Patents

Literature

74522 results about "Airflow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Airflow, or air flow is the movement of air from one area to another. The primary cause of airflow is the existence of pressure gradients. Air behaves in a fluid manner, meaning particles naturally flow from areas of higher pressure to those where the pressure is lower. Atmospheric air pressure is directly related to altitude, temperature, and composition.

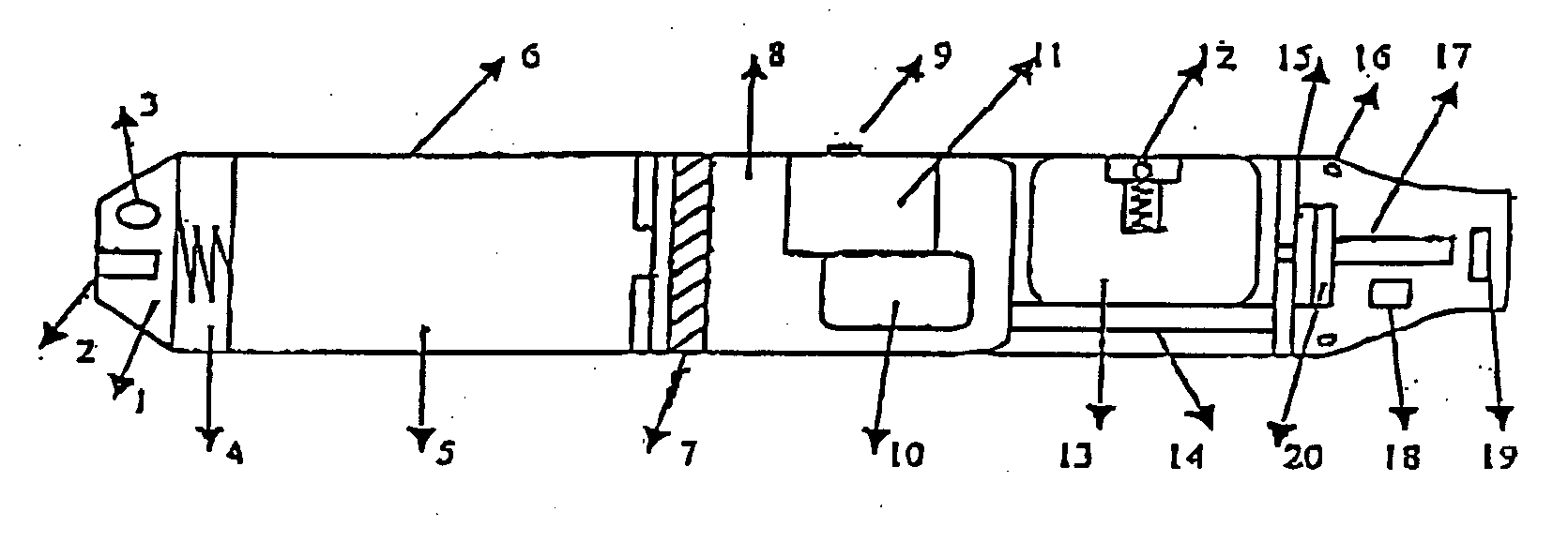

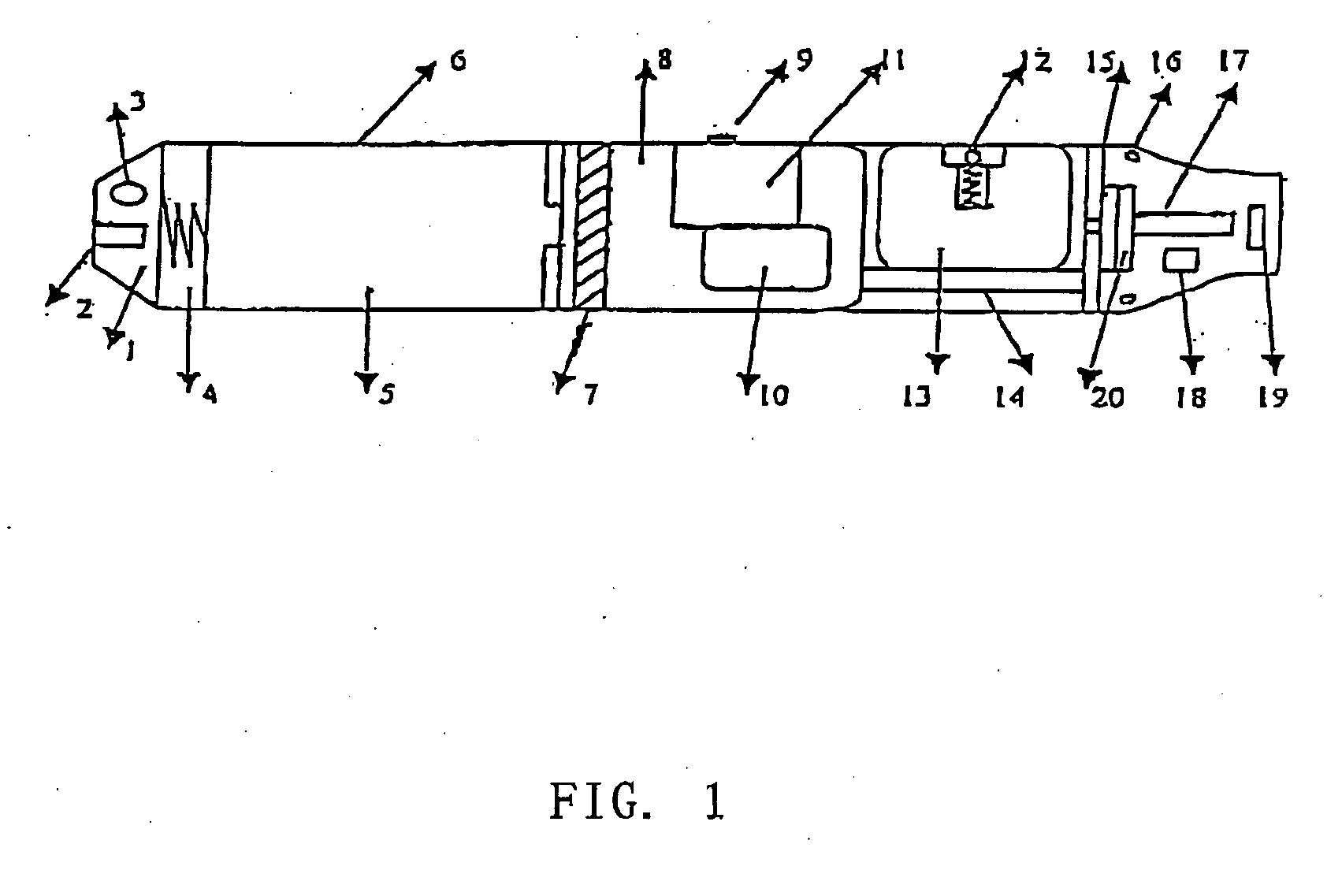

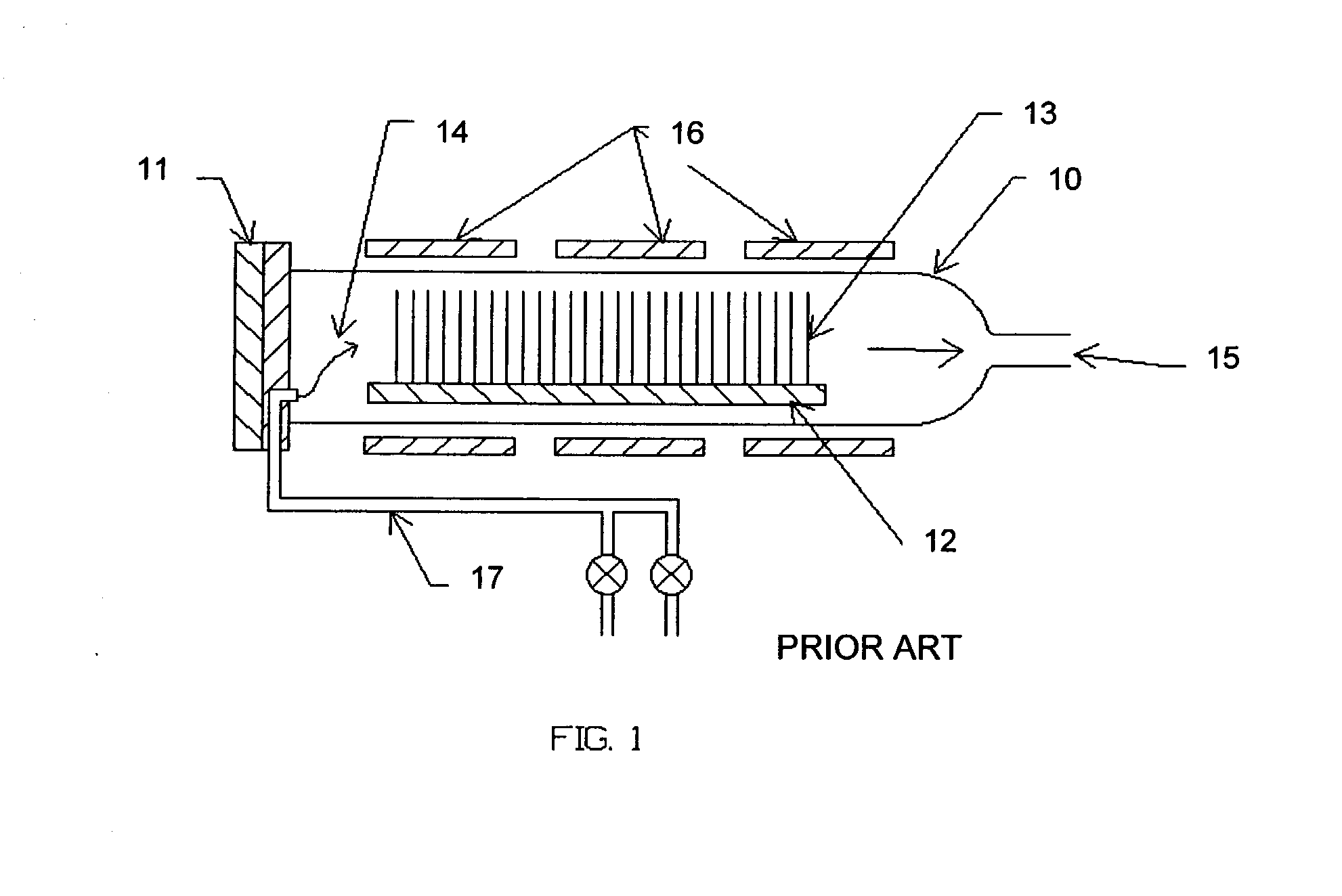

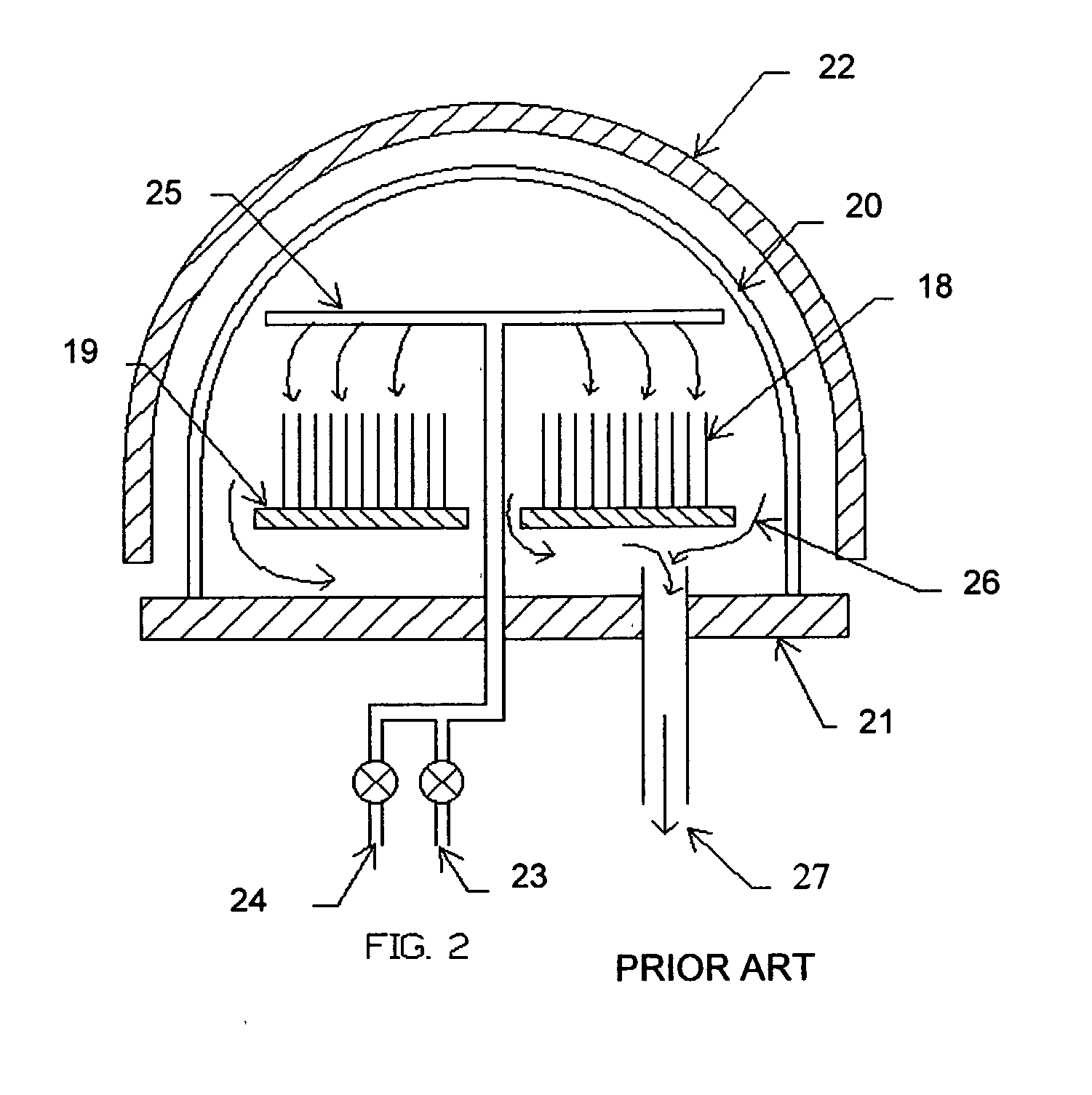

Flameless electronic atomizing cigarette

InactiveUS20060196518A1Reduce cancer riskTobacco preparationBatteries circuit arrangementsEngineeringElectric control

The invention relates to a non-smokable electronic spray cigarette which only comprises nicotine without harmful tar. The cigarette includes a smoke mouth integer comprised with a shell, a cell, a high frequency ionzer, nicotine solution storage and its container, control circuit, a display screen, a human contact sensor, a piezoelectric supersound atomizer, a high temperature vaporization nozzle and attachments, an electro-thermal vaporization nozzle installed in the air suction end of the shell goes through an electric control pump or a valve with a measuring chamber and a liquid storage container which contains nicotine solution and is connected to the electric control pump or a valve with a one-way flow valve, the control circuit plate has four export ends individually connected with the high frequency ionizer, electric heater, pump or valve and the display screen, a human resistence sensor and an air flow sensor are connected to the input end of the control circuit. The advantages of the present invention are smoking without tar, reducing the cancerogenic risk, the user still feel smoking and experiercing the excitement, the cigarette is no need to be lit and is no fire danger.

Owner:FONTEM HLDG 1

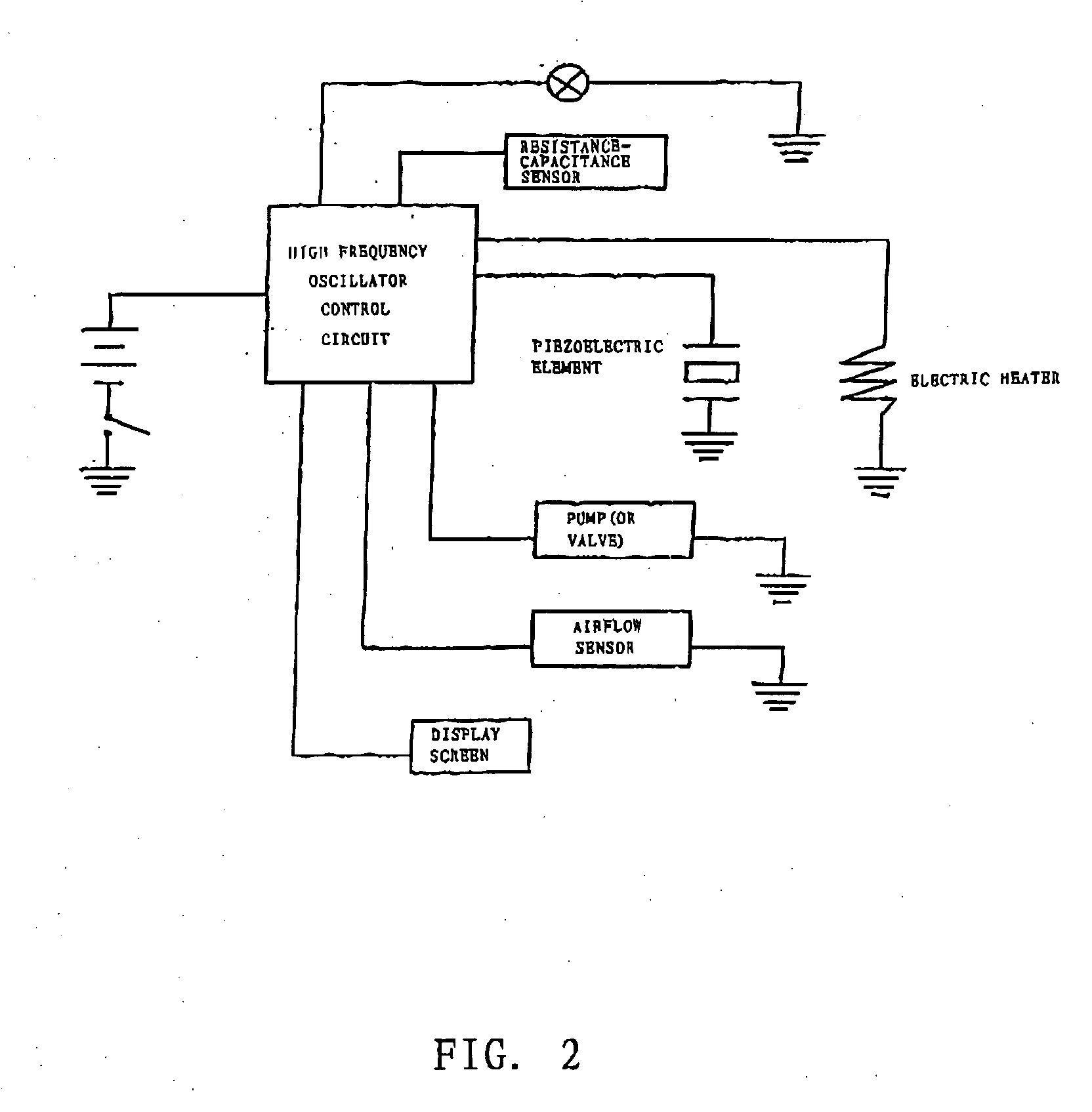

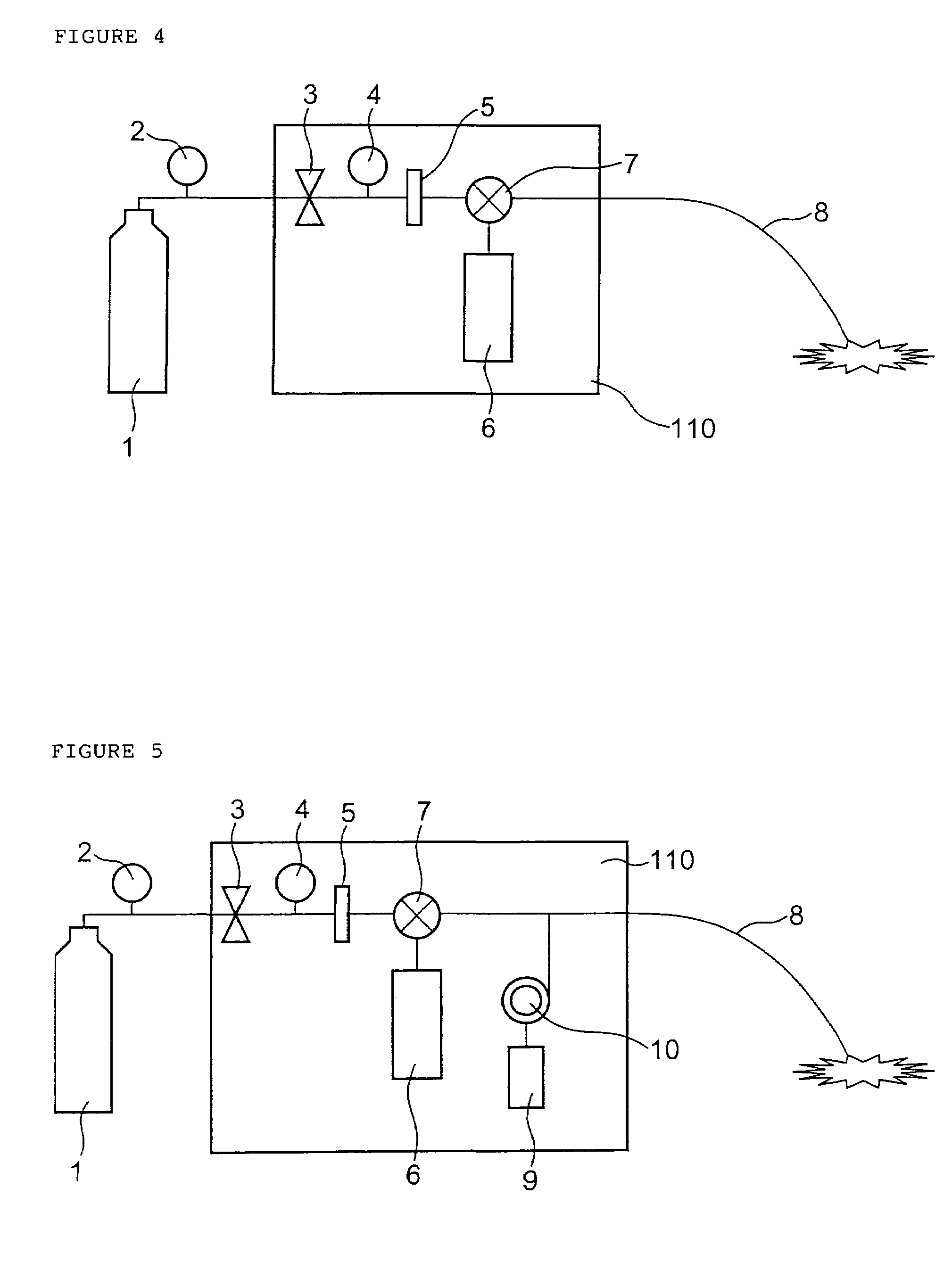

Drug administration method

InactiveUS7427607B2Reduce weightPrevention of the adhesion of an organBiocidePowder deliveryBiopolymerDrug administration

A method of administering a drug whereby a fine drug powder can be accurately administered to a target site (in particular, a target site in the body cavity) via fluidization and spraying with a gas by using a micro tube. Concerning the administration mode, in particular, the drug alone or a biopolymer is administered or the biopolymer is employed as a carrier in the above method. More specifically speaking, a method of administering a fine drug powder which comprises finely milling one or more types fine particles of the drug and / or the biopolymer, blending them each other, fluidizing the blend with a gas, then transporting the fluidized matter in a micro tube by the gas stream and spraying the fine drug powder from the tip of the micro tube toward the target site. Further, an administration method which comprises concentrically providing a capillary tube in the micro tube, supplying an aqueous solution of the drug and / or the biopolymer from the capillary tube into the gas stream and then mixing it with other fine particles of the drug and / or the biopolymer under transportation by the gas.

Owner:NEXT21 KK

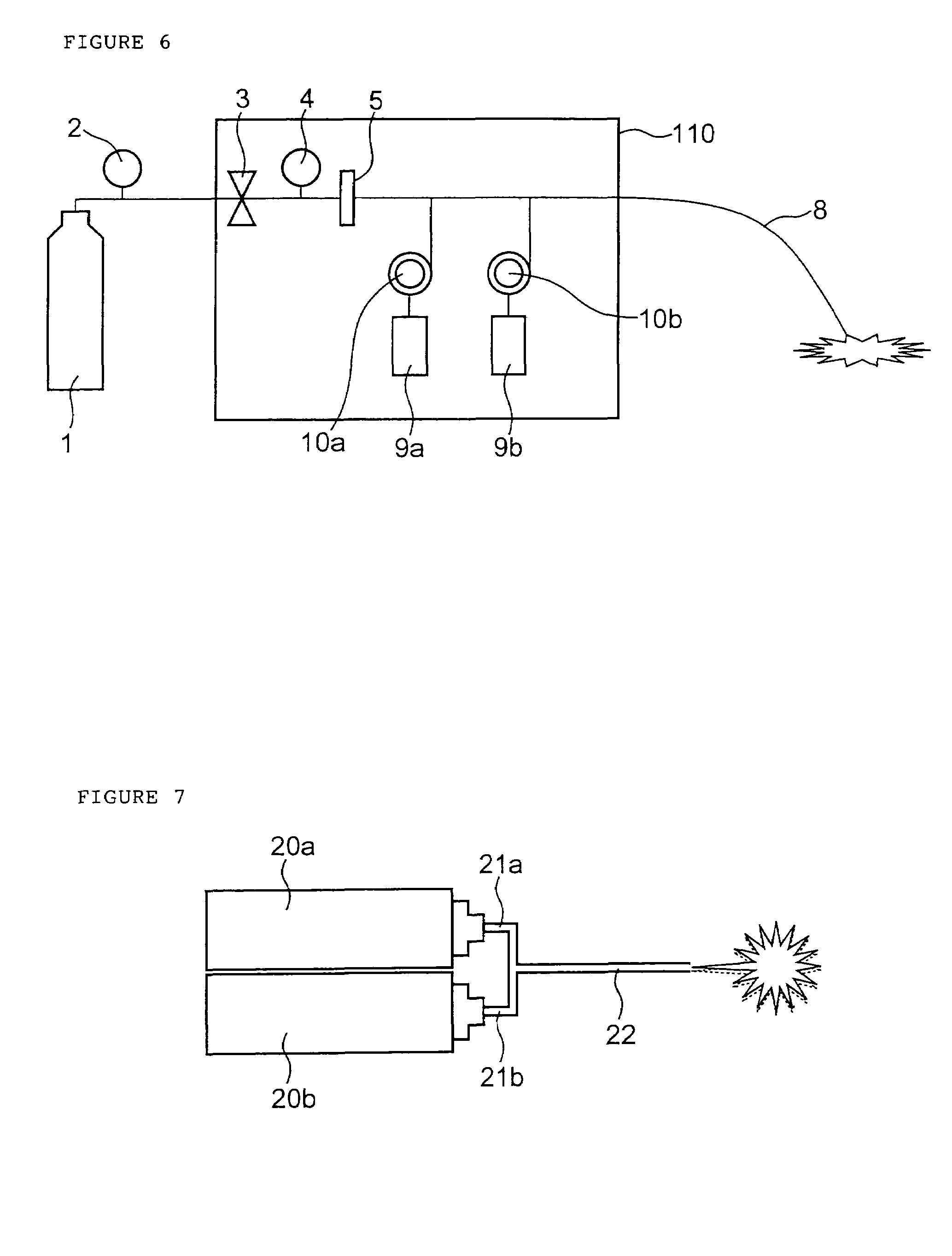

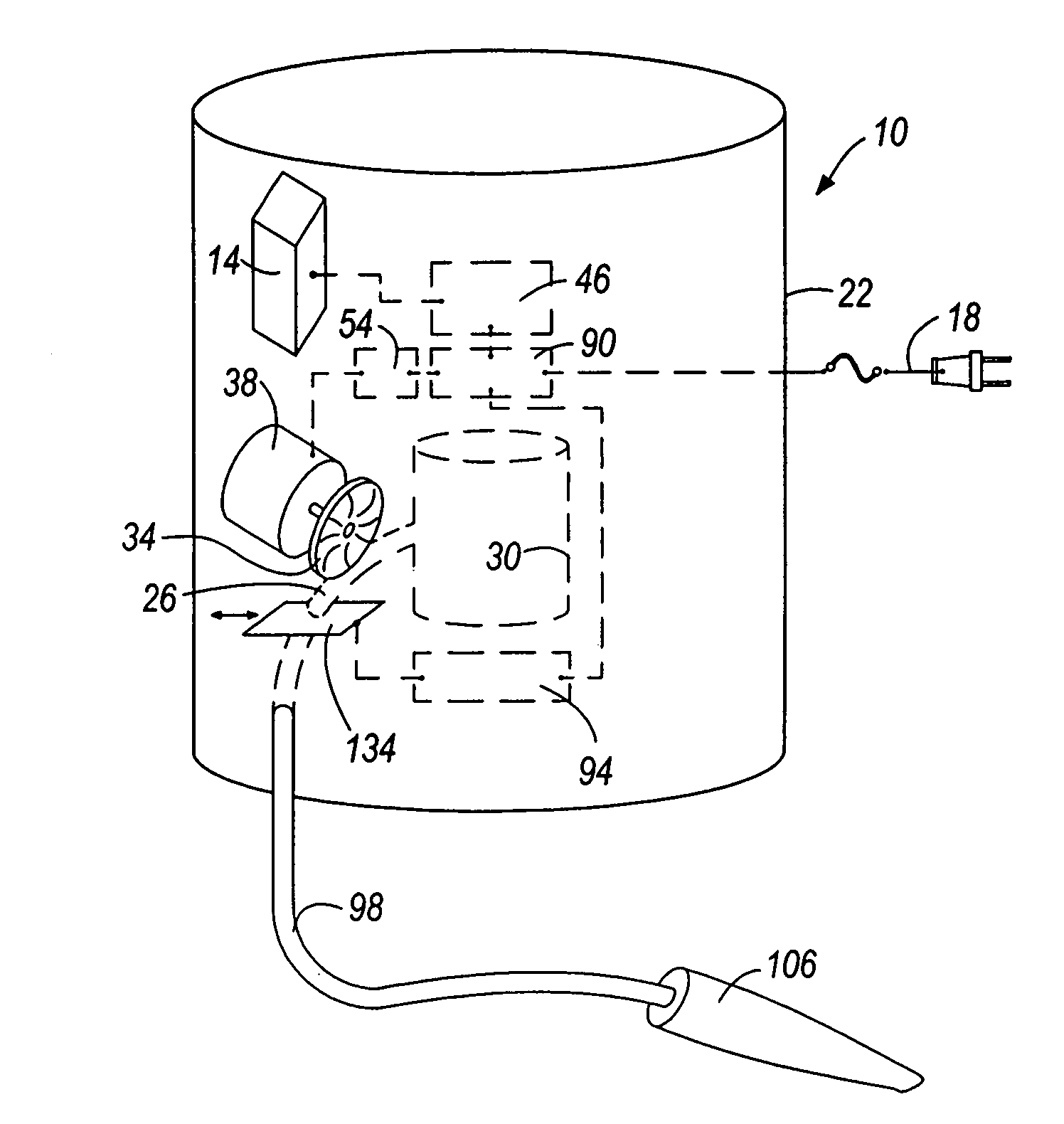

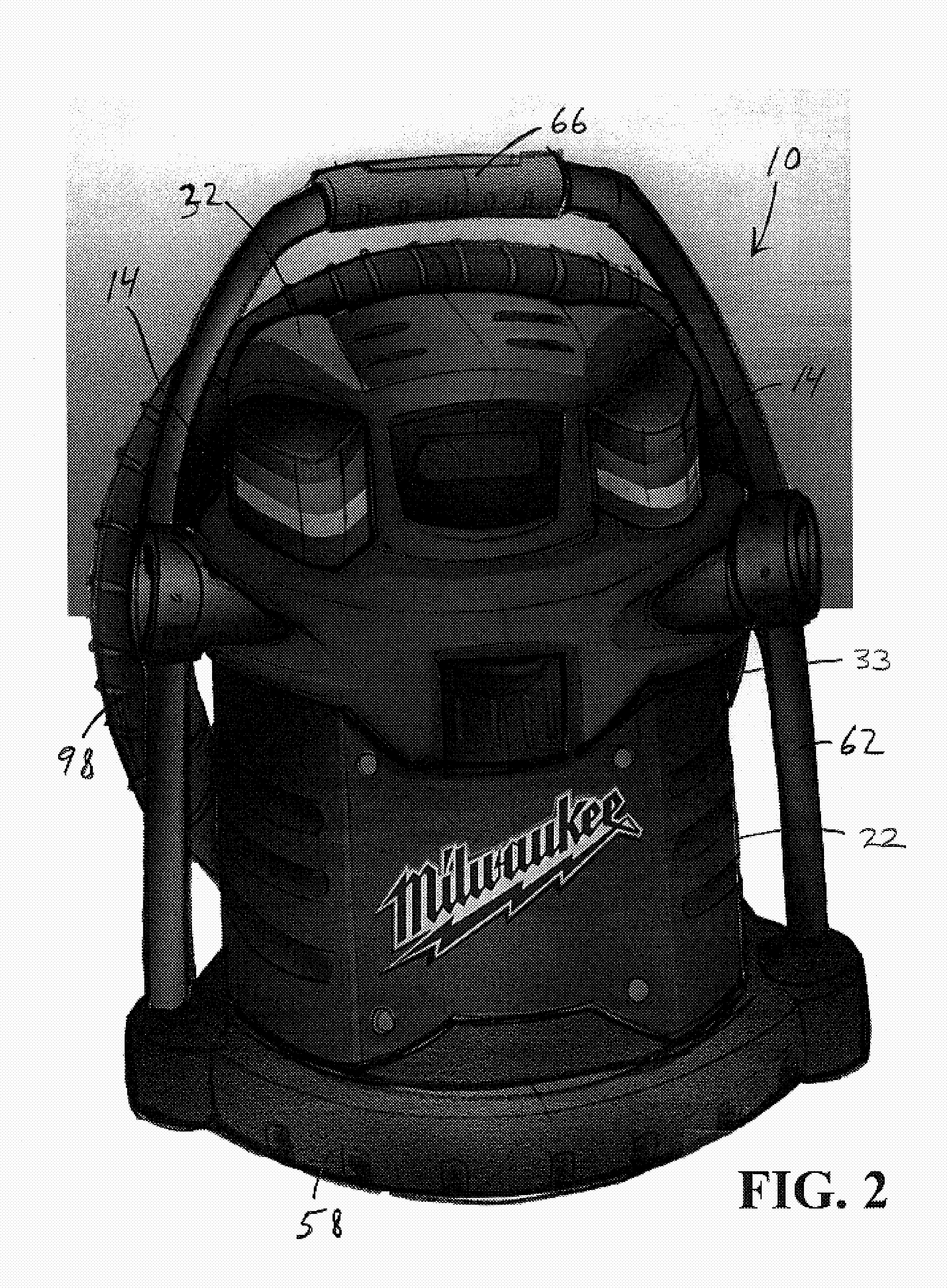

Air flow-producing device, such as a vacuum cleaner or a blower

ActiveUS7712182B2Heavy-duty constructionAvoid contactCleaning filter meansSuction filtersElectricityElectrical battery

Owner:MILWAUKEE ELECTRIC TOOL CORP

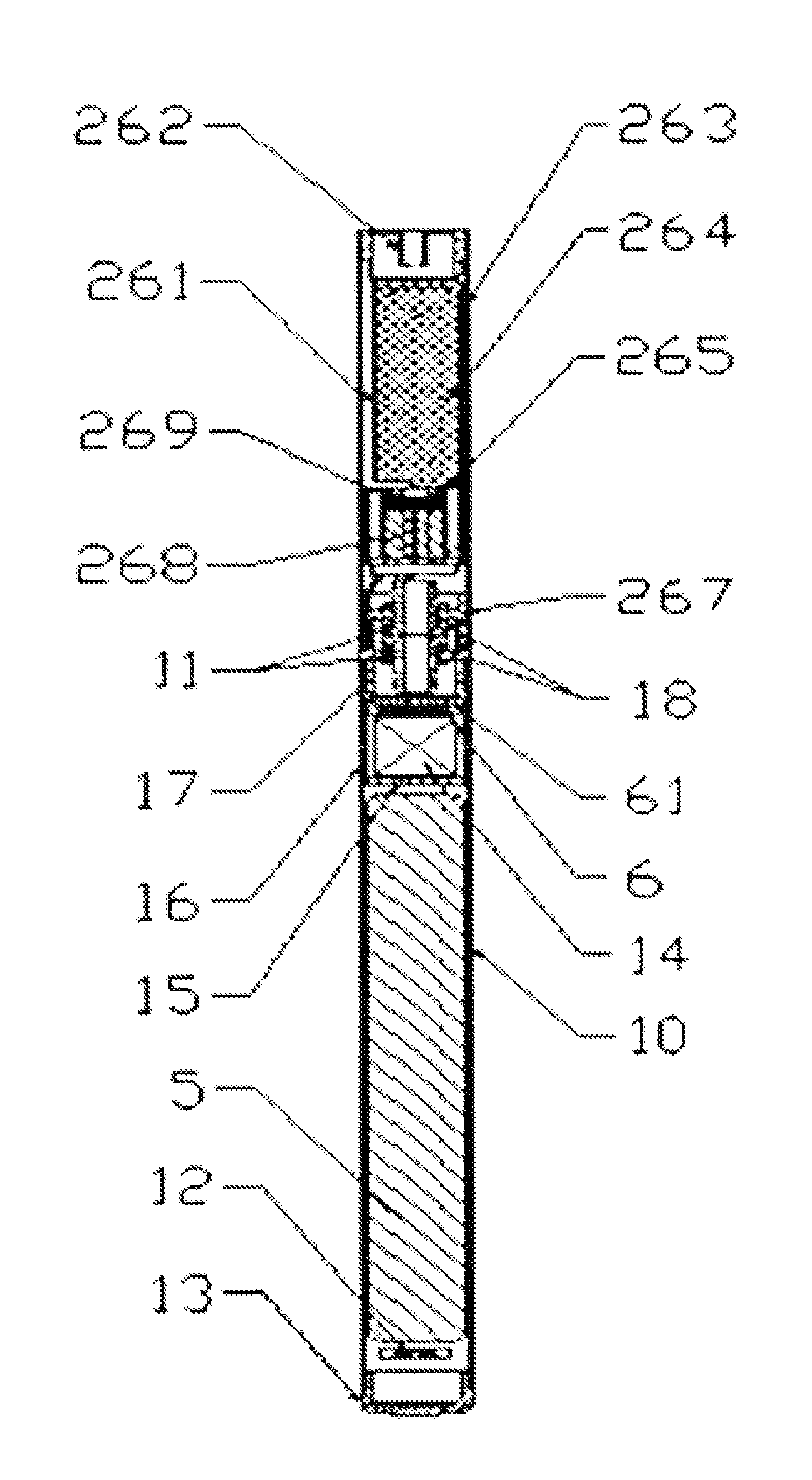

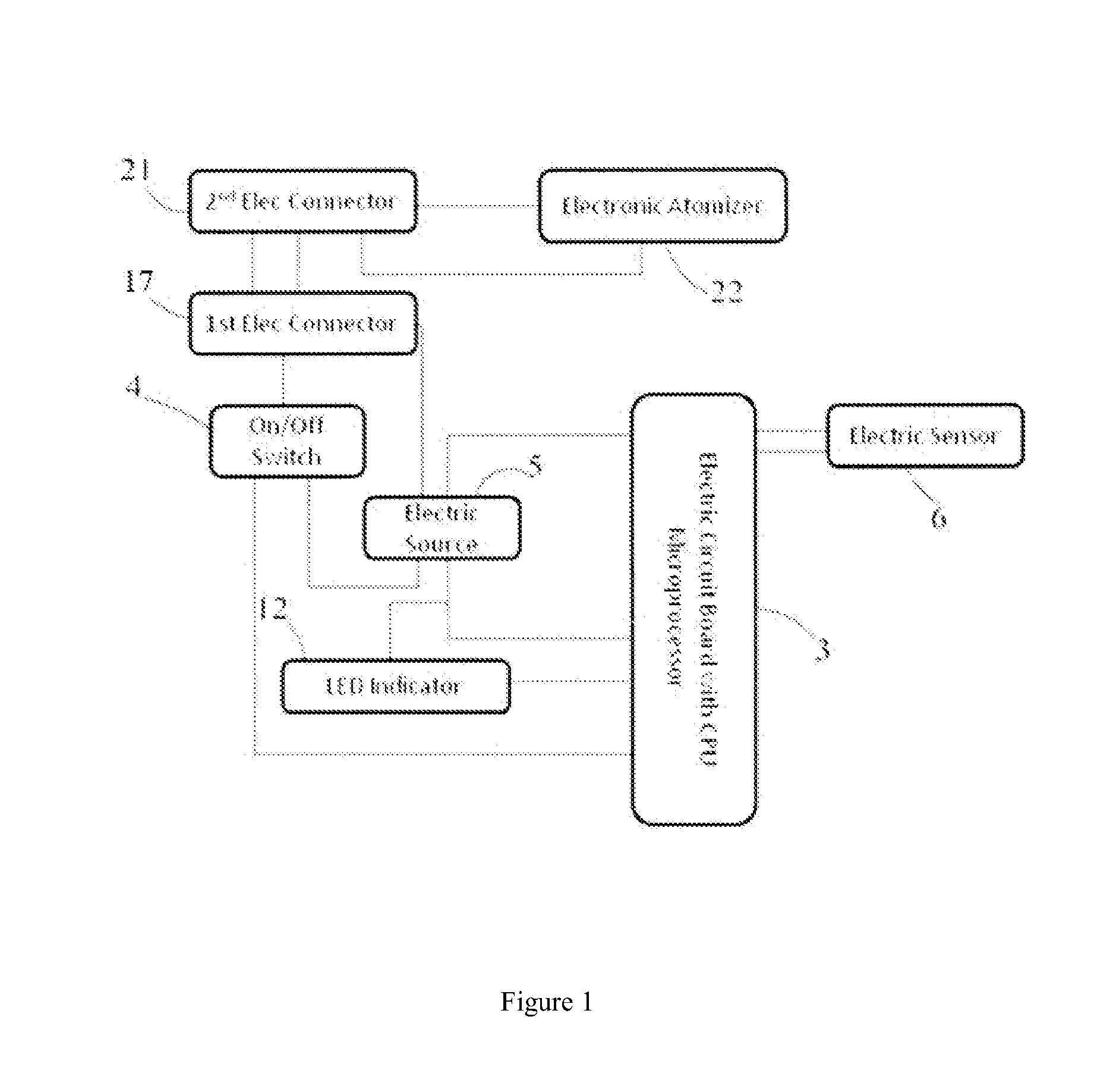

Electronic cigarette

ActiveUS8205622B2Short lifeMinimize the possibilityRespiratorsMedical devicesMicrocontrollerElectric power system

An electronic cigarette has two tubes that resemble a cigarette: an electronic inhaler and an electronic atomizer. The two tubes are connected through one or more electric connectors to form an electronic cigarette. Inside the inhaler is a rechargeable or non-rechargeable power source such as a battery, which supplies electric power to the electronic inhaler and atomizer and ensures that both work together like a cigarette. In addition to the power source, the inhaler also includes other major components: an electric airflow sensor to detect air movement generated by a user's inhaling or puffing act and a Single Chip Micyoco which controls the atomization process. The sensor's role is to collect an airflow signal that triggers the Single Chip Micyoco, which in turn instructs the electronic cigarette to supply electric power to the inhaler and atomizer connected through an electric connector. Inside the electronic atomizer are an electric connector, electric heating wire, liquid container, and atomizer cap with an air-puffing hole. The user inhales through the air-puffing hole at an end of the electronic cigarette to create an air inflow, which triggers the atomization process. The Single Chip Micyoco driven by a software program controls the electronic cigarette in an on / off manner according to the signal detected by the electric sensor on the airflow and completes a cycle of atomization, which converts a solution of a liquid form inside the liquid container to a gas form. This entire process achieves the emulated smoking process of a user, who is satisfied with scent taste that mimics cigarette smoking.

