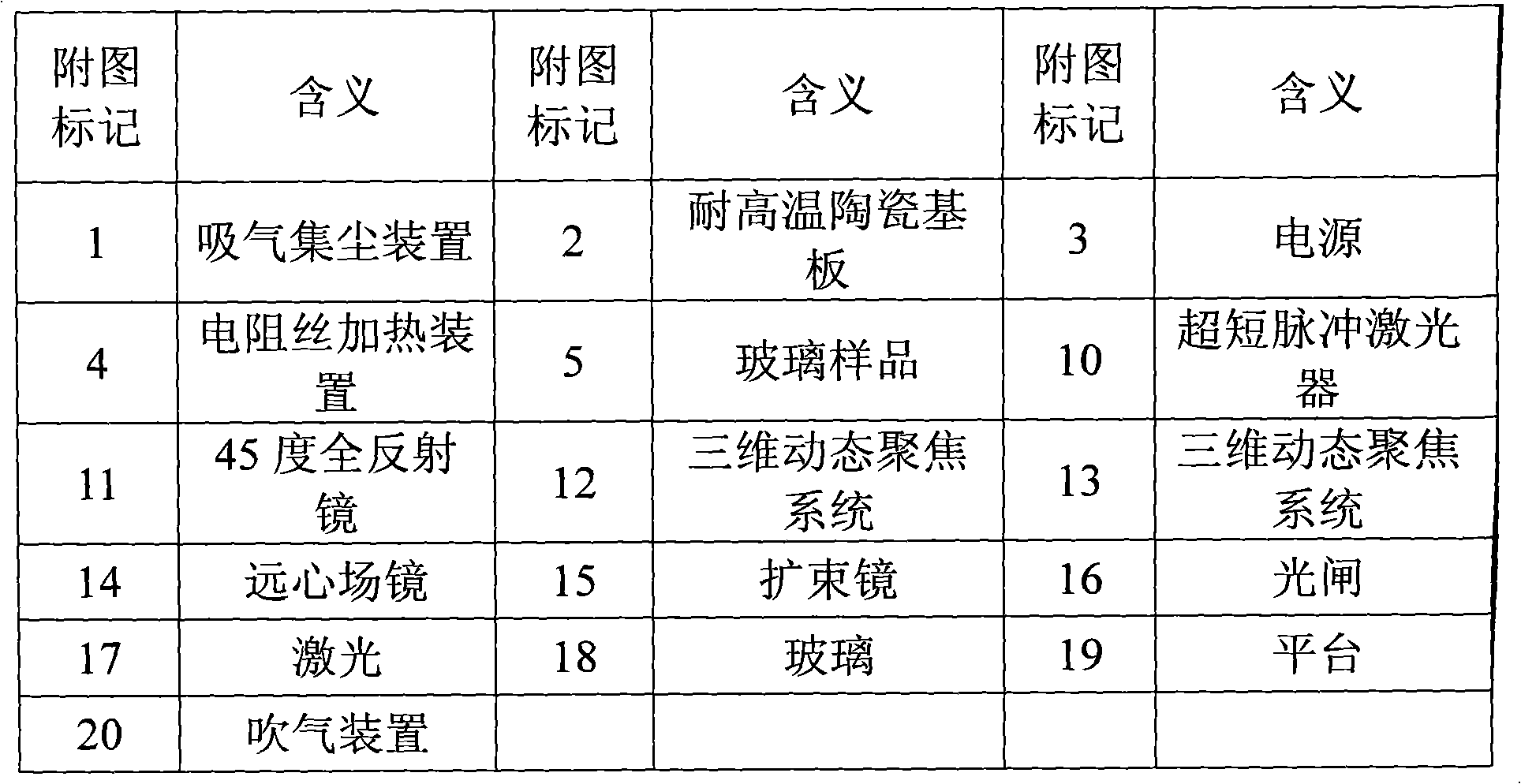

Patents

Literature

9893results about How to "Improve cutting efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

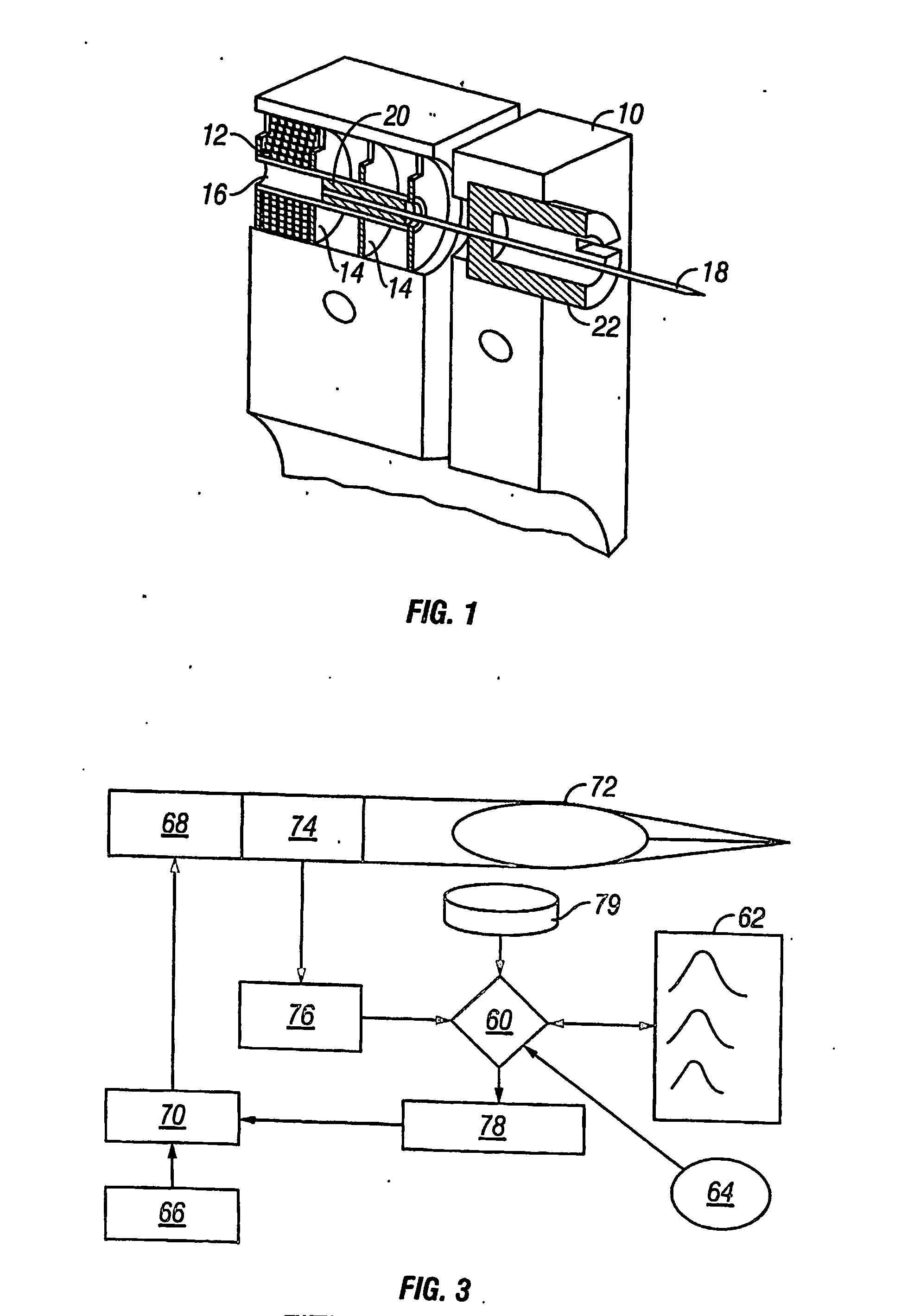

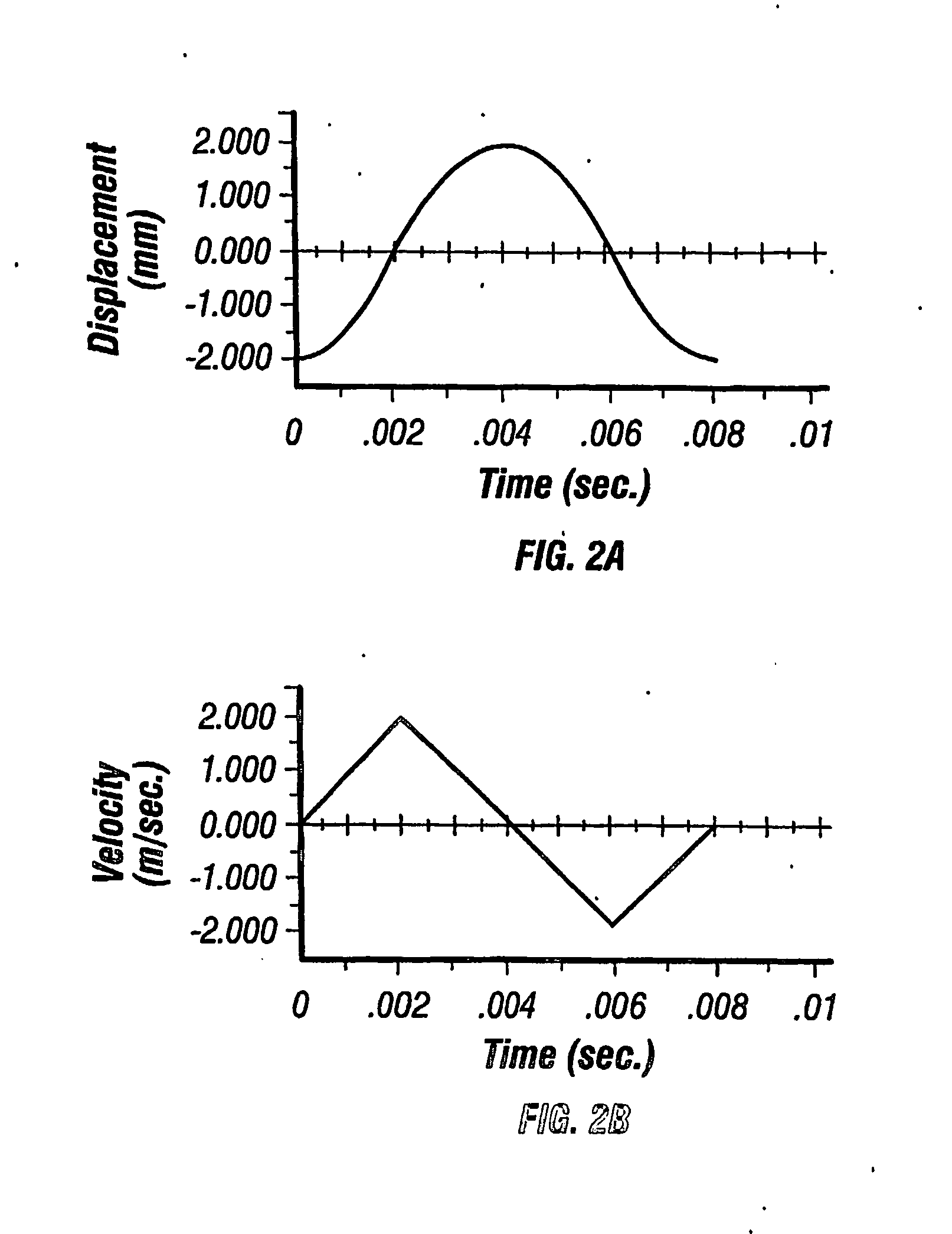

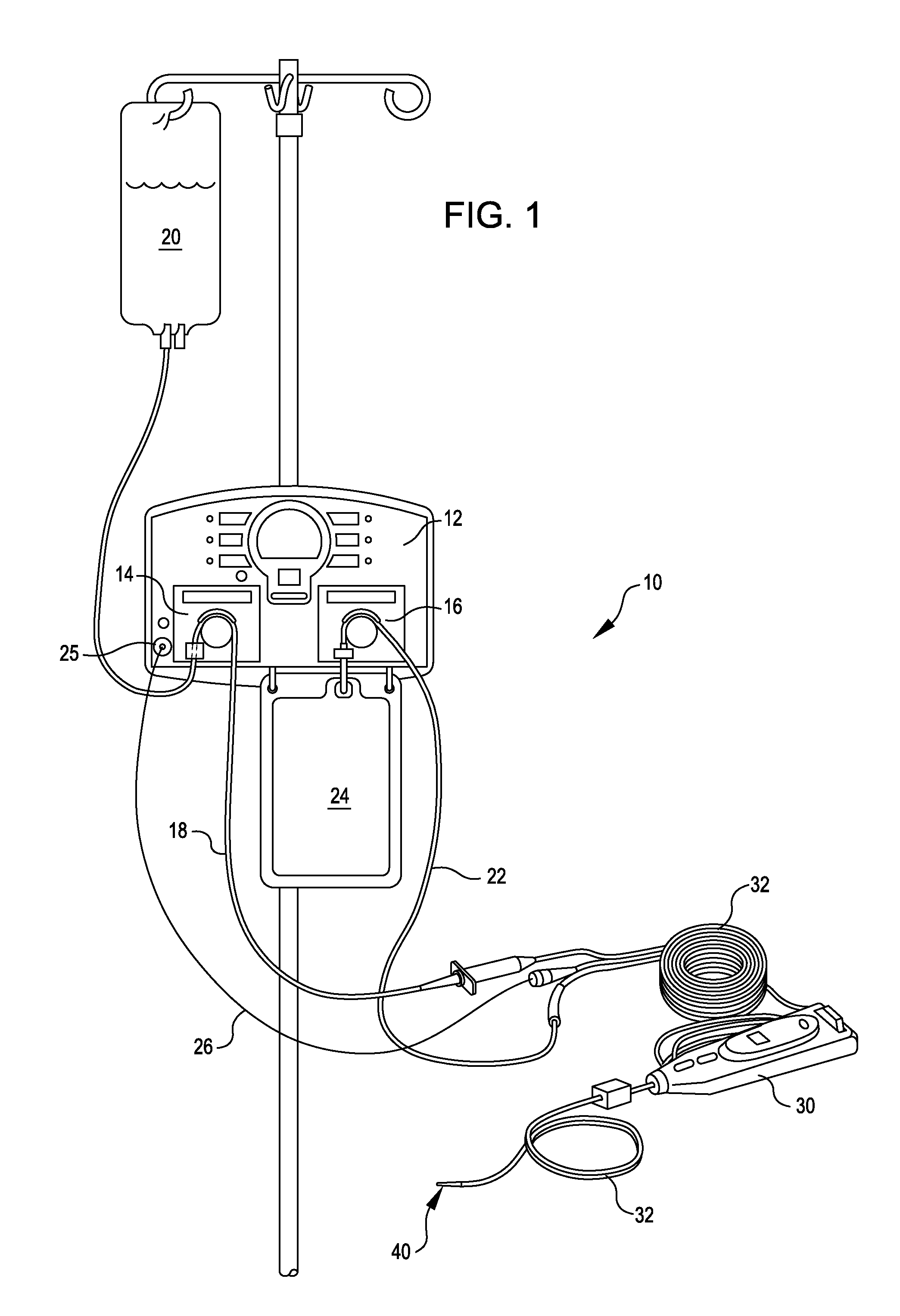

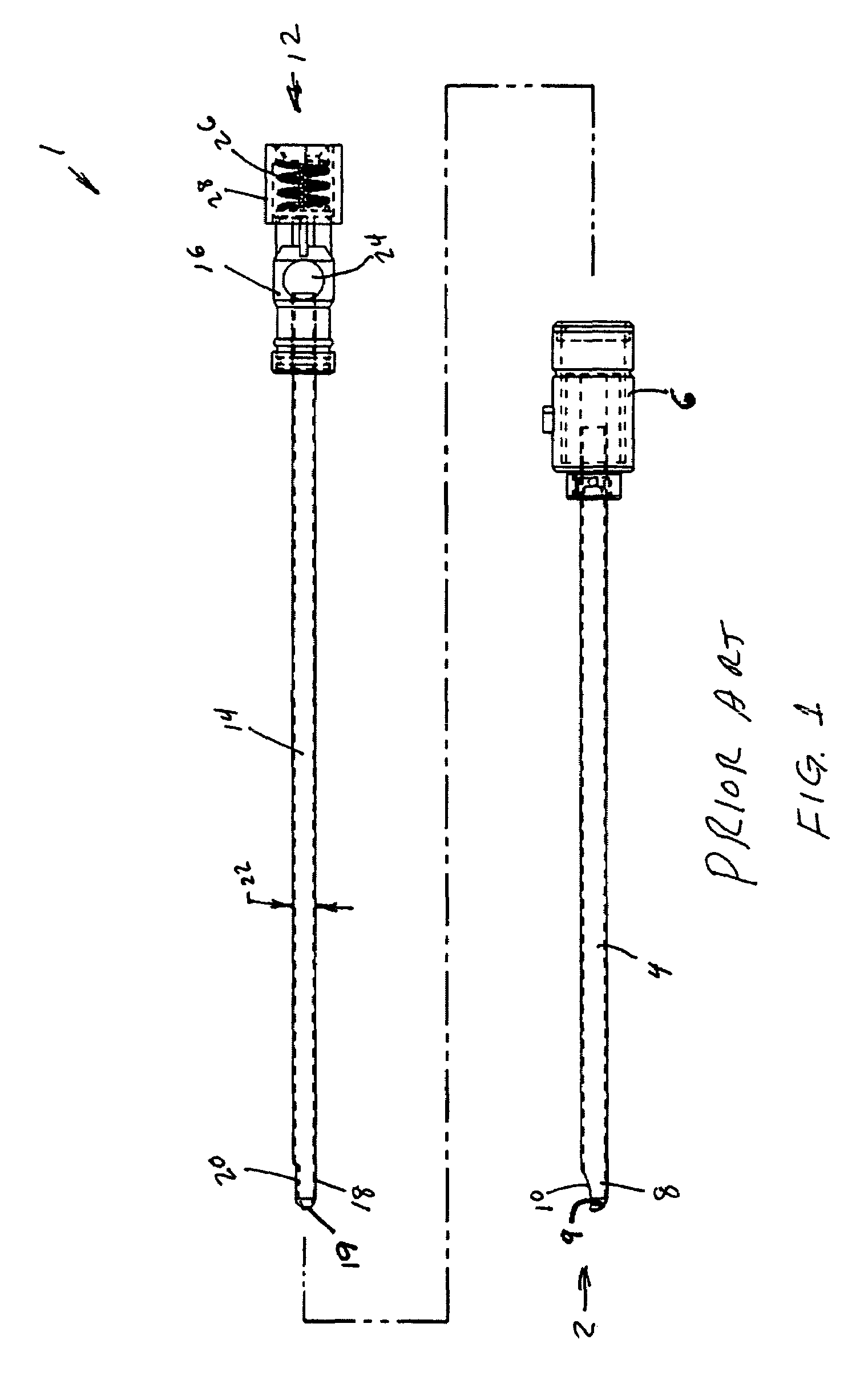

Method and apparatus for body fluid sampling and analyte sensing

InactiveUS20060241666A1Improve depth accuracyImprove cutting efficiencyIncision instrumentsBagsAnalyteEngineering

The method comprises providing a lancing device comprising a penetrating member (68) driver having a position sensor (74) and a processor (60) that can determine the relative position and velocity of the penetrating member (18, 72) based on measuring relative position of the penetrating member with respect to time; providing a predetermined velocity control trajectory based on a model of the driver (68) and a model of tissue to be contacted. Furthermore, a feedforward control is able to maintain penetrating member velocity along the trajectory.

Owner:PELIKAN TECH INC

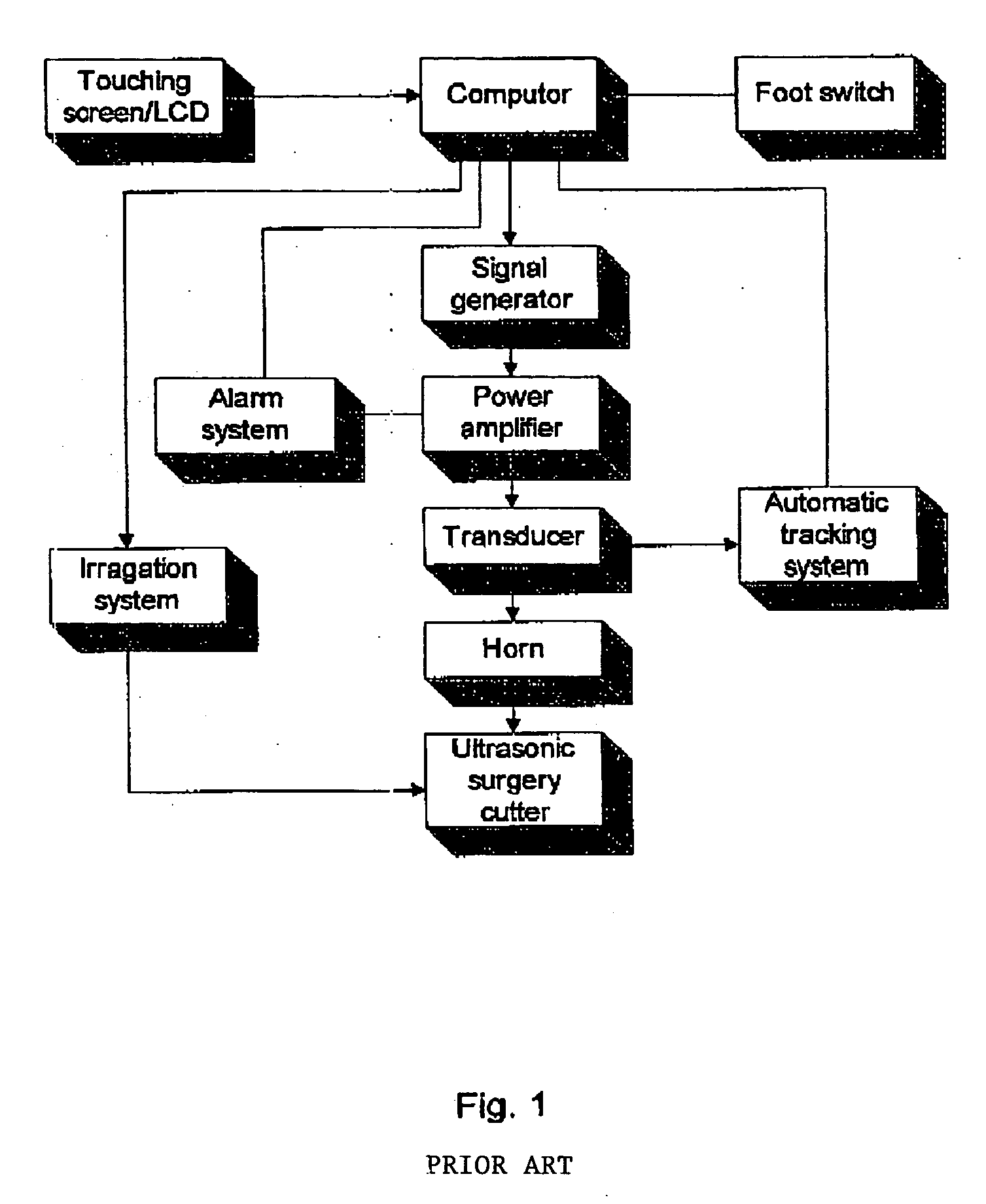

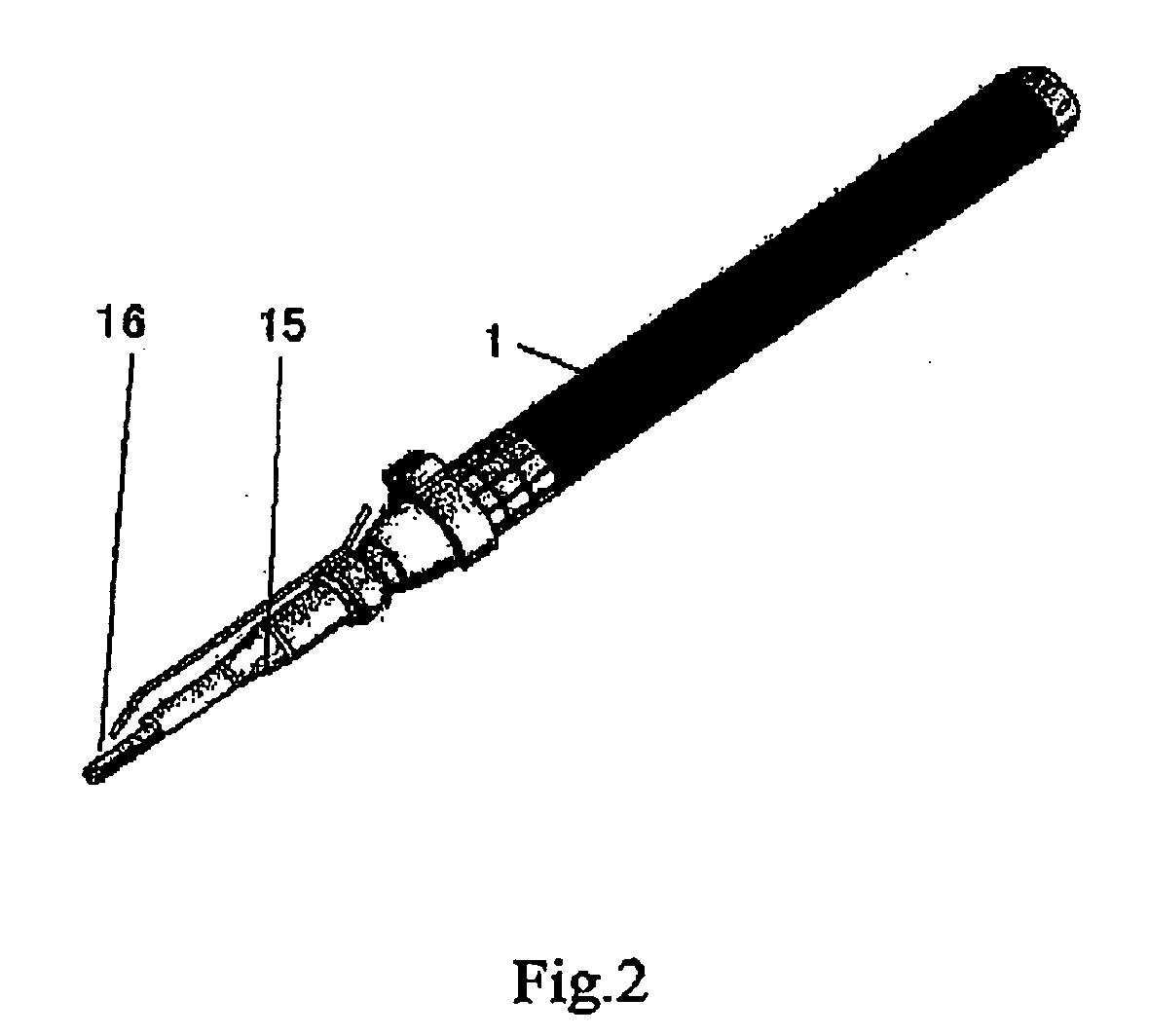

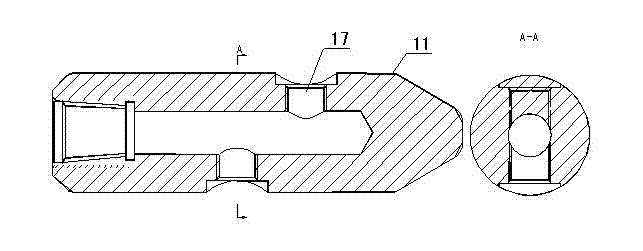

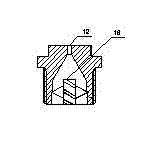

Ultrasonic orthopedic surgical device with compound ultrasound vibration

InactiveUS20060030797A1Improve cutting efficiencyAvoid local accumulationChiropractic devicesEye exercisersVibration amplitudeDrive motor

An orthopedic surgical device with compound ultrasound vibration that comprises a handpiece, a surgical cutter fixed on the anterior top of the handpiece, and an ultrasound signal generator. Inside the outer casing of said handpiece, there are provided: an ultrasound transducer for transforming the ultrasound signals from said ultrasound signal generator into ultrasound mechanical waves; a horn (or amplitude transformer) for amplifying vibration amplitude of ultrasound mechanical waves generated from said transducer and then transmitting the amplified ultrasound mechanical waves to said surgical cutter to lead to longitudinal vibration of the surgical cutter; a driving motor fixed in the back end of said handpiece for driving said ultrasound transducer and horn to accomplish the movement of swing and rotation; an adapter provided between said driving motor and said transducer for supplying ultrasonic electrical signals generated by said ultrasound signal generator to said ultrasound transducer.

