Patents

Literature

861results about "Veneer manufacture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

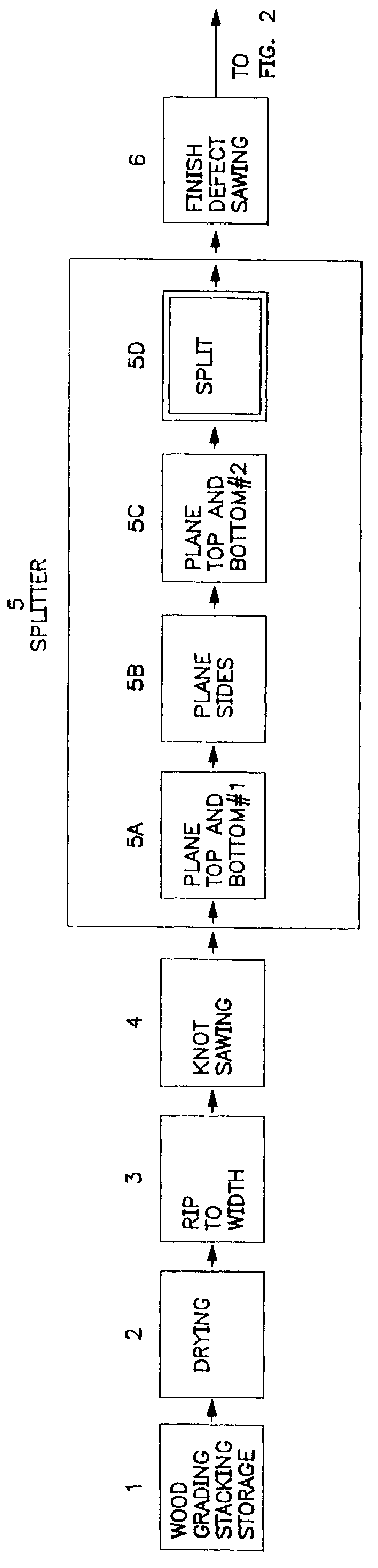

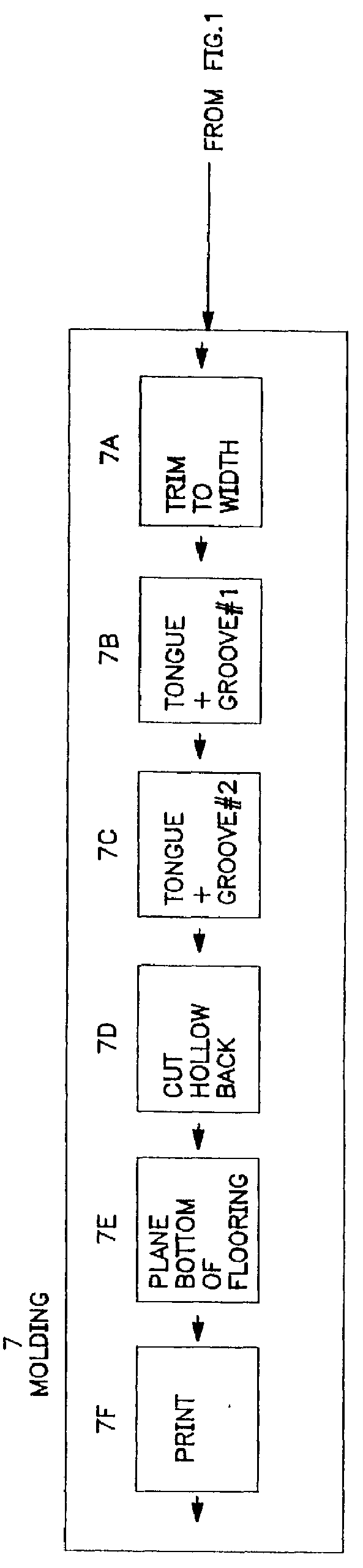

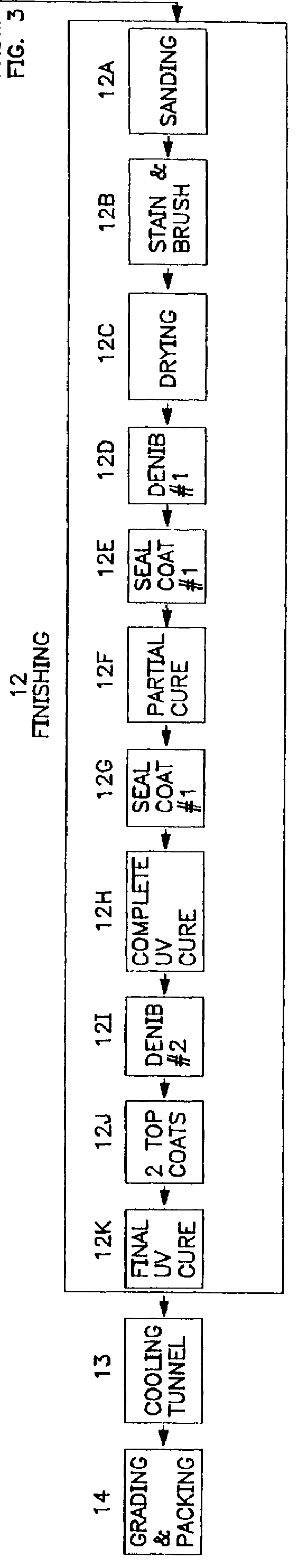

Low profile hardwood flooring strip and method of manufacture

InactiveUS6148884AConsiderable quantityImprove rigidityDovetailed workMulti-purpose machinesCircular sawTongue and groove

A method of producing a hardwood flooring product, including the steps of processing a strip of raw wood into a blank having a predetermined thickness and width, and top and bottom surfaces defining parallel planes relative to each other, and splitting the blank along the width of the blank from one side to the other to form two low profile flooring strips having the same width as the blank and a thickness less than one-half the thickness of the blank. The splitting step includes the steps of providing first and second circular saw blades mounted on spaced-apart vertical axes for rotation in a single plane intermediate and parallel to the planes of the top and bottom surfaces of the blank and positioning the blank on conveying means upstream from the saw blades with the plane of rotation of the saw blades intermediate and parallel to the planes of the top and bottom surfaces of the blank for movement of the blank from an upstream position to a downstream position relative to the saw blades. The blank is moved downstream into the plane of rotation of the saw blades during rotation of the saw blades thereby horizontally splitting the blank to form first and second low-profile flooring strips. Interlocking members, such as molded, mating tongue and groove members, are molded into first and second longitudinally-extending side edges of the flooring strips for securing together the flooring strips when placed side-to-side to form a floor.

Owner:ARMSTRONG HARDWOOD FLOORING CO +2

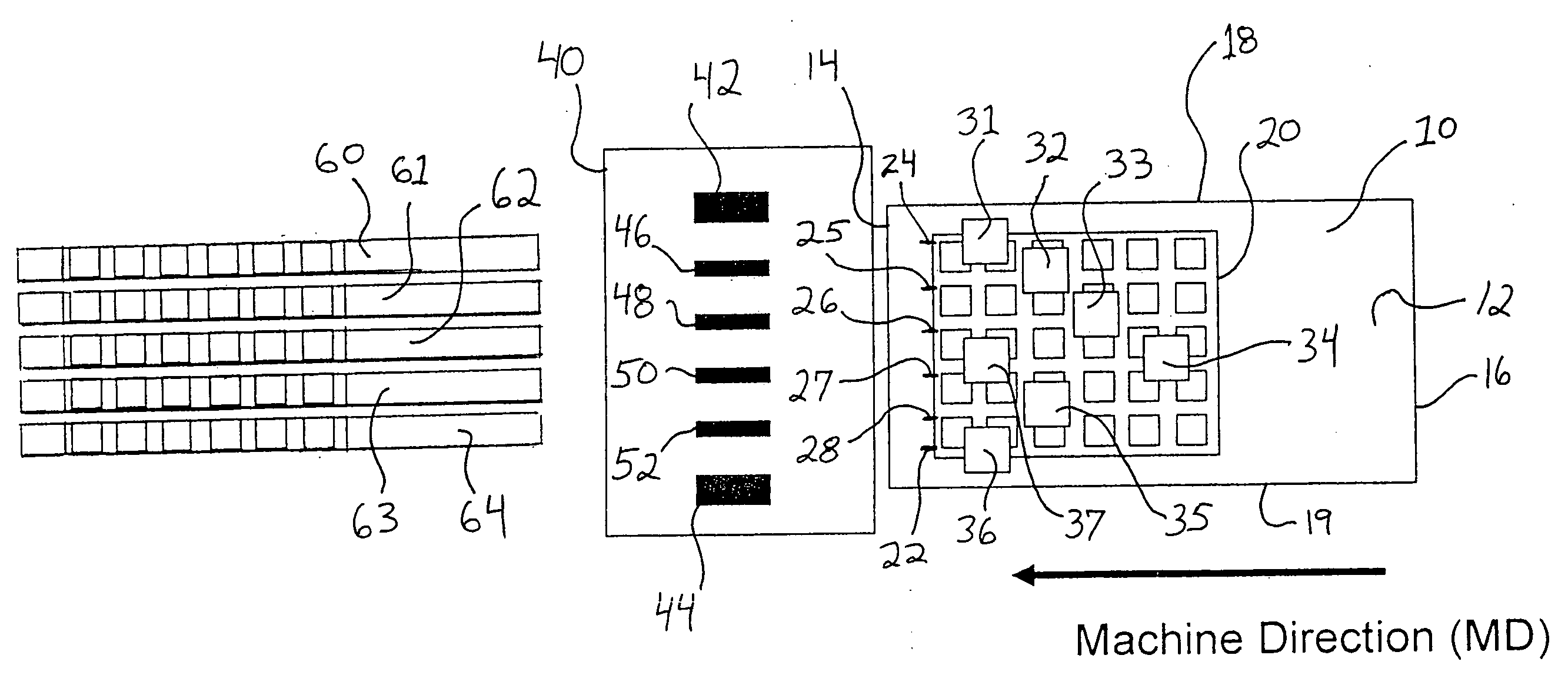

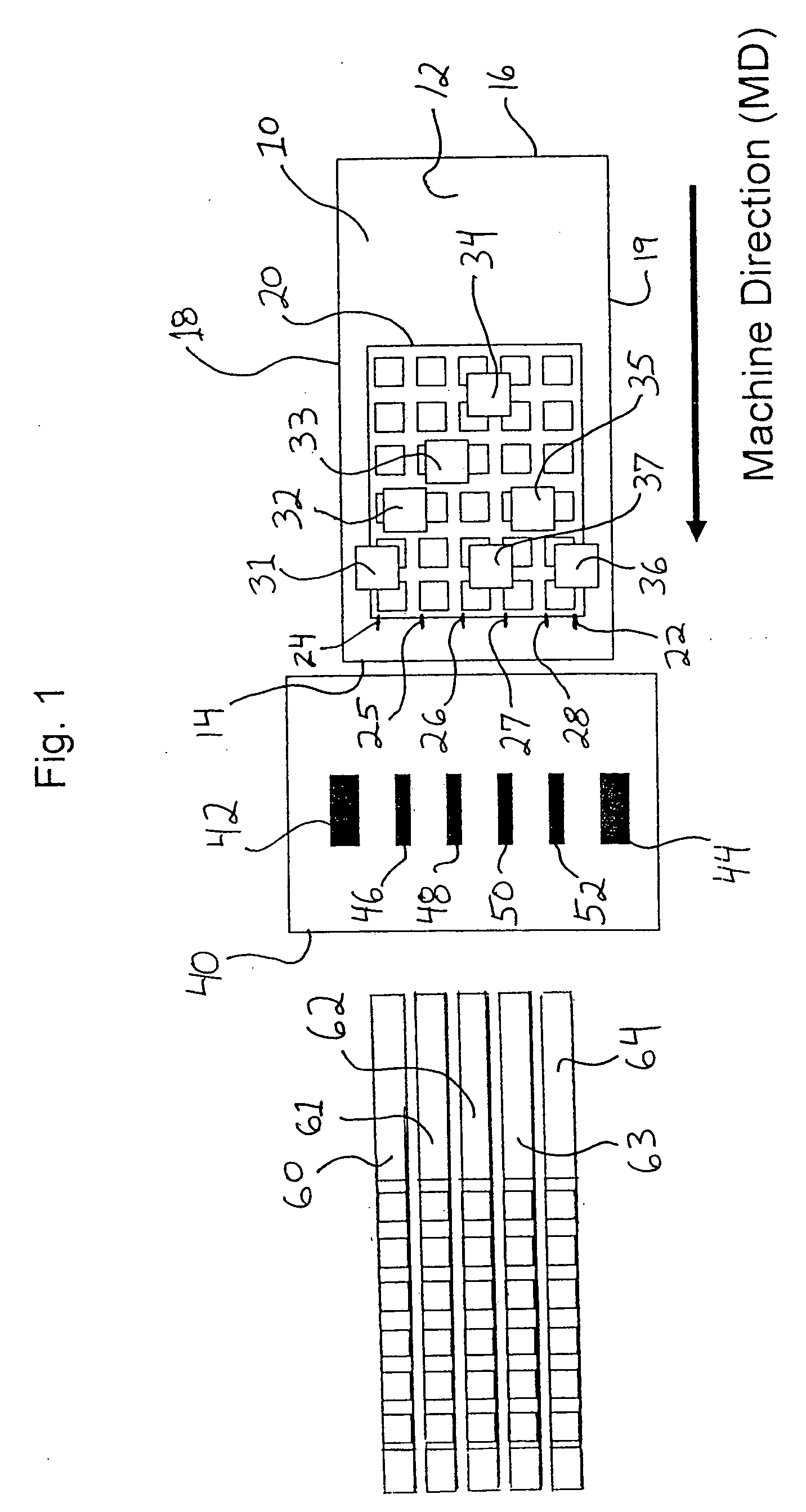

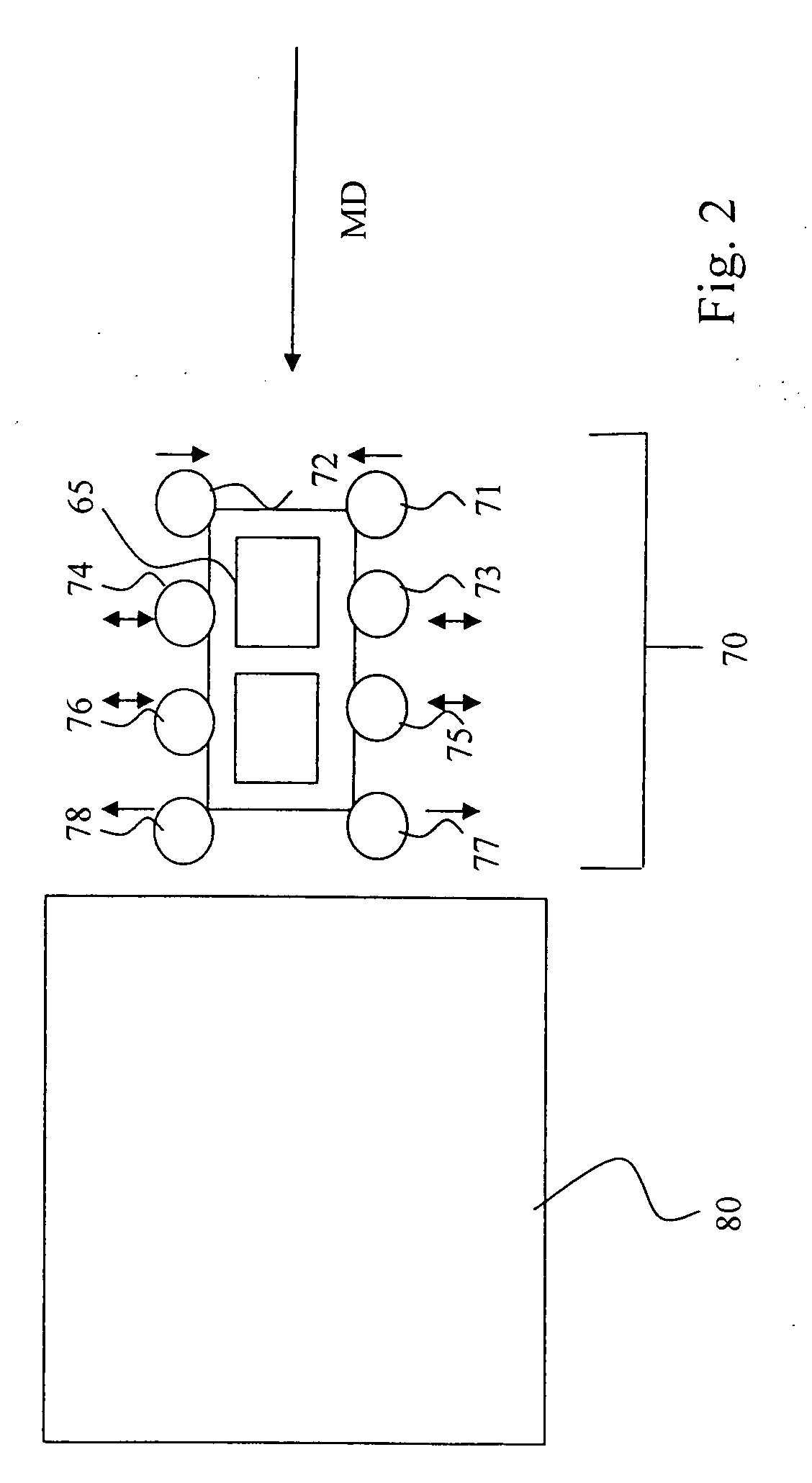

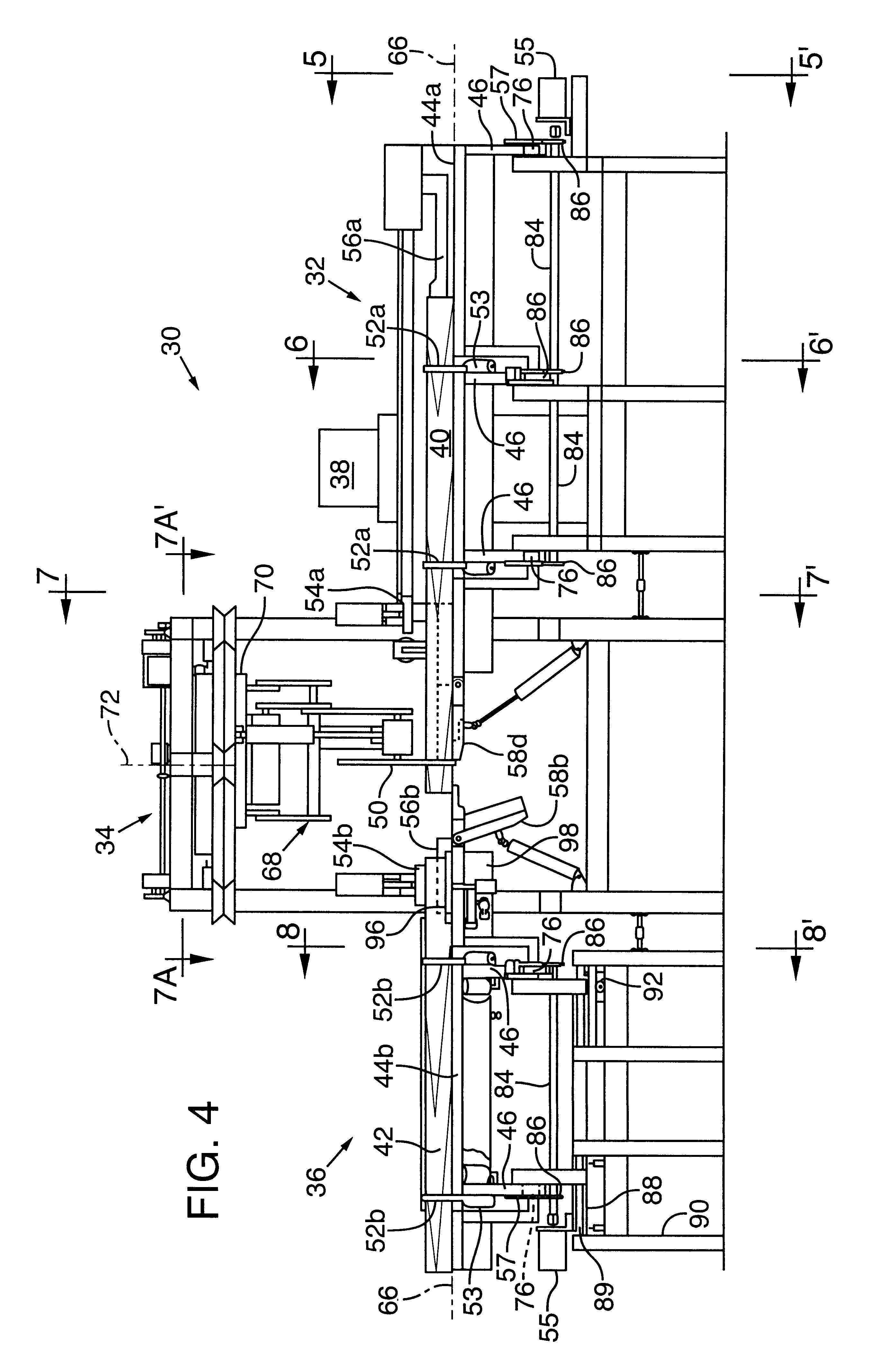

Process and system for sub-dividing a laminated flooring substrate

ActiveUS20070209736A1Good for healthAvoid mistakesMulti-purpose machinesAdjusting equipmentEngineeringControl unit

A process for sub-dividing a laminated flooring substrate into a plurality of laminated flooring planks and a system therefore are described. The process can include providing a laminated flooring substrate having a decorative pattern on a core wherein the decorative pattern can include a plurality of indicators, and independently detecting the indicators with a plurality of detecting devices, each assigned a respective indicator. The detecting devices can individually obtain the position of the detected indicators and a control unit can align a separate saw blade per each position detected. The system includes a cutting unit with individually adjustable saws or an alignment device configured to align the laminated flooring substrate with the saws, to cut the laminated flooring substrate along positions relative to the detected indicators, for example, in the center thereof or off-set therefrom.

Owner:MANNINGTON MILLS

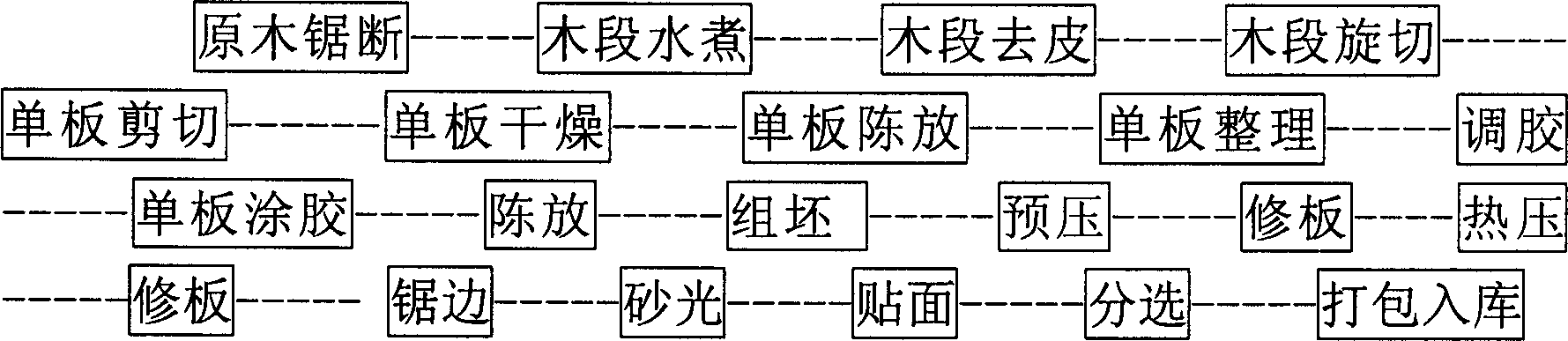

Method for producing plywood with glueing on one side and plywood mould

A method for producing the plywood with the wood plys whose one surface is coated by resin includes such steps as sawing log short, boiling in water, removing bark, spinning cutting, cutting fly, drying, ageing, coating resin on one surface of each ply, ageing, laminating, pre-pressing, trimming, hot pressing, trimming, sawing edge, sticking a paper immersed in resin, and classifying.

