Patents

Literature

2757results about How to "Unbreakable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of pellet-type formula granules

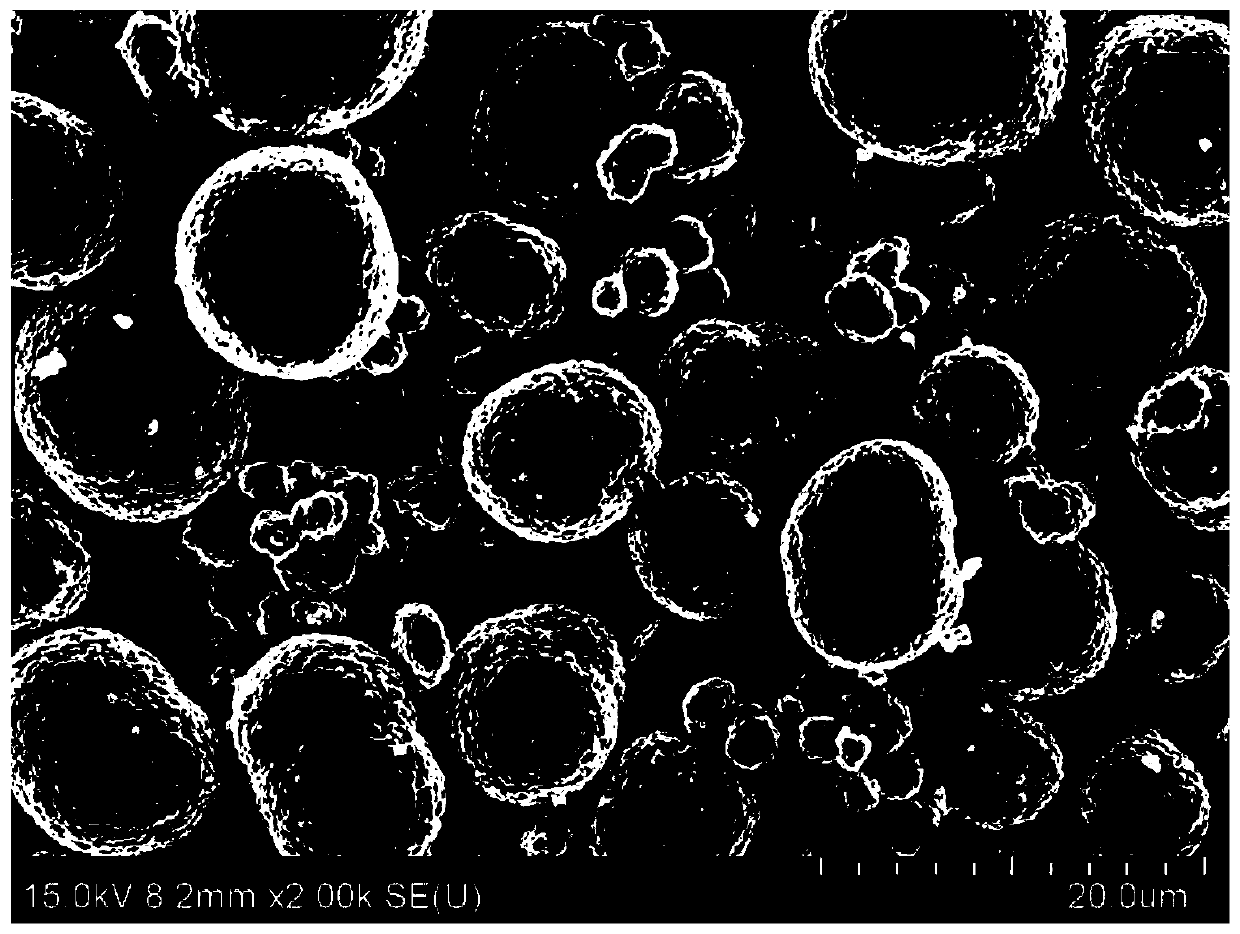

InactiveCN107744510ASimple preparation processImprove compliancePharmaceutical product form changeCoatingsMedicineMoisture absorption

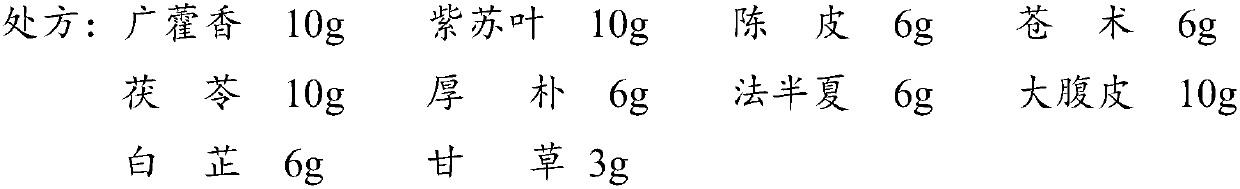

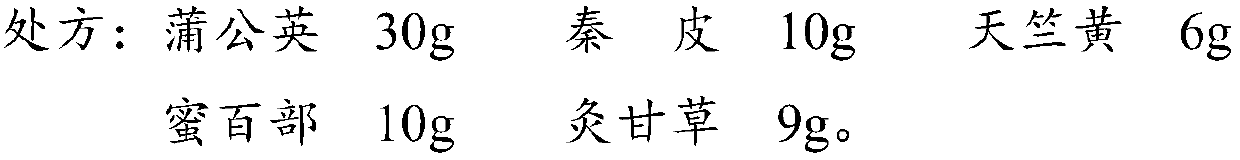

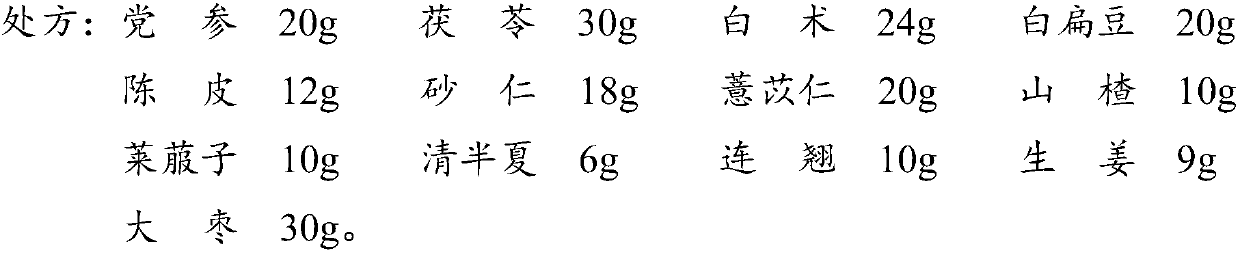

The invention discloses a preparation method of pellet-type formula granules. The method comprises the following steps: (1) selecting at least one of the traditional Chinese medicinal materials; (2) respectively extracting the medicinal materials selected in step (1) for obtaining extracts, or respectively grinding the medicinal materials, or respectively carrying out partial extraction and partial grinding, thus obtaining pretreated materials; and (3) preparing the pretreated materials obtained in step (2) into pellets, thus obtaining the pellet-type formula granules. According to the preparation method provided by the invention, on the basis of the prior art, the preparation process of the formula granules is innovated, the formula granules are innovated into pellets, the fluidity and moisture absorption resistance are good, the friability is small, the shape is round and uniform as well as regular, the content uniformity is small, and the divided dose is accurate.

Owner:GUANGDONG LUOFUSHAN SINOPHARM

Three-dimensional ordered macroporous alumina and preparation method thereof

ActiveCN102838142AGood three-dimensional orderImprove uniformityAluminium oxides/hydroxidesMicrosphereCalcination

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for preparing needle coke

The invention provides a method for preparing needle coke. The method is as follows: after delayed coking treatment of fraction or residual oil which are rich in arene through a certain temperature rise formula, green coke obtained is calcined, and the needle coke with high intermediate phase content and developed needle structure are prepared. The petroleum raw materials used comprise mixture of one type or a plurality of types among virgin wax oil, coked wax oil, catalytic cracking clarified oil, ethylene tar, coal tar, dense oil, residual oil and other hydrocarbon-enriched substances. The delayed coking temperature rise formula is characterized in that: intermediate phases generated can be driven to grow fully and are flushed by air flow with enough flow rate before solidification, thereby the granularity of the needle coke prepared is large (the content of coke breeze is not more than 25 weight percent) and the needle coke can be used for large-scale steel-making electric furnaces. When the method is used for an industrial device, people only need to adjust the prior temperature rise formula according to the characteristics of the raw materials and the technological flow.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

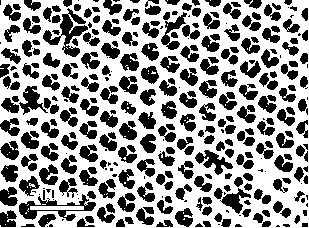

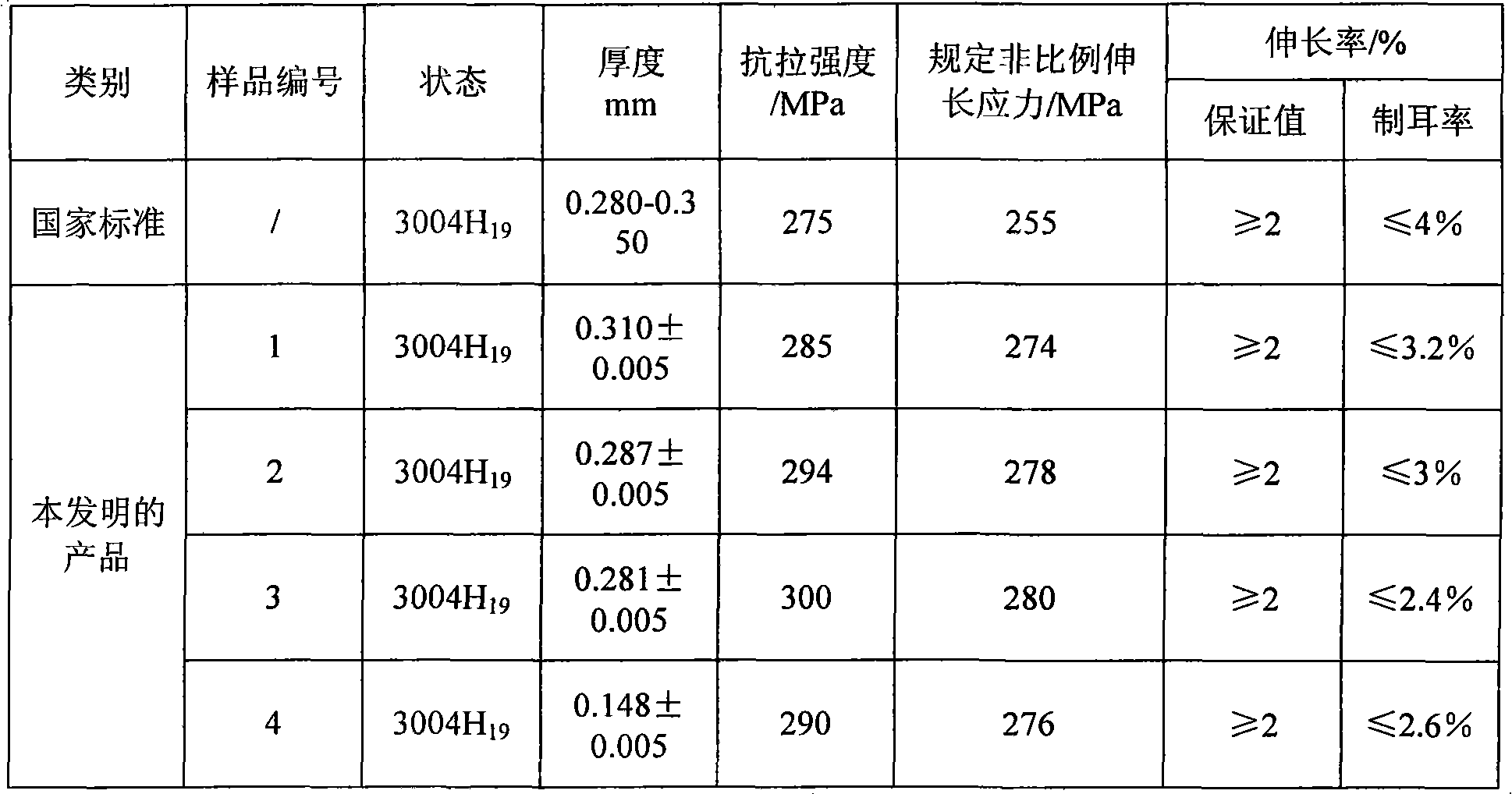

Engineering process for producing low-iron low-silicon 3004 alloy by directly cast-rolling electrolytic aluminium liquid

The invention relates to an engineering process for producing a low-iron low-silicon 3004 alloy by directly cast-rolling electrolytic aluminium liquid. The process comprises the procedures of alloy aluminium melting, ingredient adjusting, on-line refining for three times, standing, outgassing, grain refining, filtering, tilting cast-rolling, homogenizing, cold rolling, intermediate annealing, another cold rolling, full annealing, recoiling and packaging. The refining comprises powder spraying refining in a melting furnace and combined refining of on-line argon and carbon tetrachloride introducing. The annealing comprises high-temperature quick annealing, the intermediate annealing and the full annealing. During the cast-rolling, the temperature in a front box is 710-720 DEG C, and the cast-rolling speed is 600-900 mm / min. The product is the low-iron low-silicon 3004 alloy. The low-iron low-silicon 3004 alloy comprises 0.06-0.14 wt% of Si, 0.25-0.43 wt% of Fe, 0.012-0.14 wt% of Cu, 1.0-1.2 wt% of Mn, 0.8-1.0 wt% of Mg, at most 0.02 wt% of Zn, 0.015-0.03 wt% of Ti and the balance of Al. The invention has the characteristics of simple procedure, energy saving, emission reduction, goodalloy performance and low earring rate.

