Patents

Literature

1339results about How to "Guaranteed lubrication effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-based cutting fluid used in slice machining of hard brittle crystal material and preparation method of water-based cutting fluid

InactiveCN102618374AGuaranteed lubrication effectGuaranteed anti-rust performanceAdditivesWater basedTool wear

The invention discloses a water-based cutting fluid used in slice machining of a hard brittle crystal material, comprising the following compositions: base oil, organic amine, organic acid, synthetic ester, emulsifier, rust and corrosion inhibitor, dispersion flocculation and hard-water resisting agent, antiseptic bactericide, antifoaming agent, coupling agent, adjuvant and a proper amount of water. Aiming at the machining techniques of inner circle slicing and outer circle slicing, the water-based cutting fluid has good generality, lubricity, strong antirust property and a long service life; when the cutting fluid is used, the machining situation can be observed easily, the cooling property is good, the cleaning and the permeability are strong, cuttings subside easily, and the machining problems of machining error, crack and the like caused by cutter blocking, abrasion and the like are solved; according to the invention, the problems that cuttings are easy to adhere and suspend, a cutter is seriously abraded, a machined product cracks easily, the accuracy is not high, the machining efficiency is low, the later period cleaning is complex and the like existing in the current slice machining of the hard brittle crystal material are solved, and further, a machine bed is protected, and the cost is reduced.

Owner:AMER TECH CO LTD

Water-based cutting fluid used for processing neodymium-iron-boron material slices and application method thereof

ActiveCN102311860AGuaranteed lubrication effectGuaranteed anti-rust performanceLubricant compositionSolubilityWater based

The invention discloses a water-based cutting fluid used for processing neodymium-iron-boron material slices and an application method thereof. The cutting fluid comprises the following components in parts by weight: organic amine, organic acid, water-soluble phosphate, polyether, antirust corrosion inhibitor, dispersing agent and surfactant, antiseptic bactericide, anti-hard-water agent, defoaming agent, auxiliary agent and water, wherein environmentally-friendly lubricating agent, extreme-pressure agent and antirust agent are reasonably matched in the cutting fluid disclosed by the invention, thus the lubricating property, extreme pressure property and antirust property of the cutting fluid are guaranteed; organic base, organic acid and special auxiliary agent are reasonably matched, thus the corrosion dissolution phenomenon of the cutting fluid to adhesive is greatly weakened; the dispersing agent and the surfactant are used for reducing surface tension of solution, thus permeability and settlement performance of the cutting fluid are enhanced; pH value of a final product is 7.5-8.5; and solubility of the cutting fluid to adhesive used for binding neodymium-iron-boron material in a processing cycle is extremely low, and the condition that product processing accuracy error is large or a tool is damaged as the adhesive is dissolved by the cutting fluid can not be caused.

Owner:AMER TECH CO LTD

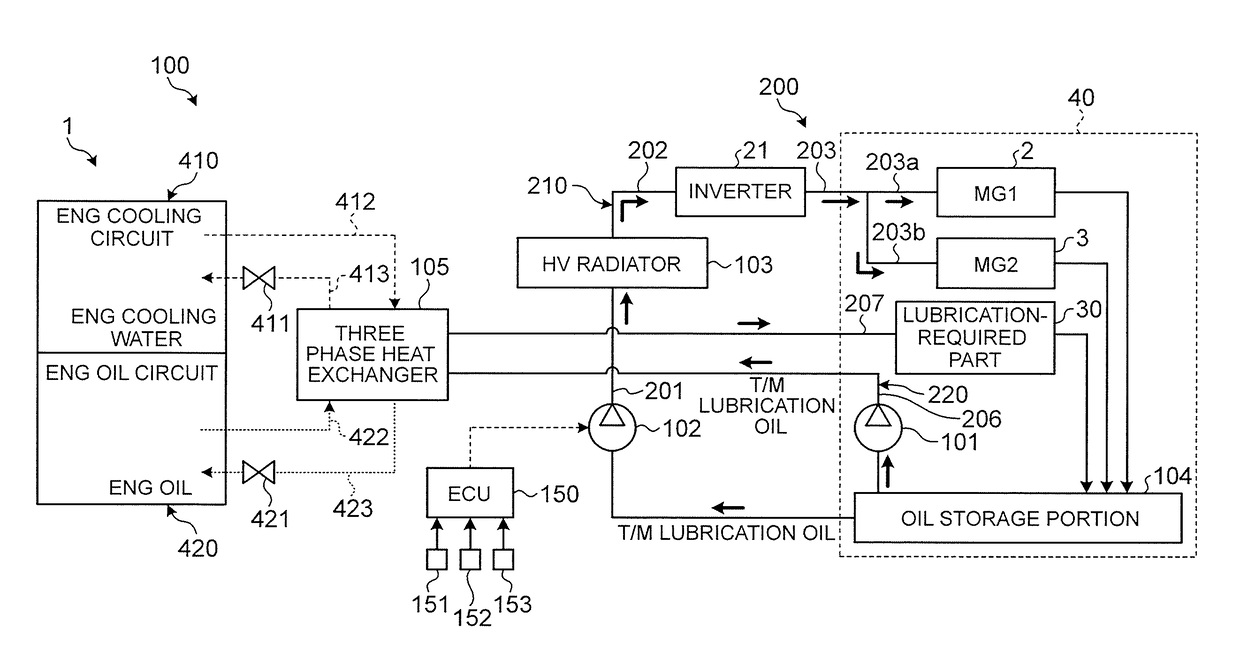

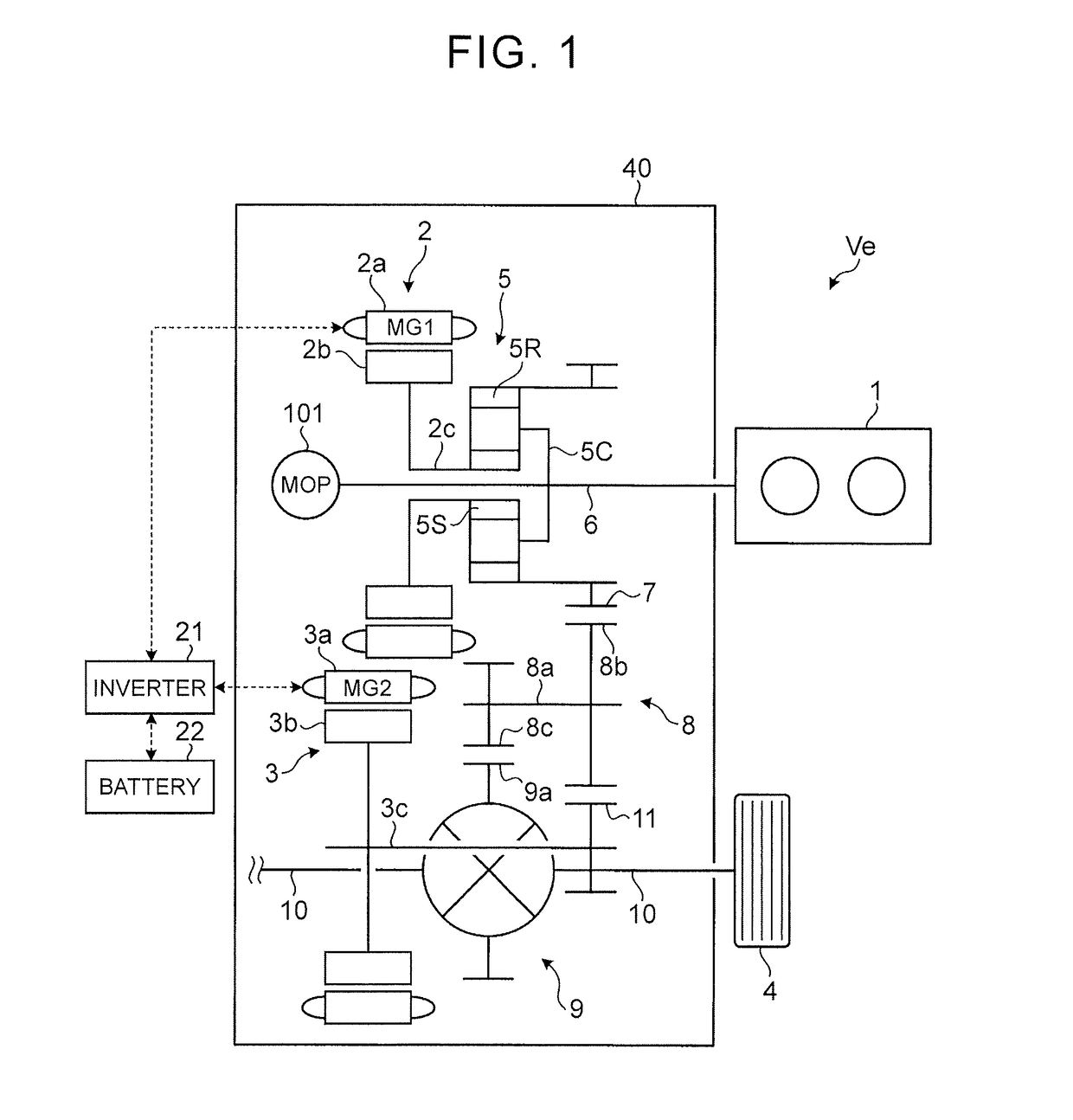

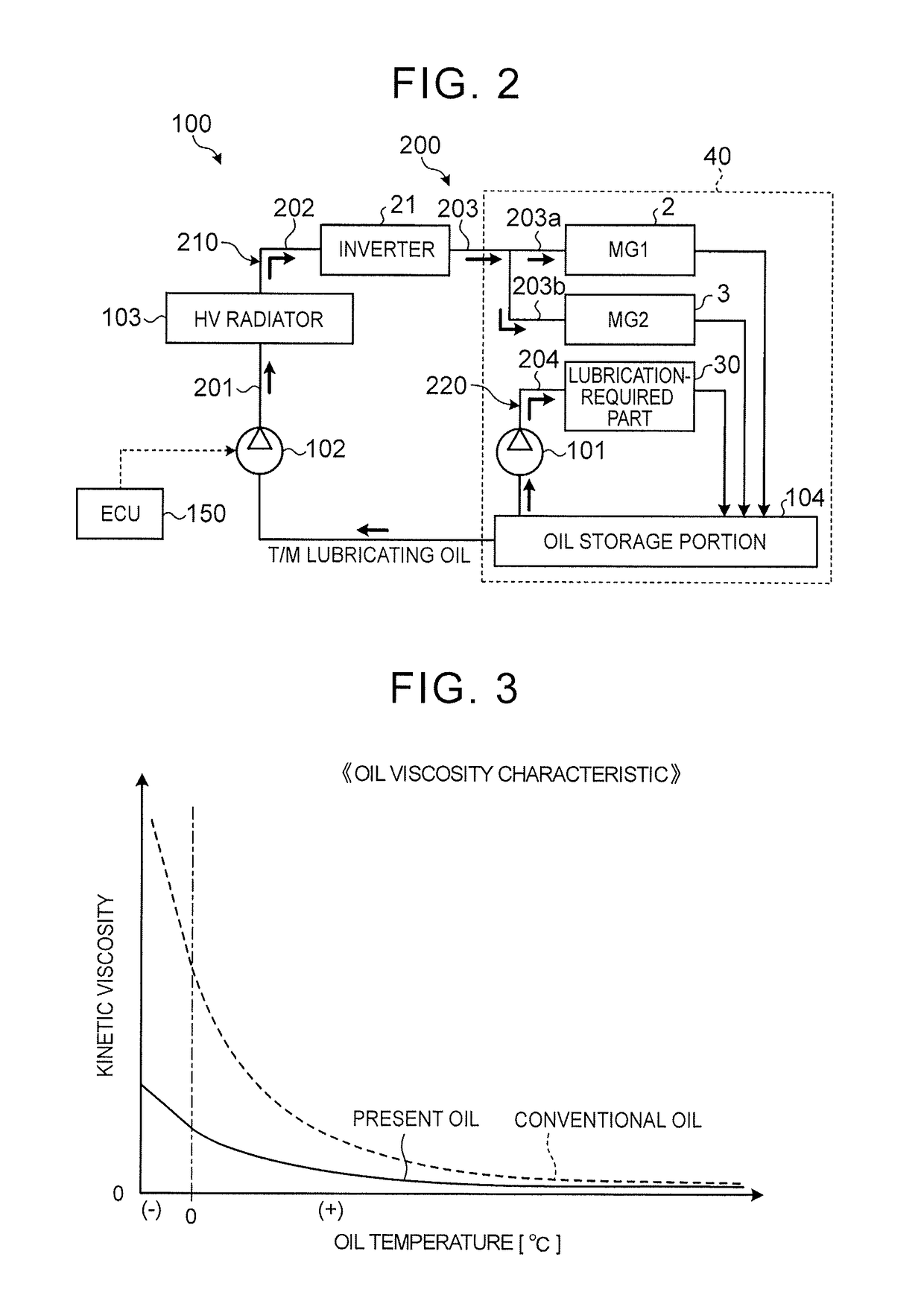

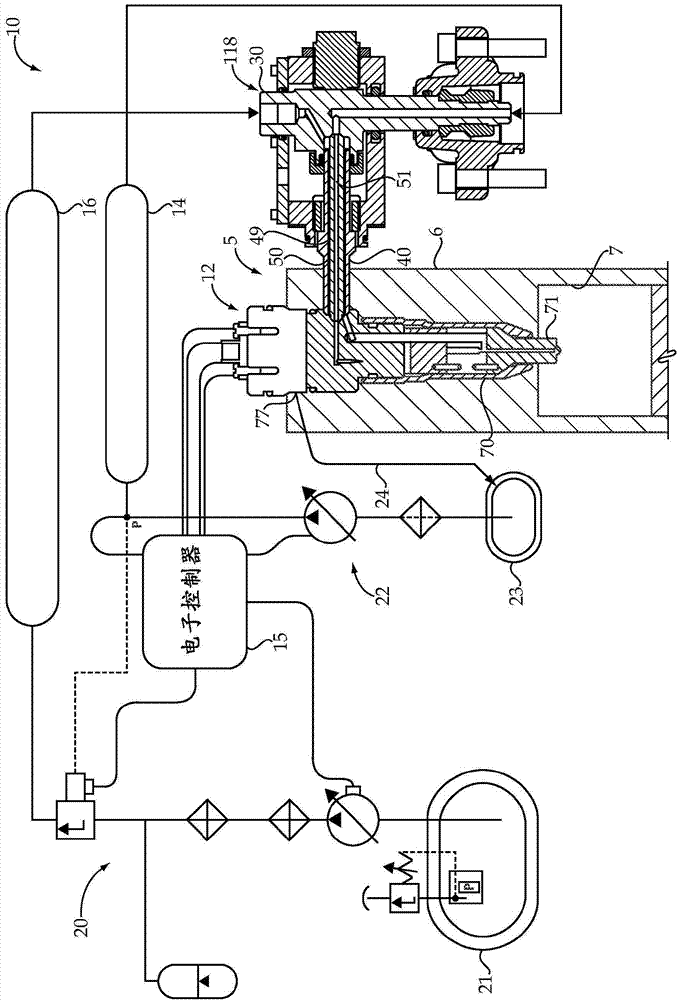

Vehicular cooling system

InactiveUS20170175612A1Small sizeEnsure performanceHybrid vehiclesLiquid coolingLubricationPetroleum engineering

An cooling system including an oil circulation circuit includes a first circuit including an electric oil pump that discharges oil as a coolant to be supplied to an inverter and respective motors, and an HV radiator that cools the oil to be supplied to the inverter and the respective motors, and a second circuit including a mechanical oil pump that discharges the oil to be supplied to a lubrication-required part without passing through the HV radiator.

Owner:TOYOTA JIDOSHA KK

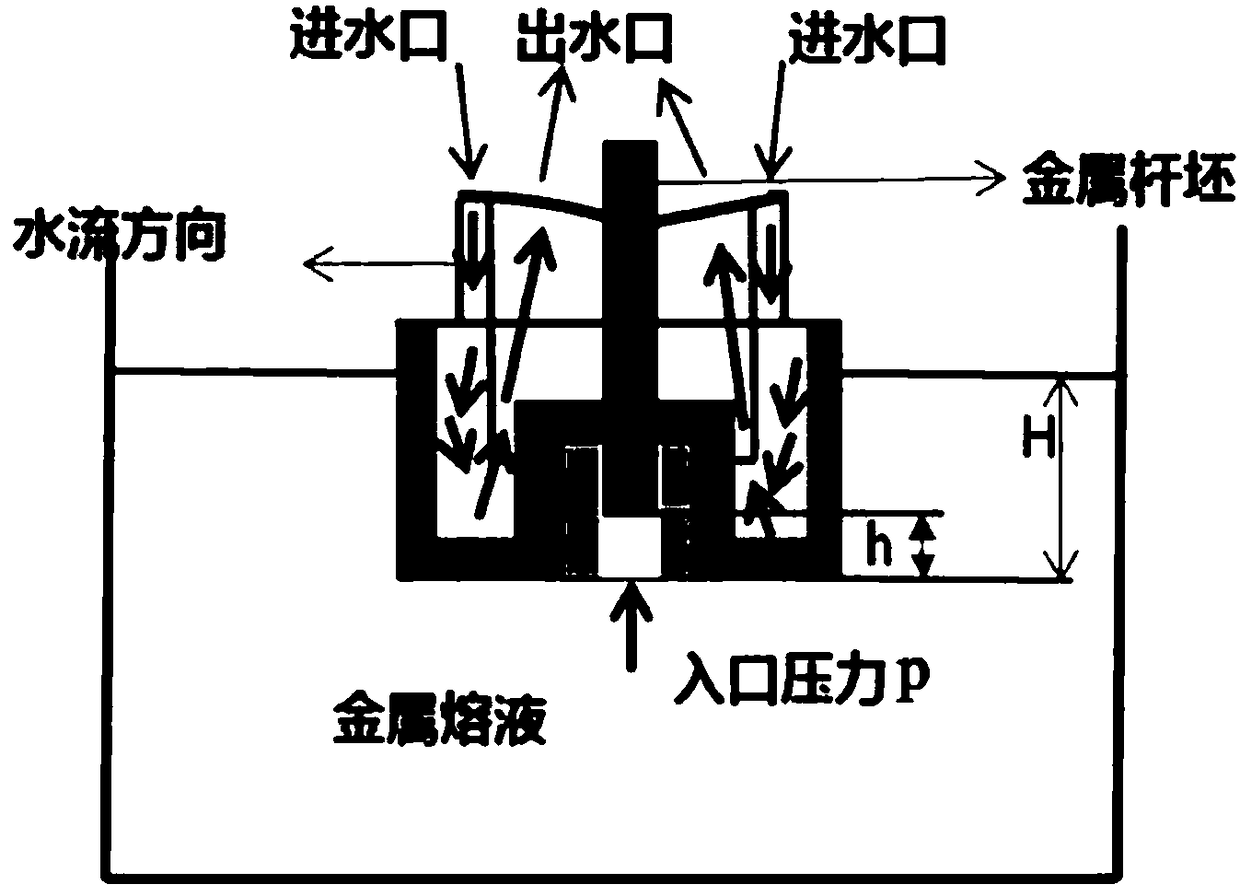

Production method of high-strength, high-conductivity and heat-resistant copper alloy

ActiveCN108526422AGuaranteed lubrication effectImprove thermal conductivityCarbon compositesShielding gas

The invention discloses a production method of a high-strength, high-conductivity and heat-resistant copper alloy, and belongs to the technical field of copper alloy machining. Accoding to the production method of high-strength, high-conductivity and heat-resistant copper alloy, the inner liner of a crystallizer adopted in the upper-induced continuous casting process is a carbon-carbon composite material so as to ensure the lubrication, high heat conduction and high temperature resistance properties; the temperature of the upper-induced continuous casting is 1180-1230 DEG C, the casting temperature is low so that the problem that molten liquid in the crystallizer is difficult to solidify and the crystallizer inner liner is worn during casting can be effectively avoided; the pressure of protective gas nitrogen in the liquid surface of an upper-induced furnace is controlled to be 0.2-0.7 atmosphere, so that the phenomenon of solid-liquid interface separation in the crystallizer is avoided, and a copper-chromium alloy product with larger weight and length is produced; according to the production method of the high-strength, high-conductivity and heat-resistant copper alloy, the cheapelement (Mg) is used for replacing the rare noble metal, and the mechanical property and the softening resistance property of the copper-chromium alloy are improved; and the production method is a non-vacuum and short-process preparation technology, the cost is low, and the production method is suitable for large-scale industrial production and has important economic and social significances.