Owner:哈尔滨市香坊区人造板胶粘剂研究所 +1

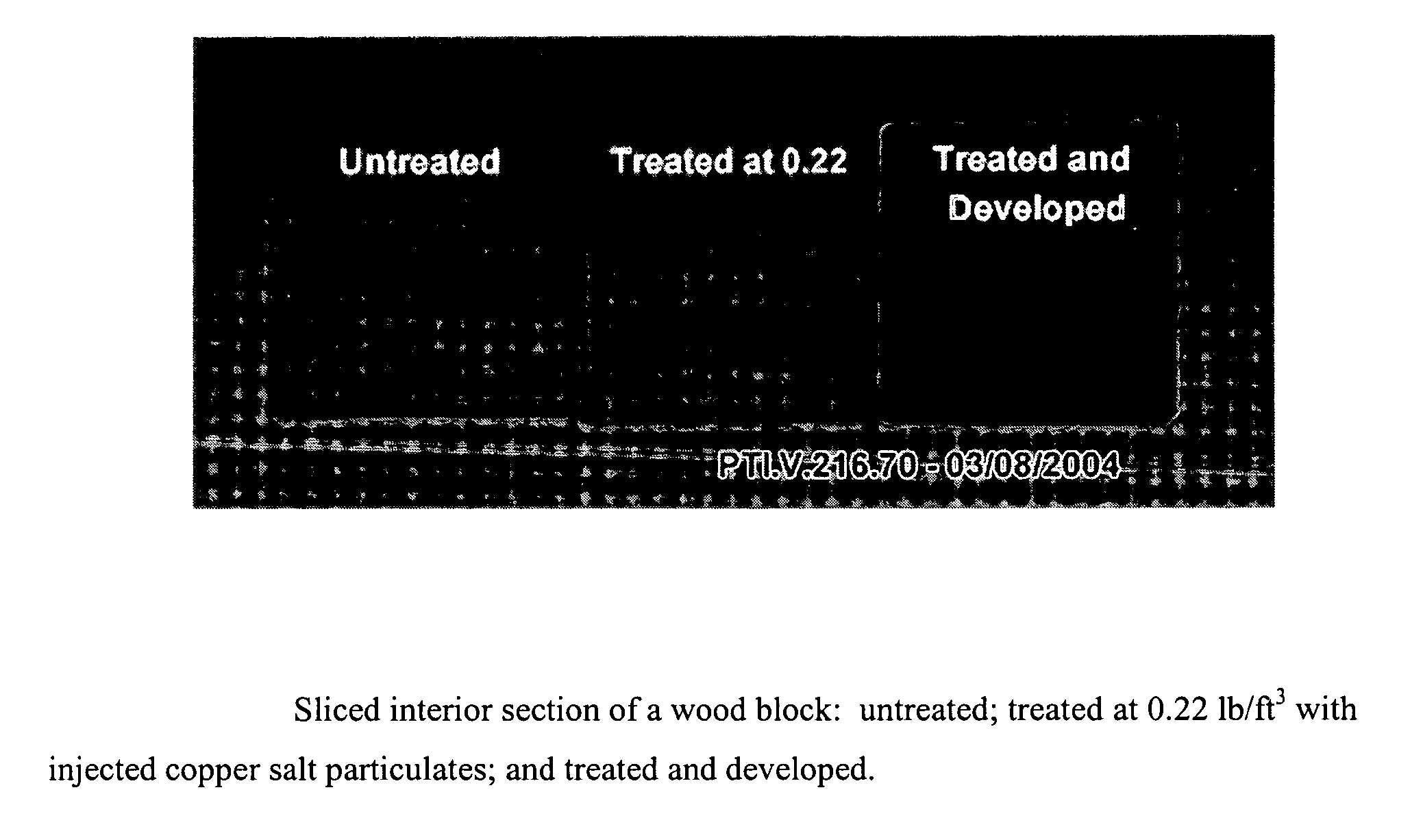

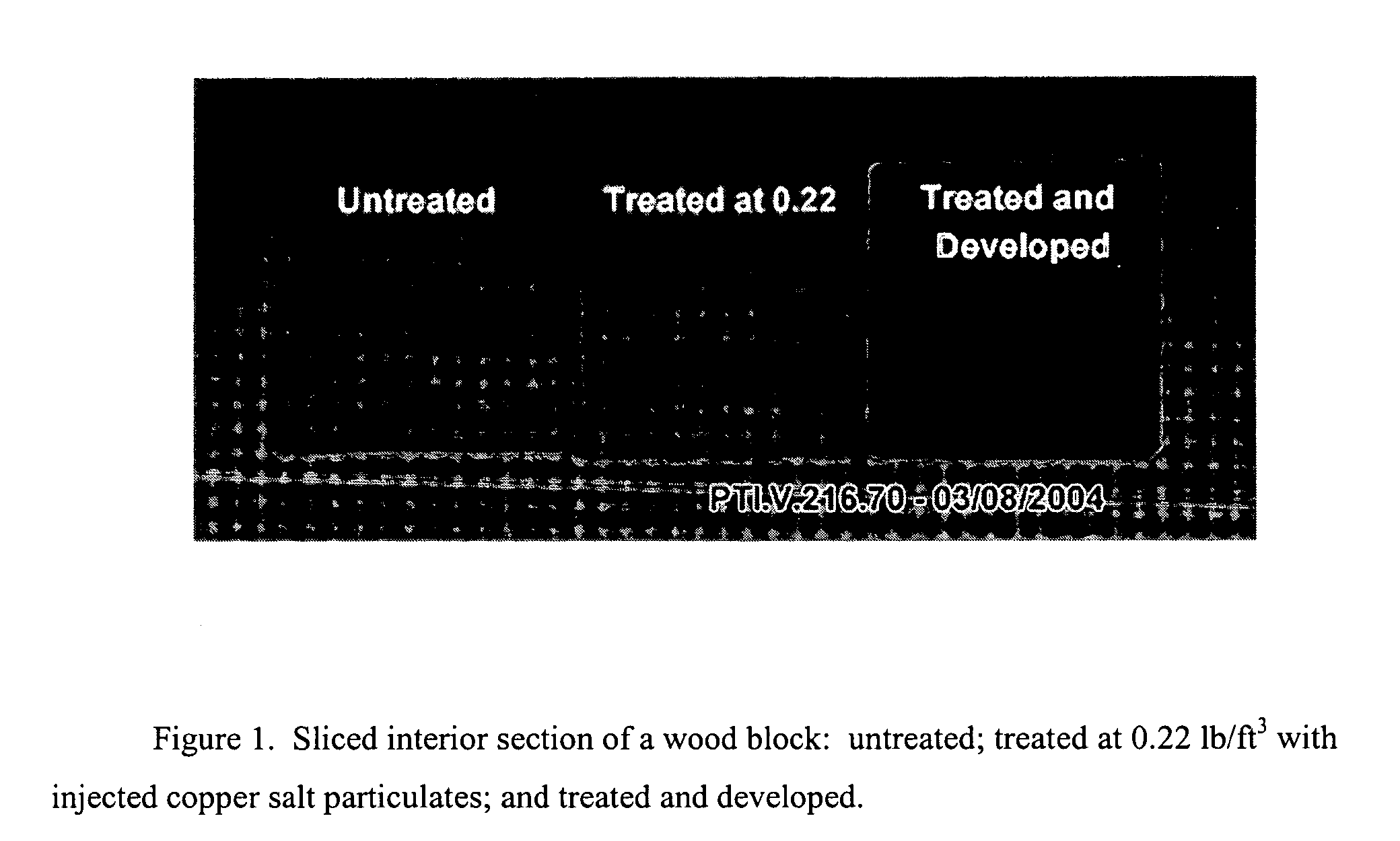

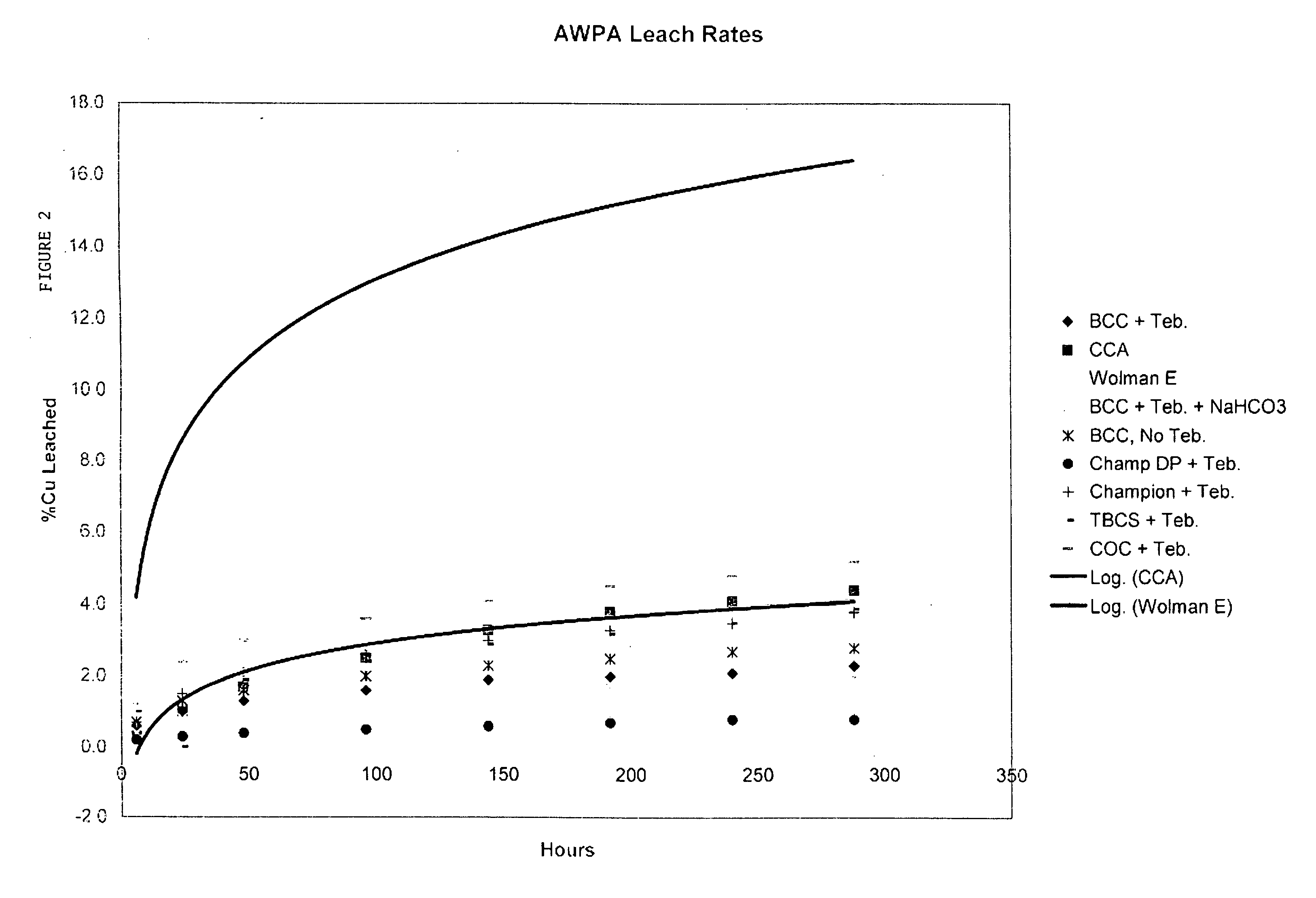

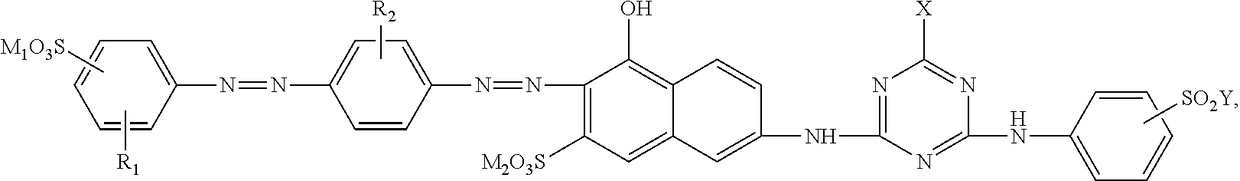

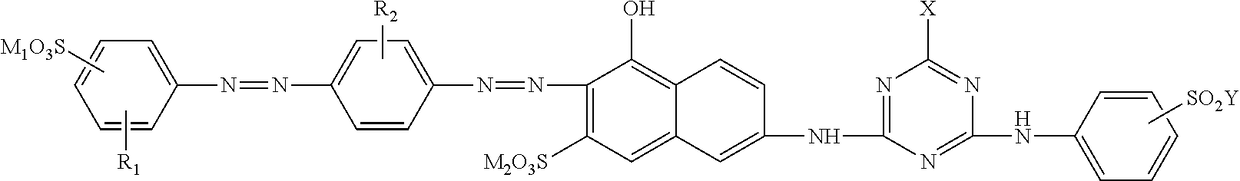

Milled submicron organic biocides with narrow particle size distribution, and uses thereof

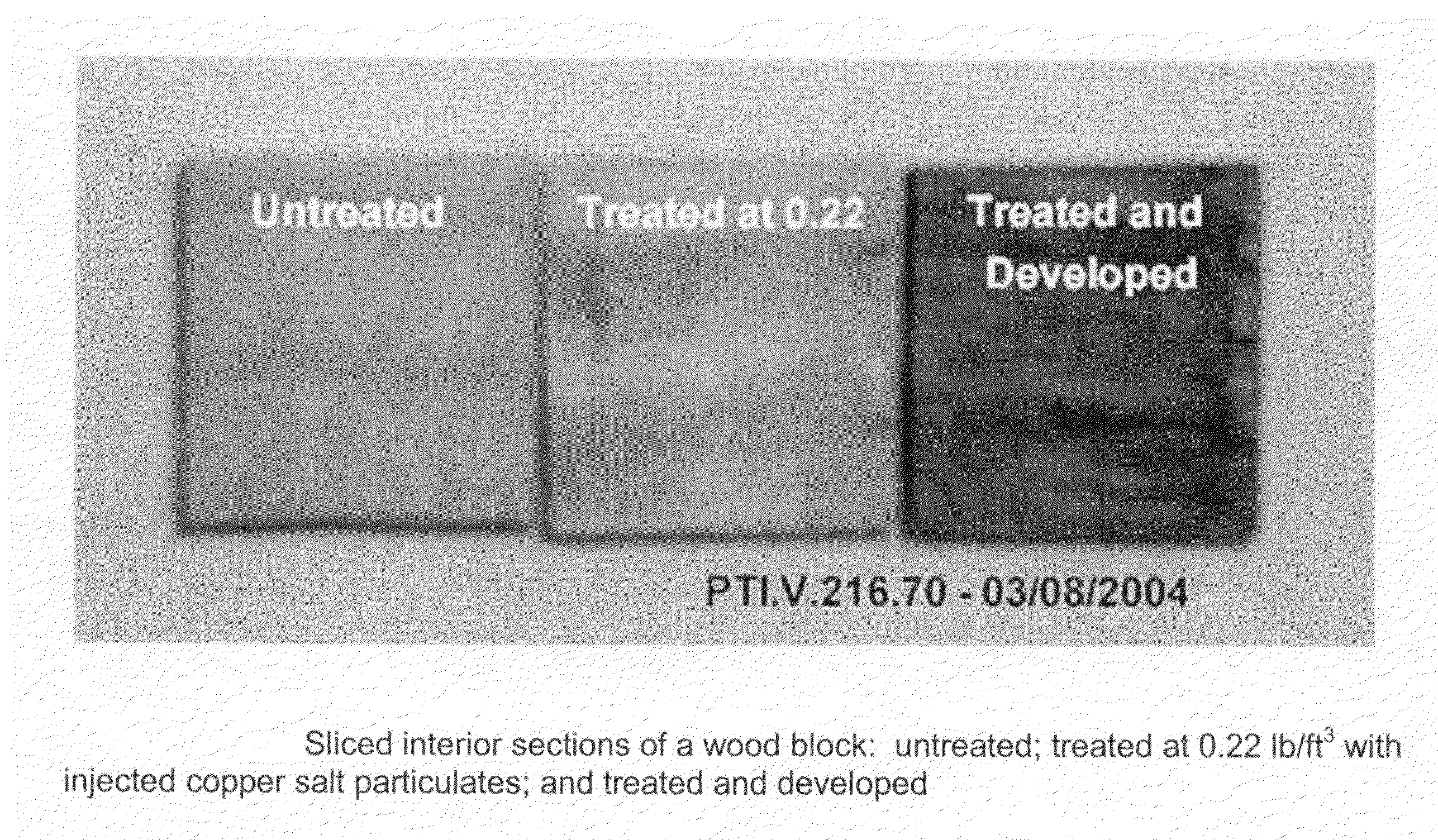

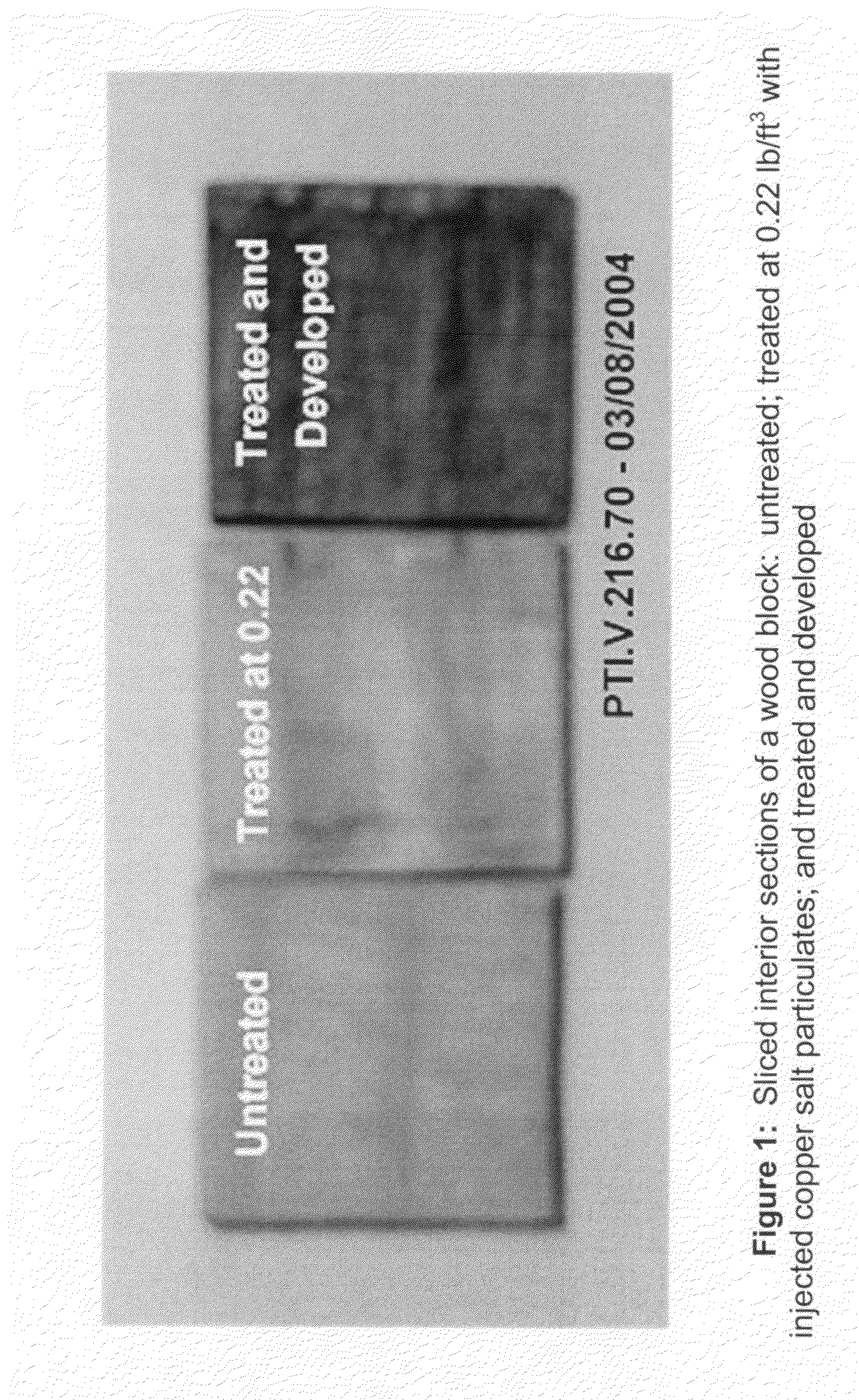

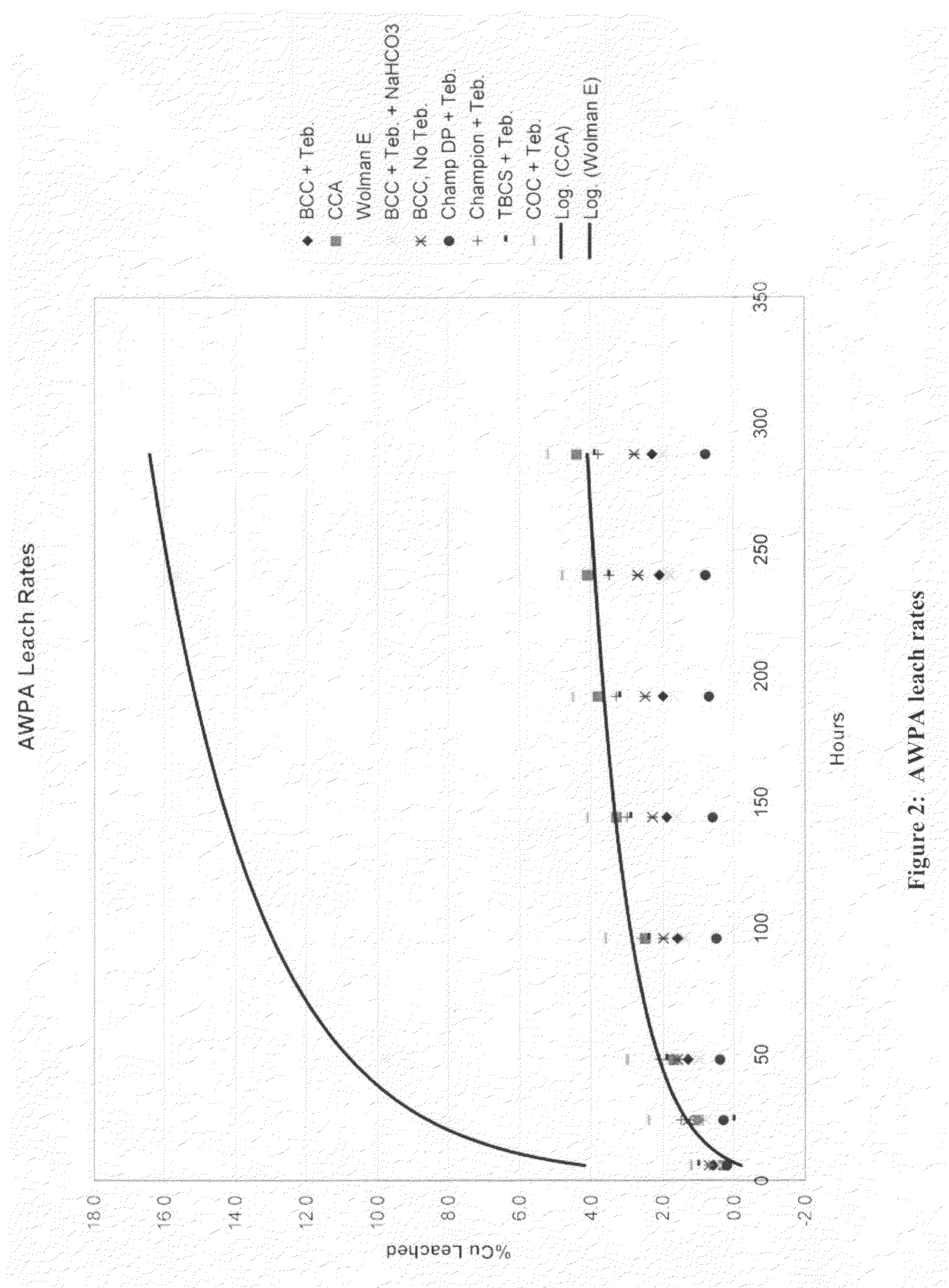

A method of milling substantially insoluble solid organic biocides to form a micron or sub-micron product having a narrow particle size distribution is presented. The milling involves wet milling of the organic biocide with high density milling media having a diameter between 0.1 mm and 0.8 mm, preferably between 0.2 mm and 0.7 mm, and a density equal to or greater than 3.8 g / cc, preferably greater than 5.5 g / cc, in a ball mill using between about 40% and 80% loading of the mill volume with milling media, and having the organic biocide suspended in an aqueous milling liquid which comprises one or more surface active agents. The milling speed is preferably high, for example from about 1000 rpm to about 4000 rpm. The milled product can be used in foliar applications at a lower effective dosage than prior art formulations, can be used in improved antifouling paint formulations, and can be used in new applications such as the direct injection of solid organic biocide particulates in wood to act as a long lasting wood preservative.

Owner:KOPPERS PERFORMANCE CHEM

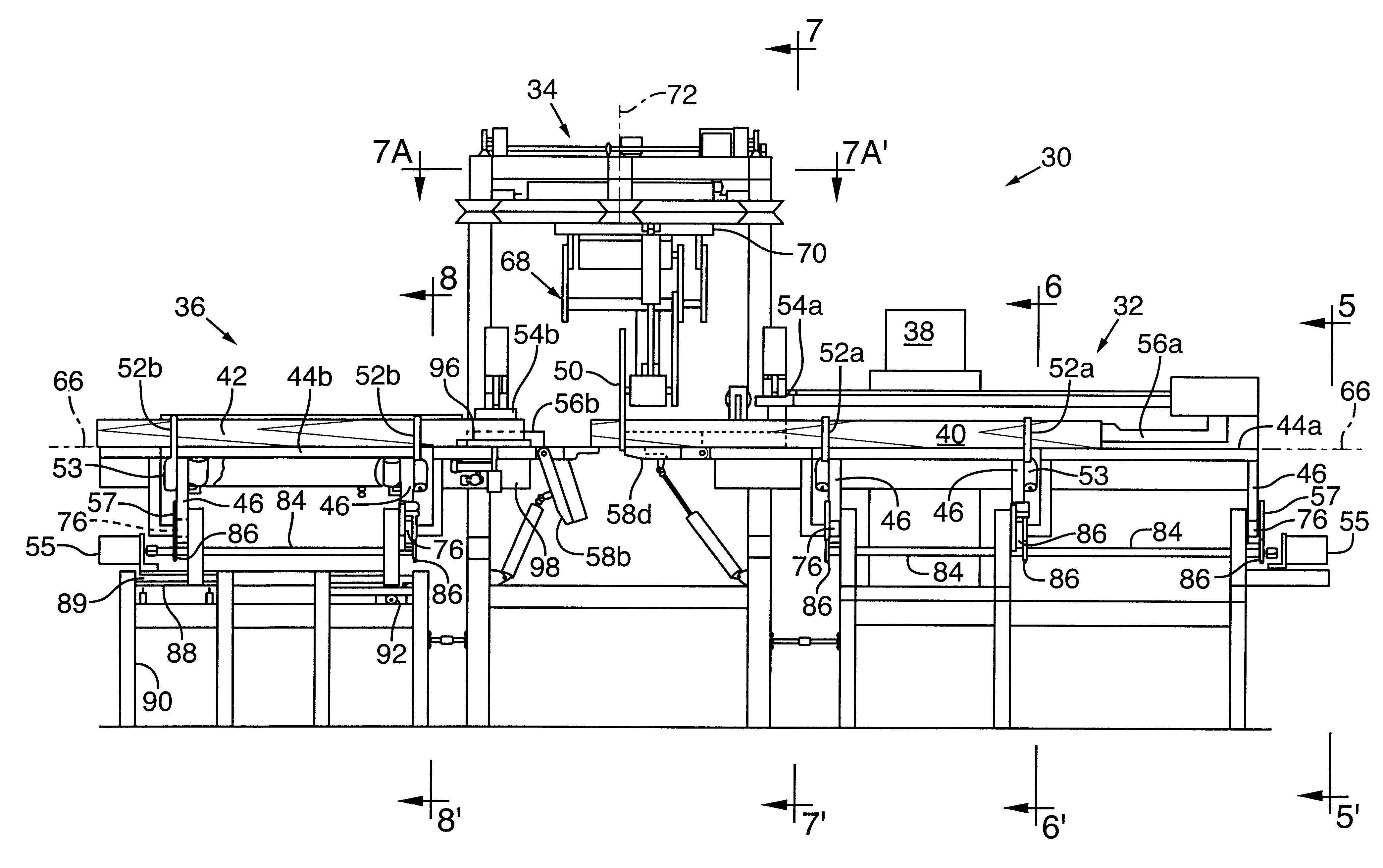

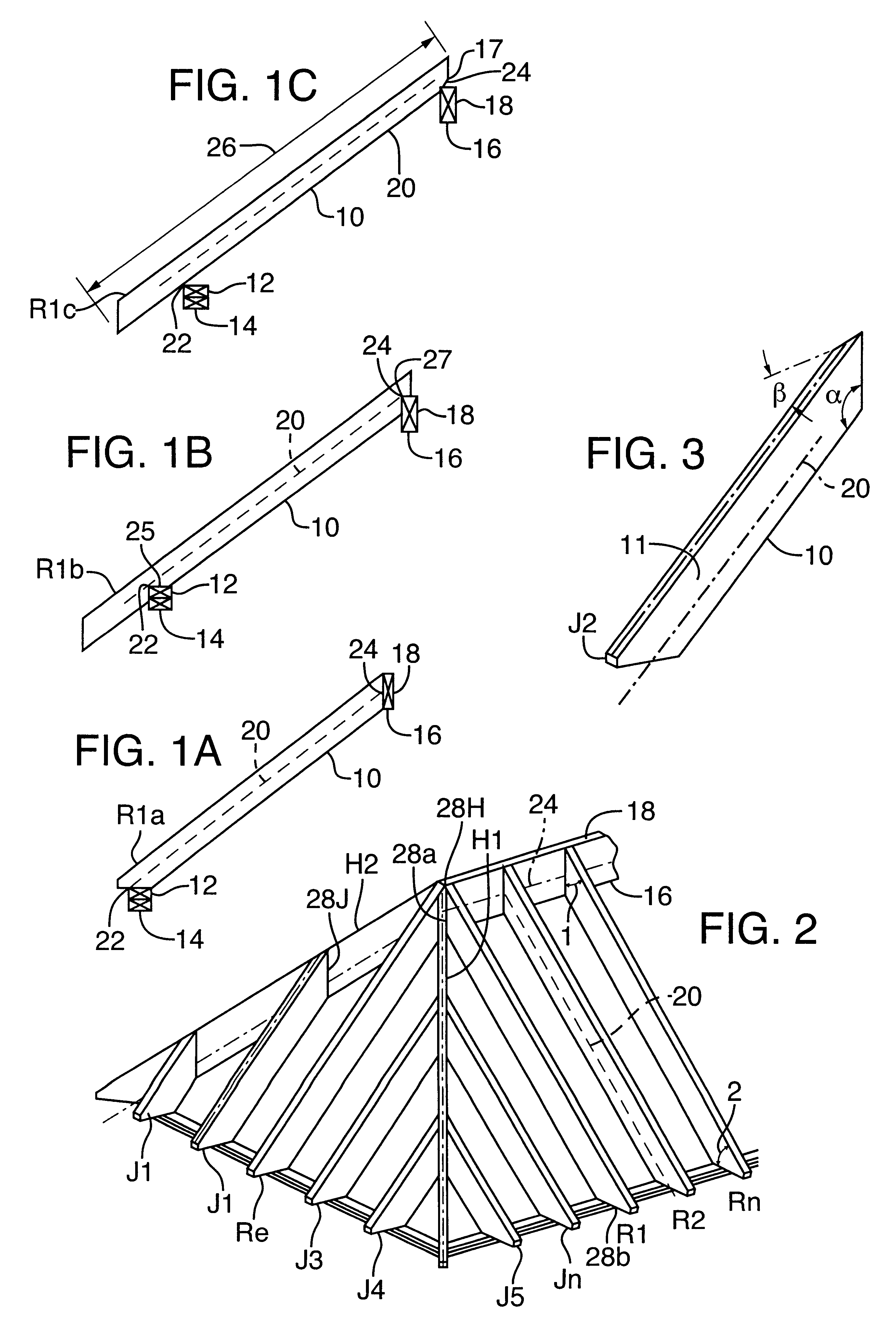

Tiltable infeed and outfeed saw table

InactiveUS6212983B1Precise positioningMinimum elapsed timeMetal sawing devicesAutomatic control devicesCircular sawEngineering

An apparatus for sequentially and automatically cutting a piece of dimension lumber at a number of predetermined angles to produce a building component, such as a rafter or truss web or chord, with composite or compound angles, is disclosed. The apparatus includes infeed and outfeed tables tiltable about a longitudinal axis and equipped with fences along which a workpiece moves longitudinally via moving devices. Clamps hold the workpiece at different positions relative to a cutting station during a cutting operation. A cutter, which for example includes a circular saw blade, is mounted for a positioning movement about a vertical axis at the cutting station, as well as for vertical movement to cut a workpiece at a predetermined composite or compound angle. The entire lumber cutting process at both ends of the workpiece, including lumber movement on the table past the cutting station, angular cutter and table adjustment, cutter movement, and clamping and unclamping, is under the control of a programmable computer operating in conjunction with appropriate sensors and pulse counters on the equipment.

