Patents

Literature

713 results about "Albite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Albite is a plagioclase feldspar mineral. It is the sodium endmember of the plagioclase solid solution series. It represents a plagioclase with less than 10% anorthite content. The pure albite endmember has the formula NaAlSi₃O₈. It is a tectosilicate. Its color is usually pure white, hence its name from Latin albus. It is a common constituent in felsic rocks.

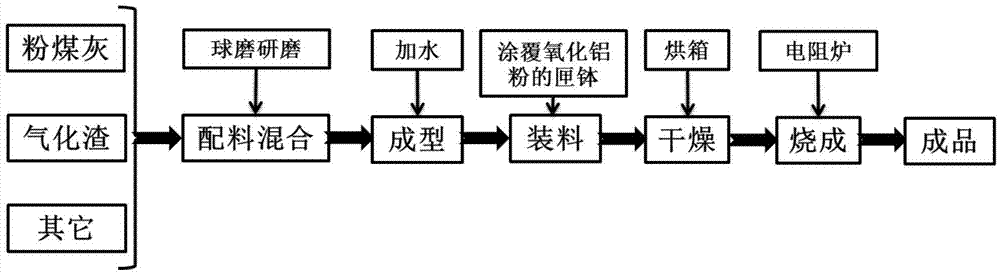

Lightweight ceramisite prepared from coal ashes and gasification slag as well as preparation method and application thereof

ActiveCN104774023ASignificant environmental benefitsImprove performanceSolid waste disposalCeramicwareSlagExpanded clay aggregate

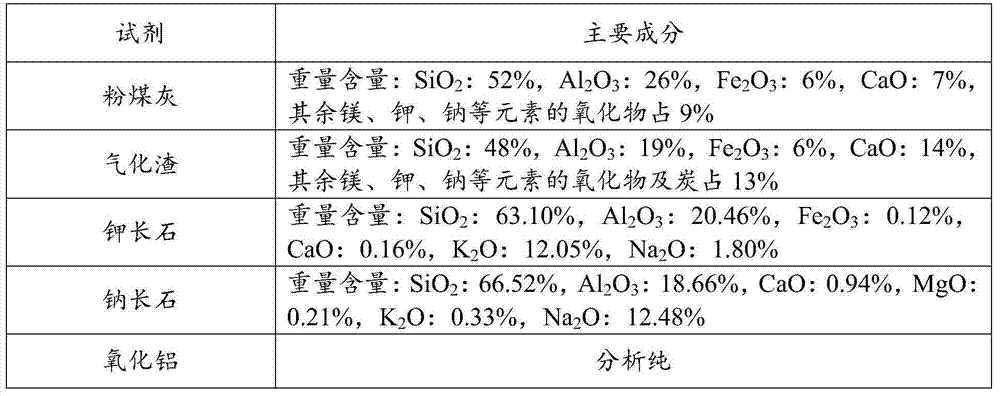

The invention relates to the technical field of building materials, and in particular relates to lightweight ceramisite prepared from coal ashes and gasification slag as well as a preparation method and an application thereof. The lightweight ceramisite is prepared from the following raw materials with the following components in parts by weight: 100 parts of base materials comprising 40-90 parts of coal ashes, 10-30 parts of gasification slag, 0-20 parts of potassium feldspar and 0-20 parts of albite; and 0-4 parts of additional auxiliaries which are selected from one or two of semicoke or silicon carbide, wherein the coal ashes account for 40-90%, and the gasification slag particles account for 10-30%; and the sintering temperature is 1120-1200 DEG C, the energy consumption is reduced, the raw material distribution is relatively wide and the raw materials are easily available. The lightweight ceramisite has bulk density lower than or equal to 700 kg / m<3>, is smaller in weight, higher in strength, wider in raw material distribution and easier to obtain, and the barrel pressure strength can be higher than 10 MPa.

Owner:北京大学包头创新研究院

Thermal spray compositions for abradable seals

Owner:SULZER METCO CANADA INC

Building external wall thermal insulation foamed ceramic material and production method thereof

InactiveCN102584326AEfficient use ofLow costSolid waste disposalCeramicwareThermal insulationEnergy conservation

The invention belongs to the field of building materials, and in particular relates to a building external wall thermal insulation foamed ceramic material and a production method thereof. The building external wall thermal insulation foamed ceramic material is prepared from the following raw materials in part by weight: 60 to 80 parts of industrial solid waste, 15 to 35 parts of fluxing material and 2 to 5 parts of foaming agent, wherein the industrial solid waste is a mixture of two or three of coal gangue, metal tailing and polishing waste in any ratio; the fluxing material is one or a mixture of two of albite and bottle waste glass in any ratio; and the foaming agent is silicon carbide powder. The method comprises the following steps of: mixing the raw materials, grinding, filling in a recrystallized silicon carbide die, feeding into a kiln, firing, naturally cooling, cutting, and inspecting to obtain the foamed ceramic material which meets the building external wall thermal insulation requirement. The building external wall thermal insulation foamed ceramic material has the characteristics of A-level non-inflammability, high thermal insulation and heat preservation performance, energy conservation, environment friendliness and low cost.

Owner:ZHONGCAI HIGH NEW MATERIAL +1

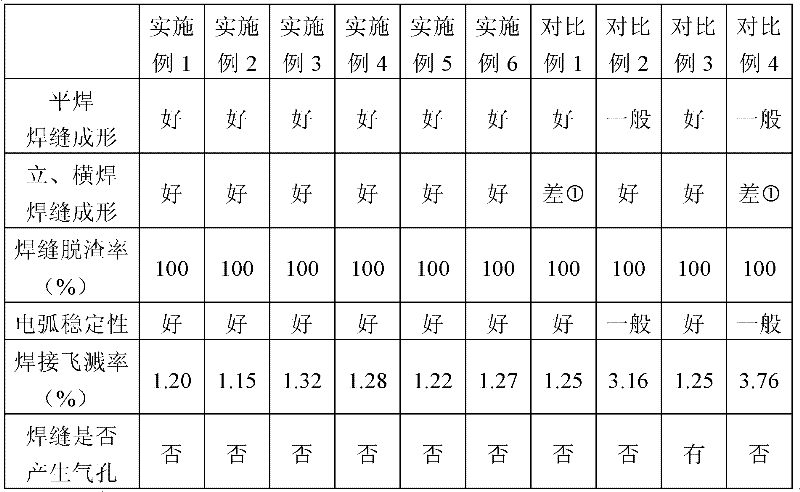

Flux-cored wire for austenitic stainless steel all-position welding

ActiveCN102229029AGood workmanshipGood slag removalWelding/cutting media/materialsSoldering mediaElectrolysisPotassium

The invention relates to a flux-cored wire for austenitic stainless steel all-position welding, and the flux-cored wire is composed of a flux core and an external stainless steel belt, wherein, the flux core accounts for 22-24wt% of the flux-cored wire, and the flux core comprises the following components in percentage by weight: 20-23% of metal chromium powder, 7-8.5% of metal nickel powder, 2-4% of electrolytic manganese metal, 3-4% of aluminium powder, 0.5-1% of ferrotitanium, 32-34% of rutile, 1-2% of quartz, 2-4% of zircon sand, 4-6% of albite, 2-4% of potassium feldspar, 1-1.5% of cryolite, 1-1.5% of lithium carbonate, 0.1-0.5% of bismuth oxide and the balance of iron powder. The ratio of the albite to the potassium feldspar in the flux core is 1.2-2, the sum of the albite and the potassium feldspar is not more than 10wt% of the flux core, the external stainless steel belt is the austenitic stainless steel 304L, the carbon content is less than 0.025wt%, the diameter of the flux-cored wire is 0.9-1.2mm, and the flux-cored wire can be used for realizing the austenitic stainless steel all-position welding.

