Patents

Literature

223 results about "Hydraulic tappet" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

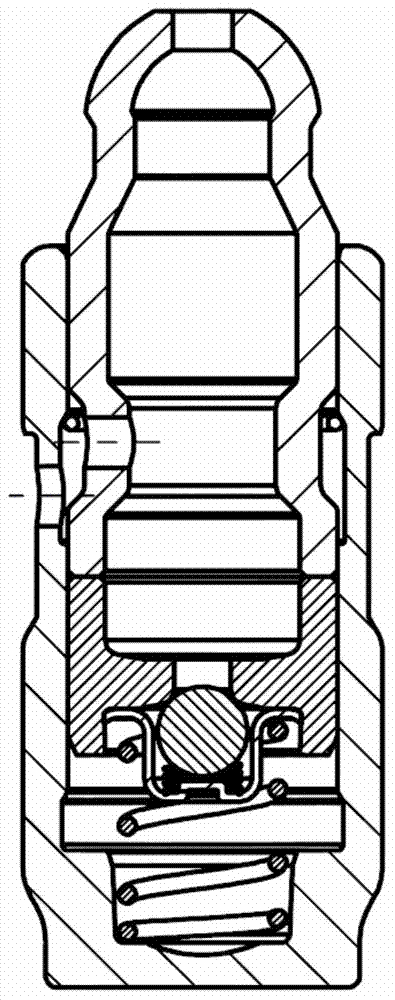

A hydraulic tappet, also known as a hydraulic valve lifter or hydraulic lash adjuster, is a device for maintaining zero valve clearance in an internal combustion engine. Conventional solid valve lifters require regular adjusting to maintain a small clearance between the valve and its rocker or cam follower. This space prevents the parts from binding as they expand with the engine's heat, but can also lead to noisy operation and increased wear as the parts rattle against one another until they reach operating temperature. The hydraulic lifter was designed to compensate for this small tolerance, allowing the valve train to operate with zero clearance—leading to quieter operation, longer engine life, and eliminating the need for periodic adjustment of valve clearance.

Variable valve timing system

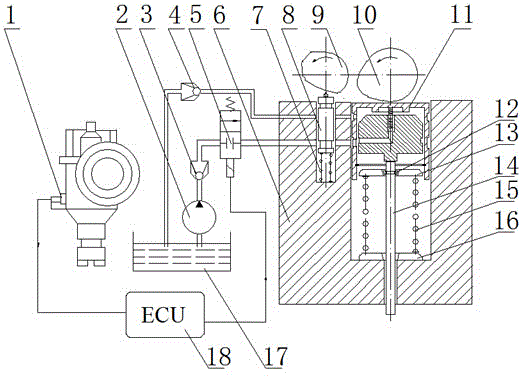

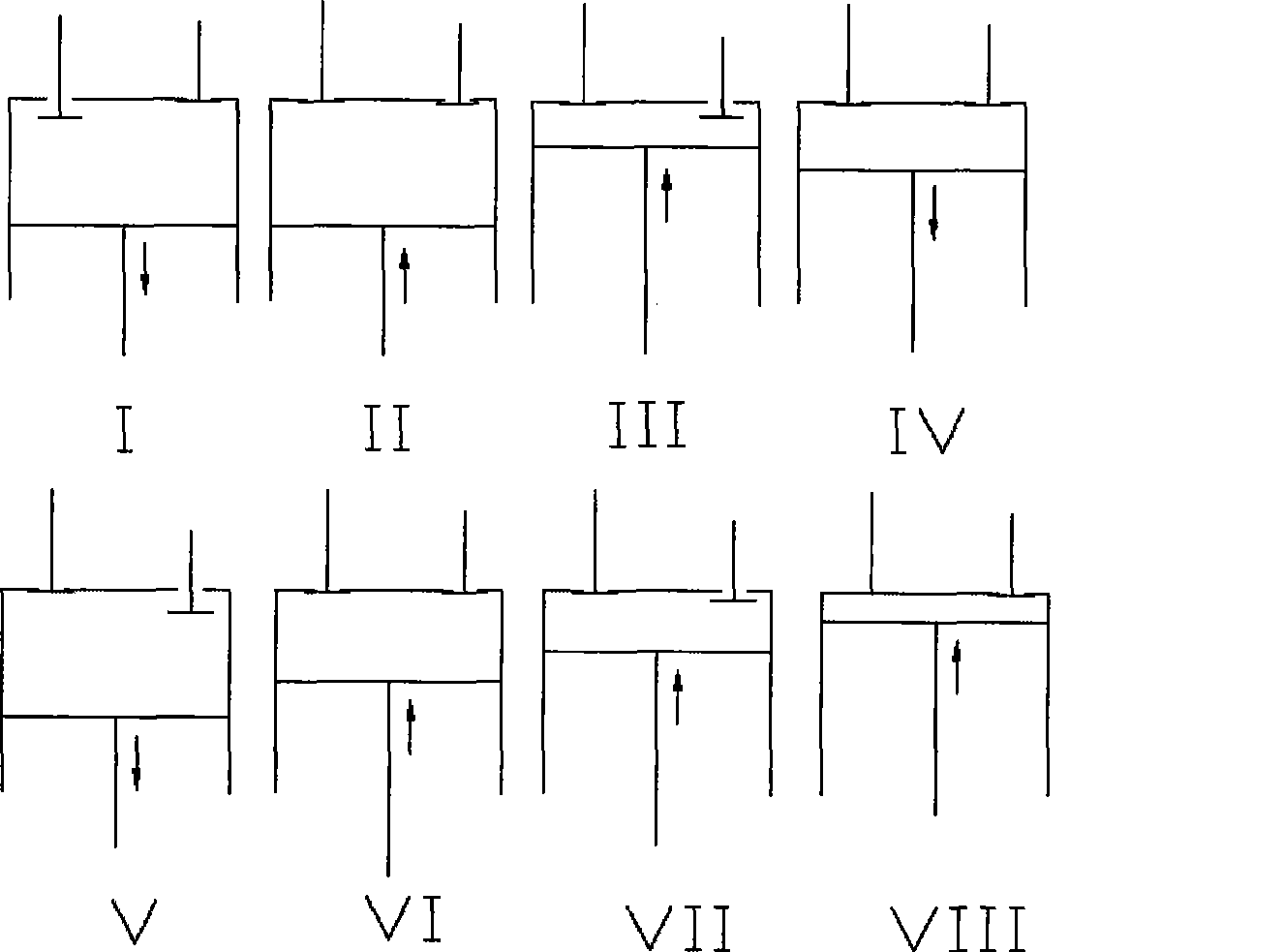

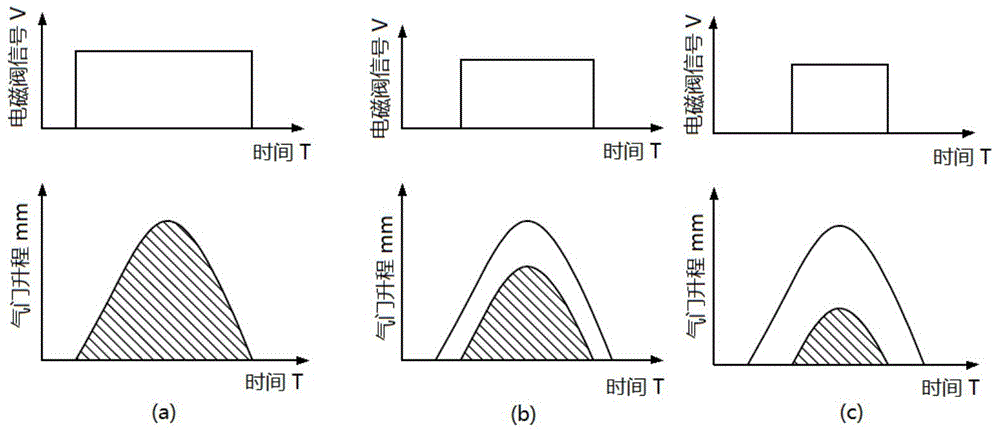

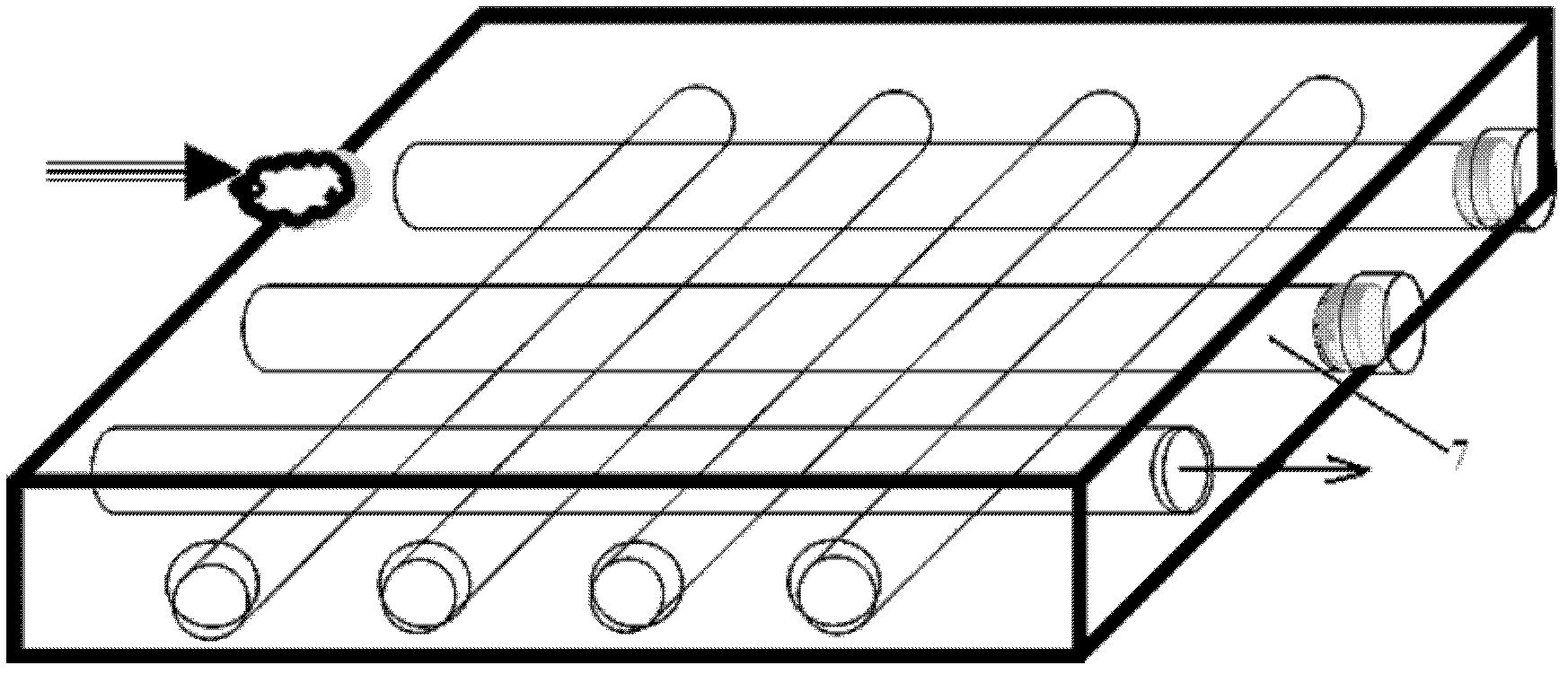

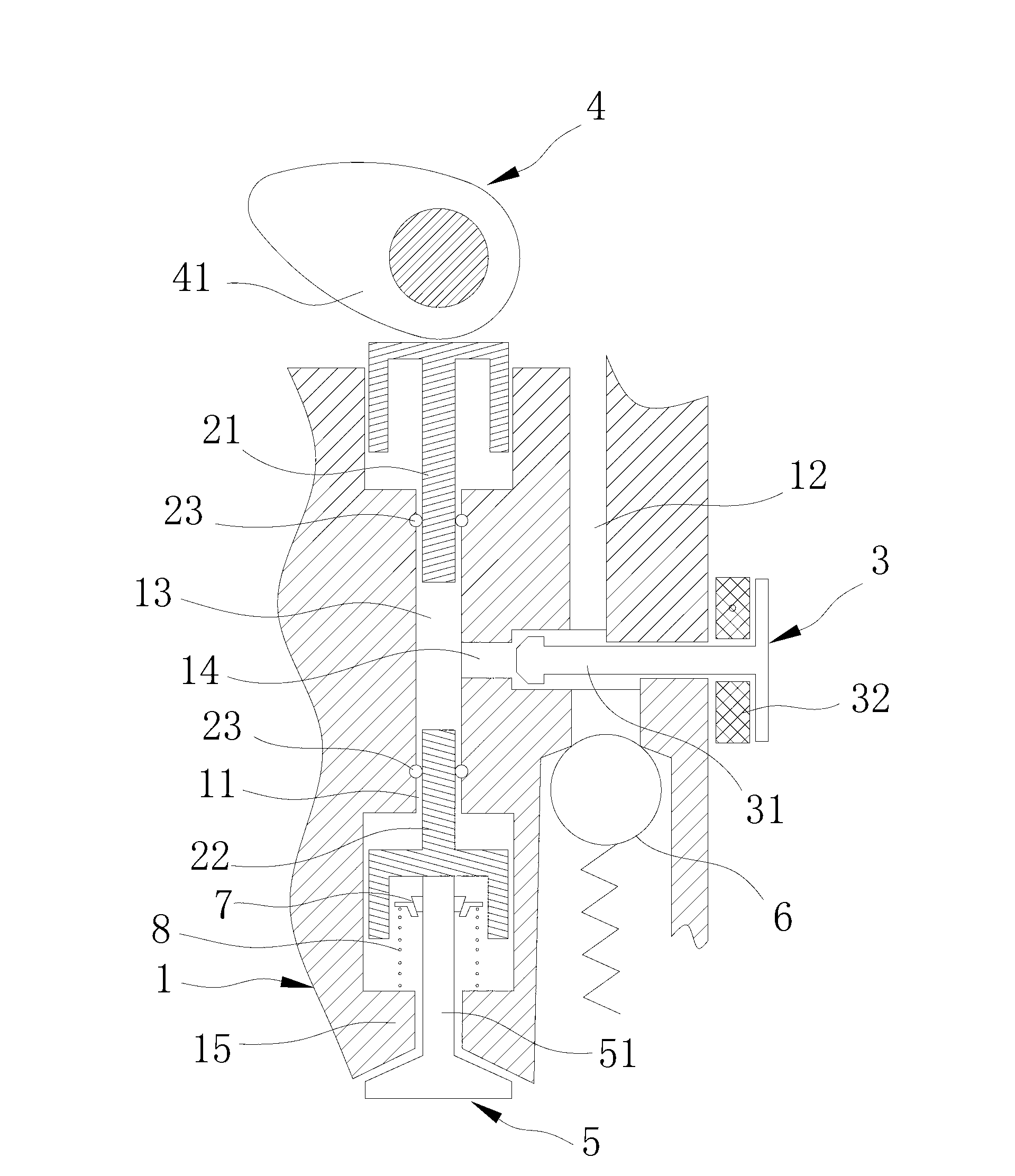

The invention discloses a variable valve timing system and relates to engines. According to the variable valve timing system, a variable lift hydraulic tappet component is arranged between an air inlet cam and an air inlet valve, an electronic device is used for judging the working conditions of an engine, when the engine speed is low, the pressure oil supply of an oil pump is cut off, the variable lift hydraulic tappet component only serves as a passive power transmission piece, the air inlet valve is only driven by the air inlet cam, and the air inlet valve has basic air valve opening / closing time, duration time and lift; when the engine speed is high, the pressure oil supply of the oil pump is opened, the variable lift hydraulic tappet component periodically charges and discharges oil under the indirect control of an air inlet valve oil distribution cam, the lift is changed, the air inlet valve is opened before the air inlet cam drive and closed after the drive, and the air inlet valve has air valve opening / closing time, duration time and lift under the high-speed working condition. The variable valve timing system is featured with compact structure, small valve seating impact and easiness in implementation.

Owner:ZHEJIANG NORMAL UNIVERSITY

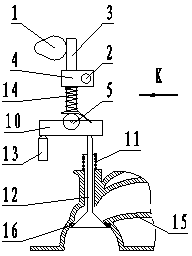

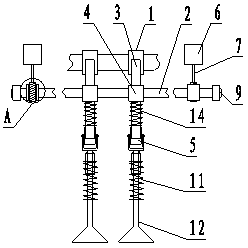

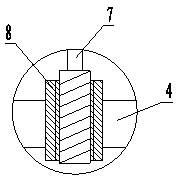

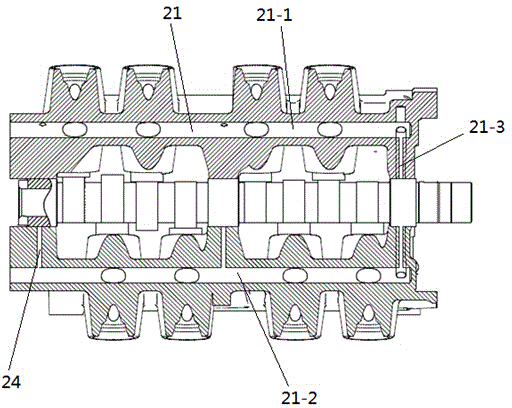

Sliding valve type two-mode engine intake valve delaying shutdown system

ActiveCN101377138AImprove performanceExtended service lifeMachines/enginesNon-mechanical valveInlet valveEngineering

