Patents

Literature

4730results about How to "Improve skid resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

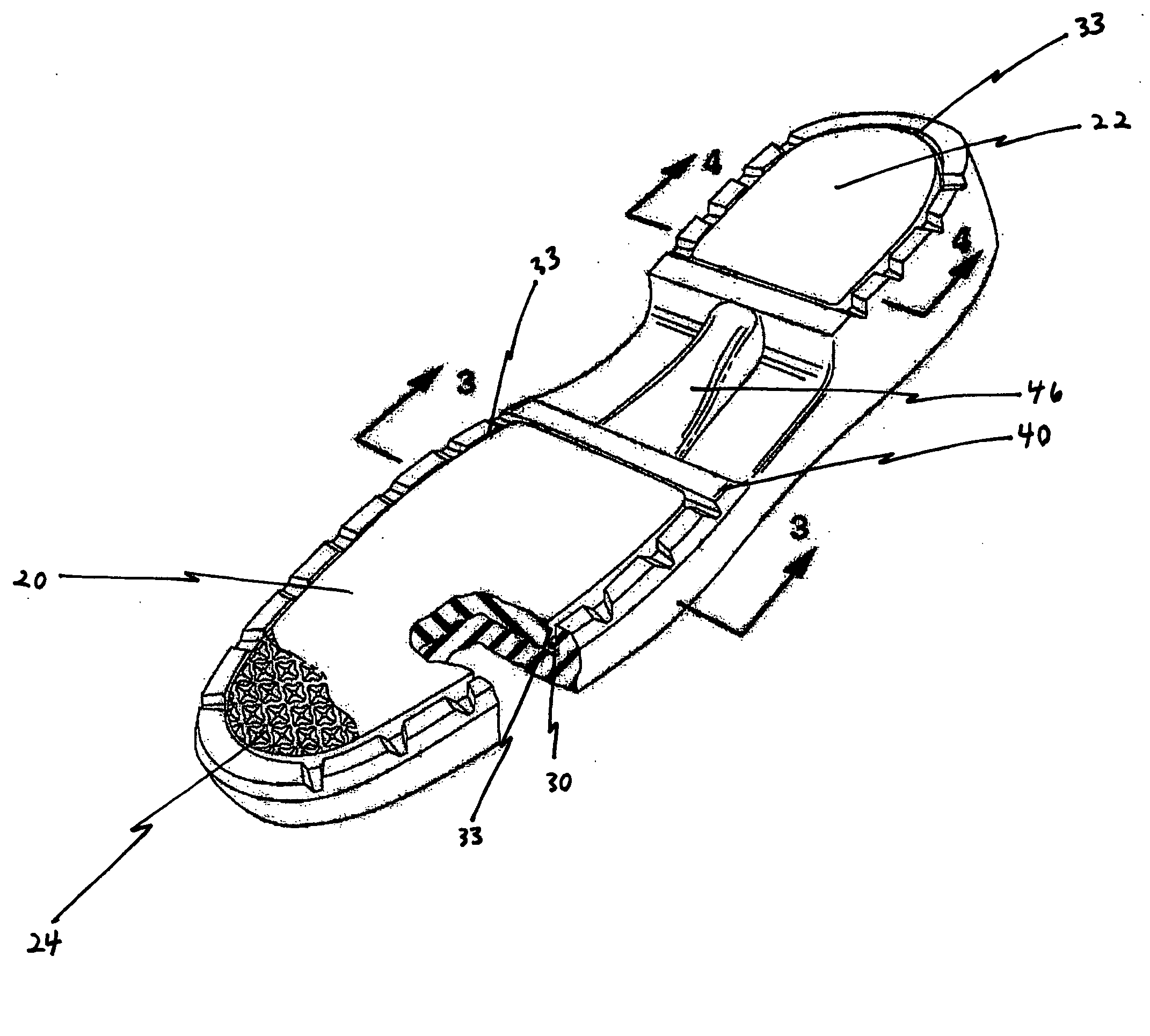

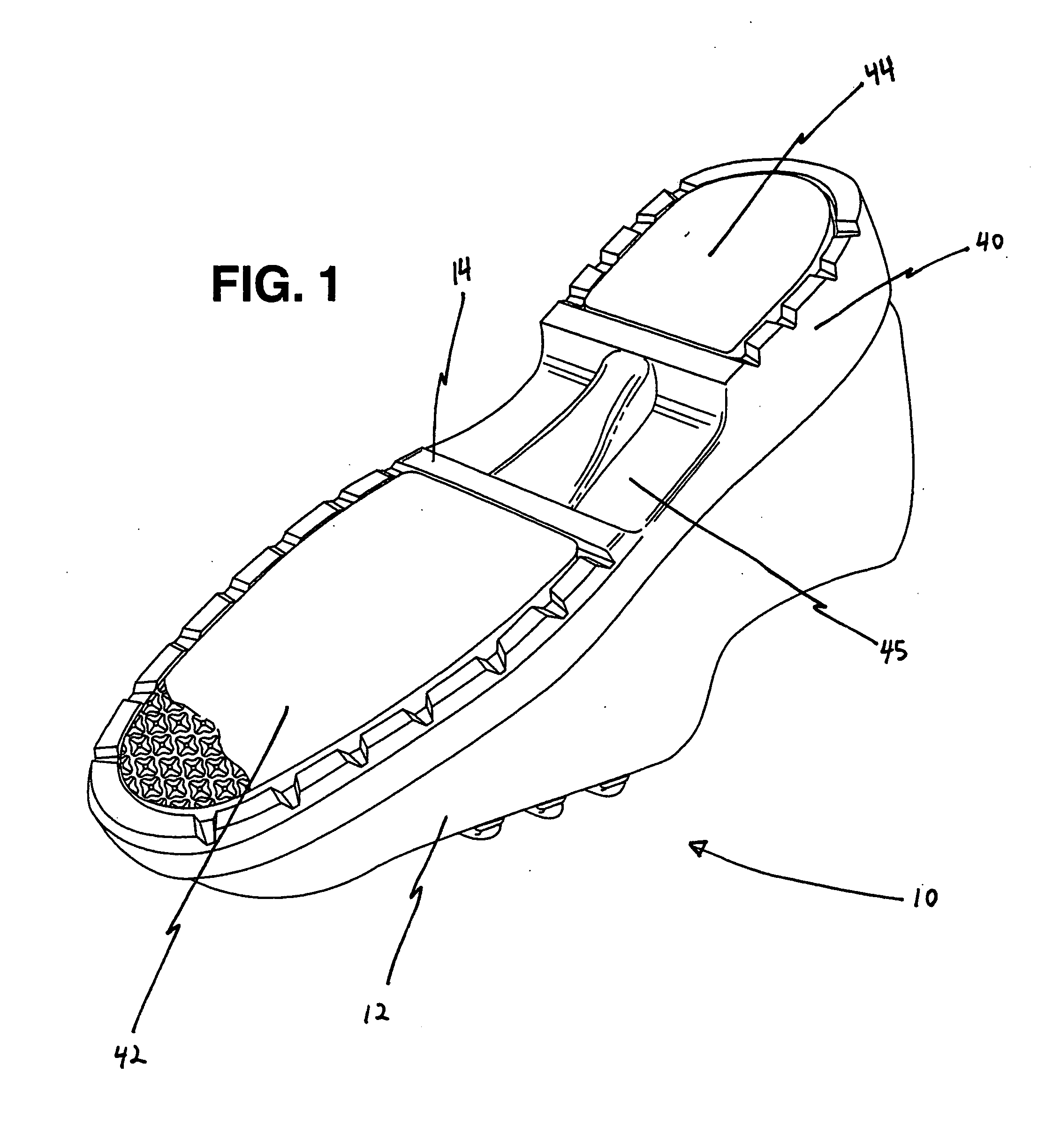

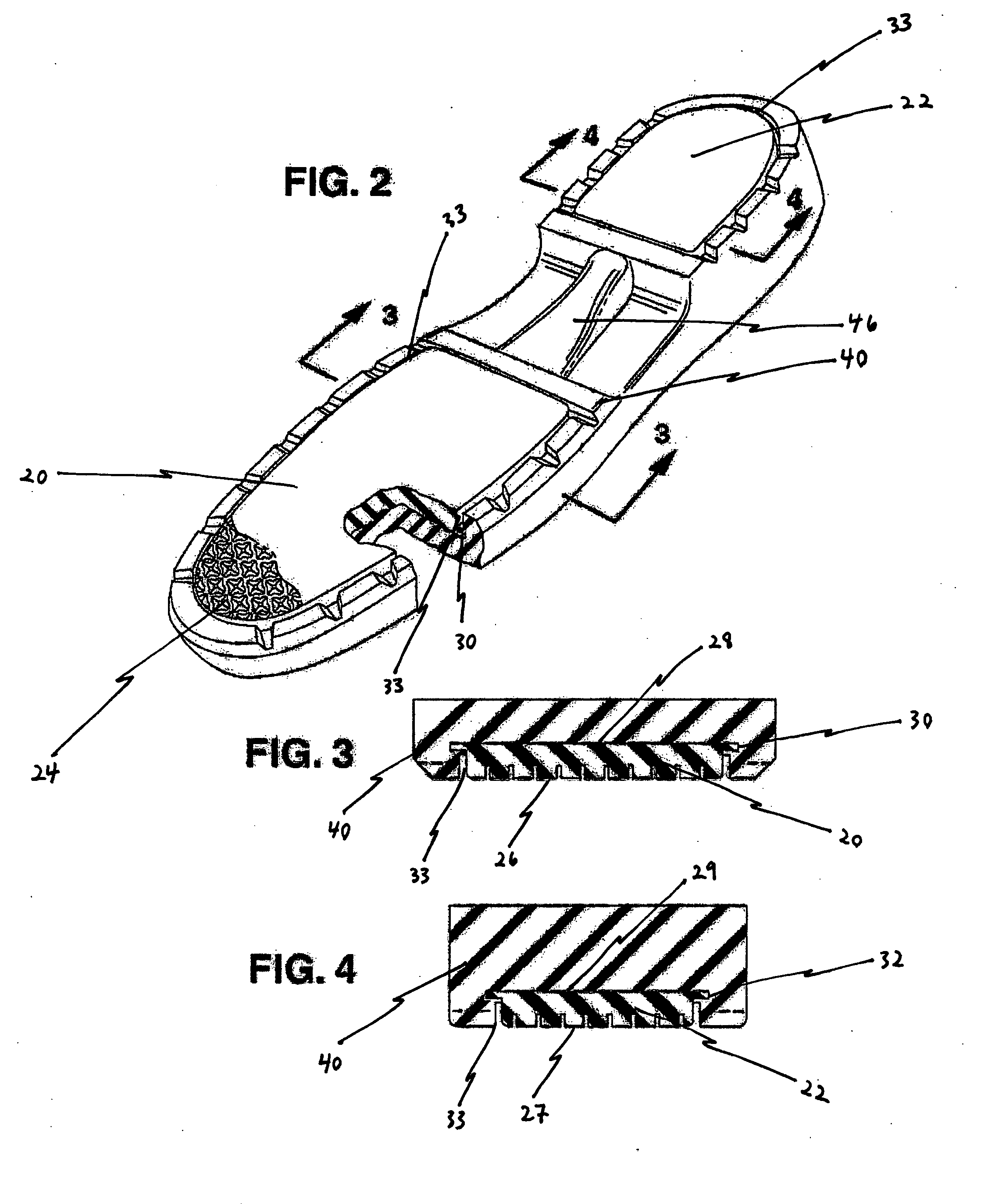

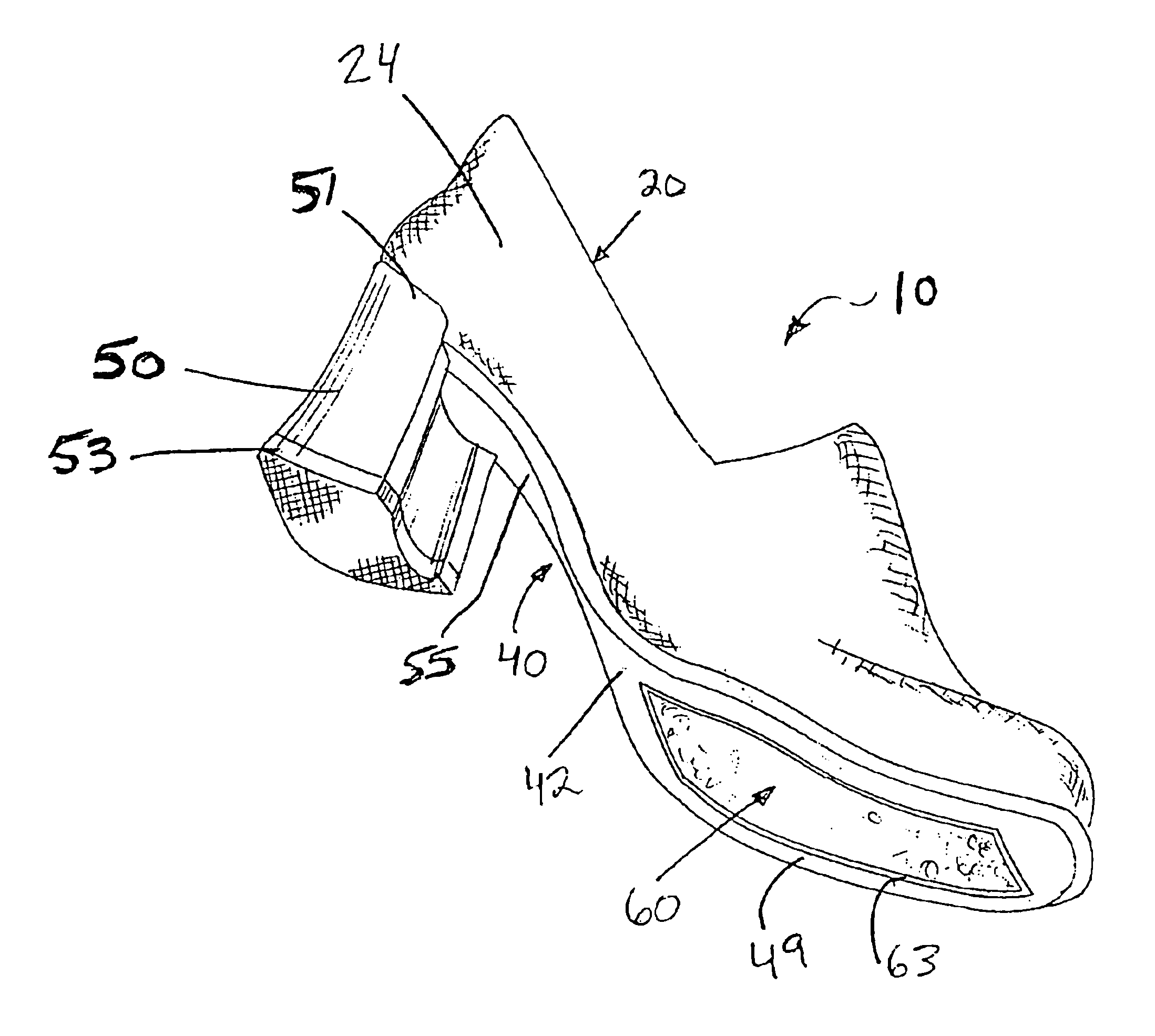

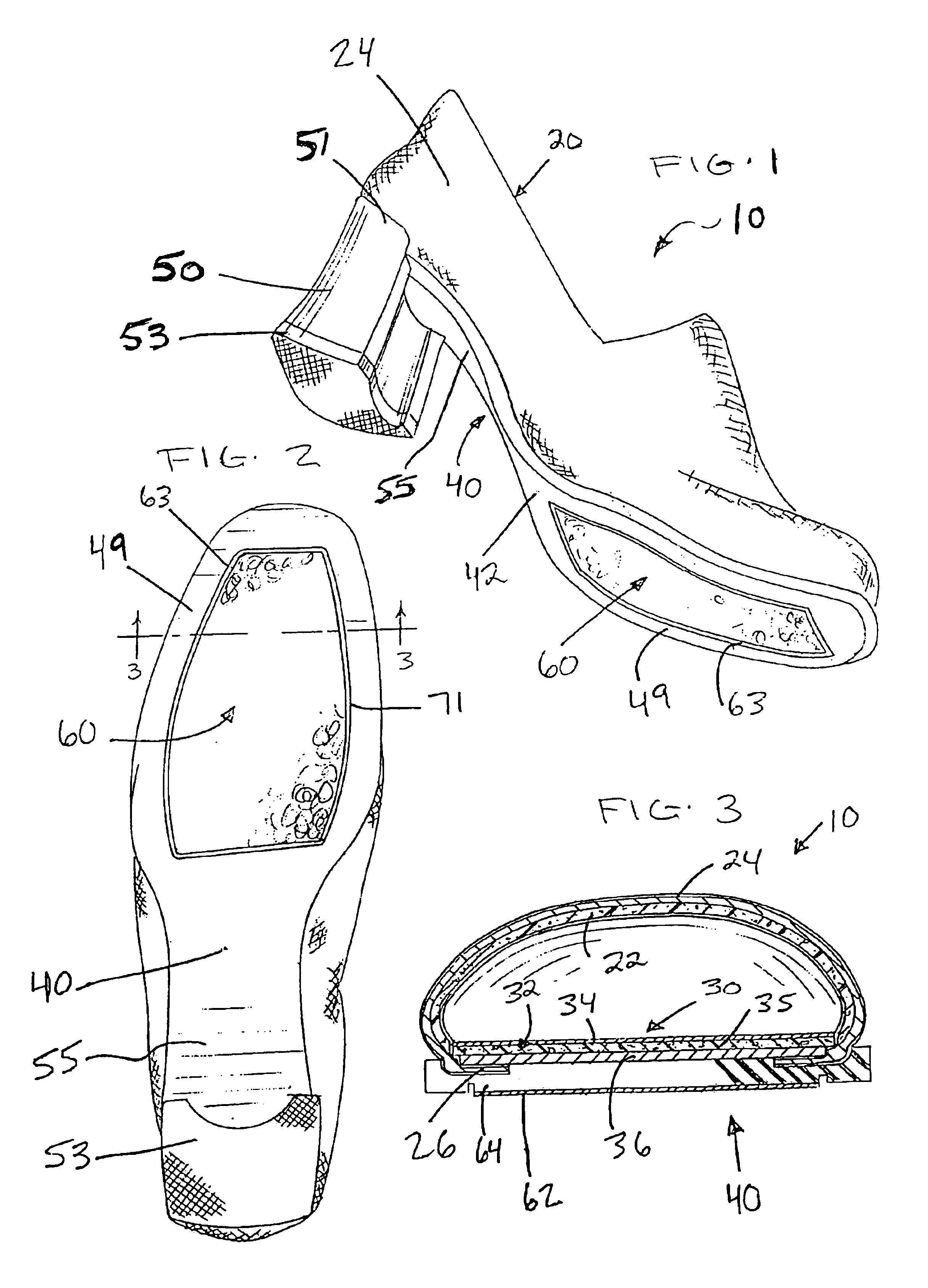

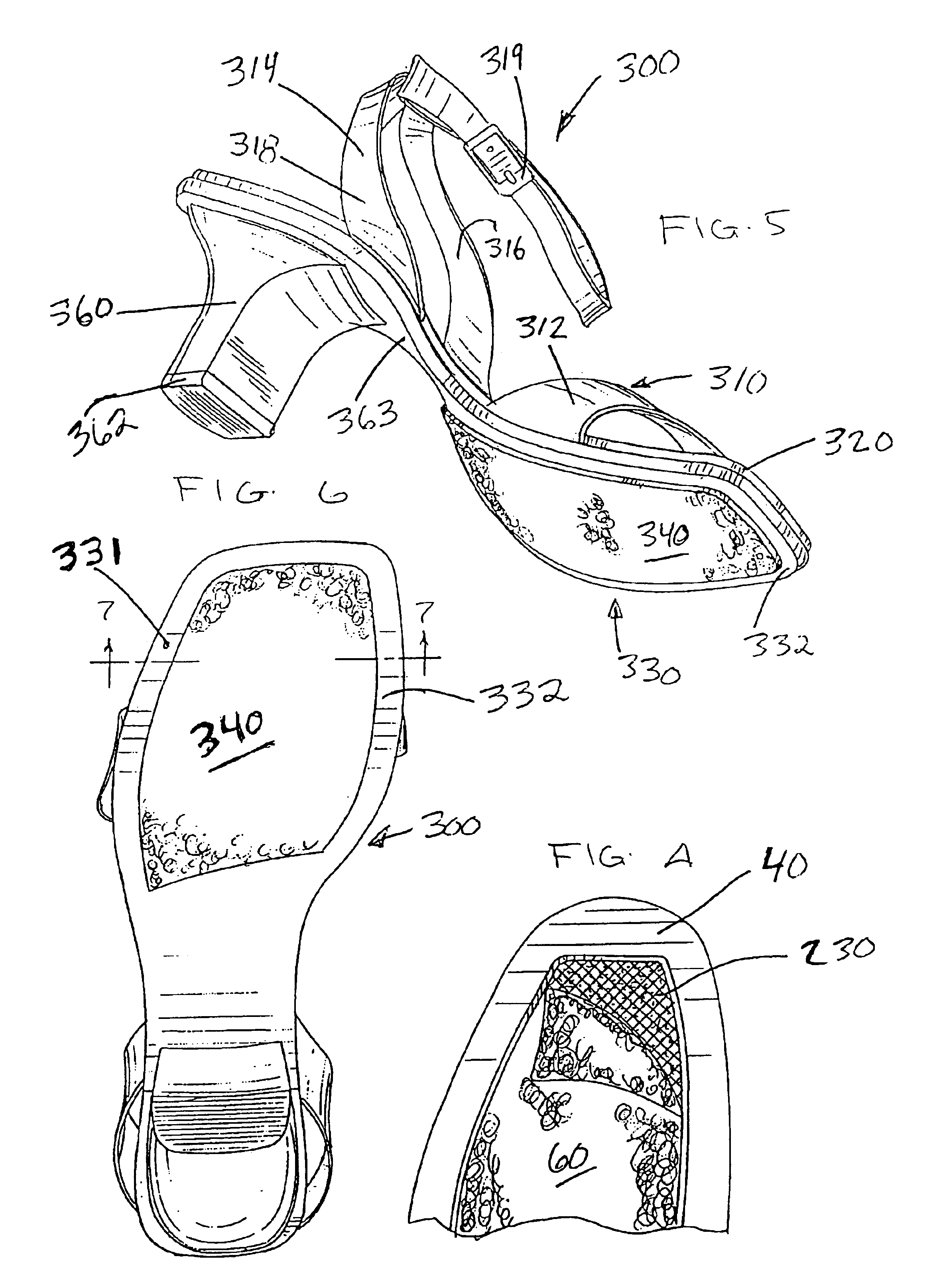

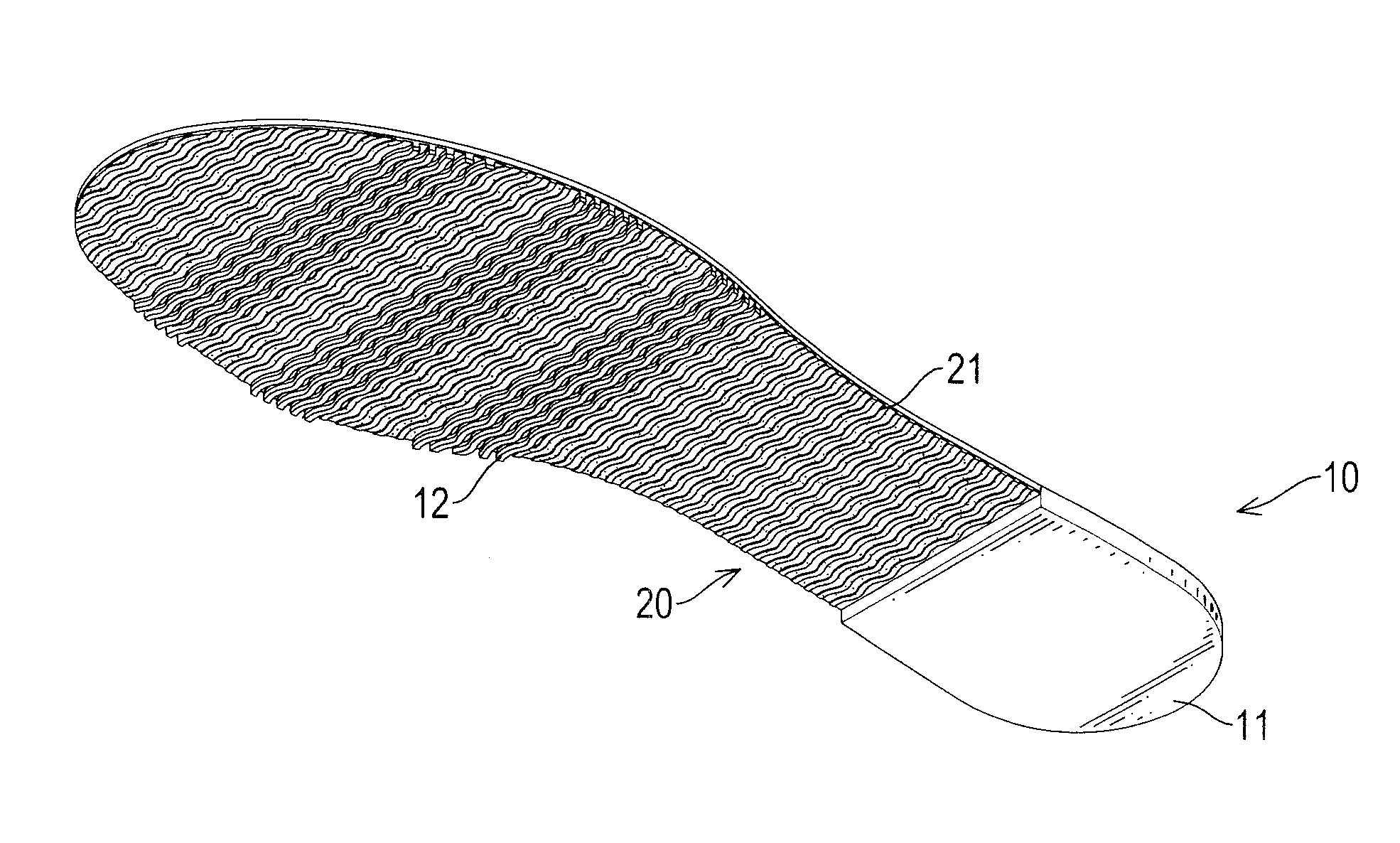

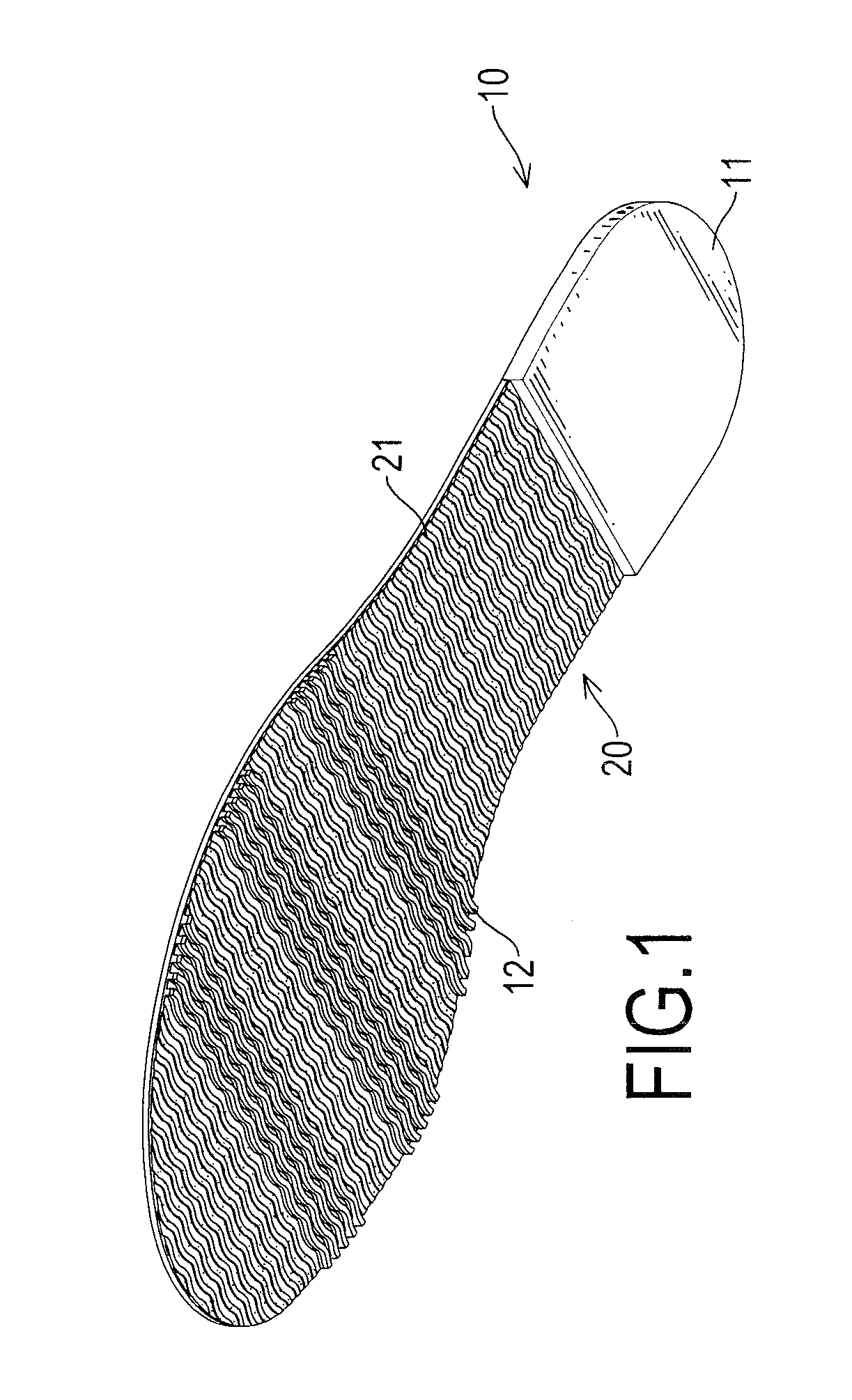

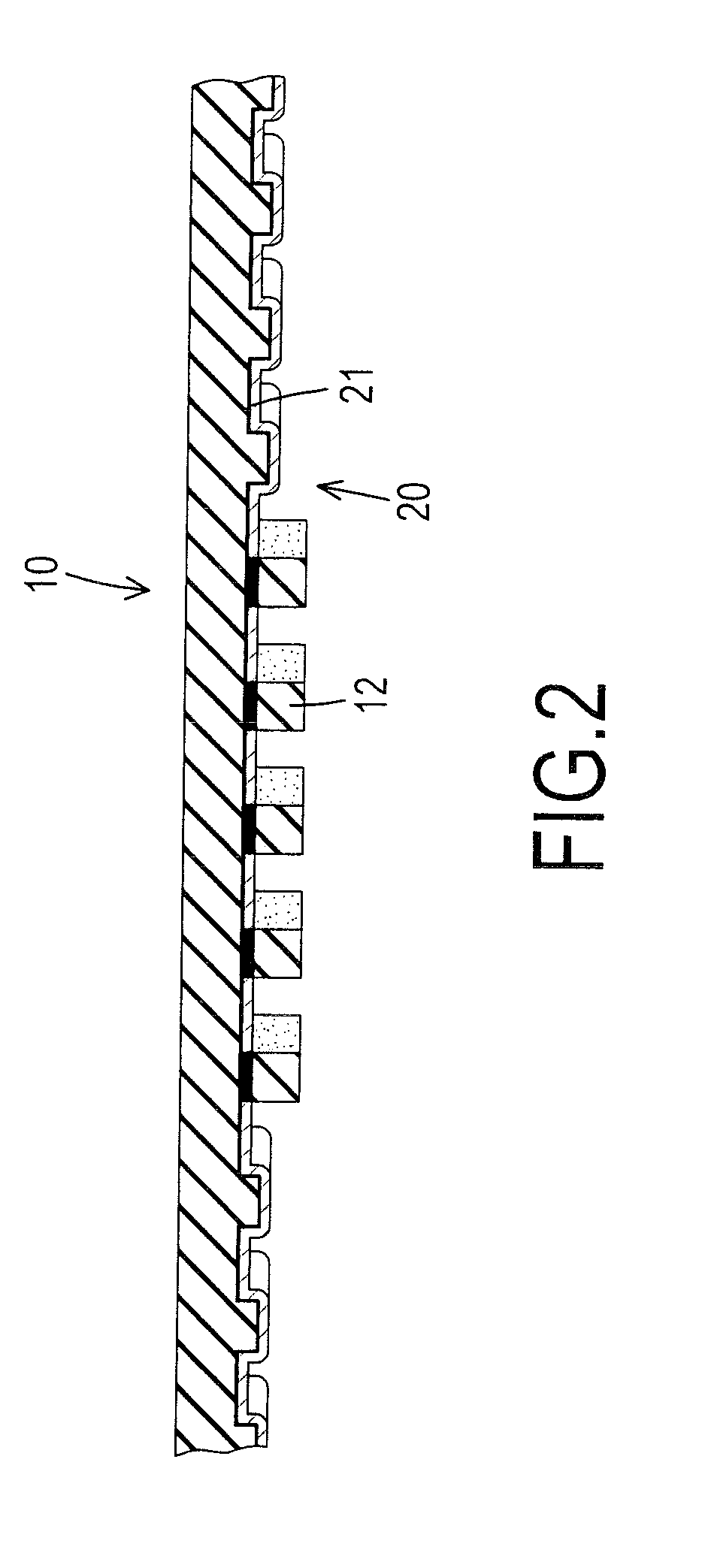

Footwear with improved sole, improved sole and method for manufacturing

Footwear with an improved sole, and an improved sole and a method for manufacturing the same are provided. The improved sole includes at least one pod secured in situ to a molded outsole. Each pod includes a ground-engaging end and an upper end having an outwardly extending flange proximate thereto. In the method for manufacture of the sole, the outsole is secured to the pods in situ. The outsole and pods are formed from different materials and are secured in situ during formation of the outsole, with each pod placed in a mold cavity section and the flange being encapsulated by the moldable outsole material.

