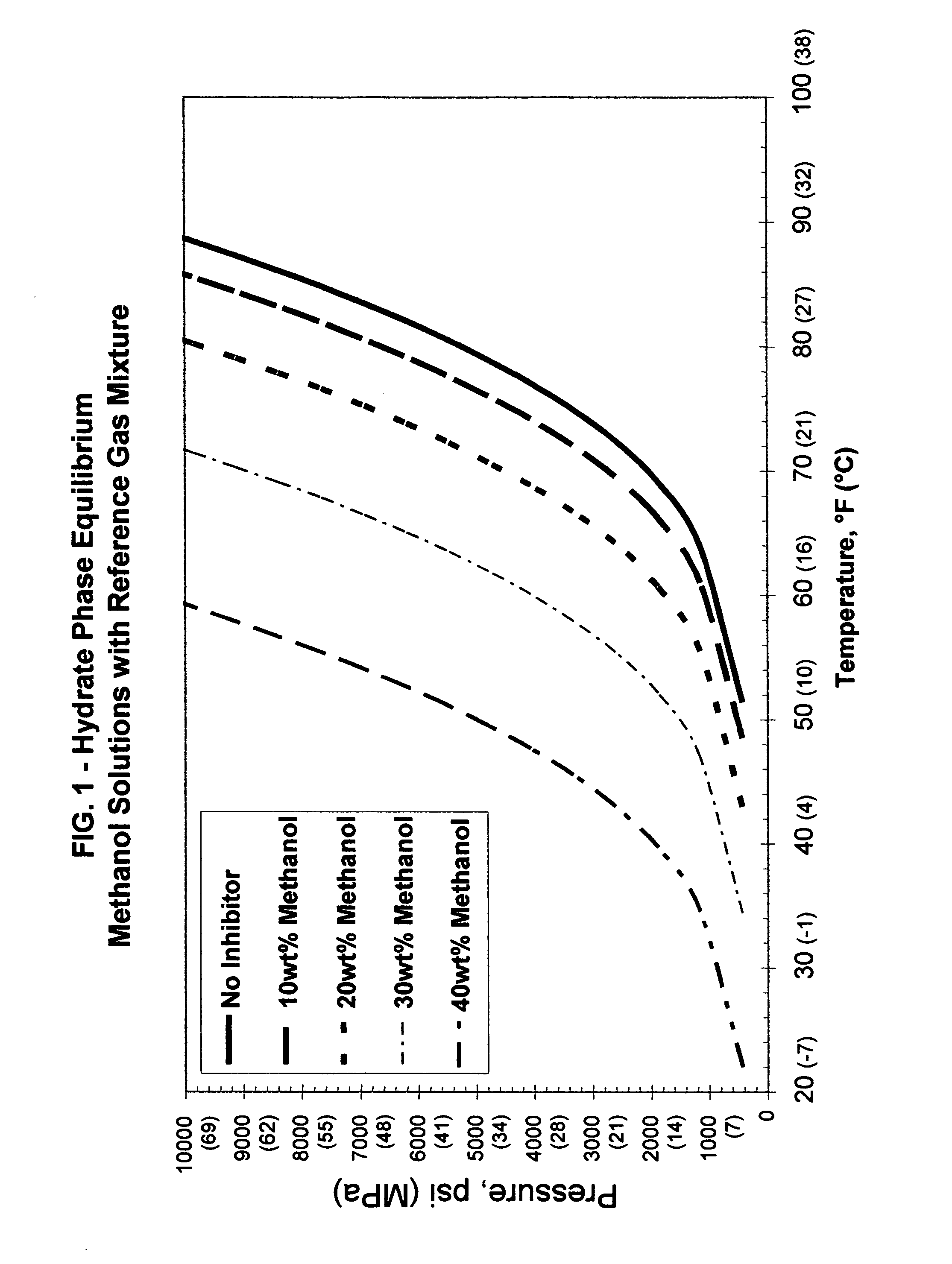

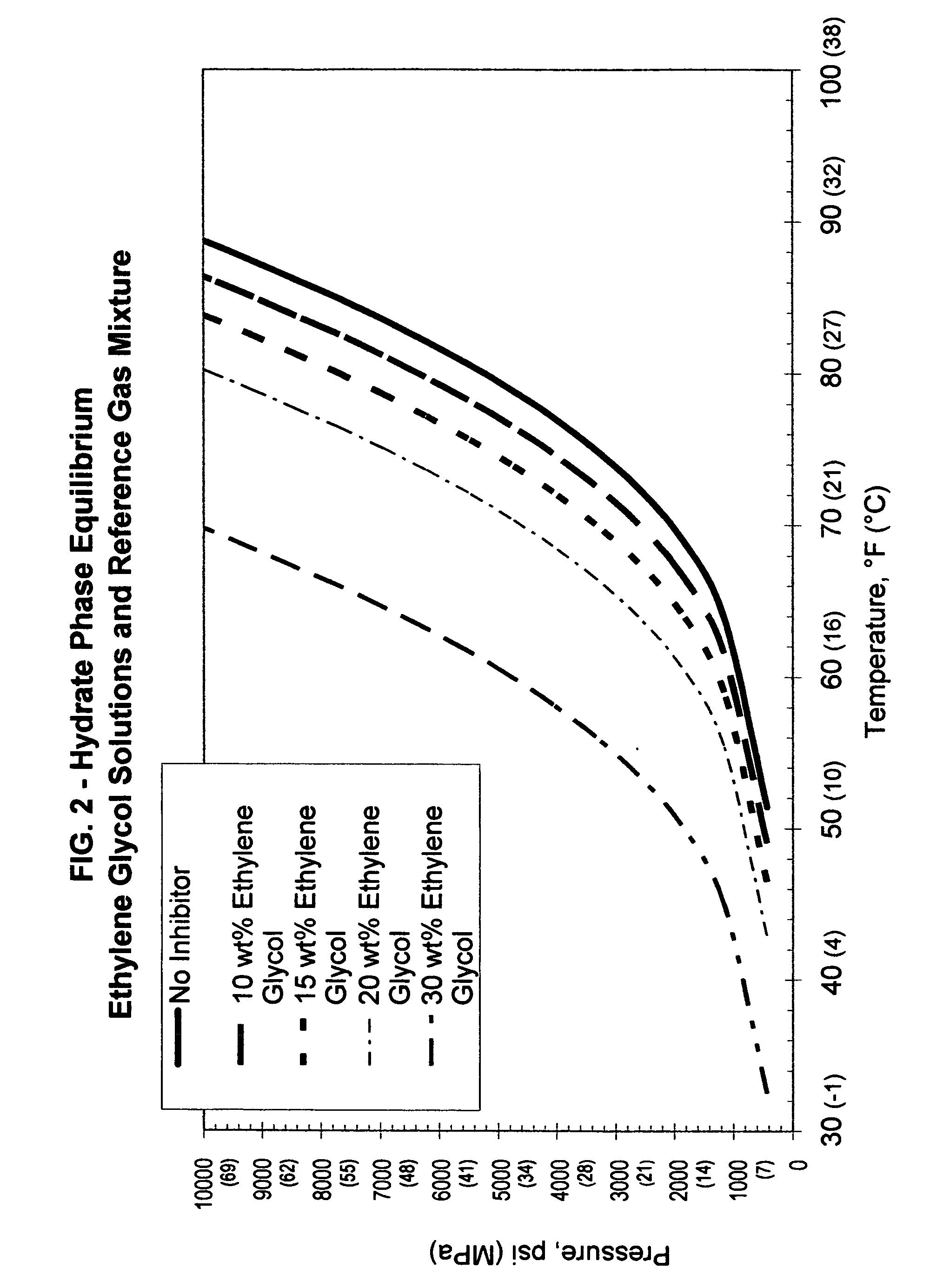

Additives for hydrate inhibition in fluids gelled with viscoelastic surfactants

An aqueous, viscoelastic fluid gelled with a viscoelastic surfactant (VES) is inhibited against hydrate formation with an effective amount of an additive that could be one or more halide salts of alkali metals and alkali earth metals, formate salts, alcohols, glycols, glycol amines, sugars, sugar alcohols, amidoamine oxides, polymers such as polyamines, polyvinylpyrrolidones and derivatives thereof, polyvinyl alcohols and derivatives thereof, polycaprolactams and derivatives thereof, hydroxyethylcellulose, and mixtures thereof. These fluids are inhibited against hydrate formation and may have increased viscosity as well. The additives may increase viscosity to the point where less VES is required to maintain a given viscosity. These inhibited, aqueous, viscoelastic fluids may be used as treatment fluids for subterranean hydrocarbon formations, such as in stimulation treatments, e.g. hydraulic fracturing fluids.