Owner:SNTO TECH GRP

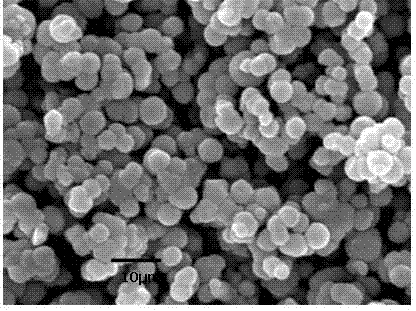

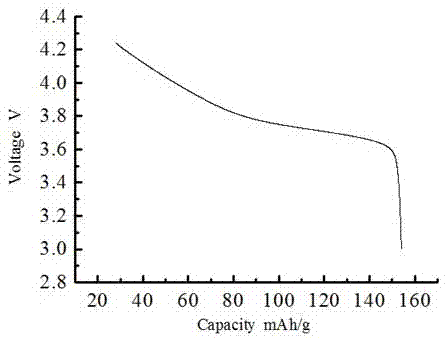

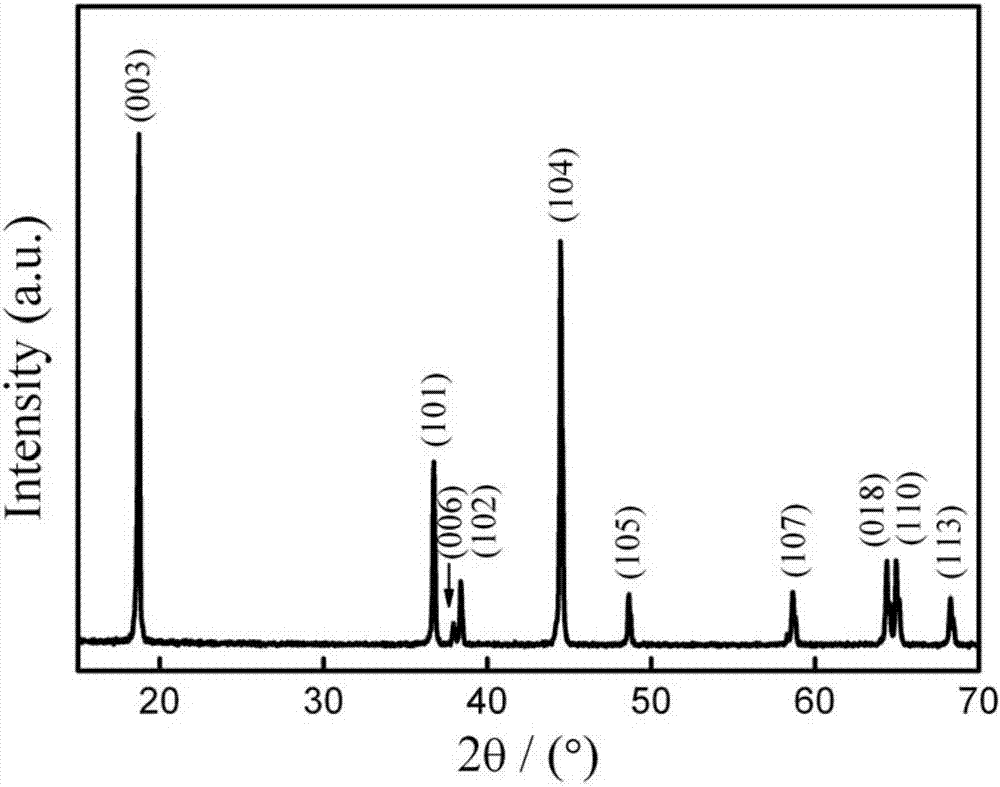

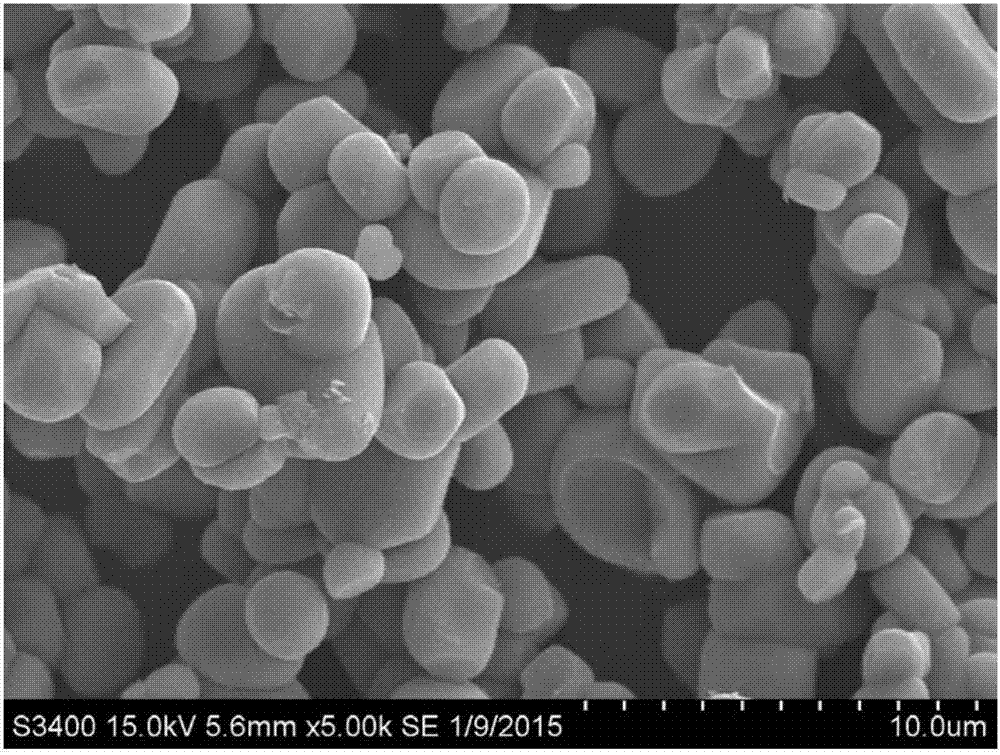

Ternary positive electrode material with special single-crystal structure, and preparation method thereof

The invention relates to a preparation method for a ternary positive electrode material with a special single-crystal structure. A general formula of the positive electrode material is LiNixCoyMnzMvO2, wherein a sum of x, y and z is 1, x is equal to or larger than 0.2 but smaller than or equal to 0.6; y is equal to or larger than 0.1 but smaller than or equal to 0.4; z is equal to or larger than 0.2 but smaller than or equal to 0.5; v is equal to or larger than 0.01 but smaller than or equal to 0.03; and M is one of Ti, Zn, Cr and F. The preparation method for the ternary positive electrode material with the special single-crystal structure comprises two steps of 1. preparing a precursor-cobalt nickel manganese oxide with the single-crystal structure; and 2. preparing a cobalt nickel manganese ternary material with the single-crystal structure.

Owner:SHANDONG GOLDENCELL ELECTRONICS TECH

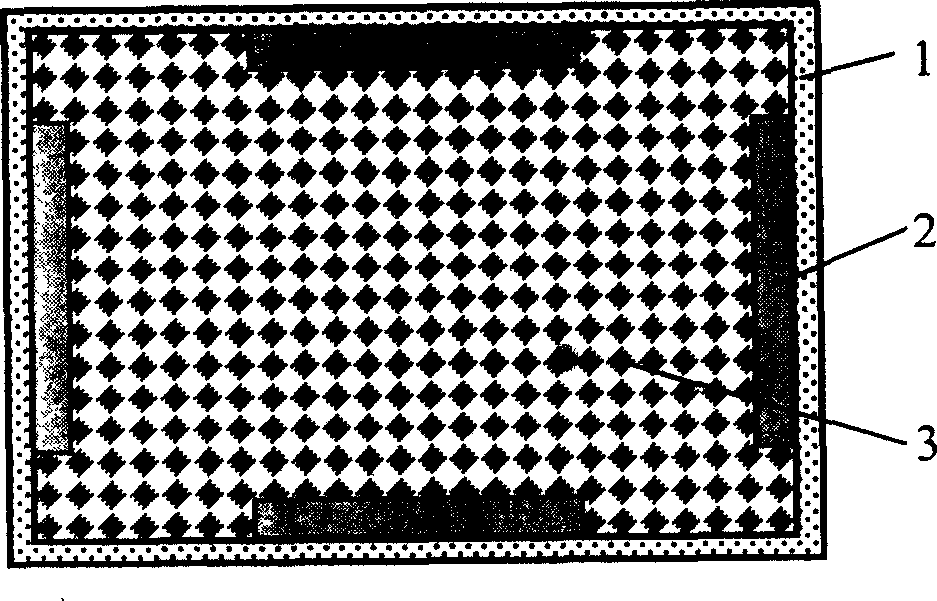

Core material used in vacuum insulation board, preparation method thereof, and purpose thereof

InactiveCN103072321AUnbreakableEasy to moveThermal insulationLayered productsRefrigerated temperatureMaterials science

The invention relates to the field of vacuum insulation board, and especially relates to a core material used in a vacuum insulation board, a preparation method thereof, and a purpose thereof. The core material comprises a sealed film bag manufactured by using an air-permeable and powder-impermeable filtering material, and a powder material filled in the film bag. The powder material is a porous material with a particle size smaller than 20mum. The filtering material can at least resist high temperature of 120 DEG C. Compared with a core material obtained with a sandwiching structure and with a sol-gel method in prior art, the vacuum insulation board provided by the invention has the advantages of crushing resistance, easy moving, and simple preparation method. With the vacuum insulation board, the requirements of fields such as refrigerators on vacuum insulation boards can be satisfied, and requirements of the field of construction energy saving and insulation on service lives of 20 years or even 50 years can be satisfied. The vacuum insulation board can be widely applied in the field of construction energy saving and insulation.

