Patents

Literature

4223results about "Aldehyde/ketone condensation polymer adhesives" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

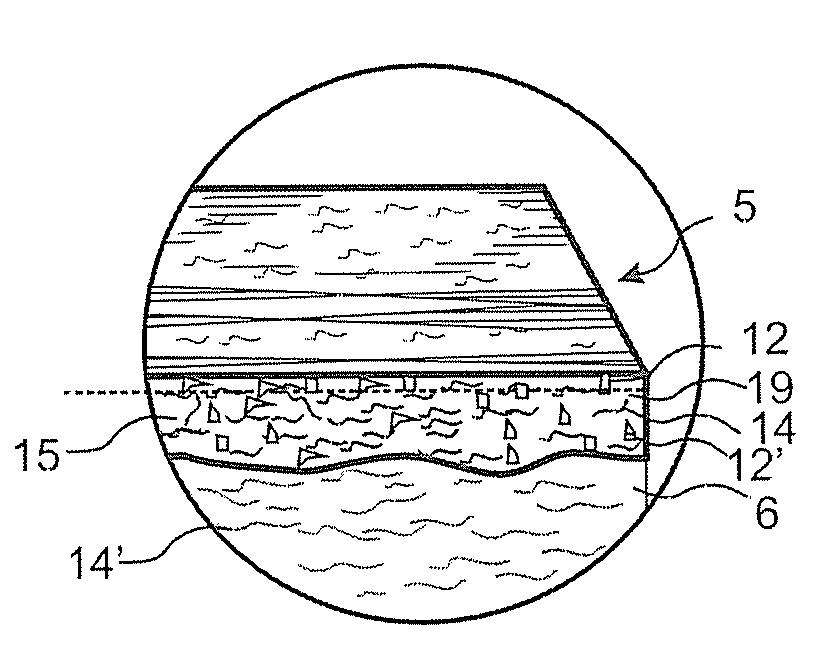

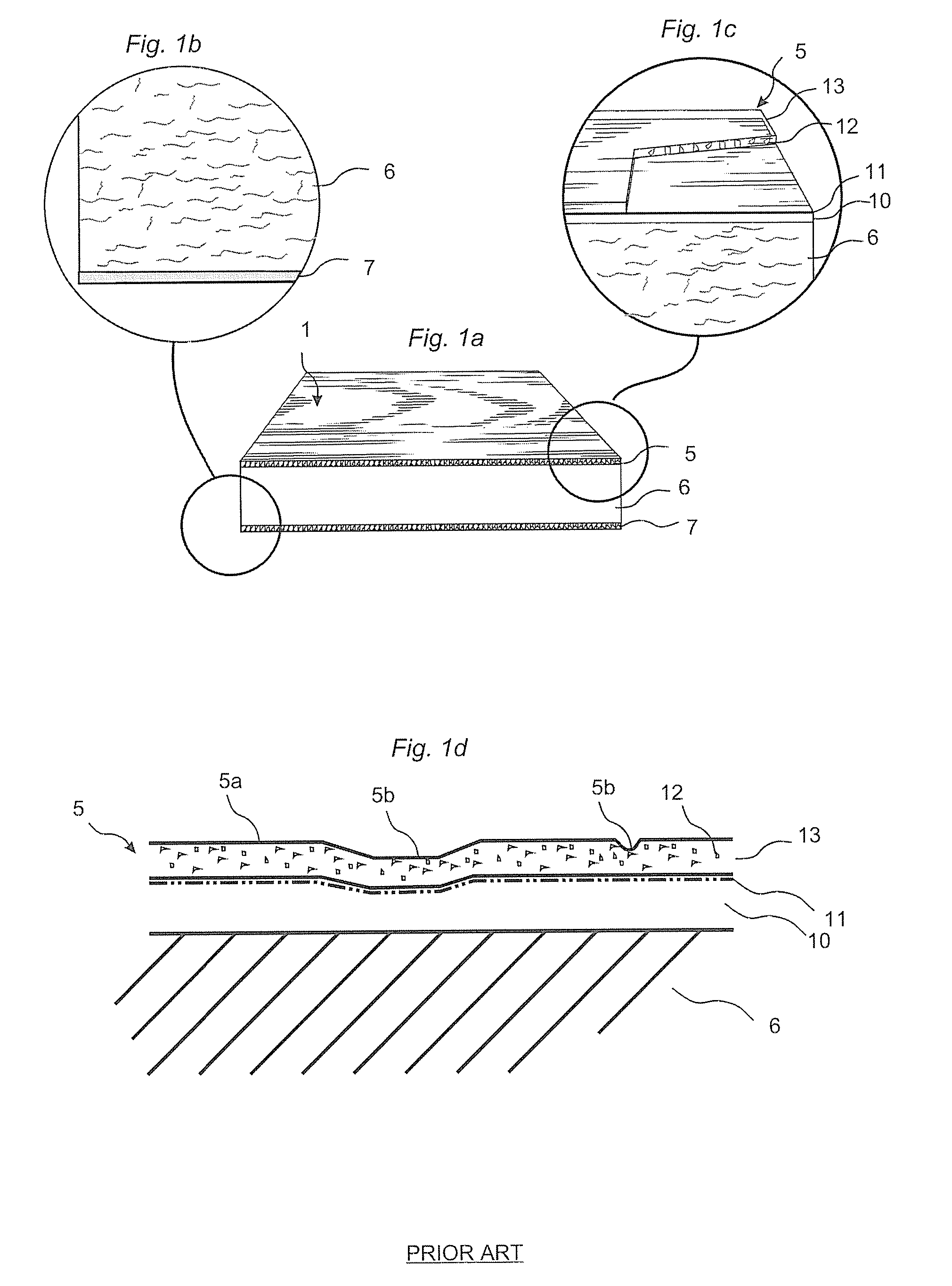

Wood fibre based panels with a thin surface layer

ActiveUS20100092731A1Large market shareImprove impact resistanceLiquid surface applicatorsCovering/liningsSurface layerWood fibre

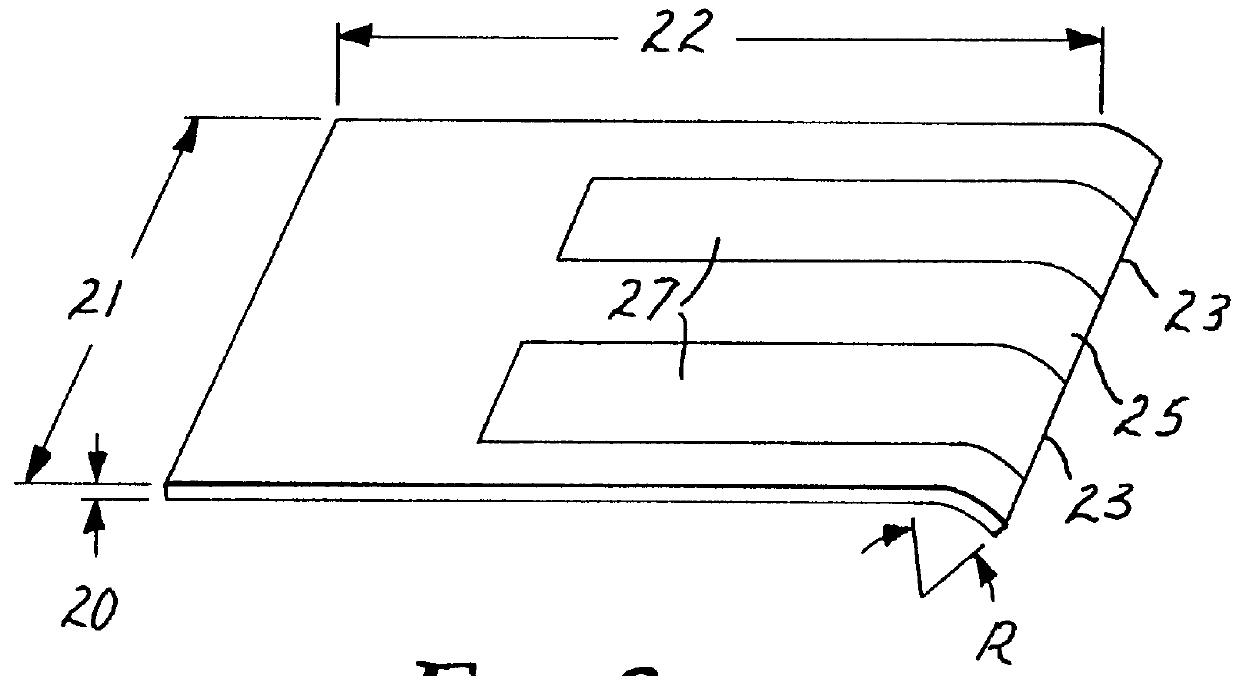

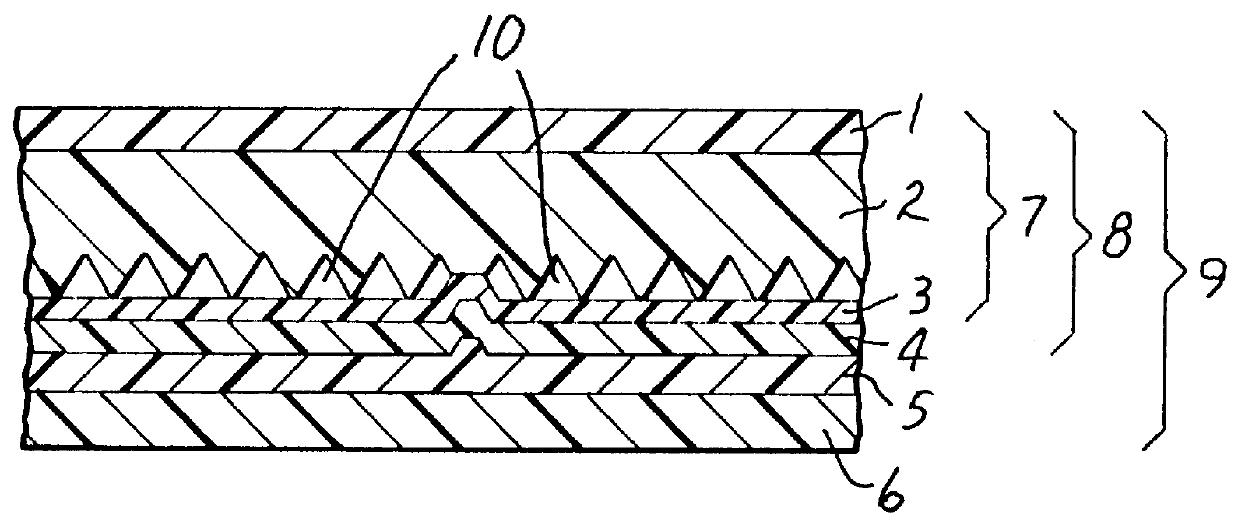

Building panels with a thin and embossed surface layer and a sub layer between a surface layer and a core.

Owner:VÄLINGE INNOVATION AB

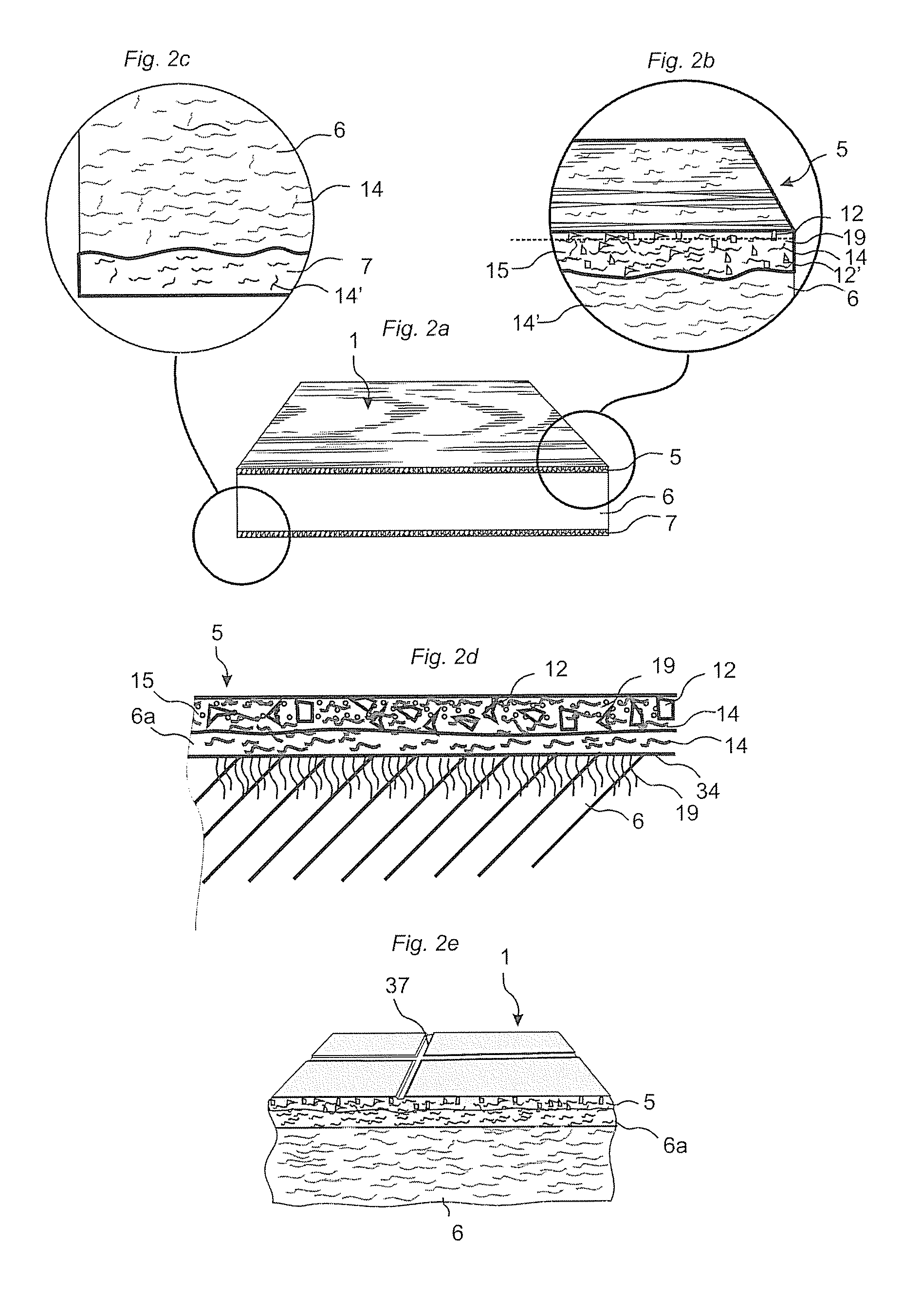

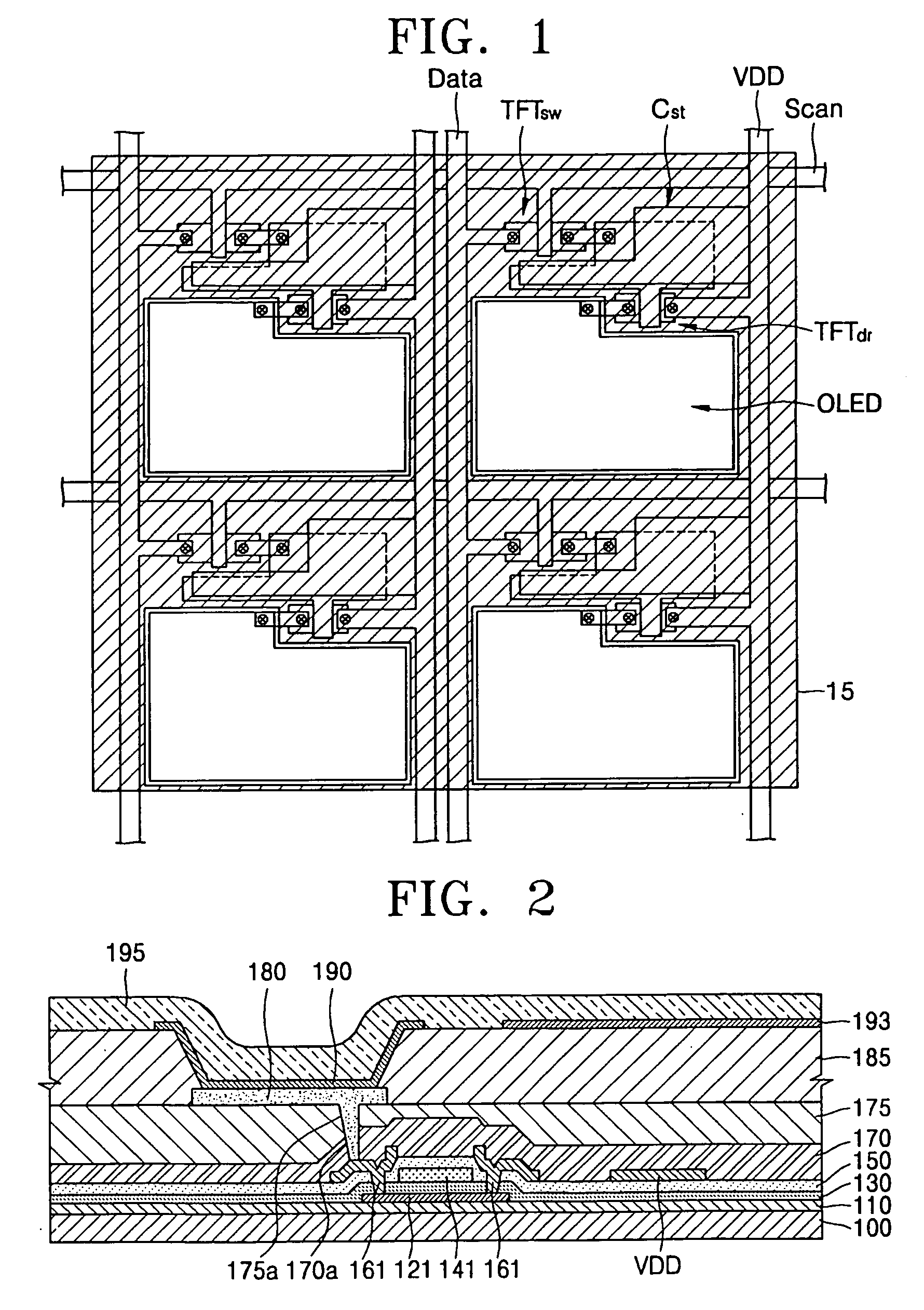

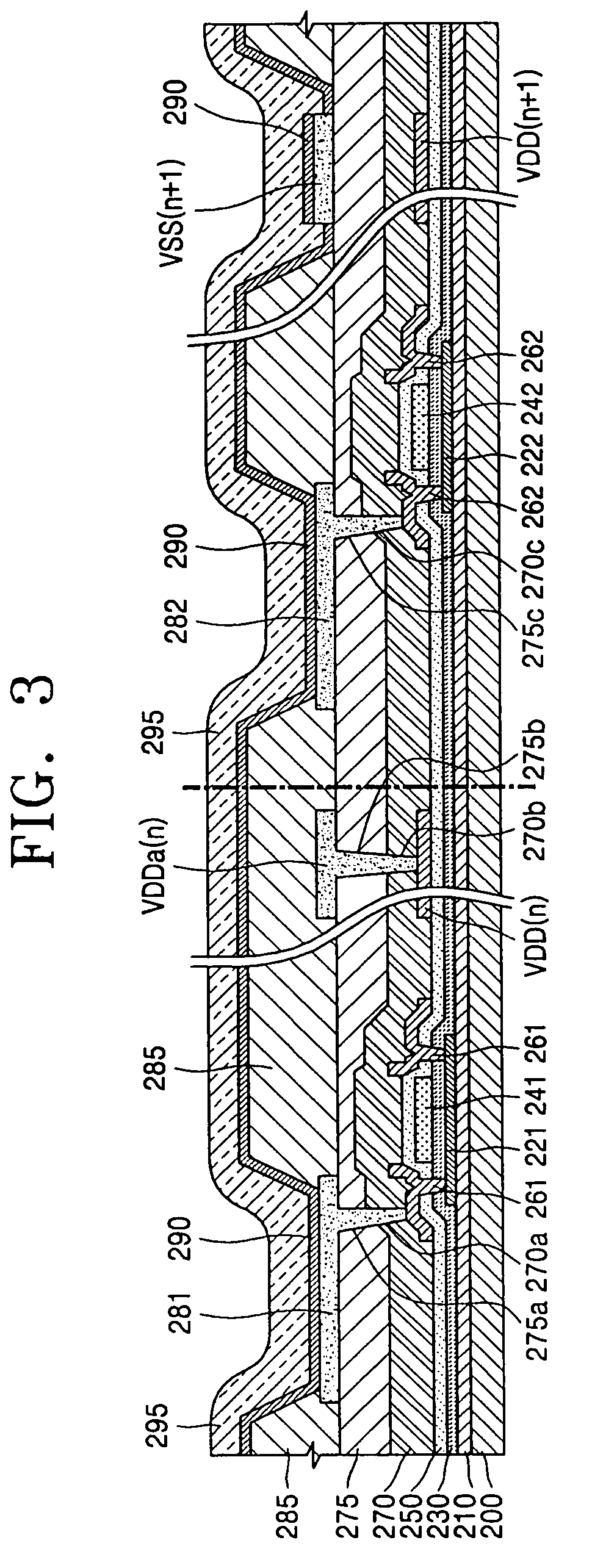

Organic electro-luminescent display device and method of manufacturing the same

ActiveUS20050179374A1Improving imaging characteristicsIncrease brightnessDischarge tube luminescnet screensNon-macromolecular adhesive additivesOrganic filmDisplay device

An organic electroluminescence device which includes a power line formed on the same layer as source and drain electrodes of a thin film transistor (TFT) and formed on a substrate on which the TFT is formed, a first insulating layer formed on the TFT, a lower electrode that electrically connected to one of the source and drain electrodes of the TFT and disposed on the first insulating layer, a first auxiliary power line and a second auxiliary power line formed on the same layer as the lower electrode in the second insulating layer, a second insulating layer formed on an edge portion of the lower electrode and not formed on the second auxiliary power line, wherein an opening that exposes a portion of the lower electrode is formed, an organic film formed on a substrate; and an upper electrode formed on the substrate.

