Complete polishing glaze archaizing brick overglaze and preparation method thereof

An antique brick and fully polished glaze technology, applied in the field of fully polished antique brick surface glaze and its preparation, can solve problems such as difficulty in stabilizing quality, and achieve the effects of reducing formula cost, reducing cost and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in further detail below in conjunction with embodiment.

[0019] The full-glazed antique brick surface glaze of the present invention is mainly prepared from albite feldspar, potassium feldspar, calcite, barium carbonate, aluminum oxide, burnt talc, zinc oxide, quartz powder, kaolin, and wollastonite.

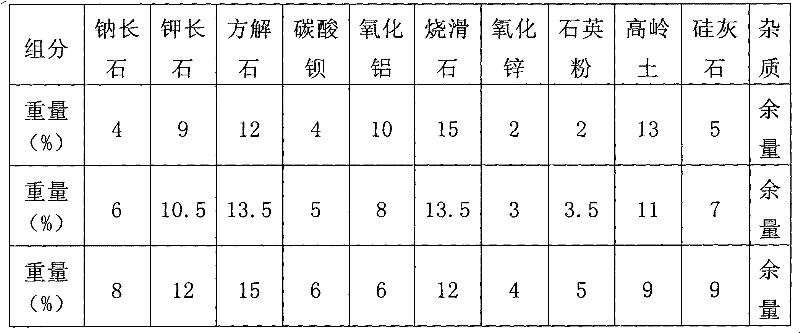

[0020] Table 1 is the embodiment that constitutes the content of different weight percentages of each component of fully glazed archaized tile surface glaze:

[0021]

[0022] Table 2: Chemical composition list (weight percentage) of full polished glazed antique brick surface glaze

[0023] chemical composition

SiO 2

Al 2 o 3

CaO

MgO

K 2 O+Na 2 o

ZnO

BaO

percentage (%)

60

8

5

10

8

2

3

4

[0024] Weigh raw materials according to the described formula, carry out ball milling according to raw materials: bal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com