Owner:FUJIAN SUPERTECH ADVANCED MATERIAL

Photo-sterilization

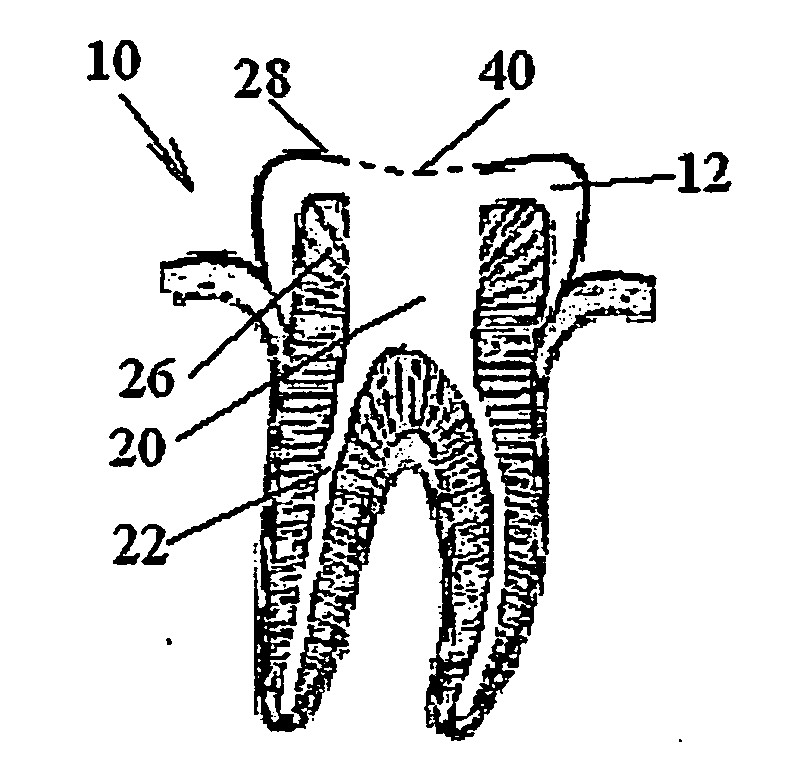

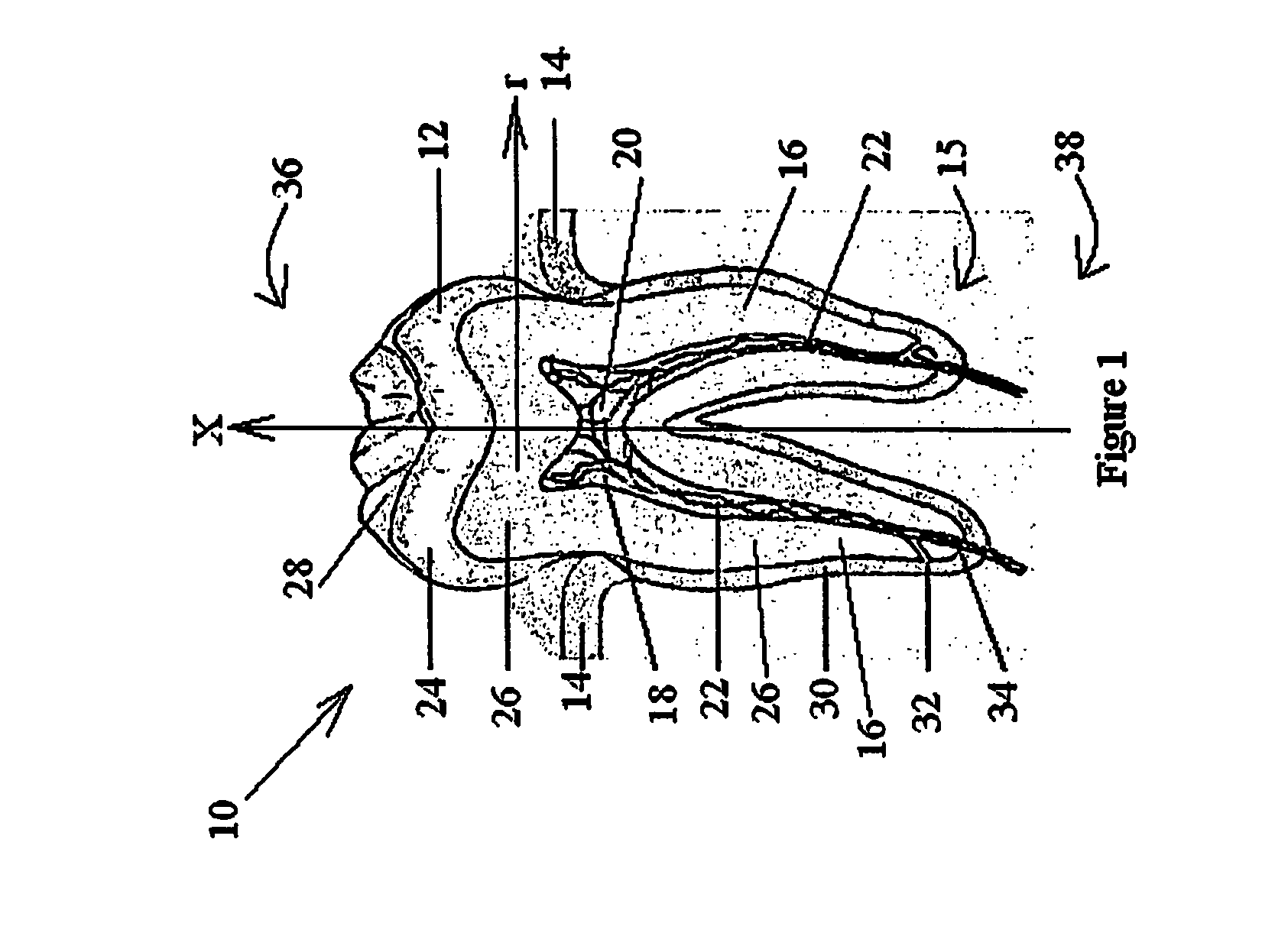

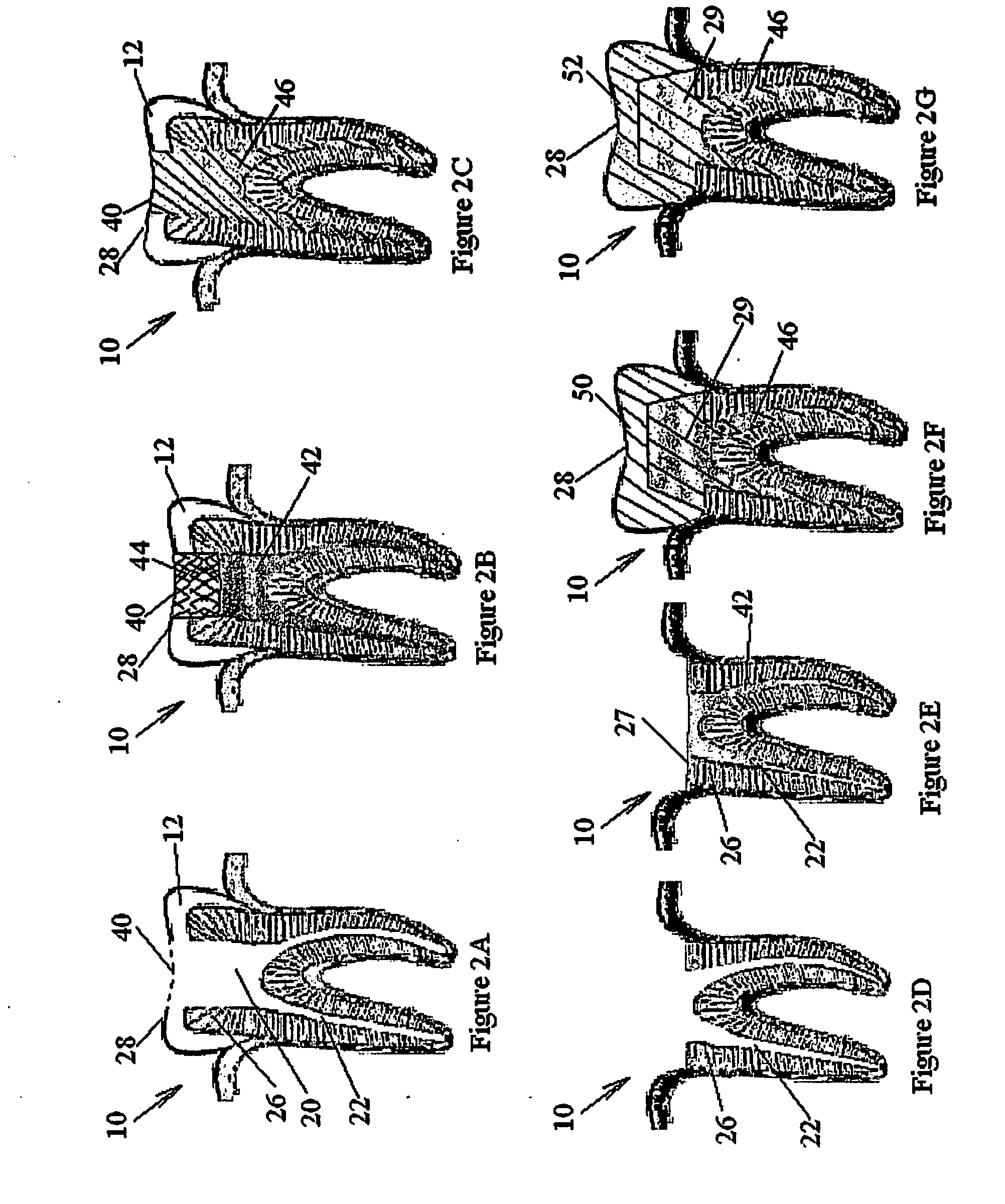

InactiveUS20070072153A1Excellent light diffusionHigh light transmittanceDisinfectionLight therapyEndodontic therapyMedicine

The present invention provides substances, devices, methods, and kits for photo-sterilization of a root canal, prior to and when performing endodontics, as well as periodically as post-endodontic prophylactic measures. The root-canal filling includes a light-transmitting element, operative as a diffuser, and methods are provided for communicating light to the diffuser, for disinfecting the walls of the root canals, by photo sterilization. The diffuser may be formed of silicone polymers, synthetic fused silica, quartz or the like, and may be surrounded by a light-transmitting sealer. The diffuser may be incorporated with an endodontic post, or a specially designed post, which may be transparent and (or) hollow. In a preferred embodiment, the diffuser is formed of a light transmitting conical shell of Cyclic Olefin Copolymers (COC), filled with a fluid such as air, distilled water, or silicone oil.

Owner:INTERLIGHT

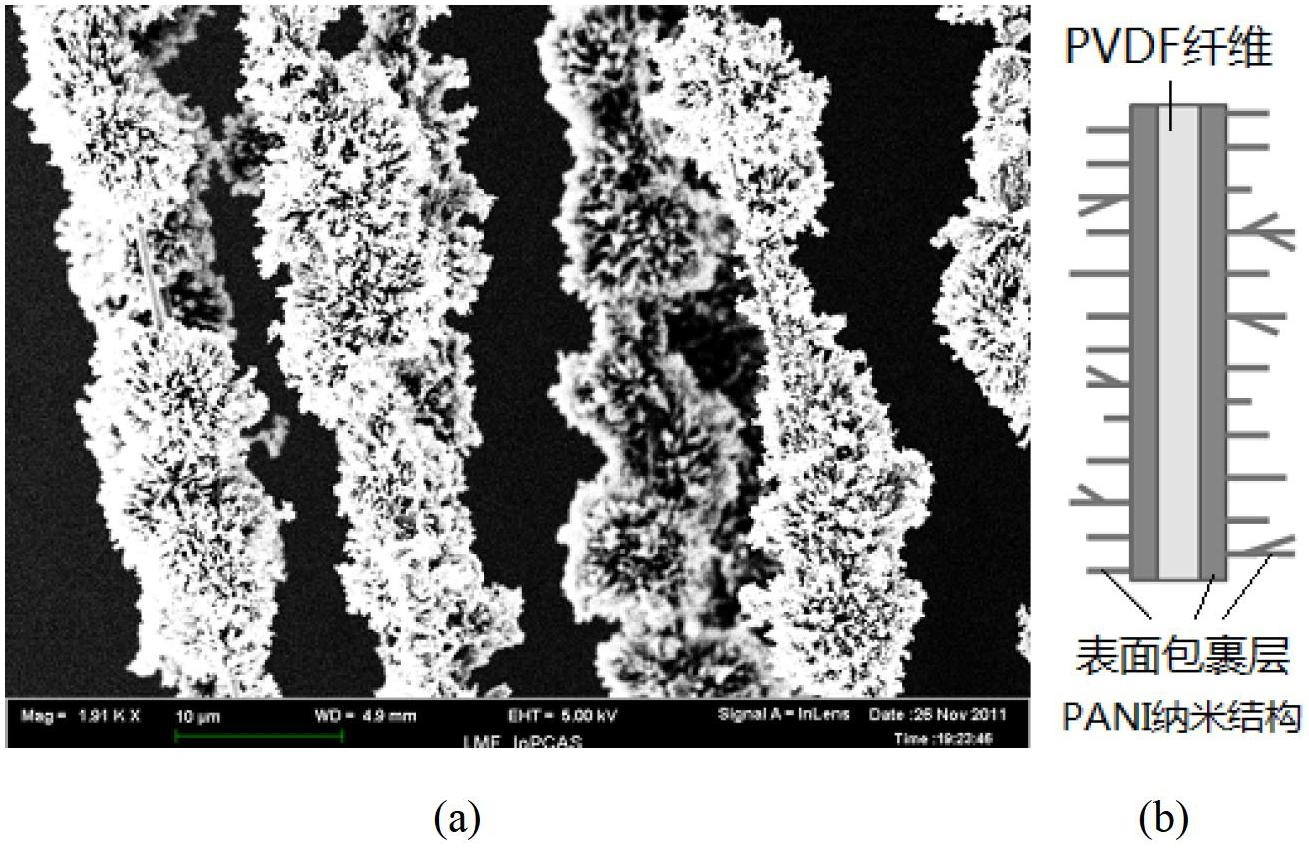

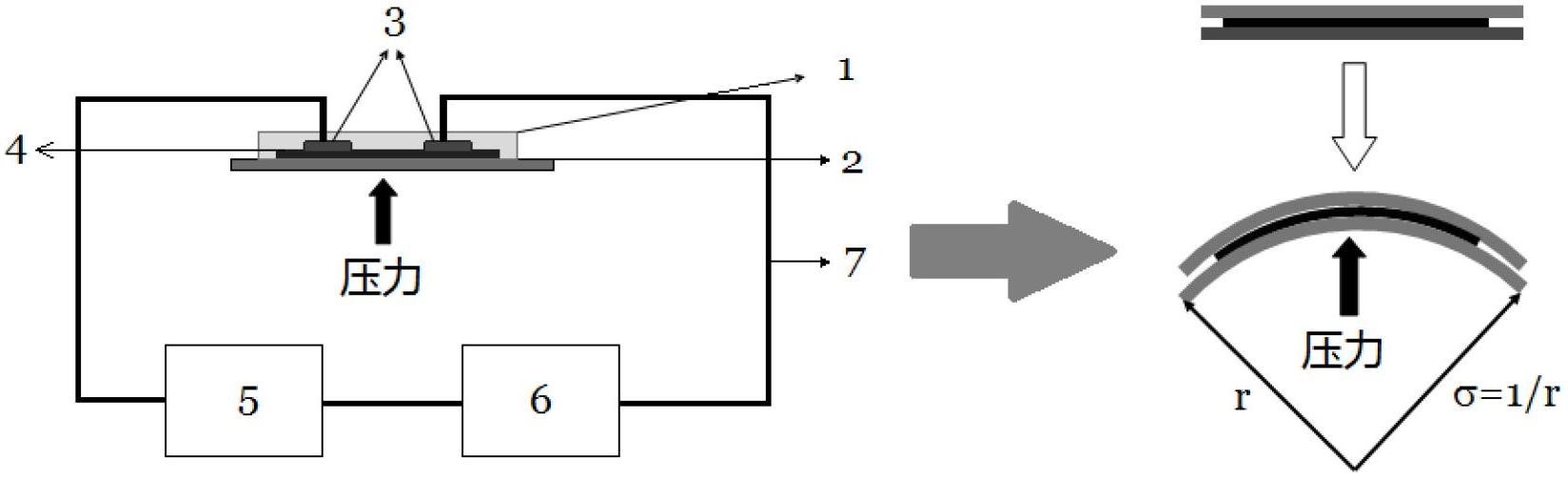

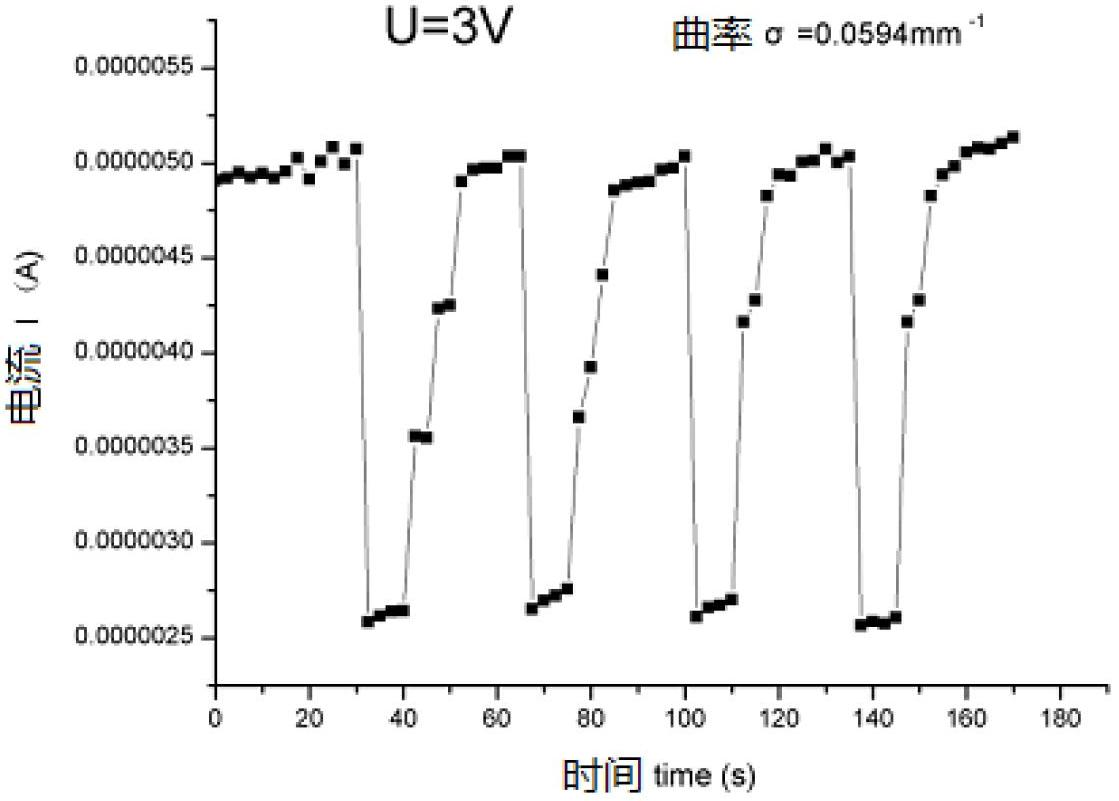

Preparation method of flexible force sensitive sensor

InactiveCN102692288ASimple structureLittle influence of temperatureForce measurement using piezo-resistive materialsTectorial membraneFiber

The invention belongs to the technical field of sensor preparation and relates to a preparation method of a flexible force sensitive sensor. According to the preparation method, an electrostatic spinning method is firstly adopted for preparing dendritic nanometer structure polyaniline coaxial ordered fibers of insulated high molecular materials of polyvinylidene fluoride (PVDF), PVDF fibers are used as reaction templates to be soaked into polyaniline reaction solution, a conducting polyaniline wrapping layer is formed on the surface of the PVDF fibers by an in-situ polymerization method in a wrapping form, the surface of the conducting polyaniline wrapping layer is subjected to self assembly to form a dendritic nanometer structure through controlling the reaction time, the polymerization temperature and the mol ratio of aniline monomers to doping agents, and coaxial structure polyaniline fibers with larger specific surface are obtained; then, the prepared coaxial structure polyaniline fibers are fixed on a bent plastic film, electrodes are prepared, protecting films are covered and are connected into a constant voltage circuit, and the flexible force sensitive sensor of the nanometer structure conducting polyaniline coaxial ordered fibers is prepared. The preparation method has the advantages that the preparation method is simple and convenient, in addition, the cost is low, the sensor structure is simple, the temperature influence is small, the mechanical property is good, the cracking is avoided, the sensitivity is high, and the response time is short.