Owner:BAKER HUGHES INC

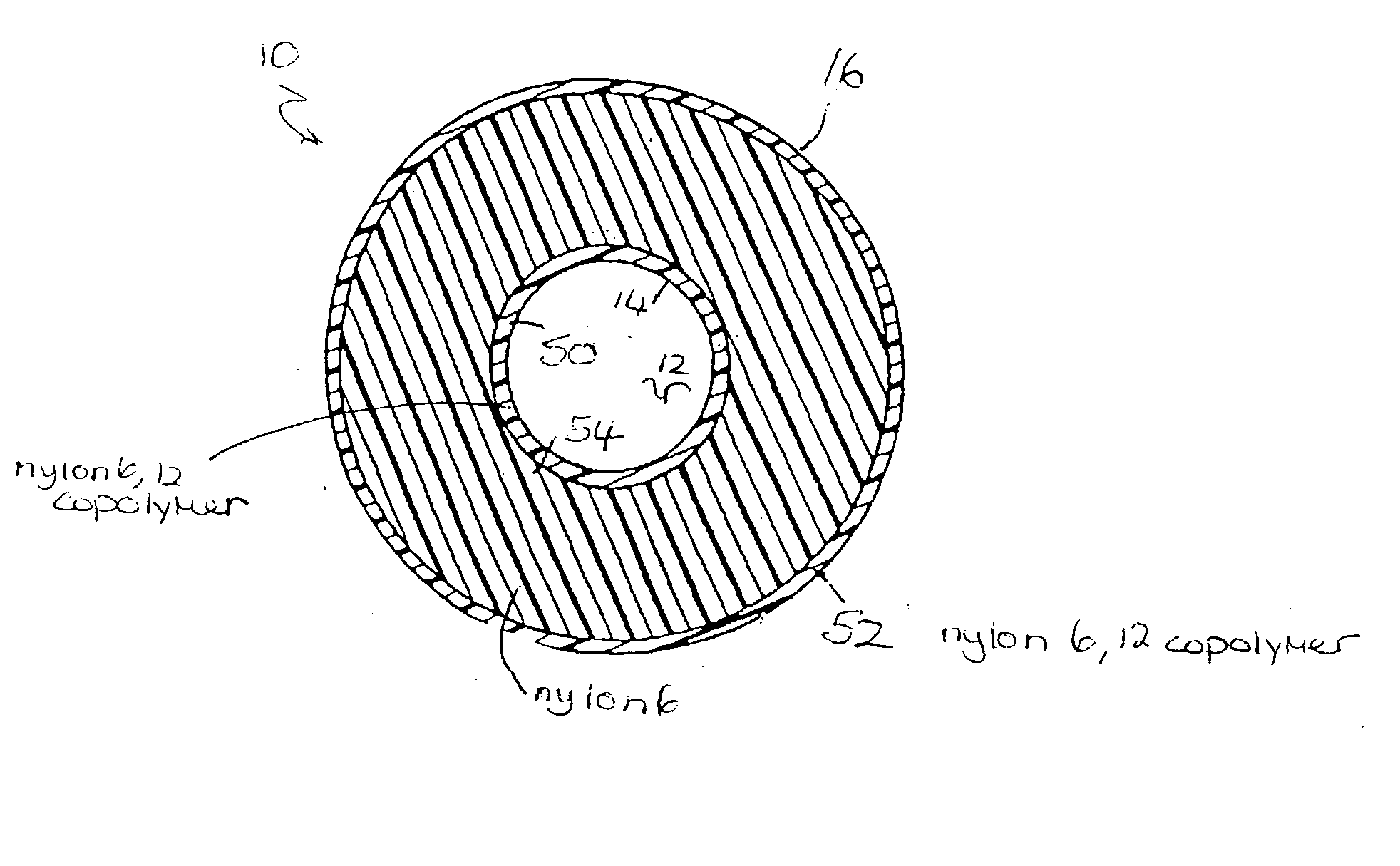

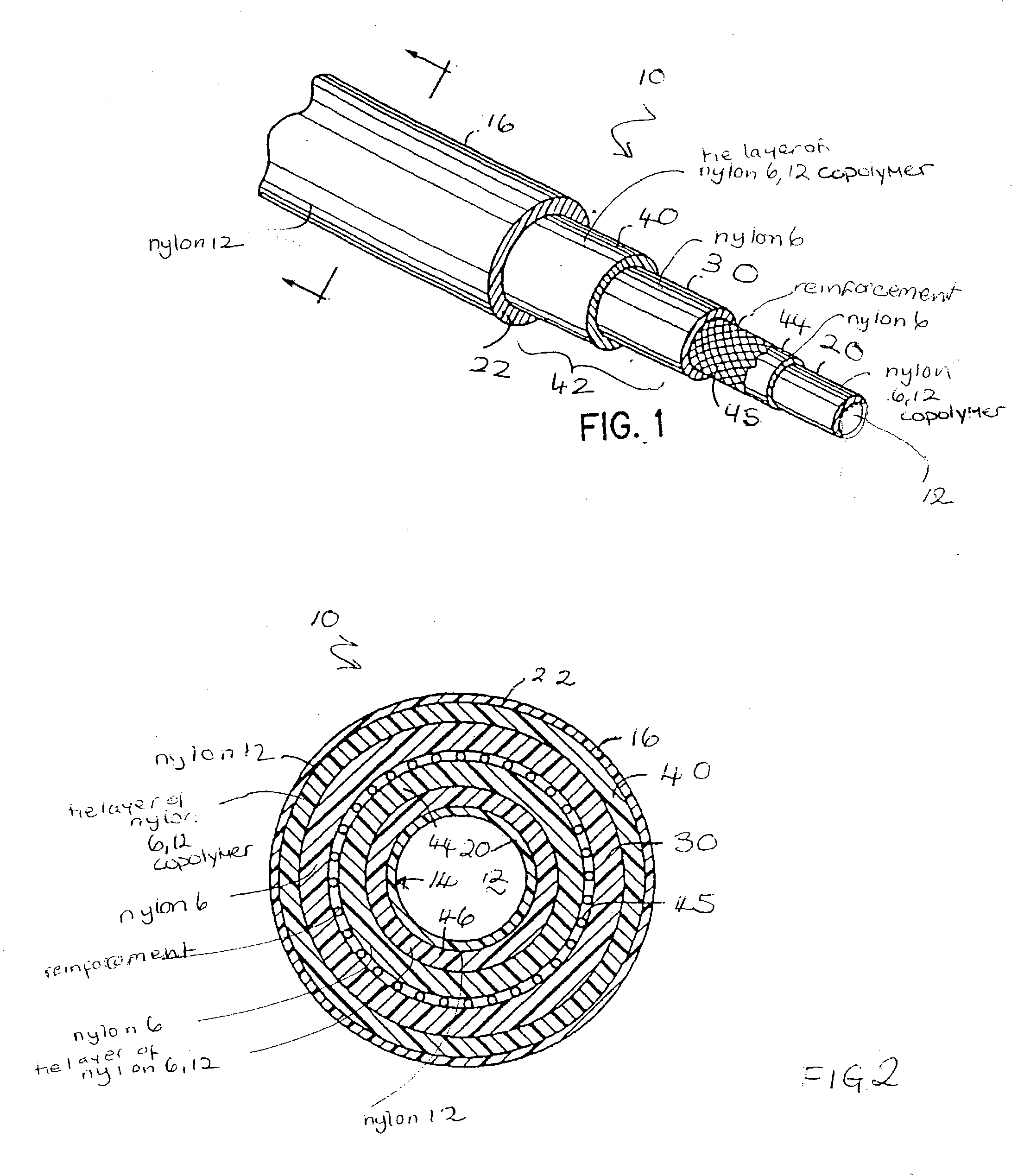

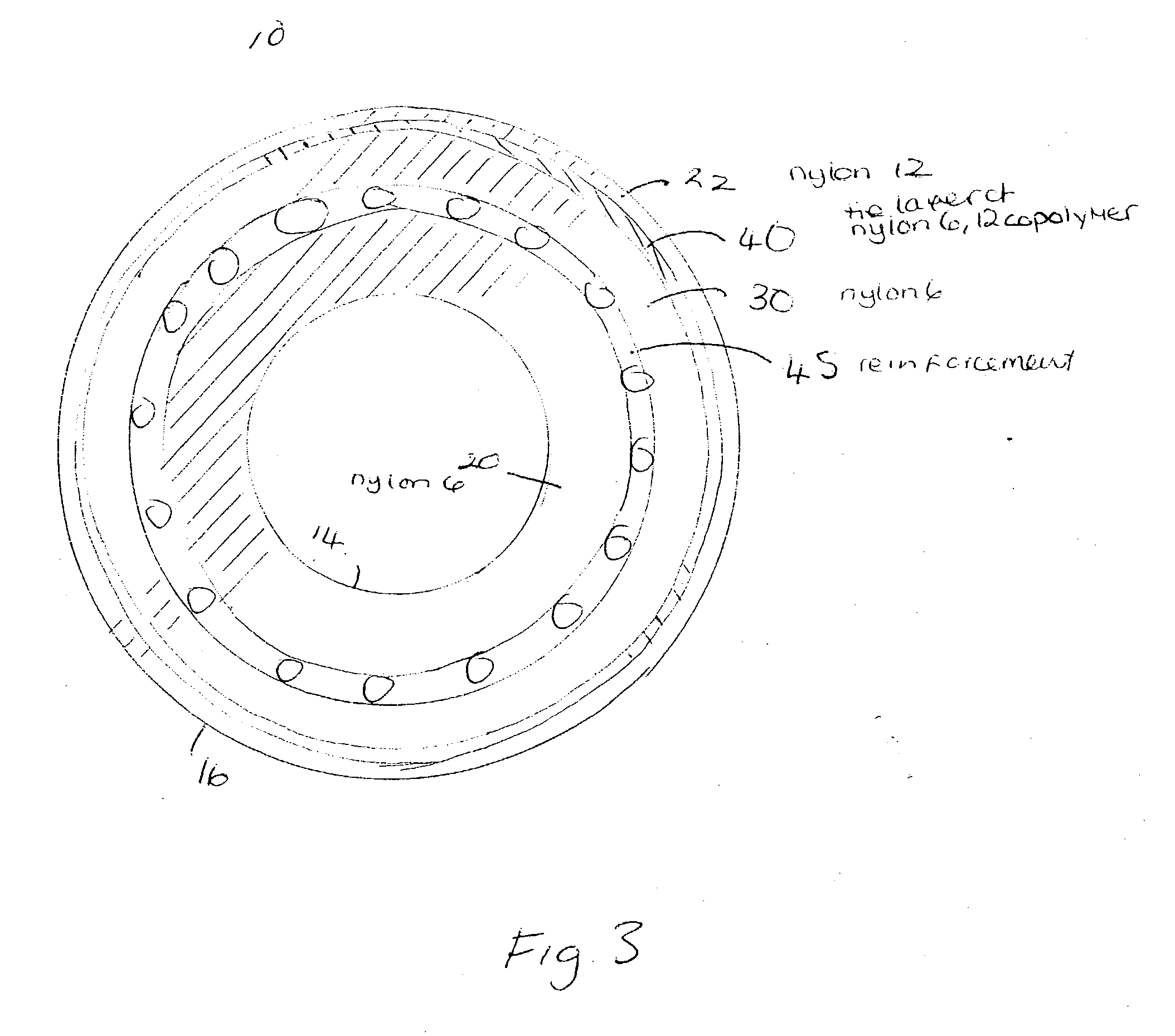

Hose comprising modified nylon 6,12 material

InactiveUS20040096615A1Improve mechanical propertiesSynthetic resin layered productsFlexible pipesPolyamideNylon 11

