Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

7713results about "Wood treatment details" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

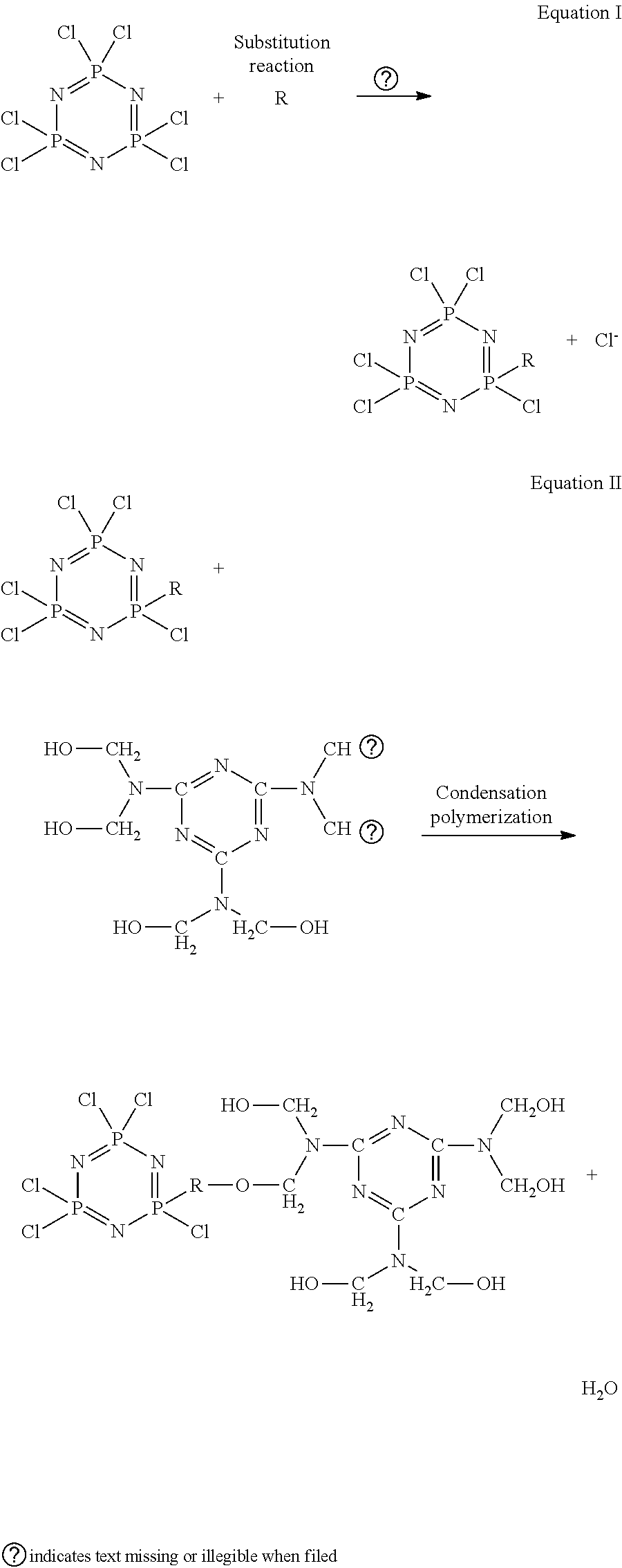

Fire retardant compositions and methods for preserving wood products

Wood preservative compositions are disclosed. Treatment of lumber, plywood, and other wood products with a novel composition comprising the boron source composition, a melamine binder resin, and a urea casein activator resin protects lumber, plywood, and other wood products from attack by termites, fungi, fire and flame. The preservative can be formed by combining a source of boron such as boric acid and the water-soluble salts thereof, a melamine binder resin, and a urea casein resin. A wood preservative is characterized by a weight ratio of the urea casing activator resin to the melamine binder resin ranging from about 1:20 to 1:4 and a weight ratio of the boron source composition to the melamine binder resin ranging from about 1.3:1 to 9.6:1.

Owner:LOPEZ RICHARD A

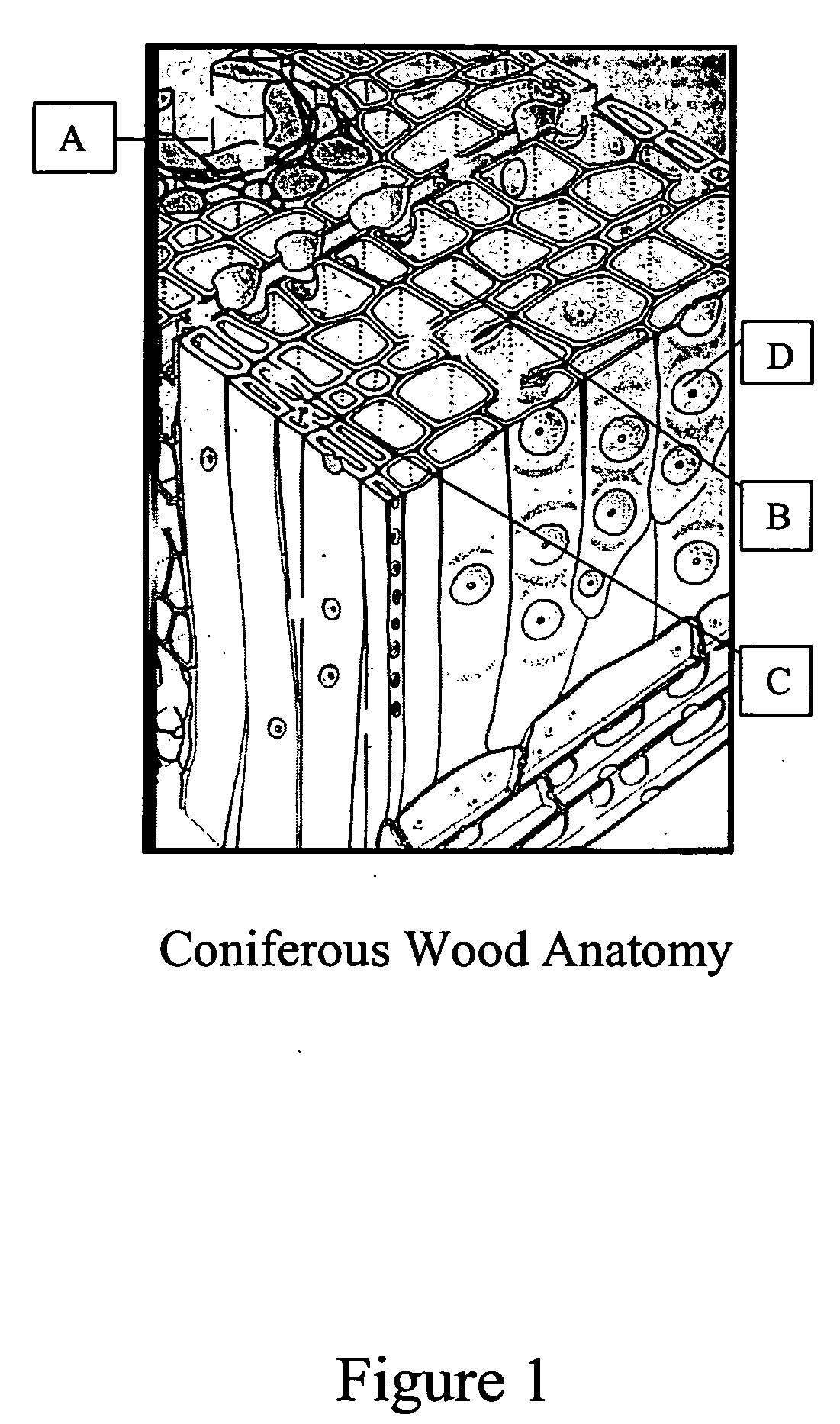

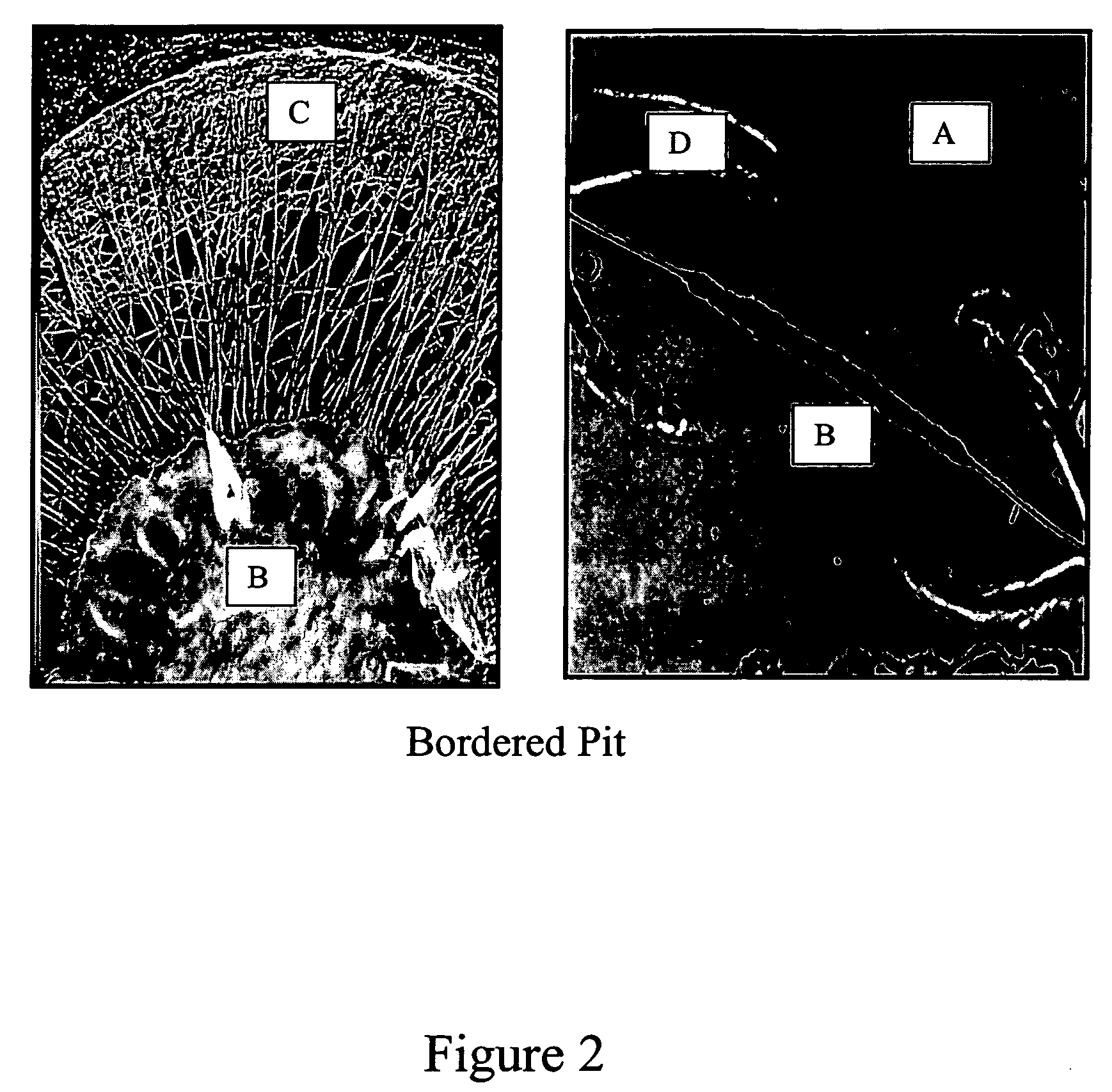

Wood treatment process

InactiveUS6274199B1High shear stabilityImprove permeabilityWood treatment detailsPretreated surfacesWater basedMolten state