Owner:CENT SOUTH UNIV

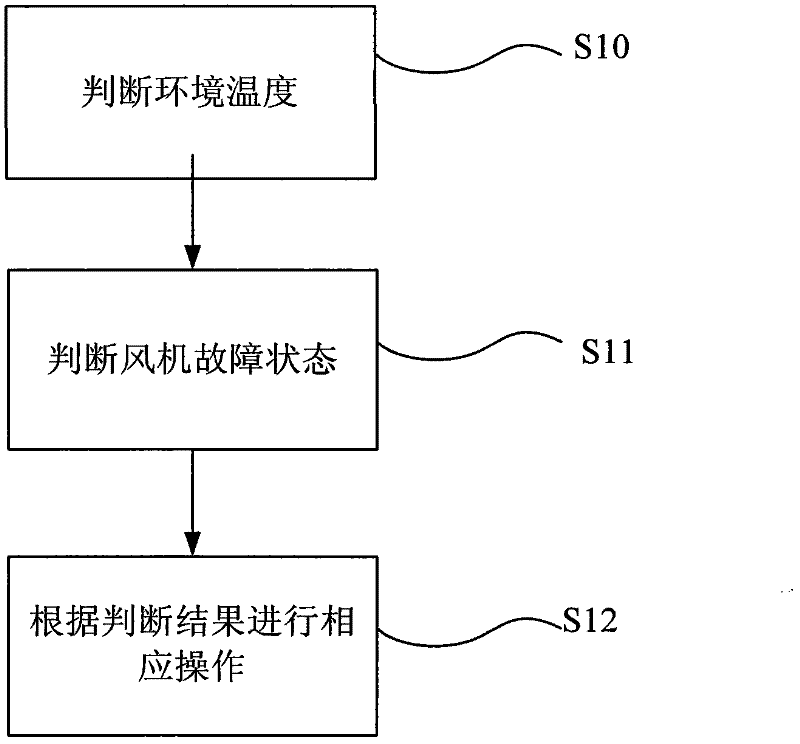

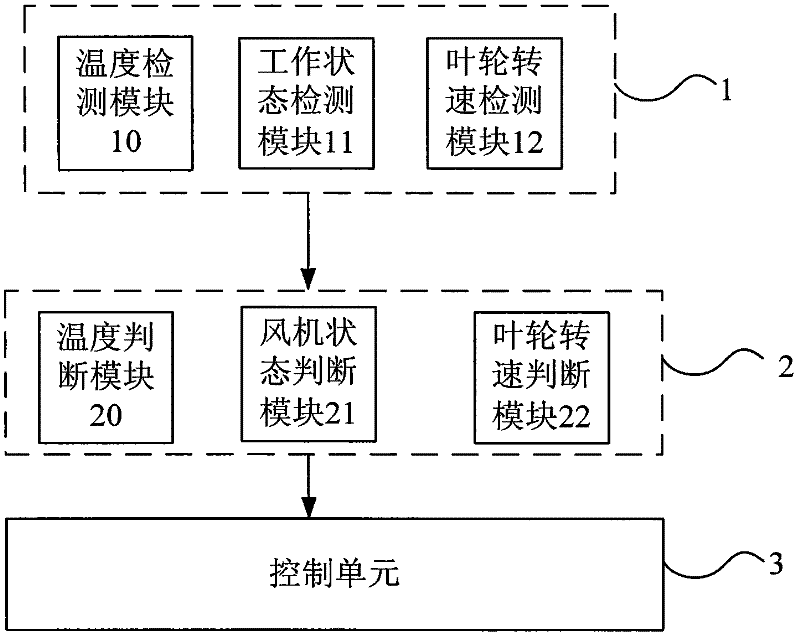

Control method and system for wind turbine generator system

ActiveCN102374120ALow failure rateGuaranteed lubrication effectWind motor controlMachines/enginesImpellerFailure rate

The invention provides a control method for a wind turbine generator system. When the wind turbine generator system is in a stopped state, the impeller of the wind turbine generator system is controlled to rotate at the rotation speed in a set rotation speed interval. The invention also provides a control system for the wind turbine generator system. The control system comprises a control unit, wherein the control unit is used for controlling the impeller to rotate at the rotation speed in the set rotating speed interval when the wind turbine generator system is in the stopped state. The control method and system for the wind turbine generator system provided by the invention can be used for controlling the impeller to keep a certain rotation speed when the wind turbine generator system halts in the low temperature environment, so that a certain heat can be generated to prevent the lubricating performance of lubricating grease from declining for the too low temperature, and then the parts including a bearing and the like can be ensured to work normally; and meanwhile, the service life of the bearing of the wind turbine generator system can be improved and the failure rate of the wind turbine generator system can be reduced.

Owner:XINJIANG GOLDWIND SCI & TECH

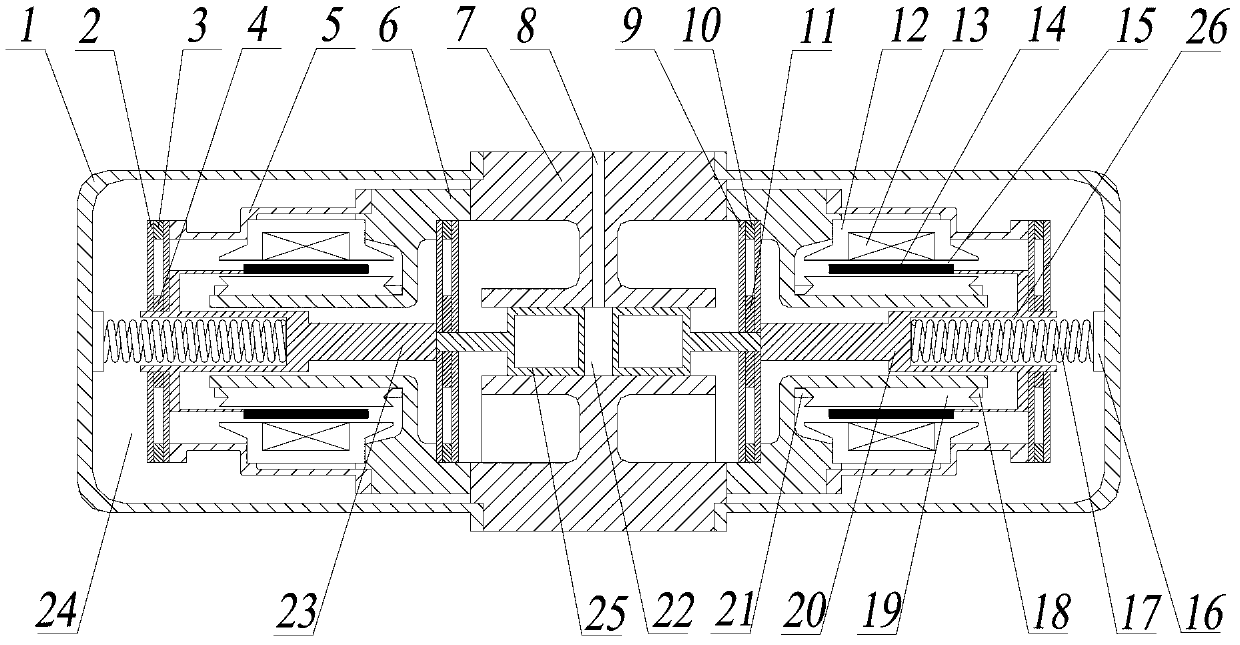

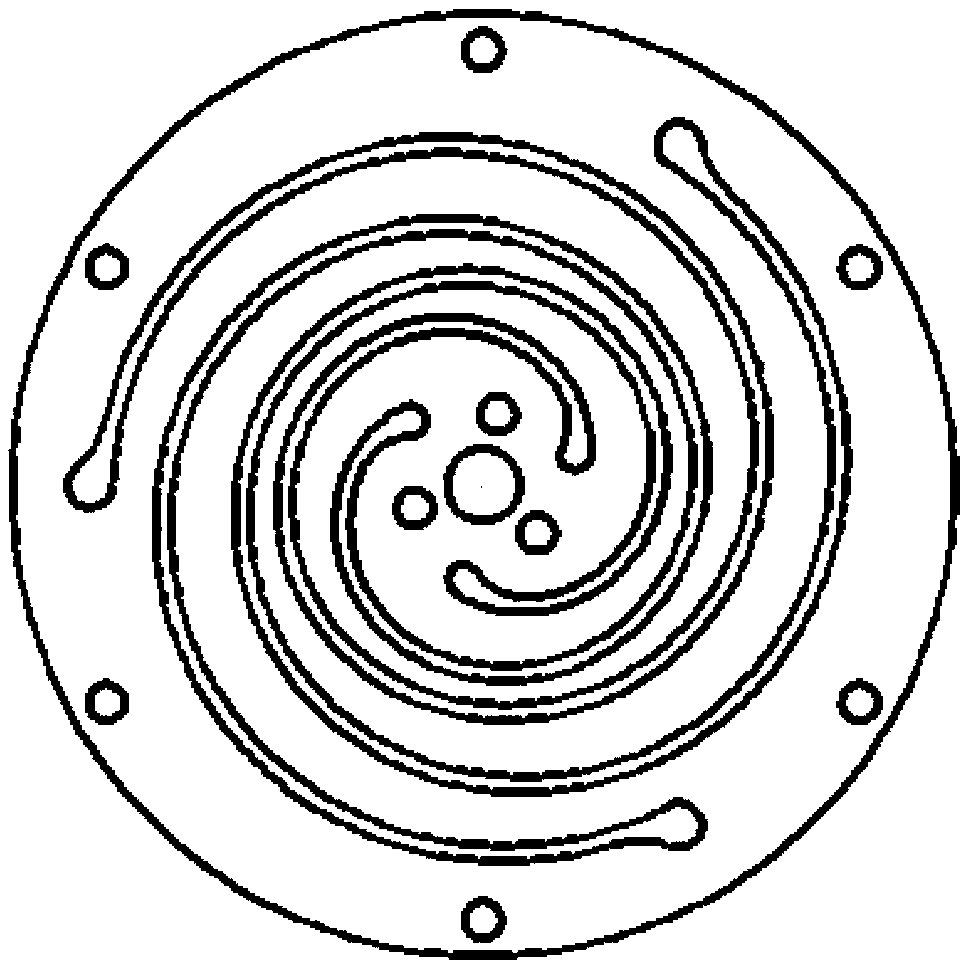

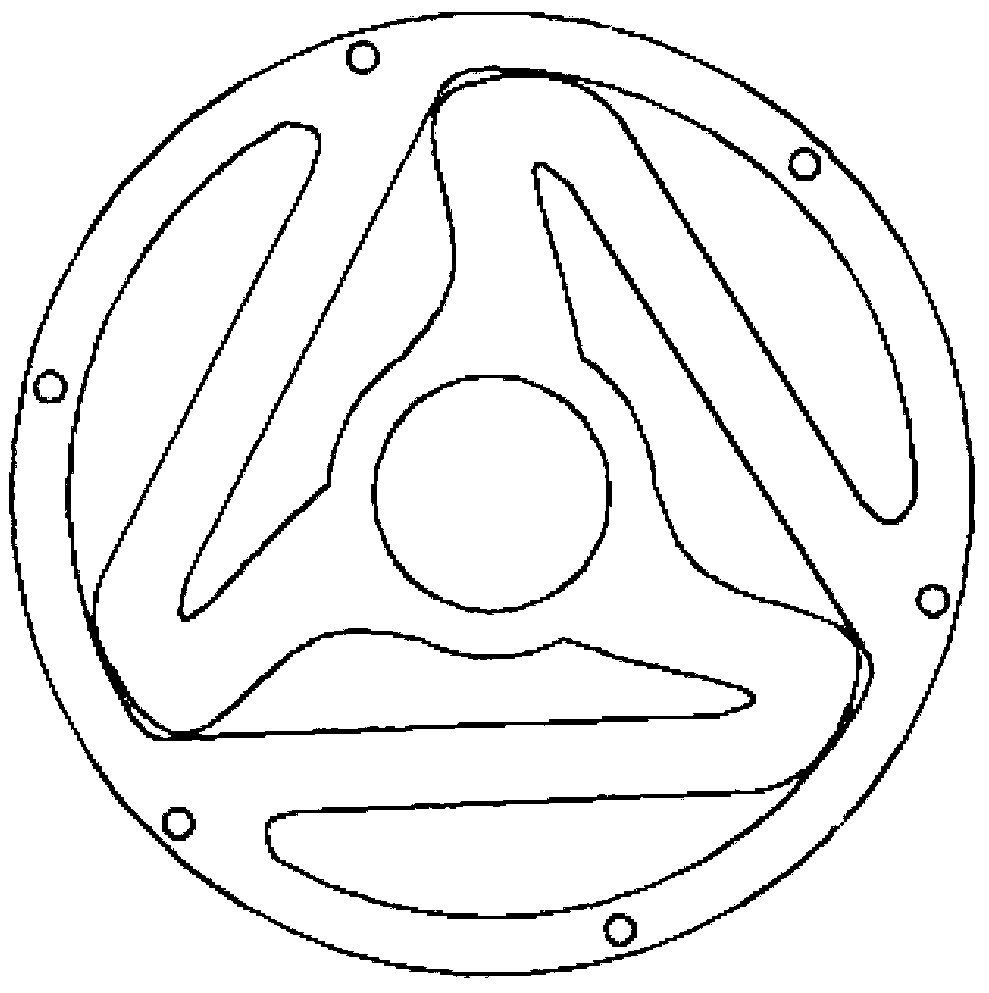

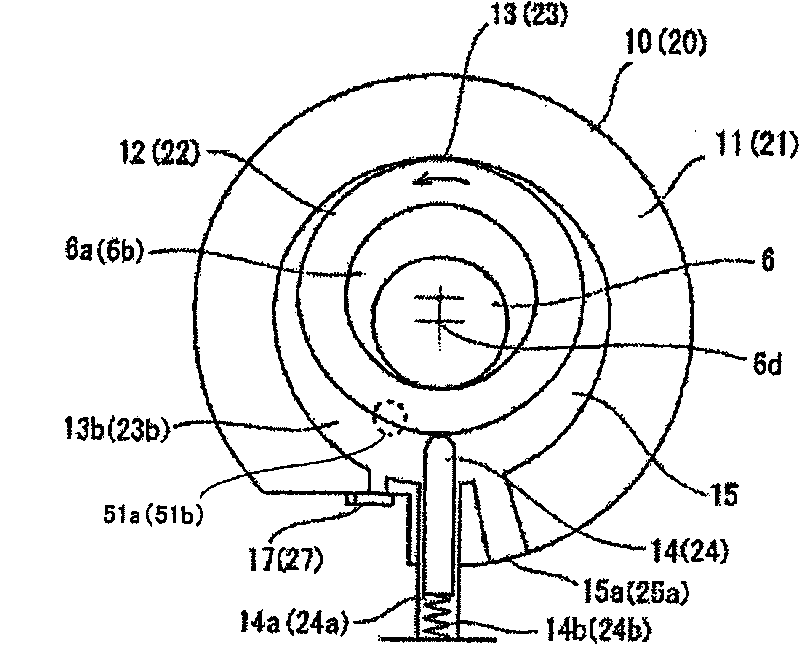

Linear compressor supported by three kinds of springs

InactiveCN103122837AEasy to fixImprove axial stiffnessPiston pumpsPositive-displacement liquid enginesReciprocating motionLinear compressor

The invention discloses a linear compressor supported by three kinds of springs. The linear compressor supported by the three kinds of springs comprises a support, a cylinder fixed with the support, two pistons in clearance fit with the inner wall of the cylinder, and two linear motors driving the two pistons to make coaxial and reciprocating motions, wherein the two linear motors are in transmission with the pistons correspondingly and respectively through piston shafts, two end portions of each piston shaft are fixed with the support respectively through a vortex arm plate spring assembly and a linear arm plate spring assembly, the vortex arm plate spring assemblies are close to the pistons, and a cylinder spiral spring used for providing axial elastic force is arranged between an end portion, far away from a corresponding piston, of each piston shaft and the support. Due to the fact that the linear compressor is supported by the three kinds of springs, clearance gap seal and oil-free lubrication technology are guaranteed, and axial rigidity of the springs is effectively improved. For a linear compressor with big rotor quality, high frequency resonance operation is achievable, operating efficiency is improved, and character match between the linear compressor and a cooling head of a low temperature refrigerator is achieved.