A copolymer of nylon 6 (caprolactam mer units) and nylon 12 (dodecanolactam mer units) and / or nylon 11 (undecanolactam mer units), which has been modified to provide improved physical properties, such as flex modulus, elastic modulus, and yield strength, serves as a layer of a hose suited to use in airbrake applications. The modified copolymer is resistant to degradation by zinc chloride and moisture and thus may be used as a peripheral layer of the hose in place of a conventional protective layer comprising a pure polyamide, such as nylon 11 or 12. Alternatively, the modified copolymer may be used as a tie layer for rendering a peripheral layer comprising nylon 12 or 11 compatible with a layer of nylon 6, allowing the less expensive nylon 6 material to comprise the bulk of the hose thickness. The layer includes a compatibilizer, such as a maleic anhydride grafted polyethylene, and may also include plasticizers and impact modifiers.

Owner:EATON CORP

Method for purifying and refining epsi-caprolactam

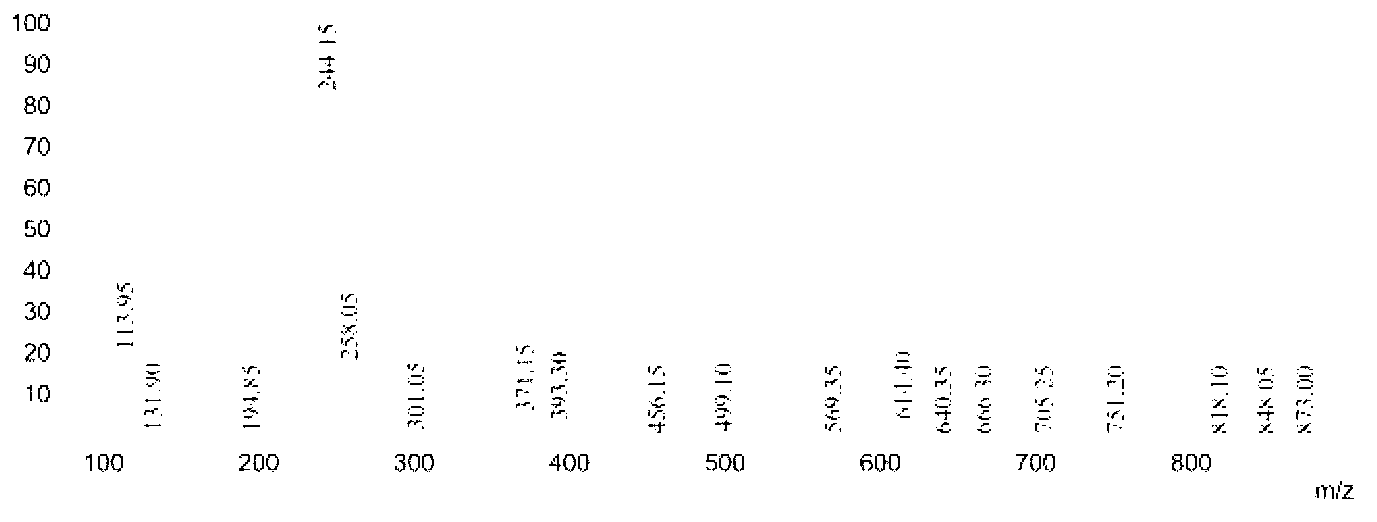

ActiveCN101070298AMeet the requirements of industrial productsLactams preparationLactams separation/purificationEtherLength wave

This invention relates to a refine means of epsilon - caprolactam by separation and purification. The feature of the invention is that it includes the step of crystallize epsilon - caprolactam from ethereal solution containing crude epsilon - caprolactam. The product purity can reach 99.98%upwards, absorption value of potassium permanganate is greater than 10000 or more, the extinction value of epsilon - caprolactam at 290nm wavelength is 0.05 or smaller. The invention wholly meets the require of industrial product.

Owner:CHINA PETROLEUM & CHEM CORP +1

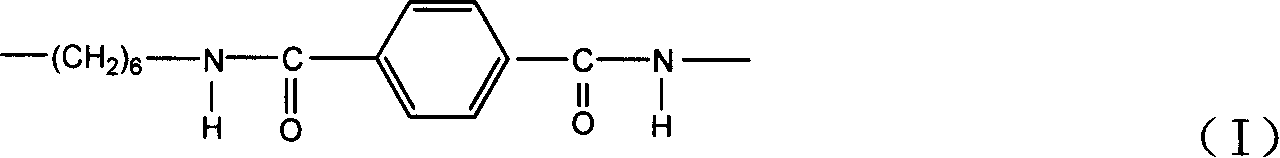

6-aliphatic hydrocarbon amido hexyl hydroximic acid collecting agent and preparation and application methods thereof

ActiveCN103301952AImprove flotation recoveryAchieve high flotation separationFlotationReaction temperatureCarboxylic acid

A structural formula of a 6-aliphatic hydrocarbon amido hexyl hydroximic acid collecting agent is represented by a formula (I), wherein R represents C2-C18 aliphatic hydrocarbon group. The preparation method comprises the steps as follows: caprolactam and hydroxylamine hydrochloride or hydroxylamine sulphate are taken as raw materials, methylbenzene is taken as a solvent, the reaction temperature ranges from 80 DEG C to 110 DEG C, the reaction lasts for 1-4 hours, and 6-amino hexyl hydroximic acid is generated; 6-amino hexyl hydroximic acid reacts with C2-C18 fat carboxylic acid at the reaction temperature ranging from 100 DEG C to 160 DEG C for 1-4 hours to generate 6-aliphatic hydrocarbon amido hexyl hydroximic acid, and the product yield can be higher than 91%; and 6-aliphatic hydrocarbon amido hexyl hydroximic acid used in flotation of scheelite, wolframite, tombarthite ore, tin ore, bauxite, titanic iron ore or fluorite ore is taken as the collecting agent, so that the flotation recovery rate can be increased by 3%-10%.

