Patents

Literature

30582 results about "Carbon black" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbon black (subtypes are acetylene black, channel black, furnace black, lamp black and thermal black) is a material produced by the incomplete combustion of heavy petroleum products such as FCC tar, coal tar, or ethylene cracking tar. Carbon black is a form of paracrystalline carbon that has a high surface-area-to-volume ratio, albeit lower than that of activated carbon. It is dissimilar to soot in its much higher surface-area-to-volume ratio and significantly lower (negligible and non-bioavailable) polycyclic aromatic hydrocarbon (PAH) content. However, carbon black is widely used as a model compound for diesel soot for diesel oxidation experiments. Carbon black is mainly used as a reinforcing filler in tires and other rubber products. In plastics, paints, and inks, carbon black is used as a color pigment.

Conductive Endless Belt, Method For Producing Same, And Image Forming Apparatus Employing Same

InactiveUS20070286957A1Fast and easy and reliable curingStable productionPretreated surfacesElectrographic process apparatusImage formationUltraviolet

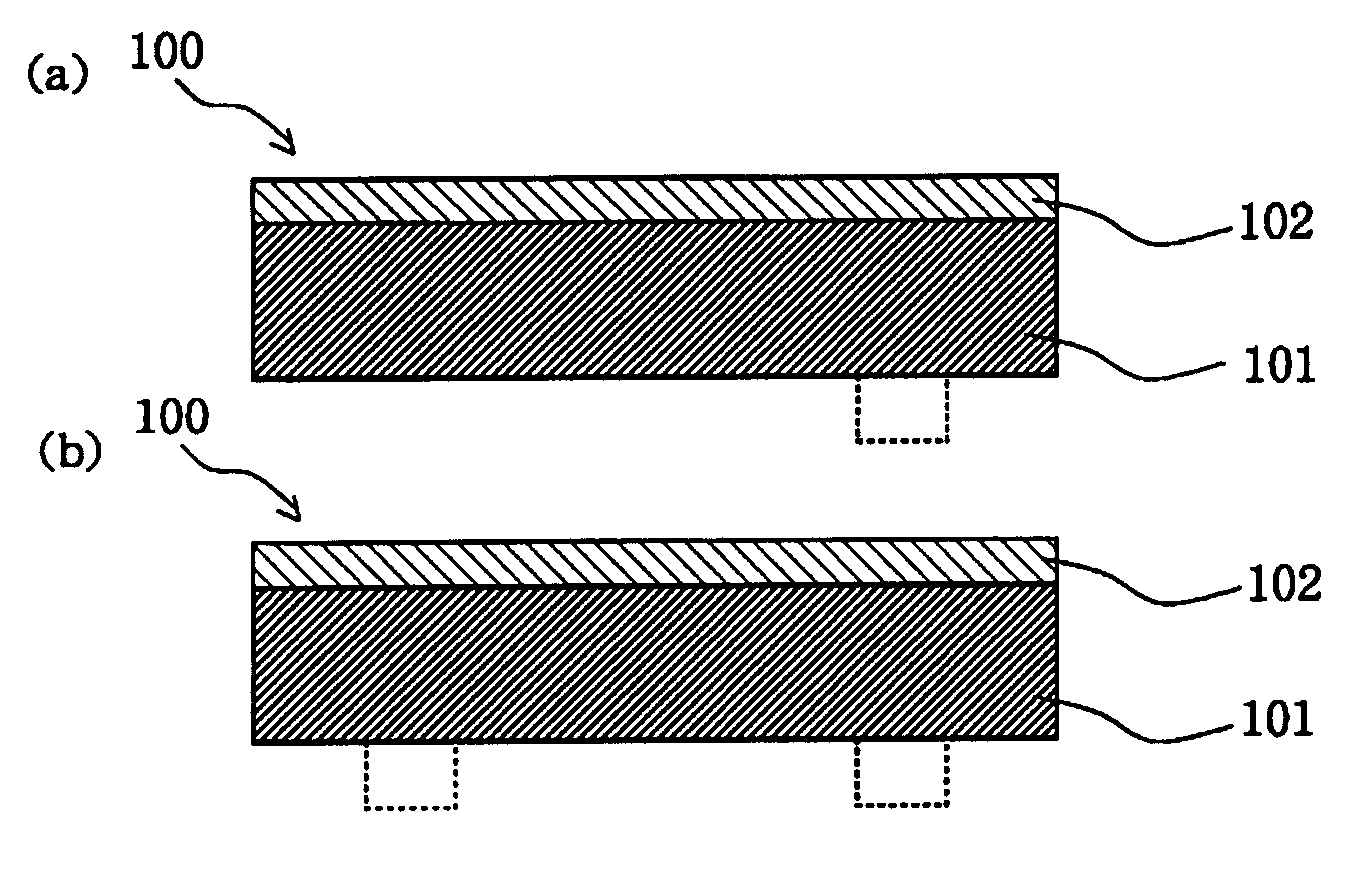

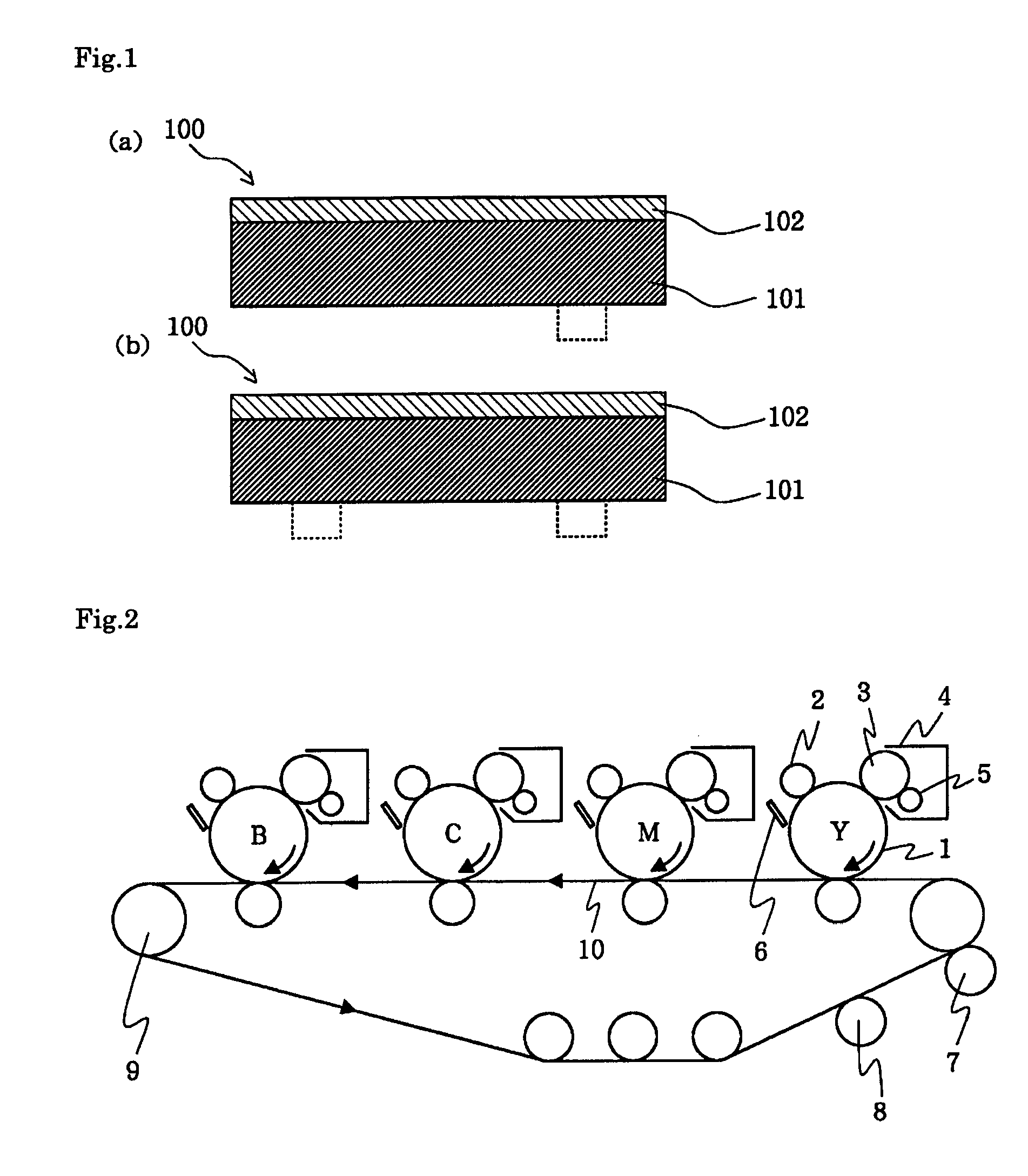

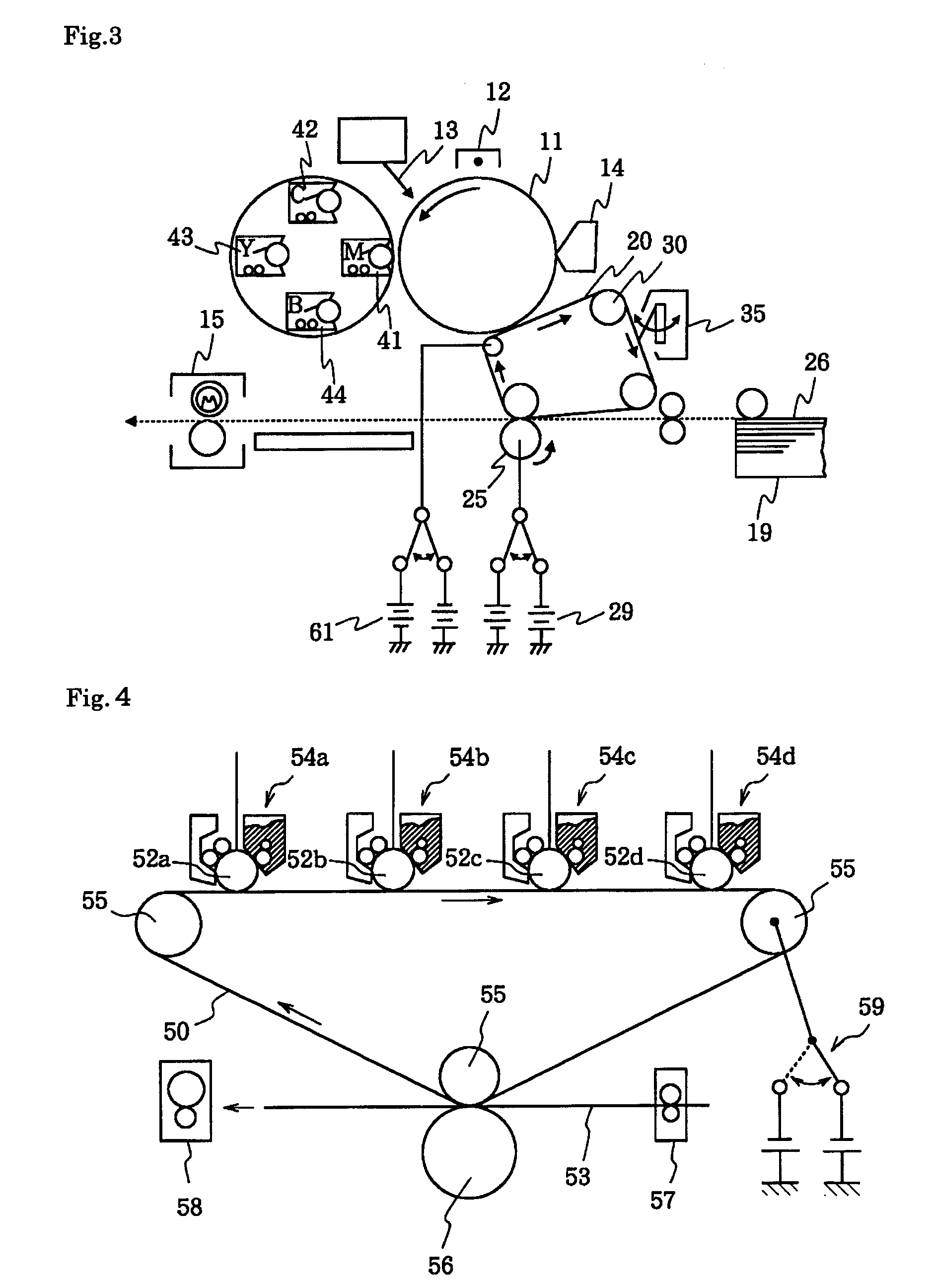

Provided are a conductive endless belt, a method of producing the same, and an image forming apparatus employing the same, the conductive endless belt having both desirable intended belt properties and surface properties, and being producible without known problems in terms of cost and quality. A conductive endless belt 100 is used as a transfer / transport conductive endless belt for a tandem system in which the conductive endless belt is circularly driven by a drive member so as to transport a recording medium held by the belt through electrostatic attraction to four differing image forming bodies, in which the toner images are sequentially transferred onto the recording medium. The conductive endless belt 100 is composed of a belt base 101 having thereon a resin layer 102, the resin layer 102 containing an ultraviolet or electron beam curable resin. The resin layer 102 preferably contains a conductive agent, specifically carbon black.

Owner:BRIDGESTONE CORP

Conformal coatings comprising carbon nanotubes

InactiveUS7118693B2Material nanotechnologyMagnetic/electric field screeningModified carbonElectromagnetic interference

Owner:EIKOS

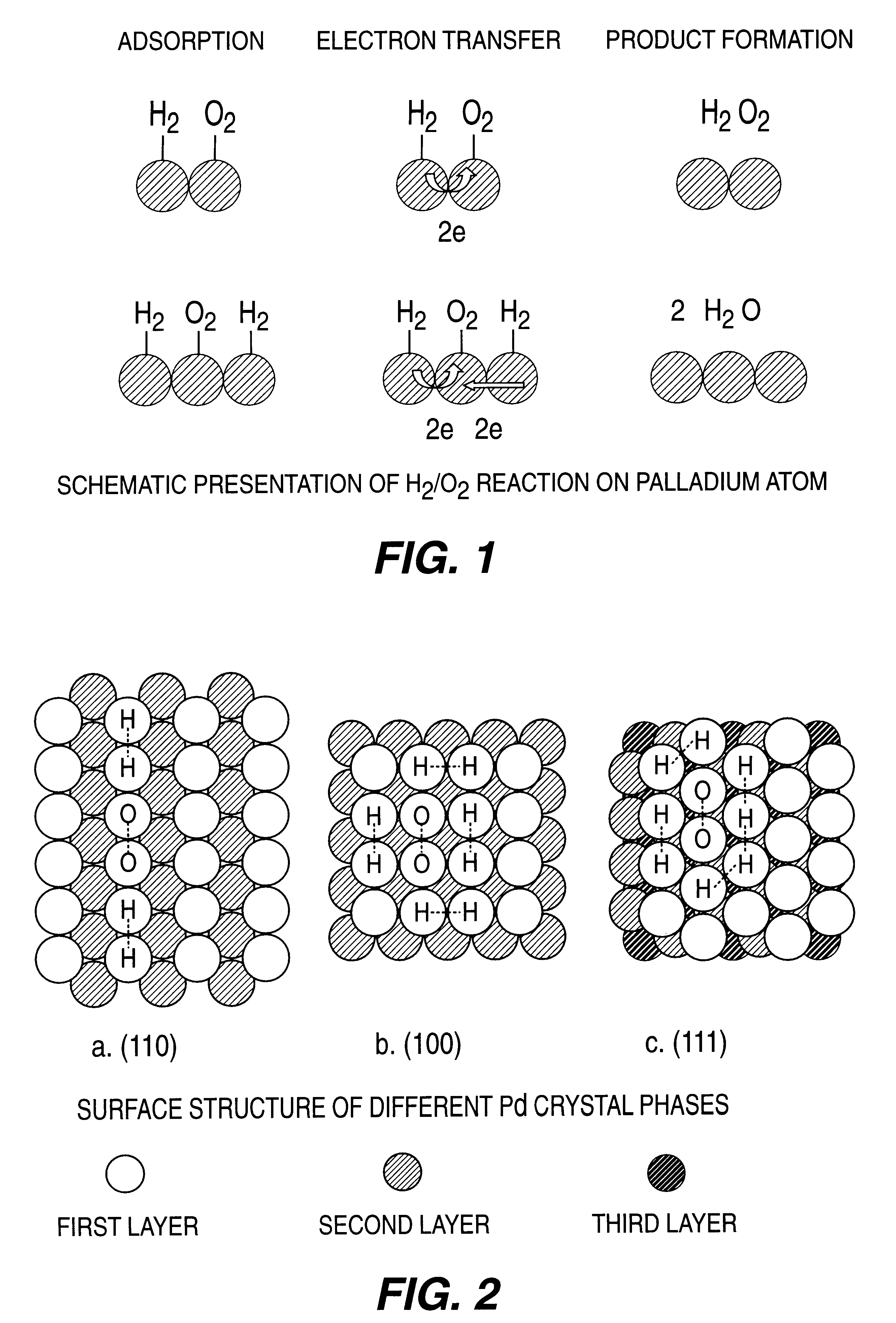

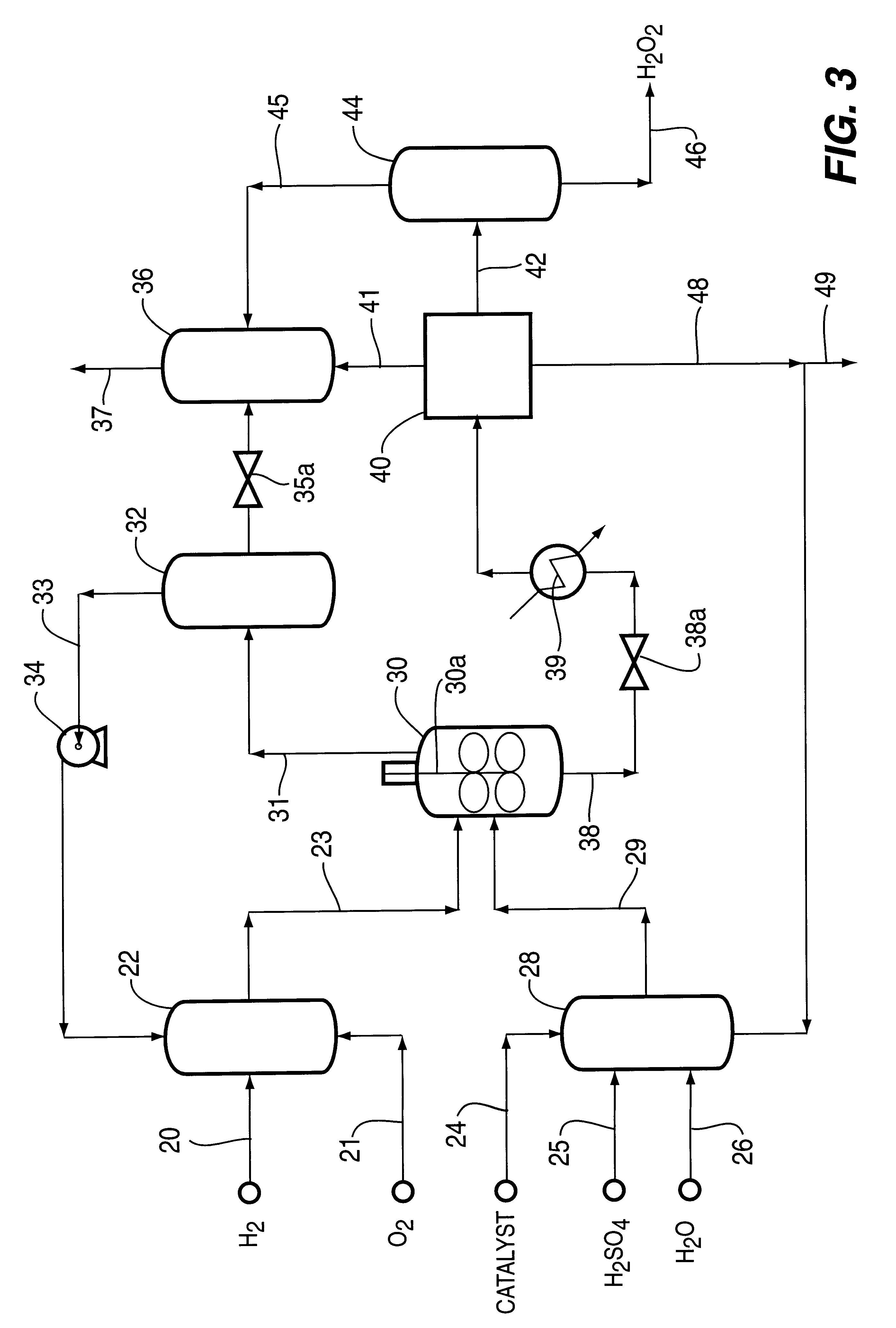

Catalyst and process for direct catalytic production of hydrogen peroxide, (H2O2)