Owner:ELAN POLO

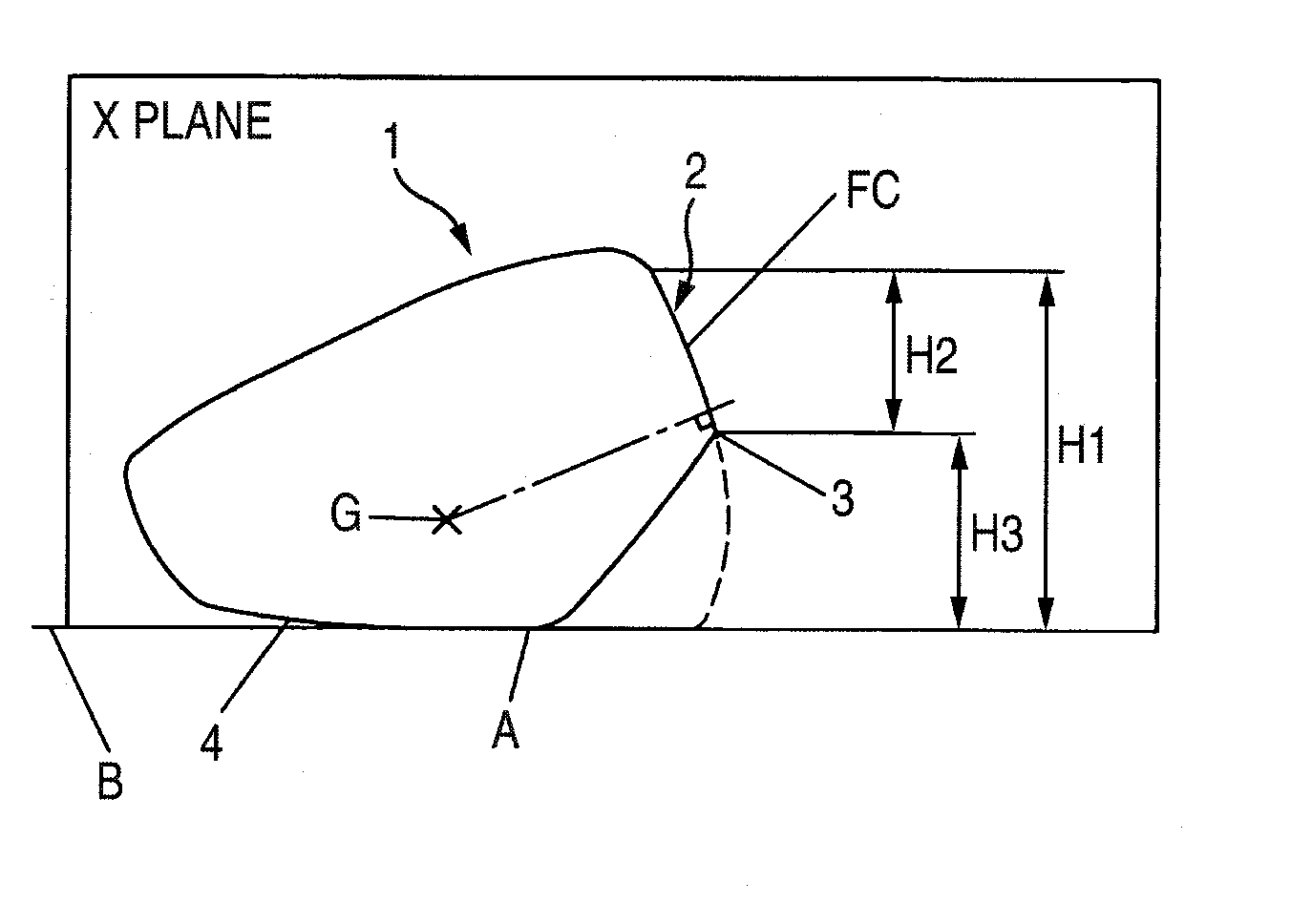

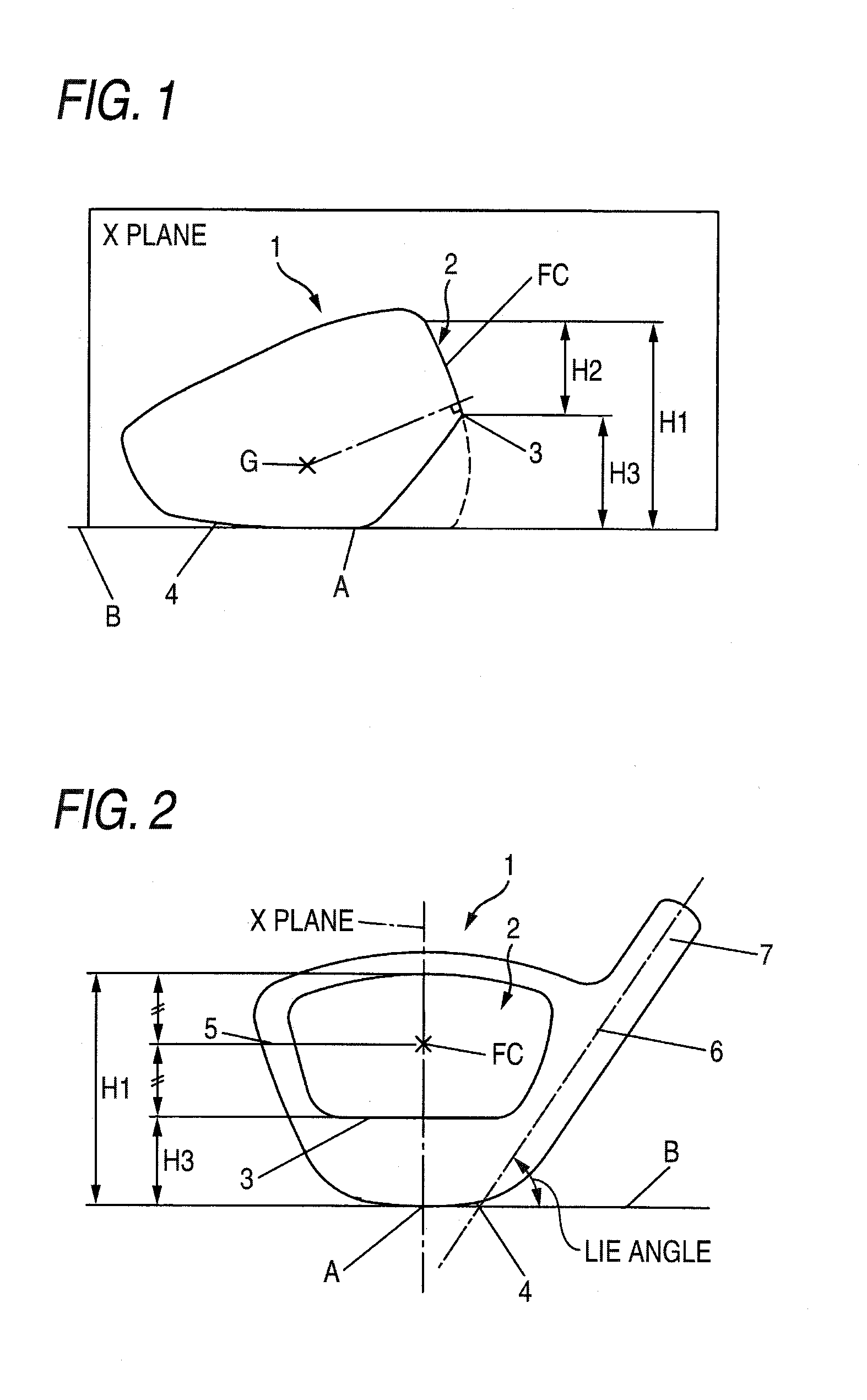

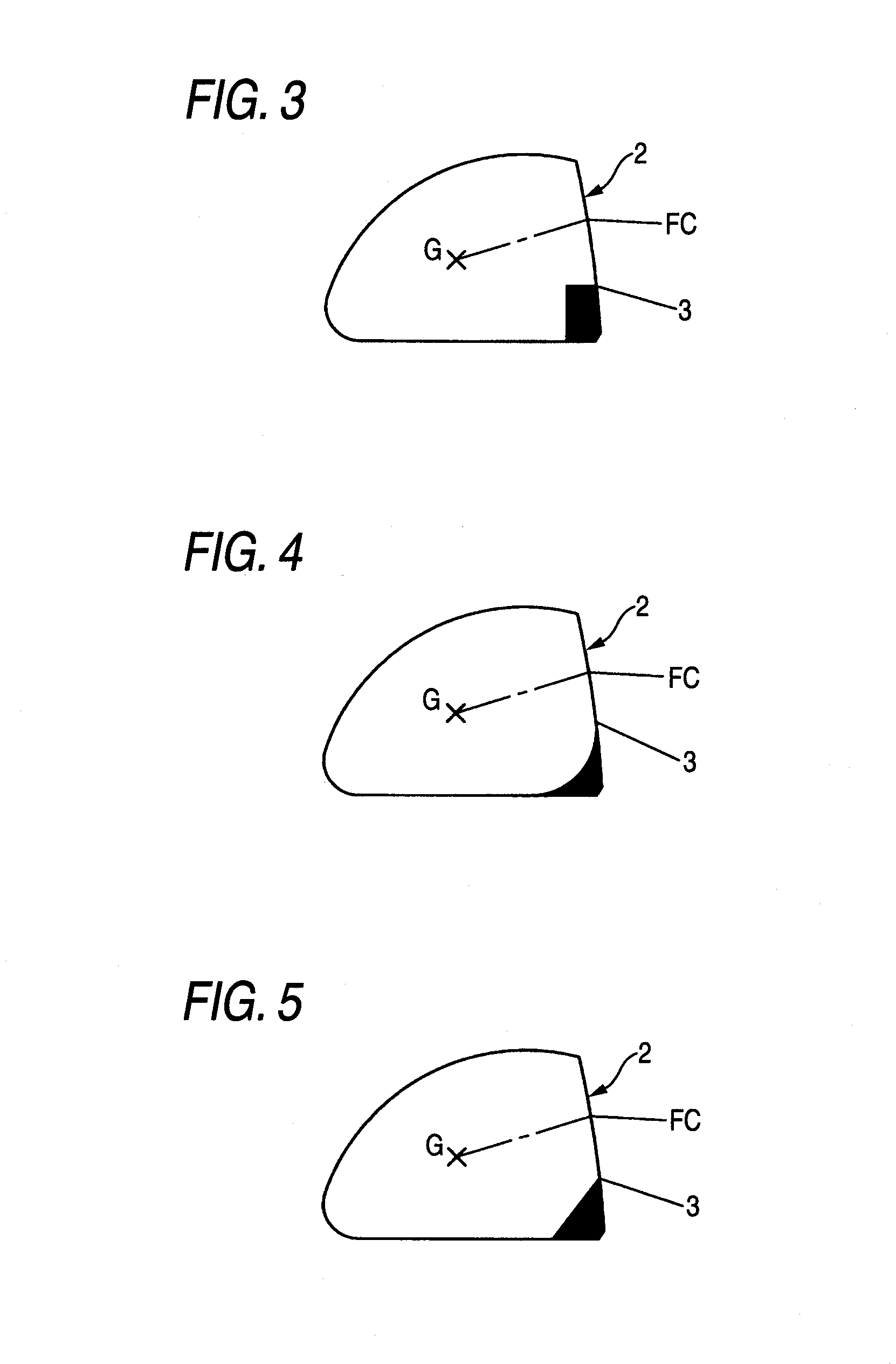

Wood-type golf club head

According to one embodiment, a wood-type golf club head includes: a face portion; a sole portion; a crown portion; a leading edge defined between the face portion and the sole portion; an upper edge defined between the face portion and the crown portion; wherein, at a basic state that the golf club head is set on a horizontal plane, a contact point between the horizontal plane and the sole portion is defined as a ground point, wherein a plane passing through the ground point and extending in a direction of a target line is defined as a vertical plane, wherein a height from the horizontal plane to a first intersection point where the face upper edge intersects the vertical plane is defined as a face height H1, and wherein a height H3 from the horizontal plane to a second intersection point where the vertical plane intersects the leading edge is defined in a range between ⅓ and ½ of the face height H1.

