Patents

Literature

1326 results about "Dodecylbenzene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dodecylbenzene is an organic compound with the formula C₁₂H₂₅C₆H₅.Dodecylbenzene is a colorless liquid with a weak oily odor. Floats on water. This colourless waxy solid consists of a dodecyl group (C₁₂H₂₅) attached to a phenyl group (C₆H₅). Dodecylbenzene is a precursor to sodium dodecylbenzenesulfonate, a surfactant that is a key ingredient of household laundry detergents, such as detergent powder.

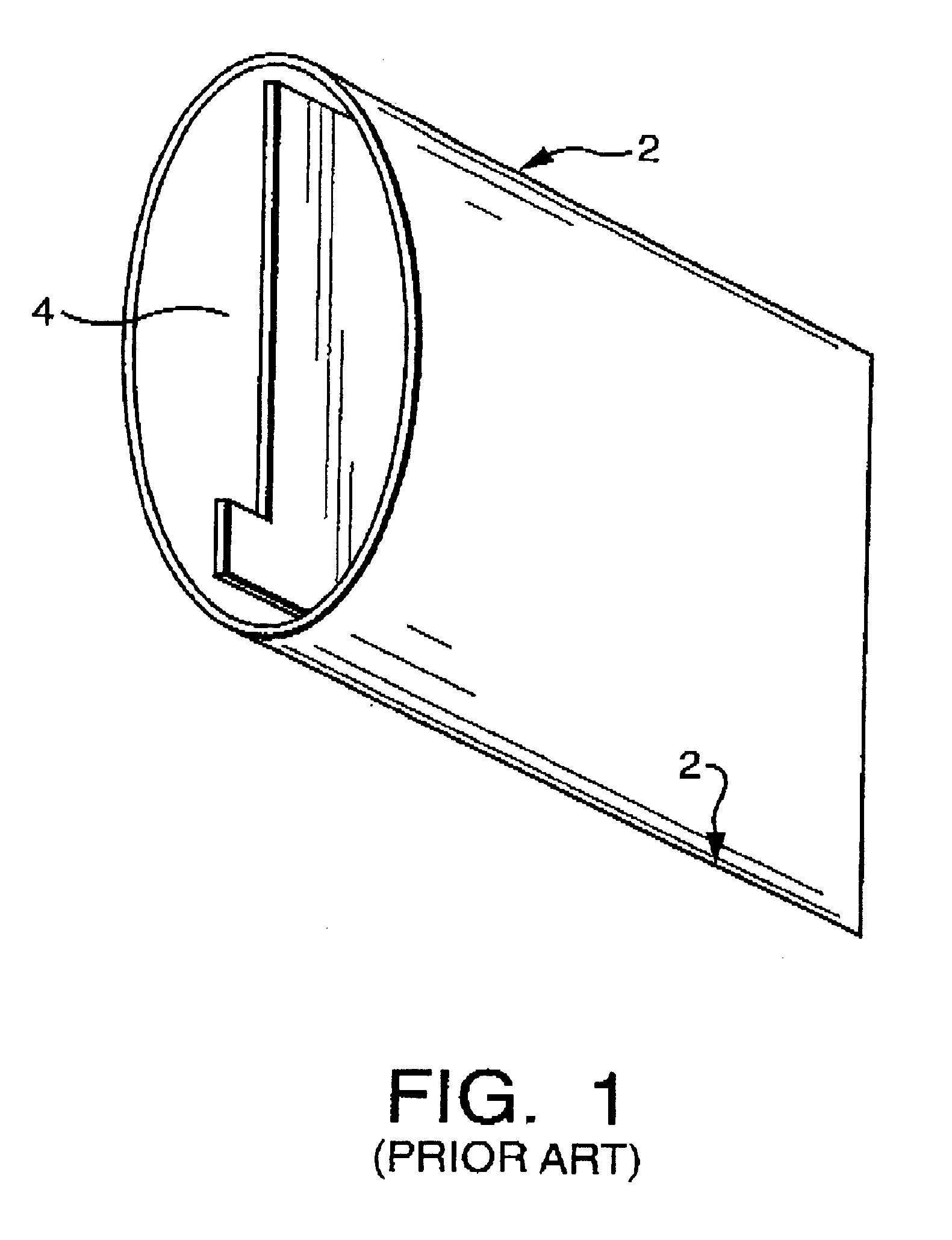

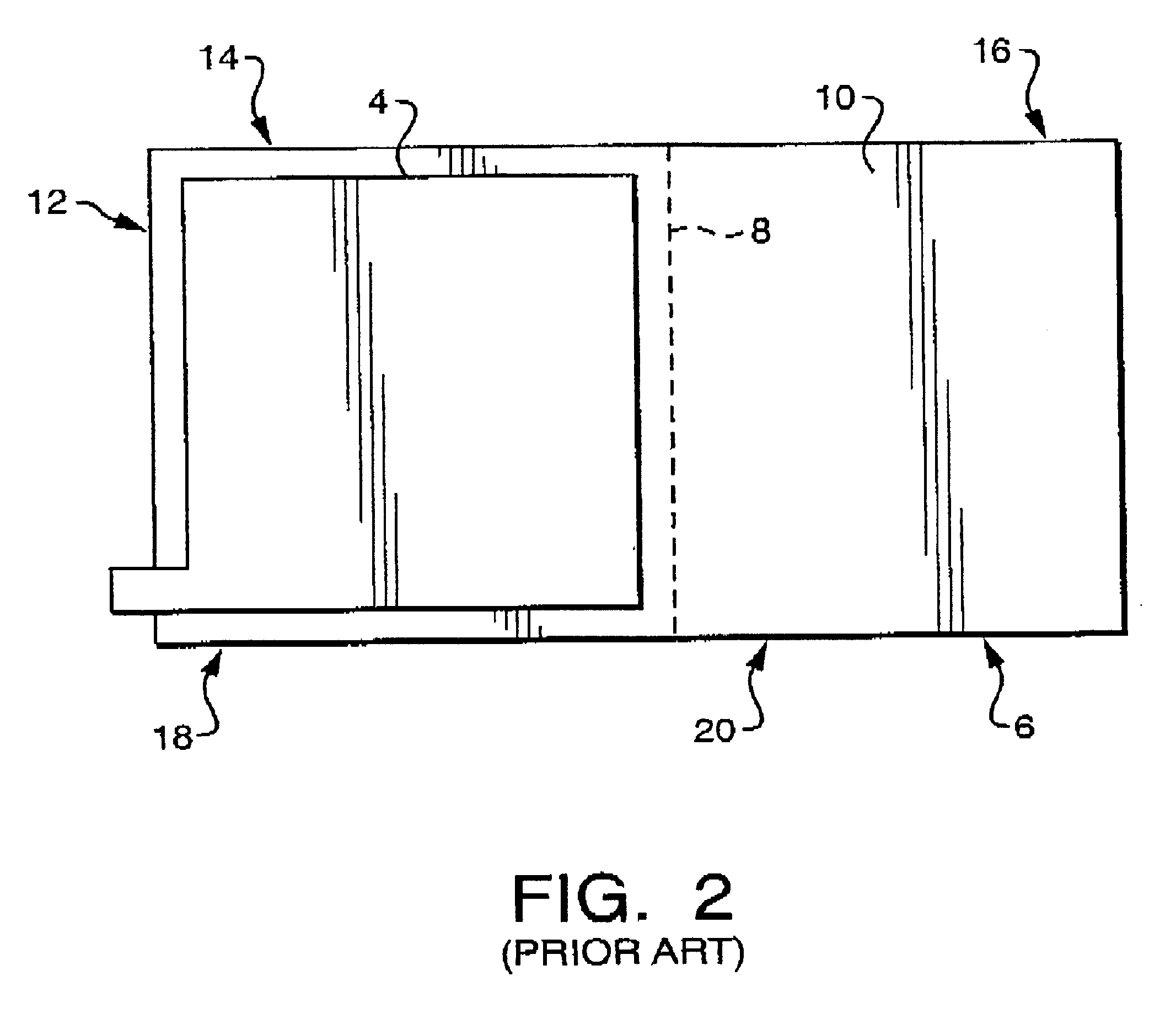

Microporous membrane battery separator for silver zinc batteries

InactiveUS6372379B1Improve cycle lifeExtended calendar lifeSilver accumulatorsCell component detailsPolyolefinFuel oil

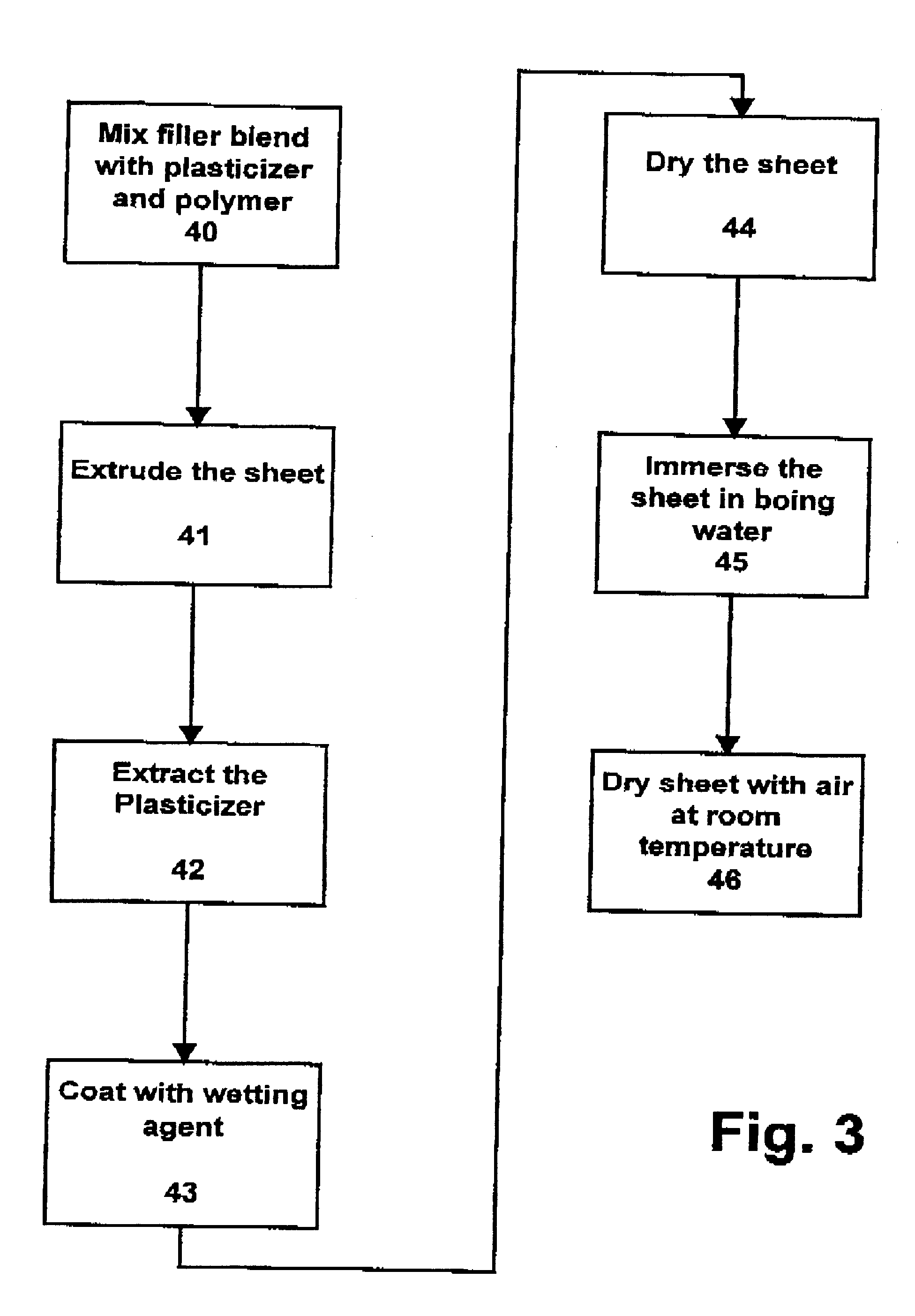

A separator membrane for use in silver-zinc batteries is produced by extruding a blend of two fillers with the same chemical formula but different particle size. A polyolefine polymer and a plasticizer are blended and extruded to form a thin sheet of 1 to 10 mil thickness. The plasticizer is then extracted to leave submicron voids in the membrane. Plasticizers are added as processing aids, and can be either soluble or insoluble in water, and include petroleum oils, lubricating oils, fuel oils, and natural oils such as tall oils and linseed oils. The oil are then extracted from the membrane by conventional procedures such as single stage extraction using a suitable solvent. Commercially available wetting agents known to the art such as dodecylphenoxy polyethoxy ethanol and isooctyl phenyl polyethoxy ethanol are coated onto the sheet to improve wettability. The sheet is then dried, and boiled in distilled water for one minute or more, before being finally dried.

Owner:ZPOWER LLC

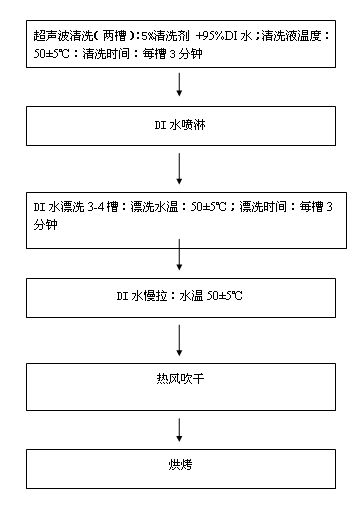

Cleaning agent for optical glass

ActiveCN102604751AEasy to cleanPromote wettingOrganic detergent compounding agentsNon-ionic surface-active compoundsOrganic baseCarbon chain

The invention discloses a cleaning agent for optical glass, which comprises the following components in weight percentage: 2-4% of long carbon chain dibasic acid; 6-10% of an anionic surfactant; 2-4% of an inorganic base; 2-6% of a nonionic surfactant; 2-4% of a special surfactant; 6-12% of a chelator; 10-20% of an organic base; and 40-70% of deionized water, wherein the long carbon chain dibasic acid is dicarboxylic acid with 21 carbon atoms, the anionic surfactant is dodecylbenzene sulfonic acid, the inorganic base is industrial NaOH, the nonionic surfactant is primary alcobol ethoxylate AEO9, the special surfactant is sodium POE nonylphenol ether sodiosulfosuccinate, the chelator is a mixture of Tetrasodium Ethylenediamine Tetraacetate and sodium gluconate, and the organic base is diethanol amine. The cleaning agent for optical glass provided by the invention has low corrosivity and good cleaning effect.