InactiveUS6168775B1High catalytic activityHigh activityHydrogen peroxideCatalyst activation/preparationParticulatesHydrogen

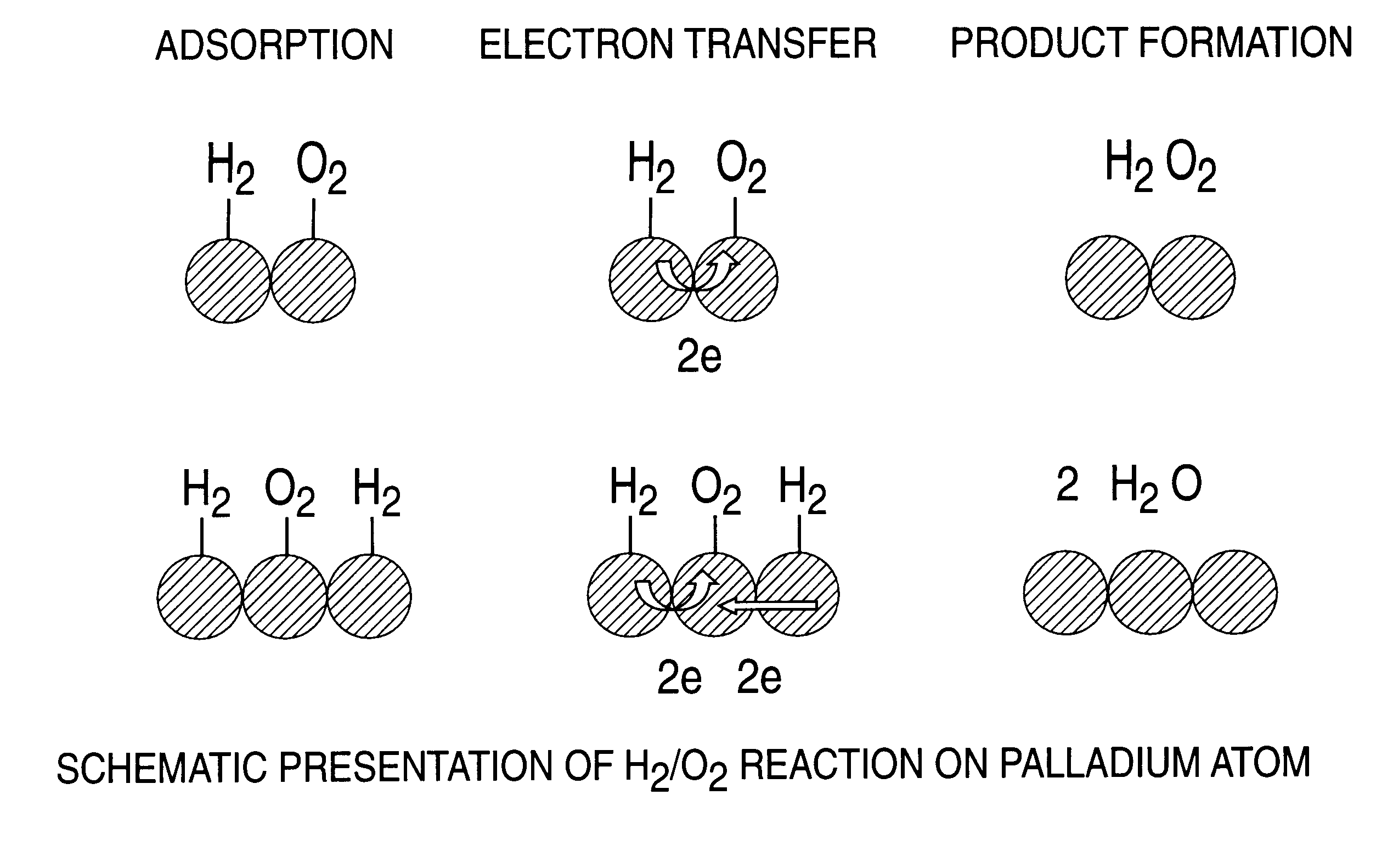

A particulate supported noble metal phase-controlled catalyst material having 5-1000 mum surface area of 50-500 m2 / gm is provided for use in direct catalytic production of hydrogen peroxide (H2O2) product from hydrogen and oxygen-containing feedstreams. The catalyst is made by depositing phase controlled crystals of a noble metal such as palladium on a suitable particulate support material such as carbon black, by utilizing a precursor solution of the metal and a suitable control ionic polymer having molecular weight of 300-8000 such as sodium polyacrylate in a selected metal to polymer molar ratio of 1:0.1 to 1:10, which procedure provides desired phase control of the noble metal atoms to form widely dispersed minute noble metal crystals on the support material. The invention includes methods for making the catalyst, and also a process for utilizing the catalyst to directly produce high yields of hydrogen peroxide (H2O2) product from hydrogen and oxygen-containing gaseous feedstreams.

Owner:BORAL IP HLDG

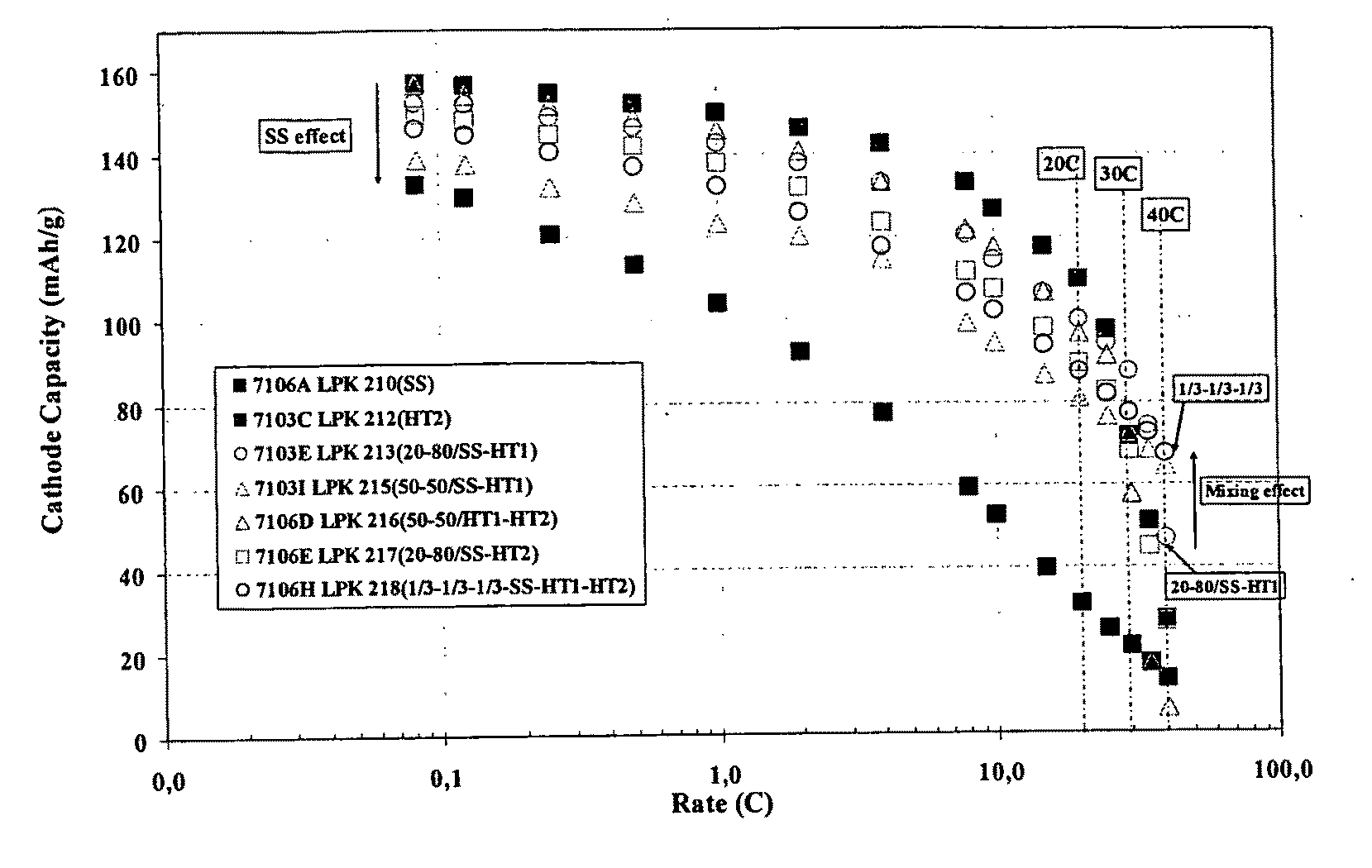

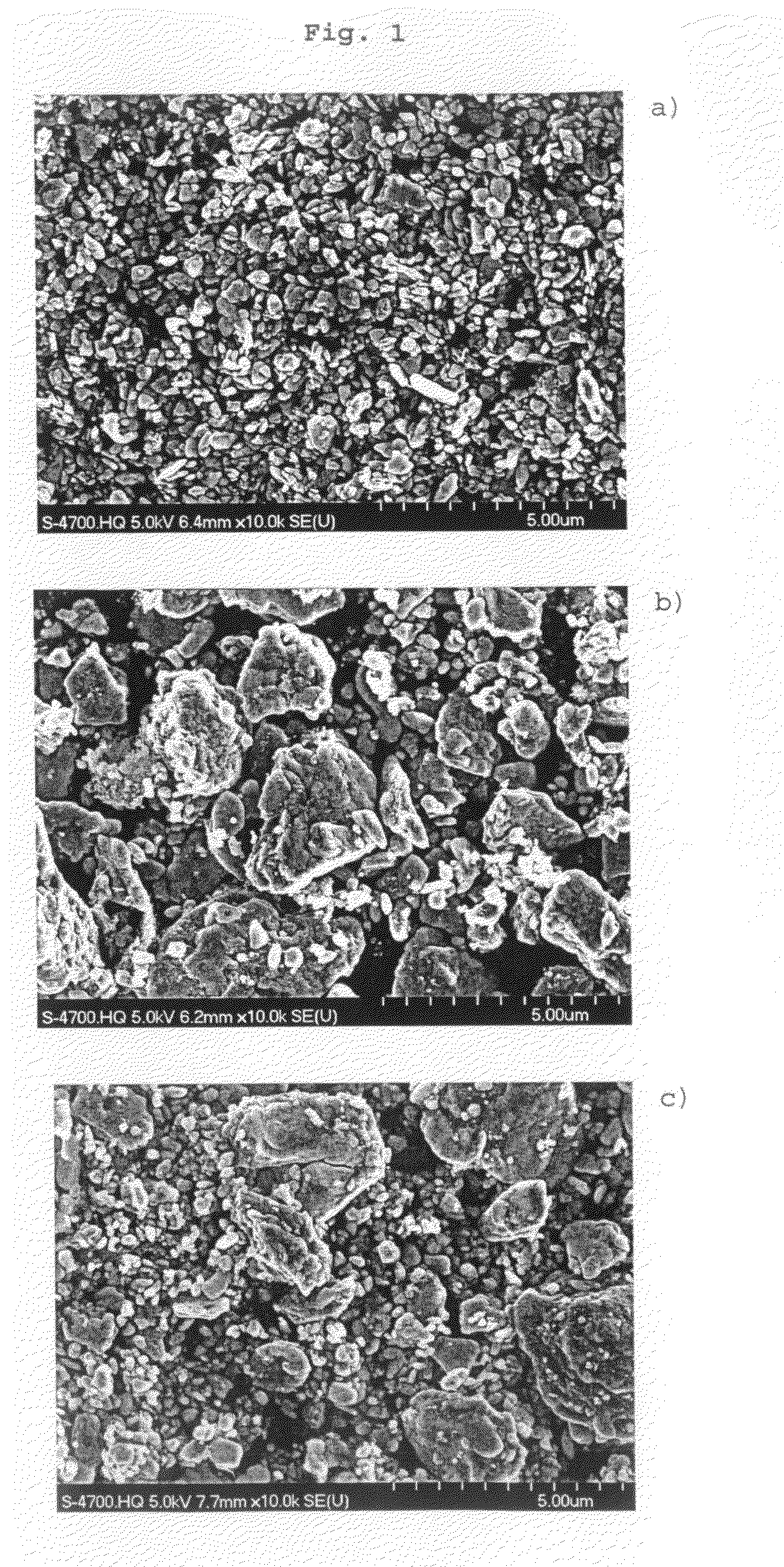

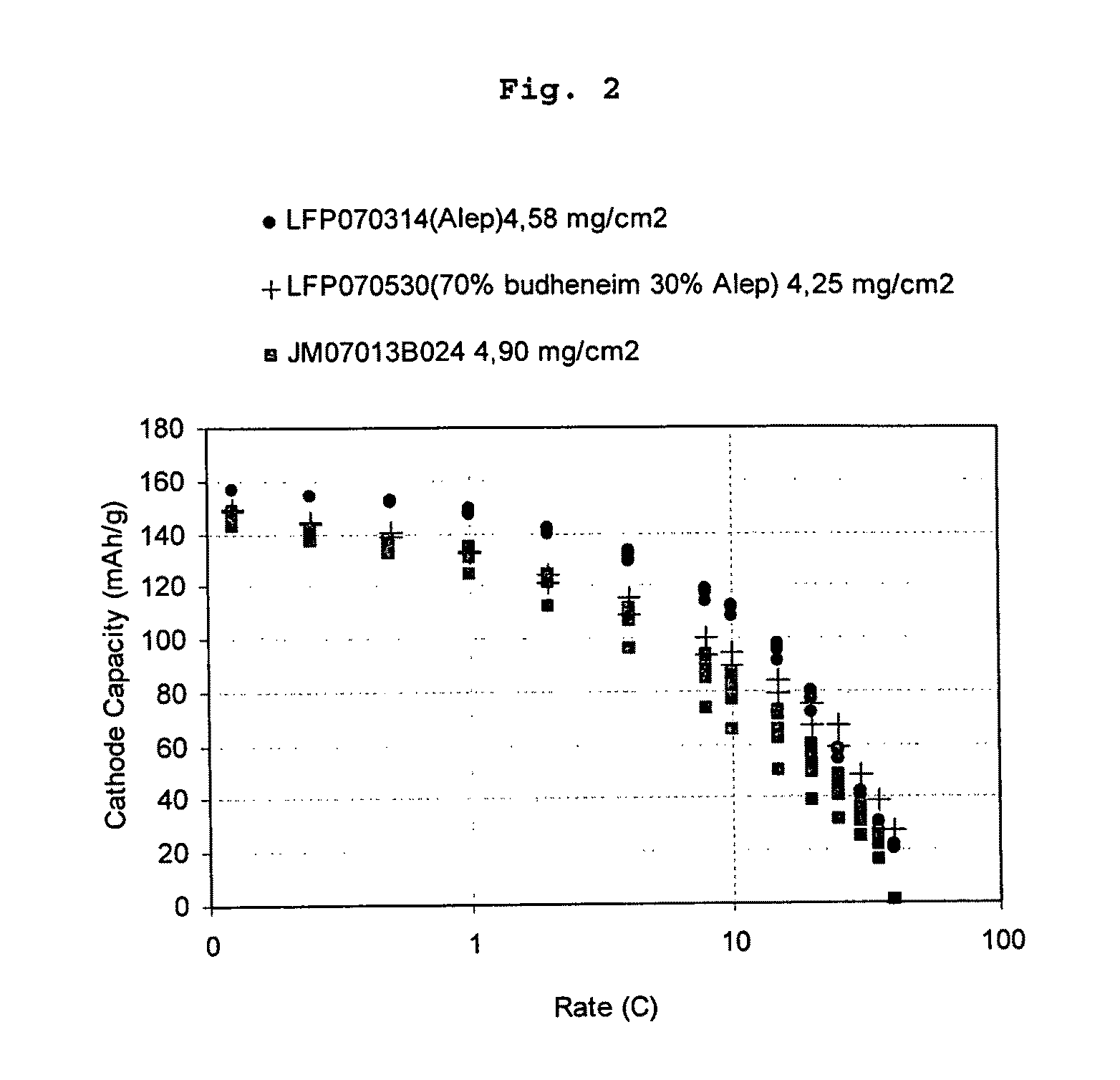

Lithium iron phosphate cathode materials with enhanced energy density and power performance

InactiveUS20090155689A1Powerful performanceHigh discharge ratePhosphatesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesFiberPhosphate

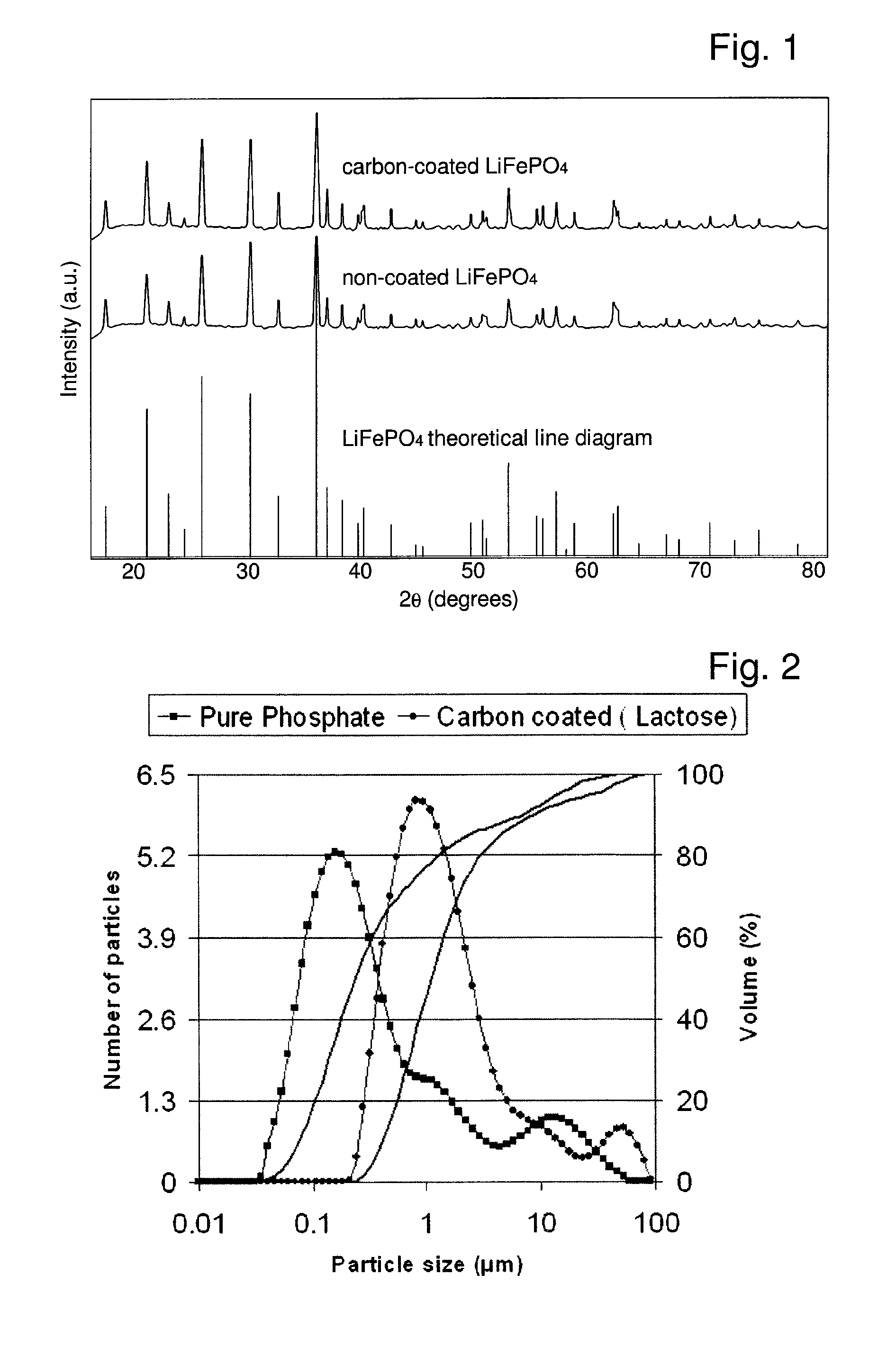

The invention is related to a cathode material comprising particles having a lithium metal phosphate core and a pyrolytic carbon deposit, said particles having a synthetic multimodal particle size distribution comprising at least one fraction of micron size particles and one fraction of submicron size particles, said lithium metal phosphate having formula LiMPO4 wherein M is at least Fe or Mn.Said material is prepared by method comprising the steps of providing starting micron sized particles and starting submicron sized particles of at least one lithium metal phosphate or of precursors of a lithium metal phosphate; mixing by mechanical means said starting particles; making a pyrolytic carbon deposit on the lithium metal phosphate starting particles before or after the mixing step, and on their metal precursor before or after mixing the particles; optionally adding carbon black, graphite powder or fibers to the said lithium metal phosphate particles before the mechanical mixing.