Owner:BRIDGESTONE SPORTS

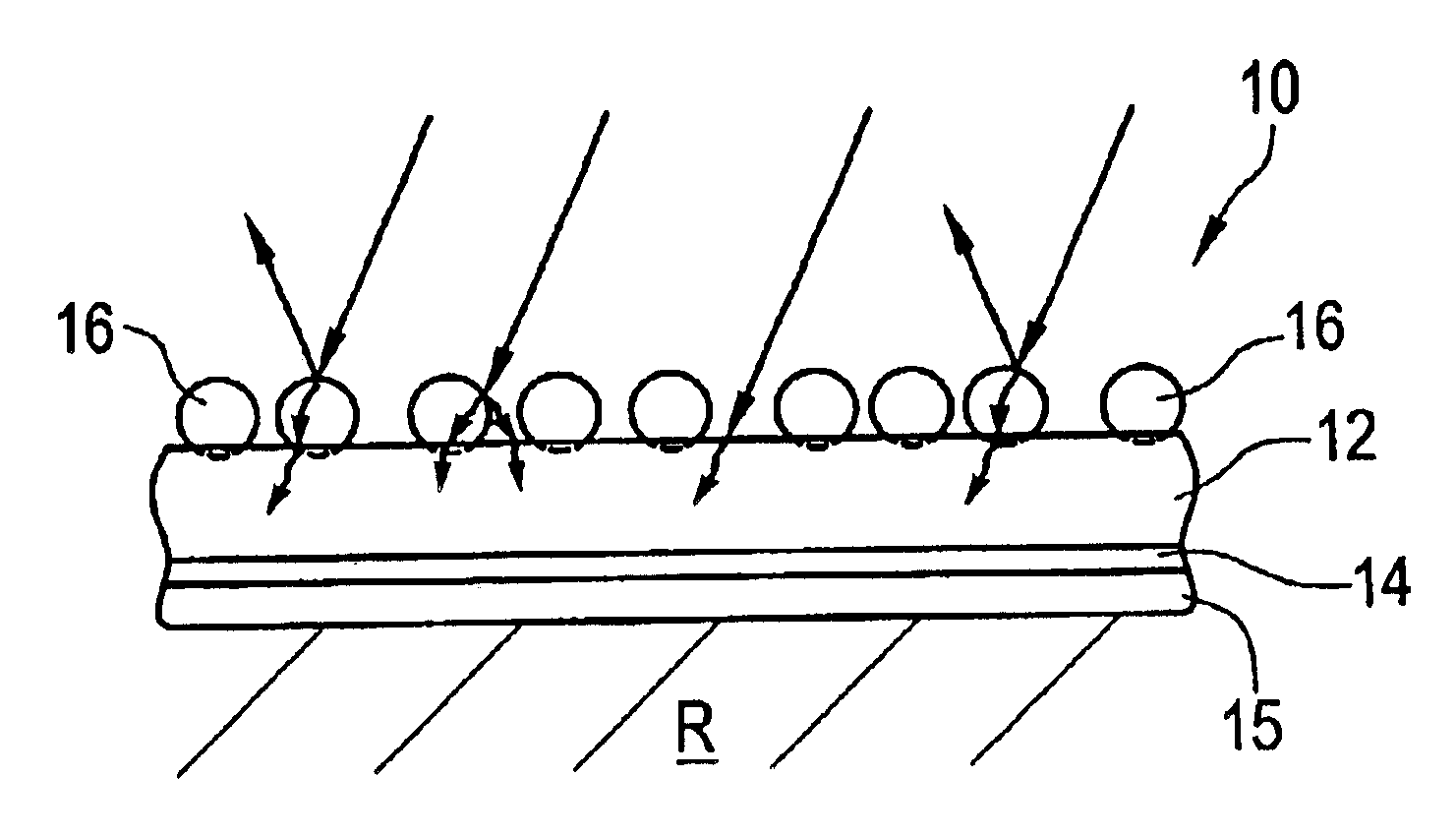

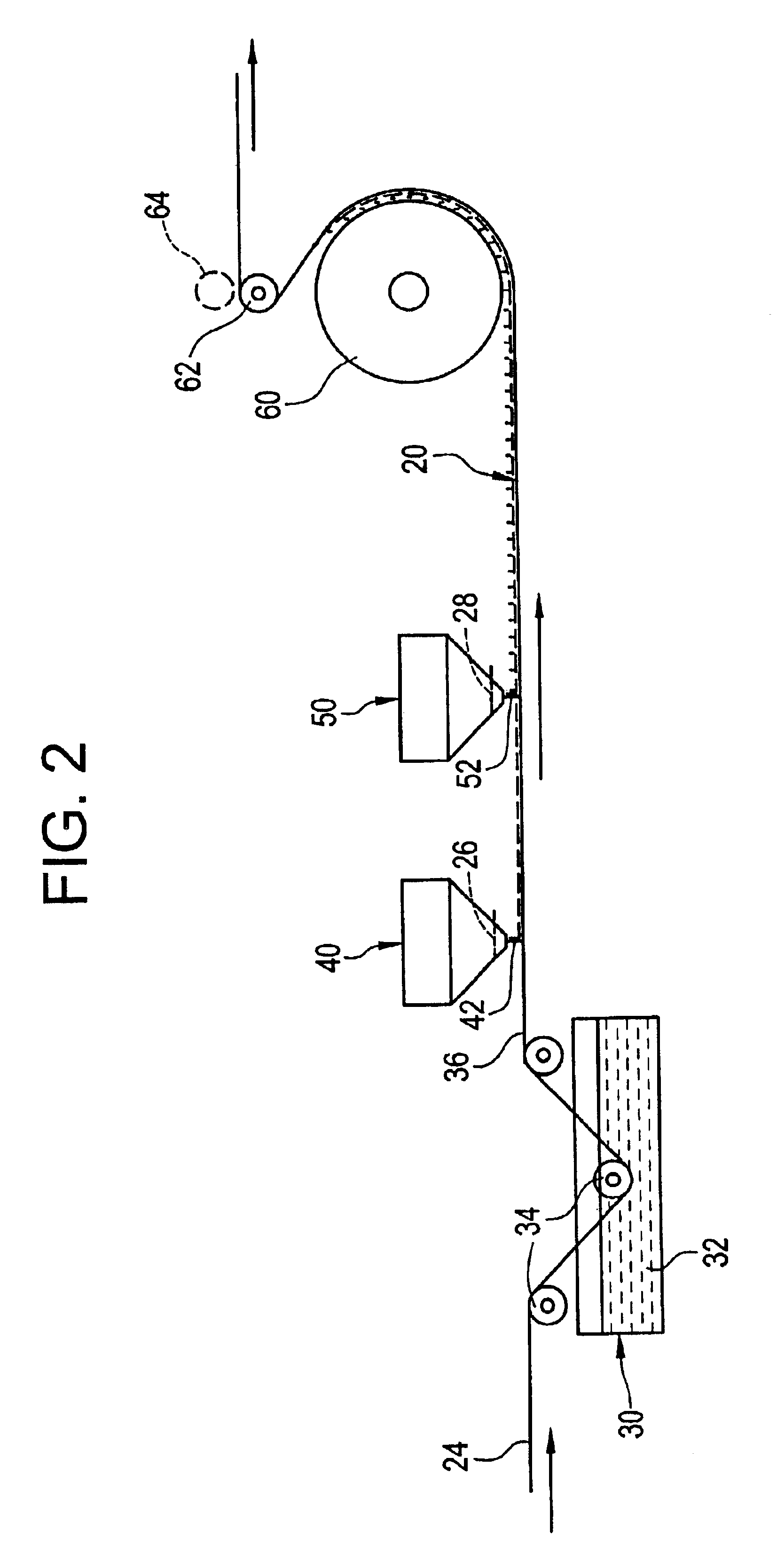

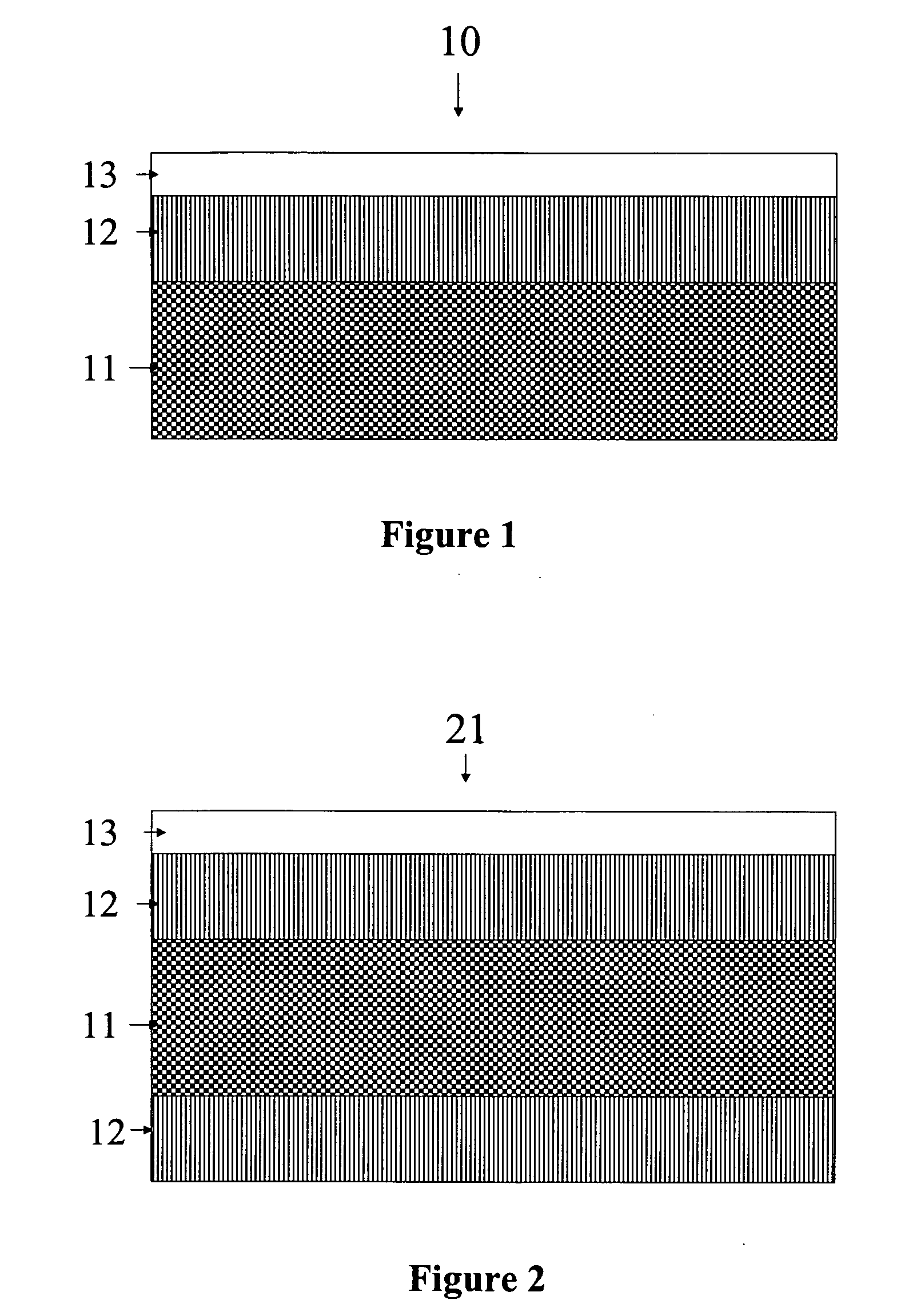

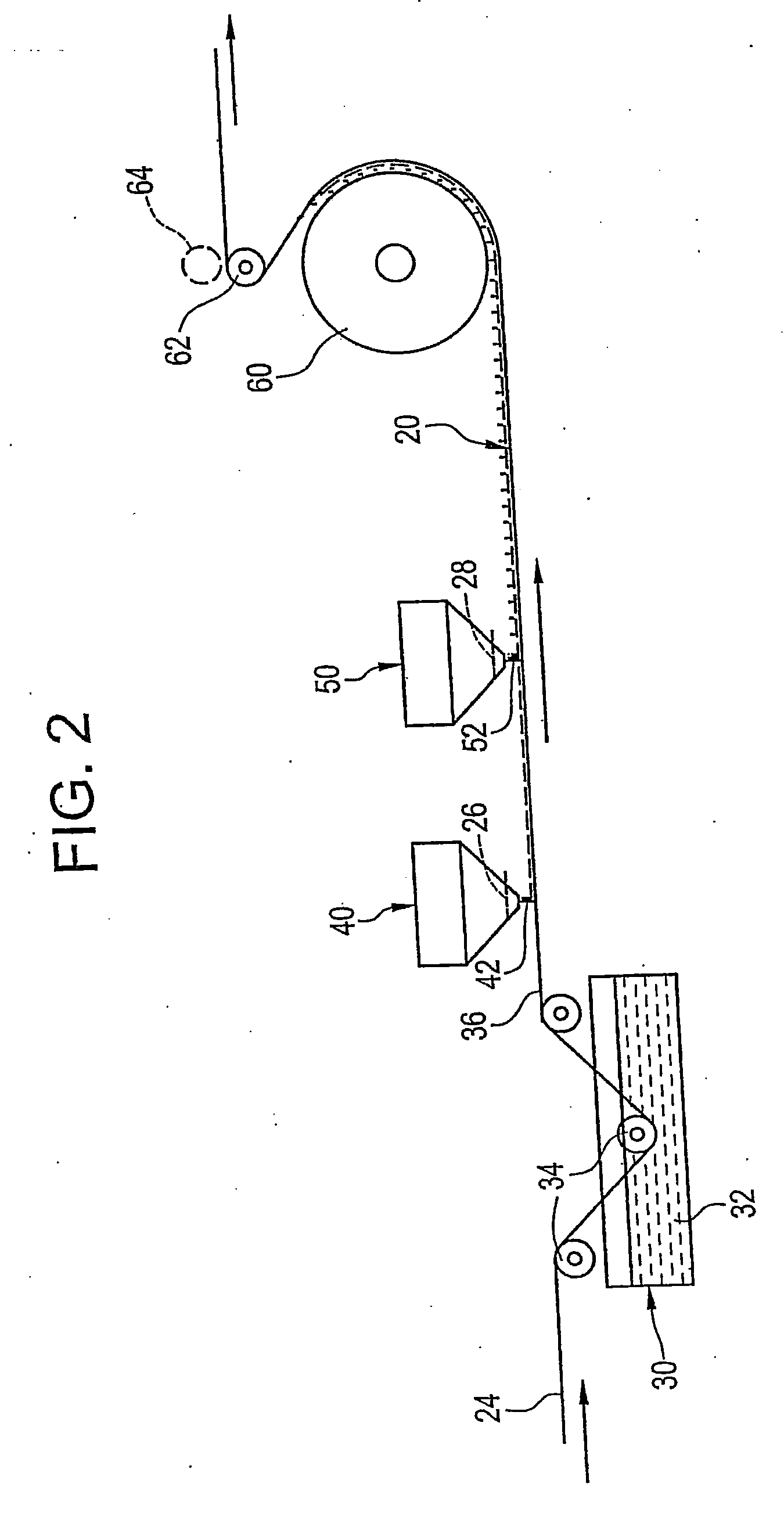

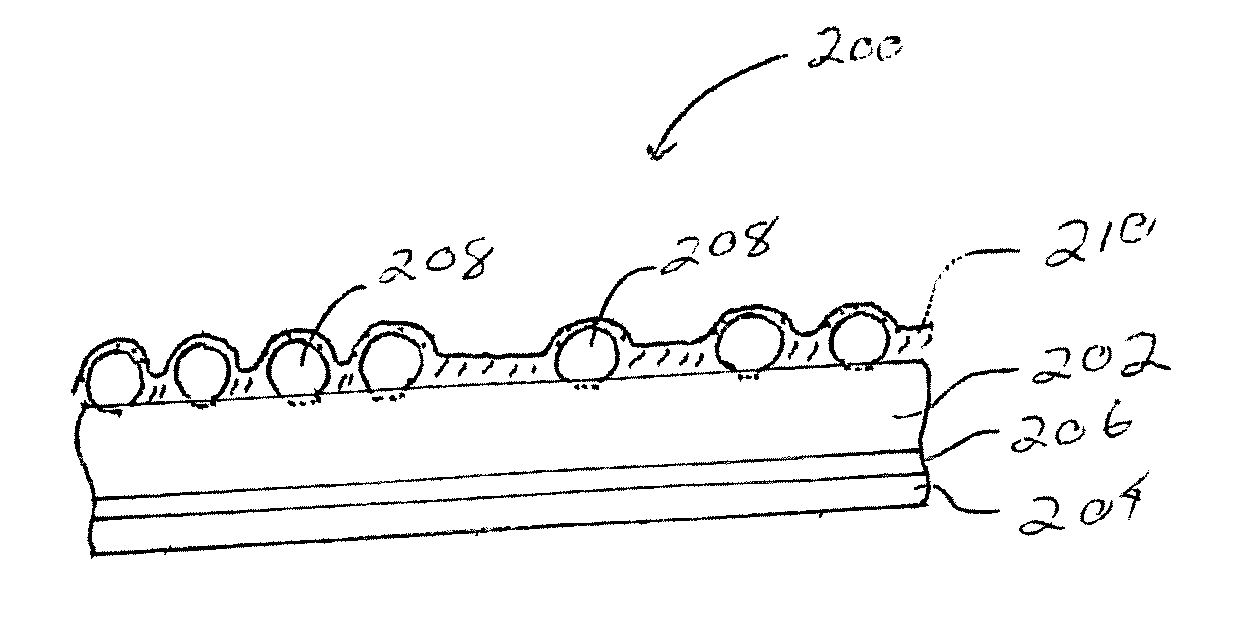

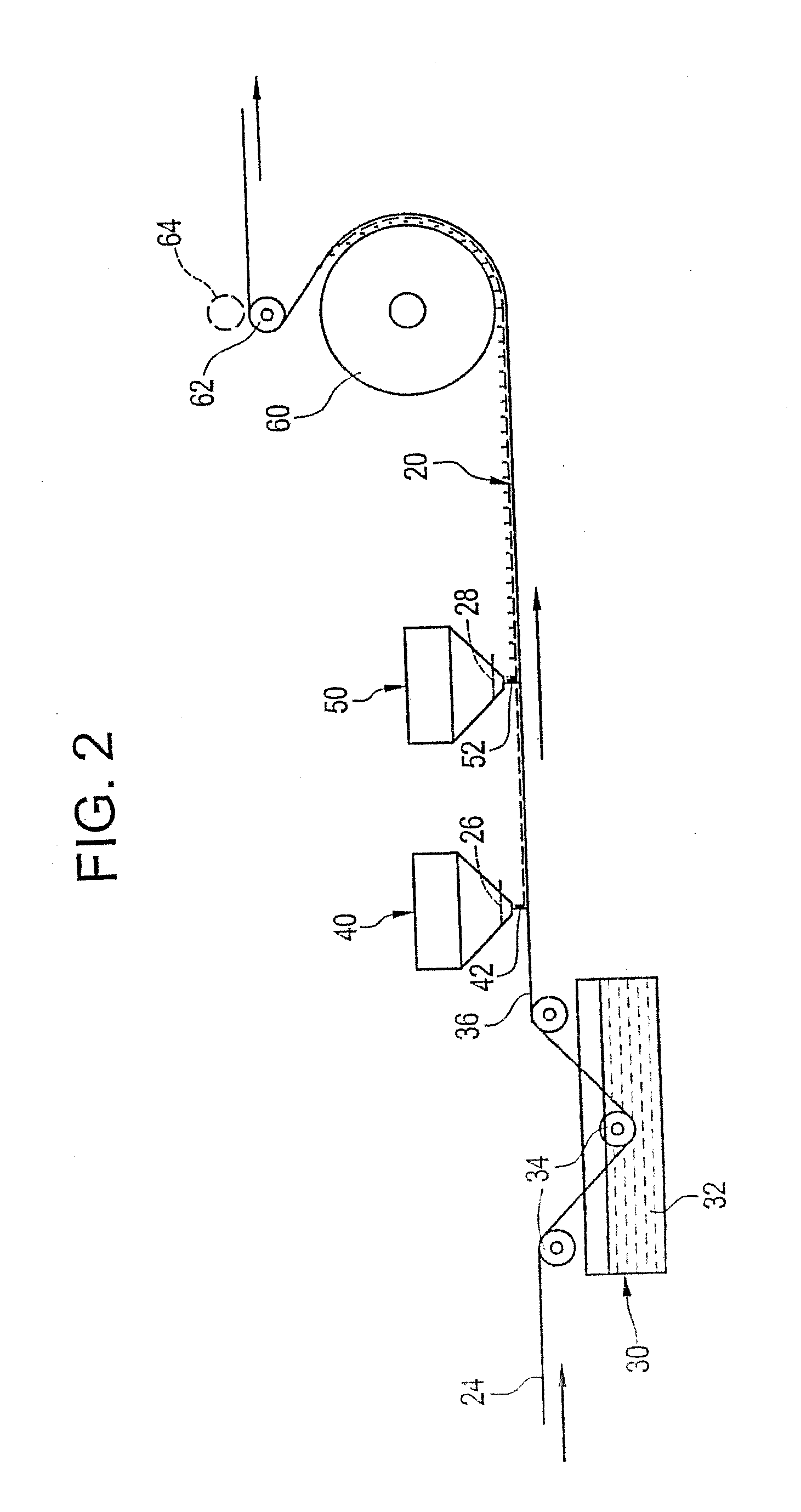

Method of forming an improved roofing material

InactiveUS6933007B2Improve reflectivityIncrease temperatureRoof covering using tiles/slatesCovering/liningsMaterials scienceReflectivity

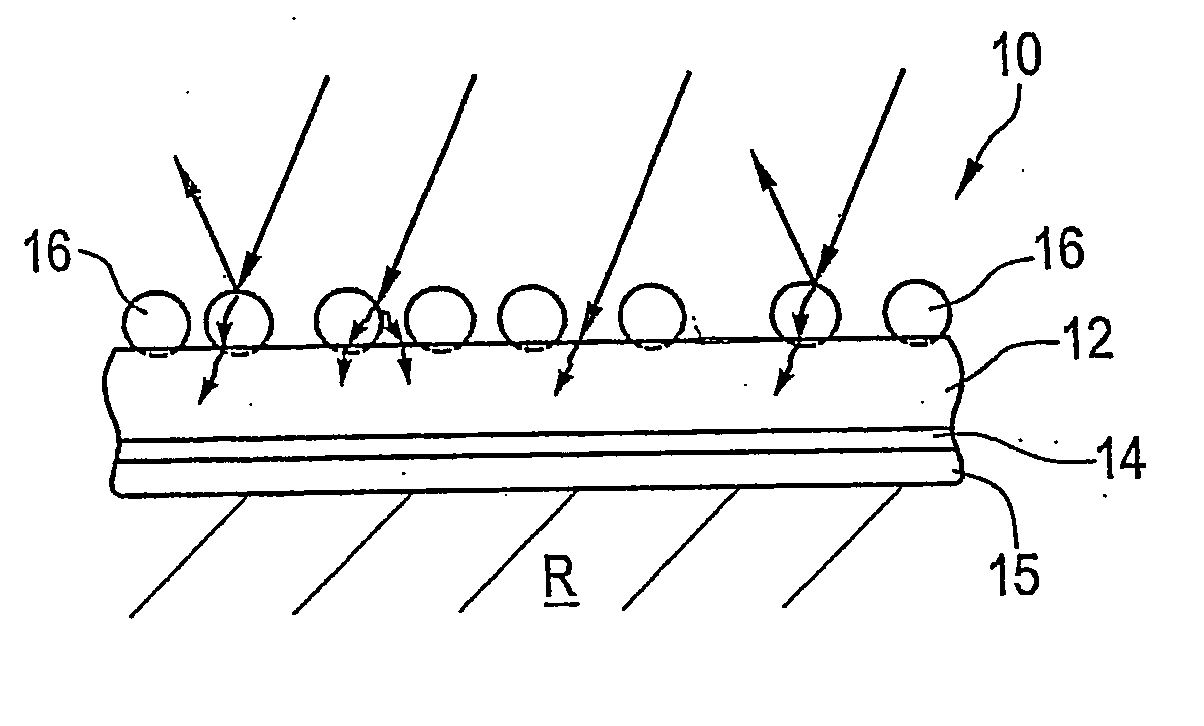

A method of coating highly reflective granules on an adhering material of a roofing or siding material to form a roofing or siding material having an average resulting reflectivity on an upper surface of at least about 45%. The method includes the selecting of highly reflective granules and applying the highly reflective granules on an adhering material until over about 95% of a top surface of the adhering material is covered by the granules.

Owner:GARLAND INDS

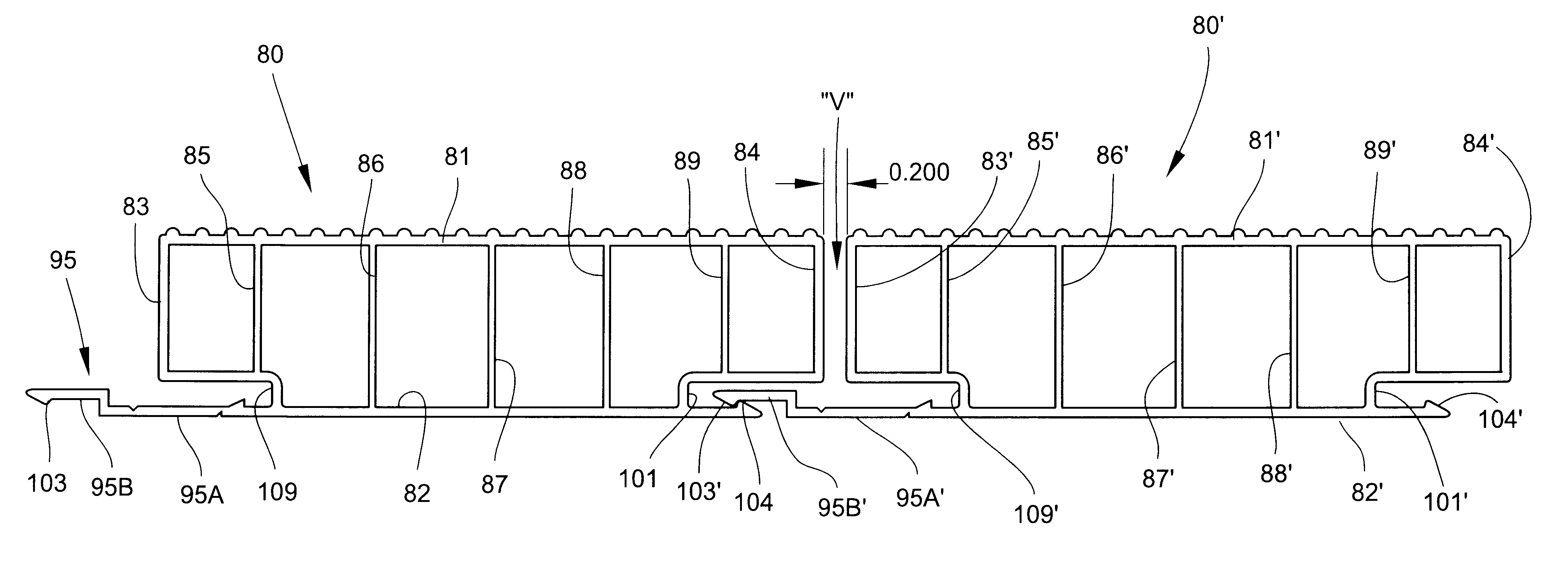

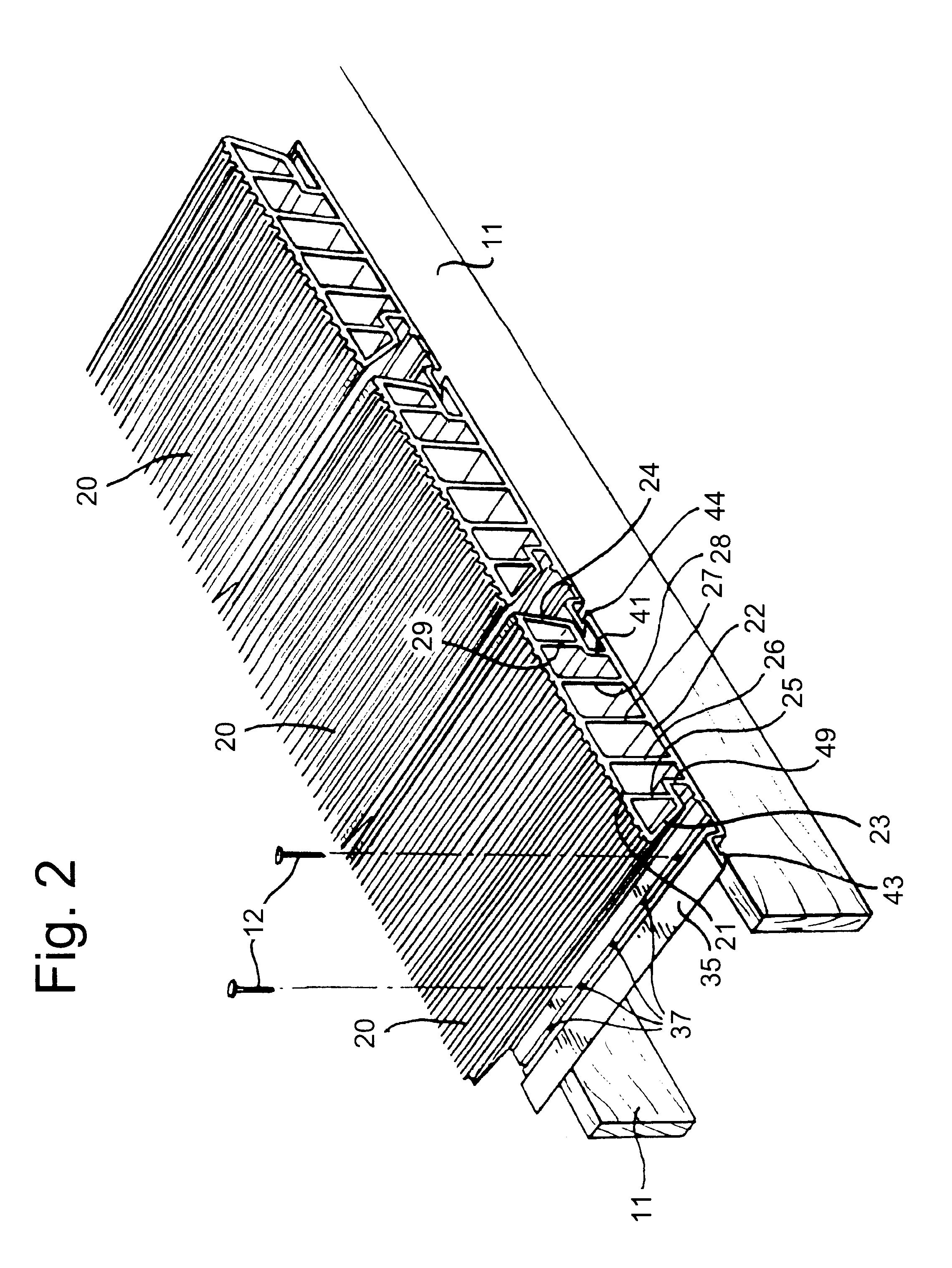

Modular construction element

InactiveUS6199340B1Easily assembled togetherEasy to assembleConstruction materialTreadsEngineeringModular structure

An elongate modular decking plank is provided for assembly on a supporting subfloor together with a plurality of like planks to form a decking structure. The decking plank has a top wall spaced-apart from a bottom wall, and opposing laterally spaced downwardly converging side walls interconnecting the top and bottom walls. An integrally-formed flange extends outwardly from the bottom wall on one of said sides of the decoding plank. The flange includes a fastening portion for receiving fasteners therethrough to the supporting subfloor to mount the decking plank on the supporting subfloor, and a connecting portion for connecting the plank to an adjacent like plank in a manner which permits limited lateral and angular adjustment between adjacent planks. The plank is preferably extruded from high-impact polymeric material, such as PVC plastic.

