Patents

Literature

910results about How to "Avoid foaming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

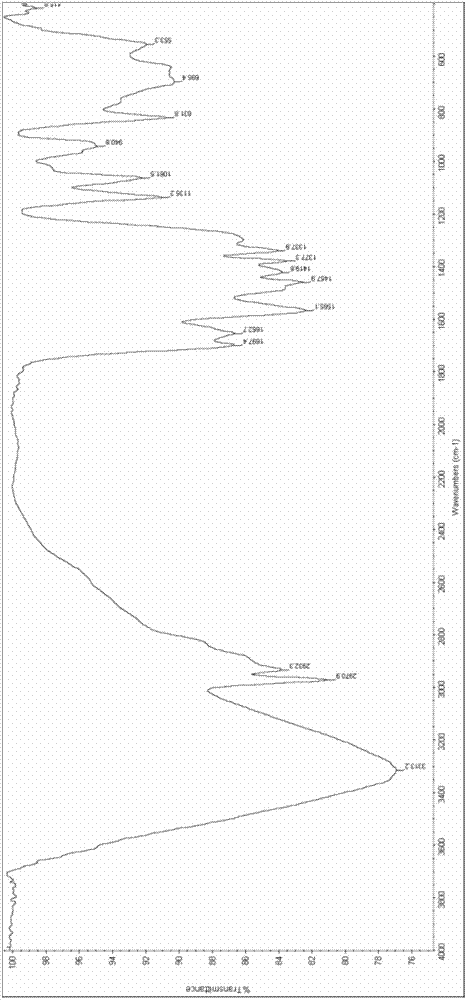

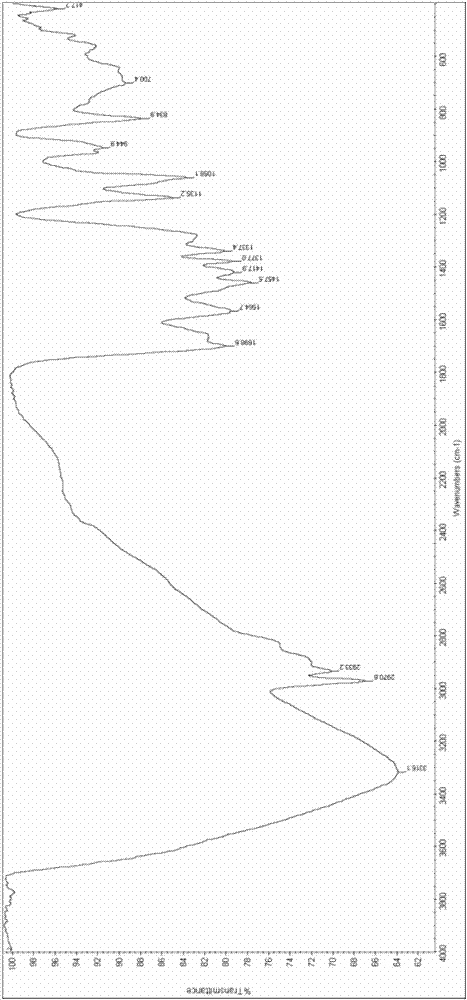

Preparation of recombinant factor VIII in a protein free medium

InactiveUS6171825B1Eliminate and at least greatly reduce riskImprove productivityFactor VIICulture processFactor iiManganese

Recombinant Factor VIII can be produced in relatively large quantities on a continuous basis from mammalian cells in the absence of any animal-derived proteins such as albumin by culturing the cells in a protein free medium supplemented with polyol copolymers, preferably in the presence of trace metals such as copper. In very preferred embodiments, the medium includes a polyglycol known as Pluronic F-68, copper sulfate, ferrous sulfate / EDTA complex, and salts of trace metals such as manganese, molybdenum, silicon, lithium and chromium. With an alternative medium which included trace copper ions alone (without polyol copolymers) we were also able to enhance the productivity of Factor VIII in recombinant cells such as BHK cells that are genetically engineered to express Factor VIII.

Owner:BAYER HEALTHCARE LLC +1

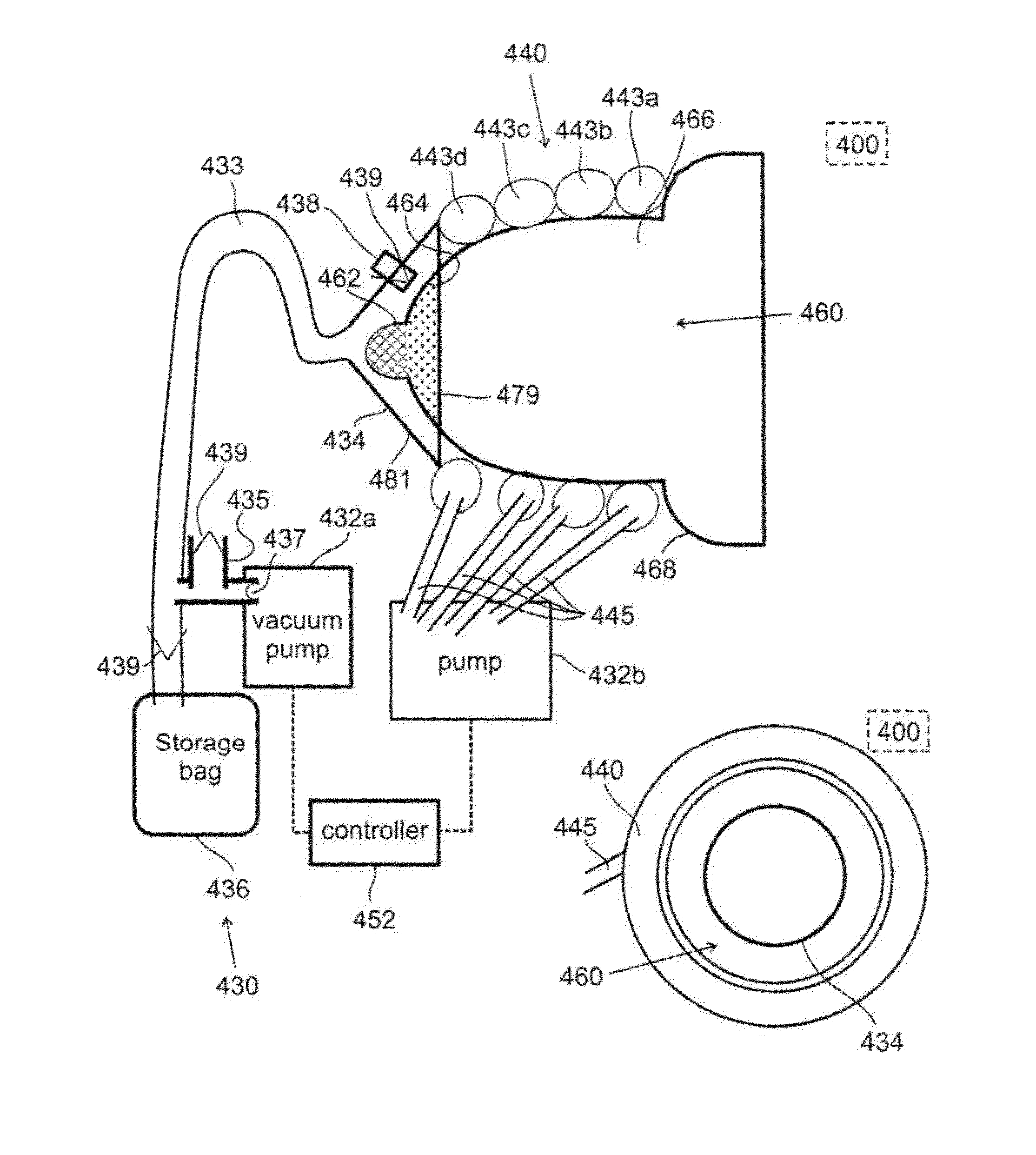

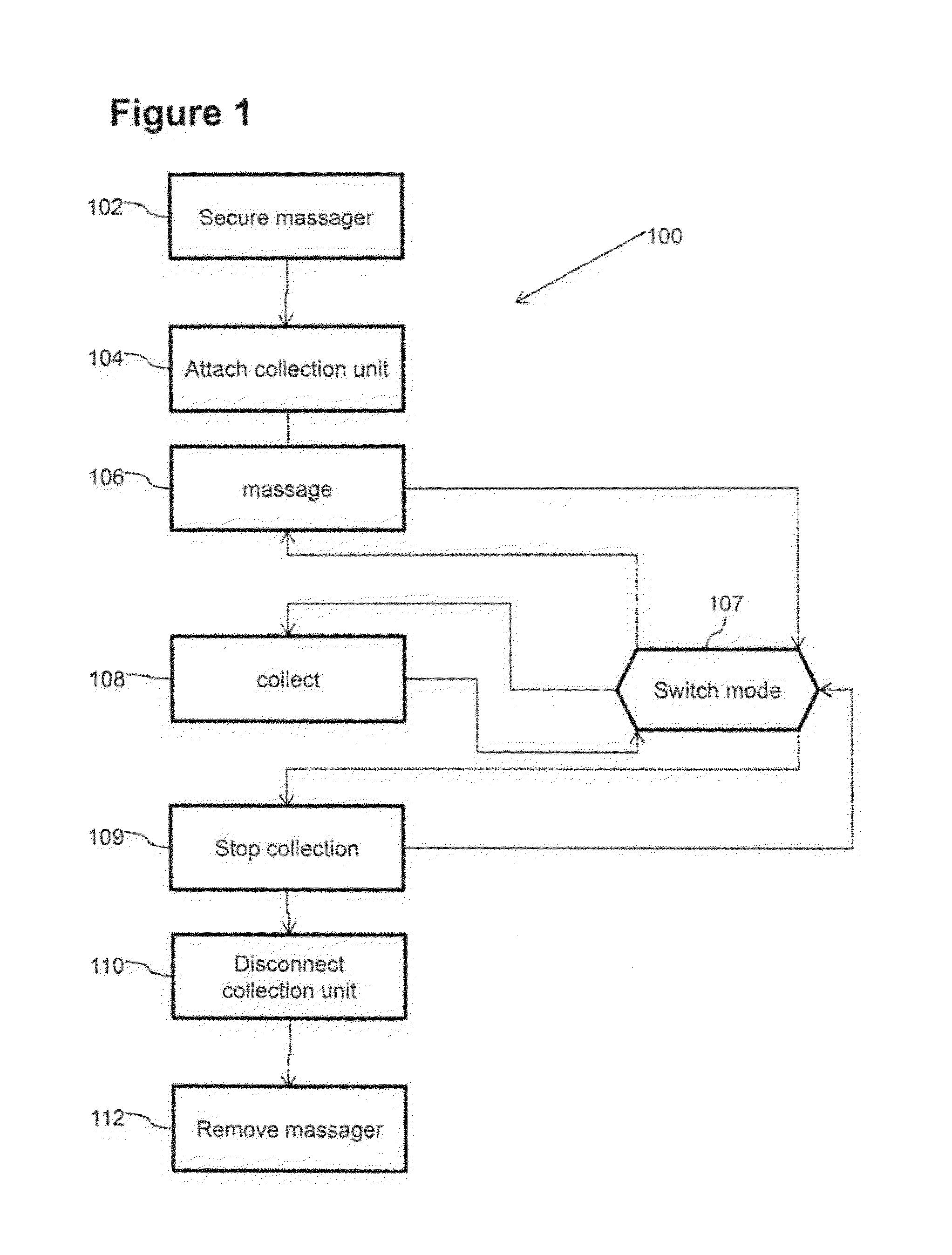

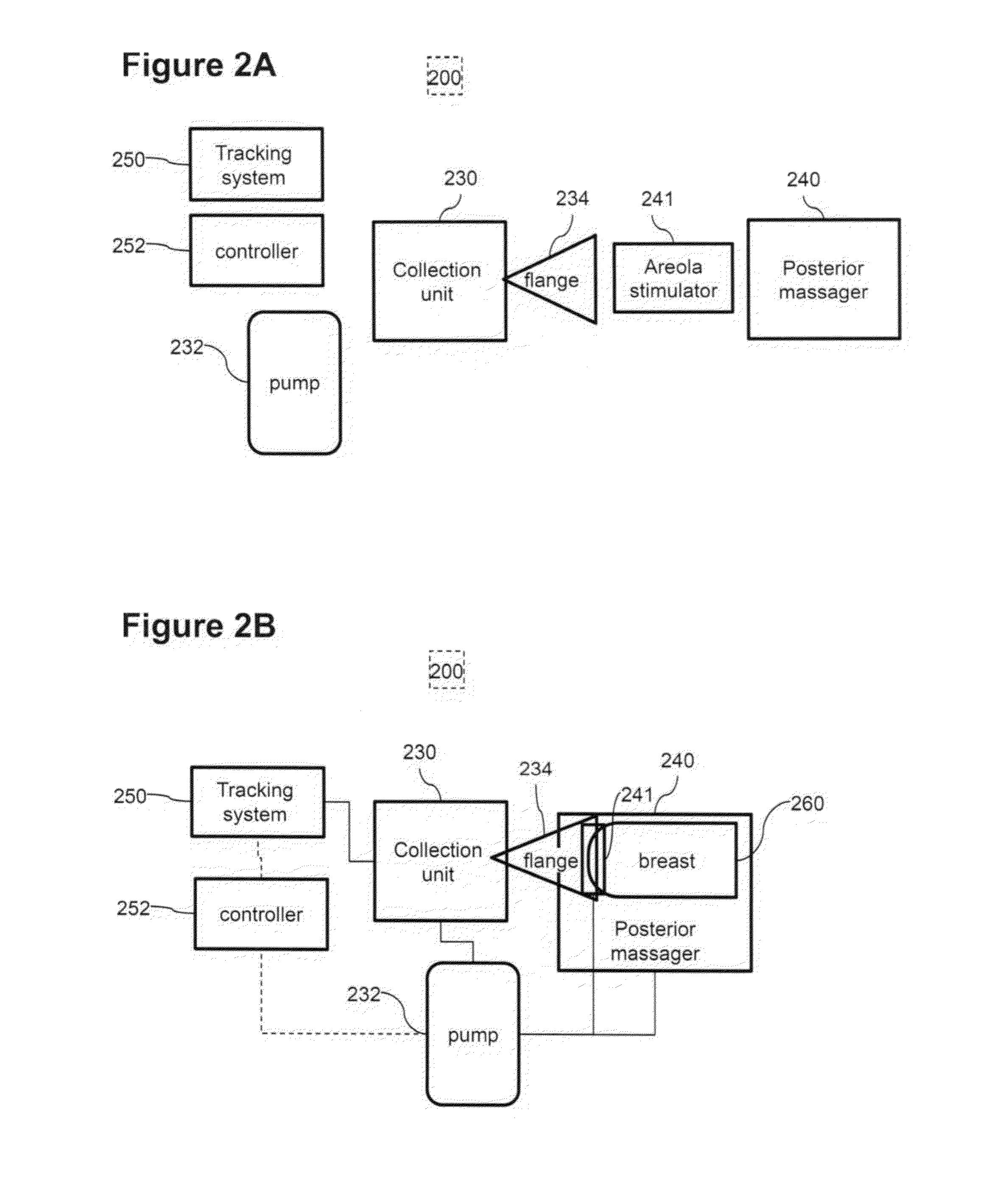

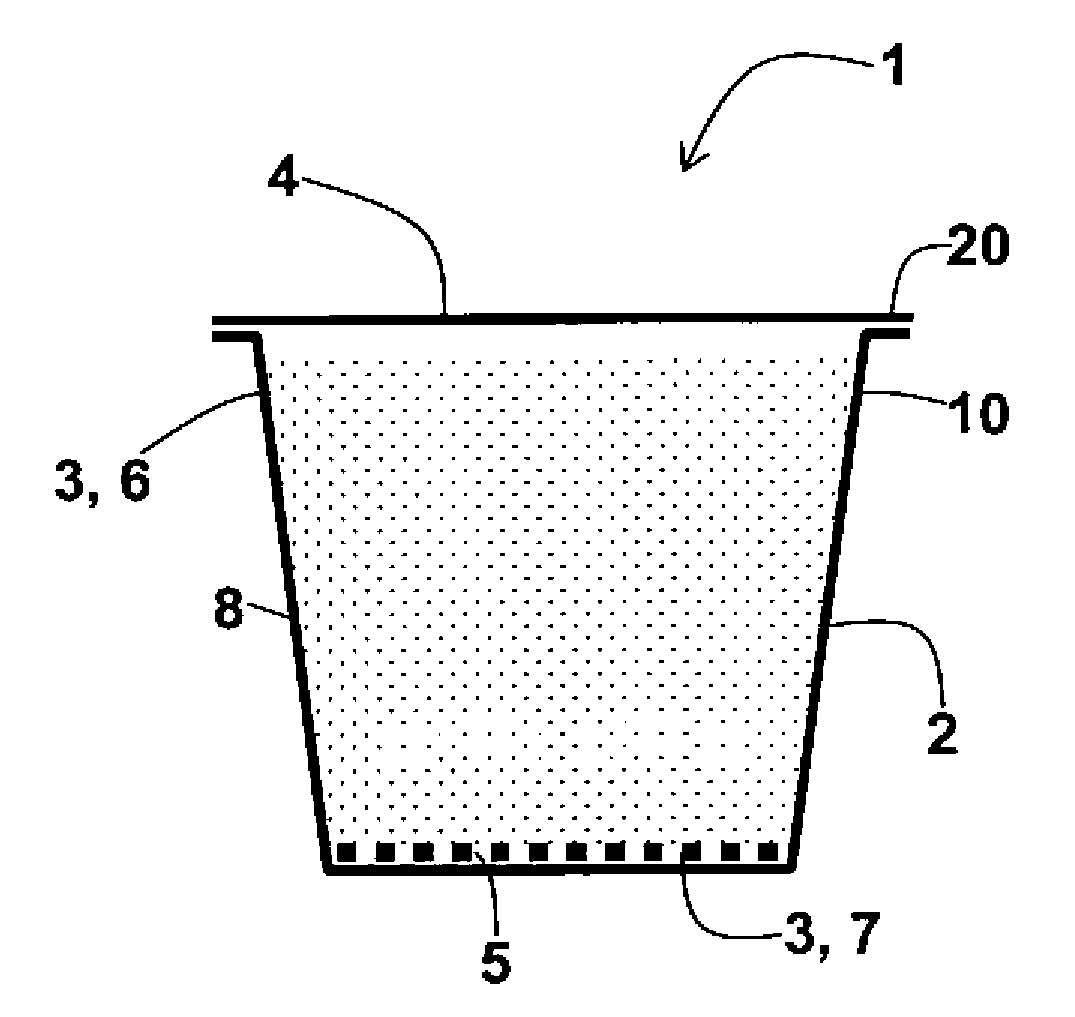

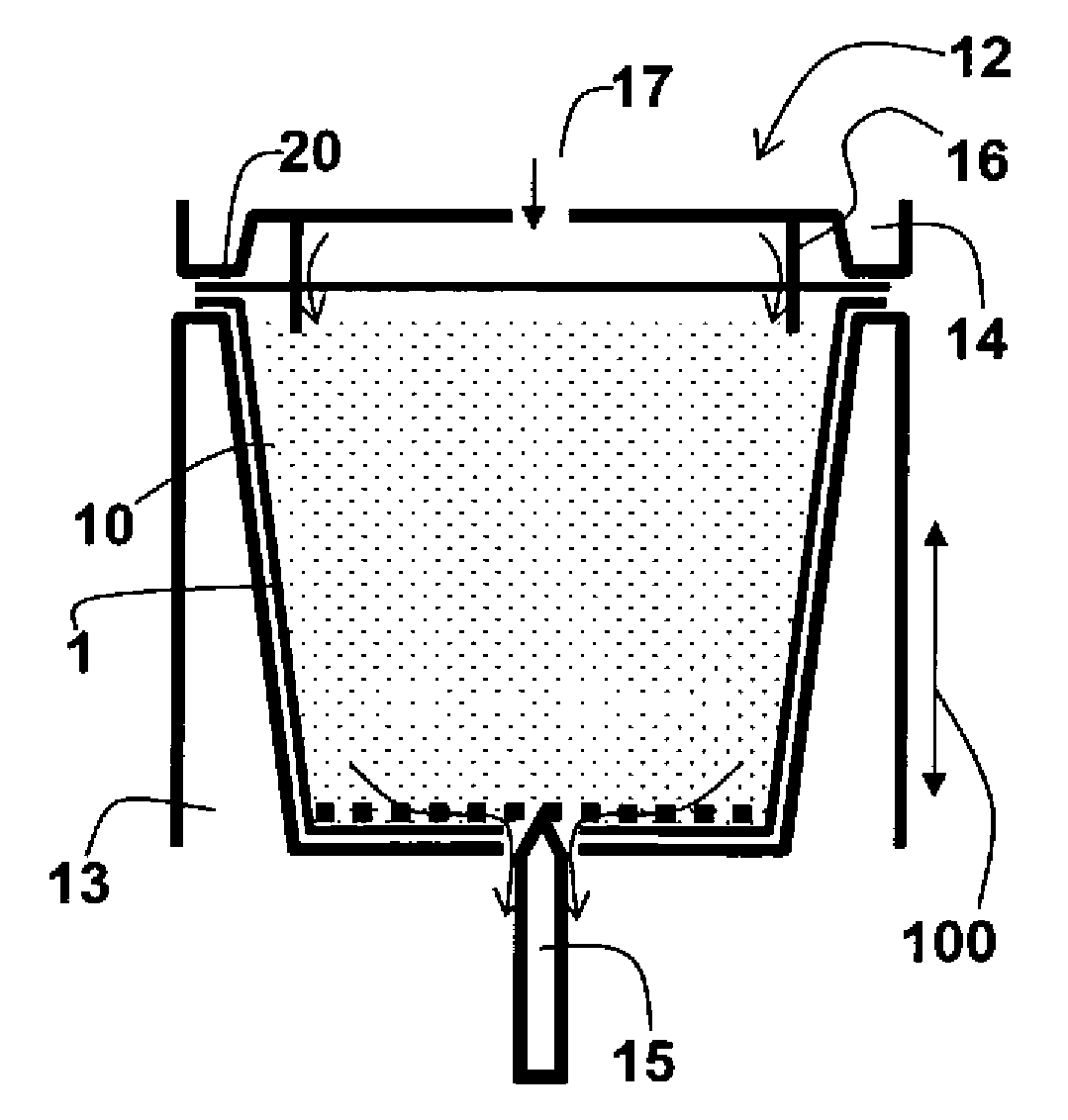

Posterior breast massage unit

A method of milk extraction system may include massaging a posterior of a breast. Massaging and collecting milk may optionally be performed simultaneously. A posterior massager may also be used and / or mounted separately from a collection unit. In some embodiments the massager may be used to improve milk collection and / or alleviate breast ailments for example engorgement, plugged ducts, and / or mastitis. A collection flange may include an air inlet manifold, to mix air and milk. Optionally as air is drawn along a tube by a vacuum, milk may be entrained in the airstream and brought towards a collection vessel. The system may include automated tracking of milk production and / or consumption.