Owner:VPR BRANDS LP

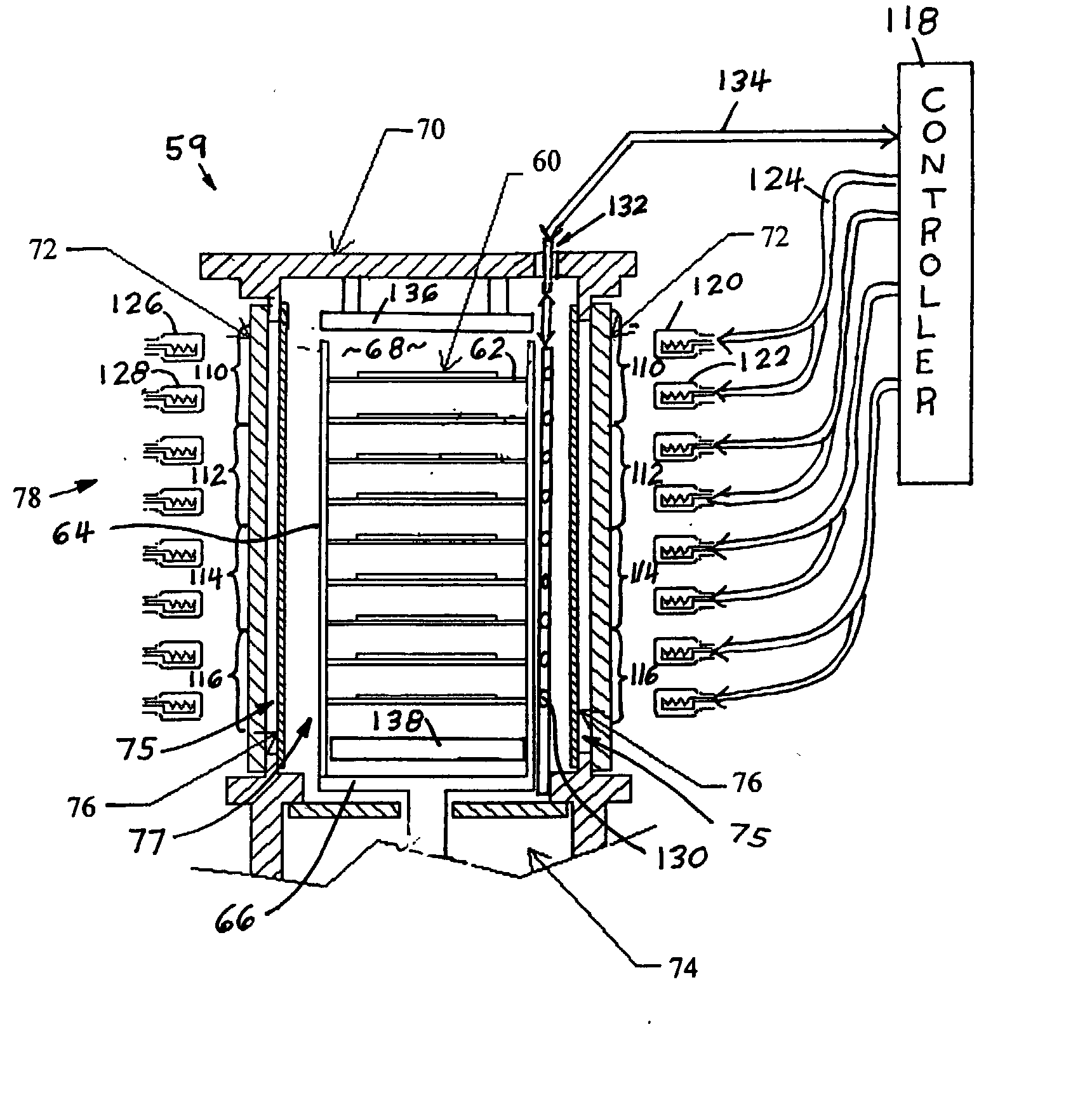

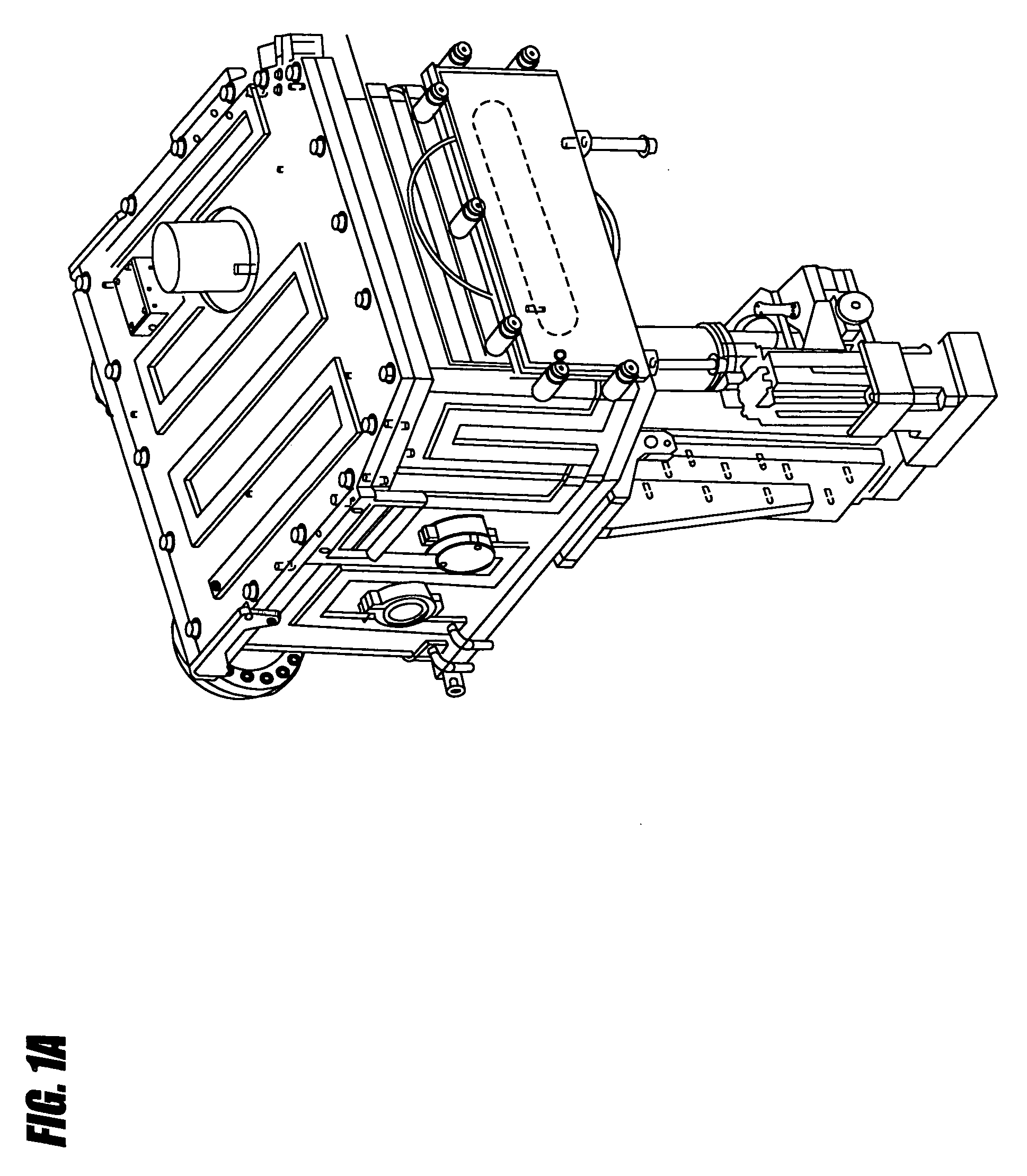

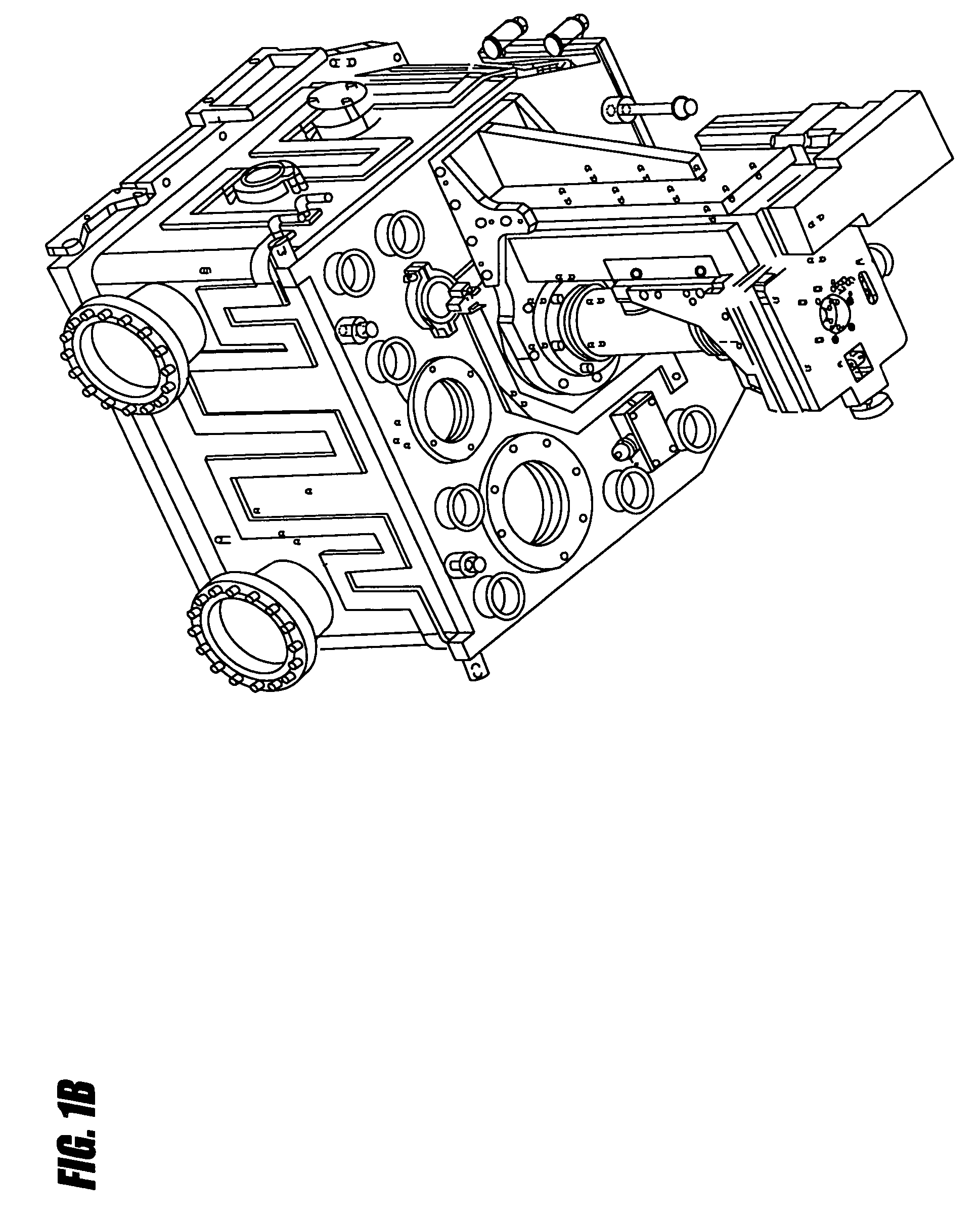

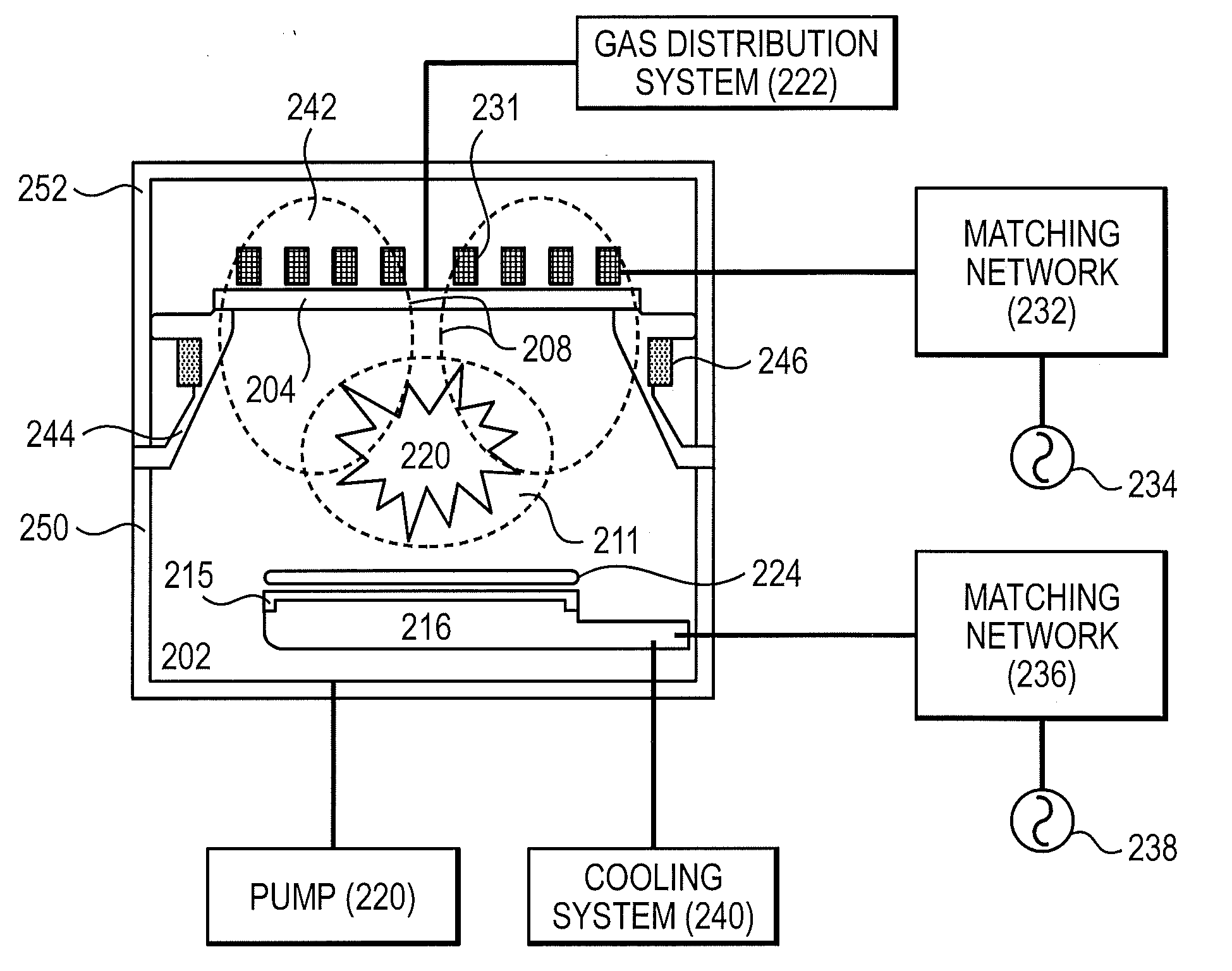

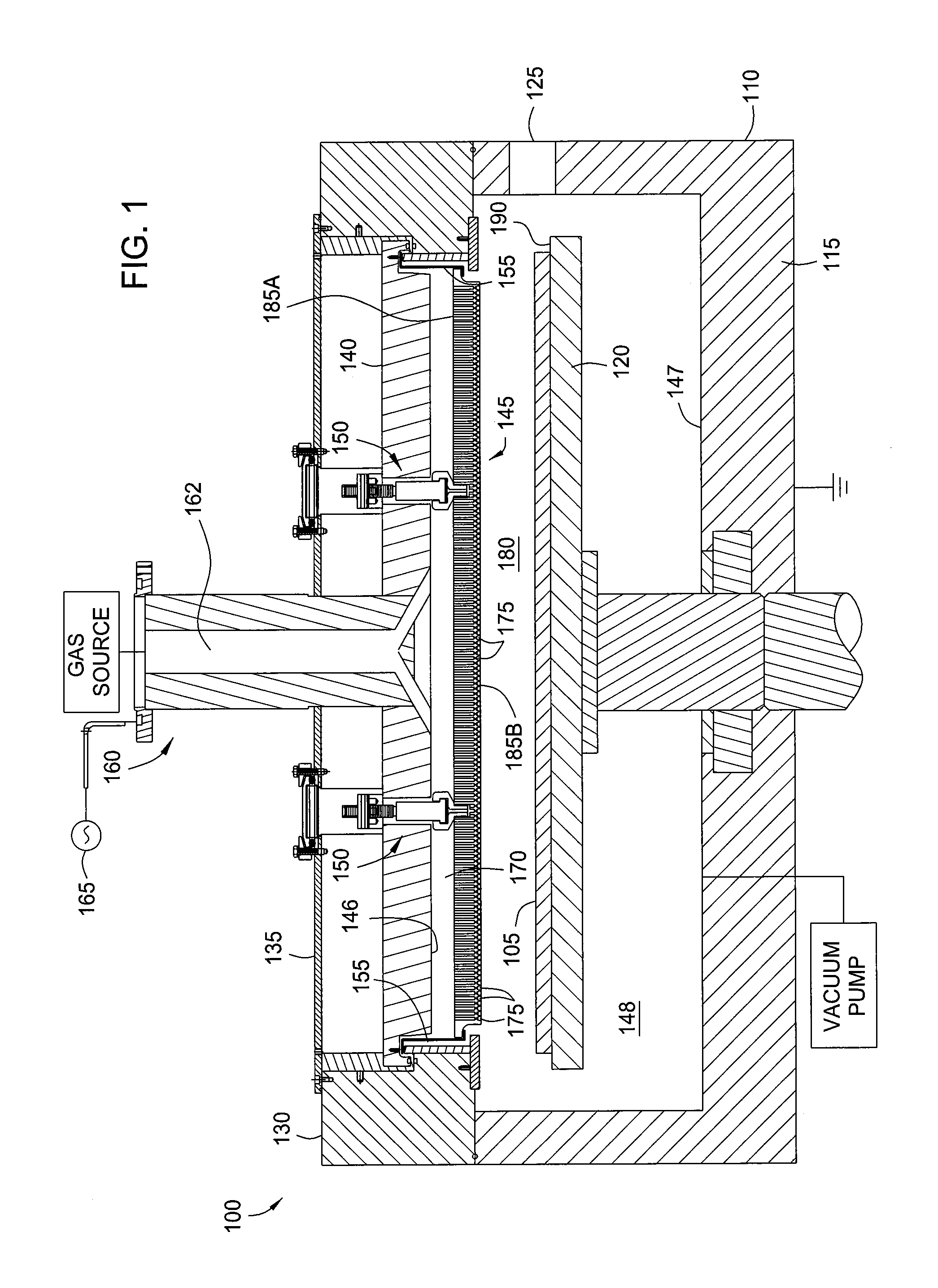

High rate deposition at low pressures in a small batch reactor

InactiveUS20030049372A1Increase ratingsRapid and uniform deposition of materialElectric discharge tubesSemiconductor/solid-state device manufacturingHigh rateSusceptor

A chemical vapor deposition reactor including a wafer boat with a vertical stack of horizontally oriented susceptors serving as thermal plates and each having pins extending upward for suspending a wafer between a pair of susceptors. Reactant gas injector and exhaust apparatus are positioned to concentrate a forceful supply of reactant gas across each wafer at a speed in excess of 10 cm / sec. The pressure is held in the range of 0.1 to 5,000 mTorr. The forceful gas flow avoids gas depletion effects, thinning the boundary layer and resulting in faster delivery of reactants to substrate surfaces, resulting in surface rate reaction limited operation. A plurality of individually controllable heaters are spaced vertically around the sides of the boat. Temperature sensors monitor the temperature along the boat height and provide input to a controller for adjusting the heater drive to optimize the temperature uniformity.