Owner:L B PLASTICS

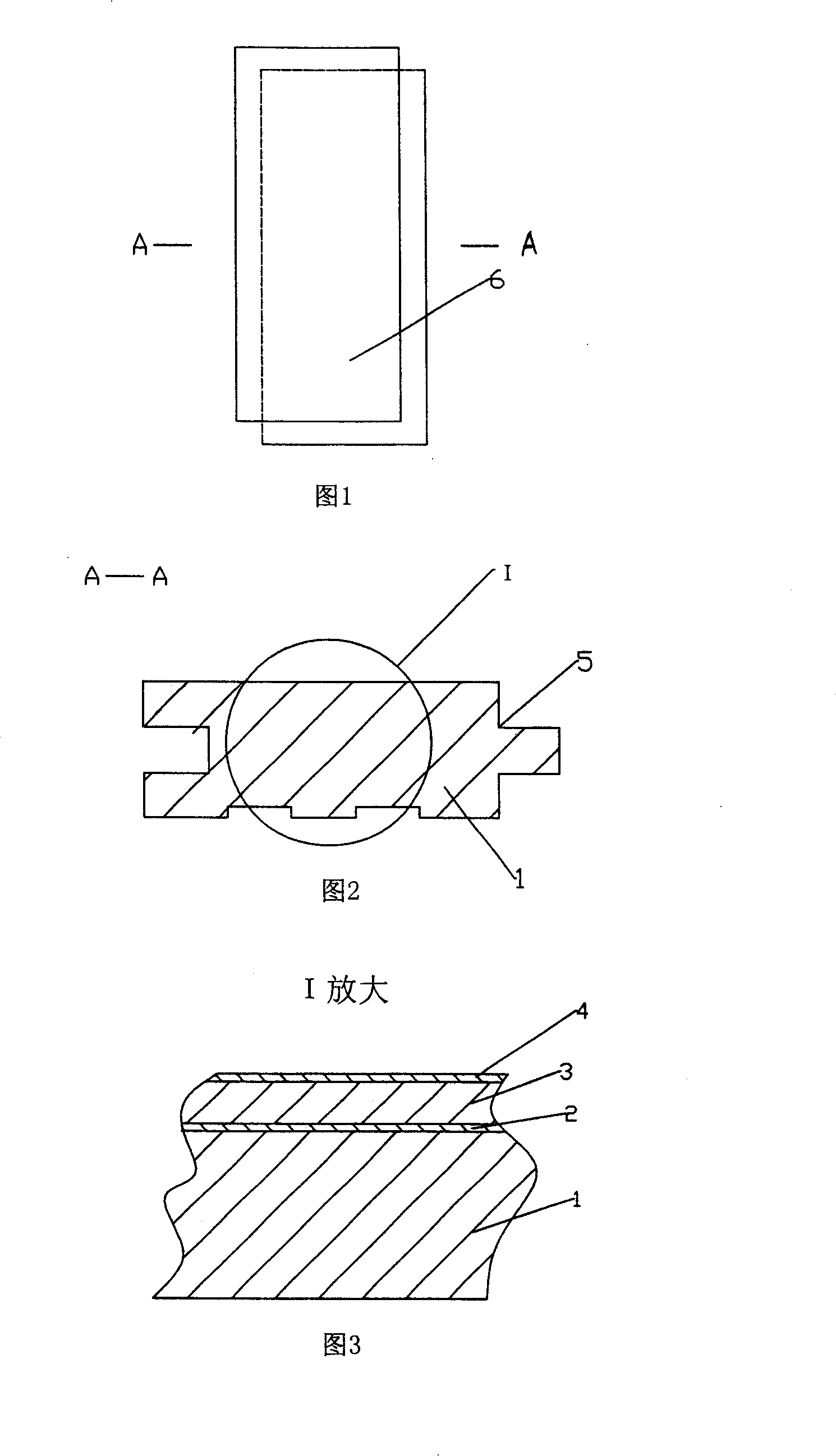

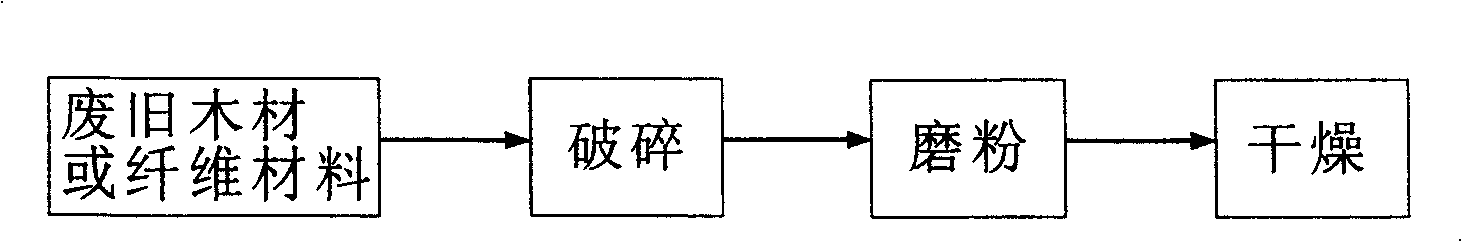

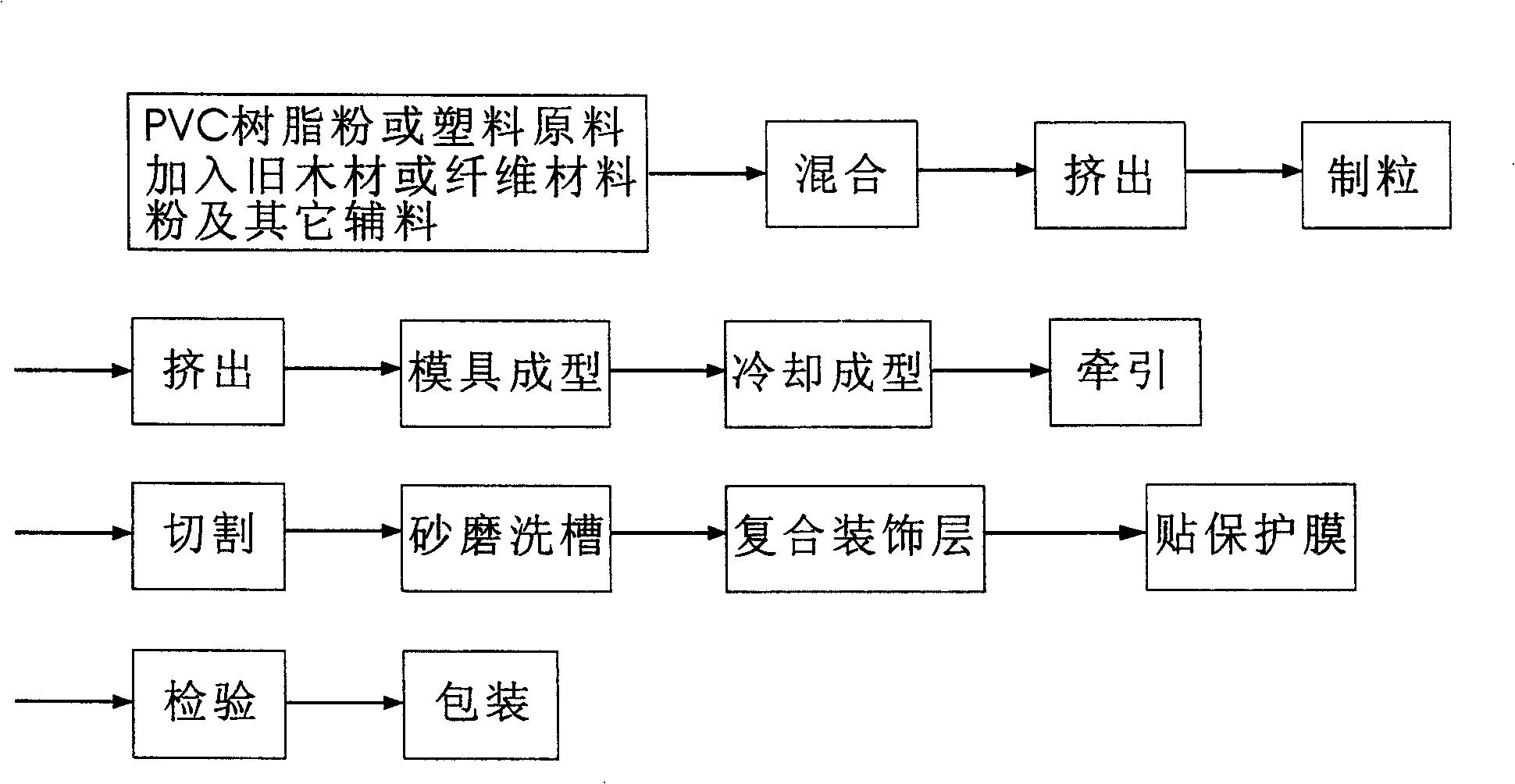

Wear-resistant wood plastic floor and its production technology

The present invention is wear-resistant wood-plastic floor board and its production process, and belongs to the field of decoration material technology. Polyvinyl chloride resin or plastic material is added with waste wood powder or fiber material powder, active calcium carbonate, assistant, stuffer, etc, and the mixture is pelletized, and further treated through extruding, molding, vacuum cooling, settling, drawing and cutting to form the basic wood-plastic board. The basic wood-plastic board is polished, groove milled and covered with surface decoration layer to form the wear resistant wood-plastic floor board product. The wear resistant wood-plastic floor board is beautiful, wear resistant, fireproof, waterproof, non-skid, anticorrosive and environment friendly and has high strength, heat insulation, electrical insulation and other advantages.

Owner:无锡市中德装饰新材料有限公司

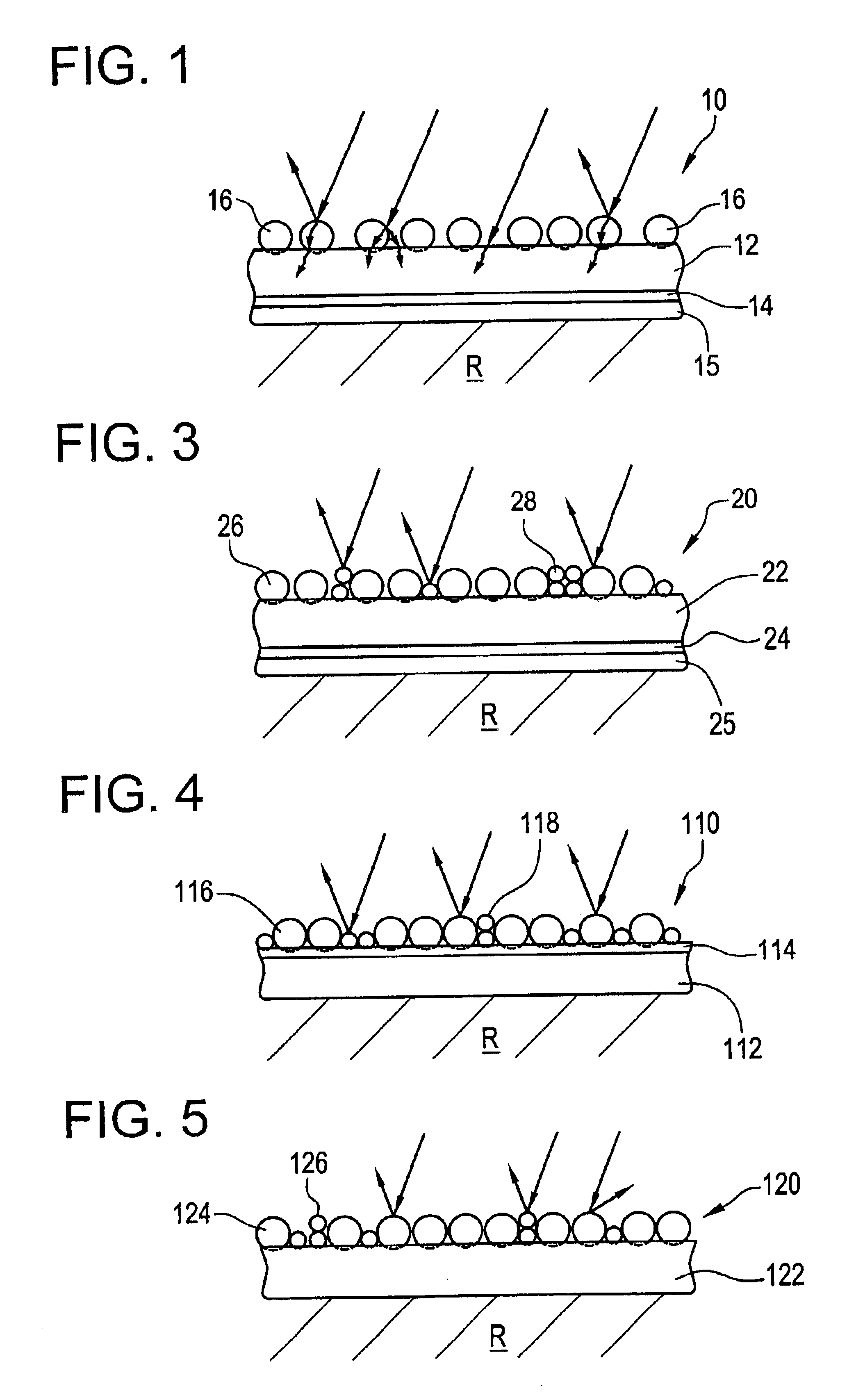

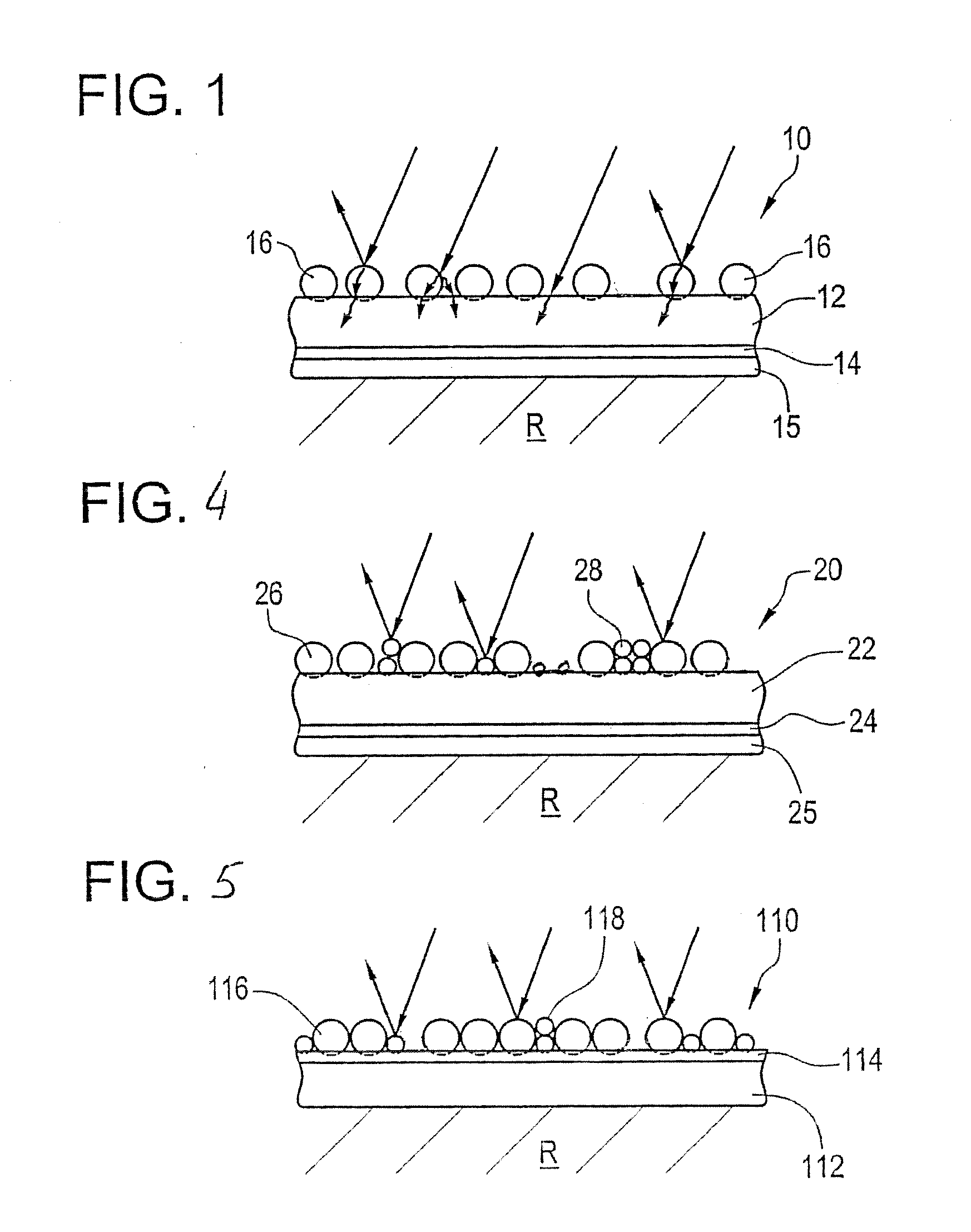

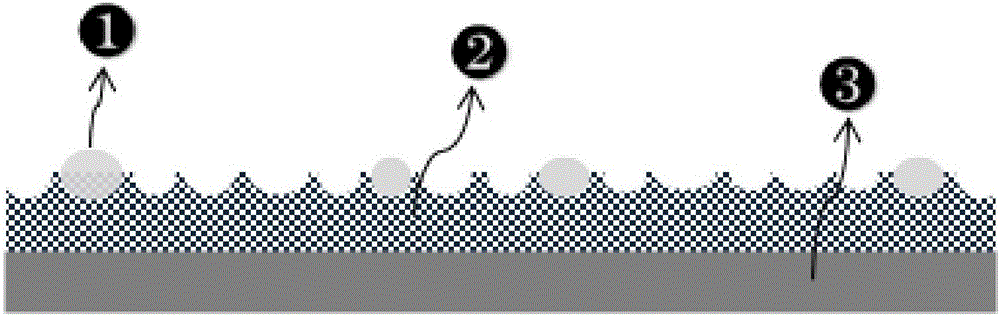

Skid resistant surfaces

InactiveUS20070044397A1Good for scrollingExcellent skidTreadsRoof covering using flexible materialsPressure sensitiveCivil engineering

Skid-resistant surfaces as described having either a pressure-sensitive adhesive layer or a highly filled, textured binder to reduce skidding. The surfaces are applied to trafficable surfaces such as roof and floors. Products such as roof underlyments bearing the surfaces are described in particular.

Owner:WR GRACE & CO CONN

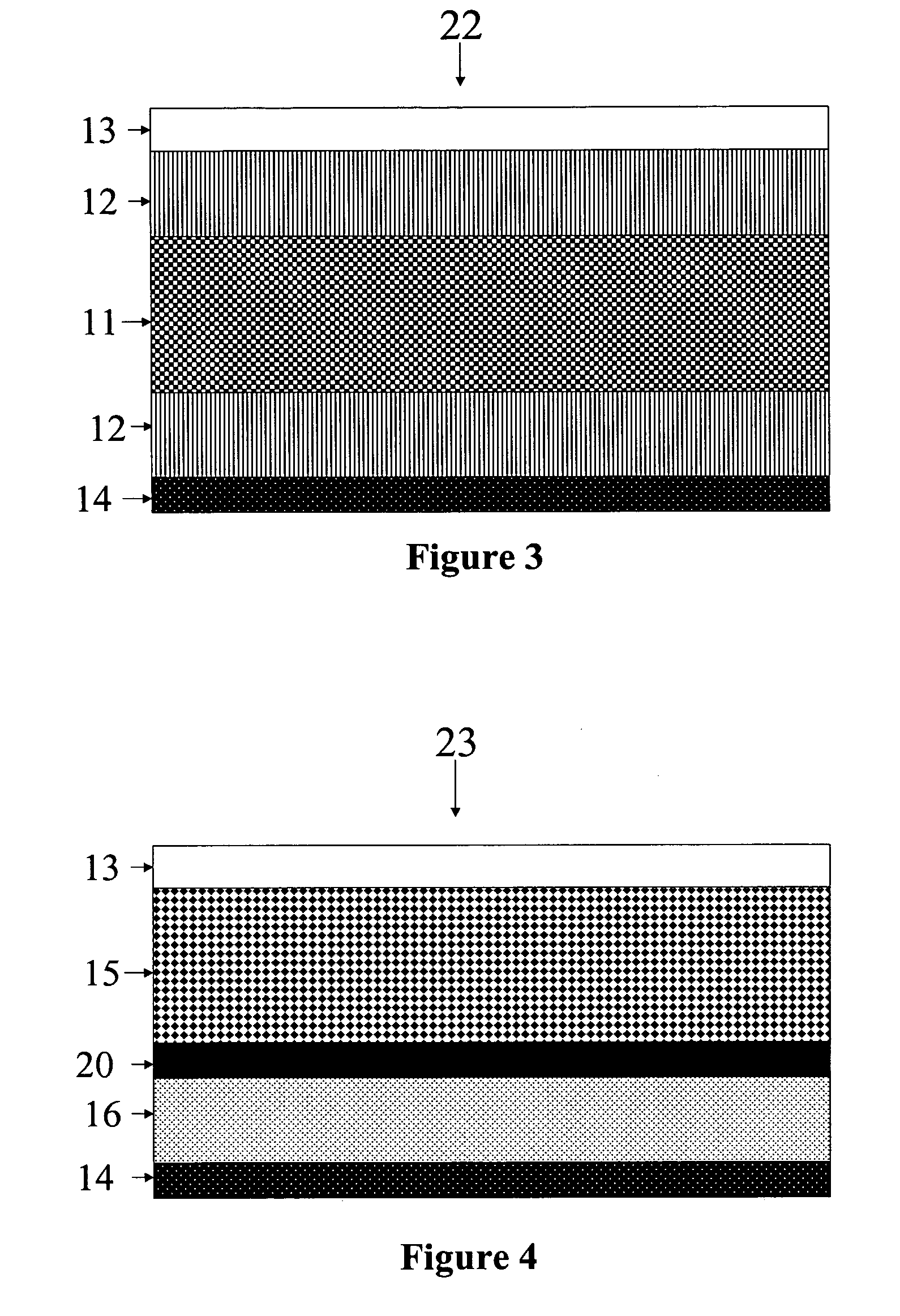

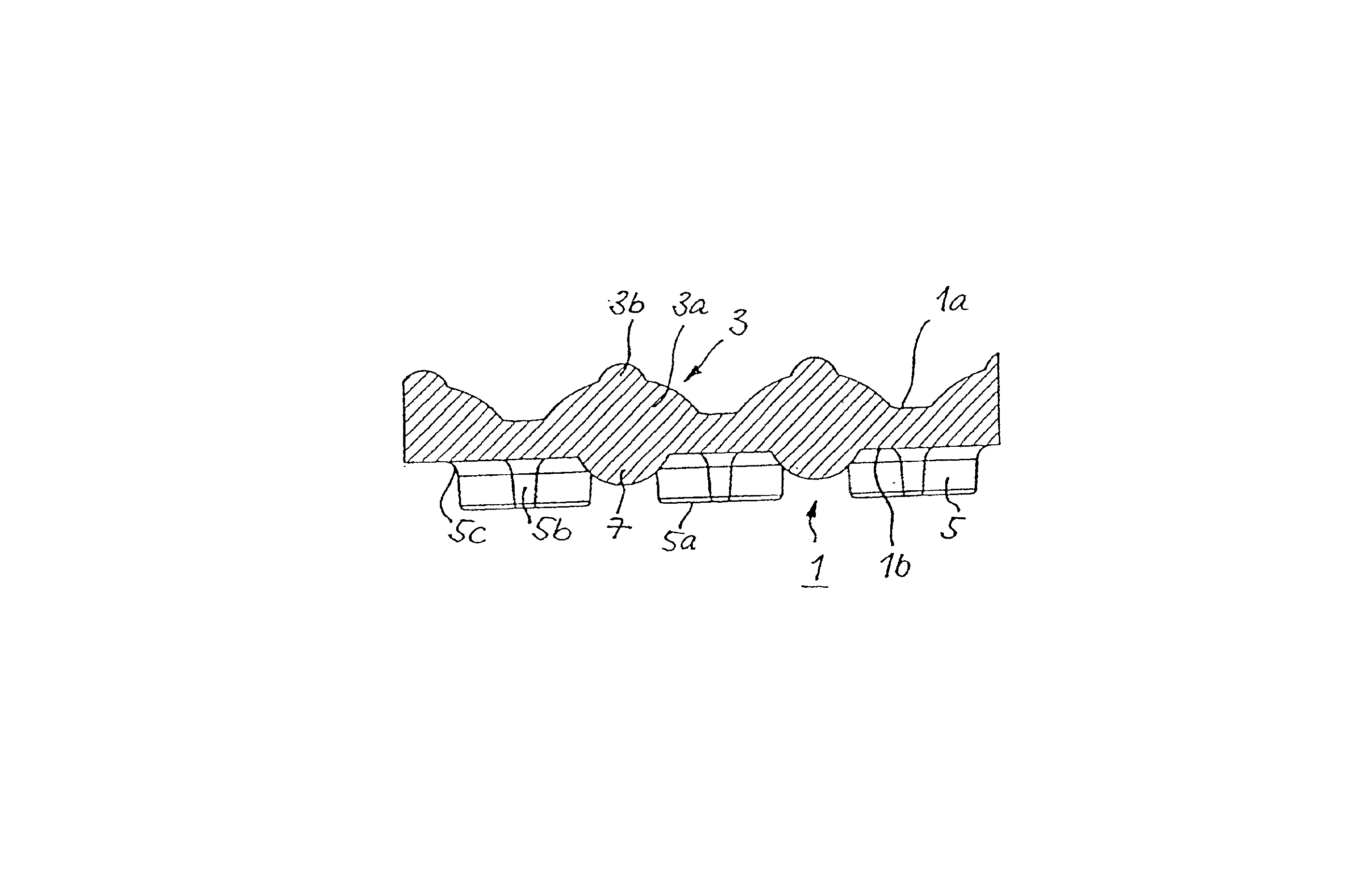

Floor covering of an elastically deformable material

InactiveUS6878430B2Easy to cleanImprove skid resistanceTreadsVehicle arrangementsEngineeringSynthetic rubber