Owner:STODDARD H PYLE REVOCABLE LIVING TRUST DATED JULY 17 1991

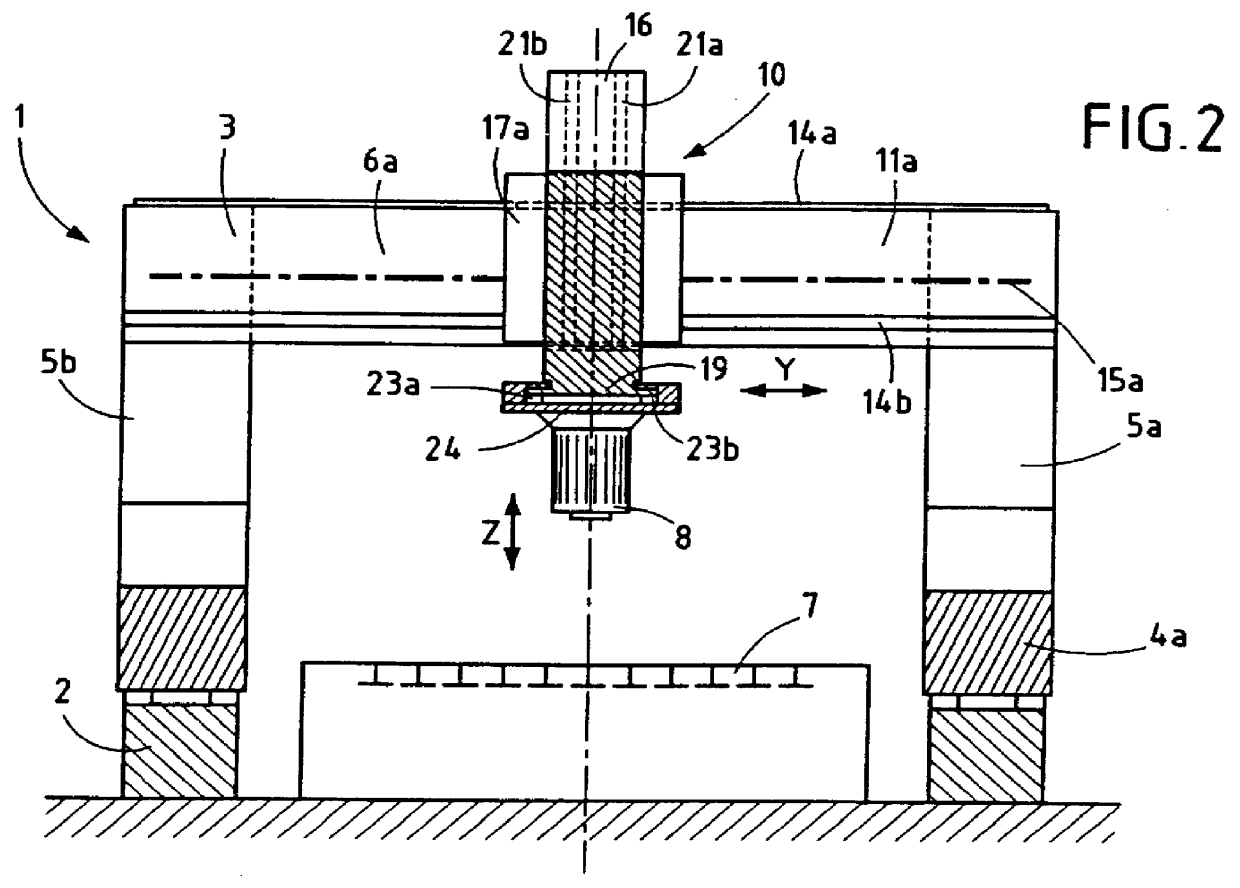

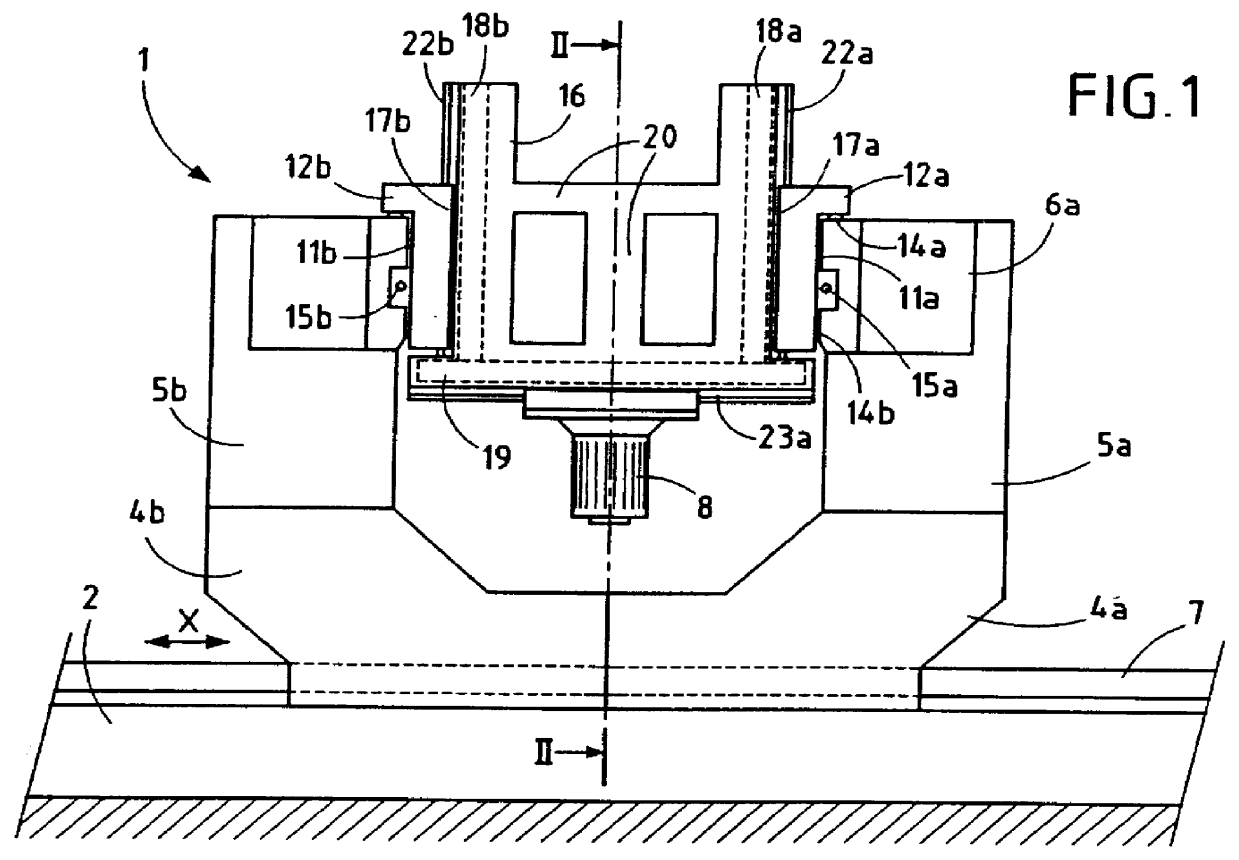

Machine tool having a gantry and a vertical spindle

InactiveUS6068431AEasy to remedy deformationReduce the total massWooden sticks manufactureMulti-purpose machinesNumerical controlEngineering

The invention relates to a machine tool having a gantry that is movable along an X axis and having a vertical spindle supported by the cross-member of the gantry. The cross-member comprises two beams that are spaced apart in the X axis direction and that have facing inside faces. Two carriages are mounted to slide on said facing faces, on opposite sides of a vertically movable cursor-carrier. The tool-carrier spindle is carried by a cursor mounted to slide on the bottom face of the cursor-carrier and movable along the X axis. Movements of the carriages, of the cursor-carrier and of cursor are under numerical control. The tool-carrier spindle can move in the X axis direction without it being necessary to move the gantry.

Owner:HELIS

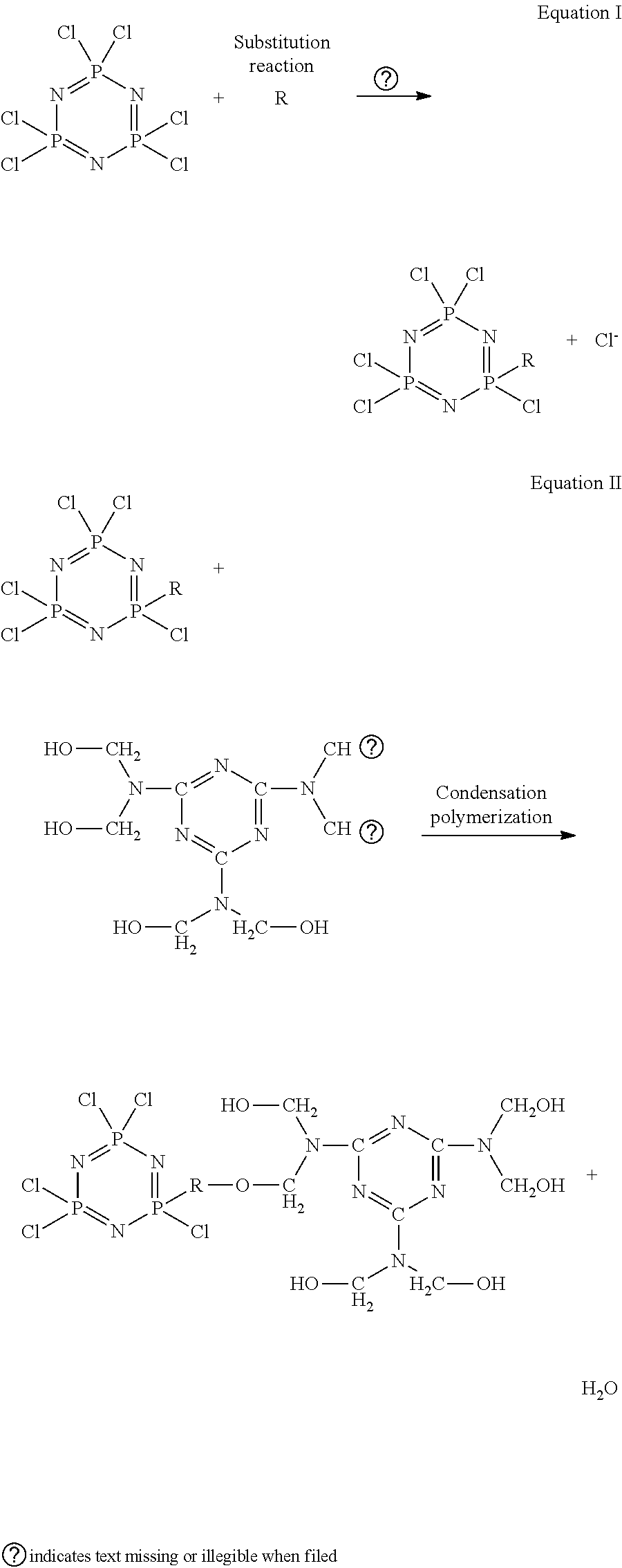

Method For Preparing Functional Engineered Wood

ActiveUS20170239836A1Improve permeabilityWell mixedLiquid surface applicatorsPressure wood treatmentFire retardantEngineered wood

The present invention relates to furniture panels, and more particularly, to a method for preparing functional engineered wood. It includes the following steps: make veneer blanks by rotary cutting or splicing, and cut the veneer blanks into desired dimensions to obtain veneers A. Soak the veneers A in a ternary mixed solution of a biomass nanocellulose solubilizer, a fire retardant and an acid dye for toughening, fire retardation and dyeing to obtain veneers B. Add a formaldehyde decomposing powder into a modified MUF adhesive, mix them up, coat the veneers B with the mixture to obtain veneers C. Assemble and cold-press the veneers C to obtain flitches D, and saw the flitches D into desired patterns and dimensions to obtain finished products.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

Improved planed thin bamboo and productive method thereof

The present invention relates to an improved planed and cut thin bamboo and its production method. Said invention method includes the following steps: pretreating natural colour or carbonized bamboo sheets, applying glue, pressing, overlapping to obtain bamboo block, pressing and impregnating the integrated bamboo block, drying, applying glue, pressing to obtain bamboo squared timber, then planing and cutting said bamboo squared timber, drying so as to obtain the invented bamboo thin sheet whose thickness is 0.15-2.00 mm, then applying glue layer and technological layer on the thin bamboo sheet.

Owner:ZHEJIANG FORESTRY UNIVERSITY

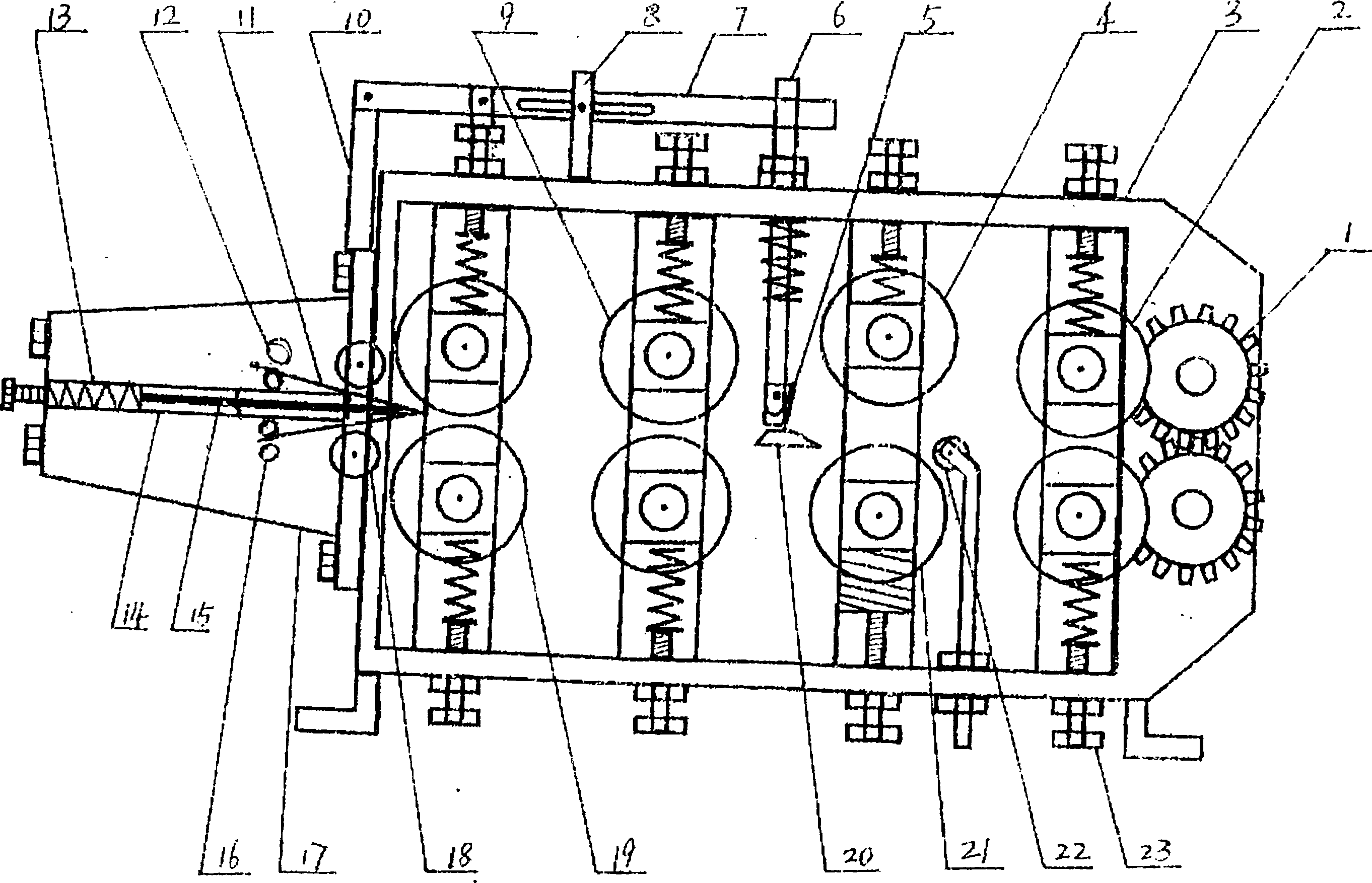

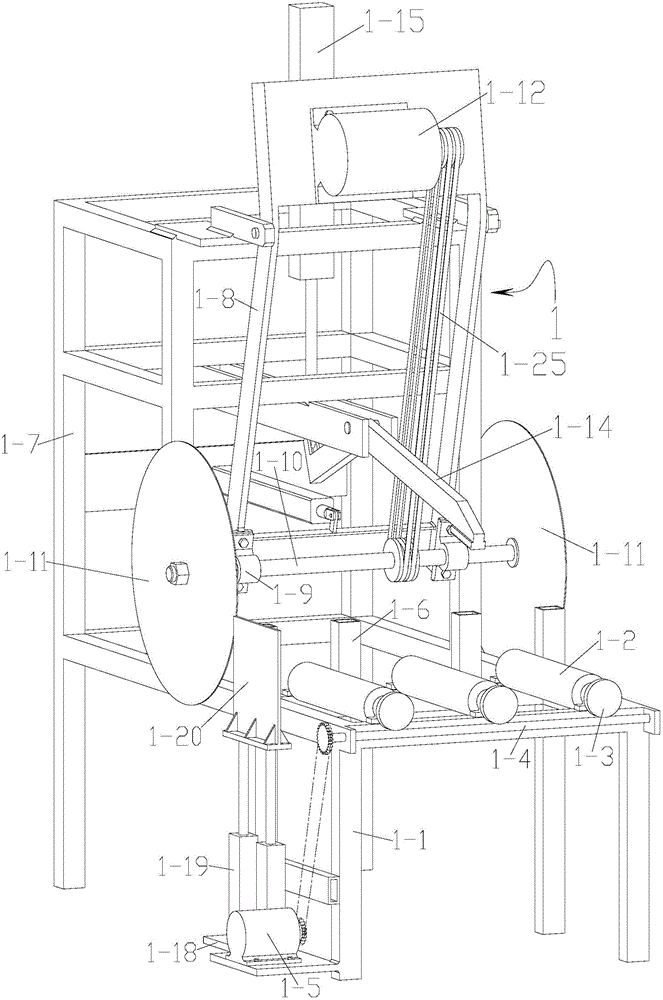

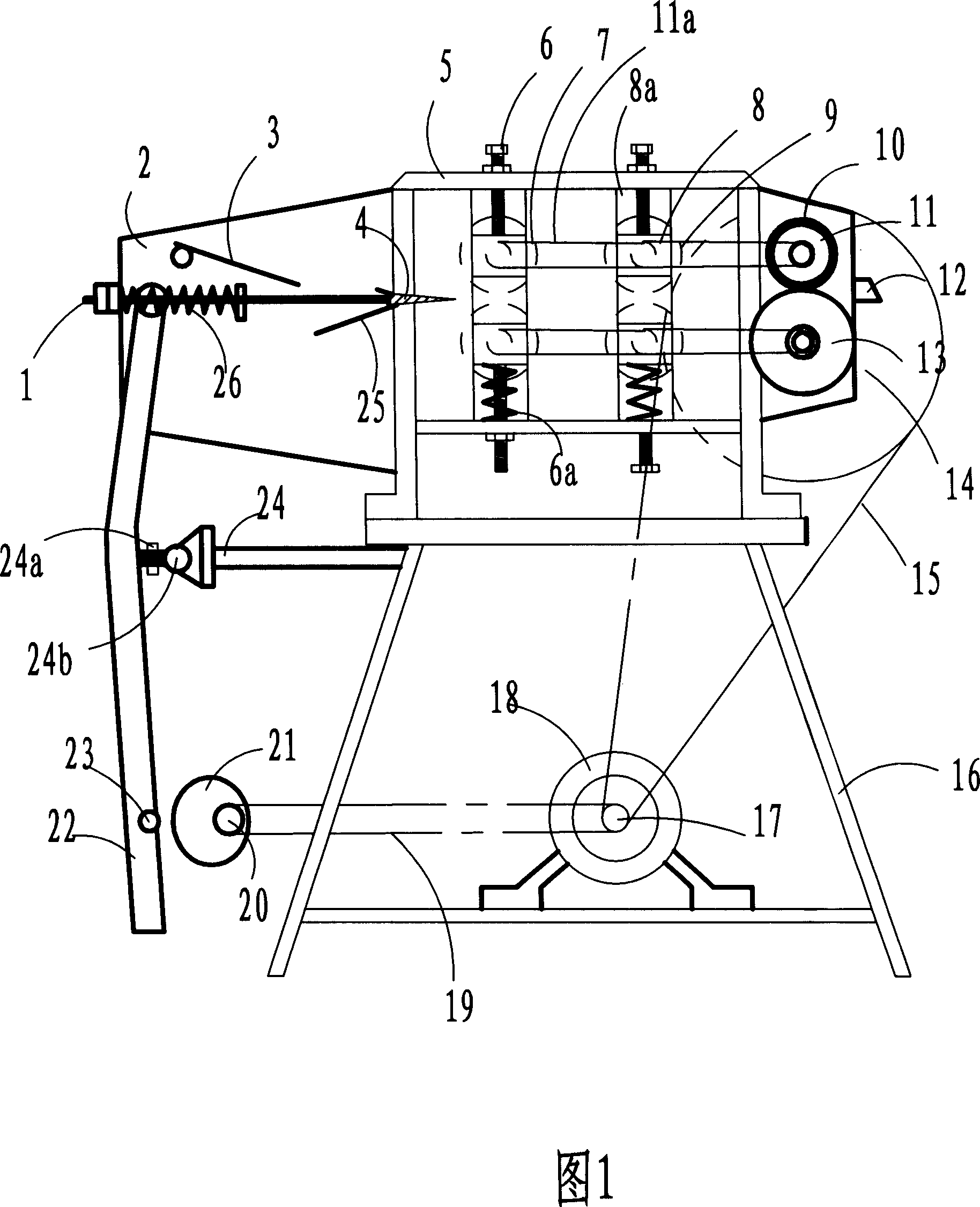

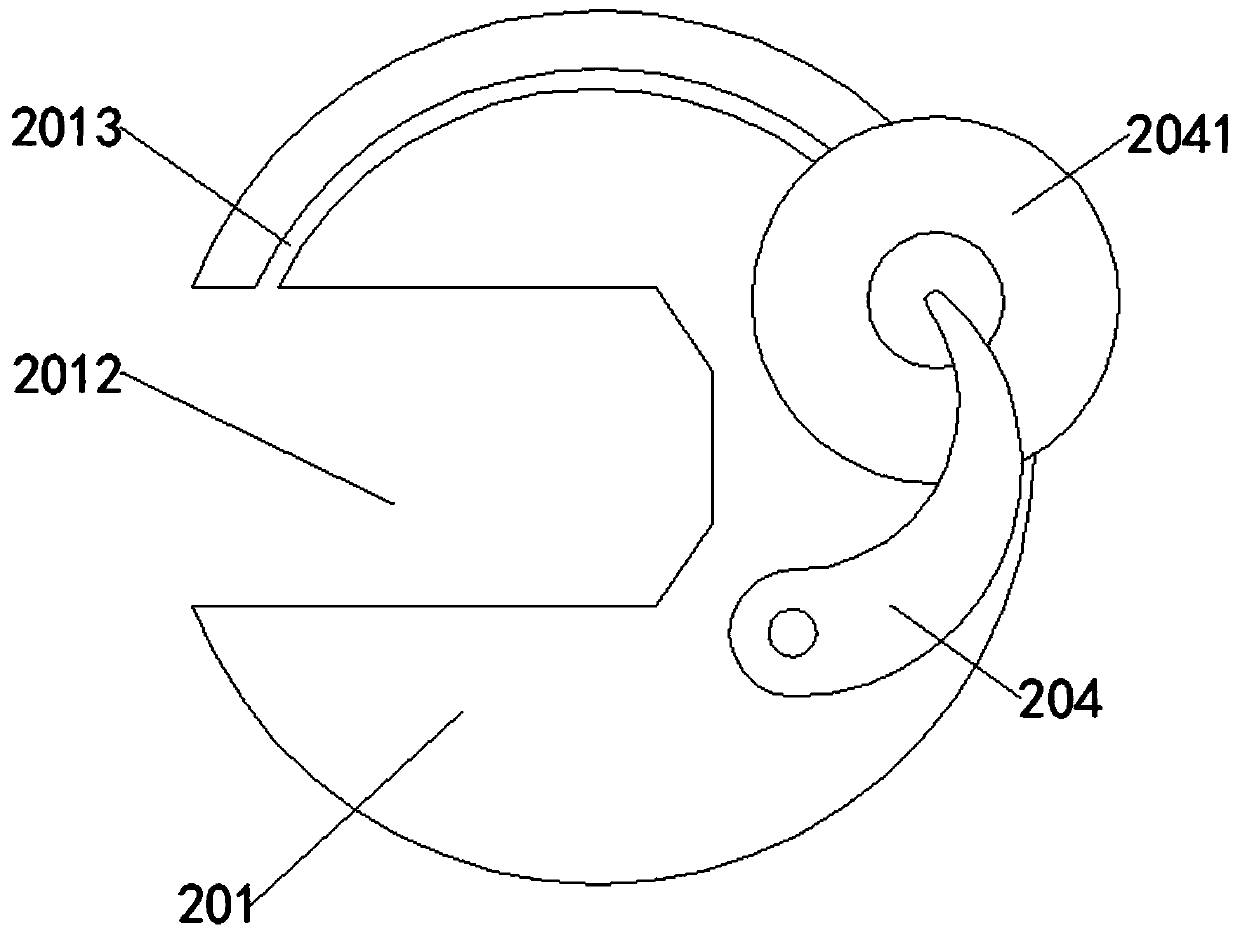

Novel numerical control bamboo splitting machine

ActiveCN102717414AAchieve broken bambooRealize empty back movementWood splittingVeneer manufactureNumerical controlMeasurement device

The invention relates to a novel numerical control bamboo splitting machine, which includes a lathe bed guide rail, a rotation mechanism, a driving chain, a bamboo tube loading mechanism, a bamboo tube diameter measurement device, a stepping motor, a cutter combination assembly, a bamboo centring combination assembly, a transmission system, a swinging mechanism, a push plate combination assembly, and a sash weight, and is characterized in that a push plate combination component is arranged on tool body guide rails; a driving chain for driving the push plate combination component to move back and forth is arranged between the two guide rails; a rotational cutter disc combination component is arranged at the front ends of the tool body guide rails; a bamboo tube loading mechanism is arranged on right sides of the tool body guide rails; two movable bamboo tube centering combination components are arranged on the upper left sides of the tool body guide rails; and when the push plate combination component does backlash motion, the bamboo tube loading mechanism conveys a bamboo tube into a measuring device to measure the diameter of a small head of the bamboo tube, the bamboo tube enters two V-shaped bearings, and combination cutters which are matched are rotated to the center of the bamboo tube and aligned; and a transmission system is reversed, and the push plate combination component pushes the bamboo tube to the combination cutters, so that the bamboo tube is split into bamboo chips. Compared with the conventional bamboo splitting machine, the numerical control bamboo splitting machine has the advantages that automatic loading, automatic tool changing and automatic centering of the bamboo tube are realized, one operator is reduced, the labor strength is lowered, the width error of the split bamboo clips is reduced, and the utilization rate of bamboo woods is improved.