Owner:SHENZHEN FISHER NEW MATERIALS CO LTD

Centrifugal casting radiant tube paint and preparation method thereof

ActiveCN101502868AWide variety of sourcesLow costFoundry mouldsFoundry coresCrack resistanceSodium Bentonite

The invention is a centrifugal casting radiant tube coating and a preparation method thereof, the coating comprises the ingredients (mass percent) of: 25-30% of diatomite of, 5-10% of zircon powder, 1.0-1.2% of titanium powder, 1.5-1.8% of iron powder, 4.5-5.0% of sodium bentonite, 2.0-2.5% of polyvinyl alcohol, 0.8-1.0% of sodium alginate, 3.5-4.0% of silica sol, 0.8-1.0% of sodium dodecylbenzene sulfonate, 0.05-0.08% of silane and 46.82-49.95% of water, wherein, the mass percent of the diatomite and the zircon powder is not less than 35% and not more than 37%, the mass percent of the titanium powder and the iron powder is not less than 2.7% and not more than 2.9%, and the mass percent of the sodium bentonite plus the polyvinyl alcohol plus the sodium alginate is not less than 8.0% and not more than 8.2%. The inventive coating is used for the centrifugal casting radiant tube after dry-blending, mixed grinding and sieving, uniformly distributed bulges (namely pitting surface) can be formed on the outer surface of the radiant tube to improve heat efficiency of the radiant tube. The inventive coating also has excellent adhesive force, high temperature strength and crack resistance, thus reducing defects on the surface of the radiant tube and improving quality of complex tube. Using the inventive coating to cast the radiant tube can result in remarkable economical benefit.

Owner:靖江市黎明铸造材料厂

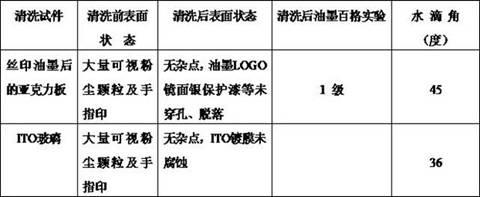

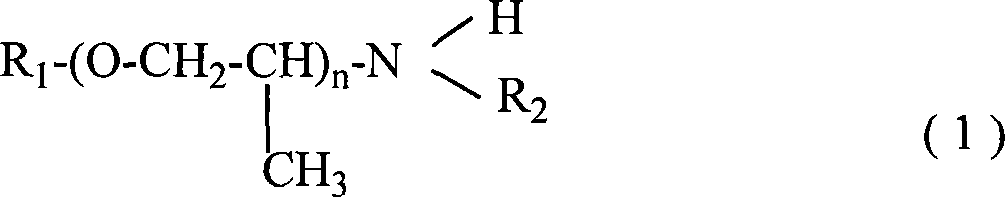

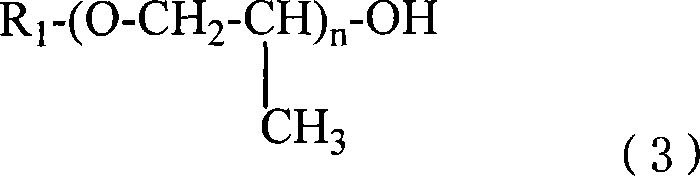

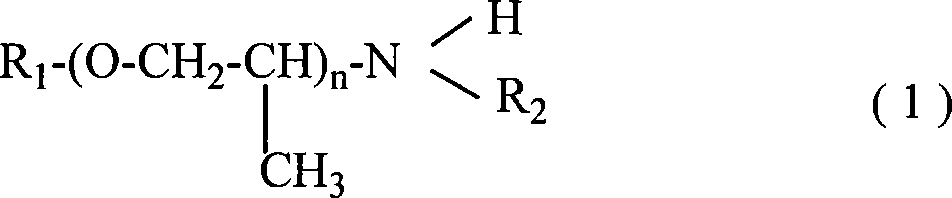

Polyethenoxyamines used as main agent of gasoline detergent and preparation method thereof

InactiveCN101225332AUnique chemical structureEasy to cleanOrganic chemistryLiquid carbonaceous fuelsCombustion chamberHydrogen

The invention relates to a polyetheramine used as the major component of gasoline detergent and the preparation method, which can be indicated by a general formula (1), in the formula (1), n is the repeated unit of the polyether segmer and the value is between 9 to 34; R1 is any one of the alkyl (C4 to C20), nonyl phenyl, octyl phenyl, dodecyl phenyl, pentadecyl phenyl, dinonyl phenyl and 2,6-di-tert-butyl-p-methylphenyl; R2 is any one of the hydrogen, methyl, ethyl, isopropyl or butyl. The preparation method comprises two steps: the preparation of polyether and the preparation of polyetheramine by the polyether with hydro-ammonification in a batch tank reactor. The polyetheramine used as the major component of gasoline detergent can be used as the major component of gasoline detergent and has the advantages of inhibiting carbon accumulation in the intake system and the combustion chamber of gasoline engine.

Owner:金浦新材料股份有限公司

Additive used for monocrystalline silicon wafer alkaline flocking and application method thereof

InactiveCN102312294AExtended failure cycleIncrease contact rateAfter-treatment detailsTO-18Temperature control

The invention relates to an additive used for monocrystalline silicon wafer alkaline flocking and an application method thereof, belonging to the technical field of solar batteries. The additive is prepared by the following components: ethanolamine, polyphosphate, sodium dodecylbenzene sulfonate, sodium hydroxide and water. A flocking agent is prepared through the following steps: (1) dissolving sodium hydroxide in deionized water so as to obtain alkaline flocking liquid; (2) adding the additive motioned above into the alkaline flocking liquid to obtain the flocking agent. During flocking, monocrystalline silicon wafers used for solar batteries are immersed in the flocking agent with temperature controlled to be 75 to 85 DEG C and flocking time controlled to be 15 to 18 minutes. The additive used for monocrystalline silicon wafer alkaline flocking in the invention enables flocking reaction time to be shortened and productivity to be enhanced; prepared texture surface pyramids have a uniform size and low reflectivity; the additive is applicable to solar battery silicon wafer alkaline flocking of different specifications and meets the purpose of industrial production.

Owner:浙江向日葵聚辉新能源科技有限公司

Extra-high voltage transformer oil and production process thereof

The invention relates to extra-high voltage transformer oil and a production process thereof. The extra-high voltage transformer oil comprises the following components in percentage by weight: 75wt%-85wt% of naphthenic-base base oil, 12wt%-22wt% of dodecyl benzene, 10ppm-200ppm of a metal de-activating agent and 0.1wt%-3wt% of a light stabilizer. Compared with the prior art, the extra-high voltage transformer oil is low in cost, simple in formula and production process, convenient to use, excellent in comprehensive performances and in particular suitable for being used as extra-high voltage transformer oil.

Owner:ANHUI KAIAO NEW ENERGY CO LTD

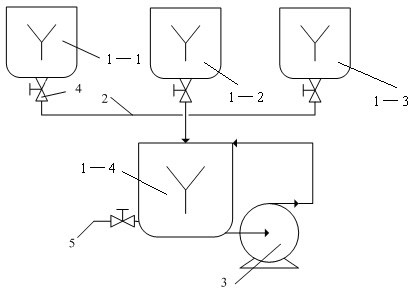

Method for manufacturing oil solubility thick oil thinner for thick oil pipe-line transportation

InactiveCN101245240AMeet flowable viscosity requirementsImprove low temperature fluidityPipeline systemsDrilling compositionSolubilityMethacrylate

The invention relates to the preparation method of oil-solute viscosity reducer used for the transportation of heavy oil tubes, which is characterized by comprising the following steps, first the preparation of the mixture of methacrylate with hydroxyl and dodecylbenzene sulfonic acid, second the preparation of acrylate high esters, third the preparation of oil-solute heavy oil viscosity reducer, according to the rate of the acrylate high esters : the mixture of methacrylate with hydroxyl and dodecylbenzene sulfonic acid equal to 1.0 to 4.5 ml : 1.0 to 7.5 ml, initiator ammonium persulfate, the mass fraction of which takes up 0.8 to 1.6 percent of the acrylate high esters and the mixture of methacrylate with hydroxyl and dodecylbenzene sulfonic acid, is added, the reaction is kept for 6 to 8 hours with the temperature of 70 DEG C, then the oil-solute heavy oil viscosity reducer can be got, the method is characterized by the good viscosity reducing effect, the simple process and the low cost.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Chromium-free treating liquid for preparing erosion-resisting oxide film on aluminum alloy surface, treating and using method thereof

ActiveCN101054664AImprove corrosion resistanceGolden colorMetallic material coating processesSodium acetateChromium free

The present invention discloses a chromium-free treatment liquid for preparing corrosion resistant oxidation film at aluminium alloy surface as well as the processing and use method thereof, characterized in that said treatment fluid utilizes a cobalt (III) salt as a main salt and a hypermanganate and a nitrate as a composite oxidizing compound to prepare a composite Co-Mn oxidation film having favorable corrosion resistance performances at aluminium alloy surface. The formula for said treatment liquid is that each litre solution contains cobalt salt of 5 g / L(-1)-20 g / L(-1), kalii permangana of 1 g / L(-1)-4 g / L(-1), sodium nitrate of 1 g / L(-1)-4 g / L(-1), promotor (chlorides and fluorides) of 1 g / L(-1)-4 g / L(-1), sodium acetate of 20 g / L(-1)-50 g / L(-1) and wetting agents (sodium dodecylbenzene sulfonate, OP-10) of 0.5 g / L(-1)-1 g / L(-1). Saic processing and use method comprises (1)sanding the aluminium alloy until its surface is smooth and even; (2) pretreating the aluminium alloy surface; (3) performing a conversion processing by using the treatment fluid; (4) cleaning-up using water and atmospheric-drying naturally. Said treatment fluid in accordance with the present invention possesses the advantages of environmental protection due to its hexavalent chromium-free, fast film-forming speed, simple process, uniform rete, strong corrosion resistance, few environment pollution, and the like.

Owner:GUANGYA ALUMINUM

Water-based metal cleaner and preparation method thereof

The invention discloses a water-based metal cleaner and a preparation method thereof. The water-based metal cleaner is prepared from sodium dodecylbenzene sulfonate, fatty alcohol-polyoxyethylene ether, alkylphenol polyoxyethylene, triethanolamine oleate, triethanolamine, 3-methyl-3-methoxy-1-butanol, polyphosphate, silicate, glycerol, primary sodium alkyl sulfate, isooctyl phosphate, benzotriazole, polyethylene glycol, dimethylaminoethyl methacrylate, 2-hydroyl-3-sulfopropyl starch ether and deionized water; the preparation method of the water-based metal cleaner comprises the following steps: firstly, adding a surfactant and the triethanolamine oleate to the glycerol, heating and stirring, next, adding the triethanolamine, the 3-methyl-3-methoxy-1-butanol, the polyphosphate and the silicate, adding the primary sodium alkyl sulfate, the isooctyl phosphate, the benzotriazole and the polyethylene glycol under the conditions of stirring and preserving heating, and finally adding the rest components under the conditions of stirring and preserving heating, and heating and stirring to obtain the cleaner. The water-based metal cleaner has excellent cleaning performance and relatively high corrosion inhibition period.

