A pipeline corrosion inhibitor coating cleaner

A technology of corrosion inhibitor and cleaner, applied in pipeline protection, pipeline anti-corrosion/anti-rust protection, coating, etc., can solve the problem of not being able to ensure sufficient coating, and achieve the effect of being conducive to clogging, reasonable control and reducing chemical waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

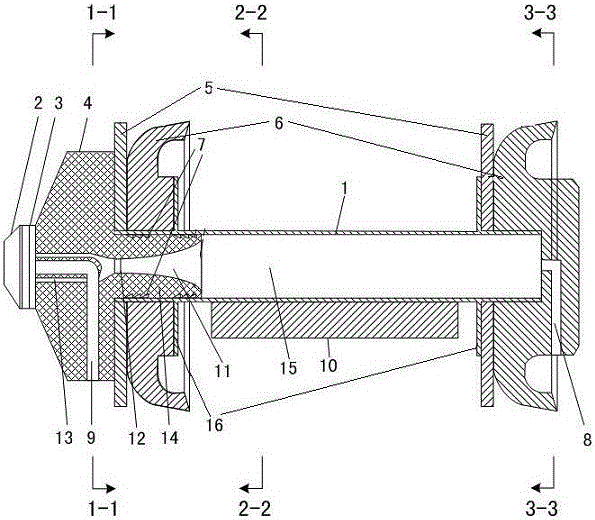

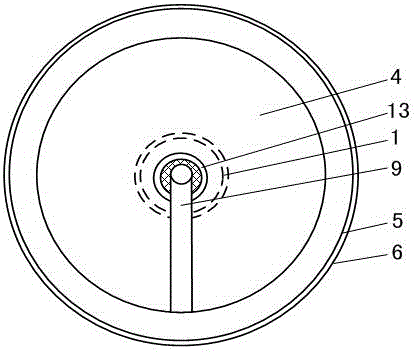

[0031] In order to overcome that the continuous injection method and the intermittent injection method of the corrosion inhibitor in the prior art cannot be evenly coated on the pipeline wall in all directions, this embodiment provides a method such as figure 1 , figure 2 , image 3 and Figure 4 The pipeline corrosion inhibitor coating cleaner shown includes a framework 1, and sealing discs 5 and leather cups 6 arranged on the front and rear ends of the framework 1. The framework 1 is cylindrical with two ends open, and the framework 1 1. The front end of the sealing plate 5 is provided with a liquid introduction end 4, and the rear end of the liquid introduction end 4 is provided with a cylindrical extension section 14, and the cylindrical extension section 14 is fixed inside the front end of the skeleton 1. The liquid introduction end 4 The front end is provided with an adjustable spray nozzle 3, and the front end of the adjustable spray nozzle 3 is provided with a guide...

Embodiment 2

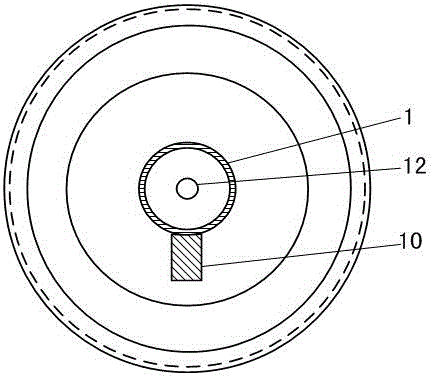

[0037] On the basis of Embodiment 1, the bottom of the skeleton 1 is fixed with a counterweight 10, and the counterweight 10 is generally selected from metal or other materials with sufficient weight to keep the pipeline corrosion inhibitor coated cleaner relatively in the process of advancing. The axial direction of gravity does not produce rotation to ensure the suction of corrosion inhibitors.

[0038] The cylindrical extension section 14 is provided with a plurality of barbs 7, which are fixedly connected to the inner surface of the frame 1; the liquid introduction end 4 made of elastic material is safely fixed on the front end of the frame 1 through the columnar extension section 14, and the column A plurality of barbs 7 on the shaped extension section 14 make the outer surface of the liquid introduction end 4 and the inner surface of the skeleton 1 tightly grasped, ensuring that the liquid introduction end 4 can be fastened on the skeleton 1, and the cylindrical extension...

Embodiment 3

[0043] In the process of corrosion inhibitor coating, if the injection amount of corrosion inhibitor is too large, it will not only cause the waste of corrosion inhibitor, but also cause the blockage of pipeline equipment; if the injection amount of corrosion inhibitor is too small, it will not be able to form Complete protective film, so it is necessary to determine the reasonable filling amount of corrosion inhibitor.

[0044] The formula for calculating the injection volume of the sustained-release agent is:

[0045] (1)

[0046] (2)

[0047] formula: K As an additional factor, generally take 1.15; Q is the injection amount of corrosion inhibitor; D 1 is the inner diameter of the pipe; H is the thickness of the corrosion inhibitor film; L is the total length of the pipe; Q 1 is the volume of the tee and sewage outlet of the upper branch of the pipeline; D 2 is the inner diameter of the branch pipe; L 2 is the length of the branch pipe; Q 其他 is the sum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com