Patents

Literature

45 results about "Fuel wood" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

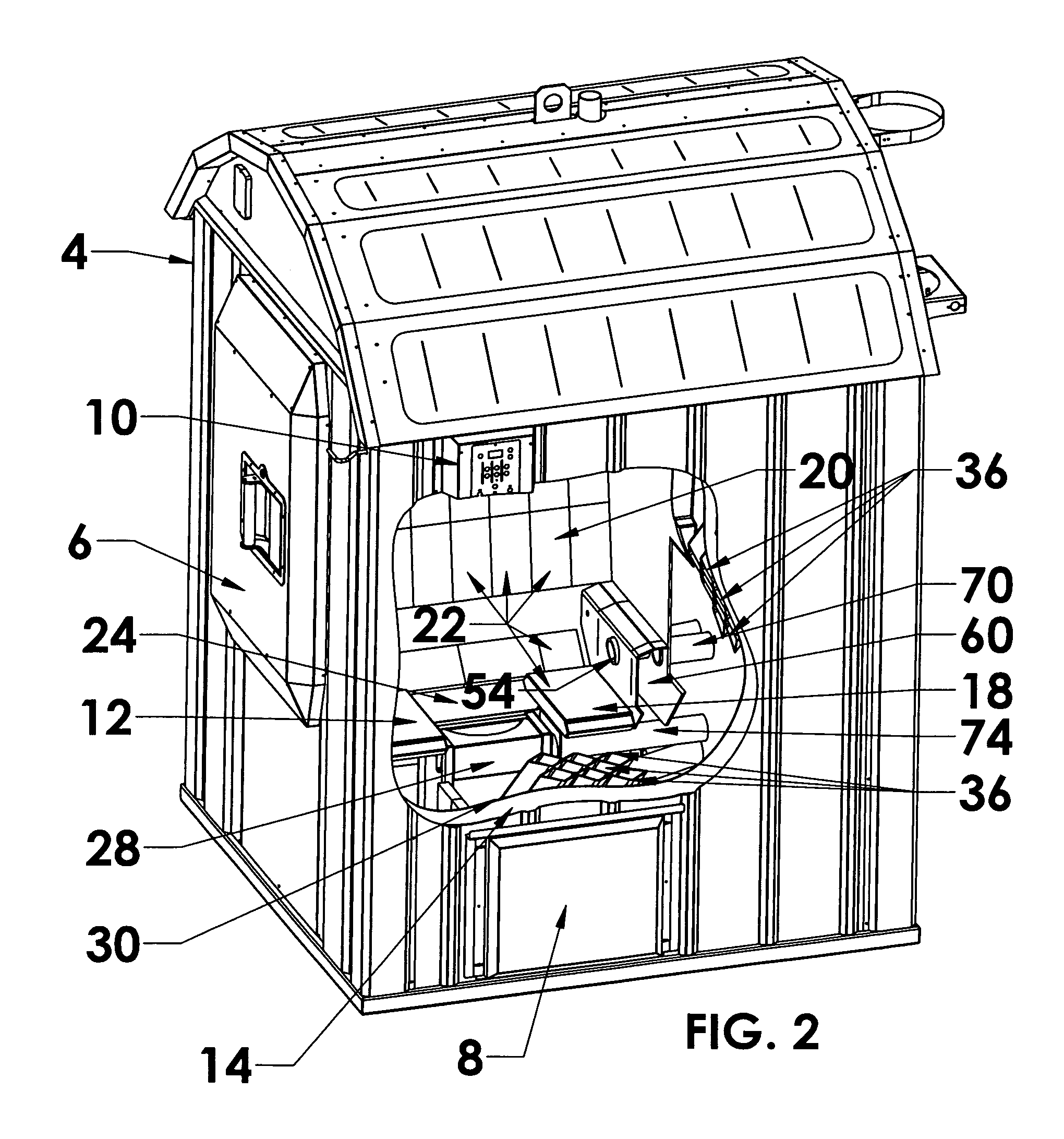

Apparatus and method of automatically regulating intake of air into heating unit

InactiveUS6041771ACounteracting forceDischarge cleaningCombustion-air/flue-gas circulation for stovesCheck valvesCombustion chamberGas pressure

This invention relates to a novel apparatus and method for automatically and dynamically regulating the intake of air into the combustion chamber of a heating unit such as a wood burning stove, furnace, or fireplace to ensure even and efficient burning of fuel. More particularly, this invention pertains to a method and apparatus that uses negative gas pressure in the heating unit's flue, and no additional temperature or pressure sensors, to automatically and dynamically control a damper regulating intake of air into the combustion chamber in inverse relation to changes in negative flue gas pressure. This method and apparatus are especially useful in combination with a heating unit having two combustion chambers, one chamber for combustion of solid fuel and a second chamber for further combustion of exhaust gases and other byproducts from combustion in the first chamber. The two-stage combustion in a dual chamber heating unit is an especially dynamic situation where traditional static controls are not very effective.

Owner:HAYES CECIL JOSEPH

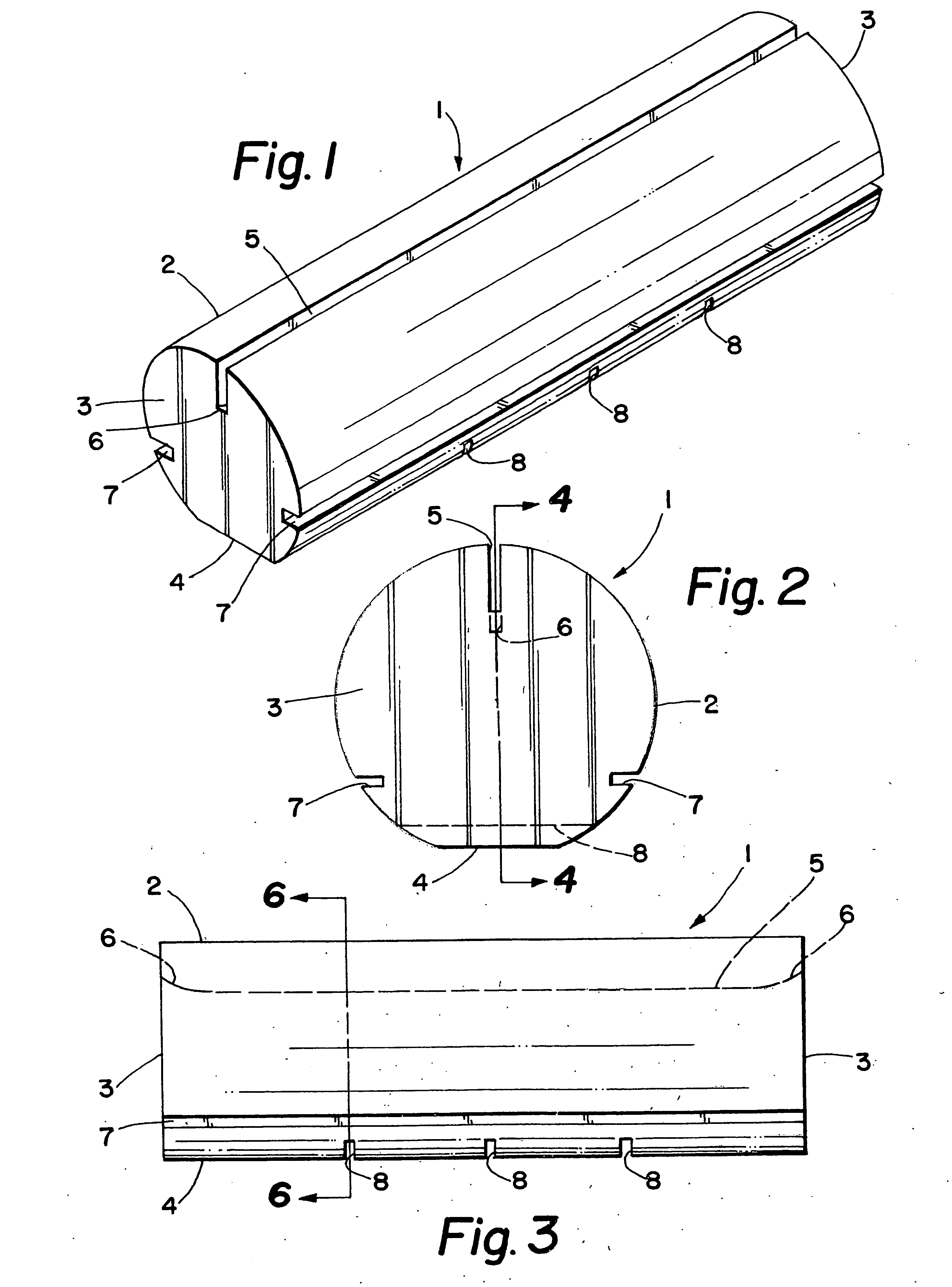

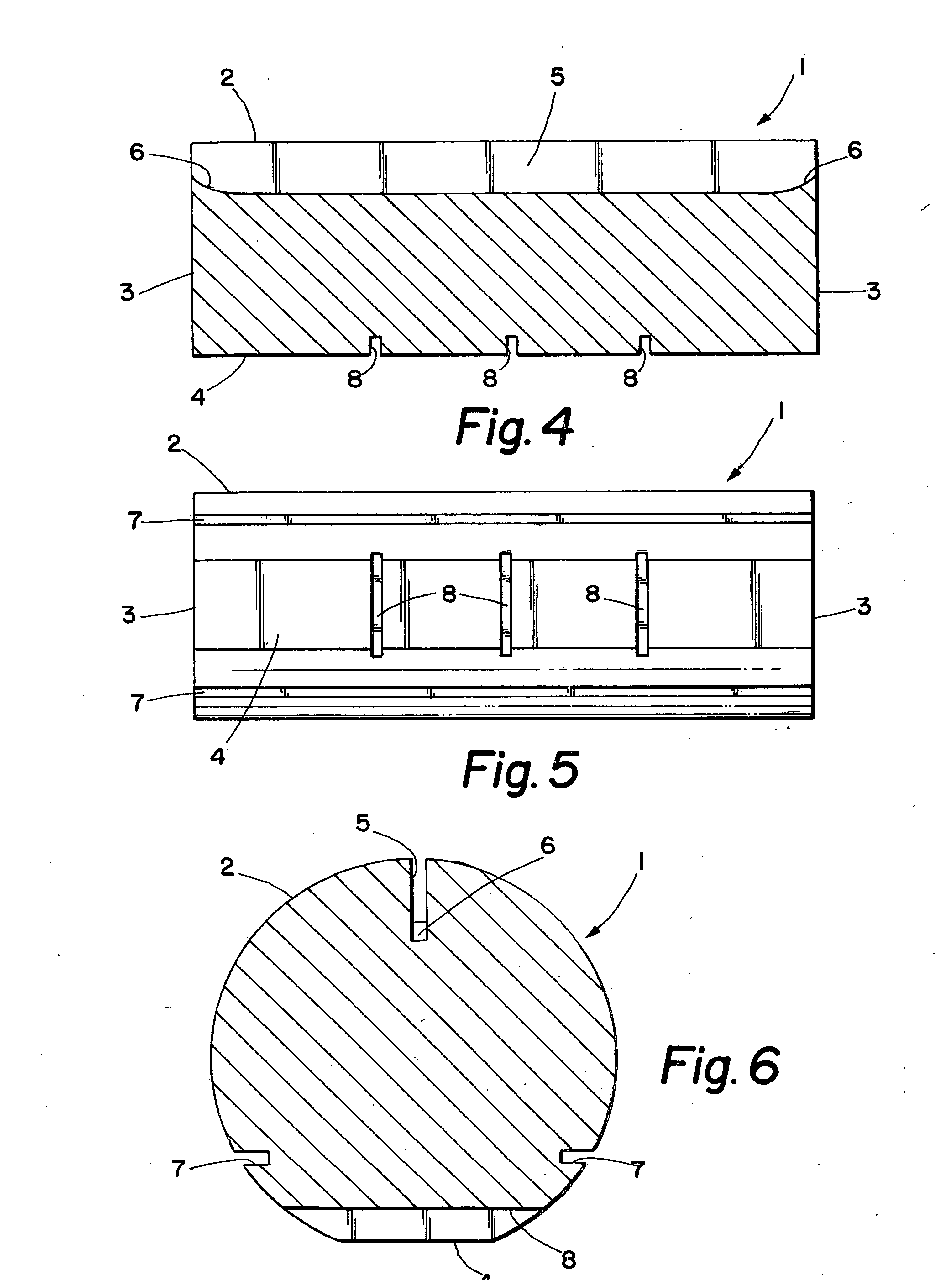

Whole timber firelog impregnated with combustible material

InactiveUS20060230673A1Process safetyProcess environmental protectionBiofuelsSolid fuelsEngineeringCombustion process

Disclosed is a new and improved firelog comprising whole timber to which highly combustible fuel is injected. The log further comprises a plurality of slits to enhance the combustion process. Various combustible fluids or combinations thereby may be used as fuel. Applicants further disclose a method of impregnating said combustible fuel into said firelog.

Owner:BARFORD ERIC DENNIS +1

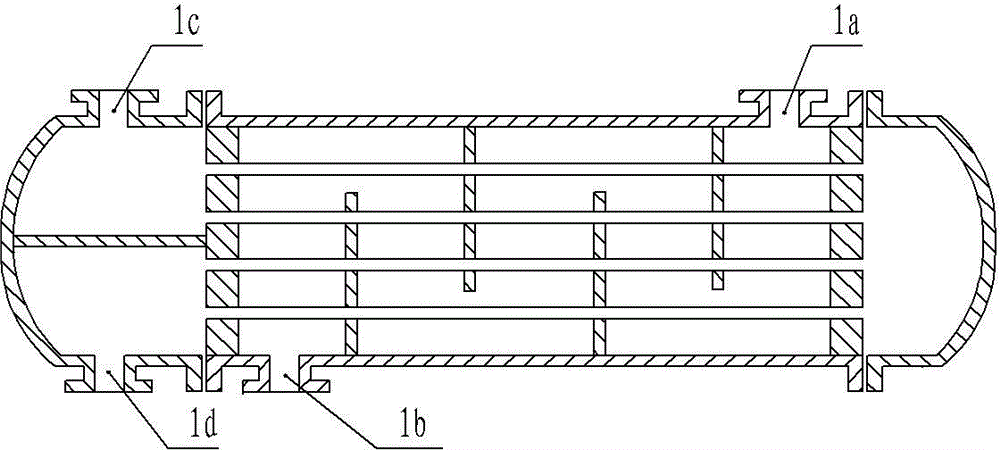

Solid fuel furnace with thermoelectric power generation device

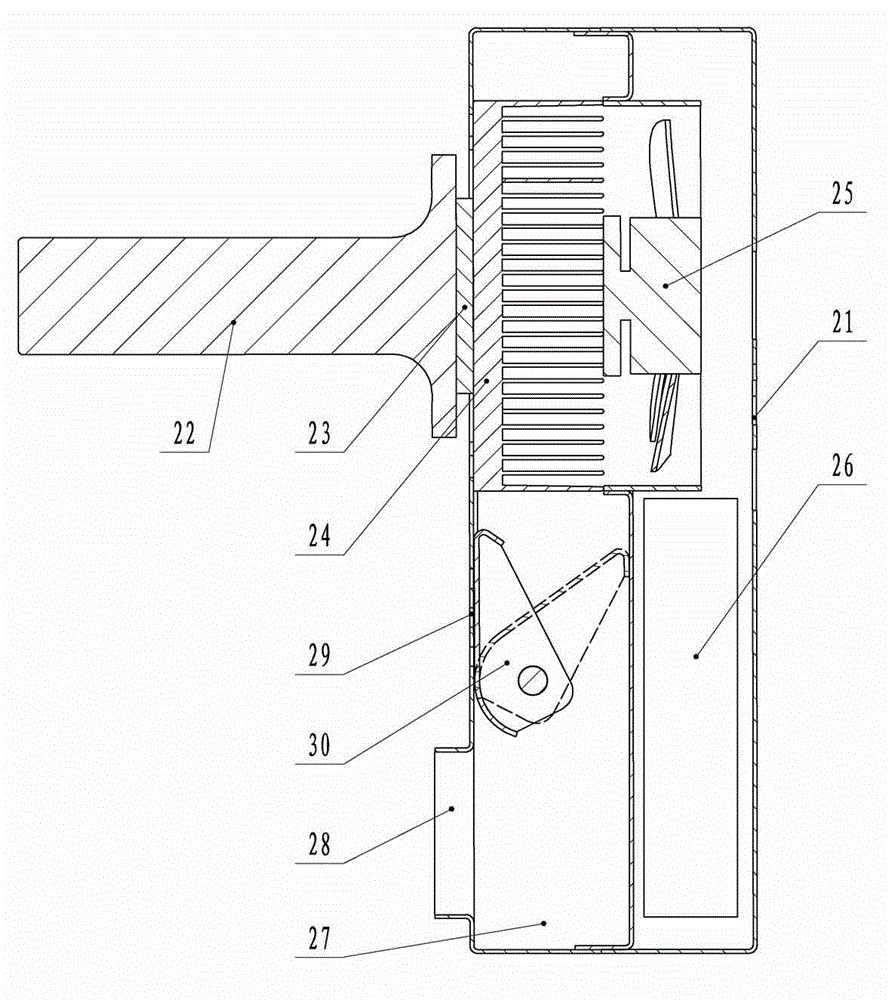

InactiveCN104633713ABurn fullyImprove combustion thermal efficiencyBatteries circuit arrangementsDomestic stoves or rangesAir volumeFuel wood

The invention relates to a solid fuel furnace with a thermoelectric power generation device. The solid fuel furnace comprises a solid fuel furnace and a thermoelectric power generation device; the lower end of a blower box of the thermoelectric power generation device is provided with an exhaust room, and the exhaust room is provided with an air pipe for connecting an exhaust hole with the solid fuel furnace; the air exhaust room is further provided with an air volume balance hole, and an air flap and an adjusting handle are installed in the exhaust room; the air flap is adjusted to close the air exhaust hole or the air volume balance hole, and make that the total air volume is unchanged while the air exhaust volumes of the air exhaust hole and the air volume balance hole are in an inversely proportional relationship. The solid fuel furnace can externally provide stable and enough power source without externally connecting the power source; through reasonable distribution of primary and secondary air, the fuel is fully burned; the solid fuel furnace is featured by simple operation, high burning heat efficiency, and few smoke gas emission; the fuel adaption is wide, and it is especially applicable to various fuel wood and other biomass solid fuels; besides, the solid fuel furnace is simple, small and light in structure, and applicable to indoor cooking and outdoor cooking.