Owner:CENT SOUTH UNIV

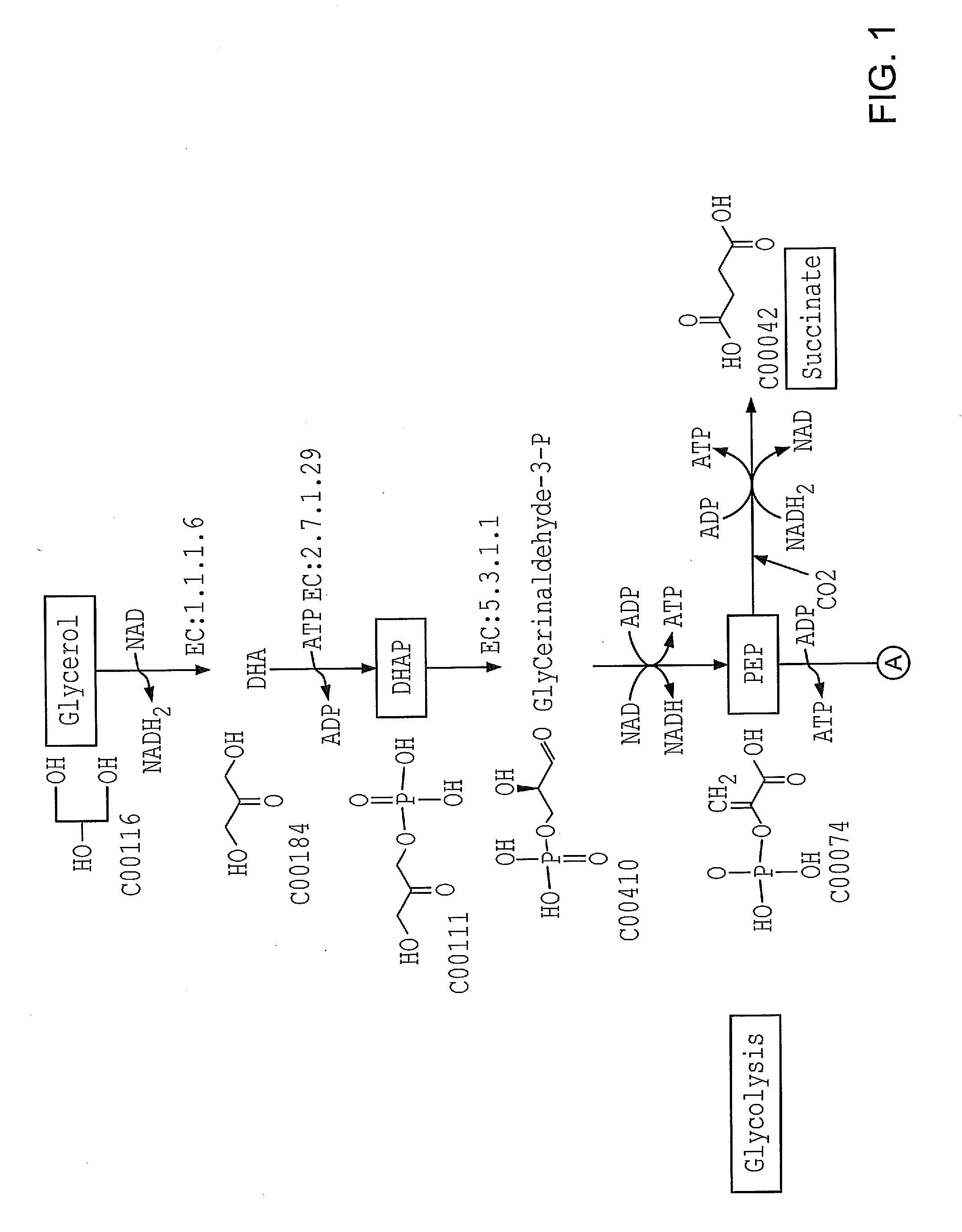

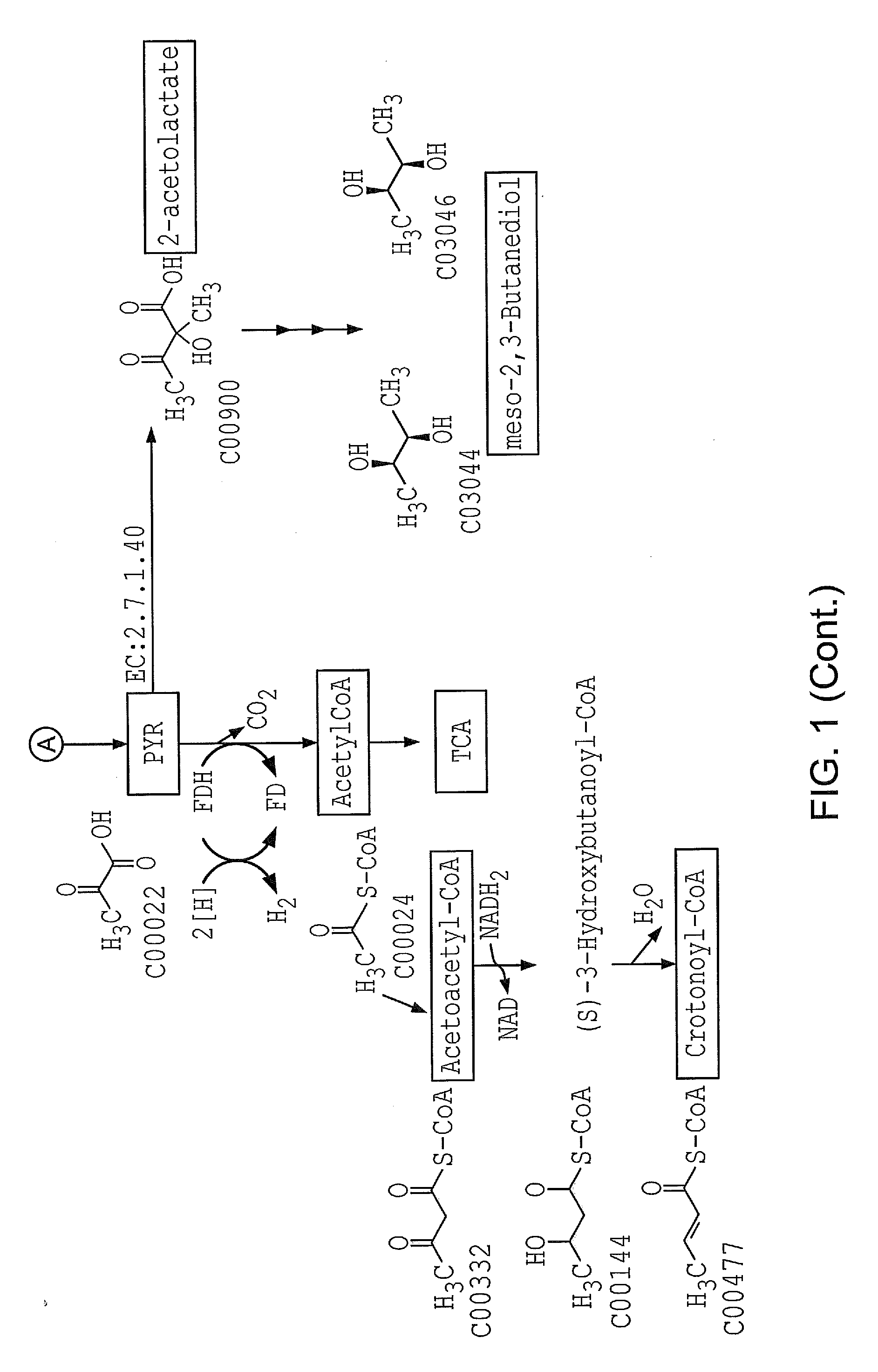

Methods of making nylon intermediates from glycerol

ActiveUS20130210090A1Reduce usageRate minimisedBacteriaHydrolases3-Hydroxypropionic acid2,3-Butanediol

Embodiments of the invention relate to the enzymatic conversion of bioderived feedstocks to commercially valuable chemicals. The enzymatic conversions of the embodiments of the invention offer the potential for lower cost routes to these value-added chemicals. Some of the chemicals that are useful include nylon intermediates such as caprolactam, adipic acid, 1,6-hexamethylene diamine; butanediols such as 1,4-butanediol, 1,3-butanediol, and 2,3-butanediol; butanols such as 1-butanol, and 2-butanol; succinic acid, butadiene, isoprene, and 3-hydroxypropanoic acid.

Owner:INV NYLON CHEM AMERICAS LLC

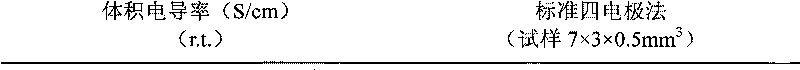

PTC thermistor and substrate applied therein and manufacturing method thereof

InactiveCN102176360AUniform cross-linked structurePromote absorptionPositive temperature coefficient thermistorsHigh resistanceCross-link

A PCT thermistor comprises a substrate and two tinsel-shaped electrodes which are combined with two surfaces of the substrate. The substrate is made of the following components in weight percentage: 28-55% of high-polymer material; 22-32% of conductive filling material; 13-46% of auxiliary filling material; and 1-5% of auxiliary agent in processing. The high-polymer material is obtained through mixing one or multiple materials selected from: polyethylene, polypropylene, maleic anhydride grafted polyethylene, ethane-vinyl acetate copolymer, ethane-acrylic acid copolymer, polyvinylidene fluoride, polycaprolactam, polyhexamethylene adipamide, polydecamethylene sebacamide and polyundecylamide. The auxiliary agent in processing is one component or a mixture of multiple components selected from: an anti-oxidant, a coupling agent, a cross-linking agent and a sensitized cross-linking agent. The sensitized cross-linking agent is one component or multiple components selected from the unsaturated compounds of multiple functional groups with higher decomposition temperature. The PTC thermistor of the invention has the following advantages: high strength, and high resistance for multiple times of large current impact.

Owner:深圳市长园维安电子有限公司

Method for synthesizing fine grain MCM-22 molecular sieve

InactiveCN1699170ALower synthesis costNot corrosiveCrystalline aluminosilicate zeolitesPolyethylene glycolSurface-active agents

Disclosed is a method for synthesizing fine grain MCM22 molecular sieve, wherein the templating agent employs the product yield of hexanolactam hydrogenation, and mainly comprises hexamethyleneimine, water, a small amount of byproduct and hexanolactam (reacted unconcompletely), the method comprises using silicon source, aluminium source, alkali source, templating agent and deionized water as reaction raw material, crystallizing for a finite period of time at 135-185 deg. C, untill completion of the reaction, obtaiting the needed molecular screen through hydrothermal synthesis, the invention is characterized in that organic additives can be charged into the reaction raw material, the organic additive can be sodium dodecylbenzene sulfonate, polyethylene glycol type surface active agent, or their mixture, the molecule ratio of the charged additive and the silicon dioxide in the reaction raw material is 0.01-2.5.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Compound low dosage natural gas hydrate inhibitor

The invention discloses a compound low dosage natural gas hydrate inhibitor. The hydrate inhibitor benchmarked against the mass of water in a deepwater drilling fluid completion fluid comprises, by mass, 0.1-2% of a hydrate kinetic inhibitor, 0.1-2% of a kinetic inhibitor synergist and 0-10% of a hydrate thermodynamic inhibitor. The hydrate kinetic inhibitor is at least one of polyvinyl pyrrolidone, polyvinyl caprolactam, and a copolymer generated through a reaction of vinyl pyrrolidone, vinyl caprolactam, alkenyl sulfonic acid and isopropylmethacrylamide. The kinetic inhibitor synergist is at least one of benzyltributylammonium chloride, tetraheptylammonium bromide, ethylene glycol phenyl ether, propylene glycol phenyl ether, polyoxyethylene and polyoxypropylene. The hydrate inhibitor can effectively inhibit generation of hydrates under a low dosage (0.2-10%), is suitable for deepwater and ultra-deep water drilling and completion, greatly reduces the cost and the logistical support burden, and has small harms to environment.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

