Patents

Literature

136results about How to "Avoid local accumulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

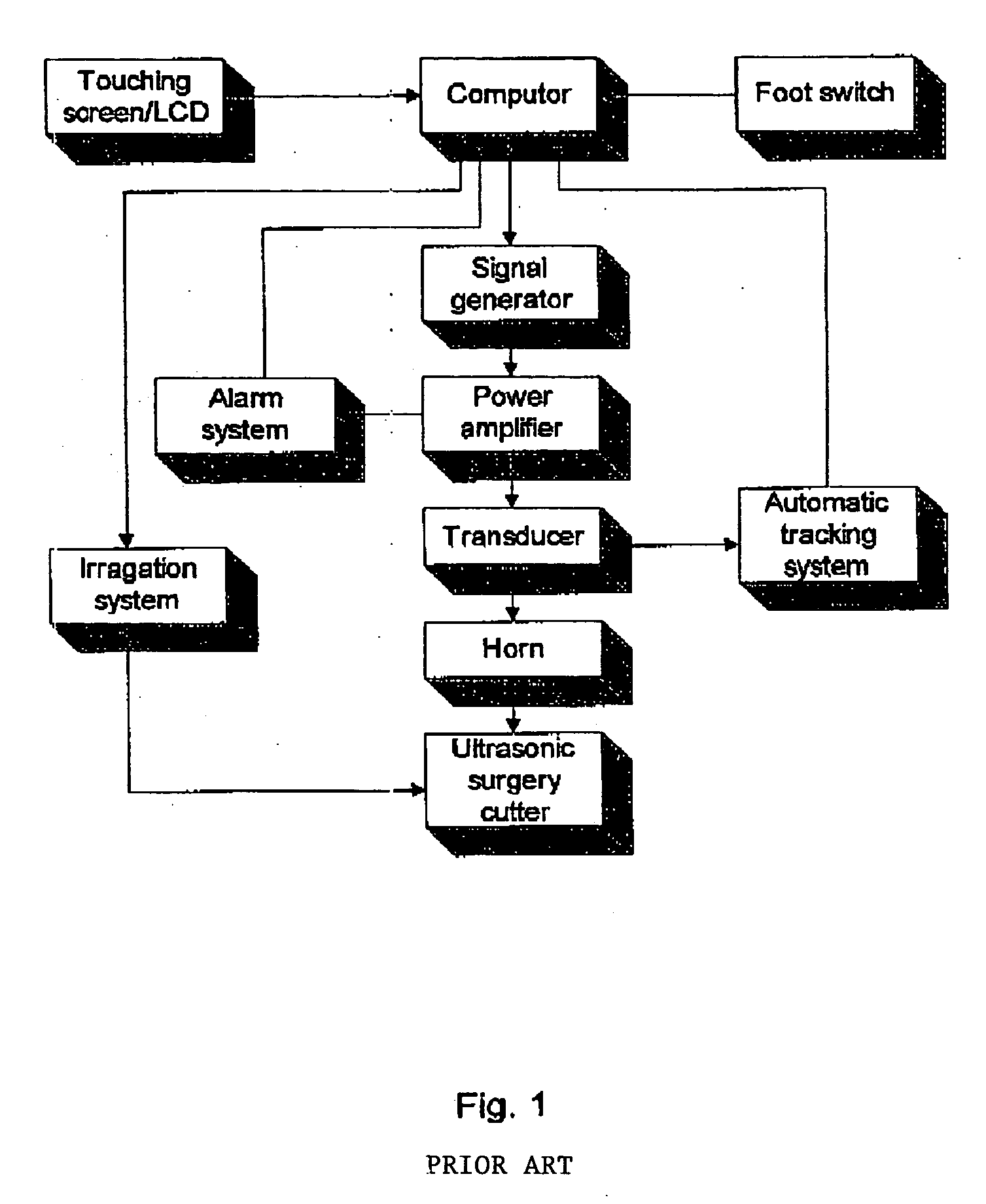

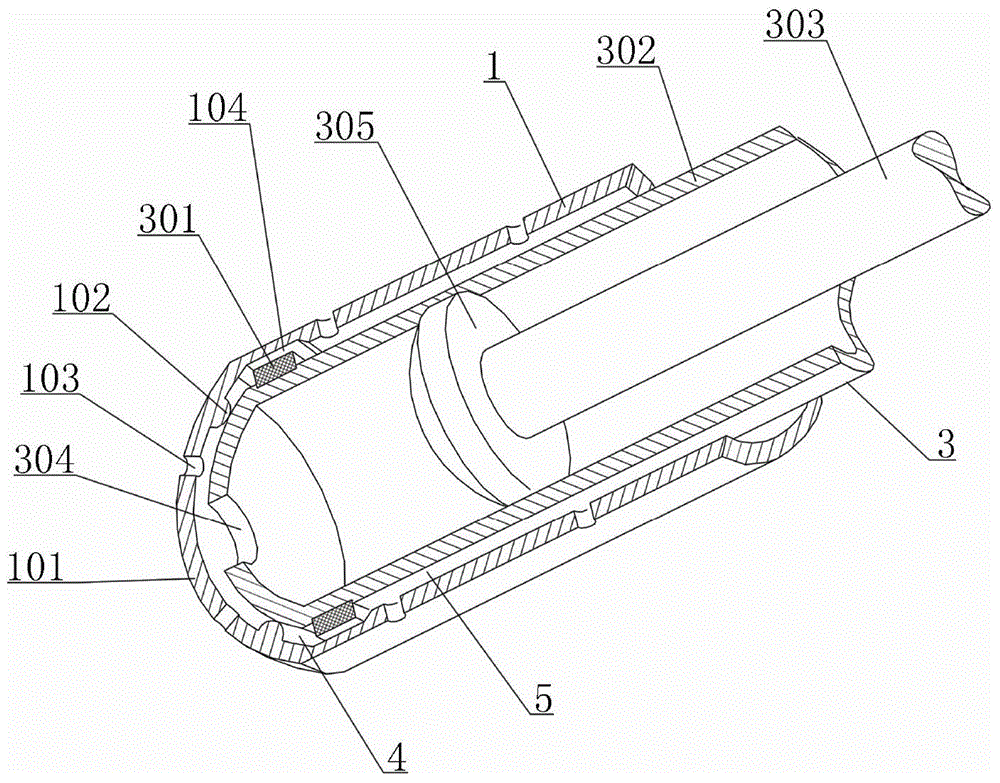

Ultrasonic orthopedic surgical device with compound ultrasound vibration

InactiveUS20060030797A1Improve cutting efficiencyAvoid local accumulationChiropractic devicesEye exercisersVibration amplitudeDrive motor

An orthopedic surgical device with compound ultrasound vibration that comprises a handpiece, a surgical cutter fixed on the anterior top of the handpiece, and an ultrasound signal generator. Inside the outer casing of said handpiece, there are provided: an ultrasound transducer for transforming the ultrasound signals from said ultrasound signal generator into ultrasound mechanical waves; a horn (or amplitude transformer) for amplifying vibration amplitude of ultrasound mechanical waves generated from said transducer and then transmitting the amplified ultrasound mechanical waves to said surgical cutter to lead to longitudinal vibration of the surgical cutter; a driving motor fixed in the back end of said handpiece for driving said ultrasound transducer and horn to accomplish the movement of swing and rotation; an adapter provided between said driving motor and said transducer for supplying ultrasonic electrical signals generated by said ultrasound signal generator to said ultrasound transducer.

Owner:ZHOU ZHAOYING +3

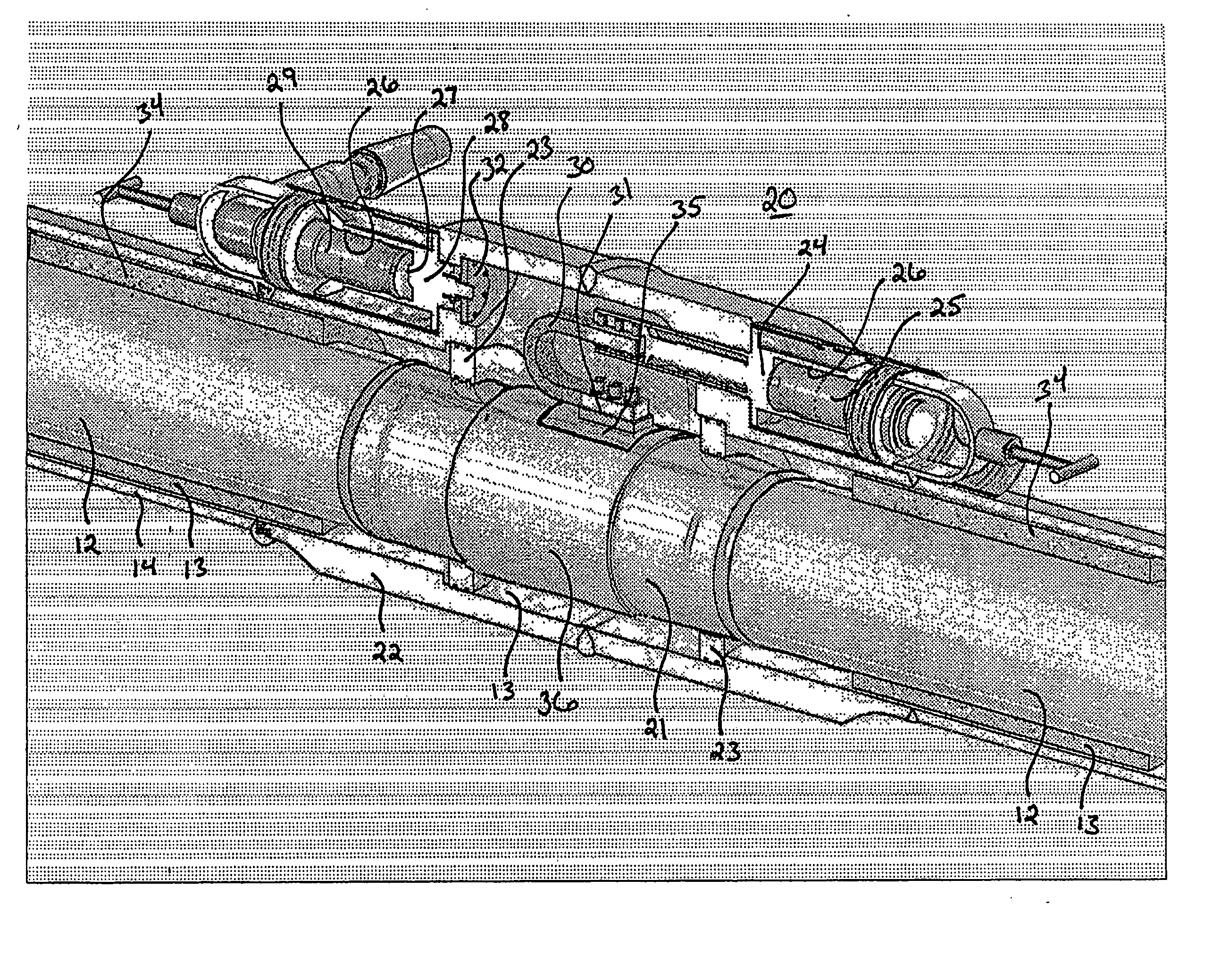

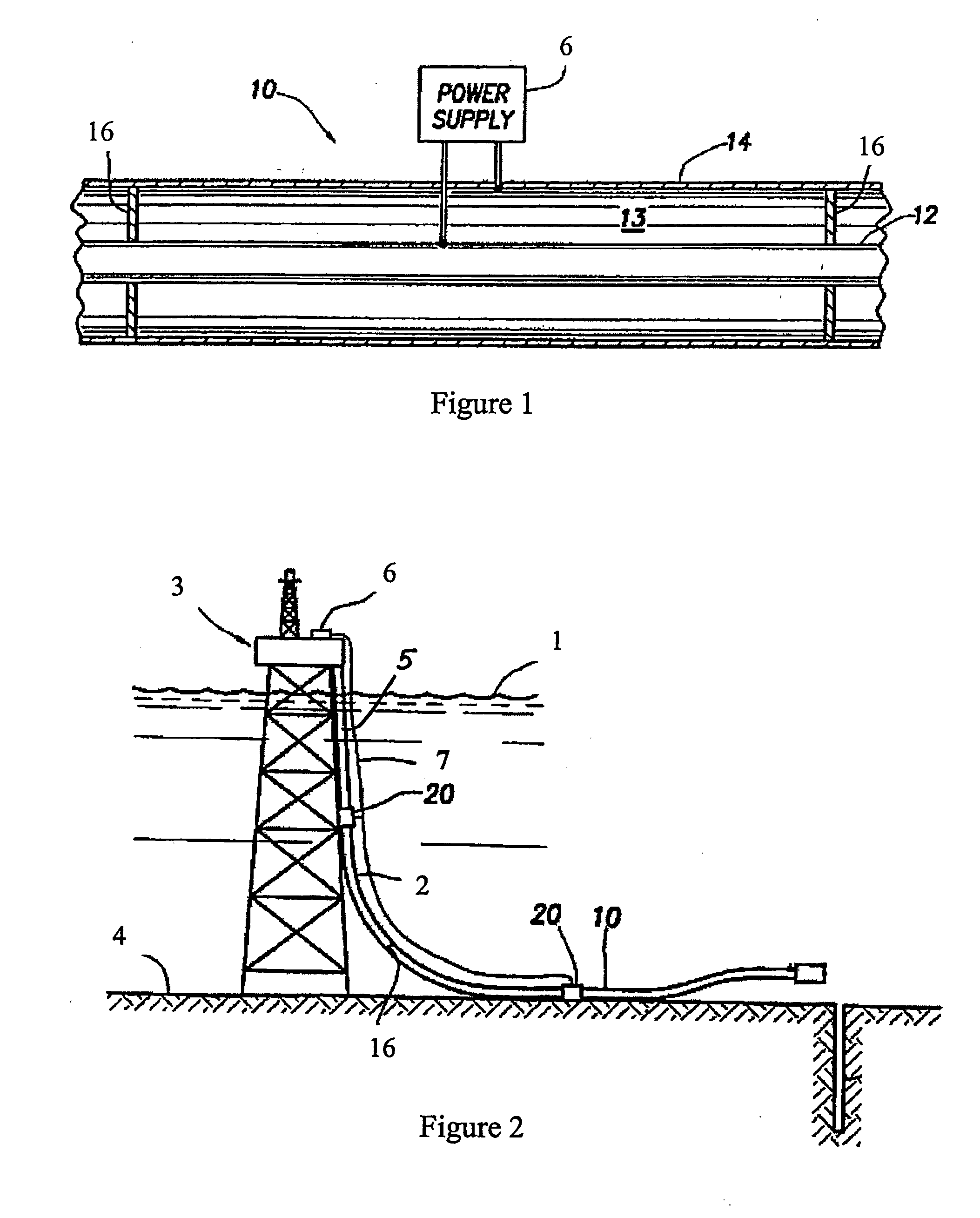

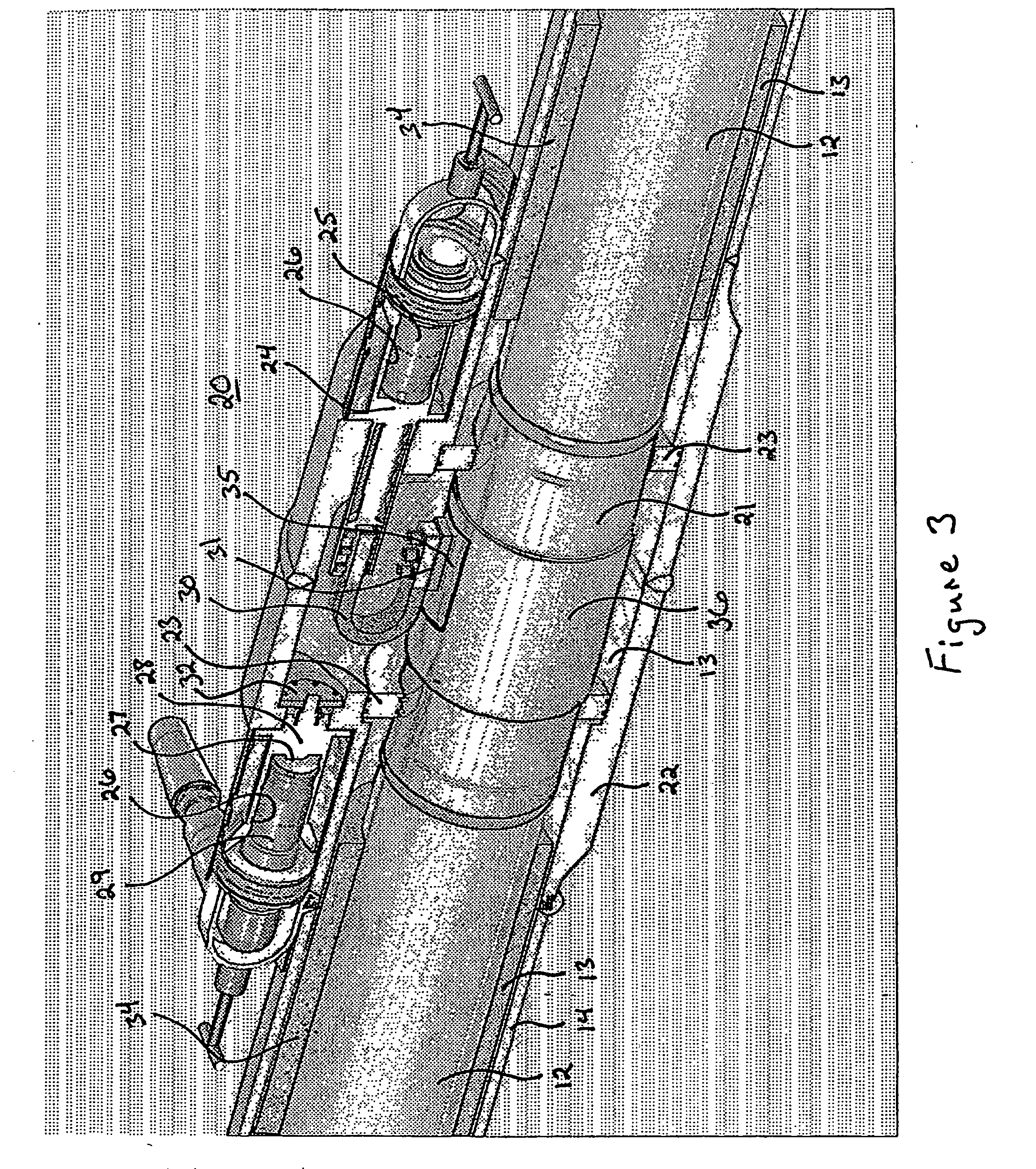

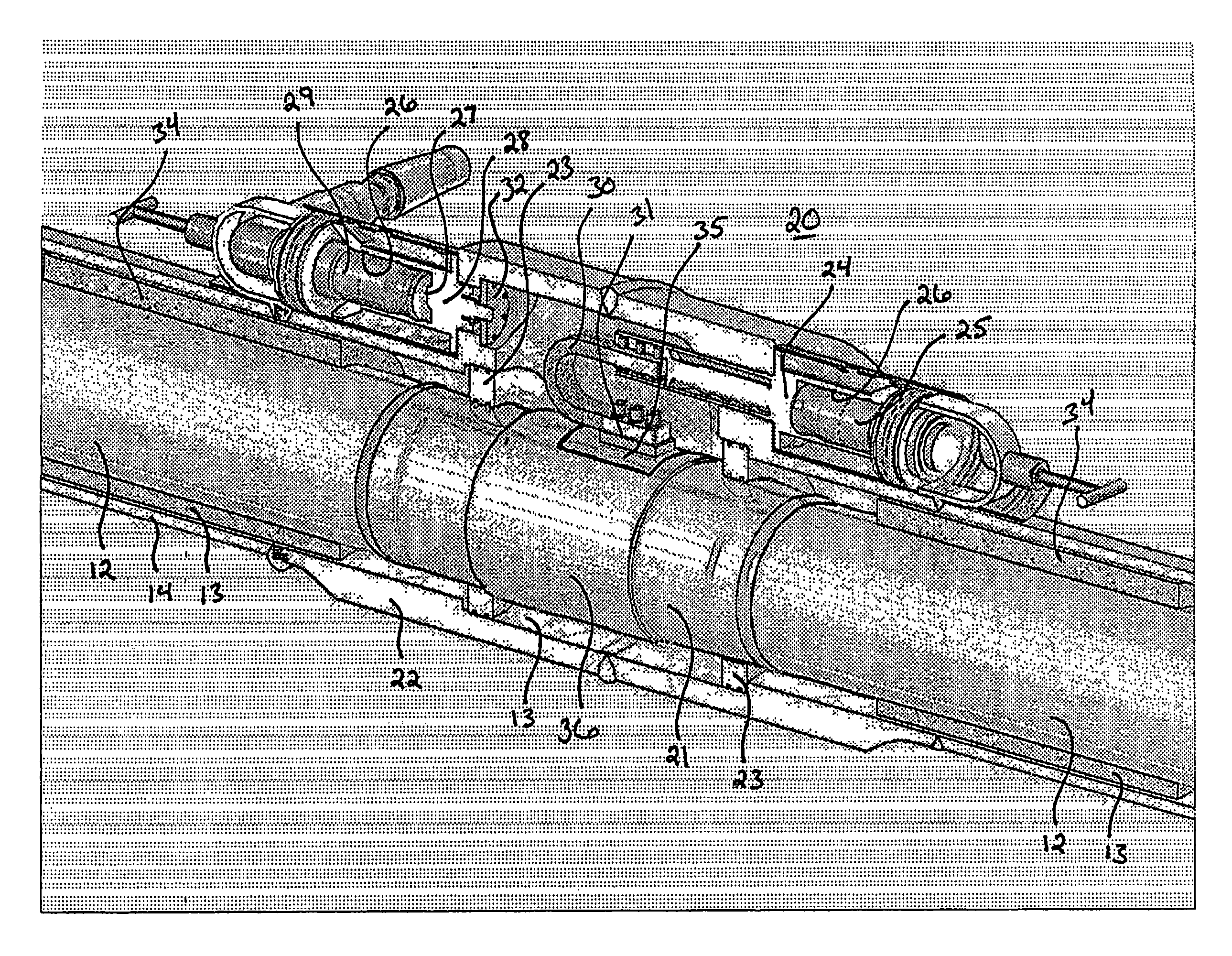

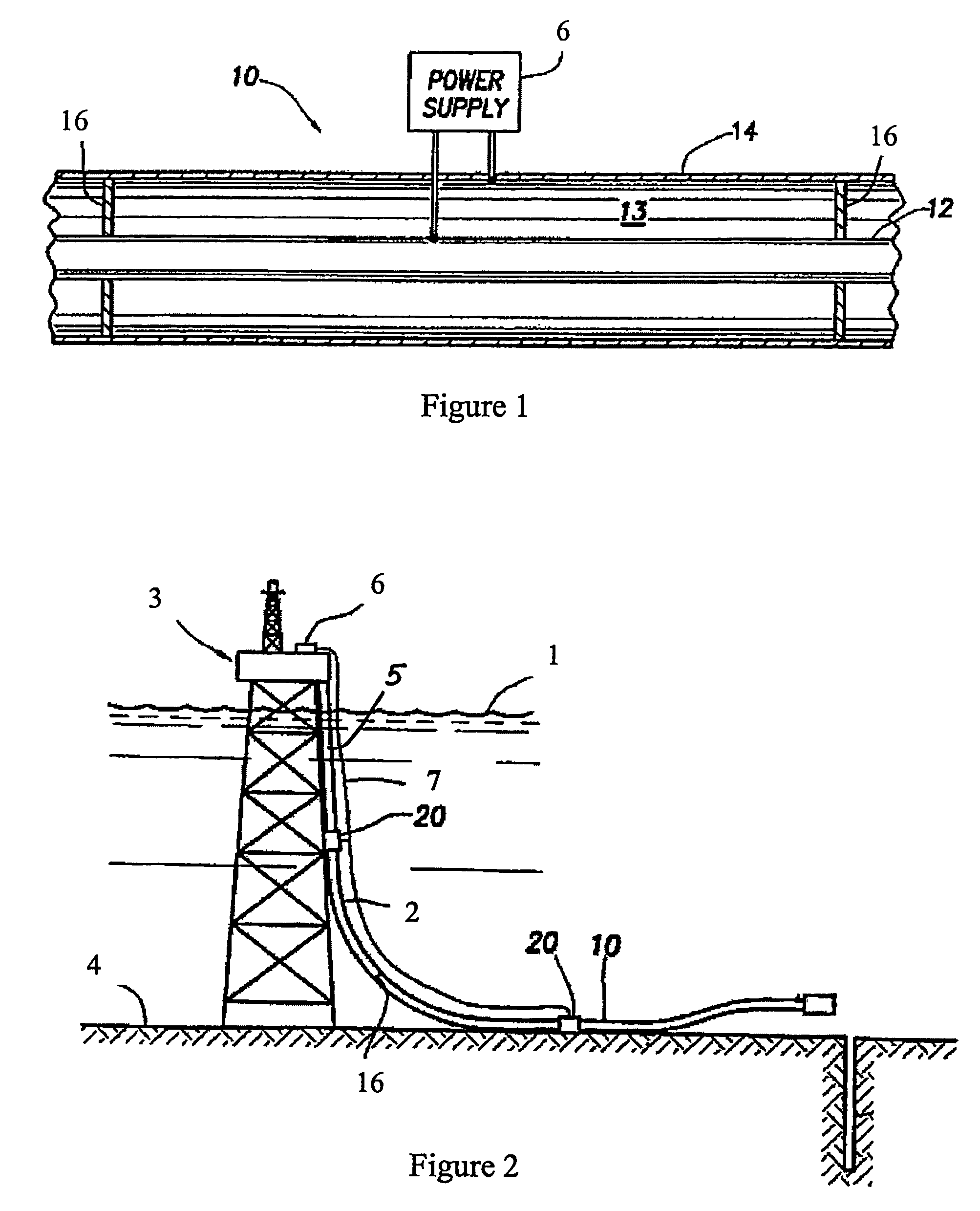

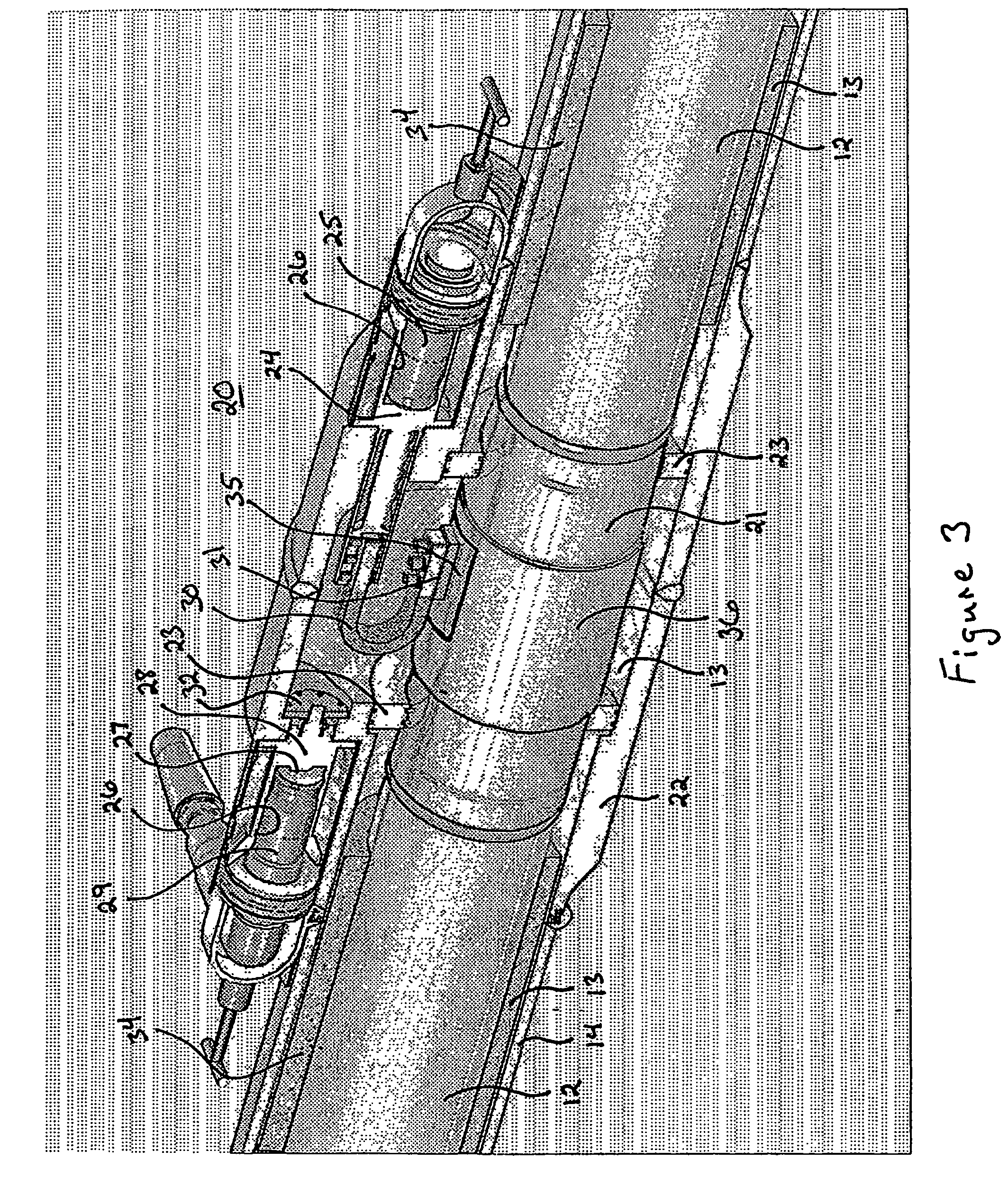

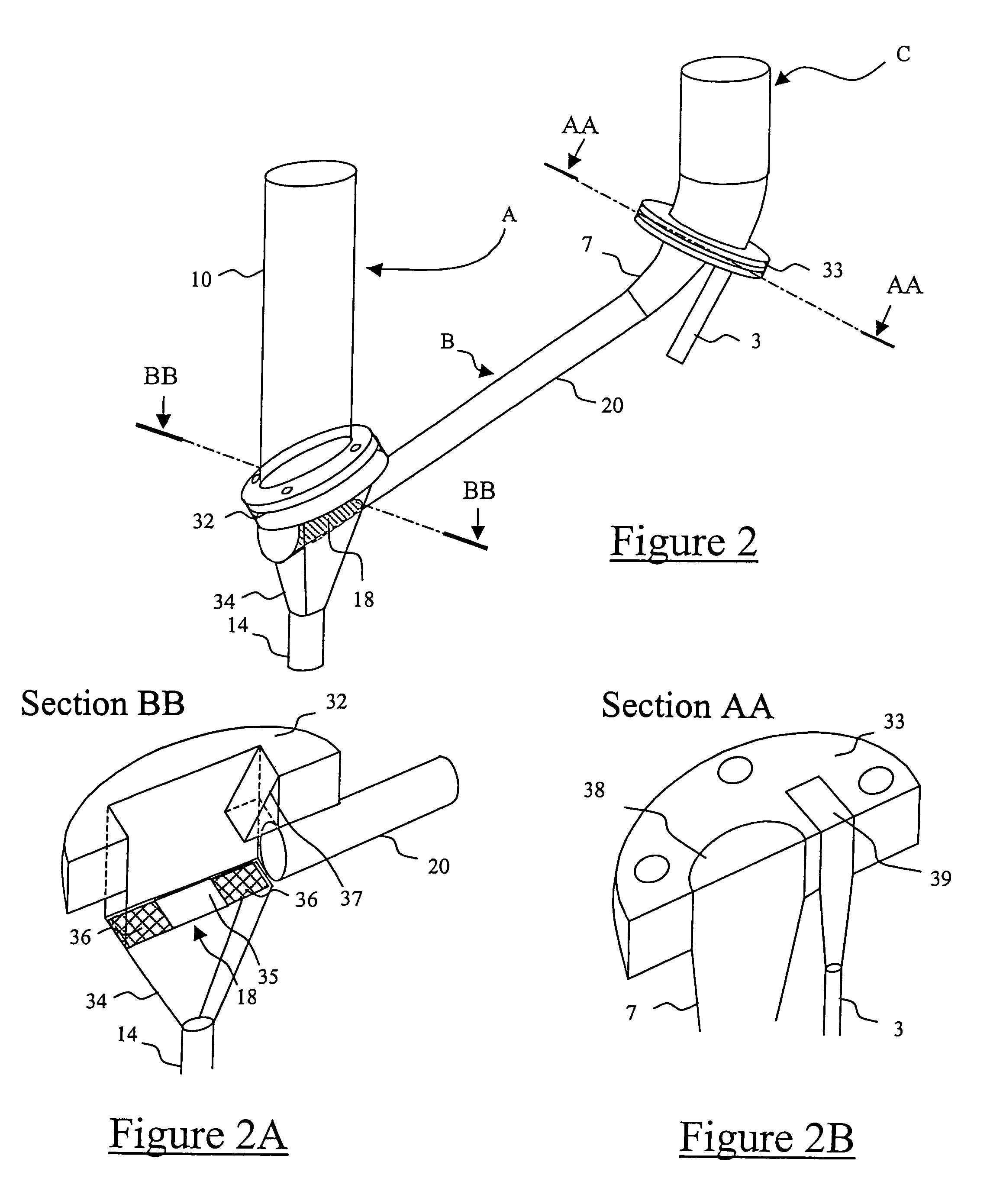

Mid-line connector and method for pipe-in-pipe electrical heating

ActiveUS20050054228A1Increase axial loadAvoid local accumulationPipe heating/coolingPipe-jointsElectricityElectrical conductor

For heating a pipe-in-pipe pipeline with power provided through an electric cable, mid-line connector is provided including: a connector housing joinable to the outer pipe of the pipeline; a blank pipe positioned within the connector housing and joinable to the inner pipe of the pipeline; at least one pocket mounted in the connector housing, wherein the cable is mateable with the at least one pocket; a blank pipe conductor electrically coupled between the at least one pocket and the blank pipe; and an outer pipe conductor electrically coupled between the at least one pocket and the outer pipe.