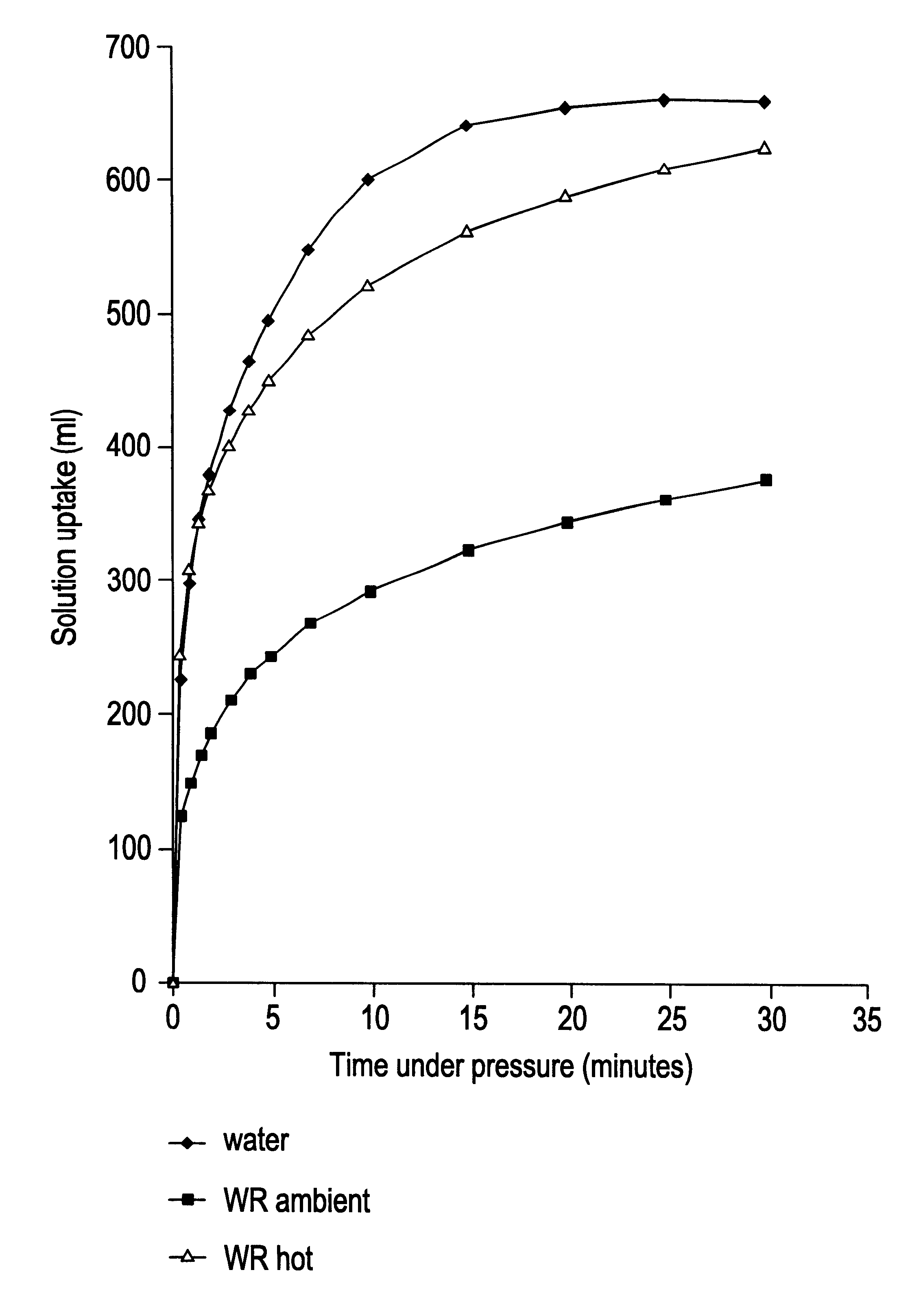

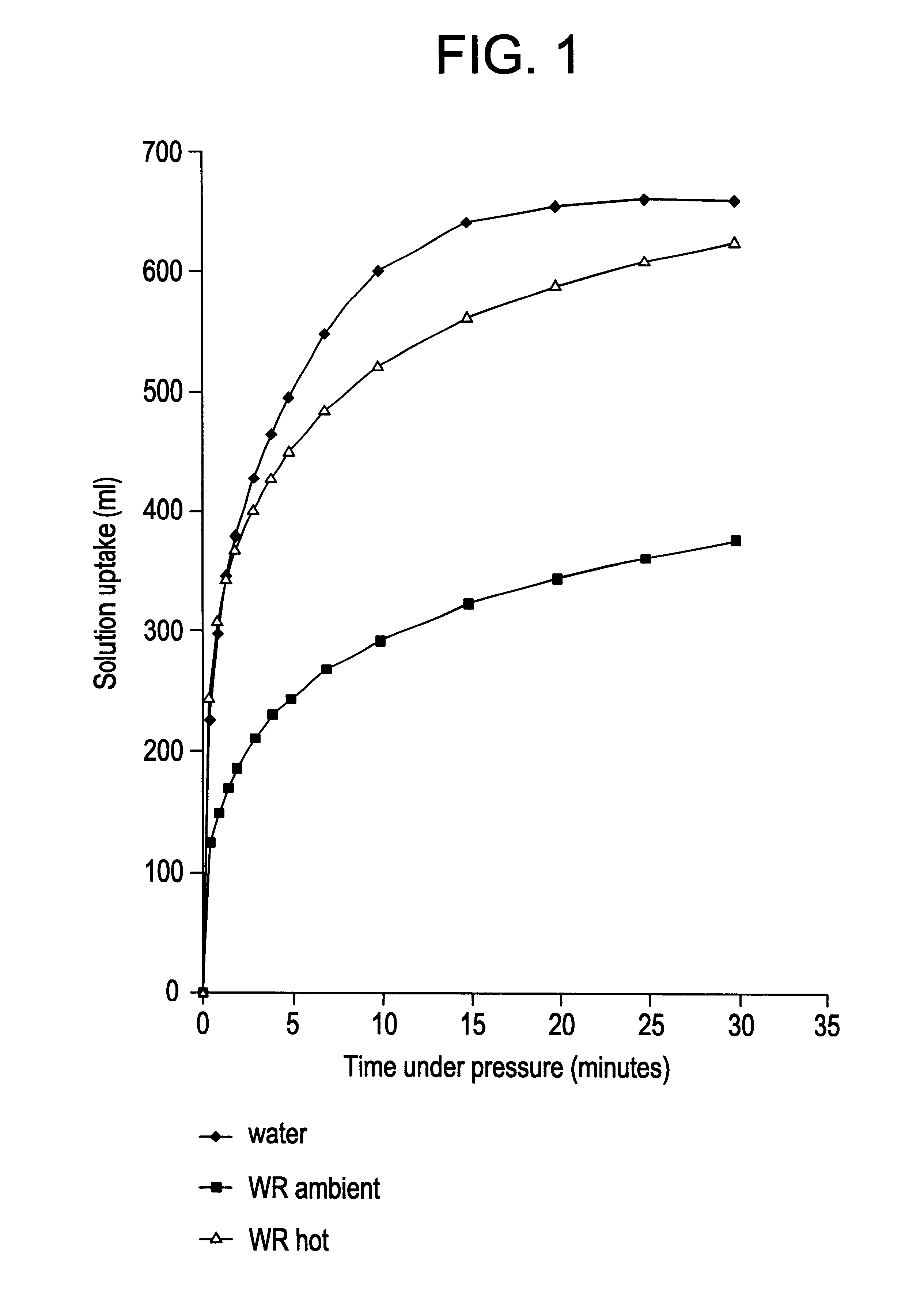

A process for treating a wood substrate with a water-based formulation containing a wax in order to confer water repellency to the substrate comprising the steps of:(a) placing the substrate in a treatment vessel and reducing the pressure in the vessel to remove air in the pores of the substrate;(b) contacting the substrate in the vessel, while reduced pressure is present in the vessel, with the formulation to allow the formulation to flow into said pores, said contacting being carried out at a temperature at or above that required to cause the wax to change into a molten state;(c) applying a positive pressure to the vessel to force the formulation into said pores; and(d) releasing the pressure in the vessel and removing the resultant wood substrate from the vessel.

Owner:VIANCE

Methods for dispersing fibers within aqueous compositions

InactiveUS6379446B1Quantity maximizationMinimize interstitial spaceNon-fibrous pulp additionProtein adhesivesFiberSolid component

Compositions and methods in which dry-committed fibers are substantially homogeneously dispersed throughout a fibrous composition. The fibrous composition is characterized as having sufficient yield stress and viscosity such that the shearing forces from the mixing apparatus are effectively transferred down to the fiber level. This is accomplished by means of an appropriate thickening agent, e.g, gelatinized starch. The dry-committed fibers are exemplified by flash dry fibers or fibrous sheets that have been cut or torn into fragments less than 2 cm across. Providing fibers that have been dry-committed greatly reduces the time that it takes to obtain substantially homogeneous dispersion of the fibers throughout the fibrous composition. This, in turn, reduces the risk of mixture spoilage and mechanical or chemical damage to the solid components within the fibrous composition.

