Patents

Literature

2877results about "Non-mechanical valve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

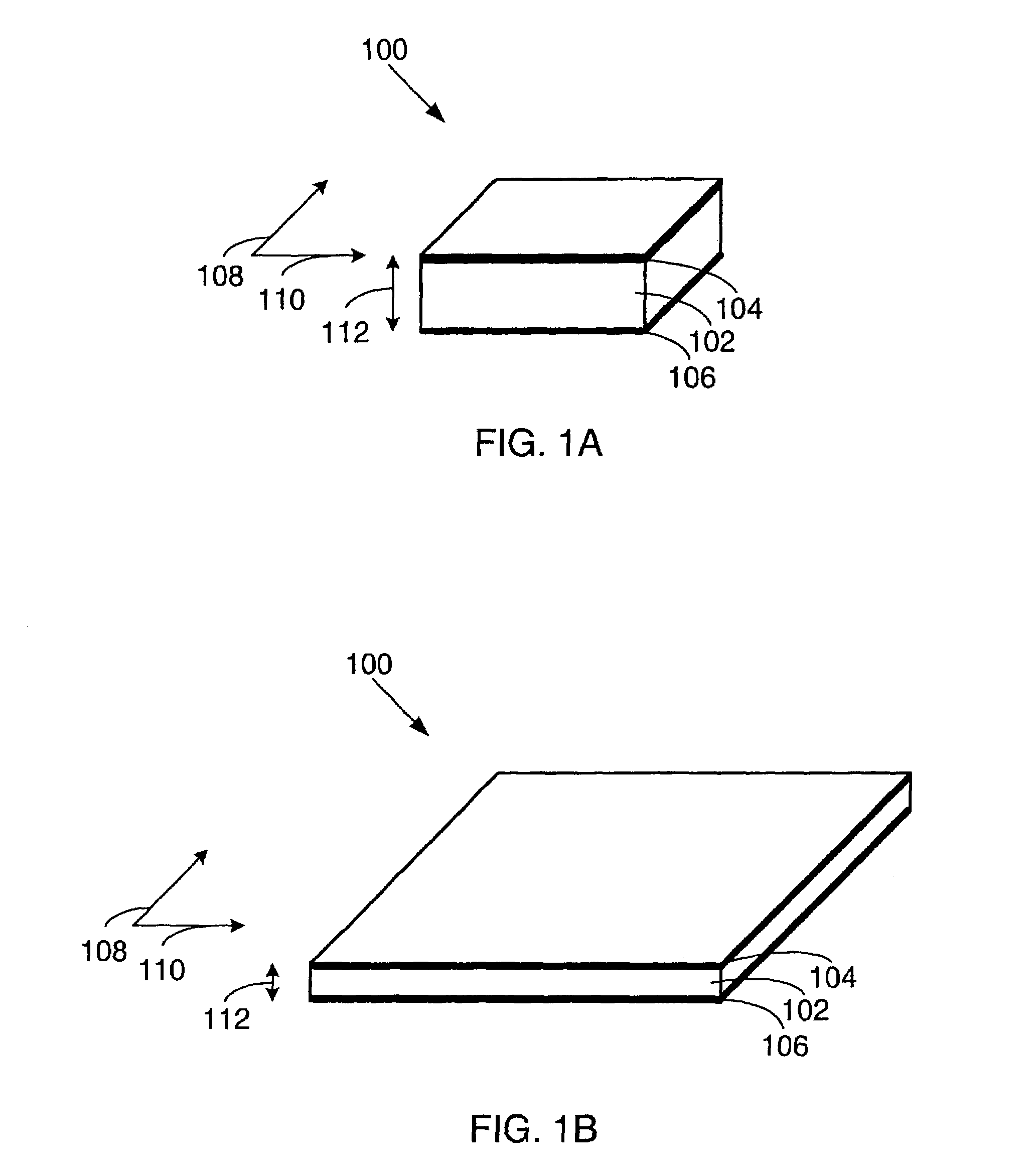

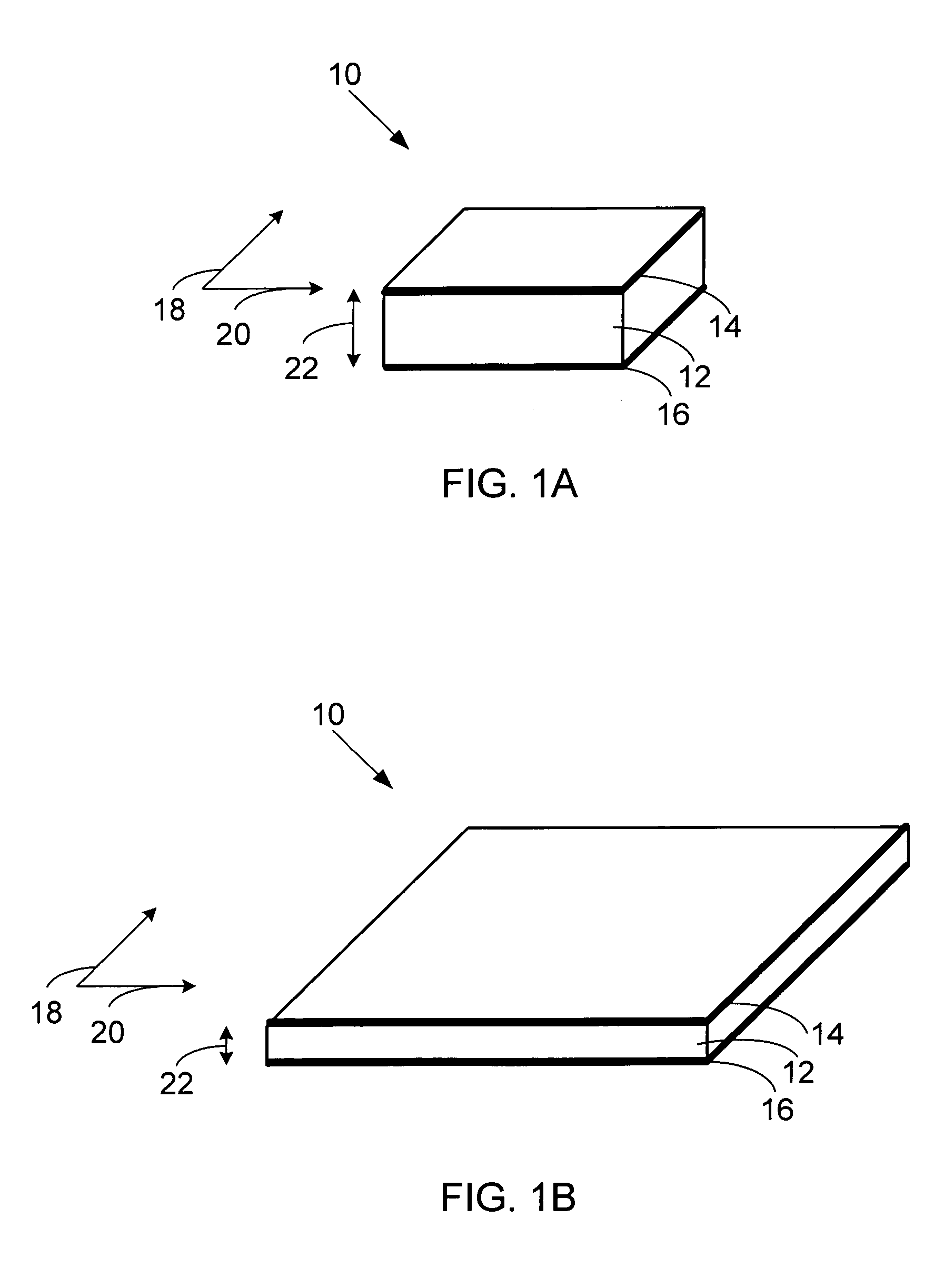

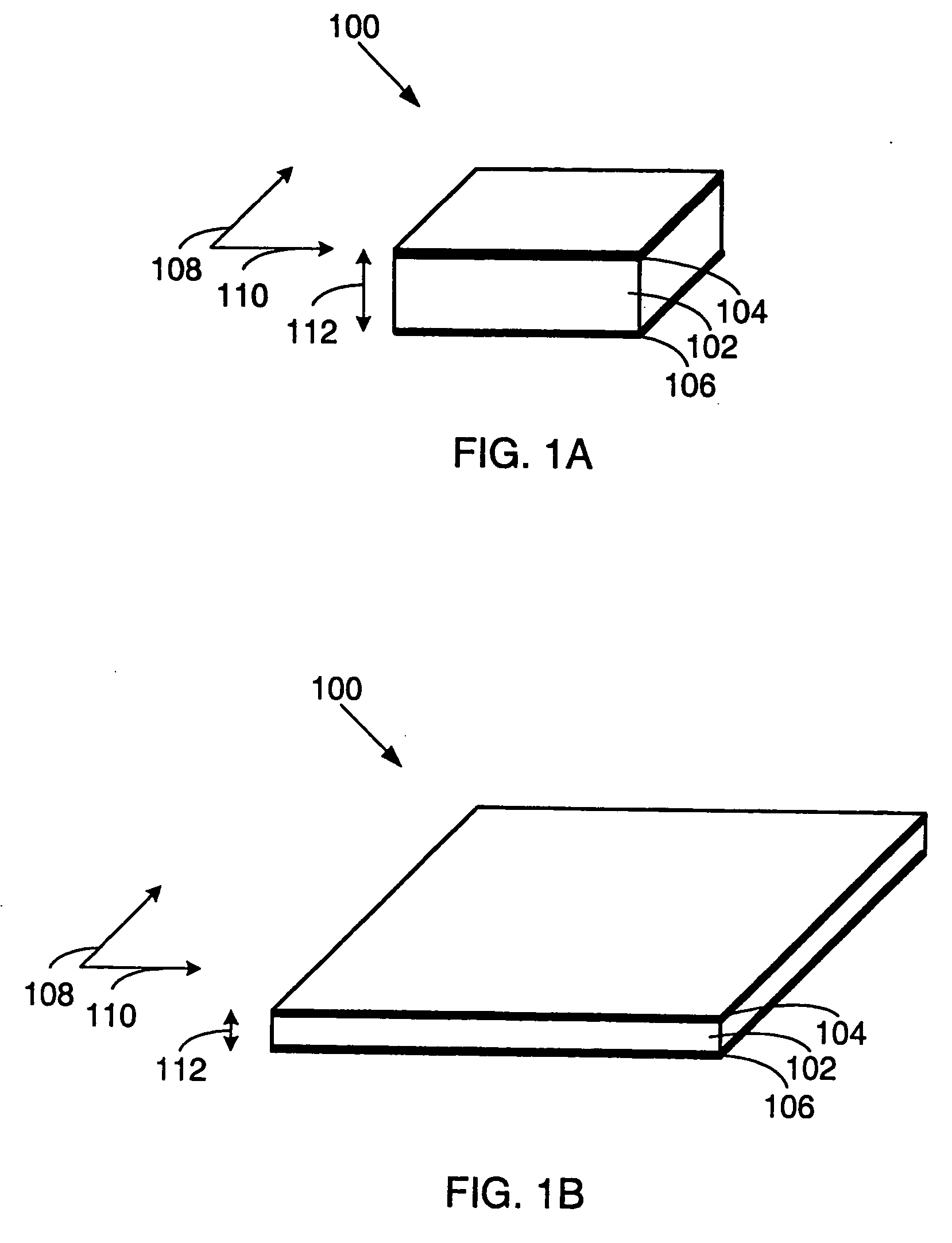

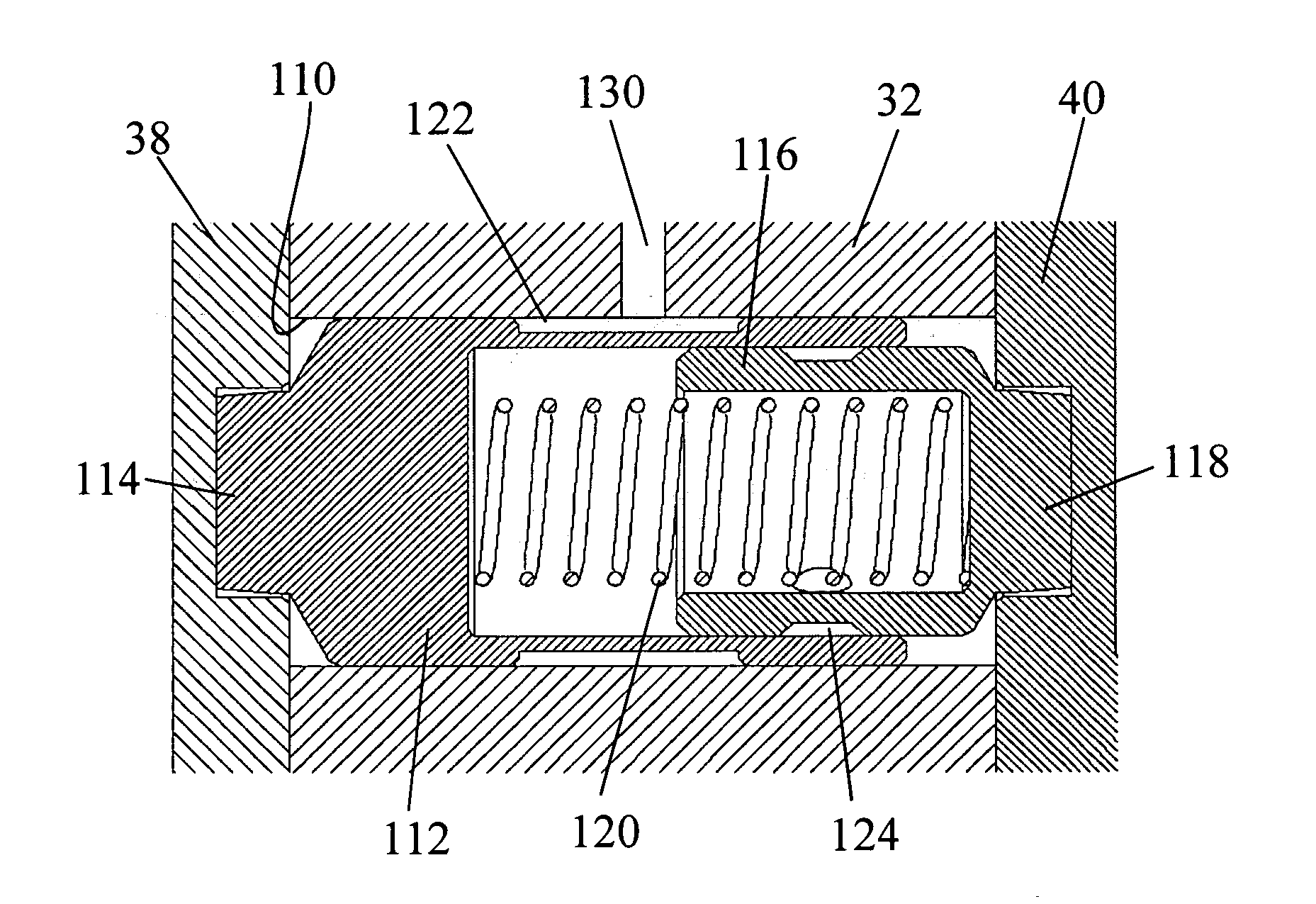

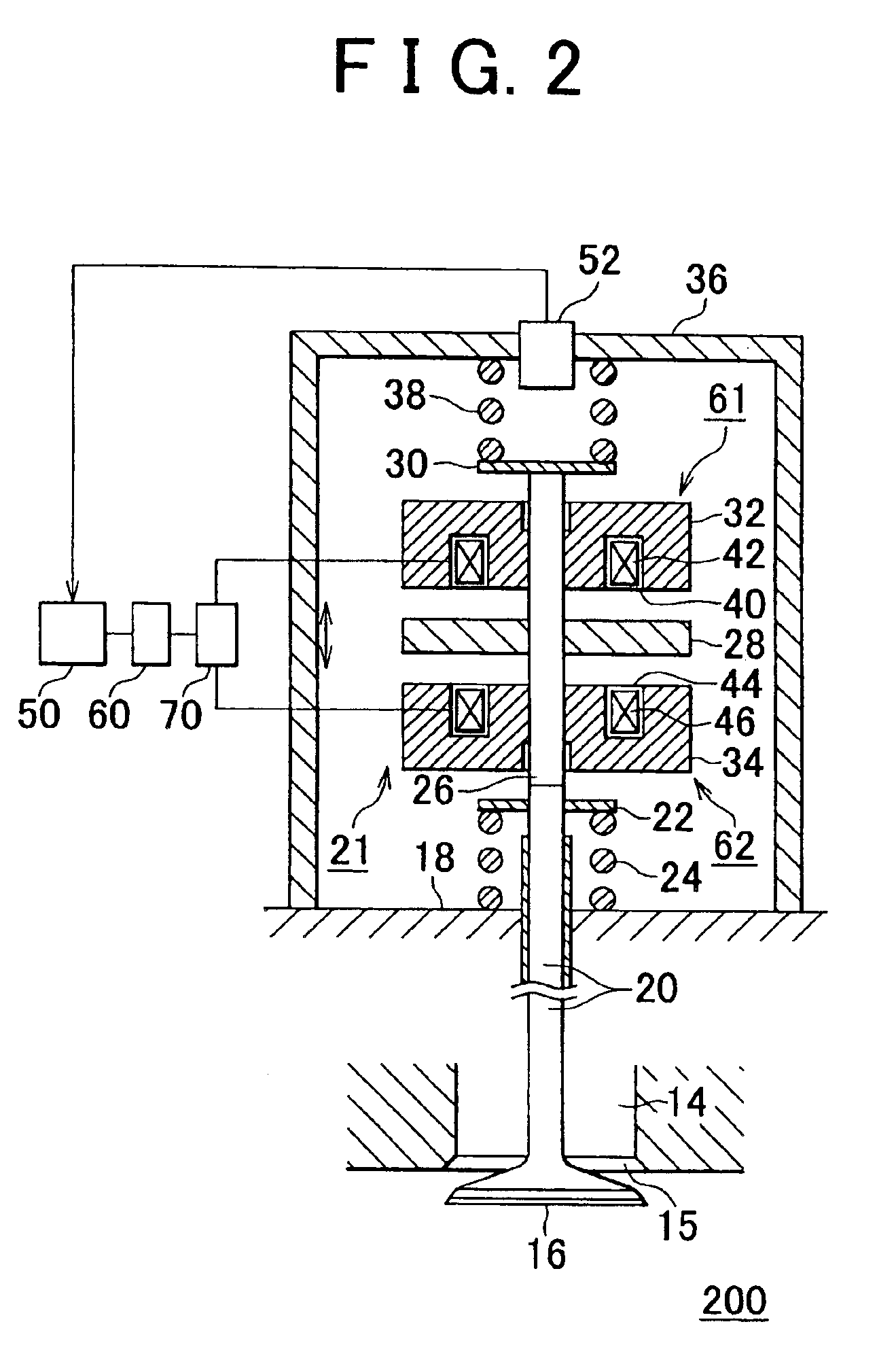

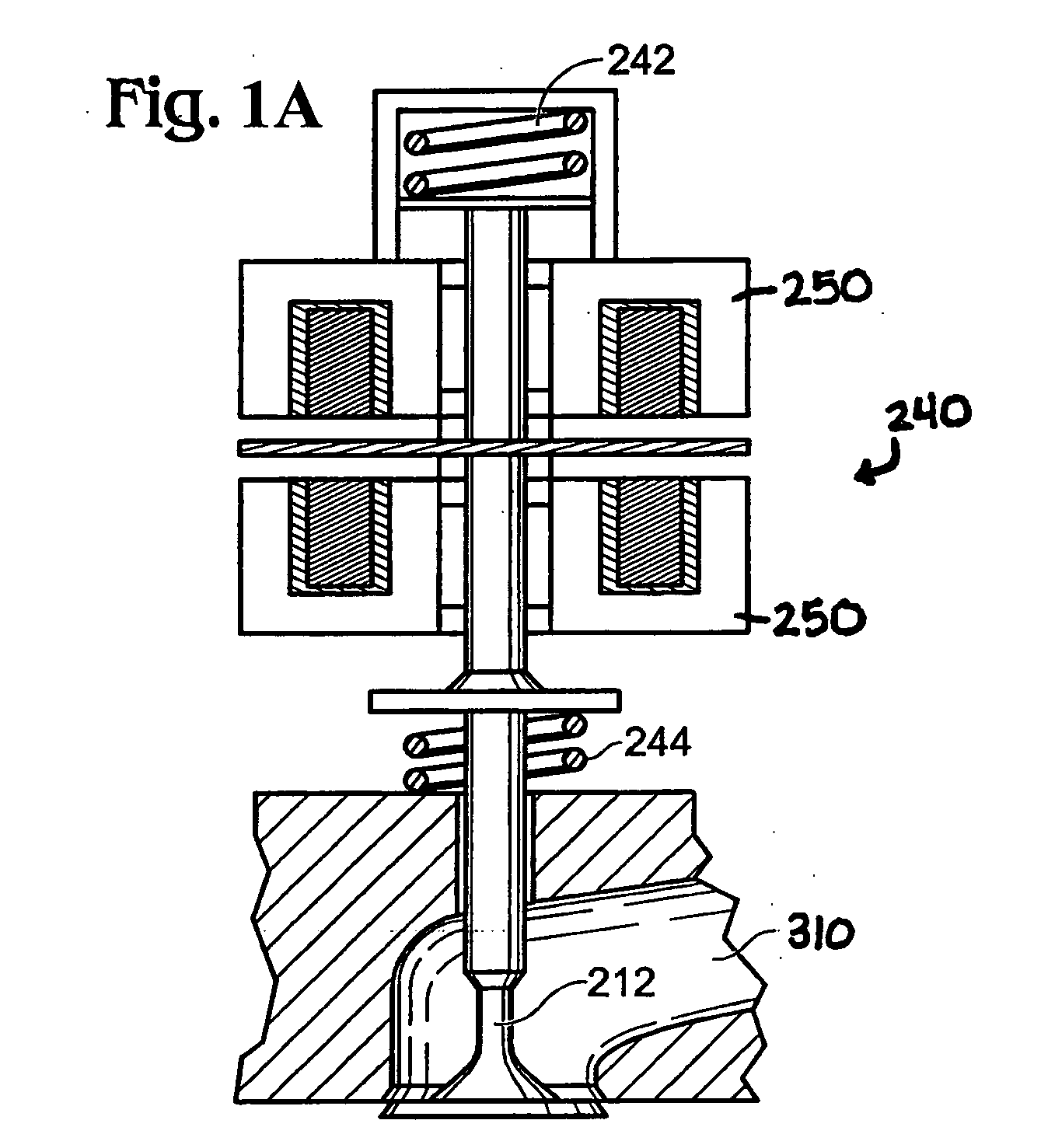

Rolled electroactive polymers

InactiveUS6891317B2Increase conversionsImprove performancePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesPolymer scienceMechanical energy

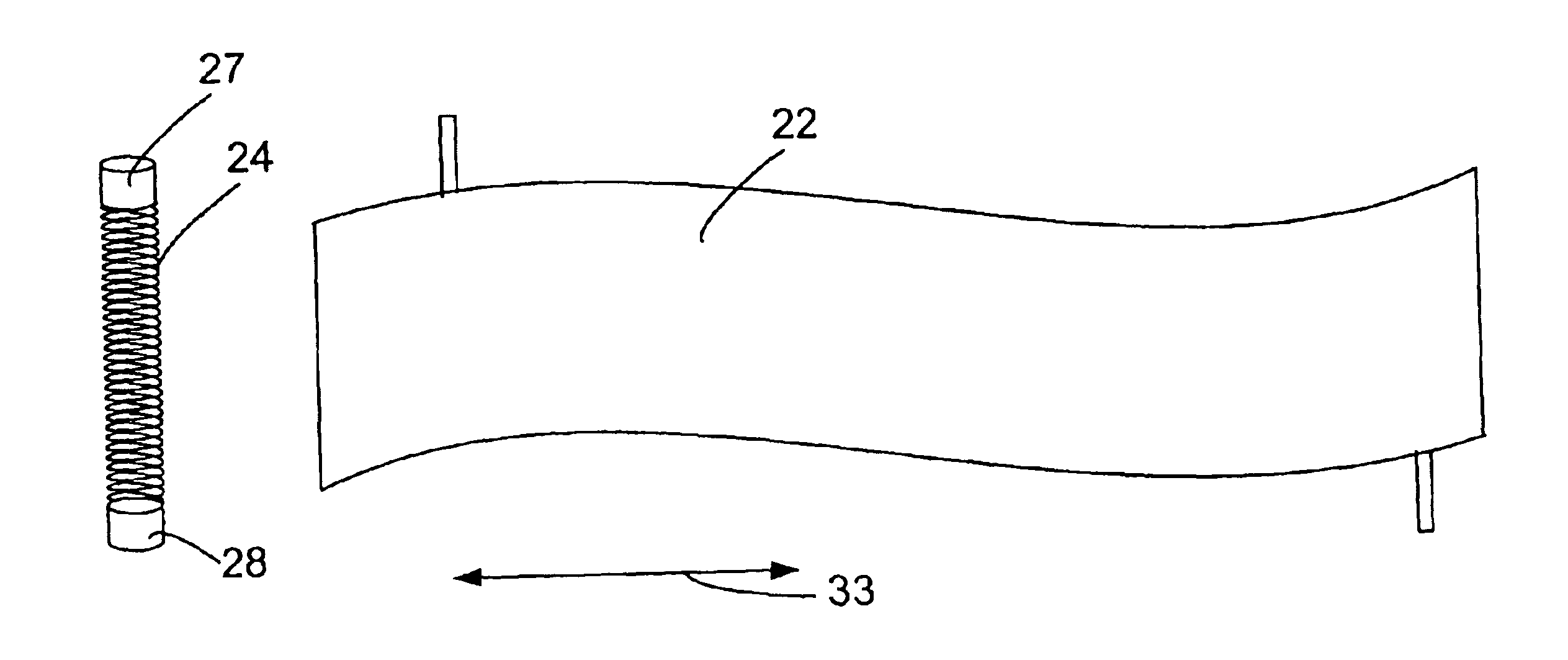

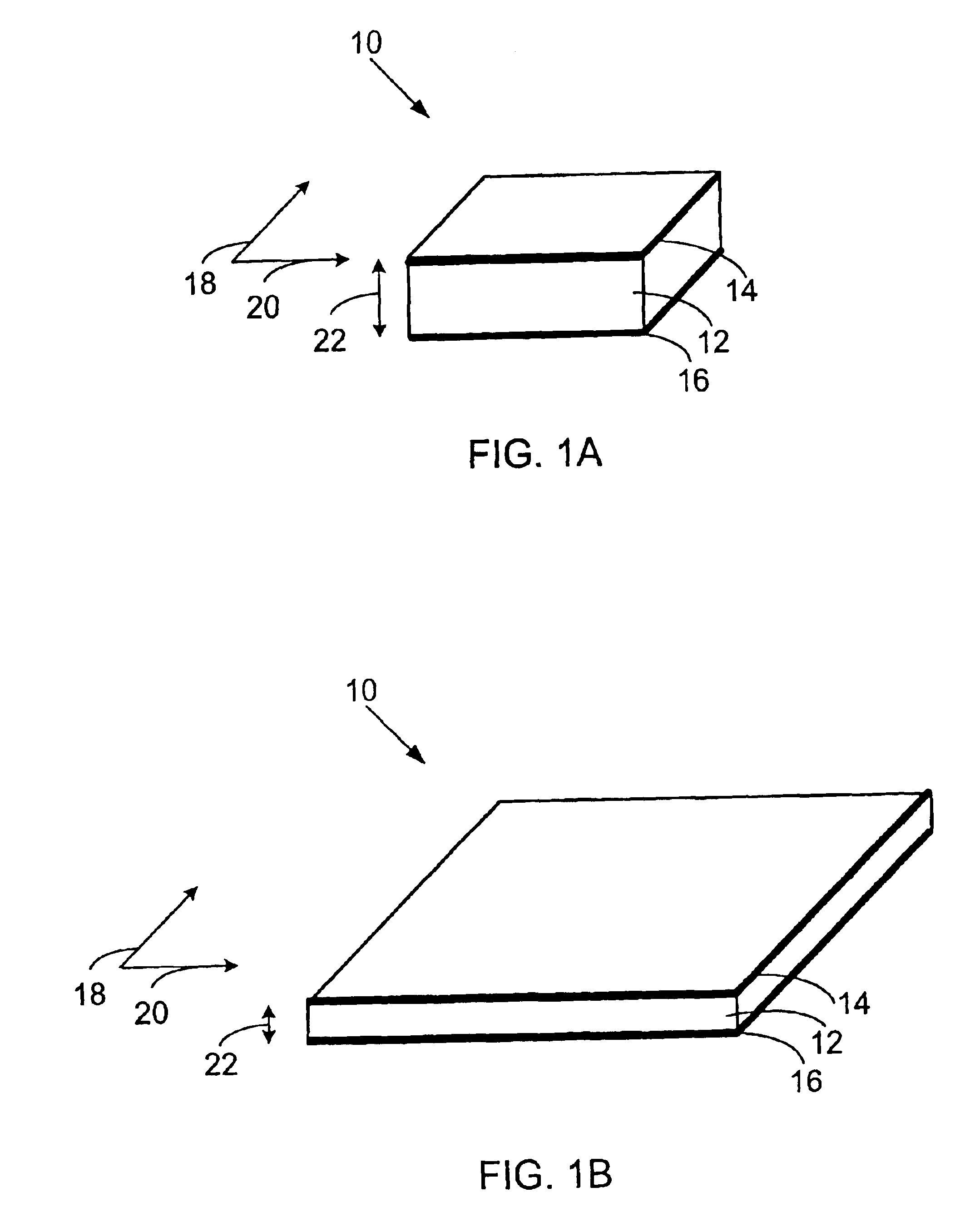

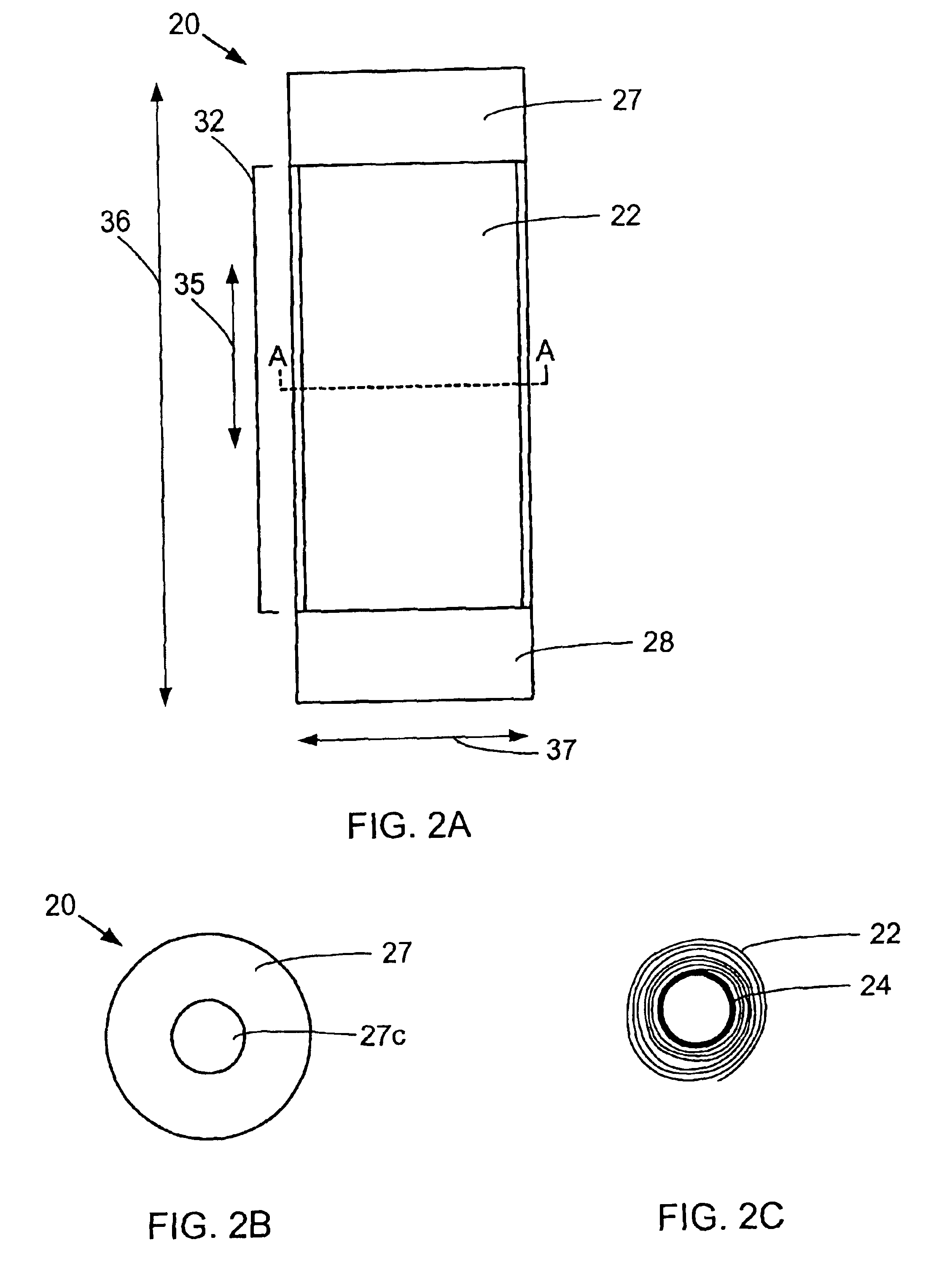

The invention describes rolled electroactive polymer devices. The invention also describes employment of these devices in a wide array of applications and methods for their fabrication. A rolled electroactive polymer device converts between electrical and mechanical energy; and includes a rolled electroactive polymer and at least two electrodes to provide the mechanical / electrical energy conversion. Prestrain is typically applied to the polymer. In one embodiment, a rolled electroactive polymer device employs a mechanism, such as a spring, that provides a force to prestrain the polymer. Since prestrain improves mechanical / electrical energy conversion for many electroactive polymers, the mechanism thus improves performance of the rolled electroactive polymer device.