Owner:北京远达国际工程管理咨询有限公司 +1

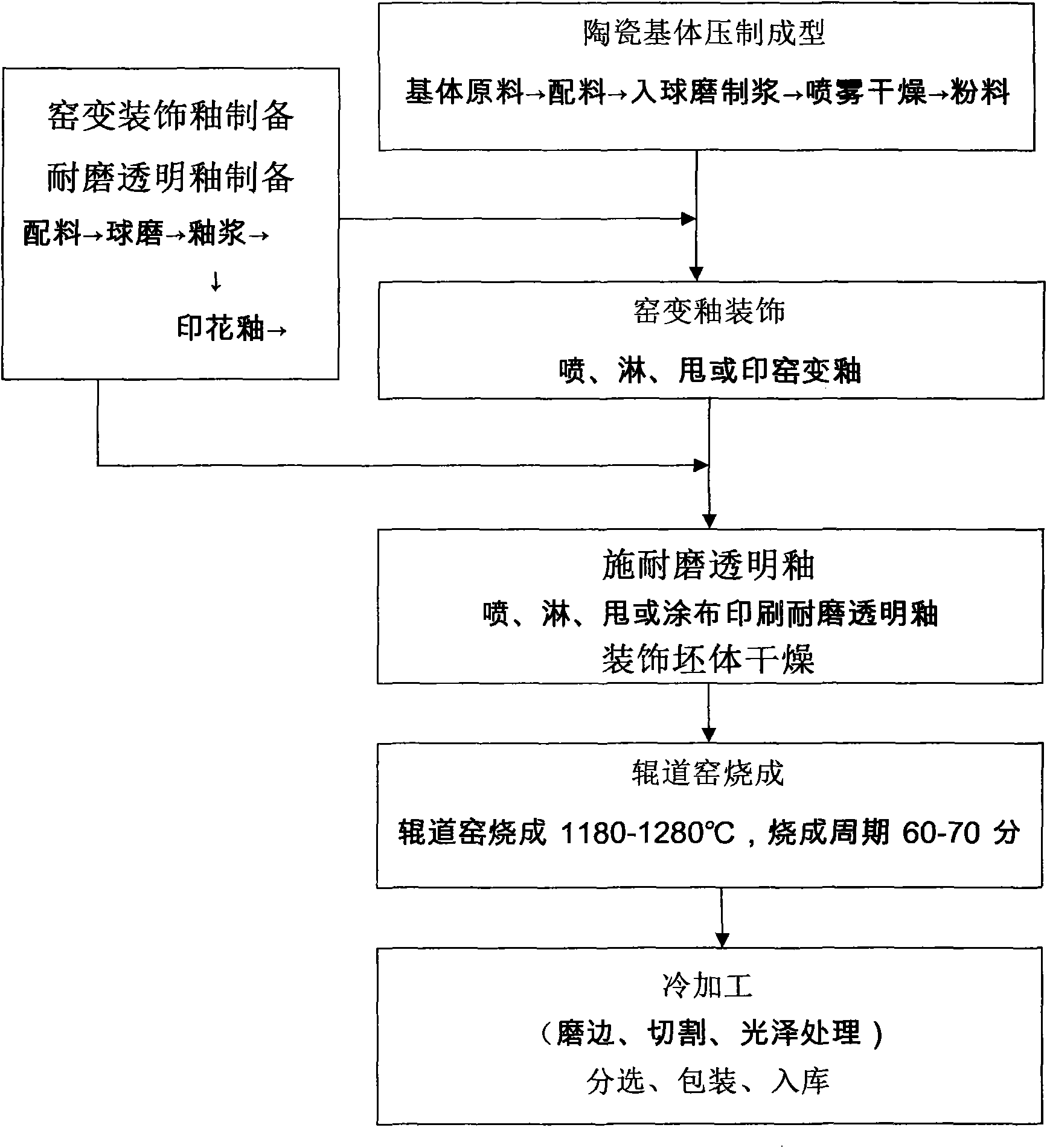

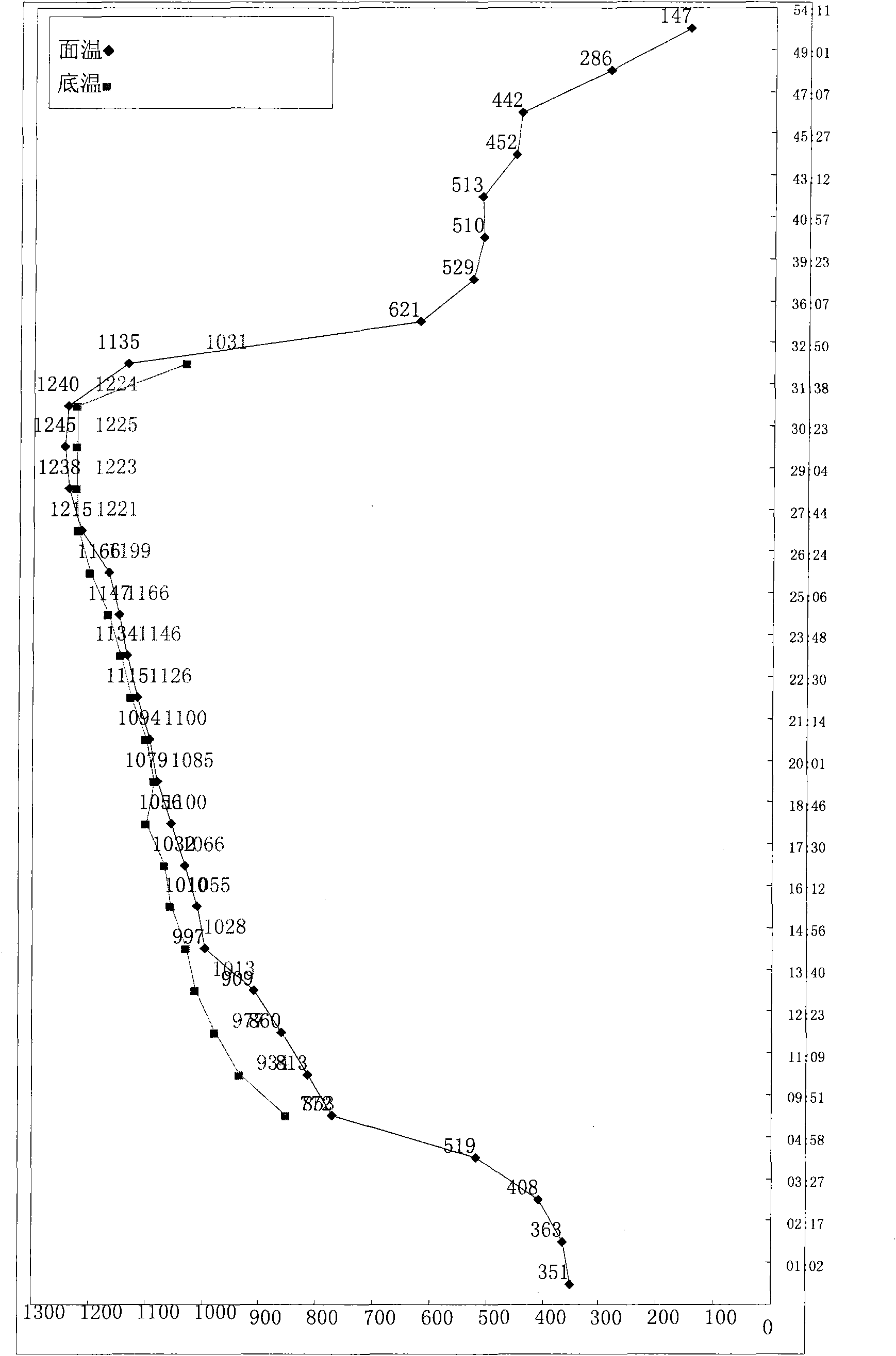

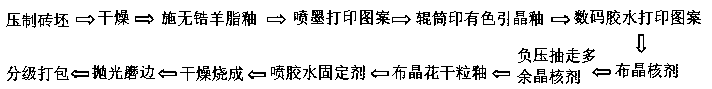

Furnace transmutation decoration glazed brick and production technology

The invention relates to a furnace transmutation decoration glazed brick and a production technique thereof. The furnace transmutation decoration glazed brick is prepared from the following componentsin percentage by weight: 10-30% of albite, 3-10% of spodumene, 5-10% of kaoline Al2O3.2SiO2.2H2O, 8-30% of zinc oxide ZnO, 3-10% of talc 3MgO.4SiO2.H2O, 0-20% of titanium TiO2, 3-10% of zirconite ZrSiO, and 1-10% of coloring metallic oxide MnO2, V2O5, Fe2O3 and CoO2. The production technique of the furnace transmutation decoration glazed brick comprises the following steps: (1) shaping the substrate of the furnace transmutation decoration glazed wall and floor bricks; (2) decorating the wall and floor brick substrate surface or anti-abrasion transparent glaze layers and drying; and (3) sintering the furnace transmutation decoration glazed wall and floor bricks once in a high-temperature roller kiln.

Owner:黄建平

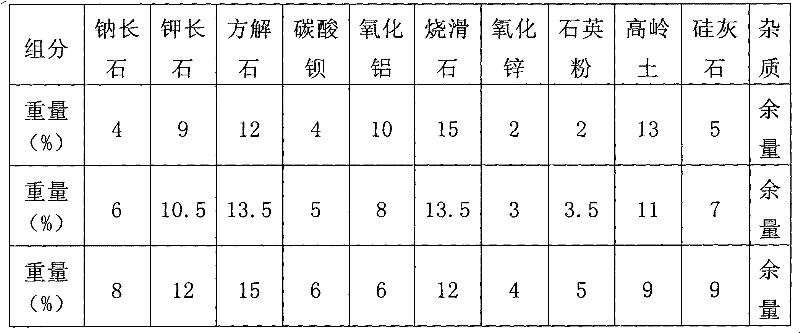

Complete polishing glaze archaizing brick overglaze and preparation method thereof

The invention relates to a complete polishing glaze archaizing brick overglaze and a preparation method thereof. The complete polishing glaze archaizing brick overglaze is prepared from the following raw materials by weight percent: 4-8% of albite, 9-12% of potassium feldspar, 12-15% of calcite, 4-6% of barium carbonate, 6-10% of alumina, 12-15% of burnt talcum, 2-4% of zinc oxide, 2-5% of quartz powder, 9-13% of kaolin, 5-9% of wollastonite and the balance of impurities. The preparation method comprises the following steps: carrying out ball milling in a ratio of weighed raw material to ballstone to ethylene glycol to squeegee oil of 1: (1.8-2): 0.25: 0.3, and simultaneously controlling the fineness degree as follows: the screenings of 325-mesh sieve is 0.3-0.4%; printing on ground glaze and fancy glaze layers through 100-mesh silk screen by using a continuous printing process; and finally, firing through a liquefied gas raceway kiln firing system. According to the invention, the purposes of improving the stability of the process and the quality of the product, reducing glaze material loss in production process, reducing cost and simultaneously avoiding the generation of a screen sticking problem in production are achieved.