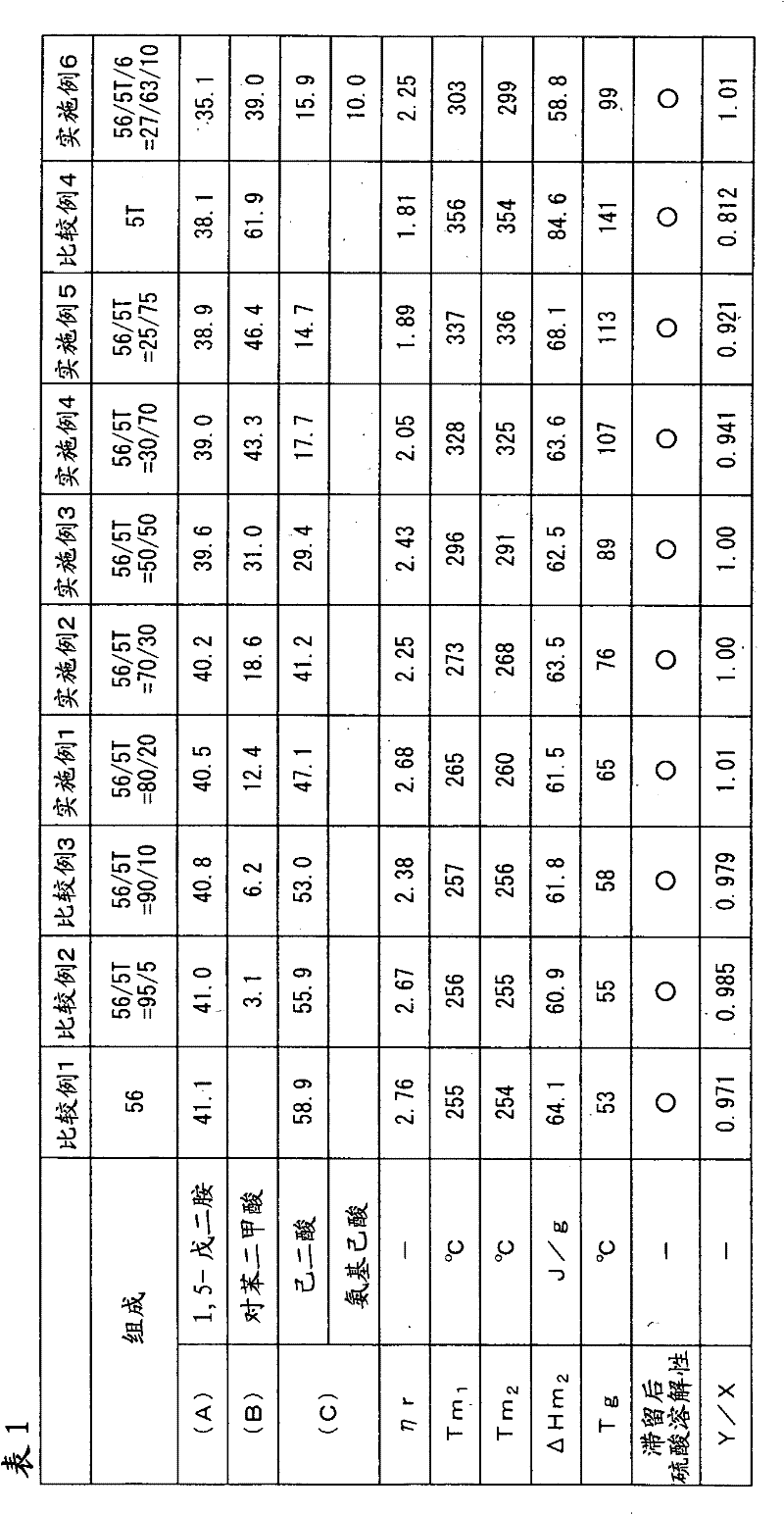

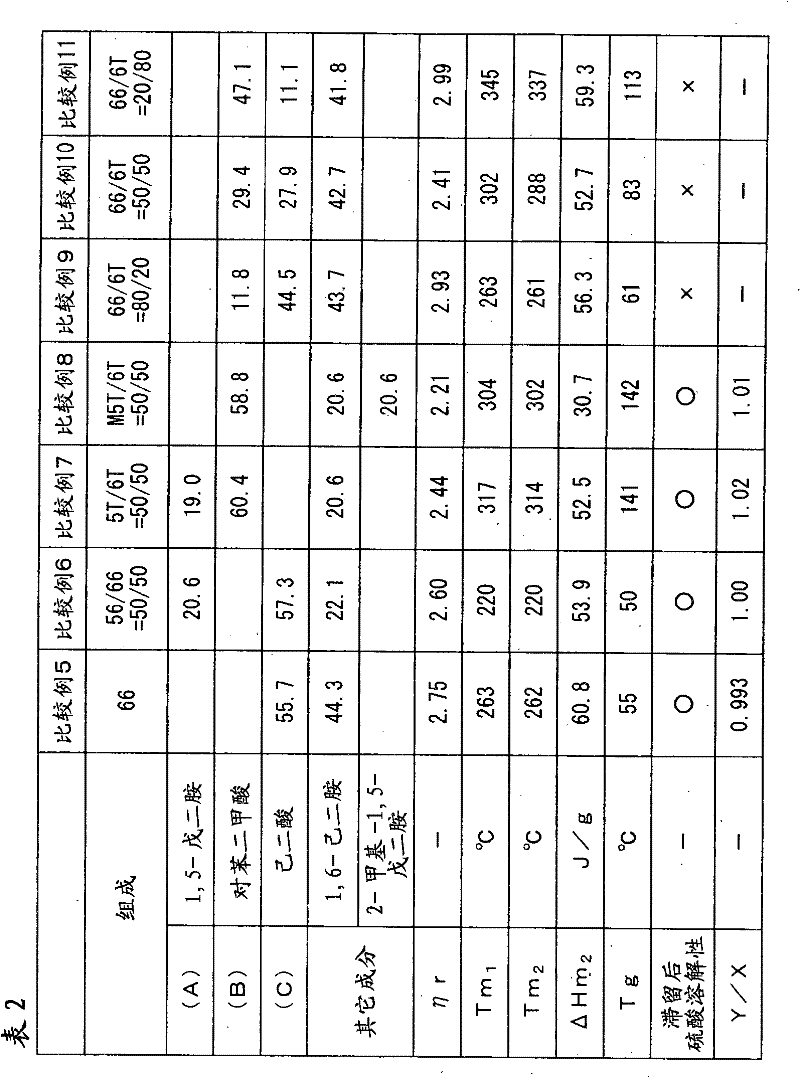

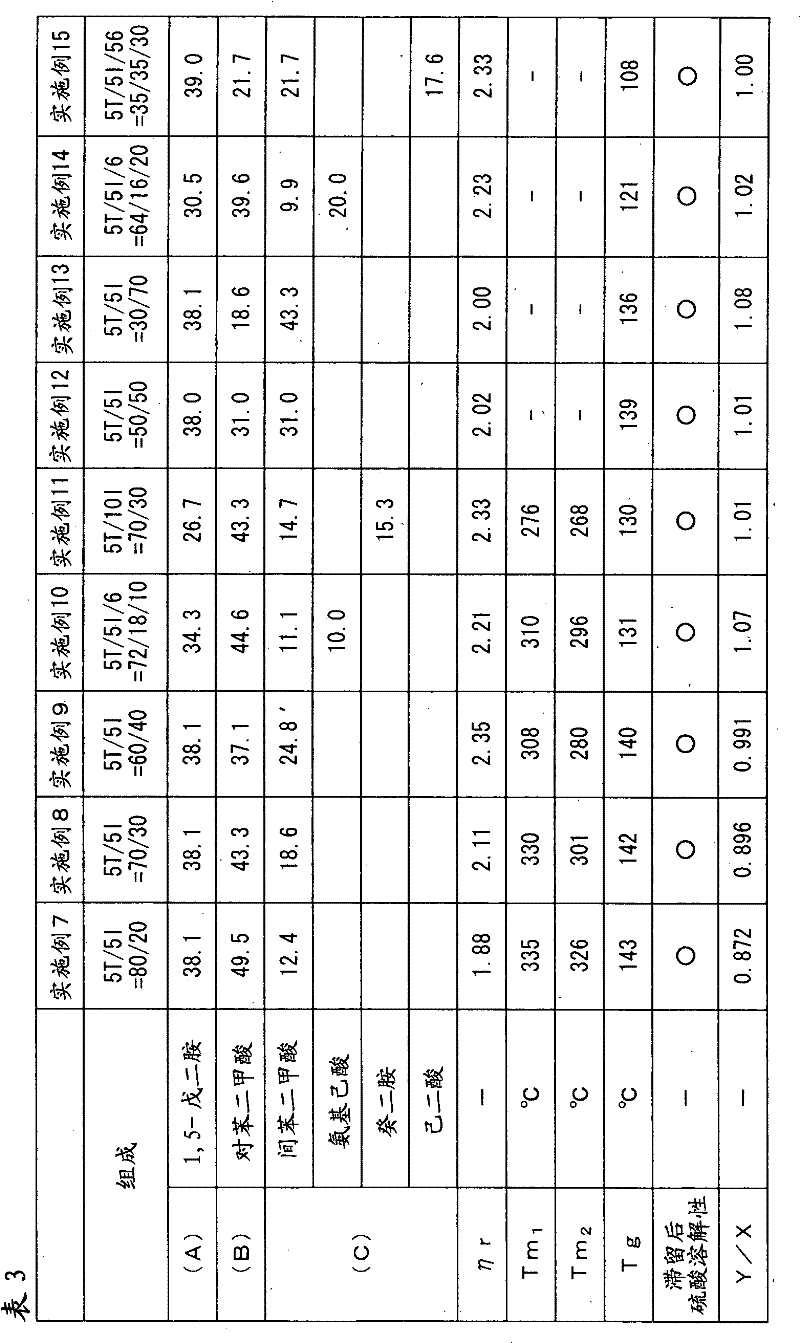

Polyamide resin, composition containing polyamide resin, and molded articles of polyamide resin and composition

