Patents

Literature

11960 results about "Silicone rubber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silicone rubber is an elastomer (rubber-like material) composed of silicone—itself a polymer—containing silicon together with carbon, hydrogen, and oxygen. Silicone rubbers are widely used in industry, and there are multiple formulations. Silicone rubbers are often one- or two-part polymers, and may contain fillers to improve properties or reduce cost. Silicone rubber is generally non-reactive, stable, and resistant to extreme environments and temperatures from −55 to 300 °C (−67 to 572 °F) while still maintaining its useful properties. Due to these properties and its ease of manufacturing and shaping, silicone rubber can be found in a wide variety of products, including: voltage line insulators, automotive applications; cooking, baking, and food storage products; apparel such as undergarments, sportswear, and footwear; electronics; medical devices and implants; and in home repair and hardware with products such as silicone sealants.

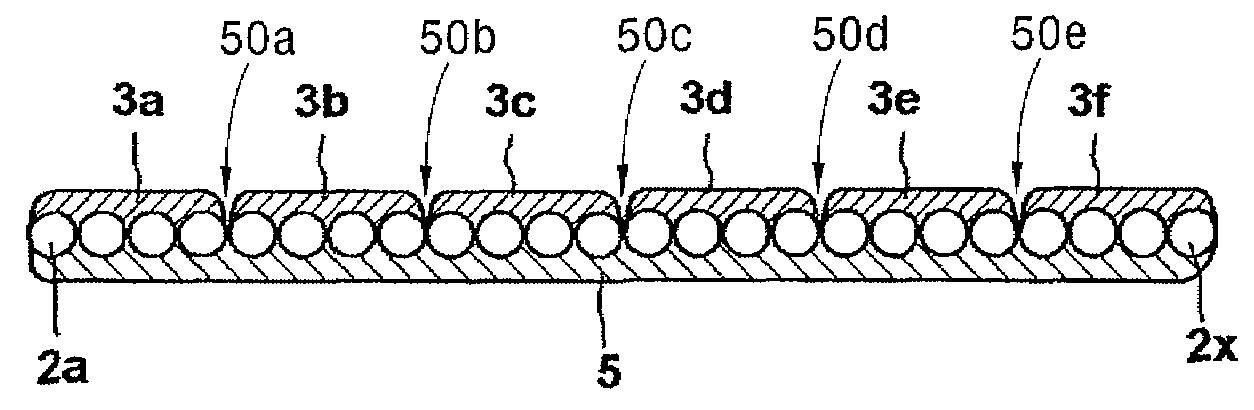

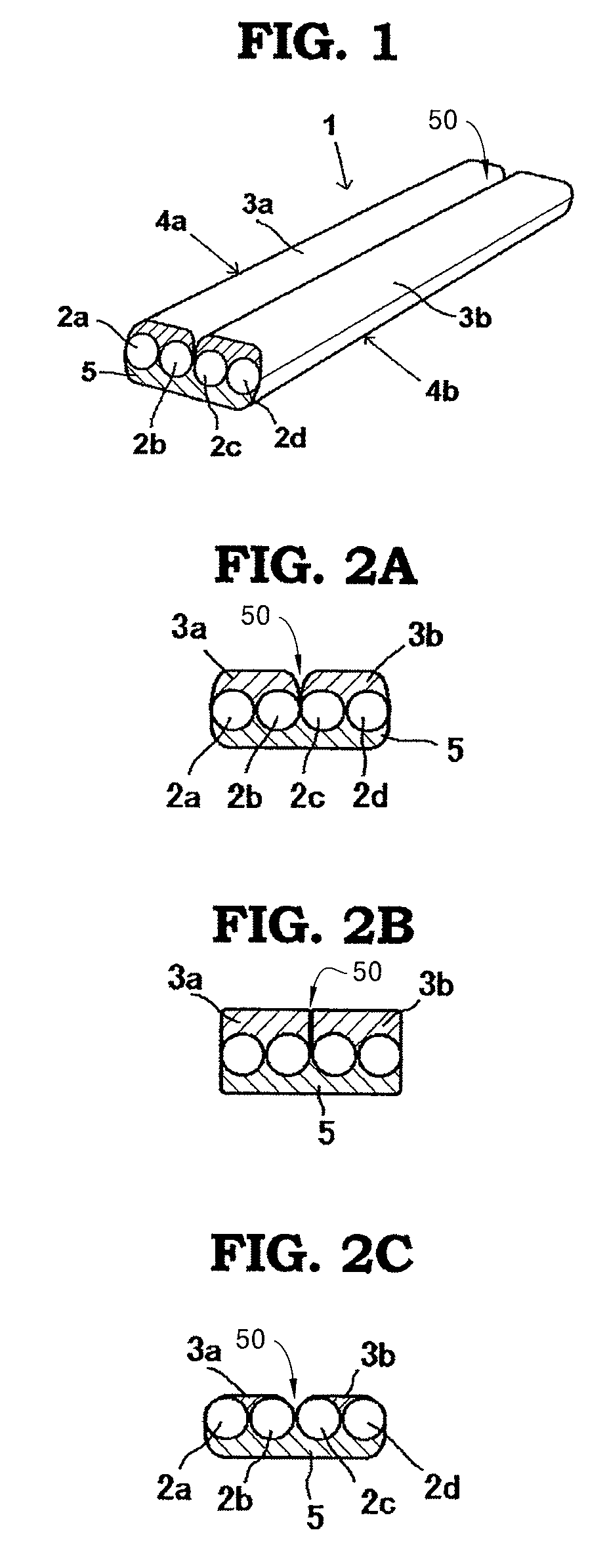

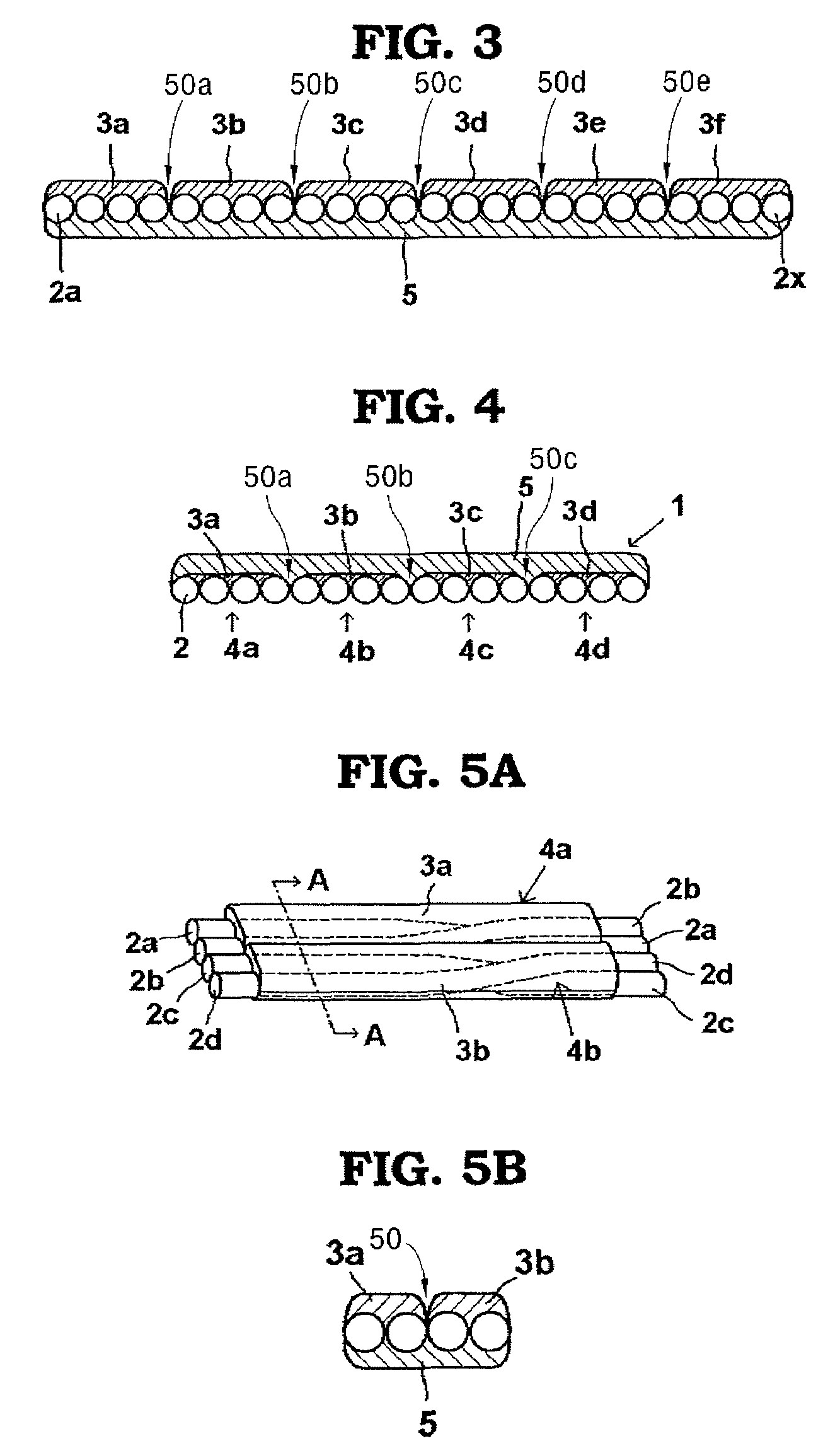

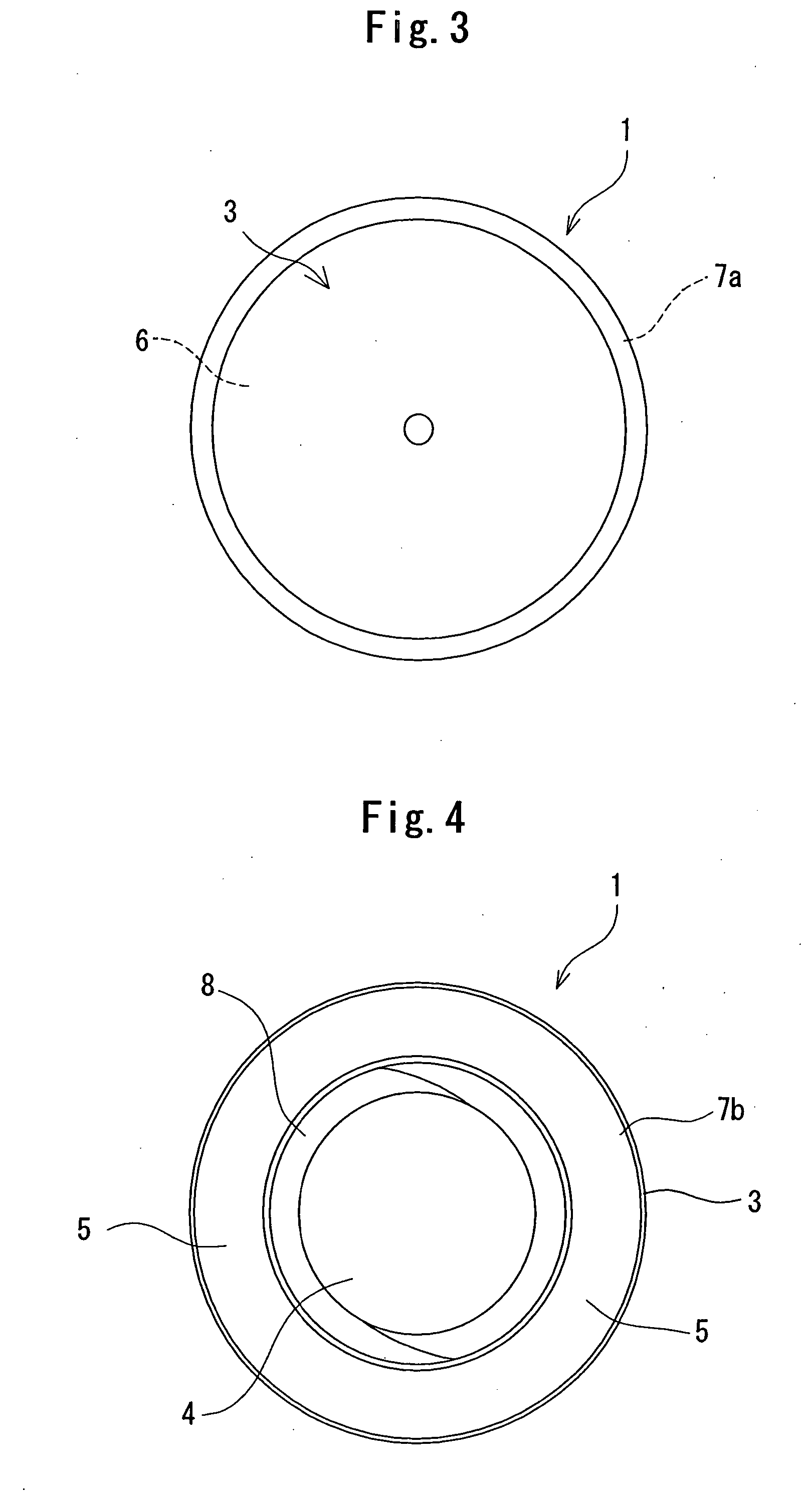

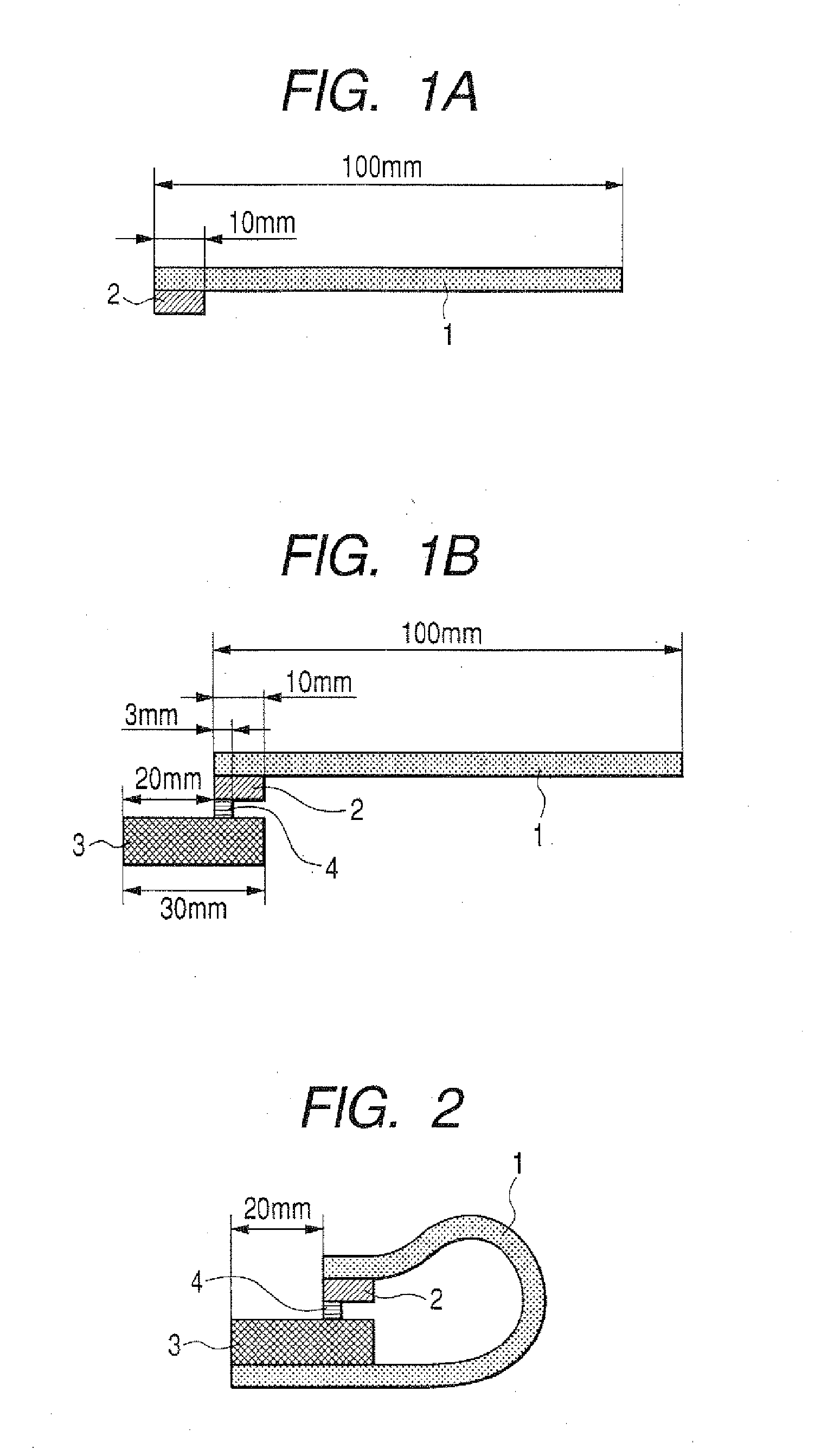

Optical fiber structure and method of manufacturing same

InactiveUS7509009B2Easily branchedPromote divisionGlass optical fibreFibre mechanical structuresEngineeringUltimate tensile strength

The present invention provides an optical fiber structure that allows for reliable and easy branching of optical fibers, as well as a method of manufacturing such optical fiber structure. The optical fiber structure proposed by the present invention is characterized by a structure wherein multiple optical fiber units, each comprising multiple optical fibers that are aligned two-dimensionally in such a way that one side is covered by a first covering body, are aligned so that the covered surfaces face the same direction, and the covered or uncovered surfaces of the multiple optical fiber units are integrally covered by a second covering body. The second covering body should preferably be made of silicone rubber having a tearing strength of 29 kgf / cm or below.

Owner:TOMOEGAWA PAPER CO LTD

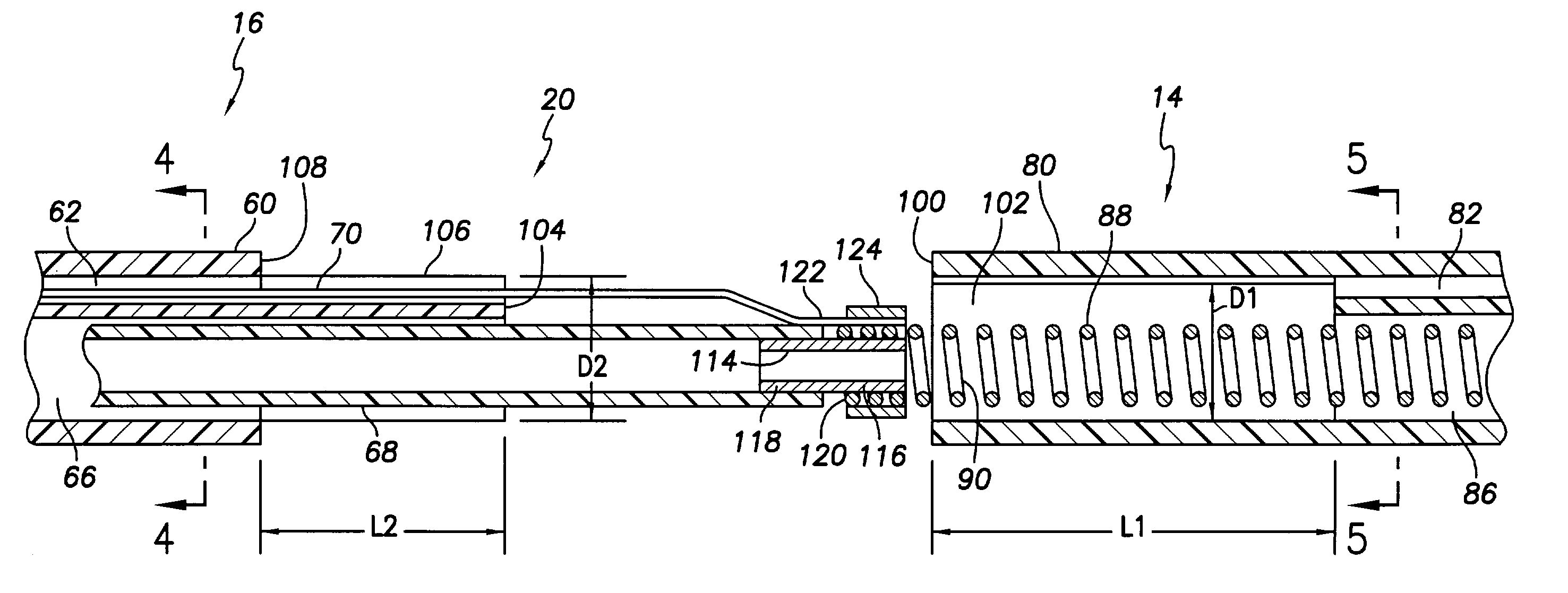

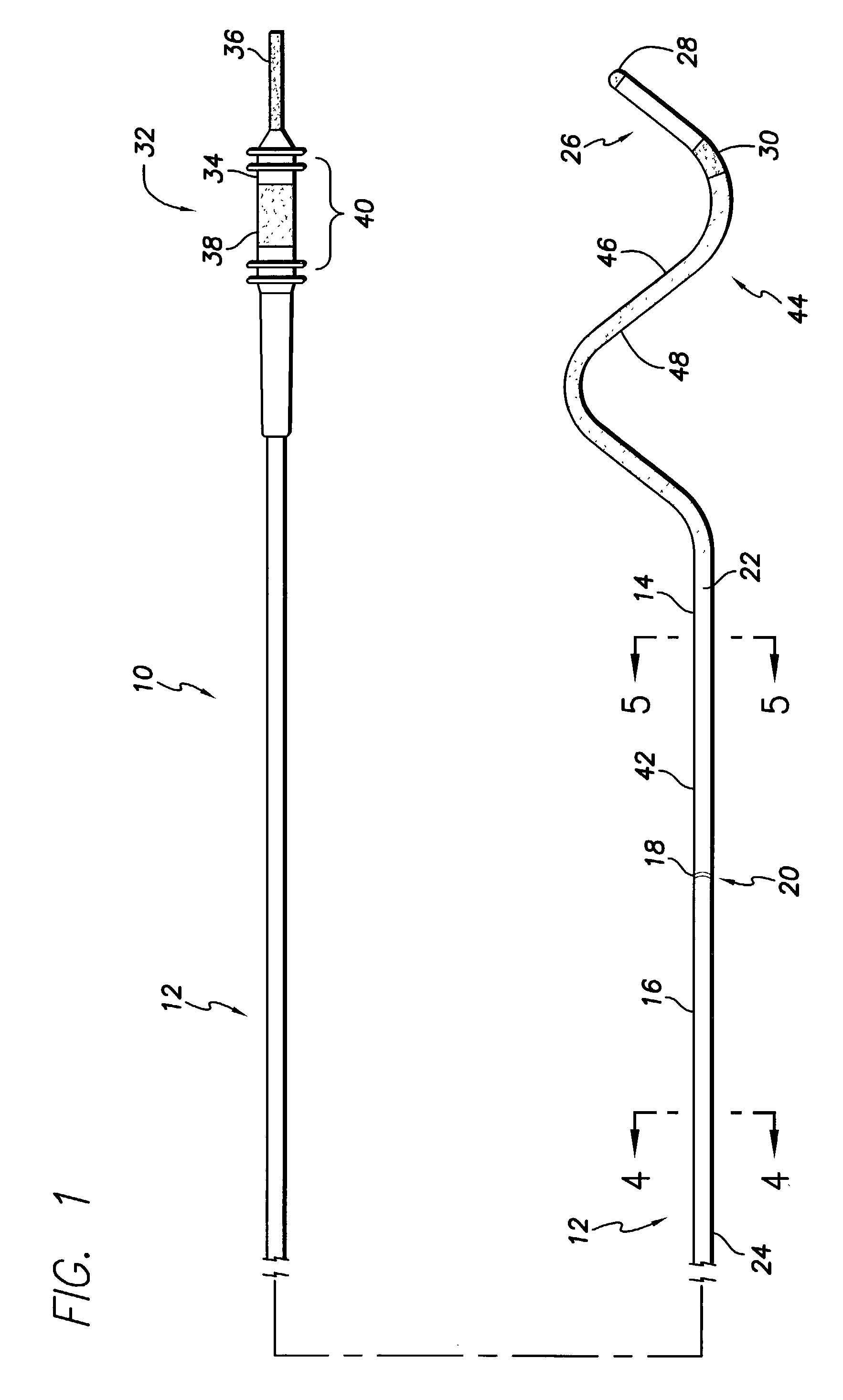

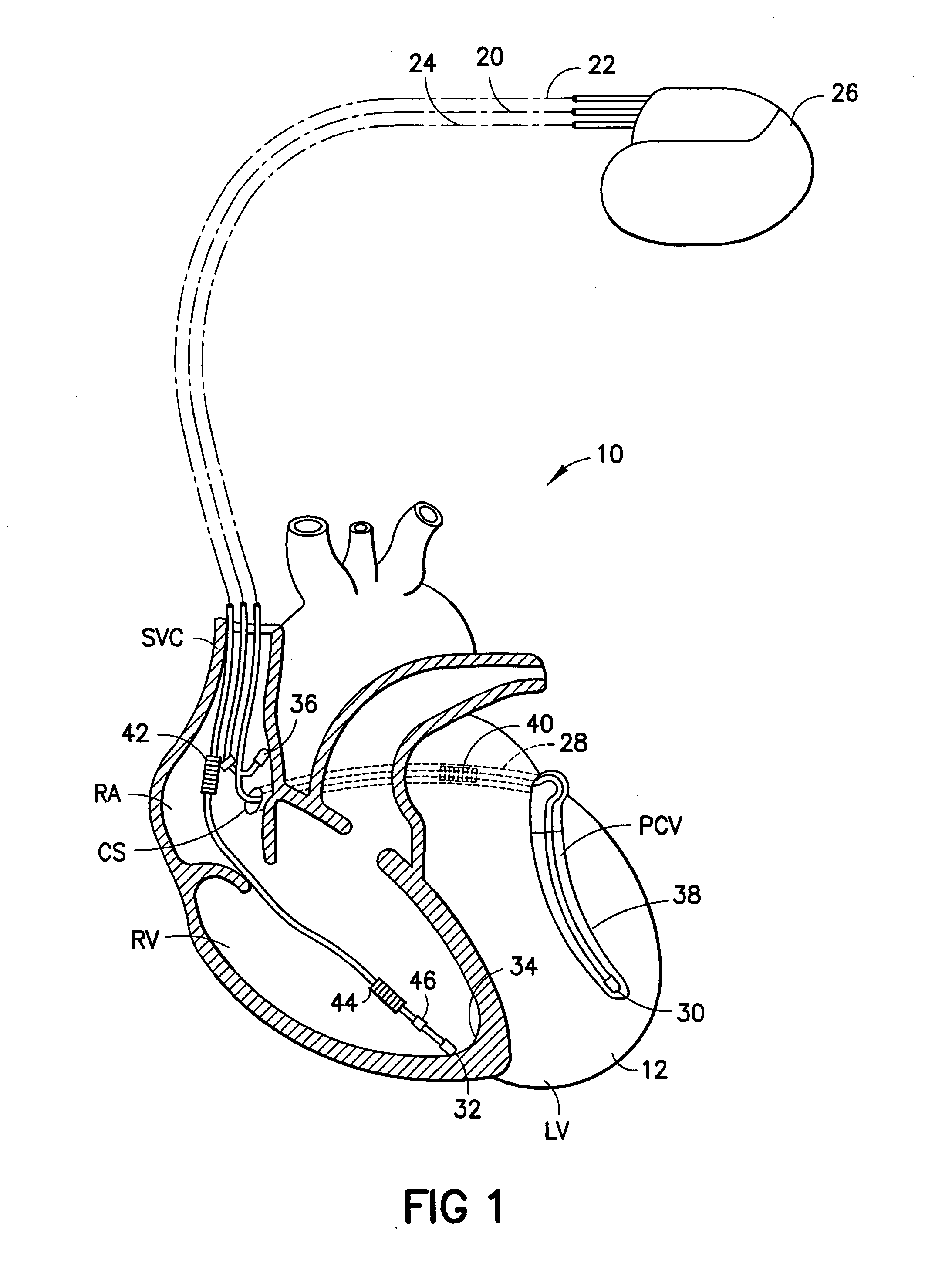

Implantable coronary sinus lead and lead system

InactiveUS6968237B2Increase flexibilitySmall diameterTransvascular endocardial electrodesExternal electrodesElectrical conductorCoronary sinus

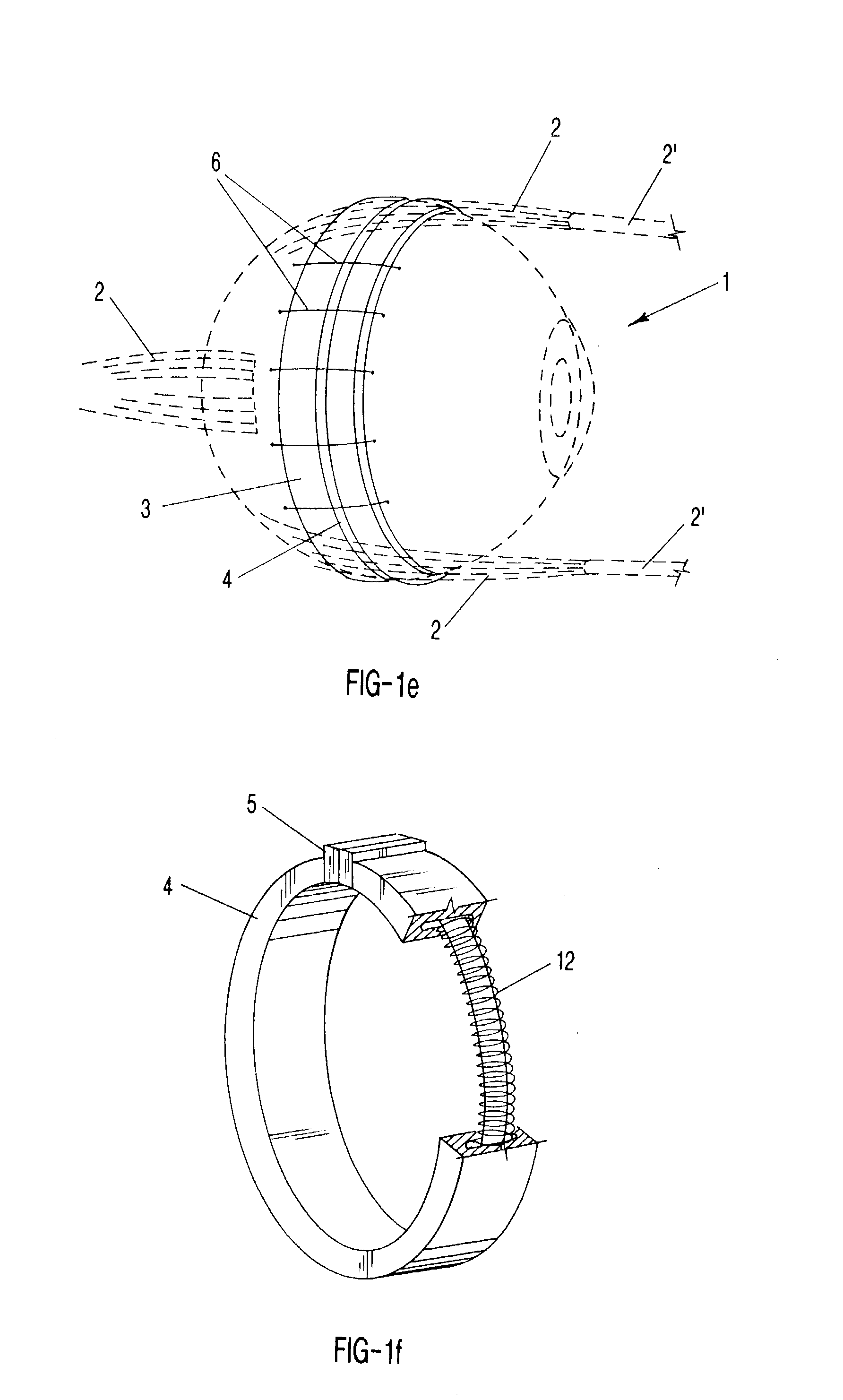

An implantable stimulation lead is disclosed for placement in the coronary sinus region and its associated coronary vessels overlying the left side of a patient's heart. The lead comprises at least one proximal connector; at least one tissue stimulation electrode; at least one conductor coupled between the at least one proximal connector and the at least one stimulation electrode; and a lead body including a housing of insulating material enclosing the at least one conductor, the lead body having a relatively flexible distal portion of, for example, silicone rubber, having a length corresponding to the coronary sinus region of the heart, and a stiffer proximal portion of, for example, polyurethane. A robust transition joint comprising telescoped sections of the distal and proximal portions of the lead body couples the two portions of the lead body.Also provided is a versatile lead delivery system including a stylet stop disposed within the distal portion of the lead body. The stylet stop defines an aperture dimensioned to pass a guide wire but not the enlarged distal tip of a stylet. The lead includes a tip electrode having a longitudinally extending bore dimensioned to permit passage of the guide wire through the tip electrode.

