Array type ultra-thin submissive force sensor and preparation method thereof

A force sensor and sensor technology, which is applied in the field of structural design of array ultra-thin compliant force sensors, achieves high force-sensitive precision and resolution, realizes linear output, and reduces the number of gate switches.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

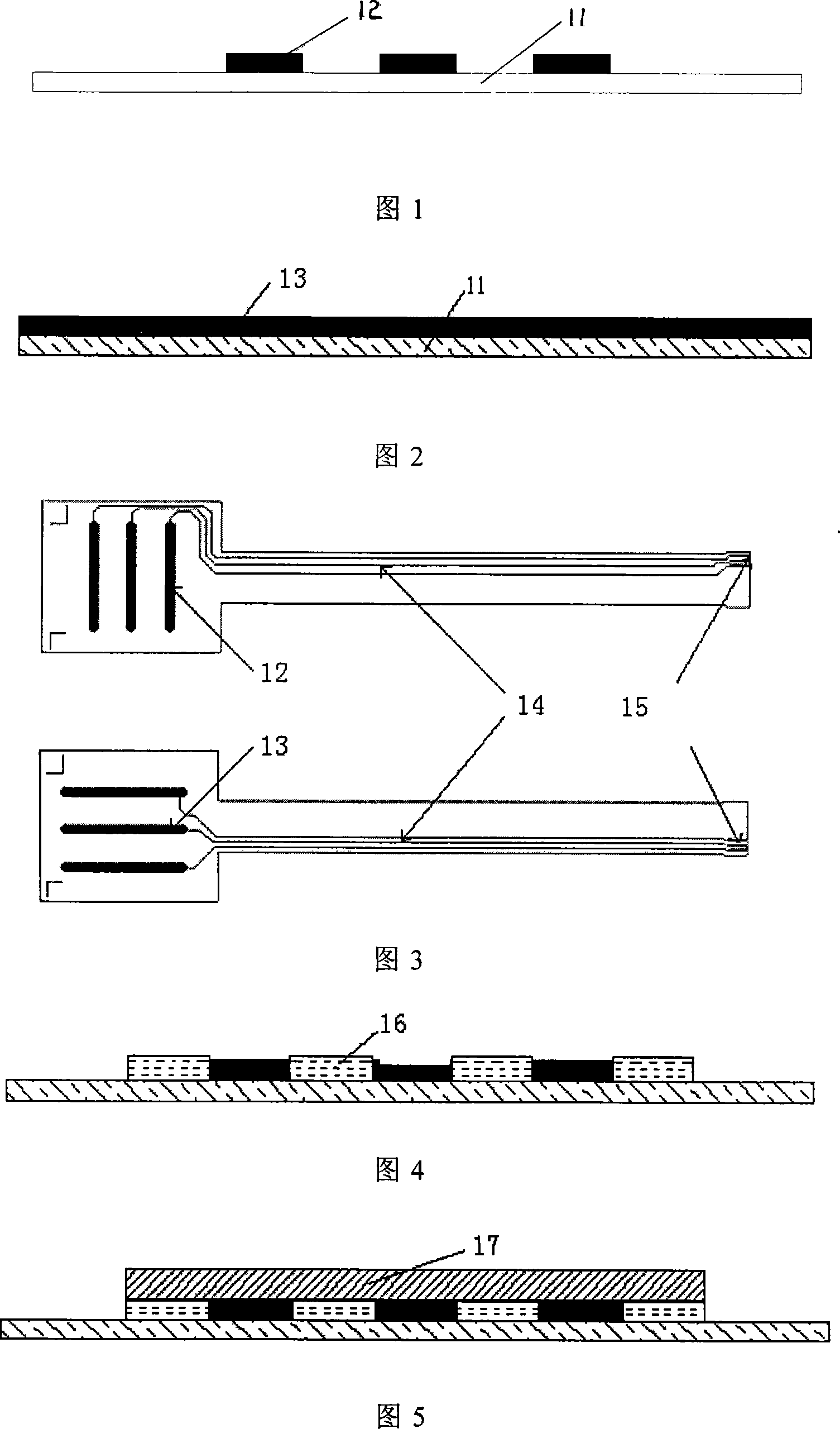

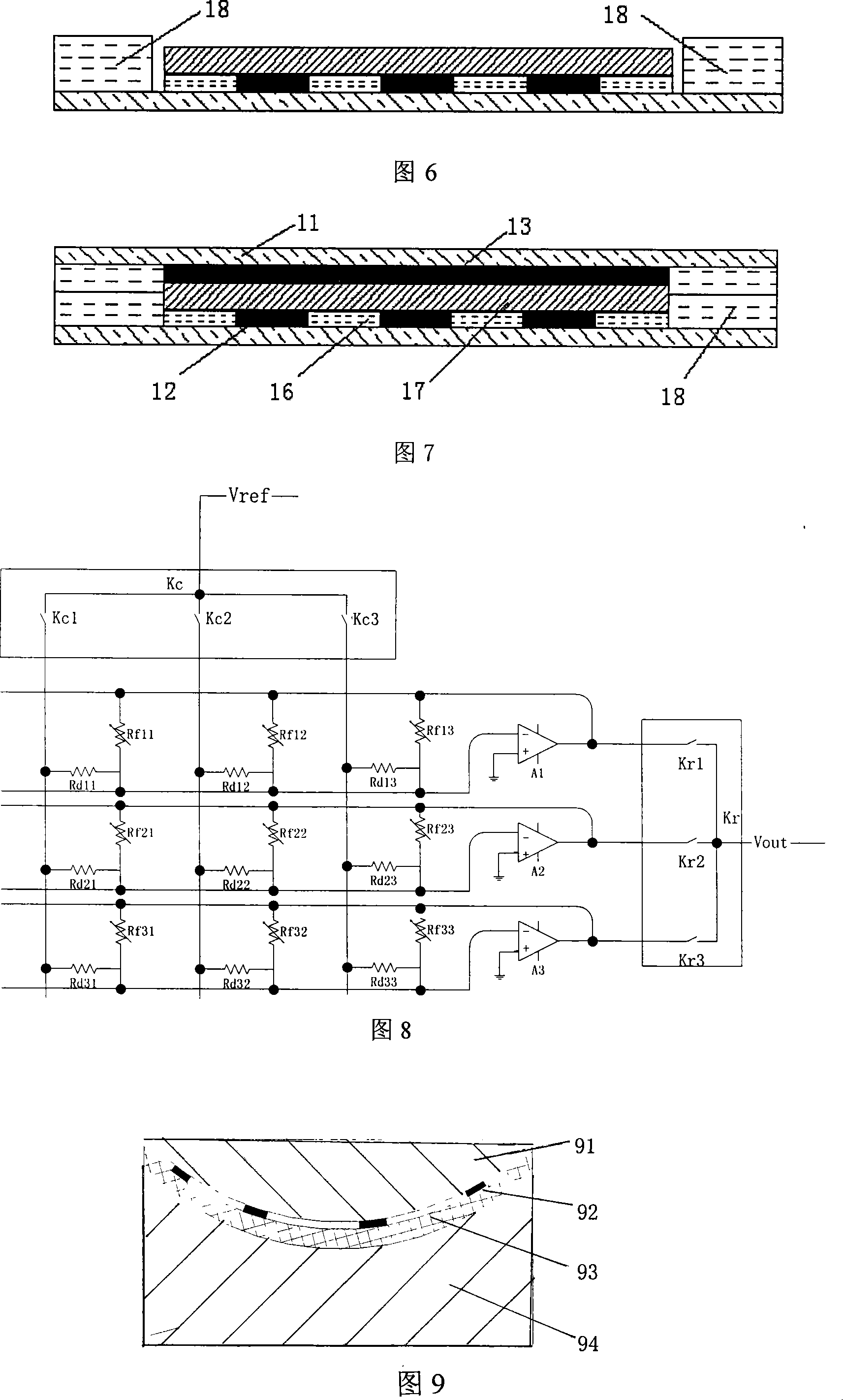

[0063] The preparation method of the array-type ultra-thin compliant force sensor proposed by the present invention includes two parts: the preparation of an ultra-thin compliant conductive polymer sensitive film and the preparation of an array-type compliant force sensor using the sensitive film. The ultra-thin compliant conductive polymer is sensitive The preparation of membrane comprises the following steps:

[0064] 11) Conductive carbon black powder with an average diameter of less than 1 μm, SiO with a diameter of 10-50 nm 2 Dispersant powder and liquid one-component silicone rubber are mixed in acetone organic solvent with a concentration of more than 95%; wherein, the volume concentration percentage of each component is: one-component silicone rubber: conductive carbon black powder: nano-SiO 2 Dispersant powder: acetone organic solvent = 100:10~15:1~3:300~500;

[0065] 12) Perform mechanical stirring under ultrasonic vibration, the temperature of the stirring environm...

Embodiment 1

[0079] 11) Conductive carbon black powder with an average diameter of less than 1 μm, SiO with a diameter of 10 nm 2 Dispersant powder and liquid one-component silicone rubber are mixed in acetone organic solvent with a concentration of more than 95%; wherein, the volume concentration percentage of each component is: one-component silicone rubber: conductive carbon black powder: nano-SiO 2 Dispersant powder: acetone organic solvent=100:10:1:300;