Owner:POSITIVE CARE

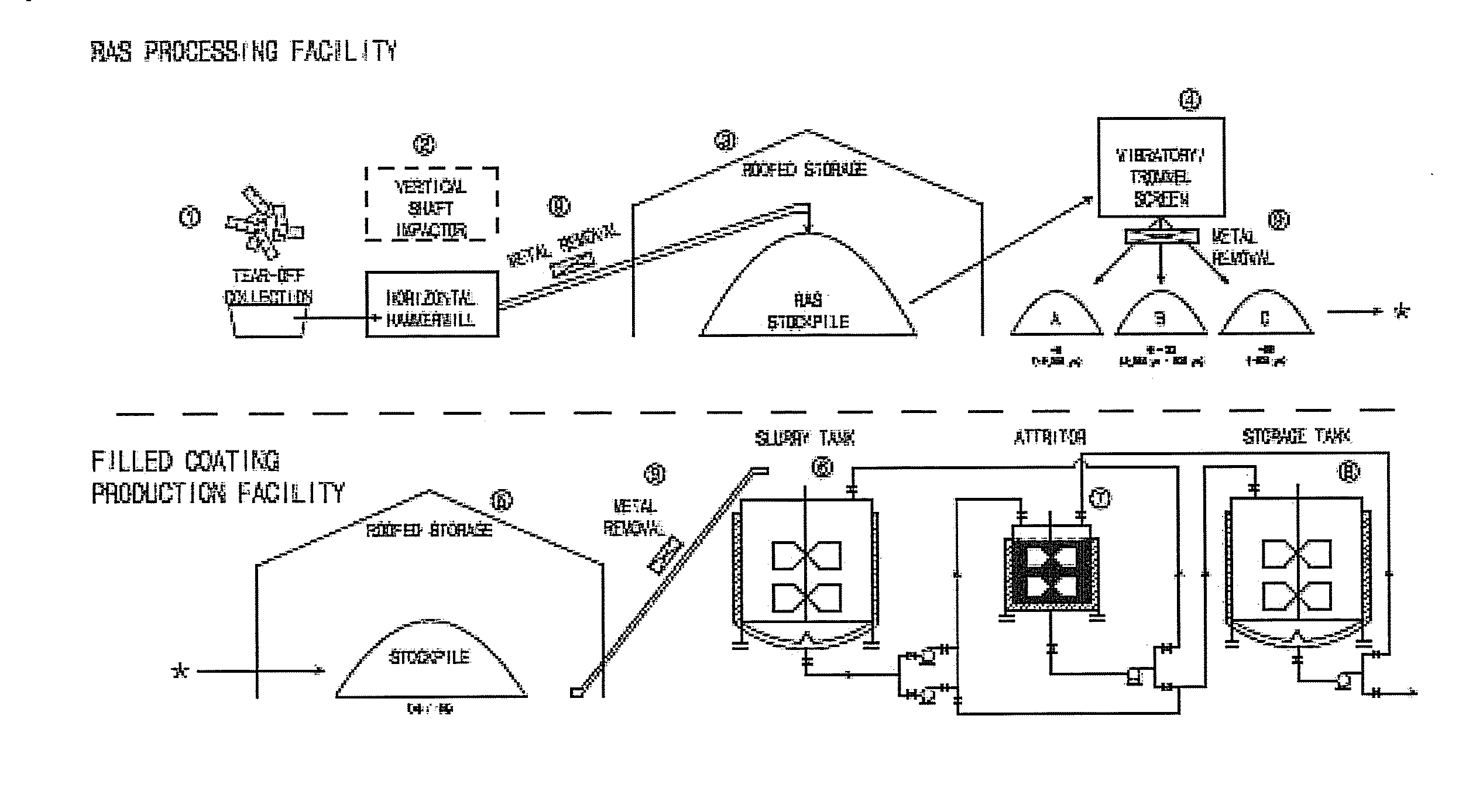

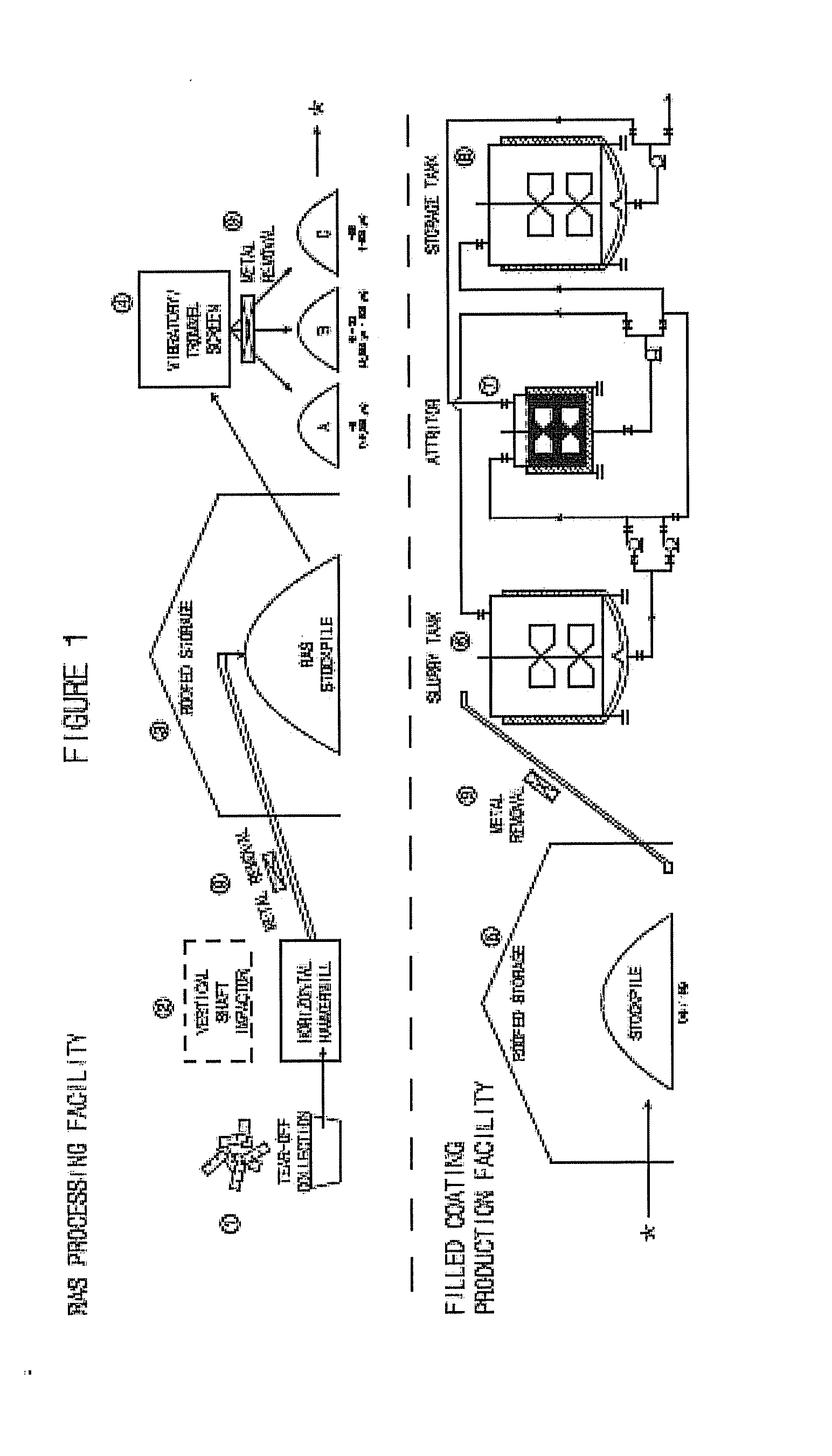

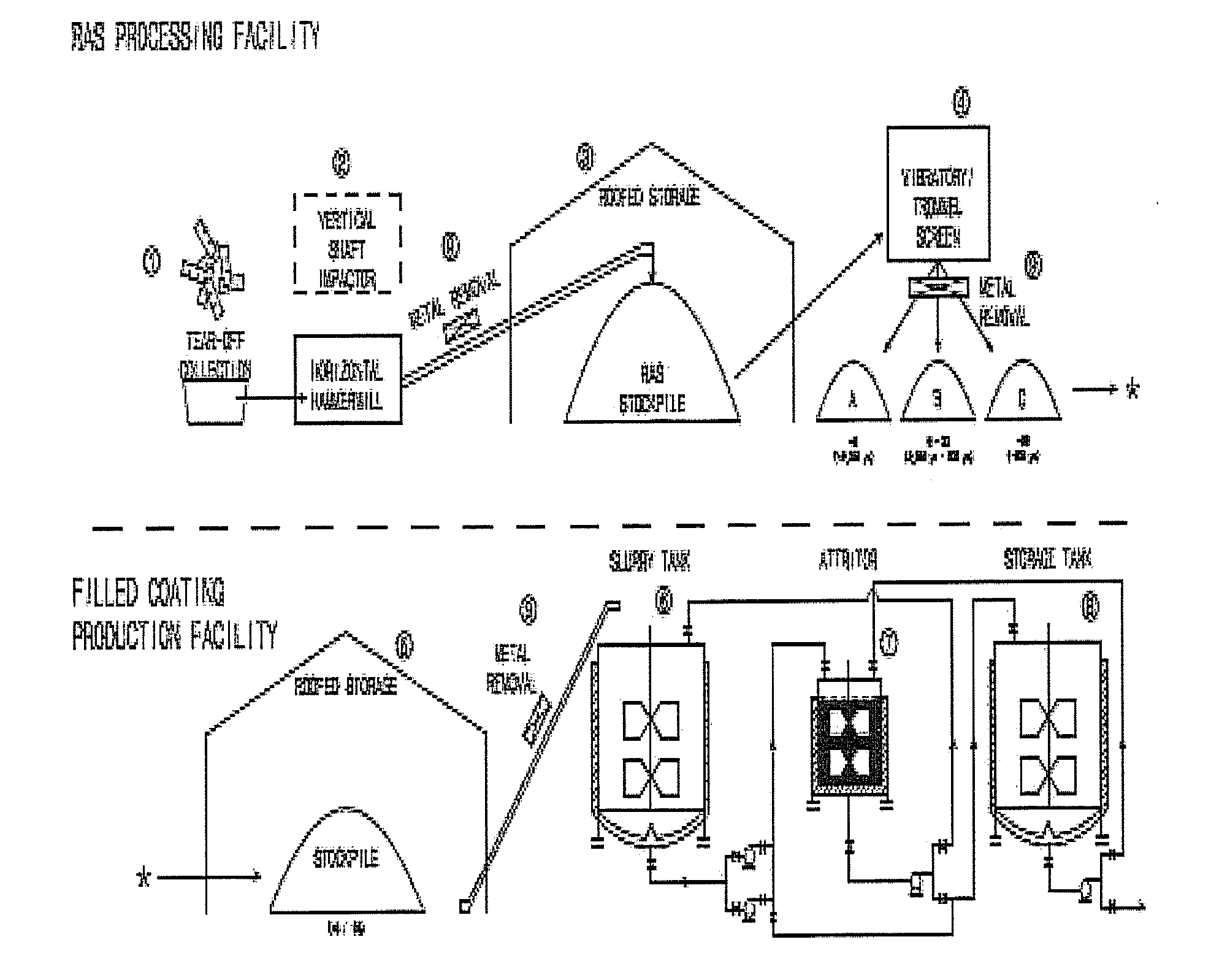

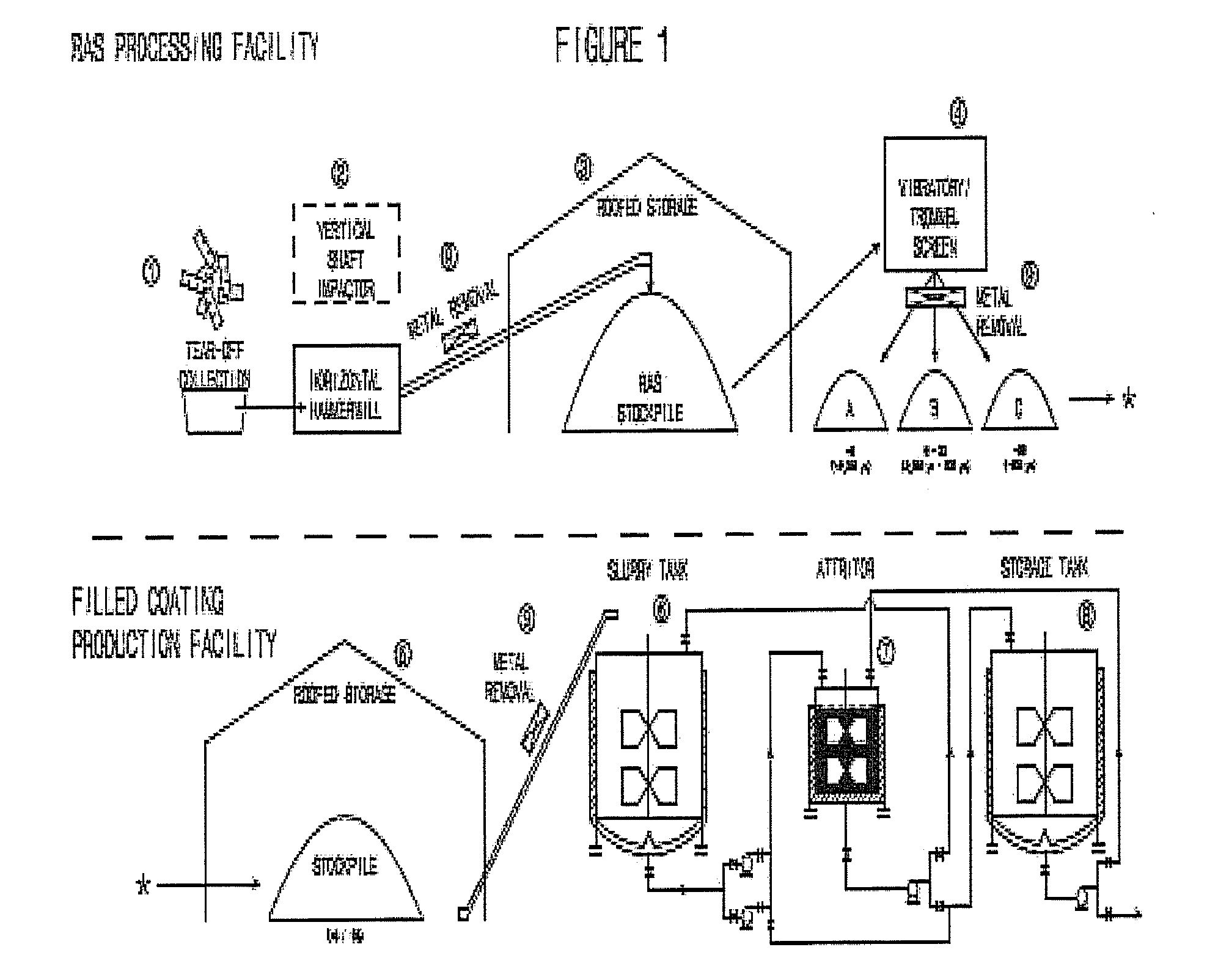

System and method for manufacturing asphalt products with recycled asphalt shingles

InactiveUS20140014000A1Minimize moisturePrevent excessive foamingIn situ pavingsRoof covering using tiles/slatesAsphalt shingleSlurry

A method for manufacturing a processed asphalt suspension is provided. The method includes dry grinding shingle waste material to a particle size of less than 1 cm, forming ground recycled shingle material, introducing virgin asphalt into a heated slurry tank and mixing the ground recycled shingle material with the virgin asphalt in the heated slurry tank, forming a mixed asphalt slurry, introducing the mixed asphalt slurry into a wet grinding machine, and recovering a processed asphalt suspension comprising particles having a size no greater than about 200 microns. Roofing and paving products manufactured from the processed asphalt suspension are also provided.

Owner:HERITAGE ENVIRONMENTAL SERVICES

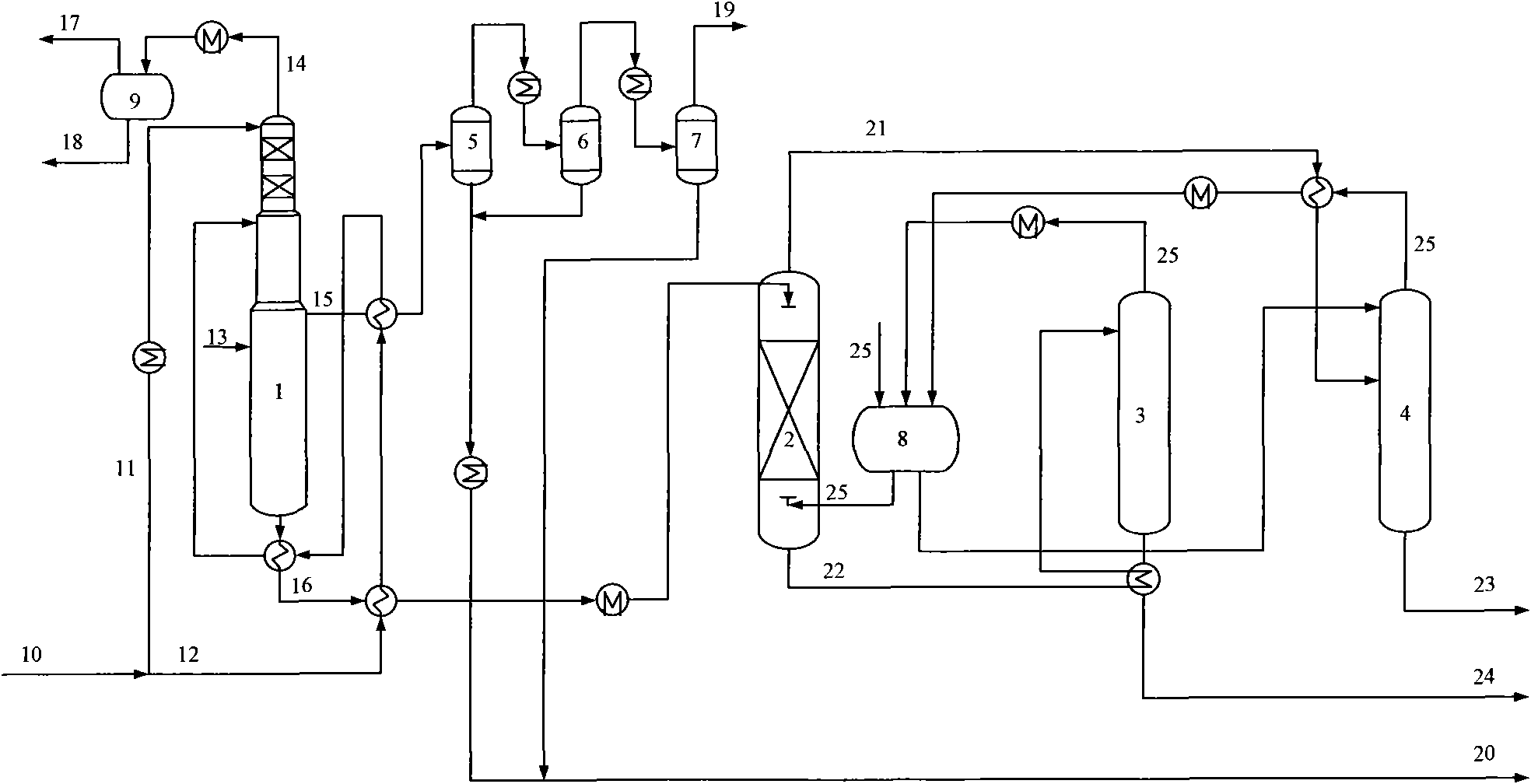

Method for treating coal gasification wastewater containing phenol and ammonia

InactiveCN101597124AEffective removal of fixed ammonia contentMeet the requirements of subsequent biochemical treatmentMultistage water/sewage treatmentWater/sewage treatment by degassingCoal gasification wastewaterHigh concentration

The invention relates to a method for treating coal gasification wastewater containing phenol and ammonia. The method comprises the following steps: single tower alkali injection and pressurization steam stripping removal of acidic gas and ammonia, three-level dephlegmation of lateral line tapped gas, extraction of phenol by diisopropyl ether and solvent recovery. The cold and hot coal gasification wastewater, according to a certain proportion, respectively enters a pressurization single tower from the upper part and middle upper part of a wastewater steam stripping tower, and acid gas is discharged from the tower top; the lateral line withdrawal mixed gas goes through three-level dephlegmation to obtain high-concentration ammonia, alkali is injected at the position below the lateral line to transform fixed ammonia into free ammonia which is to be removed; counter-current extraction is carried out on removed ammonia, residue of acid gas and diisopropyl ether to dephenolize; extraction solvent is recovered by a solvent recovery tower and a solvent steam stripping tower to obtain the byproduct, namely crude phenol. In the method of the invention, the process removing acid gas, free ammonia and fixed ammonia is carried out simultaneously on the coal gasification wastewater in the wastewater steam stripping single tower, as a result, high-concentration ammonia is obtained, the content of carbon dioxide, sulfureted hydrogen, free ammonia and fixed ammonia in tower kettle purified water is extremely low, encrustment is not prone to take place, and the purified coal gasification wastewater meets the requirement of follow-up biochemical treatment.