Owner:沛县汉腾建设发展有限公司

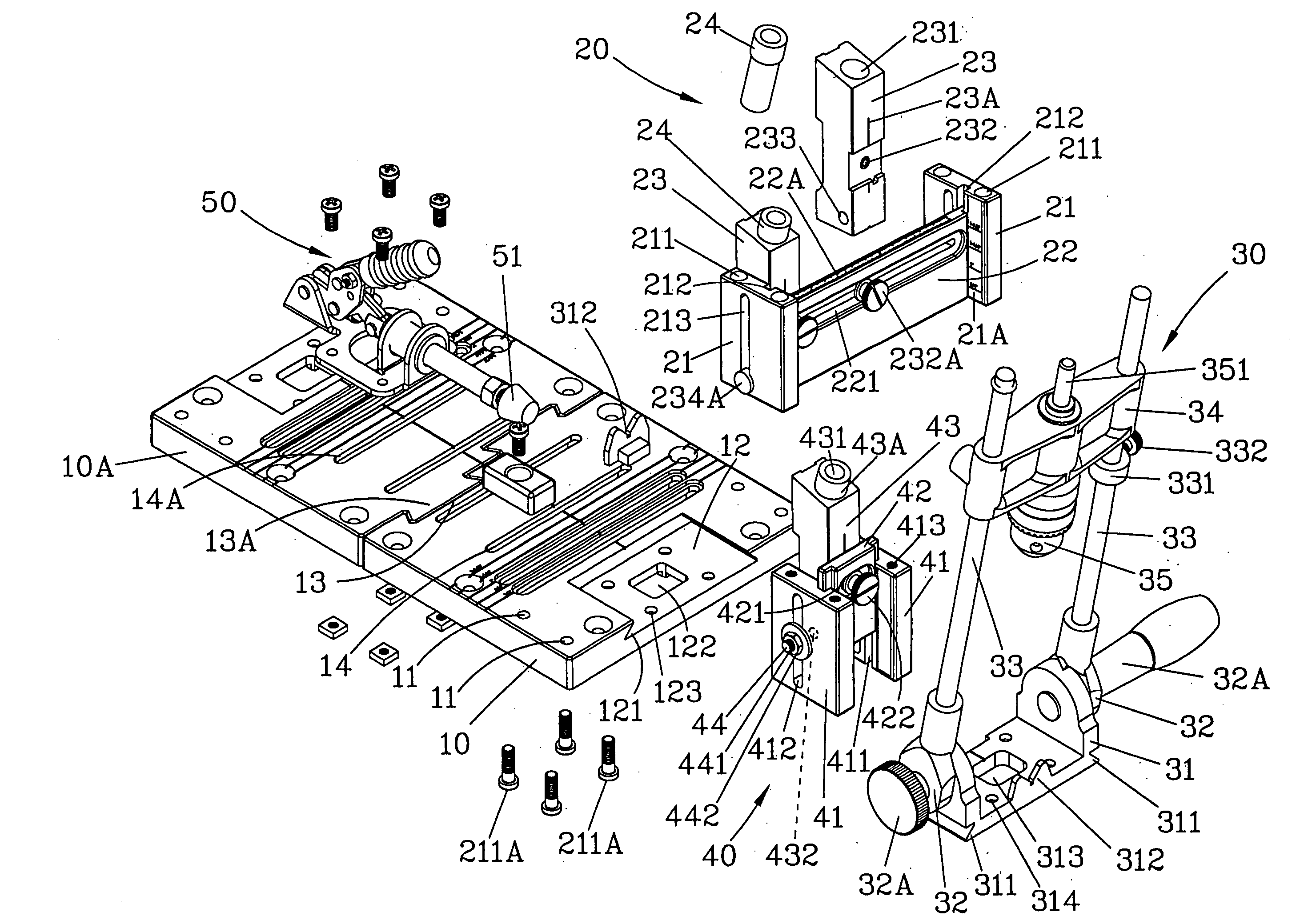

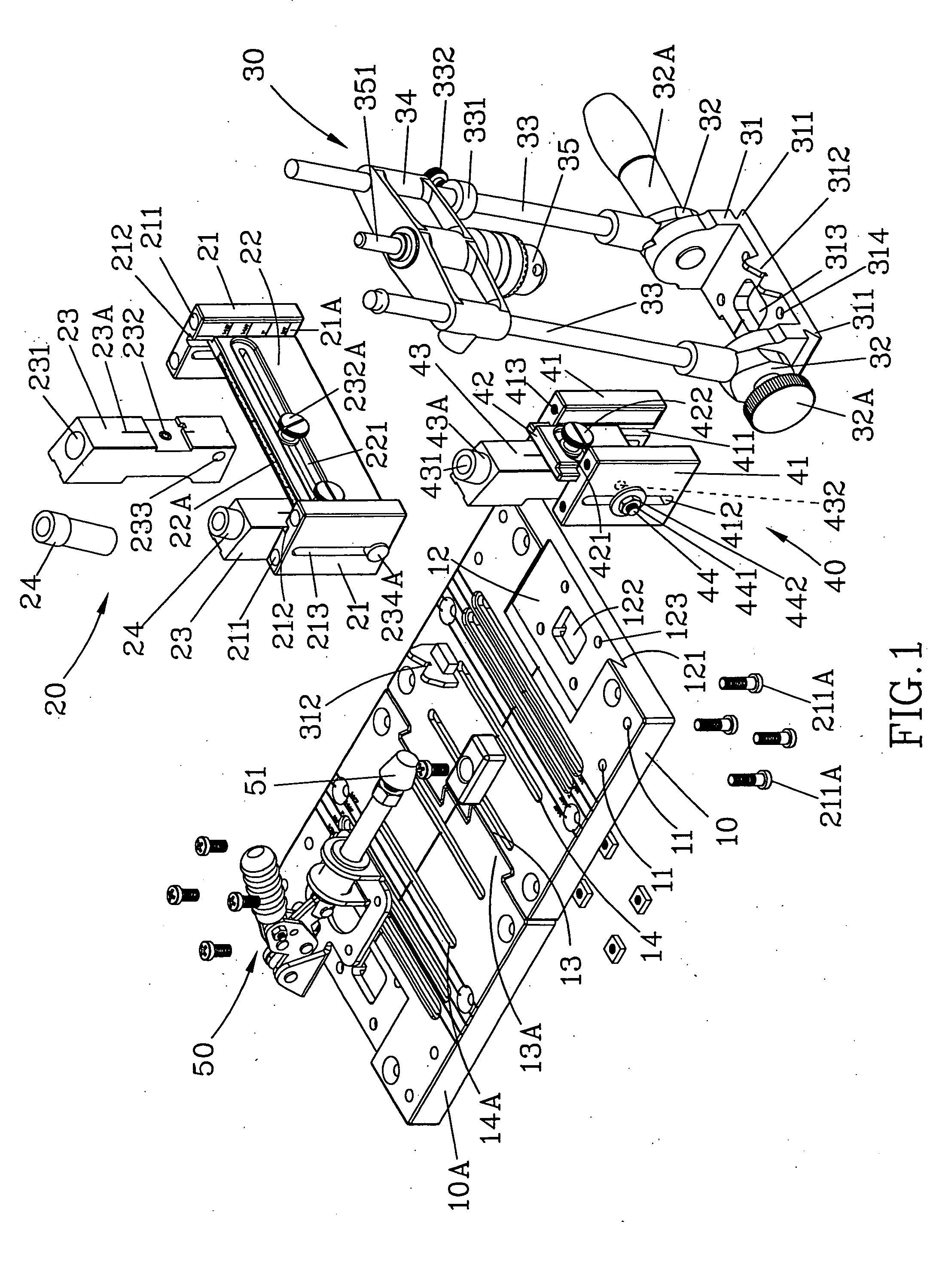

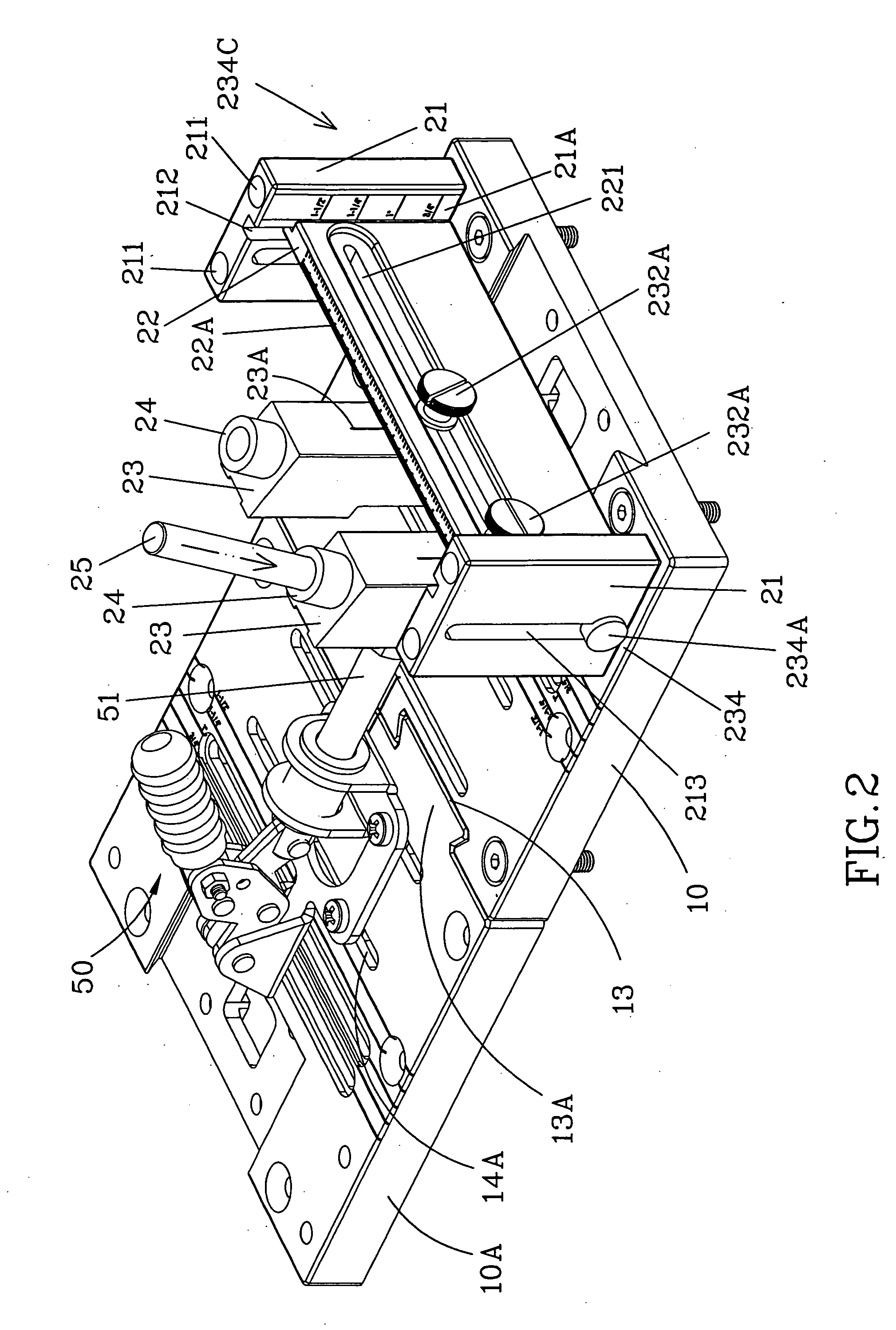

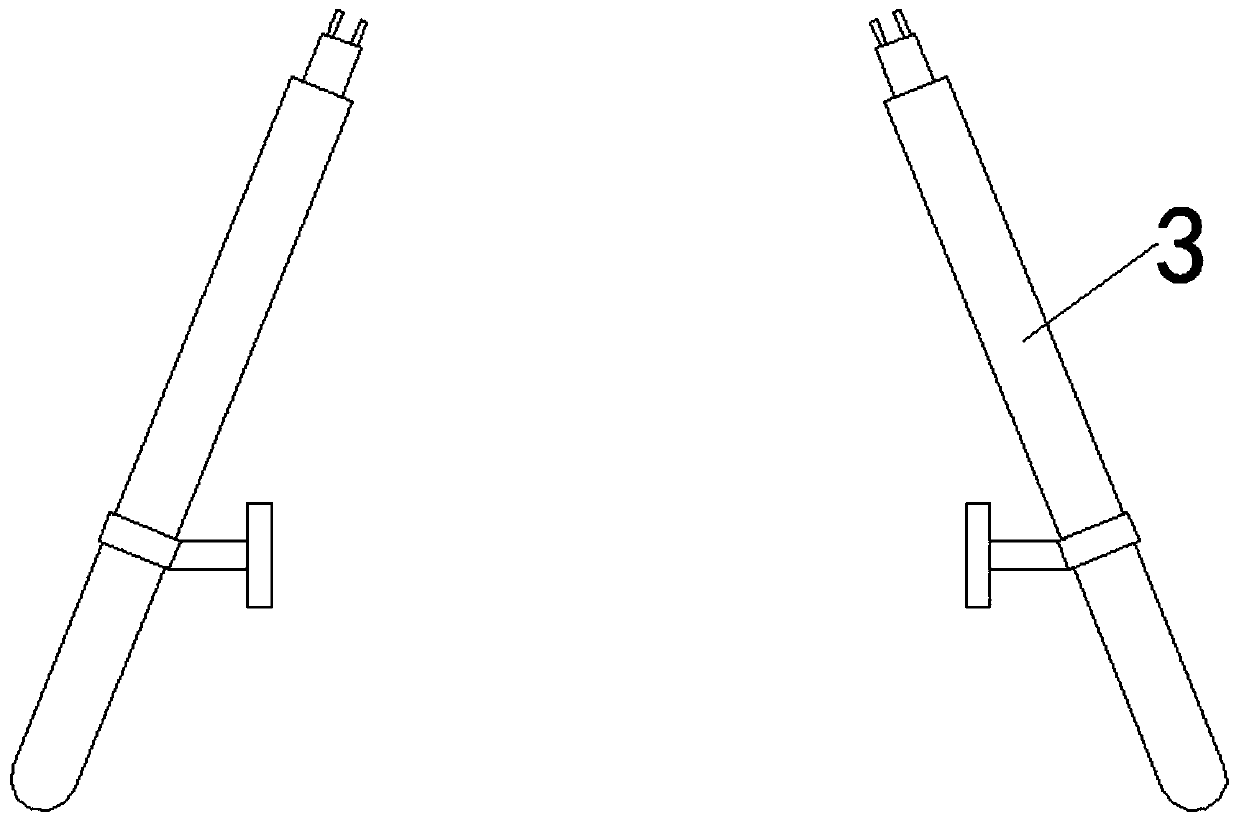

Holding fixture for all types of drilling concerning woodworking

InactiveUS20080099101A1Easy to adjustWooden sticks manufactureMulti-purpose machinesEngineeringFront edge

The invention proposes a holding fixture for use in all types of drilling concerning woodworking, comprised of at least one flat worktable having a set of dovetailing portions at the rear end for two flat worktables to dock together horizontally; a longitude-transverse adjustment module vertically arranged on the flat worktable, which secures the guide members for guiding the adjustments of height or latitude during drilling; an angle adjustment module being aligned at the front edge of said flat worktable, which guides the drilling operation on workpieces attached thereof; a height adjustment module vertically arranged at the front edge of flat worktable; a clamp member being secured on the flat worktable for securing workpieces to be worked on; as a result, the holding fixture is suitable for use in guiding the drilling operation on workpiece of all shapes and sizes.