Owner:HUNAN XUNDA JI TUAN YOU XIAN GONG SI

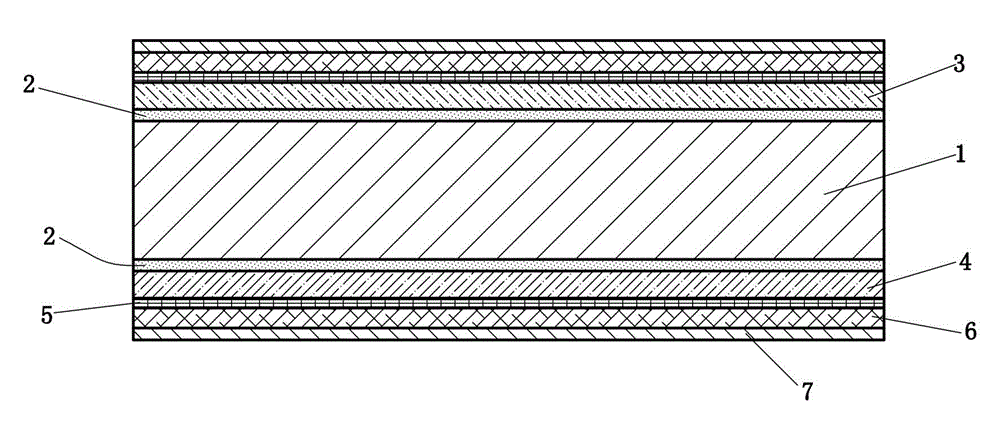

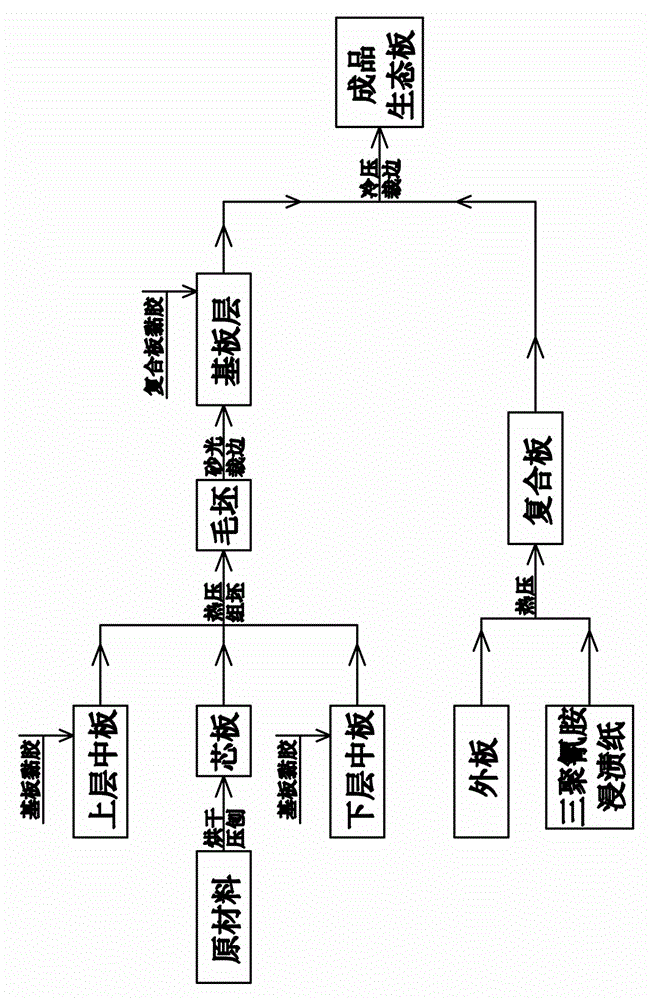

Ecological plate and preparation process thereof

InactiveCN104552487AImprove resource utilizationReduce processWood veneer joiningWood layered productsAdhesiveResource utilization

The invention discloses an ecological plate. The ecological plate comprises a base plate layer and a composite plate; the base plate layer comprises a core plate, an upper medium plate and a lower medium plate, wherein the upper medium plate and the lower medium plate are respectively adhered on the upper surface and the lower surface through base plate adhesive layers; the composite plate comprises an outer plate, and a piece of melamine impregnated paper which is externally adhered on one of the surfaces of the outer plate; the upper medium plate and the lower medium plate are both adhered to the other surface of the outer plate through the composite plate adhesive layer. A preparation process of the ecological plate comprises the steps of 1, polishing two surfaces of a blank and cutting the edge to obtain the base plate layer; thermally pressing the outer plate and the piece of melamine impregnated paper to obtain the composite plate; 2, performing cold pressing and edge cutting for the base plate layer and the composite plate to obtain the final ecological plate. With the adoption of the preparation process, three wastes with small thickness and degraded and small fuel woods can be used for preparing the base plate layer, so that the resource utilization rate is increased; the process and time can be decreased, and the probability of reject ratio is reduced; the energy consumption in the production process can be decreased.

Owner:CHONGREN COUNTY LUFENG FORESTRY DEV

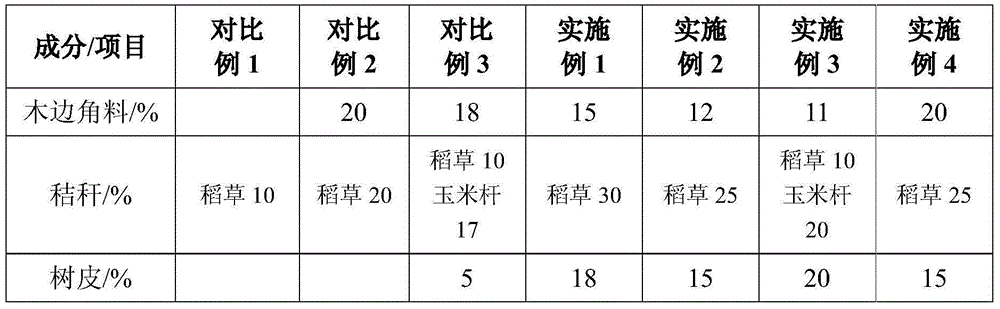

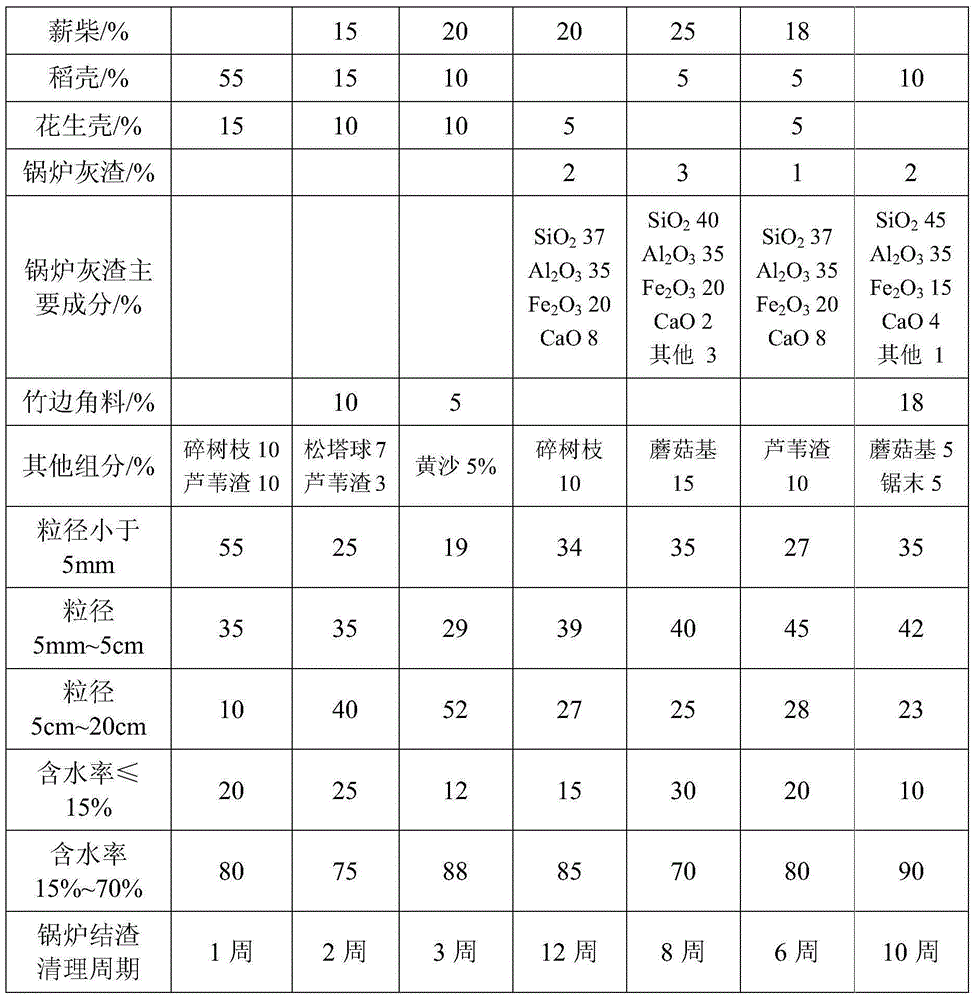

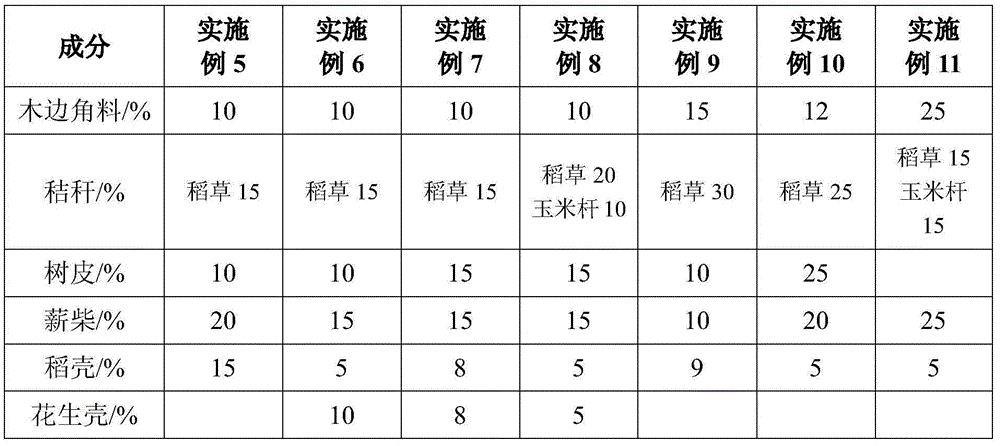

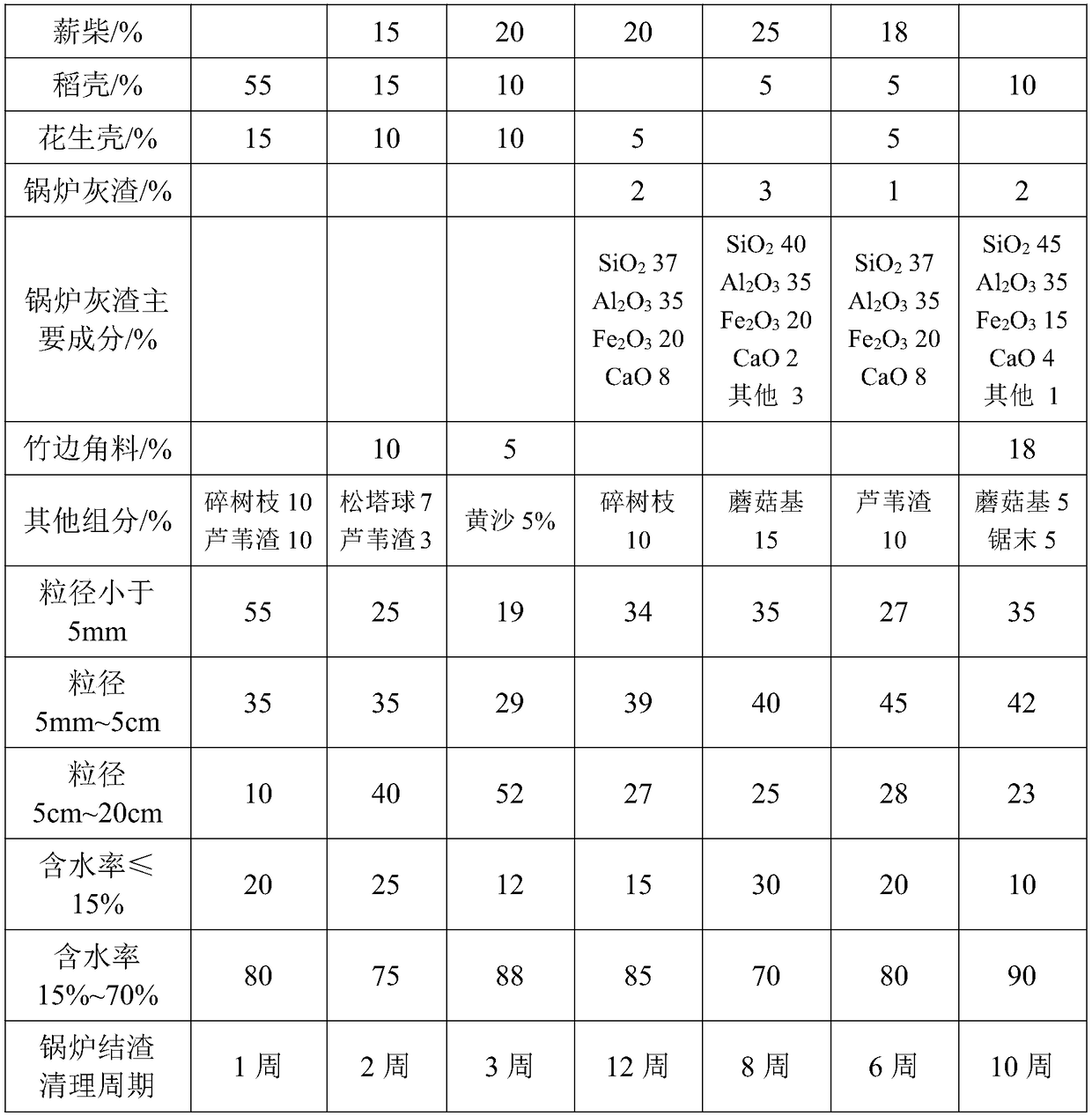

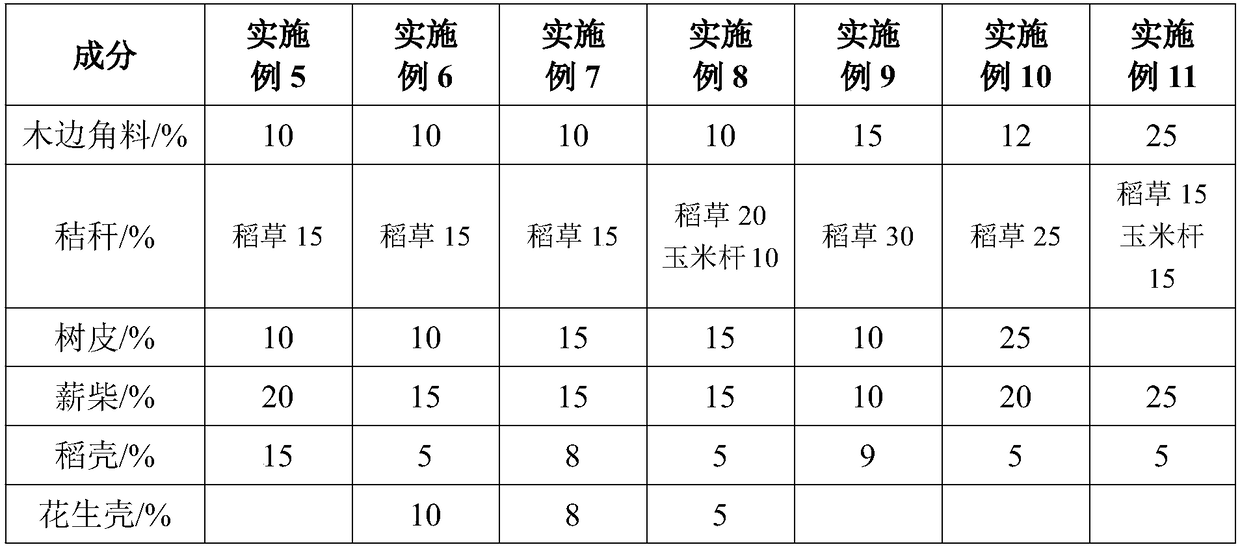

Efficient slag-accumulation resistance biomass composite fuel

The invention discloses efficient slag-accumulation resistance biomass composite fuel. The fuel comprises two or more ingredients out of wooden leftover materials, bamboo leftover materials, straw, bark, fuel wood, rice husks, peanut shells and fragmentary branches. In order to improve the slag accumulation phenomenon, boiler ash is added to the composite fuel, and the boiler ash takes up, by mass, 1%-4%. By means of the biomass composite fuel, heated devices such as a water wall of a biomass boiler can be prevented from accumulating slag, heat generated in the combustion process of the fuel can be evenly distributed inside a hearth, the combustion efficiency of the biomass fuel is improved, the utilization rate of biomass energy is higher, the thermal efficiency of the boiler is higher, and the life of a circulating fluidized bedboiler is prolonged.

Owner:格薪源生物质燃料有限公司

Pug of firewood-fired Nixing pottery and process for manufacturing Nixing pottery from pug

InactiveCN106116511AExpanded firing temperature rangeAvoid burnsCeramic materials productionClaywaresFirewoodWoody plant

The invention provides pug of firewood-fired Nixing pottery and a process for manufacturing the Nixing pottery from the pug. The pug is prepared from, by weight, 5.5-6.8 parts of eastern mud, 1.3-2.0 parts of western mud, 1-1.5 parts of wood ash and 2-2.5 parts of kaolin. The process of for manufacturing the Nixing pottery from the pug comprises the steps of blank preparation, blank body forming, blank body drying and blank body firing; according to blank preparation, the eastern mud, the western mud, the wood ash and the kaolin with the formula amount are prepared into a blank through a conventional process; according to blank body burning, the blank body is fed into a wood-fired kiln, woody plants are adopted as fuel, the firing temperature ranges from 1,160 DEG C tot 1,180 DEG C, and after firing is completed, cooling and drawing are carried out. The kaolin and the wood ash are added into conventional Nixing pottery pug, so that the firing temperature range of the Nixing pottery is greatly widened; the melting temperature of ash of fuel wood can be reduced, the melting time of the ash can be shortened, and the fuel wood cost is greatly reduced.

Owner:钦州市壮冠坭兴陶材料开发有限公司

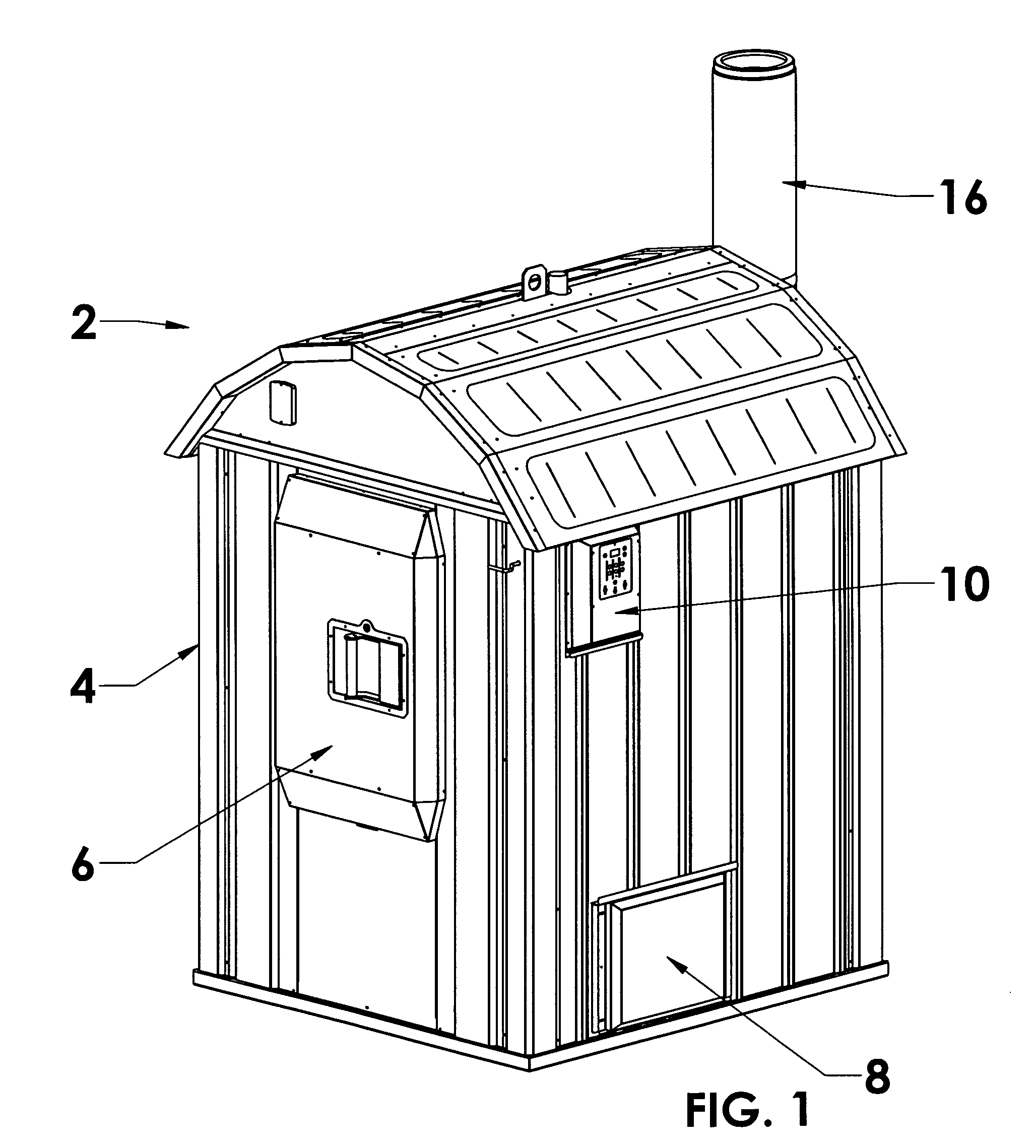

Method for making customized, wood fired pizzas in situ

A method for making wood-fired pizzas at a customer designated location for an event comprises assembling a portable wood stove at the location, setting up a customized pizza assembly station adjacent the assembled stove and then individually making TO ORDER pizza pies for rapidly baking in that wood fired stove. After everyone's had their fill, the stove can be cooled, disassembled and carted off to its next event location for customized wood-fired pizza making for that event's attendees.