Owner:SOUTH CHINA UNIV OF TECH +2

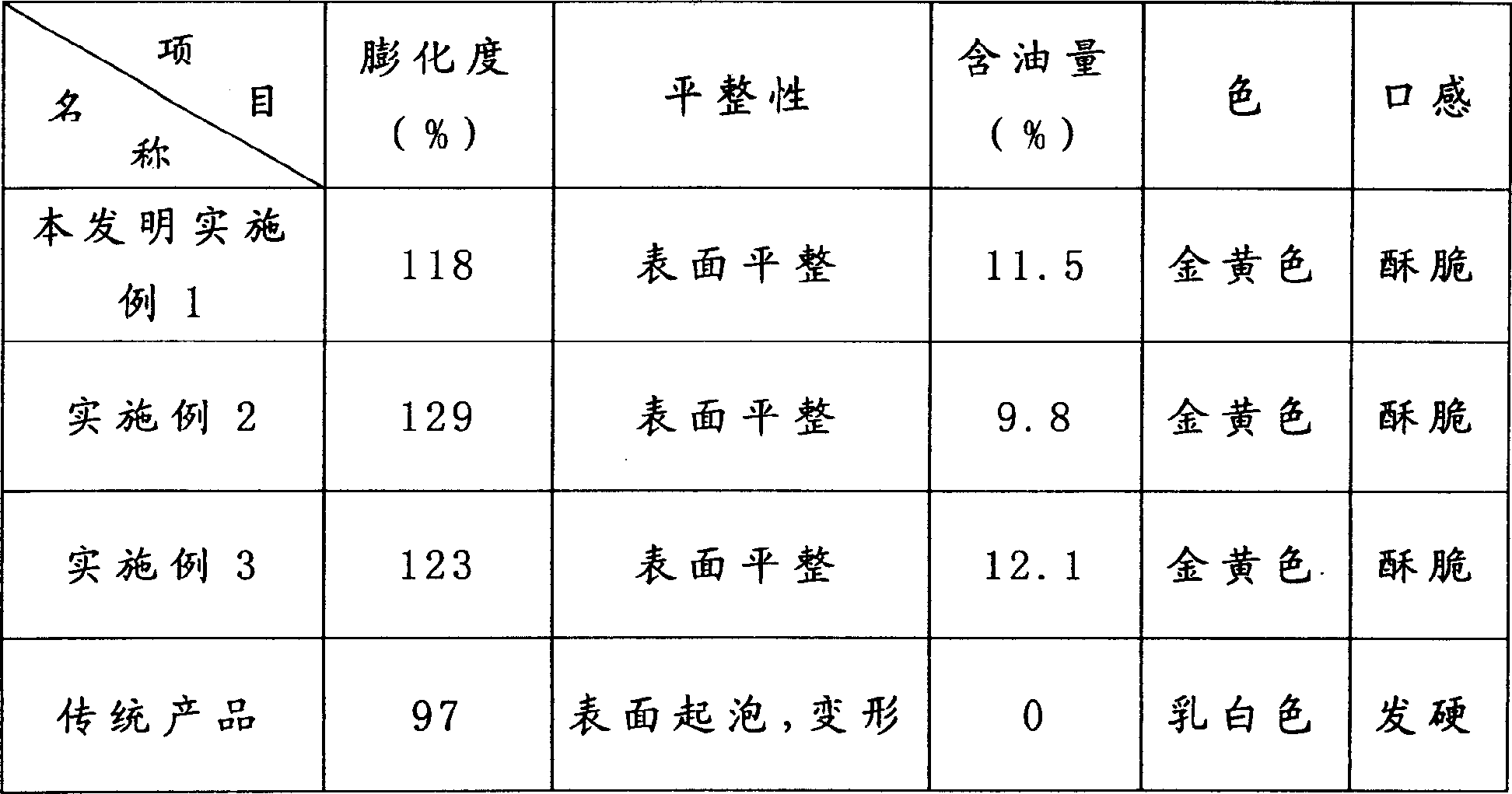

Potato crisp utilizing micro wave processing and its processing method

InactiveCN1891072AEasy to storePreserve nutrientsFood preservationFood preparationChipped potatoesMicrowave

The present invention discloses a kind of potato crisps processed by microwave and its processing method. Said processing method includes the following steps: washing potato flakes, scalding said potato flakes in boiling edible salt water, cooling, draining, freezing, drying, adding palm oil and egg yolk powder, mixing them with potato flakes, uniformly stirring them, roasting them by using microwave and spraying flavouring material so as to obtain the invented product.

Owner:HUNAN AGRICULTURAL UNIV

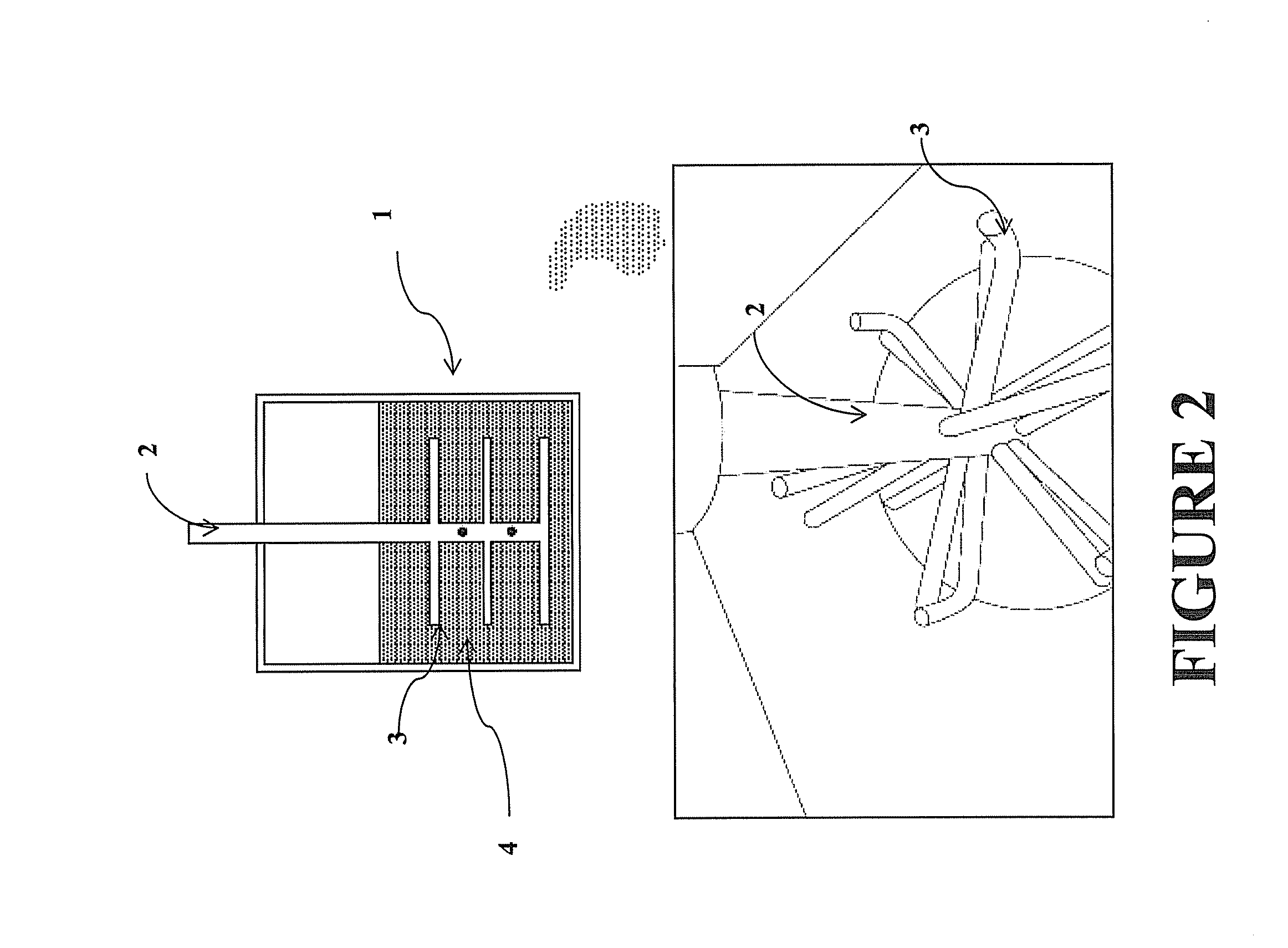

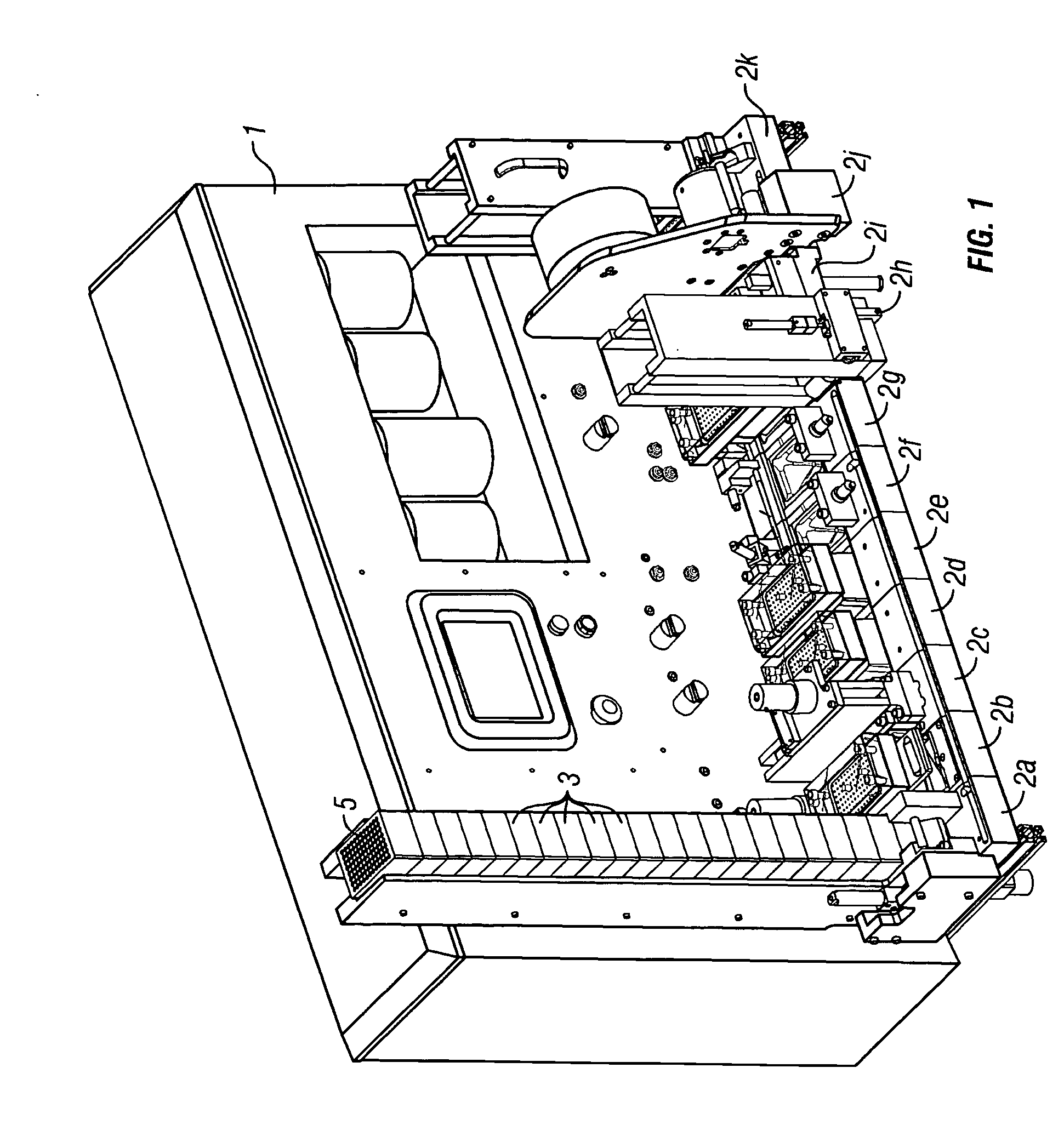

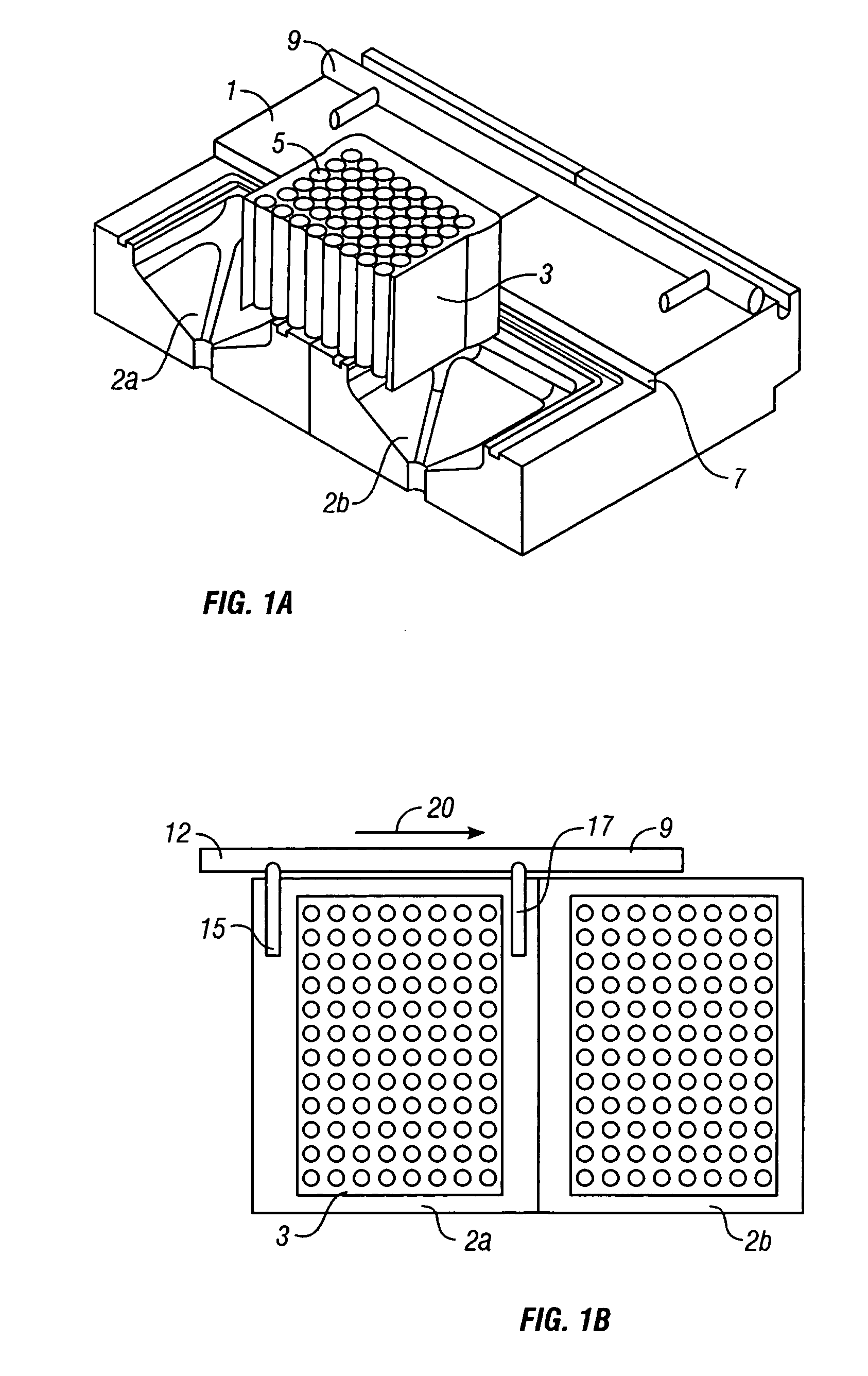

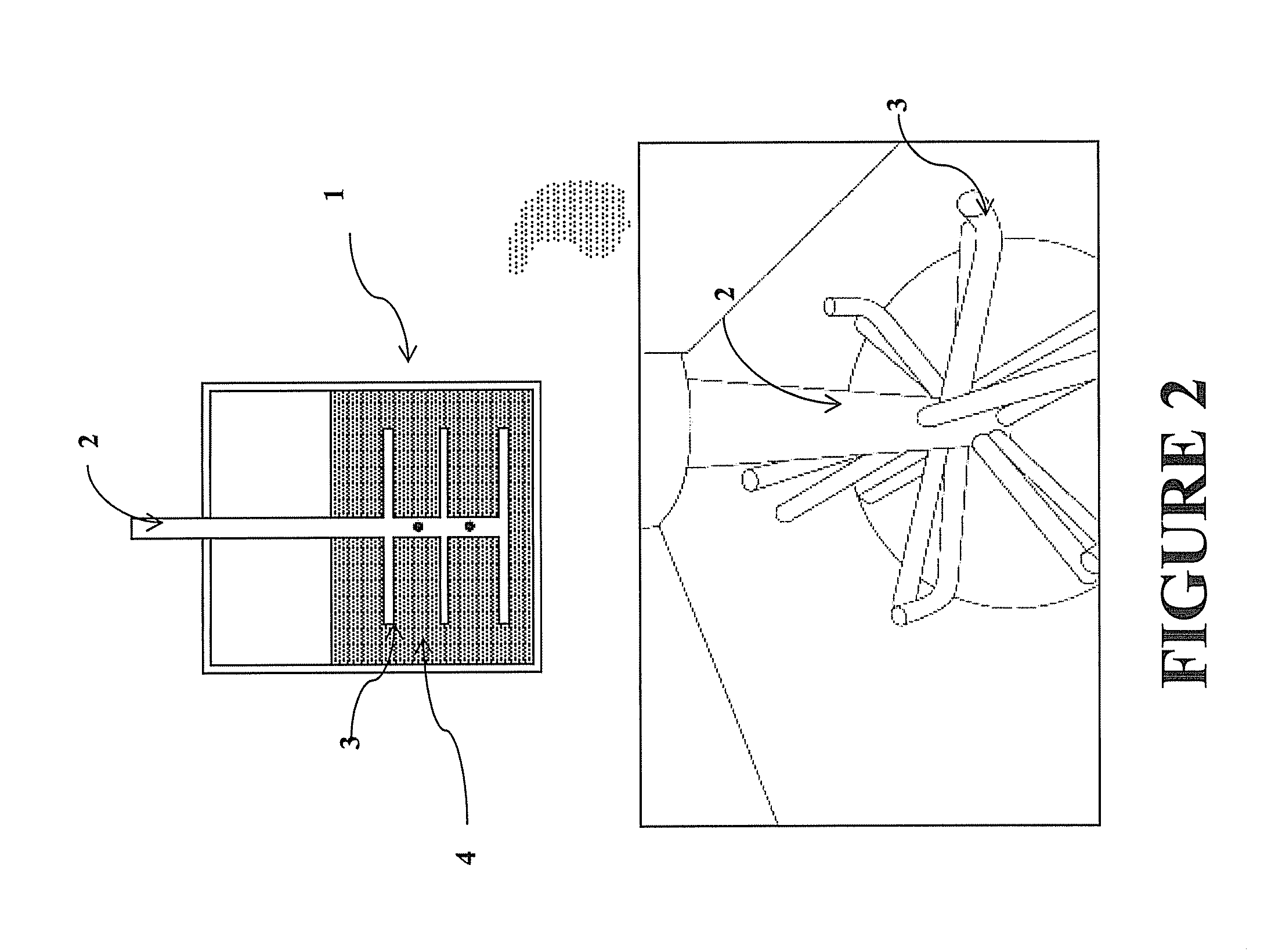

High throughput sample preparation

InactiveUS20050074360A1Easy to separateAvoid foamingAnalysis using chemical indicatorsNucleotide librariesActuatorComputer science

Methods, devices, and systems are provided for processing and manipulation of biological substances. A variety of example embodiments are shown in which enhanced processing are provided. In one non-limiting example, a device is provided for processing containers having a plurality of biological sample wells wherein at least one of the wells includes a biological sample. The device comprises processing stations, a sample guide between the at least two processing stations, and an actuator of the container from at least one processing station to at least another processing station.

Owner:DEWALCH TECH INC

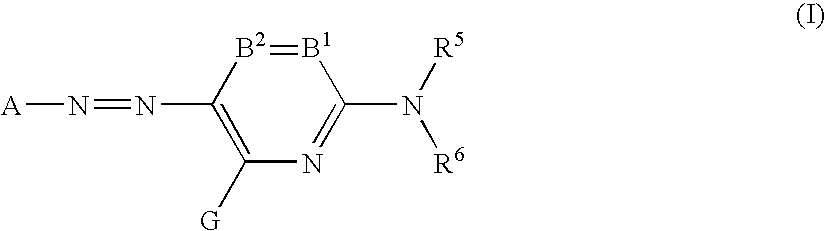

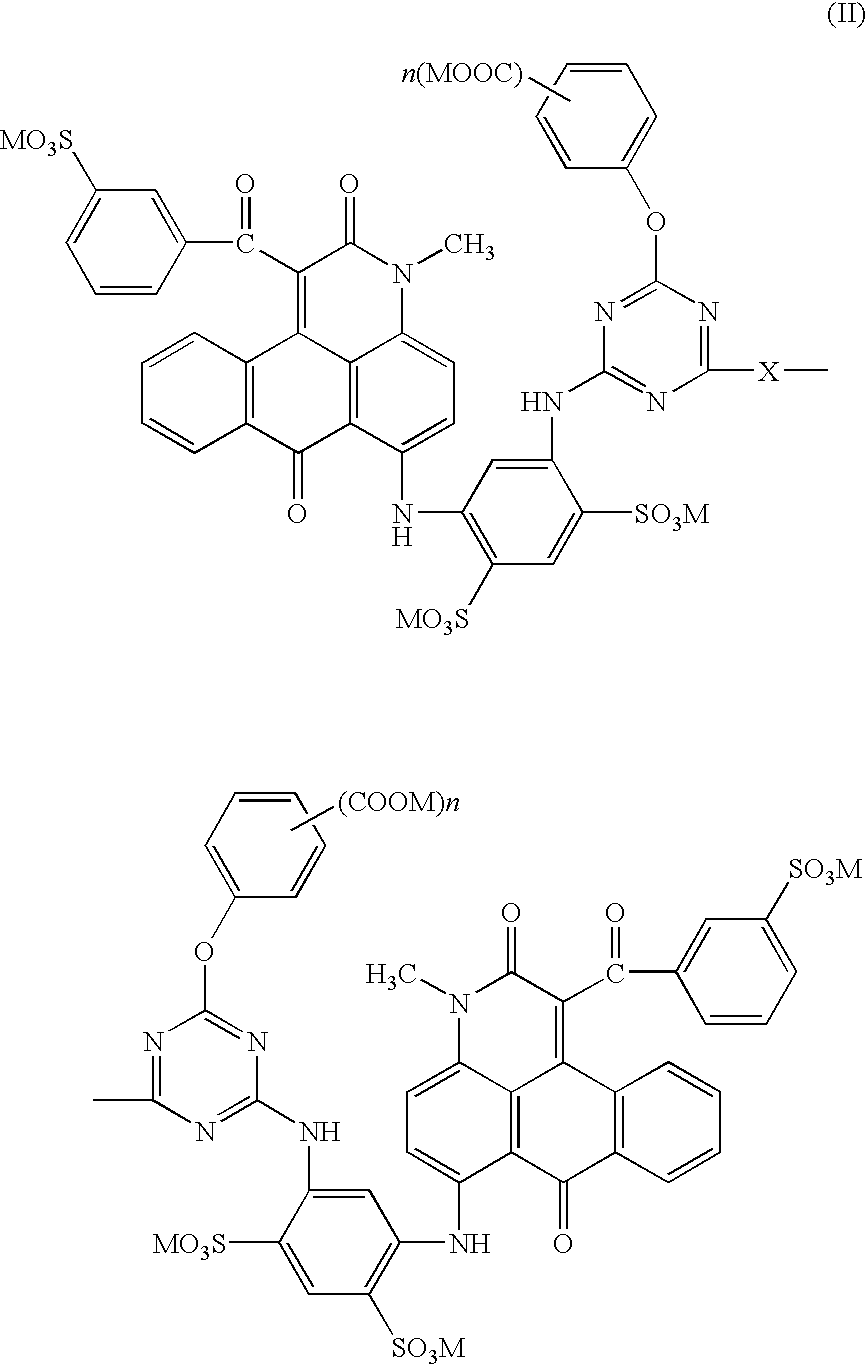

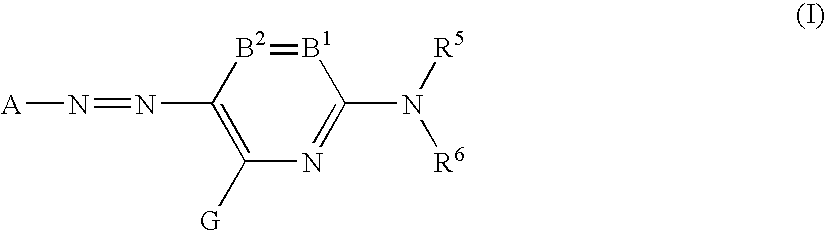

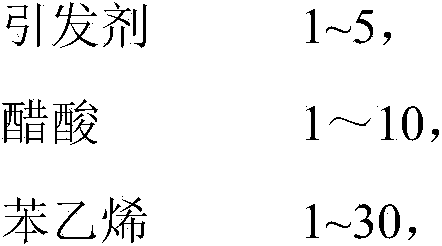

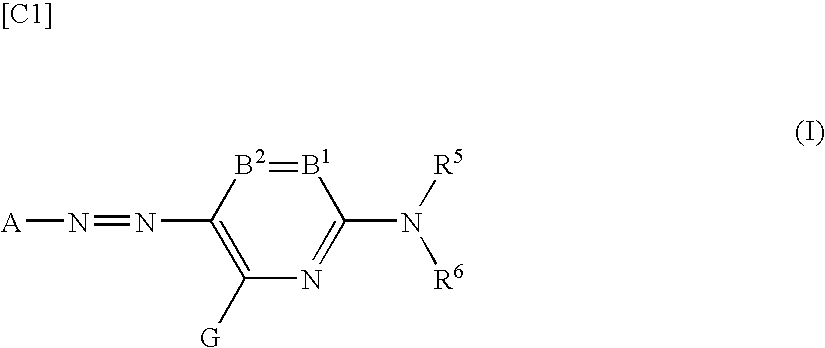

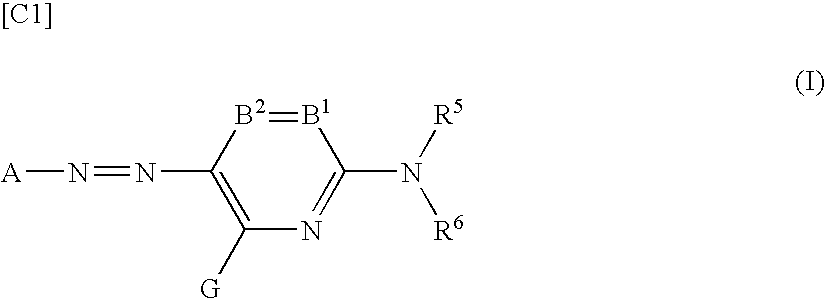

Magenta ink composition, ink set, ink cartridge, inkjet recording method and recorded product