Owner:SUZHOU CHANGSHENG ELECTROMECHANICAL

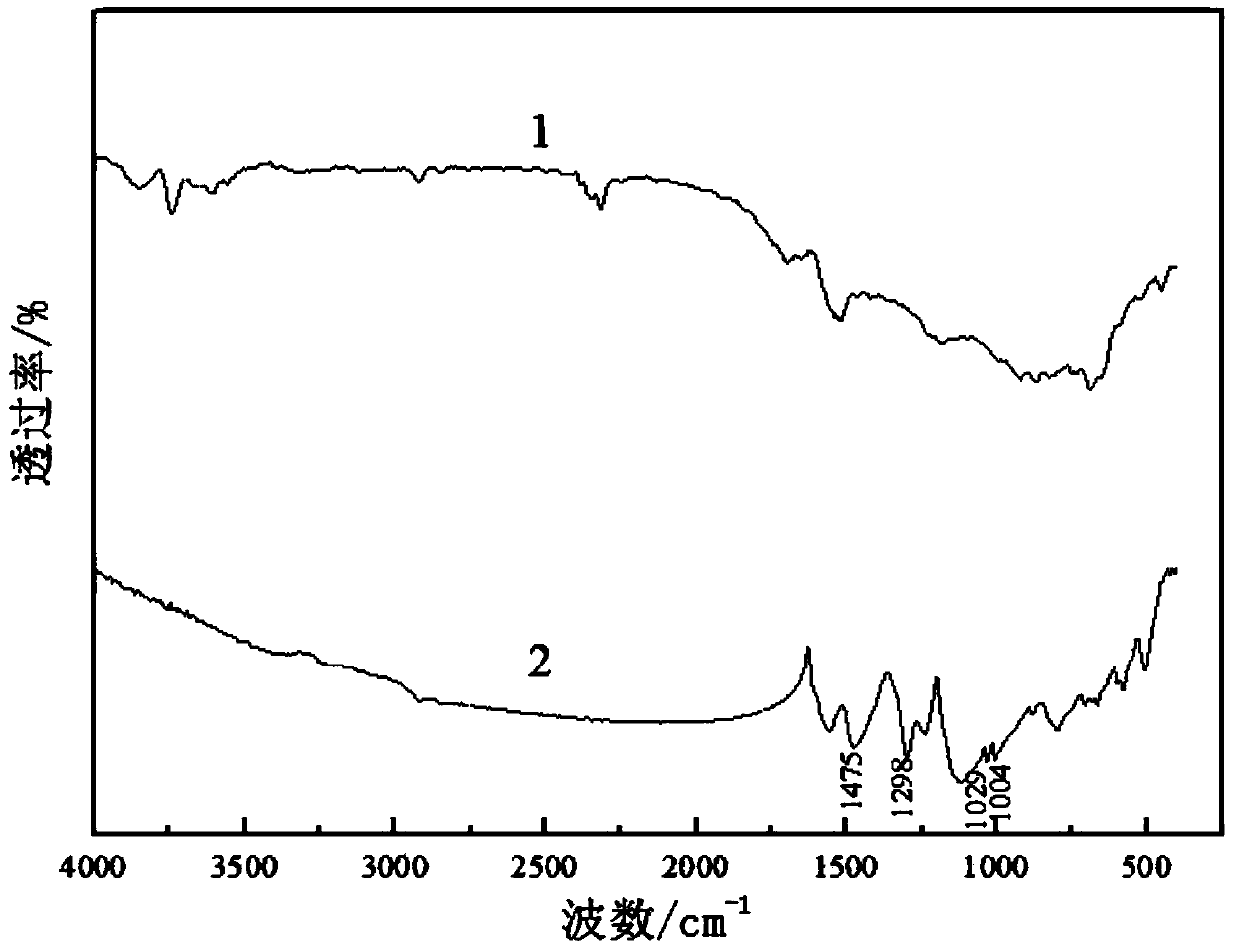

Method for preparing water-soluble conductive polyaniline

The invention relates to a method for preparing water-soluble conductive polyaniline. The water-soluble conductive emeraldine imino polyaniline is synthesized by adopting microemulsion polymerization in an ice-water bath, and taking aniline as a monomer, ammonium persulphate as an initiator, dodecylbenzene sulfonic acid as a doping agent and emulsifying agent and ethanol as an assistant emulsifying agent. The preparation method comprises the following steps: under the conditions of the ice-water bath and stirring, adding the aniline into aqueous solution of the dodecylbenzene sulfonic acid (the molar ratio of the aniline to the dodecylbenzene sulfonic acid is 1:1-1:2), adding the ethanol (the volume ratio of the ethanol to deionized water is 1:4-4:1), stirring for 30 minutes, ensuring that the concentration of the aniline in the system is 0.15 to 0.3mol / L, adding 1mol / L aqueous solution of ammonium persulphate (the molar ratio of the ammonium persulphate to the aniline is 1:1-1:1.25), and stirring for 60 minutes; and adding the reaction system to a container with the temperature of between 0 and 5 DEG C, performing reaction for 48 hours, pumping and filtering, washing the reactant with ethanol / water to obtain a filter cake, and drying the filter cake under vacuum to obtain dark green powder.

Owner:SHANGHAI UNIV

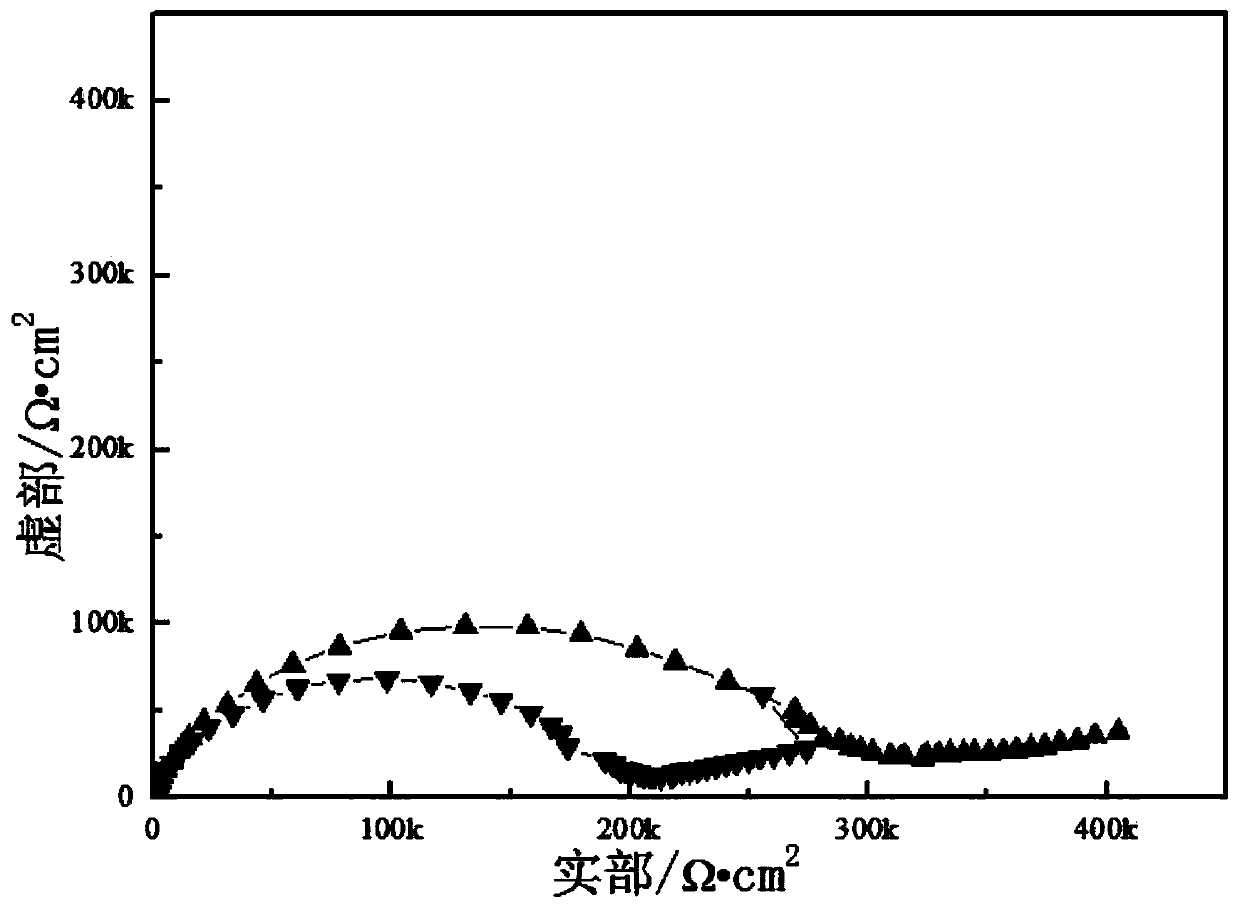

Doped-state polyaniline epoxy paint and preparation method thereof

InactiveCN103980798AImprove conductivityImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyProcess equipment

The invention discloses doped-state polyaniline epoxy paint and a preparation method thereof. The preparation method includes following steps: preparing doped-state polyaniline in a manner of chemical polymerization with ammonium persulfate being an oxidizing agent and phosphoric acid being a doping agent, preparing intrinsic-state polyaniline through a dedoping process, carrying out a secondary doping reaction between the intrinsic-state polyaniline and dodecylbenzene sulfonic acid to prepare secondarily-doped-state polyaniline, mixing the secondarily-doped-state polyaniline with epoxy resin to prepare the polyaniline epoxy paint having a good anti-corrosion performance. In the technical scheme of the invention, a coating prepared from the secondarily-doped-state polyaniline not only has a high electrical conductivity but also has a high anti-corrosion performance. The preparation method is simple in required processing equipment, is relatively low in cost and is easy to achieve industrialization.

Owner:TIANJIN UNIV

Foaming agent used in ultra-low density anti-seepage foamed concrete, and preparation method thereof

The invention relates to a foaming agent used in ultra-low density anti-seepage foamed concrete, and a preparation method thereof. The foaming agent comprises components of, by mass: 8 to 18 parts of sodium polyoxyethylene fatty alcohol sulfate, 0.1 to 7 parts of sodium dodecylsulfate, 0.5 to 7 parts of sodium dodecylbenzene sulfonate, 4 to 15 parts of pure acrylic emulsion or styrene-acrylate emulsion, 3 to 6 parts of fatty alcohol polyoxyethylene ether, 0.5 to 2 parts of hydroxyethyl cellulose or hydroxy propyl methylcellulose, 0.1 to 5 parts of modified silicon resin or modified nano-gradebentonite, 0.1 to 0.5 parts of a thickener, and balance of water. The anti-seepage foamed concrete foaming agent provided by the invention has stable property, high foaming multiple, and good workability with a substrate. The agent can be used in a foamed concrete product with a density of 100 to 600kg / m<3>. The raw materials are easy to obtain, and the cost is low. The foaming agent can be stored for a long term with out deteriorating. With the agent, foamed concrete properties such as strength and softening coefficient can be improved.

Owner:梁材

Smokeless polishing treatment solution for high-gloss aluminum profile and method of use

The invention provides a smoke-free polishing treatment solution for a high-gloss aluminum sectional material and a use method thereof. The smoke-free polishing treatment solution is characterized by comprising 85% H3PO4, 98% H2SO4, 30% hydrogen peroxide or potassium permanganate or perchloric acid or sodium molybdate or ammonium persulfate or sodium vanadate, cerium nitrate or sodium silicate, imidazoline or benzotriazole or phytic acid or thiourea, sodium dodecyl benzene sulfonate or sodium benzene sulfonate or sodium toluene sulfonate or sodium xylene sulfonate, and nickel chloride or nickel sulfate or lead acetate. Compared with the prior art, the smoke-free polishing treatment solution provided by the invention has advantage of no generation of high-pollution NOx yellow smoke, and enables the surface of the aluminum sectional material to have excellent gloss and no pitting microscopic defects.

