Conductive leather substance and preparation method thereof

A technology of leather and conductive layer, which is applied in equipment for manufacturing conductive/semiconductive layer, cable/conductor manufacturing, conductive layer on insulating carrier, etc. Achieve the effect of not easy to delaminate and avoid processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

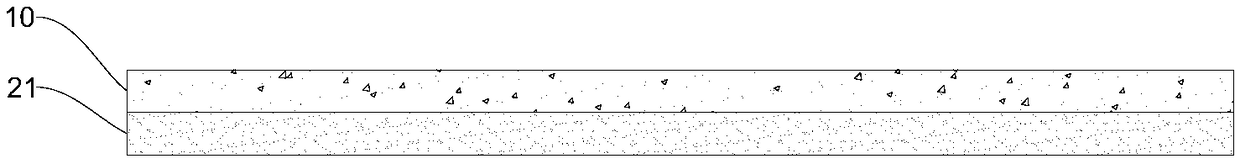

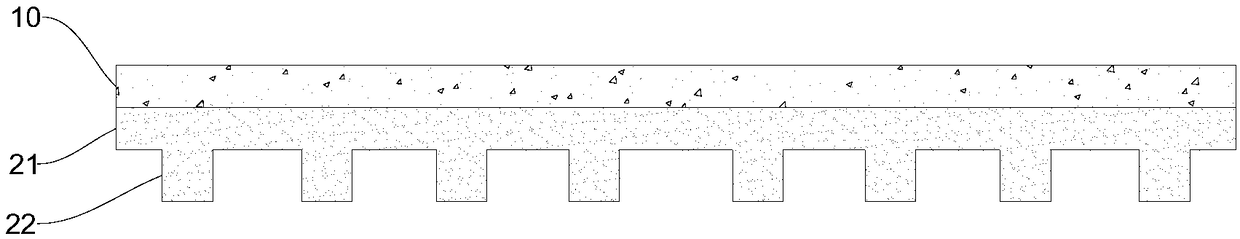

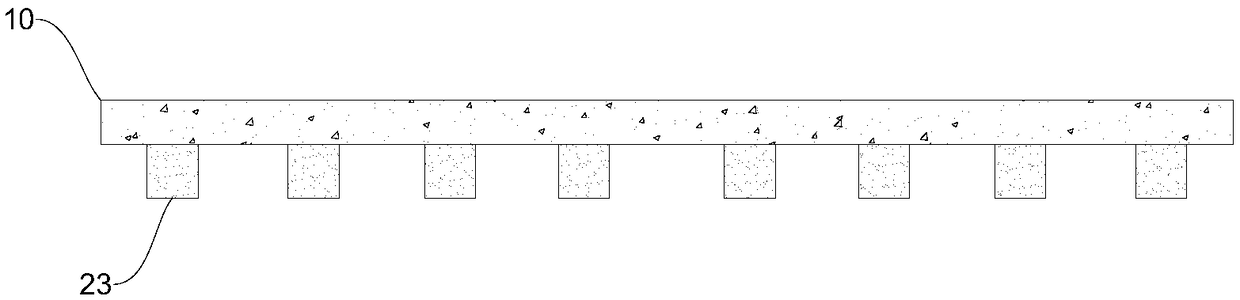

[0031] The embodiment of the present invention also provides a method for preparing a conductive leather material, which includes: after coating the conductive slurry on a film-forming mold, drying it at a temperature of 80-190°C to form a conductive structure; One side of the film mold is coated with non-conductive slurry, and dried at a temperature of 80-190° C. to form a non-conductive layer.

[0032] It should be noted that the preparation method of the conductive leather material provided in the embodiment of the present invention is to form a film through two coatings, and the conductive material finally obtained is conductive on one side and non-conductive on the other, which avoids the process of processing the insulating layer in the later stage; The surface and the non-conductive surface are fused and combined, not easy to delaminate, and the insulation effect is reliable, which is suitable for popularization and application; due to the use of polyurethane film format...

Embodiment 1

[0040] This embodiment also provides a preparation method of conductive leather material, which comprises the following steps:

[0041] Mix graphene powder, N,N-dimethylformamide and polyurethane uniformly to obtain conductive paste, wherein the weight ratio of graphene powder, N,N-dimethylformamide and polyurethane is 10:100:100. Mix N,N-dimethylformamide and polyurethane evenly to obtain a non-conductive slurry, wherein the weight ratio of N,N-dimethylformamide and polyurethane is 1:1.

[0042]After coating the conductive paste on a planar release film, dry it at 80°C for 2 hours to form a conductive film with a thickness of about 1um, and evenly coat the non-conductive paste on the dried conductive film. After drying at a temperature of ℃ for 2 hours, a non-conductive layer with a thickness of about 1 um is formed. The conductive material formed by the fusion of the conductive film and the non-conductive film is peeled off from the release film.

Embodiment 2

[0044] This embodiment also provides a preparation method of conductive leather material, which comprises the following steps:

[0045] Mix copper powder, butanone and polyurethane uniformly to obtain conductive paste, wherein the weight ratio of copper powder, methyl ethyl ketone and polyurethane is 60:80:100. Mix toluene and polyurethane uniformly to obtain non-conductive slurry, wherein the weight ratio of toluene and polyurethane is 0.8:1.

[0046] After coating the conductive paste on a flat release film, dry it at 190°C for 1.5 hours to form a conductive film with a thickness of about 1000um, and evenly coat the dry conductive film with non-conductive paste. After drying at 190°C for 1.5h, a non-conductive layer about 3000um thick was formed. The conductive material formed by the fusion of the conductive film and the non-conductive film is peeled off from the release film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com