InactiveUS7416592B2Improve printing qualityHigh fastnessMonoazo dyesMeasurement apparatus componentsArylHydrogen atom

A magenta ink composition used as a colorant, containing at least one type of compound represented by Formula (I) below and at least one type of compound represented by Formula (II) below:(wherein A represents the residue of the five member heterocyclic diazo moiety A-NH2; B1 and B2 represent —CR1═ and —CR2═, or one represents a nitrogen atom, and the other represents —CR1═ or —CR2═; R5 and R6 each independently represents a hydrogen atom, aliphatic group, aromatic group, heterocyclic group, acyl group, alkoxy carbonyl group, aryloxy carbonyl group, carbamoyl group, alkyl sulfonyl group, aryl sulfonyl group, or sulfamoyl group, each group therein being optionally substituted; G, R1 and R2 each independently represents a hydrogen atom, halogen atom, aliphatic group, aromatic group, heterocyclic group, cyano group, carboxyl group, carbamoyl group, alkoxycarbonyl group, aryloxy carbonyl group, acyl group, hydroxyl group, alkoxy group, aryloxy group, silyloxy group, acyloxy group, carbamoyloxy group, heterooxy group, alkoxycarbonyloxy group, aryloxycarbonyloxy group, amino group substituted with an alkyl group or aryl group or heterocyclic group, acylamino group, ureide group, sulfamoylamino group, alkoxycarbonylamino group, aryloxycarbonylamino group, alkyl and aryl sulphonylamino group, aryloxycarbonylamino group, nitro group, alkyl and aryl thio group, alkyl and aryl sulfonyl group, alkyl and aryl sulfinyl group, sulfamoyl group, sulfo group, or heterothio group, each group therein being optionally substituted; and R1 and R5, or R1 and R5 may optionally bond together to form a 5 or 6 member ring);(wherein M represents a hydrogen atom, ammonium group, or alkali metal atom; X represents a diaminoalkylene group; and n represents either 1 or 2).

Owner:SEIKO EPSON CORP

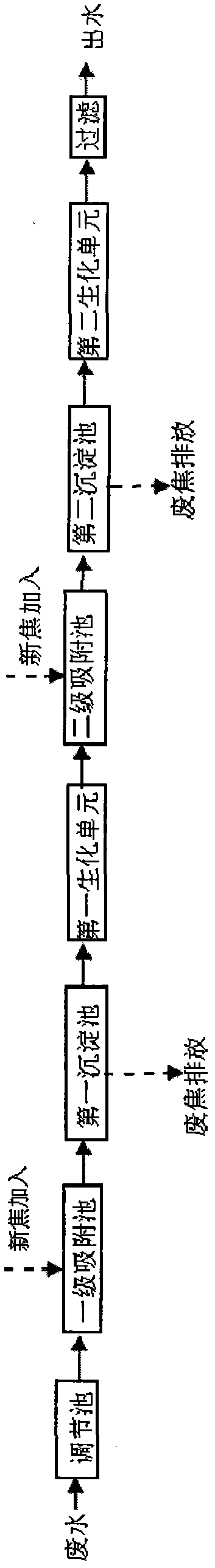

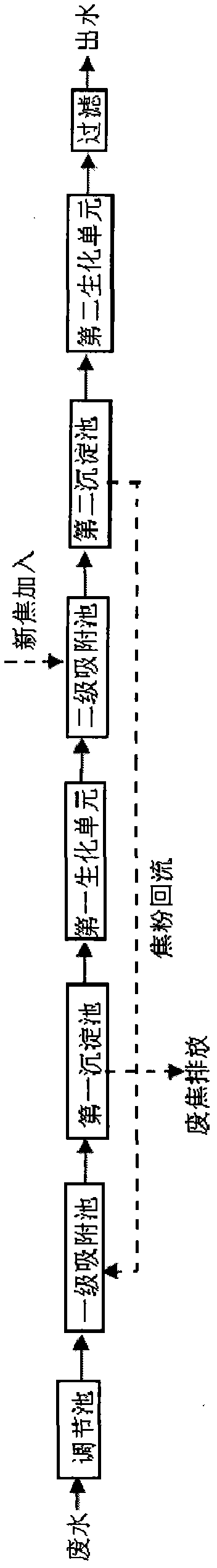

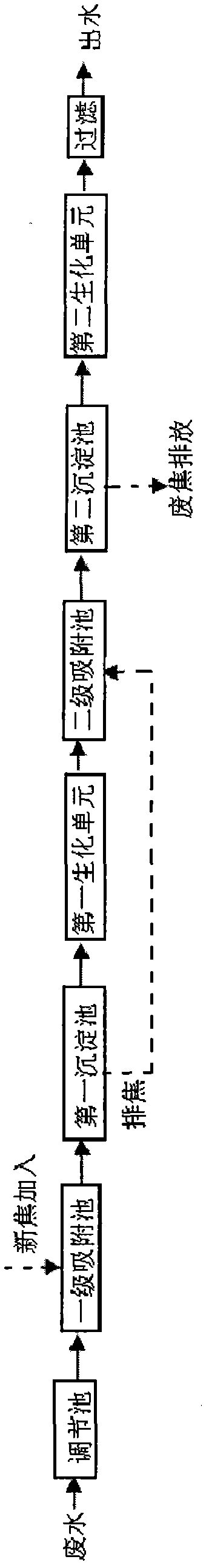

Coal gasification wastewater treatment process

InactiveCN102070277AImprove utilization efficiencyReduce dosageMultistage water/sewage treatmentCoal gasification wastewaterSalt content

The invention discloses a coal gasification wastewater treatment process, which comprises the following steps of: performing adsorption treatment in a primary adsorption tank; performing sedimentation treatment in a first sedimentation tank; performing biochemical treatment in a first biochemical unit; performing adsorption treatment in a secondary adsorption tank; performing sedimentation treatment in a second sedimentation tank; performing biochemical treatment in a second biochemical unit; and filtering and discharging. The coal gasification wastewater treatment process solves the technical problem that active carbon is added into an active sludge aeration tank to influence the effects of the biochemical treatment and the adsorption treatment in the conventional coal gasification wastewater treatment process, has the advantages of independent adsorption and biochemical treatment, combined arrangement, concise process, high treatment efficiency, no increase of salt content and stable operation, and is particularly suitable for treating coal gasification wastewater.

Owner:北京国能普华环保工程技术有限公司 +1

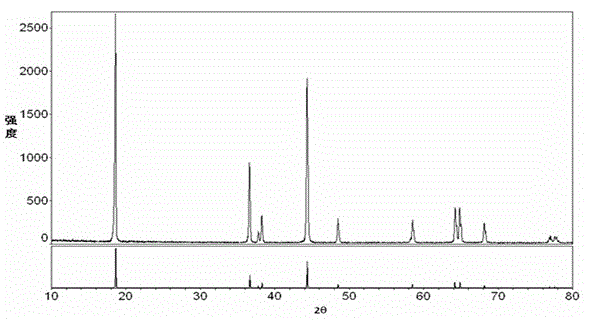

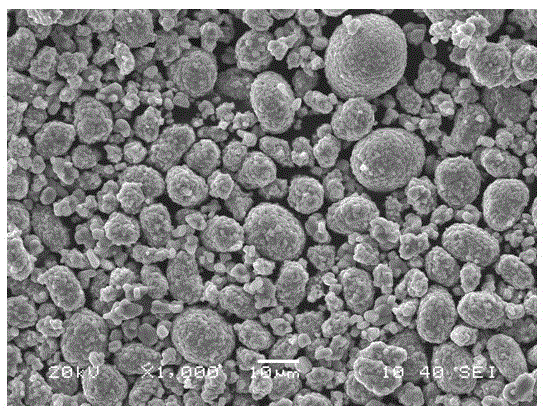

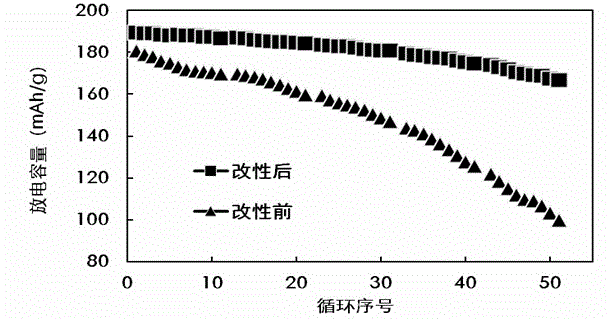

Positive electrode material of high-capacity dynamic-type nickel-rich lithium ion battery and preparation method thereof

ActiveCN103606671AStable structureImprove cycle performanceCell electrodesMaterials processingLithium-ion battery

The invention relates to a positive electrode material of a high-capacity dynamic-type nickel-rich lithium ion battery and a preparation method. The molecular formula of the positive electrode material of the high-capacity dynamic-type nickel-rich lithium ion battery is LiaNi1-x(MM')xO2.M''O, wherein a is equal to 0.9-1.2, x is more than or equal to 0 and less than or equal to 0.7, and M is at least one of Co, Mn and Al; M' is at least one of Co, Al, V, Mn, Zr, Mg, Ti, Cr, Zr, La, Ce, Pr, Nd, Nb, Mo, Y, Sr, Ba, B, Sr, Sn and Ta; M''O is a cladding layer, and M'' is Co and Al. The invention also relates to a preparation method for the positive electrode material of the high-capacity dynamic-type nickel-rich lithium ion battery. The material machining performance is excellent, the battery prepared by utilizing the material, the cycling performance and the high-voltage performance are excellent, the safety and stability in use can be realized, not only can the application performance requirement of a portable electronic device on the battery be met, but also the positive electrode material is applicable to the power battery.

Owner:HUNAN SHANSHAN ENERGY TECH CO LTD

Methods of manufacture of polylactic acid foams

A method of forming a composition of expanded polylactic acid (PLA) resin beads comprising impregnating PLA resin beads with CO2 and holding the impregnated beads at a temperature and pressure that prevents the beads from foaming while allowing the level of impregnated CO2 to reduce. The method may comprise pre-expanding the beads at a pre-expansion temperature. Promptly following pre-expansion or after a desired storage period, the method may comprise introducing the pre-expanded beads into a mould and further expanding and fusing the beads in the mould by application of a temperature greater than the temperature used for pre-expansion. Preferred moulded products include moulded blocks and shaped moulded products, especially blocks adapted to form packing material. Other preferred moulded products include convenience items such as containers including clamshell containers, pots, boxes, bowls, cups, plates and trays.