Owner:ZHOU ZHAOYING +3

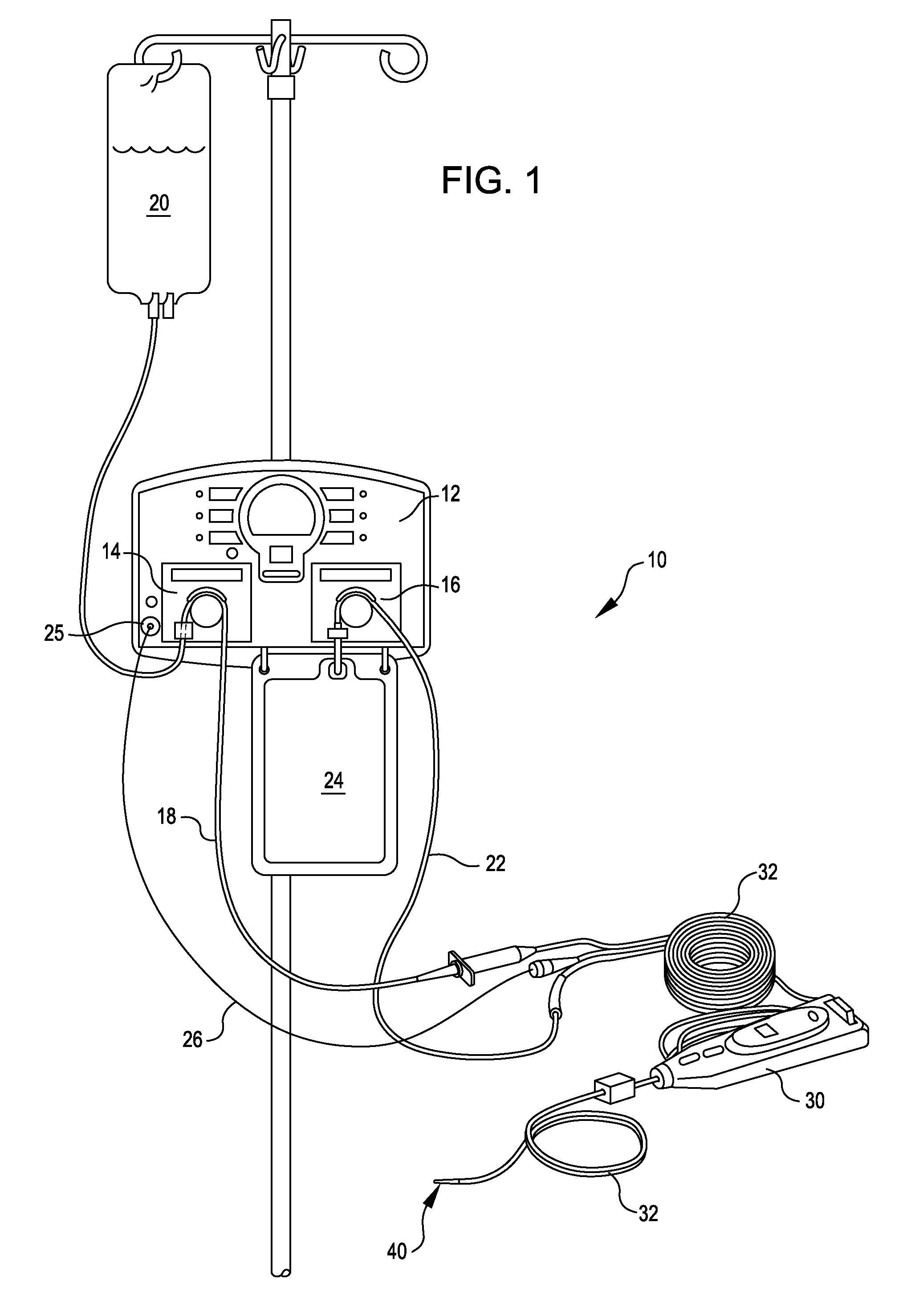

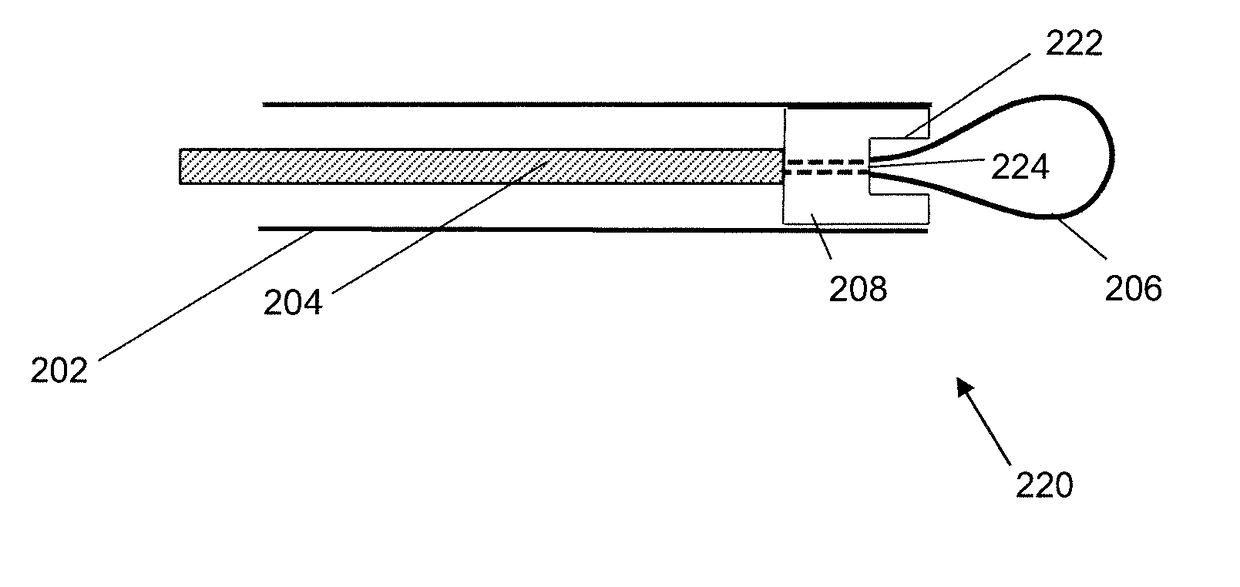

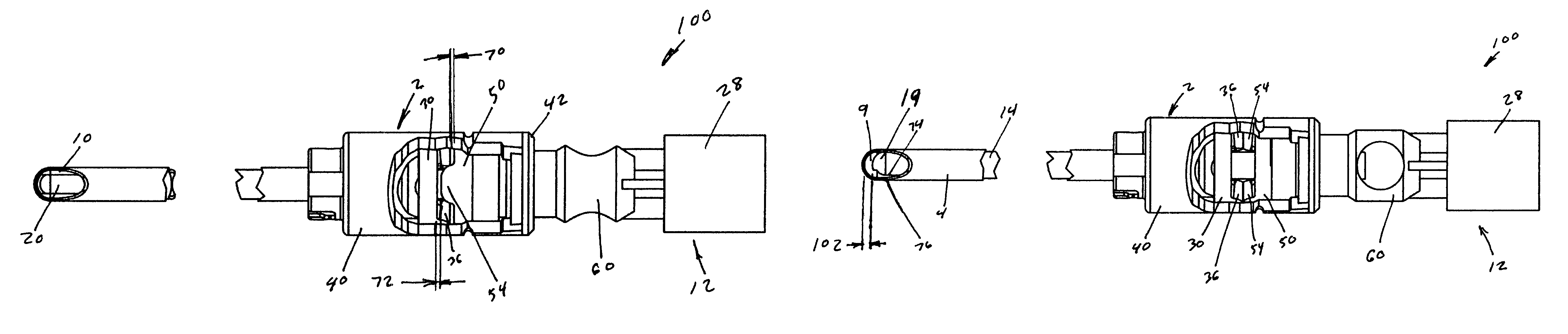

Interventional catheters incorporating an active aspiration system

An interventional catheter assembly comprises an operating head for removing obstructive material from a target site in a body lumen or cavity and at least one aspiration port located proximal to the operating head and penetrating the catheter assembly, the aspiration port being in communication with a sealed lumen that communicates with a vacuum system for withdrawing aspirate fluid and obstructive material from the target site. A rotatable member is positioned inside the catheter assembly at the site of the aspiration port and rotates during operation of the vacuum system. The rotatable member is provided with at least one upstanding bar that is sized to cooperate with the walls of the aspiration port and the inner surface of the catheter assembly to macerate debris that is drawn into the aspiration port.

Owner:BOSTON SCI MEDICAL DEVICE LTD

Interventional catheters incorporating an active aspiration system

ActiveUS20110118660A1Reduce amountHigh and consistent aspiration pressureGuide wiresExcision instrumentsCatheterTarget site

An interventional catheter assembly comprises an operating head for removing obstructive material from a target site in a body lumen or cavity and at least one aspiration port located proximal to the operating head and penetrating the catheter assembly, the aspiration port being in communication with a sealed lumen that communicates with a vacuum system for withdrawing aspirate fluid and obstructive material from the target site. The interventional catheter incorporates an elongated guidewire lumen bushing extending proximally from a distal region of the operating head to reduce the clearance between the guidewire and the internal surface of the guidewire lumen during operation of the interventional catheter. This feature restricts entry of fluid and debris into the guidewire lumen and promotes maintenance of consistent and high aspiration pressure and volume during operation of the aspiration system and interventional catheter assembly.

Owner:BOSTON SCI LTD

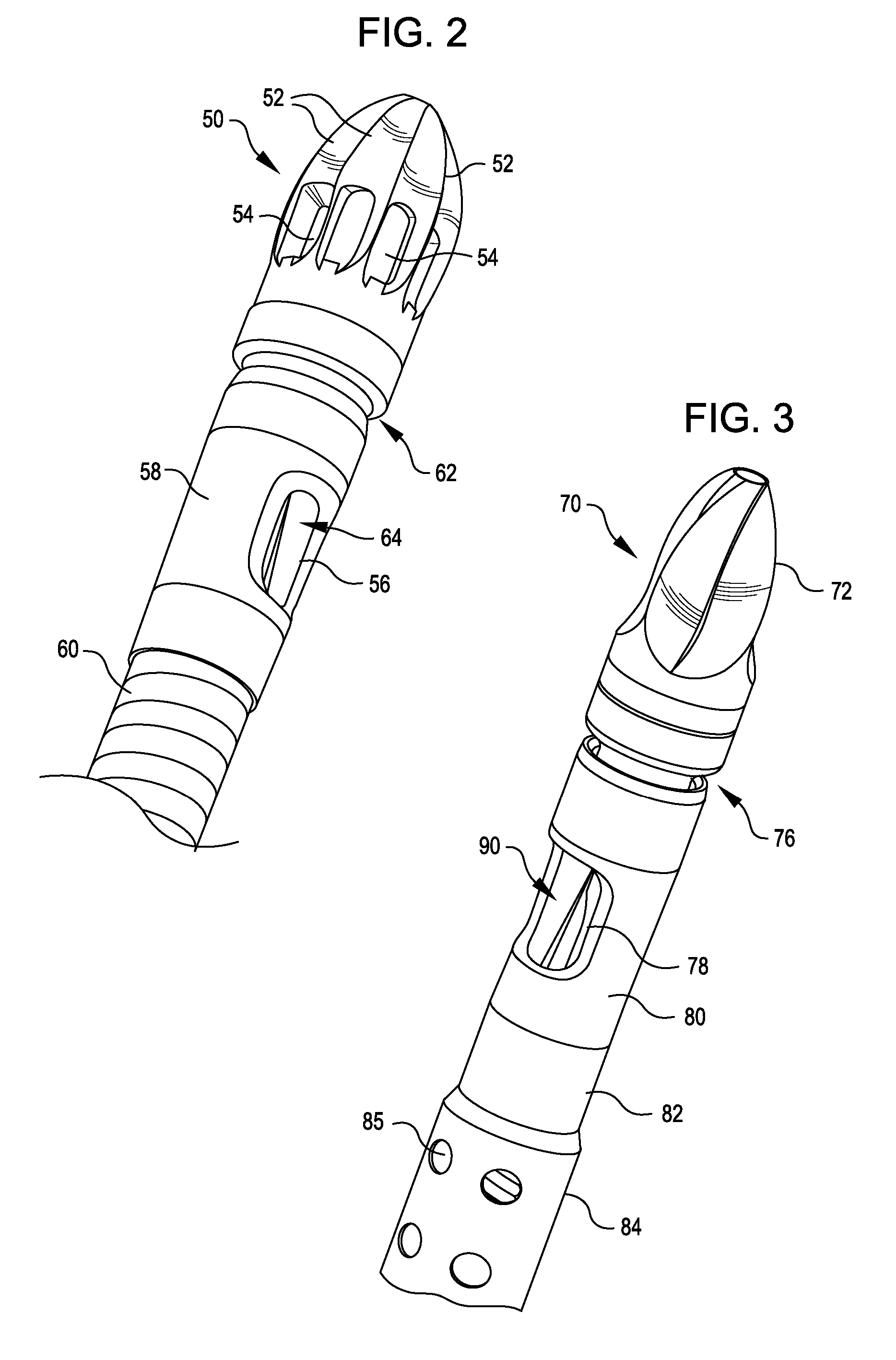

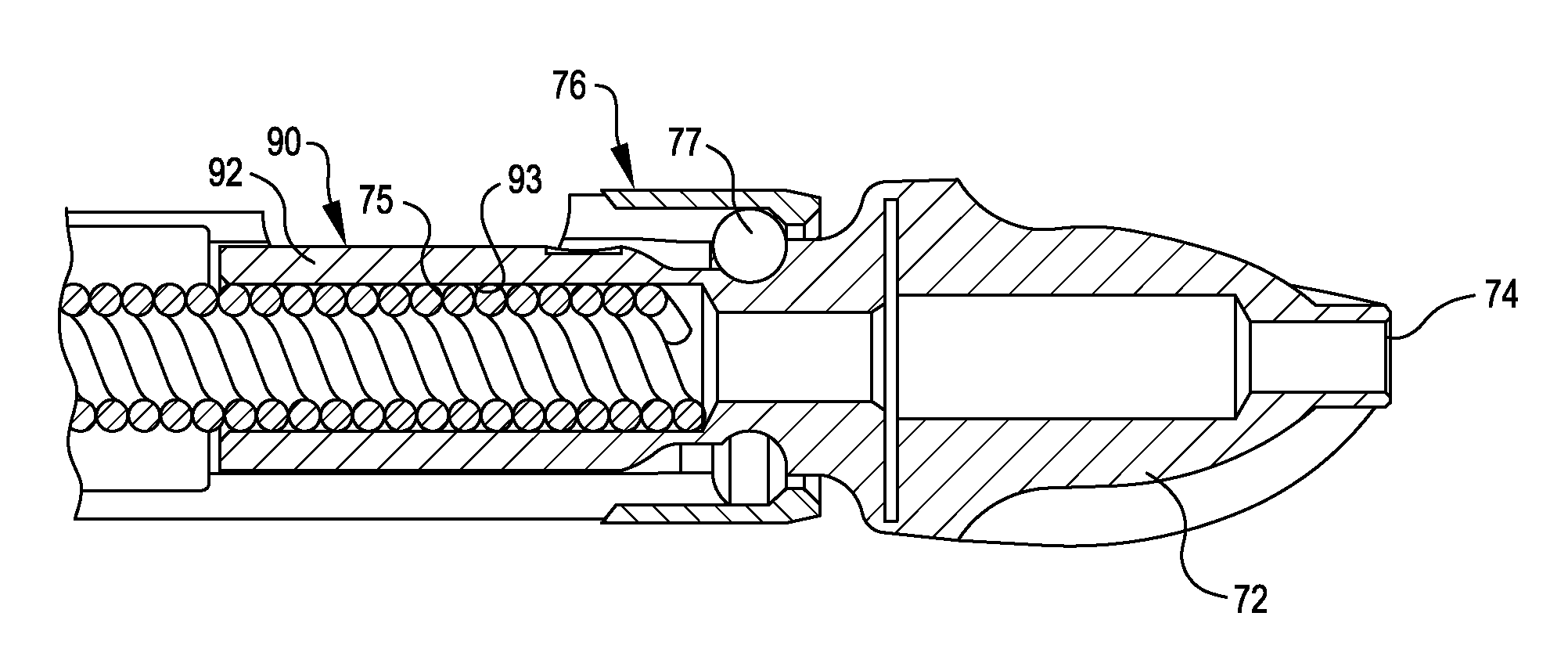

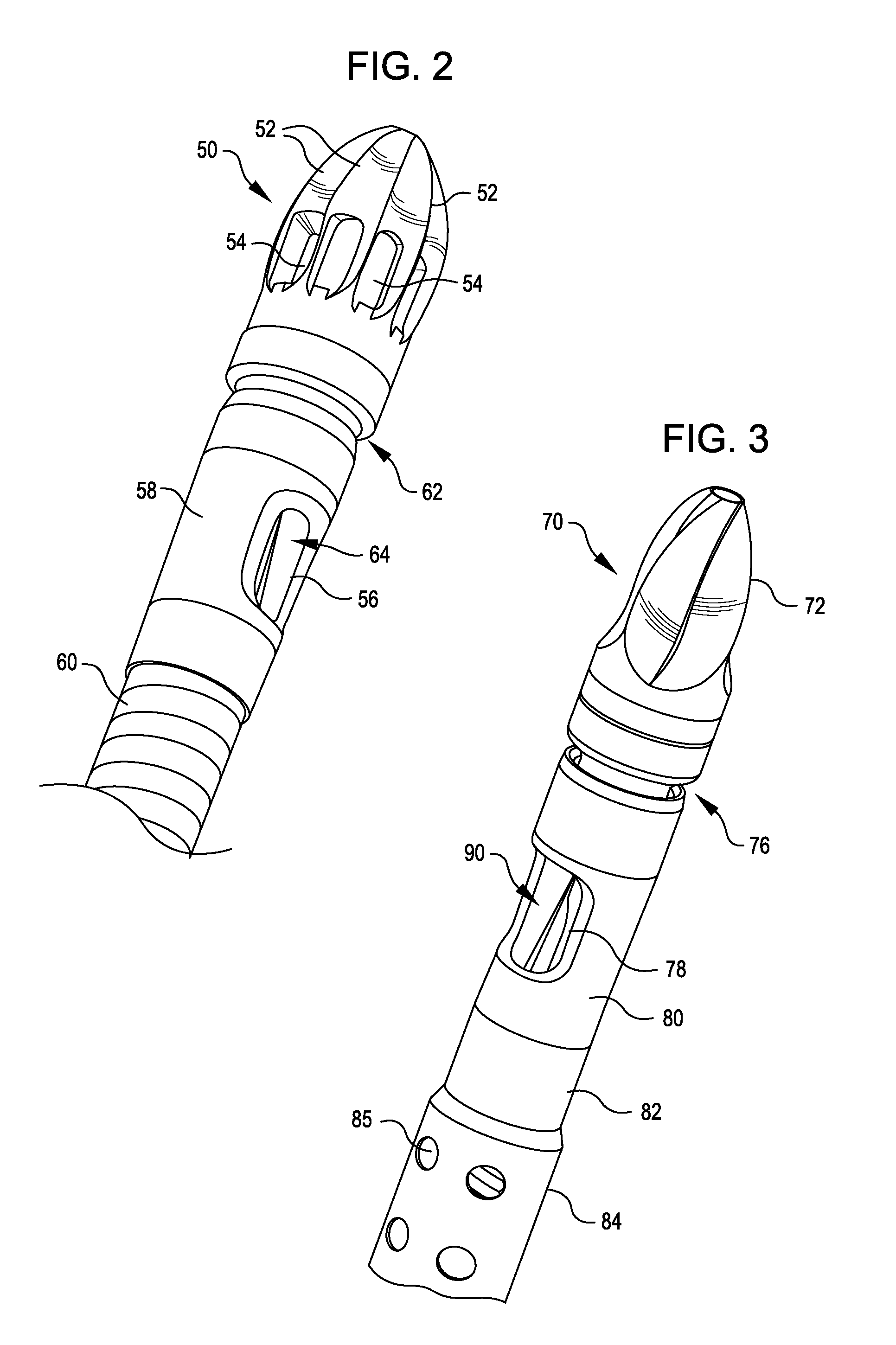

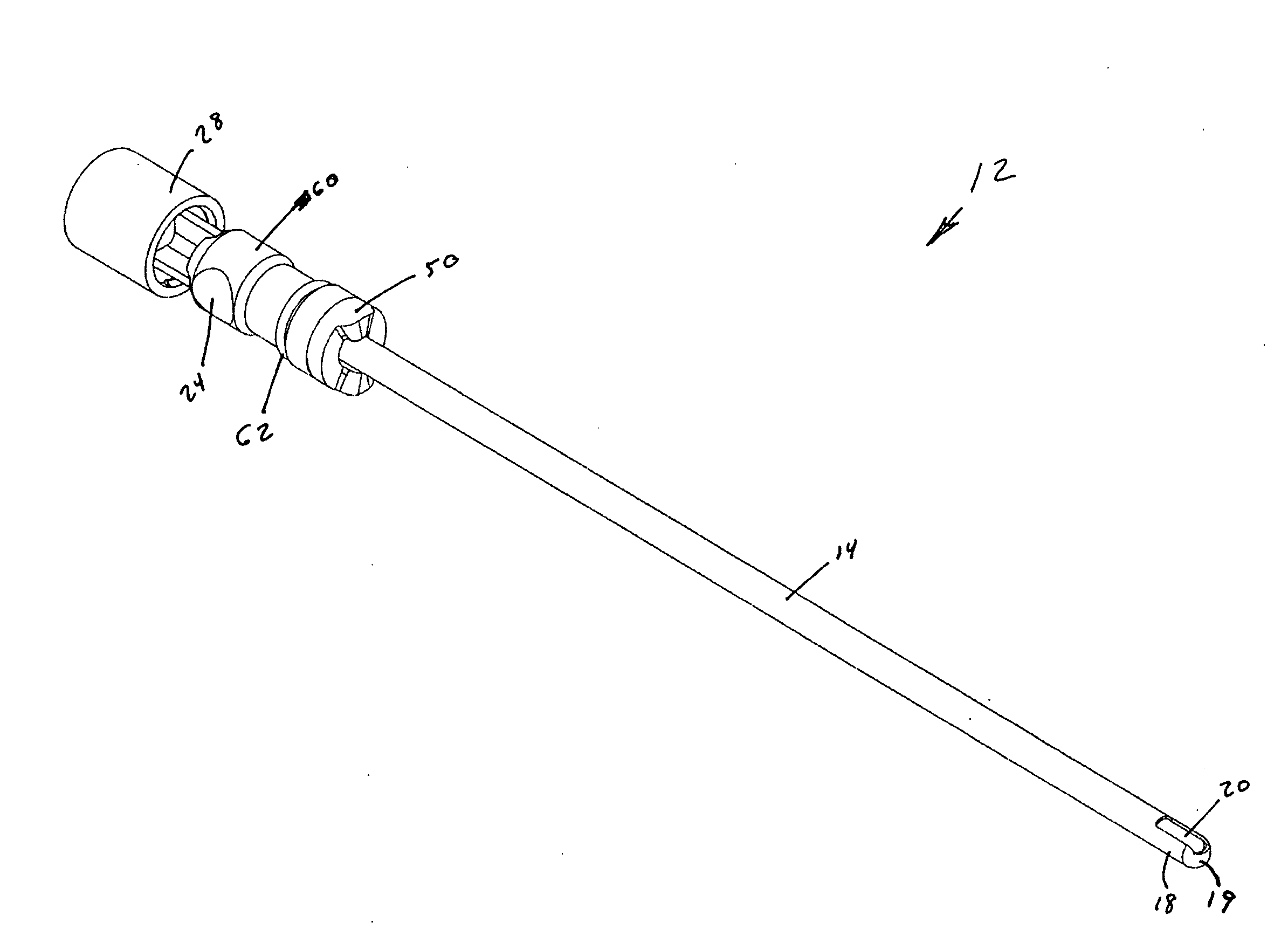

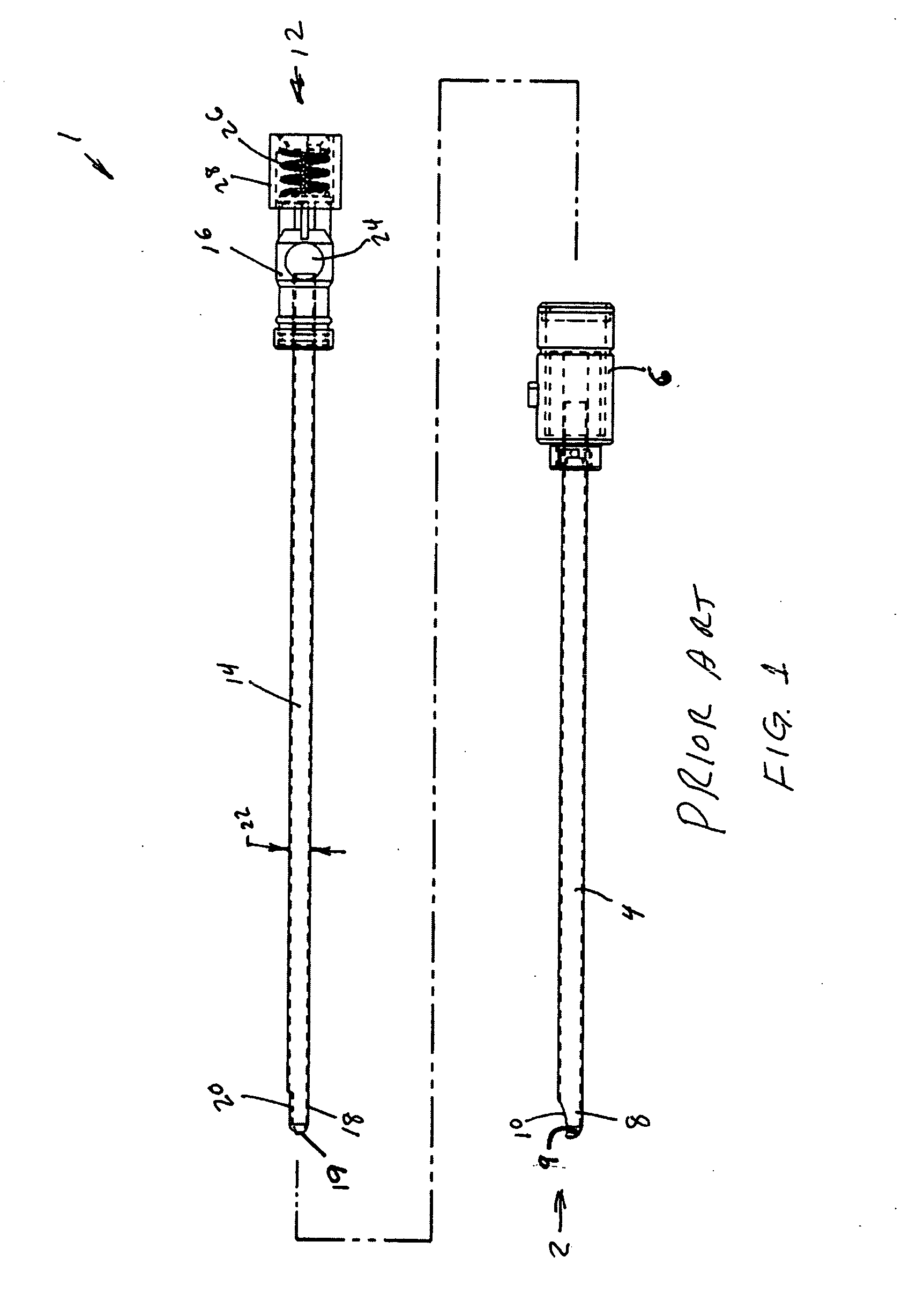

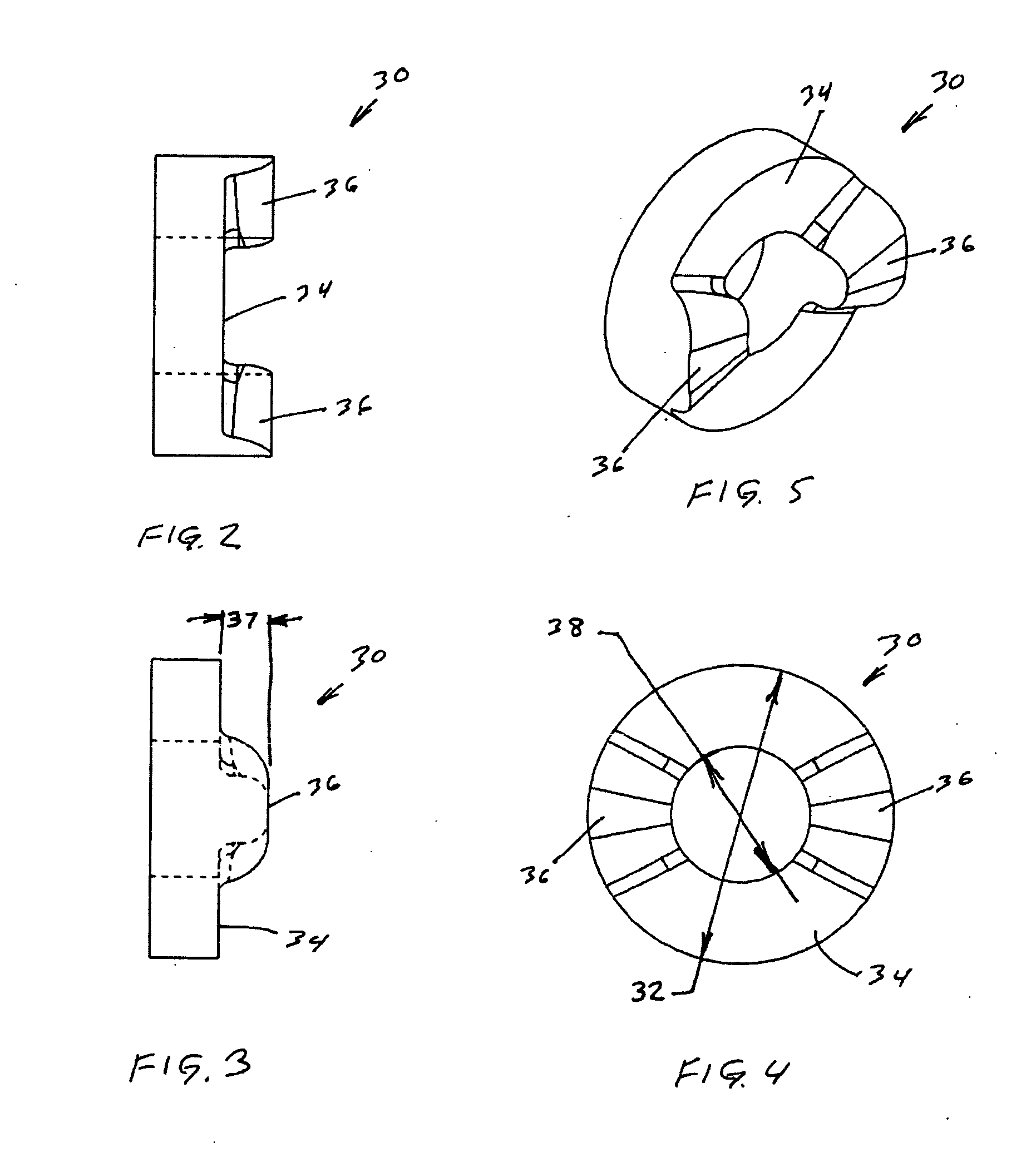

Endoscopic cutting instrument with axial and rotary motion

InactiveUS20080021487A1Improve cutting efficiencyIncrease relative motionExcision instrumentsEndoscopic cutting instrumentsEngineeringEndoscope