Owner:SAMSUNG DISPLAY CO LTD

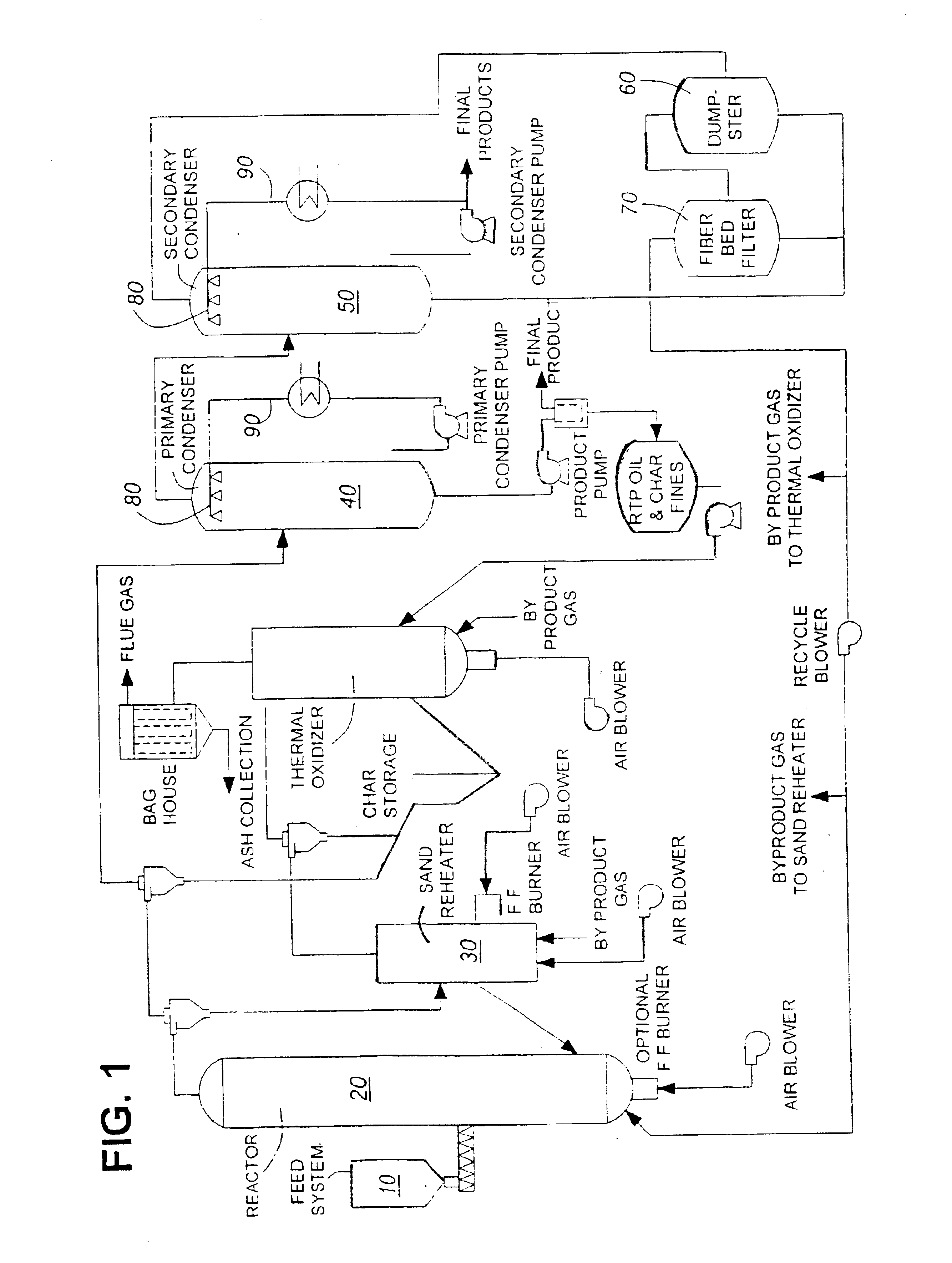

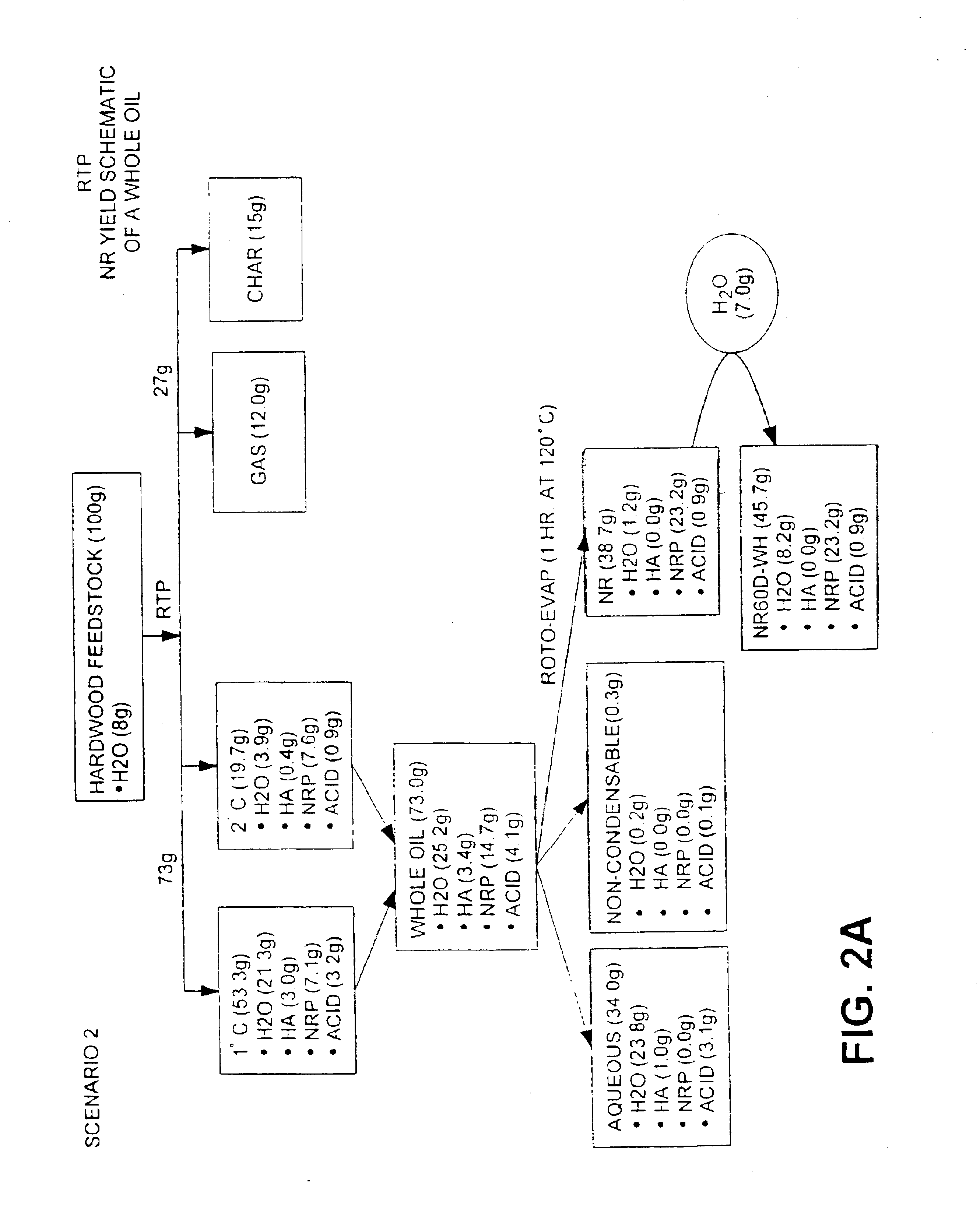

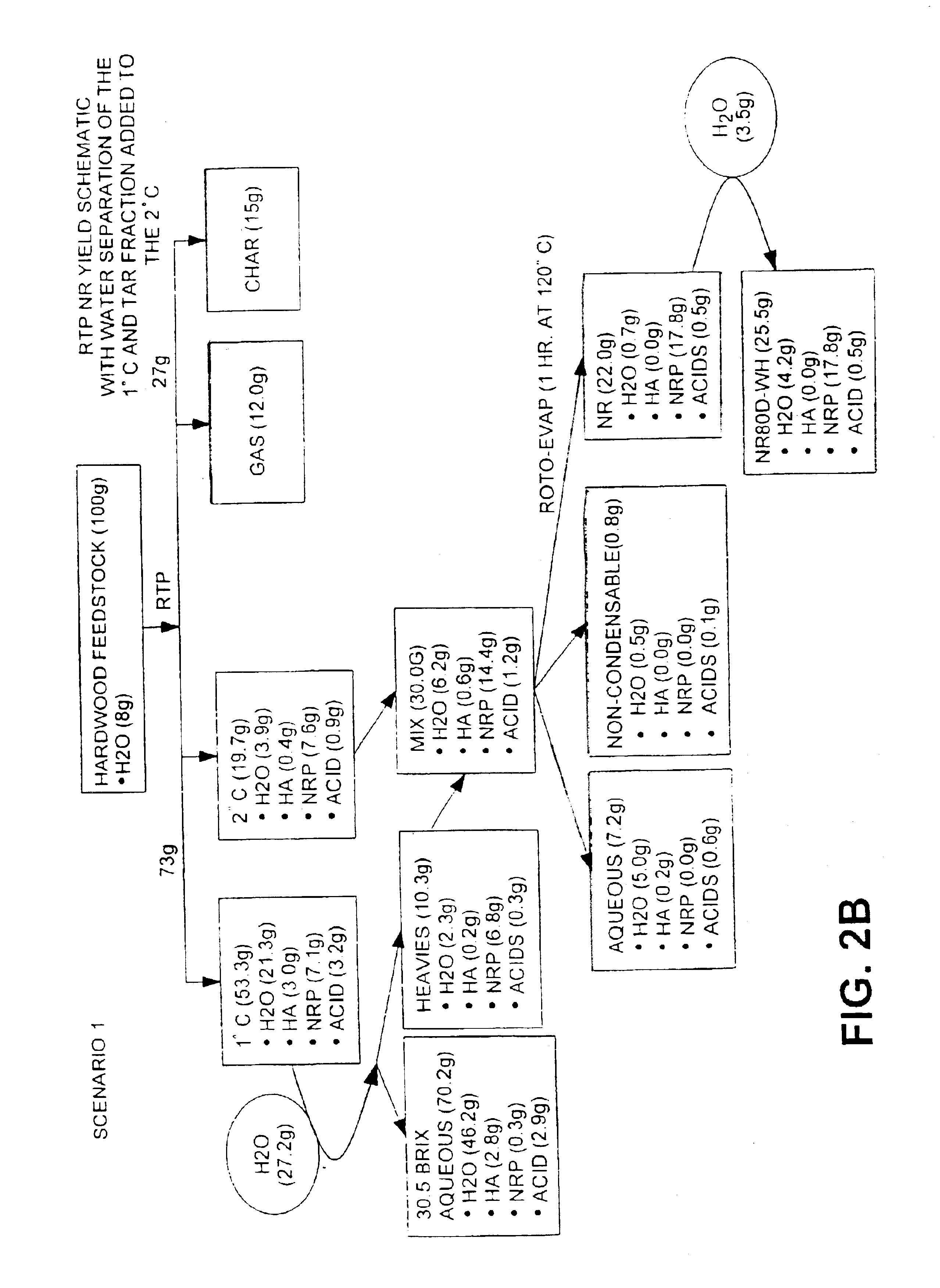

Natural resin formulations

InactiveUS6844420B1Low viscosityImprove liquidityFatty oils/acids recovery from wasteBiofuelsNatural resinDistillation

This invention is directed to a method of preparing a natural resin by liquefying wood, bark, forest residues, wood industry residues, or other biomass using rapid destructive distillation (fast pyrolysis). Fast pyrolysis produces both vapors and char from biomass, and following removal of the char from the product vapors, a liquid pitch product is recovered and processed by distillation, evaporation, or a combination thereof, in order to obtain a natural resin which may be in either liquid or solid form. The natural resin comprises a total phenolic content from about 30% to about 80% (w / w), and is a highly-reactive ligninic compound that has been found to be suitable for use within resin formulations without requiring any further extraction or fractionation procedures. Resins comprising up to 60% natural resin have been prepared and tested in board production and found to exhibit similar properties associated with commercially available resins. The natural resin may substitute for phenol, or for both phenol and formaldehyde within phenol-containing resins. Similarly, the natural resin can replace a substantial part of the components within urea-containing resins.

Owner:ENSYN RENEWABLES

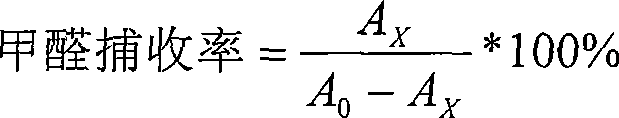

Coating for collecting formaldehyde

InactiveCN101475767AEffective absorptionAdhesive strength effectNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesActive componentAdhesive

The invention relates to adhesive for collecting formaldehyde and paint for collecting the formaldehyde, both of which use formaldehyde collecting agent as a composition of active components. The adhesive is used for adhesion of the outmost layer in a man-made board or adhesion and edge sealing at a kerf of the man-made board, can effectively absorb formaldehyde released by the man-made board, does not cause influence on the adhesive strength of the board, and is comparatively cheap. The paint is used for painting indoor walls, absorbs the formaldehyde in the indoor air, can also be used for painting the surface of the man-made board, seals and absorbs formaldehyde gas, and reduces the release amount of the formaldehyde. Compared with the prior art, the adhesive and the paint for collecting the formaldehyde have the advantages that the adhesive and the paint are cheap, can efficiently adsorb the formaldehyde and generate stable compounds, and do not re-decompose and release the formaldehyde, so the adhesive and the paint cannot generate other secondary pollutants.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

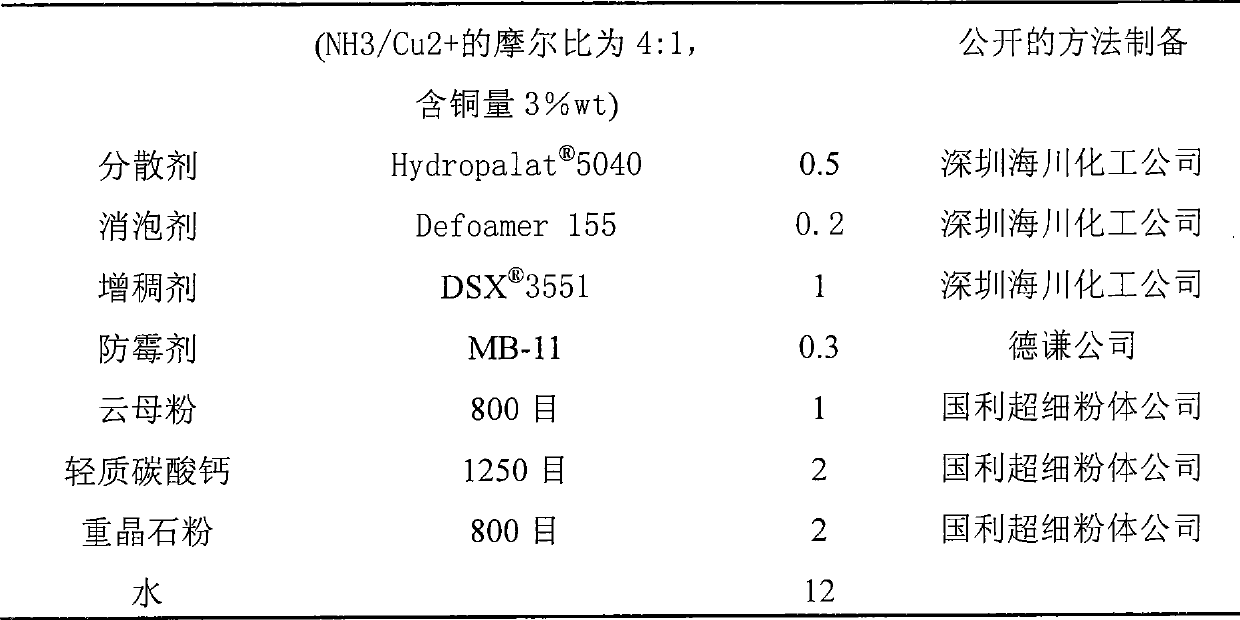

Moisture-curable adhesive composition

InactiveUS20070088137A1Safe for chronic exposureHigh peel strengthPolyureas/polyurethane adhesivesSynthetic resin layered productsRubber membraneCombustion

A moisture-curable adhesive composition that may be formulated to be free of volatile organic compounds, or substantially free of volatile organic compounds which is safe for chronic exposure, resistant to combustion, and provides a high peel strength useful for securing a rubber membrane material to a rigid roof deck includes a polymer having silicon-containing hydrolyzable terminal groups, a phenolic resin, and a non-polymeric silicon-containing hydrolyzable compound, wherein the ratio of the amount of polymer having silicon-containing hydrolyzable terminal groups by weight to the amount of phenolic resin by weight is greater than 2:1.