InactiveCN102131845AImprove heat resistanceExcellent melt retention stabilityLaurolactamPolymer science

Disclosed is a polyamide resin which is produced by the polycondensation of (A) pentamethylenediamine, (B) terephthalic acid and / or a derivative thereof, and (C) at least one compound selected from adipic acid, azelaic acid, sebacic acid, undecanedioic acid, dodecanedioic acid, isophthalic acid, 1,9-diaminononane, 1,10-diaminodecane, 1,11-diaminoundecane, 1,12-diaminododecane, caprolactam, undecalactam, laurolactam, aminocaproic acid, 11-aminoundecanoic acid, 12-aminododecanoic acid, and derivatives of these compounds. In the polyamide resin, the ratio of a repeating unit derived from the component (C) is 10 to 50 wt% (inclusive) relative to the total weight of the polymer. A solution of the polyamide resin in 98% sulfuric acid, which contains the polyamide resin at a concentration of 0.01 g / ml, has a relative viscosity of 1.5 to 4.5 at 25 DEG C.

Owner:TORAY IND INC

Monomer casting nylon composite

The invention discloses a monomer casting nylon composite which is prepared through the catalytic polymerization of caprolactam doped with graphene, wherein the weight ratio of caprolactam to graphene is 100:(0.005-0.095). The invention has the following beneficial effect: the dosage of graphene in caprolactam is changed, thus the mechanical properties and friction performances of the polymerizedmonomer casting nylon can be increased, particularly the impact resistance and wear resistance can be greatly increased, the impact strength is 2-4 times that of the material prepared by the prior art and the volume erosion rate is 7.7%-26.8% of that of the material prepared by the prior art. Therefore, the composite can be used to prepare workpieces with wider application range.

Owner:HENAN UNIV OF SCI & TECH

Process for producing epsi-caprolactam

InactiveUS6265574B1High yieldSteadily producedLactams preparationMolecular sieve catalystsBeckmann rearrangementFluidized bed

A process for producing epsi-caprolactam is provided which comprises the steps of subjecting cyclohexanone oxime to a gaseous phase Beckmann rearrangement reaction in a fluidized bed system using a solid catalyst and re-generating the catalyst, wherein said process comprises a step of treating the catalyst with an oxygen-containing gas at an elevated temperature in a re-generation step so that the nitrogen content of the catalyst falls within a range of 10 ppm to 2,500 ppm on its way to the reaction step from the re-generating step. According to the present invention, epsi-caprolactam is produced with a high conversion or a high selectivity without interrupting the rearrangement reaction or the re-generation step.

Owner:SUMITOMO CHEM CO LTD

Fiber-reinforced modified-reaction injection-molding nylon sheet and preparation method thereof

ActiveCN101525433AGuaranteed continuityThe upper and lower surfaces are flatFlat articlesCarbon fibersPolymer science

The invention relates to a fiber-reinforced modified-reaction injection-molding nylon sheet and a preparation method thereof, belonging to the field of composite material preparation. An amide monomer is used as a basal raw material; a catalyst, an auxiliary catalyst, an auxiliary antioxidant, a stabilizing agent, a surface conditioning agent, and the like are added; and the materials are injected into a high-temperature mold cavity with preset fibers by an RIM and thermally pressed and molded to prepare the reinforced modified-reaction injection-molding nylon sheet. The prepared sheet comprises the following ingredients by mass percentage: 30 to 95 of amide monomer, 3 to 70 of fiber, 0.01 to 2 of catalyst, 0.01 to 10 of auxiliary catalyst, 0.1 to 2 of antioxidant, 0.1 to 2 of stabilizing agent and 0.1 to 1 of surface conditioning agent, wherein the amide monomer is caprolactam or dodecalactam, the fiber is one of glass fiber, carbon fiber or aramid fiber and is in the form of fiber cloth, short-cut fiber or compound fiber. Compared with common reaction injection nylon and monomer cast nylon sheets, the reaction injection-molding nylon sheet has stronger carrying capability, low manufacture cost and easy popularization and application.

Owner:株洲时代工程塑料科技有限责任公司

Stainless steel etching solution and etching method

ActiveCN102234806AImprove surface chemical etching processImprove chemical etching processEtchingSkin texture

The invention provides stainless steel etching solution. The etching solution comprises the following components: 200 to 350 g / L of ferric trichloride, 0.45 to 1.16 mol / L of hydrochloric acid, 20 to 60 g / L of nitric acid, and 40 to 100 g / L of caprolactam. The invention also provides a stainless steel etching method. The method comprises the following steps of: making a stainless steel base material in contact with etching solution, etching, and controlling the temperature of the etching solution to be between 15 and 40 DEG C, wherein the etching solution is the etching solution of the invention. The etching solution can enhance lateral erosion, so that the edge is smooth, the etched edge slope is smooth, and natural transition of the etched surface and the surface of the original stainless steel base material is realized; and the etching solution is effectively applied to etching of natural textures such as skin textures, wood textures, sand surface textures, silk textures, relief andthe like, so that the simulated natural textures have vivid effect.

Owner:BYD CO LTD

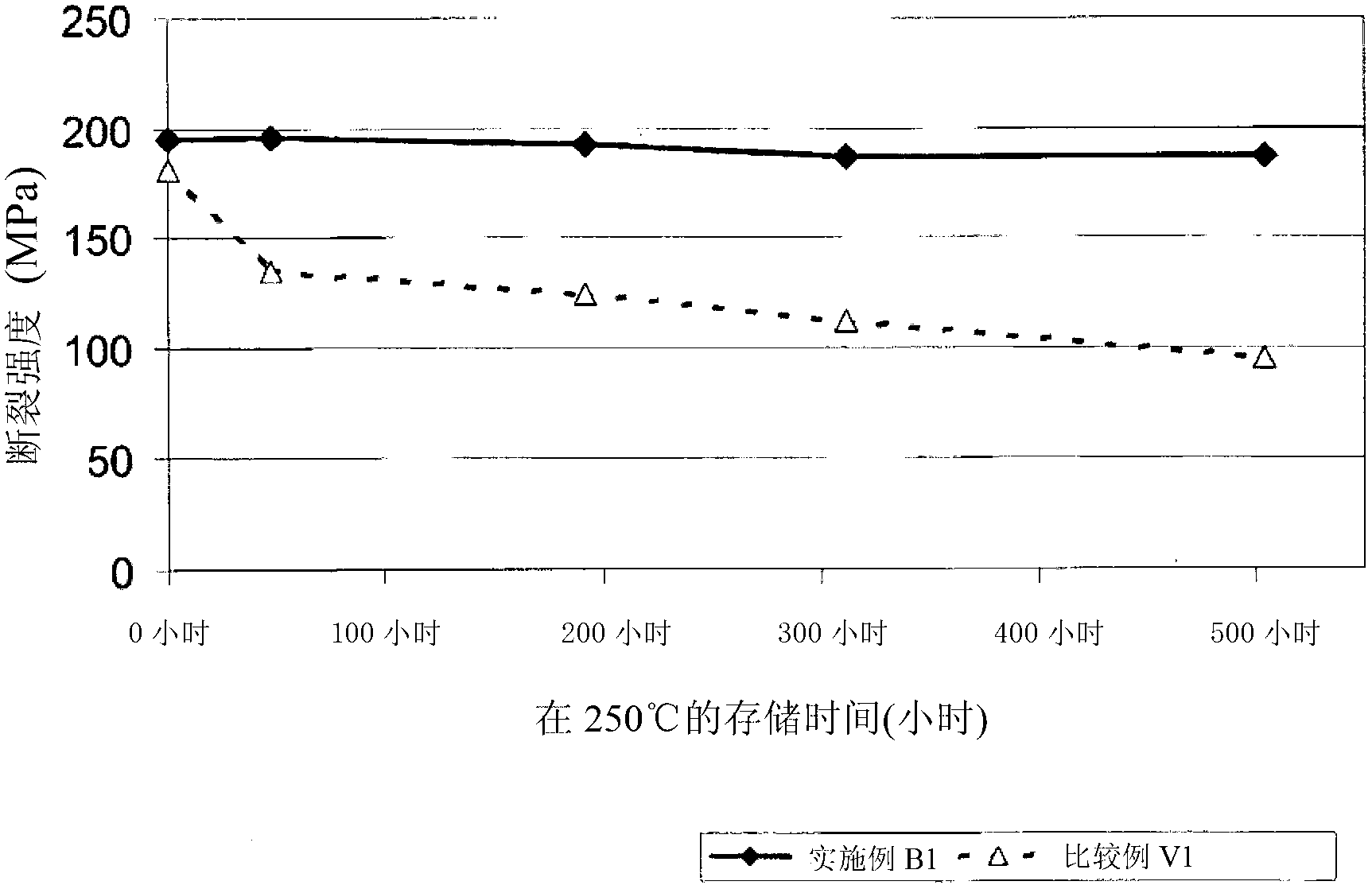

Semiaromatic moulding masses and their applications

The prevent invention provides a polyamide molding plastic and a moulded parts prepared by the polyamide molding plastic. The molding plastic is composed of (A) a polyamide mixture, (B) fillers and reinforcing agents, (C) thermal stabilizers and (D) additives, wherein the sum total of components (A) to (D) is 100 wt %. The polyamide molding plastic is free of transition metal salts and / or metallic oxides of groups VB, VIB, VIIB or VIIIB of the periodic table. The polyamide mixture consists of (A1) a semiaromatic, semicrystalline polyamide having a melting point of 275 DEG C to 330 DEG C, and (A2) a caprolactam-containing polyamide that is different from (A1) and that has a caprolactam content of at least 50 wt %, where the total caprolactam content is 22-30 wt %, with respect to the polyamide mixture.