Owner:APPLIED MATERIALS INC

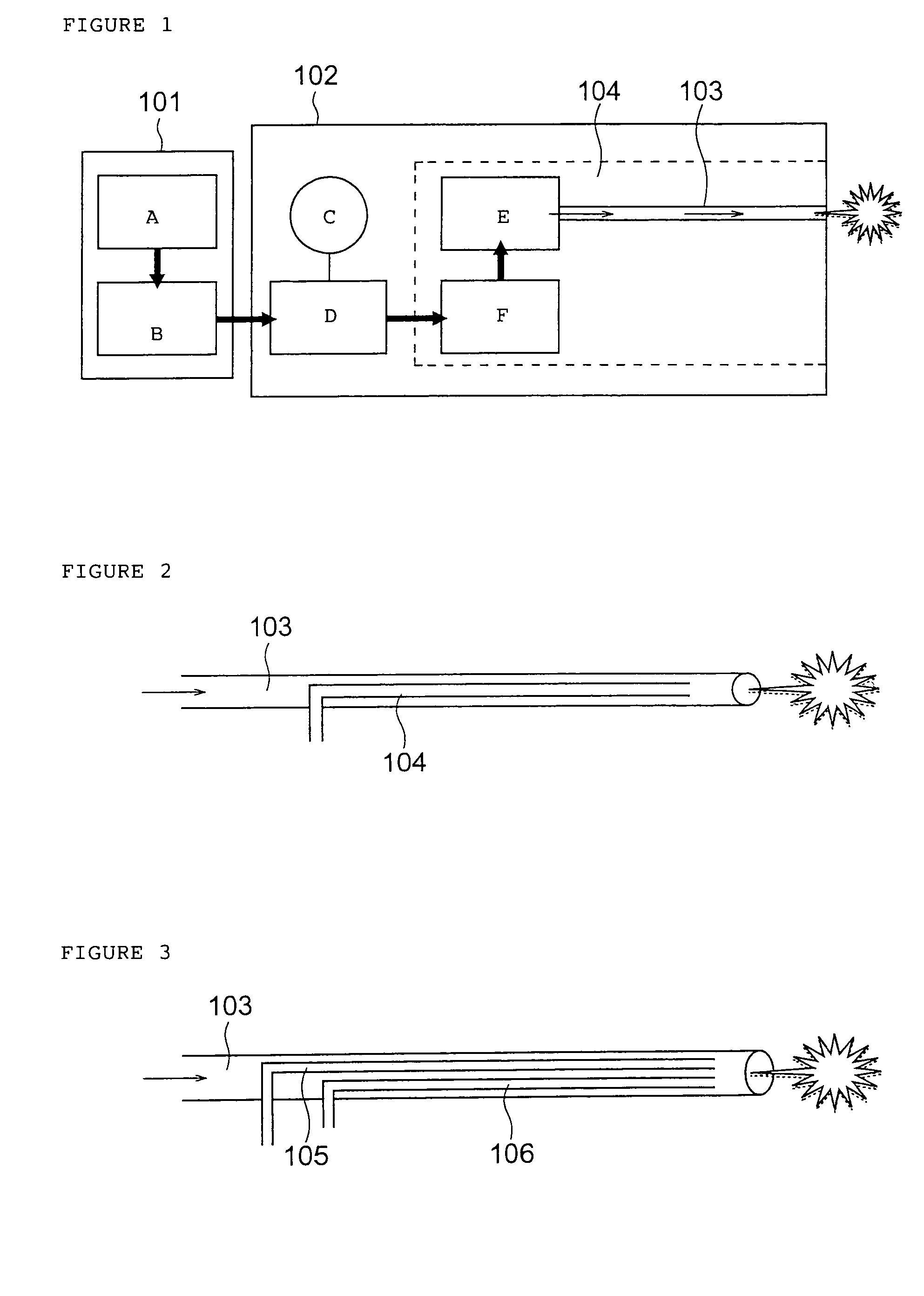

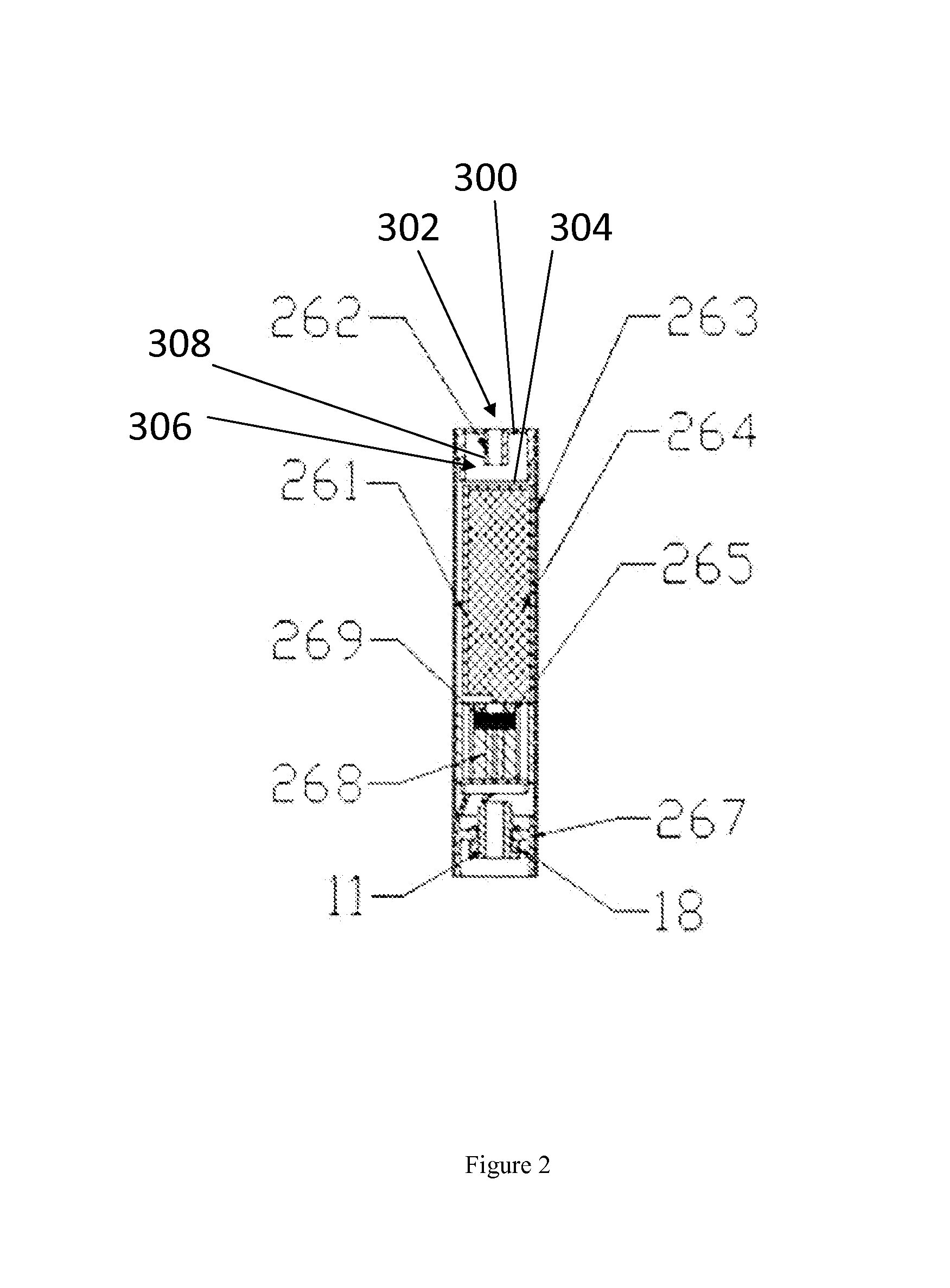

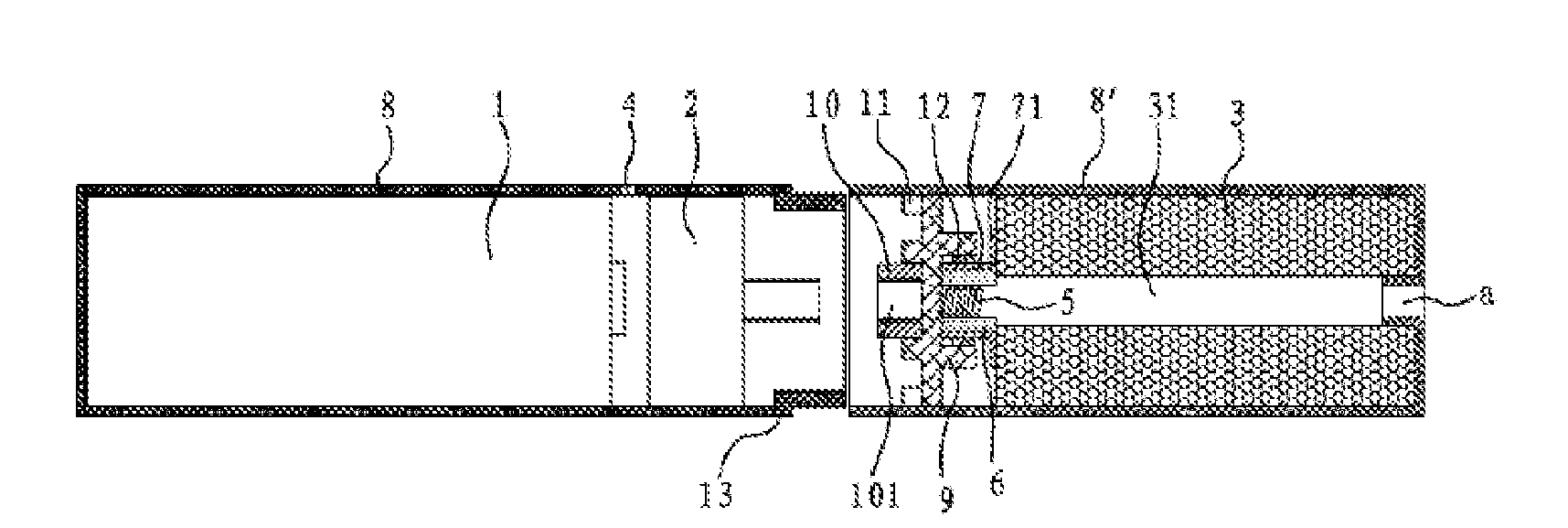

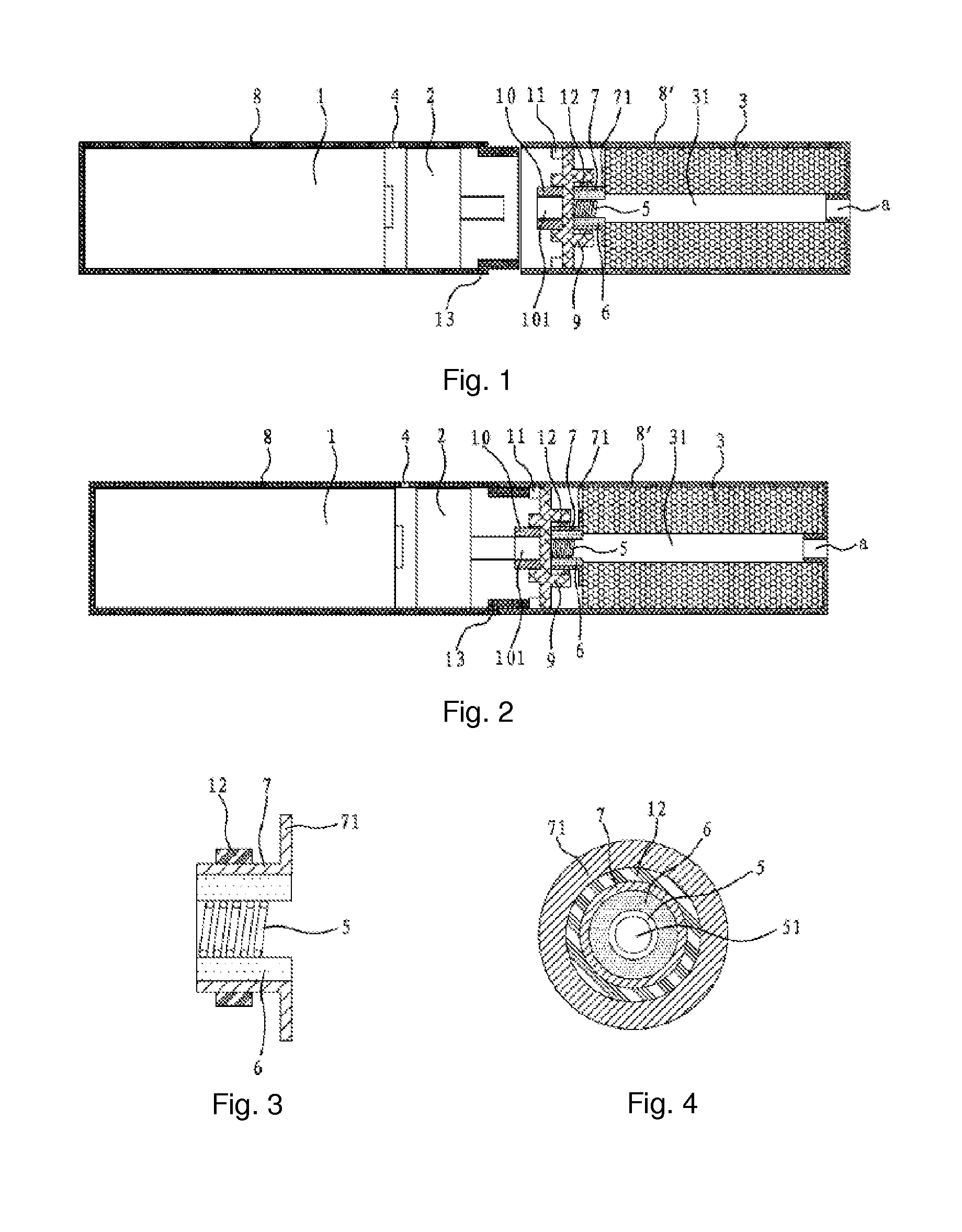

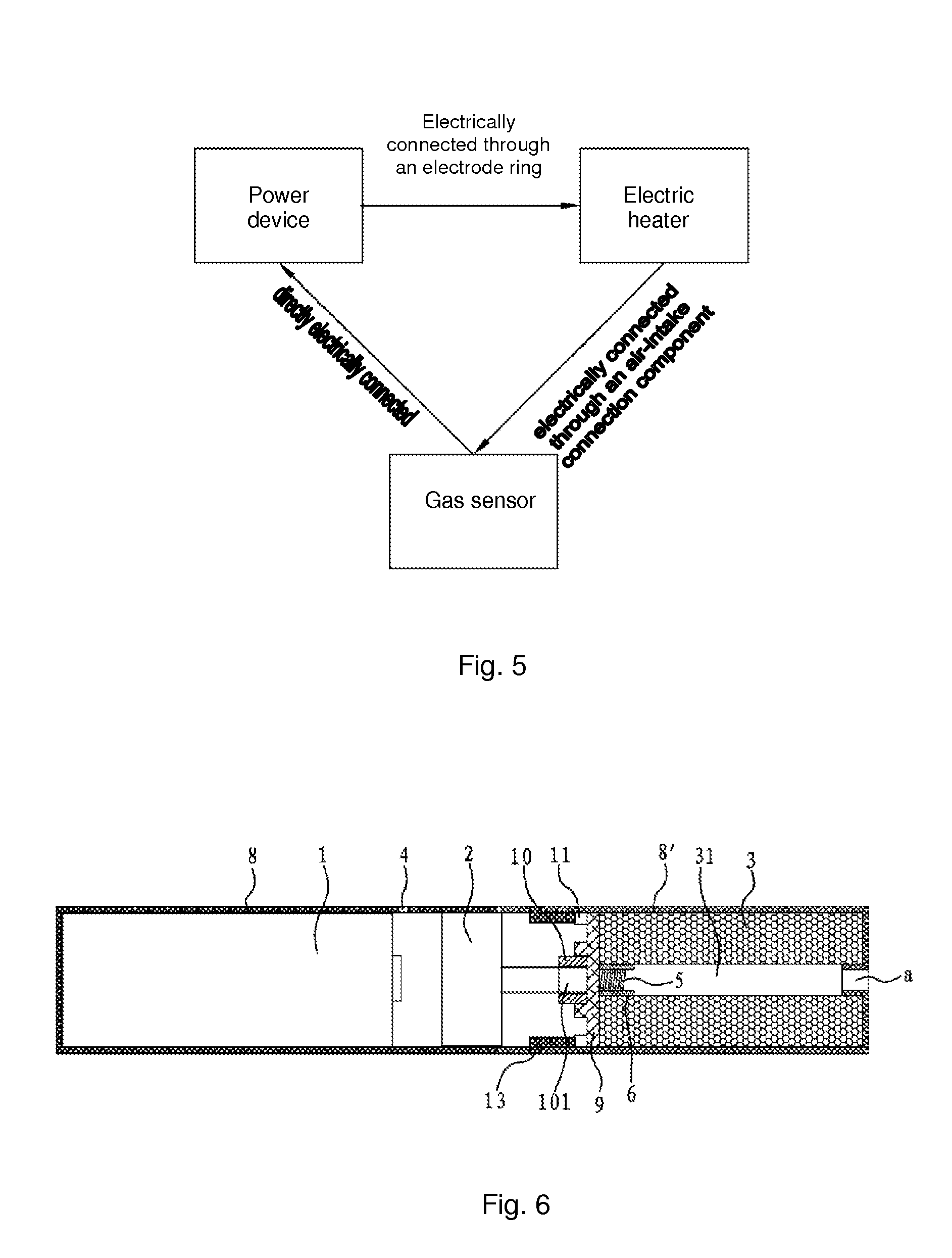

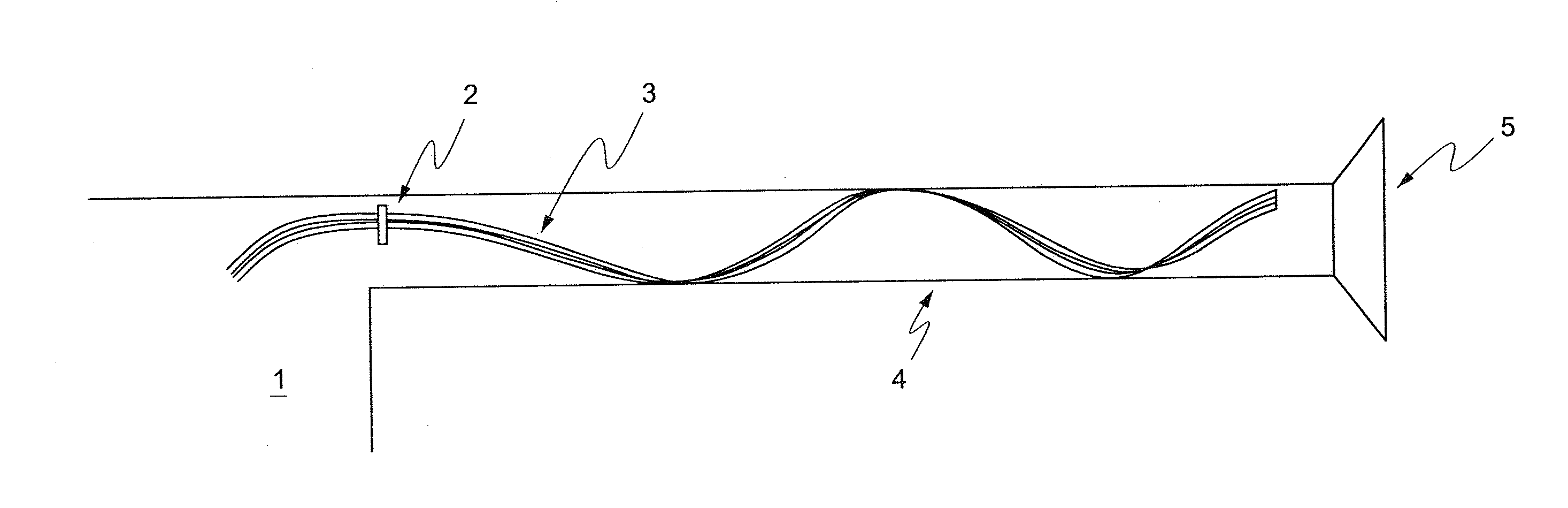

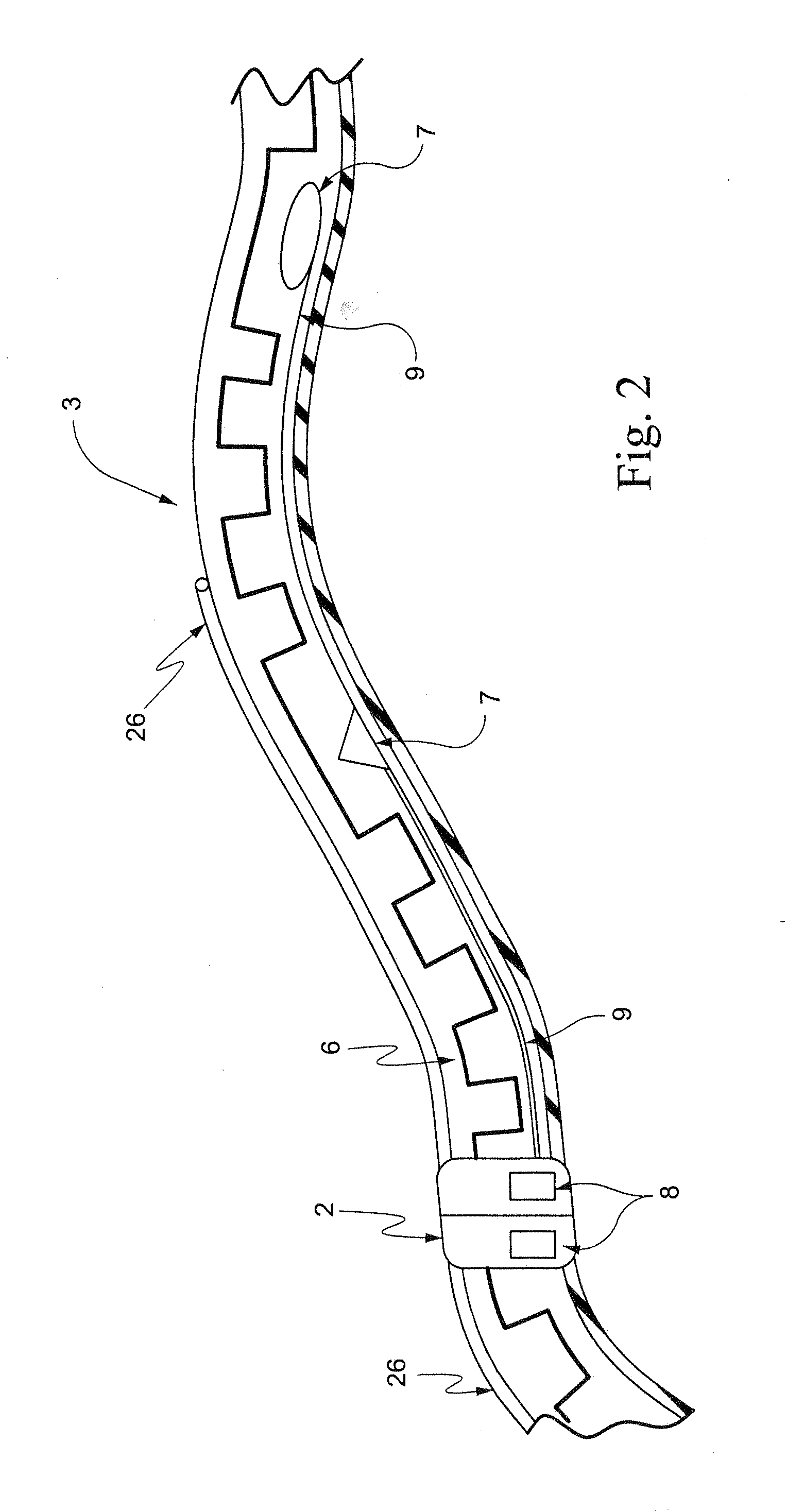

Atomizing electronic cigarette

InactiveUS20120111347A1Promote atomizationFully atomizedRespiratorsHeater elementsCore componentElectronic cigarette

An electronic cigarette has a power device (1), a sensor (2), an atomizing core component and a liquid storage component (3). The atomizing core component includes an electric heater (5) and a liquid permeating component (6). The electric heater (5) has a through hole (51), the liquid storage component (3) has a channel (31), and the sensor (2) is connected with the through hole (51) and the channel (31) to form an airflow loop by the auxiliary air inlet. The liquid permeating component (6) is directly sleeved on the electric heater (5), so that the cigarette can adequately heat gasified smoke with uniform small drops. The electric heater (5) and the liquid storage component (3) are connected with the through hole (51) and the channel (31), so that the vapor generated by the atomizing process can be cooled.

Owner:FONTEM HLDG 1

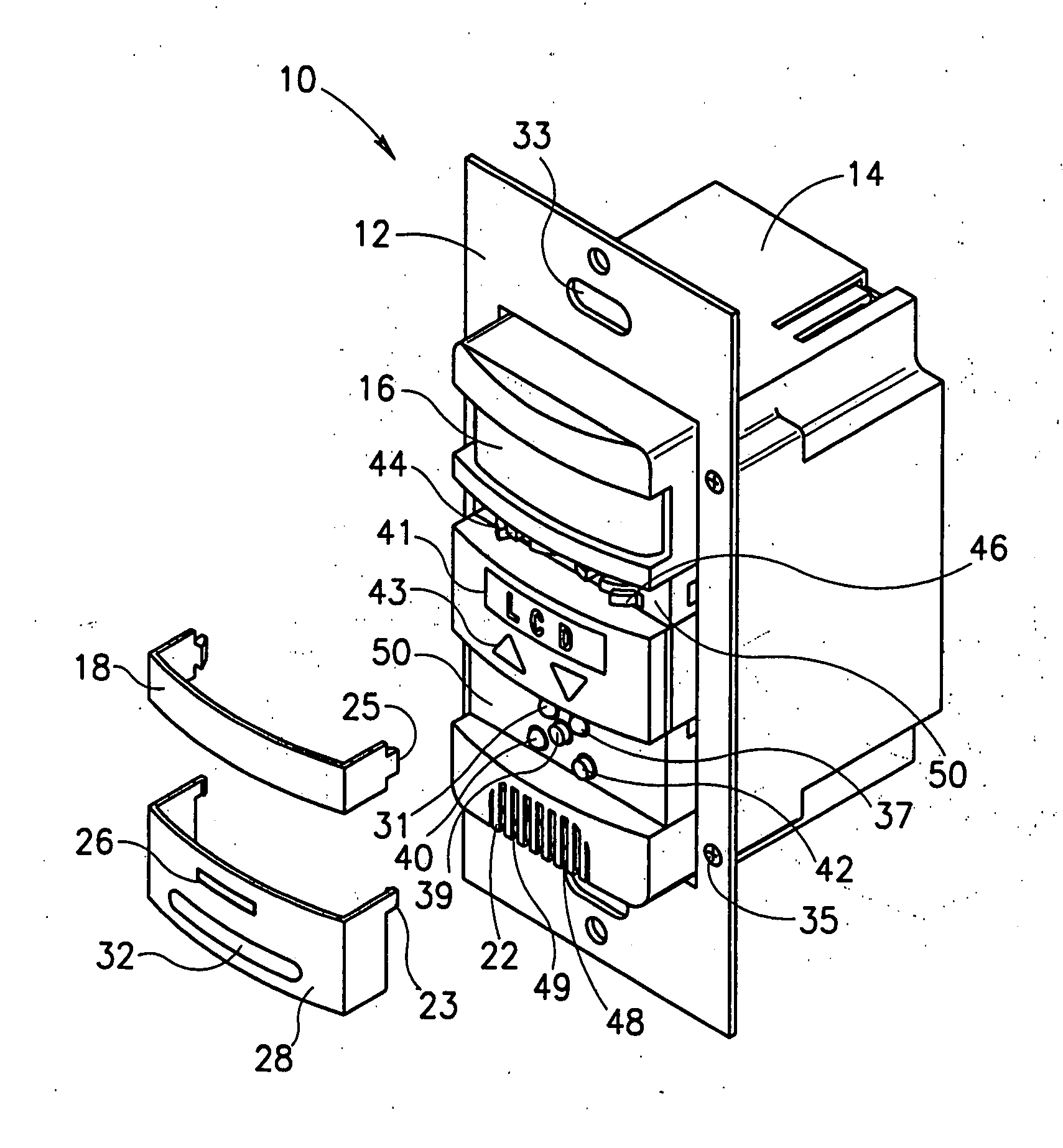

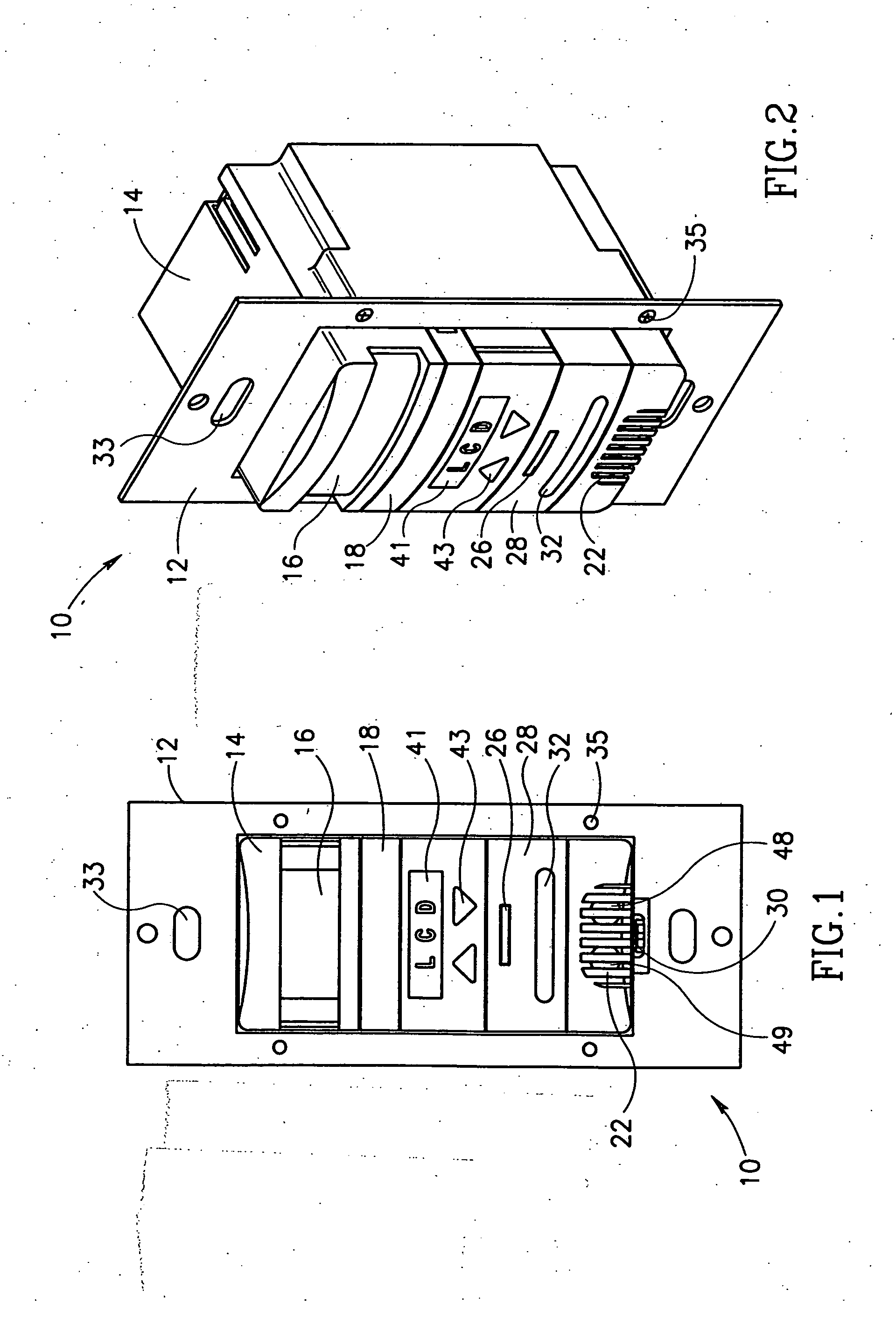

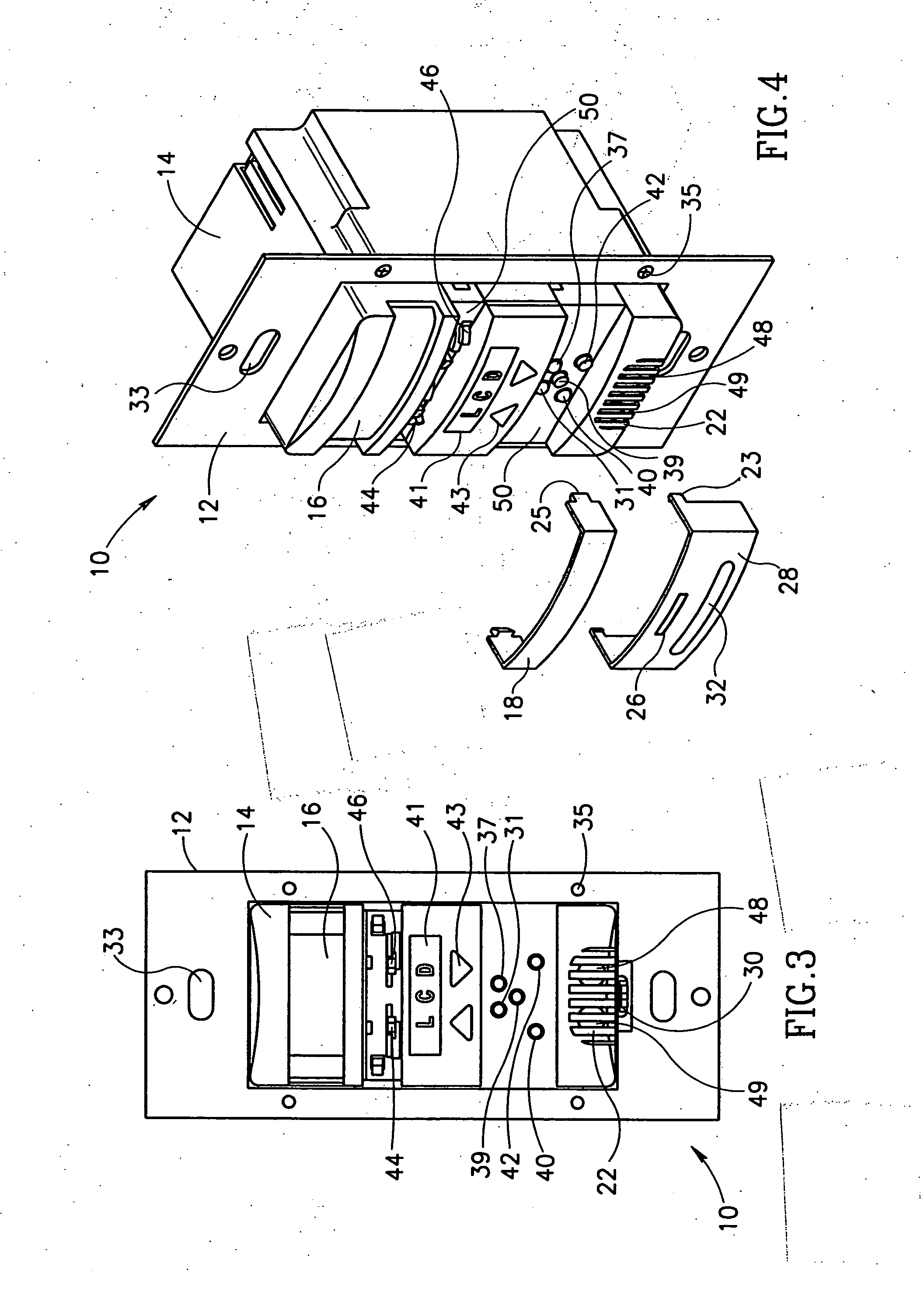

Network based multiple sensor and control device with temperature sensing and control

InactiveUS20050043907A1Minimize adverse effectsPartial latencyThermometer detailsElectric devicesMultiple sensorControl equipment

A multifunction sensor device which provides various transducer functions including means for performing temperature sensing, humidity sensing, ambient light sensing, motion detection, thermostat functions, switching functions, load switching and dimming functions, displaying actual and set temperature values, displaying time of day values and a means to put the device in an on, off or auto mode. The device has utility in environments such as that found in offices, schools, homes, industrial plants or any other type of automated facility in which sensors are utilized for energy monitoring and control, end user convenience or artificial or natural cooling, heating and HVAC control. The device can be used as a switch or dimmer, sensor or thermostat as well as to adjust and control all natural and artificial lighting, temperature and humidity devices. Key elements of the invention include overcoming the difficulty of mounting diverse sensors or transducers within the same device or housing; permitting these various sensors to exist in a single package that can be mounted to a wall in a substantially flush manner; and eliminating the requirement of an air flow channel in the device, thus minimizing any adverse effects on the motion detecting element or sensor as well as providing built in partial hysteresis. The device may include additional transducers or sensors and is constructed such that the temperature and humidity sensors are neither exposed to the flow of air in a room or area nor in an airflow channel whereby a chimney effect may occur. The device can transmit and receive real time data, relative data and actual discrete data in addition to switching and controlling loads locally or remotely. An embodiment utilizing airflow channels to direct air over the temperature and humidity sensors is also disclosed.

Owner:ECKEL DAVID P +2

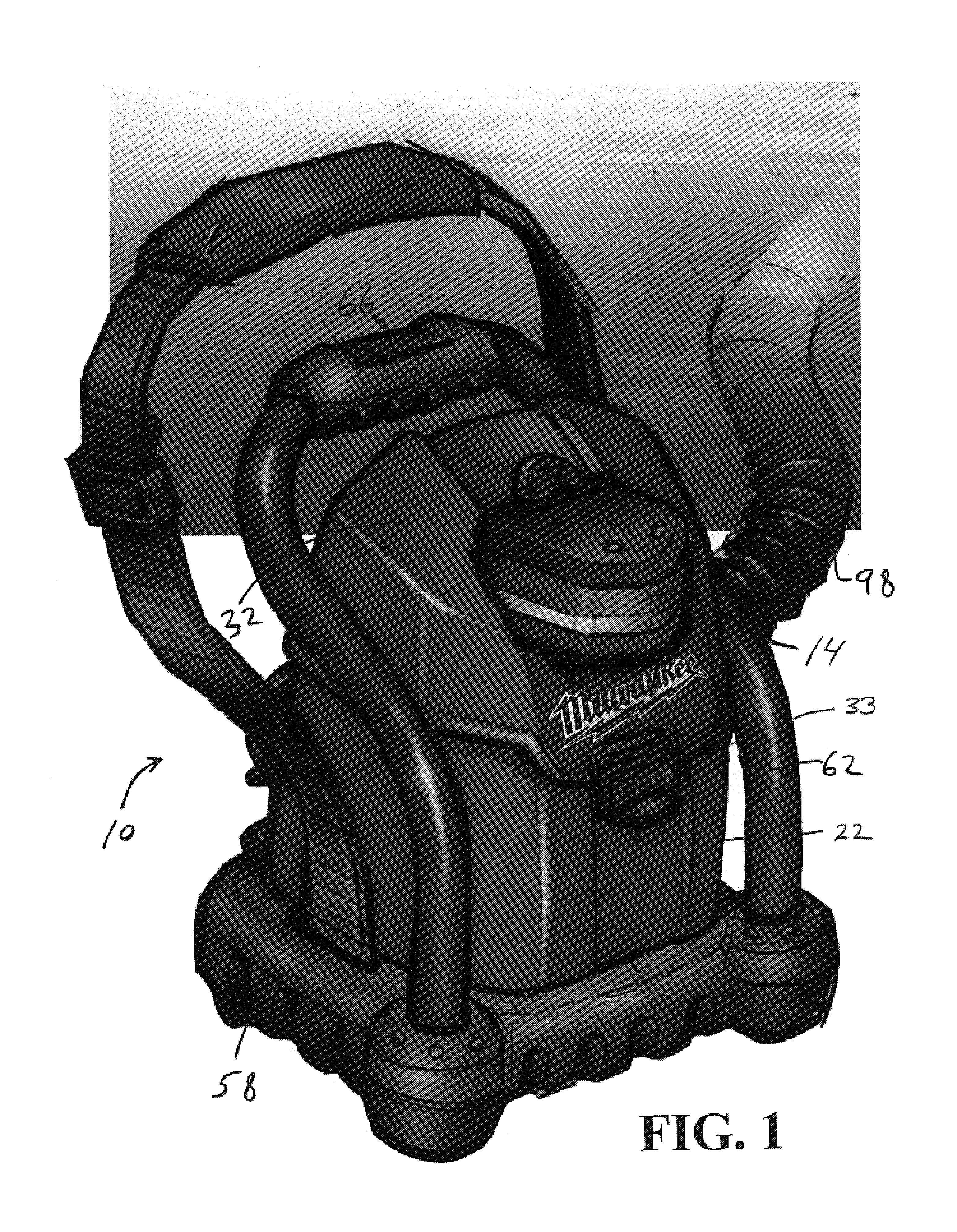

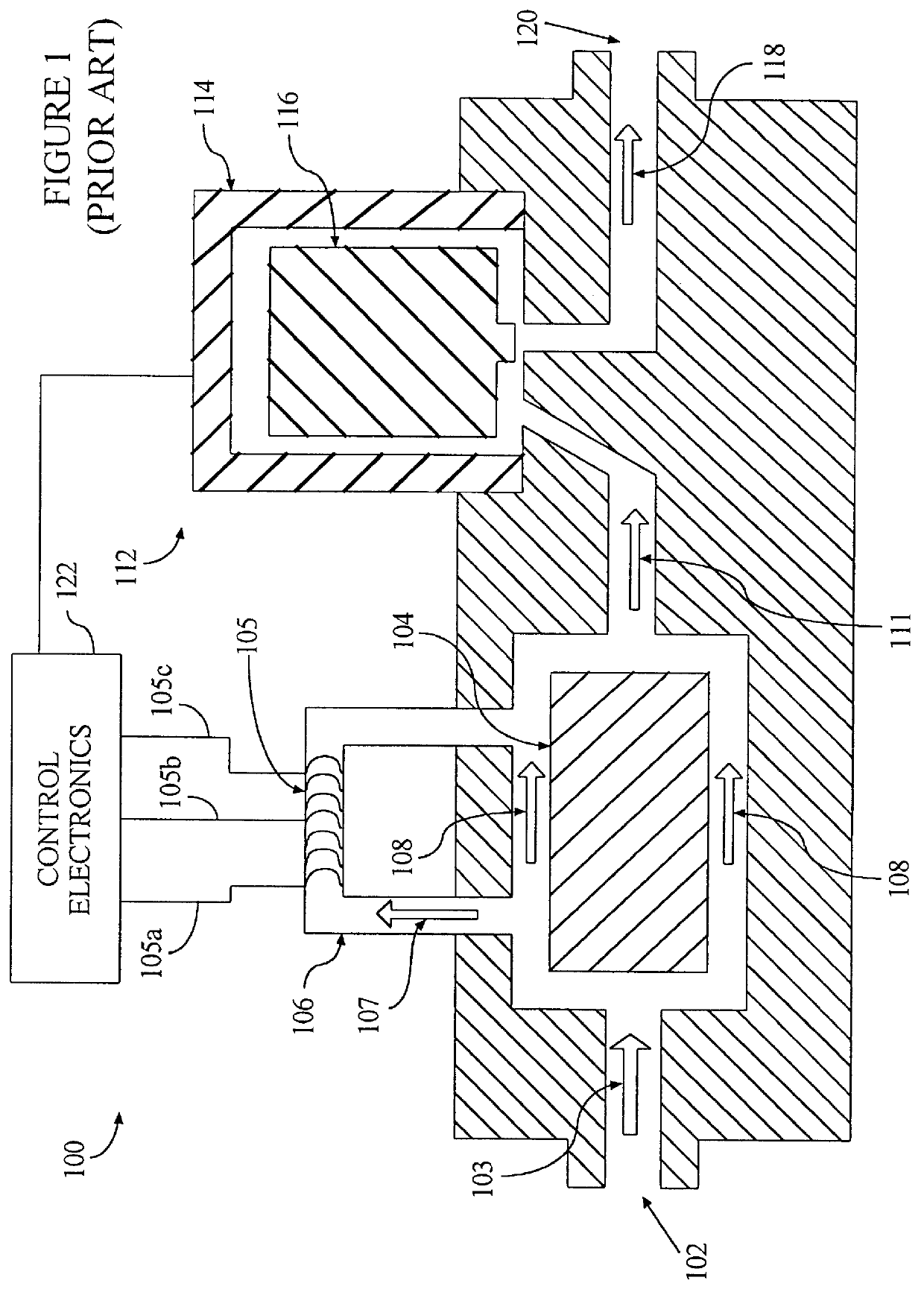

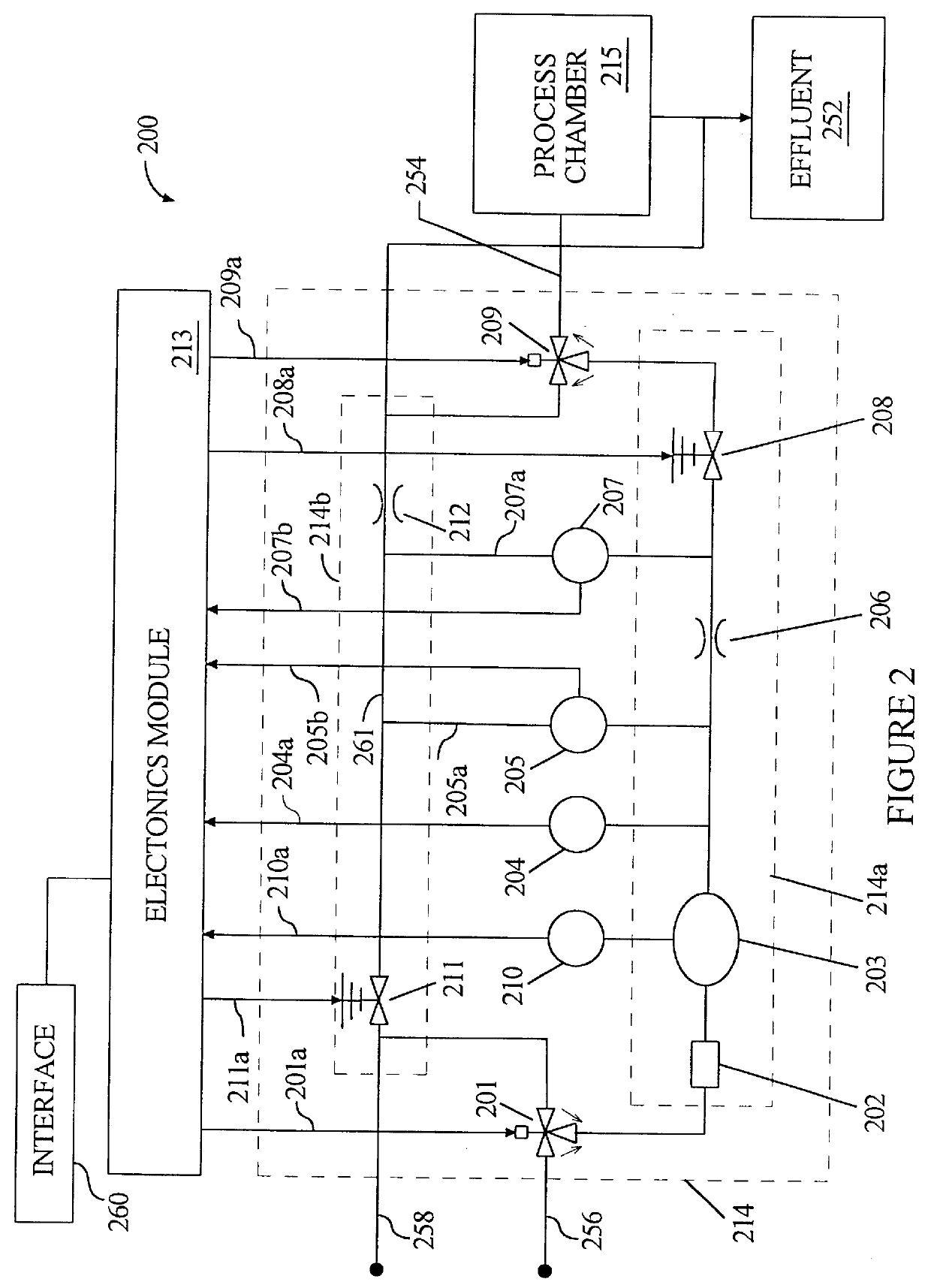

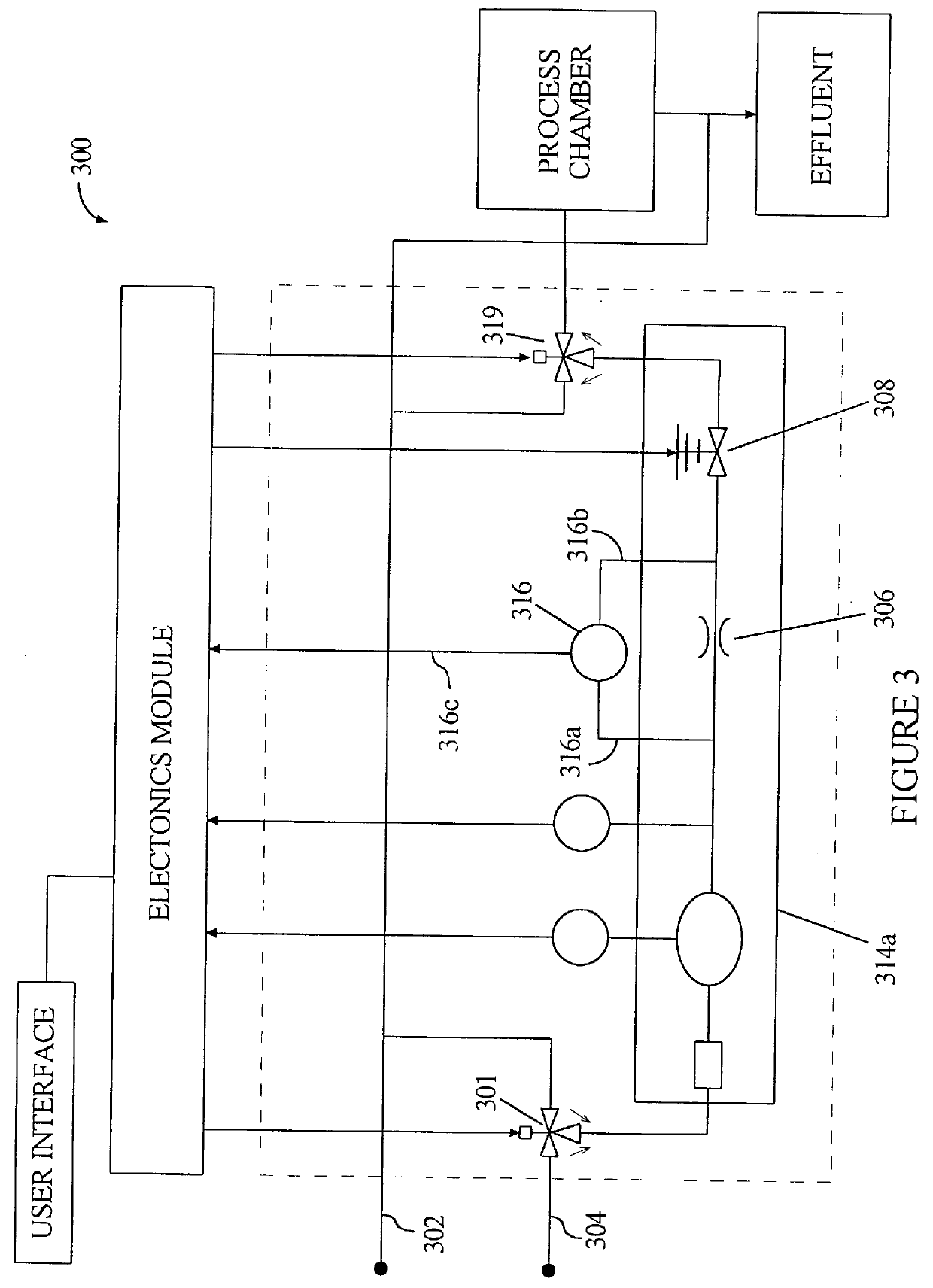

Method for wide range gas flow system with real time flow measurement and correction

InactiveUS6119710AAccurate measurementAccurate flowOperating means/releasing devices for valvesVolume/mass flow by thermal effectsDifferential pressureInlet valve

A gas delivery system accurately measures and optionally regulates mass flow rate in real time. A fluid conduit connects an inlet valve, calibration volume, flow restrictor, and outlet valve in series. Pressure and temperature sensors are coupled to the calibration volume. One or more pressure sensors may be attached across the flow restrictor. Alternatively, an absolute pressure sensor may be attached upstream of the flow restrictor. One embodiment of differential pressure sensors comprises a floating reference differential pressure sensor, including a first transducer attached to the fluid conduit upstream of the flow restrictor and a second transducer attached to the conduit downstream of the flow restrictor. In this embodiment, each transducer receives a reference pressure from a reference source, and optionally, after the calibration volume is charged, the floating reference differential pressure transducers are calibrated. When gas flow is initiated, differential and / or absolute pressure measurements are repeatedly taken, and a measured mass flow rate calculated thereon. Gas flow is adjusted until the measured mass flow rate reaches a target mass flow. Using the temperature / pressure sensors at the calibration volume, repeated calculations of actual flow rate are made to uncover any discrepancy between actual and measured mass flow rates. Whenever a discrepancy is found, the manner of calculating measured mass flow is conditioned to account for the discrepancy; thus, the measured mass flow rate more accurately represents the actual mass flow rate thereby providing an actual mass flow rate more accurately achieving the target mass flow rate.