Owner:CHEMLINK

Dicing/die bonding sheet

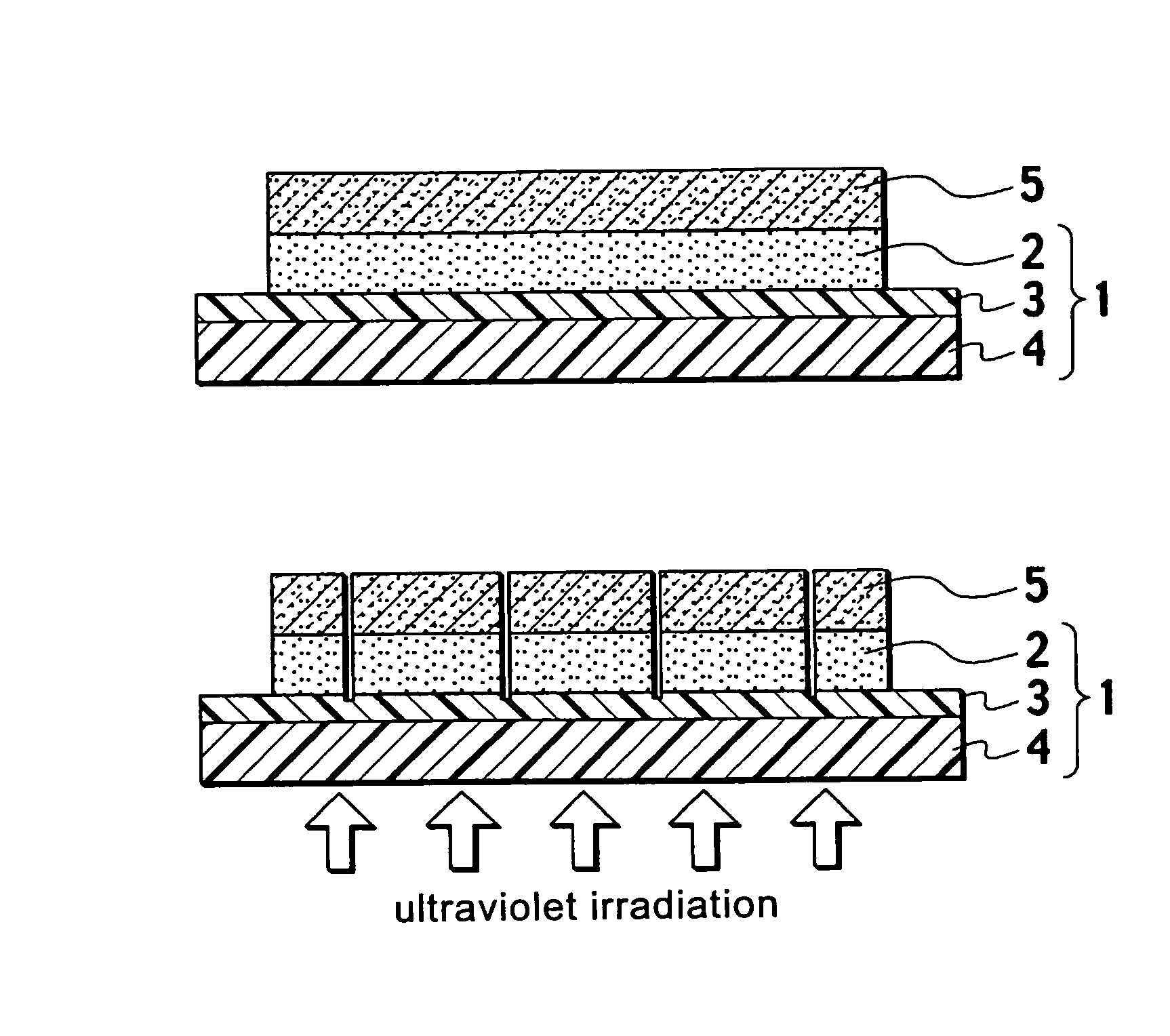

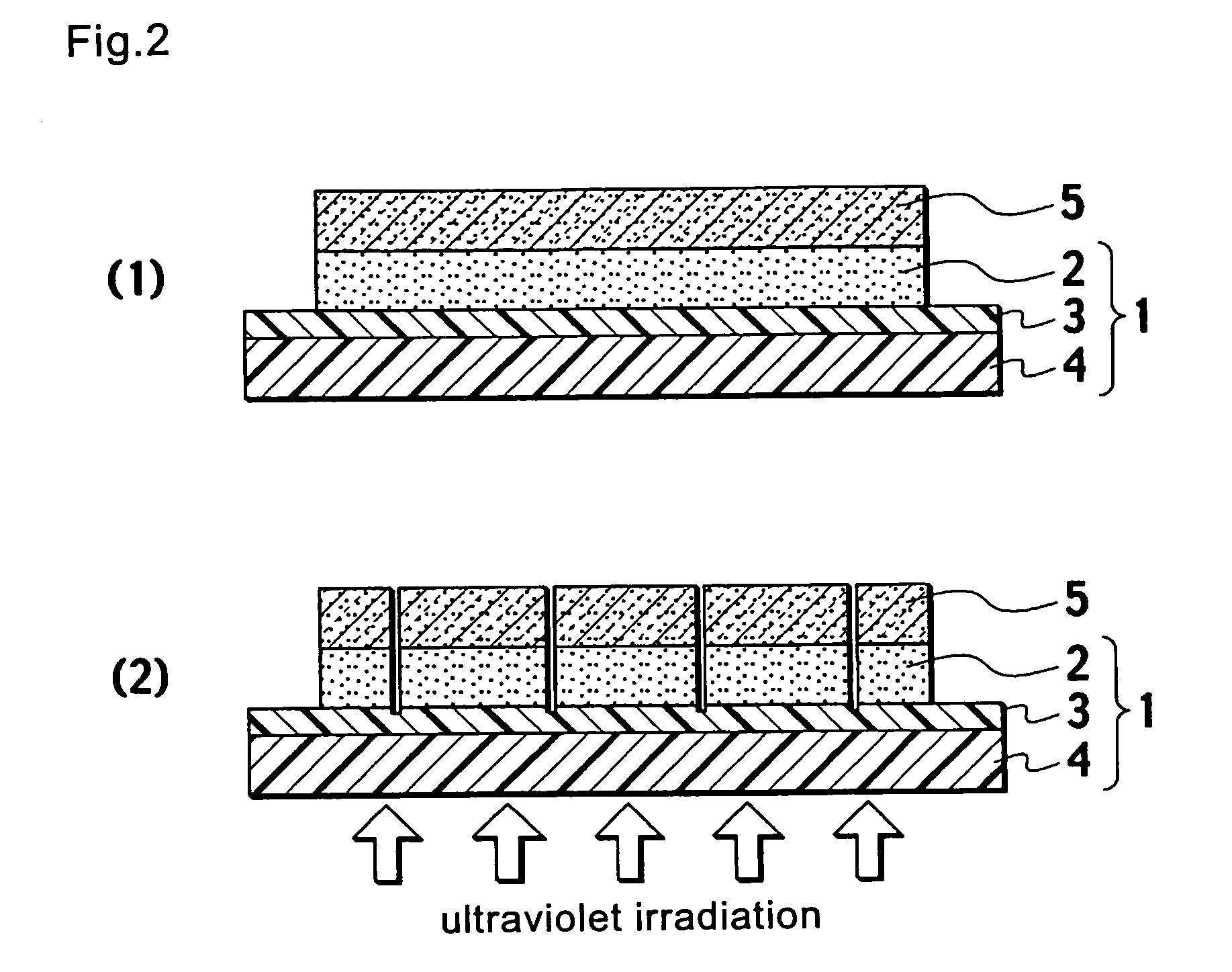

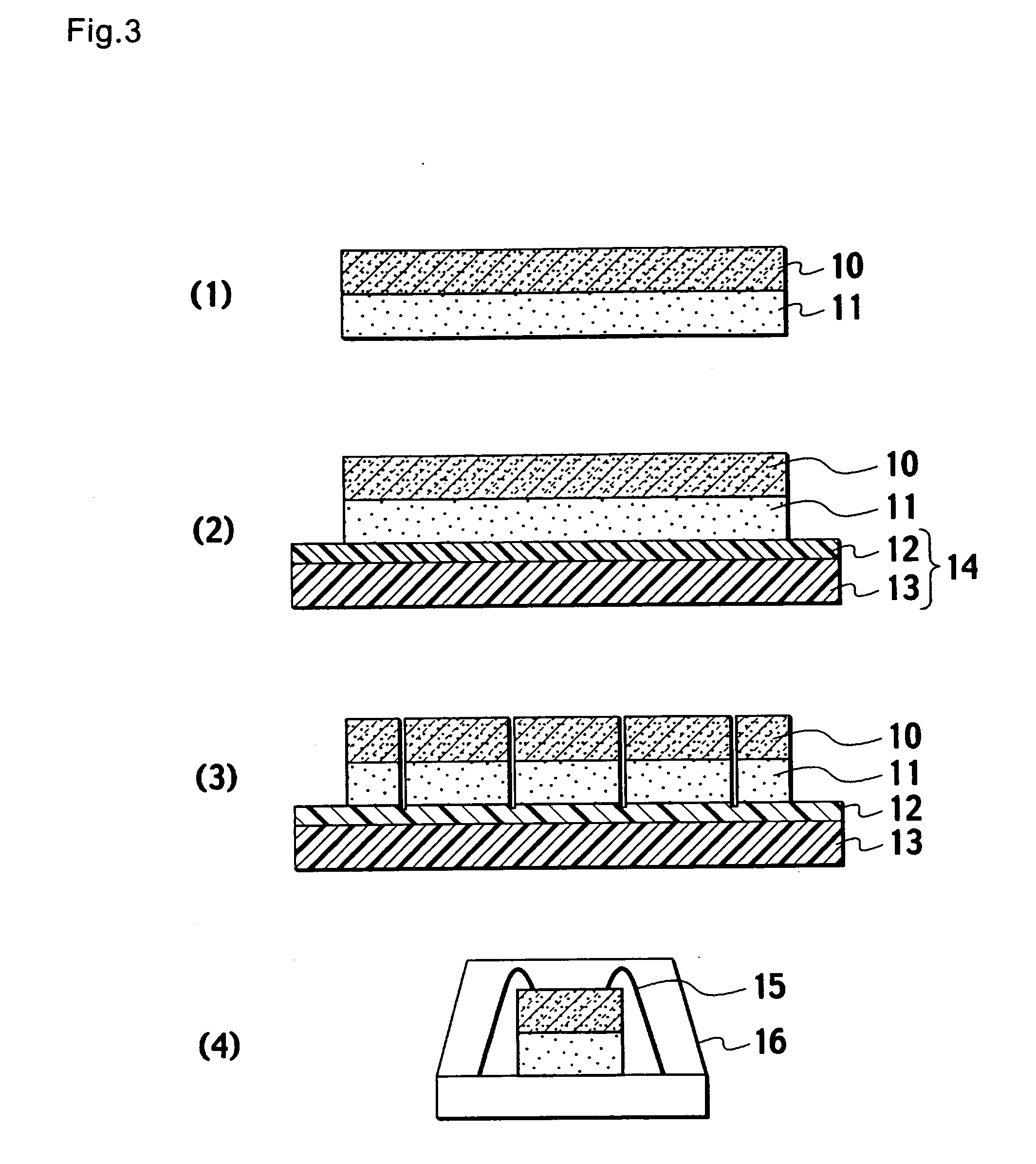

ActiveUS20070026572A1Satisfactory adhesivenessEasy to separatePolyureas/polyurethane adhesivesSynthetic resin layered productsEpoxyDicing tape

The present invention provides a dicing / die bonding sheet which can be used as a dicing tape during dicing, enables ready separation of the semiconductor element and the adhesive layer from the pressure-sensitive adhesive layer during pickup, and in which the adhesive layer has satisfactory adhesiveness as a die bonding material. A dicing / die bonding sheet in which the pressure-sensitive adhesive layer comprises a compound (A), containing intramolecular, radiation curable carbon-carbon double bonds with an iodine value of 0.5 to 20, and at least one compound (B) selected from a group consisting of polyisocyanates, melamine-formaldehyde resins, and epoxy resins, and the adhesive layer comprises an epoxy resin (a), a phenolic resin (b) with a hydroxyl equivalent of at least 150 g / eq., an epoxy group-containing acrylic copolymer (c), comprising from 0.5 to 6% by weight of glycidyl acrylate or glycidyl methacrylate, and with a weight average molecular weight of at least 100,000, a filler (d), and a curing accelerator (e).

Owner:RESONAC CORP +1

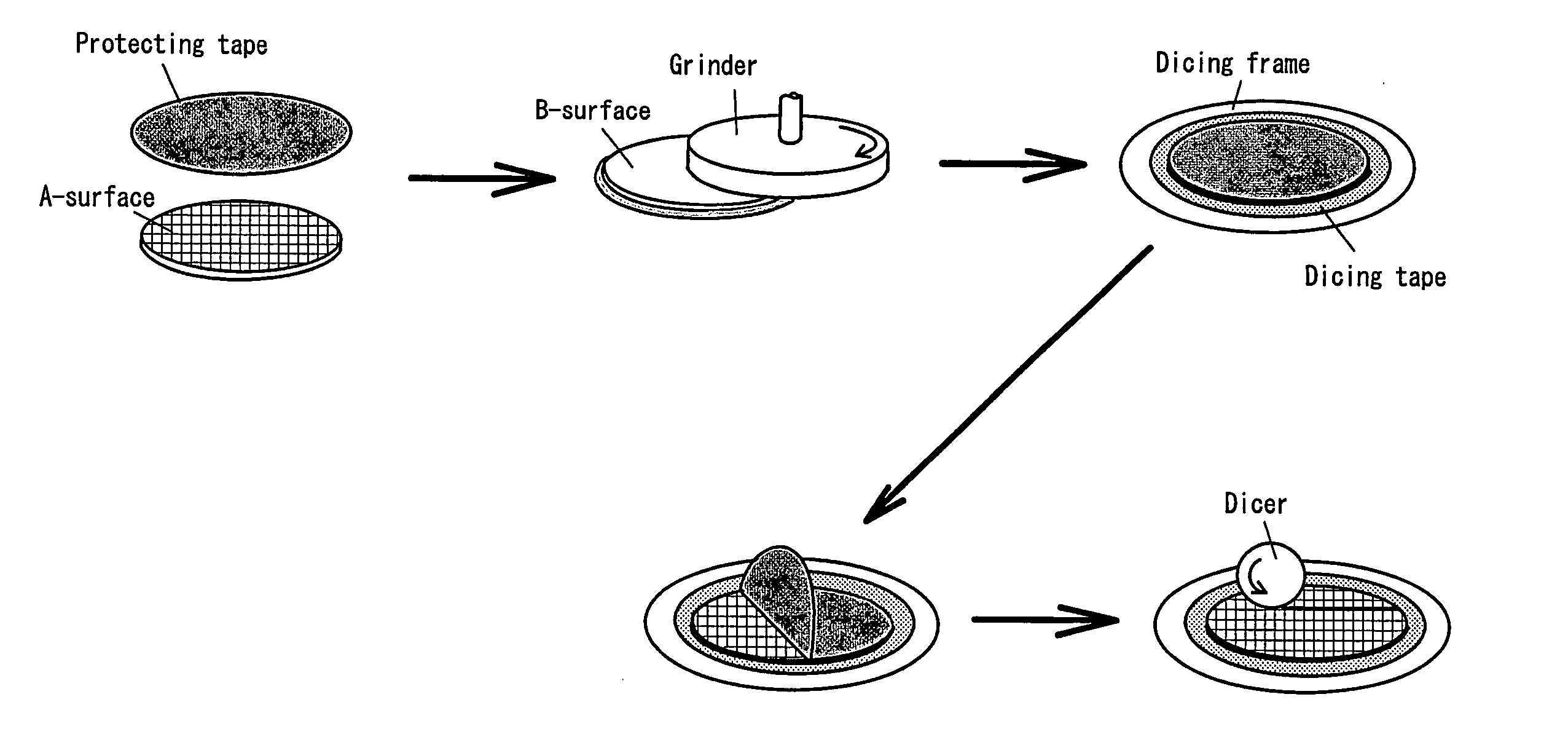

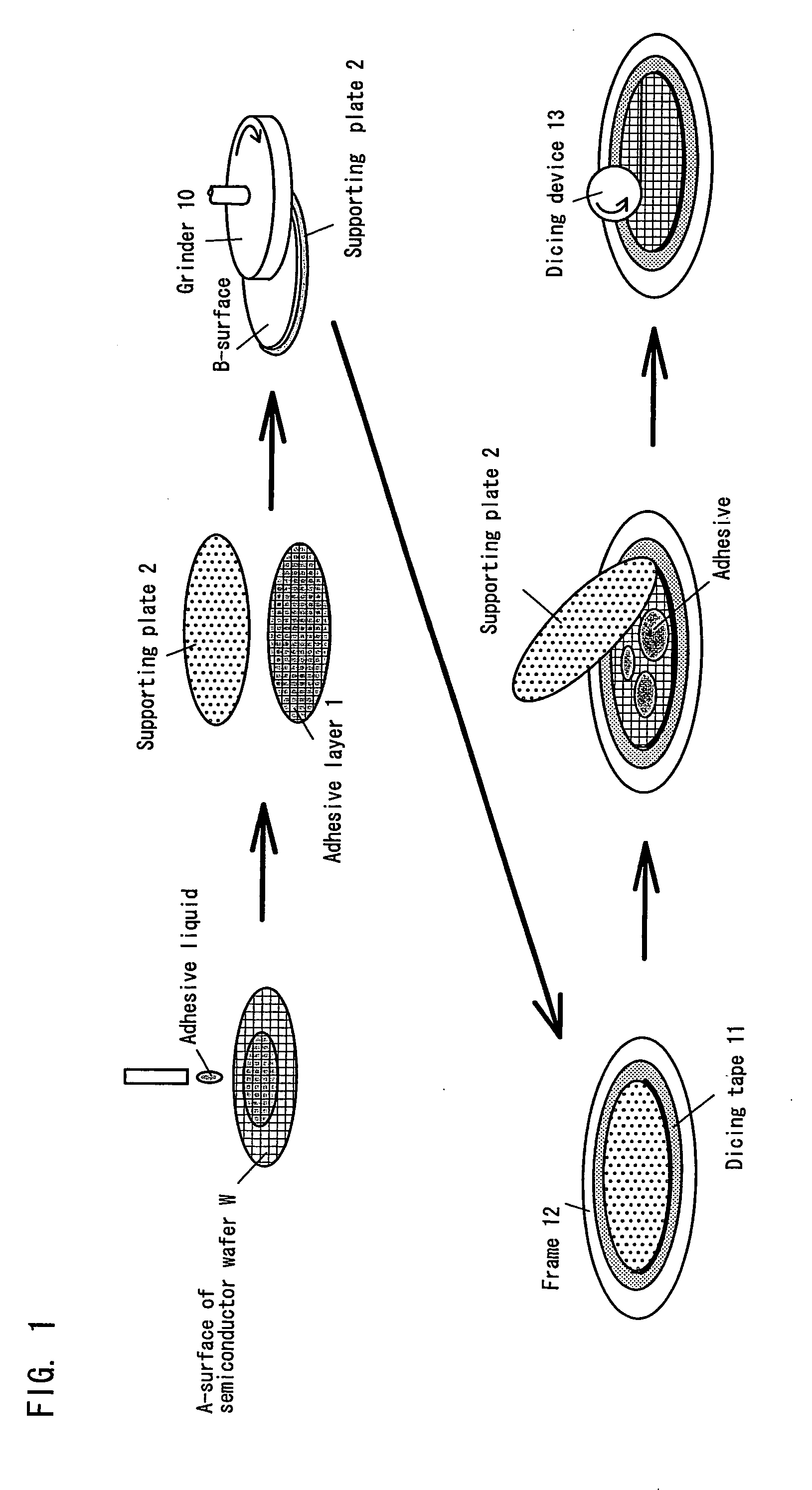

Substrate attaching method

InactiveUS20050170612A1Easy to controlPoint becomes highAdhesive processesSolid-state devicesEngineeringSemiconductor