Owner:GUANGDONG XINGFA ALUMINUM

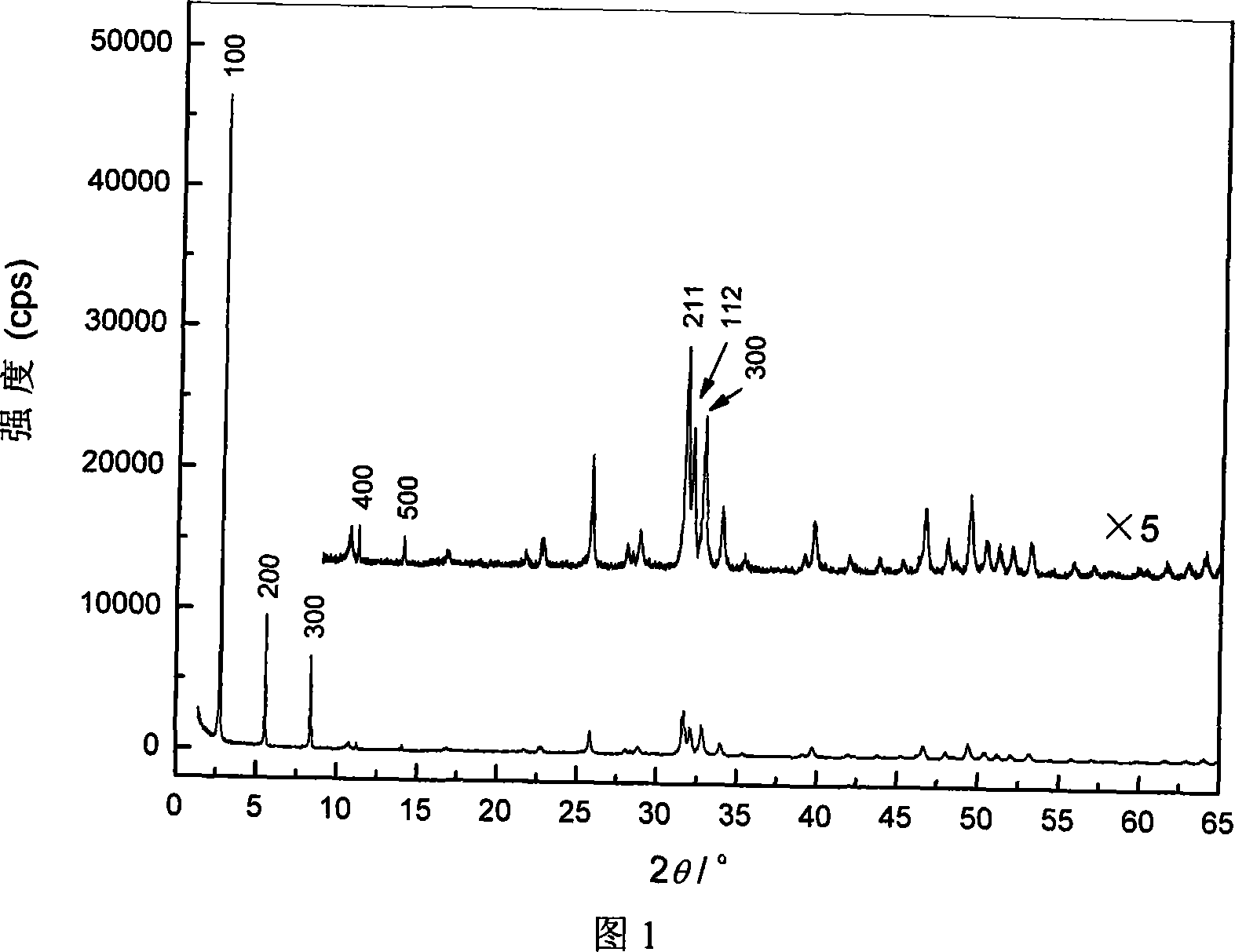

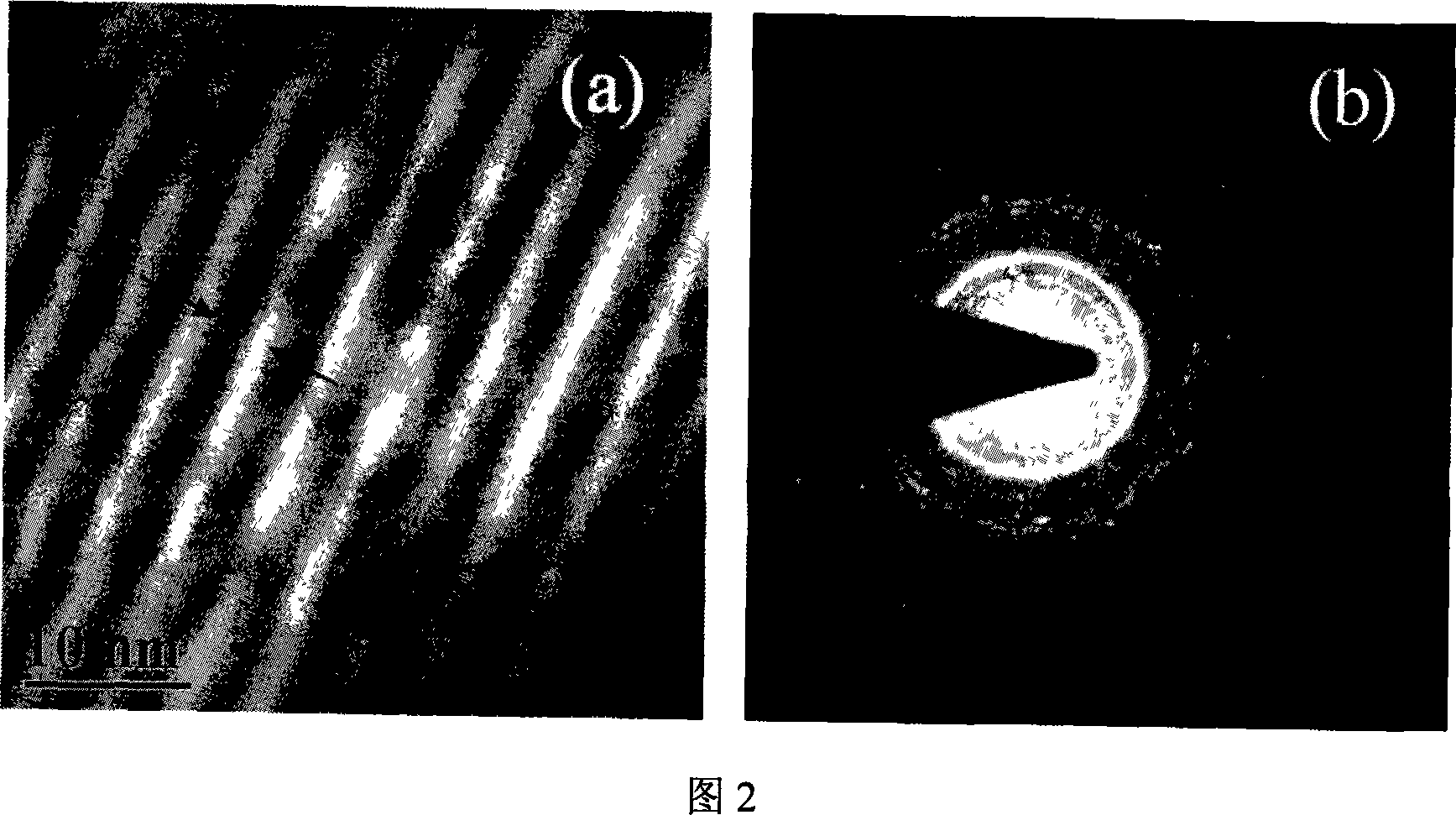

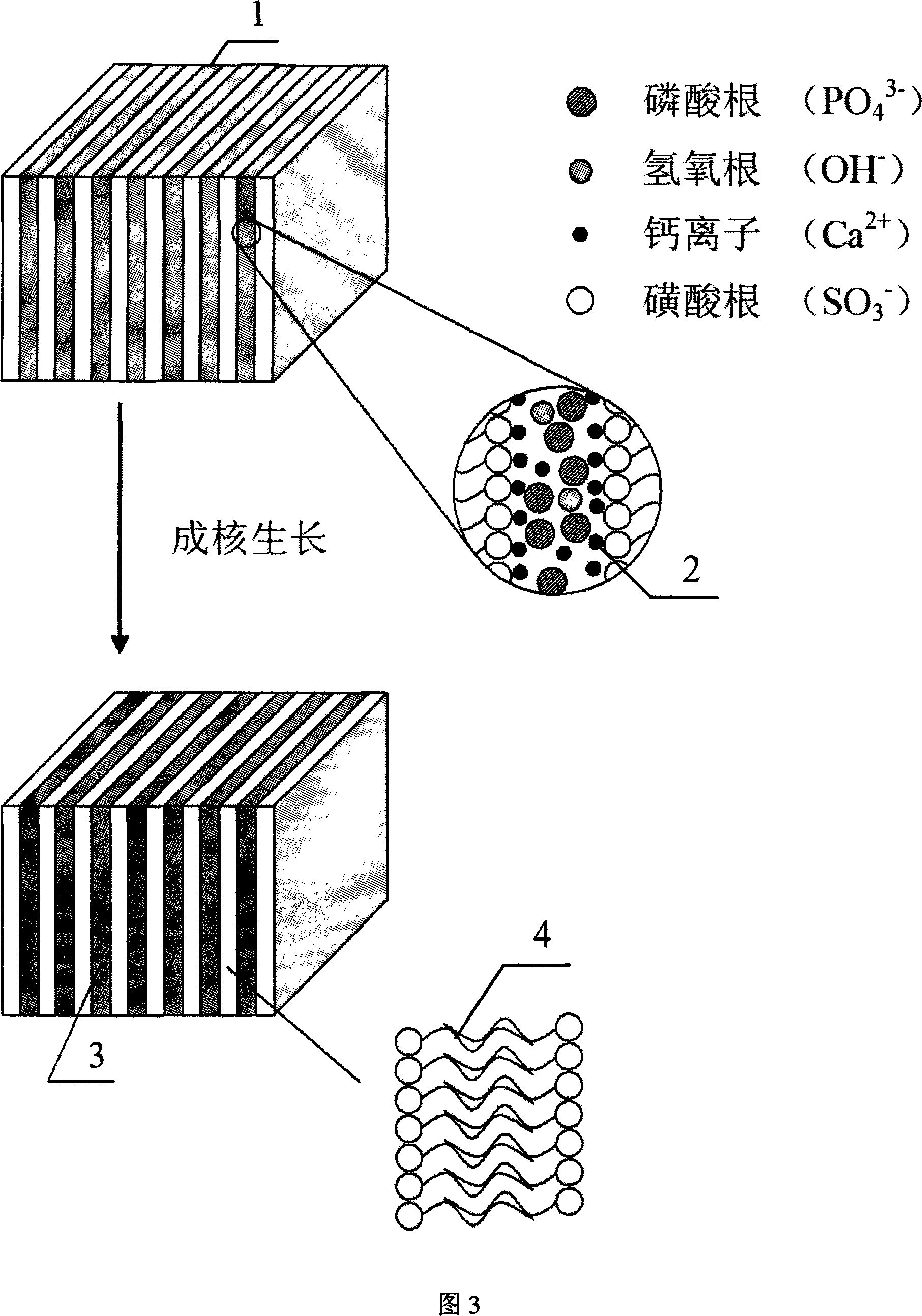

Method of preparing ordered nano hydroxyl apatite polycrystal powder

InactiveCN101058416AHigh crystallinityOvercome the disadvantage of low crystallinityPhosphorus compoundsApatiteCrystallinity

The invention discloses a making method of sequent hydroxy phosphorite polycrystalline powder and calcium phosphate, which comprises the following steps: mixing 30% 0. 00167mol calcium nitrate per ml water and 15-60% 0. 0033-0. 0667g sodium dodecylbenzene sulfonate per ml alcohol; placing the mixed solution in the flask with reflux device; adding the composite solution with 30% ammonium monohydric phosphate at 0. 01mol phosphor / ml water solution and 15-60% alcohol and the composite solution with 20% sodium hydroxide solution at 0. 05-0. 1g sodium per ml water and 10-40% alcohol; heating to the refluxing temperature at 88-92 deg. c to do hydrothermal reaction at 4-14h; centrifuging; separating; drying the white sediment under 60-80 deg. c; obtaining the product with good crystallizing degree, high-sequent (spatial symmetry) nanometer layered polycrystalline structure; simplifying the method and reducing the cost.