Owner:ZHEJIANG UNIV

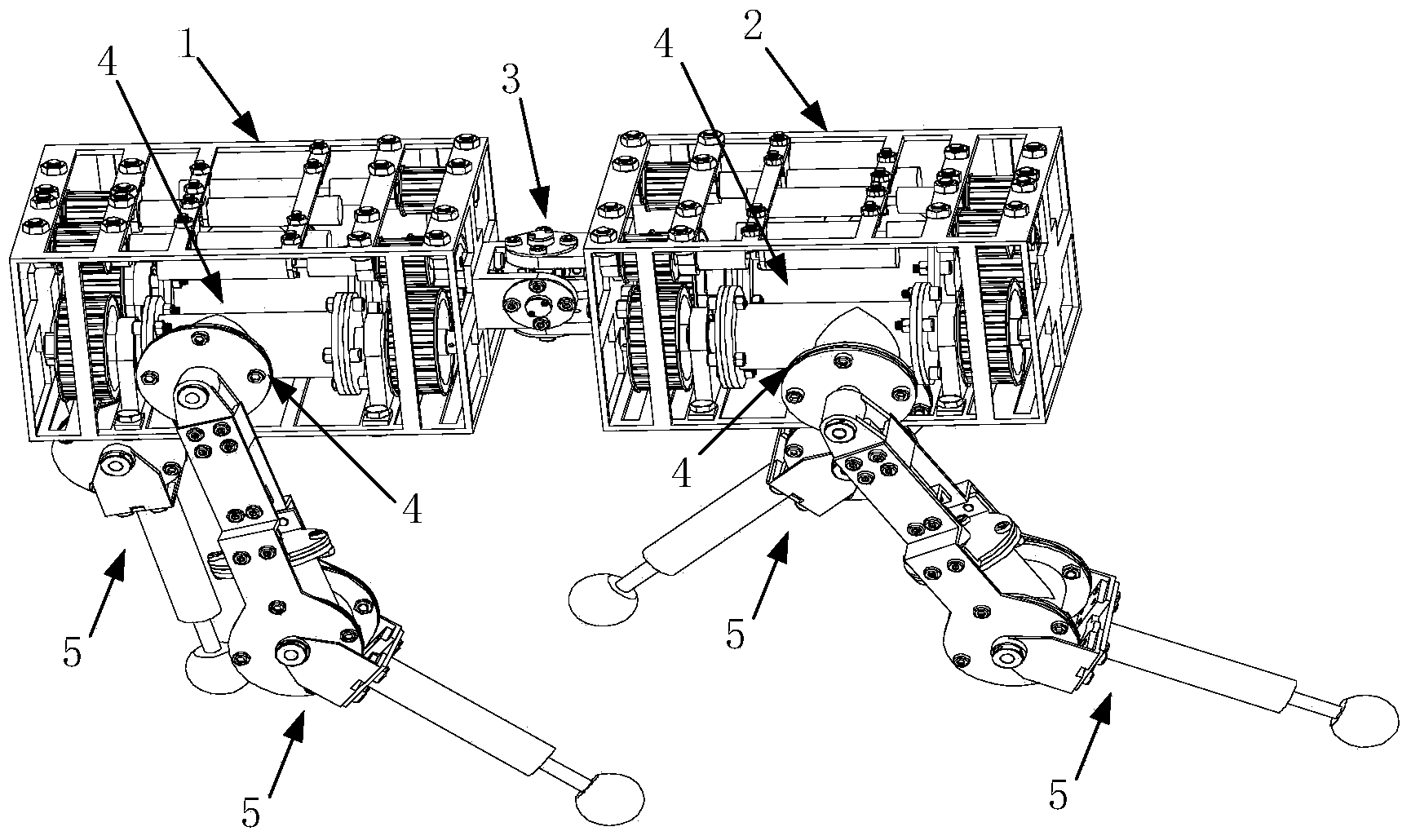

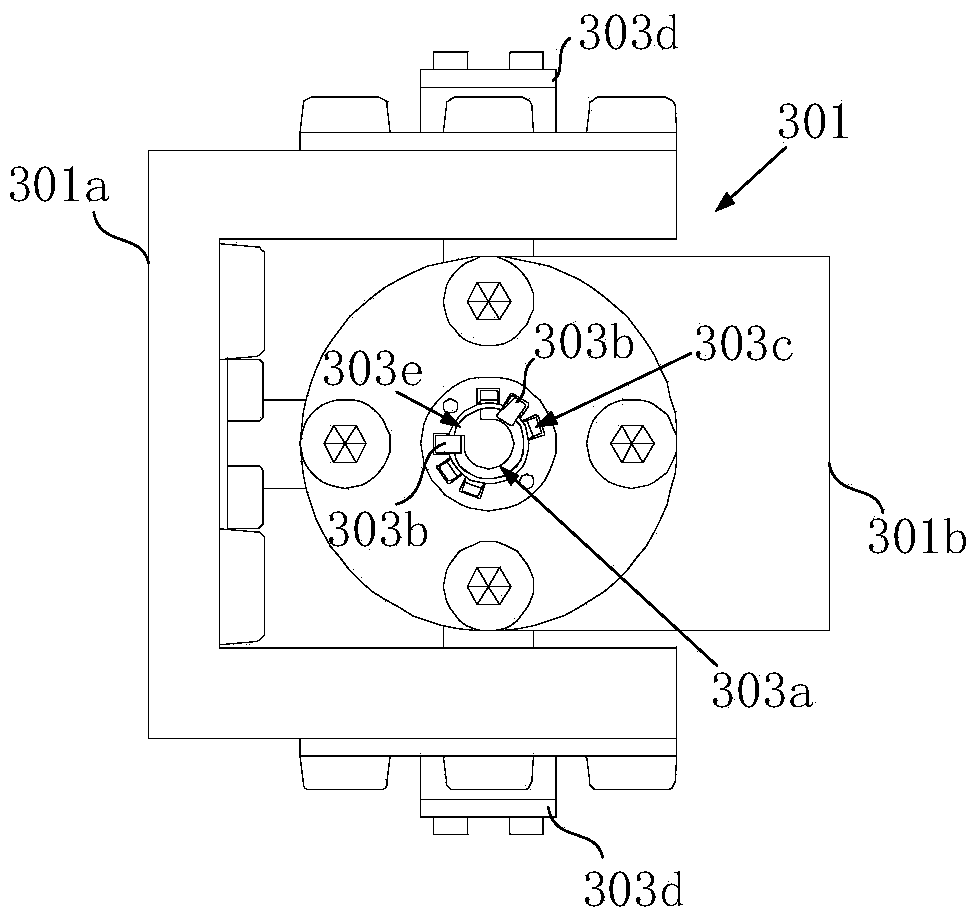

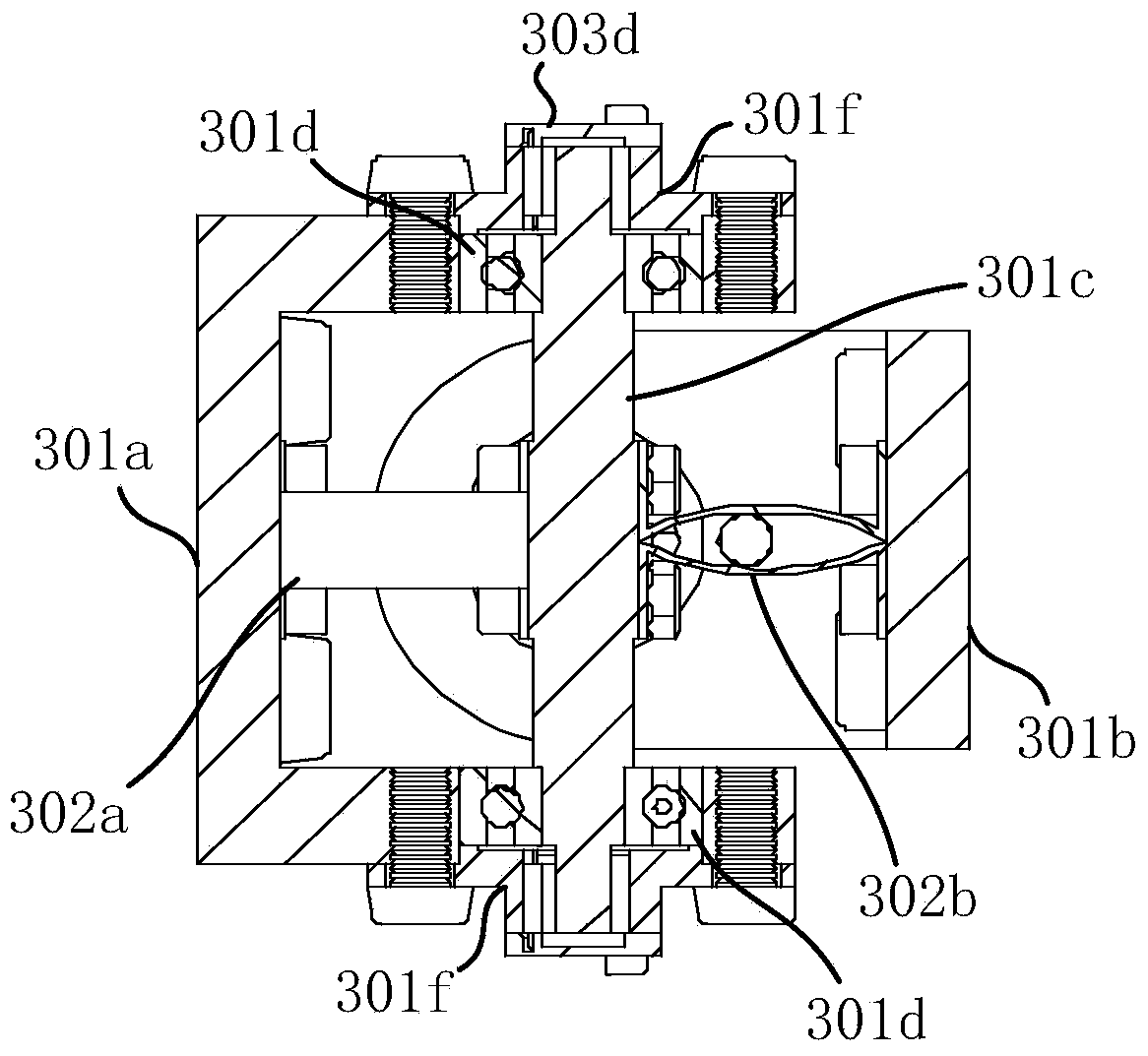

Smart quadruped robot with flexible waist

The invention discloses a smart quadruped robot with a flexible waist. The smart quadruped robot with the flexible waist comprises a front body, a rear body, a waist mechanism, crotch mechanisms and leg mechanisms. The front body and the rear body are connected through a split Hooke joint, so that relative deflection and pitching of the front body and the rear body are realized. The front body and the rear body are respectively provided with two crotch mechanisms, wherein output shafts of the crotch mechanisms are made to face the outer side of the bodies so that the leg mechanisms can be installed; the output shafts are meshed with bevel gears between transmission shafts for transmission, so that the output shafts are driven through rotation. A fixed shaft is fixed to each crotch mechanism, and the fixed shafts are driven to rotate to rotate a gearbox; in this way, the leg mechanisms can swing front and back as well as up and down. Each leg mechanism comprises a thigh part and a calf part, wherein each thigh part and each calf part are connected through a knee joint; transmission of the knee joints is realized through two bevel gears, so that the calf part made to swing front and back relative to the thigh part. The smart quadruped robot with the flexible waist has the advantages that the capability of passing through a mountain environment of the robot can be improved, the turning radius in the advancing process is reduced, rotational inertia of legs of the robot is reduced, and the energy utilization rate is increased.

Owner:BEIHANG UNIV

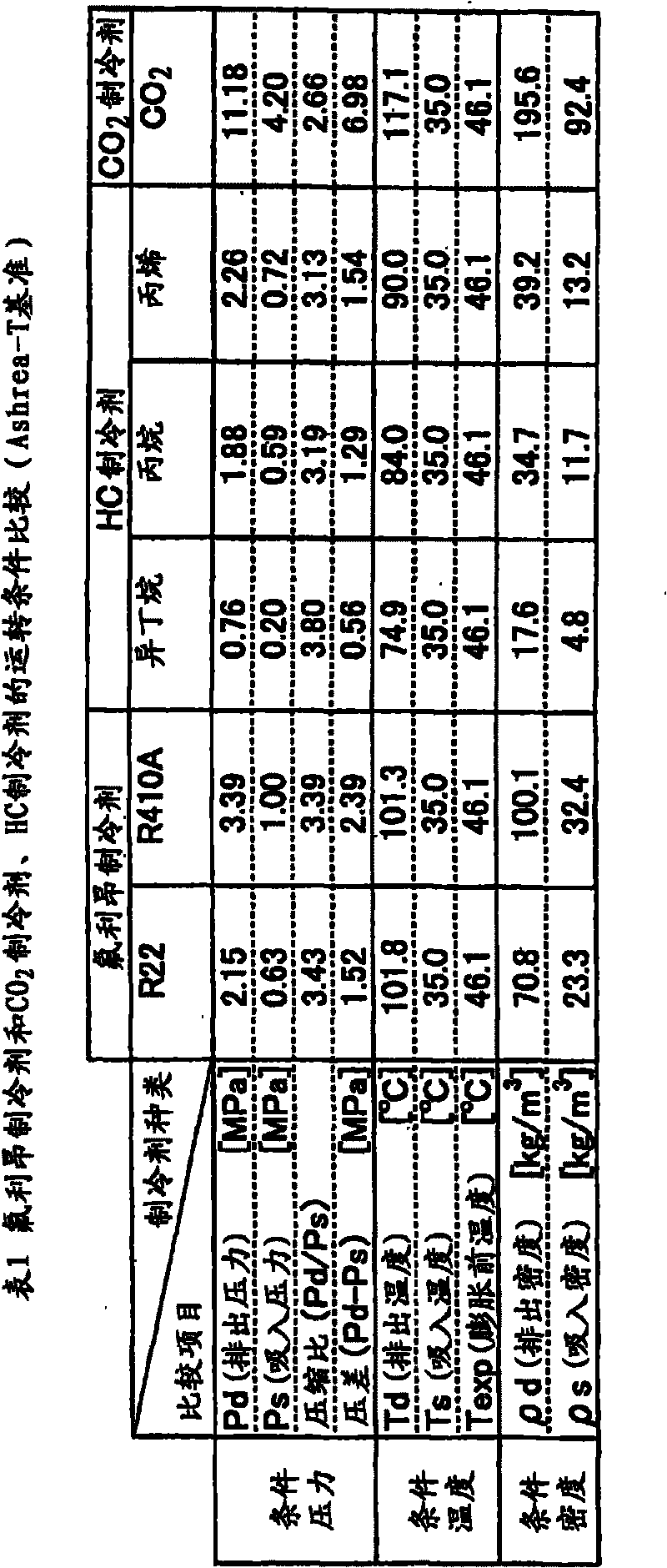

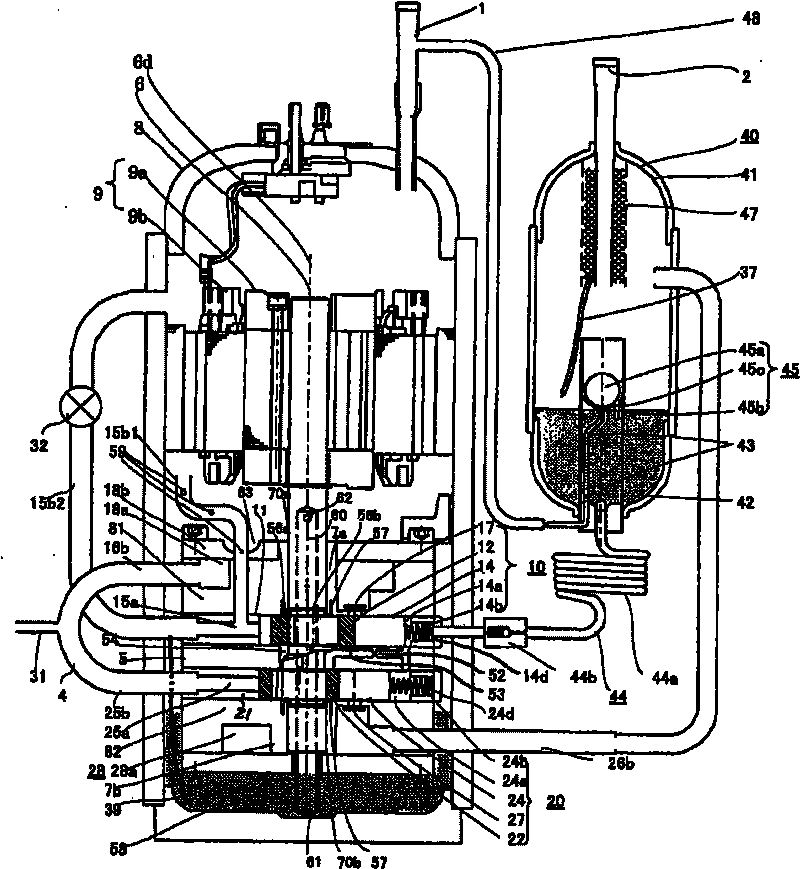

Rotary compressor

ActiveCN101743404AInhibit skippingGuaranteed lubrication effectRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsOil separationEngineering

A natural refrigerant low-pressure shell-type rotary compressor in which the amount of oil contained on the high-pressure side is reduced with sufficient lubrication and sealing performance at a sliding section secured. The compressor has a rotary refrigerant compression mechanism provided in a low-pressure enclosed container and having vanes, an oil separation element for separating lubricating oil from the refrigerant, and an oil supply passage for supplying the separated lubricating oil to a vane back pressure chamber of the compression mechanism, a crankshaft, a bearing, a cylinder, a piston, and oil supply spaces between the vanes. Vane skip is suppressed, and efficient lubrication and high sealing performance at the sliding section and a reduction in the amount of the oil contained on the high-pressure side are achieved at the same time. The compressor is highly reliable, is of low cost, has high performance, and uses a reduced amount of refrigerant.

Owner:MITSUBISHI ELECTRIC CORP

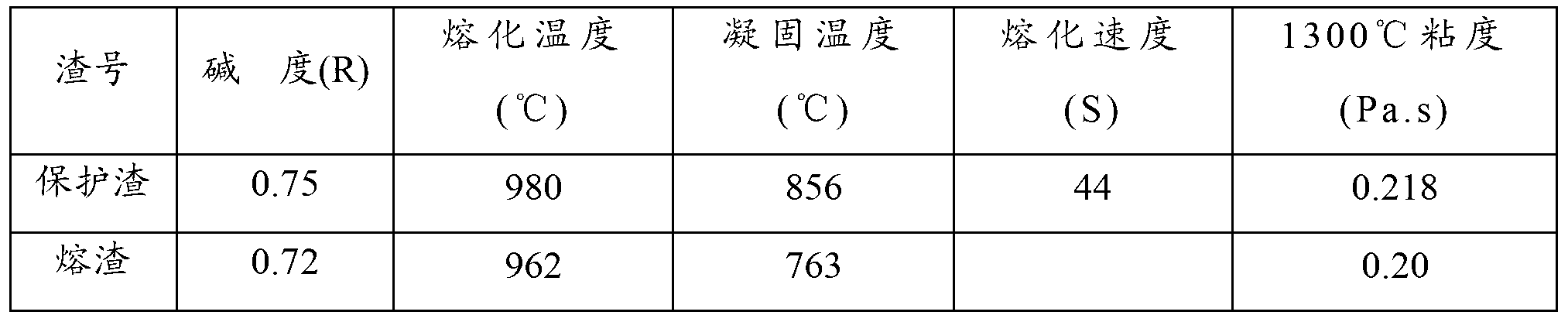

Continuous casting crystallizer covering slag for high-carbon steel

The invention relates to a continuous casting crystallizer covering slag for high-carbon steel. The continuous casting crystallizer covering slag comprises the following components in percentages by weight: 22.90-37.0% of SiO2, 22.5-27.0% of CaO, 4.35-5.0% of MgO, 1.8-6.0% of Al2O3, 2.2-3.0% of Fe2O3, 9.0-12.0% of Na2O, 5.2-6.0% of F, 6.5-9.0% of C, not more than 2.0% of K2O, not more than 1.9% of Li2O, and the balance of water and impurities. According to the continuous casting crystallizer covering slag for high-carbon steel disclosed by the invention, the using amounts of Na2O and CaF2 are properly reduced, K2O and Li2O fluxing is added, and the slag not only has proper physicochemical performance but also has good glass property and lubricating property, so that the quality and yield of casting blanks are greatly improved, and the covering slag has high economic benefit and social benefit.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

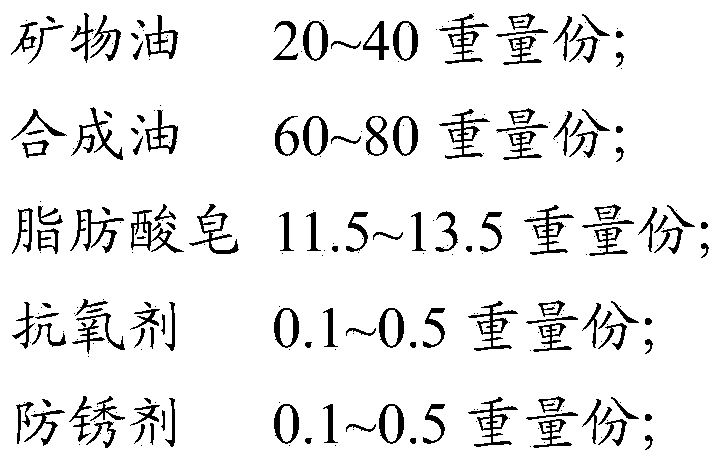

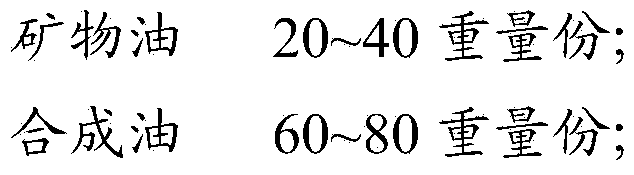

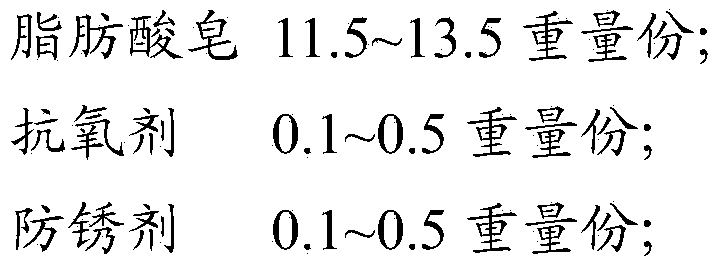

Low-temperature lubricating grease and preparation method thereof

ActiveCN103525510AHigh viscosity indexImprove viscosity indexLubricant compositionAntioxidantEvaporation

The invention provides low-temperature lubricating grease and a preparation method thereof. The low-temperature lubricating grease comprises mineral oil, synthesized oil, fatty acid soap, an antioxidant and an antirust agent. Compared with the prior art, the low-temperature lubricating grease is characterized in that semi-synthesized oil obtained by mixing III-type oil and ester oil and / or PAO (poly alpha olefin) oil is used as basic oil; the III-type oil has a high viscosity index and is high in high-temperature and low-temperature performance, oxidation stability, heat stability and evaporation performance; the ester oil and the PAO oil also have high viscosity indexes and are high in low-temperature performance; moreover, a mixture of lithium stearate and 12-hydroxy lithium stearate is used as a thickening agent for thickening the semi-synthesized oil, so that the low-temperature lubricating grease is high in low-temperature performance, and a used component can be normally lubricated under low temperature; the applicable temperature range is large; furthermore, the thickening agent is easy to synthesize.

Owner:CHINA PETROLEUM & CHEM CORP

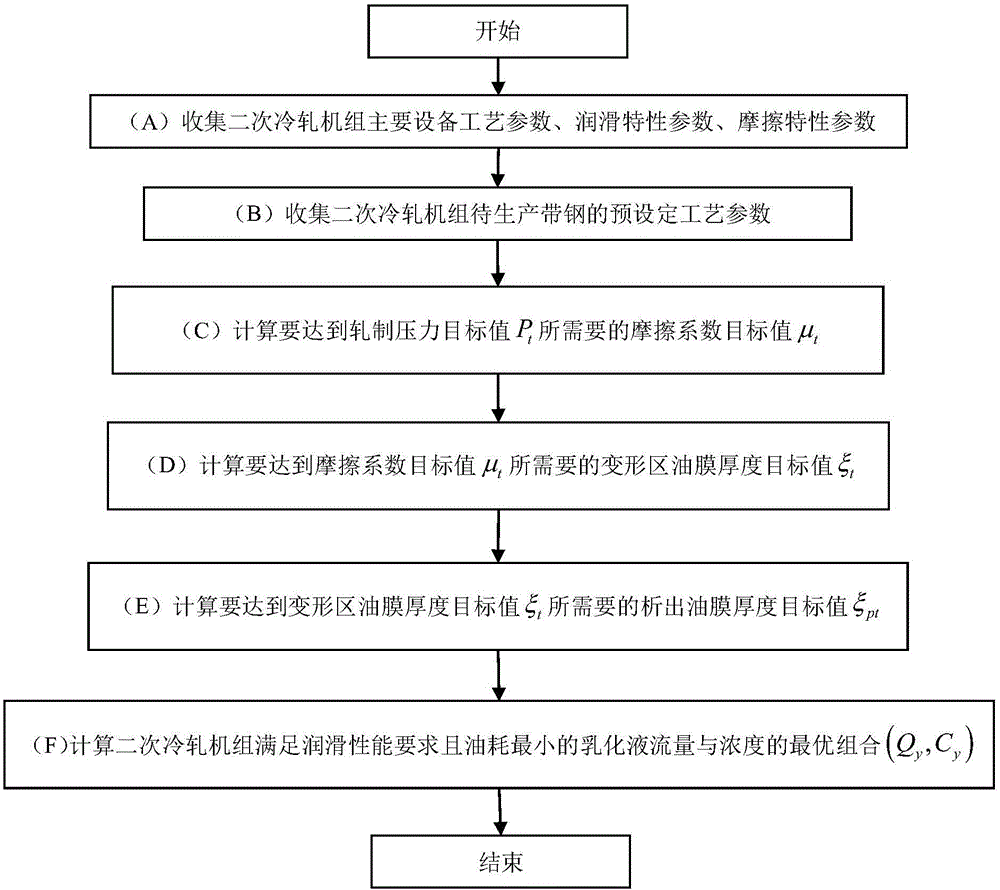

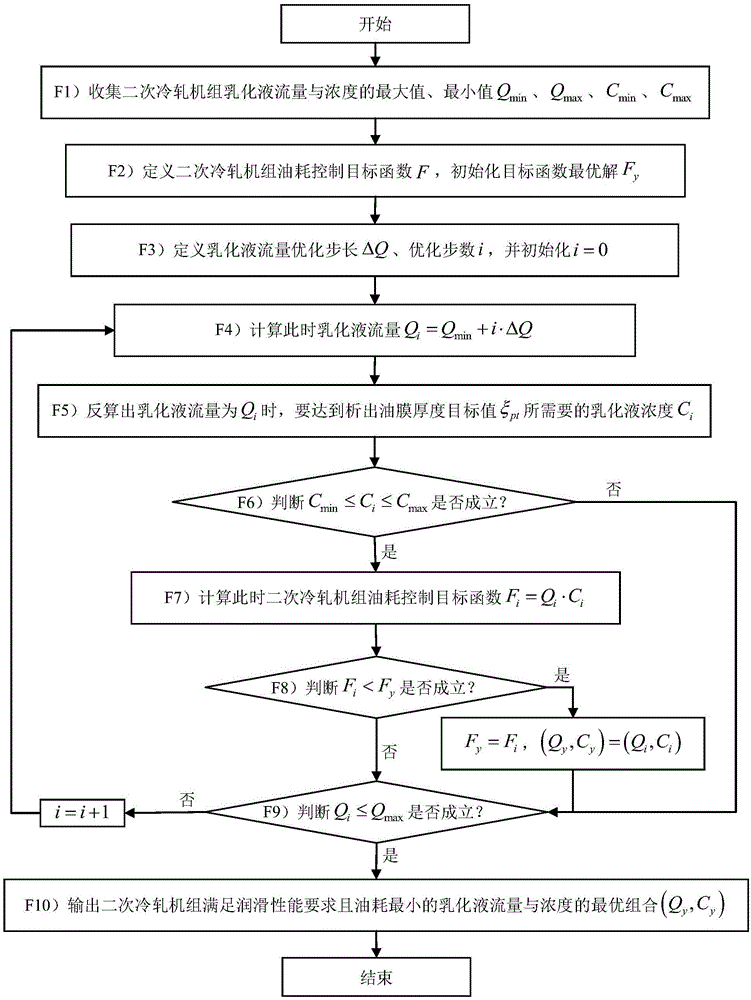

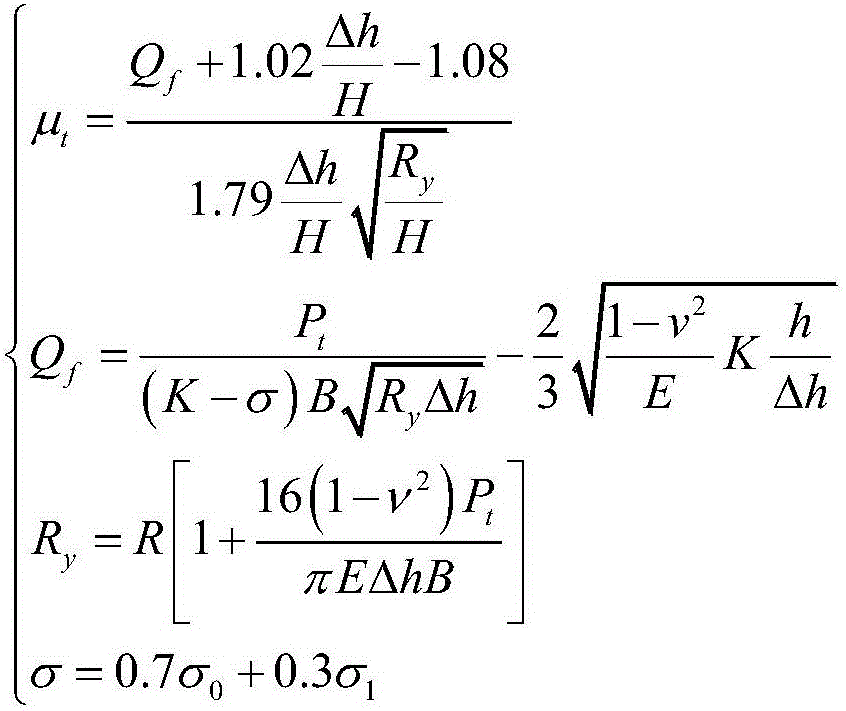

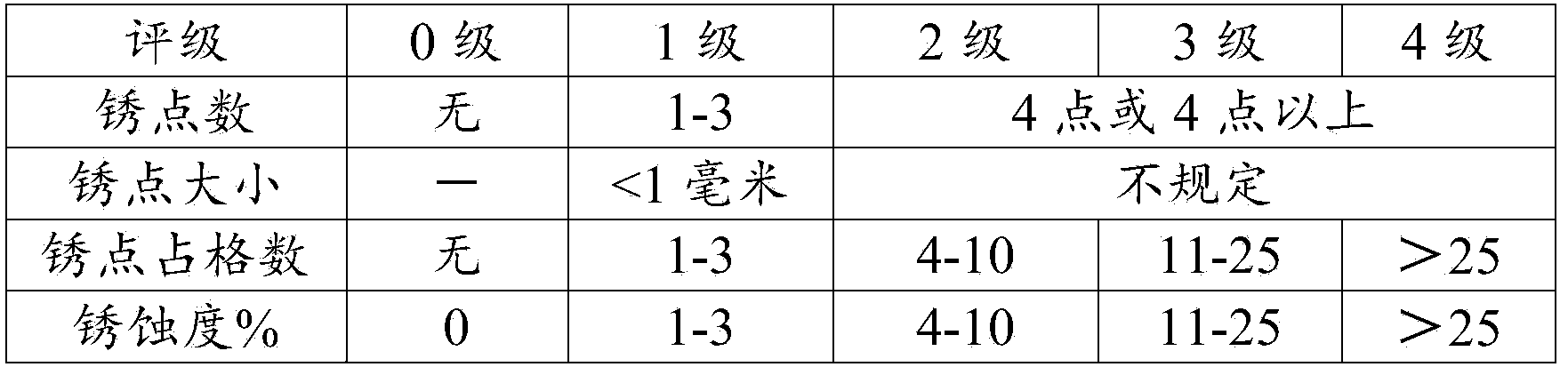

Emulsified liquid process optimization method taking oil consumption control as target by secondary cold rolling unit