Owner:E KHASHOGGI INDS

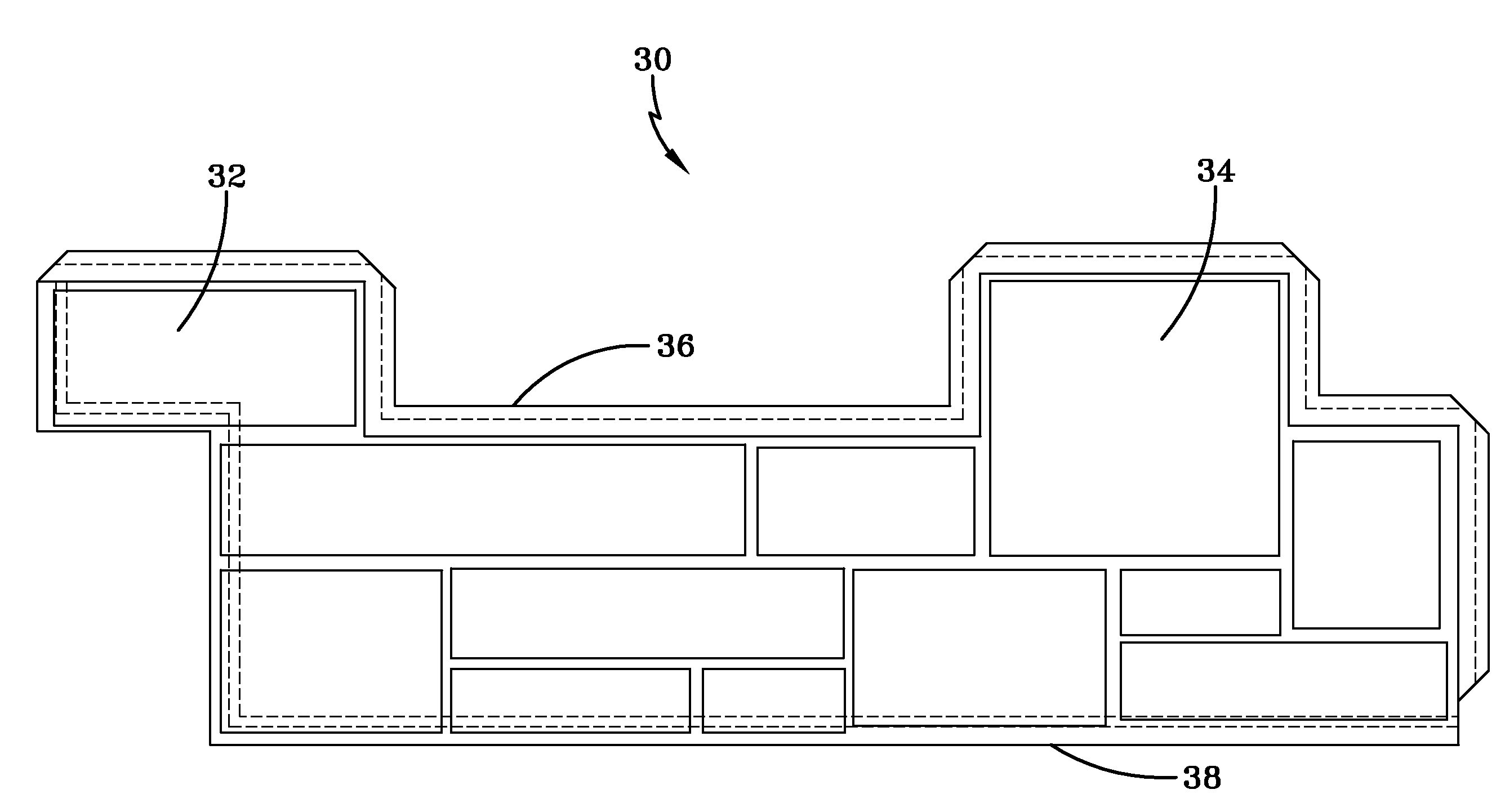

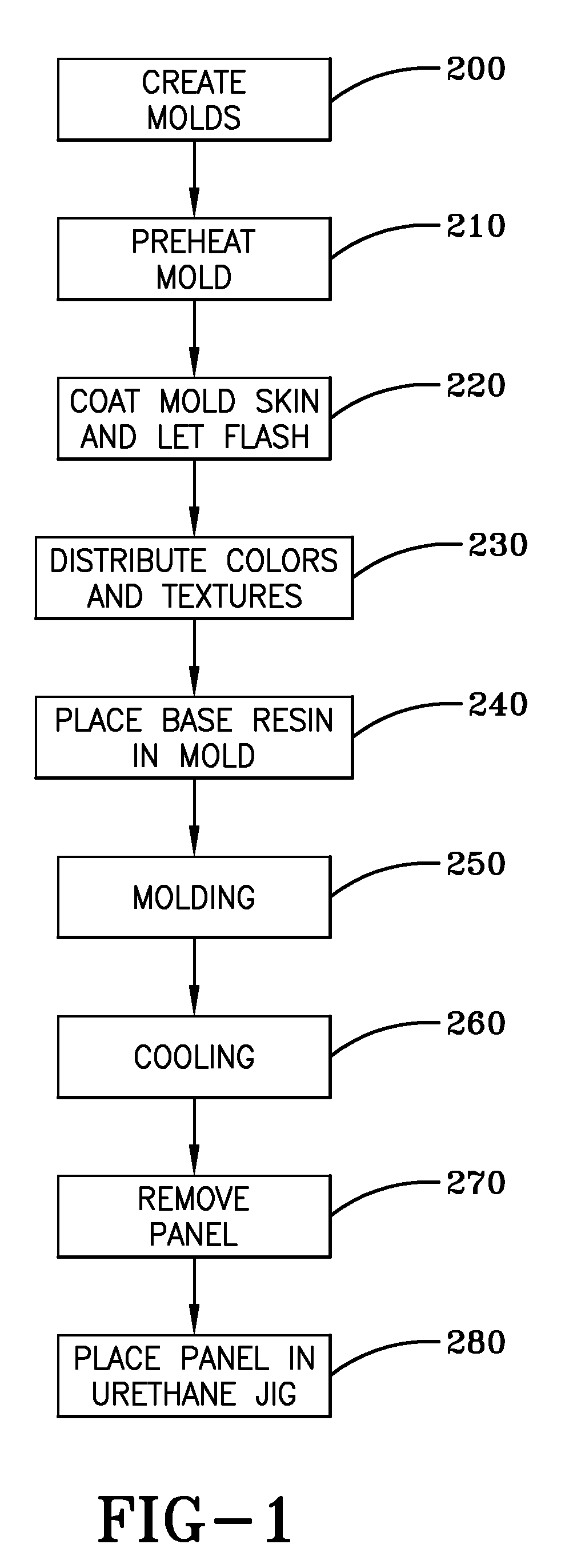

Composition of fillers with plastics for producing superior building materials

InactiveUS20090062413A1Minimize limitationEasy to assembleCovering/liningsSolid waste managementChemical LinkageBrick

The use of high aspect fillers in the production of simulated stone, masonry and brick textured products such as cladding, siding, panels, or other building and construction materials. High aspect fillers increase the dimensional stability, rigidity, thermal and sound insulation. The high aspect fillers may be included into a matrix polymer with or without chemical bonding. The disclosed invention is not limited to products in the building or construction industries and may be applied in the manufacture of a wide variety of products in other industries.

Owner:CRANE BUILDING PRODS

Method for producing charred wood by heat treatment

InactiveCN101069972AGuaranteed drying qualityShorten the timeWood treatment detailsWood charring/burningStrength lossMoisture

The invention relates to a preparation method of heat-treatment charred wood. It aims at providing the charred wood with short treatment cycle, small wood strength loss, industrialized and high maneuverability. It contains stages of preparing, preheating, heating, insulation and cooling. In the heating stage, heat the medium in the stove to 95-105 C degree with the speed of 10-18 C degree / h. Then, heat the materials to 120-130 C degree with the speed of 3-8 / C degree h for high temperature drying and reduce the inner moisture content of the woods to nearly 0. Finally, heat them to 185-220 C degree with the speed of 12-20 C degree / h. The intermittent steam-jet method is adopted to complete steam-jet treatment during the heating.