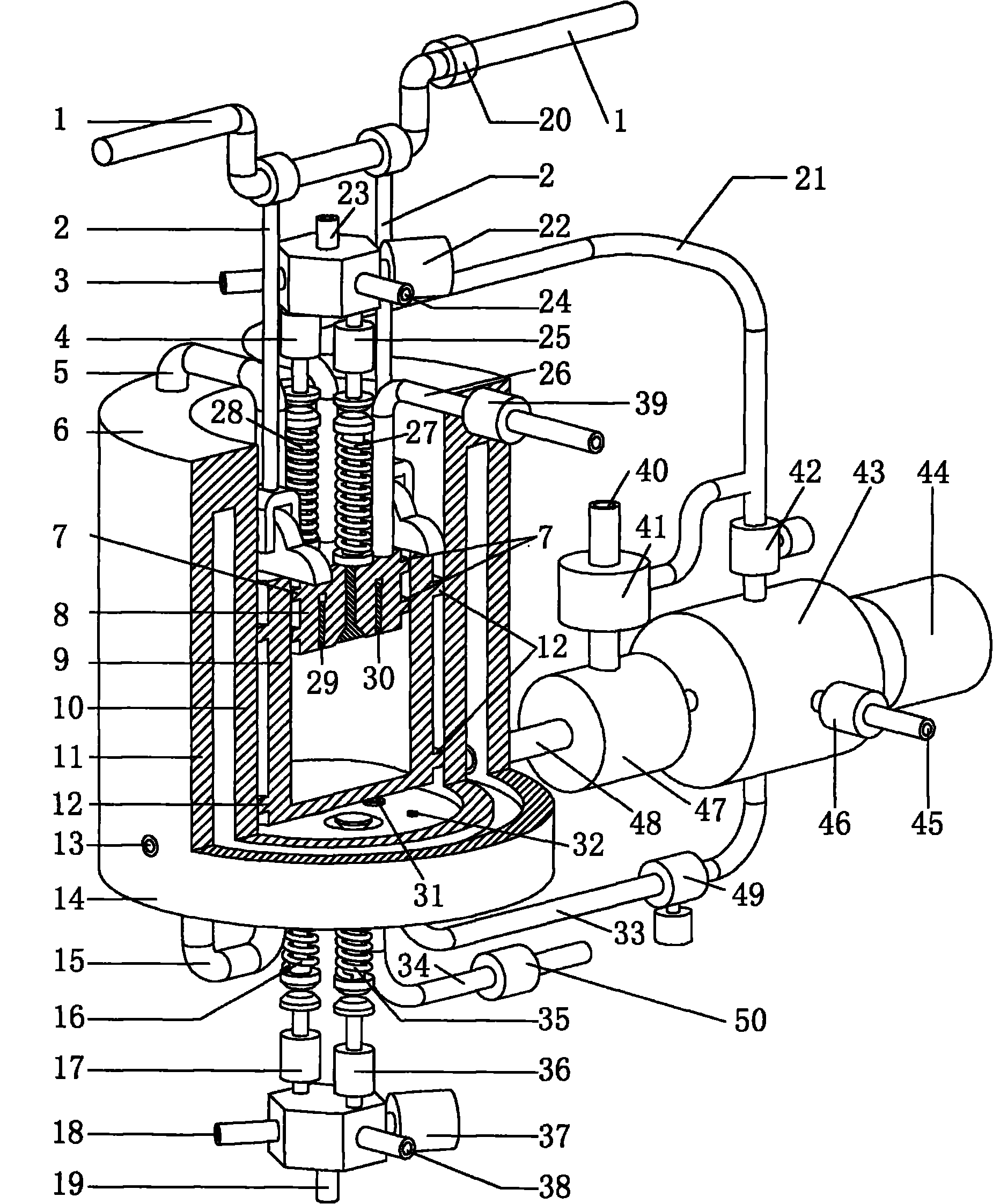

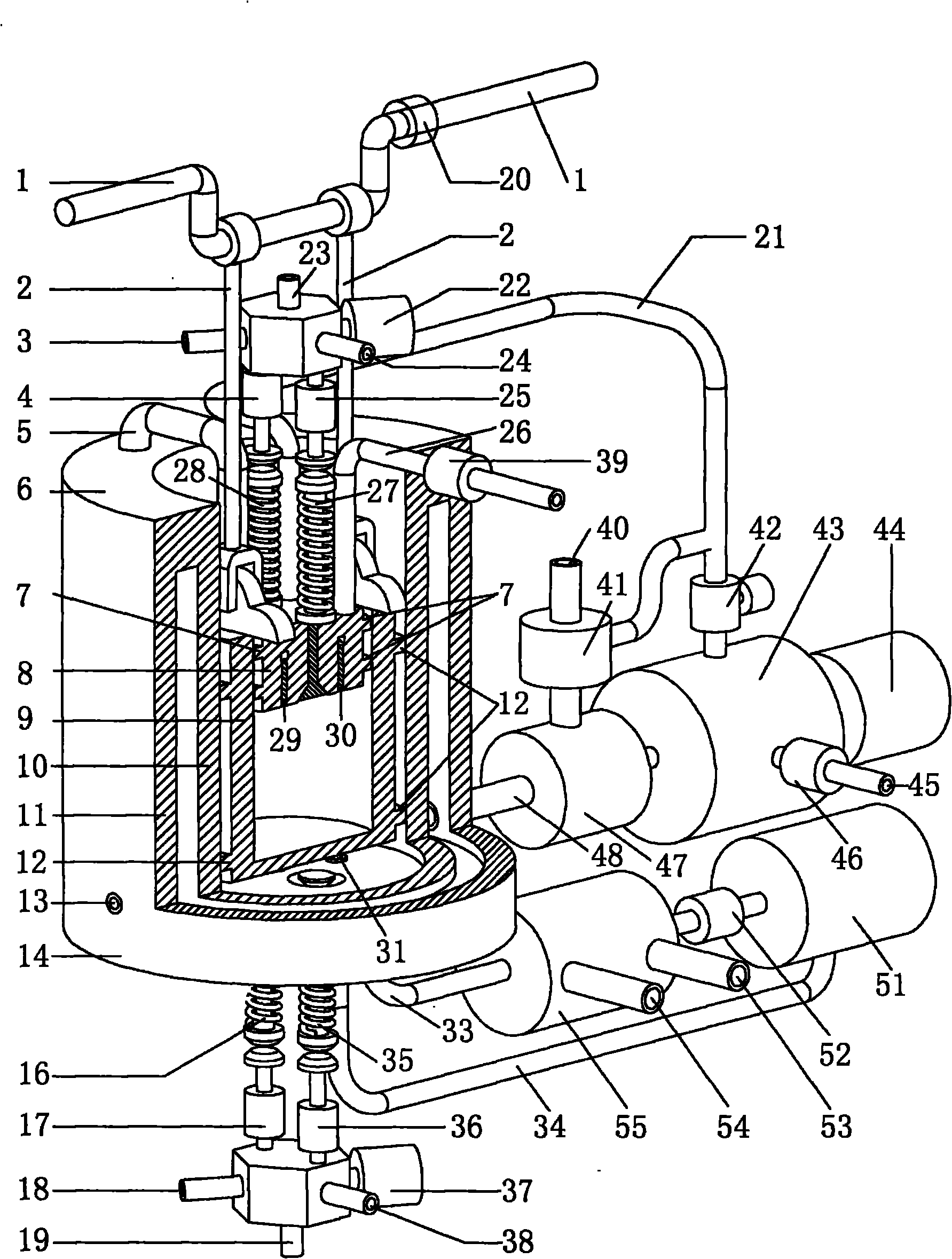

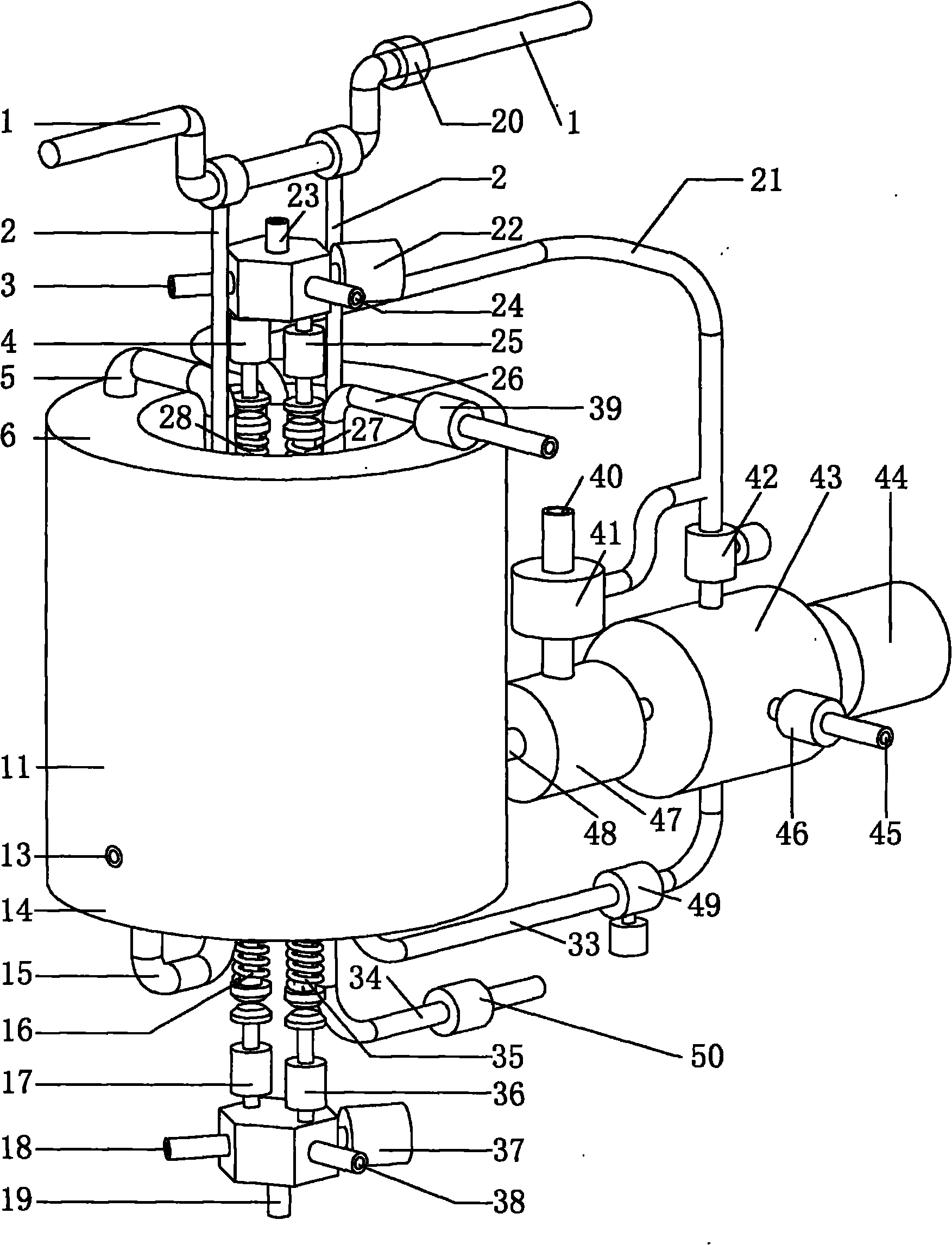

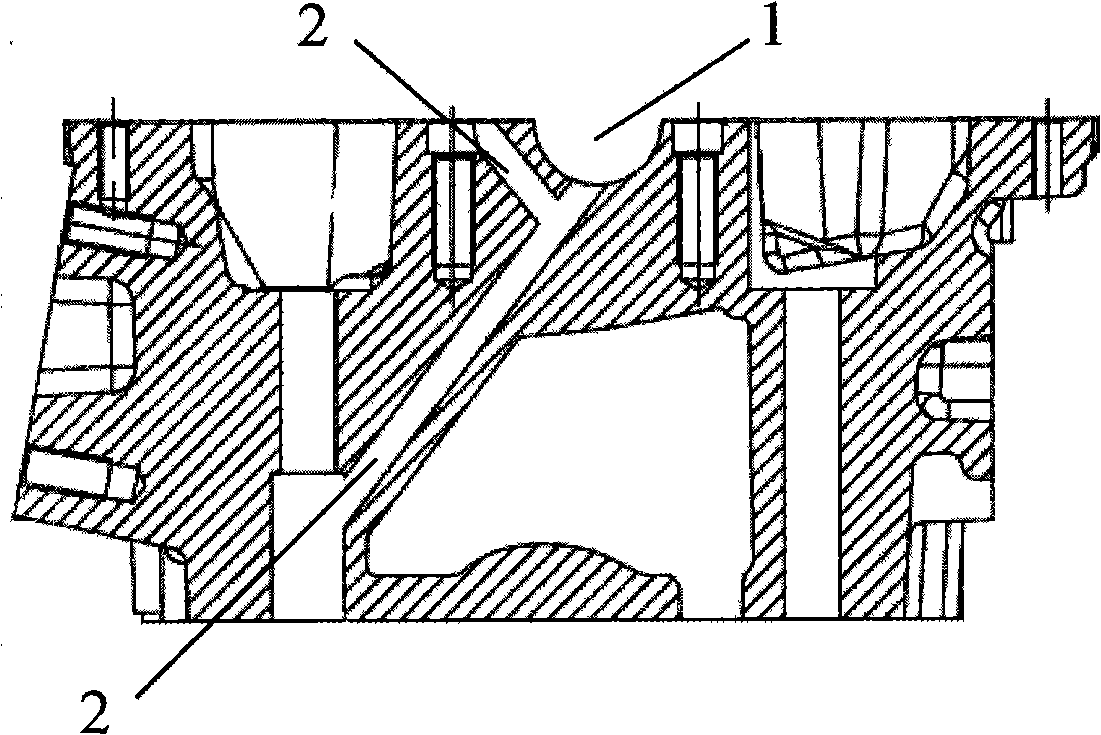

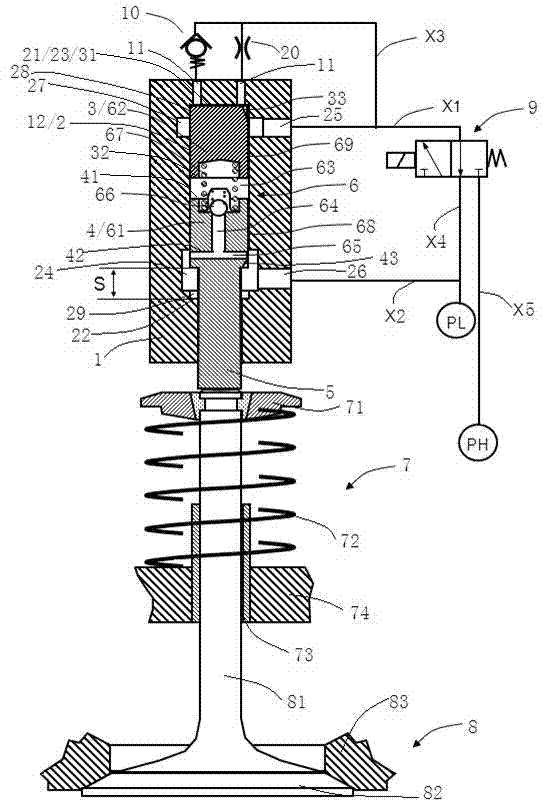

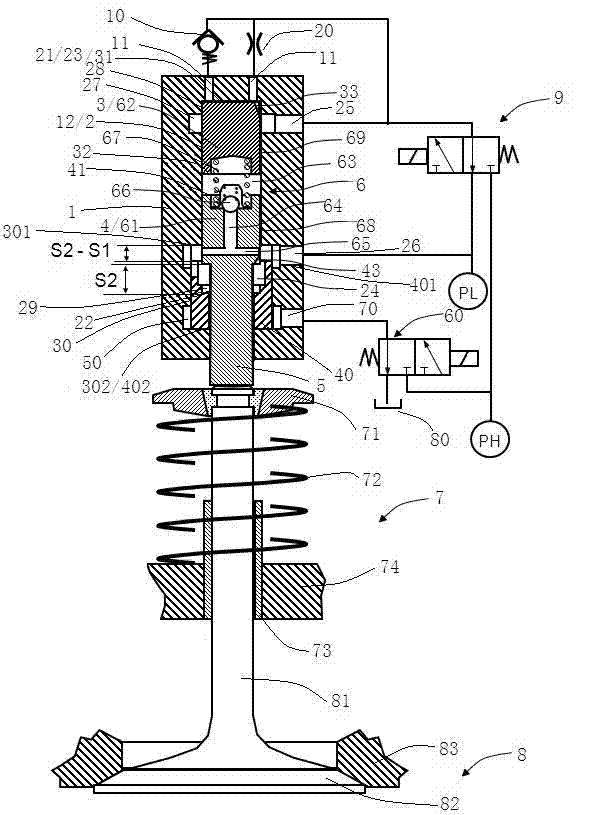

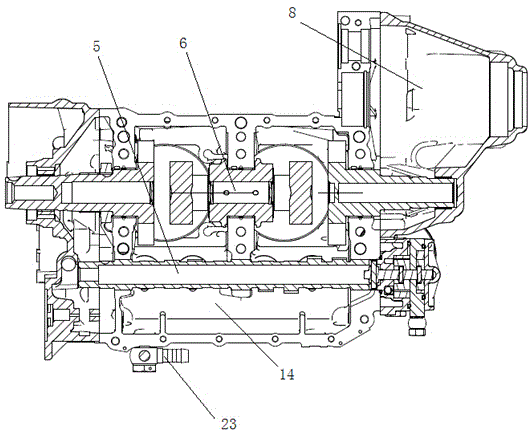

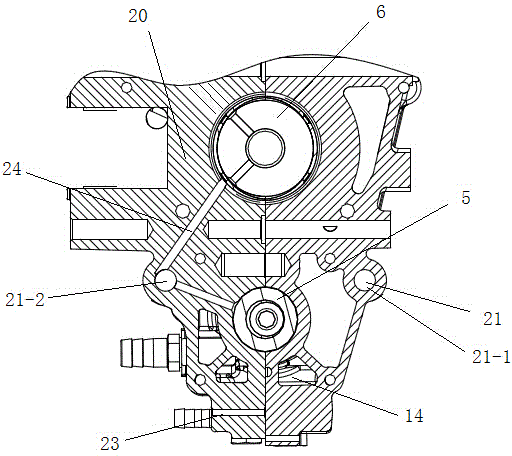

The present invention discloses a delayed closing system of an intake valve of a double-mode slide valve engine. The delayed closing system comprises a base, a hydraulic tappet assembly and an oil supply system; wherein, the hydraulic tappet assembly can slide up and down along the base; the top of the hydraulic tappet assembly is connected with a valve rocker; the lower end of the hydraulic tappet assembly is connected with an engine camshaft; the oil supply system supplies oil to the hydraulic tappet assembly; an oil-feeding assembly hole and oil-discharging assembly holes are formed on the hydraulic tappet assembly; an oil-feeding hole, one end of which is communicated with the oil supply system and the other end of which is communicated with the oil-feeding assembly hole of the hydraulic tappet assembly, is formed on the base; and oil-discharging holes, which are correspondingly communicated with the oil-discharging assembly holes of the hydraulic tappet assembly, are formed on the base as well. The delayed closing system, which has the advantages of few parts, simple structure, safe and reliable operation and low cost, can realize the mutually independent adjustment of the intake and exhaust of cylinders in order to exert the flexibility of intake phase adjustment to the max and optimize the performance of the engine, the operation process is controlled by a mechanic slide valve mode, the service lives of the elements are long, and the industrialization of the technique can be easily realized.

Owner:TIANJIN UNIV

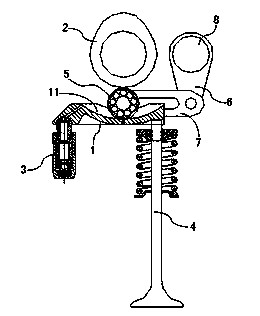

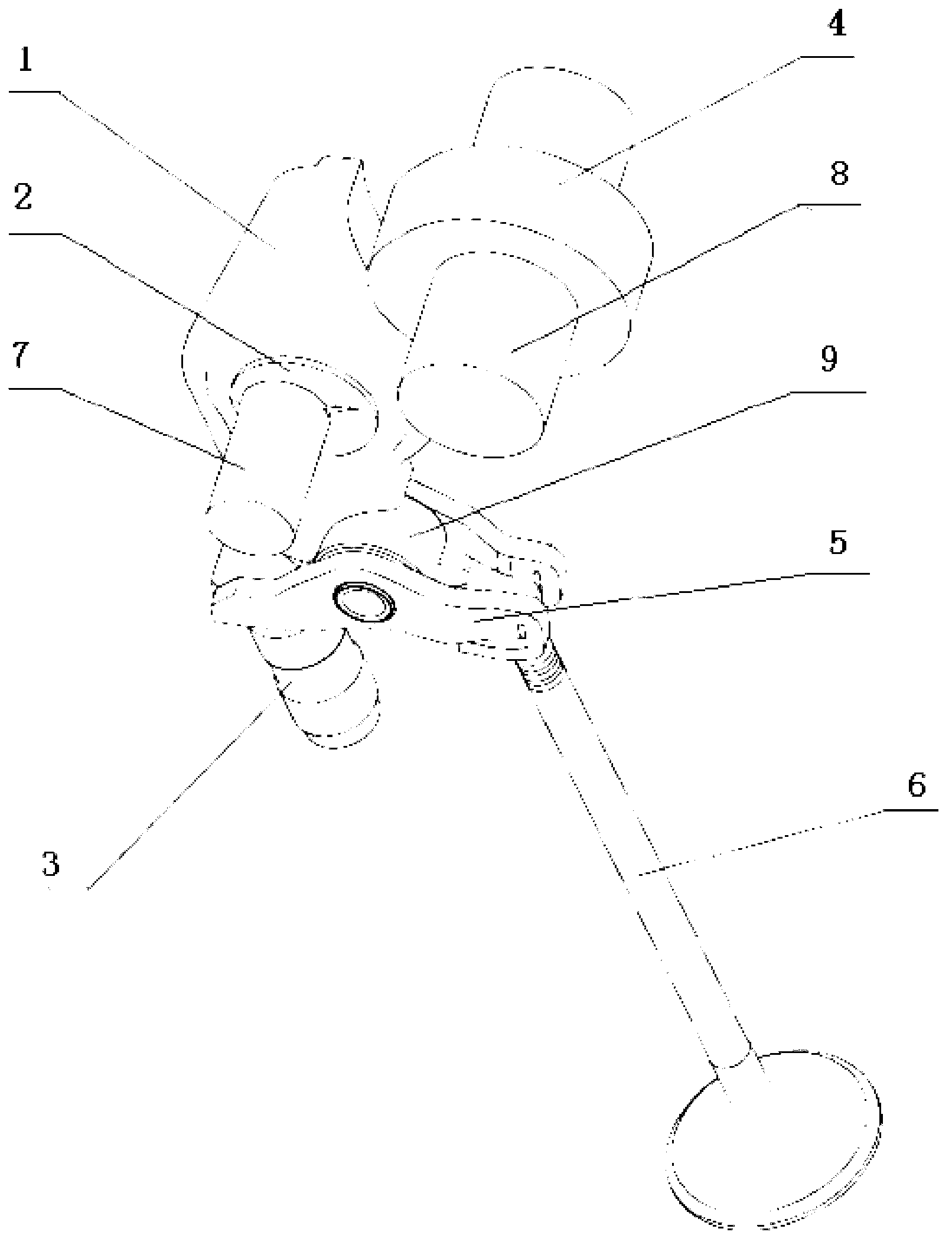

Springless poppet valve system

InactiveUS6487997B2Increase driving speedLess-costly to manufactureValve arrangementsMachines/enginesEngineeringCam

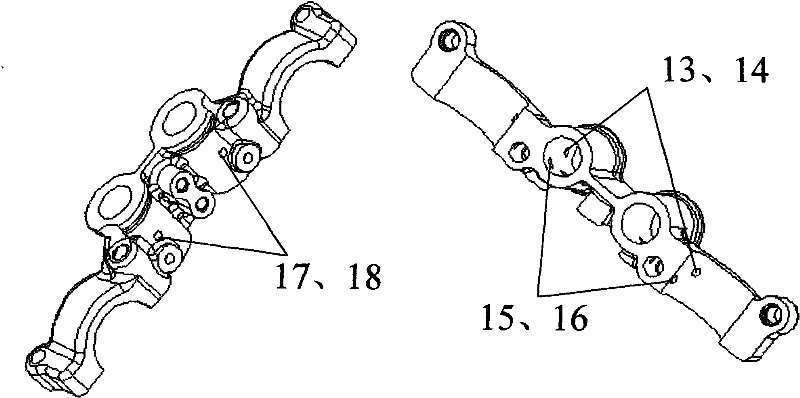

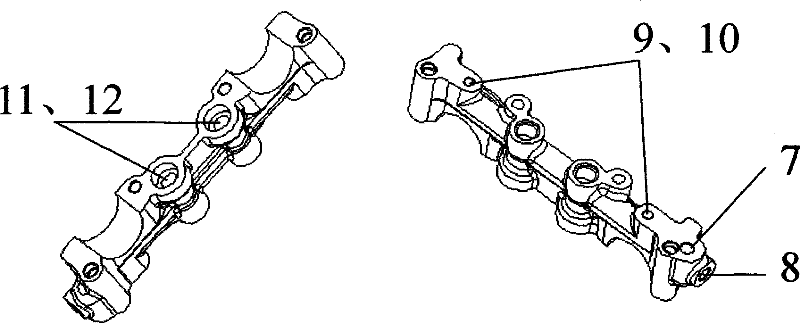

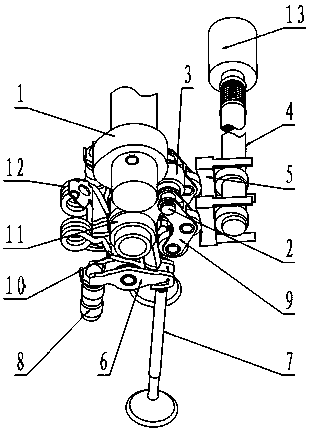

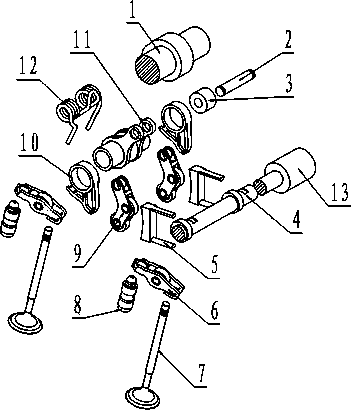

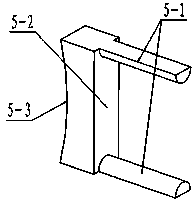

A springless poppet valve system is provided. The system includes a poppet valve movable between an open position and a closed position. The system includes an open cam and a close cam. An open rocker arm is provided which engages the open cam. The open rocker arm is operatively connected to the poppet valve so as to move the valve from the closed position to the open position. A close rocker arm is provided which engages the close cam. The close rocker arm is operatively connected to the poppet valve so as to move the valve from the open position to the close position. An open hydraulic lifter is pivotally connected to the open rocker arm. A close hydraulic lifter is pivotally connected to the close rocker arm.

Owner:PALUMBO CHRIS

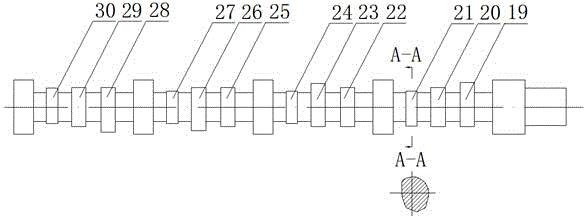

Continuously variable valve lift mechanism

ActiveCN103437850AMinor changesContinuous control of valve lift openingValve arrangementsMachines/enginesCamRocker arm

The invention relates to a continuously variable valve lift mechanism. The continuously variable valve lift mechanism comprises a rocker arm, a cam, a hydraulic tappet, a roller, a middle rod and a swing link, wherein one end of the rocker arm is supported against and connected with the hydraulic tappet, and the other end of the rocker arm is in contact with a valve rod; the swing link is hinged to one end of the middle rod through a connecting pin; the roller is arranged at the other end of the middle rod through a pin shaft; the top surface of the rocker arm is provided with a guide groove along the length direction; the roller is positioned in the guide groove and is in contact with the cam; the roller can move along the length direction of the guide groove under the driving of the middle rod. The continuously variable valve lift mechanism can realize continuously variable control of valve lift under different working conditions of an engine, has a simple structure and comprises a small number of members.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

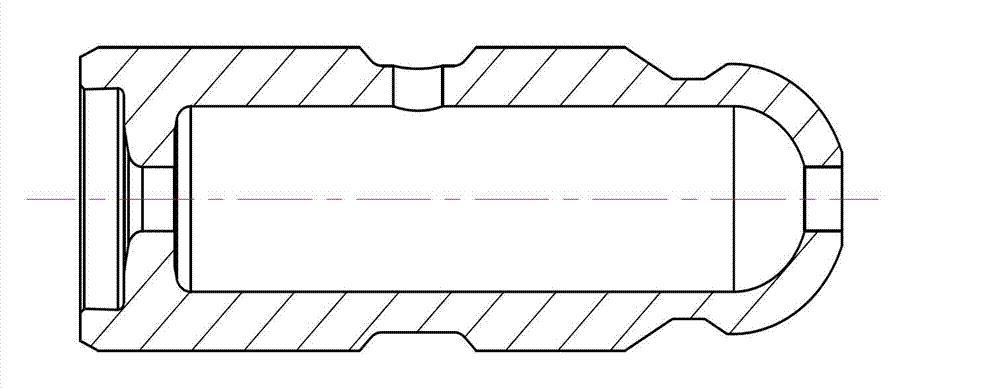

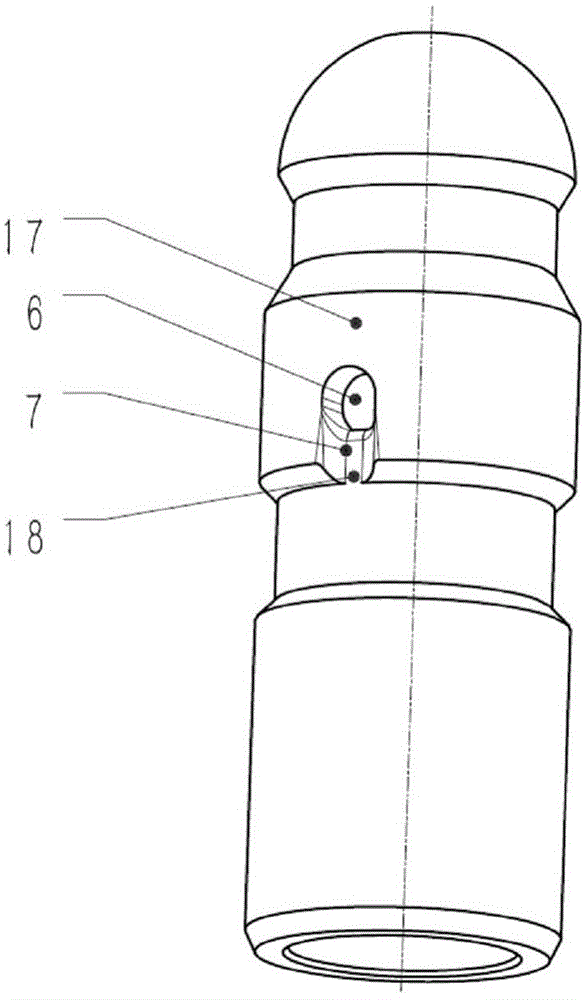

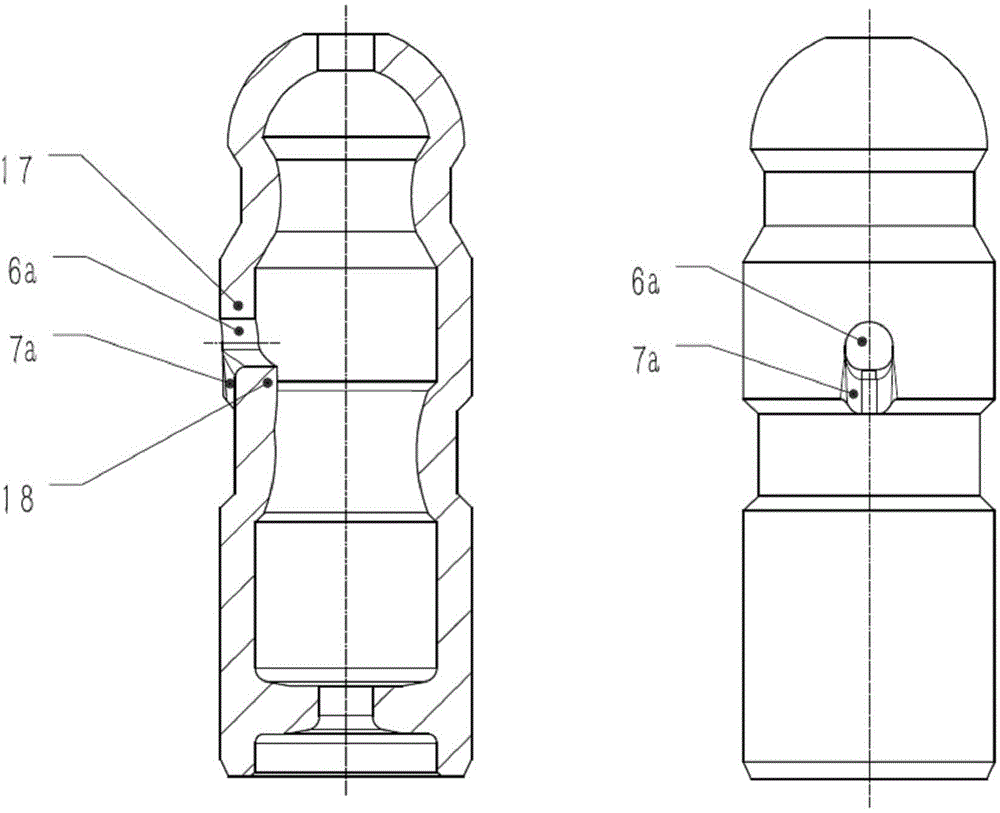

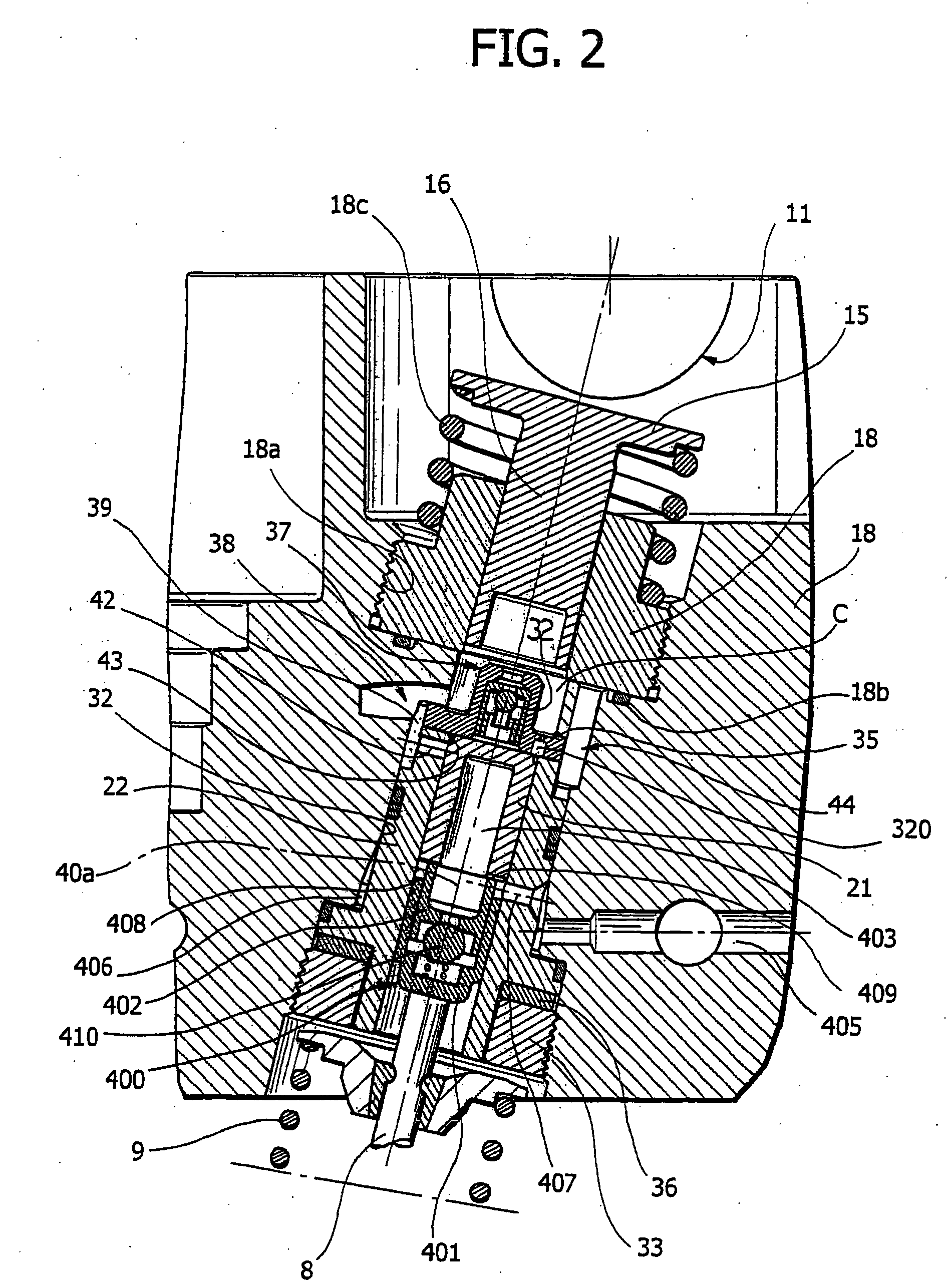

Columnar hydraulic tappet

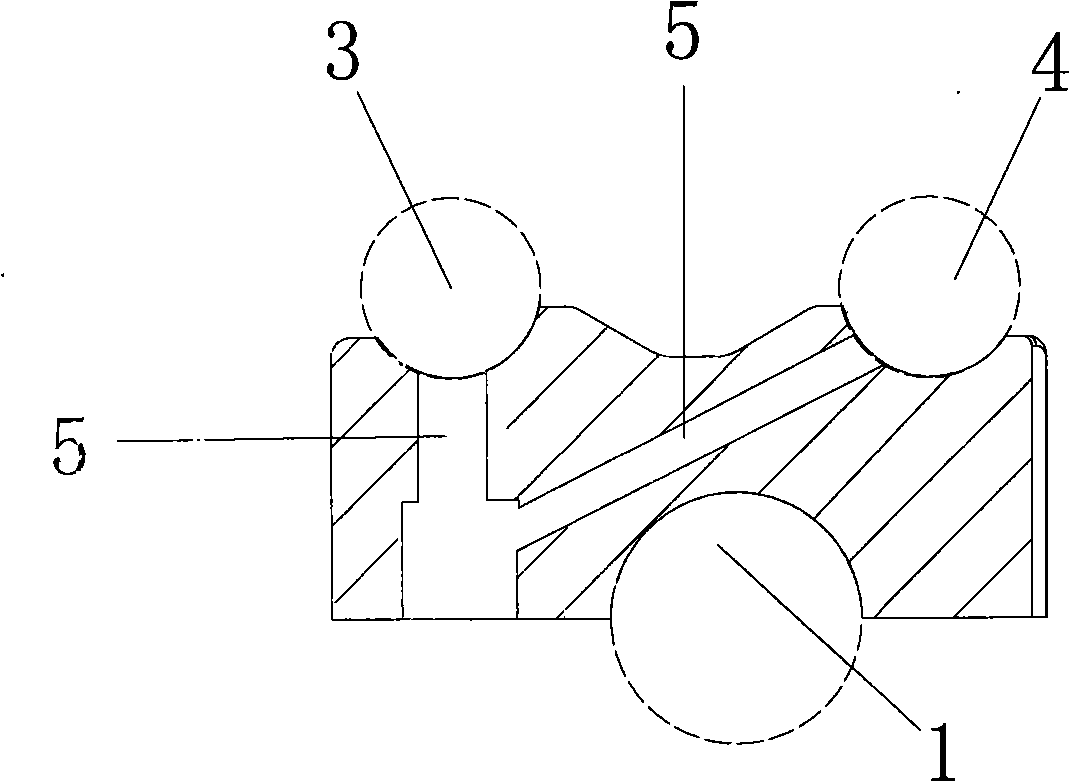

ActiveCN103939162AThe overall structure is simple and reliableIncrease oil storagePump assembliesMachines/enginesCheck valveHydraulic tappet

The invention relates to a columnar hydraulic tappet which comprises a shell. A plunger is correspondingly installed in the shell. A high-pressure cavity for a hydraulic medium extends between a sealing base of the plunger and the lower side of the shell and can be sealed through a check valve which is opened towards the high-pressure cavity. An outer ring groove for hydraulic medium circulation is formed in the outer diameter of the shell, an inner ring groove for hydraulic medium circulation is formed in the radial inner side of the shell, and one or more shell oil holes are formed between the inner ring groove and the outer ring groove. The plunger is composed of a sealed hemispherical head portion, a rod portion and a body portion. The columnar hydraulic tappet is characterized in that an inward-concave neck portion is arranged between the head portion of the plunger and the rod portion of the plunger, and the wall thickness of the neck portion is 105% to 120% the wall thickness of the rest of the plunger. The columnar hydraulic tappet is simple and firm in structure, the design that the wall thickness of the low-strengthen area of the single-body thin-walled hollow plunger is increased is adopted, and therefore both the requirement for increasing the oil storage amount in the plunger and the requirement for improving fatigue strengthen are considered.