Owner:PACESETTER INC

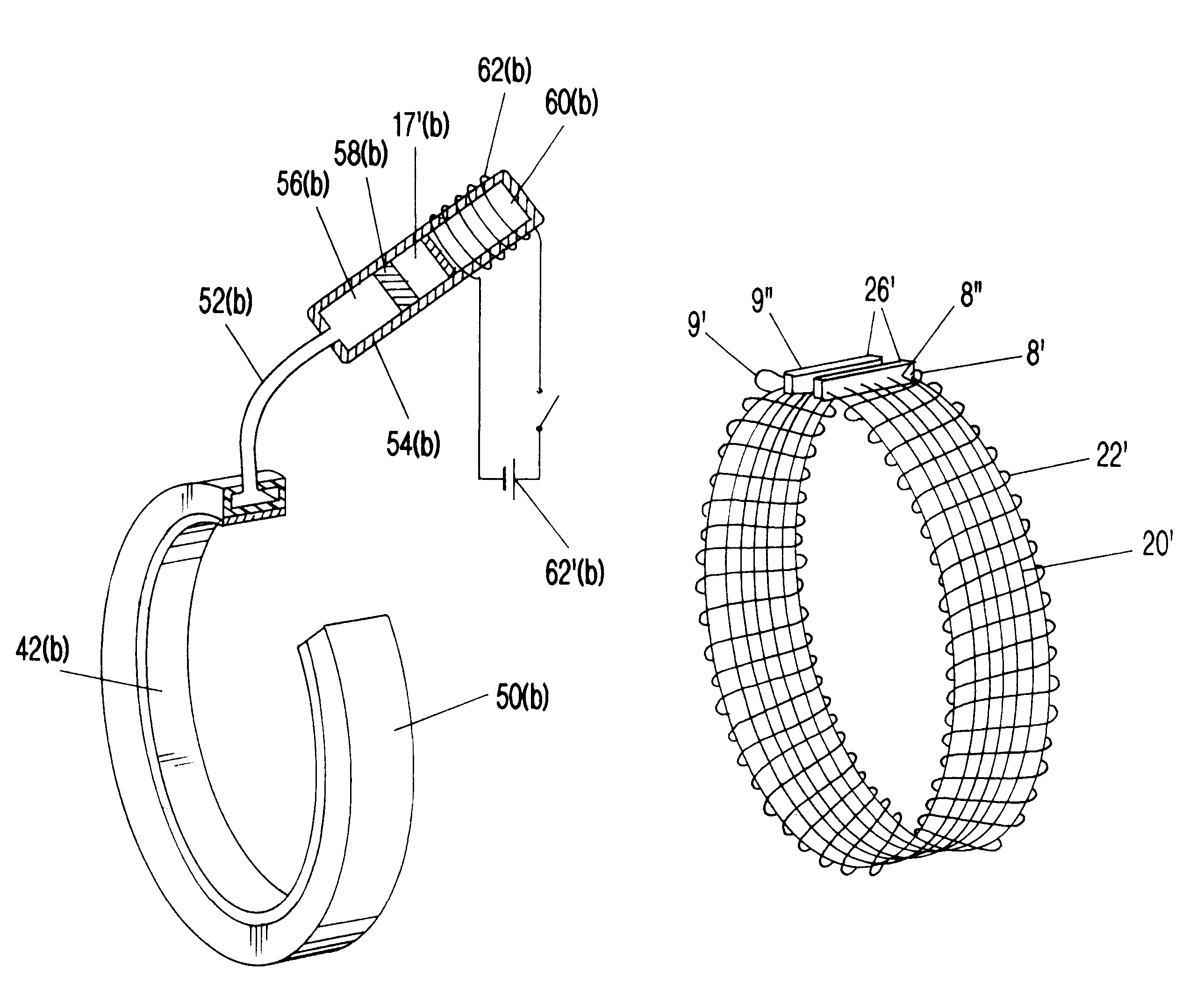

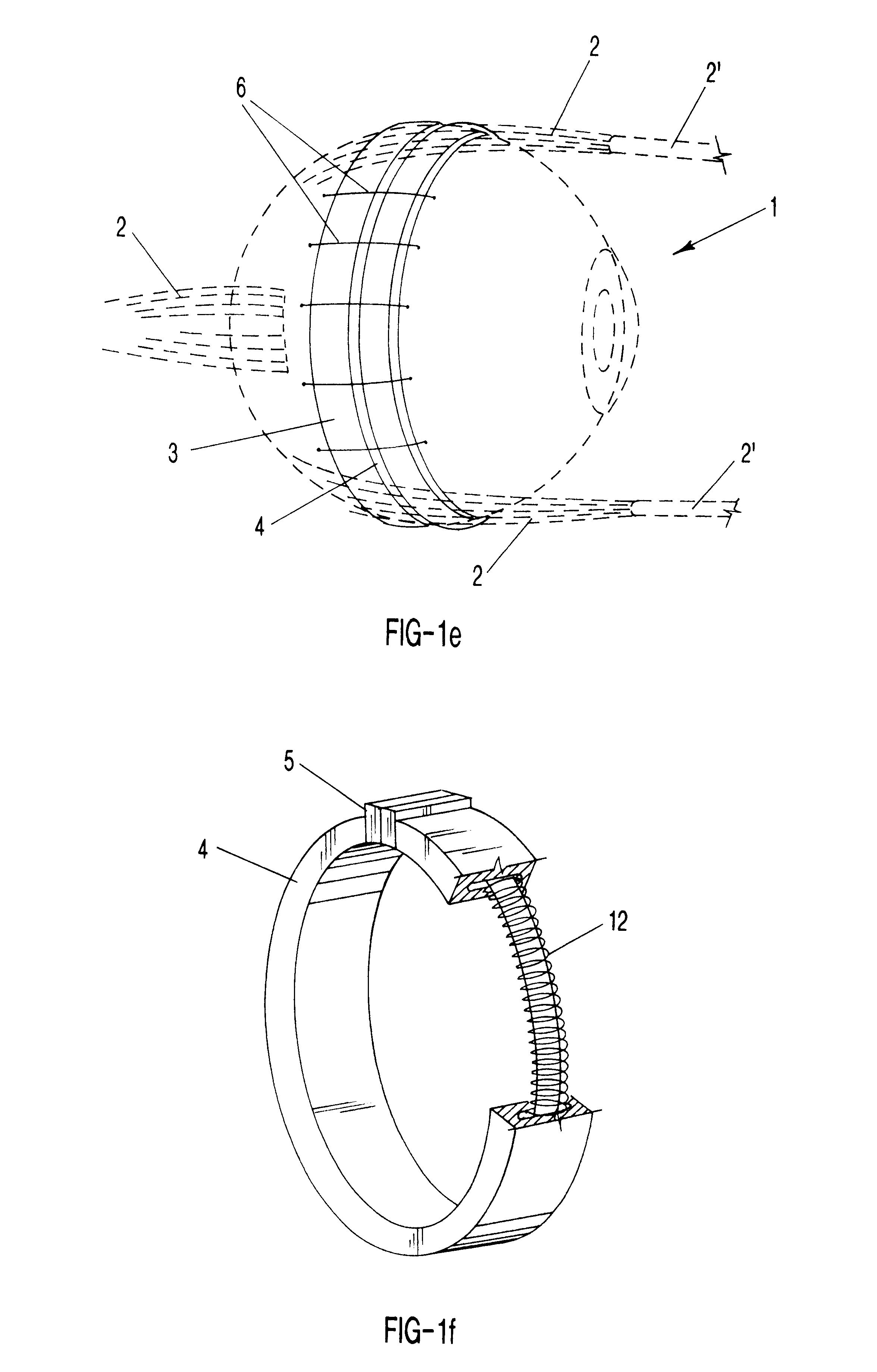

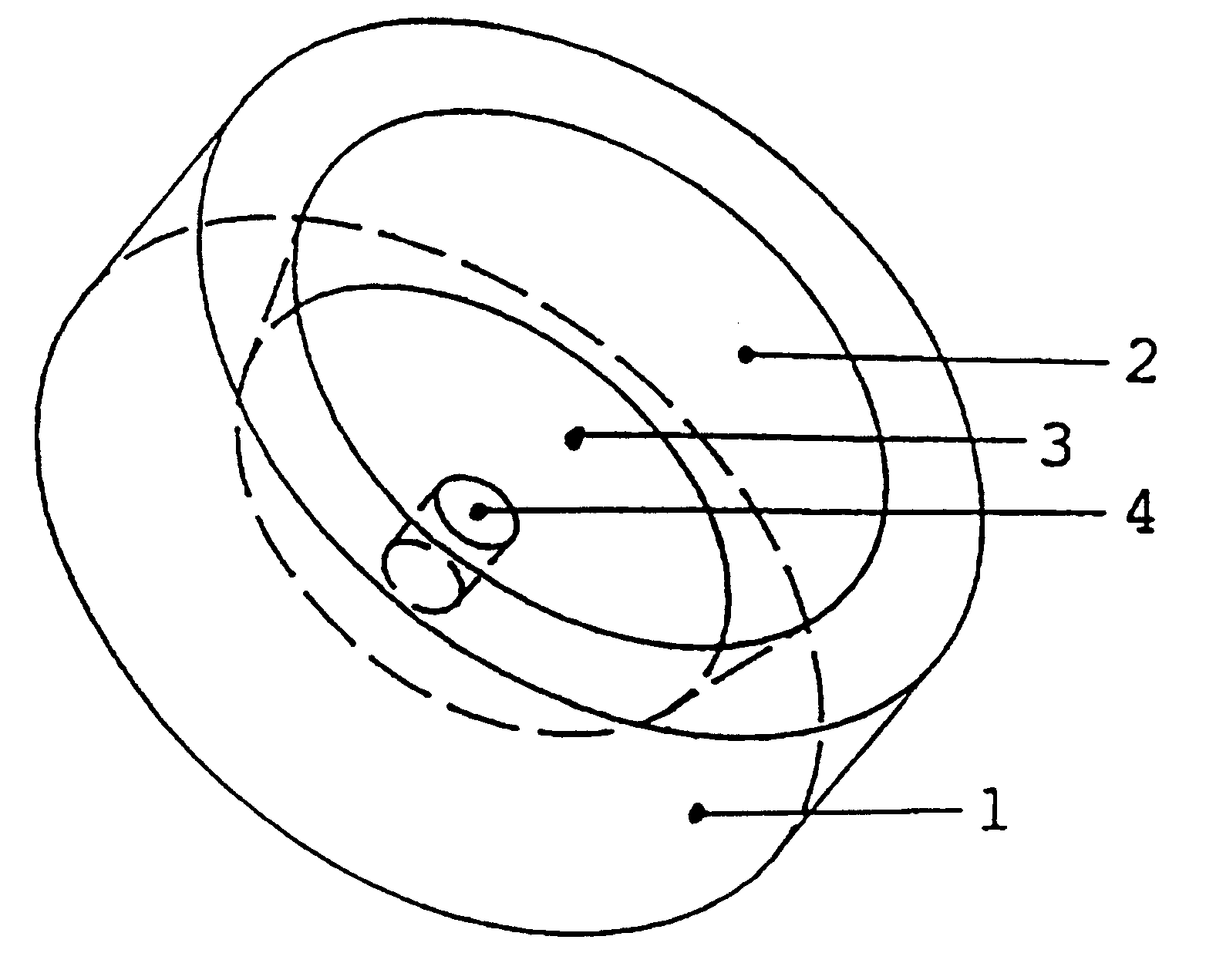

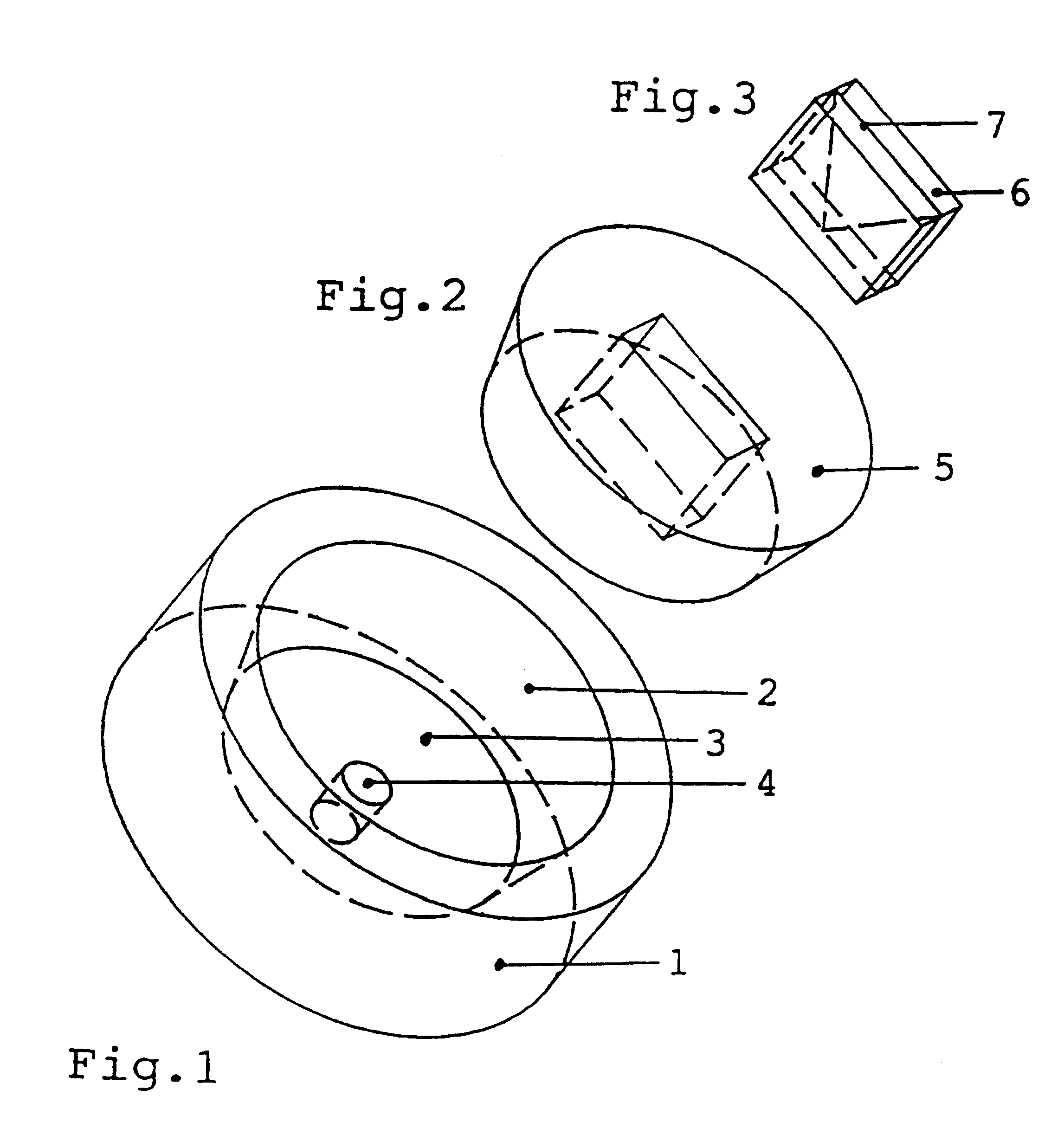

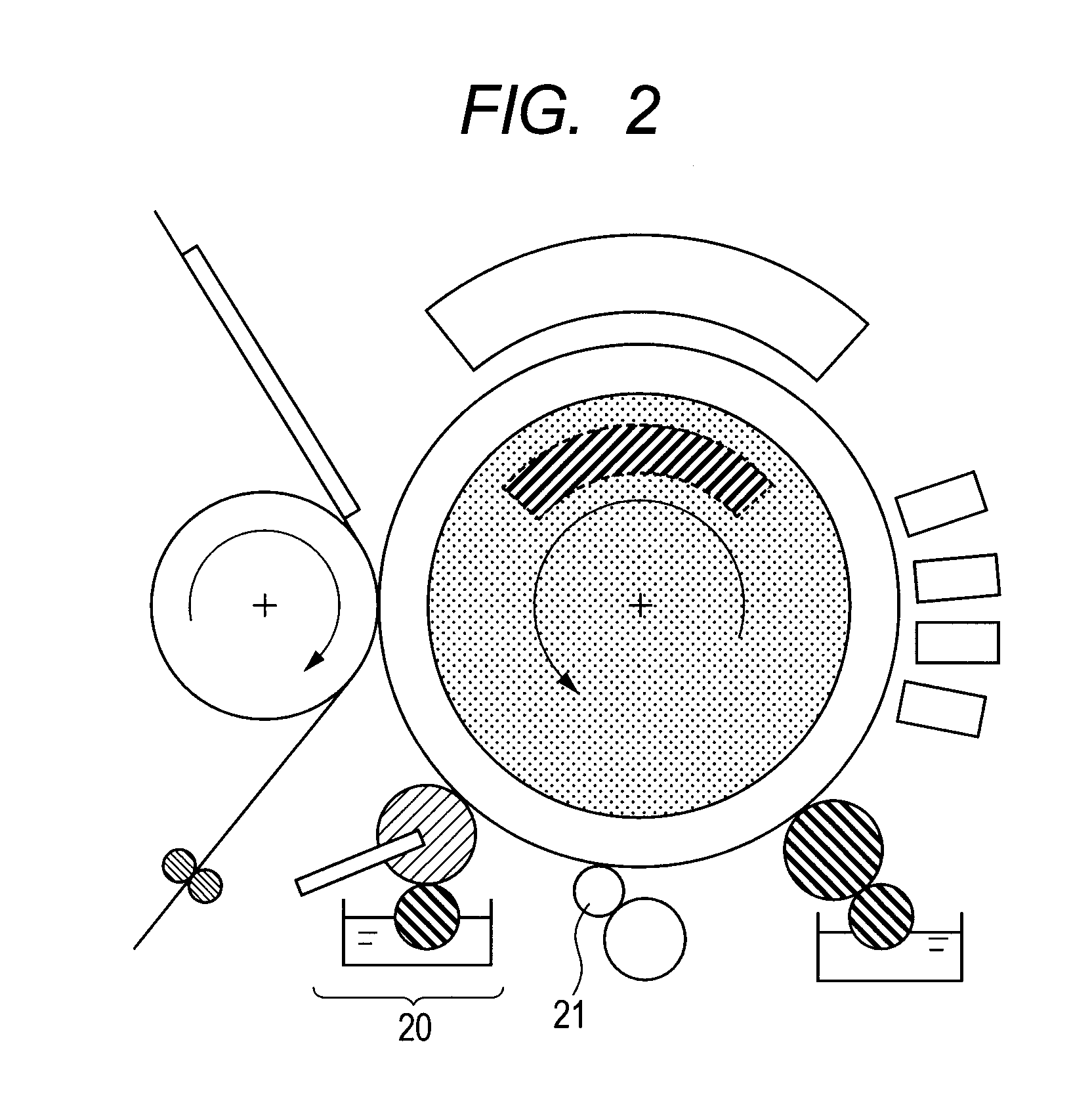

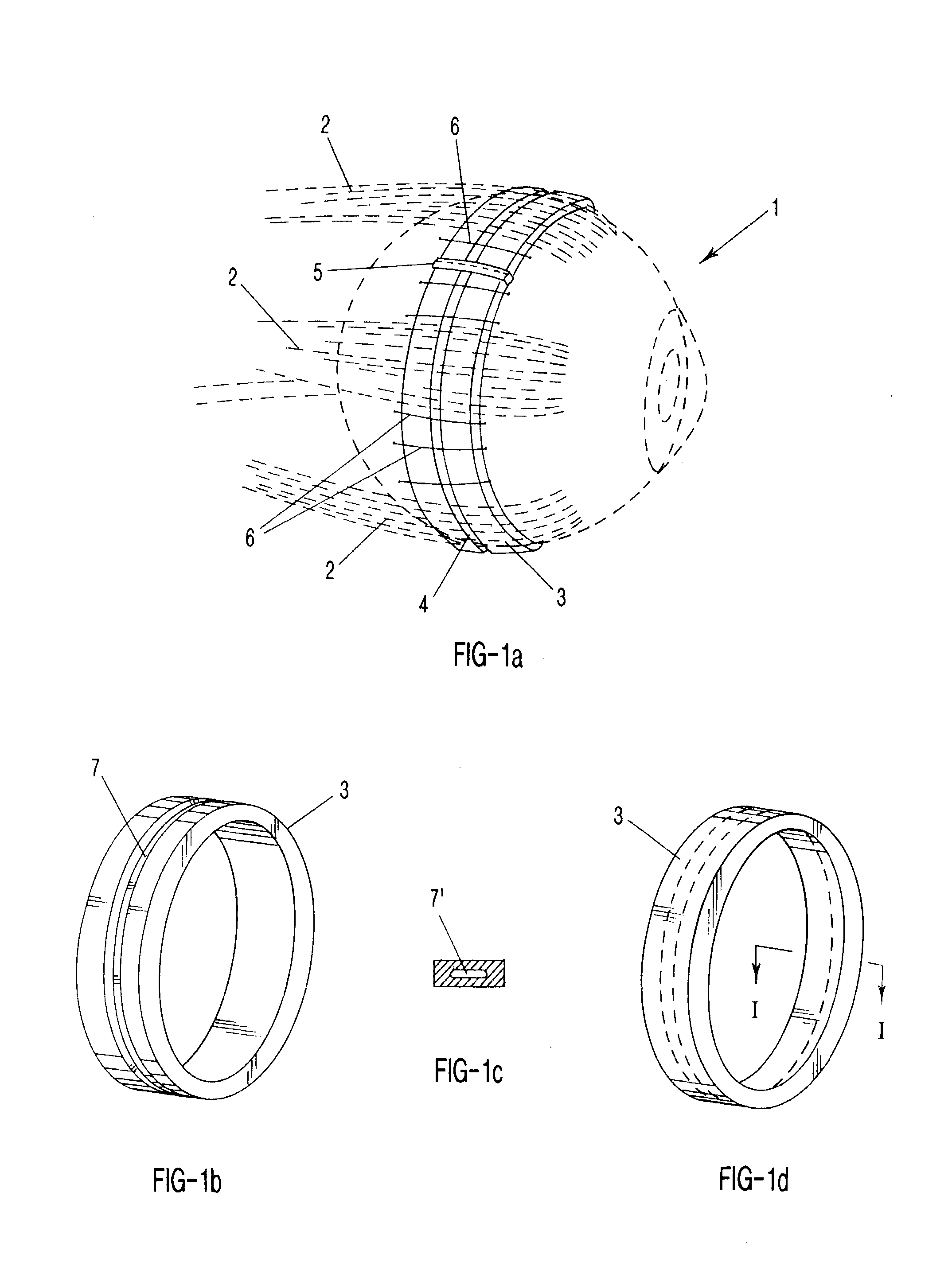

Surgical correction of human eye refractive errors by active composite artificial muscle implants

Surgical correction of human eye refractive errors such as presbyopia, hyperopia, myopia, and stigmatism by using transcutaneously inductively energized artificial muscle implants to either actively change the axial length and the anterior curvatures of the eye globe. This brings the retina / macula region to coincide with the focal point. The implants use transcutaneously inductively energized scleral constrictor bands equipped with composite artificial muscle structures. The implants can induce enough accommodation of a few diopters, to correct presbyopia, hyperopia, and myopia on demand. In the preferred embodiment, the implant comprises an active sphinctering smart band to encircle the sclera, preferably implanted under the conjunctiva and under the extraocular muscles to uniformly constrict the eye globe, similar to a scleral buckle band for surgical correction of retinal detachment, to induce active temporary myopia (hyperopia) by increasing (decreasing) the active length of the globe. In another embodiment, multiple and specially designed constrictor bands can be used to enable surgeons to correct stigmatism. The composite artificial muscles are either resilient composite shaped memory alloy-silicone rubber implants in the form of endless active scleral bands, electroactive ionic polymeric artificial muscle structures, electrochemically contractile endless bands of ionic polymers such as polyacrylonitrile (PAN), thermally contractile liquid crystal elastomer artificial muscle structures, magnetically deployable structures or solenoids or other deployable structures equipped with smart materials such as preferably piezocerams, piezopolymers, electroactive and eletrostrictive polymers, magnetostrictive materials, and electro or magnetorheological materials.

Owner:ENVIRONMENTAL ROBOTS

Silane copolymer coatings

InactiveUS6908681B2Maintain good propertiesImprove adhesionMale contraceptivesSurgerySilanesMedical device