Owner:CHIANG VANCE

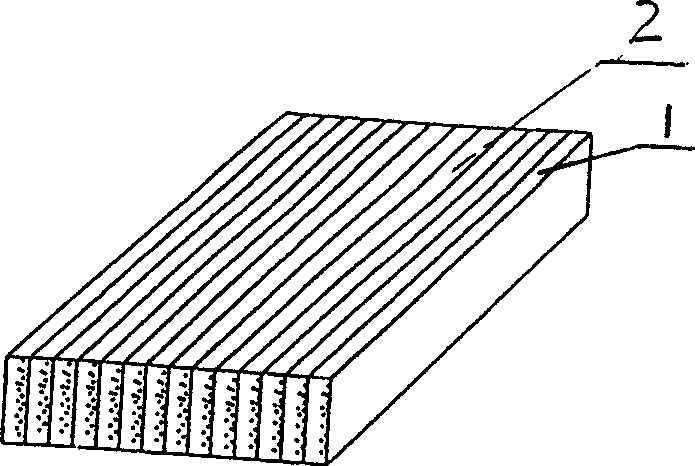

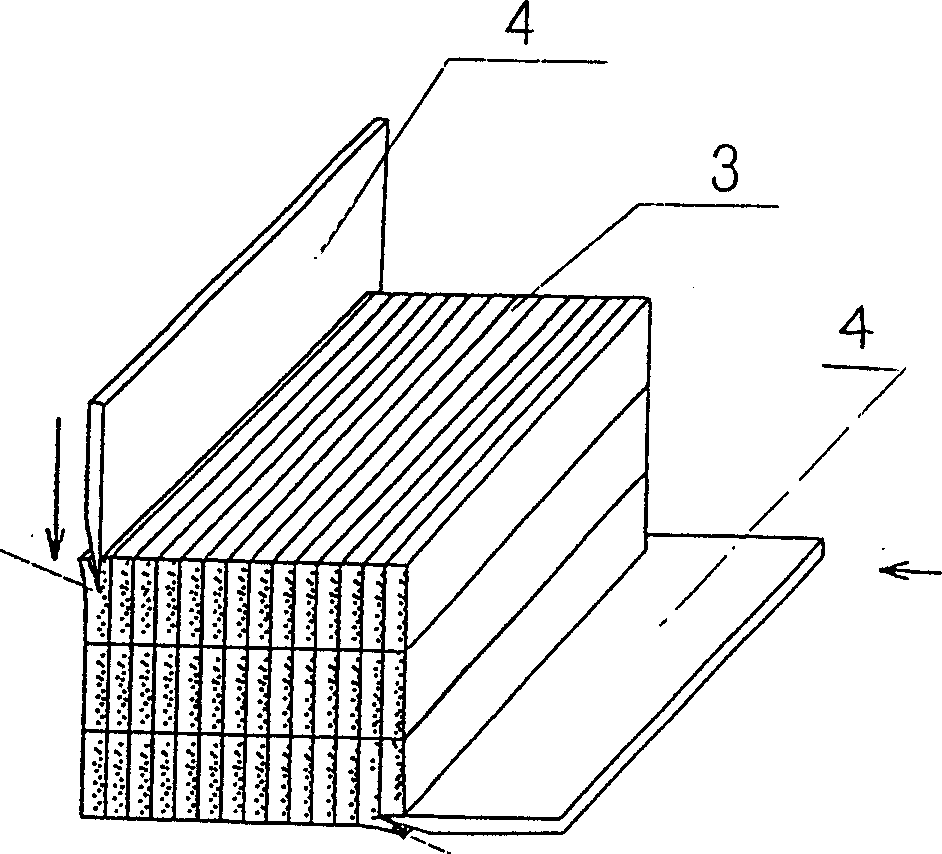

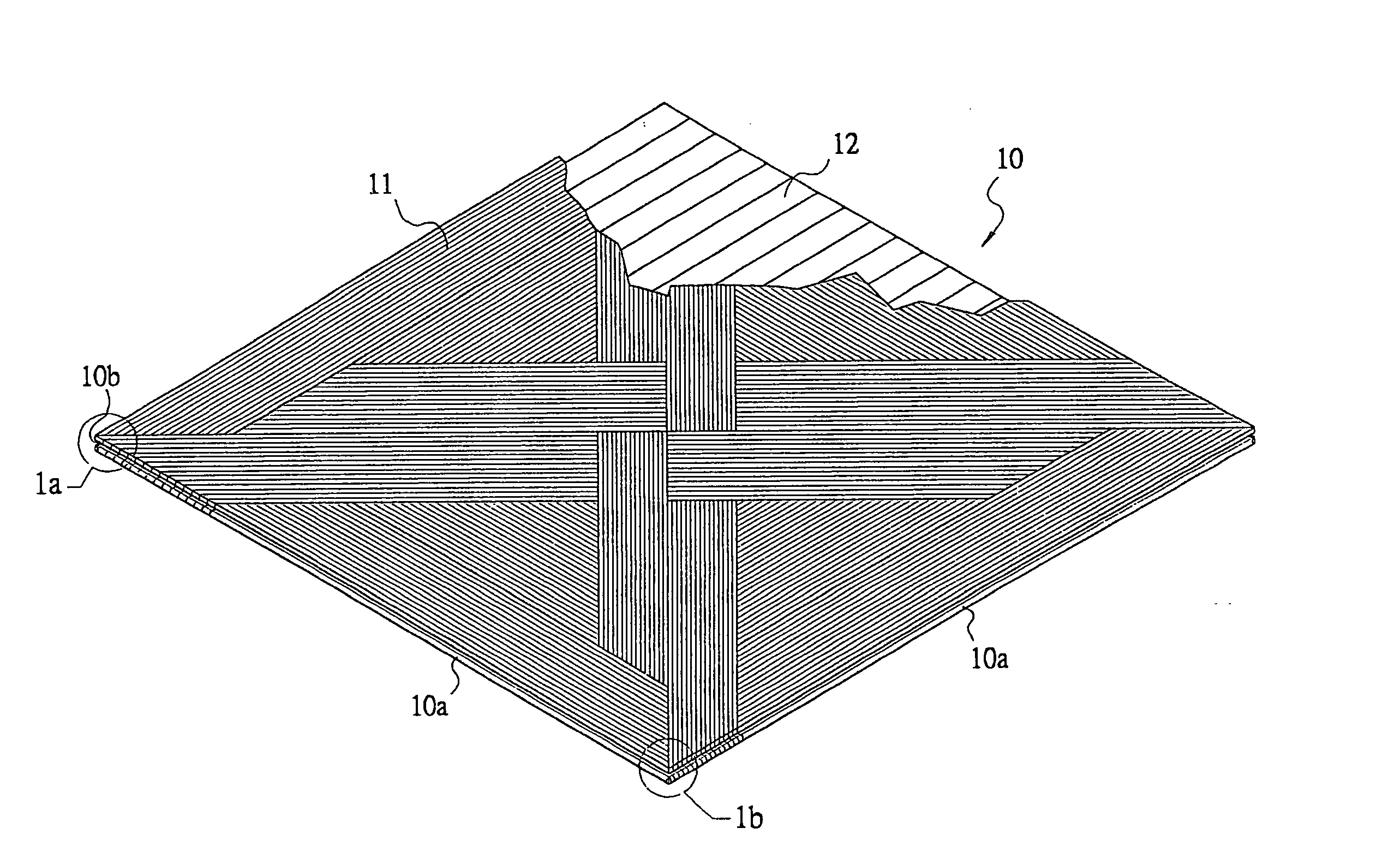

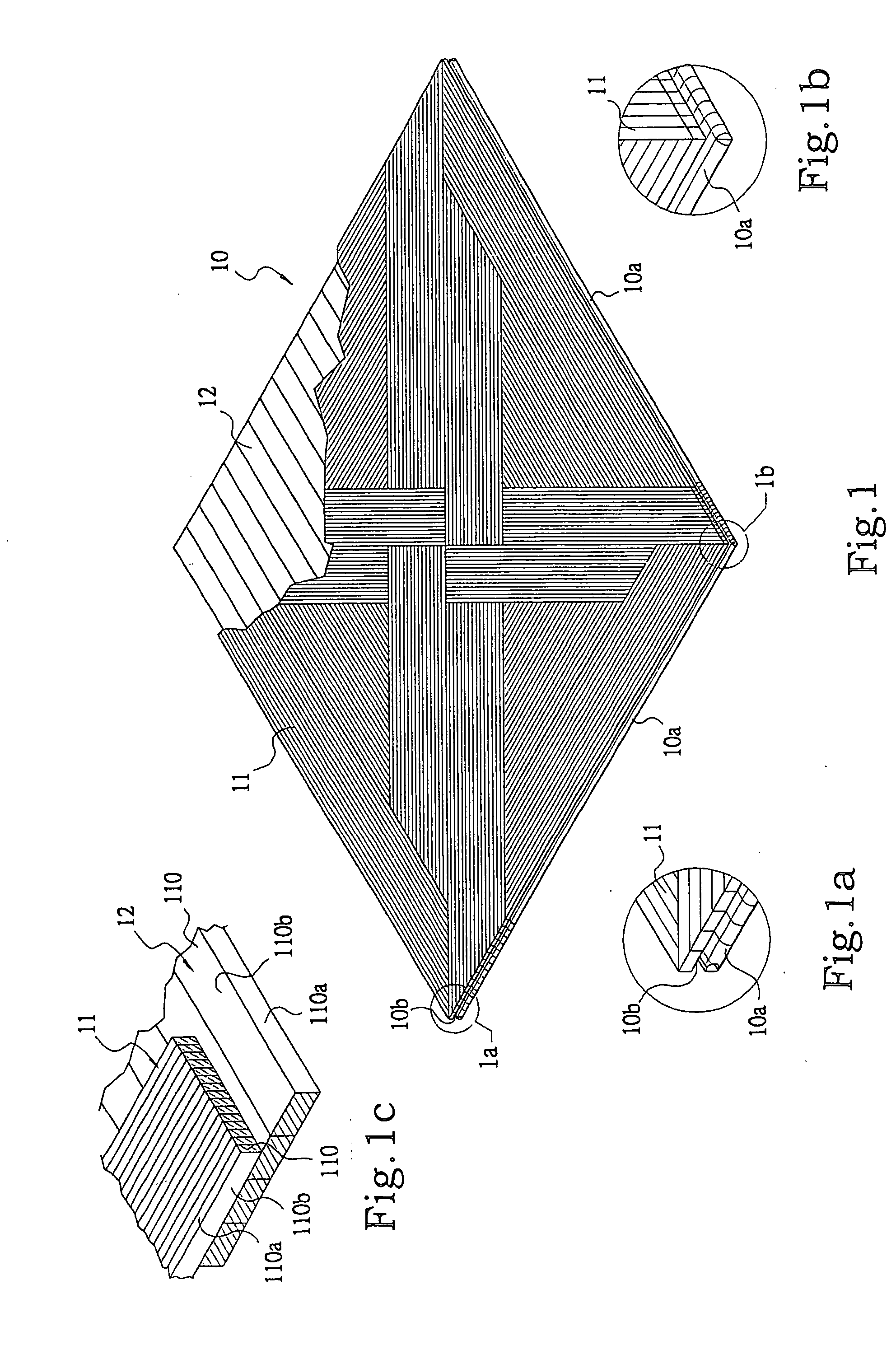

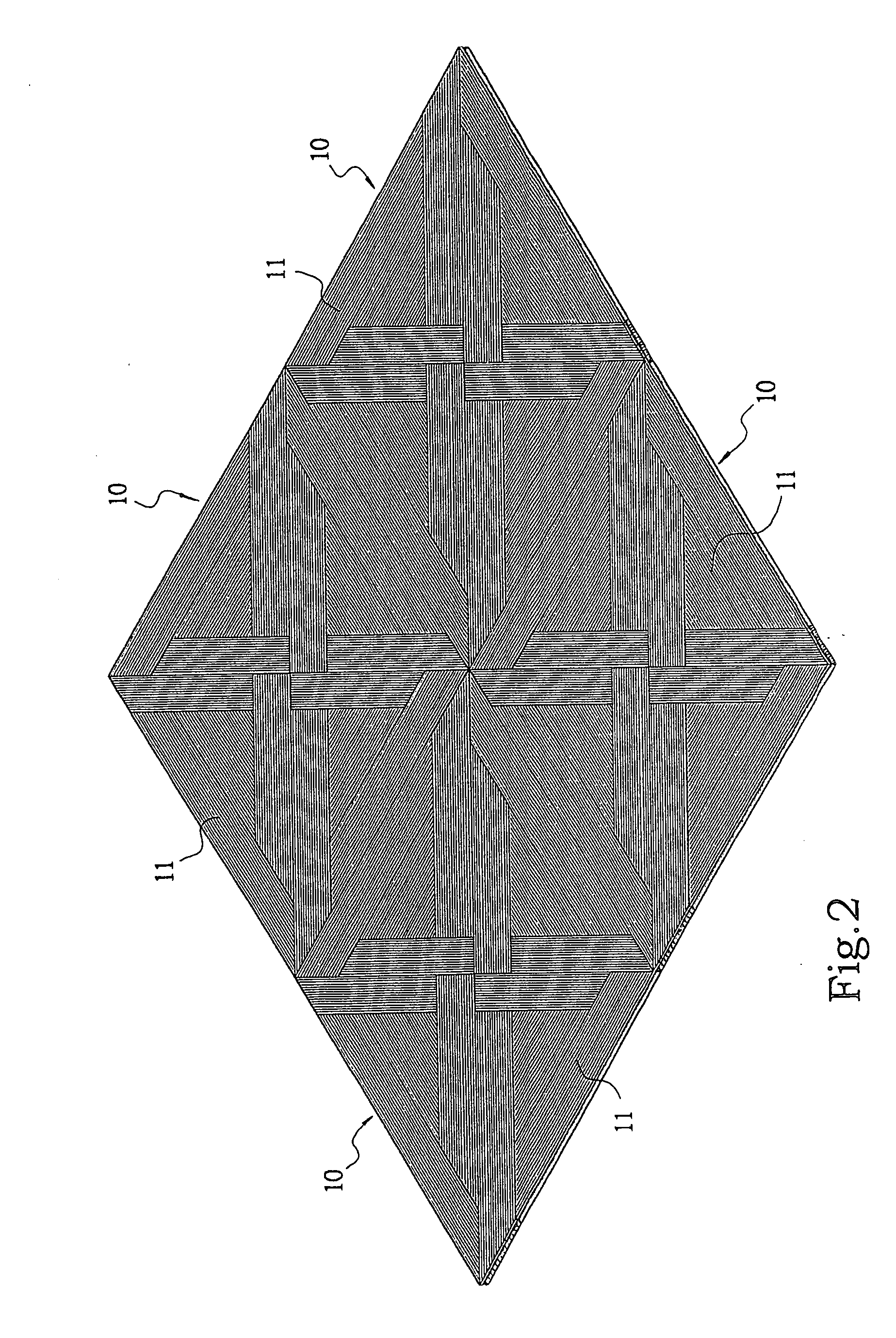

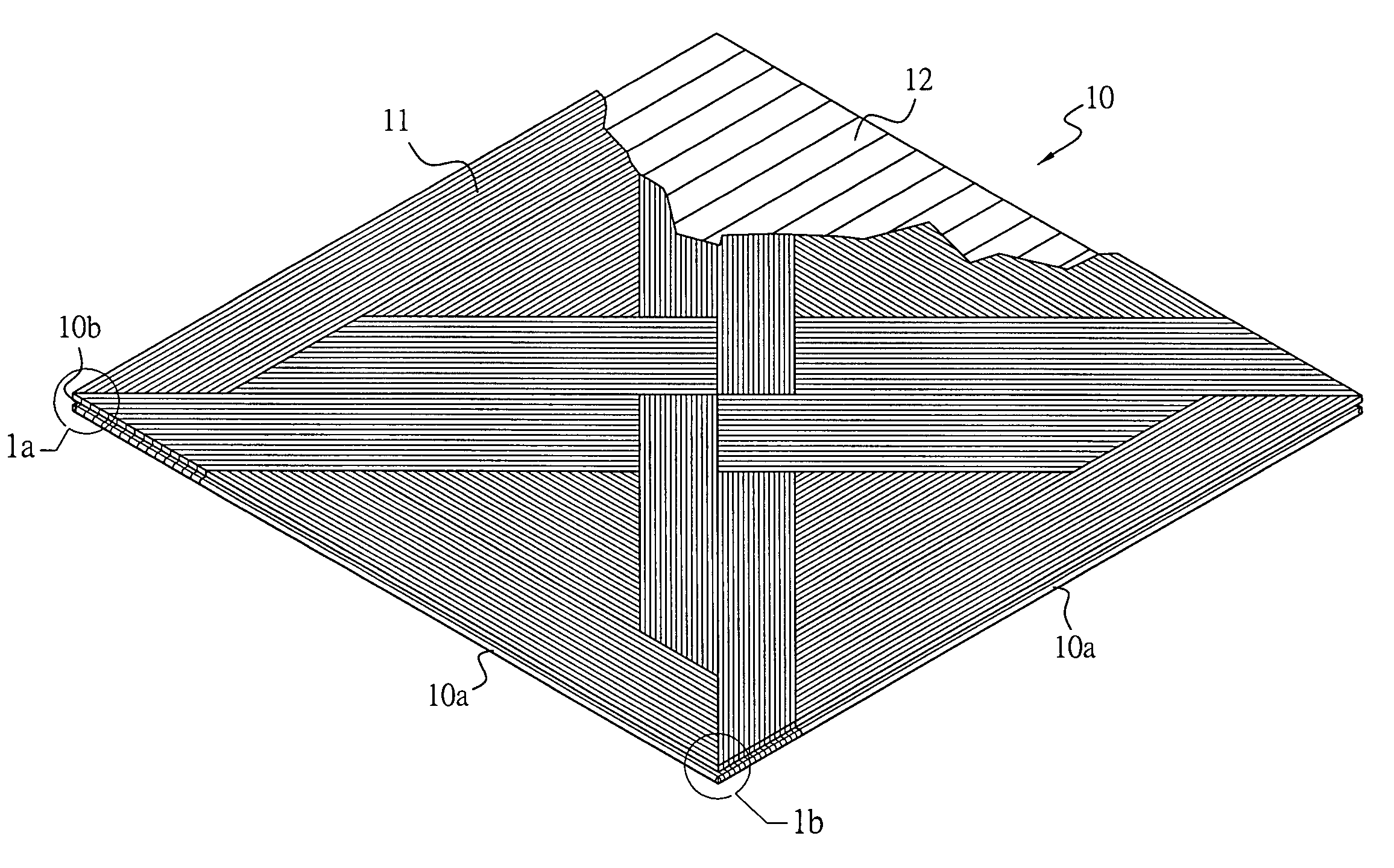

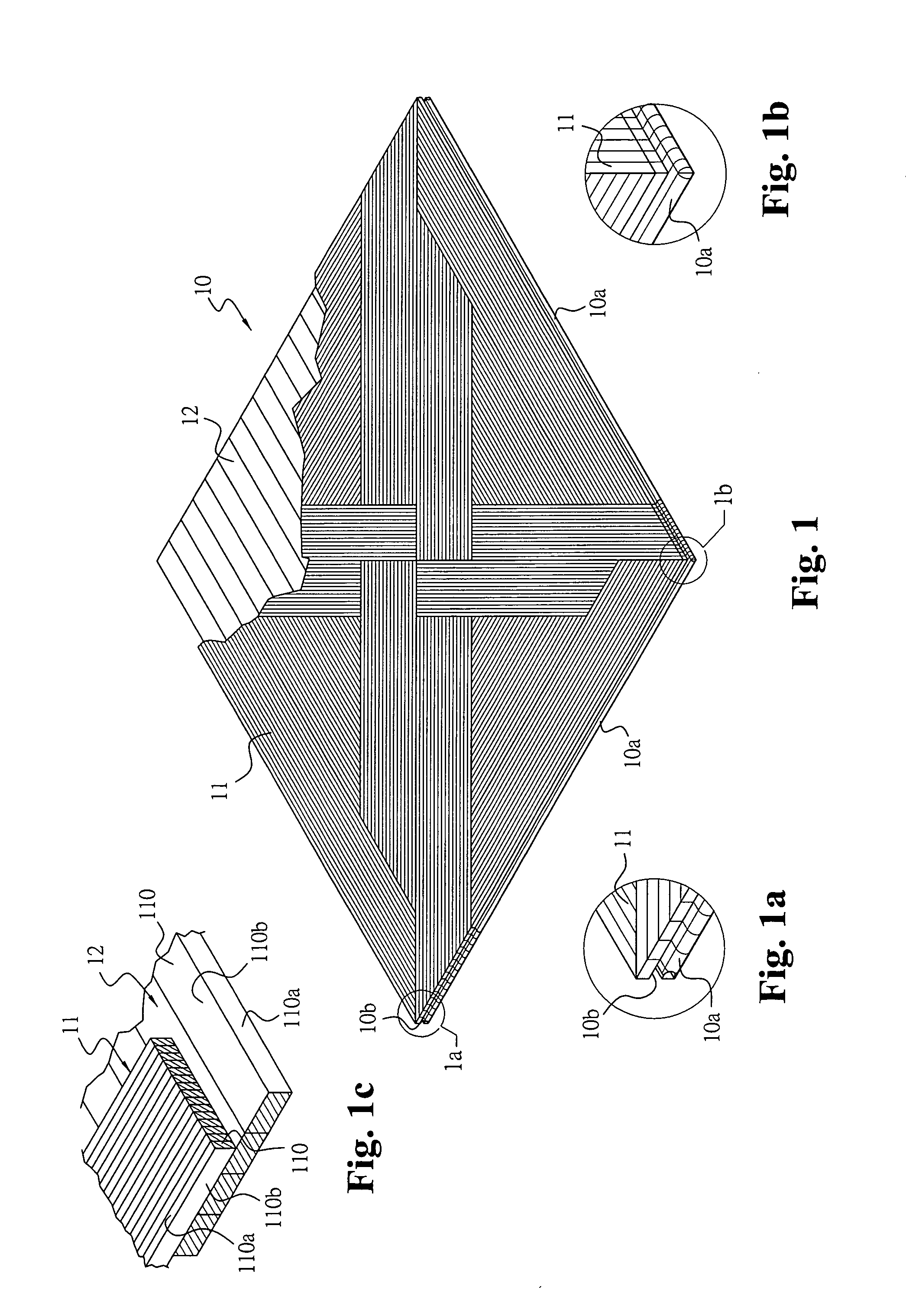

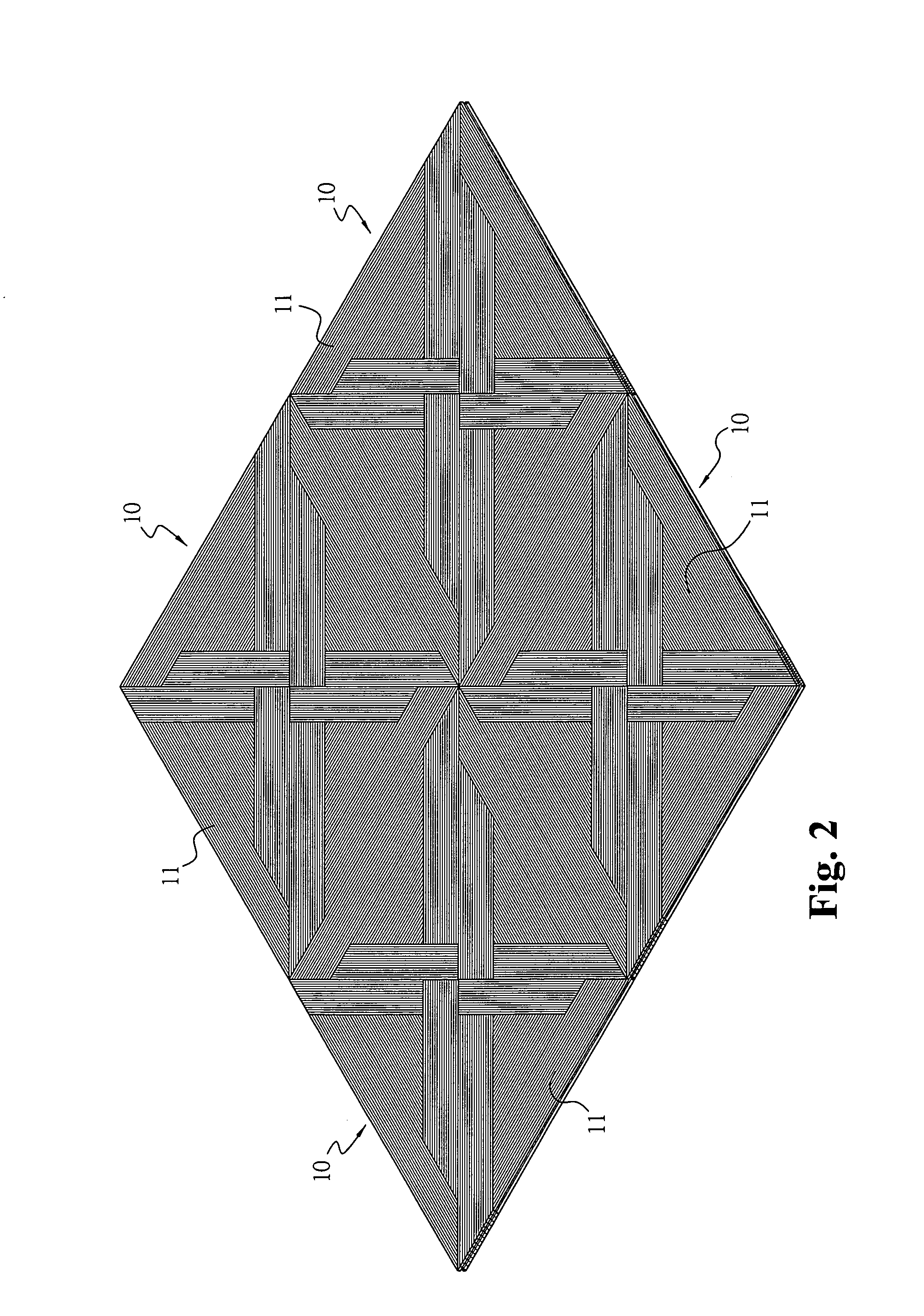

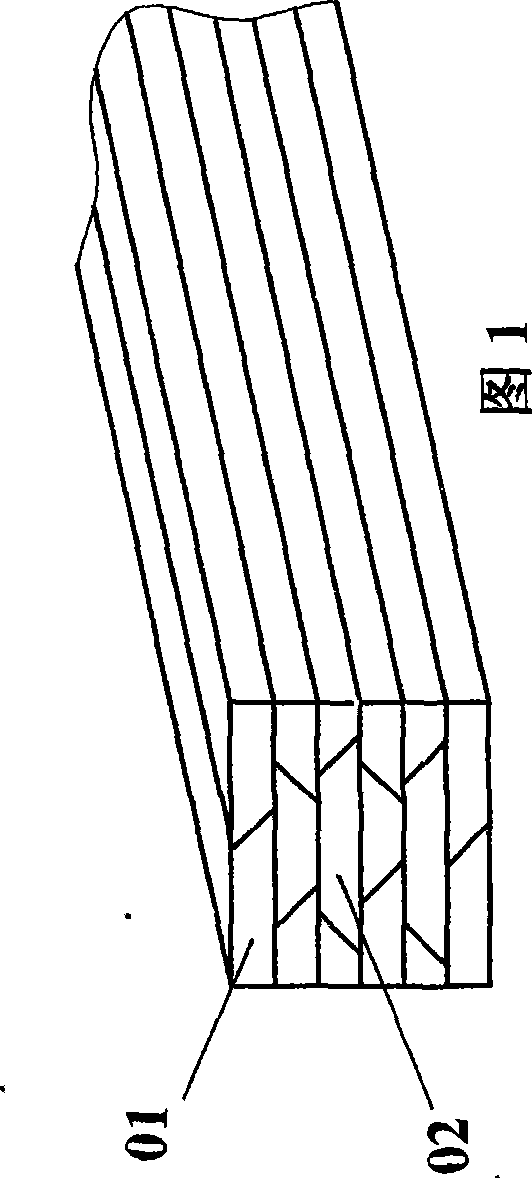

Bamboo mat board and method for producing the same

ActiveUS20050161116A1Increase stiffnessHigh economic valueCane mechanical workingWood veneer joiningSurface layerEngineering

A bamboo mat board element with a double-layered construction, a constant dimension, each of the elements is formed with a projecting tenon at each of two adjacent sides, respectively, and a concave mortise at each of the other two adjacent sides, respectively, for inter-tenoning the elements of the mat board, in which a surface layer of the mat board is obtained by matting a plurality of mat board stuffs having different orientations, shapes, and sizes, while each of the mat board stuffs is obtained by matting a plurality of lumbers having a parallel orientation, respectively, to form a plurality of patterns having parallel stripes by specially matting at the longitudinal section thickness of the lumbers. A method for producing the bamboo mat board at least comprises steps as follows: cutting step, boiling for blanching step, drying step, rough shaving, bottom layer pre-forming step, adhesive applying and pressing step, pattern selecting step, matting step, and refined shaving, etc. The sandwich mat board is then formed by pressing.

Owner:CHANG AO YU

Automatic bamboo breaking machine

ActiveCN107150393APrecise deliveryAccurate control of coordinated operationWood splittingBio-packagingControl systemControl engineering

The invention relates to an automatic bamboo breaking machine. The automatic bamboo breaking machine comprises a feeding device, a clamping and positioning device, a bamboo breaking pushing disk device, a tool rotating disk device, an output device and a control system. The feeding device and the clamping and positioning device are located on the two sides of one end of the bamboo breaking pushing disk device. The tool rotating disk device is located on the front part of the end, close to the feeding device and the clamping and positioning device, of the bamboo breaking pushing disk device, and the output device is located on the tail part of the tool rotating disk device. The control system controls the feeding device, the clamping and positioning device, the bamboo breaking pushing disk device, the tool rotating disk device and the output device to run in a cooperative manner. The automatic bamboo breaking machine has the beneficial effects that the bamboo breaking machine can accurately control cooperative running of the devices, a bamboo tube is conveyed and positioned reliably, the bamboo tube can be accurately cut into bamboo canes, the finally cut bamboo canes can be conveyed out, the automation degree is relatively high, and the production efficiency is improved.

Owner:GUANGXI NORMAL UNIV

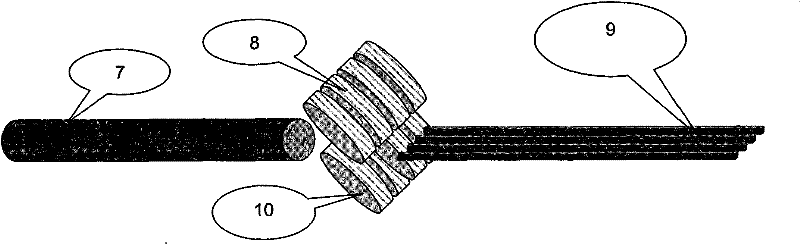

New type thin bamboo strip splitting machine

InactiveCN1785619AImprove quality requirementsControl uniformityCane mechanical workingVeneer manufactureMechanical engineering

A bamboo strip making machine is composed of plate-type machine frame, feeding gears, bamboo splitting plate, spring and regulating screw bolt, blade, movable rod, blade supporter, and bamboo strip driving gears. It features that the wheel attached to planer, green joint remover, auxiliary unit and operation regulator are additionally used.

Owner:周云龙

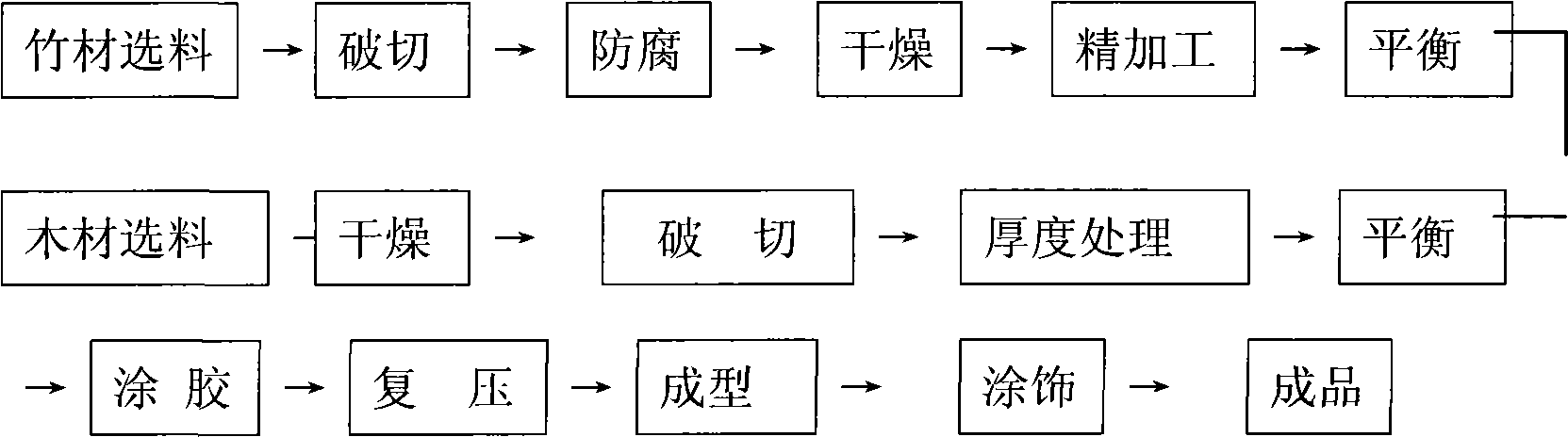

Preparation method of environmental protection type solid-wood composite floor

InactiveCN101396839ATake advantage ofReduce pollutionOther plywood/veneer working apparatusWood treatment detailsSolid woodEngineering

The invention relates to a preparation method for an engineered flooring, in particular to a preparation method for an environment-friendly engineered flooring, belonging to the wood manufacturing industry. The invention aims at providing a preparation method for an environment-friendly engineered flooring which has strong non-deformability, high processing efficiency and can fully use resources, thus overcoming the deficiencies of the prior art. Due to the adoption of the technical program, the invention has the advantages of making full use of wood resources, improving labor efficiency and relieving the pollution of formaldehyde to the environment.

Owner:汤可新

Bamboo mat board and method for producing the same

ActiveUS7021346B2Increase stiffnessHigh economic valueCane mechanical workingWood veneer joiningSurface layerMechanical engineering

A bamboo mat board element with a double-layered construction, a constant dimension, each of the elements is formed with a projecting tenon at each of two adjacent sides, respectively, and a concave mortise at each of the other two adjacent sides, respectively, for inter-tenoning the elements of the mat board, in which a surface layer of the mat board is obtained by matting a plurality of mat board stuffs having different orientations, shapes, and sizes, while each of the mat board stuffs is obtained by matting a plurality of lumbers having a parallel orientation, respectively, to form a plurality of patterns having parallel stripes by specially matting at the longitudinal section thickness of the lumbers. A method for producing the bamboo mat board at least comprises steps as follows: cutting step, boiling for blanching step, drying step, rough shaving, bottom layer pre-forming step, adhesive applying and pressing step, pattern selecting step, matting step, and refined shaving, etc. The sandwich mat board is then formed by pressing.

Owner:CHANG AO YU

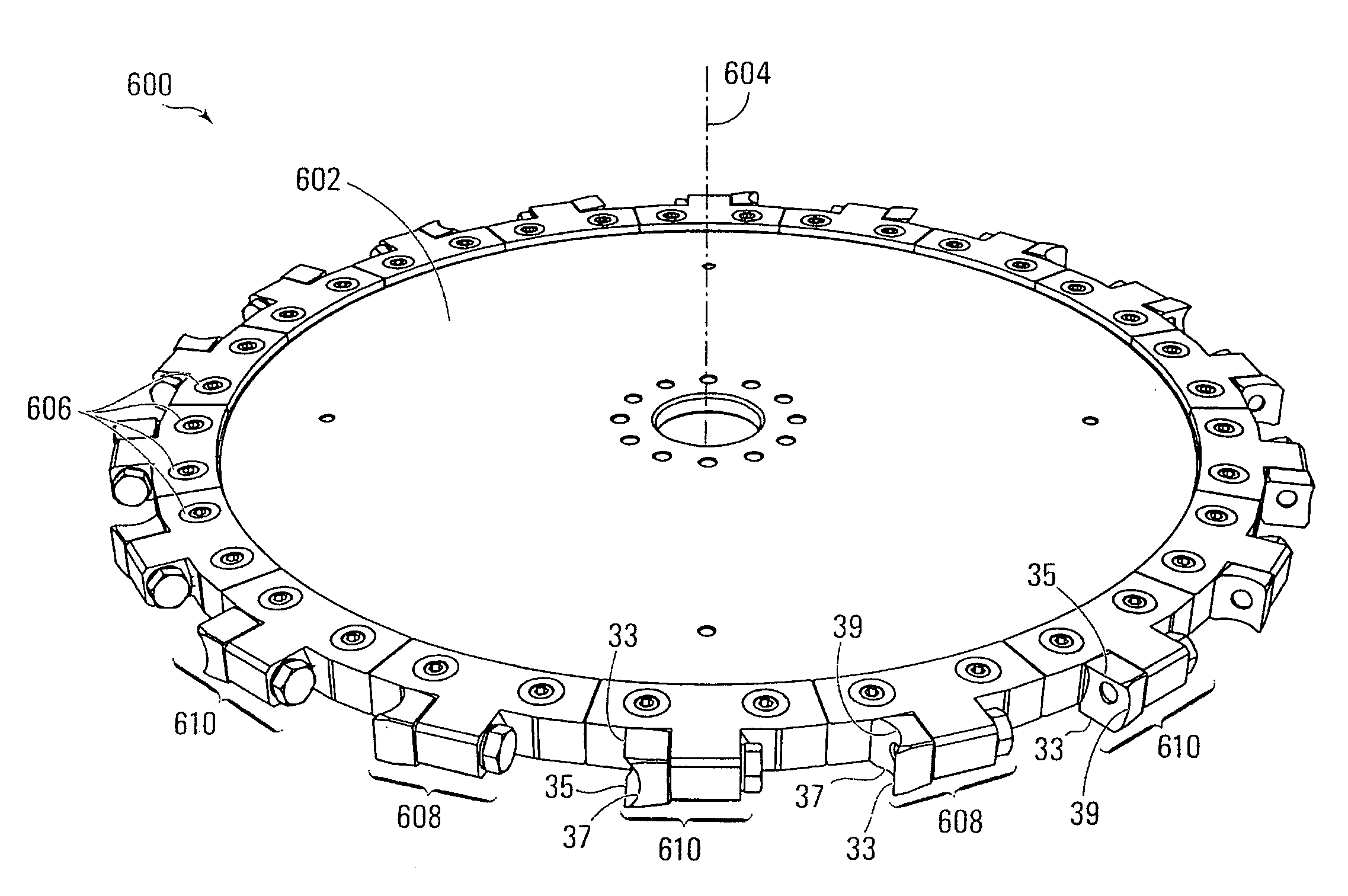

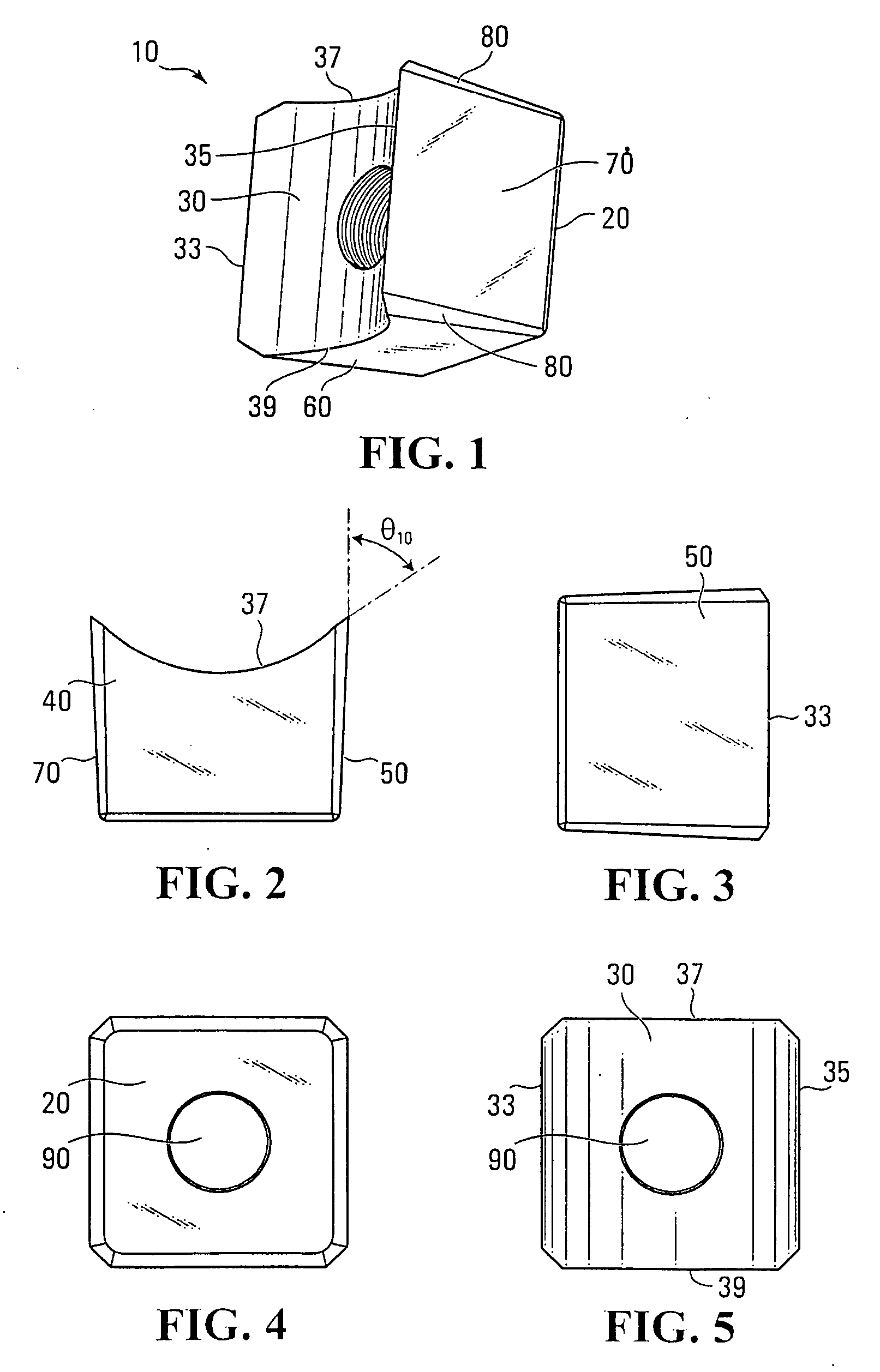

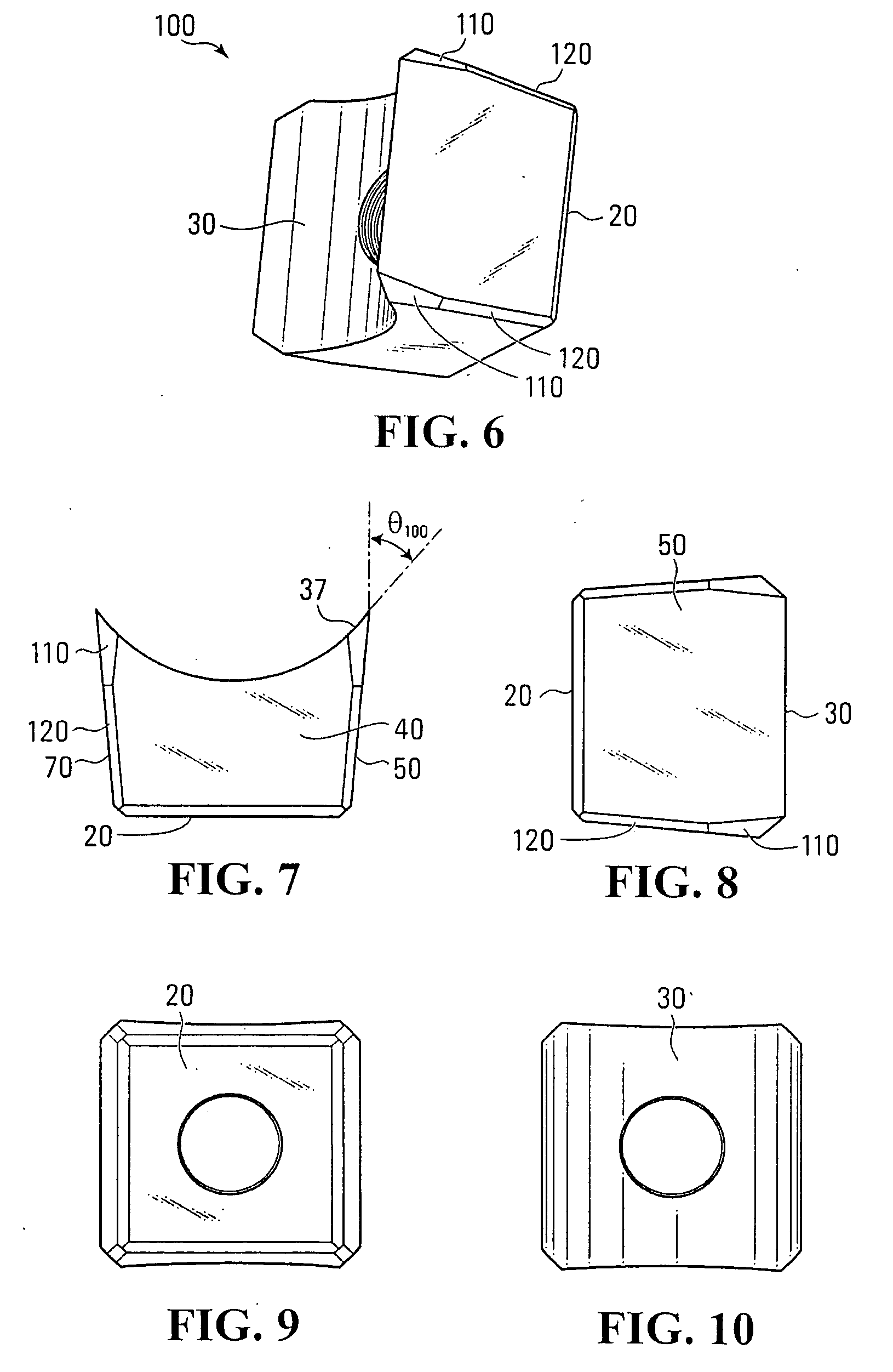

Tooth for a circular saw or mower drum

A tooth for a circular saw or a mower drum that can be used to cut standing trees or brush and undergrowth. The tooth has four cutting edges arranged in a first pair of opposed cutting edges that are generally straight and a second pair of opposed cutting edges that are generally concave. The tooth is mounted in a holder in a first or second cutting position that orients a cutting edge of the first or second pair to physically contact and effect a cutting method to a cuttable material. In a first cutting method, a generally straight cutting edge contacts the material, resulting in a slicing action. In a second cutting method, a generally concave cutting edge contacts the material, resulting in a gouging action. Teeth in the circular saw or brush mower alternate between first and second cutting positions, allowing both cutting methods to be applied to cuttable material.