Owner:BIOPOLYMER NETWORK

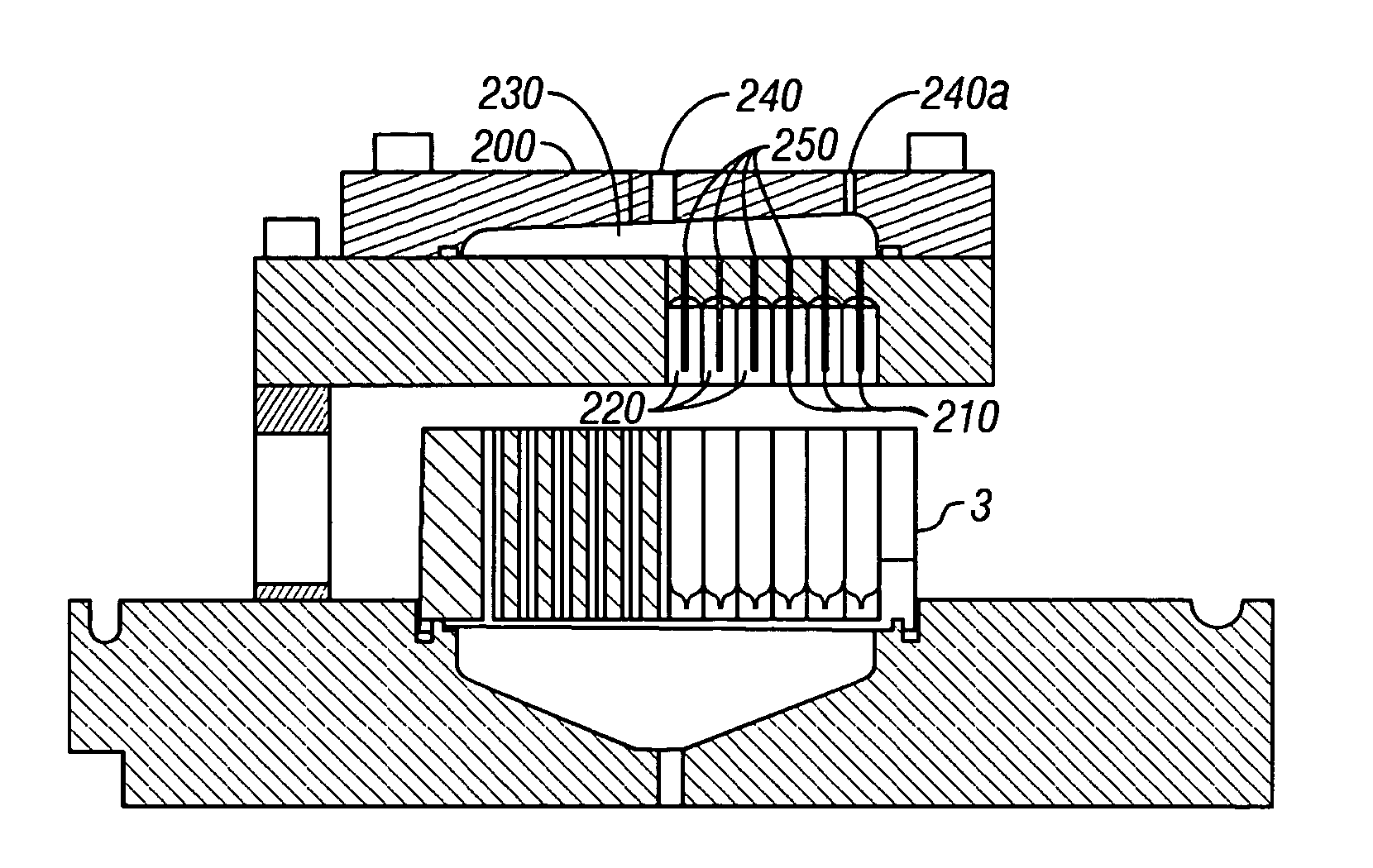

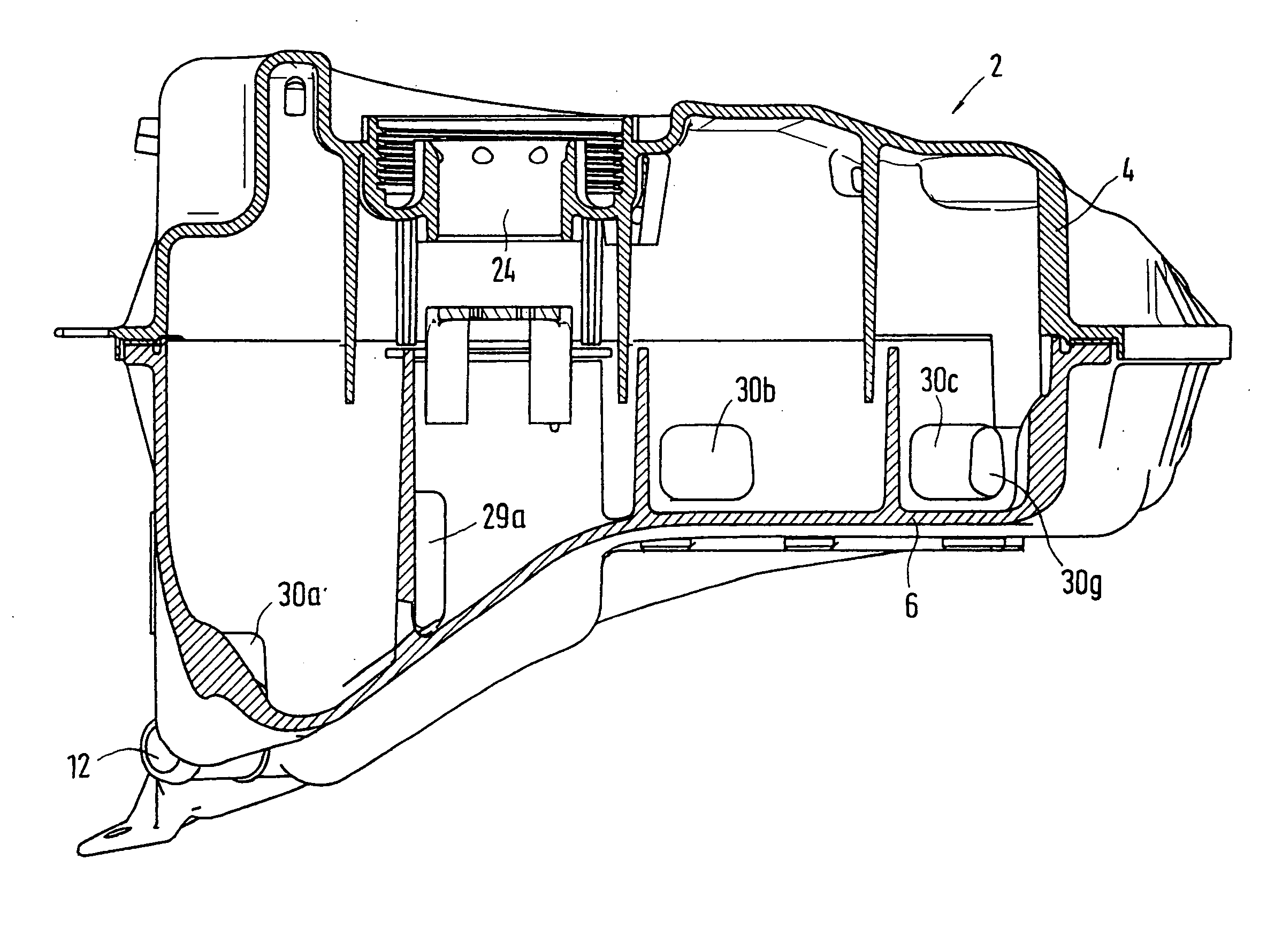

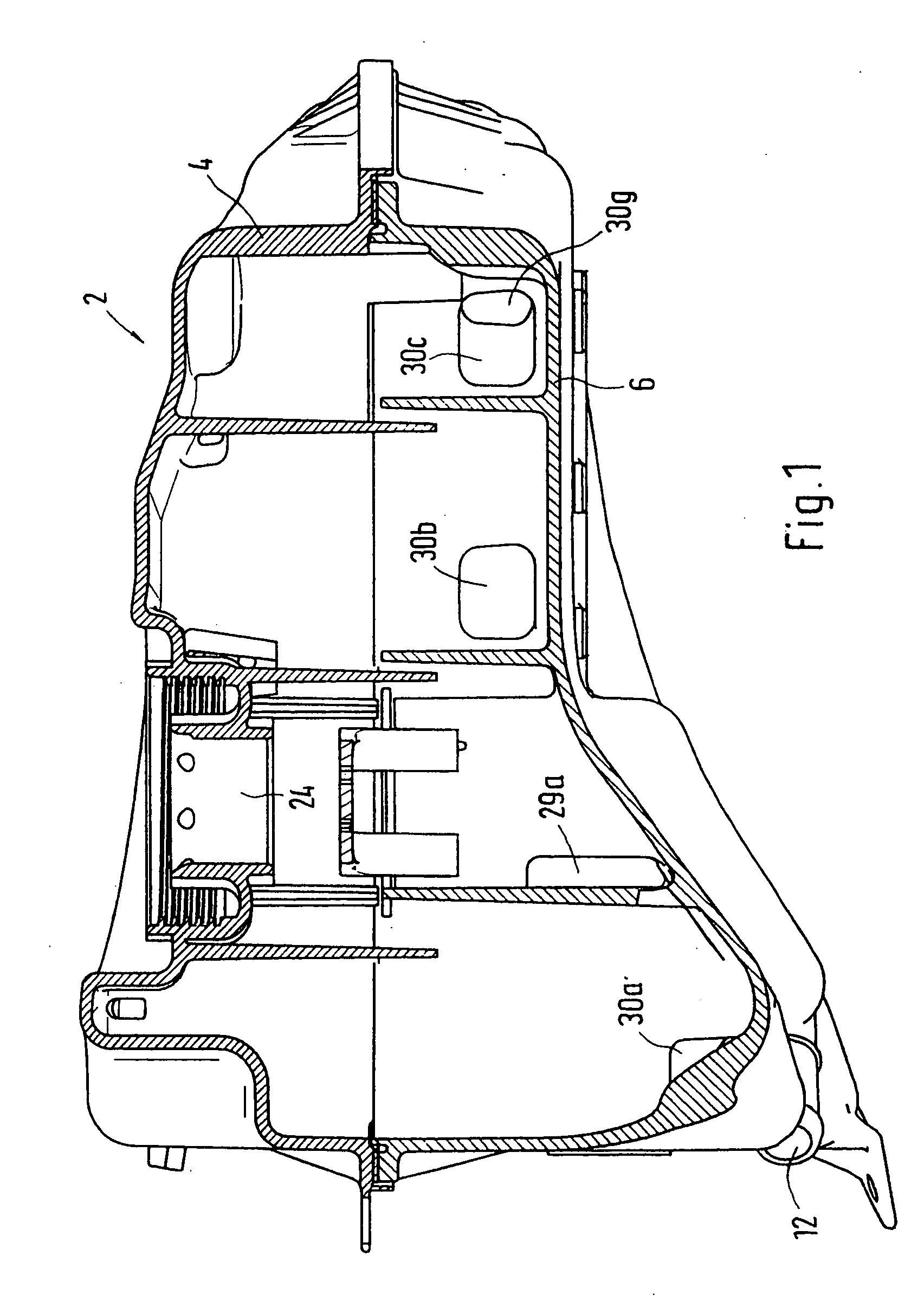

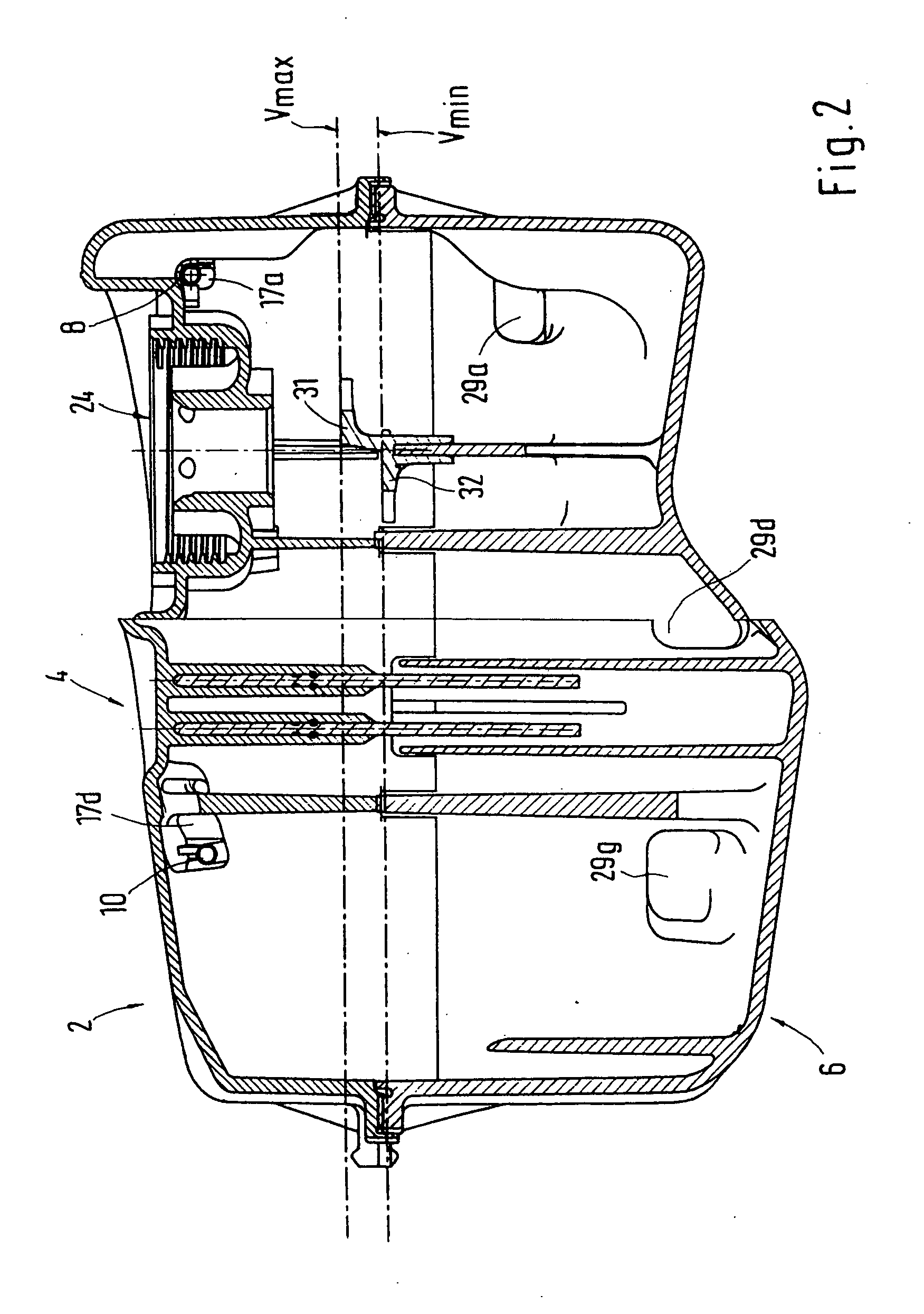

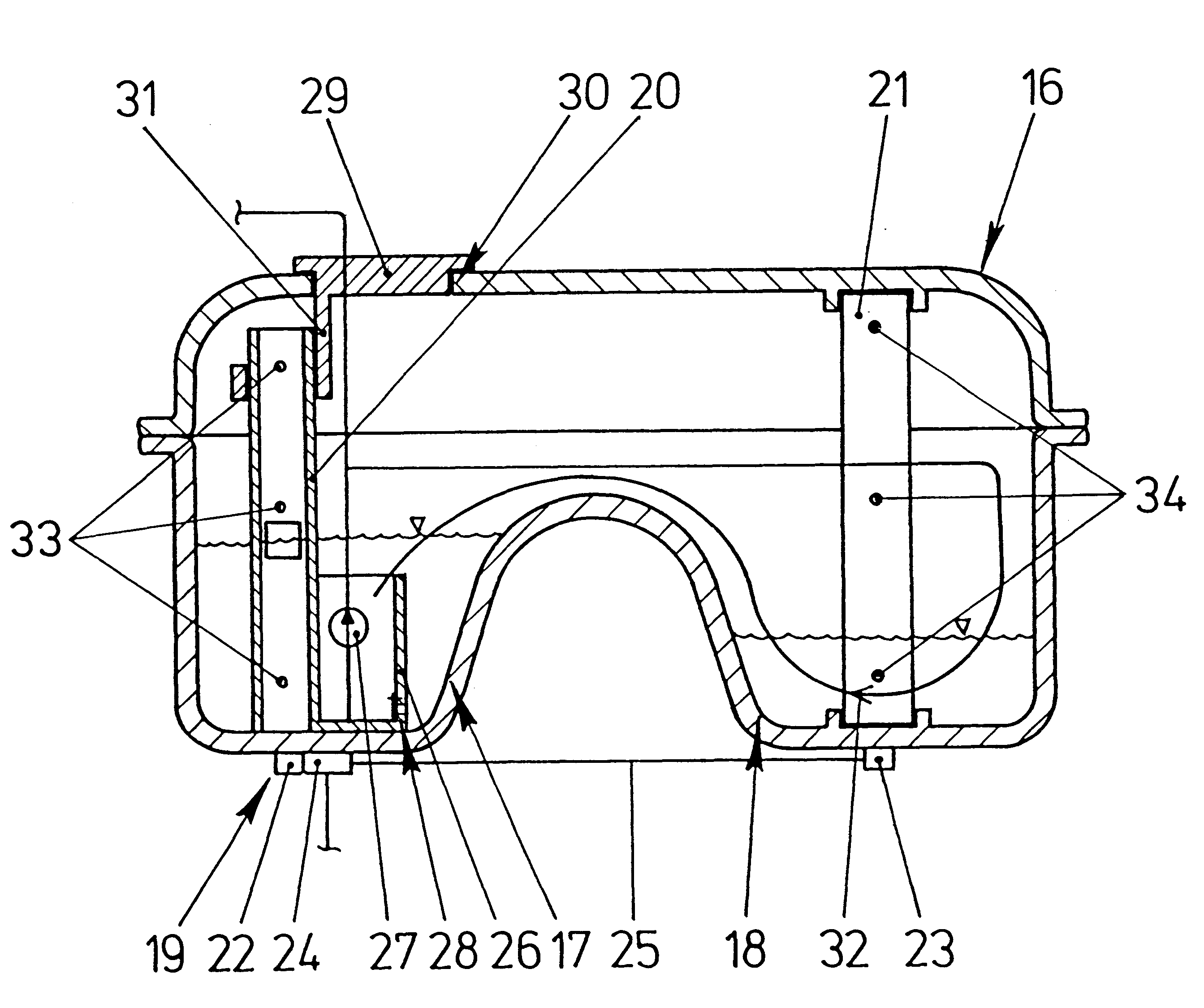

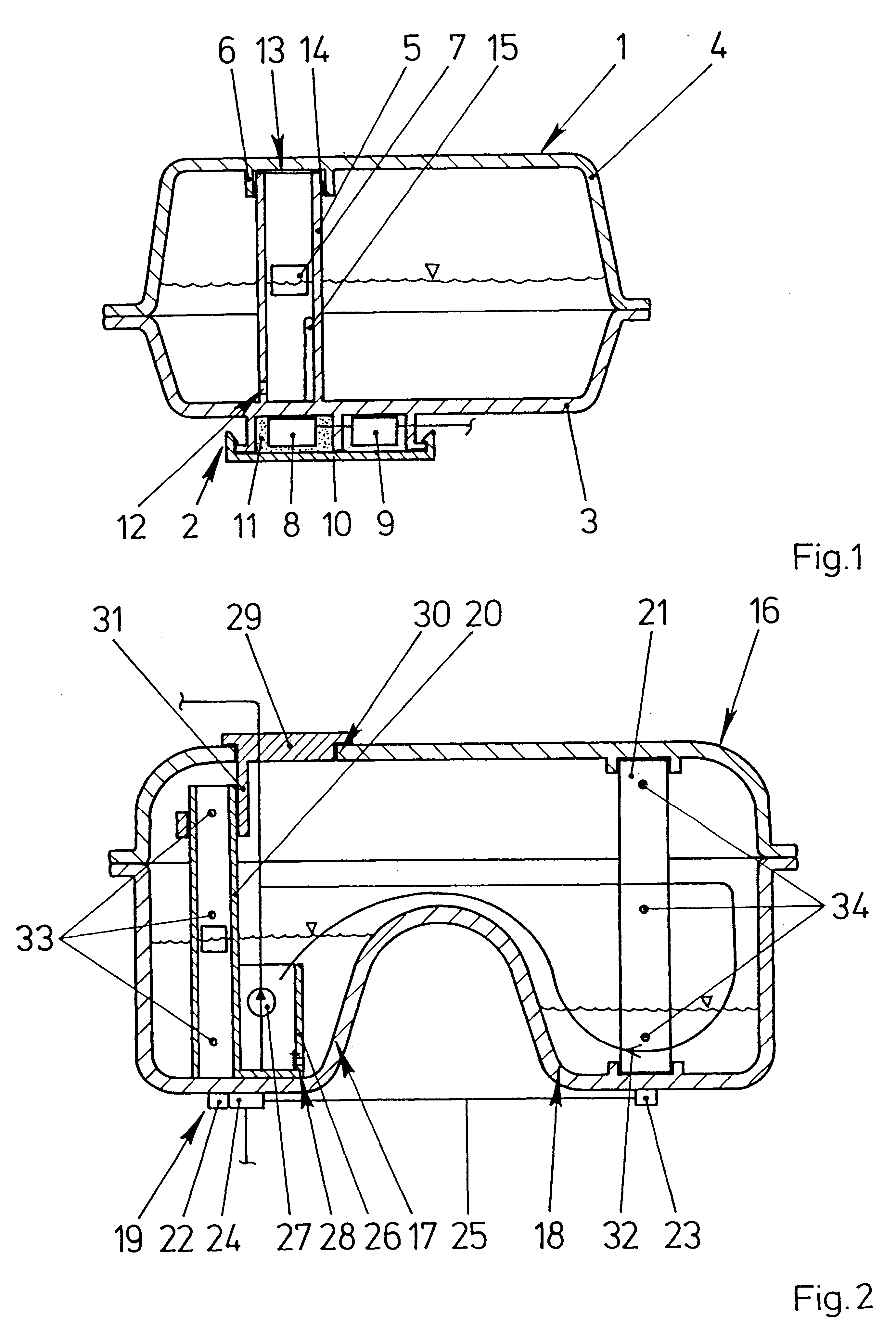

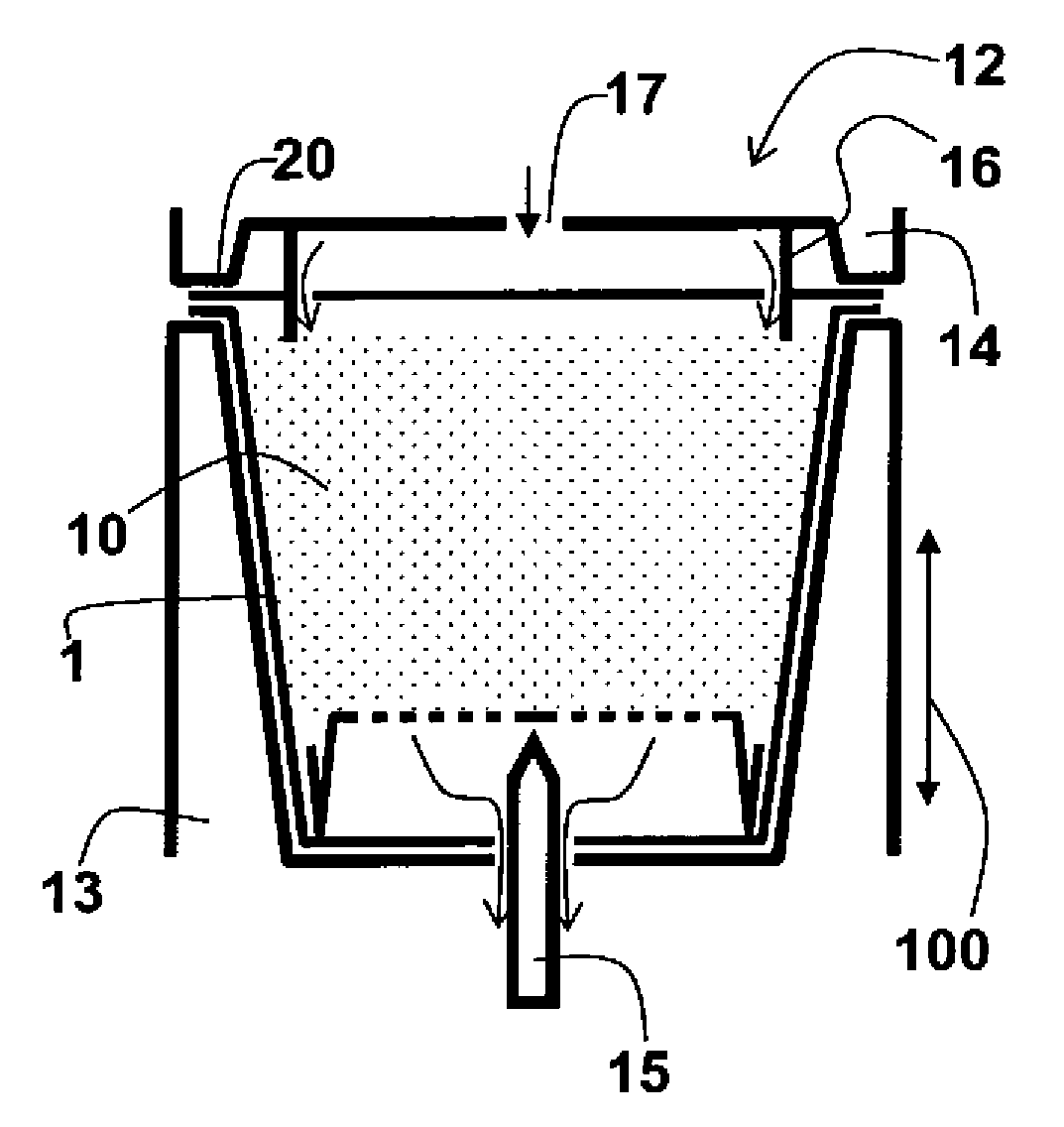

Compensation reservoir for a cooling circuit of an internal combustion engine

InactiveUS20050224021A1Reduce kinetic energyIncrease liquid viscosityLiquid coolingMachines/enginesCoolant flowInternal combustion engine

A compensating tank for a cooling circuit of an internal combustion engine has at least one inflow connection and one outflow connection, both of which are connected with the cooling circuit, a chamber system formed in the tank to receive the coolant, such that the individual chambers are at least partially interconnected via openings, and a coolant pipe connected with the inflow connection discharging into one of the chambers in which an impact element is provided for the inflowing coolant. The impact element is configured as a curved guiding wall along which the inflowing coolant is specifically guided. This inhibits, among other things, foaming of the coolant flowing into the compensating tank.

Owner:DR ING H C F PORSCHE AG

Polyurethane-water glass composite grouting material as well as preparation method and application thereof

InactiveCN103756291AImprove flame retardant performanceImprove antistatic performanceGlass compositesAntistatic agent

The invention discloses a polyurethane-water glass composite grouting material as well as a preparation method and an application thereof. The polyurethane-water glass composite grouting material comprises a component A and a component B in a weight ratio of 1:1-1:2, wherein the component A comprises the following components in percentage by weight: 72%-83% of polyurethane prepolymer, 5%-15% of plasticizer, 5%-10% of flame retardant and 2%-3% of surfactant, and the component B comprises the following components in percentage by weight: 99.2%-99.5% of water glass and 0.5%-0.8% of antistatic agent. The obtained composite grouting material has low slurry toxicity and relatively good compressive strength, is dense in jet-grouted solid and does not foam when being wet; and the flame retardancy and the anti-static performance of the composite grouting material meets the requirements of national coal industrial standards MT113-1995; and the polyurethane-water glass composite grouting material can be used for reinforcing coal seams of coal mines.

Owner:GUANGZHOU CHEM GROUTING CO LTD CAS

Device for measuring a fill level of a liquid in a container

InactiveUS6629457B1Reliable measurementSimple designEngine controllersMachines/enginesUltrasonic sensorEngineering

A device for measuring a fill level of liquid in a container includes a measuring tube arranged inside the container and an ultrasonic sensor arranged outside the container such that a portion of the wall of the container is arranged between the measuring tube and the ultrasonic sensor. The ultrasonic sensor therefore has no contact with the liquid located in the container.

Owner:MANNESMANN VDO AG

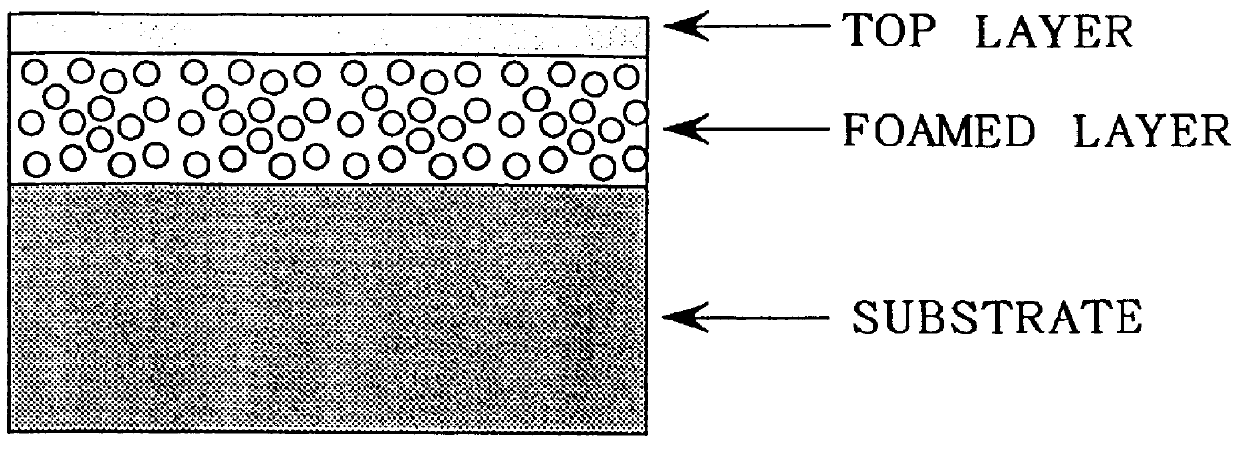

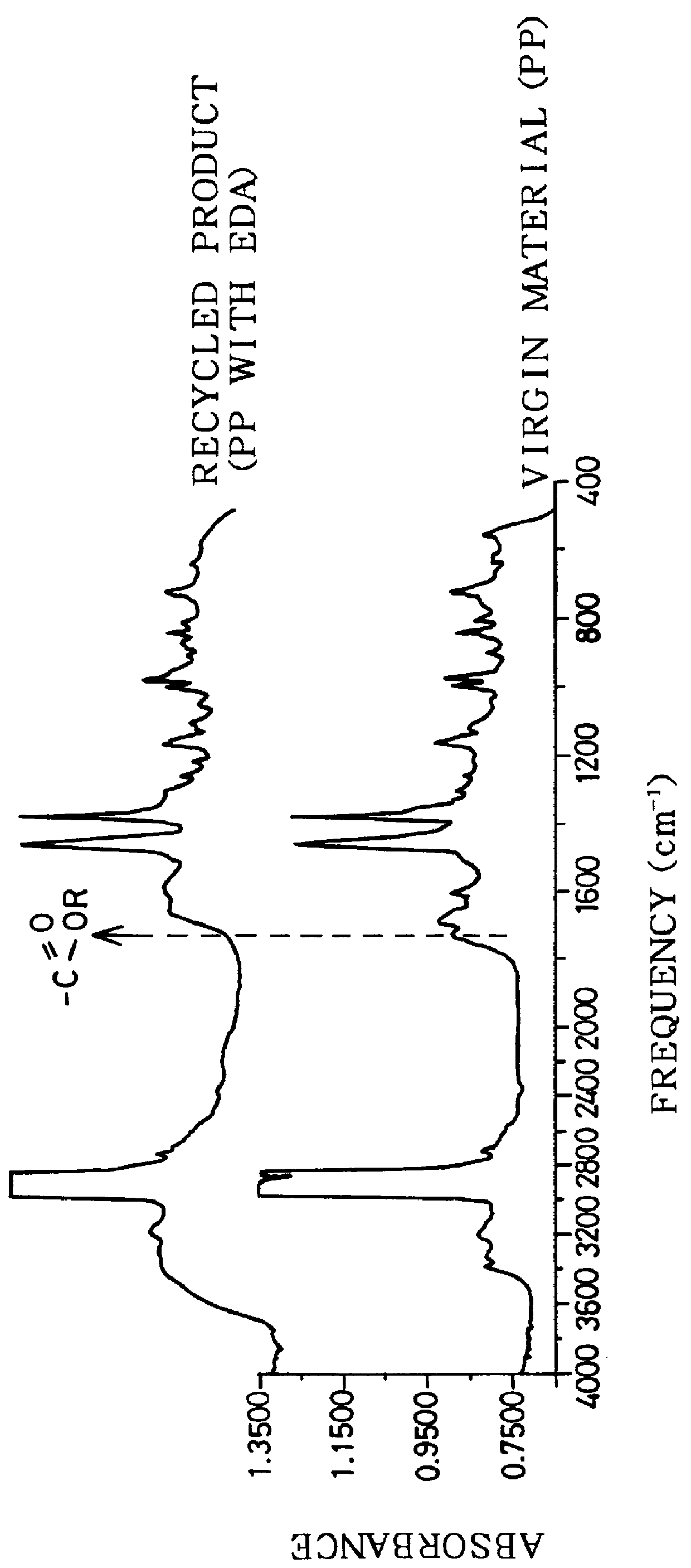

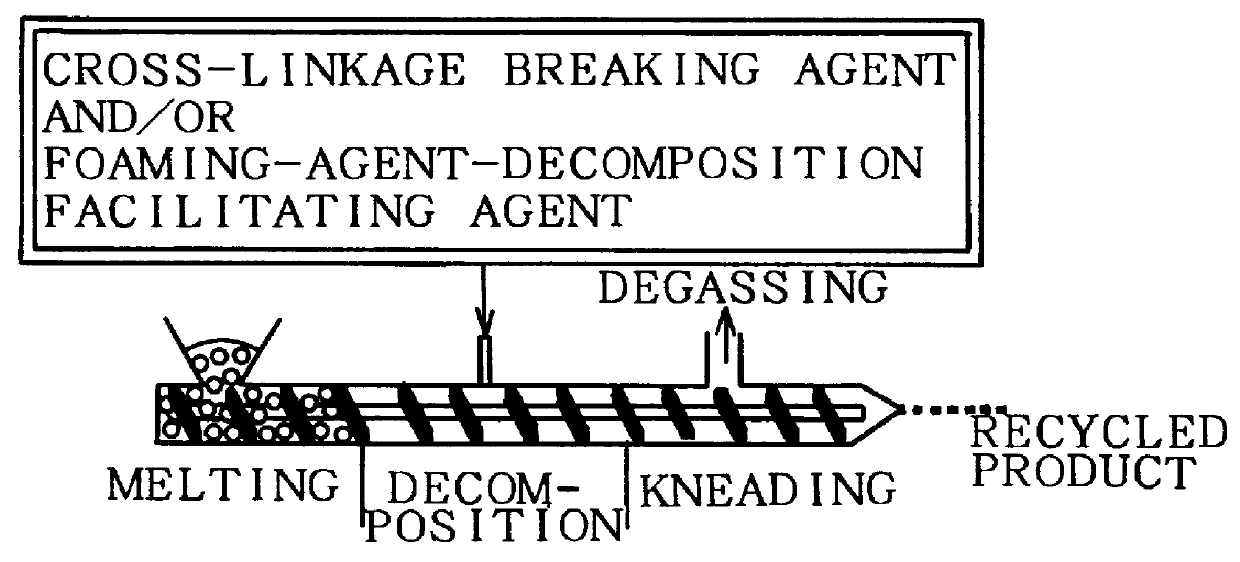

Process for recycling polyolefin cross-linked substance or polyolefin foamed substance