Owner:TARGET MEDICAL INNOVATIONS

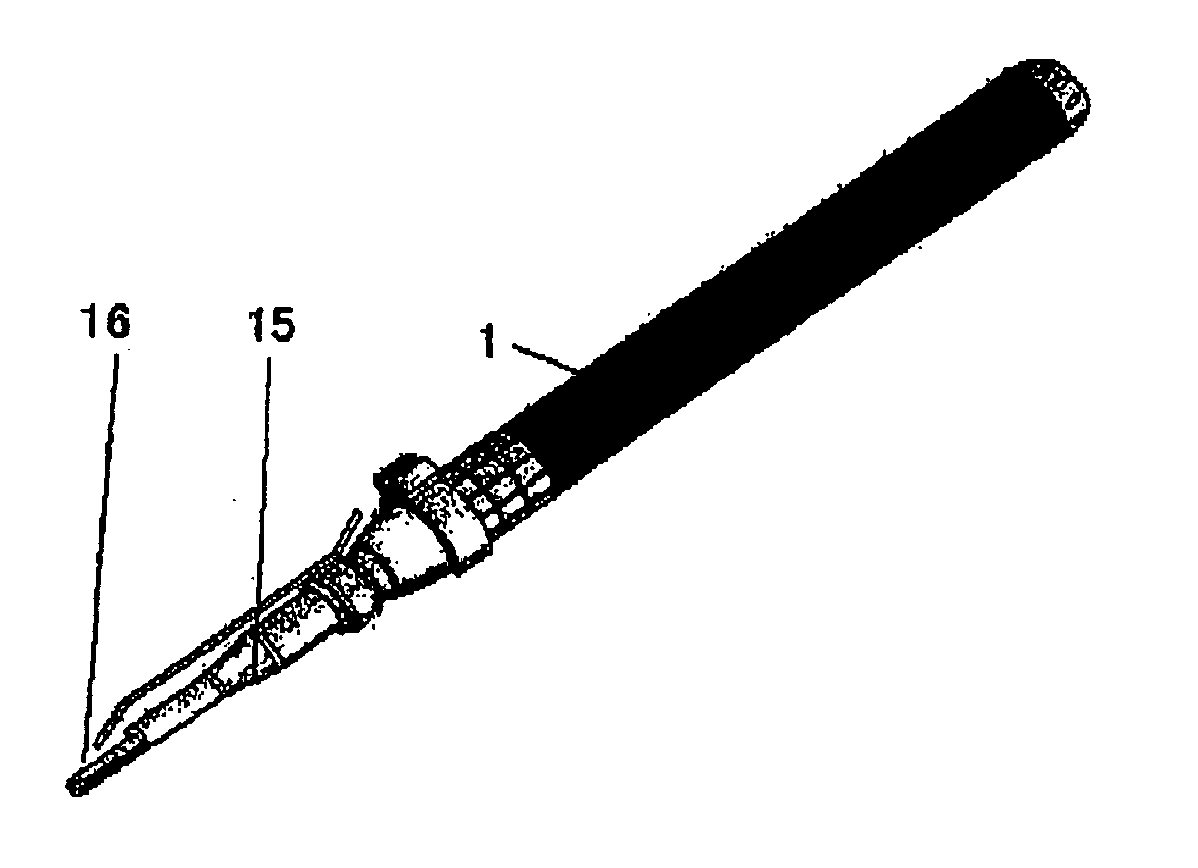

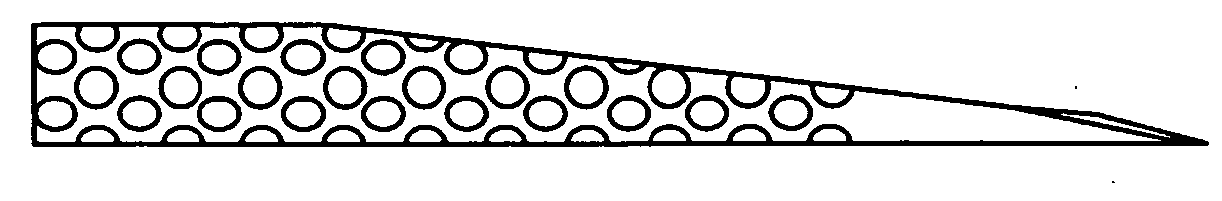

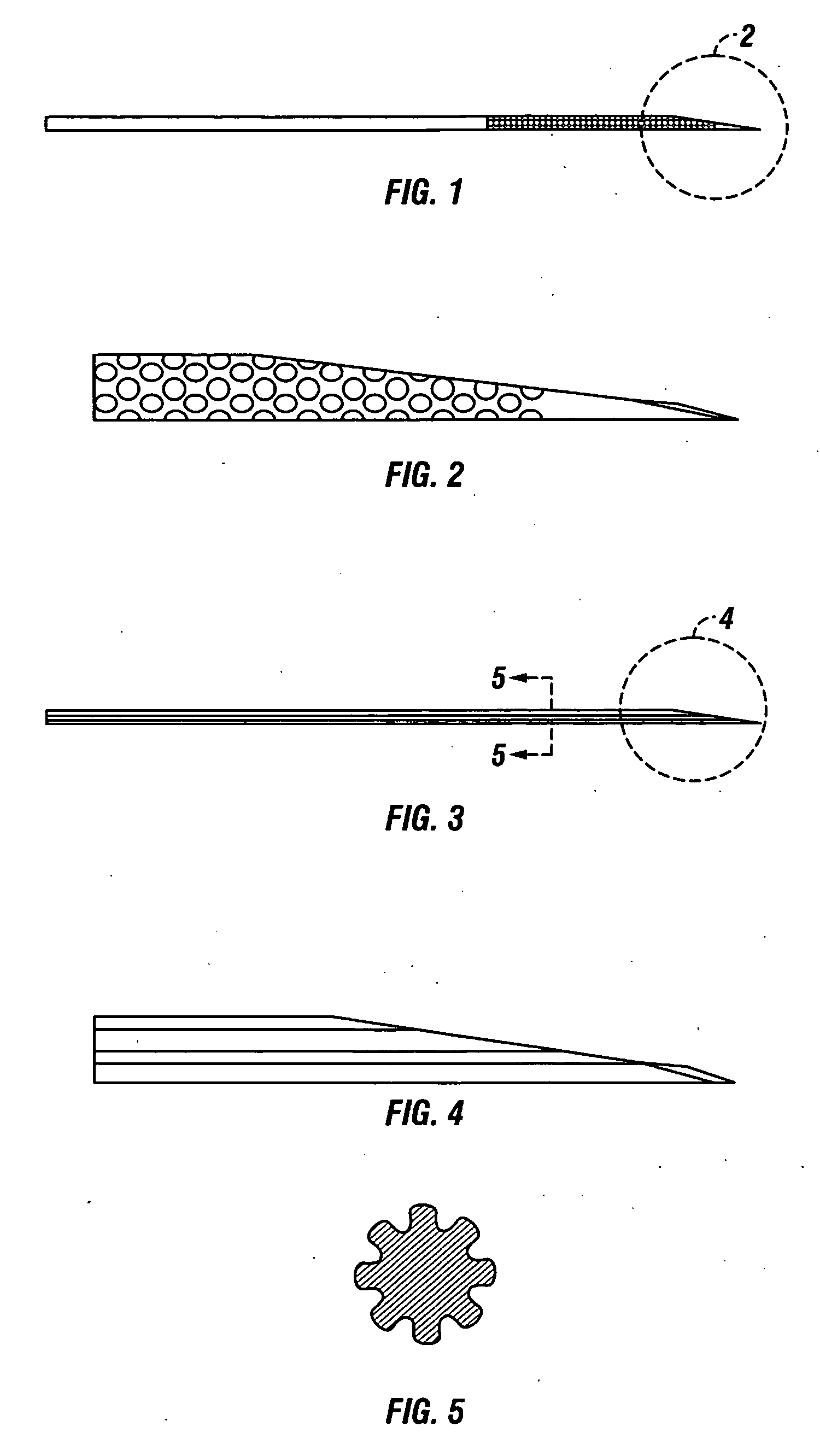

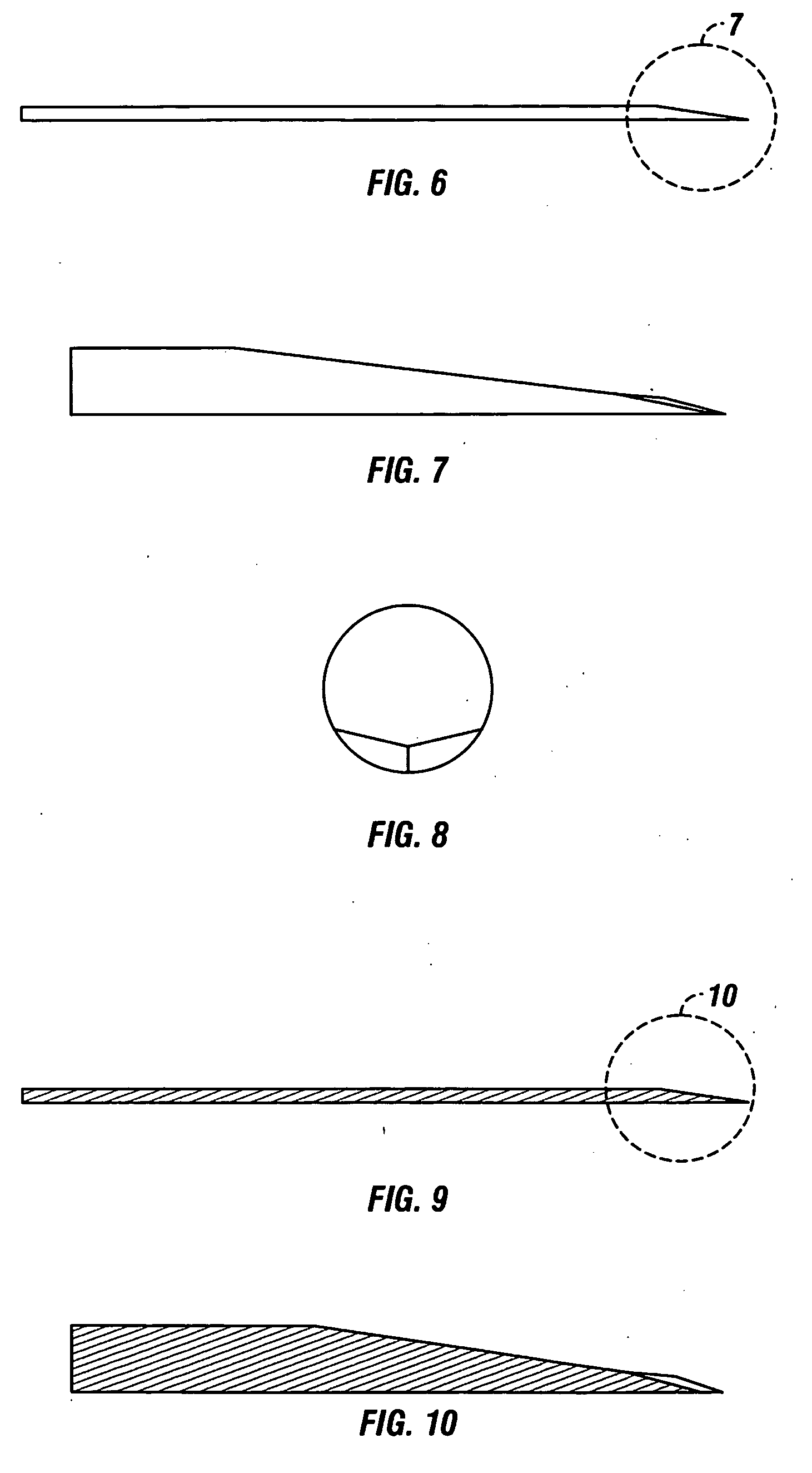

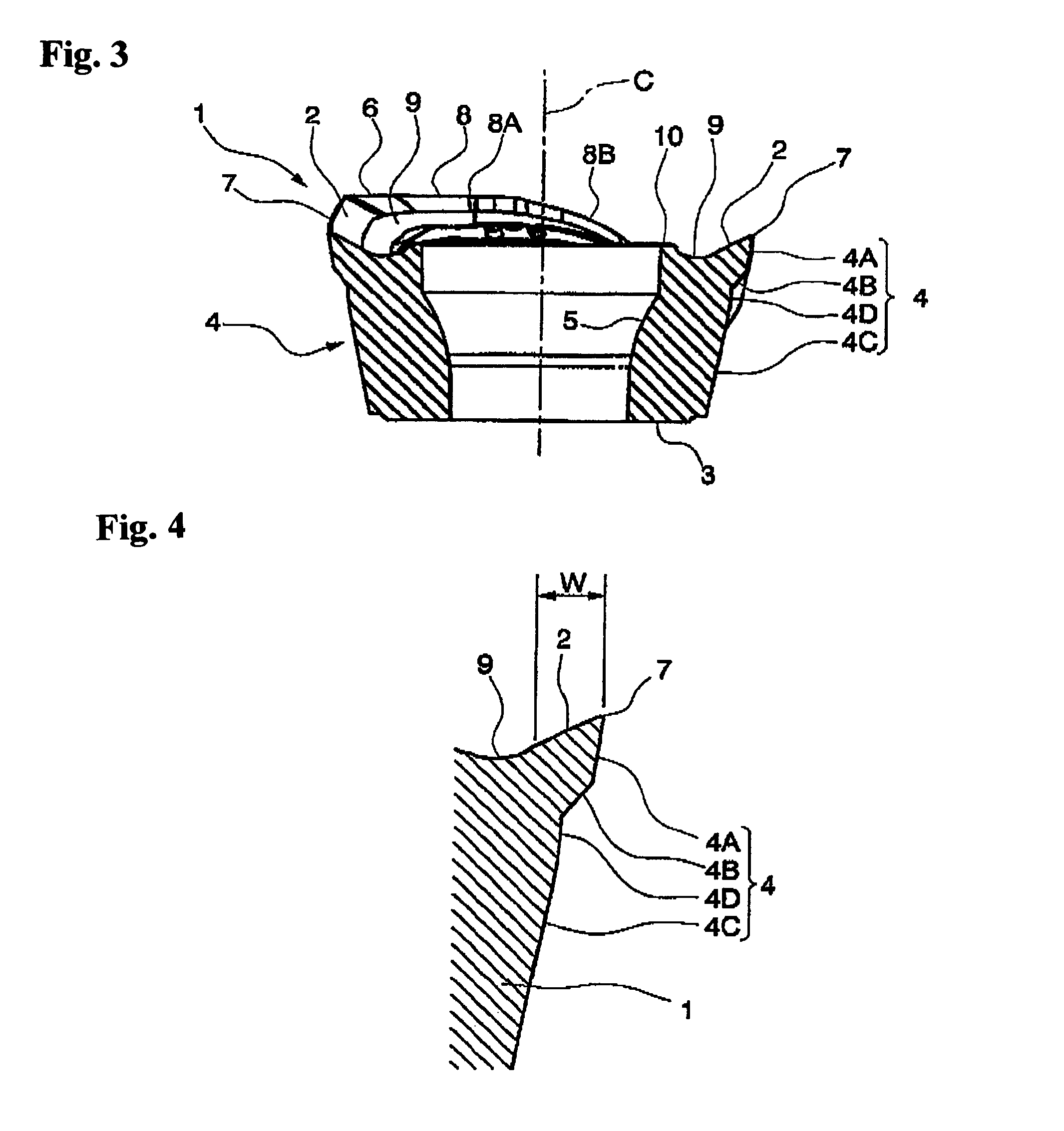

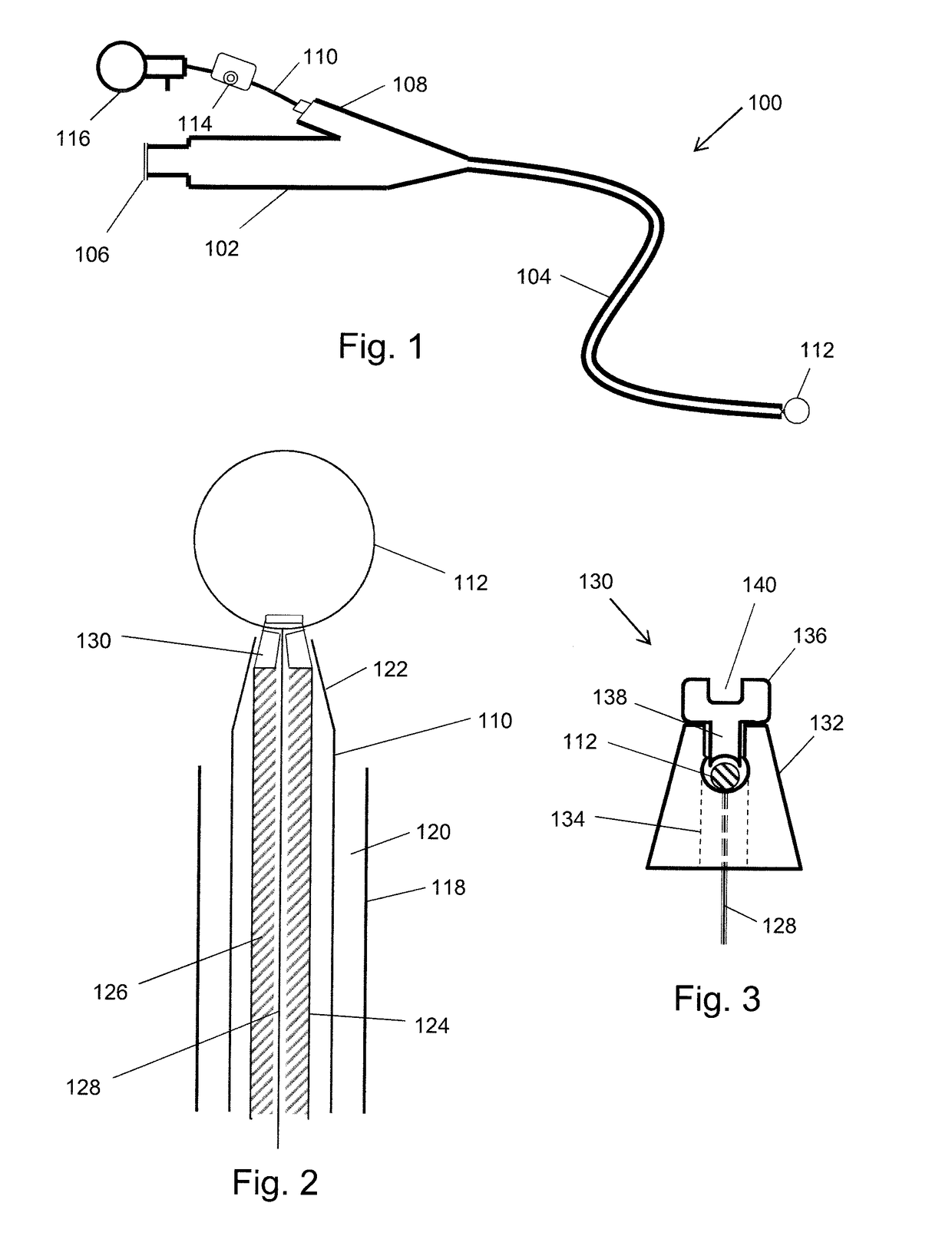

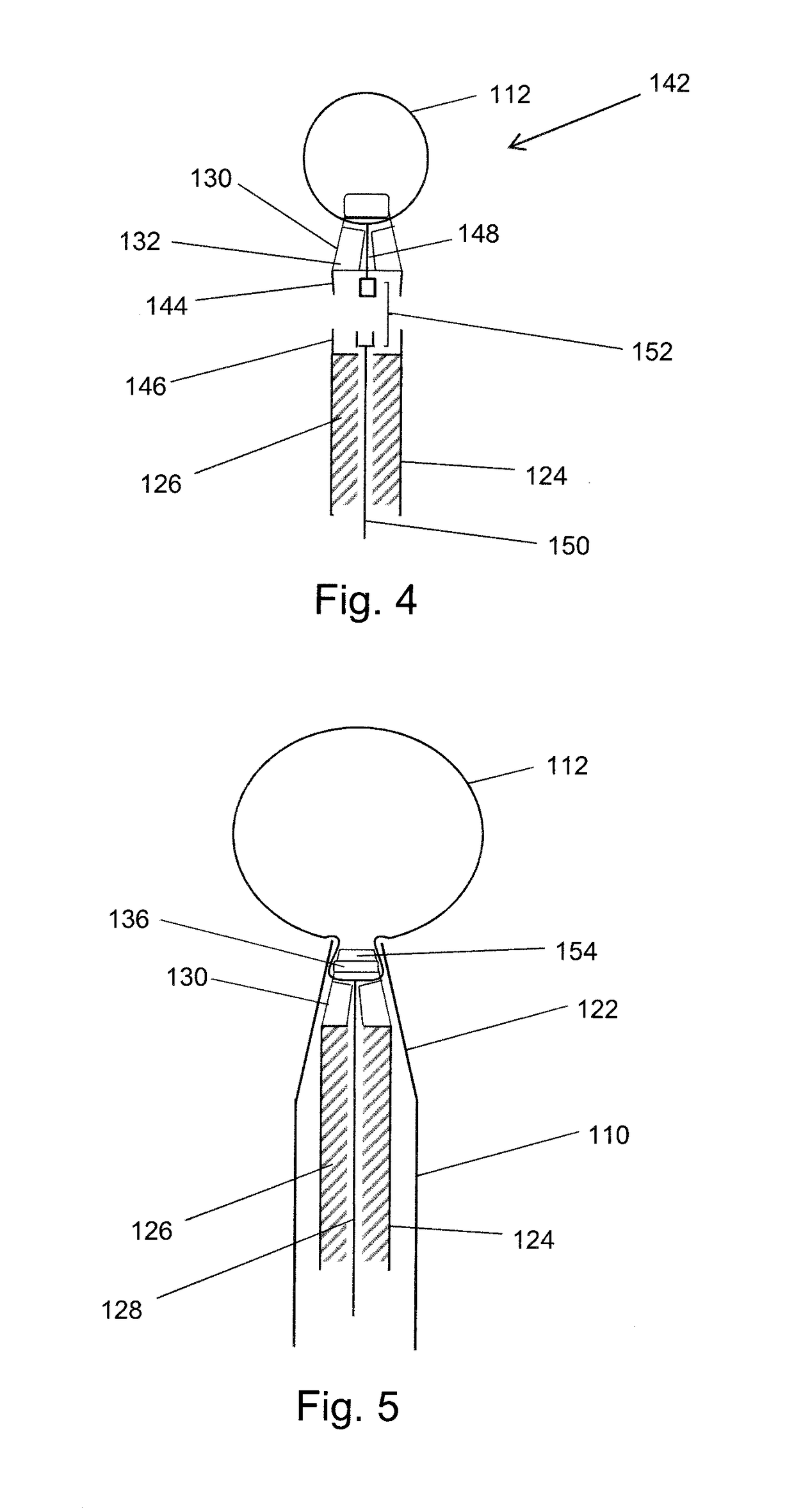

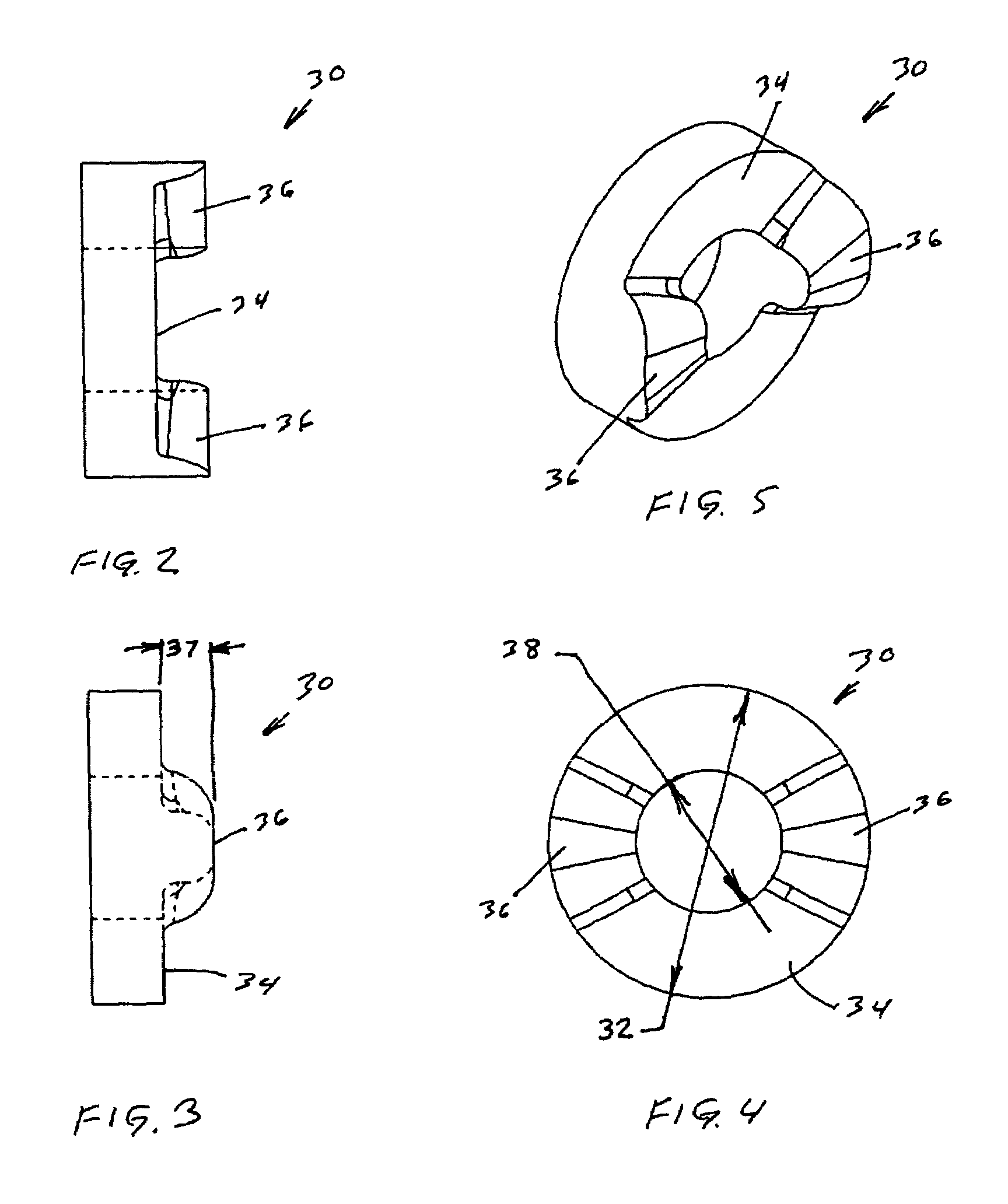

Low pain penetrating member

InactiveUS20060161194A1Improved penetrating member configurationRaise the possibilitySurgical needlesDiagnostic recording/measuringTissue skinGeneral surgery

Reducing the volume or drag on skin or sharpness of the penetrating member entering the wound during the cutting process will reduce the pain associated with lancing, and result in less power desired for retraction of the penetrating member from the skin. A variety of other penetrating member configuration as shown in the application.

Owner:SANOFI AVENTIS DEUT GMBH

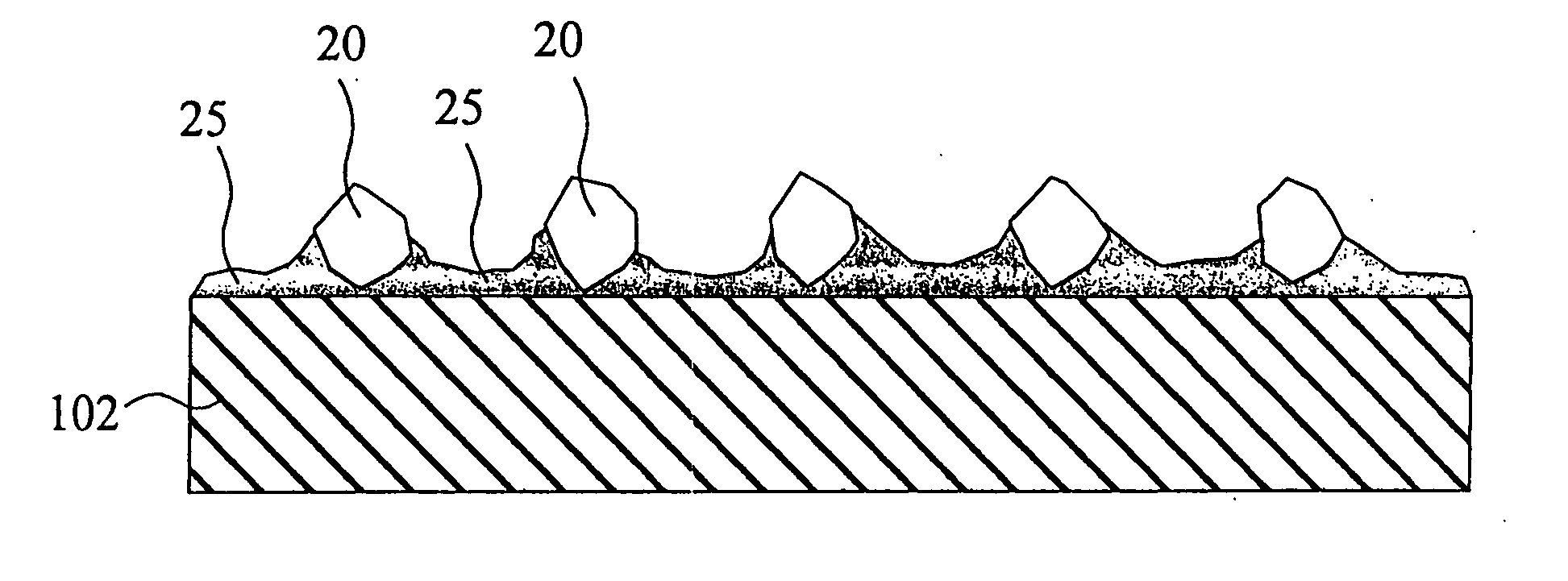

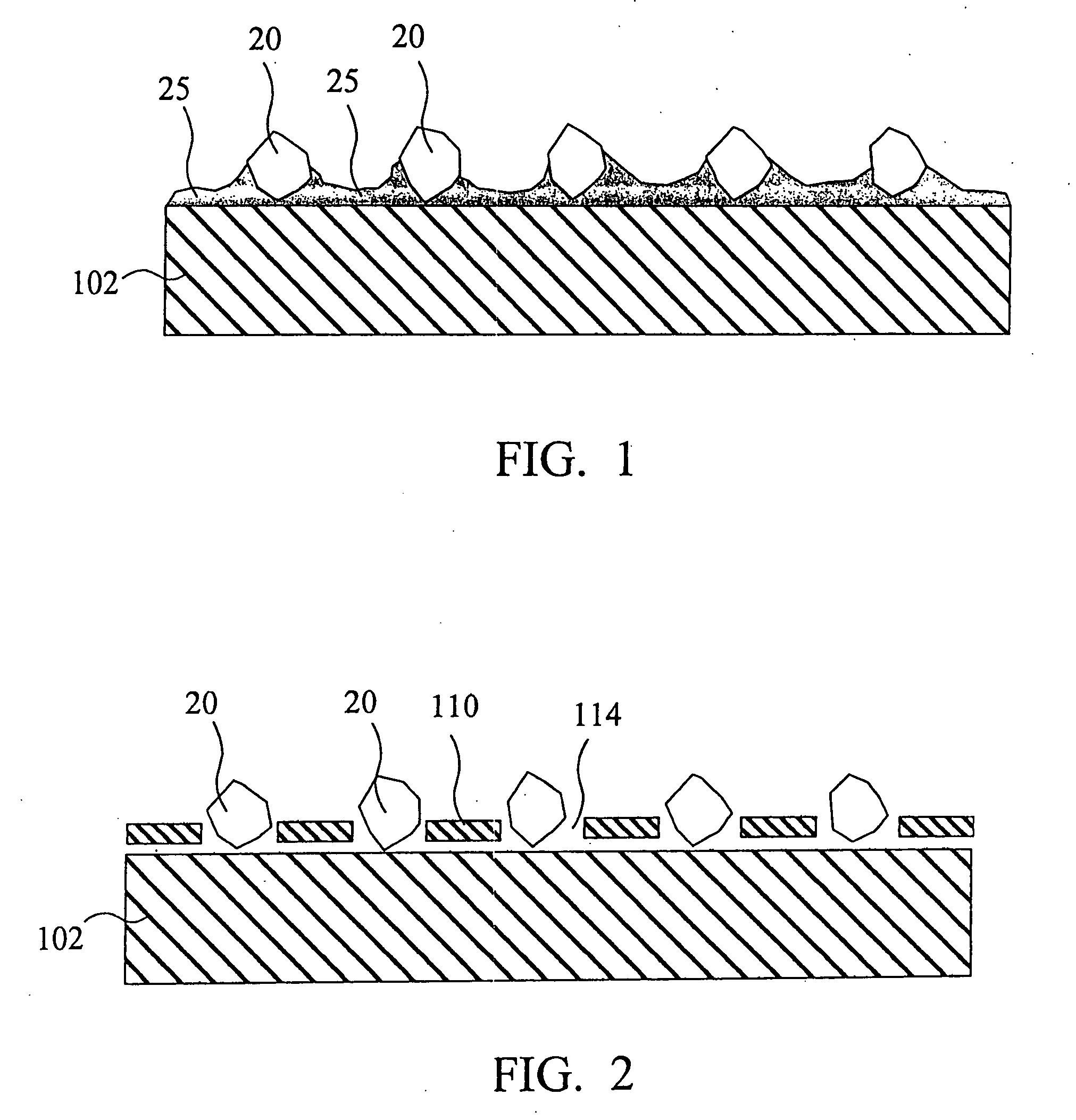

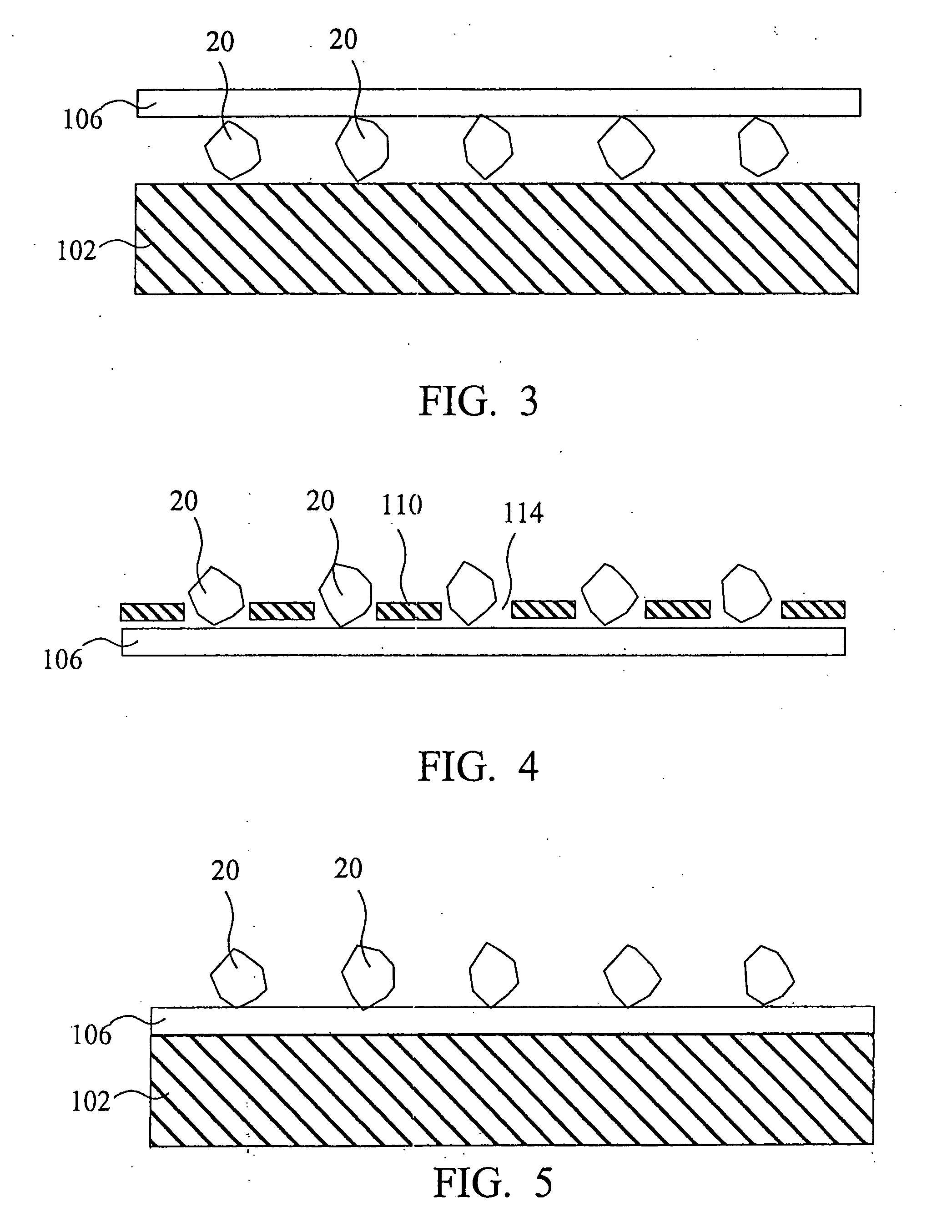

Brazed diamond tools and methods for making the same

InactiveUS20040112359A1Avoid large movementsImprove cutting efficiencyDrill bitsConstructionsChemical LinkageBraze alloy

Superabrasive tools and methods for the making thereof are disclosed and described. In one aspect, superabrasive particles are chemically bonded to a matrix support material according to a predetermined pattern by a braze alloy. The brazing alloy may be provided as a powder, thin sheet, or sheet of amorphous alloy. A template having a plurality of apertures arranged in a predetermined pattern may be used to place the superabrasive particles on a given substrate or matrix support material.