Owner:霍镰泉

Production raw material of foamed glass and process for producing foamed glass

The invention relates to raw materials for producing foam glass and a method for applying the same to produce the foam glass. The compositions by weight portion of the raw materials are: 380 to 580 portions of quartz sand, 105 to 250 portions of potassium feldspar, 130 to 270 portions of albite, 115 to 200 portions of dolomite, 5 to 25 portions of calcite, 150 to 250 portions of calcined soda, 0.5 to 30 portions of glauber salt, 1.0 to 12 portions of magnesium carbonate and 1.0 to 8.5 percent of potassium carbonate. The method comprises the following steps that: firstly, various raw material compositions are mixed into uniform glass mixture; secondly, the glass mixture is melted and cooled into cullet; thirdly, ball milling, foaming and annealing of the cullet are performed, and then foam glass is obtained. The method can automatically control and adjust the chemical compositions of the glass and add various functional compositions as required to meet the demand of producing the foam glass with different performances by adoption of common mineral and chemical raw materials of the natural world.

Owner:ZHEJIANG ZHENSHEN INSULATION TECH CORP

Celadon cracked-ice pattern tire bone and glaze material, production method for products produced thereof

The present invention relates to a celadon cracked-ice-pattern skeleton and glaze, wherein, the skeleton comprises the ingredients by weight: 38 to 42 percent of Baoxi purple red clay,13 to 17 percent of Lianligen china clay, 13 to 17 percent of china clay,18 to 22 percent of kaolin,9 to 11 percent of aluminum oxide; the glaze comprises the ingredients by weight: 23 to 25 percent of Baoxi purple red clay, 14 to 17 percent of glaze clay, 8 to 12 percent of kaolin, 14 to 17 percent of albite,23 to 27 percent of potassium stone and10 to 12 percent of limestone. The present invention also provides a method for producing the cracked-ice-pattern product with the skeleton ingredients and the glaze materials. The product that is produced with the skeleton and the glaze material in the method not only maintains the properties of the cracked-ice-pattern product that is obtained with the original method, but also resolves the original technical problem that the maximum limit of the baked celadon apparatus is increased from 30 centimeters to 50 centimeters, thereby greatly improving the beauty.

Owner:丁绍杰

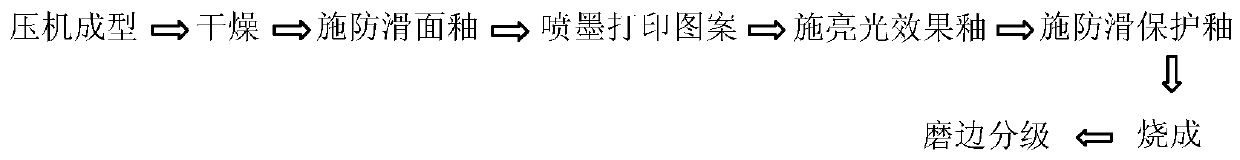

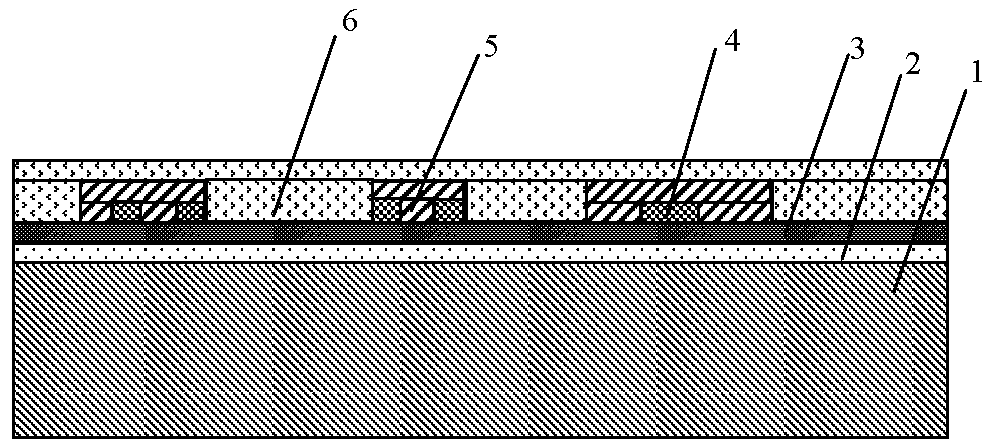

Wet water high anti-skid ink-jet ceramic tile with sunken glaze effect and preparation method of tile

The invention provides a wet water high anti-skid ink-jet ceramic tile with a sunken glaze effect and a preparation method of the tile. The preparation method includes sequentially applying anti-skidsurface glaze, decorative patterns, bright effect glaze and anti-skid protective glaze on a blank body, and then firing, wherein the mineral composition of the composition of the anti-skid surface glaze comprises 40-50% of potassium feldspar, 0-10% of albite, 7-10% of kaolin, 8-12% of quartz, 8-11% of calcined alumina, 0-5% of nepheline, 2-4% of zinc oxide, 7-10% of zirconium silicate and 6-10% ofbarium carbonate; and the mineral composition of the composition of the anti-skid protective glaze comprises 48-58% of potassium feldspar, 0-10% of albite, 10-20% of kaolin, 0-5% of quartz, 0-4% of nepheline, 2-5% of calcined alumina, 10-15% of barium carbonate and 5-8% of zinc oxide. The anti-skid ceramic tile can be used as a decorative material with a good decorative effect, excellent pollution resistance and anti-skid performance, and can be applied to the field of home decoration.

Owner:MONALISA GRP CO LTD

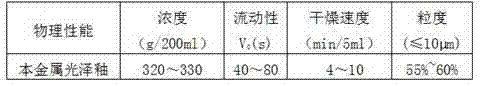

High-temperature domestic porcelain metallic bright glaze and product decorated by same

The invention relates to a high-temperature domestic porcelain metallic bright glaze and a product decorated by the same. The bright glaze produced by using natural mineral raw materials and industrial pure raw materials comprises the following materials by weight percent: 10-25 percent of potassium feldspar, 10-30 percent of albite, 0-35 percent of quartz, 0-10 percent of barium carbonate, 0-10 percent of wollastonite, 0-10 percent of kaolin, 0-5 percent of zinc oxide, 1-10 percent of aluminum oxide, 1-10 percent of bone ash, 1-5 percent of purple clay and 10-35 percent of ferric phosphate, and the glaze is obtained by mixing, ball-milling and screening the raw materials. The fabrication technology of the glaze is basically the same as the common porcelain glaze, the cost is low, not only can the pure color be guaranteed through redesigning of the formula of the glaze, but also the burning temperature of the glaze is increased to 1380 DGE C, so that the decoration effect of domestic porcelain is greatly enriched, and the high-temperature domestic porcelain metallic bright glaze has wide application prospect.

Owner:HUNAN KARPERY INDAL +1

Full polish ceramic product and preparation method thereof

The invention relates to a full polish ceramic product and a preparation method thereof. The full polish ceramic product comprises a ceramic green body and a full polish layer outside the ceramic green body, wherein the full polish layer mainly comprises powder which comprises following components by weight percent: 42-62% of albite, 2-7% of potash feldspar, 0-4% of dolomite, 4-8% of calcite, 0-2% of barium carbonate, 6-8% of aluminum oxide, 3-5% of fired talc, 2-4.6% of zinc oxide, 3-9% of quartz powder, 0.5-2.5% of soochow kaolin, 1-6% of calcined kaolin, 5-10% of aedelforsite, 0.1-3.0% of spodumene, and 0.1-2.8% of borocalcite. The full polish slurry is prepared by burdening and ball milling once. As the full polish slurry contains less wearproof materials like aluminum oxide, the ball milling time is short, and the production efficiency is higher; due to the addition of little amount of spodumene and borocalcite, the abrasion performance and hardness of the fired full polish ceramic product can be improved.

Owner:JIANGSU BAIFU TECH CO LTD +1

Ceramic tile capable of generating negative ions and effectively improving indoor air quality, and production method thereof

The invention provides a ceramic tile having air purifying and harmful gas removing effects, extremely beneficial for the health of human bodies, and capable of generating negative ions and effectively improving the indoor air quality, and a production method thereof. The ceramic tile capable of generating negative ions and effectively improving the indoor air quality comprises potash feldspar powder, albite powder, ball clay, zeolite, diatom ooze, medical stone, tourmalinite and germanite. According to the invention, natural mineral raw materials having an adsorption effect and releasing negative ions are added in the technological formula of the ceramic tile, so the ceramic tile can generate negative ions, has the air purifying and harmful gas removing effects, and is extremely beneficial for the health of the human bodies.