Owner:PHOSTECH LITHIUM

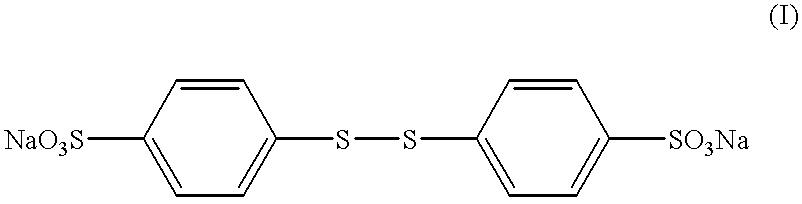

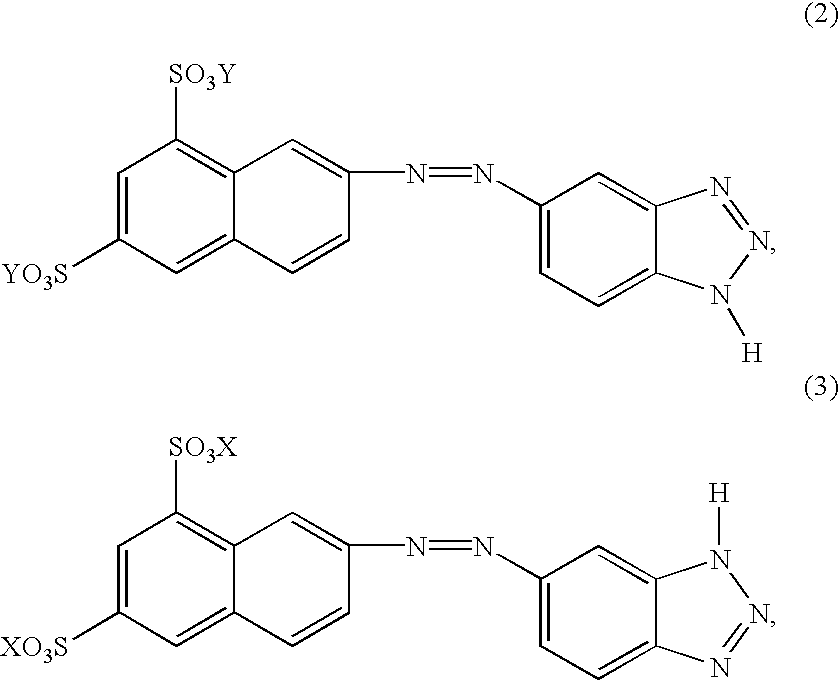

Carbon black

A carbon black with organic groups in which the organic groups are linked to the black via a sulfide- and / or polysulfide bridge. Furthermore, a method of producing the black of the invention is described in which carbon black and compounds of the general formula R-Sy-R are reacted. The carbon blacks of the invention can be used as filler, UV stabilizer, conductivity black and pigment.

Owner:DEGUSSA AG

Electrophoretic media and displays with improved binder

An electrophoretic medium comprises discrete droplets of an electrophoretic internal phase comprising a fluid and carbon black particles in the fluid. The droplets are surrounded by a polyurethane binder formed by a diisocyanate and a polyether diol, at least 20 mole per cent of the diisocyanate being an aromatic diisocyanate.

Owner:E INK CORPORATION

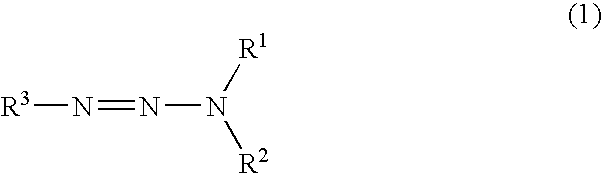

Carbon-containing material

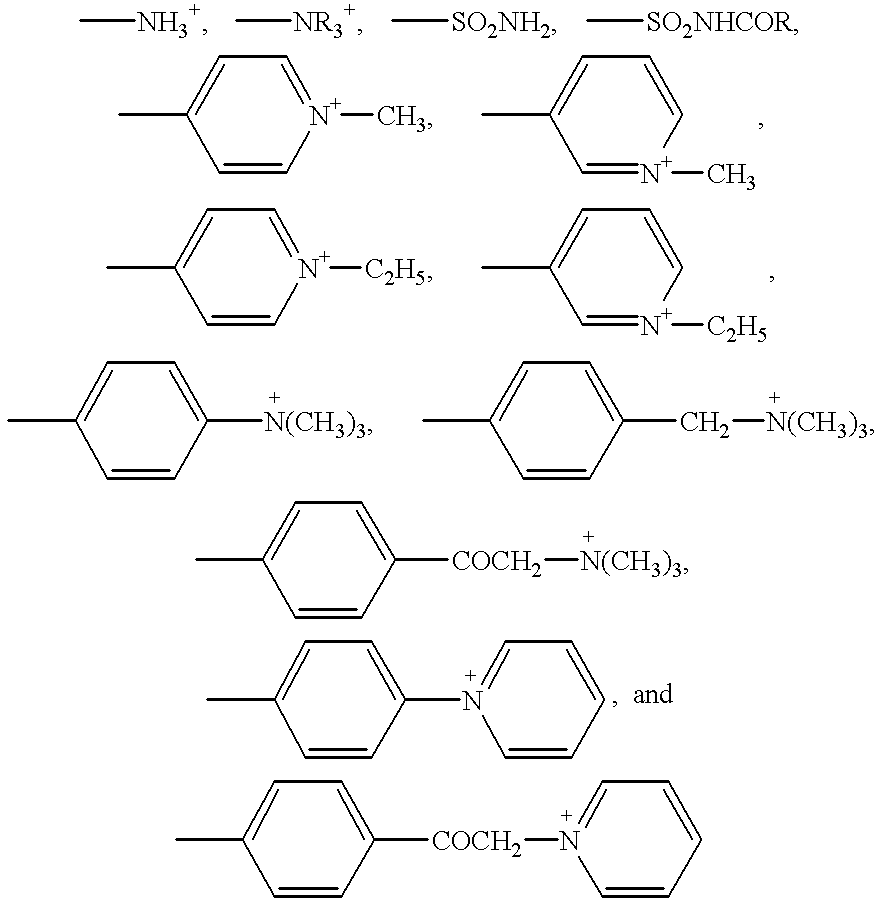

A carbon-containing material with organic groups, which is obtainable by reaction of the carbon-containing material with organic compounds of the general formula 1 A process for preparing the carbon-containing material according to the invention is also described. The carbon-containing materials according to the invention can be used as fillers, reinforcing fillers, UV stabilisers, conductivity carbon blacks or pigments.

Owner:UBS AG

Ink, ink-jet recording process, recording unit, ink cartridge and ink-jet recording apparatus

InactiveUS6375317B1Stable formationQuality improvementMeasurement apparatus componentsInksPolymer scienceAqueous medium

An ink comprising particles of self-dispersing carbon black having at least one hydrophilic group at the surface thereof, and calcium in an aqueous medium. The ink can form images excellent in fastness properties such as water fastness and light fastness and character quality, and can be stably ejected from a recording head irrespective of printing environment.

Owner:CANON KK

Carbon black composition and usage thereof

InactiveUS20130029183A1Good dispersionInhibition formationPigmenting treatmentMagnetic materials for record carriersCyclohexanoneOrganic solvent

An aspect of the present invention relates to a carbon black composition, which comprises carbon black; an organic tertiary amine selected from the group consisting of an aliphatic tertiary monoamine and an alicyclic tertiary amine; and at least one organic solvent selected from the group consisting of methyl ethyl ketone, cyclohexanone, isophorone, and ethanol.

Owner:SOITEC SA +1

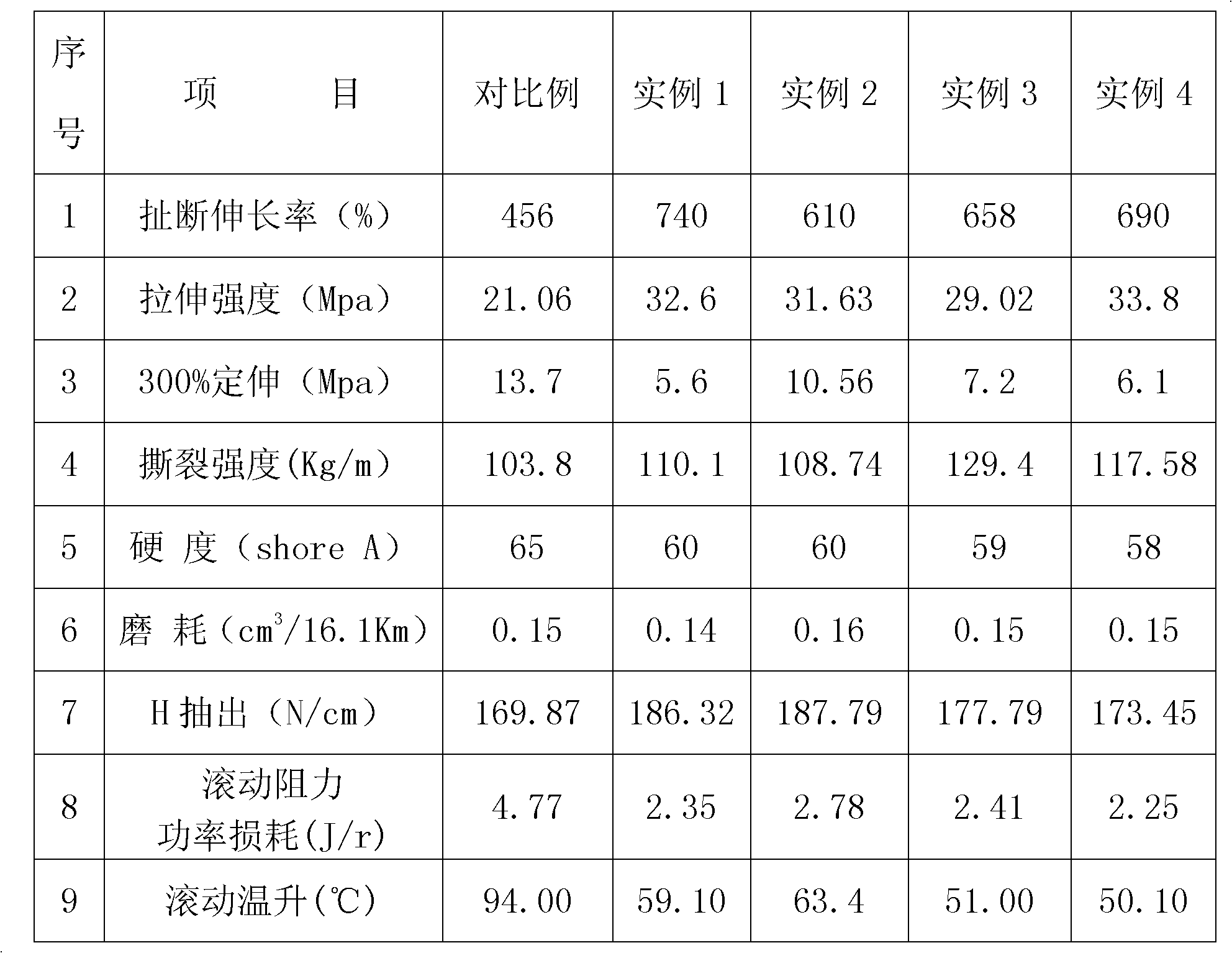

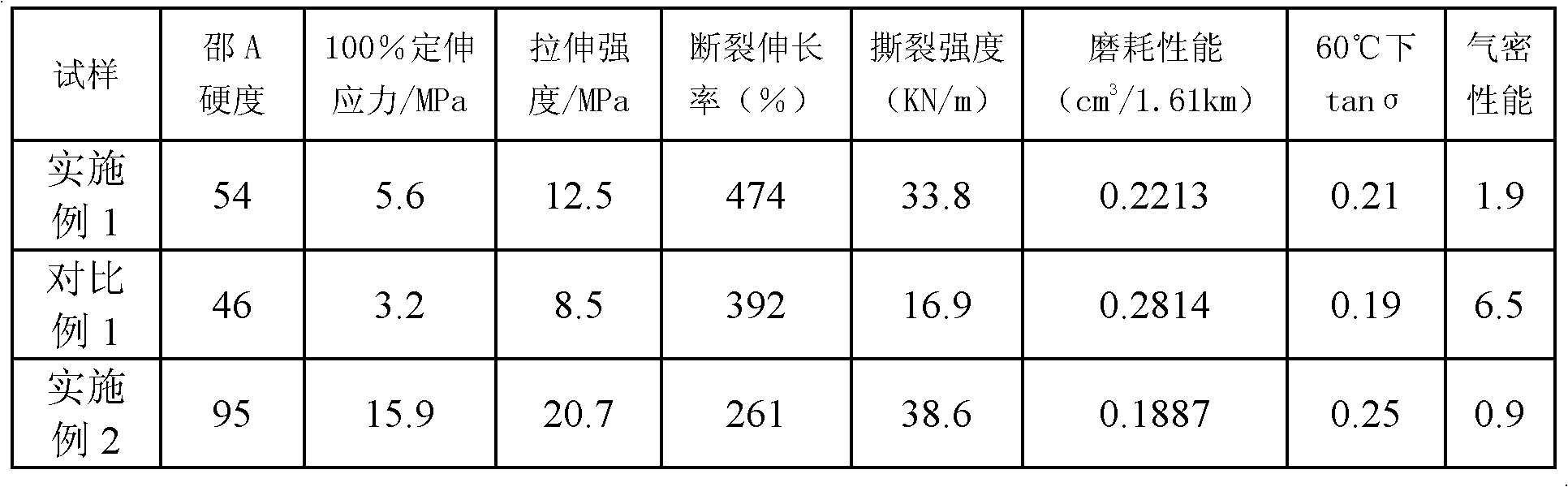

Preparation method of wet process mixed natural rubber material

ActiveCN102153792AGood dispersionImprove uniformityRolling resistance optimizationRubber materialPolymer science

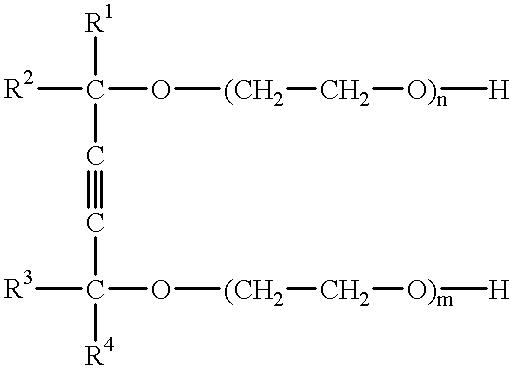

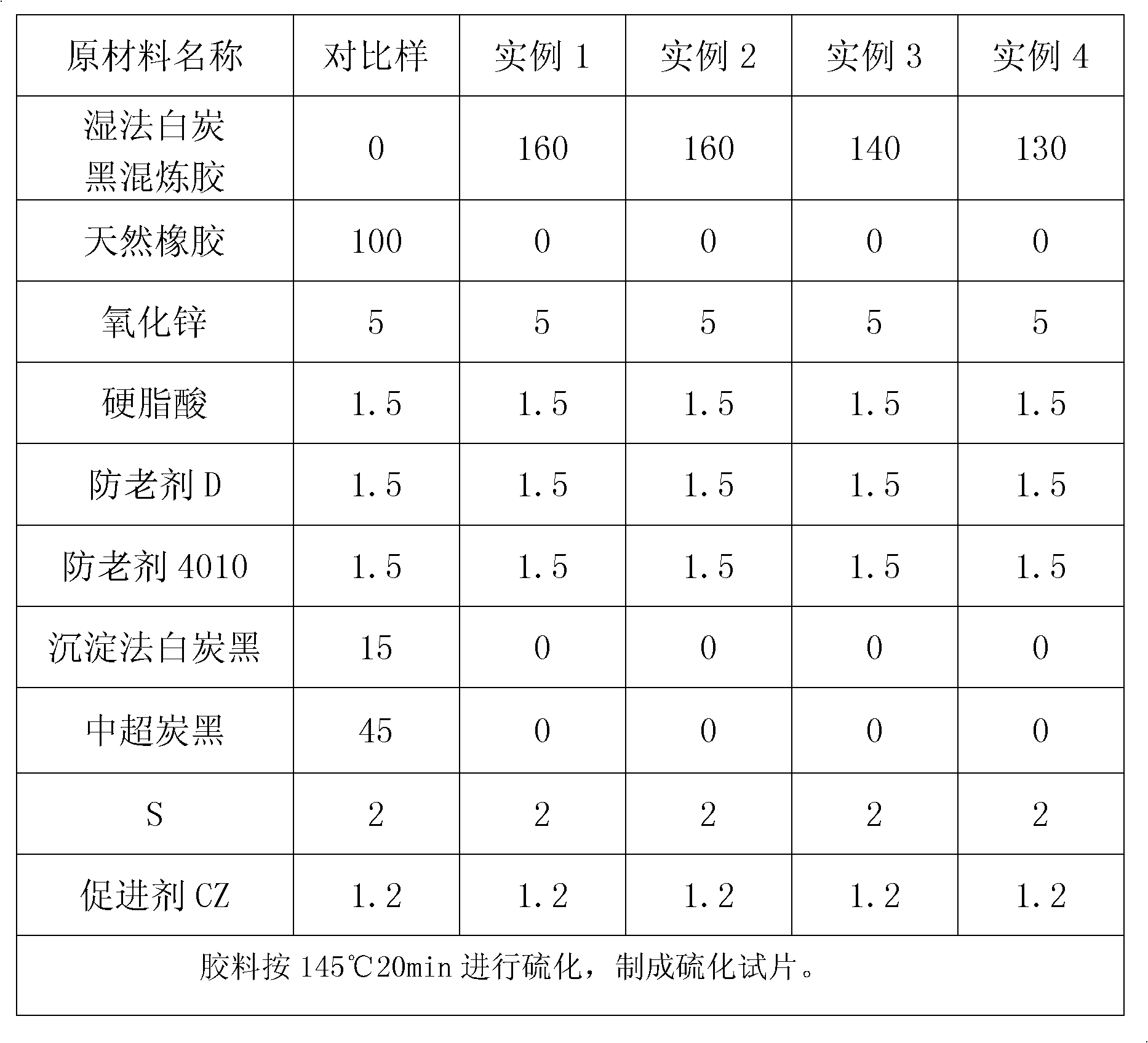

The invention relates to a preparation method of a wet process mixed natural rubber material. The method comprises the following steps of: preparing slurry and soaking 15-40 percent of dry white carbon black in 60-85 percent of deionized water; adding a coupling agent and a surfactant, uniformly mixing, grinding, preparing latex mixed liquor, extracting natural latex and adding white carbon black water dispersoid into the latex; stirring and mixing to obtain a latex mixed liquor, flocculating and adding acetic acid into the mixed liquor; performing rubber washing and dehydration by using a rubber washing machine and feeding to a rubber pelletizer for pelletizing; and feeding rubber particles into a box drying cabinet for drying. The preparation method has the advantages of simple machining process, small equipment investment, realization of various ideal performances with the most ordinary white carbon black, low dust pollution in the entire production process and energy saving. A tire manufactured with the method has small rolling resistance, low heat generation, high tensile strength, high tearing strength and high rubber material ageing resistance. Mixing of the white carbon black is performed in a liquid phase, so that the dispersivity and uniformity are enhanced.