Owner:CYBER INSTR TECH LLC AN ARIZONA LIMITED LIABILITY +1

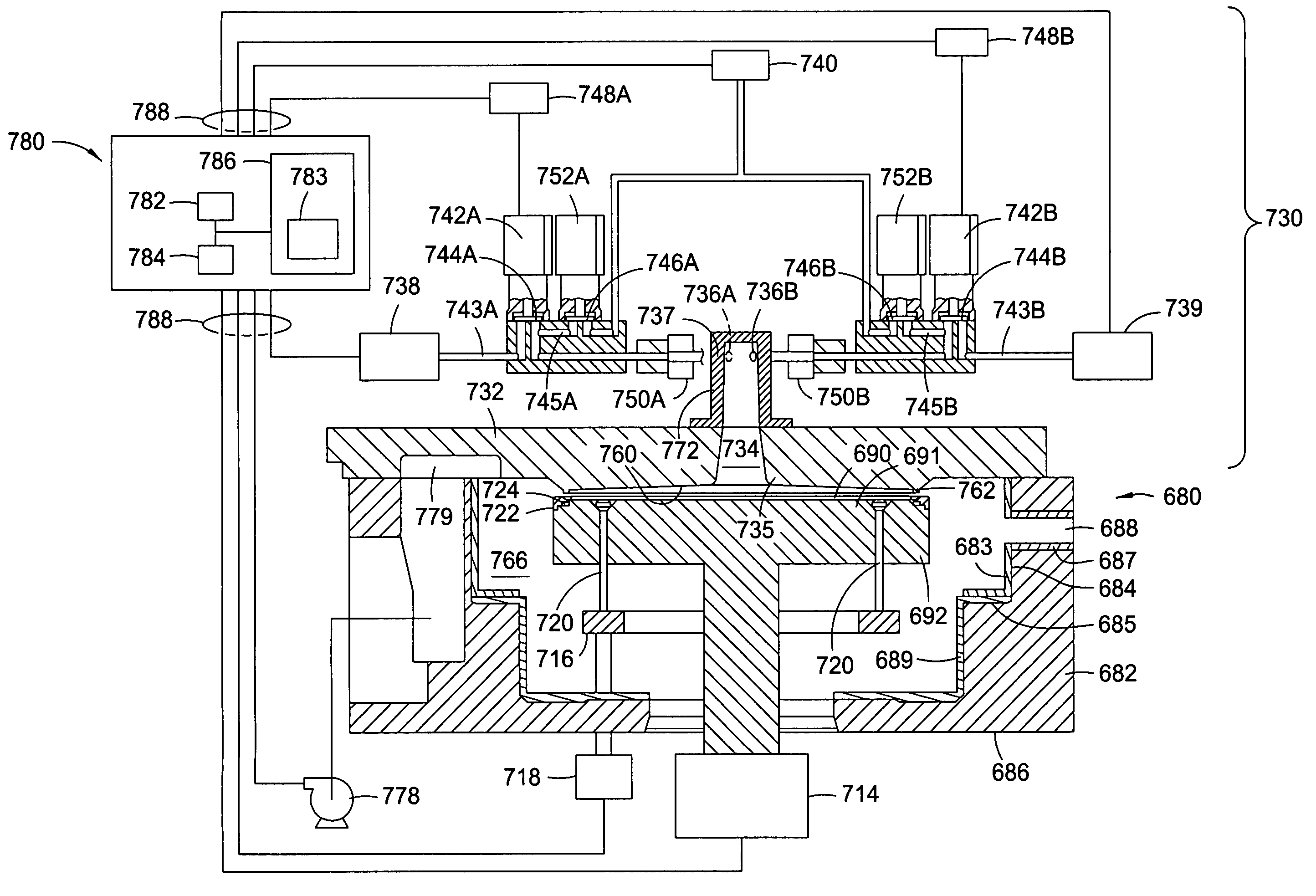

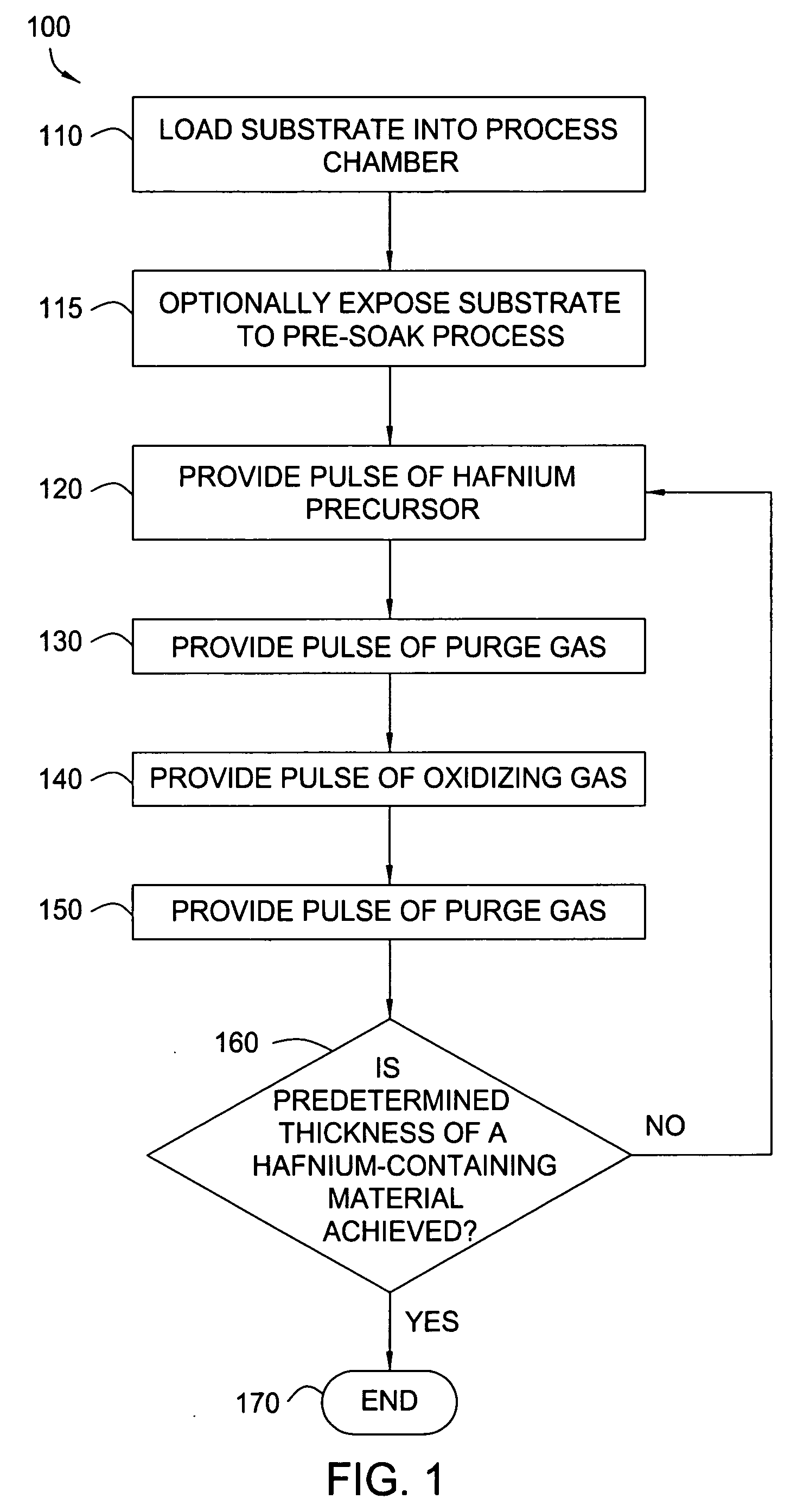

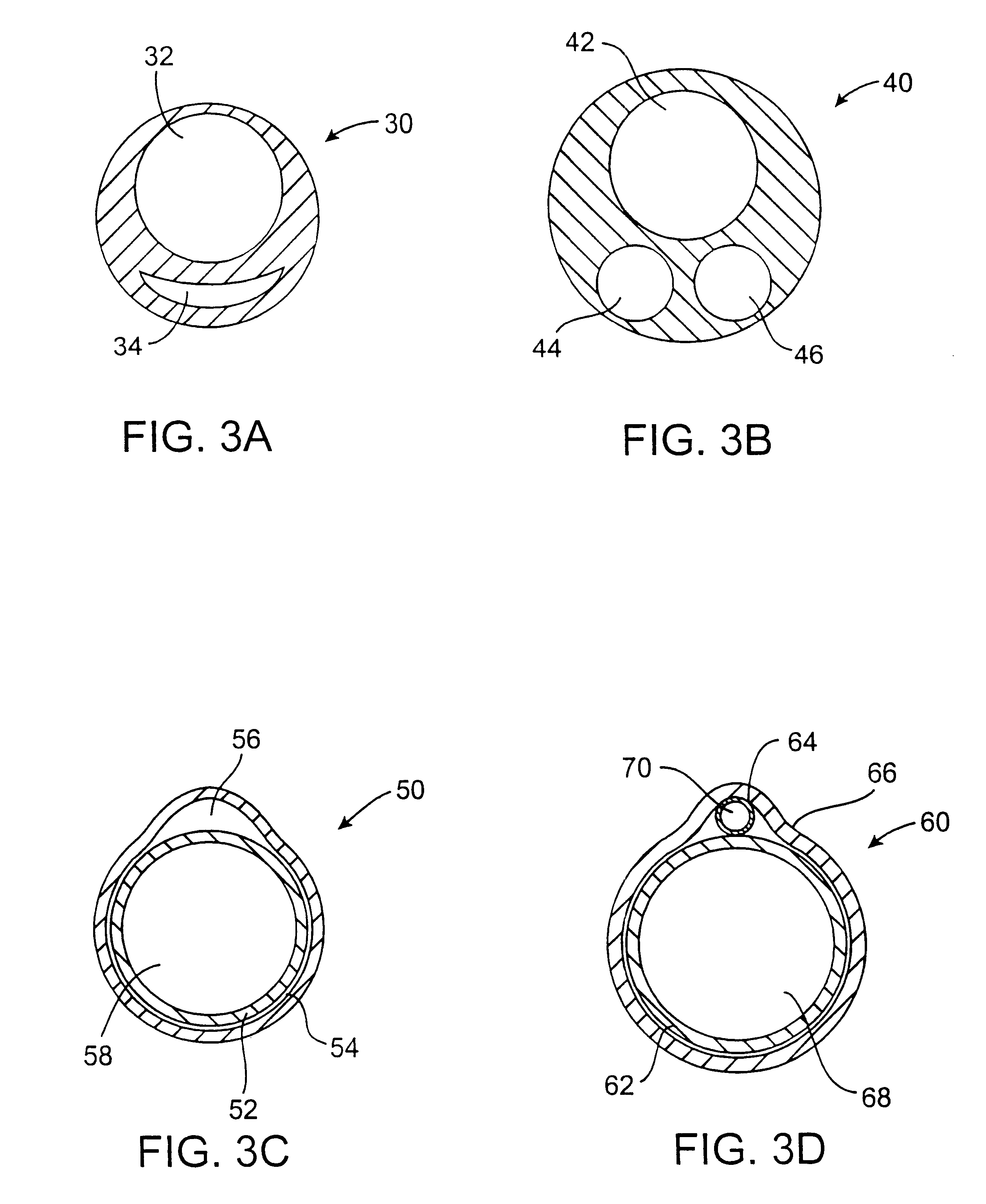

Apparatuses and methods for atomic layer deposition of hafnium-containing high-k dielectric materials

ActiveUS20050271812A1Steam generation heating methodsEfficient propulsion technologiesWater vaporGas phase

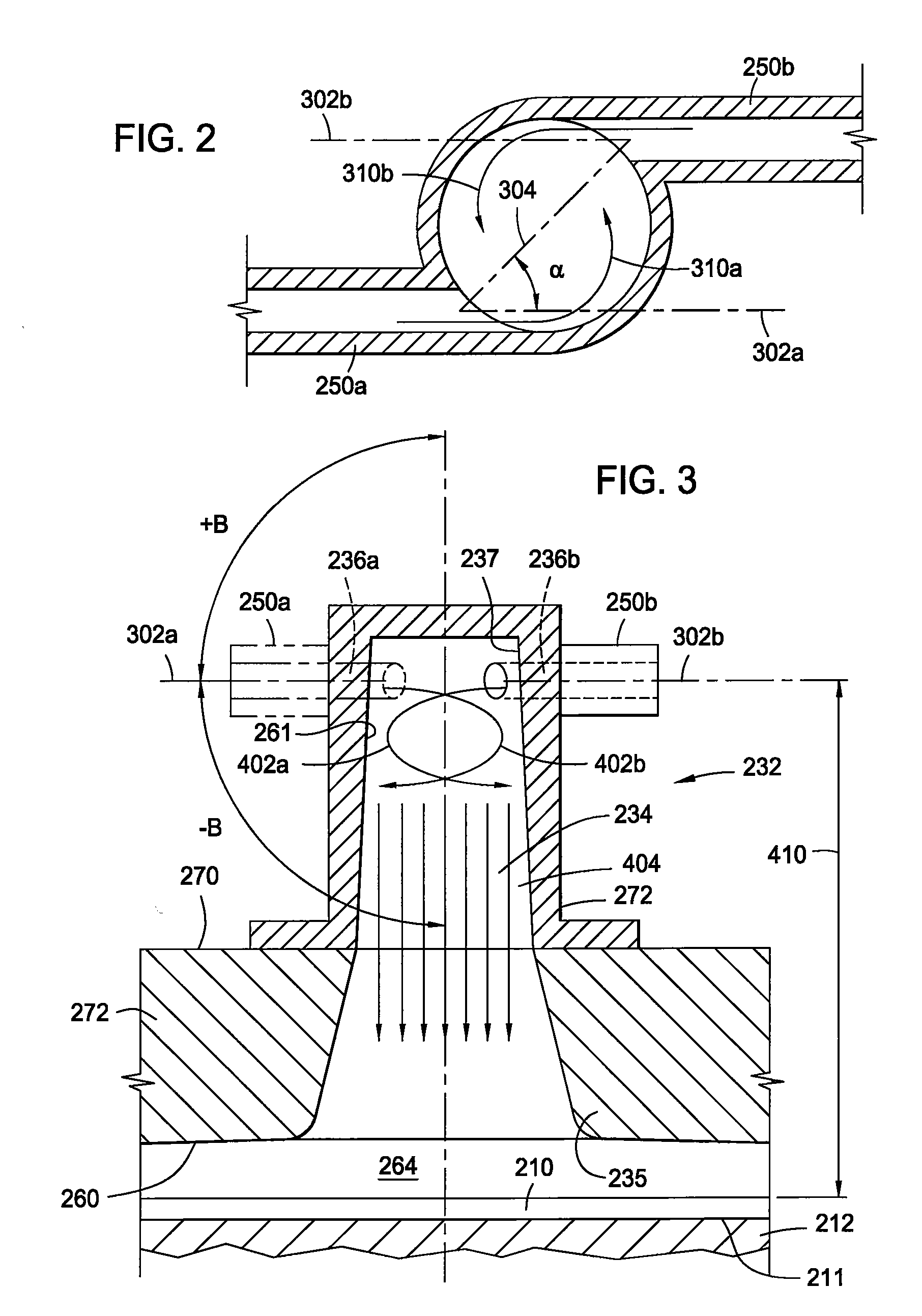

Embodiments of the invention provide apparatuses and methods for depositing materials on substrates during vapor deposition processes, such as atomic layer deposition (ALD). In one embodiment, a chamber contains a substrate support with a receiving surface and a chamber lid containing an expanding channel formed within a thermally insulating material. The chamber further includes at least one conduit coupled to a gas inlet within the expanding channel and positioned to provide a gas flow through the expanding channel in a circular direction, such as a vortex, a helix, a spiral or derivatives thereof. The expanding channel may be formed directly within the chamber lid or formed within a funnel liner attached thereon. The chamber may contain a retaining ring, an upper process liner, a lower process liner or a slip valve liner. Liners usually have a polished surface finish and contain a thermally insulating material such as fused quartz or ceramic. In an alternative embodiment, a deposition system contains a catalytic water vapor generator connected to an ALD chamber.

Owner:APPLIED MATERIALS INC

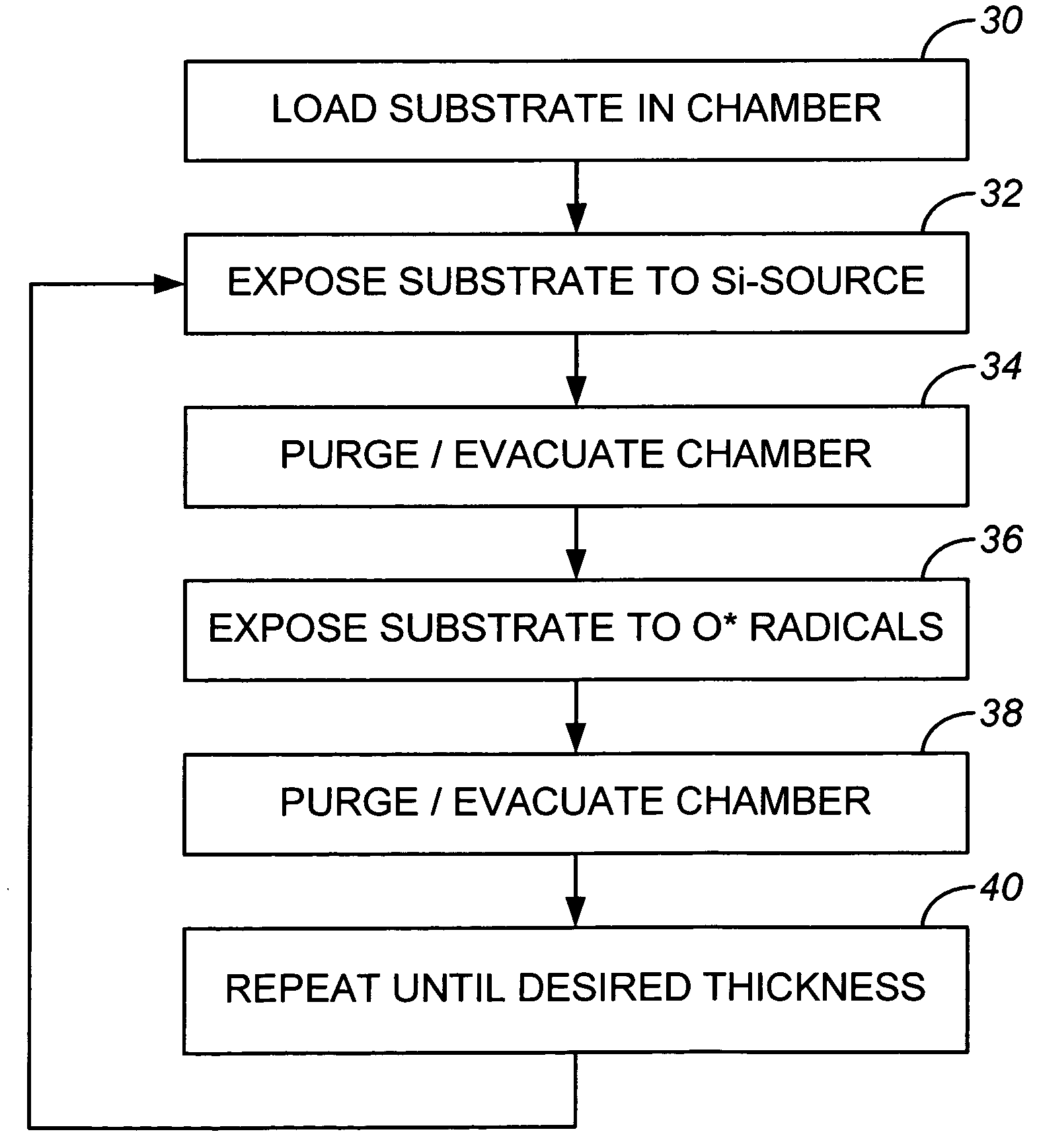

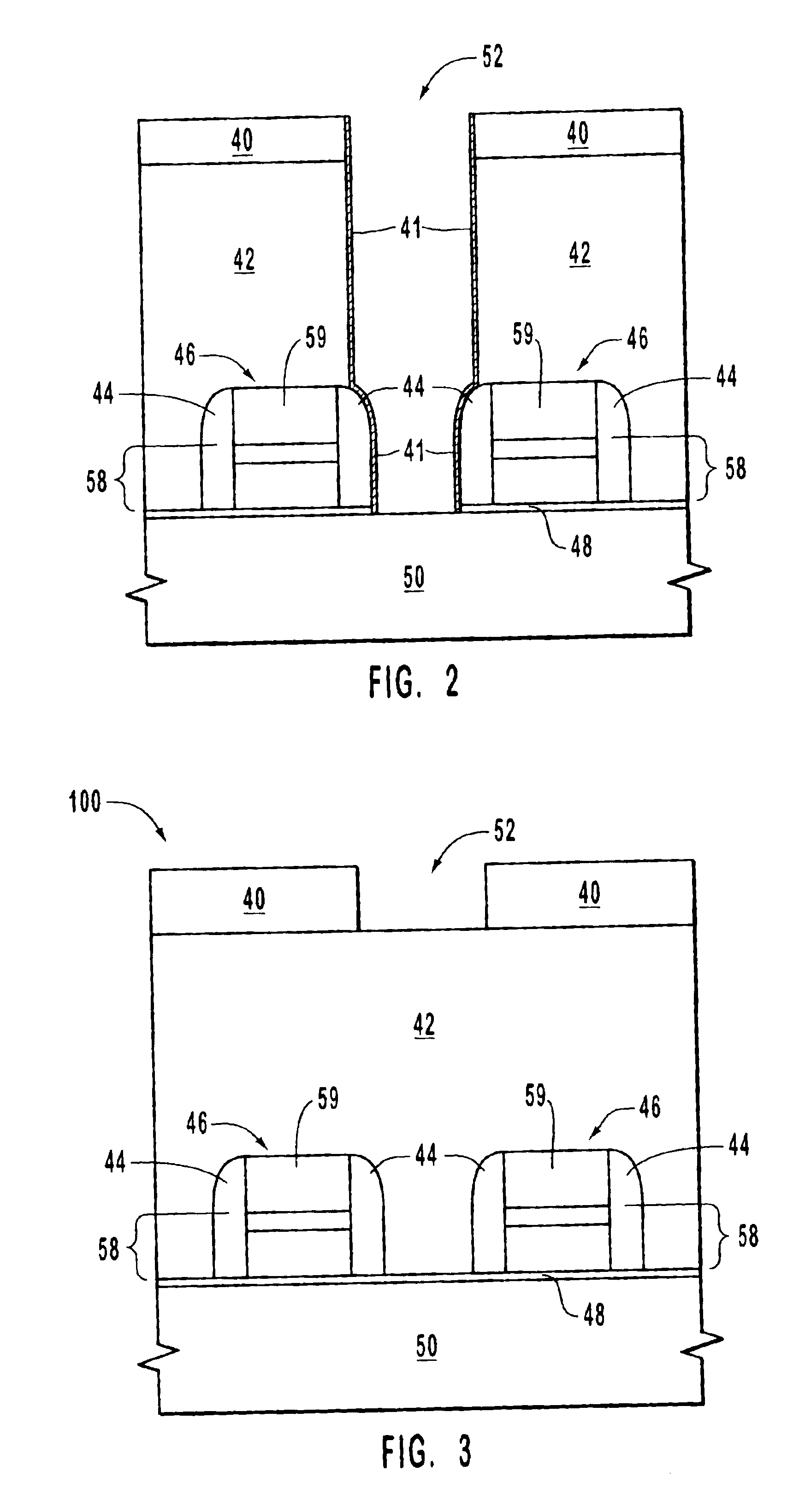

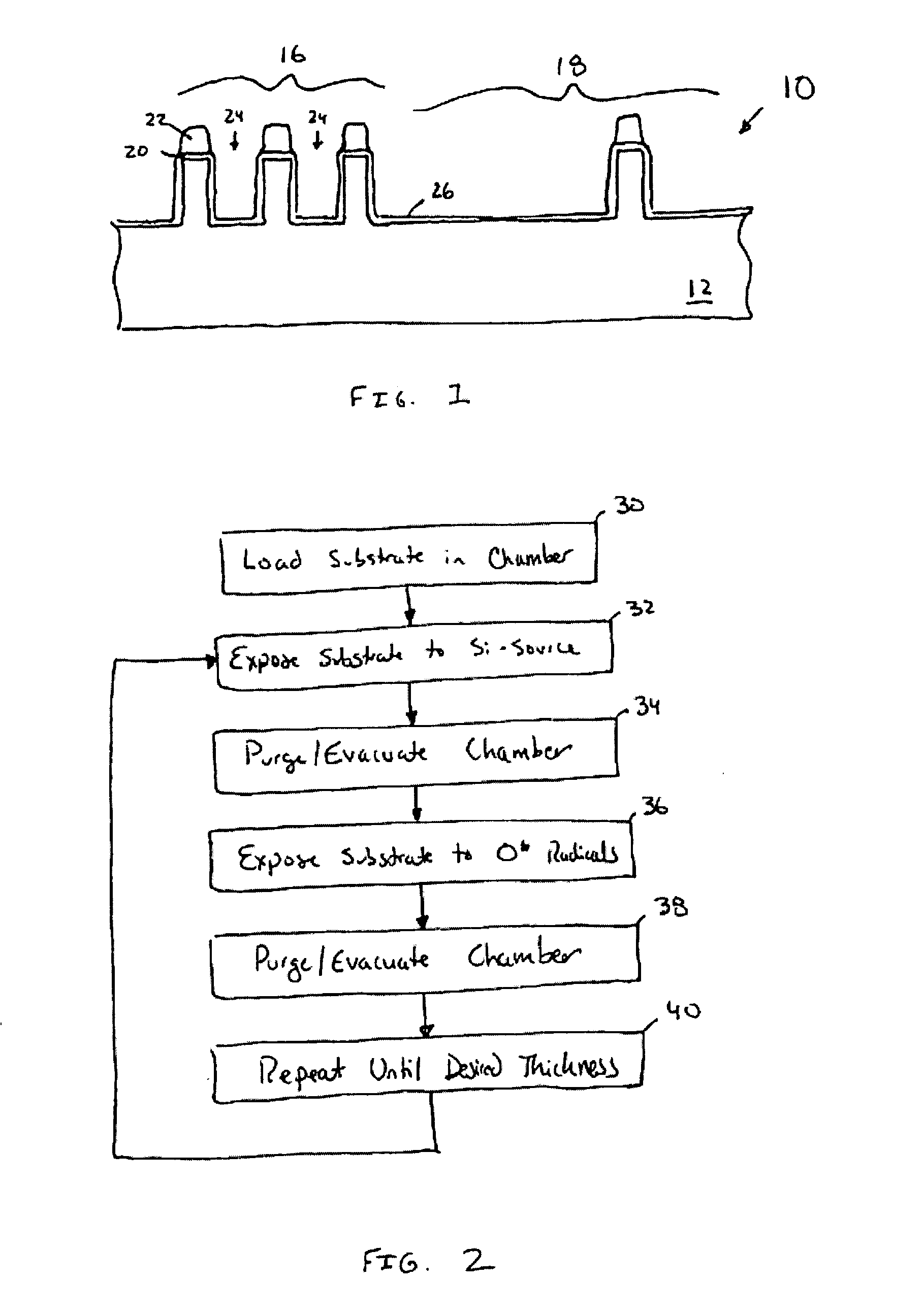

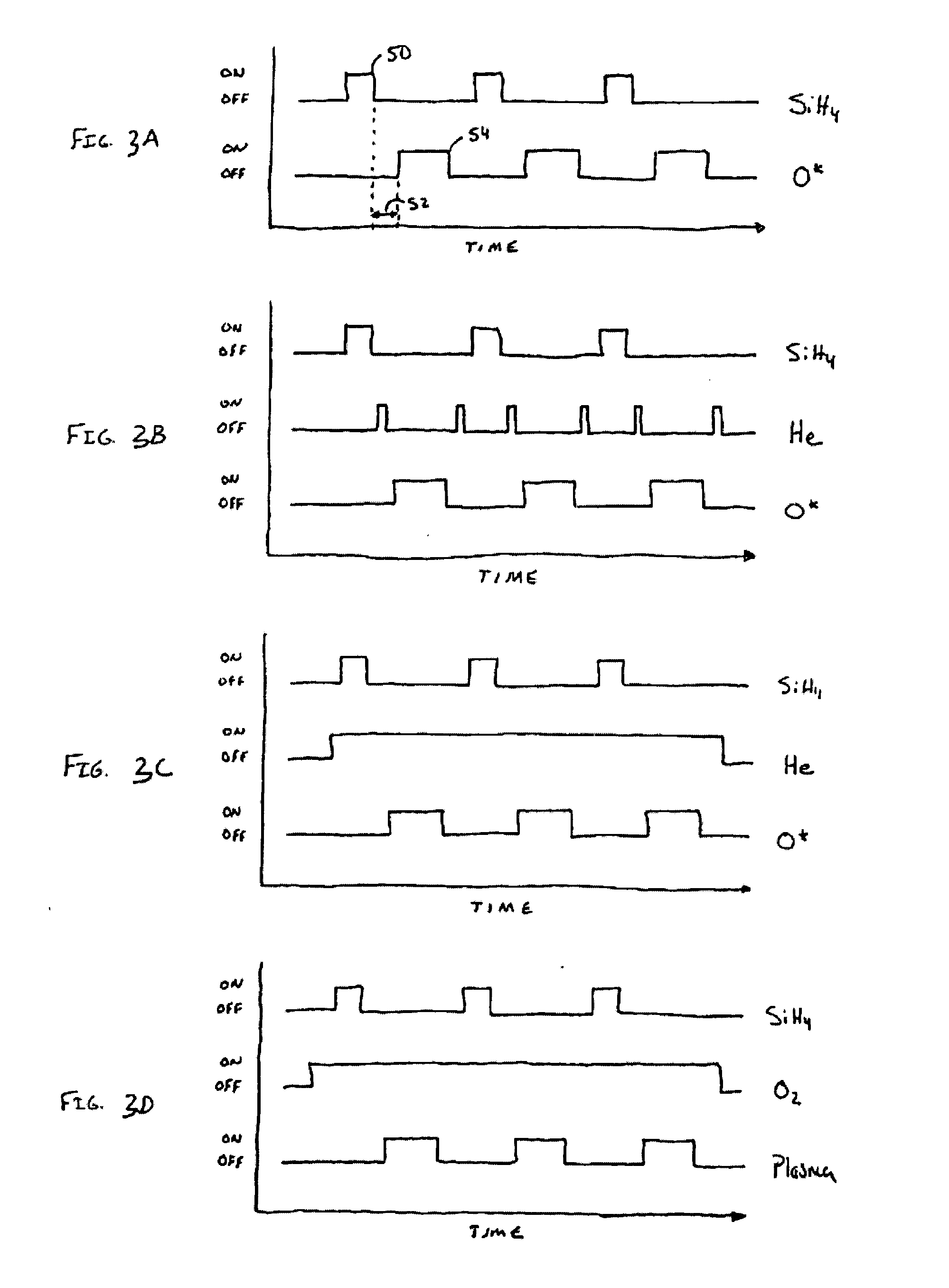

Sequential gas flow oxide deposition technique

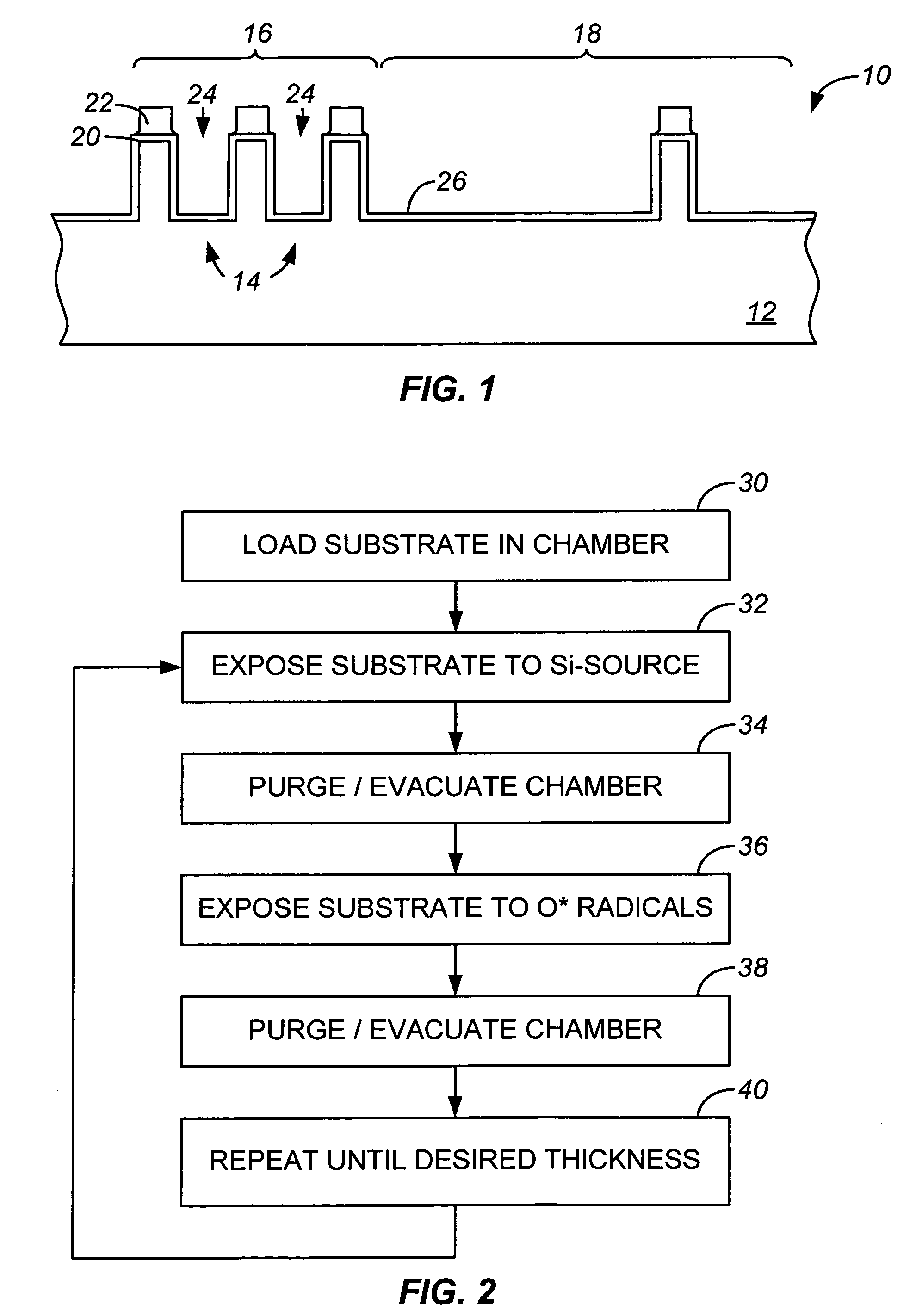

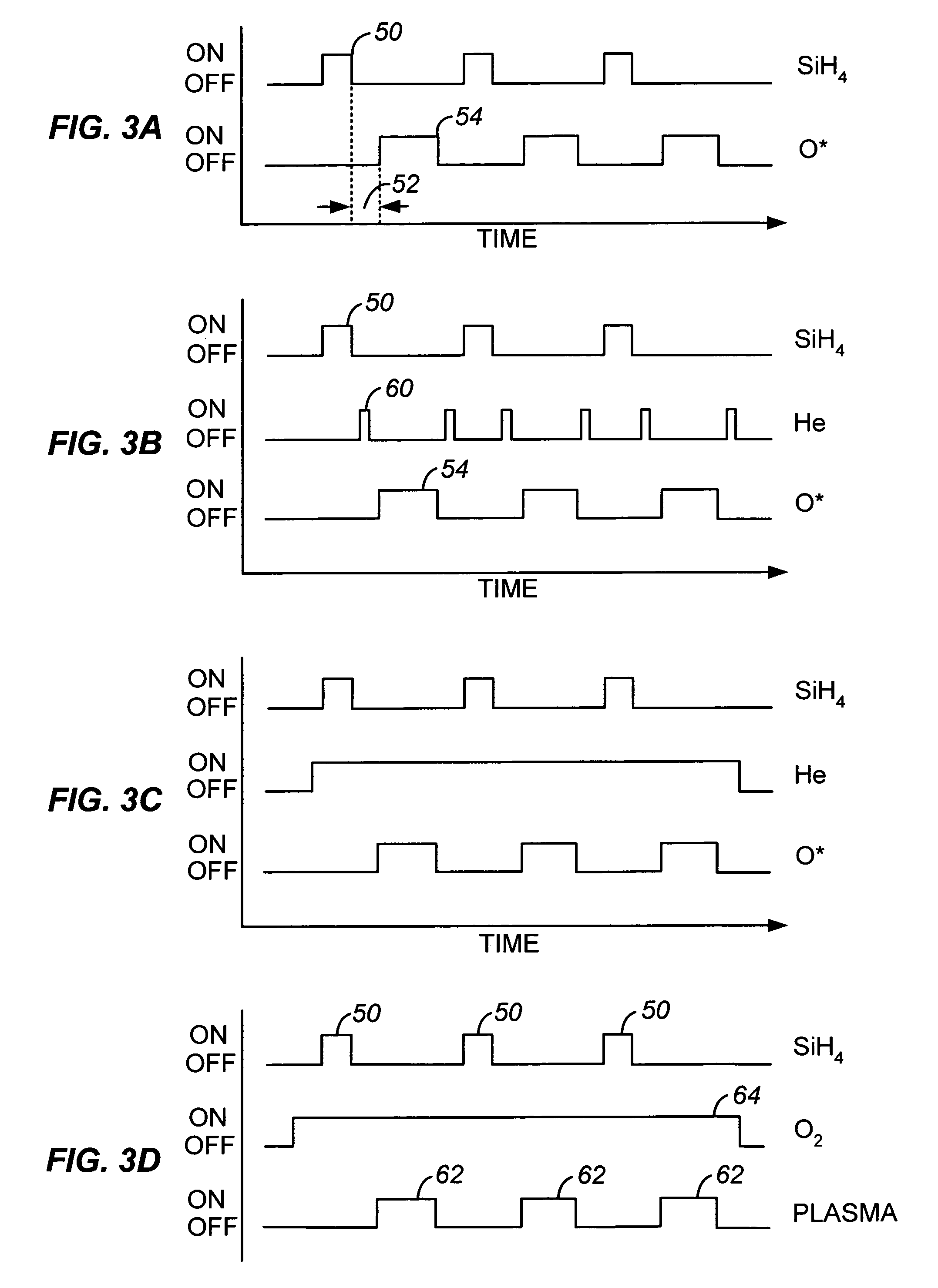

A method of depositing a silica glass insulating film over a substrate. In one embodiment the method comprises exposing the substrate to a silicon-containing reactant introduced into a chamber in which the substrate is disposed such that one or more layers of the silicon-containing reactant are adsorbed onto the substrate; purging or evacuating the chamber of the silicon-containing reactant; converting the silicon-containing reactant into a silica glass insulating compound by exposing the substrate to oxygen radicals formed from a second reactant while biasing the substrate to promote a sputtering effect, wherein an average atomic mass of all atomic constituents in the second reactant is less than or equal to an average atomic mass of oxygen; and repeating the exposing, purging / evacuating and exposing sequence a plurality of times until a desired film thickness is reached.

Owner:APPLIED MATERIALS INC

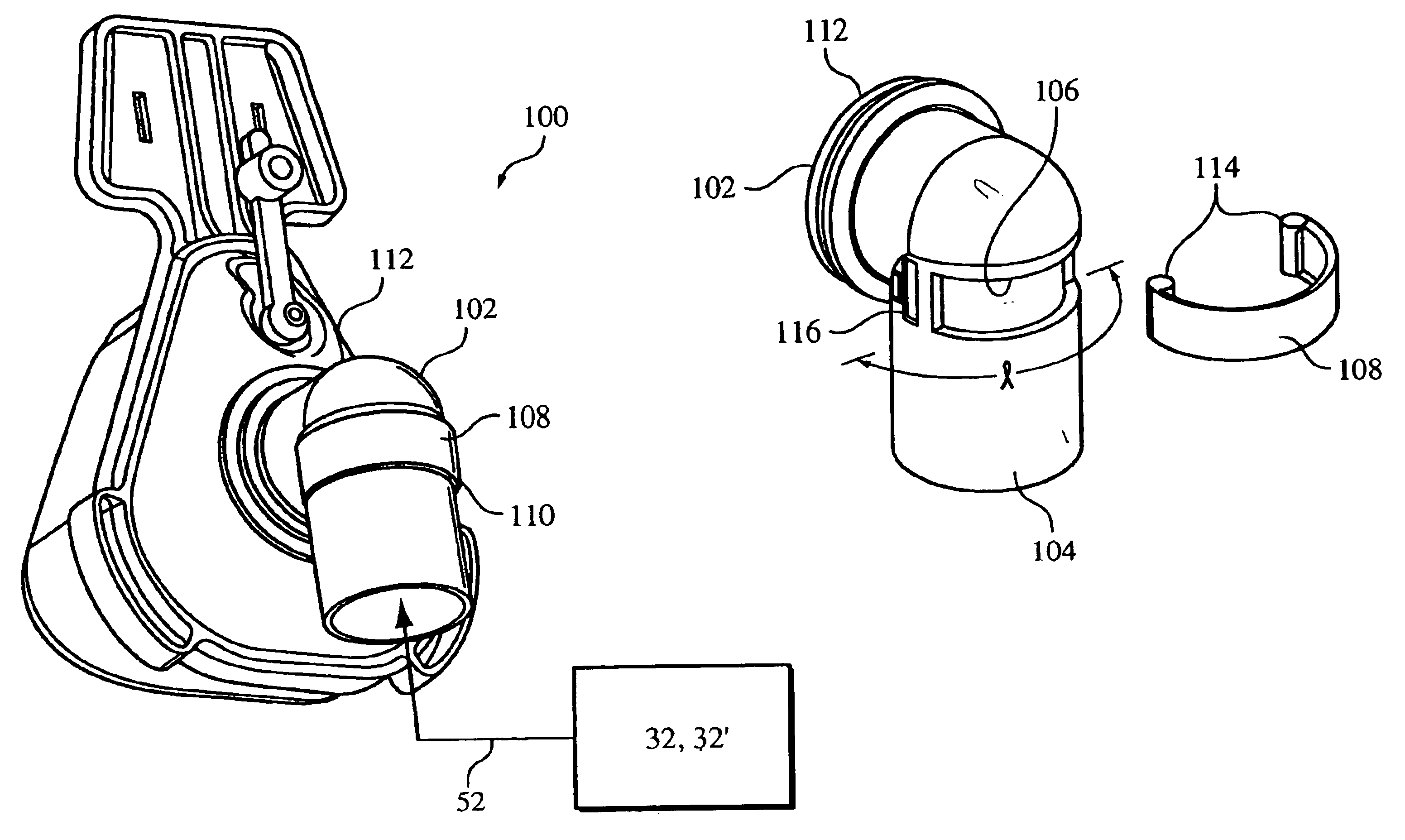

Exhaust port assembly for a pressure support system

InactiveUS6851425B2Noise minimizationArea minimizationBreathing masksRespiratory masksSupporting systemAtmospheric air

An exhaust port assembly comprising a conduit carries a flow of gas. A vent assembly having a fixed exhaust area is provided on the conduit for venting a flow of exhaust gas from within the conduit to ambient atmosphere. The vent assembly is configured so as to minimize noise associated with the flow of exhaust gas passing to atmosphere, diffuse the flow of exhaust gas passing to ambient atmosphere over a relatively large area, and minimize the area occupied by the venting assembly on the conduit.