Owner:HANGZHOU XZB TECH

Engine braking device and method

InactiveCN101368517AFast brakingSimple structureValve arrangementsOutput powerExhaust valveEngineering

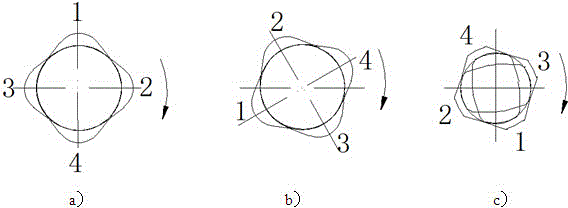

The invention relates to a device and a method for realizing the engine brake; the device comprises an engine exhaust valve, a valve spring, an exhaust cam and a variable hydraulic tappet mechanism; wherein, the exhaust cam is a double-cam structure composed of an outer cam and an inner cam; the variable hydraulic tappet mechanism is positioned between the exhaust valve and the exhaust cam and is able to realize the switching between the inner cam and the outer cam; the engine exhaust valve is controlled by the outer cam in the normal operating stage and controlled by the inner cam in the brake stage; according to the designed profile line of the inner cam, the exhaust valve is controlled to be opened in the late period of the compression stroke and during the expansion stroke to realize the engine brake effect. The device and the method for realizing the engine brake have the advantages of simple structure, easy control, high reliability, realizing the engine brake and particularly realizing the rapid brake of the diesel engine.

Owner:CHERY AUTOMOBILE CO LTD

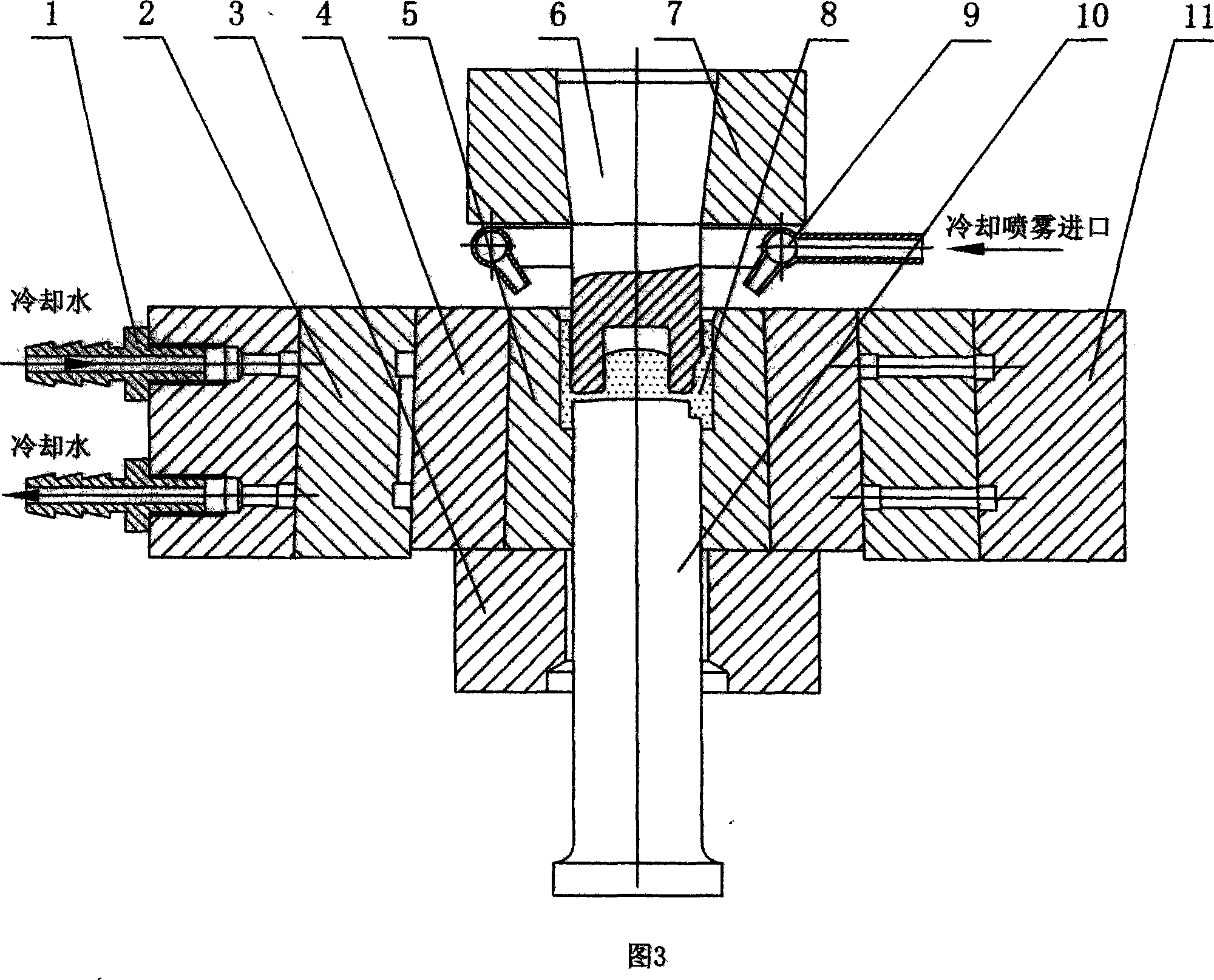

Self-cooling backheating movable cylinder fuel-air engine and Stirling engine

InactiveCN102094708ACompact structureEasy to assembleNon-fuel substance addition to fuelInternal combustion piston enginesEngineeringElectric control

The invention relates to a self-cooling backheating movable cylinder fuel-air engine and Stirling engine. The engine comprises a crankshaft, a connecting rod component, a pipeline, a hydraulic tappet, a cylinder head, a piston ring, a piston, a movable cylinder, a middle cylinder, an outer cylinder, a sensor, a valve component, an electric control hydraulic valve, a nozzle, a high-pressure electronic pump, an electric flow valve, an exhaust gas recirculation system, a booster, a power machine, a valve, a turbine, a compressor and a cooler, and is characterized in that: two internal combustion engines, namely a heat release engine and a heat absorption engine consist of the movable cylinder, the piston fixed in the movable cylinder and the middle cylinder outside the movable cylinder; the engine has a compact structure and is convenient to assemble and maintain; the heat absorption engine absorbs heat from the periphery of the heat release engine and an exhaust gas regenerator to do work and reduce temperature, so that the cylinder temperature is appropriate; a cylinder cooling system is saved; the heat is prevented from being taken away by cooling, exhaust heat is recovered outside, the heat is absorbed inside for doing work and self-cooling, most of consumed heat is recycled, and the heat efficiency of the whole engine is obviously improved; and the engine also can be taken as an air engine, is energy-saving, environmental-friendly, high-efficiency and ideal and can be widely applied to various fields.

Owner:罗吉庆

Engine with novel oilway

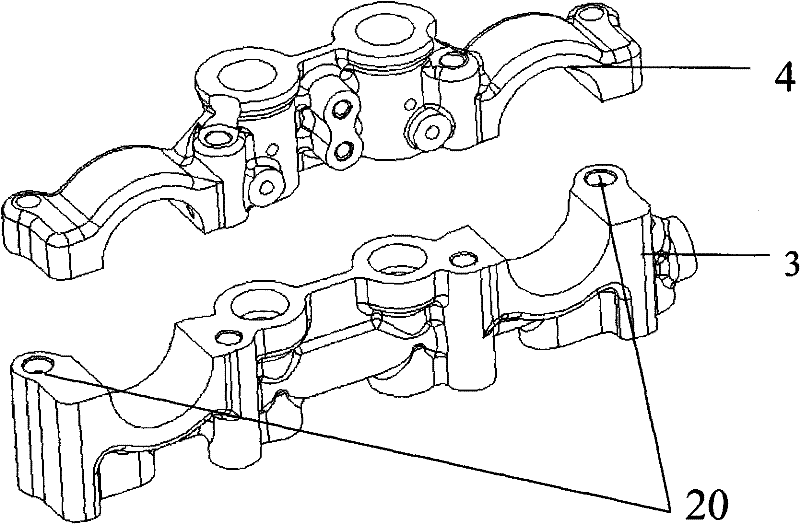

ActiveCN101344024AImprove the lubrication effectShorten the lengthLubrication of auxillariesLubricant conduit arrangementsEngineeringCam

The invention aims at disclosing an engine with a novel oil line; the engine has simple structure and low cost, is lubricant and reliable and comprises an air cylinder cover, a bearing cover of a cam shaft which is fixed on the air cylinder cover by a positioning pin and a bolt, and a rocker shaft, a rocker, a hydraulic tappet and the cam shaft which are supported in the bearing cover of the cam shaft; particularly, the air cylinder cover is internally provided with a main oil-feeding pipeline which goes to a neck hole of a main shaft of the cam shaft and the middle position of the internal part of the bearing cover of the cam shaft from the air cylinder cover; the bearing cover of the cam shaft is internally provided with a main oil pipeline which is communicated with the main oil-feeding pipeline and the center installation hole of the rocker shaft, and multiple secondary oil pipelines which are communicated with the installation holes of the two sides of the rocker shaft and the neck hole of the secondary shaft of the cam shaft; the rocker shaft is internally provided with oil pipelines which are communicated with the center installation hole of the rocker shaft, the installation holes of the two sides and the installation holes of all the rockers; and the rocker is internally provided with the oil pipeline of the rocker which is communicated with the installation hole of the rocker and the internal part of the hydraulic tappet. The internal oil pipeline of the engine of the invention adopts the design of feeding the oil from the middle part, is easy to be processed and is lubricant and reliable.