Owner:CR BARD INC

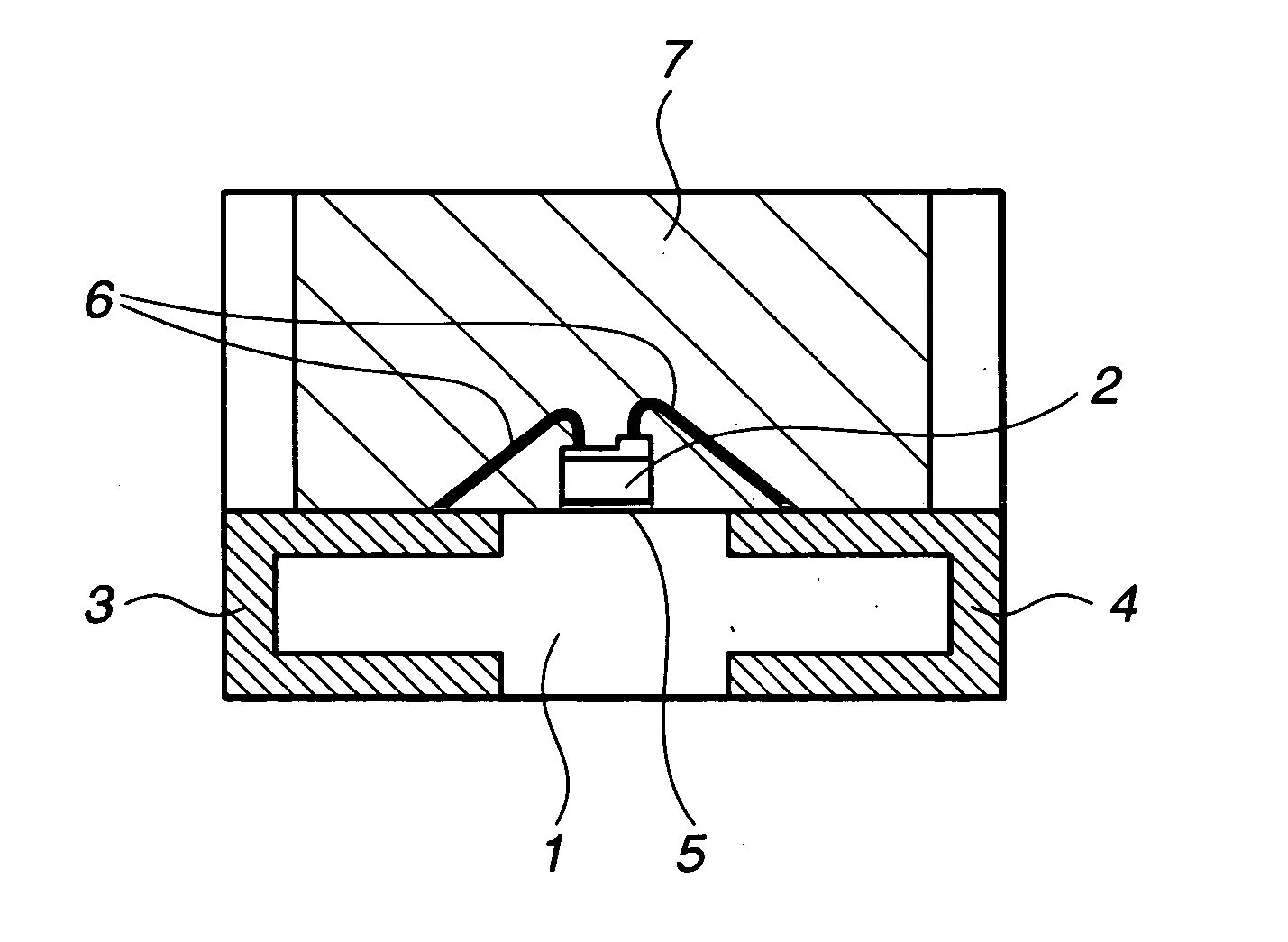

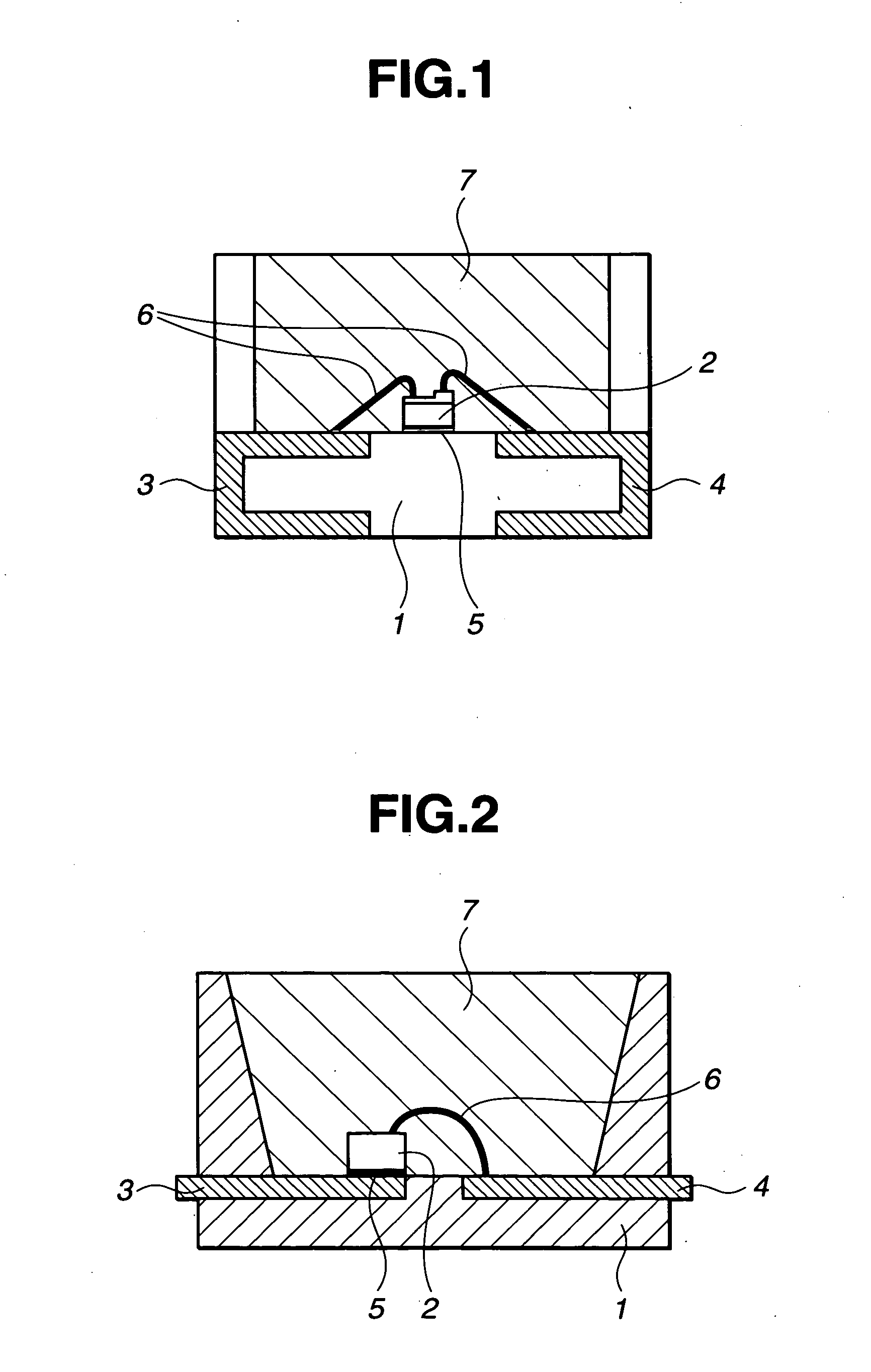

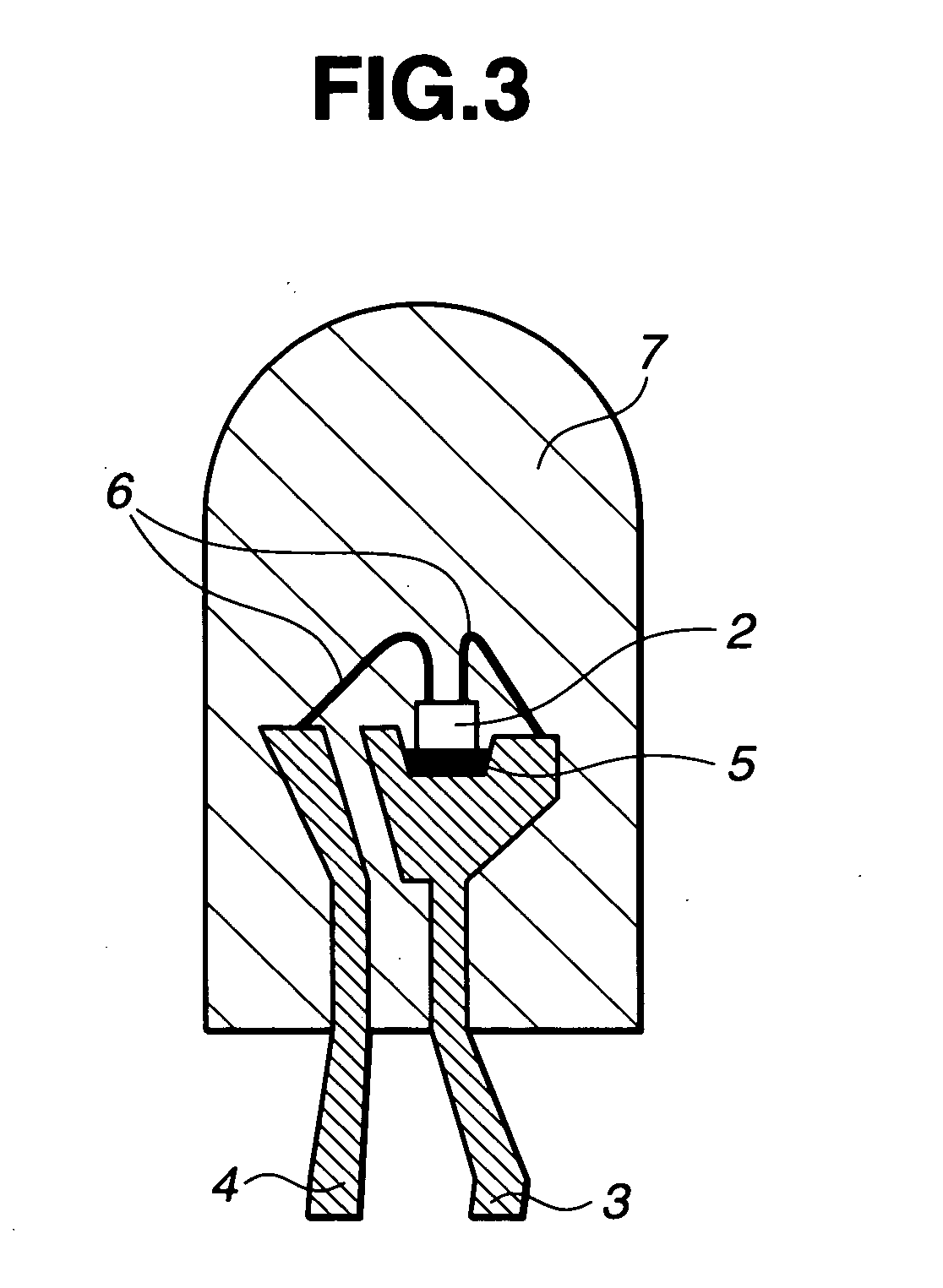

Silicone rubber composition, light-emitting semiconductor embedding/protecting material and light-emitting semiconductor device

ActiveUS20050006794A1Eliminates surface tackSolve low adhesionSemiconductor/solid-state device detailsSolid-state devicesPolymer scienceDevice material

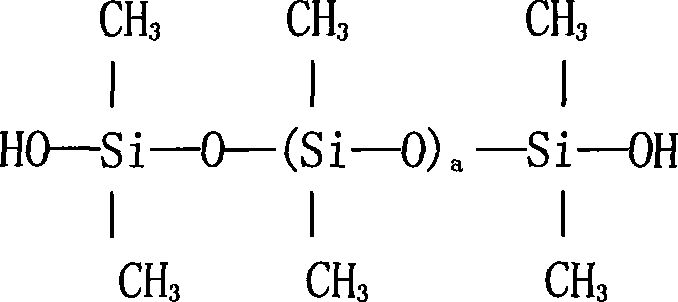

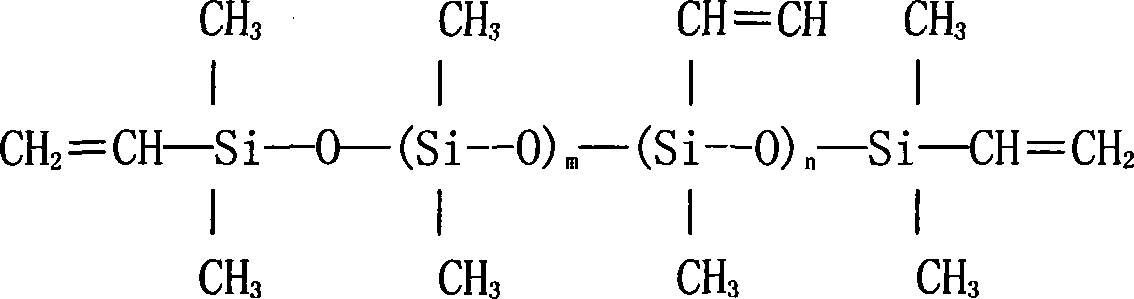

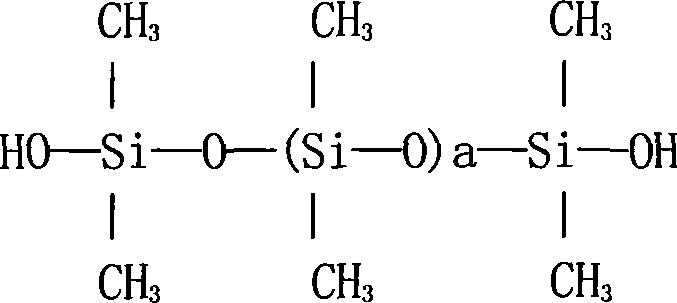

A silicone rubber composition comprising (A) an organopolysiloxane containing at least two aliphatic unsaturated bonds, (B) an organopolysiloxane of resin structure comprising SiO2 units, R3nR4pSiO0.5 units and R3qR4rSiO0.5 units wherein R3 is vinyl or allyl, R4 is a monovalent hydrocarbon group free of aliphatic unsaturation, n is 2 or 3, p is 0 or 1, n+p=3, q is 0 or 1, r is 2 or 3, q+r=3, (C) an organohydrogenpolysiloxane having at least two SiH groups, and (D) a platinum catalyst cures into a silicone rubber having excellent rubbery and strength properties and little surface tack.

Owner:SHIN ETSU CHEM IND CO LTD

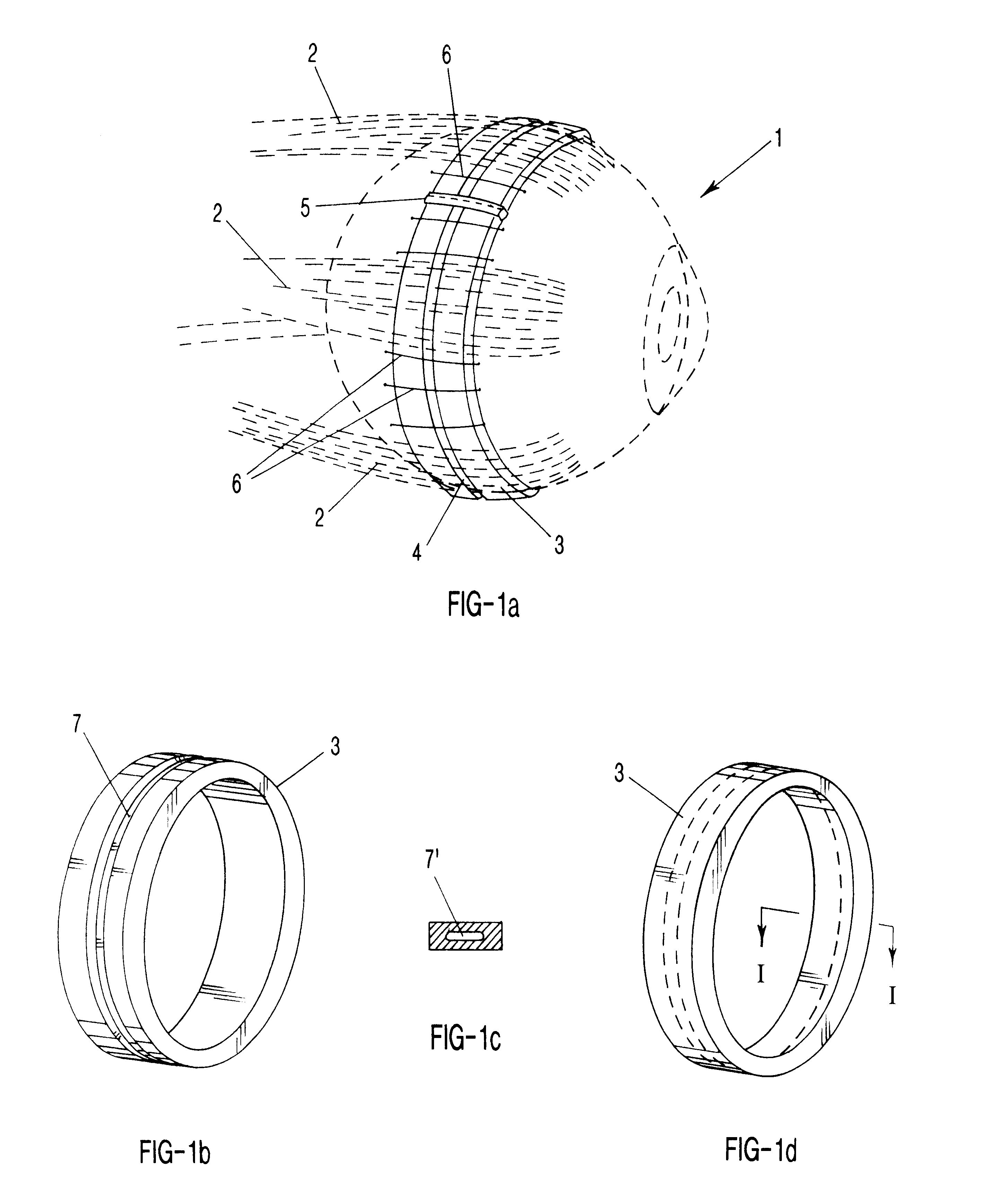

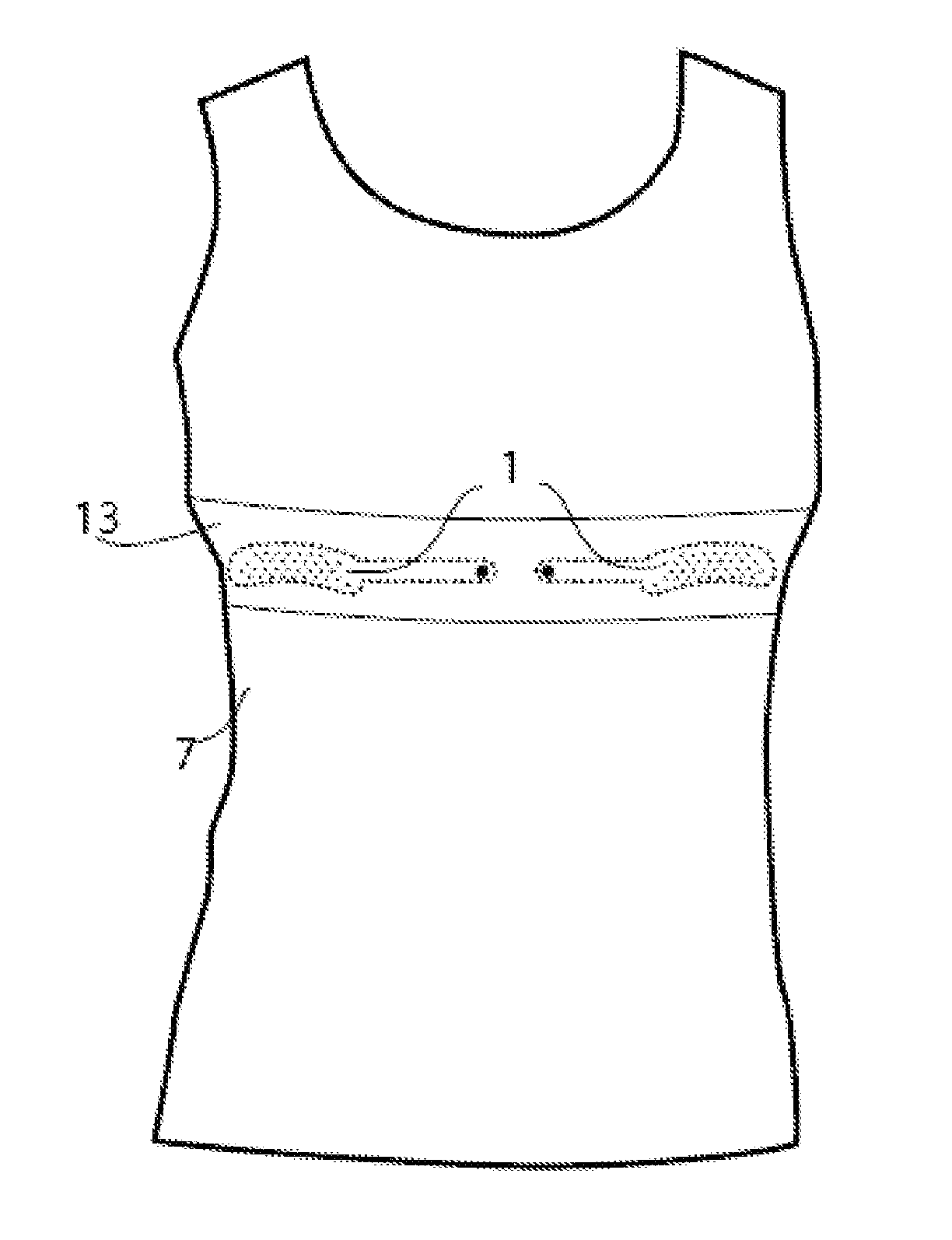

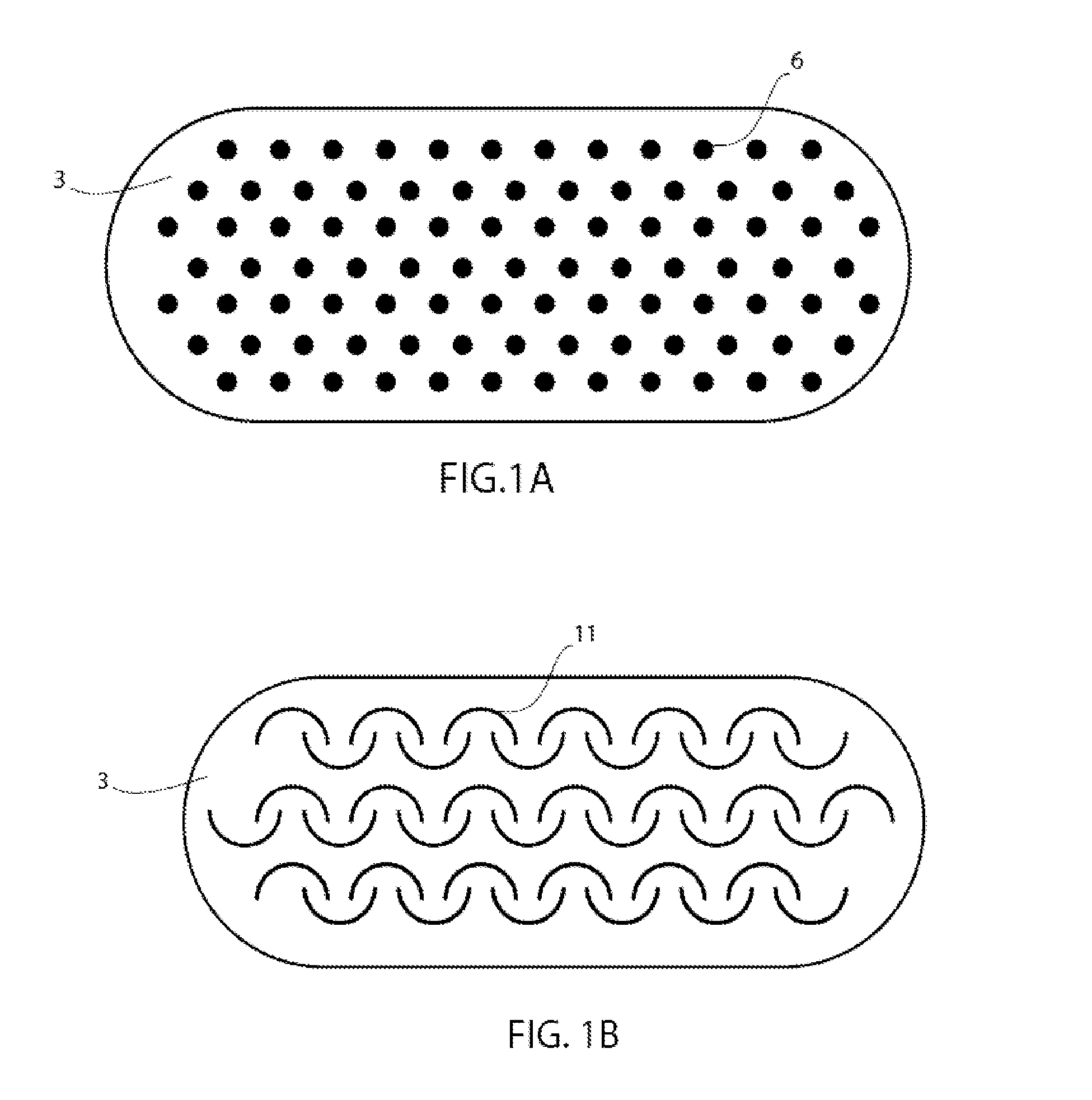

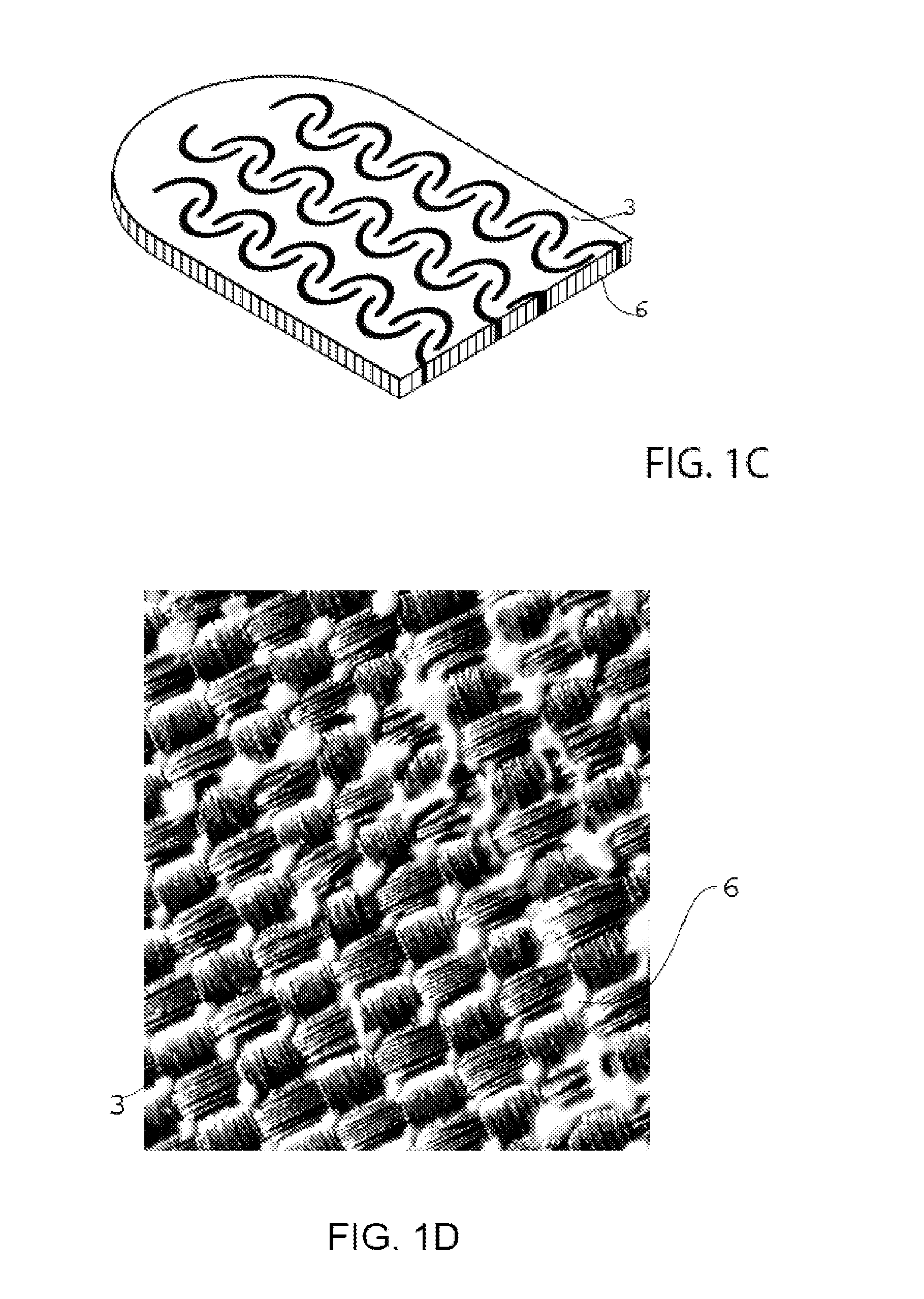

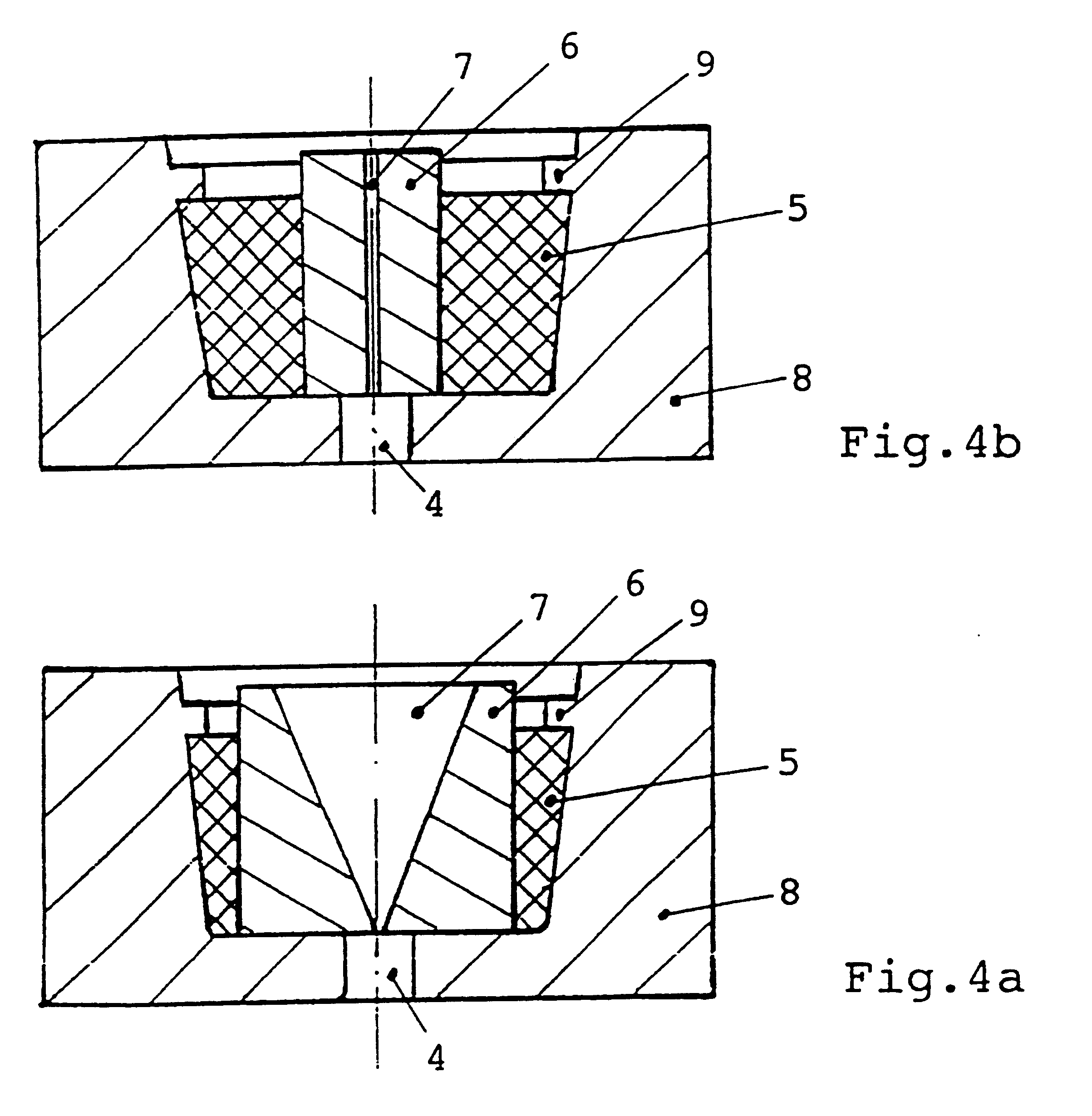

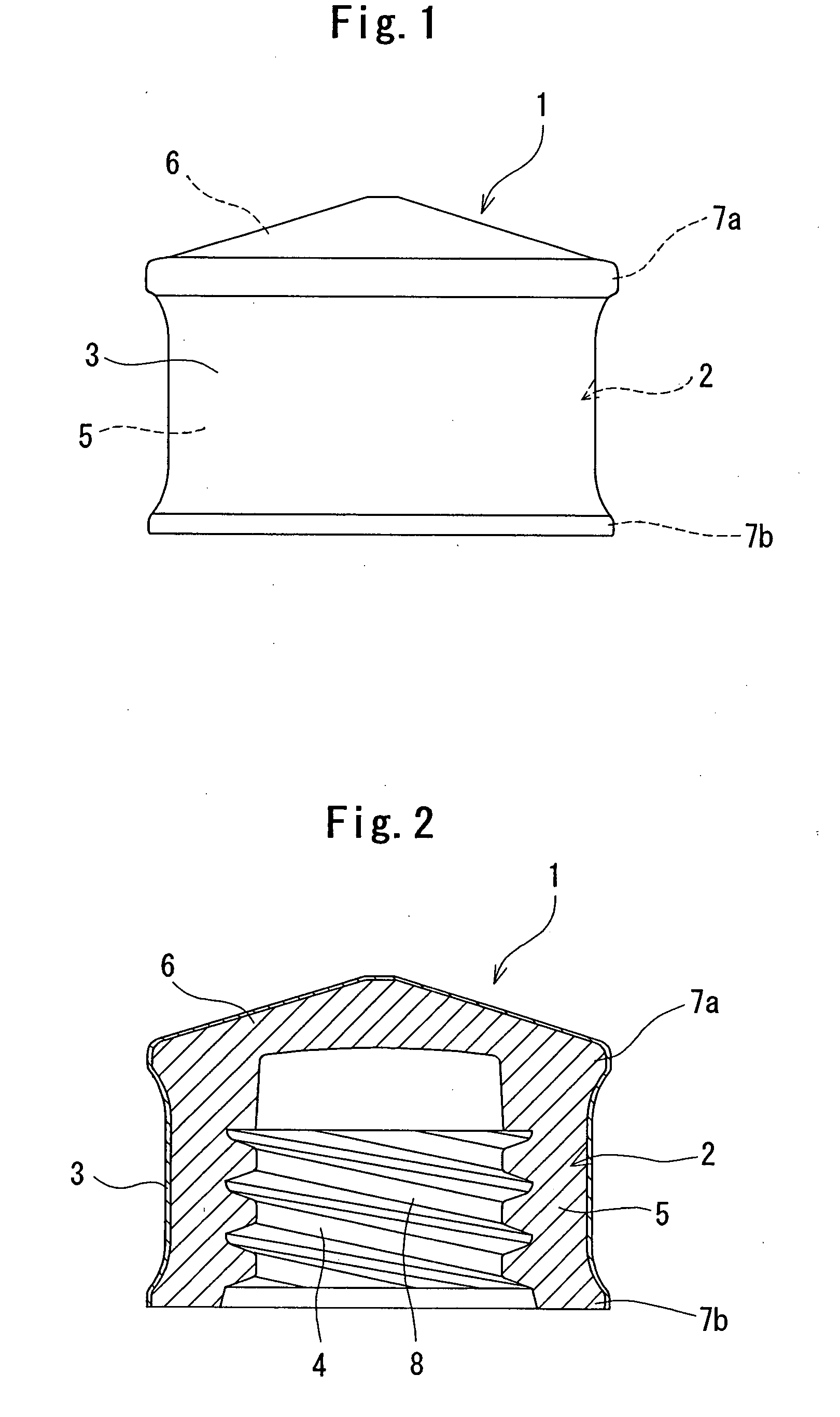

Sensor for Acquiring Physiological Signals

ActiveUS20130225966A1Improve skid resistanceGood flexibilityElectrocardiographySensorsEngineeringSilicone rubber

The present invention relates to a sensor 1 for acquiring physiological signals with improved silicone rubber in particular when the sensor 1 is included in a garment 7 and the person who wears the garment 7 is in high level activity, the invention furthermore relates to a device comprising the sensor, as well as garments 7 comprising the device.