Owner:QUADCO

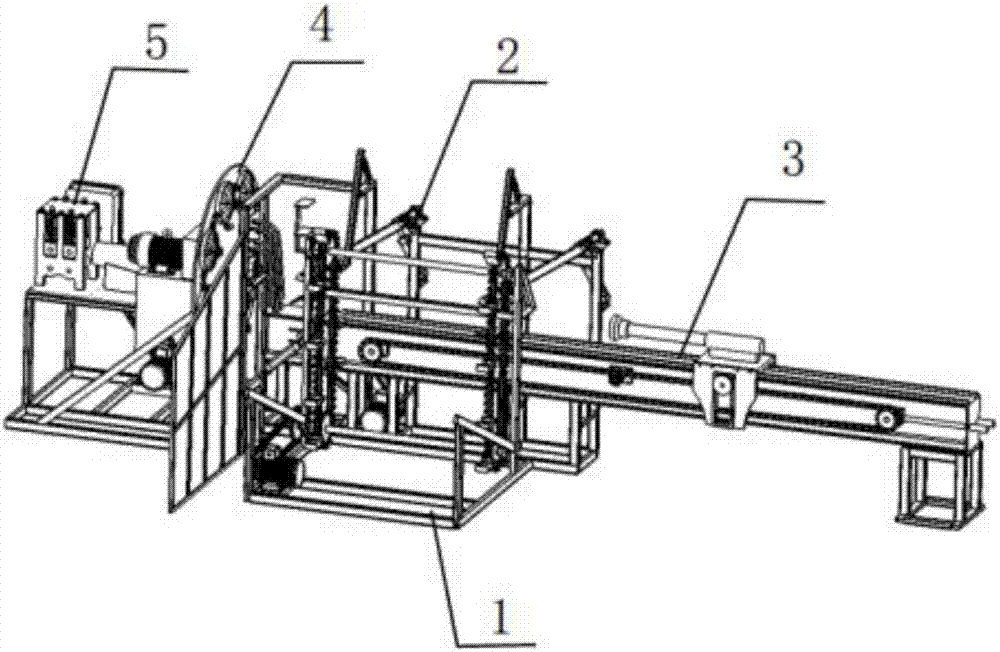

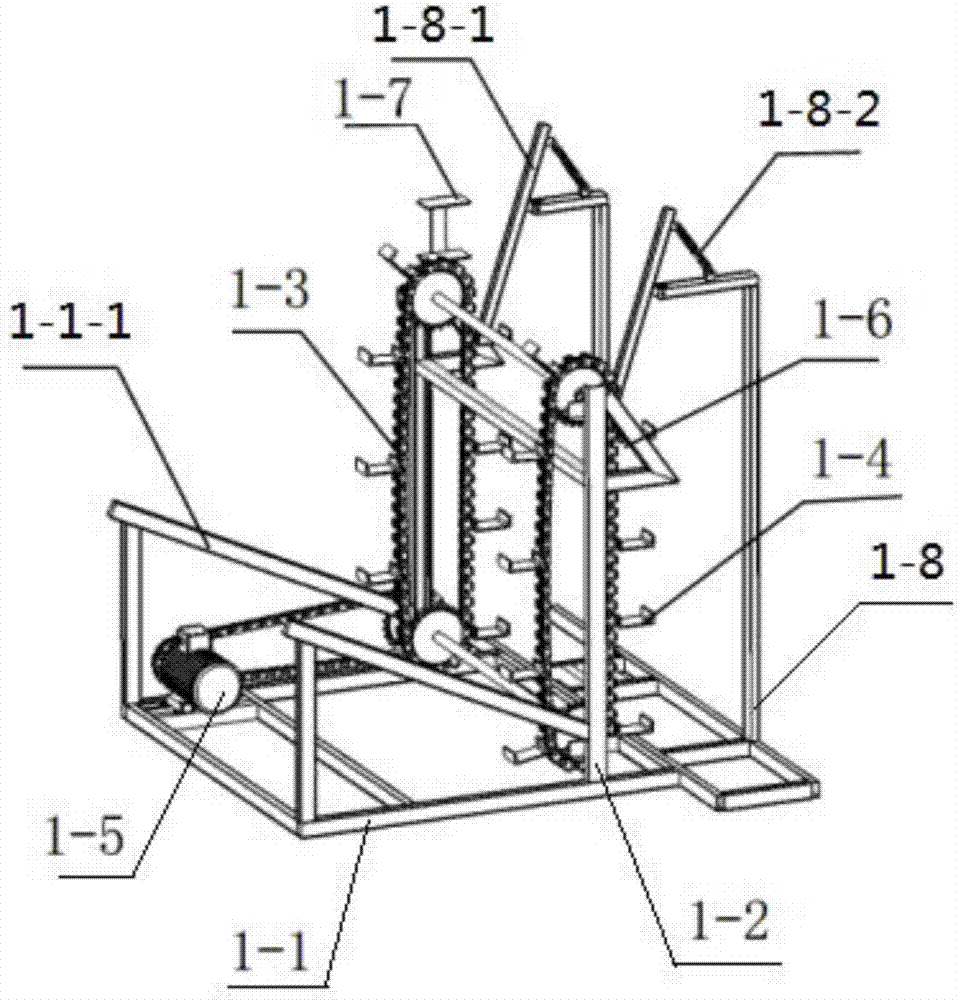

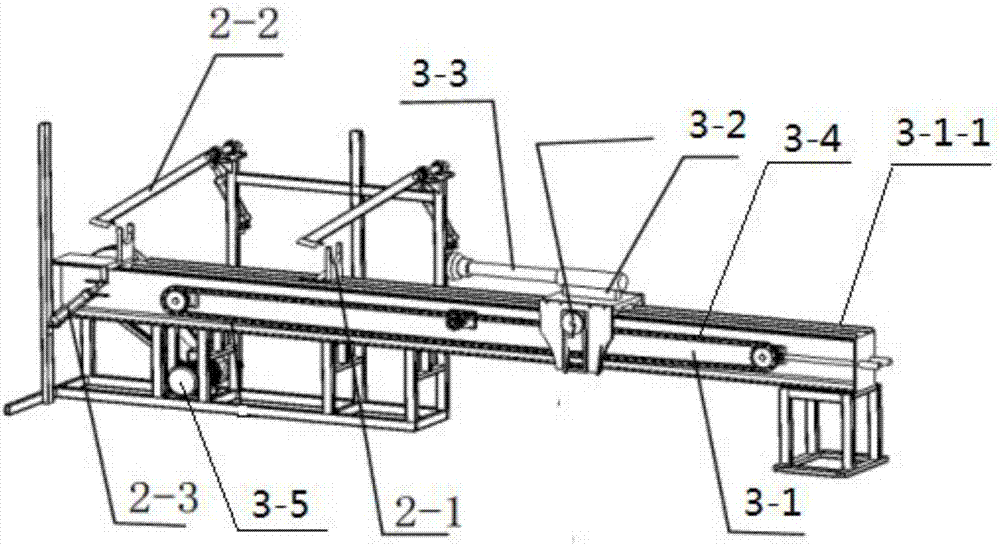

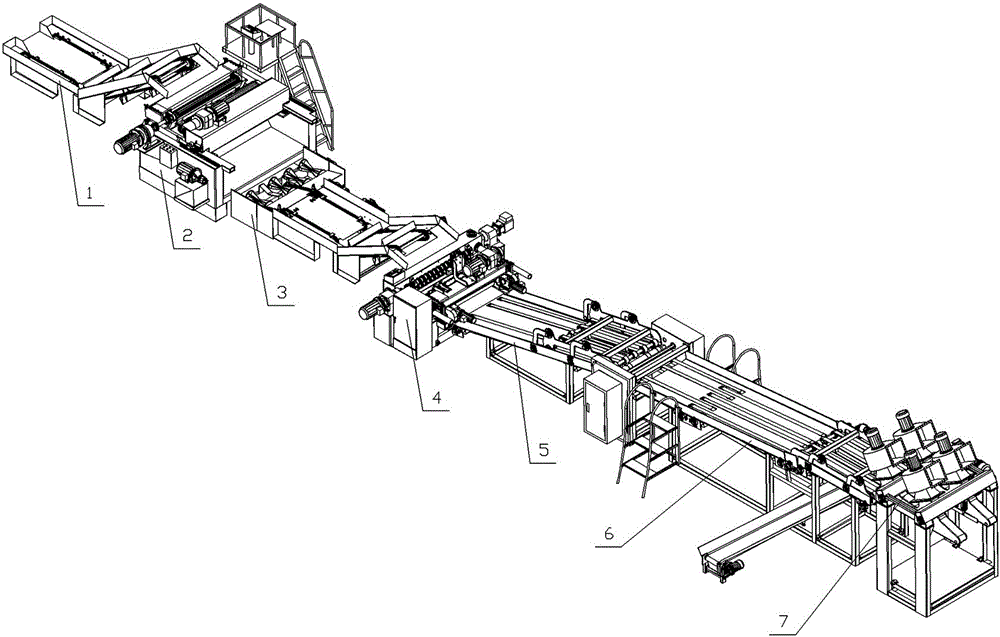

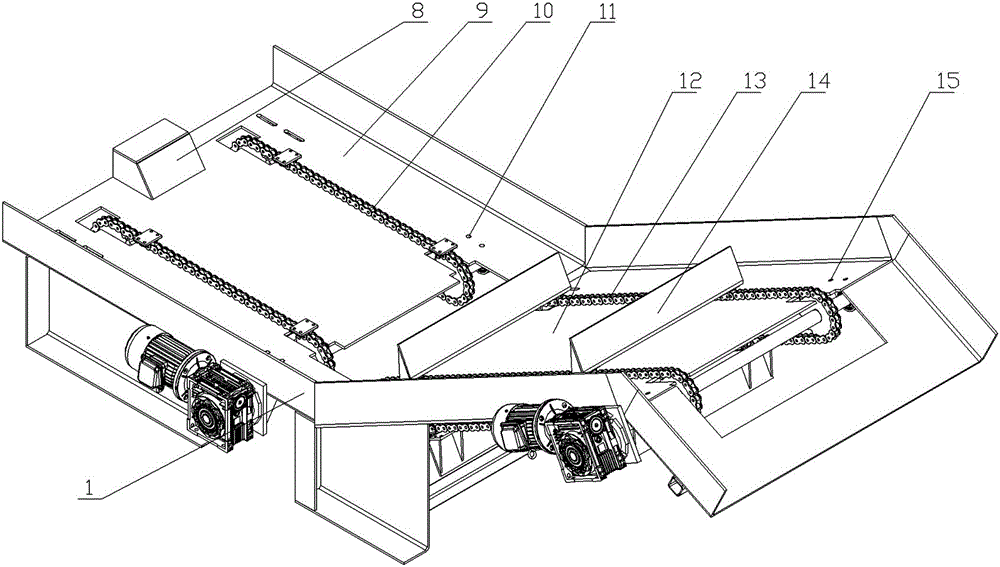

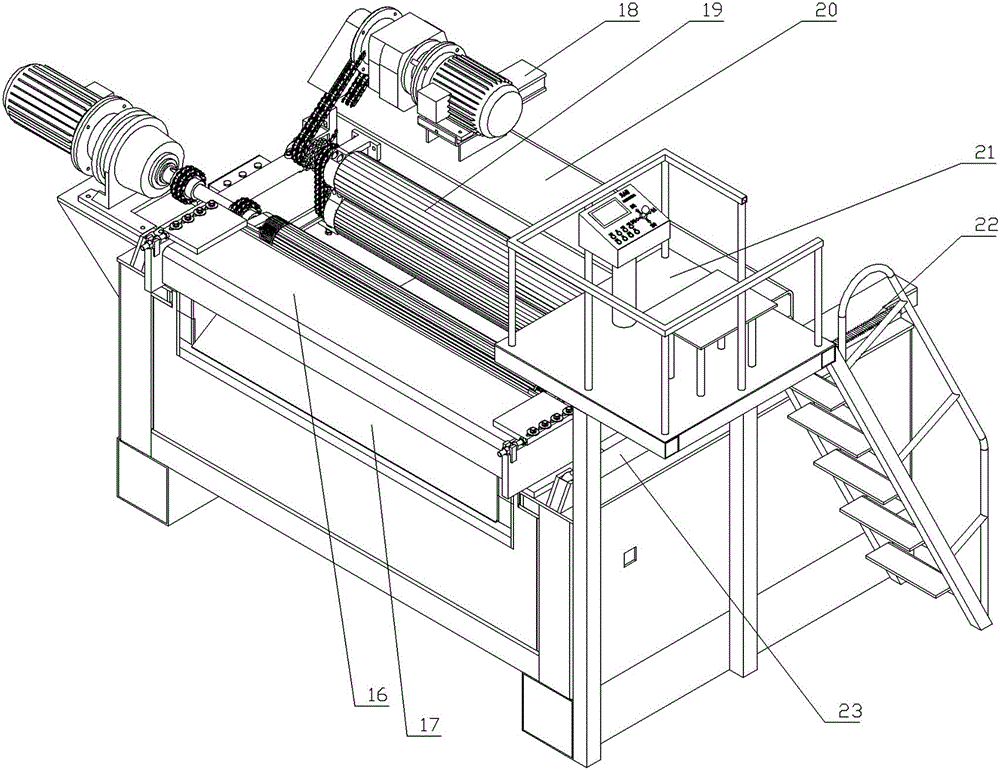

Panel feeding, rotary-cutting and stacking integrated device

ActiveCN105084055ARealize fully automatic flow operationVeneer manufactureArticle feedersRoundingEngineering

The invention belongs to the technical field of rotary-cutting of timber and discloses a panel feeding, rotary-cutting and stacking integrated device. The panel feeding, rotary-cutting and stacking integrated device comprises a rounding machine and a rotary-cutting machine. The panel feeding, rotary-cutting and stacking integrated device is characterized in that a feeding device is arranged at the feeding end of the rounding machine, and a timber collator is arranged at the discharging end of the rounding machine; the back side of the collator is connected with the rotary-cutting machine through the feeding device; a conveying rack is arranged at the discharging end of the rotary-cutting machine and is connected with a vacuum adsorption automatic panel collector through a screening device. According to the panel feeding, rotary-cutting and stacking integrated device, rounding, rotary-cutting and stacking of timber are integrated, the feeding device, the collator and the screening device are additionally arranged, fully-automatic streamlined production is achieved, and the technical problems that in the prior art, dangerousness is high, time consumption and labor consumption are high, occupied space is large, and working efficiency is low are effectively solved.

Owner:SHANDONG XUANJIN MACHINERY CO LTD

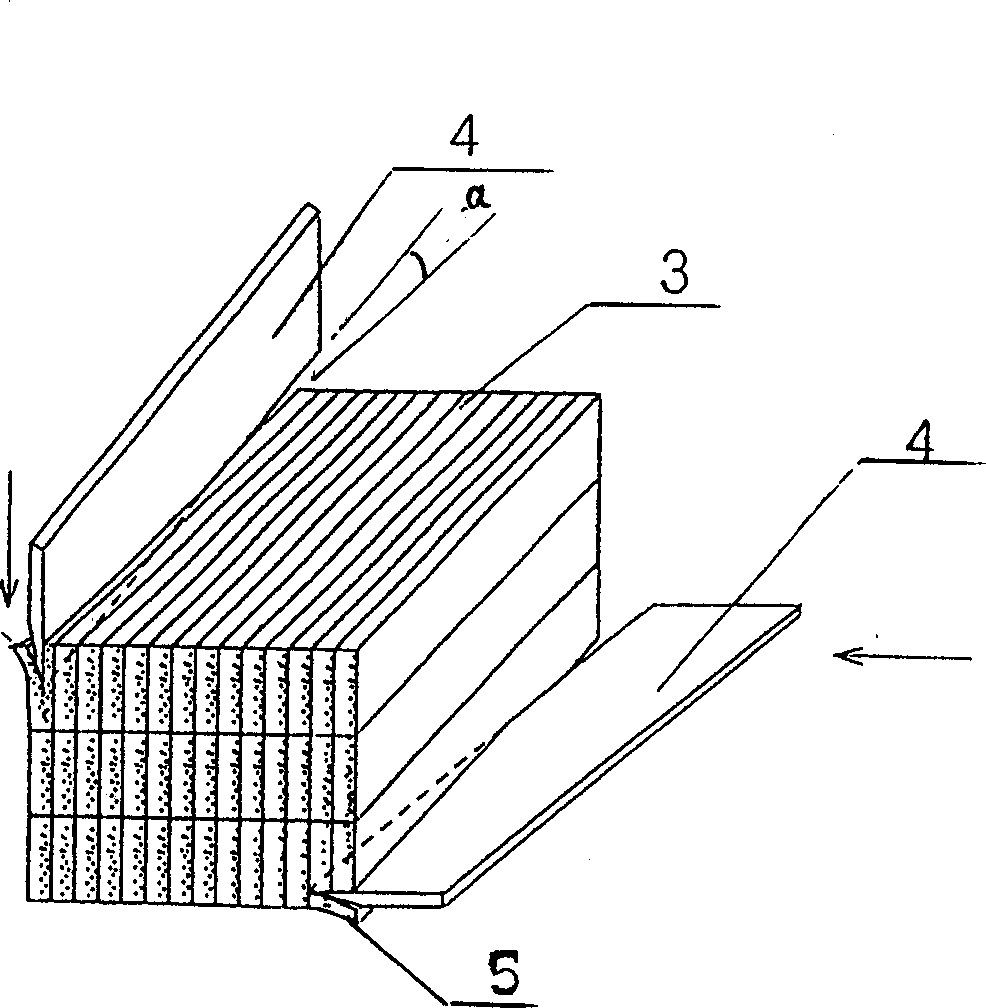

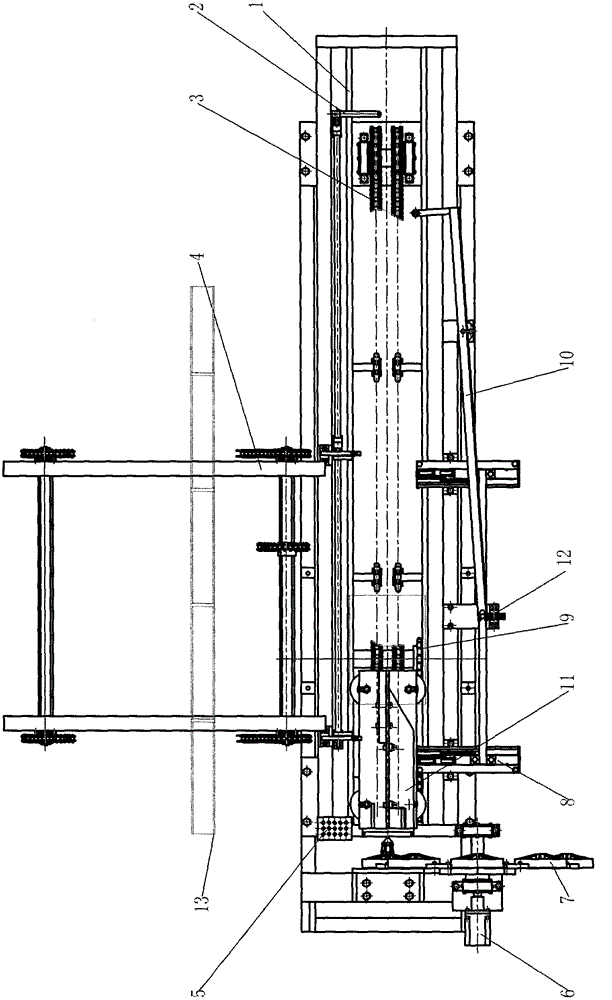

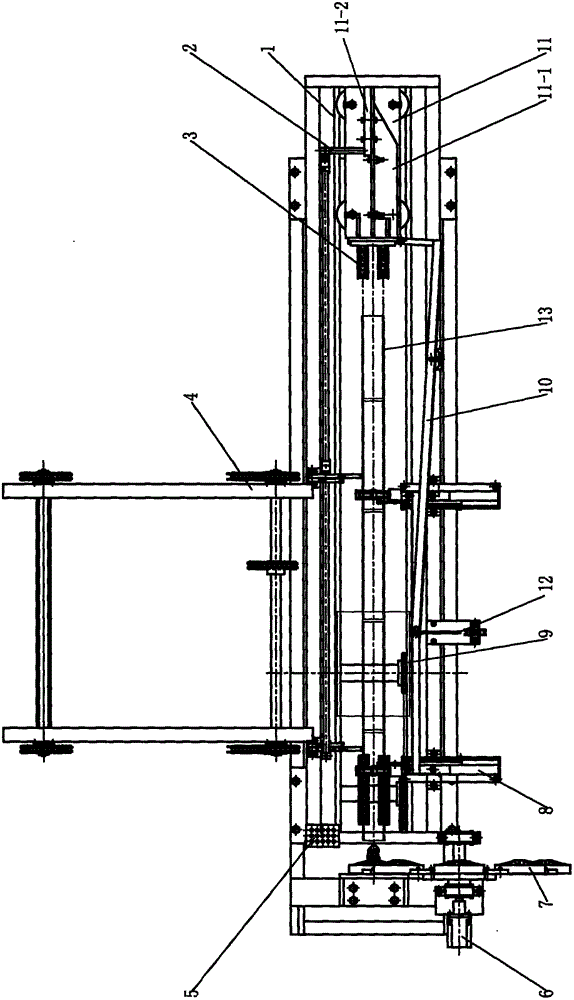

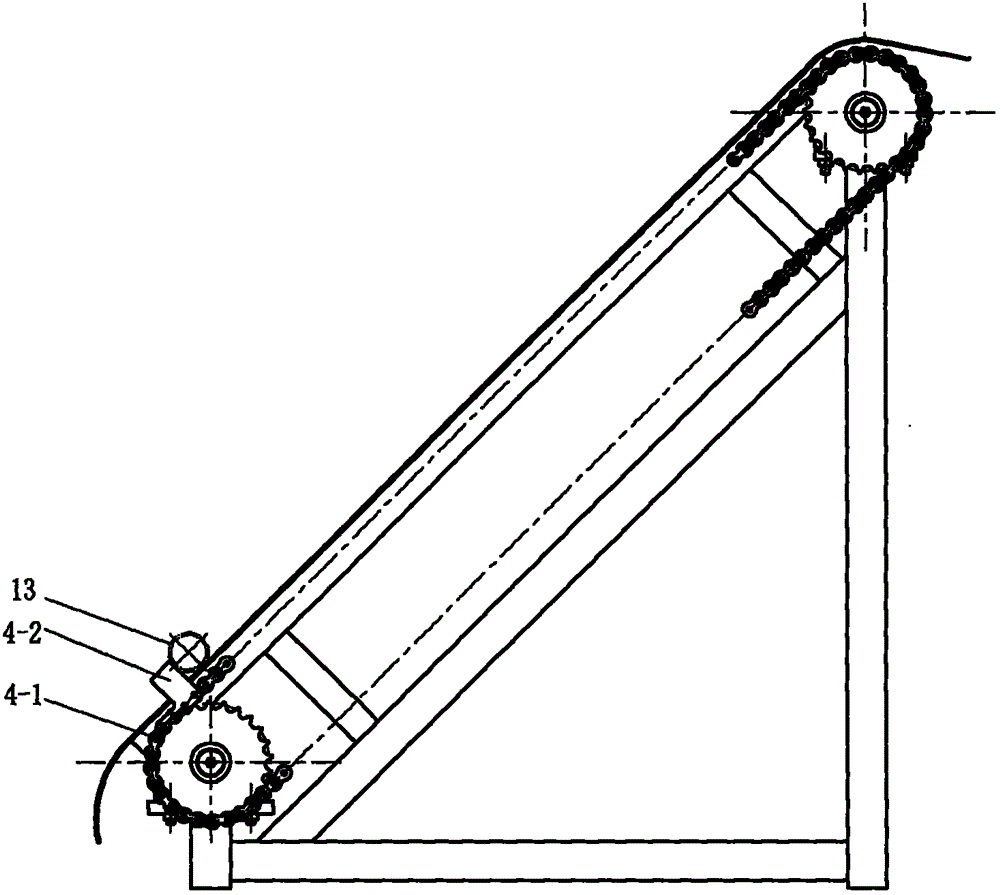

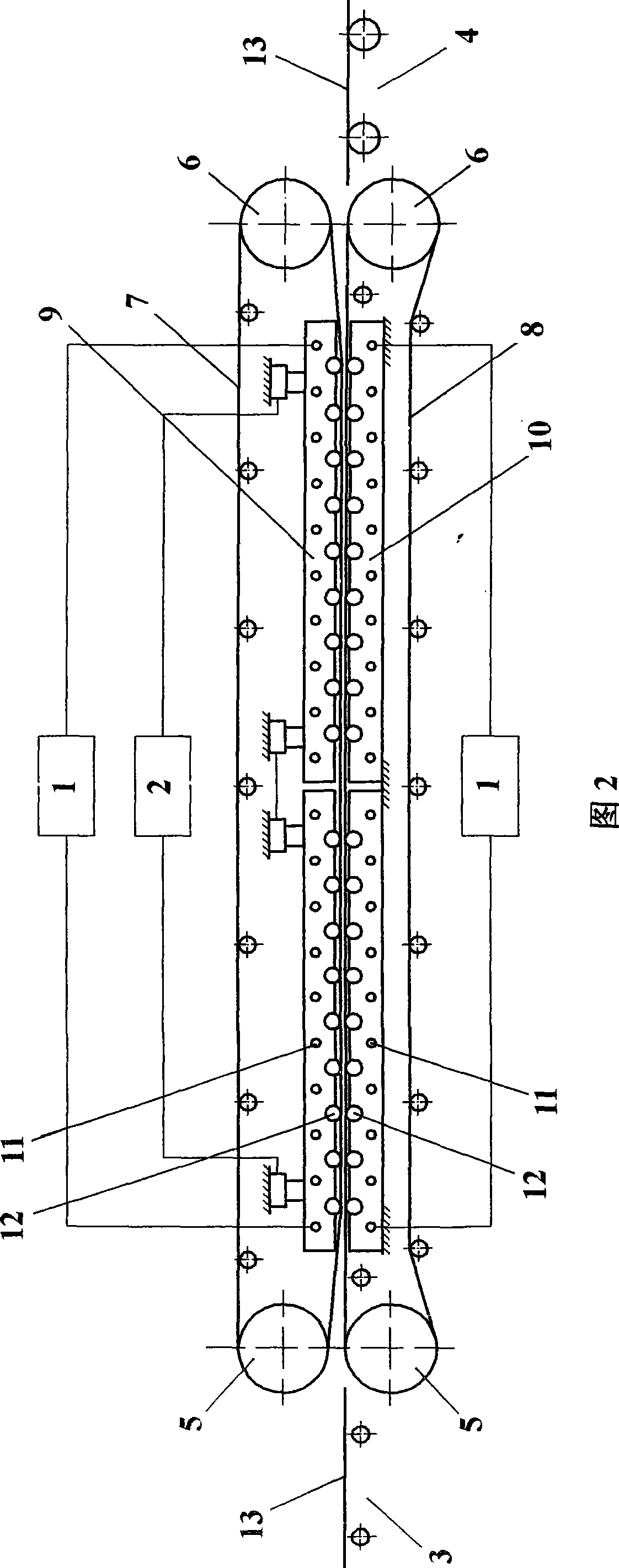

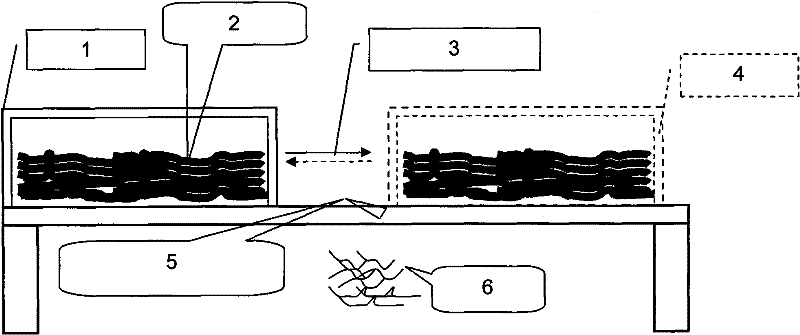

Small wood integrated shaving thin-wood manufacture method and leveling drying device thereof

InactiveCN101417451AHighlight substantiveSignificant technological progressVeneer manufacturePressure impregnationAdhesive cementEconomic benefits

The invention relates to a manufacturing method of small-diameter wood glulam slicing veneers and a leveling drying device. Small-diameter wood, tended wood, inferior wood or cordwood produced in the cutting and manufacturing process, and the like which are not easily efficiently used are softened by a composite agent by being infused with pressure, and then after flitches are integrated by finger joining and obliquely slotting the wood with a moisture-curable type adhesive, the flitches are sliced into wet veneers, and the wet veneers are then sent to a special continuous high-temperature ironing leveling dryer to be leveled and dried into sliced veneers in the clamping of upper and lower steel belts. The invention integrates a series of special technologies and transforms small-diameter wood which is not easily used into sliced veneers which meet requirements of various technical specifications with very wide application ranges. Low-grade wood is fully used, which improves the added value of products and comprehensive utilization efficiency of forest resources. The invention has the advantages of simple and reasonable technique method, low equipment cost, good product quality, broad development prospects and the like. Significant social and economic benefits can be produced after the implementation.

Owner:BEIHUA UNIV

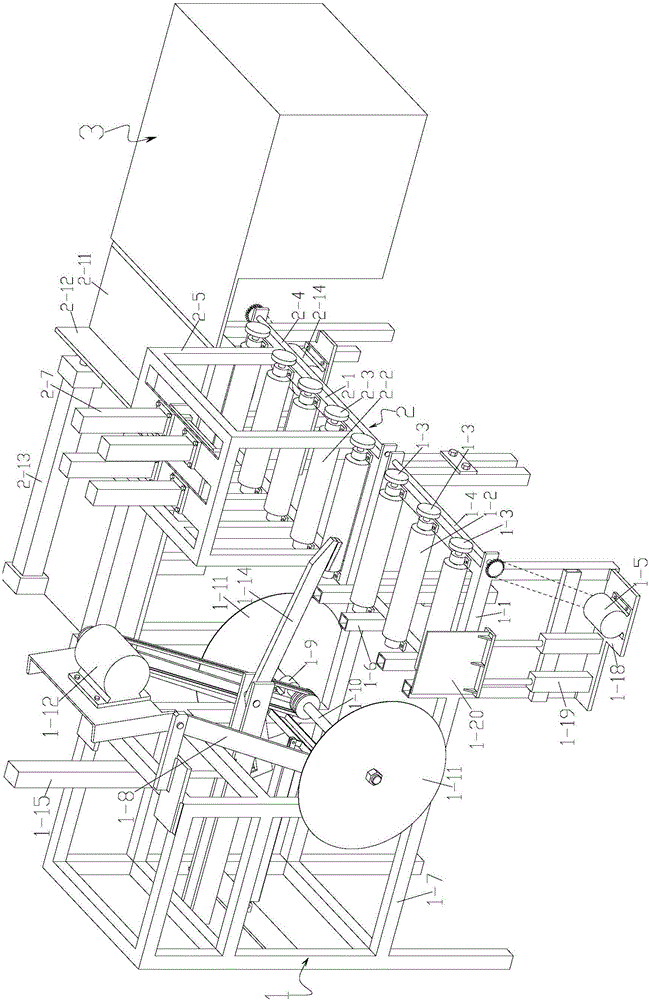

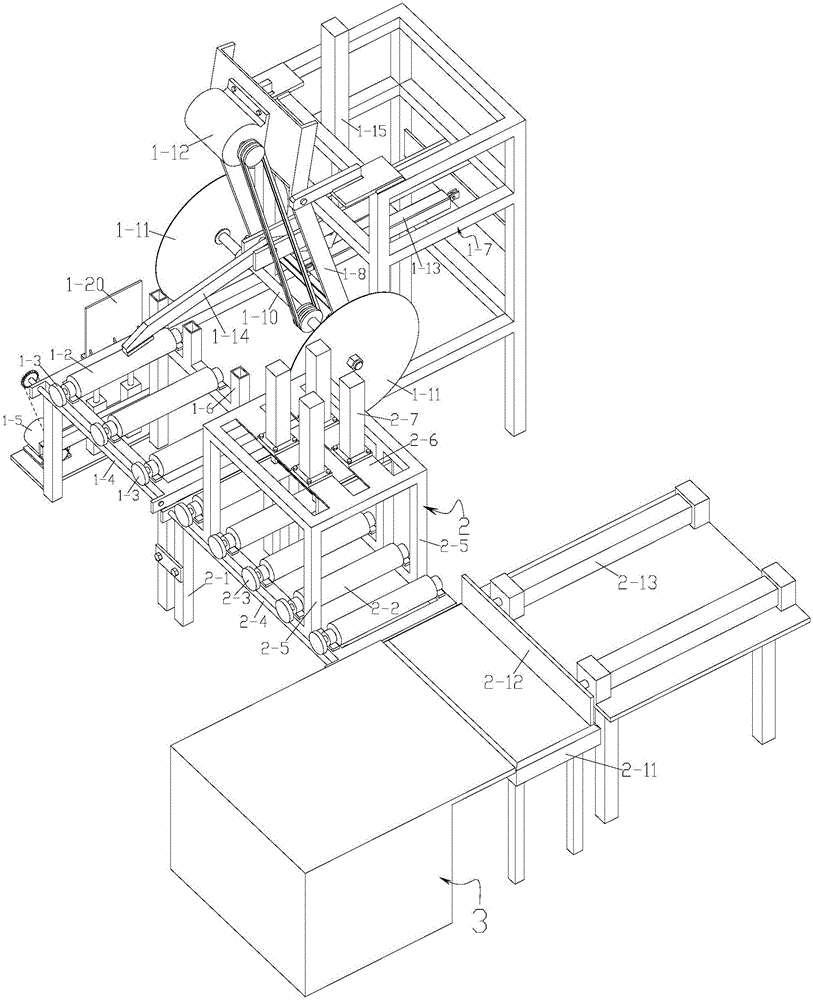

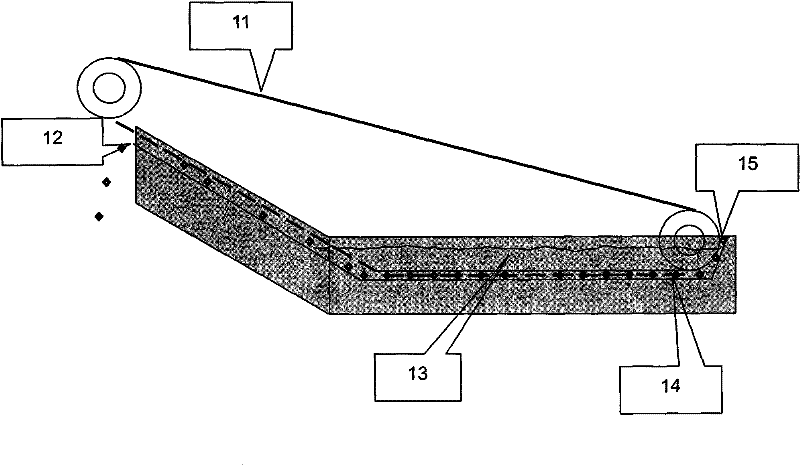

Wood thin-board machining process and wood thin-board automatic machining equipment

ActiveCN105818216AEasy to pushEasy to processFeeding devicesGripping devicesMachining processEngineering

A wood thin-board machining process comprises the following steps: A) clamping a log; B) cutting both ends of the log; C) conveying the cut log; D) machining the cut log. Wood thin-board automatic machining equipment comprises a log clamping and cutting device, a log conveying device and a wood thin-board machining device; a base I disposed on the log clamping and cutting device and a base II disposed on the log conveying device are matched with each other by position, and linked together; a material receiving platform disposed on the log conveying device and a base III disposed on the wood thin-board machining device are matched with each other by position, and linked together. The equipment disclosed by the invention achieves an ingenious and reasonable structure design. The process and equipment disclosed by the invention can greatly improve the efficiency of machining logs into wood thin-board, and are worth popularizing and applying.