Owner:EMS PATENT AG

Radiation-curable ink for ink jet recording, record made using the same, and ink jet recording method using the same

InactiveUS20120189822A1Good adhesivenessIncrease resistanceLayered productsDecorative surface effectsSemiconductorHeat treated

A radiation-curable ink for ink jet recording contains N-vinylcaprolactam. The N-vinylcaprolactam content is in a range of 5% by mass to 20% by mass, inclusive, relative to the total mass of the ink. The ink is for the purpose of making a marking on a recording medium, and the recording medium is a package substrate or a semiconductor substrate. The ink is applied to the package substrate or the semiconductor substrate, exposed to radiation, and then subjected to a heat treatment at a temperature in a range of 150° C. to 200° C., inclusive.

Owner:SEIKO EPSON CORP

Method for preparing nylon 6/graphite oxide nanocomposite

The invention relates to a method for preparing a nylon 6 / graphite oxide nanocomposite. In the method, caprolactam is adopted for in situ hydrolysis and ring-opening polymerization to prepare the nylon 6 / graphite oxide nanocomposite, so that caprolactam monomers are easy to perform in-situ intercalative polymerization to dissociate a graphite oxide lamella, and the dispersing uniformity of the graphite oxide lamella in a polymer substrate is improved; and the composite prepared has better conductivity and high-efficiency flame retardancy. The nylon 6 substrate is converted from an insulator to a semiconductor and the flame retardant rating can reach V-0 rating of a UL94 standard, and the integral good mechanical property of the material per se is maintained simultaneously. The method has the advantage of simple and effective process; the conductivity and flame retardancy of the obtained composite are obviously improved; the material has good secondary-working character; an additive graphite oxide does not pollute the environment; and the nylon 6 / graphite oxide nanocomposite has wide application range.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Sea-island ultrafine fiber, polyurethane leather and base fabric thereof and preparation method

ActiveCN101787586AFeel goodUniform feelFilament/thread formingTextile/flexible product manufactureLow-density polyethyleneMicrofiber

The invention discloses a sea-island ultrafine fiber, polyurethane leather and base fabric thereof and preparation method. The sea-island ultrafine fiber is composed of sea component and island component; wherein the sea component is low density polyethylene, the island component is polycaprolactam, and the mass ratio of the sea component and the island component is 70:30 to 75:25. The preparation method includes that the sea-island ultrafine fiber is composed of the components by the mass ratio and is prepared by conventional technology. The polyurethane leather and base fabric thereof related by the invention are all prepared by the sea-island ultrafine fiber of the invention, and conventional preparation technology is adopted. The sea-island ultrafine fiber of the invention can recycle related sea phase material and reduce production cost when being used for preparing polyurethane leather and base fabric thereof.