Owner:SUNG CHIEN MIN

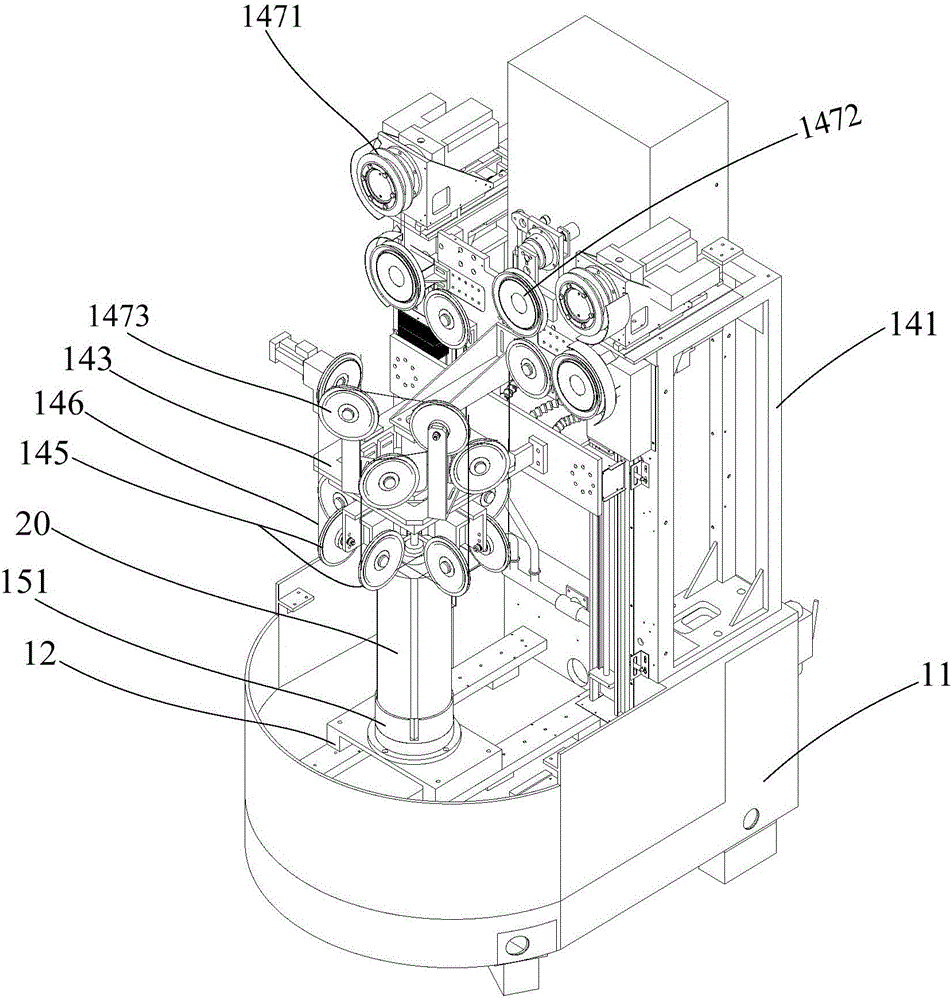

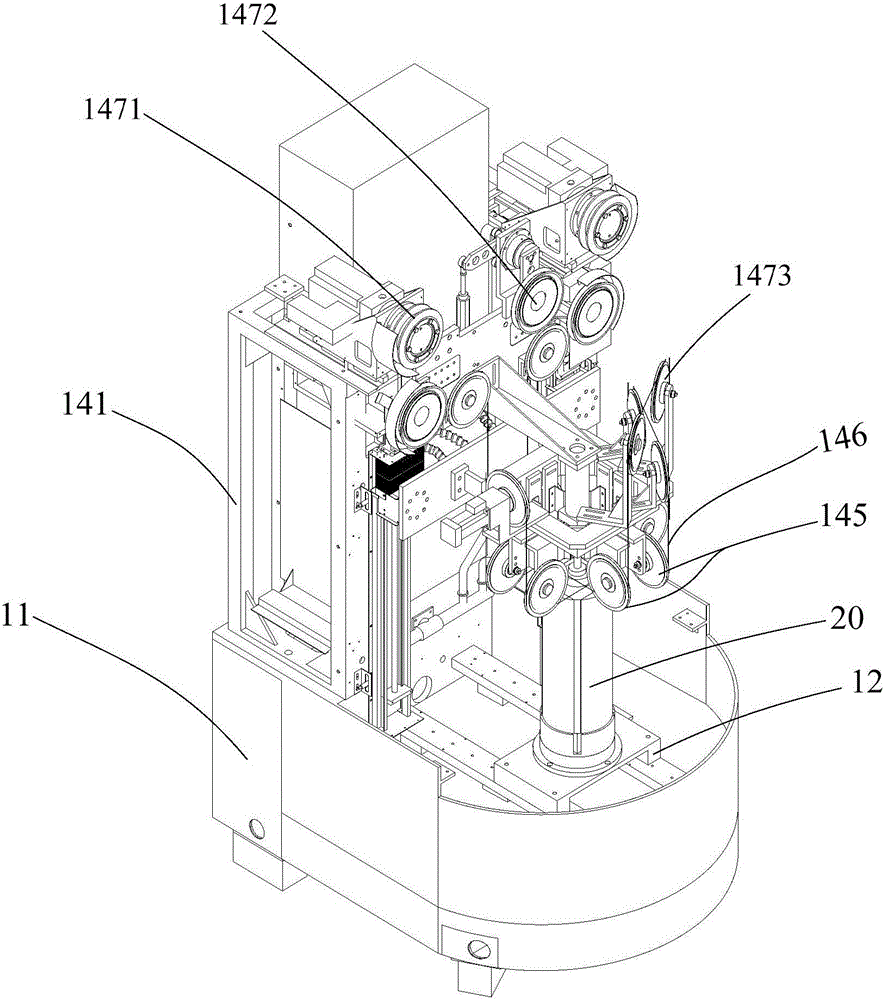

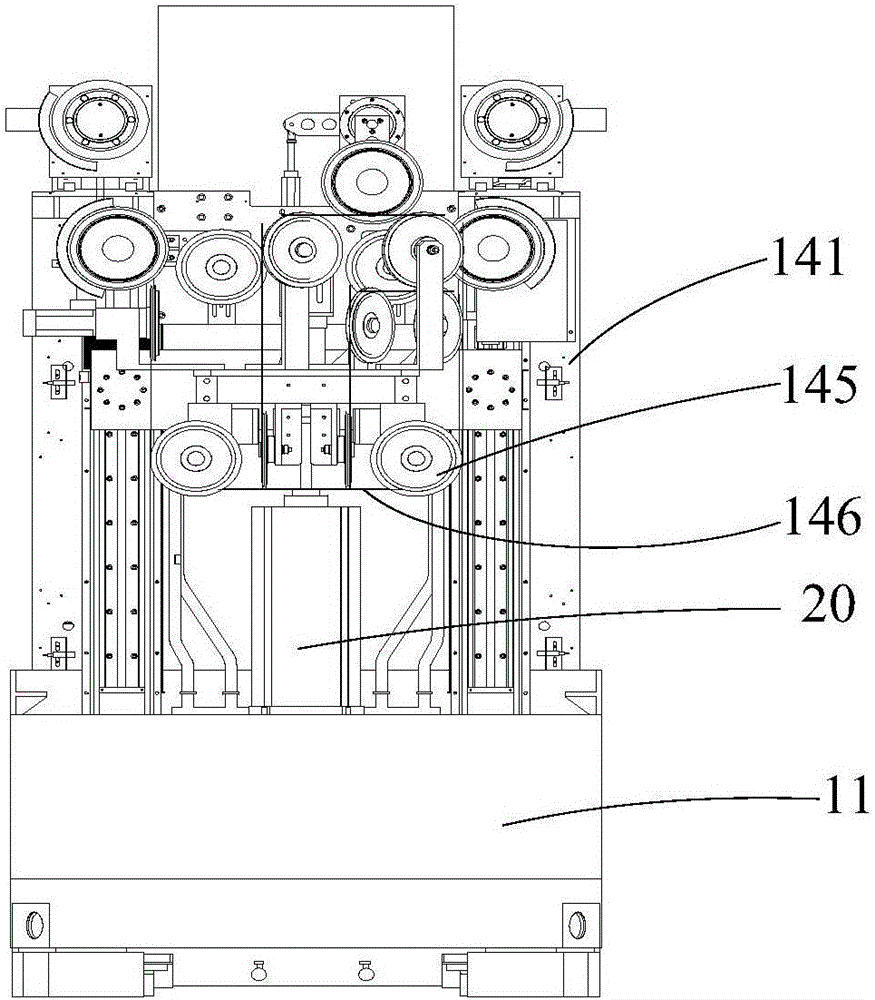

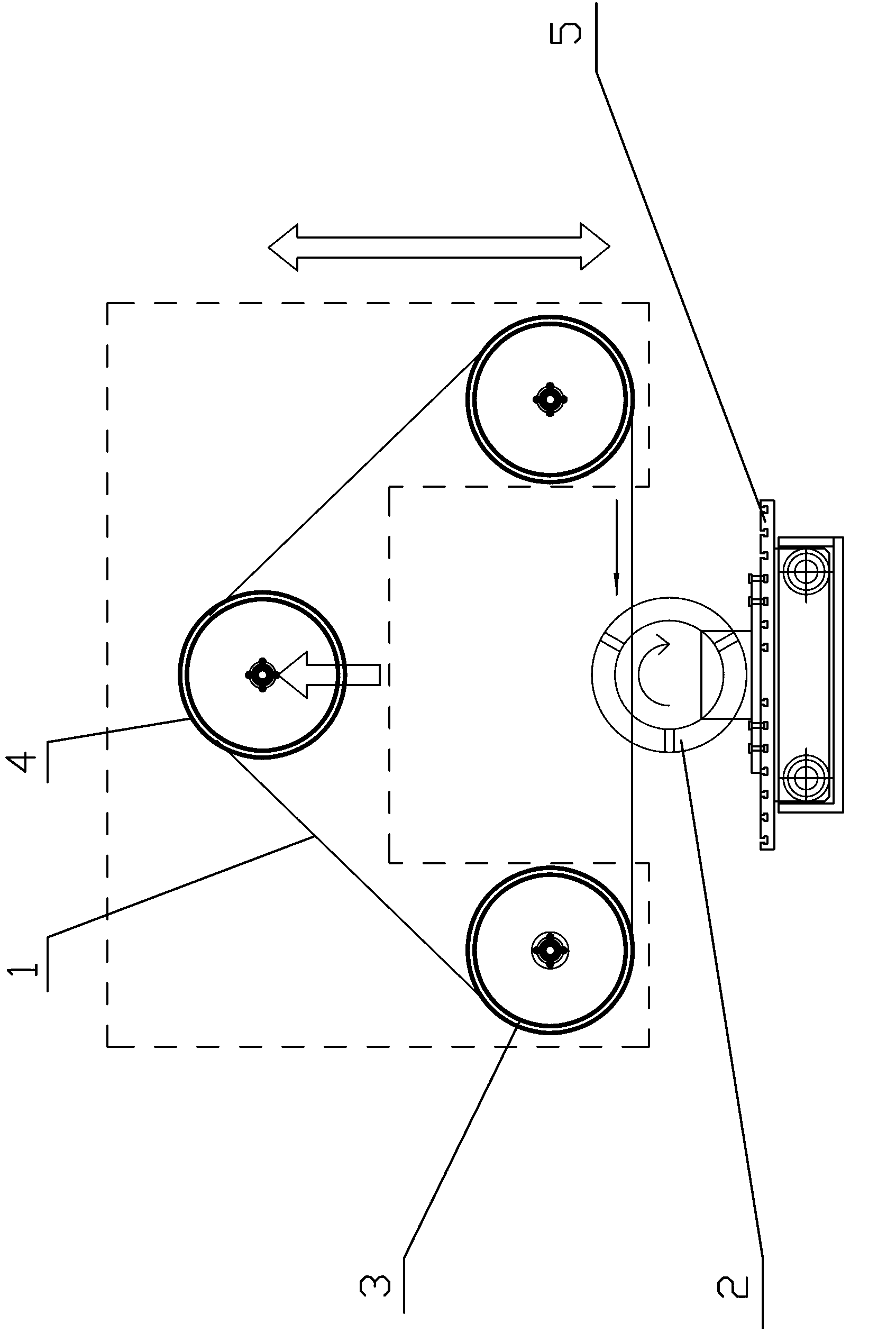

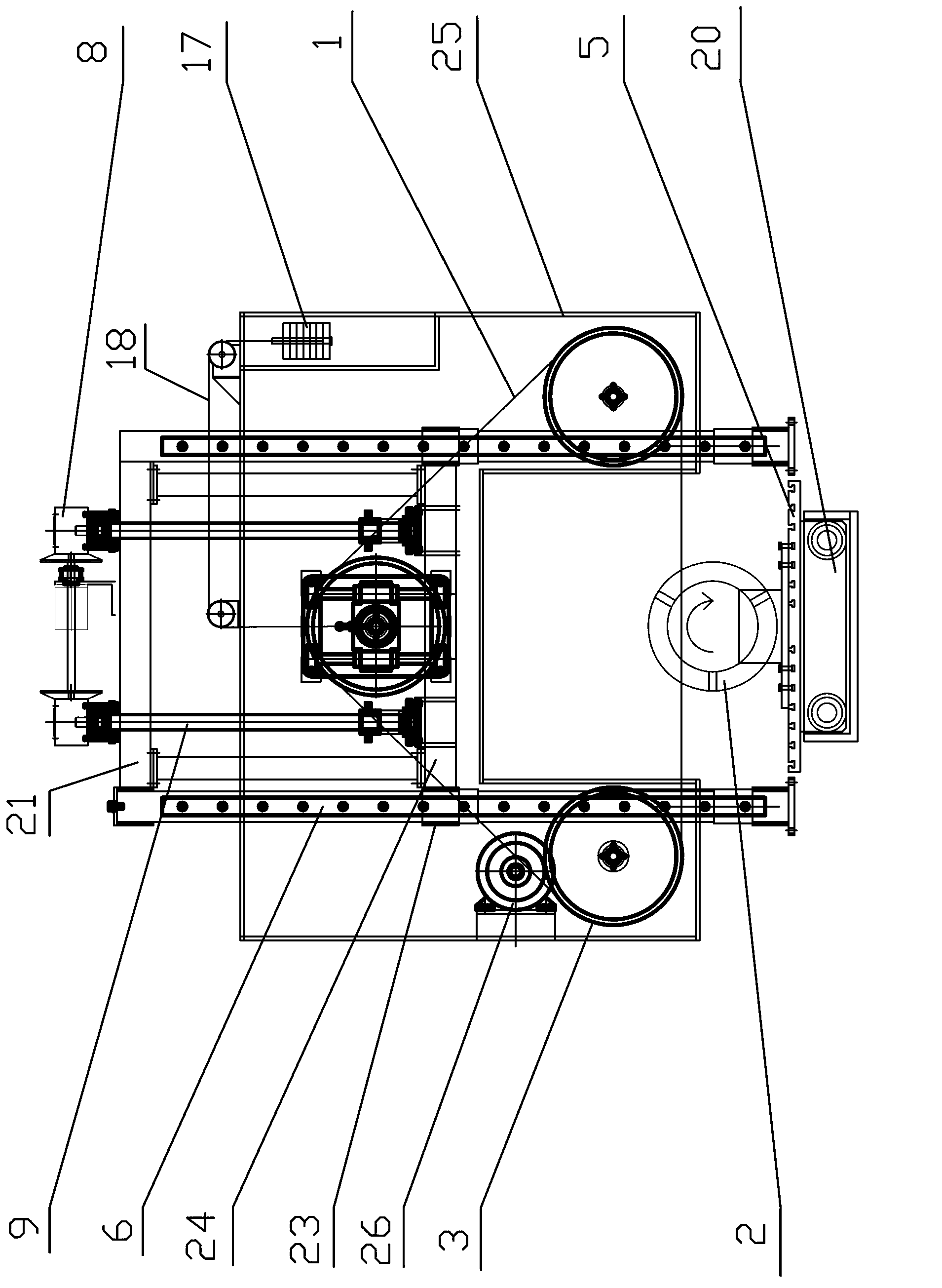

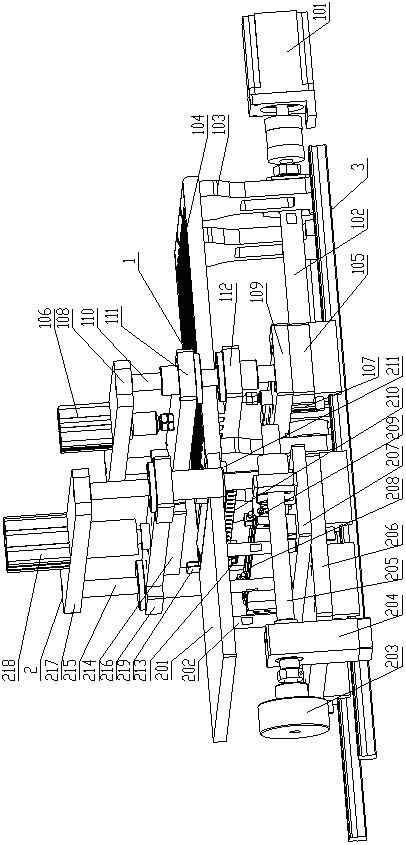

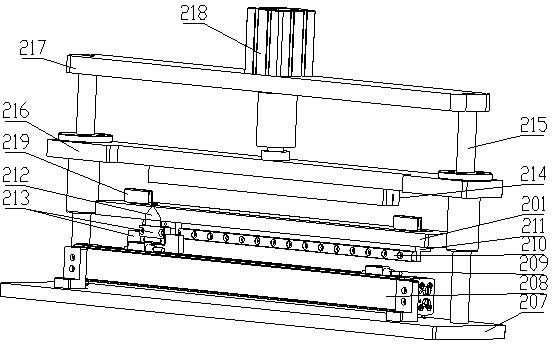

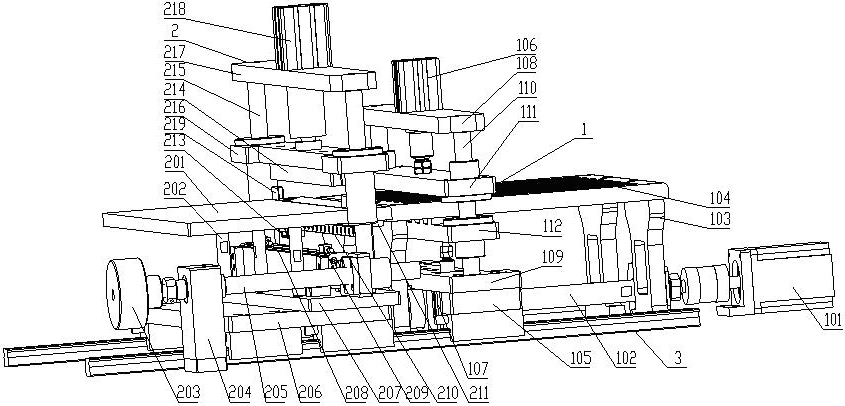

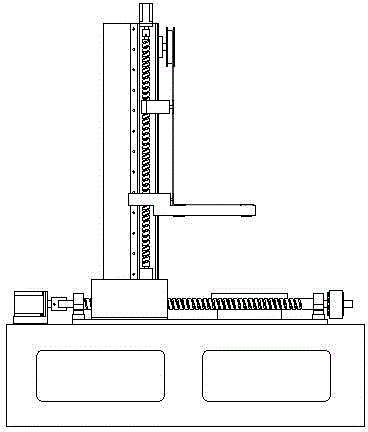

Silicon rod squarer

InactiveCN105818285AReduce labor costsIncrease productivityWorking accessoriesFine working devicesWire cuttingIngot

The invention provides a silicon rod squaring machine, comprising: a machine base with a square cutting area; a bearing platform arranged on the machine base and located in the square cutting area for carrying vertically placed silicon rods; The wire cutting equipment on the machine base includes: a cutting frame, which is arranged on the machine base and adjacent to the bearing table; The cut lines that form the cut line mesh. Compared with the prior art, the silicon ingot squaring machine of the present invention uses the supporting platform to carry the vertically placed silicon ingots, and cuts the silicon ingots below in a straight line through the wire cutting equipment, which can realize automatic cutting and complete the silicon ingot squaring operation. Save labor cost and improve production efficiency.

Owner:TDG NISSIN PRECISION MACHINERY CO LTD

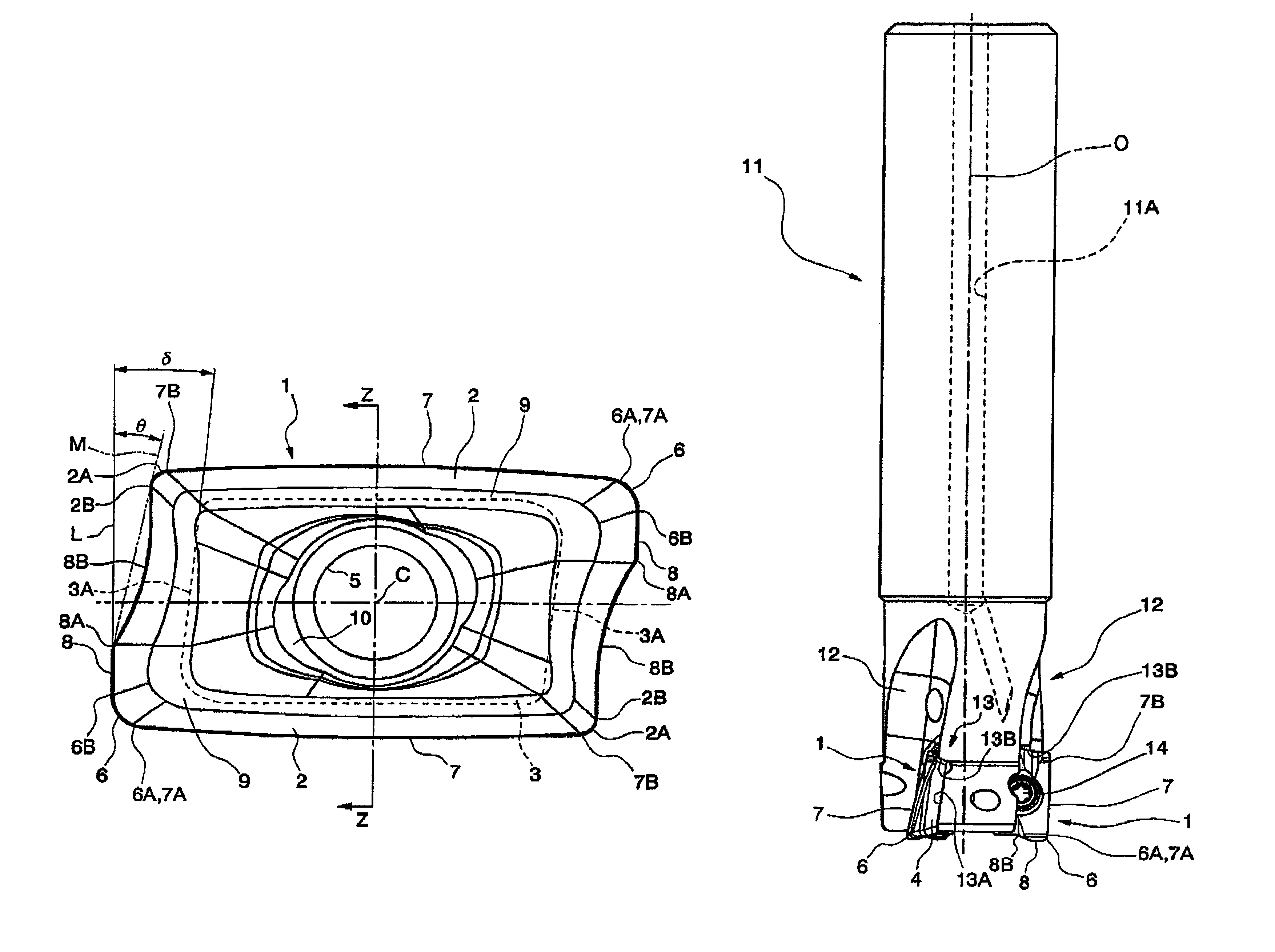

Throwaway insert and throwaway-type rotary cutting tool

ActiveUS7040844B1Improve accuracyImprove chip separationMilling cuttersAdverse effect compensationProjection lineCurve line

A tool main cutting edge extends rearward in a rotating direction as it approaches a rear end at the outer periphery. The main cutting edge is a convexly curved line protruding toward the outside of a rake face viewed from the top and another convexly curved line extending toward the seat face, convexly curving from one end of the main cutting edge to the other, viewed from the side. When mounted, an inclination angle defined by the rake face gradually decreases from one end toward the other, and a projection line of a rotation about a rotation axis of the tool forms a convex arc smoothly coming, at a middle portion of the main cutting edge, into contact with a cylindrical surface about the axis and gradually retreats inward from the cylindrical surface as it approaches both ends of the main cutting edge.

Owner:MITSUBISHI MATERIALS CORP

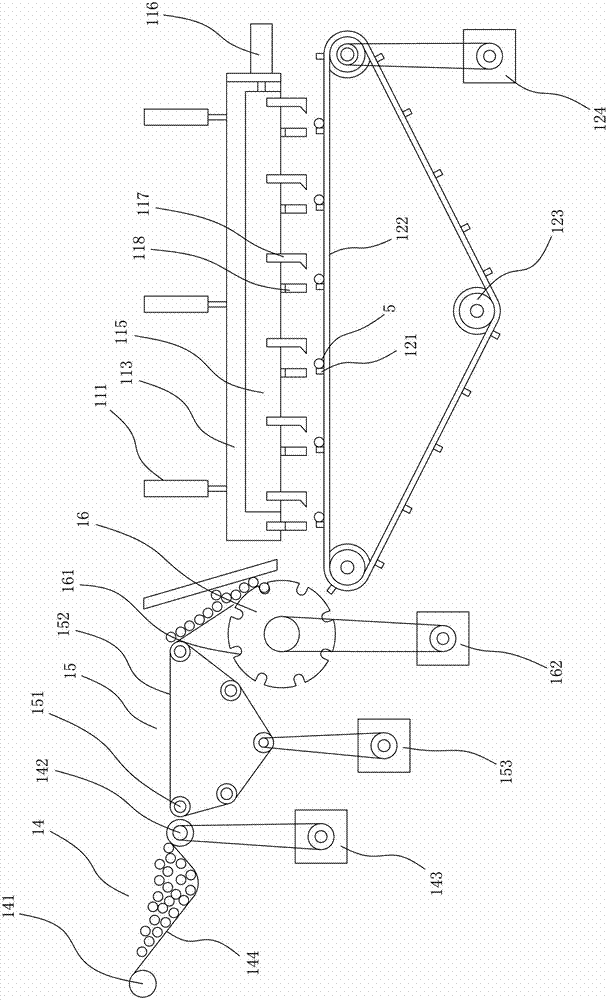

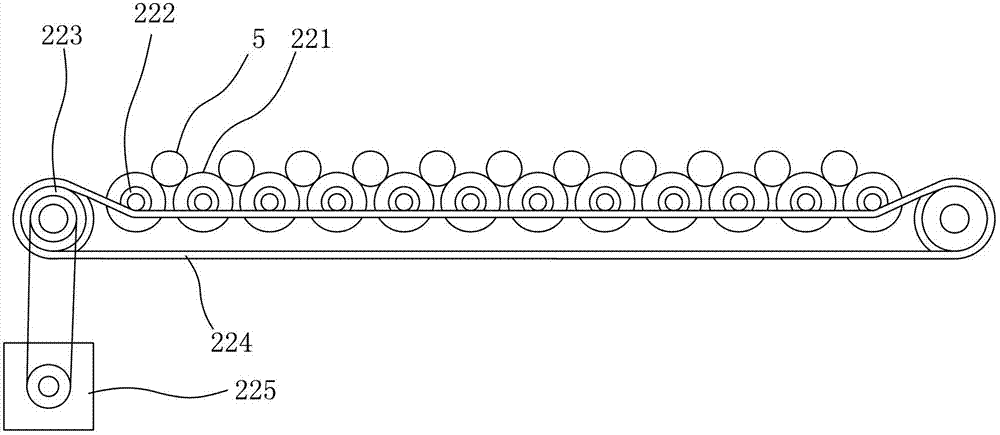

Full-automatic pipe cutting machine

ActiveCN102814547ARealize automatic controlPrecise deliveryMetal sawing devicesCircular sawEngineering

The invention provides a full-automatic pipe cutting machine comprising a frame, and a charging device, a feeding device, a cutting device, a measuring device and a control device which are sequentially arranged on the frame horizontally; the cutting device comprises a cutter holder which is arranged on the frame, a plurality of first motors which are lined horizontally along a longitudinal direction and can be arranged on the cutter holder by moving up and down, a first cylinder which is connected with and drives each first motor to move up and down synchronously, a circular saw blade which is arranged on the output shaft of each first motor, a second motor which is in transmission connection with the input shaft of each first motor through a first transmission mechanism, and a bearing piece which is arranged on the tool rest below each circular saw blade and is used for bearing a pipe at a cut part; and the measuring device comprises a guide rail which is horizontally arranged on the frame, a slide frame which is movably arranged on the guide rail, a driving mechanism which is connected with and drives the slide frame to move along the guide rail, a pipe baffle which is arranged on the slide frame and a first pipe clamping mechanism which is horizontally arranged on the slide frame along the longitudinal direction. According to the full-automatic pipe cutting machine, more than one pipe can be cut at one time, and the machine has the advantages of high cutting efficiency, good cutting quality and the like.