InactiveUS6090862AHigh elongationGood moldabilityPlastic recyclingPeptide preparation methodsCross-linkPolymer science

A process is developed for recycling a polyolefin cross-linked substance having a cross-linkage, a polyolefin foamed substance free from a cross-linkage or a polyolefin foamed substance having a cross-linkage. The process includes the step of heating the polyolefin cross-linked substance together with a cross-linkage breaking agent, whereby breaking the cross-linkage to recycle the polyolefin cross-linked substance into a moldable thermoplastic resin. Further, the process includes the step of adding a foaming-agent-decomposition facilitating agent to the polyolefin foamed substance in the course of thermally melting the polyolefin foamed substance, whereby decomposing a residual foaming agent remaining in the polyolefin foamed substance. Furthermore, the process includes the step of adding a foaming-agent-decomposition facilitating agent to the polyolefin foamed substance in the course of heating the polyolefin foamed substance to break the cross-linkage, whereby decomposing a residual foaming agent remaining in the polyolefin foamed substance. The resulting recycled product is improved in terms of moldability, strength, elongation and superficial appearance.

Owner:TOYOTA JIDOSHA KK +1

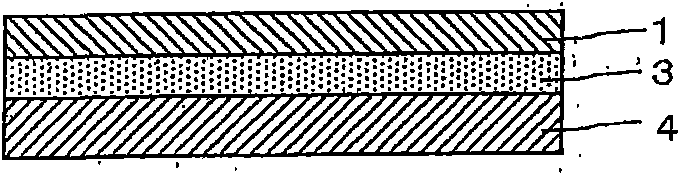

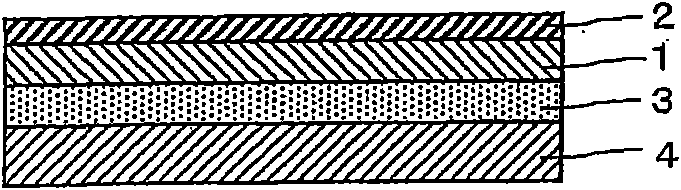

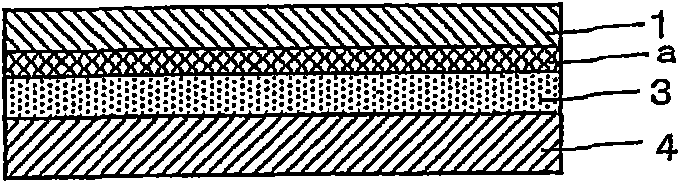

Adhesive composition for optical member, adhesive layer for optical member, adhesive optical member, transparent conductive laminate, touch panel, and image display device

ActiveCN101679819AAvoid yellowingAvoid foamingConductive layers on insulating-supportsNon-macromolecular adhesive additivesMeth-High humidity

Disclosed is an adhesive composition for optical members, which contains a (meth)acrylic polymer containing 0.2-20 parts by weight of a carboxyl group-containing monomer as a monomer unit, namely as acopolymerization component, per 100 parts by weight of an alkyl (meth)acrylate having an alkyl group with 4-14 carbon atoms. The adhesive composition for optical members also contains, as crosslinking agents, 0.02-2 parts by weight of a peroxide and 0.005-5 parts by weight of an epoxy crosslinking agent per 100 parts by weight of the (meth)acrylic polymer. The adhesive composition for optical members can be suppressed in yellowing at high temperatures and in high-temperature high-humidity environments. Consequently, the adhesive composition enables formation of an adhesive layer which is suppressed in foaming, separation and the like at high temperatures and in high-temperature high-humidity environments.

Owner:NITTO DENKO CORP

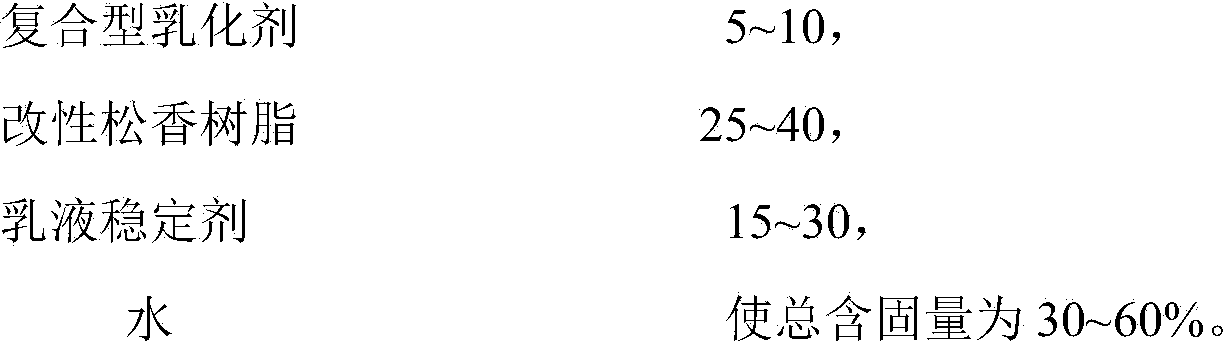

Novel cationic rosin sizing agent and application thereof

ActiveCN103628356AImprove mechanical stabilityGood chemical stabilityWater-repelling agents additionTotal solid contentEmulsion

The invention relates to the field of papermaking, aims at solving the problems that in the preparation process of the existing cation dispersing rosin latex, a solvent does not have a complete environment-friendly effect and is troublesome in recovery; after the solvent is removed, instability is possibly brought to an emulsifying agent and dispersed rosin, so that a rosin sizing agent is poor in mechanical stability, and the rosin sizing efficiency is not ell improved. The invention provides a novel cationic rosin sizing agent and application of the novel cationic rosin sizing agent in papermaking additive. The novel cationic rosin sizing agent comprises the following components by weight percent: 3-15% of a composite type emulsifying agent, 15-40% of modified rosin resin and 5-30% of an emulsion stabilizer; water is added into the components, so that the total solid content is 30-80%. When the sizing agent is used, emulsion particles are stable in performance, the sizing effect is remarkable, and the environment-friendly production is achieved.

Owner:HANGZHOU HANGHUA HARIMA PAPER CHEM

Magenta ink composition, ink set, ink cartridge, inkjet recording method and recorded product

InactiveUS20070263055A1Improve printing qualityHigh fastnessMonoazo dyesMeasurement apparatus componentsArylHalogen

A magenta ink composition used as a colorant, containing at least one type of compound represented by Formula (I) below and at least one type of compound represented by Formula (II) below: (wherein A represents the residue of the five member heterocyclic diazo moiety A-NH2; B1 and B2 represent —CR1═ and —CR2═, or one represents a nitrogen atom, and the other represents —CR1═ or —CR2═; R5 and R6 each independently represents a hydrogen atom, aliphatic group, aromatic group, heterocyclic group, acyl group, alkoxy carbonyl group, aryloxy carbonyl group, carbamoyl group, alkyl sulfonyl group, aryl sulfonyl group, or sulfamoyl group, each group therein being optionally substituted; G, R1 and R2 each independently represents a hydrogen atom, halogen atom, aliphatic group, aromatic group, heterocyclic group, cyano group, carboxyl group, carbamoyl group, alkoxycarbonyl group, aryloxy carbonyl group, acyl group, hydroxyl group, alkoxy group, aryloxy group, silyloxy group, acyloxy group, carbamoyloxy group, heterooxy group, alkoxycarbonyloxy group, aryloxycarbonyloxy group, amino group substituted with an alkyl group or aryl group or heterocyclic group, acylamino group, ureide group, sulfamoylamino group, alkoxycarbonylamino group, aryloxycarbonylamino group, alkyl and aryl sulphonylamino group, aryloxycarbonylamino group, nitro group, alkyl and aryl thio group, alkyl and aryl sulfonyl group, alkyl and aryl sulfinyl group, sulfamoyl group, sulfo group, or heterothio group, each group therein being optionally substituted; and R1 and R5, or R1 and R5 may optionally bond together to form a 5 or 6 member ring); (wherein M represents a hydrogen atom, ammonium group, or alkali metal atom; X represents a diaminoalkylene group; and n represents either 1 or 2).