Owner:LIPINSKI ADAM

Method for outdoor cultivation of Gastrodia elata Blumein in northern area

InactiveCN109429962AImprove waterloggingImprove drought resistanceCultivating equipmentsRoot crop cultivationMother cultureFuel wood

The invention discloses a method for outdoor cultivation of Gastrodia elata Blume in northern area, which comprises the following steps: selecting a land, opening a hole, digging a ditch, preparing bacterial rods and fuel wood, inoculating Armillaria mellea, sowing, and daily management and harvesting, wherein the method also comprises a cultivation method of Armillaria mellea mother culture. Theculture mode of the Armillaria mellea mother culture comprises the selection of the formula for preparing the mother culture culture medium, the preparation of the mother culture culture medium and the inoculation culture of the Armillaria mellea mother culture, wherein the Gastrodia elata Blume can be harvested one year after the seeding of the Gastrodia elata Blume, the Gastrodia elata Blume harvest period is better from September to February of the next year in Chinese calendar, meanwhile, the fuel wood added in the previous year can also be used as a bacterial material after the harvest, and then 3 to 5 new bacterial rods are added for sowing the Gastrodia elata Blume. The method for outdoor cultivation of Gastrodia elata Blume in northern area has the advantages of high wood utilization rate, good quality of the Gastrodia elata Blume, high content of various nutrient components and good medicinal effect of the wild Gastrodia elata Blume.

Owner:宿彤

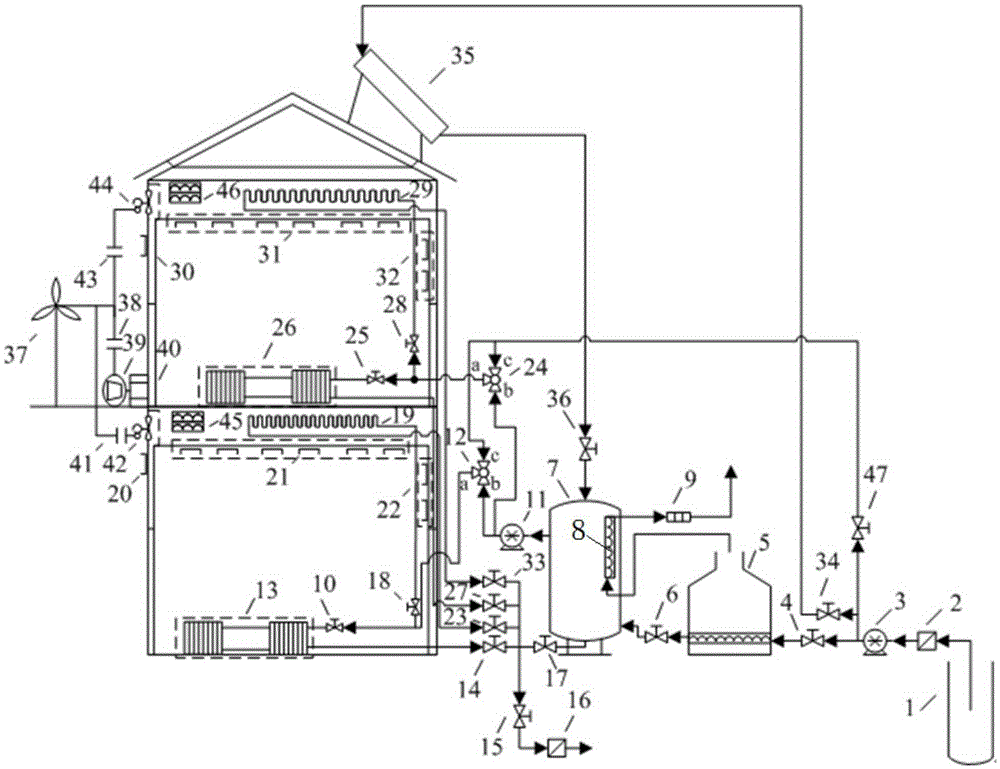

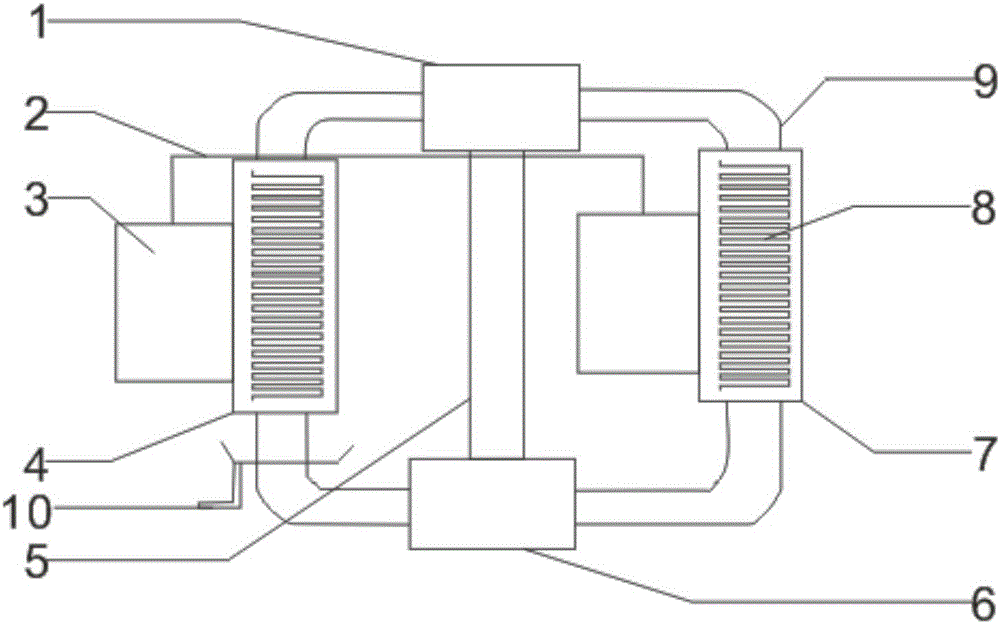

Cooling and heating system for double-deck residence

ActiveCN105333546AReduce usageEmission reductionDucting arrangementsMechanical apparatusResidenceFuel wood

The invention relates to a cooling and heating system for a double-deck residence. The cooling and heating system comprises a boiler heating unit, a solar heat collecting unit, a wind power supplying unit and a cooling and heating heat-exchanging unit. According to the cooling and heating system, traditional fossil fuel or straw or fuel wood can serve as an energy source, and auxiliary power supplying by combining solar energy and wind power is achieved to provide cold and heat for the double-deck residence. According to the cooling and heating system, unified cooling or unified heating of the double-deck residence can be achieved, and the energy supplying mode can be flexibly adjusted according to the different energy demands of different storeys, so that the cooling and heating system is efficient and flexible.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Black liquid charcoal and manufacturing method thereof

InactiveCN103131497ACarbonization production cycle is shortUnbreakableBiofuelsSolid fuelsCarbonizationPapermaking

The invention provides black liquid charcoal. The raw materials of the charcoal comprise at least fuel wood, shrubs, branches, barks, wood processing residues or deserted artificial boards and the like, two components of the raw materials and alkali lignin are mixed, and then cooling compression molding is conducted through a pressing machine, and carbonization is conducted so that the black liquid charcoal is made. The fuel wood, the shrubs, the branches, the barks, the wood processing residues or the deserted artificial boards and the like are hard to be utilized by machine-made charcoal manufacturing and are usually burned off or rotted, utilization degree is low, the alkali lignin is also a problem in black liquid recycling management, the alkali lignin is produced by soda pulping or sulfate pulping through acidification, the alkali lignin has the characteristics of high-viscosity and high-calorific value, the two components of the raw materials and the alkali lignin are mixed and then the cooling compression molding is conducted through the pressing machine, and carbonization is conducted so that the black liquid charcoal is made. The produced carbon is high in caloric value, not prone to crushing, high in application range and utilization rate, in addition a large number of alkali lignin resources produced in the process of pulping and papermaking can be utilized sufficiently, and therefore the pressure of environmental management is relieved.

Owner:仇峰

Pesticide application method for handling monochamus alternatus in bursaphelench xylophilus diseased wood

In a bursaphelench xylophilus disease area, dead and dying trees whose forest stand is not cleared and pines around houses of farmers are collected on the spot before the eclosion and migration of monochamus alternatu imagoes, and are cut into wood segments with length less than 2 cm, thiamethoxam moiety powder is sprayed on the wood segments, and the wood segments are tightly covered by plastic films. The handled wood segments can be used as fuel wood whenever being taken, and after being used, the handled wood segments are covered tightly. By the next summer, monochamus alternatus in the forest stand of the handled wood segments died, and the monochamus alternatu imagoes cannot lay eggs on the wood segments and decompose and decay voluntarily after the plastic films are opened. The pesticide application method for handling the monochamus alternatus in the bursaphelench xylophilus diseased wood can effectively reduce the amount of the monochamus alternatus, and thereby the spreading of the bursaphelench xylophilus disease is controlled, people and livestocks cannot be damaged, time and labor are saved, and the cost is low.

Owner:ZUNYI INST OF FORESTRY

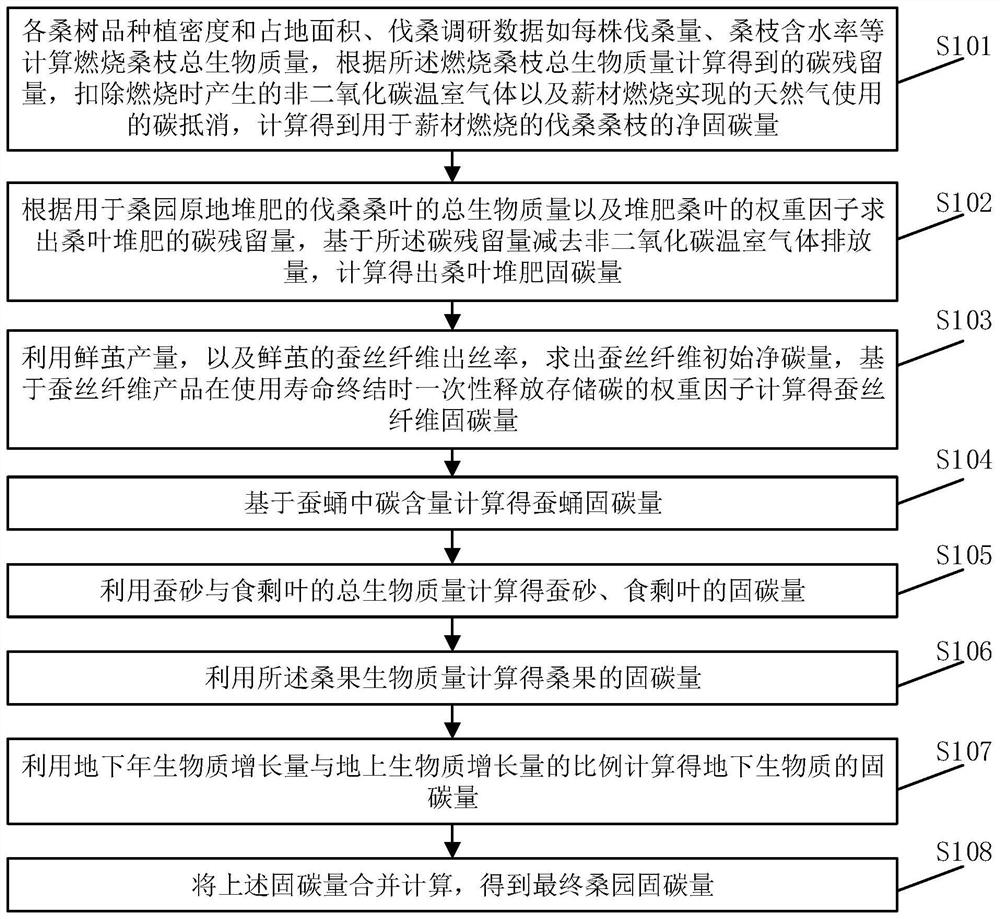

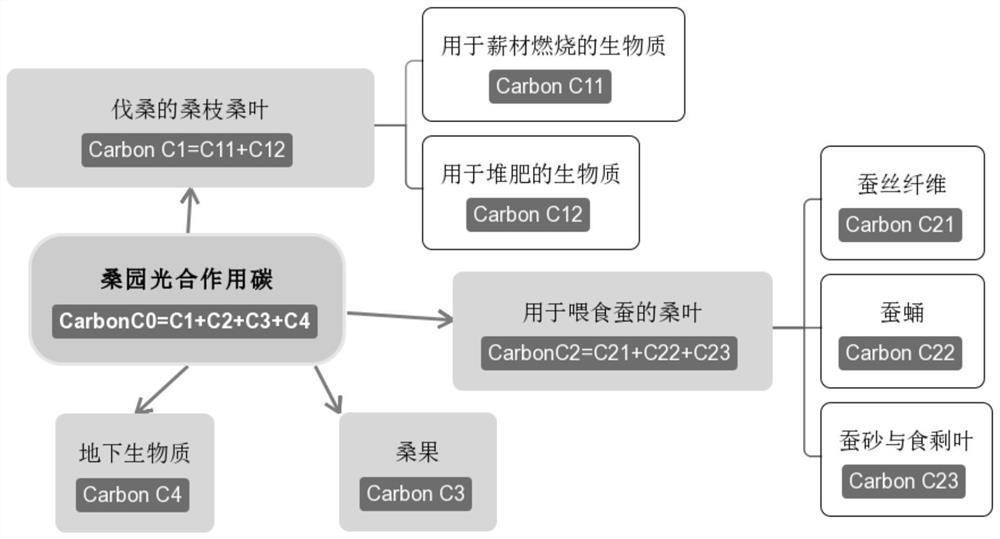

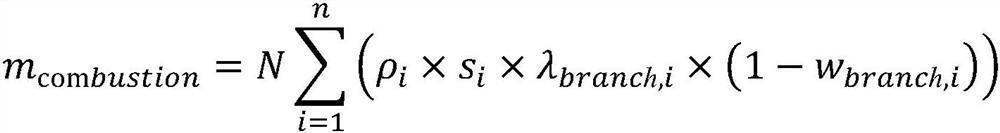

Modeling method for carbon sequestration accounting of ecological system of mulberry field

The invention discloses a modeling method for mulberry field ecosystem carbon sequestration accounting, which comprises the following steps: calculating the total biomass of mulberry twigs for fuel wood combustion by using basic planting information and mulberry felling quantity data of a mulberry field so as to establish a carbon sequestration accounting model for the mulberry felling twigs for fuel wood combustion, which considers carbon offset and greenhouse gas emission during combustion; a carbon release model of mulberry leaf in-situ compost is established to solve the carbon residue of compost, and a carbon sequestration accounting model of cut mulberry leaves is obtained; establishing a carbon sequestration amount model of the silk fibers and the silkworm chrysalis within a 100-year evaluation period; establishing an accounting model for the carbon sequestration amount in the silkworm excrement and the residual food leaves in consideration of compost greenhouse gas emission and carbon dioxide emission by silkworm respiration; seven carbon circulation path modeling such as a mulberry and underground biomass carbon sequestration amount accounting model is established. According to the method, modeling is carried out on carbon loss and carbon offset of seven circulation paths of photosynthesis carbon, an accurate and reliable mulberry field carbon sequestration accounting model is explored, and the method has important significance on quantitative evaluation of mulberry field carbon sequestration.

Owner:SUZHOU UNIV

Hot compression plasticizing molding charcoal and manufacturing method thereof

Raw materials of hot compression plasticizing molding charcoal comprises at least fuel wood, shrubs, branches, bark, wood processing residuum or waste artificial boards and the like, with alkali lignin serving as two components. A molding method is hot compression plasticizing molding. After being molded, discharged materials are cut into required specifications through saws and enter a carbonization furnace to be carbonized in a pile mode. The hot compression plasticizing molding charcoal is obtained by cooling after full carbonization. The fuel wood, the shrubs, the branches, the bark, the wood processing residuum, the waste artificial boards and the like are difficult to utilize when machine-made charcoal is manufactured. The fuel wood, the shrubs, the branches, the bark, the wood processing residuum, the waste artificial boards and the like are burned or corrupted, and therefore the utilization degree is not high. The alkali lignin is a difficult problem of black liquid recycling management, generated through acid-out treatment after pulping by means of a caustic soda method or a sulfate method, has the characteristics of high viscosity and a high heat value. After being mixed, the two components are molded by means of the hot compression plasticizing molding technology and carbonized, and therefore the charcoal is obtained with the high heat value.

Owner:仇峰

Novel sanitation and epidemic prevention disinfection smoke agent

The invention relates to a novel sanitation and epidemic prevention disinfection smoke agent. The product belongs to the field of daily chemical product and sanitation and epidemic prevention disinfectant. The product is suitable to be used in epidemic focus disinfection in relatively confined spaces such as families, schools, dormitories, workshops, tunnels, and the like. In the product, a disinfectant active ingredient is prepared from well compounded and pressed materials such as kresoxim-methyl, chlorine isonitrile uric acid, and the like, and a proper fuel wood powder, a combustion improver potassium chlorate, a smoke agent ammonium chloride, a flame retardant clay, and an adhesive hydroxymethyl cellulose. The product is convenient to use. When in use, the product is ignited for smoking. When tested according to a method defined in Ministry of Health. disinfection technical specifications (2002), the product has a killing rate reaching 99.9% against staphylococcus aureus, escherichia coli, and bacillus subtilis black variant spores. When in use, the product is placed on a tile on ground; a dosage is calculated according to a volume; channels such as doors and windows are closed; the product is ignited; and fumigation is carried out for 120min.