Owner:ZHUZHOU ANBAOLINFENG NEW MATERIALS

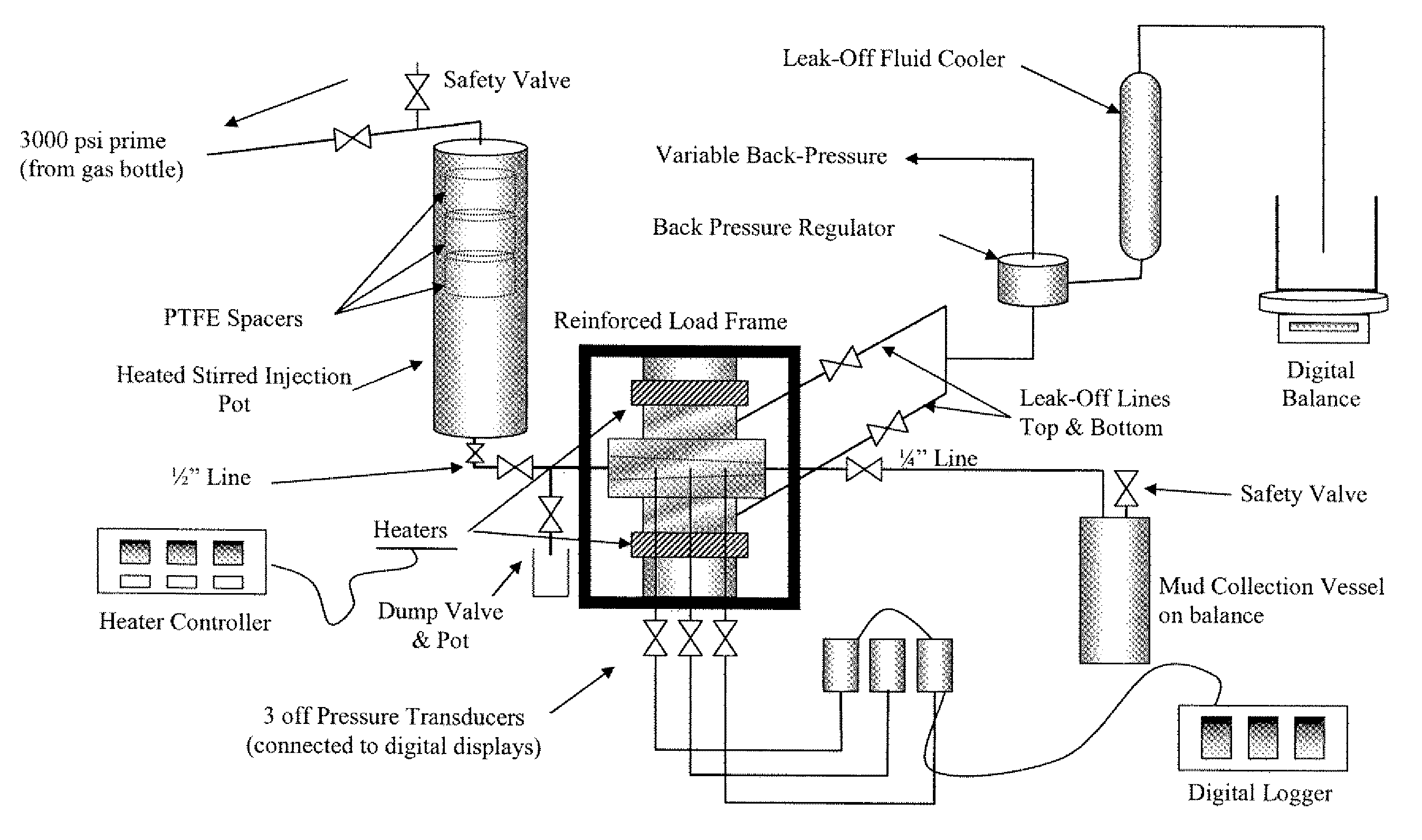

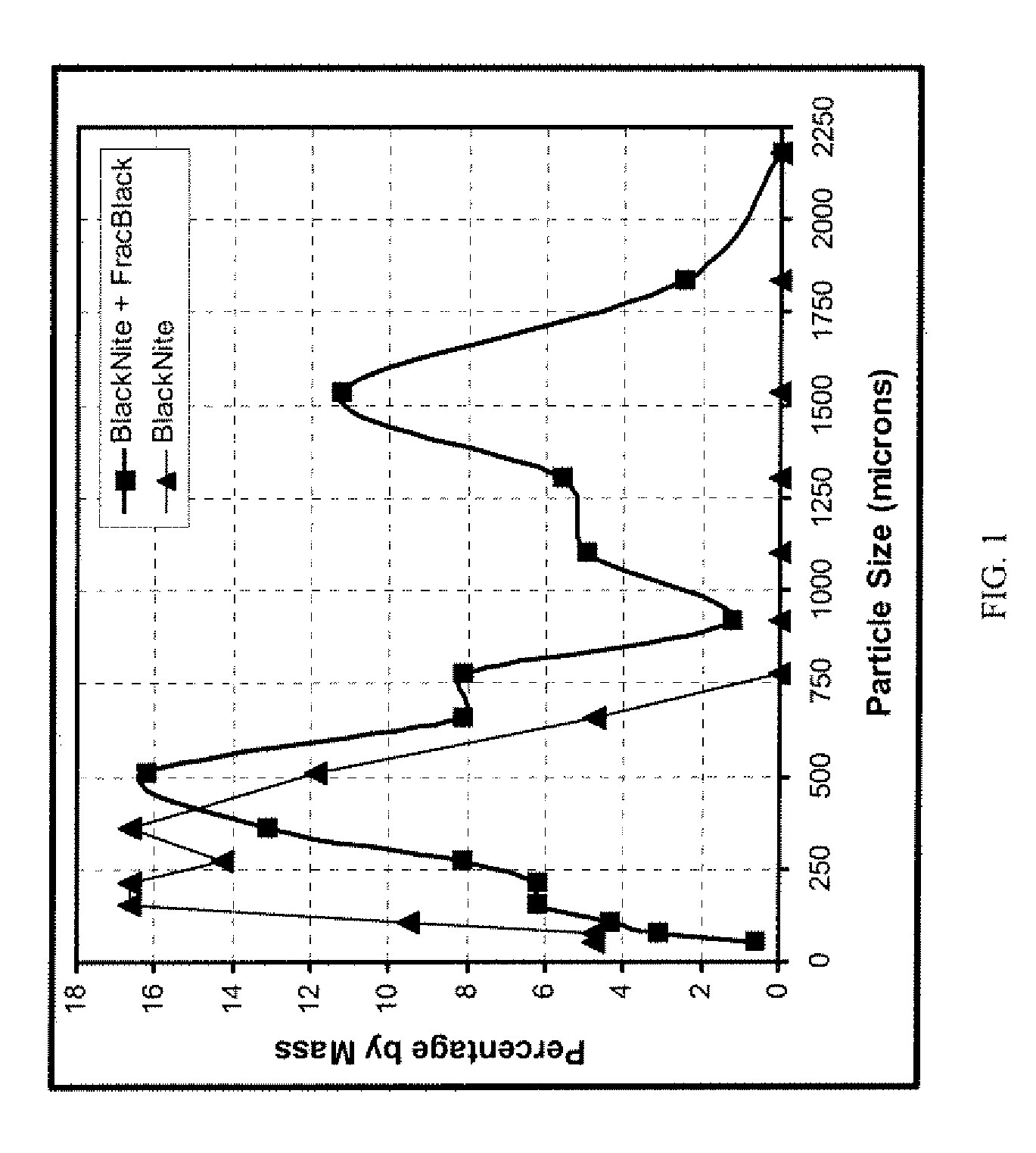

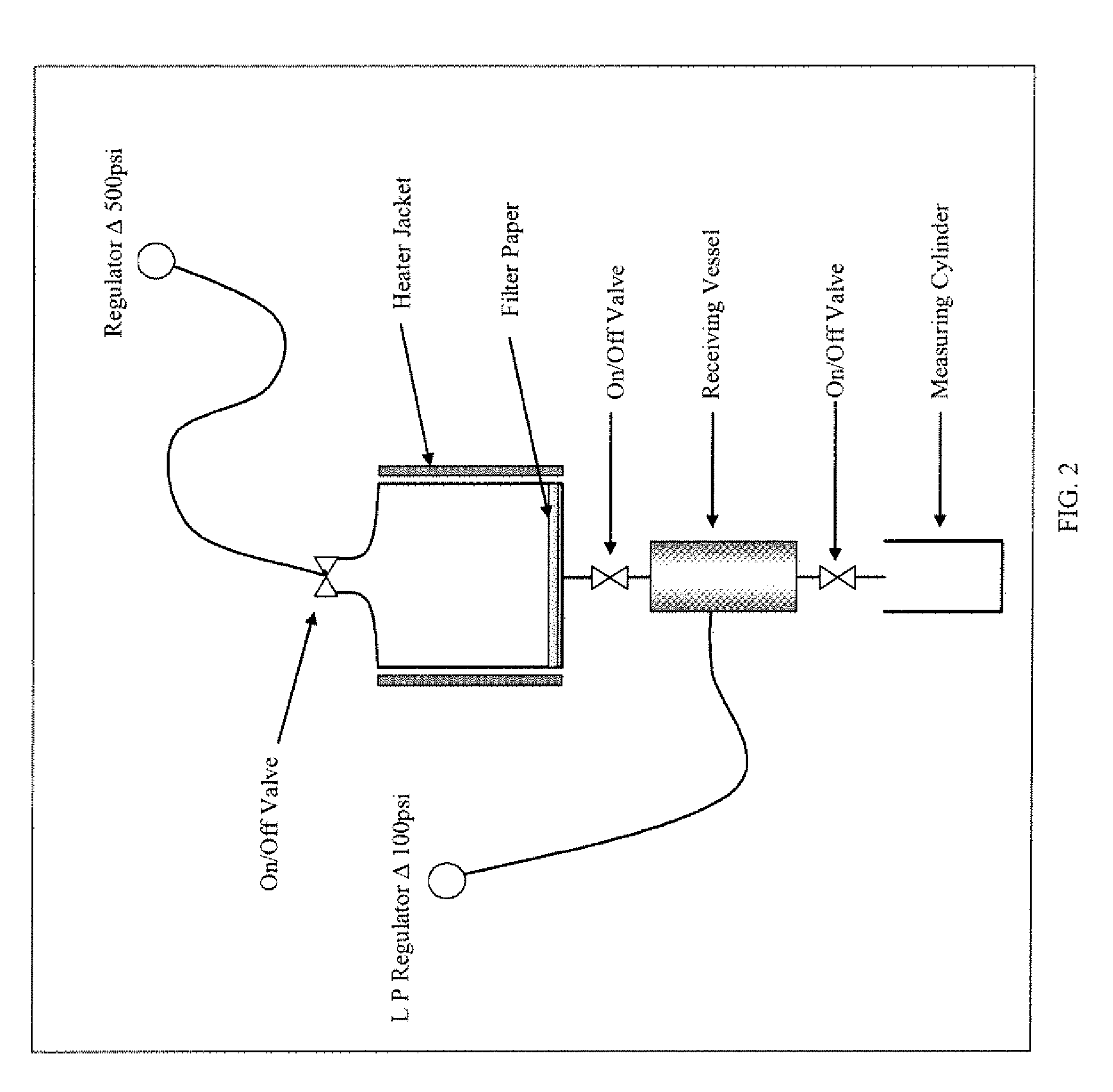

Drilling fluid, drill-in fluid, completition fluid, and workover fluid additive compositions containing thermoset nanocomposite particles; and applications for fluid loss control and wellbore strengthening

InactiveUS20090029878A1Loss in formationHigh strengthFlushingDrilling compositionWater basedDivinylbenzene

In one aspect, this invention relates to the use of thermoset nanocomposite particles as components of drilling fluid, drill-in fluid, completion fluid, and workover fluid additive packages to reduce fluid losses to a formation and / or to enhance a wellbore strength. In another aspect, this invention relates to the use particles of specific gravity ranging from about 0.75 to about 1.75 as components of drilling fluid, drill-in fluid, completion fluid, and workover fluid additive packages to reduce fluid losses to a formation and / or to enhance a wellbore strength. Using embodiments of the invention, reduction of fluid loss and / or enhancement of wellbore strength may be achieved while working with water-based, oil-based, invert emulsion, or synthetic drilling muds. The currently most preferred embodiments of the invention use substantially spherical thermoset nanocomposite particles, possessing a specific gravity from approximately 1.02 to approximately 1.15 wherein the matrix is a terpolymer of styrene, ethylvinylbenzene and divinylbenzene, and wherein carbon black particles possessing a length that is less than about 0.5 microns in at least one principal axis direction are incorporated as a nanofiller.

Owner:SUN DRILLING PRODS

Nanocarbon-activated carbon composite

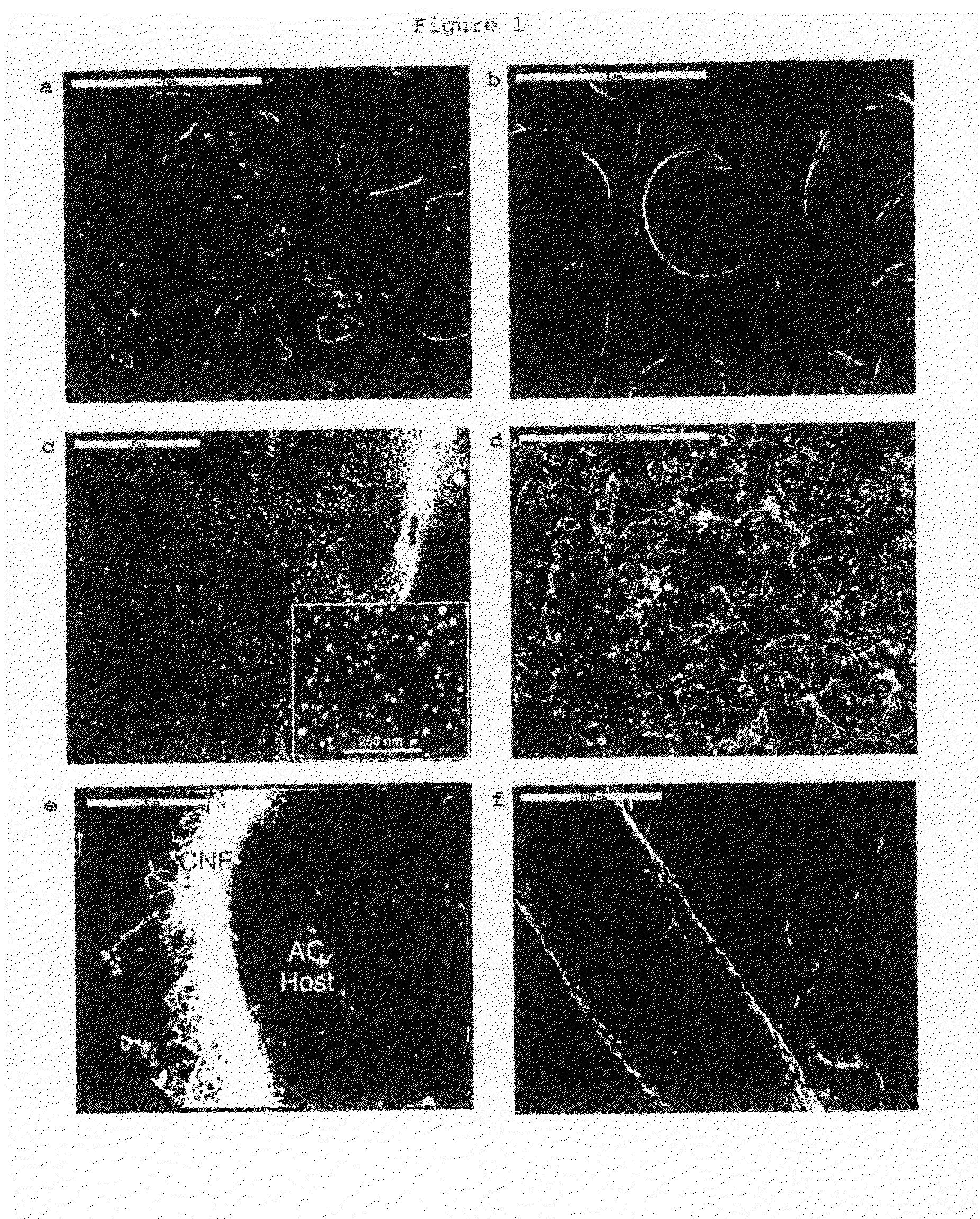

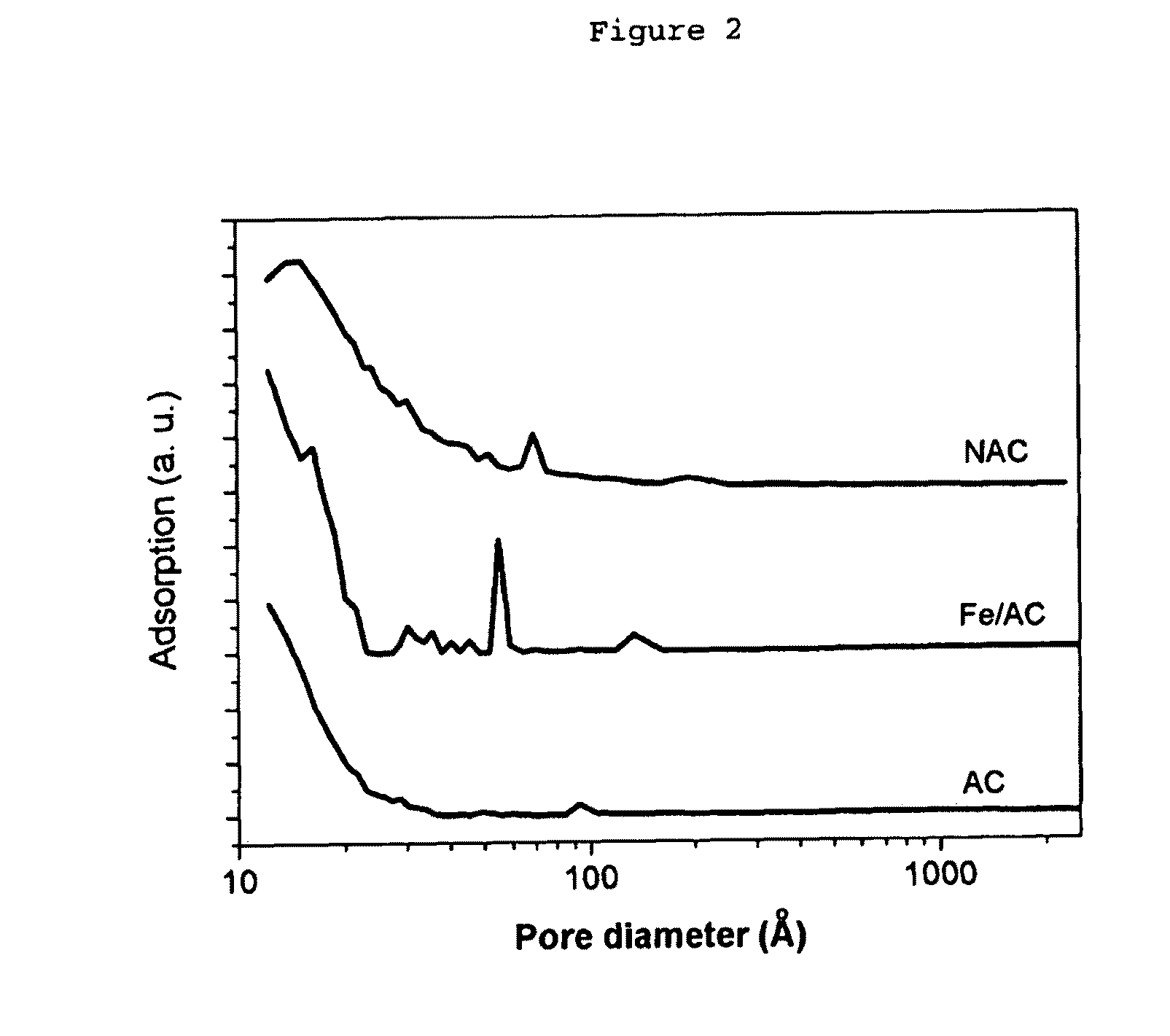

InactiveUS20090220767A1Percolation limitAvoid combiningPigmenting treatmentMaterial nanotechnologyCarbon compositesPorosity

The present invention relates to carbon-carbon composite material comprising a carbonaceous carrier and nanosize carbon structures (e.g. CNT or CNF), wherein the nanosize carbon structures are grown on the carbonaceous carrier. The carrier may be porous, as in activated carbon or consists of carbon black particles. In accordance with the invention, nanocarbon growth in the pores of porous carriers can be realized. The process for the manufacture of a this carbon-carbon-composite material comprises the steps of treating a carbonaceous carrier material with a metal-containing catalyst material, said metal being capable of forming nanosize carbon structures, and growing nanosize carbon structures by means of a CVD (chemical vapour deposition) method on the treated carrier in a gas atmosphere comprising a carbon-containing gas, followed by an optional surface modification step. This process allows optimising porosity, hydrodynamical properties and surface chemistry independently from each other, which is particularly beneficial in respect of the use of the composite for water purification. Carbon black-based composites are particularly useful for filler applications.