Owner:SEIKO EPSON CORP

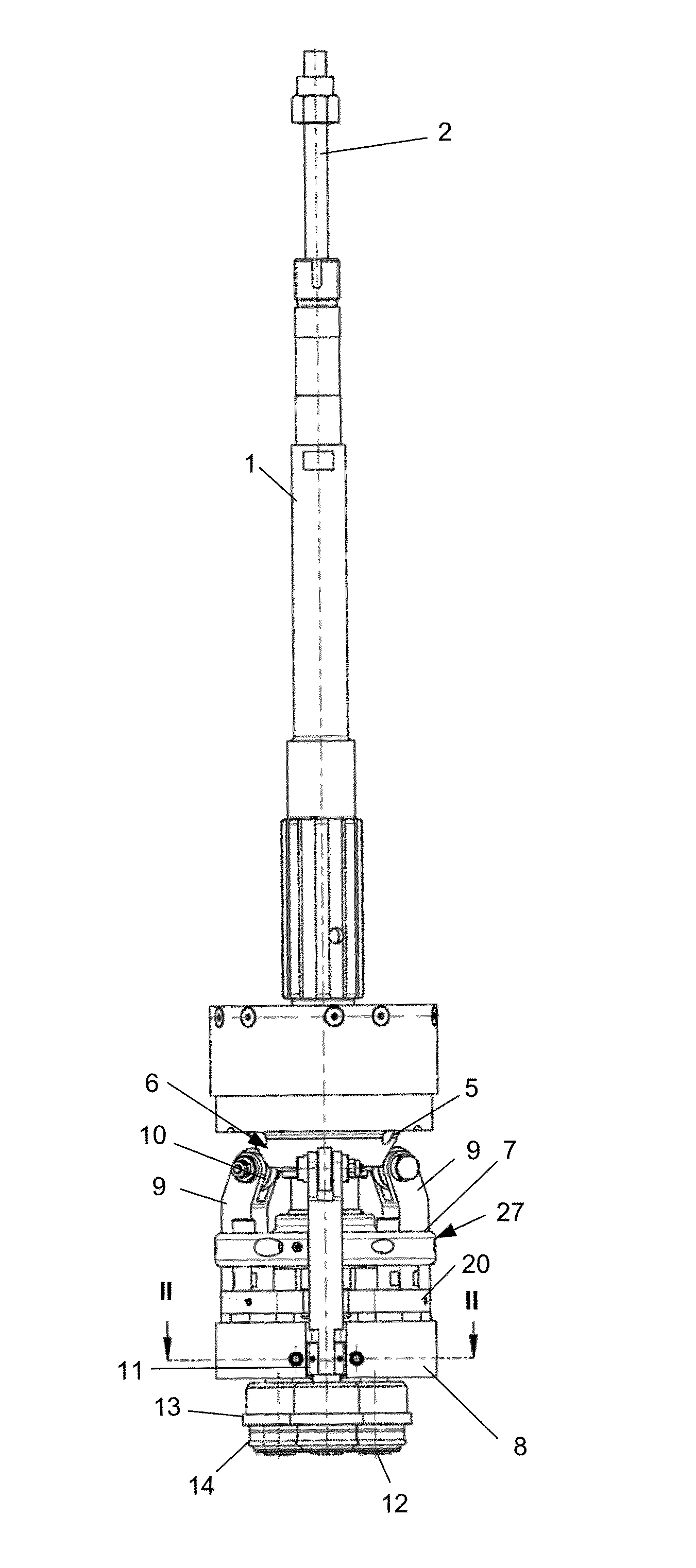

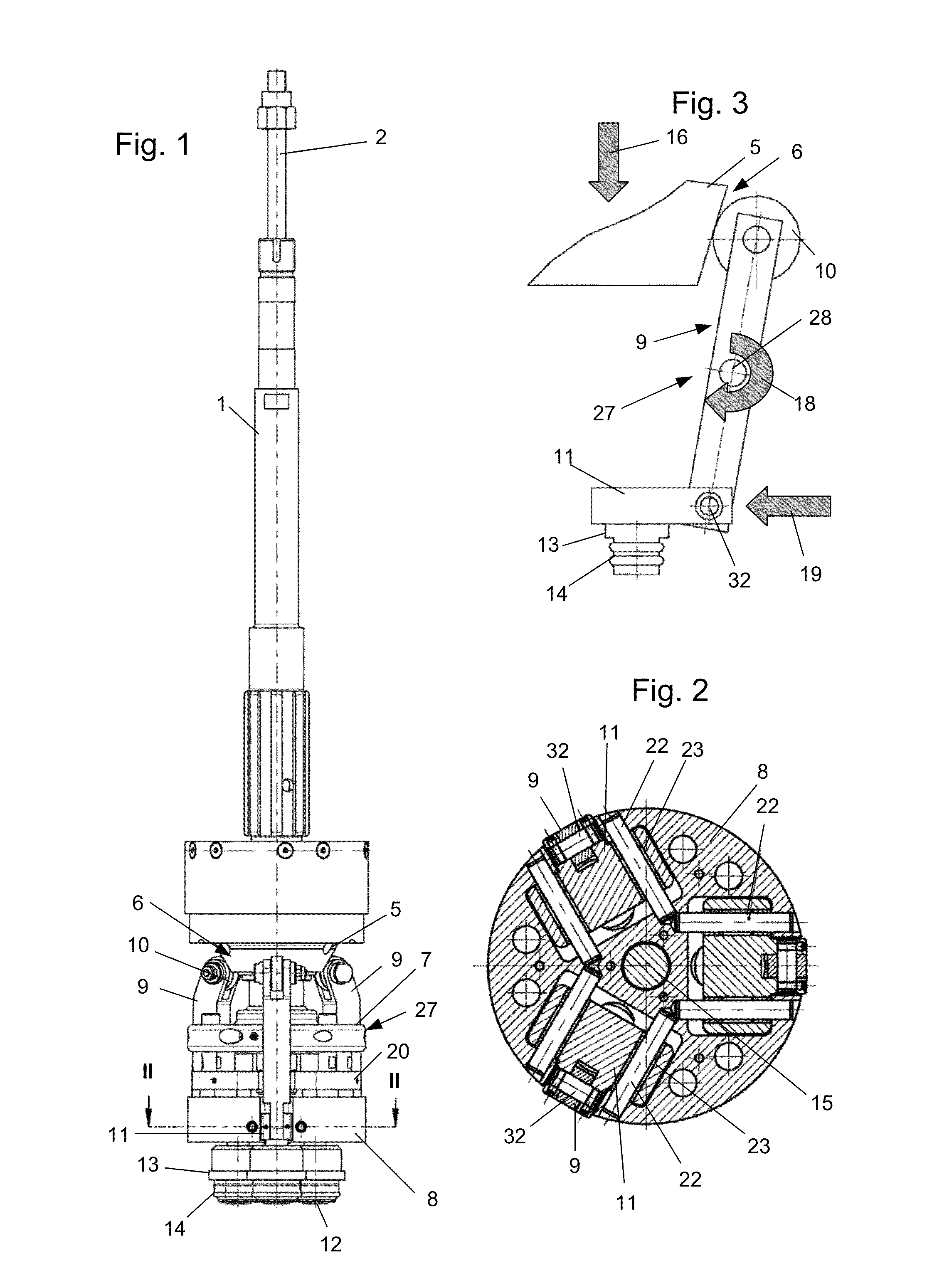

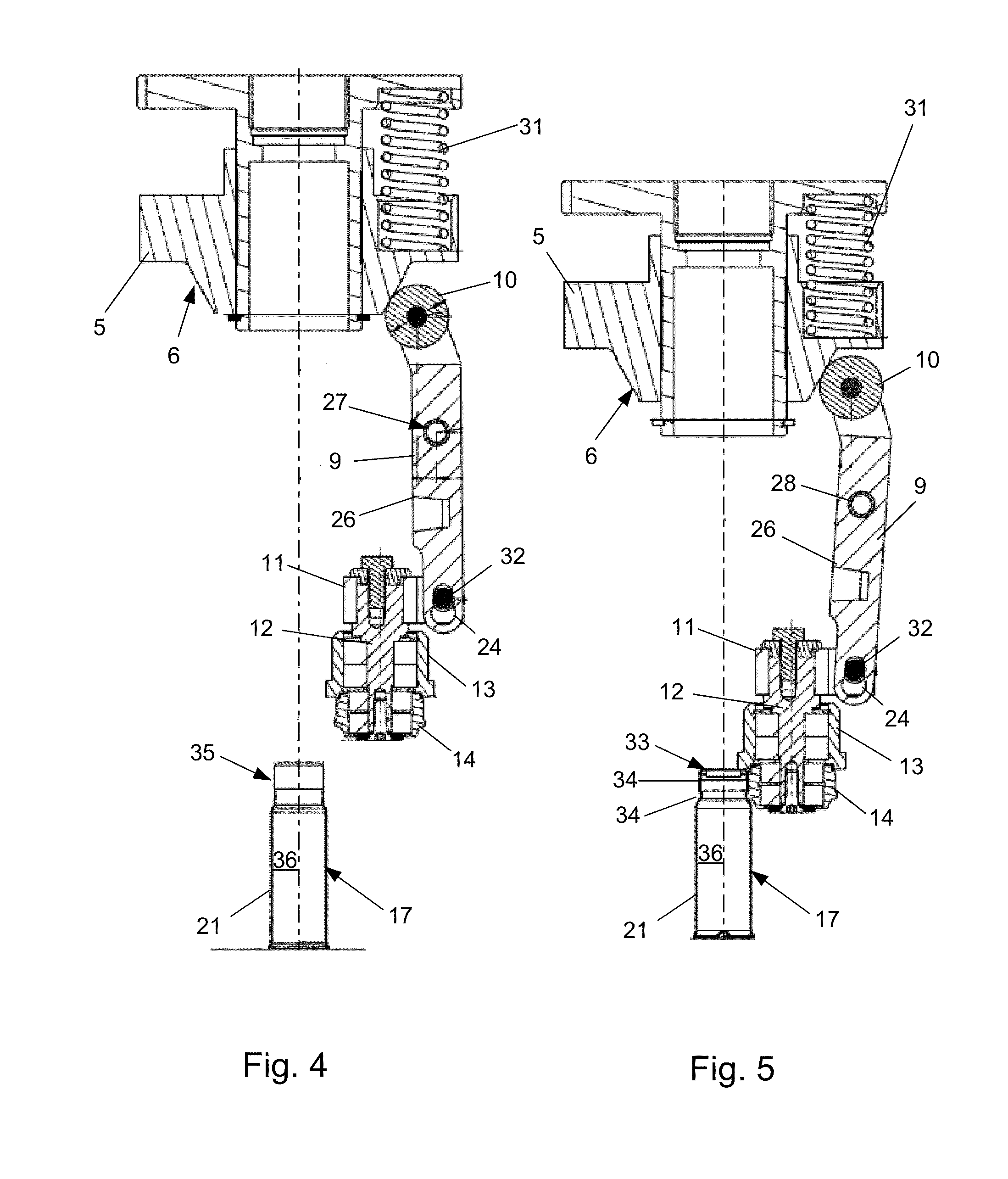

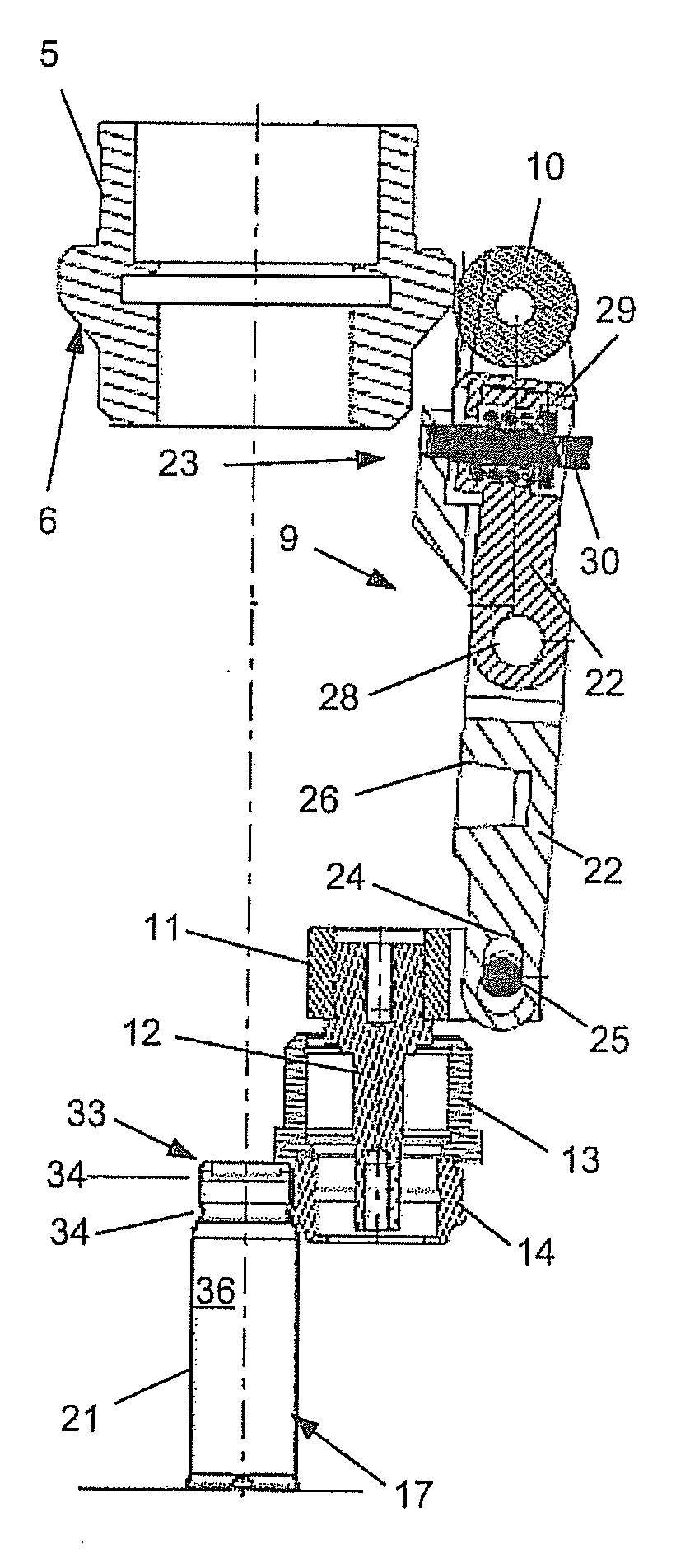

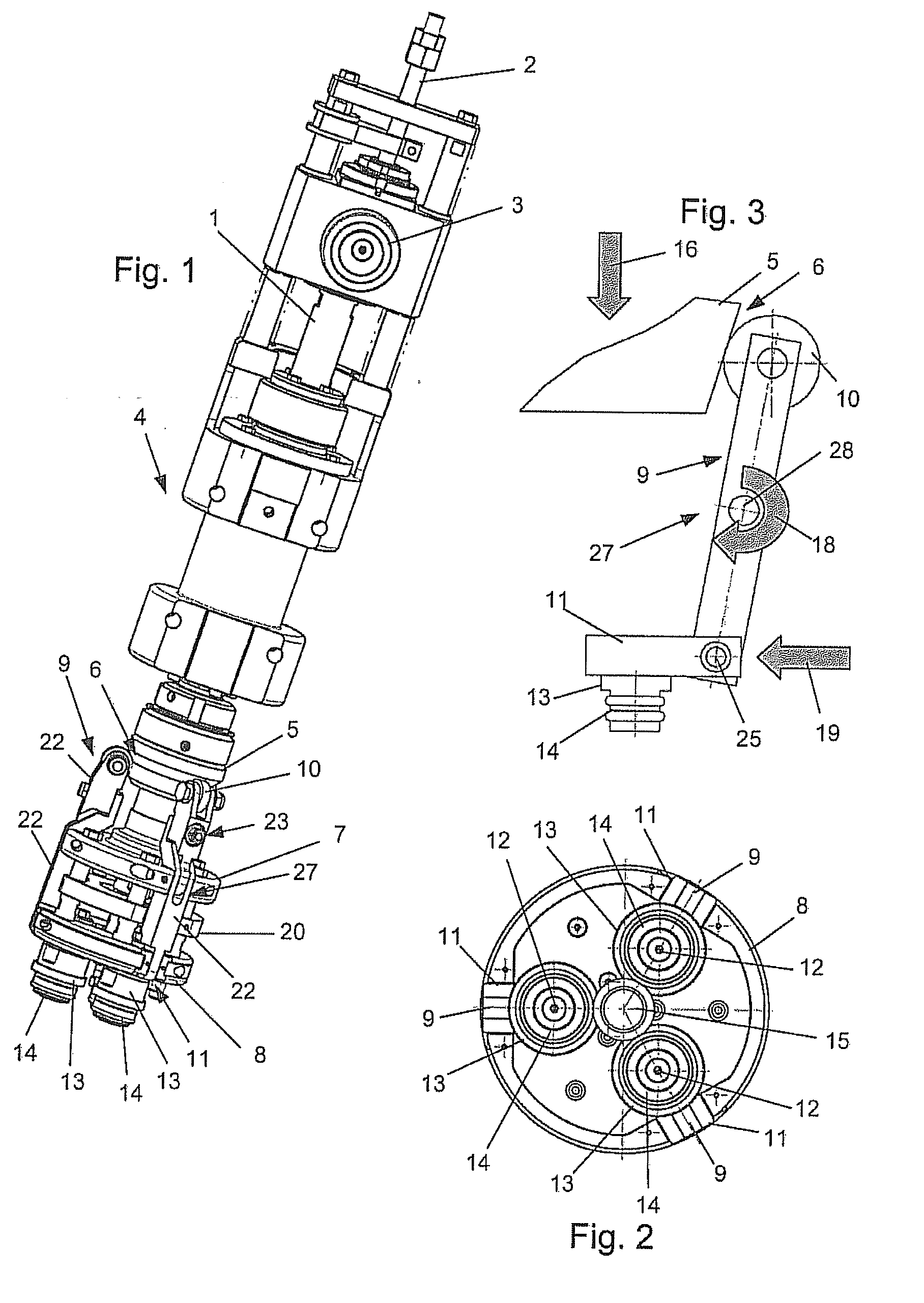

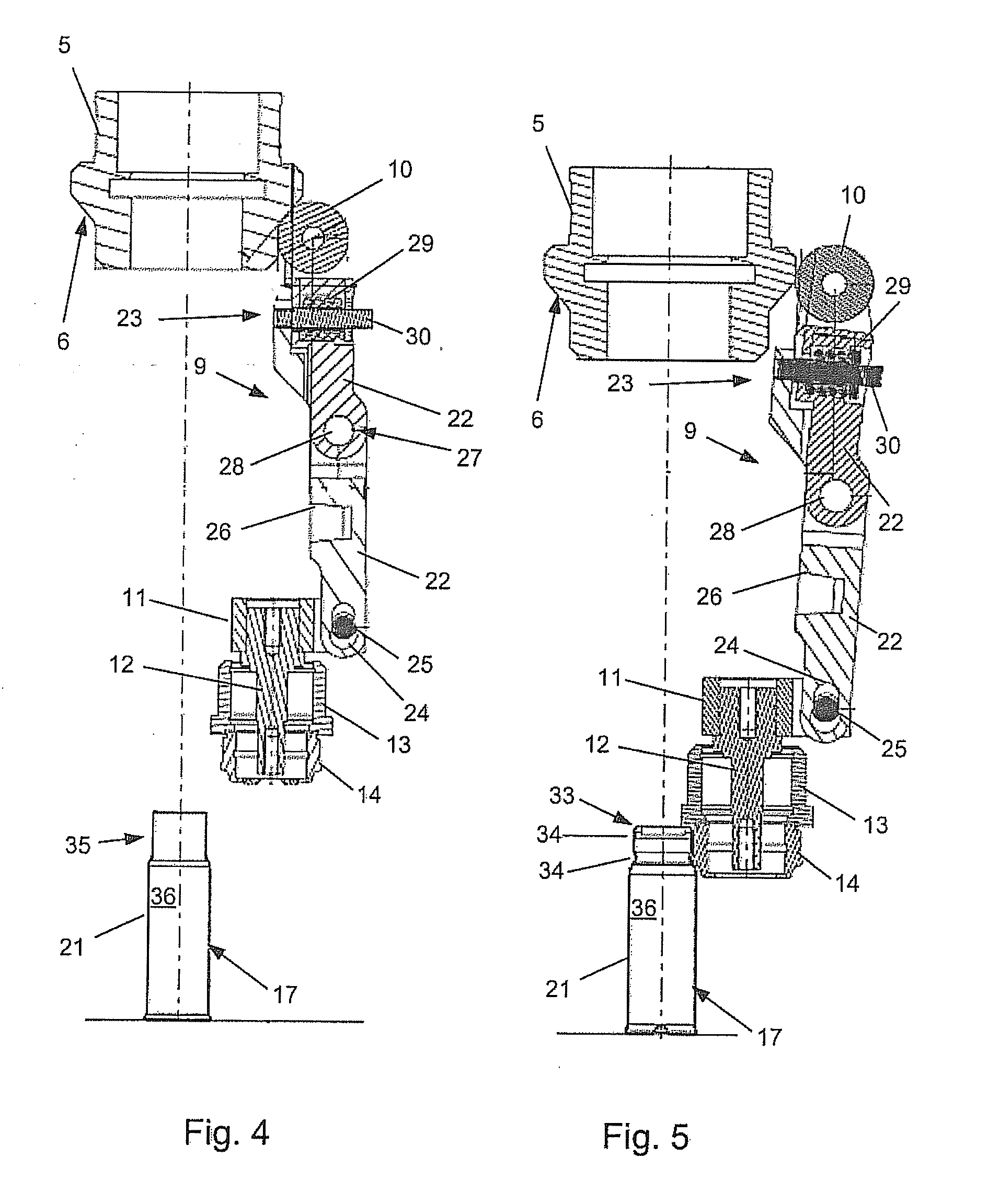

Shaping tool having a rotatable base member

ActiveUS8495901B2Guaranteed uptimeAvoid foamingForging press detailsSingle-unit apparatusRotational axisEngineering

Owner:BOEHRINGER INGELHEIM INT GMBH

Atomic layer deposition processes

InactiveUS20100227476A1Easy to control accuratelyGood step coverageSemiconductor/solid-state device manufacturingChemical vapor deposition coatingChemisorptionThin membrane

This invention relates to method of forming a thin film on a substrate in a reaction chamber by an atomic layer deposition process comprising a plurality of individual cycles. The plurality of individual cycles comprise at least two groupings of individual cycles. The individual cycles comprise (i) introducing a gaseous metal containing precursor into the reaction chamber and exposing the substrate to the gaseous metal containing precursor, wherein at least a portion of the metal containing precursor is chemisorbed onto the surface of the substrate to form a monolayer thereon, (ii) stopping introduction of the metal containing precursor and purging the volume of the reaction chamber; (iii) introducing a gaseous oxygen source compound into the reaction chamber and exposing the monolayer to the gaseous oxygen source compound, wherein at least a portion of the oxygen source compound chemically reacts with the monolayer; and (iv) stopping introduction of the oxygen source compound and purging the volume of the reaction chamber. The method involves repeating the individual cycles until a thin film of desired thickness is obtained. The method also involves carrying out at least two groupings of individual cycles at different process conditions. The methods are useful for producing a thin film on a semiconductor substrate, particularly metal containing thin films for electrode applications in microelectronics.

Owner:PRAXAIR TECH INC

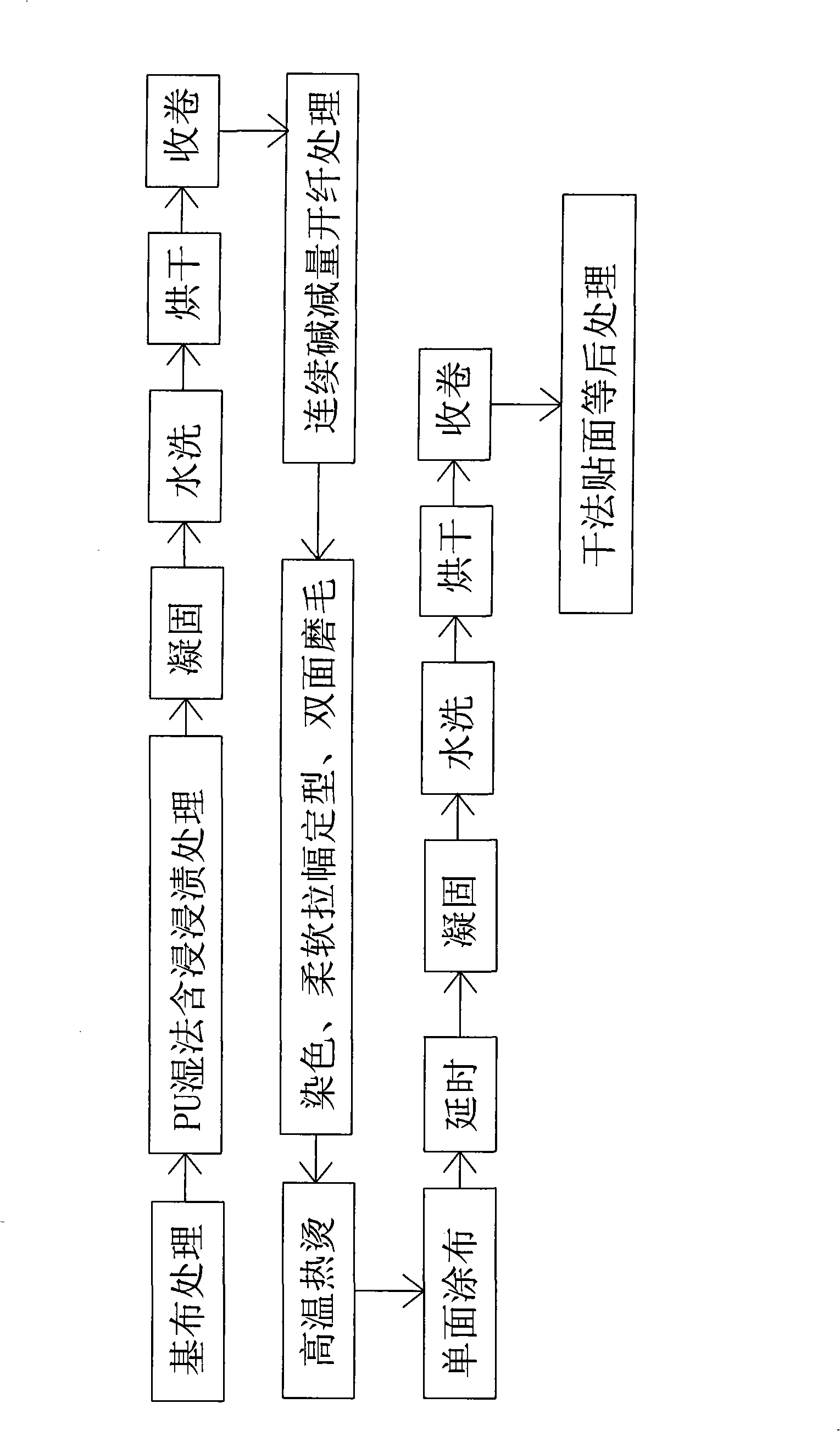

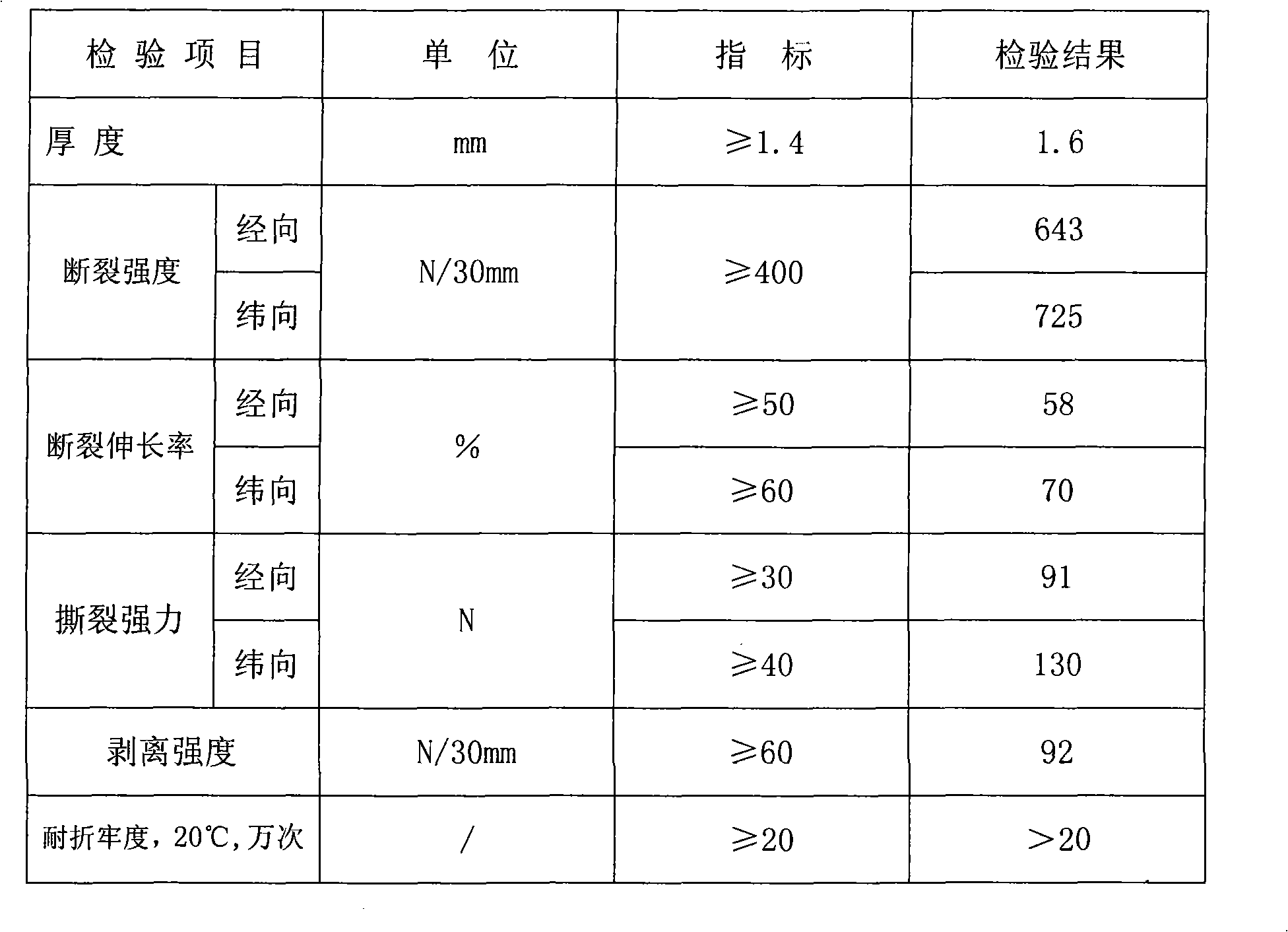

Method for processing island ultra-thin fiber high-density needling non-woven fabrics emulation leather

InactiveCN101260619AUniform thicknessHigh tear strengthFibre treatmentHeating/cooling textile fabricsHigh concentrationTime delays

The invention relates to a method for machining an island superfine fiber high density pinprick non-woven fabrics artificial leather, which is applied to the artificial leather manufacture and comprises the following processes: (1) the foundation process; (2) the PU wet method dipping process; (3) the continuous alkali abatement fiber opening process; (4) the pigmentation, the flexible tentering and shaping, the peached finish on two sides by a roughing-up machine; (5) the post treatments such as the dry method facing. The method is characterized in that the following processes are performed between the (4) process and the (5) process which are as follows: (6) the rolling blanching at a high temperature of 80 to 120 DEG C; (7) the high concentration polyurethane DMF solution with a weight ratio of PU: DMF of 100:50-93 is coated on the single side of the fabrics; (8) the time delay of 30 to 80 seconds; (9) a low temperature of 10 to 15 DEG C high concentration of 15 to 25 percent of DMF solution coagulating basin is coagulated, washed by water, dried and wrapped up. The method has the advantages that the manufactured finished leather has even thickness, excellent anti-tear strength and good ventilation property, the shortcoming that the cross breaks of the fibril synthetic leather is concave is overcome; the single spreading effectively avoids the foaming phenomenon on the coating surface; the section color is constant, etc.

Owner:NANPING JINYUE ARTIFICIAL LEATHER

High-temperature-resistant rubber sealing ring for automobiles

The invention discloses a high-temperature-resistant rubber sealing ring for automobiles. The high-temperature-resistant rubber sealing ring comprises the following raw materials in parts by weight: 70-90 parts of ethylene-propylene-diene-terpolymer rubber, 10-30 parts of chloroprene rubber, 1-4 parts of an anti-aging agent, 0.8-1.5 parts of active zinc oxide, 0.2-0.4 part of magnesium oxide, 0.5-1.0 part of calcium oxide, 0.6-1.5 parts of butyltin mercaptide, 30-40 parts of modified kaolin, 10-15 parts of magnesium methacrylate, 1-3 parts of a promoter, 6-10 parts of soybean oil, 1-2 parts of ethyl methacrylate, 40-80 parts of paraffin oil, 0.2-0.5 part of triallyl phosphate, 1.0-1.5 parts of a crosslinking agent BIBP, 0.5-1.2 parts of an assistant crosslinking agent TAIC, 0.3-0.5 part of microcrystalline wax, 2-3 parts of a vulcanizing agent and 0.5-1 part of phthalic anhydride. The sealing ring disclosed by the invention has strong weather resistance, corrosion resistance and ozone resistance, and can be suitable for being used as the high-temperature-resistant rubber sealing ring for the automobiles.

Owner:TONGLING SANSHENG ELECTRONICS

Shaping tool having a rotatable base member

ActiveUS20100242557A1Guaranteed uptimeAvoid foamingSingle-unit apparatusMedical atomisersEngineeringMechanical engineering

Owner:BOEHRINGER INGELHEIM INT GMBH

System and method for manufacturing asphalt products with recycled asphalt shingles

ActiveUS20160362339A1Minimize moisturePrevent excessive foamingIn situ pavingsRoof covering using tiles/slatesAsphalt shinglePrill

A method for manufacturing a processed asphalt suspension is provided. The method includes dry grinding shingle waste material to a particle size of less than 1 cm, forming ground recycled shingle material, introducing virgin asphalt into a heated slurry tank and mixing the ground recycled shingle material with the virgin asphalt in the heated slurry tank, forming a mixed asphalt slurry, introducing the mixed asphalt slurry into a wet grinding machine, and recovering a processed asphalt suspension comprising particles having a size no greater than about 200 microns. Roofing and paving products manufactured from the processed asphalt suspension are also provided.