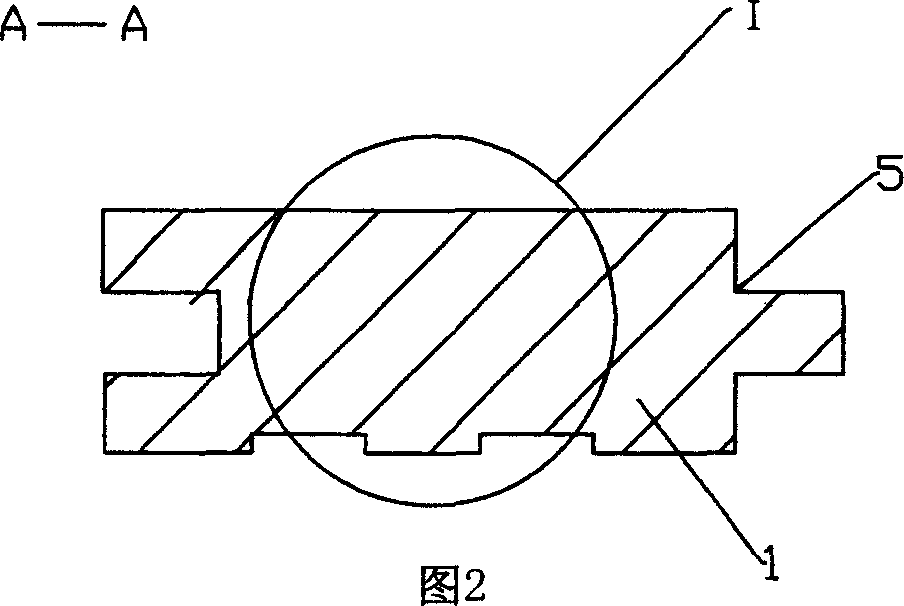

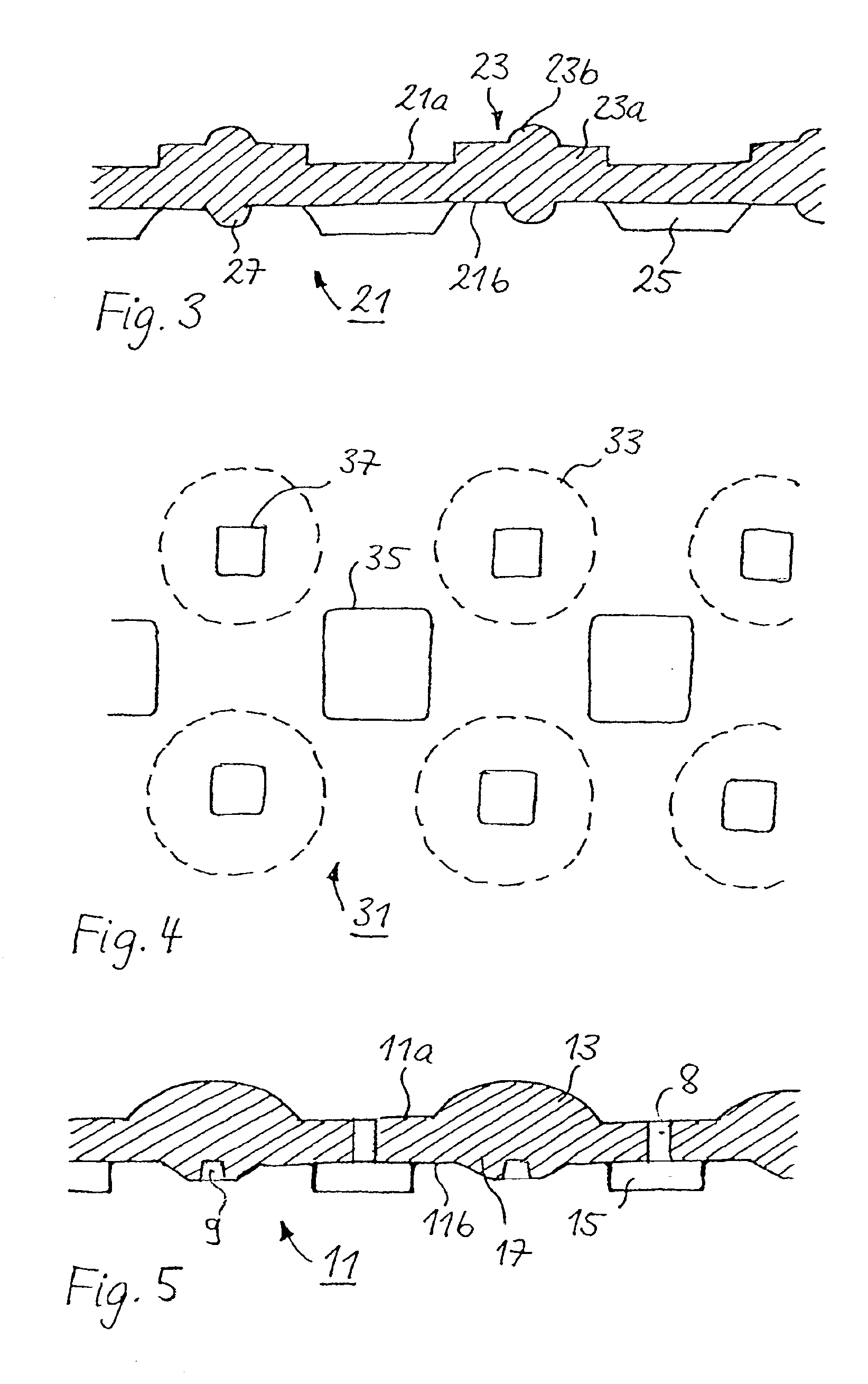

A floor covering (1) made of an elastically moldable material, in particular from a synthetic rubber, which is provided with a regular arrangement consisting of first projections (3) on the upper side (1a) and with a regular arrangement of second projections (5) on the underside (1b), the projections of the first projections and of the second projections not exhibiting any overlapping area on the plane of the covering and that, on the underside within the projections of the first projections, third projections (7) are provided in each case which have a smaller height vis-à-vis the second projections such that the floor covering only touches a floor with the second projections when it is in an unloaded state, however, when a preset load is exceeded locally, the third projections come in contact with the floor.

Owner:WERKSITZ W MILEWSKI

Fast baking process of environment protecting water and air permeable brick in roller kiln

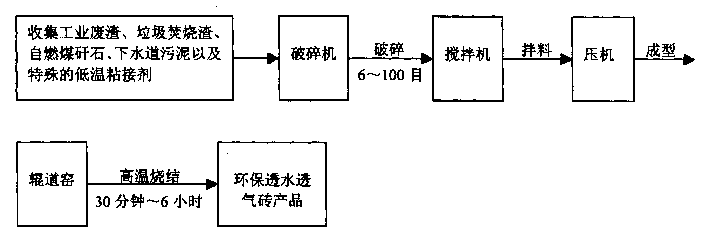

InactiveCN1436750AReduce the temperatureStable water tableSolid waste managementSolid waste disposalEnvironmental resistanceCooking & baking

Owner:广东唯美新技术实业有限公司

Highly reflective roofing materials

InactiveUS20070110961A1Reduce the amount requiredLow reflecting surfaceLiquid surface applicatorsRoof covering using flexible materialsReflectivityCivil engineering

A roofing or siding system having an improved average resulting reflectivity. The roofing and / or siding system is at least partially coated with a plurality of granules. At least one layer of paint is applied to the roofing and / or siding system to increase the resulting reflectivity of the roofing and / or siding system.

Owner:GARLAND INDS

Cement concrete permeable brick, permeable road and production methods thereof

InactiveCN101671987AComply with quality deviationMitigate the heat island effectSingle unit pavingsClimate change adaptationPondingBrick

The invention relates to a cement concrete permeable brick, a cement concrete permeable road and production methods thereof. At present, most of urban construction adopting the rigid hardened ground has the problems of dust blowing at a fine day, water accumulation and impermeable ground at a rainy day, no groundwater level supplement, no relief of urban heat island effect, and the like. The invention aims to develop a cement concrete permeable brick, a cement concrete permeable road and production methods thereof. The cement concrete permeable brick is formed by pressing and molding a base material layer and a surface material layer, and both the base material layer and the surface material layer contain cement, sand, stone, water adsorbing resin, asphalt powder, diffusant and a water reducing agent. The production method of the permeable brick is realized by molding the permeable brick by a computer full-automatic building block forming machine; and the production method of the cement concrete permeable road is realized by directly pressing the cement concrete permeable road through a road roller. The invention can achieve the aims of water adsorption, water retention, permeability and practicability, can be widely used for a highway, an airport runway, a roadway, a footway, a square, garden construction, and the like and solve the problem of road icing.

Owner:SHAANXI SUNSHINE RAIN ECOLOGICAL TECH

Ventilated polyurethane plastic race-track surface layer cementing material

ActiveCN103666233AGuaranteed bonding strengthGood weather resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesMass ratioEnd-group

The invention discloses a ventilated polyurethane plastic race-track surface layer cementing material, and belongs to the technical field of race-track construction. The ventilated polyurethane plastic race-track surface layer cementing material consists of a component I and a component II at the mass ratio of 1:(3-4), wherein the component I is prepolymer containing isocyanate end group prepared from environment-friendly polyisocyanate, polyether glycol and an addition agent by reacting in a reaction kettle for 3 to 4 hours at the temperature of 70 to 80 DEG C, and the component II comprises polyether glycol with three functionalities, inorganic filler, pigment, a plasticizing agent, a curing agent, an antioxygen, an ultraviolet light absorber and the like. The obtained plastic race-track has the advantages that surface particles are not easy to fall out, the surface is smooth, the quality of the plastic race-track is improved, the service life of the plastic race-track is prolonged, the qualification rate of the plastic race-track is increased to more than 95% as compared with the conventional 82%, the production cost and the use cost are reduced. Moreover all of the used raw materials are environmental protection materials, and belongs to environment friendly materials, the environmental pollution is avoided, and security is provided for the health safety of sporters.

Owner:金华市一家建设工程有限公司

Shoe having a fabric outsole and manufacturing process thereof

InactiveUS6944975B2Improve skid resistanceCompetitive manufacturing advantageSolesDomestic footwearMulti materialGround contact

Improvements in shoe constructions are provided that provide ground contacting surfaces of multiple materials that resist separation from one another and which provide traction and tariff benefits.

Owner:E S ORIGINALS

Manufacture method of environment friendly composite ceramic water-permeable brick

ActiveCN1919564AHigh strengthImprove wear resistanceSolid waste managementMixing operation control apparatusBrickComposite ceramic

The invention discloses a manufacturing method of environment-friend composite ceramic permeable brick, which comprises the following steps: adopting industrial slag with combustible substance as bottom aggregate and waste ceramic particle as layer aggregate, sieving at 10-20 order to obtain 55-65% material, sieving at 20-30 order to obtain 35-45% material, adding high-temperature adhesive and organic adhesive CMC, allocating, aging, moulding, drying, sintering.

Owner:JINGDEZHEN CERAMIC UNIV

Sintered water permeable brick and preparation method thereof

ActiveCN106087631AImprove water permeabilityLittle tortuousnessSingle unit pavingsPaving detailsBiomass fuelsSurface layer

The invention discloses a sintered water permeable brick and a preparation method thereof, and belongs to the technical field of sintered ceramics. According to the water permeable brick, structural pug in a surface layer is composed of, by weight, 45-65% of structural fine aggregates, 20-30% of plastic high-temperature binders and 15-25% of water, pore forming pug in the surface layer is composed of, by weight, 20-50% of pore forming agent aggregates, 45-80% of plastic pore adding binders and 0-5% of biomass fuel internal combustion catalysts, and a blank of a secondary surface layer is composed of, by weight, 70-75% of coarse structural aggregates, 10-15% of plastic high-temperature binders, 0-5% of pore adding agent coarse aggregates and 10-15% of water. A blank of the surface layer and the blank of the secondary surface layer are prepared firstly, the blank of the surface layer contains the orderly distributed structural pug and the pore forming pug, and then single-shaft extrusion forming, drying and sintering are conducted to obtain the water permeable brick. The water permeable brick has high water permeable rate, high strength, high abrasion resistance and durability and is a paving material with excellent ecological and environmental functions.

Owner:四川绿岛环境工程有限公司

Skid Resistant Surfaces

InactiveUS20080289289A1Readily unrollableExcellent skidBuilding roofsCovering/liningsMechanical engineeringPedestrian

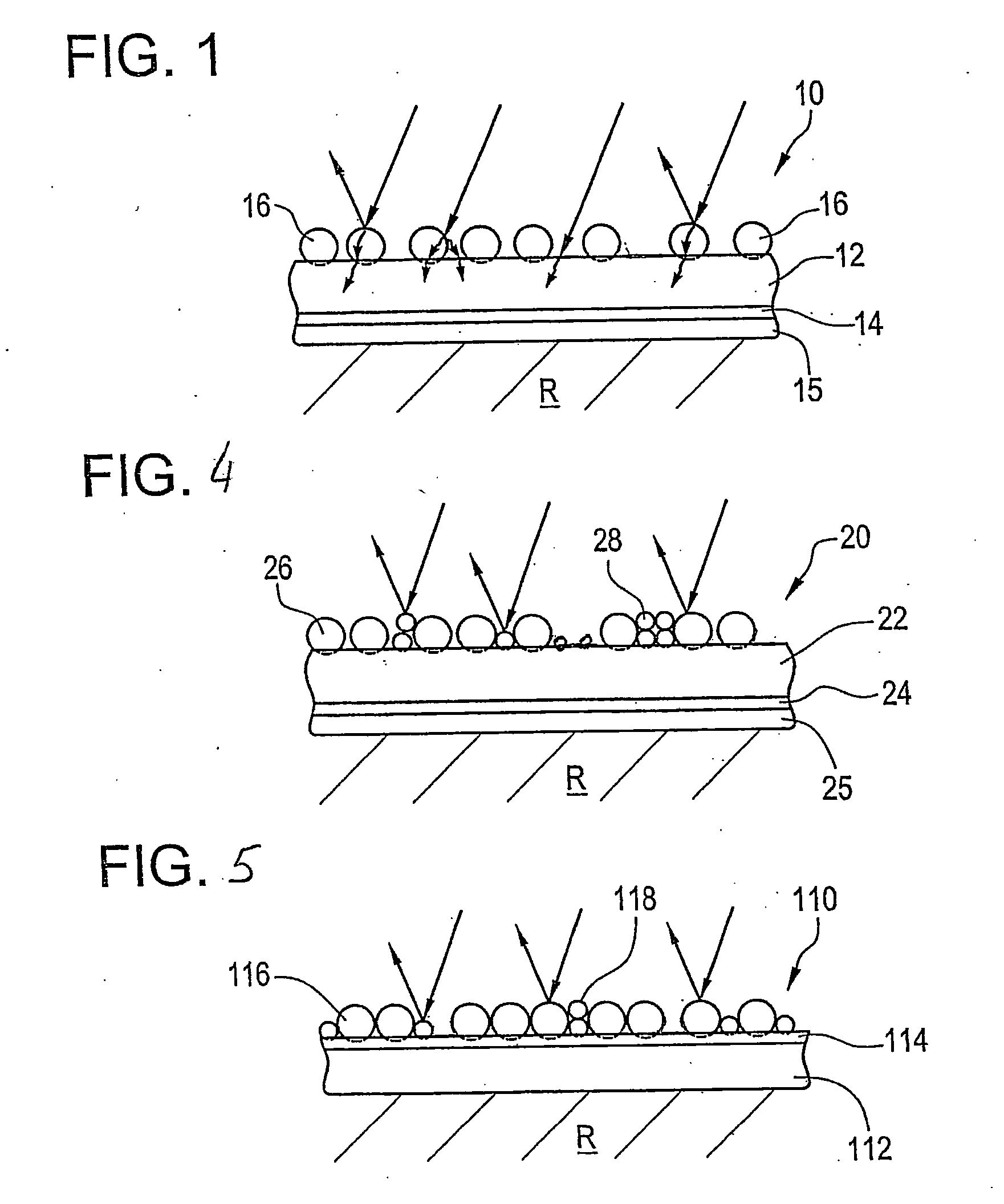

Pedestrian trafficable skid-resistant flexible articles (24) are described. These articles (24) include a flexible substrate (17) having a non-skid coating that may be either a pressure-sensitive adhesive (13) or a highly- filled, textured binder. These articles may be applied to trafficable surfaces such as roof and floors. Articles in the form of roof underlayments having a skid-resistant surface are described in particular.

Owner:WR GRACE & CO CONN

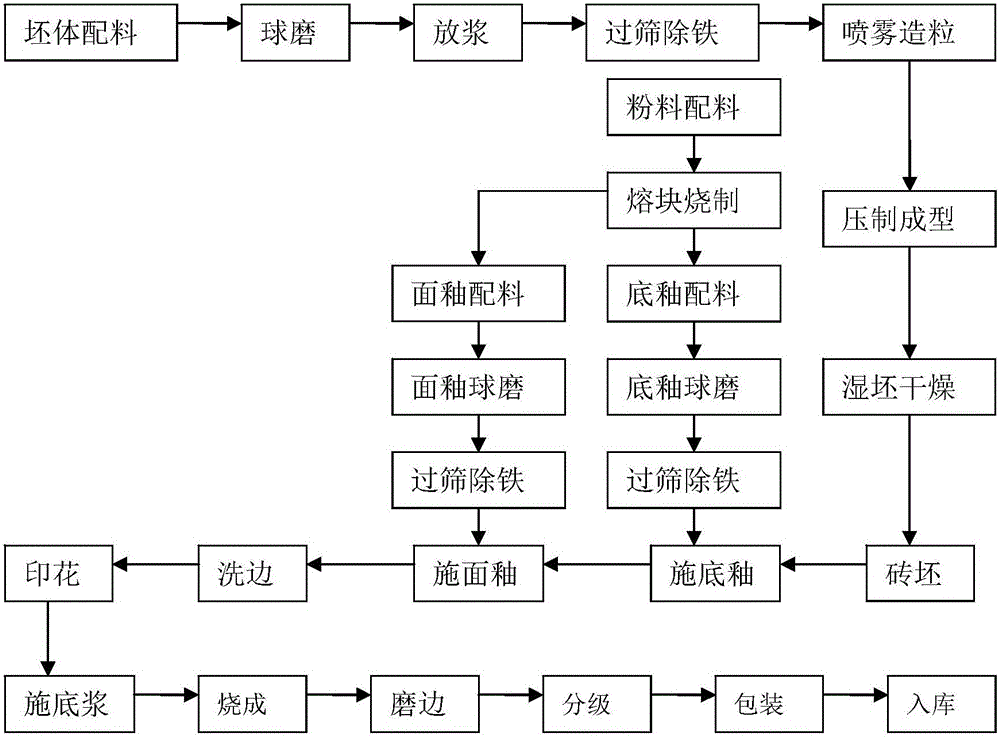

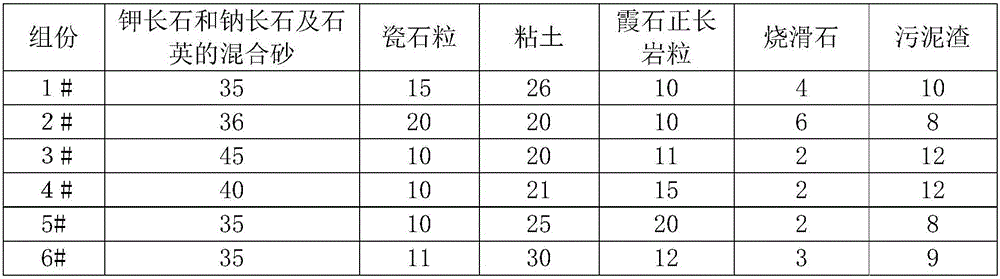

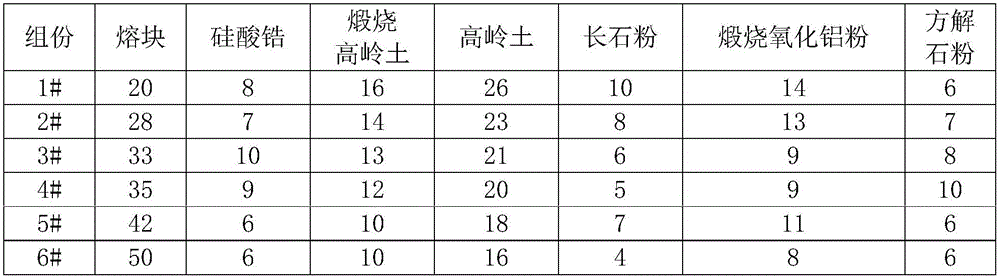

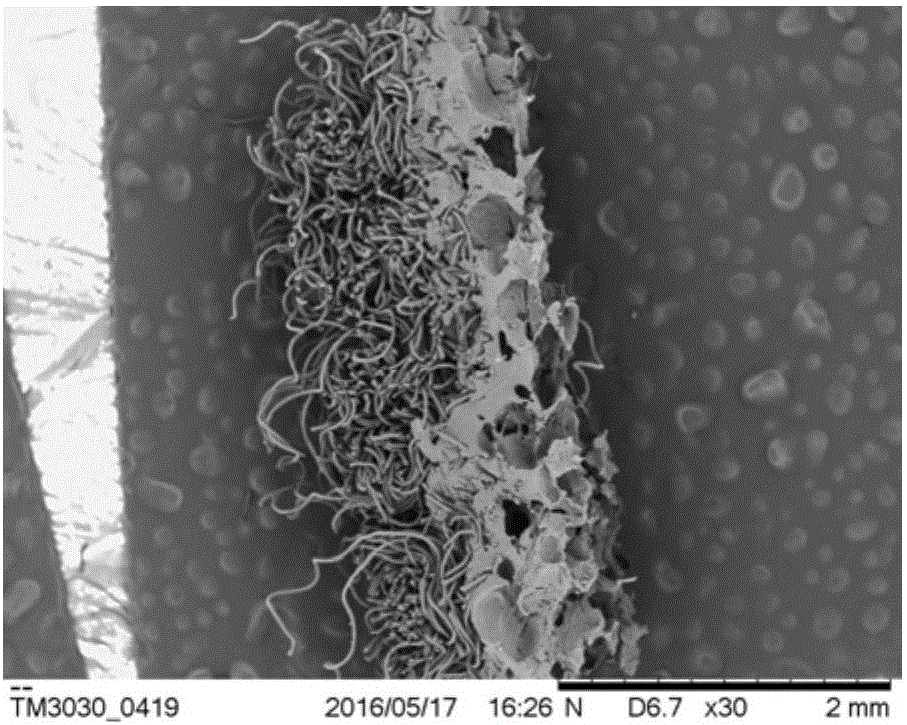

Resource-saving glazed ceramic tile having antiskid effect on surface and preparation method thereof

ActiveCN105837172AAchieve anti-slip effectGood quality glazeCeramic materials productionClaywaresBrickSludge

A resource-saving glazed ceramic tile having an antiskid effect on surface and a preparation method thereof. Without great change on production process of the glazed ceramic tiles, formula composition of a blank body, composition of ground and cover glaze frits and formula composition of ground and cover glaze are regulated and optimized focusedly, so that the glazed ceramic tile, which has excellent performance and the antiskid effect, can be prepared even large quantity sludge residue is added to the blank body. Through a high-magnification scanning electronic microscopy for observing the surface of glaze on the product, it is found that projects which are hard and needle-like and look like aluminum spinel crystal are formed on the surface, and the glaze is 0.8 in antiskid coefficient and is R12 in antiskid level when a less quantity of water is sprayed on the glaze. The glazed ceramic tile has good antiskid effect, can reach 4000 r / four grade in wear-resisting revolution through detection, and has good anti-wear performance, surface anti-fouling performance and water permeation resistance. The glaze has no defects such as needle pores, bubbles and the like, has clear decorative pattern grains and is highly stone-simulated. The technology has strong adaptability and is easy to promote in the field.