Owner:SRI INTERNATIONAL

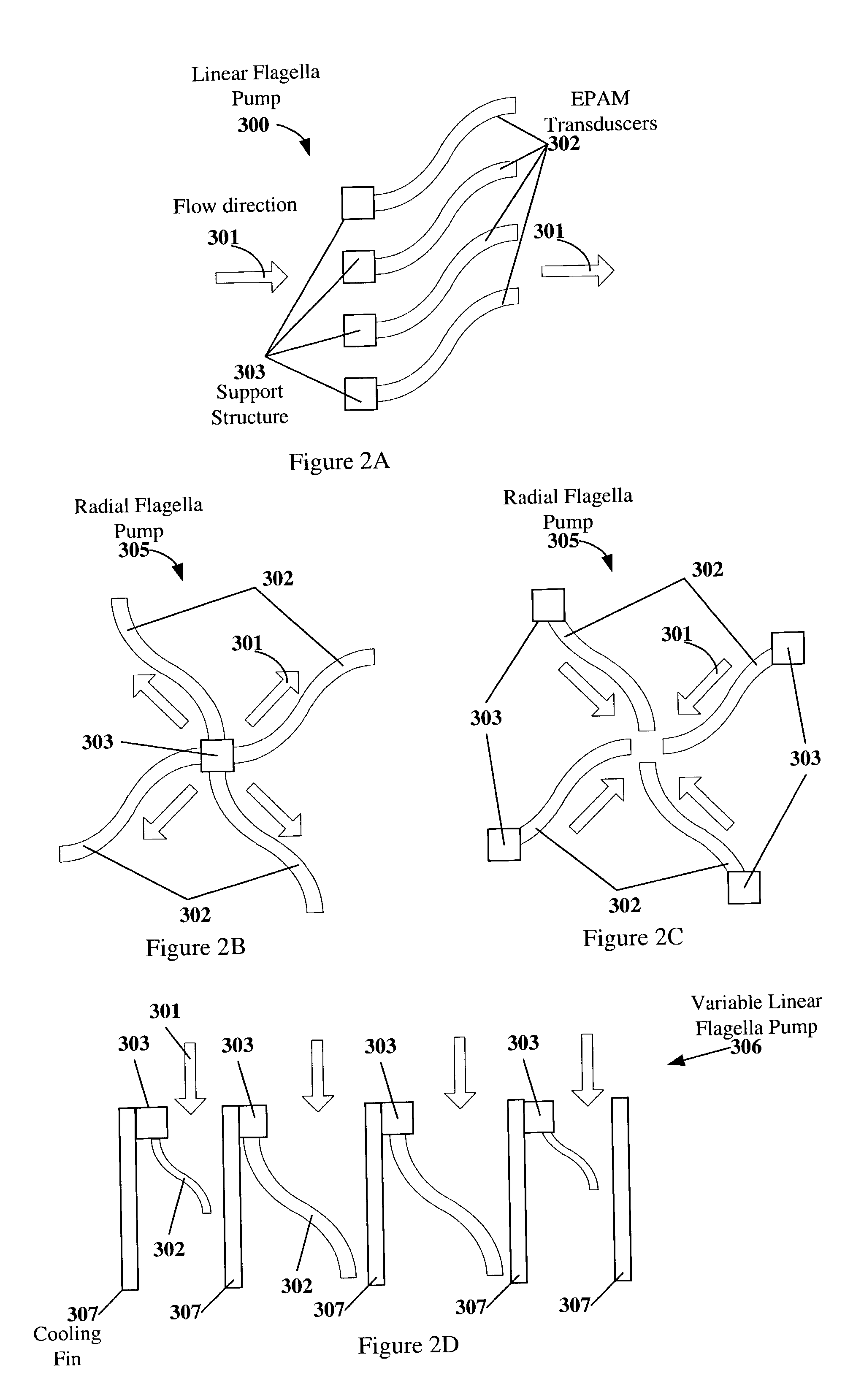

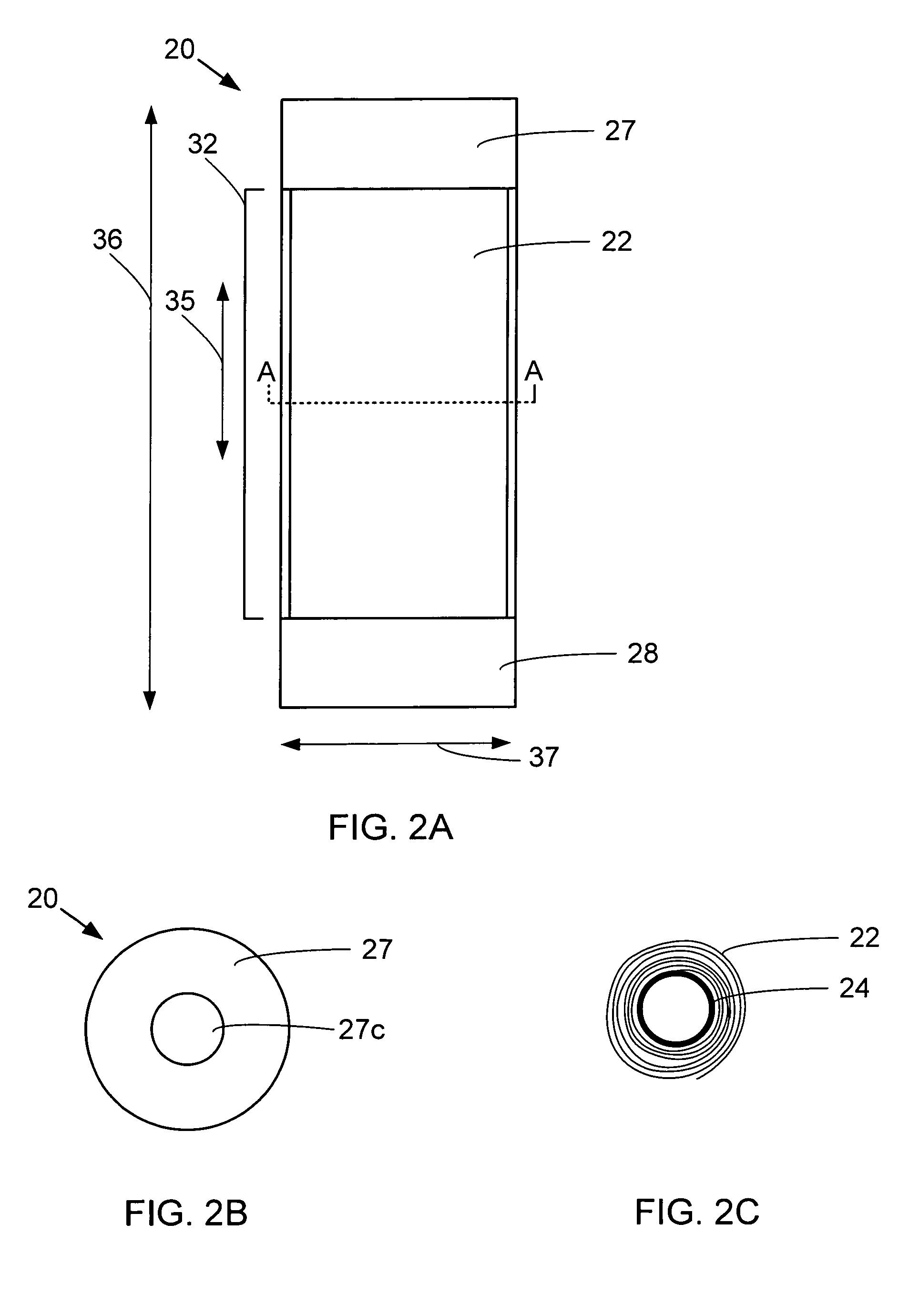

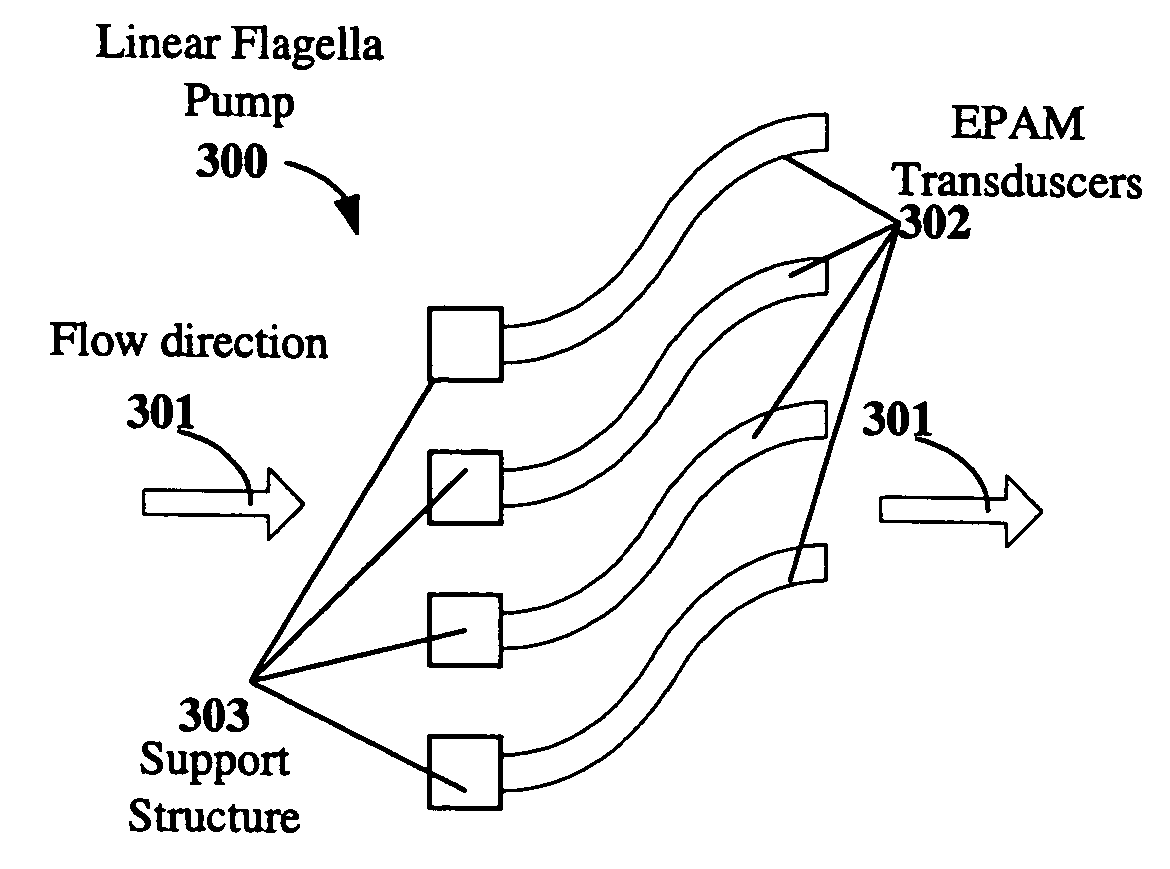

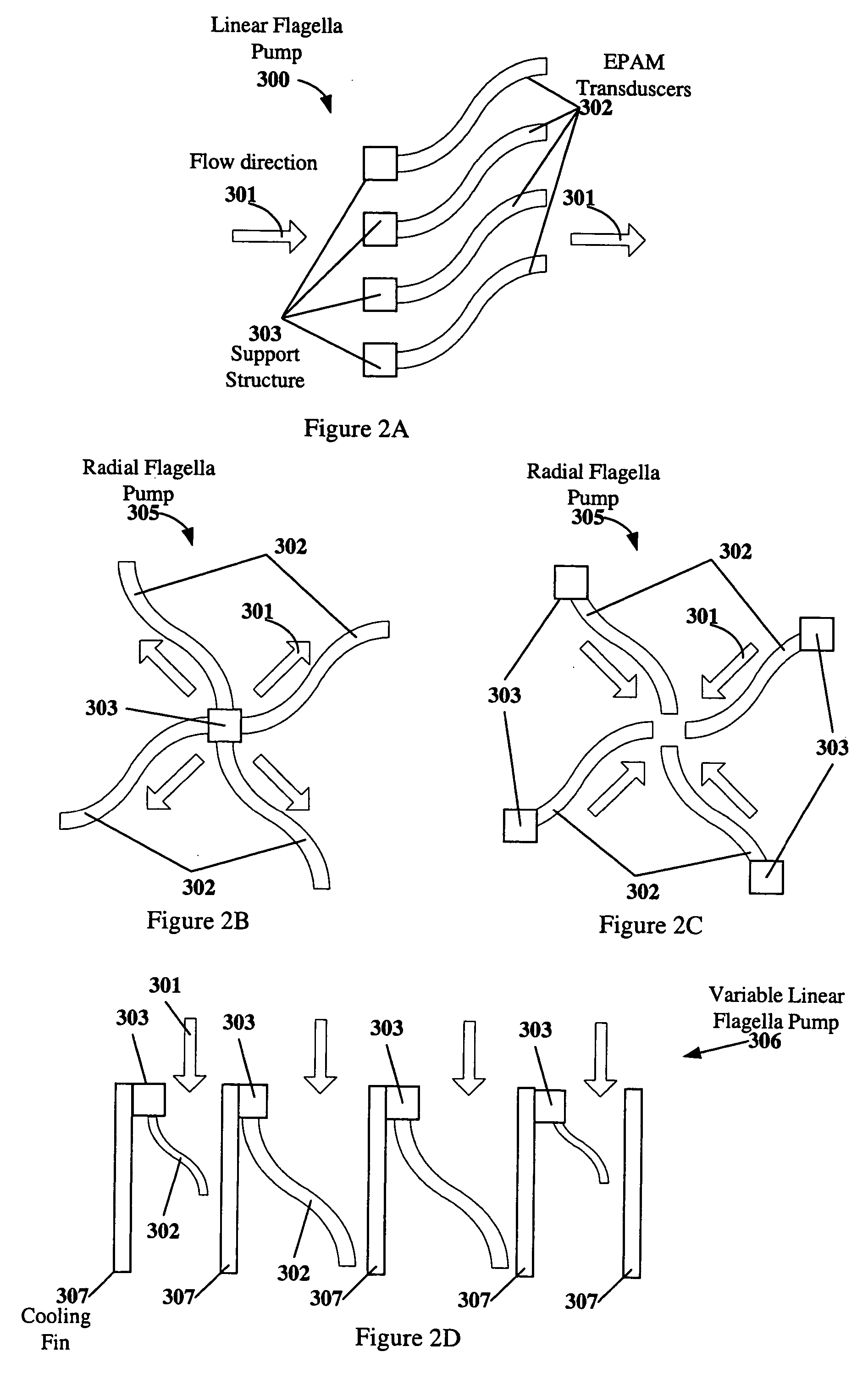

Electroactive polymer devices for moving fluid

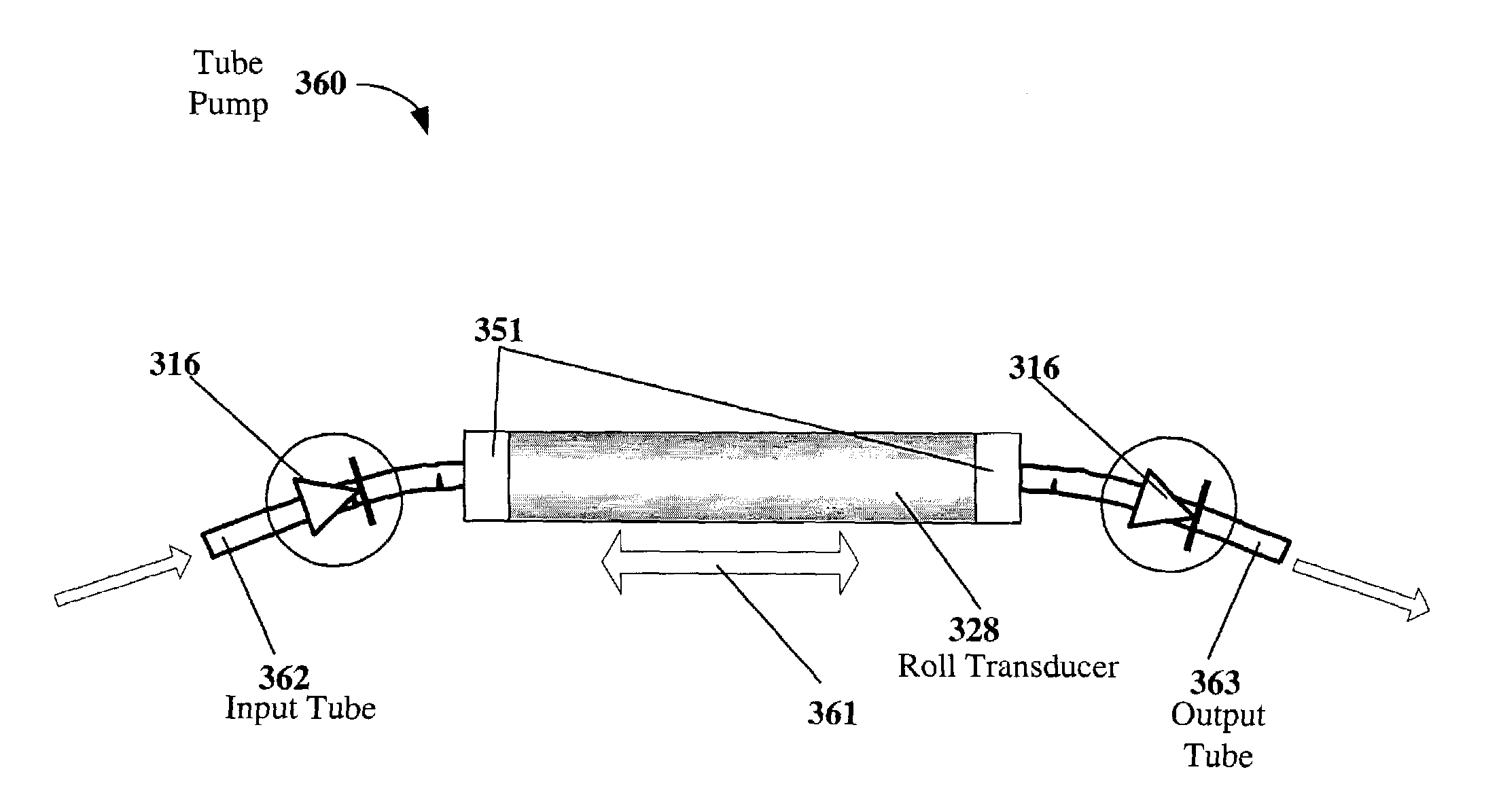

InactiveUS7064472B2Improve mechanical responseImprove responseTransducer detailsFlexible member pumpsHearing rangeThermal force

The invention describes devices for performing thermodynamic work on a fluid, such as pumps, compressors and fans. The thermodynamic work may be used to provide a driving force for moving the fluid. Work performed on the fluid may be transmitted to other devices, such as a piston in a hydraulic actuation device. The devices may include one or more electroactive polymer transducers with an electroactive polymer that deflects in response to an application of an electric field. The electroactive polymer may be in contact with a fluid where the deflection of the electroactive polymer may be used to perform thermodynamic work on the fluid. The devices may be designed to efficiently operate at a plurality of operating conditions, such as operating conditions that produce an acoustic signal above or below the human hearing range. The devices may be used in thermal control systems, such as refrigeration system, cooling systems and heating systems.

Owner:SRI INTERNATIONAL

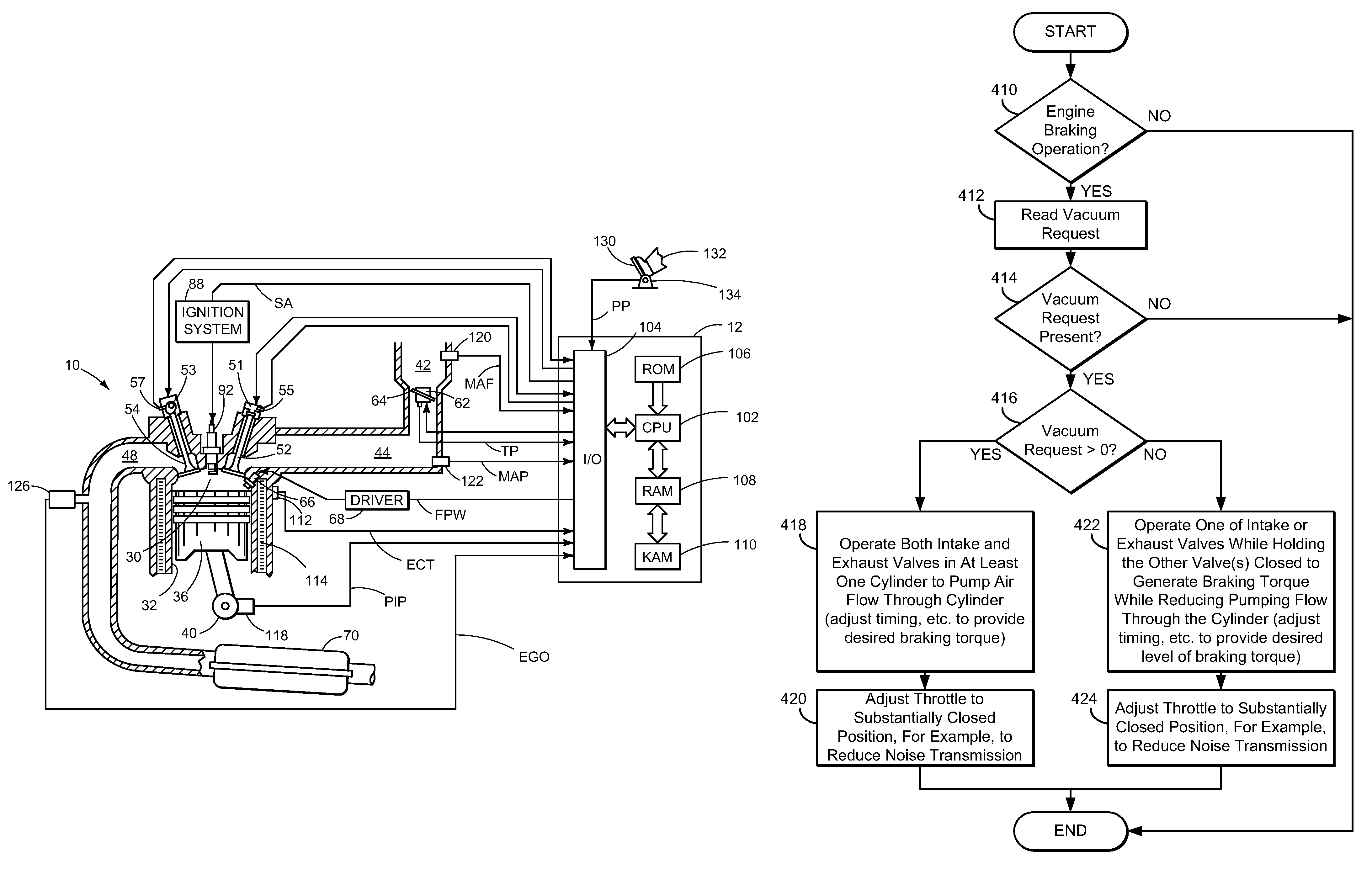

Vehicle braking control

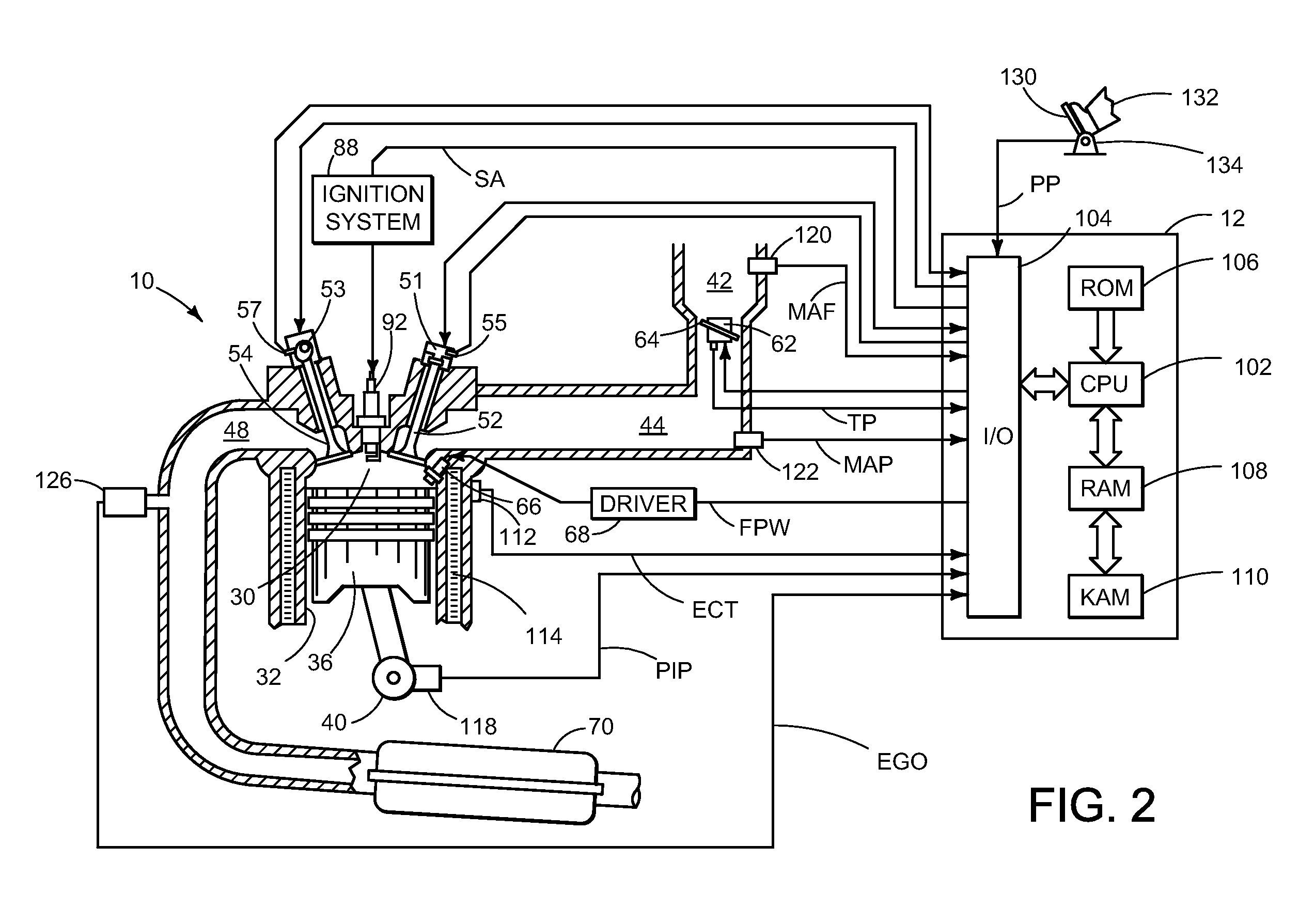

ActiveUS7930087B2Reduced effectivenessImprove fuel economyElectrical controlInternal combustion piston enginesExhaust valveInlet valve

A method of operating an engine for a vehicle having at least a first cylinder, the method comprising of operating the first cylinder to provide at least one of compression braking and expansion braking by holding one of an intake valve and an exhaust valve of the first cylinder closed while opening, closing, and opening the other of the intake valve and the exhaust valve during a cycle of the first cylinder and during a first vacuum level of an intake manifold upstream of the first cylinder; and operating the first cylinder to provide at least one of compression braking and expansion braking by operating both the intake valve and the exhaust valve of the first cylinder during a cycle of the first cylinder to allow at least some air to flow through the first cylinder during a second vacuum level of the intake manifold.

Owner:FORD GLOBAL TECH LLC

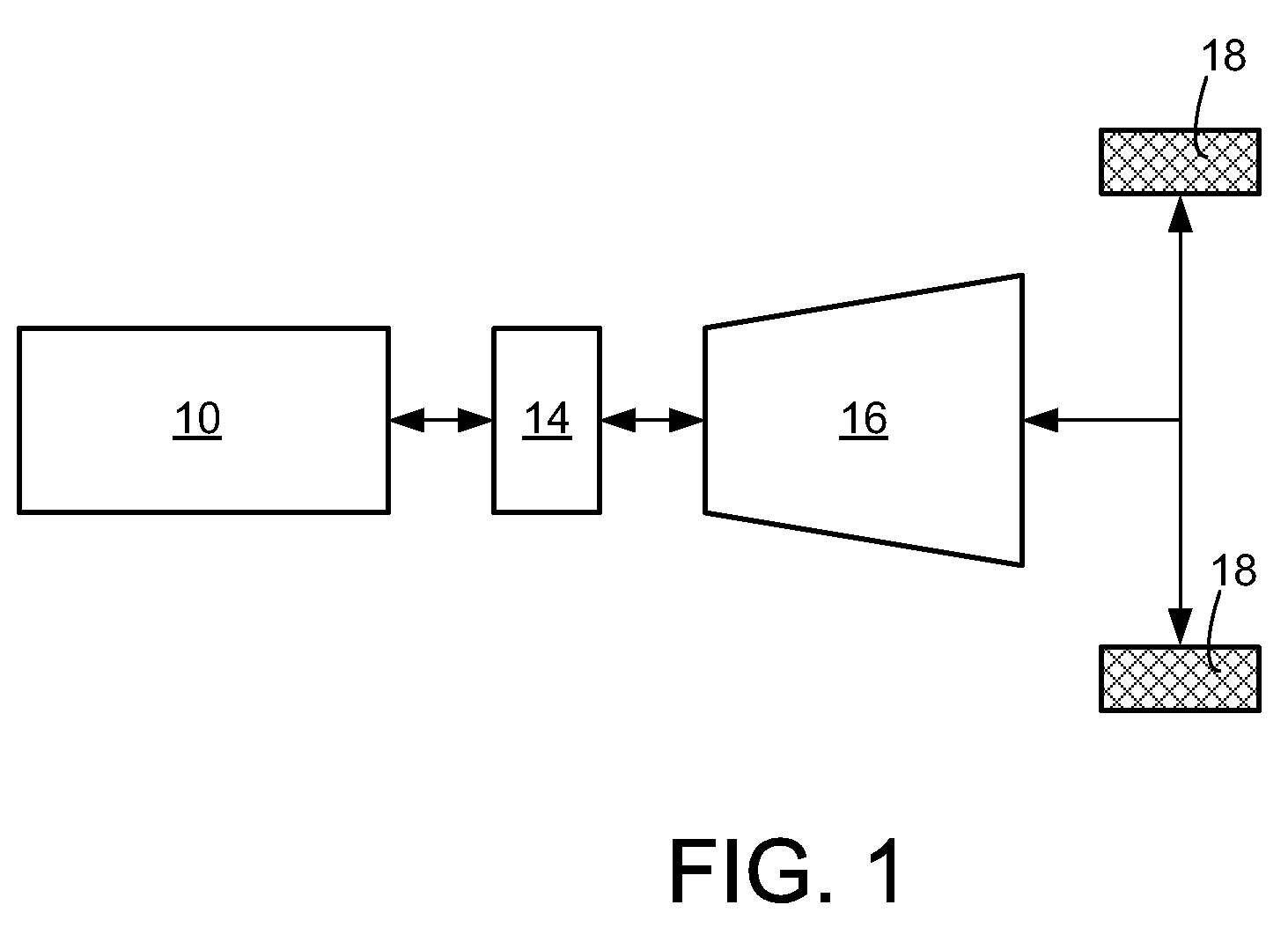

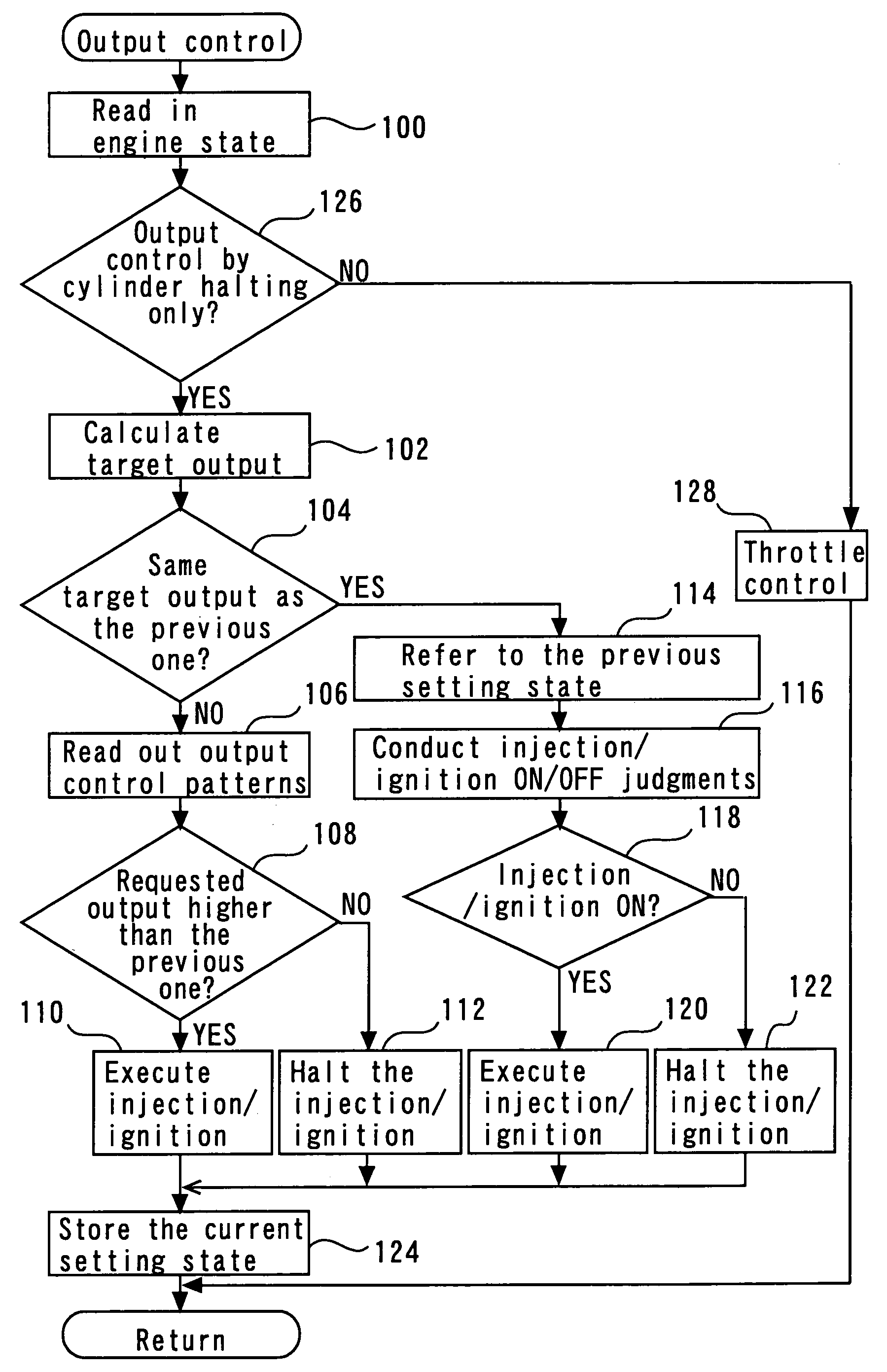

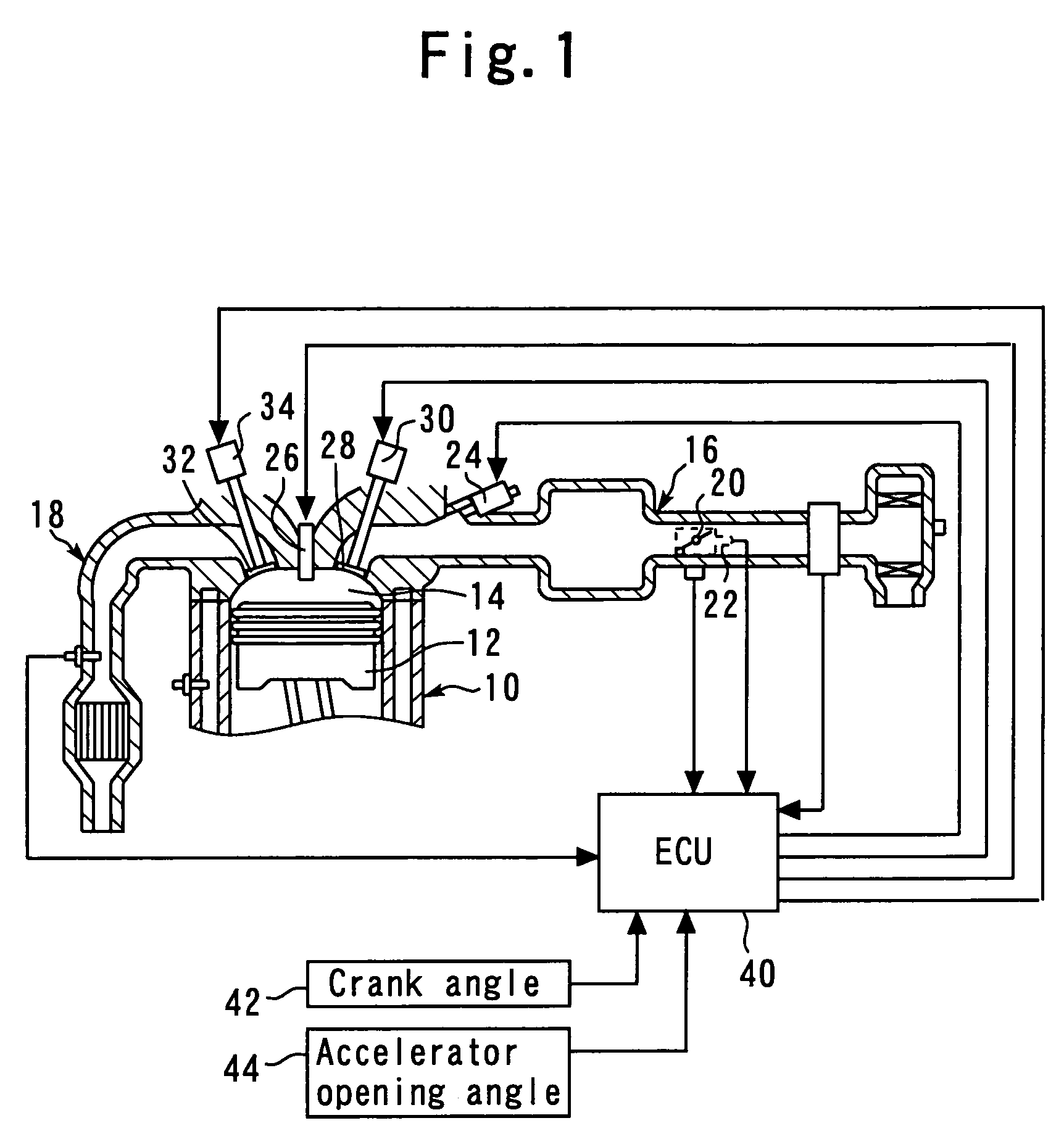

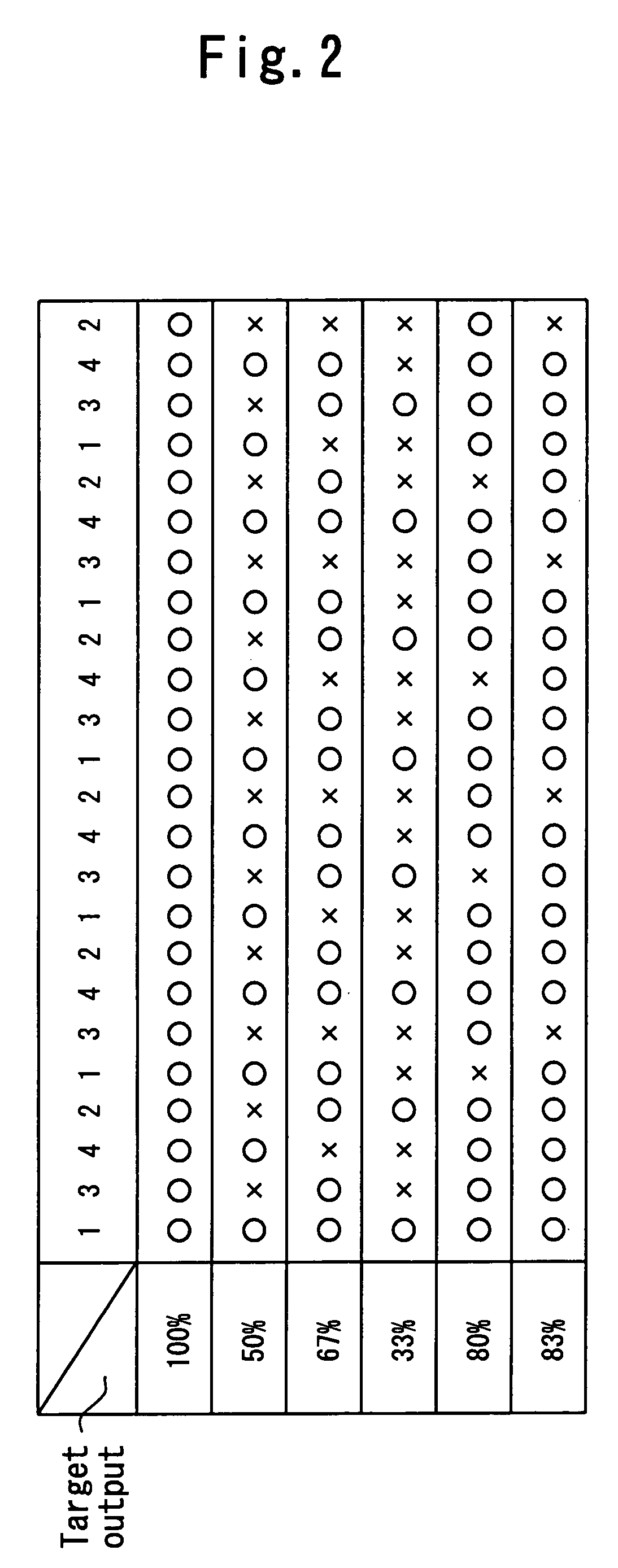

Output control system for internal combustion engine

InactiveUS7066136B2Easy to controlElectrical controlInternal combustion piston enginesCombustionExhaust valve

An intake electromagnetic driving valve and an exhaust electromagnetic driving valve are provided which use electromagnetic force to drive an intake valve and an exhaust valve, respectively. In step 102, the ratio between the number of combustion execution cycles and the number of combustion halts is set to obtain a desired target output value. Output control patterns that each consist of combustion execution timing equivalent to the required number of combustion execution cycles, and combustion halt timing equivalent to the required number of combustion halts are set in step 106, 114. In steps 108 to 112, or 118 to 122, in accordance with the output control patterns, whether combustion is to be executed is set with respect to the explosion timing that arrives in each cylinder in order.

Owner:TOYOTA JIDOSHA KK

Rolled electroactive polymers

InactiveUS7233097B2Improves mechanical/electrical energy conversionImprove performancePiezoelectric/electrostriction/magnetostriction machinesFlexible member pumpsPolymer scienceMechanical energy

The invention describes rolled electroactive polymer devices. The invention also describes employment of these devices in a wide array of applications and methods for their fabrication. A rolled electroactive polymer device converts between electrical and mechanical energy; and includes a rolled electroactive polymer and at least two electrodes to provide the mechanical / electrical energy conversion. Prestrain is typically applied to the polymer. In one embodiment, a rolled electroactive polymer device employs a mechanism, such as a spring, that provides a force to prestrain the polymer. Since prestrain improves mechanical / electrical energy conversion for many electroactive polymers, the mechanism thus improves performance of the rolled electroactive polymer device.

Owner:SRI INTERNATIONAL

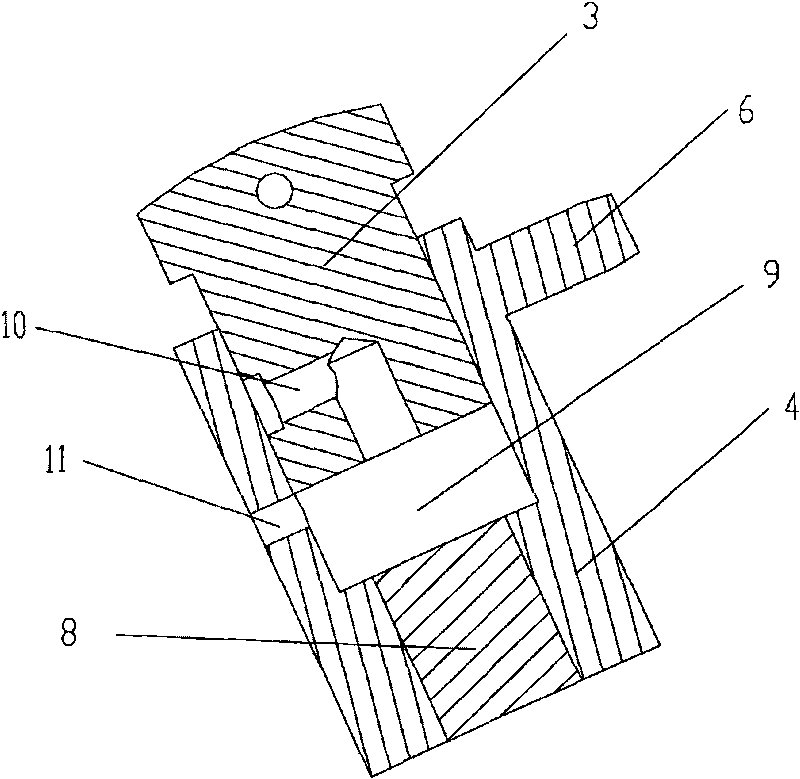

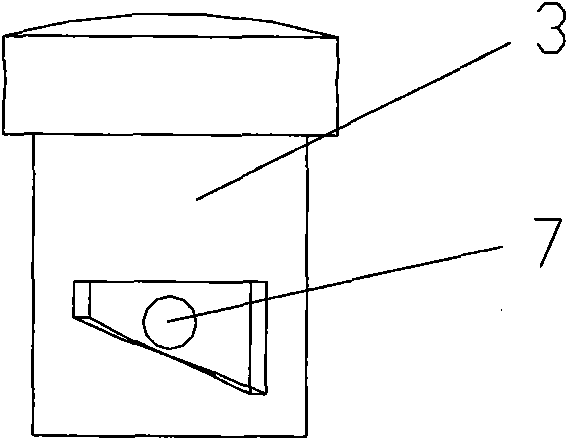

Hydraulic valve mechanism of variable valve lift

ActiveCN101713308AImprove performanceNo significant change in volumeMachines/enginesNon-mechanical valveGear wheelEngineering

The invention discloses a hydraulic valve mechanism of a variable valve lift. The hydraulic valve mechanism of the variable valve lift comprises a valve spool of a puller cam, a sleeve capable of rotating relative to the valve spool and a seal gland connected with a valve. The top end of the sleeve is adapted to the valve spool; the bottom of the sleeve is adapted to the seal gland and an oil chamber is formed in the middle part of the sleeve. The hydraulic valve mechanism of the variable valve lift is characterized in that a valve spool oil duct is formed in the valve spool; an inlet of the valve spool oil duct is movably adapted to a sleeve oil duct; the outlet of the valve spool oil duct is communicated with the oil chamber; and the inlet of the valve spool oil duct is in shape of a helical notch. Part of gears are arranged outside the sleeve so as to drive the sleeve to rotate by racks or other similar mechanisms. A return spring is further arranged on the valve spool. The problems of complicated structure, high cost and low reliability existing in prior art are solved. The hydraulic valve mechanism of the variable valve lift is a hydraulic valve mechanism which is capable of realizing quick response.

Owner:CHERY AUTOMOBILE CO LTD

Electroactive polymer devices for moving fluid

InactiveUS20060158065A1Improve responseTransducer detailsFlexible member pumpsHearing rangeThermal force

The invention describes devices for performing thermodynamic work on a fluid, such as pumps, compressors and fans. The thermodynamic work may be used to provide a driving force for moving the fluid. Work performed on the fluid may be transmitted to other devices, such as a piston in a hydraulic actuation device. The devices may include one or more electroactive polymer transducers with an electroactive polymer that deflects in response to an application of an electric field. The electroactive polymer may be in contact with a fluid where the deflection of the electroactive polymer may be used to perform thermodynamic work on the fluid. The devices may be designed to efficiently operate at a plurality of operating conditions, such as operating conditions that produce an acoustic signal above or below the human hearing range. The devices may be used in thermal control systems, such as refrigeration system, cooling systems and heating systems.