Owner:冠达星股份有限公司

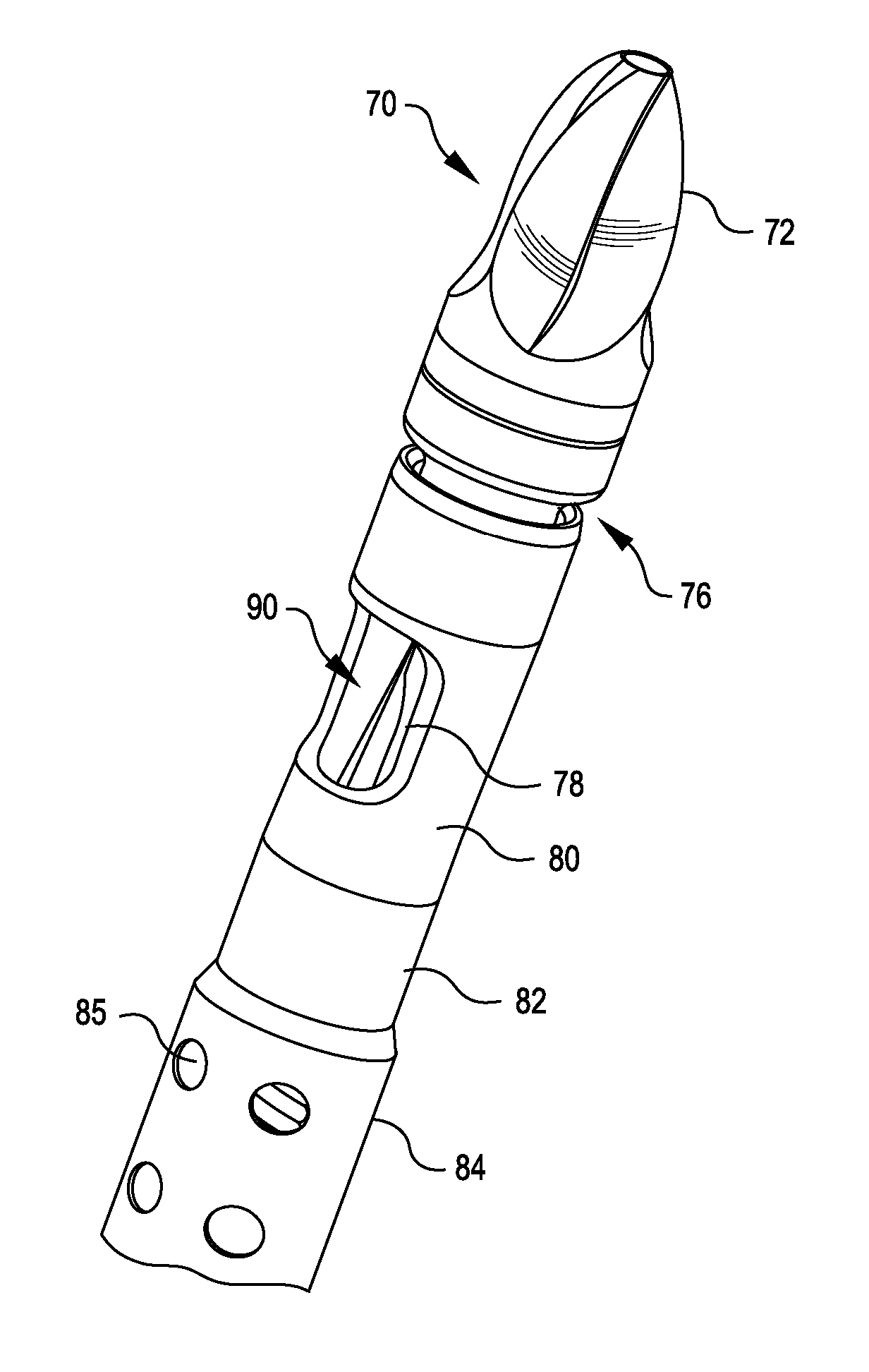

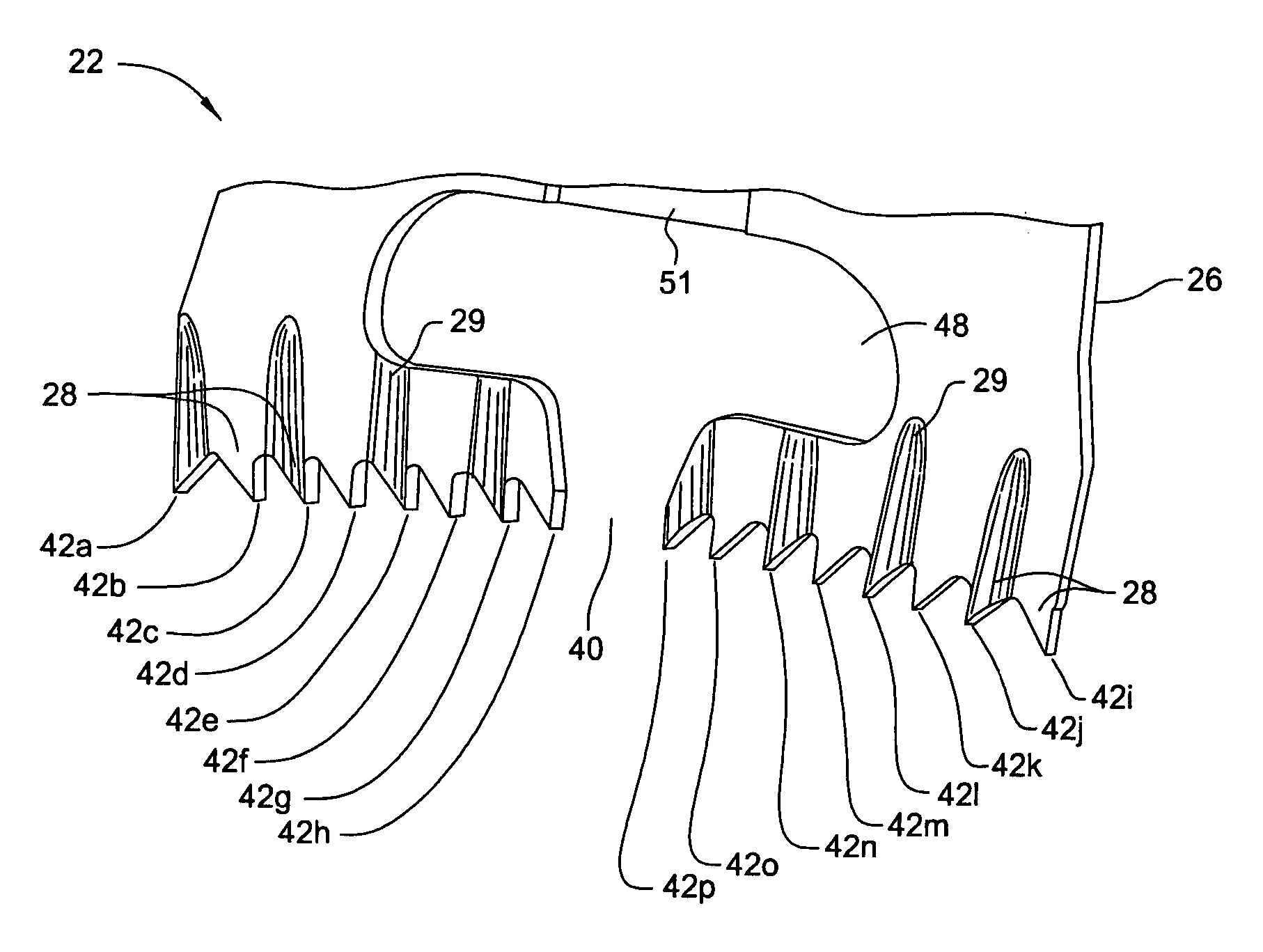

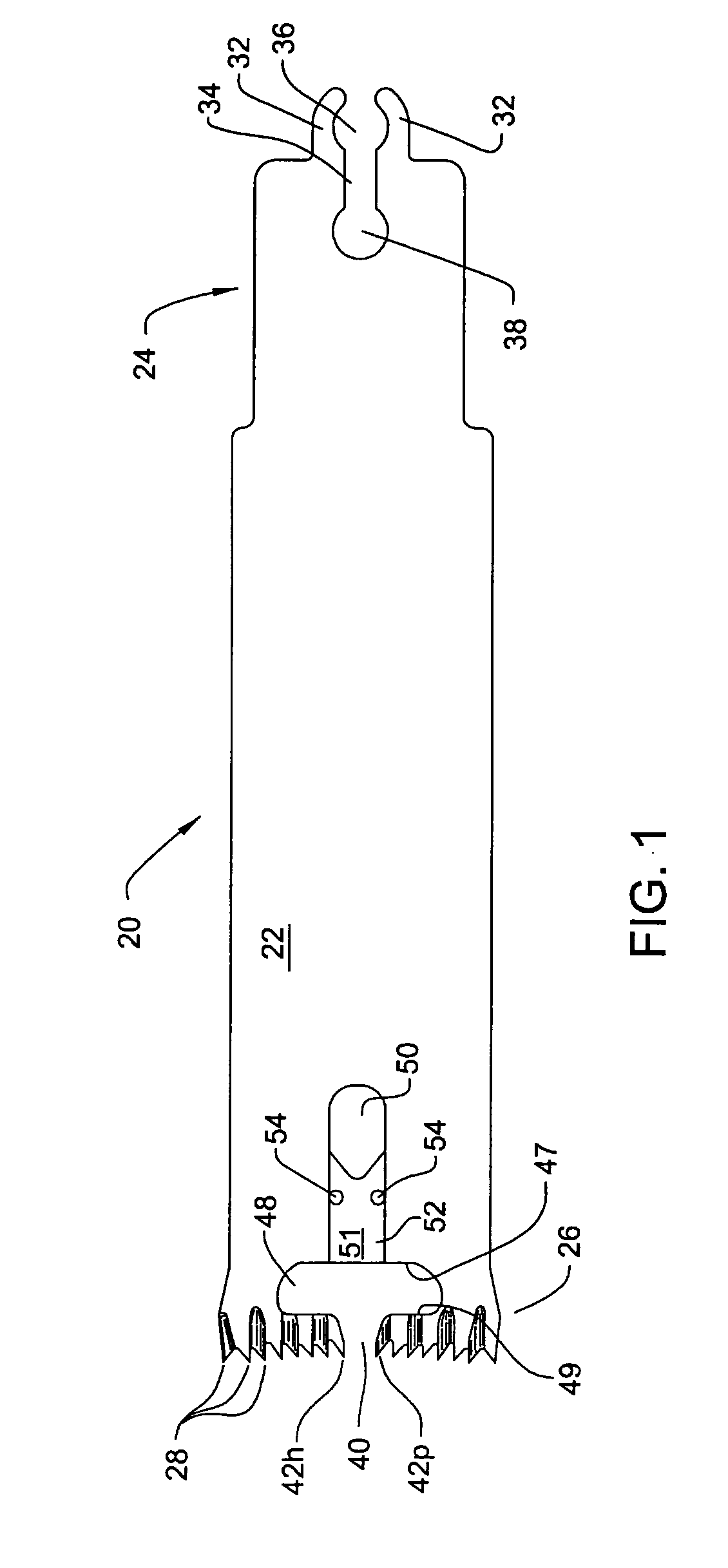

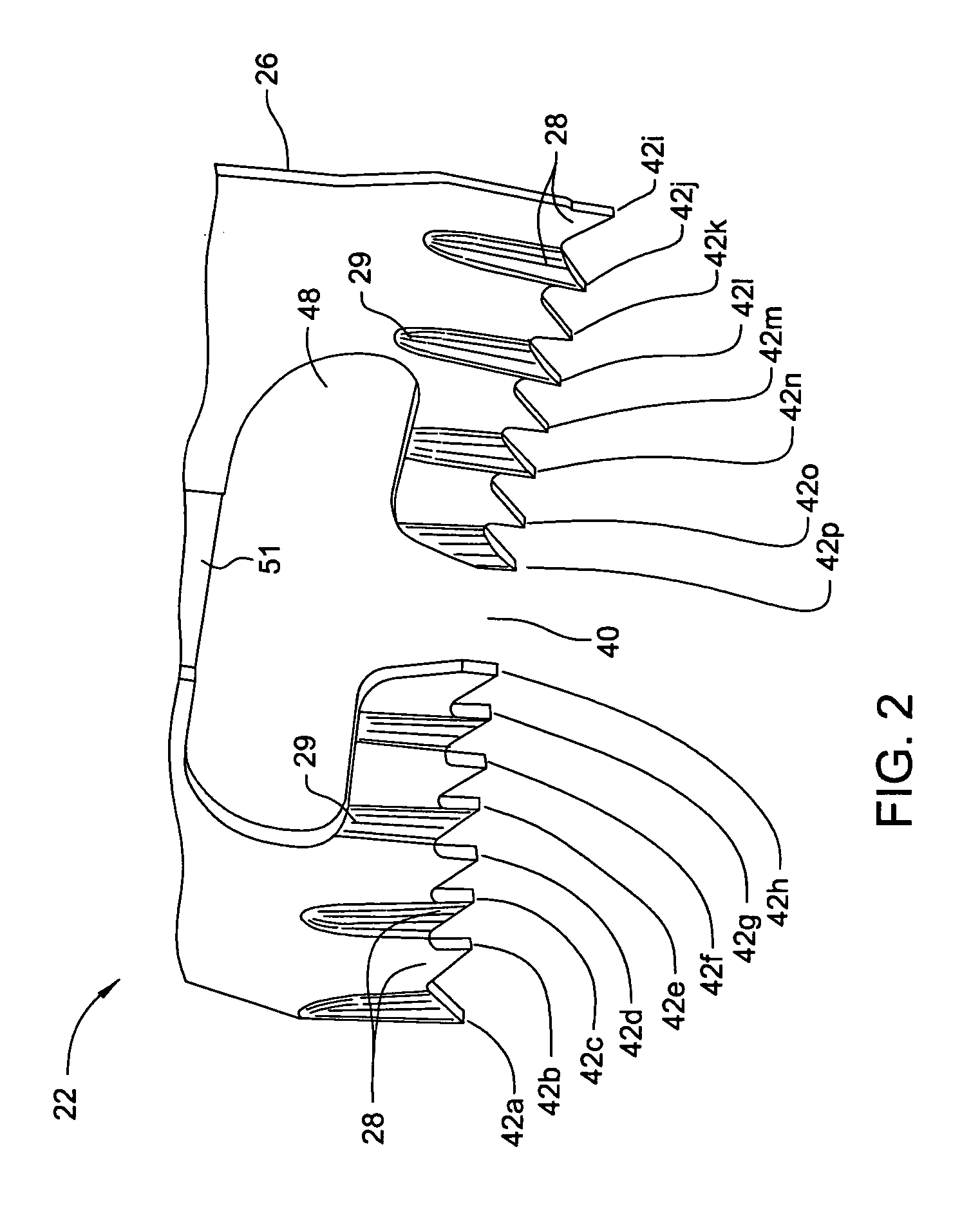

Surgical sagittal saw blade with angled teeth and chip catchment and reciprocating saw blade with broached teeth

A sagittal saw blade wherein the teeth are arranged so that relative to the teeth located closer to the outer sides of the blade, the inner located teeth are located closer to the proximal end of the blade. The blade is further formed to have an opening between at least two of the teeth that extends proximally rearward. The opening increases in width as the opening extends proximally along the length of the blade. The opening opens into a void space that functions as a chip catchment space.

Owner:STRYKER EURO OPERATIONS HLDG LLC

Surgical snare

ActiveUS20170231647A1Improve cutting efficiencyGood effectExcision instrumentsCombined useEngineering

Embodiments of the invention provide a surgical snare structure in which the material used for the snare and the deployment mechanism of the snare are configured to improve the cutting efficacy of the snare. In particular, the surgical snare structure of the invention may omit the kink or nib present in the loop of known surgical snares and / or may provide a reaction surface against which the cutting action of the snare is effective. The surgical snare of the invention may be a cold, i.e. mechanical-only effect, snare, or may be used in conjunction with radiofrequency (RF) and / or microwave energy to enhance a cutting or coagulation effect.

Owner:CREO MEDICAL LTD

On-site land mine removal system

InactiveUS20090223355A1Reduced effectivenessReduce eliminateDefensive equipmentDefence devicesLiquid jetDetonation

A method of deactivating land mines buried in ground comprises projecting high-pressure water jets into ground, cutting through ground with the high-pressure water jets, and making at least one cut through a land mine or cutting through at least one land mine that had been under the ground, the cutting of the land mine reducing the performance of the land mine. The method may reduce the performance of the land mine by rendering the land mine inactive to normal detonation procedures for the land mine. To reach as many surface areas on the buried landmines, it is preferable that at least two high-pressure water jets are spaced apart are used to cut through the ground. The method may be practiced with the high-pressure water jet being carried on a vehicle and cutting is done in a line that is formed at least in part by movement of the vehicle over the ground while the high-pressure water jet is cutting ground. An apparatus for the reduction in effectiveness of land mines buried in ground may comprise a self-contained push-cart unit or a unit attached or attachable to a vehicle. A complete system could comprise a vehicle having a source of liquid, a high-pressure pump to move the liquid under high pressure, a nozzle directing a liquid jet path for the liquid, a support for the nozzle, abrasive delivery system, and nozzle being controllable to direct the liquid towards the ground while the nozzle is fixed relative to the vehicle.

Owner:MANDERS STEPHEN M

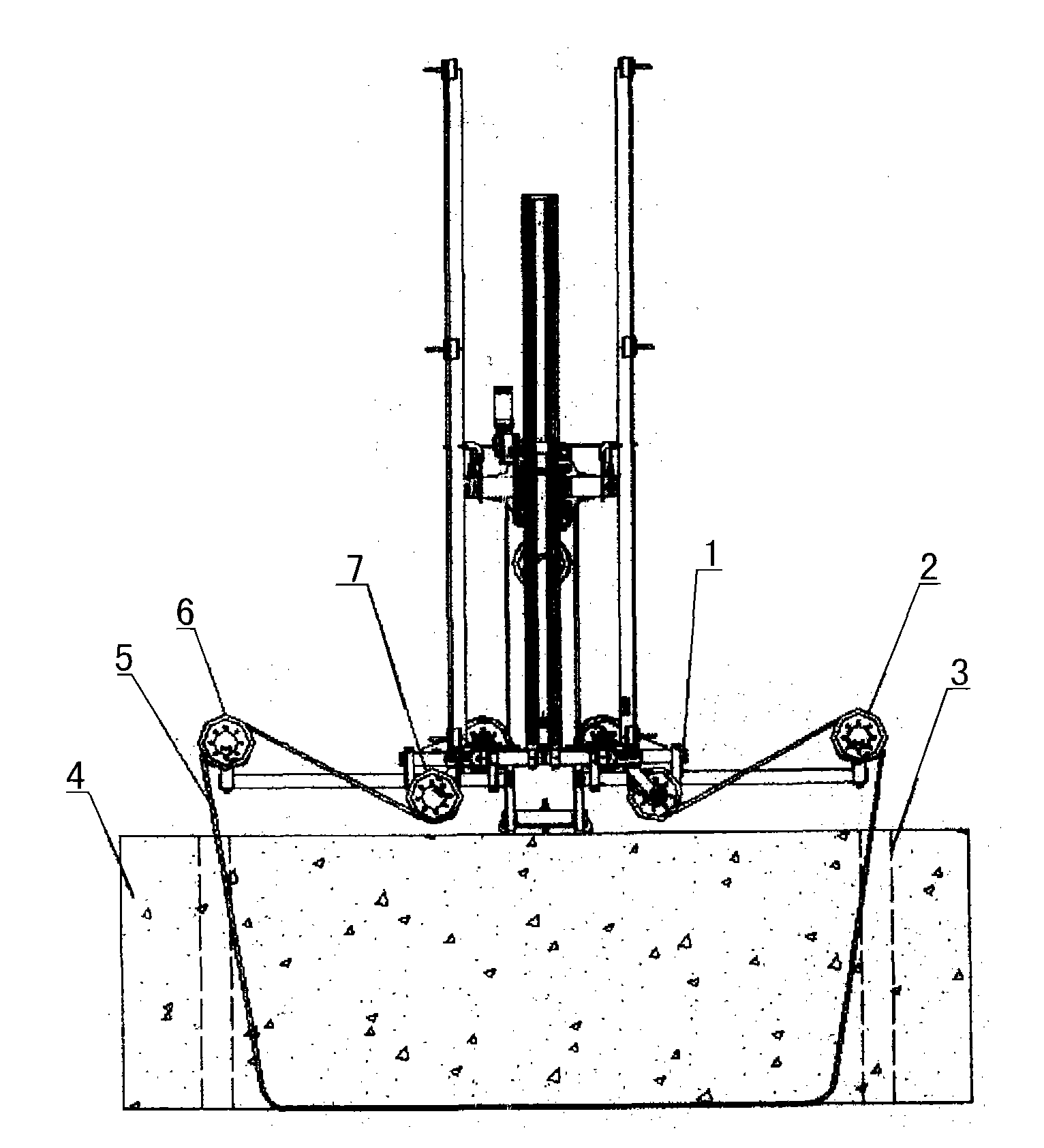

Diamond rope saw static force cutting method

InactiveCN101768926AImprove cutting efficiencySimple construction processBuilding repairsGrinding machinesHydraulic motorReinforced concrete

The invention provides a diamond rope saw static force cutting method, relating to a diamond cutting method. In the invention, an adopted hydraulic pressure diamond rope saw is driven by an hydraulic motor to move at a high speed around the cut surface of a cutting object (4) so as to cut the cutting object (4); the grinding material of diamond rope saw (5) is diamond particles, so the diamond rope saw can be used for cutting stone, reinforced concrete or other hard materials; the power source of the cutting is the hydraulic motor, a hydraulic pump is driven by the hydraulic motor to operate smoothly; and the hydraulic motor can be distantly controlled by a high-pressure oil pipe to reduce vibration and noise in cutting process and enable the cutting object (4) is cut and separated stably. The invention has the advantages of high safety and efficiency and environment protection.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

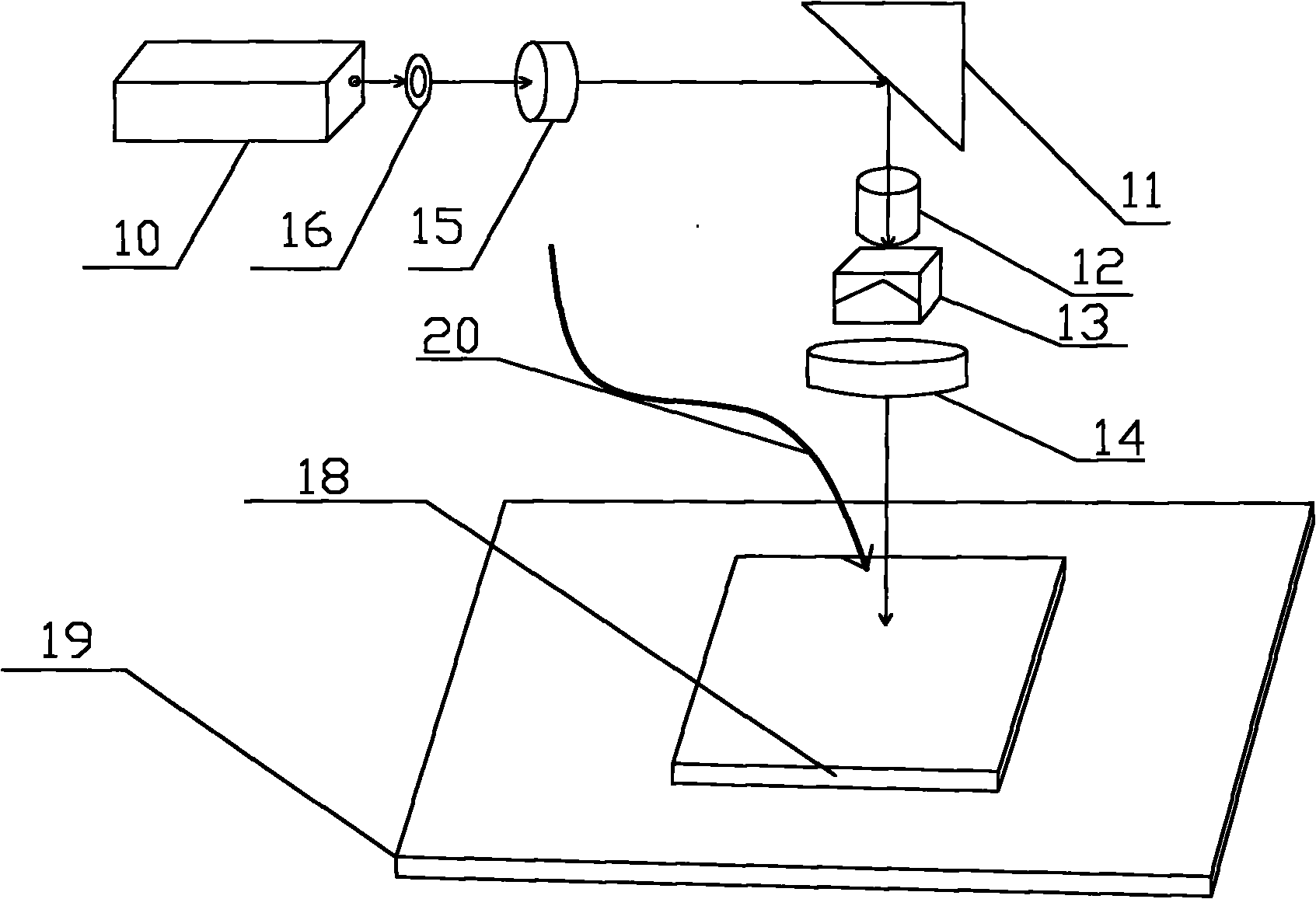

Device and method for abnormally cutting toughened glass by ultra-short pulse laser

InactiveCN102248302AImprove smoothnessImprove cutting efficiencyLaser beam welding apparatusBeam expanderSlag

The invention relates to a device and method for abnormally cutting a toughened glass by ultra-short pulse laser. An output end of an ultra-short pulse laser apparatus is provided with an optical gate, an output end of the optical gate is provided with a beam expander, an output end of the beam expander is provided with a 45-degree holophote, an output end of the 45-degree holophote is provided with a three-dimensional (3D) dynamical focusing system, an output end of the 3D dynamical focusing system is provided with a telecentric field lens which is arranged facing to a platform above which a blowing device is arranged. When the ultra-short pulse laser device is used to cut, a heating device is used for heating the glass; the ultra-short pulse laser is focused in the glass by the 3D dynamical focusing system to abnormally scan the glass along with the laser, and the whole processing procedure is in helical processing; a suction dust-collecting device at the bottom of the platform is used for collecting the scanned glass slag; and the blowing device on the platform is used for blowing the slag and dust particles processed on the surface of the glass. The abnormal graph processing to the toughened glass is a processing form with smooth cutting surface and high cutting efficiency.

Owner:SUZHOU DELPHI LASER

Endoscopic cutting instrument with axial and rotary motion

InactiveUS7666200B2Improve cutting efficiencyIncrease relative motionExcision instrumentsEndoscopic cutting instrumentsEngineeringEndoscope

Owner:TARGET MEDICAL INNOVATIONS

Coal seam reaming system using three-dimensional (3D) swirling water jet and reaming and fracturing method for permeability enhancement

InactiveCN102213077AEasy to crackLarge range of pressure reliefDrill bitsConstructionsHydraulic pumpHigh pressure water

The invention relates to coalmine gas extraction and permeability enhancement equipment and technology, and discloses a coal seam reaming system using three-dimensional (3D) swirling water jet. The system is connected to a high-pressure rotary joint through a high-pressure hose provided with a stop valve by virtue of a high-pressure hydraulic pump station and is characterized by being connected to a high-pressure water jet drill stem through a drilling machine, wherein the front end of the high-pressure water jet drill stem is connected with a high-pressure water jet head with nozzle bases; and high-pressure swirling water jet nozzles are arranged on the nozzle bases. The invention further discloses a coal seam reaming and fracturing method for permeability enhancement using the 3D swirling water jet. In the coal seam reaming method using the 3D swirling water jet, coal is sheared so as to lower the hydraulic pressure loss, improve the cutting efficiency and increase the cracks and bore diameter of the coal; high-pressure water is injected so as to fracture the coal between a hydraulic reamed hole and control bored holes; and a coal seam is fully depressurized within a large range so as to shorten the pre-extraction time of the coal seam.

Owner:CCTEG SHENYANG RES INST +1

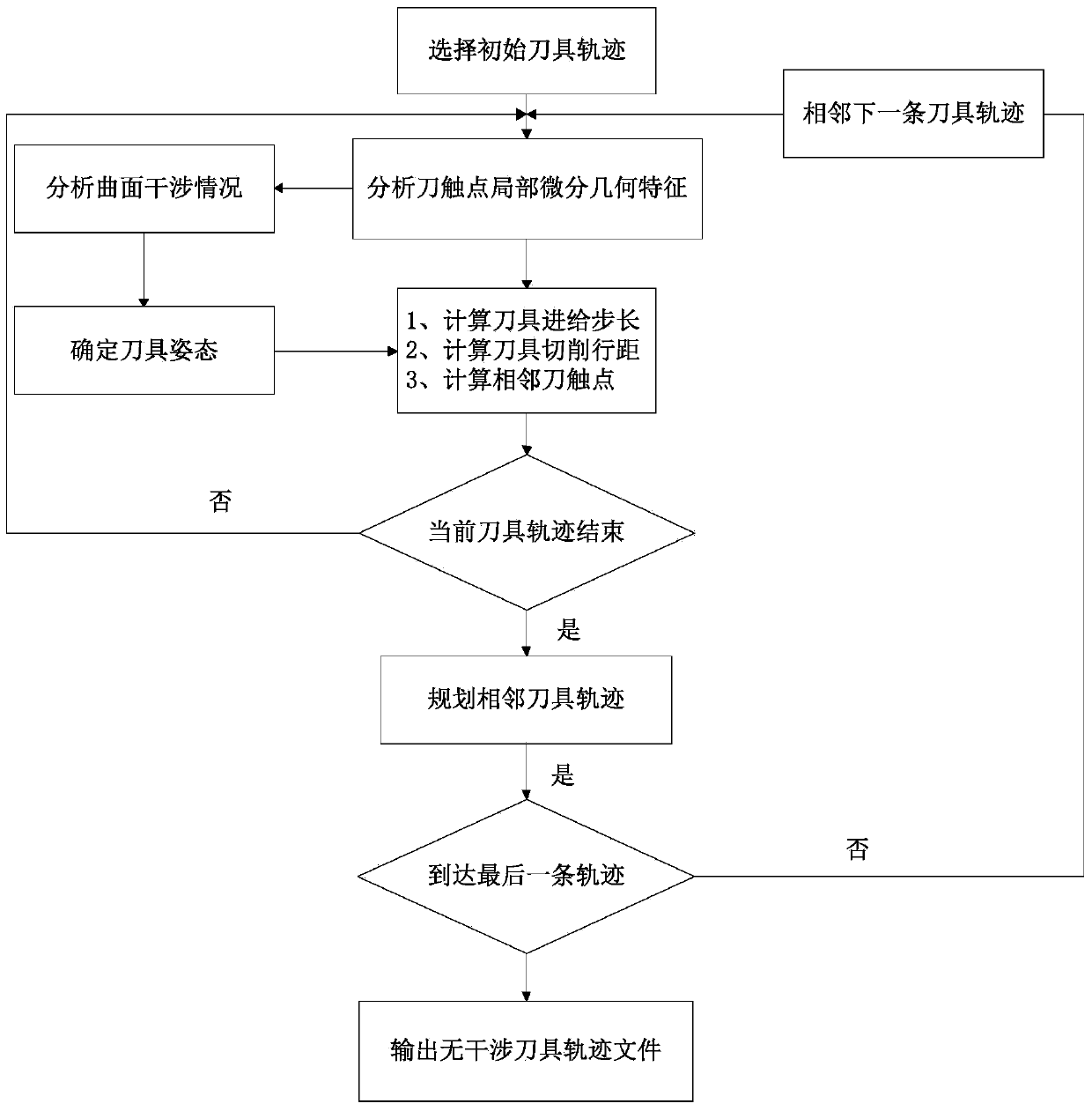

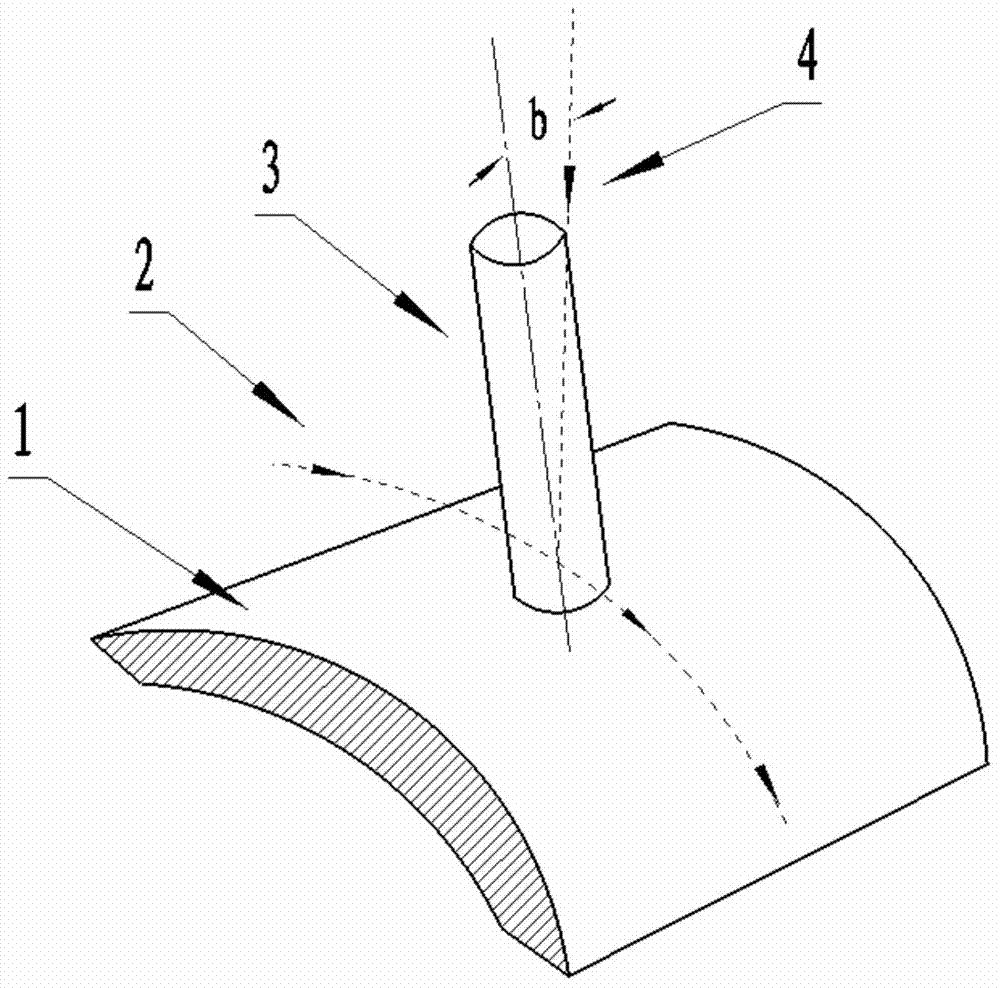

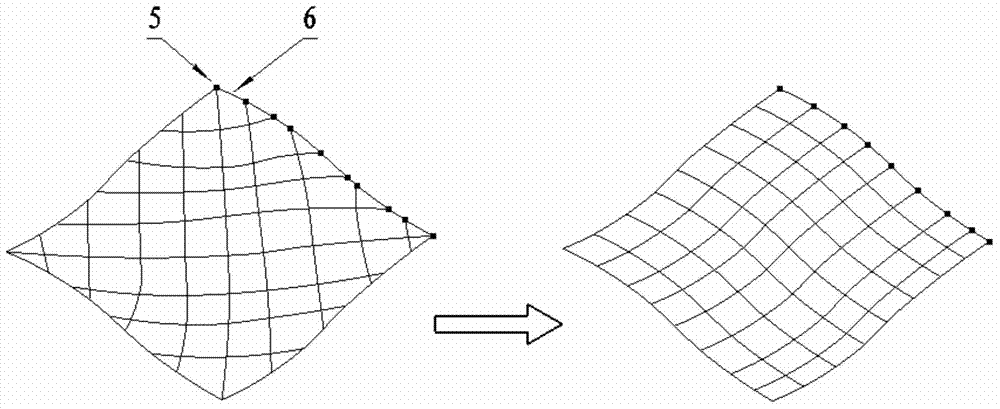

Interference-free tool path generation method in machining of transitional surfaces by flat-end milling cutter

InactiveCN103744349AImprove processing efficiencyReduce surface roughnessNumerical controlMilling cutterPath generation

The invention discloses a method for generating interference-free flat-end milling cutter process path along the ridge direction of transitional surfaces. The method comprises the following steps: (1) initial machining tool path is set, a tool is processing along the ridges of transitional surfaces, a current tool contact is calculated to obtain effective curvature of the machining tool at the tool contact; (2) curvature interference analysis of transitional surface machining is carried out according to the effective curvature of the machining tool at the tool contact, tool bottom interference is analyzed, and the angle of the tool is deflected at the tool contact to obtain interference-free tool posture; (3) parameter calculation is carried out on the adjusted tool path so as to obtain step-length and cut row distance; and (4) adjacent tool path lines are calculated, including calculation of adjacent tool contacts and calculation of tool location data, and interference-free tool path is finally obtained. By the method, automatic planning of interference-free tool path can be realized; large cut row distance is obtained; cutting efficiency is high; machining surface roughness is low; surface fairness is good; and problems of low cutting efficiency, poor machining surface quality and the like by machining of a ball-end milling cutter are solved.