Owner:ZHEJIANG FORESTRY UNIVERSITY

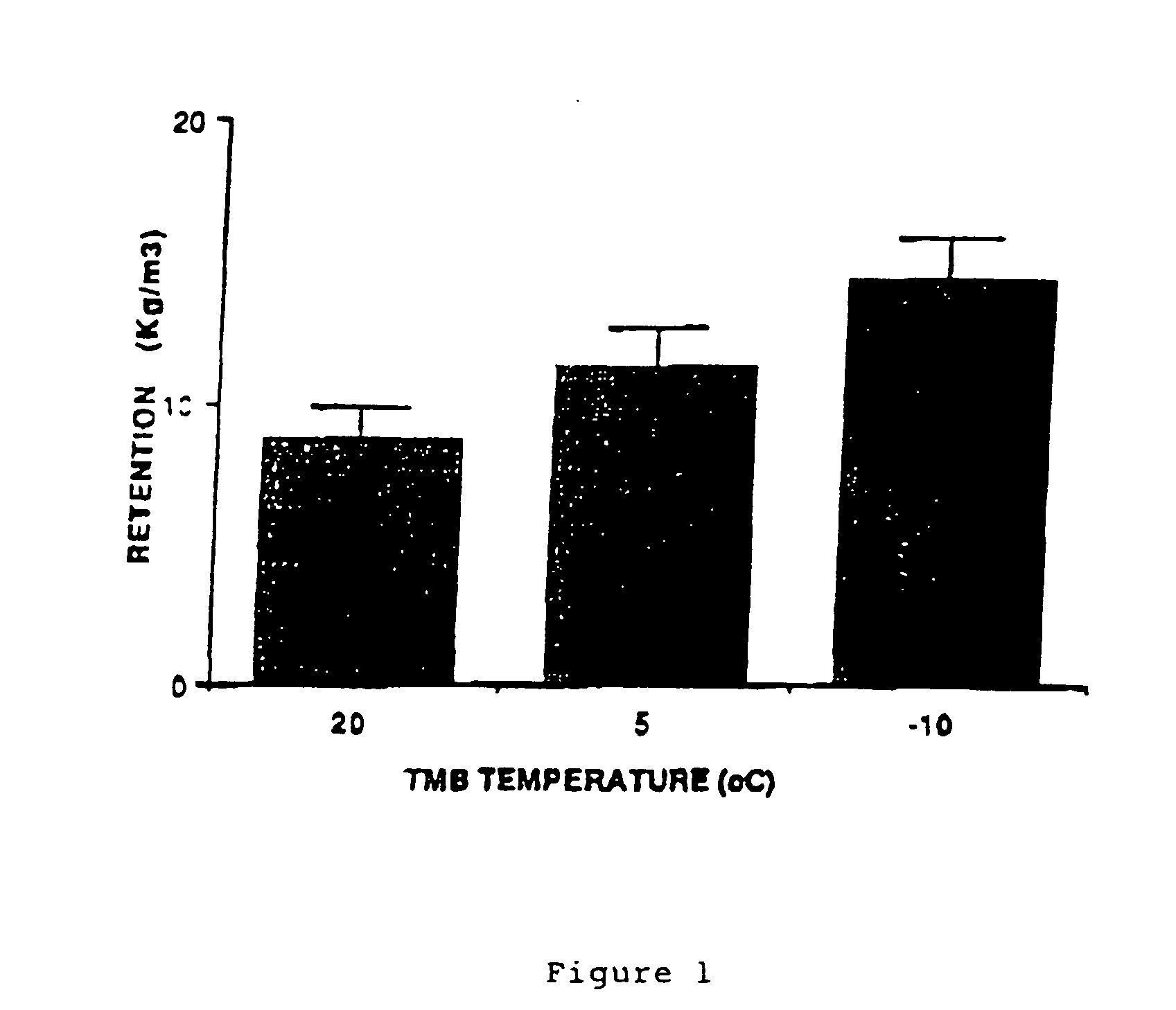

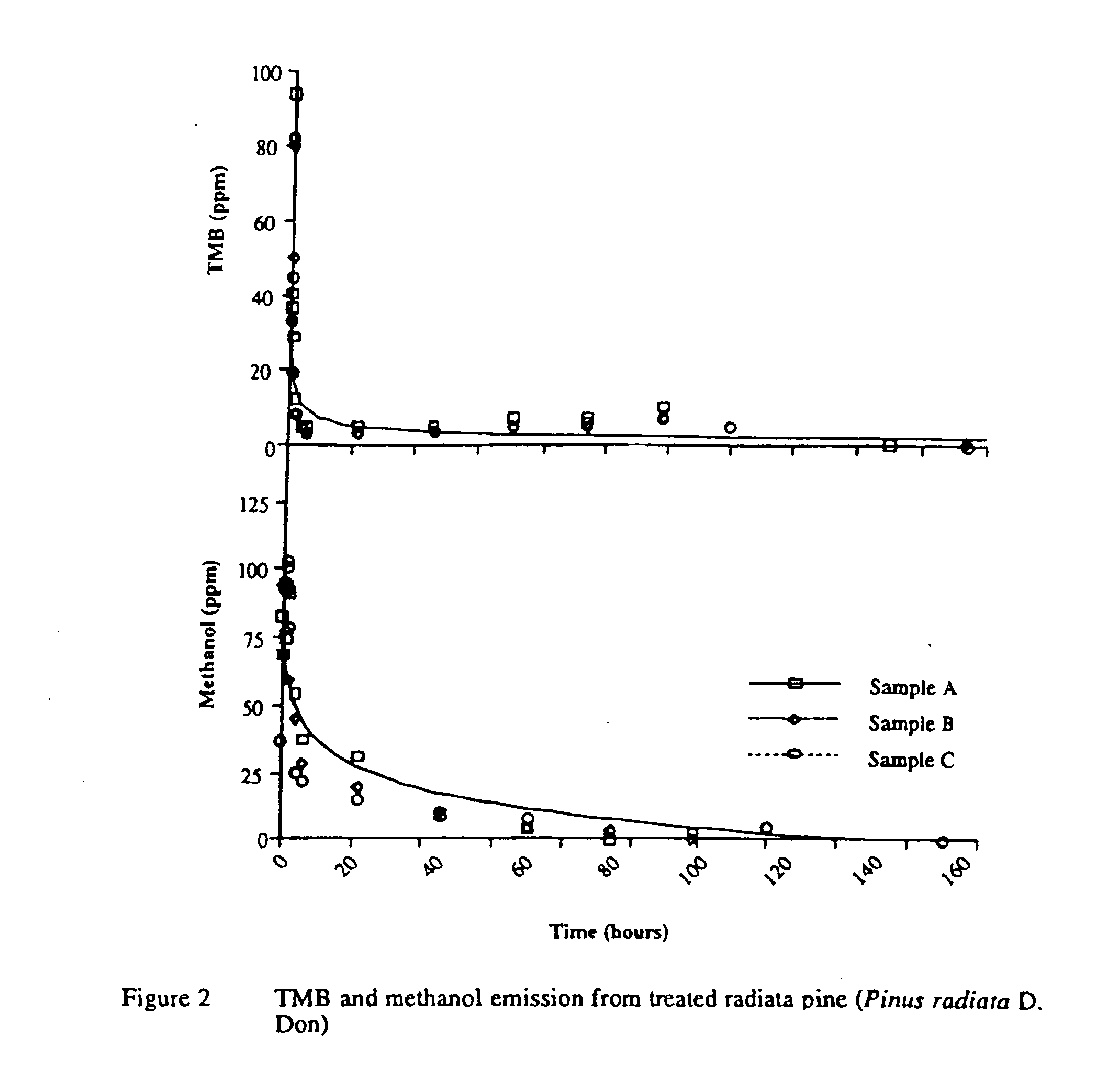

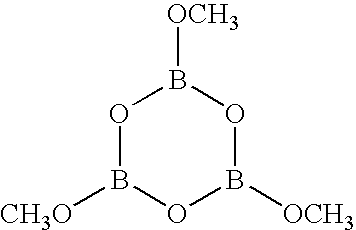

Boron-based wood preservatives and treatment of wood with boron-based preservatives

InactiveUS20050013939A1Safe handlingConvenient treatmentBiocideBoron compound active ingredientsAlcoholPreservative

A process for treating wood comprising applying to the surface of the wood a boron based preservative which reacts with moisture within the wood to form a boron compound and alcohol and subjecting the wood with the applied preservative to a substantially moisture-free and enclosed environment for a period sufficient for the applied preservative to be absorbed into the wood and to produce the boron compound on reaction with the moisture in the wood and for the alcohol by-product of the reaction to be adsorbed within the wood structure.

Owner:UNIVERSITY OF MELBOURNE

Wood carbonization treatment method

ActiveCN1868704AAvoid defectsQuality improvementWood treatment detailsCarbonizationSaturated water vapor

A carbonization process for increasing the quality of wood by continuous gradient heating method includes such steps as heating to 120-140 deg.C, eating to 160-240 deg.C, spraying atomized water for slowly cooling to 100 deg.C, filling the saturated steam at 100 deg.C to return the water content back to 4-6%, and cooling to 15-30 deg.C.

Owner:ZHEJIANG SHIYOU TIMBER

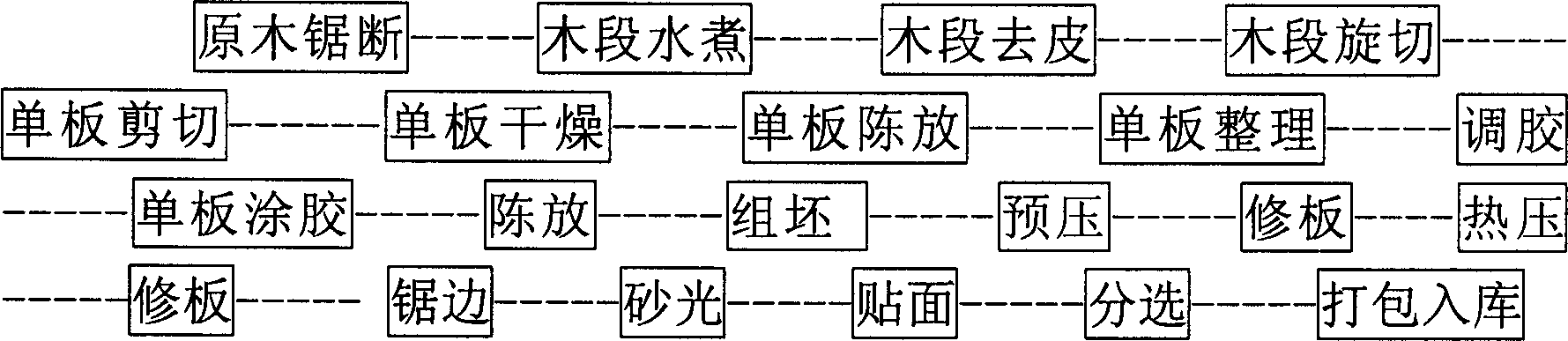

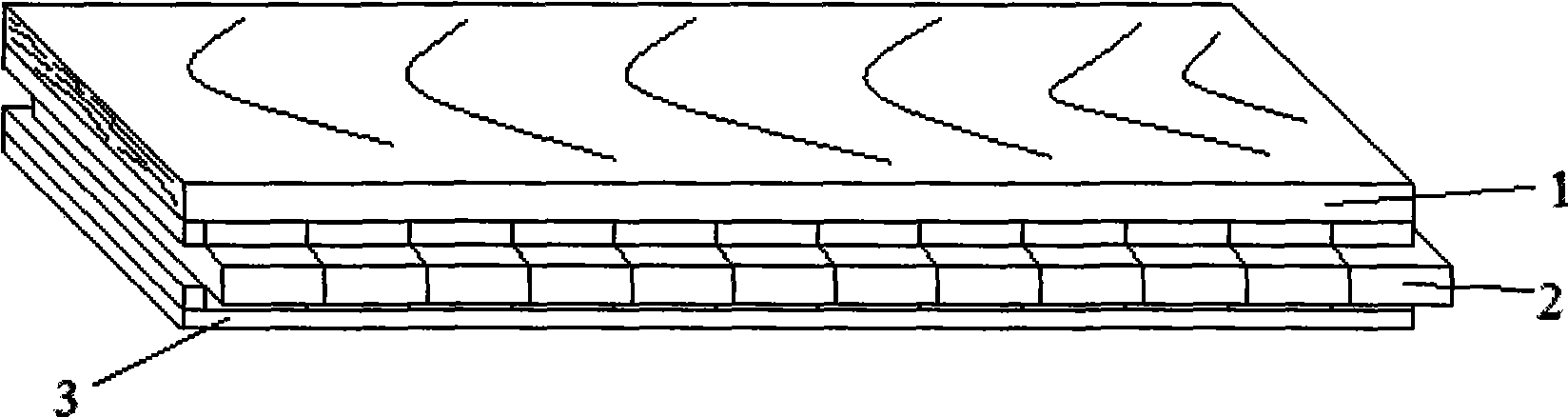

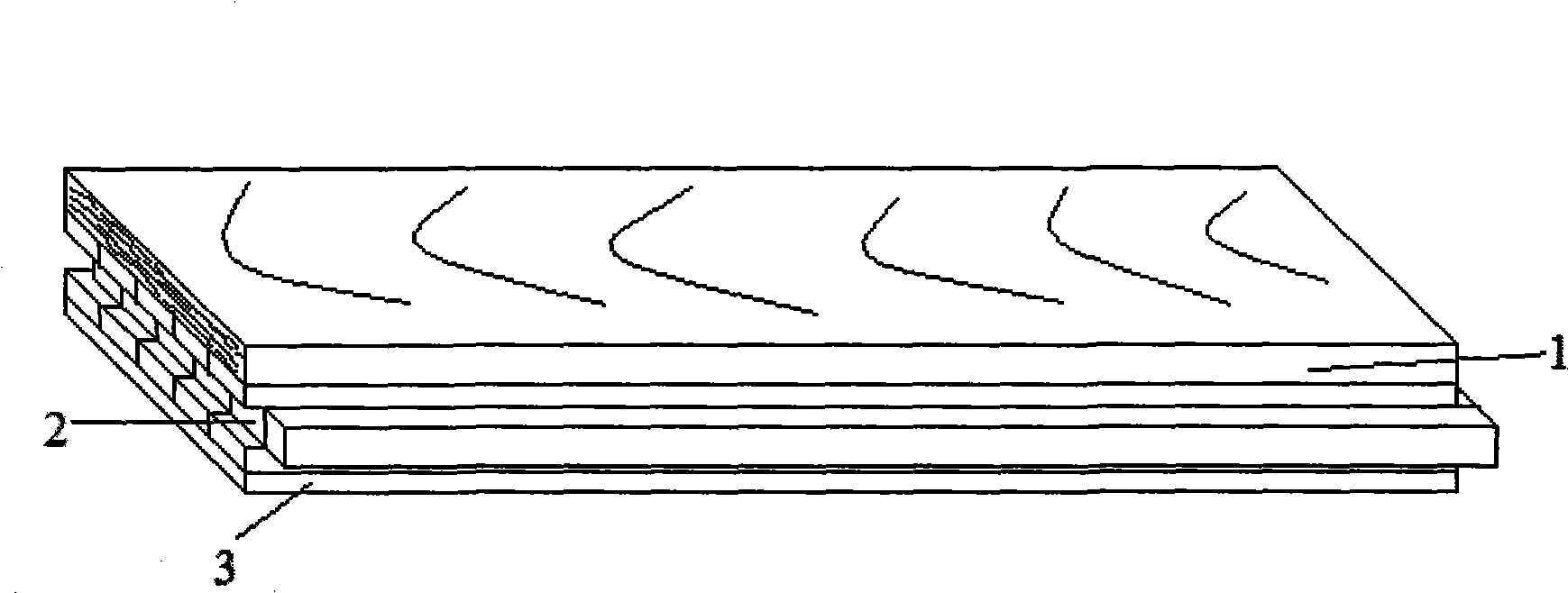

Method for producing plywood with glueing on one side and plywood mould

A method for producing the plywood with the wood plys whose one surface is coated by resin includes such steps as sawing log short, boiling in water, removing bark, spinning cutting, cutting fly, drying, ageing, coating resin on one surface of each ply, ageing, laminating, pre-pressing, trimming, hot pressing, trimming, sawing edge, sticking a paper immersed in resin, and classifying.