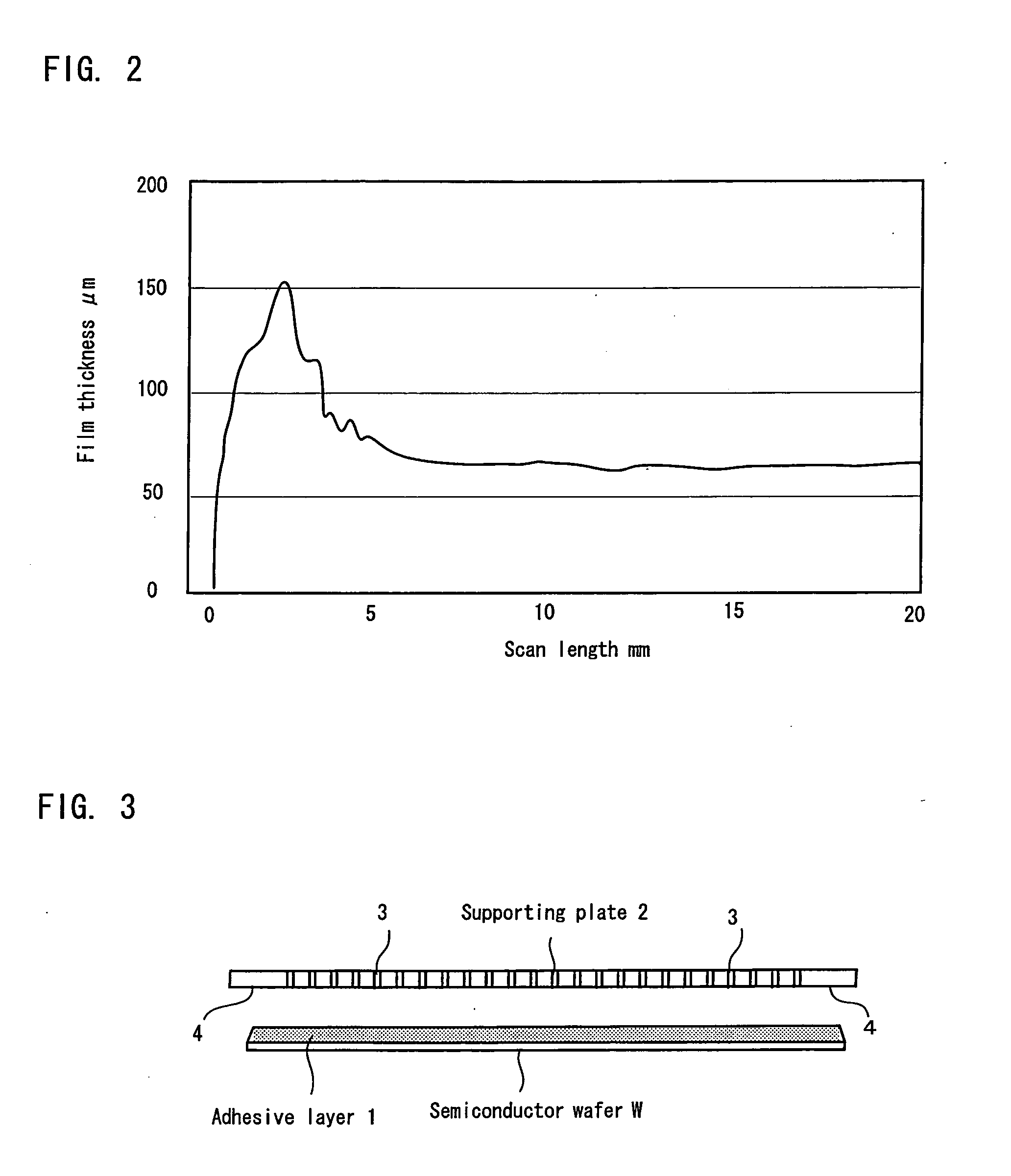

A method for attaching a substrate such as a semiconductor wafer in which cracking or chipping can be prevented when the substrate is thinned involves applying adhesive liquid onto a circuit (element)-formed surface of a semiconductor wafer. The adhesive liquid undergoes preliminary drying, so that its flowability is reduced and it can keep its shape as an adhesive layer. For the preliminary drying, heating is conducted for 5 minutes at a temperature of 80° C. by using an oven. The thickness of the adhesive layer is determined based on the irregularities of the circuit which has been formed on the surface of the semiconductor wafer. Next, a supporting plate is attached to the semiconductor wafer on which the adhesive layer of a desired thickness has been formed.

Owner:NXP BV +1

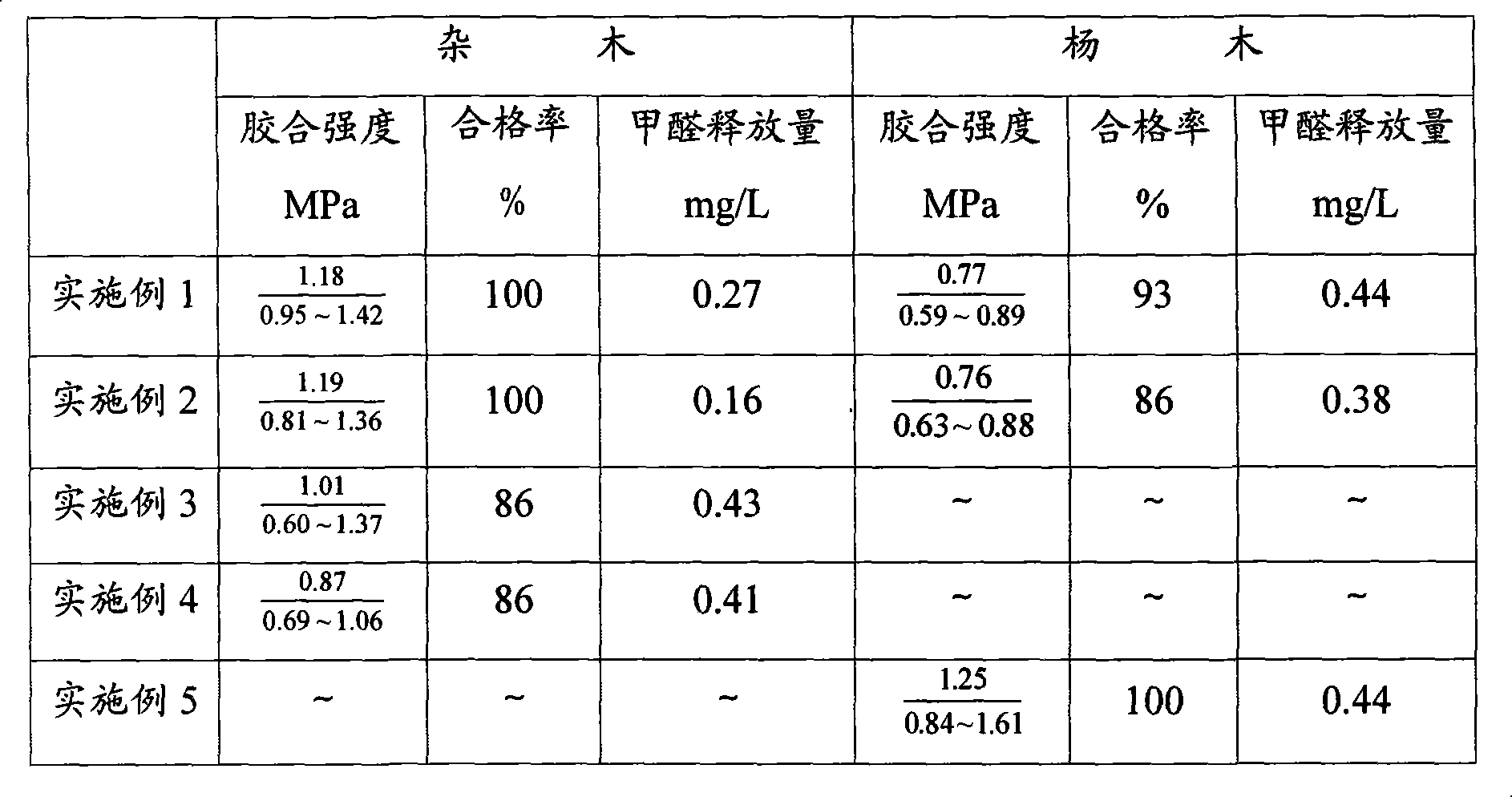

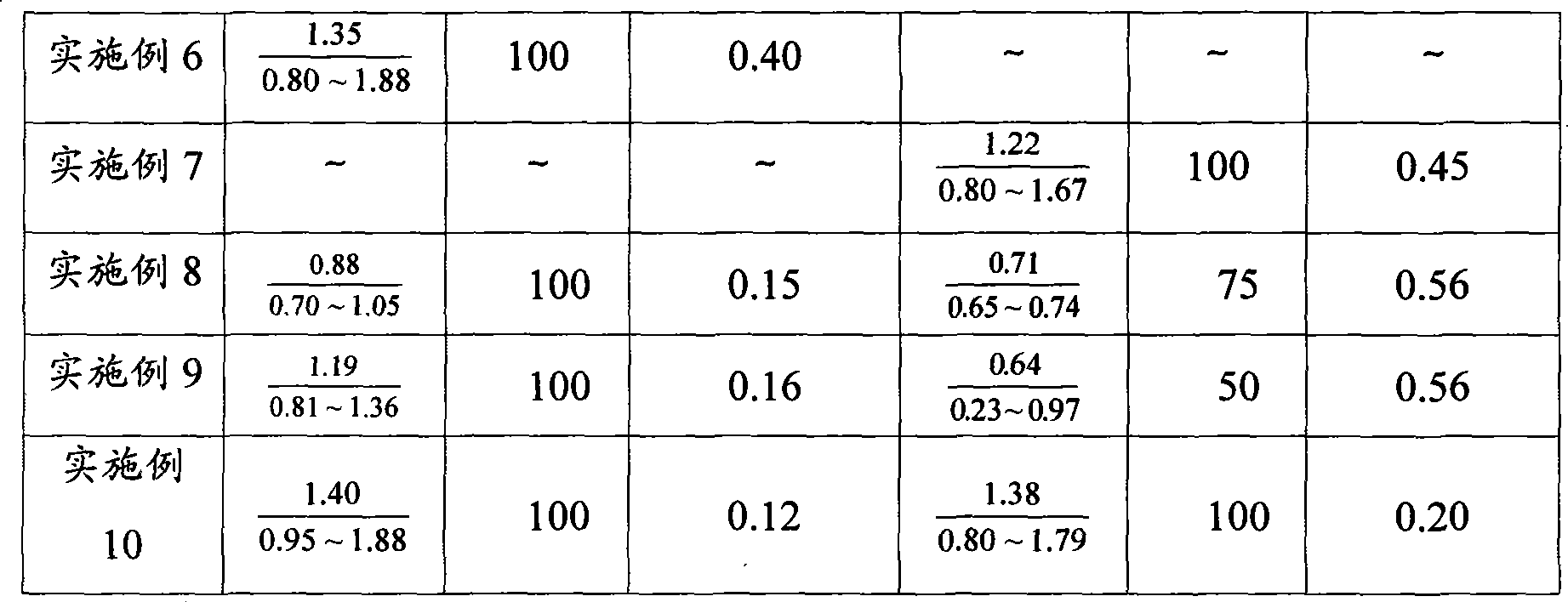

Production method for melamine modified urea-formaldehyde resin with low residual quantity of formaldehyde

ActiveCN103408711AResidue reductionReduce the gel phenomenon of polymerization reactionAldehyde/ketone condensation polymer adhesivesMaterials sciencePolymerization

The invention provides a production method for a melamine modified urea-formaldehyde resin with low residual quantity of formaldehyde. Main raw materials used in the invention comprise formaldehyde, melamine and urea, wherein formaldehyde is fed in one step, and urea is fed in three steps. Production of the urea-formaldehyde resin comprises the three stages of prepolymerization, polymerization and later polymerization; the addition amounts of urea and reaction temperatures in each stage are different; the phenomenon of gelatinization is avoided in the process of polymerization by using the production method; the obtained urea-formaldehyde resin has narrow molecular weight distribution and low residual quantity of formaldehyde, is used for production of artificial boards and can reduce formaldehyde emission of the artificial boards.

Owner:广西横州丽冠环保材料有限公司

Wood Adhesives Containing Reinforced Additives for Structural Engineering Products

The present disclosure relates to additives used in conjunction with adhesives to give enhanced performance. Engineered composite wood materials and methods of making such materials are also provided by the subject application. A reinforced adhesive includes an adhesive and an additive material comprising nanoscopic and microscopic materials.

Owner:UNIV OF TENNESSEE RES FOUND

Process for producing fast curing molding compounds bonded with phenolic resin

A process is provided for producing fast curing bonded with phenolic resin, which comprises pulverulent phenolic resins mixed with or applied to the substrate to be adhered together with pulverulent addition polymers selected from the group consisting of polyvinyl alcohols and addition polymers, stabilized by hydroxyl-containing protective colloids of at least one monomer selected from the group consisting of the vinyl esters of branched or unbranched carboxylic acids of 1 to 12 carbon atoms, the esters of acrylic acid and methacrylic acid with branched or unbranched alcohols of 1 to 12 carbon atoms, vinylaromatics, vinyl halides, olefins and dienes, and subsequently, by the employment of elevated temperature and optionally elevated pressure, cured and processed into a shaped article.