Owner:QINGDAO UNIV

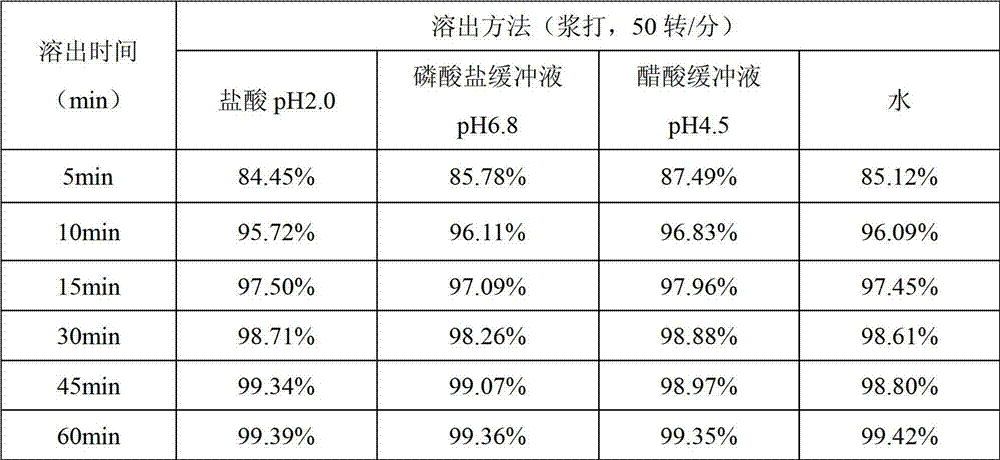

Slow-releasing preparation containing metformin hydrochloride and glipizide and its preparation method

InactiveCN101057849AEvenly distributedReduce local irritationOrganic active ingredientsMetabolism disorderMedicineMetformin Hydrochloride

The invention discloses a diabecron and glipizide -containing slow-release agent and the method for preparing the same. The glipizide micro-pill takes blank micro-pill as carrier, and combines glipizide and other medical findings with it. The diabecron-containing slow-release micro-pill comprises diabetosan pill, slow-release coating membrane material or other medical findings. The method for preparing diabecron-containing slow-release micro-pill takes extrusion rolling method or blank micro-pill loading method. The product is characterized by safety, high efficient, low toxicity and convenient usage. It can be used to treat non-insulin-dependent diabetes mellitus.

Owner:QIQIHAR MEDICAL UNIVERSITY

Rare earth polishing powder and production method thereof

The invention discloses rare earth polishing powder and a production method thereof. As an abrasive substance, the polishing powder comprises CeO2, La2O3 and Pr6O11. The total rare earth oxides (TREO) are above 90wt%. Meanwhile, in the TREO of the 877-3 rare earth polishing powder, CeO2 accounts for 70-80%, La2O3 19-29%, Pr6O11 0.05-2% and Nd2O3 less than 0.2%. To ensure necessary polishing speed, fluorine element which has chemical action is added to the wet synthesis process and initial shaping of product granularity is controlled, so that the obtained 877-3 rare earth polishing powder can be used for fast producing polished surface with good polishing effect.

Owner:甘肃稀土新材料股份有限公司

Cigarette water capsule with water and hydrotropic substance as core materials and manufacturing method of cigarette water capsule with water and hydrotropic substance as core materials

ActiveCN104305521AValid packageHave mechanical strengthTobacco smoke filtersEssential-oils/perfumesFood gradeWater soluble

The invention relates to a water capsule with water and hydrotropic substance as core materials and a manufacturing method of the water capsule. The water capsule is composed of a certain number of water capsule wall materials and the core materials, wherein the water capsule wall materials are compositions of long-chain ester materials and food-grade coagulant aids in specific proportion; the core materials are compositions of pure water, water-soluble substance and the hydrotropic substance. The water capsule is not used as an existing capsule capable of containing oil-soluble flavor substance only, the water and water substance can be included in the water capsule, and meanwhile the single-layer wrapped water capsule is achieved due to the fact that the wall materials are made of the long-chain ester materials and the specific coagulant aids. The water capsule is relatively simple in process; multi-layer wrapping is not needed; the commercial production is easily achieved; raw materials are easily obtained; the water capsule is easy to operate.

Owner:SHANGHAI HUABAO BIOLOGICAL TECH

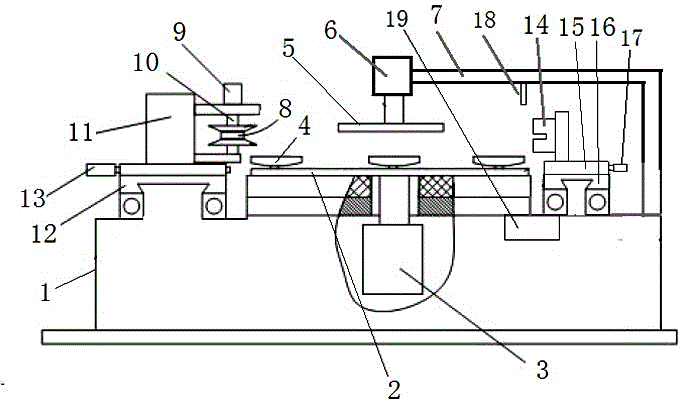

Glass edge grinding machine

InactiveCN105922098AAvoid damageAvoid affecting the grinding effectEdge grinding machinesGrinding work supportsDrive motorEngineering

The invention discloses a glass edge grinding machine which comprises a machine frame, wherein a glass fixing mechanism, a grinding mechanism and a scrap removing mechanism are mounted on the machine frame; the glass fixing mechanism comprises a rotary table, a rotary table driving motor, a pressing plate and a pressing plate driving air cylinder; the grinding mechanism comprises a grinding tool, a tool rotation driving motor, a tool bracket and a tool bracket driving motor; the scrap removing mechanism comprises a cleaner, a removing mechanism bracket and a sliding driving motor; the rotary table, sucking discs and the pressing plate can fix glass; the rotary table driving motor can drive the rotary table to rotate; the tool bracket is mounted on the machine frame in a sliding way; the tool rotation driving motor controls the grinding tool to rotate; a grinding surface of the grinding tool faces a glass mounting part between the rotary table and the pressing plate; the removing mechanism bracket is mounted on the machine frame in a sliding way; and a glass embedding opening is formed in the cleaner. According to the glass edge grinding machine, by removing glass scrap formed in a grinding process, the influence on a follow-up grinding procedure caused by the glass scrap is avoided, and the grinding efficiency and fineness are improved.

Owner:苏州市灵通玻璃制品有限公司

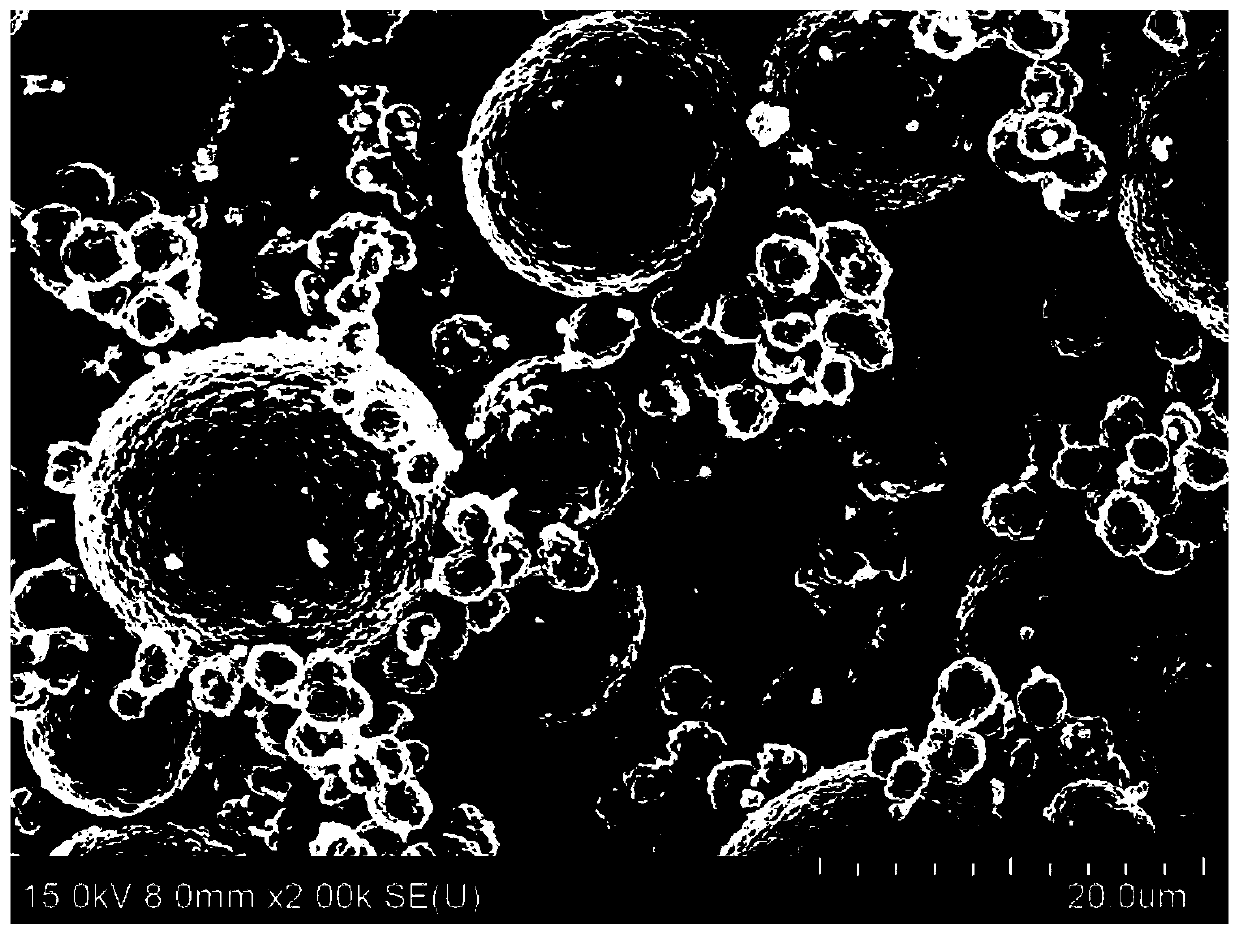

High-compaction and high-stability high-nickel cathode material and preparation method thereof, and lithium ion battery

ActiveCN110010889AImprove powder compactionIncrease the ultimate compaction densitySecondary cellsPositive electrodesHigh energyCerium

The invention discloses a high-compaction and high-stability high-nickel cathode material and a preparation method thereof, and a lithium ion battery. The high-nickel cathode material comprises a basematerial and a coating layer coating the surface of the base material, the base material is a compound as shown in the formula I: LinNixMyO2, wherein in the formula I, 0.98<n<=1.20, 0.50<x<1.00, 0.00<y<1.00, and 0.00<x+y<=1.00; the base material is consisted of a large-particle substrate and a small-particle substrate; and M is at least one selected from a group consisting of lithium, manganese,aluminum, molybdenum, chromium, vanadium, lanthanum, scandium, cerium, niobium, molybdenum, cobalt, magnesium, zirconium, strontium, yttrium, barium, titanium, fluorine, silicon, boron and phosphorus.The cathode material prepared by the invention has low residual alkali, uniform primary particle coating, primary particle pressure resistance and difficult breakage, so that the prepared lithium ionbattery has high energy density, lower internal resistance and excellent rate capability, safety performance and cycle performance.

Owner:GUIZHOU RONGBAI LITHIUM BATTERY MATERIAL CO LTD

Superfine dry granular porcelain glazed tile

The invention discloses a superfine dry granular porcelain glazed tile which belongs to the field of preparation of porcelain glazed tiles. The superfine dry granular porcelain glazed tile comprises agreen body, ground glaze and surface glaze, wherein the surface glaze comprises the following raw materials in percent by weight: 22-25wt% of potassium feldspar, 6-8wt% of calcined talc, 17-20wt% ofbarium carbonate, 2-5wt% of calcined alumina, 3-5wt% of calcined zinc oxide, 3-5wt% of quartz, 5-8wt% of kaolin, 6-8wt% of dolomite and 26-30wt% of 10,139 # dry granules. The green body of the tile islow in water absorption and high in breaking strength; the green body, the bottom glaze and the surface glaze are good in combinability, and the tile in good in flatness; the superfine dry granules form a slightly rugged surface in the surface glaze, and the grain size of each of granular crystals protruding out of the glaze is 0.12-0.18mm, so that an anti-skidding and abrasion-proof effect can be achieved on the glaze, and the defect that dirt is hided and adsorbed in the glaze can be overcome.

Owner:FUJIAN DESHENG NEW BUILDING MATERIAL CO LTD

Environment responding aquogel copolymer and its prepn

The present invention relates to one kind of environment responding aquogel copolymer and its preparation process. The aquogel consists of: N-isopropyl acrylamide 10-90 wt% and methacrylate dextran derivative 10-90 wt%. The preparation process of the environment responding aquogel copolymer includes chemical modification of dextran with GMA to synthesize methacrylate dextran derivative, MA-Dex, with reaction activity; and subsequent copolymerization of MA-Dex and NIPA to obtain the said environment responding aquogel copolymer P(NIPA-co-MA-Dex). The aquogel copolymer has high temperature sensitivity and quick responding speed as well as high strength and excellent biocompatibility. The preparation process is simple, needs no special apparatus and is easy to realize in industry.

Owner:TIANJIN POLYTECHNIC UNIV

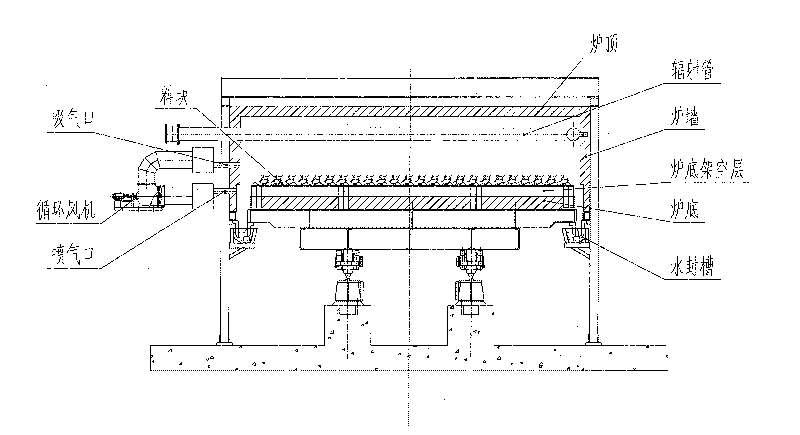

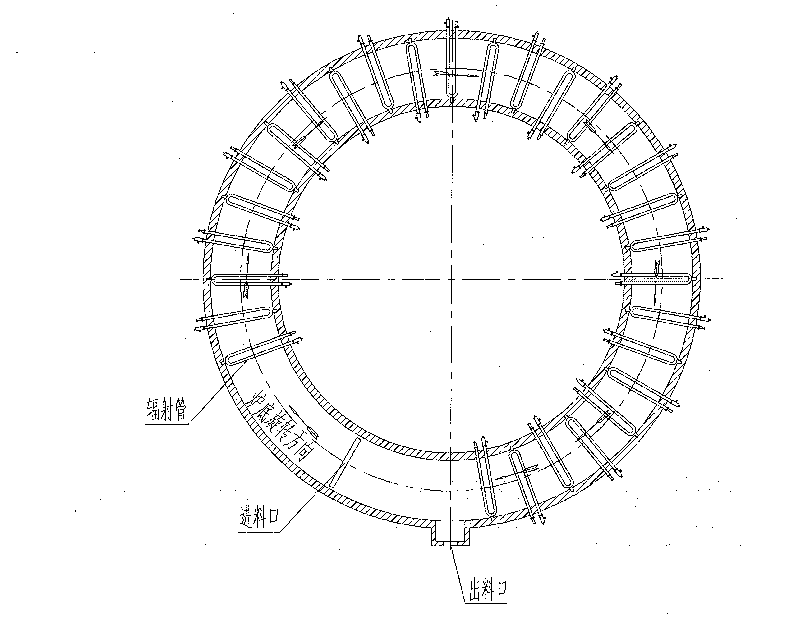

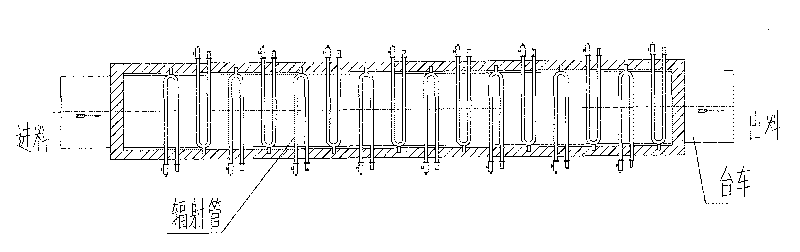

Moving-bed retorting furnace heated comprehensively by radiant tube and circulating airflow

ActiveCN101712878AUnbreakableUniform heating temperatureDirect heating destructive distillationIndirect heating destructive distillationHearthMoving bed

The invention discloses a moving-bed retorting furnace heated comprehensively by a radiant tube and a circulating airflow, comprising a hearth formed by furnace walls, a furnace top and a furnace bottom. The furnace bottom is a circular or through movable furnace bottom; and the upper space of the hearth is provided with a radiant tube heater. By adopting the radiant tube heater to heat, burning products can not be doped in retorting gas, generated retorting oil can keep inherent components, and the retorting gas has high heat value. The furnace bottom is in an overhead layer structure, and afurnace gas-circulating device is arranged between the overhead space and the hearth space above the furnace bottom. The invention has high heat-transferring rate and uniform material-heating temperature and is widely used to retort materials, such as oil shale, coal, lignite, oil sand, plants, and the like.