InactiveCN107520253AReduce on-site production costsMinimum consumptionMass flow control deviceMetal rolling arrangementsProcess optimizationFrictional coefficient

The invention relates to an emulsified liquid process optimization method taking oil consumption control as a target by a secondary cold rolling unit. The method comprises the following steps executed by a computer; (A) collecting a primary equipment process parameter, a lubricating characteristic parameter and a frictional characteristic parameter of the secondary cold rolling unit; (B) collecting a preset process parameter of to-be-produced strip steel of the secondary cold rolling unit; (C) calculating a frictional coefficient target value [mu]t needed to reach a rolling pressure target value Pt; (D) calculating a deformation region oil film thickness target value xit needed to reach the frictional coefficient target value [mu]t; (E) calculating a separated out oil film thickness target value xipt needed to reach the deformation region oil film thickness target value xit; and (F) calculating the optimum combination (Qy and Cy) of flow and concentration f an emulsified liquid, wherein the secondary cold rolling unit meets the demand on the lubricating performance and the oil consumption is the minimum. By comprehensively optimizing concentration and flow of the emulsified liquid, the minimum consumption of rolling oil is achieved, and the field production cost of the secondary cold rolling unit and the sewage treatment cost of the emulsified liquid are lowered.

Owner:唐山格诺金属科技有限公司

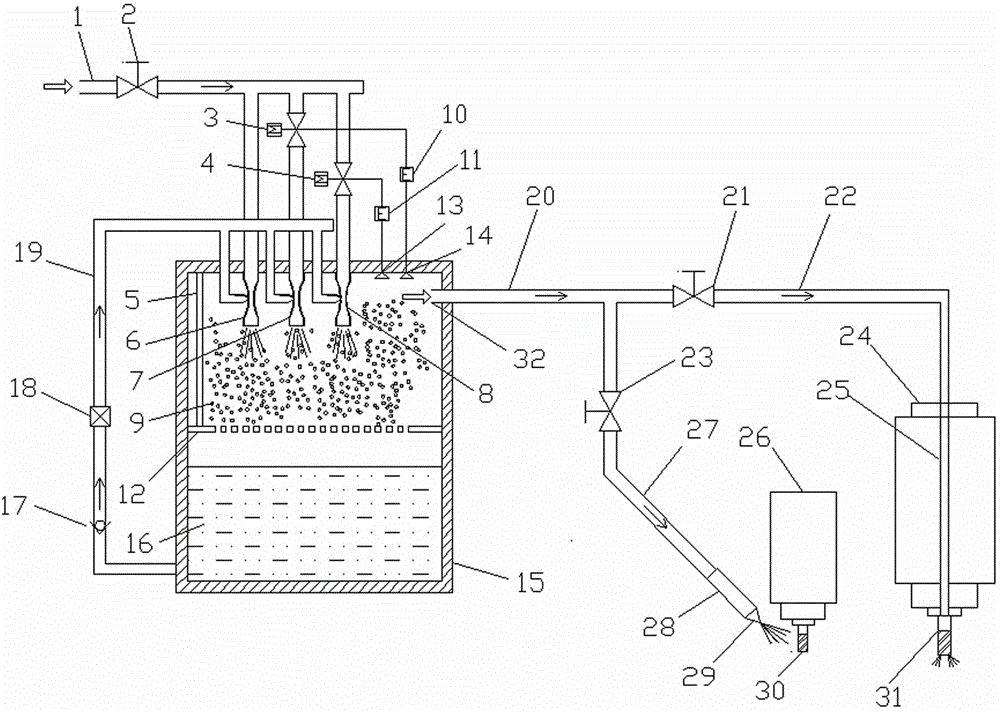

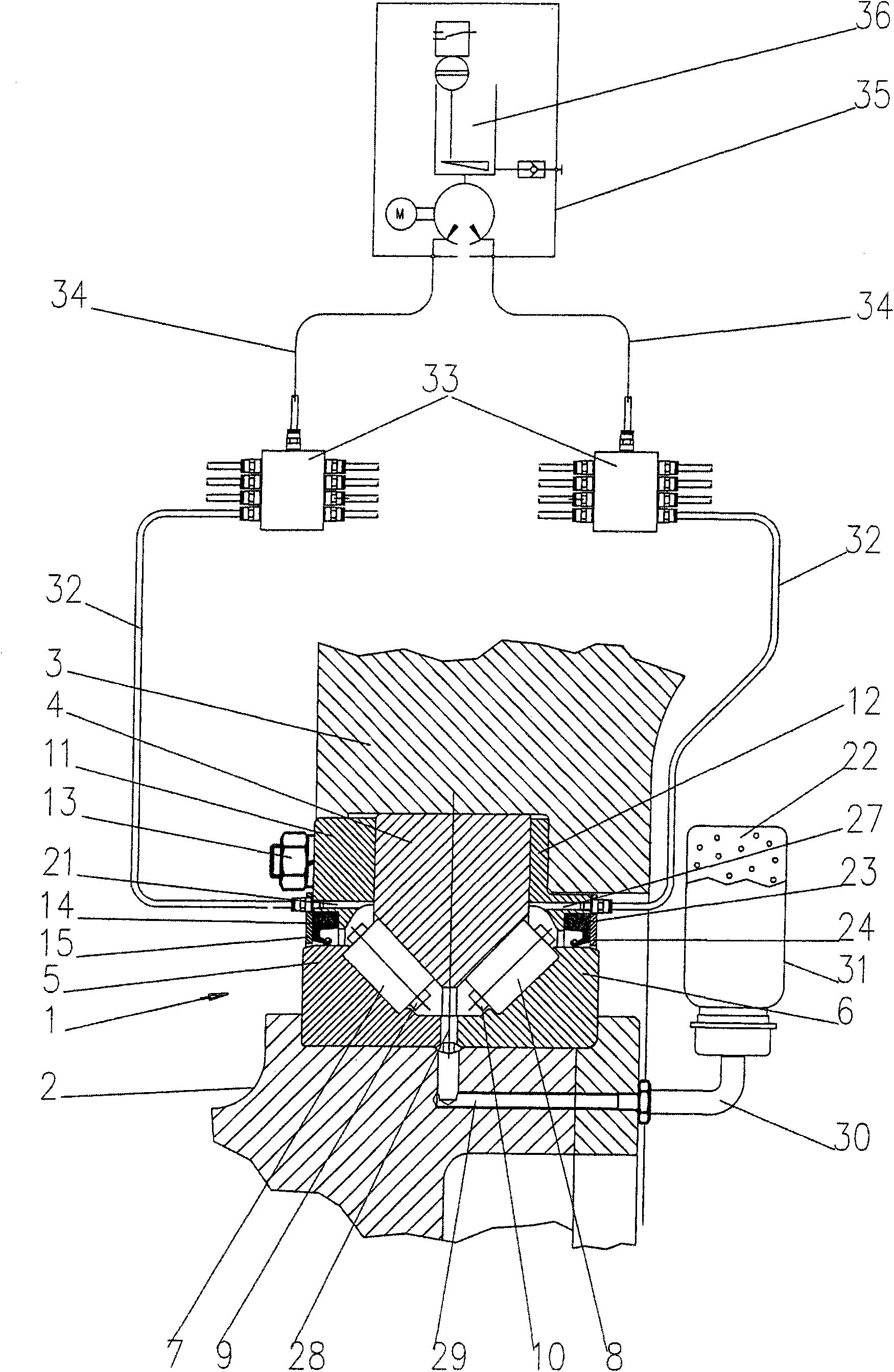

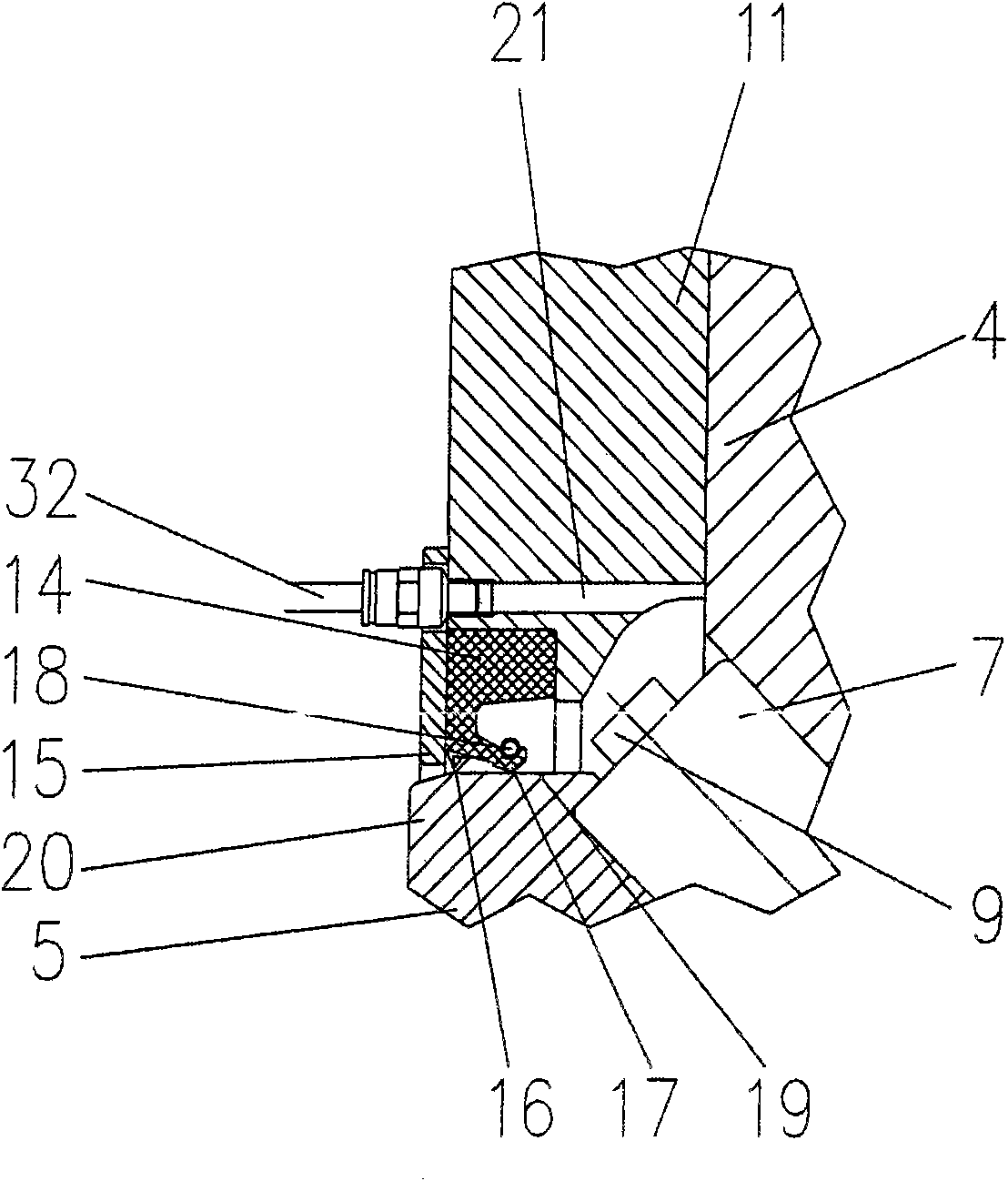

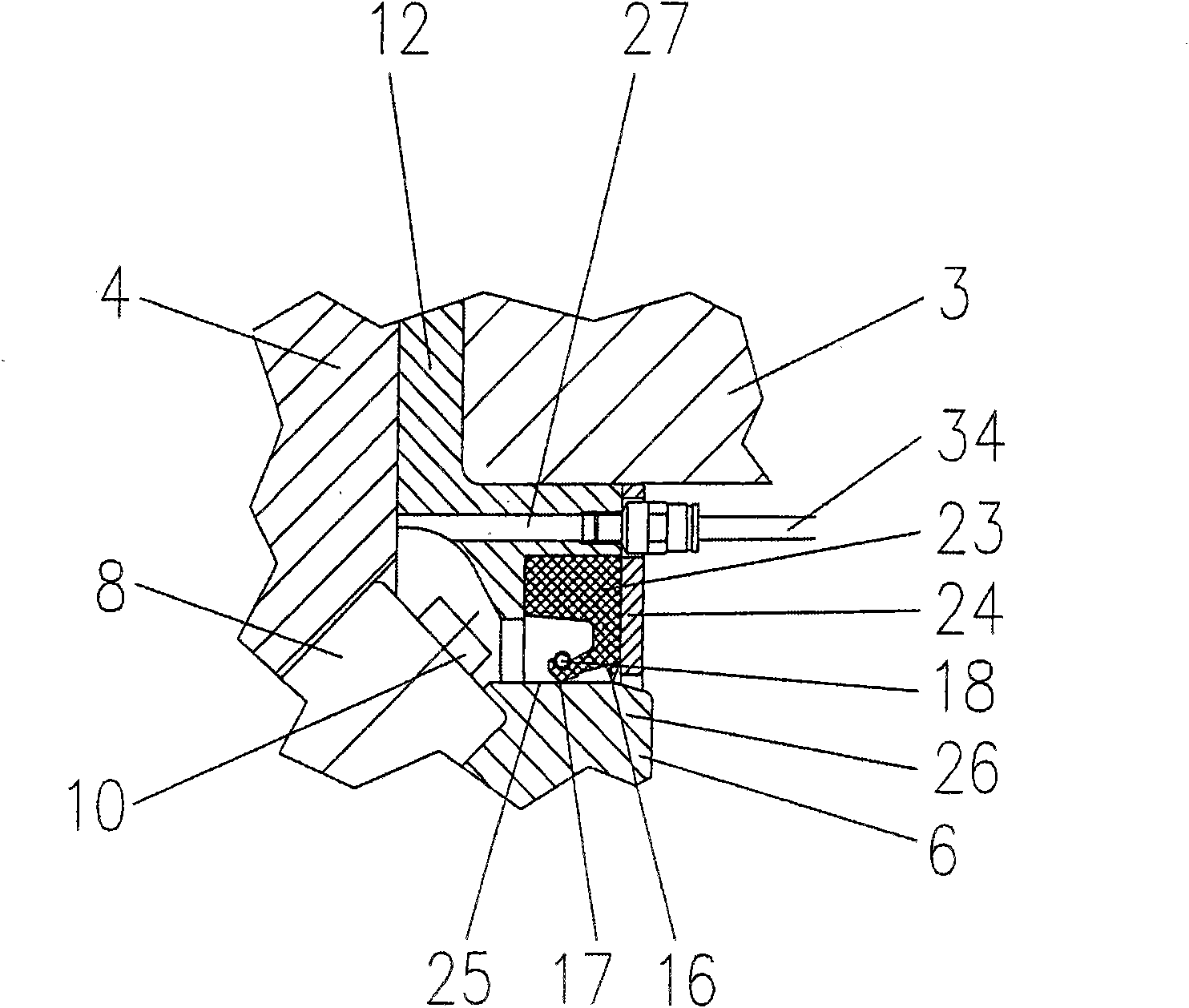

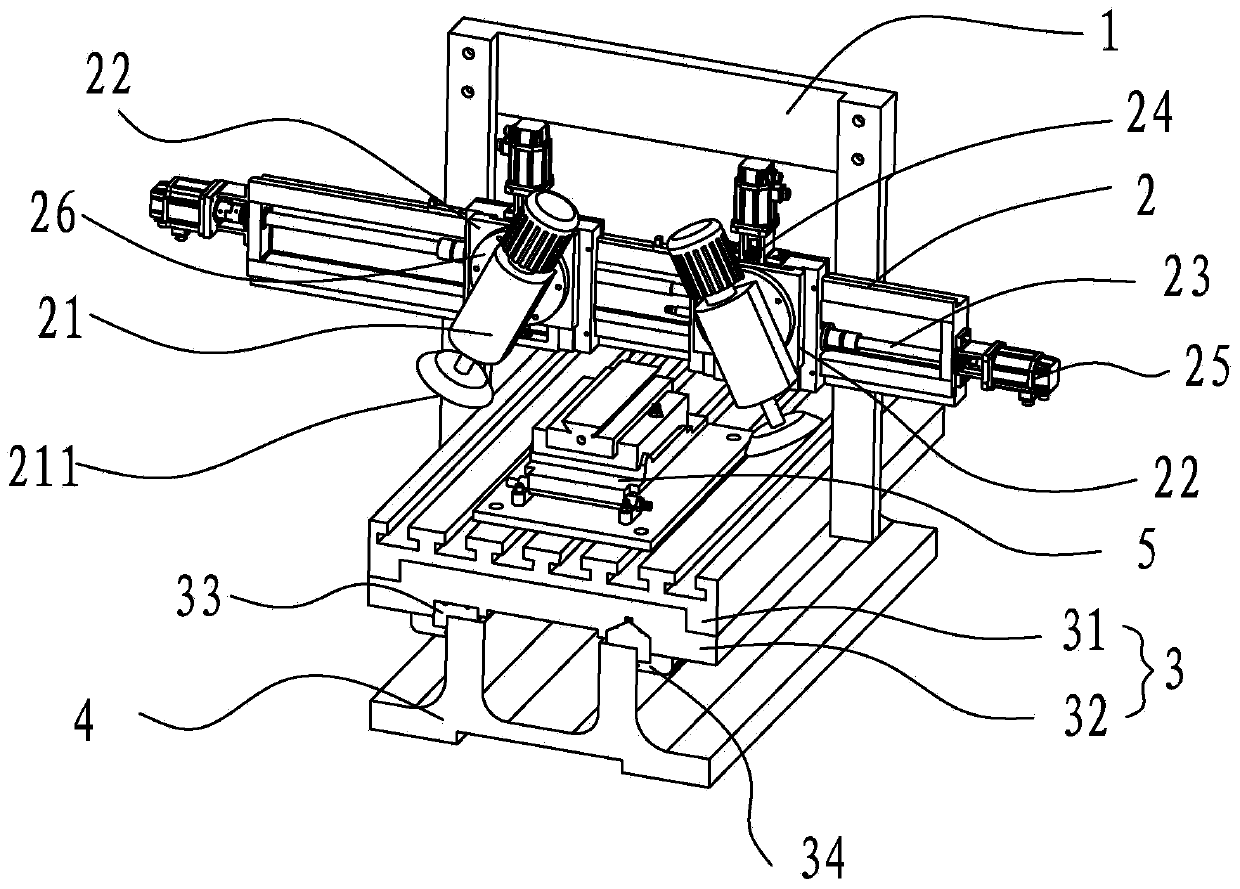

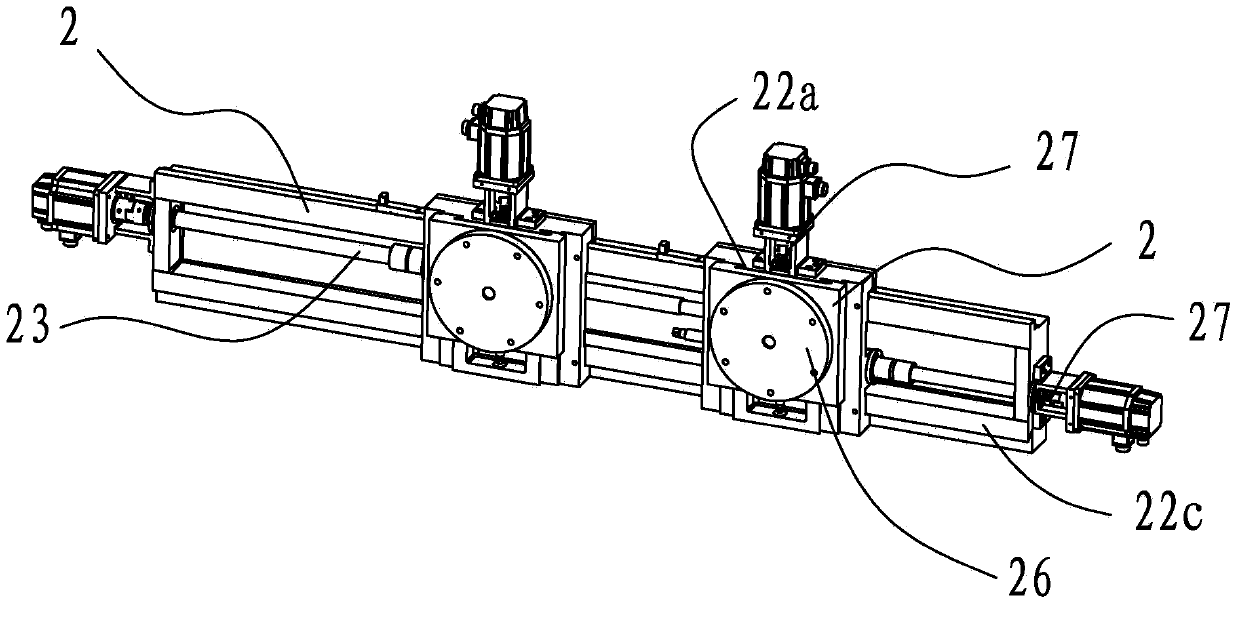

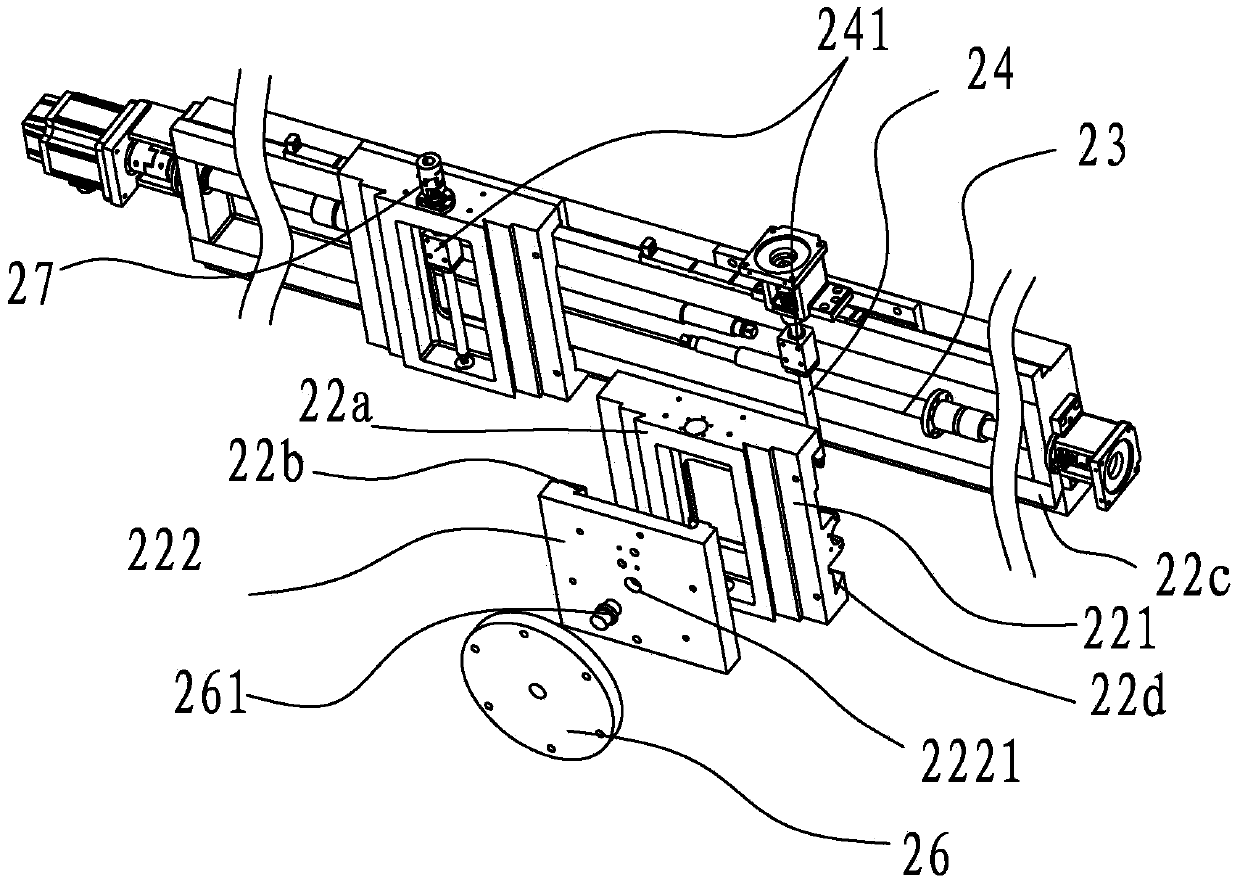

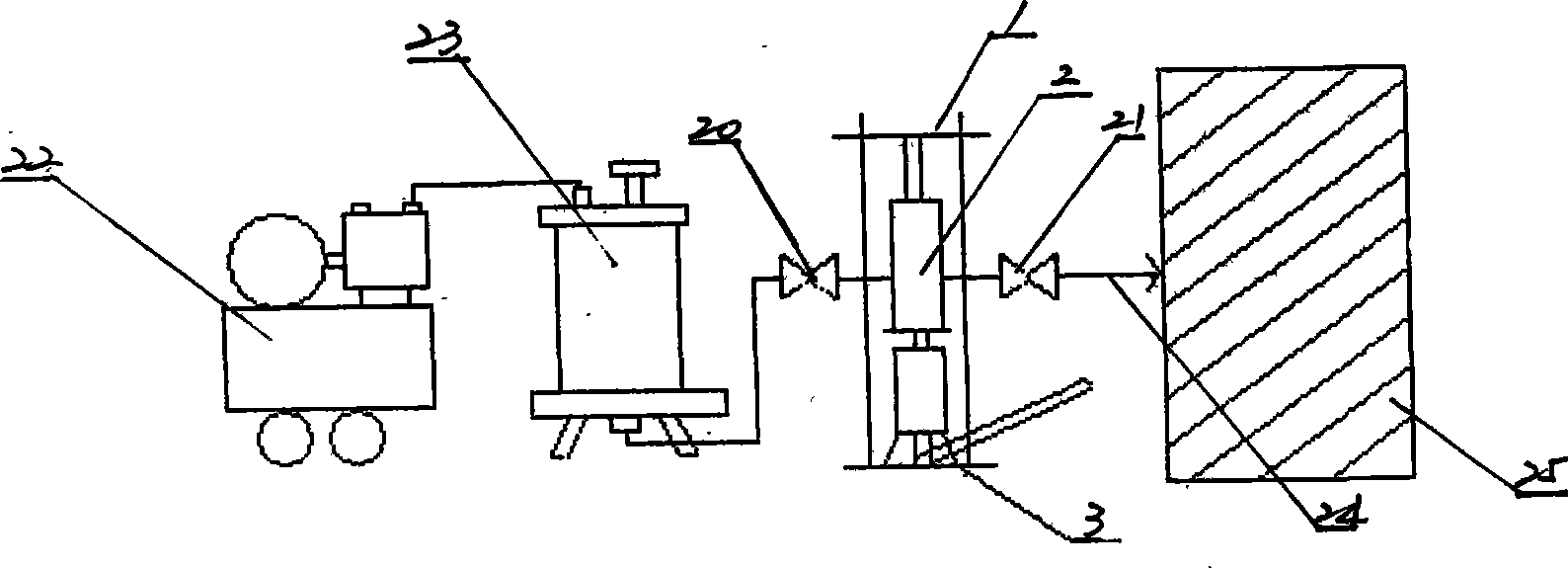

Minimum quantity lubrication supply system capable of automatically regulating oil mist quantity for machine tool processing

ActiveCN104476318AFully automatedReduce workloadMaintainance and safety accessoriesEngineeringControl valves

The invention relates to a minimum quantity lubrication supply system capable of automatically regulating the oil mist quantity for machine tool processing. The minimum quantity lubrication supply system comprises a gas conveying switch, at least one electromagnetic switch, a one-way valve, a flow rate control valve and an atomizing chamber, wherein the atomizing chamber contains cutting oil, the inner side wall of the top of the atomizing chamber is provided with at least two Venturi atomizing spray heads, the gas conveying switch is sequentially connected with one Venturi atomizing spray head through a gas conveying pipe, the gas conveying switch and the at least one electromagnetic valve are respectively and sequentially connected with the at least one Venturi atomizing spray head through a gas conveying pipe, the one-way valve and the flow rate control valve are sequentially connected through an oil liquid conveying pipeline, the bottom of the oil liquid