Owner:SMART SOLUTIONS TECH

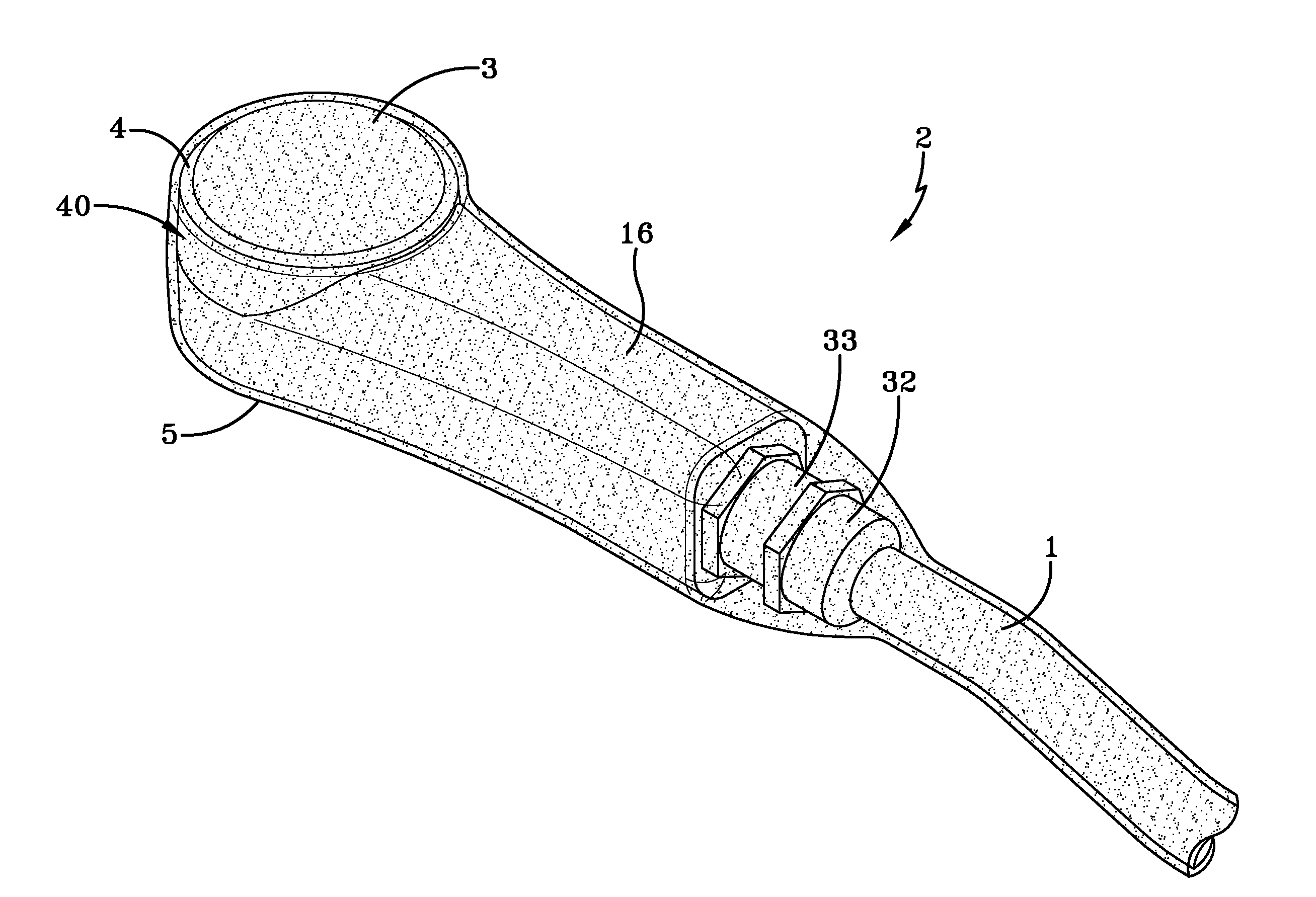

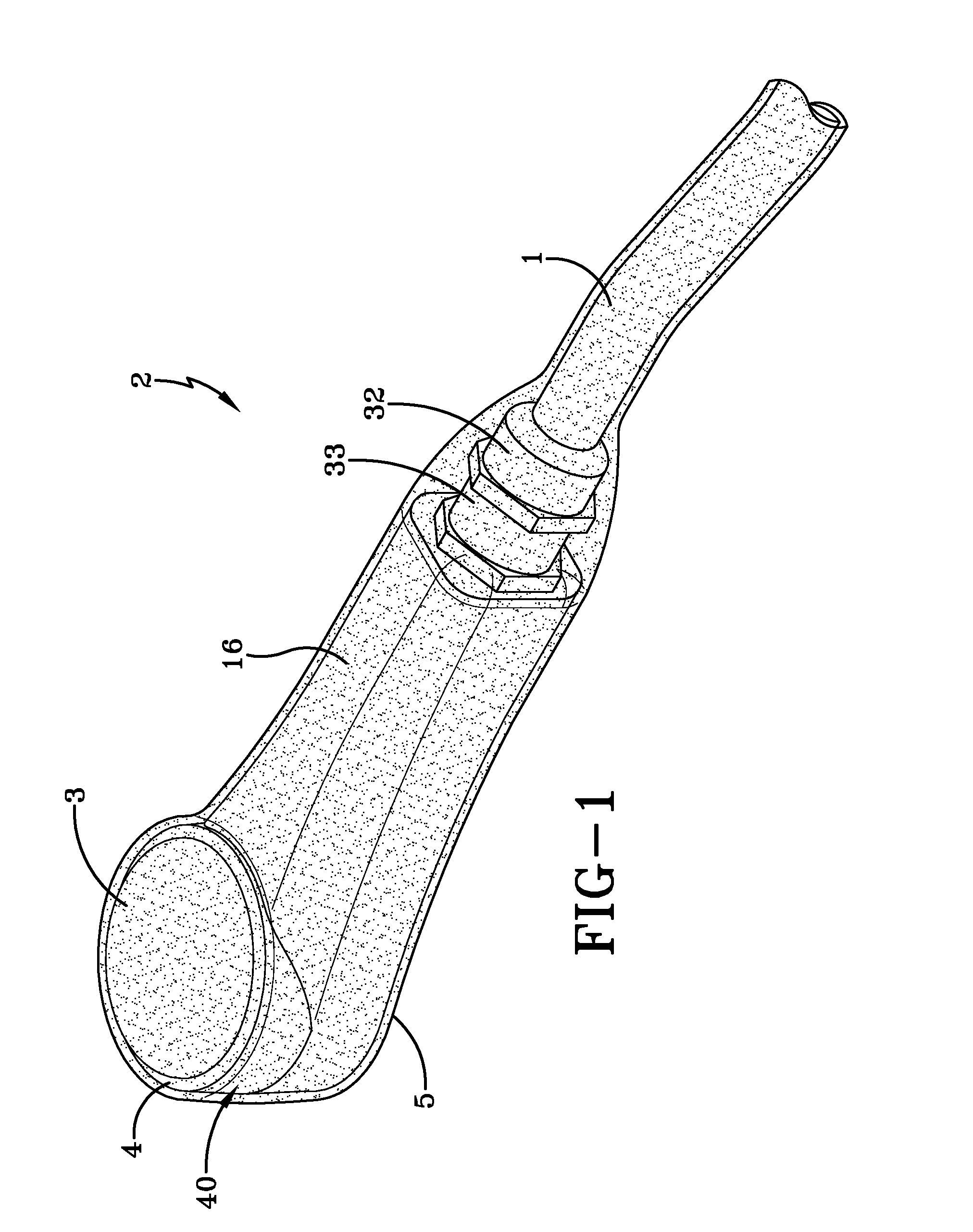

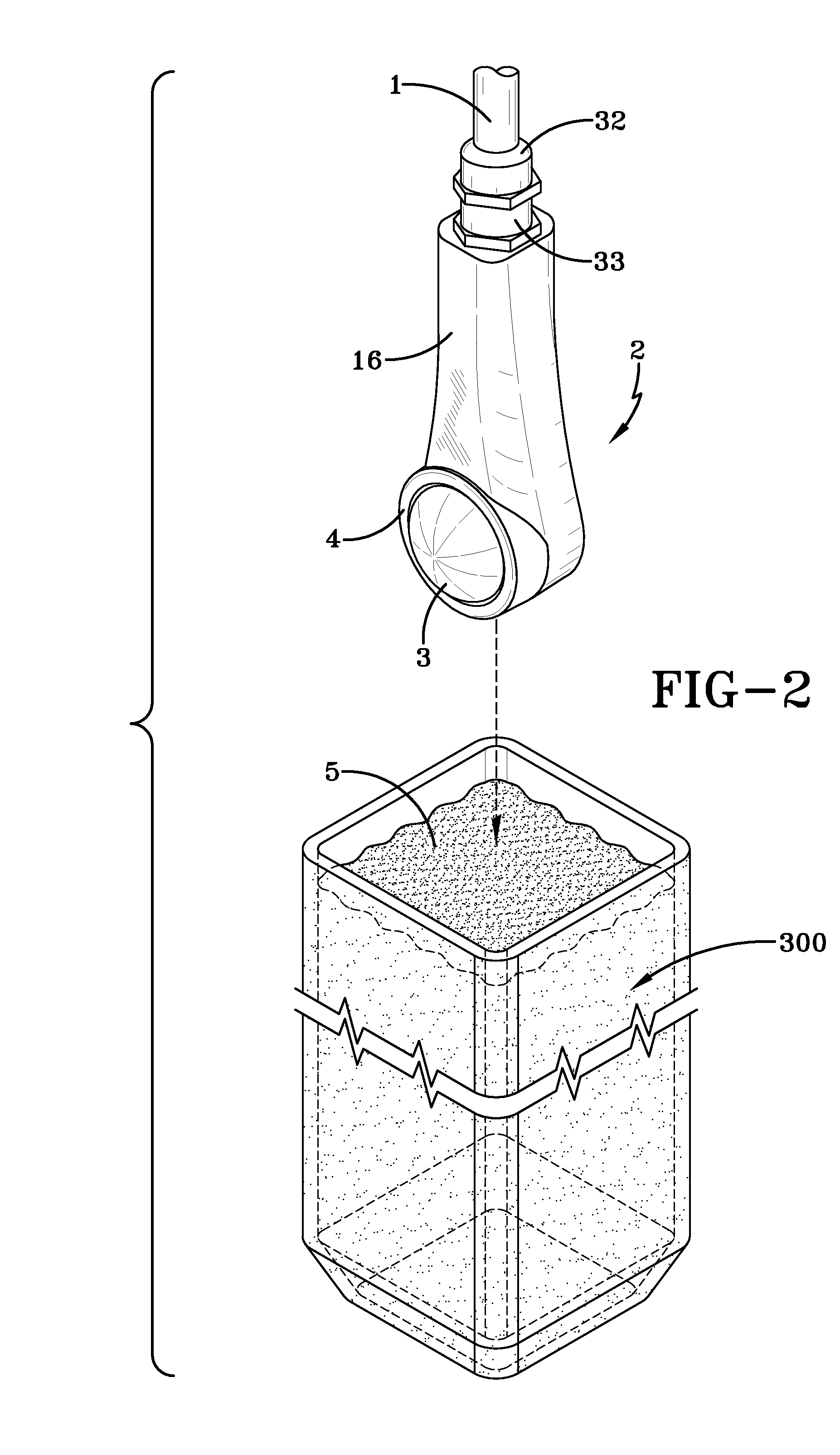

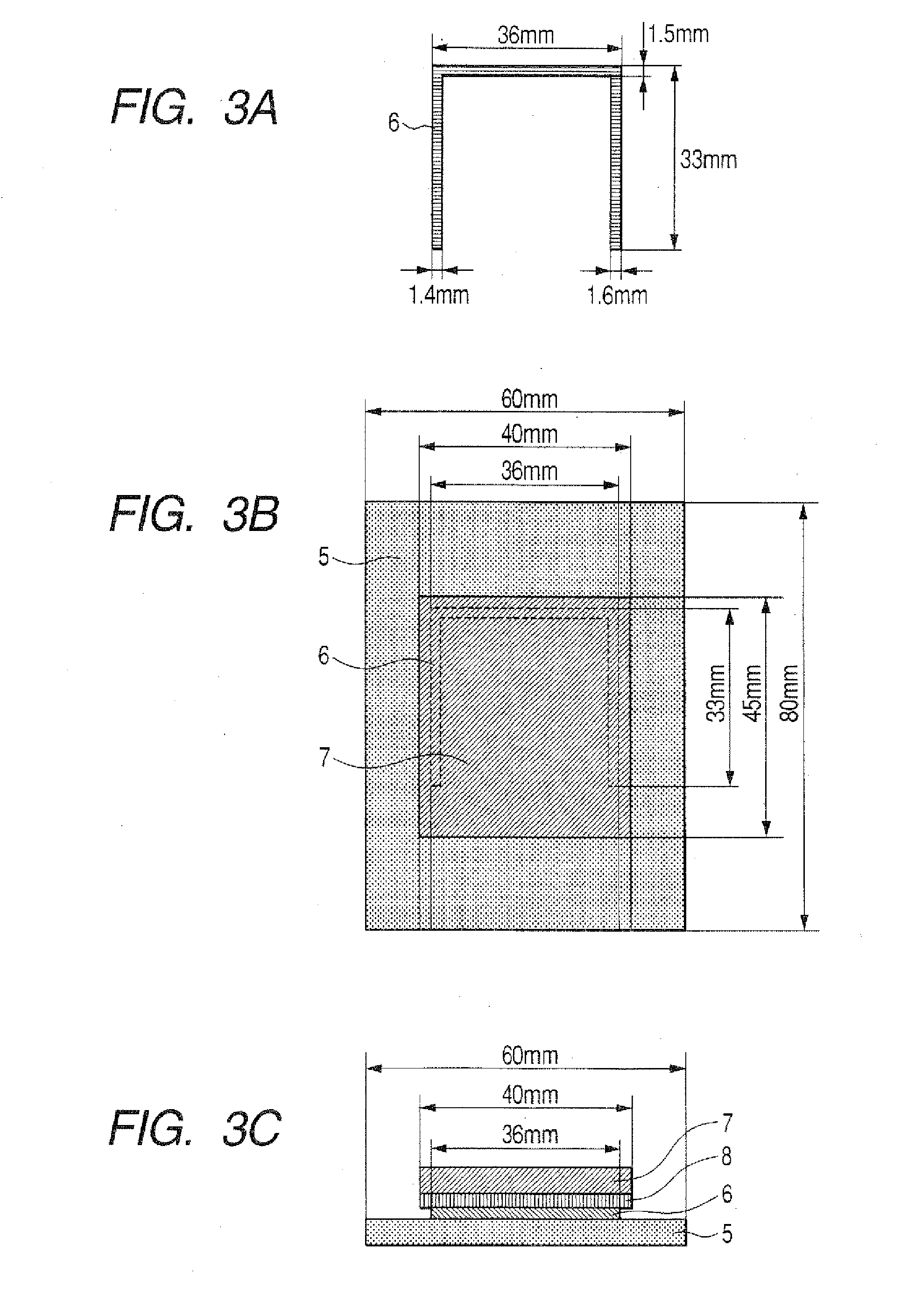

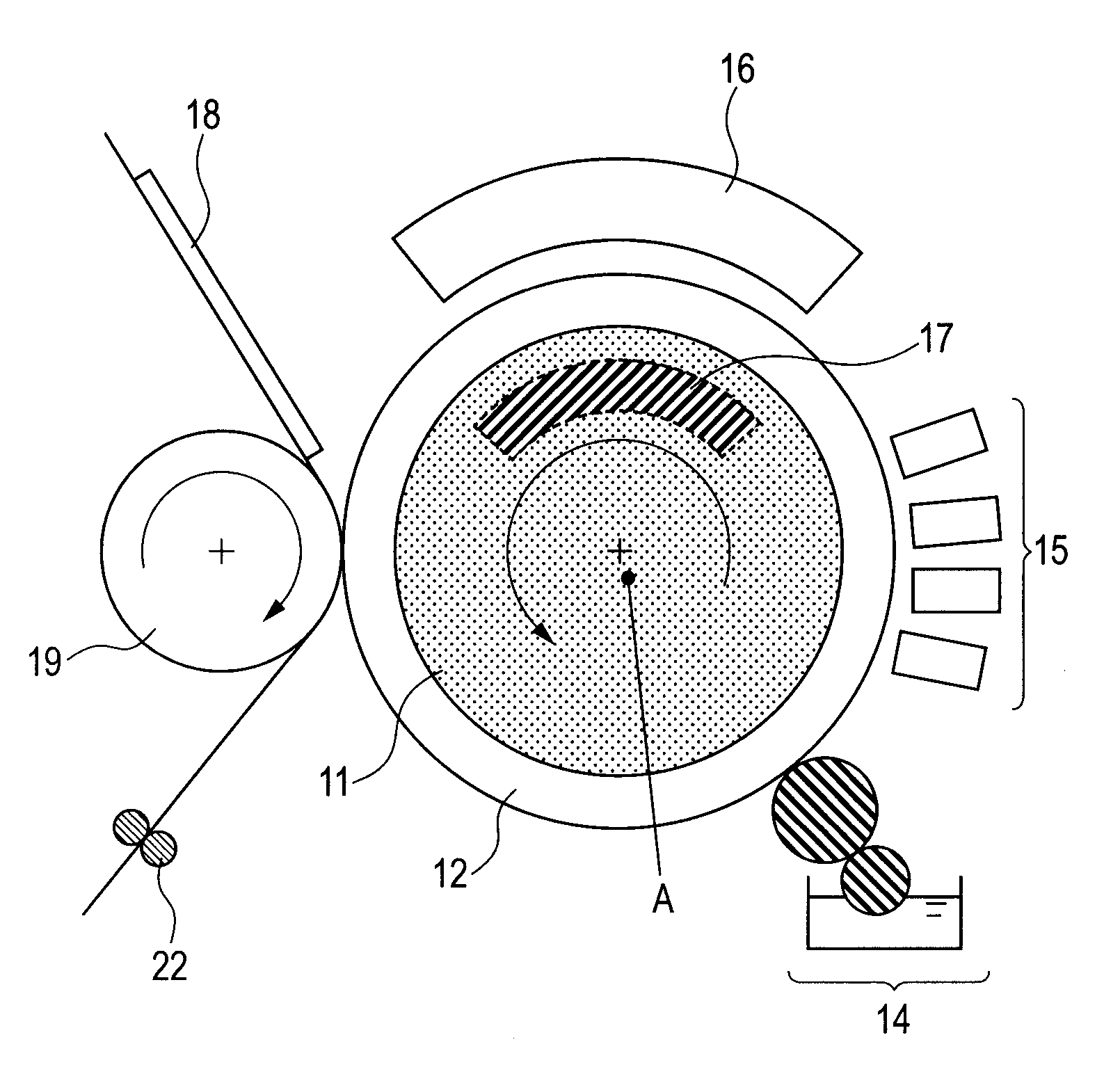

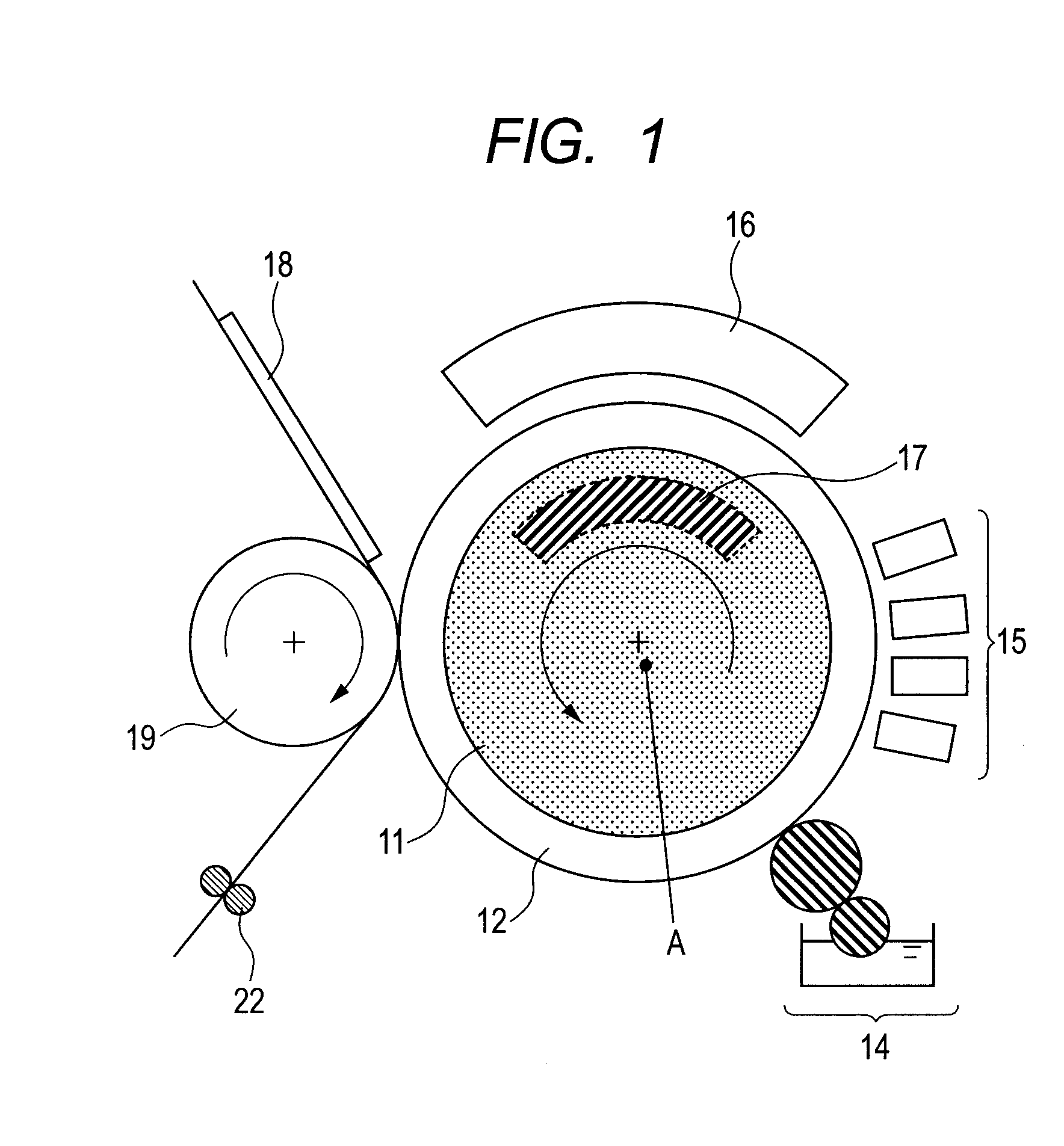

Shock Wave Treatment Device

The system for treating an internal organ has a generator source for producing a shock wave connected to a handheld or small shock wave applicator device 2, wherein the external housing 16 of the device 2 is hermetically sealed in a non-electrically conductive insulating skin membrane 5 being of a polymer material, preferably a silicone rubber or polyurethane rubber. Preferably the entire device 2 including the connectors 32, 33 and at least a 20 cm portion of attached cable 1 is sealed using a dip coating process or alternatively can use an insert molding process wherein the device 2 is placed in a mold 400 and the skin membrane 5 is injection molded around the entire housing 16 and the cable 1 has an outer skin 5 that abuttingly seals at a connection 32, 33 to the housing 16. The device 2 may further include an internal vacuum conduit connected to a vacuum system to detect leakages and in use may be used with a sterile sleeve cover with a similar vacuum system for leakage detection.