Owner:SHENWU TECH GRP CO LTD

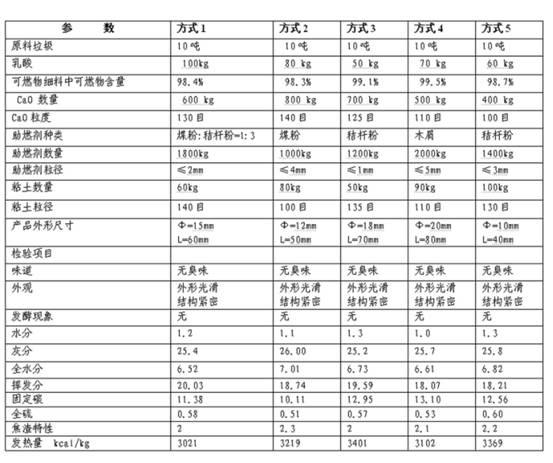

Preparation method for preparing derived fuel by utilizing combustible materials in garbage

InactiveCN102041127AImprove sorting rateSuppress generationBiofuelsSolid fuelsRefuse-derived fuelAdhesive

The invention relates to a preparation method for preparing a derived fuel by utilizing combustible materials in garbage, comprising the following steps: (1) disinfecting; (2) carrying out rough selection on the garbage; (3) carrying out fine selection on the garbage; (4) adding CaO the weight of which accounts for 4%-8% of the total weight of the combustible materials into fine combustible materials, mixing and stirring uniformly; (5) adding a combustion improver and an adhesive, mixing and stirring uniformly; (6) draining and drying the fine combustion materials; (7) carrying out extrusion molding; (8) drying and cooling to obtain a finished product; and (9) detecting the heating value of the derived fuel. The preparation method has the beneficial effects that 1, the sorting index of the garbage is high, so that harmful substances in the derived fuel are effectively controlled; 2. the heat value of the derived fuel is high; 3, the CaO is added in the derived fuel of the garbage, effective disinfection is achieved and the generation of the harmful substances such as dioxin and the like in the combustion process is restrained; 4, the adhesive is added, so that the strength of a product is good, the product is not easy to break, and the structure shape is smooth; 5, the space formed by accumulation of the size of the shape of the finished product on a boiler grate is most beneficial to combustion; and 6, the resource utilization is maximized, the cost of production and manufacture is low, the production efficiency is high, the product quality is good, and the transportation and storage are convenient.

Owner:杨健

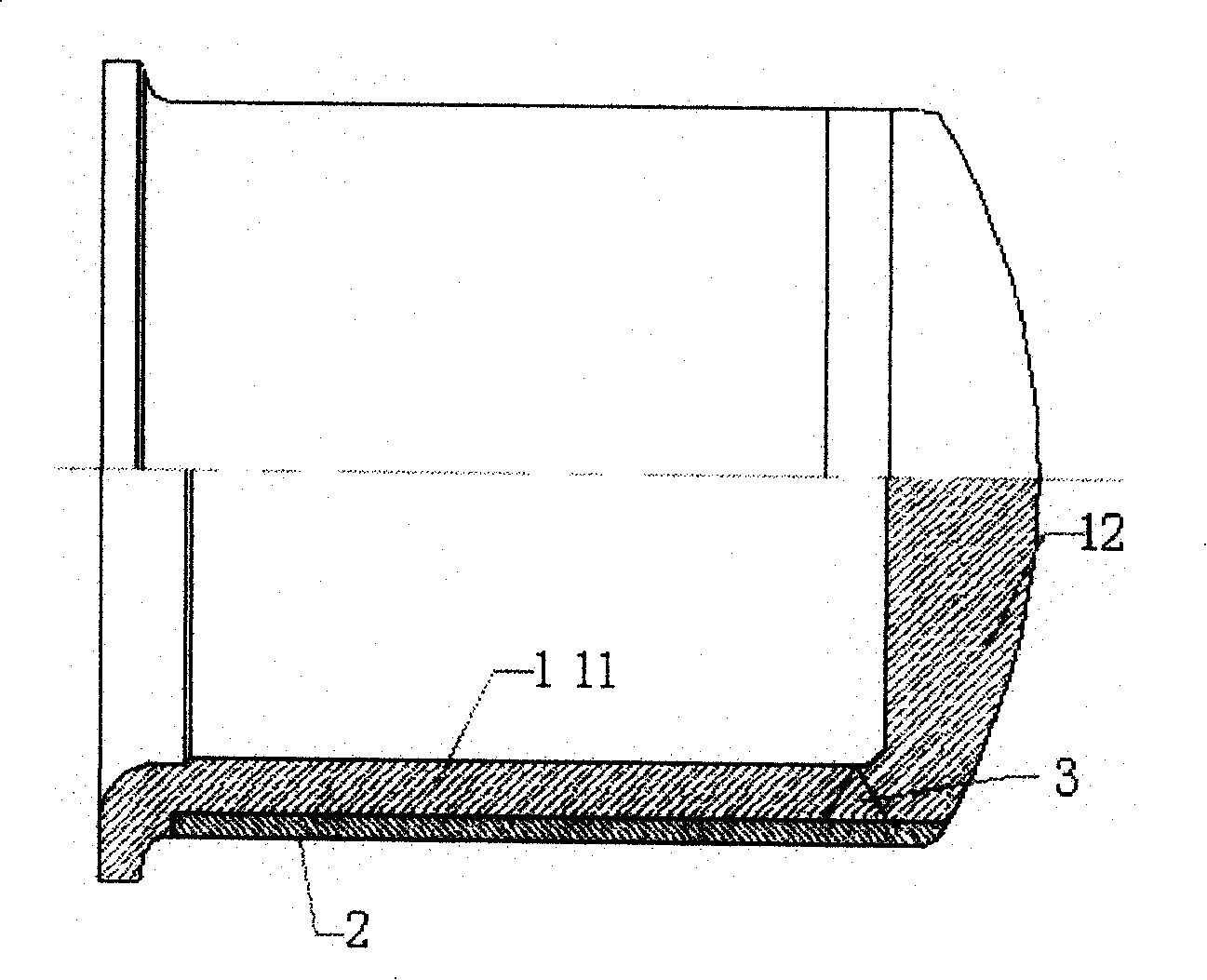

Dip-roll sleeve and method for manufacturing the same

InactiveCN101205598AIncrease profitImprove adaptabilityHot-dipping/immersion processesUltimate tensile strengthZinc

The invention provides a sink-roll sleeve, which consists of a stainless steel substrate 1 and a Co-base laser-clad layer 2, with the Co-base laser-clad layer covered on the stainless steel substrate 1. The invention also provides a method for manufacturing the sink-roll, and is characterized in that: the procedures are: 1. processing of the stainless steel substrate 1; 2) mechanical processing; 3) laser cladding, which is cladding a bottom layer first, and then a functional layer on the outer circle of the stainless steel substrate 1, with the parameters for laser cladding including a laser power of between 3000 and 5000 W, a diameter of faculae of between 2 and 5mm, a scan speed of between 2 and 10 mm / s; 4) mechanical processing to the designed dimension. The sink-roll sleeve and the manufacturing method provided by the invention has the advantages of high material utilization rate, molten zinc corrosion resistance layer more than 2 mm millimeter thick, high strength in aspect of the sink-roll sleeve, and of strong adaptability, simple and easy operation, high normative, low production costs and great application value in aspect of the manufacturing method.

Owner:SHENYANG DALU LASER TECH

Atorvastatin calcium tablet and preparation method thereof

ActiveCN102920675AHigh dissolution rateImprove bioavailabilityMetabolism disorderPharmaceutical non-active ingredientsFiller ExcipientHardness

The invention discloses an atorvastatin calcium tablet and a preparation method thereof. The tablet consists of the following components in parts by mass: 7.22 parts of main medicine atorvastatin calcium, 84.55 parts of filler, 6 parts of disintegrating agent croscarmellose sodium, 1.33 parts of adhesive hydroxy propyl cellulose, 800.4 parts of cosolvent polysorbate and 0.5 part of lubricating agent magnesium stearate, wherein the filler comprises the following raw materials in parts by mass: 22.01 parts of calcium carbonate, 21.87 parts of milk sugar and 40.67 parts of microcrystalline cellulose. The atorvastatin calcium tablet has the characteristics of short disintegrating time, fast dissolving-out speed, high bioavailability and small particle diameter, and is convenient to take. Furthermore, the hardness of the tablet can reach 60-70N, so that the tablet is hardly broken, and therefore, the packing and transporting costs are reduced, and the industrialized popularization of the tablet is easily realized.