Owner:李心红

Ceramic tile with heat-preservation and heat-insulation functions and production method of same

InactiveCN103693993AImprove thermal insulationStrong mechanical propertiesClaywaresSodium BentoniteMullite

The invention discloses a ceramic tile with heat-preservation and heat-insulation functions and a production method of the same, belonging to the technical field of ceramic tiles. The ceramic tile disclosed by the invention is prepared by burning a ceramic tile billet and a layer of heat-preservation and heat-insulation glaze sprayed on the surface of the ceramic tile, wherein the glaze is composed of the following raw materials: potassium feldspar, albite, kaolin, sepiolite, expanded perlite, nanometre SiO2, magnesium carbonate powder, calcium carbonate powder, ZnO powder, and TiO2 powder; the ceramic tile billet is composed of the following raw materials: kaolin, quartz sand, mullite, sepiolite, talcum powder, bentonite, dolomite and glass fibres. The ceramic tile disclosed by the invention can be widely used in the construction field, and is excellent in heat-preservation and heat-insulation performances, simple in preparation process, low in production cost, very wide in market prospect, and convenient to industrialize, popularize and apply.

Owner:宾阳县明翔新材料科技有限公司

Low-temperature, high-hardness and high-abrasion-resistance fully-polished glaze and preparation method thereof

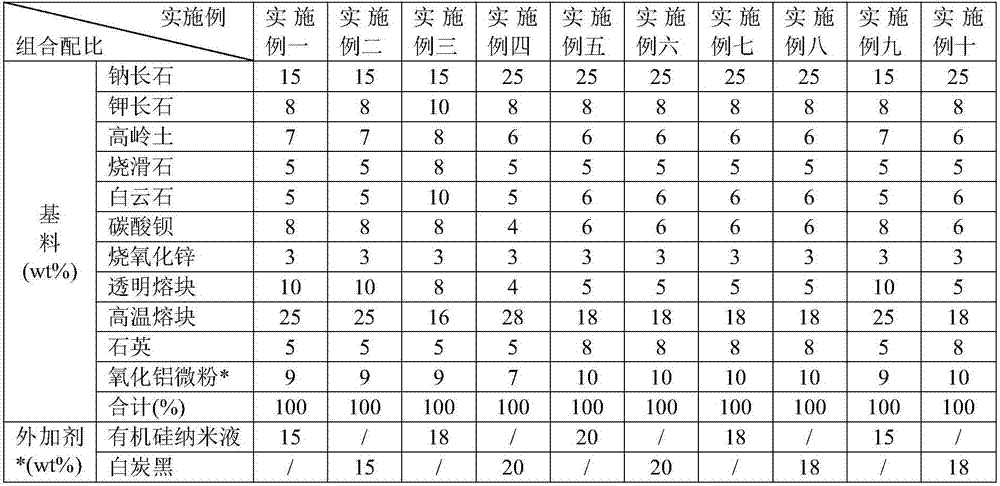

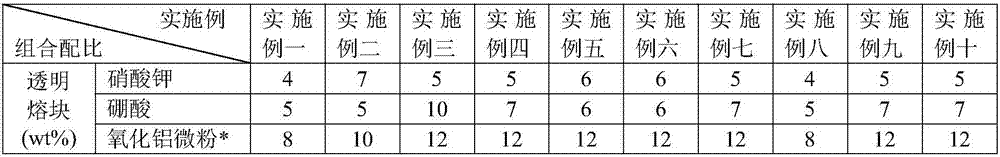

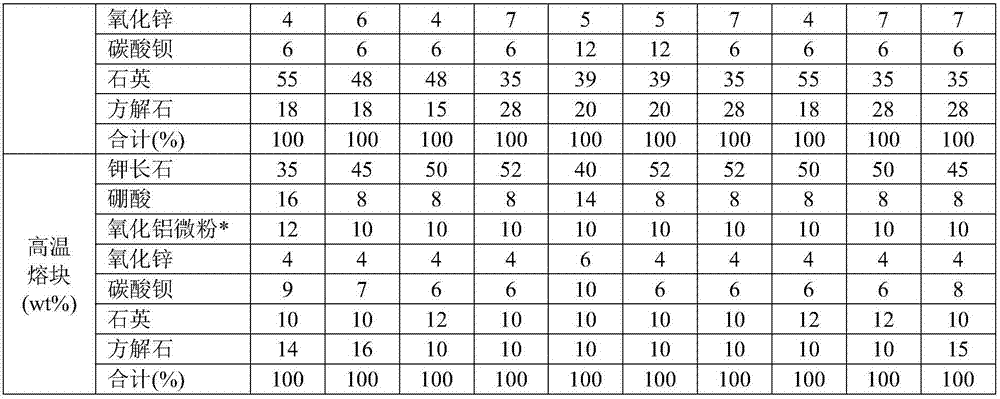

The invention discloses a low-temperature, high-hardness and high-abrasion-resistance fully-polished glaze which contains a base material and an admixture. The base material is prepared from, by weight, 15-25% of albite, 8-16% of potassium feldspar, 6-10% of kaolin, 5-8% of calcined talc, 5-10% of dolomite, 4-12% of barium carbonate, 3-5% of calcined zinc oxide, 4-20% of transparent frit, 16-28% of high-temperature frit, 5%-18% of quartz and 7-15% of alumina micro-powder, wherein the admixture is an organic silicon nano-solution or white carbon black, and the usage amount of the admixture is 15-2% by weight. In addition, the invention further discloses a preparation method of the low-temperature, high-hardness and high-abrasion-resistance fully-polished glaze and a product prepared by the same. The melting temperature is reduced through a reasonable formula system, the melting temperature range of the glaze is enlarged while energy saving and emission reduction are promoted, the hardness and abrasion resistance of the glaze surface are remarkably improved, the higher usage requirements can be very well met, and technical progress and application development of the industry of architectural ceramics are promoted.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Granular double-layer reaction glaze and preparation method

The invention belongs to the technical field of ceramic glazes and particularly relates to a granular double-layer reaction glaze and a preparation method. The granular double-layer reaction glaze comprises the following ingredients in parts by weight: a ground glaze: 30-40 parts of soda feldspar, 5-15 parts of quartz, 5-15 parts of wollastonite, 2-6 parts of calcined alumina, 25-35 parts of kaolin and 15-25 parts of toner; and an overglaze: 35-45 parts of high-boron clinker, 15-25 parts of quartz, 5-10 parts of wollastonite, 5-15 parts of spodumene, 10-20 parts of calcined zinc oxide, 5-15 parts of kaolin, 5-10 parts of calcined talcum, 5-10 parts of titanium dioxide powder and 5-15 parts of zirconium silicate. The granular double-layer reaction glaze is short in firing time and has relatively high thermal shock resistance and glazed surface hardness.

Owner:HUNAN HUALIAN CHINA IND

External wall thermal insulation light foamed ceramic and preparation method thereof

The invention belongs to the field of building materials, and in particular relates to external wall thermal insulation light foamed ceramic. The light foamed ceramic is prepared by performing wet grinding on 60 to 90 mass parts of industrial solid waste and 10 to 40 mass parts of fluxing material to form slurry, and foaming, wherein the industrial solid waste is one or a mixture of any two or three of coal gangue, metal tailing and red mud in any ratio; and the fluxing material is one or a mixture of any two or three of bottle waste glass, albite and perlite in any ratio. A preparation method comprises the following steps of: mixing the raw materials, grinding, adding active aluminum powder, a foam stabilizer and concentrated hydrochloric acid or a sodium hydroxide solution in turn, stirring, performing foam forming to prepare a foamed ceramic biscuit, feeding into a kiln, firing, naturally cooling, cutting, and inspecting to obtain the external wall thermal insulation light foamed ceramic. The external wall thermal insulation light foamed ceramic has the characteristics of level-A non-inflammability, high thermal insulation and heat preservation performance, energy conservation,environment friendliness and low cost.

Owner:ZHONGCAI HIGH NEW MATERIAL +1

Ceramic permeable bricks and method for producing the same

The invention provides a ceramic water permeable brick and a method for manufacturing the same. The ceramic water permeable brick comprises the following components in weight percentage: 75 to 85 percent of waste ceramic powder, 2 to 5 percent of waste glass powder, 10 to 20 percent of low-temperature clay, 2 to 5 percent of limestone, 2 to 5 percent of dextrin, 0 to 6 percent of albite and 2 to 5 percent of water. The preparation process comprises the following steps: (1) the waste ceramics, the waste glass, the low-temperature clay and the limestone are crushed and sieved; (2) material mixing; (3) the dextrin is added to water and heated; (4) waste ceramic grains are mixed with dextrin water; (5) other powder materials are added and stirred; (6) the mixing pulp is added into a die and subjected to press forming by a pressing machine; (7) drying; (8) the mixing pulp after drying is burned at a temperature of between 1,100 and 1,200 DEG C for 5 to 6 hours; and (9) checking. The application of the water permeable brick has the advantages of having short burning time, simple process method, lower production cost, good water permeable performance, high strength and high utilization rate of waste, and solving the problem of utilizing waste ceramics, protecting the environment and saving natural resources, and so on; and the ceramic water permeable brick can be widely used to pave roads in public places such as squares, parks, sidewalks, parking lots.