Owner:INST OF PLA FOR DISEASE CONTROL & PREVENTION

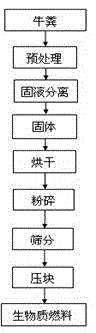

Method for producing new type of biomass fuel using cow dung

InactiveCN104560260ASolve pollutionReduce the use of direct combustionBiofuelsSolid fuelsEcological environmentResource utilization

The invention provides a method for producing a new type of biomass fuel using cow dung. The method includes the following steps: (1) pre-processing: enabling the cow dung to react for 20 minutes under the conditions of 150-180 DEG C and 0.8-1.2 Mpa in the presence of a catalyst; (2) solid-liquid separation: separating the solid cow dung from the liquid after preprocessing; (3) biomass fuel production: producing biomass particle fuel using the separated solid dung. The method provided by the invention solves the problem of environmental pollution caused by the cow dung produced in farms; the cow dung is processed into the biomass fuel which is clean and environment-friendly and reduces greenhouse effects caused by fossil energy consumption; the cow dung solid fuel basically realizes zero emission standards of the environmental protection, can efficiently replace three major types of energy with high pollution and high emissions, and reduces the usage amount of direct-fired fuel wood; the resource utilization of agricultural wastes such as the dung of grazing cows is a strategic measure for promoting energy conservation and emission reduction and a powerful action for protecting the ecological environment, drives the establishment of a resource-saving and environment-friendly society, and maintains the harmonious development of human beings, nature and economy.

Owner:TIANJIN DEWEI ENVIRONMENTAL PROTECTION ENG EQUIP

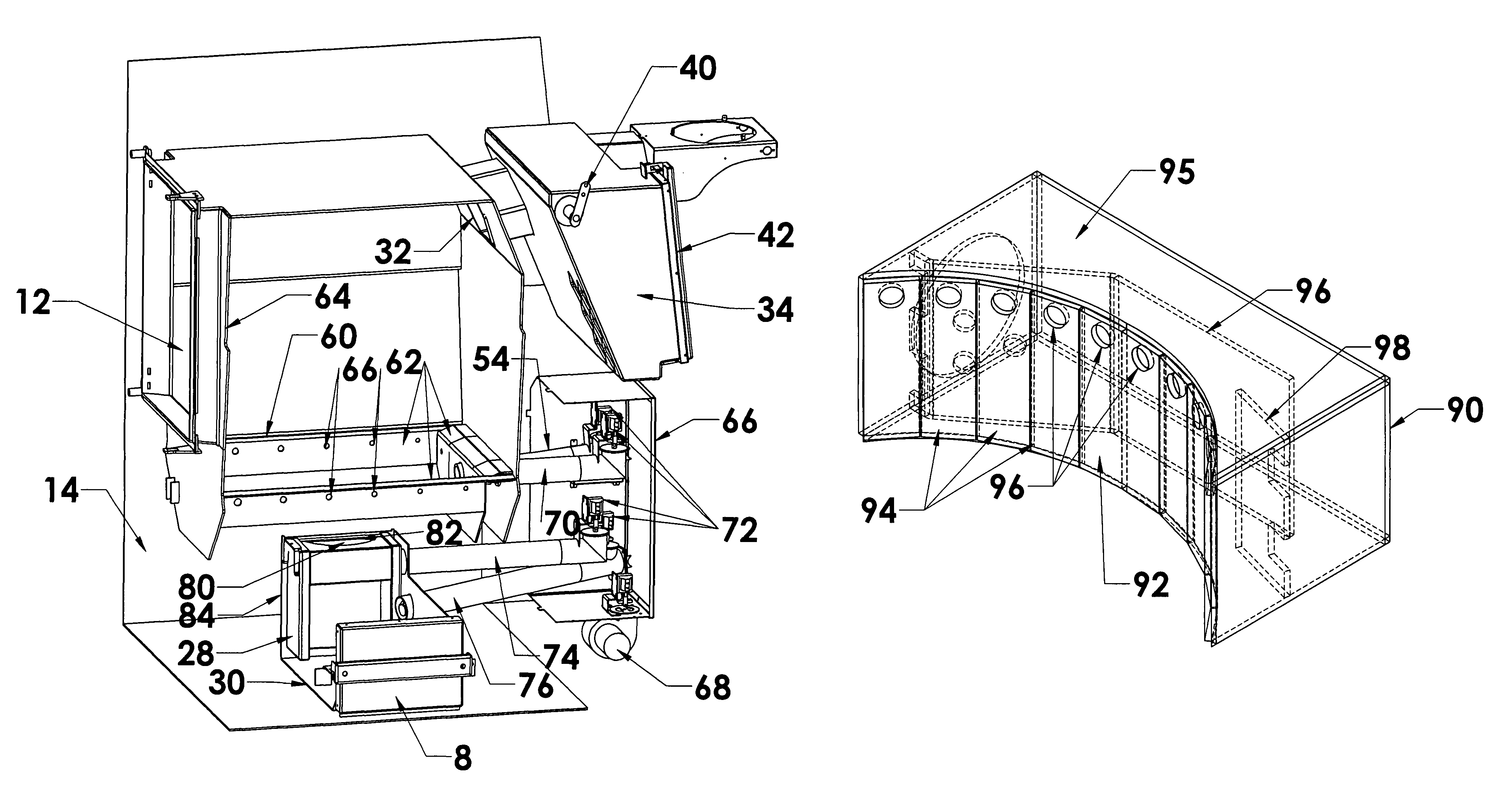

Wood fired boiler

ActiveUS7954438B2Promote lowerAdjust operation to fuel costsDomestic stoves or rangesFurnace componentsCombustion chamberEngineering

A bio-mass fueled boiler operating at delivered efficiencies in excess of 90%. Pre-heated, pressurized primary combustion air is supplied to a primary burn chamber via horizontal and vertical orifice containing conduits. Exhaust gases are directed past a reflective secondary burner supplying pre-heated, pressurized secondary combustion air into a secondary burn / ash collection chamber. Exhaust gases are directed from the secondary burn chamber via exhaust conduits having axial and cross-sectional shapes and wall geometries that promote internal turbulence and heat transfer. One or more gas / oil fired burners are fitted to or between the primary and secondary combustion chambers. Several operating modes are provided via associated blowers, air baffles, liquid and gas fuel conduits, pumps and sundry stove sensors and servos coupled to microprocessor control circuitry.

Owner:CENTRAL BOILER

Preparation method of high-utilization-rate machine-made charcoal

The invention discloses a preparation method of high-utilization-rate machine-made charcoal. The preparation method comprises the following steps: crushing raw materials by a crusher and uniformly stirring with phenolic resin to obtain a blank; molding the blank into a blank with the density of 1-1.3g / cm < 3 > by a blank hot press under the conditions that the pressure intensity is 10-20MPa and the temperature is 150-200 DEG C and sawing the blank into a required specification after discharging; carrying out semi-finished product molding processing by a rod molding machine and carrying out rodmolding; heating in the machine at 350-420 DEG C to obtain a semi-finished product for later use; stacking and airing the obtained semi-finished product for later use; and filling the aired semi-finished product into a carbonization furnace, carbonizing at 500-600 DEG C under the condition of introducing air and naturally cooling to obtain the machine-made charcoal. According to the preparation method of the high-utilization-rate machine-made charcoal, disclosed by the invention, the utilization rate of fuel wood, shrubs, branches, barks, wood processing residues or waste artificial boards can be improved to be more than 60%.

Owner:HUZHOU MINQIANG CARBON IND CO LTD

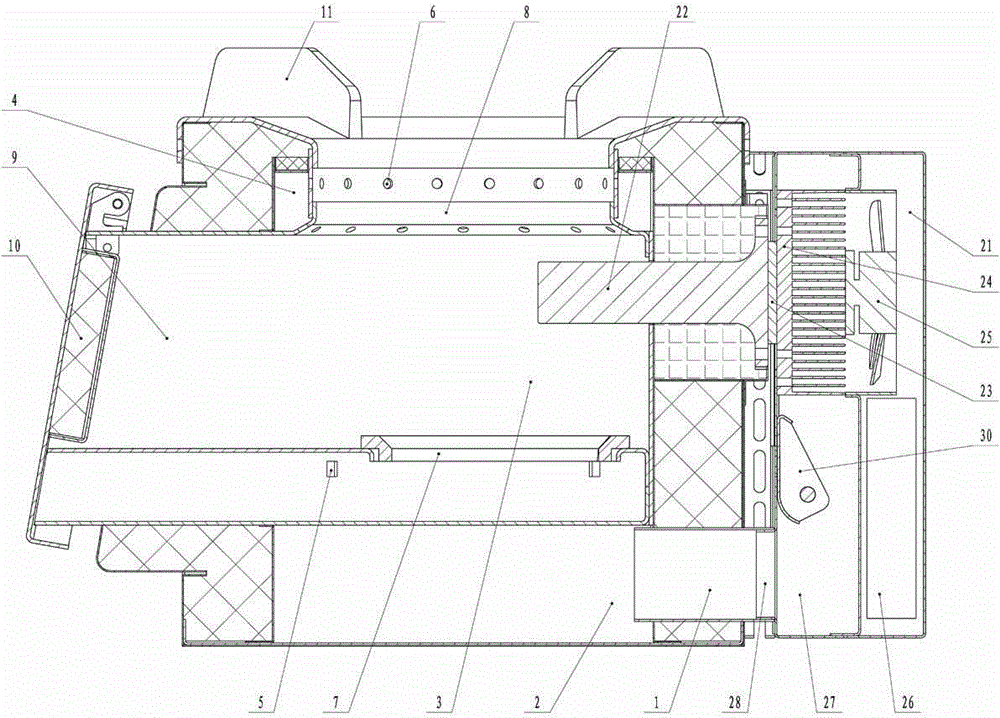

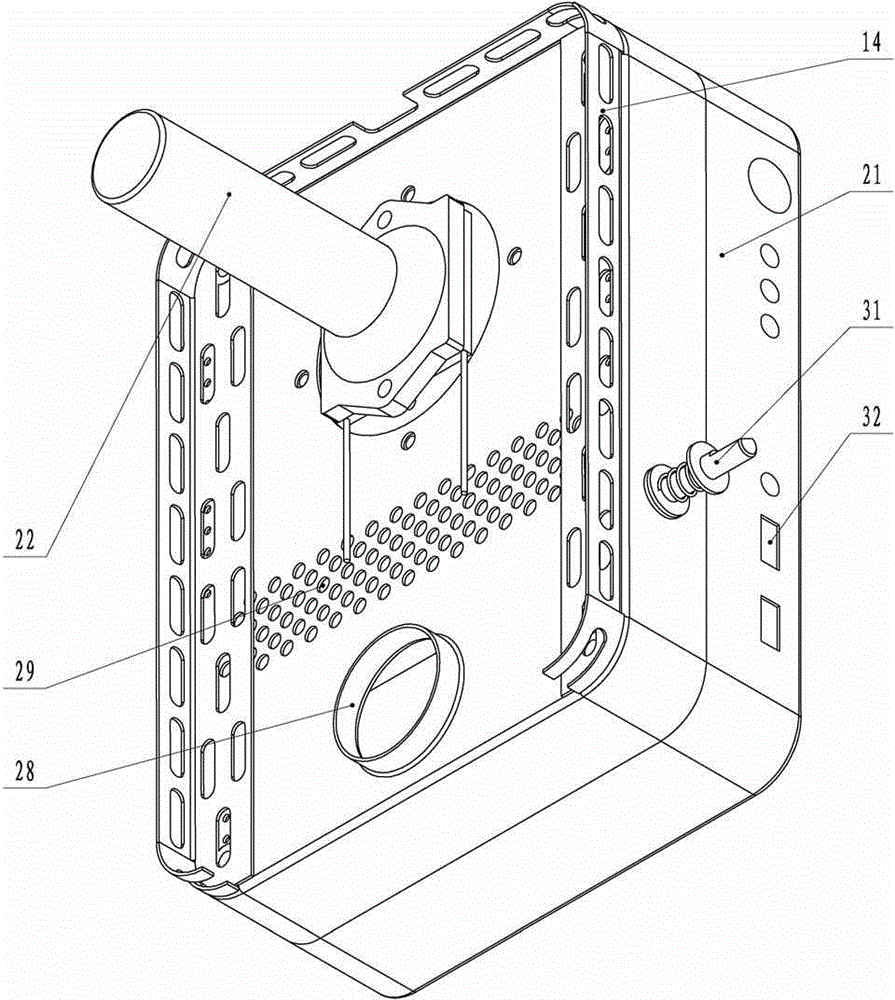

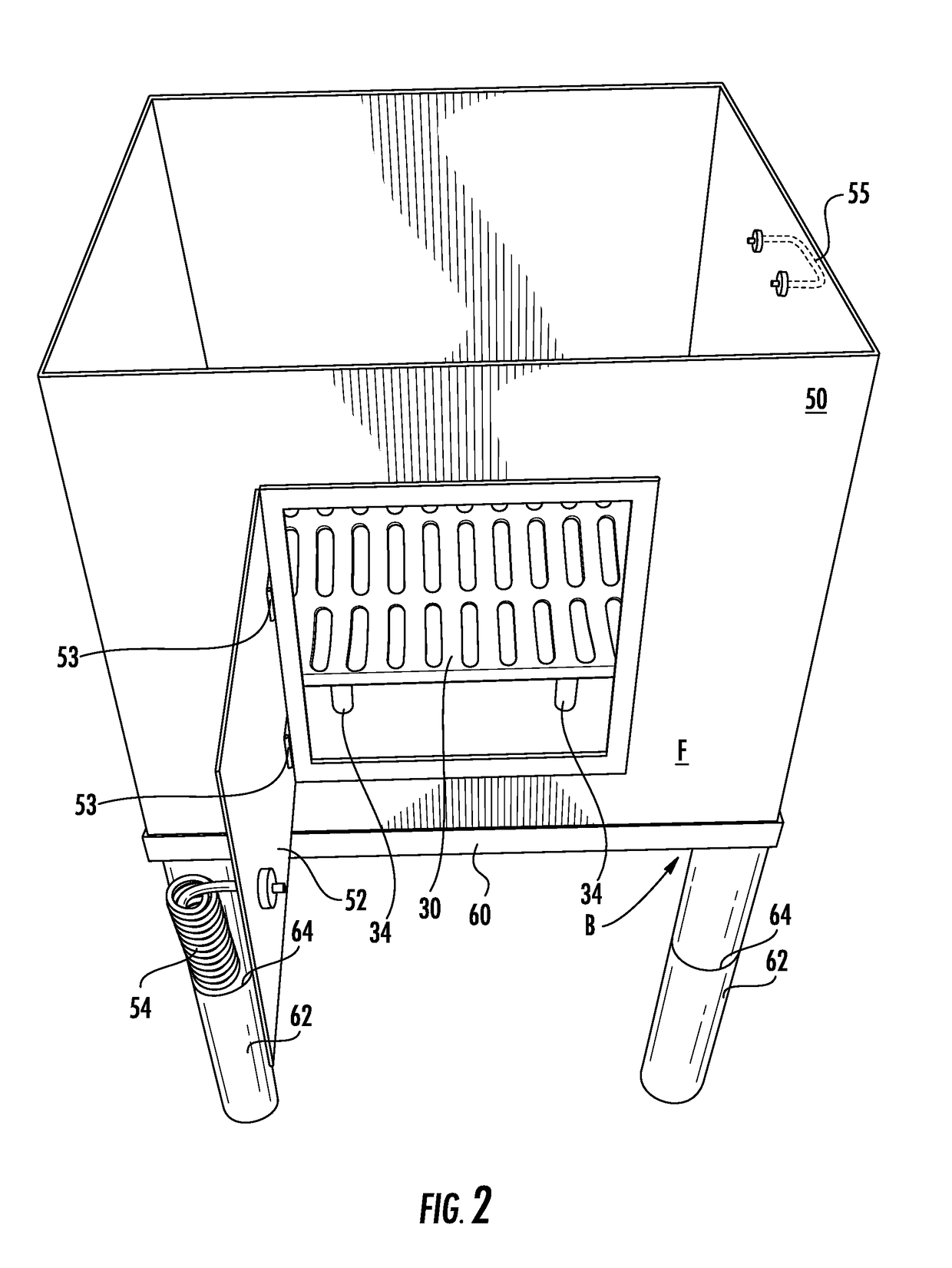

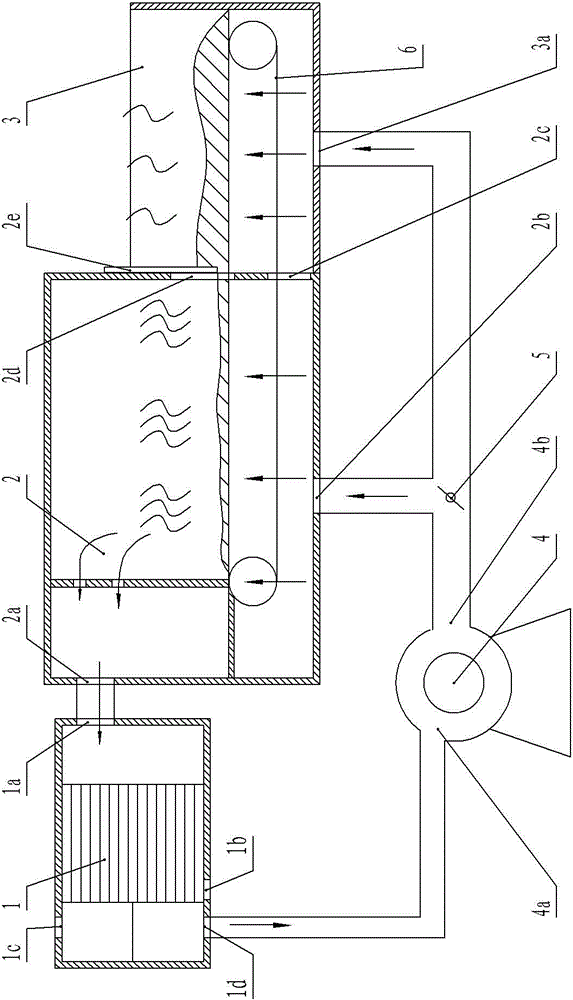

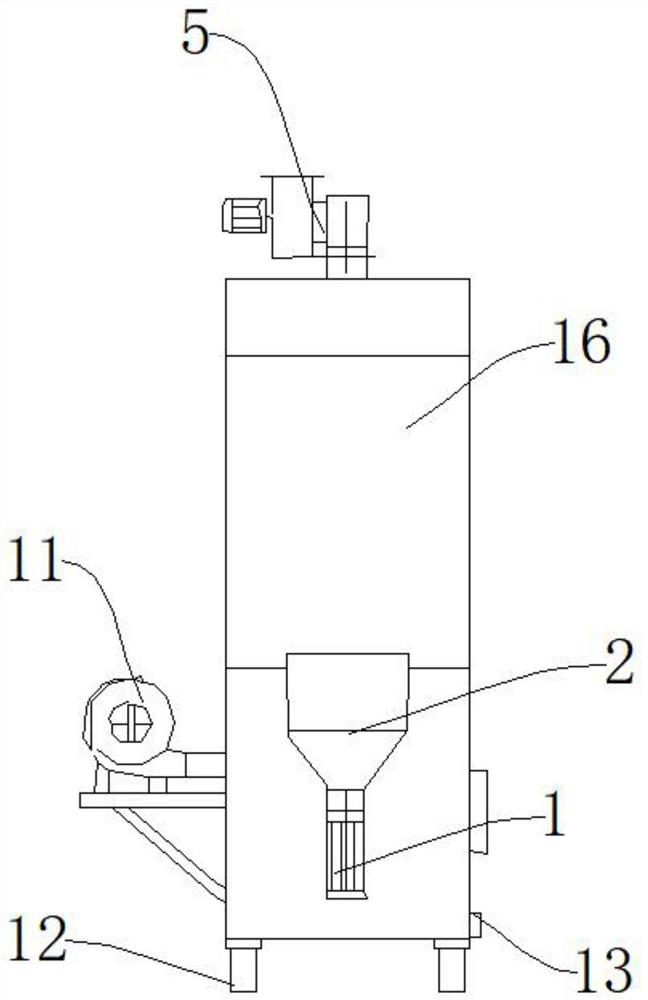

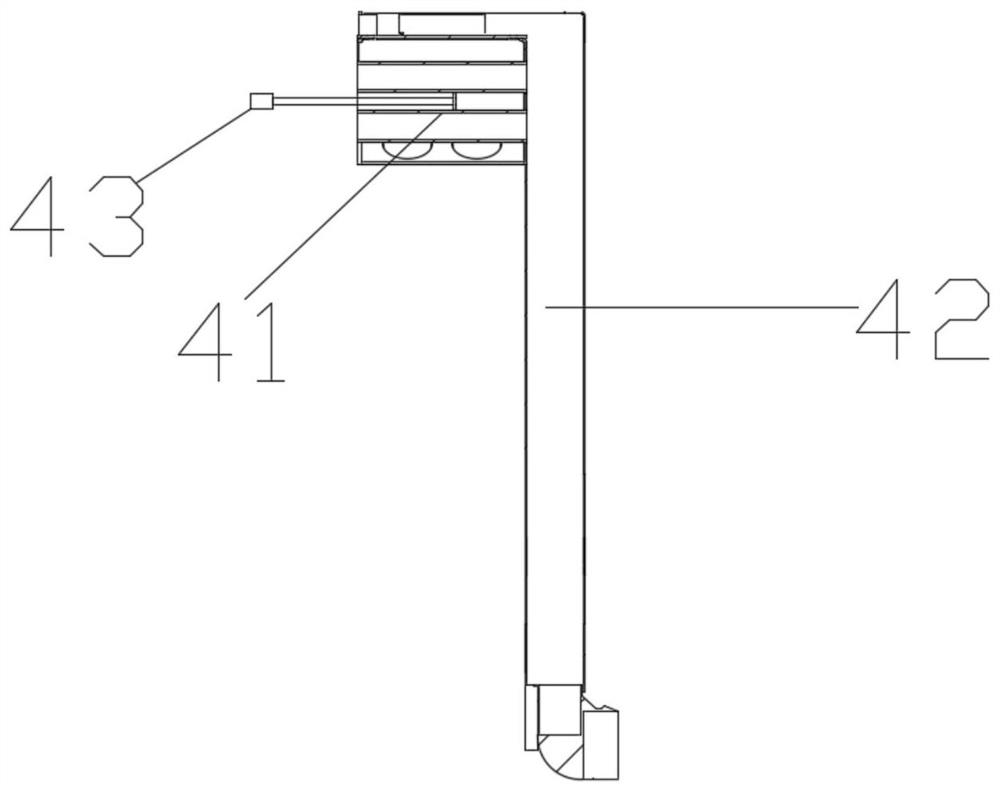

Fuel wood boiler

InactiveCN104456529AReduce manufacturing costImprove combustion efficiencySolid fuel combustionCombustion apparatusNatural resourceCombustion chamber