conveying pipeline is communicated with the bottom of the atomizing chamber, the top of the flow rate control valve is connected with the at least two Venturi atomizing spray heads through an oil liquid conveying pipeline, and a baffle plate is fixedly arranged in the atomizing chamber. The minimum quantity lubrication supply system has the advantages that the structure is simple, the oil mist spraying quantity at the outlet part can be automatically regulated, and in addition, the oil mist can be simultaneously used for a plurality of machine tools.

Owner:DG ARMORINE ENERGY EFFICIENT & ECO FRIENDLY TECH

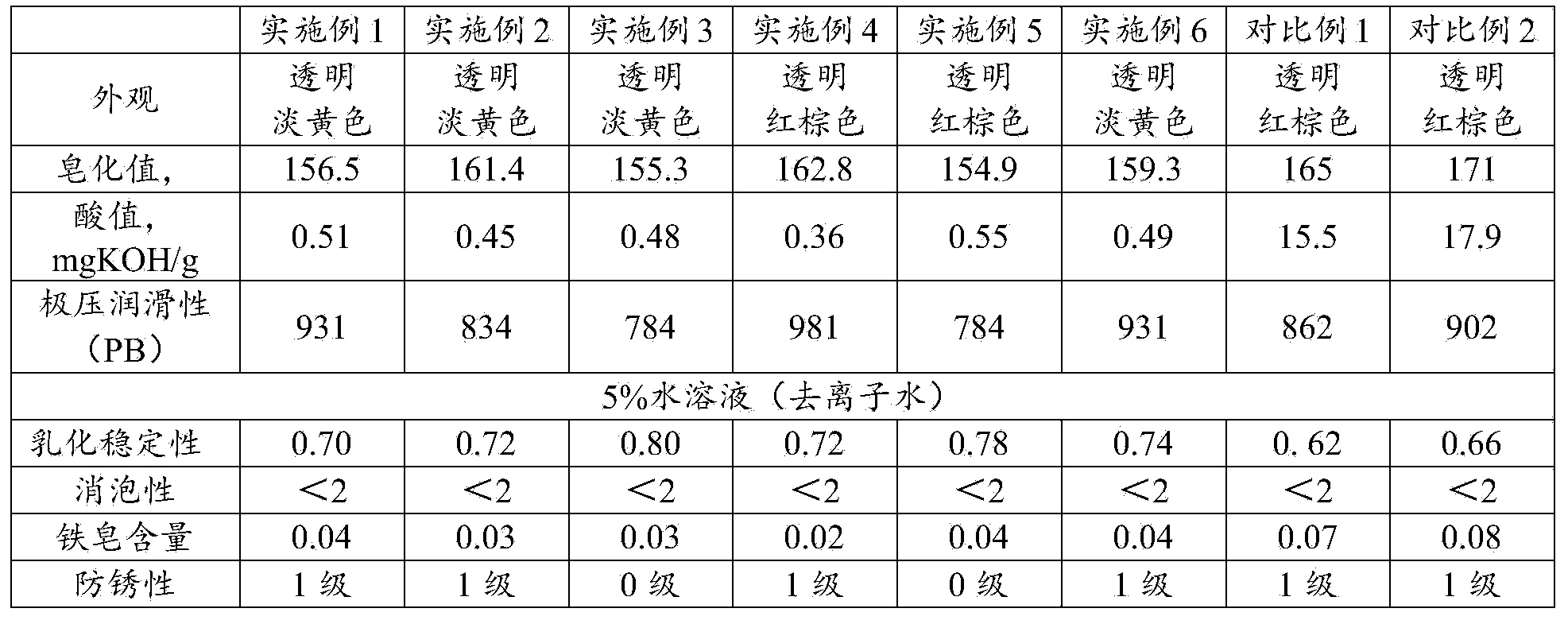

Emulsified oil composition and use thereof

InactiveCN104342261AGood synergyGuaranteed lubrication effectLubricant compositionActive agentPhysical chemistry

The invention relates to an emulsified oil composition and use thereof. The emulsified oil composition is mainly used for solving the problem that the quality of plate faces and the use performance of emulsified liquid are affected due to the fact that iron soaps are excessive, block pipelines and are difficultly filtered during the use of the existing emulsified liquid technologies. By adopting the technical scheme that the emulsified oil composition contains the following ingredients in parts by weight: (a) 30-40 parts of base oil, (b) 40-50 parts of non fatty acid type lubricant, (c) 2-5 parts of extreme pressure agent, (d) 1-5 parts of anti-rust agent, (e) 5-10 parts of surfactant and (f) 0.1-5 parts of antioxidant, the problem is better solved, the requirements of a straight carbon steel cold-rolling rolling process are met, and the emulsified oil composition can be applied to a rolling process of a modern large-sized multi-rack continuous-rolling rolling mill and a rolling process of a multi-roller mono-rack reversible rolling mill.

Owner:CHINA PETROLEUM & CHEM CORP

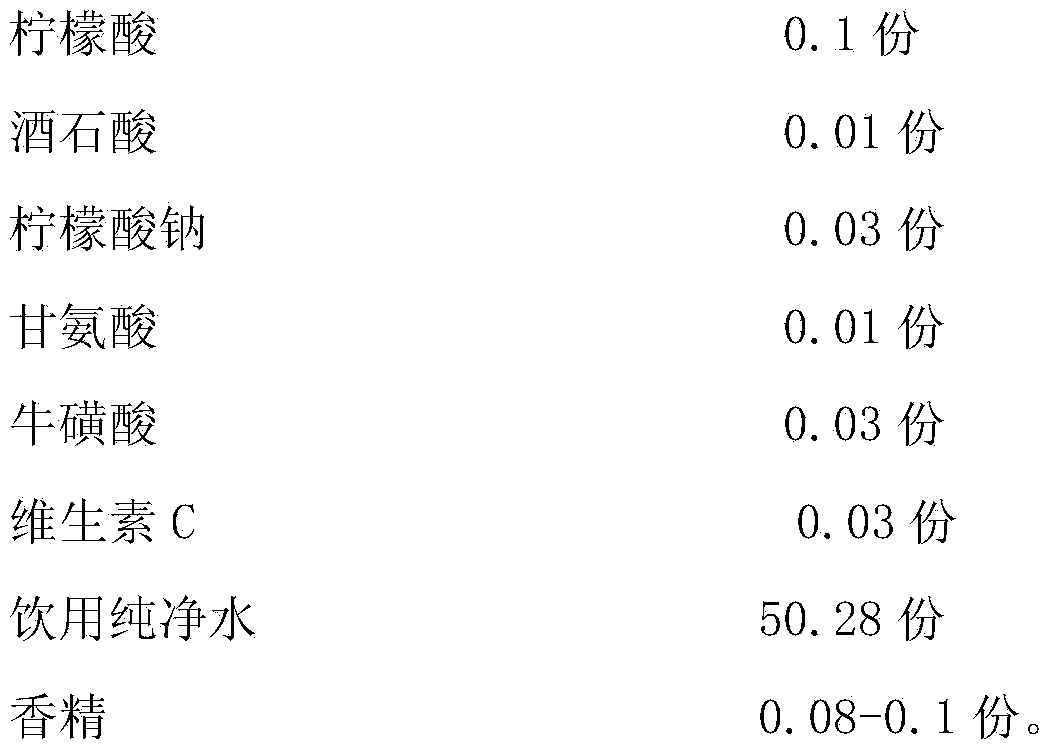

Okra juice drink and preparation method therefor

InactiveCN103637331AEnhance anti-cancer and anti-cancer abilityImprove the immunityNatural extract food ingredientsFood ingredient functionsGlycineVitamin C

The invention discloses an okra juice drink and a preparation method therefor. The drink comprises the following ingredients, by weight, 45 parts of okra original juice, 4 parts of white granulated sugar, 0.5 part of xylitol, 0.01 part of sucralose, 0.1 part of citric acid, 0.01 part of tartaric acid, 0.03 part of sodium citrate, 0.01 part of glycine, 0.03 part of taurine, 0.03 part of vitamin C, 50.28 parts of purified water for drinking and 0.08-0.1 part of essence. The drink has good taste, and is beneficial for absorption of nutrition and health care components in human body. The bioavailability of active ingredients is raised, and the drink is suitable for popularization and application.

Owner:HEBEI KUI FU KANG DRINKS

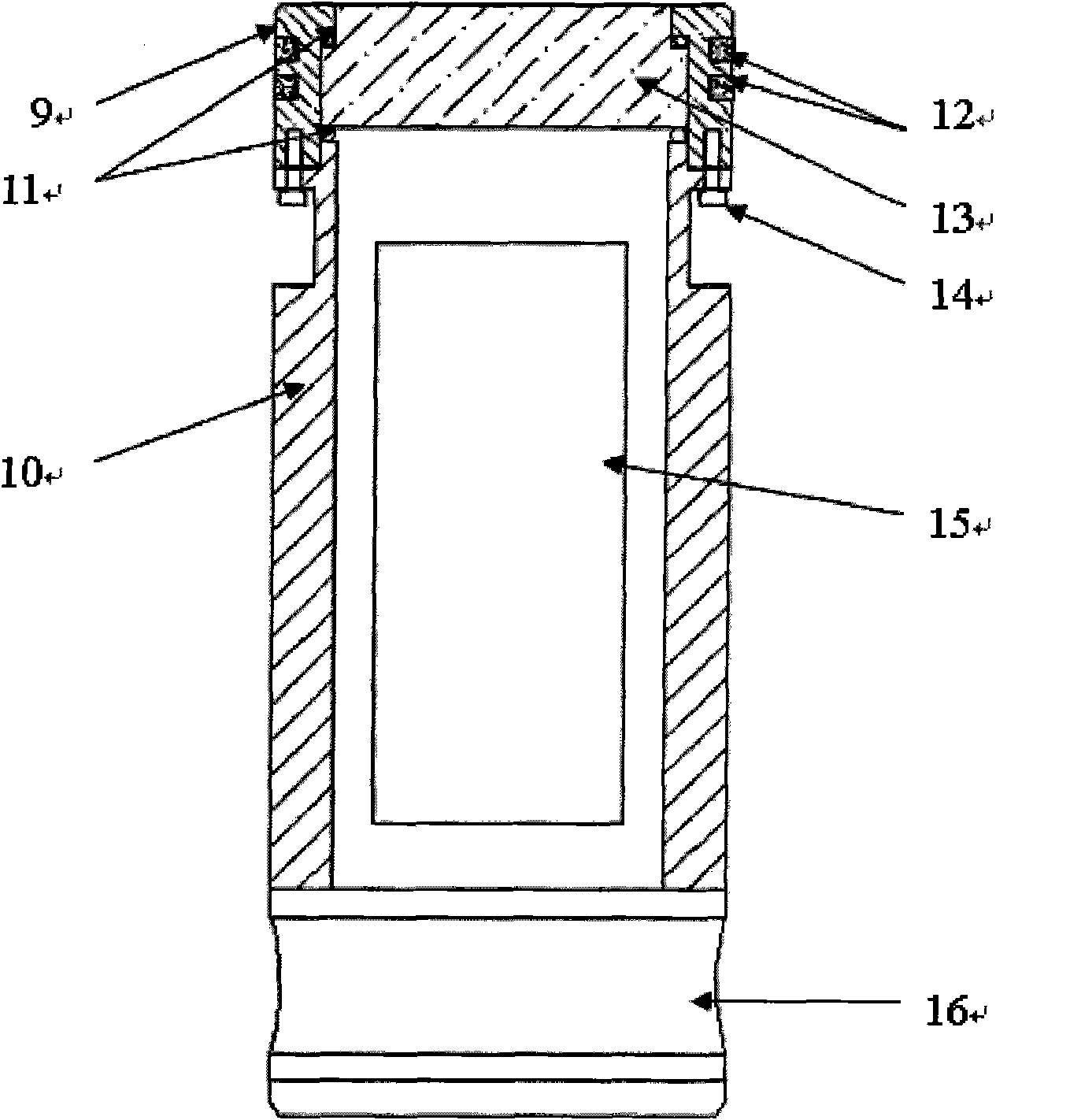

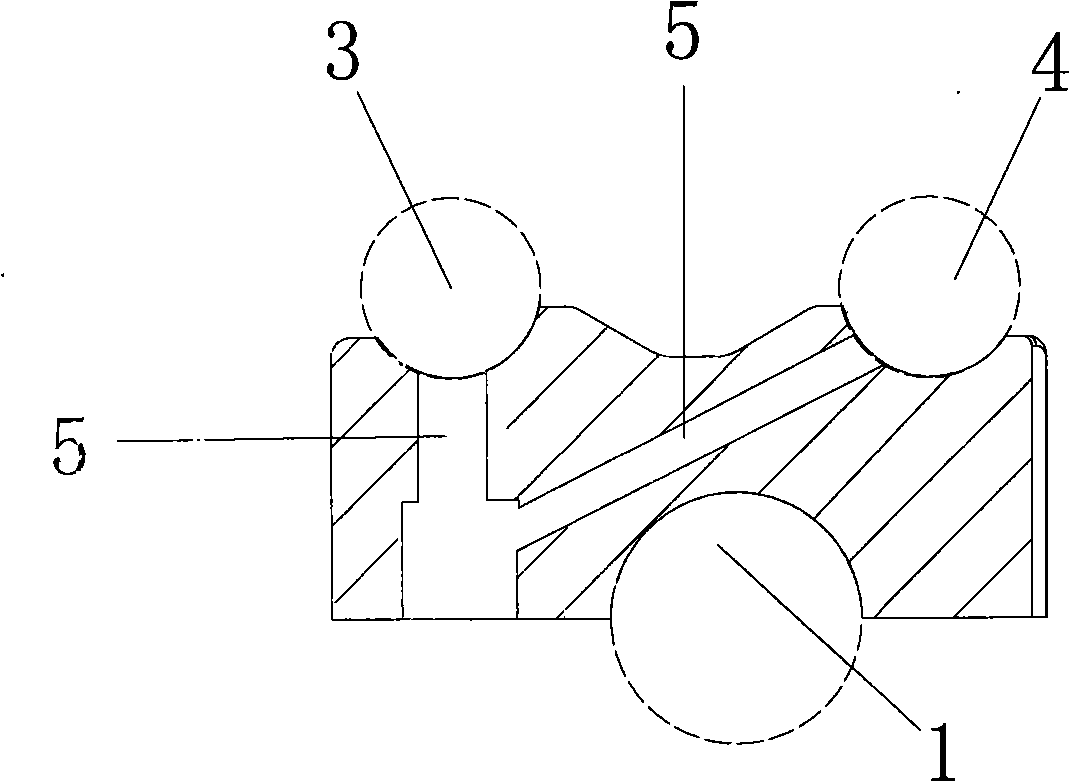

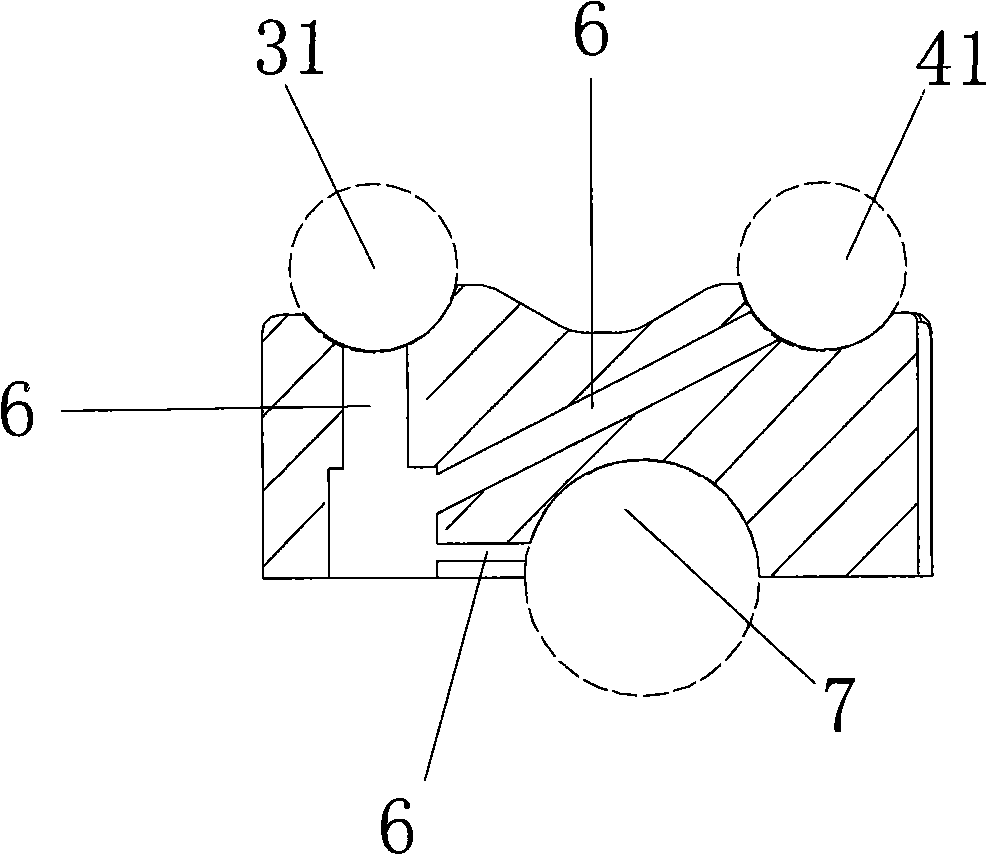

Two-row roller bearing and bearing system with such a roller bearing and a lubricating device