Owner:SUD CHEM IP GMBH & CO KG

Process for abstracting earth silicon, oxide of alumina and gallium oxide from high-alumina flying ash

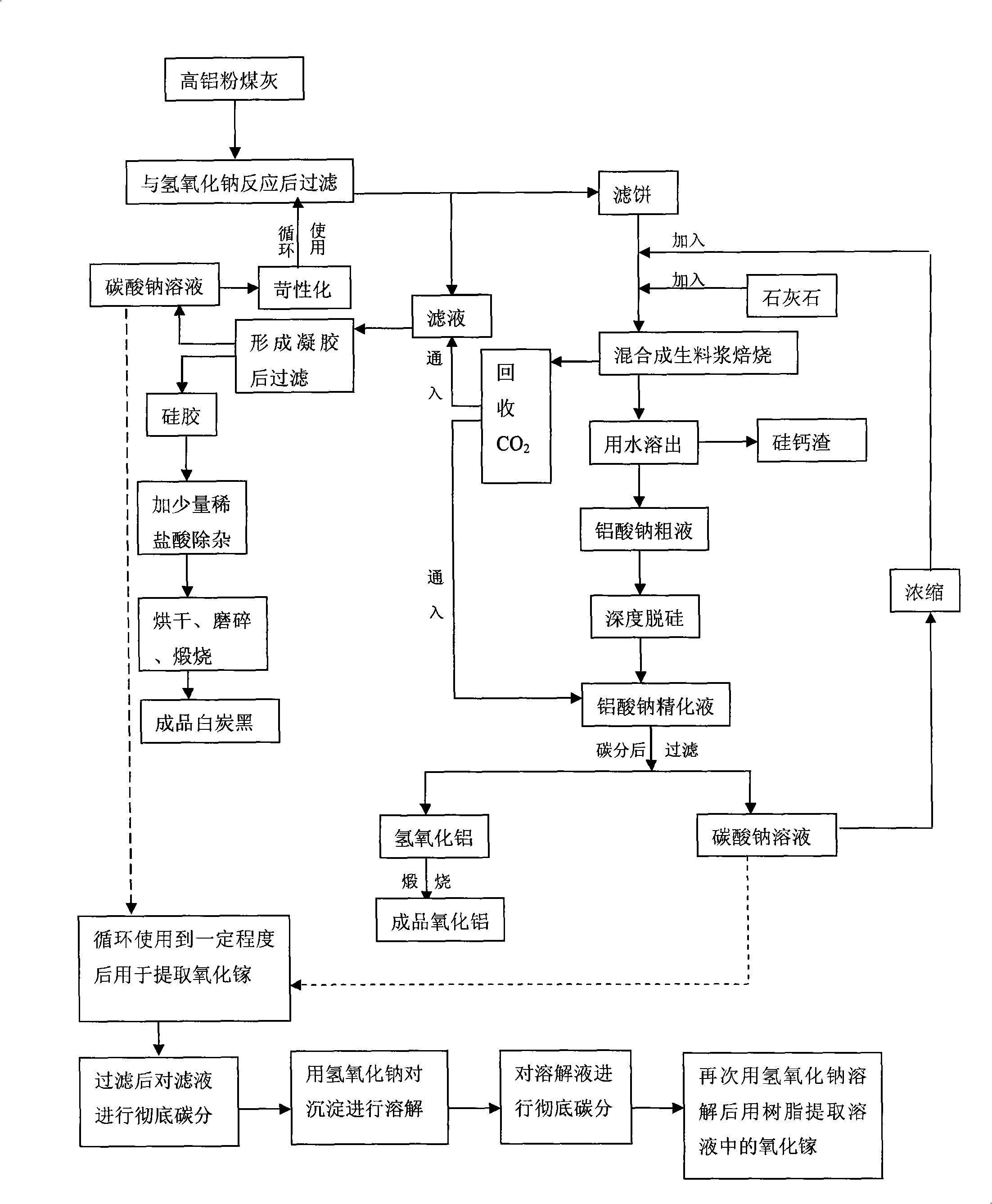

ActiveCN101284668AReduce the total massLow firing temperatureGallium/indium/thallium compoundsSilicon oxidesChemical industryFiltration

A method for extracting silicon dioxide, alumina and gallium oxide from high-alumina fly ash relates to the technology fields of environmental mineralogy and material, chemical industry and metallurgy. The method comprises the main steps as follows: causing the high-alumina fly ash to react with sodium hydroxide solution; filtering the solution; introducing CO2 to the filtrate for full gelation; cleaning, purifying, drying, grinding and calcining the silica gel after gel filtration to obtain finished white carbon black; adding limestone and a sodium carbonate solution into the filter mass after the reaction and filtration of the high-alumina fly ash and the sodium hydroxide solution; ball grinding the mixture into raw slurry; dissolving out the clinker obtained by baking the raw slurry; subjecting the filtrate to deep desiliconization to obtain sodium aluminate extraction liquid; filtrating the sodium aluminate extraction liquid after subjecting the sodium aluminate extraction liquid to carbon dioxide decomposition; baking the aluminum hydroxide after washing the filter mass to form the aluminum hydroxide product; and extracting the gallium oxide from the carbon dioxide decomposition mother solution and desiliconized solution. The method has the advantages of low material price, simple operating procedures, low investment, low production cost, low energy consumption and less slag.

Owner:TSINGHUA UNIV +1

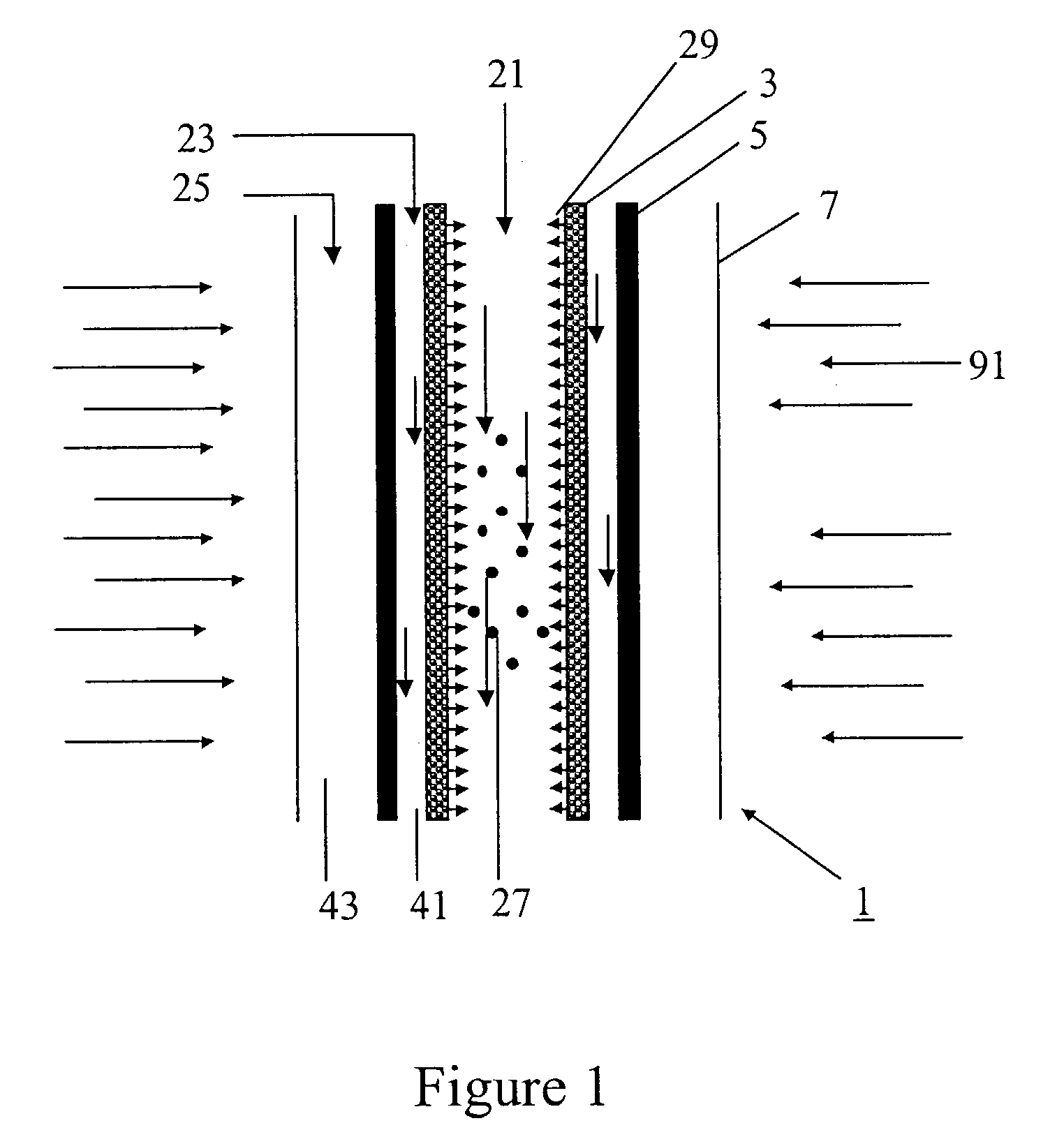

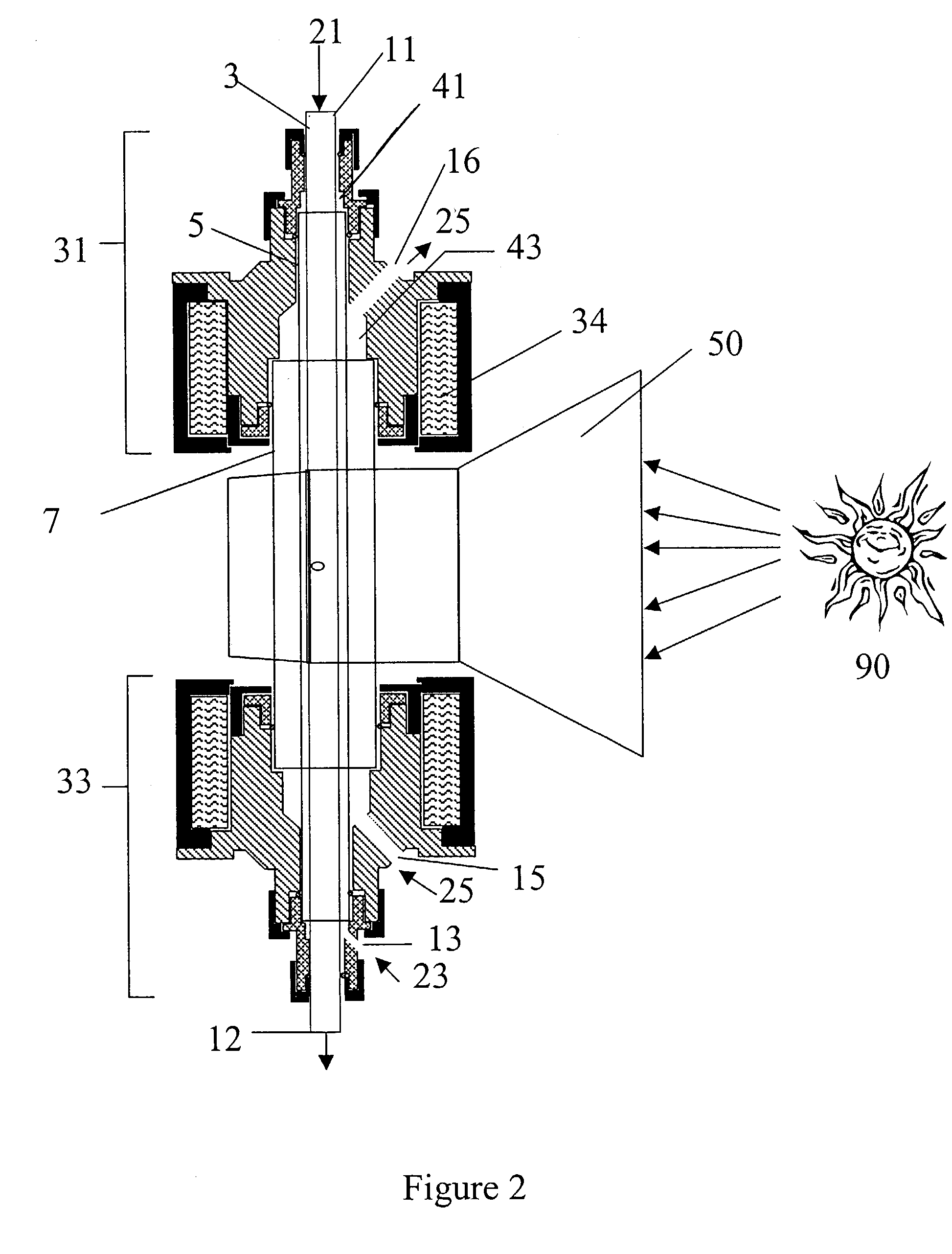

Solar-thermal fluid-wall reaction processing

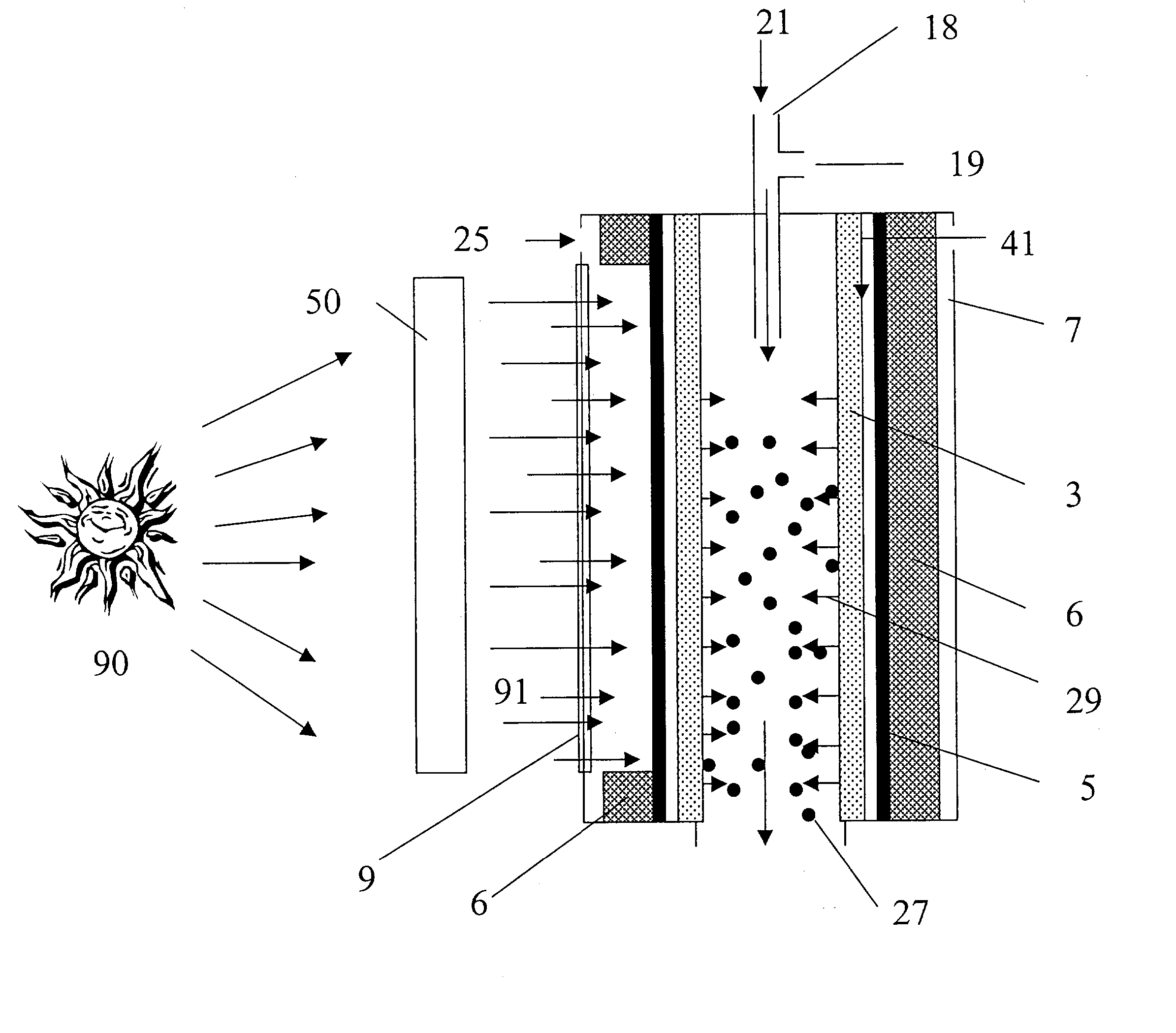

InactiveUS7033570B2Reduce and preventShort stayThermal non-catalytic crackingSolar heating energyHydrogenReactor system

The present invention provides a method for carrying out high temperature thermal dissociation reactions requiring rapid-heating and short residence times using solar energy. In particular, the present invention provides a method for carrying out high temperature thermal reactions such as dissociation of hydrocarbon containing gases and hydrogen sulfide to produce hydrogen and dry reforming of hydrocarbon containing gases with carbon dioxide. In the methods of the invention where hydrocarbon containing gases are dissociated, fine carbon black particles are also produced. The present invention also provides solar-thermal reactors and solar-thermal reactor systems.

Owner:ALLIANCE FOR SUSTAINABLE ENERGY +1

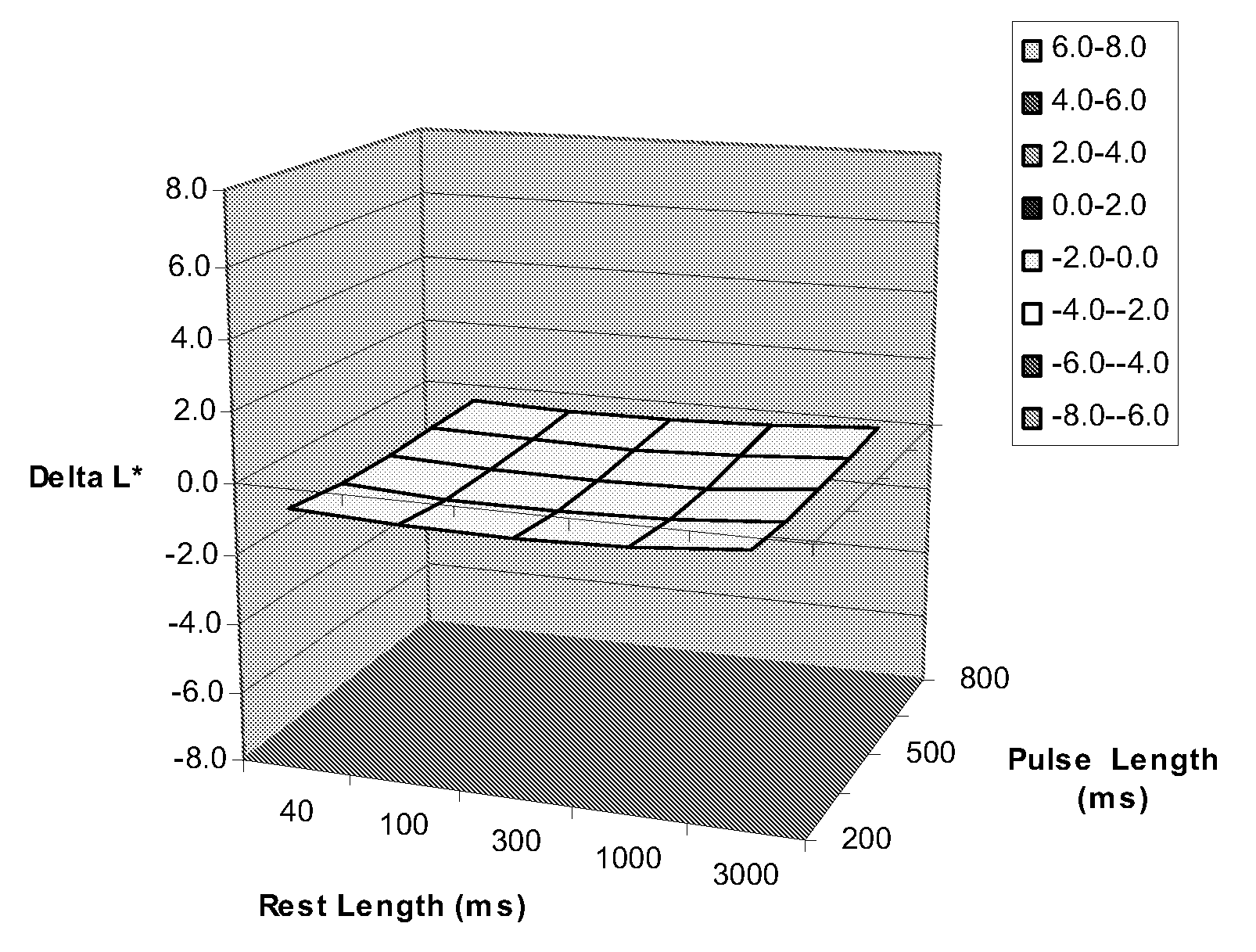

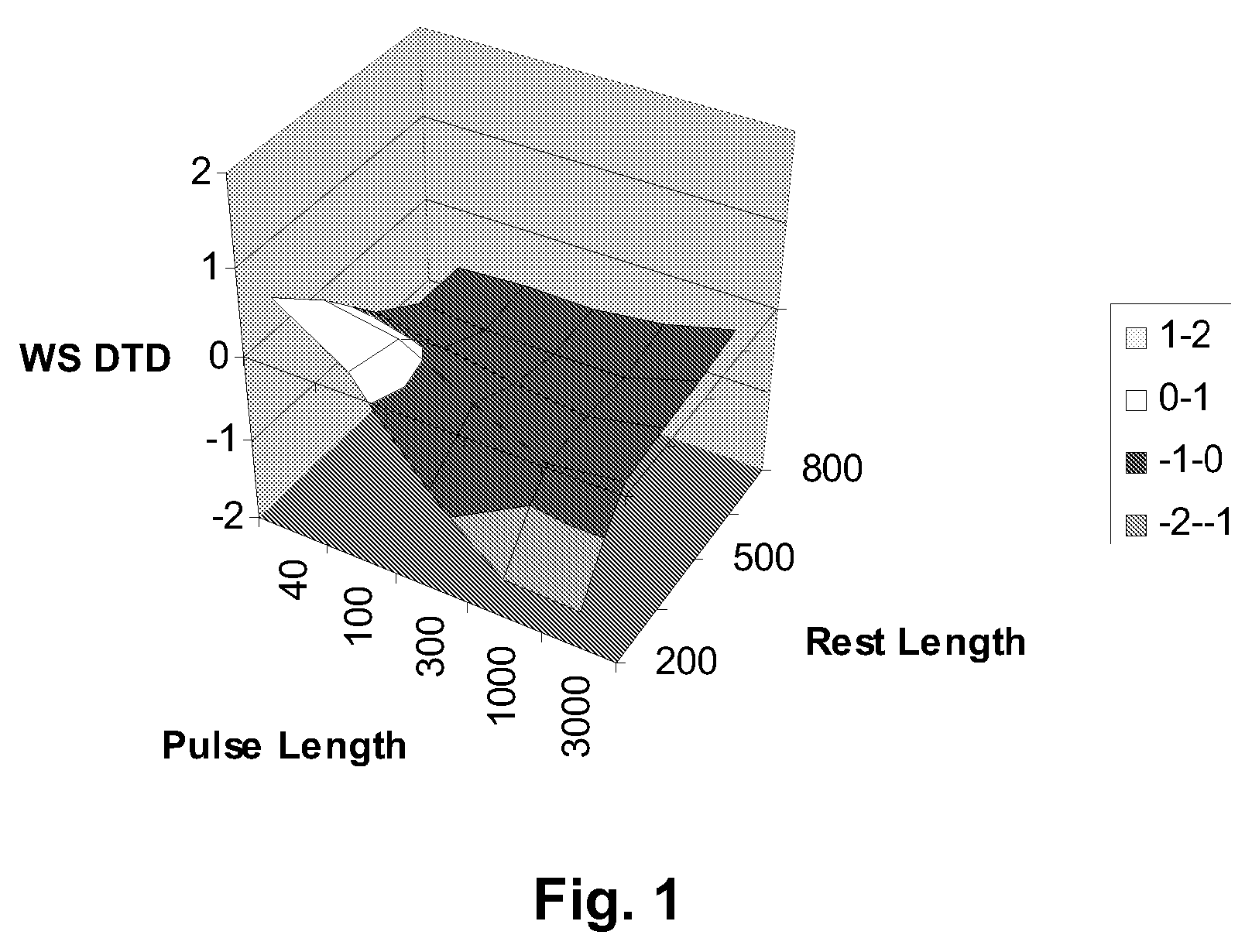

Magnetic recording medium, magnetic signal reproduction system and magnetic signal reproduction method