Owner:RIC INVESTMENTS LLC

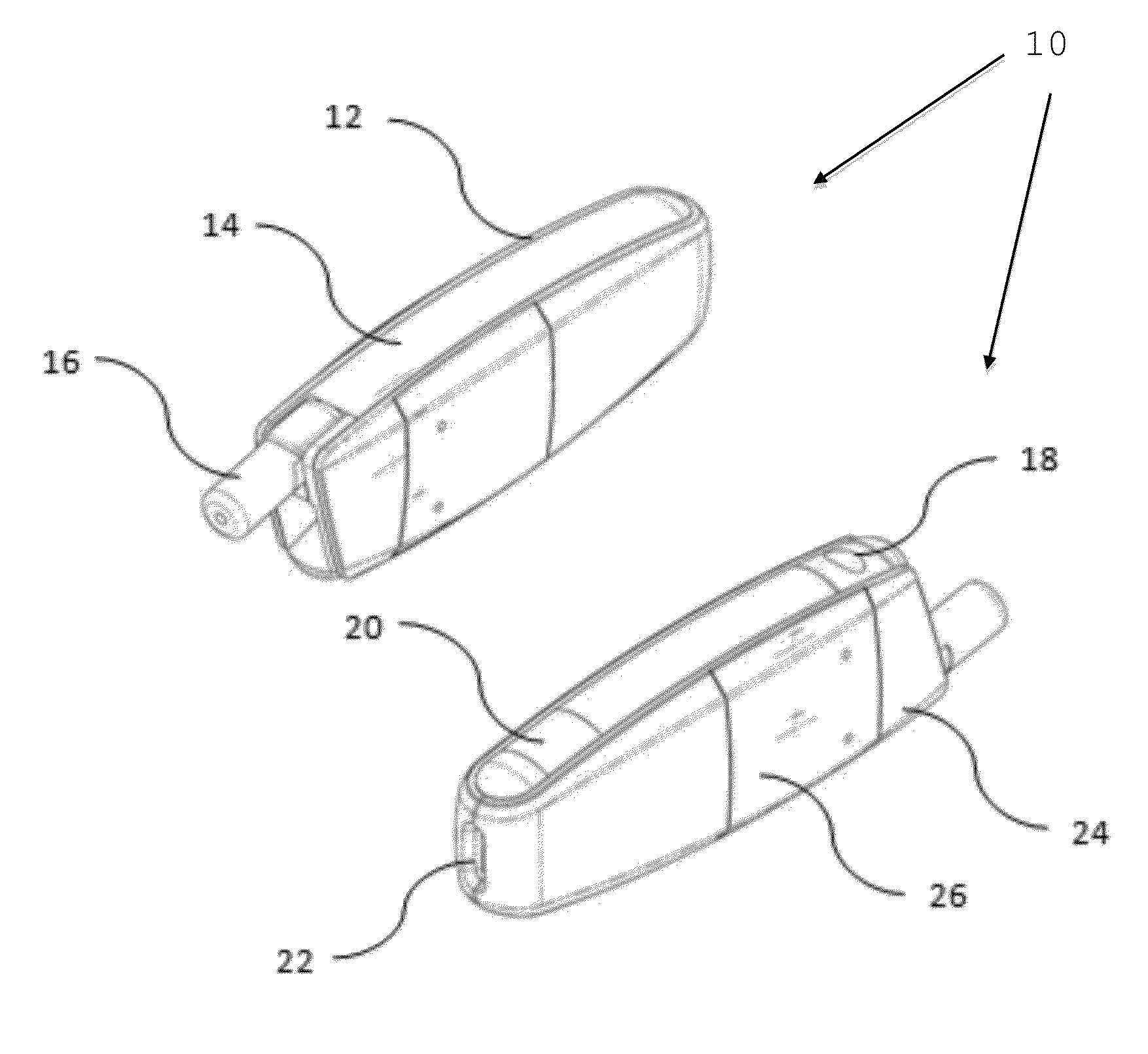

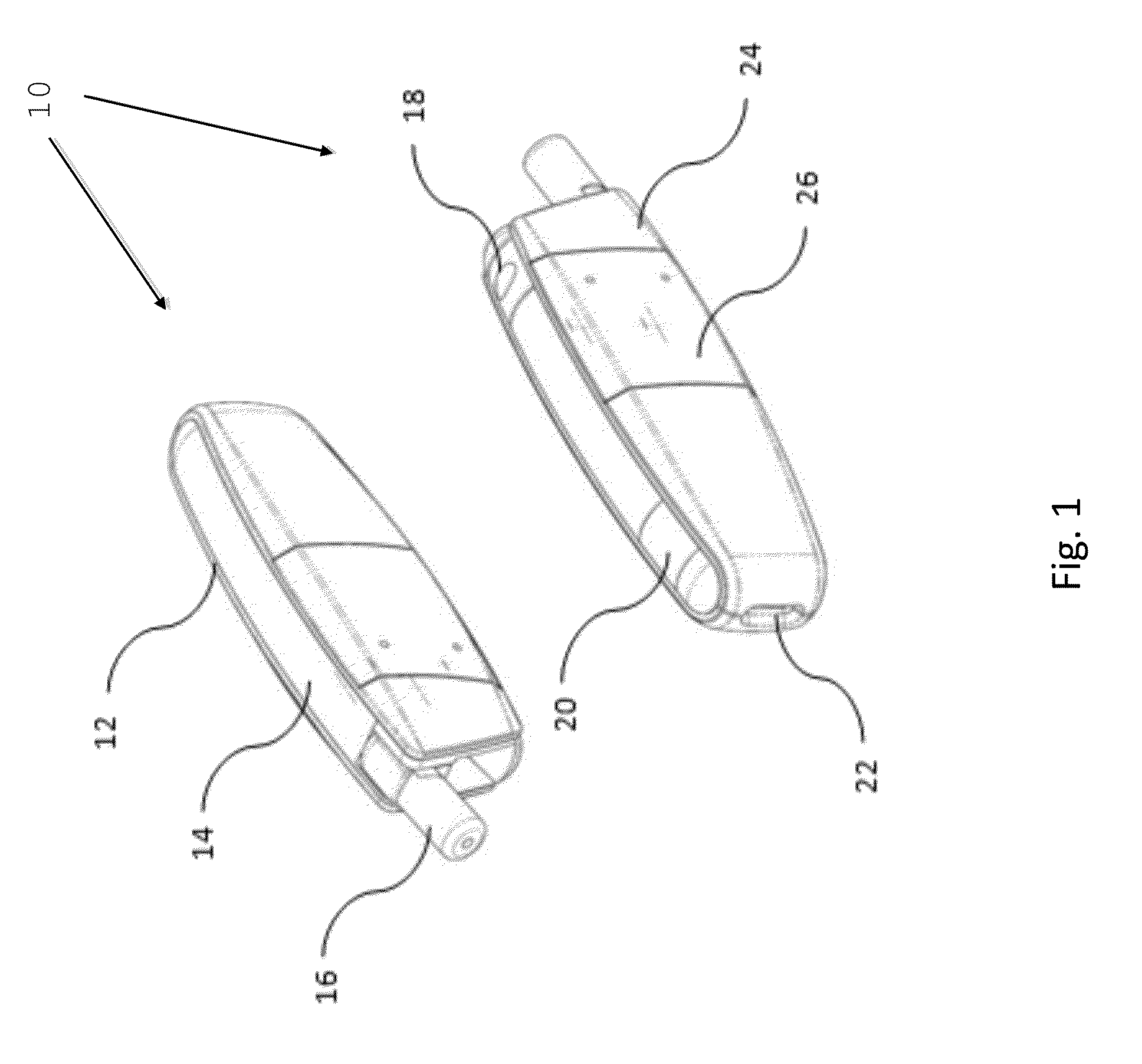

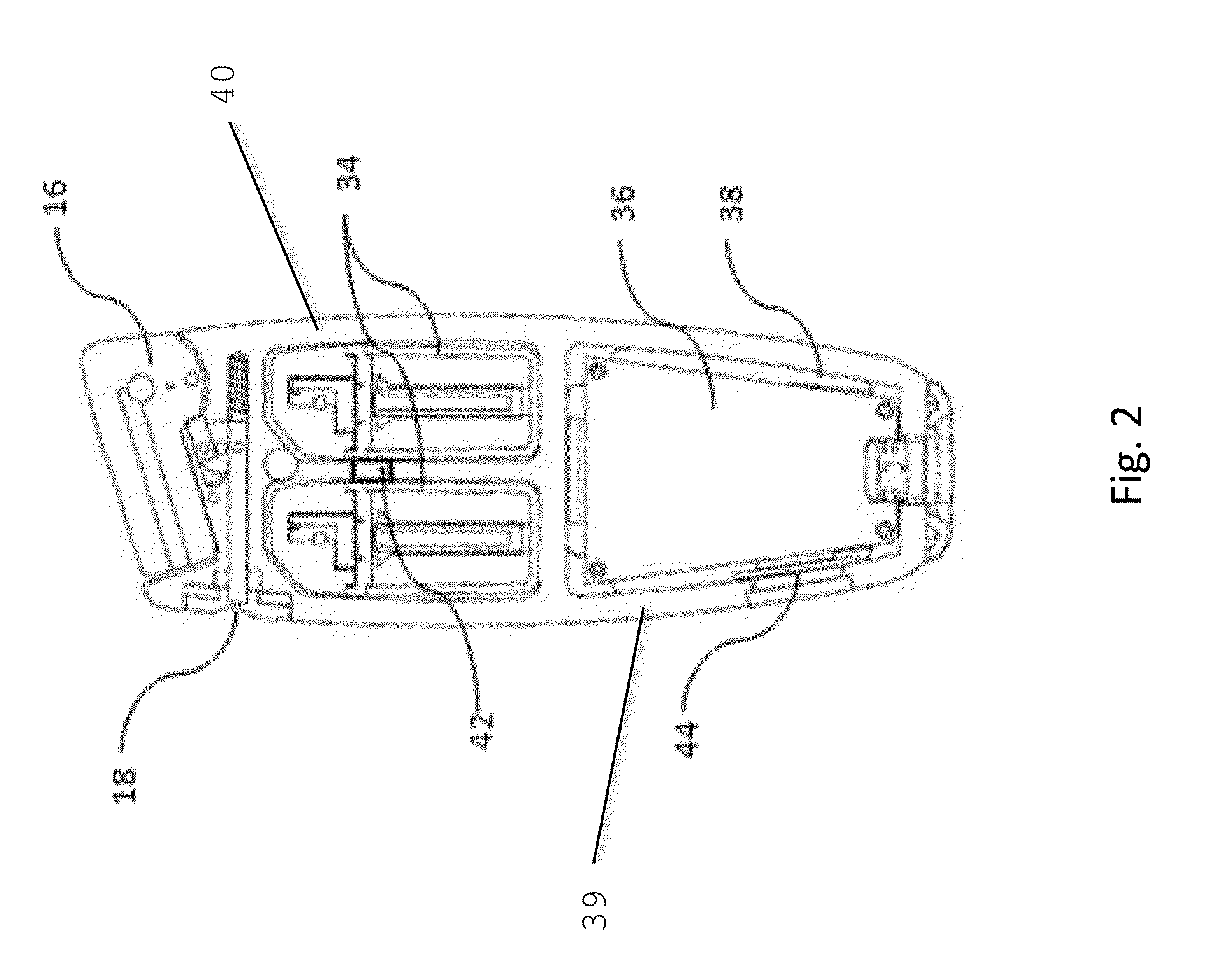

Electronic cigarette

An electronic cigarette with inlet air constructed and arranged to contact a delivery substance and minimize airflow over electronic components.

Owner:LBS IMPORTS

Temperature controlled multi-gas distribution assembly

InactiveUS20080099147A1Easy to understandSemiconductor/solid-state device manufacturingChemical vapor deposition coatingTemperature controlProcess region

An apparatus and method for a gas distribution plate is provided. The gas distribution plate has a first manifold which includes a plurality of concentric channels for providing at least two distinct gases to a processing zone above a substrate. A portion of the plurality of channels perform a thermal control function and are separated from the remaining channels, which provide separated gas flow channels within the gas distribution plate. The gas flow channels are in fluid communication with a second manifold which includes a plurality of concentric rings. Apertures formed in the rings are in fluid communication with the gas flow channels and the processing zone. The gases are provided to the processing zone above the substrate, and do not mix within the gas distribution plate.

Owner:APPLIED MATERIALS INC

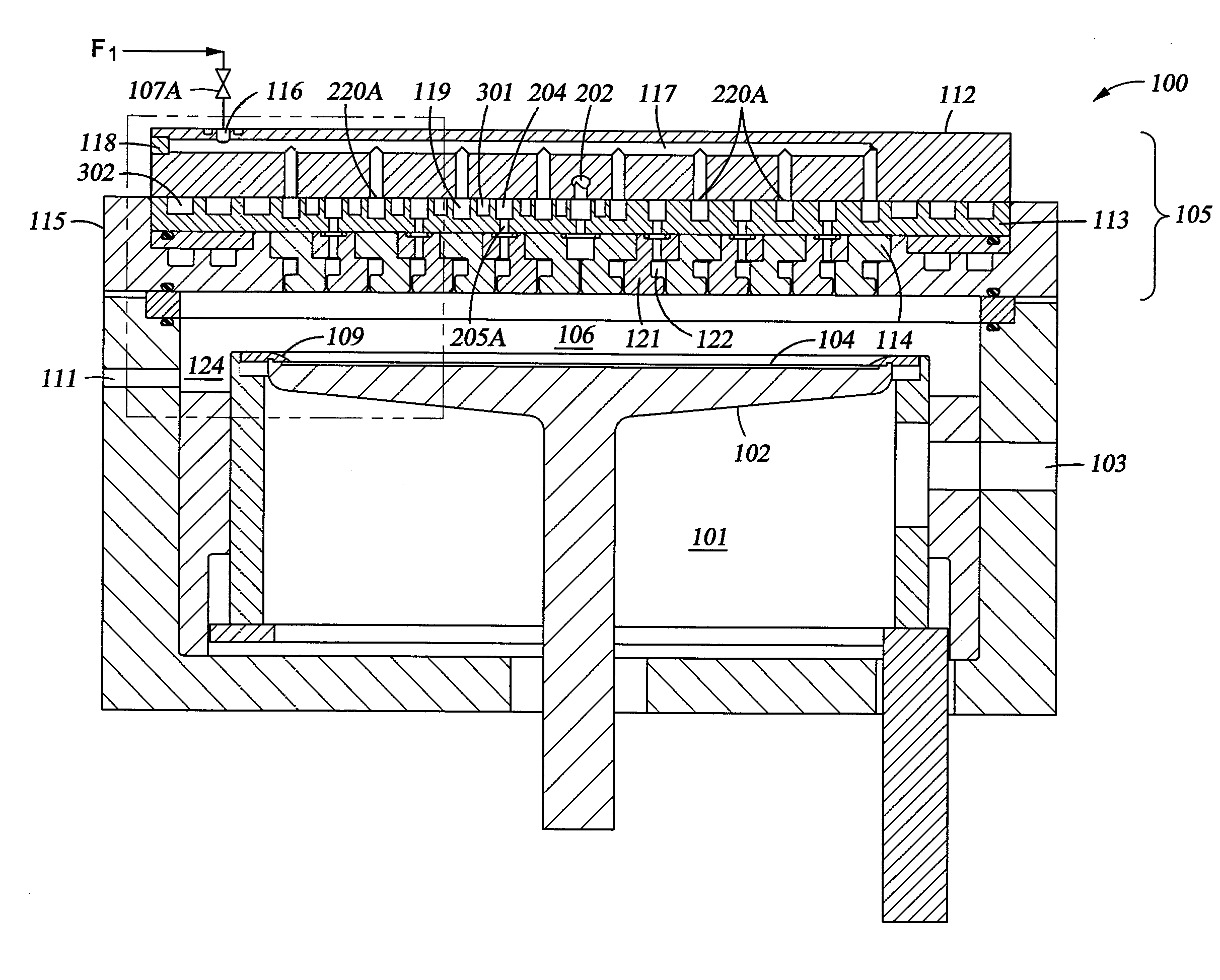

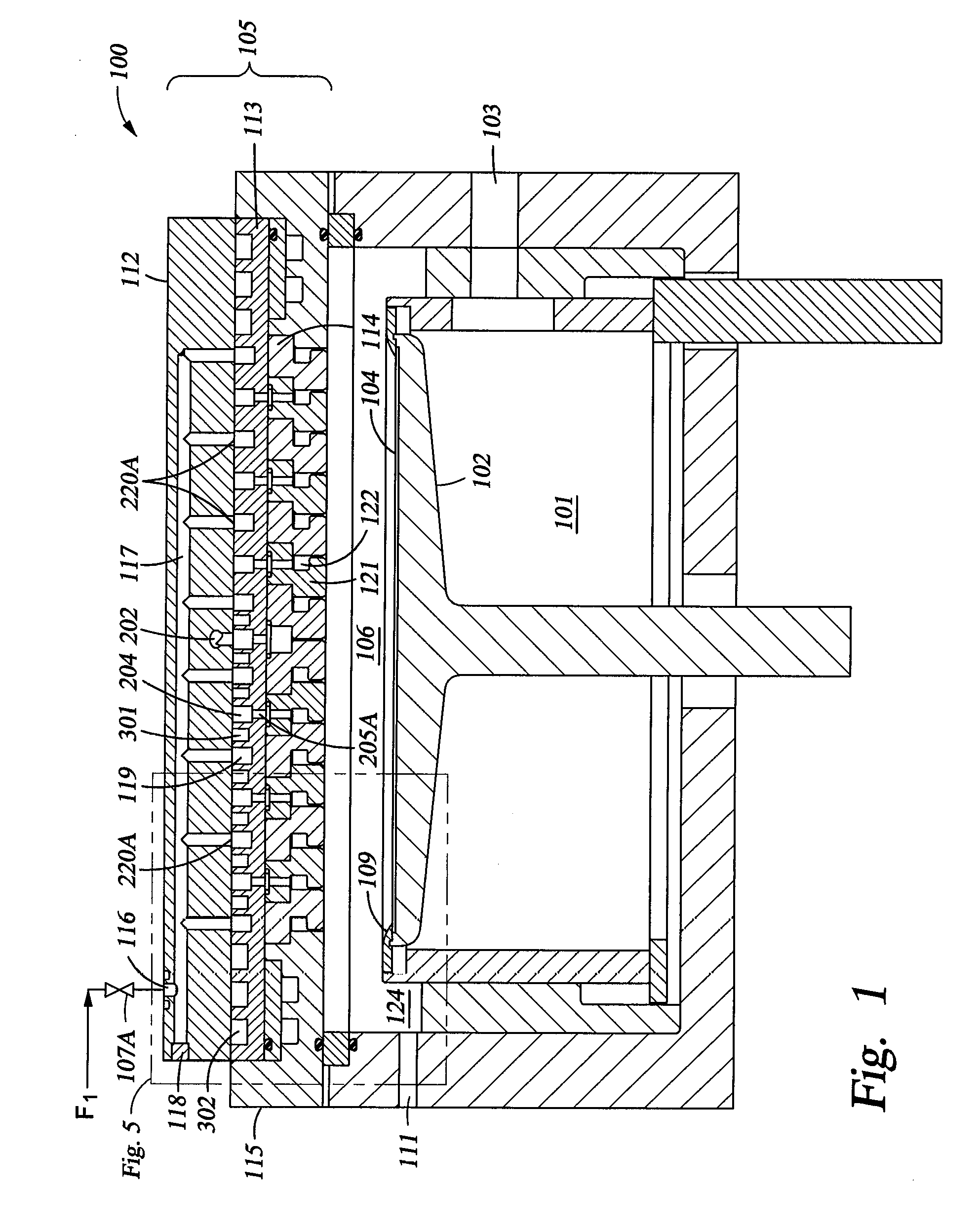

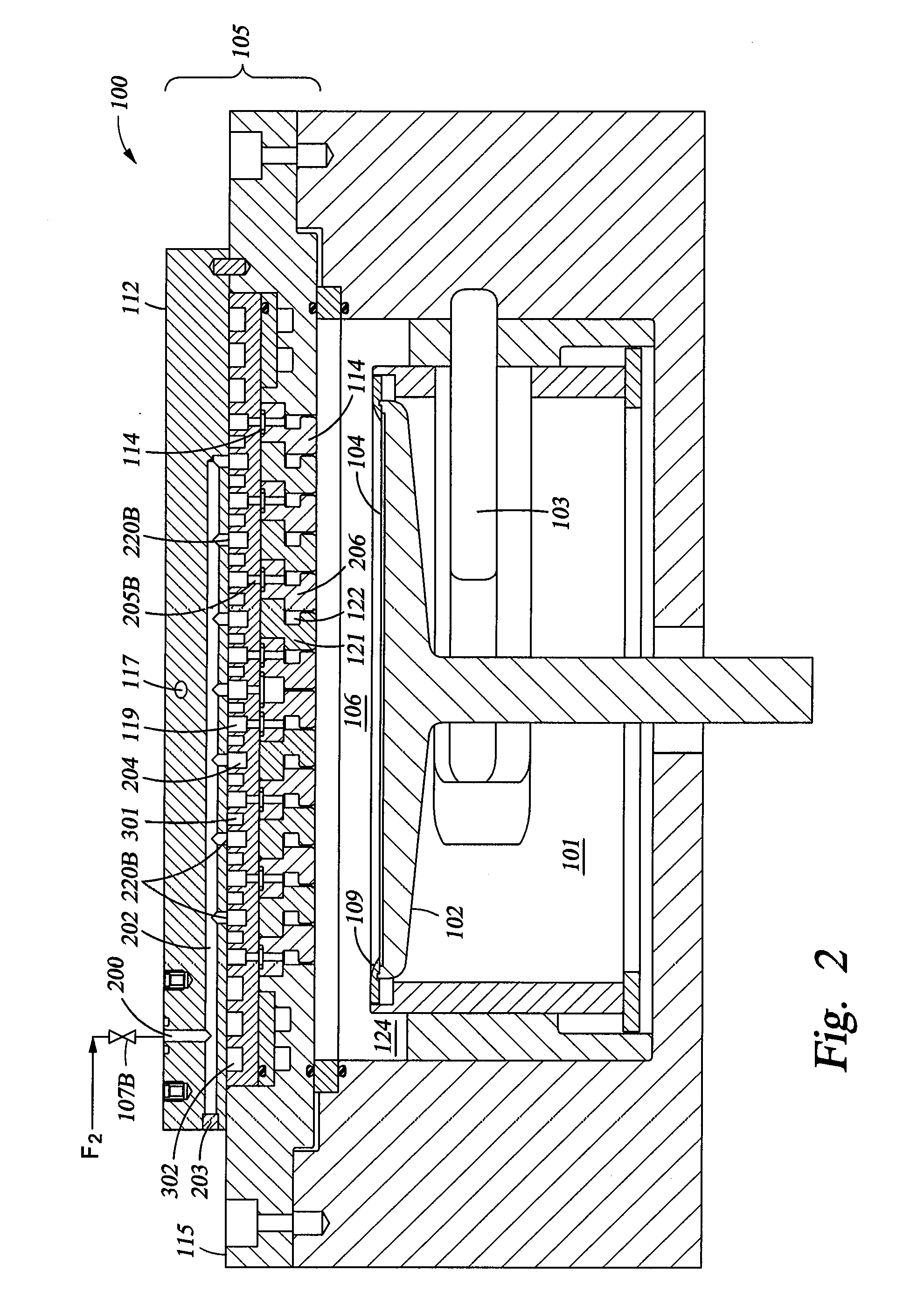

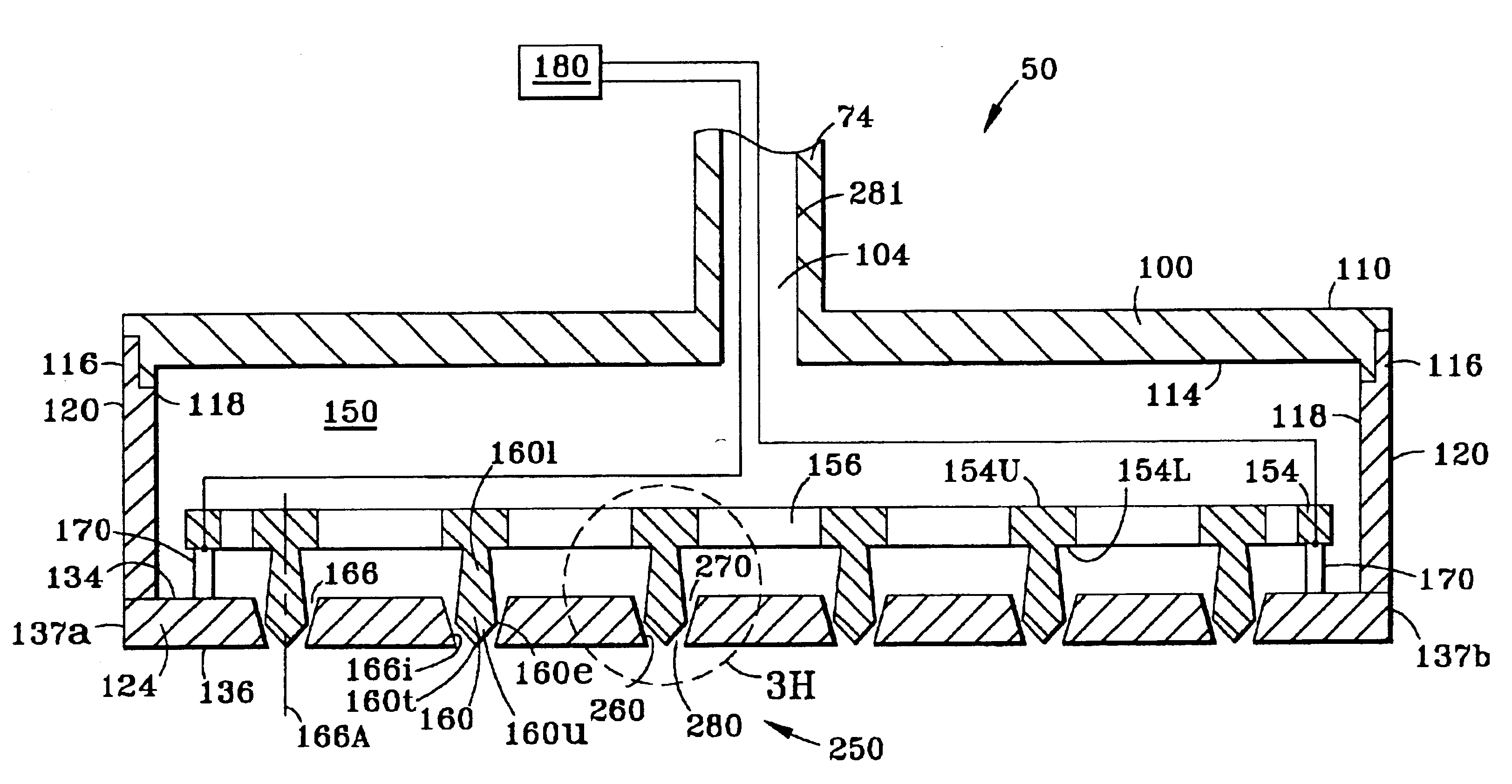

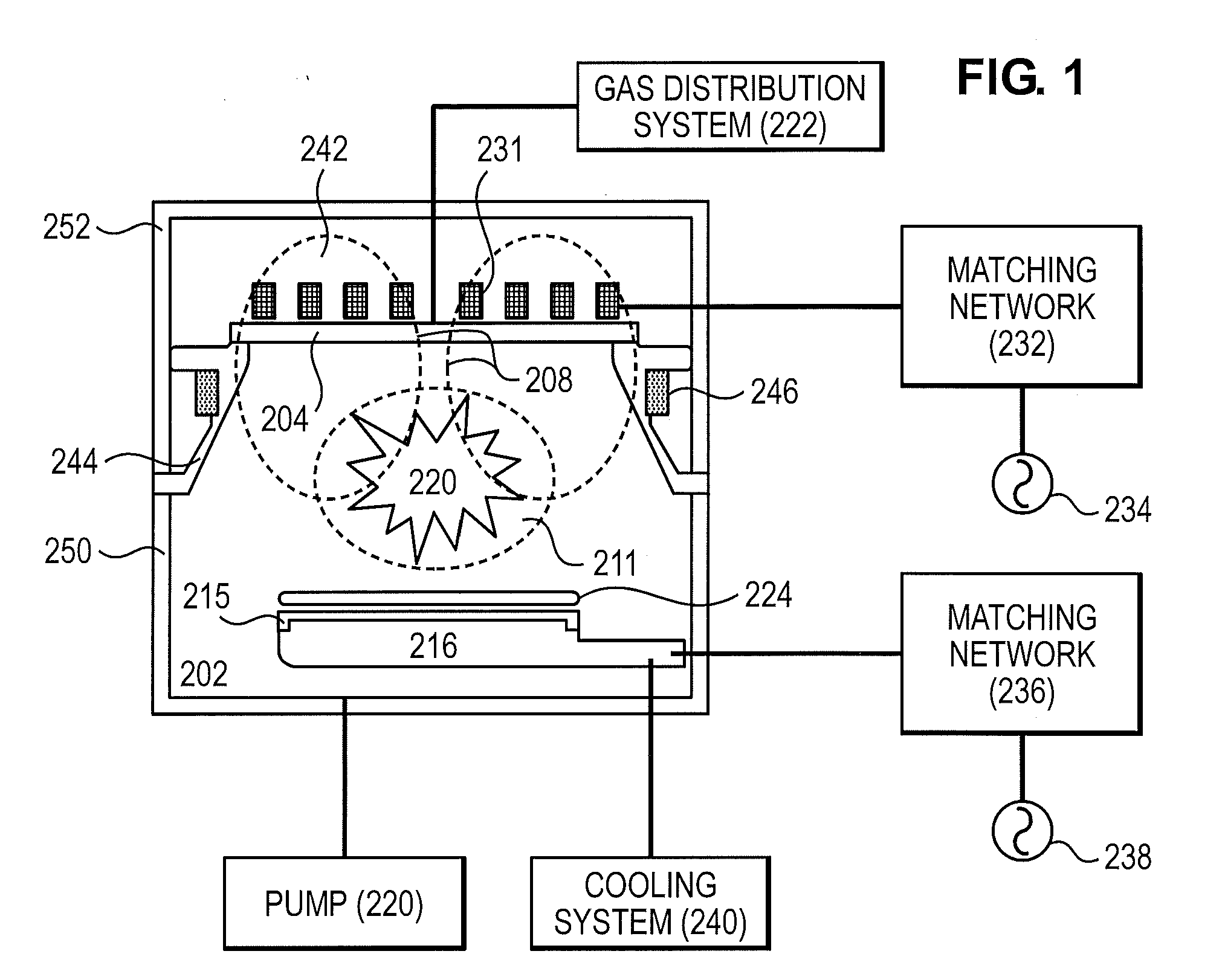

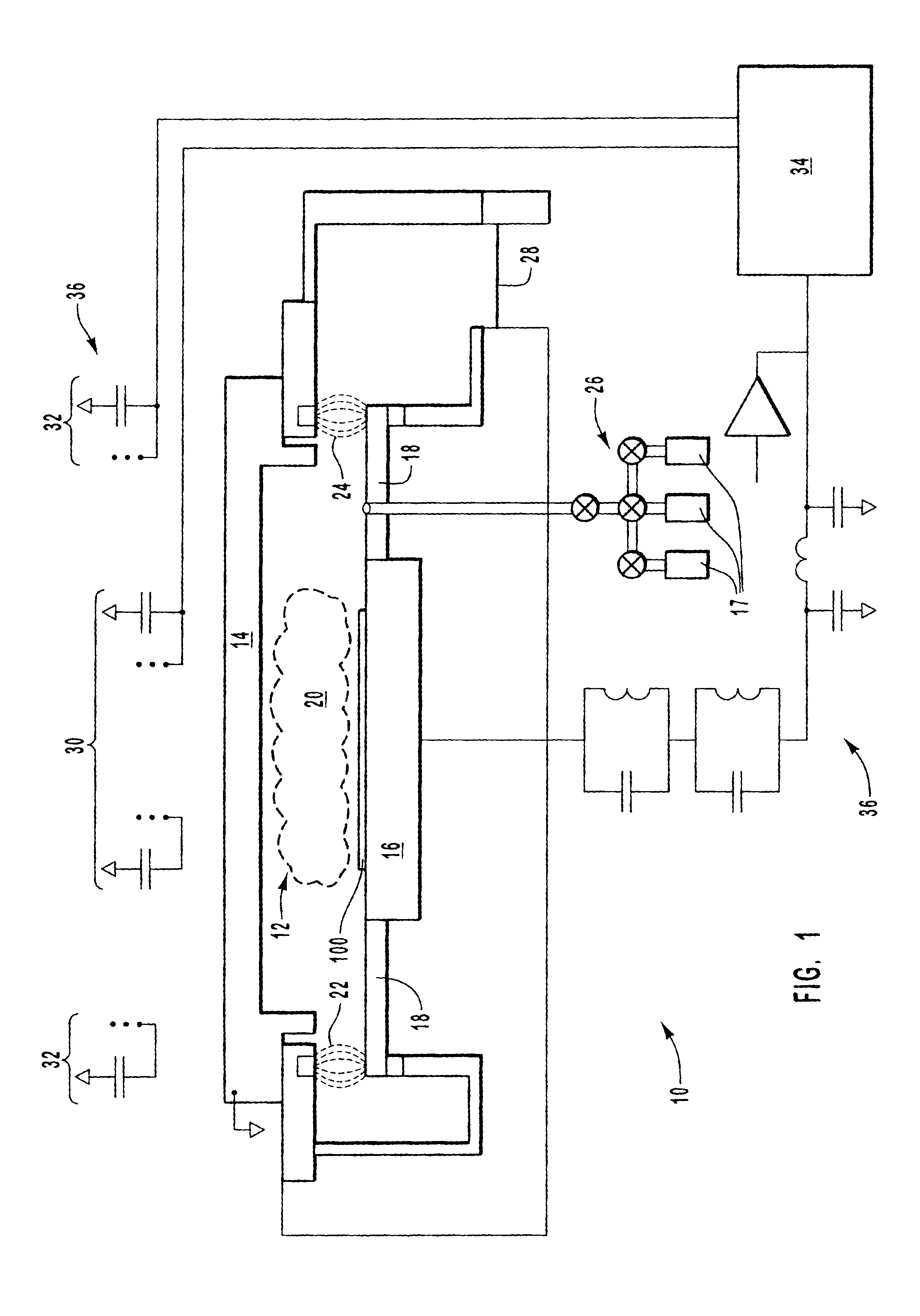

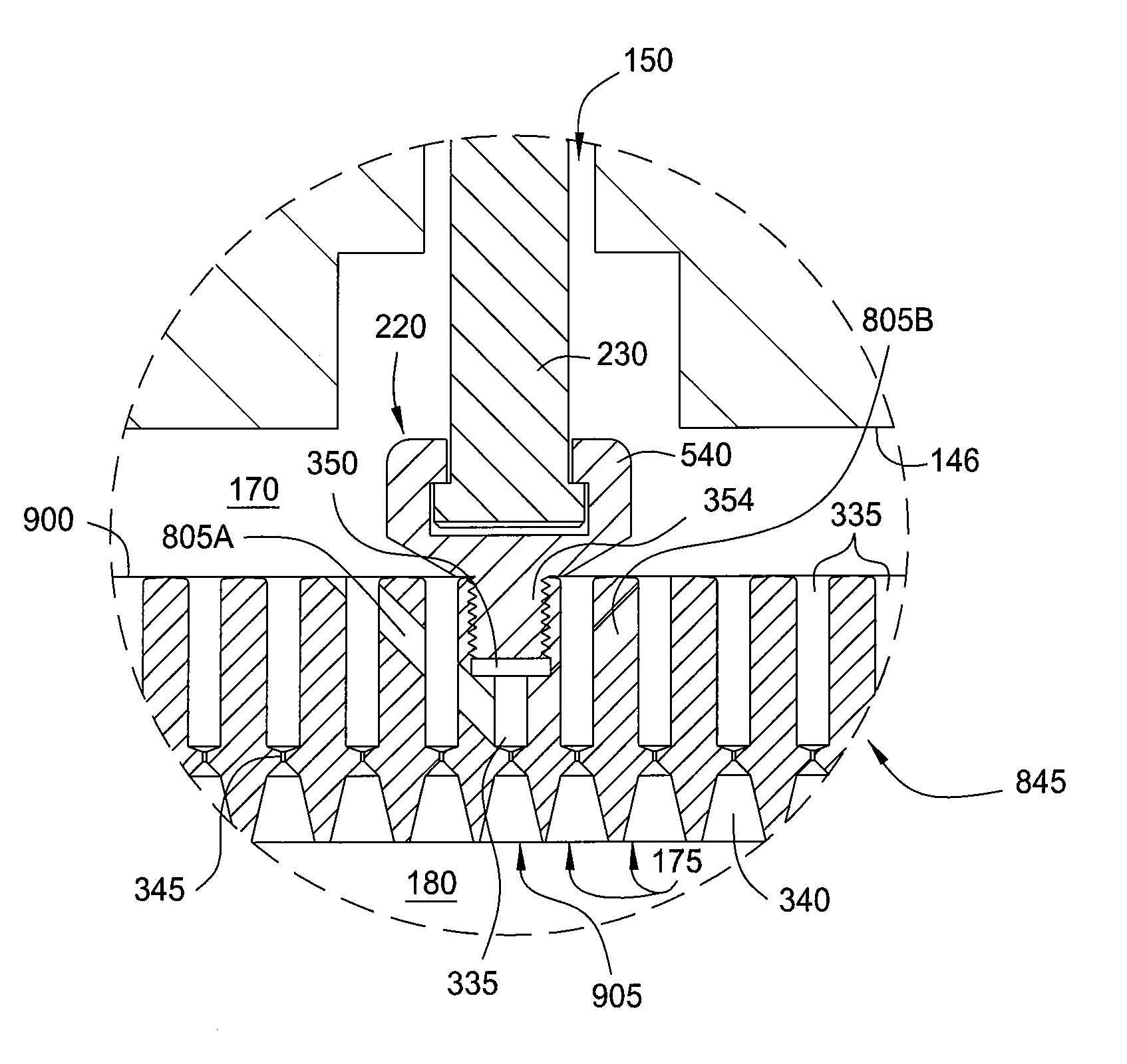

Method of and apparatus for tunable gas injection in a plasma processing system

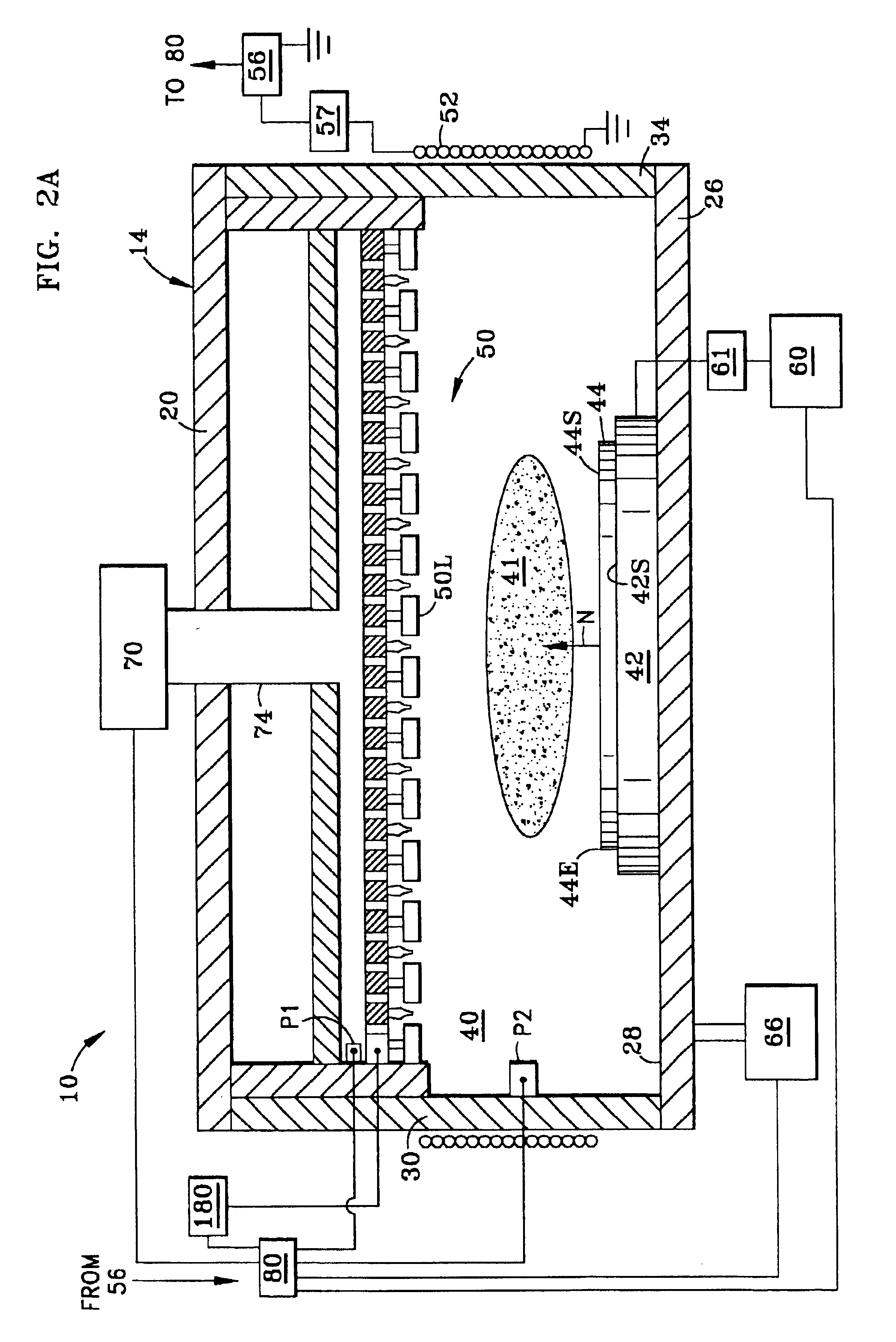

InactiveUS6872259B2Control expansionElectric discharge tubesSemiconductor/solid-state device manufacturingElectronic communicationProduct gas