Owner:ZHEJIANG DOLO IND

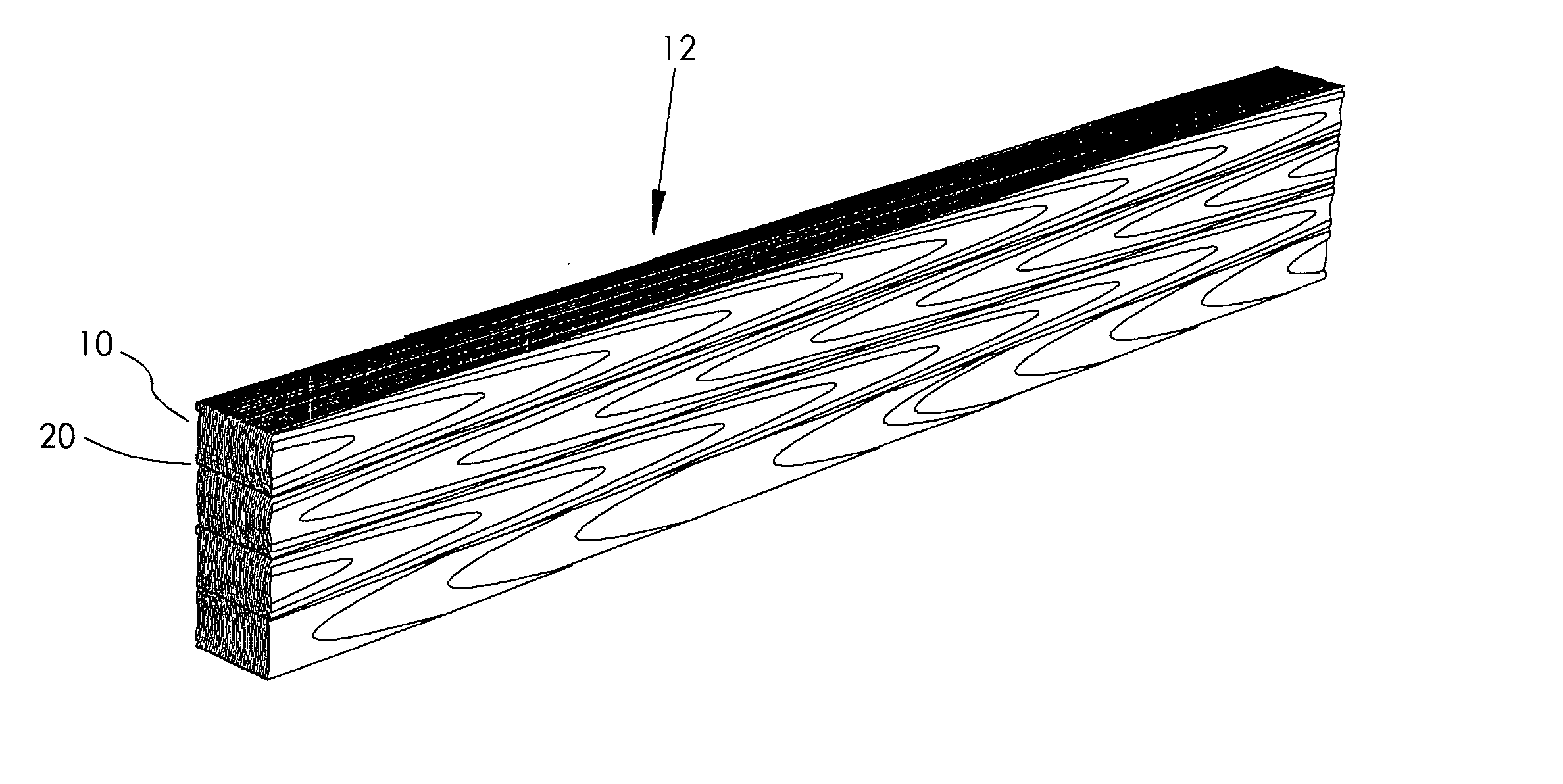

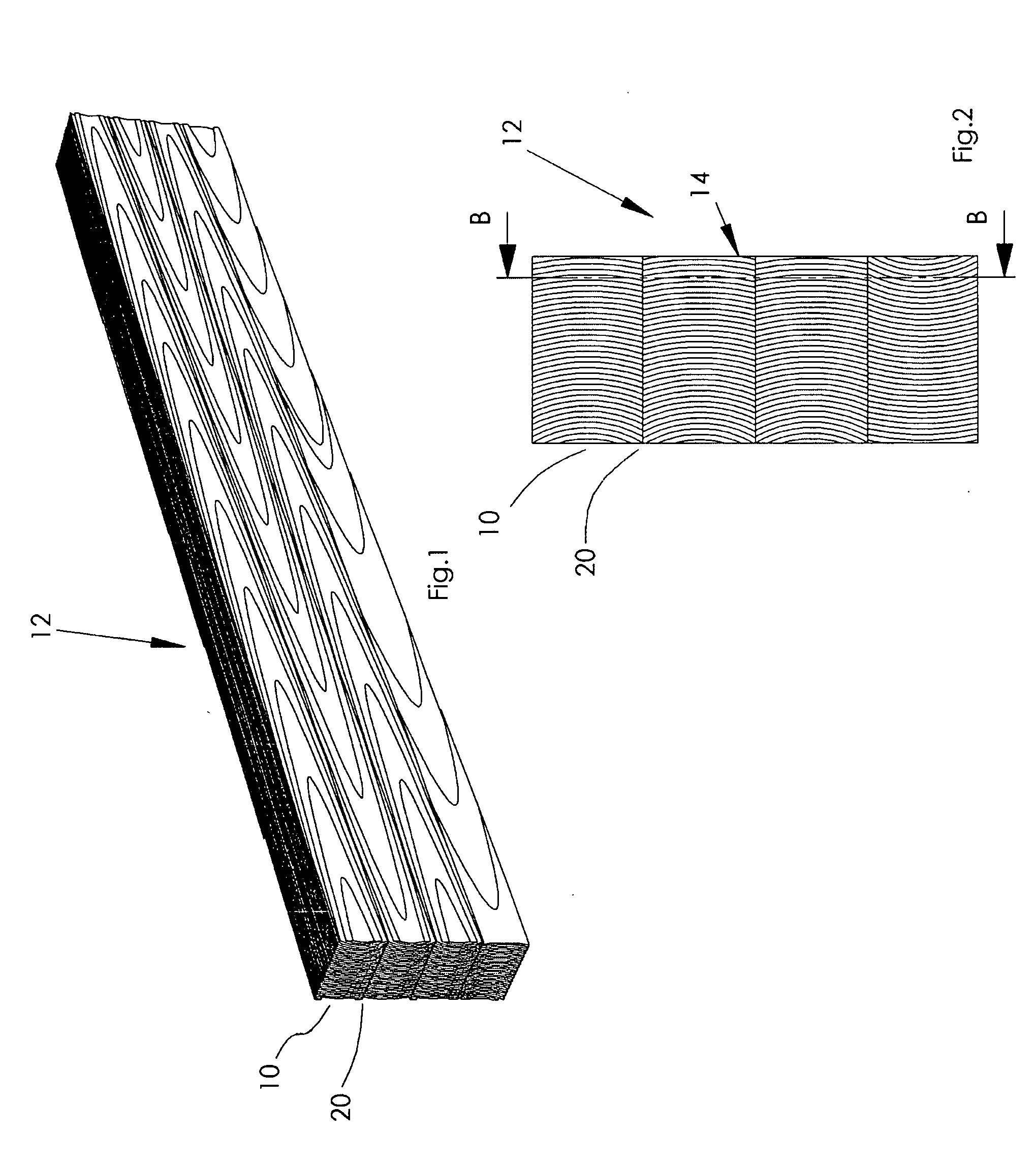

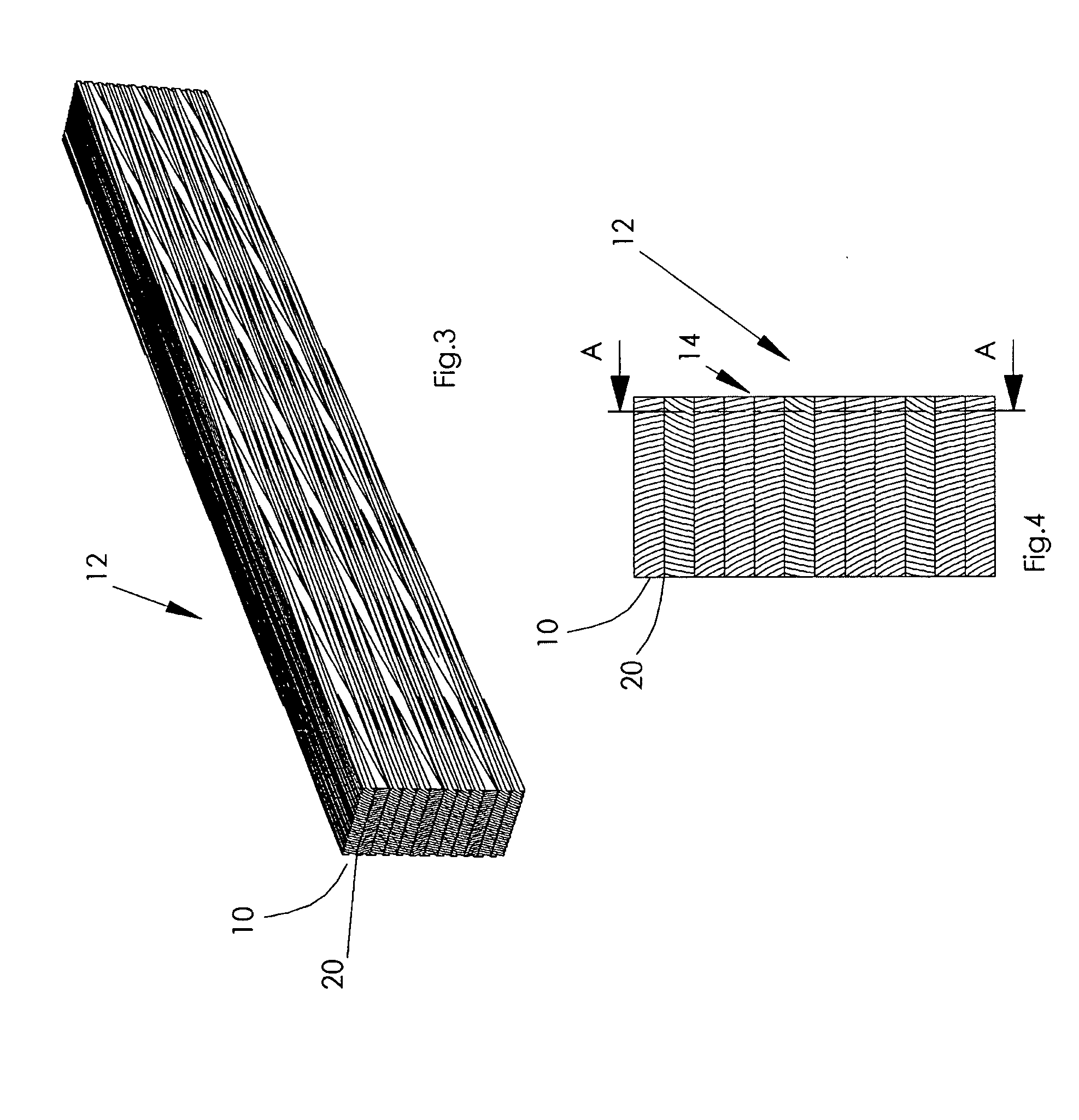

Process for the manufacture of a veneer

ActiveUS20060162851A1Solution value is not highIncrease shipping costsMechanical working/deformationLamination ancillary operationsFiber saturation pointPulp and paper industry

A process for the manufacture of veneer comprises gluing board-like, plane pieces of wood together with an adhesive to form a beam-like block of wood. The humidity content of the beam-like block of wood is increased. Veneer is cut from the beam-like block of wood and dried until the humidity content is below a fiber saturation point. Because of the rules governing abstracts, this abstract should not be used to construe the claims.

Owner:HD WOOD TECH

Bamboo slicer

A bamboo split opening machine comprises a frame and a bamboo strip feeder on the frame, and a bamboo strip inlet and an opening device respectively mounted on two sides of the bamboo strip feeder. The opening device comprises a blade relative to the outlet of the bamboo strip feeder, wherein the blade is fixed at the end of one flexible rod whose back part is connected with a swing rod. The swing rod can accelerate the flexible rod to move to the bamboo strip feeder. Based on high density and rigidity of bamboo fiber, the invention is designed to simulate the blade feeding operation when cutting the bamboo, to obtain straight shape at the bamboo joint, therefore the inventive bamboo split has high quality.

Owner:周云龙

Method for producing high-density recombined wood

InactiveCN102172940AHigh static bending strengthHigh surface hardnessWood compressionVeneer manufactureHigh densityEngineering

The invention relates to a method for producing high-density recombined wood, which is used for manufacturing plates and recombined module timber by the following steps of planning, processing by high-temperature steam, drying, dipping glue, draining glue, drying after draining glue, tidying or weaving, balancing for nourishing, pressing to shape, solidifying at a high temperature and the like. The density of the high-density recombined wood can reach 0.7-1.2kg / cm<3>; the high-density recombined wood has the characteristics of peculiar texture, fine grain, excellent performance, small possibility of cracking and deforming and the like, does not need to prevent insects, prevent mildew, prevent corrosion, prevent from cracking and the like, and can be directly used for the fields of floor, furniture, building and the like. The method disclosed by the invention has simple working procedures, and abandoned secondarily secondary small fuel wood and secondary small wood are utilized to produce plates and module wood, thereby changing waste materials into things of value, and greatly saving forest resource. The wood is an ideal log substitute.

Owner:浙江仕强竹业有限公司

Milled submicron organic biocides with narrow particle size distribution, and uses thereof

A method of milling substantially insoluble solid organic biocides to form a micron or sub-micron product having a narrow particle size distribution is presented. The milling involves wet milling of the organic biocide with high density milling media having a diameter between 0.1 mm and 0.8 mm, preferably between 0.2 mm and 0.7 mm, and a density equal to or greater than 3.8 g / cc, preferably greater than 5.5 g / cc, in a ball mill using between about 40% and 80% loading of the mill volume with milling media, and having the organic biocide suspended in an aqueous milling liquid which comprises one or more surface active agents. The milling speed is preferably high, for example from about 1000 rpm to about 4000 rpm. The milled product can be used in foliar applications at a lower effective dosage than prior art formulations, can be used in improved antifouling paint formulations, and can be used in new applications such as the direct injection of solid organic biocide particulates in wood to act as a long lasting wood preservative.

Owner:KOPPERS PERFORMANCE CHEM

Production process of fire-retardant particleboard

InactiveCN105965660AProcess stabilityMoisture-proofVeneer manufactureDomestic articlesFire retardantEnvironmentally friendly

The invention relates to a production process of a fire-retardant particleboard. The process comprises the following steps: cutting into pieces; flaking; drying; sieving; winnowing; making and applying glue; paving; pre-pressing to form; thermally pressing; cooling a plain board, and stacking; then intermediately storing and transporting; sanding; sawing; and finally packaging and warehousing. The fire-retardant particleboard produced by the process has the characteristics of being stable in process, stable in internal performances, damp-proof, hard to break, environmentally friendly, and easy to secondarily process.

Owner:鸿伟木业(仁化)有限公司

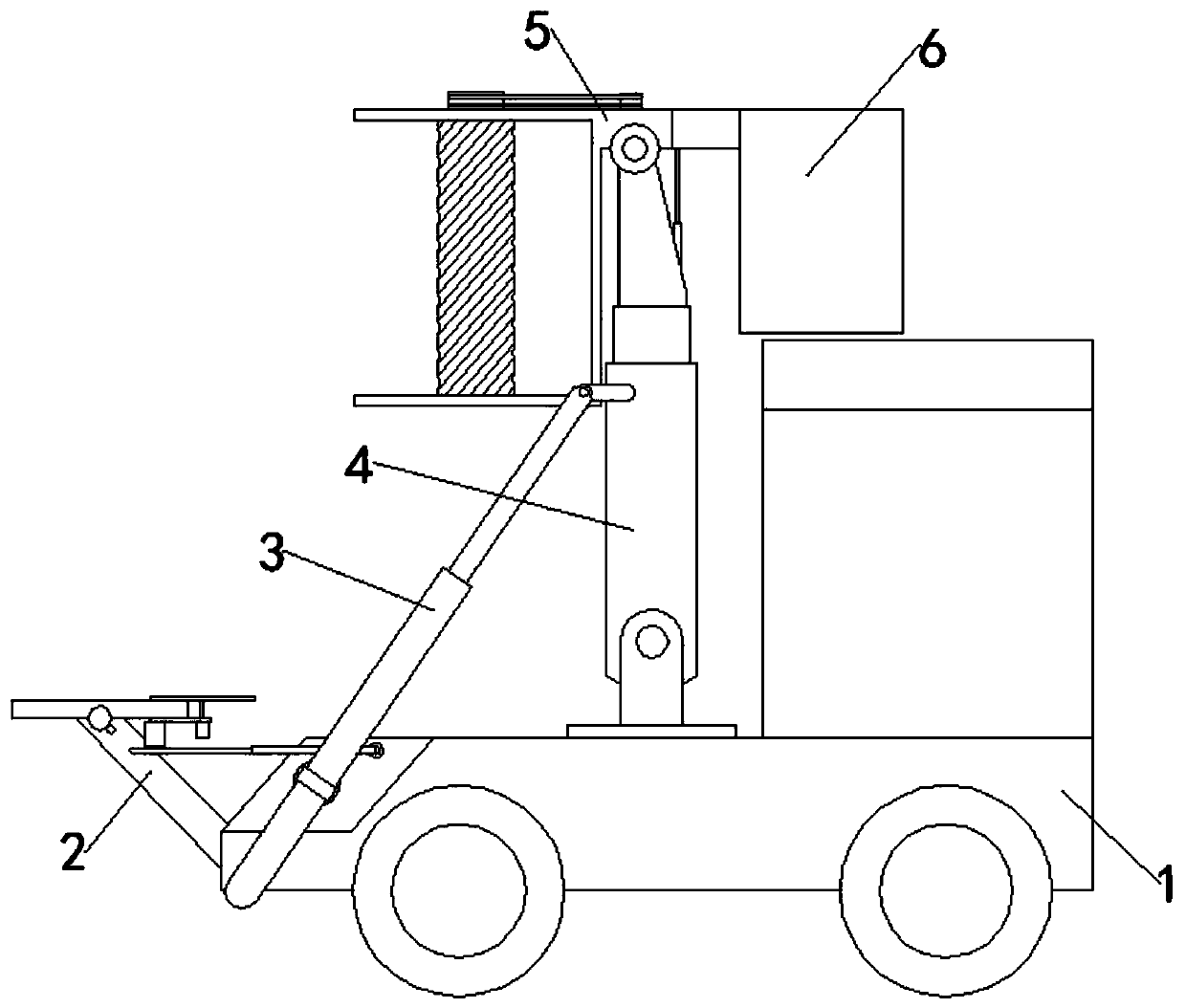

High-efficiency wood chip cutting device capable of processing in cedar growing place

The invention provides a high-efficiency wood chip cutting device capable of processing in a cedar growing place, and belongs to the technical field of wood chip processing. The high-efficiency wood chip cutting device capable of processing in the cedar growing place comprises a carrier, a cab, wheels, a bottom support, a platform, a gear, a groove, a sliding chute, a motor, a hydraulic rod, a rotating support, a cutting plate, a hydraulic rod II, an electric telescopic column, a platform II, a fitting plate, an oval groove, a fitting groove, an indented rotary shaft, an electromotor, a cutting plate, a knife switch plate, an ovoid gear, a spring, a guide plate, a roller and a collecting frame, wherein the cab is fixedly connected to the top part of the right side of the carrier; the wheels are rotatably connected to the periphery of the bottom part of the carrier; the bottom support is rotatably connected to the left side of the cab; the platform is rotatably connected to the top partof one side of the bottom support; the gear is fixedly connected to the bottom part of the platform; the groove is nested on one side surface of the platform; the sliding chute is nested on the surface of the platform; and the motor is fixedly connected to one side surface of the bottom support and meshes with the gear through a transmission gear.

Owner:HEBEI JIRONG FURNITURE

Method for preparing wood bamboo composite floor

ActiveCN101544008ASolve the coolnessSolve the cognitive bias of easy mothReed/straw treatmentVeneer manufactureEcological environmentEngineering

The present invention discloses a method for preparing a wood bamboo composite floor, including the steps of preparing material firstly; selecting perennial raw bamboo to form bamboo splints or bamboo threads after processing; selecting hard broad-leaf forest lumber to form wooden veneer after processing; then assembling; glueing a wooden veneer and a bamboo board layer into a floor blank; finally molding: the blank is made into a finished product after molding and finishing. The present invention resolves a recognition deviation of people that the bamboo has large cool quality and is amiable bristletail, and ensures people to enjoy the nobility comfort of the wooden floor as much as one likes based on the full usage of the bamboo wood; be means of using hard broad leaf lumber having close hardness, strength, density and thermal conduction effect with the bamboo wood as a overlay, the performance of the lumber after composting with the bamboo wood is stabile without deformation; the utilization ratio of the bamboo wood is greatly improved, the exchange is saved by means of avoiding a good deal of importation lumber, which is in favor of sustainable development of the ecologic environment. The invention not only increase farmer income, also improves the additive value of the raw bamboo, increases enterprise effectiveness and accelerates budgetary income increase.

Owner:安徽新河竹业有限公司

Plastic-bamboo composite tube coiled forming technology method

InactiveCN101143453AEasy to produceSimple production process conditionsWood treatment detailsVeneer manufactureFilling materialsRoom temperature

The invention relates to a bamboo-plastic composite pipe rolling forming technique, which solves a problem that present bamboo-plastic composite pipe centrifugal casting has the defects of easy offset and exposure, loose bamboo filling materials, low content, etc. The specific processing steps are to cut bamboo materials into bamboo long strips, on which degreasing, dehydration and surface active agent activation treatments are implemented. A mat bamboo weaved object are precast. Resin mortars are evenly coated on the mat bamboo weaved object. Silicon oil demould agent is coated on the outer surface of the mould pipe. More than one layer of the mat bamboo weaved object is helicoidally tensioned and winded on the mould pipe and is heated and solidified for forming. Then, the object is cooled to the room temperature and is demoulded to obtain the bamboo-plastic composite pipe. The manufacturing process condition requirements of the invention are relative simple. The compactness of the bamboo filling materials is greatly improved. The strength and the rigidity of the pipe are improved. And the content of the bamboo materials reaches to 50-70 percentage, which is beneficial to the further lowering of the cost. The invention is especially applied to the production of pipe products with large diameter.

