A kind of electrode manufacturing method for radio frequency hyperthermia instrument

An electrode manufacturing and electrode technology, applied in the field of electronic medical devices, can solve the problems of large electrode volume, cumbersome metal electrode shielding method, poor metal electrode shielding effect, etc., and achieve controllable manufacturing, excellent shielding effect, and high insulation properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

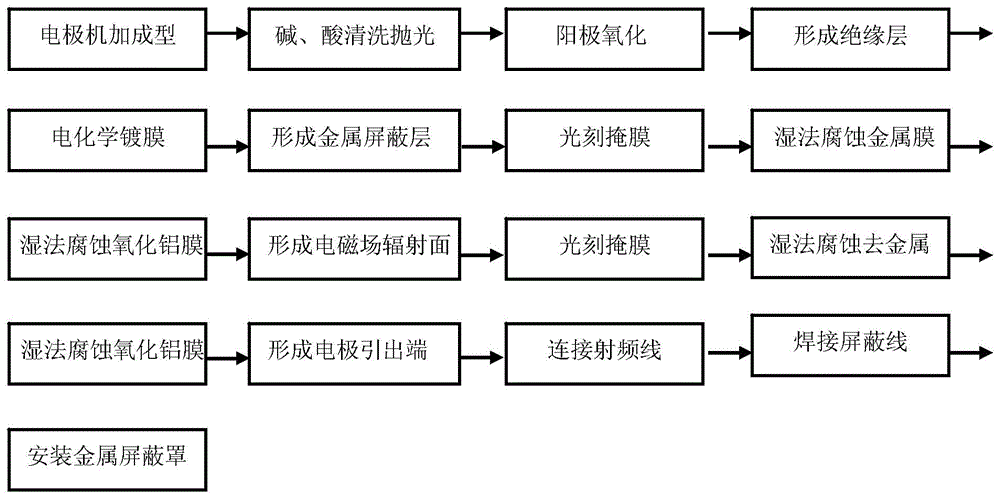

[0023] refer to figure 1 , which represents the block flow chart of the aluminum-based electrode manufacturing process for radio frequency hyperthermia. The process is summarized as the following seventeen steps: Electrode machining - alkali, acid cleaning and polishing - anodic oxidation - insulating layer formation - electrochemical Plating metal film - forming metal shielding layer - photolithography mask - wet etching to remove metal film - wet etching to remove aluminum oxide film - forming electromagnetic field radiation surface - photolithography mask - wet etching to remove metal film - wet etching to remove Alumina film - forming electrode leads - screwing radio frequency signal lines - welding shielding lines - installing shielding covers. The manufacturing methods between the various working steps can be combined arbitrarily according to specific requirements.

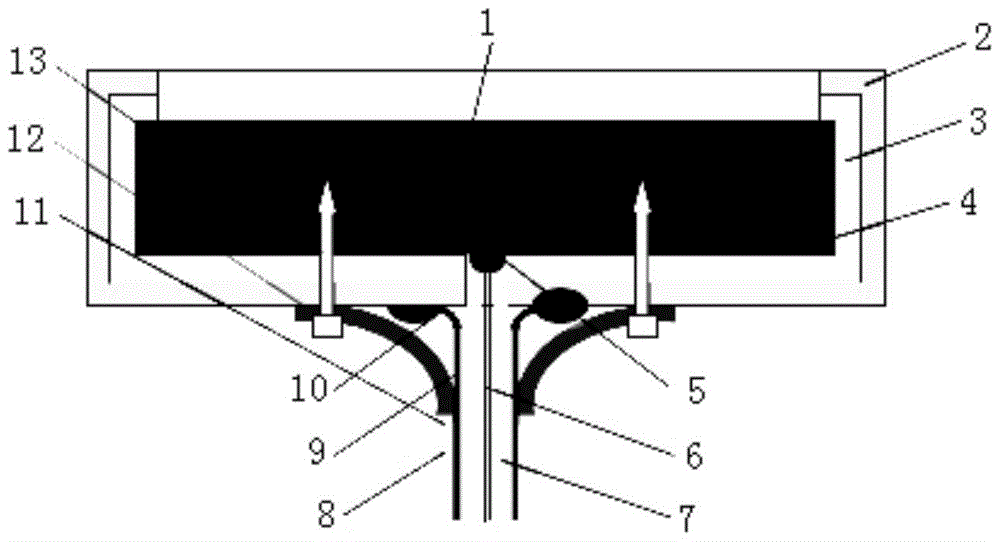

[0024] refer to figure 2 Schematic diagram of the cross-section of the metal aluminum-based electrode ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com