ActiveUS20100246073A1Excellent electromagnetic characteristicExcellent running durabilityMagnetic materials for record carriersTape carriersMohs scale of mineral hardnessHardness

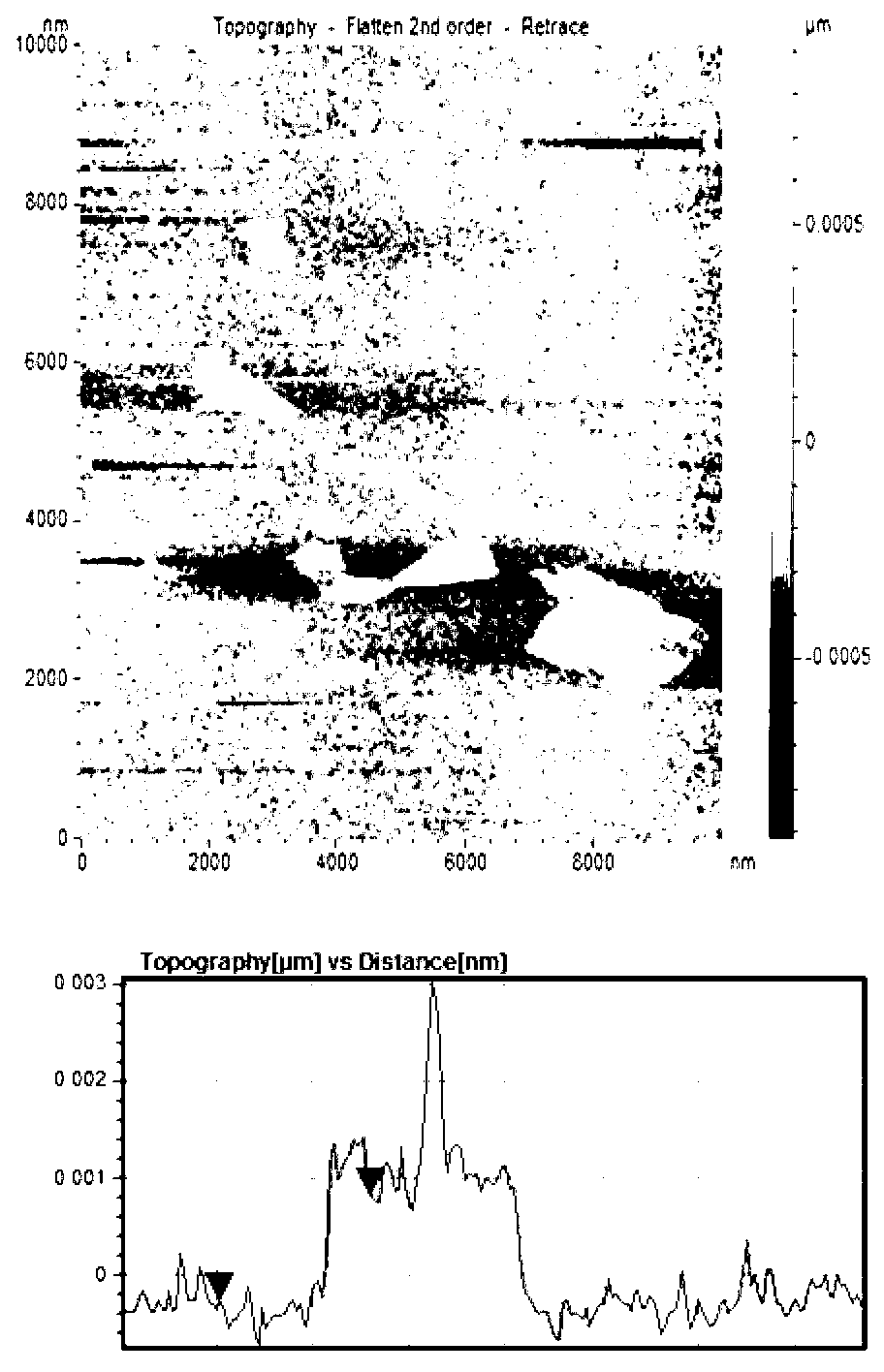

An aspect of the present invention relates to a magnetic recording medium comprising a magnetic layer comprising a ferromagnetic powder and a binder on a nonmagnetic support. A height of protrusions with a protrusion density of 0.002 protrusion / μm2 or lower on a surface of the magnetic layer as measured by AFM is 40 nm or lower; a density of protrusions that are 15 nm or higher in height on the surface of the magnetic layer as measured by AFM ranges from 0.01 to 0.18 protrusion / μm2; and the protrusions that are 15 nm or higher in height include protrusions formed of carbon black and protrusions formed of a substance with a Mohs' hardness exceeding 7, and an average height of the protrusions formed of carbon black is greater than an average height of the protrusions formed of the substance with a Mohs' hardness exceeding 7.

Owner:FUJIFILM CORP

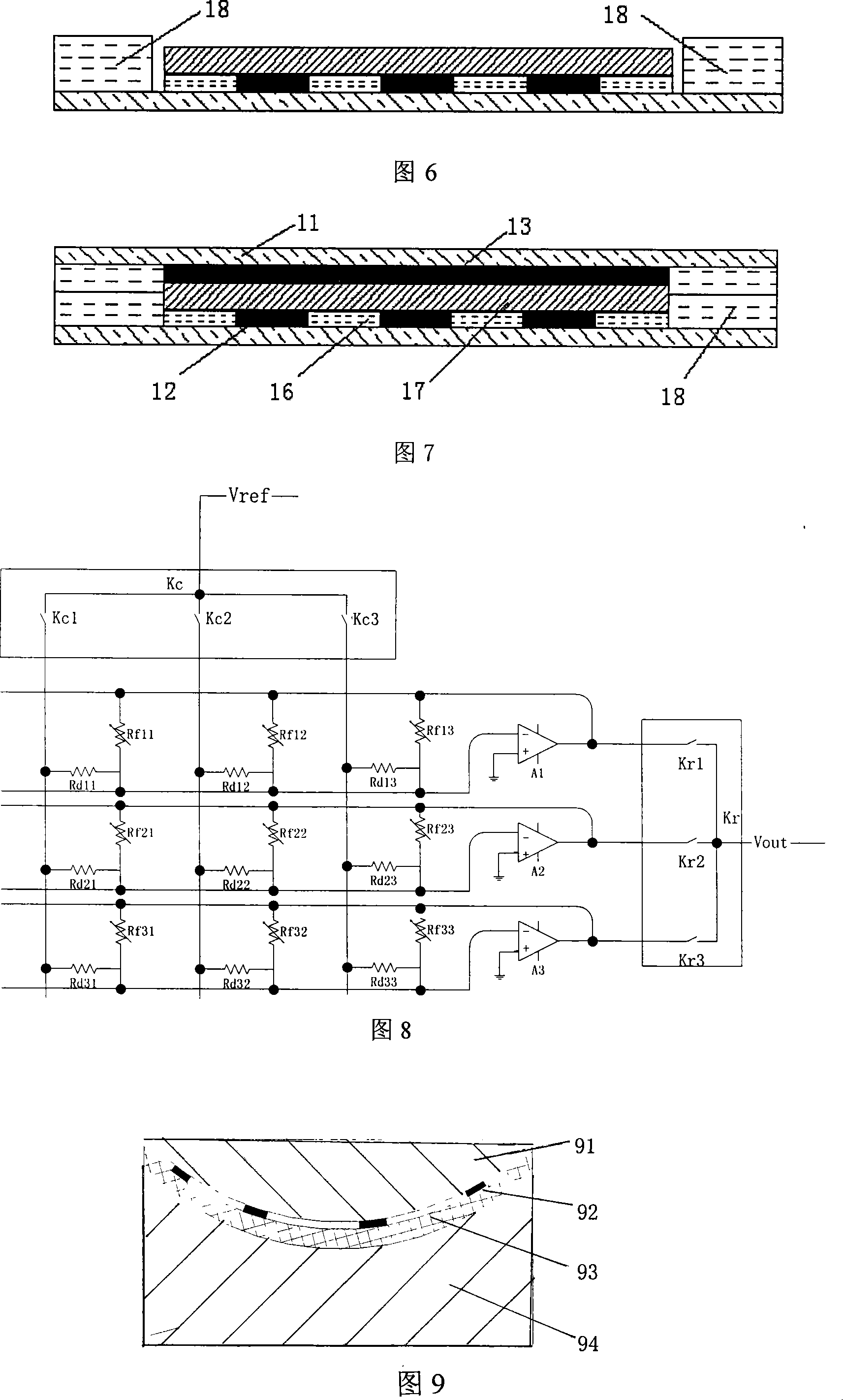

Array type ultra-thin submissive force sensor and preparation method thereof

InactiveCN101201277ALarge rangeHigh precisionForce measurement using piezo-resistive materialsImage resolutionCarbon black

The invention relates to an array-type compliant force sensor and a method of preparation thereof, and belongs to the technical field of a force sensor. The sensor comprises upper and lower poles which are enclosed into one piece, and a conduction macromolecule sensitive film compressed between the poles, and a front end circuit connected with the upper and lower poles through signal lines. The conduction macromolecule sensitive film primarily adopts the conduction macromolecule sensitive film having the compressive resistance effect consisting of graphitized carbon black as the conduction phase, single-component silastic as the insulation phase, and nanometer SiO2 dispersant. The upper and lower poles are a plurality of poles made on the substrate of the film by making use of flexible printed circuit board process and signal lines connected with each strip-shaped pole. The upper and lower strip-shaped poles are crossed and constitute an N*N sensitive cell array with the conduction macromolecule sensitive film. The signal lines are gathered to form led-out closely spaced cables. The invention has the characteristics of fine and thin structure, good flexibility, large range, high precision and high resolution.

Owner:TSINGHUA UNIV

Cable semiconducting shields

A semiconducting composition comprising (i) an olefinic polymer and (ii) about 25 to about 45 percent by weight, based on the weight of the composition, of a carbon black having the following properties: (a) a particle size of at least about 29 nanometers; (b) a tint strength of less than about 100 percent; (c) a loss of volatiles at 950 degrees C in a nitrogen atmosphere of less than about 1 weight percent based on the weight of the carbon black; (d) a DBP oil absorption of about 80 to about 300 cubic centimeters per 100 grams; (e) a nitrogen surface adsorption area of about 30 to about 300 square meters per gram or an iodine adsorption number of about 30 to about 300 grams per kilogram; (f) a CTAB surface area of about 30 to about 150 square meters per gram; and (g) a ratio of property (e) to property (f) of greater than about 1.1.

Owner:UNION CARBIDE CHEM & PLASTICS TECH CORP

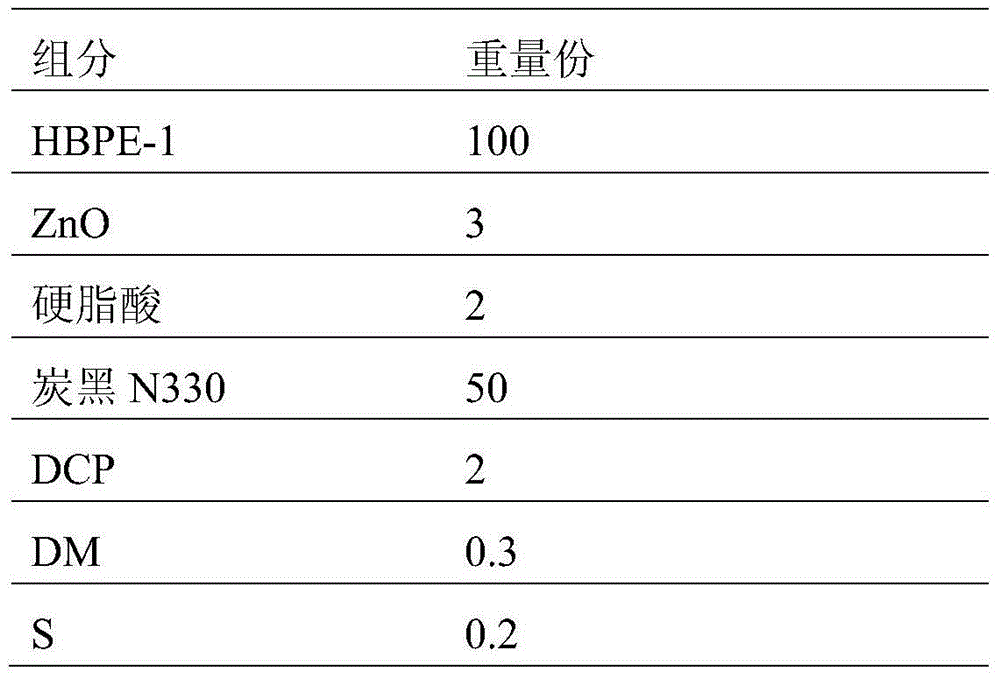

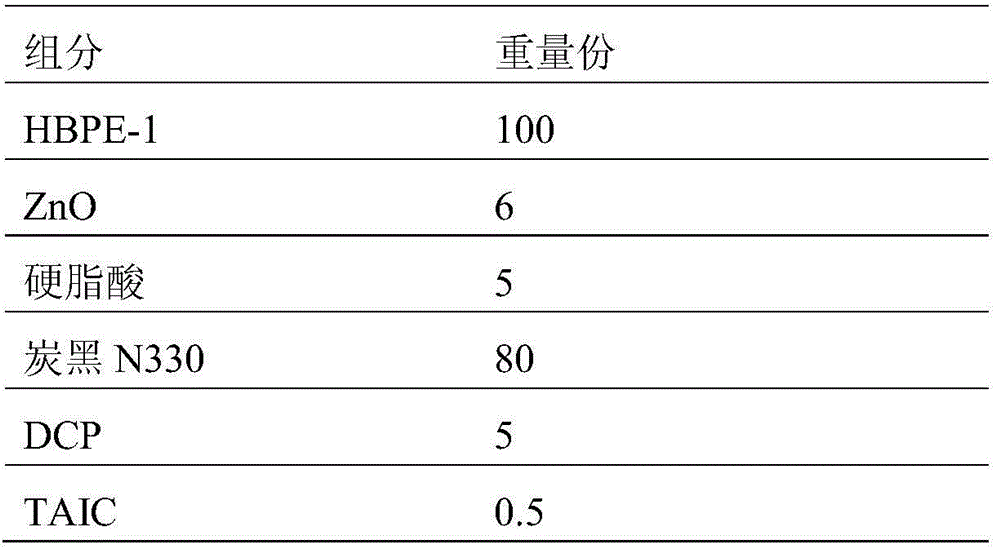

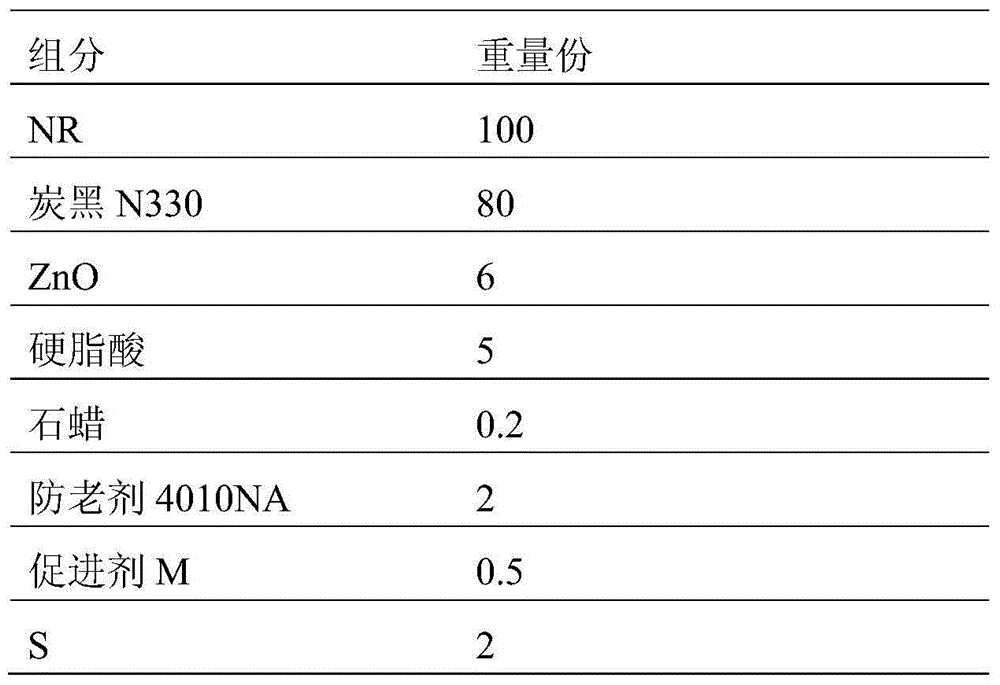

Polyethylene rubber and processing method thereof

The invention belongs to the technical field of rubber, and particularly relates to polyethylene rubber and a processing method thereof. The polyethylene rubber comprises following raw materials by weight: 100 parts of hyper branched polyethylene, 50-80 parts of carbon black, 2-5 parts of a peroxide crosslinking agent, 0-6 parts of zinc oxide, 0-5 parts of a lubricant, 0.3-0.5 part of an accelerant, and 0-0.2 part of sulfur. Beneficial effects of the polyethylene rubber and the processing method thereof are that: the hyper branched polyethylene (HBPE) is sulfurized by utilization of a peroxide sulfurization system, has good mechanical performances through stress-strain performance tests, and has a characteristic of high elasticity of rubber. The processing method of the polyethylene rubber is totally different from preparation methods of chlorinated polyethylene rubber and chlorosulfonated polyethylene rubber at present. The polyethylene rubber and the processing method thereof break the limit that polyethylene can be only used for making plastic products, expand the application scope of the polyethylene, and largely increase the additional value of polyethylene homopolymers.