Owner:TISSUE REGENERATION TECH

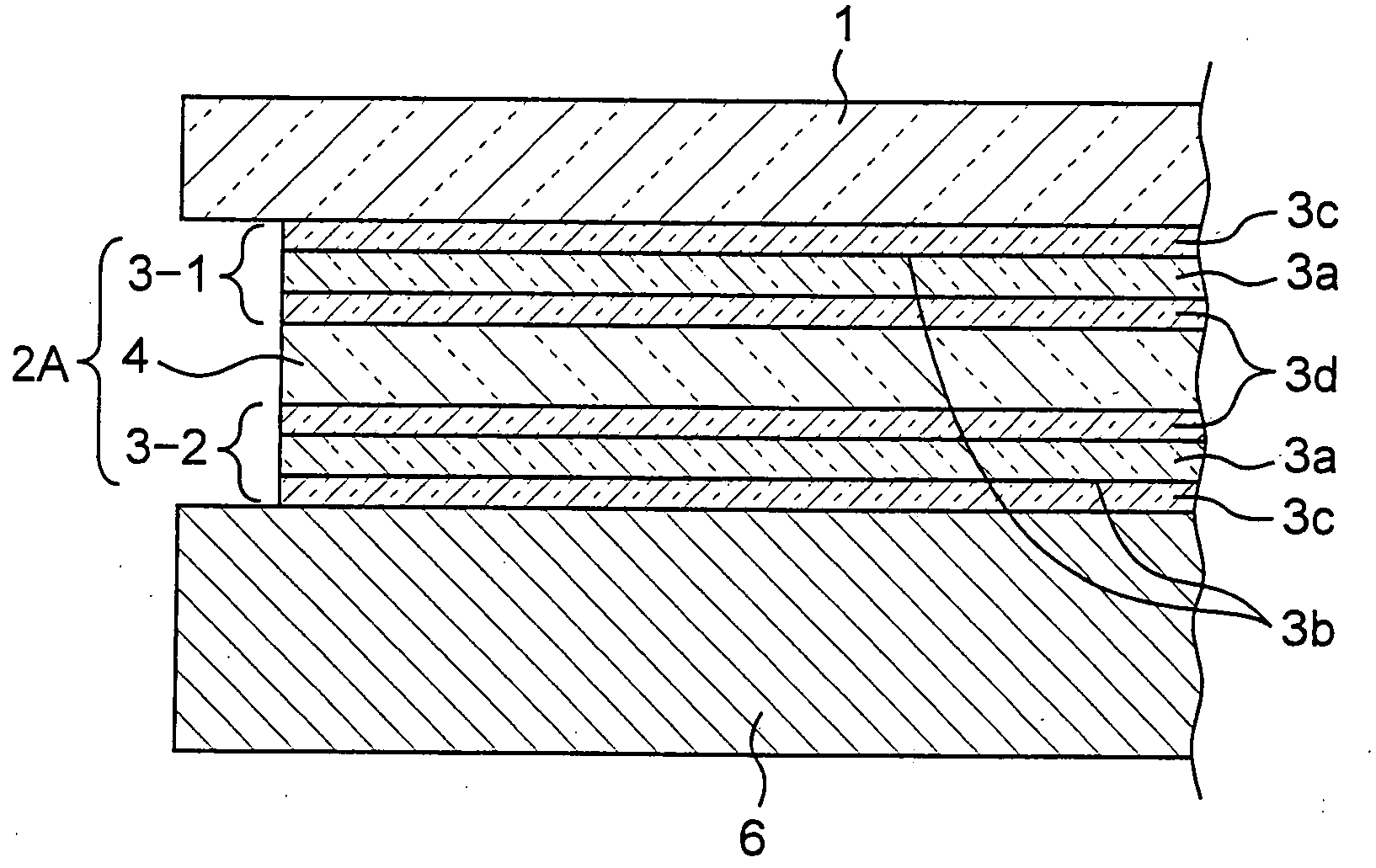

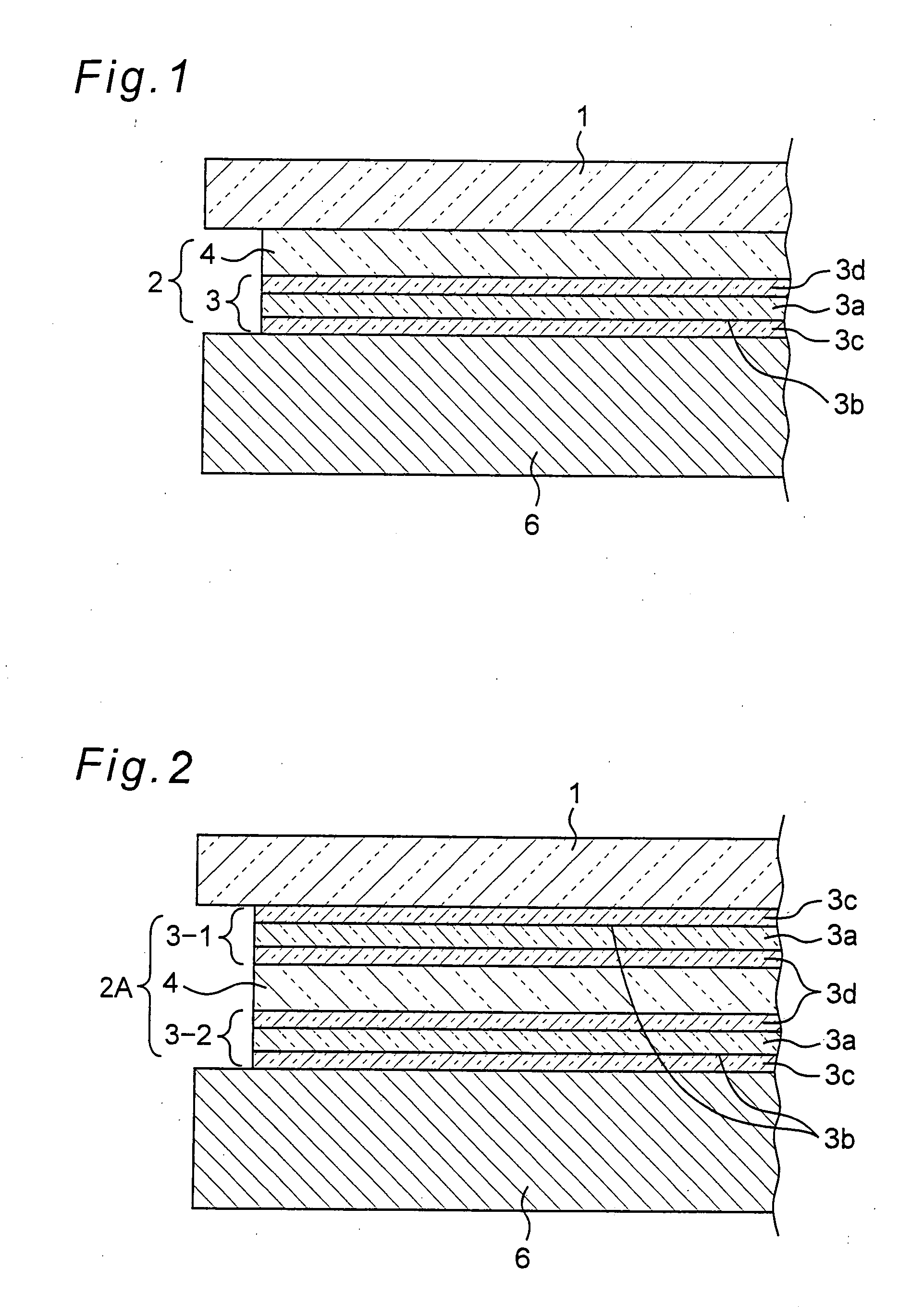

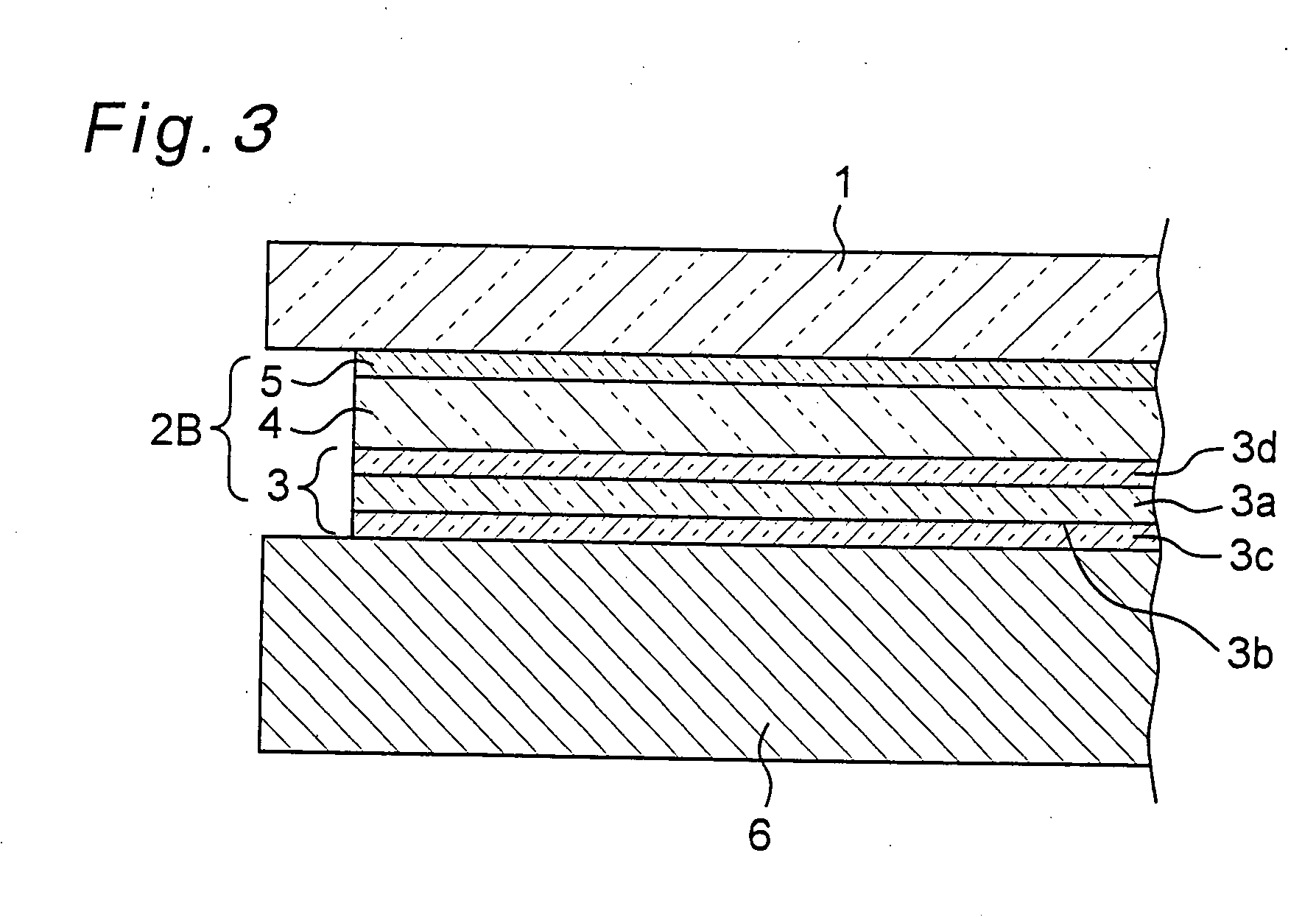

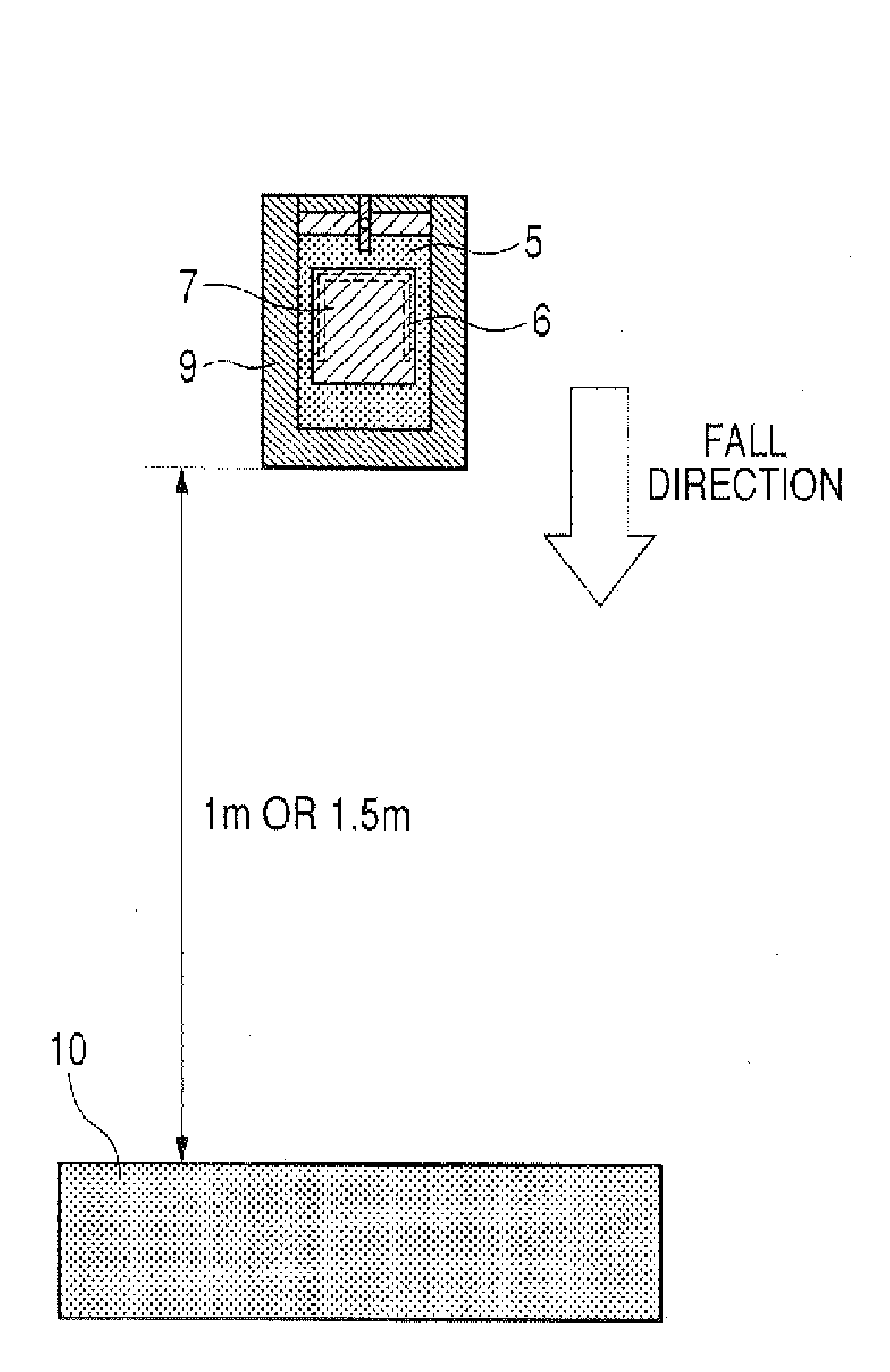

Mounting structure of re-peelable protective panel and mounting sheet using the same

InactiveUS20090087655A1Improve buffering effectAvoid elevationDetails for portable computersElectrical equipmentDisplay deviceEngineering

A transparent mounting sheet has a structure in which a one-sided re-peelable sheet, provided with a core member of a plastic film, a silicone rubber sheet that is laminated on a primer treated surface formed by one surface of the core member having been subjected to a primer treatment, and an acrylic adhesive agent layer that is laminated on the other surface of the core member, is bonded to at least one of surfaces of a gel sheet by the acrylic adhesive agent layer, and this transparent mounting sheet is used so that a protective panel for an electronic apparatus display window is mounted on a surface of a display in a manner so as to be re-peelable.

Owner:NISSHA PRINTING COMPANY

Device for mounting a component exposed to a pressurized fluid

The mounting of a component subjected to pressure from a fluid requires special precautions if the component is made of wear resistant, hard and hence generally brittle material and may be destroyed by locally raised stresses. A fluidic component of this kind, made, for example, of silicon / glass is arranged in an elastomeric shaped component, made, for example, of silicon rubber. The inner contours of the elastomeric shaped component correspond to the outer contours of the fluidic component. The outer contours of the shaped component corresponds to the inner contours of a holder. Due to this "floating mounting" there are no unacceptable local pressure peaks and no deformation of the fluidic component. The device is particularly suitable for mounting a fluidic component made of glass or silicon, or miniature dimensions, subject to high pressure.

Owner:BOEHRINGER INGELHEIM INT GMBH

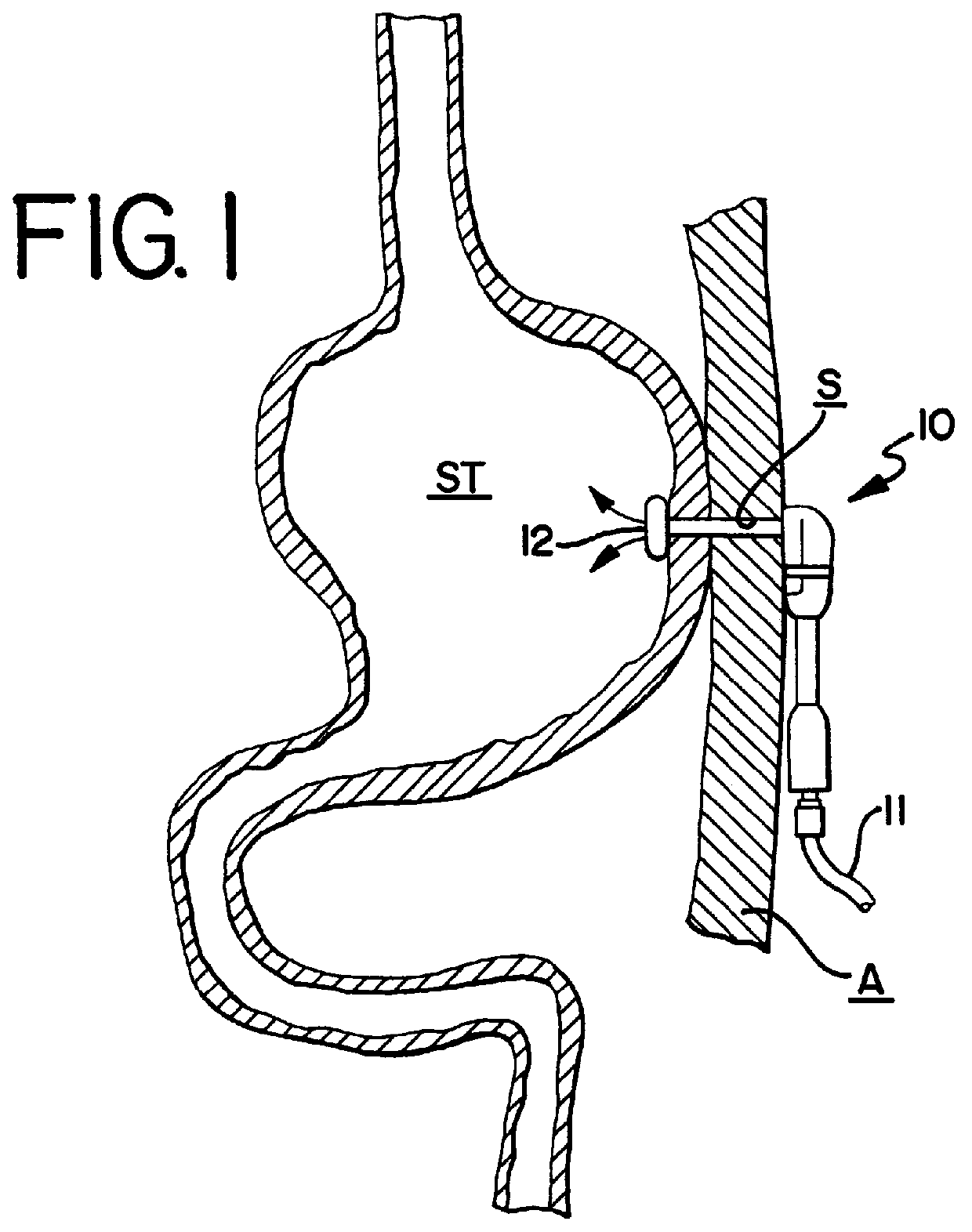

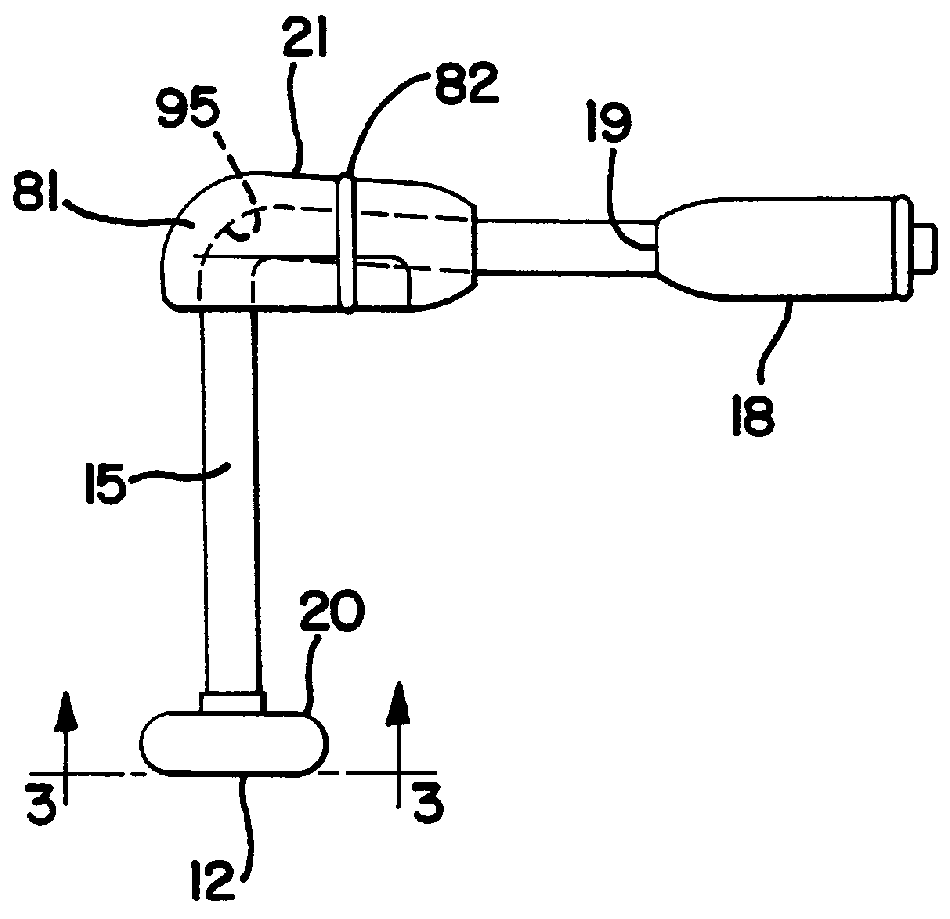

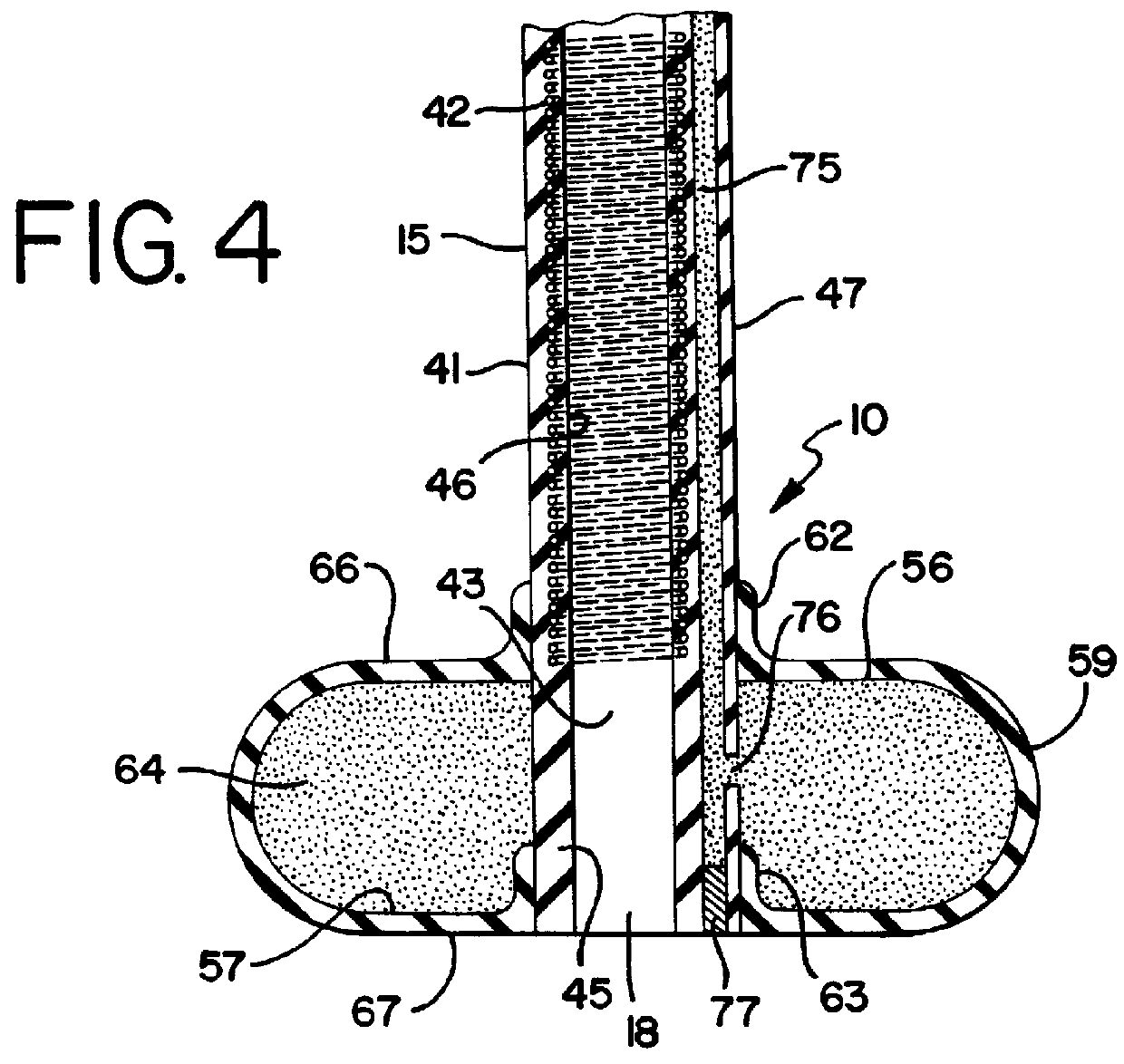

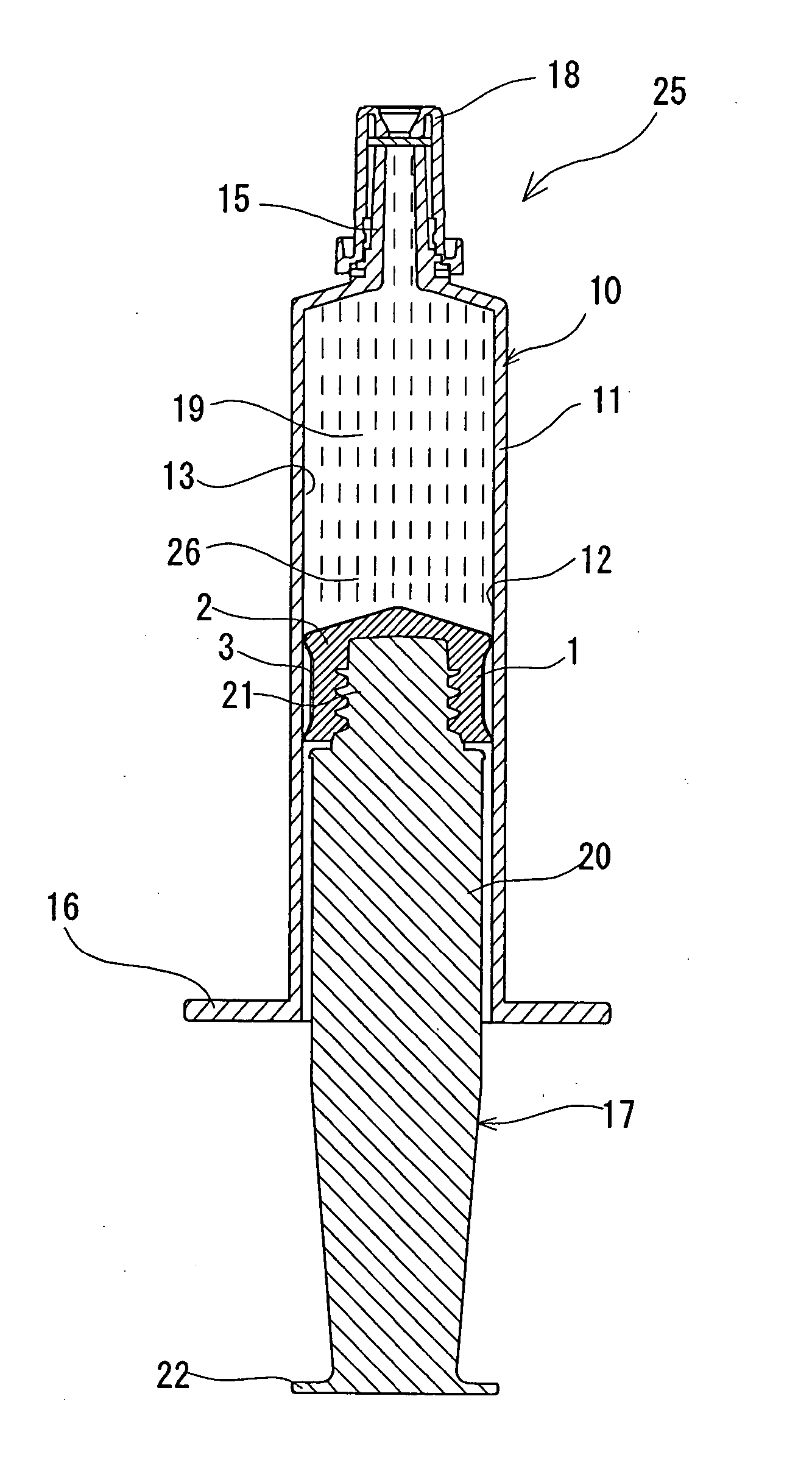

Retention balloon for a corporeal access tube assembly

An improvement in an internal bolster for a corporeal access tube assembly wherein a retention balloon is preformed of relatively thick silicone rubber film. The balloon includes parallel front and rear sidewalls connected by a semi-circular treadwall, the front sidewall having a front retention surface thereon with a radial width equal to the radius of the treadwall. Annular sleeves at the inner periphery of each sidewall are sealed to the outer surface of a tube segment. Each sleeve extends forwardly of its corresponding sidewall.

Owner:CR BARD INC

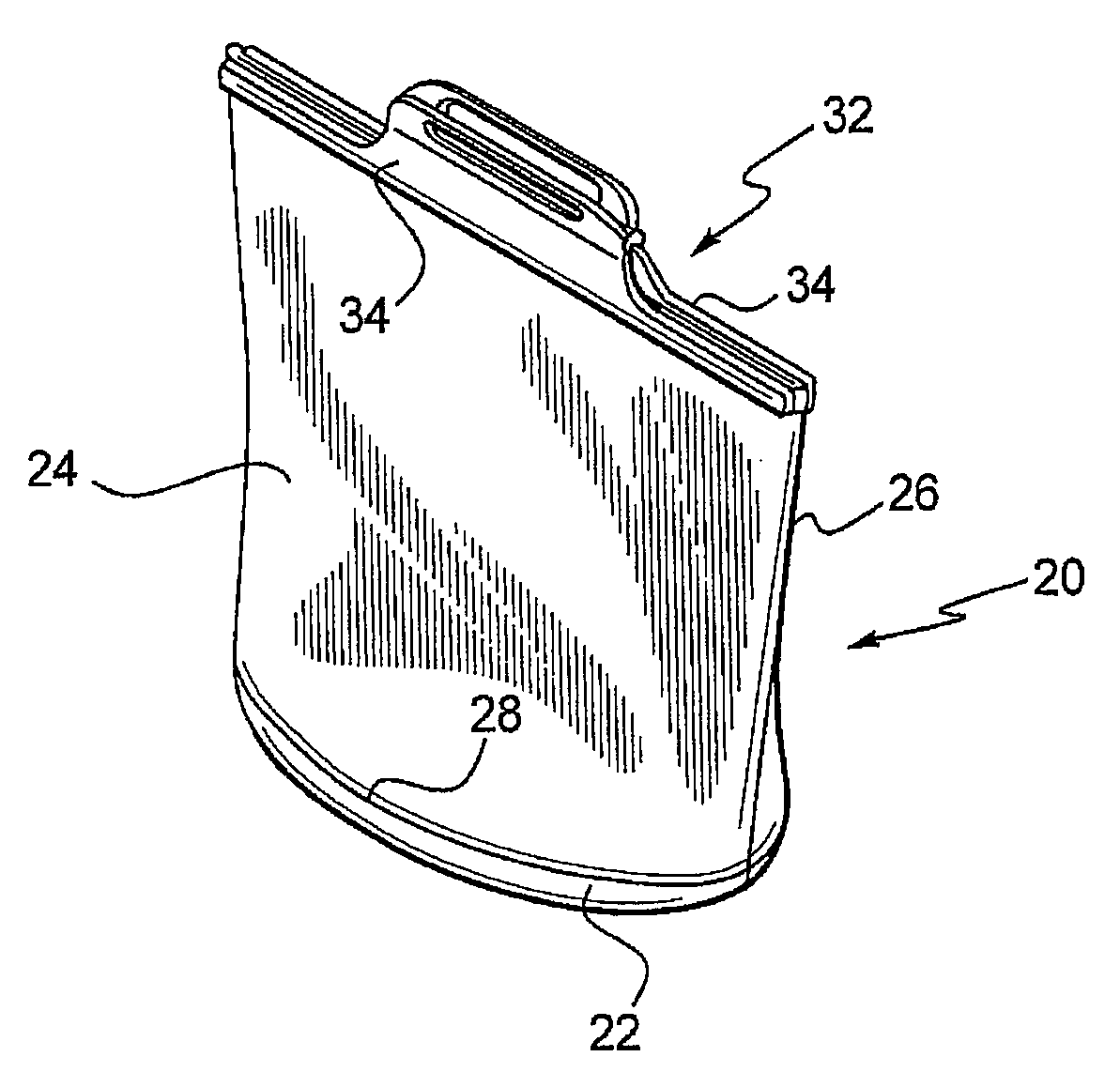

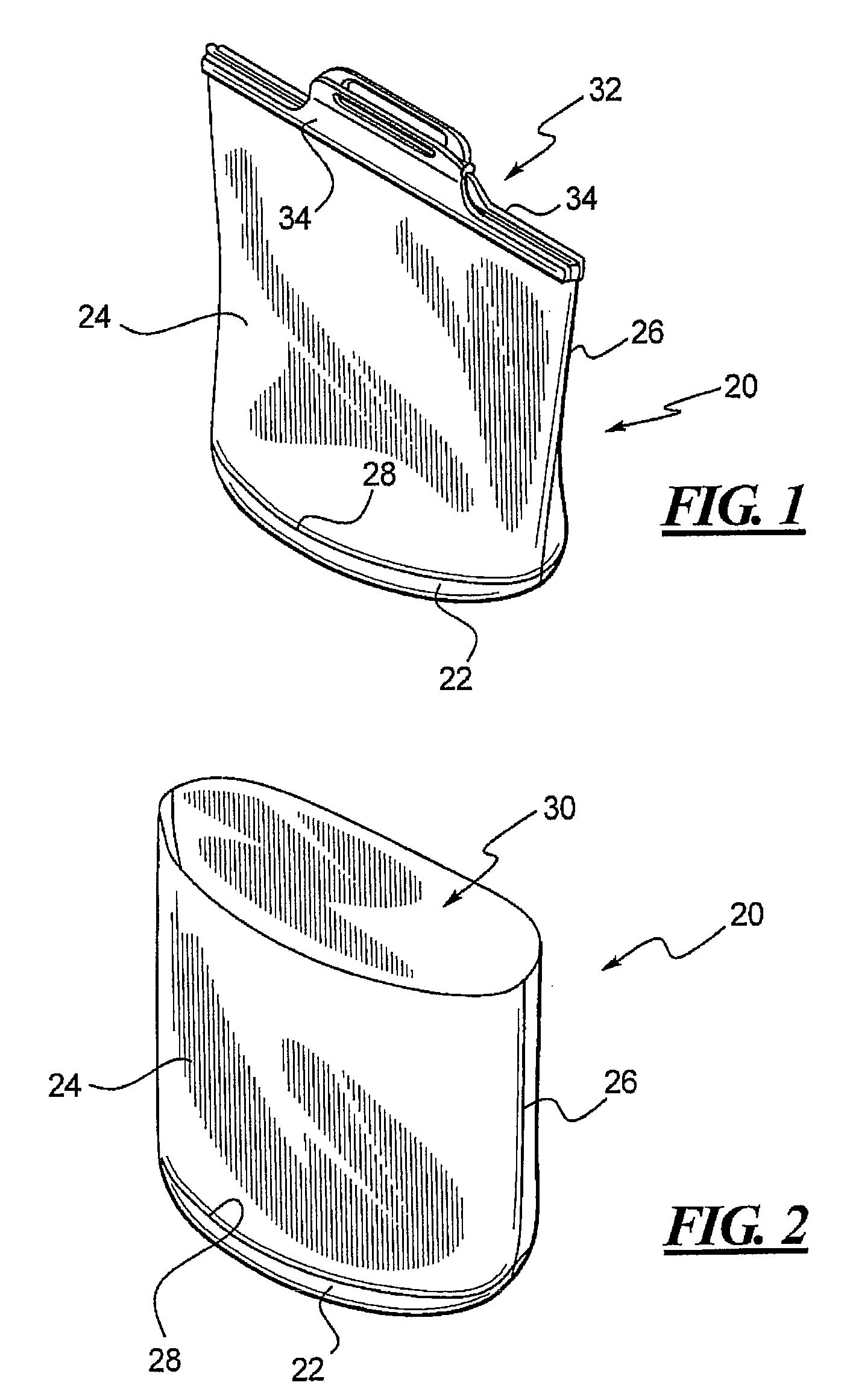

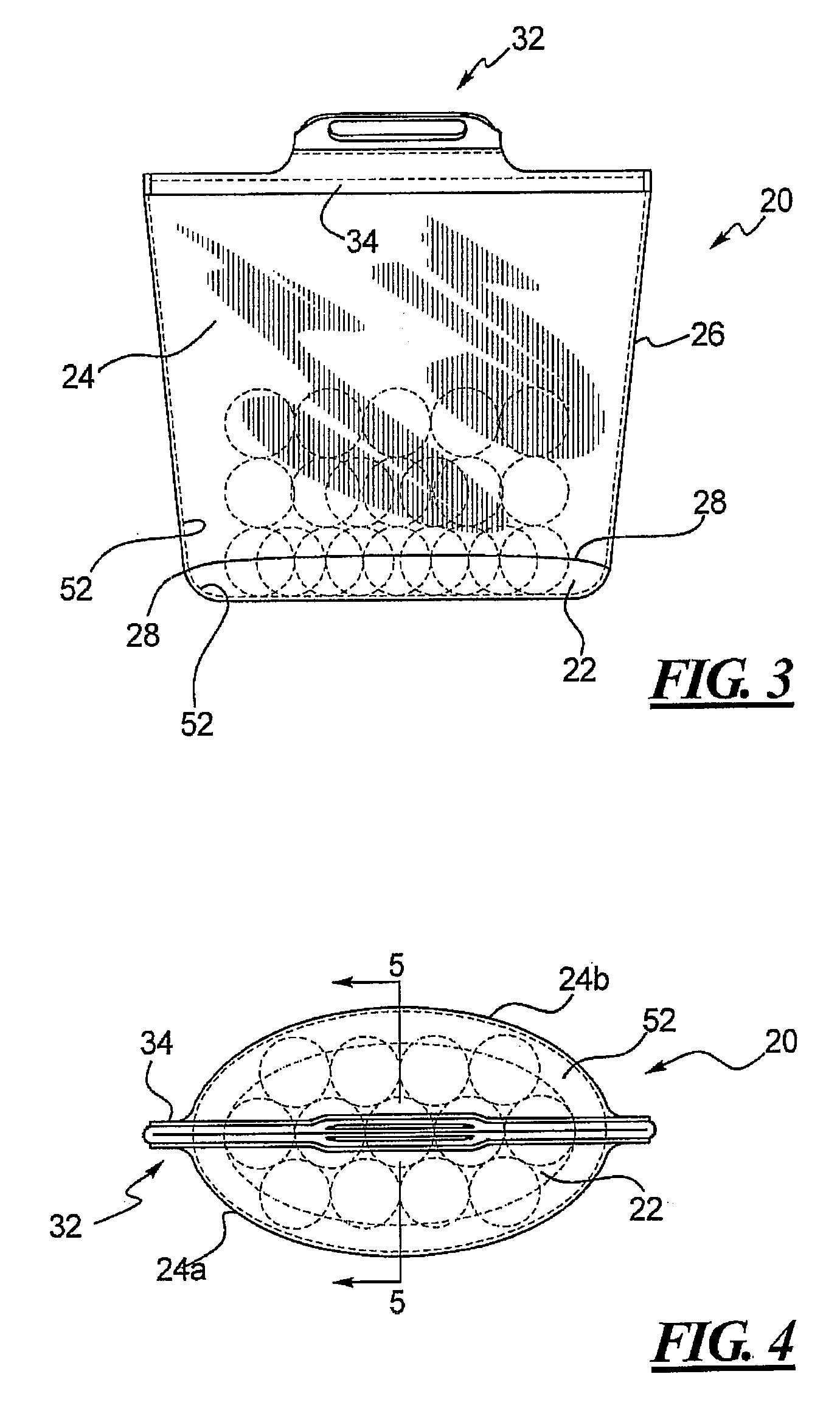

Durable freezer to conventional oven bag with mating seal

A reclosable food storage bag able to withstand a wide temperature range manufactured from environmentally sensitive materials is disclosed. The bag can be manufactured from such materials as silicone rubber and thermoset resins. By using such materials, the bag can easily withstand the temperature ranges encountered in residential kitchens extending from the freezer to the oven and all ambient temperatures therebetween. In addition, by manufacturing the bag from such materials, the environmental impact of using petroleum based polymers is avoided.