Owner:SHELL OIL CO

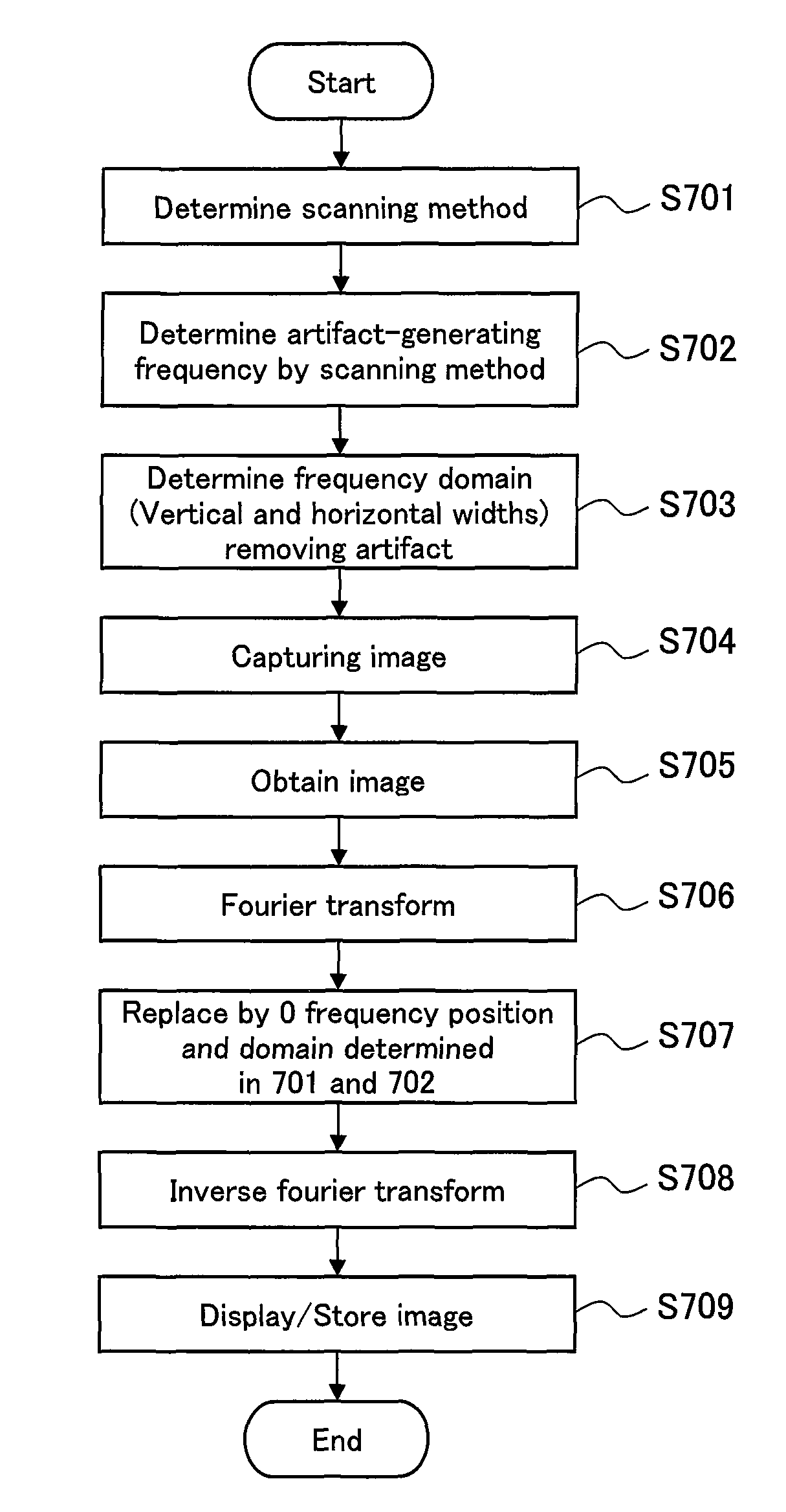

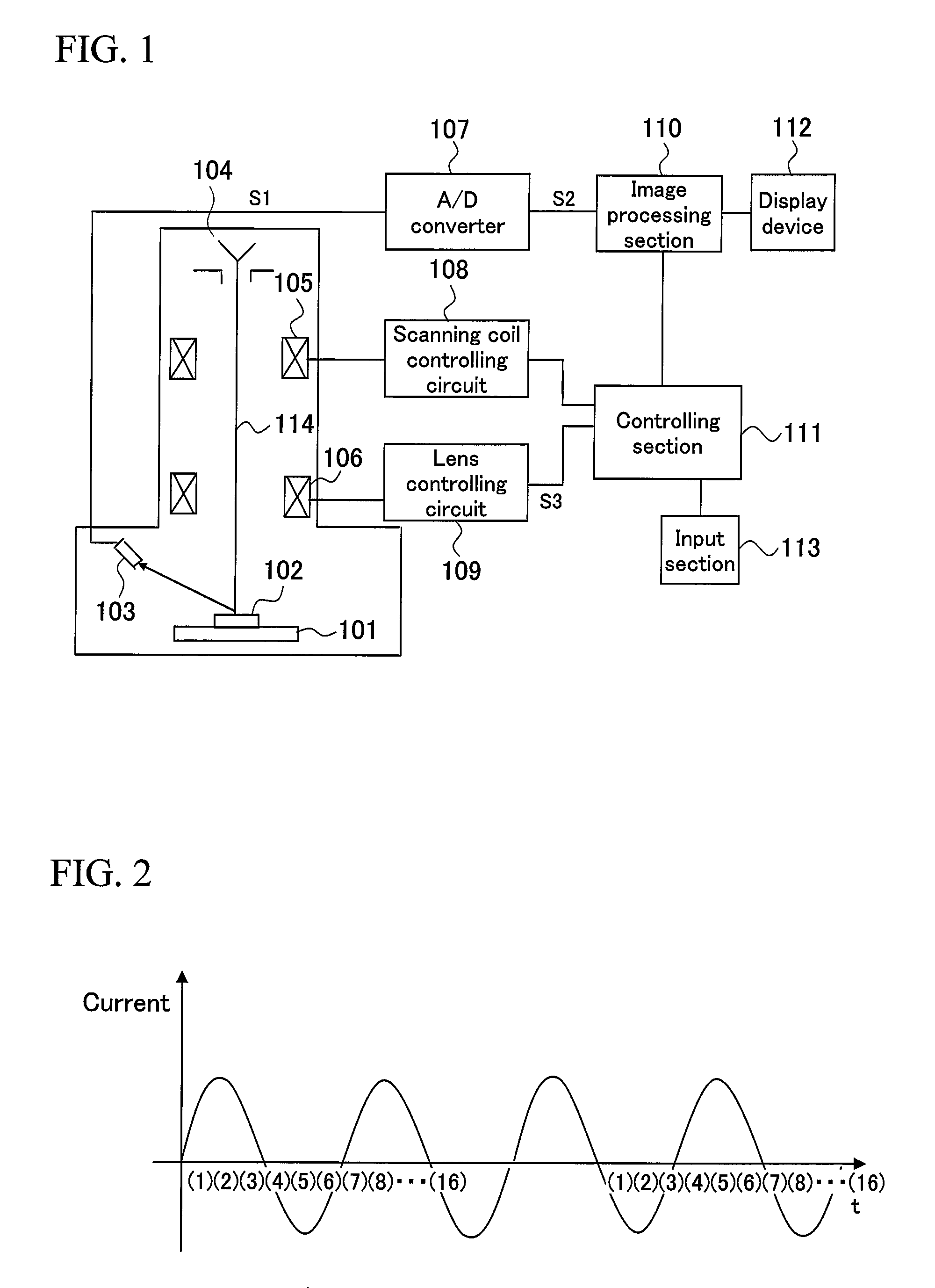

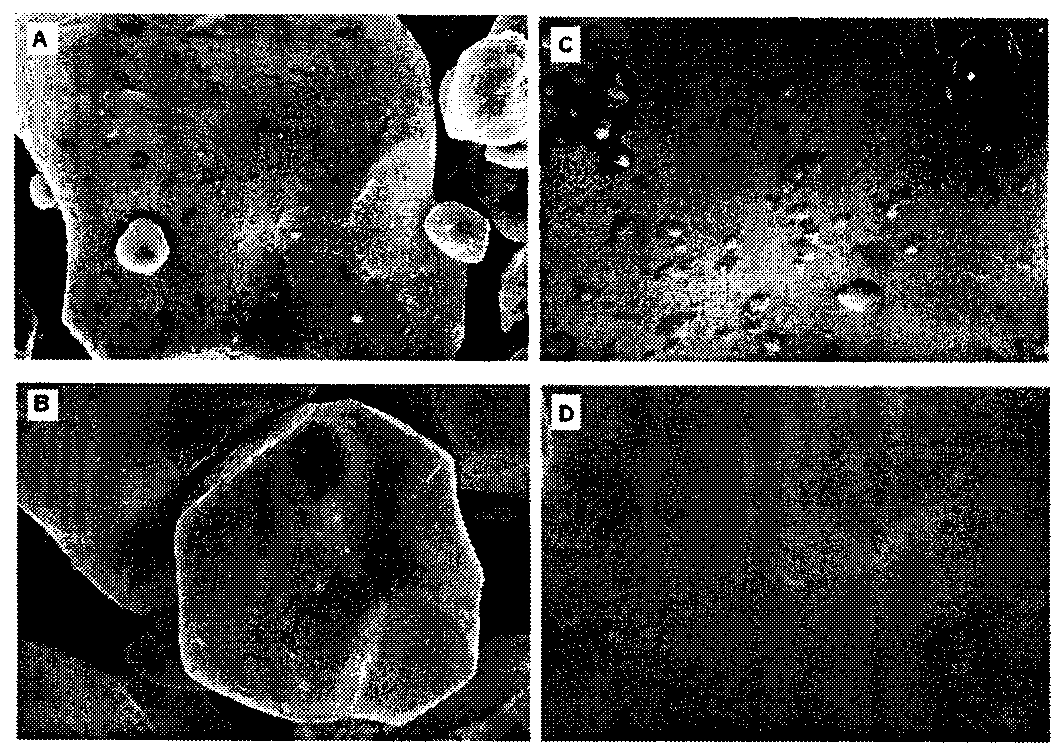

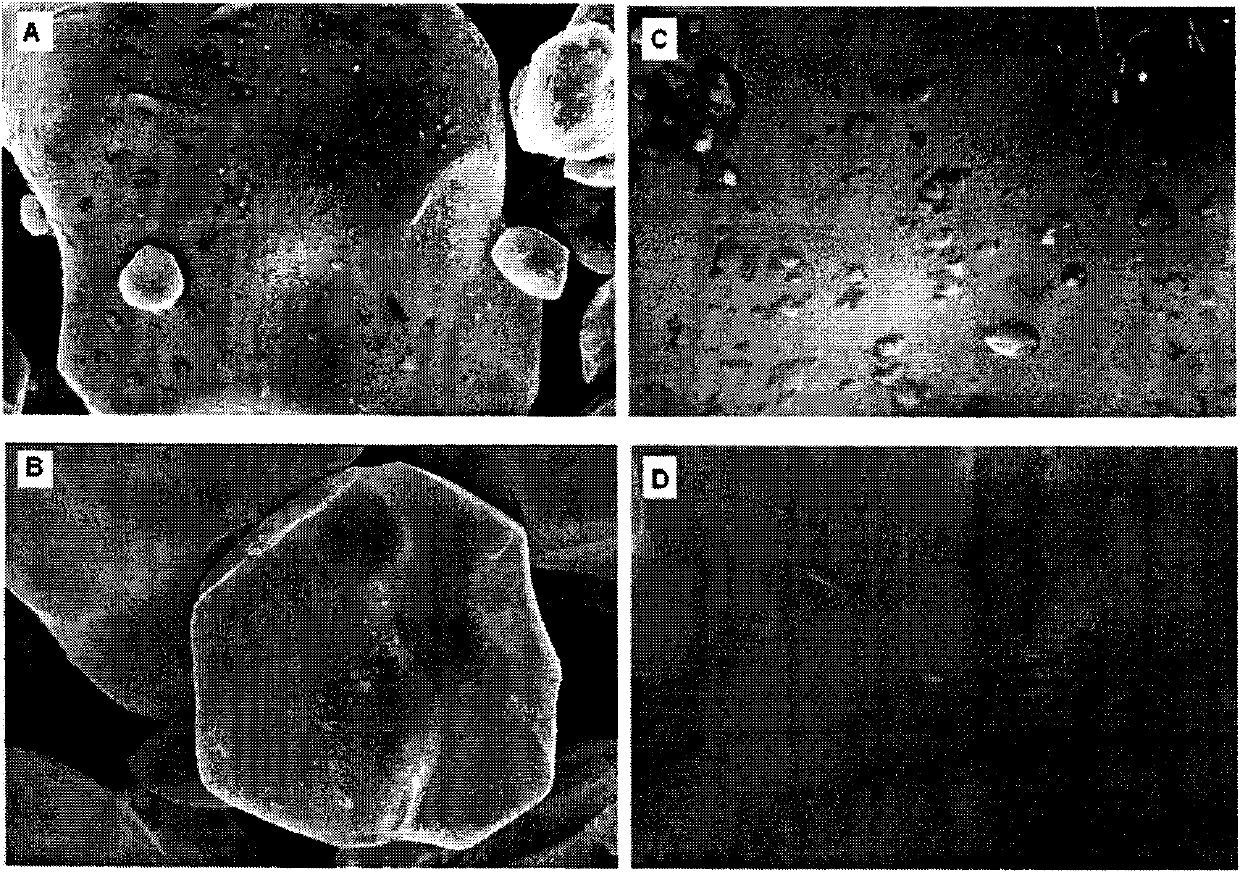

Charged particle beam apparatus

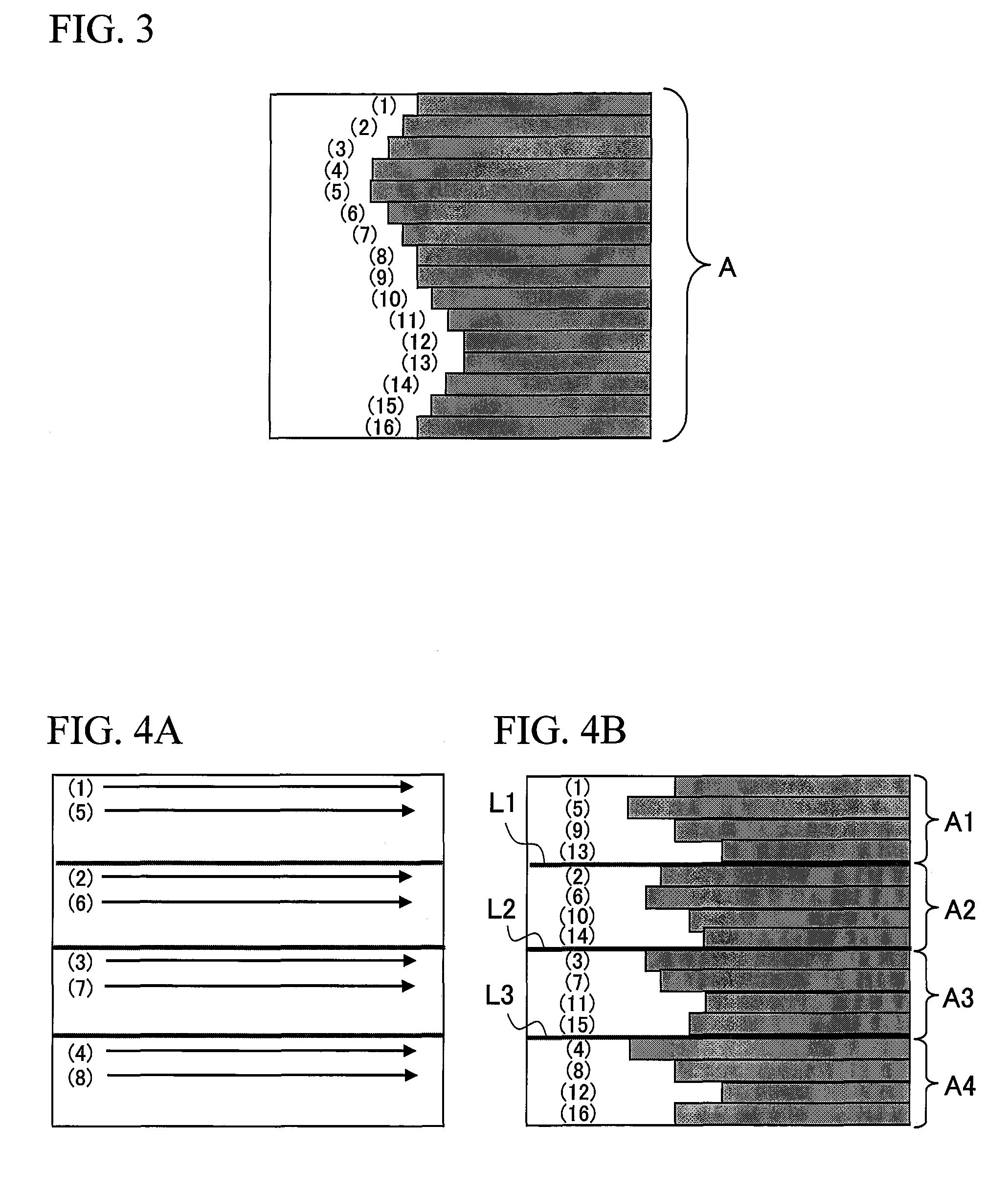

ActiveUS8335397B2Avoid local accumulationMaterial analysis using wave/particle radiationElectric discharge tubesParticle beamBeam scanning

In a method and apparatus for removing artifacts from an image generated a charged partial beam scanning device, a scanning method is determined, and the frequency of an artifact appearing on an image can then be determined, based on scanning method. A step 703, a frequency domain for removing an artifact can be determined from the vertical and horizontal widths determined by experimentation in advance with respect to the frequency position Photography is performed to obtain an image, which is Fourier transformed and the determined frequency domain is replaced, for example, by “0.” The resulting image is subjected to inverse Fourier transformation, and displayed and stored. The flow of such processing enables decreasing an artifact appearing on an image, depending on a scanning method. The frequency domain (vertical and horizontal widths) that is to be eliminated and a method for replacement by “0” are determined in advance, depending on the kind of inspected samples and a method can be selected depending on the kind of samples.