Owner:SRI INTERNATIONAL

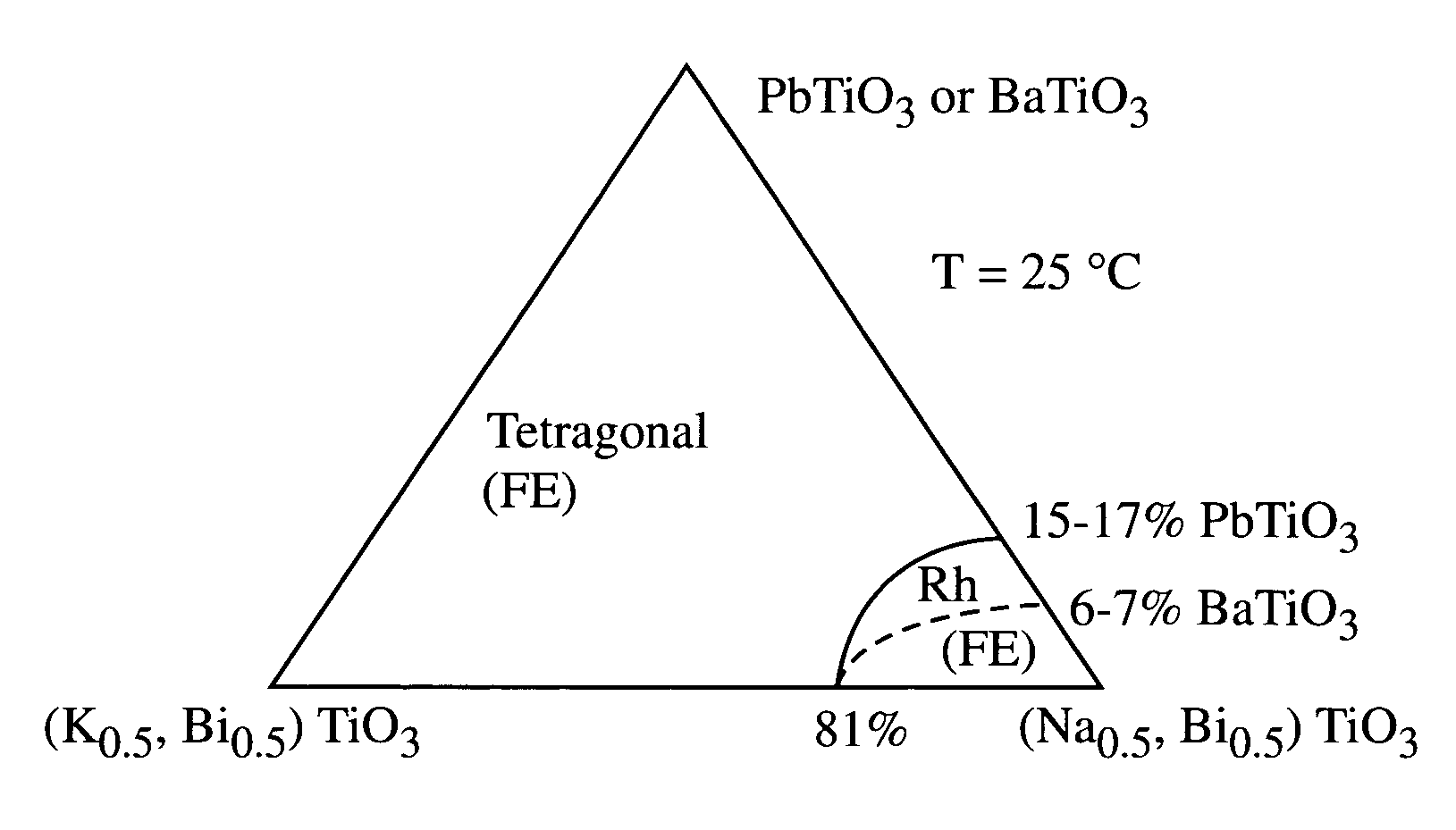

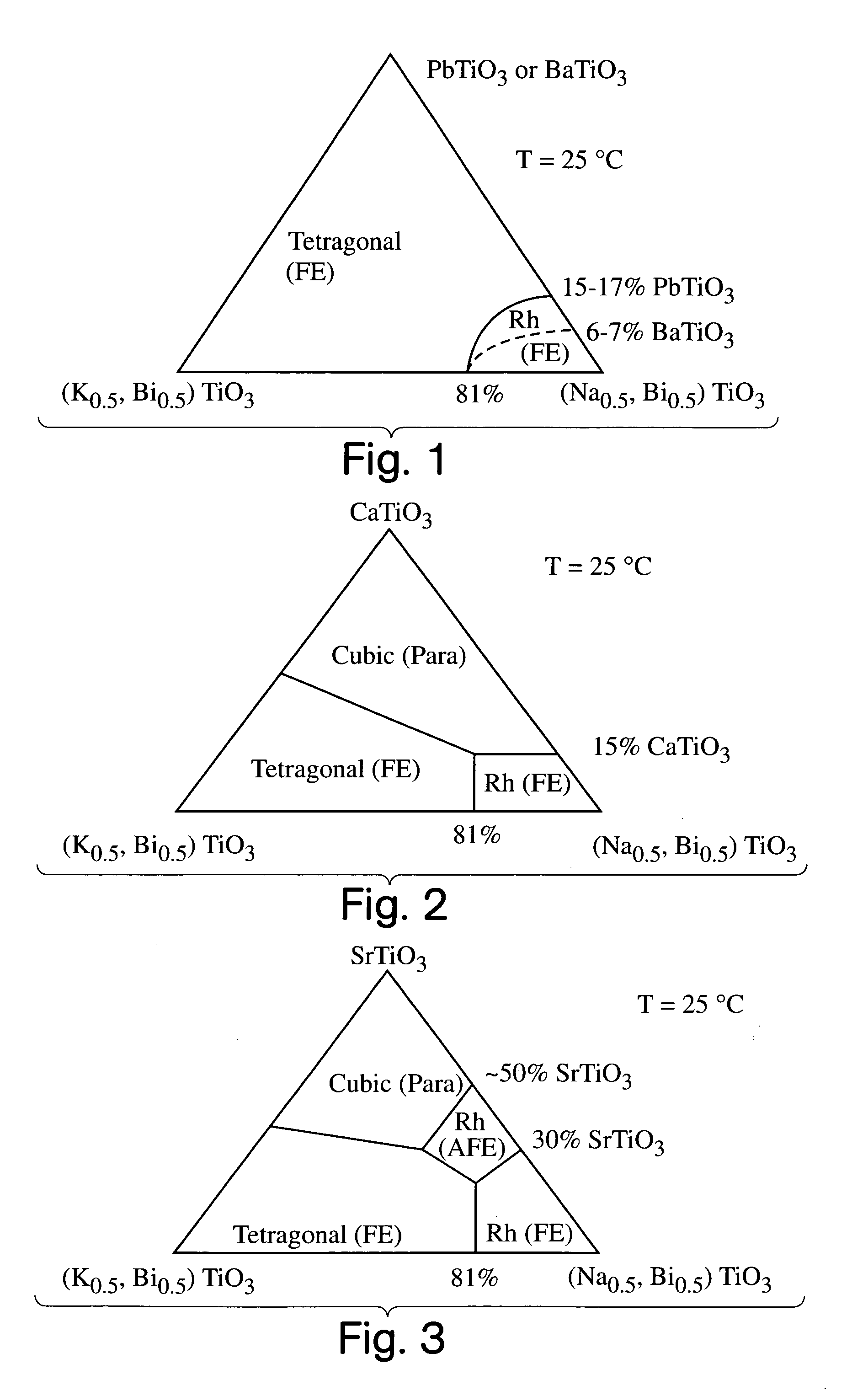

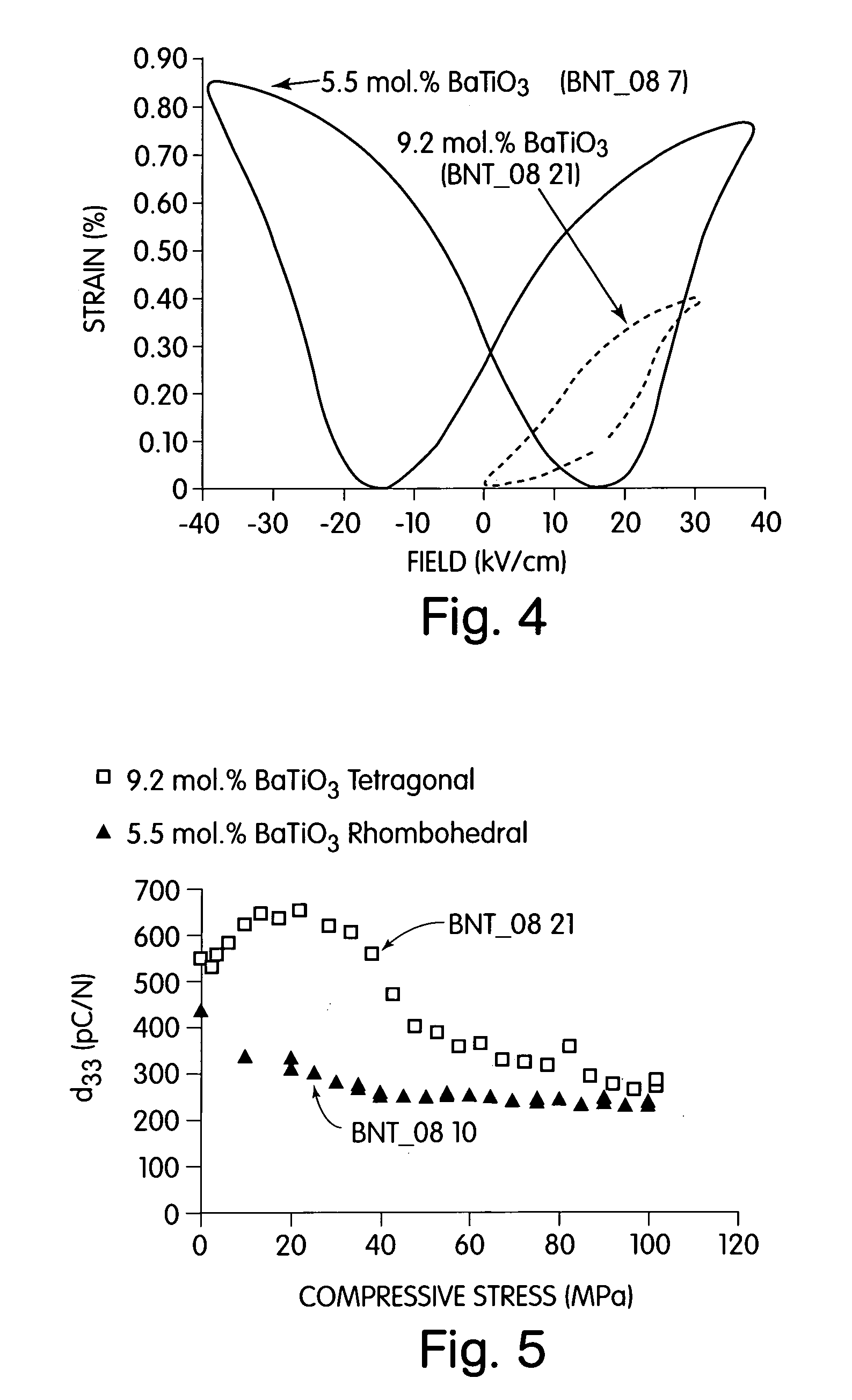

Electromechanical actuators

InactiveUS7090785B2Increased doping of BaTiOImprove propertiesAlkaline earth titanatesLighting support devicesElectroactive materialsMaterials science

A perovskite compound of the formula, (Na1 / 2Bi1 / 2)1-xMx(Ti1-yM′y)O3±z, where M is one or more of Ca, Sr, Ba, Pb, Y, La, Pr, Nd, Sm, Eu, Gd, Th, Dy, Ho, Er, Tm, Yb and Lu; and M′ is one or more of Zr, Hf, Sn, Ge, Mg, Zn, Al, Sc, Ga, Nb, Mo, Sb, Ta, W, Cr, Mn, Fe, Co and Ni, and 0.01<x<0.3, and 0.01<y<0.3, and z<0.1 functions as an electromechanically active material. The material may possess electrostrictive or piezoelectric characteristics.