Owner:邱陶辉

Colored seeding glaze, and positioning crystal pattern ceramic tile prepared using same

The invention discloses a colored seeding glaze, and a positioning crystal pattern ceramic tile prepared using. The colored seeding glaze comprises a base glaze and a coating pigment, and raw materials of the base glaze comprises, by mass, 24-30% of potassium feldspar, 6-10% of albite, 10-14% of calcined kaolin, 3-5% of calcite, 1-3% of dolomite, 7-9% of barium carbonate, 3-5% of strontium carbonate, 5-7% of wollastonite, 1-3% of calcined talc, 2-4% of zinc oxide, 14-20% of seeding agent frit, 1-3% of tungsten oxide, 2-4% of calcium phosphate and 1-3% of tin oxide.

Owner:MONALISA GRP CO LTD

Micro slag gas protection flux-cored wire suitable for electric arc additive manufacturing of die

ActiveCN106077992ANo flowWell formedArc welding apparatusWelding/cutting media/materialsLiquid metalMagnesite

The invention relates to a micro slag gas protection flux-cored wire suitable for electric arc additive manufacturing of a die. The flux-cored wire is formed by wrapping a powder core with a steel strip and comprises a component A, a component B and a component C. The component A comprises, by weight, 30-45% of rutile, 4-7% of cryolite, 8-14% of fluorite, 10-20% of marble, 8-14% of magnesite, 8-14% of potassium titanate and 10-22% of albite. The component B comprises, by weight, 5-20% of aluminum magnesium alloy, 5-15% of ferrotitanium, 26-40% of nickel, 8-20% of molybdenum, 12-24% of chrome, 10-18% of 45# silicon iron and 10-28% of manganese. The component C is composed of iron powder and impurities. After the flux-cored wire is welded, a micro amount of molten slag is formed and thinly and uniformly covers the surface of deposited metal, the molten slag cocks and falls off automatically after cooling, and multilayer welding can be achieved without slag removing; and in addition, weld spatter hardly appears, electric arcs are stable, molten metal does not flow, the appearance is attractive, excellent welding technological performance is achieved, and the deposited metal has good comprehensive mechanical performance.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

Preparation method for super white ceramic vitrified tile produced by using magnesium aluminum silicate as raw material

The invention provides a preparation method for a super white ceramic vitrified tile produced by using magnesium aluminum silicate as a raw material. The super white ceramic vitrified tile comprises components of potassium feldspar, albite, calcined talc, black clay, a water reducing agent, a lithium feldspar, diopside, an intensifier, washed mud and quartz. The ultralow temperature fast firing vitrified tile belongs to a special ultralow temperature, high-strength, high-hardness, high abrasion-resistance, strong antifouling, low-radiation, environment-friendly, healthy and novel vitrified tile material and product. The technology can reduce firing temperature and shorten a firing period greatly and is favorable for energy conservation and emission reduction of ceramic industry, green manufacturing and low carbon production.