Owner:HITACHI HIGH-TECH CORP

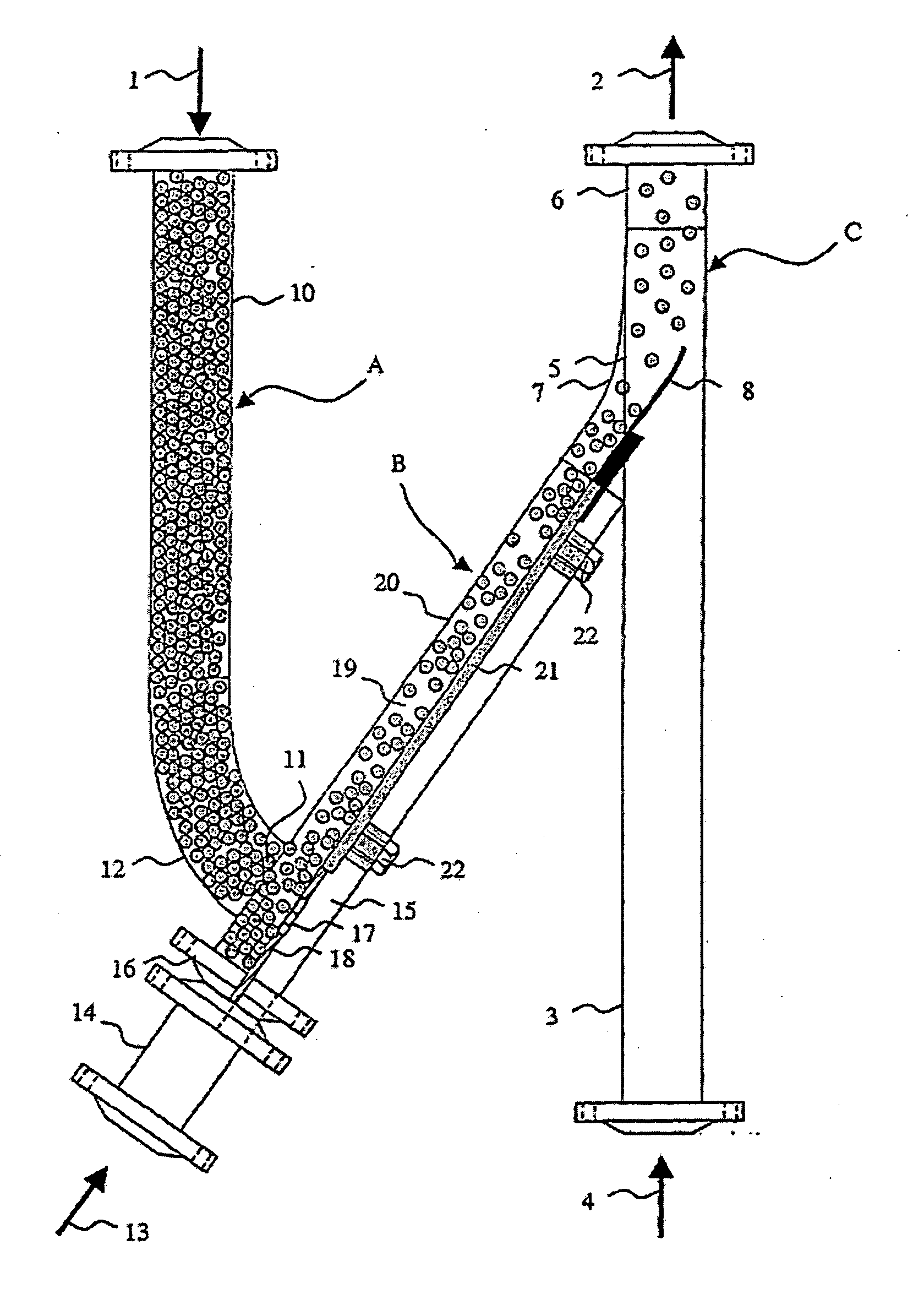

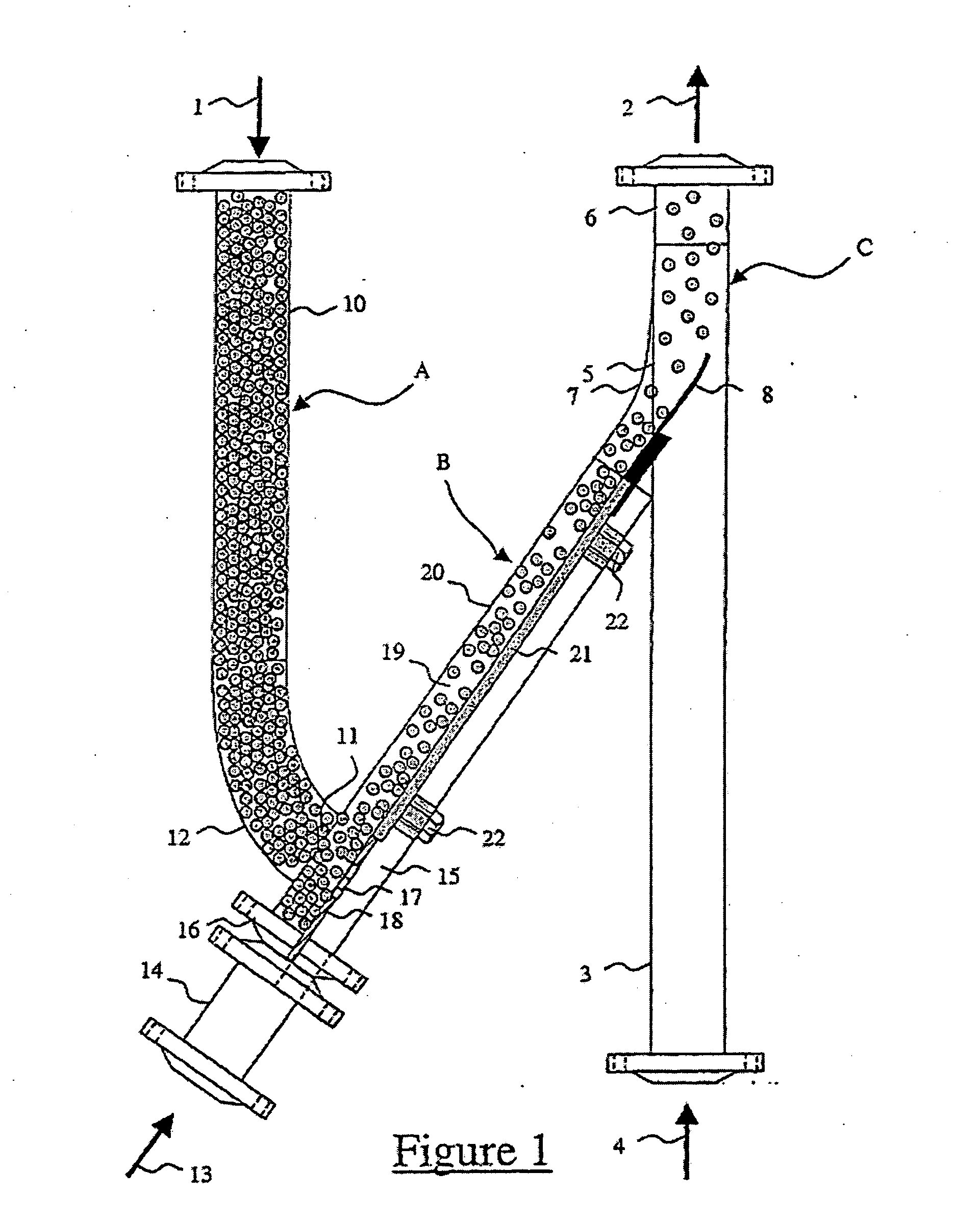

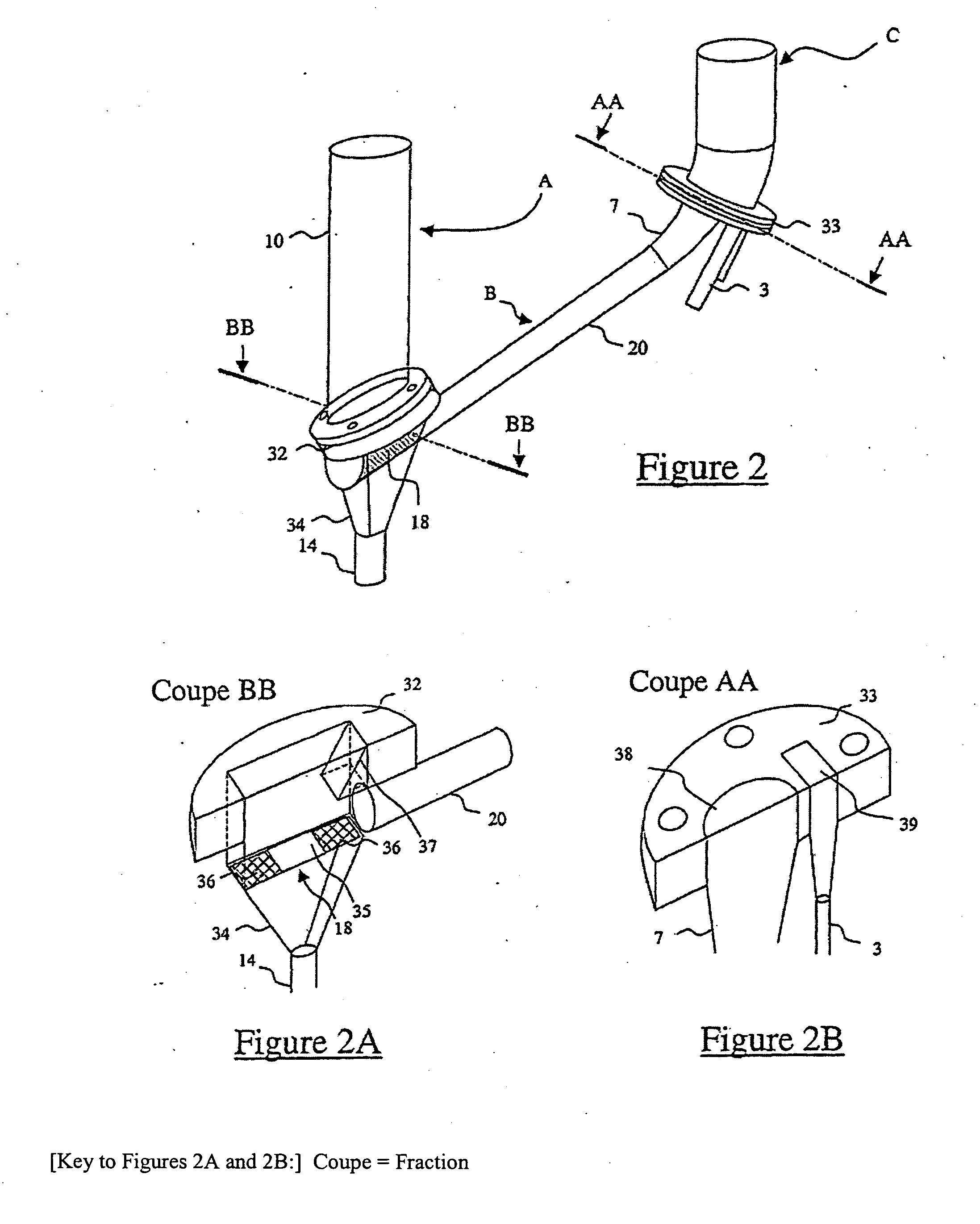

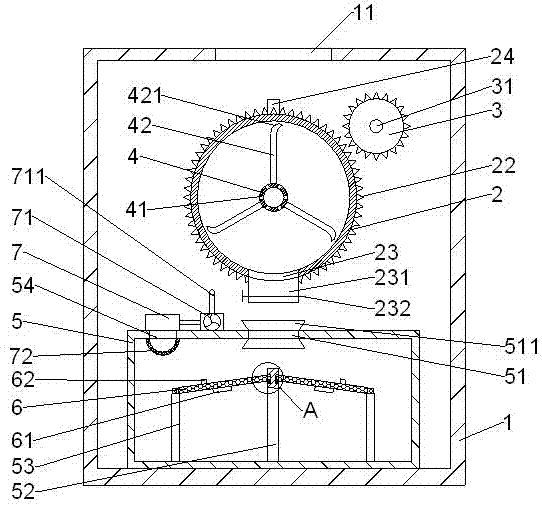

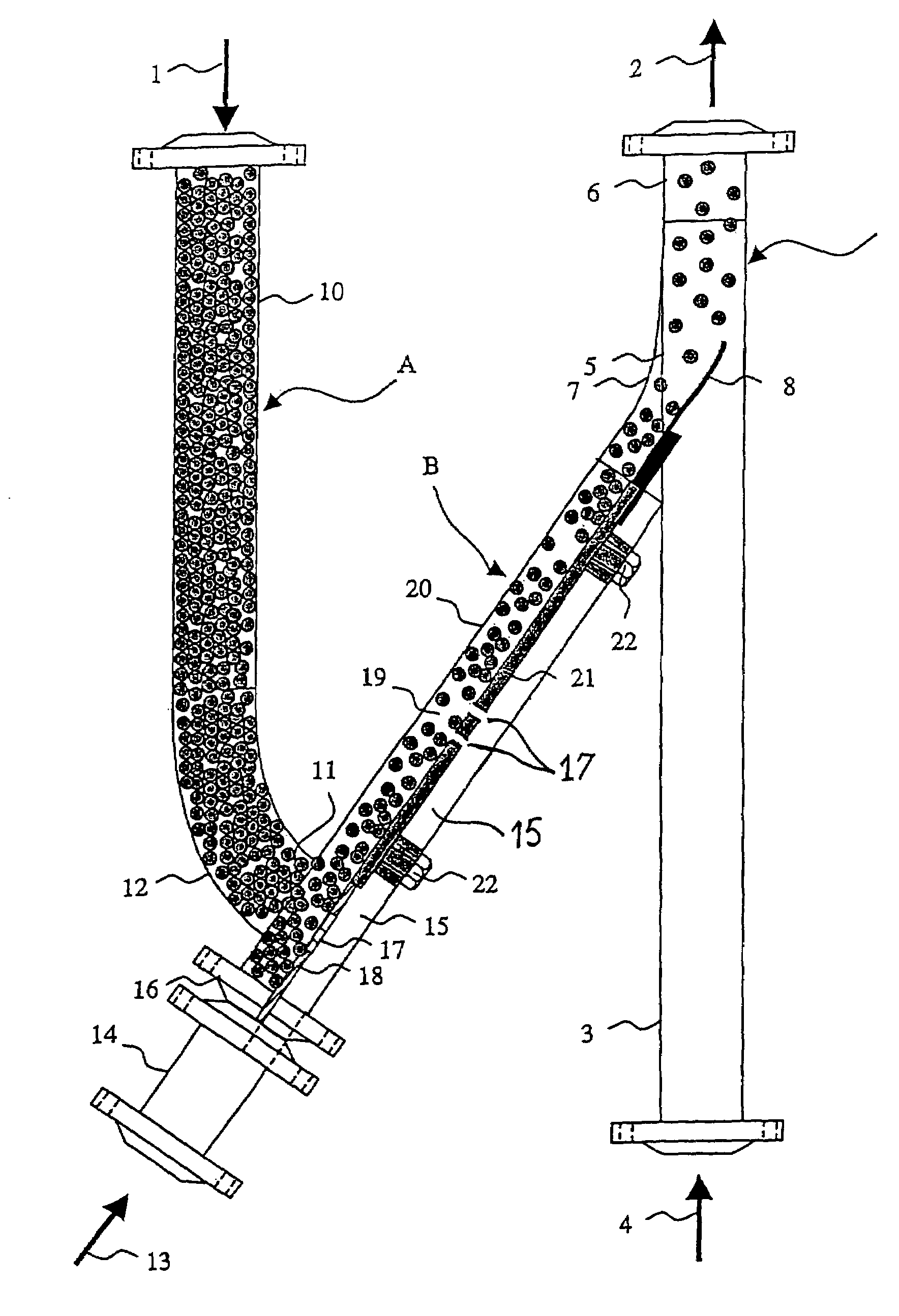

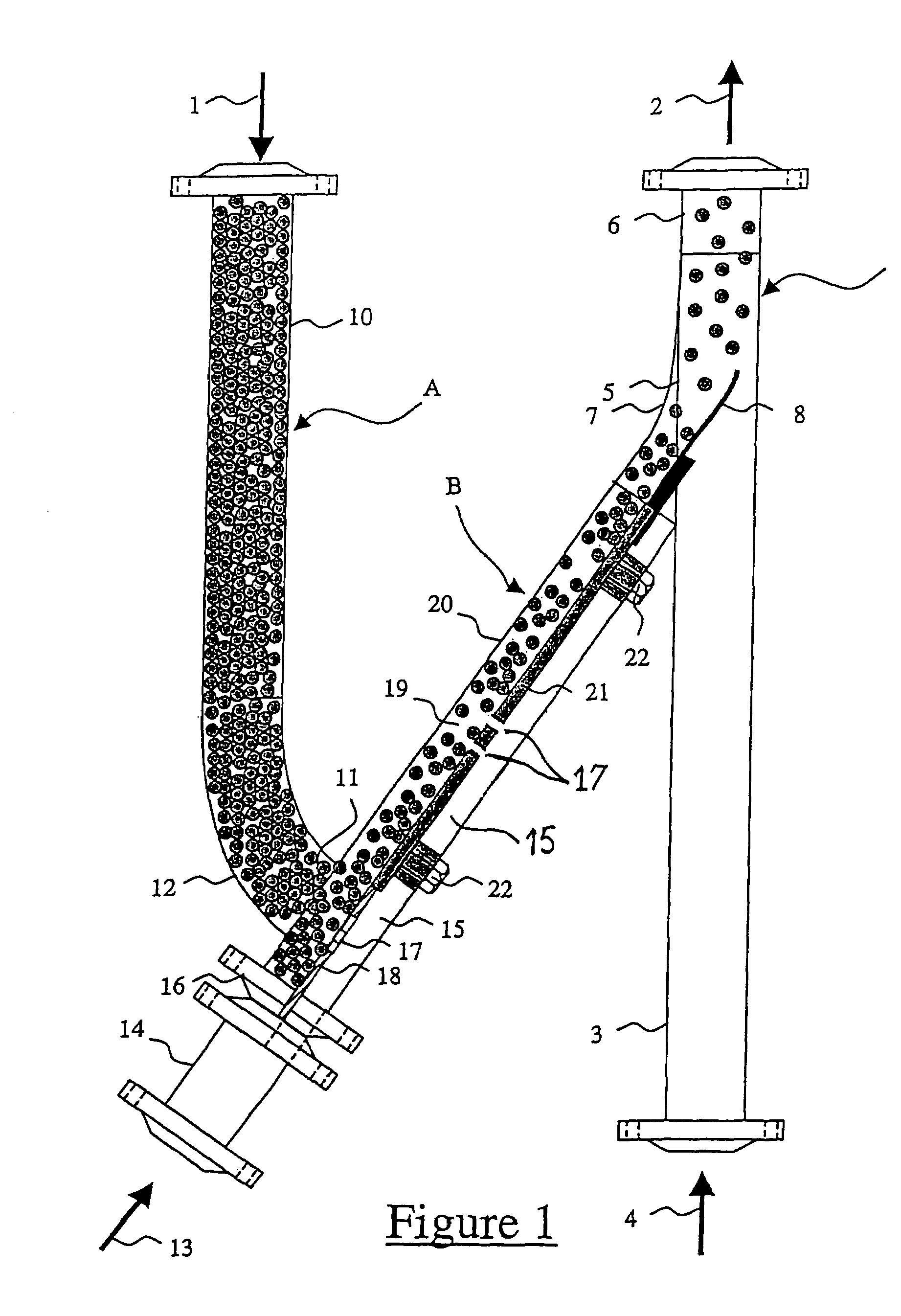

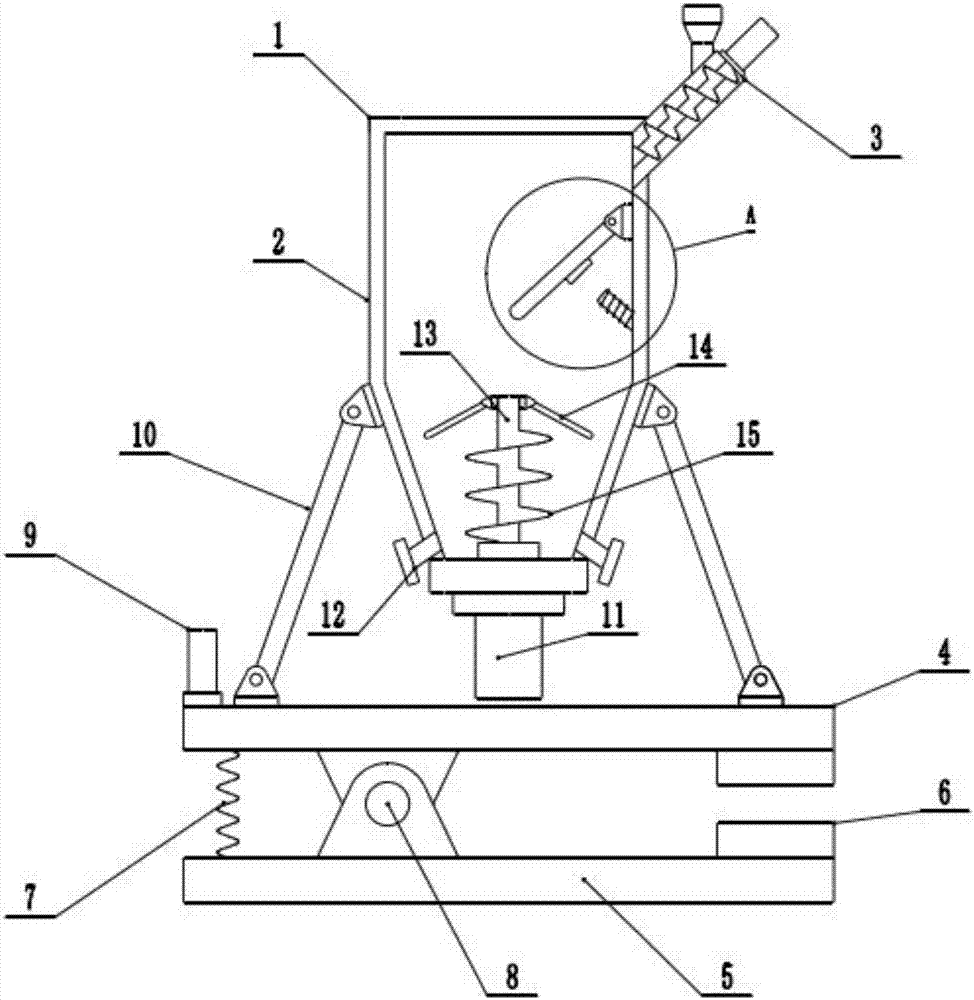

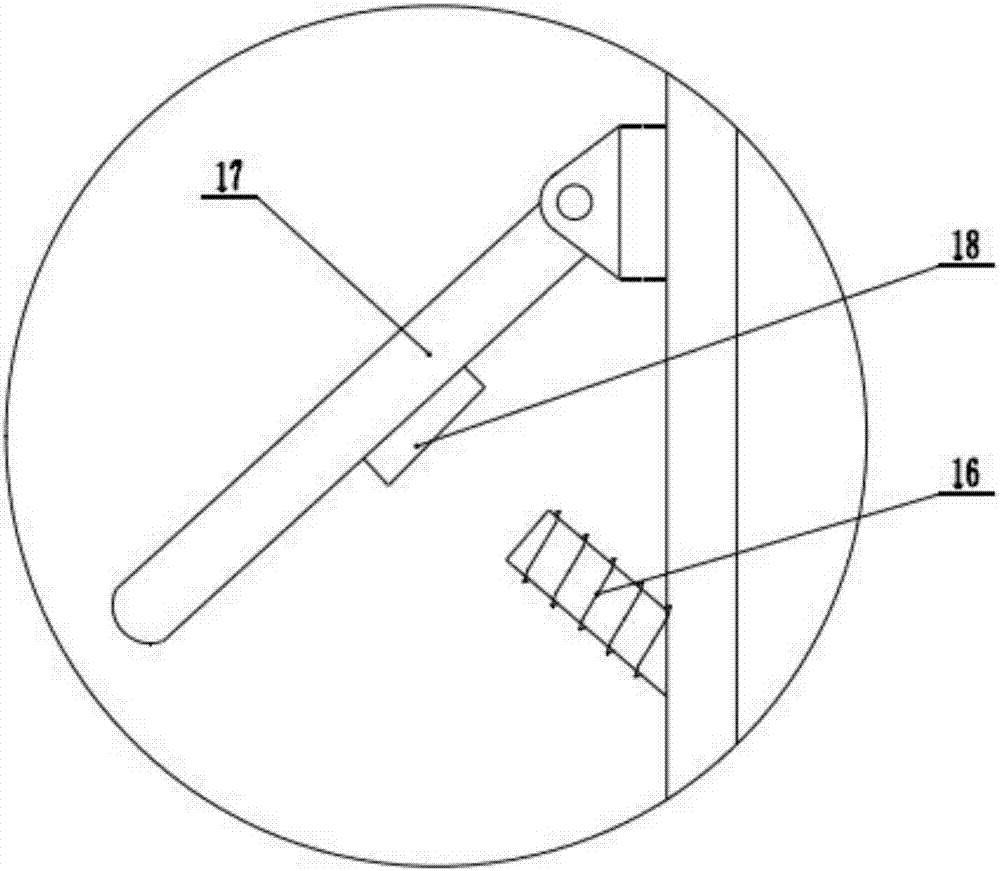

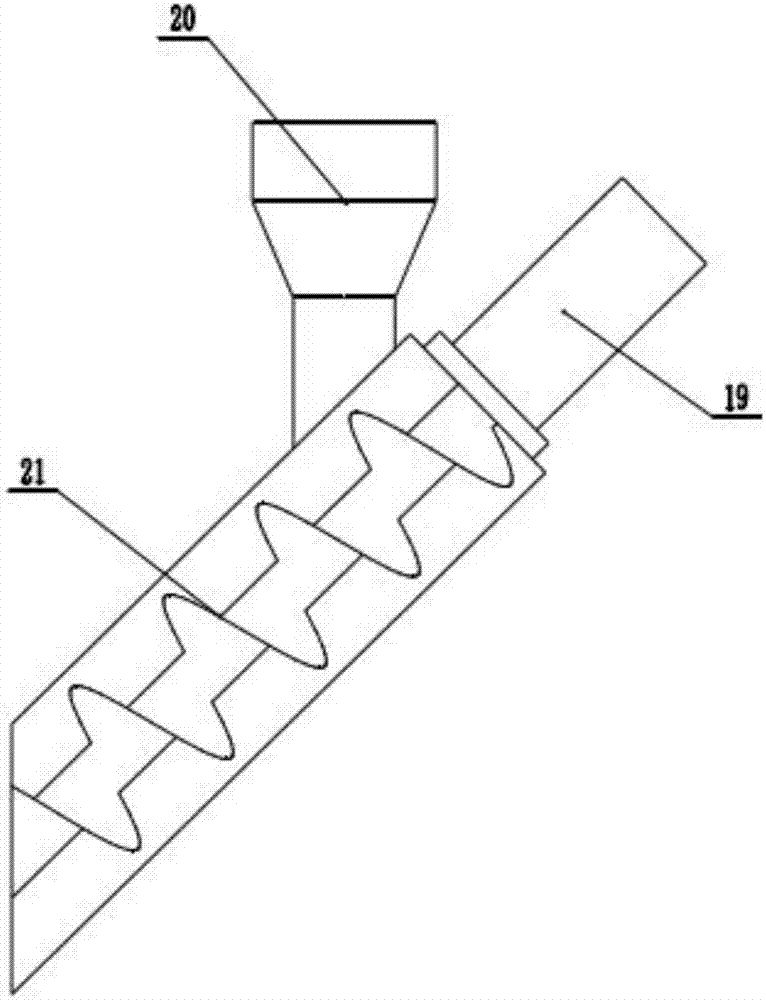

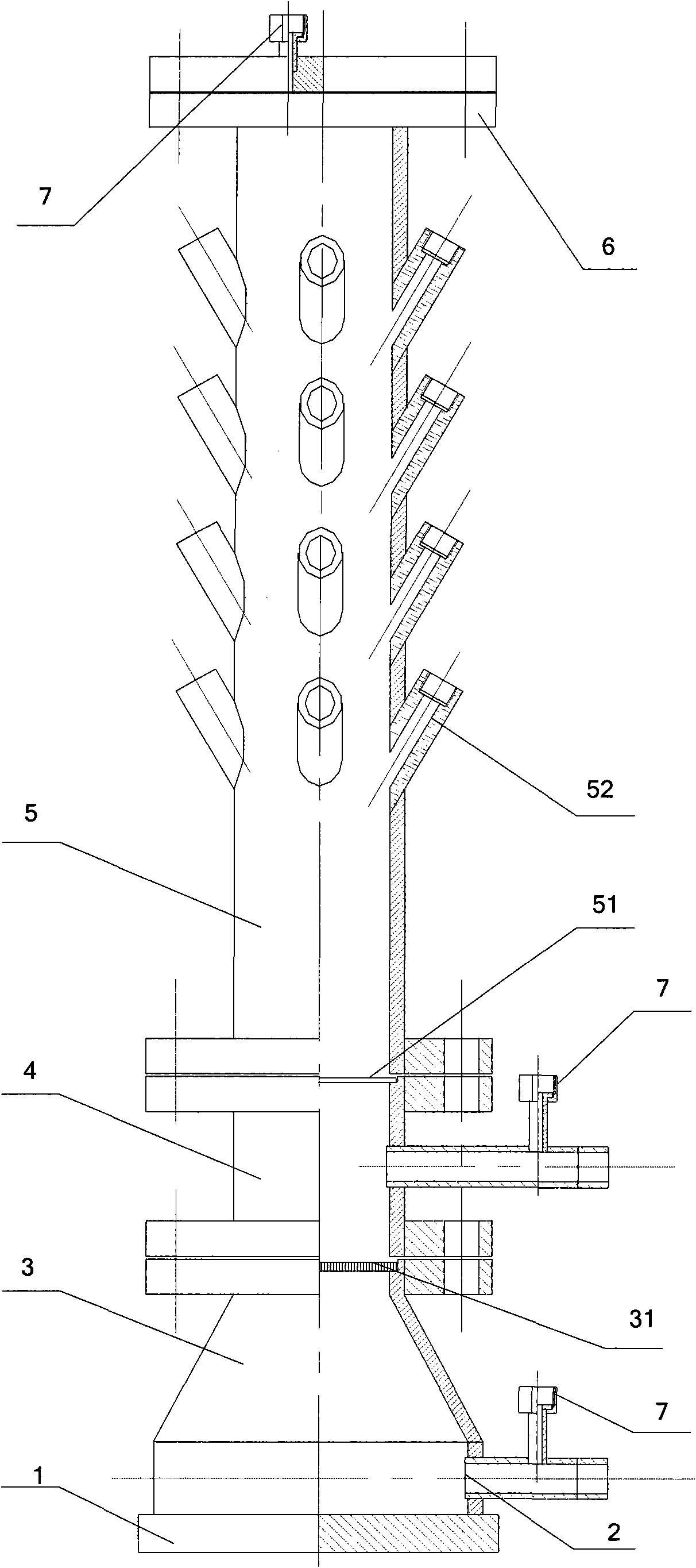

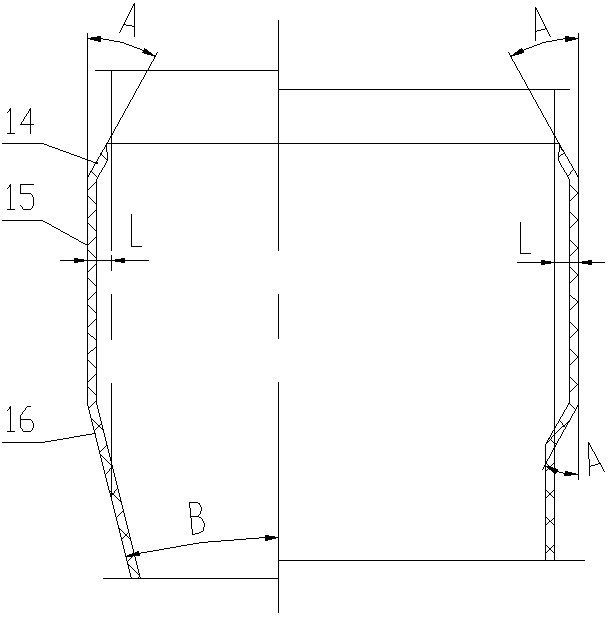

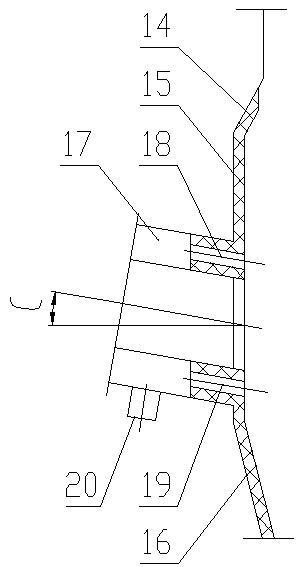

Device for the transport of granular solid particles with a controlled flow rate

ActiveUS20050058516A1Easy flow adjustmentReduce sensitivityVolume/mass flow measurementBulk conveyorsPtru catalystEngineering

Process and device for the transport of granular solids with a controlled flow rate, in particular for the transport of catalyst in a hydrocarbon reforming unit. The device comprises a gravity-feed pipe (A) for solid particles in the dense phase, a pneumatic transport pipe (C) in the dilute phase, and an inclined transfer pipe (B) that connects, without a buffer space, the base of the feed pipe to the pneumatic transport pipe, whereby this transfer pipe comprises means (17, 18, 35) for injection of a secondary gas located at the junction between the feed pipe and the transfer pipe.