Owner:MASSACHUSETTS INST OF TECH

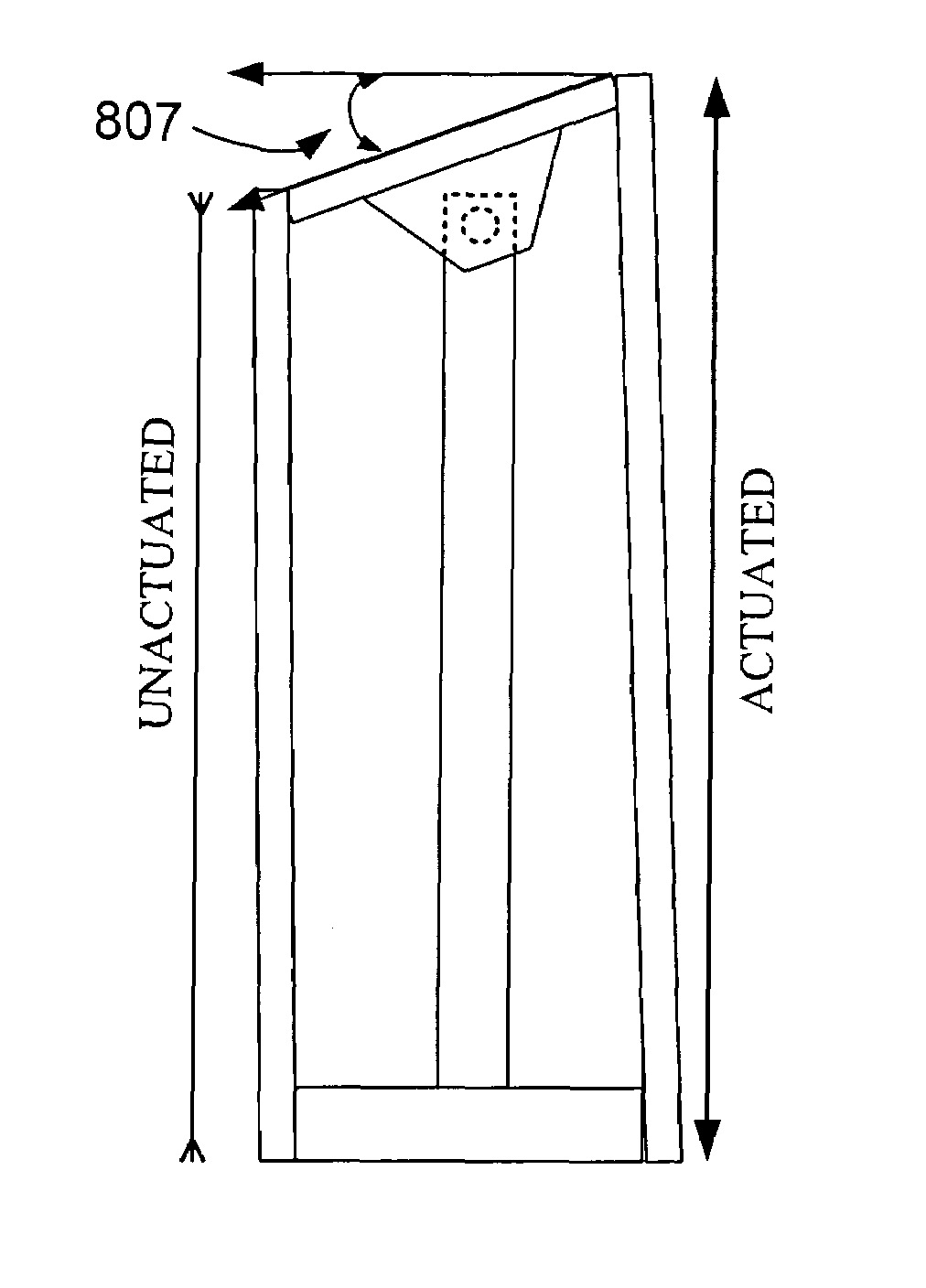

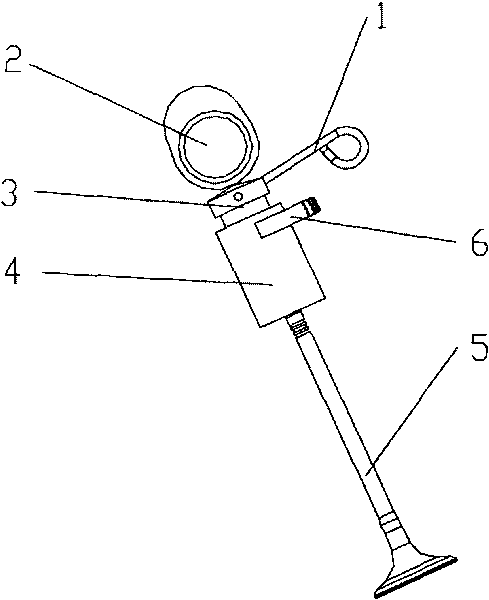

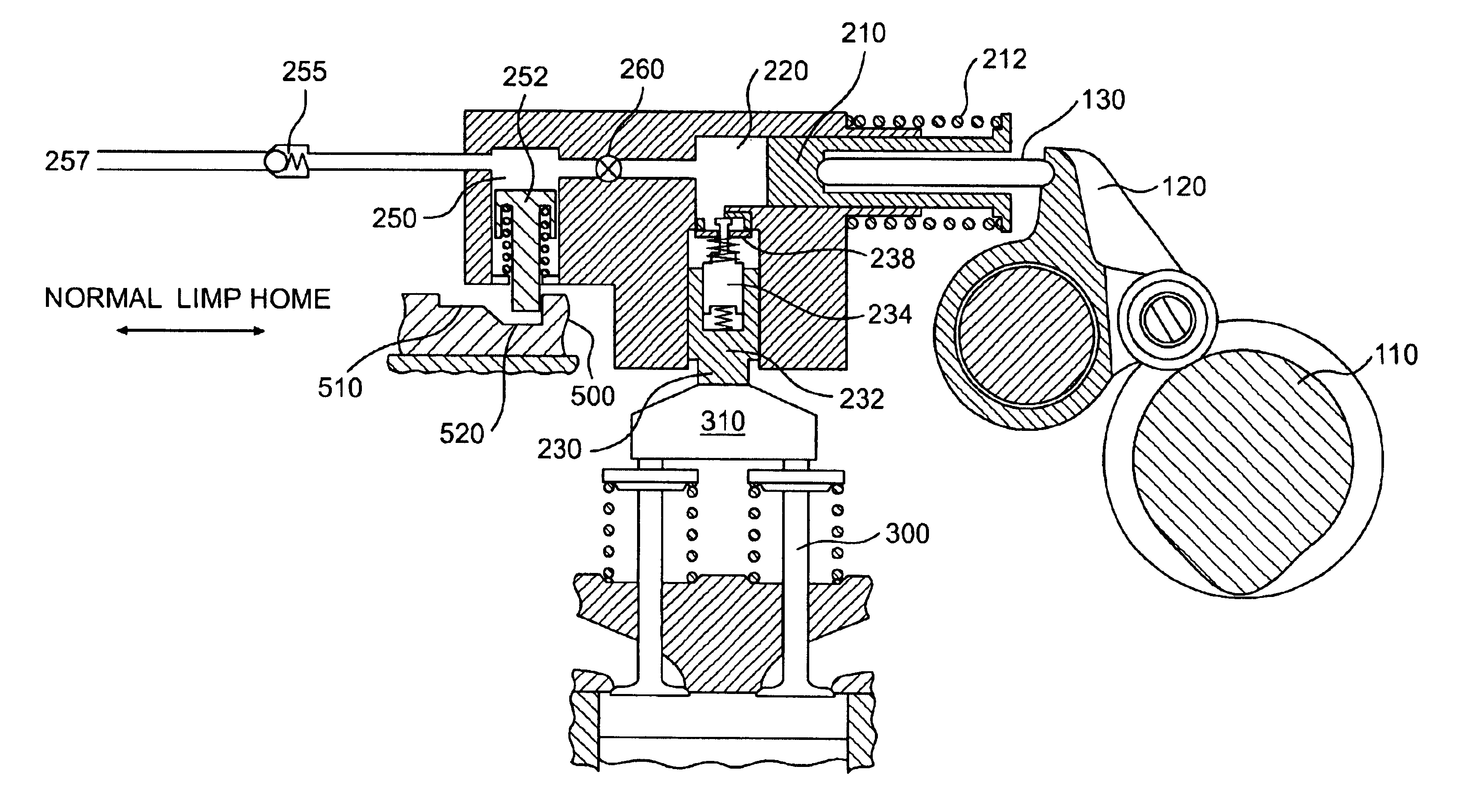

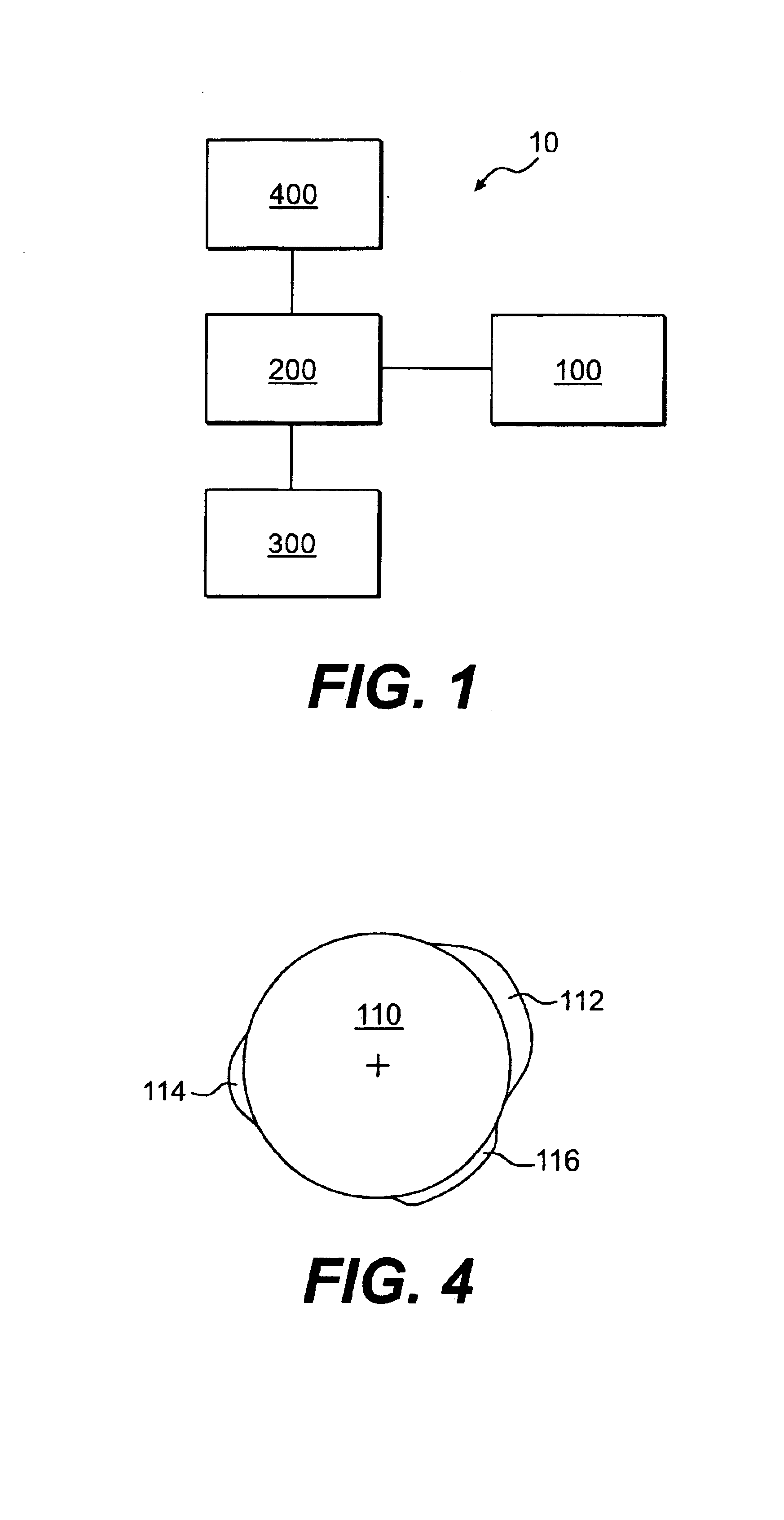

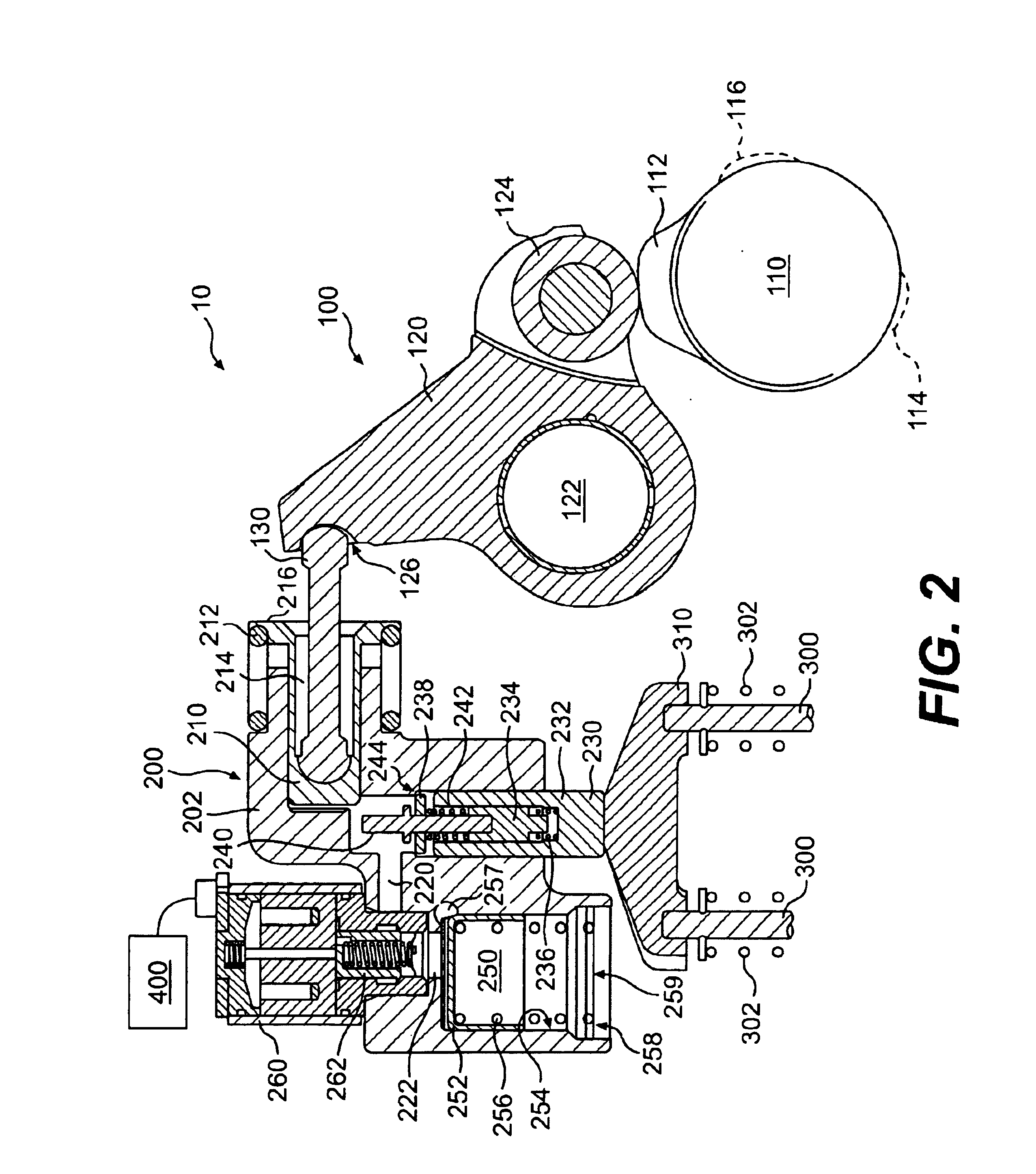

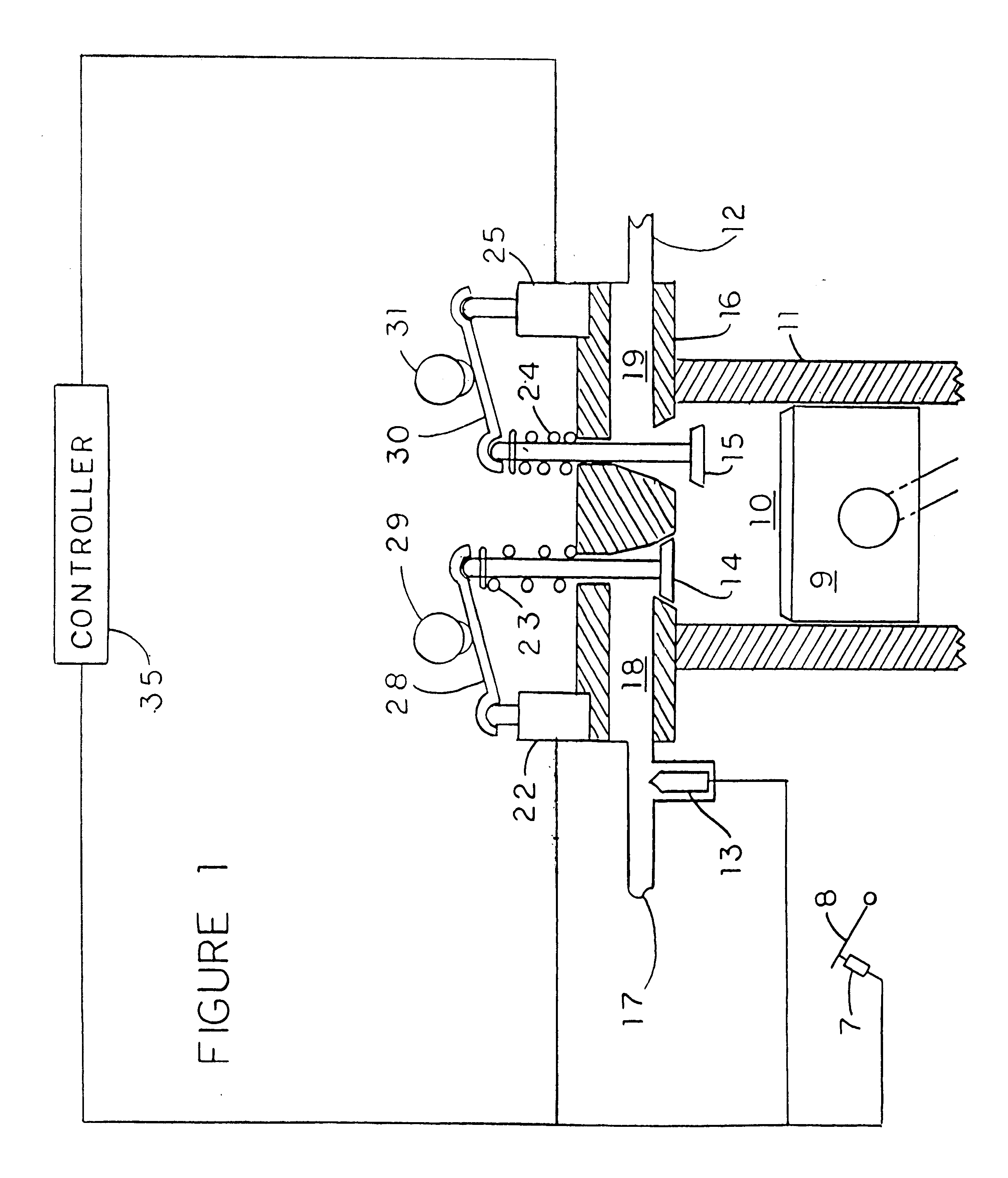

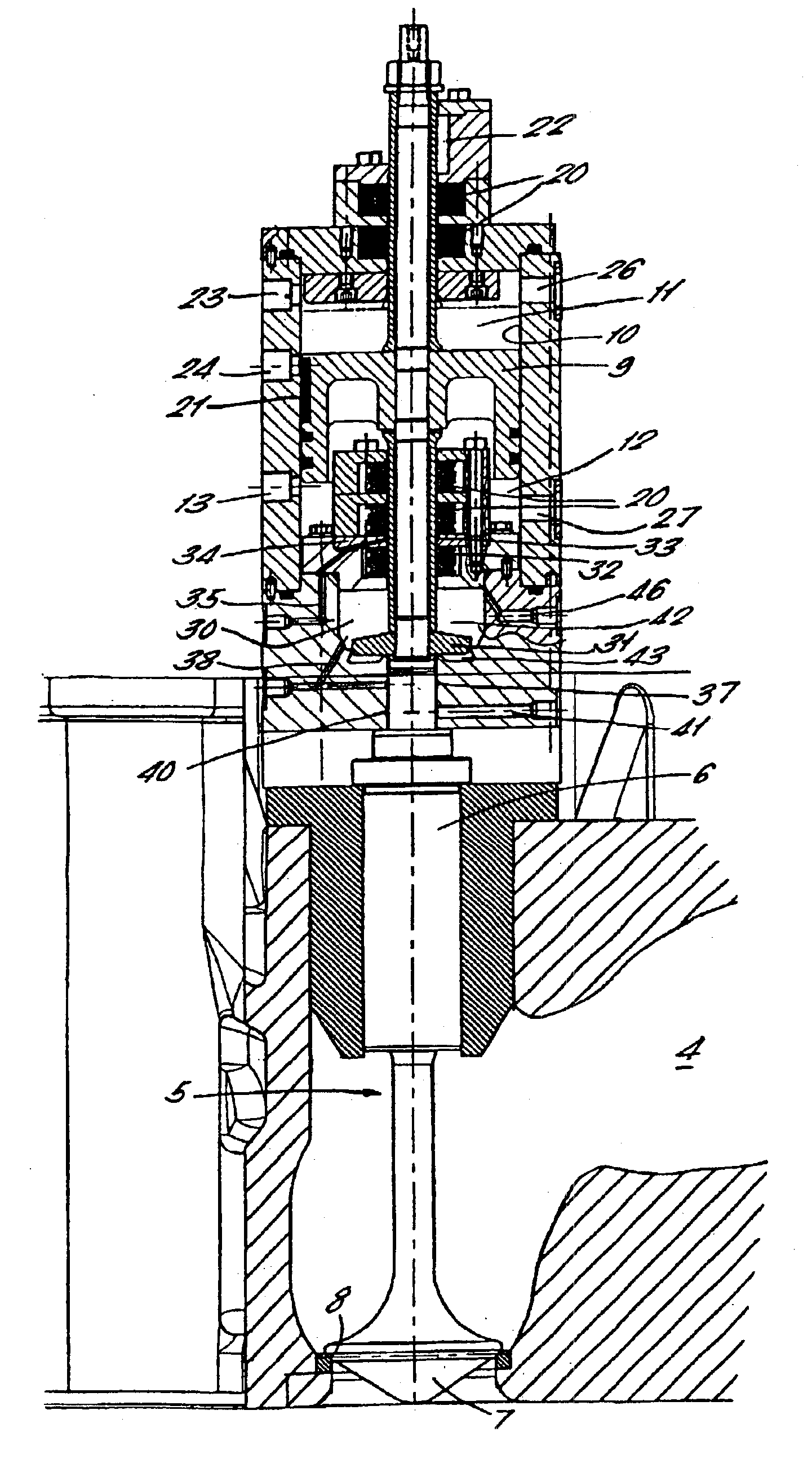

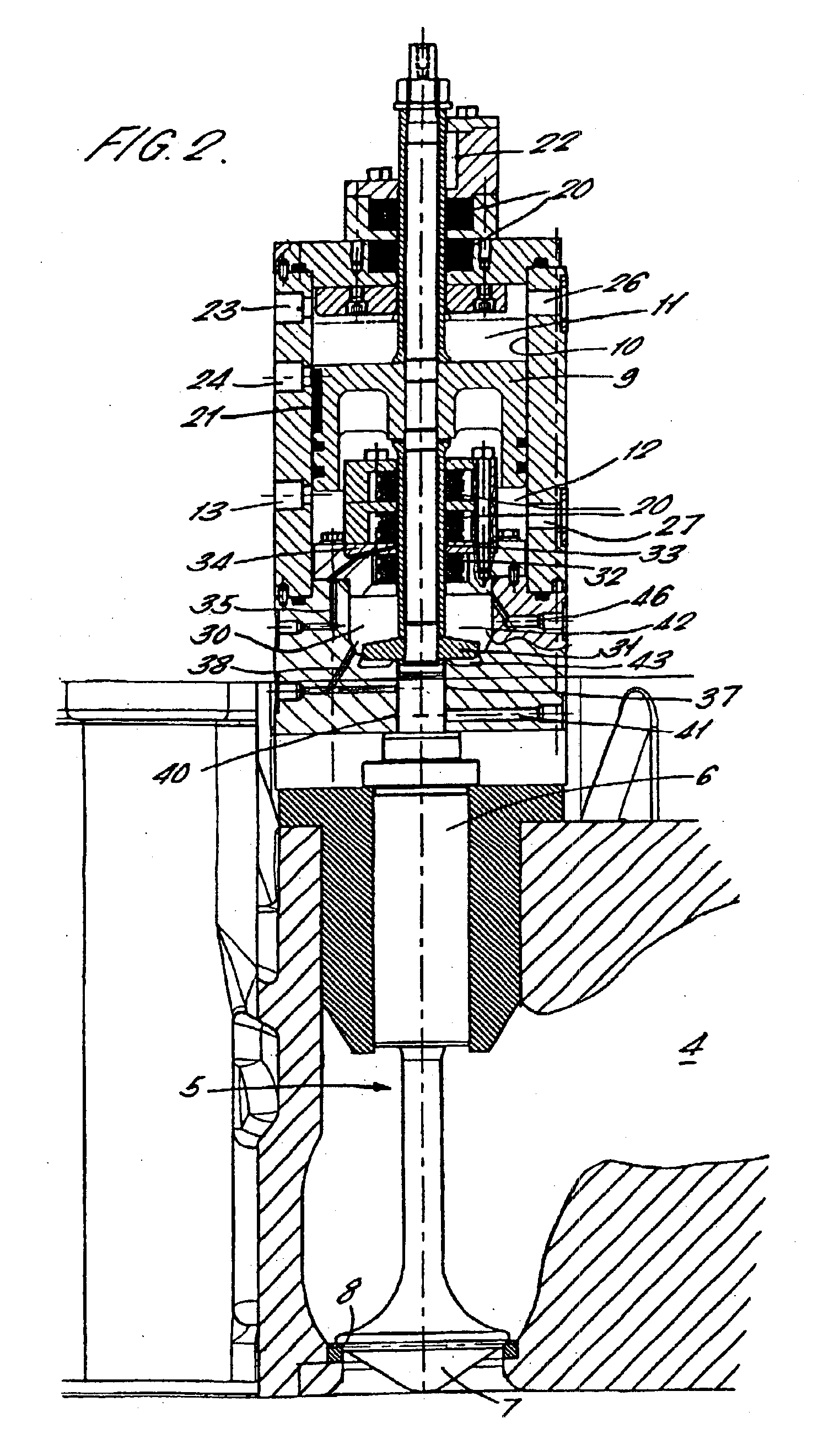

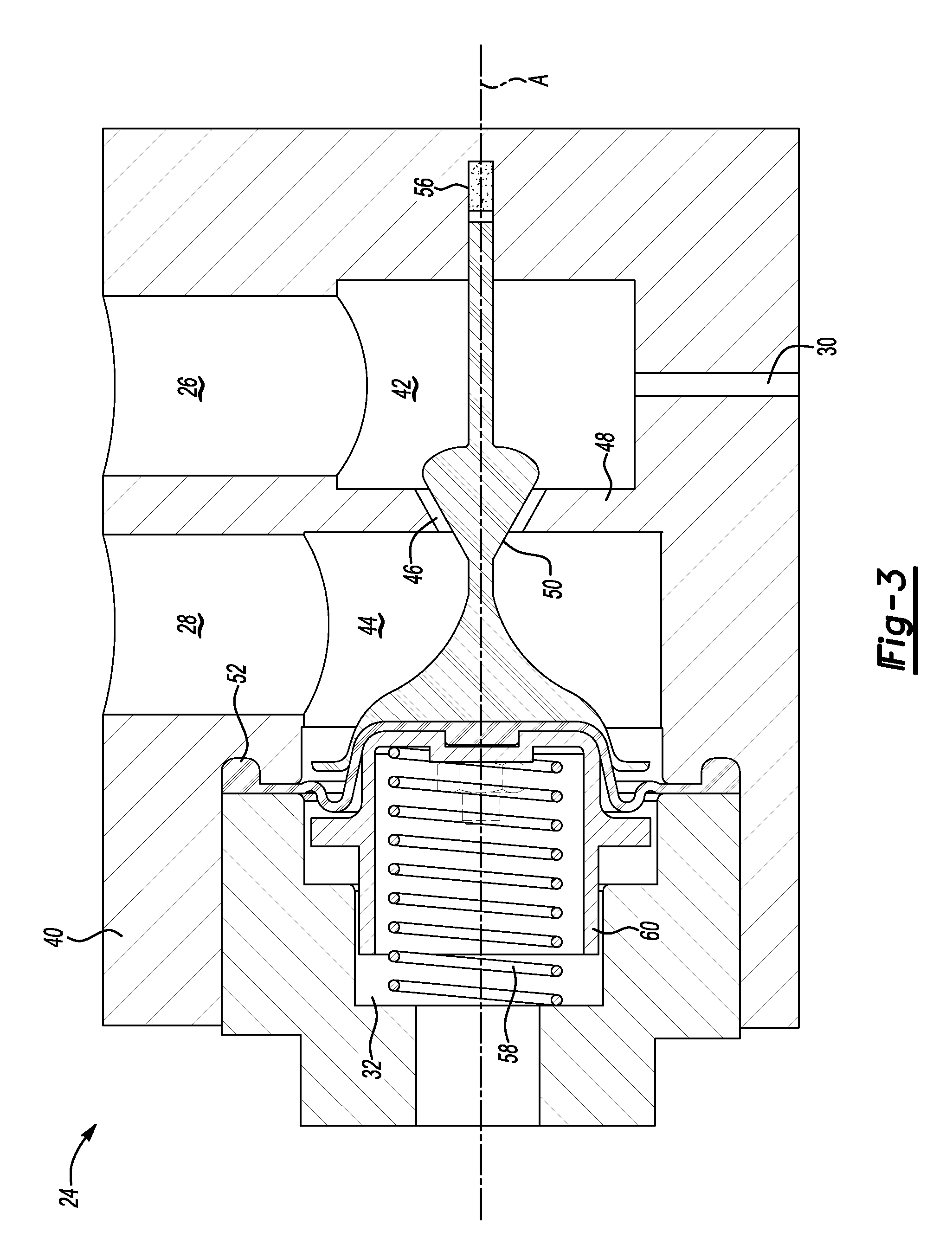

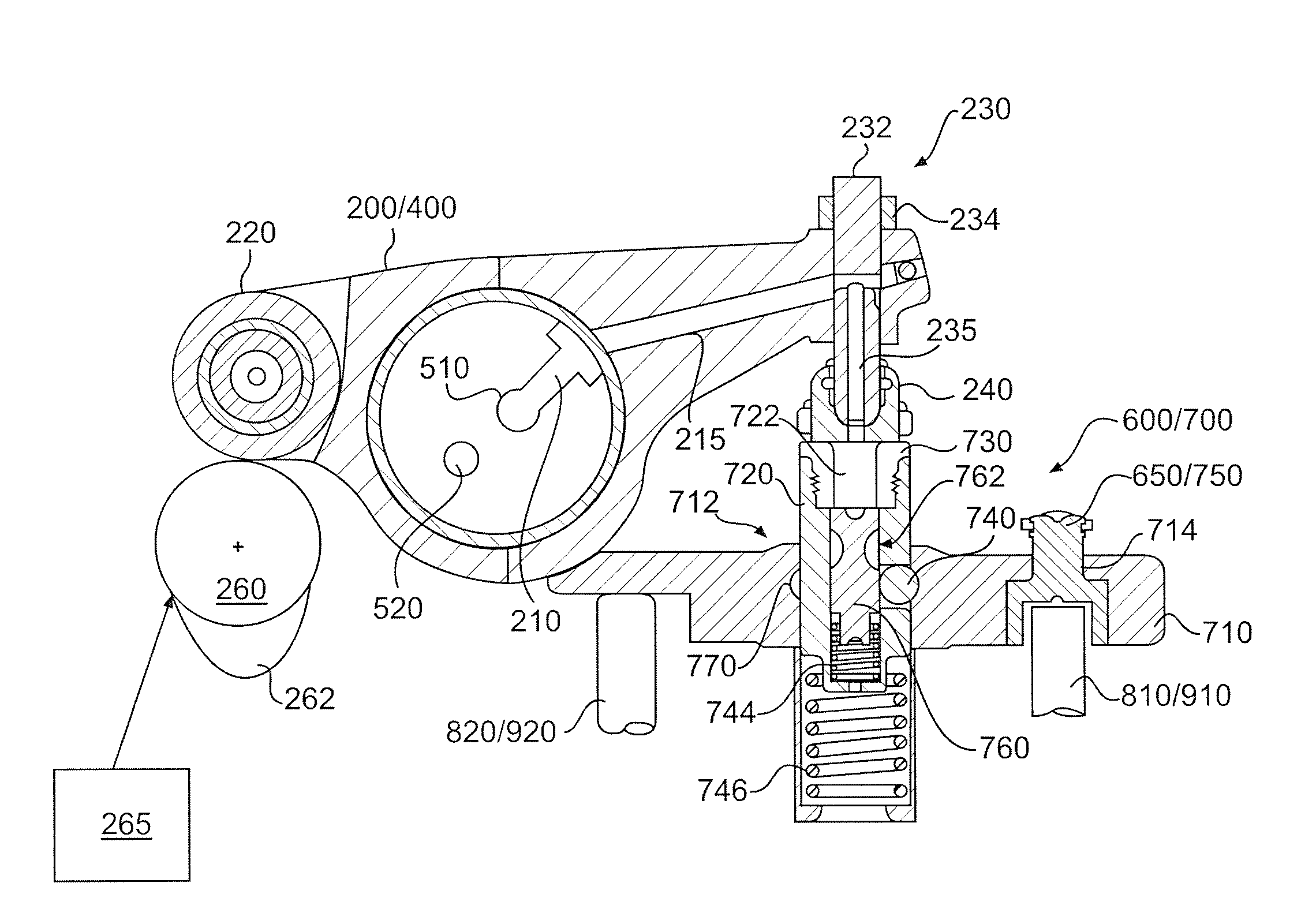

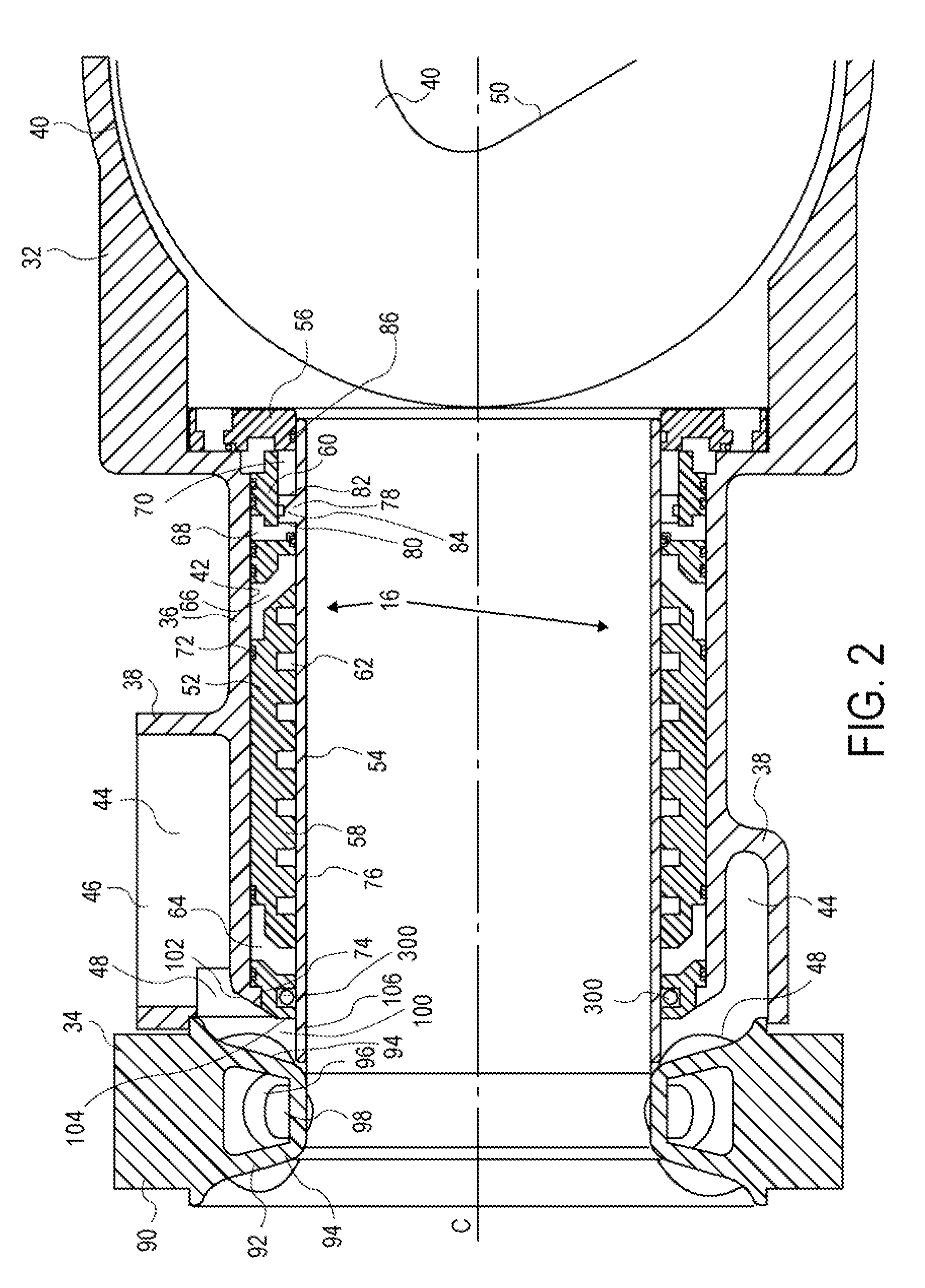

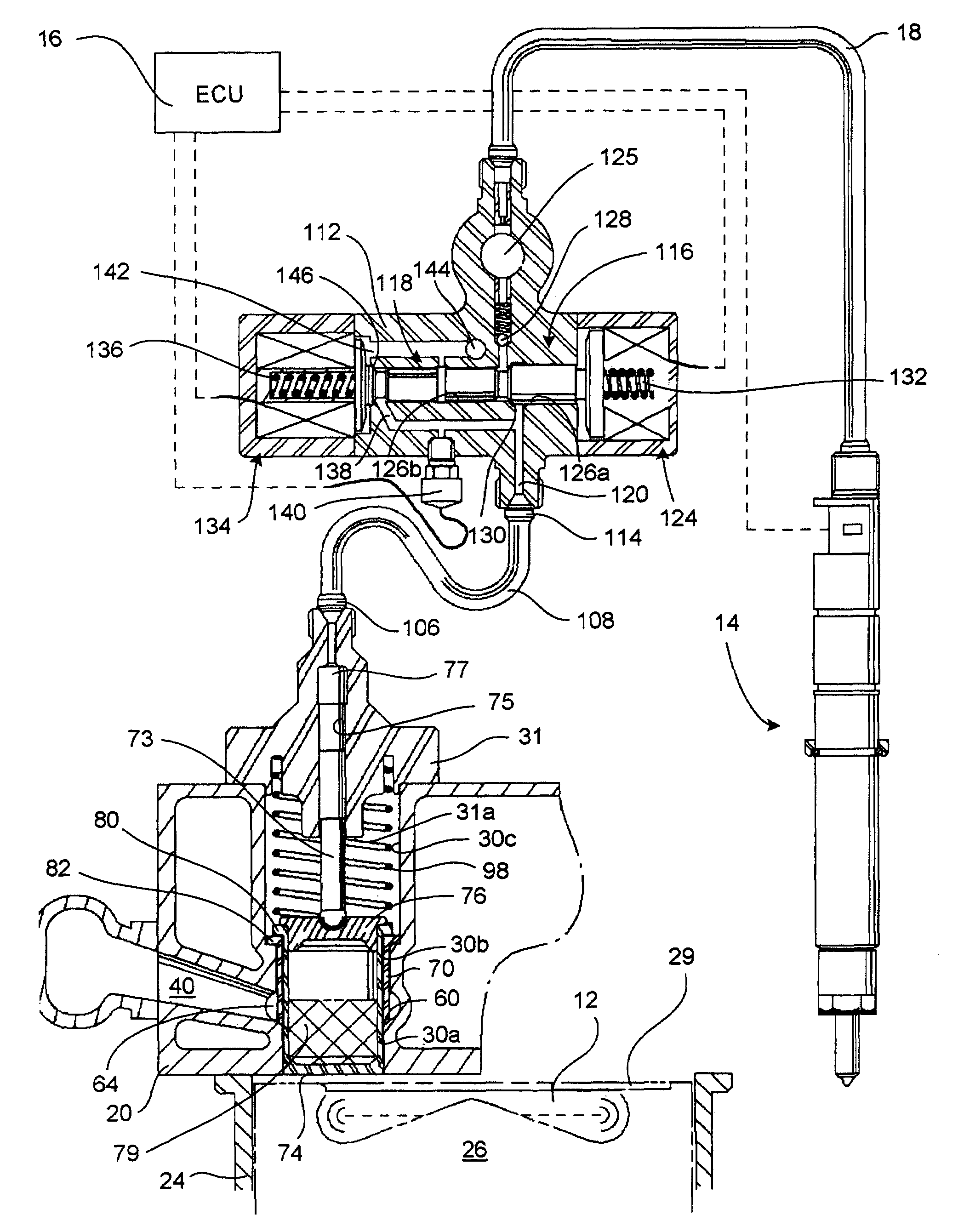

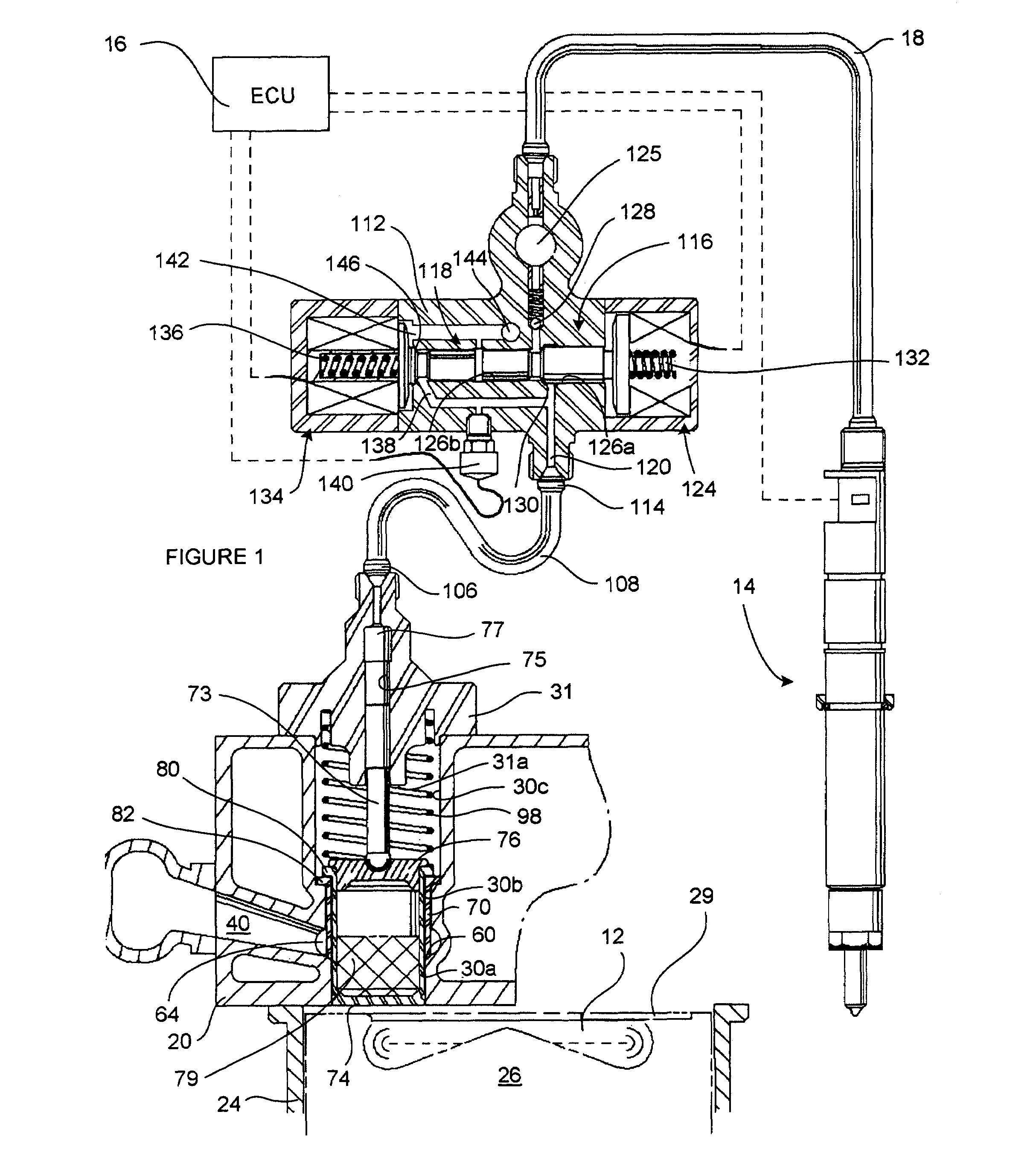

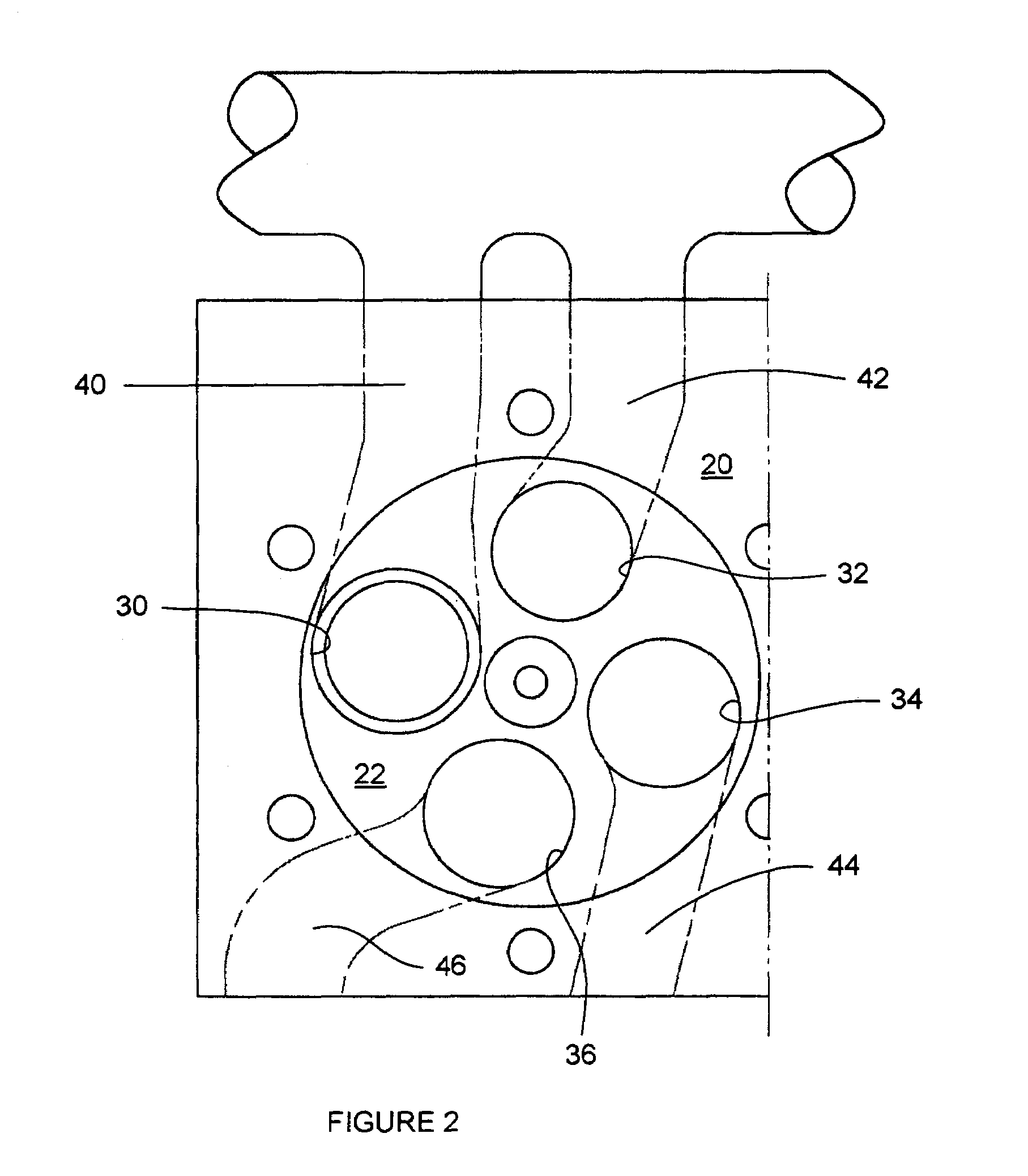

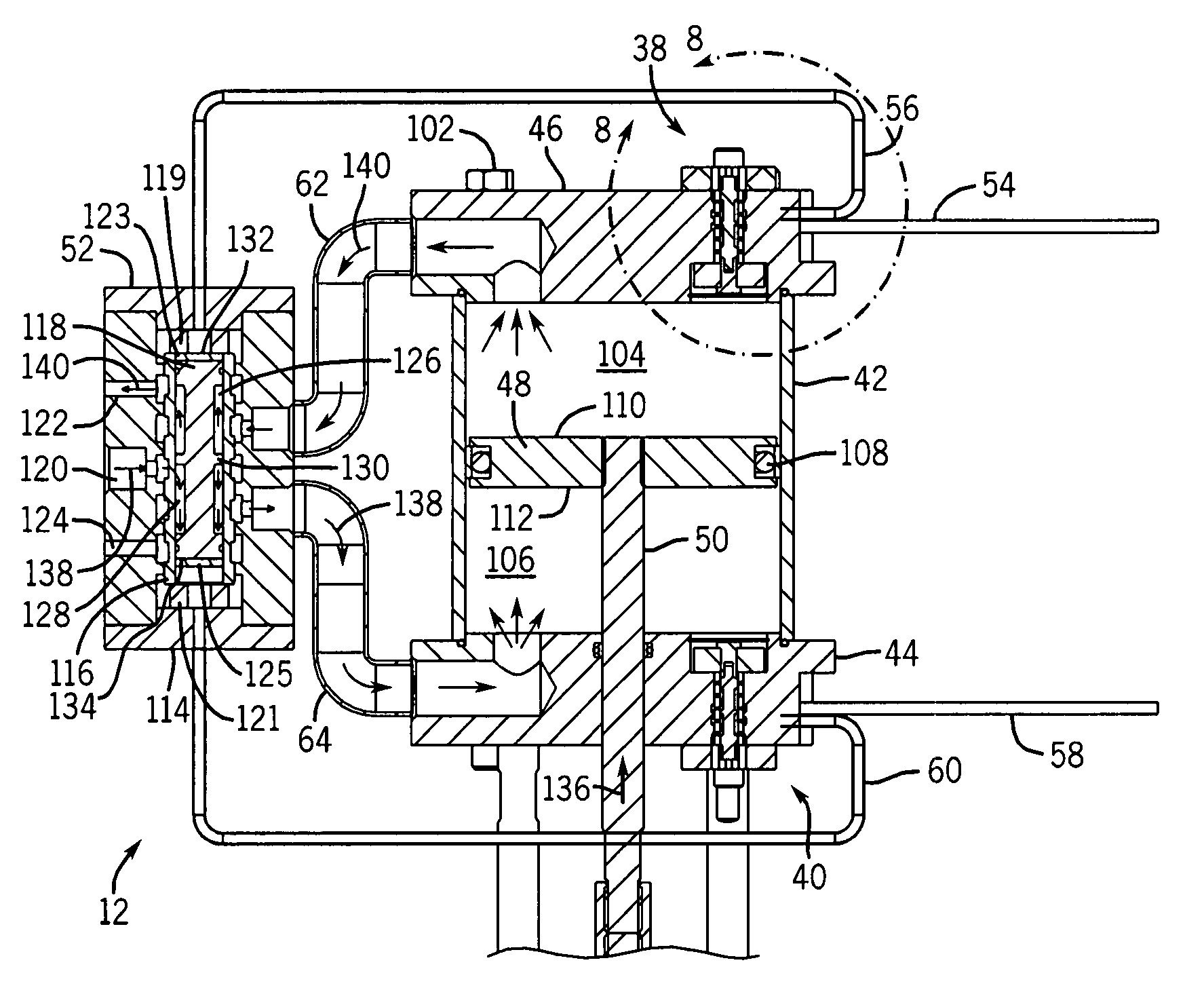

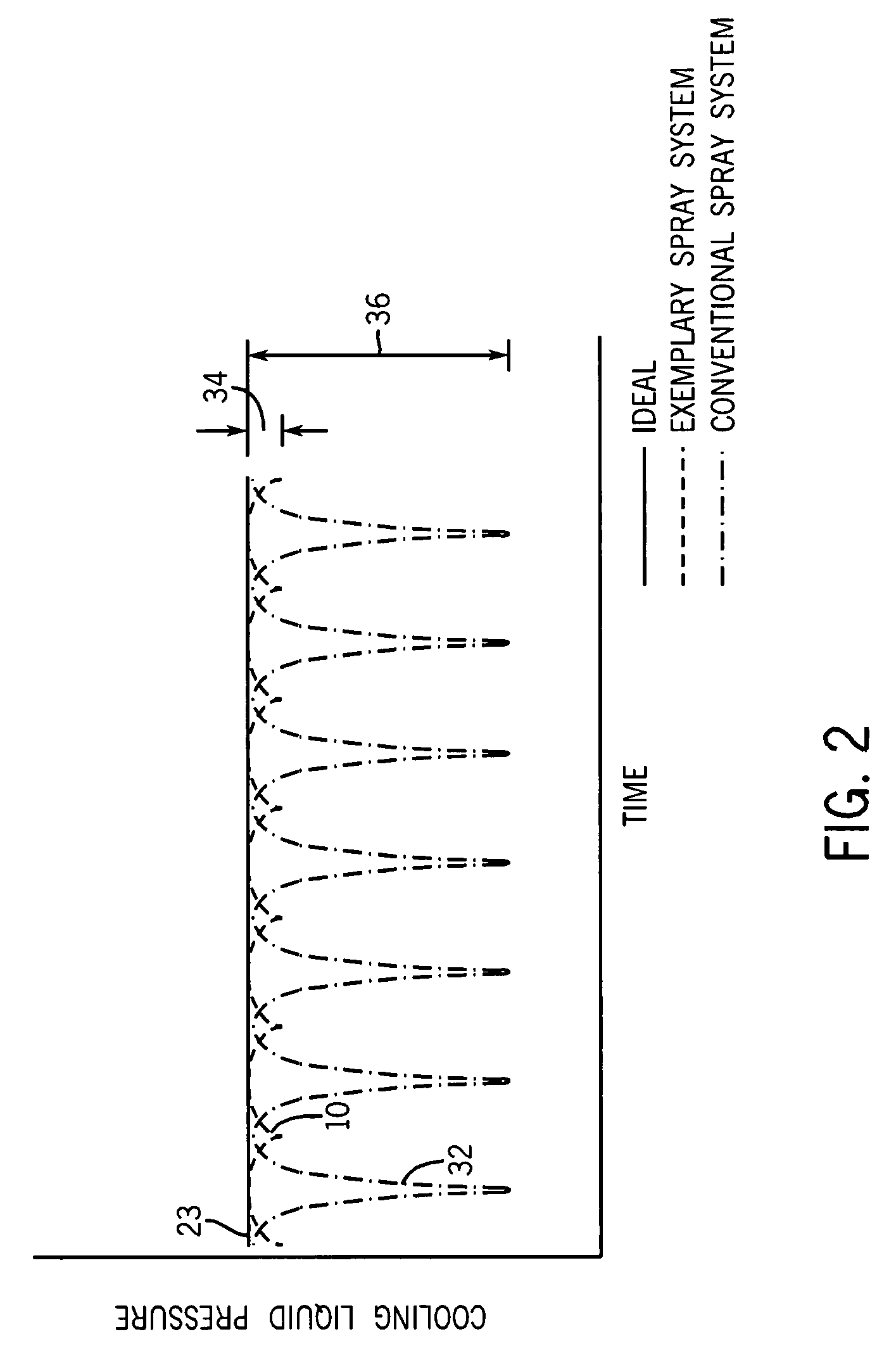

Compact lost motion system for variable valve actuation

InactiveUS6883492B2Wide rangeNon-fuel substance addition to fuelInternal combustion piston enginesVariable valve timingHydraulic circuit

Lost motion systems and methods for providing engine valves with variable valve actuation for engine valve events are disclosed. The system may include a master piston hydraulically linked to a slave piston, and a dedicated cam operatively connected to the master piston. The slave piston may be disposed substantially perpendicular to the master piston in a common housing. The slave piston is adapted to actuate one or more engine valves. The slave piston may incorporate an optional valve seating assembly into its upper end. A trigger valve may be operatively connected to the master-slave hydraulic circuit to selectively release and add hydraulic fluid to the circuit.

Owner:JACOBS VEHICLE SYST

Engine valve disabler

A method for improving efficiency and reducing emissions of an internal combustion engine. Variable displacement engine capabilities are achieved by disabling engine valves during load changes and constant load operations. Active cylinders may be operated at minimum BSFC by intermittently disabling other cylinders to provide the desired net torque. Disabling is begun by early closing of the intake valve to provide a vacuum at BDC which will result in no net gas flow across the piston rings, and minimum loss of compression energy in the disabled cylinder; this saving in engine friction losses is significant with multiple disablements.

Owner:MOYER DAVID F

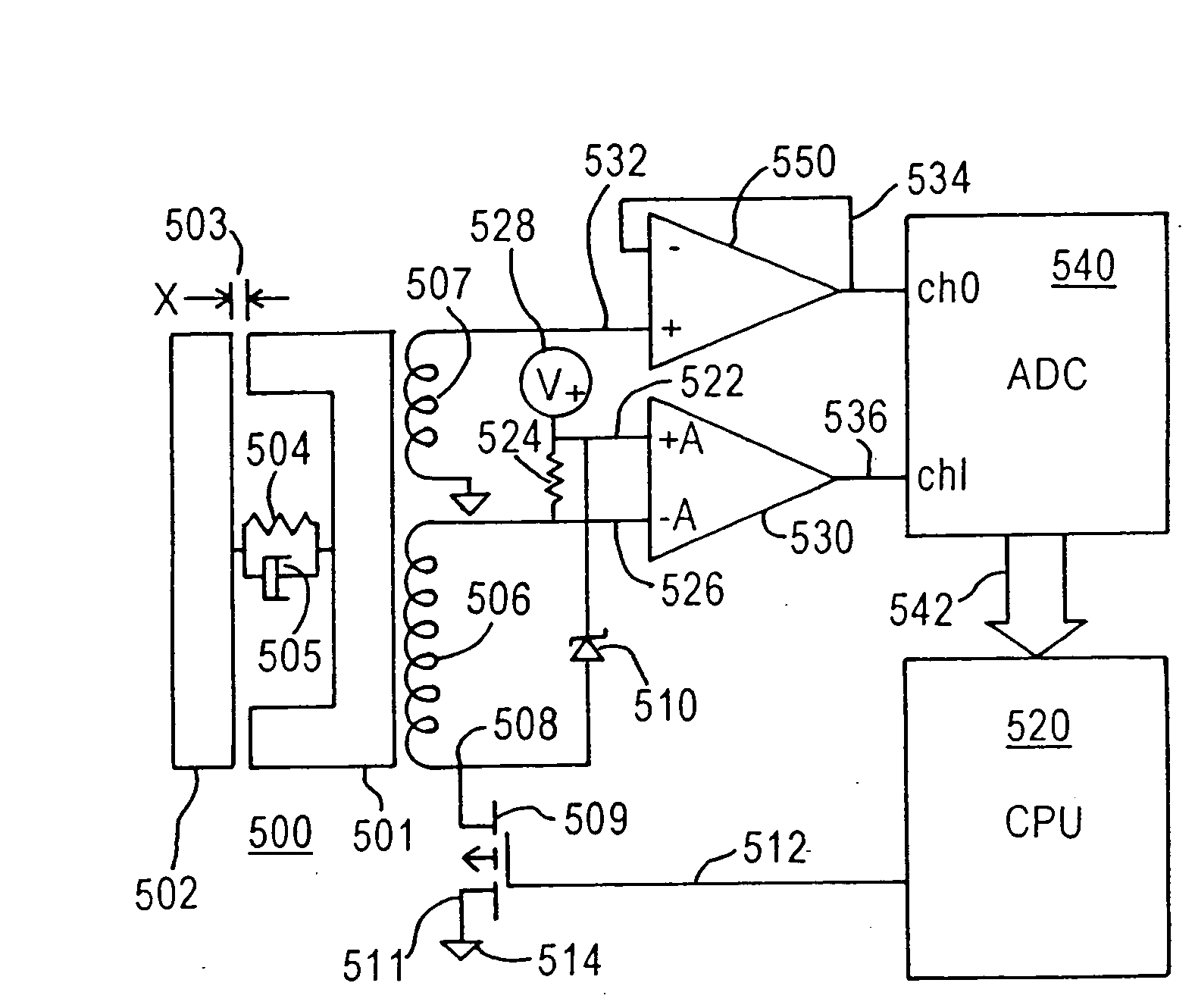

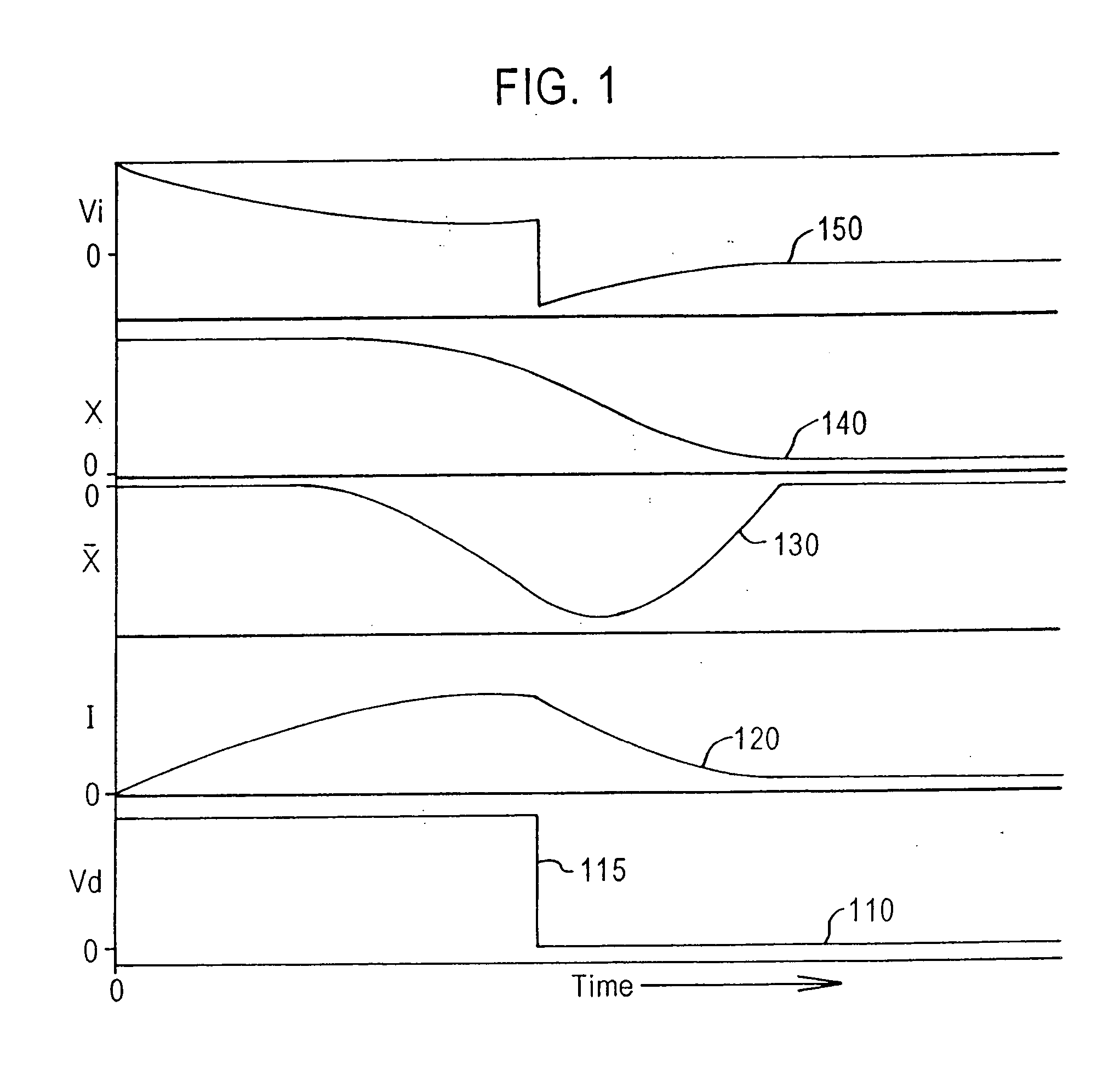

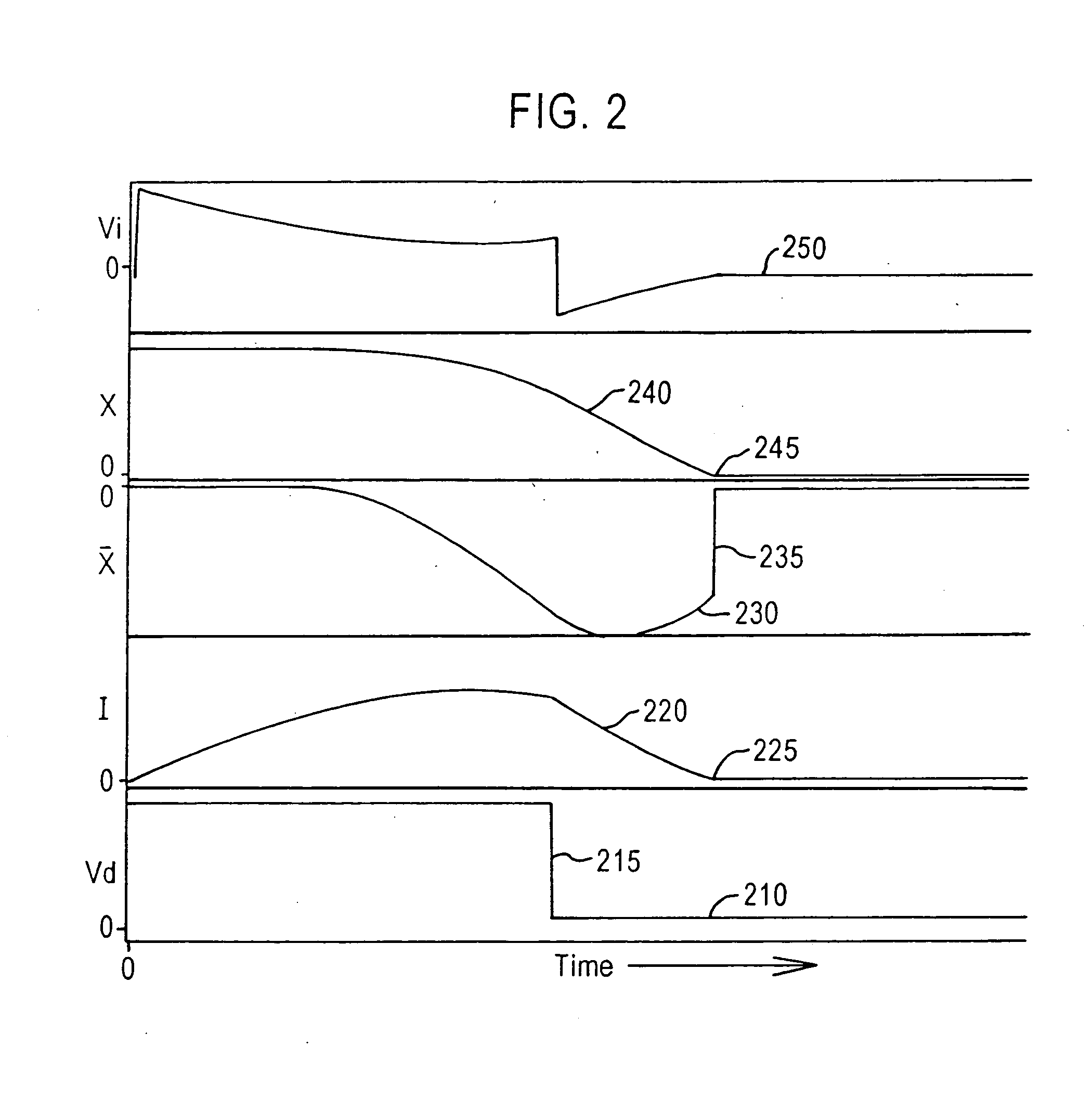

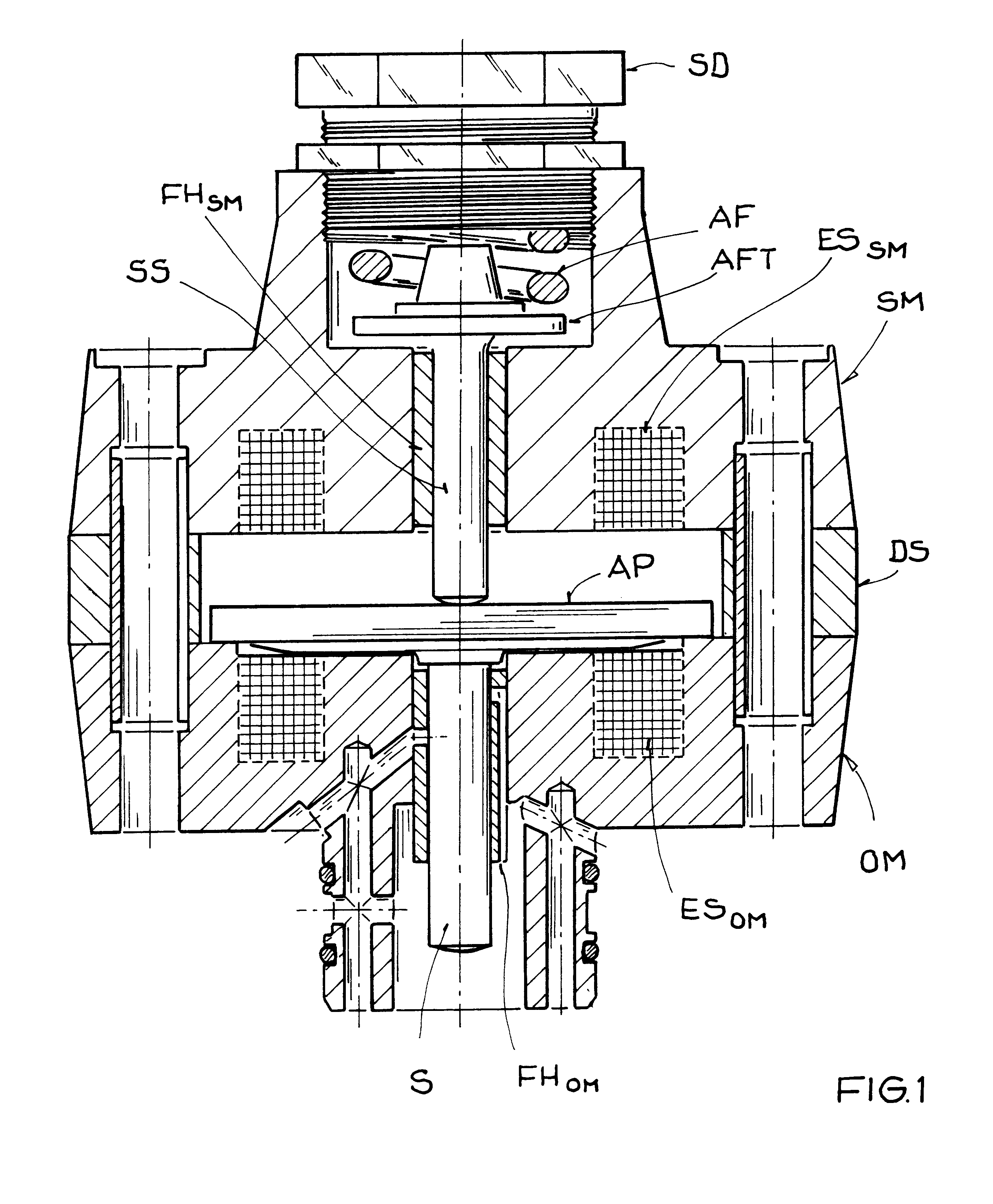

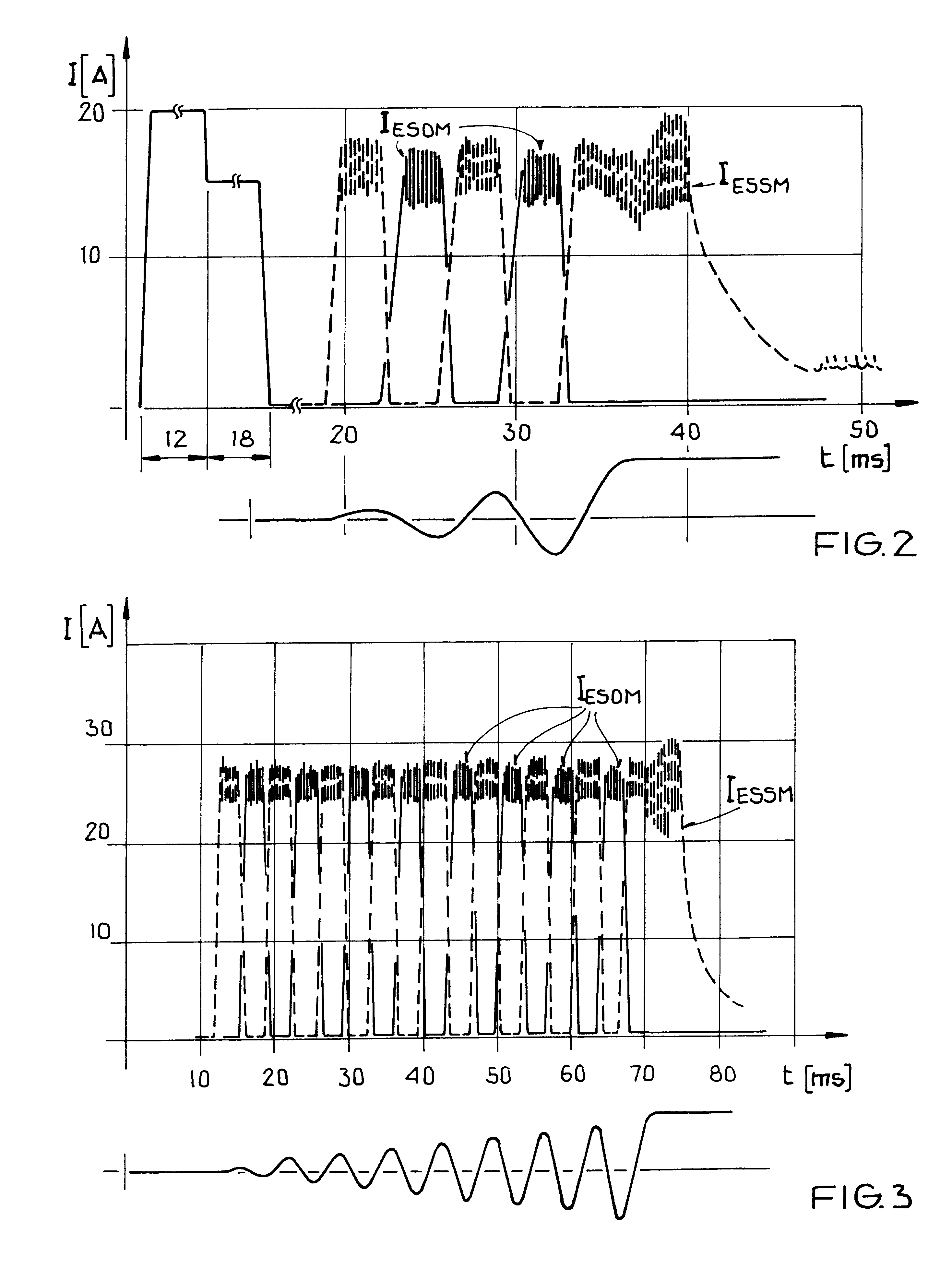

System and method for servo control of nonlinear electromagnetic actuators

InactiveUS20060171091A1Eliminate impactRemove noiseElectrical controlAC motor controlResonance measurementInstability

Servo control using ferromagnetic core material and electrical windings is based on monitoring of winding currents and voltages and inference of magnetic flux, a force indication; and magnetic gap, a position indication. Third order nonlinear servo control is split into nested control loops: a fast nonlinear first-order inner loop causing flux to track a target by varying a voltage output; and a slower almost linear second-order outer loop causing magnetic gap to track a target by controlling the flux target of the inner loop. The inner loop uses efficient switching regulation, preferably based on controlled feedback instabilities, to control voltage output. The outer loop achieves damping and accurate convergence using proportional, time-integral, and time-derivative gain terms. The time-integral feedback may be based on measured and target solenoid drive currents, adjusting the magnetic gap for force balance at the target current. Incorporation of permanent magnet material permits the target current to be zero, achieving levitation with low power, including for a monorail deriving propulsion from the levitation magnets. Linear magnetic approximations lead to the simplest controller, but nonlinear analog computation in the log domain yields a better controller with relatively few parts. When servo-controlled solenoids provide actuation of a pump piston and valves, electronic LC resonance measurements determine liquid volume and gas bubble volume.