ActiveCN101846129AImprove the lubrication effectFirmly connectedRolling contact bearingsShaftsRolling-element bearingMechanical engineering

The invention relates to a two-row roller bearing (1) for supporting a mechanical part (2) rotatably relatively to a rotation axis. According to the invention, the roller bearing (1) has an outer ring (4) with the outer diameter of at least 1 m, a first inner ring (5), a second inner ring (6) arranged at the side of the first inner ring (5) axially relatively to the rotation axis, a group of first rolling bodies (7) rolling between the outer ring (4) and the first inner ring (5), a group of second rolling bodies (8) arranged at the side of the first rolling bodies (7) along the axial direction relatively to the rotation axis and rolling between the outer ring (4) and the second inner ring (6). The roller bearing (1) is characterized in that a first lubricating grease conveyor (21) is arranged at the first axial side of the outer ring (4) with respect to the rotation axis for supplying the first roller body with lubricating grease (22) and a second lubricating grease conveyor (27) is arranged at the second axial side of the outer ring (4) with respect to the rotation axis for supplying the second roller body with lubricating grease (22).

Owner:AB SKF

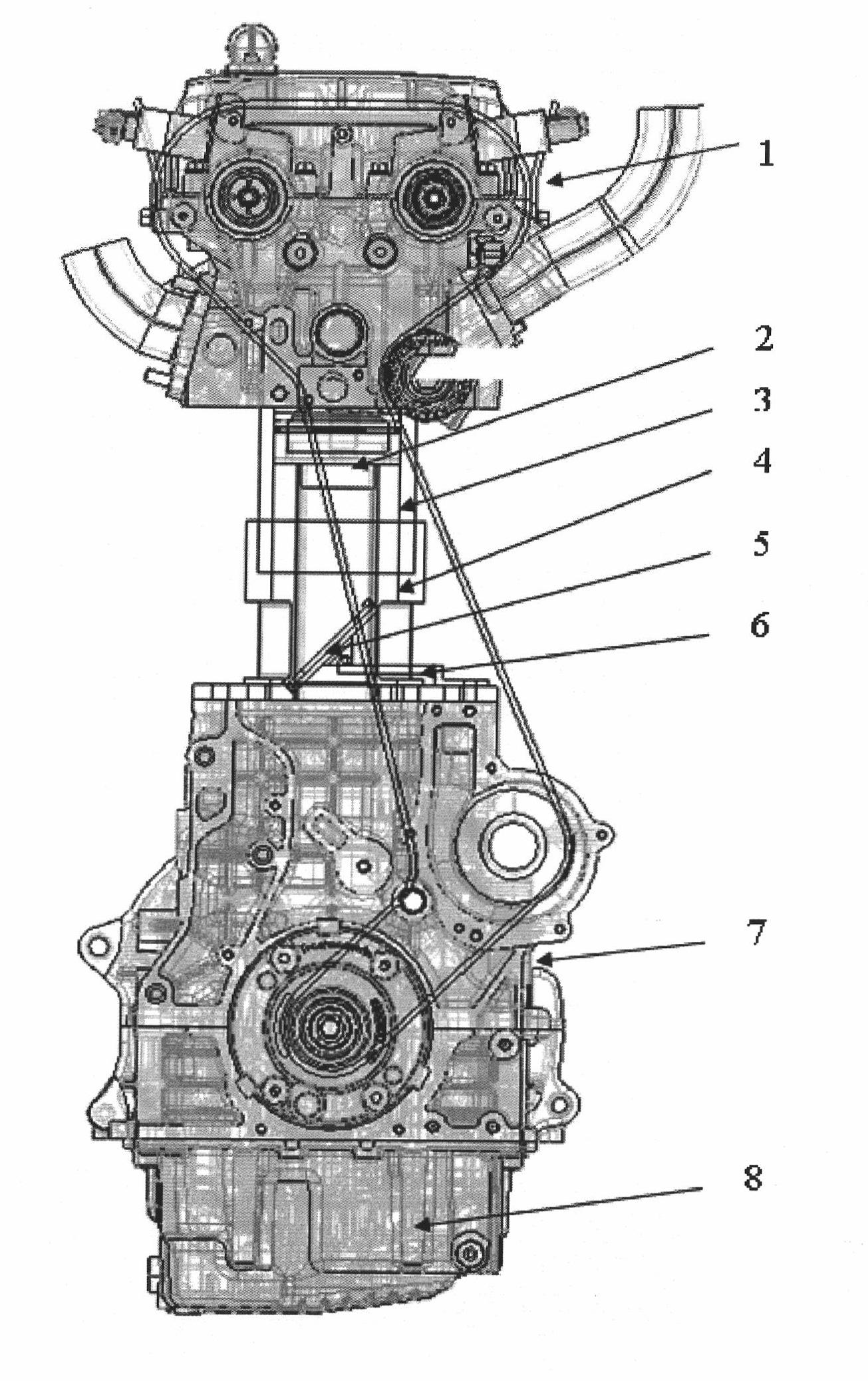

Optical engine

The invention relates to an optical engine which comprises a cylinder cover, an original cylinder casing and a piston; a transparent quartz glass cylinder casing is arranged between the cylinder cover and the original cylinder casing; the piston is an extended piston; the top of the extended piston is provided with a round window; transparent quartz glass is arranged in the round window; the length of the transparent quartz glass cylinder casing is more than the sum of the stroke of the engine and the distance between a ring at the bottommost of the piston and the top surface of the piston; and an engine cylinder body, the original cylinder casing, the cylinder cover and the transparent quartz glass cylinder casing are fixedly connected by bolts.

Owner:CHERY AUTOMOBILE CO LTD

Preparation of hydrophobic magnetic lubricating grease for hydrophobic magnetic lubricating bearing

InactiveCN101117606AExtended service lifeLow costBearing componentsAdditivesMagnetic liquidsLubrication

The present invention discloses a preparation of dewatering magnetic grease lubricant used in dewatering magnetic lubrication bearing. Firstly, nano-meter magnetic liquid (magnetic fluid) which composed of nano-meter magnetic powder and base liquid is prepared, the nano-meter powder of magnetic fluid adopts soft magnetic particle powder Fe3O4 (ferroferric oxide) or MnZnFe2O4 (manganese-zinc ferrite), the base liquid of the magnetic fluid is dewatering magnetic lubricant, then the thickening agent is added in and mixed evenly to get the grease lubricant with both dewatering property and magnetic property, on the basis that the existing bearing structure is not changed, the dewatering magnetic grease lubricant is filled into the inner cavity of the bearing position in magnetic field, under the action of the magnetic field force, the grease lubricant is enabled to resist the washing of water from the outside, and can be kept inside the bearing without flowing to the outside. The grease lubricant with dewatering and magnetic properties is used to replace the current common universal grease lubricant, thus being able to guarantee the lubrication of the rolling and sliding bearing, and greatly prolong the service life of the bearing. The production cost of the present invention is low, the effect is good and the practicality is wide.

Owner:CHINA UNIV OF MINING & TECH

Engine with novel oilway

ActiveCN101344024AImprove the lubrication effectShorten the lengthLubrication of auxillariesLubricant conduit arrangementsEngineeringCam

The invention aims at disclosing an engine with a novel oil line; the engine has simple structure and low cost, is lubricant and reliable and comprises an air cylinder cover, a bearing cover of a cam shaft which is fixed on the air cylinder cover by a positioning pin and a bolt, and a rocker shaft, a rocker, a hydraulic tappet and the cam shaft which are supported in the bearing cover of the cam shaft; particularly, the air cylinder cover is internally provided with a main oil-feeding pipeline which goes to a neck hole of a main shaft of the cam shaft and the middle position of the internal part of the bearing cover of the cam shaft from the air cylinder cover; the bearing cover of the cam shaft is internally provided with a main oil pipeline which is communicated with the main oil-feeding pipeline and the center installation hole of the rocker shaft, and multiple secondary oil pipelines which are communicated with the installation holes of the two sides of the rocker shaft and the neck hole of the secondary shaft of the cam shaft; the rocker shaft is internally provided with oil pipelines which are communicated with the center installation hole of the rocker shaft, the installation holes of the two sides and the installation holes of all the rockers; and the rocker is internally provided with the oil pipeline of the rocker which is communicated with the installation hole of the rocker and the internal part of the hydraulic tappet. The internal oil pipeline of the engine of the invention adopts the design of feeding the oil from the middle part, is easy to be processed and is lubricant and reliable.

Owner:CHERY AUTOMOBILE CO LTD

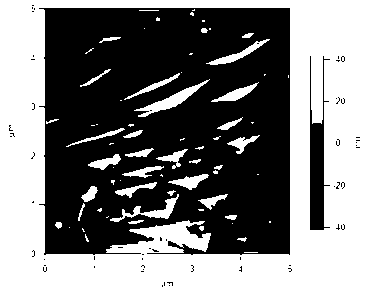

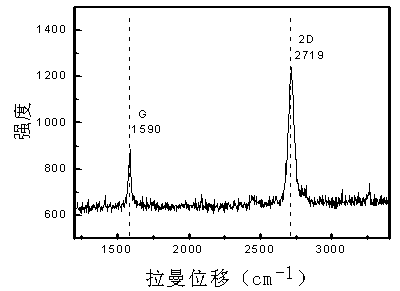

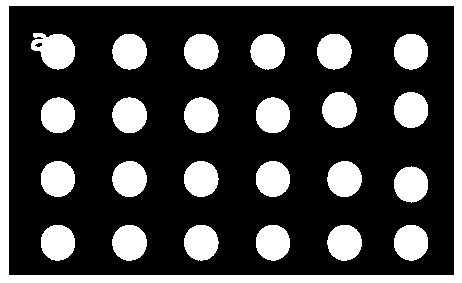

Wear-resistant graphene surface modification method

InactiveCN103225076AGuaranteed lubrication effectImprove wear lifeVacuum evaporation coatingSputtering coatingGraphiteGraphene

The invention relates to a wear-resistant graphene surface modification method, which adopts a magnetron sputtering technology to embed metal elements into the surface of graphene to form a column-shaped array structure and fulfills the aims of reducing friction and prolonging wear-resistant life through surface micro-structuration. The wear-resistant graphene surface modification method comprises the following steps of: 1) preparing the graphene by a chemical vapor deposition method; and 2) embedding the column-shaped array structure into the surface of the graphene, wherein the step 2) comprises the following steps of: 1, placing the graphene and a substrate into a magnetron sputtering furnace and placing a metal mask plate on the surface of the graphene, wherein the metal mask plate is provided with holes arranged in an array mode and a source electrode is a 99.99 percent pure metal target; 2, turning on a vacuum pump, vacuumizing in the magnetron sputtering furnace to the ultimate vacuum of 1.0*10<-5>Pa-5.0*10<-5>Pa, introducing high-purity argon until the gas pressure is 2 to 6 Pa and pre-bombarding a test sample for about 1 to 3 minutes; 3, sputtering under the power of 30 to 80 W at room temperature for 10 to 15 minutes; and 4, turning off a power supply of the source electrode, vacuumizing the furnace to ultimate vacuum, cooling to room temperature and discharging from the furnace.

Owner:魏颖

Grinding machine tool for dovetail guide rail

InactiveCN104044030AGuaranteed accuracyGood precisionPlane surface grinding machinesEngineeringGrinding wheel

The invention discloses a grinding machine tool for a dovetail guide rail. The grinding machine tool for the dovetail guide rail comprises a portal frame, a workbench, a machine tool guide rail and a base. A driving assembly frame is transversely fixed to the portal frame and provided with a grinding wheel, two driving mechanisms which are capable of moving transversely and longitudinally are arranged on the left side and the right side of the front face of the driving assembly frame, the grinding wheel can rotate on the driving mechanisms, the driving mode of the workbench is the hydraulic driving mode, the workbench comprises two layers, the bottom face and the side faces of the machine tool guide rail are all fixed to the base, the side faces of the machine tool guide rail are covered with covering plates, the contact faces between the covering plates and the side faces of the U-shaped ends of the base and the contact faces between the covering plates and the machine tool guide rail are provided with lubricating oil grooves, and through lubricating oil grooves are formed in the top of the guide rail face of the machine tool guide rail. After the scheme is adopted, the inclined faces of a V-shaped groove of the dovetail guide rail can be ground fully, the precision of ground products is higher, the driving stability of the workbench of the grinding machine tool can be guaranteed, and the service life of the machine tool is longer.

Owner:浙江瑞远数控设备股份有限公司

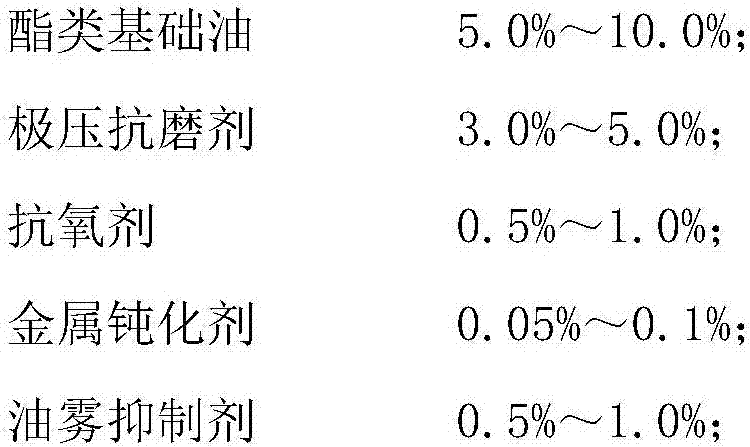

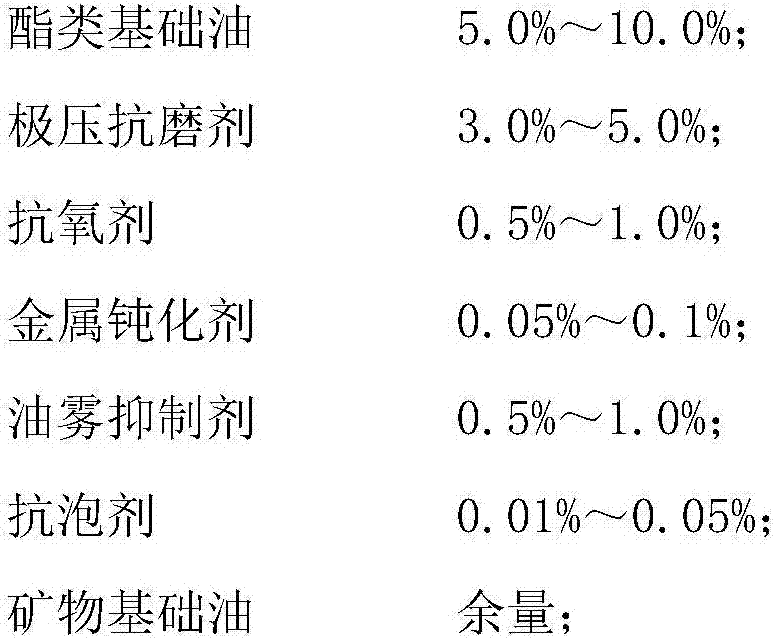

Environmentally-friendly super-finishing grinding oil and preparation method thereof

The invention relates to environmentally-friendly super-finishing grinding oil and a preparation method thereof. The environmentally-friendly super-finishing grinding oil is prepared from, by weight, 5.0%-10.0% of ester base oil, 3.0%-5.0% of an extreme-pressure and anti-wear agent, 0.5%-1.0% of an antioxygen, 0.05%-0.1% of a metal desactivation agent, 0.5%-1.0% of an oil mist inhibitor, 0.01%-0.05% of an anti-foaming agent and mineral base oil balance. The sum of the percentages of the above components is 100%. The environmentally-friendly super-finishing grinding oil has high lubrification, cooling, rust protection and corrosion protection performances; meanwhile, heavy metals, chlorine and low oil mist do not exist in the environmentally-friendly super-finishing grinding oil, so that the environmental-friendly super-finishing grinding oil is harmless to an operator and the environment.

Owner:辽宁海华科技股份有限公司

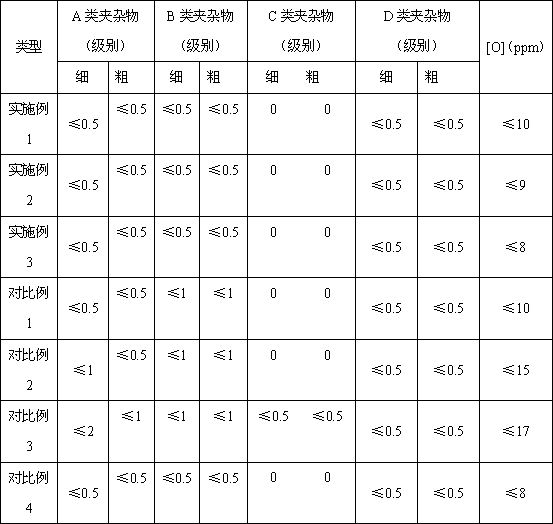

Manufacturing method of low-oxygen low-inclusion bearing steel

The invention discloses a manufacturing method of low-oxygen low-inclusion bearing steel. The manufacturing method comprises the steps of preparing of raw materials, converter smelting and alloying, LF+VD refining, continuous casting, rolling and slow cooling, wherein the mass percent of chemical components of the bearing steel in content is controlled to reach the standards of 1.06-1.1% of C, 0.7-0.75% of Si, 1.30-1.35% of Mn, 0.02-0.05% of Mo, 0.06-0.08% of Ni, 1.85-1.9% of Cr, 0.02-0.04% of Co, 0.02-0.03% of V, 0.01-0.03% of Als, 0.02-0.03% of Hf, 0.01-0.02% of Ta, 0.005-0.008% of Te, 0.05-0.1% of Cu, less than or equal to 0.025% of S, less than or equal to 0.025 of P, less than or equal to 10*10<-6> of O, less than or equal to 2*10<-6> of H and the balance Fe and inevitable impurities.According to the manufacturing method of the low-oxygen low-inclusion bearing steel smelting, the raw materials, the refining process, refining slag, crystallizer casting powder and the continuous casting process are controlled, so that the content of the obtained non-metal impurities of the bearing steel is low, and the content of the Ti is low; the phenomenon of nozzle nodulation is avoided inthe continuous casting process of square billets, blank throwing is smooth, the solidification speed of a blank shell is high, and safety of continuous casting is ensured, so that a final product is uniform in component, stable in performance and good in strength; and after heat treatment, the yield strength reaches 700 MPa, the tensile strength reaches 910 MPa, and the elongation at the cross section reaches 35%.