Owner:HUAZHONG UNIV OF SCI & TECH

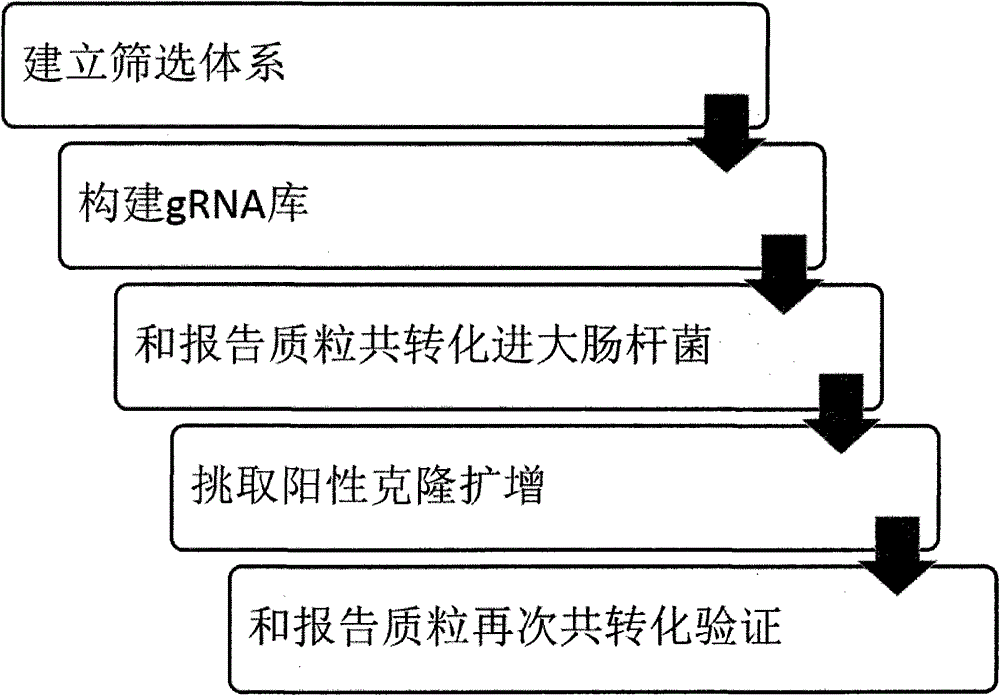

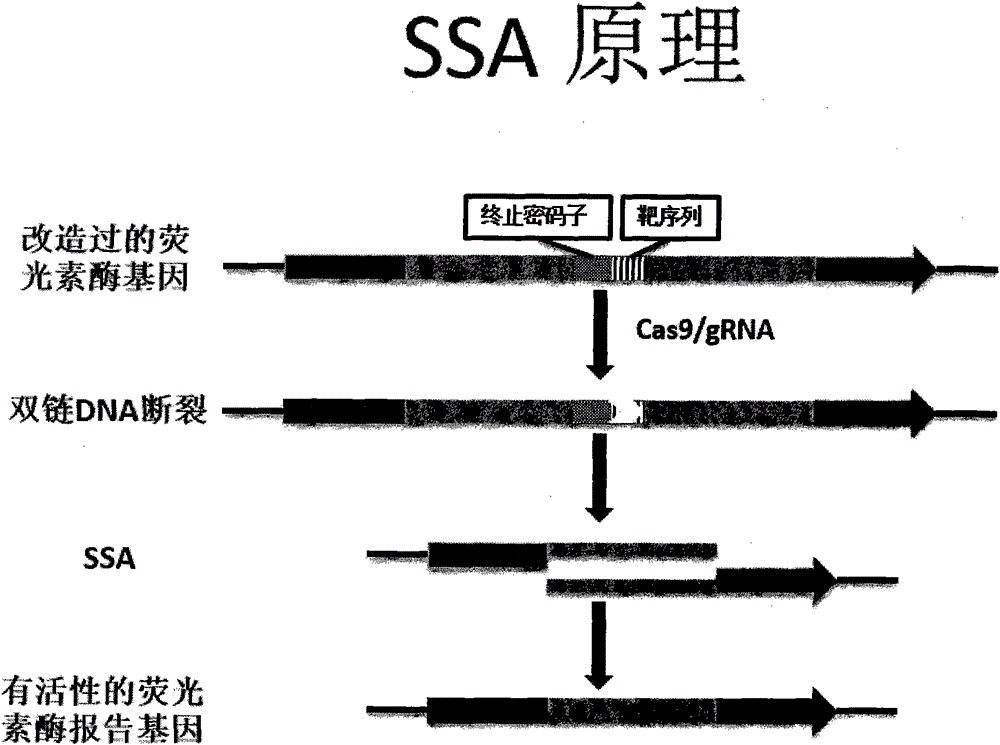

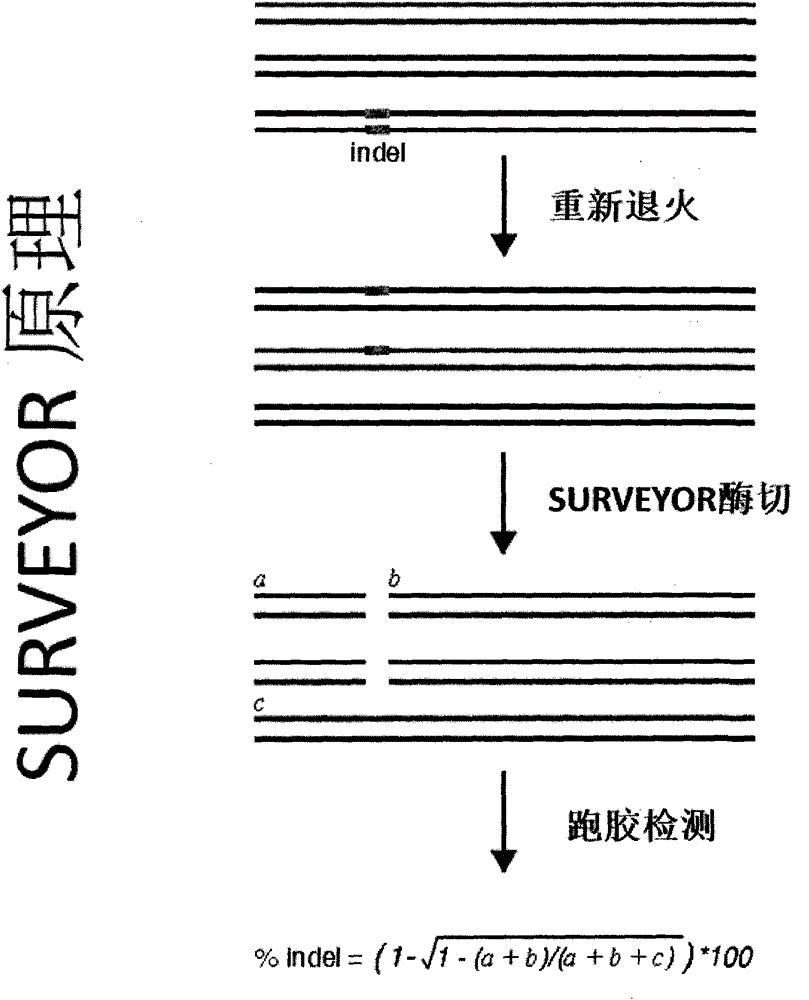

Design, synthesis and use of RNA molecule for high-efficiency genome editing

InactiveCN104805078AImprove cutting efficiencyDNA preparationDNA/RNA fragmentationSelf protectionProkaryote

In prokaryote, a cas9 protein of a clustered regularly interspaced short palindromic repeals and CRISPR associated (CRISPR / Cas) system and two small RNAs (of crRNA and tracrRNA) can be combined and used for recognition and direct shearing of exogenous nucleic acid so that self-protection is realized. Scientists fully utilizes the above characteristic and utilizes cas9 and gRNA (which is a long RNA obtained by fusion of crRNA and tracrRNA) to shear a DNA sequence so that gene fixed point modification is realized. The existing Cas9 / gRNA has low target gene cutting efficiency generally of 5-30% and is limited in use. Through a high efficiency screening system, a series of gRNAs for improving Cas9 activity are selected.

Owner:PEKING UNIV

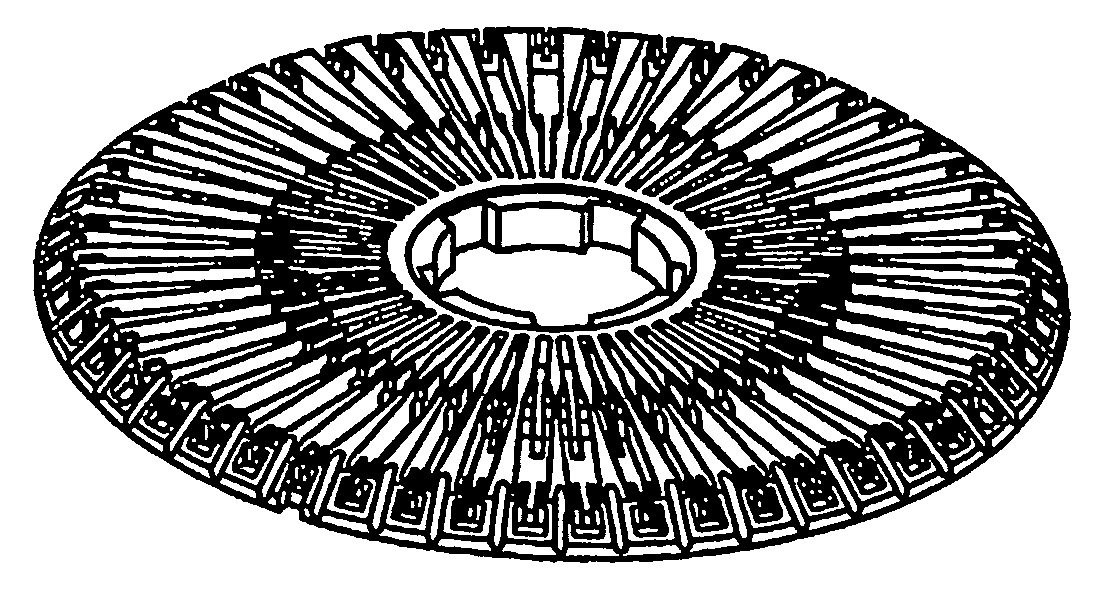

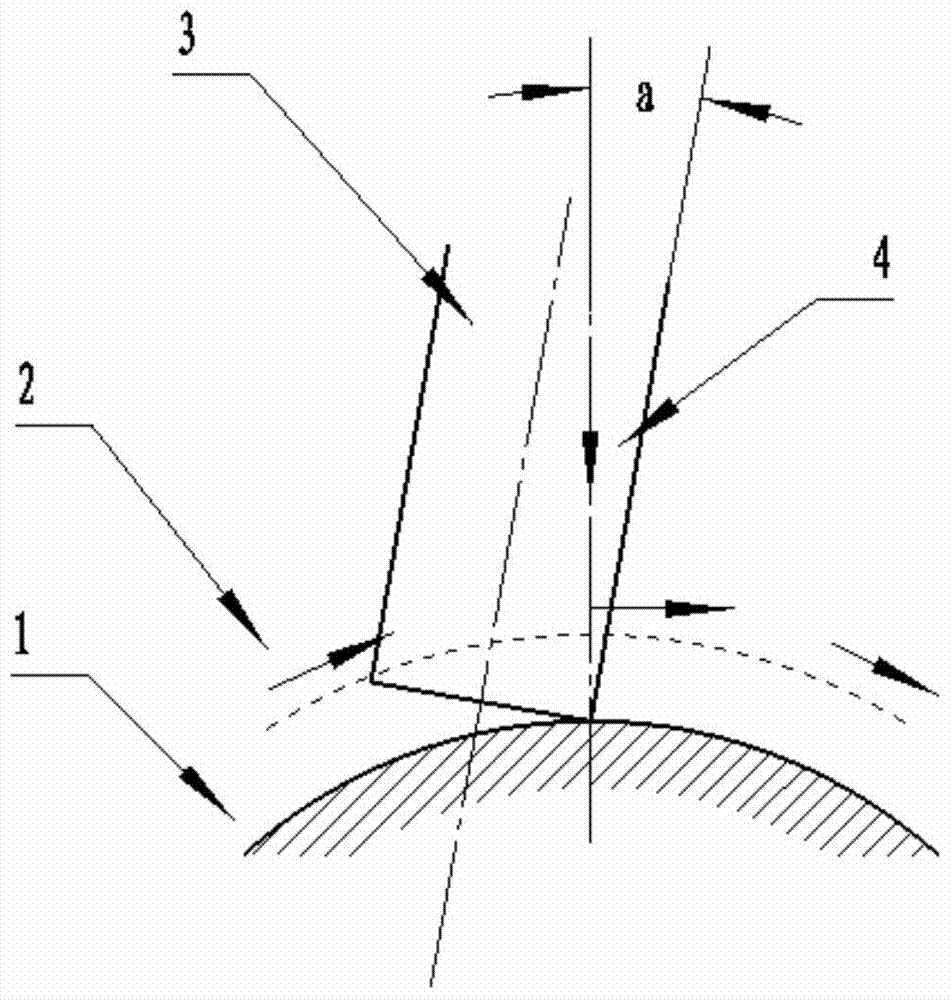

Diamond fretsaw cutting method and device

ActiveCN103302754AImprove cutting efficiencyFast cutting accuracyFine working devicesDiamond cuttingDrive wheel

The invention discloses a diamond fretsaw cutting method and device. An annular diamond fretsaw is used for cutting a crystal ingot workpiece; the annular diamond fretsaw surrounds a plurality of horizontal guide wheels and is tensioned by a tension mechanism; under the driving of one of the guide wheels, namely, a driving wheel, the annular diamond fretsaw operates at a high speed; under the driving of a lifting mechanism, the annular diamond fretsaw is fed to a crystal ingot cutting workpiece and retracts upward; and in a cutting process of the annular diamond fretsaw, the crystal ingot workpiece is driven by a rotary mechanism to rotate uni-directionally around a shaft of the workpiece. According to the method and the device, the annular diamond fretsaw has a higher linear speed; when a workpiece rotates uni-directionally and continuously, point contacting type cutting between the diamond fretsaw and the crystal ingot workpiece is realized; and diamond particles can be pressed into a cut material more easily, so that the device has a cutting efficiency about ten times of that of the ordinary fretsaw diamond cutting.

Owner:CHINA NONFERROUS METAL (GUILIN) GEOLOGY & MINING CO LTD

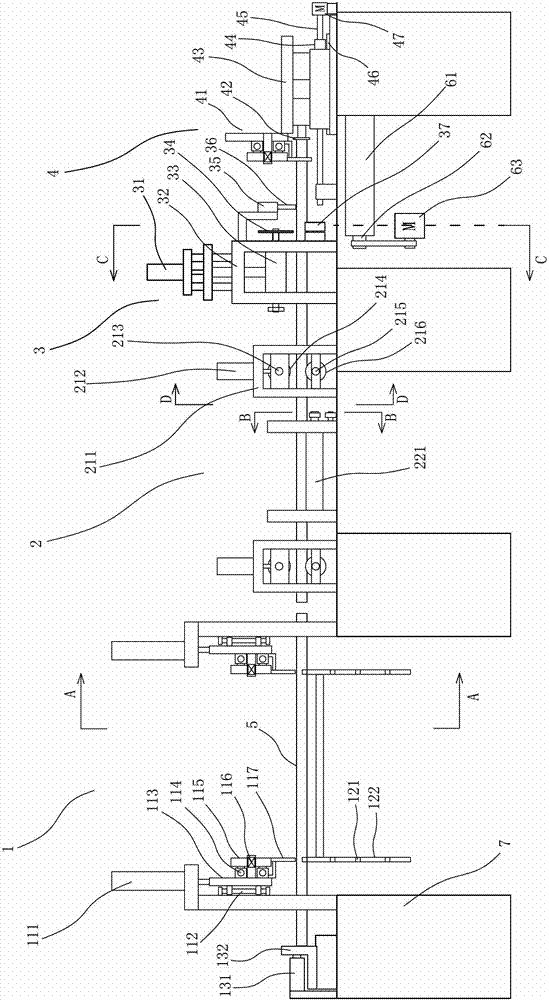

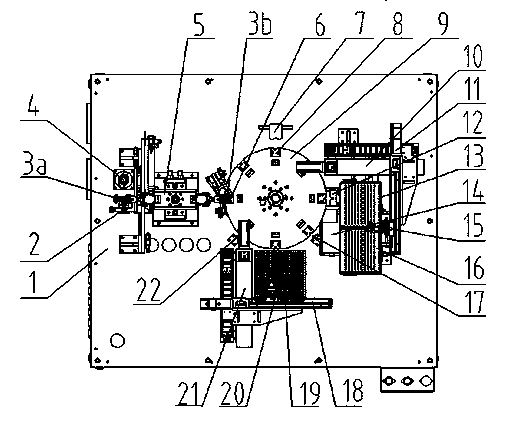

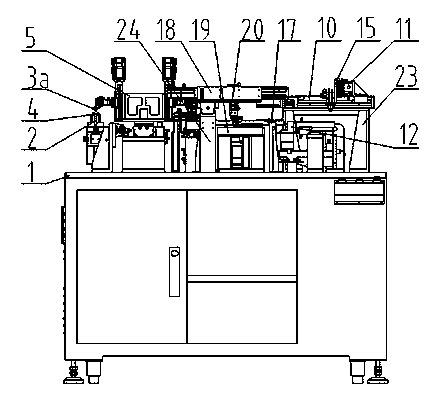

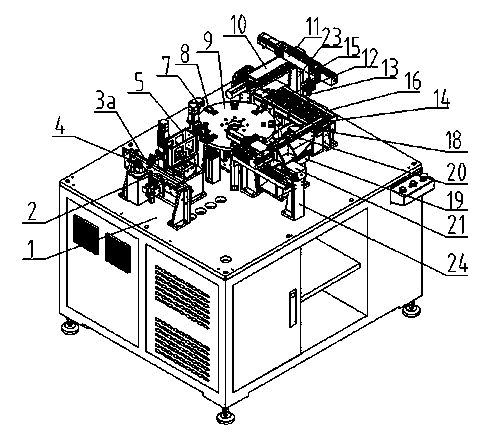

Optical sub-module detecting machine and detecting method

InactiveCN104280209ARealize full automationReduce labor costsOptical apparatus testingControl systemSemi automatic

The invention provides an optical sub-module detecting machine and detecting method. Through the detecting machine, optical sub-modules which include but are not limited to an optical transmitting sub-module and an optical receiving sub-module are fully automatically fed and detected, and good and bad products can be respectively discharged. The detecting machine comprises an optical fiber end face detecting and cleaning and optical fiber inserting and coupling mechanism, a full-automatic feeding mechanism, a feeding mechanism assembly, a discharging mechanism assembly, a high-accuracy station transferring mechanism (such as a rotating mechanism and a linear reciprocating conveying mechanism), a workbench, a control panel, a closed loop automatic detection control system, a human-machine conversion interface, a protecting cover and a fault alarming system. The optical sub-module detecting machine and detecting method make up for the blank in the field of full-automatic detection of optical sub-modules, and solve the problems that because of manual detection or semi-automatic detection, the detecting accuracy of parts to be detected is not high, the detecting efficiency is low, and the detecting cost is high.