Owner:SEALE JOSEPH B +1

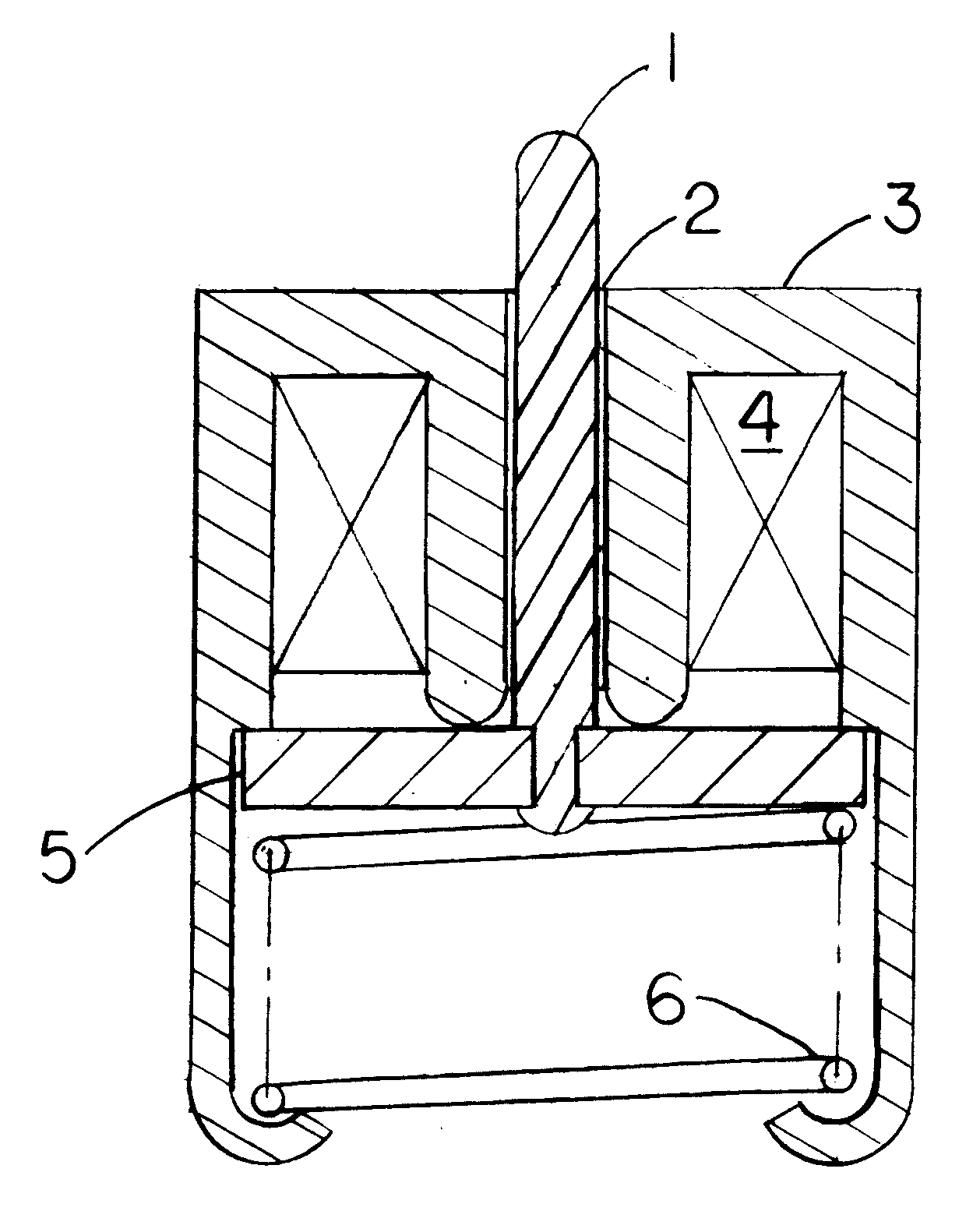

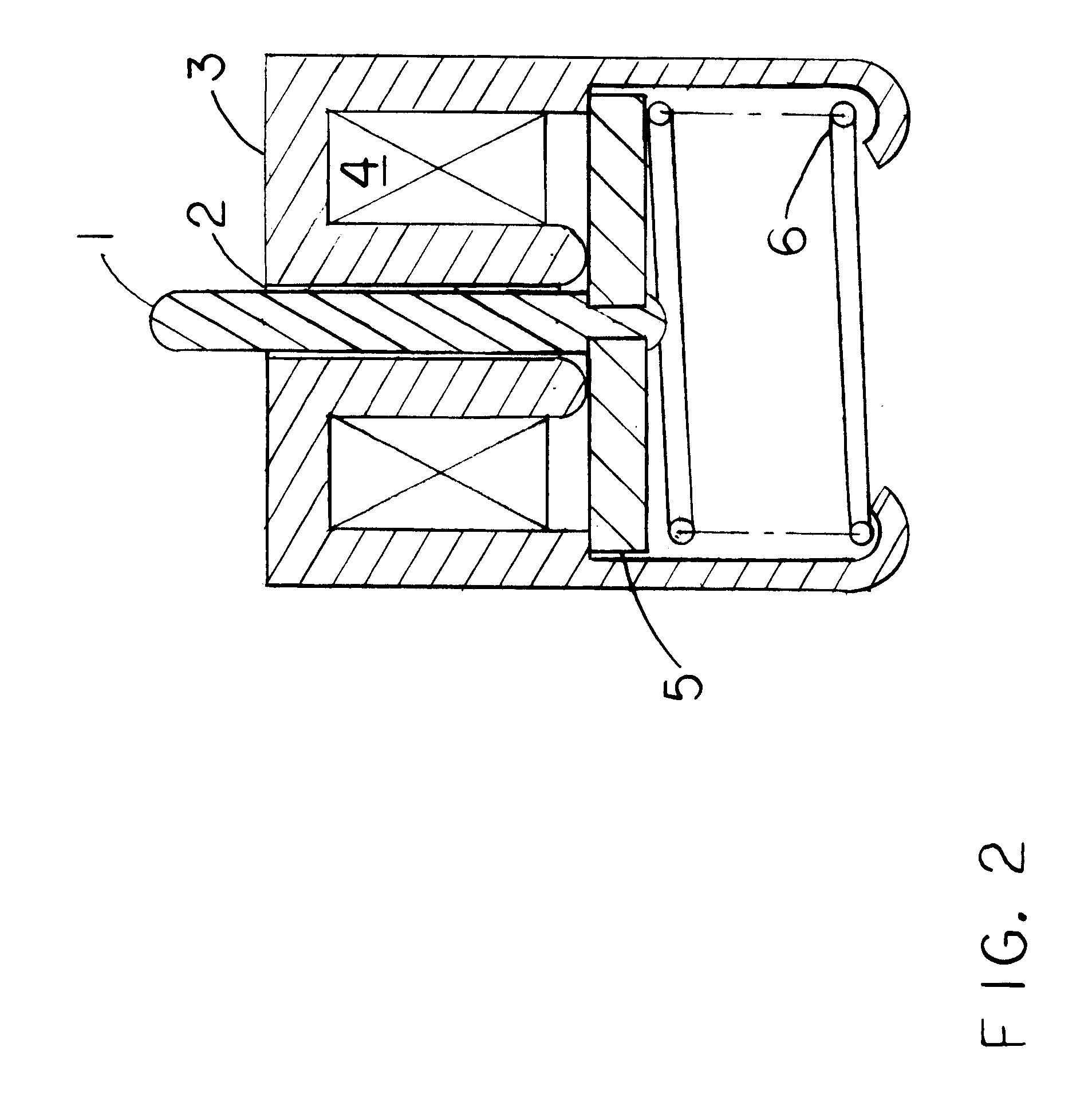

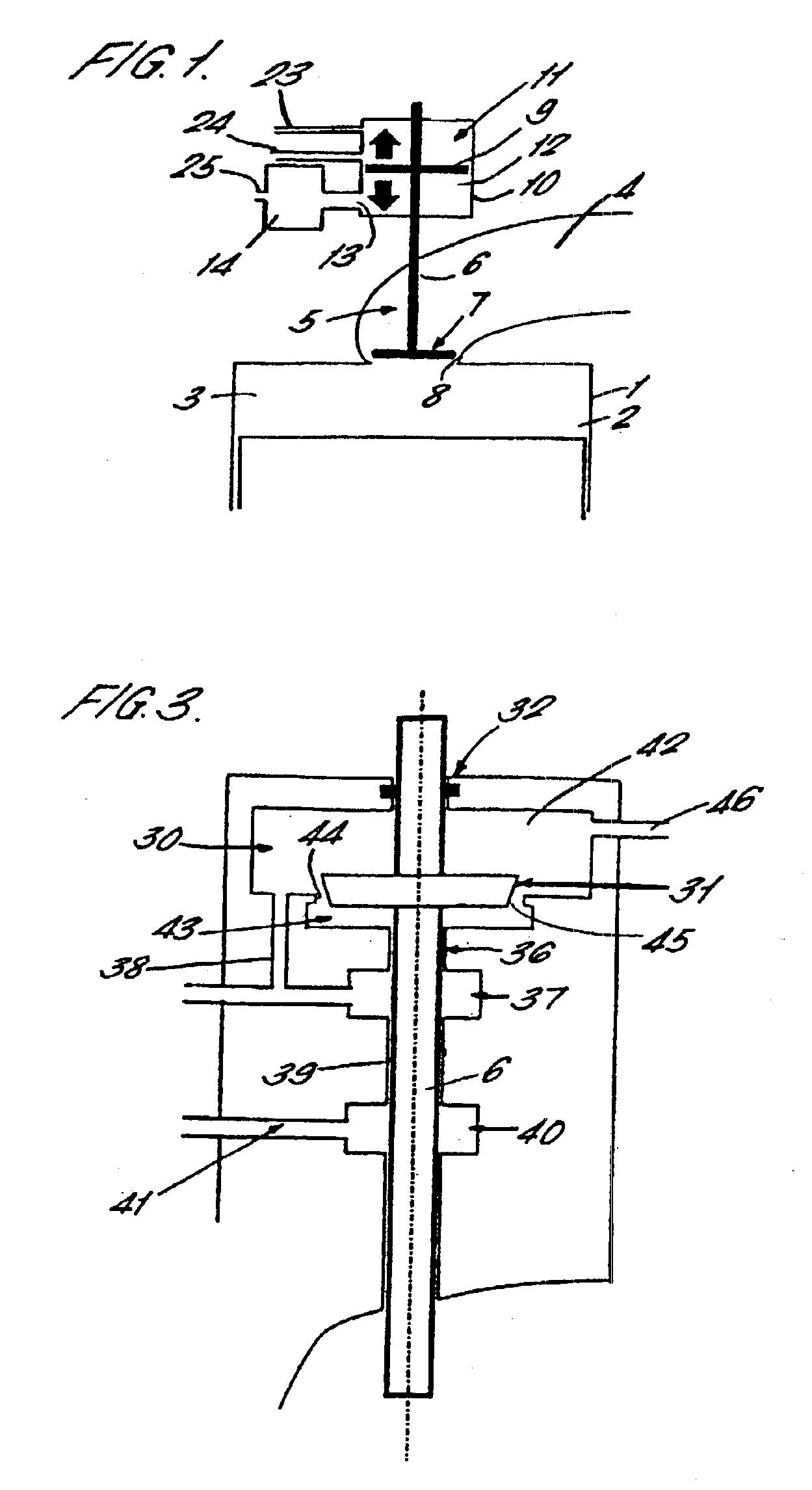

Passive valve assembly

InactiveUS6883775B2Open timeParasitic losses are smallOperating means/releasing devices for valvesMachines/enginesReciprocating motionPiston

A passive valve assembly for controlling the flow into or out of chamber (3) through a port (4). The valve assembly comprises a valve element (5) arranged to open in the direction of flow through the port. The valve element (5) has a piston (9) which is reciprocable in a cylinder (10) containing gas. On opening of the valve, gas is compressed in a first chamber (11) of the cylinder (10), and this energy of compression is used to reverse the direction of the valve element (5) and return it to its seat.

Owner:INNOGY

Device for the determination of glycated hemoglobin

InactiveUS20060205029A1Retain and improve accuracySpeed the ultimate determinationMicrobiological testing/measurementVolume/mass flow measurementTotal hemoglobinCathode reaction

A method of determining the percentage of glycated hemoglobin in a blood sample is disclosed wherein at least one of the assay steps is performed electrochemically. The method includes determining the total amount of hemoglobin in a sample by electrochemically measuring, in an oxygen electroreduction reaction at a cathode, the amount of oxygen in the sample. Because the amount of oxygen dissolved in the sample is known, the total hemoglobin is determined by subtracting the amount of free oxygen from the total oxygen measured, recognizing the fast equilibrium Hb+O2⇄HbO2. This can be followed by determining the amount of glycated hemoglobin in the sample. The cathode reaction is accomplished by contacting the sample with an enzyme, the enzyme being a copper-containing enzyme having four copper ions per active unit. The family of these enzymes includes, for example, laccases and bilirubin oxidases. A device associated with such a process or method is also provided.

Owner:ABBOTT DIABETES CARE INC

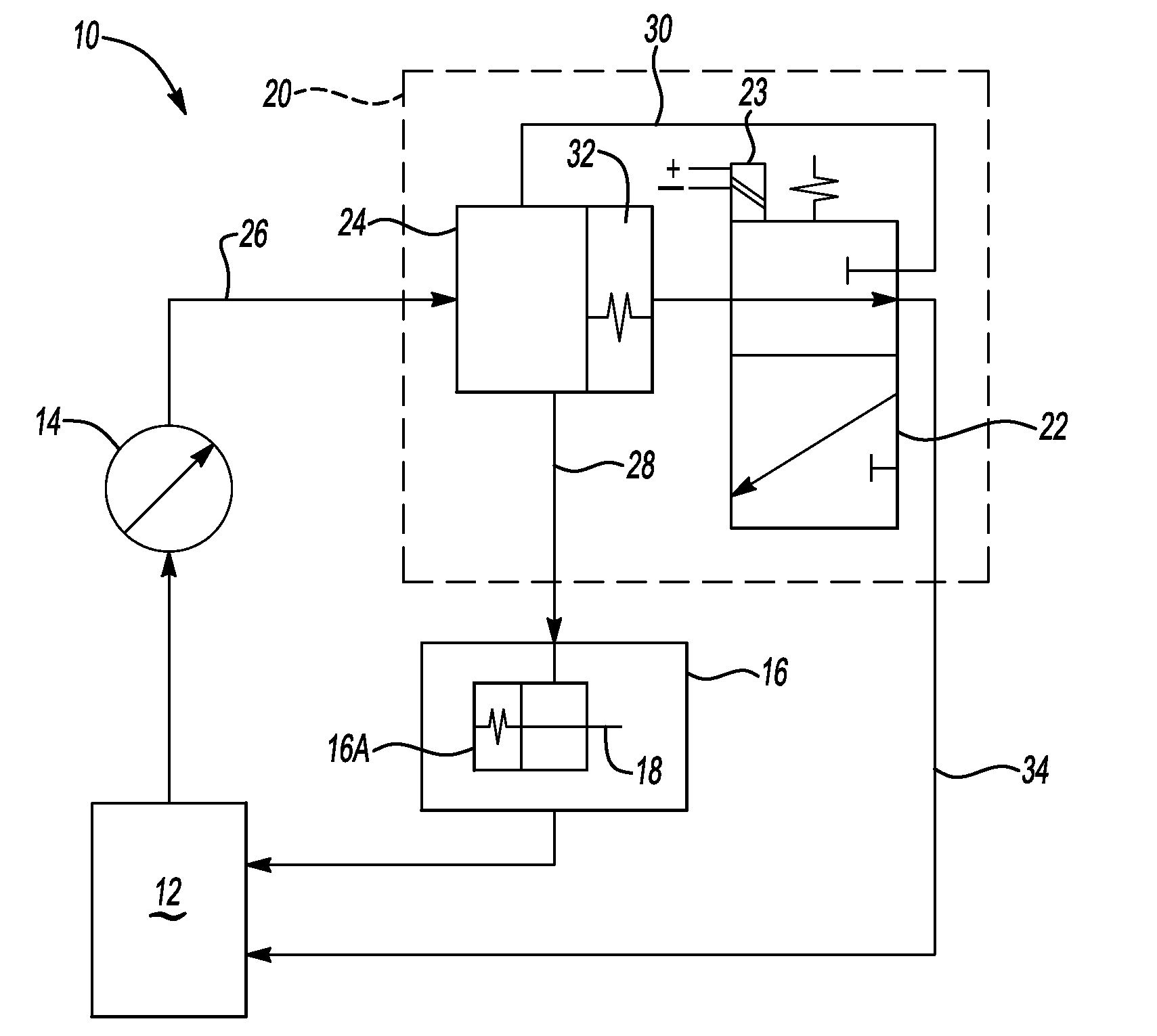

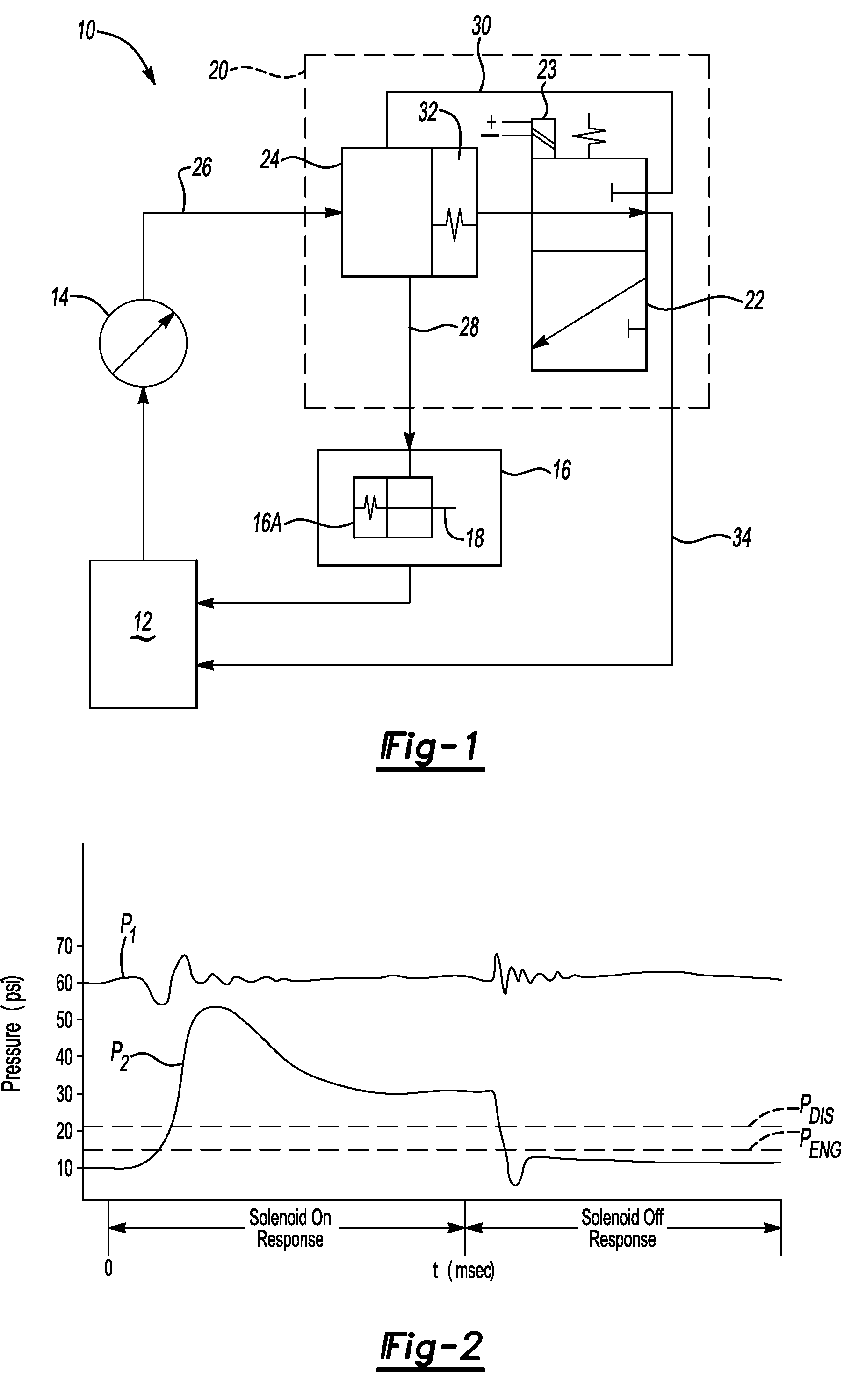

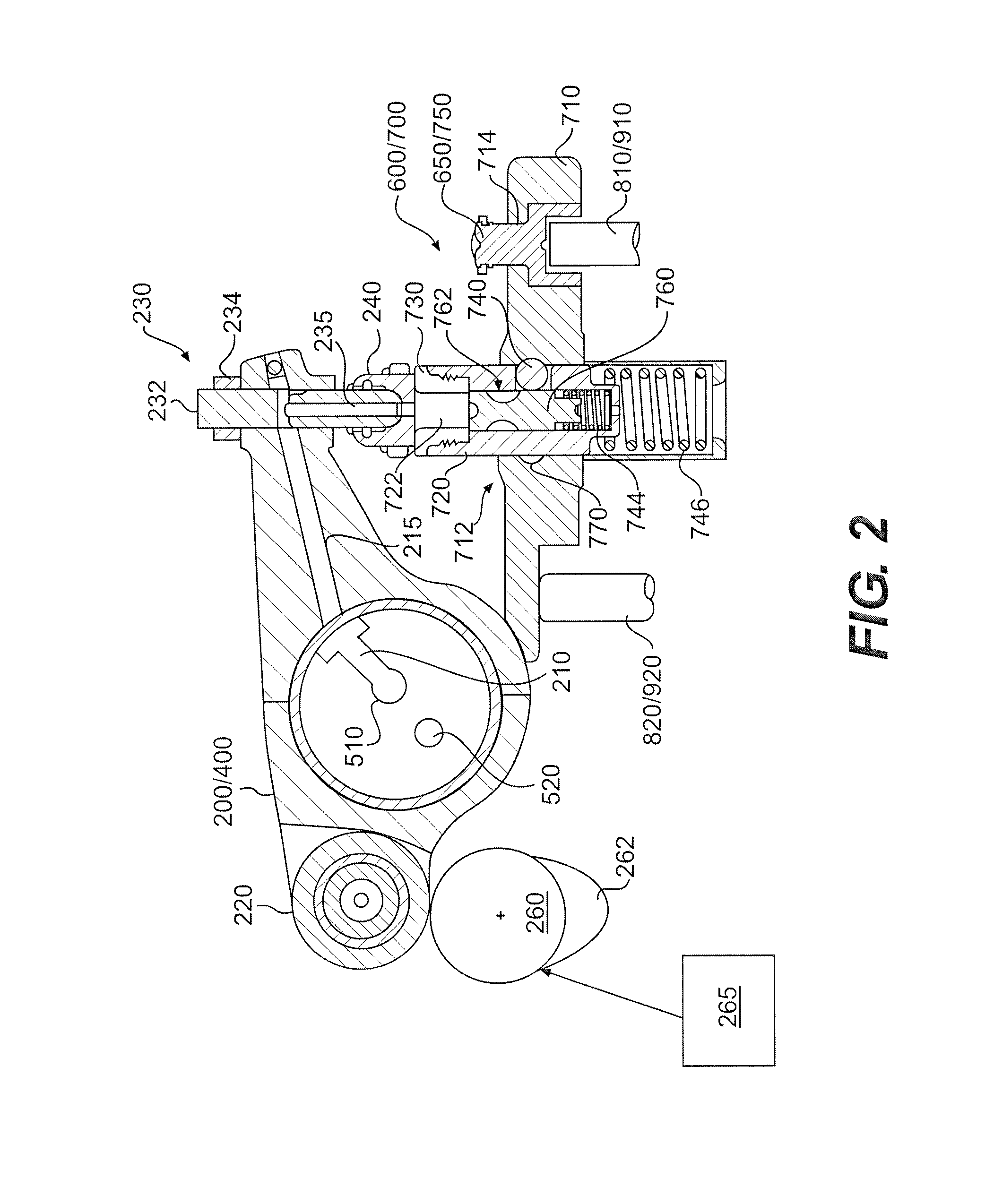

Valvetrain oil control system and oil control valve

InactiveUS20100018482A1Reduce fuel consumptionOperating means/releasing devices for valvesPipeline systemsControl systemEngineering

A hydraulic control system includes an oil control valve to control oil flow within a valvetrain. The control valve varies the flow rate to actuate an engine component from a first position to a second position based upon fluid pressure from the control valve. Varying the flow rate through the control valve includes increasing the flow rate through the control valve to increase the pressure to a first level to actuate the engine component to the first position. After the engine component is actuated, the flow rate through the control valve is maintained at a level sufficient to maintain the engine component in the first position. To actuate the engine component to the second position the flow rate through the control valve is then decreased. The fluid flow rate through the control valve is then maintained at a level sufficient to maintain the engine component in the second position.

Owner:EATON CORP

Method for operating actuators for electromagnetically controlling a valve

InactiveUS6216652B1Operating means/releasing devices for valvesMachines/enginesInternal combustion engineActuator

A method of operating an actuator for electromagnetically controlling a valve in an internal combustion engine involves supplying a heating current to the operating coils of the actuator before starting the internal combustion engine from a cold start condition. Thereby, the operating coils, the components surrounding them, and the lubricant are heated to ensure proper viscosity of the lubricant and thus proper operation of the actuator.

Owner:CONTI TEMIC MICROELECTRONIC GMBH

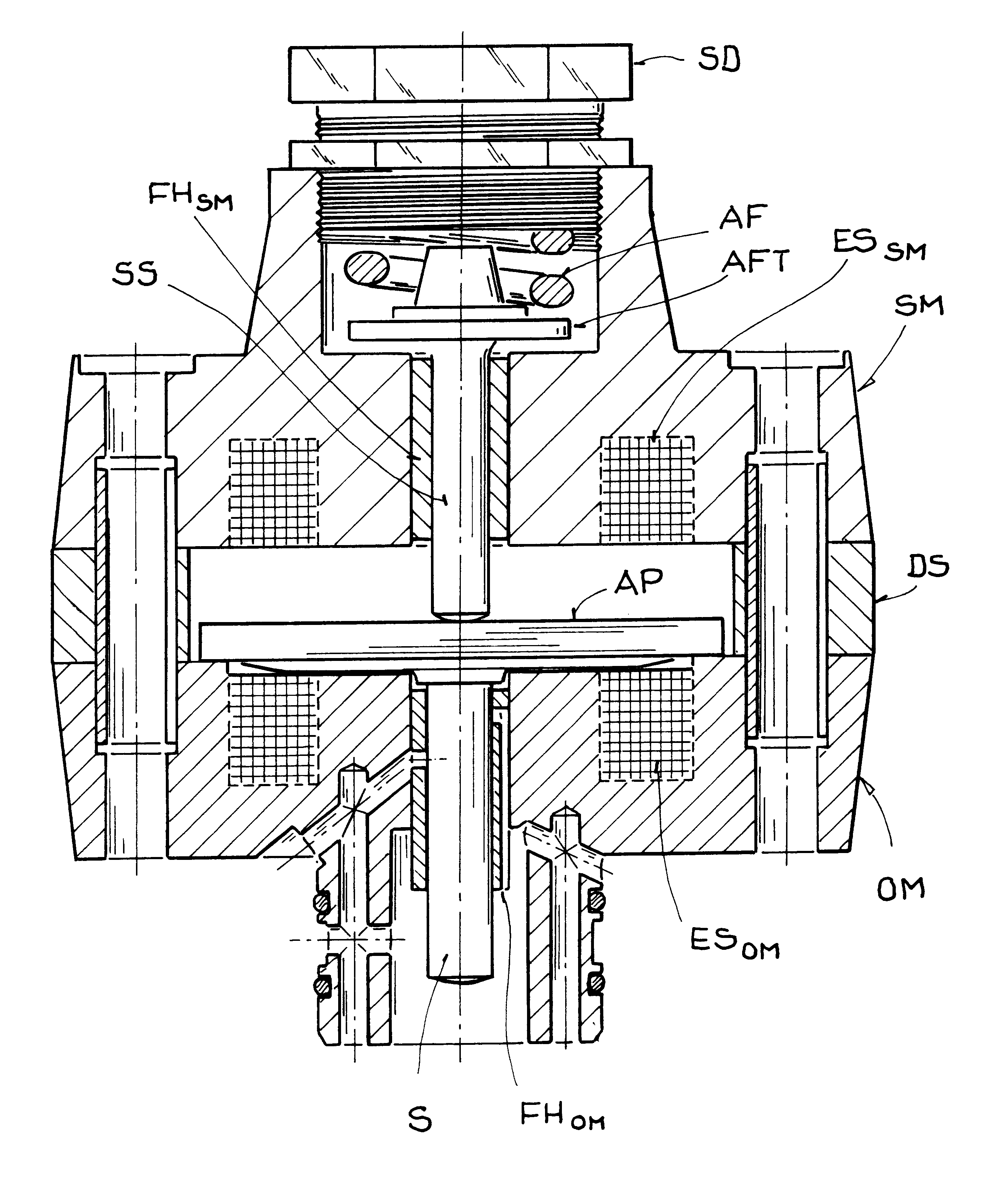

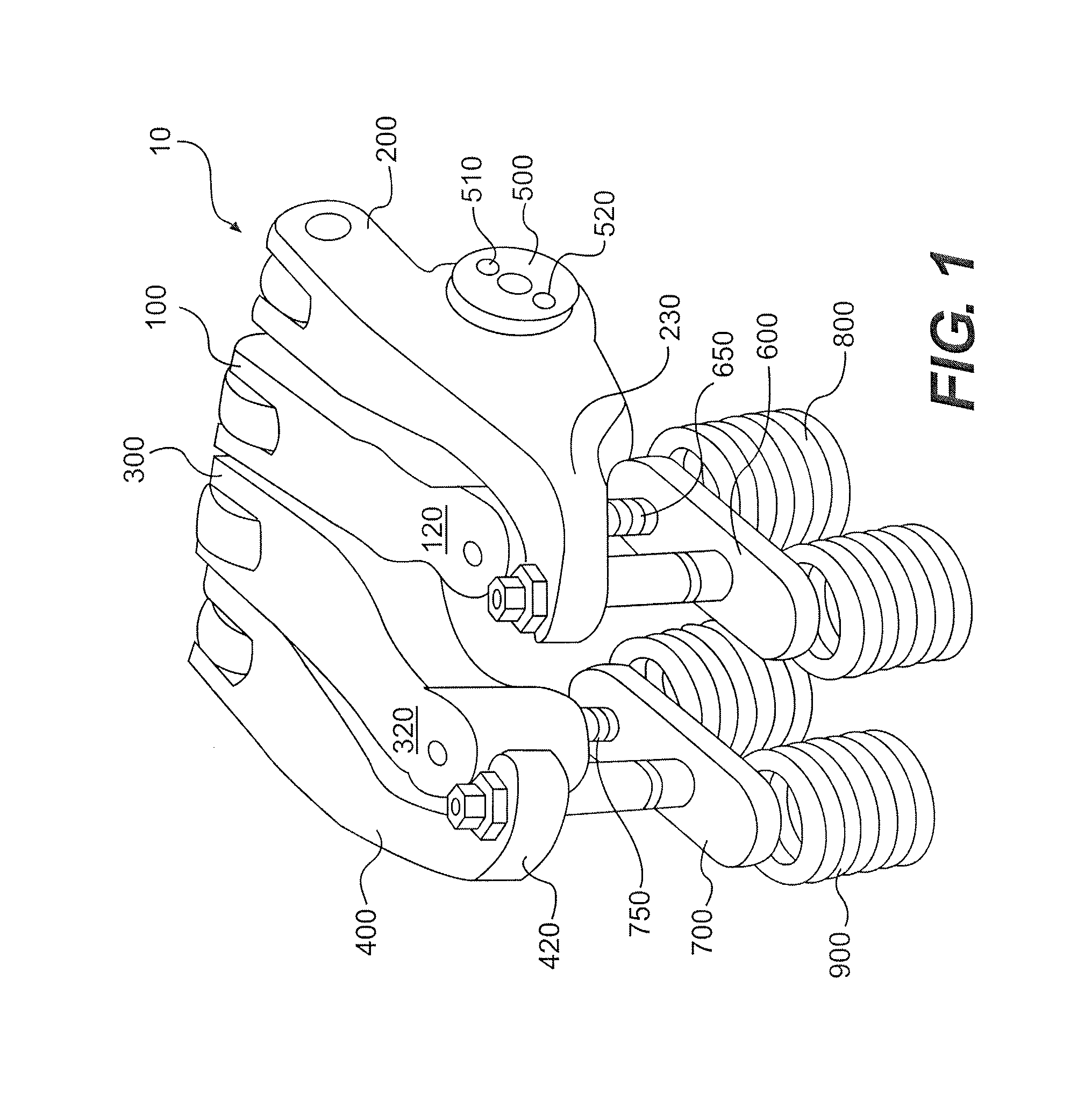

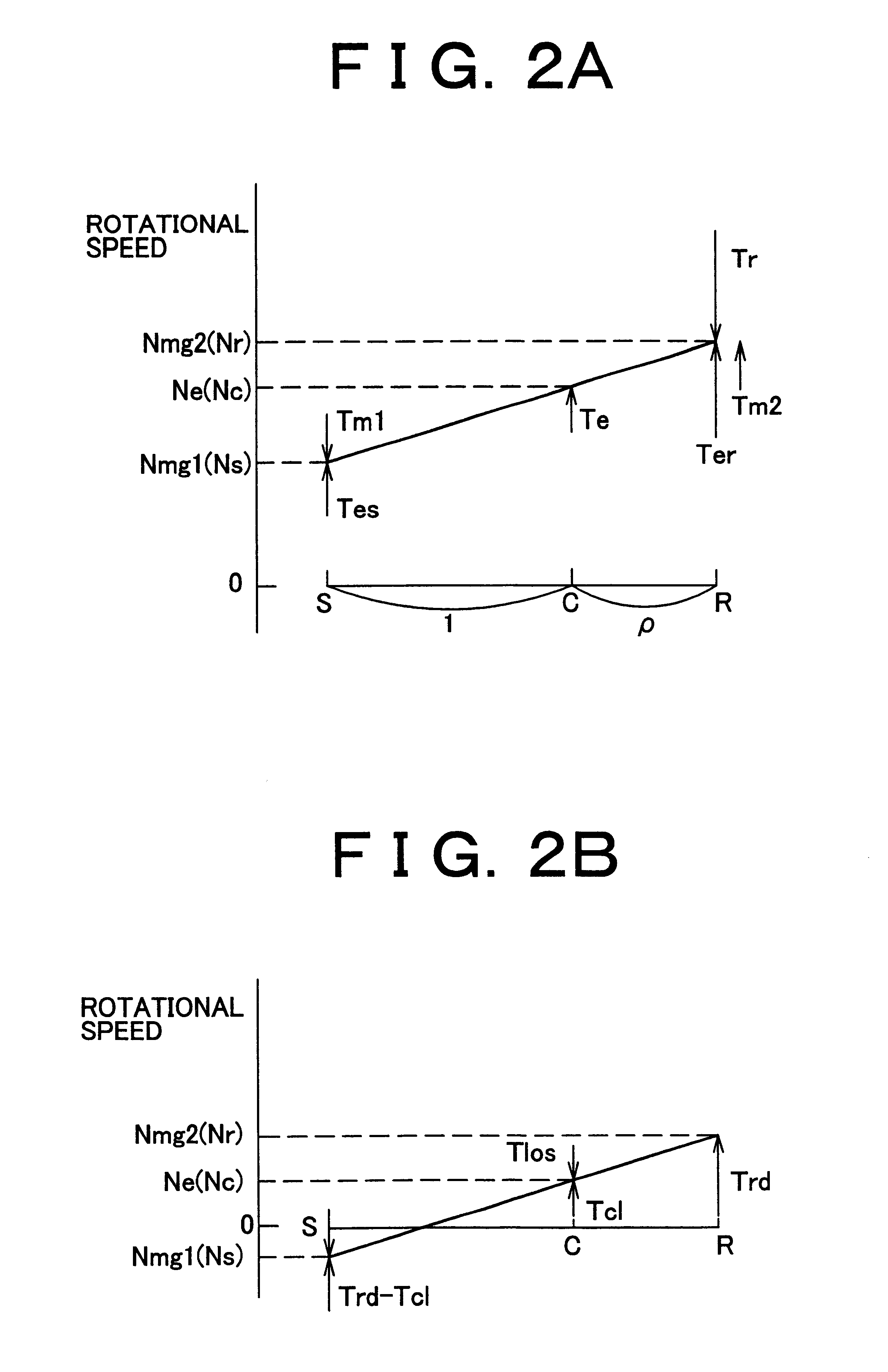

Combined engine braking and positive power engine lost motion valve actuation system

A system for actuating one or more engine valves for positive power operation and engine braking operation is disclosed. In a preferred embodiment, an exhaust valve bridge and intake valve bridge each receive valve actuations from two sets of rocker arms. Each valve bridge includes a sliding pin for actuating a single engine valve and an outer plunger disposed in the center of the valve bridge to actuate two engine valves through the bridge. The outer plunger of each valve bridge may be selectively locked to its valve bridge to provide positive power valve actuation. During engine braking, application of hydraulic pressure to the outer plungers may cause the respective valve bridges and outer plungers to unlock so that all engine braking valve actuations are provided from a rocker arm acting on one engine valve through the sliding pin.