Owner:HUAFON MICROFIBER SHANGHAI

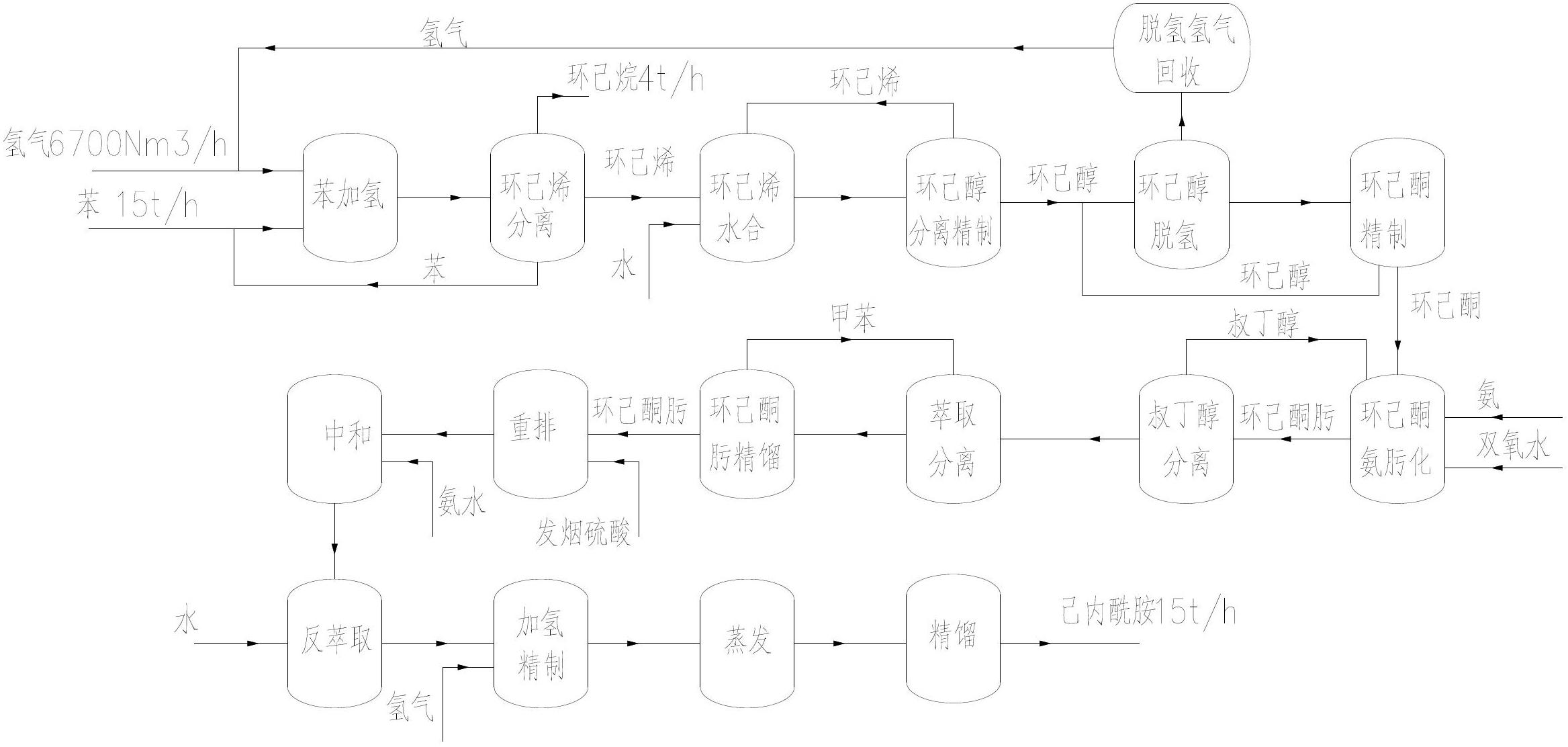

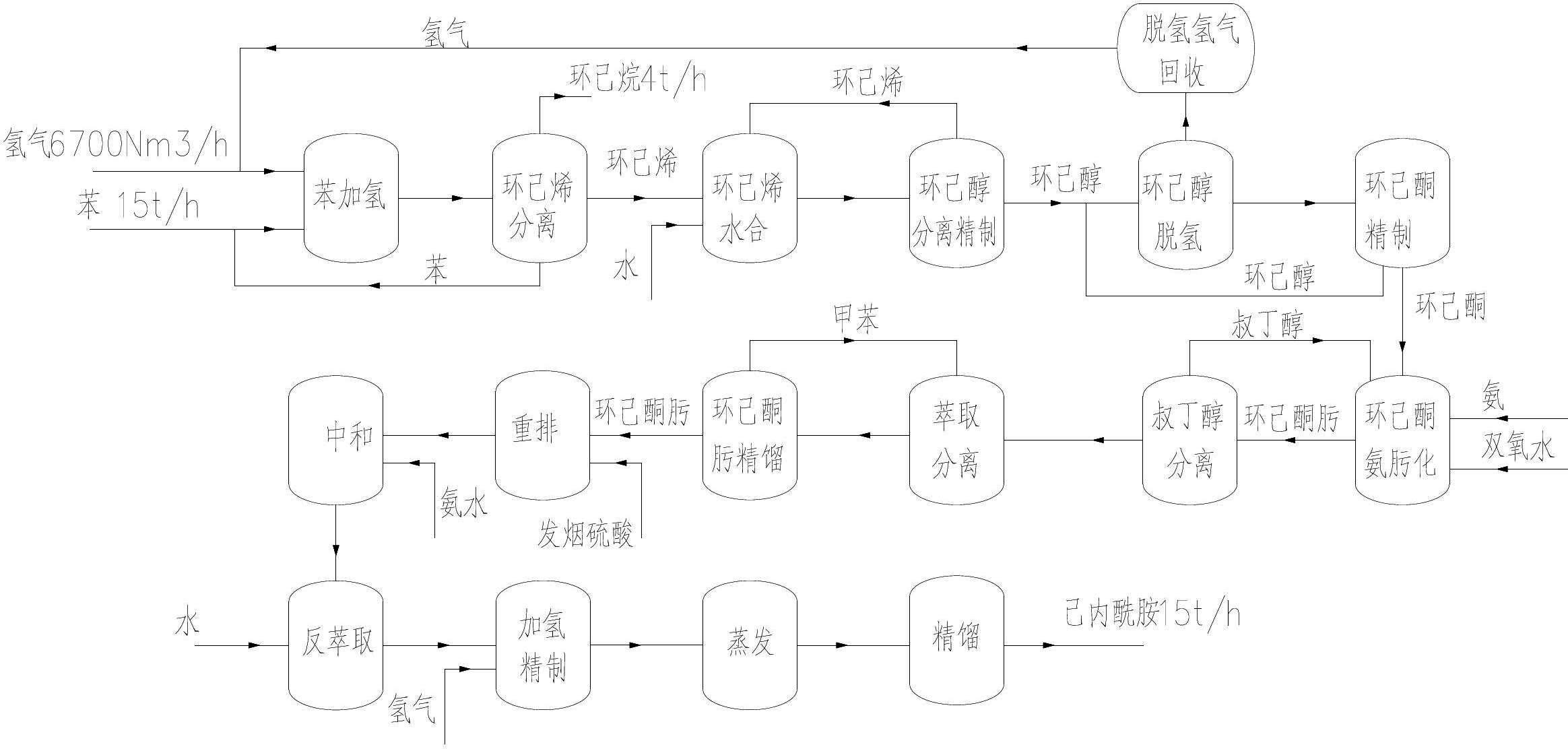

Method for producing caprolactam by taking high-purity benzene as raw material

ActiveCN102675176AAvoid it happening againQuality improvementLactams preparationHydration reactionCyclohexene

The invention provides a method for producing caprolactam by taking high-purity benzene as a raw material, and the method comprises the following steps of: A. preparing cyclohexene from the raw material benzene through hydrogenation; B. separating and purifying cyclohexene; C. carrying out hydration on the cyclohexene for preparing cyclohexanol; D. separating and purifying cyclohexanol; E. carrying out dehydrogenation on cyclohexanol for preparaing cyclohexanone; F. refining cyclohexanone; G. carrying out oximation on cyclohexanone so as to prepare cyclohexanone-oxime; H. refining cyclohexanone-oxime; I. carrying out rearrangement on refined cyclohexanone-oxime so as to prepare caprolactam; and J. refining caprolactam, wherein the high-purity benzene is adopted as a raw material, so that the purity of benzene is more than 99.95%, the sulphur content is less than 5ppm, and the methylbenzene is not more than 100ppm. The method has the beneficial effects that the high-purity benzene is adopted as a raw material, so that the impurity is less, and the product quality is high; the raw material is high in comprehensive utilization rate and low in hydrogen consumption; and the mass of the raw material and intermediate products generated in all the steps of reaction can be strictly controlled, so that the direct commercial value of the intermediate products is fully exerted, and the optimal quality of the product caprolactam can be reached.

Owner:CHINA TIANCHEN ENG +3

Method for preparing high temperature nylon

The present invention provides a preparation method of high-temperature nylon, including the following steps: (a) dicarboxylic acid and diamine are used to prepare 6T salt or 6I salt under the temperature of 80 to 110 DEG C and the carbon atomicity n of the obtained paraphthaloyl acidhexamethylene diamine salt or m-phthalic acryl acidhexamethylene diamine salt is 4 to 16; (b) 6T salt or 6I salt obtained in step (a) and 66 salt or hexanolactam are polymerized to obtain primary condensation compound and the characteristic viscosity of the primary condensation compound in dense sulfuric acid is 0.09 to 0.25dl / g under the temperature of 30 DEG C; (c) the primary condensation compound obtained in step (b) is under solid phase condensation and polymerization to obtain the high-temperature nylon under the temperature of not more than 250 DEG C. The method provided by the present invention can increase the polyamide size stability, mechanic performance and heat resistance, reduce the molecular weight distribution of the high-temperature nylon, and prevent the occurrence of amine exchange, thermal degradation, gelation and other side reactions.

Owner:北京瑞宝知春时代印刷技术开发有限公司

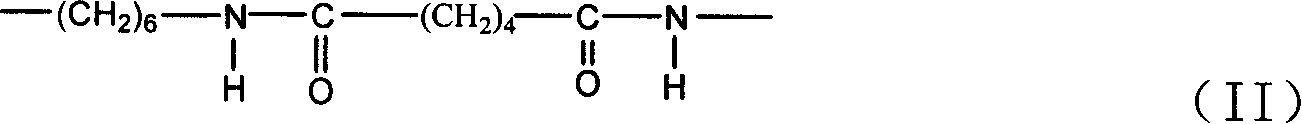

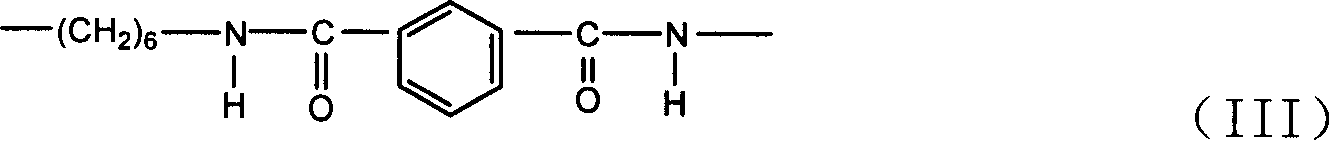

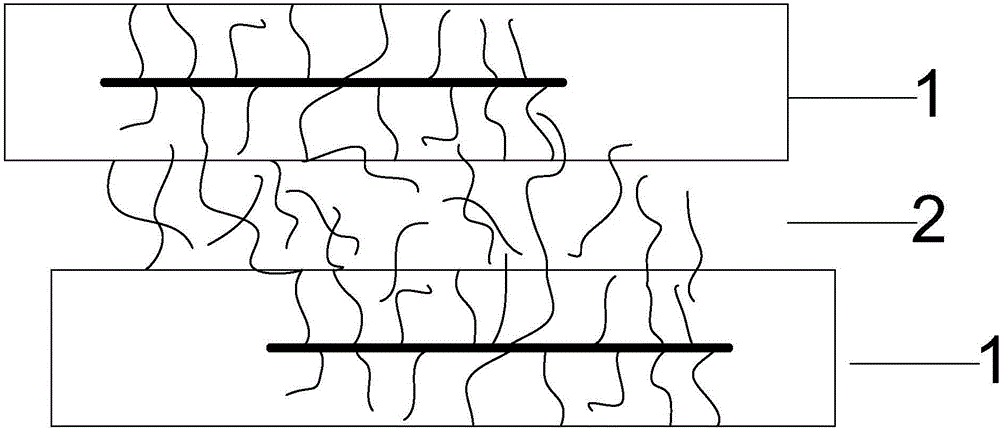

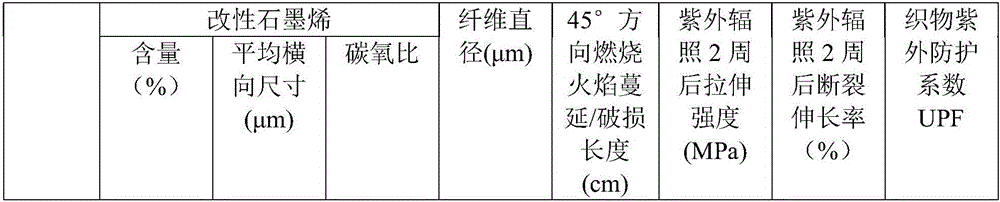

Graphene/nylon 6 fiber with flame-retarding and ultraviolet-proof properties and preparation method of graphene/nylon 6 fiber

ActiveCN106835333AAvoid cloggingImprove bindingFlame-proof filament manufactureMonocomponent polyamides artificial filamentGraphene nanocompositesNylon 6

The invention discloses a graphene / nylon 6 fiber with flame-retarding and ultraviolet-proof properties and a preparation method of the graphene / nylon 6 fiber and belongs to the technical field of functional high molecular materials. The graphene / nylon 6 fiber with the flame-retarding and ultraviolet-proof properties is prepared through high-speed melting spinning of a graphene / nylon 6 nano composite material; the graphene / nylon 6 nano composite material is prepared by compounding modified graphene, caprolactam and various auxiliary agents. The graphene / nylon 6 nano composite material obtained by the invention can continuously pass through a melting spinning hole at a high speed and continuous high-speed spinning is realized; the diameter of the fiber is 5mum to 50mum; compared with a pure nylon 6 fiber, the prepared graphene modified nylon 6 fiber has excellent flame-retarding, melt-dripping-resisting and ultraviolet-proof performances and the like.

Owner:HANGZHOU GAOXI TECH CO LTD

Fiberglass reinforced fire retardant engineering plastics and preparation method

The invention discloses glass fiber reinforced flame retardant engineering plastic and a preparation method thereof. Besides glass fiber, 30-70 parts of polycaprolactam, 8-30 parts of acrylonitrile-butadiene-styrol copolymer, 3-6 parts of compatilizer, 12-16 parts of flame retardant, 0.3-0.5 parts of antioxidant and 0.3-0.8 parts of lubricant are put in a high-mixing machine to blend for 2-5 minutes, then the blending material is put in a double screw extruder; meanwhile, 18-35 parts of glass fiber are put in the rear half section of the double screw extruder to mix together to be granulated and molded; wherein, the processing temperature is 180-245 DEG C and the screw speed is 240-560 revolutions per minute. The prepared glass fiber reinforced flame retardant engineering plastic is characterized by high size stability, large mechanical strength, excellent heat resistance, etc. The combustibility can reach UL94 V-0(1.6mm) level, thus expanding the application in electronics.

Owner:MITAC PRECISION TECH CO LTD SHUNDE DISTRICT FOSHAN CITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com