Hydraulic valve mechanism of variable valve lift

A valve lift and hydraulic valve technology, applied in the field of hydraulic valve mechanism, can solve the problems of low reliability, high cost, complex structure, etc., and achieve the effect of fully variable lift, improved performance, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

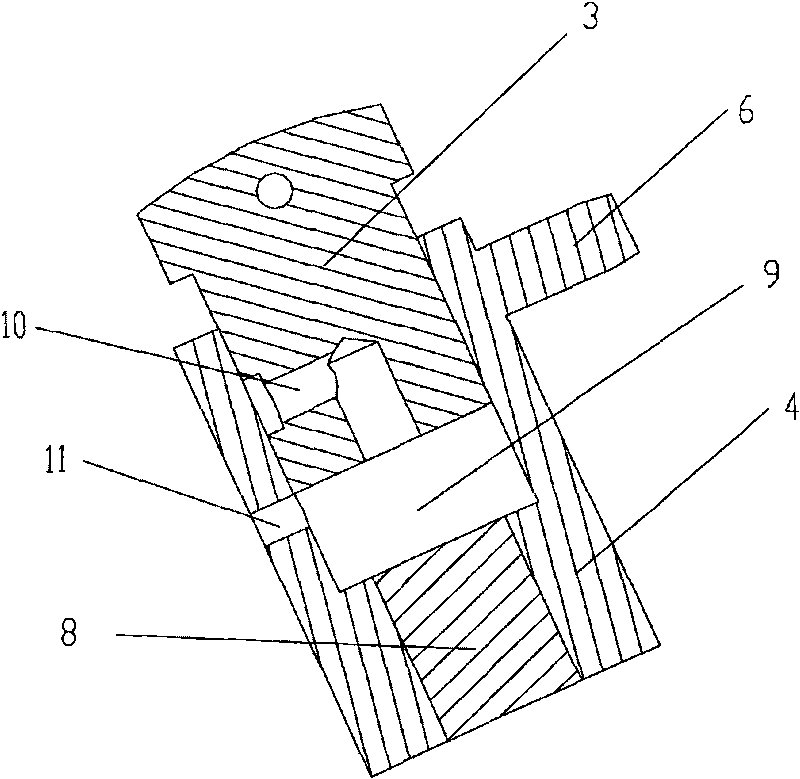

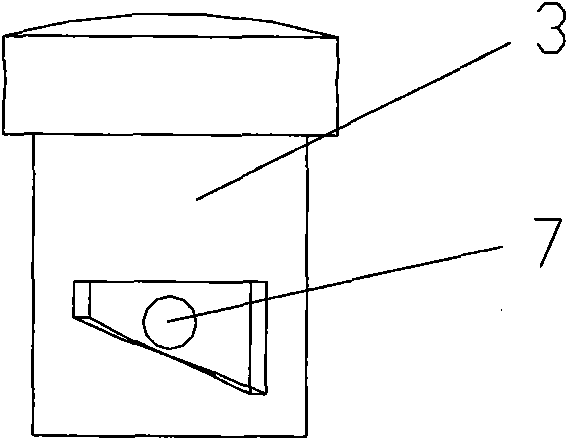

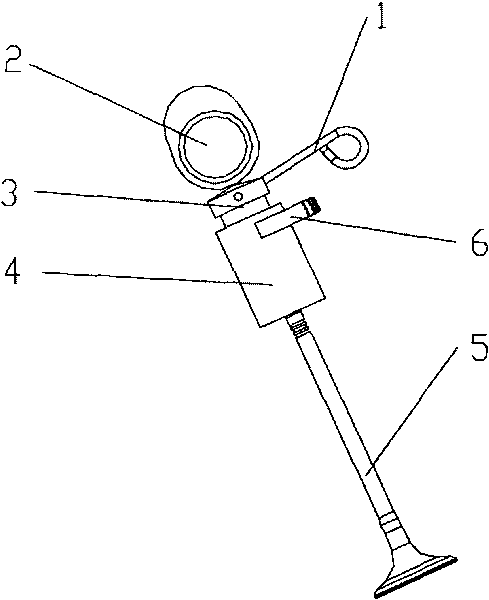

[0025] Example 1, such as figure 1 , 2 As shown in , 3, a hydraulic valve mechanism with variable valve lift includes a valve core 3 that presses against the cam 2, a sleeve 4 that can rotate relative to the valve core, and a sealing sleeve 8 that connects the valve. The sleeve 4 The top end is adapted to the spool 3, the bottom end is adapted to the sealing sleeve 8, and the middle part of the sleeve forms an oil chamber 9. A spool oil passage 10 is set in the spool 3, the inlet of the spool oil passage 10 is movably adapted to the sleeve oil passage 11, and the outlet of the spool oil passage 10 communicates with the oil chamber 9; the valve The core oil passage inlet 7 is a spiral notch.

[0026] In order to make the sleeve rotate relative to the valve core reliably, a partial gear 6 is arranged outside the sleeve 4 . In order to drive the sleeve to rotate through a rack or other similar mechanism.

[0027] In order to make the spool 3 rise back in time, a return spring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com