Owner:WUHAN YIKE SIDE TECH

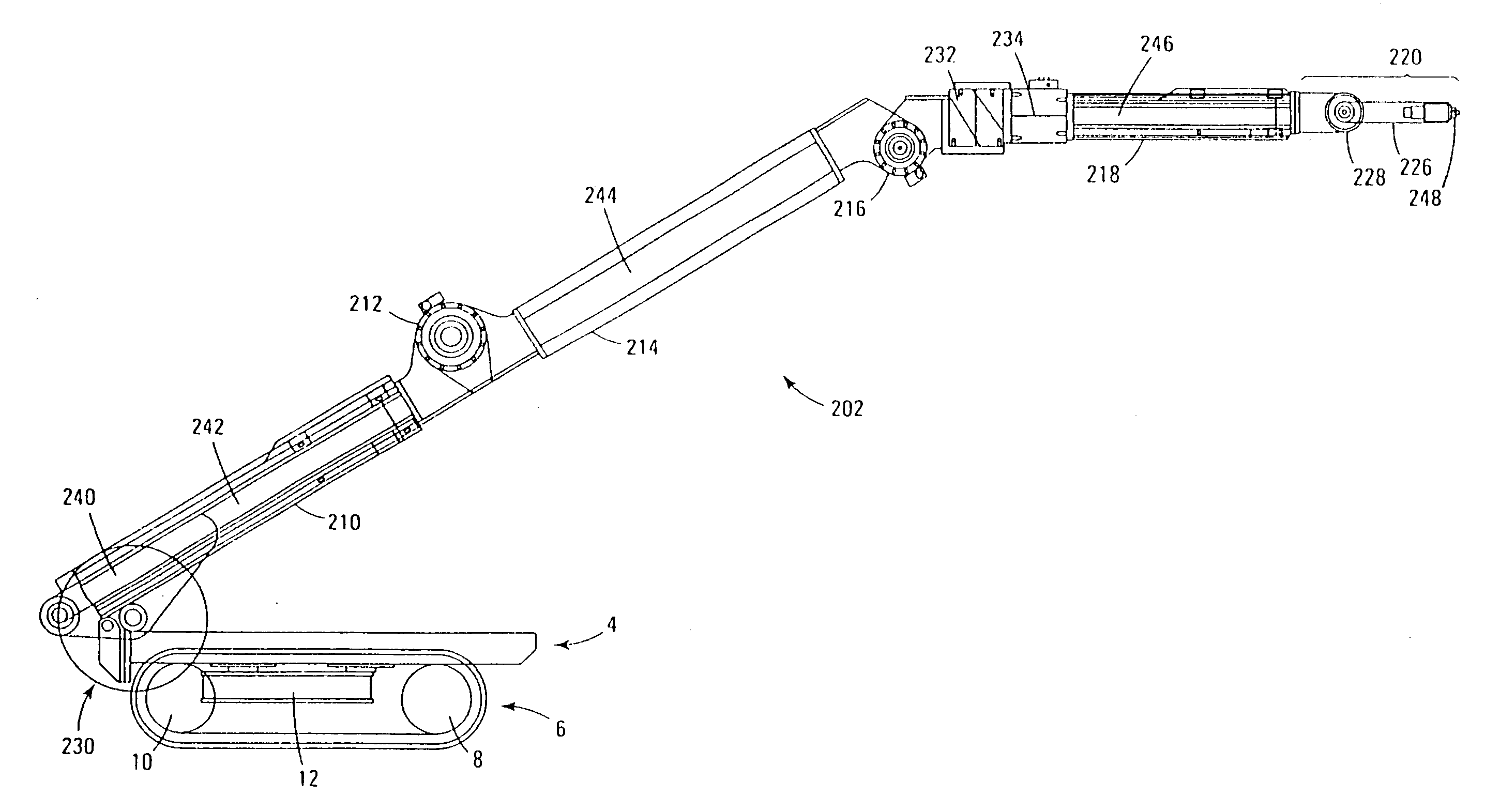

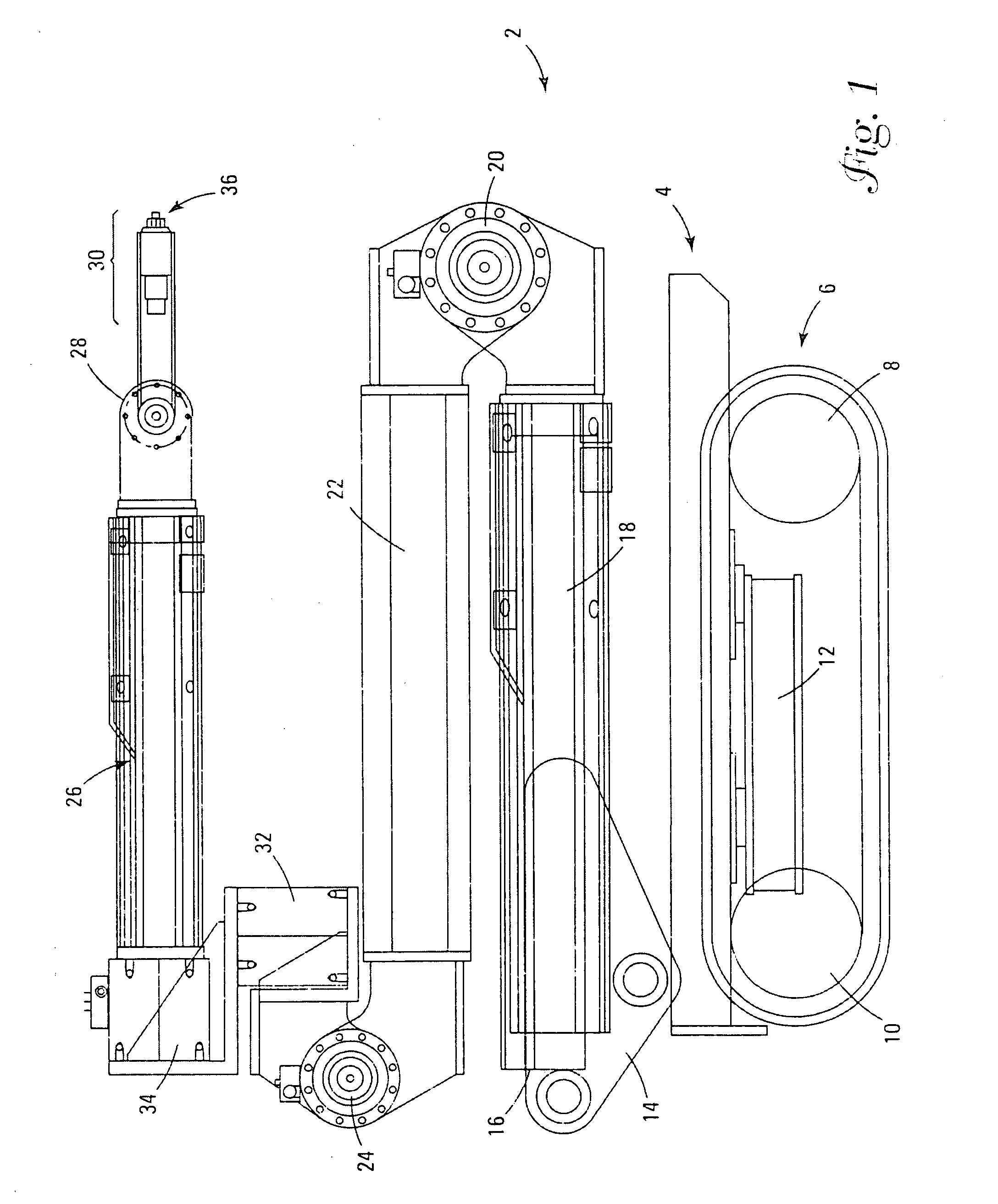

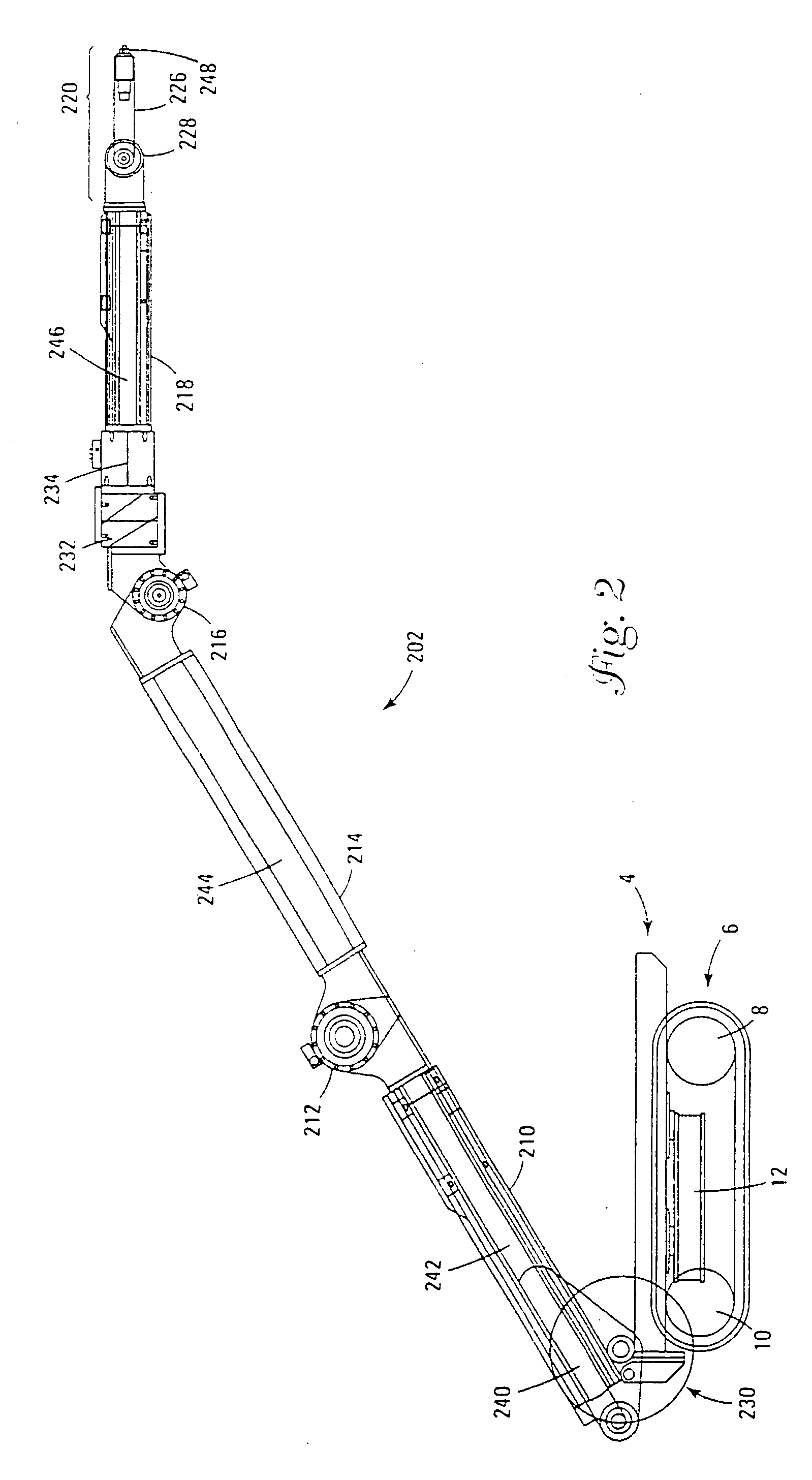

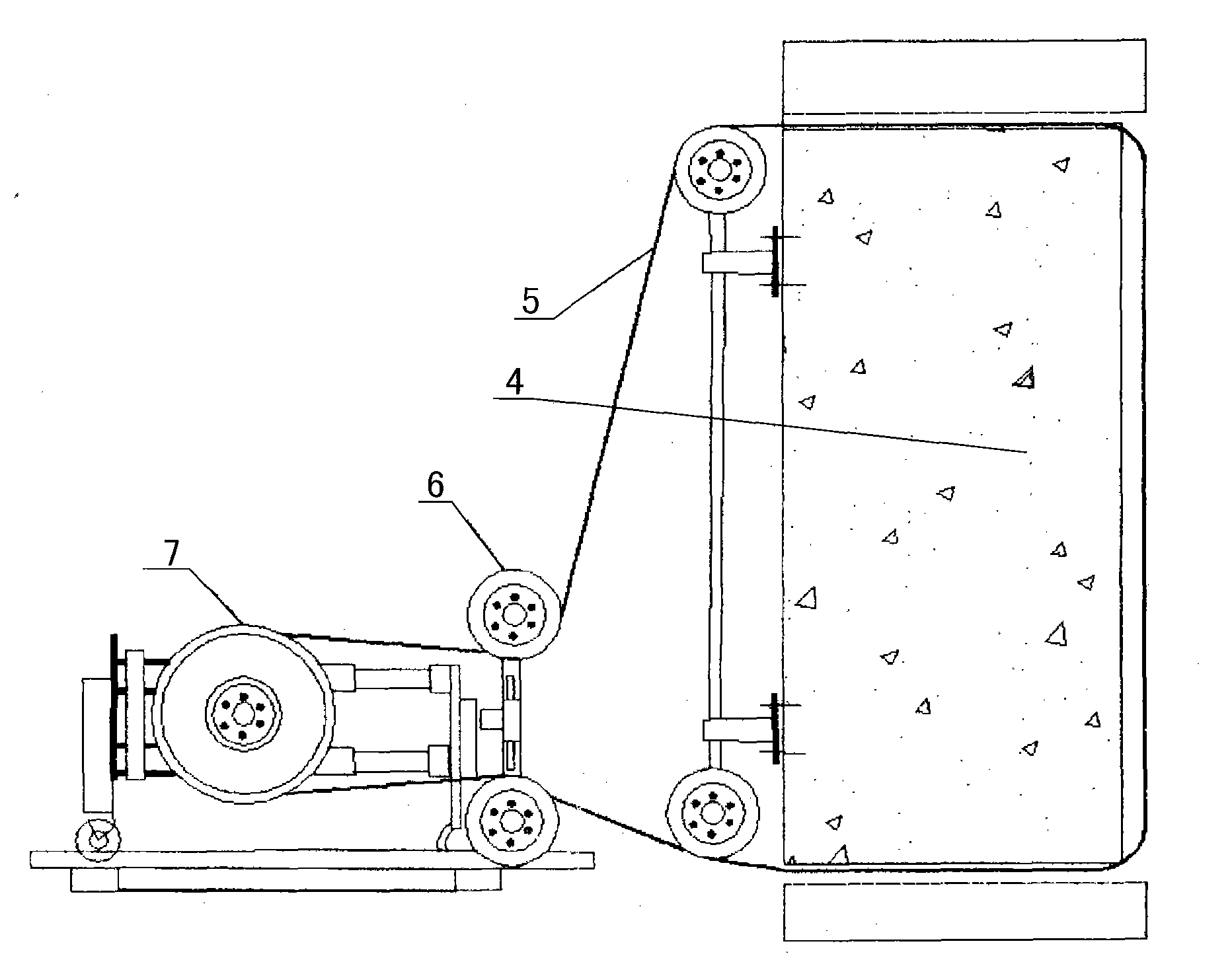

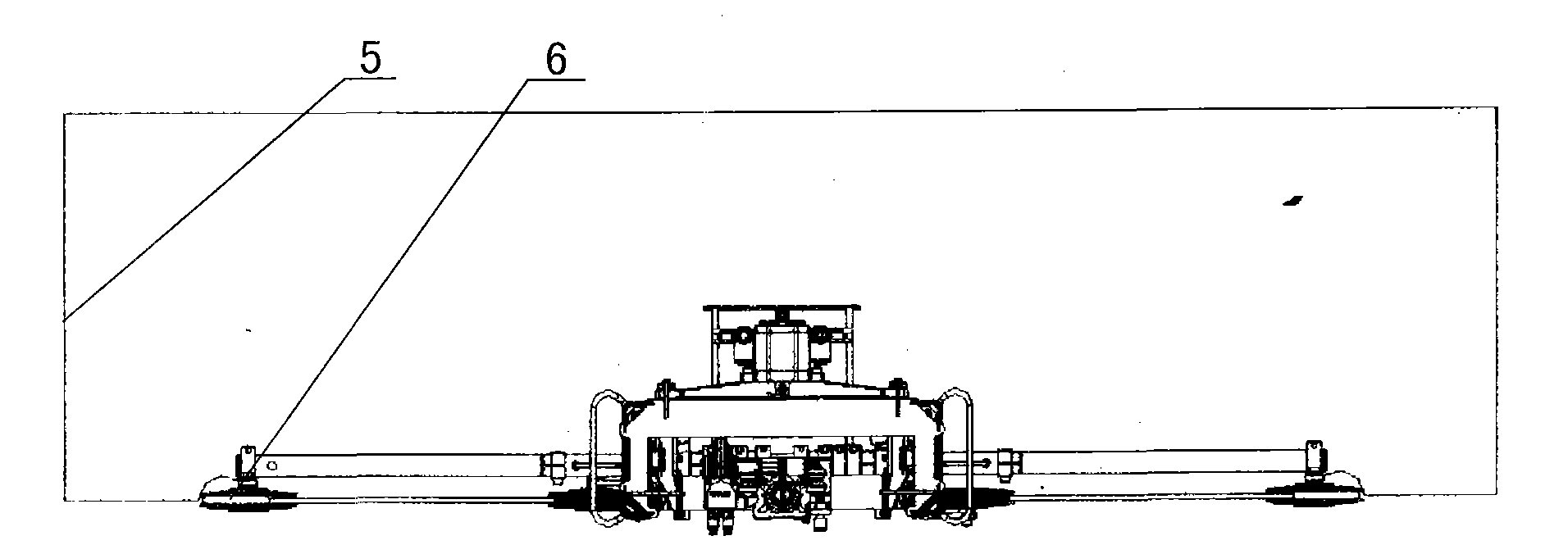

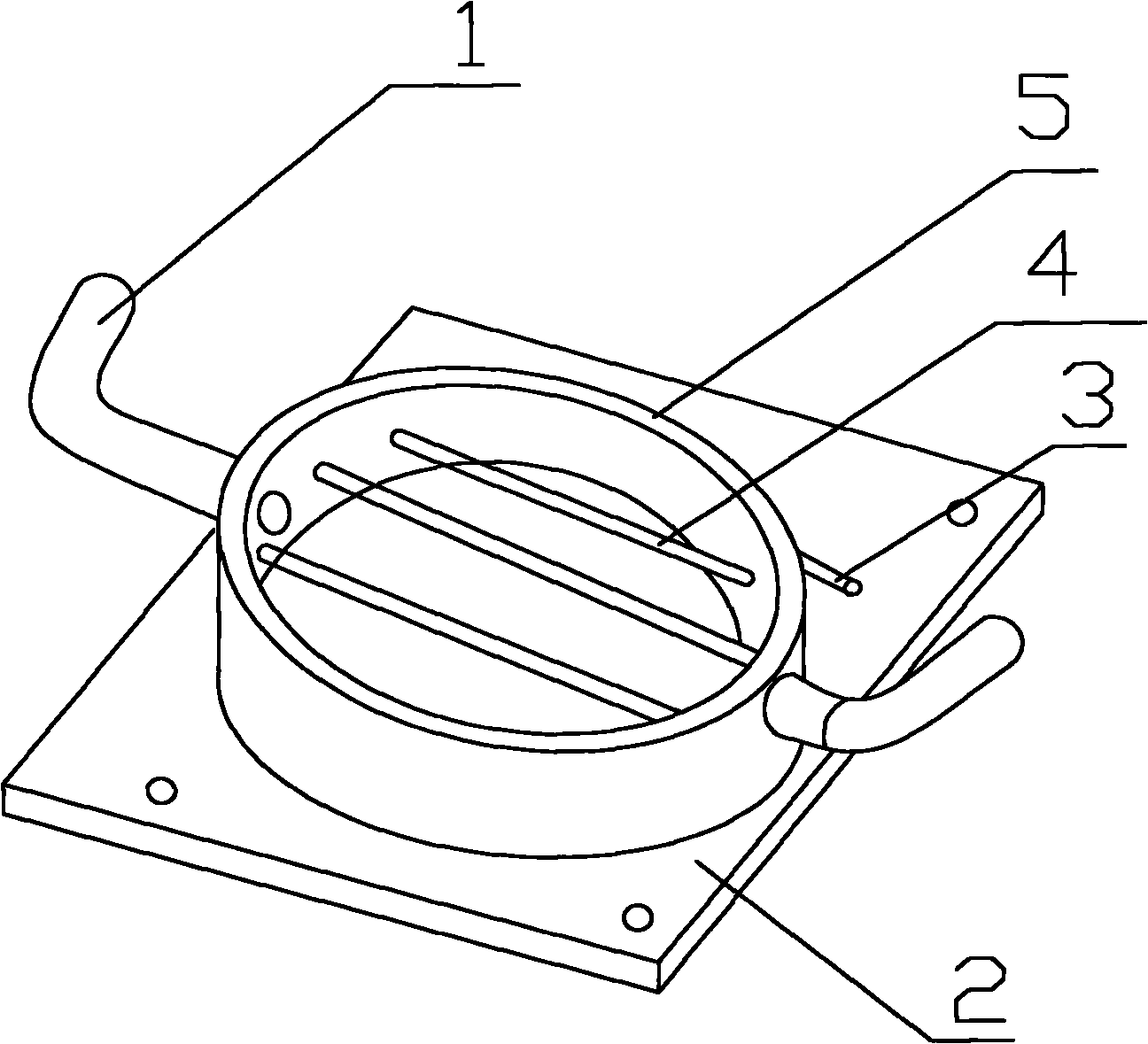

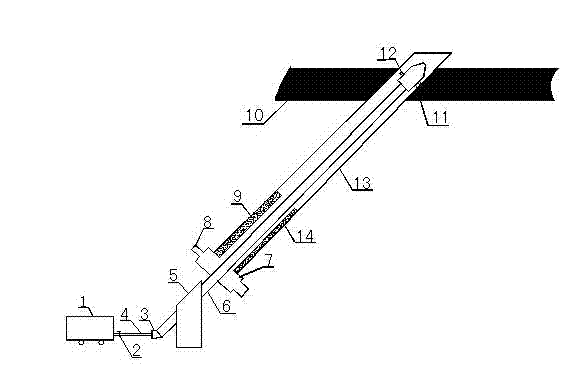

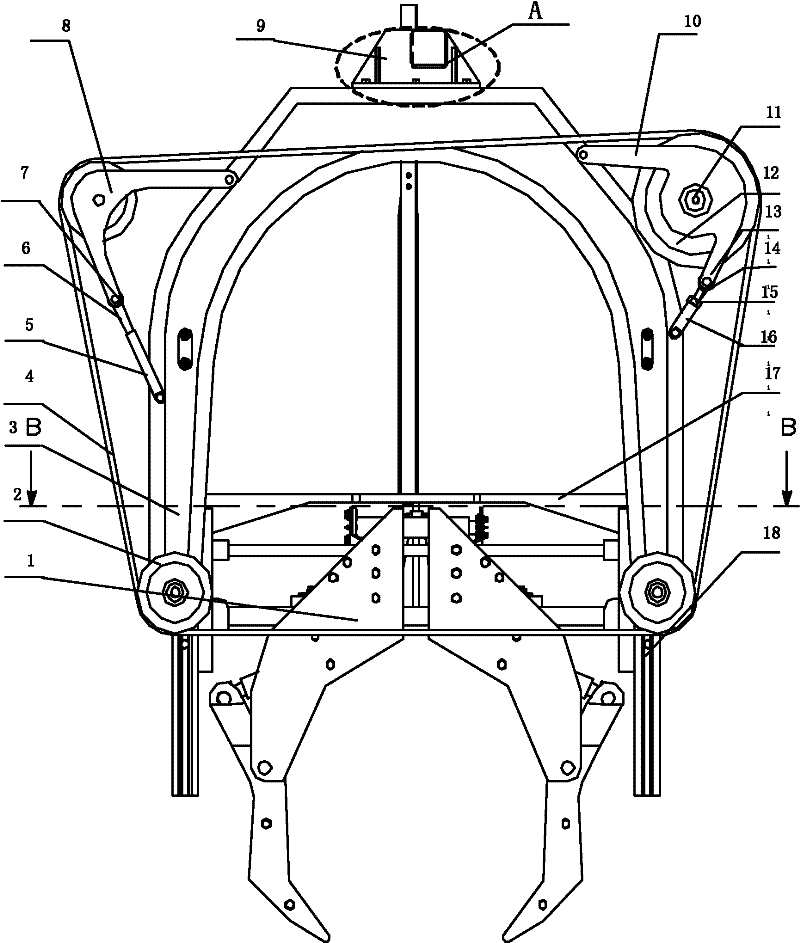

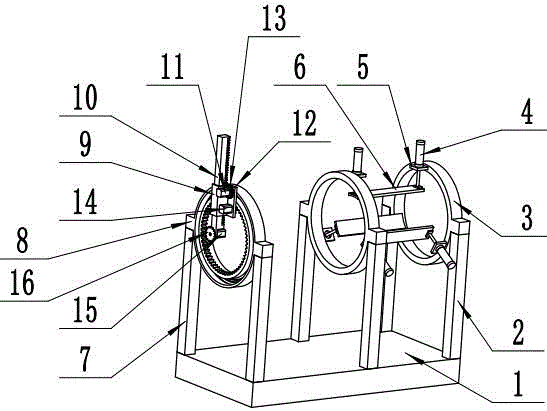

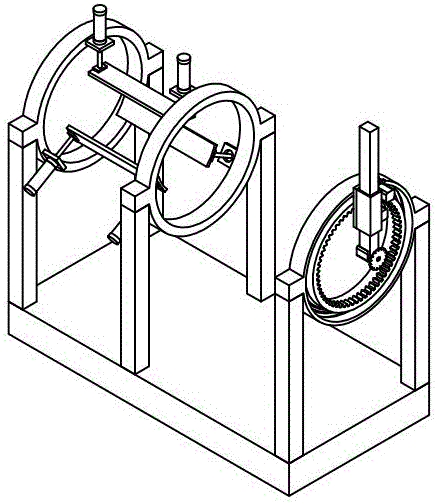

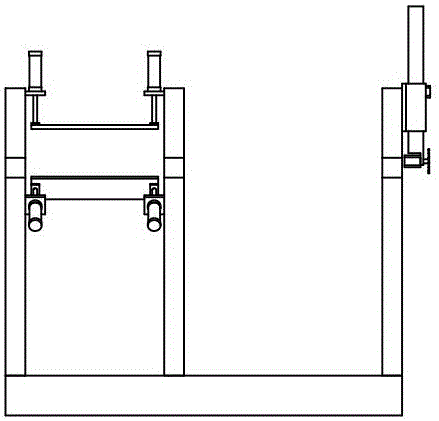

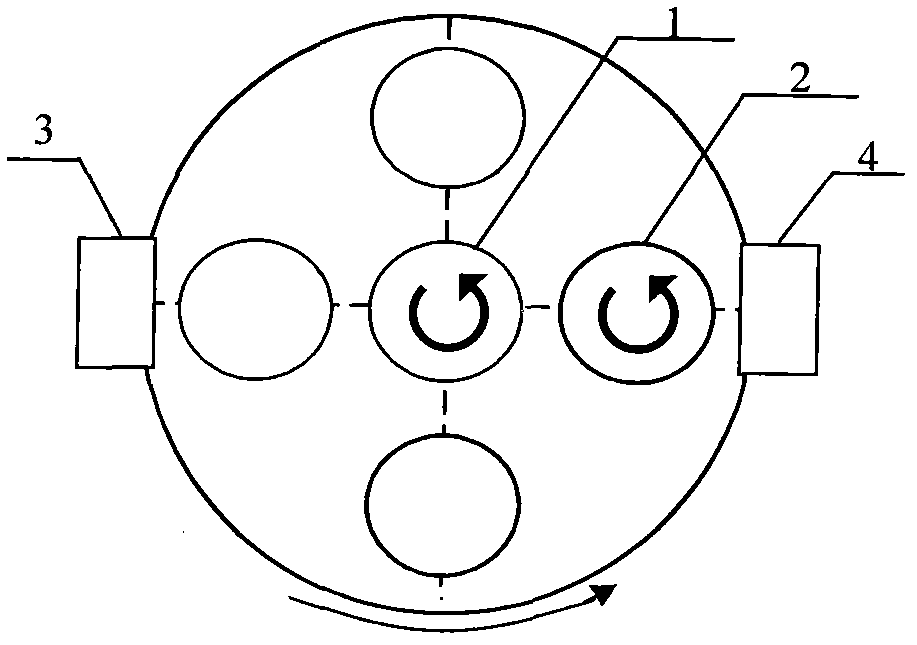

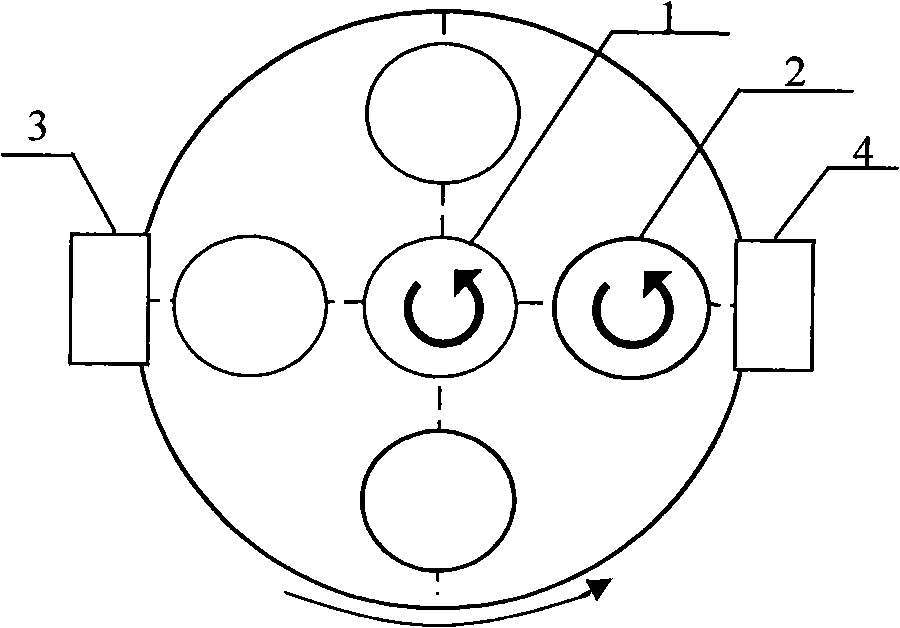

Variable structure adaptive feed type rope saw

InactiveCN102229009ALarge diameter rangeGuaranteed tensionMetal sawing devicesHydraulic cylinderControl system

The invention mainly aims to provide a variable structure adaptive feed type rope saw for cutting composite pipes with different diameters amphibiously. The rope saw consists of a clamping mechanism, a cutting mechanism, a feeding mechanism and a tensioning mechanism; the clamping mechanism comprises a V-shaped plate, the V-shaped plate is formed by folding two mutually independent half plates, each half plate is connected with respective sliding block, and the sliding block and a guide rail I form a sliding pair; the two half plates fixed on respective sliding blocks can move relatively in the radial direction along the guide rail I; the half plates are connected with a hydraulic cylinder respectively, and the hydraulic cylinder is connected with a control system; and the lower ends of the half plates are connected with clamping claws through fixing pins, and the rear ends of the clamping claws are connected with the hydraulic cylinder. The rope saw is suitable for the pipes with diameters of phi 300 to phi 1,500 millimeters, so the diameter range of the cut pipes is greatly expanded; and meanwhile, different cutting speeds can be automatically adjusted according to different cutting states to adapt the rope saw, and the cutting efficiency is improved.

Owner:HARBIN ENG UNIV

Outer-pipe circular cutting robot for steel pipe

ActiveCN106001735AImprove cutting efficiencyFast cutting speedTube shearing machinesShearing machine accessoriesGear wheelElectric machinery

The invention relates to an outer-pipe circular cutting robot for a steel pipe. The robot comprises a base, a steel pipe pressing plate, a circular cutting frame, an expansion link sleeve, an expansion link, an expansion link motor, a cutting mechanism fixing plate, a rotary motor, a cutting blade, an electric brush, an expansion link rack and an expansion link cutting motor fixing frame, wherein steel pipe frame stand columns of the expansion link motor fixing plate is fixedly arranged on the base, a steel pipe fixing sleeve is fixedly arranged on the steel pipe frame stand columns, the circular cutting frame is fixedly arranged on circular cutting frame stand columns, and the circular cutting frame stand columns are fixedly arranged on the base; the expansion link is arranged on the expansion link sleeve in a sliding way, the expansion link motor is fixedly arranged on the expansion link motor fixing plate, a stretching motor gear is fixedly arranged on an expansion link motor shaft, and the stretching motor gear is meshed with the expansion link rack; and the cutting motor is fixedly arranged on the expansion link cutting motor fixing frame, and the cutting blade is fixedly arranged on the cutting motor shaft. The robot can improve the steel pipe cutting efficiency, and is high in cutting speed, trim in notches and good in effect.

Owner:青岛昊坤机械制造有限公司

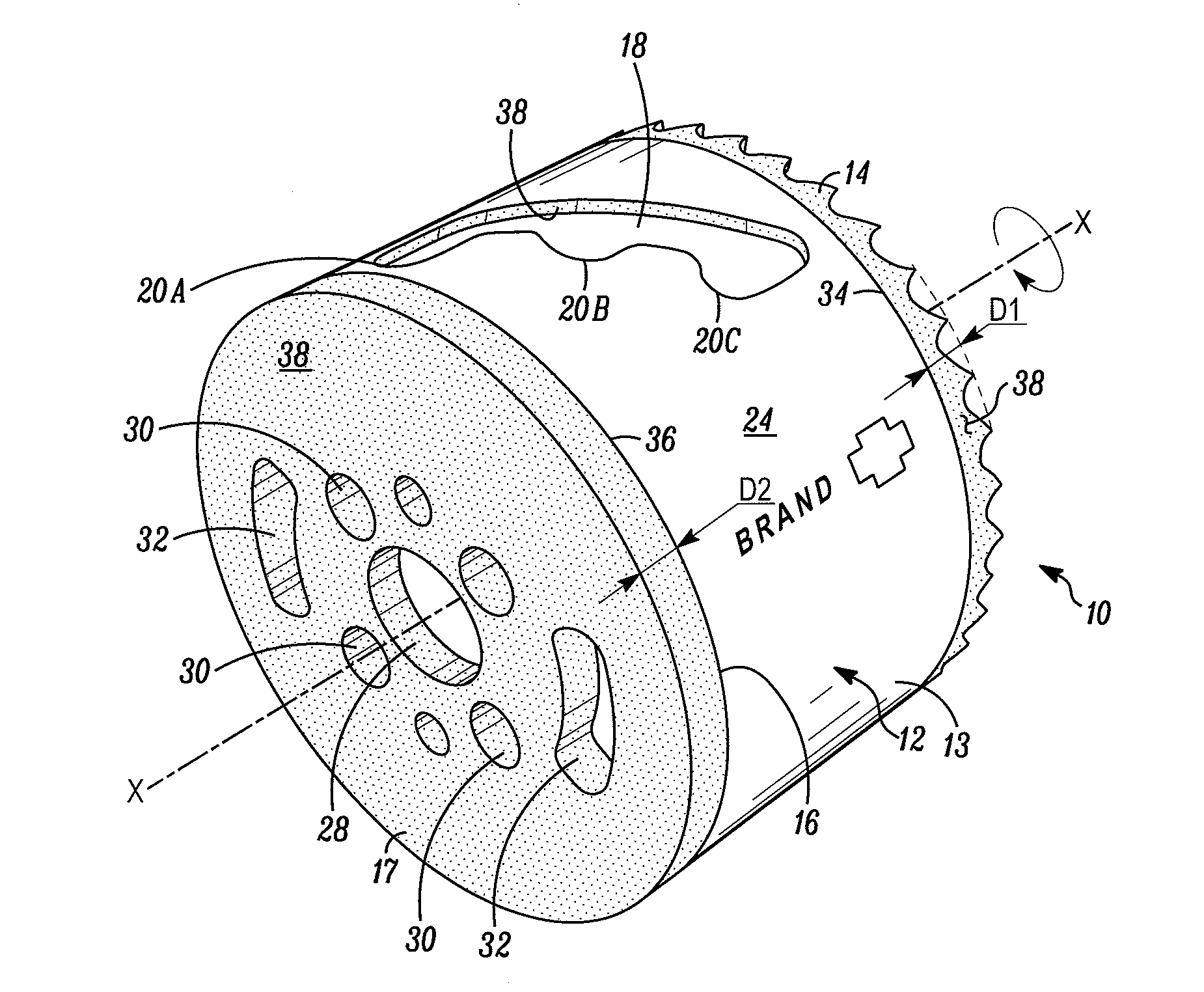

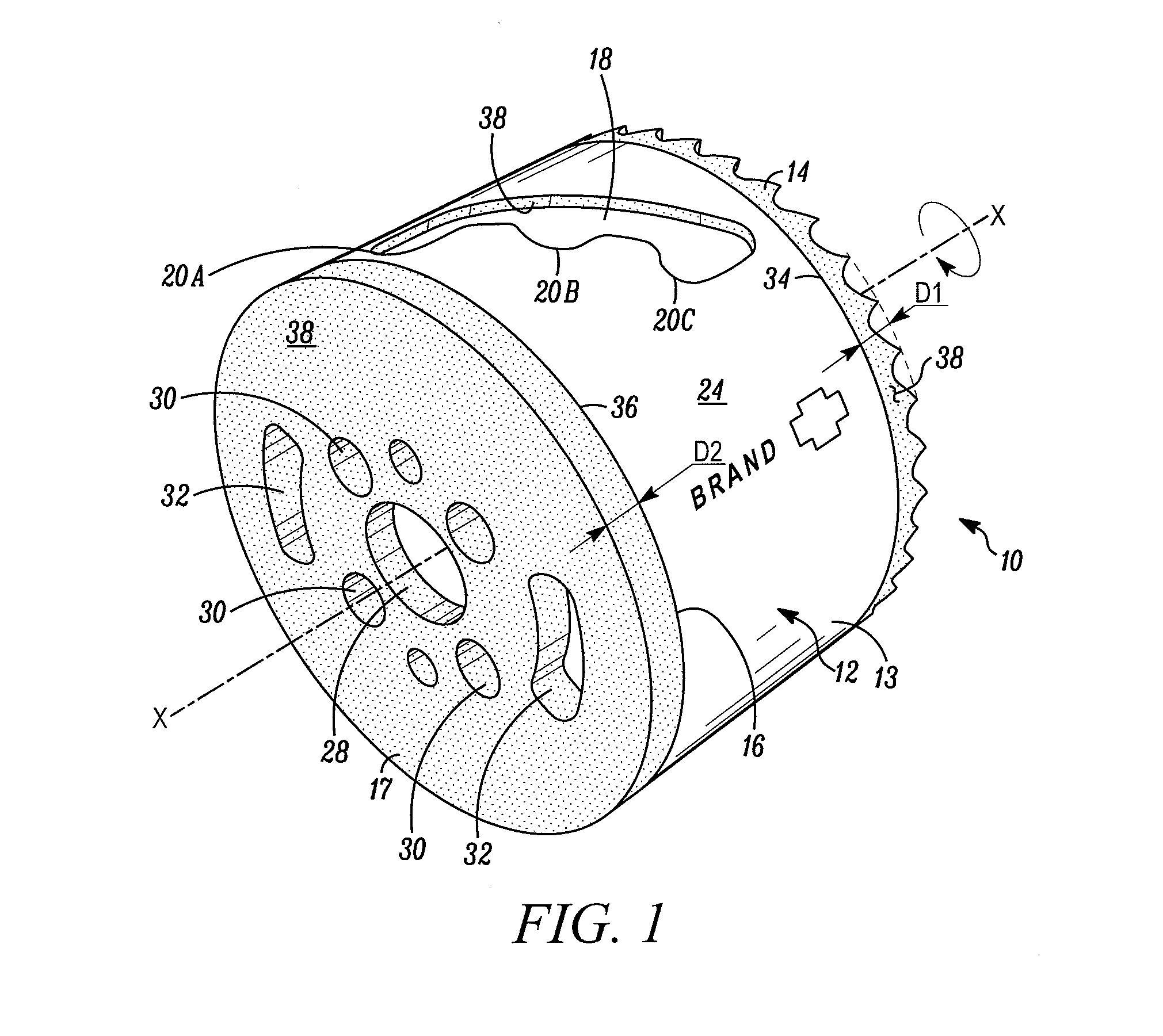

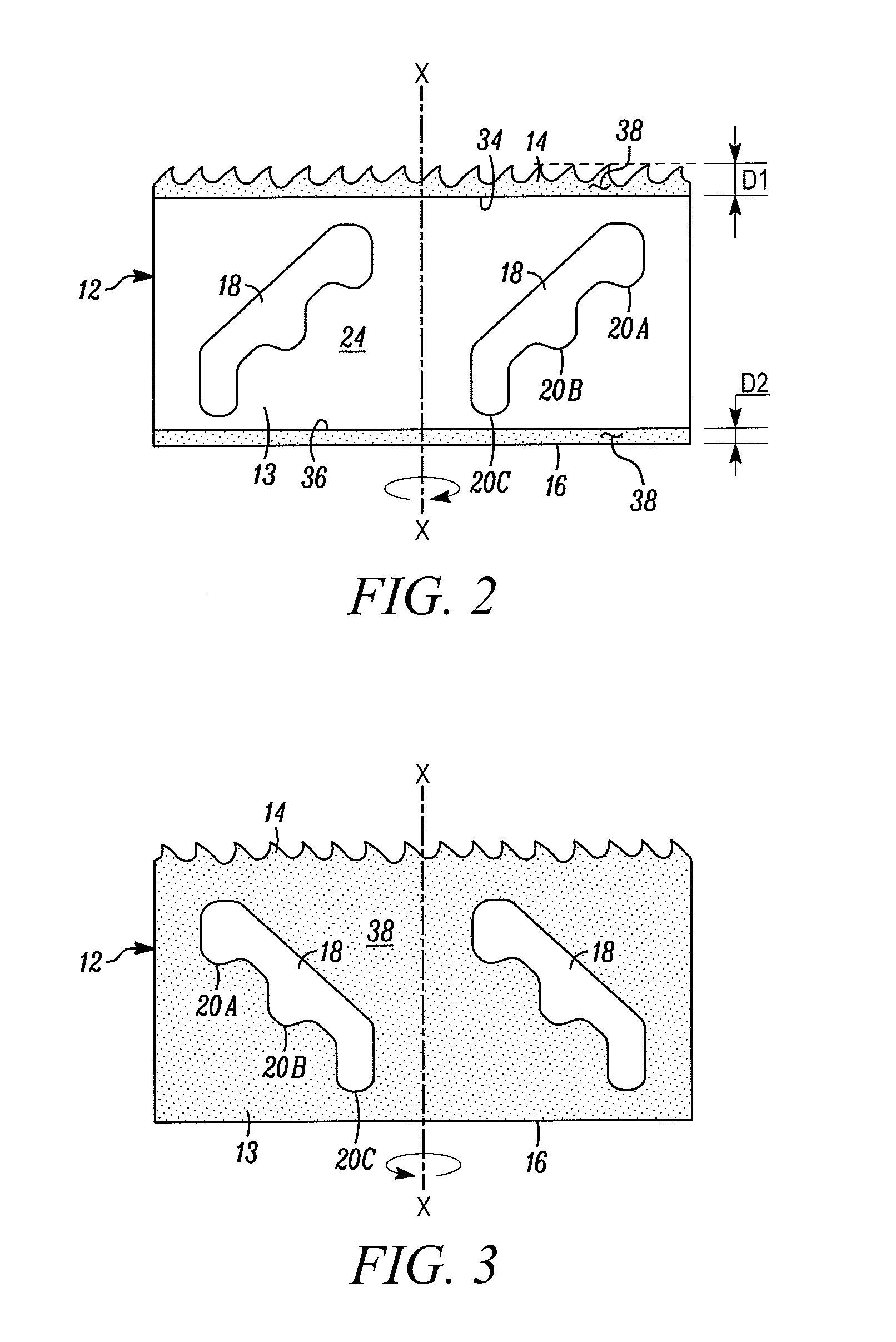

Coated hole cutter

ActiveUS20110170972A1Improve cutting efficiencyImprove efficiencyTransportation and packagingWorkpiecesUltraviolet lightsEngineering

A coated hole cutter including an ink-based colored coating applied only to the external surface of the cylindrical blade body of the hole cutter, but not to the surfaces of a circumferentially-extending cutting edge or to the interior surface of the blade body. The ink-based color coating is an ultraviolet activated ink that cures when the coating is exposed to a specific ultraviolet light intensity and wavelength. At least the surfaces of the cutting edge and the internal surface of the blade body, which do not include the coating, have a steam tempered oxide finish that imparts a color that contrasts with the color imparted by the coating.