Owner:CHERY AUTOMOBILE CO LTD

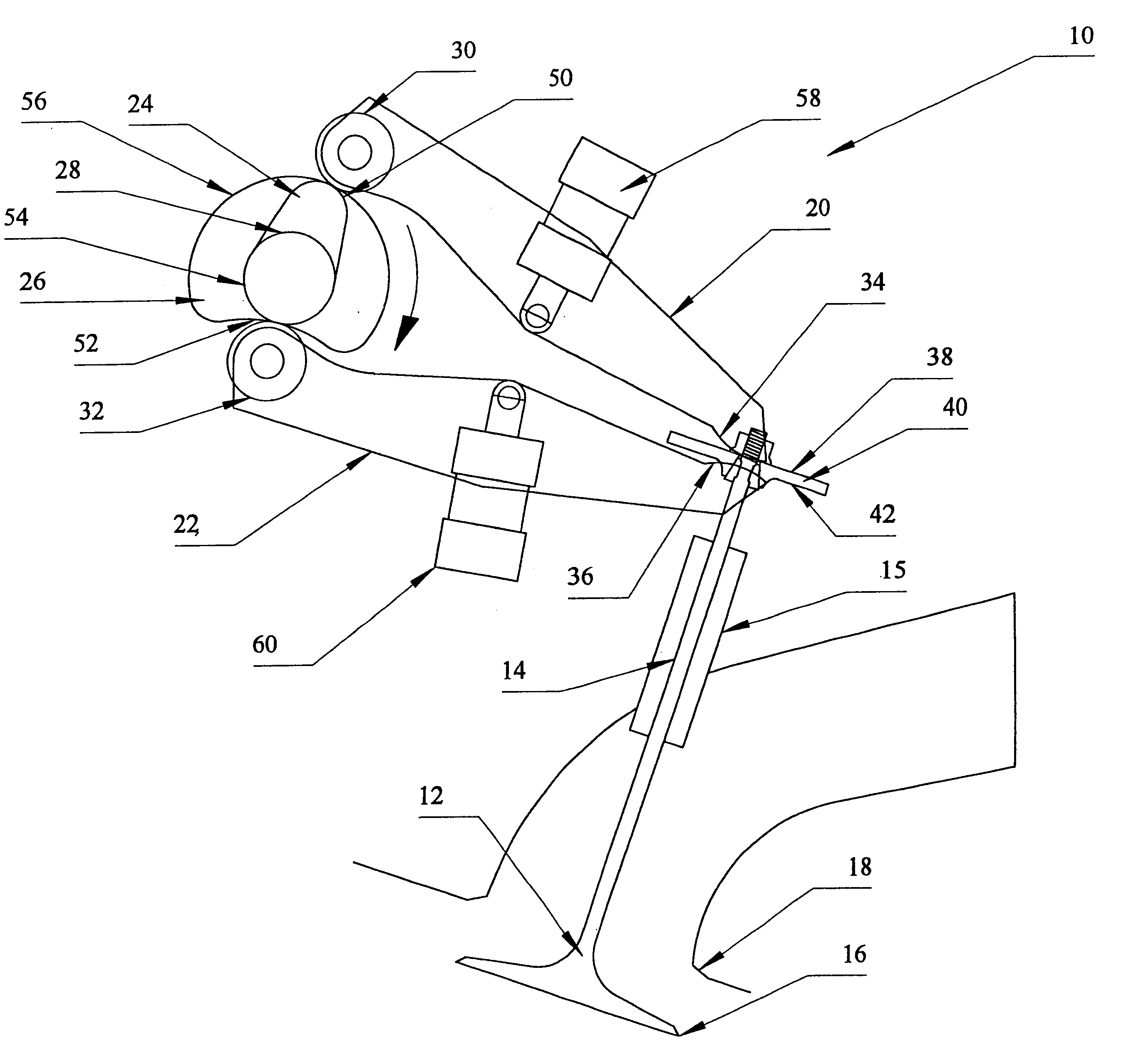

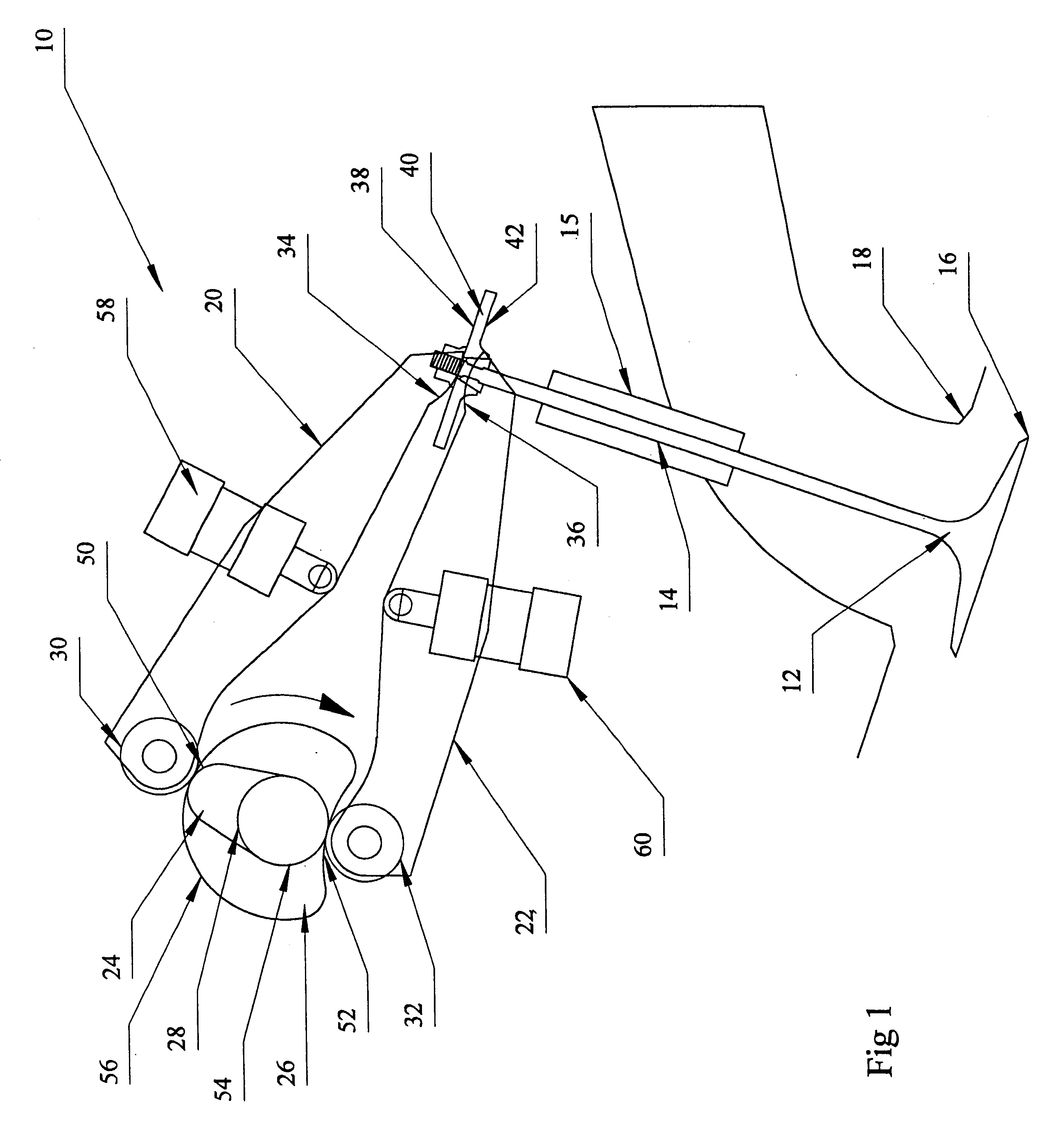

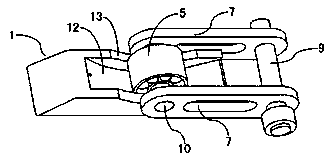

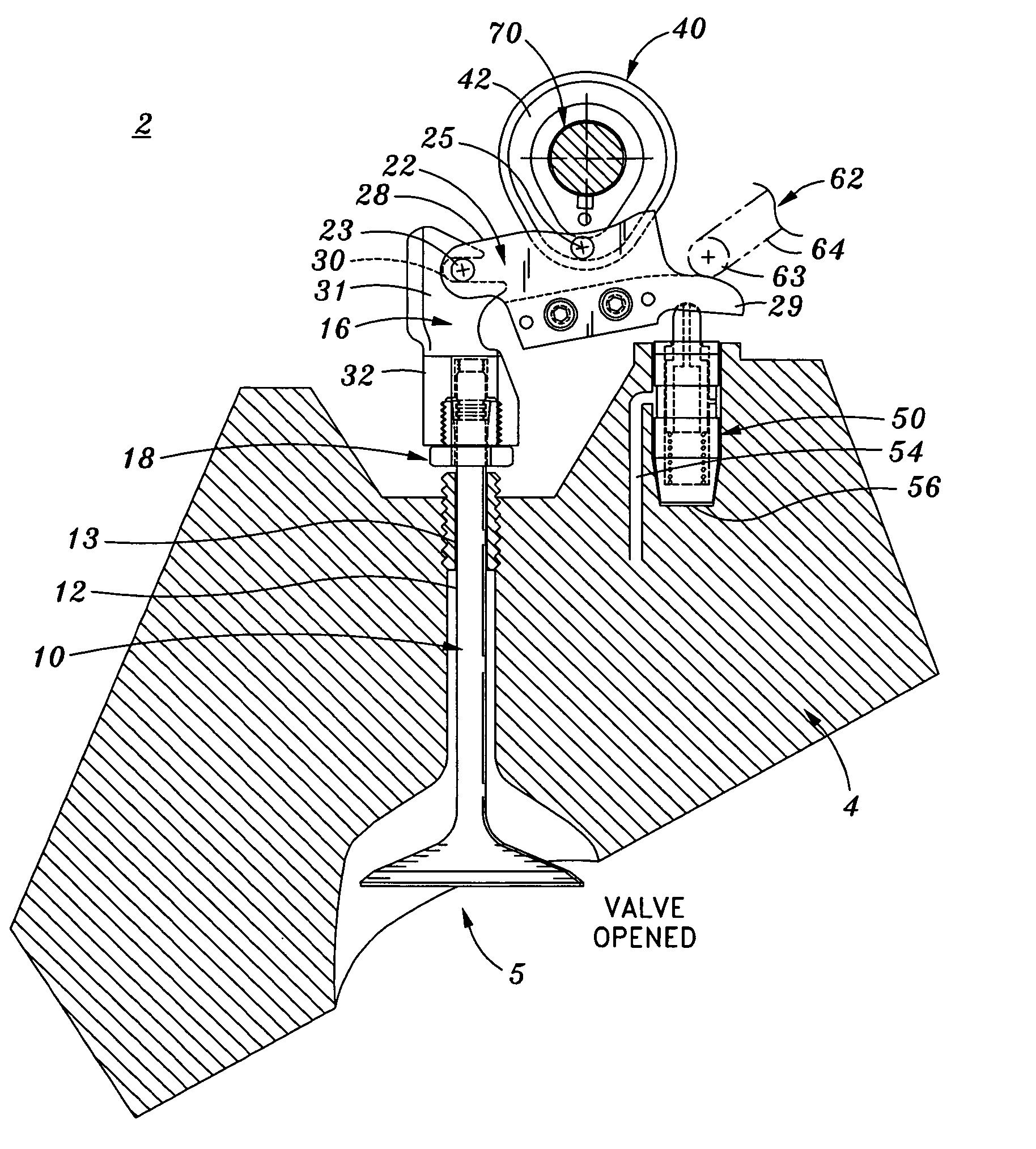

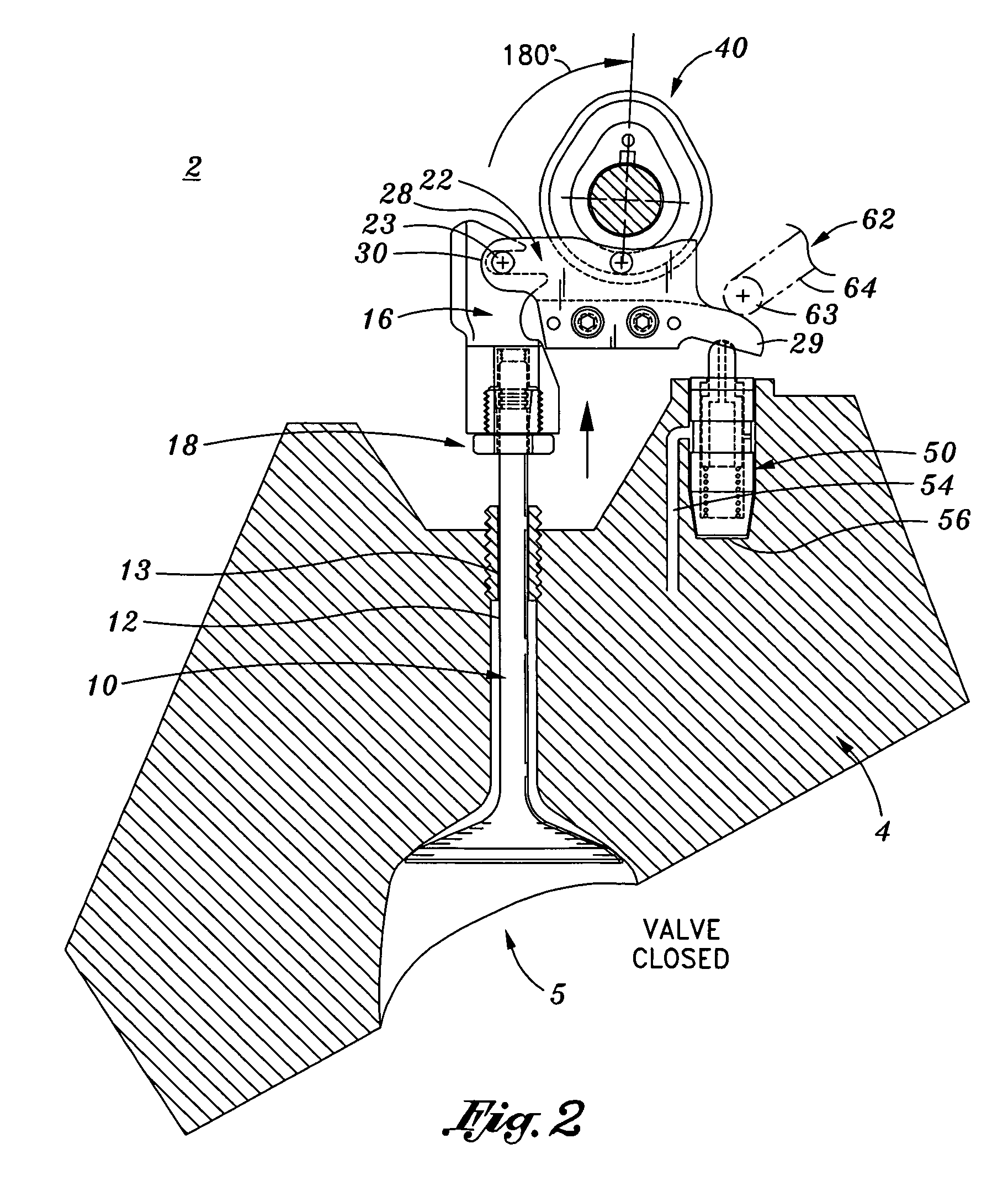

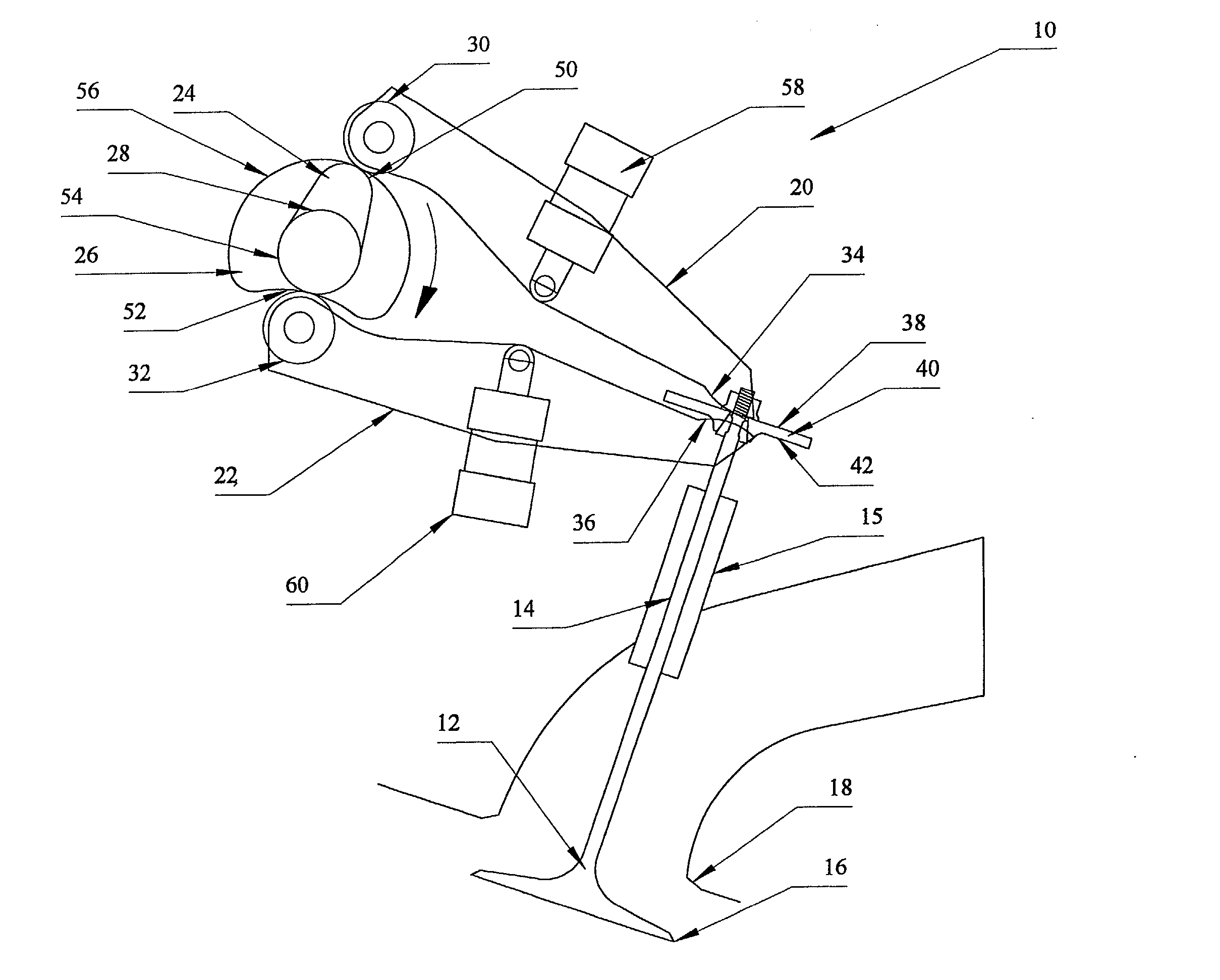

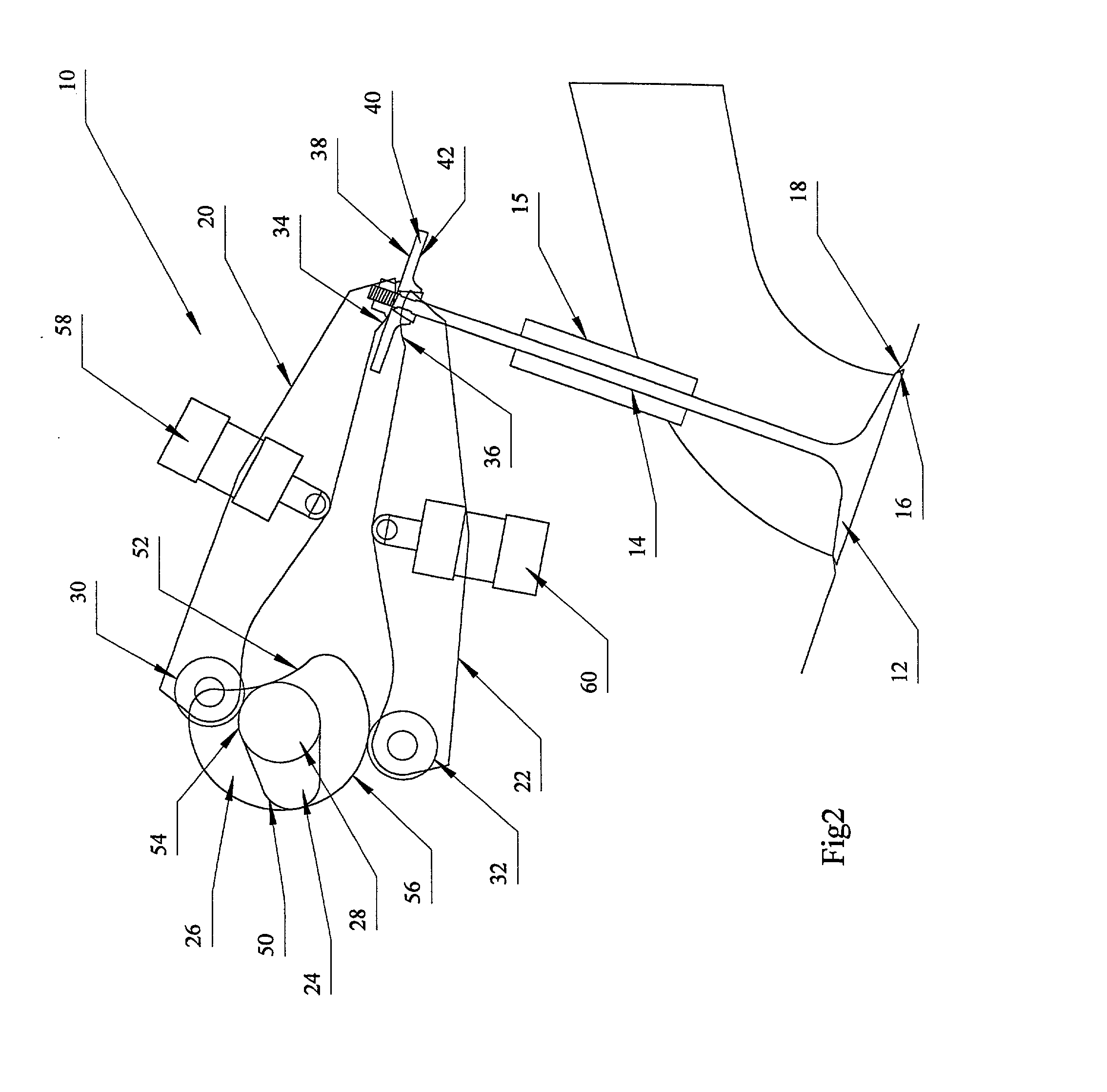

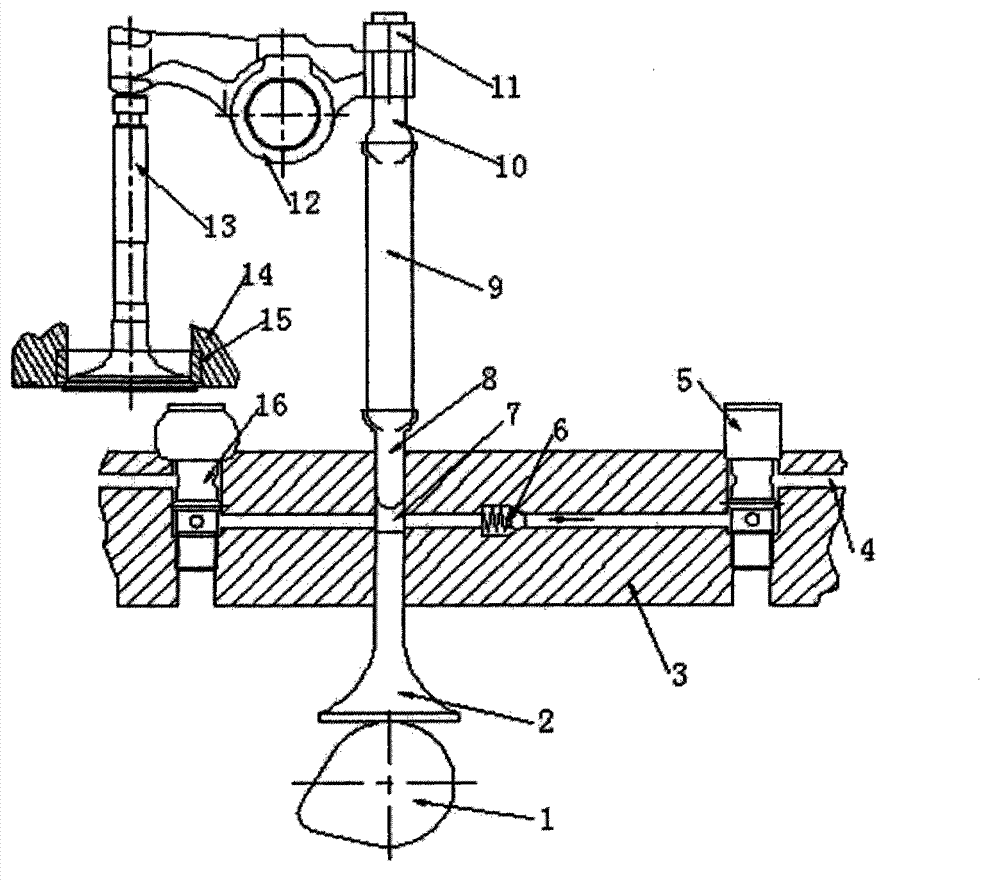

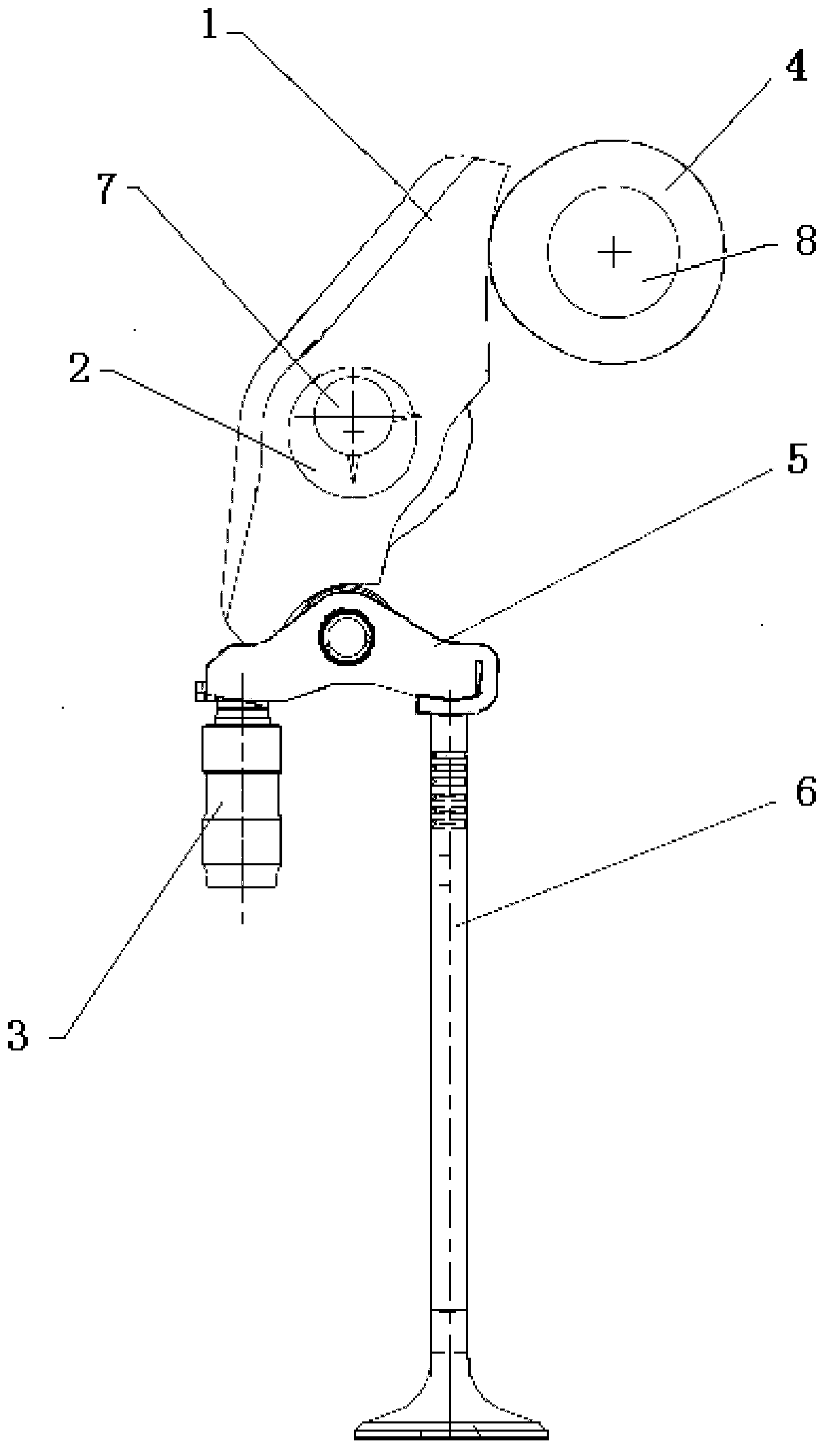

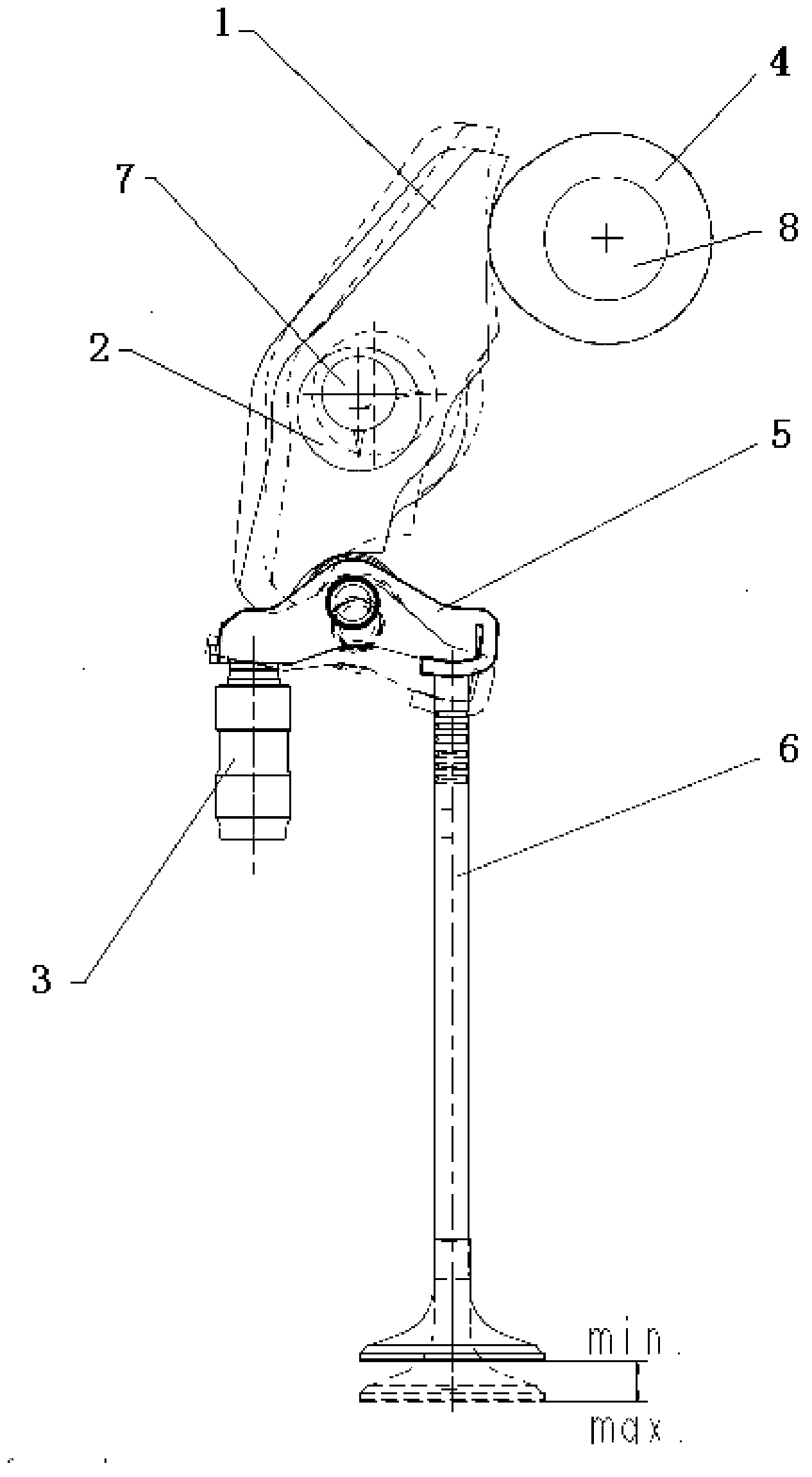

Desmodromic valve retrofit system with replaceable cam lobes for adjusting duration and hydraulic lifters for reliability

InactiveUS7077088B1High horsepowerImprove fuel economyOperating means/releasing devices for valvesValve drivesExhaust valveEngineering

A desmodromic “springless” valve and adjustable cam system is provided which is adapted to be installed onto a head configured for an overhead cam for an internal combustion engine having at least one intake and one exhaust valve per cylinder. The system includes a main camshaft, a cam lobe with a follower groove formed in each side of the cam, at least one intake and one exhaust valve assigned to each cylinder, a valve connector installed onto the distal tip of each valve, a hydraulic lifter assigned to each valve. The system further includes a rocker defined by a valve movement end and lifter end, wherein the valve movement end is adapted to be mechanically linked to a respective valve connector and the lifter end is adapted to be pressed against a respective piston tip by a rocker retainer. During operation (i.e., when the main camshaft rotates), the valve movement end of the rocker moves in manner which results in each valve being moved upwards and downwards as a function of the cam duration and lift, thereby opening and closing each respective valve.

Owner:DECUIR JR JULIAN A

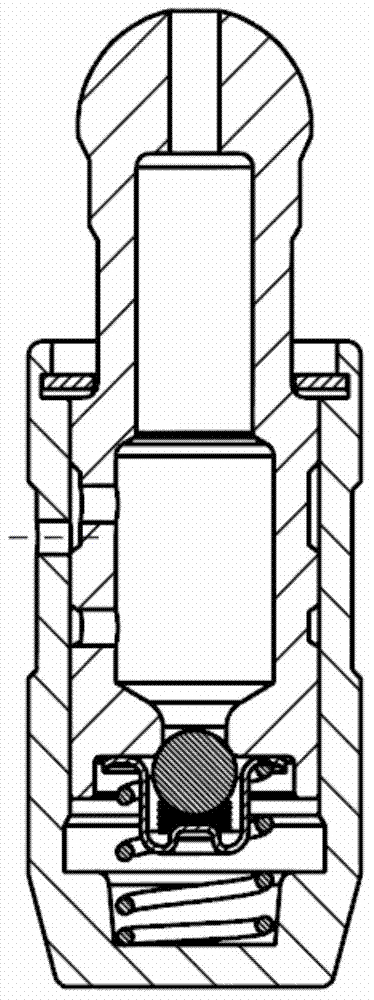

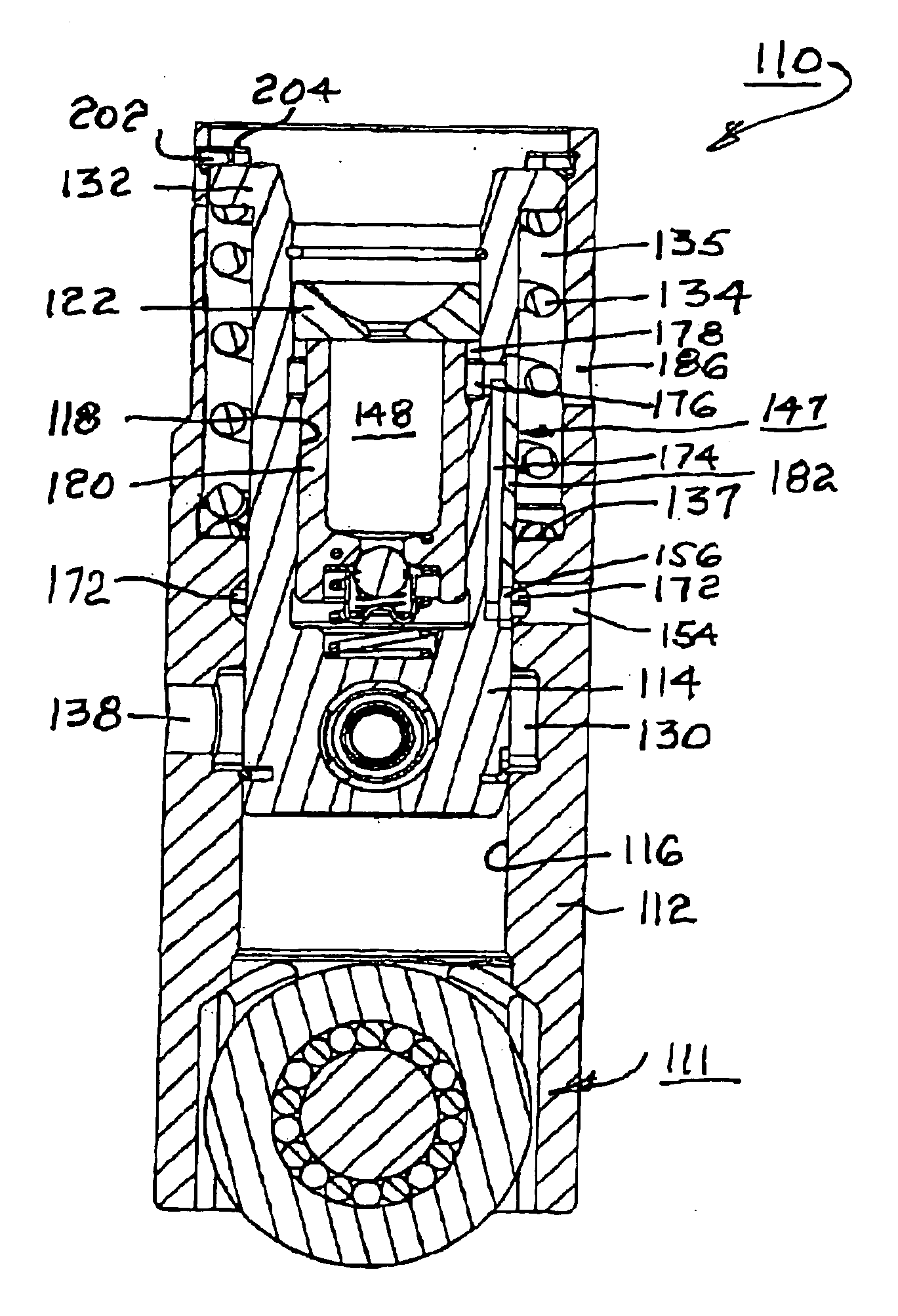

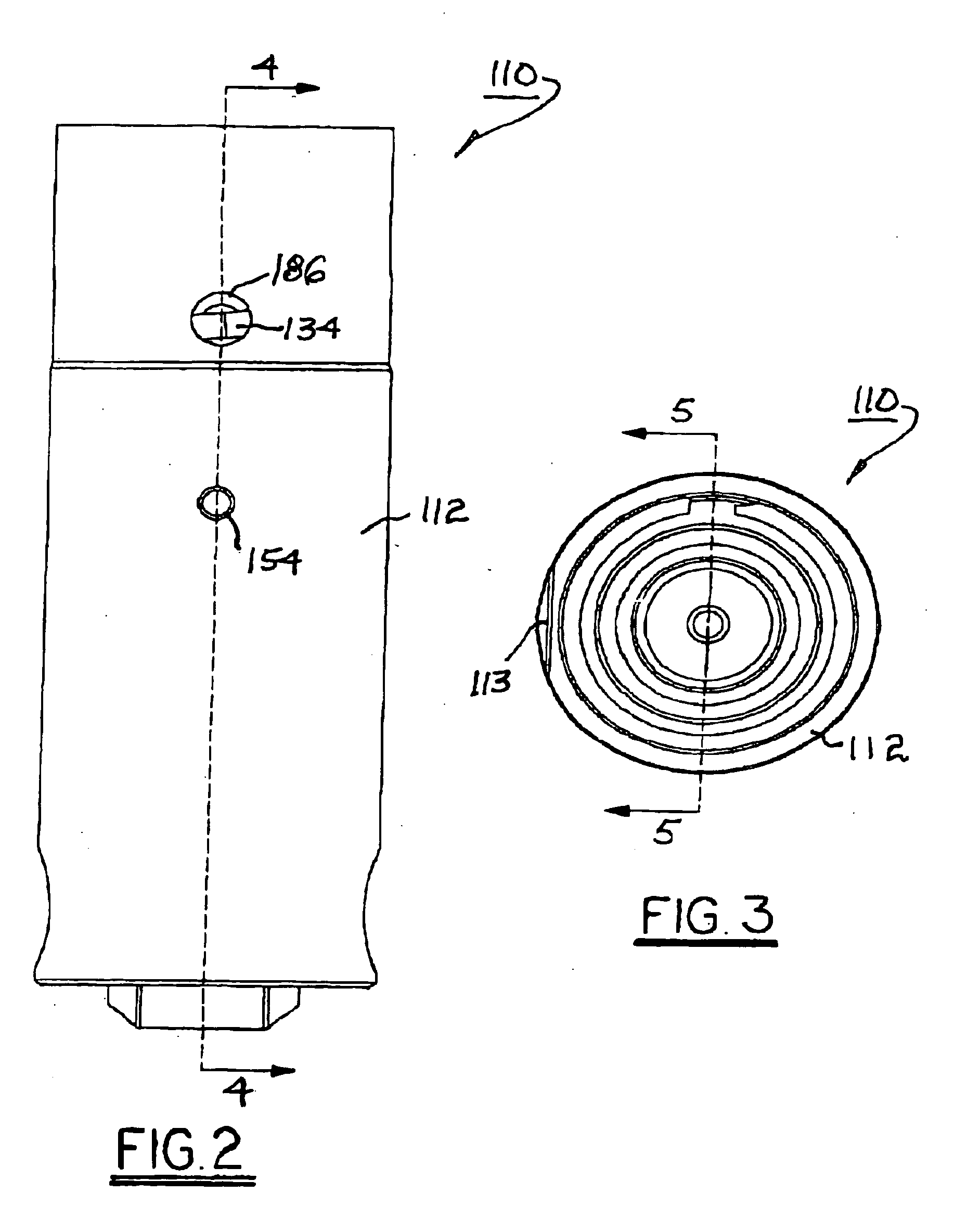

Valve-deactivating hydraulic lifter having a vented internal lost motion spring

A deactivating hydraulic valve mechanism includes a hydraulic element assembly disposed within a pin housing slidably disposed within a bore in a body. A transverse bore in the pin housing contains selectively-retractable locking pins that engage a groove in the body to selectively lock together the body and the pin housing. A lost motion spring is disposed in an annular chamber between the body and the pin housing. An oil passage from an engine gallery to the hydraulic element assembly includes an axial component and bypasses the lost motion chamber. A ring holds the lifter assembly together and also sets mechanical lash. The ring may be provided as a standard-thickness ring and a shim selected to provided a predetermined amount of mechanical lash in the assembled mechanism to ensure facile engagement and disengagement of the locking pins in the body.

Owner:DELPHI TECH INC

Camshaft bearing structure for engine

ActiveCN101749064AReduce front sizeSmall sizeValve arrangementsLubrication of auxillariesEngineeringCylinder block

The invention discloses a camshaft bearing structure for an engine, which consists of a first camshaft bearing and a plurality of same second camshaft bearings. The camshaft bearing structure for the engine is characterized in that: lower-half bearings of the second camshaft bearings are integrated on a cylinder cover; the first camshaft bearing is independent and not integrated on the cylinder cover. The first camshaft bearing is divided into an upper bearing cover and a lower bearing cover, is positioned by a positioning sleeve and is fixed on the cylinder cover through a fastening bolt. Oil ways are distributed in the upper cover and the lower cover of the first camshaft bearing and are used for introducing the pressure oil from the cylinder and providing oil for a hydraulic tappet, camshaft lubrication and a VVT phaser. By the independence of the first camshaft bearing, the front-end size of the cylinder cover can be obviously reduced, and the compactness of the engine can be improved. Meanwhile, the oil ways are arranged in the camshaft bearing covers, so that the camshaft bearing structure for the engine has the function of building a lubricating oil way, thereby simplifying the arrangement of the lubricating oil way of the cylinder cover.