Owner:HENAN RUNHONG PHARMA

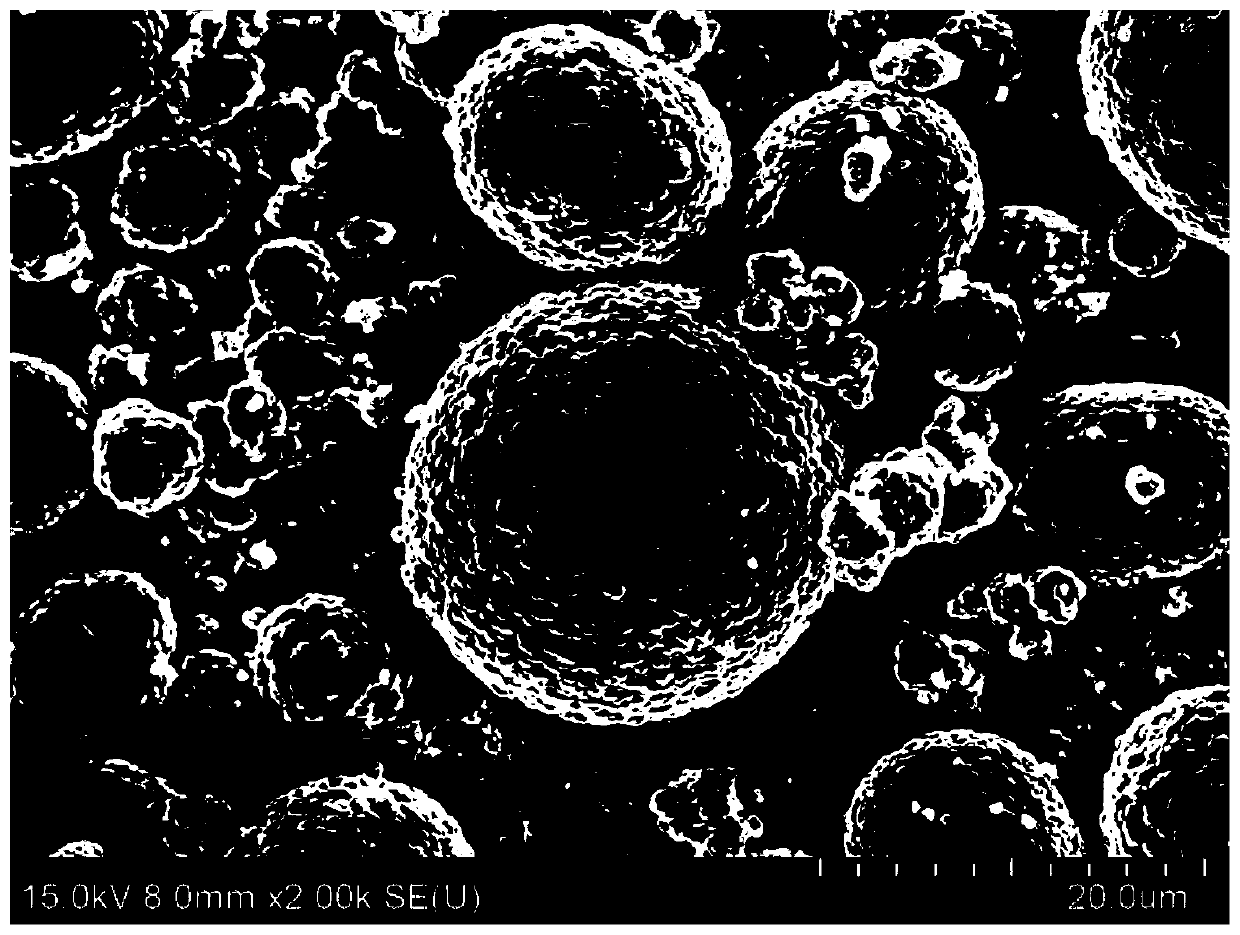

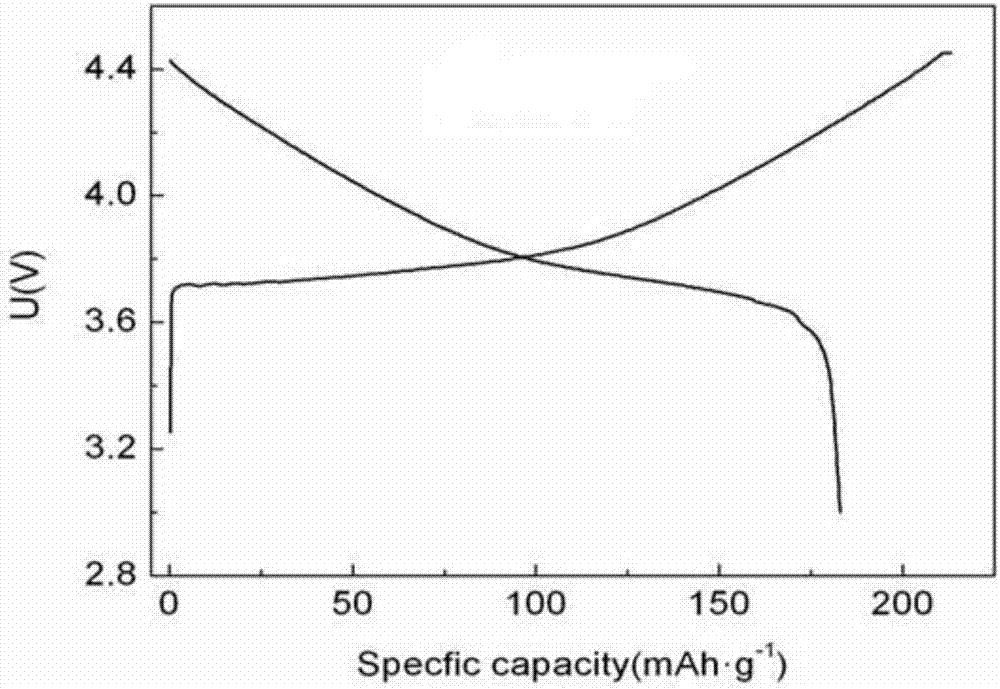

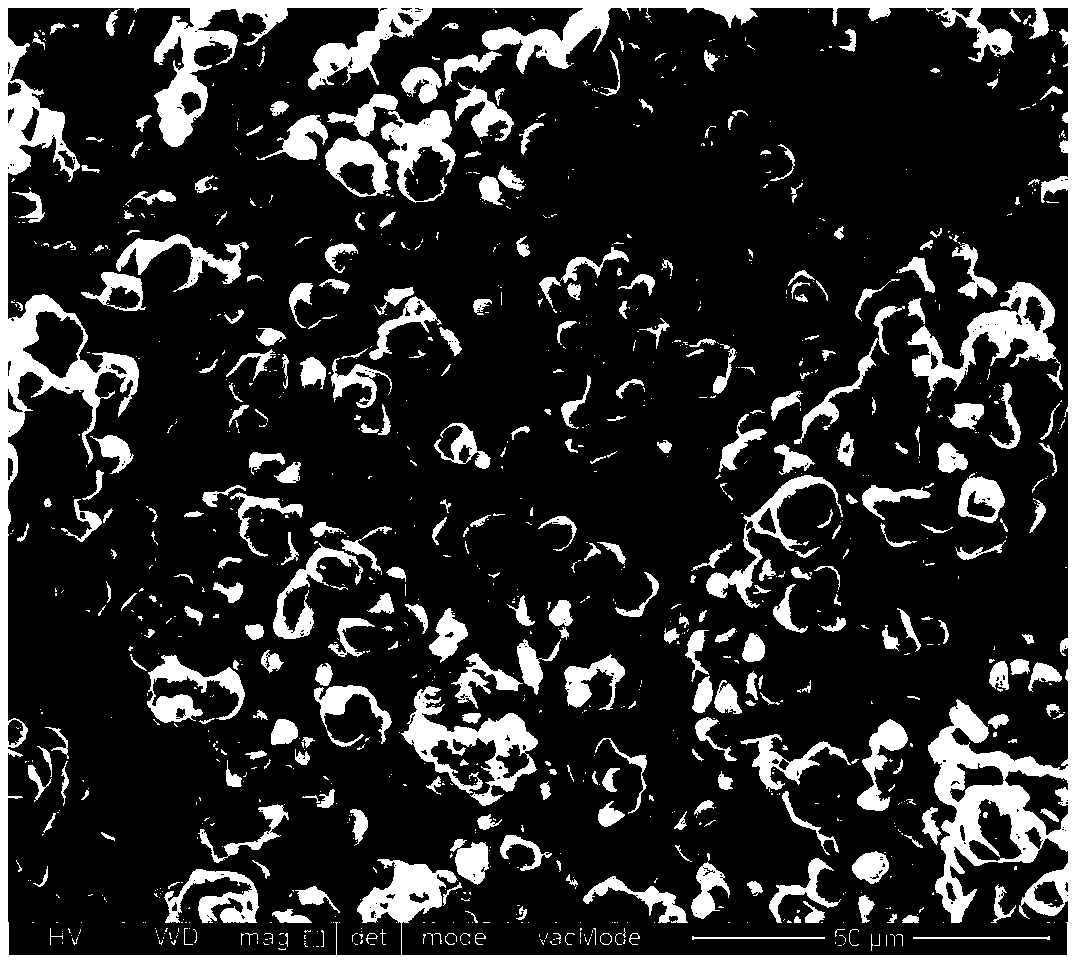

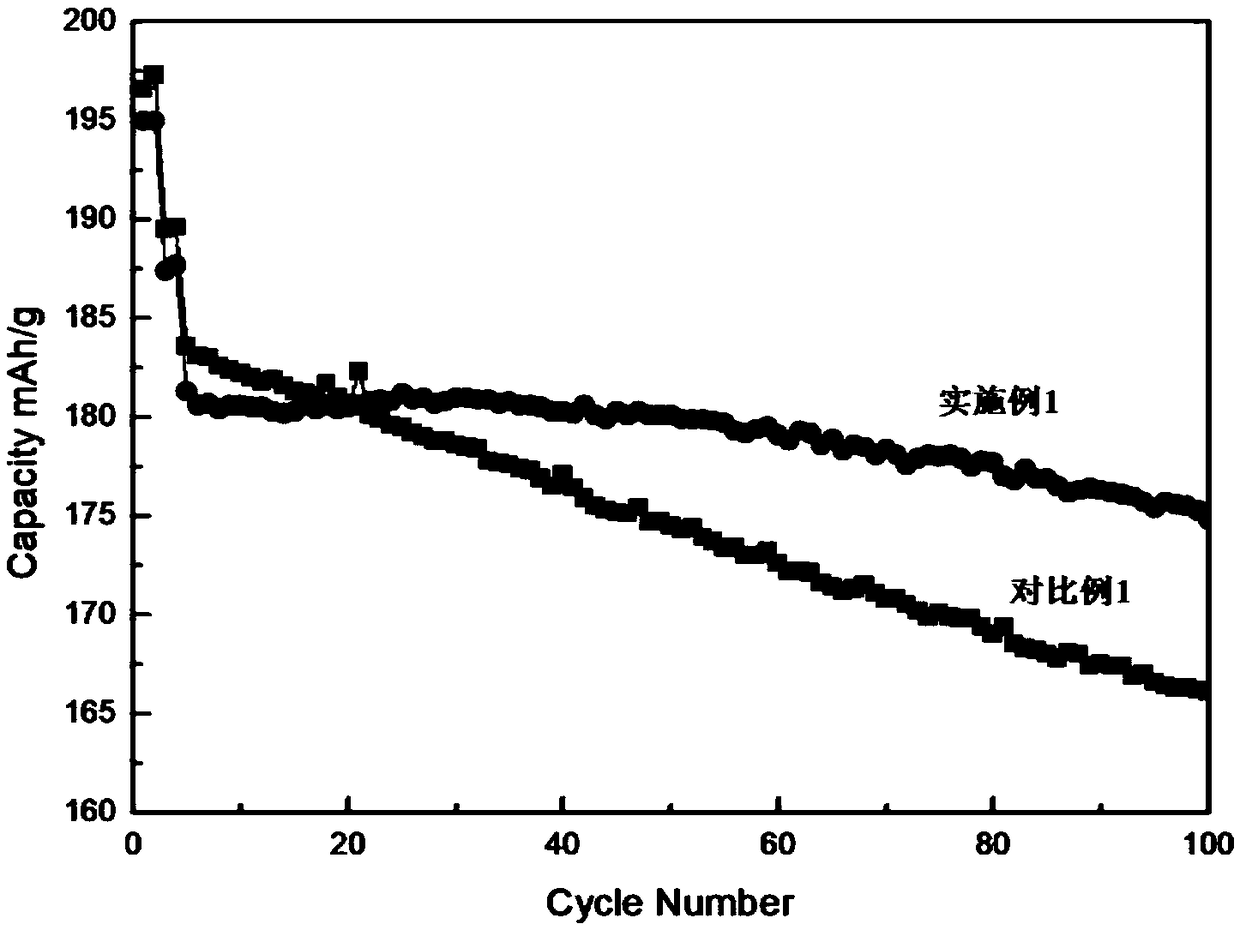

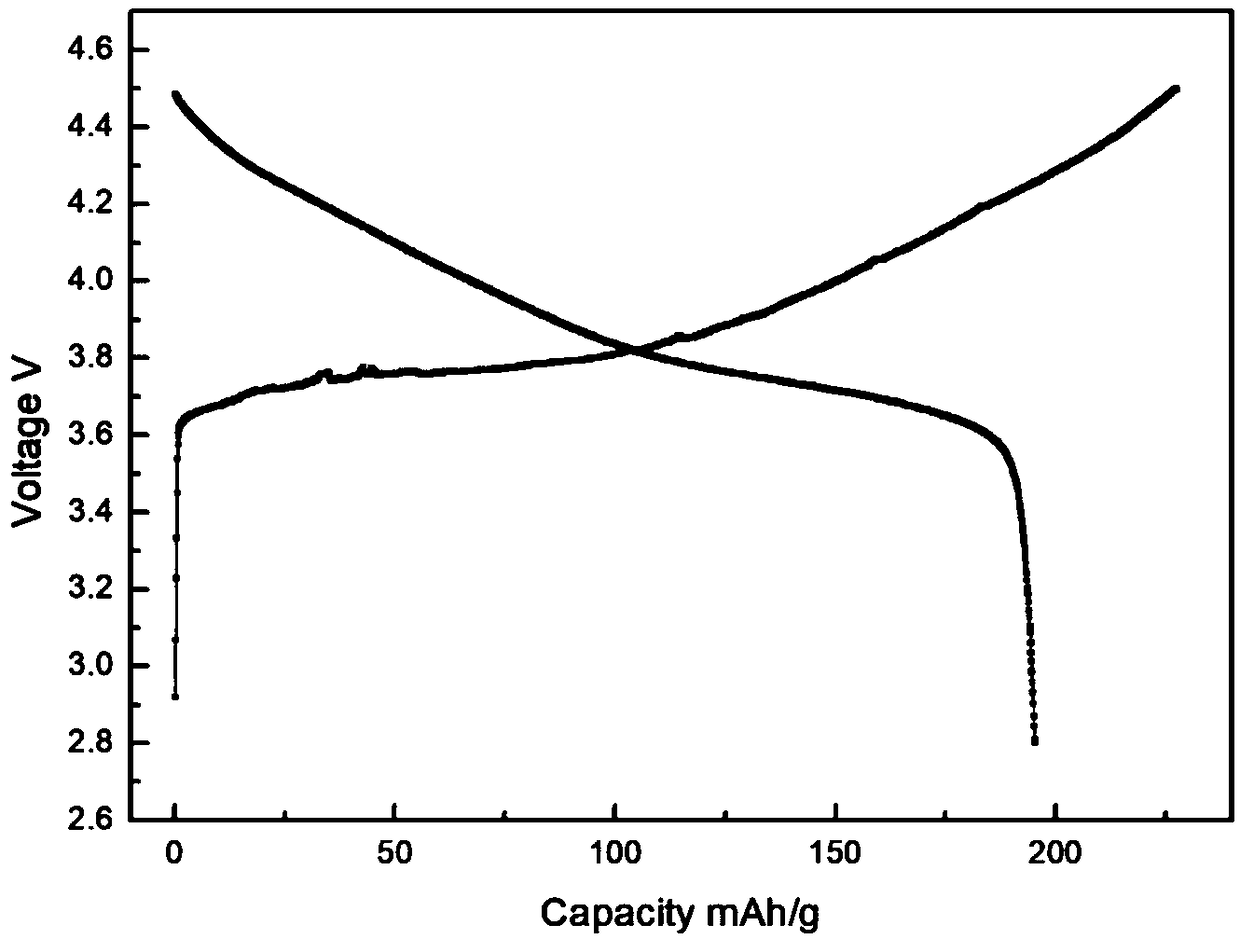

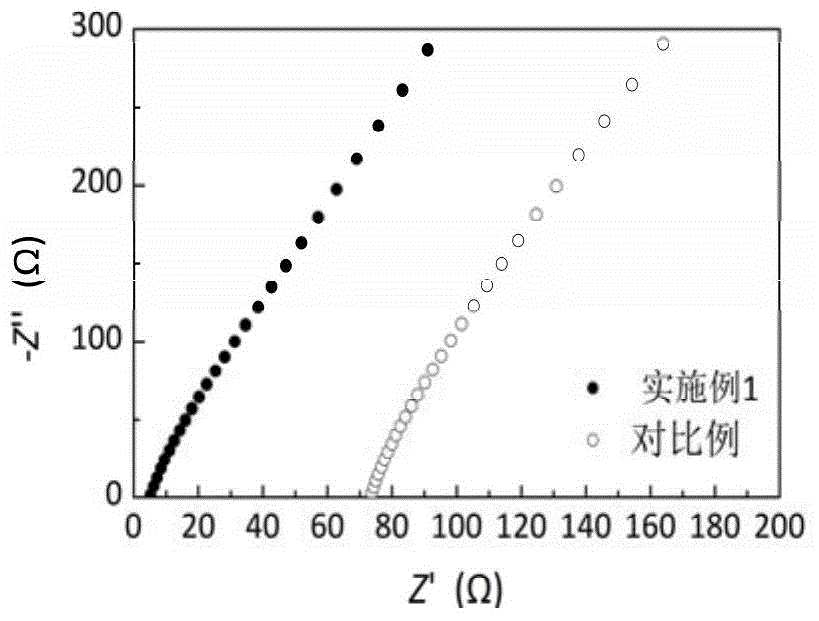

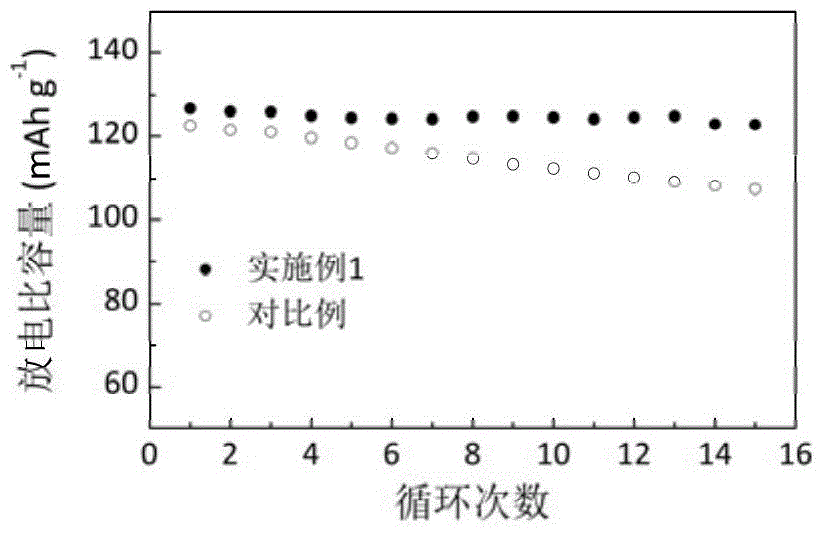

High-voltage and single-crystal ternary positive electrode material and preparation method thereof

InactiveCN107293744AEasy transferImprove cycle lifeCell electrodesHigh temperature storageChemical synthesis

The invention discloses a high-voltage and single-crystal ternary positive electrode material and preparation method thereof. The general formula of the material can be expressed with Li<x>Ni<1-m-n>Co<m>Mn<n>O2, wherein x is more than 0.96 but less than 1.12, m is more than 0 but less than 1, n is more than 0 but less than 1, and (m+n) is less than 1. The preparation method comprises the steps of preparing a precursor by taking a nickel salt, a cobalt salt and a manganese salt as raw materials and by employing a co-precipitation method or a chemical synthesis method, mixing the precursor with a lithium source, adding a modifying agent into the mixture after pre-processing, and performing sintering, smashing and sieving after uniform mixing to obtain the high-voltage and single-crystal ternary positive electrode material. The grain size of the prepared high-voltage and single-crystal ternary positive electrode material is 2-15 micrometers, and the compaction density reaches 3.8-3.9g / cm<3>; meanwhile, the surface of the ternary positive electrode material is modified by a wet process to package Al, the material structure is stabilized, and side reaction of the material and an electrolyte is prevented; and according to actual detection, the cycle property, the high-temperature storage performance and the safety performance of the lithium ion battery under high voltages of 4.4V and 4.5V are effectively improved.