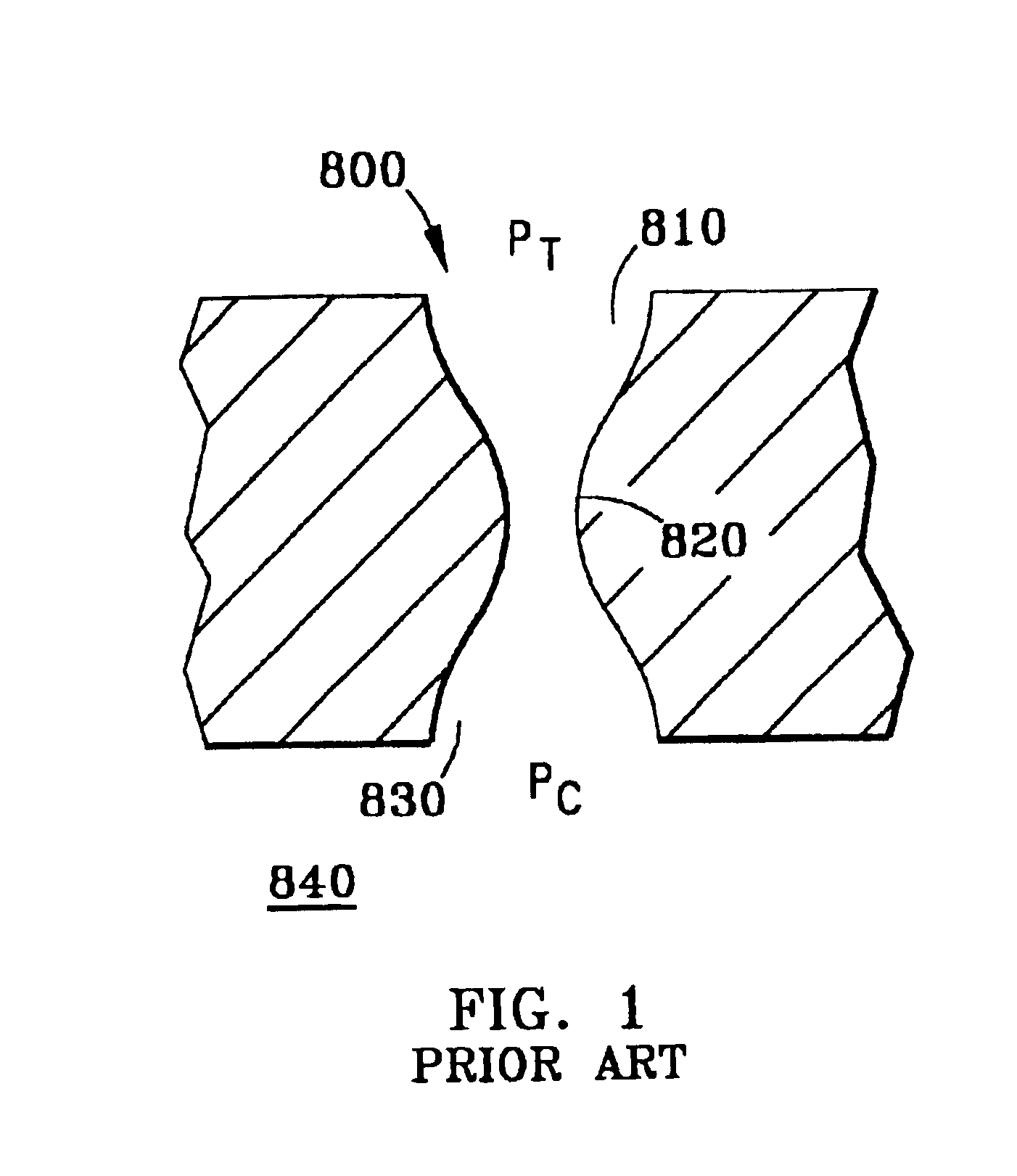

A method of and apparatus for providing tunable gas injection in a plasma processing system (10, 10′). The apparatus includes a gas injection manifold (50) having a pressurizable plenum (150) and an array of adjustable nozzle units (250), or an array of non-adjustable nozzles (502, 602), through which gas from the plenum can flow into the interior region (40) of a plasma reactor chamber (14) capable of containing a plasma (41). The adjustable nozzle units include a nozzle plug (160) arranged within a nozzle bore (166). A variety of different nozzle units are disclosed. The nozzle plugs are axially translatable to adjust the flow of gas therethrough. In one embodiment, the nozzle plugs are attached to a plug plate (154), which is displacable relative to an injection plate (124) via displacement actuators (170) connecting the two plates. The displacement actuators are controlled by a displacement actuator control unit (180), which is in electronic communication with a plasma processing system control unit (80). The gas flow into the chamber interior region is preferably controlled by monitoring the pressure in the plenum and in the chamber and adjusting the nozzle units accordingly. Where the nozzle units are not adjustable, a portion of the nozzles are sized to a first flow condition, and another portion of the nozzles are sized to a second flow condition.

Owner:TOKYO ELECTRON LTD

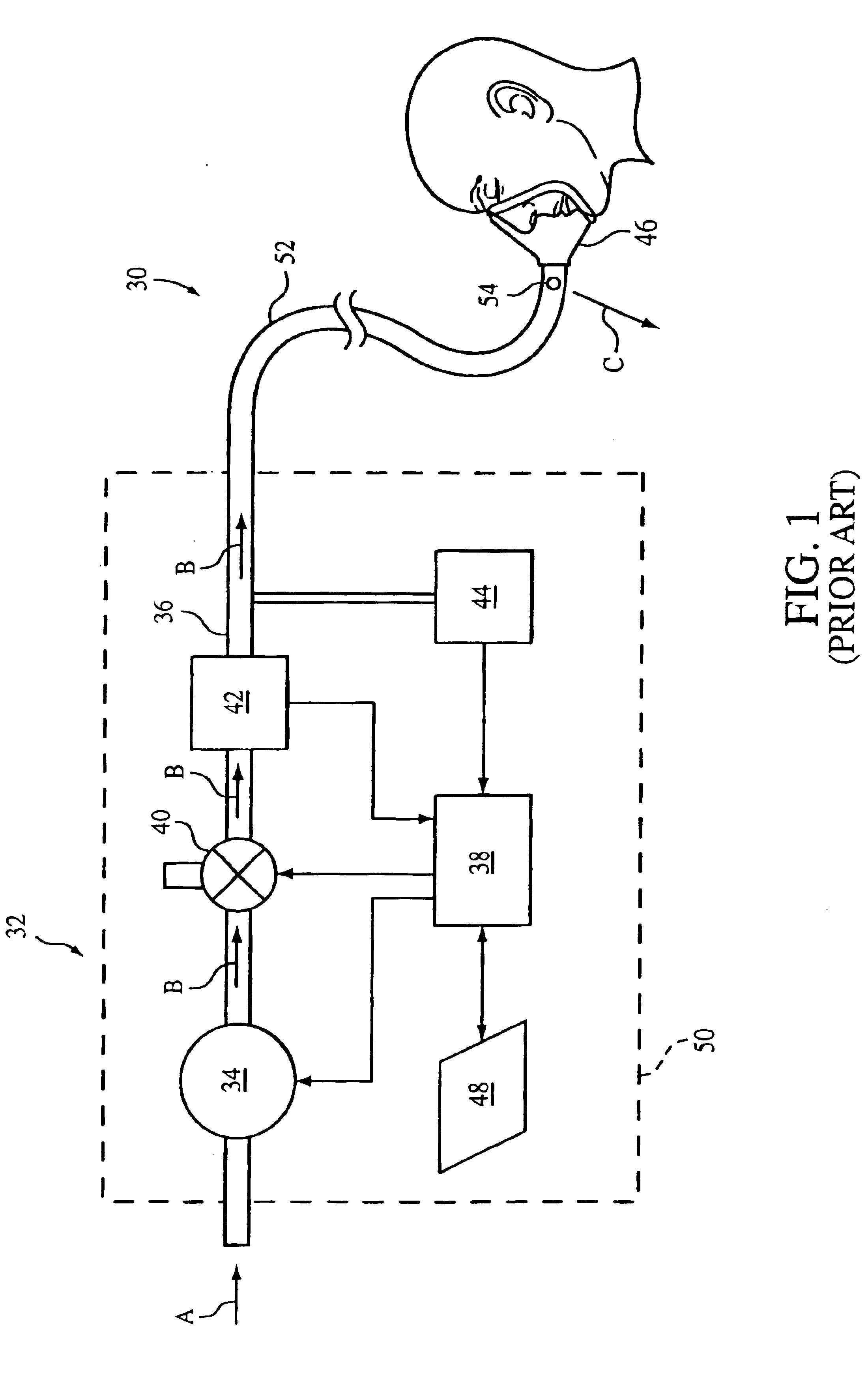

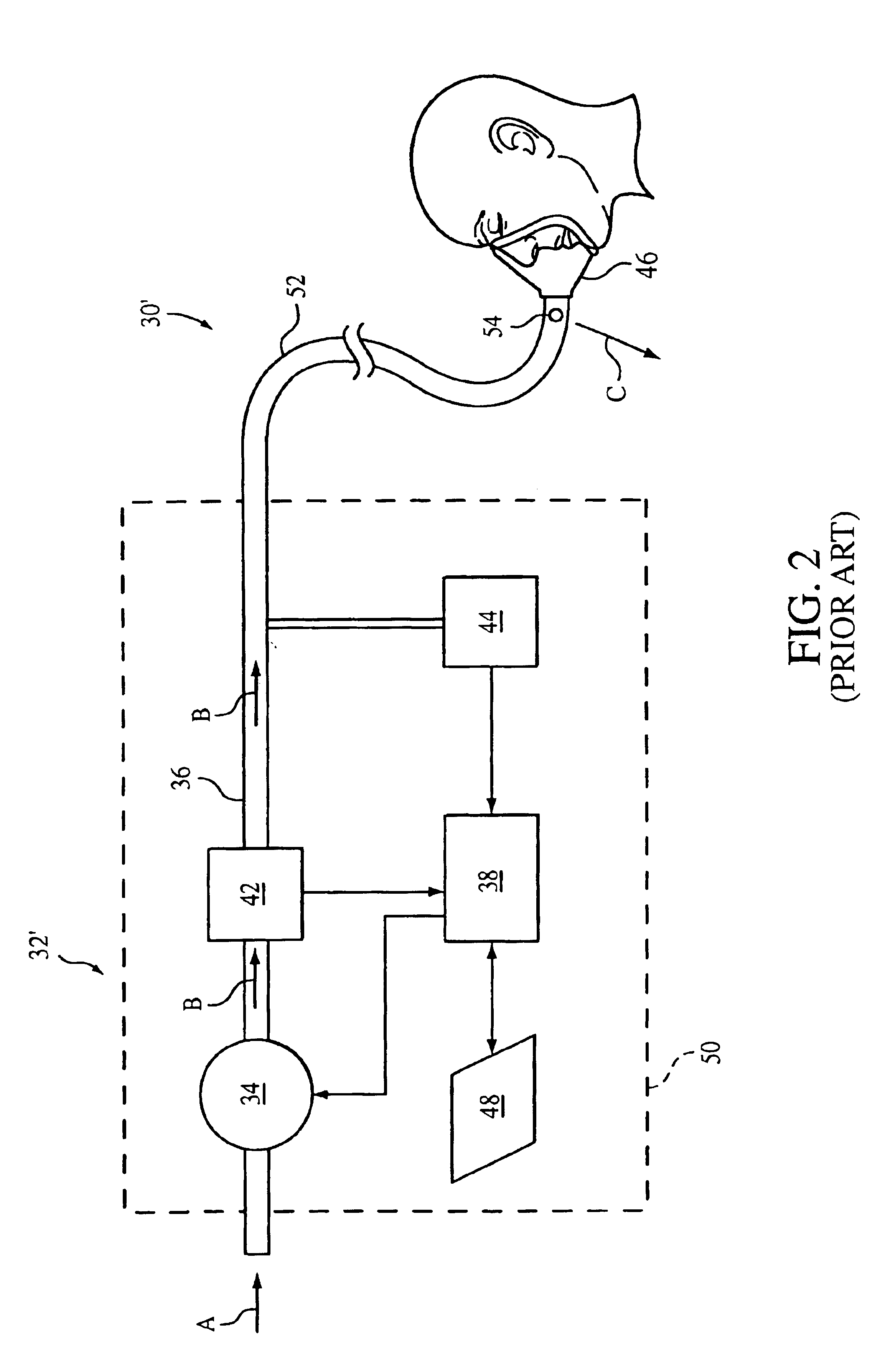

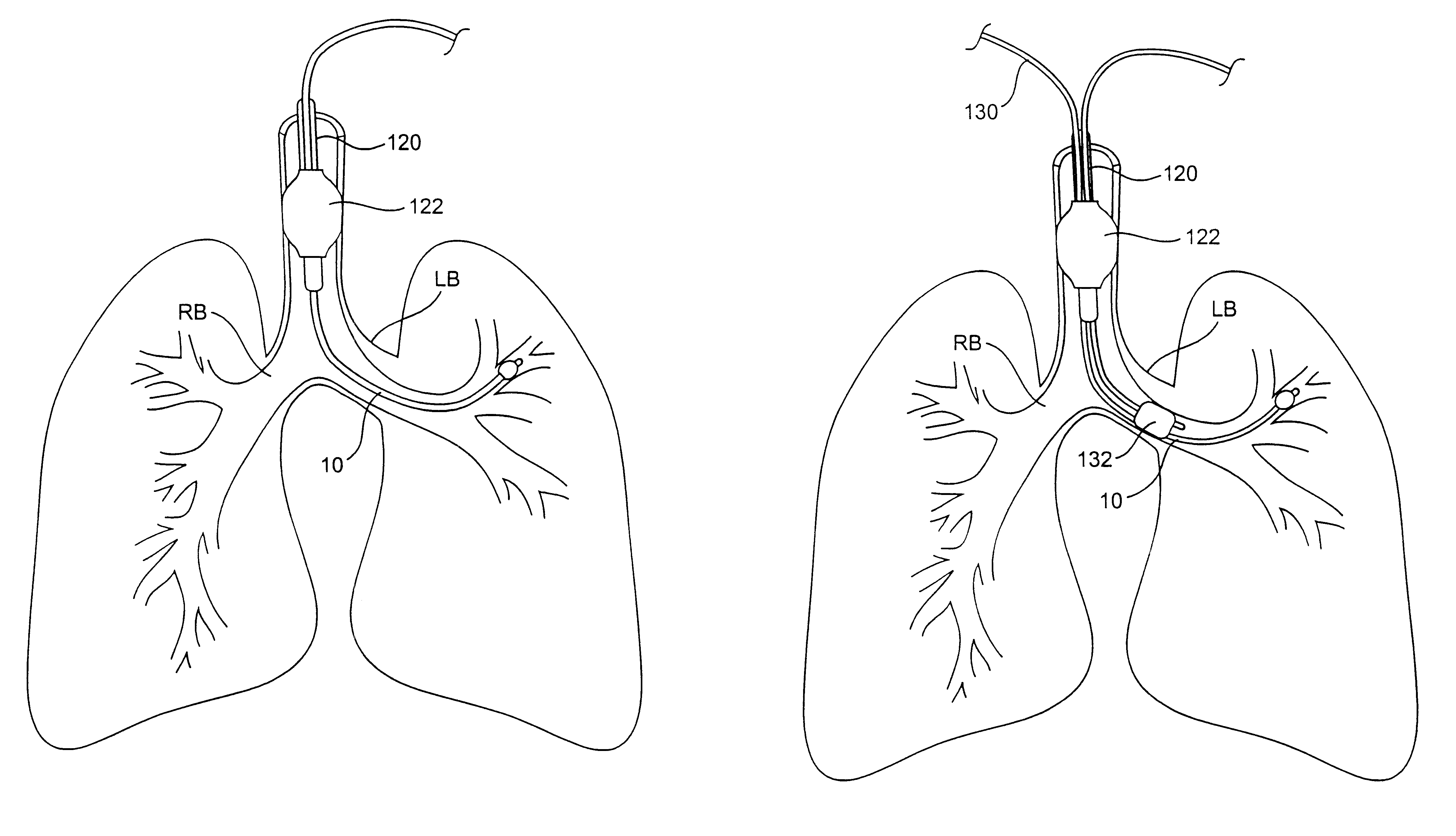

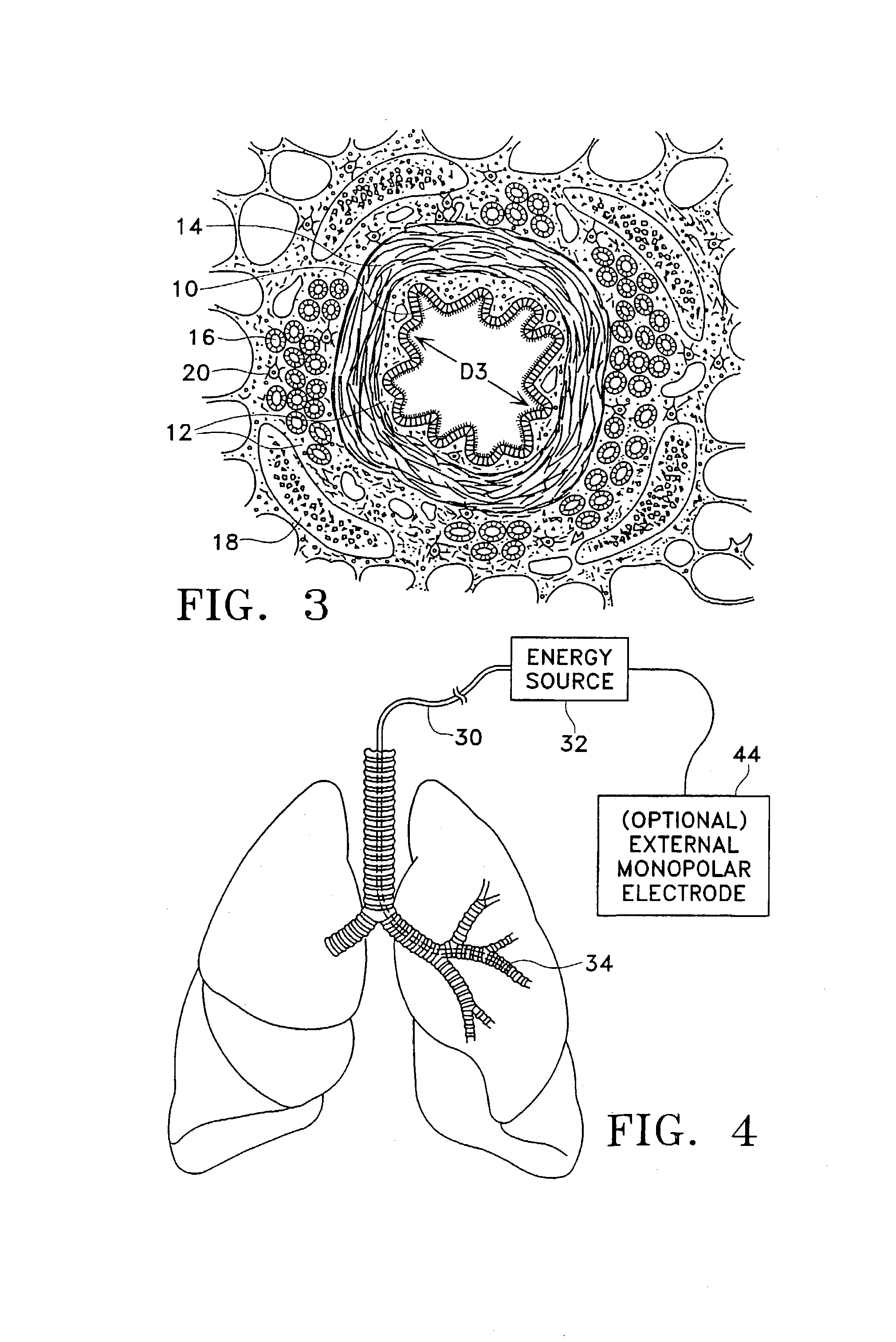

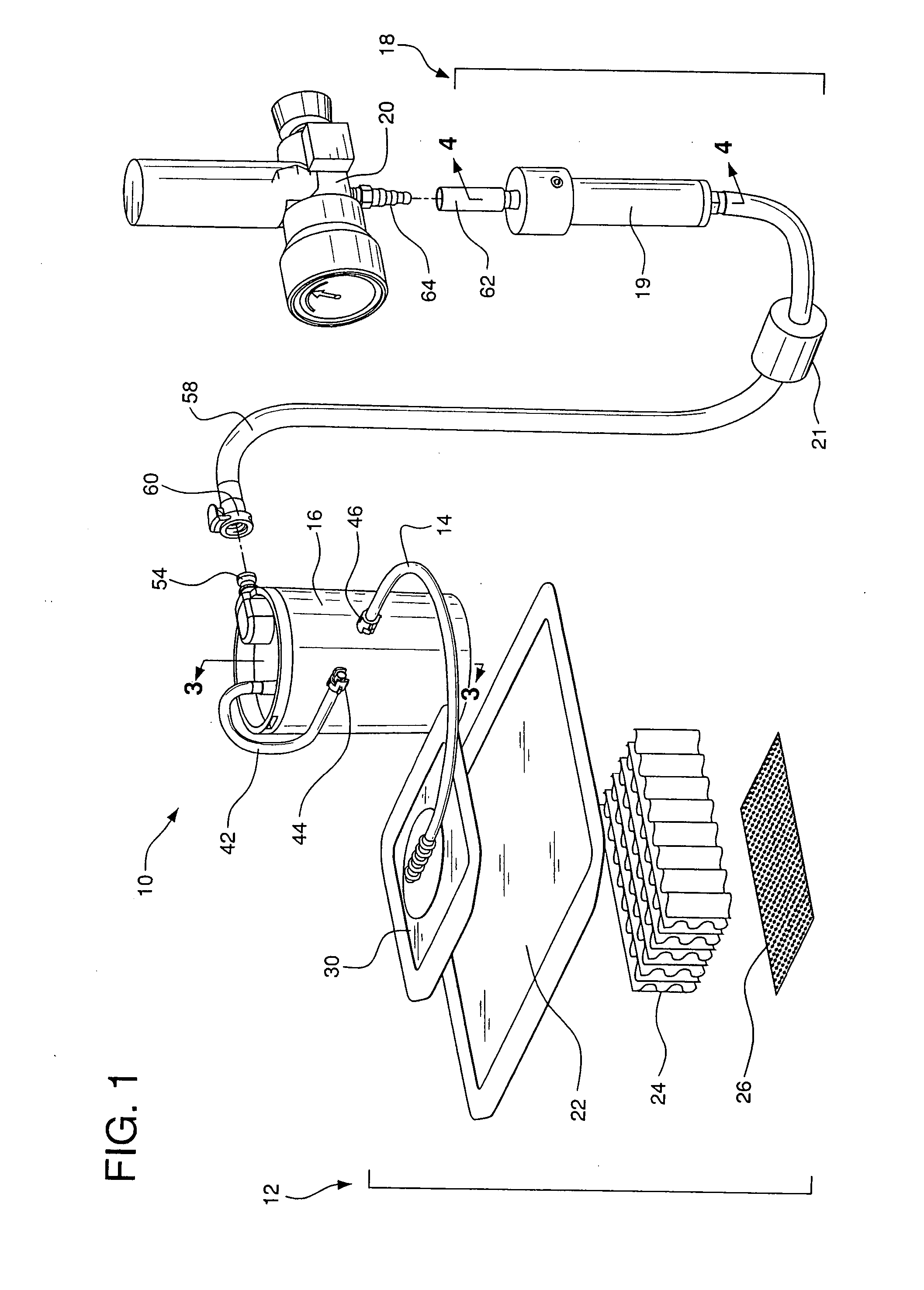

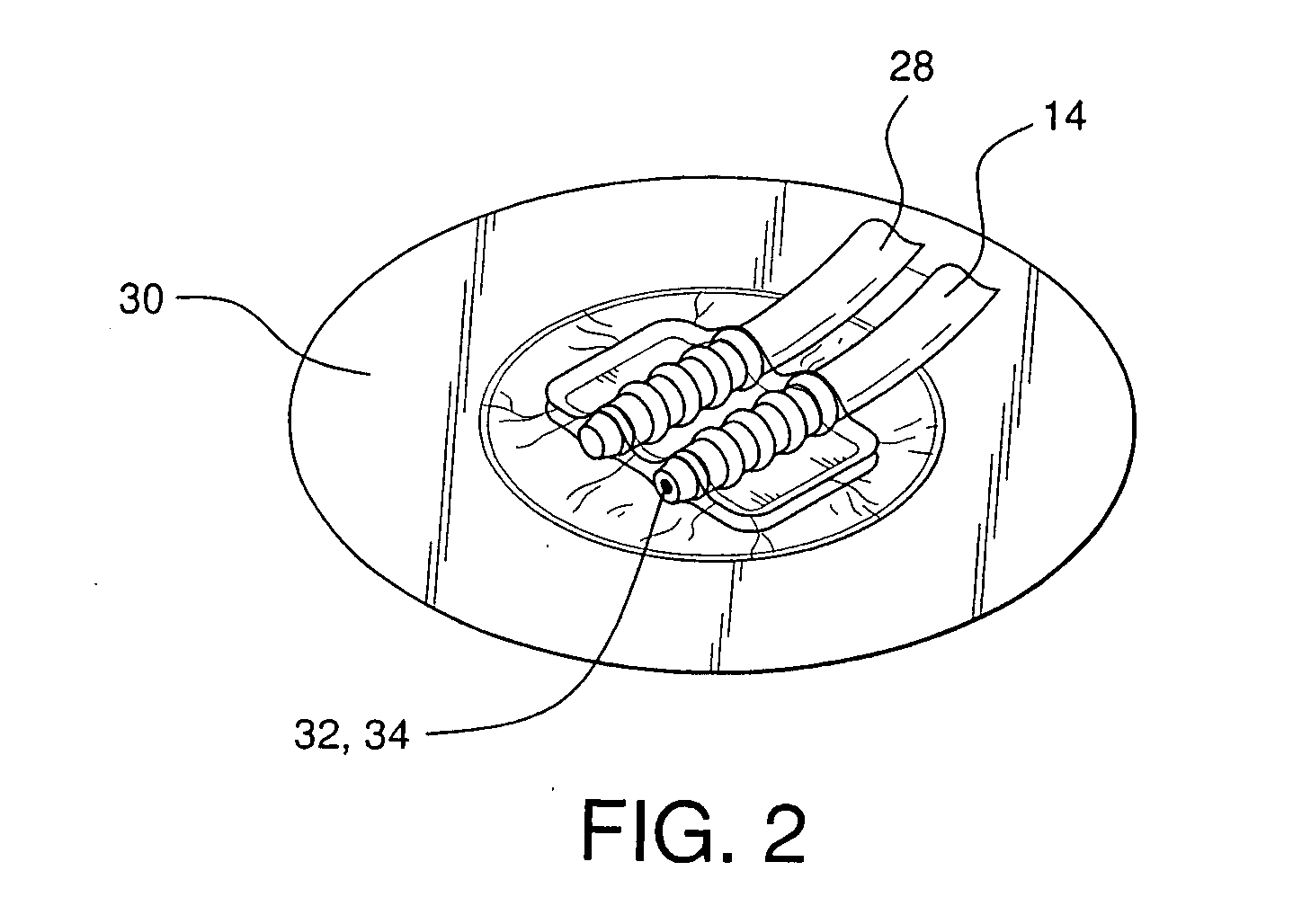

Methods, systems, and kits for lung volume reduction

InactiveUS6287290B1Improve deflection problemMaximal accessTracheal tubesBronchoscopesAirflowExternal pressure

Lung volume reduction is performed in a minimally invasive manner by isolating a lung tissue segment, optionally reducing gas flow obstructions within the segment, and aspirating the segment to cause the segment to at least partially collapse. Further optionally, external pressure may be applied on the segment to assist in complete collapse. Reduction of gas flow obstructions may be achieved in a variety of ways, including over inflation of the lung, introduction of mucolytic or dilation agents, application of vibrational energy, induction of absorption atelectasis, or the like. Optionally, diagnostic procedures on the isolated lung segment may be performed, typically using the same isolation / access catheter.

Owner:PULMONX

Reaction system for growing a thin film

ActiveUS20060266289A1Easy to cleanEliminates and significantly reduces dead pocketAfter-treatment apparatusSemiconductor/solid-state device manufacturingEngineeringReaction system

An atomic deposition (ALD) thin film deposition apparatus includes a deposition chamber configured to deposit a thin film on a wafer mounted within a space defined therein. The deposition chamber comprises a gas inlet that is in communication with the space. A gas system is configured to deliver gas to the gas inlet of the deposition chamber. At least a portion of the gas system is positioned above the deposition chamber. The gas system includes a mixer configured to mix a plurality of gas streams. A transfer member is in fluid communication with the mixer and the gas inlet. The transfer member comprising a pair of horizontally divergent walls configured to spread the gas in a horizontal direction before entering the gas inlet.

Owner:ASM IP HLDG BV

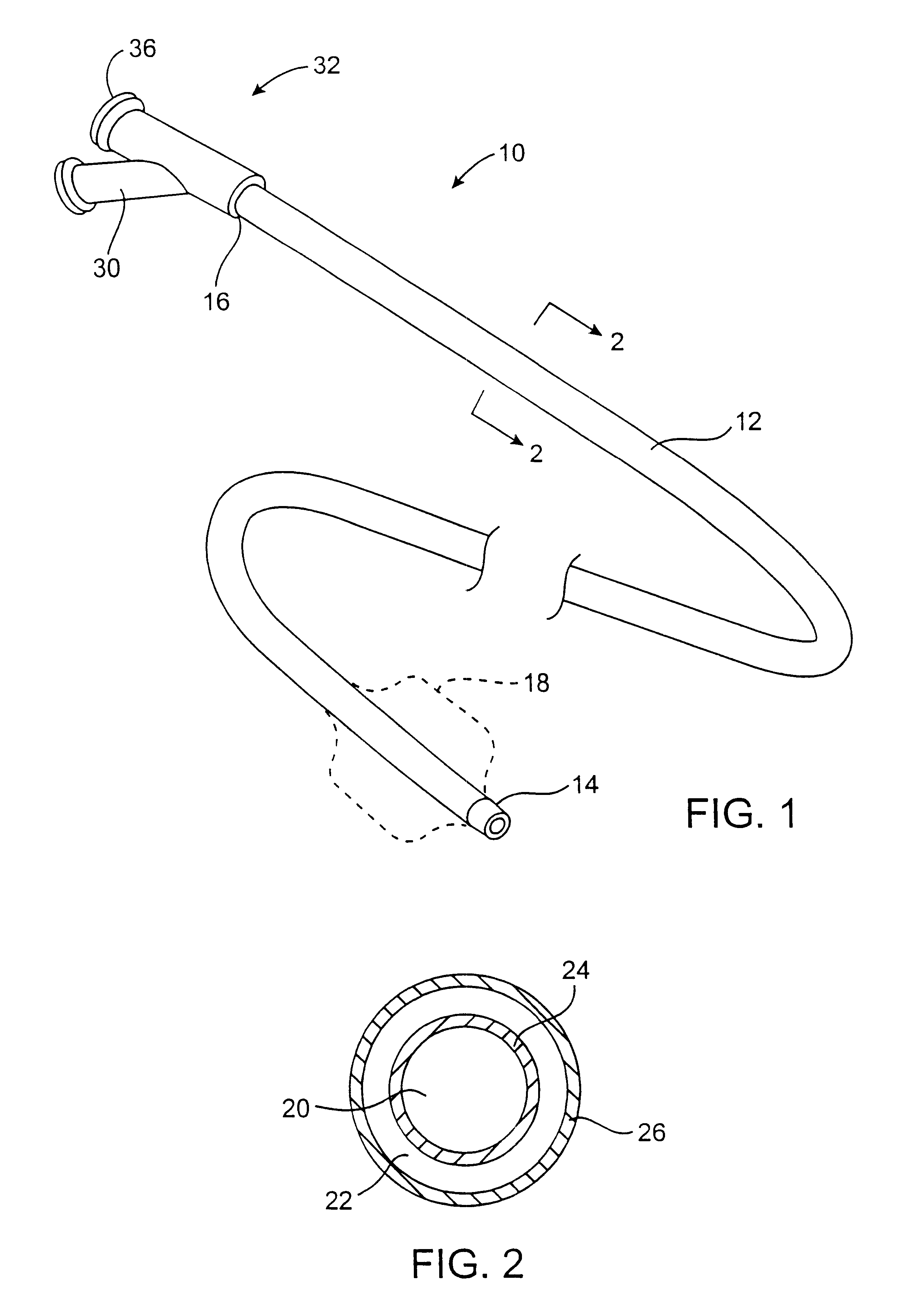

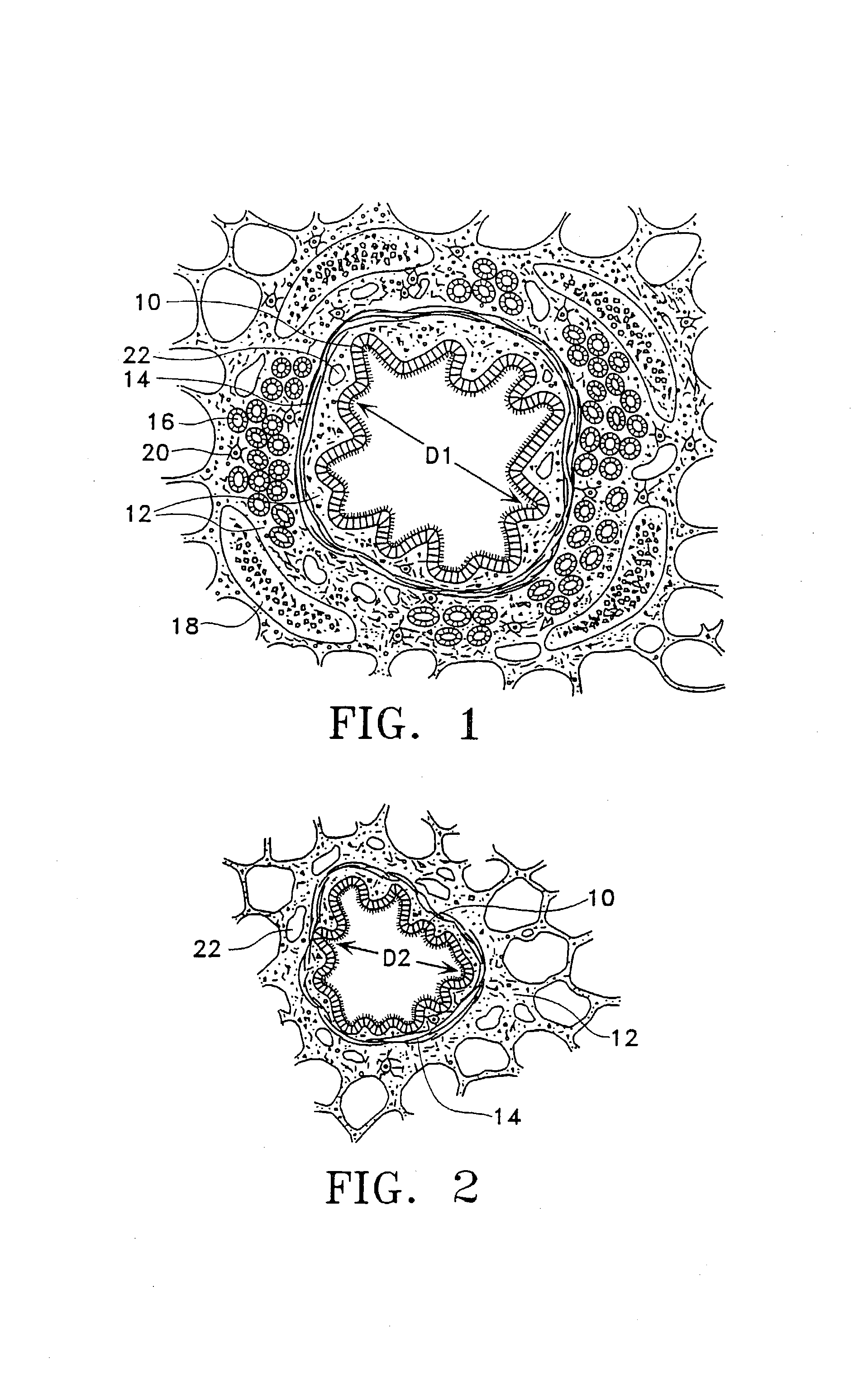

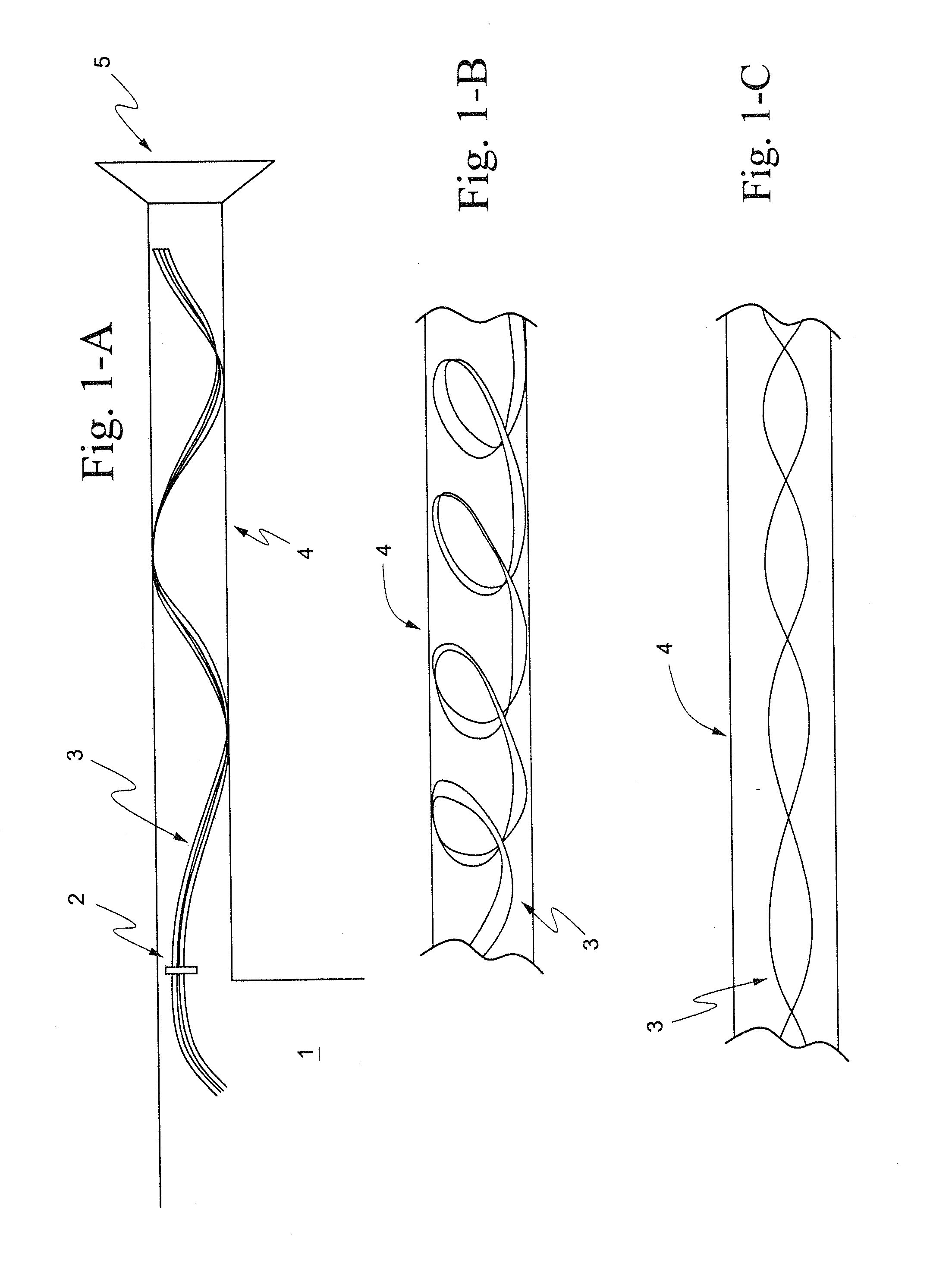

Modification of airways by application of energy

InactiveUS7198635B2Reduce plugging of the airwayPrevent the airway from being able to constrictElectrotherapySurgical needlesPatient complianceObstructive Pulmonary Diseases

This relates to methods and devices for treating reversible chronic obstructive pulmonary disease, and more particularly, relates to a device for exchanging energy with airway tissue such as that found in the airway of human lungs. The exchange of energy with this airway tissue in the airways reduces the ability of the air ways to constrict and / or reduces the resistance within the airway to the flow of air through the airway. This also relates to a method for decreasing responsiveness or decreasing resistance to airflow of airways involves the transfer of energy to or from the airway walls to prevent or reduce airway constriction and other symptoms of lung diseases. The treatment reduces the ability of the airway to contract during an acute narrowing of the airways, reduces mucus plugging of the airways, and / or increases the airway diameter. The methods according to the present invention provide a longer duration and / or more effective treatment for lung diseases than currently used drug treatments, and obviate patient compliance issues. This also includes additional steps that reduce the ability of the lung to produce at least one of the symptoms of reversible obstructive pulmonary disease and to reduce the resistance to the flow of air through a lung.