Owner:温州市赢创新材料技术有限公司

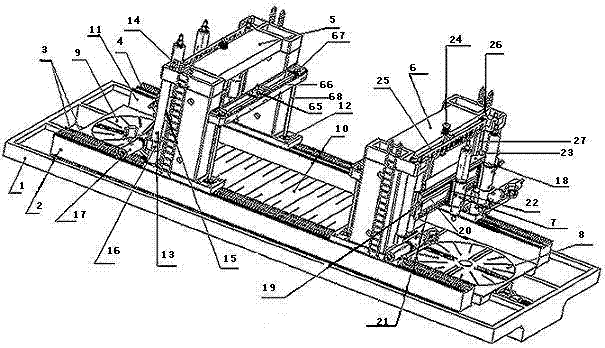

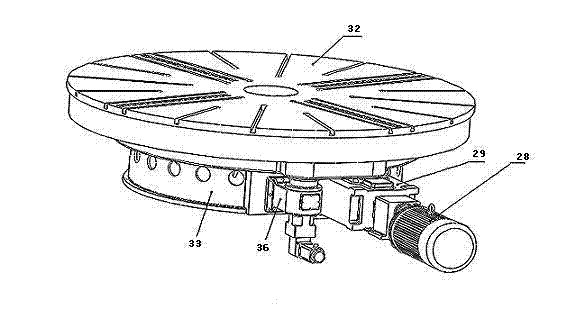

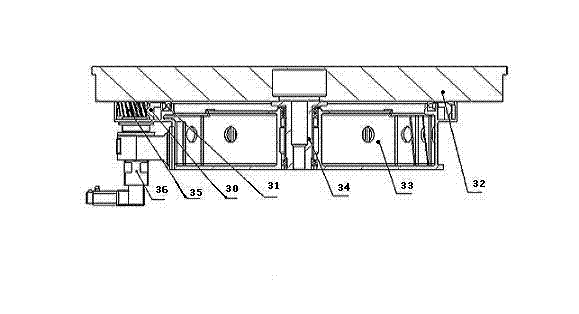

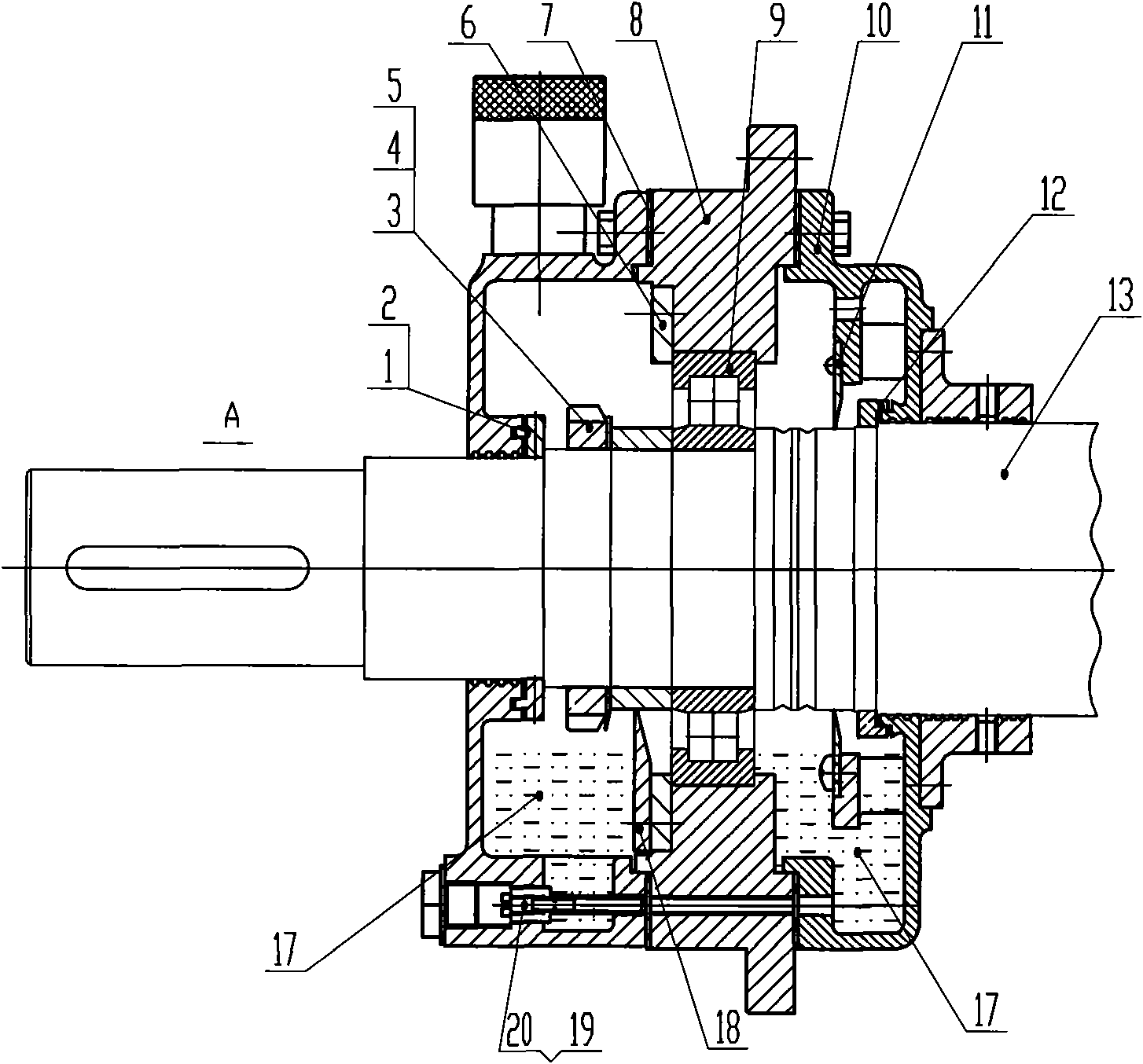

Gantry-movable drilling, boring and milling compound machine tool

InactiveCN102862053AGuaranteed lubrication effectGuaranteed long-termOther manufacturing equipments/toolsLarge fixed membersNumerical controlThick wall

A gantry-movable drilling, boring and milling compound machine tool is guided by matching of typical cylinders and cylindrical sliding sleeves and adopts a stepless variable frequency speed regulation mechanism and a numerical control mode. Large-scale swing bearings are adopted for support and rotation of workbenches. In the material aspect, vertical column guide rails and cylindrical movable cutters are manufactured by structural alloy steel thick-walled seamless pipes and are subjected to grinding and hard chromium plating, and the workbenches are casted by ductile cast iron. The gantry movable drilling, boring and milling compound machine tool has the advantages that the machine tool can be used for drilling and boring and has functions of excircle, inner bore, section and curved surface turning, flat surface, inclined surface, curved surface and groove milling, thread tapping and the like, lubrication, dust prevention and durability of the guide rails are guaranteed, and long-term precision is maintained. Double gantries are movable, work efficiency can be improved by machining long and large pieces by the juxtaposed double gantries together, the large-scale rotating workbenches additionally arranged at two ends can be used as two numerical control lathes, equipment utilization rate is increased, and the gantry-movable drilling, boring and milling compound machine tool is simple in structure and can meet customer machining requirements particularly when parts are large in machining face and machining length.

Owner:SHANDONG YIXIN HEAVY MACHINERY MFG

PVC waterproof coiled material and preparation process thereof

InactiveCN101962458AFlame retardantAnti-corrosionRoof covering using flexible materialsProtective foundationFilling materialsRed mud

The invention discloses a PVC (polyvinyl chloride) waterproof coiled material. The PVC waterproof coiled material is characterized in that: boric sludge or red mud serving as a filling material is added into raw materials of the PVC waterproof coiled material, and the mass percent of the adding amount of the boric sludge or the red mud in the raw materials of the PVC waterproof coiled material to the adding amount of PVC resin is 40-50: 100. The PVC waterproof coiled material has the advantages of flame resistance, corrosion resistance and color exposure; the boric sludge or the red mud serving as the filling material in the PVC waterproof coiled material remarkably improves the use stability and ageing resistance of the PVC waterproof coiled material, and increases the functions of corrosion resistance, fire resistance, self cleaning and the like. A preparation process for the PVC waterproof coiled material is simple, and the boric sludge or the red mud used as the common filling material only needs to be blended.

Owner:北京立高科技股份有限公司 +1

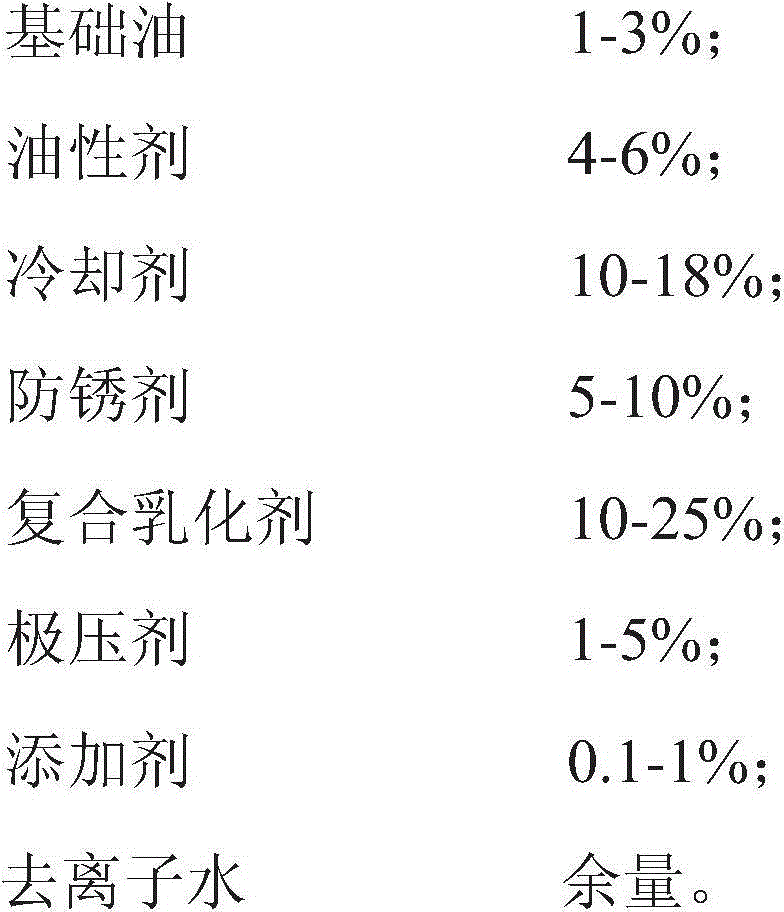

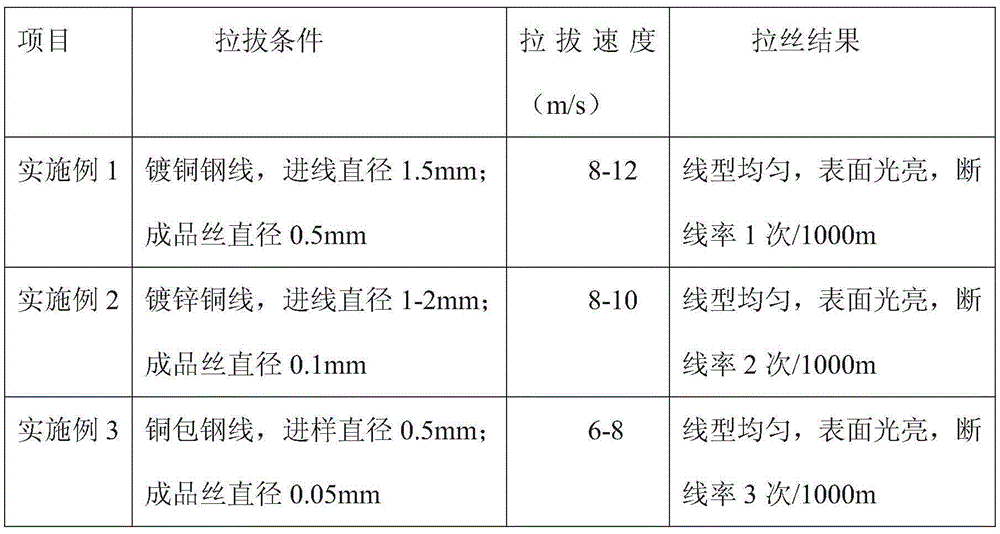

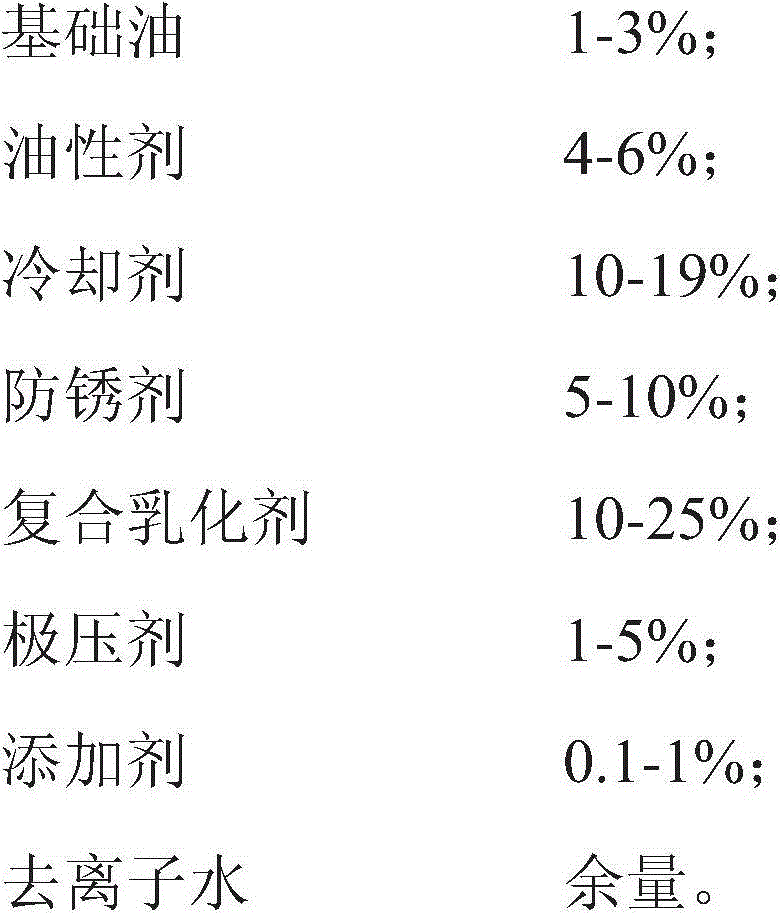

Semi-synthetic metal wire drawing lubricant liquid and preparation method thereof

InactiveCN104450120AImprove the lubrication effectLess friction residueLubricant compositionSurface finishNonferrous metal

The invention discloses a semi-synthetic metal wire drawing lubricant liquid, which comprises base oil, an oiliness agent, a cooling agent, an antirust agent, a compound emulsifier, an extreme pressure agent, an additive and deionized water. According to the semi-synthetic metal wire drawing lubricant liquid disclosed by the invention, the defects in the prior art are overcome; the drawing speed can be increased; the abrasion of a drawing mold is reduced; the breeding of bacteria is inhibited; the lubrication in the drawing process is ensured; the surface smoothness of a product is improved; the semi-synthetic metal wire drawing lubricant liquid is especially suitable for rapid drawing of nonferrous metals; and the oxidation of the nonferrous metals can be well prevented by a protective film formed in the drawing process.

Owner:苏州禾川化学技术服务有限公司

Thin oil-lubricated bearing device for horizontal motor

InactiveCN101924412ALow viscosityGuaranteed lubrication effectBearing componentsSupports/enclosures/casingsFixed bearingRespirator

The invention relates to a thin oil-lubricated bearing device for a horizontal motor. The thin oil-lubricated bearing device for the horizontal motor is characterized in that: a motor shaft is arranged in a bearing bush; a gasket, a respirator, a respiratory tube and an oil duct are arranged on an outer cover of a bearing; a fixed bearing retainer ring, the outer cover of the bearing, an inner cover of a bearing, and a semi-ring are arranged on the bearing bush; a fixed baffle plate is arranged on the inner cover of the bearing; and an outer cover oil throwing disk, a rolling bearing, a round nut, a sleeve and an inner cover oil throwing disk are fixed on the motor shaft sequentially. The thin oil-lubricated bearing device for the horizontal motor has the advantages of completely guaranteeing the lubricating of the bearing of the horizontal motor with heavy load and high rotating speed due to thin oil lubrication and effectively improving the permissible working rotating speed of the motor bearing and prolonging the service life of the motor bearing, along with compact and reasonable structure.

Owner:WUXI ZHONGDA MOTORS

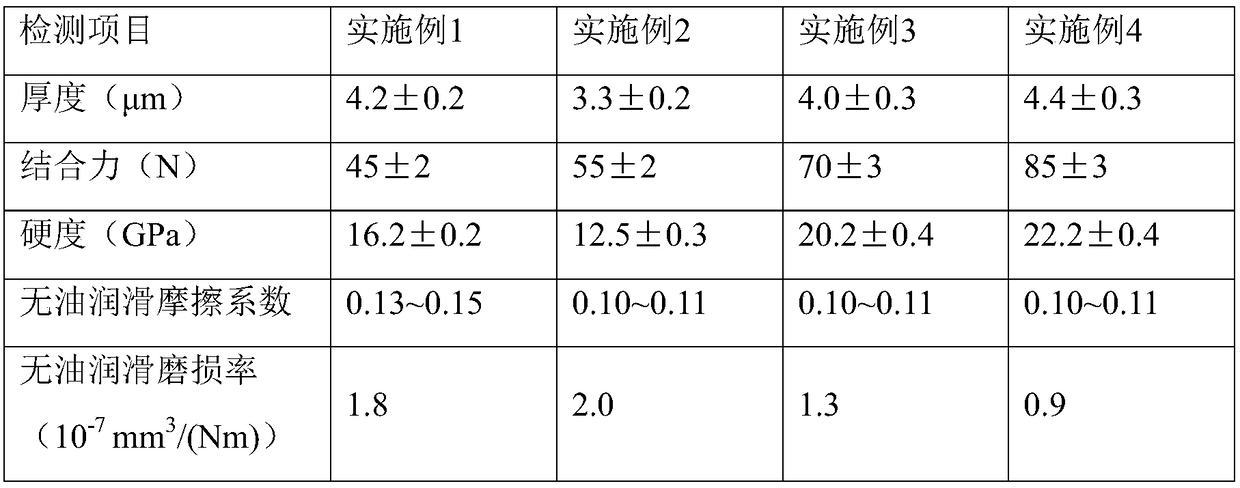

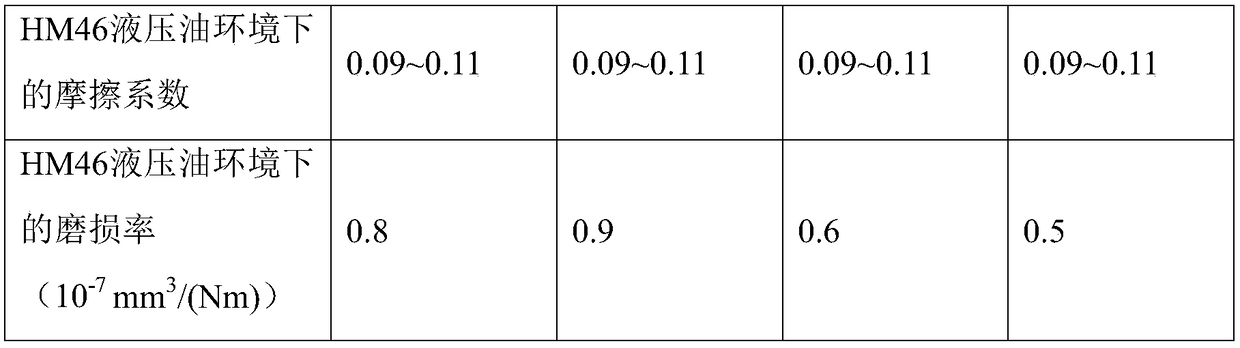

Surface anti-impact abrasion-resisting lubricating composite coating for hydraulic valve rod and preparation method thereof

ActiveCN109023362AExtended service lifeIt has the treatment effect of impact resistance, wear resistance and lubrication integrationVacuum evaporation coatingSputtering coatingFriction reductionComposite function

The invention discloses a surface anti-impact abrasion-resisting lubricating composite coating for a hydraulic valve rod. The coating is composed of a gradient transition layer, a composite multifunctional layer and an amorphous carbon top layer which are sequentially arranged on the surface of a substrate in a stacked mode front bottom to top, and the total thickness is controlled to be 3.0-5.0 microns. The invention further provides a preparation method of the composite coating, the gradient transition layer is prepared through the magnetron sputtering technology or the arc ion plating technology, the composite multifunctional layer is prepared through the magnetron sputtering technology, and the amorphous carbon top layer is prepared through the magnetron sputtering technology or the plasma chemical vapor deposition technology. The surface hardness of the surface anti-impact abrasion-resisting lubricating composite coating for the hydraulic valve rod is larger than or equal to 12 GPa, the friction coefficient is lower than 0.15, high hardness, high toughness, abrasion resistance and friction reduction are integrated, the coating can be better applied to severe working conditions, high-reliability and long-life operation of the hydraulic valve rod is achieved, the coating-plating process is simple, and application value is large.

