Resource-saving glazed ceramic tile having antiskid effect on surface and preparation method thereof

A resource-saving, ceramic tile technology, applied in the production of ceramic materials, household appliances, clay products, etc., can solve the problems of easy falling, potential safety hazards of ground slipping, easy slippage, etc., to achieve clear texture, resource saving, strong strength. Universal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

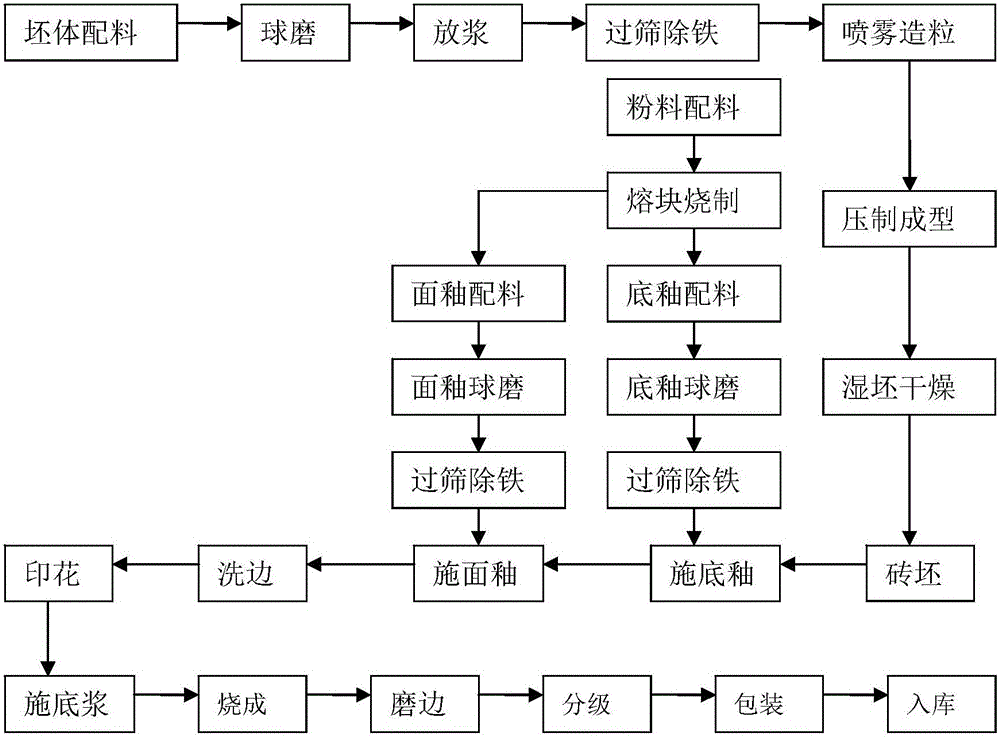

Method used

Image

Examples

example 1

[0040] A method for preparing a resource-saving glazed ceramic tile with an anti-skid effect on the surface, comprising the following steps:

[0041] A. Prepare green body:

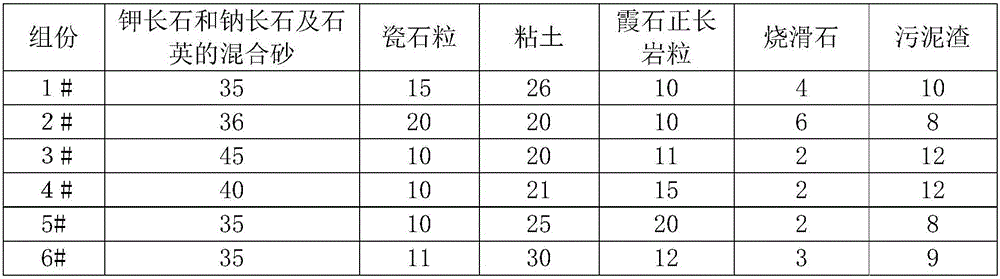

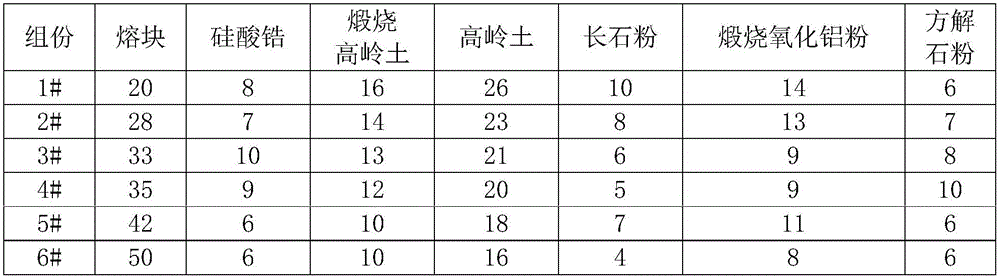

[0042] The formula composition of green body is shown in the following table 1:

[0043] Table 1: Composition list (parts by weight) of green body

[0044]

[0045] According to the composition of the green body in Table 1, weigh the mixed sand of potassium feldspar, albite and quartz, porcelain stone grains, clay, nepheline syenite grains, burnt talc, sludge slag, and 1 to 2 parts of water glass, 0.2-0.4 parts of sodium tripolyphosphate, 0.2-0.4 parts of ceramic water reducer, and 50-55 parts of water are mixed and ground together to form a slurry with a fineness of 250 mesh sieves and a mass percentage of 0.5% to 2%. Iron sieved and spray-dried to make a powder with a mass percentage of 5.5% to 7.5% moisture, at 300 to 400 kg / cm 2 Under the pressure range, use an automatic hydraulic press to form,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com