Owner:GUANGDONG WINTO CERAMICS +3

Construction method for reconstructing old concrete pavement by paving asphalt-concrete surface layer

InactiveCN101691736ALow costShorten the construction periodRoads maintainenceSurface layerRoad surface

The invention relates to pavement reconstruction, in particular to a construction method for reconstructing an old concrete pavement by paving an asphalt-concrete surface layer, which is characterized by comprising the following: 1) a step of old concrete pavement processing, which comprises breaking and removing damages blocks and pouring again, mudjacking the old concrete pavement, impacting and rolling old concrete pavement, crack pouring and replacing hardened verges; and 2) a step of paving a asphalt-concrete pavement, which comprises spraying a prime coat and viscous oil and spreading the asphalt-concrete pavement. The breaking and removing damages blocks and pouring again comprise: breaking and removing seriously damaged blocks of the old pavement; shoveling loose parts of an old cement stabilized base away, and pouring concrete in a 15-centimeter thickness which is the same as that of the old base for leveling; filling up the pits on the base with cement mortar and tamping the filled cement mortar; and pouring a 24-centimeter C35 concrete pavement board. In the method, the requirements on cost, quality, construction period, environmental protection and the like are met when the old concrete pavement is reconstruction by paving the asphalt-concrete pavement.

Owner:中交二公局第六工程有限公司

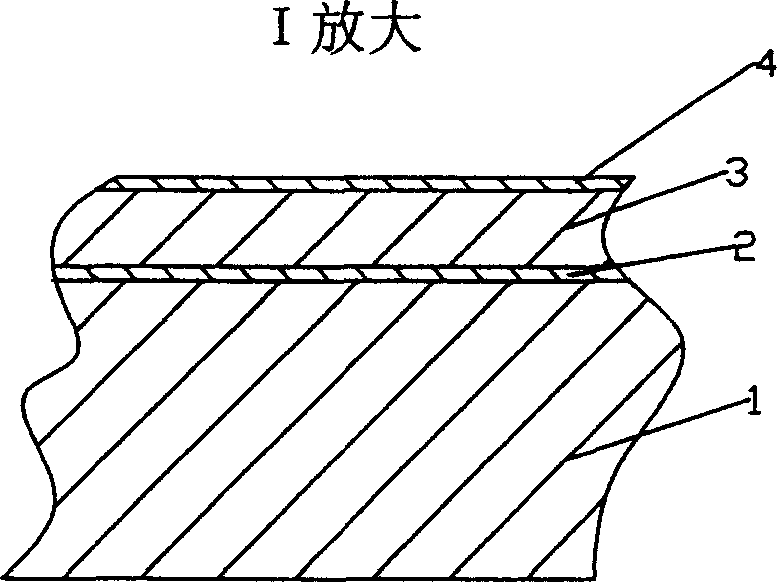

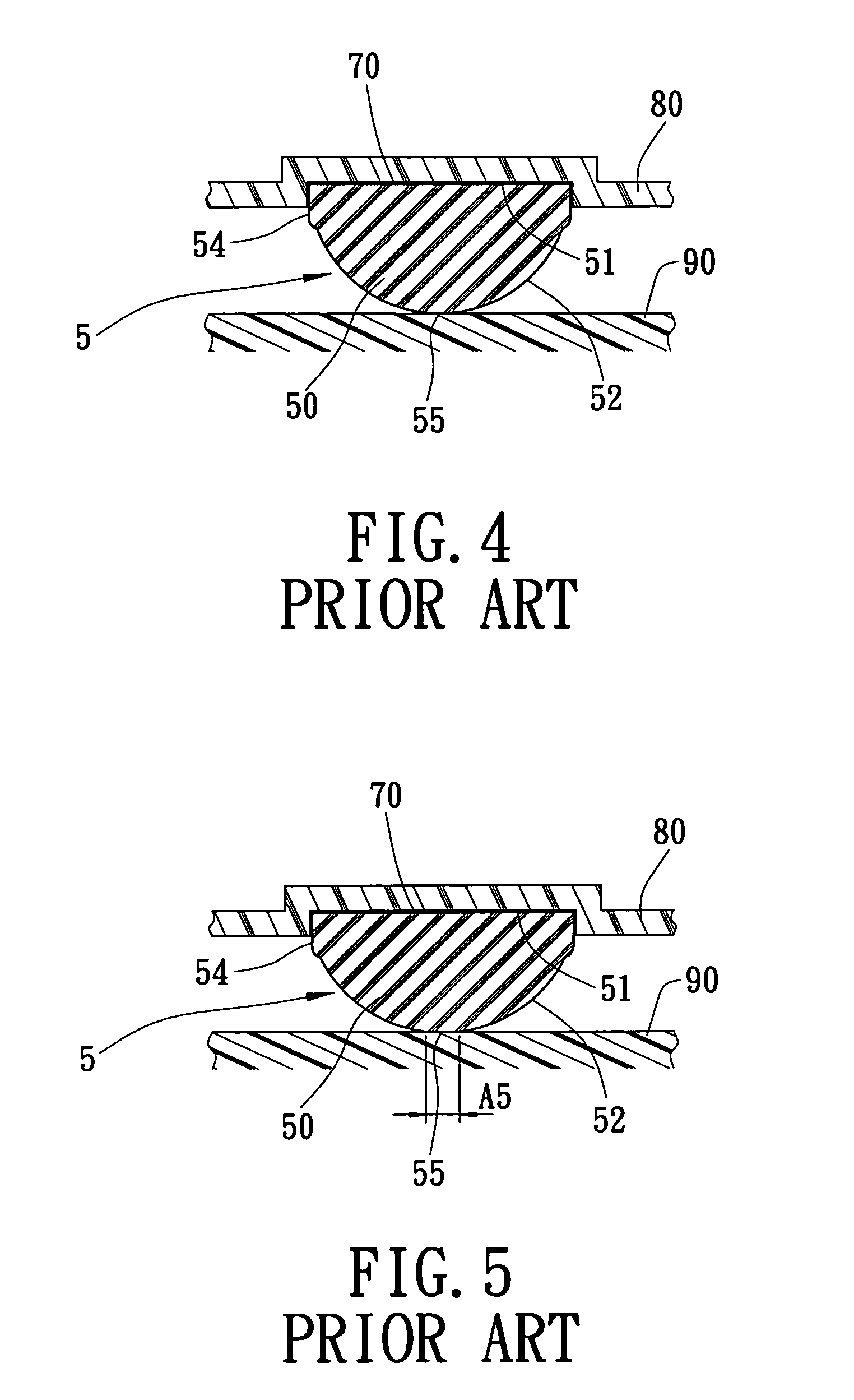

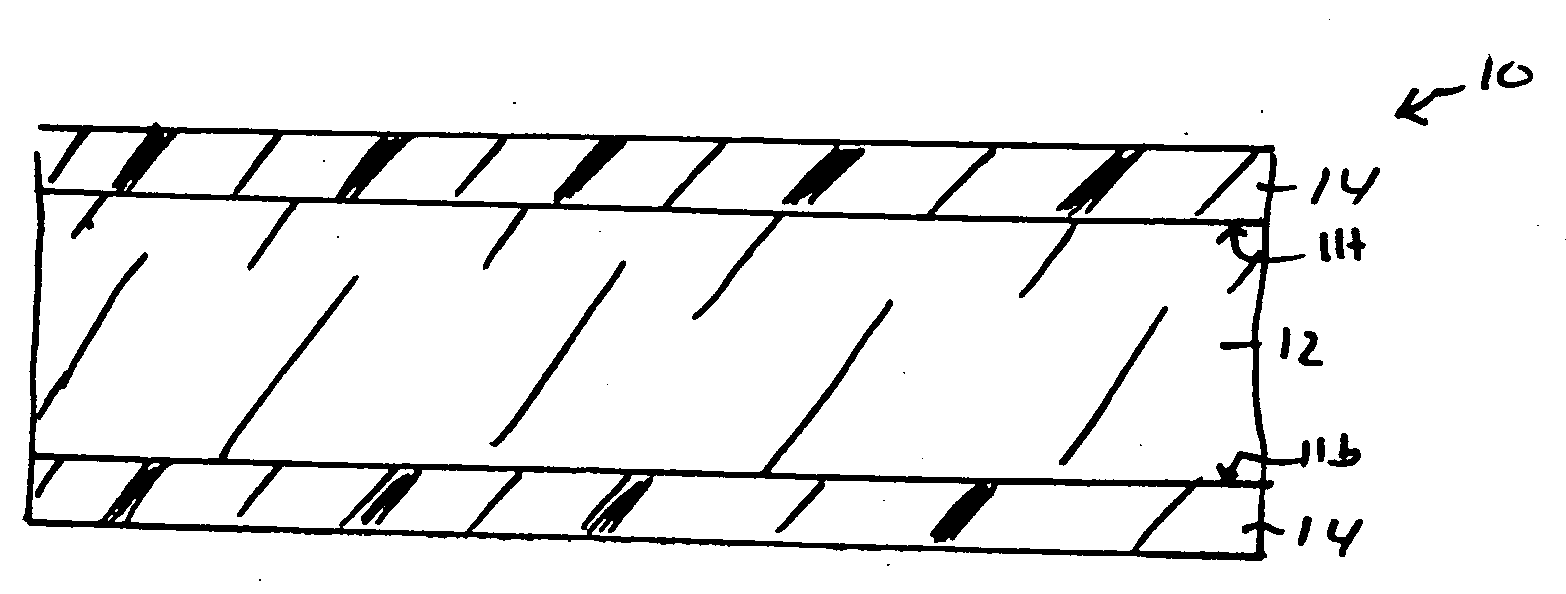

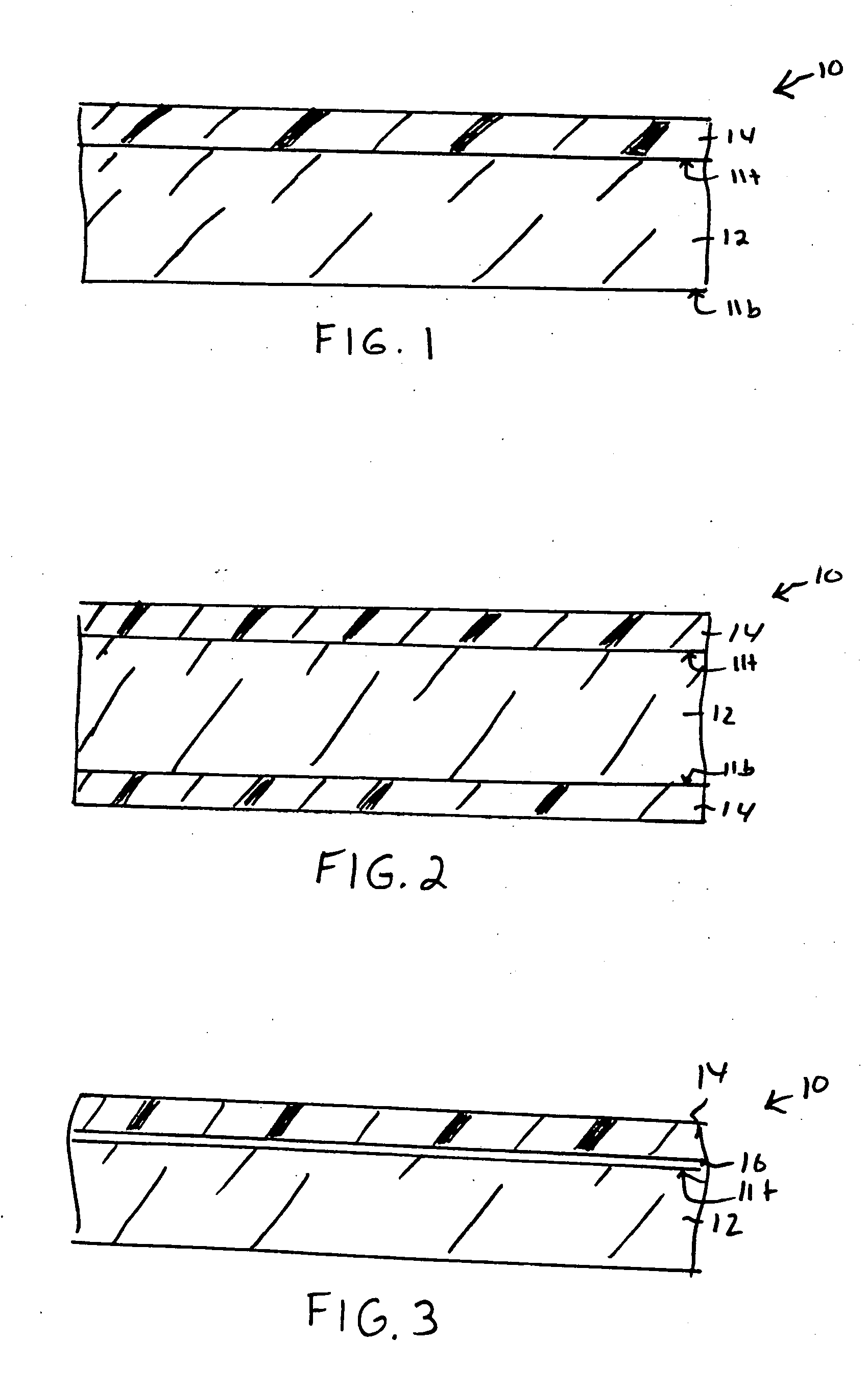

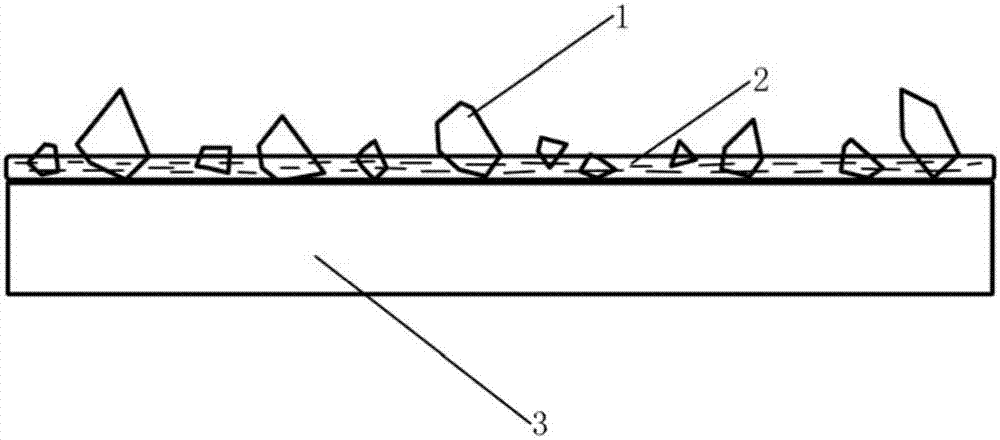

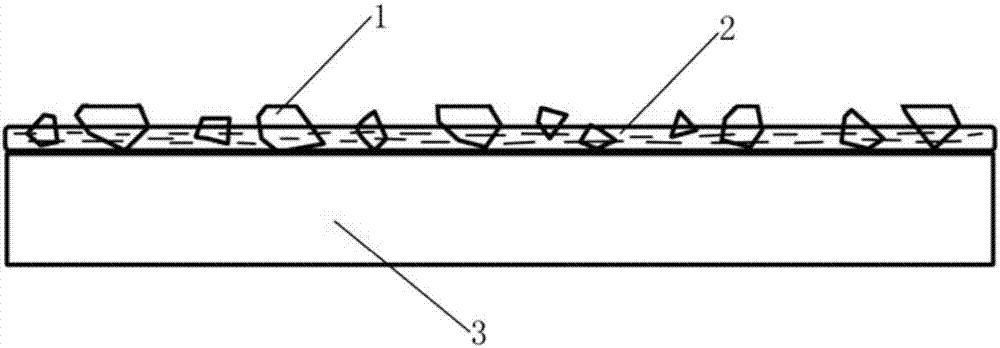

Outsole with an embedded fabric layer

An outsole with an embedded fabric layer has a fabric layer and an outsole. The fabric layer has a top surface and a bottom surface. The outsole has a bottom surface and multiple non-slip protrusions. The bottom surface of the outsole is attached to the top surface of the fabric layer. The non-slip protrusions are formed integrally on the bottom surface of the outsole, extend through the fabric layer and protrude out from the bottom surface of the fabric layer. With the non-slip protrusions, the outsole can provide excellent anti-slip effect and aesthetically pleasing decoration. Additionally, import tariffs on the outsole may be lowered because the shoe is a composite material.

Owner:TREASURY

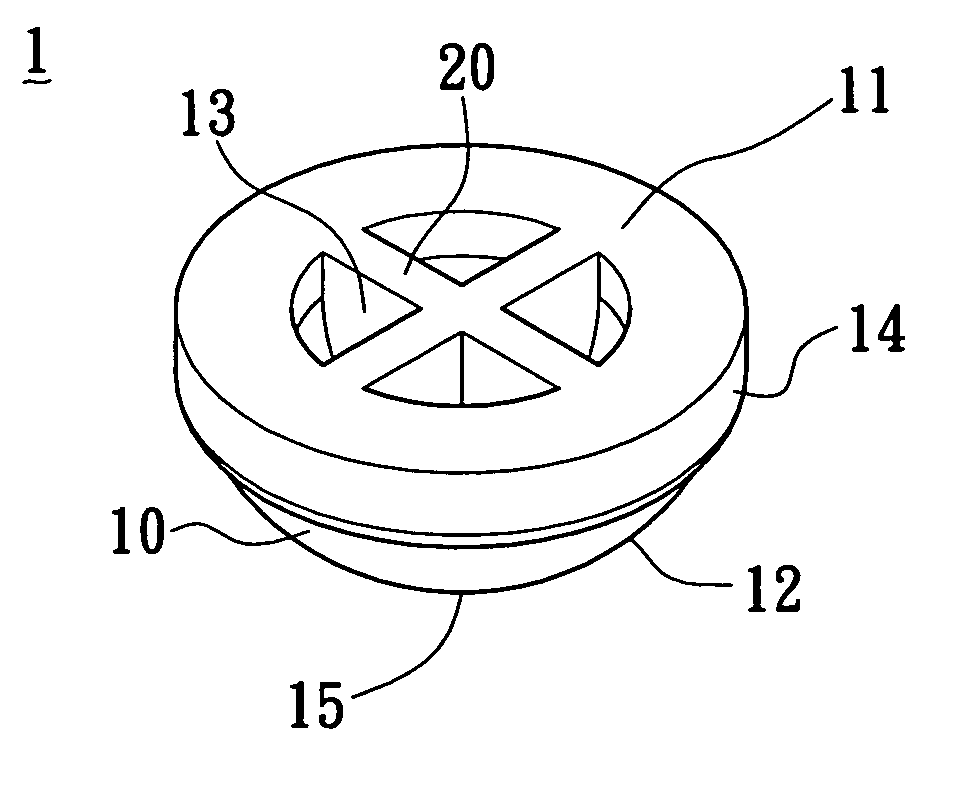

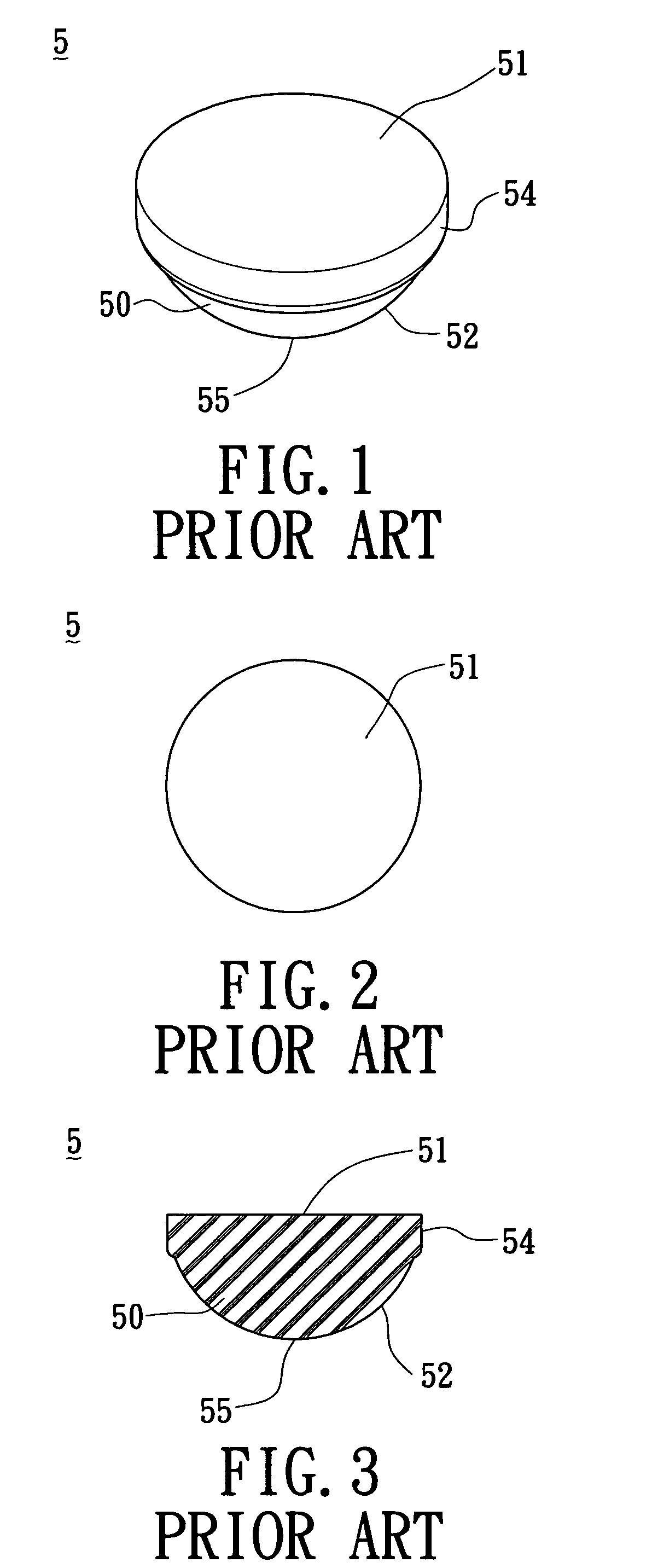

Foot pad

InactiveUS6979778B2Good effectIncrease elasticityPortable framesInstallation of lighting conductorsSupport surfaceConical surface

A foot pad has an elastic conical body and at least one elastic rib. The elastic conical body defines a connecting surface and an outer conical surface. The connecting surface defines a hollow portion, and the elastic rib integrally connects to the elastic conical body at a surface of the hollow portion. The outer conical surface has a root portion connecting with an outer edge of the connecting surface. A thickness of the elastic conical body at the root portion of the outer conical surface is greater than a thickness of the elastic conical body at other portions of the outer conical surface. Elasticity of the foot pad is thereby increased so as to enlarge a contact area contacting an outer supporting surface, so that an anti-skid effect is improved and the foot pad is capable of absorbing a deformation of an electronic product.

Owner:LITE ON TECH CORP

Anti-skid sole and preparation method thereof

ActiveCN102871291AEnhanced grip and slip resistanceExcellent oil-water wet grip performanceSolesActive agentAntioxidant

The invention discloses a sole and a manufacturing method for the sole, and aims to provide a sole with high abrasion resistance and anti-skid property. According to the technical scheme, the sole consists of the following components in part by mass: 45 to 55 parts of nitrile rubber, 18 to 22 parts of brombutyl rubber, 21 to 25 parts of butadiene rubber, 6 to 8 parts of natural rubber, 28 to 32 parts of nano silicon dioxide, 18 to 22 parts of glass fiber, 3.5 to 4.5 parts of nylon fiber, 0.8 to 1.2 parts of polyethylene glycol 4000 (PEG 4000), 1.8 to 2.2 parts of rubber white smoke active agent, 1.4 to 1.6 parts of stearic acid, 3.5 to 4.5 parts of ZnCO3, 0.8 to 1.2 parts of antioxidant, 1.8 to 2.2 parts of coupling agent, 4.5 to 5.5 parts of anti-skid agent, 0.5 part of microcrystalline wax, 1.5 to 2.0 parts of sulfur, and 2.0 to 2.5 parts of vulcanization accelerator. The invention belongs to the technical field of making of shoes.

Owner:广州市邦尔福鞋材有限公司

Wear-resistant wood plastic floor and its production technology

The present invention is wear-resistant wood-plastic floor board and its production process, and belongs to the field of decoration material technology. Polyvinyl chloride resin or plastic material is added with waste wood powder or fiber material powder, active calcium carbonate, assistant, stuffer, etc, and the mixture is pelletized, and further treated through extruding, molding, vacuum cooling, settling, drawing and cutting to form the basic wood-plastic board. The basic wood-plastic board is polished, groove milled and covered with surface decoration layer to form the wear resistant wood-plastic floor board product. The wear resistant wood-plastic floor board is beautiful, wear resistant, fireproof, waterproof, non-skid, anticorrosive and environment friendly and has high strength, heat insulation, electrical insulation and other advantages.