Owner:HEFEI UNIV OF TECH +1

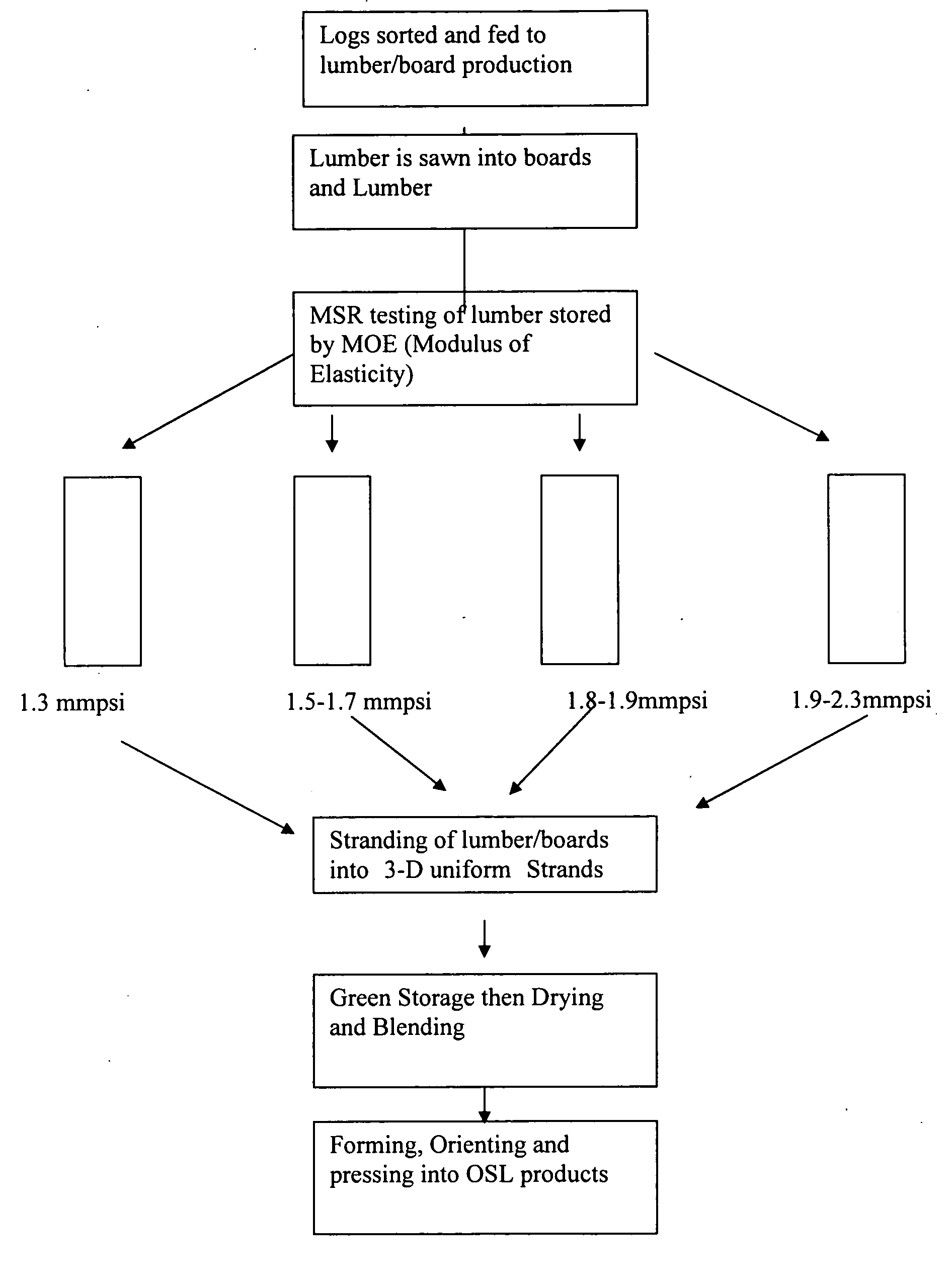

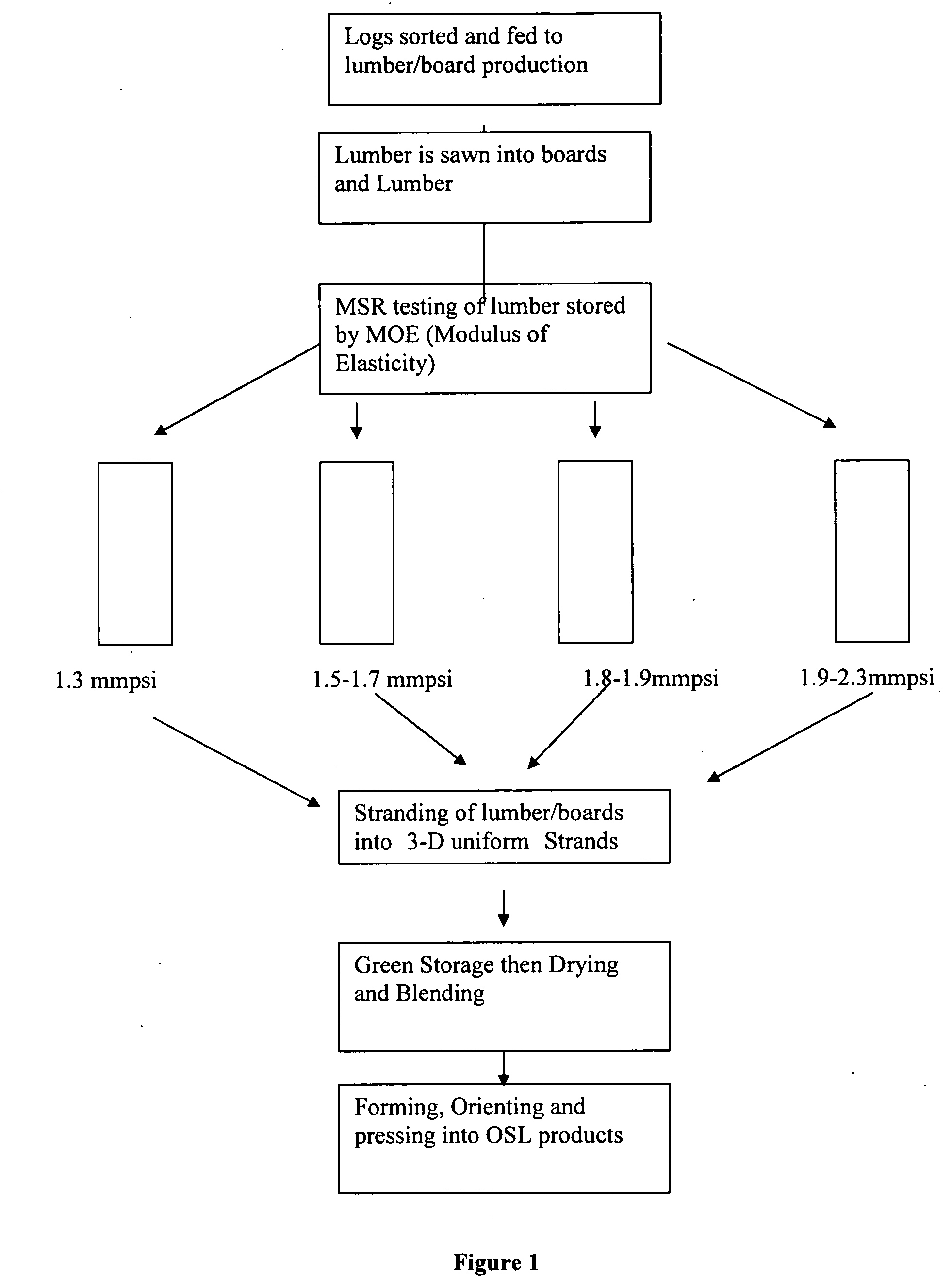

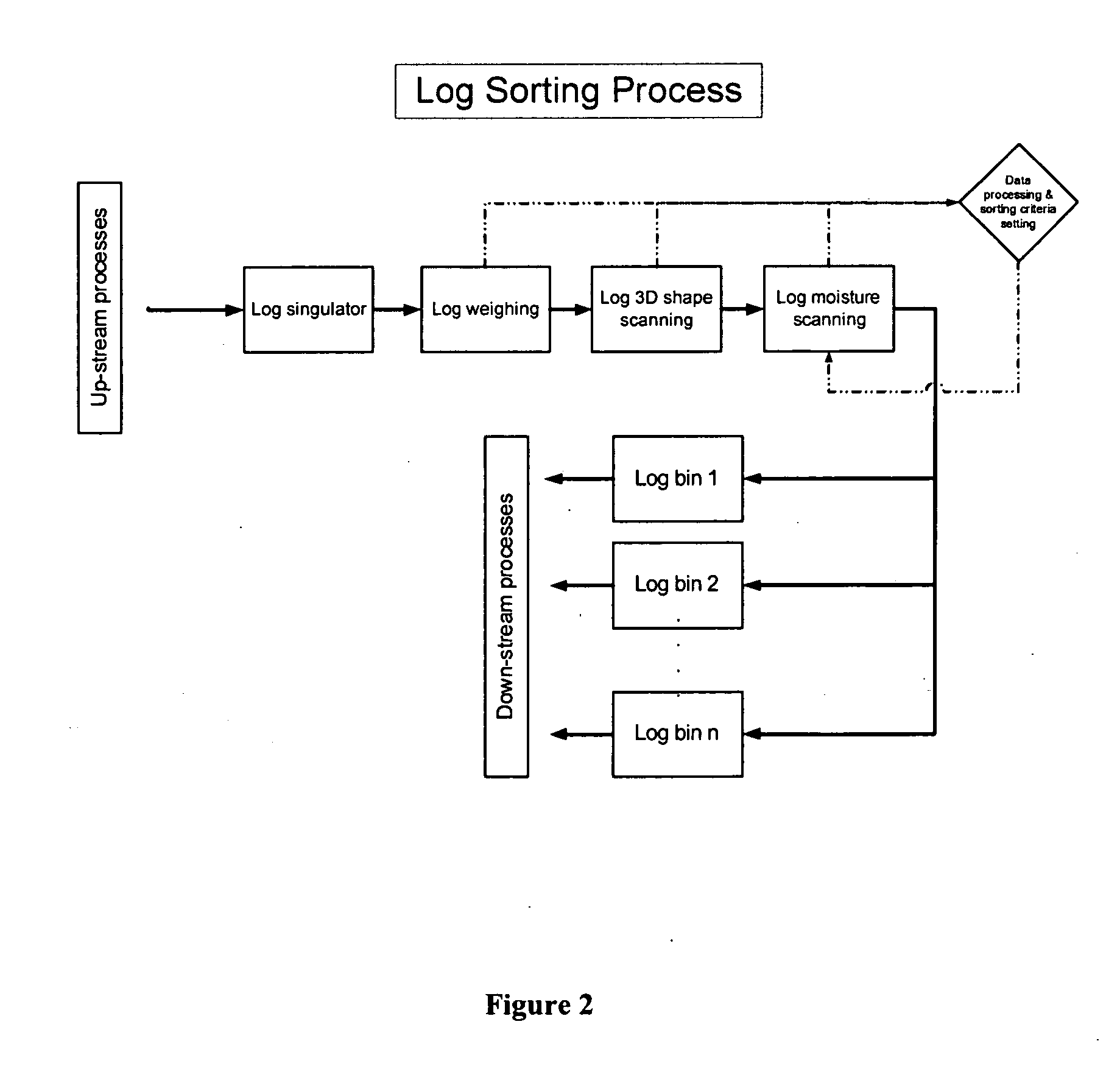

Methods for making improved strand wood products and products made thereby

An overall method of making engineered strand wood products in relation to a number of different possible criteria is provided. Such a method may involve any combination of different screening procedures to determine the best wood sources from which individual strands may be prepared. Such screening procedures may include initial determinations of certain physical characteristics of individual logs, further or initial determinations of certain physical characteristics of portions of sawn logs, further or initial determinations of certain physical characteristics of individual strands, and any combinations thereof. Additionally, after the initial physical characteristic sorting is completed, optionally the wood may be cut into uniformly sized and shaped strands for incorporation within a target strand product. Still further, such strands, in substantially uniform size and shape, as well as substantially uniform physical characteristics, may then be incorporated into a target strand product in specific predetermined configurations. Such various possible combinations of screening procedures and / or selective stranding processes results in strand products (boards, lumber, and the like) of improved properties over previously made strand products. Thus, encompassed within this invention are processes involving each of these procedures either individually or in combination with other sequential processes for the production of desired strand products.

Owner:HUBER ENGINEERED WOODS

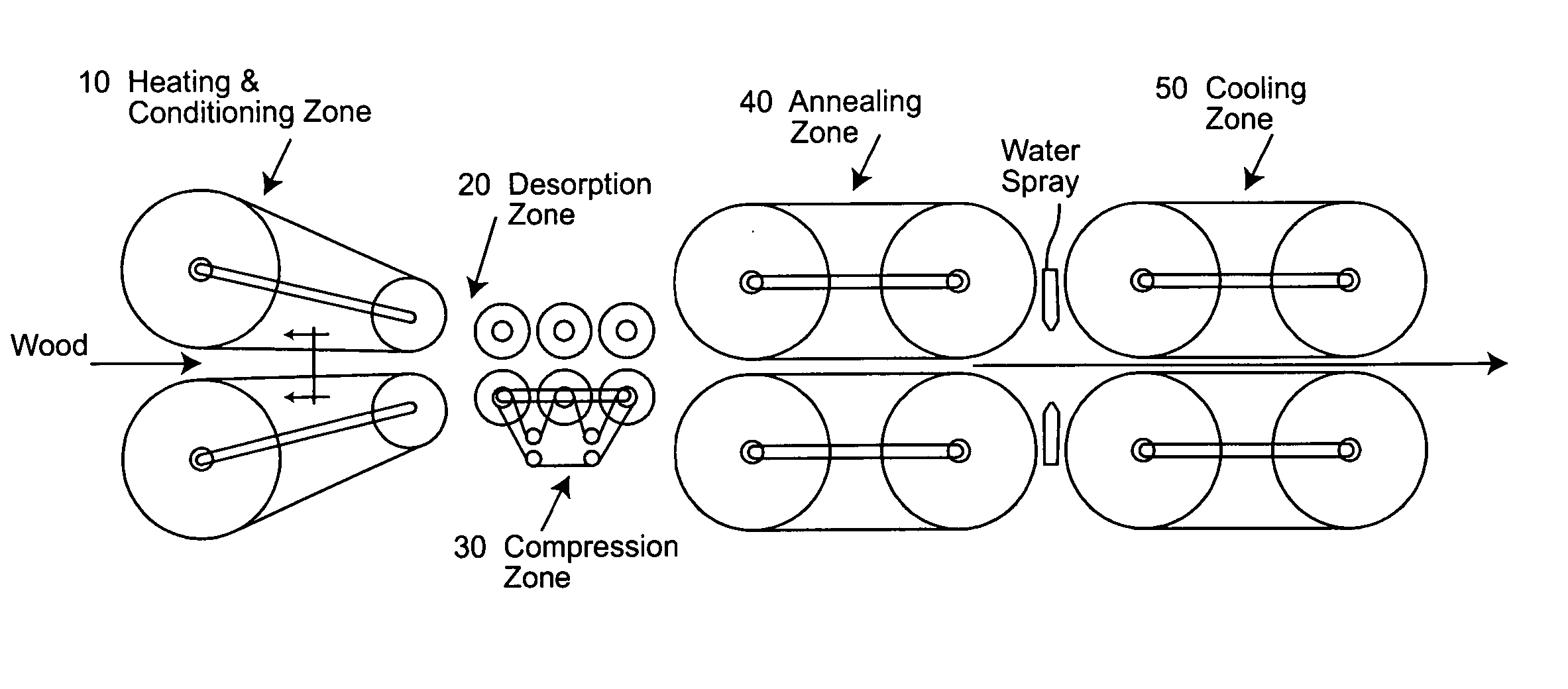

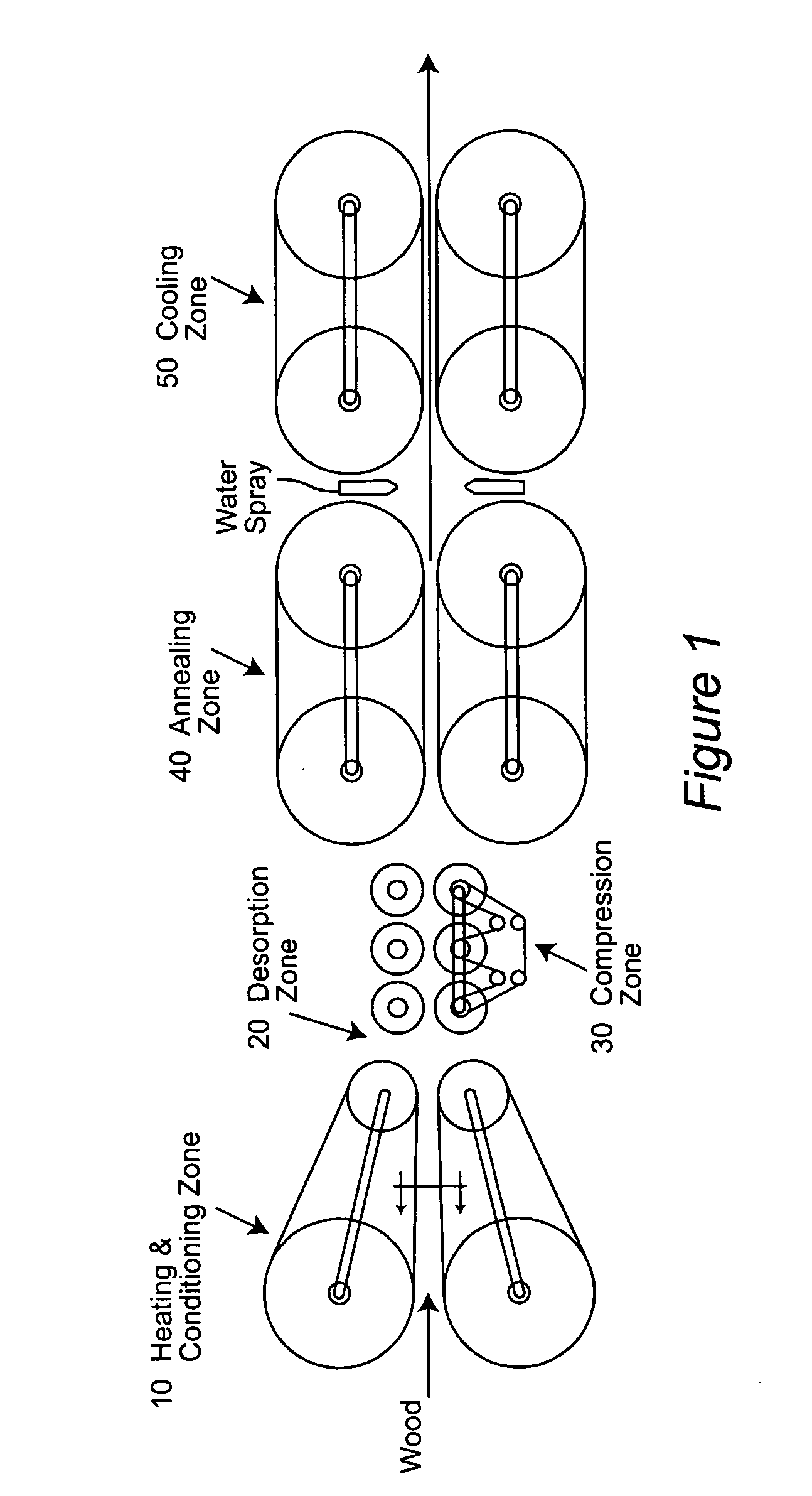

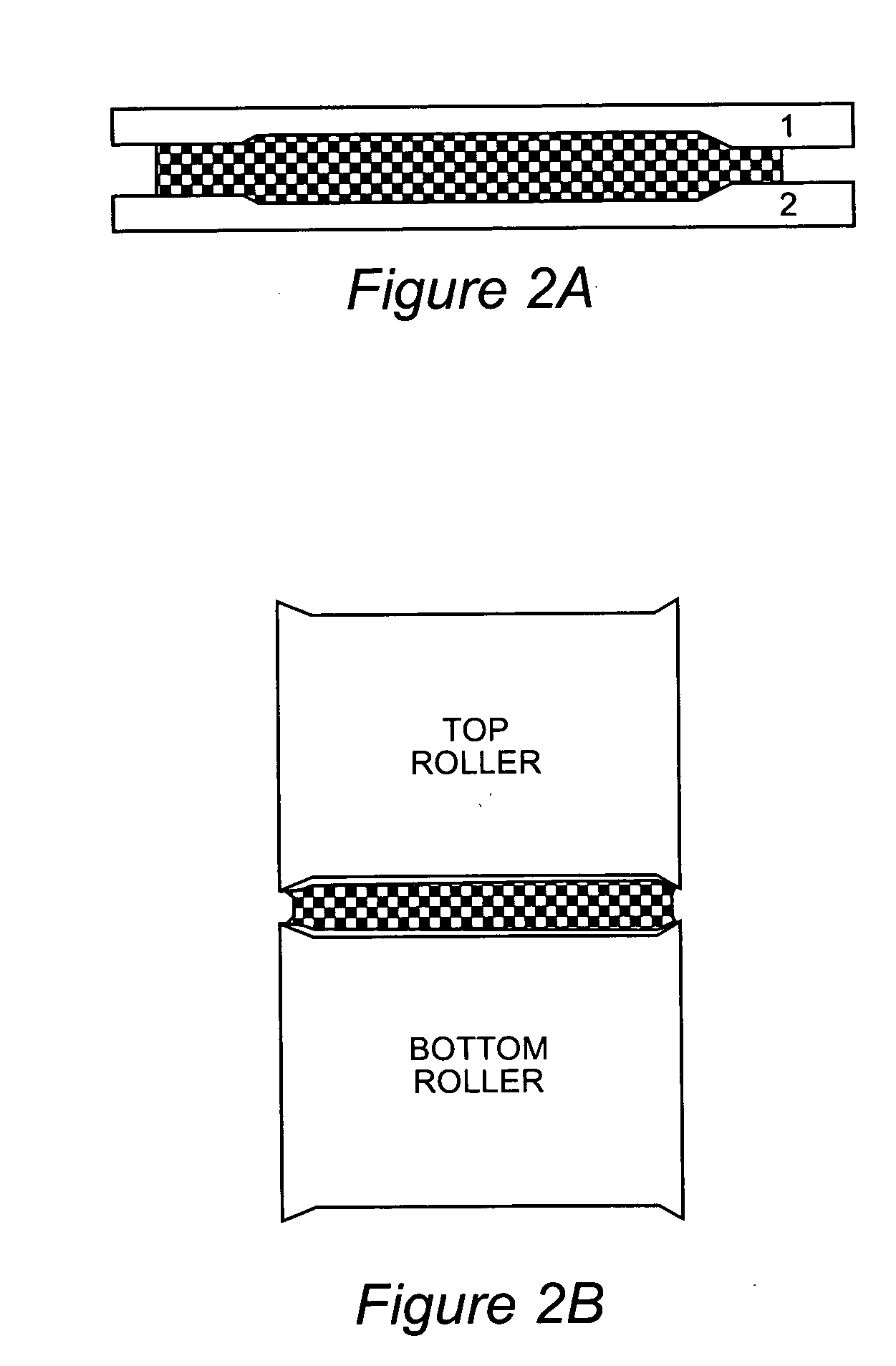

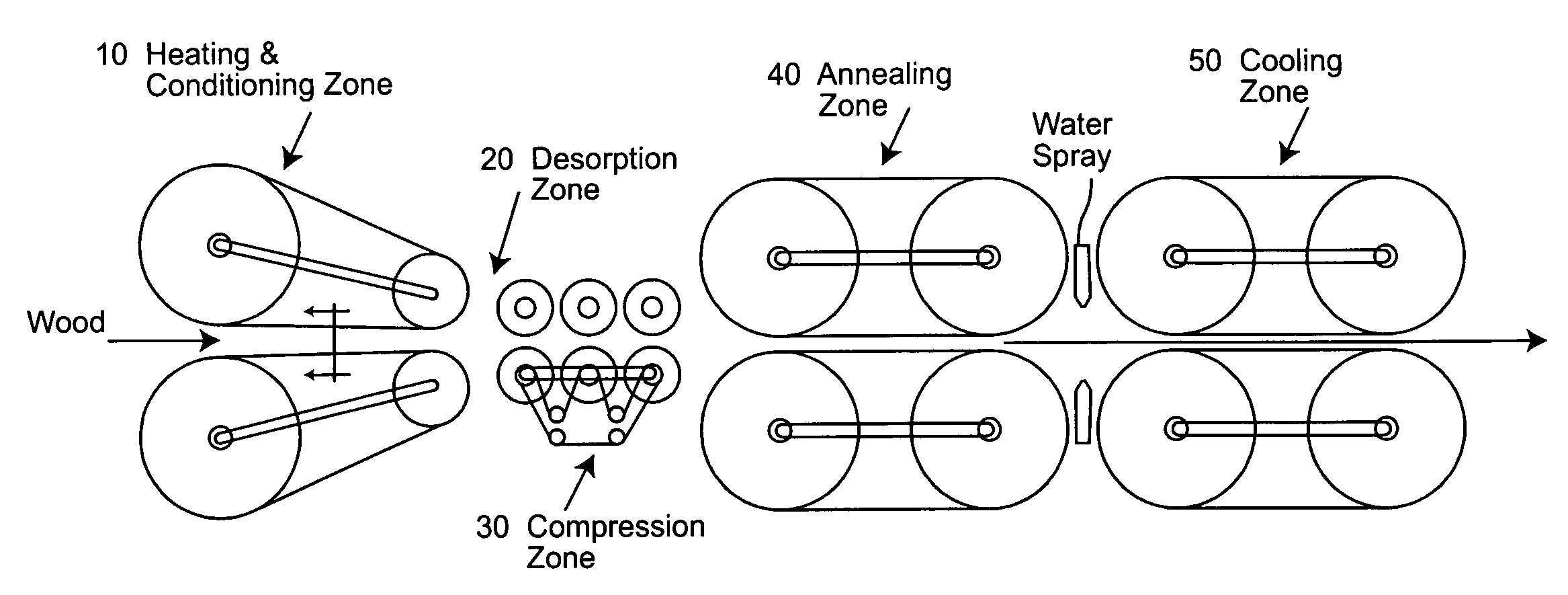

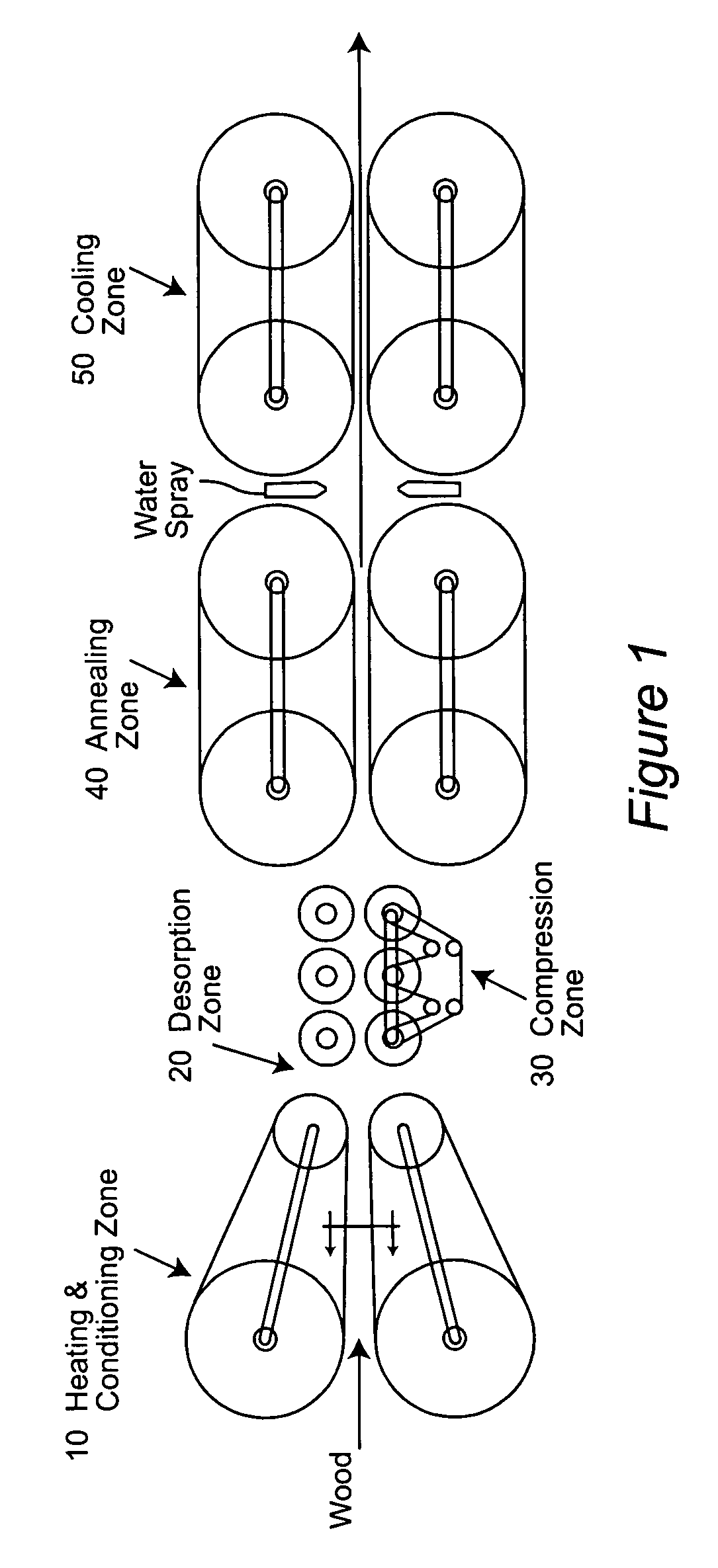

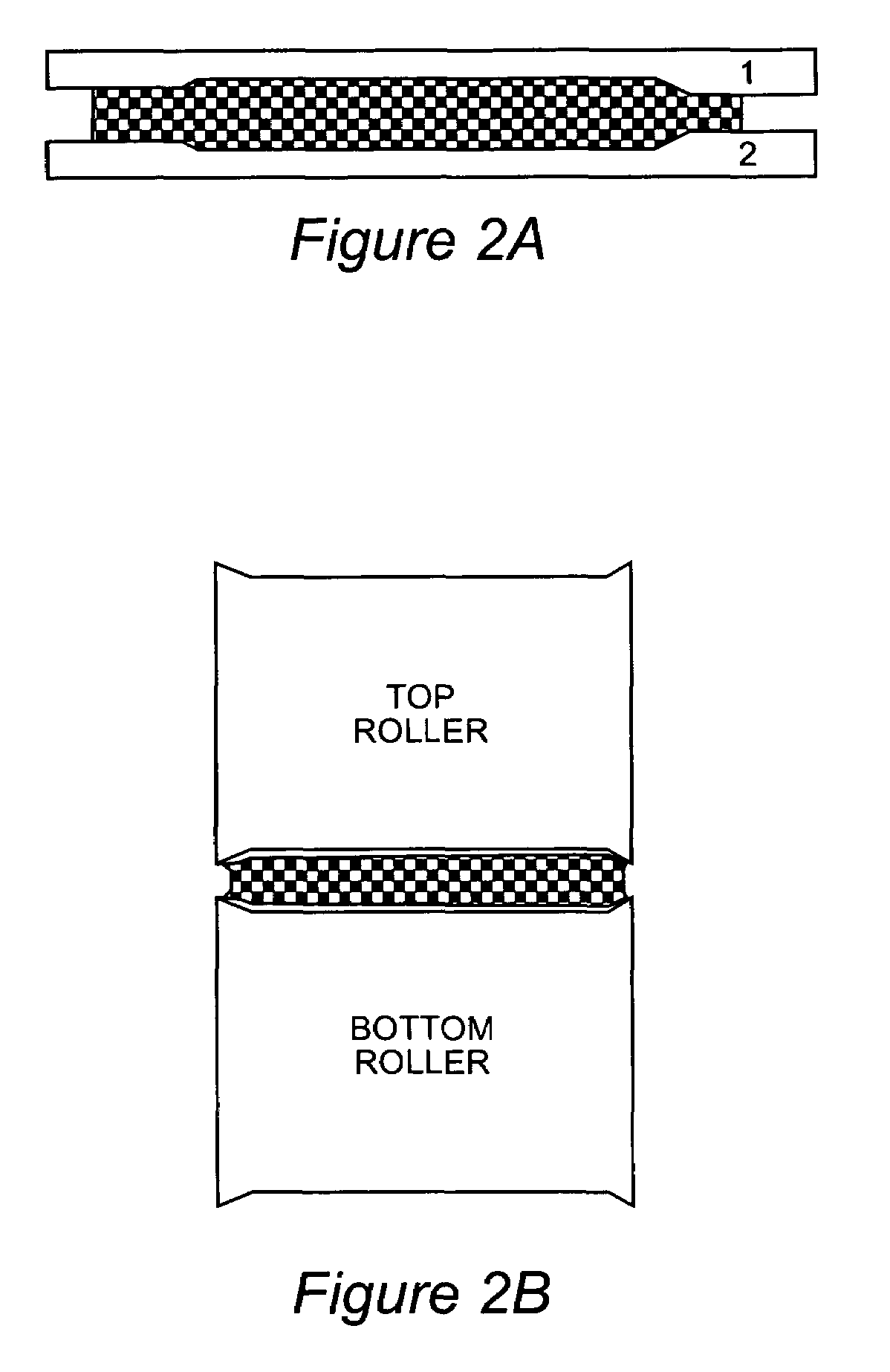

Viscoelastic thermal compression of wood

ActiveUS20050006004A1High density and strength and dimensional stabilityHigh stiffnessWood compressionWood treatment detailsHigh densityThermal compression

A high density wood product that is made from low-density wood is provided. The wood product is made using a continuous viscoelastic thermal compression (VTC) process and exhibits high density, strength and dimensional stability, compared to the lower density starting material (typically composite panels such as strand board) from which it is made.

Owner:THE STATE OF OREGON ACTING BY & THROUGH THE OREGON STATE BOARD OF HIGHER EDUCATION ON BEHALF OF OREGON STATE UNIV

Viscoelastic thermal compression of wood

ActiveUS7404422B2High density and strength and dimensional stabilityHigh stiffnessWood compressionWood treatment detailsHigh densityThermal compression

A high density wood product that is made from low-density wood is provided. The wood product is made using a continuous viscoelastic thermal compression (VTC) process and exhibits high density, strength and dimensional stability, compared to the lower density starting material (typically composite panels such as strand board) from which it is made.

Owner:THE STATE OF OREGON ACTING BY & THROUGH THE OREGON STATE BOARD OF HIGHER EDUCATION ON BEHALF OF OREGON STATE UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com