Owner:中国人民解放军空军勤务学院

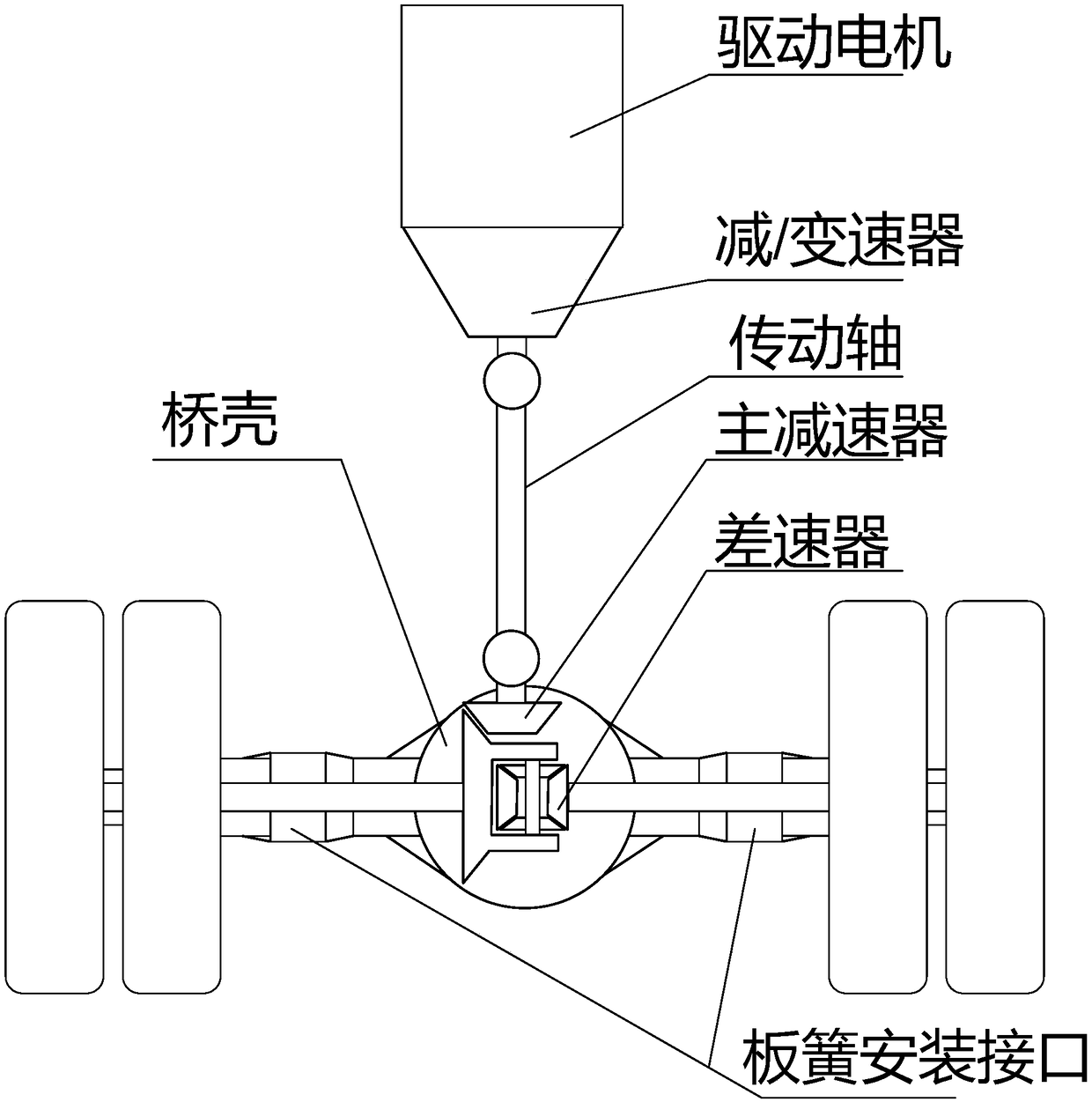

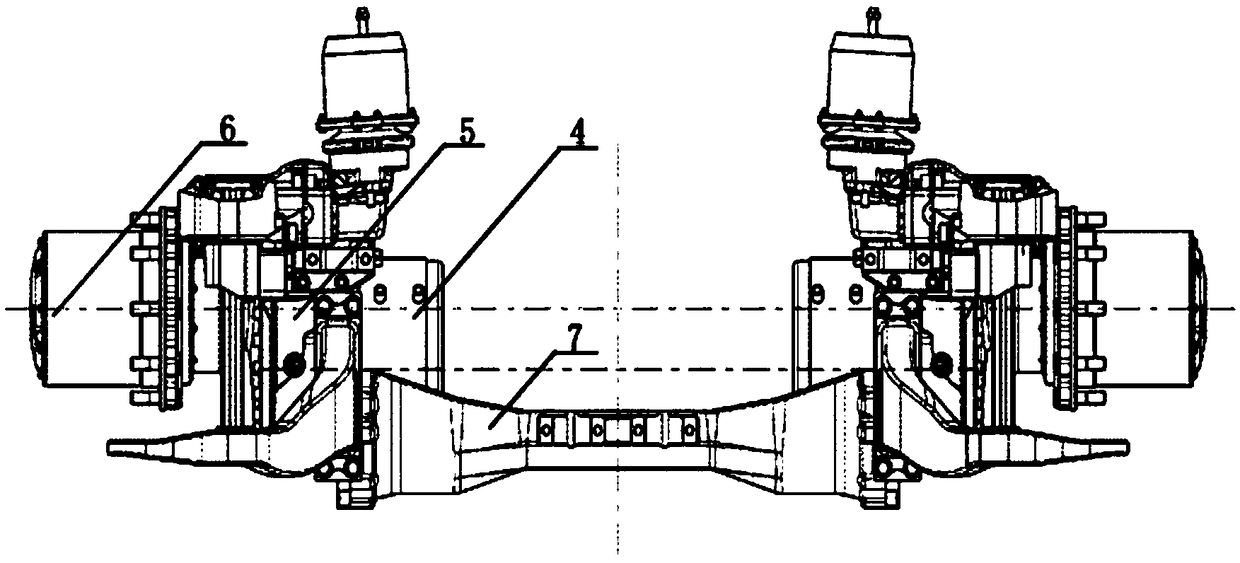

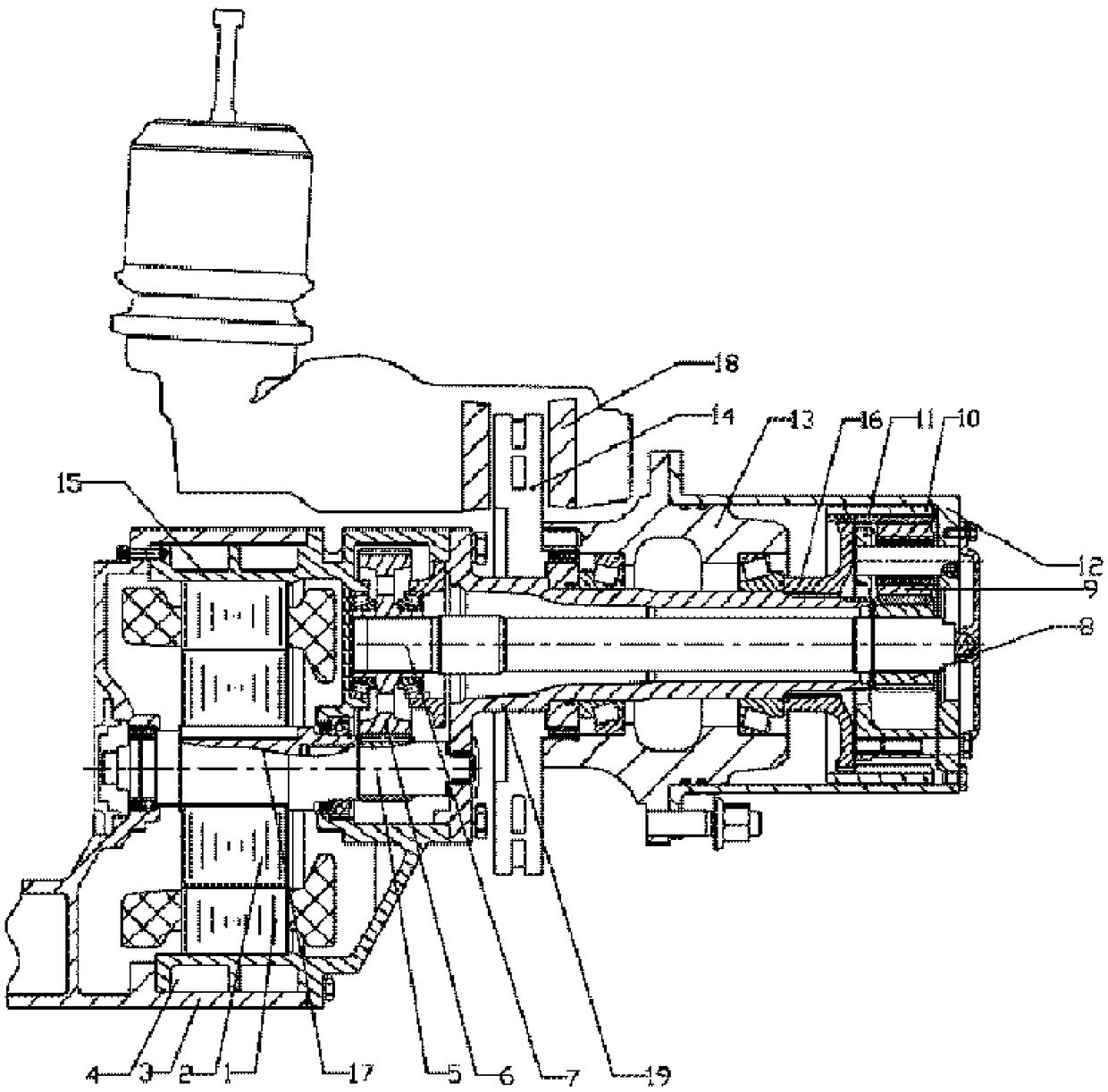

Low-floor electric axle assembly

ActiveCN108638839APromote wideningImprove transmission efficiencyBraking element arrangementsToothed gearingsShaped beamHigh transmission

The invention provides a low-floor electric axle assembly. The low-floor electric axle assembly comprises an axle shell, hub motors, a planetary gear reduction gearbox, a wheel hub, braking systems, aC-shaped beam and a suspension system. The mechanical installation of the suspension system is compatible with a traditional axle. The layout form of the braking system, the hub motors and the planetary gear reduction gearbox can widen the width of a bus lane. According to the low-floor electric axle assembly, the motor is coaxially arranged on the axis of a wheel in a rim, the first-stage transmission of a cylindrical gear, a bevel gear or a hypoid gear is removed, the planetary gear reduction gearbox with a variable structure is adopted to ensure high transmission ratio and transmission efficiency, and the braking systems are arranged at both ends of the axle inside the motor, the space at both ends of the axle can be fully used to form the low-floor electric axle assembly.

Owner:南京清研易为新能源动力有限责任公司

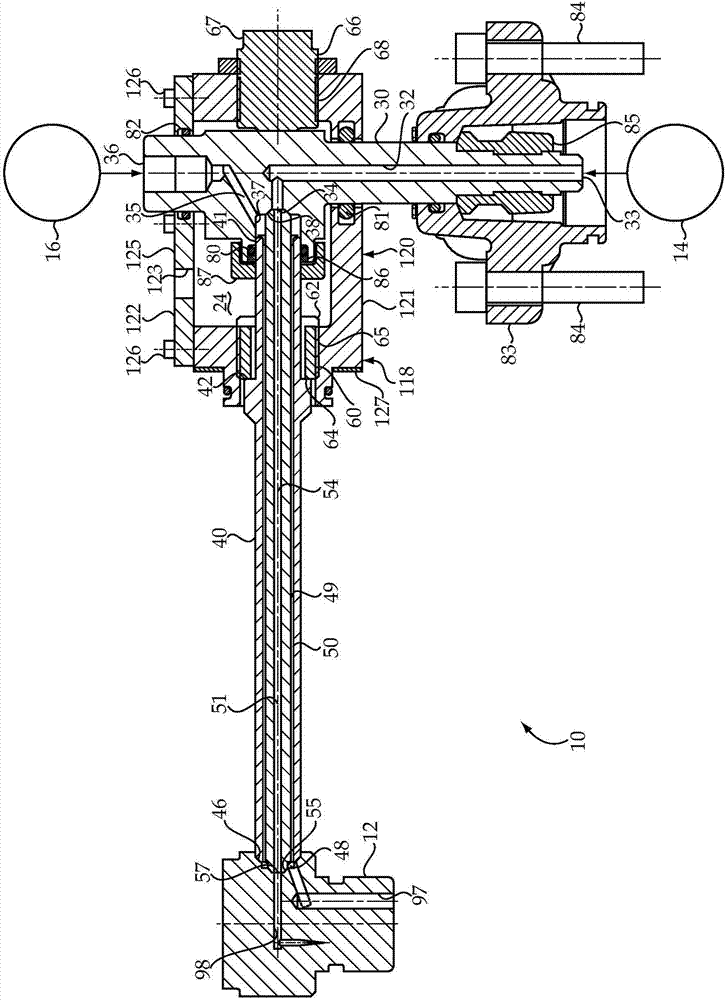

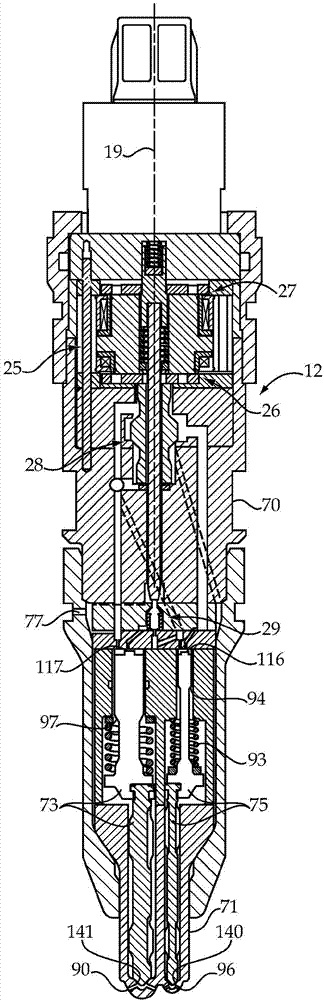

Fuel injector for dual fuel common rail system

InactiveCN103782021AGuaranteed lubrication effectDelicate cross-leakage problemInternal combustion piston enginesEngine controllersCommon railLiquid fuel

A duel fuel system (10) includes a plurality of fuel injectors (12) that have a non-injection configuration, a liquid fuel injection configuration, a gaseous fuel injection configuration and a combined fuel injection configuration. Each of the fuel injectors (12) is fluidly connected to a gaseous fuel common rail (14) and a liquid fuel common rail (16). Each of the fuel injectors (12) includes a three way gas control valve (28) and a three way liquid control valve (29) that move along a common centerline (19). A gas control chamber (92) of each fuel injector (12) is fluidly connected to the liquid fuel common rail (16) by two passages (152, 154) in parallel when the gas control valve member (105) is in a first position corresponding to the non-injection configuration. The liquid control chamber (95) of each fuel injector (12) is also fluidly connected to the liquid fuel common rail (16) by two passages (150, 151) in parallel when the liquid control valve (29) is in a first position, again corresponding to the non-injection configuration.

Owner:CATERPILLAR INC

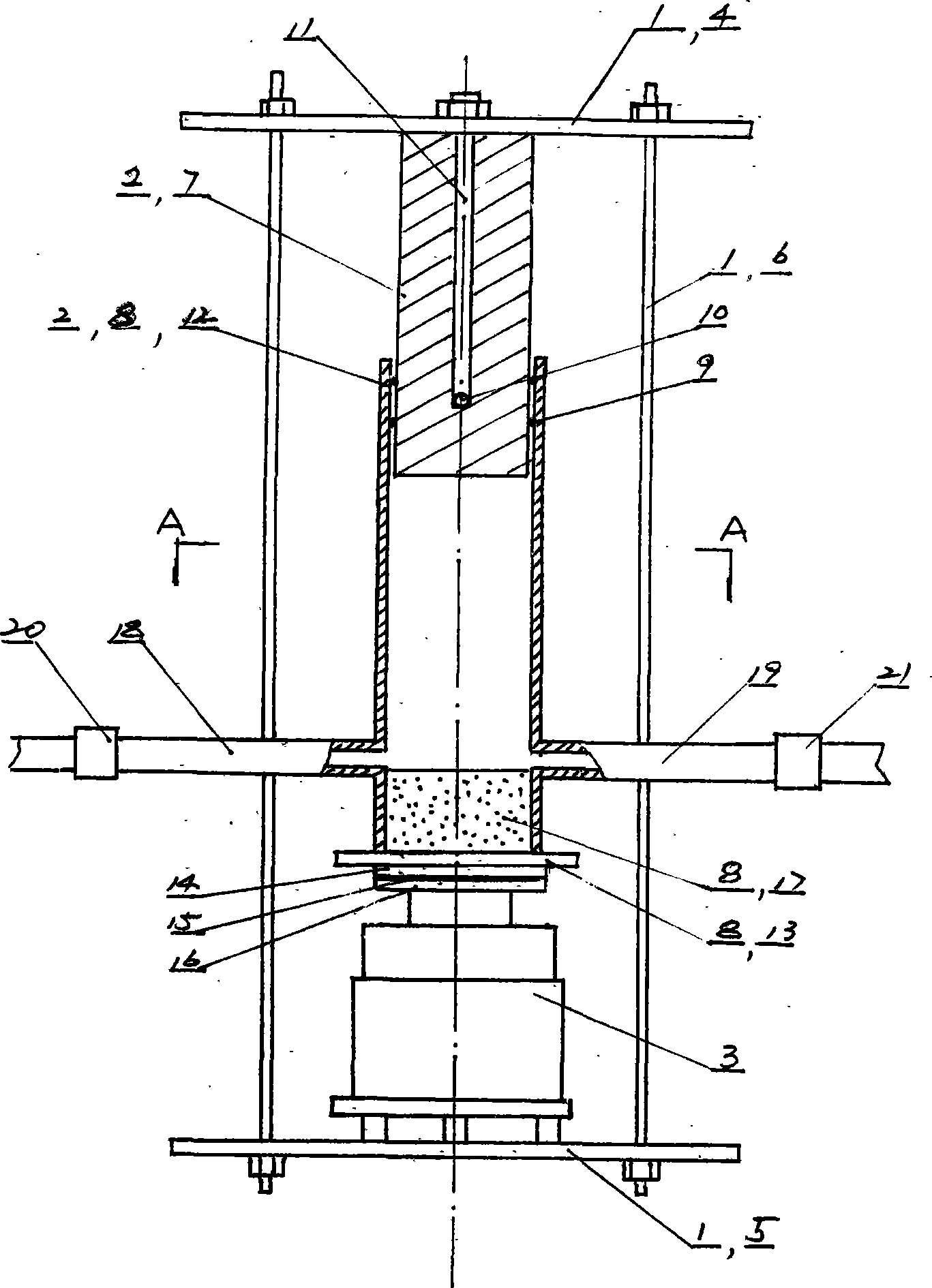

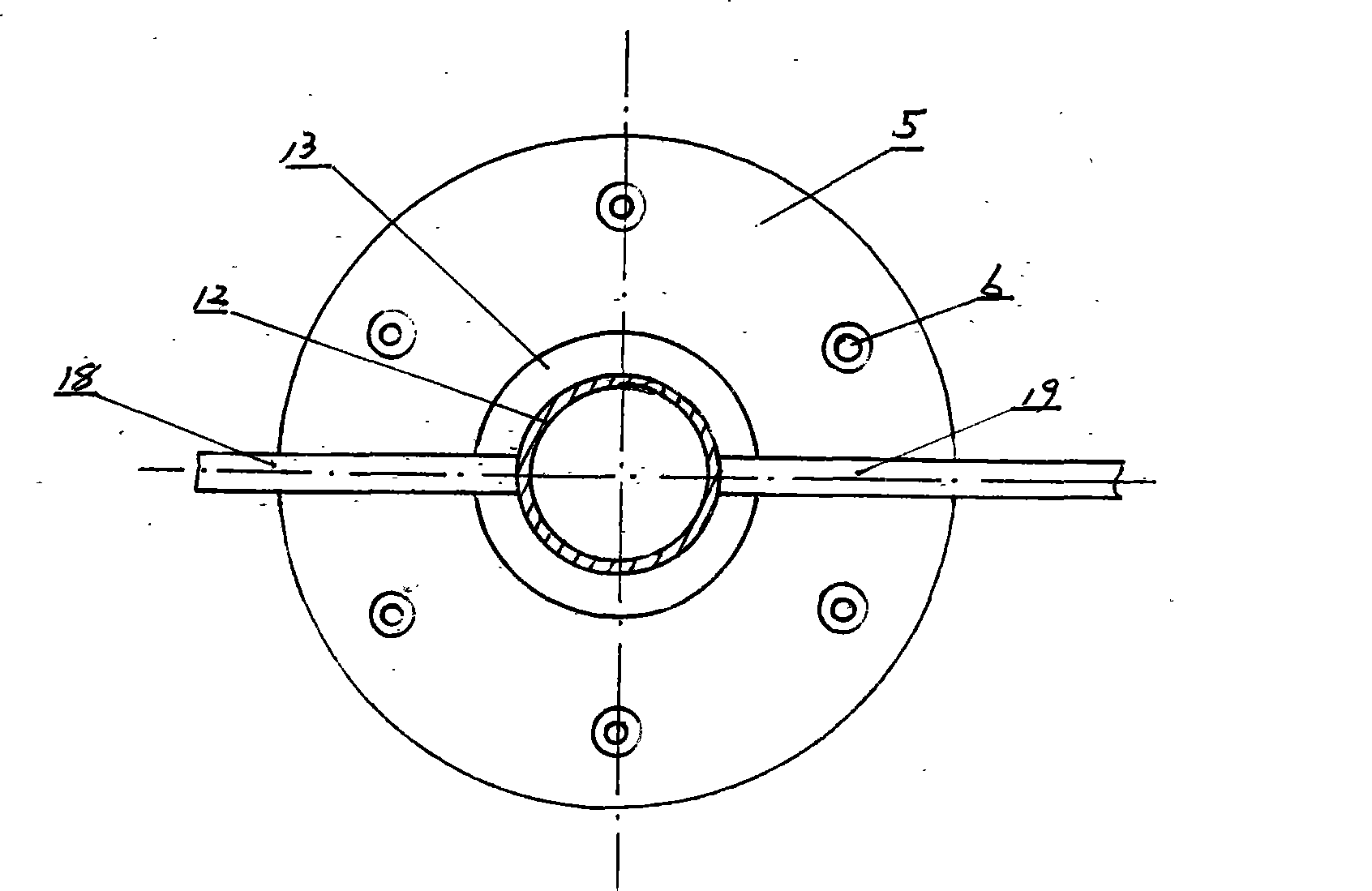

Inorganic material pressurization grouter used for mending concrete hole and seam

InactiveCN101429818AGuaranteed lubrication effectGood restorativeBuilding repairsCircular discRubber ring

The invention discloses an inorganic material pressure grouting machine for repairing holes and seams of concrete, which relates to a pressure grouting machine. The pressure grouting machine can generate powerful extrusion force, and can extrude slurry of an inorganic material into the holes and the seams of the concrete to guarantee the full repair of defects of the concrete. The pressure grouting machine comprises a support, a plunger cylinder and a jack, wherein the support comprises an upper round disk, a lower round disk and a plurality of bolts which are fixedly connected between the upper round disk and the lower round disk; the plunger cylinder comprises a plunger and a cylinder body, the upper end of the plunger is fixed under the upper round disk, the lower end of the plunger is inserted into the cylinder body, and the plunger and the cylinder body are glidingly connected by two sealing rubber rings; the plunger between the two sealing rubber rings is provided with a lubricating oil outlet; the cylinder body comprises a cylinder barrel, a cylinder bottom cover, and a rubber block; the cylinder bottom cover is arranged on the top end of the jack; the cylinder bottom cover in the cylinder barrel is provided with the rubber block; and the lower part of the cylinder barrel is provided with a slurry inlet pipe and a slurry outlet pipe. The pressure grouting machine is used for repairing the holes and the seams of the concrete by using inorganic slurry to overcome the defects caused by adopting organic material fillers.

Owner:王镇生 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com