Owner:HEBEI UNIV OF TECH

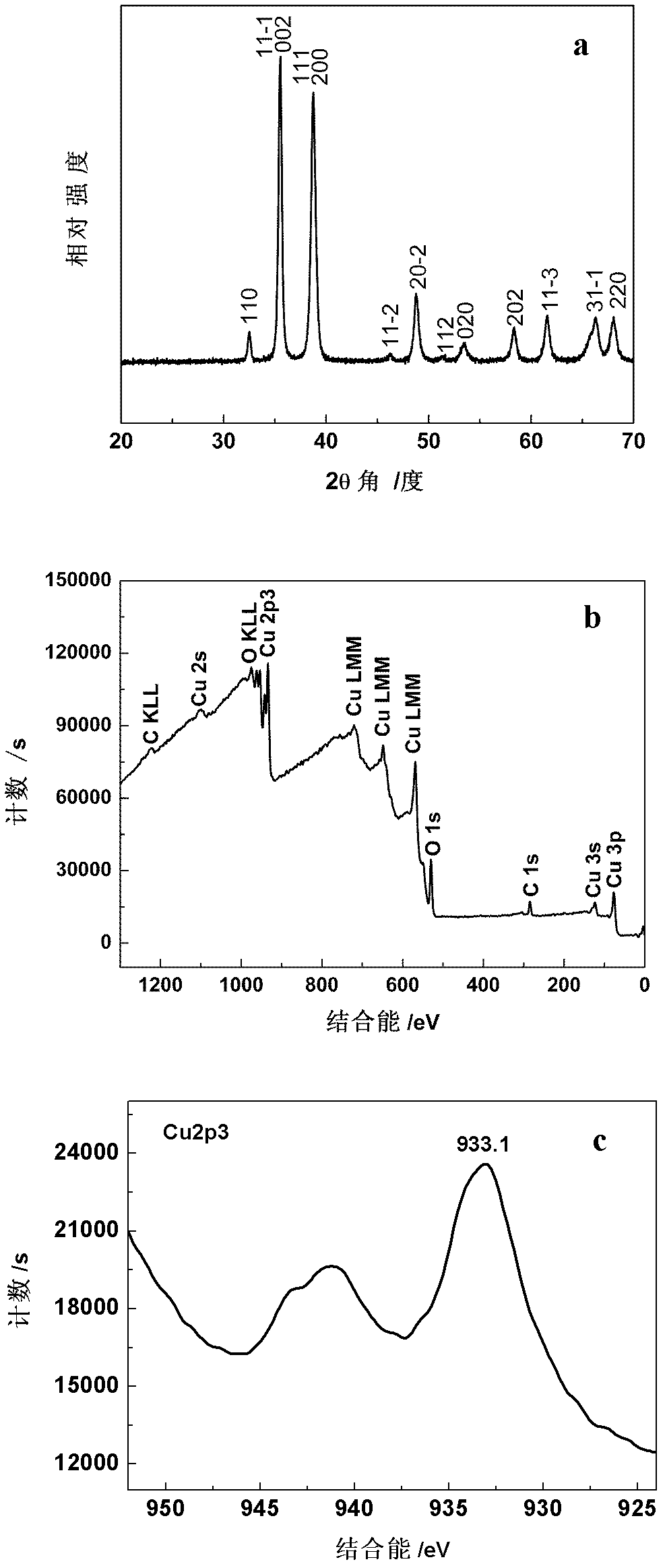

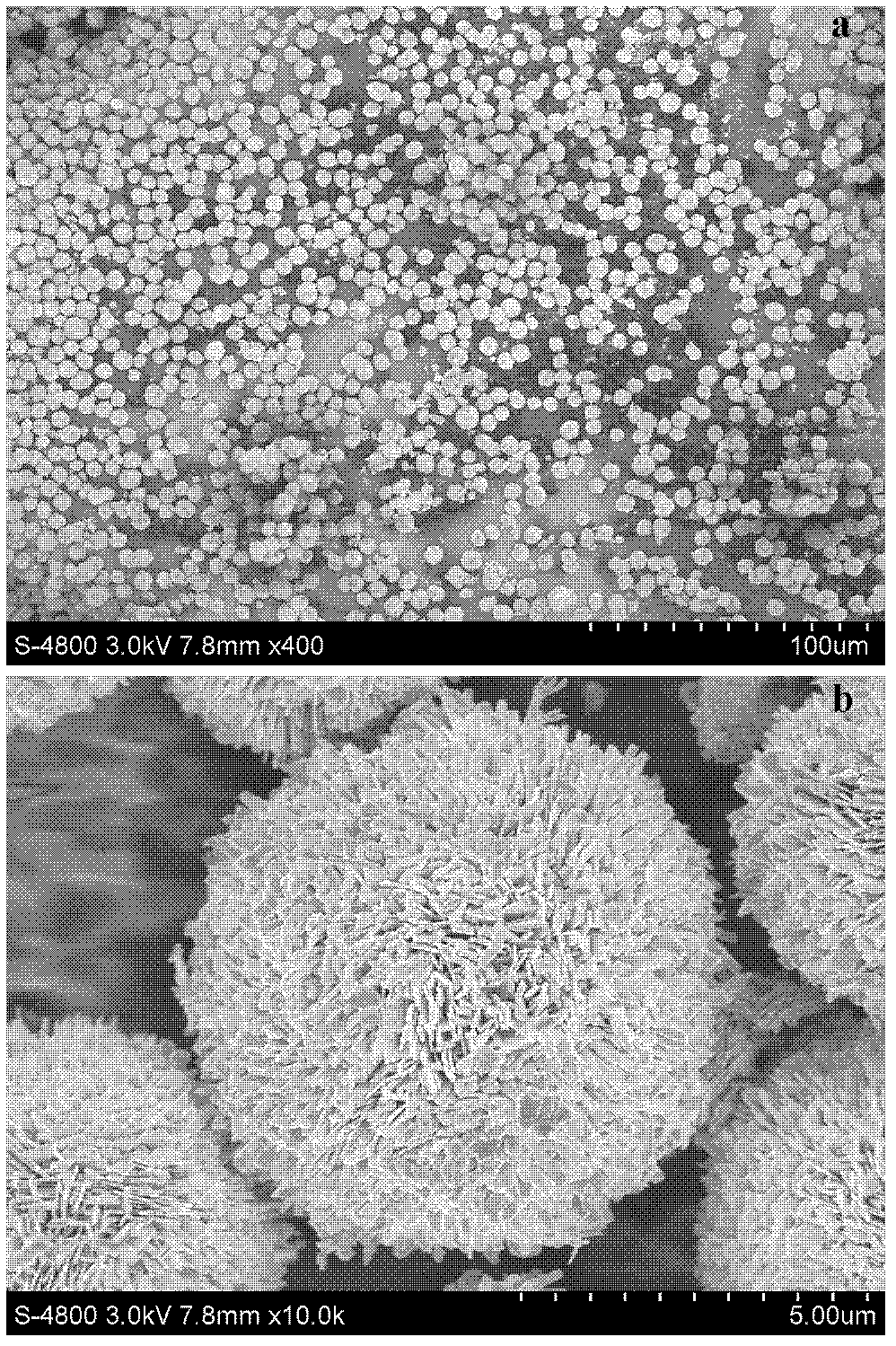

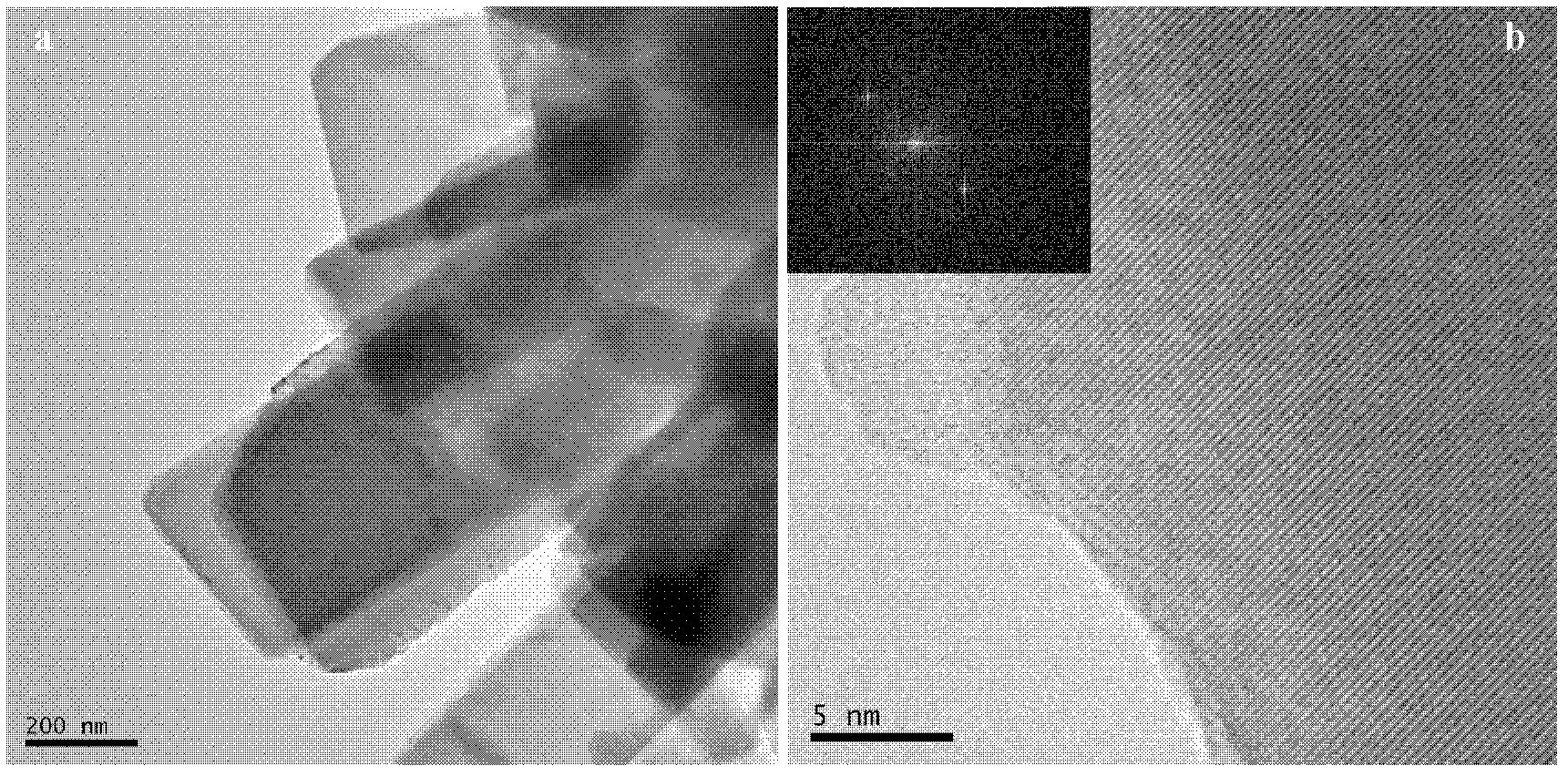

Copper oxide micro-nano composite structural material and preparation method thereof

InactiveCN102491404AReduce manufacturing costMild reaction conditionsNanotechnologyCopper oxides/halidesMicrosphereCopper oxide

The invention discloses a copper oxide micro-nano composite structural material, which consists of CuO microspheres with nano flaky secondary structures, fan-shaped / bar-shaped CuO and CuO nanosheets in any ratio, wherein the CuO microspheres are 7-10 microns in diameter, and are formed by self-assembling nanosheets; the fan-shaped / bar-shaped CuO is formed by self-assembling bar-shaped CuO; and CuO bars are 6-12 microns in length and 400-600 nanometers in diameter. The copper oxide micro-nano composite structural material can be taken as a solar energy transformation material, a photocatalyst and a fluorescent material. A preparation method of the copper oxide micro-nano composite structural material comprises the following step of: preparing by taking copper chloride, ammonia water and sodium hydrate as raw materials and taking sodium dodecylbenzene sulfonate as a template under a low-temperature condition with a hydro-thermal method. The preparation method has the advantages of mild reaction condition, easiness for operating, low preparation cost, high product structure controllability, high repeatability and easiness for realizing large-scale production, contributes to large-scale popularization and application, and has great production and practical meanings.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Fertilizer for spraying on leaf surface with biologic raw materials as main material

InactiveCN1445202ASignificantly prevent and control the effect of crop diseases and insect pestsDisease controlBiocidePlant growth regulatorsSolubilityVitamin C

A leaf fertilizer is prepared from biologic material as main raw material such as dried potato, rice bran, wine yeast, weathered coal, extraction liquid of garlic, etc and 20 other materials including urea, potassium dihydrogen phosphate, boric acid, copper sulfate, VC, etc. Its advantages are high chemical stability and water solubility, easy absorption, high effect on increasing yield, and no environmental pollution.

Owner:王兴中

Carbon fiber and ceramic fiber reinforced wet paper-based friction sheet and manufacturing method thereof

ActiveCN103438127AGuaranteed stabilityGood physical and mechanical propertiesOther chemical processesNon-macromolecular organic additionStatic friction coefficientCarbon fibers

The invention relates to a carbon fiber and ceramic fiber reinforced wet paper-based friction sheet and a manufacturing method thereof. The wet paper-based friction sheet provided by the invention has the characteristics of high friction coefficient, stable friction performance, good wear resistance, adjustable dynamic / static friction coefficient ratio and high energy absorption capacity; the manufacturing method has the characteristics of simple working procedure and convenience and easiness in manufacture. The technical scheme is as follows: the carbon fiber and ceramic fiber reinforced wet paper-based friction sheet comprises ingredients including a substrate material, a friction performance regulator and a forming binder and further comprises an appropriate amount of polyacrylamide, an appropriate amount of polyoxene and an appropriate amount of sodium dodecylbenzene sulfonate; the manufacturing method of the carbon fiber and ceramic fiber reinforced wet paper-based friction sheet comprises the following steps of preparing base paper of a carbon fiber and ceramic fiber reinforced wet paper-based friction material; manufacturing the carbon fiber and ceramic fiber reinforced wet paper-based friction sheet.

Owner:杭州汉乐科新材料科技有限公司

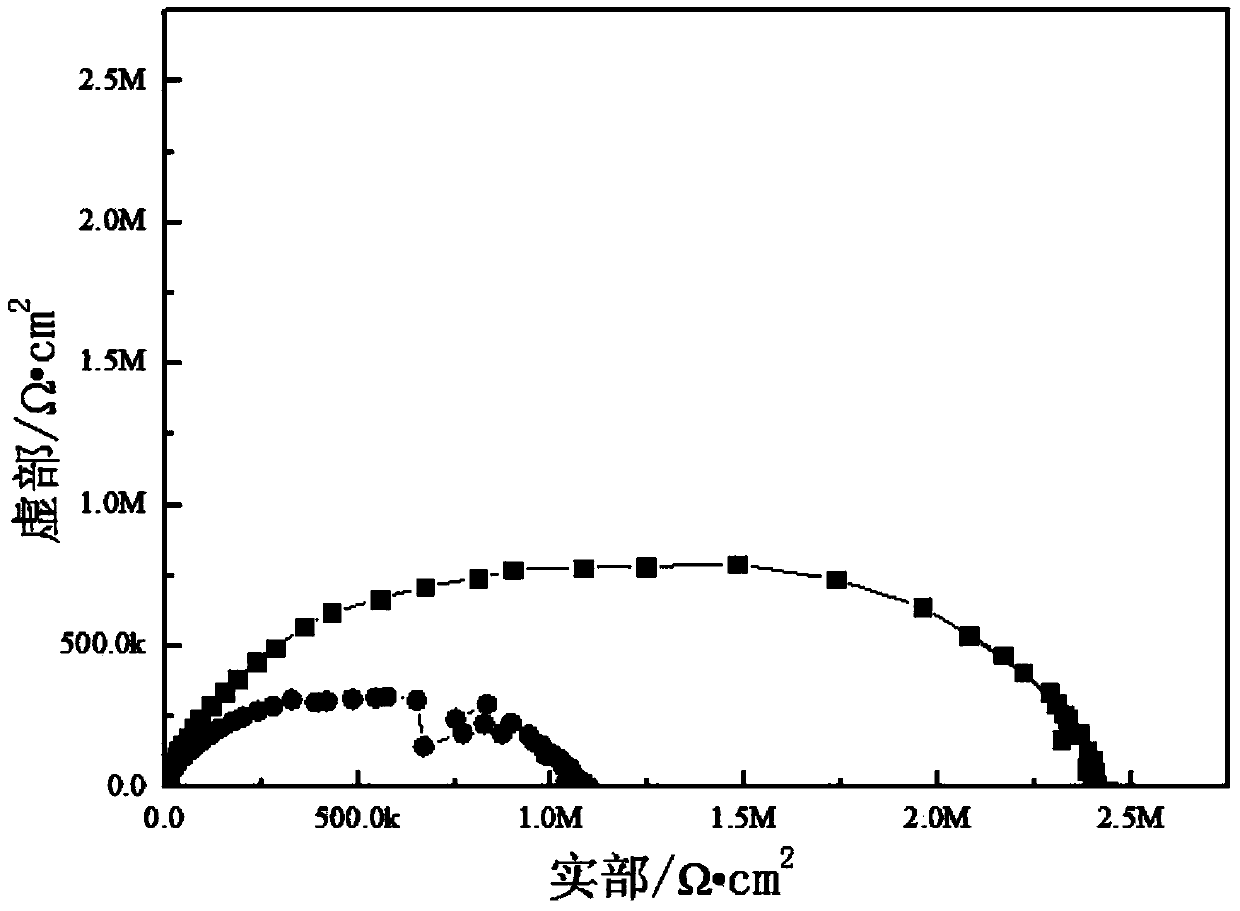

Nano-composite electric conduction anticorrosive paint and preparation method thereof

InactiveCN103627297AImprove conductivityImprove corrosion resistanceAnti-corrosive paintsPigment treatment with macromolecular organic compoundsEpoxySolubility

The invention discloses nano-composite electric conduction anticorrosive paint and a preparation method thereof. The preparation method is characterized in that firstly organic acid dodecylbenzene sulfonic acid is used as a doping agent so as to overcome the low solubility of doped polyaniline, a carbon nanotube is used for improving the electric conductivity of composite powder, and then the carbon nanotube is compounded with a precursor of organic acid dodecylbenzene sulfonic acid doped polyaniline and epoxy resin so as to prepare the nano-composite electric conduction anticorrosive paint. According to the technical scheme, the polyaniline / carbon nanotube and the epoxy resin are compounded, so that the excellent characteristics of the polyaniline / carbon nanotube and the epoxy resin are organically combined together. The nano-composite electric conduction anticorrosive paint has relatively high electric conduction performance and very high anticorrosive performance and is relatively low in cost; required processing equipment is simple; the industrialization of the nano-composite electric conduction anticorrosive paint is easy to realize.

Owner:TIANJIN UNIV

Optical clearing agent for bone tissue

ActiveCN102749231AUniform refractive indexReduce scatterPreparing sample for investigationSodium bicarbonateOptical clearing

The present invention discloses an optical clearing agent for bone tissue. The optical clearing agent comprises dimethyl sulfoxide, sodium bicarbonate, and at least two materials selected from polyethylene glycol-400, methyl salicylate, ethylenediaminetetraacetic acid, sodium diatrizoate, glycerol, glucose, sodium dodecylbenzene sulfonate, sorbitol and laurinol, wherein a volume percentage of the dimethyl sulfoxide in the optical clearing agent for bone tissue is 40-80%, a mass percentage of the sodium bicarbonate in the optical clearing agent for bone tissue is 1-2%, the balance is other materials, and the pH value of the optical clearing agent for bone tissue is 6-11. After the optical clearing agent for bone tissue in the present invention acts on bone tissue, a refractive index inside the tissue can be quickly homogenized, and scattering inside the tissue can be reduced, such that the tissue provides improved transparency for light, the imaging depth is increased, and a new method for obtaining cortex neuron subcellular structures and microvascular information is provided. After the optical clearing agent for bone tissue is locally coated on the bone tissues or is adopted to soak the bone tissues, the bone tissue can provide improved transparency for light.