Owner:哈尔滨市香坊区人造板胶粘剂研究所 +1

Method for producing compressed charing poplar three-layer wood composite flooring

InactiveCN101486212ALow costHigh densityWood treatment detailsWood veneer joiningSolid woodSurface layer

The invention discloses technology for producing compressed and carbonized poplar three-layer solid wood composite floor fully through utilization of a fast-growing material of poplar. A poplar sheet obtained by a special densification process is used as a surface layer; a common poplar core veneer is used as a core layer; a poplar veneer is used as a bottom layer to manufacture three-layer solid wood composite floor; each performance reaches the requirement of national standard GB / T 18103-2000 on the solid wood composite floor; the technology totally adopts the fast-growing material of the poplar as a raw material, does not add any chemical reagent in the special densification process of the poplar sheet, and does not cause any pollution to environment; after the poplar sheet is subjected to compaction treatment, the density and the hard sense of the wood are strengthened; the late high-temperature carbonization treatment solves the problem of rebounding after the poplar is compressed, changes luster of the wood, and strengthens high grade; and the technology is simple and feasible and has low manufacturing cost.

Owner:NANJING FORESTRY UNIV

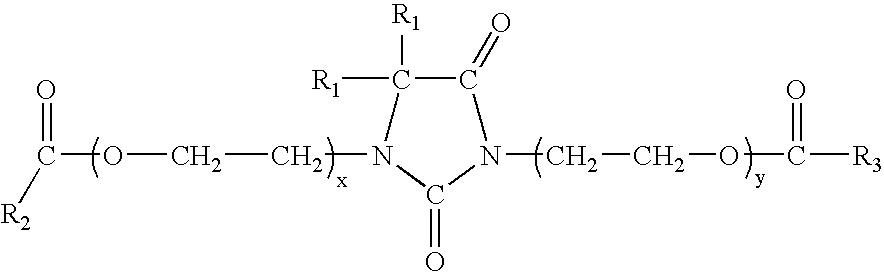

Non-wood fiber plastic composites

This invention is directed to an extrudable compound, an extrusion method using a polymer, a cellulosic fiber, and at least one lubricant selected from the group consisting of ethoxylated esters of hydantoins, ethoxylated esters of sorbitol and sorbitan, and ethylene bisamides made from fatty acids containing 6-10 carbons and composites manufactured through such processes which simulate conventional wood products. Another embodiment of the invention is directed to a composition containing polymer, a cellulosic fiber from an agricultural waste product and a lubricant containing a mixture of an alkylene bisamide derived from a C10-C18 is fatty acid and an alkaline earth salt of a fatty acid.

Owner:ARXADA LLC

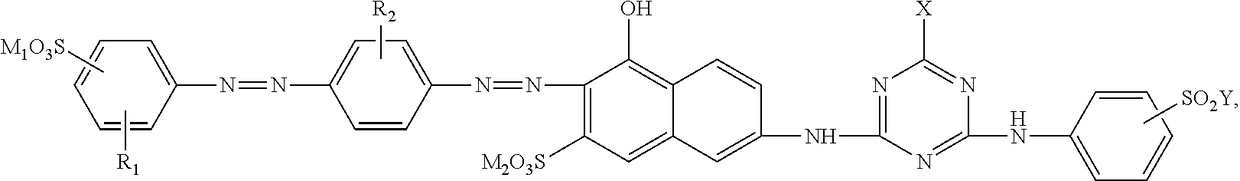

Composition and process for coloring and preserving wood

InactiveUS20060147632A1Preserving it from biological degradationGood outdoor weather resistanceFireproof paintsAntifouling/underwater paintsPolymer sciencePolymer chemistry

Provided is a composition which can color and preserve wood. The composition comprises both micronized pigments and inorganic and / or organic biocides, which may be present as a dispersion, emulsion or in solution also provided is a one step method for the coloring and preservation of wood.

Owner:OSMOSE

Bamboo pulp denatured productive technology

InactiveCN1385287AEmission reductionConducive to the sustainable development of productionPretreatment with alkaline reacting compoundsWood treatment detailsPulp and paper industryViscose fiber

The production process of bamboo fibre viscose pulp includes the following main steps: pre-alkalizing, secondary cooking, plate (belt) type washing and bleaching, and is characterized by mixing insoluble bamboo pulp undergo the process of modification treatment to produce soluble viscose bamboo pulp. As compared with cotton pulp production process it can reduce discharge of waste water by 35%, and is approaching to or superior to cotton pulp in quality.

Owner:上海第五化学纤维厂

Method for producing flame-retardant glued board

ActiveCN101412231AReduce releaseImprove flame retardant performanceOther plywood/veneer working apparatusWood treatment detailsAdhesivePyrophosphate

The invention discloses a method for producing a flame-retardant veneer plywood, which comprises the following steps: placing wood veneers into a flame retardant aqueous solution to perform dipping treatment, applying the mixed adhesive to the upper surfaces and the lower surfaces of the veneers after the veneers are dried, assembling the veneers into a plate blank according to the principle that odd layers are crossed and symmetrical with even layers, and then performing the processes of cold pressing, hot pressing, cutting edge, sanding, surface treating and the like to obtain the flame-retardant veneer plywood product the thickness of which is between 2.7 and 20 millimeters. The flame retardant in the method is a mixture of low ammonium polyphosphate, ammonium phosphate, ammonium pyrophosphate, urea phosphate, boric acid and pentaerythritol, and the mixed adhesive is a uniform mixture of wood adhesive, filler, and a curing agent. The flame-retardant decorative veneer plywood prepared by the method has the advantages of excellent flame-retardant and fireproof performance, environmental prevention performance, and good mechanical properties.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

Carpet Waste Composite

A composite material is produced from carpet waste and a binding agent, in intimate association, and may also include wood fiber or chips and / or other additives. A method of manufacturing a composite material includes shredding carpet waste, coating the carpet waste with a binding agent, and subjecting the shredded, coated carpet waste to elevated heat and pressure. As an additional step, the composite material may be actively cooled to prevent deformation of the material.

Owner:MATERIAL INNOVATIONS LLC

Water repellent compositions for wood preservatives

InactiveUS7264886B2Improve permeabilityImprove waterproof performanceFireproof paintsWax coatingsWaxWater based

Water-based wax emulsions, optionally for use in conjunction with alkaline copper and / or quaternary ammonium based preservatives systems, are described. These emulsions are comprised of natural or synthetic wax, nonionic surfactants having HL B values greater than 11, anionic surfactants, and water. Certain emulsion compositions as described in this specification posses the unique property of maintaining emulsion stability in wood preservatives during extended use in typical wood treatment processes. Water-repellant wood treated with the wax emulsions are described. A method of treating wood, comprising providing wood and treating the wood with the wax emulsion under conditions effective to increase its water repellency is also disclosed.

Owner:VIANCE

Composition And Process For Coloring Wood

InactiveUS20070131136A1Uniform colorGood outdoor weather resistanceHeavy metal active ingredientsBiocidePigment dispersionPigment

Provided is a method for coloring and, optionally, preserving wood and wood products. The method comprises application of pigment dispersions, and optionally biocide dispersions, to wood such that the wood is impregnated. A composition for coloring and, optionally, preserving wood is disclosed, comprising dispersions of micronized pigment and, optionally, micronized biocide.

Owner:OSMOSE

Compositions and methods for treating cellulose-based materials with micronized additives

InactiveUS20050265893A1Increase costIncrease residueBiocideDrying using combination processesCelluloseMaterials science

Owner:OSMOSE +1

Modifying method for wood elements

InactiveUS6632326B1Good dimensional stabilityReduce processing timeCellulosic pulp after-treatmentLiquid surface applicatorsManufacturing cost reductionAcetic acid

The present invention's modifying method for wood elements includes a step for soaking wood elements in one or a mixture of acetic anhydride, acetic acid, or chloroacetic acid; and a step for acetylating the impregnated wood elements in a gaseous phase. This method makes it possible to reduce the time required for the step of acetylating the wood elements, simplifies the process, reduces fabrication costs, and enables fabrication of a wood fiberboard having high dimensional stability.

Owner:YAMAHA CORP

Method of treating fire retardant wood using microwave

InactiveCN101306547ASolve the phenomenon of wet centerNo wet heart phenomenonWood treatment detailsPressure impregnationElectric fieldVacuum pressure

The invention provides a method for processing fire retarding wood with microwave. The method comprises the following steps: heating and processing wood through microwave; subjecting to vacuum pressure treatment; soaking the wood in flame retardant solution with mass ratio being 5-50% and under the atmospheric pressure of 0.1-10MPa for 3-720 minutes; subjecting to vacuum pressure treatment; and heating and treating through microwave to obtain the fire retarding wood. Since heat is not conducted from the outer part of the wood, but in the wood through the interaction between the microwave alternative electric field and water molecules, so as to quickly raise the whole temperature of the wood and improve the permeability of the heat, and meanwhile, kill bristletails and ova in the wood, improve the distribution state of flame retardant in the wood, and enable the flame retardant not to be segregated in-situ along with the migration of the solution, thus basically solving the problems with the traditional method that the flame retardant is present in large amounts on the surface of the wood and serious segregation occurs to the flame retardant when the fire retarding wood is treated. In addition to microwave heating, no additional heat energy is consumed. The fire retarding wood can be directly used as architectural decorative materials.