Owner:BOSTON SCI SCIMED INC

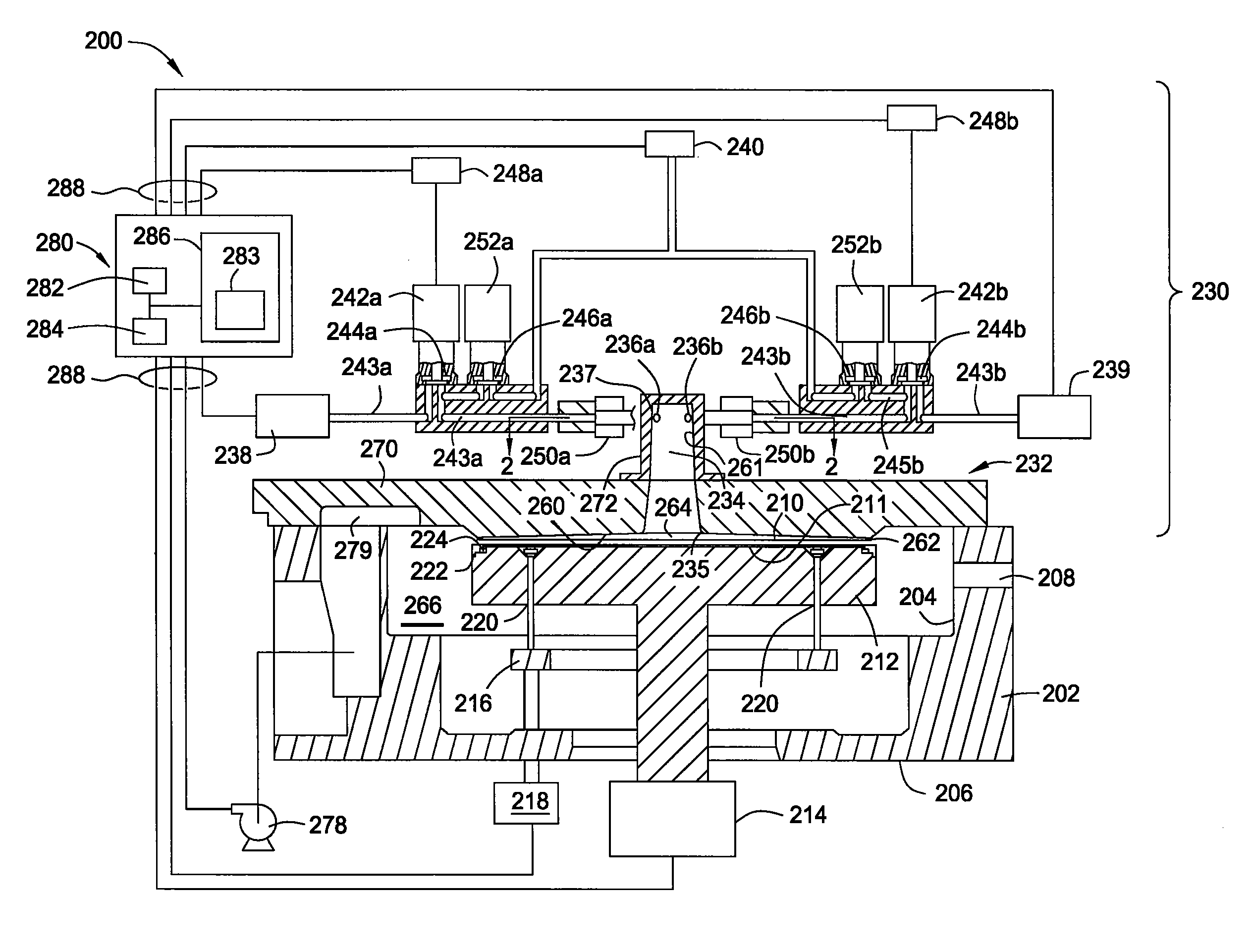

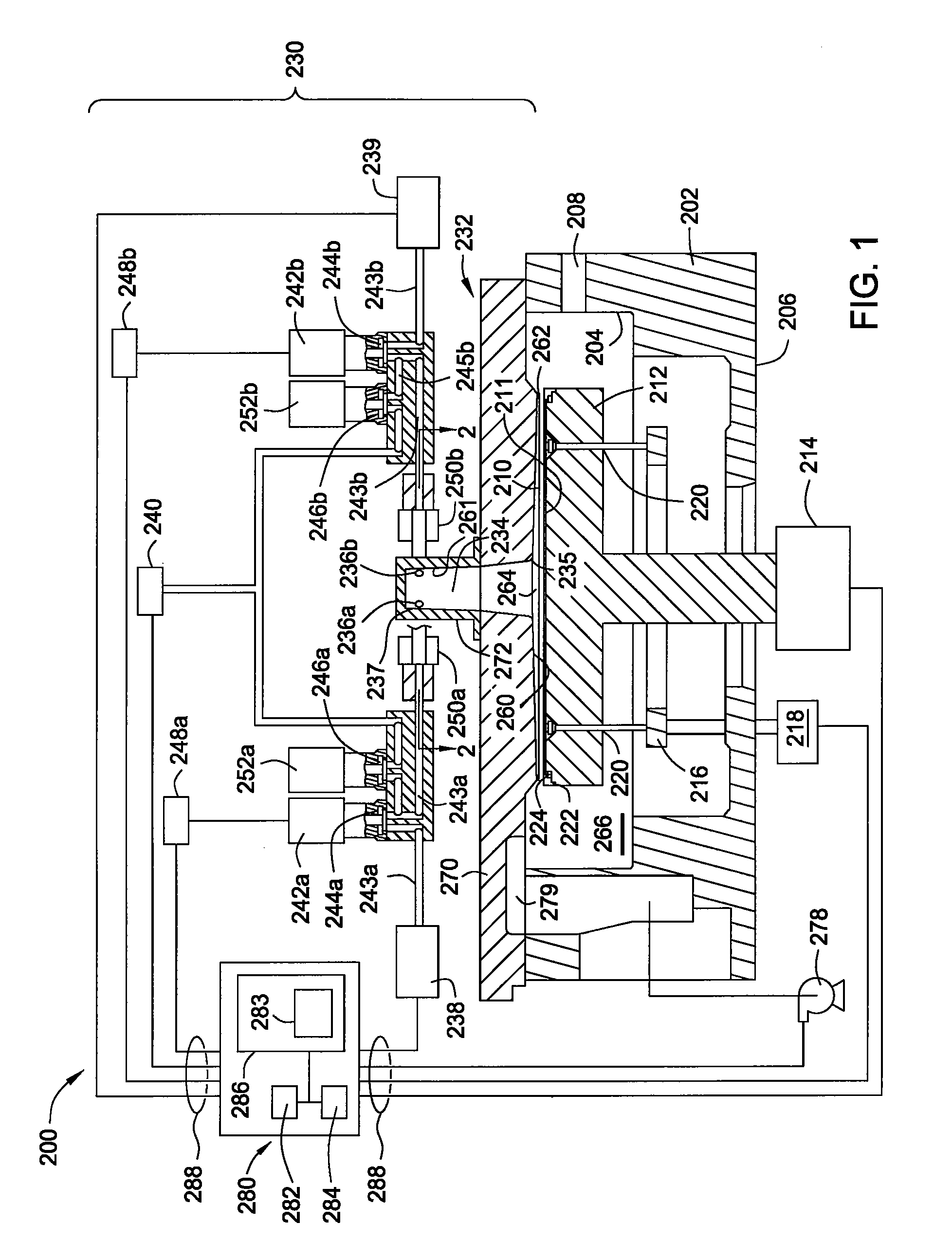

Replaceable upper chamber parts of plasma processing apparatus

ActiveUS20110056626A1Minimizing transferElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringPlasma reaction

An upper chamber section of a plasma reaction chamber includes a ceramic window with blind bores in an upper surface for receipt of a thermal couple and a resistance temperature detector, a top chamber interface which comprises an upper surface which vacuum seals against the bottom of the window and a gas injection system comprising 8 side injectors mounted in the sidewall of the top chamber interface and a gas delivery system comprising tubing which provides symmetric gas flow to the 8 injectors from a single gas feed connection.

Owner:LAM RES CORP

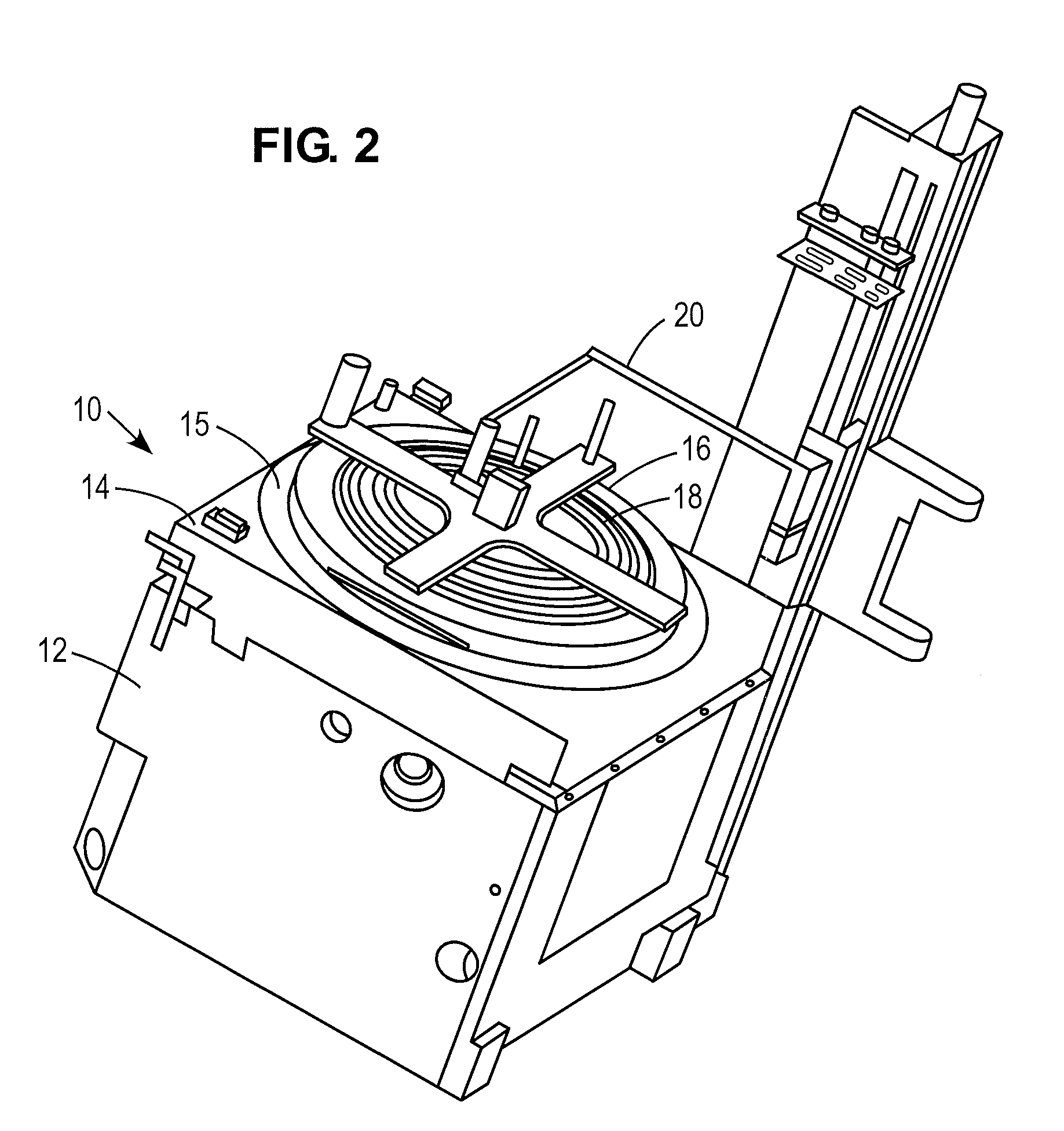

Vortex chamber lids for atomic layer deposition

InactiveUS20080102203A1Reduce gas velocitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingSurface roughnessEngineering

Embodiments of the invention relate to apparatuses and methods for depositing materials on substrates during atomic layer deposition processes. In one embodiment, a chamber for processing substrates is provided which includes a chamber lid assembly containing an expanding channel at a central portion of the chamber lid assembly, wherein an upper portion of the expanding channel extends substantially parallel along a central axis of the expanding channel, and an expanding portion of the expanding channel tapers away from the central axis. The chamber lid assembly further contains a conduit coupled to a gas inlet, another conduit coupled to another gas inlet, and both gas inlets are positioned to provide a circular gas flow through the expanding channel. In one example, the inner surface within the upper portion of the expanding channel has a lower mean surface roughness than the inner surface within the expanding portion of the expanding channel.

Owner:APPLIED MATERIALS INC

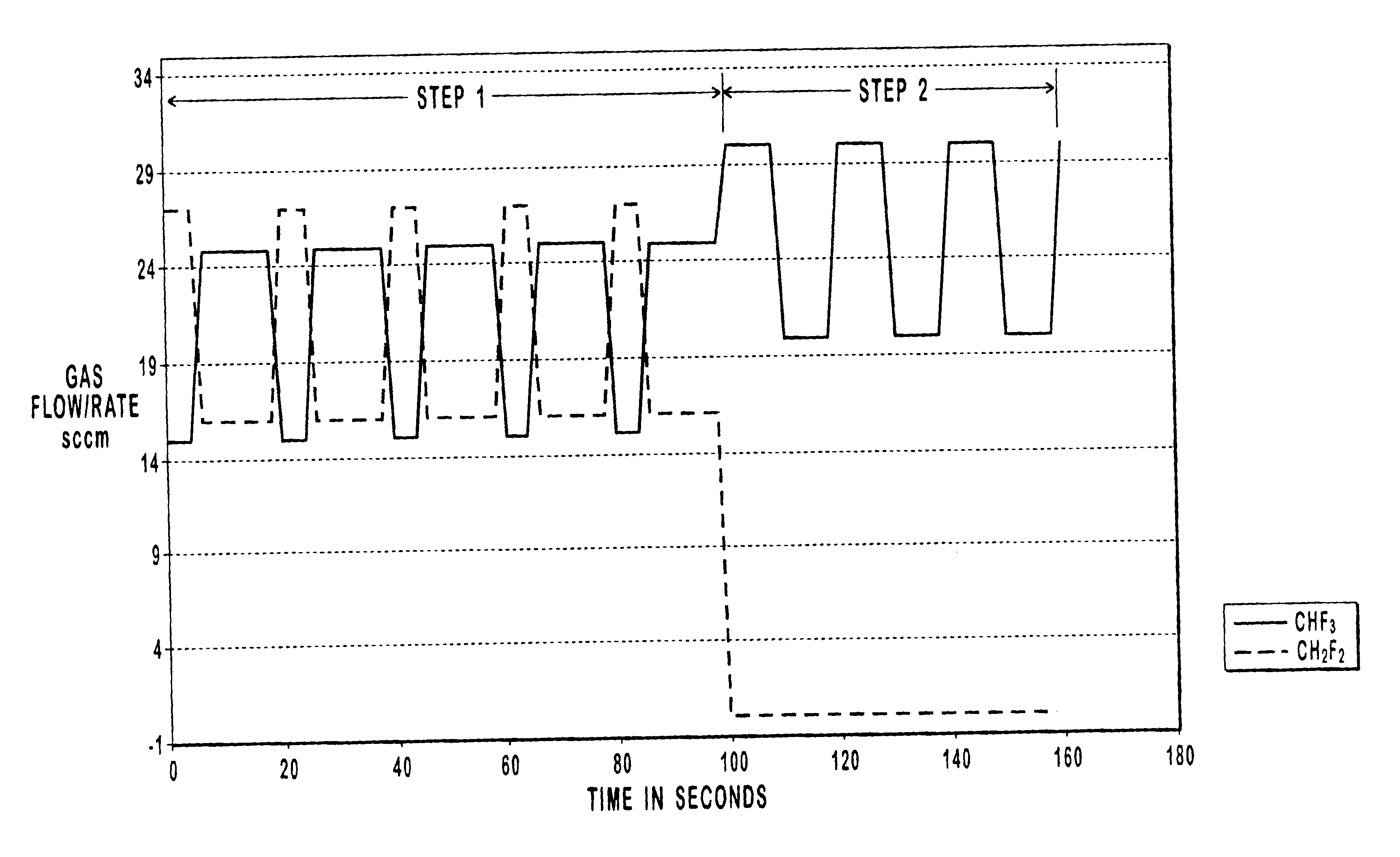

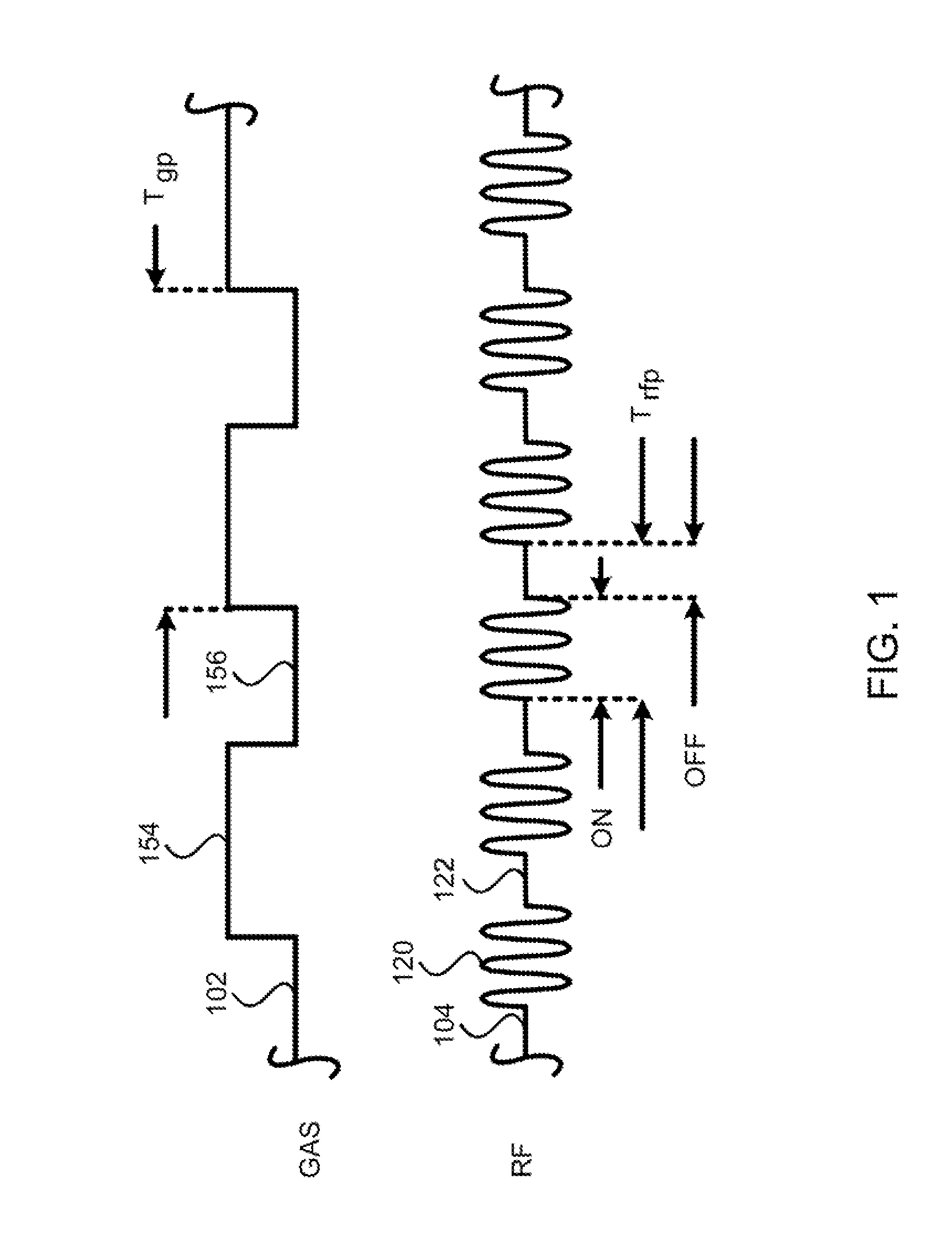

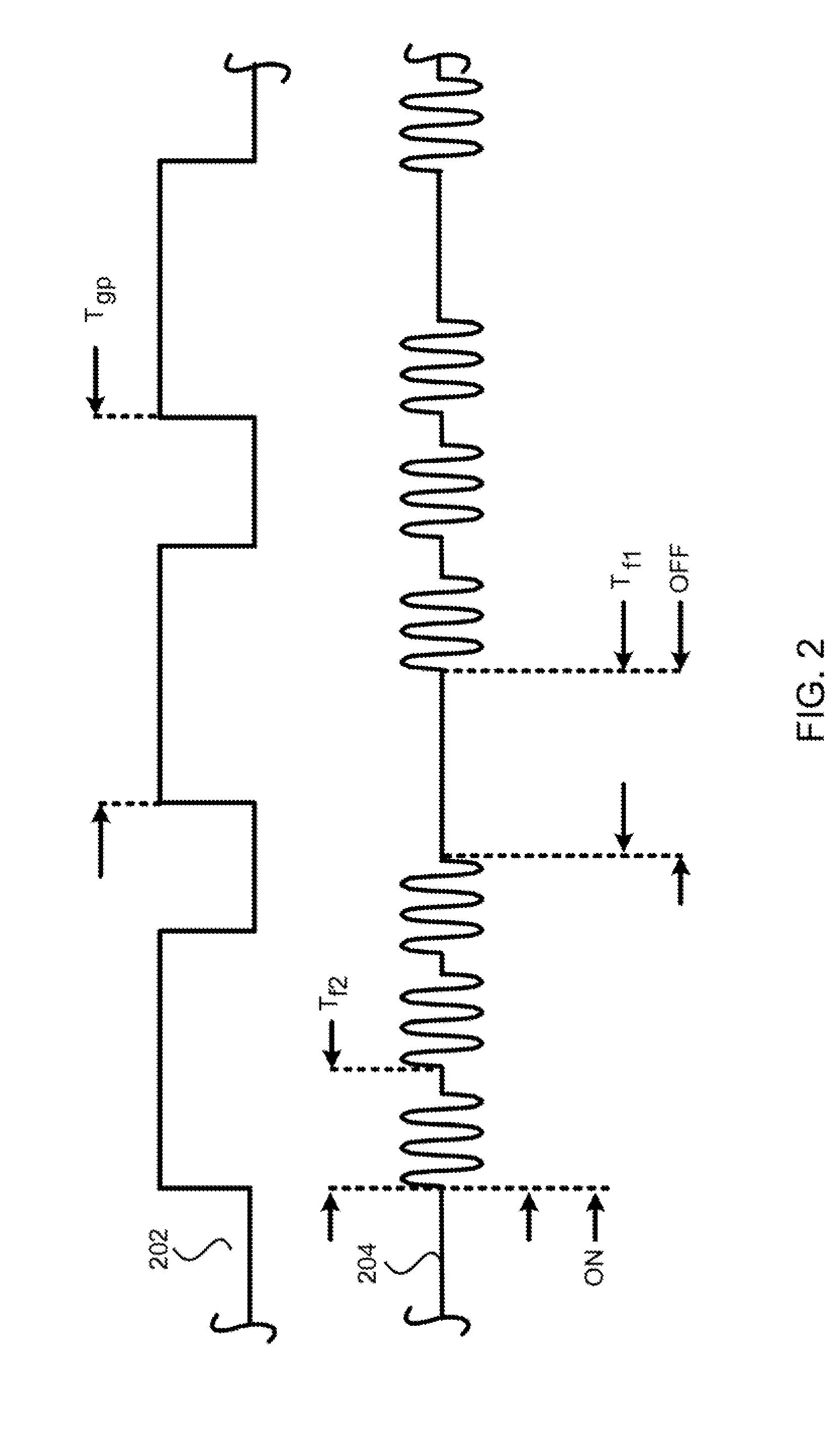

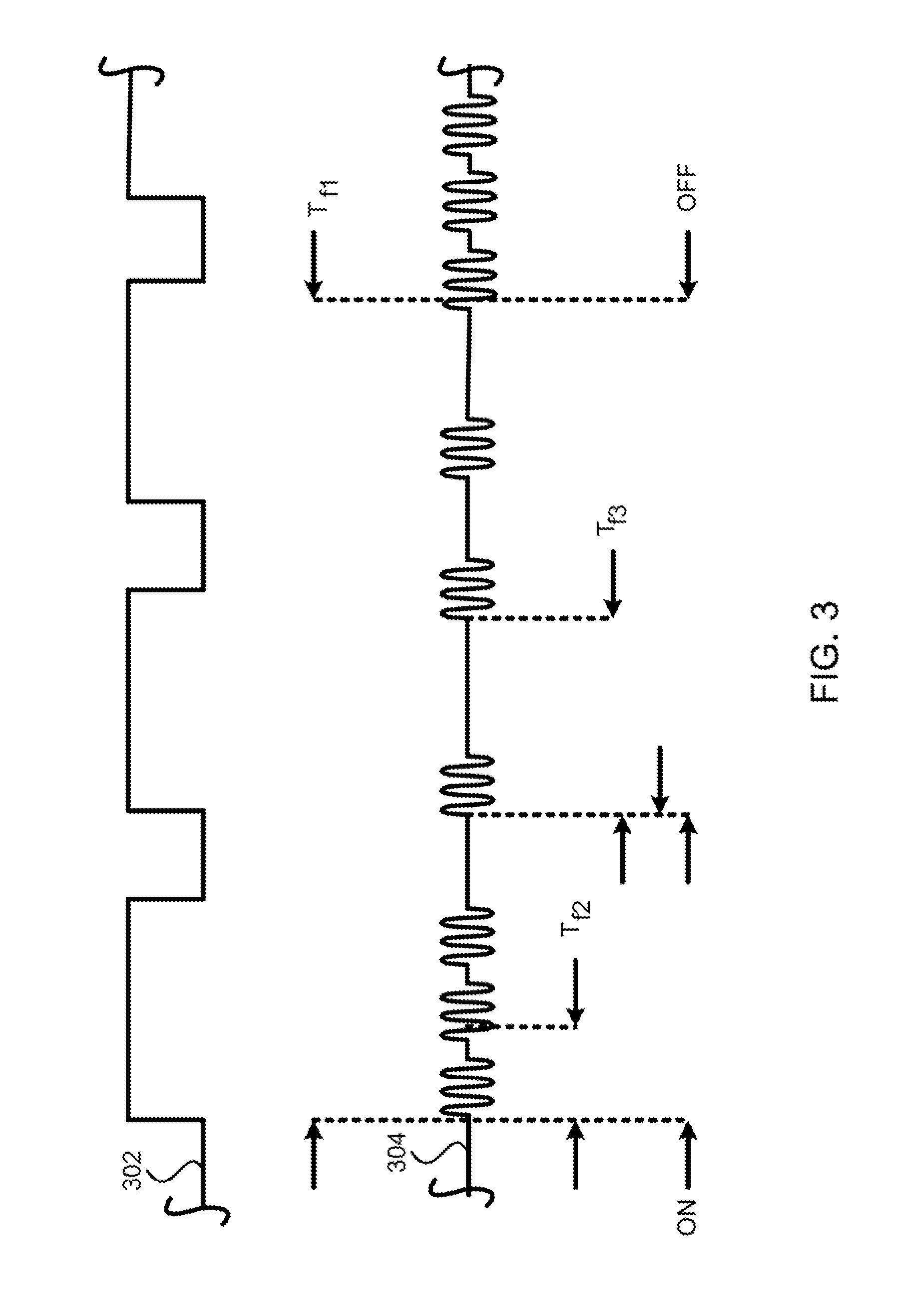

Gas pulsing for etch profile control

InactiveUS6784108B1Increase flow rateReduce flow rateElectric discharge tubesDecorative surface effectsEngineeringAnisotropic etching

Etch profile control with pulsed gas flow and its applications to etching such as anisotropic etching of high aspect ratio features and etching of self-aligned contact structures in various processes. Pulsing can be applied according to this invention to the flow rate of a gas such as an etchant gas, a gas that leads to the deposition of a protective layer, a gas that modifies the deposition of a protective layer, and a gas that modifies etching.

Owner:MICRON TECH INC

Mixed mode pulsing etching in plasma processing systems

A method for processing substrate in a chamber, which has at least one plasma generating source, a reactive gas source for providing reactive gas into the interior region of the chamber, and a non-reactive gas source for providing non-reactive gas into the interior region, is provided. The method includes performing a mixed-mode pulsing (MMP) preparation phase, including flowing reactive gas into the interior region and forming a first plasma to process the substrate that is disposed on a work piece holder. The method further includes performing a MMP reactive phase, including flowing at least non-reactive gas into the interior region, and forming a second plasma to process the substrate, the second plasma is formed with a reactive gas flow during the MMP reactive phase that is less than a reactive gas flow during the MMP preparation phase. Perform the method steps a plurality of times.

Owner:LAM RES CORP

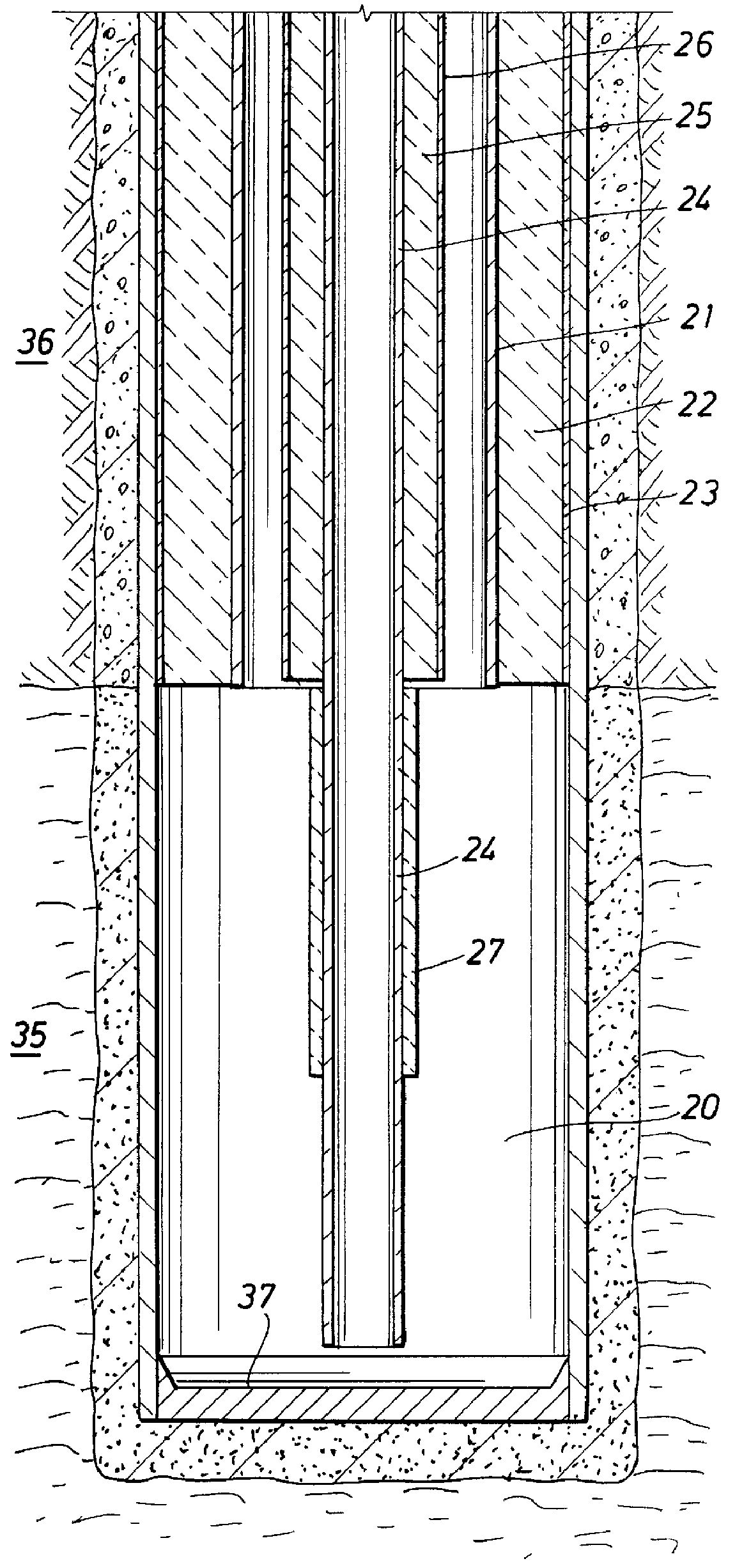

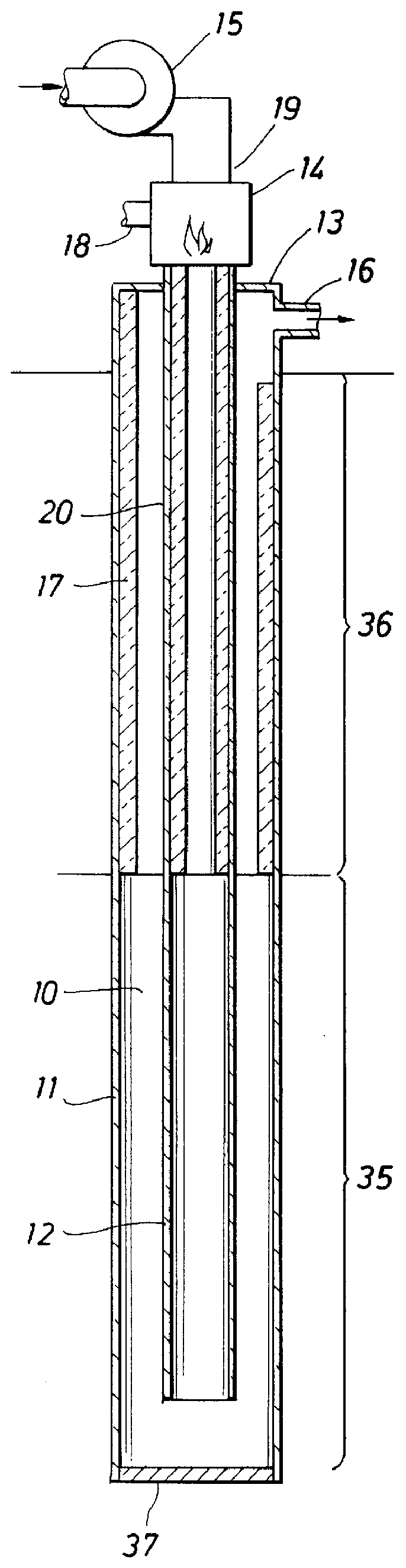

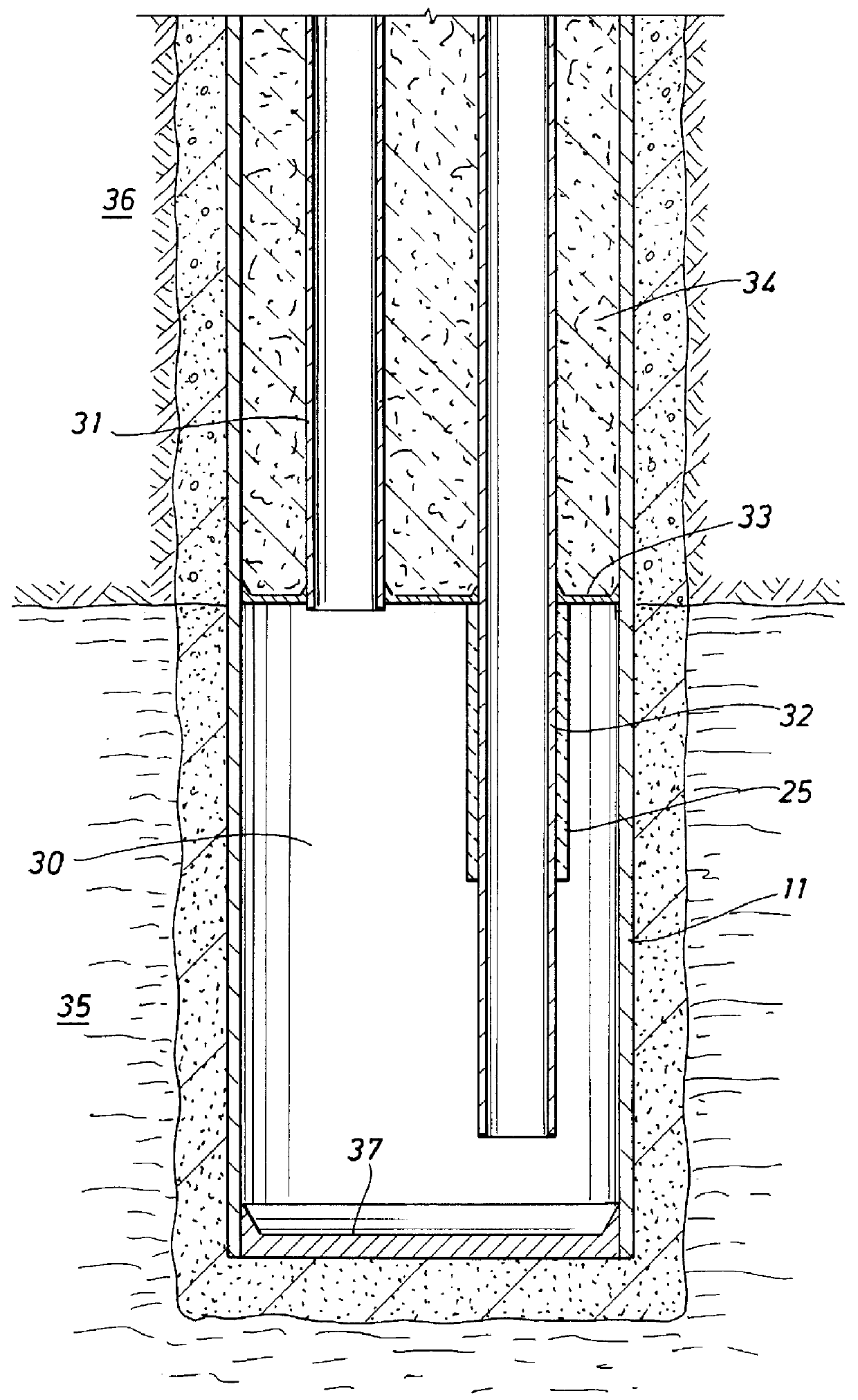

Heater well method and apparatus

InactiveUS6079499AImprove efficiencyImprove completenessInsulationFluid removalGeomorphologyWellbore

A method and apparatus is disclosed for heating of formations using fired heaters. The method includes the steps of: providing a wellbore within the formation to be heated, the wellbore comprising a casing within the formation to be heated, a tubular defining, in the inside of the tubular, a flowpath for hot gases from the surface to a point in the wellbore near the bottom of the formation to be heated, and a volume between the tubular and the casing providing a flowpath for hot gases from near the bottom of the formation to be heated to the top of the formation to be heated, wherein the flowpaths are in communication with each other near the bottom of the formation to be heated and the volume between the casing and the tubular at the top of the formation to be heated is in communication with a point above the surface, and insulation for a portion of the length of the wellbore within the formation to be heated between the flowpath for hot gases from the surface to the point in the wellbore near the bottom of the formation to be heated and the flowpath for hot gases from near the bottom of the formation to be heated to the surface; and supplying a flow of hot gases to the flowpath for hot gases from the surface to a point in the wellbore near the bottom of the formation to be heated.