Owner:HUAZHONG UNIV OF SCI & TECH

Admixture for vegetation-form ecological concrete and compounding method thereof

The invention discloses an admixture for vegetation-form ecological concrete and a compounding method thereof, which relate to the technical field of cement concrete admixtures. The admixture is compounded by, by weight, calcium carbonate 5-10 parts, silica powder 40-50 parts, lignosulfonic acid 5-8 parts, sodium nitrite early strength agent 1-3 parts, hydroxy carboxylic acid high-efficiency water reducing agent 1-3 parts, polyacrylamide water-retaining agent 0.3-0.4 part and dodecyl sodium sulfate air entraining agent 0.01-0.02 part. The admixture compounded by the components is added into the vegetation-form ecological concrete so that the admixture can improve the mechanical strength and durability of the concrete, controls and ensures water permeability, porosity, homogeneity and the like of the concrete, and improves chemical resistance, potential of hydrogen, biocompatibility and other functions of the inside and the surface of the concrete.

Owner:NANTONG INST OF TECH

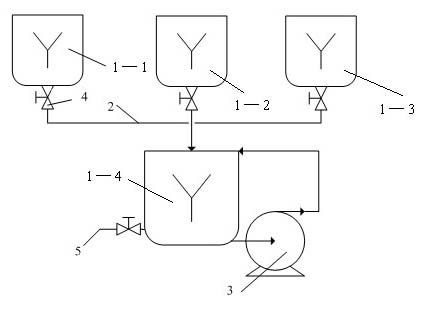

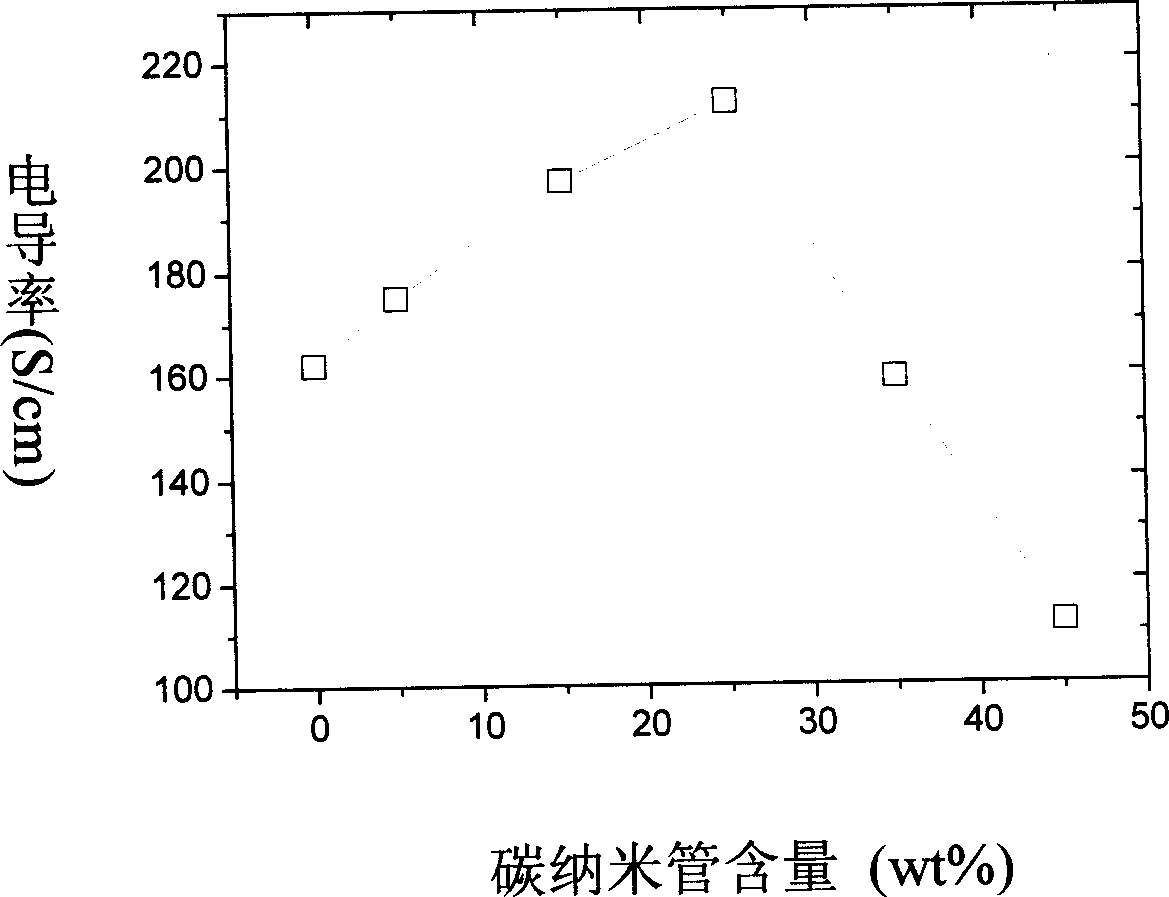

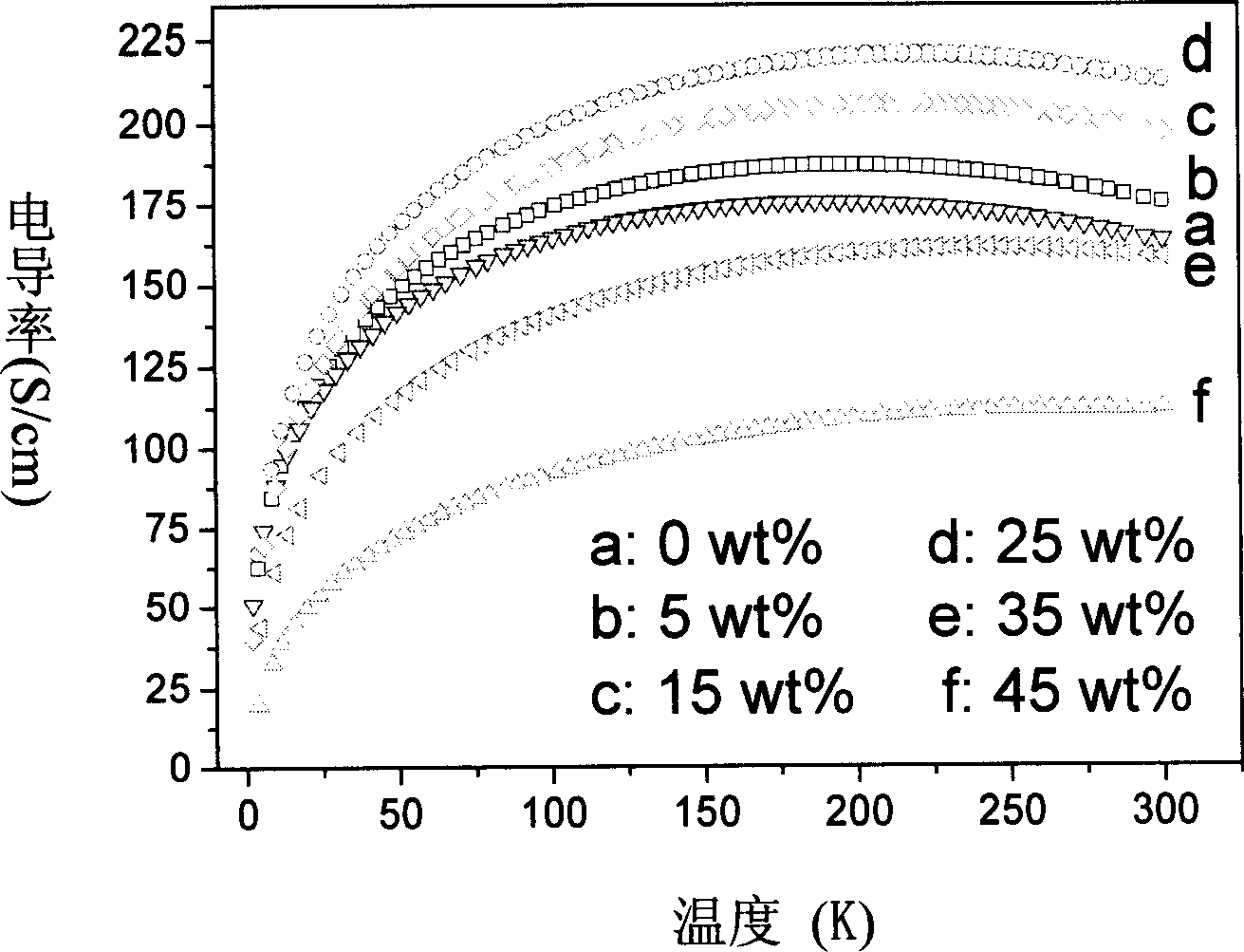

Electricity conductive polyaniline carbon nanotube combined electromagnetic shielding composite material and its production method

The invention relates electromagnetic screen complex film made by electric polyaniline and carbon nano pipe and preparing method. The method comprises the following steps: dispersing the carbon nano pipe into chloroform tobacco extract mixed with 4-dodecylbenzene sulfonic acid, then mixing it with polyaniline m-cresol solution doped with camphor sulfonic acid to form filming solution, pouring the filming solution on the slide glass, getting the complex film of polyaniline and carbon nano pipe whose concentration is 5wt%-50wt% in form filming solution. The optimum electric conductivity of complex film is 212 S / cm and mechanics intensity is 14.53Mpa. When the frequency of complex film is between 106Hz and 109Hz and thickness of complex film is 20ª–m, the electromagnetic screen efficiency is between 35dB and 40dB. The more the electric conductivity and thickness of complex film, the higher the electromagnetic screen efficiency.

Owner:INST OF CHEM CHINESE ACAD OF SCI

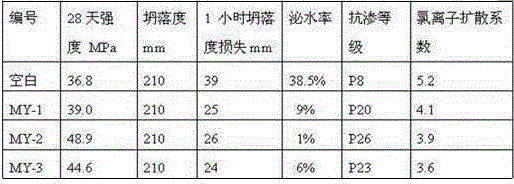

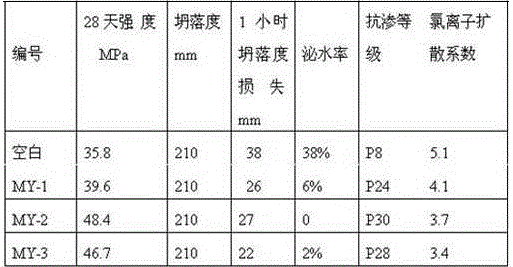

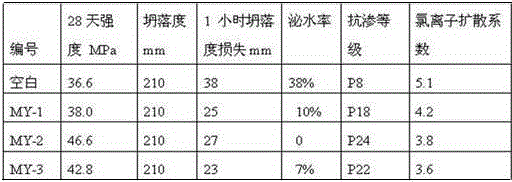

Chloridion-corrosion resistant concrete synergist and production technology thereof

The invention discloses a chloridion-corrosion resistant concrete synergist. The component percentage is anti-bleeding component : anti-permeability waterproof component : enhancing component : dispersing component : entraining component : coordinating component; the anti-bleeding component comprises polysaccharide and / or cellulose ether and / or polyacrylamide, the anti-permeability waterproof component comprises methyl sodium silicate and / or organosilicon waterproofing agent, the enhancing component comprises glycol monoisopropanolamine, composition of the glycol monoisopropanolamine and triethanolamine and triisopropanol, the dispersing component comprises MF and / or TCL and / or NNO, the entraining component comprises dodecyl benzene acid sodium and / or dodecyl benzene sodium sulfate, and the coordinating component comprises polymeric alcohol amine and polymeric polyhydric alcohol. The invention further provides a production technology for the chloridion-corrosion resistant concrete synergist. The chloridion-corrosion resistant concrete synergist is capable of improving the concrete strength, reducing the bleeding rate and reducing the slump loss.

Owner:株洲市中建新材料有限公司

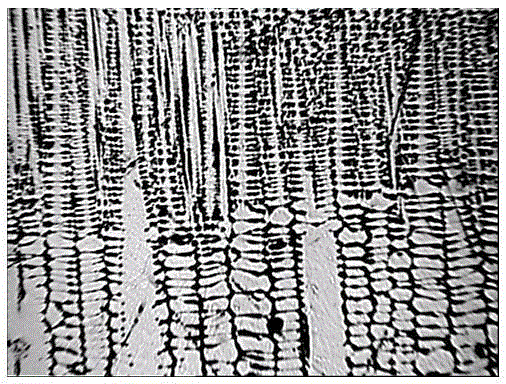

Erosion agent capable of displaying solidified dendritic structure of Fe-36 Ni invar alloy and erosion method of erosion agent

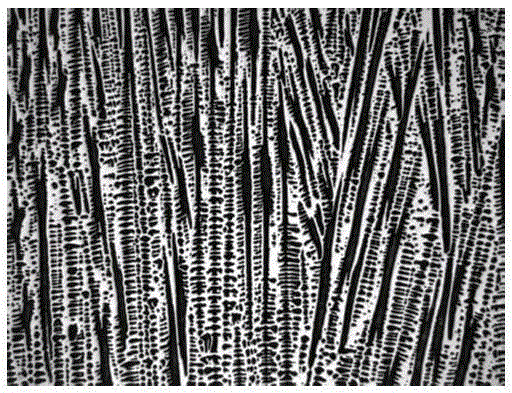

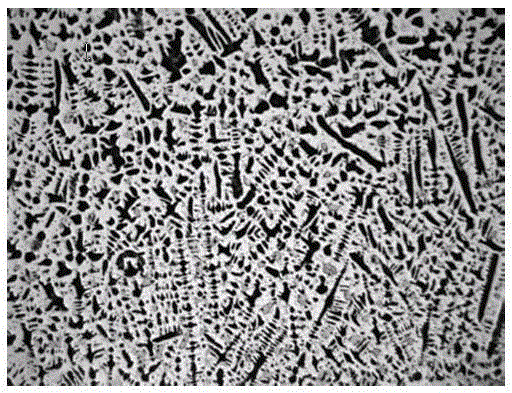

ActiveCN105386057AModerate erosion timeSimplify operating proceduresPreparing sample for investigationInvar alloyAlcohol

Disclosed are an erosion agent capable of displaying the solidified dendritic structure of a Fe-36 Ni invar alloy and an erosion method of the erosion agent. The erosion agent includes 1 g-2 g of picric acid, 0.5 g-1 g of anhydrous cupric chloride, 50 ml-60 ml of absolute ethyl alcohol, 0.5 ml-1 ml of hydrochloric acid and 1 g-2 g of sodium dodecylbenzene sulfonate. The erosion method of the erosion agent includes the steps that the prepared erosion agent is heated to the temperature of 50 DEG C-60 DEG C, a processed sample with the downward polishing face is suspended in the heated erosion agent to be eroded for 20 s-30 s, the eroded surface is wiped with ethyl alcohol firstly after erosion is completed, and then the sample is slightly polished at the one fourth radius position of a polishing machine for 4 s-6 s so that a copper film generated on the eroded surface can be removed. According to the method, the operating procedure is simple, the erosion effect is good, and the solidified dendritic structure of an invar alloy can be observed quickly and clearly, so that the solidification condition corresponding to continuous casting is obtained, and technical bases are provided for optimizing the continuous casting process technologies.