Owner:KUNMING UNIV OF SCI & TECH

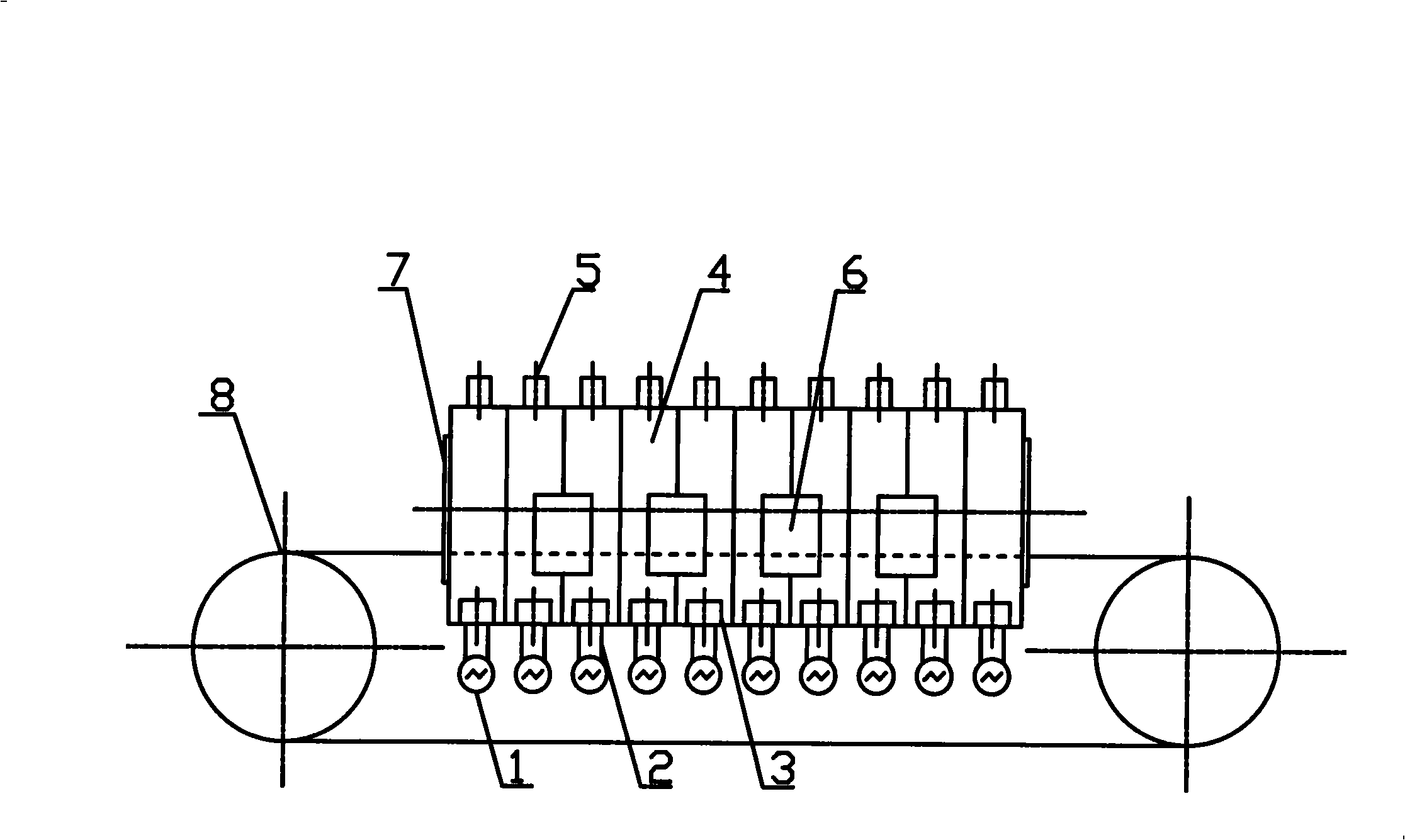

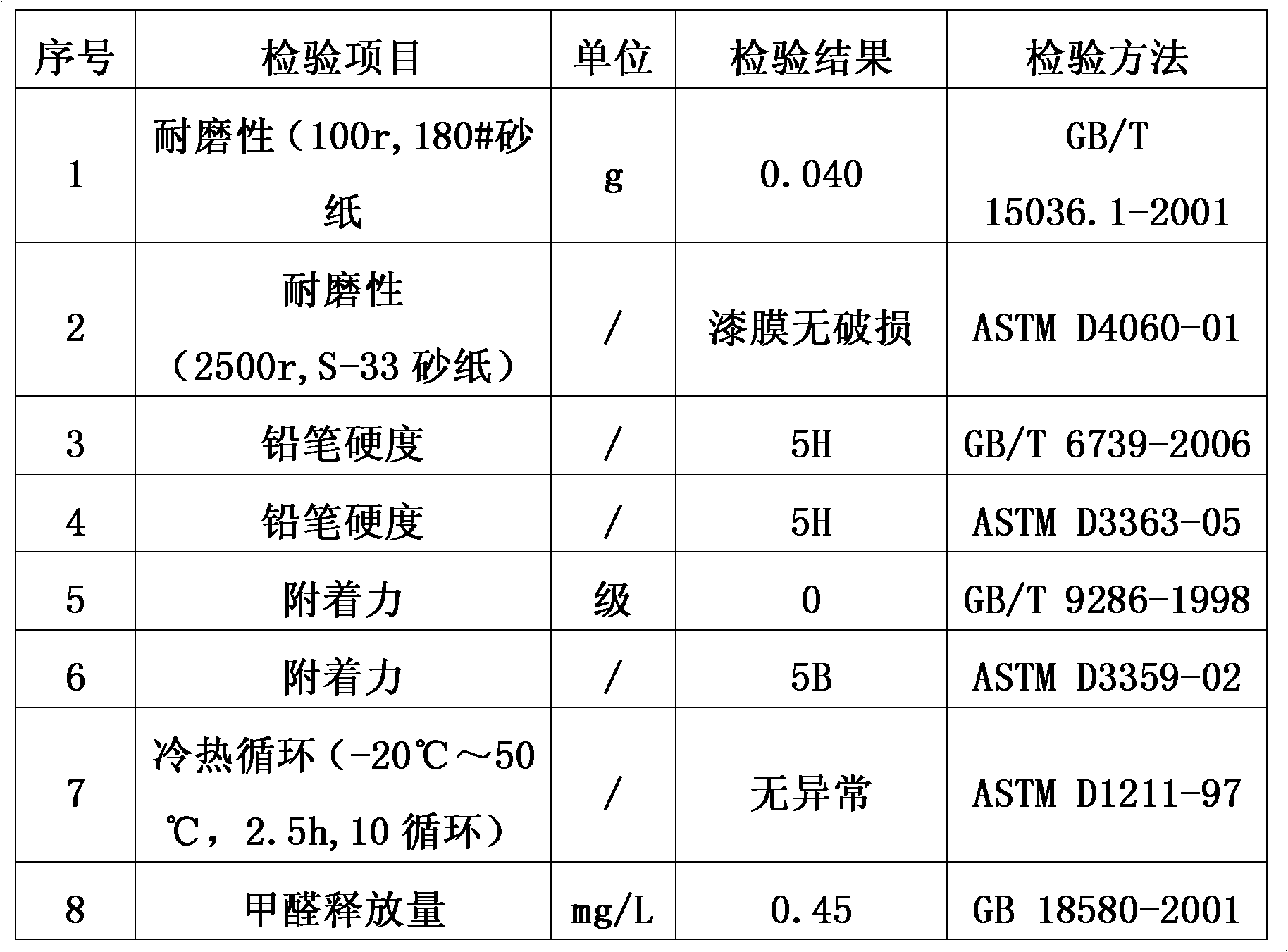

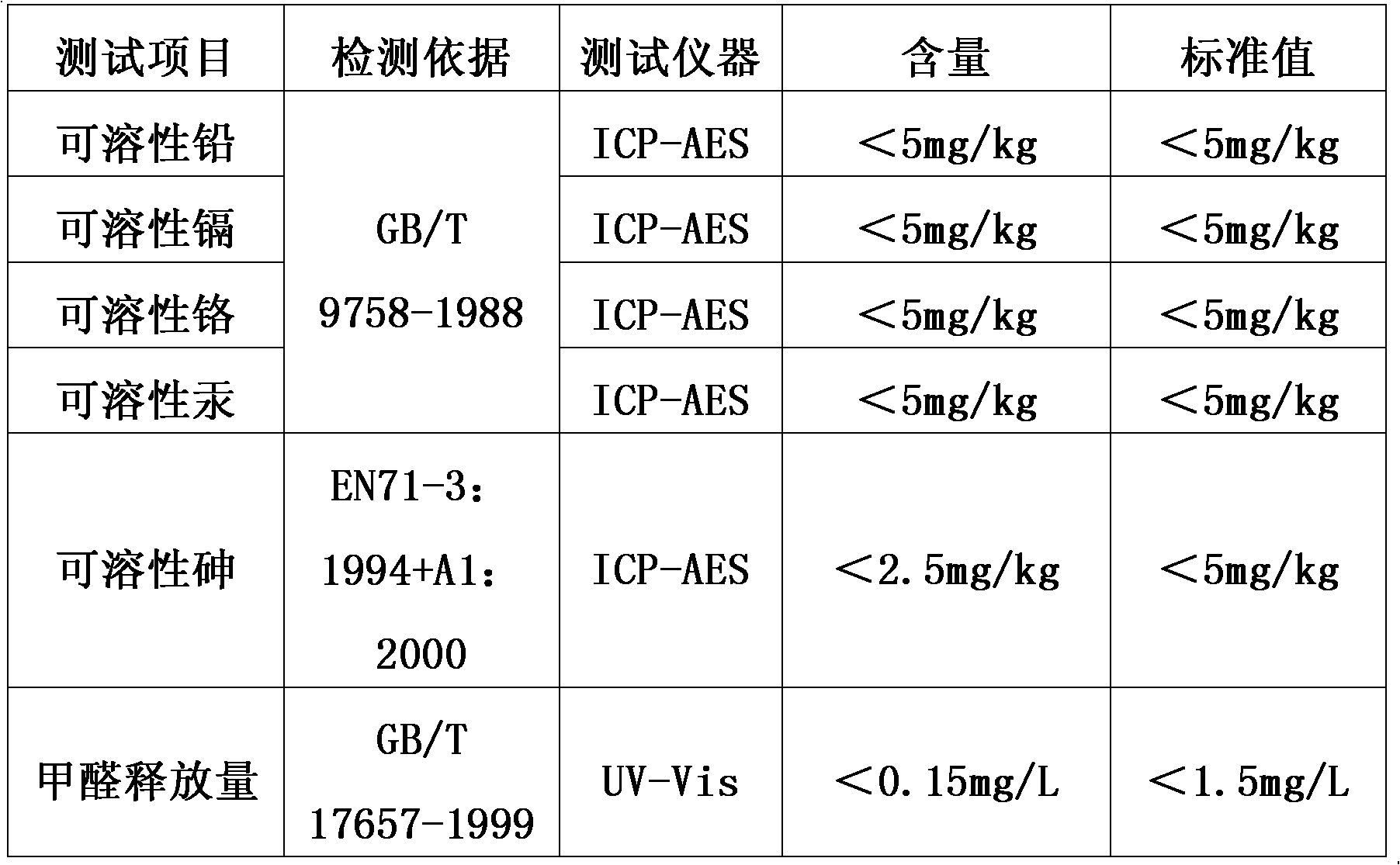

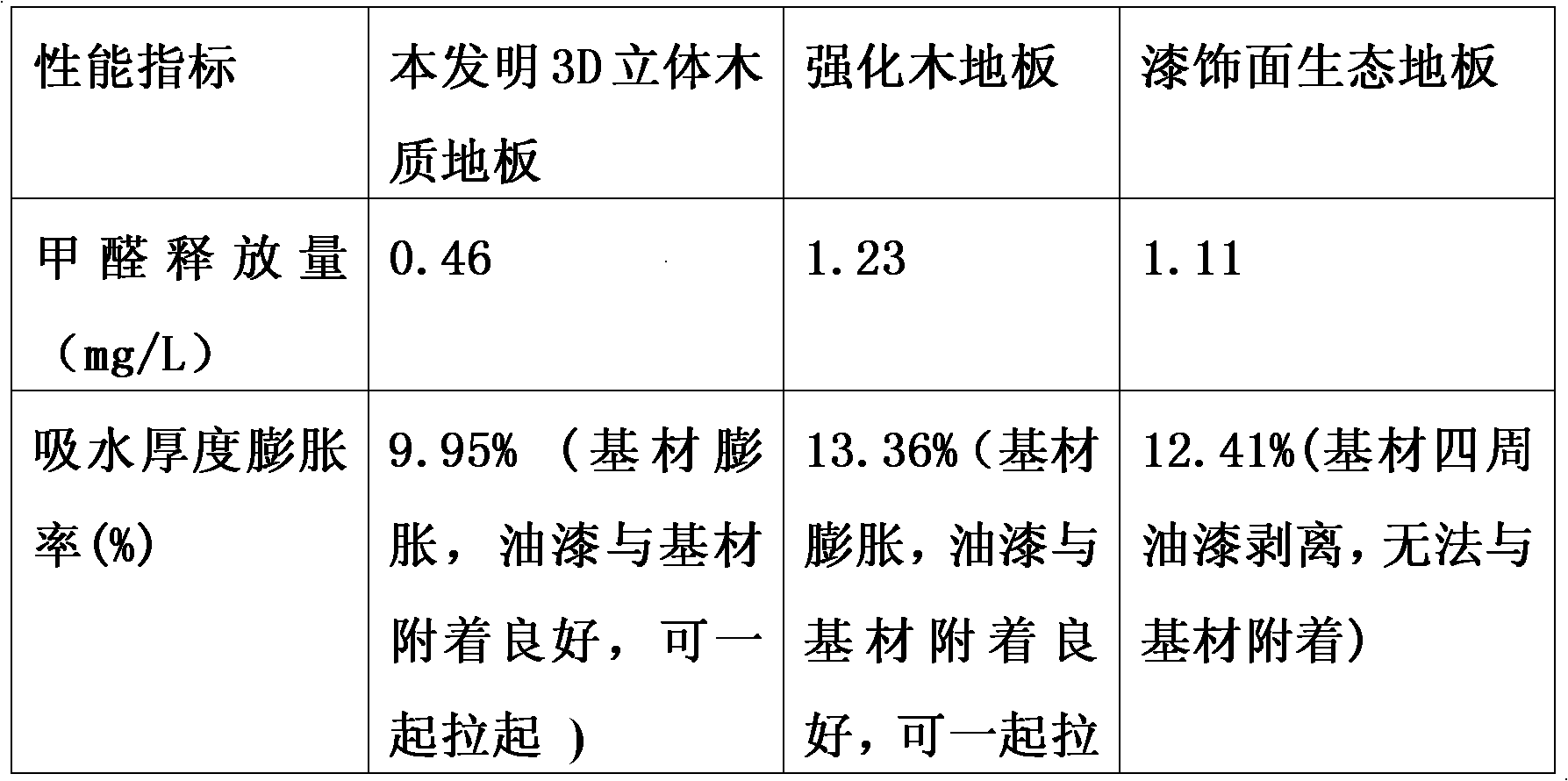

Method for producing high-emulation three-dimensional (3D) wood floor and high-emulation 3D wood floor