Owner:INST FR DU PETROLE

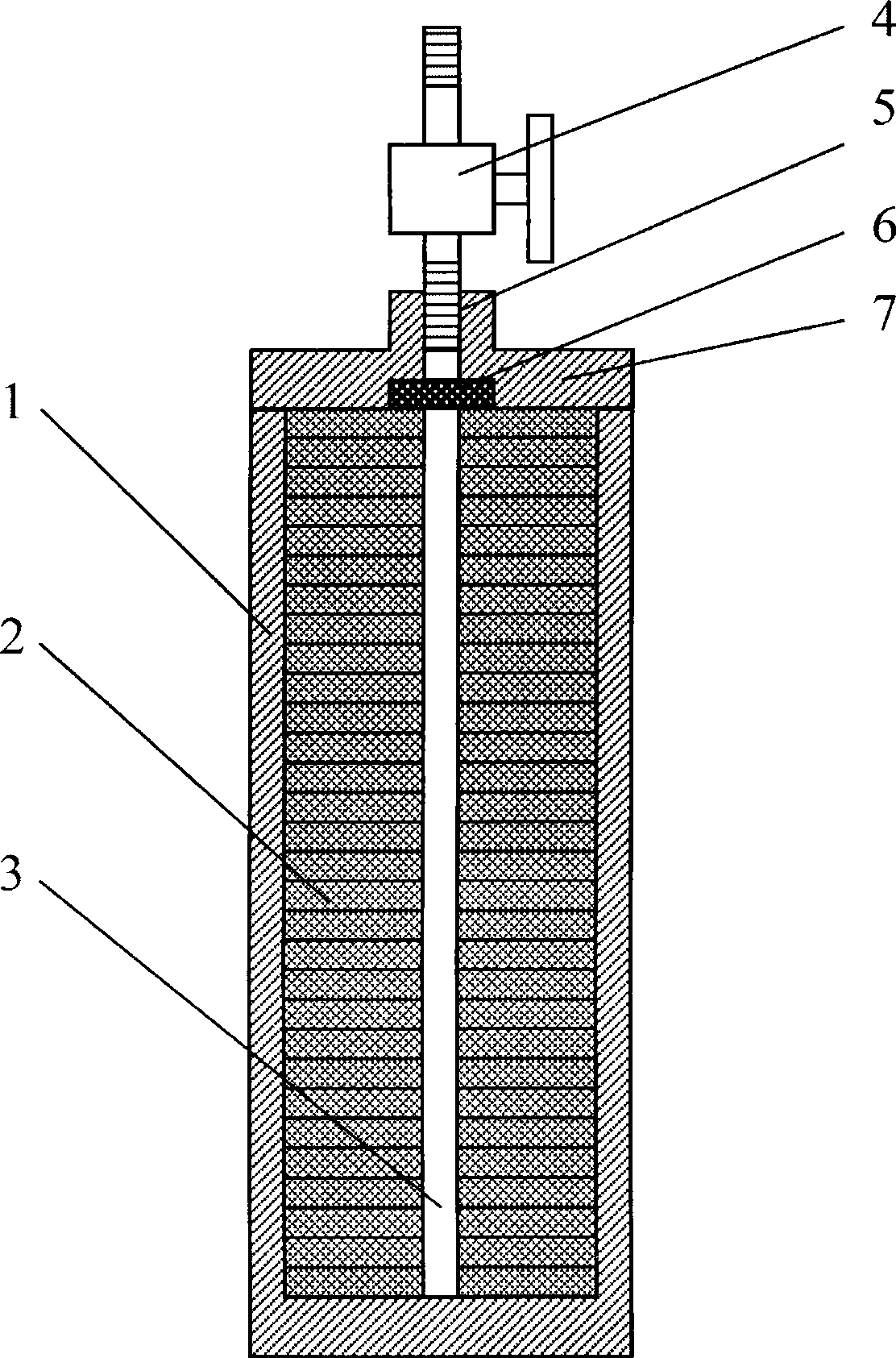

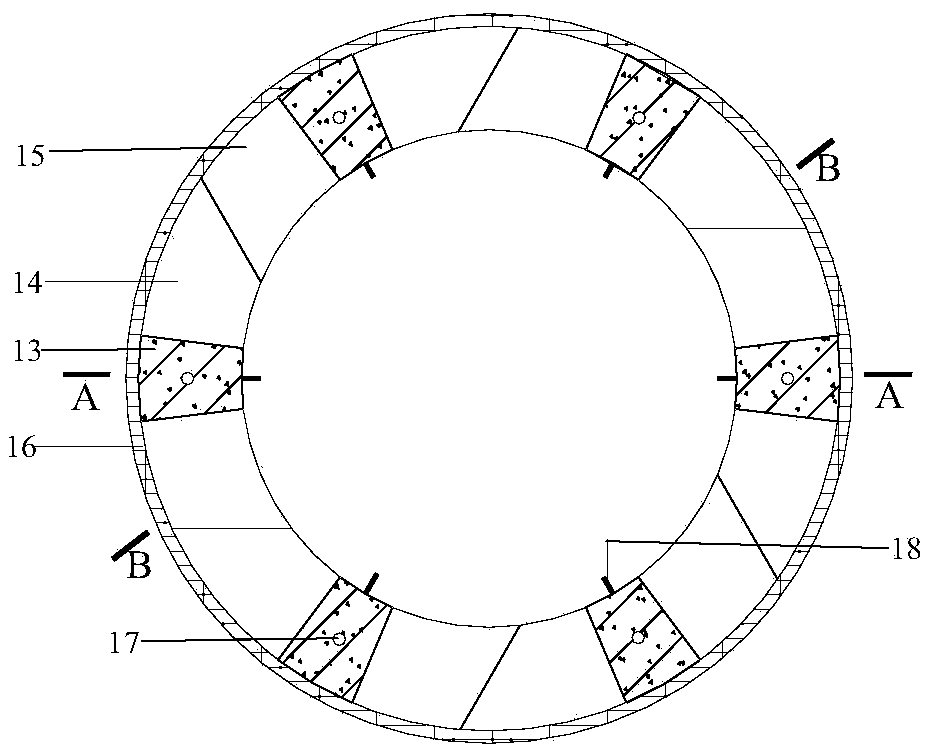

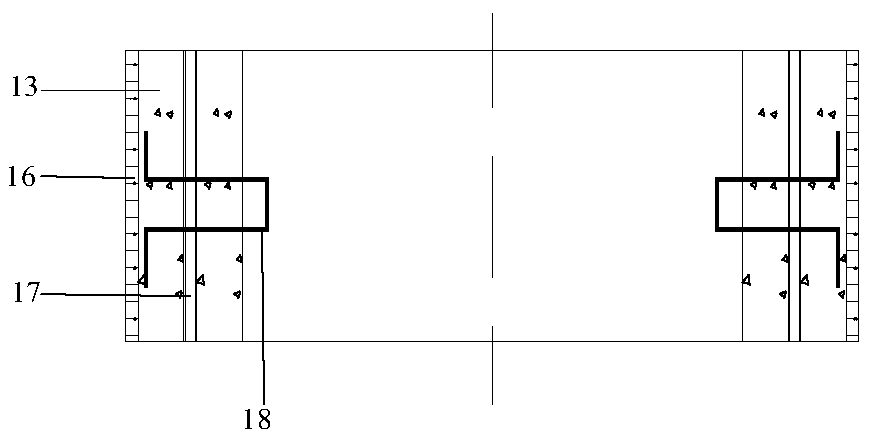

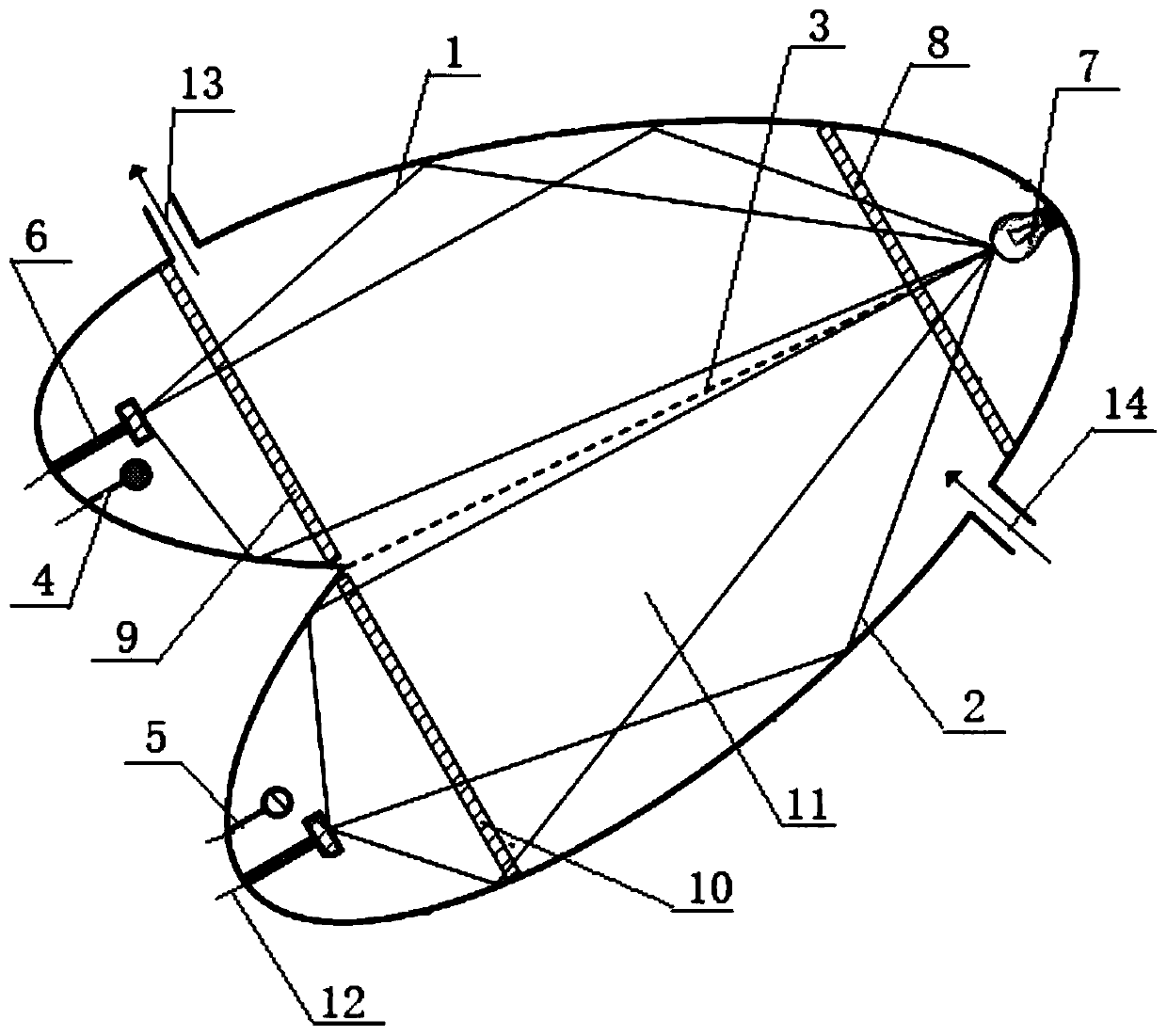

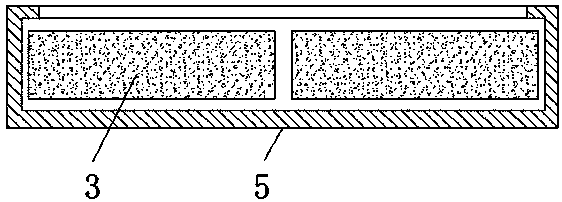

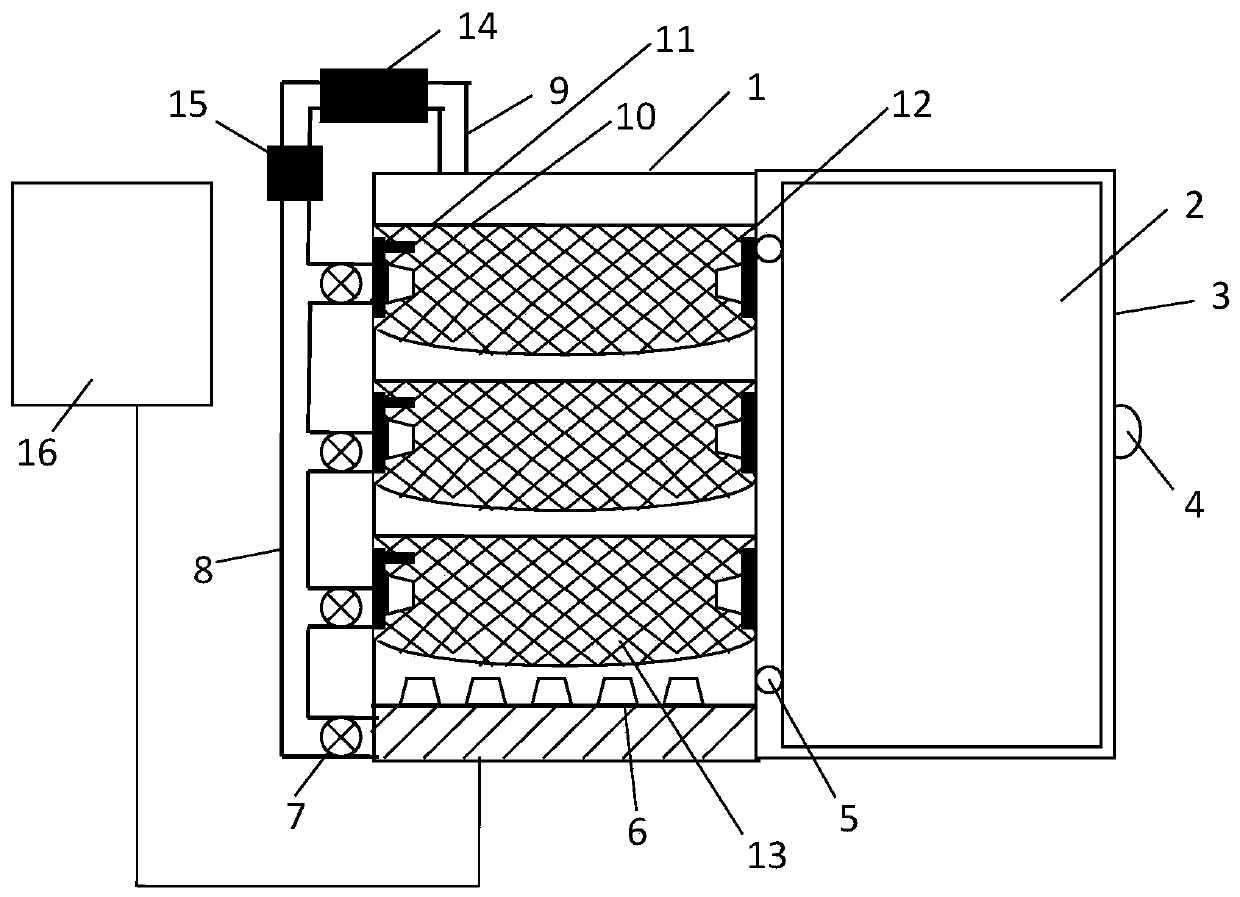

Hydrogen storing apparatus of metal hydrides and manufacturing method thereof

ActiveCN101413624AAvoid deformationAvoid destructionFixed capacity gas holdersHeat transmissionAdhesive

The invention relates to a metal hydride hydrogen storage device and a preparation method thereof; wherein, the device comprises a shell which is filled in superposed hydrogen-storage material sheet which consists of a spumescent metal substrate which absorbs no hydrogen and mixture of hydrogen-storage alloy powder and adhesive which are filled in the gap of the spumescent metal substrate; the hydrogen-storage material sheet is provided with a central hole which is coincident to the central hole of the shell head and is connected with the central hole of the head by a filter sheet which is embedded in the head; the central hole of the head is fixed with a joint pipe which is provided with a valve. The hydrogen storage device can effectively improve the heat transmission performance of the hydrogen storage alloy and hydride powder, effectively prevents the flowing and accumulating of the hydrogen-storage alloy and the hydride, solves the hydrogen absorption expansion problem of the hydrogen storage alloy powder, thus having the advantages of high-efficiency running, safety and reliability and being suitable for the production of meta hydride hydrogen-storage devices applied to various sites.

Owner:ZHEJIANG UNIV

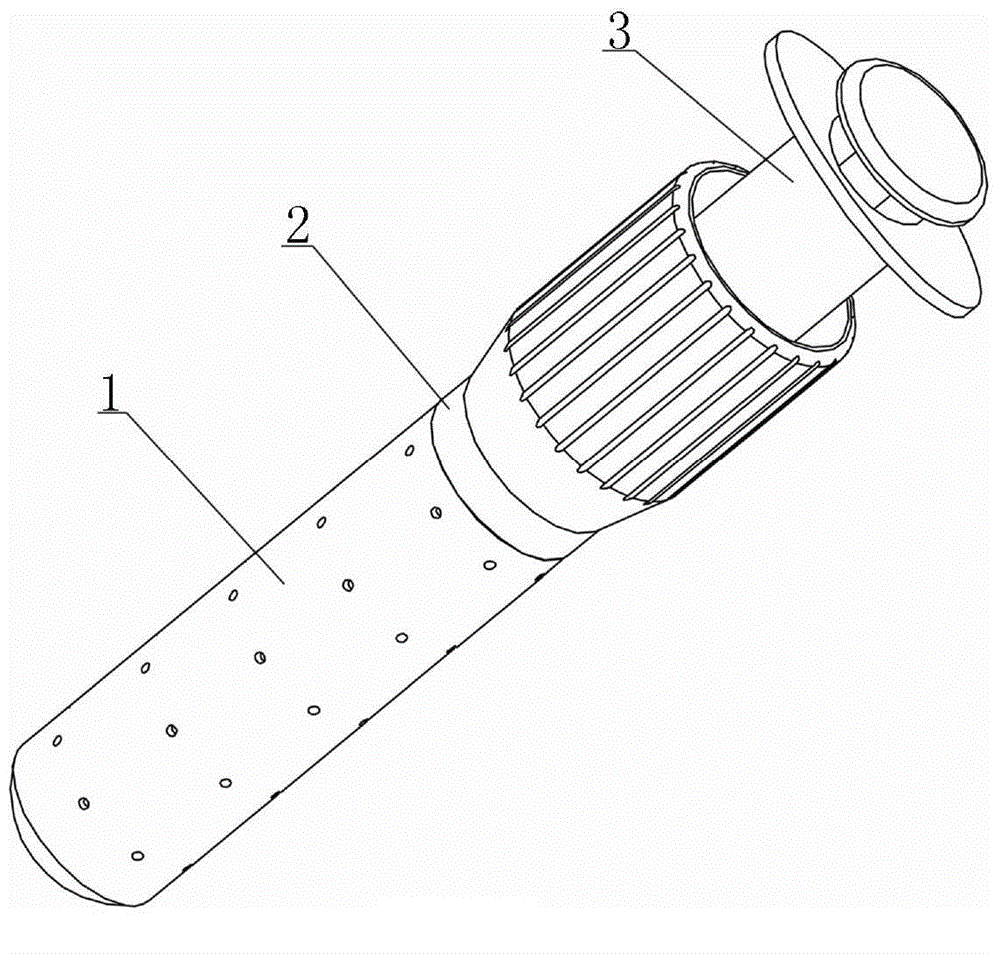

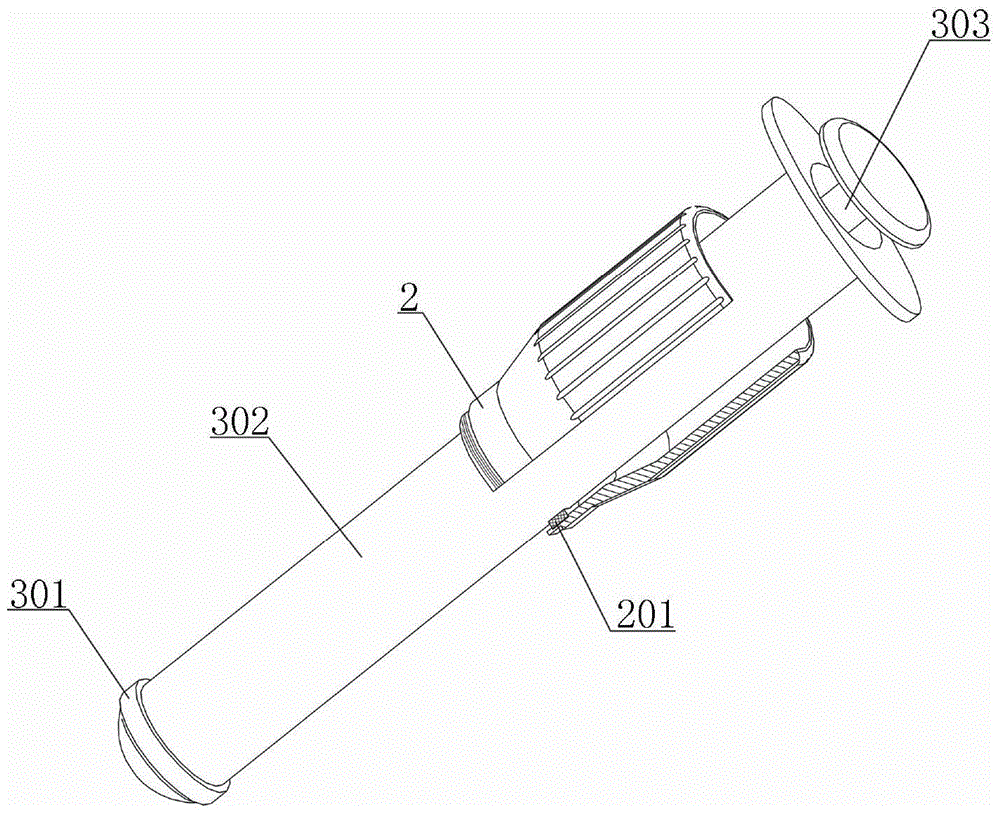

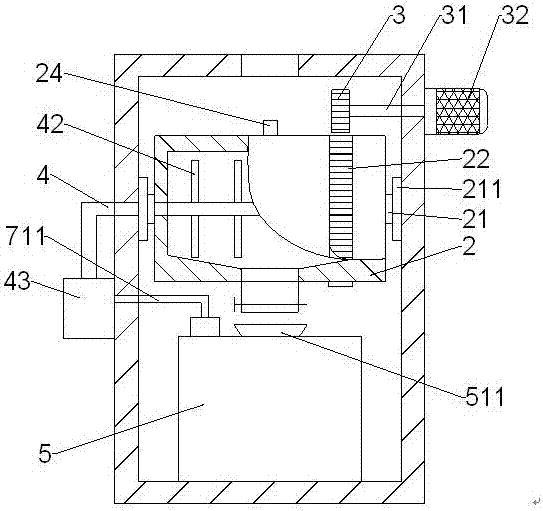

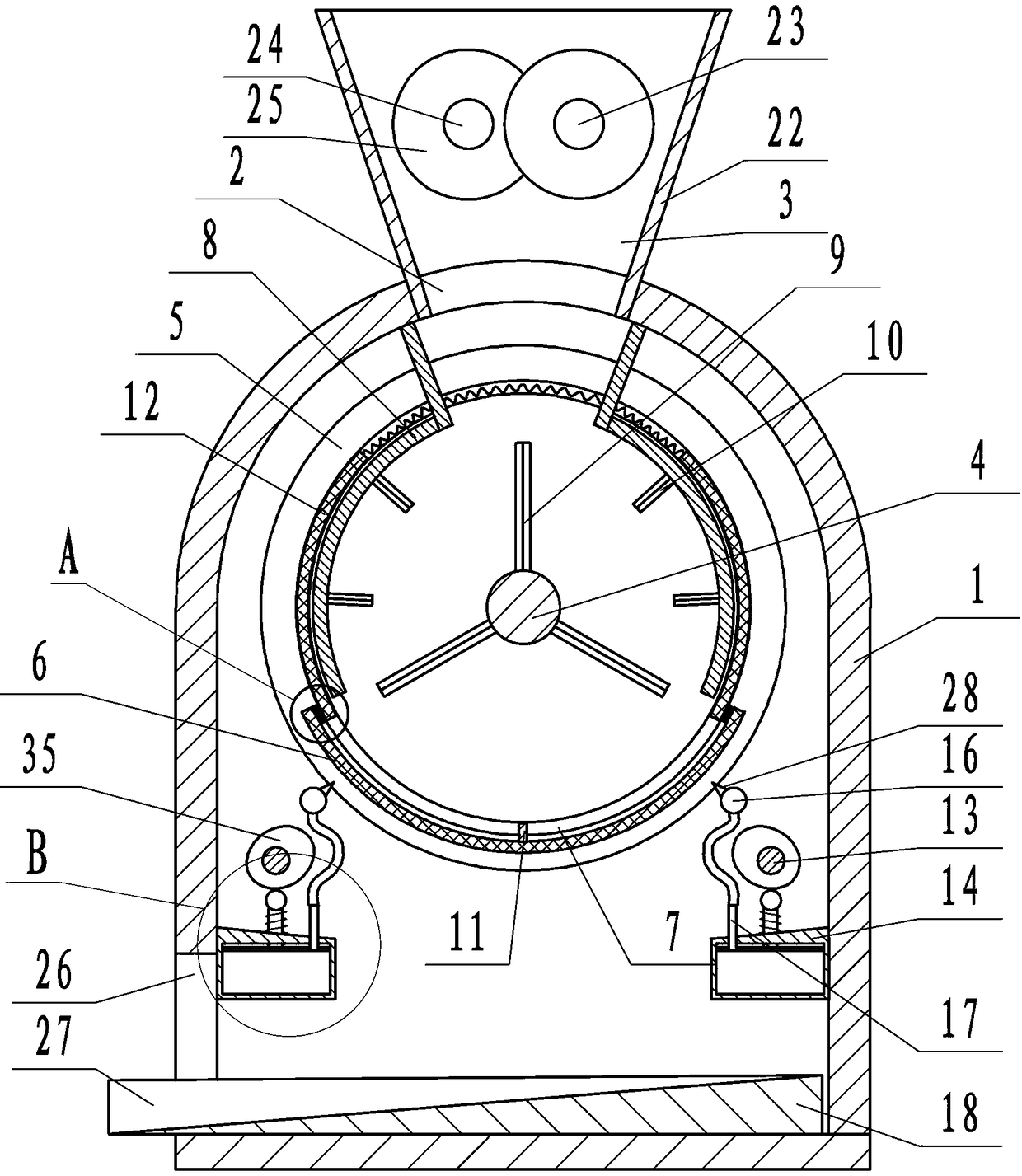

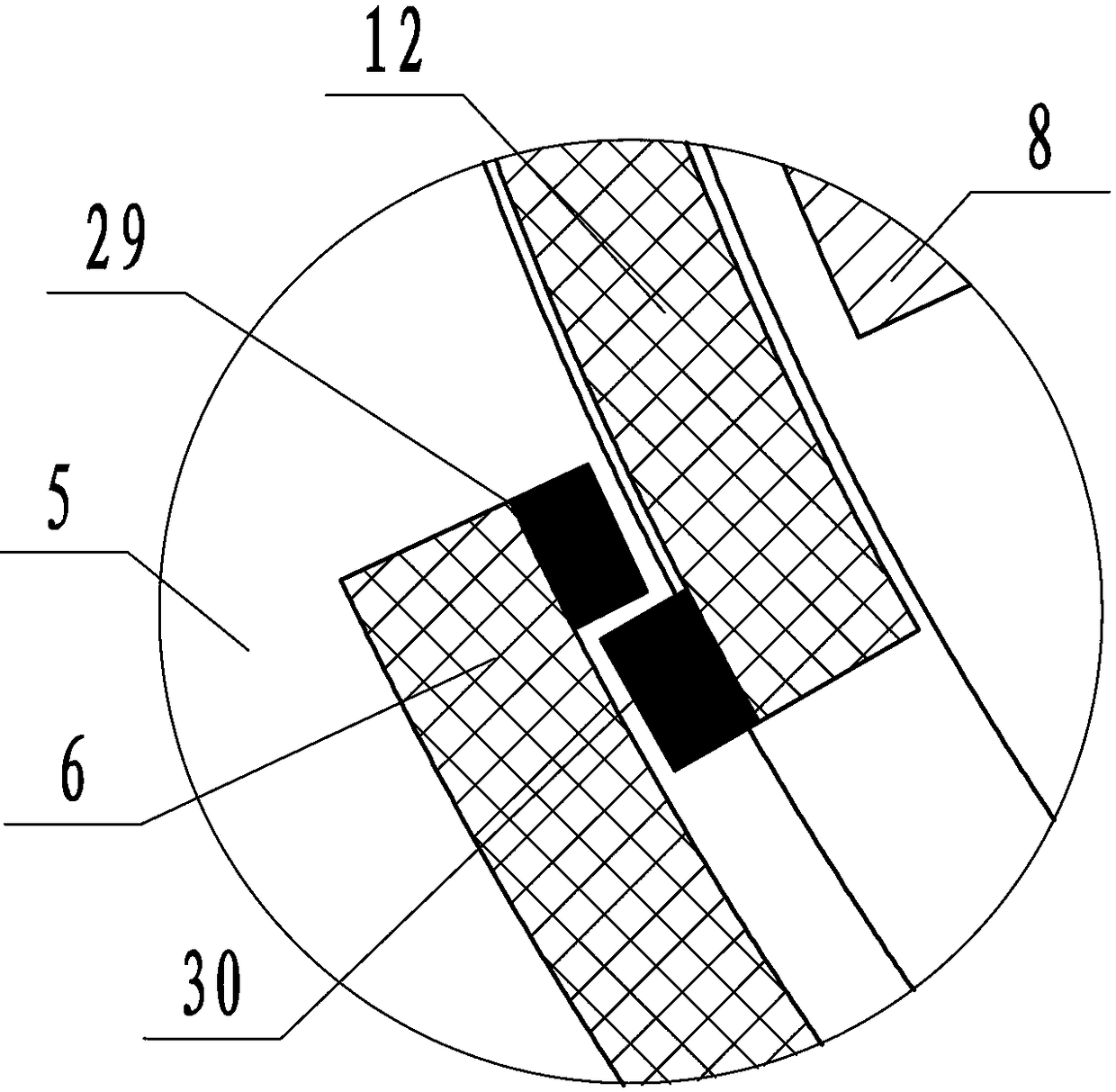

Gynecology administration device

The invention discloses a gynecology administration device. The gynecology administration device comprises a drug pushing tube, an outer sleeve and a drug distributing tube, wherein the drug pushing tube is provided with a drug inlet and outlet hole in the front end face, and a first O-type ring is fixed to the outer side wall of the front end of the drug pushing tube; the outer sleeve is arranged outside the drug pushing tube in a sleeving mode, and a second O-type ring is fixed to the inner side of the front end of the outer sleeve; the drug distributing tube is arranged outside the drug pushing tube in a sleeving mode, the rear end of the drug distributing tube is connected with the outer sleeve in a sealed mode, administration holes are formed in the bottom and the side wall of the drug distributing tube, a communicating groove is formed in the inner tube wall of the drug distributing tube, and when the front end of the drug pushing tube abuts against a limiting protrusion, interlayer spaces before and after the first O-type ring are communicated. The administration device discharges a drug through the multiple holes, administrates the drug evenly, is large in acting surface, prevents the drug from accumulating locally, and ensures that the drug fast takes effect on the focus portion in time, and therefore the use efficiency and the treatment effect of the drug are improved; the drug distributing tube is disposable, so that the gynecology administration device is safe and sanitary, the drug pushing tube and the outer sleeve are convenient to clean and can be recycled, and therefore the cost of treating gynecological disease is reduced; excessive drug residue can be avoided, drug waste is reduced, and the gynecology administration device can be operated coherently, smoothly and easily.

Owner:杨海霞

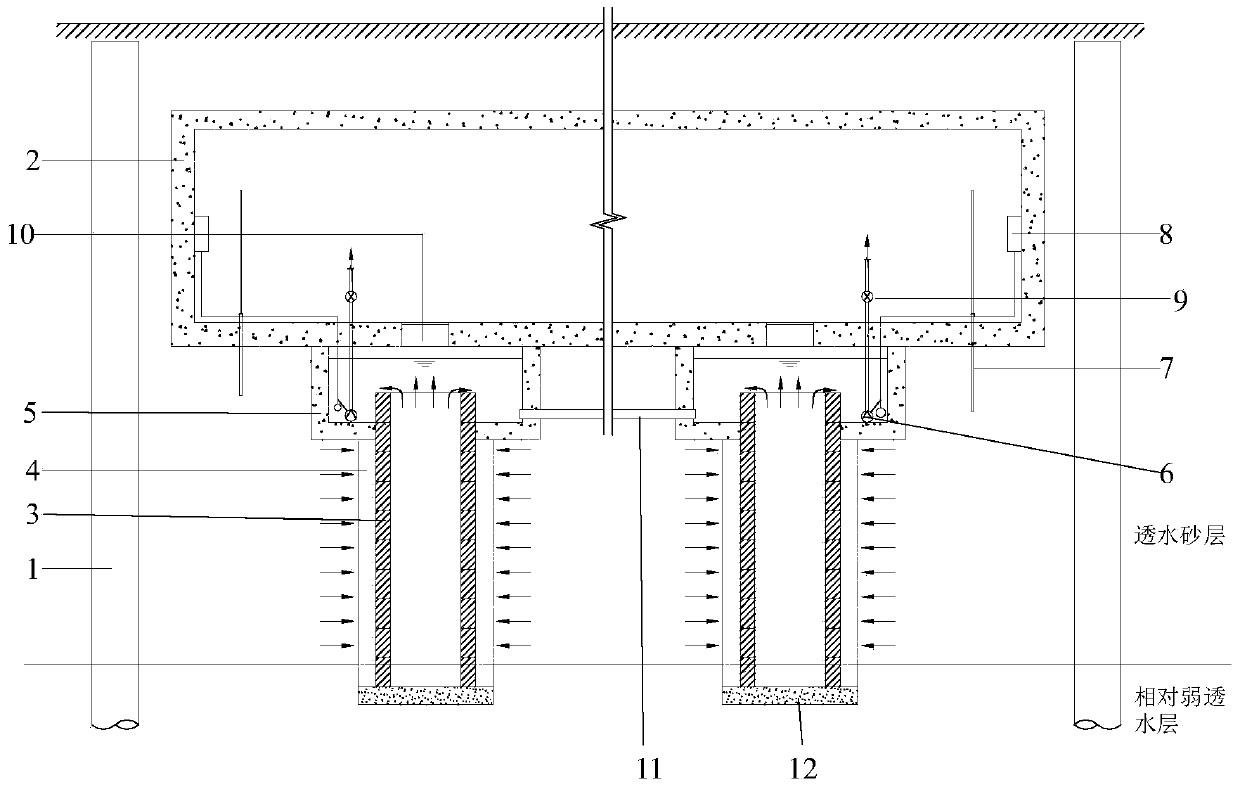

Interception and drainage pressure-reduction anti-floating system

The invention discloses an interception and drainage pressure-reduction anti-floating system which comprises a waterproof curtain arranged around an underground structure. A plurality of water collecting pits are formed below a bottom plate of the underground structure. Immersible pumps and water level induction switches are arranged in the water collecting pits. Well holes are formed in the bottoms of the water collecting pits. Pressure-reduction well pipes are arranged in the well holes. Anti-filtration layers are arranged around the pressure-reduction well pipes. The tops of the pressure-reduction well pipes are higher than openings of the well holes. The anti-filtration layers are located in the water collecting pits. The pressure-reduction well pipes are mainly formed by axially and vertically stacking a plurality of non-fine concrete well rings. The non-fine concrete well rings comprise upper annular ring beams, lower annular ring beams, stand columns and non-fine concrete wedge-shaped blocks. By means of cooperative work of the system, buoyant force on the bottom plate can be effectively reduced, the drainage amount can be controlled, the surrounding is protected against surface subsidence caused by the too large drainage amount, the number of uplift piles and the number of uplift anchor rods are greatly decreased, non-fine concrete blocks can be conveniently dismounted and replaced, and it is guaranteed that a pressure-reduction well has enough durability.

Owner:SOUTH CHINA UNIV OF TECH

Mid-line connector and method for pipe-in-pipe electrical heating

ActiveUS7033113B2Increase axial loadAvoid local accumulationPipe laying and repairWaterborne vesselsElectricityElectrical conductor

Owner:SHELL OIL CO

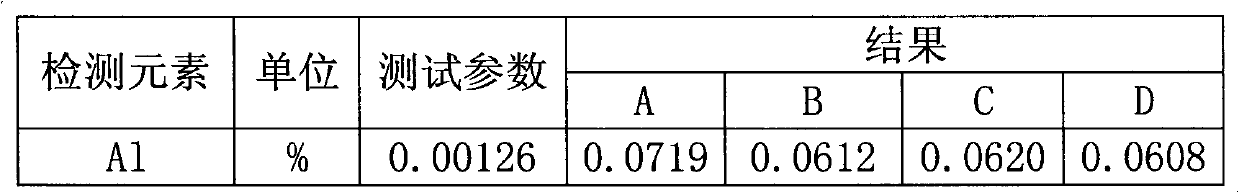

Drying device for traditional Chinese medicine preparation

InactiveCN107401903AEvenly heatedImprove functionalityDrying gas arrangementsDrying machines with non-progressive movementsMedicinal herbsAgricultural engineering

The invention discloses a drying device for traditional Chinese medicine preparation. The drying device comprises a frame, a drying drum and a screening box, wherein the drying drum and the screening box are arranged in an inner cavity of the frame; a feeding inlet is formed in the center of a top plate of the frame; the drying drum is rotatably arranged on the upper portion of the inner cavity of the frame; the drying drum is provided with a feeding and discharging port; a hot air box is installed on the exterior of the frame and connected with a hot air pipe, a rotation shaft arranged on the end face of the front side of the drying drum is designed to be hollow, and the hot air pipe penetrates through the rotation shaft from the axis of the rotation shaft to stretch into the drying drum and then extend; the screening box is located under the drying drum, and an air suction inlet is formed in the left side of a top plate of the screening box; a dehumidifying box is installed on the portion, corresponding to the air suction inlet, of the top of the screening box and connected with an exhaust fan through a pipeline, the exhaust fan is connected with an air pipe, and the air pipe is connected with the hot air box. According to the drying device, medical materials are heated uniformly, and then the drying effect is guaranteed; meanwhile, reutilization on heat can be completed, and therefore energy conservation and environment protection are achieved.

Owner:华润三九(郴州)制药有限公司

Device for the transport of granular solid particles with a controlled flow rate

ActiveUS7021870B2Easy flow adjustmentReduce sensitivityVolume/mass flow measurementBulk conveyorsControl flowEngineering

Process and device for the transport of granular solids with a controlled flow rate, in particular for the transport of catalyst in a hydrocarbon reforming unit. The device comprises a gravity-feed pipe (A) for solid particles in the dense phase, a pneumatic transport pipe (C) in the dilute phase, and an inclined transfer pipe (B) that connects, without a buffer space, the base of the feed pipe to the pneumatic transport pipe, whereby this transfer pipe comprises means (17, 18, 35) for injection of a secondary gas located at the junction between the feed pipe and the transfer pipe.