Owner:WACKER CHEM GMBH

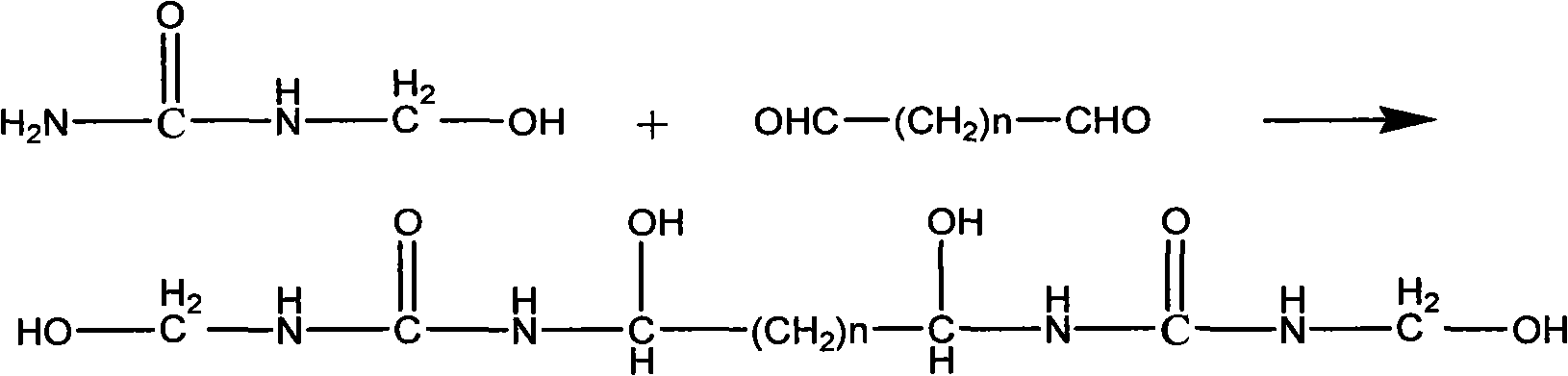

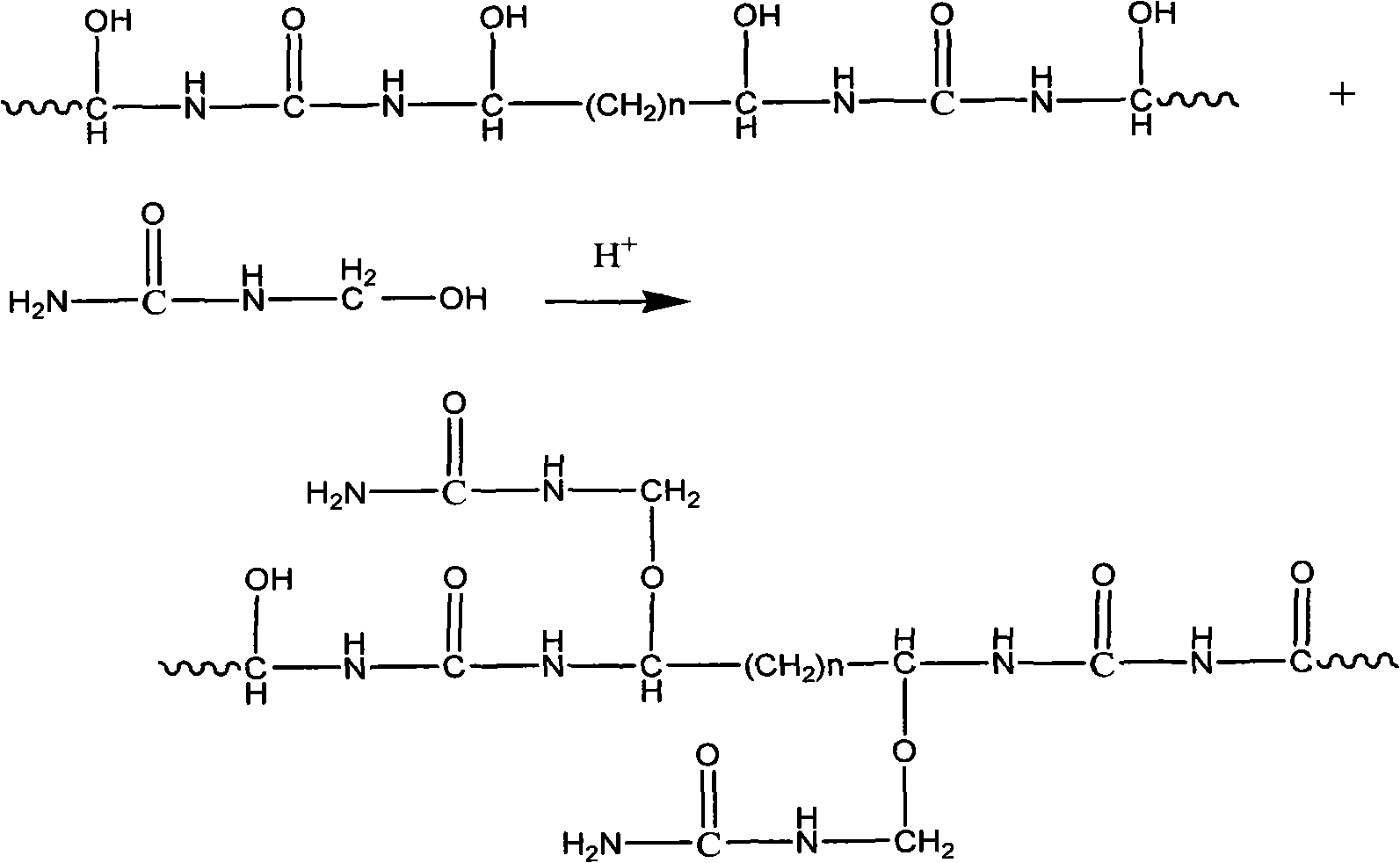

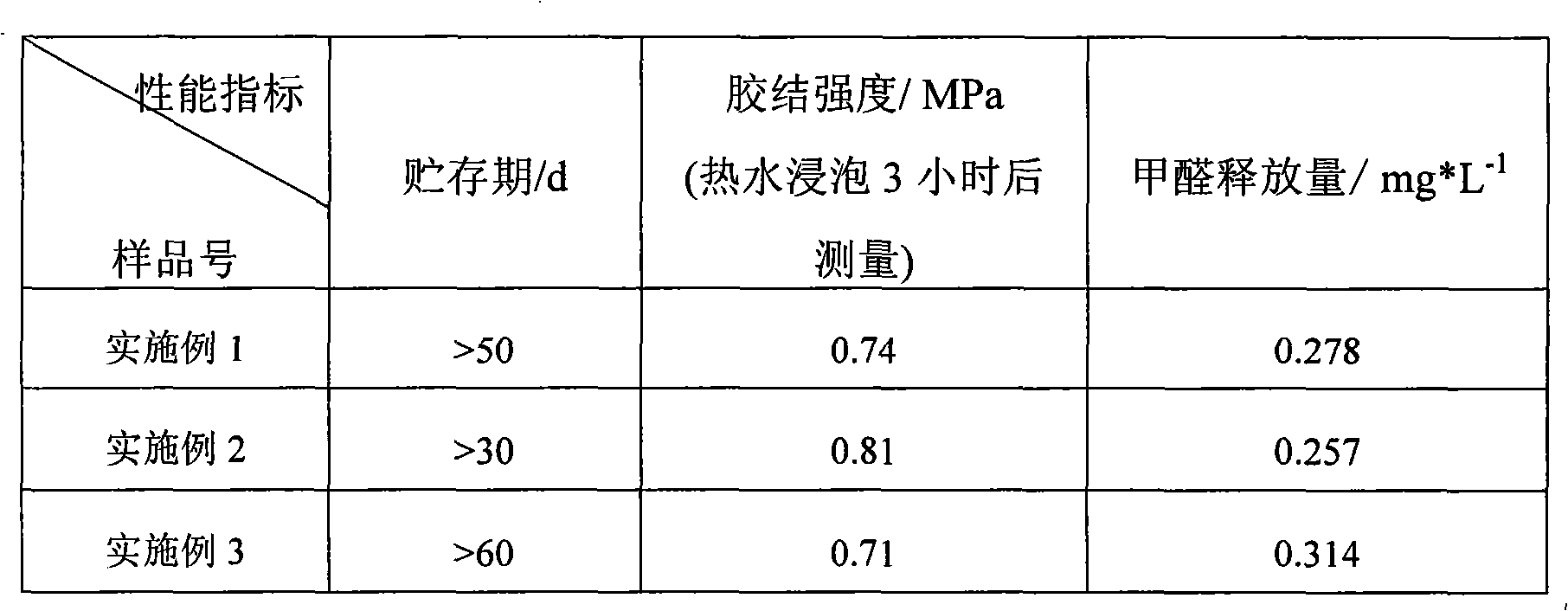

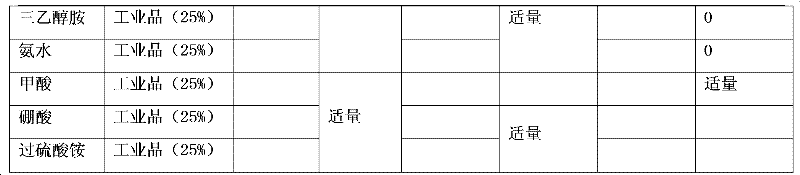

Environmental protection urea-formaldehyde resin and preparation method thereof

InactiveCN101265314ALow free formaldehyde contentExtended shelf lifeAldehyde/ketone condensation polymer adhesivesThermal waterWeak base

A novel environmental protective urea-formaldehyde resin and a preparation method belong to the field of wood processing adhesives. The urea-formaldehyde resin is formed by the reaction of urea, formaldehyde, aldehyde, one or more stabilizers and modifier according to the route of weak base-weak acid-weak base. The method firstly controls the F / U feed ratio, the pH value and the temperature during the reaction process to reduce the content of free formaldehyde in the resin; then the aldehyde is introduced to allow the resin to generate the stable alkyl ether (-(CH2)n-O-(CH2)n-) structure, thus reducing the content of methylene-ether bond (-CH2-O-CH2-) in the resin structure, simultaneously reducing the using amount of the formaldehyde and further greatly reducing the release amount of the formaldehyde during the using process of a plate from the two aspects; in addition, the introduction of a long chain and polyaldehyde can ensure the resin to have great bonding strength and water resistance. The urea-formaldehyde resin which is prepared by the invention has the advantages of low content of free formaldehyde, simple process, low cost, etc., the release amount of the formaldehyde of the plate which is prepared by using the adhesive achieves the E0 level standard, and the high bonding strength can be maintained after being boiled in hot water.

Owner:BEIJING UNIV OF CHEM TECH

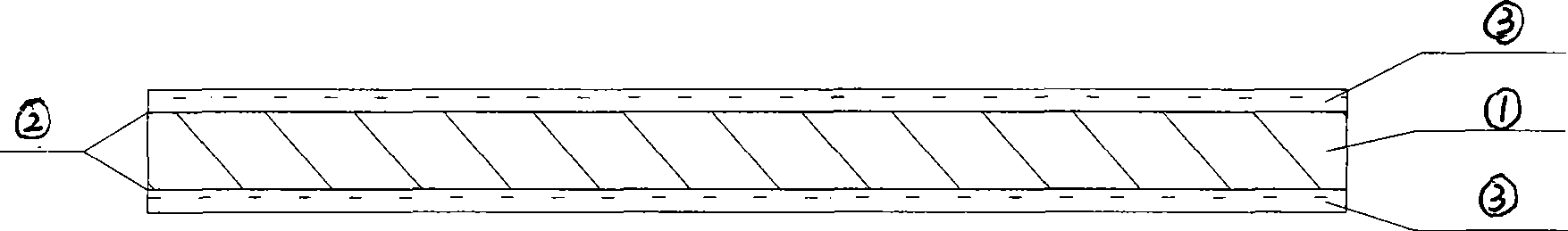

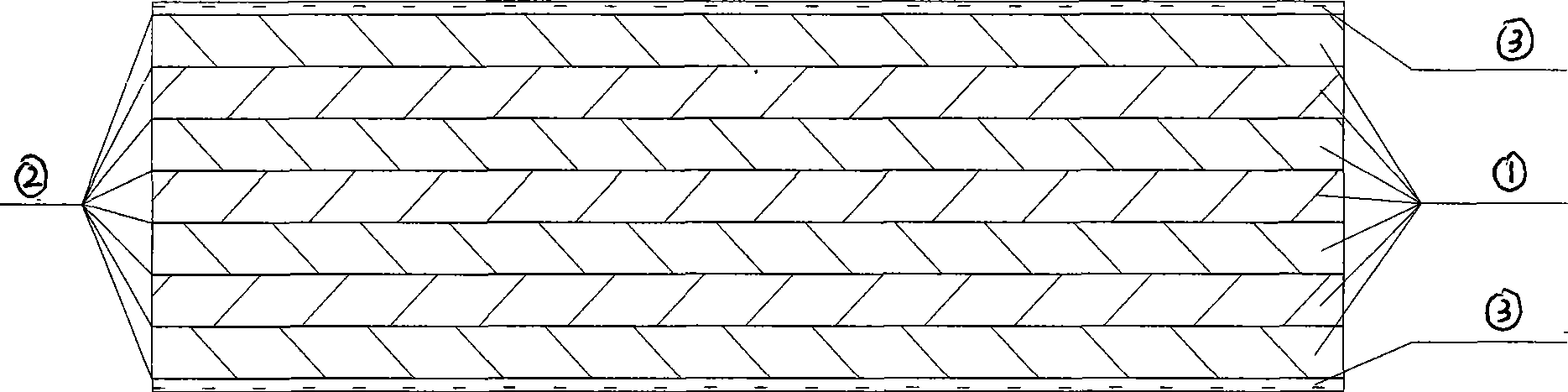

Method for producing flame-retardant glued board

ActiveCN101412231AReduce releaseImprove flame retardant performanceOther plywood/veneer working apparatusWood treatment detailsAdhesivePyrophosphate

The invention discloses a method for producing a flame-retardant veneer plywood, which comprises the following steps: placing wood veneers into a flame retardant aqueous solution to perform dipping treatment, applying the mixed adhesive to the upper surfaces and the lower surfaces of the veneers after the veneers are dried, assembling the veneers into a plate blank according to the principle that odd layers are crossed and symmetrical with even layers, and then performing the processes of cold pressing, hot pressing, cutting edge, sanding, surface treating and the like to obtain the flame-retardant veneer plywood product the thickness of which is between 2.7 and 20 millimeters. The flame retardant in the method is a mixture of low ammonium polyphosphate, ammonium phosphate, ammonium pyrophosphate, urea phosphate, boric acid and pentaerythritol, and the mixed adhesive is a uniform mixture of wood adhesive, filler, and a curing agent. The flame-retardant decorative veneer plywood prepared by the method has the advantages of excellent flame-retardant and fireproof performance, environmental prevention performance, and good mechanical properties.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

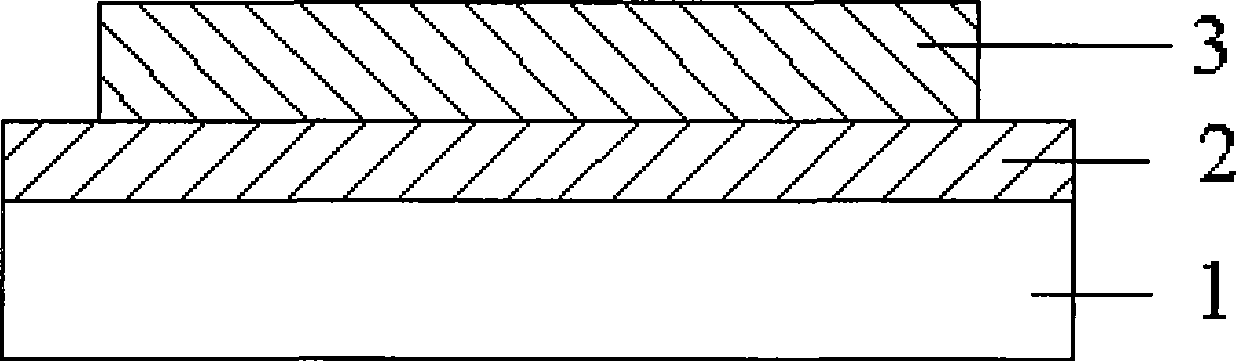

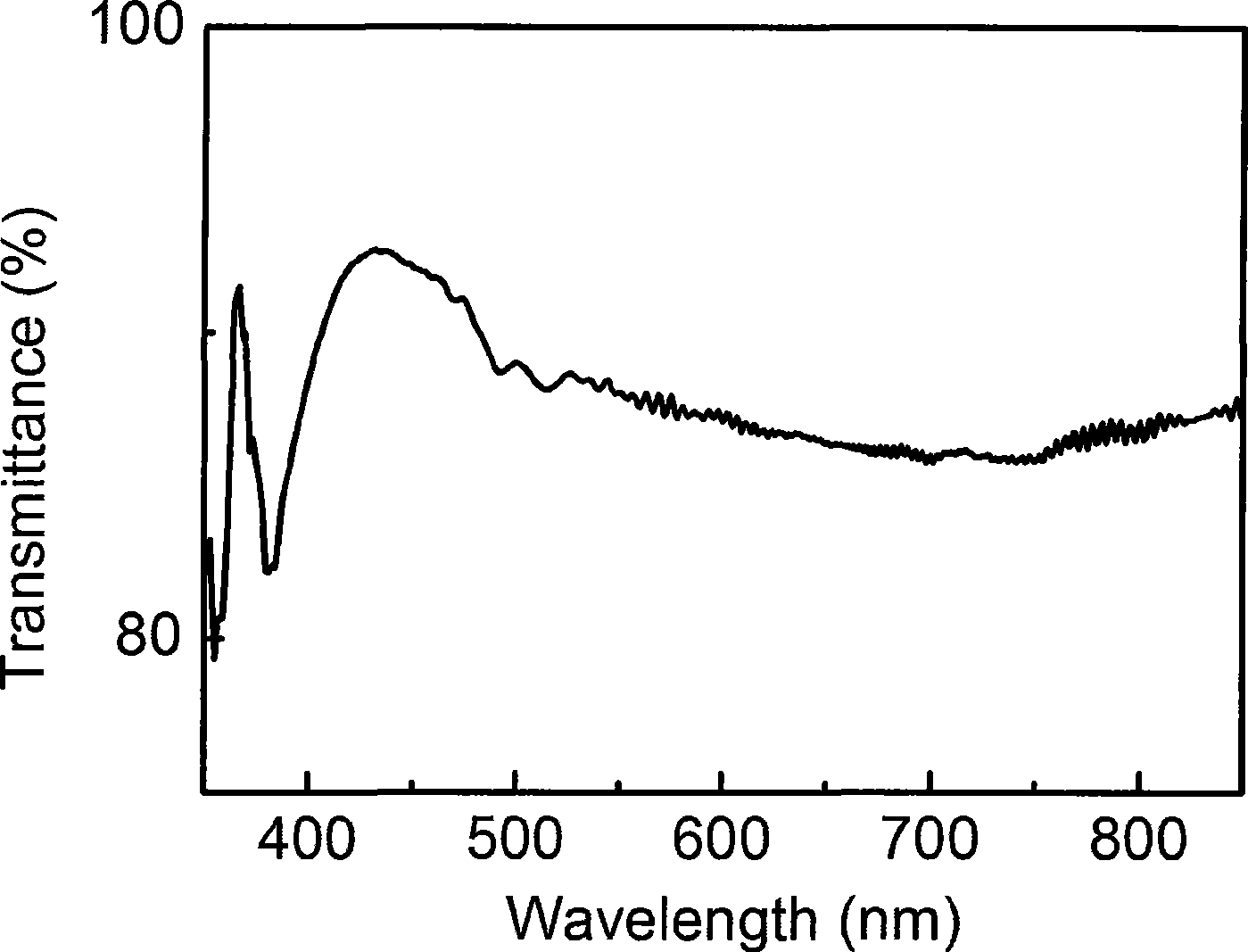

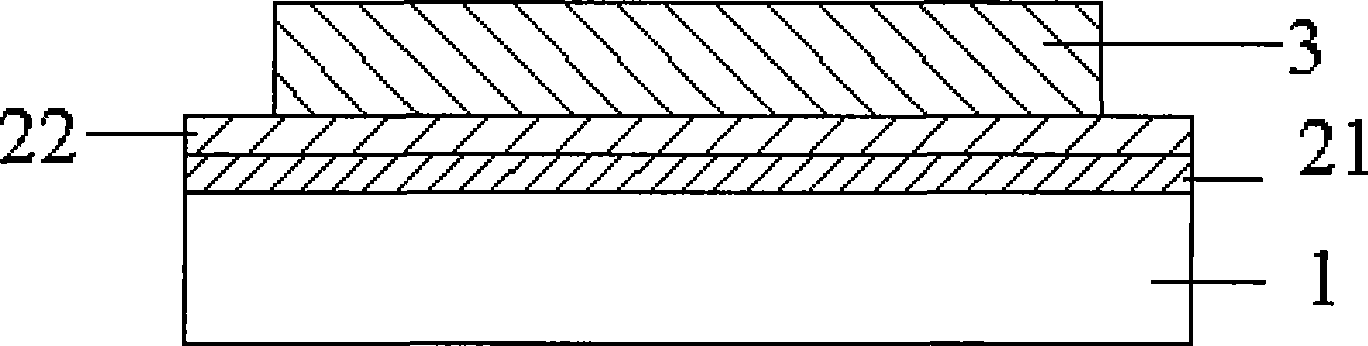

Substrate for flexible organic optoelectronic device and preparation method thereof

InactiveCN101465409AImprove flatnessImprove adhesionSolid-state devicesSemiconductor/solid-state device manufacturingUV curingAdhesive

The invention discloses a flexible substrate used for optoelectronic devices and comprises a flexible substrate; the invention is characterized in that a bonding layer and a conductive thin film are arranged on the surface of the flexible substrate; the conductive thin film is deposited on the surface of the bonding layer; and the material of the bonding layer is an adhesive with a double-curing system comprising UV curing-thermal curing or UV curing-microwave curing or UV curing-anaerobic curing or UV curing-electron beam curing. The substrate solves the problem of poor adhesion between the deposited conductive thin film and the substrate due to low surface energy of the flexible substrate and improves the barrier properties of the substrate on water and oxygen, and also achieves good smoothing effect on the surface of the substrate; besides, the preparation method is simple and effective, which can significantly reduce the substrate production cost and process difficulty and increase the substrate yield rate in the etching process.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