The invention discloses a fuel wood boiler and belongs to the technical field of boilers. The fuel wood boiler comprises a boiler body, a feeding hopper is arranged on one side of the boiler body, a smoke exhausting port is formed in the upper portion of the boiler body, the boiler body is provided with a combustion chamber, a first air supplying port is formed in the lower portion of the combustion chamber, a feeding port communicated with the feeding hopper is formed in the boiler body, a chain grate stoker penetrating through the lower portion of the feeding port is arranged in the combustion chamber and the feeding hopper, a gate for adjusting the size of the feeding port is arranged on the boiler body, a second air supplying port is formed in the lower portion of the feeding hopper, the smoke exhausting port is communicated with a heat source port of a heat exchanger, a heated end outlet of the heat exchanger is communicated with an air inlet of an air blower, and an air outlet of the air blower is communicated with the first air supplying port and the second air supplying port. According to the fuel wood boiler, barks discarded by people serve as fuels of the boiler, and heat energy discharged by a boiler flue is fully utilized to improve the combustion efficiency and save energy, natural resources are fully utilized, and the production cost is saved.

Owner:LIUZHOU RUNCHENG KNITTING CO LTD

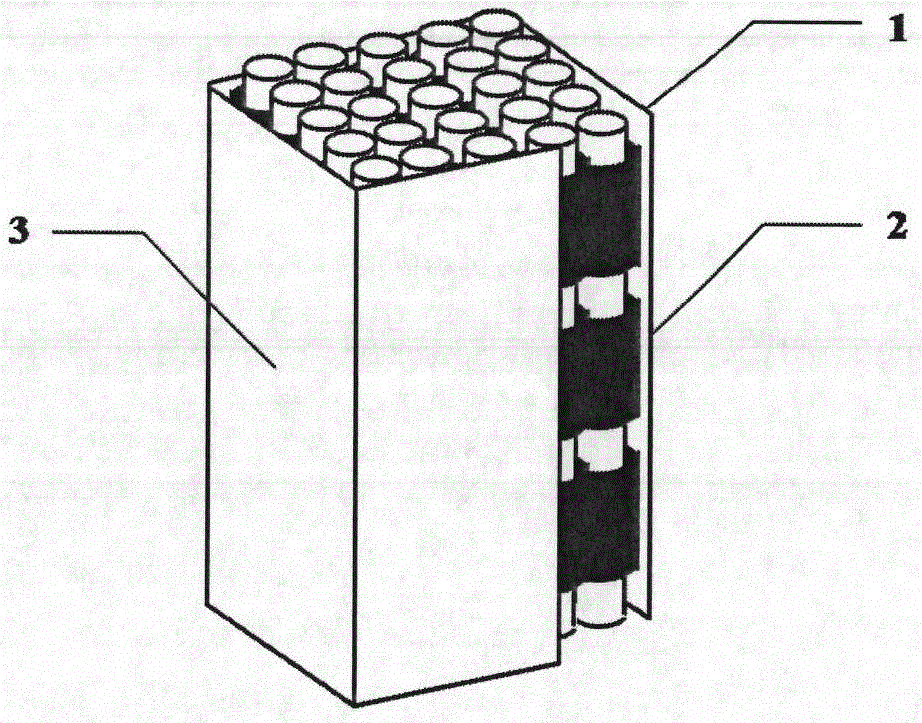

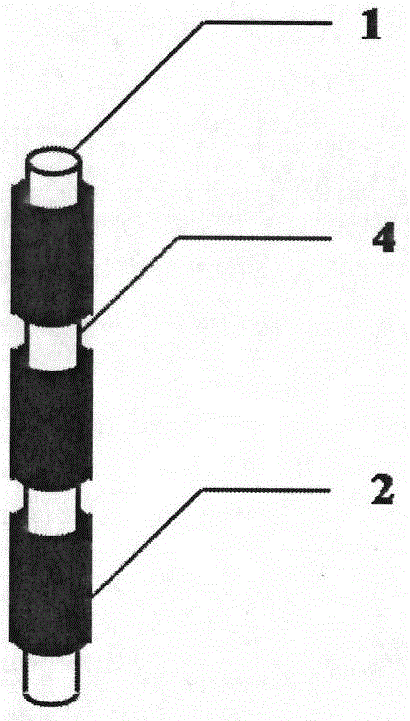

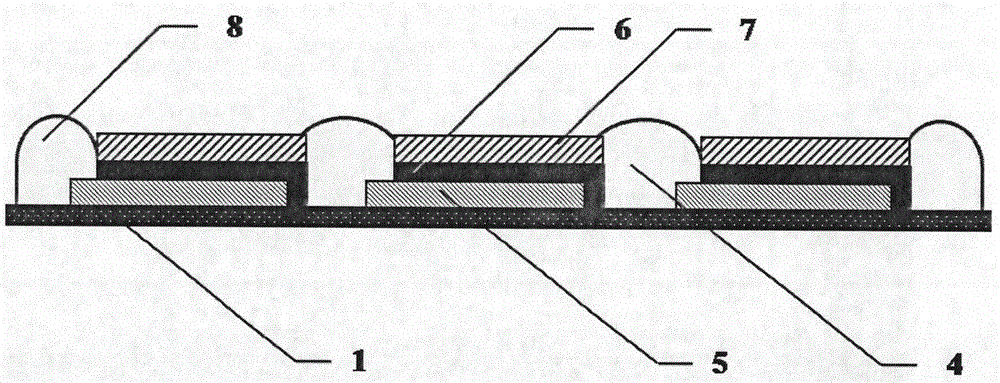

Portable tubular solid oxide fuel cell power generation apparatus

Disclosed is a portable tubular solid oxide fuel cell power generation apparatus. The power generation apparatus is characterized by comprising a protection shell and supporting pipes which are coated with fuel cell assemblies and are arranged in the protection shell. Exhaust gases and afterheat generated by incomplete combustion of coal, fuel wood and the like are reacted through the fuel cell to realize power generation. The power generation apparatus has the characteristics of portability and environment protection.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Biomass fuel and preparing method thereof

The invention discloses biomass fuel and a preparing method thereof. The biomass fuel is prepared from, by weight, 18-25 parts of cornstalk, 21-25 parts of wheat straw, 20-28 parts of straw, 15-20 parts of bark, 8-12 parts of peanut shells, 25-35 parts of fuel wood, 10-12 parts of bagasse, 2-4 parts of a binder, 6-20 parts of fruit shells, 1-3 parts of a desulfurizing agent and 1-2 parts of a combustion improver. The biomass fuel which is prepared from different raw materials by weight is a clean and low-carbon renewable energy source, is high in caloric value, sufficient in combustion, long in combustion time and economical and causes no pollution to the environment.

Owner:YUNNAN CONSTR ENG GRP NO 10 CONSTR

Anti-slagging Biomass Composite Fuel for Circulating Fluidized Bed Boiler

The invention discloses efficient slag-accumulation resistance biomass composite fuel. The fuel comprises two or more ingredients out of wooden leftover materials, bamboo leftover materials, straw, bark, fuel wood, rice husks, peanut shells and fragmentary branches. In order to improve the slag accumulation phenomenon, boiler ash is added to the composite fuel, and the boiler ash takes up, by mass, 1%-4%. By means of the biomass composite fuel, heated devices such as a water wall of a biomass boiler can be prevented from accumulating slag, heat generated in the combustion process of the fuel can be evenly distributed inside a hearth, the combustion efficiency of the biomass fuel is improved, the utilization rate of biomass energy is higher, the thermal efficiency of the boiler is higher, and the life of a circulating fluidized bedboiler is prolonged.

Owner:格薪源生物质燃料有限公司

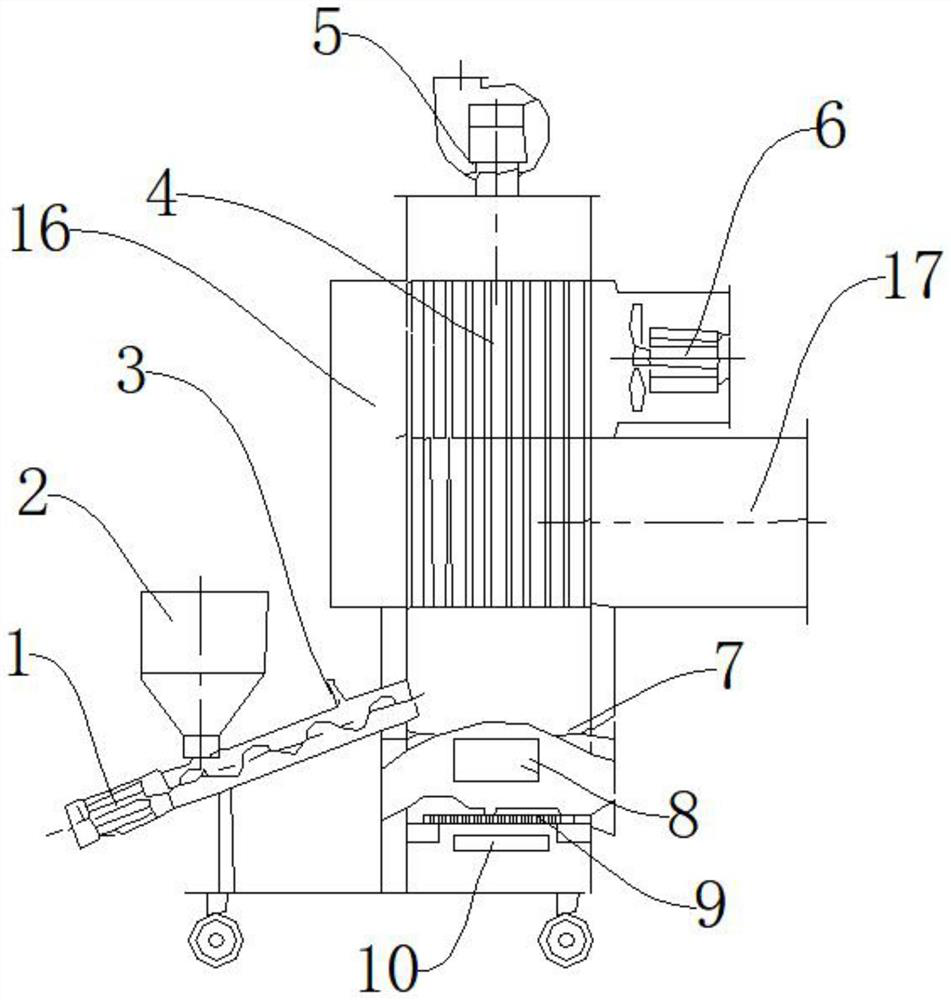

Wood drying machine

InactiveCN105157360AReduce smoke pollutionImprove drying yieldDrying solid materialsDrying machines with local agitationFuel woodNoise pollution

The invention discloses a wood drying machine, and relates to the technical field of wood processing. The wood drying machine comprises a compressor, a circulation pipe, heat regenerators, an evaporator, a drying controller, an expansion valve, a condenser, evaporation pipes and a conduction pipe. The evaporator is connected with the condenser through the compressor and the expansion valve. The compressor is connected with the expansion valve through the drying controller. The evaporation pipes are of a multi-layer folding structure and are arranged inside the evaporator and the condenser. By means of a closed dehumidifying drying manner, waste gas and waste heat are not discharged, and noise pollution is avoided. The wood drying machine is a high-environment-friendly product and is not affected by the outside, and pollution of emitted smoke of a fire coal and fuel wood boiler is reduced. The wood drying period is shortened, the wood water content can be controlled, and all parts of wood can be evenly dried. The water content of the wood is accurate, stable and even. The shrinkage rate of the dried wood is greatly reduced, the wood surface quality is high, and the phenomenon of surface hardening is not likely to happen.

Owner:涟水县中林木制品厂

Devices for reducing harmful emissions from domestic heating appliances

The present invention relates to a method for reducing harmful emissions to the atmosphere from domestic heating appliances such as pellet stoves, oil and wood-burning stoves, or gas-fired boilers, and for reducing emissions from wood-burning ovens for domestic and commercial use. Apparatus and related methods for emissions and emissions from industrial plants and large ships.

Owner:TECHS SRL

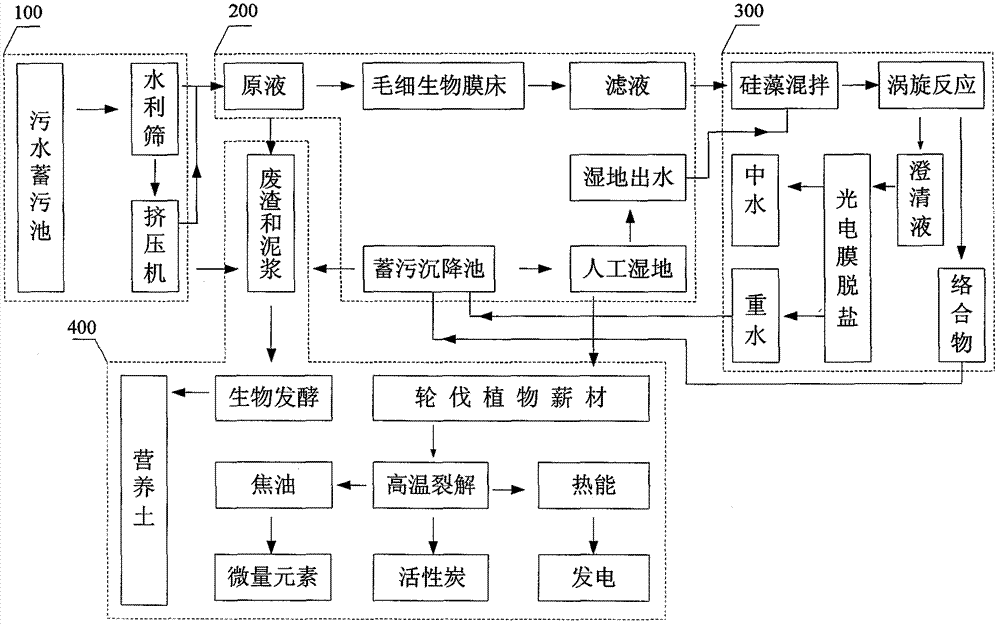

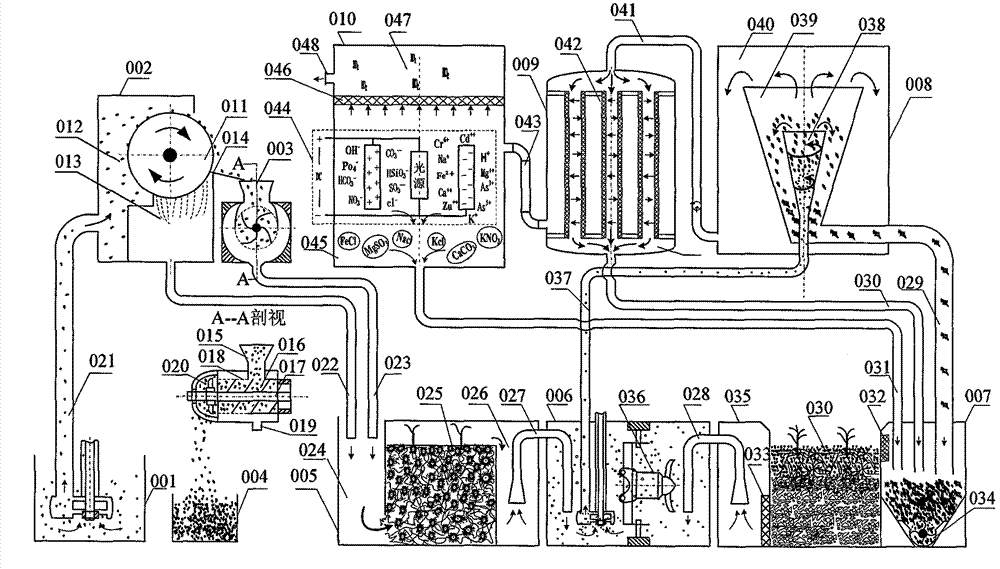

Sewage treatment process of complex biochemistry, coupled physicochemical and removal of heavy metals

InactiveCN103232133BReduce SS valueReduce COD valueBio-organic fraction processingCarbon compoundsFiltrationHazardous substance

The invention relates to composite biochemical, coupled physicochemical, and heavy-metal-removing sewage treatment process and technology. The invention mainly discloses a continuous operation system composed of a mechanical solid-liquid separation unit, a composite biochemical treatment unit, a coupling physicochemical treatment unit, and a waste comprehensive utilization unit. According to the invention, a plant capillary biofilm bed technology, a shrub-type plant heavy metal removing technology, a flocculation complexation reaction technology, an inorganic membrane filtration technology, and optical, electrical, and membrane coupled desalination technology are adopted, such that harmful substances and heavy metal elements in sewage can be effectively removed. Treated water reaches a discharge standard, and can be recycled. Also, according to the invention, with microbial fermentation technology and high-temperature cracking technology, waste, sludge, and shrub-type plant fuel-wood are converted into nutritive soil, active carbon, tar and electrical power, such that waste is turned valuable, and pollutant discharge reduction or zero discharge is realized. The process and technology provided by the invention can be applied in organic sewage and industrial sewage treatment, and especially provides a good treatment effect against garbage leachate.