Owner:ZHEJIANG UNIV

Tire with silica reinforced tread and/or sidewall components

The present invention relates to the preparation of rubber compositions for tire tread and tire sidewall component applications. A tire is provided having tread of such composition designed for relatively heavy loads such as, for example, truck tires. A tire having a sidewall of such composition is also provided. Such tire component rubber compositions are of rubber compositions reinforced with precipitated silica and selected carbon black in specified amounts and prepared with a prescribed order of addition to the rubber composition and composed of elastomers as a specific combination of natural or synthetic cis 1,4-polyisoprene rubber together with cis 1,4-polybutadiene rubber or with a combination of cis 1,4-polybutadiene rubber and trans 1,4-polybutadiene rubber.

Owner:THE GOODYEAR TIRE & RUBBER CO

Zeolite colored coating powder having air-purifying function

InactiveCN105272114ASolving difficult-to-disperse reunionsImprove the bactericidal effectPorosityPyrophosphate

The invention discloses zeolite colored coating powder having an air-purifying function. According to the technical scheme, the zeolite colored coating powder having the air-purifying function is characterized in that ingredients include attapulgite pottery clay powder having the air-purifying function, acidified zeolite particles, colored portland cement, Paris plaster, white carbon black, calcium chloride, aerosil, expanded perlite, nanometer silver-loaded antibacterial powder, nanometer titanium dioxide, sodium pyrophosphate and powder defoaming agents. The ingredients of the zeolite colored coating powder having the air-purifying function are input three times into a stirring machine to be stirred evenly and packaged into the finished product. By the adoption of the colored coating, in indoor wall decoration, an artistic emboss effect of various embossed three-dimensional colored patterns can be achieved through spraying and manufacturing, after spraying, a coating is hard, the porosity is high, the specific surface area is large, adhesion is strong, indoor formaldehyde, ammonia nitrogen, benzene and other harmful substances can be adsorbed and decomposed, and the functions of automatic humidification, mould prevention, sterilization, deodorization and air purification are achieved.

Owner:蒋文兰

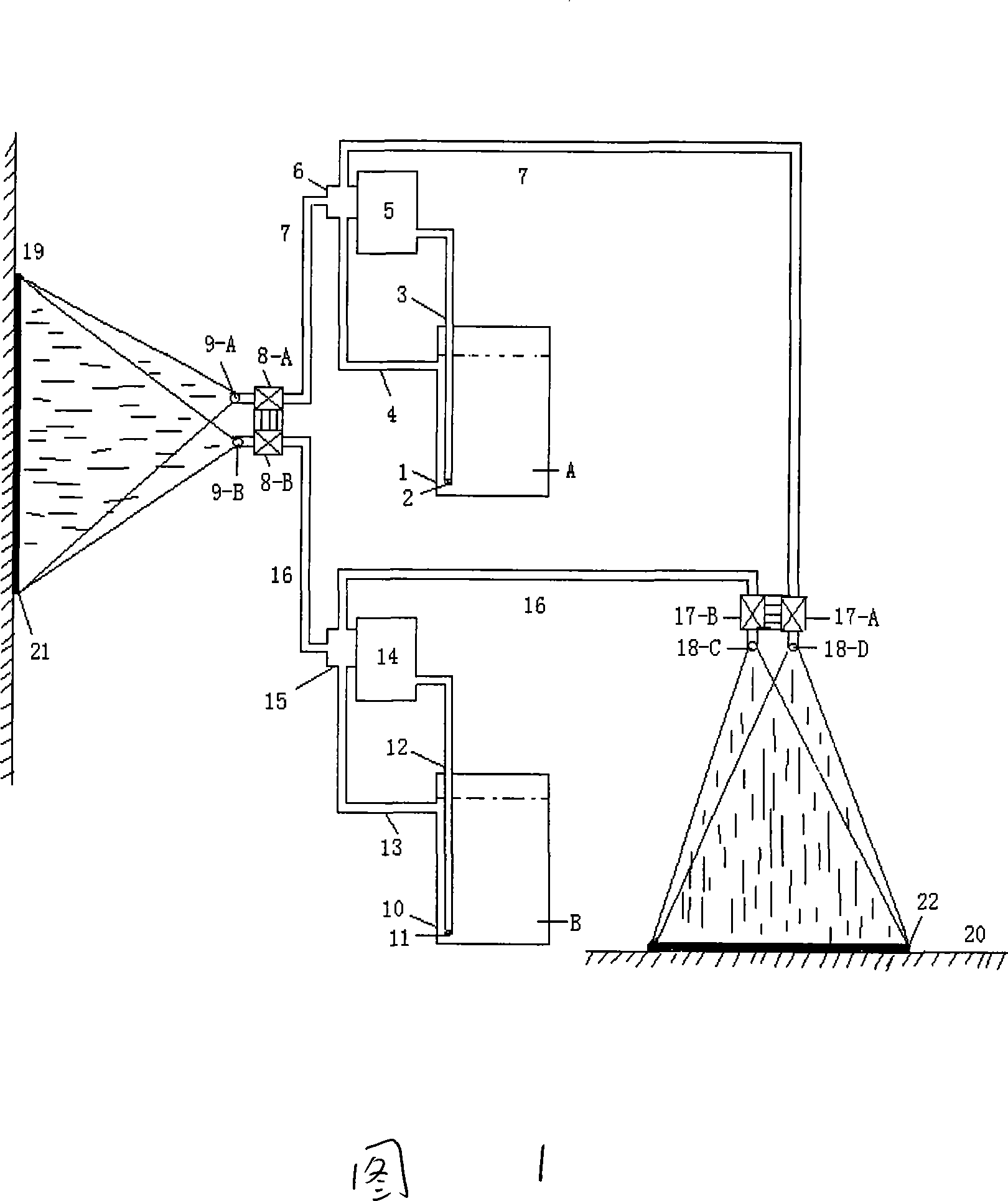

Multifunctional liquid rubber spray-coating material, preparation method, using method and special-purpose device

InactiveCN101235252AGood extensibilityImprove performanceSpraying apparatusConjugated diene hydrocarbon coatingsPolymer scienceSpray coating

Multifunctional liquid rubber spray coating comprises components of A, B, wherein A component comprises liquid rubber asphalt emulsion whose solid content is 50-75%, wherein 2-65% rubber elusion content, 30-97% asphalt elusion content, 0.0-5.0% carbon black, 0.0-6.0% ultra-fine powder, 0.025-2.50% anion dispersing agent and 0.025-3.00% anion surface activator, which is waterborne spray coating, and B component is water solution which comprises 3.0-18.0% concentration calcii chloridum (89.0-99.2%), sodium chloride (0.50-4.0%) and composite aluminum iron polymer (0.3-7.0%). The two components are sprayed on the same basal plane through adopting a double-component airless spraying device to form a gelatin film with 0.5-4mm after 3-5 seconds solidification, which has the characteristics of strong bonding, temperature resistance, weather resistance, and excellent chemical stability, heat insulation and puncture resistance. The A component can be individually sprayed, or can be combined with the double components.

Owner:大连美宸特环保节能产品有限公司

Core / shell-type catalyst particles comprising metal or ceramic core materials and methods for their preparation

ActiveUS20100092841A1High specific activityLow precious metal contentMaterial nanotechnologyCell electrodesFuel cellsAlloy

The invention is directed to core / shell type catalyst particles comprising a Mcore / Mshell structure with Mcore=inner particle core and Mshell=outer particle shell, wherein the medium diameter of the catalyst particle (dcore+shell) is in the range of 20 to 100 nm, 5 preferably in the range of 20 to 50 nm. The thickness of the outer shell (tshell) is about 5 to 20% of the diamet the inner particle core of said catalyst particle, preferably comprising at least 3 atomic layers. The inner particle core (Mcore) of the particles comprises metal or ceramic materials, whereas the material of the outer shell (Mshell) comprises precious metals and / or alloys thereof. The core / shell type catalyst particles are preferably supported on suitable support materials such as carbon black and can be used as electrocatalysts for fuel cells and for other catalytic applications.

Owner:UMICORE AG & CO KG

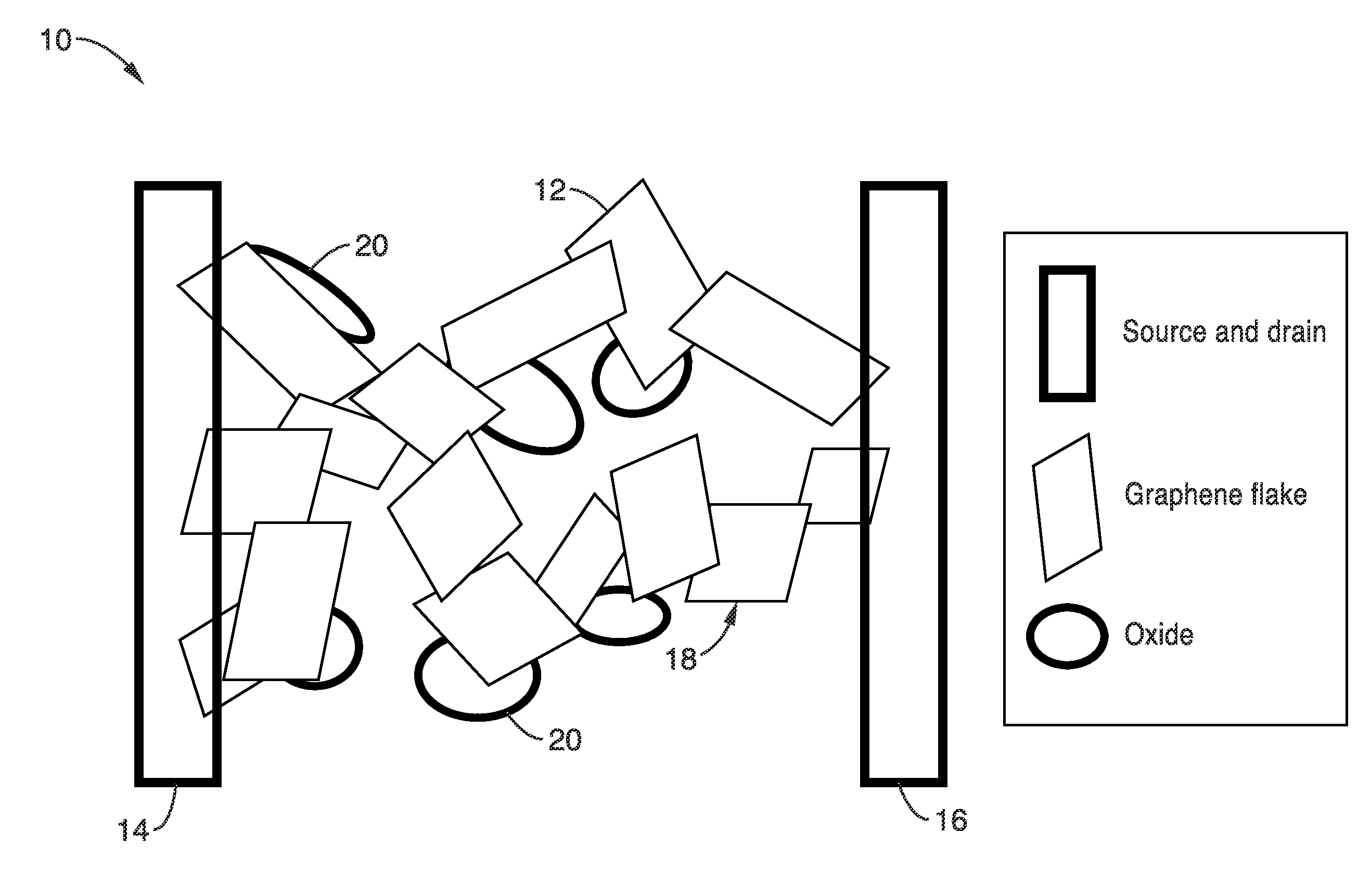

Interpenetrating networks of carbon nanostructures and nano-scale electroactive materials

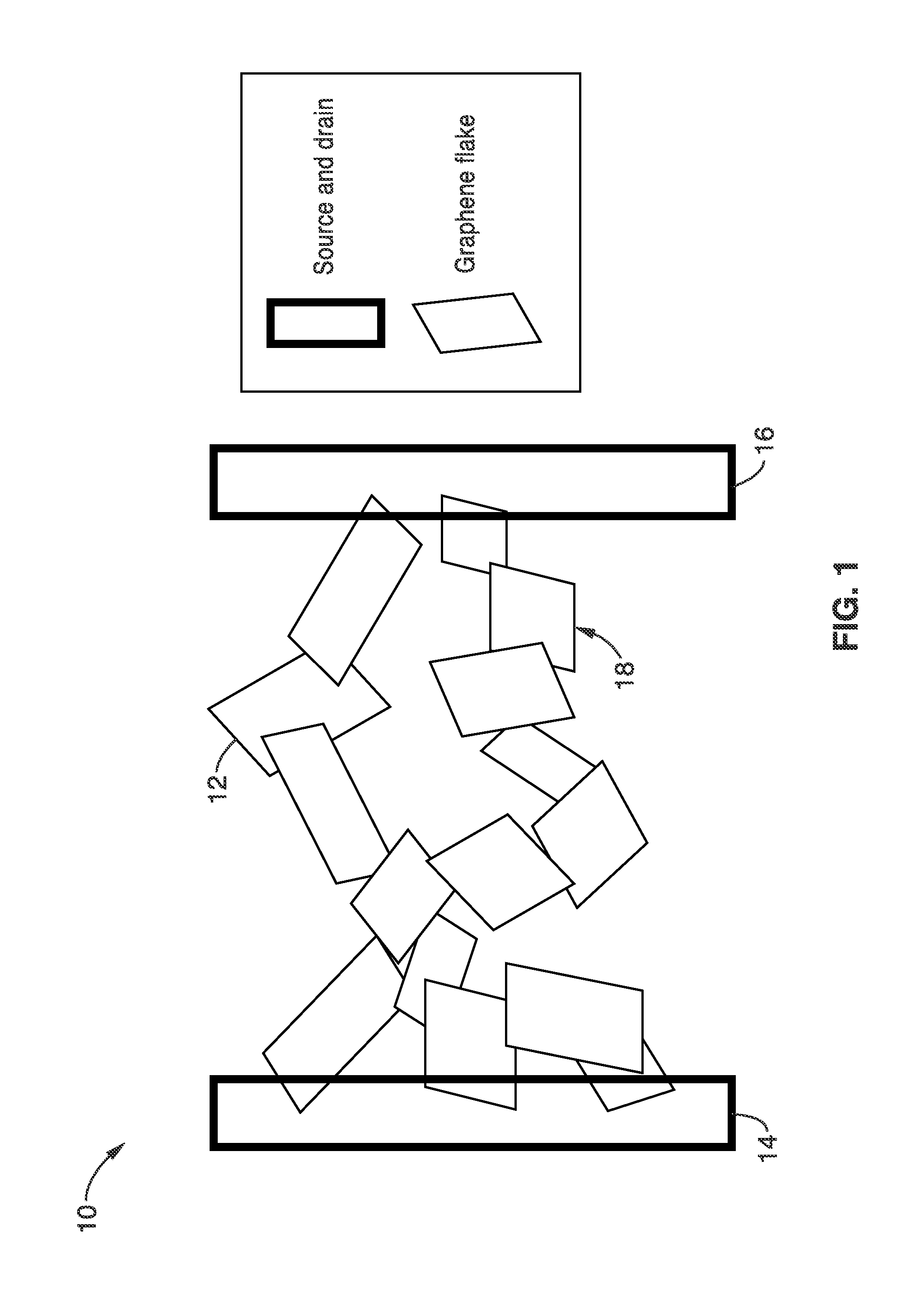

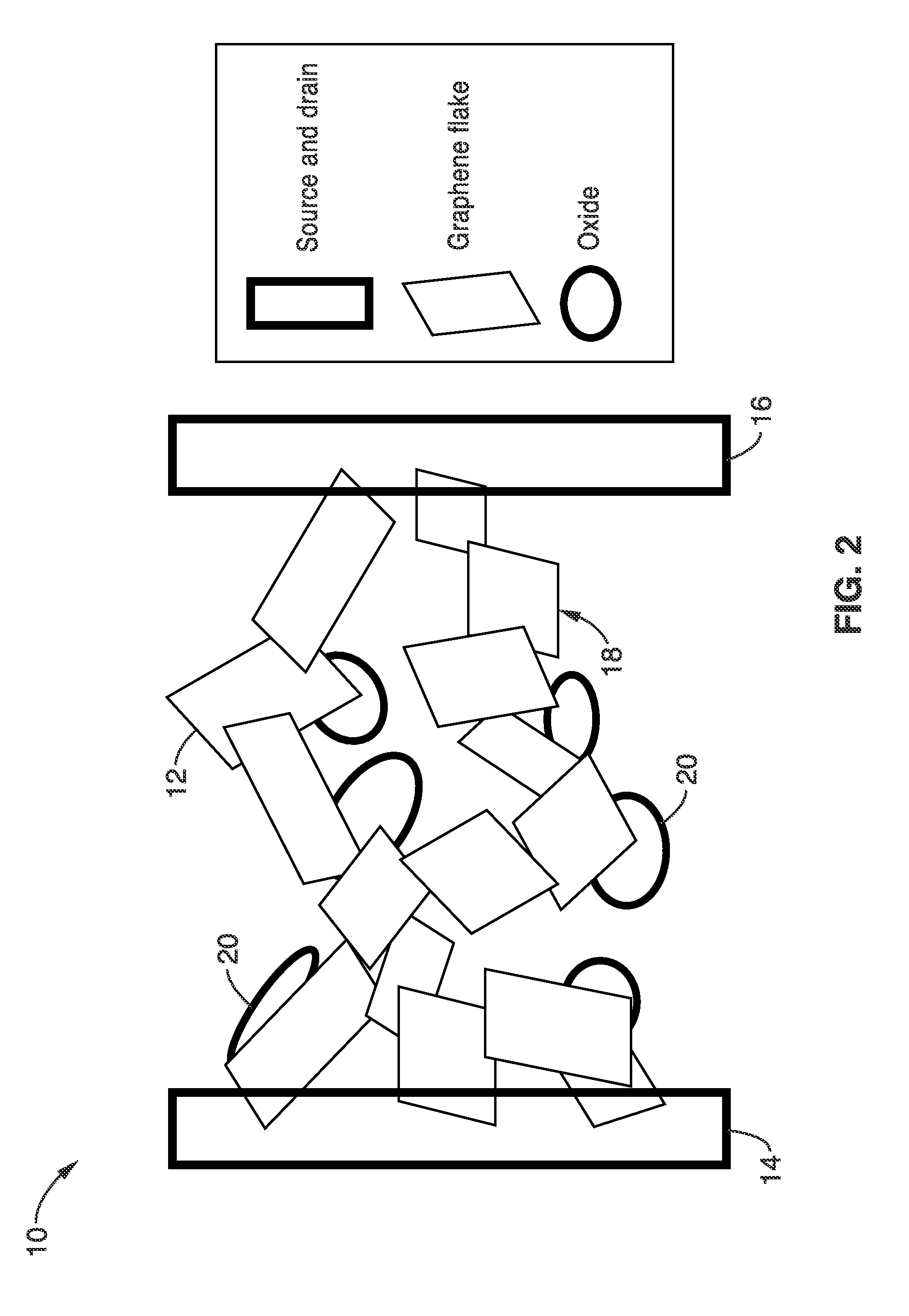

InactiveUS20140042390A1Improve conductivityLarge specific surface areaElectrolytic capacitorsHybrid capacitor electrodesActivated carbonGraphene flake

An interpenetrating network assembly with a network of connected flakes of nano-scale crystalline carbon and nano-scale particles of an electroactive material interconnected with the carbon flakes is provided. The network assemblies are particularly suited for energy storage applications that use metal oxide electroactive materials and a single charge collector or a source and drain. Interpenetrating networks of graphene flakes and metal oxide nanosheets can form independent pathways between source and drain. Nano-scale conductive materials such as metal nanowires, carbon nanotubes, activated carbon or carbon black can be included as part of the conductive network to improve charge transfer.

Owner:RGT UNIV OF CALIFORNIA

Rubber Compositions Comprising Graphene and Reinforcing Agents and Articles Made Therefrom

Compositions comprising graphene sheets. at least one reinforcing agent, and at least one rubber. The compositions may further comprise carbon black. The compositions may be formed into articles including tire components.

Owner:VORBECK MATERIALS CORP

Carbon-containing material

A carbon-containing material with organic groups, which is obtainable by reaction of the carbon-containing material with organic compounds of the general formula 1A process for preparing the carbon-containing material according to the invention is also described. The carbon-containing materials according to the invention can be used as fillers, reinforcing fillers, UV stabilizers, conductivity carbon blacks or pigments.