Owner:JACOBS VEHICLE SYST

Internal combustion engine

InactiveUS7559298B2Assist in containment of heat energyReduce energy lossLiquid coolingInternal combustion piston enginesCombustion chamberCylinder head

An internal combustion engine is provided. Facing pistons eliminate a cylinder head, thereby reducing heat losses through a cylinder head. Facing pistons also halve the stroke that would be required for one piston to provide the same compression ratio, and the engine can thus be run at higher revolutions per minute and produce more power. An internal sleeve valve is provided for space and other considerations. A combustion chamber size-varying mechanism allows for adjustment of the minimum size of an internal volume to increase efficiency at partial-power operation. Variable intake valve operation is used to control engine power.

Owner:CLEEVES ENGINES

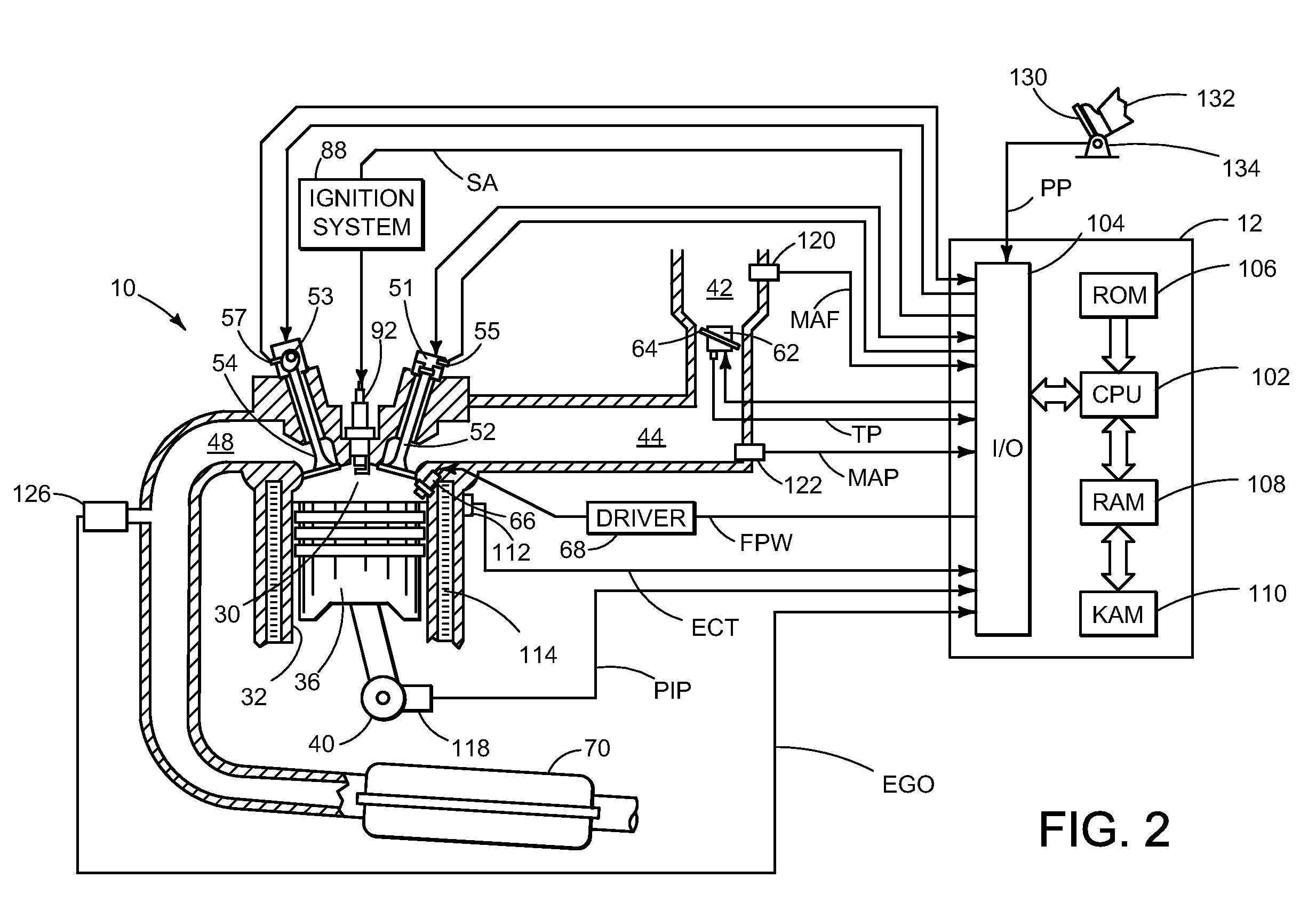

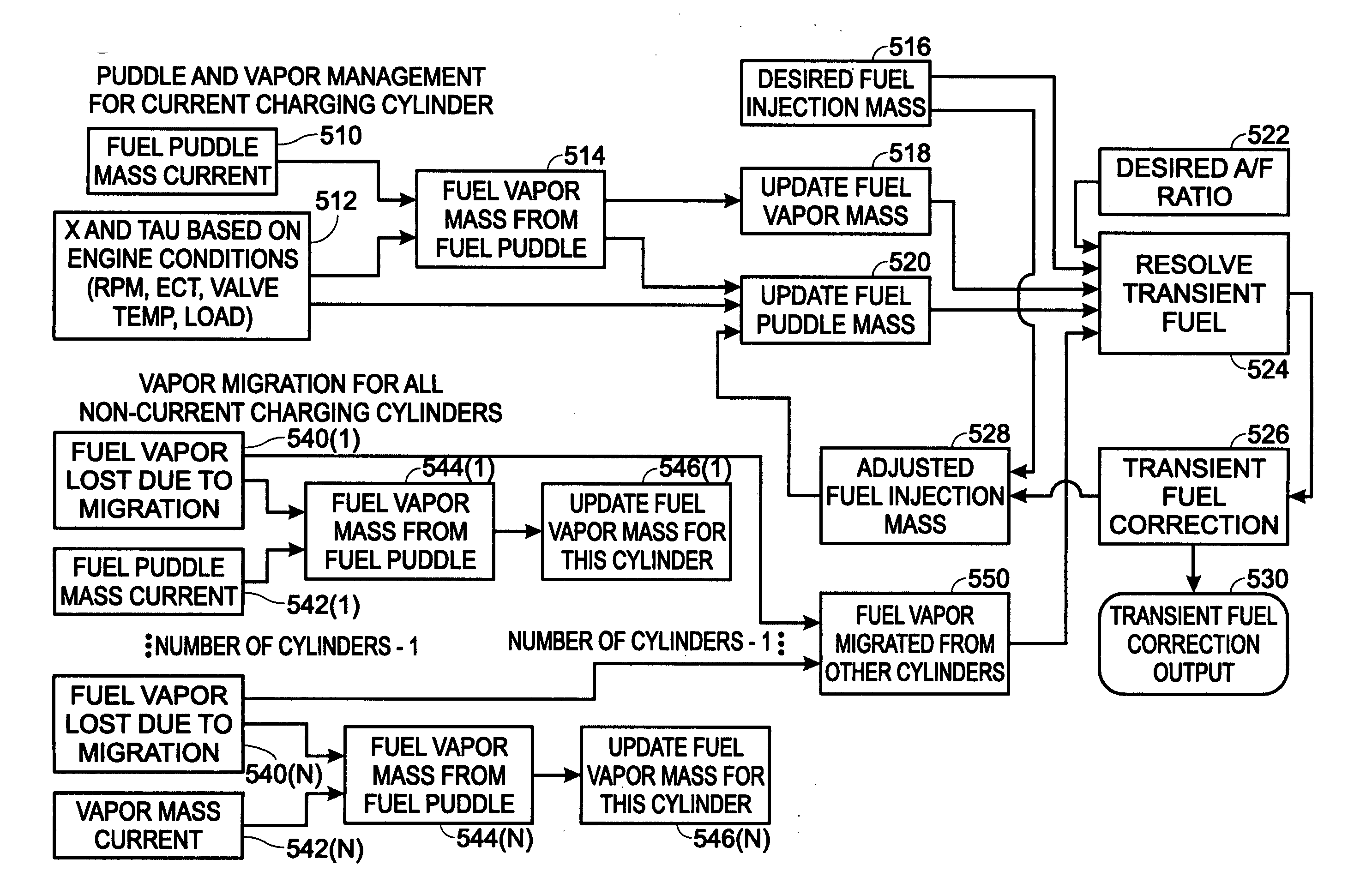

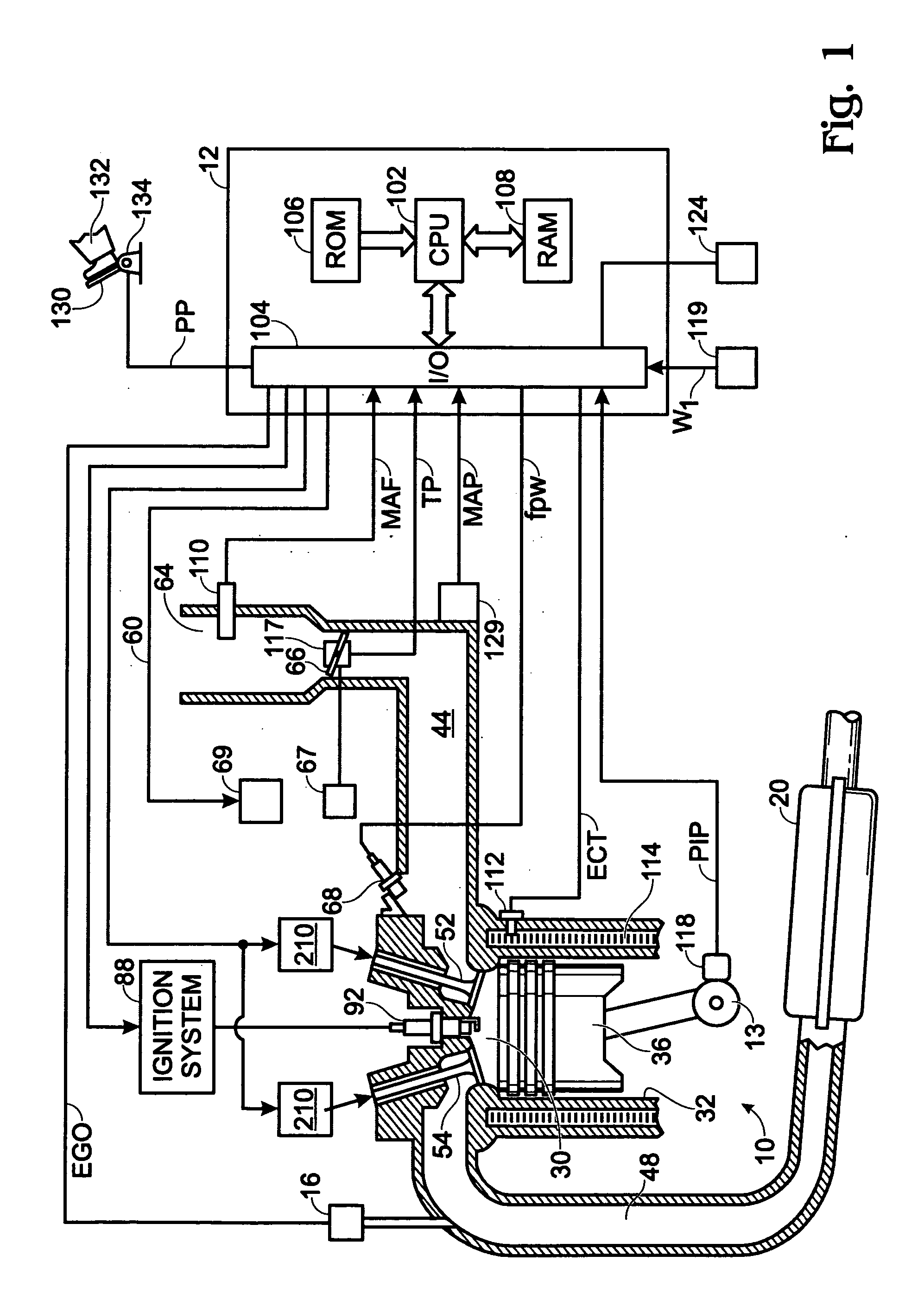

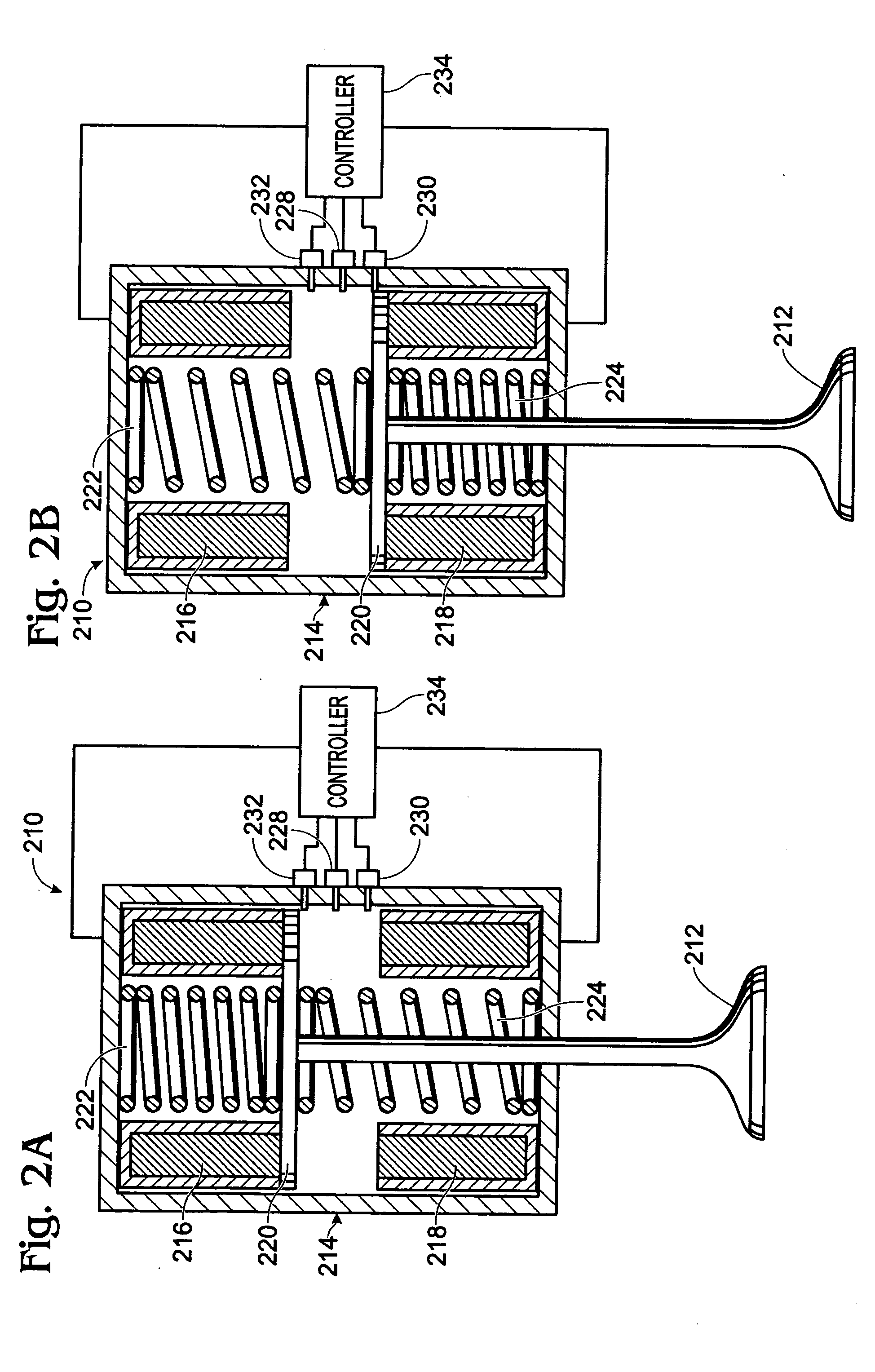

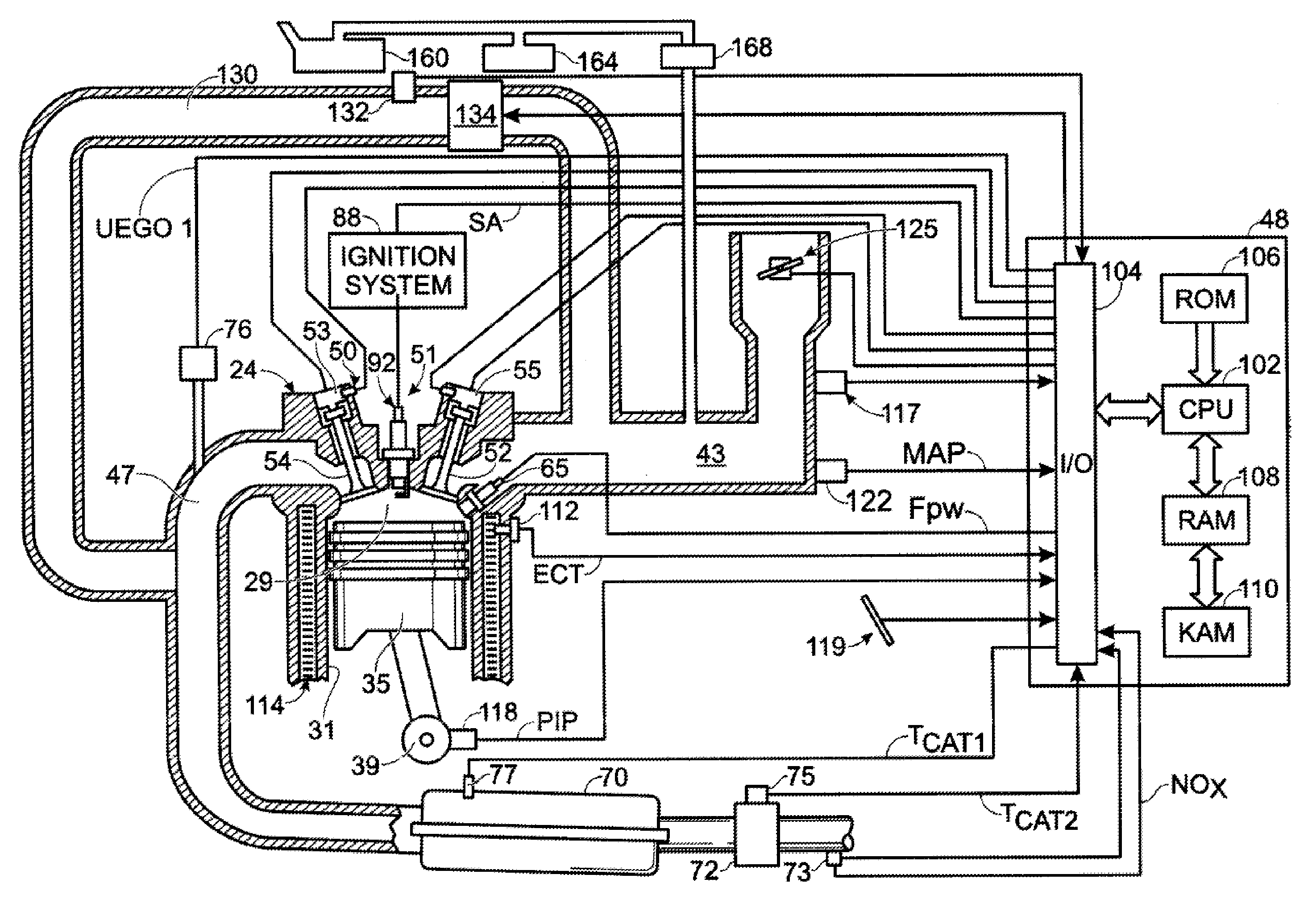

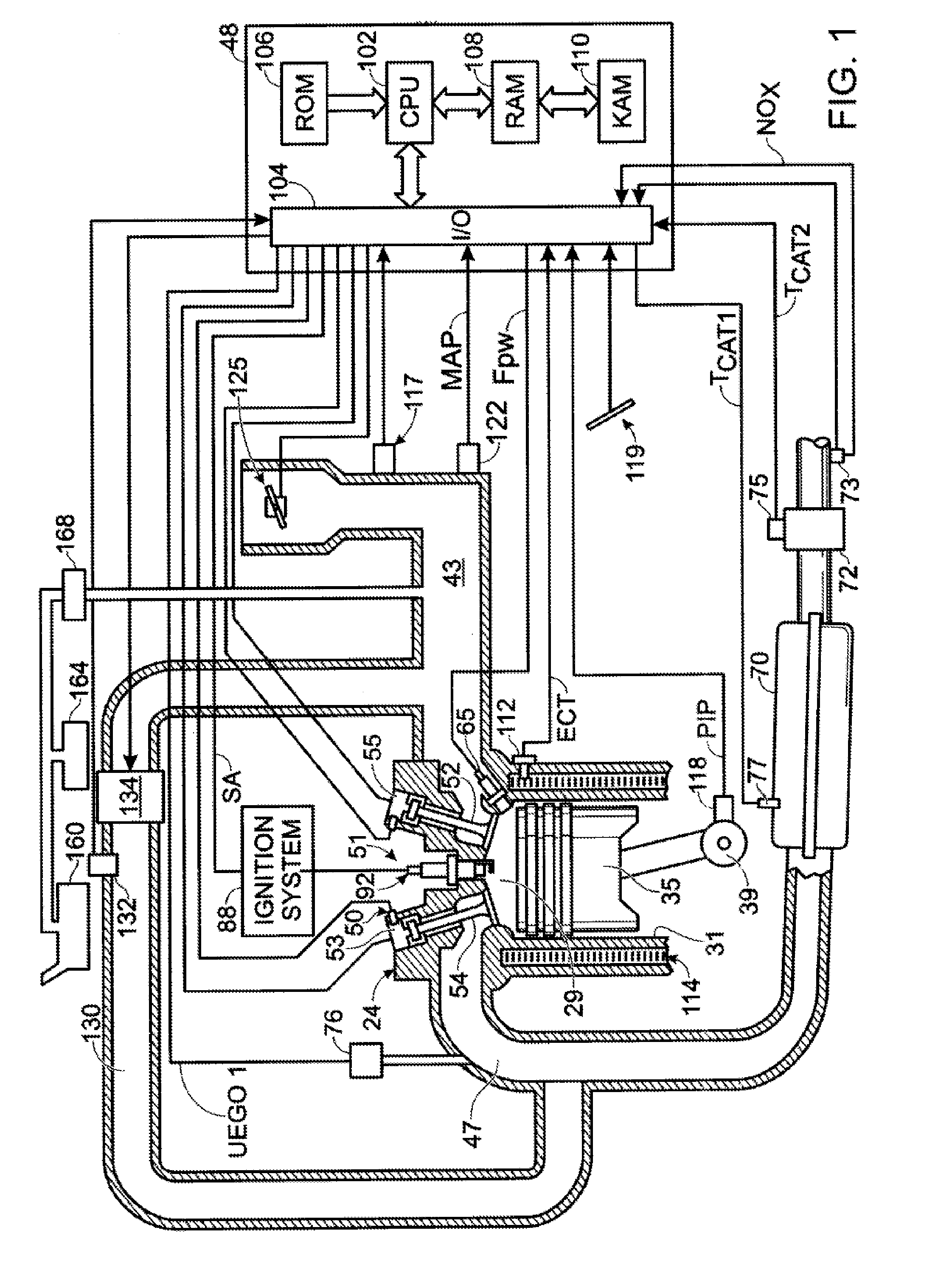

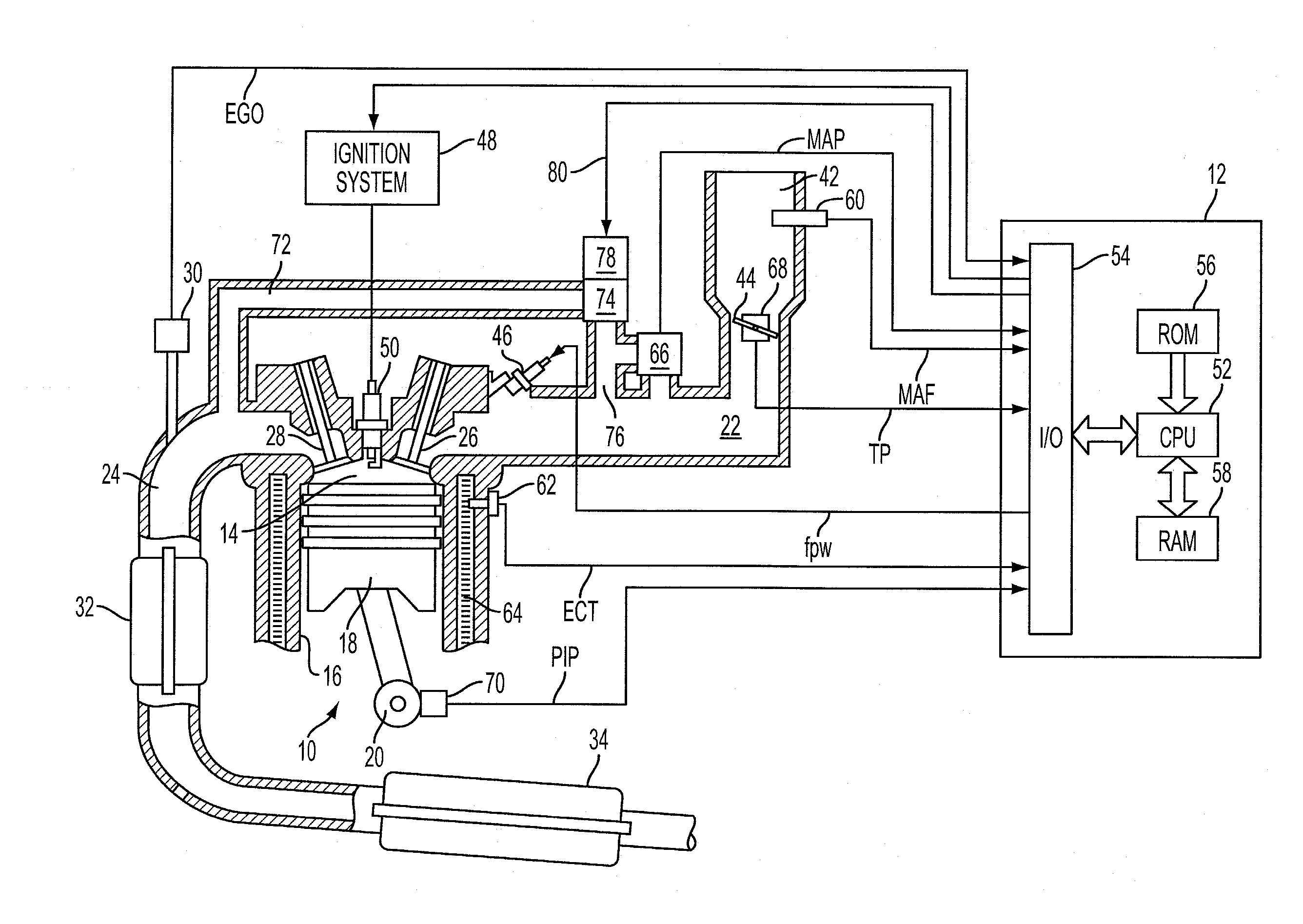

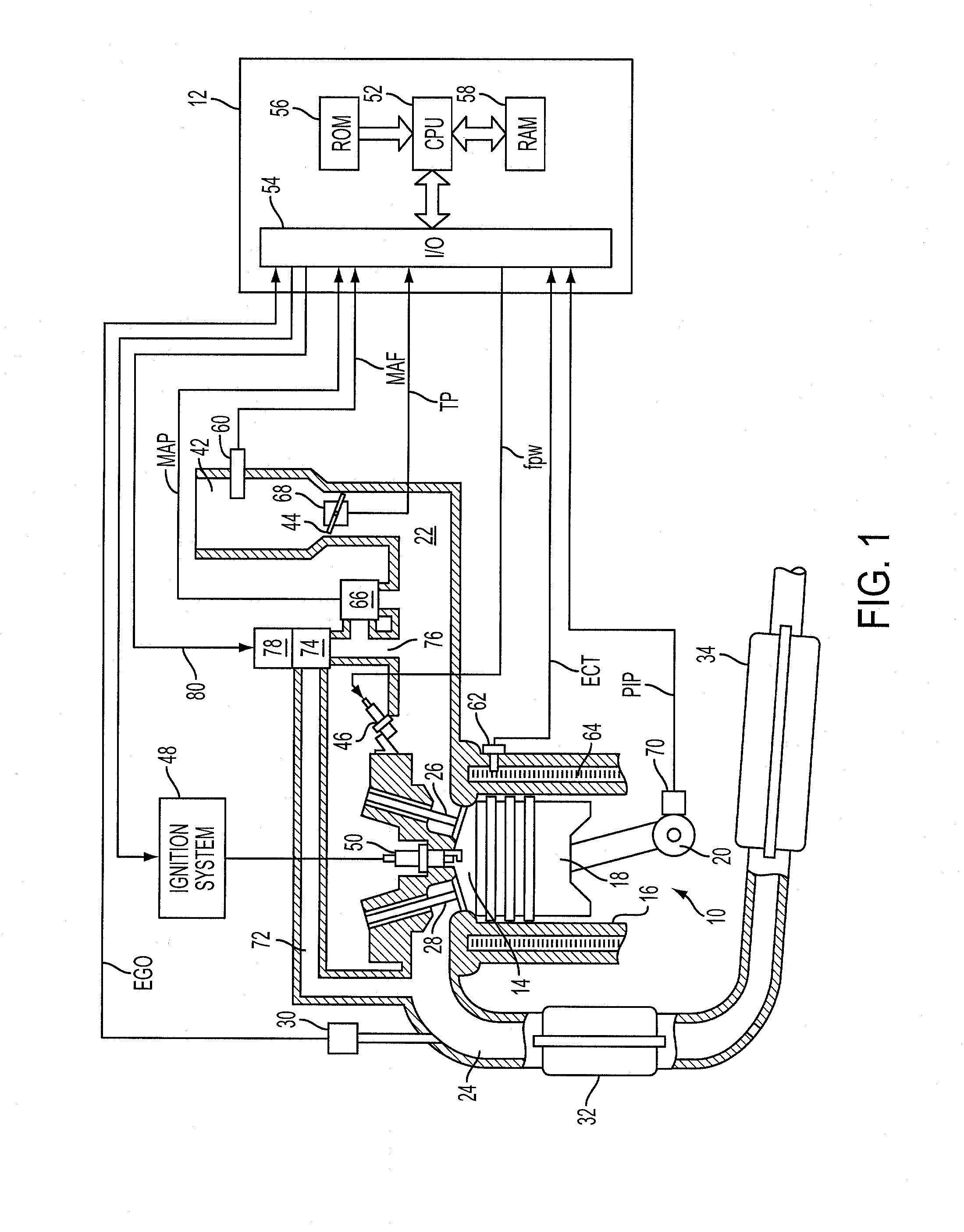

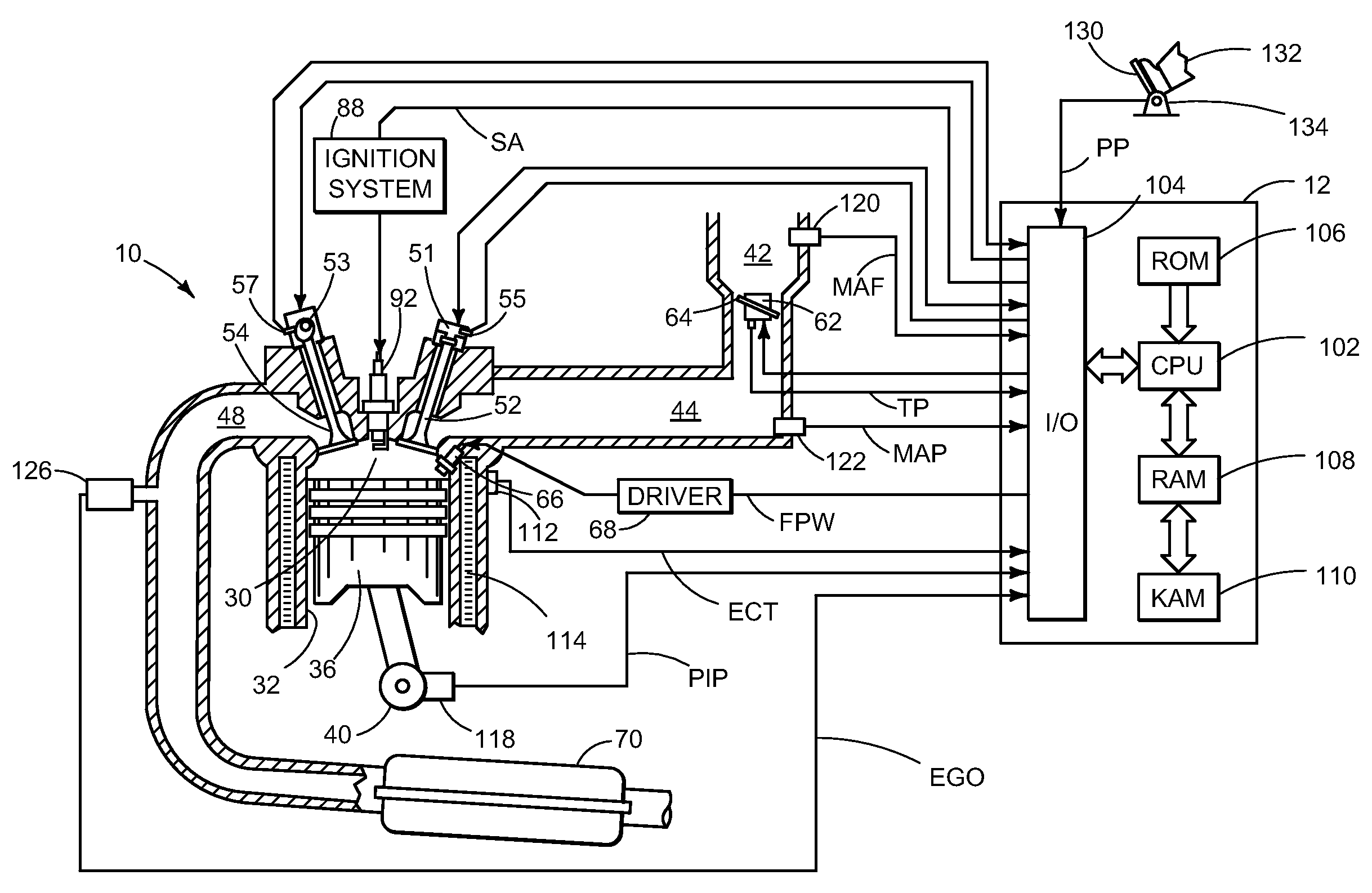

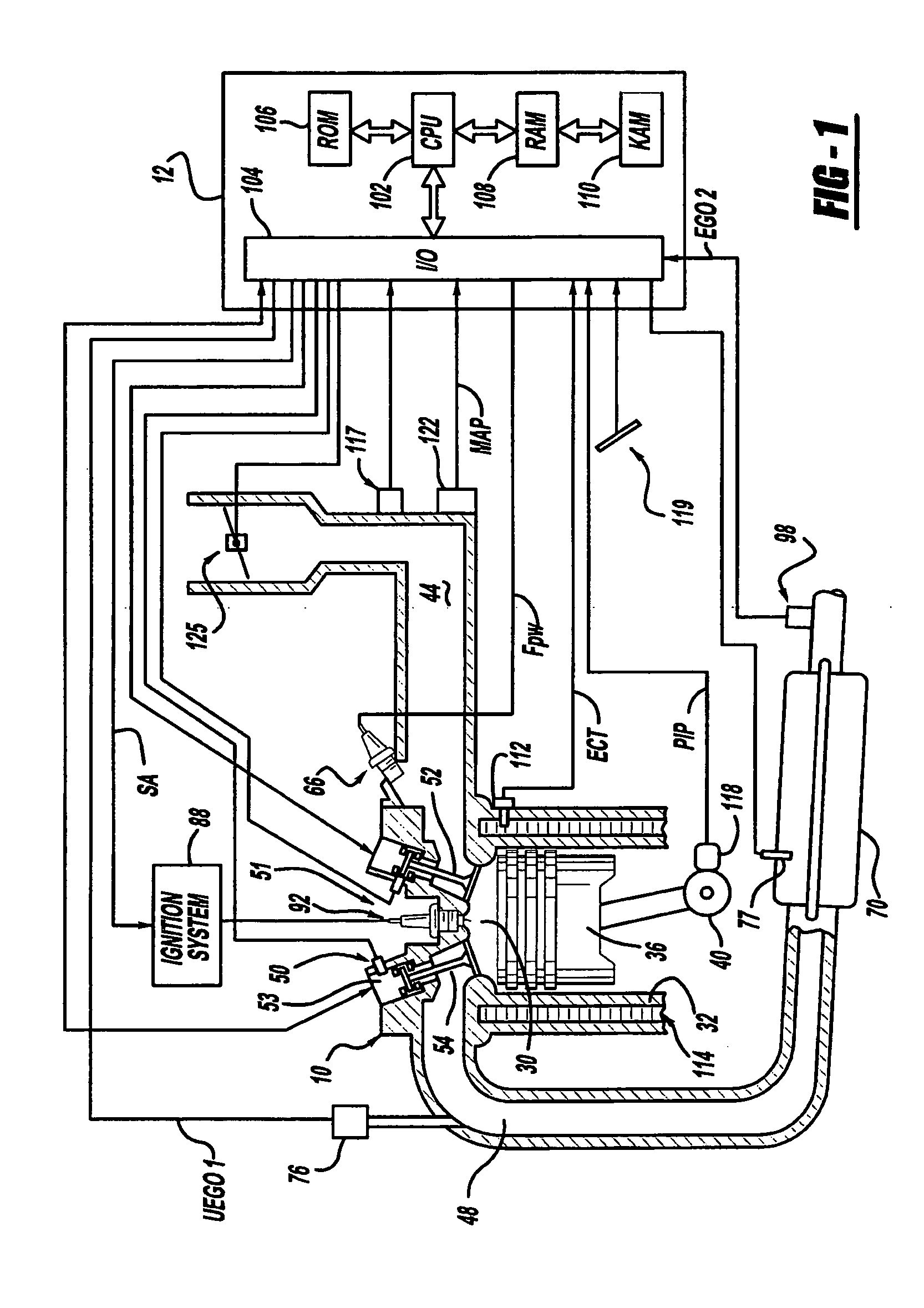

Engine control to compensate for fueling dynamics

ActiveUS20050166900A1Accurate air-fuel ratio controlEasy to controlElectrical controlInternal combustion piston enginesVaporizationCylinder Valve

A method for calculating transient fuel wall wetting characteristics of an operating engine is described. The method accounts for cylinder valve deactivation of cylinders in the engine in calculating the dynamic fueling compensation. In one example, fuel vaporization effects from fuel puddles in deactivated cylinders is considered when calculating the fueling compensation for active cylinders.