Owner:FOSHAN SHI WAN YING BRAND CERAMICS CO LTD +2

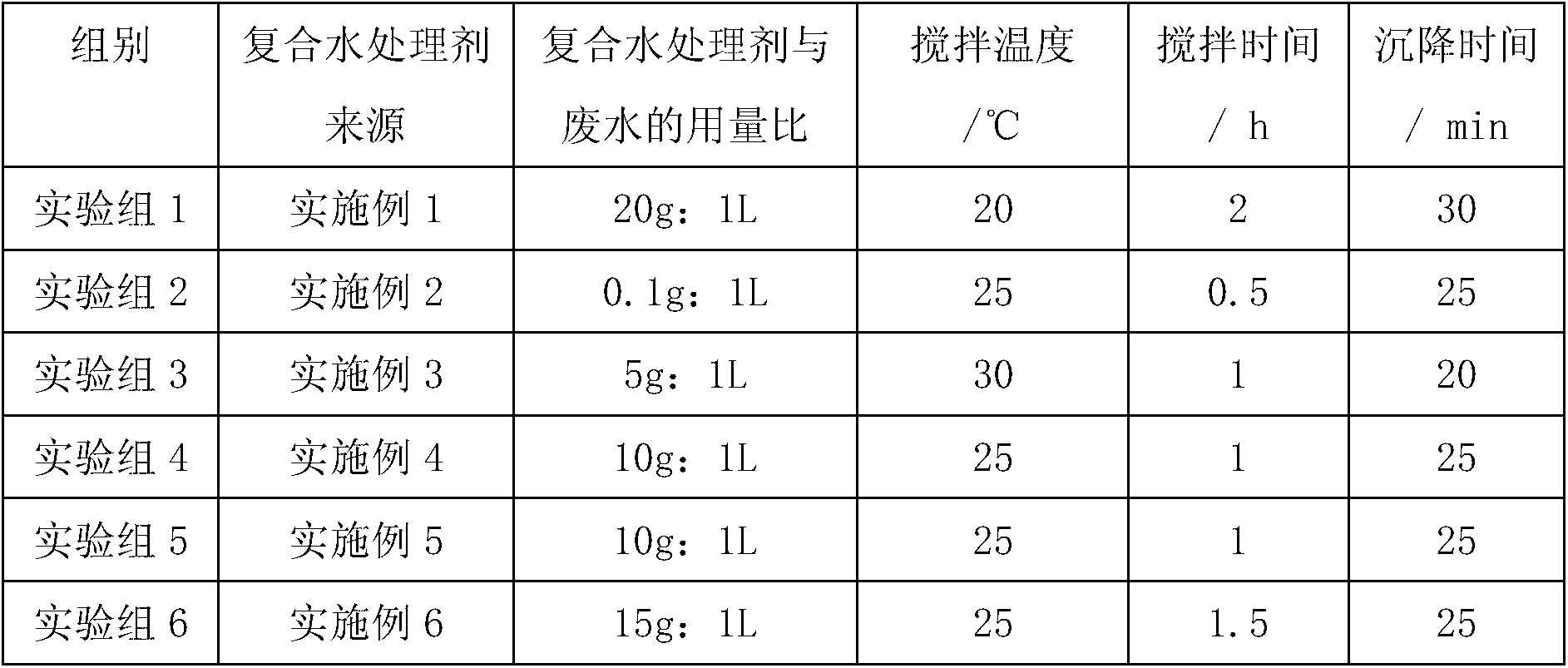

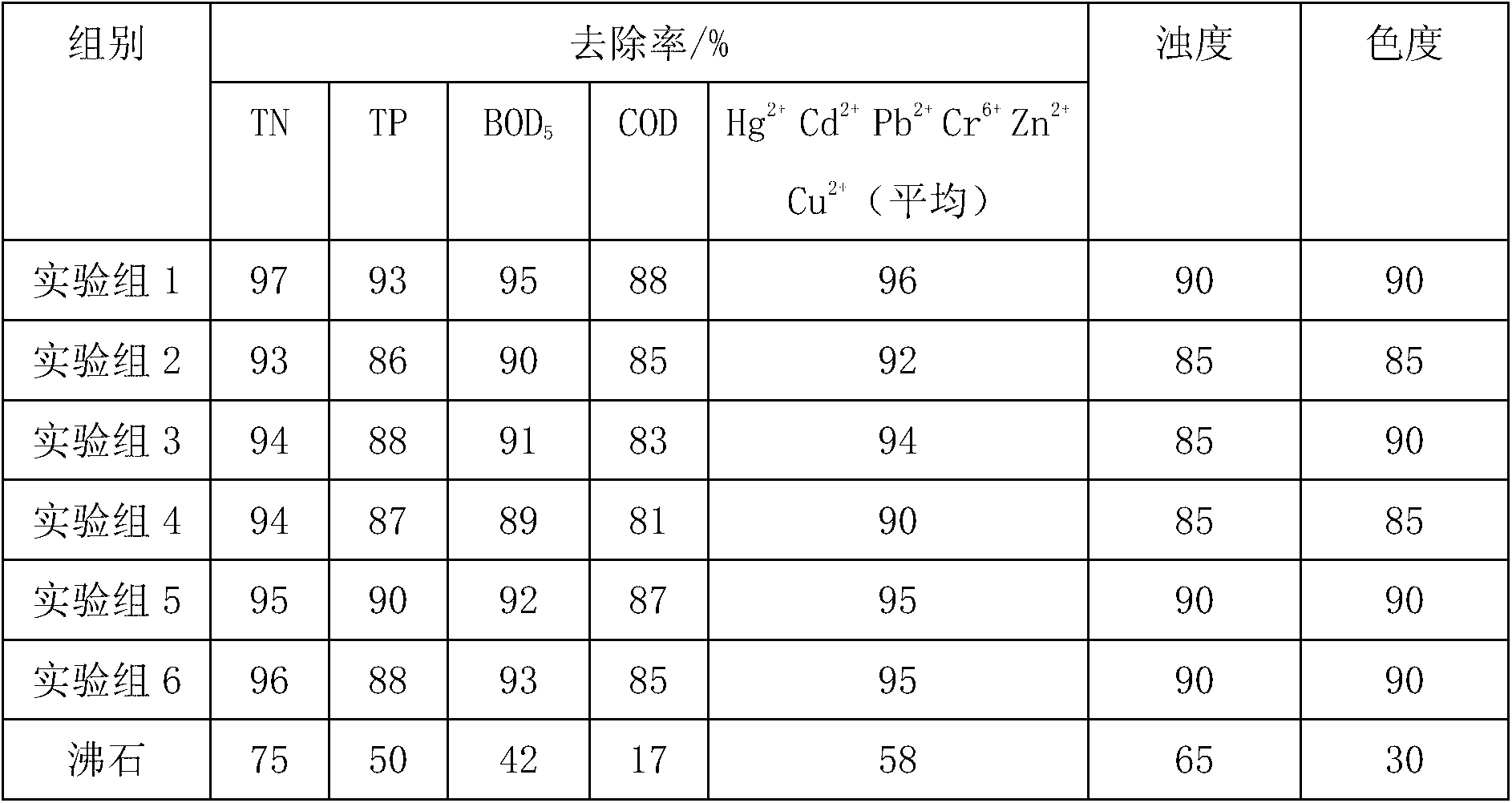

Compound water treatment agent as well as preparation method and application thereof

ActiveCN103055804ALow costLarge specific surface areaOther chemical processesAluminium silicatesDispersityHigh activity

The invention provides a compound water treatment agent which is prepared from the following components in parts by weight: 0.1-5 parts of hydroxyapatite, 40-65 parts of natural zeolite, 1-10 parts of quartz, 1-10 parts of albite, 1-10 parts of illite, 10-40 parts of attapulgite and 0.1-5 parts of sepiolite. The invention further provides a preparation method and an application of the compound water treatment agent. The compound water treatment agent provided by the invention has the advantages of low cost, large specific surface area, high activity, high dispersity and high treatment efficiency.

Owner:HOHAI UNIV

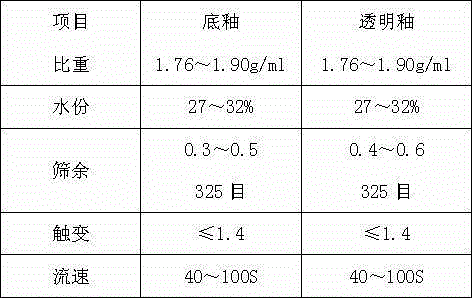

Glaze of brunet ceramic and preparation method of glaze

The invention discloses glaze of brunet ceramic. The glaze is prepared from, by weight, 88-92% of ground glaze and 8-12% of transparent glaze; the ground glaze is prepared from, by weight, 2-5 parts of super white zirconium silicate, 18-22 parts of feldspar powder, 23-27 parts of albite, 3-5 parts of aluminum oxide, 8-10 parts of kaolin and 5-7 parts of calcined kaolin; the transparent glaze is prepared from, by weight, 3-7 parts of burned zinc oxide, 6-10 parts of barium carbonate, 28-32 parts of feldspar powder or 28-32 parts of albite, 0-3 parts of calcined alumina, 11-14 parts of calcinedtalc, 8-12 parts of calcite, 4-6 parts of quartz, 8-10 parts of kaolin and 7-14 parts of calcined kaolin. By means of the method, a product is rich in texture design and pattern, good in texture and soft, vivid, stable in performance, free of corrosion and free of crack.

Owner:GUANGDONG JIA MEI CERAMIC

Ultra-high hardness brown glaze for insulator and preparation method thereof

The invention discloses ultra-high hardness brown glaze for an insulator and a preparation method thereof. The glaze is characterized by being prepared from the following components in percentages by weight: 6-7% of white corundum micropowder, 10-13% of self-made microcrystal ceramic powder, 30-33% of quartz, 10-15% of zirconium silicate micropowder, 6-8% of albite, 5-7% of lithium feldspar, 5-7% of wollastonite, 1-2% of barium carbonate, 8-13% of synthesized cordierite, 7-12% of standard clay, 1-2% of ferric oxide, 1-2% of chromic oxide and 3-5% of manganese oxide. The glaze disclosed by the invention has the advantages that the glaze has good scratch resistance, the glaze hardness reaches 7-level Moh's hardness or above, the glaze of the insulator can bear metals, invasion of sand blown by the wind, and scratches are not generated.

Owner:SINOMA JIANGXI ELECTRICAL PORCELAIN ELECTRIC CO LTD

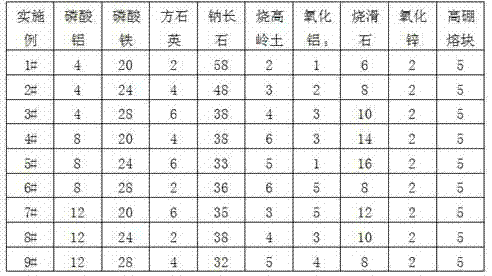

Purple bronze glaze with metallic luster and preparation method thereof

ActiveCN103833419ALittle acid and alkali resistanceLittle high temperature fluidityTalcMaterials science

The invention discloses a purple bronze glaze with metallic luster and a preparation method thereof. The purple bronze glaze with metallic luster is prepared from the following raw materials by weight through sintering: 4 to 12% of a ceramic catalyst, 20 to 28% of a crystallization agent, 2 to 6% of cristobalite, 32 to 58% of albite, 2 to 6% of calcined kaolin, 1 to 5% of alumina, 6 to 16% of calcined talcum, 2% of zinc oxide and 5% of high-boron frit, wherein the ceramic catalyst is a P-Al catalyst, and the crystallization agent is a P-Fe crystallization agent. According to the invention, chemical composition of a formula is reasonably adjusted, the leadless P-Al catalyst and the P-Fe crystallization agent are employed, a stable spinel crystal structure is obtained through recrystallization of the glaze, metal coloring ions (Fe<2+> and Zn<2+>) and the like are enriched on the surface of a glaze layer, so the whole surface of the glaze presents metal-like luster. The glaze shows a purple bronze metal effect, and the hardness of the glaze is almost equal to the glaze of common sanitary china; acid resistance and alkaline resistance of the glaze reach national standards in China; and defects like pin holes and small holes of the glaze are substantially improved, and the glaze is applicable to production under conventional production kiln condition.

Owner:HUIDA SANITARY WARE

Self-cleaning glaze and application thereof as well as ceramic sanitary ware

The invention discloses a self-cleaning glaze and an application thereof as well as a ceramic sanitary ware. The self-cleaning glaze comprises the following components according to weight percentage: 15-26% of potash feldspar, 11-21% of albite, 5-13% of kaolin, 7-17% of calcite, 26-36% of quartz, 1-5% of barium carbonate, 2-5% of zinc oxide, and 3-9% of dolomite. The surface of a self-cleaning glaze layer takes on a beautiful snow-shaped decorative pattern and has smooth hand feeling. Marks of a pencil left on the surface of the self-cleaning glaze can be erased lightly while the opacified glaze leaves marks, so that the self-cleaning glaze has very strong dirt resistance unmatched by traditional opacified glaze, furthermore, the scratches are not left on the surface of the self-cleaning glaze layer when the surface is curved by the pencil, so that the self-cleaning glaze layer has high hardness and is wear resistant.

Owner:GUANGDONG SUNCOO TECH

Sound insulation anion ceramic tile

The invention relates to a ceramic tile, and provides a sound insulation anion ceramic tile which is good in sound insulation effect, capable of releasing anions, free of hazardous substances and environmentally friendly. The sound insulation anion ceramic tile comprises a blank, a phenolic resin plate arranged in the blank and a glaze body arranged on the outer surface of the blank, the blank comprises, by weight, the raw materials of 87 to 96 parts of kieselguhr, 40 to 46 parts of waste ceramic chips, 10 to 16 parts of clay, 20 to 30 parts of gravel, 18 to 26 parts of electrical stone powder, 27 to 35 parts of water and 16 to 26 parts of quartz, and the glaze body comprises, by weight, the raw materials of 52 to 73 parts of kaolin, 32 to 41 parts of albite powder, 19 to 31 parts of talcum powder, 13 to 18 parts of aluminum oxide, 30 to 44 parts of silica sol, 21 to 35 parts of calcium oxide, 18 to 30 parts of magnesium oxide, 20 to 26 parts of wood fibers and 14 to 20 parts of agate powder.