ActiveCN101885200AThree-dimensionalUnique wood grain printing effectWood treatment detailsWood dampingPulp and paper industrySubstrate surface

The invention discloses a method for producing a high-emulation 3D wood floor and the high-emulation 3D wood floor. The method comprises the following steps of: processing the surface of a base material to form a convex-concave three-dimensional surface; transferring wood grain on a rubber covered roller by using a steel roller with the wood grain, printing the wood grain on a substrate for 2 to 3 times by using the rubber covered roller, and coating finish on the substrate surface for 1 to 2 times; and printing the wood grain on the substrate for 2 to 3 times; and finally, coating finish on the substrate surface for 2 to 5 times. The wood floor produced by the method has high-emulation 3D wood grain layering and visual effects; the wood grain is clear and very vivid; and the produced floor voids repeated wood grain and has a good footfeel and the smooth and soft surface.

Owner:ZHEJIANG SHIYOU TIMBER

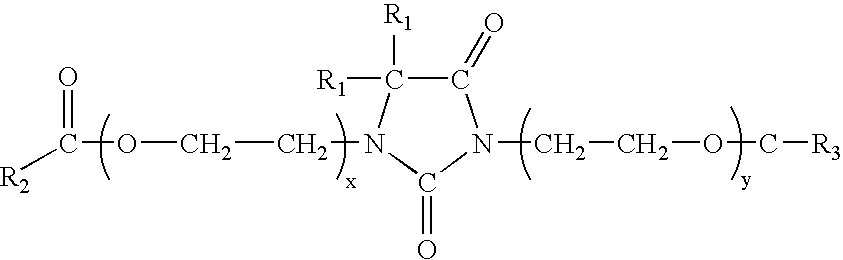

Method For Preparing Functional Engineered Wood

ActiveUS20170239836A1Improve permeabilityWell mixedLiquid surface applicatorsPressure wood treatmentFire retardantEngineered wood

The present invention relates to furniture panels, and more particularly, to a method for preparing functional engineered wood. It includes the following steps: make veneer blanks by rotary cutting or splicing, and cut the veneer blanks into desired dimensions to obtain veneers A. Soak the veneers A in a ternary mixed solution of a biomass nanocellulose solubilizer, a fire retardant and an acid dye for toughening, fire retardation and dyeing to obtain veneers B. Add a formaldehyde decomposing powder into a modified MUF adhesive, mix them up, coat the veneers B with the mixture to obtain veneers C. Assemble and cold-press the veneers C to obtain flitches D, and saw the flitches D into desired patterns and dimensions to obtain finished products.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

Wood preservative concentrate

InactiveUS6896908B2Easy on-site dilutionHigh strengthBiocideHeavy metal active ingredientsDissolutionGround contact

This invention relates to a leach-resistant borate preservative for lignocellulosic-based products, providing resistance against insect and fungal attack for use in exterior and ground contact applications. The preservative compositions of this invention may be provided as a high strength liquid concentrate, suitable for transportation, storage and easy on-site dilution, or as a ready-to-use treatment solution. These wood preservative compositions include a borate preservative component and a co-biocidal metal fixative such as copper or zinc. The preservative compositions also contain volatile organic acid, free ammonia and ammonium salts to aid dissolution. Methods for the application of these preservative compositions to wood are also provided.

Owner:U S BORAX INC

High temperature water heat processing method for timber

ActiveCN1876343AImprove water absorptionSmall water absorptionWood treatment detailsWood dampingMetallurgyIncrease size

Owner:HUNAN TAOHUAJIANG BAMBOO SCI & TECH CO LTD

Preparation method of crop straw fiber ecological composite material

ActiveCN102085680AImprove mechanical propertiesGood heat insulationWood treatment detailsDomestic articlesCelluloseMass ratio

The invention relates to a preparation method of a crop straw fiber ecological composite material, which is characterized by comprising the following steps of: mechanical separation: mechanically separating crop straws into short straws to improve the accessibility of alkali treatment to the crop straws; alkali treatment: carrying out alkali treatment on the short straws in a sodium hydroxide solution with mass percent of 3-6 percent, wherein the mass ratio of the sodium hydroxide solution to the short straws is (30-50):1; carrying out alkali treatment, washing and acid neutralizing and then drying for 2-10h at a temperature of 60-80 DEG C to obtain straw fibers; with the straw fibers as an enhancement phase and a polylactic acid material as a substrate, thermally pressing to obtain a composite material; and keeping pressure, naturally cooling or water-cooling the obtained composite material at normal temperature to obtain a porous composite material plate. The straw fiber extracted in the invention has the advantages of high cellulose content, good fineness, good mechanical property of the composite material and more and small gaps inside straw fibers inside the composite material, and excellent heat insulation and sound isolation performances.

Owner:万华禾香生态科技股份有限公司

Wood softener, and preparation method and application thereof

ActiveCN102303332ALow elastic modulusShorten the timeWood treatment detailsWood impregnation detailsPolymer scienceAlcohol

The invention provides a wood softener, wherein components included in the wood softener and the weight percentage of each component are as follows: 10-80% glycerol, 0.2-3% anionic penetrating agent, and rest being water. The invention also provides a preparation method of the wood softener, wherein the following process is adopted: proportionally and evenly mixing glycerol with anionic penetrating agent and water, and stirring the mixture using a stirrer at 25-40 DEG C and at a speed ranging from 50-200 r / min for 1-3 min. The invention further provides a method for performing softening treatment on the wood, comprising the following steps of: adding the prepared softener to a container; putting small wood pieces in the softener; and heating to a range of 70-100 DEG C and keeping the temperature for 3-10 h. The invention additionally provides a method for processing wood slices, comprising the following steps of: adding the prepared softener to the container; heating to a range of 70-100 DEG C and keeping the temperature for 3-10 h; and then putting the softened wood pieces into mixed solution of absolute ethyl alcohol and anhydrous glycerol, and oscillating for 0.5-5 hours, thereby forming the wood pieces into wood slices. The wood slice is processed by the wood softener, which is used for identifying the type of wood.

Owner:山东省纤维检验局

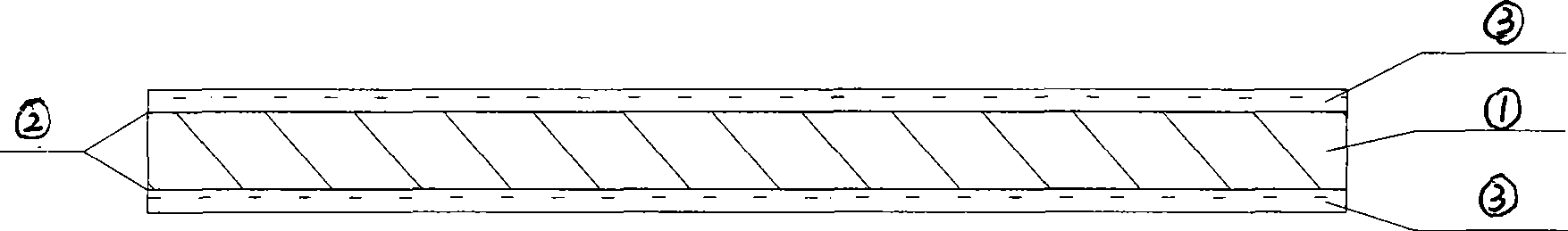

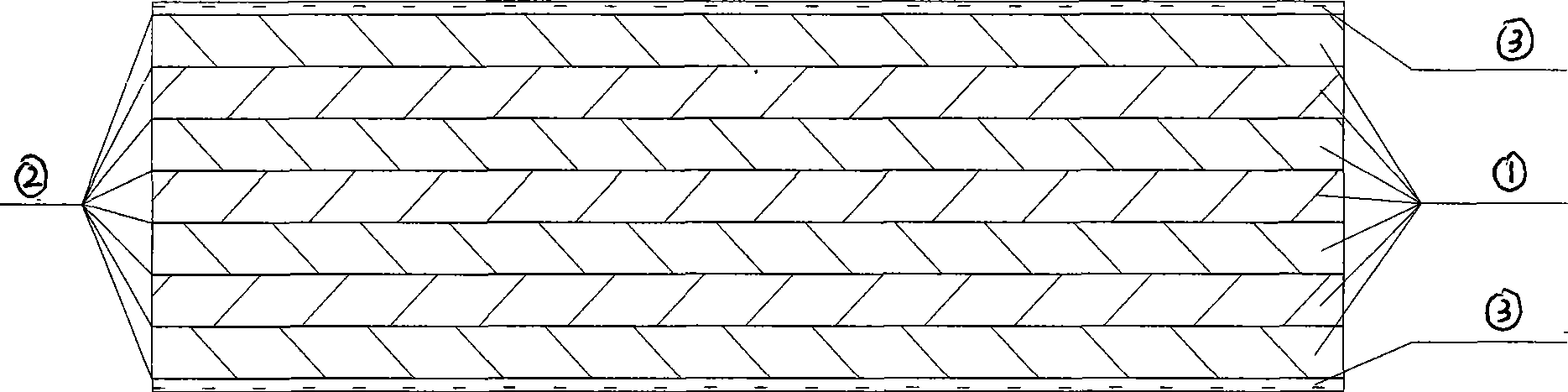

Anti-corrosion recombined composite bamboo material and manufacturing method thereof

ActiveCN103770168AImprove corrosion resistanceGood weather resistanceWood treatment detailsWood veneer joiningNano zinc oxideCorrosion prevention

The invention discloses an anti-corrosion recombined composite bamboo material and a manufacturing method thereof. The anti-corrosion recombined composite bamboo material is manufactured by utilizing bamboo as a main raw material, the density of the anti-corrosion recombined composite bamboo material is 0.9-1.50g / cm<3> and the water-absorbing thickness expansion ratio in the thickness direction and width direction of the anti-corrosion recombined composite bamboo material is respectively less than 1.5%; the anti-corrosion recombined composite bamboo material achieves a strong anti-corrosion level and has a bacterium damaged degree of zero level. The manufacturing method comprises the following steps: processing raw bamboo into bamboo strips, and then rolling the bamboo strips to obtain defibered bamboo bundles; digesting the defibered bamboo bundles by use of a dilute base solution and water sequentially, drying the bamboo bundles, and performing high-pressure transfusing on the bamboo bundles by use of a mixed aqueous solution of nano zinc oxide and bamboo mildew remover; then performing oxygen-exclusion drying treatment, high-temperature treatment and humidifying treatment; performing gumming, drying, curtain weaving, cold pressing and sizing, thermosetting and cooling equalization treatment, so as to obtain the anti-corrosion recombined composite bamboo material. The anti-corrosion recombined composite bamboo material has the advantages of corrosion resistance, weather resistance, insect prevention and good dimensional stability, and can be used for outdoor decoration.