Owner:CHERY AUTOMOBILE CO LTD

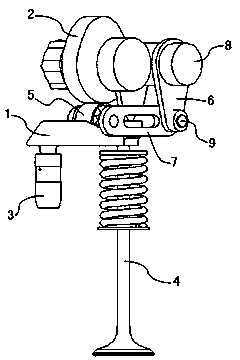

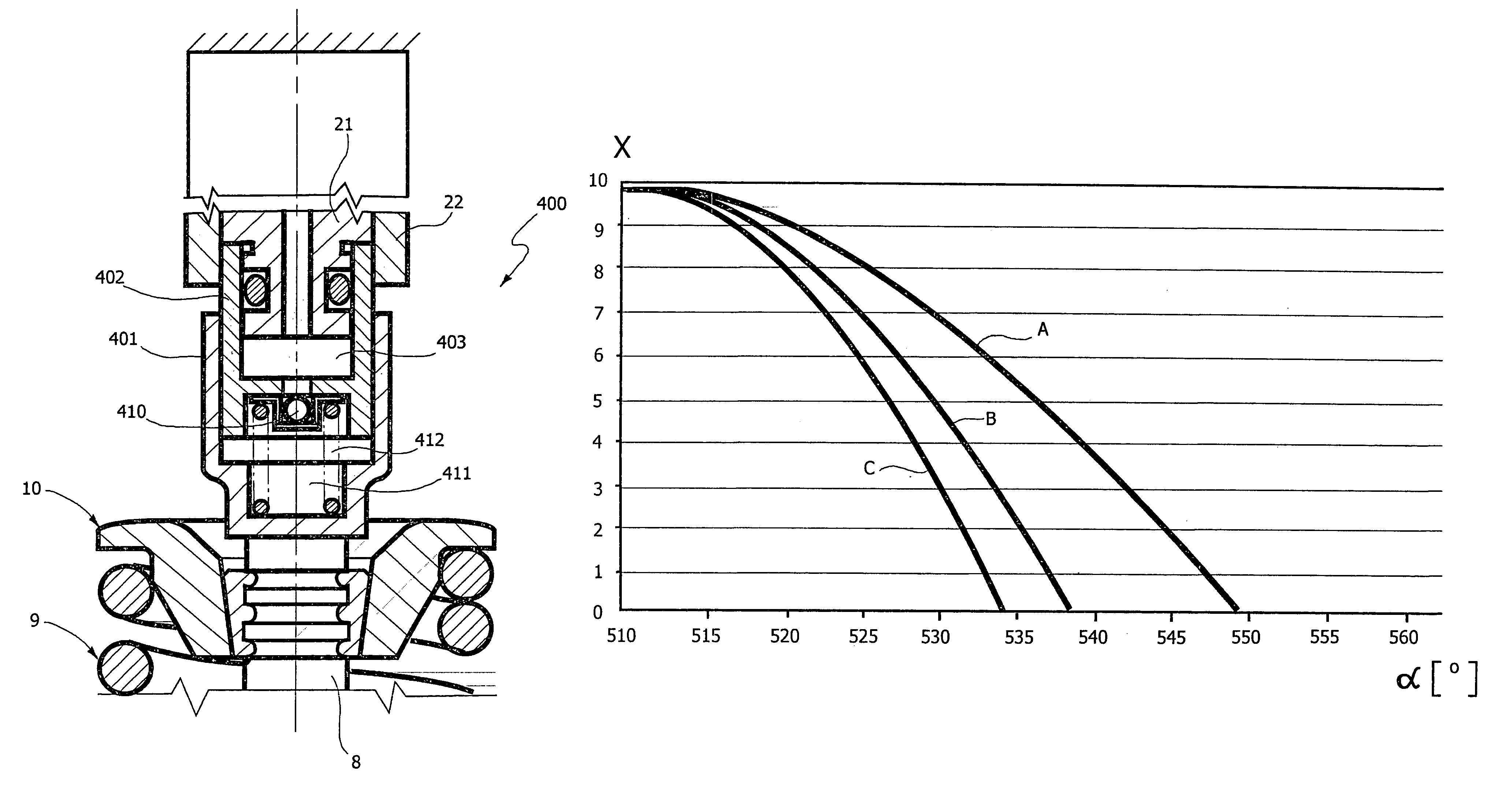

Driver with hydraulic tappet

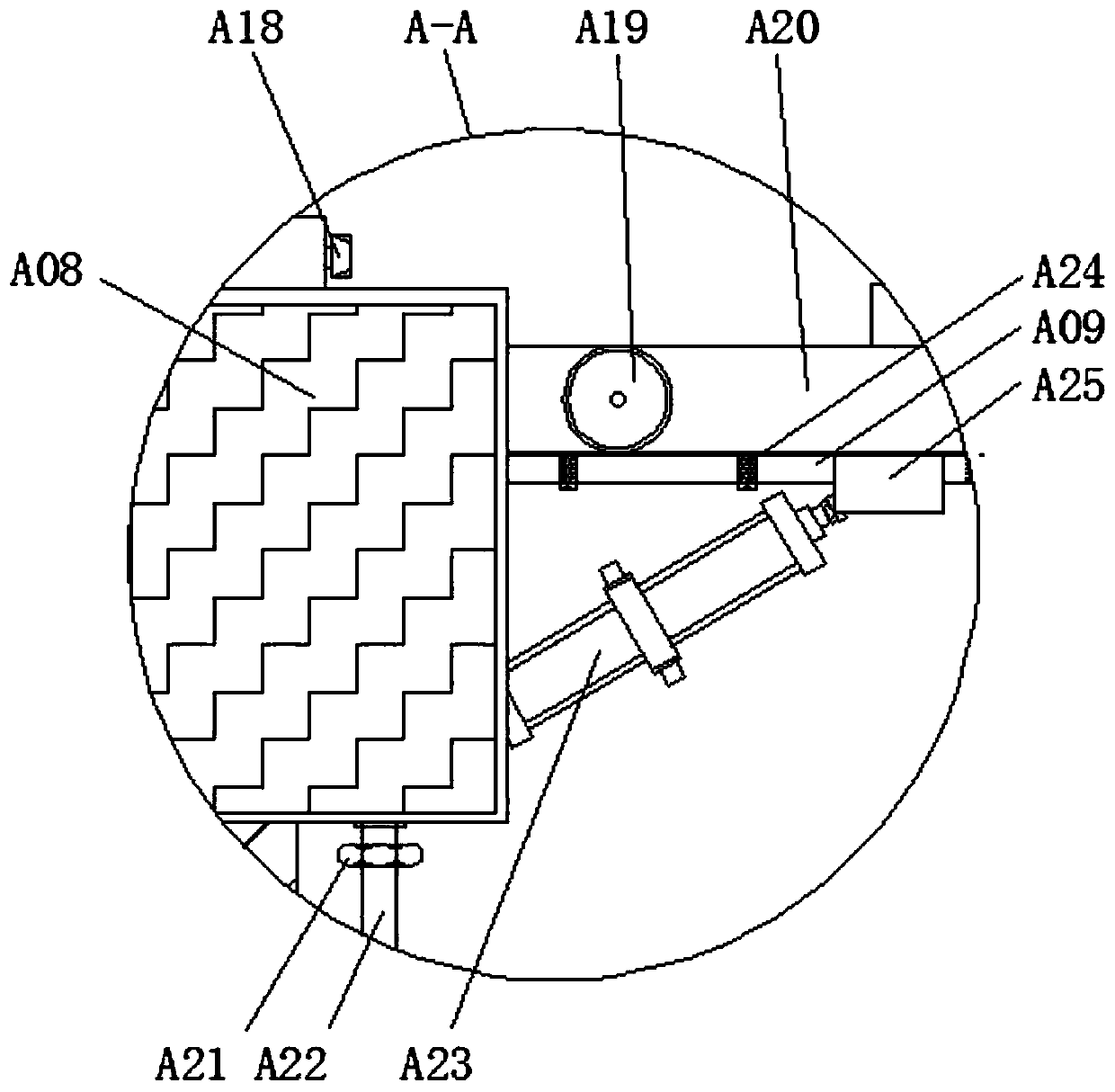

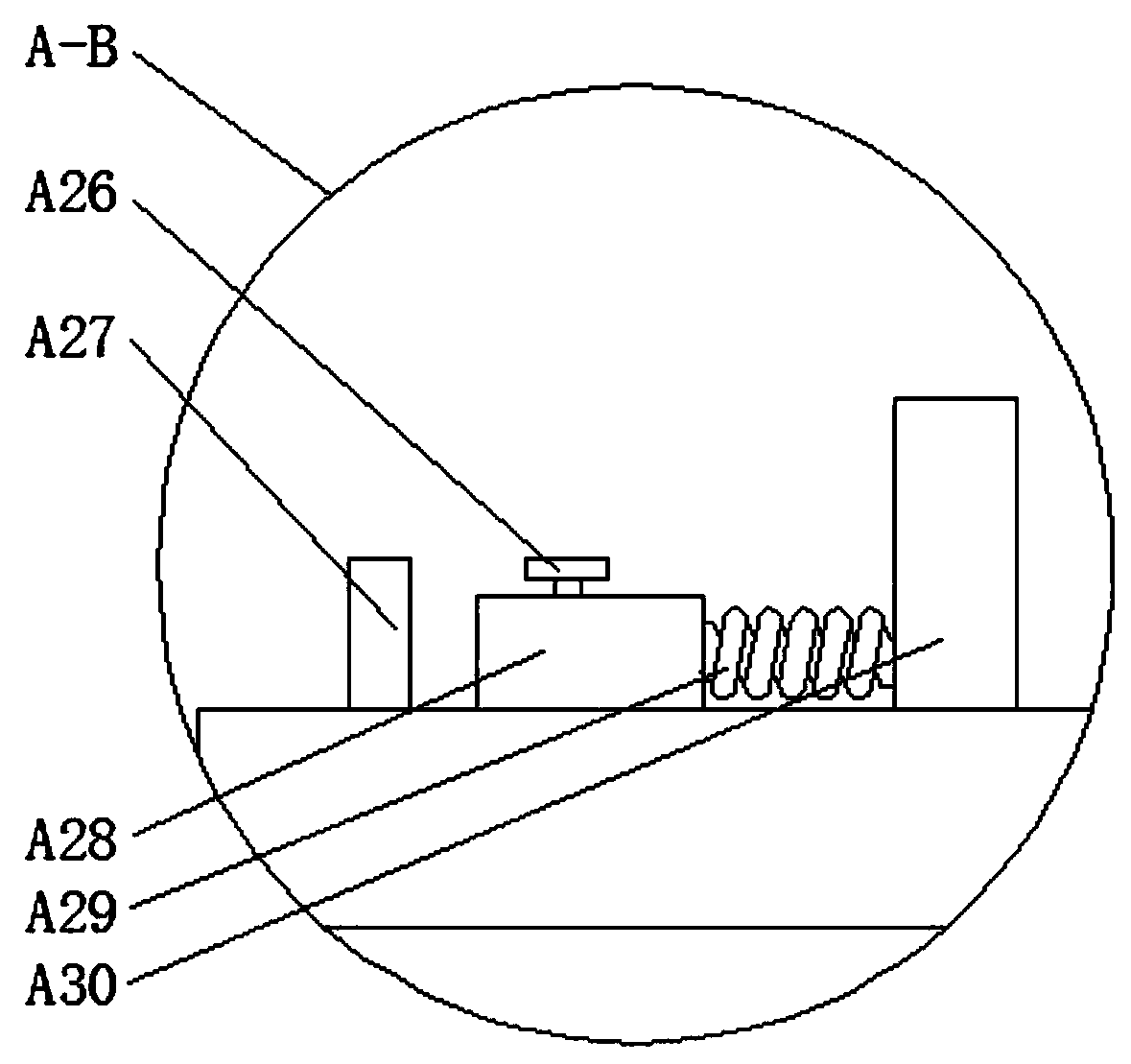

InactiveCN103696822ALarge diameterReduce high pressureValve arrangementsMachines/enginesLow noiseManufacturing cost reduction

The invention discloses a driver with a hydraulic tappet. The driver comprises a driver shell, a driving cylinder, a first piston, a second piston, a piston rod and the hydraulic tappet, wherein the hydraulic tappet further comprises a tappet plunger, a tappet body, a tappet high-pressure chamber, a tappet inflow channel, a discharge channel, a tappet one-way valve and a plunger return spring. The hydraulic tappet is optimized in design, and the driver with the hydraulic tappet has comprehensive advantages in terms of spatial size, high-pressure chamber pressure and cost, and is particularly applicable to valve clearance control of a variable valve driver. The hydraulic tappet is combined among the wall of the driving cylinder and the two pistons of the driver, the tappet body includes a tappet body end and a tappet body wall, the first piston serves as the tappet body end, the wall of the driving cylinder serves as the tappet body wall, so that the tappet high-pressure chamber can have a diameter as large as that of the driving cylinder to reduce the internal high pressure of the tappet high-pressure chamber, a normal air distribution function, low noise and reasonable service life are ensured, an additional tappet body wall structure and an additional high-precision matching structure are omitted, and manufacturing cost is reduced.

Owner:NINGBO HOYEA MACHINERY MFG

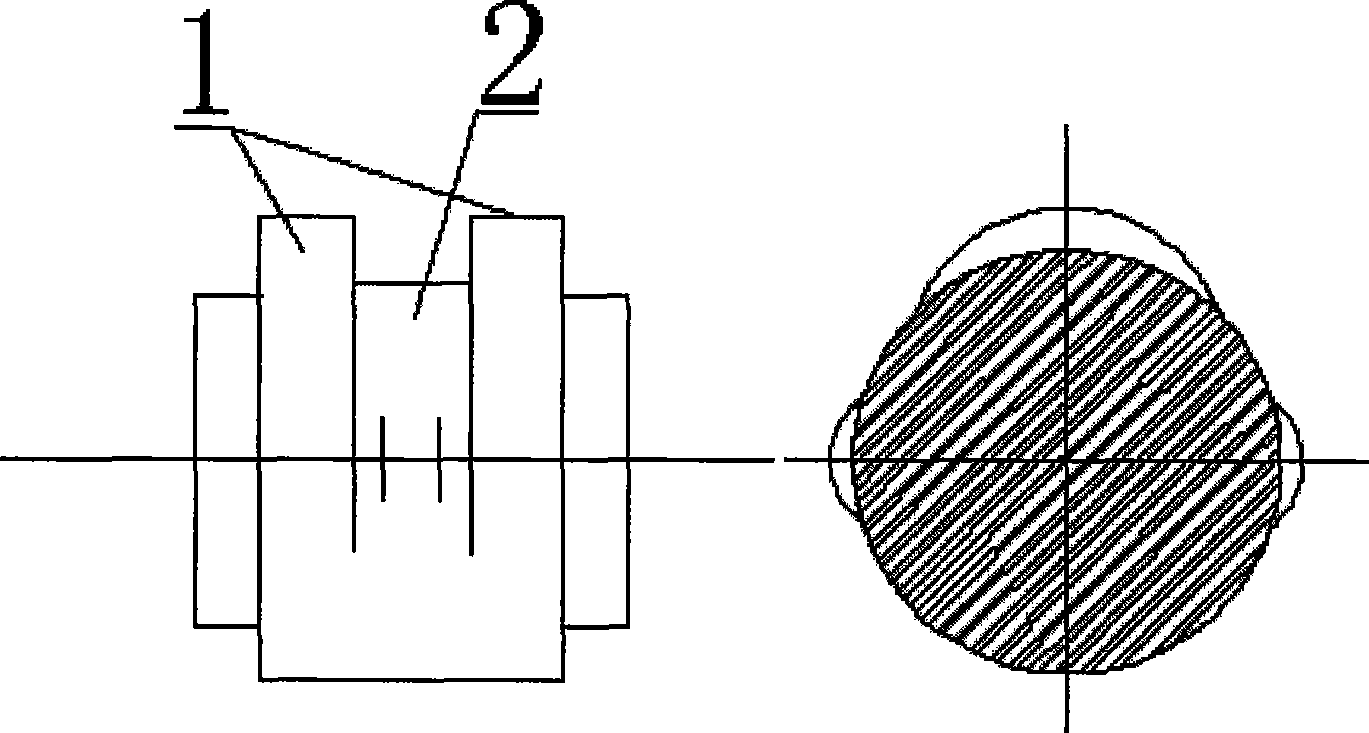

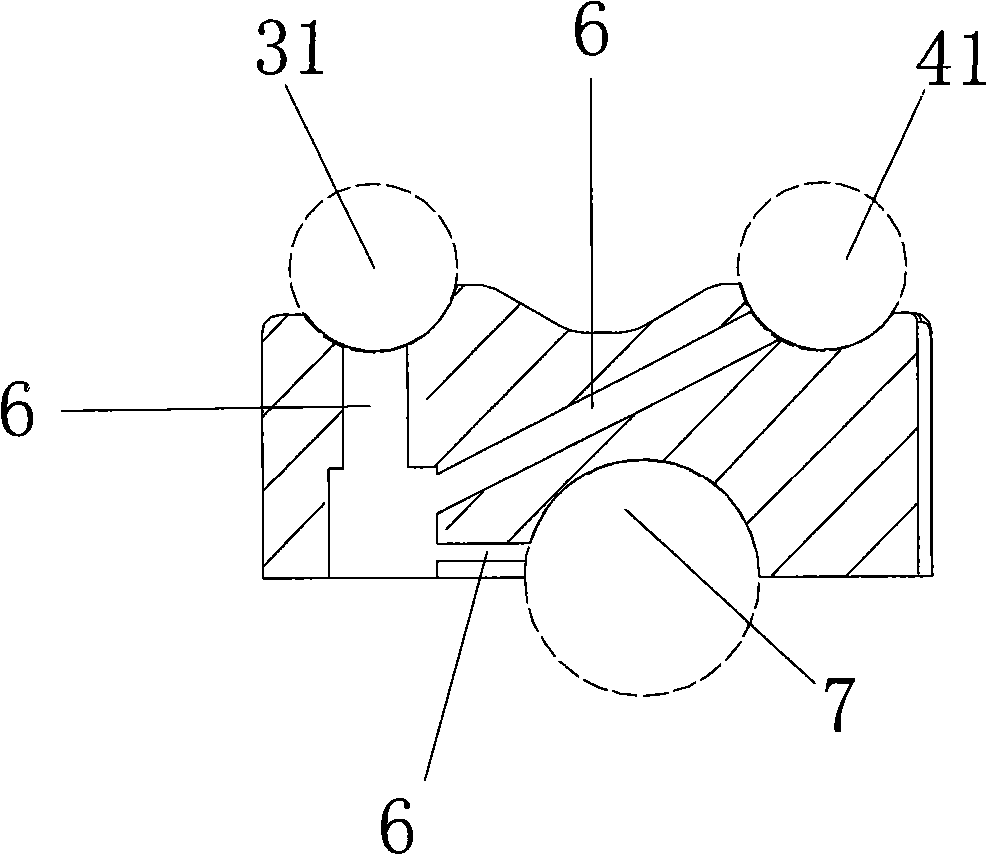

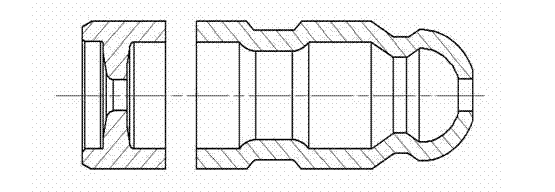

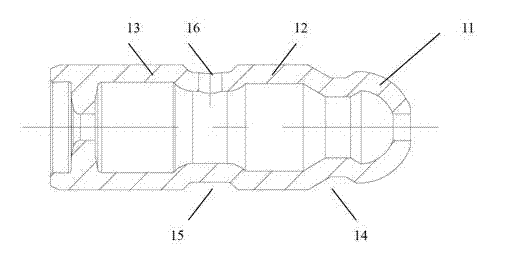

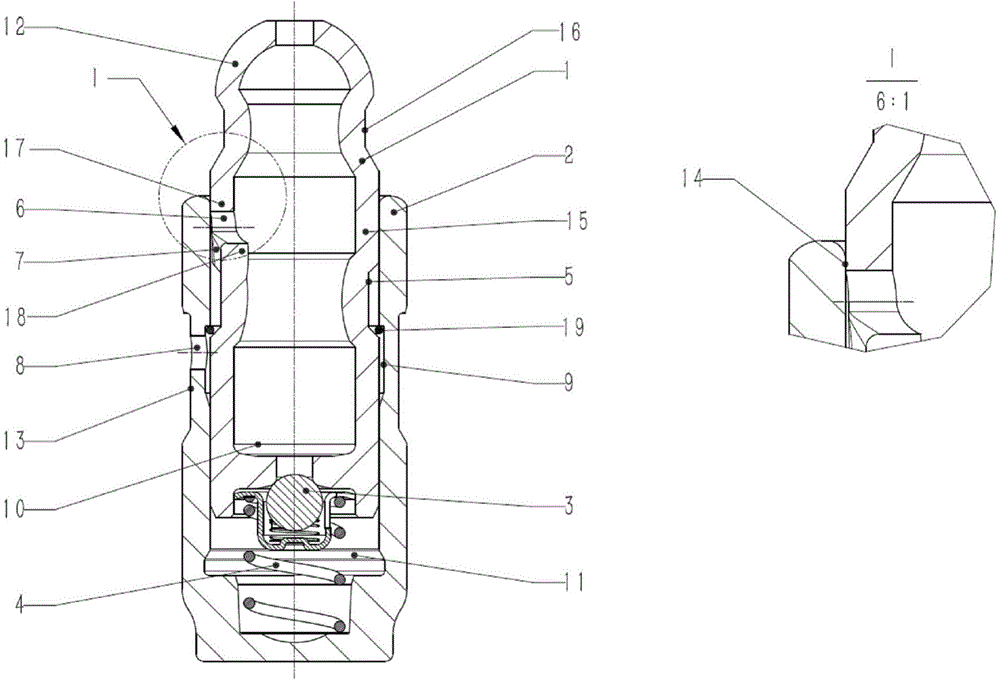

Integrated hydraulic tappet plunger and integral roller forming method thereof

ActiveCN102788154AReduce investmentImprove consistencyValve arrangementsPlungersBiochemical engineeringUltimate tensile strength

The invention belongs to the technical field of cold forming, and particularly relates to an integral roller forming method of an integrated hydraulic tappet plunger in a hydraulic gap adjuster in an automobile engine. The integrated hydraulic tappet plunger comprises a cylindrical body, one end of the body is a hemisphere, a rod is arranged in the middle of the body, the other end of the body is a main portion, a first circular groove is arranged between the hemisphere and the rod, a second circular groove is arranged between the rod and the main portion, and a fluid opening is arranged in the second circular groove. The integrated hydraulic tappet plunger is characterized in that the hemisphere, the rod and the main portion are integrally formed, and the wall thicknesses of the hemisphere, the rod and the main portion are equal. The integrated hydraulic tappet plunger and the processing forming method have the advantages that the integrated hydraulic tappet plunger is simple in structure and is processed and formed conveniently, investment of plunger production equipment can be reduced according to the scheme, production efficiency of the plunger is improved, and the produced integrated plunger is higher in integral strength and longer in service life as compared with a plunger in the prior art.

Owner:HANGZHOU XZB TECH

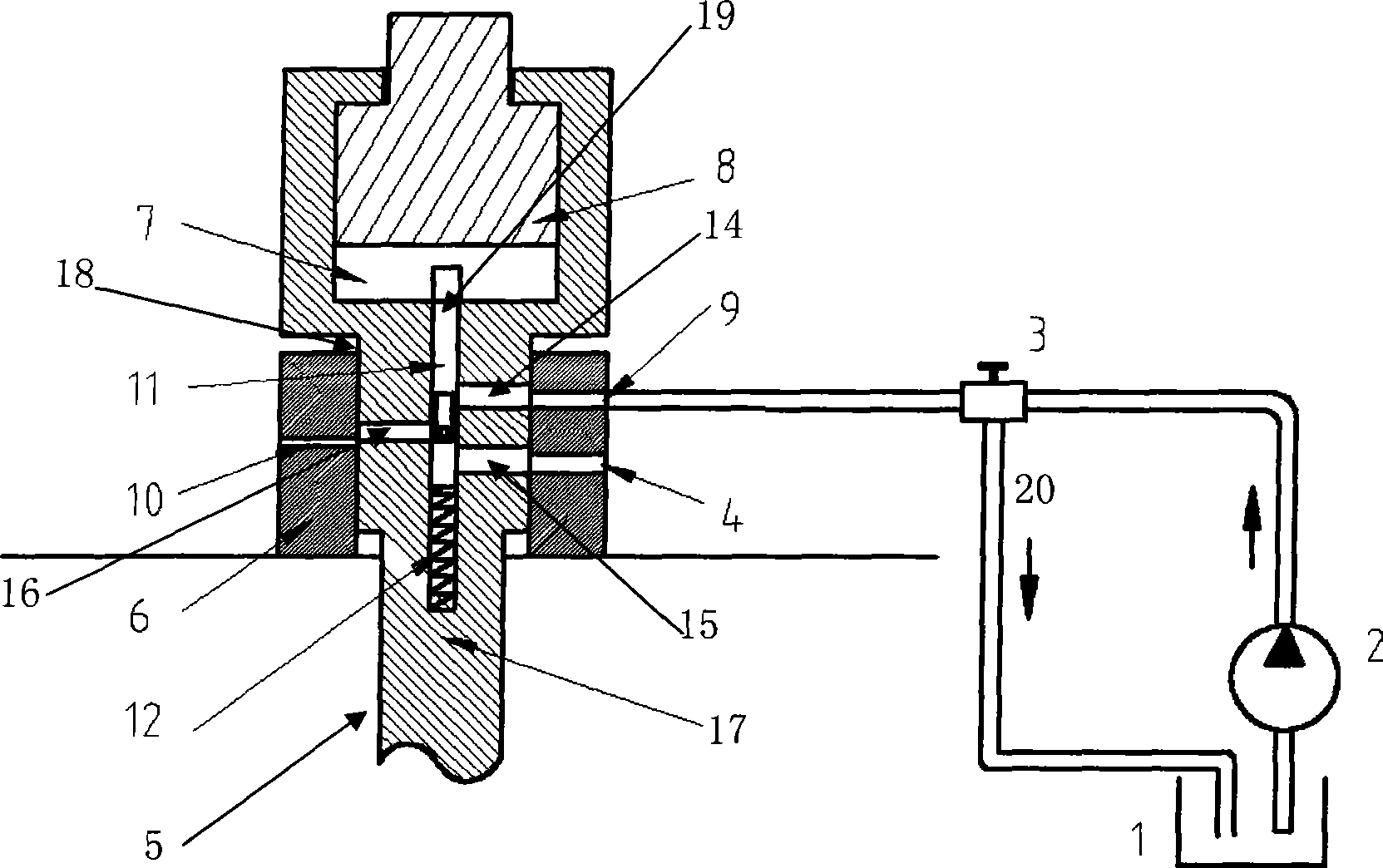

Hydraulic variable valve and control method thereof

InactiveCN106285816AReal-time adjustmentAvoid changes that cannot follow engine operating conditionsValve arrangementsInternal combustion piston enginesSolenoid valveHydraulic pump

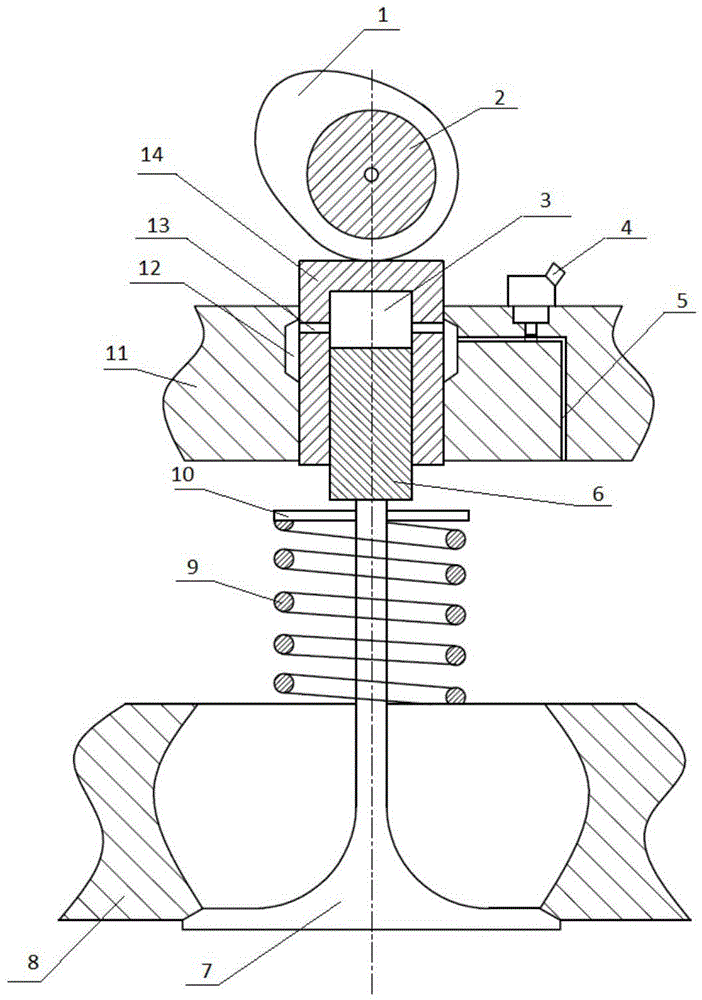

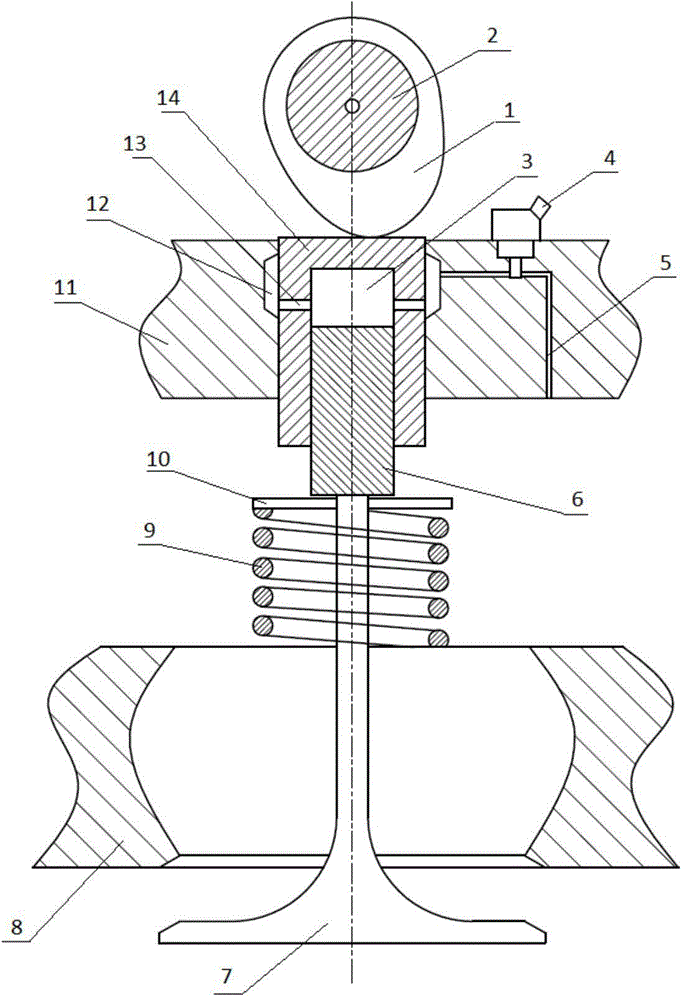

The invention discloses a hydraulic variable valve and a control method thereof. The hydraulic variable valve comprises a cam, a hydraulic tappet, a hydraulic plunger, a cylinder cover, a valve body and an control electromagnetic valve, wherein a guide hole is formed in the cylinder cover and corresponds to the valve body in position, the hydraulic tappet is a hollow cylinder with the lower end being open, the outer circle of the hydraulic tappet is matched with the guide hole, and the outer surface of the upper end of the hydraulic tappet makes contact with the cam; the hydraulic plunger is mounted in an inner cavity of the hydraulic tappet, the lower end face of the hydraulic plunger makes contact with the tail end of the valve body, and the outer circle of the hydraulic plunger is matched with the inner cavity of the hydraulic tappet; a pressure cavity is formed between the upper end of the hydraulic plunger and the inner surface of the upper end of the hydraulic tappet, and oil holes are formed in the side faces, corresponding to the pressure cavity, of the hydraulic tappet; and an oil duct is formed in the cylinder cover, the oil holes communicate with one end of the oil duct, and the control electromagnetic valve is mounted on the oil duct. By the adoption of the technical scheme, engine parameters can be adjusted and controlled flexibly, and accordingly a good air distribution effect can be achieved for an engine under various working conditions.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