Owner:北京新创宏力投资控股有限公司 +2

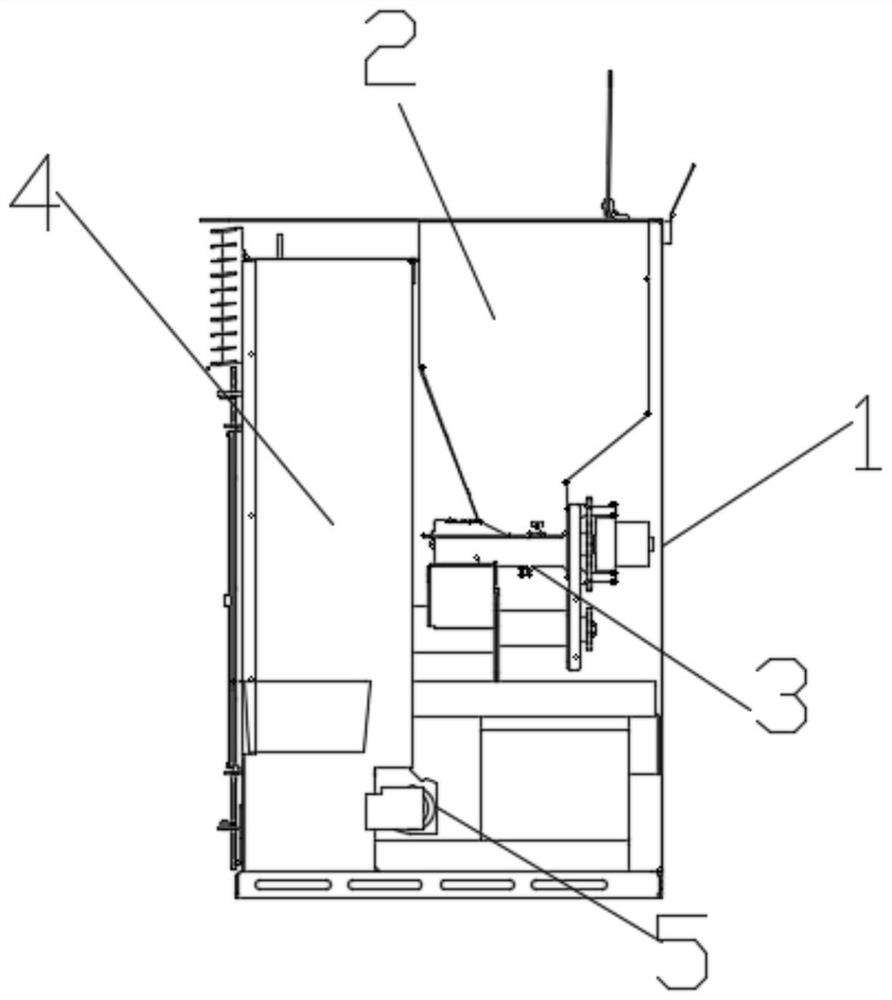

Biomass air heater

The invention discloses a biomass air heater which comprises a spiral feeder, a hopper, a cabinet body and a plate type heat exchanger. An induced draft fan is installed at the upper end of the cabinet body, moving wheels are installed at the lower end of the cabinet body, an ash outlet is formed in the lower side of the front end of the cabinet body, and an ignition fan is arranged at the rear end of the cabinet body. According to the biomass air heater, cold air introduced by the combustion fan is heated in an encircling mode in the furnace wall, the heated hot air enters a combustion chamber through a secondary air port, sufficient oxygen can be provided for a hearth to make biomass particles combusted sufficiently, a large quantity of black smoke and volatile components are reduced, and the heat loss can be reduced; cold and heat isolation is adopted in the heat exchange process of the plate type heat exchanger, the obtained hot air is clean and free of contamination, the heat exchange area is sufficient, and the heat exchange amount is larger; biomass particle fuel can be provided for a combustion furnace through the spiral feeder, biomass fuel such as fuel wood and straw can be provided for the combustion furnace through a furnace door, and multiple feeding modes are achieved; and the biomass air heater is small in size, movable and capable of working flexibly.

Owner:HUNAN AGRICULTURAL UNIV

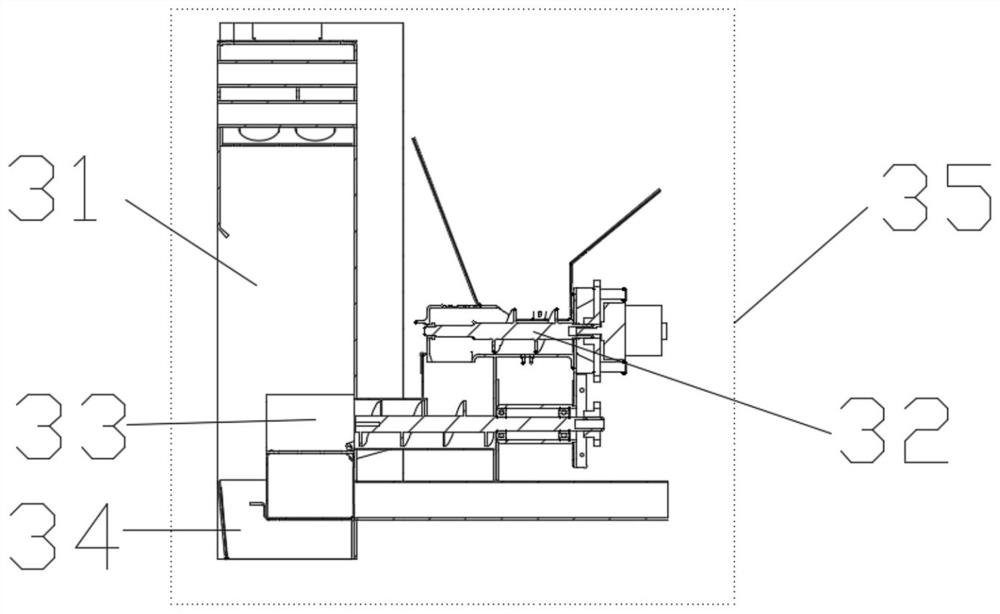

Novel wood-burning particle furnace

PendingCN112879897AAvoid accumulationPrevent backfireSolid fuel combustionLump/pulverulent fuel feeder/distributionCombustion systemConverters

The invention provides a novel wood-burning particle furnace. The furnace comprises a shell, a feeding port, a burning system, a heat converter and an exhaust device, wherein the feeding port is formed in the upper end of the shell and is connected with the input end of the burning system, and the output end of the burning system is connected with the input end of the heat converter; the burning system comprises a burning chamber, a conveyor, a burning bowl and an ash tray, the burning chamber is arranged on one side of the shell, the input end of the conveyor is connected with an outlet of the feeding port, the output end of the conveyor is arranged on one side of the burning chamber and is connected with the burning bowl, the burning bowl is arranged on the inner side wall of the burning chamber, and the ash tray is arranged under the burning bowl; and the heat converter comprises a heat transfer pipe set and an air duct, the heat transfer pipe set is horizontally arranged at the upper end in the burning chamber, the input end of the air duct is arranged above the heat transfer pipe set and communicates with the upper surface of the burning chamber, and a pipe body of the air duct is tightly attached to the inner side wall of the burning chamber.

Owner:烟台炉旺节能科技有限公司

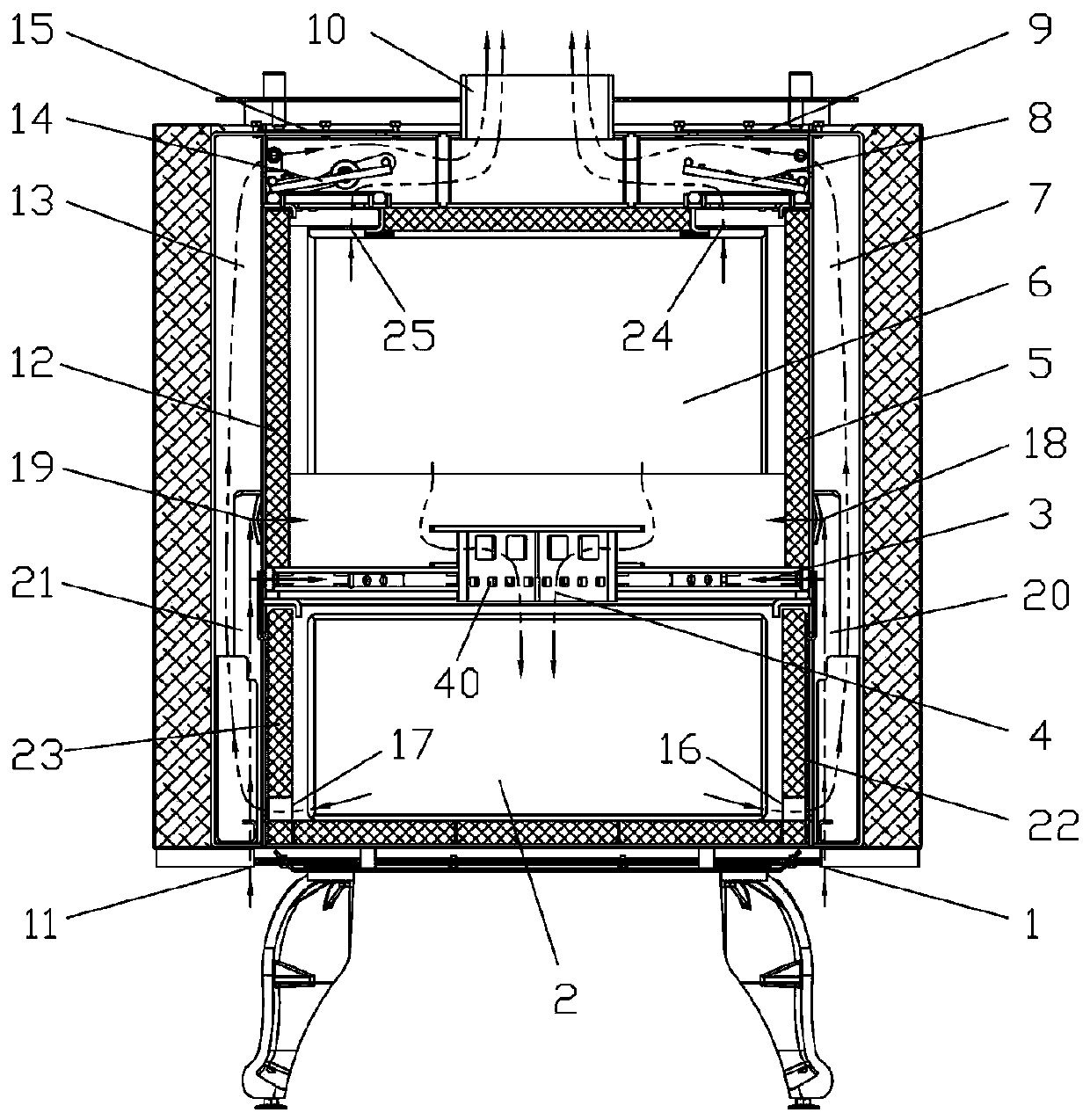

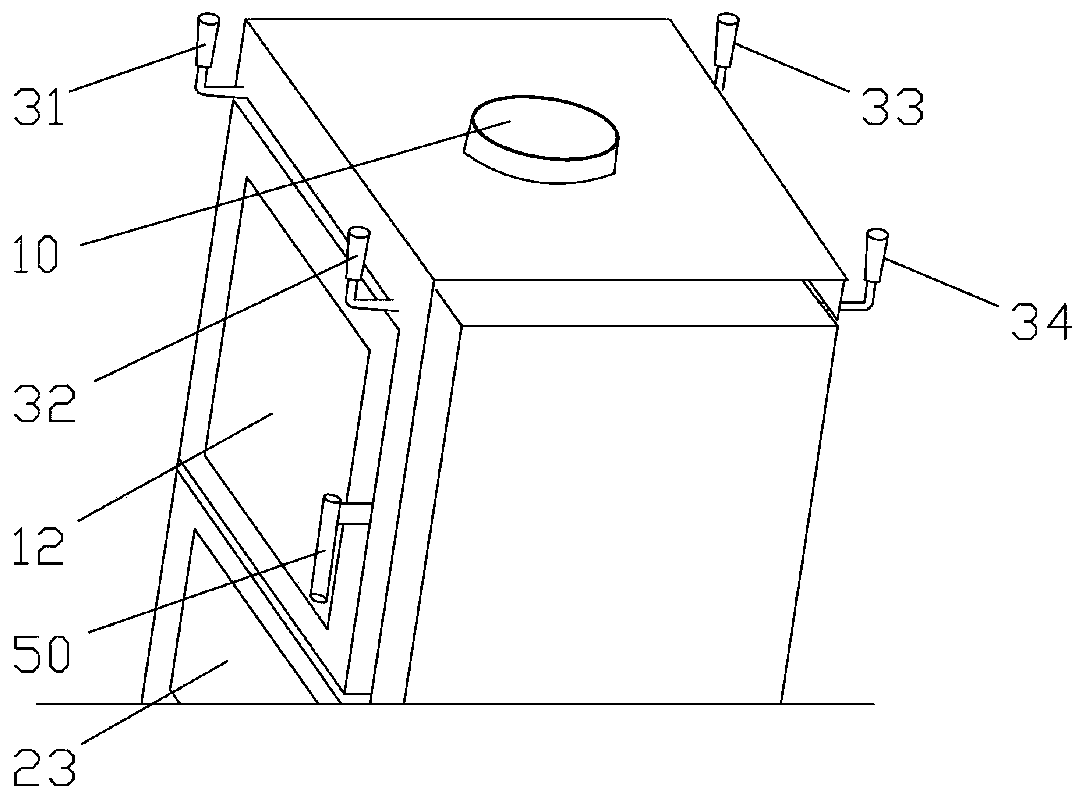

Embedded dual-hearth wood-burning furnace

PendingCN111365708AResolve Insufficient CombustionTroubleshooting Installing Multiple Wood Burning StovesSolid fuel combustionCombustion apparatusCombustion chamberFuel wood

The invention discloses an embedded dual-hearth wood-burning furnace. The furnace comprises a dual-hearth wood-burning furnace body formed by communicating a primary combustion chamber with a secondary combustion chamber. One side of the primary combustion chamber is provided with a first primary combustion chamber furnace door, a first upper air inlet, a first smoke outlet and a first air supplement device. The first smoke outlet communicates with a smoke discharging port and is provided with a first valve cover, the other side of the primary combustion chamber is provided with a second primary combustion chamber furnace door, a second upper air inlet, a second smoke outlet and a second air supplement device. The second smoke outlet communicates with the smoke discharging port and is provided with a second valve cover, one side of the secondary combustion chamber is provided with a first secondary combustion chamber furnace door, a first air outlet and a first secondary smoke discharging channel connected with the first air outlet, and the first air outlet communicates with the smoke discharging port through the first secondary smoke discharging channel. The other side of the secondary combustion chamber is provided with a second secondary combustion chamber furnace door, a second air outlet and a second secondary smoke discharging channel connected with the second air outlet,and the second air outlet communicates with the smoke discharging port through the second secondary smoke discharging channel.

Owner:宁波圣菲机械制造有限公司

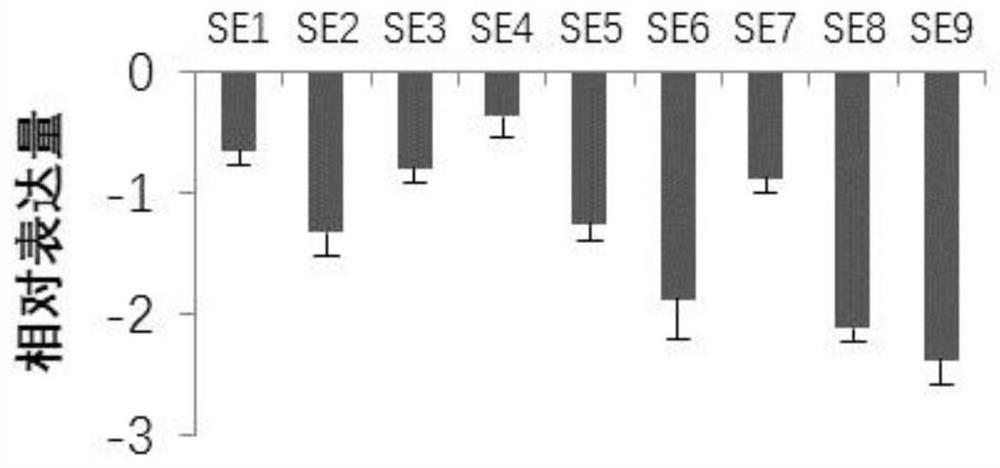

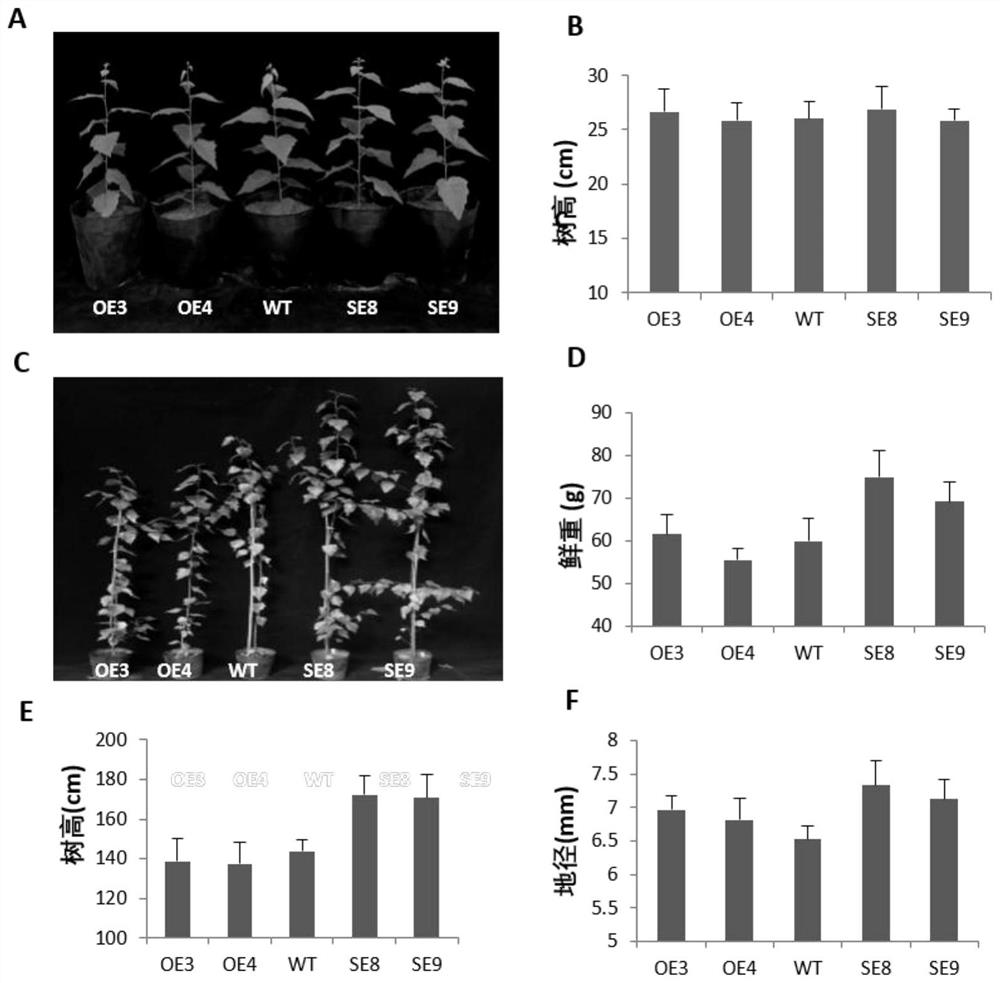

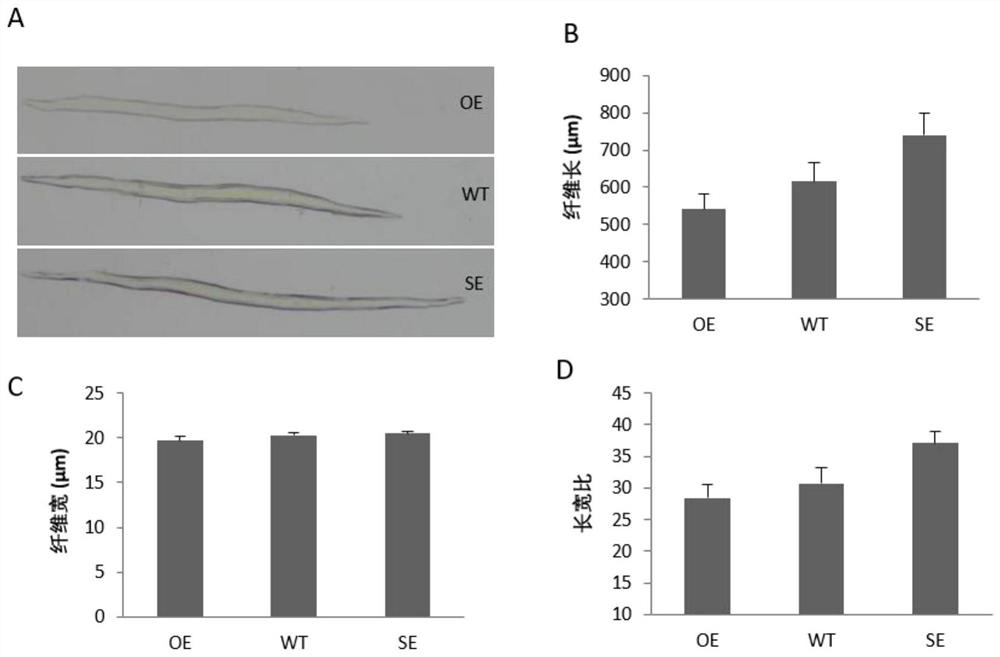

Application of bpvnd1 gene

The invention relates to the application of BpVND1 gene and belongs to the technical field of birch cultivation. The present invention provides the application of BpVND1 gene in increasing the growth of birch. The nucleotide sequence of the BpVND1 gene is shown in SEQ ID NO.1. The application of the BpVND1 gene of the present invention can increase the growth and biomass of white birch compared with wild type white birch, increase the cellulose content and fiber length, and reduce the lignin content, which is suitable for the cultivation of pulp wood and fuel wood.