Owner:INST FR DU PETROLE

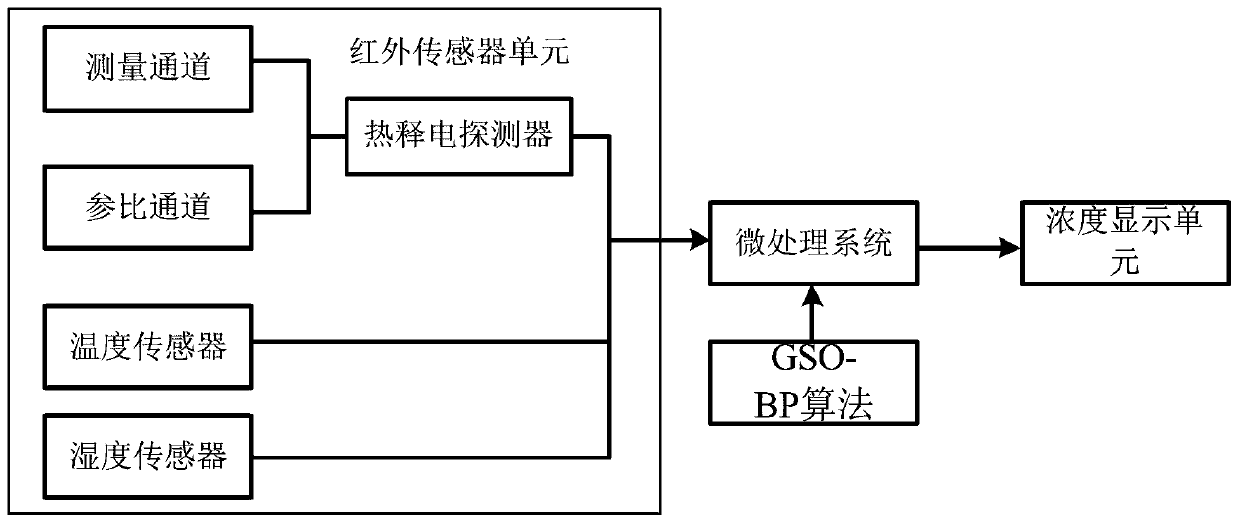

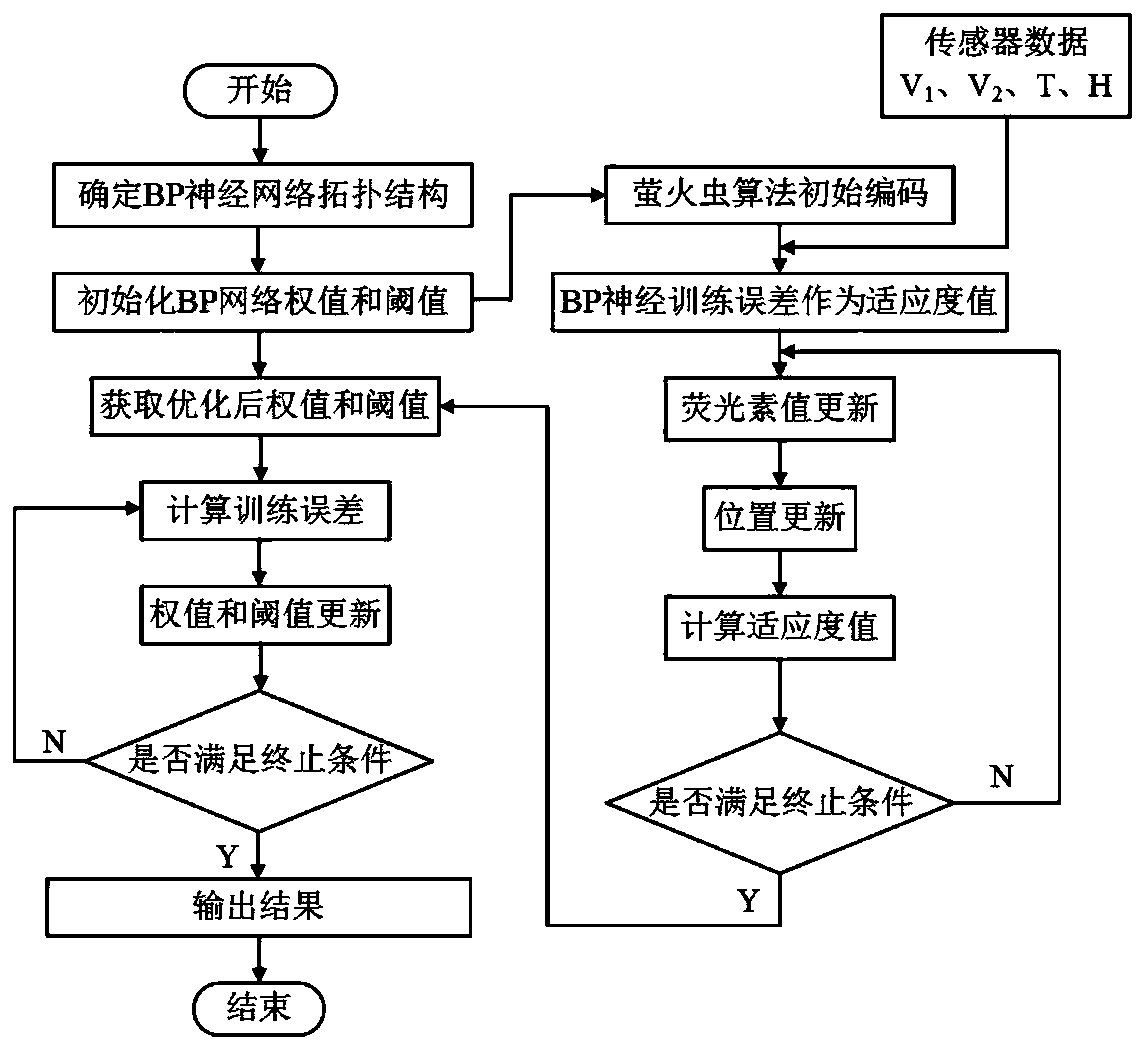

NDIR gas sensor system and temperature and humidity compensation method thereof

InactiveCN110006837AControl volumeMiniaturizationColor/spectral properties measurementsNeural architecturesPyroelectric detectorsHandling system

The invention relates to an NDIR gas sensor system. The NDIR gas sensor system comprises an infrared sensor unit, a microprocessor and a concentration display unit, wherein the microprocessor system is connected with the infrared sensor unit and the concentration display unit; a sampling air chamber can effectively prolong an optical path and can control the volume of the air chamber to facilitatethe miniaturization of the sensor. The potassium bromide (KBr) window piece is arranged to avoid corrosion of a pyroelectric detector, the service life of the sensor is prolonged, and the optical paths of the measuring channel and the reference channel are completely symmetrical, so that the structural design of the single light source dual-optical path can eliminate the influence of external factors such as light source shake, optical device pollution and the like on the measuring precision to a certain extent. The NDIR gas sensor system and the temperature and humidity compensation method thereof employ a GSO-BP neural network to perform temperature and humidity compensation to overcome the defects of the empirical formula compensation method and the circuit compensation method in the prior art and lead the compensation process to be simpler and more accurate, and therefore, the precision is high, the cost is low and the structure is small compared to the prior art.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

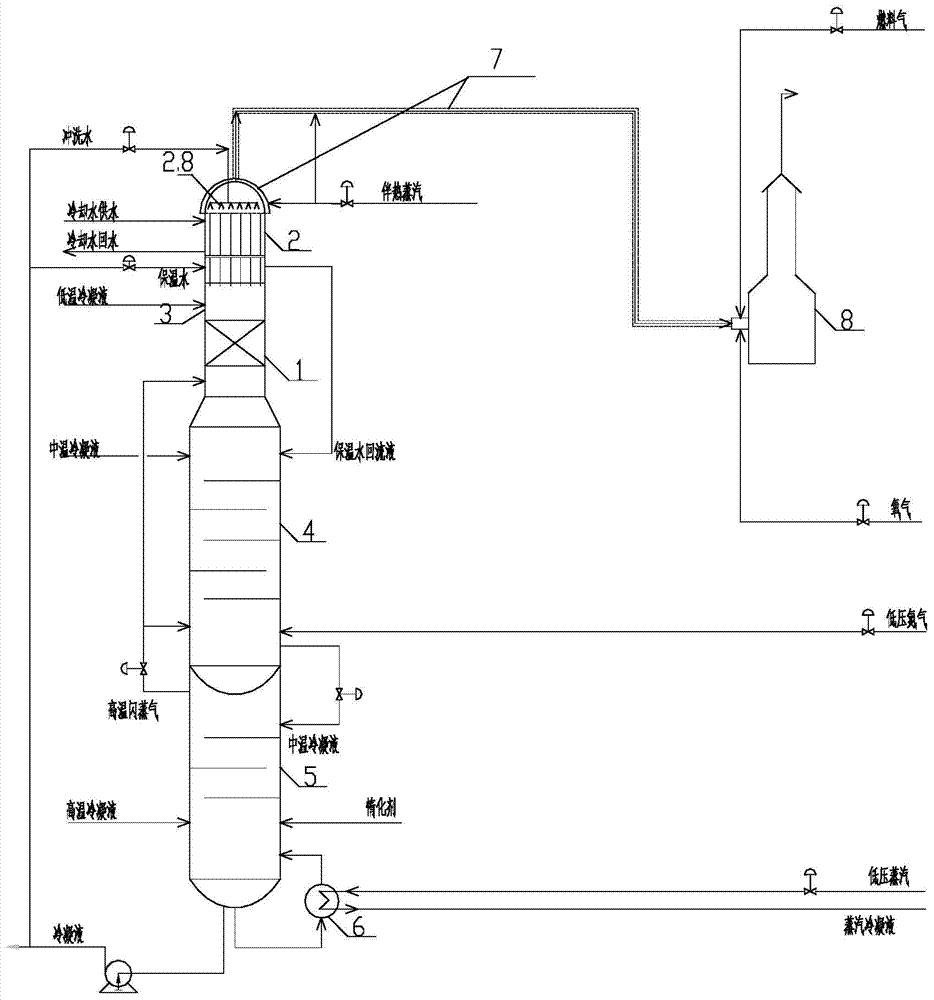

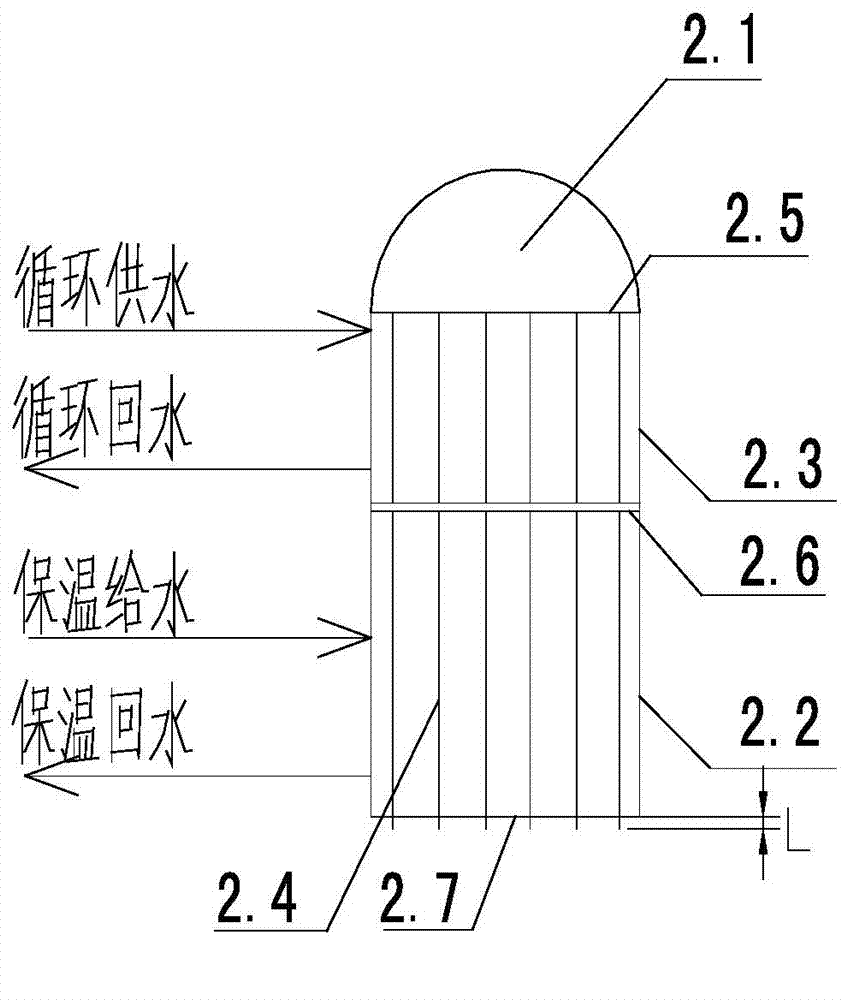

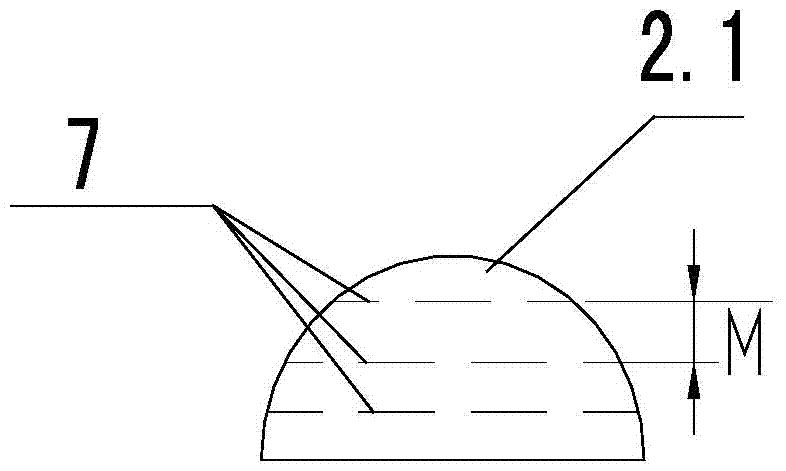

Amino acid-containing condensate steam stripping system and tail gas treatment method

ActiveCN103785193AReasonable process configurationReduce energy consumptionDistillation regulation/controlSteam distillationReboilerFlash-gas

The invention discloses an amino acid-containing condensate steam stripping system and a tail gas treatment method for solving the problems of an existing steam stripping system that a treatment method is complex, system energy consumption is high, corrosion to pipe plates and pipelines is serious and equipment investment is high. The method comprises the steps of correspondingly feeding high temperature condensate, medium temperature condensate and low temperature condensate to a high temperature condensate stripping section, a medium temperature condensate stripping section and a low temperature condensate stripping section of a stripping tower, respectively, reducing the temperature of stripping gas at a stripping tower top to be 85-90 DEG C through an overhead condenser, and feeding into an incineration furnace, wherein the high temperature condensate stripping section is provided with a reboiler, low-pressure steam used as a heat source is used for carrying out steam stripping to the condensate, the medium temperature condensate stripping section and the low temperature condensate stripping section adopt high temperature flash gas generated by the high temperature condensate stripping section as the heat source, and low-pressure nitrogen gas is introduced for gas stripping. The process is simple, the operation can be controlled flexibly, the system stability is good, energy is saved, the consumption is reduced, the corrosion of the steam stripping system can be reduced to the maximum extent and the service life of the equipment can be prolonged.

Owner:湖北华庆石化设备有限公司

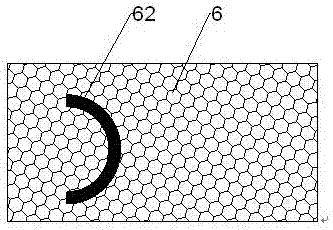

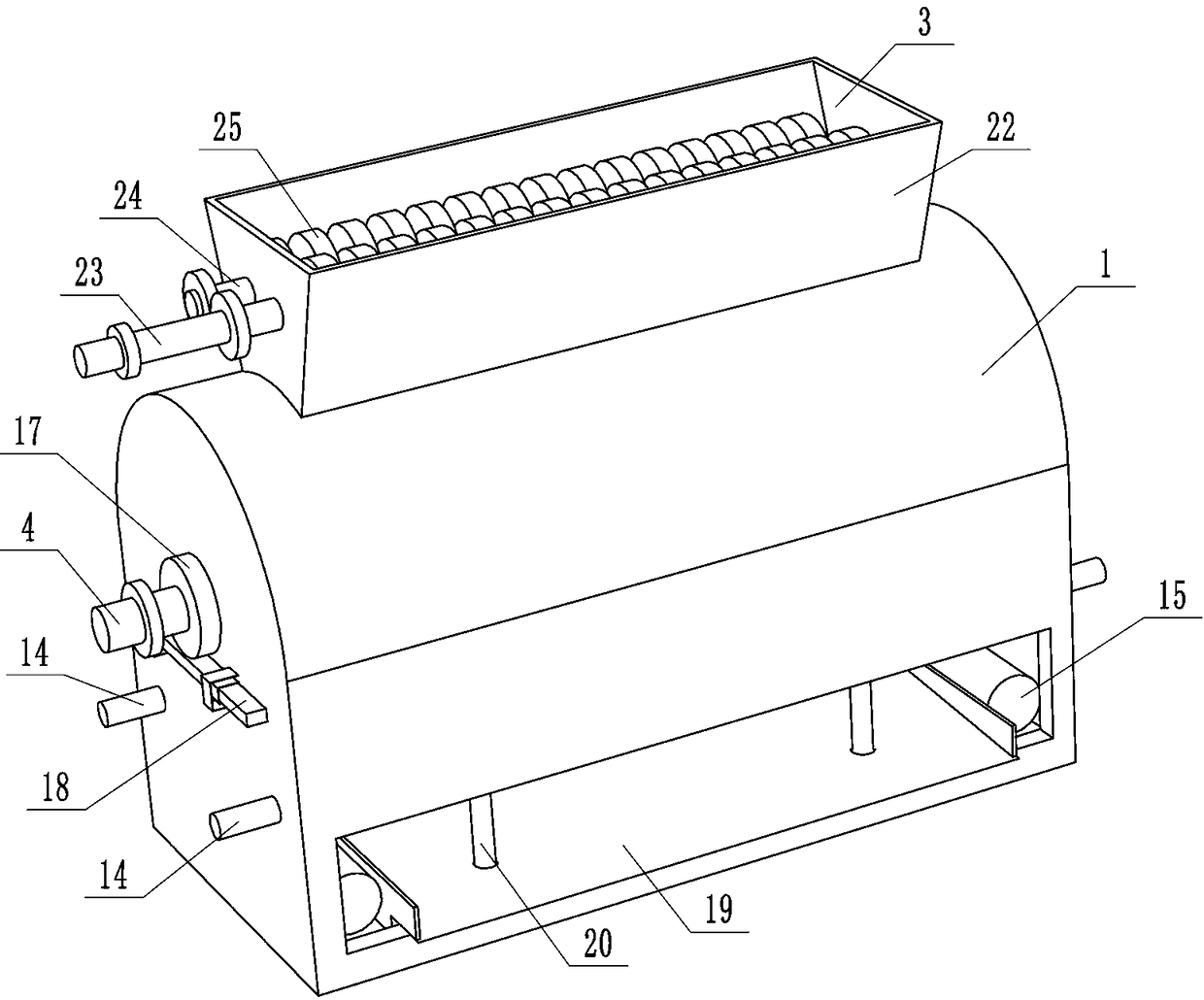

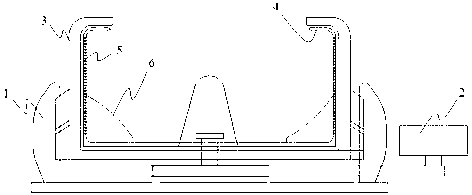

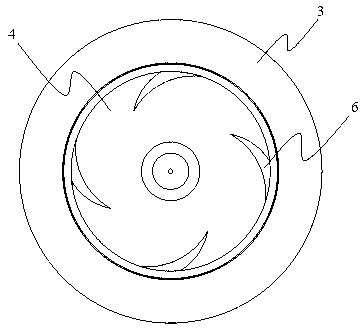

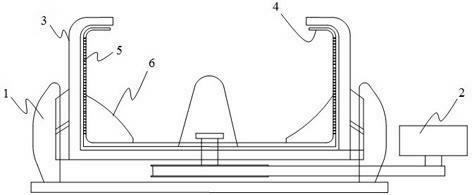

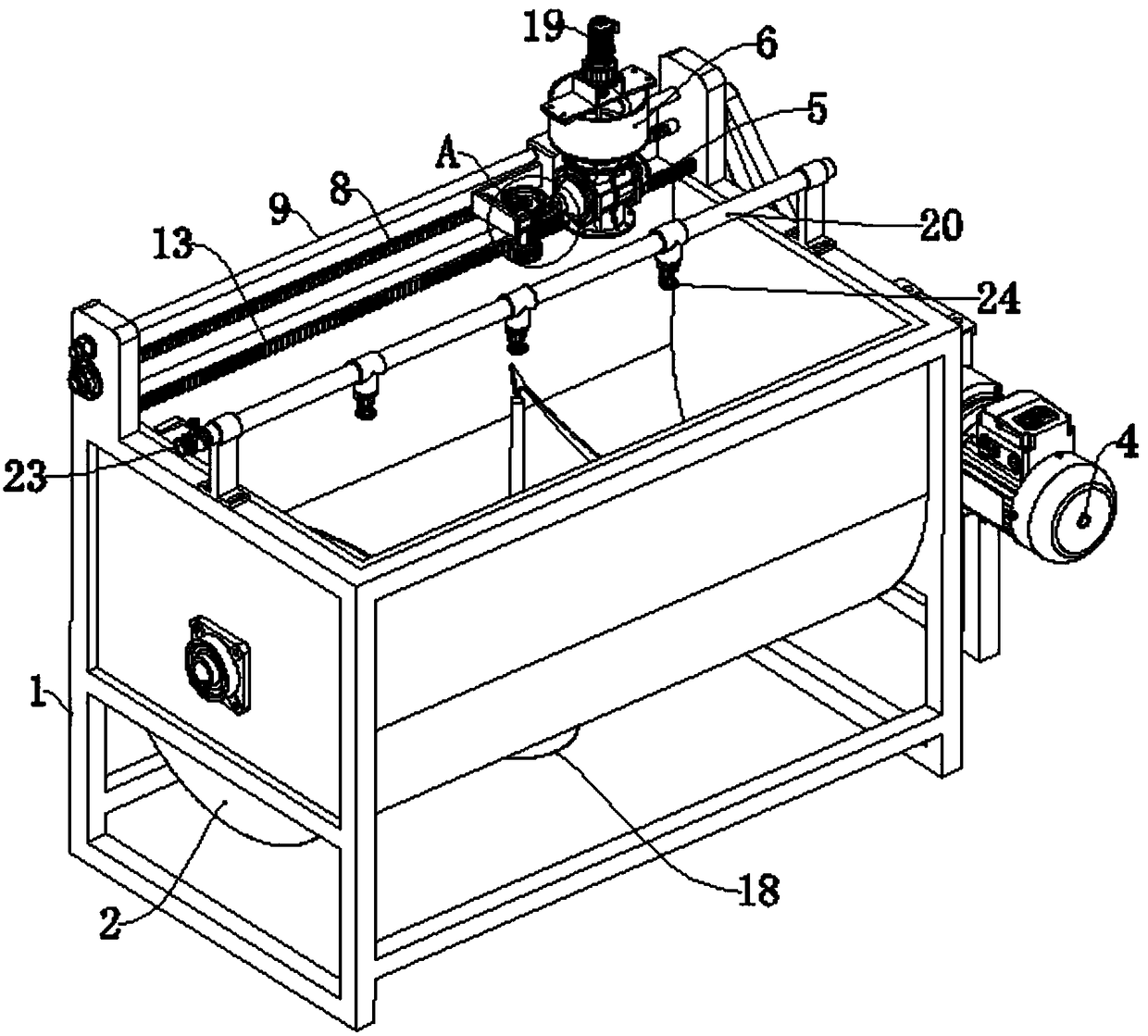

Efficient circulation type rubber crushing machine

ActiveCN109225530AGood for repeated crushingAvoid local accumulationSievingScreeningCircular discEdge surface

The invention relates to an efficient circulation type rubber crushing machine, which effectively solves the problems that dead corners exist at the bottom of a machine body; the rubber crushing is not thorough. In order to solve the problems, the efficient circulation type rubber crushing machine has the technical scheme that the efficient circulation type rubber crushing machine comprises a horizontal machine body, wherein a tearing type crushing machine is arranged on the machine body; a first rotating shaft is arranged in the machine body in a penetrating way; a front circular disc and a back circular disc are arranged on the first rotating shaft; a first filter screen is arranged between the circular discs; a baffle plate is arranged at the bottom of the first filter screen; a secondfilter screen capable of sliding relative to the inner edge surface of the first filter screen is arranged on the inner edge surface of the first filter screen; two arc-shaped plates used for blockingmaterials are arranged in the machine body; crushing cutters are arranged between the first rotating shaft and the arc-shaped plate; a second rotating shaft is arranged in the box body; a box body isarranged under the second rotating shaft; an extruding plate is arranged in the box body; the second rotating shaft rotates to drive the driving plate to vertically move, so that the gas in the box body upwards blows; a material conveying plate is arranged under the machine body; the material conveying plate is matched with a first chain wheel through a lead screw; the first chain wheel rotates to drive the lead screw and the material conveying plate to do forward and backward movement. The efficient circulation type rubber crushing machine provided by the invention has the advantages that the use is convenient; the crushing effect is good.

Owner:漯河市利道液压科技有限公司

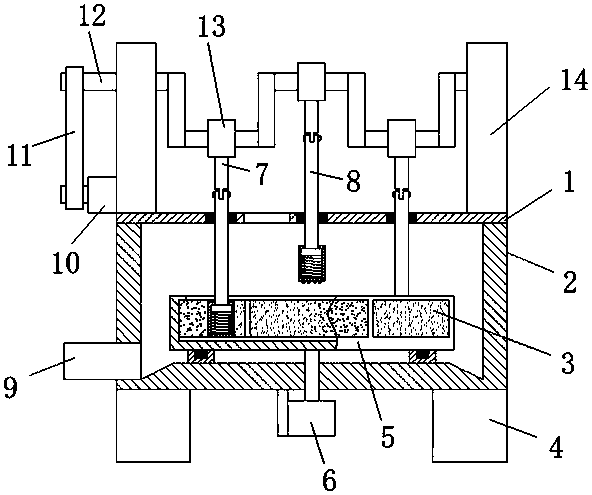

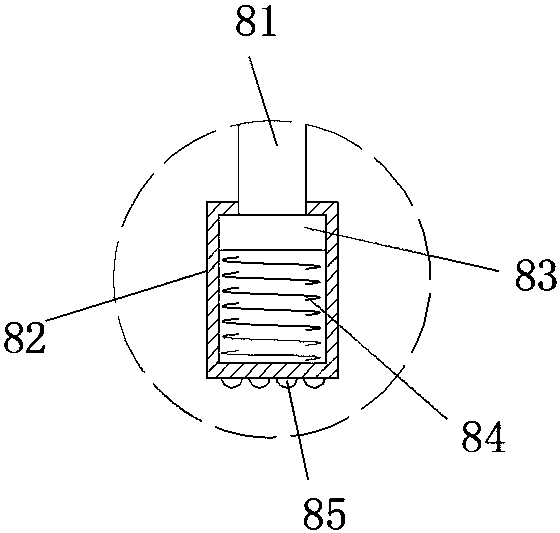

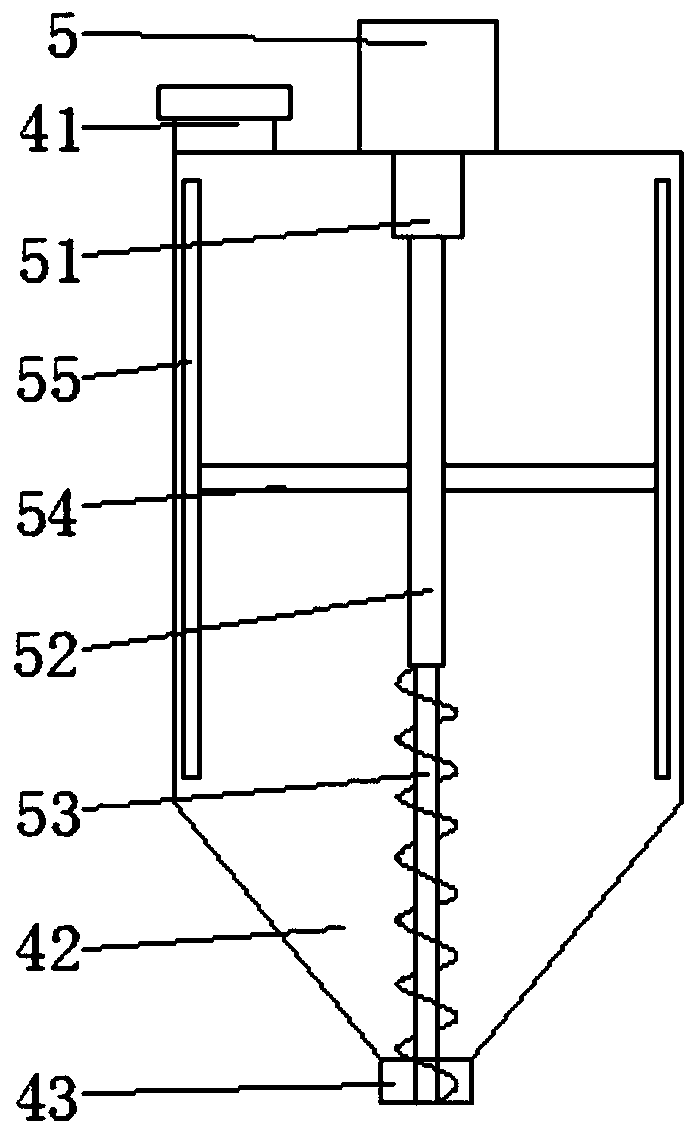

Efficient crushing and stirring device with high stability

InactiveCN107051301AImprove mixing and crushing efficiencyAvoid local accumulationShaking/oscillating/vibrating mixersTransportation and packagingDrive motorEngineering

The invention discloses an efficient crushing and stirring device with high stability. The efficient crushing and stirring device comprises a device body. The device body is mainly composed of a crushing and stirring barrel, a feeder and a discharge port. The bottom of the crushing and stirring barrel is fixedly connected with a driving motor, a rotating shaft is arranged in the crushing and stirring barrel, a stirring rod is hinged to the top of the rotating shaft, a connecting rod is hinged to the side wall of the crushing and stirring barrel, and a bottom plate is hinged to the tail end of the connecting rod. A base is arranged at the bottom of the device body, the right surface of the base and the right lower surface of the bottom plate are fixedly connected with a magnetic plate, and the bottom plate is connected with the left end of the base through a spring. The left side of the surface of the bottom plate is fixedly connected with an exciter. According to the device, the stirring and crushing efficiency of materials is improved, local accumulation of the materials is avoided, stirring is convenient, when the device crushes and stirs the materials, the crushing and stirring barrel swings left and right, the materials are turned over in the crushing and stirring barrel left and right, the stirring efficiency and the stirring effect of the materials are improved, and convenience is brought to use by people.

Owner:长沙鼎成新材料科技有限公司

Reverse blowing type rubber efficient crushing device

ActiveCN109225531AGood for repeated crushingAvoid local accumulationGrain treatmentsEdge surfaceScrew position

The invention relates to a reverse blowing type rubber efficient crushing device, which solves the problems of machine body bottom dead corner and unthorough rubber crushing. In order to solve the technical problems, the reverse blowing type rubber efficient crushing device comprises a horizontal machine body; a tearing type crushing machine is arranged on the machine body; a first rotating shaftis arranged in the machine body in a penetrating way; a front gearwheel and a back gearwheel are arranged on the first rotating shaft; a first filter screen is arranged between the gearwheels; a baffle plate is arranged at the bottom of the first filter screen; the inner edge surface of the first filter screen is provided with a second filter screen capable of performing relative sliding to the first filter screen; two arc-shaped plates used for blocking materials are arranged in the machine body; a crushing cutter is arranged between the first rotating shaft and the arc-shaped plate; a plurality of pinions engaged with the gearwheel are arranged under the box body; the pinions can drive a lead screw positioned in the center to forwards and backwards move after the rotation; the lead screwis connected with the feeding plate through a vertical rod, so that the feeding plate can forwards and backwards move; air bags are arranged at the front side and the back side of the feeding plate;an air bag is extruded through the forward and backward movement of the feeding plate, so that air in the air bag can blow the materials. The reverse blowing type rubber efficient crushing device hasthe advantages that the use is convenient; the crushing effect is good.