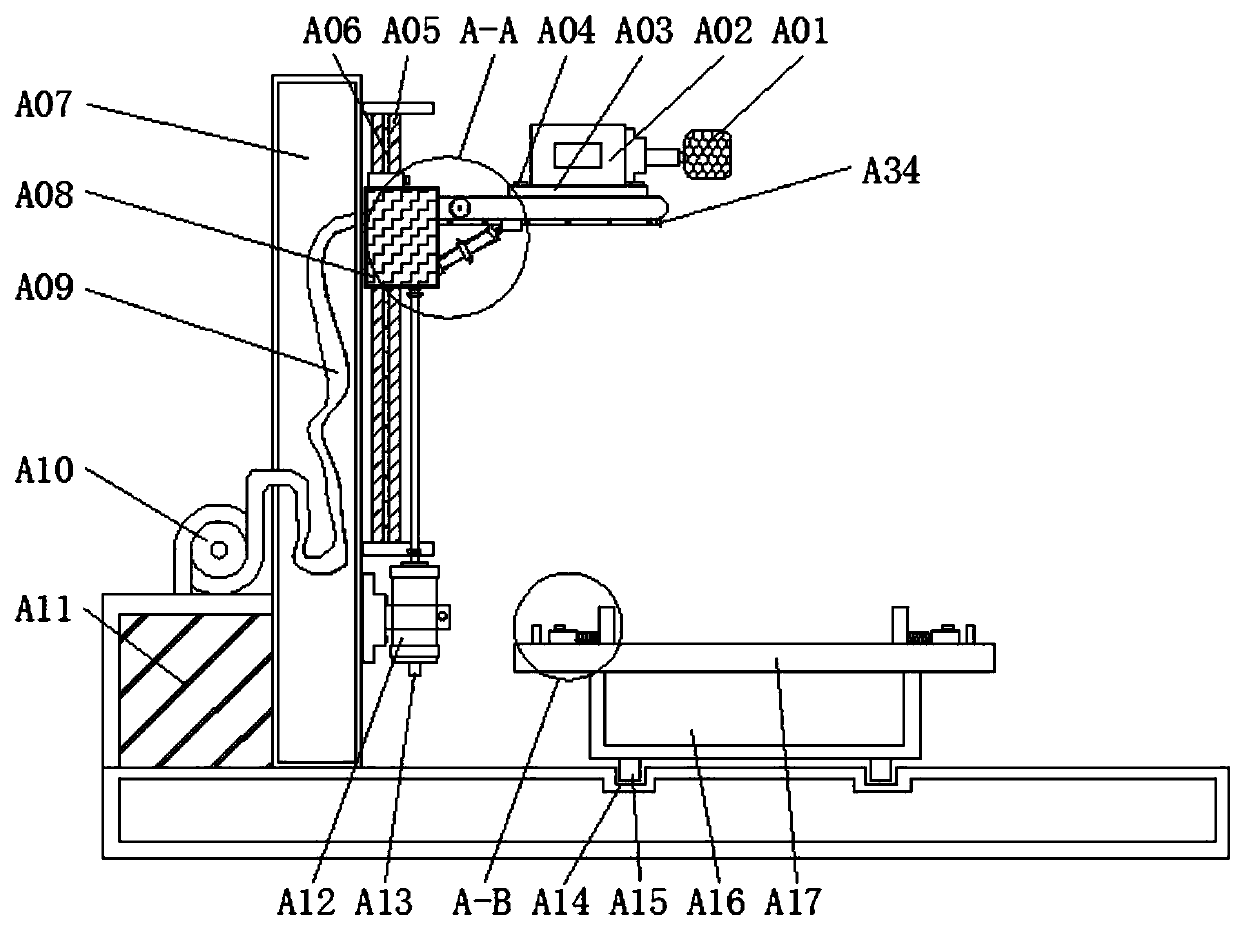

New-energy automotive parts polishing device with cleaning function

InactiveCN110026904AEasy to adjustEasy to adjust and grindGrinding carriagesGrinding drivesNew energyElectric machinery

The invention discloses a new-energy automotive parts polishing device with a cleaning function. The polishing device comprises a polishing drill bit, a column and a worktable, wherein a motor is installed on the left side of the polishing drill bit; fixing bolts are arranged inside a engine base; a fixing buckle is arranged at the lower portion of a transverse plate; the left side of a third sliding block is provided with a hydraulic tappet; a water pump is arranged on the left side of the column; a water pipe is arranged inside the column; a limiting plate is arranged at the upper portion ofthe worktable; a second fixing screw is installed at the upper portion of a limiting block; and a clamp is arranged on the right side of a spring. Compared with an existing polishing device, the new-energy automobile parts grinding device with the cleaning function can clean and collect waste debris generated by polishing at the first time, so that the pollution to the surrounding environment isreduced; most of new energy automobile parts can be polished, so that the applicability is wide; and the clamping is stable and convenient, and the polishing from different angles can be achieved, sothat the working time is saved, and the labor efficiency is improved.

Owner:诸暨市奔宝弹簧有限公司

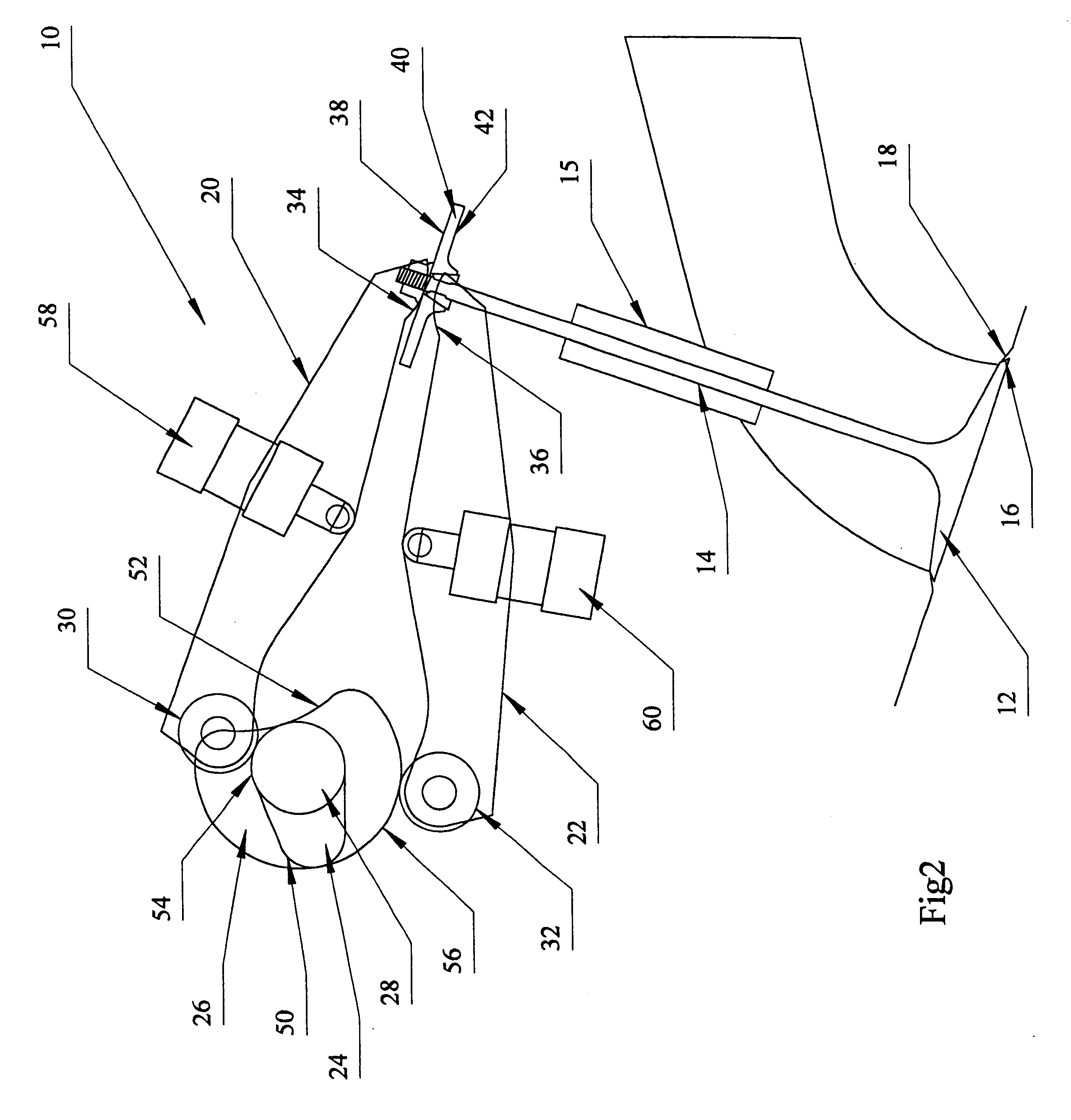

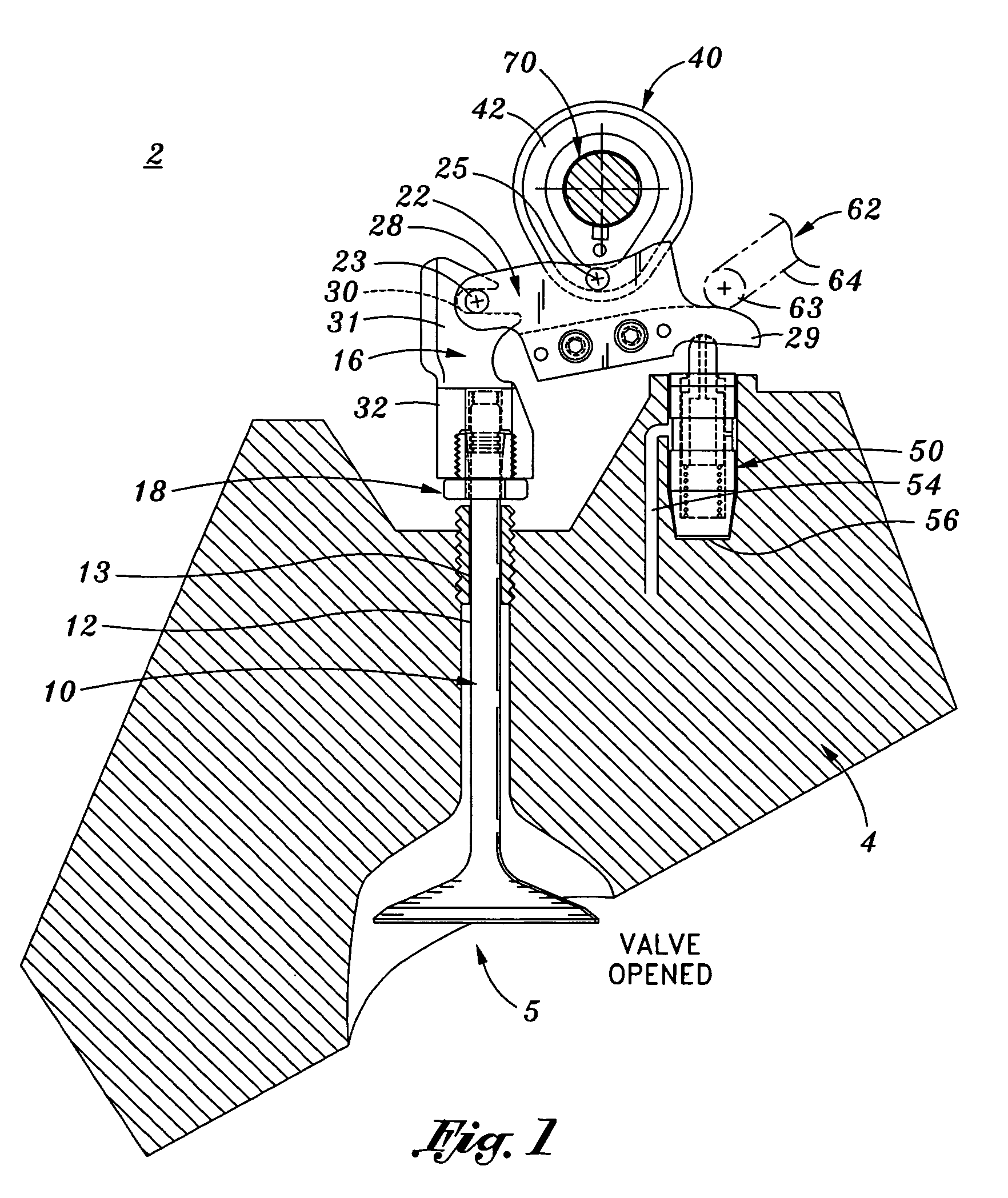

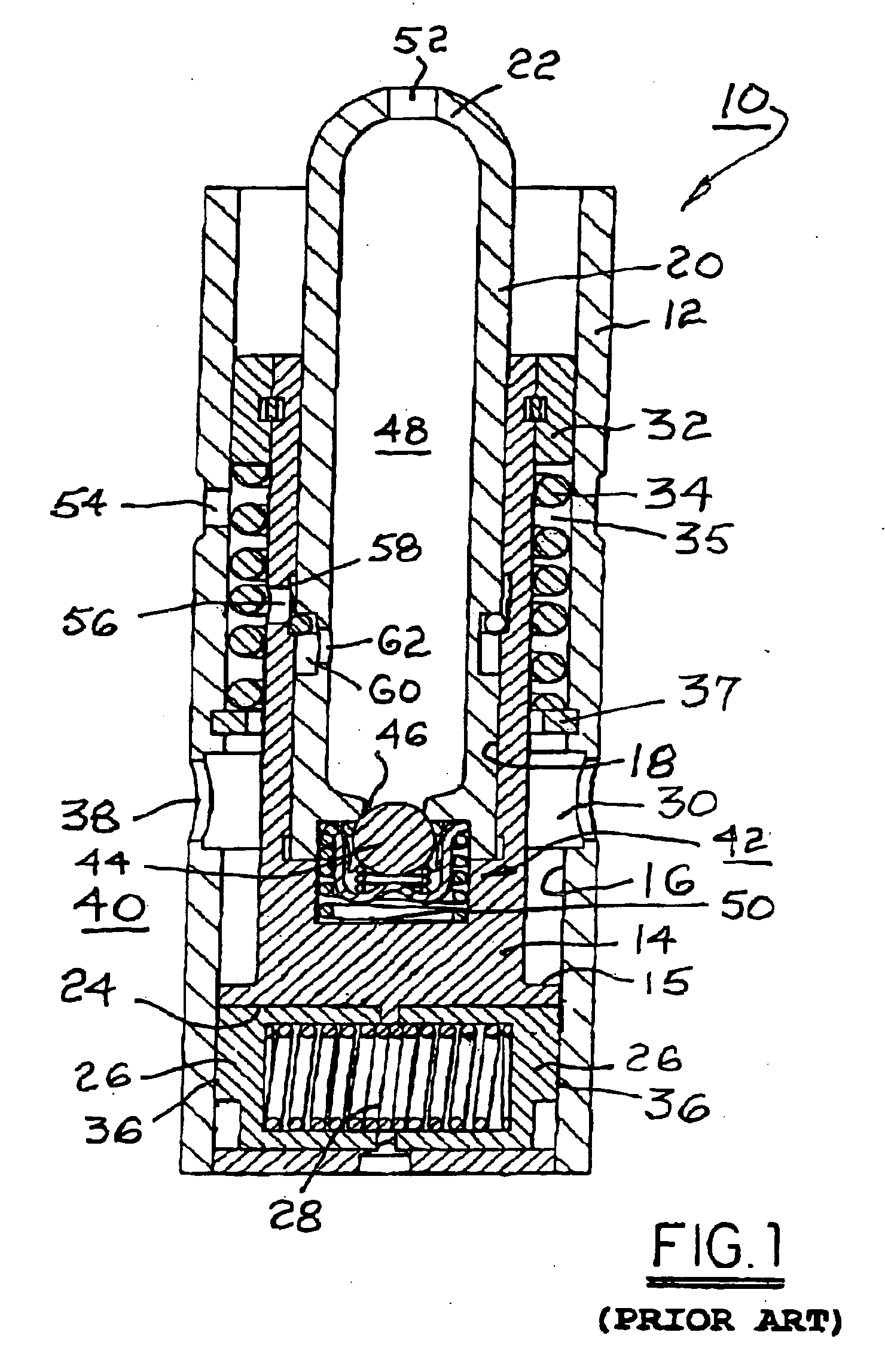

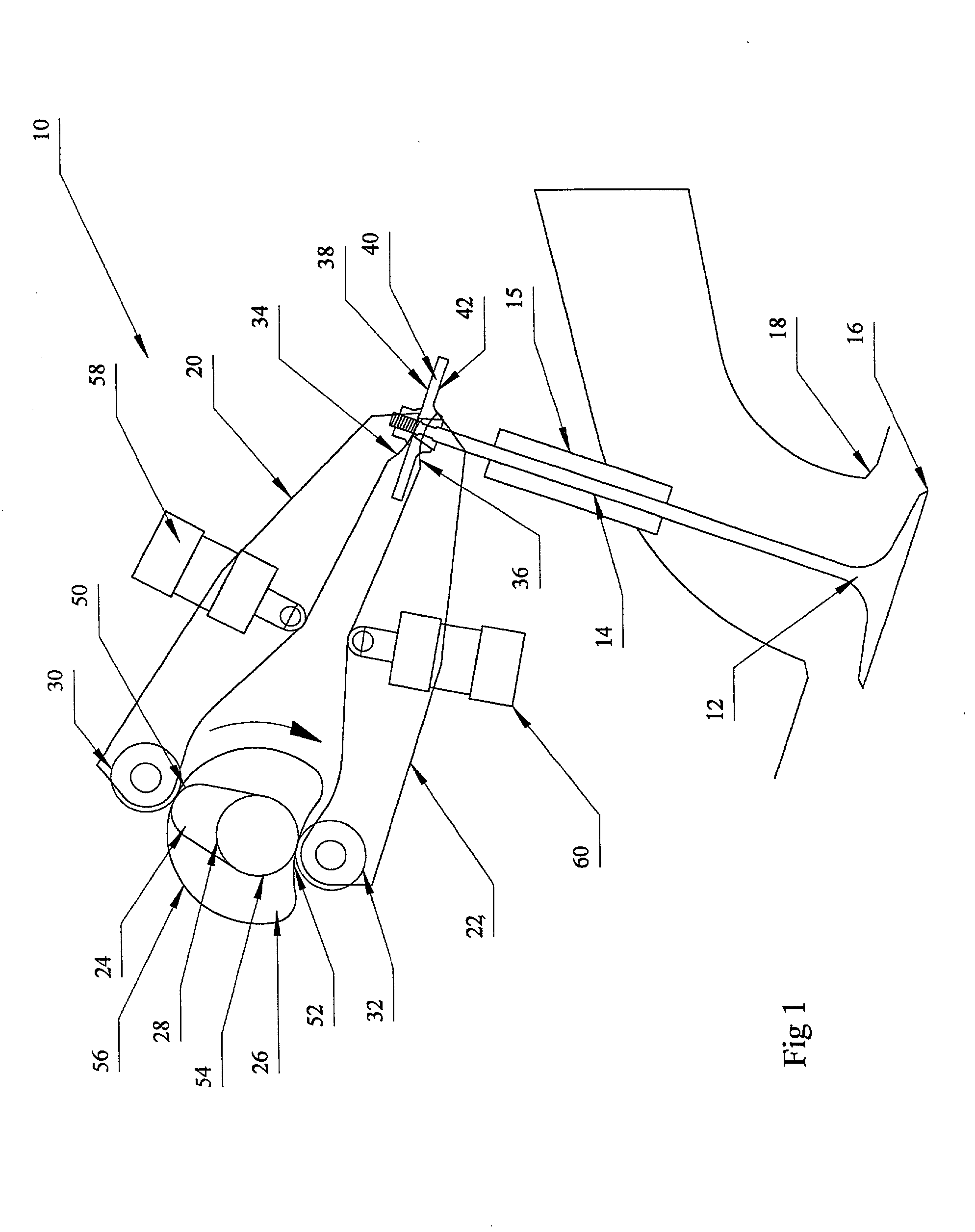

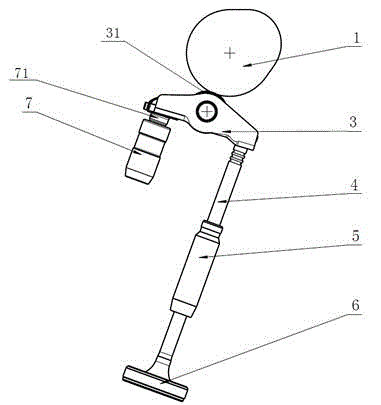

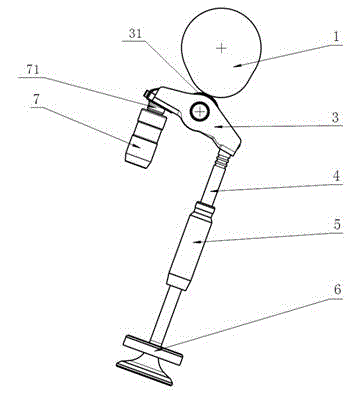

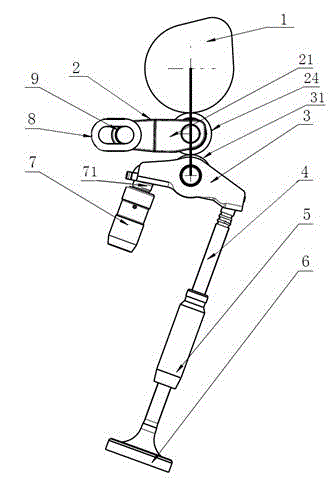

Springless poppet valve system

InactiveUS20020139335A1High valve actuation speedLess-costly to manufactureValve arrangementsMachines/enginesHigh liftEngineering

A springless poppet valve system is provided. The system includes a poppet valve movable between an open position and a closed position. The system also includes a cam shaft having an open cam and a close cam disposed thereon. An open rocker arm is also provided which has an open roller disposed to engage the open cam. The open rocker arm is operatively connected to the poppet valve so as to move the valve from the closed position to the open position when a high lift portion of the open cam engages the open roller. A close rocker arm is provided which has a close roller disposed to engage the close cam. The close rocker arm is operatively connected to the poppet valve so as to move the valve from the open position to the close position when a high lift portion of the close cam engages the open roller. An open hydraulic lifter is pivotally connected to the open rocker arm and operable to hold the open rocker arm in operative connection with the poppet valve. A close hydraulic lifter is pivotally connected to the close rocker arm and operable to hold the close rocker arm in operative connection with the poppet valve.

Owner:PALUMBO CHRIS

Cylindrical hydraulic tappet

ActiveCN104131852ASimple processing technologyImprove processing efficiencyValve arrangementsMachines/enginesEngineeringNoise reduction

Owner:HANGZHOU XZB TECH

Variable valve lift mechanism of engine

The invention discloses a variable valve lift mechanism of an engine. The variable valve lift mechanism comprises a cam arranged on a cam shaft, a hydraulic tappet positioned and mounted in a cylinder cover, a swinging arm of which one end is supported on the hydraulic tappet, a valve connected with the other end of the swinging arm, a swinging arm roller arranged in the middle of the swinging arm, a driving device, a slide bar which is connected with the driving device and is driven by the driving device to slide, a bar-shaped sliding chute component which is positioned and mounted in the cylinder cover and is matched with the slide bar, and a rocker arm located between the cam and the swinging arm, wherein the rocker arm consists of a supporting seat, a roller shaft and a rocker arm roller; one end of the supporting seat sleeves the slide bar, and the supporting seat can rotate relative to the slide bar; the roller bearing is positioned and mounted at the other end of the supporting seat; the rocker arm roller is connected to the roller shaft, and can rotate in the supporting seat relative to the roller shaft; the rocker arm roller is matched with the cam and the swinging arm roller, and the rotation of the cam is transferred to the swinging arm roller. Through the adoption of the mechanism, the lift of the valve can be changed, and more ideal gas distribution is achieved. At the same time, the structure is simplified, the reliability is improved, and the cost is reduced.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