[0080] 12) Perform mechanical stirring under ultrasonic vibration, the temperature of the stirring environment is 40°C, and the stirring time is 2 hours, until the mixture is in a gel state;

[0081] 13) Add 3% butadiene rubber particles (10 μm) of the total volume of the mixture into the mixture, and continue mechanical stirring for 20 minutes to volatilize the acetone;

[0082] 14) Drop the volatilized mixture into the rotating platform, and spin-coat to form a conductive polymer film with a thickness of 70 μm;

[0083] 15) Vulca...

Embodiment 2

[0085] 11) Conductive carbon black powder with an average diameter of less than 1 μm, SiO of 50 nm 2 Dispersant powder and liquid one-component silicone rubber are mixed in acetone organic solvent with a concentration of more than 95%; wherein, the volume concentration percentage of each component is: one-component silicone rubber: conductive carbon black powder: nano-SiO 2 Dispersant powder: acetone organic solvent=100:15:3:500;

[0086] 12) Perform mechanical stirring under ultrasonic vibration, the temperature of the stirring environment is 60°C, and the stirring time is 4 hours, until the mixture is in a gel state;

[0087] 13) Add 5% butadiene rubber particles (30 μm) of the total volume of the mixture into the mixture, and continue mechanical stirring for 30 minutes to volatilize the acetone;

[0088] 14) Drop the volatilized mixture into the rotating platform, and spin-coat to form a conductive polymer film with a thickness of 100 μm;

[0089] 15) Vulcanize the conduc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com