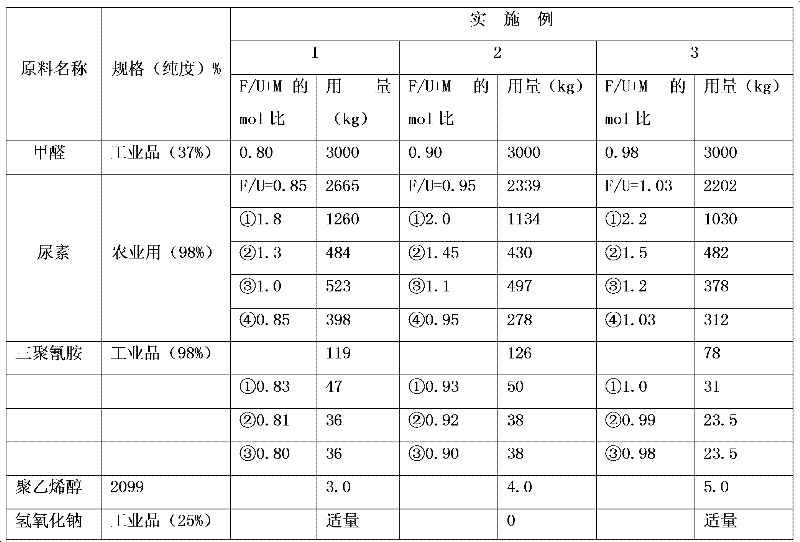

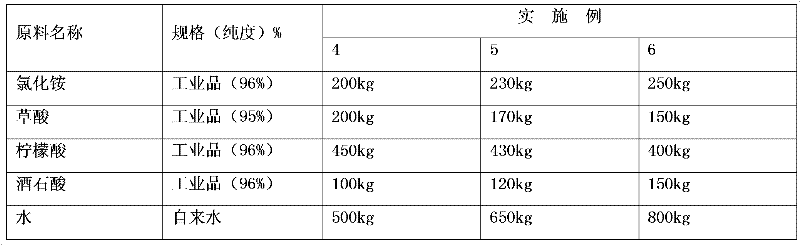

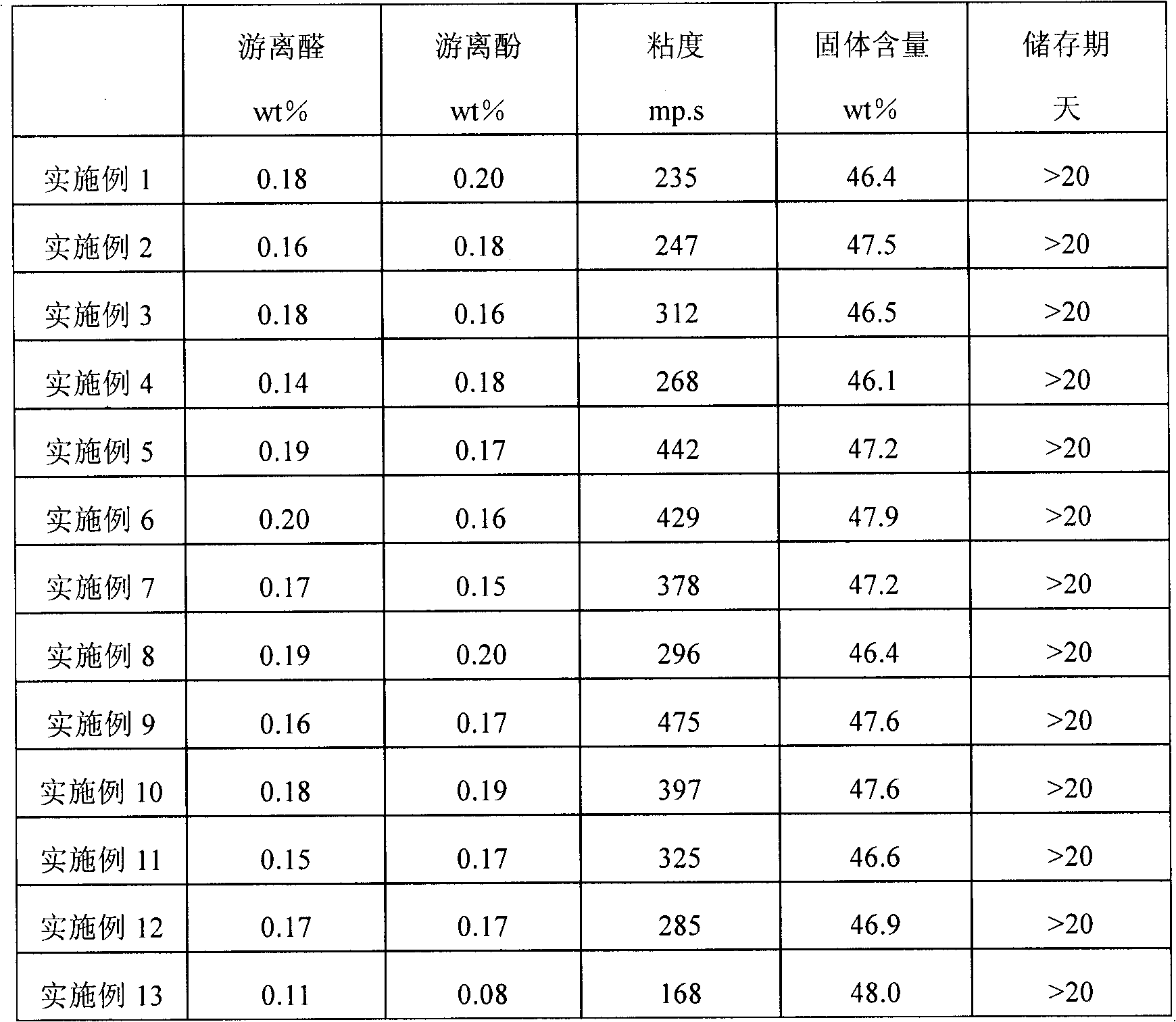

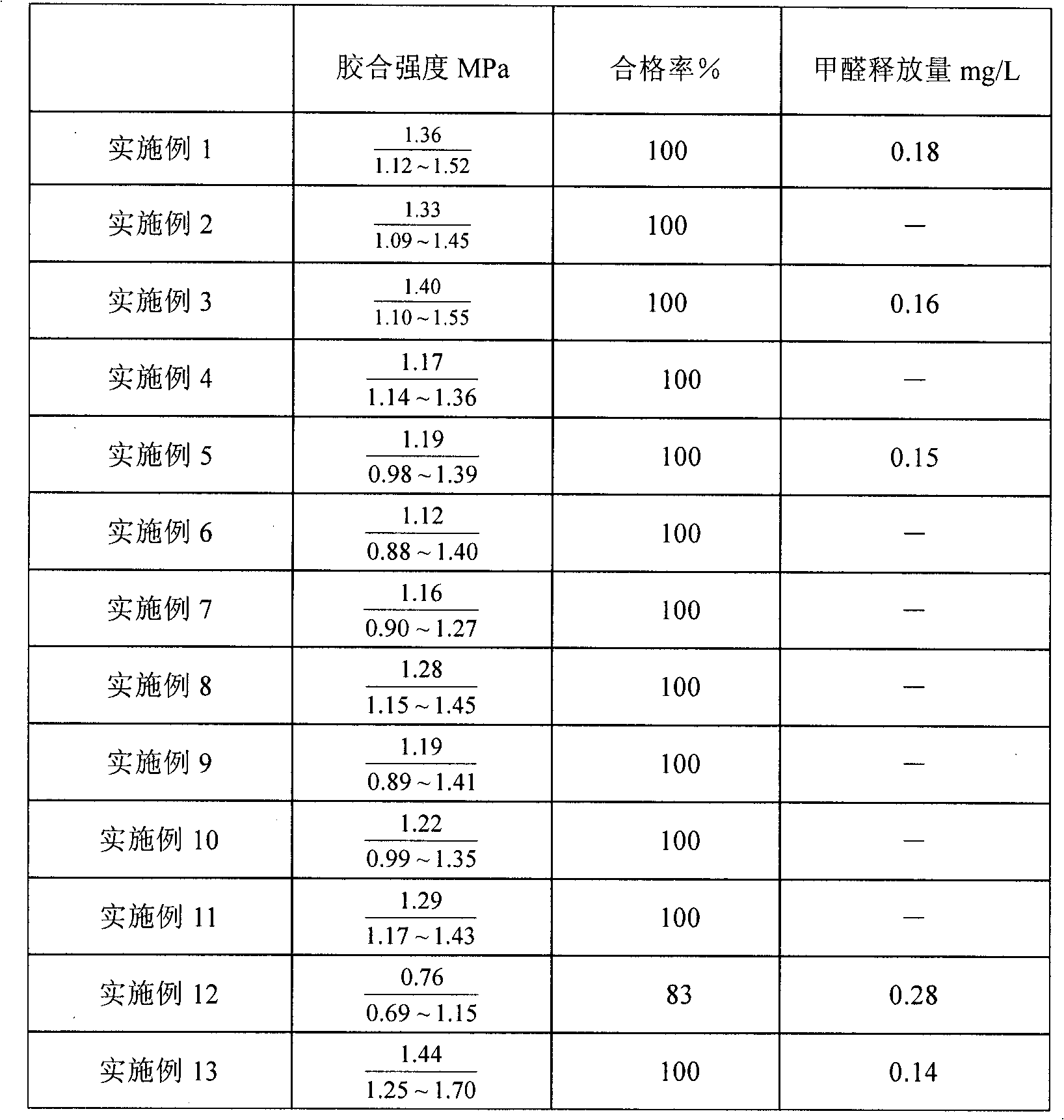

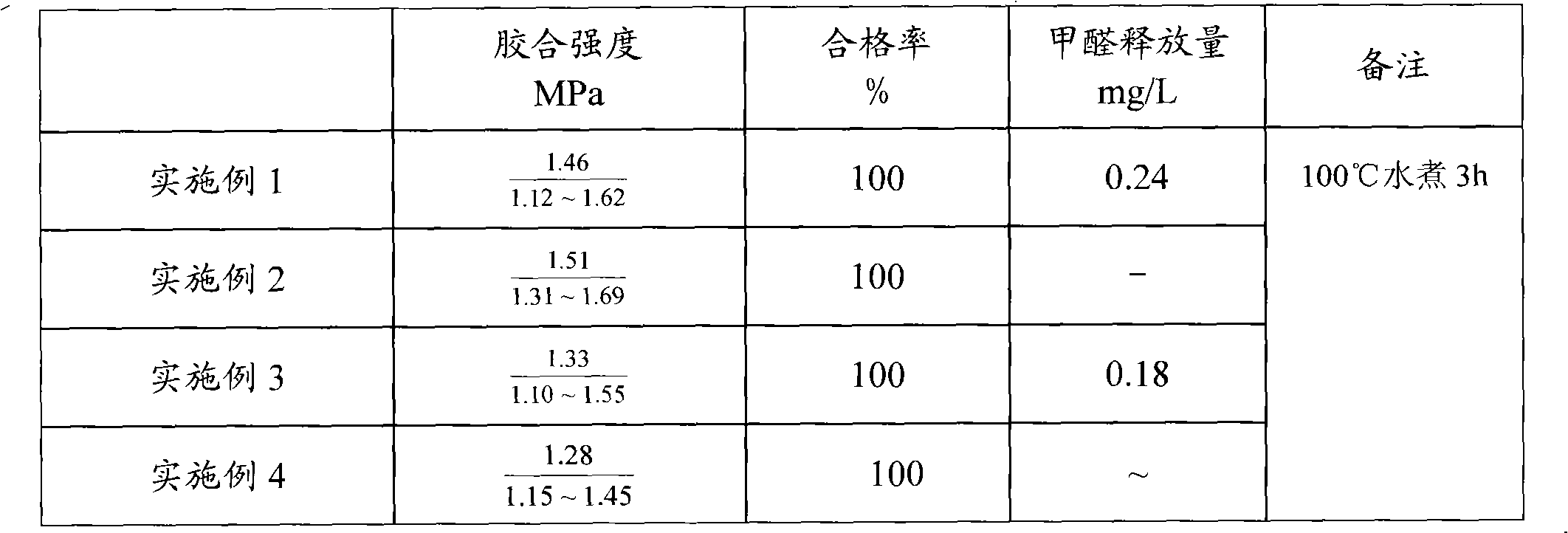

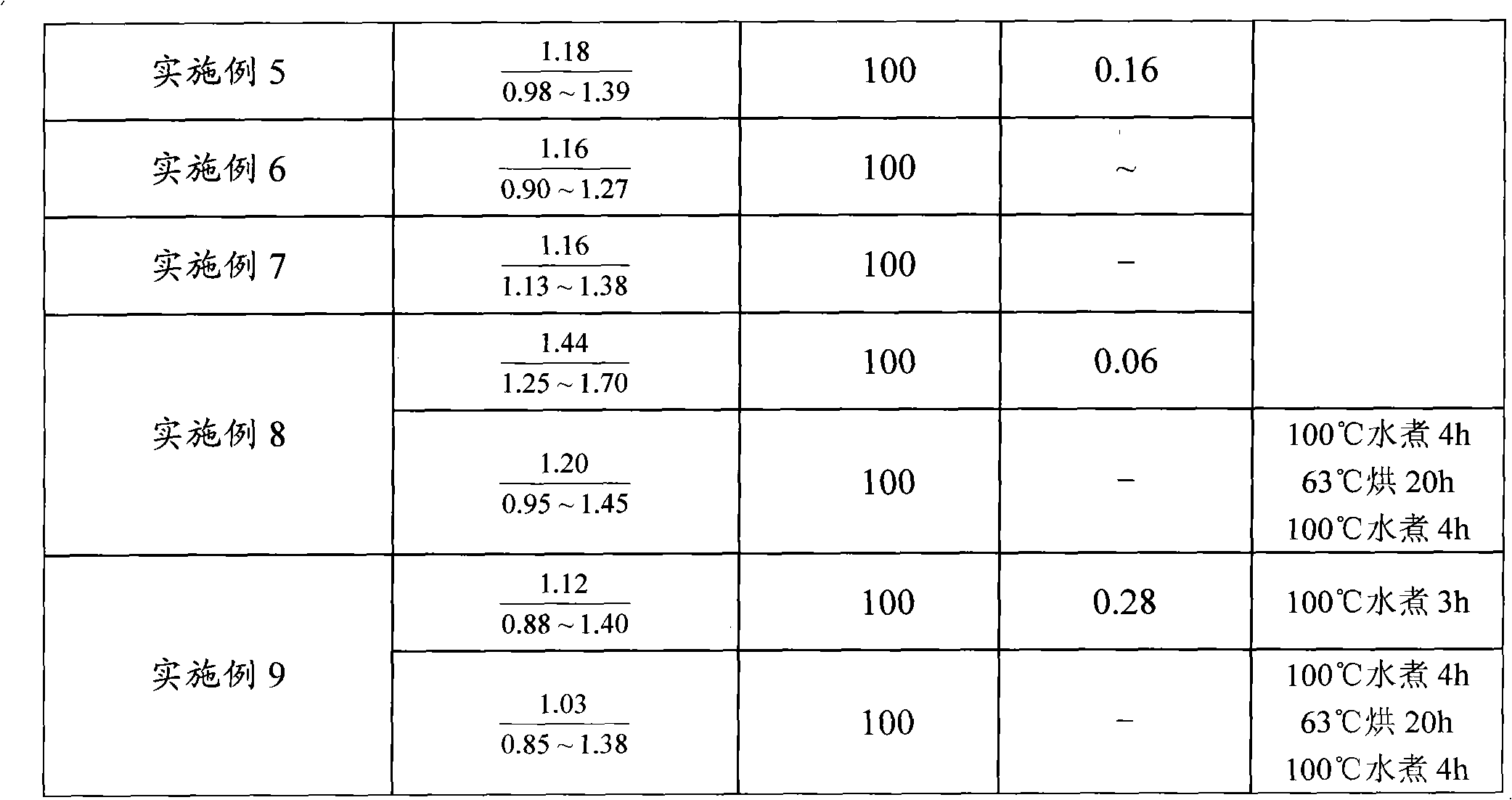

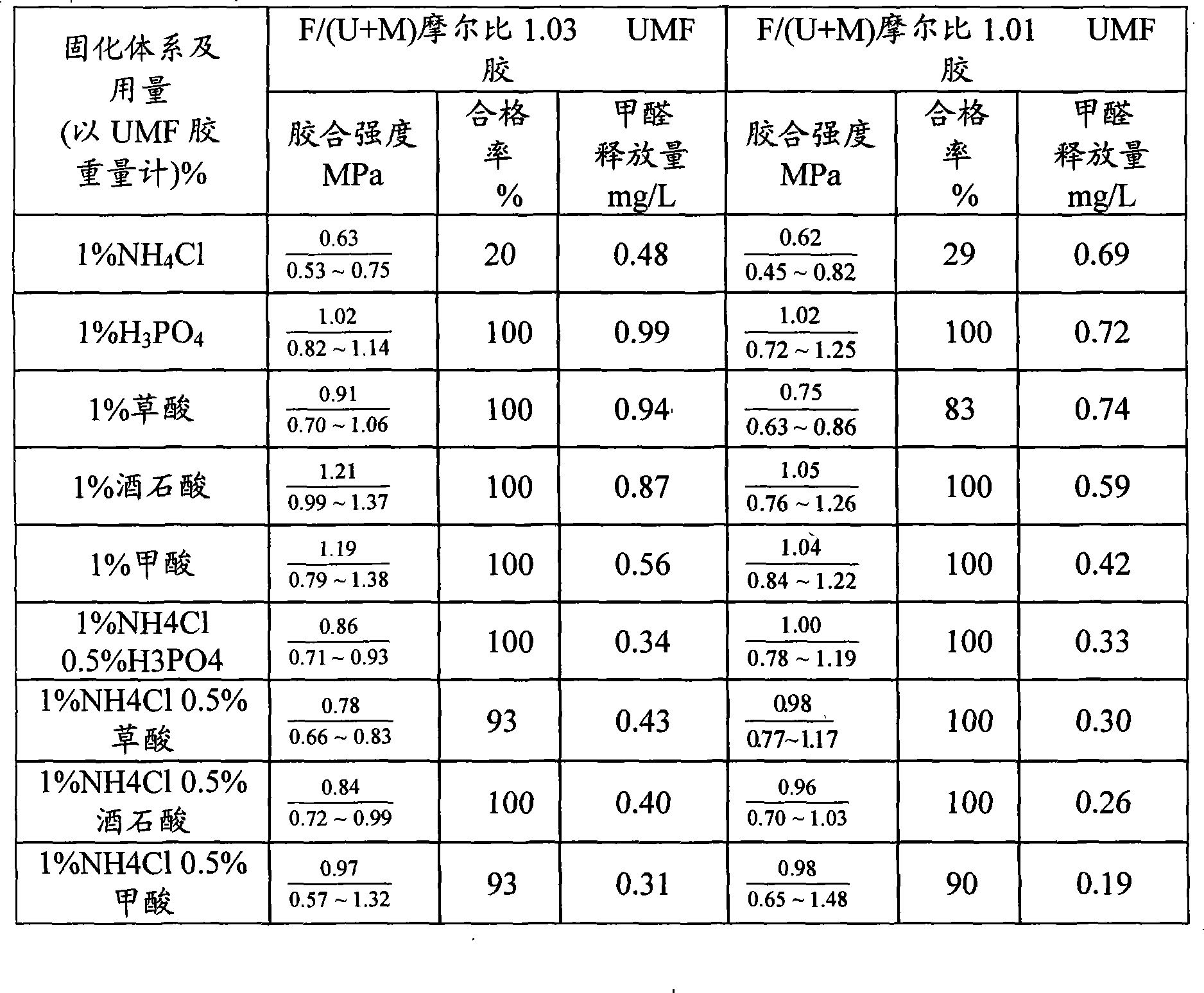

E0-grade melamine modified urea-formaldehyde resin adhesive, and preparation method and application thereof

InactiveCN102604573AImprove stabilityLow costAldehyde/ketone condensation polymer adhesivesMelamineResin adhesive

The invention relates to an E0-grade melamine modified urea-formaldehyde resin adhesive, and a preparation method and application thereof. The E0-grade melamine modified urea-formaldehyde resin adhesive is characterized by comprising an E0-grade melamine modified urea-formaldehyde resin, a composite curing agent and a composite filler, wherein the E0-grade melamine modified urea-formaldehyde resin is prepared from the following raw materials in parts by mass: 100 parts of formaldehyde, 0.1-0.5 part of polyvinyl alcohol, 100-200ml of basic catalyst and 200-400ml of acidic catalyst; the mol ratio of the formaldehyde to the urea+melamine (F / (U+M)) is equal to 0.80-0.98; the composite curing agent is prepared from the following raw materials in parts by mass: 200-250 parts of ammonium chloride, 150-200 parts of oxalic acid, 400-450 parts of citric acid, 100-150 parts of tartaric acid and 500-800 parts of water; and the composite filler is prepared from the following raw materials in parts by mass: 60 parts of industrial flour, 20 parts of 800-mesh light calcium carbonate and 20 parts of 800-mesh wood meal. The E0-grade melamine modified urea-formaldehyde resin adhesive is used for gluing plates. The E0-grade melamine modified urea-formaldehyde resin adhesive has the advantages of low free formaldehyde content, low cost, favorable precompression performance, good gluing performance and the like.