Owner:山西高义钢铁有限公司

bathroom cleaning deodorant

The invention relates to a bathroom cleaning deodorant, which comprises 50-65% of potassium hydrogen persulfate complex, 2-8% of sulfamic acid, 0-25% of sodium citrate and 0-25% of sodium tartrate in terms of mass percentage. %, sodium hexametaphosphate 0-10% and sodium dodecylbenzenesulfonate 0-1%. The bathroom cleaning and deodorizing agent of the present invention is suitable for cleaning and disinfecting bath products such as bathtubs and bath towels in households, hotels / guesthouses, beauty and bathing places, has dual functions of cleaning and disinfection, and has good deodorizing effect, without specific temperature requirements. Good security.

Owner:宋海鹏 +1

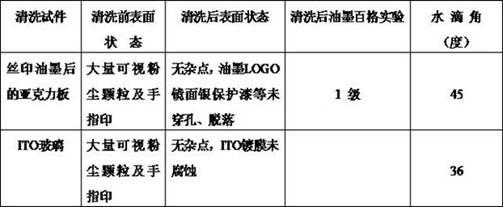

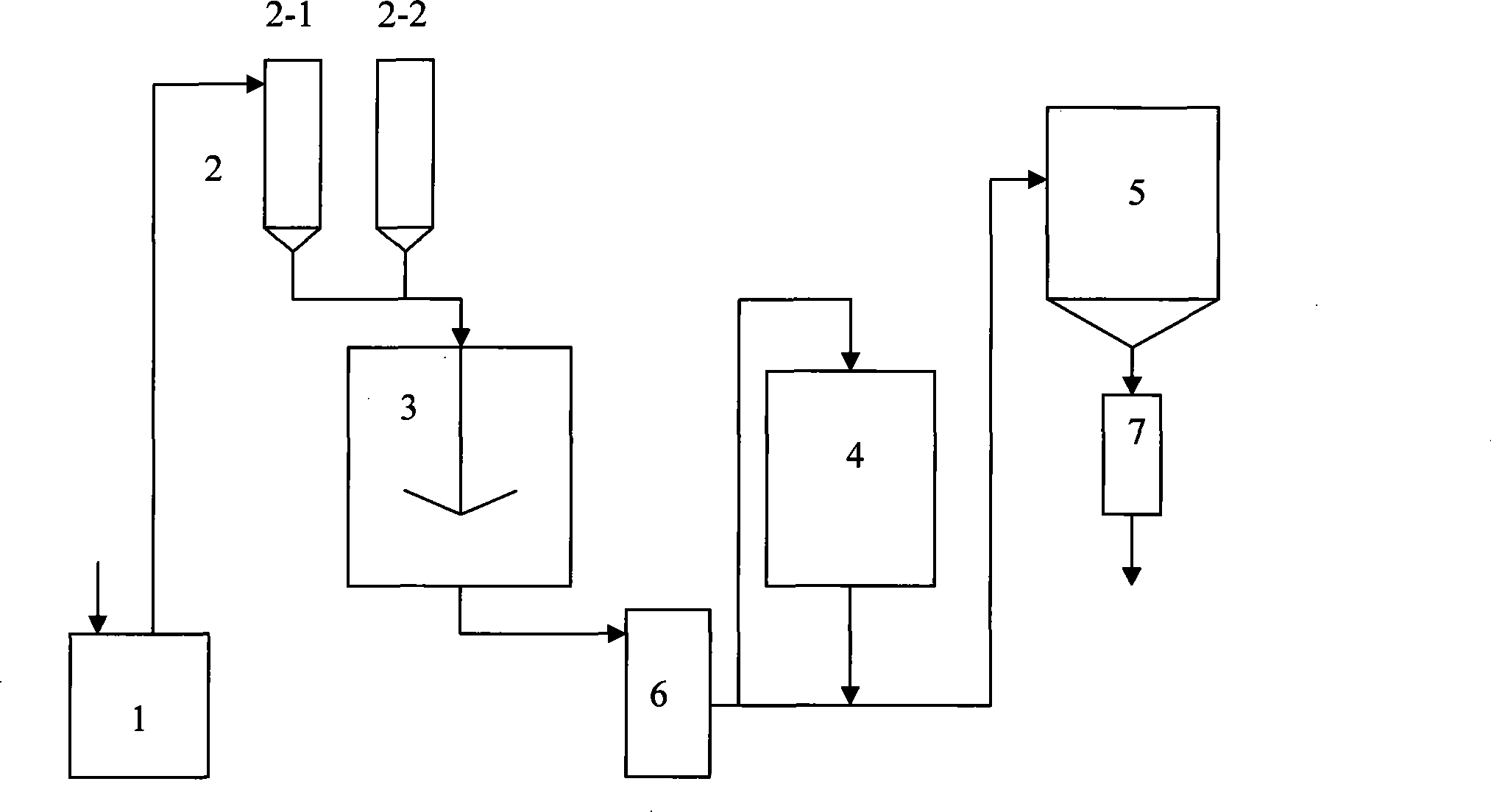

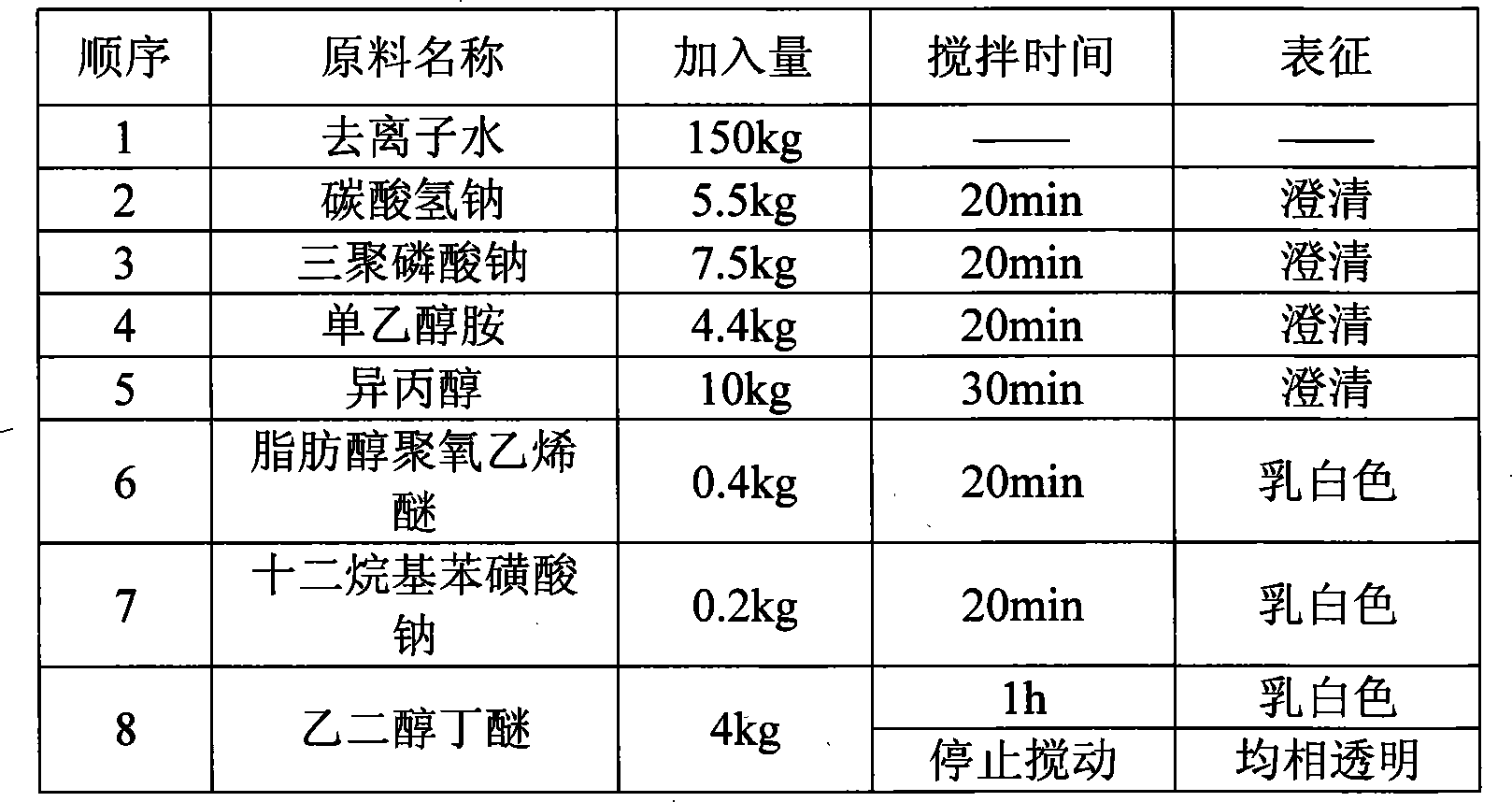

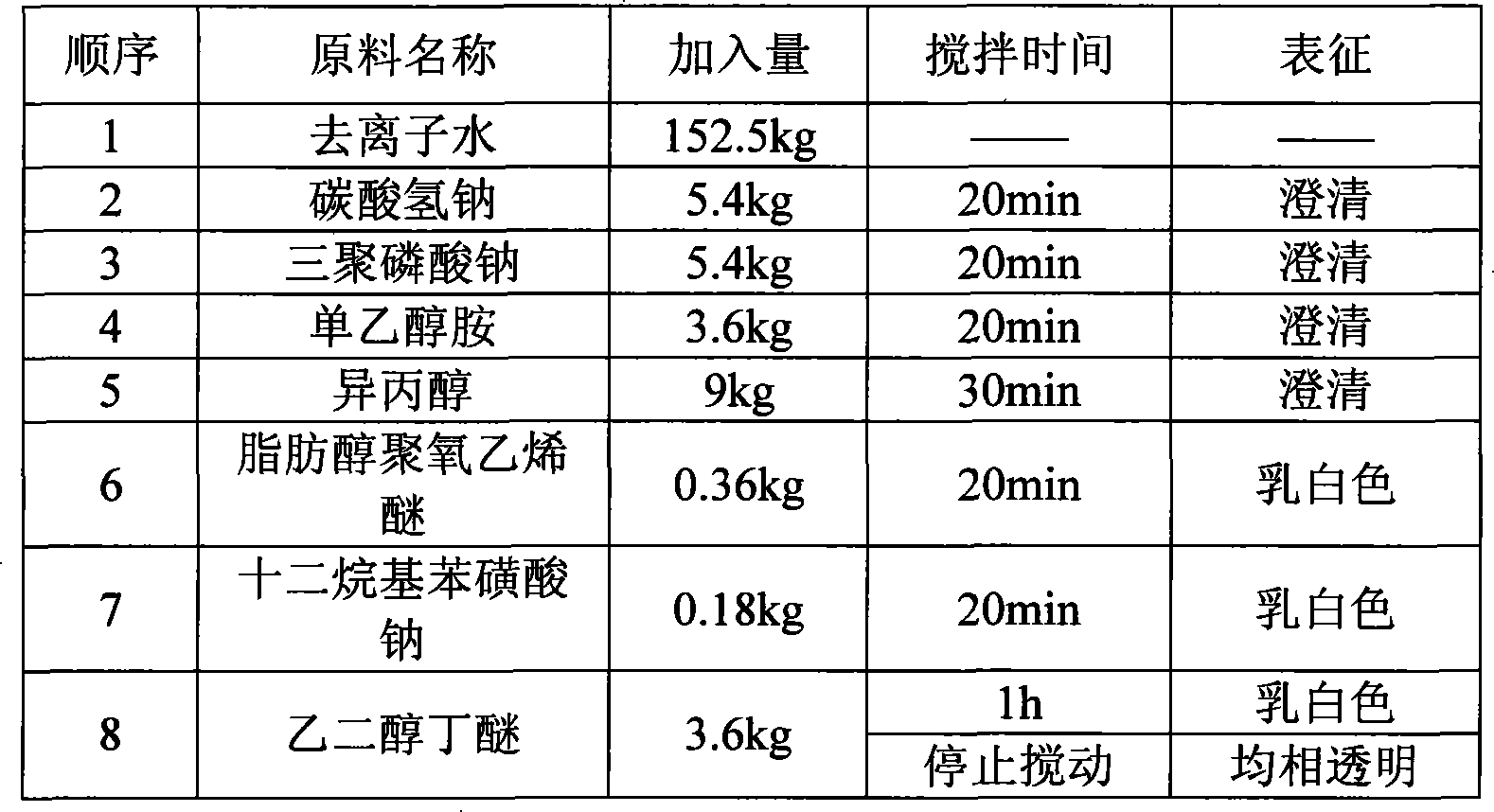

Electro-conductive glass substrate cleaning agent and preparation method thereof

InactiveCN101250465ASystem stabilityLower pHInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsSolubilityCleansing Agents

The invention discloses an electro-conductive glass base plate cleaning agent, which is formed by components with the following percentage by weight, baking soda 3-5%, sodium tripolyphosphate 3-5%, monoethanolamine 2-4%, isopropyl alcohol 5-10%, alkyl alcohol polyoxyethylene ether 0.2-0.4%, sodium dodecylbenzene sulfonate 0.1-0.5%, ethylene glycol monobutyl ether 2-5% and the rest is water. The process for preparation comprises the following steps: adding the above raw materials into an emulsion tank in turn, and then preparing the cleaning agent after mixing, homogenizing, cooling, exhausting and filtering. The electro-conductive glass base plate cleaning agent of the invention has low pH value, when in use, the electro-conductive glass base plate cleaning agent has microvesicle or has no bubbles, which has strong water solubility, the surface of glass has no residues and particulate matters after cleaning. The cleaning agent has excellent cleanness, nontoxic, nonirritant and easy biodegradation, which is easy to discharge and process discard solution. And the cleaning agent has the advantages of simple process for preparation, high yield, only little deposition and residue, low power consumption, convenient process and operation, easy automation, no environmental contamination and high economic benefit.