Owner:HUNAN TAOHUAJIANG BAMBOO SCI & TECH CO LTD

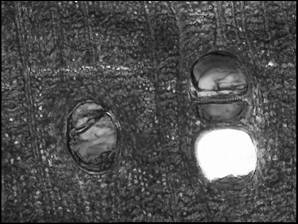

Method for densifying wood and densified wood

The invention discloses a method for densifying wood and densified wood manufactured by the same. The method comprises: sealing the cross section of wood by using a hydrophobic material, wherein the water content of the wood is less than 12 weight percent; coating softener on the surface and / or shallow layer of the sealed wood; and performing the hot pressing of the wood of which the cross section is sealed and which is coated with the softener at a temperature above the boiling point of the softener to densify the wood. The method for densifying wood can compress the wood to different extent according to needs. The method is simple and easy to operate, requires short time and simple equipment and makes product cost low. The densified wood manufactured by the method of the invention is greatly improved in surface density, hardness and wear resistance.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

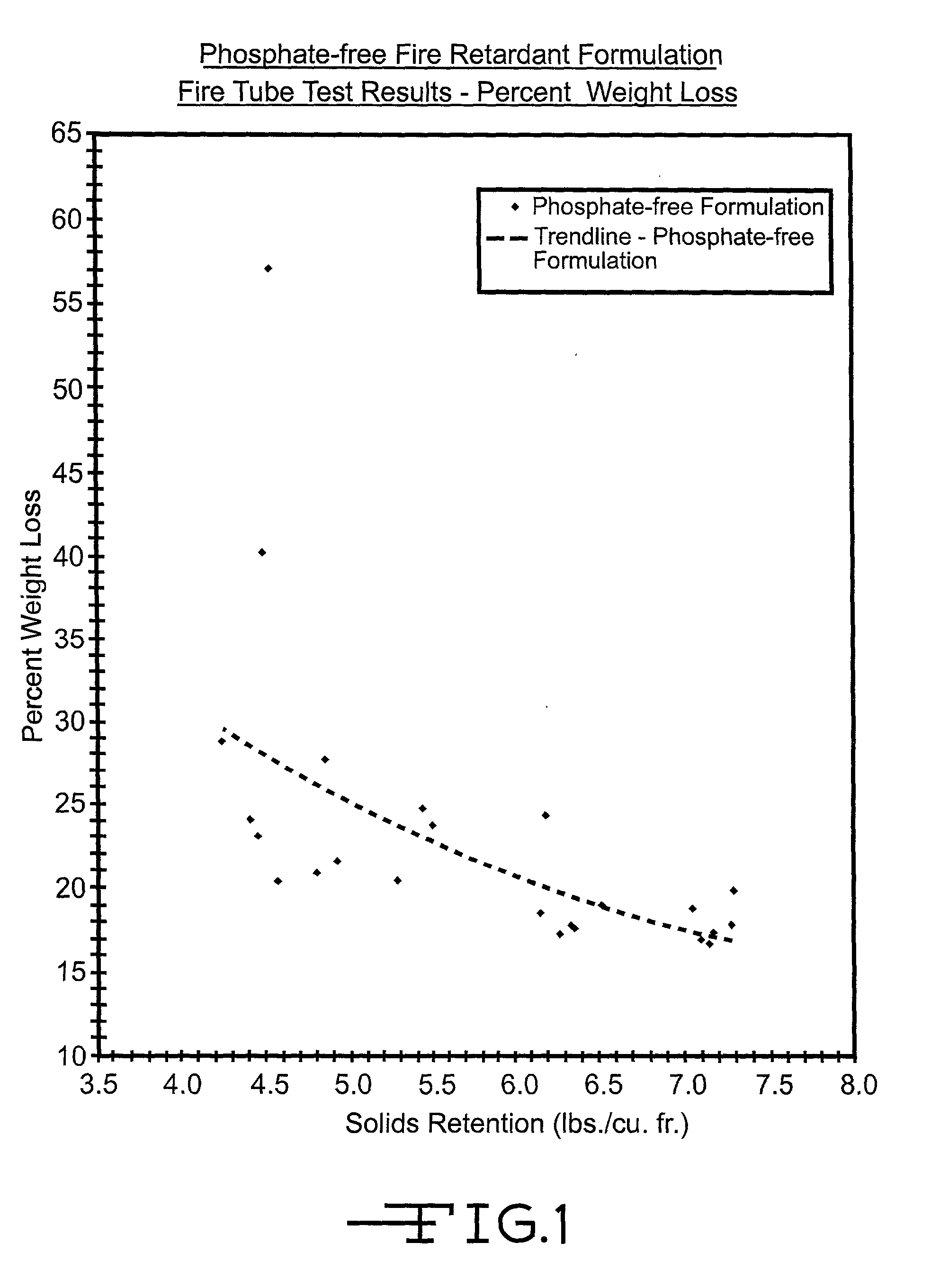

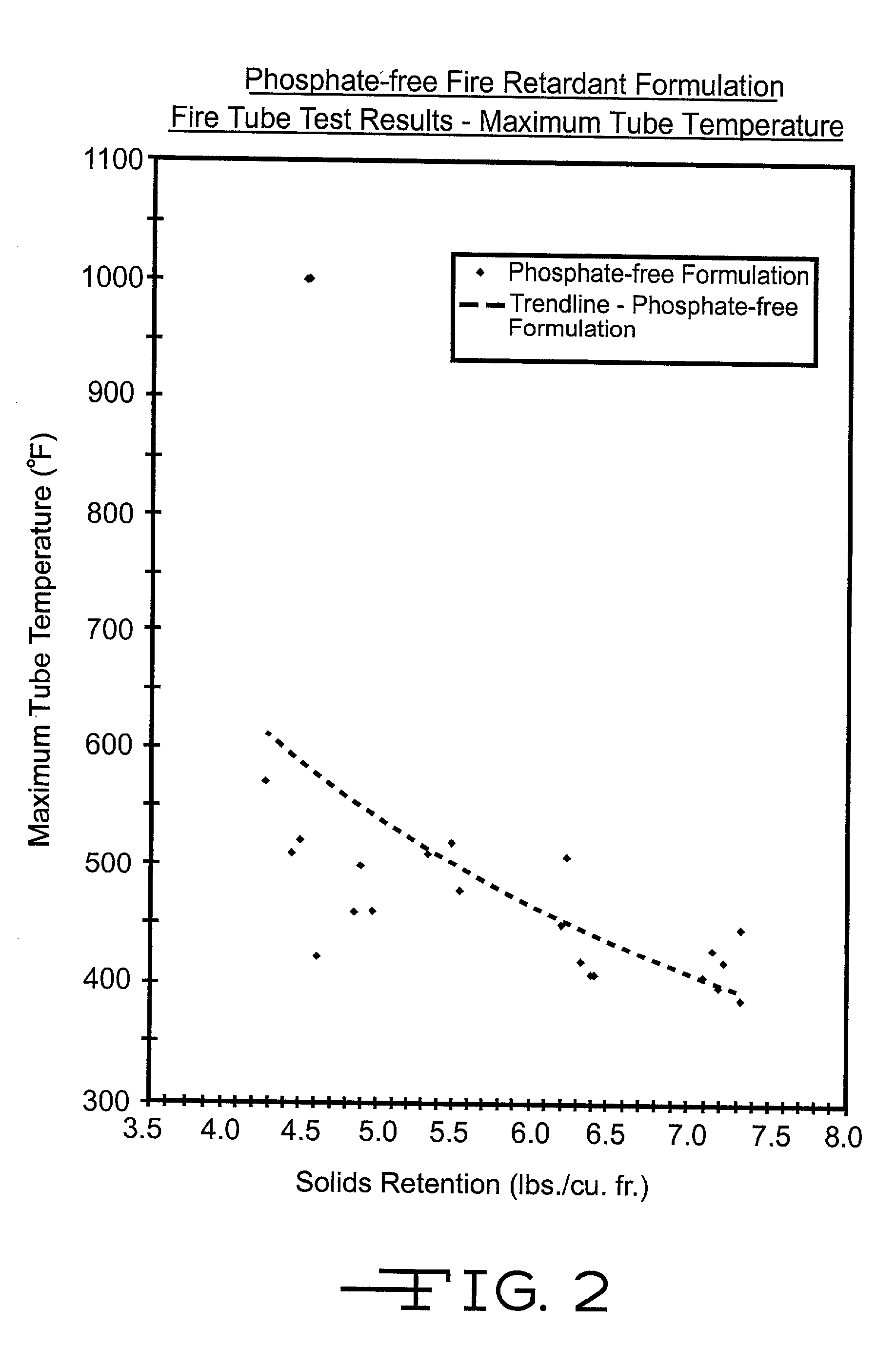

Phosphate free fire retardant composition

A phosphate and ammonia free composition for treating an object (i.e., lumber, plywood and other wood products) is described. The treating solution may be applied to the object by dipping, soaking, brushing, spraying, etc., however, vacuum and / or pressure techniques may be used to impregnate the object according to the method of this invention, including both the empty-cell process and the full-cell process. The composition achieves fire retardant qualities without object degradation when the treated object is subjected to heat and humidity over time. The composition of this invention includes nitrogen in a predetermined ratio to boron.

Owner:KOPPERS PERFORMANCE CHEM

Wooden wares surface archaizing treatment technology

InactiveCN1730255AEasy to produceVariety of colorsWood treatment detailsPretreated surfacesLacquerDiluent

The invention relates technology of surface treatment of wooden wares, comprising the following steps: drying the wood and blanking according to the requirement, processing and charring; brushing or spraying the archaized color priming paint which is compounded by diluent and mixture of yellow paint, red paint, black paint, and white paint in proper proportion, after drying, repairing the surface of the wood, then spraying the priming paint repeatedly twice or thrice, making it dry naturally; sanding the said wooden wares by fineness abrasive cloth, taking out the paint around 20%; spraying the press polish archaized paint to the surface of the wooden wares. The invention processes simple technology, good effect of imitation antique, convenience production, economy and utility.

Owner:DAKANG HLDG GROUP

Rattan treatment agent for wickerwork

InactiveCN104026172AIncrease profitNo toxicityBiocideWood treatment detailsMonkshoodsTraditional medicine

The invention relates to a rattan treatment agent for wickerwork, which comprises mustard, salvia officinalis, fruit of cubeb litsea tree, allspice, rod chilli, monkshood, folium artemisiae argyi, fructus evodiae, clove and remote lemongrass Herb. The rattan treatment agent provided by the invention is prepared by adopting pure traditional Chinese medicines, the rattan is treated by adopting a soaking mode, the process is simple and good in effect, juice decocted by the treatment agent can be repeatedly utilized, the insect-resistant and anti-mould effect of the treated rattan can be over 10 years, and the rattan treatment agent has faint scent and does not have a side effect on the skin and body.

Owner:阜南腾强工艺品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com