Owner:FORESTRY RES INST OF HEILONGJIANG PROVINCE +1

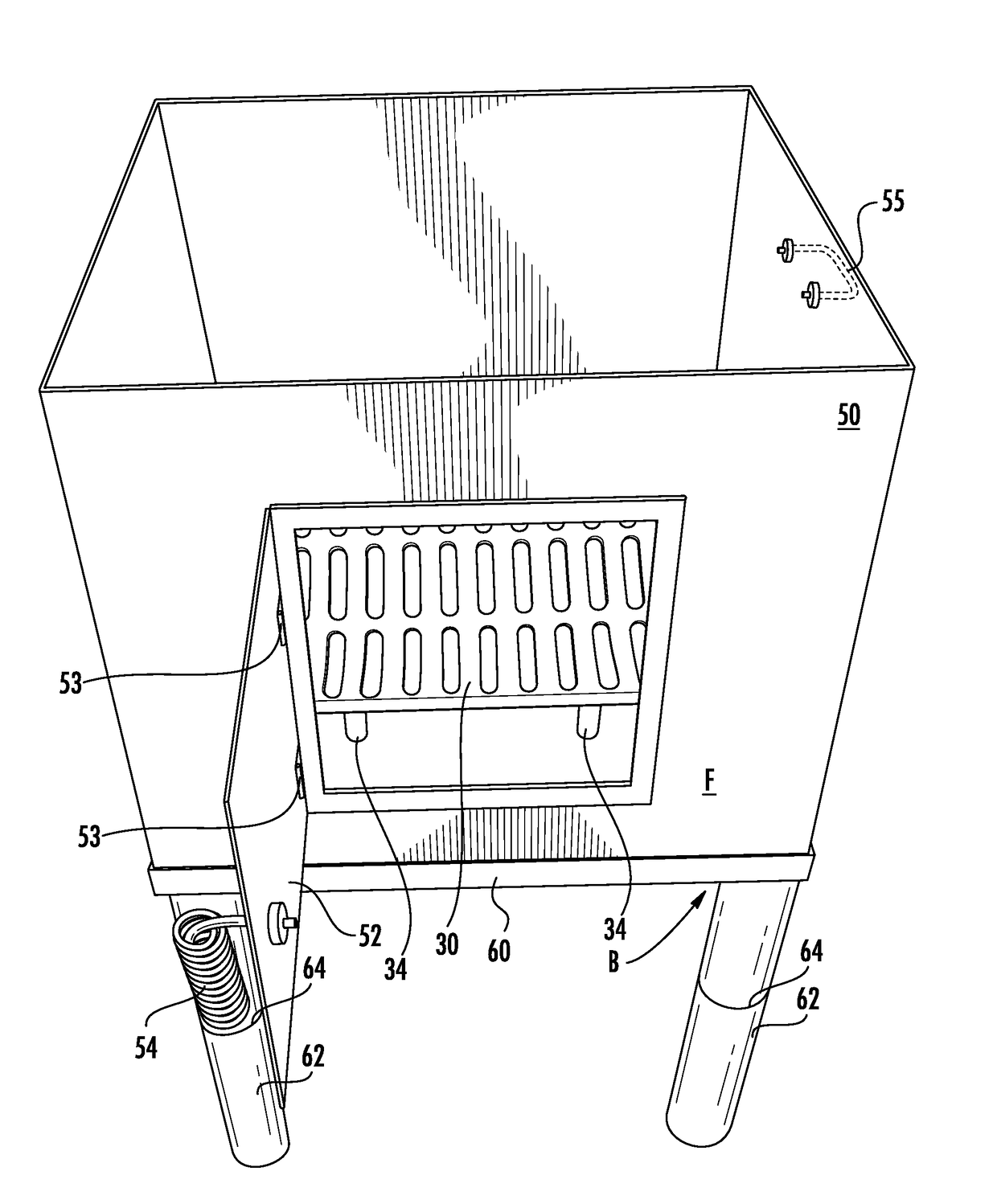

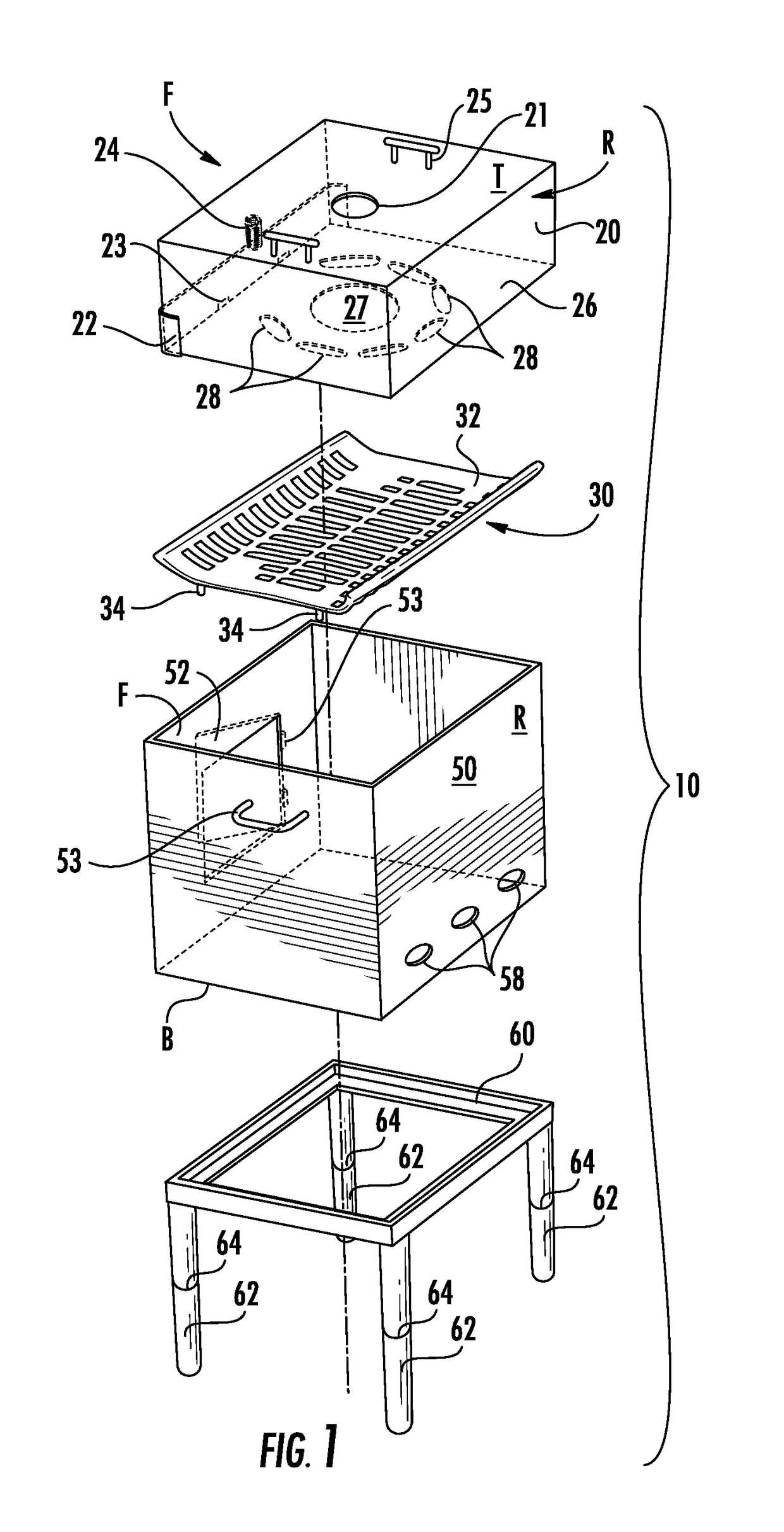

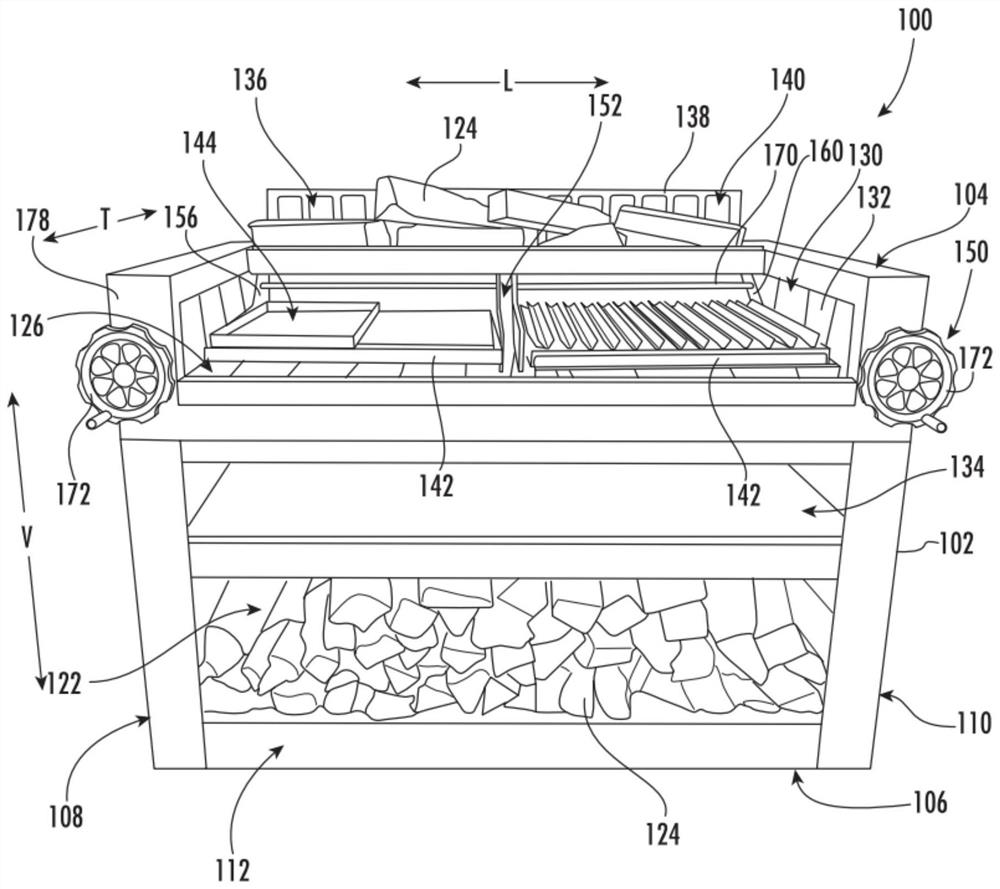

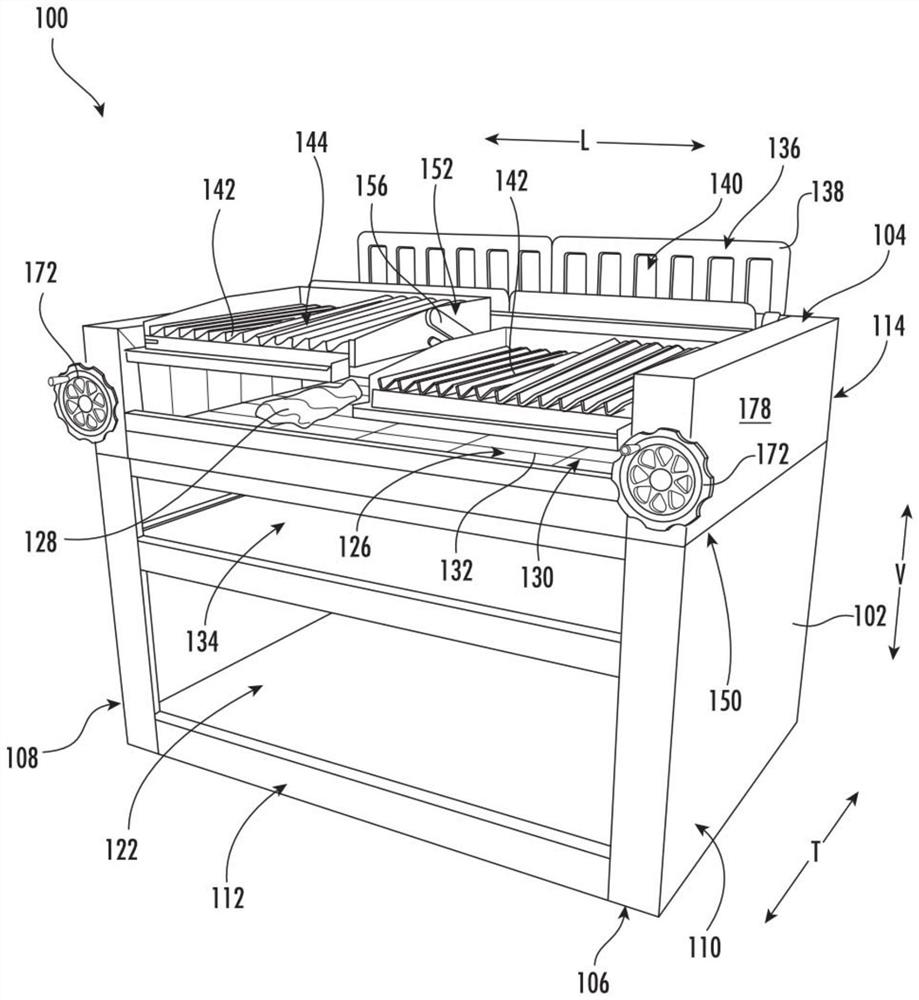

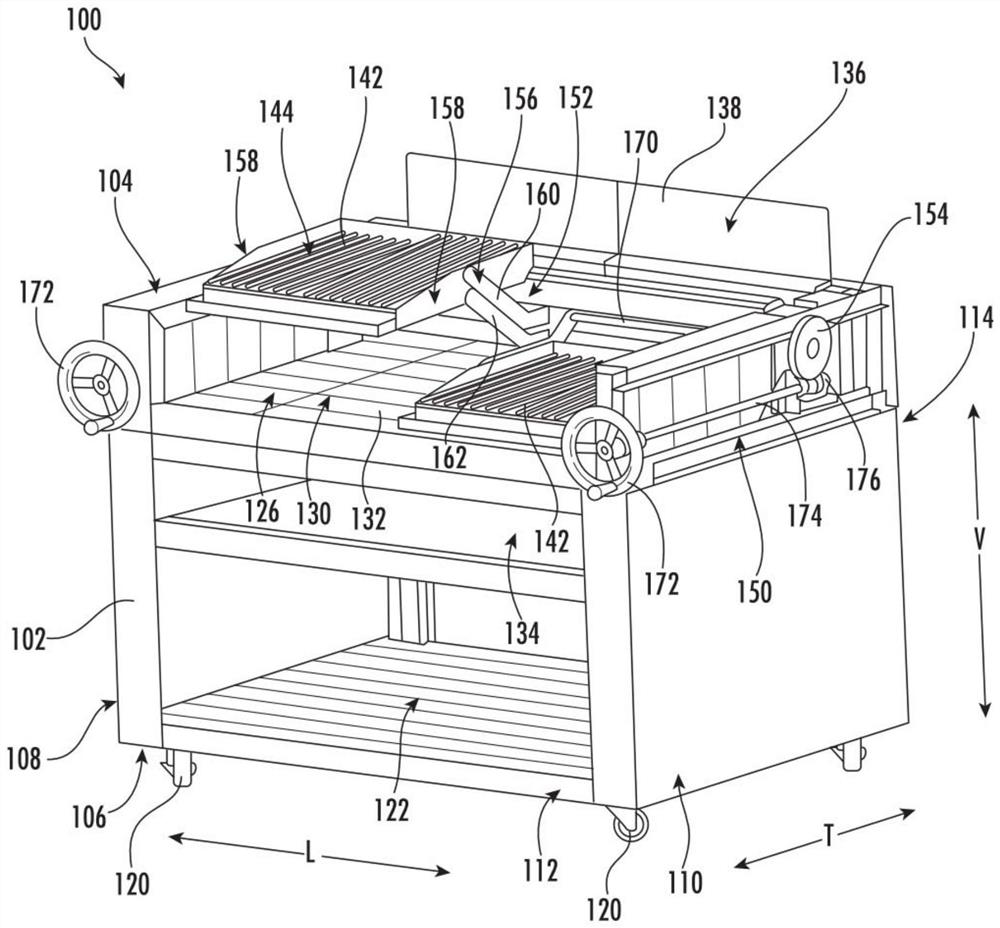

Wood-burning grill and grate bar positioning assembly for wood-burning grill

PendingCN113475952AEasy to manageDomestic stoves or rangesLighting and heating apparatusFuel woodProcess engineering

The present application provides a wood-burning grill defining a vertical direction, a lateral direction and a transverse direction, comprising: a box defining a charcoal support platform for supporting wood burning during a grilling process; a grate positioned above the charcoal support platform in the vertical direction and defining a cooking surface for containing food; and a grate bar positioning assembly mechanically coupling the grate bar to the housing; wherein the grate bar positioning assembly comprises: a link arm system, which mechanically couples the grate bar to the box body; and a drive gear mechanically coupled to the link arm system and rotatable to move the grate between a raised position and a lowered position. In this way, the grate bar can move between the raised position and the lowered position in a rotating mode, and charcoal management can be easily conducted below the grate bar. The invention further provides a grate bar positioning assembly for the wood-burning grill.