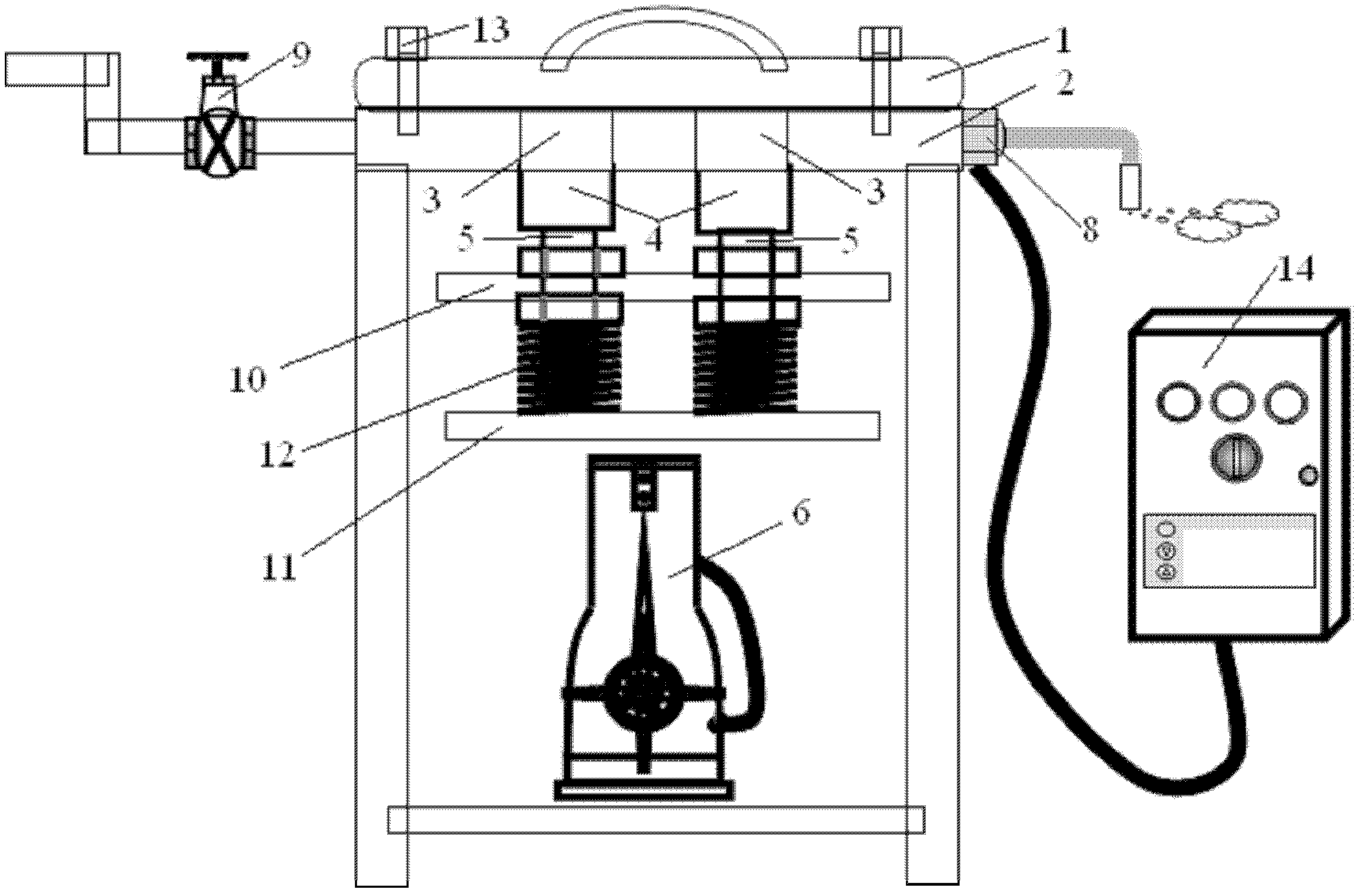

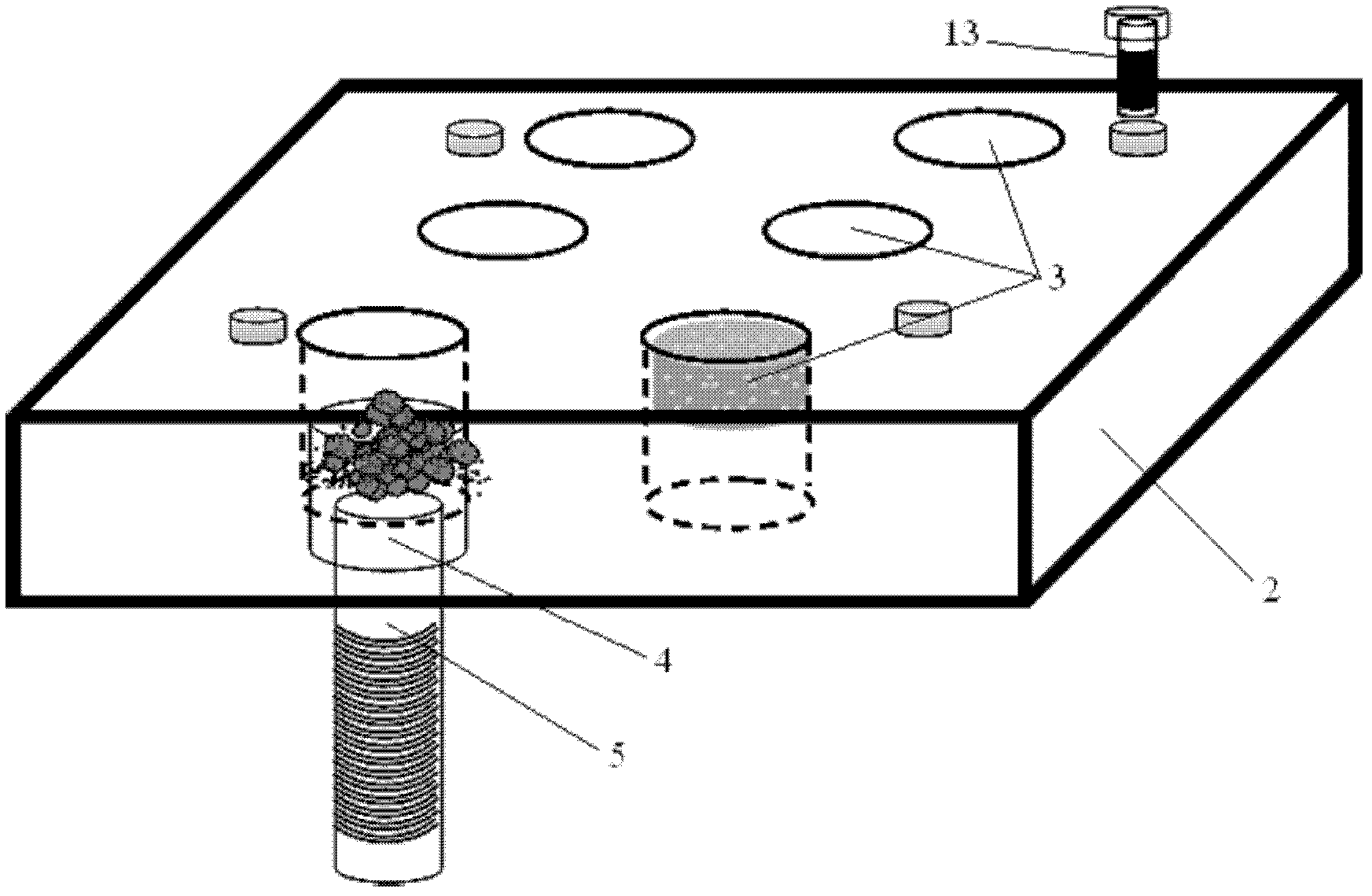

Multifunctional metallic phase sample inlaying machine

InactiveCN102359904ASolve the labor-intensiveImprove production efficiencyPreparing sample for investigationTemperature controlEngineering

The invention provides a multifunctional metallic phase sample inlaying machine, relating to a sample inlaying machine, which solves the problems that the existing sample inlaying machine has only one die cavity to press only one sample each time, and manual pressurizing wastes physical strength and has great labor intensity. The sample inlaying machine comprises a pressure cover board, a steel plate die, six die cavities, a plurality of plugs, a plurality of adjusting screw rods, a jack, a plurality of stem heating pipes, a temperature sensor, a heating control valve, No.1 support plate and a temperature control box; the pressure cover board is fixed on the steel plate die; the steam heating pipes are orthogonally arranged in the internal part of the steel plate die in a mesh shape; the six penetrating die cavities are uniformly arranged on the steel plate die; the plugs are arranged in the internal cavities of the die cavities; the plugs are fixed on the upper ends of the adjusting screw rods; the lower ends of the adjusting screw rods are fixed on the No.1 support plate; the No.1 support plate is fixed on the upper surface of a hydraulic tappet of the jack; the temperature sensor is arranged in the steel plate die; the steam heating pipes are communicated with a steam pipeline through a heating control valve; and the temperature sensor is connected with the temperature control box. The sample inlaying machine is used for manufacturing coal-rock analyzing sample.

Owner:HEILONGJIANG JIANLONG IRON & STEEL

Novel adjustable hydraulic tappet

The invention relates to a novel adjustable hydraulic tappet. The novel adjustable hydraulic tappet can remove engine valve clearance, and can enable an exhaust valve to keep continuously open through adjustment of hydraulic pressure under the working condition of engine brake, the opening degree is controlled by the hydraulic pressure, and therefore the power of engine brake is adjustable. The novel adjustable hydraulic tappet comprises a tappet disk which makes direct contact with an engine air distribution cam and a plunger which makes direct contact with a push rod, wherein an oil duct which is machined on an engine body is arranged between the tappet disk and the plunger, a proportional valve is arranged at the inlet of the oil duct, a solenoid valve is arranged at the outlet of the oil duct, and a one-way valve is installed at the inlet of a hydraulic chamber between the tappet disk and the plunger. When an engine normally works, the proportional valve inputs low oil pressure to remove the valve clearance; under the working condition of engine brake, the opening degree of a valve can be adjusted in a dynamic mode through the fact that the pressure of oil which flows into the oil duct can be adjusted through the proportional valve, and requirements of engine brake under different working conditions can be met. The novel adjustable hydraulic tappet can be used in matching with an engine exhaust emission retarder to achieve a better braking effect.

Owner:ZHEJIANG NORMAL UNIVERSITY

Continuously variable valve lift system

ActiveCN102852584AChange the amount of liftSimple structure and principleValve arrangementsMachines/enginesEngineeringEngine valve

The invention discloses a continuously variable valve lift system, which relates to the field of engine valve design; the continuously variable valve lift system comprises a first rocker arm; the bottom side of a first end of the first rocker arm is in contact with a valve and can push the valve; the bottom side of a second end of the first rocker arm is supported by a hydraulic tappet; the continuously variable valve lift system further comprises a second rocker arm which is used for pushing the first rocker arm and driven by a fixedly arranged driving cam; the second rocker arm is arranged on an eccentric wheel and uses the center of the eccentric wheel as rotation center; the position of the rotation center of the second rocker arm is changed; correspondingly, directions and sizes of a power arm and a resisting arm as well as an angle between the second rocker arm and a horizontal plane are changed; and then the rotation quantity of the first rocker arm is driven to be changed; and finally, the lift of the valve in contact with the first rocker arm is changed; and according to the invention, problems of incomplete performance, complicated structure and expensive manufacturing cost of a lifting engine of the traditional valve lift system are solved.

Owner:HANGZHOU BRANCH ZHEJIANG GEELY AUTOMOBILE RES INST +2

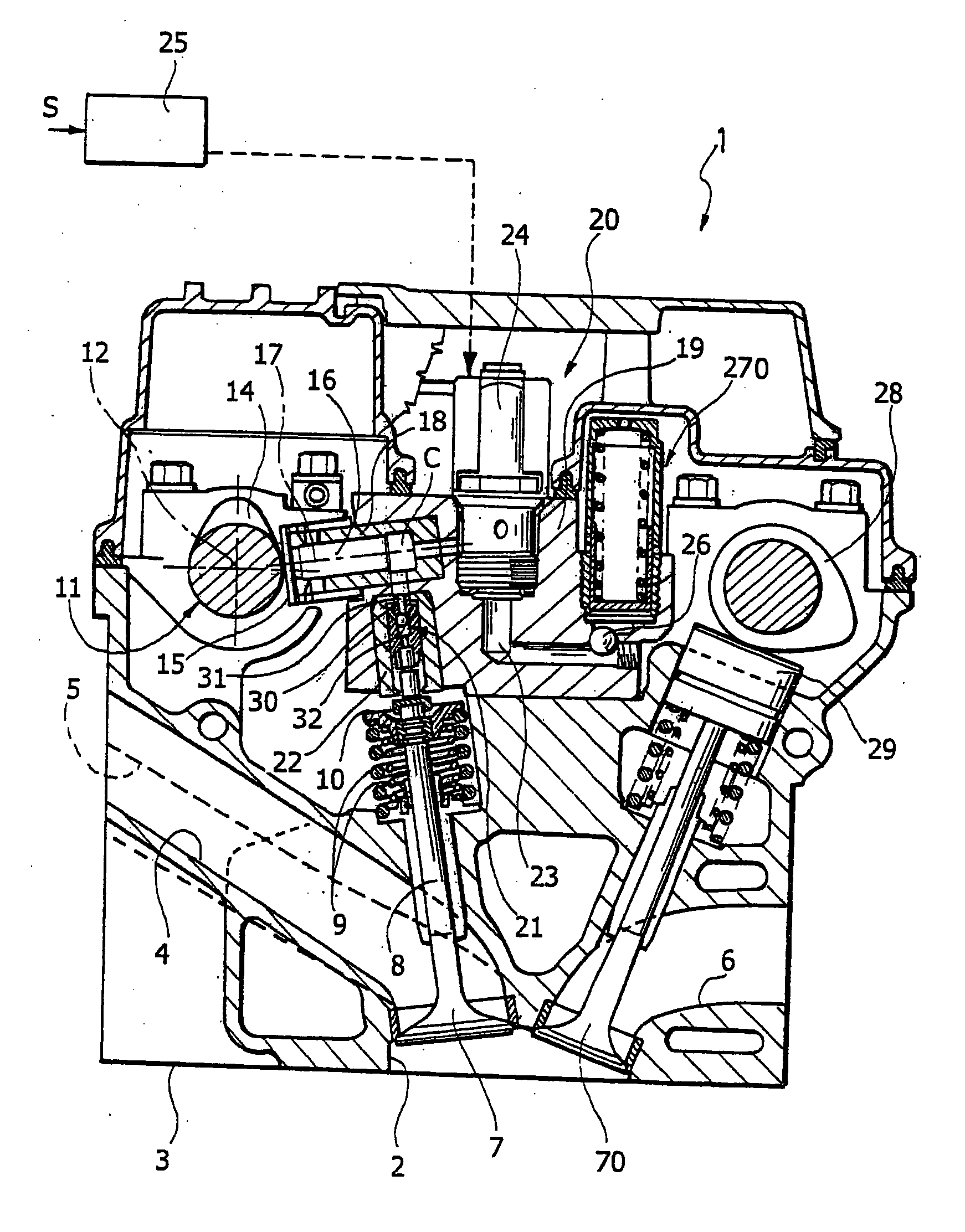

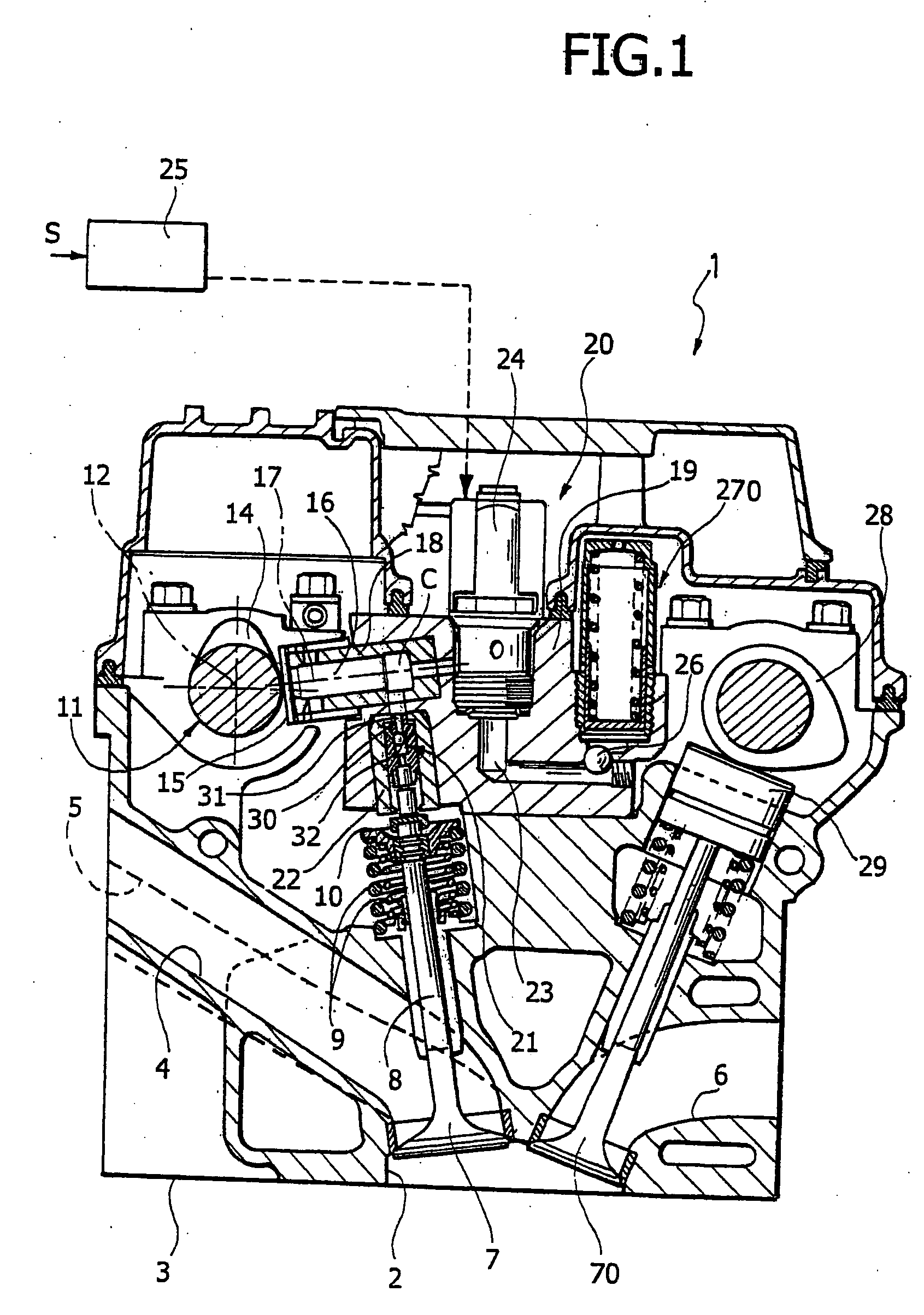

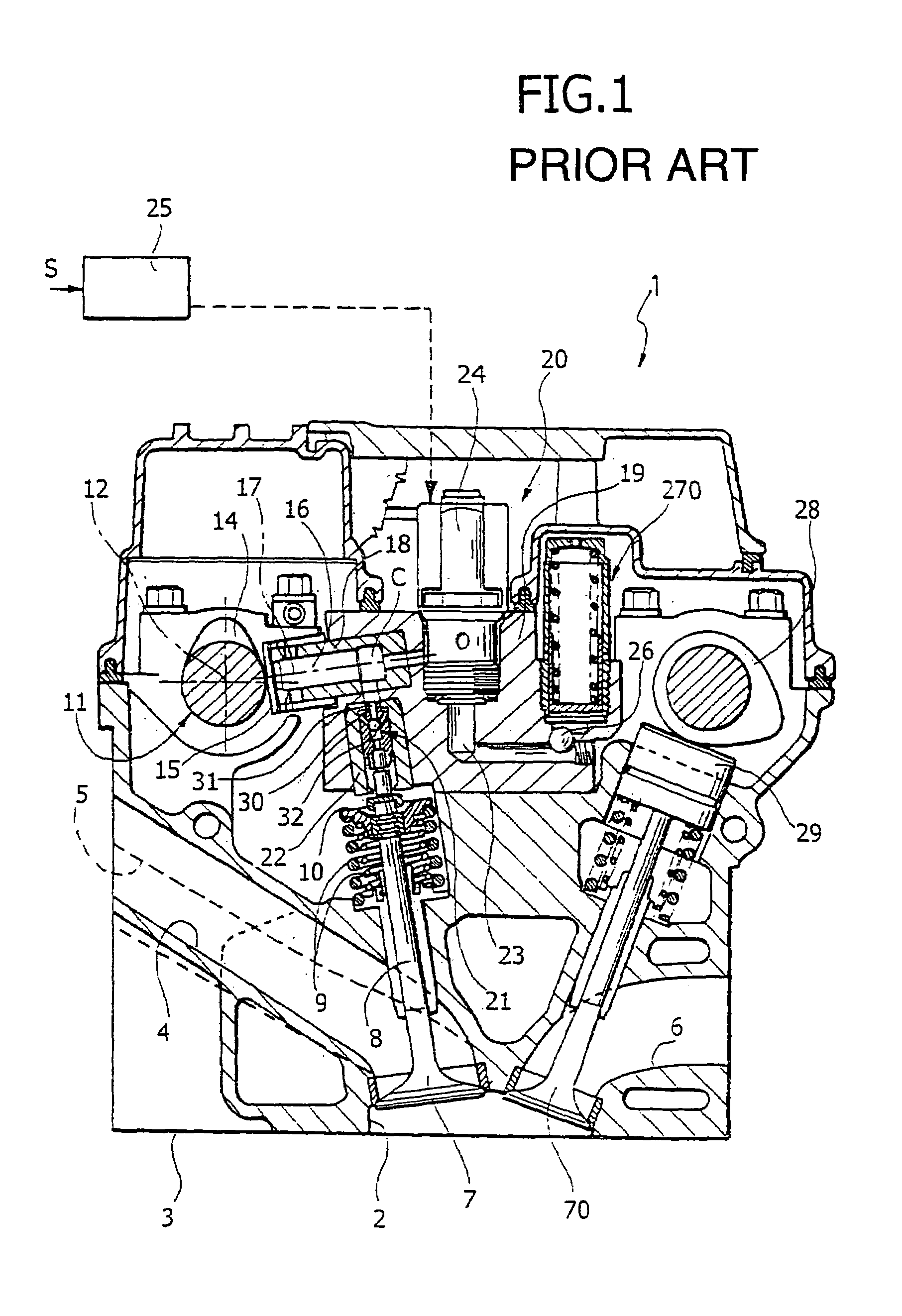

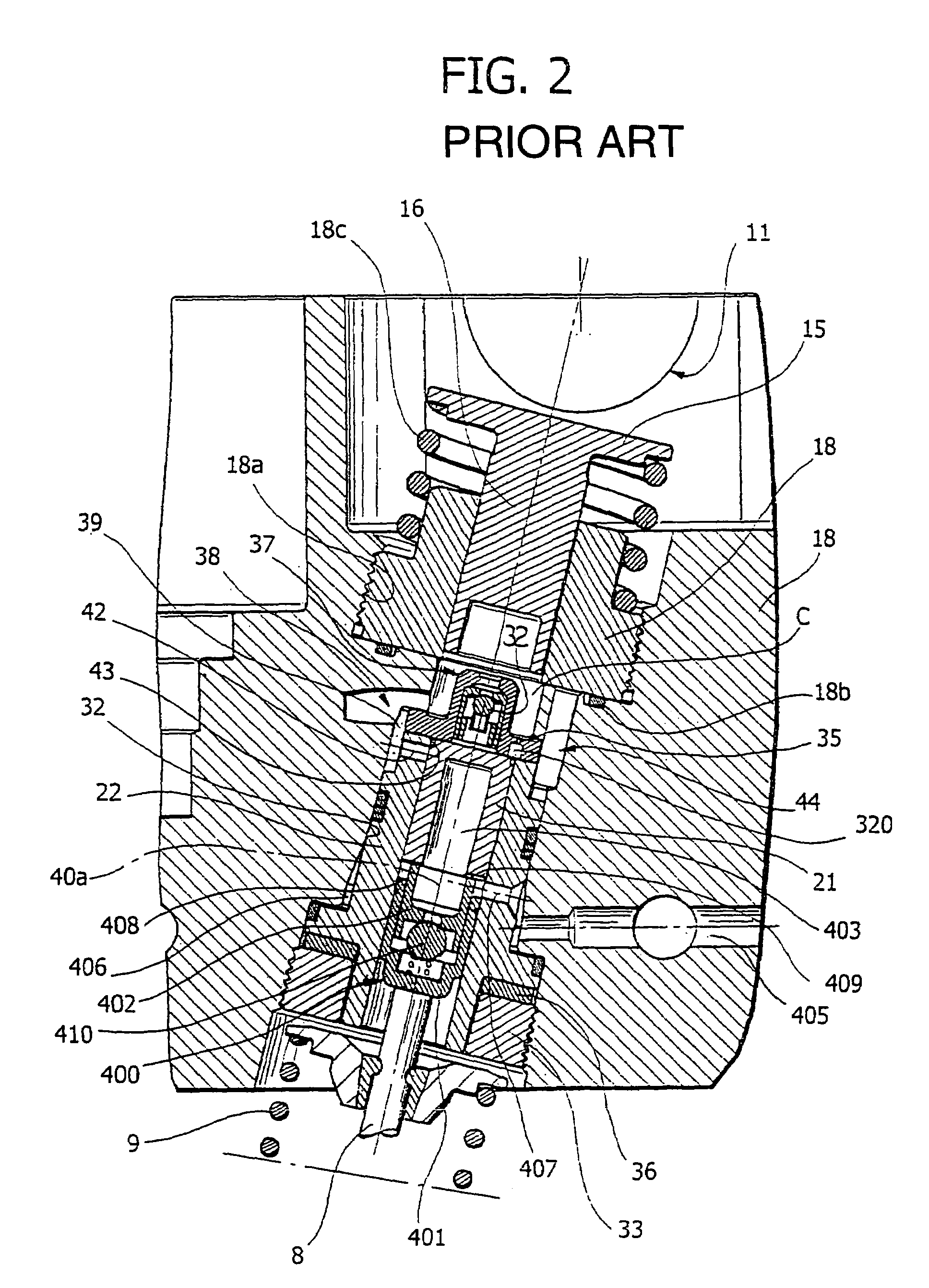

Internal combustion engine with valves with variable actuation which are driven by a single pumping piston and controlled by a single solenoid valve for each engine cylinder

ActiveUS20060137634A1Reduce the overall diameterMinimized volumeInternal combustion piston enginesOutput powerSolenoid valveEngineering

In an internal combustion engine with variable actuation valves, each variable actuation valve is actuated by an actuator assembly including an actuating piston slidably mounted in a guide bushing. Between the actuating piston and the stem of the respective valve is interposed an auxiliary hydraulic tappet positioned outside the guide bushing of the actuating piston, so that said bushing can be dimensioned with a relatively small diameter, regardless of the outer diameter of the auxiliary hydraulic tappet. The intake valves of a same cylinder are actuated by a single cam, by means of a single pumping piston and by means of a single pressure chamber controlled by a single solenoid valve.