Owner:BEIHUA UNIV

Phenolic resin/phosphate hybrid adhesive and preparation method thereof

InactiveCN101875830AEasy to prepareImprove thermal stabilityNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesPhosphateWorking temperature

The invention provides a phenolic resin / phosphate hybrid adhesive and a preparation method thereof, relating to an adhesive and a preparation method thereof. The invention solves the problems of low working temperature, rigorous curing process and low adhesion strength of the conventional high-temperature resisting phenolic resin adhesive. The adhesive is prepared from phenolic resin, heat-resistant reinforced resin, a coupling agent, a toughening agent, phosphate, a curing agent, a framework material, fillers and a dispersing agent. The preparation method comprises the following steps of: mixing the phenolic resin, the heat-resistant reinforced resin, the coupling agent and the toughening agent and then evenly stirring to obtain a phenolic resin component; then mixing the phosphate, the curing agent, the framework material and the fillers and then evenly stirring to obtain a phosphate component; and then adding the phosphate component and the dispersing agent into the phenolic resin component and evenly stirring. The adhesive can be applied in aerospace, military and machining industries with the working temperature above 800 DEG C.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

Method for preparing environmentally-friendly adhesive for lignin-based timber

ActiveCN102061141AAdequate responseLow in free phenolsAldehyde/ketone condensation polymer adhesivesAdhesiveTime ratio

The invention discloses a method for preparing an environmentally-friendly adhesive for a lignin-based timber. The method comprises the following steps of: 1) adding phenol, formaldehyde solution, lignin, first alkali liquor and diluting water into a reactor, heating to the temperature of between 75 and 85 DEG C and reacting for 2.5 to 3.5 hours, wherein the molar ratio of formaldehyde to the phenol is 2.20:1-2.40:1; the formaldehyde solution is added for three times in a mass ratio of 1.5 to 1.0 to 1.0; and the reaction time ratio of the added formaldehyde solution is 1.2 to 1.0 to 1.0; 2) cooling to 70 DEG C, adding a formaldehyde collector and second alkali liquor, and reacting at the temperature of between 65 and 70 DEG C for 20 to 50 minutes; and 3) cooling to the temperature of between 30 and 40 DEG C, adding an intensifier, stirring for 10 to 30 minutes, cooling and discharging. In the method, a 50 to 60 percent petroleum-based phenol raw material can be substituted; the methodis stable in reaction, easy to control and easy for industrial production; formaldehyde emission of a plywood reaches E0 level; adhesive strength meets the requirements of national class I plates; and a new approach is provided for the development of an environmentally-friendly biomass-based timber adhesive and recycling of wastes.

Owner:青岛生物能源与过程研究所

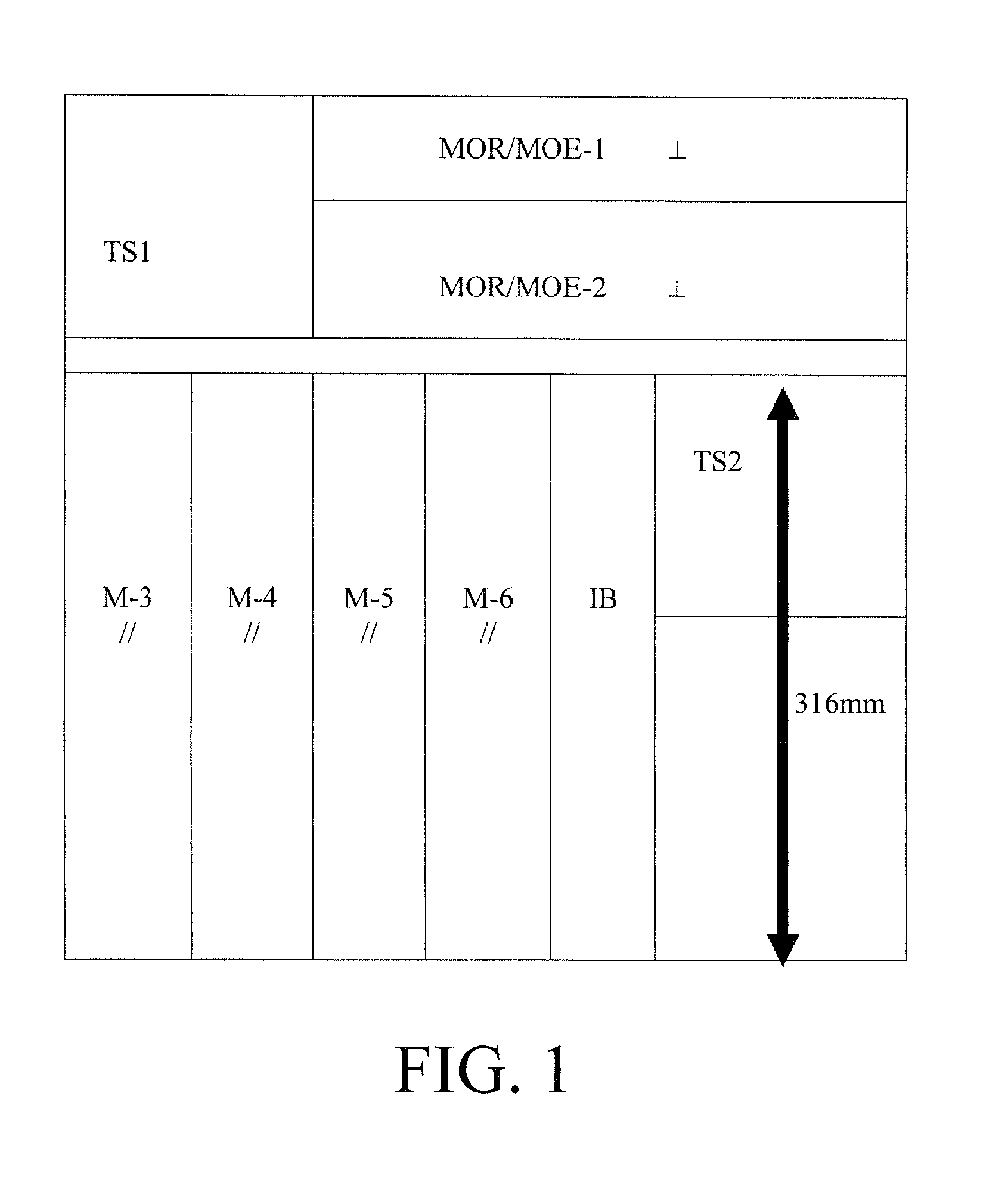

Assemblies and Methods for Reducing Warp and Bow of a Flexible Substrate During Semiconductor Processing

Methods are described for addressing the bowing and / or warping of flexible substrates, attached to a rigid carrier, which occurs as a result of the thermal challenges of semiconductor processing. In particular, viscoelastic adhesives are provided which can bond a flexible substrate to a rigid carrier and mediate the thermal mismatch which often is present due to the distinctly different materials properties of most flexible substrates, such as plastic films, with respect to rigid carriers, such as silicon wafers. Assemblies are also provided which are produced according to the methods described herein.

Owner:ARIZONA STATE UNIVERSITY

Retroreflective sheeting articles

InactiveUS6012818ASuitable flexibility and transparencyReduce cohesionLayered productsAldehyde/ketone condensation polymer adhesivesDynamic viscoelasticityAdhesive

A retroreflective sheet comprises a film having a substantially flat surface and a large number of pyramidal projections having retroreflectivity on the opposite surface, and a colored layer and an adhesive layer disposed on the surface of the film having the projections. The adhesive layer comprises a heat-sensitive adhesive containing an acrylic polymer and a phenolic resin, and exhibits an elastic modulus (by dynamic viscoelasticity measurement, compression mode) at 30 DEG C. ranging from about 1x106 to 1x108 dyn / cm2.

Owner:3M INNOVATIVE PROPERTIES CO

Method of preparing alkali lignin modified phenolic resin

InactiveCN101492522AOrderly and fast responseAdequate responseAldehyde/ketone condensation polymer adhesivesResource utilizationAdhesive

A method for preparing alkali lignin modified phenol-formaldehyde resin comprises the following steps: phenol, a first batch of formaldehyde solution, alkali lignin, metal oxide and dilution water are added into a reactor; a second batch of formaldehyde solution is added into the reactor; and a third batch of formaldehyde solution and a first batch of alkaline solution are added, formaldehyde trapping agent and a second batch of alkaline solution are added, and then material is discharged after cooling. The invention adopts the copolymerization technique to prepare an alkali lignin phenol formaldehyde adhesive, lignin and the phenol are added simultaneously, obtained hydroxymethylated lignin is reacted with hydroxymethyl phenol, a small part of the obtained hydroxymethylated lignin participates in the polycondensation of the hydroxymethyl phenol to form a main chain, and a large part of the obtained hydroxymethylated lignin forms branch chains through graft copolymerization, therefore, the lignin is introduced into a molecular chain and the aim of modifying phenol-formaldehyde resin is achieved. The invention can replace the use of 30-50 percent of the phenol, realizes stable and easy reaction control and easy industrial production; the bonding strength satisfies the requirements of national I-level plates; formaldehyde release reaches E0 level; therefore, the invention provides a new approach to the development of environment-friendly biomass-based wood adhesive and resource utilization of waste materials.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Method for preparing phenolic aldehyde adhesive based on lignin phenolized liquid and application thereof

InactiveCN101260283AImprove liquidityGood storage stabilityAldehyde/ketone condensation polymer adhesivesThermal insulationResin adhesive

The invention provides a preparation method for phenolic adhesive based on lignin phenolization liquid and application thereof. Under the condition of normal pressure heating or thermalcatalysis, phenol is taken as liquefaction reagent, lignin is added, the temperature is raised to 90 to 150 DEG C, the thermal insulation liquefaction reaction is made to cool to obtain a lignin liquefaction product; basic catalyst and formaldehyde are directly added into the liquefaction liquid, the temperature is raised to 70 to 97 DEG C under normal pressure to react for 1 to 3 hours, the reaction is terminated when the viscosity is measured to meet the preset requirement, and low-free formaldehyde environmental protection type phenolic adhesive based on lignin phenolization liquid is obtained. The adhesive obtained by the invention has lower cost and lower content of free formaldehyde than the prior phenolic resin adhesive. The plywood pressed by using the adhesive obtained by the invention has good bonding performance.

Owner:HUANGSHAN UNIV

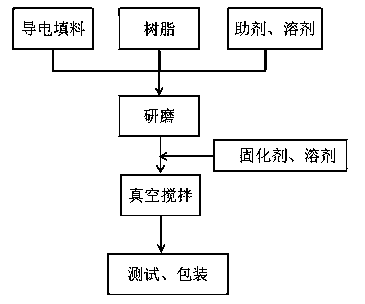

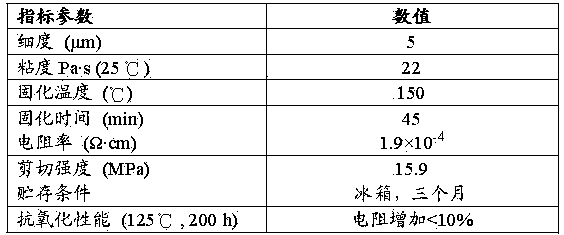

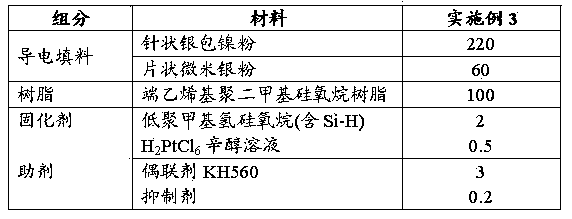

Silver coated nickel powder conductive adhesive and preparation method thereof

InactiveCN103468159AImprove antioxidant capacitySimple production processPolyureas/polyurethane adhesivesAldehyde/ketone condensation polymer adhesivesPolymer sciencePolymer chemistry

The invention relates to a silver coated nickel powder conductive adhesive. The silver coated nickel powder conductive adhesive comprises, by mass, 40-90% of a conductive filler, 5-45% of a resin, 0.5-20% of a curing agent, 0-50% of a solvent and 0.1-20.0% of an assistant, and the conductive filler comprises at least one of micro-silver coated nickel powder and nano-silver coated nickel powder. The silver coated nickel powder conductive adhesive has the advantages of excellent conductivity, low cost, no lead, no halogens and the like. The invention also discloses a preparation method of the silver coated nickel powder conductive adhesive. The method is characterized in that the curing agent is added in a dispersion process after grinding, so the conductivity, the cementability, the viscosity and the like can be effectively regulated, and the untoward influences of the interaction of all components of the conductive adhesive in the dispersion and grinding processes to the storage, application and stability of the conductive adhesive are avoided.

Owner:SUZHOU NIUJIAN NEW MATERIAL

Cyanurotriamide modified urea resin and prepn. process

InactiveCN1834186AImprove boiling water resistanceHigh activityAldehyde/ketone condensation polymer adhesivesCyanurotriamideAmmonium hydroxide

This invention provides a method for manufacturing melamine-modified urea-formaldehyde resin adhesive used on wood cement templates. The method adopts formaldehyde and urea at a molar ratio of 1.2-1.4 as the raw materials, and urea is added into formaldehyde in four times. Before the first time of urea addition, formaldehyde is activated at 50 minus or plus 5 deg.C for 15-25 min. in the third time of urea addition, melamine 3-20 wt. % of total urea is also added. After the fourth time of urea addition, ammonia solution is added for post treatment so that the content of free formaldehyde in the modified urea-formaldehyde resin adhesive is below 0.2 wt. %. at the same time the boiling water-resistance of the urea-formaldehyde resin adhesive can be improved. This invention can be used as a substitute for expensive phenol-formaldehyde resin adhesive; therefore the cost is reduced while the performance of wood cement templates can be guaranteed.

