Novel adjustable hydraulic tappet

A hydraulic tappet, a new type of technology, is applied to non-mechanically actuated valves, engine components, machines/engines, etc. It can solve problems such as limited working length adjustment range, inability to drive exhaust valves to open, and enhance engine effects, etc., to achieve The effect of enhancing the braking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] An embodiment of the present invention will be described in detail with reference to the accompanying drawings.

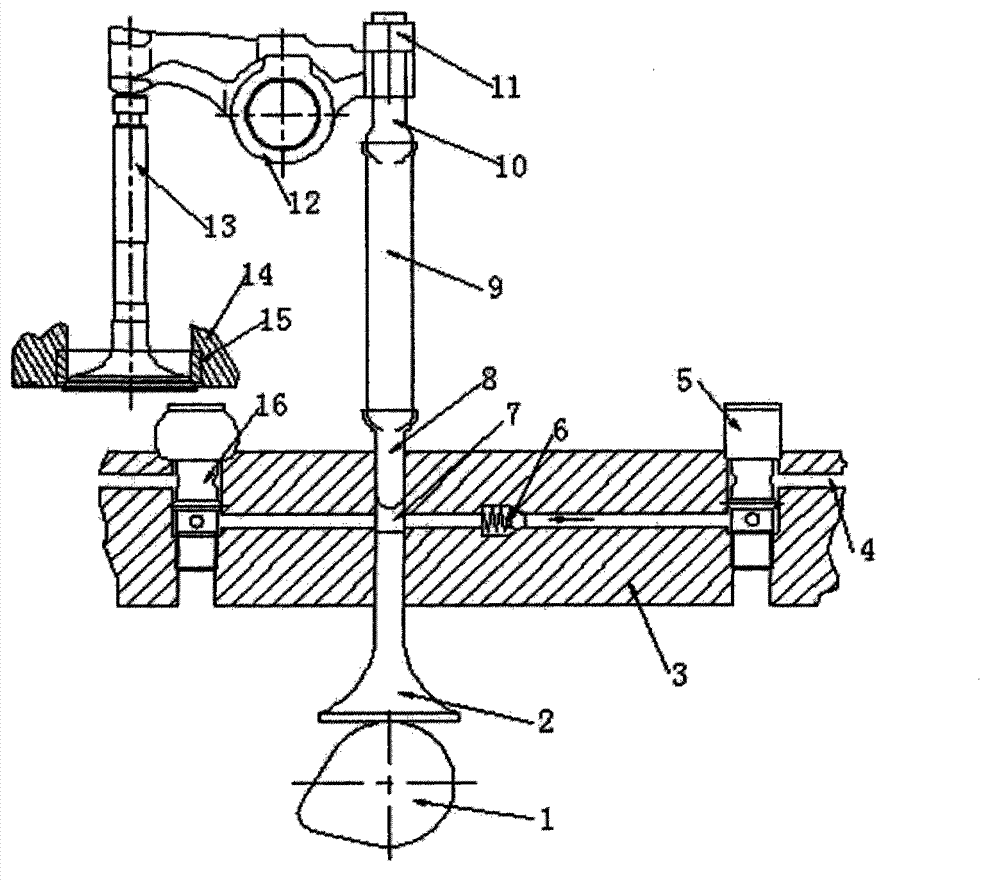

[0015] Such as figure 1 As shown, a new type of adjustable hydraulic tappet includes a tappet disk (2) in direct contact with the gas distribution cam (1), a plunger (8) in direct contact with the push rod (9), and the plunger (8) The lower end surface is spherical, and forms a hydraulic oil cavity (7) with the upper end surface of the tappet disk (2). A check valve (6) is arranged at the inlet of the hydraulic oil chamber (7), and a solenoid valve (16) is arranged at the outlet. When the valve lift is zero, the hydraulic oil chamber (7) communicates with the oil passage (4) processed on the body. The inlet of the oil passage (4) is provided with a proportional valve (5), which is controlled by the engine ECU and can dynamically adjust the oil pressure entering the oil passage (4) and the hydraulic oil chamber (7). When the engine was running normally, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com