Owner:HENAN KELONG NEW ENERGY CO LTD

Macromolecule material cold keeping agent making method

InactiveCN1570016ALow costUse low concentrationHeat-exchange elementsPolymer science(Hydroxyethyl)methacrylate

The invention discloses a macromolecule material cold keeping agent making method which consists of, preparing aqueous solution of polymers having strong hydrophilic radicals in the molecular structure, charging propenoic acid, hydroxyethyl methacrylate and maleic anhydride monomer, mixing homogeneously, charging bis-ethyl acrylate cross linking agent, agitating homogeneously, charging potassium peroxodisulfate initiating agent, mixing homogeneously, obtaining macromolecular material, dissolving into water of different mass.

Owner:TSINGHUA UNIV +2

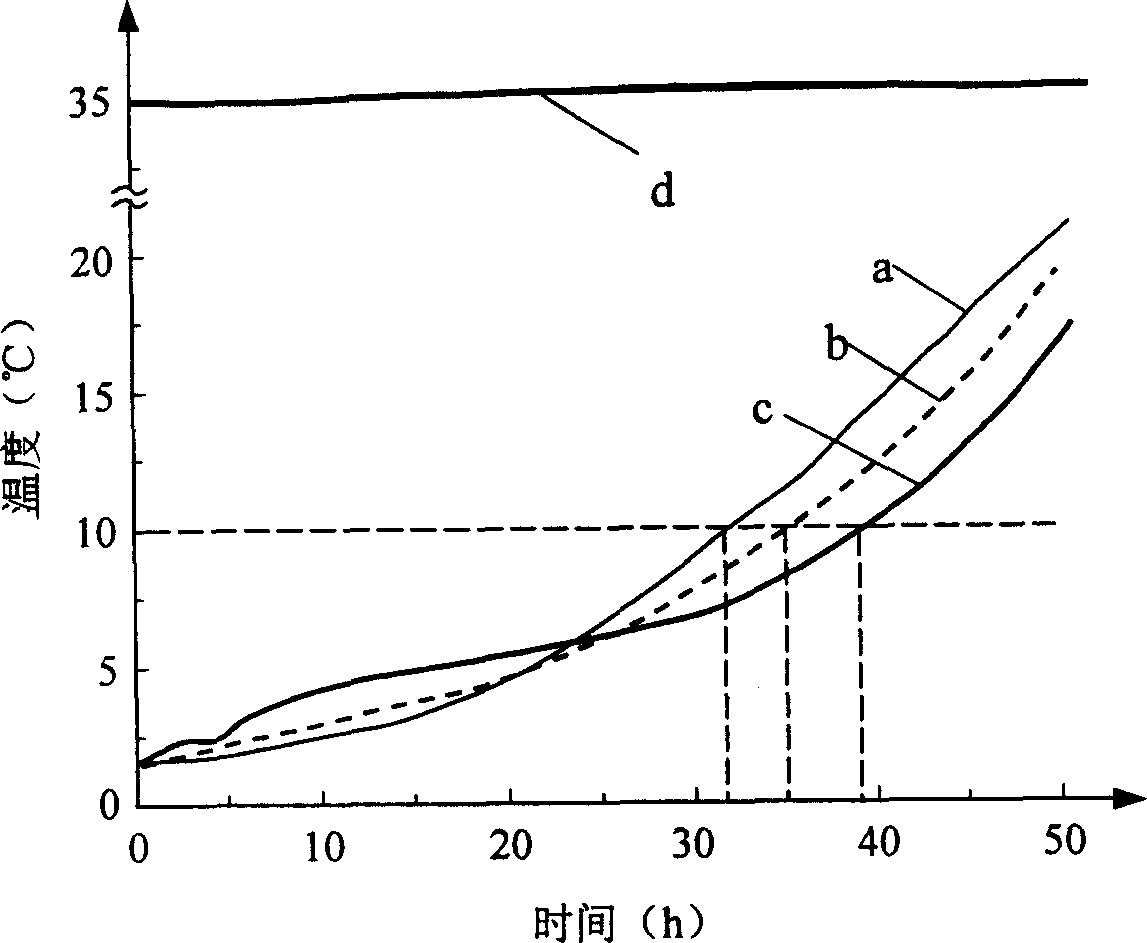

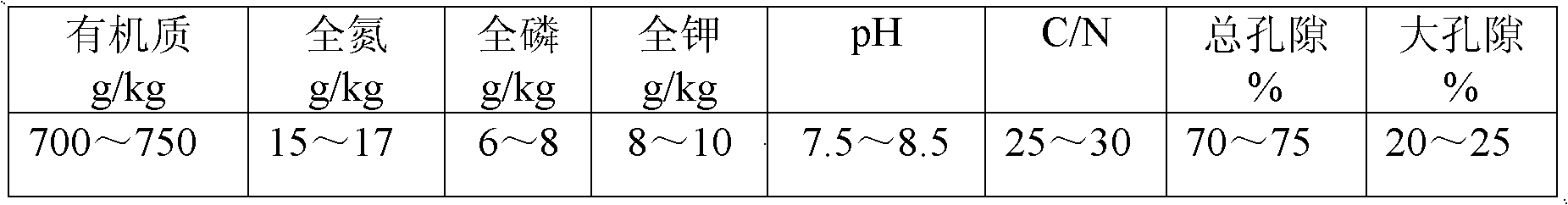

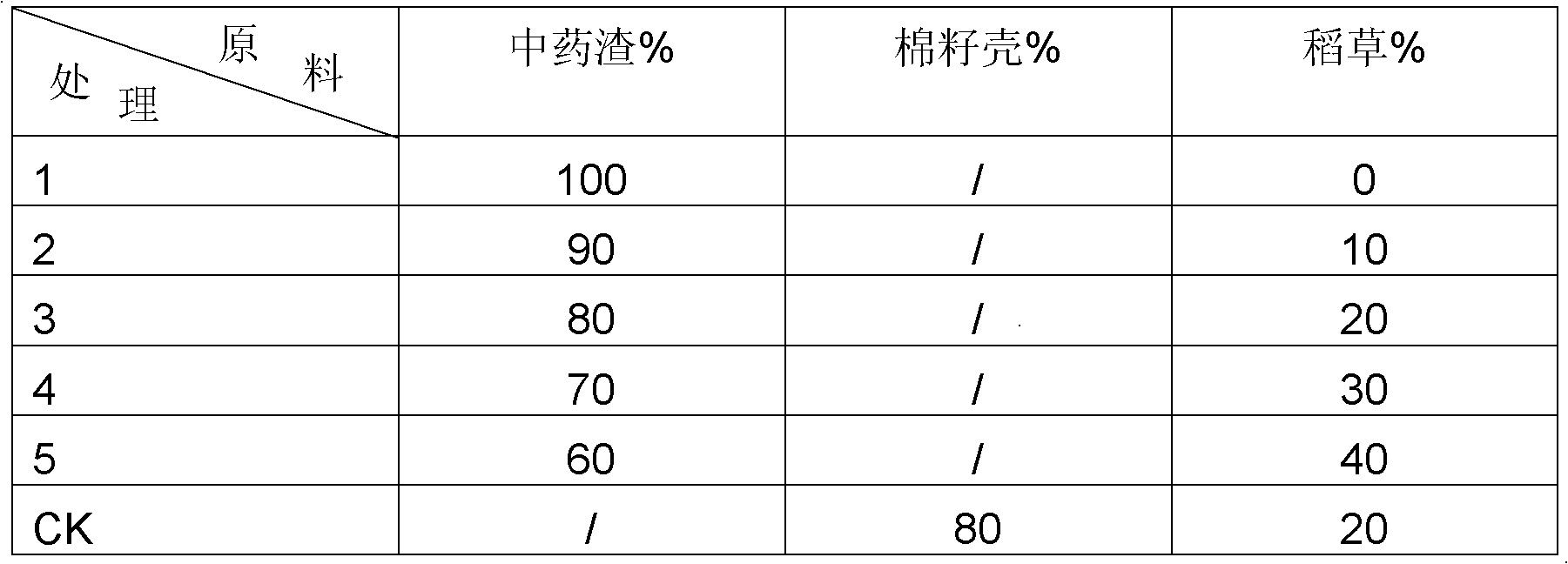

Straw mushroom culture medium and method for circularly cultivating straw mushrooms

InactiveCN102173949ANo pollutionImprove ventilationHorticultureFertilizer mixturesBiotechnologySulfate

The invention discloses a straw mushroom culture medium and a method for circularly cultivating straw mushrooms. The straw mushroom culture medium comprises 70 to 90 weight percent of Chinese medicament dreg, 10 to 30 weight percent of straws and a production increasing agent with the dose of 5 to 10 kg / m<3>, wherein the production increasing agent is prepared by mixing the following components in percentage by weight: 0.006 to 0.01 percent of vitamin B1, 15 to 20 percent of superphosphate, 40 to 60 percent of quick lime, 1.5 to 2 percent of magnesium sulfate, 0.2 to 0.4 percent of zinc sulfate, 0.2 to 0.3 percent of boric fertilizer, 0.2 to 0.4 percent of triacontanol and 22 to 37 percent of starch. By the straw mushroom culture medium and the method for circularly cultivating the straw mushrooms, resources can recycled; energy is saved due to short fermentation time of the medium; the medium can increase yield of the straw mushroom, can improve the quality of the straw mushroom and can increase the flavonoid content of the straw mushrooms; and by the multi-time circularly cultivating method, the utilization ratio of the medium is increased and production cost is reduced.

Owner:NANJING INST OF VEGETABLE SCI

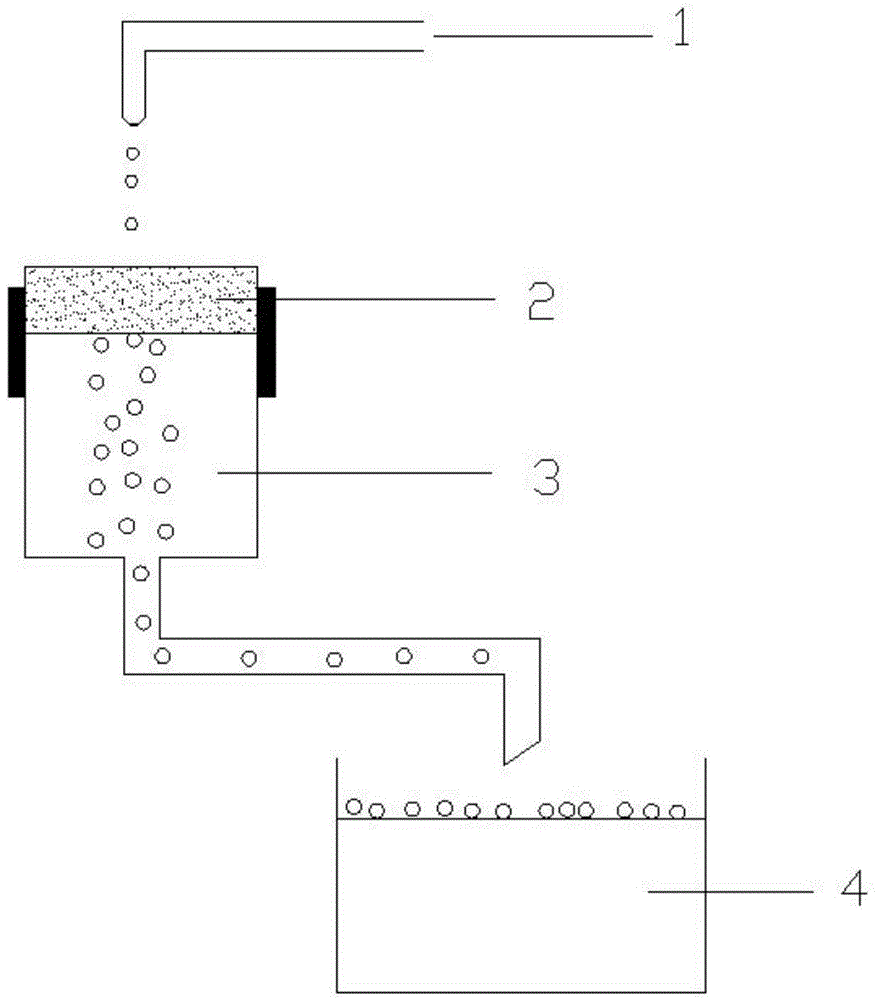

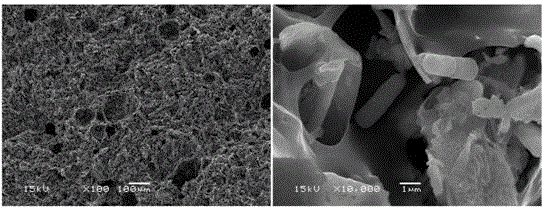

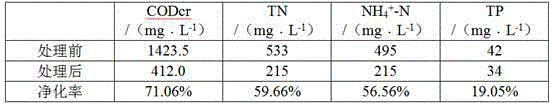

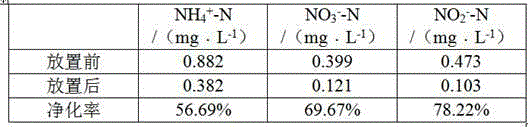

Bacteria immobilization particles for water purification and preparation method of bacteria immobilization particles

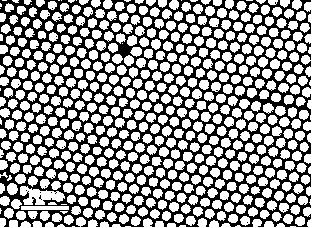

ActiveCN104894099AImprove adsorption capacityReduce harmOn/in organic carrierOn/in inorganic carrierActivated carbonEnvironmental chemistry

The invention discloses bacteria immobilization particles for water purification and a preparation method of the bacteria immobilization particles, and belongs to the technical field of water treatment. The preparation method comprises the following steps: preparing a bacteria concentrate through flocculation by utilizing activated carbon, diatomite and a chitosan acetic acid solution; adding diatomite, bentonite, silicon dioxide and a polyvinyl alcohol-sodium alginate mixed solution into the concentrate for stirring; carrying out granulation with a granulator to prepare the bacteria immobilization particles. The prepared bacteria immobilization particles are high in biological activity, high in bacteria content (5*10<9>-1*10<10> CFU / g), short in starting time, and high in reaction speed, has a honeycomb structure (100-300 m<2> / g in specific surface area) suitable for bacteria apposition growth and mass transfer, and can be used for immobilizing bacteria for long, prohibiting the invasion of external hazardous materials, and permanently and efficiently treating sewage in different environments and of different water quality types; meanwhile, industrialized production is available for a whole bacteria immobilization particle preparation process, and the prepared bacteria immobilization particles are high in mechanical property, long in service life, and convenient to store and convey.