Owner:HERITAGE RES GROUP LLC

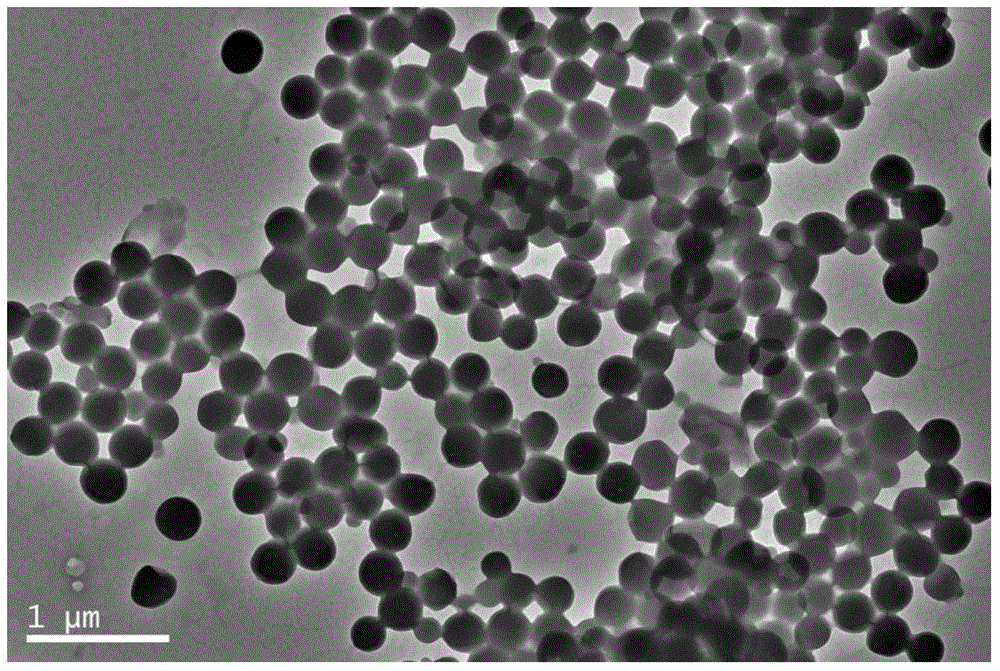

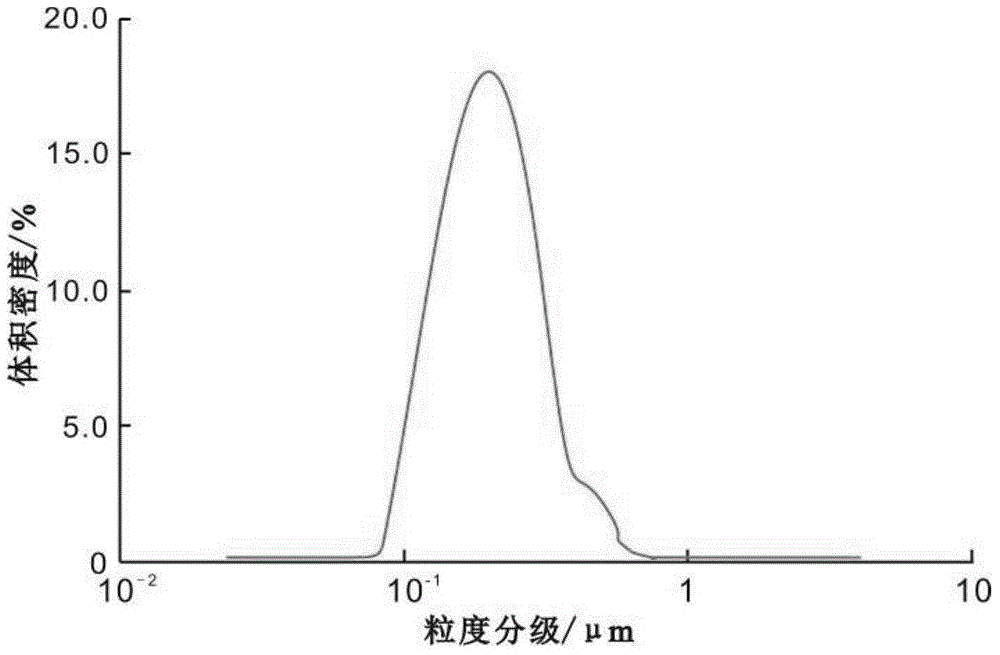

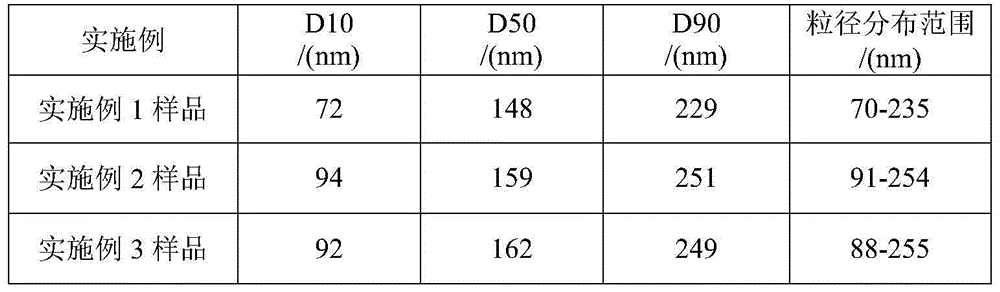

Temperature-sensitive-type intelligent nano particles used in drilling fluid and preparation method thereof

InactiveCN105038728AGood dispersionImprove water resistanceDrilling compositionHydrophilic monomerPressure transmission

The invention relates to a temperature-sensitive-type intelligent nano particles used in a drilling fluid and a preparation method thereof. In the invention, a silane coupling agent is used for performing ultrasound surface modification to nano SiO2 and a vinyl functional group is introduced. With the surface-modified nano SiO2, a temperature-sensitive-type monomer and a hydrophilic monomer are subjected to a polymerization reaction in a water medium with a co-solvent with addition of an initiator, wherein granularity distribution of the temperature-sensitive-type intelligent nano particles is D10 <= 100 nm, D 50 <= 165 nm and D90 <= 260 nm. When the temperature is higher than a sensitive value, the nano particles achieve double functions of both physical blocking and chemical inhibition, so that a continuous compact hydrophobic blocking layer is formed inside shale, thereby achieving effects of preventing and delaying pressure transmission and filtration invasion, and further enhancing stability of a shale well wall.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Beverage substance, portion capsule, and method for producing a beverage

ActiveCN103501624AEfficient brewingFaster and cleaner brewingPre-extraction tea treatmentTea extractionParticulatesFood science

Owner:K FEE SYST

Method for preparing cermet material

ActiveCN101423901AHigh strengthImprove bending strengthAldehyde/ketone condensation polymer adhesivesOrganic acidFlexural strength

The invention provides a method for preparing cermet materials. The method comprises the following steps of well mixing raw cermet materials with binder, performing crushing and injection molding so as to obtain blanks, degreasing the obtained blanks and sintering the degreased blanks in a vacuum environment, so as to obtain the cermet materials, wherein the binder consists of paraffin, ethylene-vinyl acetate copolymer, high-density polyethylene and organic acid, and the organic acid is oleic acid and / or stearic acid. By using the binder consisting of the paraffin, the ethylene-vinyl acetate copolymer, the high-density polyethylene and the organic acid selected from the oleic acid and / or the stearic acid, the method avoids the blistering, deformation, cracking and other defects of the blanks in a degreasing process, so as to ensure that the obtained cermet materials have better strength and bending-resistant strength.

Owner:靖江市华信科技创业园有限公司

Foam Control Composition

ActiveUS20130327364A1Avoid foamingInorganic/elemental detergent compounding agentsCosmetic preparationsSurface tensionAqueous medium

A process for washing a substrate. The process involves providing a detergent composition that includes a surfactant and an antifoam. The antifoam comprises a hydrophobic fluid having a surface tension of at least 27 mN / m and less than 40 mN / m and a finely divided solid hydrophobic filler dispersed in the hydrophobic fluid. The process further involves washing the substrate in an aqueous medium with the detergent composition. The antifoam does not affect foaming during the washing step. During the washing step, the detergent composition is applied to the substrate. The process further involves rinsing the substrate with the applied detergent composition with water, whereby foaming during the rinsing step is inhibited.

Owner:DOW SILICONES CORP

Organic amine salt compound with negative ion as CO2 donor and application thereof as foaming agent

ActiveCN107089927AAppropriate decomposition temperatureImprove performanceCarbamic acid derivatives preparationOrganic compound preparationFoaming agentChemical compound

Owner:SHANDONG UNIV OF TECH

High-durability concrete shield system capable of rapid construction and preparation method thereof

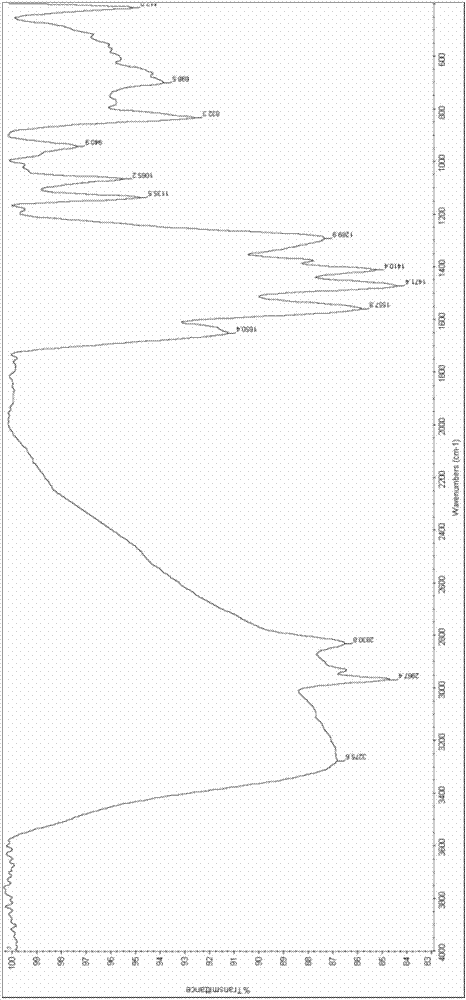

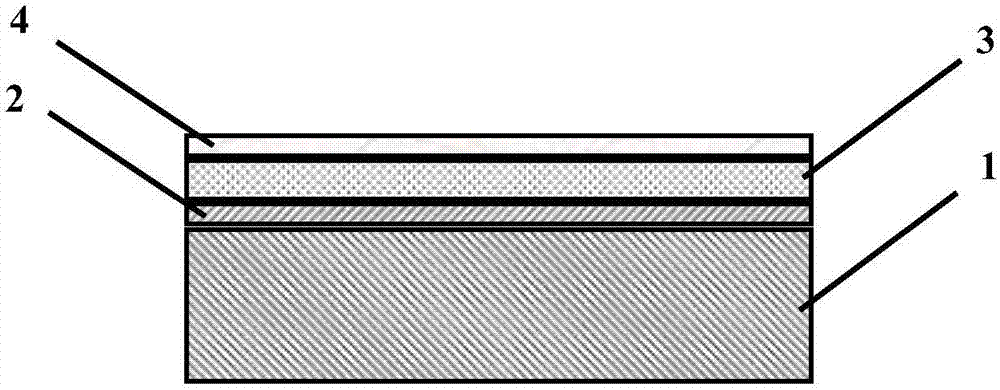

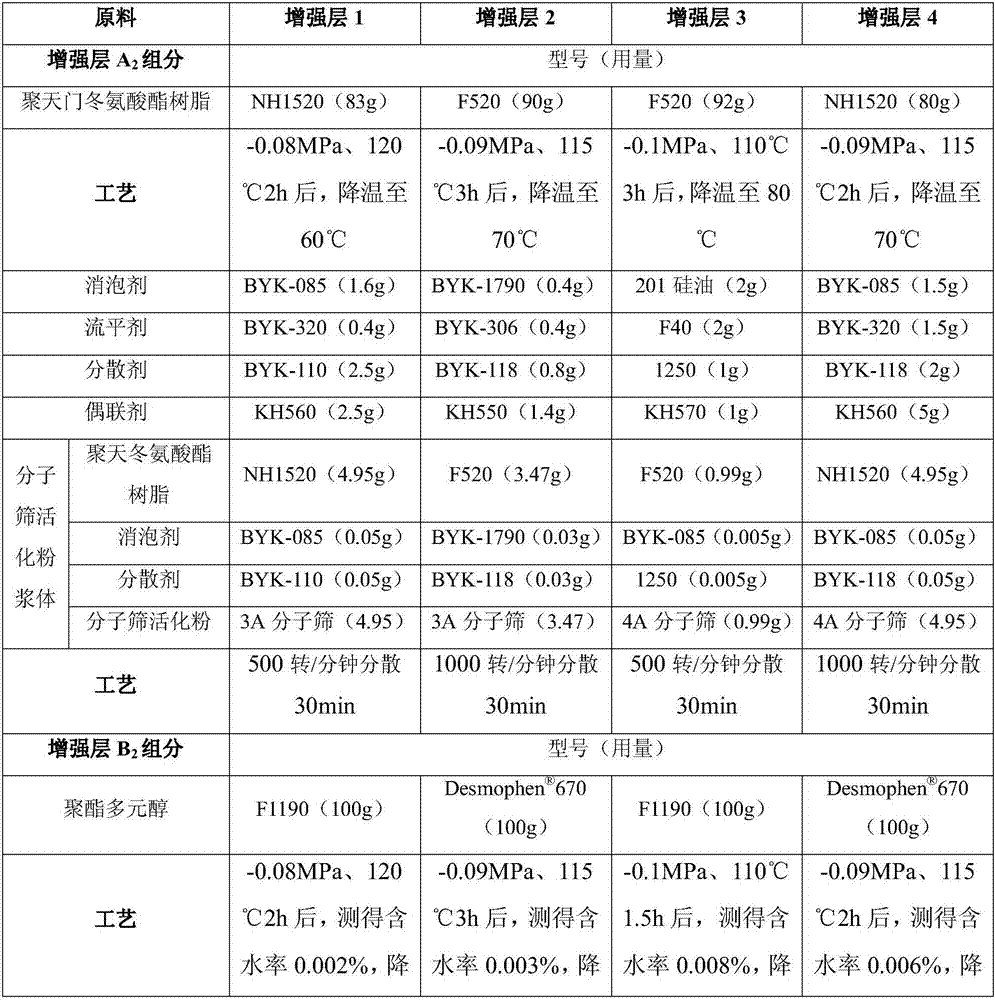

ActiveCN107337993AFast curing rateImprove adaptabilityPolyurea/polyurethane coatingsLow temperature curingEngineering

The invention discloses a high-durability concrete shield system capable of rapid construction and a preparation method thereof. The concrete shield system comprises a concrete base layer, a polyaspartate permeation primer layer, a polyaspartate elasticity enhancement layer and a fluorine-silicon-modified polyaspartate high-weather-resistance finish paint layer from bottom to top. Compared with the prior art, the system has the advantages of short construction cycle, high weather resistance and the like, can be constructed on a wet basal plane, can implement construction within one day and low-temperature curing, has the multiple functions of high mechanical strength, fatigue resistance, aging resistance, high elasticity, corrosion resistance and the like, and has the characteristics of simple construction, high safety and environment friendliness.

Owner:辽宁苏博特船牌制漆有限公司 +2

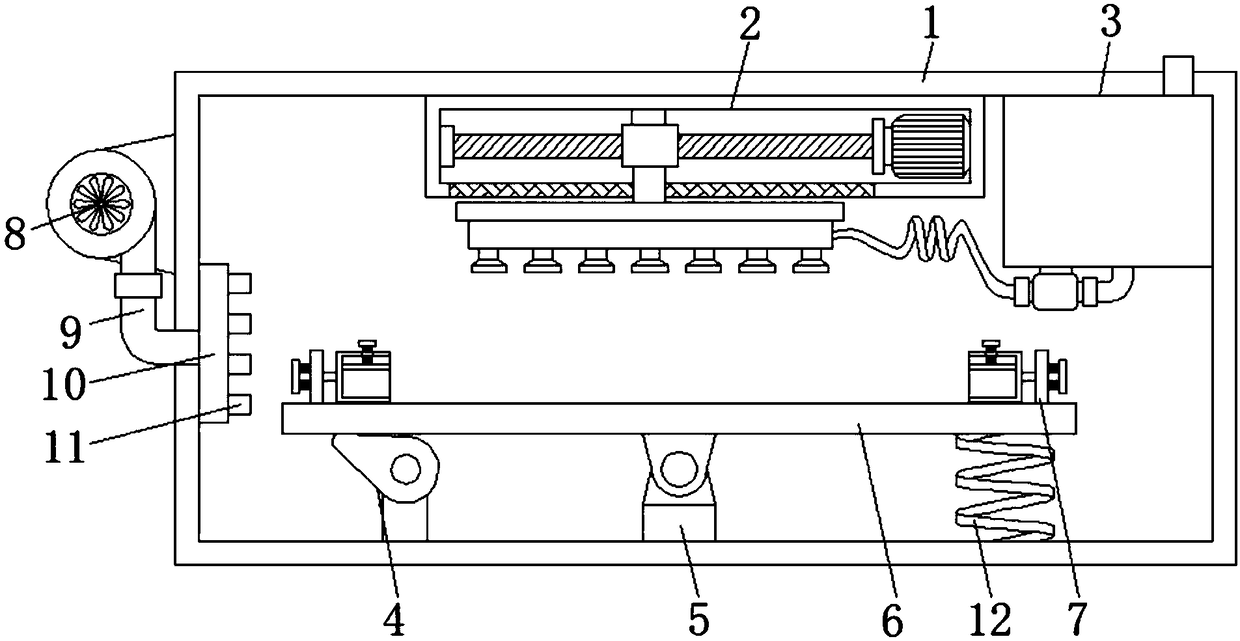

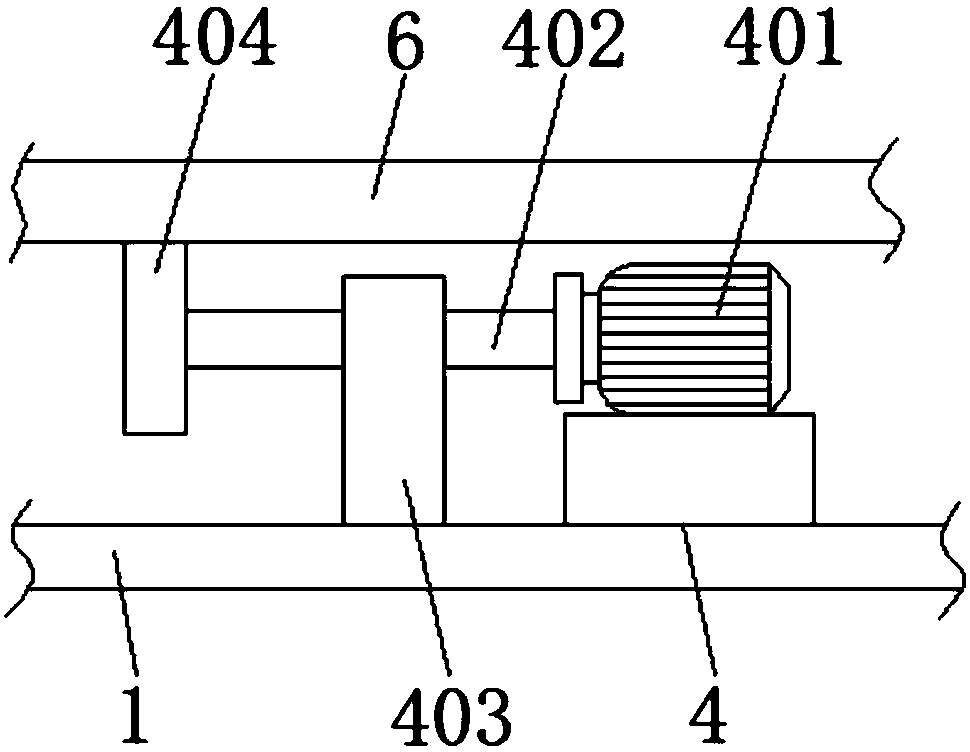

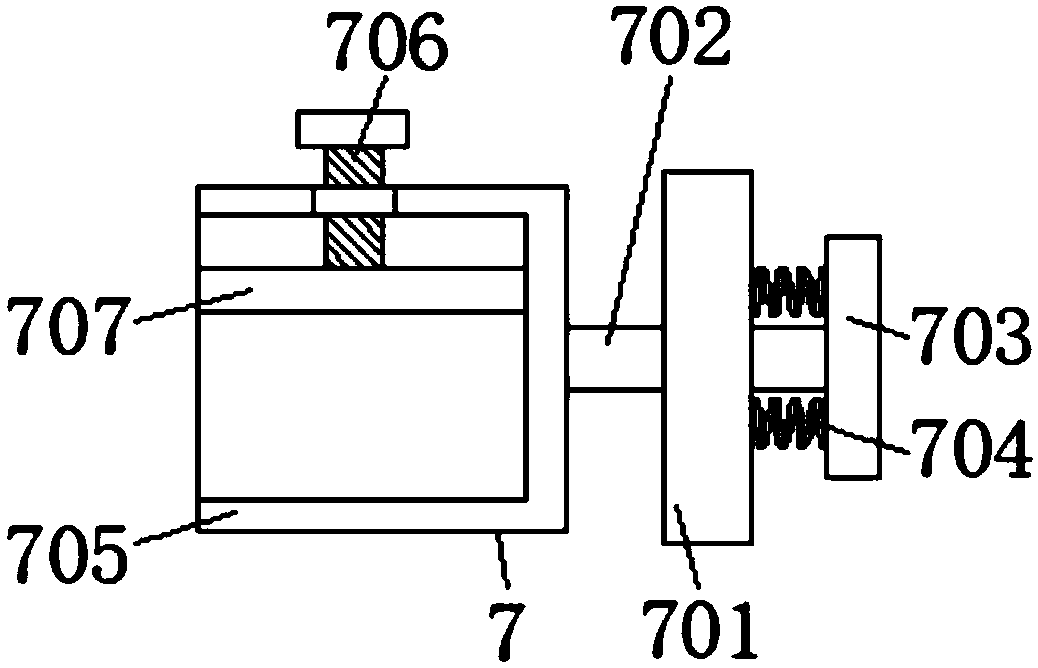

Furniture wood surface spraying equipment

InactiveCN108405255AImprove efficiencyQuality assurancePretreated surfacesLiquid spraying apparatusEngineeringMechanical engineering

The invention relates to the technical field of wood spraying devices and discloses furniture wood surface spraying equipment. The furniture wood surface spraying equipment comprises an equipment body; the inner top wall of the equipment body is fixedly connected with a mobile device; a spraying device is fixedly installed at the inner top wall of the equipment body; a swing device and a bracket are movably and fixedly installed from left to right at the inner bottom wall of the equipment body; the top of the bracket is hinged with a placing plate through a bolt pin; two symmetric clamping devices are fixedly installed at the top of the placing plate; a fan is fixedly installed at the left side surface of the equipment body; and an air outlet of the fan communicates with an air guide pipe.The furniture wood surface spraying equipment provided by the invention solves the problems that a traditional spraying method is low in efficiency and affects the body health of a worker, bubbles are easily generated in the sprayed paint surface, the quality is poor and the drying time is long; and the furniture wood surface spraying equipment achieves the effects of being high in spraying efficiency, preventing generation of bubbles and adsorption of dust after spraying and simultaneously protecting the body health of the worker.

Owner:汪永平

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com