Owner:BLACK & DECKER INC

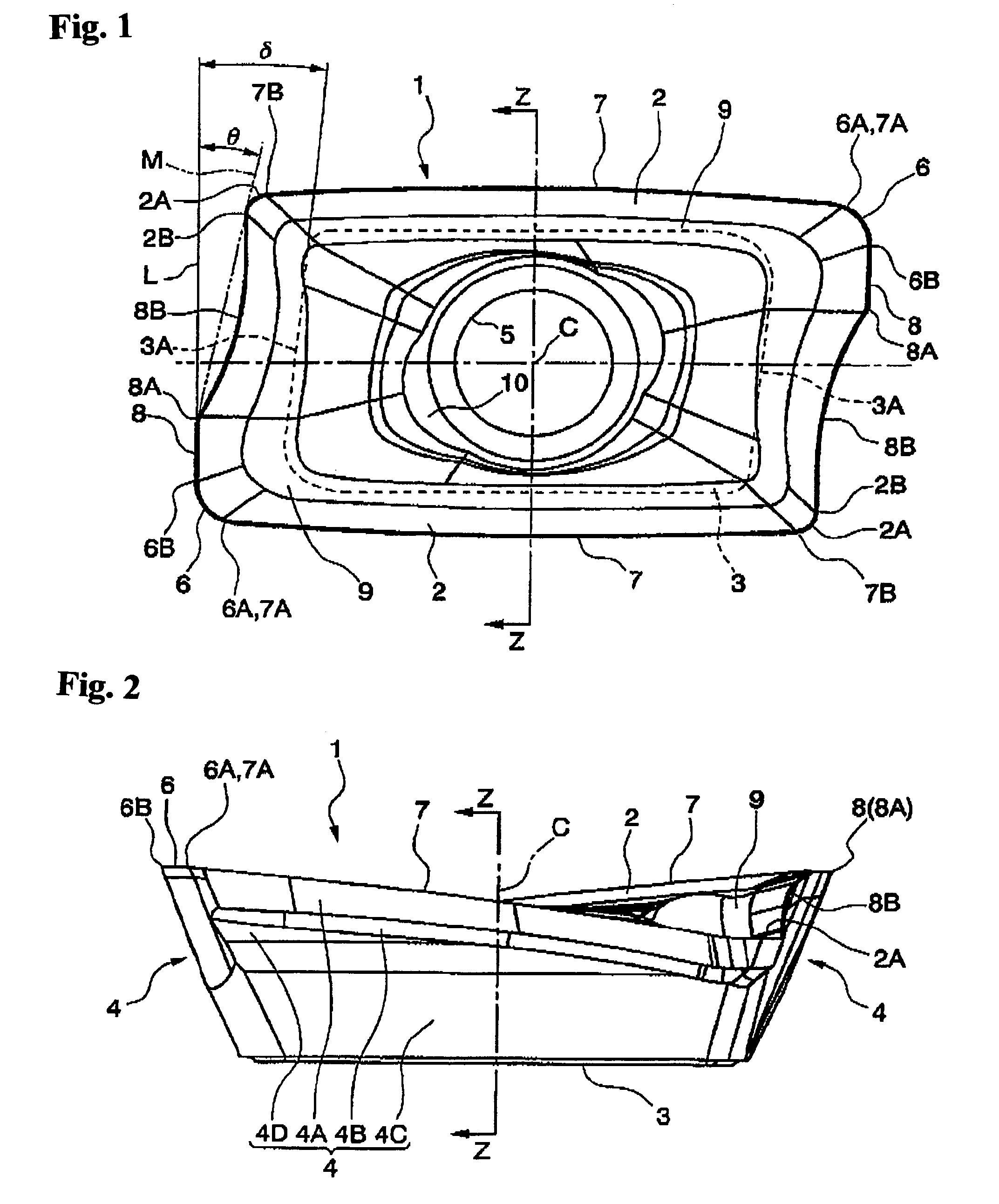

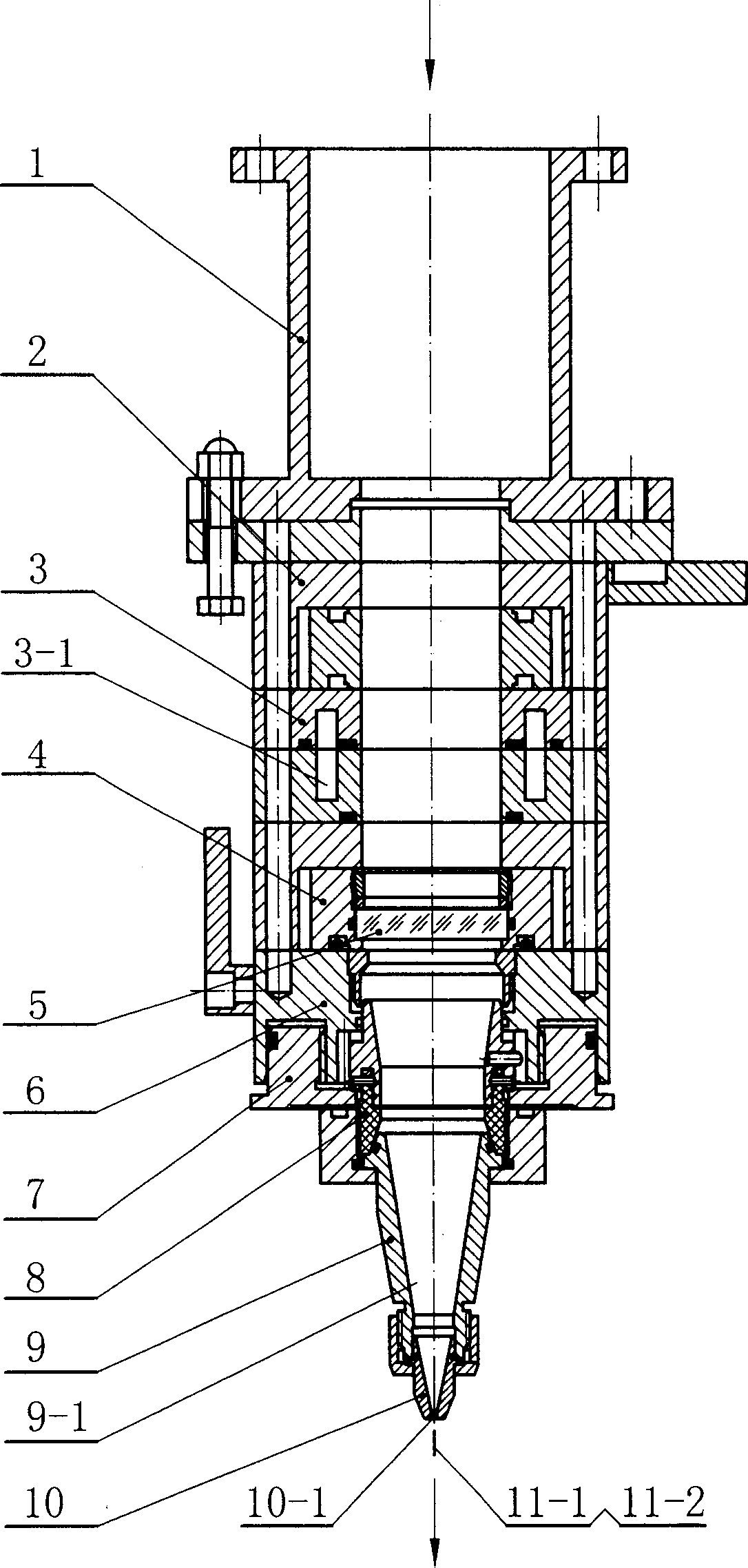

Digital-control laser cutting head and method for making same

InactiveCN1827282AIncreasing the thicknessIncrease profitLaser beam welding apparatusLight energyLaser cutting

The invention discloses a digital control laser cutter head used in CO2 digital control laser cutter and relative producing method. Wherein, the digital control layer cutter head comprises a connecting tube 1, a glass base box 2, a water cooling element 3, a focusing glass base element 4, a focusing glass 5, an aeration element 6, an adjusting nut 7, a high-strength insulated separating sheath 8, a transition nozzle 9, and a cutting nozzle 10. The inner hole 9-1 of said transition nozzle is in reverse taper shape; the upper and lower parts of water cooling element are integrated annular cooling water channels, while the annular cooling water channel 3-1 is one-time mechanically processed; the main elements as glass base box 2, water cooling element 3, focusing glass base element 4, aeration element 6 and adjusting nut 7 are made from ultrahigh strength rigid duralium LC4. With said invention, the consumed pressure and light energy of digital control laser cutter head is lower and the focusing effect is better. And said invention has better sealing property, thicker cut plate, high plate utilization, high strength, high pressure resistance and high heat conductivity.

Owner:LONGYAN LISHANG PRECISION MACHINERY

Conveying and slitting device for diaphragm bags

ActiveCN102658992AAccurate and stable transmissionEasy to controlFinal product manufactureElectrolyte accumulators manufactureEngineeringMechanical engineering

Owner:SHENZHEN YINGHE TECH

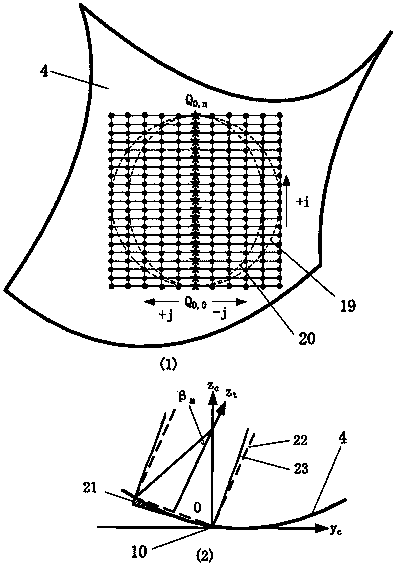

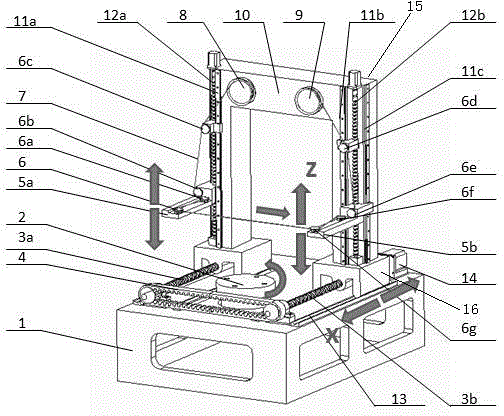

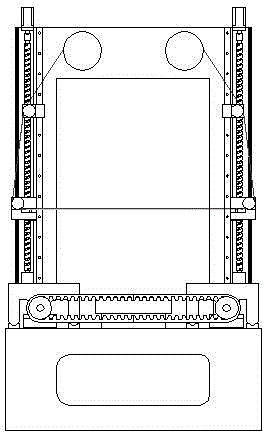

Multi-axis curved surface type numerically-controlled method for machining complicated curved surface part

ActiveCN103537743AImprove cutting efficiencySmall residualAutomatic control devicesFeeding apparatusNumerical controlMilling cutter

The invention discloses a multi-axis curved surface type numerically-controlled method for machining a complicated curved surface part. According to the method disclosed by the invention, the axis of a cutter can be arranged according to the directions of longitude and latitude normal lines for forming a curved surface, an inclined angle is adjusted to generate a cutter path, and the machining efficiency and the part surface smoothness can be improved. The numerically-controlled method can be realized by the following technical scheme: a part is fixed in a rotary center of a five-shaft machine tool; a curved surface is reconstructed according to the curvature change, the normal line direction of the curved surface and a machining path; a space change of an axis vector of the cutter is controlled by adjusting the front inclined angle and the side inclined angle of a cutter shaft of a flat-bottom end mill so that the cutter always keeps that a cutter tip participates in curved surface cutting in the five-axis continuous cutting process; a curved surface projection machining manner is adopted in the programming process so that the mill can carry out multi-axis linked milling machining according to the curvature change of the curved surface; the axis of the cutter is similar with a relatively small front inclined angle alpha overlapped to the normal line direction of the cutter path and a side inclined angle is set as 0; the axis of the cutter is kept vertical to the direction of the machining path to implement a five-axis linked machining numerical control procedure.

Owner:四川泛华航空仪表电器有限公司

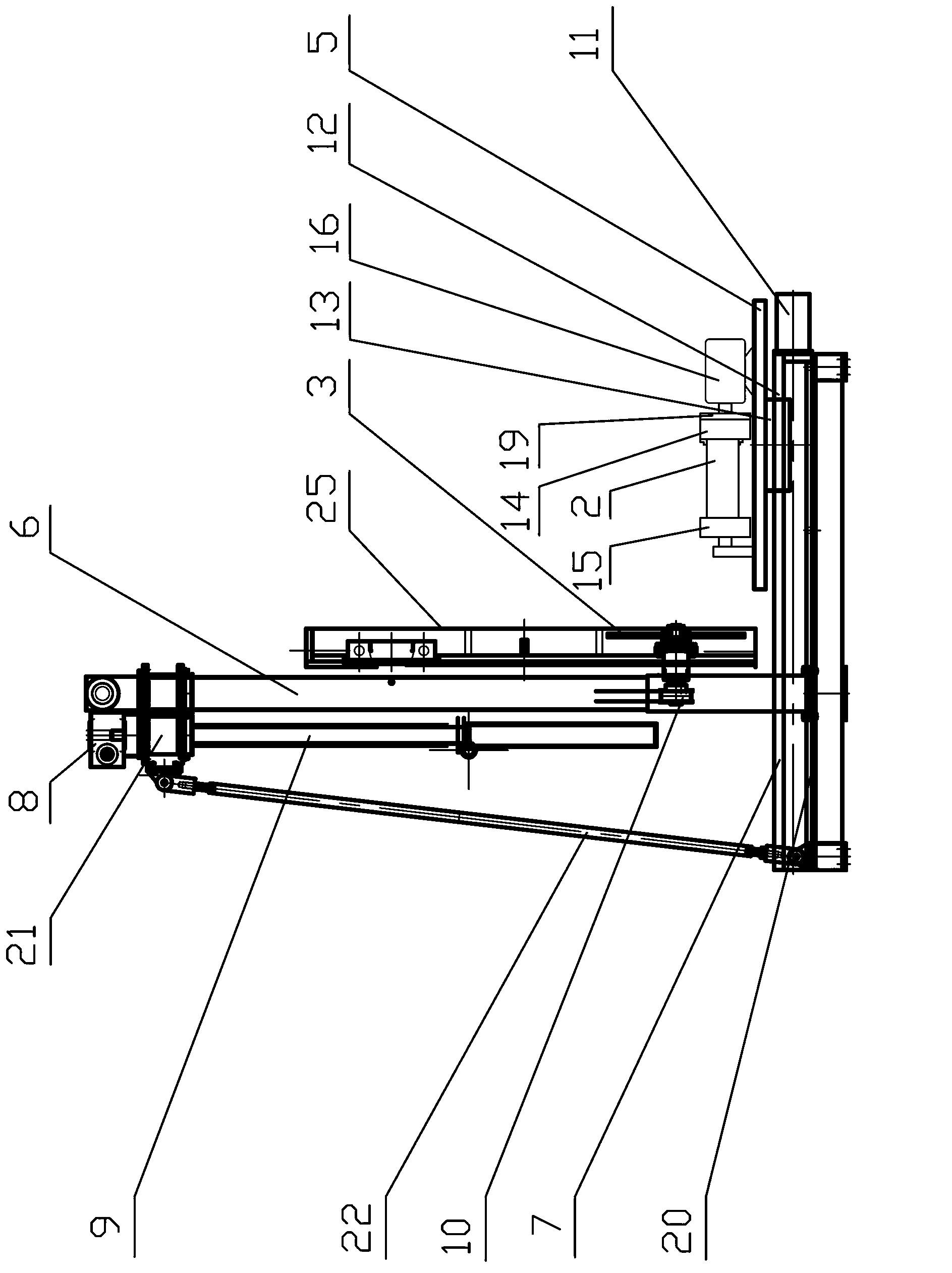

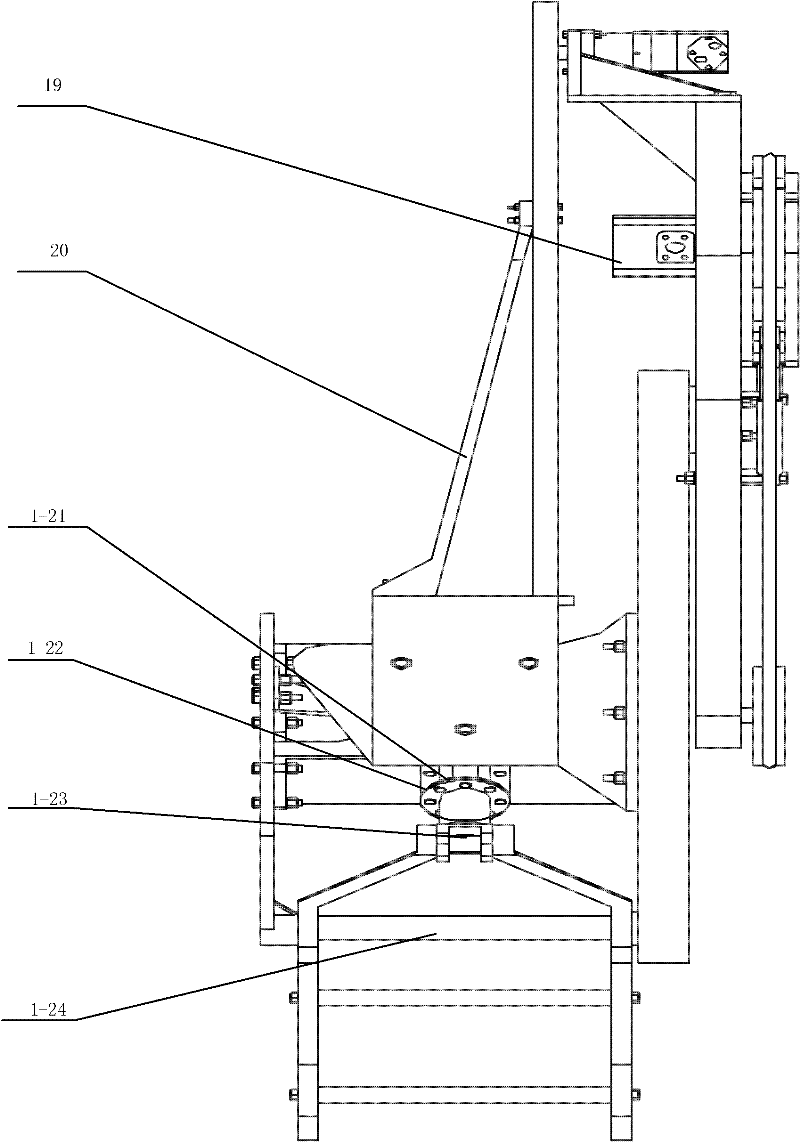

Horizontal diamond wire cutting machine tool

ActiveCN104890036AEasy clampingAvoid breakingMetal working apparatusStone-like material working toolsWire cuttingEngineering

Disclosed is a horizontal diamond wire cutting machine tool. The horizontal diamond wire cutting machine tool comprises a tool body (1), the tool body (1) is provided with a rotary worktable (2) for fixing workpieces, a portal frame (15), and a guide wheel group on the portal frame (15), wherein the portal frame (15) can be driven by an X-direction transmission mechanism on the tool body to move in an X direction. The horizontal diamond wire cutting machine tool is characterized in that the beam (10) of the portal frame (15) is provided with a pay-off drum (8) and a take-up drum (9), the stand columns on both sides of the portal frame (15) are respectively provided with an extending plate, and the cantilever end of each extending plate is provided with a cantilever end guide wheel; the extending plates on both sides are driven by the same or a separated Z-direction transmission mechanism to move up and down along the stand columns to control the height and accordingly to maintain a horizontal state so that a diamond wire on the cantilever end guide wheels on the cantilever ends can maintain a horizontal state and participate in cutting of the workpieces. The horizontal diamond wire cutting machine tool is convenient to fixe and high in machining efficiency and yield rate.

Owner:TAIZHOU CHEN HONG NC EQUIP MFG CO LTD +2

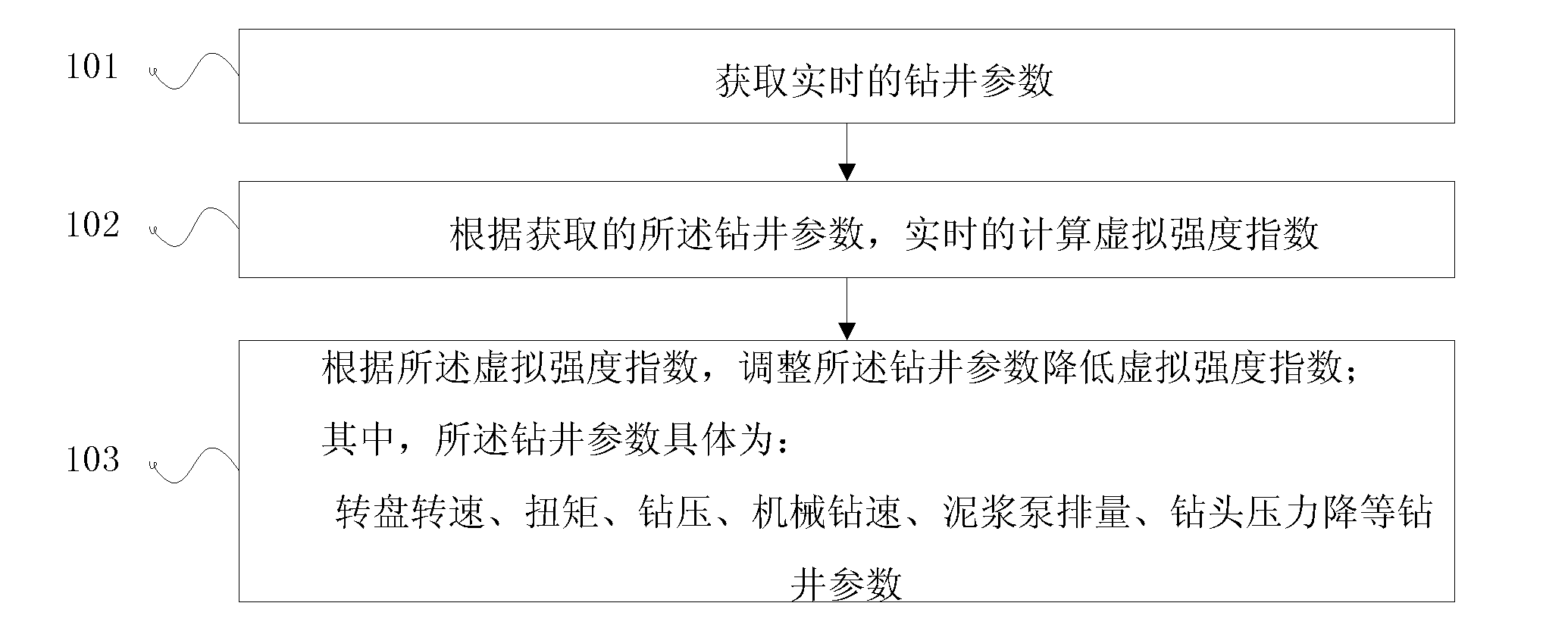

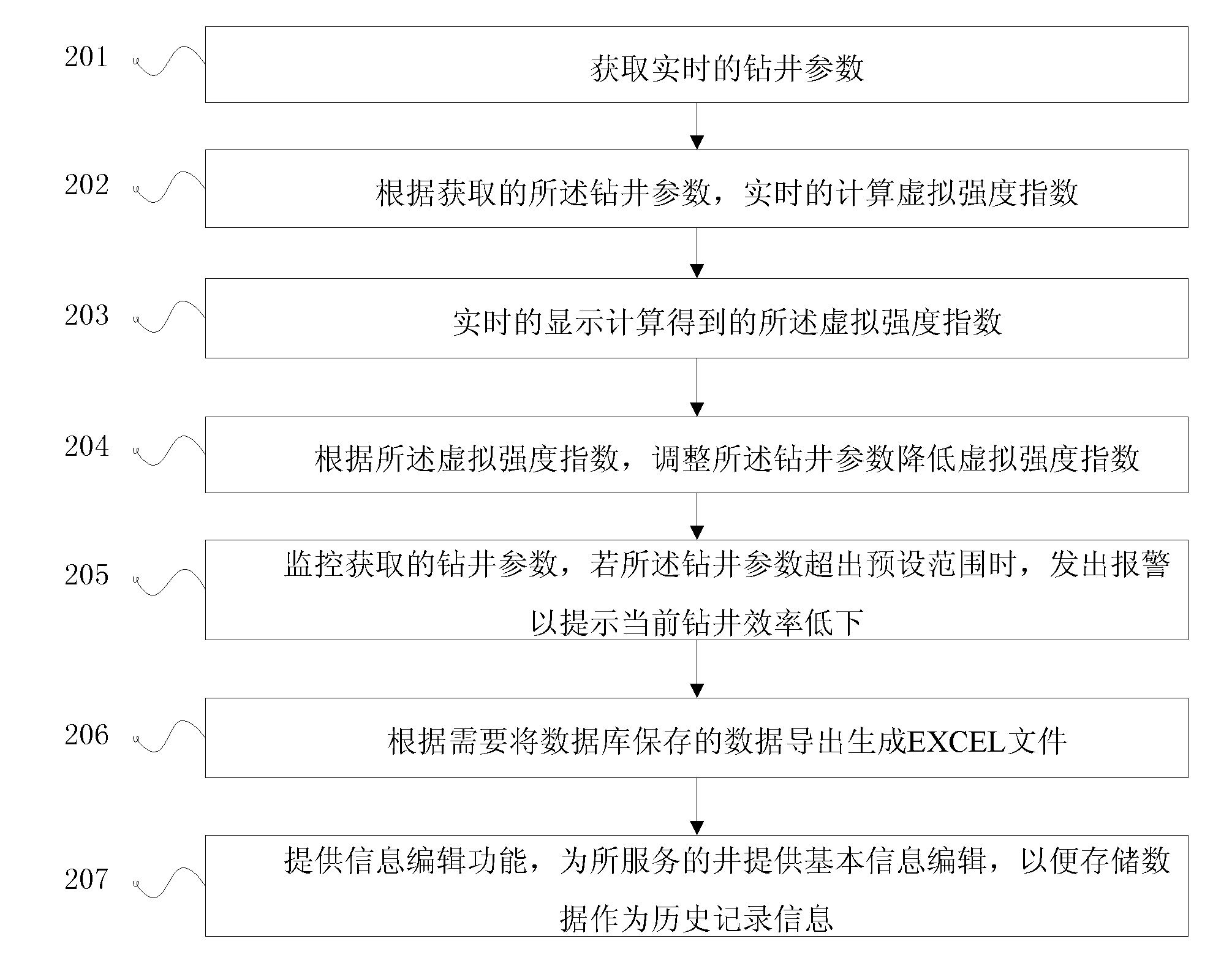

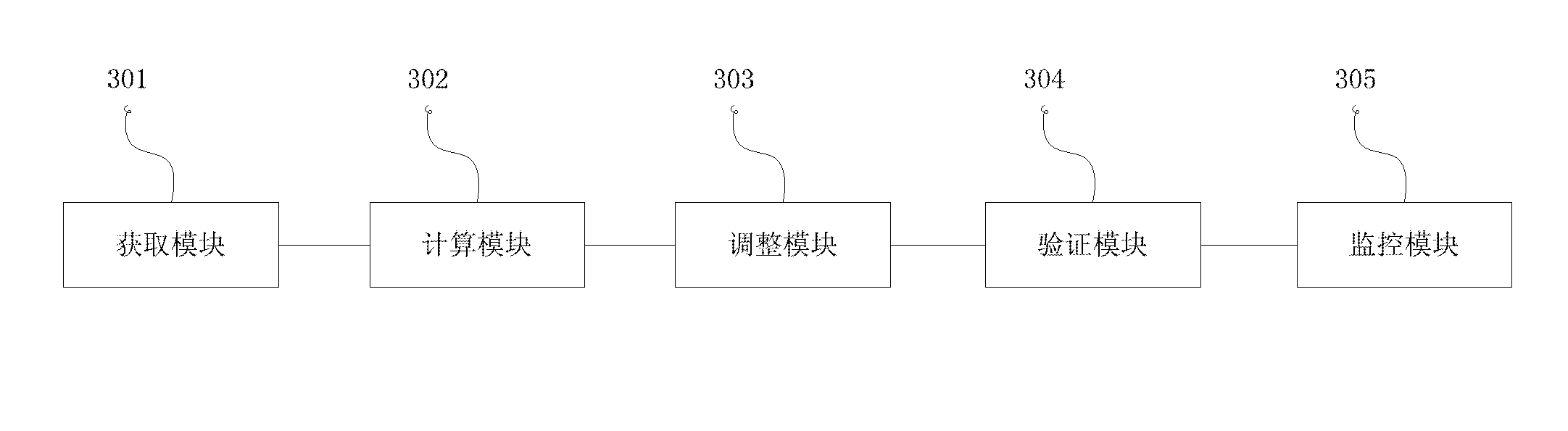

Method and system for optimizing drilling parameters

ActiveCN103046918AImprove cutting efficiencySurveyAutomatic control for drillingWell drillingOil drilling

The invention discloses a method and a device for optimizing drilling parameters, and belongs to the oil drilling field. The method comprises obtaining drilling parameters obtained in real time; calculating a virtual strength index (VSI) in real time according to the obtained drilling parameters which comprise rotary disc rotation speed, torque, drilling pressure, mechanical drilling speed, slush pump displacement, bit pressure drops and the like; and adjusting the drilling parameters to reduce the VSI according to the virtual strength index. According to the method and the device for optimizing drilling parameters, the VSI is calculated in real time through the drilling parameters fed back through real-time geological environment changes, and the drilling parameters are adjusted in real time according to the VSI relevant to an actual strength index, so that the bit cutting efficiency is in a possible optimal state, and the drilling efficiency is improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

TiAlN/TiAlCN multilayer coating of substrate surface and preparing method thereof

ActiveCN102011090AMitigate defectsAlleviate dislocationVacuum evaporation coatingSputtering coatingSputteringHardness

The present invention discloses a TiAlN / TiAlCN multilayer coating of substrate surface and preparing method thereof, wherein a transitional layer is between a substrate and a TiAlN / TiAlCN multilayer coating; the multilayer coating is formed by alternating periodic arrangement of TiAlN films and TiAlCN films; in a period, the thickness sum of the TiAlN films and the TiAlCN films is 1-20 nano; the percentage by weight of C atom in the TiAlCN films is 0.1-5%. The multilayer coating of the present invention has the advantages of high hardness, low internal stress and high tenacity; the cutting efficiency and corrosion resistance of the substrate can be improved, and the service life of the substrate can be prolonged. In the present invention, the multilayer coating is deposited by high power pulse magnetron sputtering technique; the problems that cathode arc ion plating and depositing speed is too fast to prepare a nano epitaxial film and that target poisoning is caused during the procedure for preparing films by DC magnetron sputtering are solved; the nano modulation period is controlled via adjusting the autorotation and revolution speeds of the substrate and adjusting the quantity of targets.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com