Owner:UBS AG

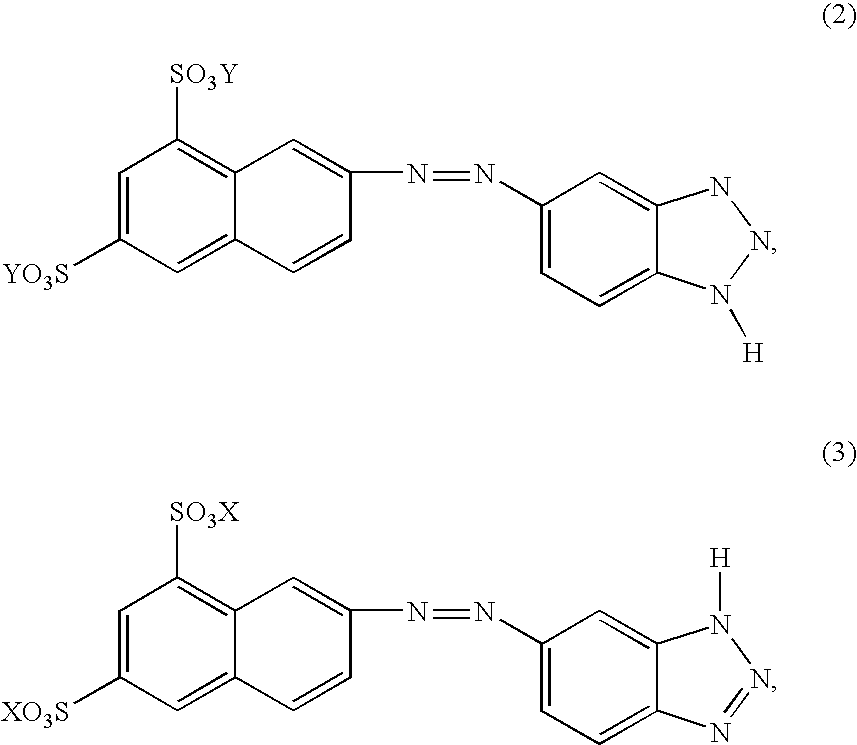

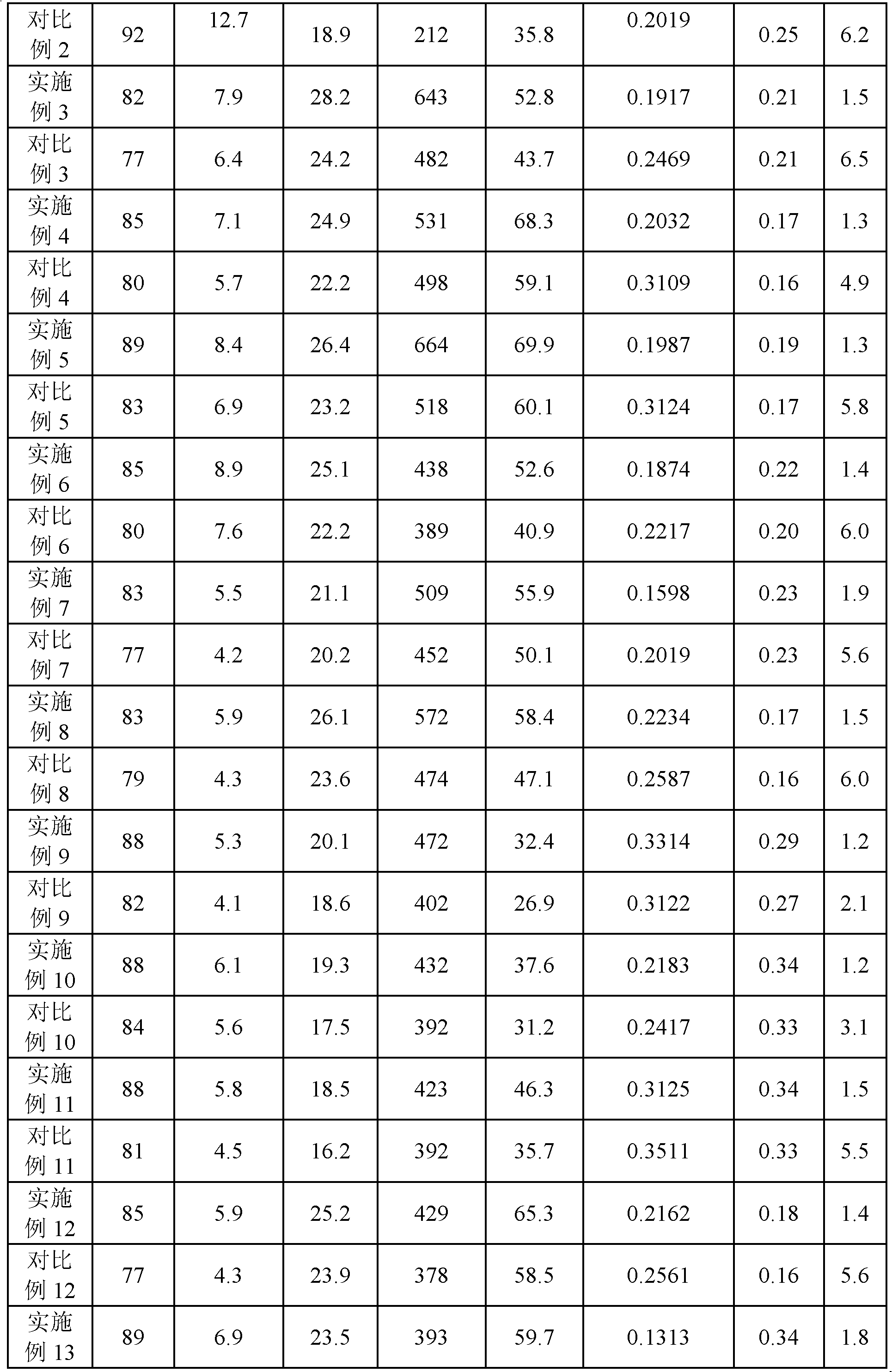

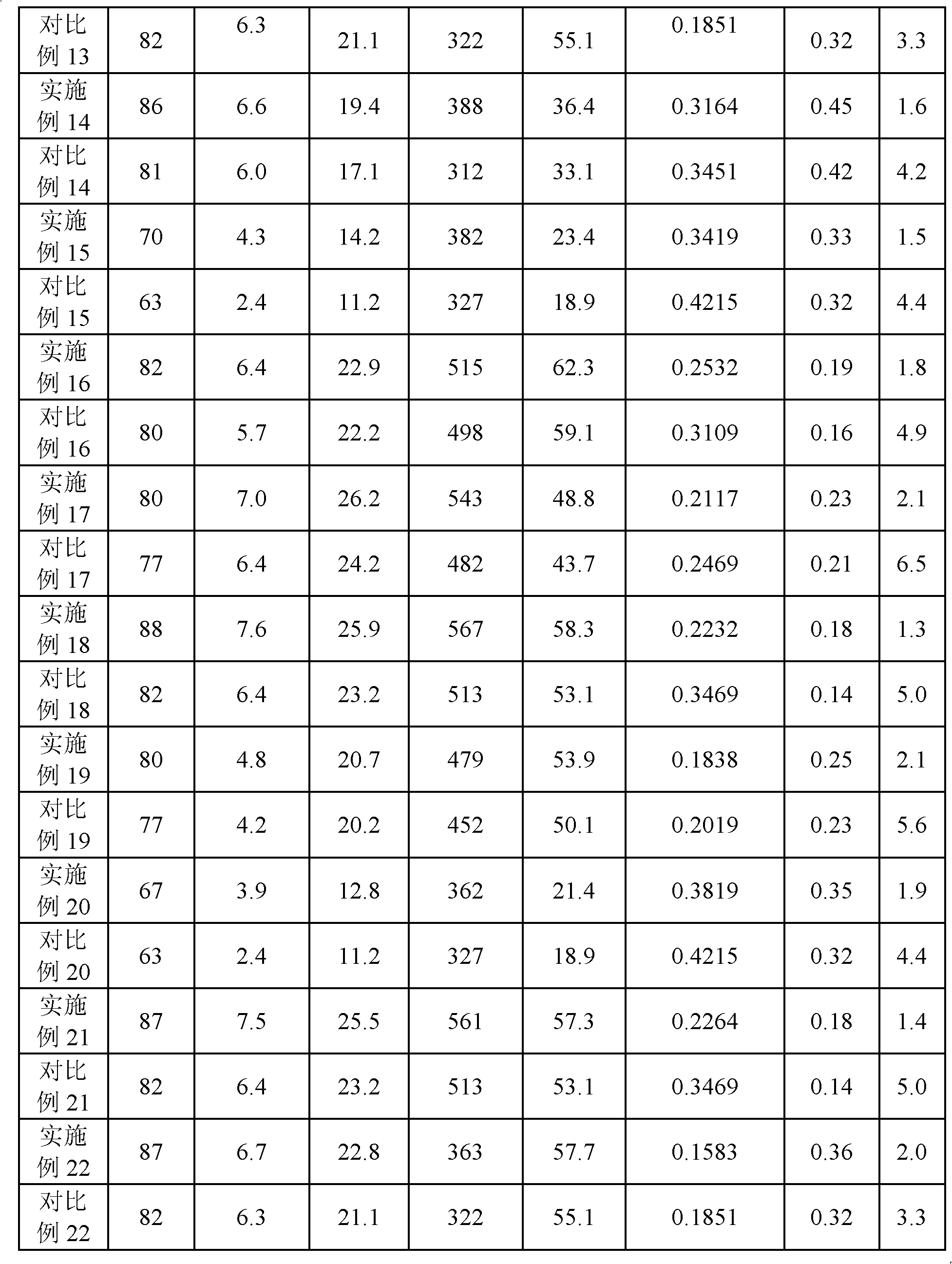

Method for preparing graphene oxide/white carbon black/rubber nanocomposite

The invention relates to a method for preparing a graphene oxide / white carbon black / rubber nanocomposite, which adopts a solution blending method or a mechanical blending method. In the graphene oxide / white carbon black / rubber nanocomposite prepared by the method provided by the invention, graphene and white carbon black are inserted with each other to effectively effective the aggregation of the two fillers, so as to obtain a highly-dispersed highly-stripped nano-sized composite. Not only the composite has high modulus and low rolling resistance, but also the wear resistance of a rubber material is greatly improved, and the modulus and tear resistance of the composite are further improved; in addition, due to the lamellar structure and good self-recovery capability of graphene oxide, the rubber material is also endued with good gas barrier performance and self-recovery capability, and the nanocomposite has the advantages that cannot be matched by any traditional filler. The method provided by the invention is simple and feasible, and suitable for industrial production, and has low cost, wide application range and good economic and social benefits.

Owner:BEIJING UNIV OF CHEM TECH

Silica-rubber mixtures having improved hardness

InactiveUS20050277717A1Eliminates and reduces filler network effectReduce hardnessSpecial tyresSilanesOrganic group

A method for increasing the hardness of silica / rubber mixtures is disclosed wherein the method comprises blending with said mixture at least one silane and a hardness-increasing amount of at least one member selected from the group consisting of thixotropic fumed silica; precipitated silica; an MQ resin wherein Q is SiO4 / 2, M is R1R2R3SiO1 / 2, and R1, R2, and R3 are the same or different functional or non-functional organic groups; carbon black; a thermoplastic resin; and a thermosetting resin.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

Open porous electrically conductive nanocomposite material

ActiveUS20100233538A1Easy to getFaster and energy efficientElectrode manufacturing processesFinal product manufactureHigh energyConductive polymer

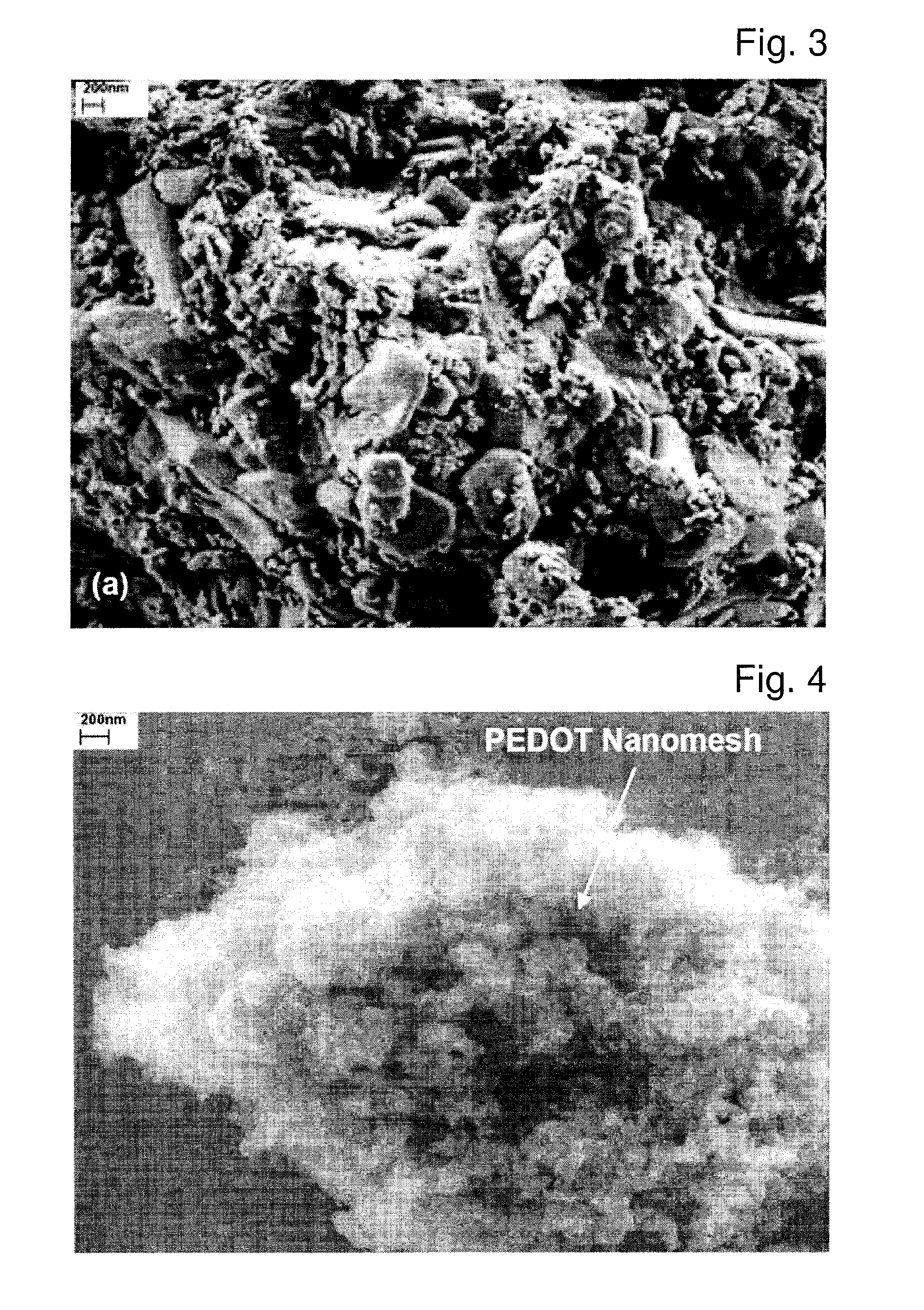

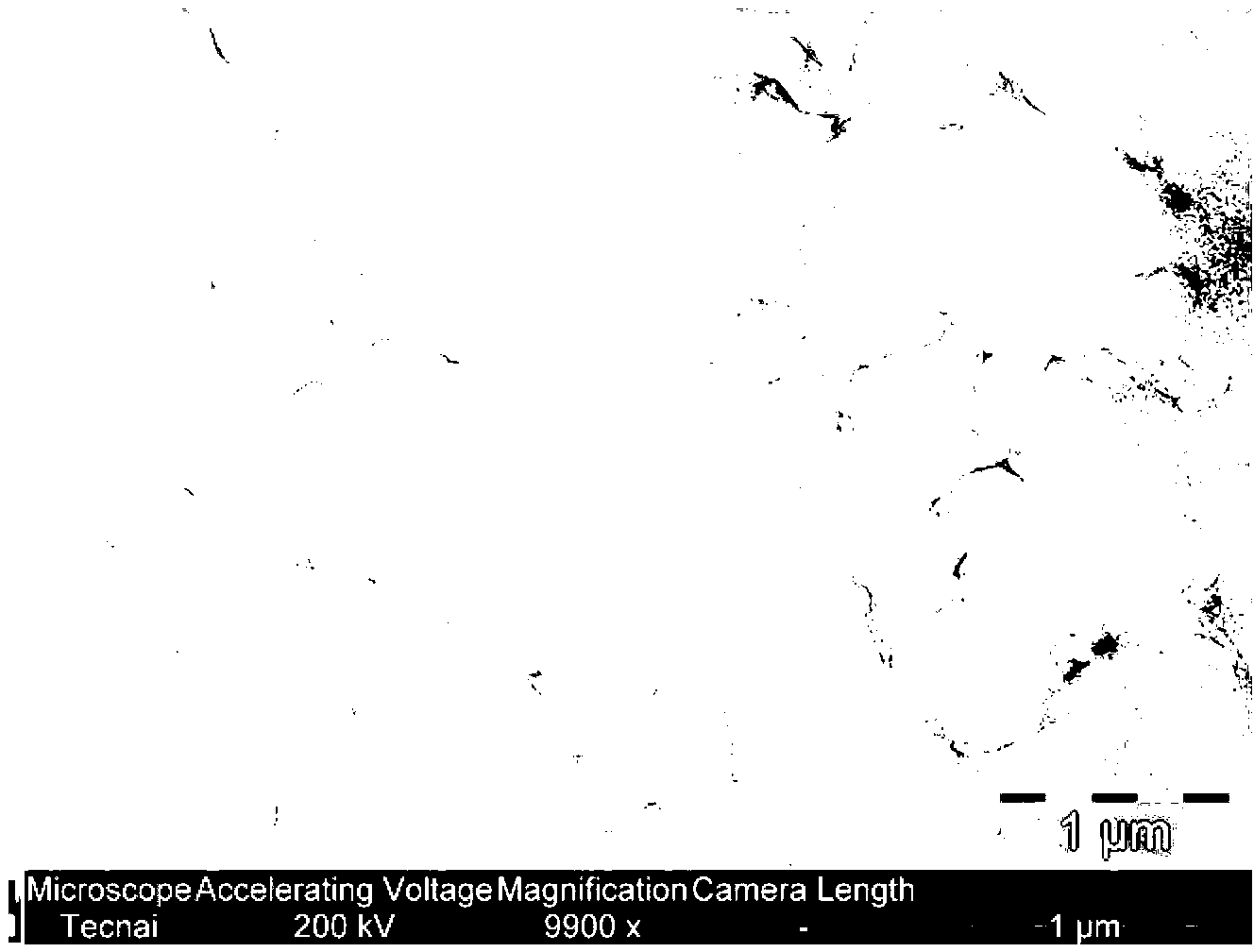

Nanocomposits of conductive, nanoparticulate polymer and electronically active material, in particular PEDOT and LiFePO4, were found to be significantly better compared to bare and carbon coated LiFePO4 in carbon black and graphite filled non conducting binder. The conductive polymer containing composite outperformed the other two samples. The performance of PEDOT composite was especially better in the high current regime with capacity retention of 82% after 200 cycles. Hence an electrode based on composite made of conductive, nanoparticulate polymer and electronically active material, in particular LiFePO4 and PEDOT nanostubs, with its higher energy density and increased resistance to harsh charging regimes proved to dramatically extend the high power applicability of materials such as LiFePO4.

Owner:BELENOS CLEAN POWER HLDG

Silica coated carbon blacks

InactiveUS6197274B1Alkali metal halidesPigment treatment with organosilicon compoundsElastomerOrganic group

Silica coated carbon blacks are disclosed and can be prepared by coating a fine dispersion of carbon black, such as a carbon black having an attached organic group(s). Compositions and articles of manufacture, including elastomeric compositions, containing such carbon black are also disclosed.

Owner:CABOT CORP

Oxidized grapheme/carbon black rubber nanocomposite and preparation method thereof

The invention provides an oxidized grapheme / carbon black rubber nanocomposite and preparation method thereof, which belongs to the field of rubber nanocomposite technology. The nanocomposite comprises the following basic compositions by mass: 100 parts of diene series rubber matrix, 0.5-5 parts of oxidized grapheme, 30-70 parts of hard carbon black of average particle size 11-30nm, 1-10 parts of plasticizer, 6-10 parts of activator, 0.5-4 parts of anti-aging agent, 1-4 parts of sulfuration promoter and 1-6 parts of insoluble sulphur; oxidized grapheme modifier. The oxidized grapheme powder is dispersed in deionized water for ultrasound, and a natural rubber emulsion is added, and masterbatch after flocculation, washing and drying is mixed uniformly with other additives, after sulfuration, the product is obtained. The oxidized grapheme / carbon black rubber nanocomposite has the advantages of excellent processing performance and obviously reduced dynamic themogenesis, thereby improving the usage life of tyre.

Owner:BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com