Owner:曹学增

Phenol-formaldehyde resin by colophony modified with alkyl phenol being mixed and its preparation method

A rosin modified mixed alkylphenol-phenolic resin is prepared from reaction between p-tert-octylphenol, p-nonylphehnol, dodecylphenol and formaldehyde in alkaline condition, modifying by rosin, and esterifying by glycerin and then trihydroxymethyl propane. Its advantages are high soft point, good viscoelasticity, and excellent solubility in fatty hydrocarbon band oil. It can be used for high-speed print color ink.

Owner:山西省应用化学研究所

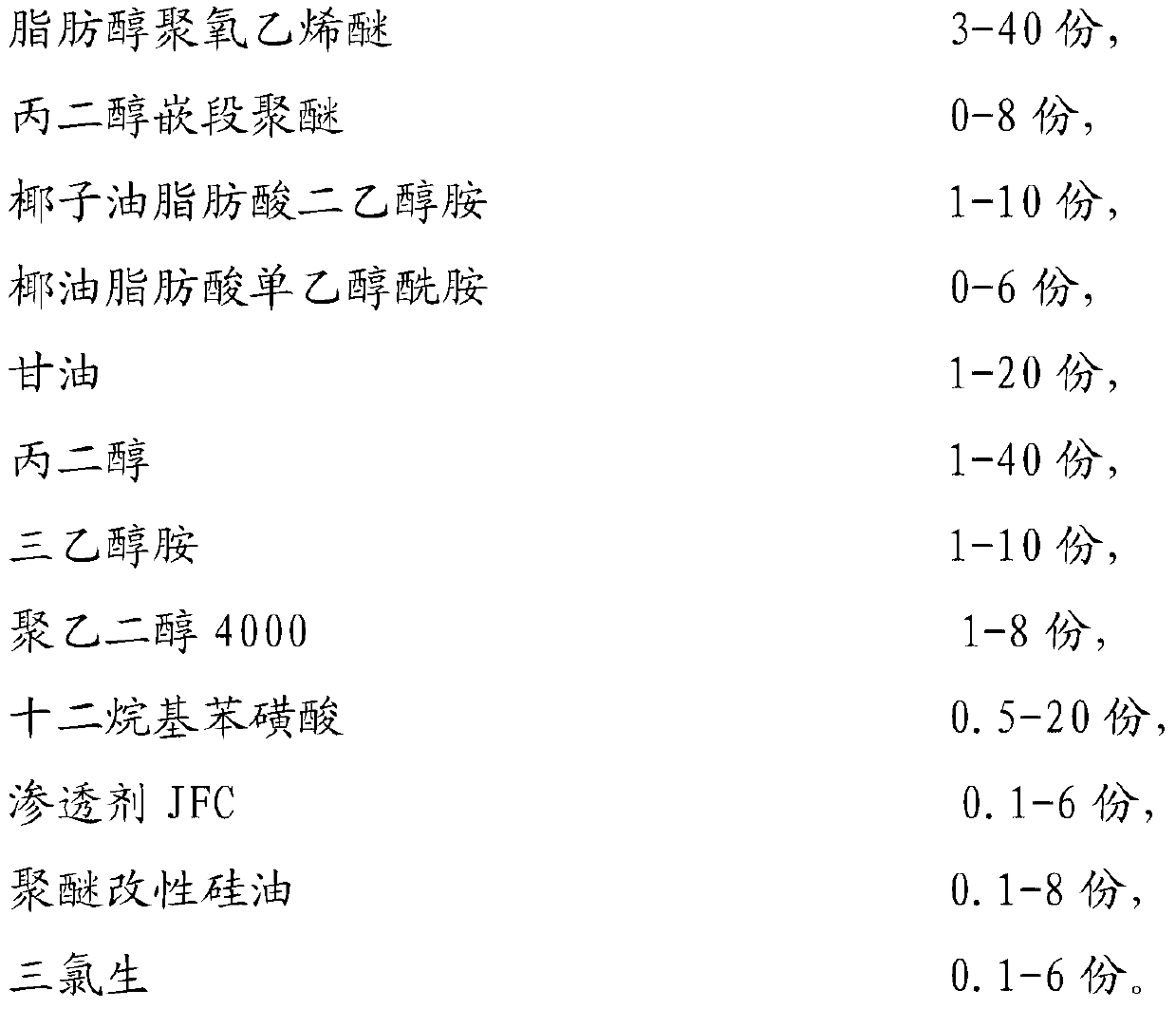

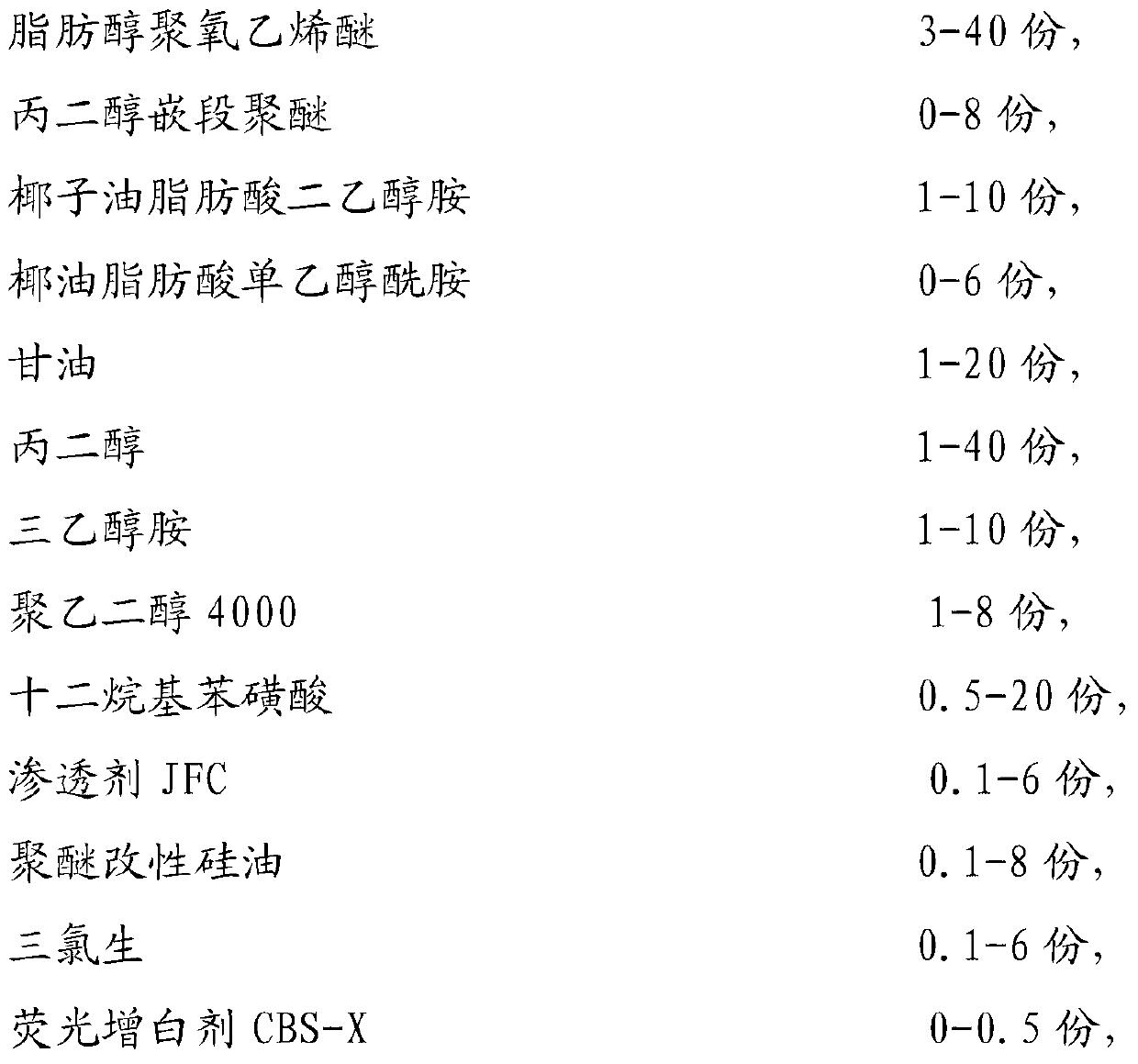

Non-water-based high-active-substance-content clothing detergent, preparation method thereof and packaging bag therefor

The invention discloses a non-water-based high-active-substance-content clothing detergent, a preparation method thereof and a packaging bag therefor. The detergent comprises the following components in parts by weight: 3-40 parts of fatty alcohol polyethenoxy ether, 0-8 parts of propanediol block polyether, 1-10 parts of coconut oil fatty acid diethanolamine, 0-6 parts of coconut oil fatty acid monoethanolamide, 1-20 parts of glycerol, 1-40 parts of propanediol, 1-10 parts of triethanolamine, 1-8 parts of polyethylene glycol 4000, 0.5-20 parts of dodecylbenzene sulfonic acid, 0.1-6 parts of penetrant JFC, 0.1-8 parts of polyether modified silicon oil and 0.1-6 parts of triclosan. The packaging bag is made of a water-soluble packaging material. According to the invention, the detergent is high in active component content; the product is high in effective concentration; multiple surfactants synergistically exert decontamination effect; and the detergent is high in decontamination power and convenient to use. Besides, after the detergent is packaged, the package is small in size and light in weight, and the transportation cost is saved.

Owner:山东丽波日化股份有限公司

Organosilicon microemulsion antisticking agent and preparation method thereof

InactiveCN101406928ALow freezing pointSmall viscosity-temperature coefficientFoundry mouldsFoundry coresSilanesFatty alcohol

The invention relates to an organosilicon micro-emulsion mould release agent which consists of the following compositions in weight percentage: 20 to 35 percent of dimethyl cyclic siloxane, 3 to 7 percent of alkyl triethoxy silane, 2 to 6 percent of fatty alcohol-polyoxyethylene ether, 0.1 to 0.5 percent of ethylenediamine tetracetic acid, 4 to 8 percent of dodecyl benzene sulfonic acid and 50 to 70 percent of deionized water; the sum of the compositions is 100 percent; and the PH value is neutral. The organosilicon micro-emulsion mould release agent overcomes the disadvantages that the prior gaseous mould release agent is inflammable and explosive, pollutes environment and the like. The organosilicon micro-emulsion mould release agent has the advantages of convenient use, good mould release effect, low cost and the like. The organosilicon micro-emulsion mould release agent also releases a method for preparing the organosilicon micro-emulsion mould release agent.

Owner:武汉亿强科技开发股份有限公司

Bicomponent environment-friendly type adhesive and preparing method thereof

InactiveCN101210159AHigh bonding strengthShorten drying timeOrganic non-macromolecular adhesiveUnsaturated alcohol polymer adhesivesOrganic acidPersulfate

The invention relates to a bicomponent environment-friendly adhesive of enhanced type which comprises base and curing agent. The main point of the technology is that a certain amount of polyvinyl alcohol and water are added in a reaction vessel to be continuously stirred to lead the temperature to be increased; after the mixture is fully dissolved and cooled, a certain amount of emulsifier OP-10 and dodecyl benzene sodium sulfate are added into the obtained material and stirred, then added with proper amount of persulphate water solution and prepared alkenyl unsaturated acid ester and alkeneyl unsaturated anhydride or acid mixture; after the temperature is increased to 80 DEG C, the rest alkenyl unsaturated acid ester and alkeneyl unsaturated anhydride or acid mixture are added, then evenly added with the rest persulphate water solution; the obtained material is added with addictive after 2-4 hours, stirred and cooled to 30 DEG C, and the final base product is obtained. The curing agent is prepared by the method of subpackage polyisocyanate, or mixing and continuously stirring compound containing more than one hydroxyl, polyisocyanate and organic acid ester, thus getting the curing agent finished product.

Owner:王喆

Preparation method of nano-silica rosin modified phenolic resin

ActiveCN104693679APromote polycondensation reactionIncrease stickinessHigh volume manufacturingHeat resistance

The invention belongs to the technical field of preparation of phenolic resin, and in particular relates to a preparation method of nano-silica rosin modified phenolic resin. The method is that xylenol, tert-butylphenol, dodecyl-phenol, hydrogenated bisphenol A and formaldehyde are used as the raw materials; the weak-base and weak-acid process is carried out to prepare phenolic resin; rosin and nano-silica are utilized for modifying, so as to prepare the nano-silica rosin modified phenolic resin. The preparation method is simple in process; the prepared phenolic resin is high in viscosity, high in softening point, small in free formaldehyde content, high in heat resistance and corrosion resistance, suitable for industrial mass production, and applicable to preparation of coating and ink, and can be also used as adhesive and rubber components.

Owner:桂林兴松林化有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com