Owner:FORD GLOBAL TECH LLC

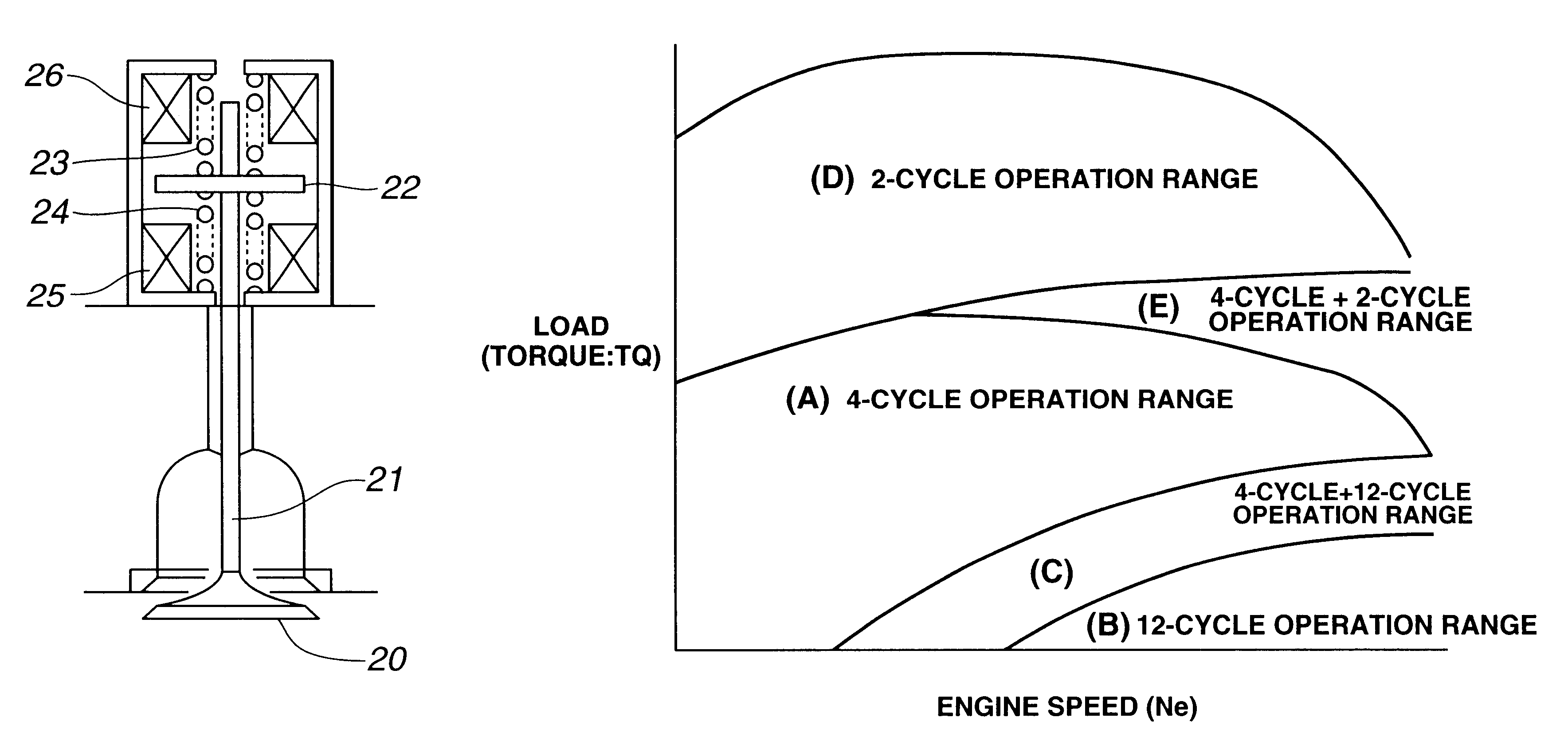

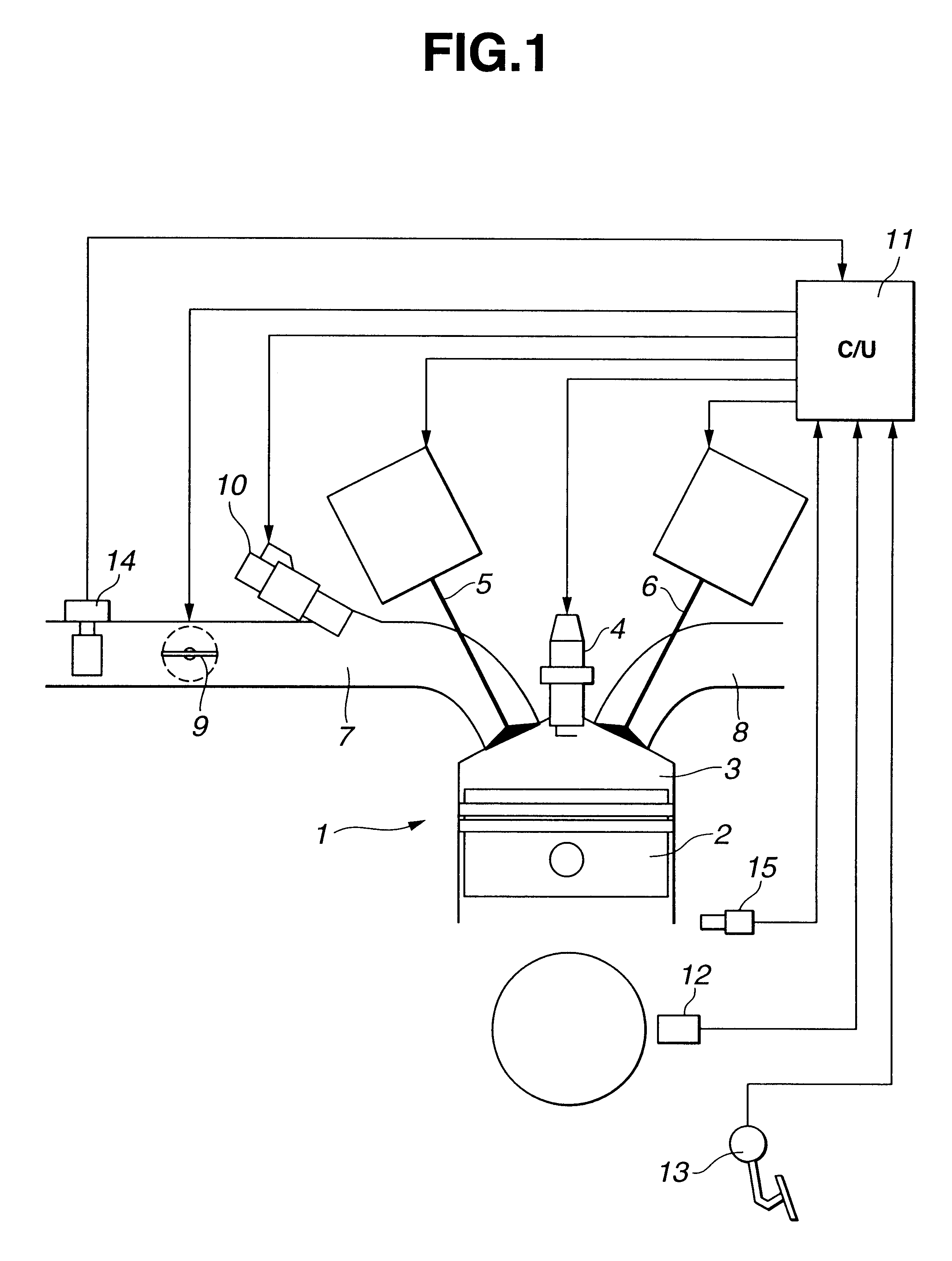

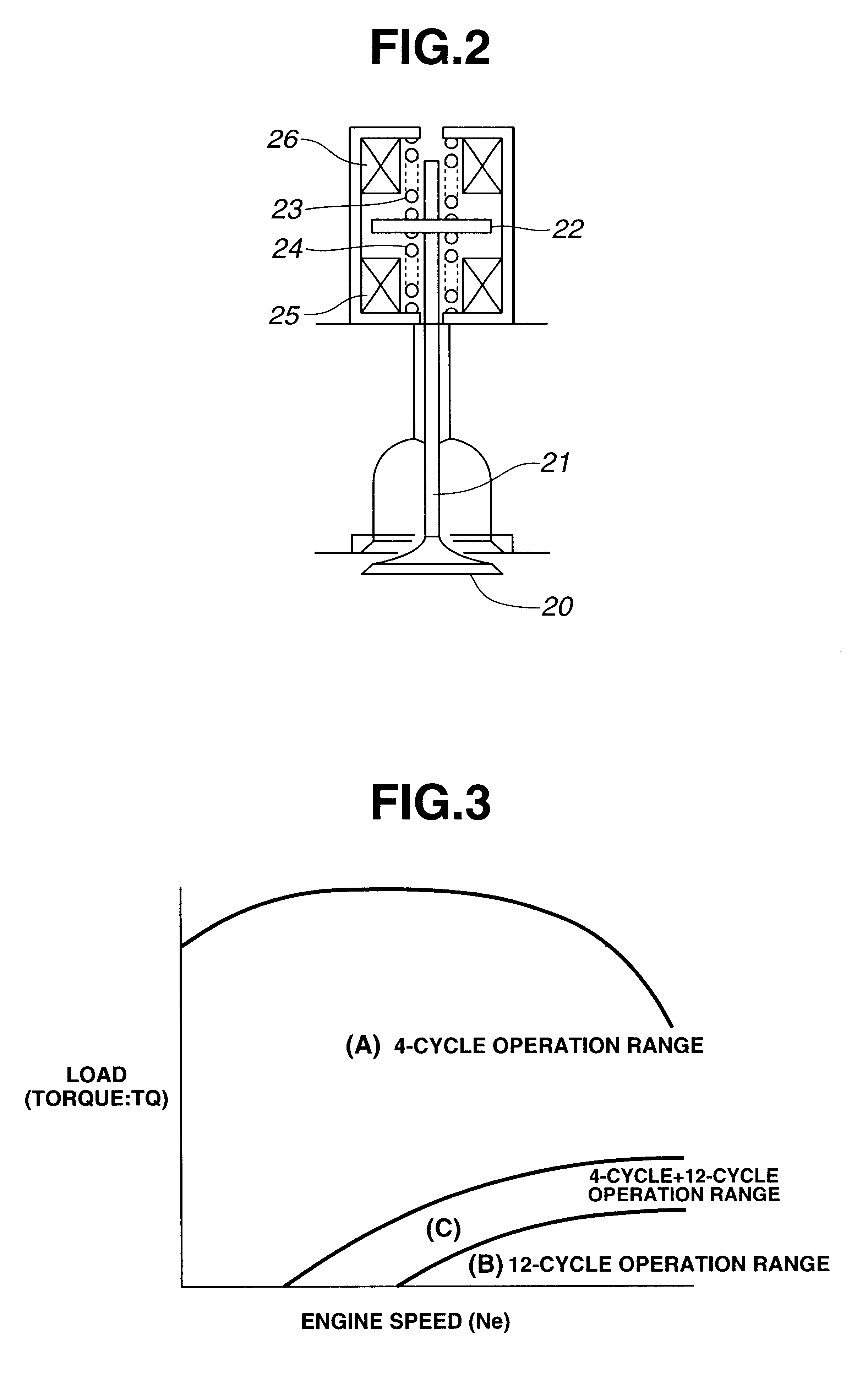

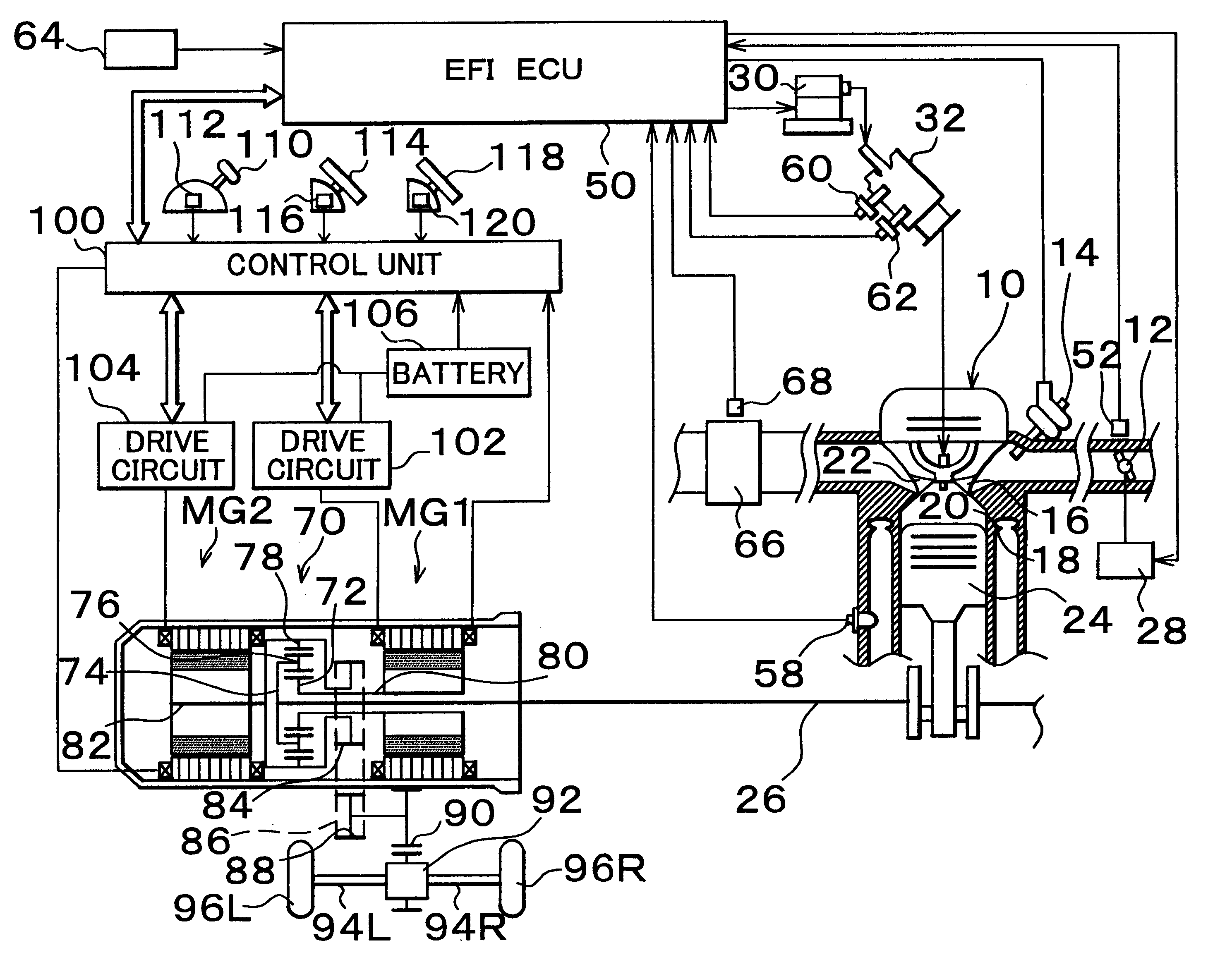

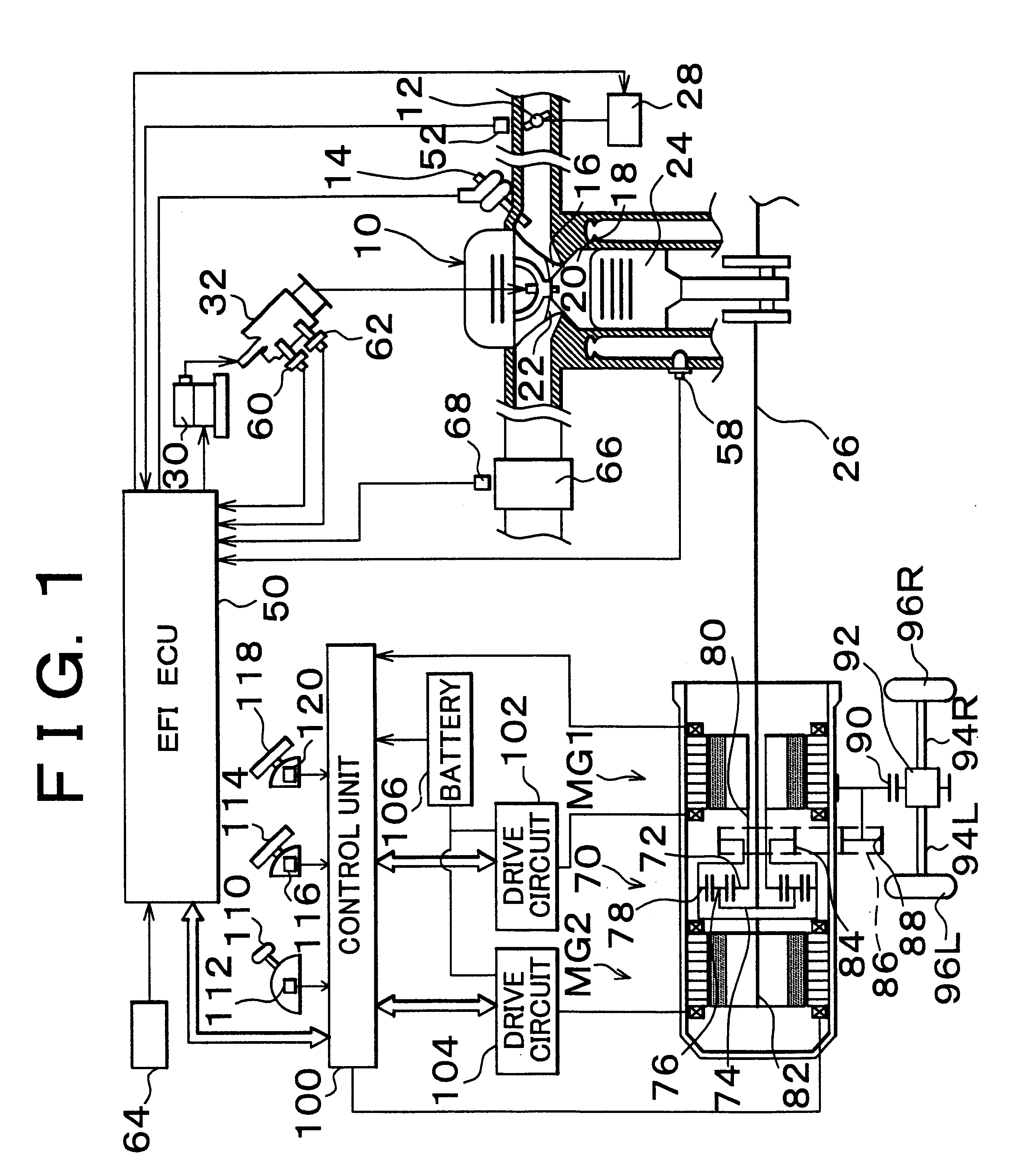

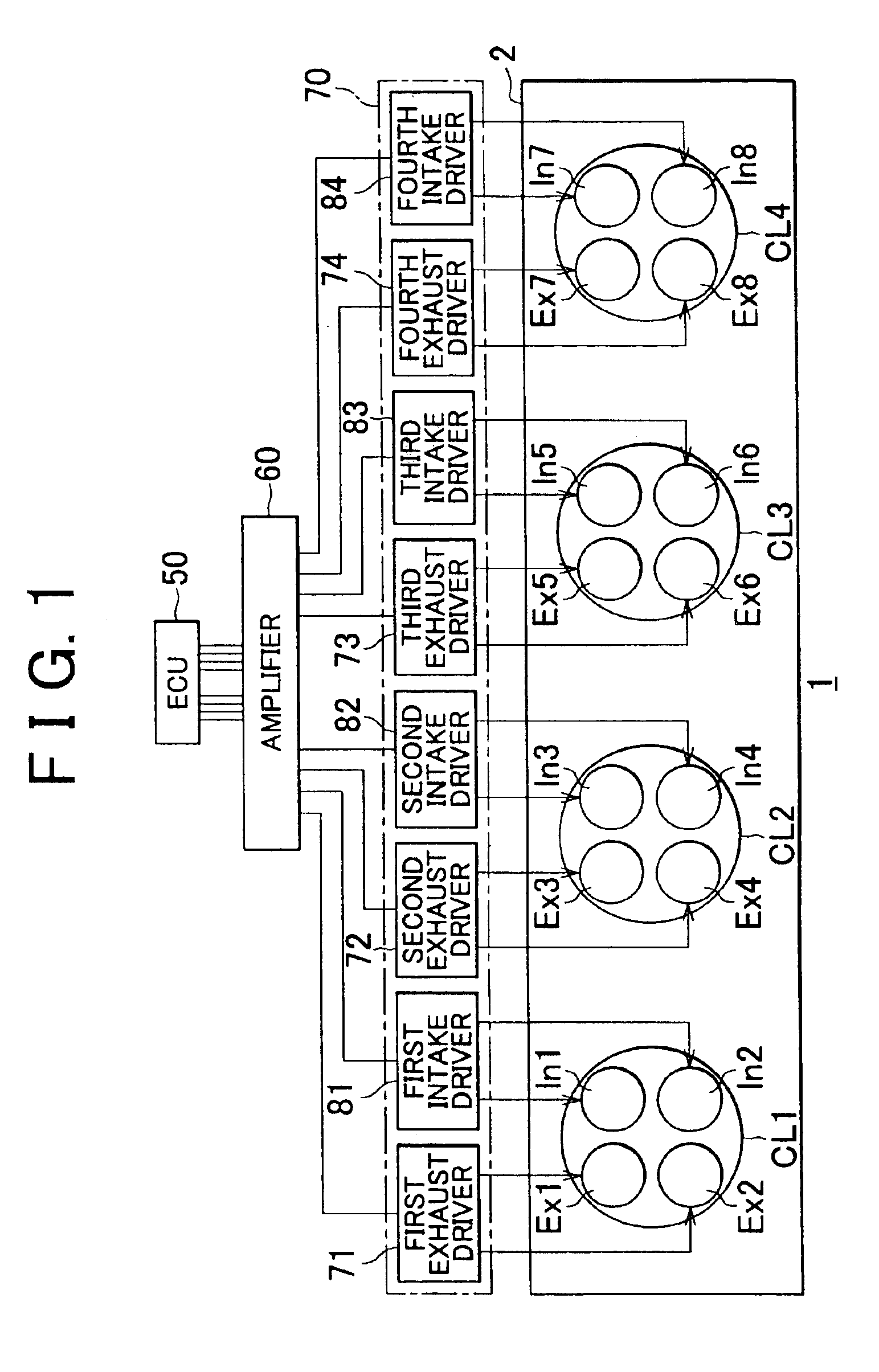

Control system for controlling variable valve type internal combustion engine

InactiveUS6523504B2Increase fuel consumptionImprove drivabilityElectrical controlInternal combustion piston enginesControl systemInternal combustion engine

A control system for an engine comprises an operation range judging section that judges an operation range assumed by the engine, a variable cycle operating section that switches the operation of the engine between 4-cycle operation and a different cycle operation in accordance with a judgment made by the operation range judging section, the different cycle operation being of an operation whose cycle is different from 4-cycle, and an intermediate variable cycle operating section that allows part of the cylinders to carry out 4-cycle operation and remaining part of the cylinders to carry out the different cycle operation when the operation range judging section judges that the engine is under an intermediate operation range assumed between an operation range provided by 4-cycle operation and an operation range provided by the different cycle operation.

Owner:NISSAN MOTOR CO LTD

Control apparatus and control method for motor vehicle

A control apparatus for a motor vehicle detects a catalyst temperature during fuel cut. If the catalyst temperature is higher than a predetermined temperature, the control apparatus almost completely opens a throttle valve and increases an amount of intake air to thereby reduce pumping loss. If the catalyst temperature is equal to or lower than the predetermined temperature, the throttle valve is almost completely closed. Thereby it becomes possible to reduce pumping loss of the engine while preventing an excessive decrease in catalyst temperature.

Owner:TOYOTA JIDOSHA KK

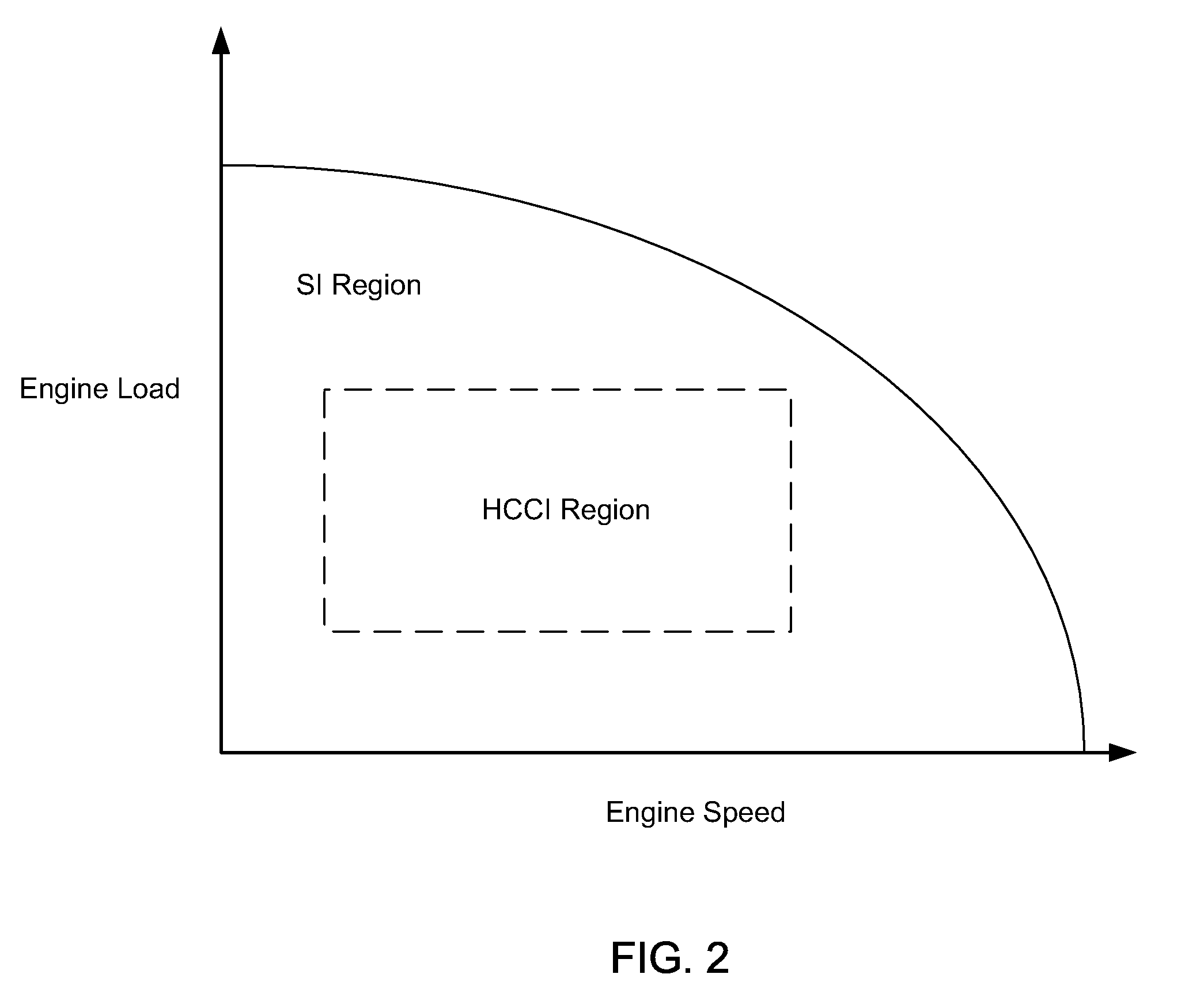

Approach for Facilitating Engine Mode Transitions

ActiveUS20080066713A1Increasing negative overlapElectrical controlInternal combustion piston enginesHomogeneous charge compression ignitionExhaust valve

A method of transitioning a cylinder of an engine from a spark ignition mode to a homogeneous charge compression ignition mode, the cylinder having at least one electrically actuated intake valve and at least one exhaust valve, the method comprising of before a transition, operating the cylinder with at least some overlap between an opening event of the intake valve and an opening event of the exhaust valve in the spark ignition mode; in response to a transition request, operating the cylinder with at least some negative overlap between an opening event of the intake valve and an opening event of the exhaust valve, retarding the intake valve opening and closing timing by different amounts and retarding ignition timing; and further increasing negative overlap and performing the homogeneous charge compression ignition mode.

Owner:FORD GLOBAL TECH LLC

Exhaust valve arrangement and a fuel system incorporating an exhaust valve arrangement

InactiveUS7533656B2Small diameterSecure attachmentMachines/enginesFuel injecting pumpsCombustion chamberExhaust valve

Owner:DELPHI INT OPERATIONS LUXEMBOURG S A R L

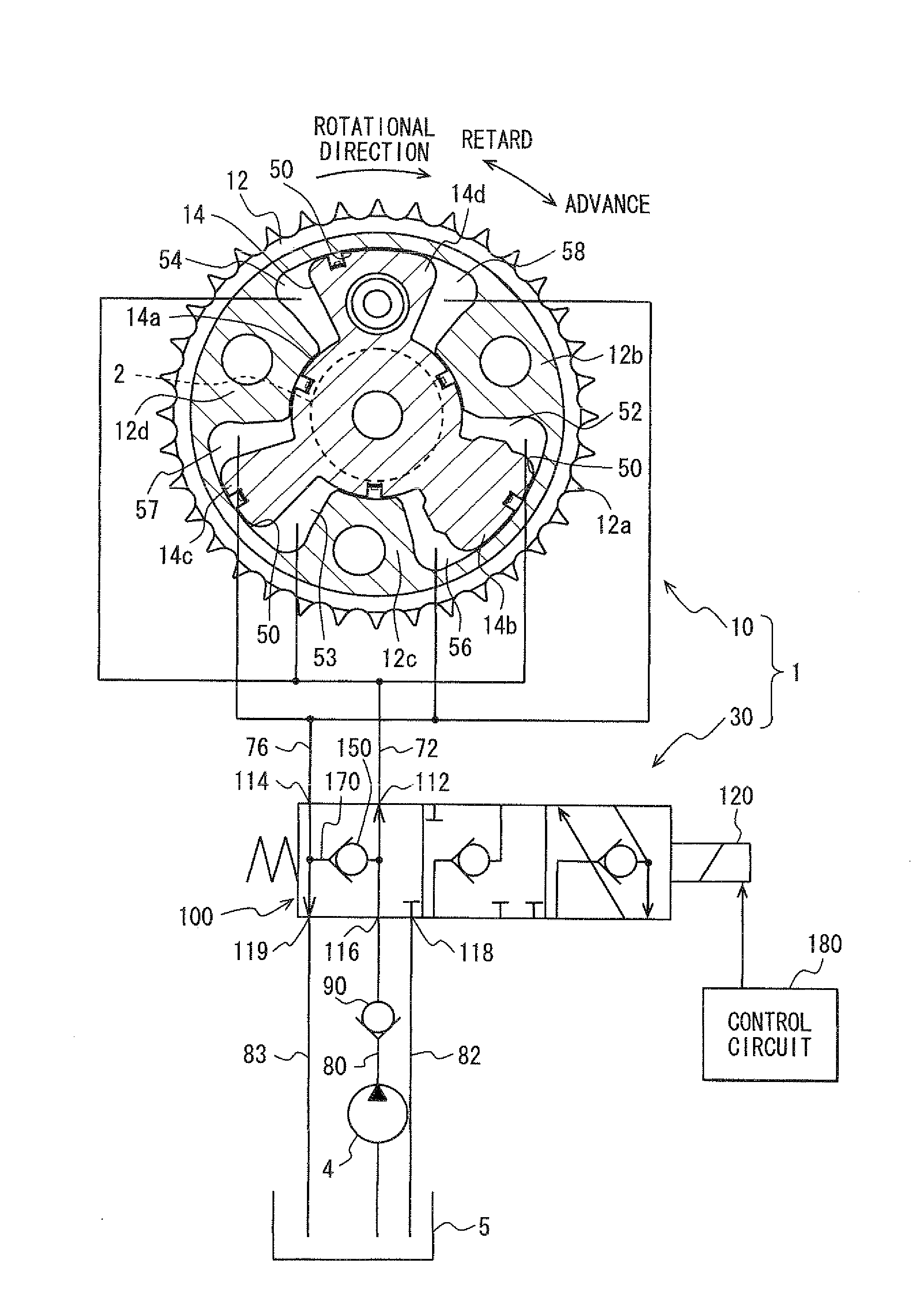

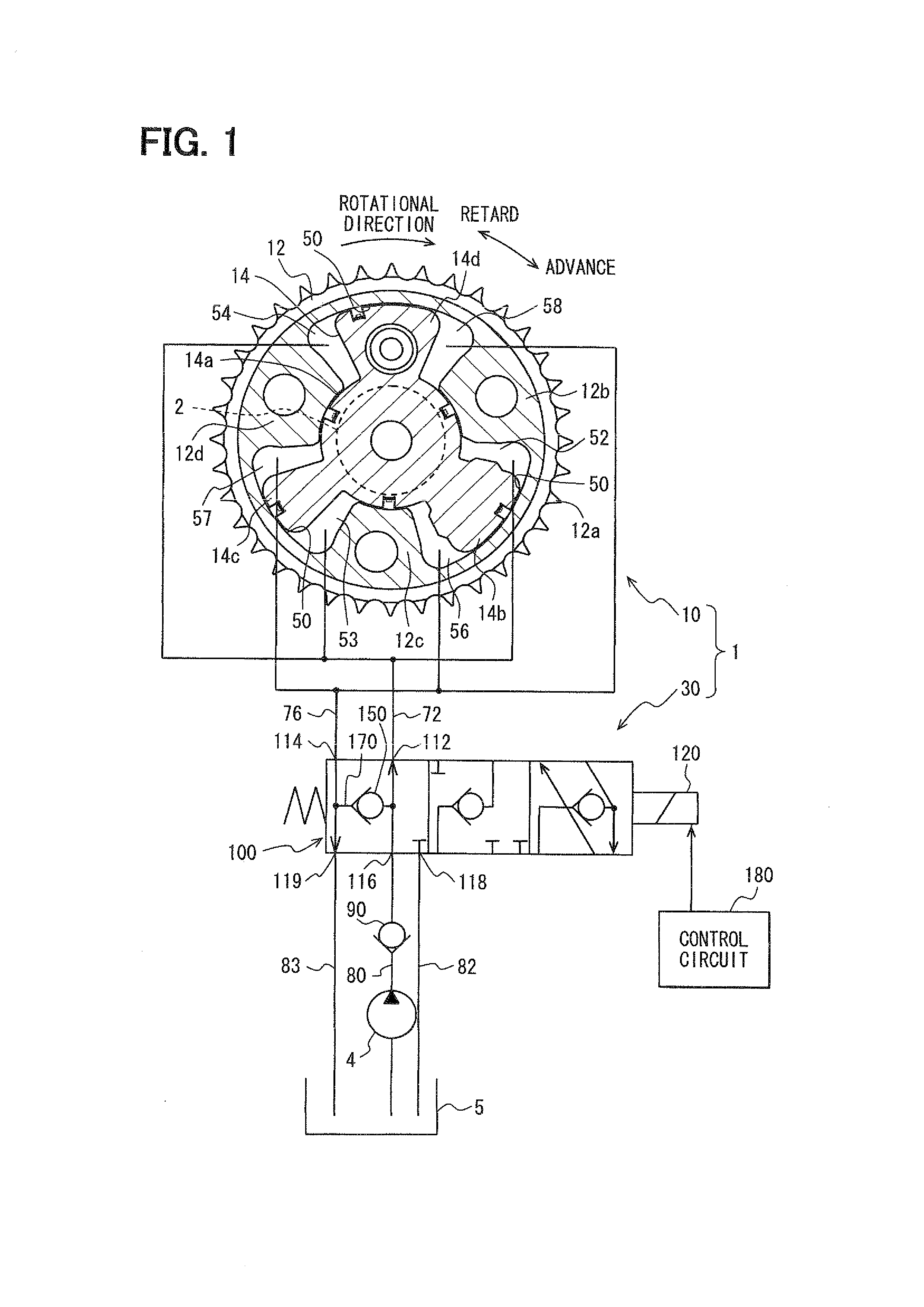

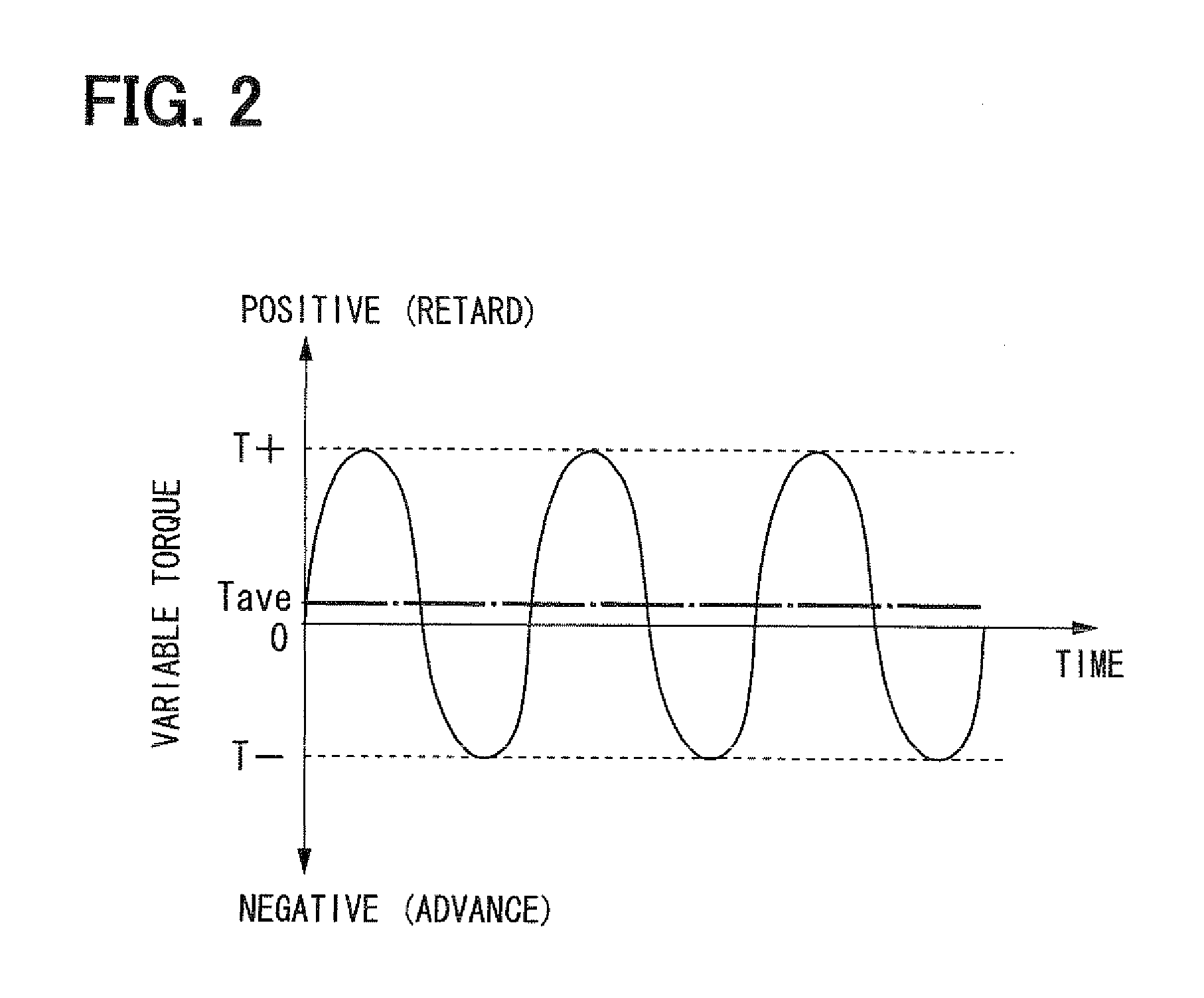

Valve timing control apparatus

A valve timing control apparatus for controlling valve timing includes a first rotor, a second rotor, and a controller. The second rotor and the first rotor defines therebetween an advance chamber and a retard chamber. The controller includes a supply passage, at least one drain passage, a spool valve, at least one connection passage, and at least one check valve. The at least one connection passage connects the supply passage to the at least one drain passage when a spool of the spool valve is moved to one of the advance and retard positions. The at least one check valve is respectively provided in the at least one connection passage. The check valve allows working fluid to flow in a direction from the at least one drain passage toward the supply passage and limits working fluid from flowing in an opposite direction.