Owner:福建省南安市荣达建材有限公司

Low-temperature golden yellow metallic luster glaze and manufacturing method thereof

The invention discloses low-temperature golden yellow metallic luster glaze and a manufacturing method thereof. The low-temperature golden yellow metallic luster glaze comprises a ferro phosphorus material and ceramic-based glaze in a mass ratio of 0.5-1:1, wherein the ferro phosphorus material consists of sodium ferric pyrophosphate and ferric phosphate or the sodium ferric pyrophosphate and a mixture of ferric oxide and aluminum phosphate; and the ceramic-based glaze comprises albite, quartz, limestone and kaolin in a weight ratio of 20-50:5-10:2-8:3-10. The low-temperature golden yellow metallic luster glaze has the advantages of a few types of raw materials, low manufacturing cost, one-time sintering at a low temperature, contribution to energy conservation and environmental protection, bright golden yellow metallic luster of the sintered product, obvious decorative effect and wide application range; and the method is particularly suitable for manufacturing ceramic wall tiles, ceramic waist lines, ceramic mosaic and the like with golden yellow appearance.

Owner:广东道氏陶瓷材料有限公司

Metallic glaze and its preparation method

The invention discloses a metallic glaze. The metallic glaze comprises the following components: 5-25 parts by weight of feldspar, 10-30 parts by weight of albite, 25-40 parts by weight of quartz, 1-15 parts by weight of calcite, 5-20 parts by weight of kaolin, 15-40 parts by weight of frit powder, 0.1-5 parts by weight of titanium oxide, 0.5-5 parts by weight of vanadium pentoxide, 5-20 parts by weight of manganese dioxide, 0.1-5 parts by weight of copper oxide, 0.1-3 parts by weight of cobalt oxide and 0.1-5 parts by weight of nickel oxide, wherein the frit powder comprises potassium chloride, sodium chloride, silica, alumina, magnesia, boric acid and spodumene. The invention also discloses a preparation method for the metallic glaze. With the formula and preparation method for the metallic glaze, the prepared metallic glaze has excellent metallic luster and high glaze hardness and totally appears to be golden yellow.

Owner:湖南铜官海旭陶瓷有限公司

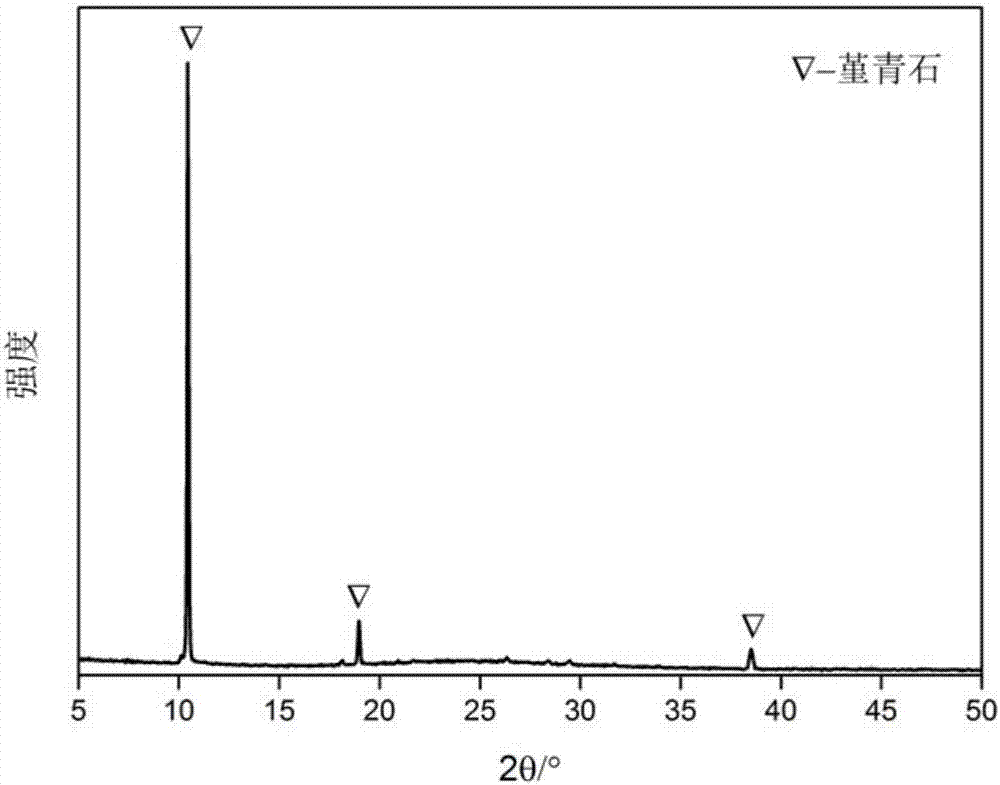

Cordierite transparent wear resistant glaze and preparation method thereof

The invention discloses a cordierite transparent wear resistant glaze, which comprises the following components in percentage by weight: 50 to 55% of kaolin, 25 to 32% of talcum, 2 to 8% of albite, 5 to 8% of calcium containing compound, 4 to 8% of boric acid, 1 to 5% of lithium carbonate, and the balance being quartz. The invention also discloses a preparation method of the cordierite transparent wear resistant glaze. The wear resistant performance of conventional ceramic tiles is enhanced, the raw material utilization rate is improved, during the preparation process, no nucleating agent is needed, the sintering temperature is low, the sintering technology is simple, and the glaze coloring caused by a nucleating agent is avoided.