Owner:LEBOEUF WILLIAM E

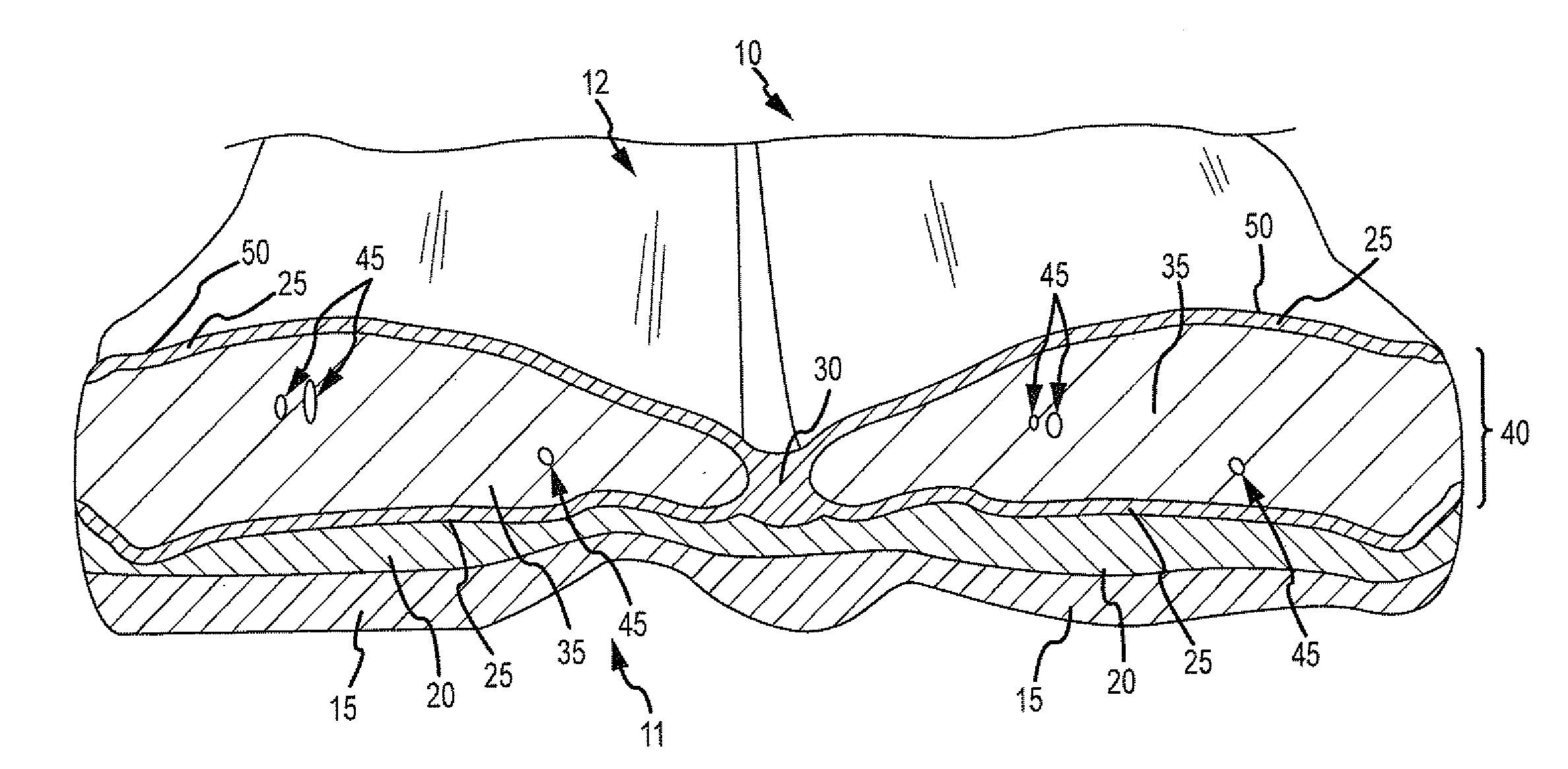

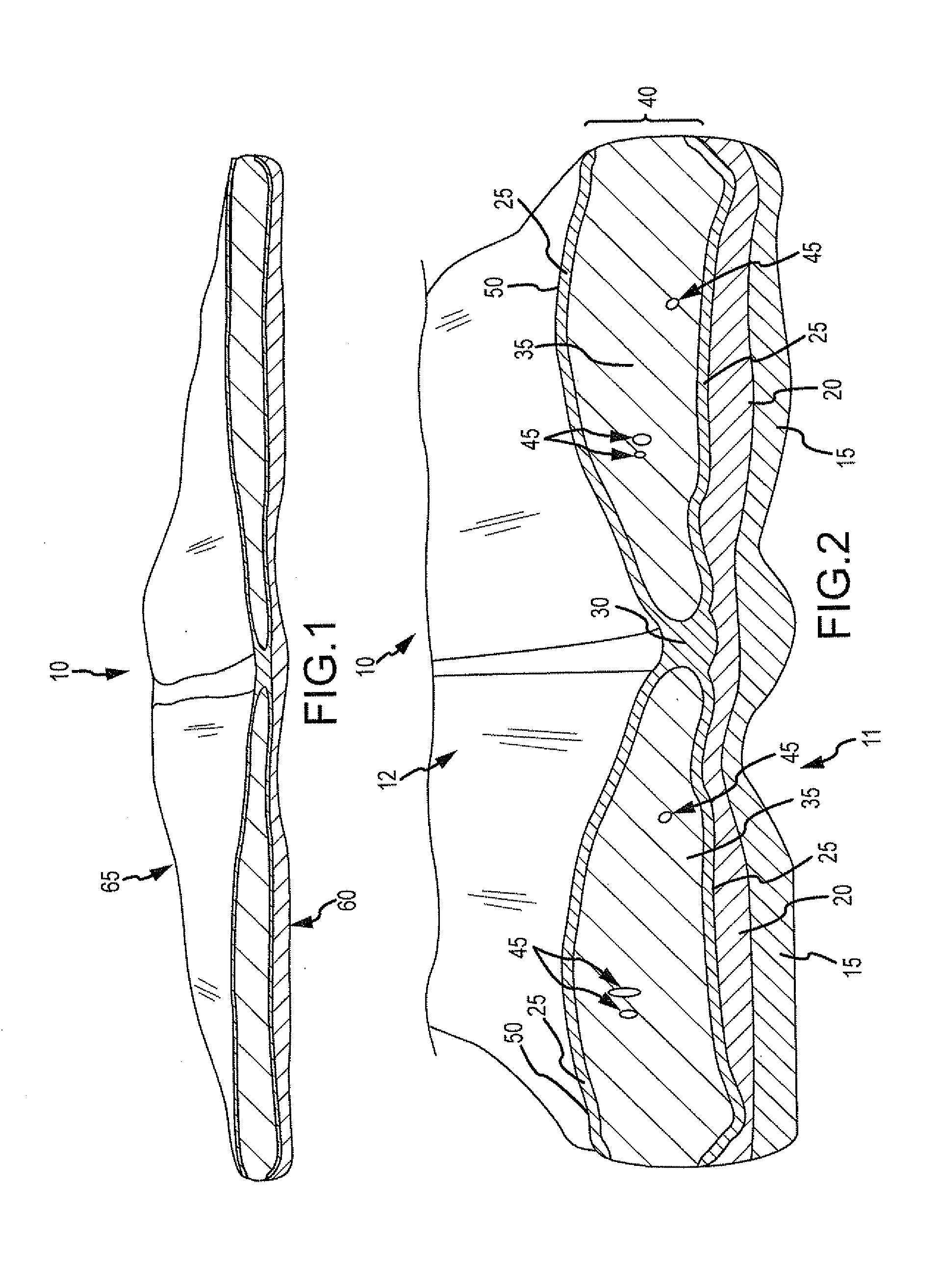

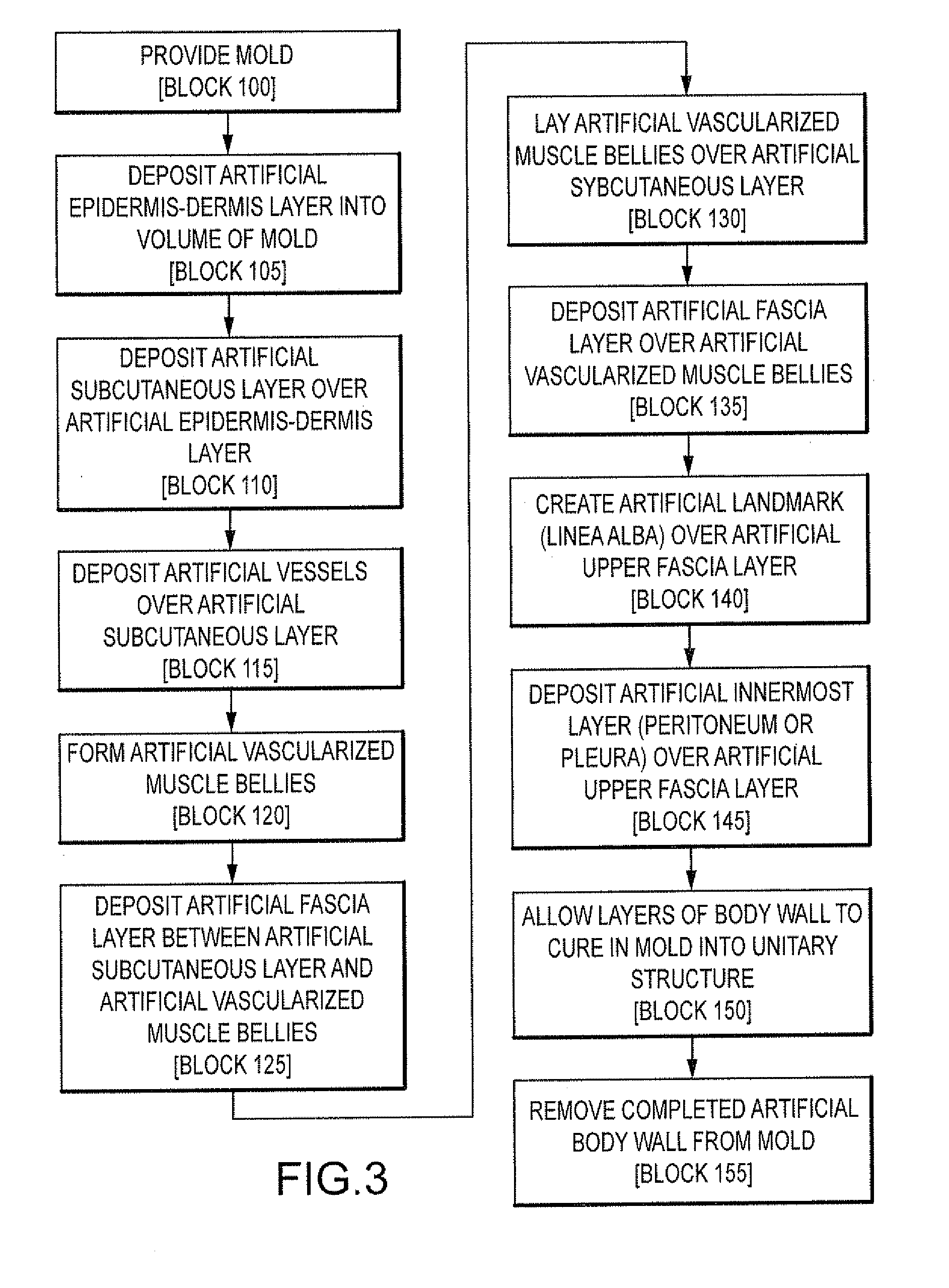

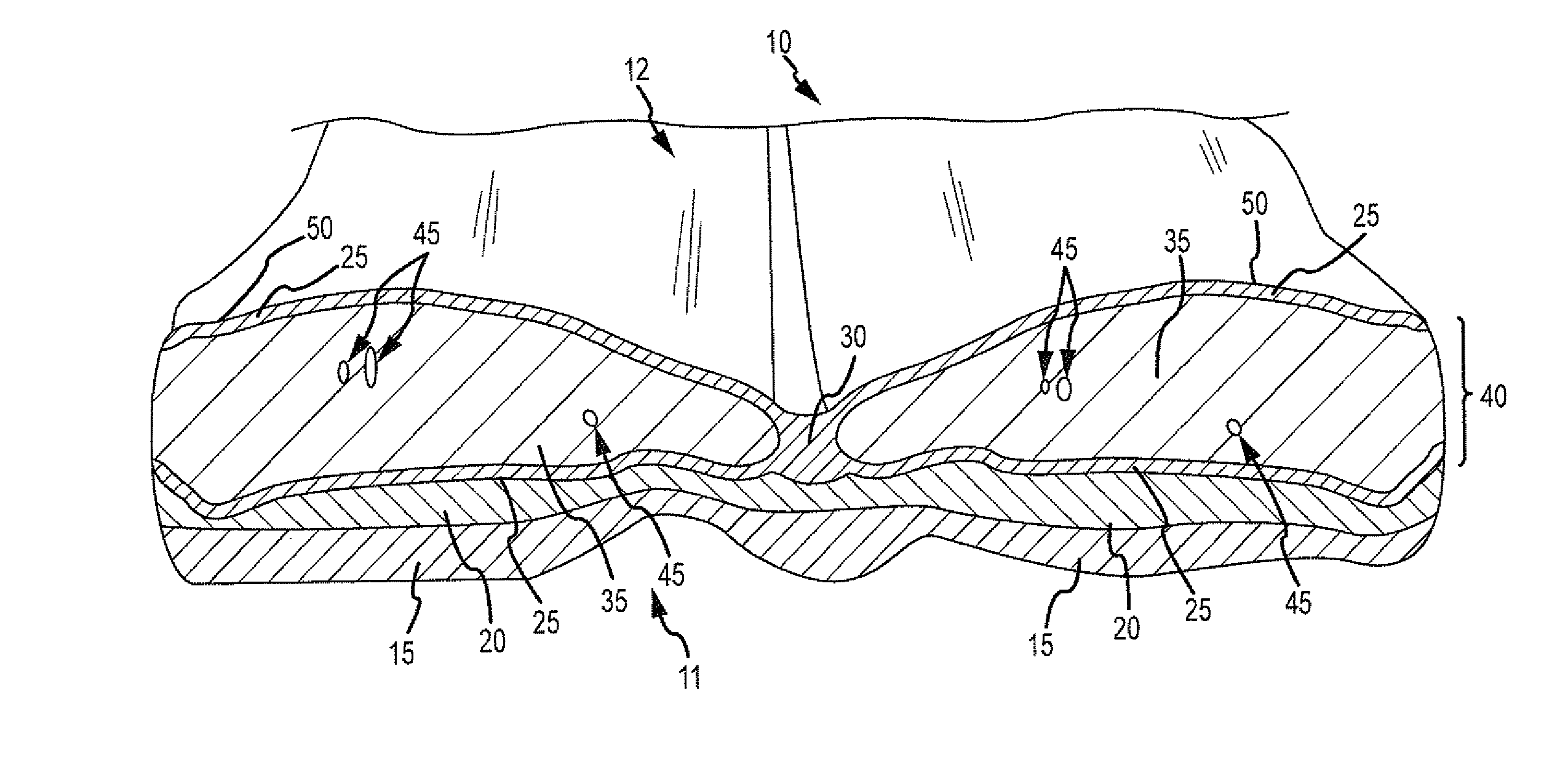

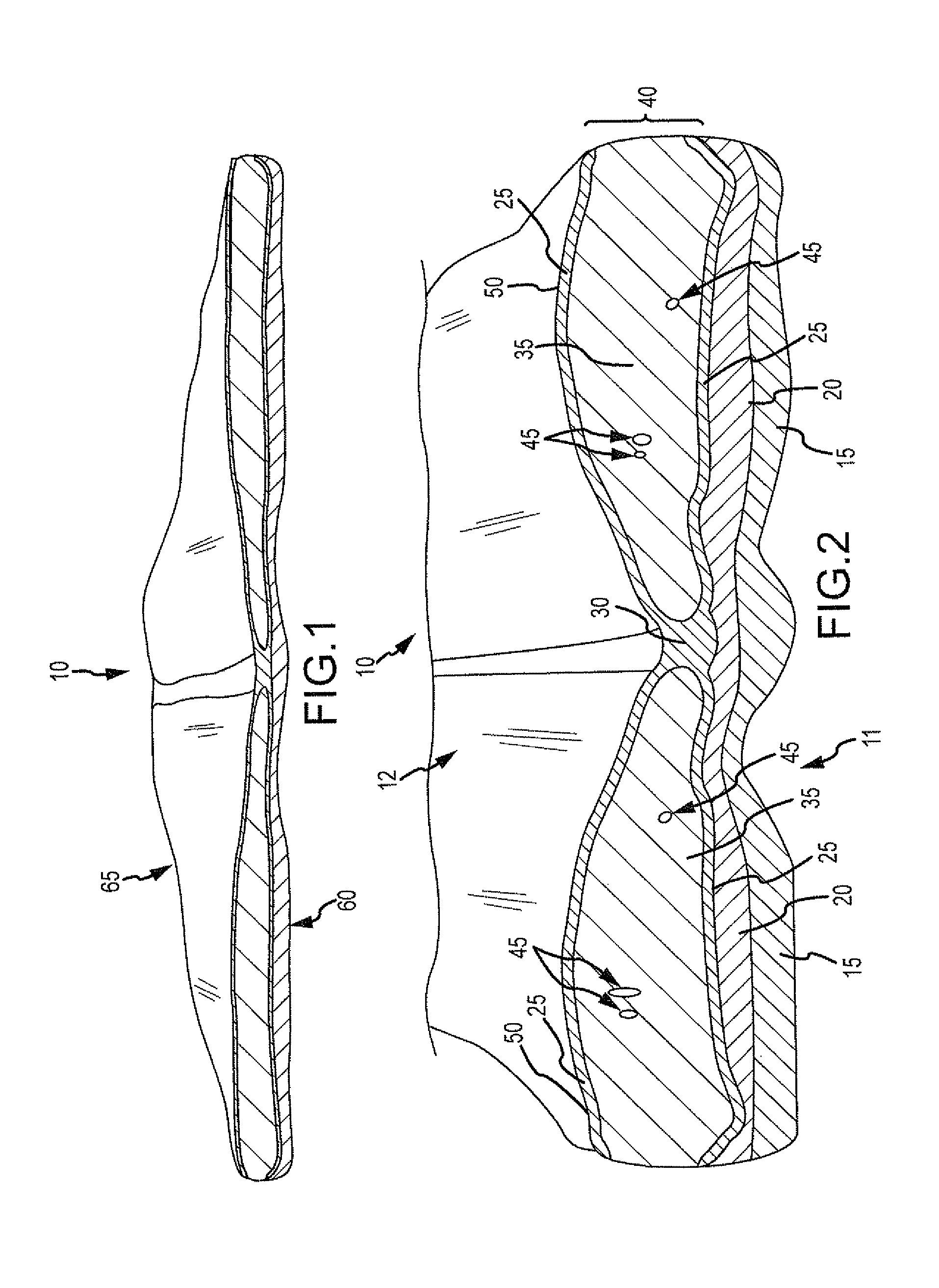

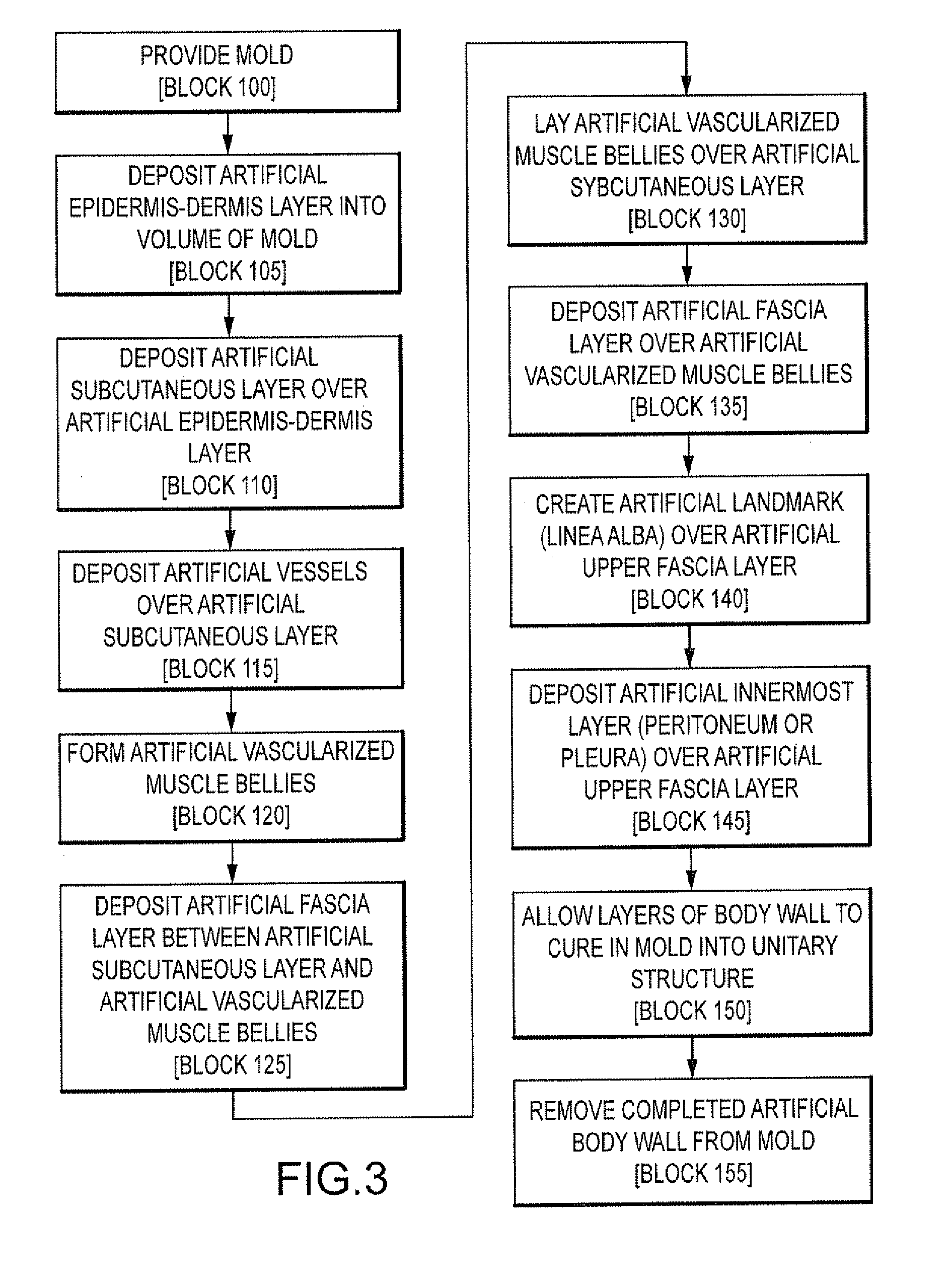

Simulated tissue, body lumens and body wall and methods of making same

An artificial body wall is disclosed herein. The artificial body wall may include a first layer and a second layer. The first layer is substantially formed of a silicone rubber and includes at least one of an artificial epidermis-dermis layer or an artificial subcutaneous layer. The second layer extends along and below the first layer and is substantially formed of a silicone rubber. The second layer includes at least one of an artificial fascia layer or an artificial muscle layer. At least one of the first layer or second layer may be vascularized.

Owner:COLORADO STATE UNIVERSITY

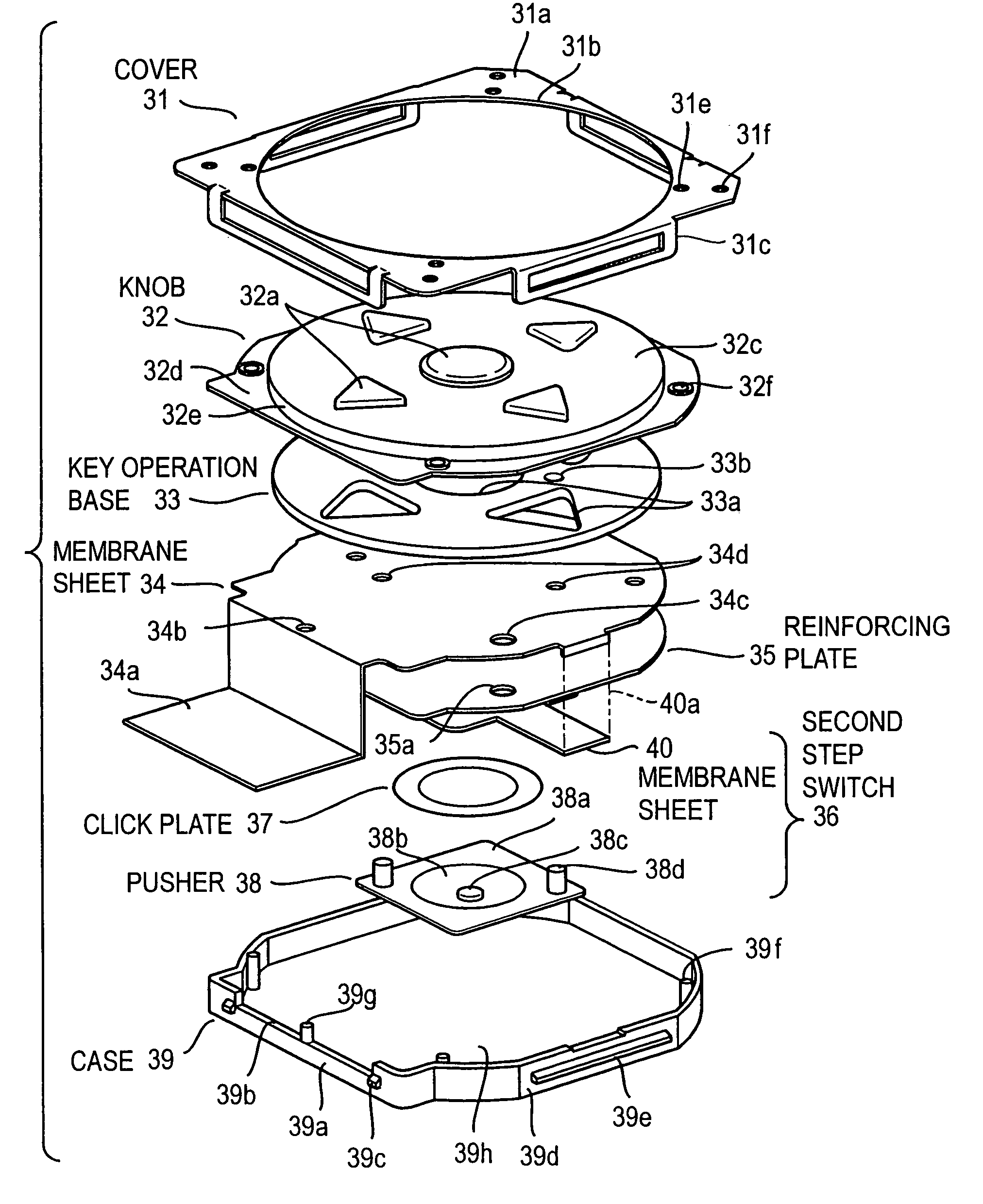

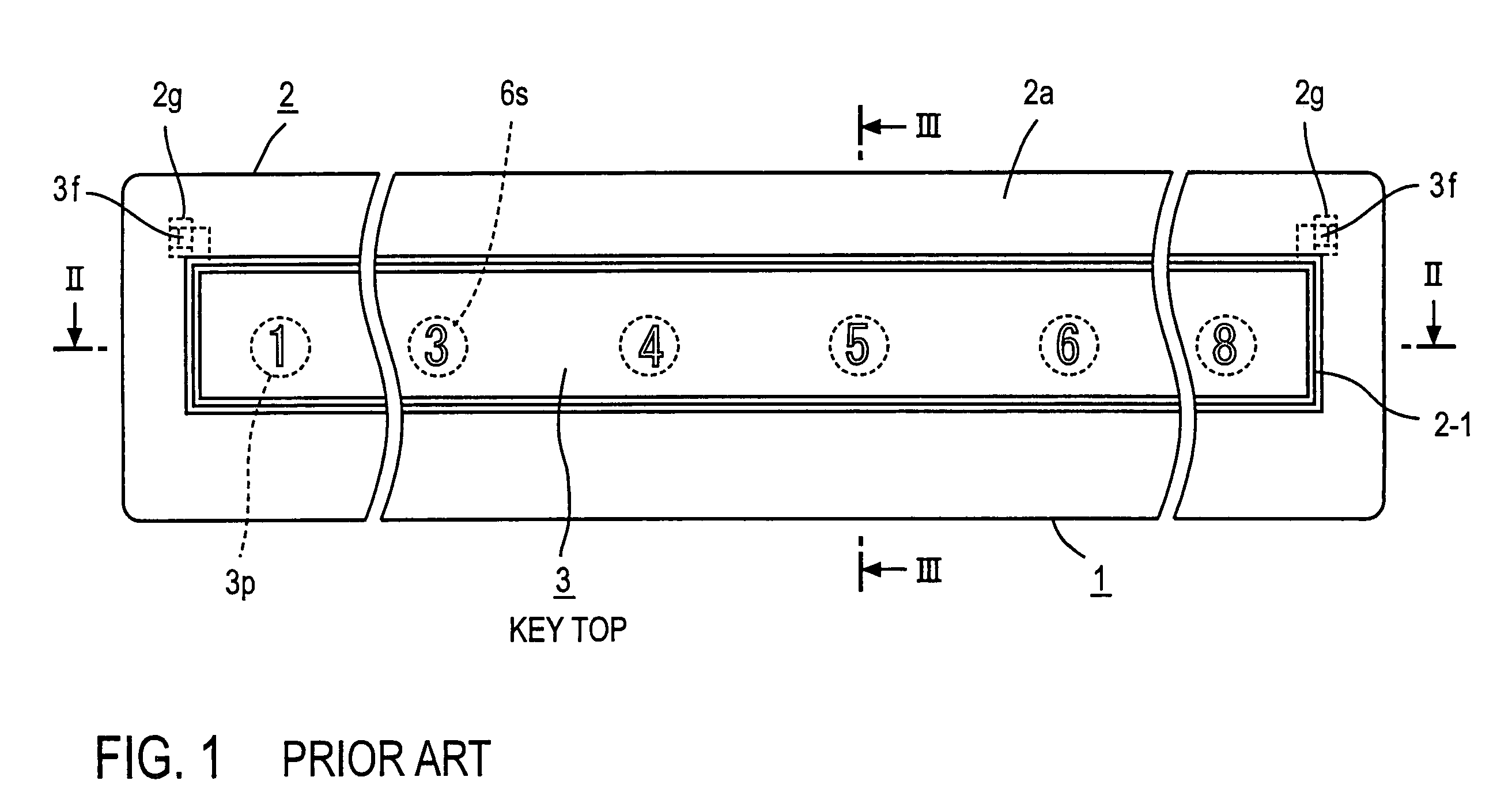

Depression responsive switch unit

InactiveUS7019225B2Reliably turnedExtended service lifeEmergency actuatorsContact operating partsRubber materialThermoplastic elastomer

A pusher formed of a rubber material, a click plate, a membrane switch which serves as a second step switch, a reinforcing plate, a membrane sheet on which a plurality of first step switches are formed, a key operation base and a knob are sequentially assembled into a case. The knob includes a plurality of depressing pieces having on its internal surface a projection which moves into contact with each membrane switch and also includes a marginal portion which is supported by the top surface of the case. The knob is thin-walled except for the depressing piece, and the thin-walled portion comprises a thermoplastic elastomer or silicone rubber. The knob, the key operation base and the reinforcing plate are secured together. As the depressing piece is depressed, the thin-walled portion which is located therearound becomes flexed, whereby the membrane switch is depressed by the projection to turn the switch on. When the depressing piece is further depressed, the reinforcing plate moves and the click plate reverses, turning the switch on.