Owner:CENT LAB FUJIAN ACADEMY OF AGRI SCI +1

Welding method of tungsten target material component

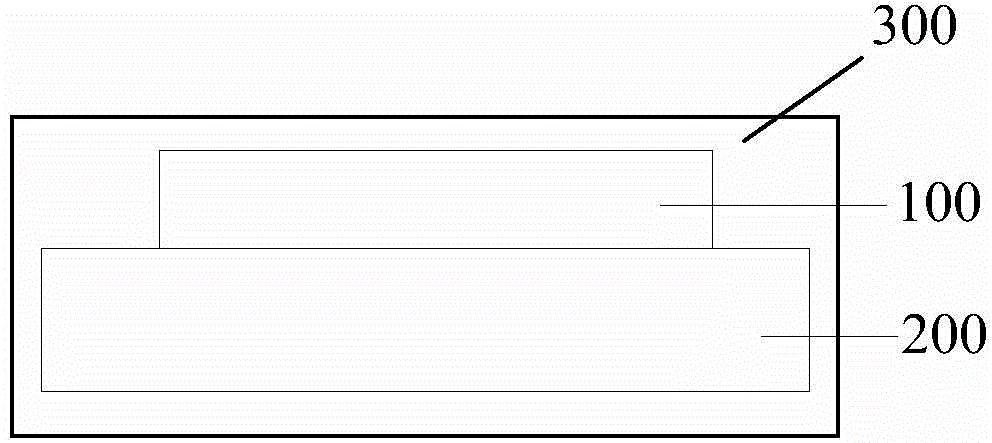

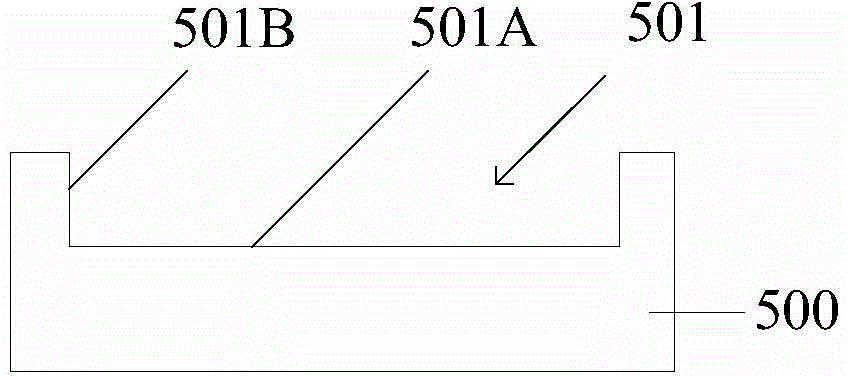

ActiveCN104551381AReduce deformationUnbreakableWelding/soldering/cutting articlesMetal working apparatusHot isostatic pressingWeld strength

The invention discloses a welding method of a tungsten target material component. The welding method comprises the following steps: providing a tungsten target material and a copper back plate; turning threads in the welding surface of the tungsten target material; forming a groove in the copper back plate; mounting the tungsten target material in the groove; welding the tungsten target material and the copper back plate by a hot isostatic pressure method. Through the use of the welding method, the threads are turned in the welding surface of the tungsten target material, the groove is formed in the copper back plate, and the tungsten target material and the copper back plate are mounted together, so that the tungsten target material is positioned in the groove; then welding by the hot isostatic pressure method is performed, in the welding process, the deformation quantity of the tungsten target material is small, and a fragmentation phenomenon not easily occurs; in addition, because of the threads, the area of the welding surface of the tungsten target material is enlarged, and the welding strength of the tungsten target material component is improved; after welding, the threads are embedded in the copper back plate from the welding surface of the tungsten target material, so that the welding strength of the tungsten target material component is further improved.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Preparation method of ternary cathode material, ternary cathode material prepared through preparation method, lithium-ion battery and electric vehicle

InactiveCN109378469AReduce the amount of residual alkaliImprove electrochemical performanceCell electrodesSecondary cellsSingle crystalSide reaction

The invention discloses a preparation method of a ternary cathode material, the ternary cathode material prepared through the preparation method, a lithium-ion battery and an electric vehicle, and relates to the technical field of ternary cathode materials of lithium-ion batteries. The preparation method of the ternary cathode material comprises the following steps: a ternary precursor, a lithiumsource and a flux are evenly mixed and primarily sintered, and a mono-like-shaped ternary cathode material is obtained; and then the mono-like-shaped ternary cathode material is added into an alumina-titanium oxide sol mixed solution, the solution is heated and evaporated to be dried, and the aluminum-titanium coated mono-like-shaped ternary cathode material is obtained through secondary sintering. By adding the flux, the sintering temperature is decreased, and the mono-like-shaped material is obtained; and meanwhile, through a liquid phase coating method, the residual alkali quantity on the surface of the ternary material is decreased, the structural stability of material crystals is improved, a side reaction of the material surface is inhibited, and the electrochemical properties of thematerial are further improved.

Owner:QINGYUAN JIAZHI NEW MATERIAL RES INST CO LTD

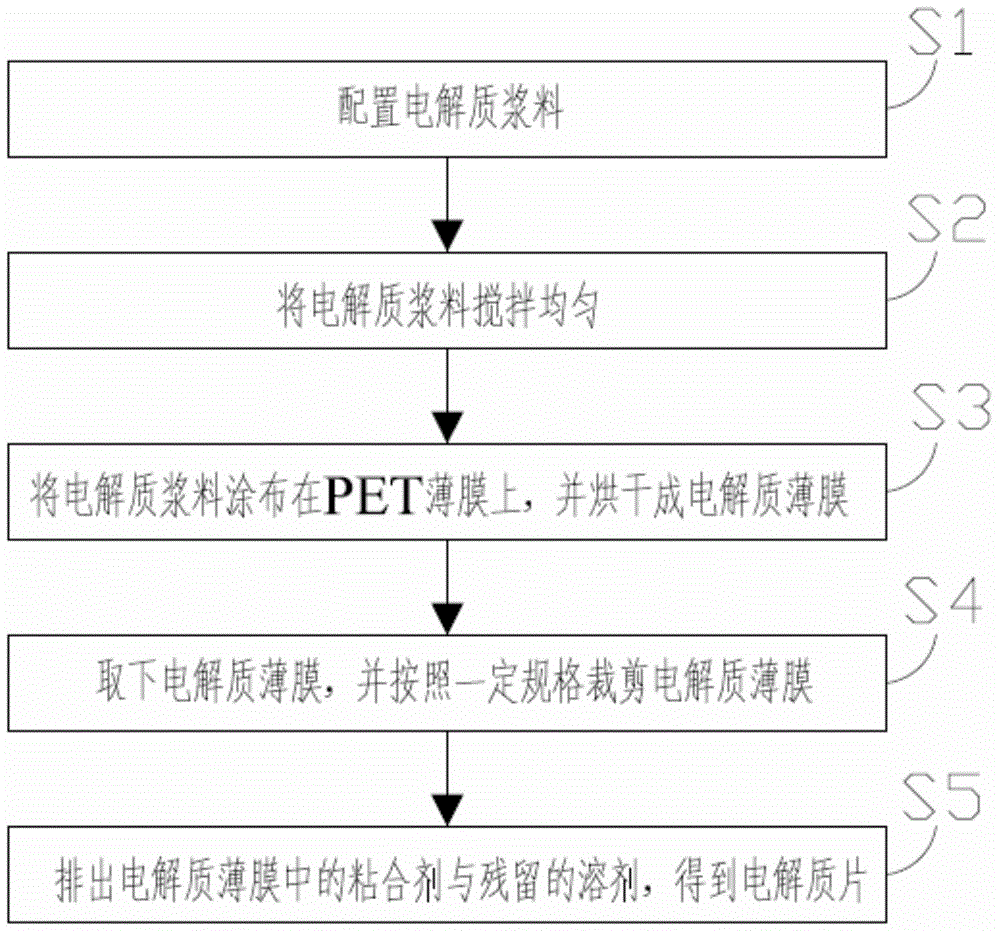

Preparation method of sulfide solid electrolyte material

InactiveCN105870497AUniform thicknessThin and uniformNon-metal conductorsSecondary cellsAll solid stateElectrolysis

The invention provides a preparation method of a sulfide solid electrolyte material. The preparation method comprises the following steps: sulfide lithium ion conductor electrolyte powder, an adhesive and a solvent are mixed, and electrolyte slurry is obtained; the electrolyte slurry is uniformly stirred and dispersed, and uniform electrolyte slurry is obtained; the uniform electrolyte slurry is uniformly coated on a PET film, the electrolyte slurry which is coated on the PET film is dried at a set drying temperature, in order to evaporate the solvent part, and an electrolyte film is obtained; the electrolyte film is taken from the PET film, and the electrolyte film is cut according to a certain specification; the adhesive and the residual solvent in the cut electrolyte film are discharged, and a compact sulfide lithium ion conductor electrolyte sheet is obtained. The preparation method of the sulfide solid electrolyte material can effectively solve the problem that when an electrolyte sheet is prepared according to the prior preparation method of the all solid state electrolyte sheet, the electrolyte sheet which is thicker influences electrical performance of an all solid state battery.

Owner:新余赣锋新能源产业投资合伙企业(有限合伙)

Permanent antistatic paint and its prepn

InactiveCN1441012AThe preparation method is simple and easyEasy constructionPolyurea/polyurethane coatingsEpoxy resin coatingsPolyesterEpoxy

The antistatic paint is prepared with resin varnish 100(in weight portions, the same below), high structure carbon black 5-40 and preferably 20-25, solvent 15-50, and coupling agent 0.1-0.3. The resin varnish is acrylate, epoxy resin, polyester or polyurethane. The production process includes stoving carbon black at 60-100 deg.c, spraying carbon black with coupling agent, adding carbon blac, resin and solvent successively into container while stirring, and ball milling. The paint of the present invention has the same antistatic effect as antistatic plastic but much less consumption and thus much lower cost, and has no influence on the other performance, such as mechanical performance, of the painted body.

Owner:NANJING PANDA ELECTRONICS

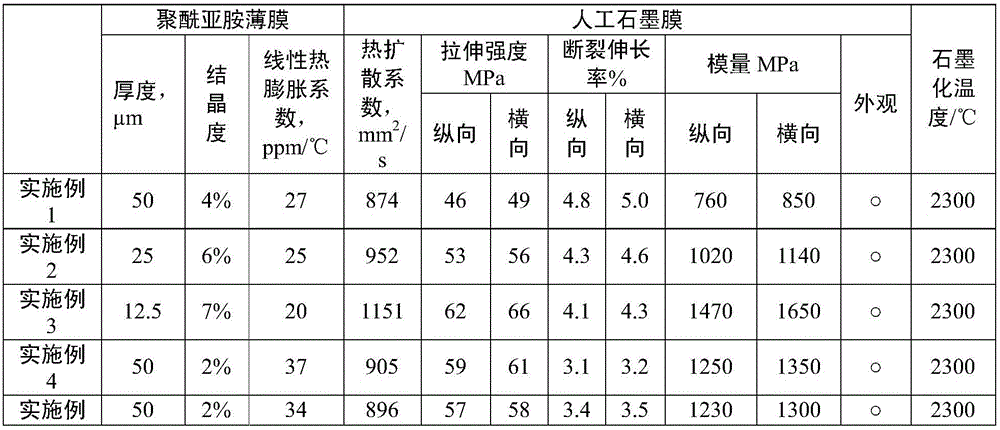

Polyimide thin film for preparing artificial graphite film and preparation method of polyimide thin film

The invention provides a polyimide thin film for preparing an artificial graphite film with excellent mechanical properties and a preparation method of the polyimide thin film. The polyimide thin film is prepared from a raw material diamine monomer which comprises 0 to 75 mol ratio of p-phenylenediamine; the raw material dianhydride monomer, comprises 40 percent to 100 mol ratio of of pyromellitic dianhydride; two types of inorganic fillers, including a calcium-containing compound and transition metal oxide, are uniformly dispersed in the polyimide thin film. The polyimide thin film provided by the invention is applicable to a graphitization process of single-sheet, multilayered stacking and continuous coiled materials and can be used for carrying out graphitization at temperature of 2300 DEG C; the crystallization degree is less than 10 percent. The graphite film prepared from the polyimide thin film has an excellent heat conducting property and has excellent mechanical properties in longitudinal and lateral directions of the thin film; the modulus is less than or equal to 2000MPa, the elongation at break is more than or equal to 3 percent, the tensile strength is more than or equal to 40MPa and the difference of the longitudinal and lateral directions is less than 15 percent.

Owner:RAYITEK HI TECH FILM CO LTD

Catalyst for ethene polymerization or multipolymer, preparing method thereof

A catalyst for polymerization or copolymerization of ethylene is prepared through dissolving magnesium halide in organic epoxy compound, organic phosphorus compound or inertial diluent, adding alkane educing aid, porous inertial carrier and halide of Ti, and educing. It is possible to add alcohol compound and / or electron donor. Its advantages are high activity and copolymerizing performance, and high sensitivity to hydrogen regulation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Large size barium borate bismuth nonlinear optical crystal and preparation thereof

InactiveCN101302647AFast growthWide band of light transmissionPolycrystalline material growthBy pulling from meltNonlinear optical crystalSpace group

The invention relates to a large-sized bismuth barium borate non-linear optic crystal, which belongs to the orthorhombic system with a space group equal to Pna21 and a molecular formula equal to BaBiBo4. The crystal is made from a mixed system of bismuth barium borate, fluxing agent Bi2O3 and BaB2O4, or BaO and Bi2O3; the nonlinear optical effect of the crystal is approximately five times of that of (KH2PO4) KDP; and the crystal is transparent within a wave band of between 200 and 3,000 nm, and has the large size with 1 to 100mmx1 to 100mmx1 to 100mm. The large-sized bismuth barium borate non-linear optic crystal has the advantages of quick making speed, simple operation, low cost, large-sized and transparent crystal made by the non-linear optic crystal, wide light-transmission wave band, ideal mechanical property, infrequent fragmentation, stable physicochemical properties, no deliquescence and easy processing and preservation; moreover, the non-linear optic crystal can be used to make non-linear optical devices such as a multiple frequency generator, an upper frequency converter or a lower frequency converter and an optical parametric oscillator.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com