Owner:SOUTH CHINA UNIV OF TECH

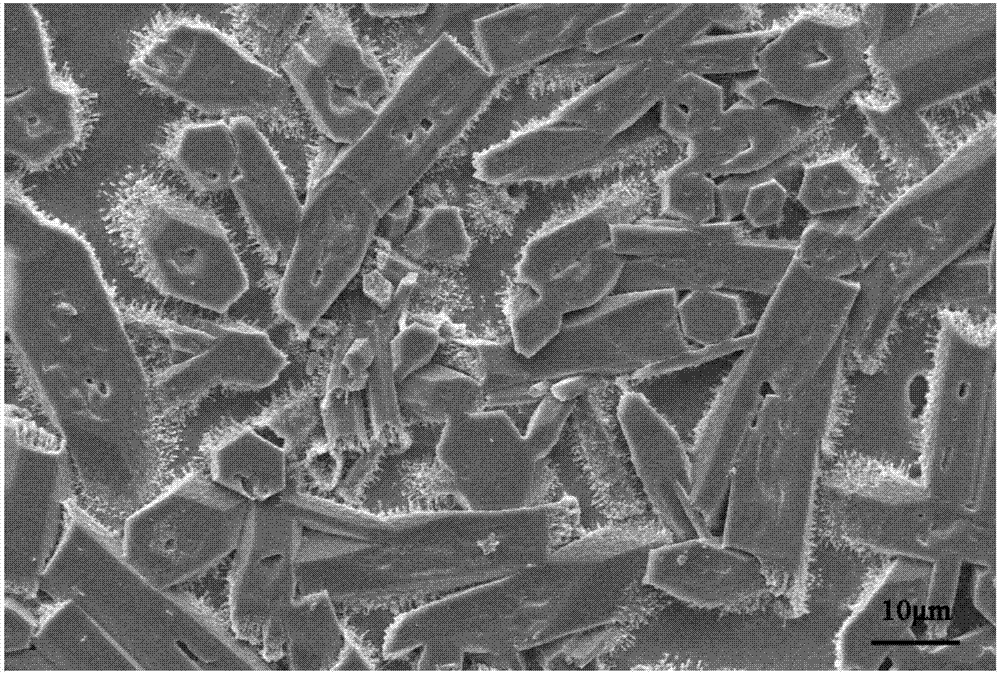

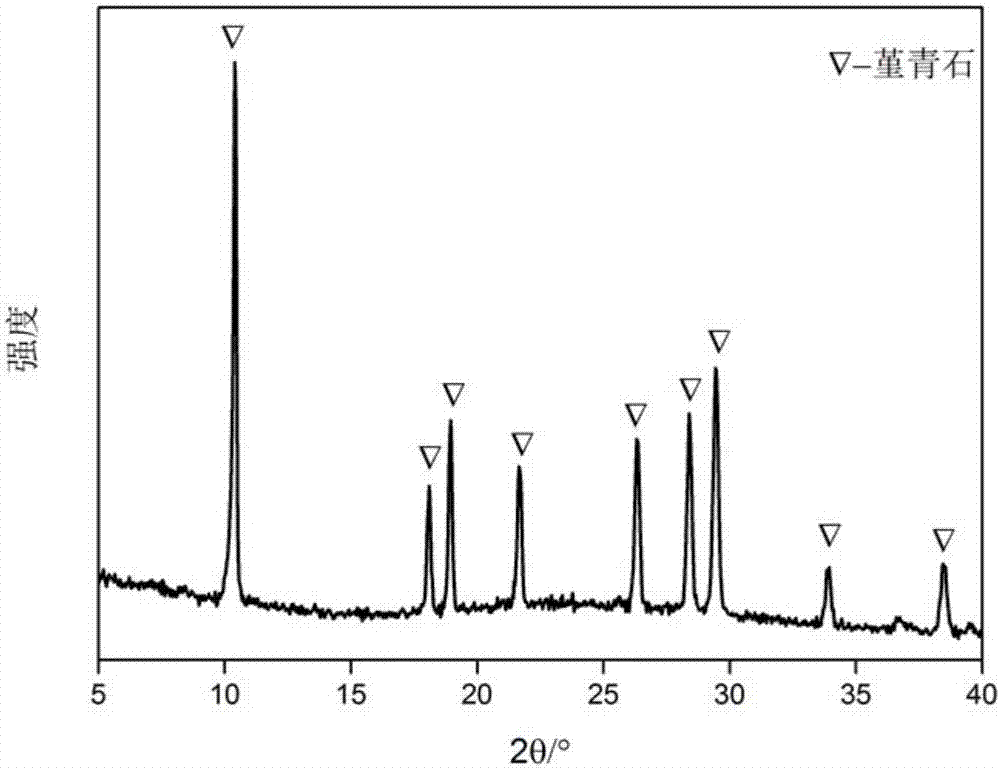

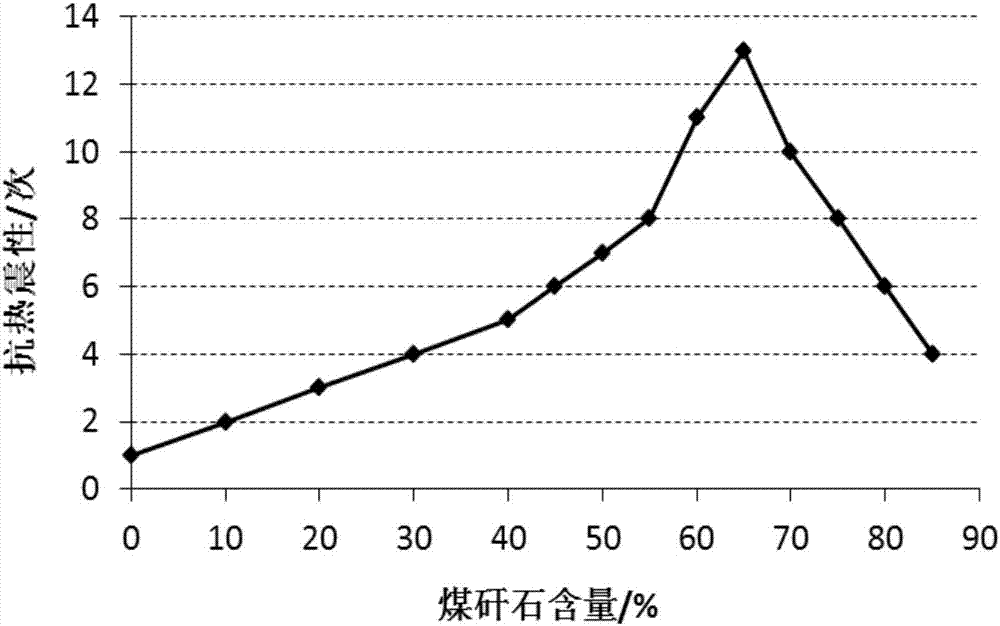

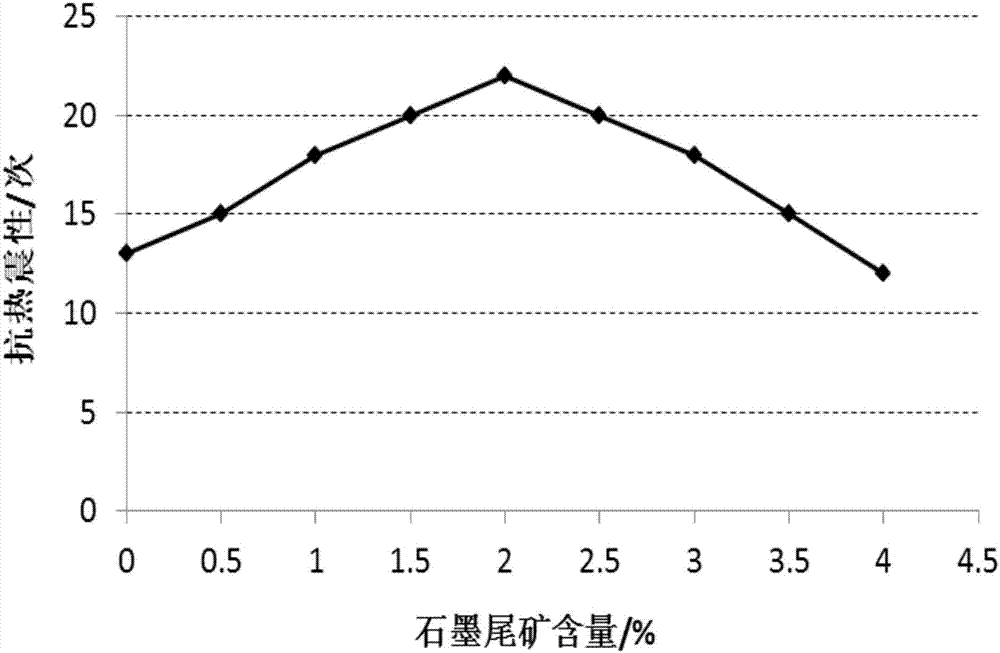

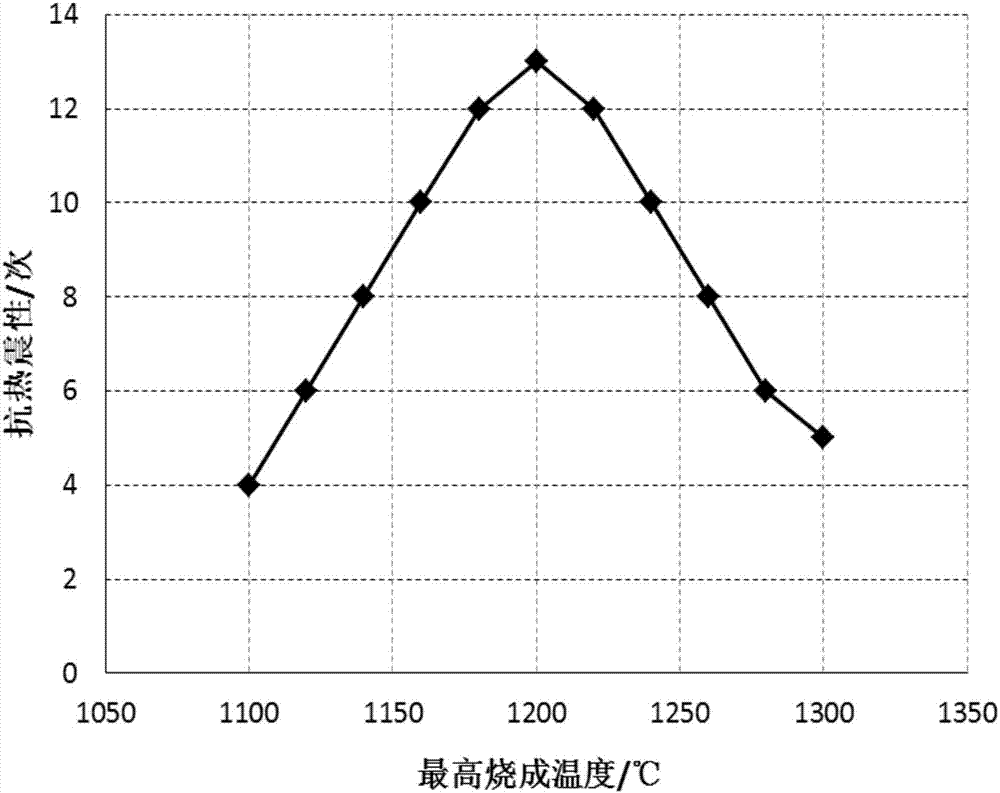

Foamed ceramic light inner wall board prepared from coal gangue and graphite tailings and preparation method

ActiveCN107352972AImprove thermal shock resistanceImprove other propertiesHeat proofingSound proofingThermal insulationChemical stability

The invention belongs to the technical field of foamed ceramic light inner wall board preparation, and particularly relates to a foamed ceramic light inner wall board prepared from coal gangue and graphite tailings and a preparation method. The foamed ceramic light inner wall board is prepared from, by weight, 60-70% of coal gangue, 10-15% of albite, 1-3% of foaming agent and 15-25% of microlite aggregates. The foamed ceramic light inner wall board has the advantages of being good in chemical stability, high in strength, resistant to quick heating and cooling, capable of achieving class-A fire protection, resistant to corrosion, high in adsorption performance, low in specific gravity, good in heat preservation performance, capable of achieving sound insulation, easy to cut and the like. The foamed ceramic light inner wall board is the fireproof thermal insulation material needed in the market; in addition, the foamed ceramic light inner wall board has the advantages that the comprehensive cost is low, installation is convenient, the foamed ceramic light inner wall board can be repeatedly used, the construction speed is twice faster than that in the prior art, energy is saved, consumption is reduced, the wall body is a half or less as thin as a traditional building block, the usable area of a house can be increased, the service life of the foamed ceramic light inner wall board is as long as the building, and the foamed ceramic light inner wall board is an ideal interior and exterior wall material for a fabricated building.

Owner:BRIGHT OCEANS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com