Owner:DENSO CORP

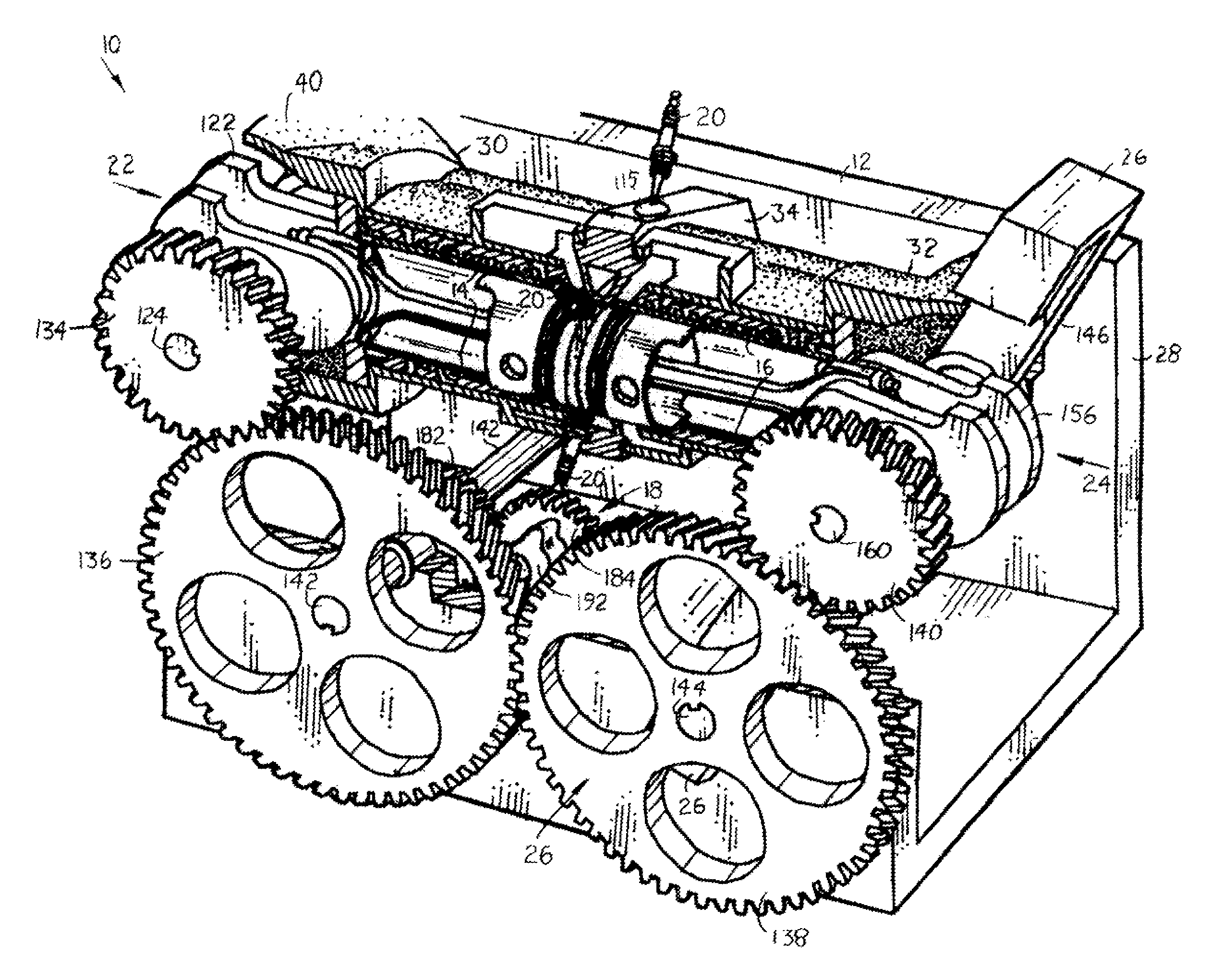

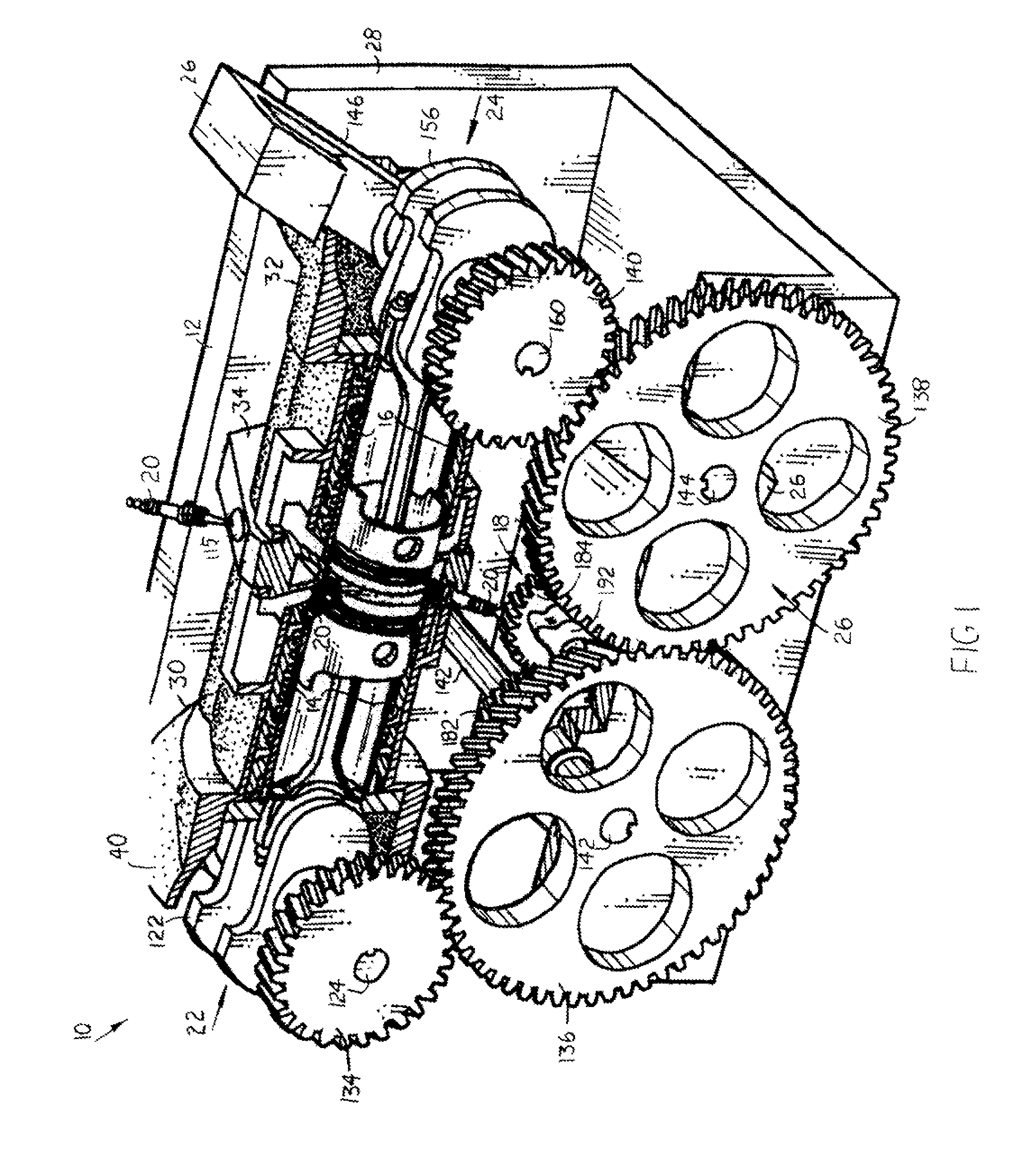

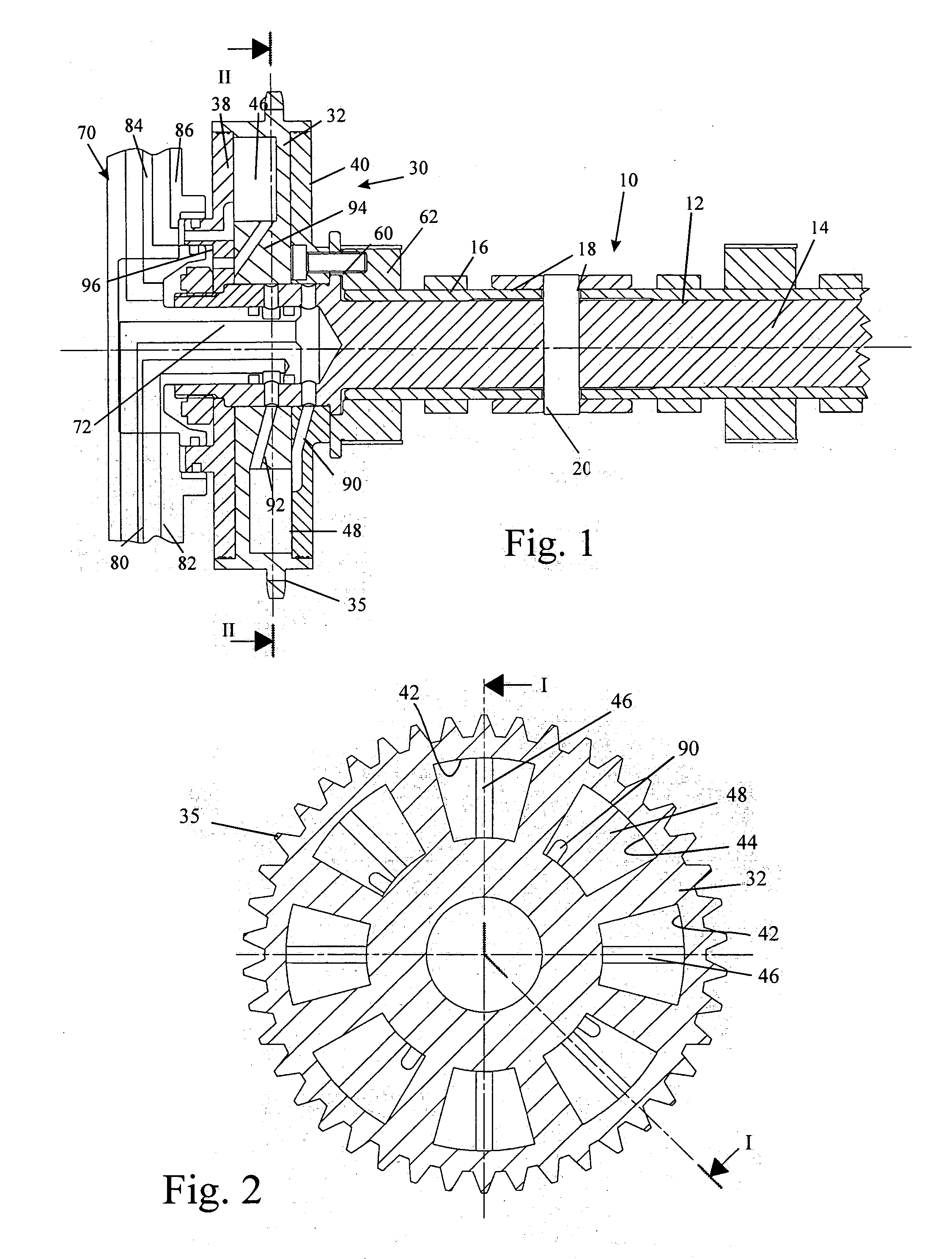

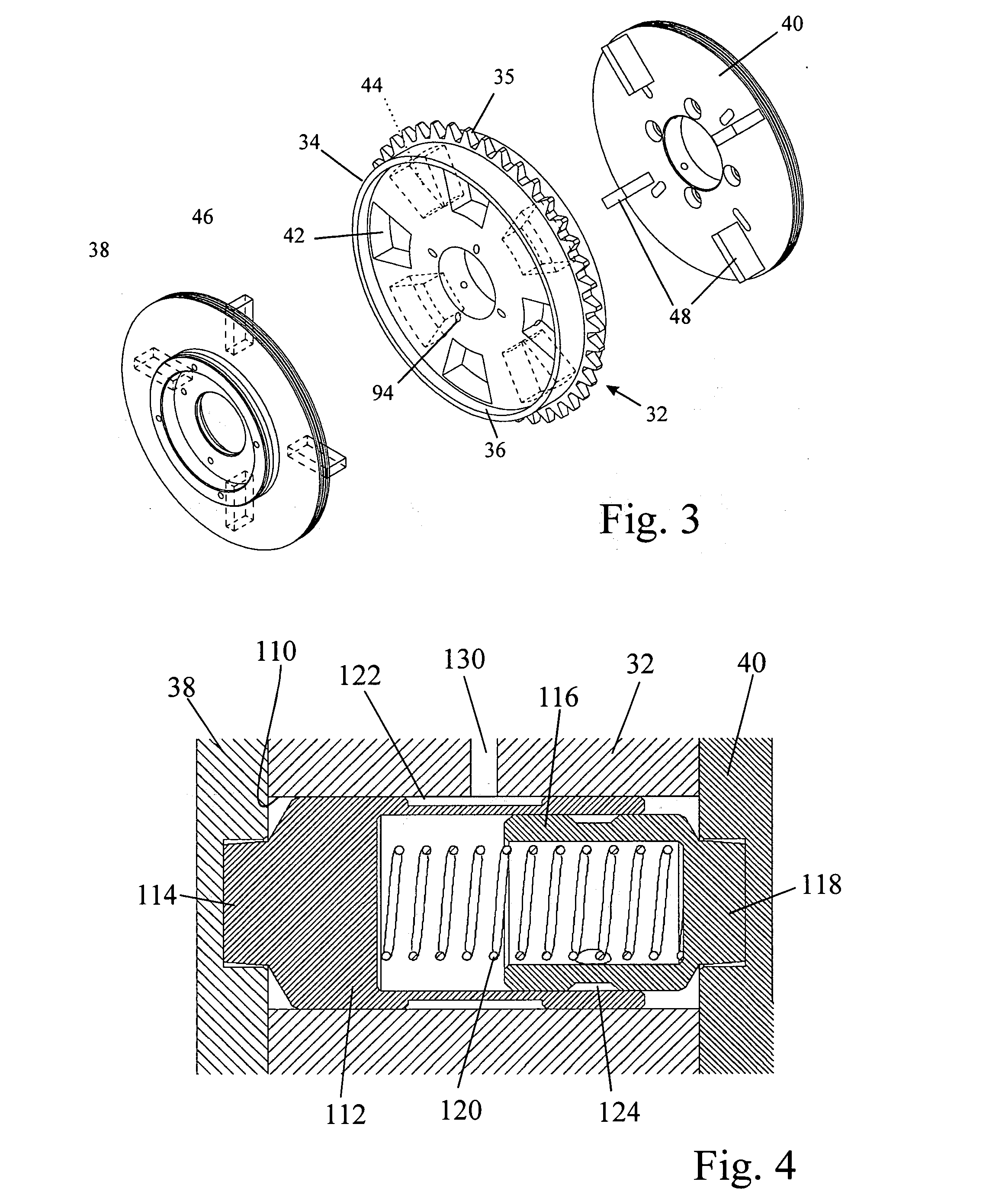

Variable phase drive mechanism

InactiveUS20050226736A1Reduce riskLess spaceYielding couplingOscillating piston enginesLocking mechanismEngineering

A twin vane-type phaser is described which is provided with a locking mechanism for locking the drive member to the driven members when the pressure in the working chambers is a below is predetermined value. The locking mechanism comprises two coaxial locking pins 114, 118 mounted in a common bore 110 in the centrally located member 32. The locking pins are resiliently urged apart by a spring 120 into bores in the two outer members 38, 40 and are retracted by pistons 112, 116 when the hydraulic pressure in the working chambers attains the predetermined value.

Owner:MECHADYNE LTD

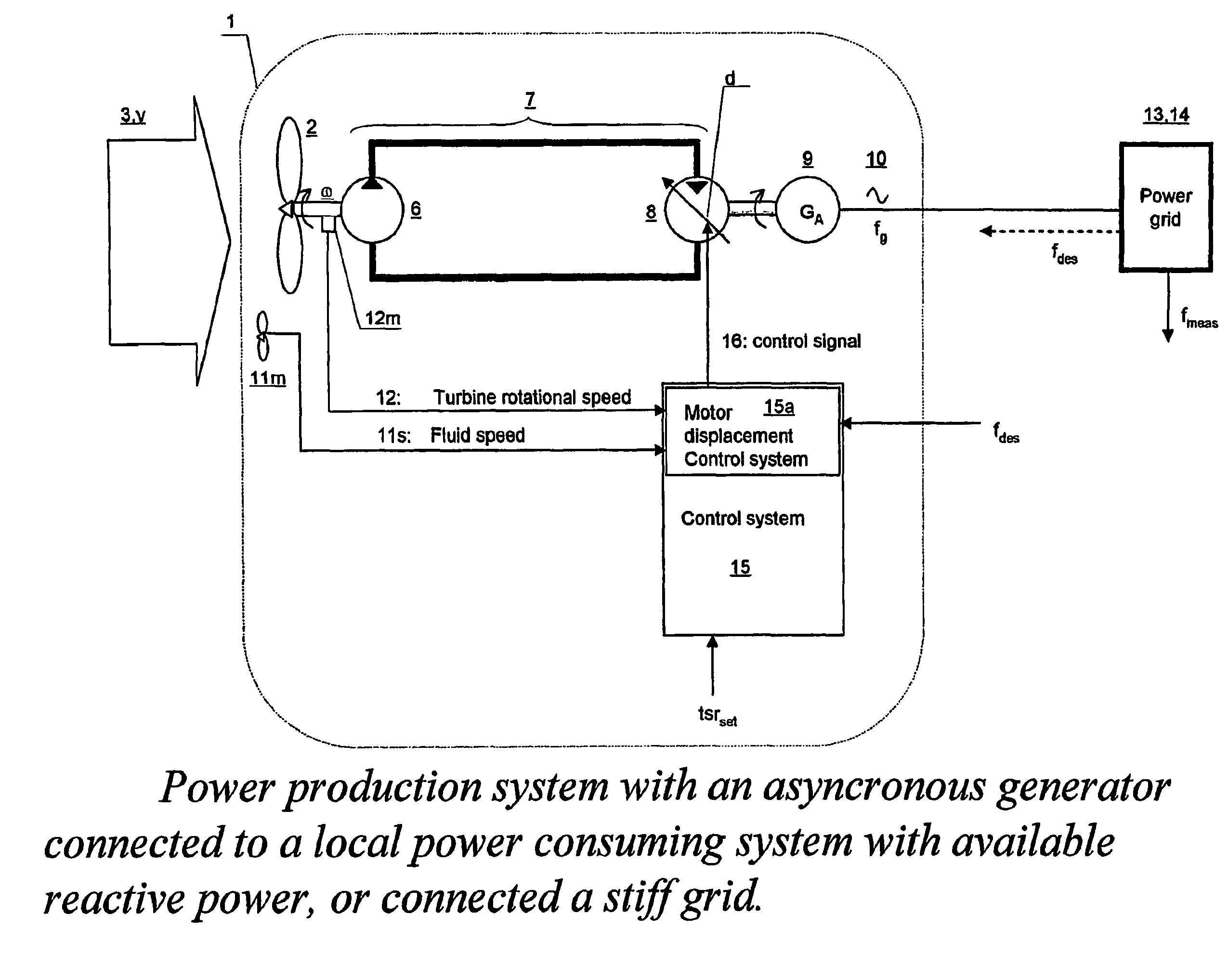

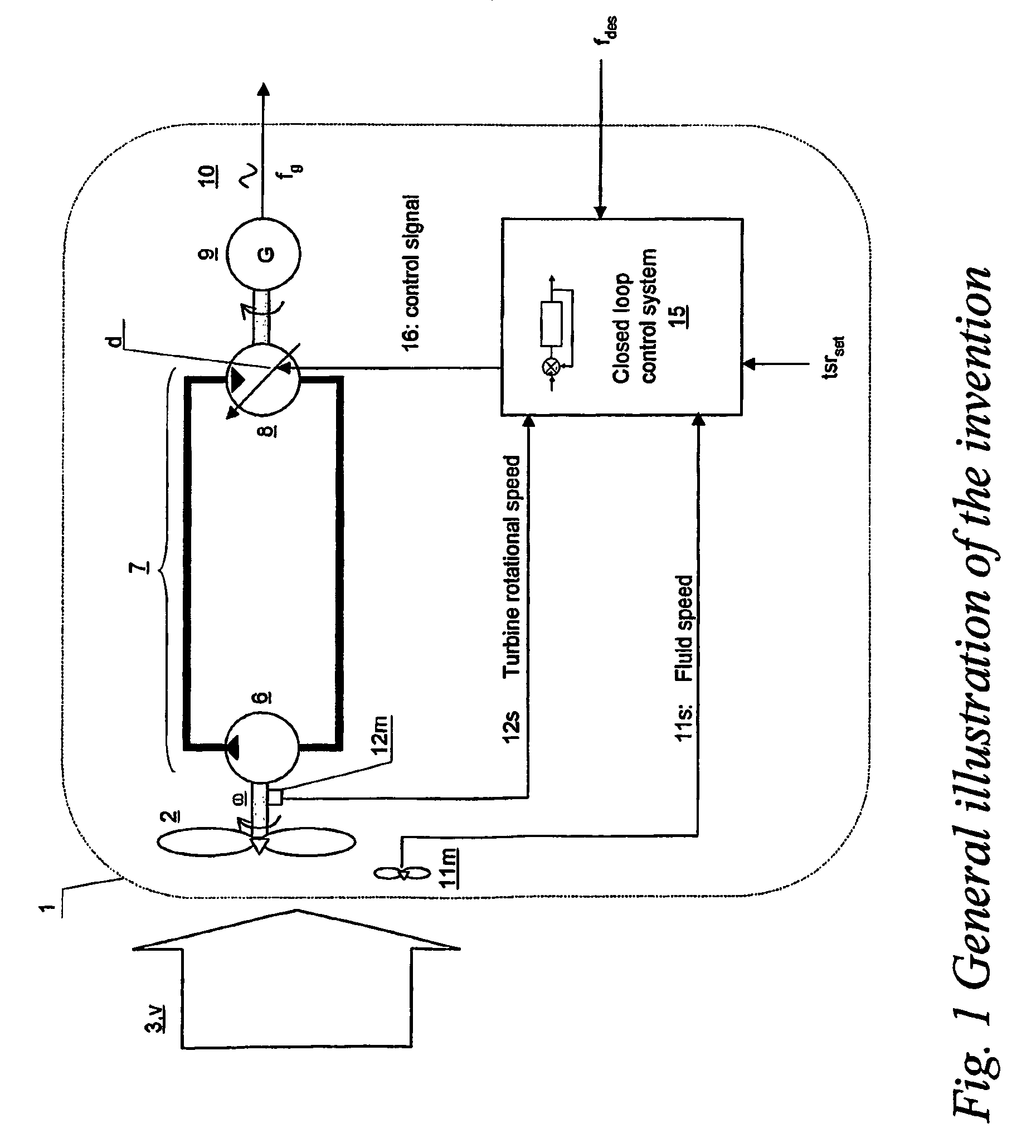

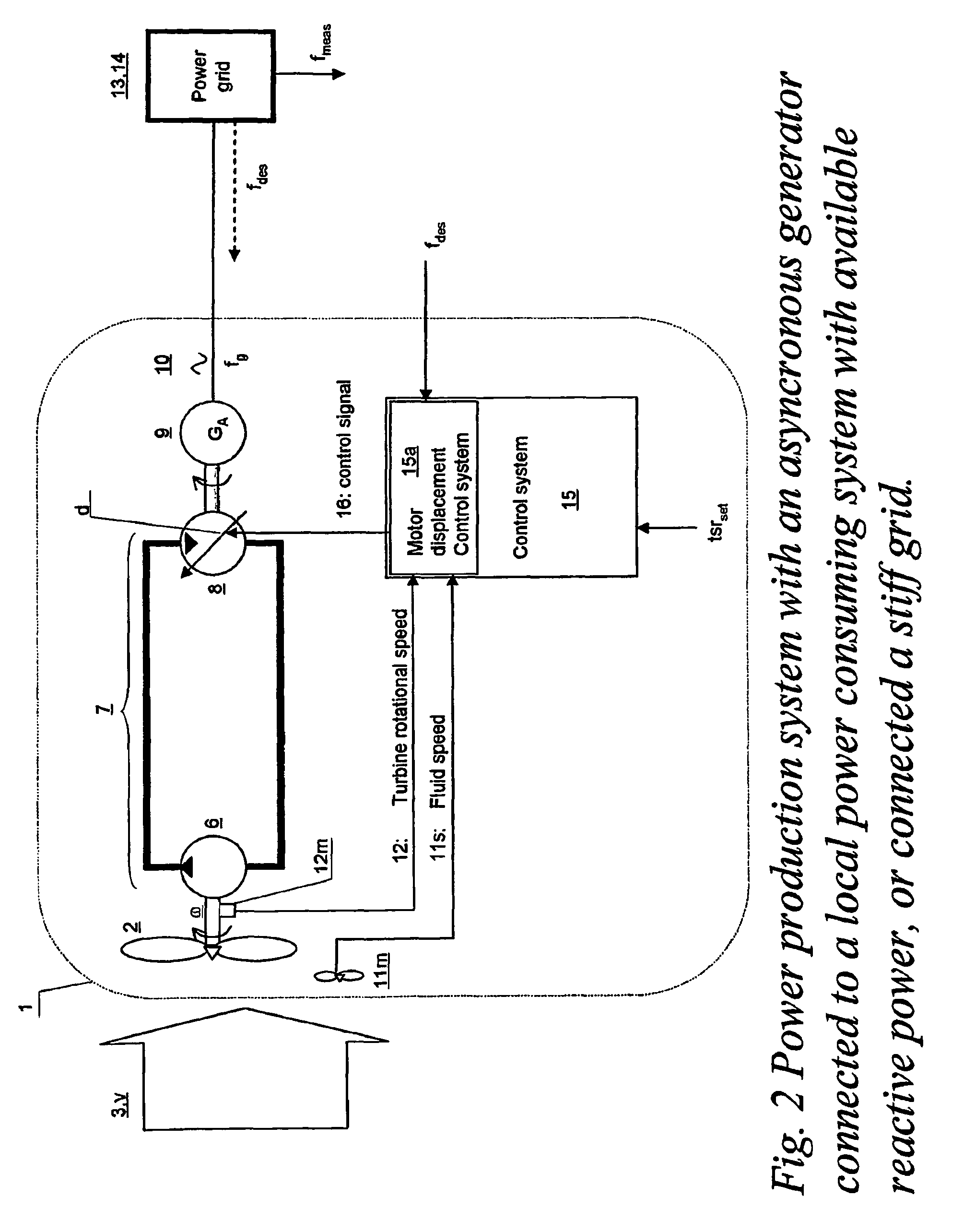

Turbine driven electric power production system and a method for control thereof

InactiveUS7863767B2Improve accuracyLow variabilityDomestic stoves or rangesWind motor controlControl signalClosed loop

Owner:CHAPDRIVE AS

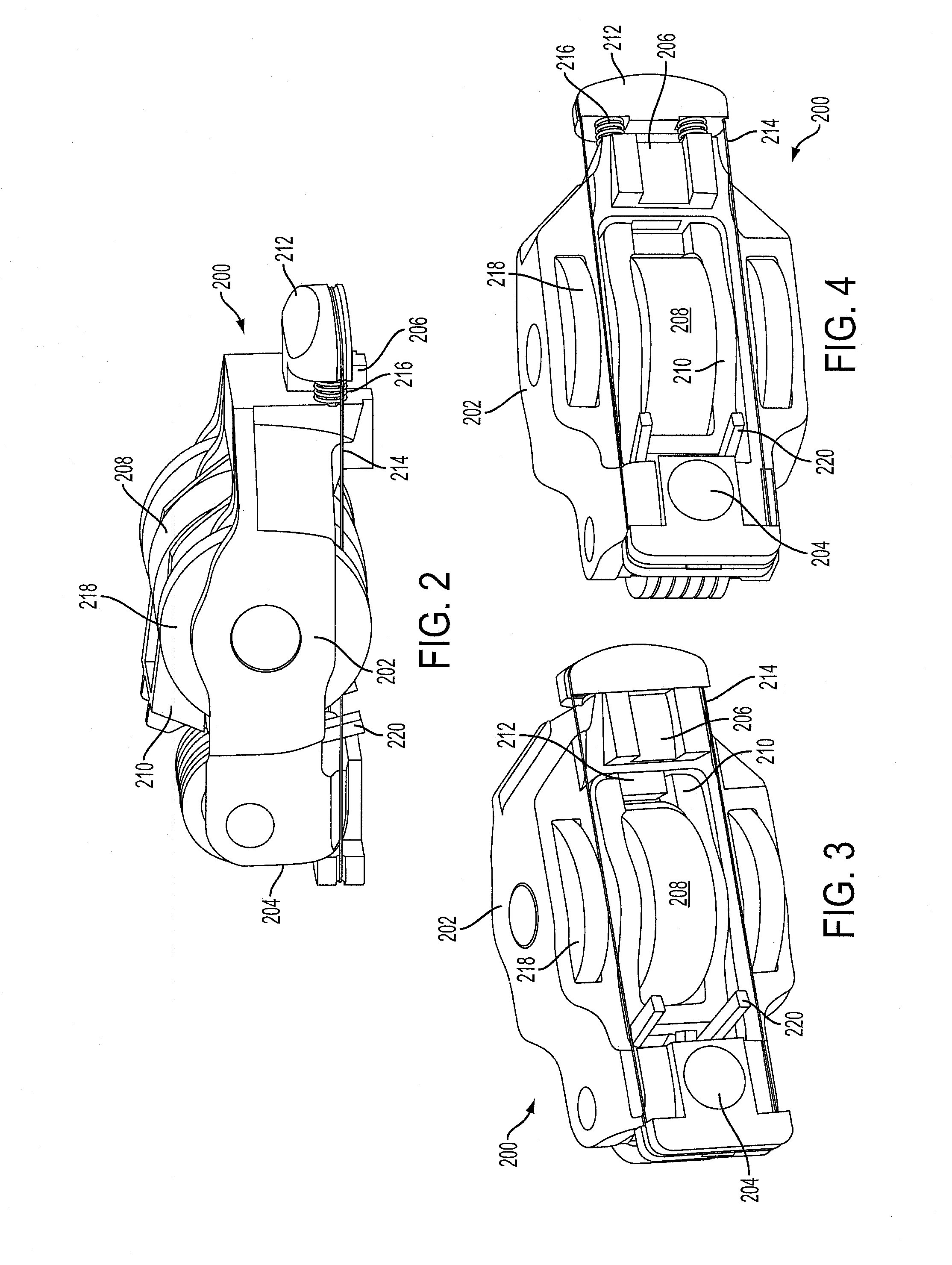

Mode-Switching Cam Follower

A mode-switching cam follower is disclosed, wherein the follower includes a body, a cam contact movably coupled to the body, a latch member movably coupled to the body, wherein the latch member is movable between a coupled position in which the cam contact is held in a fixed relation to the body by the latch member and a decoupled position in which the cam contact is decoupled from the latch member and movable relative to the body, and an actuator in communication with the latch member, wherein the actuator comprises a shape memory alloy member

Owner:FORD GLOBAL TECH LLC

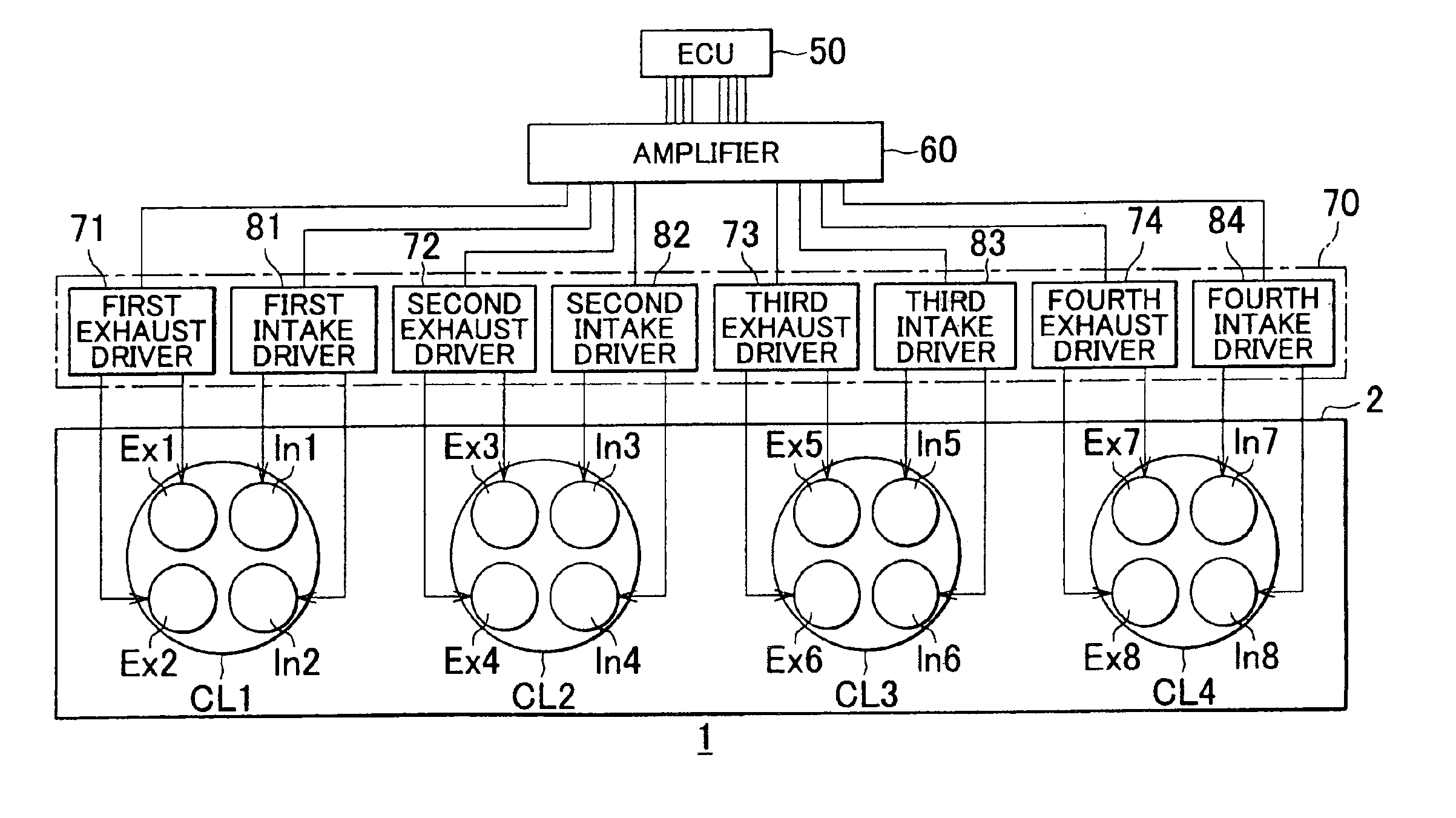

Electromagnetically driven valve control apparatus and electromagnetically driven valve control method for internal combustion engine

InactiveUS6866012B2Increase the number ofEffective controlAnalogue computers for vehiclesElectrical controlHigh speed controlLow speed

A main CPU determines whether or not there is a request for one valve driving based on an engine operating state such as an engine speed and a load factor, with reference to a control map. When it is determined that there is a request for one valve driving, it is determined whether or not there is an overlapping period between opening periods. When it is determined that there is no overlapping period, a high speed control is performed for controlling electromagnetically driven valves. When it is determined that there is no request for one valve driving, or when it is determined that there is the overlapping period, a low speed control is performed for controlling electromagnetically driven valves.

Owner:TOYOTA JIDOSHA KK

Vehicle Braking Control

ActiveUS20080041336A1Increased intake manifold vacuumEasy to controlElectrical controlInternal combustion piston enginesExhaust valveVacuum level

A method of operating an engine for a vehicle having at least a first cylinder, the method comprising of operating the first cylinder to provide at least one of compression braking and expansion braking by holding one of an intake valve and an exhaust valve of the first cylinder closed while opening, closing, and opening the other of the intake valve and the exhaust valve during a cycle of the first cylinder and during a first vacuum level of an intake manifold upstream of the first cylinder; and operating the first cylinder to provide at least one of compression braking and expansion braking by operating both the intake valve and the exhaust valve of the first cylinder during a cycle of the first cylinder to allow at least some air to flow through the first cylinder during a second vacuum level of the intake manifold.

Owner:FORD GLOBAL TECH LLC

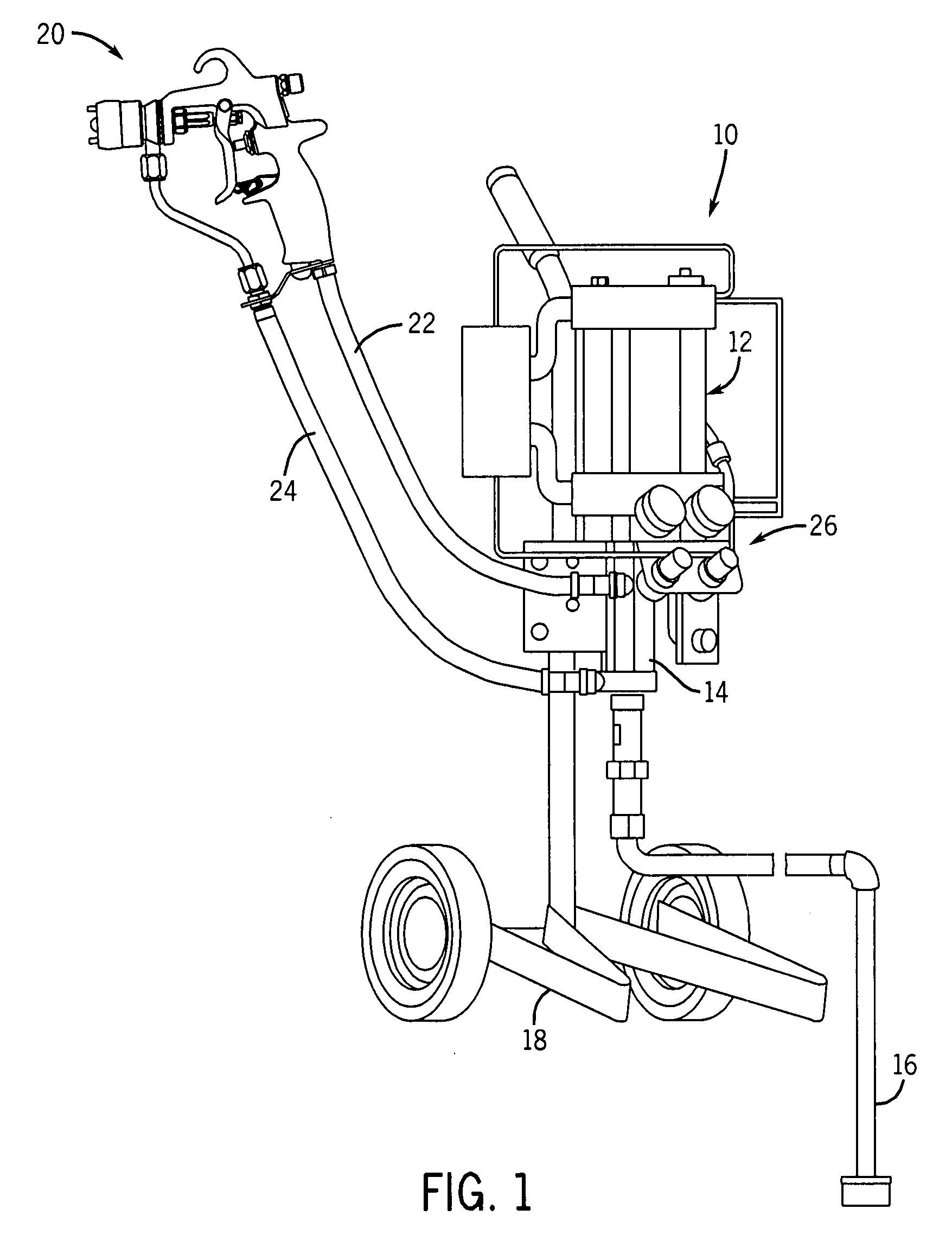

Magnetically sequenced pneumatic motor

A pneumatic motor having a piston and a magnetically actuated valve. The magnetically actuated valve may be adjacent the piston and, in some embodiments, include a spool valve.

Owner:CARLISLE FLUID TECH INC

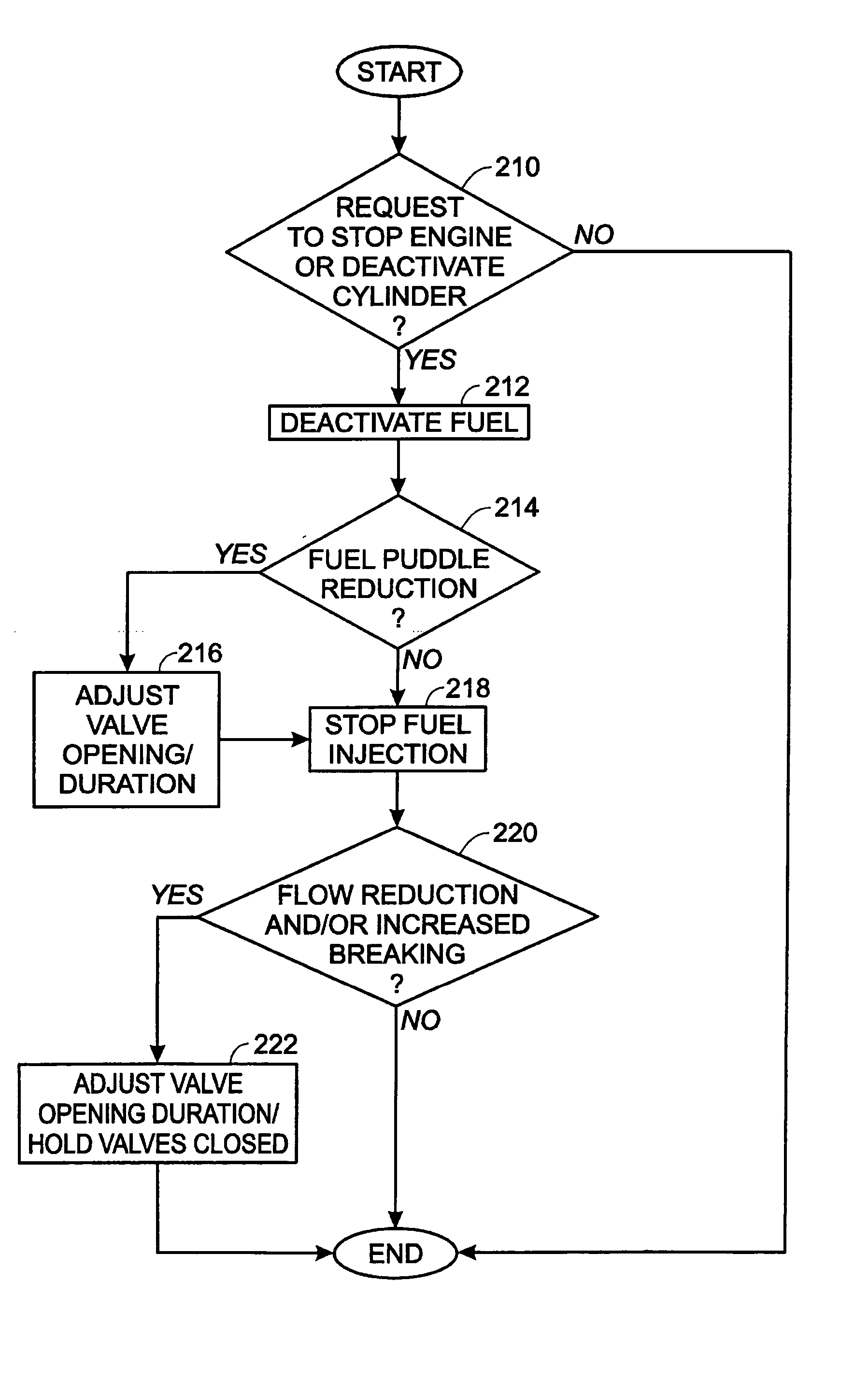

Engine shut-down for engine having adjustable valve timing

ActiveUS20050205049A1Reduce stopping engine stopping timeLess gasAnalogue computers for vehiclesElectrical controlBrake torqueExhaust valve

A method for operating at least an intake and exhaust valve in a cylinder with a piston of an engine in a vehicle, comprising during conditions of an engine shut-down, maintaining at least one of the intake and exhaust valves in a closed position, and during conditions where said at least one valve is in said closed position operating with the other of the intake and exhaust valve open, then closing the other of the intake and exhaust valve, and then opening the other of the intake and exhaust valve to generate braking torque to slow the engine.

Owner:FORD GLOBAL TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com