Owner:漯河市利道液压科技有限公司

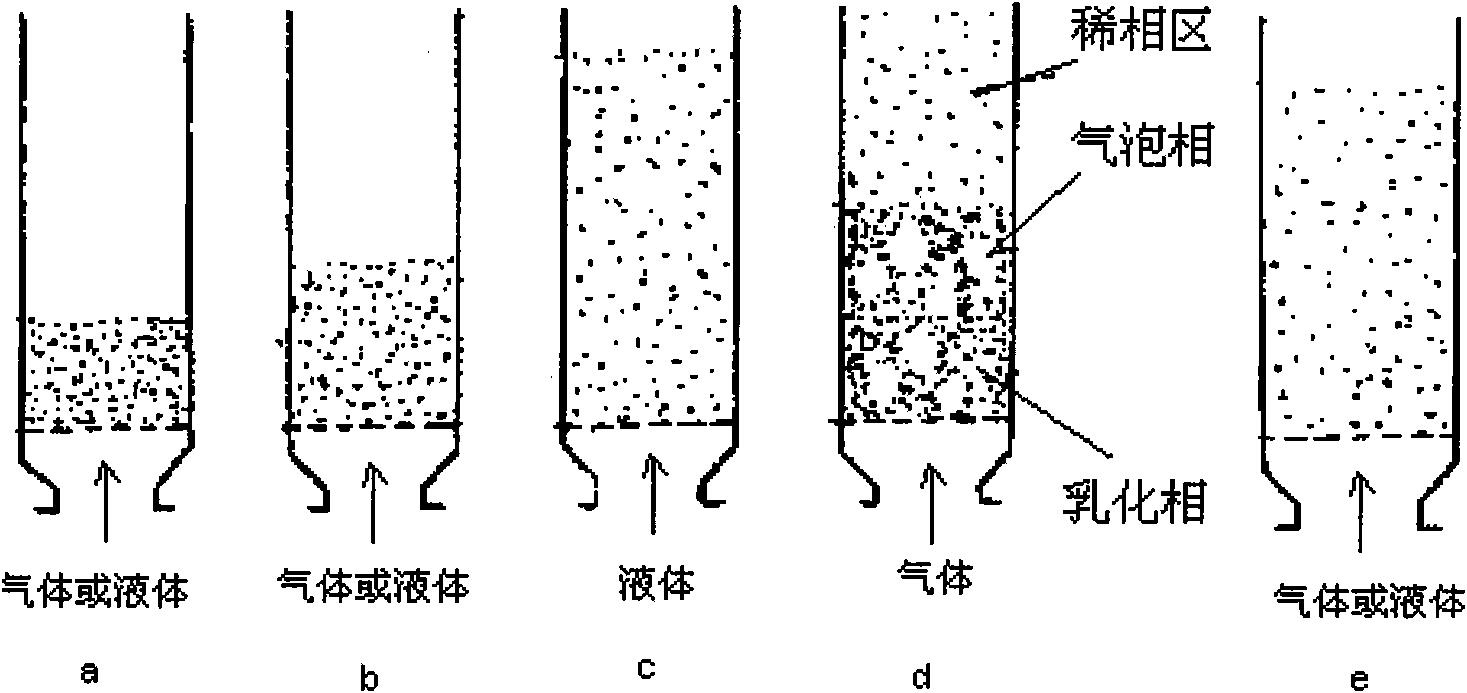

Solid particle player

ActiveCN101912752AEvenly distributedAvoid wall effectChemical/physical processesSpray nozzleInstability

The invention discloses a solid particle player which is in a coaxial segmented sealing cylindrical structure and comprises a base plate, a spray nozzle, an acceleration section, a rectifying section, a fluidized section and a cover plate. A rectifying plate which is uniformly provided with millimeter grade through holes is fixedly arranged at the inner wall of the connected part of the acceleration section and the rectifying section; an air distribution plate which is uniformly provided with nano-grade gaps is fixedly arranged on the inner wall at the connection part of the rectifying section and the fluidized section; solid particles are stacked on the air distribution plate; a plurality of layers of fluidized substance outlets are machined at the positions in different heights at the upper side of the fluidized section; and an included angle of 15-50 degrees is formed between the axis of the fluidized substance outlets and the axis of the solid particle player. The solid particle player is formed by sintering metal powder; air current is diffused by the air distribution plate with nano-grade gaps so as to obtain the uniformly-distributed incoming current and avoid the wall-surface effect; and according to the distance among various sections and the opening mode of the air distribution plate and the side wall, the invention ensures enough flowing resistance, reduces the wall-surface effect due to the nonuniform air inlet speed and pressure distribution, overcomes the instability of focus fluidization and inhibits the abnormal phenomenon of channeling and slugging in a bed layer.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

Production process for heat preservation vessel inner cavity heat-resistant glass or enamel coating layer

ActiveCN105862039AChemically stableNo corrosionMolten spray coatingContainers with thermal insulationRough surfaceThermal expansion

The invention discloses a production process for a heat preservation vessel inner cavity heat-resistant glass or enamel coating layer; the production process comprises the following steps: step S1, selecting a heat preservation vessel blank made of a metal material, carrying out sandblasting operation on the surface of an inner cavity of the heat preservation vessel blank, and making the surface of the inner cavity of the heat preservation vessel blank form a rough surface; step S2, carrying out enamel spraying operation on the rough surface, to make glass or an enamel glaze sprayed on the rough surface of the heat preservation vessel; step S3, drying the glaze on the rough surface; step S4, placing the heat preservation vessel blank after drying on a bracket; step S5, carrying out sintering operation on the heat preservation vessel blank; and step S6, after completion of sintering, taking the heat preservation vessel blank down from the bracket to obtain the finished product. In the process, in the preparation process of a moisturizing vessel, after a glass layer or an enamel layer is formed on the surface of the inner cavity, the self chemical properties of the glass layer or the enamel layer are relatively stable, no corrosion condition is generated, at the same time, changes of thermal expansion and cold contraction are relatively small, and the finished product is suitable for use as a container such as a heat preservation cup.

Owner:SOHOME HOUSEWARE (NANJING) CO LTD

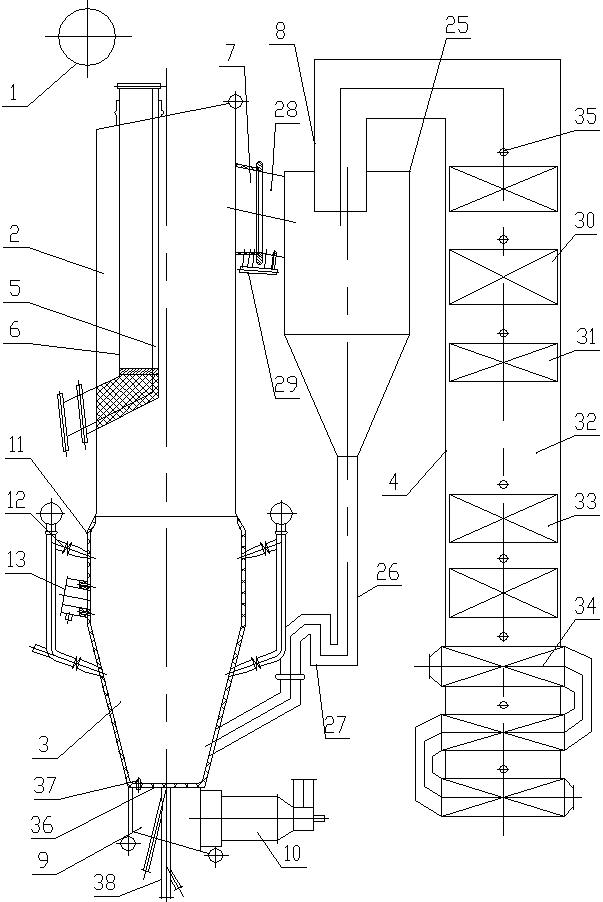

Ultra-low emission energy-saving biomass circulating fluidized bed boiler

PendingCN110260301AImprove combustion efficiencyImprove low-load operation capabilityFluidized bed combustionSteam boilersCombustion chamberThree stage

The invention discloses an ultra-low emission energy-saving biomass circulating fluidized bed boiler. The ultra-low emission energy-saving biomass circulating fluidized bed boiler comprises a drum, a full-membrane fireplace hearth, a fluidized bed combustion chamber, a separation and return system and a tail shaft flue. The lower part of the full-membrane fireplace hearth is connected with the top of the fluidized bed combustion chamber through a three-stage outwardly-convex avoiding pipe structure with membrane walls. Secondary air inlet structures are arranged on the front membrane wall and the rear membrane wall of the three-stage outwardly-convex avoiding pipe structure. A feeding joint pipe of an air-cooled structure with broadcast wind and compressed air is arranged on the front membrane wall of the three-stage outwardly-convex avoiding pipe structure. The ultra-low emission energy-saving biomass circulating fluidized bed boiler has the good automatic ash cleaning characteristic, so that corrosion on the heated surface is avoided, the wear of the heated surface is reduced, the biomass bulk material entering the hearth ignites rapidly, the combustion effect is enhanced, the burning is facilitated, the thermal efficiency of the boiler is improved, meanwhile the boiler has the self-removal performance of pollutants, emission reduction in the pollutant furnace is achieved from the combustion source, and ultra-low emission, low energy consumption, low bed pressure, low wear, high-efficiency combustion and stable operation of the boiler are achieved.

Owner:曹德鸣

Method for modifying anode active material of lithium ion battery

The invention relates to a method for modifying an anode active material of a lithium ion battery, comprising the following steps of: stirring and mixing hydrolysis liquid of salt compounds containing metal elements with the anode active material for over one hour, and adjusting the pH value of a mixture to be 2-10; then removing a solution by centrifugation in a centrifugal machine and flushing the anode active material with a water-soluble liquid until the pH value of the flushing liquid is between 1 and 7; drying and sintering the flushed anode active material in the presence protective gases; removing an excessive solution and hydrolysate of metal ions by centrifugal treatment to avoid metallic oxide from being locally deposited on the surface of the active material and uniformly redistribute the metal oxide on the surface of the active material; and flushing the active material with a hydrophilic substance, thereby avoiding other materials from being resided on the surface of theactive material, further avoiding the side effect of the lithium ion battery and improving the overall performance of the lithium ion battery.

Owner:东营亿德新材料有限公司

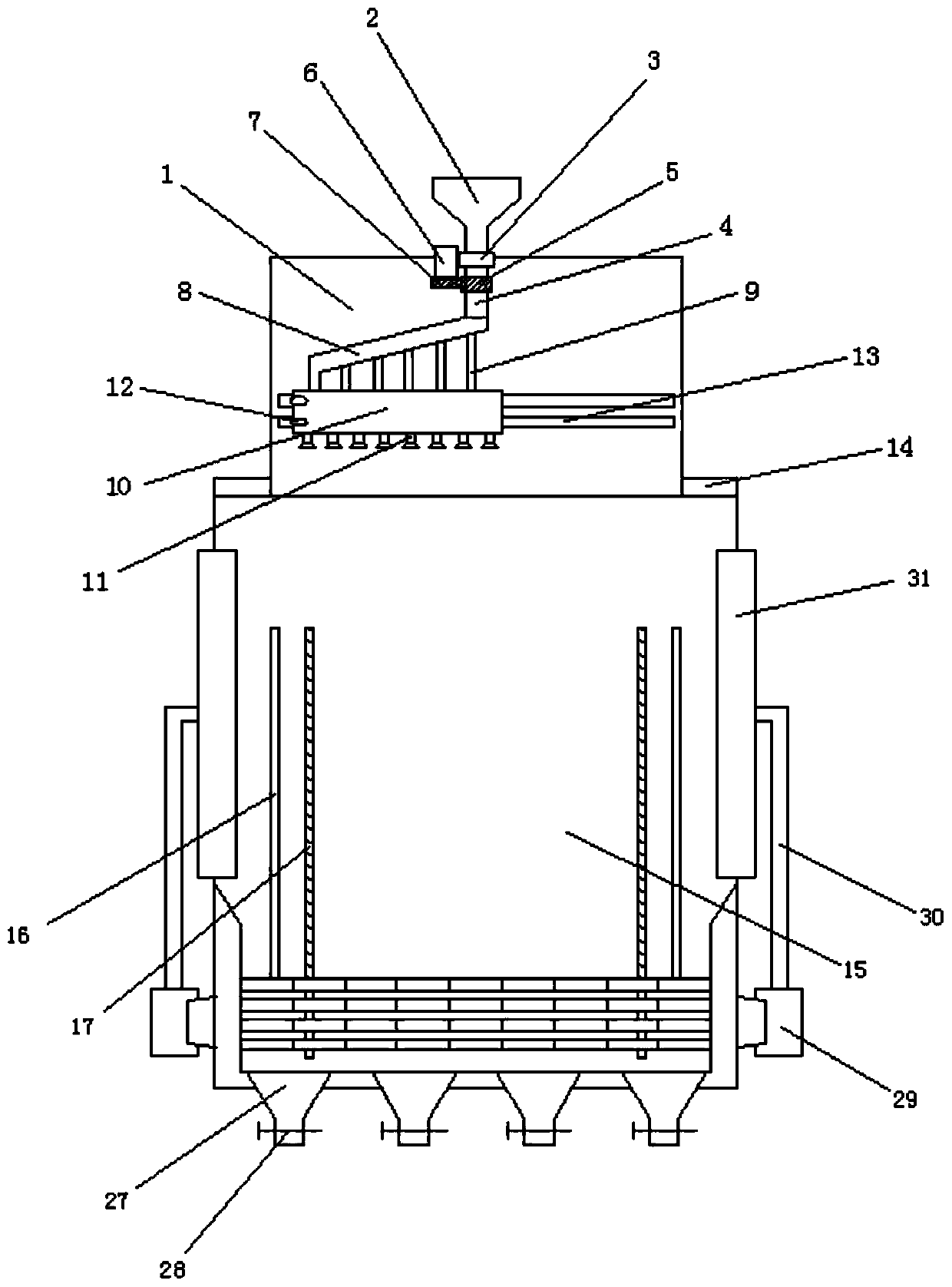

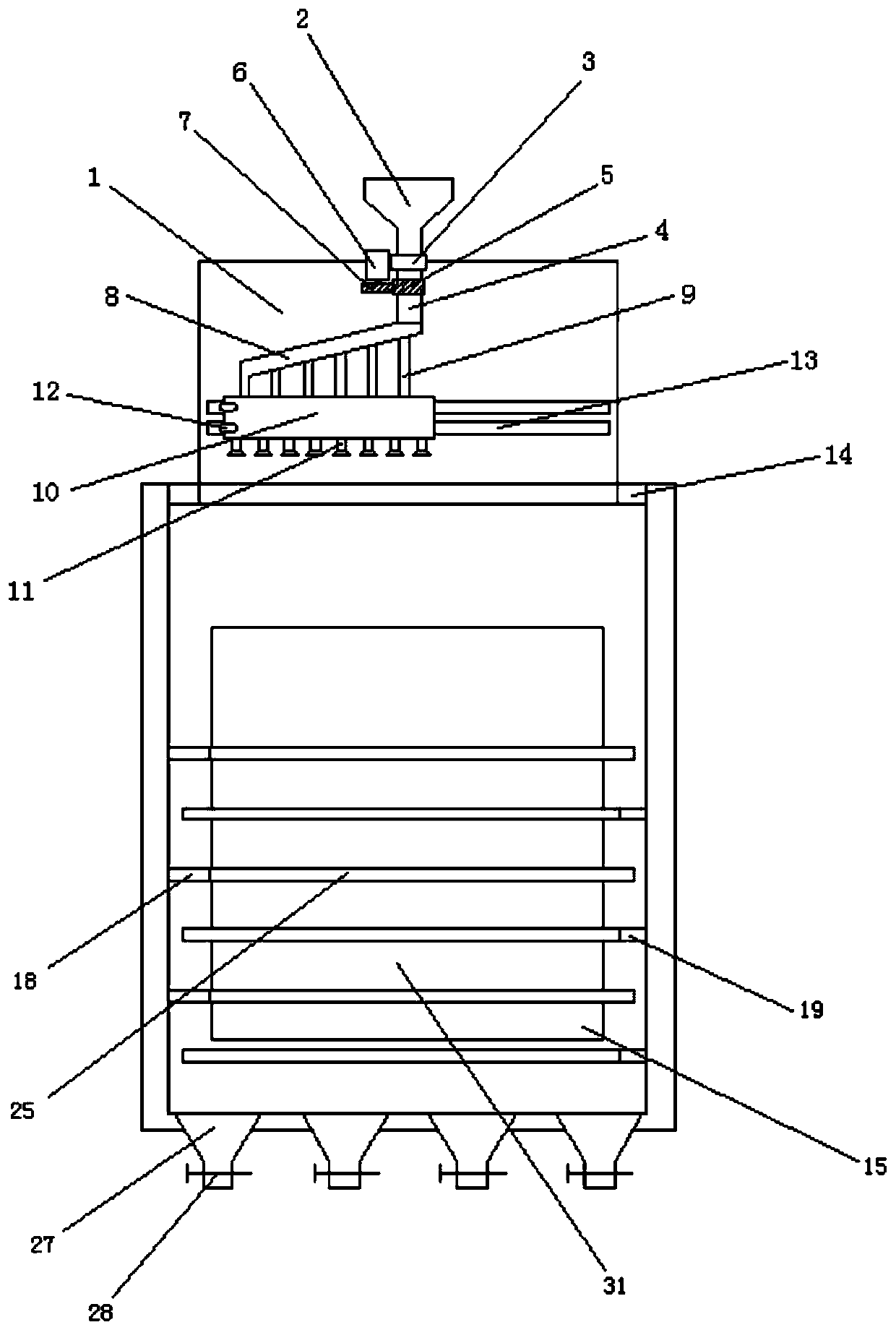

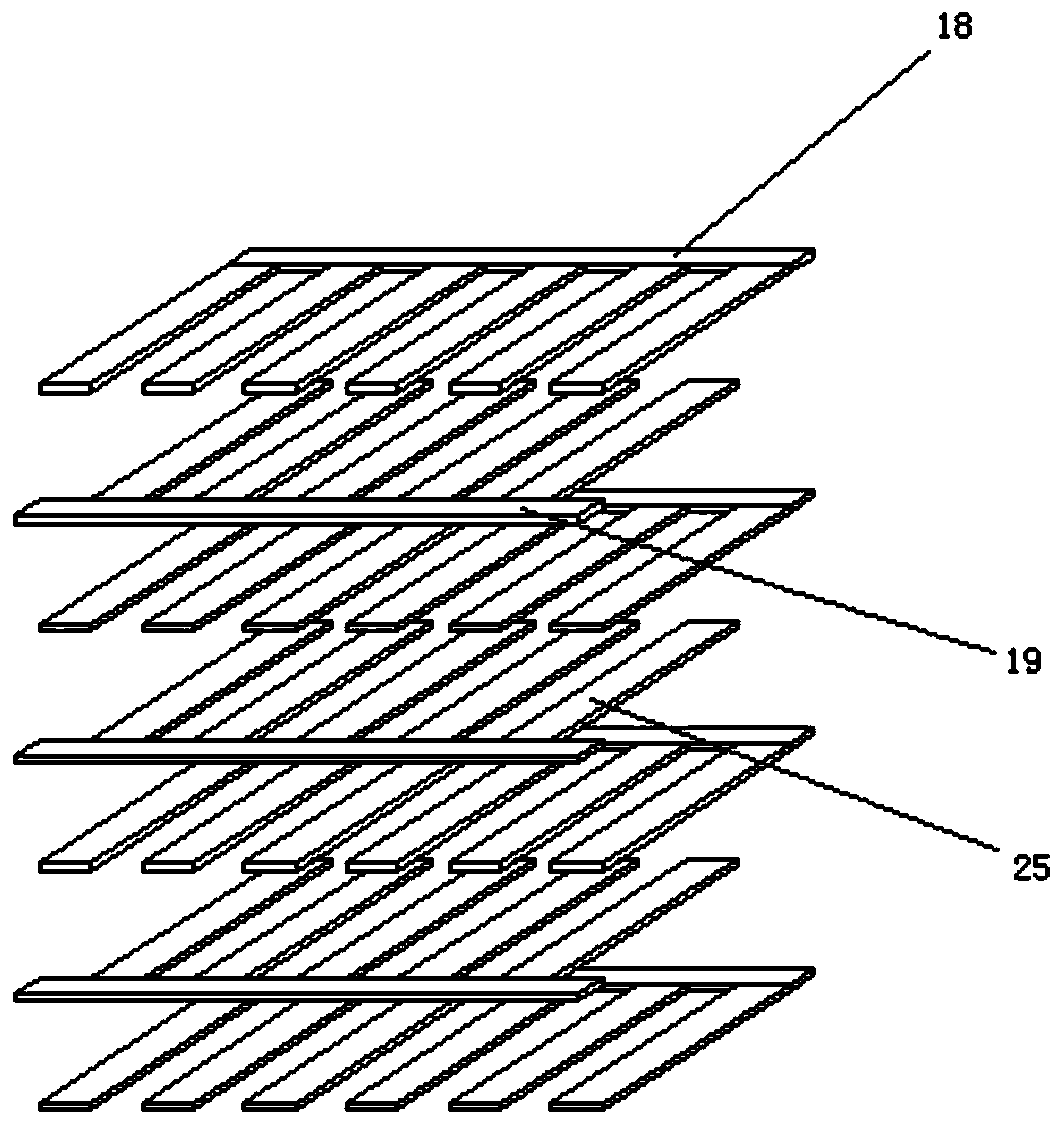

Grain drying device

InactiveCN111156795AUniform feedingAvoid insufficient dryingDrying gas arrangementsSeed preservation by dryingGear wheelAgricultural engineering

The invention discloses a grain drying device. The grain drying device comprises a feeding bin and a drying bin, and the feeding bin is located at the top of the drying bin; a feed hopper is fixedly mounted in the top center of the feeding bin; a first motor is fixedly mounted on the side wall of the feed hopper; two sets of rails and two sets of toothed rails are mounted on the side walls of thetwo sides of an inner cavity of the drying bin correspondingly, the rails on the side walls of the two sides of the inner cavity of the drying bin are movably connected with three sets of first lifting frames and second lifting frames correspondingly, two sets of second motors are fixedly mounted on the rear sides of the first lifting frame and the second lifting frame of each set, one sides of the second motors are fixedly connected with second gears, the second gears are mutually engaged with the corresponding toothed rails, and the inner side walls of the first lifting frames and the secondlifting frames are horizontally provided and connected with a plurality of sets of bearing plates; and a plurality of discharge hoppers are fixedly mounted at the bottom of the drying bin. The graindrying device is simple in structure, convenient and practical, grain can be distributed on all the bearing plates layer by layer, the drying area is increased, and the drying efficiency is improved.

Owner:杨文耀

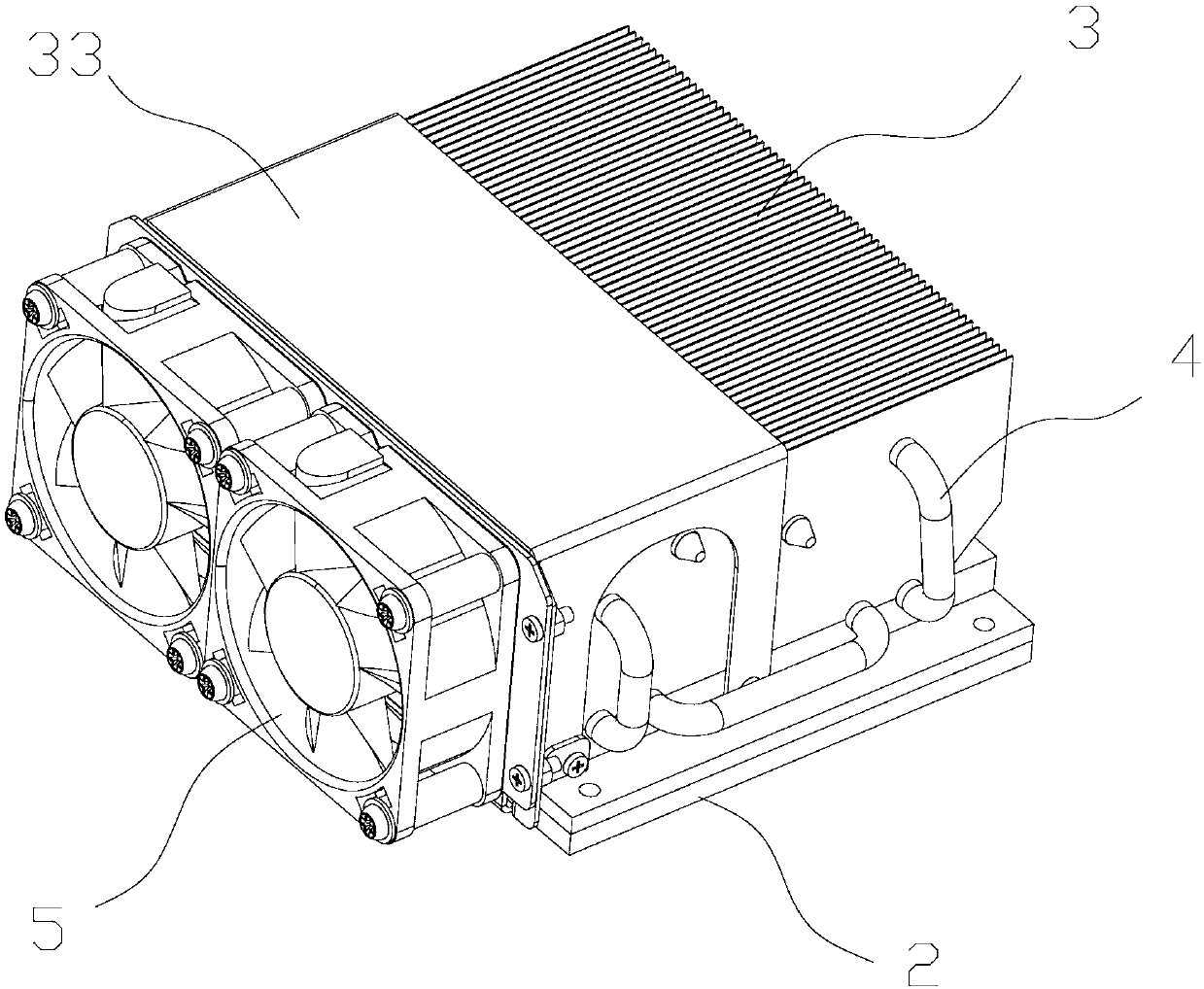

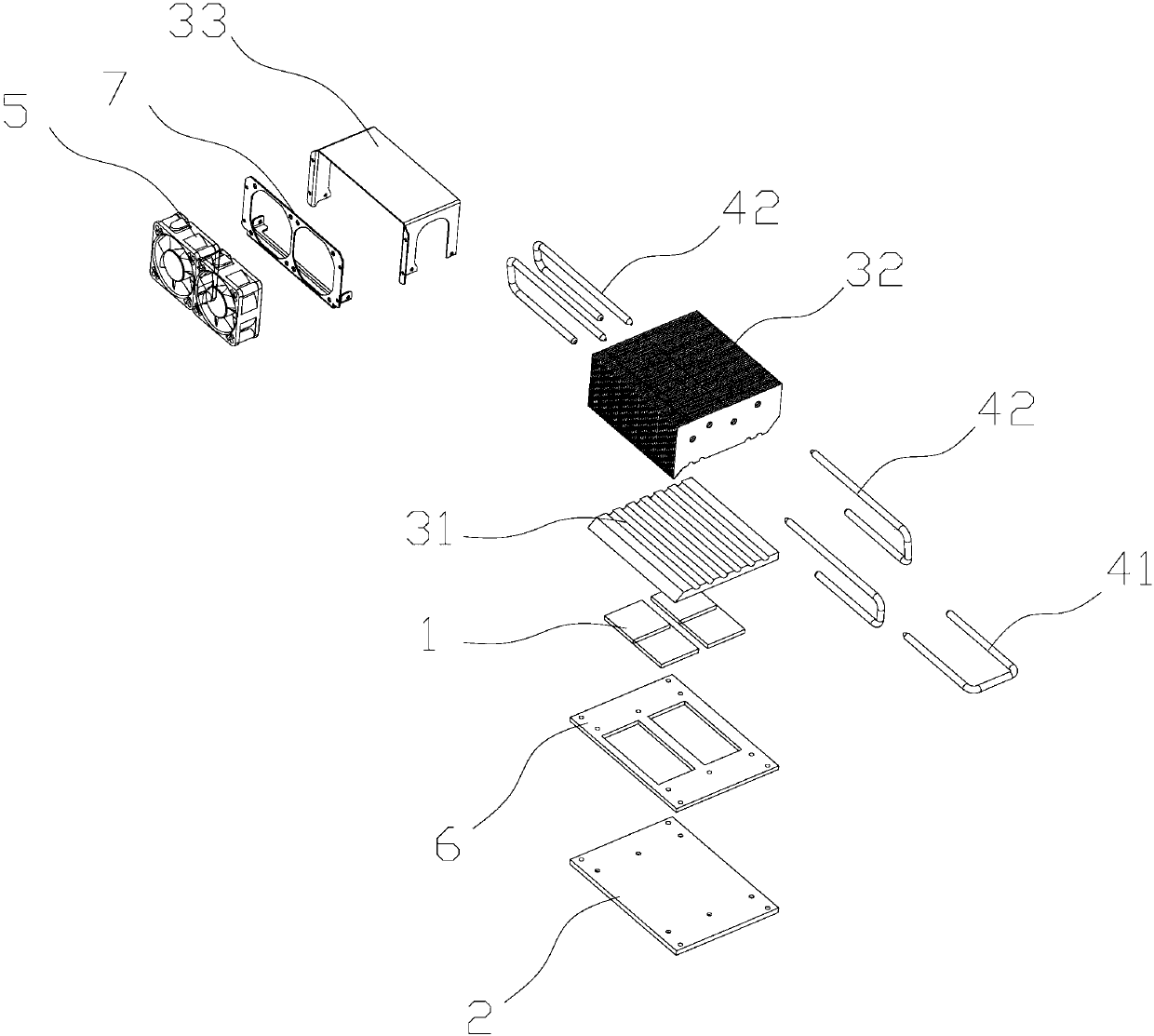

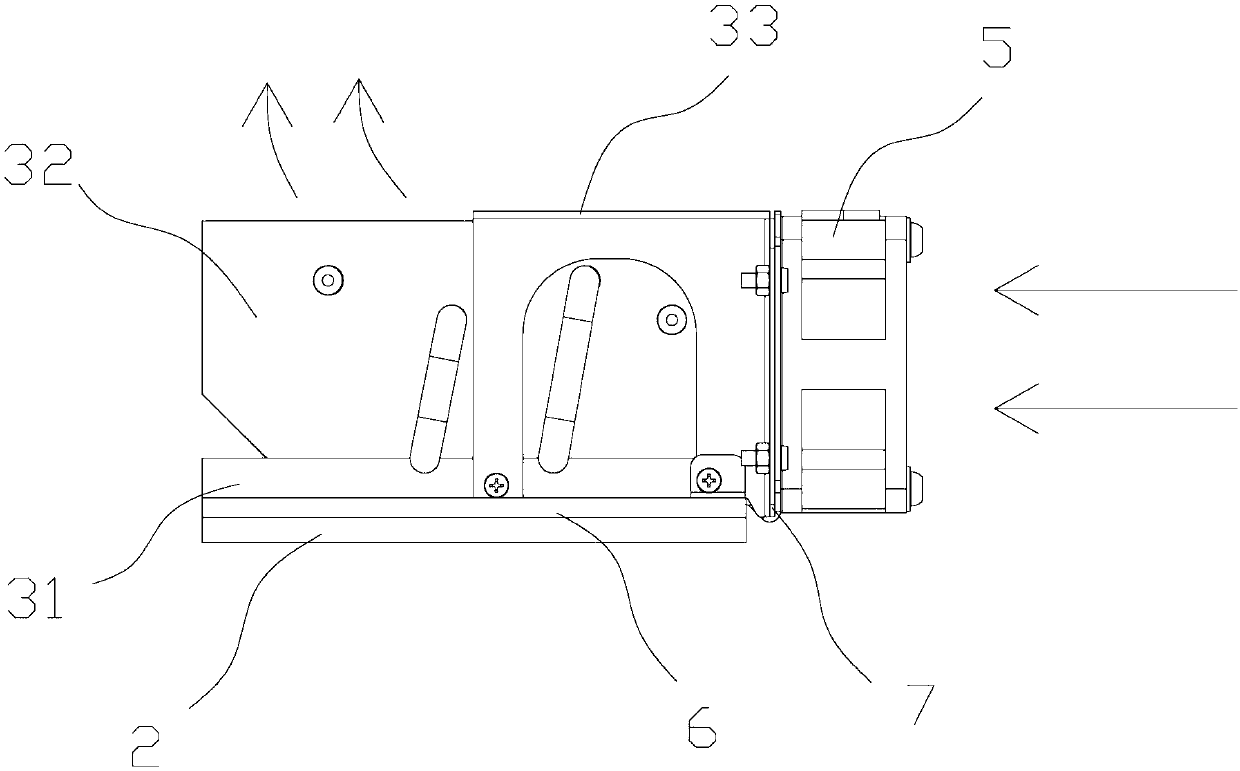

Novel semiconductor refrigeration heat dissipation module

ActiveCN109668346AReduce wind resistanceEasy to passIndirect heat exchangersMachines using electric/magnetic effectsEngineeringCold plate

The invention discloses a novel semiconductor refrigeration heat dissipation module. A semiconductor refrigeration sheet, a cold plate arranged at the cold end of the semiconductor refrigeration sheet, and a radiator arranged at the heat end of the semiconductor refrigeration sheet are included. The radiator is a heat pipe radiator, and cooling fans are arranged on the front end face of the radiator. The radiator comprises a base and a fin set arranged on the base. The heat pipe radiator is adopted in the novel semiconductor refrigeration heat dissipation module, the flow guiding design of heat dissipation airflow is matched, the wind resistance of heat dissipation airflow is greatly reduced, heat transmitted to the base from the semiconductor refrigeration sheet is better transmitted to the upper portions of fins through heat pipes, the temperature of the front part and the rear part of the base and the upper sides and the lower sides of the cooling fins is balanced, uniformity of thetemperature of the whole radiator is guaranteed, the heat of the lower side, with the highest temperature, of the rear section of the radiator cannot be stacked and is better dissipated, the heat dissipation effect is good, the refrigeration efficiency is high, and the space utilization rate is high.