Owner:JAPAN AVIATION ELECTRONICS IND LTD

Asymmetric Gas Separation Membranes with Superior Capabilities for Gas Separation

InactiveUS20080143014A1Excellent permeation fluxHigh selectivityMembranesSemi-permeable membranesCellulose diacetatePolymer science

This invention relates to a method of making flat sheet asymmetric membranes, including cellulose diacetate / cellulose triacetate blended membranes, polyimide membranes, and polyimide / polyethersulfone blended membranes by formulating the polymer or the blended polymers dopes in a dual solvent mixture containing 1,3 dioxolane and a second solvent, such as N,N′-methylpyrrolidinone (NMP). The dopes are tailored to be closed to the point of phase separation with or without suitable non-solvent additives such as methanol, acetone, decane or a mixture of these non-solvents. The flat sheet asymmetric membranes are cast by the phase inversion processes using water as the coagulation bath and annealing bath. The dried membranes are coated with UV curable silicone rubber. The resulting asymmetric membranes exhibit excellent permeability and selectivity compared to the intrinsic dense film performances.

Owner:UOP LLC

Silane copolymer coatings

InactiveUS20020128419A1Simple and efficientMaintain good propertiesMale contraceptivesLayered productsSilanesMedical device

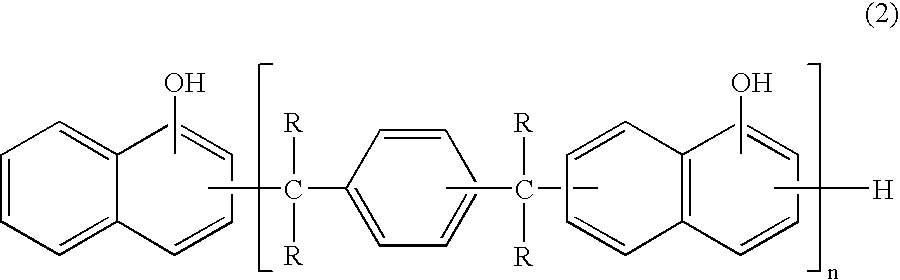

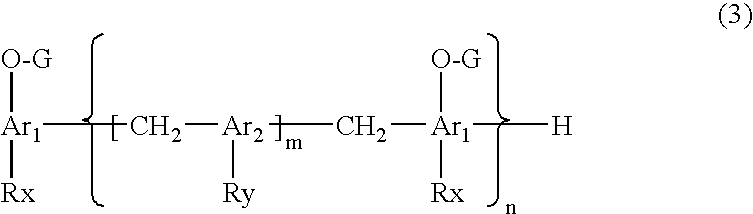

The invention is drawn to silane copolymers prepared from the reaction of one or more polyisocyanates with one or more lubricious polymers having at least two functional groups, which may be the same or different, that are reactive with an isocyanate functional group and with one or more organo-functional silanes having at least two functional groups, which may be the same or different, that are reactive with an isocyanate functional group and at least one functional group reactive with a silicone rubber substrate. The silane copolymer coatings of the invention are elastic, lubricious, and resist wet abrasion. They are useful as coatings for polysiloxane (rubber) and other difficult to coat substrates, especially for medical devices, such catheters.

Owner:CR BARD INC

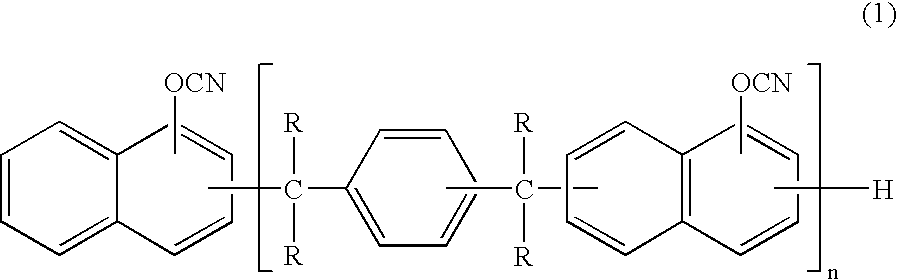

Prepreg and laminate

ActiveUS20090017316A1Improve flame retardant performanceImprove heat resistanceSpecial tyresElectrical equipmentThermal dilatationPolymer science

A prepreg for a printed wiring board, comprising a cyanate ester resin having a specific structure, a non-halogen epoxy resin, a silicone rubber powder as a rubber elasticity powder, an inorganic filler and a base material, which prepreg retains heat resistance owing to a stiff resin skeleton structure, has high-degree flame retardancy without the use of a halogen compound or a phosphorus compound as a flame retardant, and has a small thermal expansion coefficient in plane direction without using a large amount of inorganic filler, and a laminate comprising the above prepreg.

Owner:MITSUBISHI GAS CHEM CO INC

Silicone rubber for composite insulator and preparation method thereof

The invention discloses a silicone rubber for a composite insulator, wherein the silicone rubber comprises the following raw materials in parts by weight: 30-50 parts of methyl vinyl silicone rubber A, 50-70 parts of methyl vinyl silicone rubber B, 25-50 parts of fumed silica, 100-130 parts of aluminium hydroxide, 1-6 parts of silane coupling agent, 0.2-2 parts of ultraviolet absorber, 2-6 parts of zinc oxide, 0.5-3 parts of triethanolamine, 0.2-1 parts of stearic acid, 0.5-2 parts of hydrogen-containing silicone oil, 0.2-1 parts of vinyl silicone oil, 0.5-3 parts of color masterbatch rubber, 2-6 parts of hydroxyl silicone oil and 0.5-1 parts of vulcanizing agent. The silicone rubber provided by the invention can achieve the following performances: the tensile strength is larger than 4 MPa; the breaking elongation is larger than 350%; the peel strength is larger than or equal to 12 KN.m<-1>; the shore hardness is 60+ / -5 degrees; the thermal aging tensile strength retention is larger than or equal to 90%; the anti-creep track passes a grade of 1A4.5; the flame retardance reaches a grade of FV-0; the average static contact angle is larger than 105 degrees; the electrical surface resistivity is larger than 2*10<15> omega; the dielectric constant is smaller than 3.8; and the dielectric loss angle tangent is smaller than 0.01.

Owner:PINGGAO GRP +2

Silicone rubber compositions

InactiveUS20120133079A1Low densityReduce weightCeramic shaping apparatusCoatingsPolymer scienceSilicone Elastomers

The present invention relates to silicone rubber compositions, methods for their preparation and uses thereof. In particular, the invention relates a heat curable silicone rubber composition comprising: 100 parts by weight of a defined HCR silicone elastomer; 0.5 to 30 parts by weight of hollow filler; and 0.1 to 3.0 parts by weight of a curing agent.

Owner:MEGGITT AEROSPACE +1

Medical appliance-coating composition and medical appliance

A medical appliance-coating composition contains a solvent-based silicone rubber, and in addition, carbon nanotubes, and fine particles of silicone resin. A medical appliance having a slidable coating film formed thereon moves in contact with an inner surface of a medical member or an inner surface of a lumen. The slidable coating film is disposed at a portion, of the medical appliance, which contacts the medical member or the lumen. The slidable coating film is comprised of silicone rubber, the carbon nanotubes and the fine particles of the silicone resin.

Owner:TERUMO KK

Highly ripping-resistant high temperature sulfidation silicon rubber and method for making same

The invention relates to a high anti-tearing and high temperature vulcanized silicon rubber, which is made through mixing and vulcanization of peroxide vulcanization agent and a combination which uses methylvinyl silicone rubber as base adhesive. The combination, according to weight proportion, comprises 100 of methylvinyl silicone rubber with low vinyl content, 1 to 30 of hydroxyl silicone oil, 0.1 to 3 of inner mold release agent, 15 to 80 of reinforcement agent, 1 to 10 of methylvinyl silicone rubber with high vinyl content and 1 to 10 of hydrogen-containing silicone oil; wherein, the vinyl molar content of the low vinyl-content methyvinyl silicone rubber is 0.01 percent to 0.15 percent; the vinyl molar content of the high vinyl-content methylvinyl silicone rubber is 1 percent to 10 percent. The invention has the advantages that the high vinyl-content methylvinyl silicon rubber is added into the methylvinyl silicone rubber, leading unsymmetrical concentration-crosslinking or one place multiple crosslinking to be formed during sulfuration period and the silicone rubber to generate so large resistance at the place that the rubber is difficult to be torn. In addition, the broken and tensile strength of vulcanized silicon rubber products is up to 8.5 MPa, and the tear strength is up to 45 N / mm.

Owner:SHANGHAI HUITIAN NEW CHEMICAL MATERIALS CO LTD

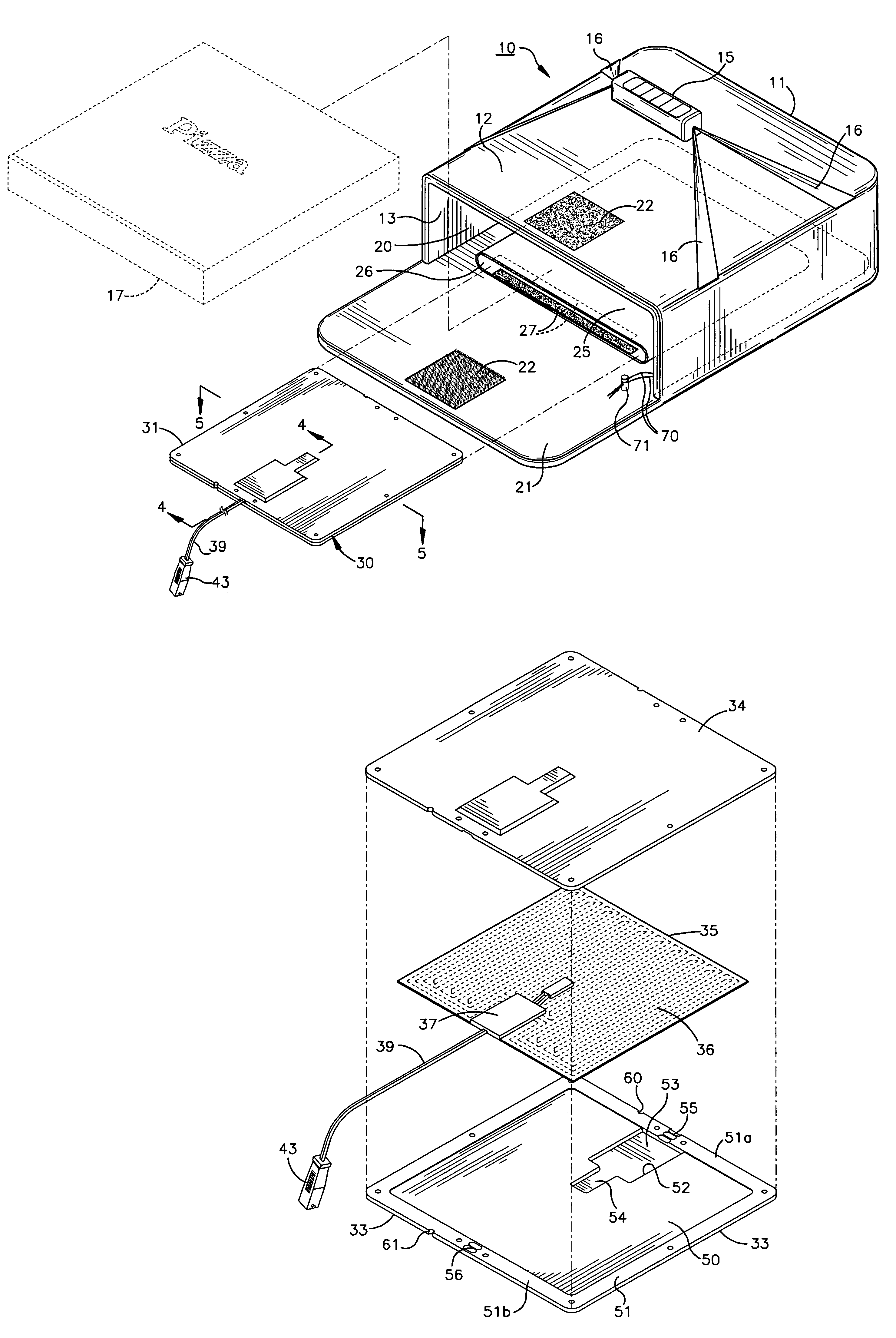

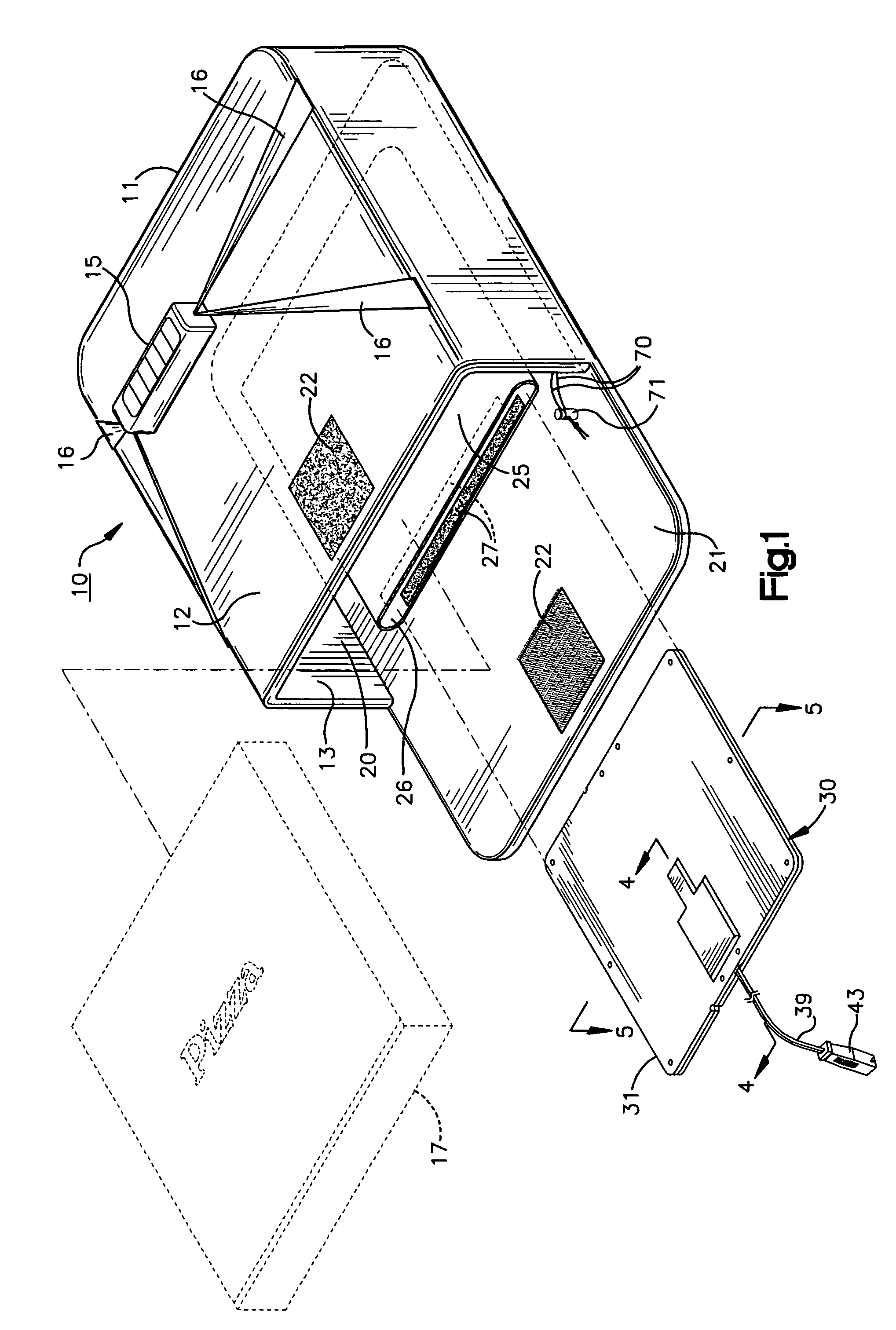

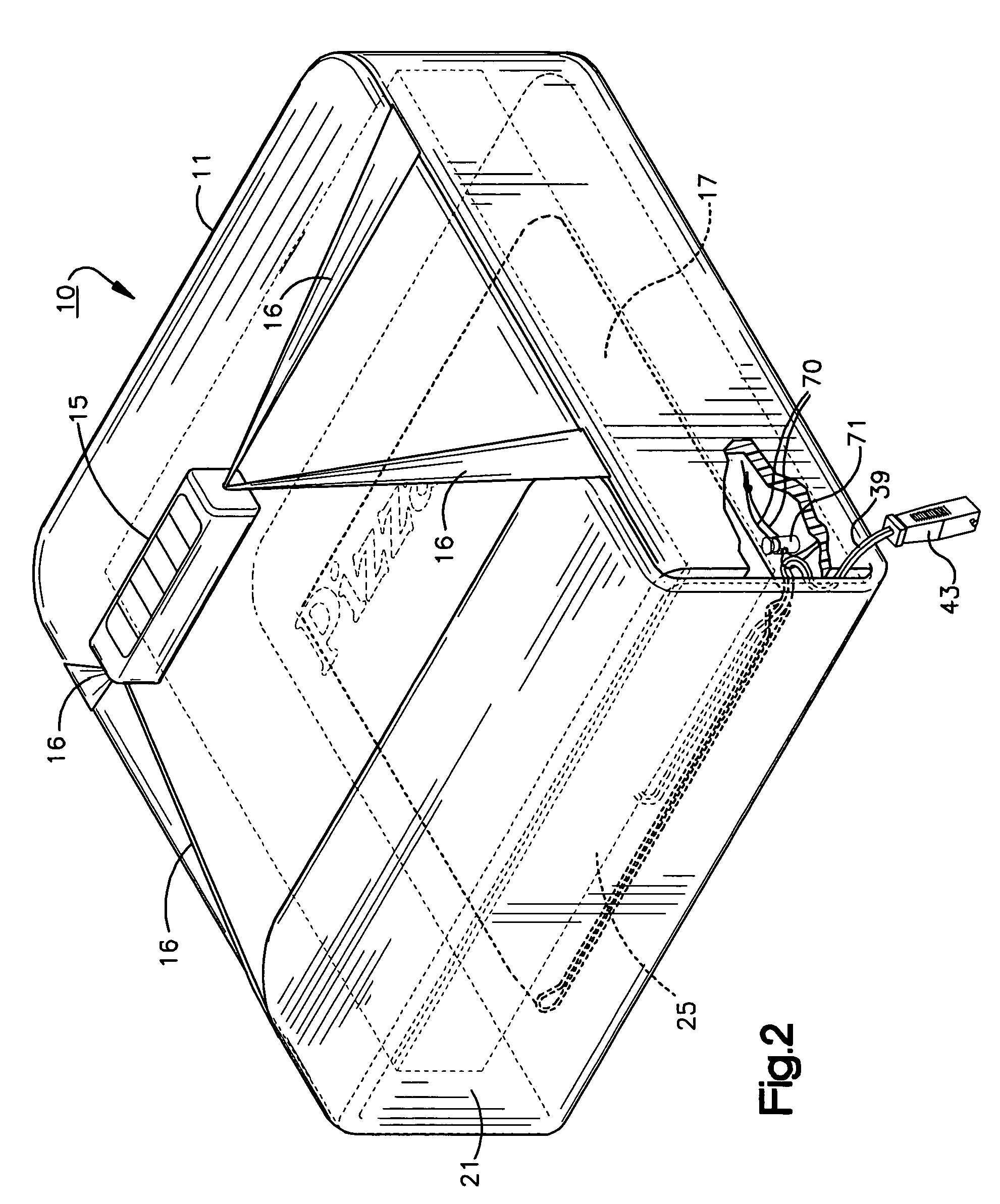

Heated delivery system

ActiveUS7034254B2Low costCheap to makeDomestic stoves or rangesElectrical heating fuelElectrical resistance and conductanceTemperature control

A heated delivery system for pizza and the like including a thermally insulated receptacle, an electrical resistance heating unit having a heat storing shell molded from thermosetting resin, and an electrical resistance heating member within the shell, the member having the capacity of being heated and maintained at a desired temperature. The heating member may be silicone rubber containing resistance heating elements, and its temperature may be regulated by a suitable temperature control, such as a thermostat or other means.

Owner:DB REDIHEAT +1

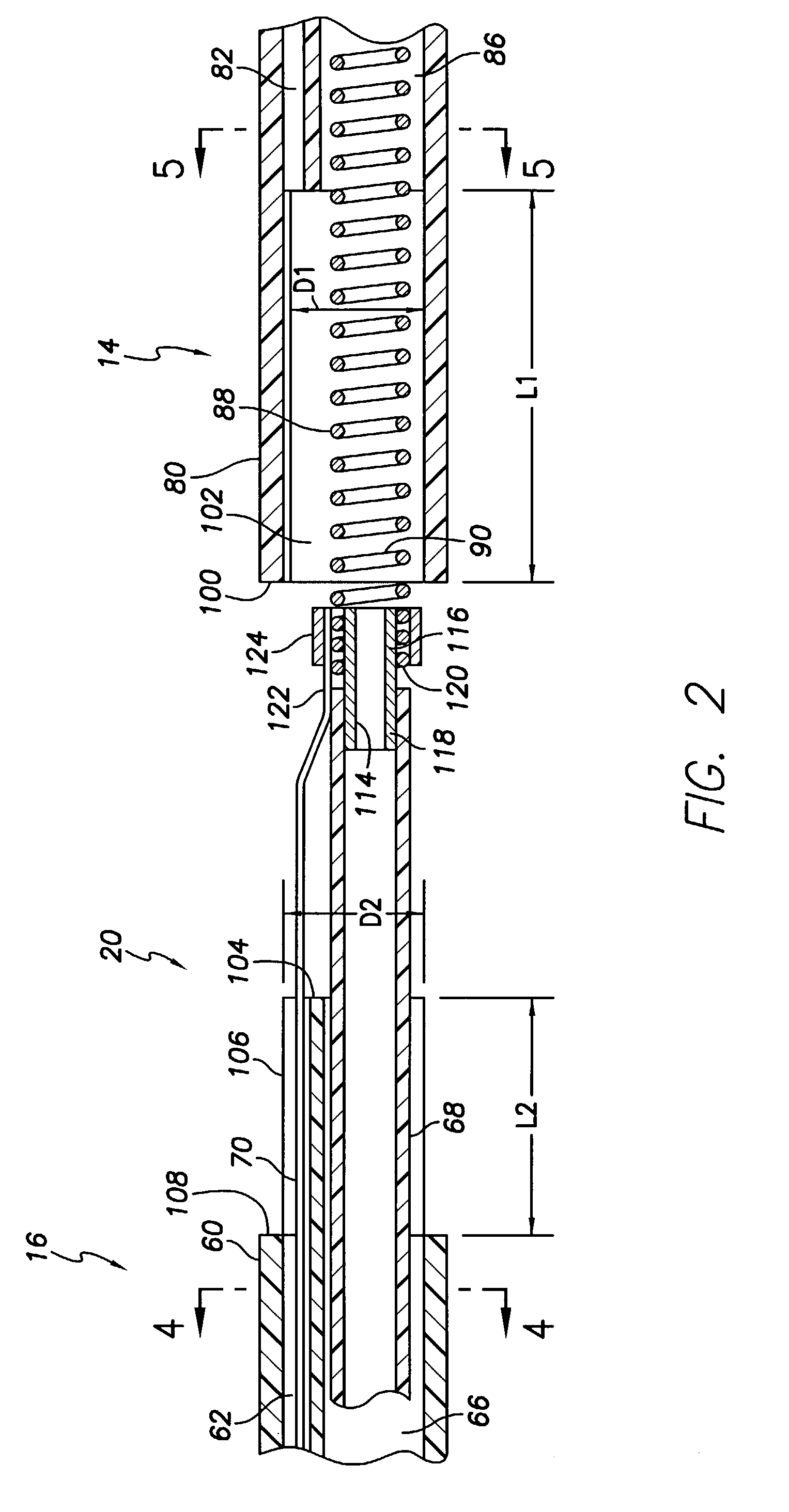

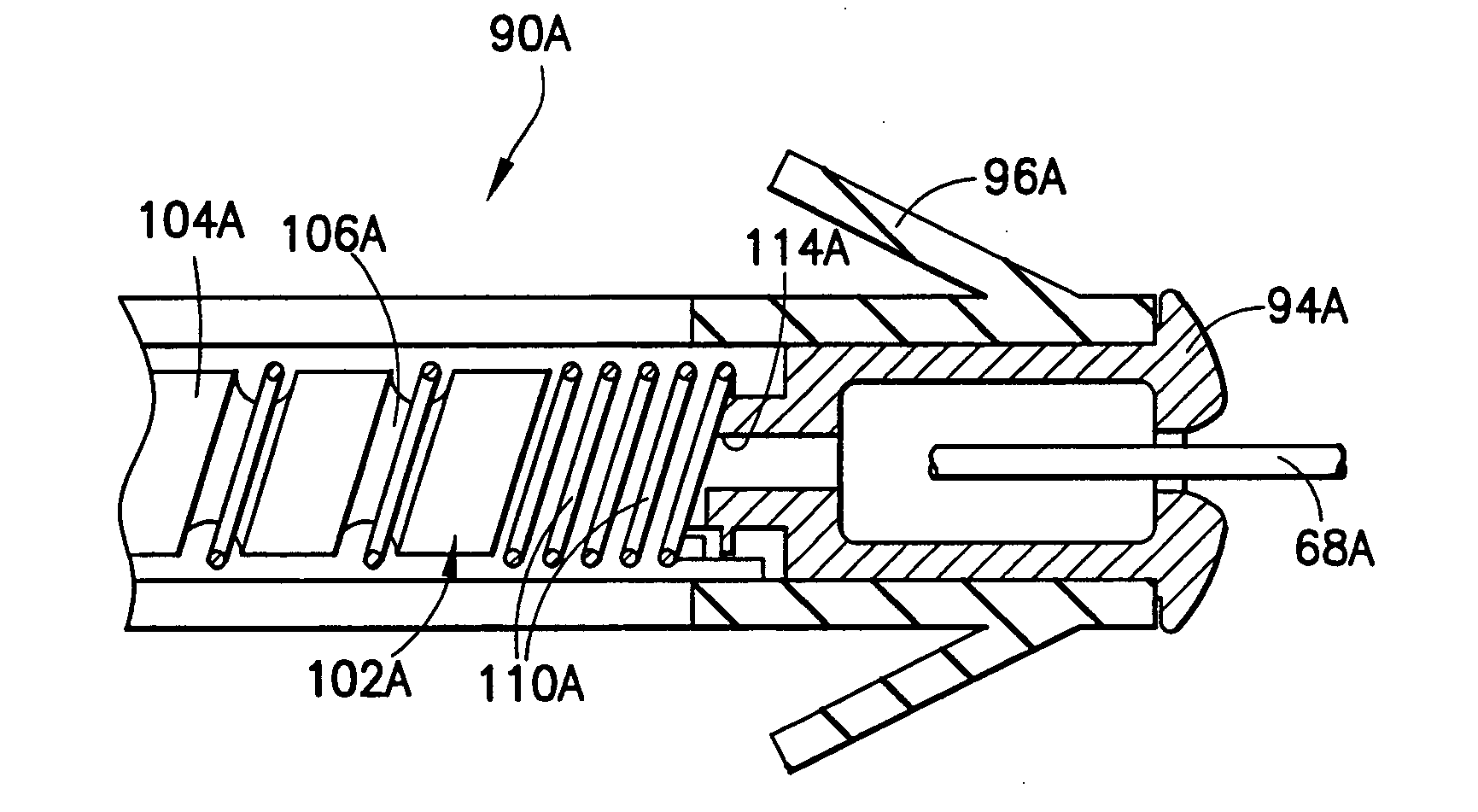

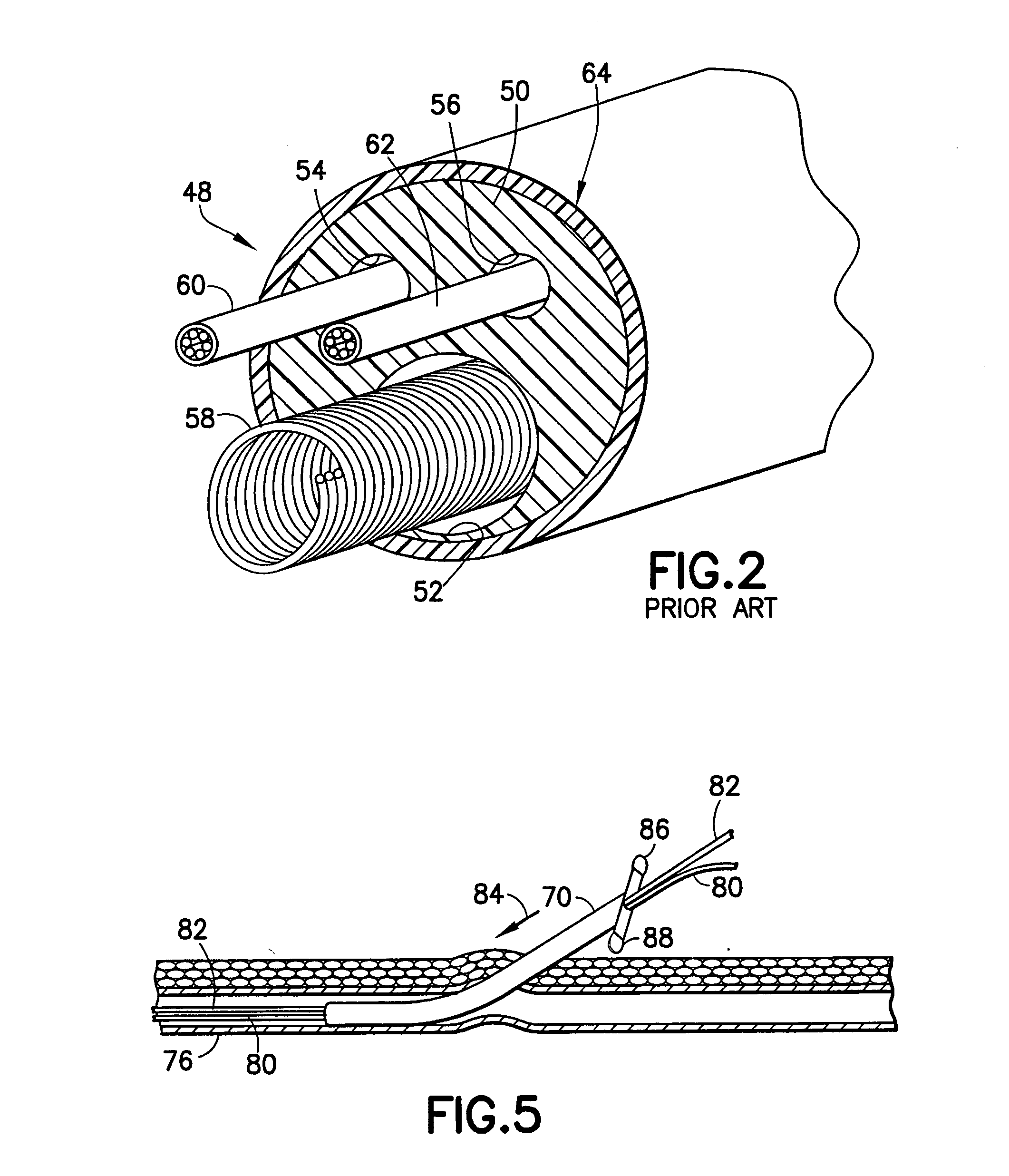

Lead body construction

InactiveUS20050080471A1Alleviate “ whip-like ” actionStiffnessTransvascular endocardial electrodesExternal electrodesElectrical conductorYoung's modulus

An implantable cardiac stimulation lead system for use with a stimulation device includes a lead body preferably having an outer diameter of less than 4 French and formed of a biocompatible material having a Young's modulus of at least 20,000 pounds per square inch. In the lead body, an inner insulator is composed of a suitable polymer such as PTFE or ETFE with an outer peripheral surface formed with a helical groove containing a conductor extending between a proximal connector and a distal tip electrode, and an outer insulator composed of polyurethane or silicone rubber or a combination thereof is positioned around the inner insulator. The lead system may be formed with a lumen for receiving a guidewire longitudinally through the lead body. A pair of insulated conductors may be received in the helical groove, one extending to the distal tip electrode, the other extending to a ring electrode proximally spaced from the distal tip electrode.