Owner:EVERFIRST WISEFUND TECH BEIJING +1

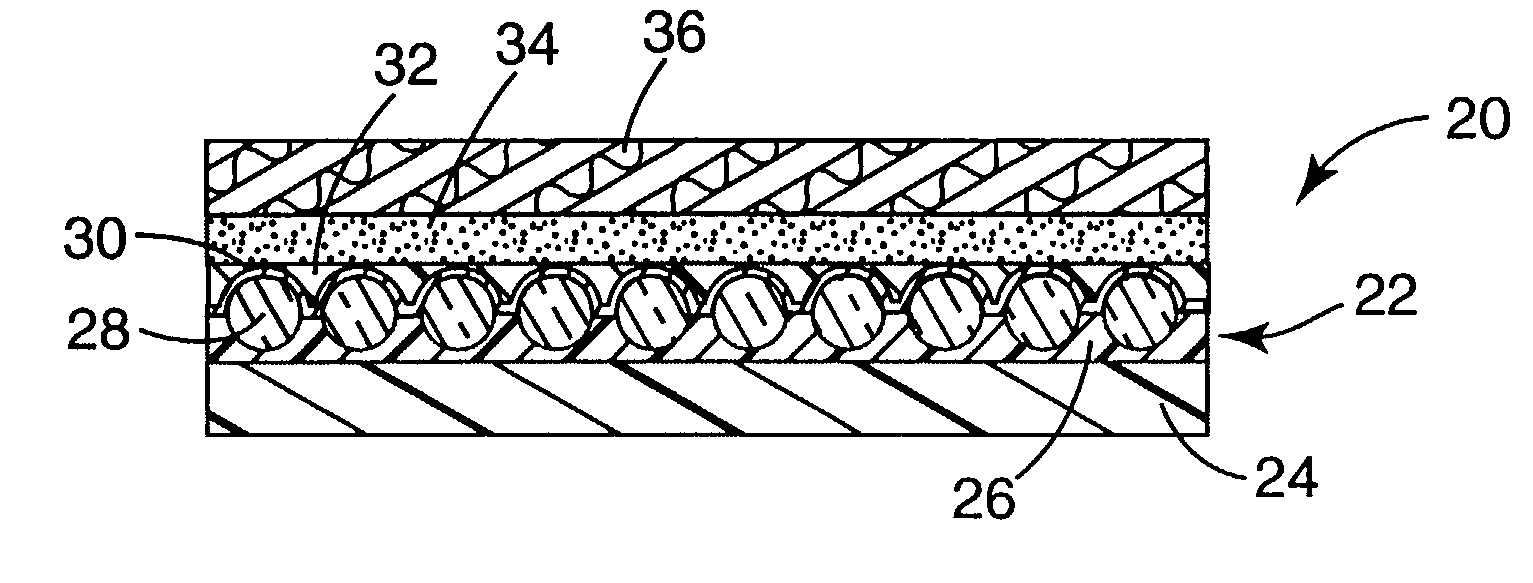

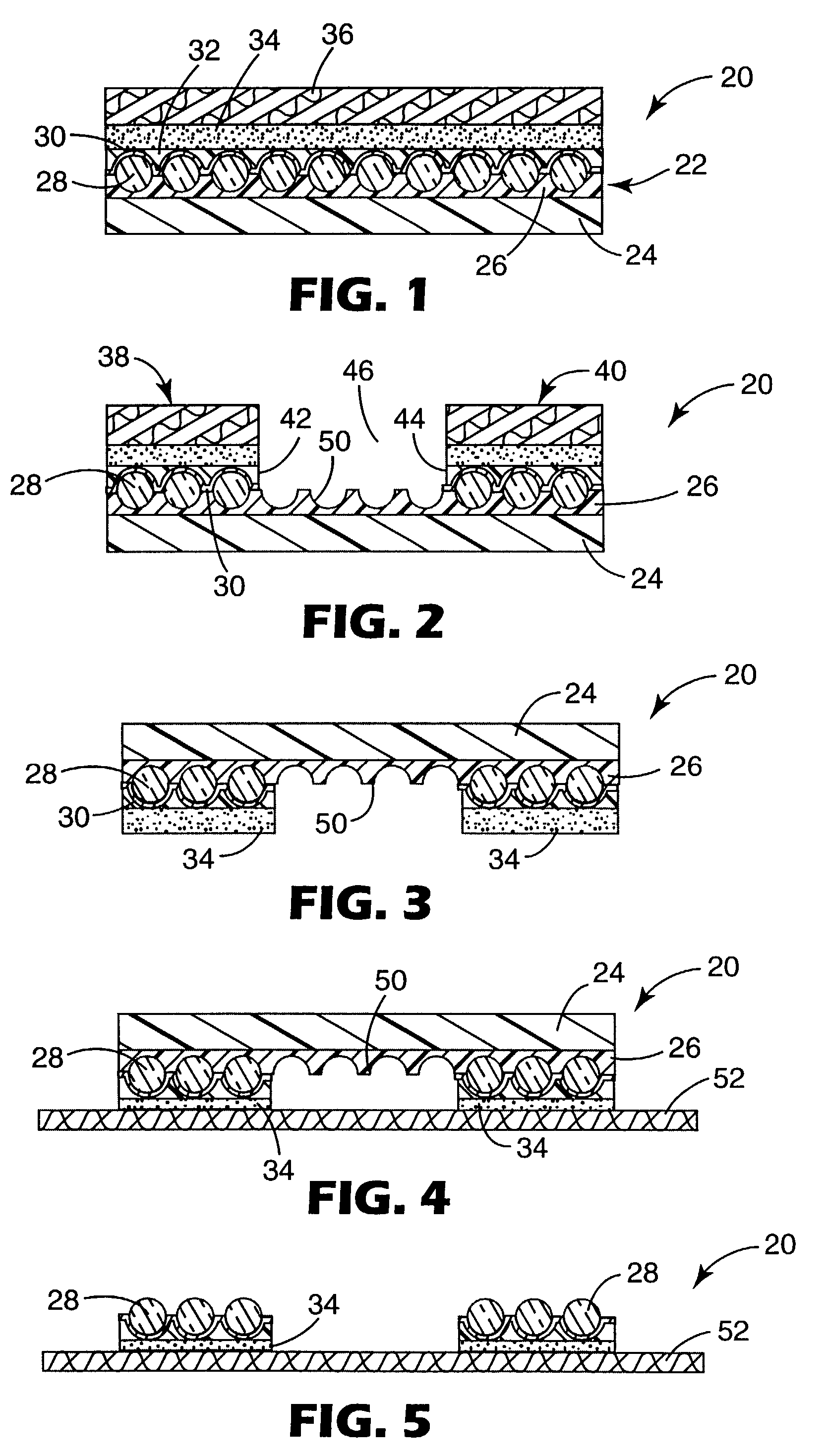

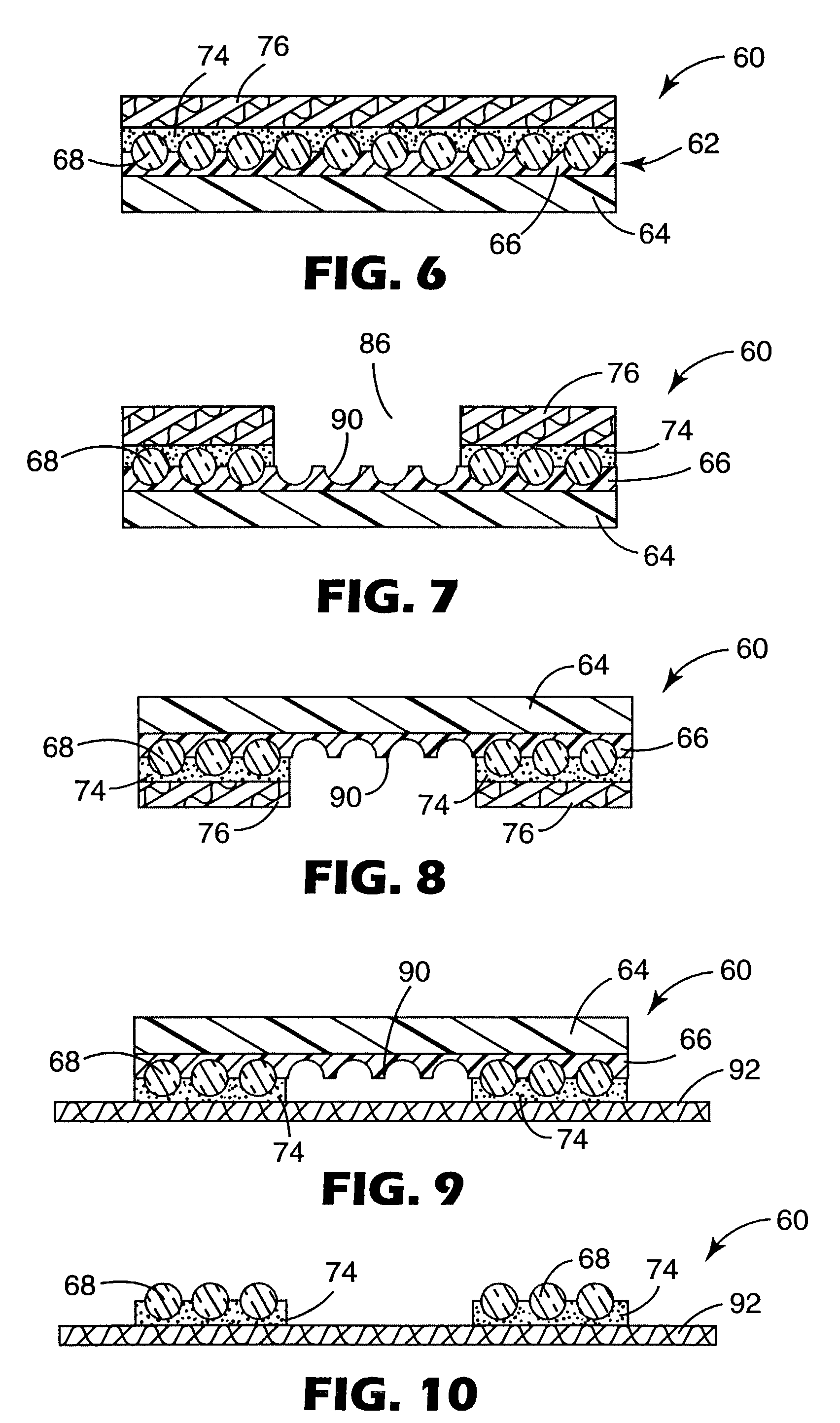

Particulate transfer film with improved bead carrier

InactiveUS20040023019A1Avoiding unintentional adhesionInhibit transferFilm/foil adhesivesDecorative surface effectsEngineeringElectrical and Electronics engineering

A transfer film configured for transferring optical beads to a substrate is disclosed. The transfer film typically contains optical beads, a temporary bead carrier layer retaining the optical beads, and an optional adhesive layer configured to permanently adhere the optical beads to a substrate. The temporary bead carrier layer contains a carrier backing and a heat-resistant carrier coating that temporarily holds the beads during application at elevated temperatures to a substrate. The carrier coating is formed such that it initially softens to retain the beads, but is then hardened or thermoset (such as by crosslinking) to prevent the carrier coating from softening during transfer of the beads to a substrate.

Owner:3M INNOVATIVE PROPERTIES CO

Method for manufacturing E0 level wood veneer

InactiveCN101244571AReduce releaseIncrease the degree of cross-linkingAldehyde/ketone condensation polymer adhesivesWood veneer joiningWood veneerEther

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Production method for clutch surface adopting formaldehyde-phenol resin as cementing compound

InactiveCN101285512AAvoid pollutionGood dispersionAldehyde/ketone condensation polymer adhesivesFriction liningFiberOrganic solvent

The invention discloses a method for making a clutch facing by using phenolic resin as adhesive. The method comprises the following steps that: (1) the latex modified water soluble phenolic resin is used as the adhesive to make the clutch facing, and water is used as solvent, and the adhesive and the solvent are mixed by stirring and prepared into pulp; (2) fibers are impregnated in the pulp; (3) fibers containing the pulp are dried; (4) the dried fibers containing the pulp are wound to become blanks; (5) blanks are heat moulded; (6) the clutch facing is obtained after subsequent treatments. The method of the invention has the advantages of saving a large amount of organic solvent, avoiding the environmental pollution caused by the consumption and the volatilization of the solvent, greatly saving the energy used for the preparation of the pulp and saving equipment cost on aspects of safety, fire fighting and environmental protection and management cost; moreover, the clutch facing made by the method of the invention is excellent in performance.

Owner:海盐华强树脂有限公司

Wood composites bonded with protein-modified urea-formaldehyde resin adhesive

InactiveUS20050070635A1Aldehyde/ketone condensation polymer adhesivesResin adhesiveUrea-formaldehyde

An adhesive binder composition containing a urea-formaldehyde resin modified with a protein, preferably with a source of soy protein and the use of the binder for preparing wood composites, especially particleboard.

Owner:GEORGIA PACIFIC RESINS INC

Wood composites, methods of production, and methods of manufacture thereof

ActiveUS20070020476A1Monocarboxylic acid ester polymer adhesivesProtein adhesivesMethods of productionOrganic chemistry

An adhesive binder comprising a phenol-formaldehyde resin, polyvinyl ester resin, and a protein is disclosed. The adhesive binder is useful for preparing wood composites.

Owner:HEXION INC

Modified urea-formaldehyde resin adhesive and production method thereof

ActiveCN103450832AHigh viscosityViscosity increases relatively gentlyNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesPolymer sciencePhosphoric acid

The invention provides a modified urea-formaldehyde resin adhesive low in formaldehyde residue and a production method thereof. The modified urea-formaldehyde resin adhesive is characterized by being prepared from the following raw materials in parts by weight: 100 parts of modified urea-formaldehyde resin, 20-25 parts of reinforcing agent and 0.1-0.2 part of defoamer, wherein the reinforcing agent is any one or a composition of several of white carbon black, titanium dioxide, calcium carbonate and kaolin having the particle size greater than 300 meshes; the defoamer is polydimethylsiloxane or tributyl phosphate. The formaldehyde residue of the modified urea-formaldehyde resin adhesive provided by the invention is less than 0.1 mg / L; the modified urea-formaldehyde resin adhesive is used as an adhesive for an artificial board; as the modified urea-formaldehyde resin adhesive is low in release amount of formaldehyde, the health of customers is protected.

Owner:广西横州丽冠环保材料有限公司

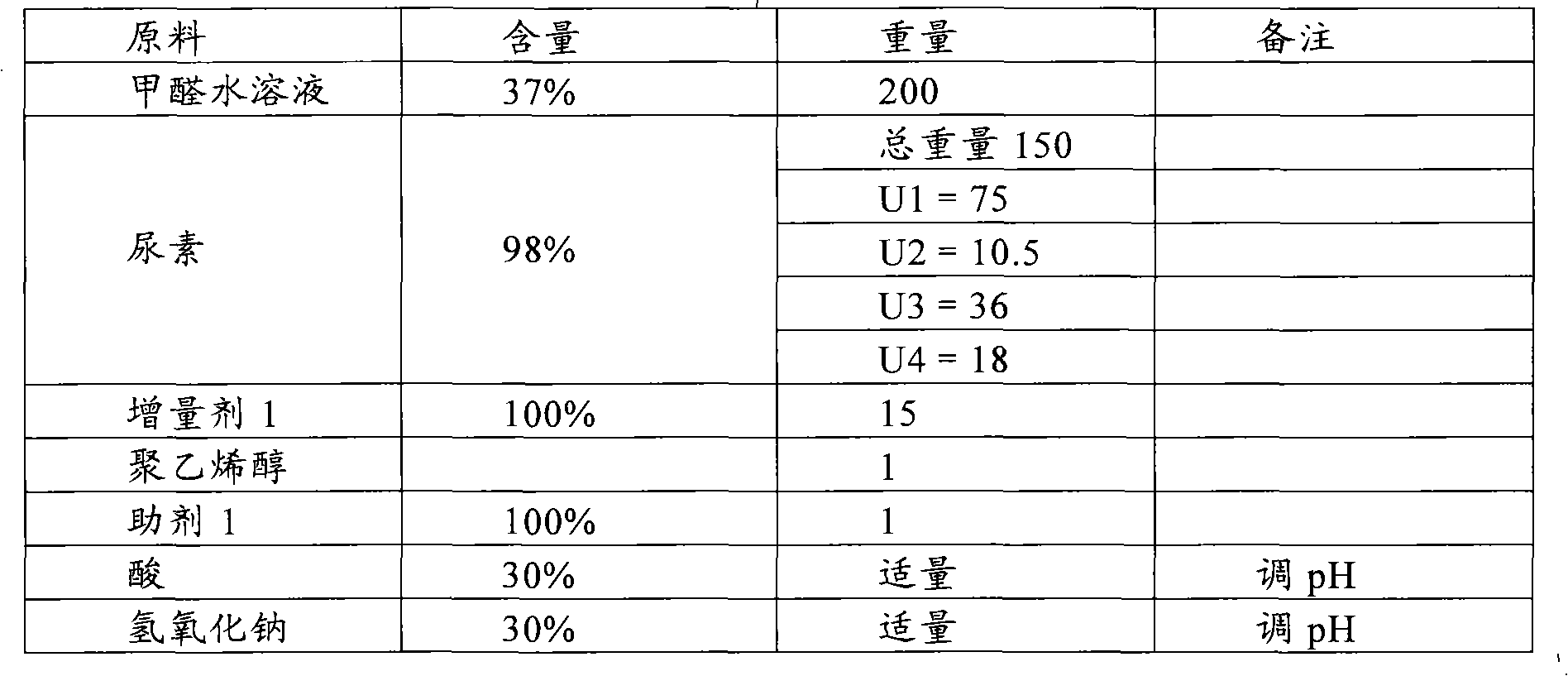

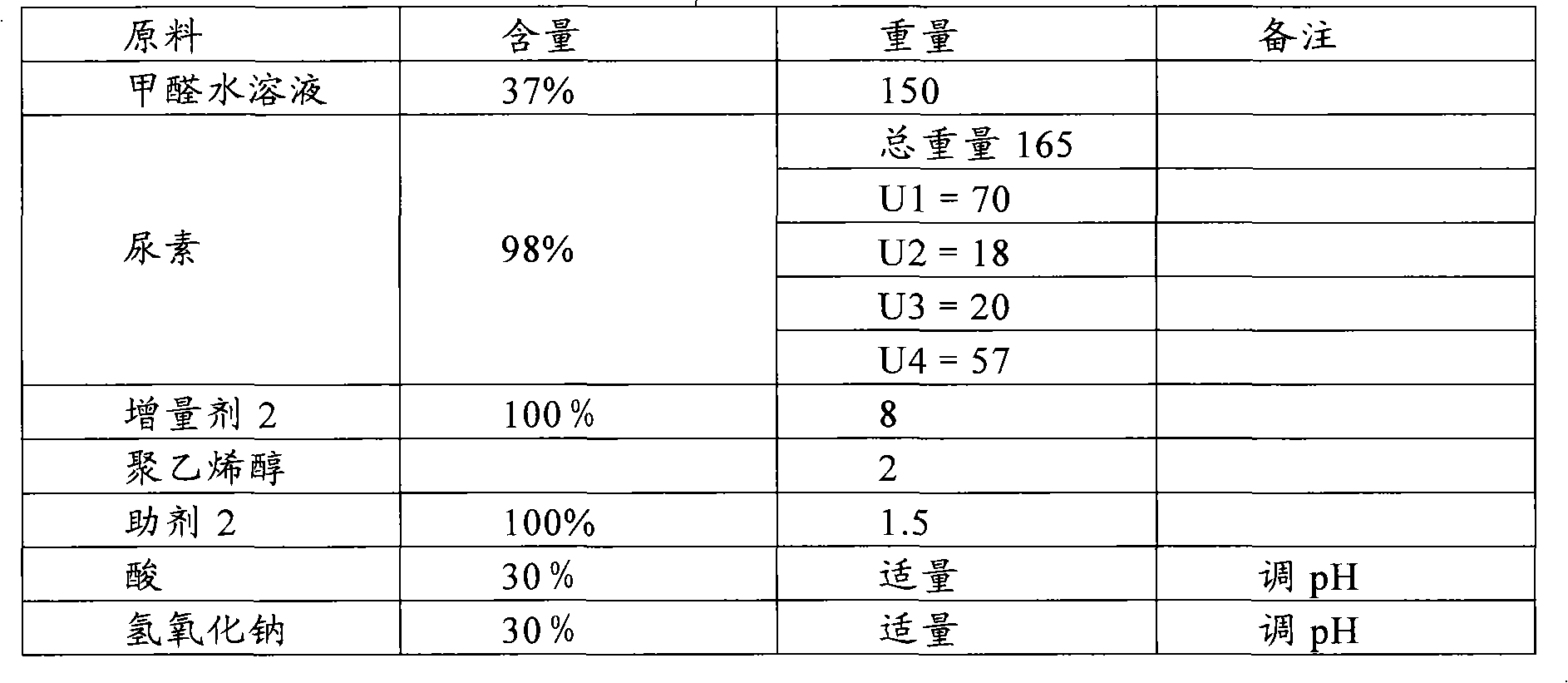

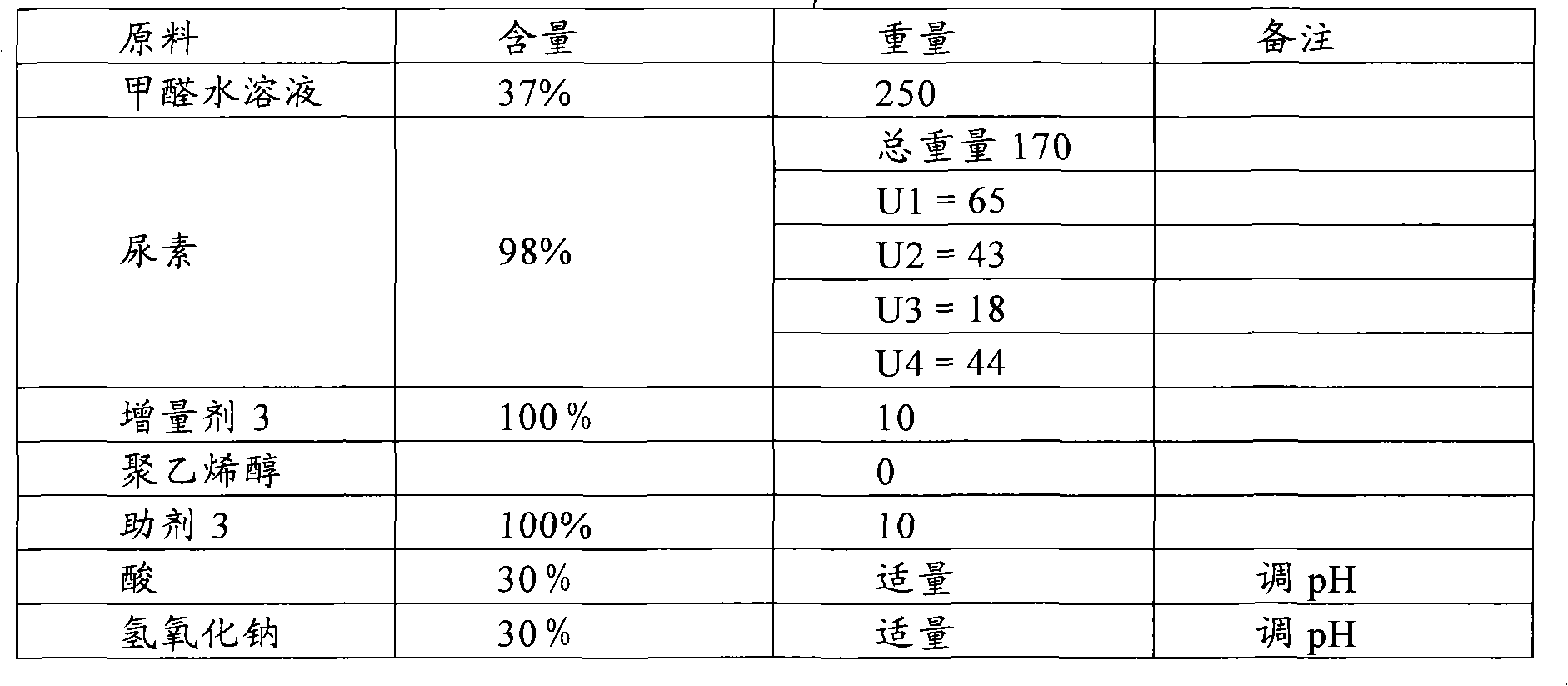

Urea-formaldehyde resin for non-dewatering particleboard and preparation method thereof

ActiveCN102086295AShorten the production cycleLower unit production costAldehyde/ketone condensation polymer adhesivesPolyvinyl alcoholWastewater

The invention relates to urea-formaldehyde resin and a preparation method thereof. The urea-formaldehyde resin comprises the following components in parts by weight: 200 parts of formaldehyde solution, 120-170 parts of urea, 0-2 parts of polyvinyl alcohol, 1-10 parts of additive and 3-20 parts of extender, wherein the concentration of formaldehyde solution is 37%; in the preparation process, ureais added three or four times and the reaction is performed in weakly alkaline medium, weakly acidic medium and neutral medium in turn; and additive and extender are added in the synthesis of urea-formaldehyde resin. The urea-formaldehyde resin can be used in the production of the particleboard without being dewatered, thus the problems of wastewater discharge and environmental pollution can be solved and the production cost of the particleboard can be greatly reduced; and the urea-formaldehyde resin is suitable for various large, medium and small particieboard enterprises.

Owner:江苏露水河人造板有限公司

Composite modification method for phenolic resin adhesive

ActiveCN102108275ASimple processEasy to controlAldehyde/ketone condensation polymer adhesivesPolymer scienceResin adhesive

The invention provides a composite modification method for a phenolic resin adhesive. A mixture of organic silicon and (or) a polyhydric compound serves as a modifier in a synthetic process of phenolic resin. The composite modification method is technically characterized in that: the modifier is added in a prepolymerization reaction process or after the prepolymerization reaction; formaldehyde is added at one time under an alkaline condition; dehydration is not performed in the later period of the reaction; the whole process flow is simple and is easy to operate; the product has stable performance and does not pollute environment; and the content of free formaldehyde is low.

Owner:江苏泰尔新材料股份有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com