Owner:HANGZHOU DAHE THERMO MAGNETICS CO LTD

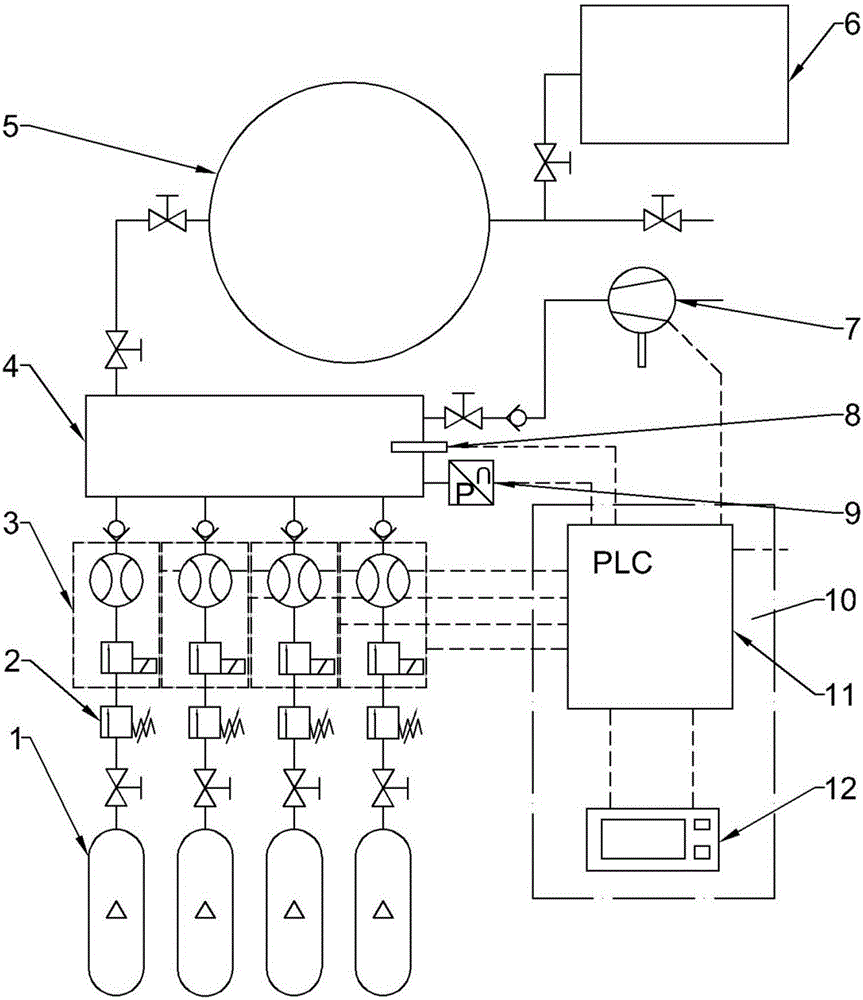

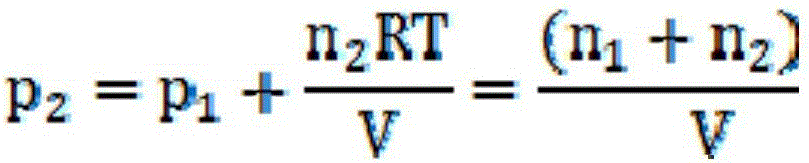

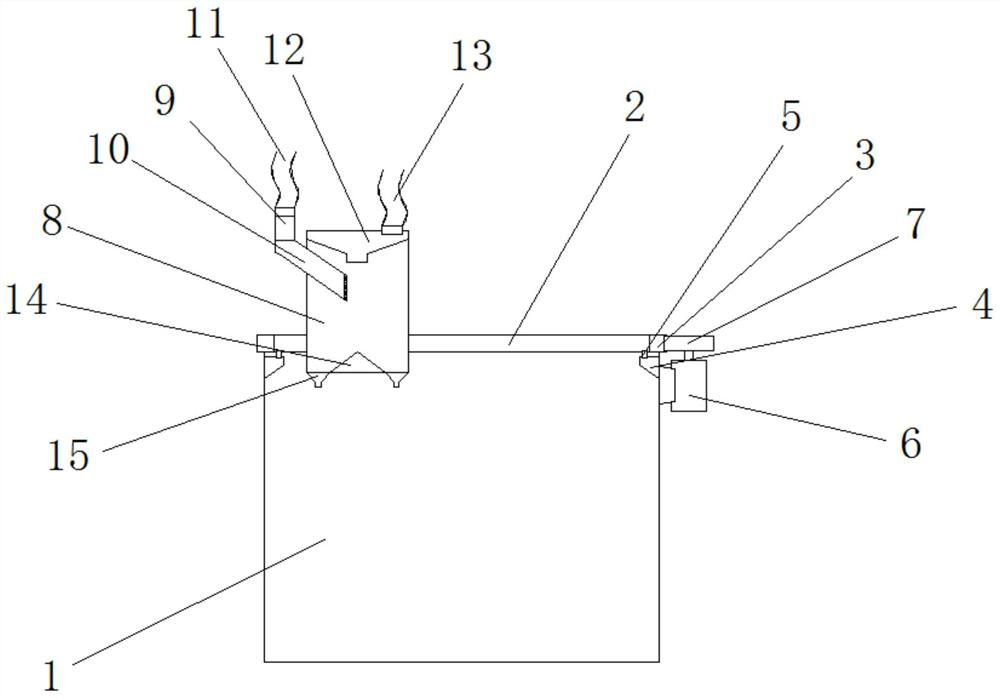

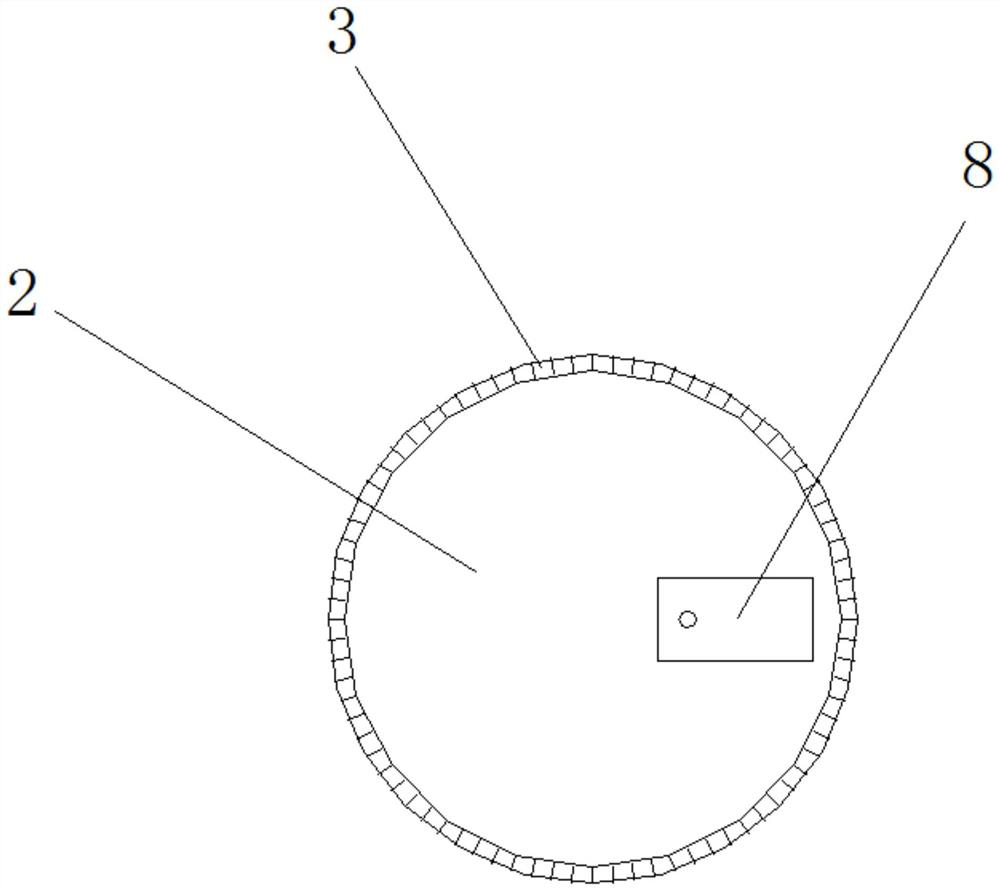

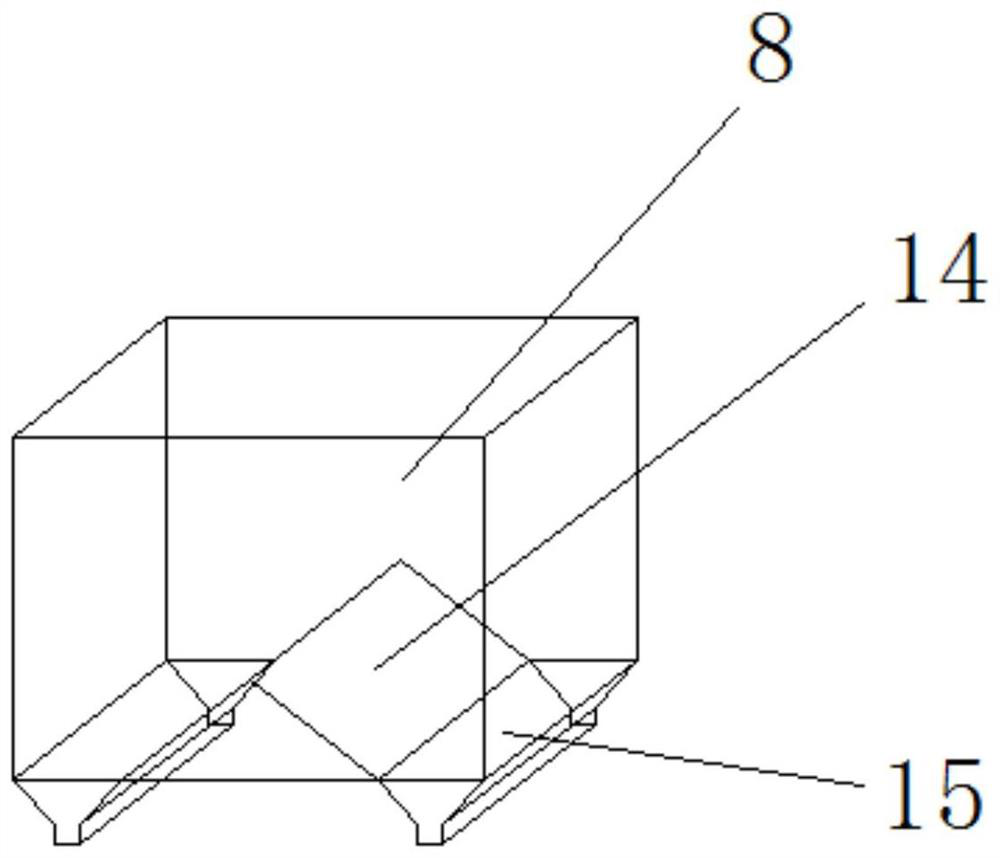

Multi-component fuel gas mixing system for pre-combustion heating type constant volume bomb

InactiveCN106474949AAvoid the problem of uneven gas mixtureAvoid local accumulationFlow mixersEngine testingAutomatic controlGas cylinder

The invention provides a multi-component fuel gas mixing system for a pre-combustion heating type constant volume bomb. The system comprises a gas exhaust system, a gas supply system, a gas exhaust system and a control system, wherein the gas supply system comprises a gas cylinder, a gas mixer and a constant volume bomb; a pressure sensor and a micro-pressure sensor are arranged on the gas mixer; and a flowmeter with connecting and disconnecting functions is arranged on an access of the gas cylinder and the gas mixer. According to the system, advanced stepwise mixing is adopted, automatically controlled operation is realized in the gas mixing process, various parameters can be set at any time through a data input device, and a gas mixing result can be analyzed by a gas component analyzer, so that the safety coefficient can be improved, gases can be mixed more uniformly, and the gas mixing component has higher precision.

Owner:HARBIN ENG UNIV

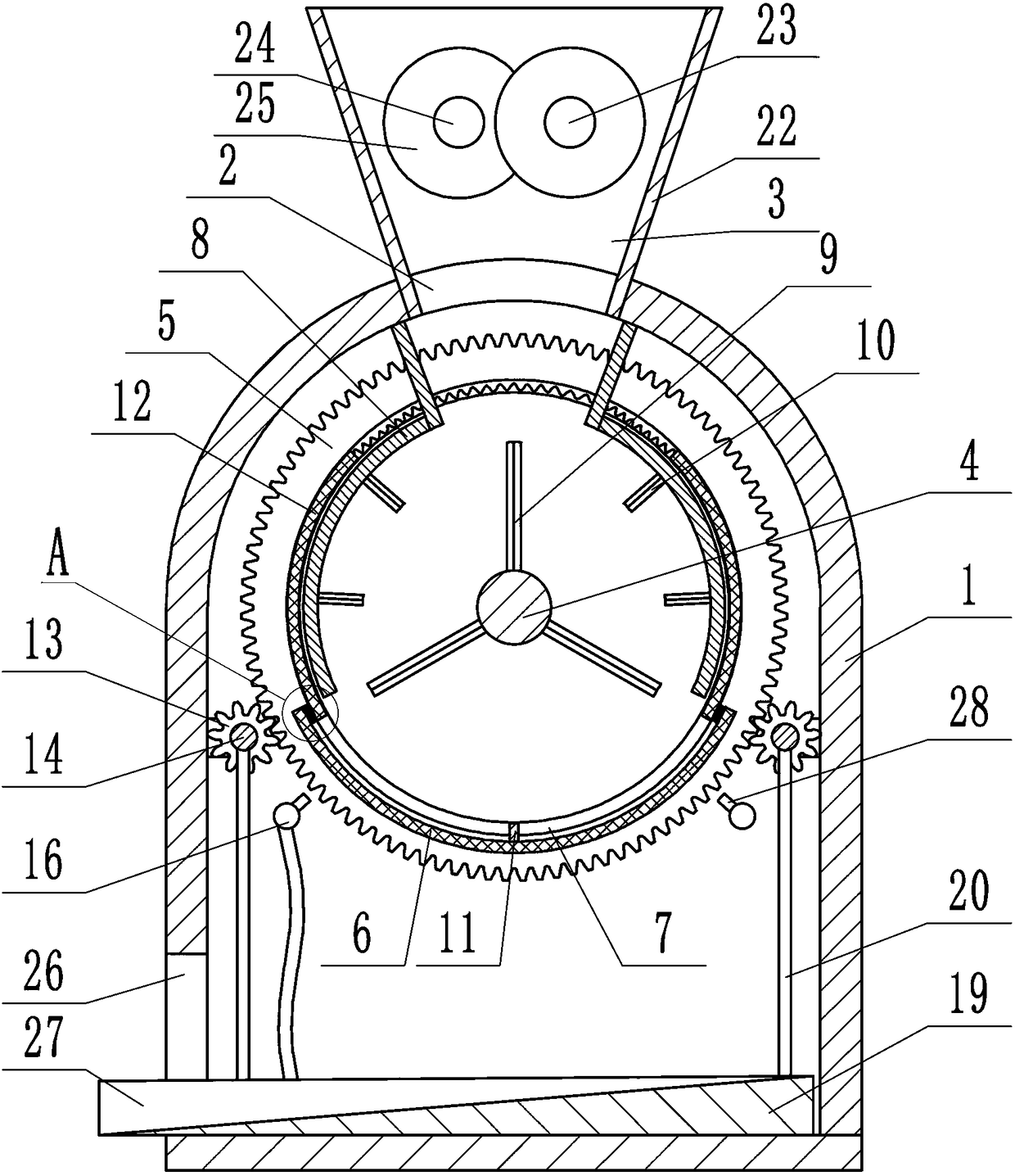

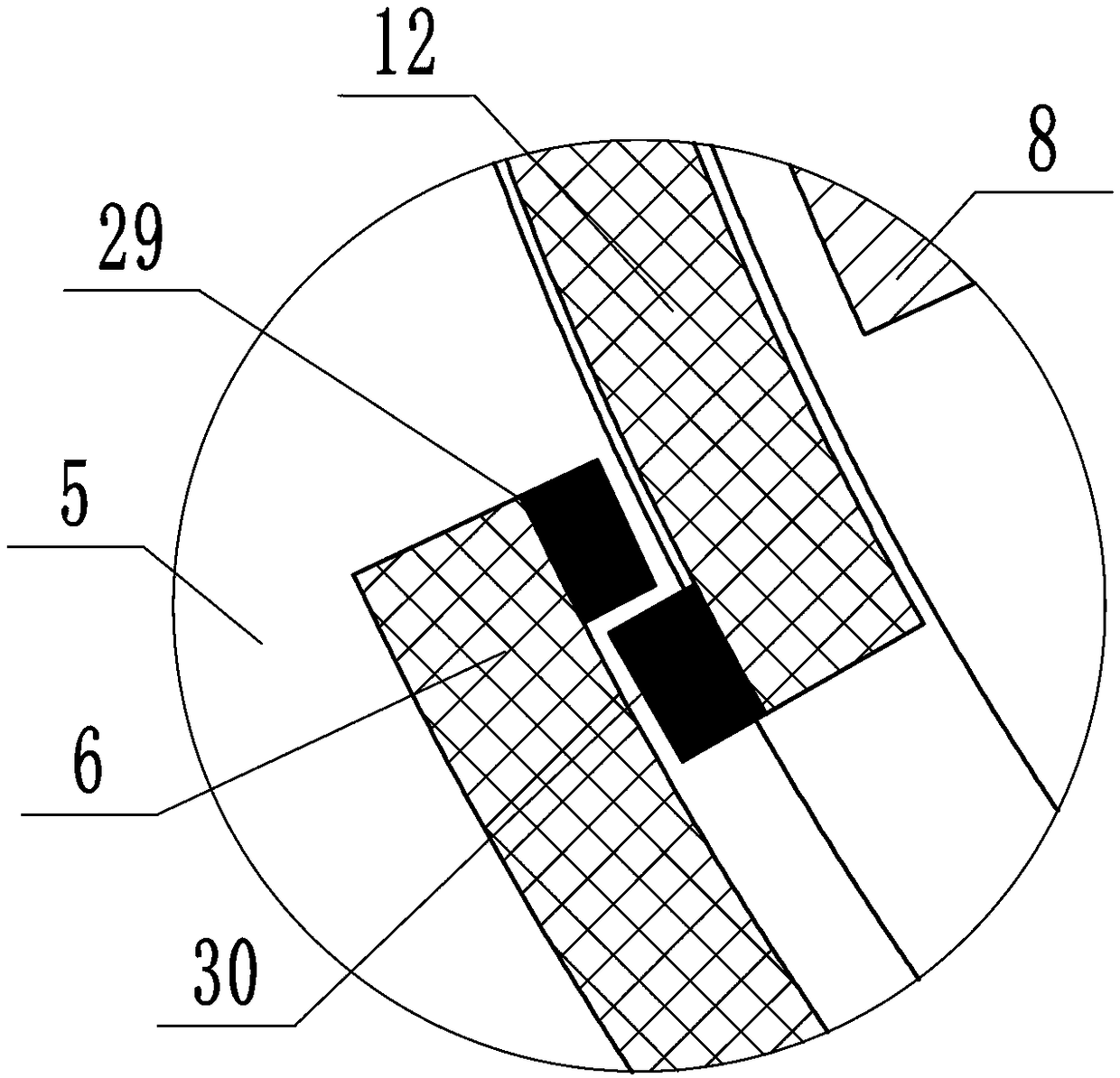

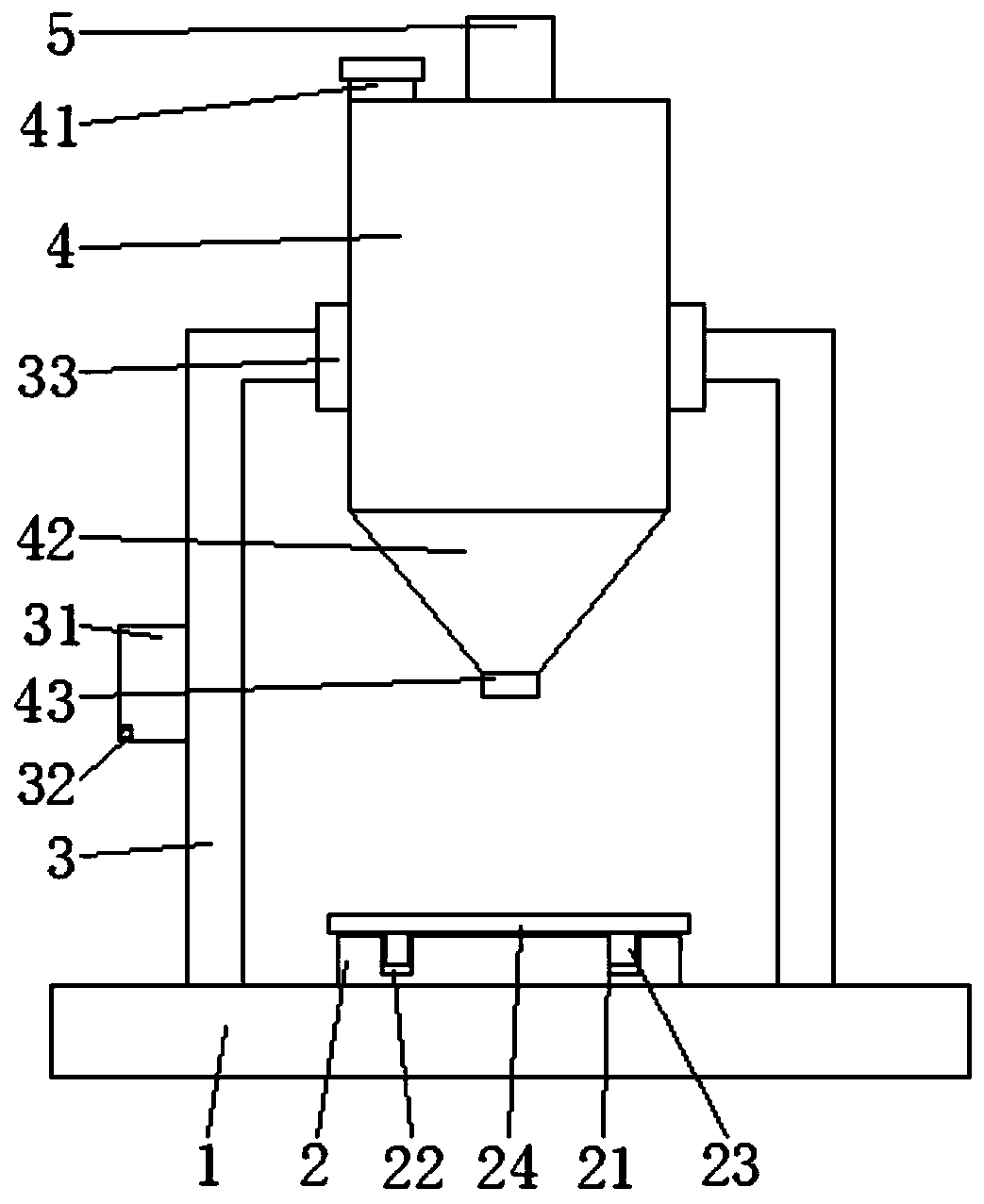

Rotating disc type grain discharging and storing device

InactiveCN111661572AAvoid local accumulationEasy to suck outThrowing machinesCleaning using gasesGear wheelElectric machinery

The invention discloses a rotating disc type grain discharging and storing device. The rotating disc type grain discharging and storing device comprises a material bin, the material bin is arranged tobe in a barrel shape, an annular rail is fixedly installed at the top of an inner cavity of the material bin, a rotating disc is rotationally connected to the top of the annular rail, a gear ring isfixedly connected to the outer side of the rotating disc, a motor is fixedly installed on the side wall of the top of the material bin, the top of the motor is fixedly connected with a gear, the gearmeshes with the gear ring, a discharging bin is fixedly installed at the edge position of the rotating disc, a discharging hopper is fixedly installed at the bottom of the discharging bin, and the discharging hopper is located on the lower side of the rotating disc. According to the rotating disc type grain discharging and storing device, the structure is simple, convenience and practicality are achieved, the technical effect of uniform discharging can be achieved, the situation that storage is affected due to the fact that grains are locally accumulated in a stock bin is avoided, and dust mixed in the grains can be removed in the discharging process.

Owner:ANHUI JIESHOUSHI YUNLONG FOOD MACHINE ENG

Crushing device for activated carbon processing

PendingCN108273588AHas the function of shock and noise reductionConvenient and efficient crushingGrain treatmentsActivated carbonElectric machinery

The invention discloses a crushing device for activated carbon processing. The crushing device for activated carbon processing comprises a recycling barrel; a first motor is installed at the bottom ofthe recycling barrel; an output shaft of the first motor upwards penetrates the recycling barrel and is provided with a rotating disk; the side edge of the rotating disk is provided with installing holes distributed in a circumferential array; a screen net is installed in the installing holes; an annular slider is installed at the bottom of the rotating disk; an annular sliding base is installedat the bottom in the recycling barrel; an annular sliding groove is formed in the top of the sliding base; the slider is arranged in the sliding groove in a sliding manner; a discharging port is formed in the bottom of the side edge of the recycling barrel; a cover plate is installed on the top of the recycling barrel; two fixing bases are installed on the top of the cover plate; and a crank shaftis rotationally installed between the two fixing bases, and is movably sleeved with a lantern ring. The crushing device for activated carbon processing can achieve continuous crushing, has a certainvibration attenuating and noise lowering effect, and is very sufficient in crushing, very high in efficiency and easy to operate.

Owner:贵州森环活性炭有限公司

Metering device for nylon material

The invention discloses a metering device for a nylon material. The metering device comprises a base, a mounting platform is fixedly connected to the intermediate portion of the upper surface of the base, clamping grooves are formed in the left and right ends of the upper surface of the mounting platform, pressure sensors are fixedly connected to the bottoms of the clamping grooves, clamping plates are placed at the upper ends of the pressure sensors, the upper ends of the clamping plates are fixedly connected with placing plates, support frames are fixedly connected to the left and right ends of the upper surface of the base, and the upper ends of the support frames are fixedly connected with a storage box through mounting plates; and a hopper is fixedly connected to the bottom of the storage box, and a motor is fixedly connected to the intermediate portion of the upper surface of the storage box. According to the metering device for the nylon material, the motor drives a screw guide rod and a scraping plate to rotate, uniform discharging is facilitated through the screw guide rod, partial accumulation of raw materials in the storage box is prevented through the scraping plate, metering is carried out through the pressure sensors, the clamping plates and the clamping grooves are matched, and the stability of the placing plates is improved.