Owner:PACESETTER INC

Double-faced pressure-sensitive adhesive tape or sheet, and liquid crystal display apparatus

InactiveUS20070218276A1Improve the immunityIncrease crosslink densityFilm/foil adhesivesEster polymer adhesivesPolymer scienceLiquid-crystal display

The present invention relates to a double-faced pressure-sensitive adhesive tape or sheet, which comprises: a base material; a pressure-sensitive adhesive layer disposed on one surface of the base material, which is a pressure-sensitive adhesive layer (A) including a pressure-sensitive adhesive composition containing an acrylic polymer (A1), and a silicone rubber fine particle (A2) in a proportion of from 3 to 50 parts by weight with respect to 100 parts by weight of the acrylic polymer (A1), the layer (A) being used so as to adhere to the liquid crystal display module unit; and another pressure-sensitive adhesive layer disposed on the other surface of the base material, which is a pressure-sensitive adhesive layer (B) including a pressure-sensitive adhesive composition containing an acrylic polymer (B1), and a low-molecular weight polymer component (B2), which contains, as a principal monomer component, an ethylenic unsaturated monomer having a glass transition temperature of from 60 to 190° C. when it is formed into a homopolymer and having a cyclic structure within the molecule thereof, and which has a weight-average molecular weight equal to or higher than 3,000 but lower than 20,000, in a proportion of from 5 to 35 parts by weight with respect to 100 parts by weight of the acrylic polymer (B1), the layer (B) being used so as to adhere to the backlight, in which the pressure-sensitive adhesive tape or sheet is for use in fixing a liquid crystal display module unit and a backlight unit.

Owner:NITTO DENKO CORP

High-temperature resisting methyl vinyl silicone rubber

The invention discloses high-temperature resisting methyl vinyl silicone rubber as well as a prescription and a preparation process thereof. The high-temperature resisting modified silicon rubber material which has more than 300 DEG C of application temperature and can not crack when according with requirements of 550 DEG C, 4mm distance and high-temperature radiation for more than 12 minutes is prepared by adopting the following steps of: adding cerium oxide and polymide into the prescription in which methyl vinyl silicon crude rubber is taken as a rubber raw material to improve the heat-resisting temperature, adding hydroxy silicone oil, dimethyl silicon oil and a silane coupling agent to improve the oil-resisting performance, adding precipitation method white carbon black and gas-phase method white carbon black to improve the tearing-resistance strength, adding quartz power and kieselguhr to improve the tensile strength and matching technical schemes of the preparation process. The high-temperature resisting methyl vinyl silicone rubber overcomes the problems and the defects of poor high-temperature and aging resistance performance and short service life of the common silicone rubber in the prior art, satisfies the special requirements for the heat-resisting performance, the electrical strength and the mechanical strength of automotive rubber products, and ensures that the silicone rubber products achieve the aims of improving the high-temperature resistance performance and prolonging the service life.

Owner:NINGBO GUANGMING RUBBER & PLASTIC

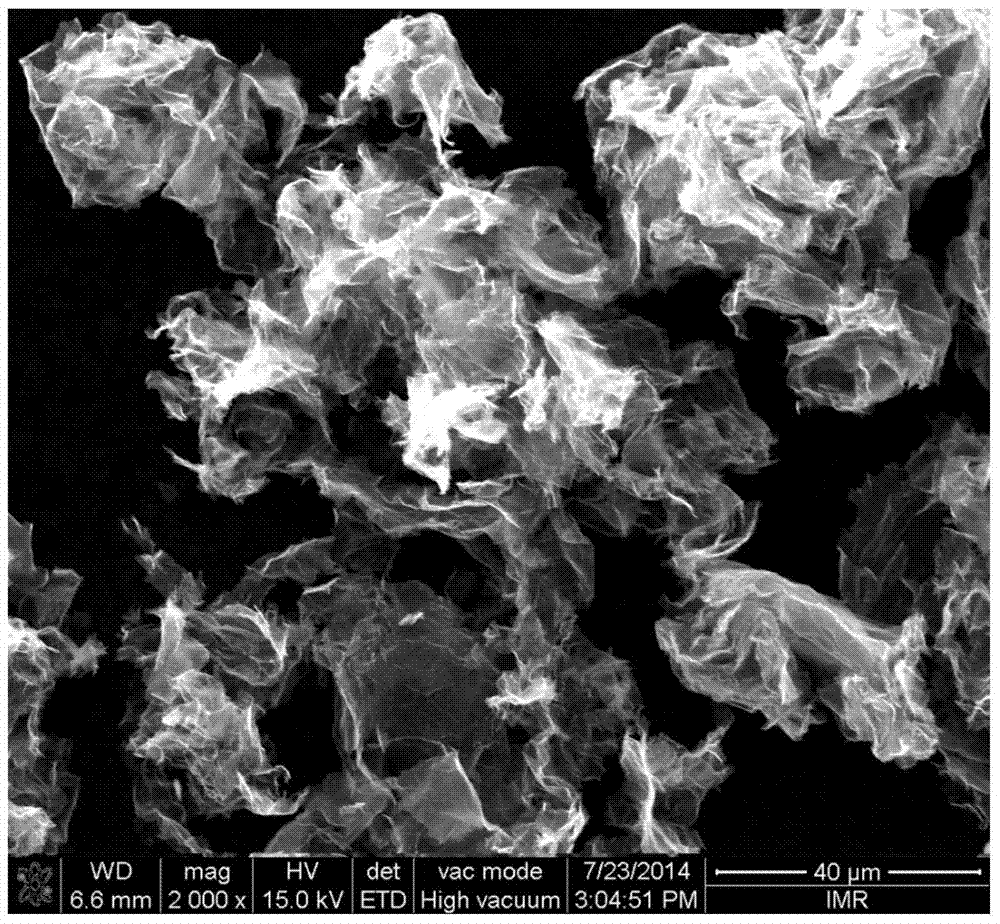

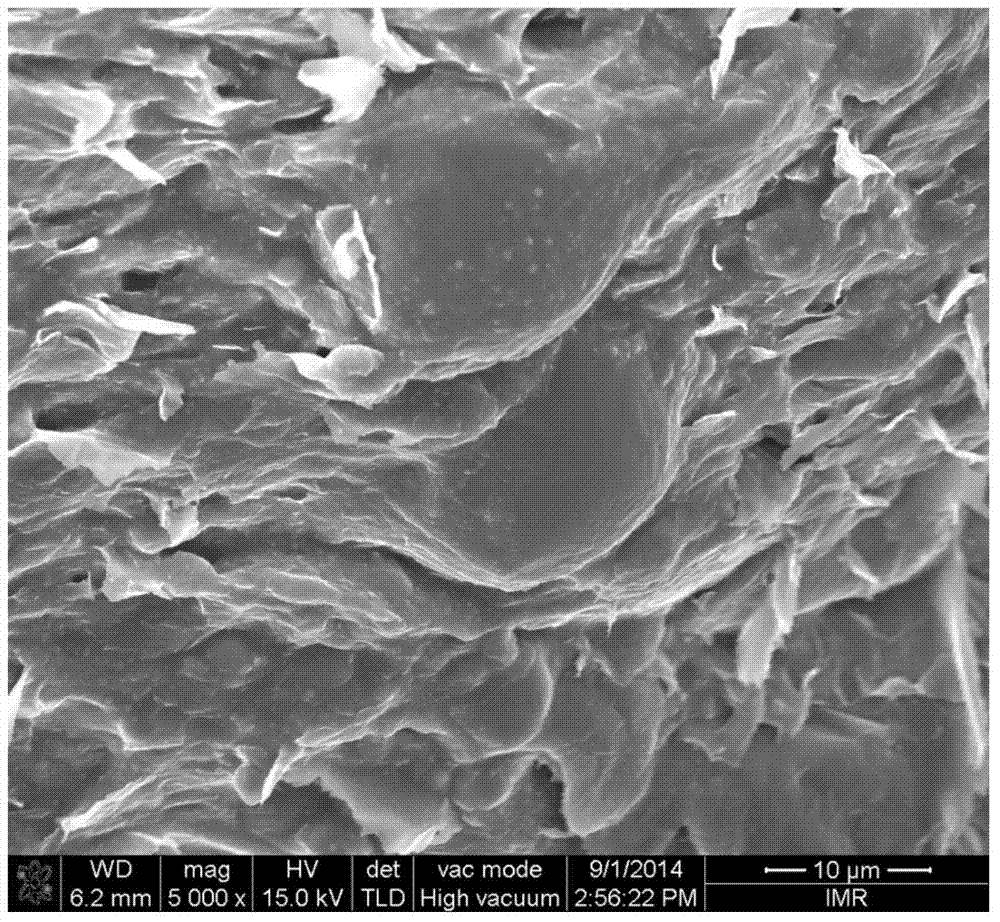

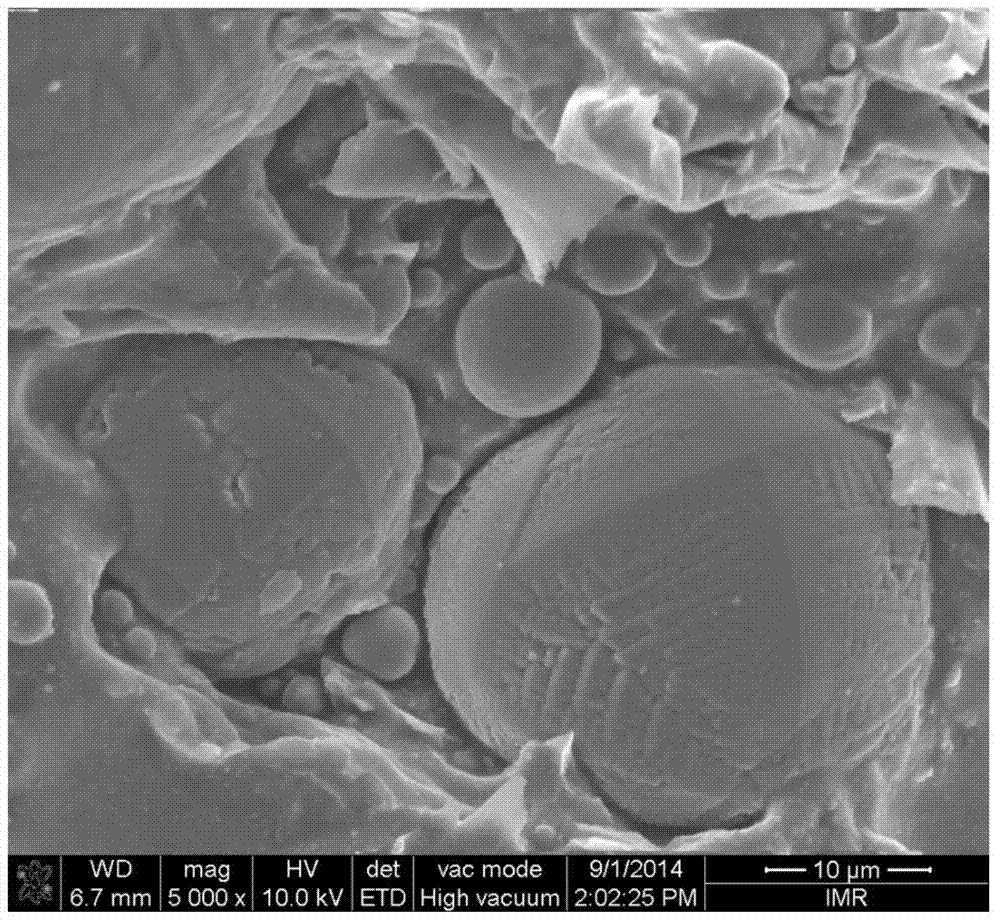

Graphene-containing silicon rubber heat-conducting composite material and preparation method thereof

The invention relates to the field of heat-conducting high-polymer composite materials, particularly a graphene-containing silicon rubber heat-conducting composite material and a preparation method thereof. The heat-conducting composite material is mainly composed of graphene, an inorganic heat-conducting filler and a silicon rubber matrix, wherein the graphene accounts for 0.1-10 wt% of the silicon rubber heat-conducting composite material, and the graphene constitutes a heat-conducting network in the heat-conducting composite material. The method comprises the following steps: uniformly compounding the inorganic heat-conducting filler, graphene, crosslinking agent and other assistants and silicon rubber on a double-roll open mill to obtain a heat-conducting silicon rubber prepolymer; and carrying out primary vulcanization on the prepolymer on a flat vulcanizing machine, and carrying out secondary vulcanization in a drying oven to finally obtain the composite heat-conducting silicon rubber. Since the two-dimensional graphene has large thickness-diameter ratio and can easily constitute an effective heat-conducting network in the silicon rubber, a small amount of two-dimensional graphene can obviously enhance the heat-conducting property of the silicon rubber (the heat conductivity coefficient at 40 DEG C is 4.98 W / m.K). The silicon rubber composite heat-conducting material can be widely used in the field of heat dissipation of electronic products.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

Transfer ink jet recording apparatus

Disclosed herein is a transfer ink jet recording apparatus equipped with a substrate; an intermediate transfer member that is arranged on the substrate and has a surface containing at least one material of fluorine-containing rubber and silicone rubber, said surface being subjected to a modification treatment by a plasma treatment and an application treatment with a compound represented by the general formula (1) defined in the specification; an application unit for applying a component that causes ink viscosity increase to the modification-treatment-subjected surface of the intermediate transfer member; an ink jet recording unit for ejecting an ink on the intermediate transfer member to which the component has been applied to form an intermediate image; and a transfer unit for transferring the intermediate image formed on the intermediate transfer member to a recording medium.

Owner:CANON KK

Surgical correction of human eye refractive errors by active composite artificial muscle implants

Correction of eye refractive errors such as presbyopia, hyperopia, myopia, and astigmatism by using either pre-tensioned or transcutaneously energized artificial muscle implants to change the axial length and the anterior curvatures of the eye globe by bringing the retina / macula region to coincide with the focal point. The implants are scleral constrictor bands, segments or ribs for inducing accommodation of a few diopters, to correct the refractive errors on demand or automatically. The implant comprises an active sphinctering band encircling the sclera, implanted under the conjunctiva and under the extraocular muscles to uniformly constrict the eye globe, to induce active temporary myopia (hyperopia) by increasing(decreasing) the length and curvature of the globe. Multiple and specially designed constrictor bands enable surgeons to correct astigmatism. The artificial muscles comprise materials such as composite magnetic shape memory (MSM), heat shrink, shape memory alloy-silicone rubber, electroactive ionic polymeric artificial muscles or electrochemically contractile ionic polymers bands.

Owner:OPHTHALMOTRONICS

Simulated tissue, body lumens and body wall and methods of making same

Owner:COLORADO STATE UNIVERSITY

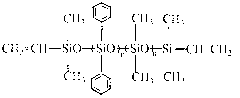

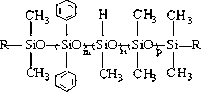

Silicon rubber with high refractive index and high transparency for optical encapsulation and preparation method thereof

ActiveCN103122149AHigh refractive indexImprove mechanical propertiesSemiconductor devicesHydrogenPolymer science

The invention relates to silicon rubber with high refractive index and high transparency for optical encapsulation and a preparation method thereof. The silicon rubber is prepared from a phenyl vinyl polysiloxane component A, a silicon resin component B containing phenyl vinyl, a phenyl component C containing hydrogen polyoxyalkylene, a platinum catalyst component D, a catalytic inhibitor component E, a modified polysiloxane component F, and a water remover component G in a mixing manner. The silicon rubber not only has over 1.50 of refractive index, but also is good in transparency, excellent in adhesion, and stable in performance, can resist heat and ultraviolet radiation for a long period of time, can meet various requirements of LED (light-emitting diode) encapsulation, and is an ideal encapsulation material of the LED. The silicon rubber can be packaged into a bi-component product; the product has good storage stability; and high transparency is still kept after the product is stored for over 6 months.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

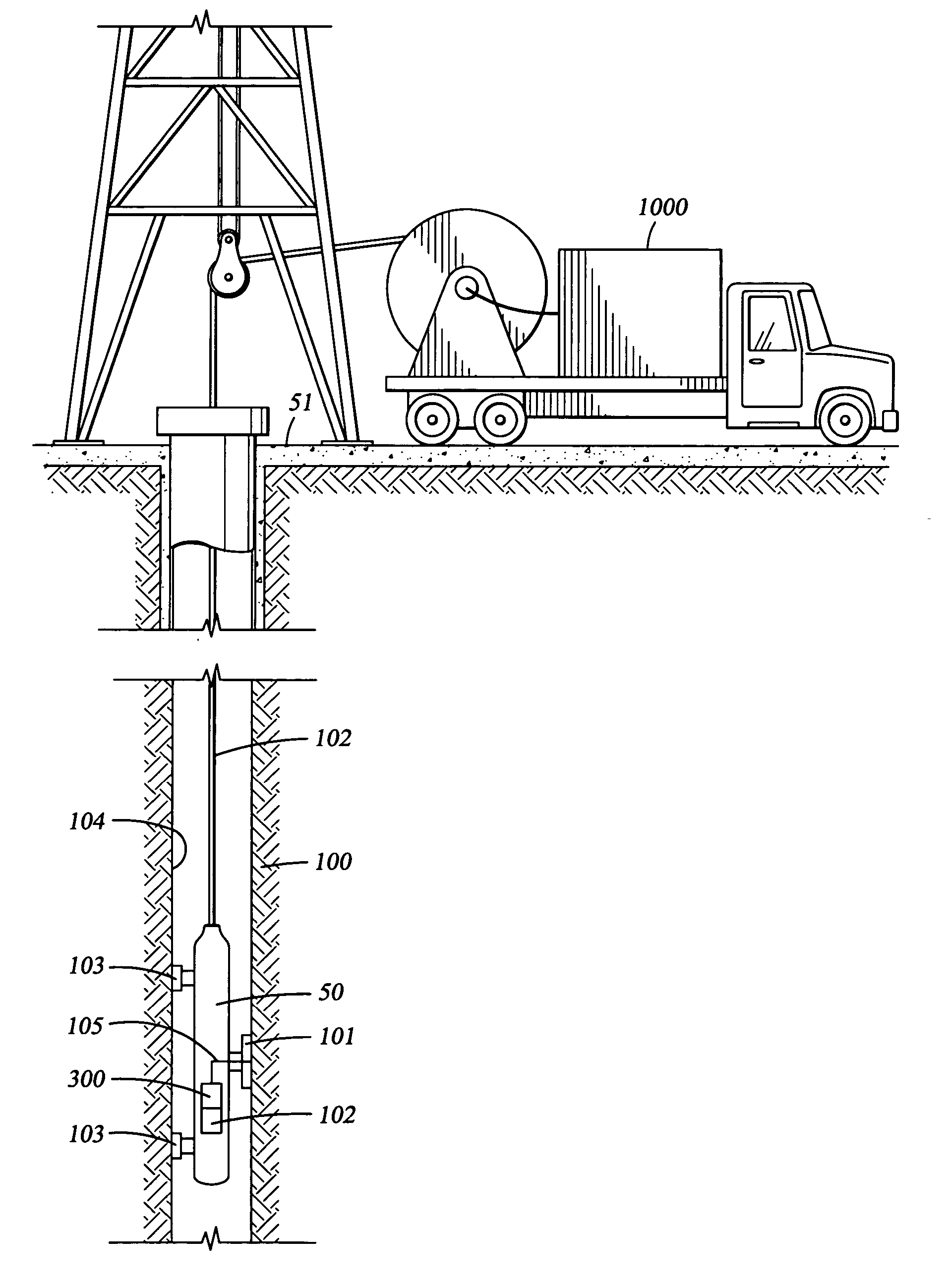

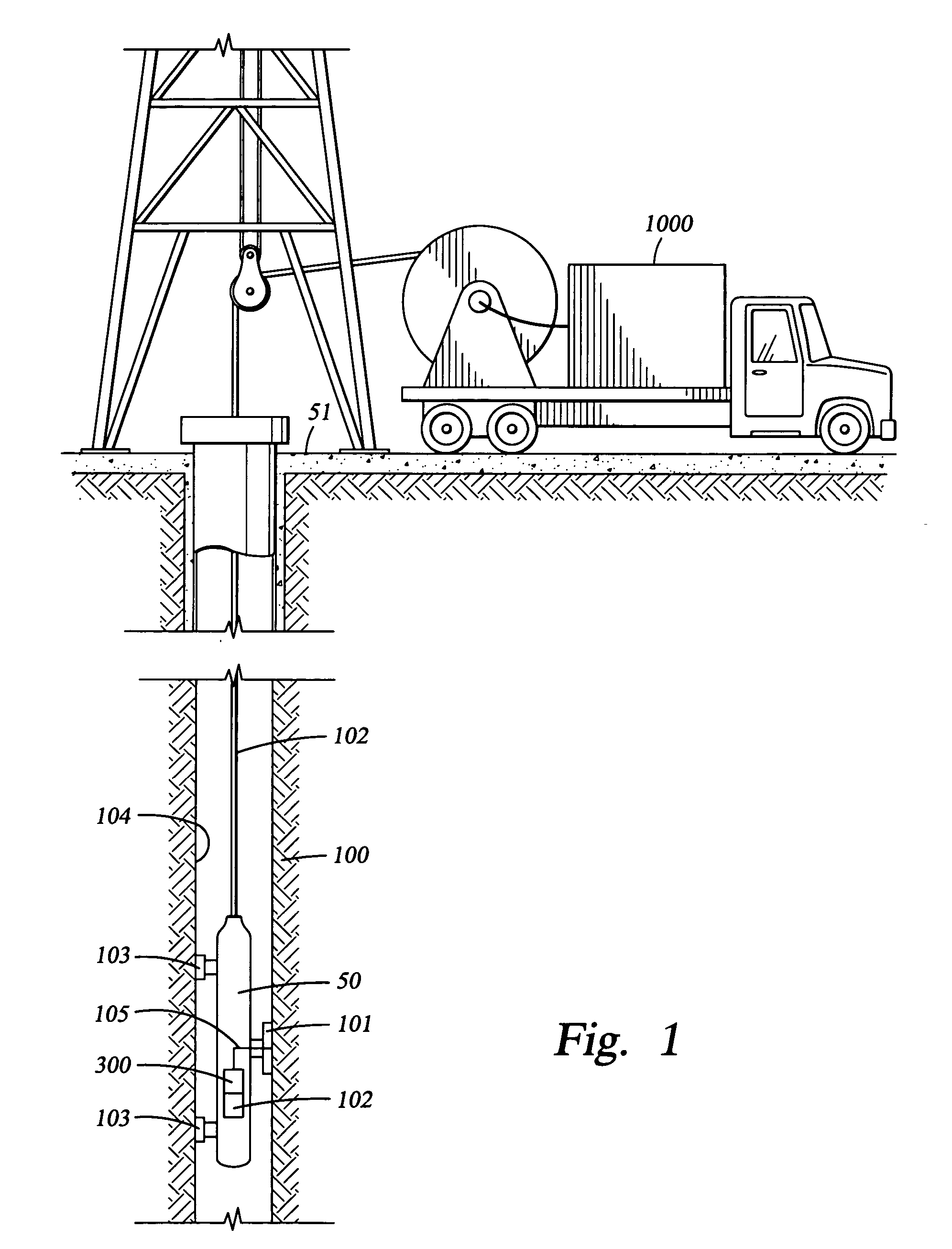

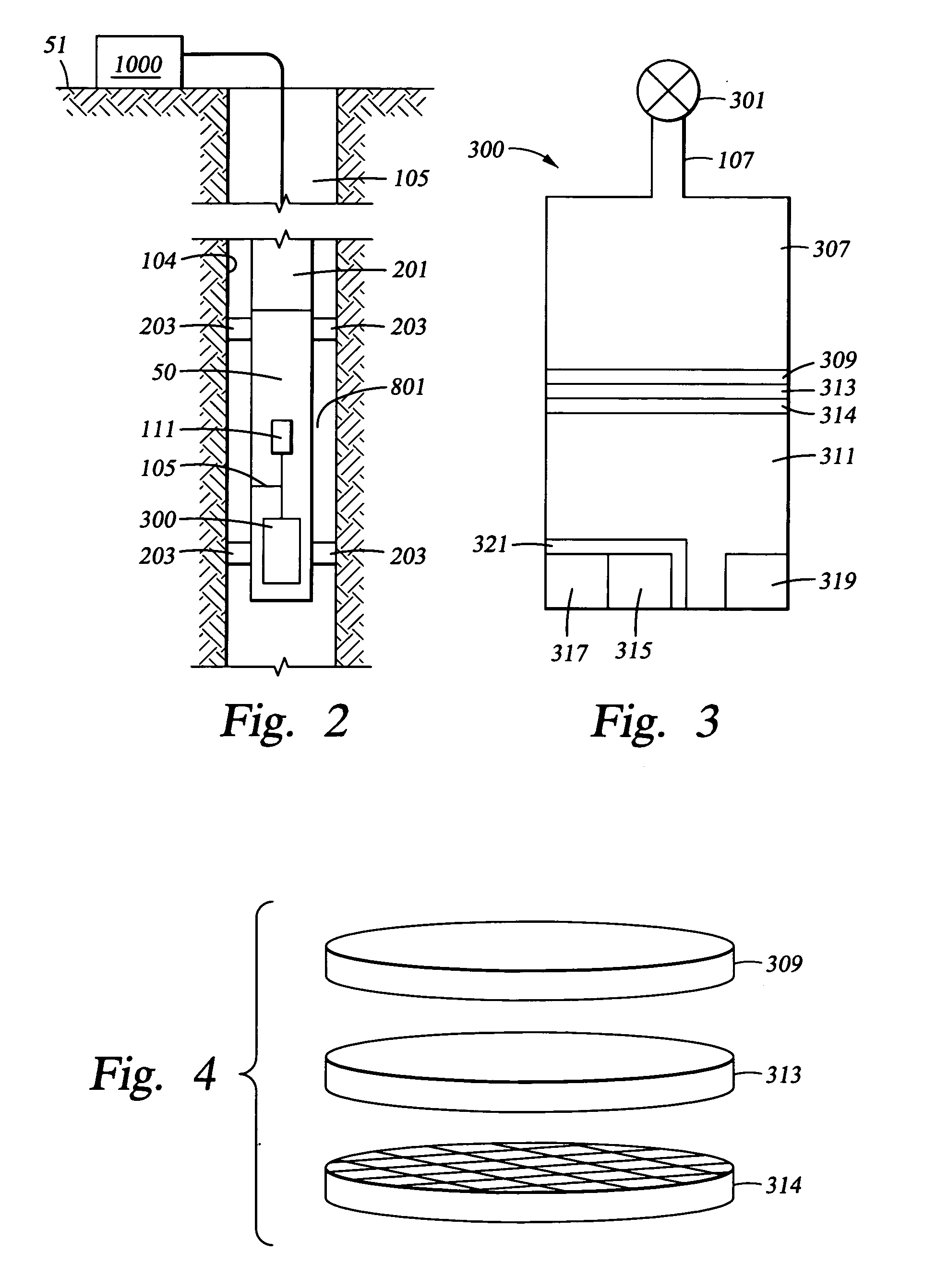

Method and apparatus for downhole fluid analysis for reservoir fluid characterization

InactiveUS20050205256A1Interfere with measurementSurveyParticle separator tubesResidual gas analyzerSorbent

A formation fluid sample is exposed to a rigidly-supported semi-permeable membrane such as silicone rubber to permit diffusion of gases and vapors from the formation fluid into a vacuum chamber, while at the same time, blocking the passage of any liquids. The membrane-transmitted gas is analyzed in the vacuum chamber by a residual gas analyzer. An ion pump or sorbent is associated with the evacuated chamber to maintain the vacuum. The ion pump or sorbent removes gases and vapors from the chamber that diffuse into the chamber from the reservoir sample that is on the opposite side of the semi-permeable membrane.

Owner:BAKER HUGHES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com