Owner:无锡市中德装饰新材料有限公司

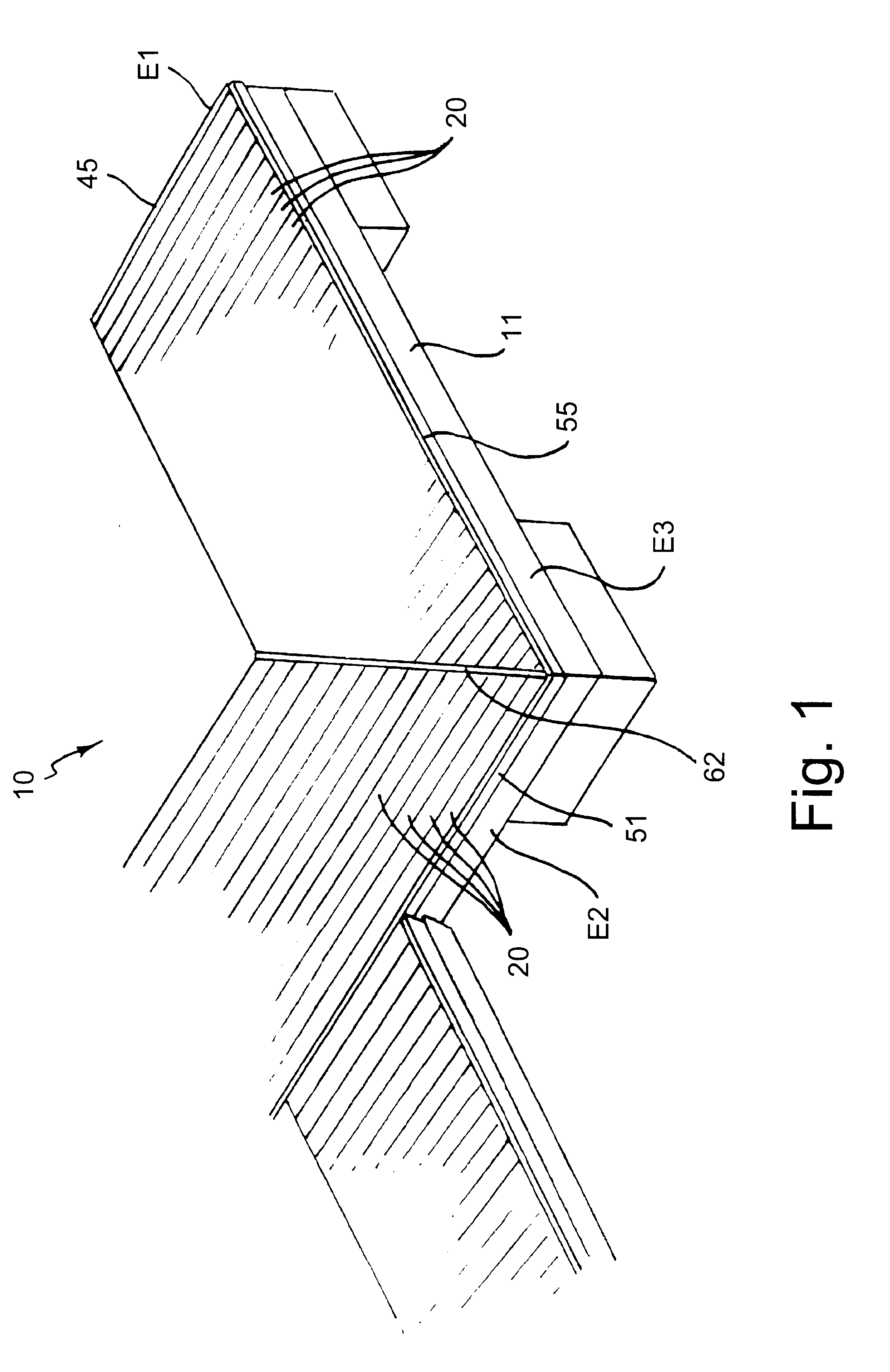

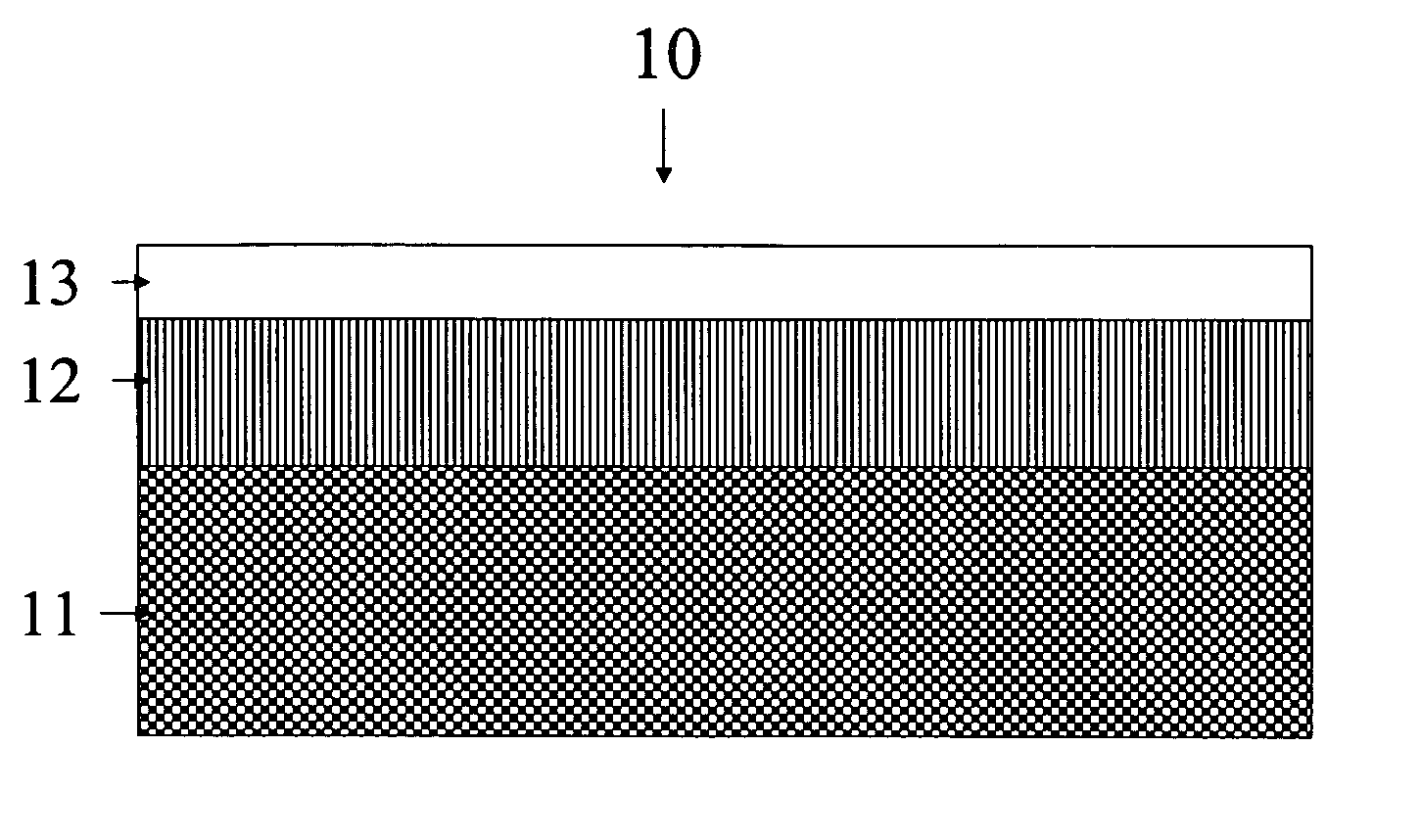

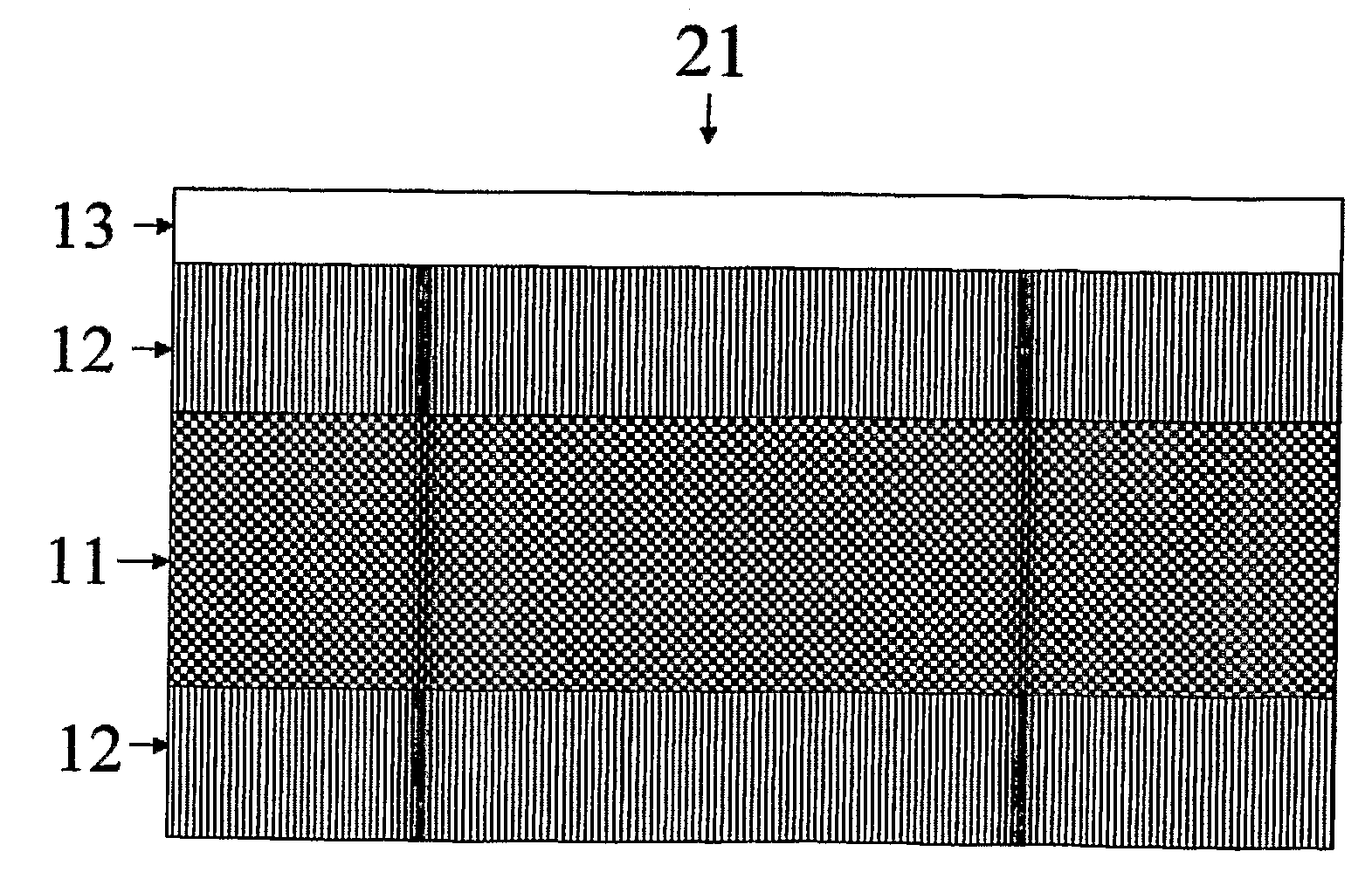

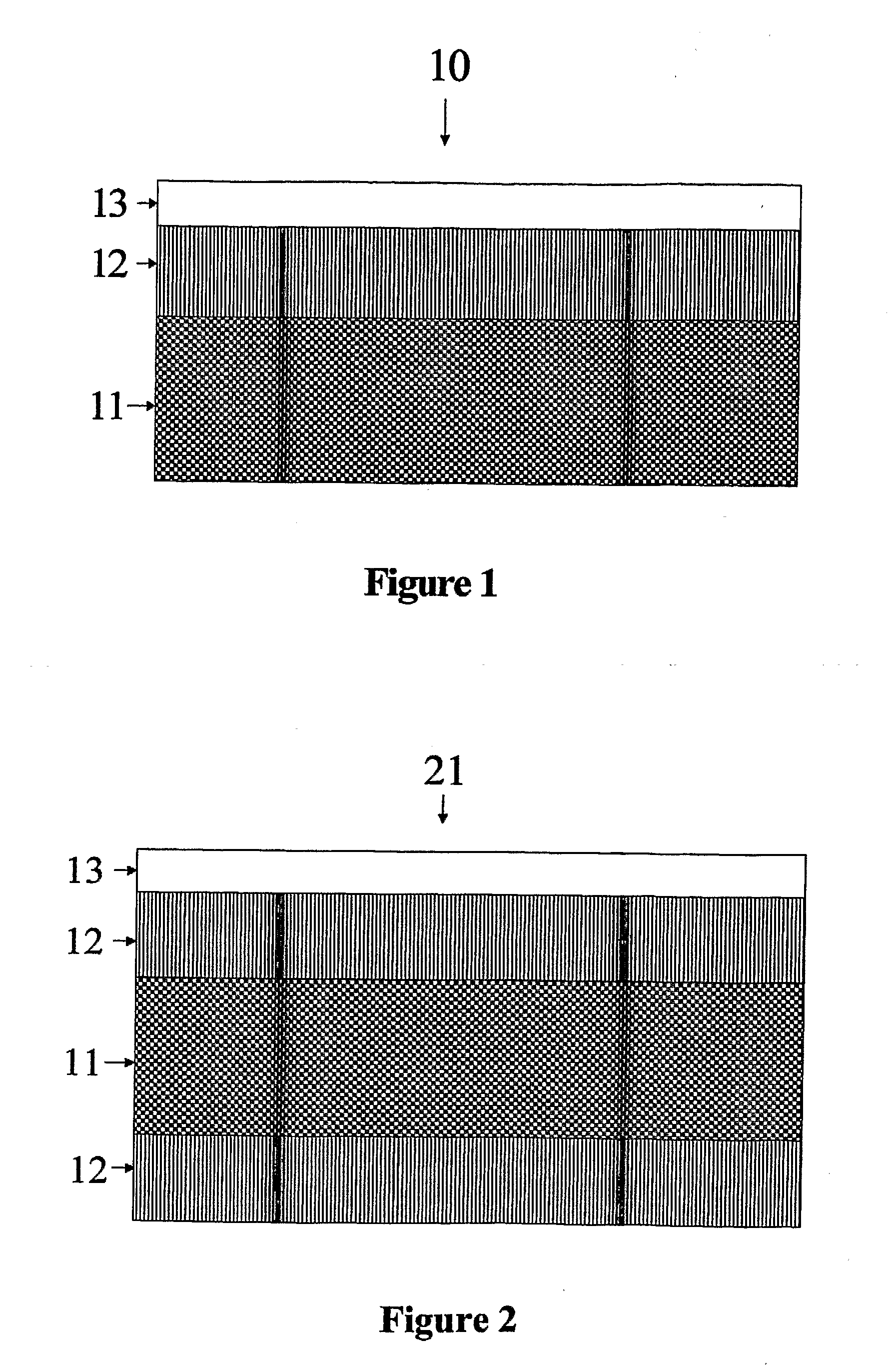

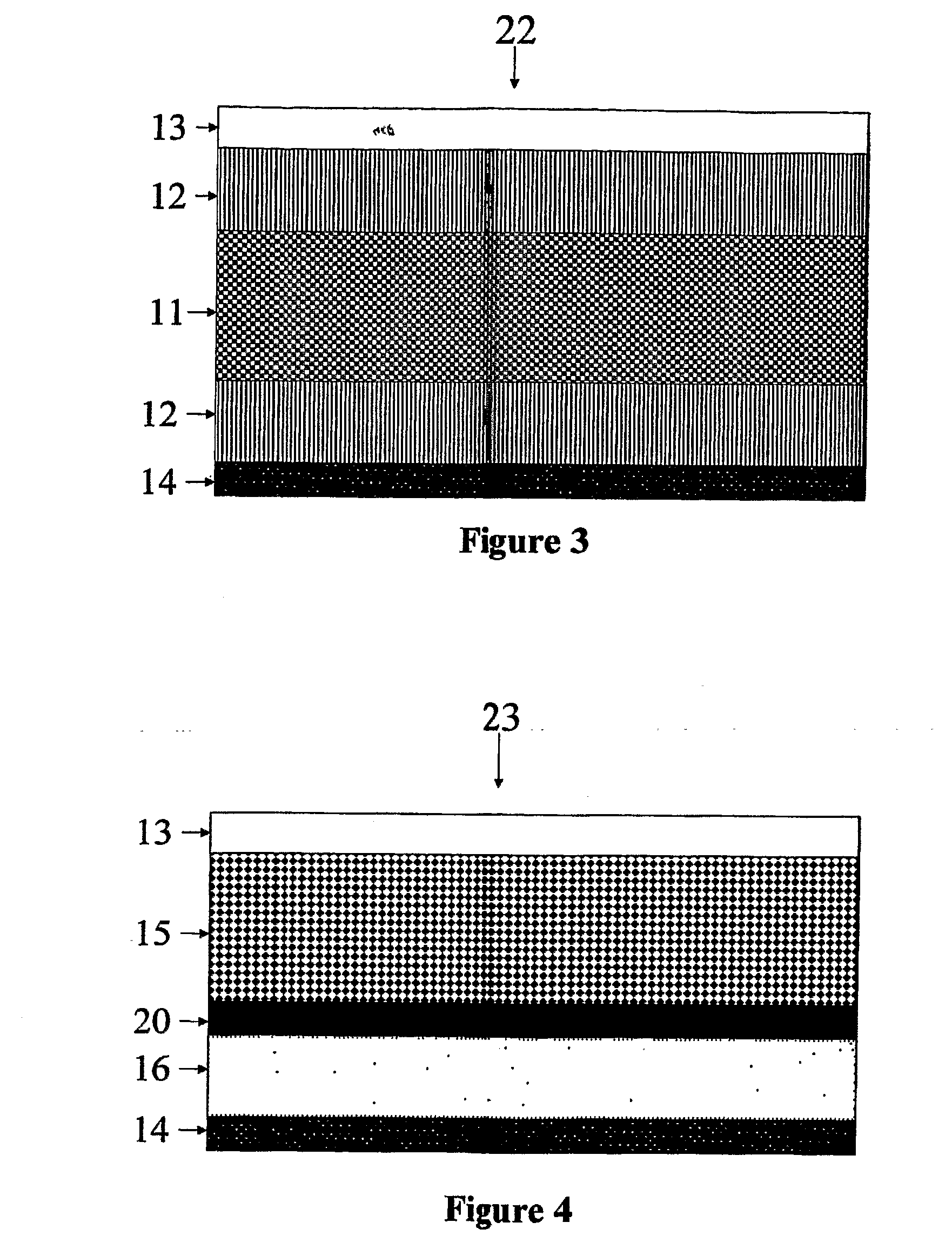

Breathable non-asphaltic roofing underlayment

ActiveUS20050097857A1Imparts breathabilityImprove skid resistanceRoofingSynthetic resin layered productsThermoplasticEngineering

A non-asphaltic roofing underlayment that is breathable, water resistant and skid-resistant is disclosed. The non-asphaltic roofing underlayment includes a woven or non-woven substrate in which at least one surface thereof includes a breathable thermoplastic film disposed thereon. The breathable thermoplastic film imparts water-resistant to the substrate as well as maintains the breathability of the substrate.