Owner:QINGDAO HAIER SMART TECH R & D CO LTD +2

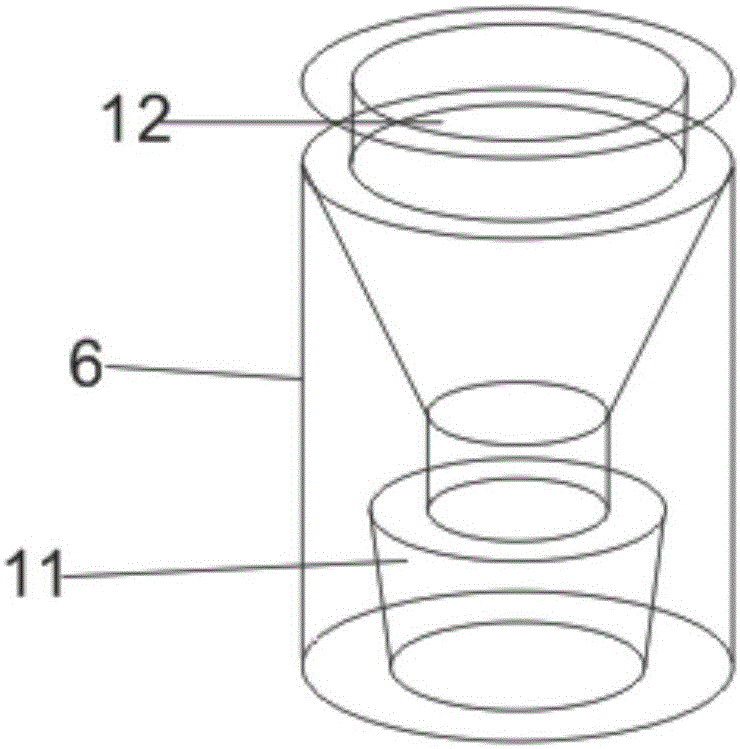

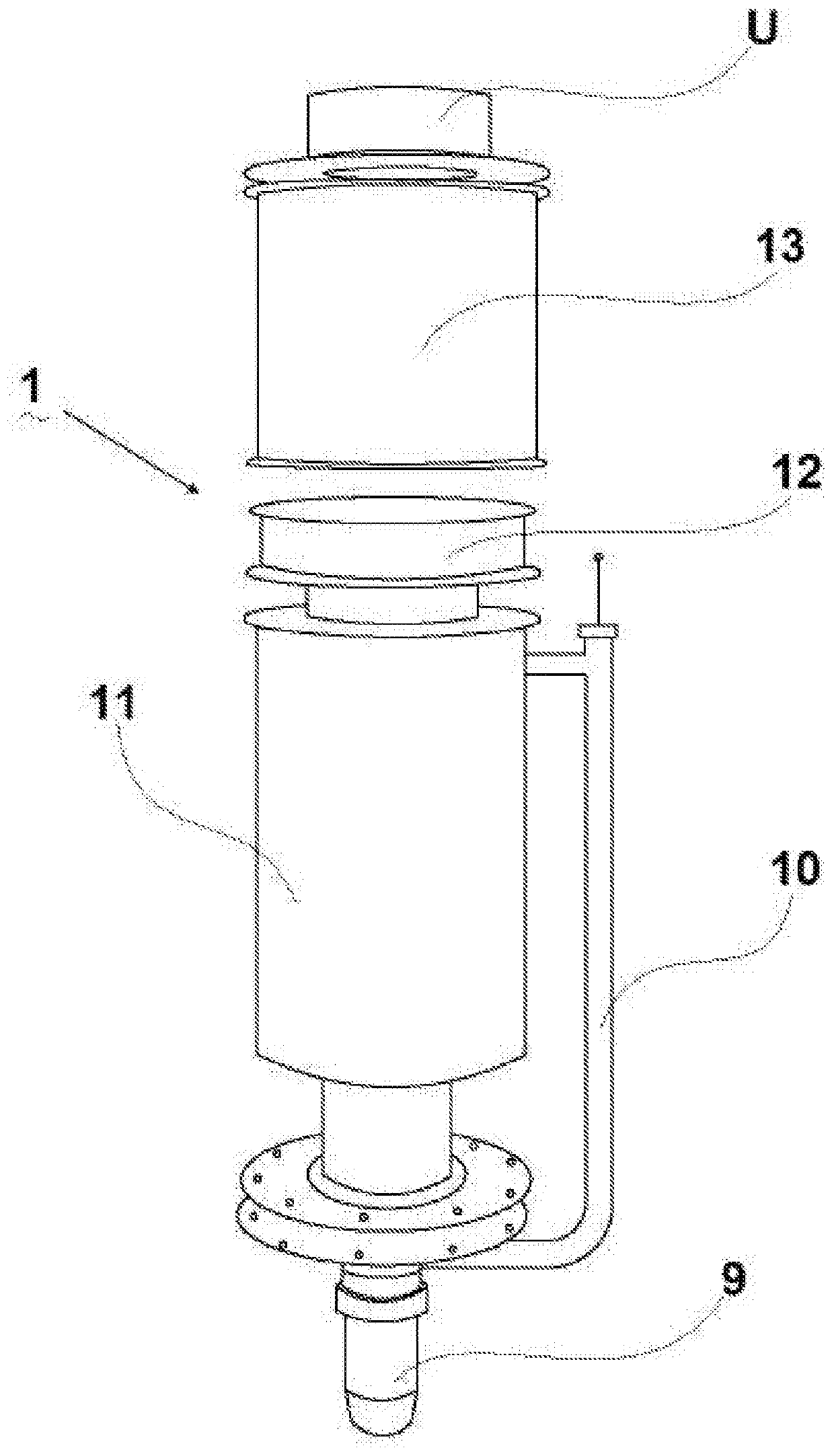

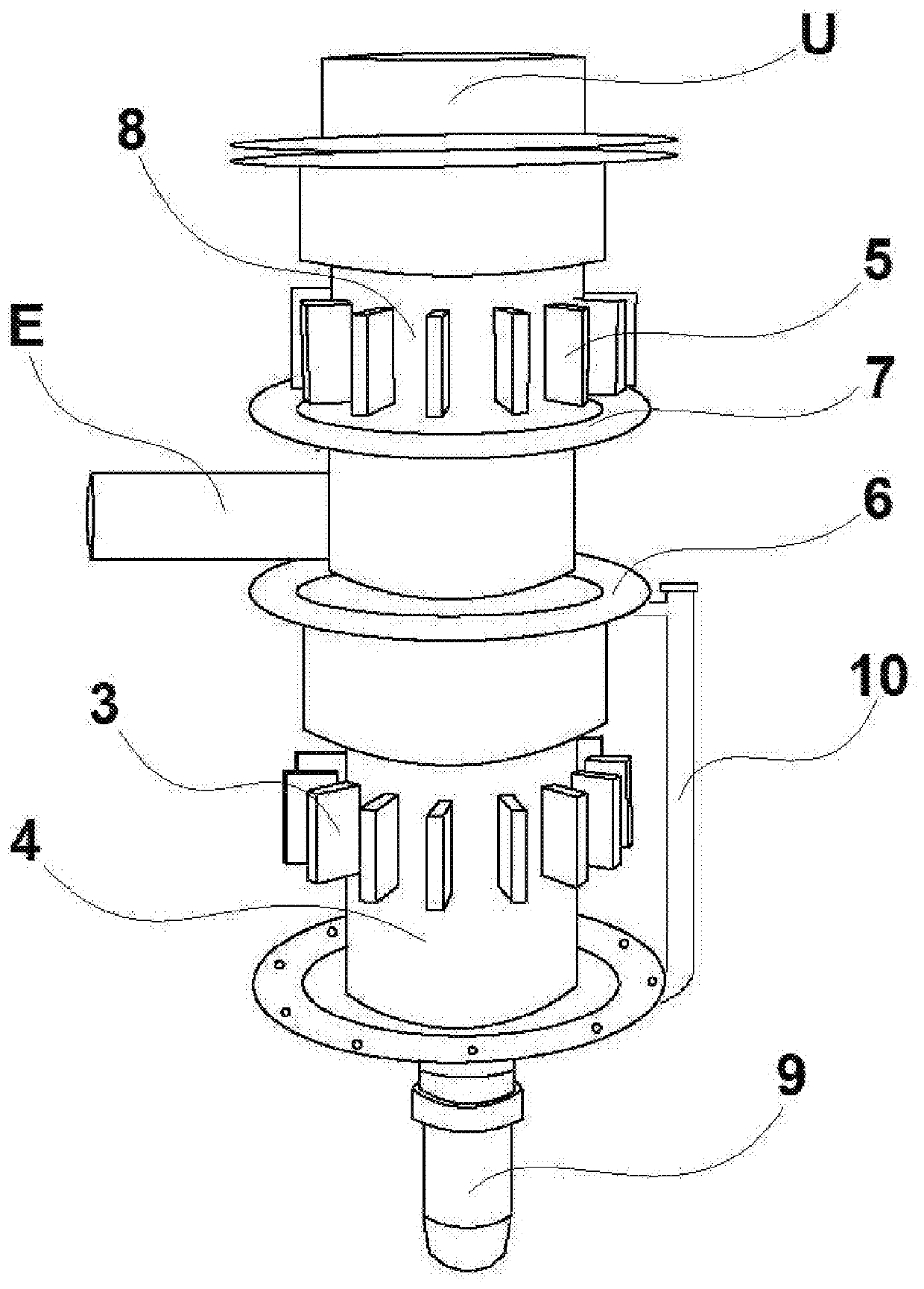

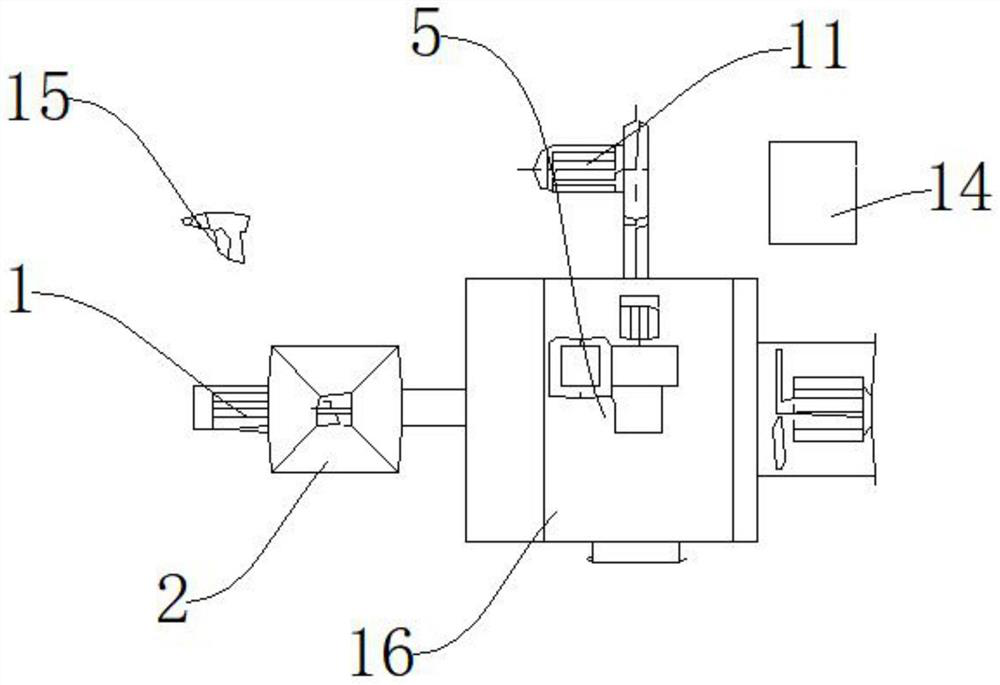

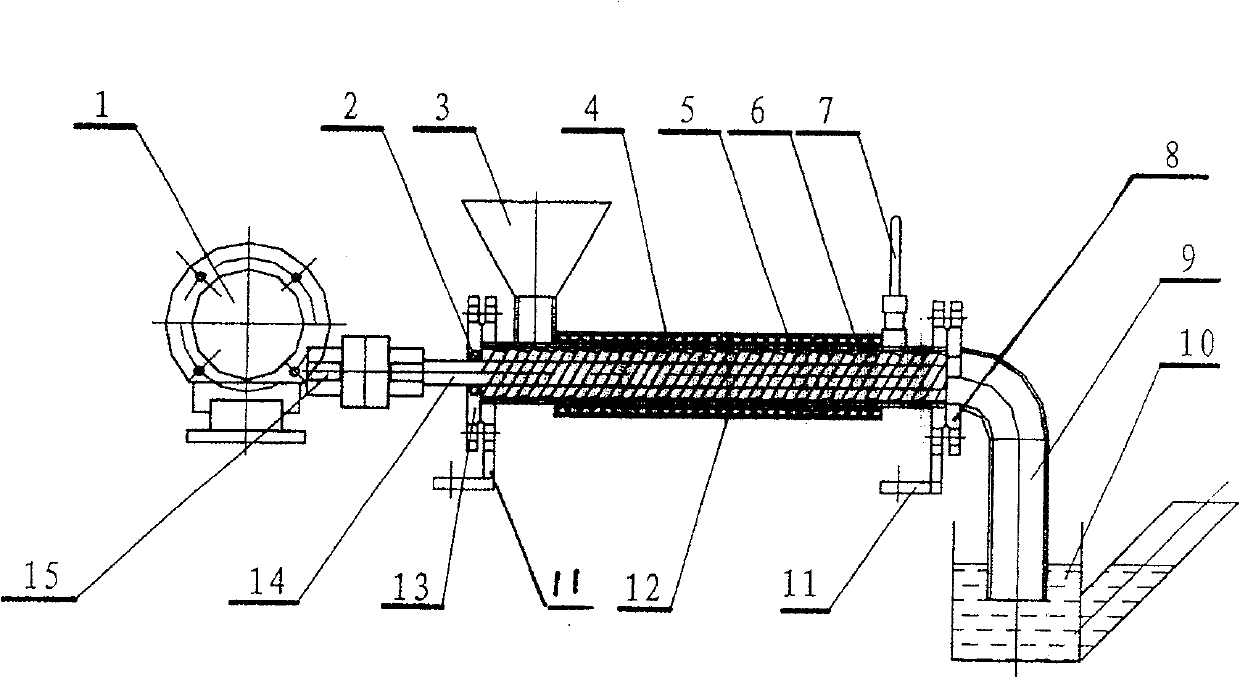

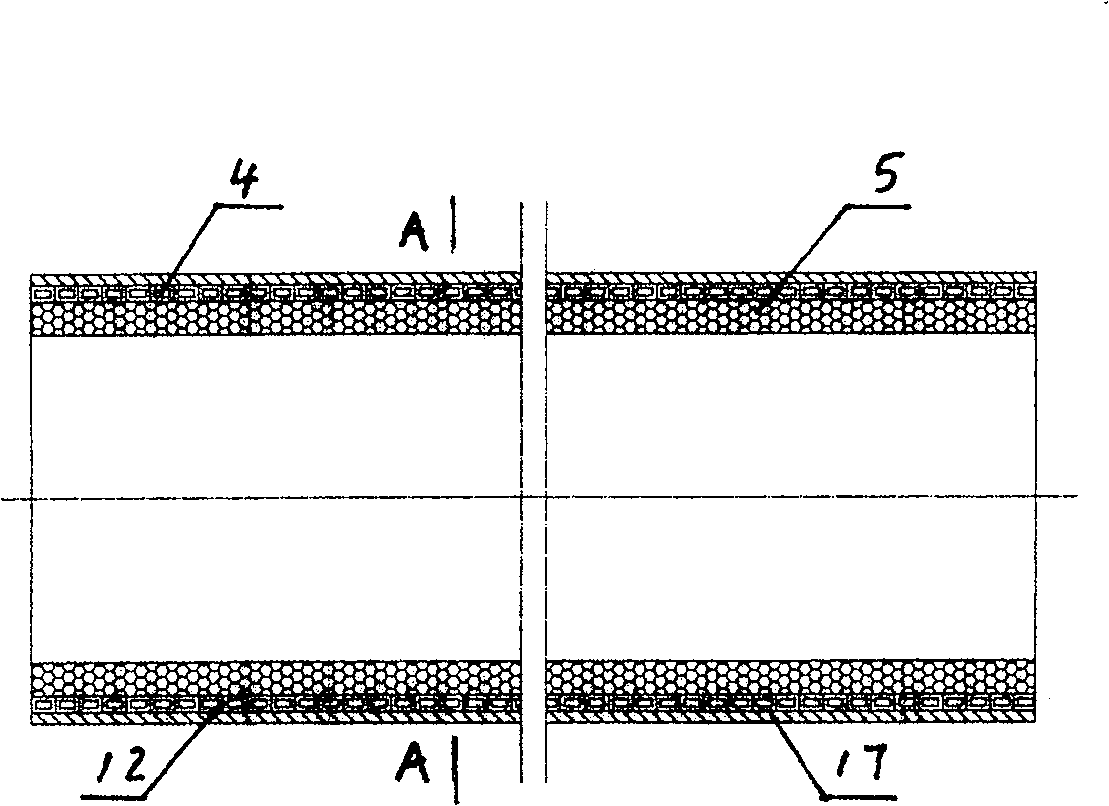

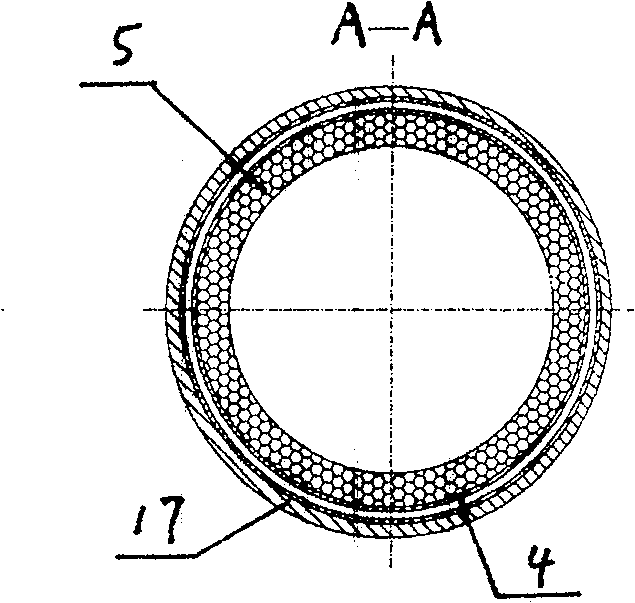

Electromagnetically inducing biomass pyrolyzing and liquefying reactor

InactiveCN100516174CImprove heating uniformityGuaranteed uptimeLiquid hydrocarbon mixture productionReduction driveSlag

The invention relates to the field of pyrolysis of carbon-containing materials, and is a biomass electromagnetic induction pyrolysis and liquefaction reactor, which is characterized in that: it comprises a screw feeder arranged on a support frame, and the screw feeder is composed of a shell and is The feeding hopper, the exhaust pipe and the slag discharge pipe arranged on the casing are composed of a screw shaft arranged in the casing; an inductive coil is wound on the casing; The core tube, the hollow core of the hollow core tube is the cooling liquid flow channel; the lower port of the slag pipe is placed in the water seal groove; the screw shaft is connected with the reducer shaft of the motor; there is an exhaust groove on the axial direction of the screw shaft mouth. It has the advantages of simple structure, convenient operation, continuous operation, uniform heating, fast pyrolysis speed, good quality, cleanliness, environmental protection, low cost and long service life. It is especially suitable for the pyrolysis of fuelwood, crop straw, aquatic plants and other biomass, and also suitable for the pyrolysis of solid fuels such as coal, oil shale and municipal waste.

Owner:NORTHEAST DIANLI UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com