Owner:建湖县兴隆尼龙有限公司

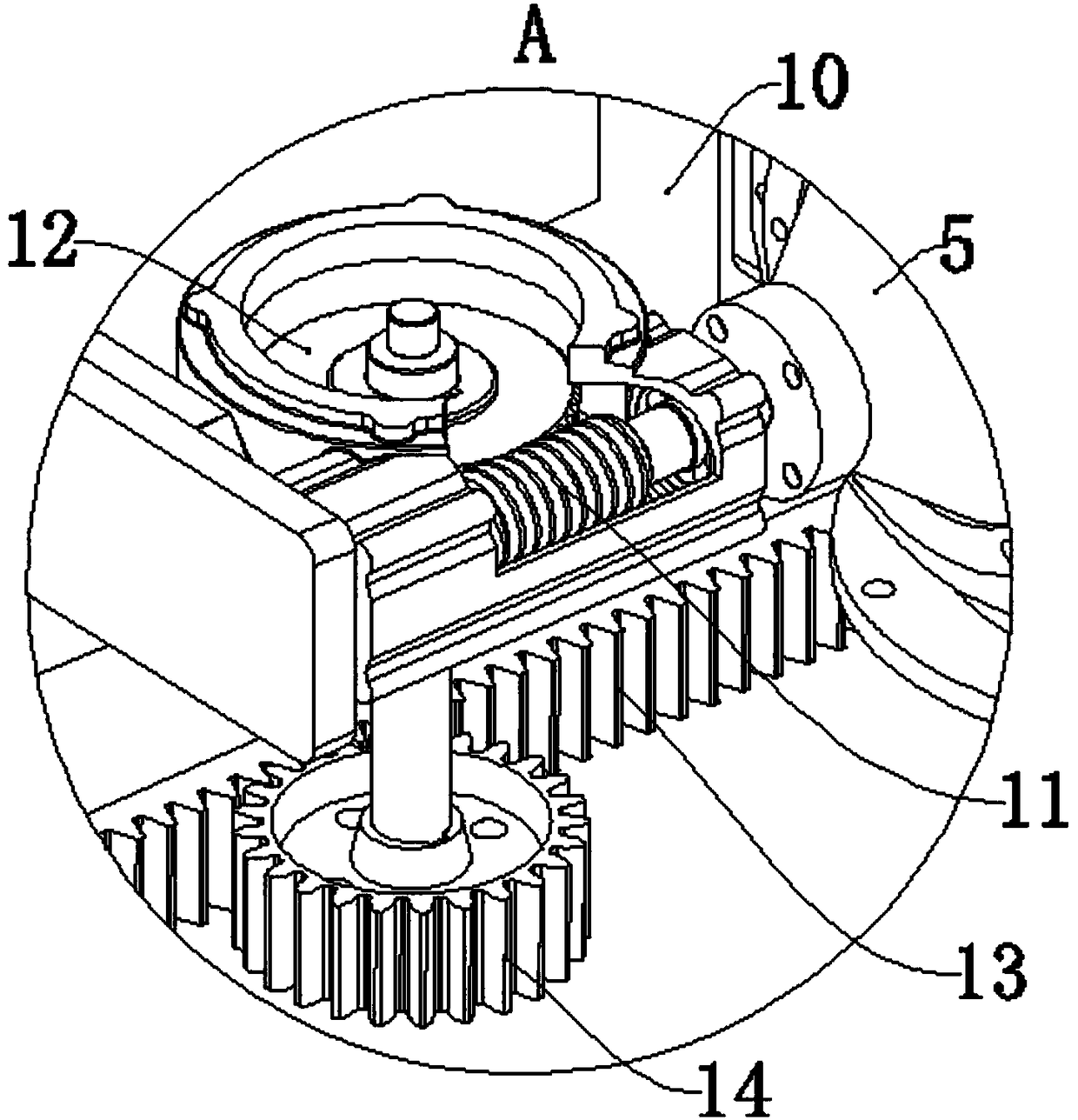

Feather dehydrator

InactiveCN102706130ASimple structureAvoid local accumulationDrying chambers/containersEngineeringPromotion effect

The invention discloses a feather dehydrator which comprises a frame, a driving device, an outer cylinder arranged on the frame, and a rotating liner arranged in the outer cylinder. Dehydration holes are arranged on the side wall of the rotating liner; the rotating liner is provided with a plurality of reinforcing ribs; the reinforcing ribs extend for certain distance from the side wall of the rotating liner to the center of the rotating liner; and the side surface of the reinforcing rib is cambered. The feather dehydrator has a novel and simple structure, the reinforcing ribs obviously improve the dehydration effect and prevent the local accumulation of feather, and after the speed of rotating liner is gradually reduced, most of the feather can concentrate to the part close to the middle and are convenient to clean and collect. According to the feather dehydrator, the reinforcing ribs can effectively destroy the structure of feather and have certain promotion effect on the subsequent processing of feather in practical use.

Owner:句容市红掌食品有限公司

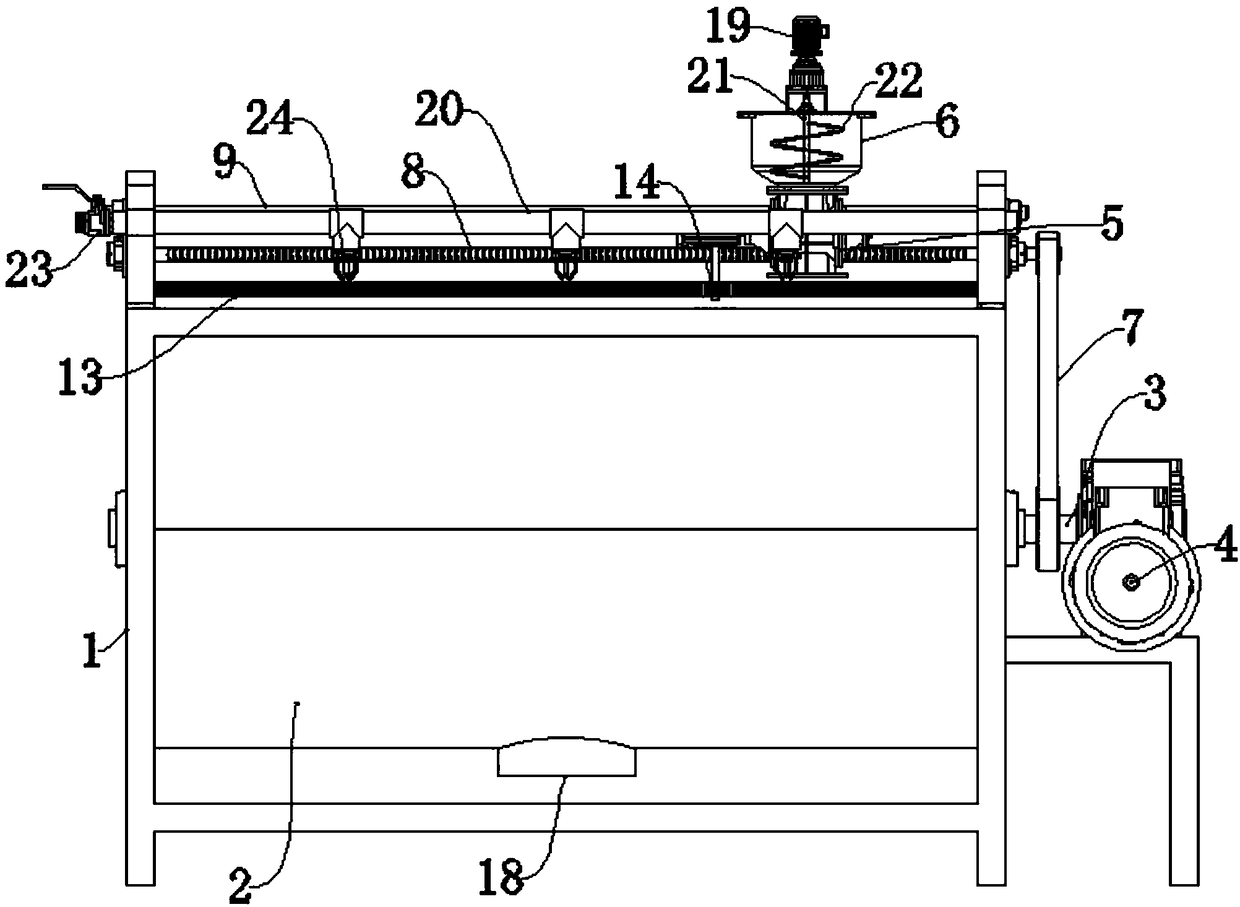

Wet material blender and use method thereof

PendingCN108435022AReduce in quantityUniform materialRotary stirring mixersTransportation and packagingImpellerEngineering

The invention relates to the technical field of agitation equipment, in particular to a wet material blender. The wet material blender comprises a rack, a tank body, a main shaft, a driving motor, a rotating feeding device, an auxiliary material hopper, a belt transmission mechanism, an auxiliary material stirring motor, a spray pipe, a two-way lead screw, a guide column, a sliding block, a worm,a worm gear, a rack and a gear; the rotating feeding device is internally provided with an impeller; the two-way lead screw and the guide column are both arranged on the rack, and the main shaft is connected with the two-way lead screw; the sliding block is slidably connected with the guide column, and in threaded cooperation with the two-way lead screw; the worm is coaxially connected with the impeller, the worm is meshed with the worm gear, and the axis of the worm is vertical; the rack is arranged on the rack, the gear is coaxially connected with the worm gear, and the gear is meshed with the rack. The wet material blender aims to solve the deficiencies in the prior art, and has the advantages that auxiliary materials accounting for smaller proportions can be uniformly added into the main material during the stirring, prevent the accumulation of the auxiliary materials, and improve the product quality.

Owner:HEZE UNIV

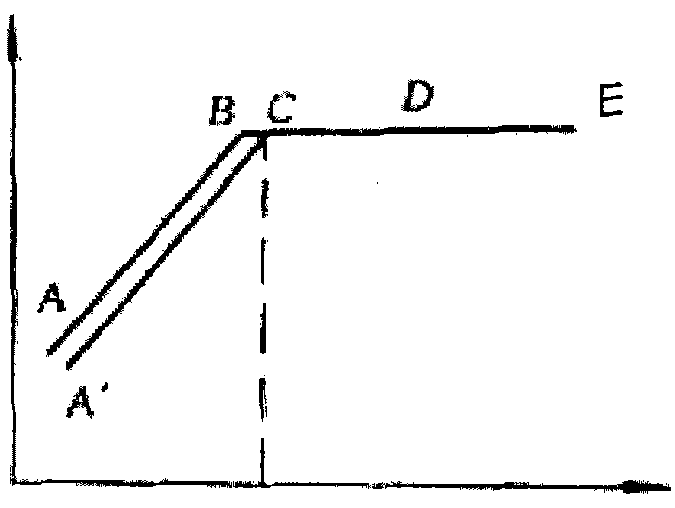

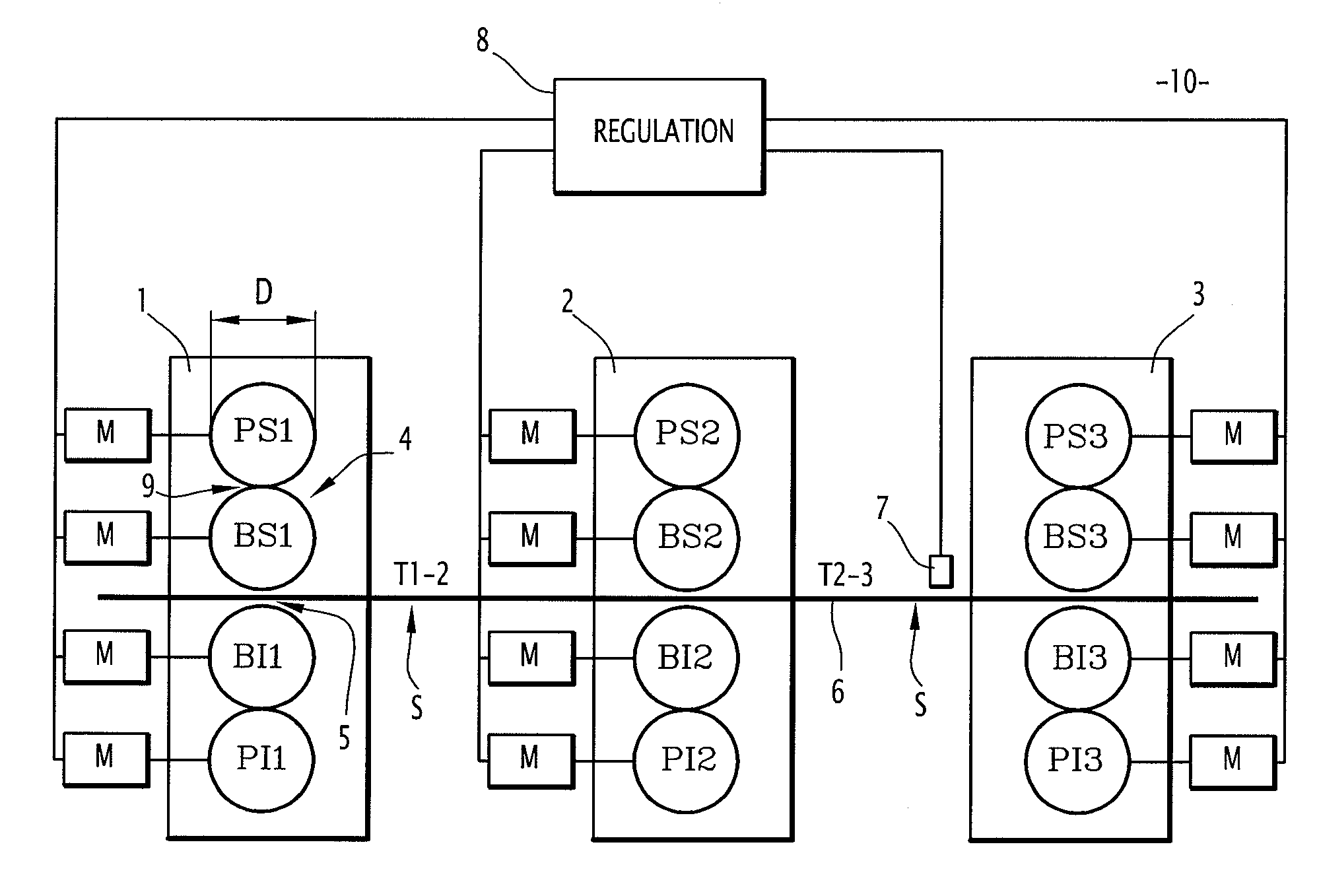

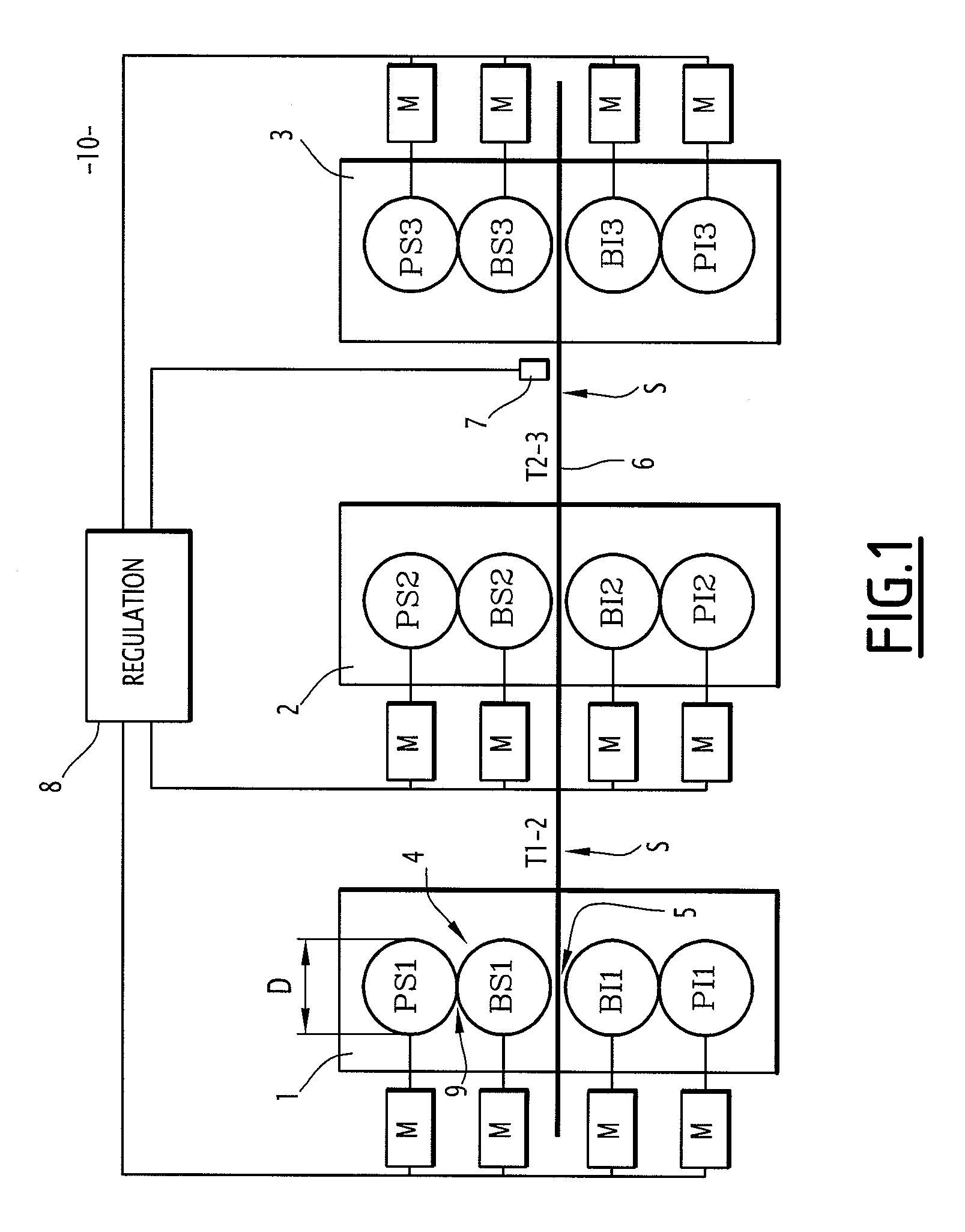

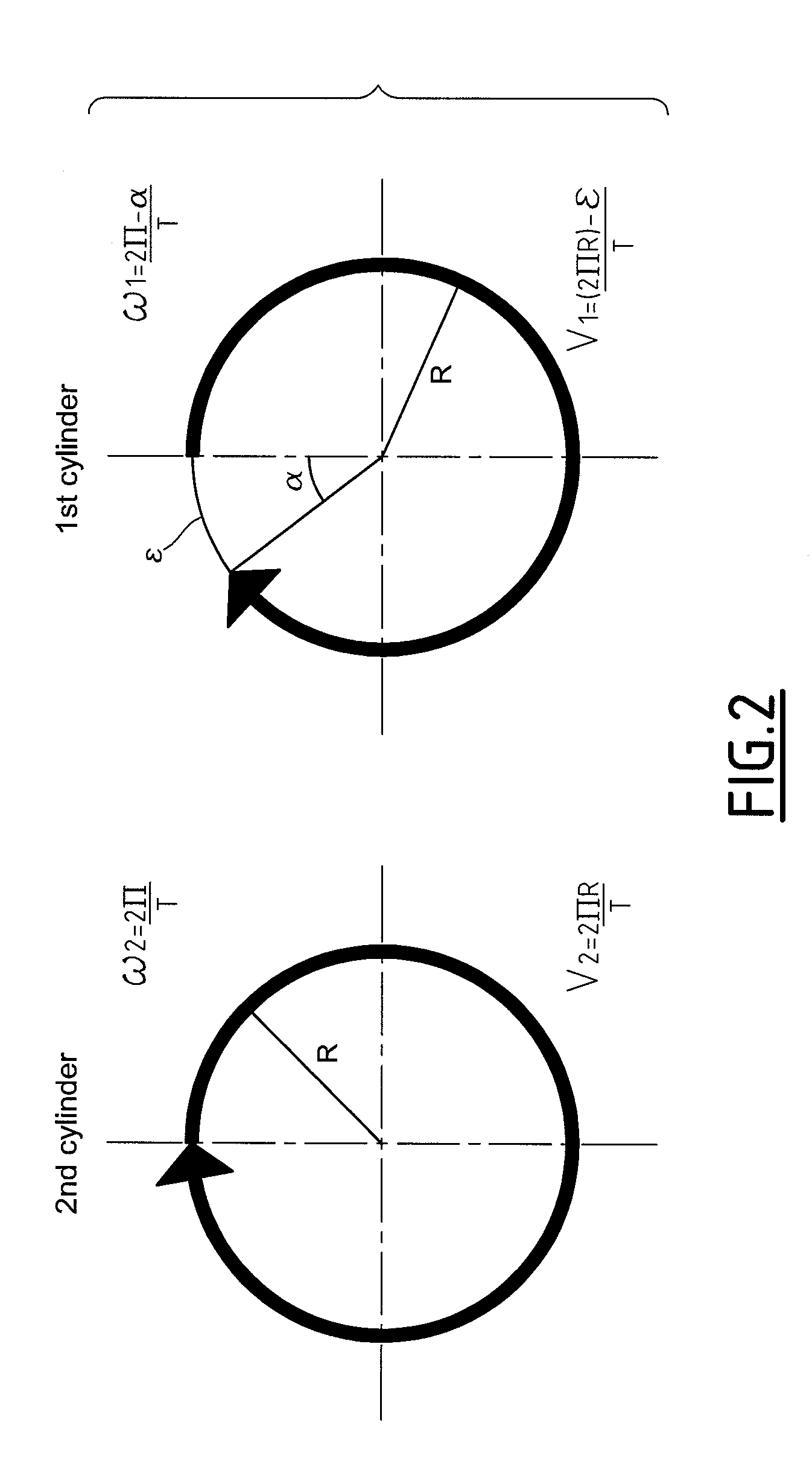

Method for Regulating the Angular Velocity of Printing Cylinders

InactiveUS20110018471A1Reliable and simple and flexible mannerLess-powerful motorMultiple dynamo-motor startersDynamo-electric converter controlCounter pressureAngular velocity

A method for regulating a first printing unit is provided. The first printing unit includes a plate cylinder, a first blanket cylinder carrying a tubular blanket and an impression cylinder. The first blanket cylinder defines a region of contact with the plate cylinder. The impression cylinder defines a region of counter-pressure with the first blanket cylinder. The method includes when the first printing unit is printing, a regulating step of a duration greater than or equal to six minutes in respect of the angular printing velocity ω1 of the first blanket cylinder relative to the angular printing velocity ω2 of the plate cylinder so that, for at least part of the duration of the regulating step, the ratio ω1 / ω2 of the angular velocities is different from the ratio D2 / D 1 between the diameter D2 of the plate cylinder and the diameter D1 of the first blanket cylinder in order to define a difference in velocity Δω=ω1−ω2×D2 / D1, any difference in velocity Δωbeing of the same sign throughout the entire duration of the regulating step.

Owner:GOSS INT MONTATAIRE

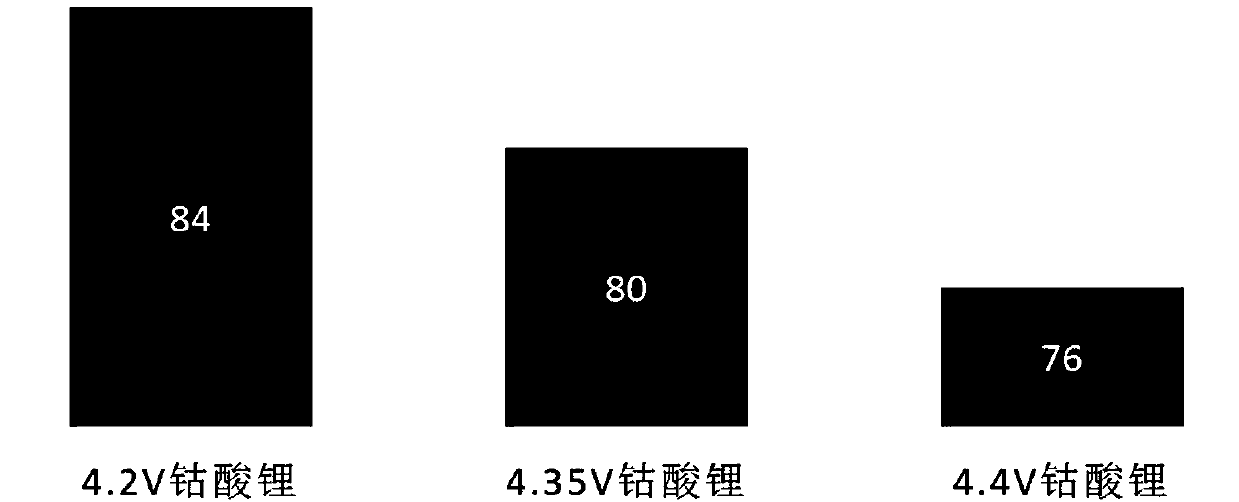

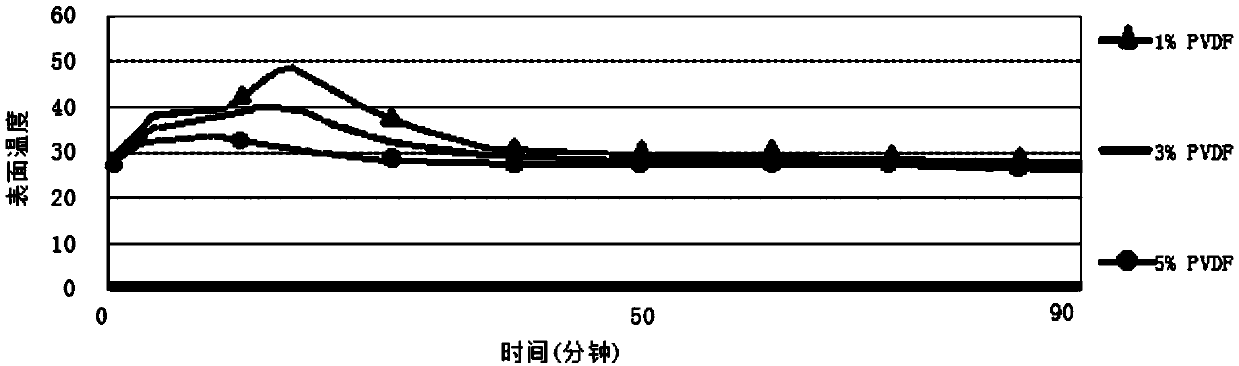

A lithium ion battery and a preparation method thereof

InactiveCN109585840AAvoid fireAvoid explosionFinal product manufactureCell electrodesMicrosphereHigh pressure

The invention discloses a lithium ion battery and a preparation method thereof. A positive electrode of the lithium ion battery adopts high pressure lithium cobaltate positive active materials, and anegative electrode of the lithium ion battery adopts mesophase carbon microsphere graphite as active materials. The separator is composed of a base film layer formed by sequentially stacking three base films of PP, PE and PP and ceramic materials coated on the base film layer. In the above manner, the lithium ion battery of the present invention can effectively suppress the thermal runaway of thebattery caused by 10V overcharge in 1C charging of the battery at different ambient temperatures (such as 5 DEG C, 25 DEG C and 50 DEG), preventing the battery from igniting and explosion; and at thesame time the lithium ion battery can withstand heavy impact, thermal shock, short circuit, acupuncture, extrusion and other destructive collisions without ignition and explosion, and has high safetyperformance.

Owner:SPRINGPOWER TECHNOLOGY (SHENZHEN) CO LTD

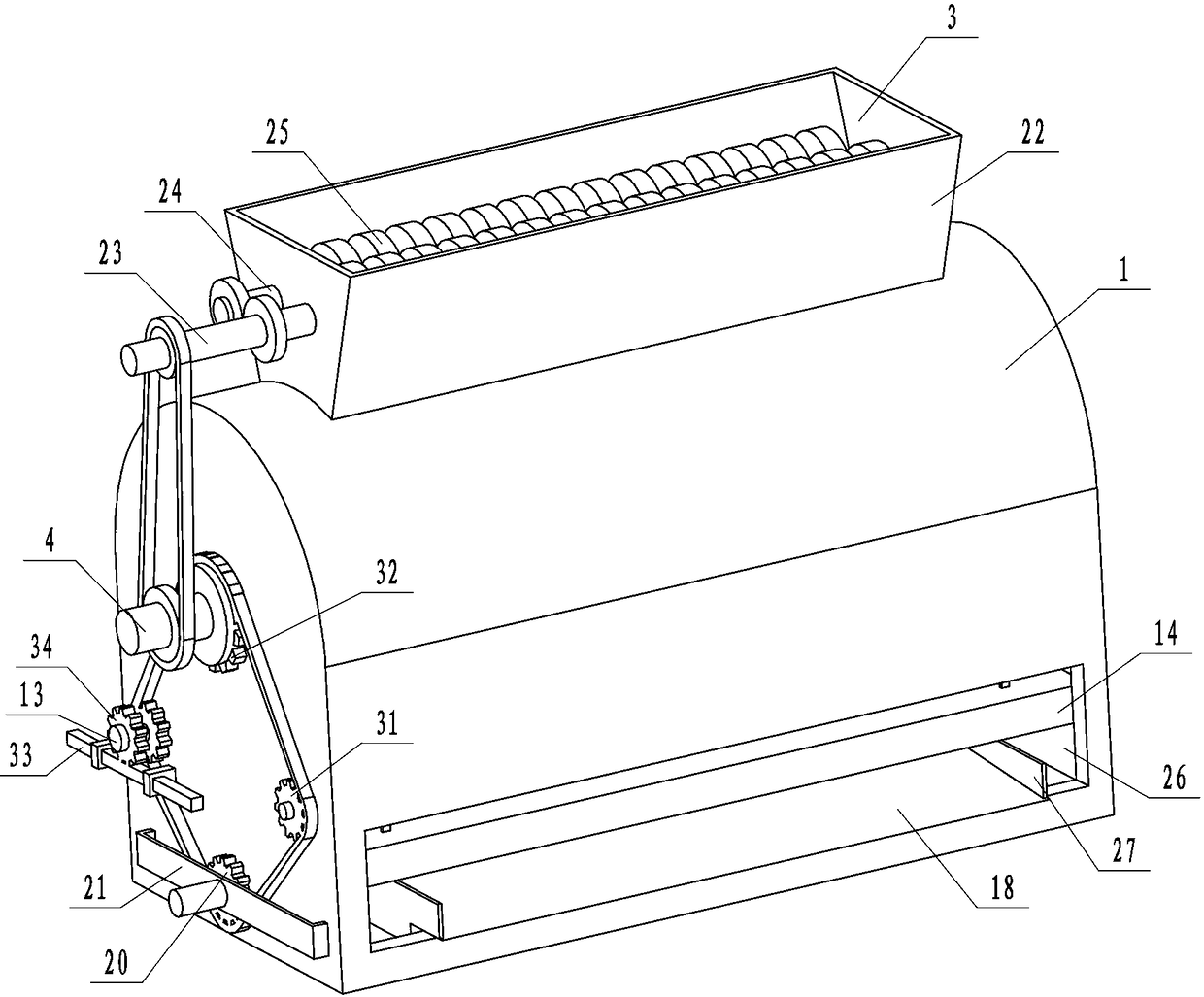

Method and device for stir-frying Chinese traditional medicine decoction pieces by hot air flow

ActiveCN109718108ASmooth flipAvoid local accumulationPharmaceutical product form changeMicrowave heatingMicrowaveEngineering

The invention discloses a method and device for stir-frying Chinese traditional medicine decoction pieces by hot air flow. The device includes an enclosed container, a bottom air inlet pipe, a sidewall air inlet pipe, an exhaust pipe, a circulating pipeline, microwave heating devices, mesh pots and booster pumps; The method includes the following steps: step one, putting stir-fried decoction pieces into the mesh pots with different apertures of the device according to dimensions; step two, starting the booster pumps after the circulating pipeline is heated, adjusting the power of the booster pumps, controlling flow velocity to make the flow velocity of the bottom air inlet pipe being 3-5 times of that of the sidewall air inlet pipe; step three, setting different temperatures during stir-frying according to different stir-frying requirements of stir-fried to yellow, stir-fried to brown and stir-fried to scorch, and starting the microwave heating devices or electrothermal tubes corresponding to the positions of the mesh pots to perform heat supplementing when the temperatures in the mesh pots are lower than required temperatures; and step four, taking out stir-fried traditional Chinese medicine decoction piece finished products from the mesh pots after stir-frying, and performing cooling and packaging. The method and device can enhance the quality and the preserving rates of effective components during the stir-frying of the traditional Chinese medicine decoction pieces.

Owner:湖南药圣堂中药科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com