Owner:BMIC LLC

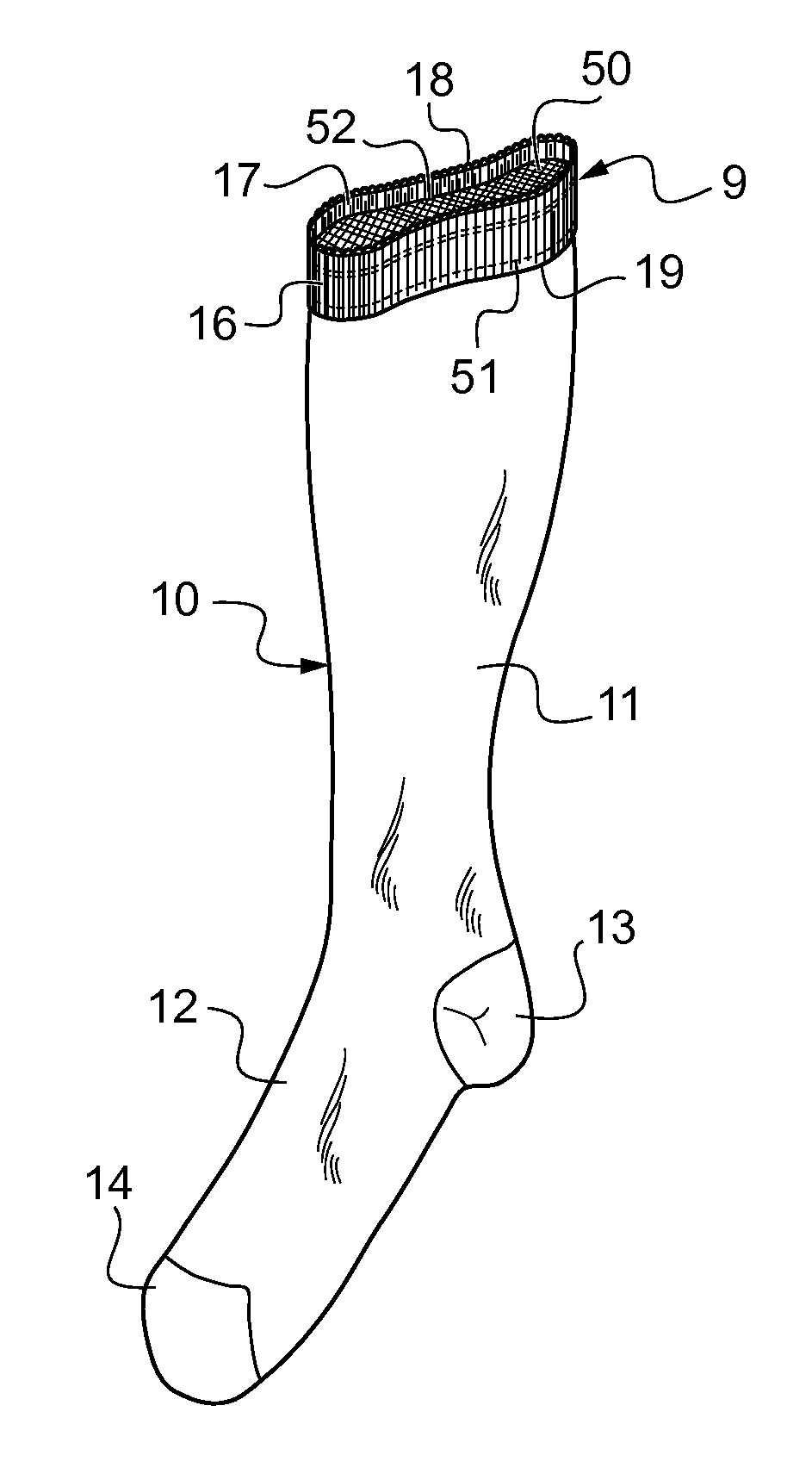

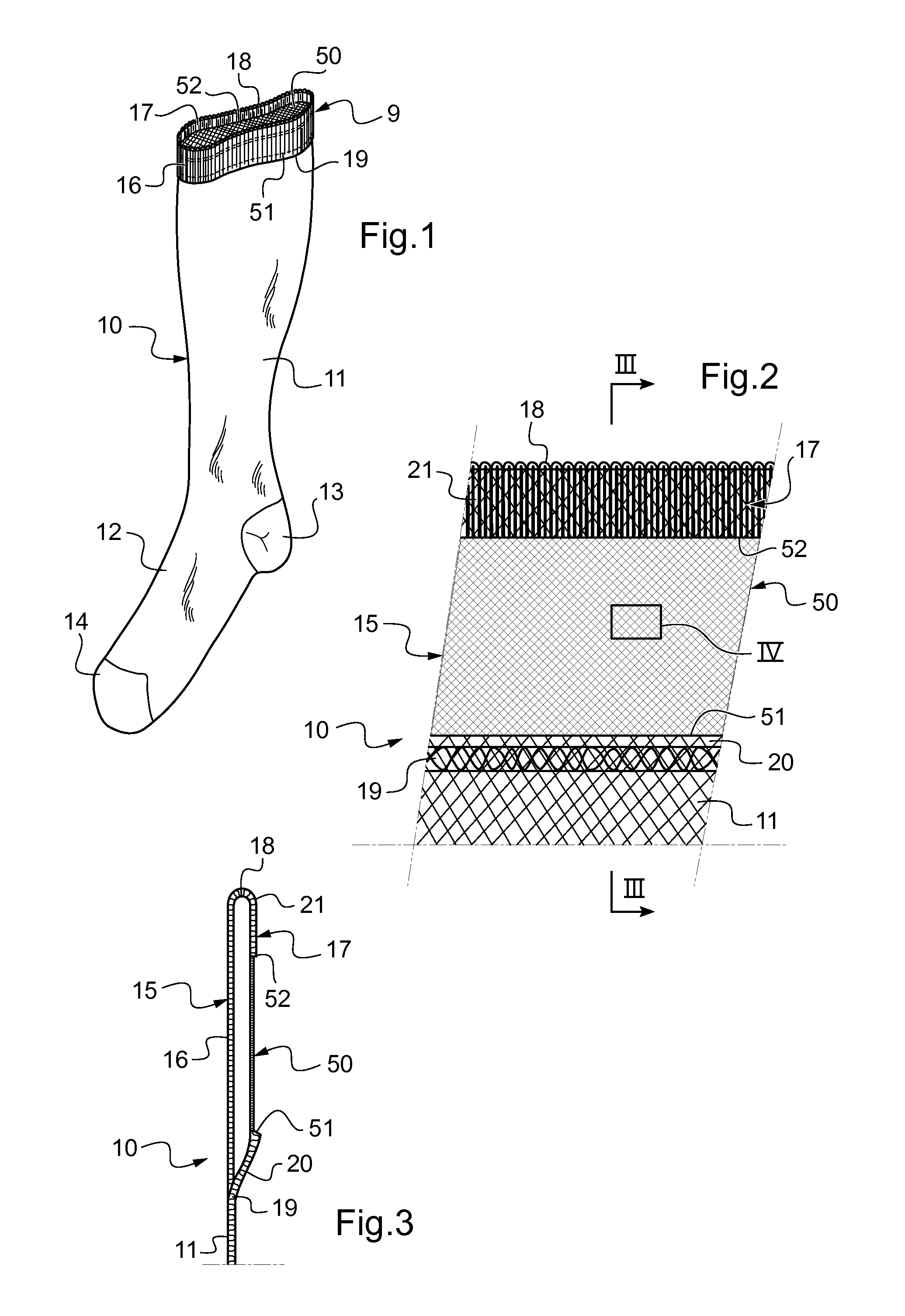

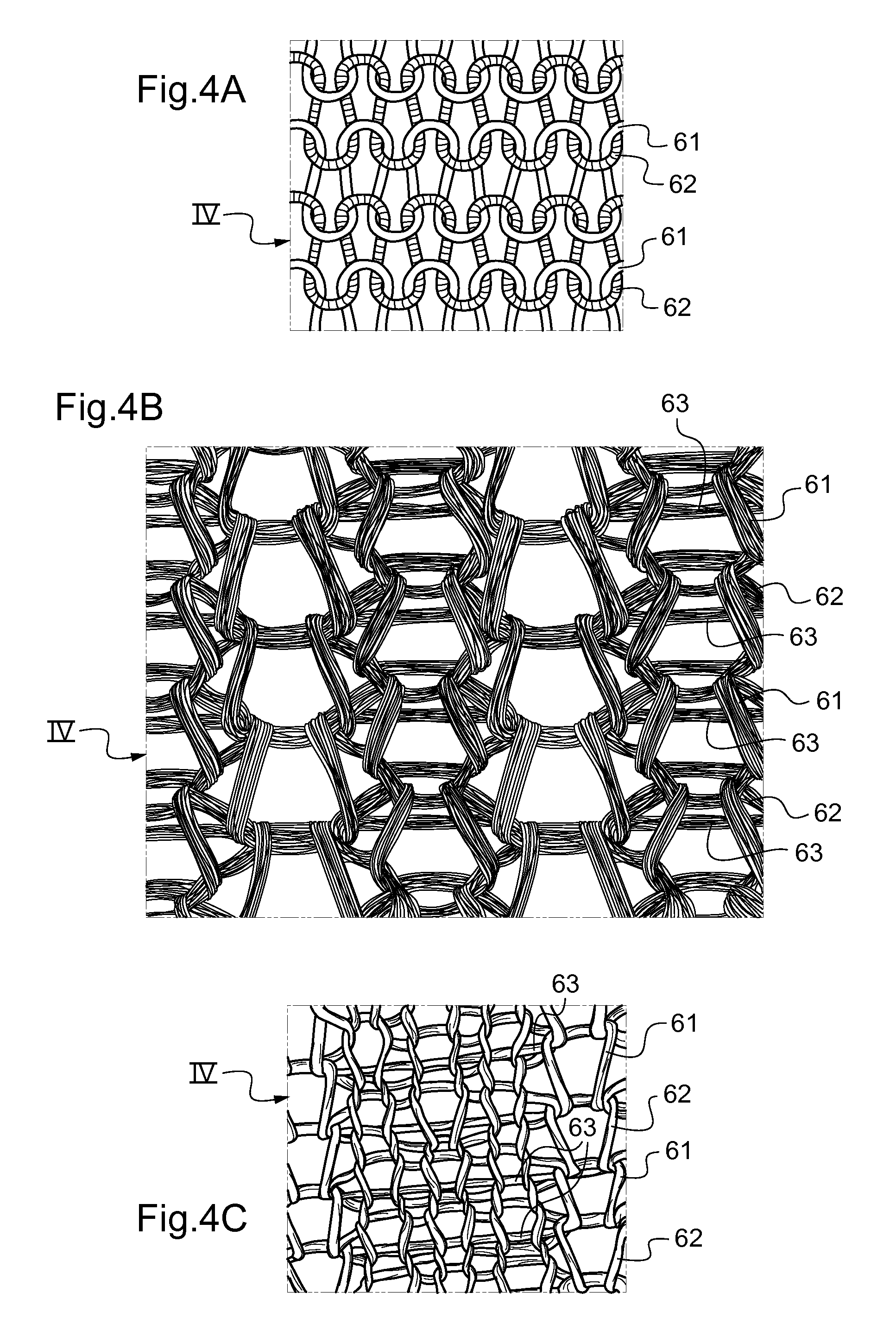

Garment, in particular a compression garment for medical use

InactiveUS20120324961A1Reduce riskAchieve anti-slip effectFeet bandagesStraight-bar knitting machinesYarnBiomedical engineering

The invention relates to a garment (10; 100) including a knitted, circumferentially-extending welt portion having a anti-slip zone (50) comprising a high friction yarn (61, 62, 63) integrally formed on a inner face of a main garment portion (11; 110) such that the high friction yarn contacts a wearer's skin to increase the anti-slip properties of the garment. The invention also relates to a method for constructing such a garment.

Owner:RADIANTE OY

Roofing and/or siding material and a method of forming thereof

ActiveUS20090317593A1Reduce the amount requiredLow reflecting surfaceLiquid surface applicatorsRoof covering using tiles/slatesReflectivityCivil engineering

A roofing and / or siding system having an improved average resulting reflectivity. The roofing and / or siding system is at least partially coated with a plurality of granules. At least one layer of paint is applied to the roofing and / or siding system to increase the resulting reflectivity of the roofing and / or siding system.

Owner:GARLAND INDS

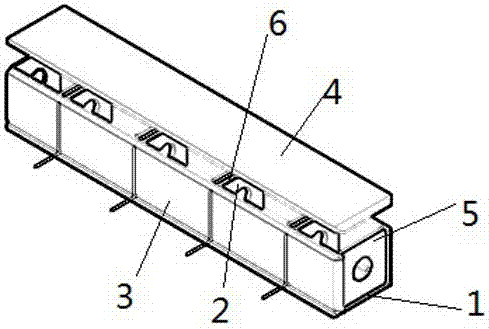

Abnormal shape box column and processing craft thereof

InactiveCN106884498ASimple structureGuaranteed sizeStrutsWelding apparatusEngineeringAbnormal shapes

The invention discloses an abnormal shape box column. The abnormal shape box column comprises a panel, partition plates, web plates and an upper flange plate, the partition plates are arranged on the panel, the web plates are arranged on the two sides of the partition plates and are fixedly connected with the panel, the upper flange plate is arranged at the upper parts of the two web plates, technical partition plates are arranged at the two ends of the panel, and the partition plates and the web plates are matched with the upper flange plate. According to the abnormal shape box column, the web plates are arranged on the panel to form a box body, the parathion plates are arranged in the box body, the upper flange plate is arranged at the upper part of the box body, and the technical partition plates are arranged at the two ends of the box body, so that the structure of the box column is improved, moreover, the size of the end part of the box body is effectively guaranteed, the processing of a large connector is facilitated on site, the supporting performance and the stability are also greatly improved, and the construction requirement is further better met.

Owner:JIANGSU HUNING STEEL MECHANISM

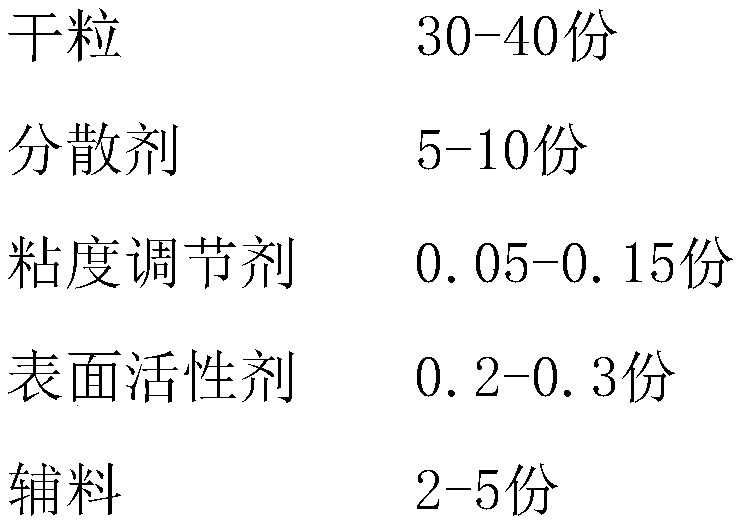

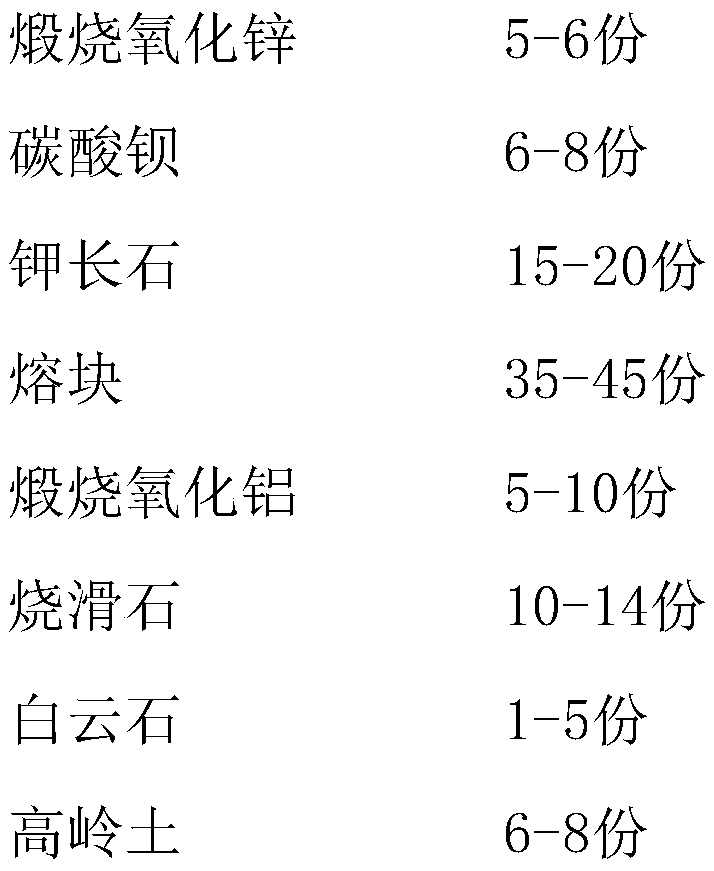

Ink-jet dry granular decorative ceramic tile and manufacturing method thereof

The invention relates to the technical field of ceramic tiles, in particular to an ink-jet dry granular decorative ceramic tile and a manufacturing method thereof. The manufacturing method includes the following steps: A. bottom glaze decoration; B. pattern decoration; C. drying for the first time; D. dry granular decoration; E. spraying a protective glaze; and F. calcining to obtain the product.The method for preparing the dry granular decorative ceramic tile has the advantages of simple operation steps, convenient control, simplified process flow, improved production efficiency, reduced production difficulty and production cost, so that the method is suitable for industrial large-scale production; by spraying with dry granular ink, spray printing can be carried out on a designated position on the surface of a blank body, so as to enable a spray printed texture to be accurately correspond to a pattern decorative texture, and thus the distribution uniformity and adhesion of dry granules on the surface of the blank body are improved, and the prepared ceramic tile product has clear and distinct patterns, low glaze gloss, good anti-skid effect, obvious dry granular feeling, strong stereoscopic impression, rich colors, stable physicochemical properties and wide temperature adaptation range.

Owner:JIANGXI HEMEI CERAMICS +3

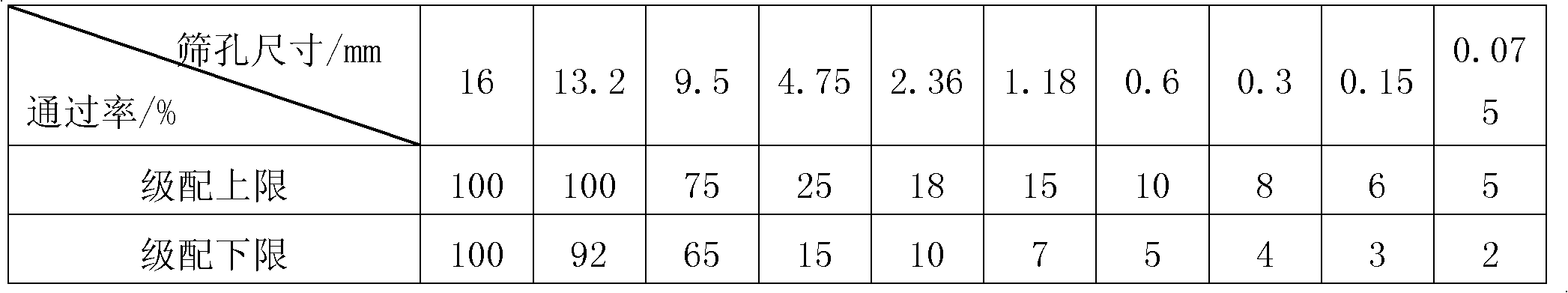

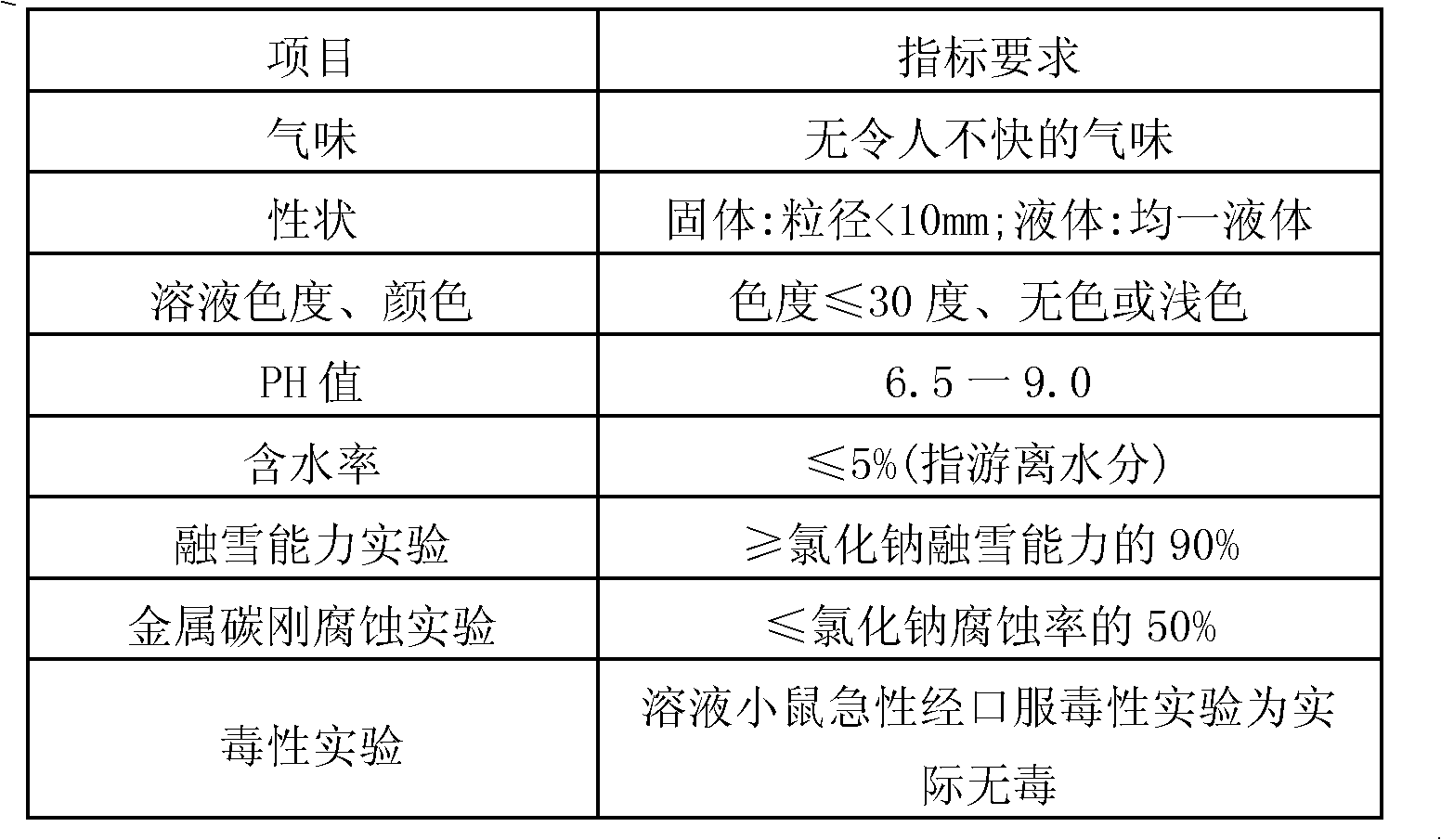

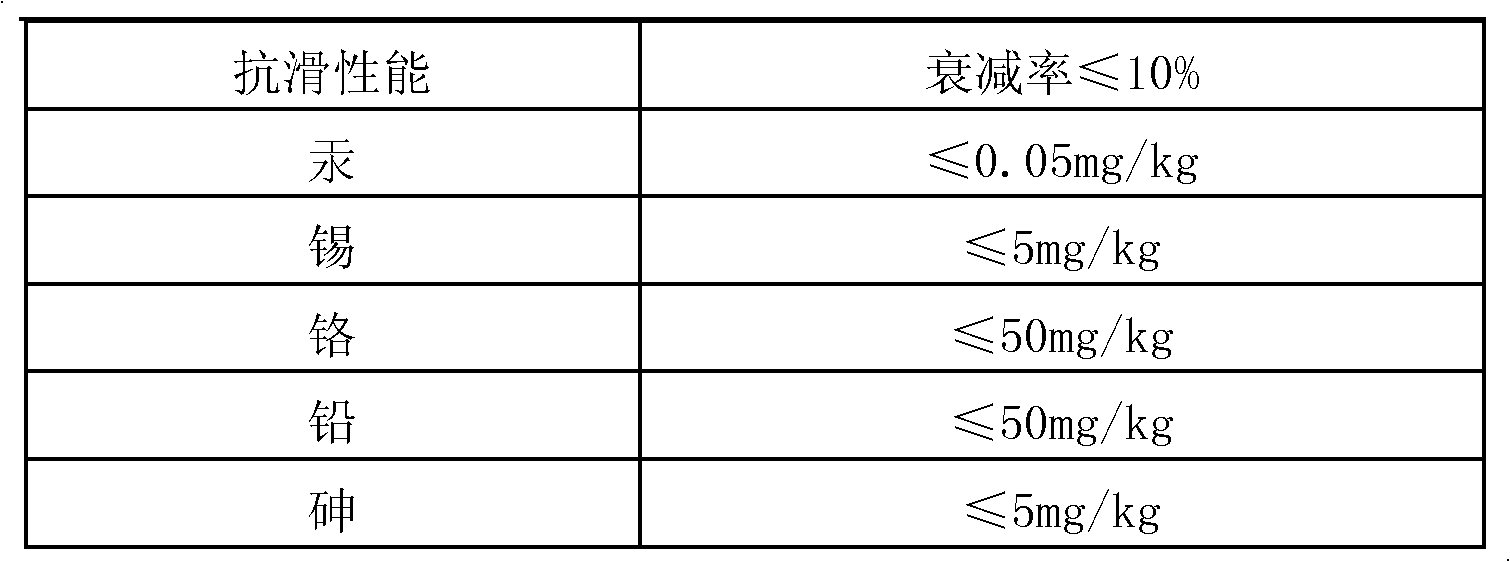

Preparation method for deicing, antiskid and denoising asphalt pavement material

The invention relates to a preparation method for a deicing, antiskid and denoising asphalt pavement material. The method is characterized by comprising the following steps: 1) preparation of rubber modified asphalt with high viscosity and high elasticity; 2) preparation of an organic / inorganic ice inhibiting material; 3) selection of mineral aggregate gradation; 4) preparation of the deicing, antiskid and denoising asphalt pavement material, which is realized by preparing mineral aggregate, the rubber modified asphalt with high viscosity and high elasticity, the organic / inorganic ice inhibiting material and fibers according to a mass ratio of 100: 4.8-5.1: 1.05-2.1: 0.225-0.533, heating the rubber modified asphalt with high viscosity and high elasticity at a temperature of 165 to 175 DEGC, and mixing and stirring the mineral aggregate, the rubber modified asphalt with high viscosity and high elasticity, the organic / inorganic ice inhibiting material and the fibers at a temperature of180 to 190 DEG C for 60 to 90 s, with paving temperature being 165 to 180 DEG C, so as to obtain the deicing, antiskid and denoising asphalt pavement material. The asphalt pavement material prepared by using the method has the characteristics of ice removal, skid resistance and noise reduction.

Owner:WUHAN UNIV OF TECH

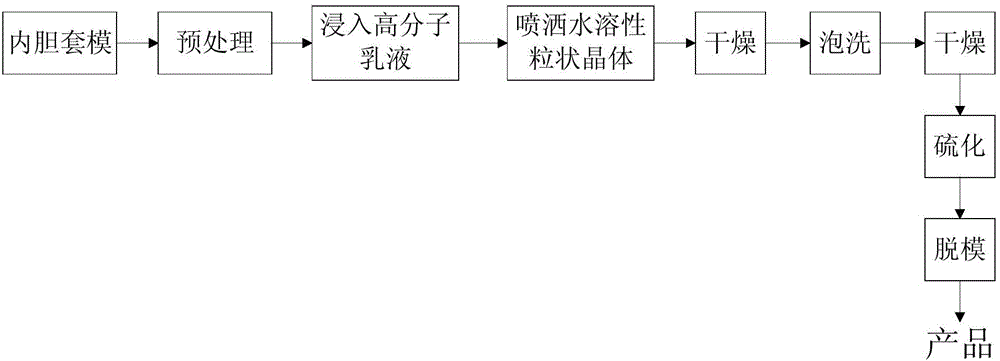

Anti-slip breathable operating gloves and preparation method thereof

ActiveCN106072923AGood anti-skid effectGood air permeabilityGlovesProtective garmentPre treatmentEmulsion

The invention provides a pair of anti-slip breathable operating gloves and a preparation method thereof. The preparation method comprises the steps that 1, macromolecular emulsion is prepared; 2, a mold is sleeved with an inner container of each glove, the inner container of each glove is immersed into the prepared macromolecular emulsion to form a macromolecular coating after pretreatment; 3, water-soluble granular crystals are sprayed on the surface of the unsolidified macromolecular coating, then drying treatment is performed, and the water-soluble granular crystals on the surface of the unsolidified macromolecular coating are dissolved with water; 4, the inner containers of the gloves treated in the step 3 are subjected to coating drying, vulcanization and demoulding treatment to obtain glove products. The macromolecular coating is formed on the inner container of each glove, the water-soluble granular crystals are sprayed on the surface of the unsolidified macromolecular coating, the water-soluble granular crystals are dissolved with water after the macromolecular coating solidifies, accordingly a large amount of micropores are formed on the macromolecular coating so as to form a concave-convex structure, and the gloves have an excellent anti-slip effect, good breathability, softness and abrasion resistance.

Owner:WONDERGRIP CHINA CO LTD

Preparation process of dry-particle tile with strong tile surface stereoscopic sensation

The invention provides a preparation process of a dry-particle tile with strong tile surface stereoscopic sensation. The preparation process comprises the following steps: (1) drying a tile blank to obtain a dried blank; (2) mixing high-temperature dry particles with ceramic glue to obtain dry-particle slurry; (3) coating the dry-particle slurry on the surface of the dried blank to form a dry-particle layer; (4) coating base glaze on the surface of the tile blank with the dry-particle layer to form a base glaze layer, wherein the thickness of the base glaze layer is smaller than the maximum particle diameter of the high-temperature dry particles; and (5) putting the tile blank coated with the base glaze into a kiln and firing to obtain the dry-particle tile. Through the preparation process of the dry-particle tile, the high-temperature dry particles are combined with the ceramic glue to directly coat the dry particles on the surface of the blank body; then through combination of the covering effect of the base glaze, the prepared dry-particle tile is better in tile surface stereoscopic effect, more stable in structure, more abundant, fine and smooth in texture and high in skidding resistance and fouling resistance.

Owner:FOSHAN DONGPENG CERAMIC +2

Preparation method of functional ceramic tile with high-simulation 3D (Three-Dimensional) digital-glaze-spraying stereoscopic-pattern effect

ActiveCN107235632APrecise Digital ControlPrevent wrong version and missing versionAdditive manufacturing apparatusCeramic shaping apparatusVeinMicrowave

The invention discloses a functional ceramic tile with a high-simulation 3D (Three-Dimensional) digital-glaze-spraying stereoscopic-pattern effect and a preparation method thereof. According to the method, a ground glaze is applied on a ceramic tile green body; a relief pattern file is printed on the ceramic tile green body by utilizing a relief ink inkjet machine; 3D relief ink is spread on the ground glaze corresponding to the sunken position of the relief pattern file through the relief ink inkjet machine; afterwards, a relief overglaze is applied on the tile green body through a stereoscopic glaze spraying machine to obtain a glazed body; a simulative relief vein is formed by utilizing the nature difference between the 3D relief ink and the relief overglaze and through changing the spreading position of the 3D relief ink and the use level of the relief overglaze; an ink jetted pattern is enabled to be exquisite on an edge and is stable-attachment in color by adopting a microwave drying means; the problem that colored ink and a protective glaze are immiscible to cause the distortion and fuzziness of a pattern is solved; the functionality of the ceramic tile is enhanced through a wearproof protective glaze, a dry granular and functional ink. The digital stereoscopic glaze-spayed ceramic tile provided by the invention is high in functionality, stereoscopic and vivid in relief, accurate and expressive in the pattern and extremely excellent in simulation effect.

Owner:广东协进陶瓷有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com