Owner:CENT RICERCHE FIAT SCPA

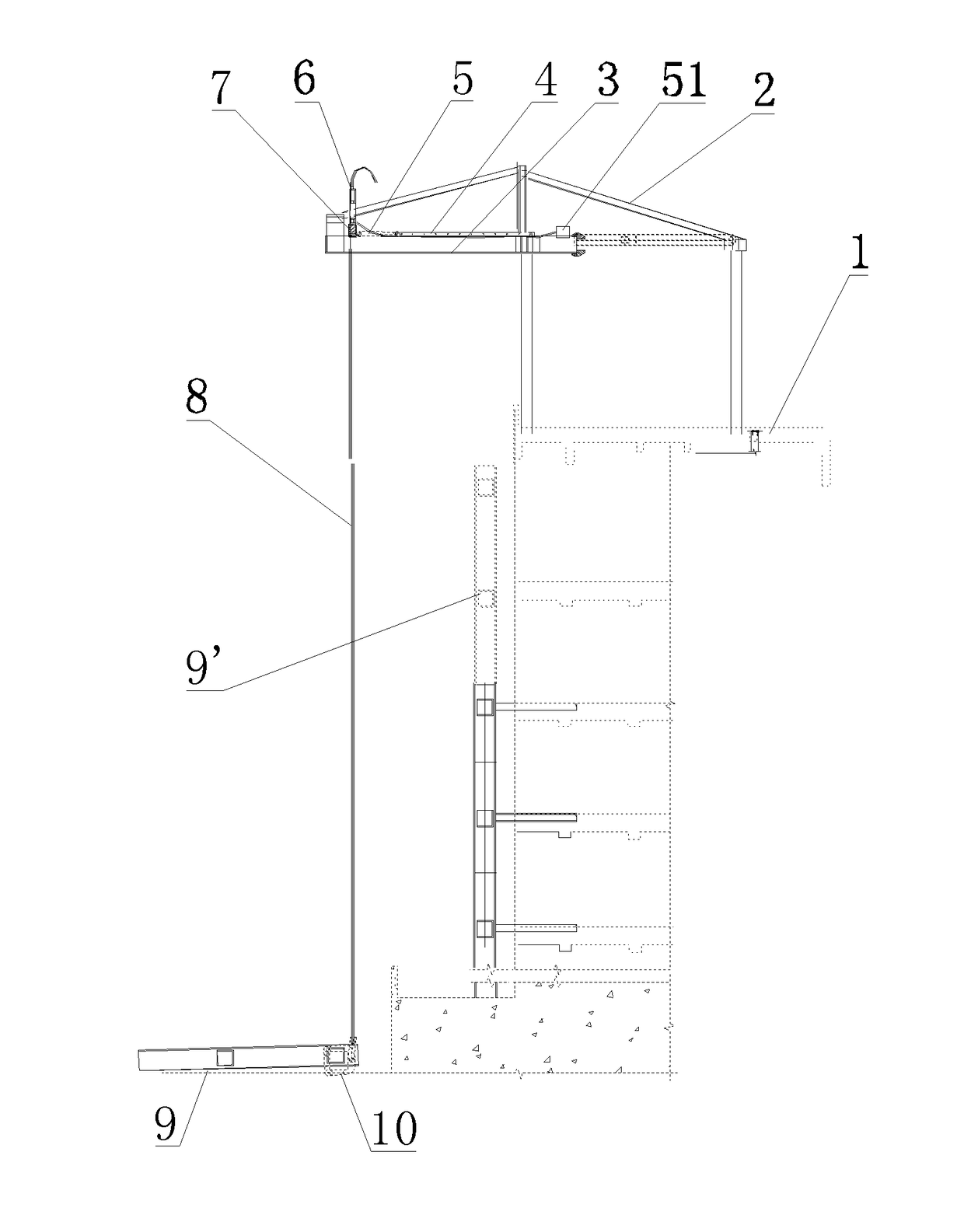

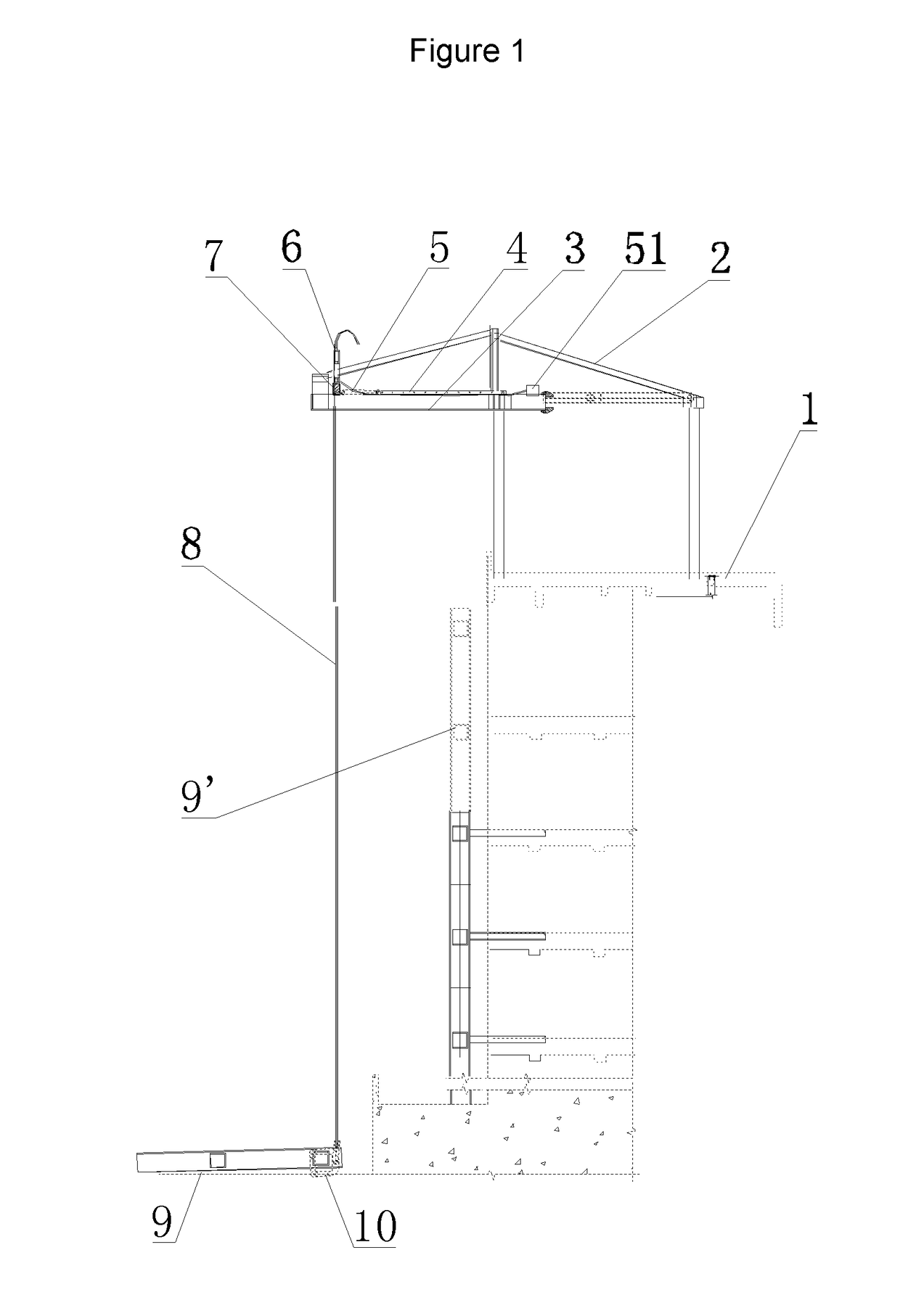

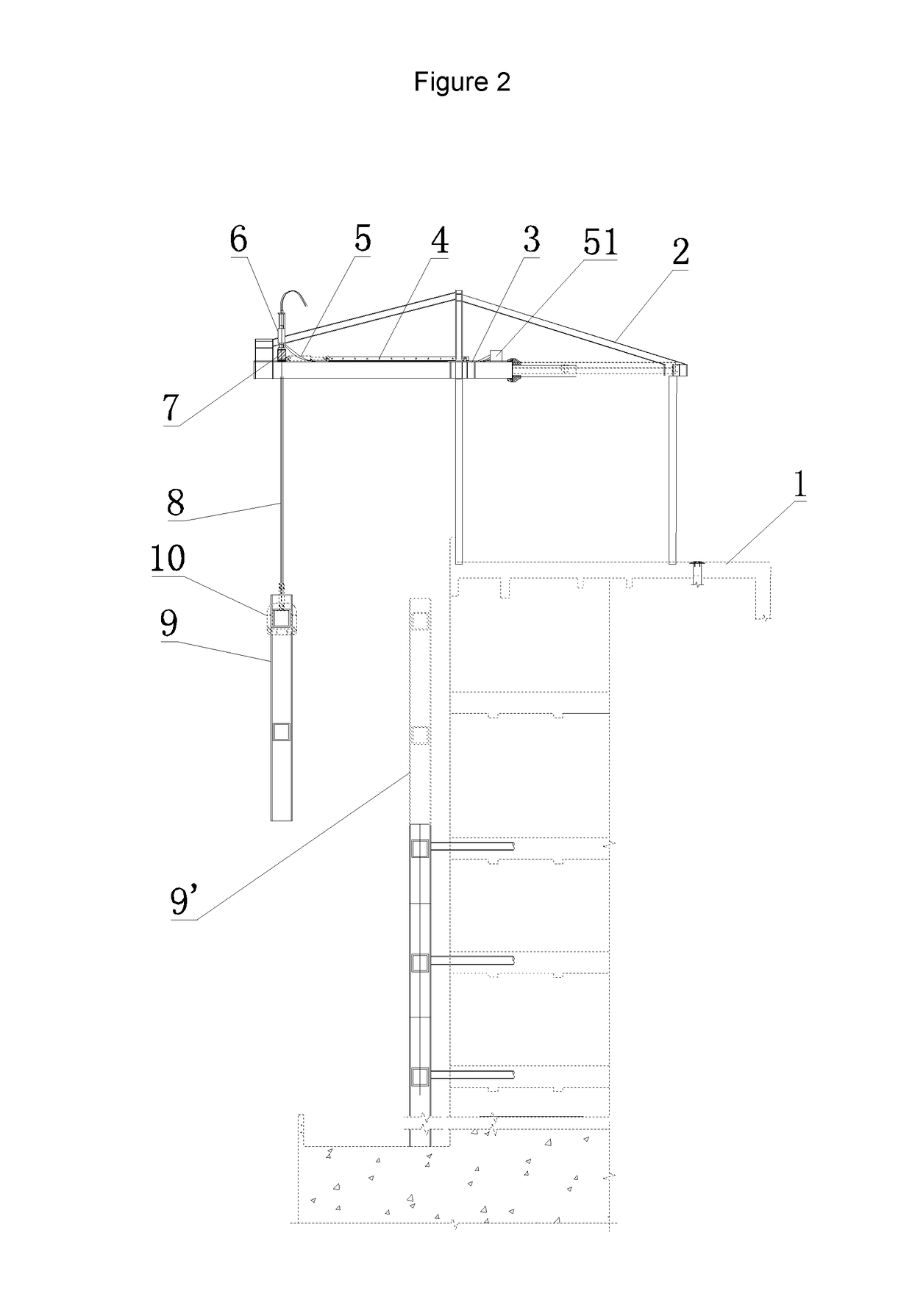

Apparatus and method for lifting and sliding a structure attached to the wall

InactiveUS20170089082A1Smooth slidingConnection or disconnection between the lifter and the structure convenientWallsBuilding material handlingMarine engineeringHydraulic tappet

Owner:GUANGZHOU DI ER CONSTR & ENG CO LTD +1

Mechanism for continuously adjusting engine valve lift

ActiveCN103670579AEasy to openReduce openingValve arrangementsMachines/enginesReciprocating motionElectric machine

A mechanism for continuously adjusting engine valve lift is used for solving the problem of matching between the engine valve lift and engine running conditions. The mechanism comprises an adjusting arm assembly, a swinging arm, a connecting arm, a rocking arm, an eccentric shaft and a motor, the adjusting arm assembly is hinged to the connecting arm through an adjusting pin, the connecting arm is fixedly assembled with the swinging arm which is assembled with the rocking arm, two ends of the rocking arm are assembled with a valve and a hydraulic tappet respectively, the eccentric shaft is connected with a motor output shaft, and a set of eccentric wheel is arranged on the eccentric shaft. The mechanism is characterized in that a set of eccentric shaft adjusting plate is further arranged, the eccentric shaft adjusting plate is assembled with the eccentric shaft through a reciprocating motion support, a first working face matched with the eccentric wheel and a second working face matched with the adjusting arm assembly are arranged on the eccentric shaft adjusting plate, and the second working face is a circular-arc working face. By the mechanism, requirements on air inflow of an engine under different working conditions are met, the number of parts is reduced, and manufacturing cost of the parts is lowered.

Owner:GREAT WALL MOTOR CO LTD

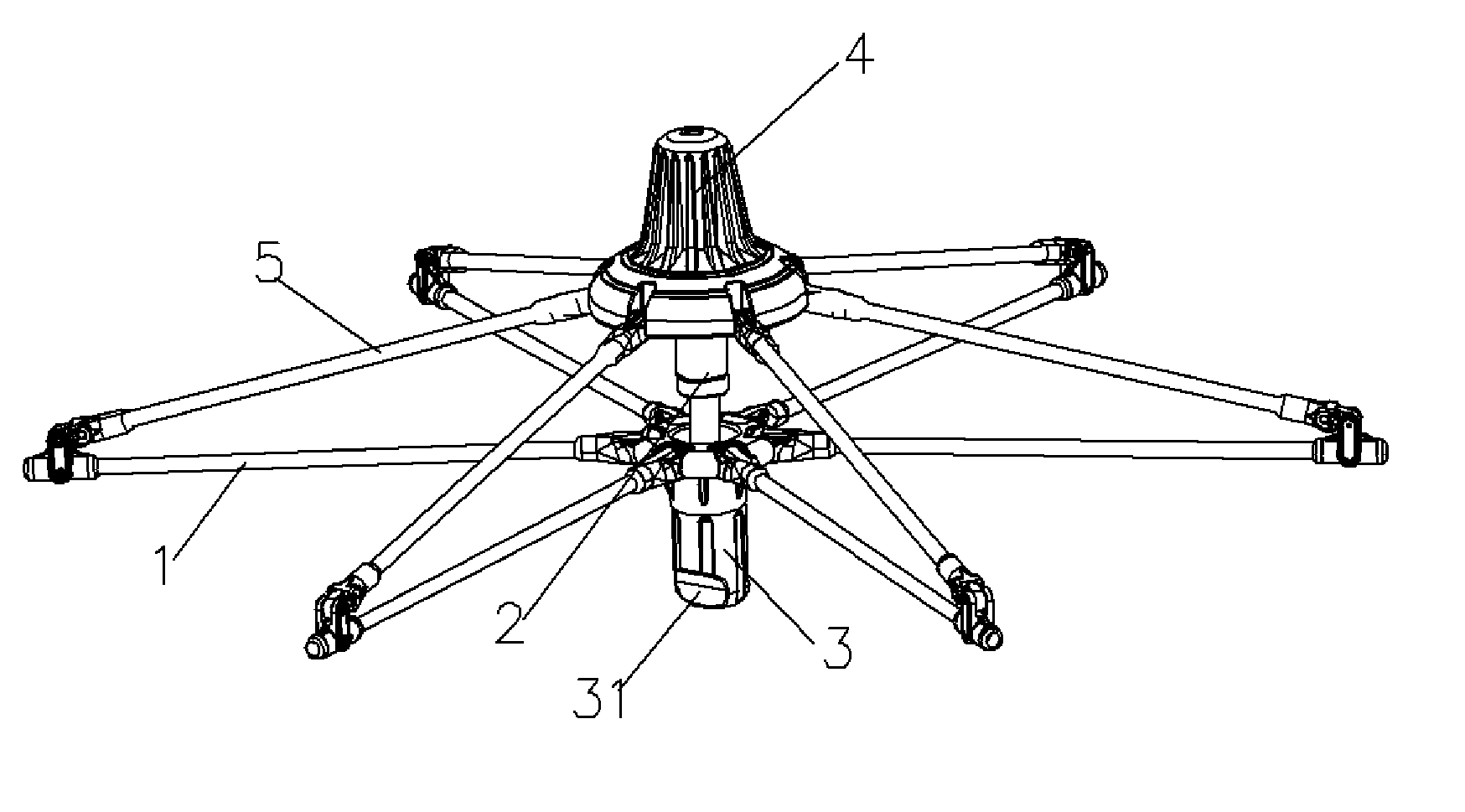

A Top Frame for Foldable Tent

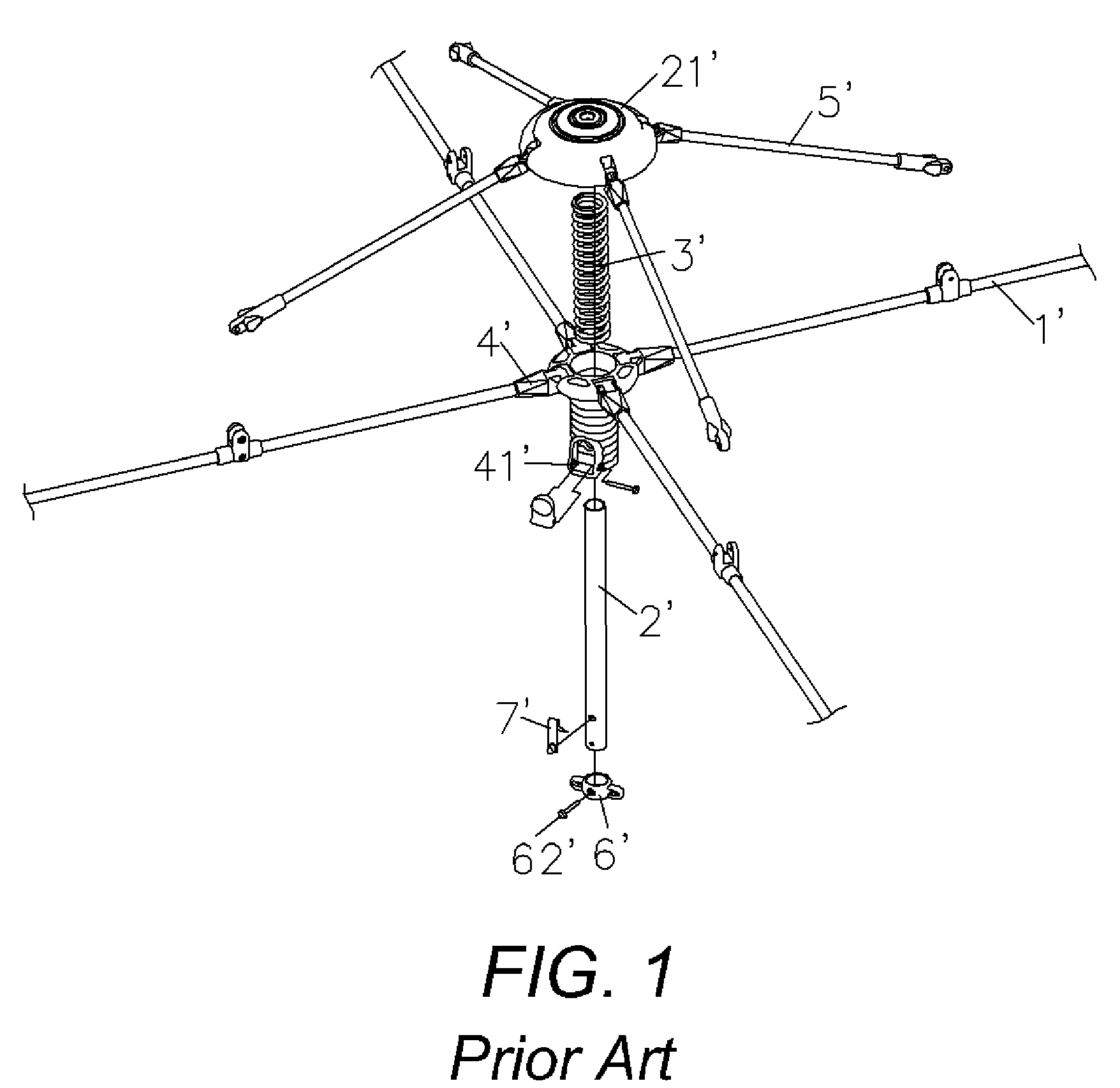

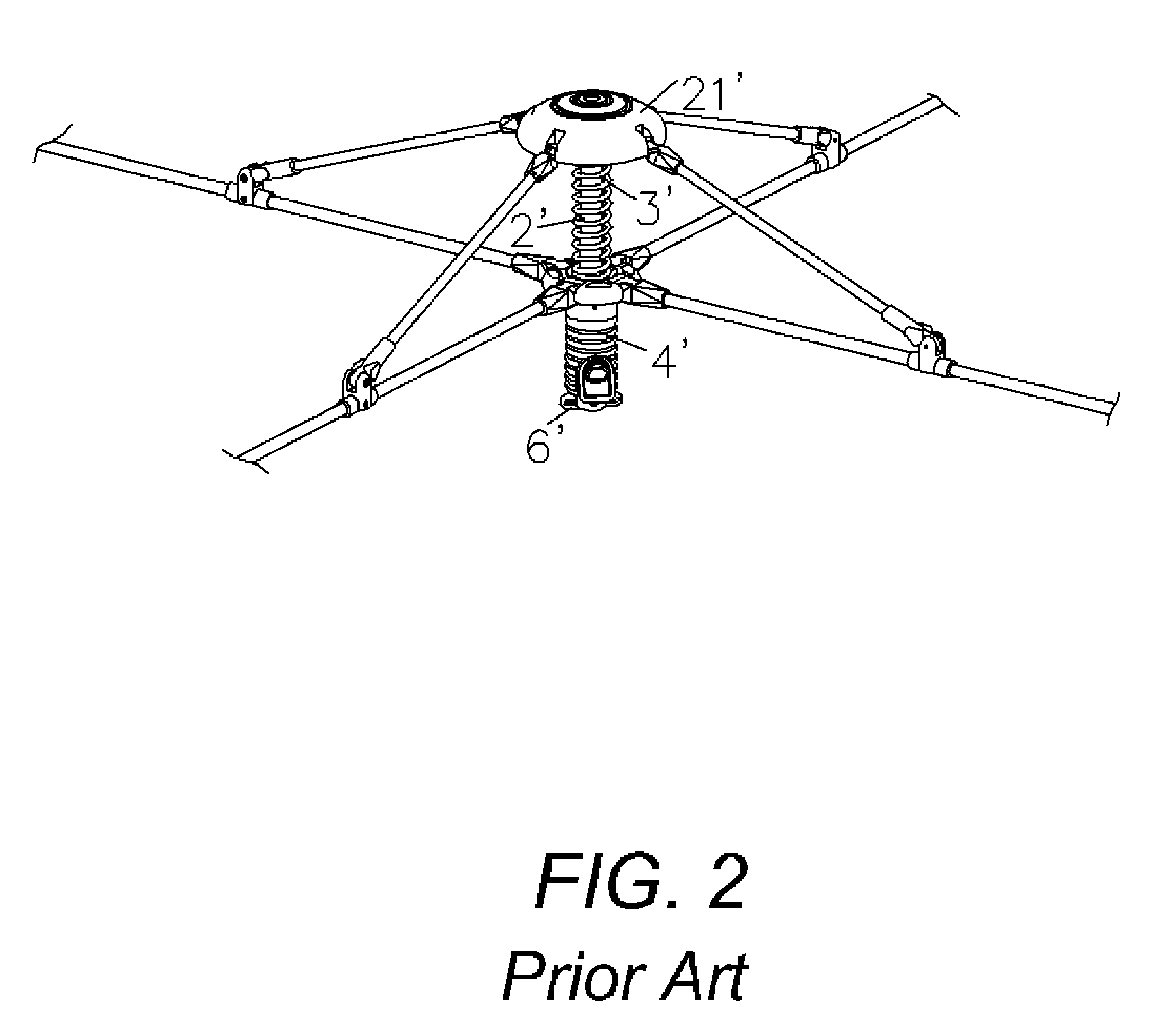

InactiveUS20070131265A1Simple structureFacilitating to manufacturing and combinationTents/canopiesEngineeringHydraulic tappet

The present invention provides a top frame of foldable tent including a set of foldable roof braces and a set of coordinated sub-braces constructing the main frame is typically employed with a hydraulic tappet fixed between the static pivot hub pivoting all the sub-braces and spreader pivoting all the roof braces with both ends, by means of the jack-up and hold-on features of the hydraulic tappet, said spreader is pushed down and kept in the ultimate position to bring the entire roof braces q and sub-braces to expend out. Said structure has fewer parts, simple, convenient for manufacturing and combination features.

Owner:CHOI KWAN JUN

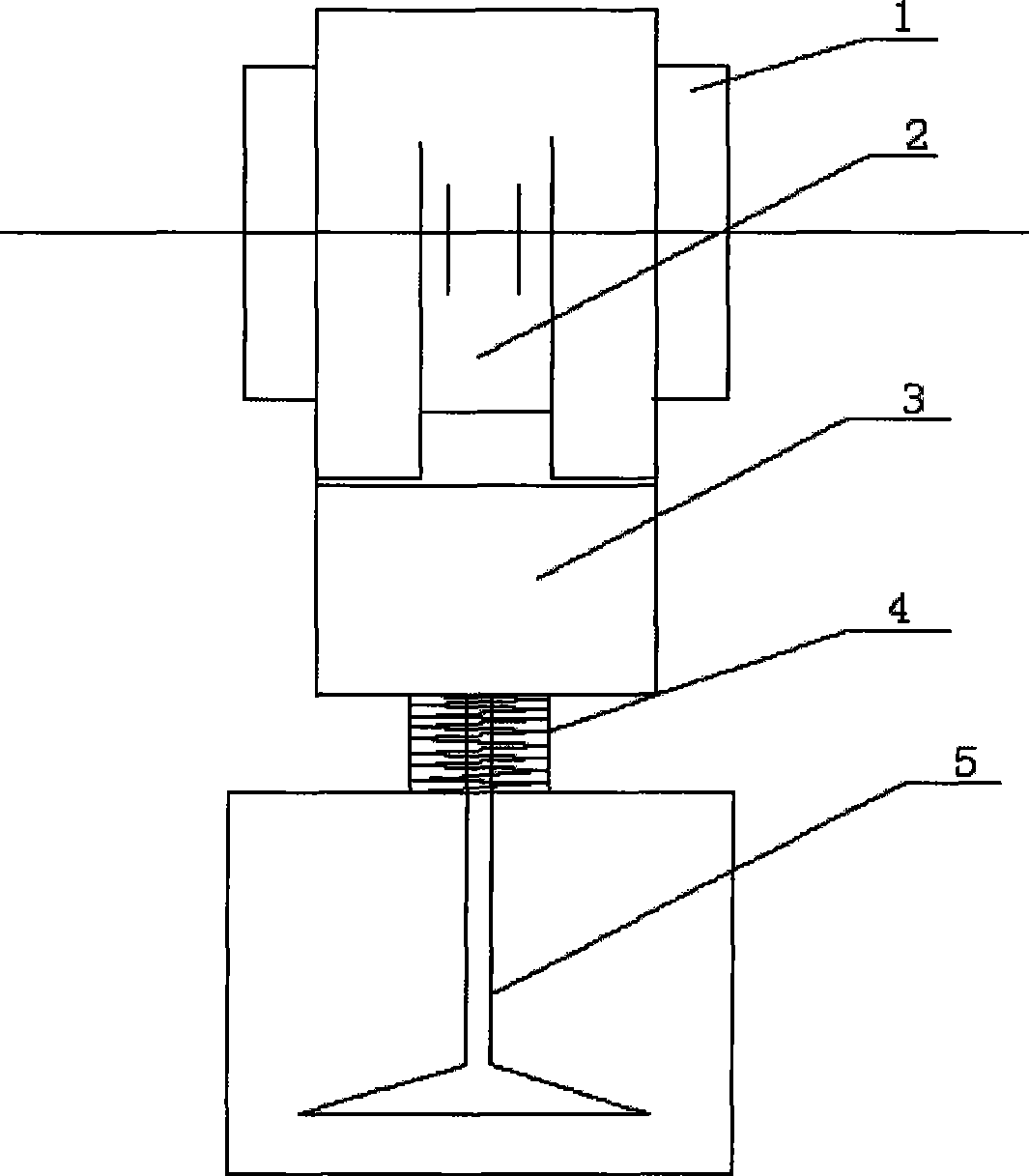

Process for formed hydraulic tappet guide cylinder

InactiveCN101028681ADense tissueImprove mechanical propertiesValve arrangementsExtrusion diesMetallic materialsEngineering

A technology for forming a guide barrel body of hydraulic tappet includes such steps as providing rod material, blanking by sawing, extruding to form front and back cavity, rolling to form annular oil slot and reinforcing ribs, and machining. It has high mechanical performance and fatigue resistance.

Owner:SHANGHAI UNIV OF ENG SCI

Continuous and changeable valve lift control mechanism

InactiveCN102852585AGood inflation efficiencyImprove powerValve arrangementsMachines/enginesVariable valve timingEngineering

Disclosed is a continuous and changeable valve lift control mechanism. The control mechanism is used for solving the control problem of valve lift matched with different working conditions of an engine. The control mechanism comprises a transmission component and a valve component. The transmission component comprises a cam, a rocker, a rocker supporting block, a rocker shaft, a rocker arm roller, a rocker arm and a hydraulic tappet. The control mechanism is characterized in that the rocker shaft can move up and down driven by a height adjusting motor which is fixedly mounted on an engine cylinder cover. The continuous and changeable valve lift control mechanism matched with a variable valve timing (VVT) system can be matched with the engine working conditions to adjust the valve opening lasting period and opening and closing moments, so that the gas feeding efficiency of the engine in all working conditions is the best, and the control mechanism is helpful for improving dynamic and economic properties and the discharge of the engine.

Owner:GREAT WALL MOTOR CO LTD

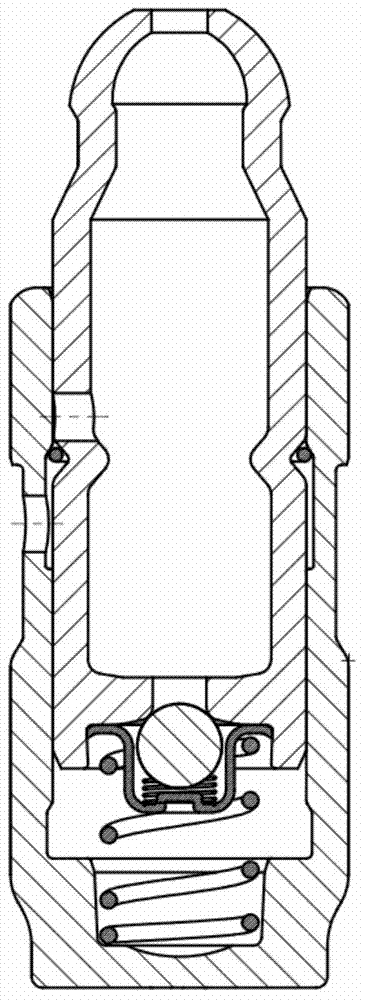

Internal combustion engine having valves with variable actuation each provided with a hydraulic tappet at the outside of the associated actuating unit

ActiveUS7210438B2Quick closeReduce the overall diameterMachines/enginesNon-mechanical valveExternal combustion engineHydraulic pump

In an internal combustion engine with variable actuation valves, each variable actuation valve is actuated by an actuator assembly including an actuating piston slidably mounted in a guide bushing. Between the actuating piston and the stem of the respective valve is interposed an auxiliary hydraulic tappet comprising a first bushing and a second bushing positioned inside the first bushing in such a way as to define a first chamber between the second bushing and the actuating piston, and a second chamber between the two bushings of the hydraulic tappet. The first chamber is fed a pressurized chamber of the engine lubrication loop. A check valve controls a communication between the two chambers of the tappet, to allow the passage of fluid in the direction of the second chamber. The first bushing of the auxiliary hydraulic tappet is positioned outside the guide bushing of the actuating piston, so that said bushing can be dimensioned with a relatively small diameter, regardless of the outer diameter of the auxiliary hydraulic tappet.

Owner:CENT RICERCHE FIAT SCPA +1

Engine lubrication system

ActiveCN104879183ASimple resultImprove the lubrication effectLubrication of auxillariesMachines/enginesTurbochargerKinematic pair

An engine lubrication system comprises a cabinet. A turbocharger, a lubricating oil tank, an oil cooler, an oil pump and an oil filter which are connected sequentially are arranged on the cabinet. The oil filter is connected with a main oil way in the cabinet. A bent axle hole and a camshaft hole are formed in the cabinet. The main oil way is communicated with the bent axle hole, the camshaft hole and mounting holes, used for mounting hydraulic tappets, on two sides of the camshaft hole. An oil storage tank communicated with the bent axle hole, the camshaft hole and the mounting holes is arranged at the bottom of the cabinet. An oil drainage hole is formed in the lower portion of the oil storage tank. The engine lubrication system is simple in structure, bent axle kinematic pairs, camshaft kinematic pairs and the like can be lubricated at different angles, and lubrication efficiency is improved.

Owner:重庆宗申航空发动机制造股份有限公司

Valve mechanism

ActiveCN103061845ARealize stepless adjustmentTimingValve arrangementsMachines/enginesHydraulic pumpEngineering

The invention discloses a valve mechanism which comprises a cylinder cover, a first hydraulic tappet, a second hydraulic tappet, a switch valve, a drive part, and a valve. The cylinder cover is provided with a passage and a high-pressure oil duct, the first hydraulic tappet and the second hydraulic tappet are respectively and slidingly arranged at two ends of the passage, the first hydraulic tappet, the second hydraulic tappet and the inner wall of the passage enclose to form a hydraulic cavity, the hydraulic cavity is communicated with the high-pressure oil duct through a connecting oil duct, the switch valve is arranged on the connecting oil duct and controls the on-off of the connecting oil duct, the drive part is connected with the first hydraulic tappet and drives the first hydraulic tappet to slide in the passage, and the valve is connected onto the second hydraulic tappet. By the aid of the valve mechanism, stepless regulation of valve lift and valve control can be achieved, and the valve mechanism is simple in structure and low in cost.

Owner:HANGZHOU BRANCH ZHEJIANG GEELY AUTOMOBILE RES INST +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com