Owner:SHELL OIL CO

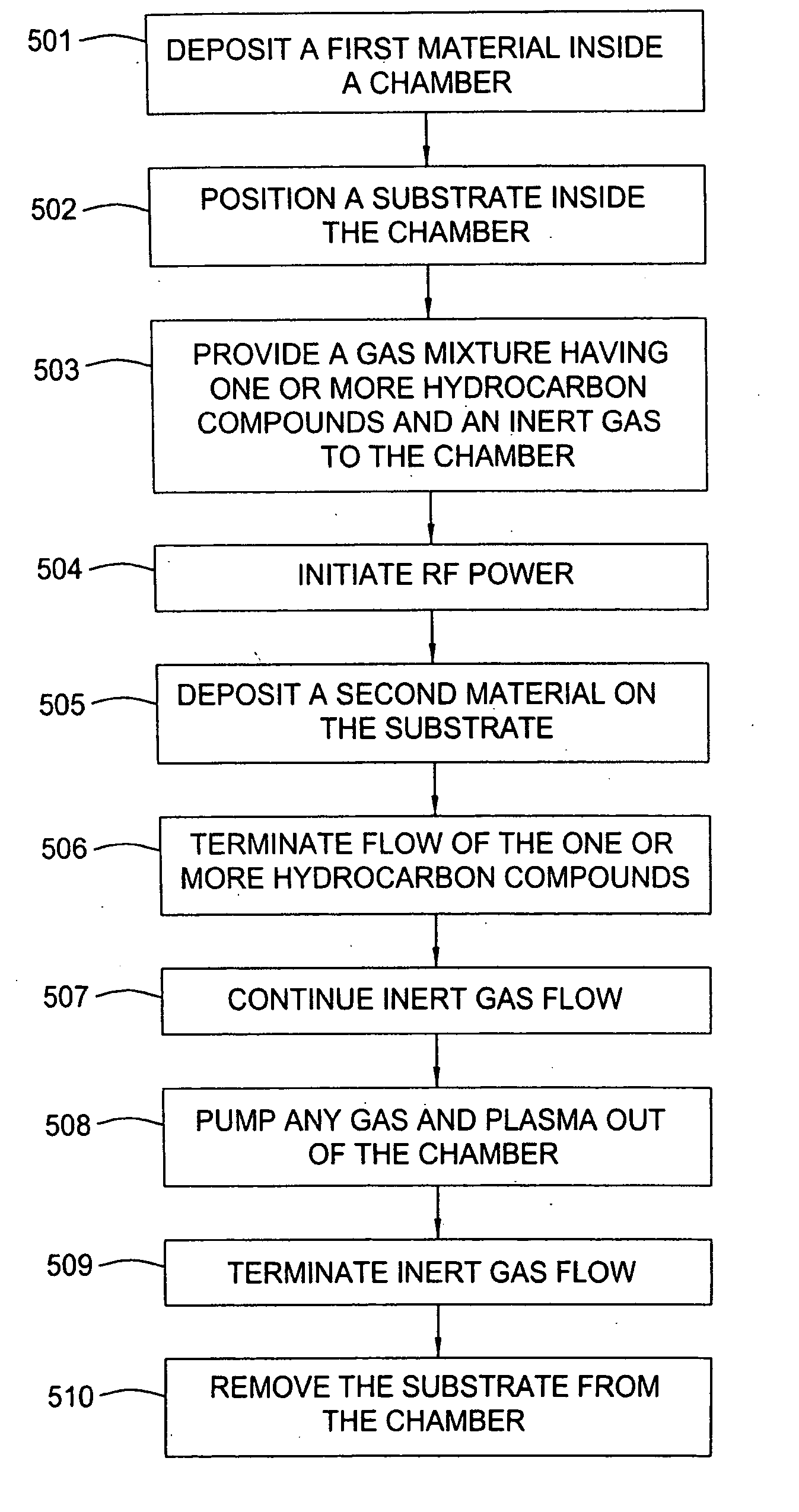

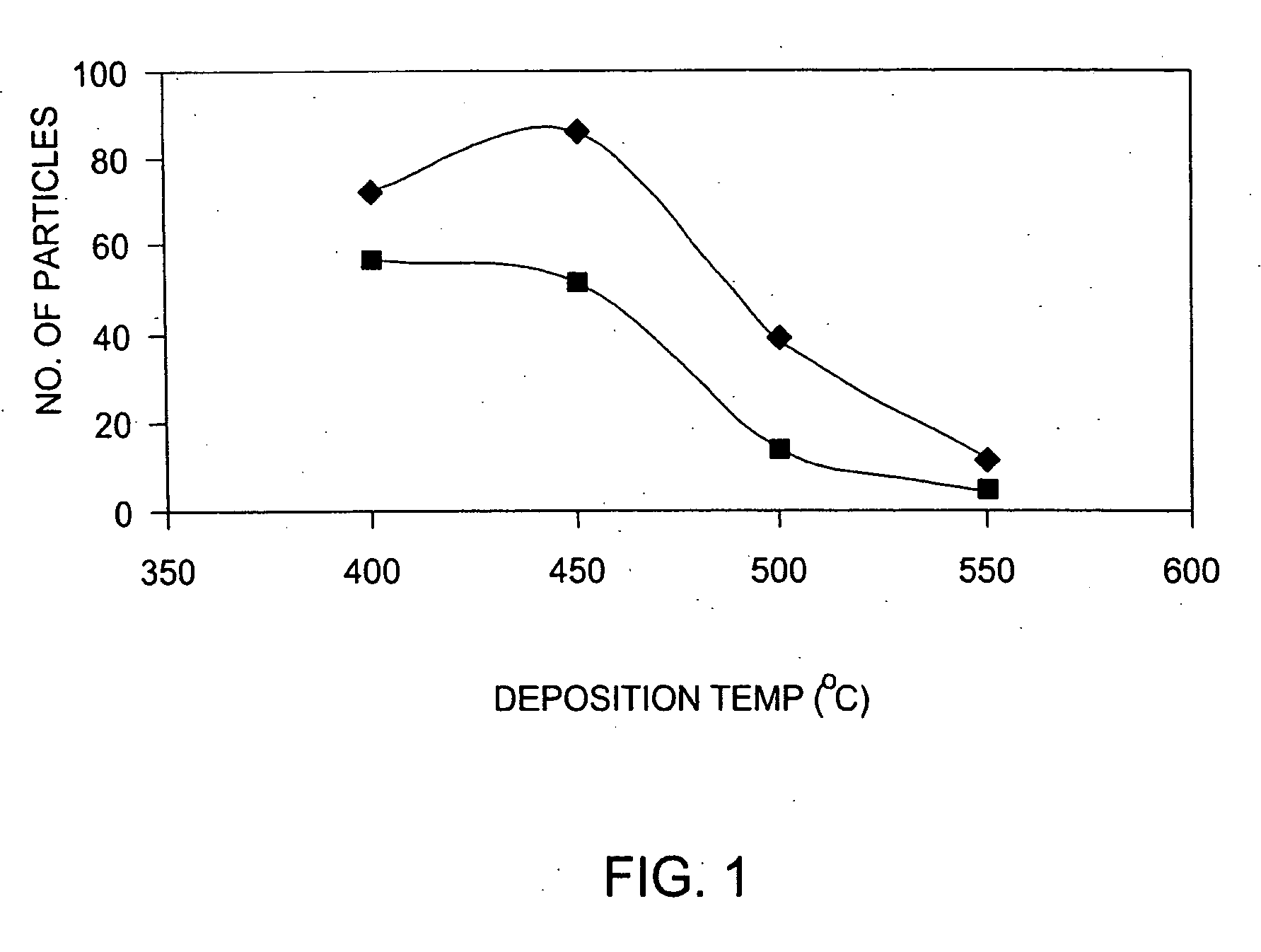

Methods for the reduction and elimination of particulate contamination with CVD of amorphous carbon

InactiveUS20060014397A1Minimal defect formationReduce particle pollutionSemiconductor/solid-state device manufacturingSpecial surfacesVariable thicknessMicroparticle

A method is provided for forming an amorphous carbon layer, deposited on a dielectric material such as oxide, nitride, silicon carbide, carbon doped oxide, etc., or a metal layer such as tungsten, aluminum or poly-silicon. The method includes the use of chamber seasoning, variable thickness of seasoning film, wider spacing, variable process gas flows, post-deposition purge with inert gas, and post-deposition plasma purge, among others, to make the deposition of an amorphous carbon film at low deposition temperatures possible without any defects or particle contamination.

Owner:APPLIED MATERIALS INC +1

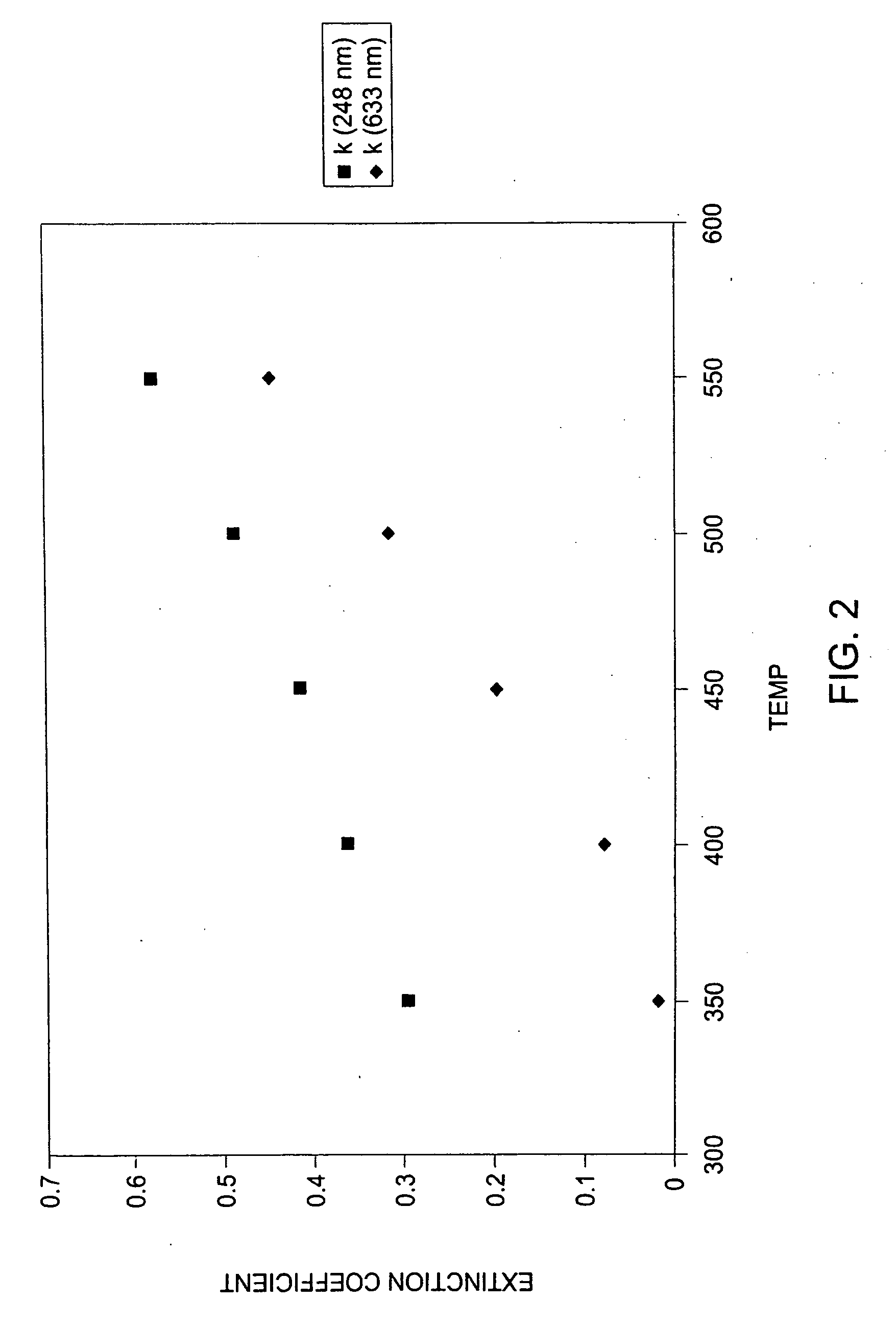

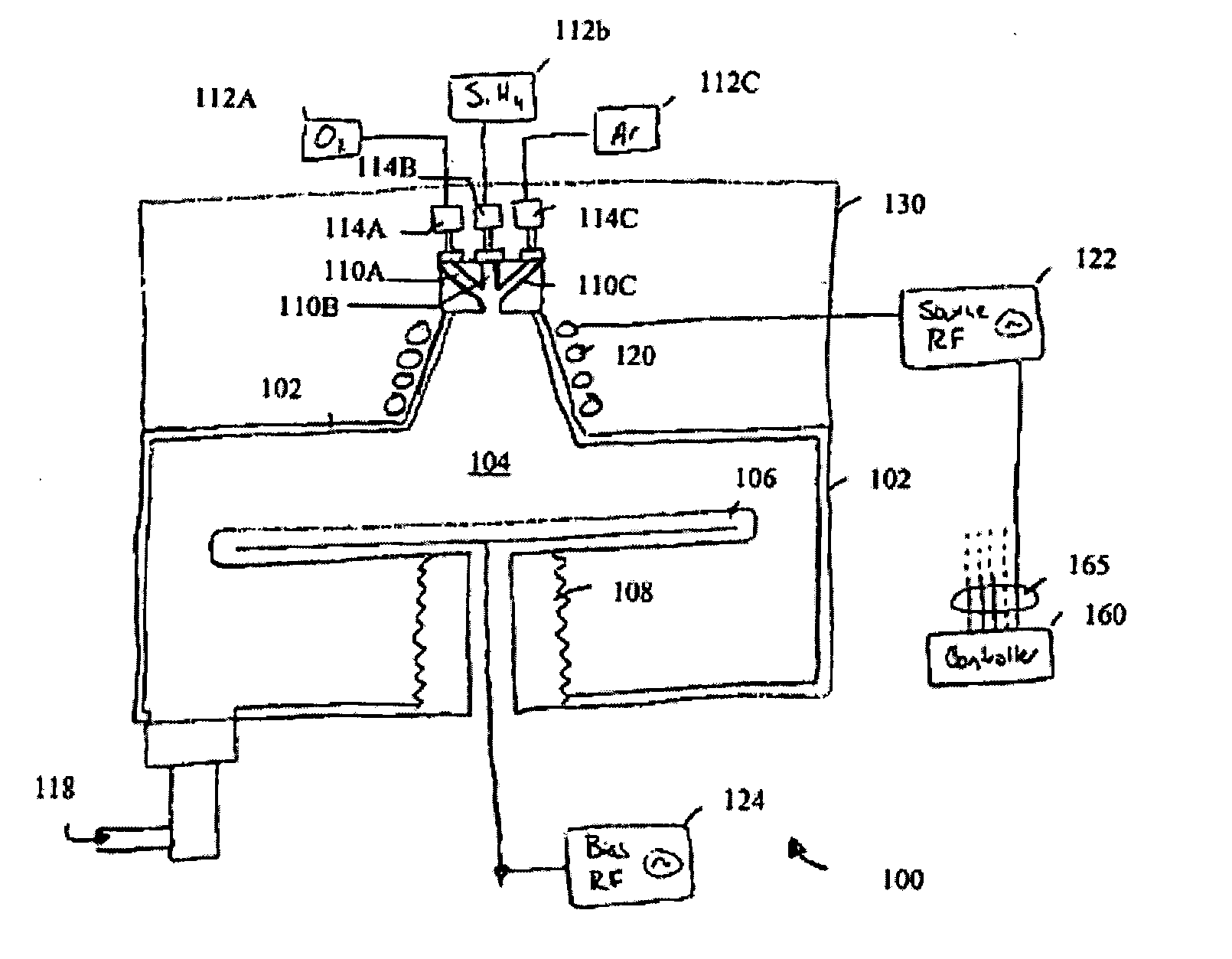

Sequential gas flow oxide deposition technique

InactiveUS20050019494A1High aspect ratioGood effectVacuum evaporation coatingSputtering coatingOxygenSilicon dioxide

A method of depositing a silica glass insulating film over a substrate. In one embodiment the method comprises exposing the substrate to a silicon-containing reactant introduced into a chamber in which the substrate is disposed such that one or more layers of the silicon-containing reactant are adsorbed onto the substrate; purging or evacuating the chamber of the silicon-containing reactant; converting the silicon-containing reactant into a silica glass insulating compound by exposing the substrate to oxygen radicals formed from a second reactant while biasing the substrate to promote a sputtering effect, wherein an average atomic mass of all atomic constituents in the second reactant is less than or equal to an average atomic mass of oxygen; and repeating the exposing, purging / evacuating and exposing sequence a plurality of times until a desired film thickness is reached.

Owner:APPLIED MATERIALS INC

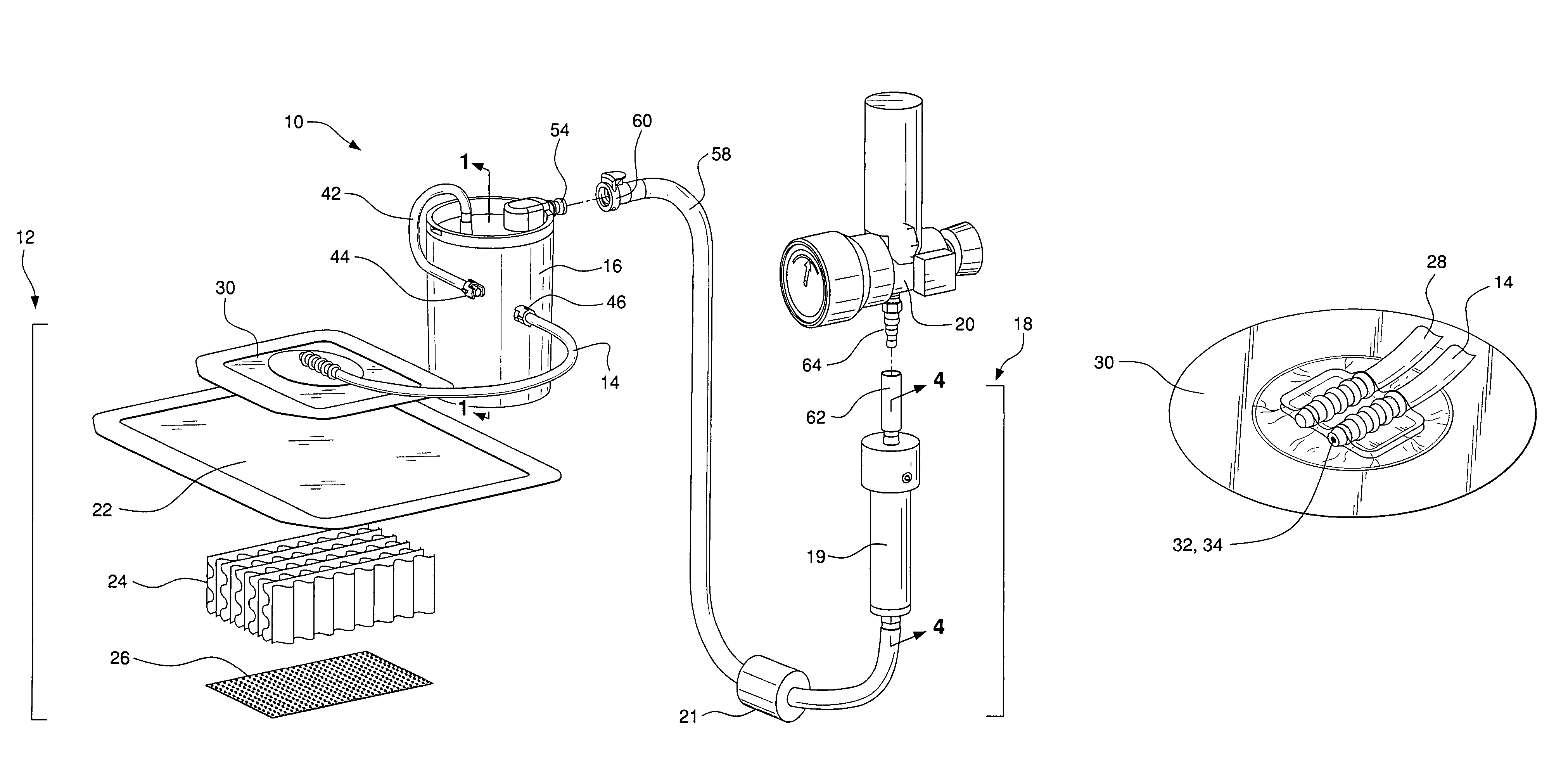

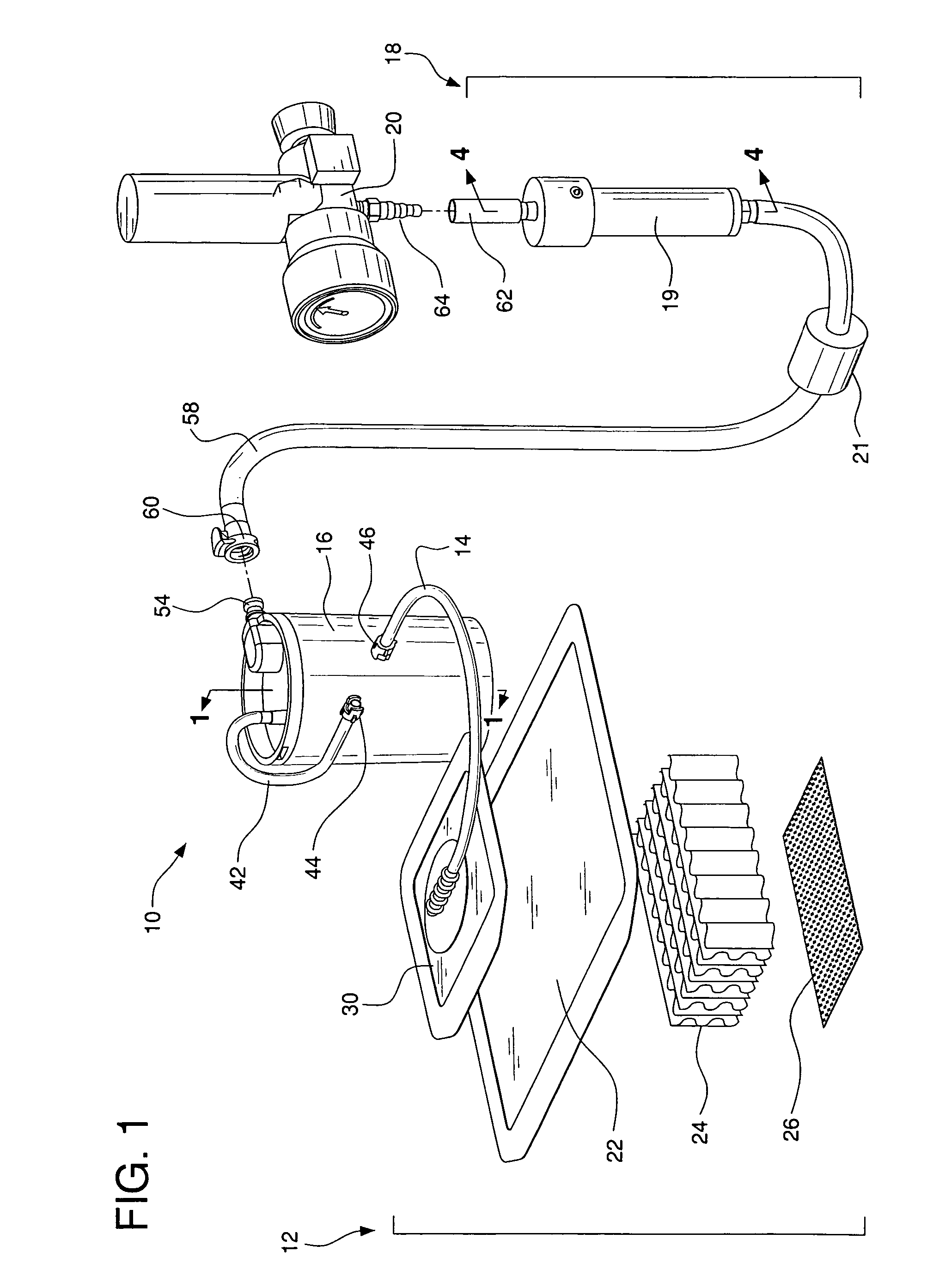

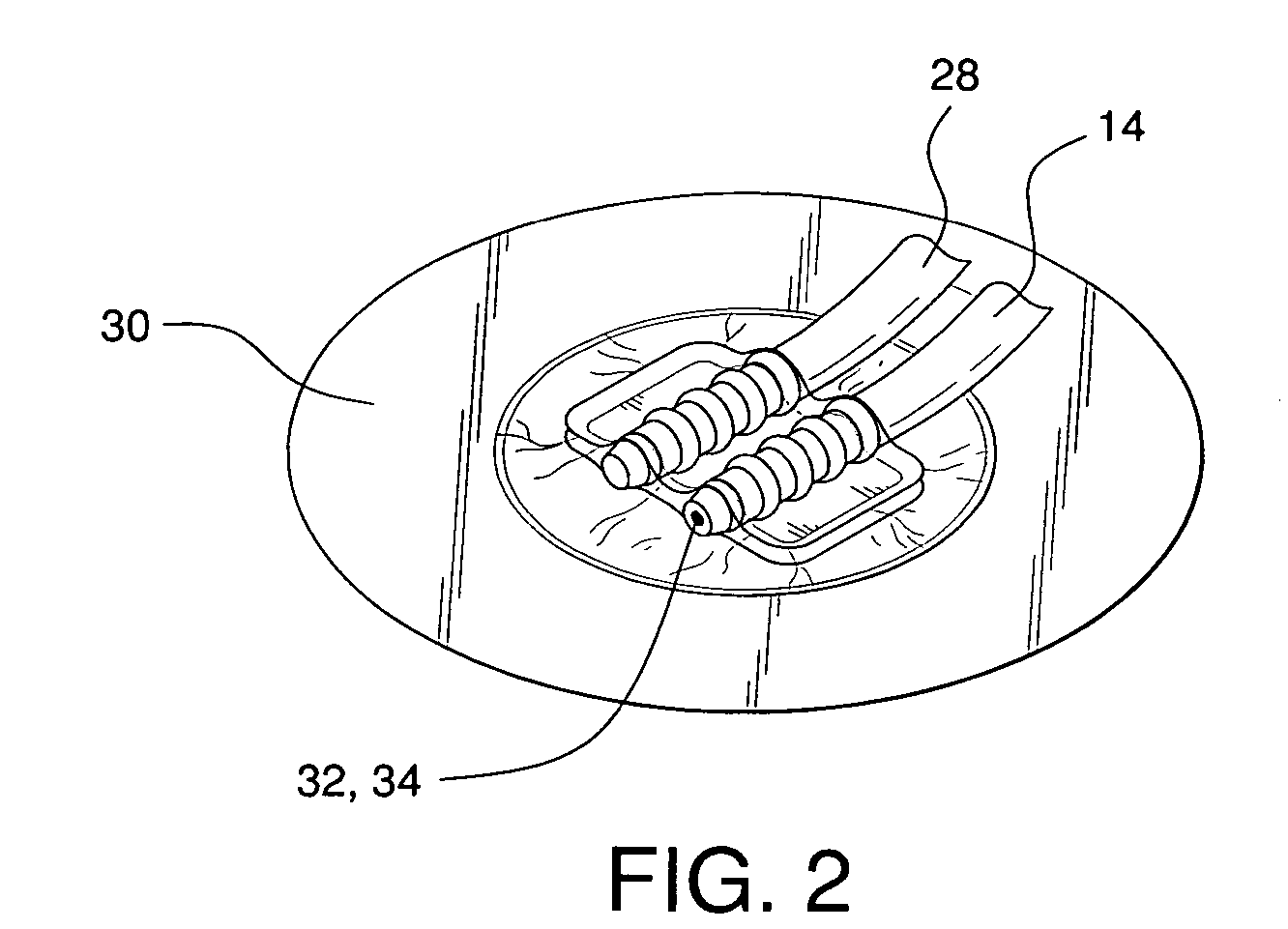

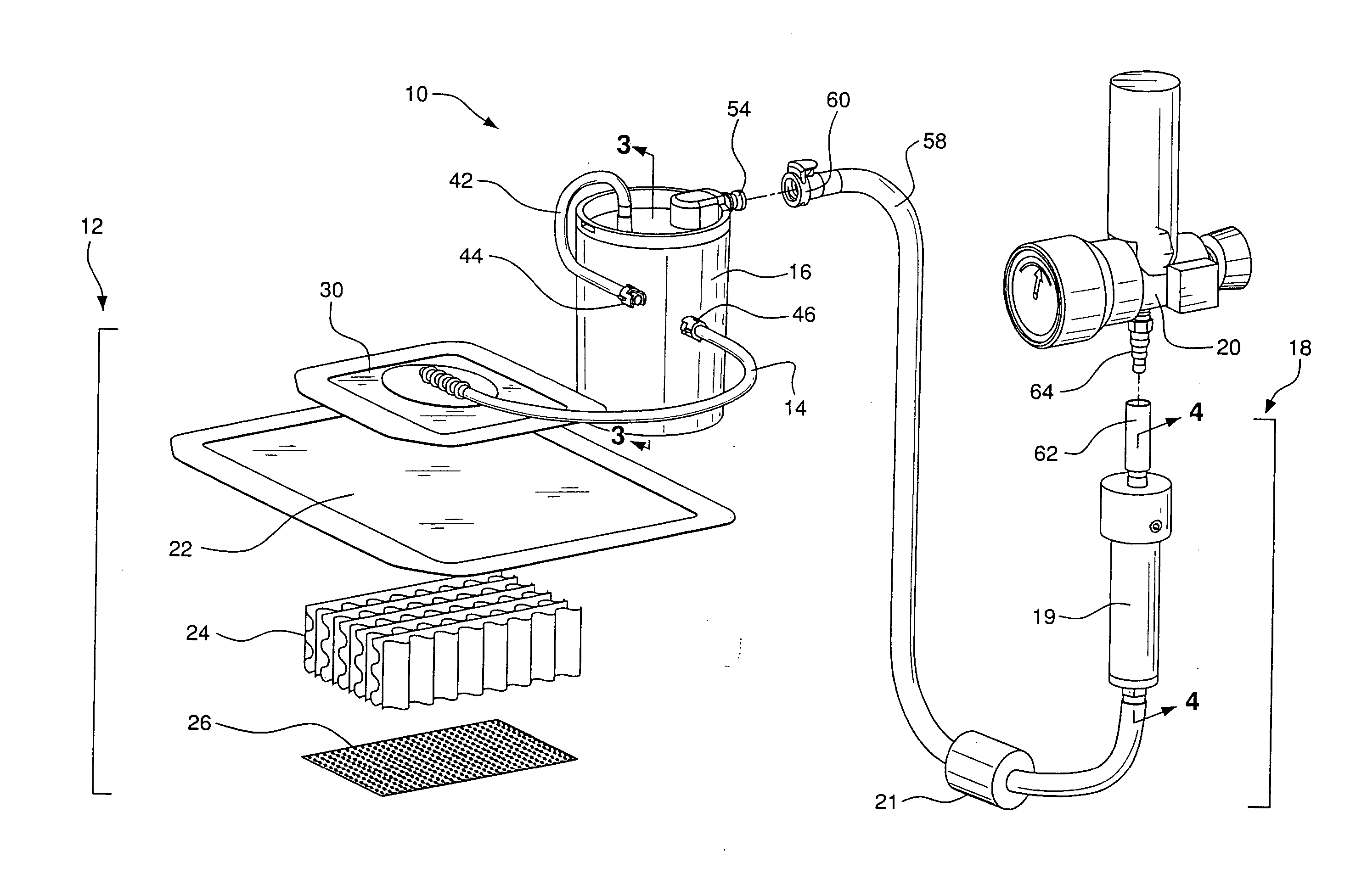

System for treating a wound with suction and method of detecting loss of suction

InactiveUS7438705B2Minimize the possibilityReduce the possibilityWound drainsMedical devicesMonitoring systemCatheter

A system for applying suction to a wound uses a reference airflow for monitoring system operation. A reference airflow (or “controlled leak”) to the suction source is provided when the system is in operation, such that deviation from the reference airflow can be monitored as an indication of a change in operation, such as a leak in the seal of the wound cover, a blockage of airflow from crimping of the suction conduit or overfill of the waste collector, or an inadvertent turn off or disconnect from the suction source.

Owner:PAUL HARTMANN AG

Pump system for negative pressure wound therapy

ActiveUS20070219532A1Reduce the possibilityTrend downWound drainsMedical devicesLevel sensorEngineering

A pump system for applying negative pressure to a wound, including a flow monitor capable of detecting a deviation from a reference airflow rate provided by a controlled leak to determine whether the system is operating normally or abnormally, and a flow status annunciator to indicate a normal operating condition or whether an abnormal condition is a leak or an occluded line in the system. The pump system further includes a pressure controller for regulating operation of a pump to control pressure in the system at a range around a user-selected setpoint. The pump system may also include a waste collector and a level sensor for detecting when the collector is full.

Owner:PAUL HARTMANN AG

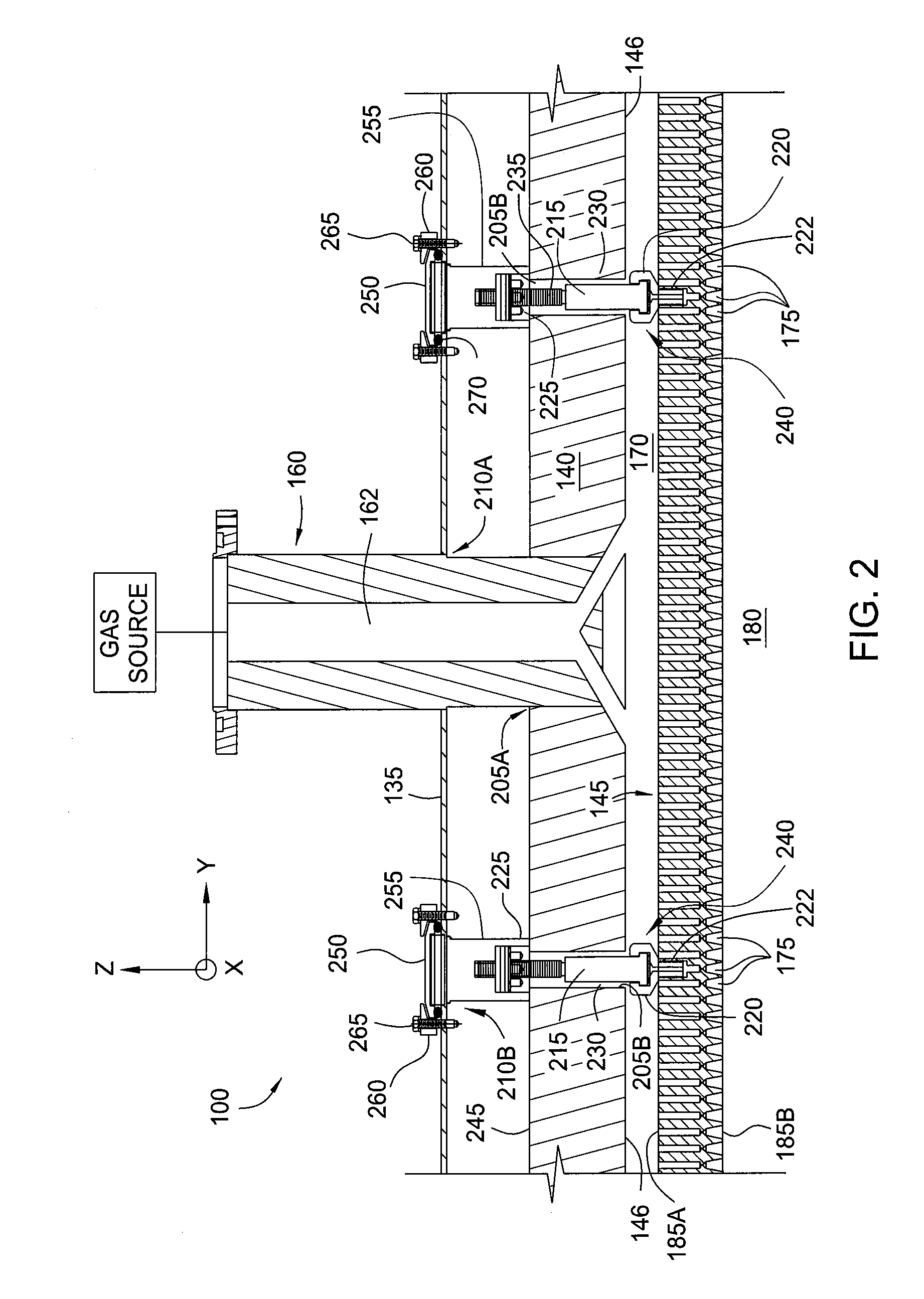

Showerhead support structure for improved gas flow

ActiveUS8721791B2Electric discharge tubesSemiconductor/solid-state device manufacturingEngineeringVacuum chamber

Embodiments of the present invention generally provide apparatus and methods for supporting a gas distribution showerhead in a processing chamber. In one embodiment, a gas distribution showerhead for a vacuum chamber is provided. The gas distribution showerhead comprises a body having a first side and a second side opposite the first side, and a plurality of gas passages formed through the body, the gas passages comprising a first bore formed in the first side that is fluidly coupled to a second bore formed in the second side by a restricting orifice, and a suspension feature formed in the first bore of at least one of the gas passages.

Owner:APPLIED MATERIALS INC

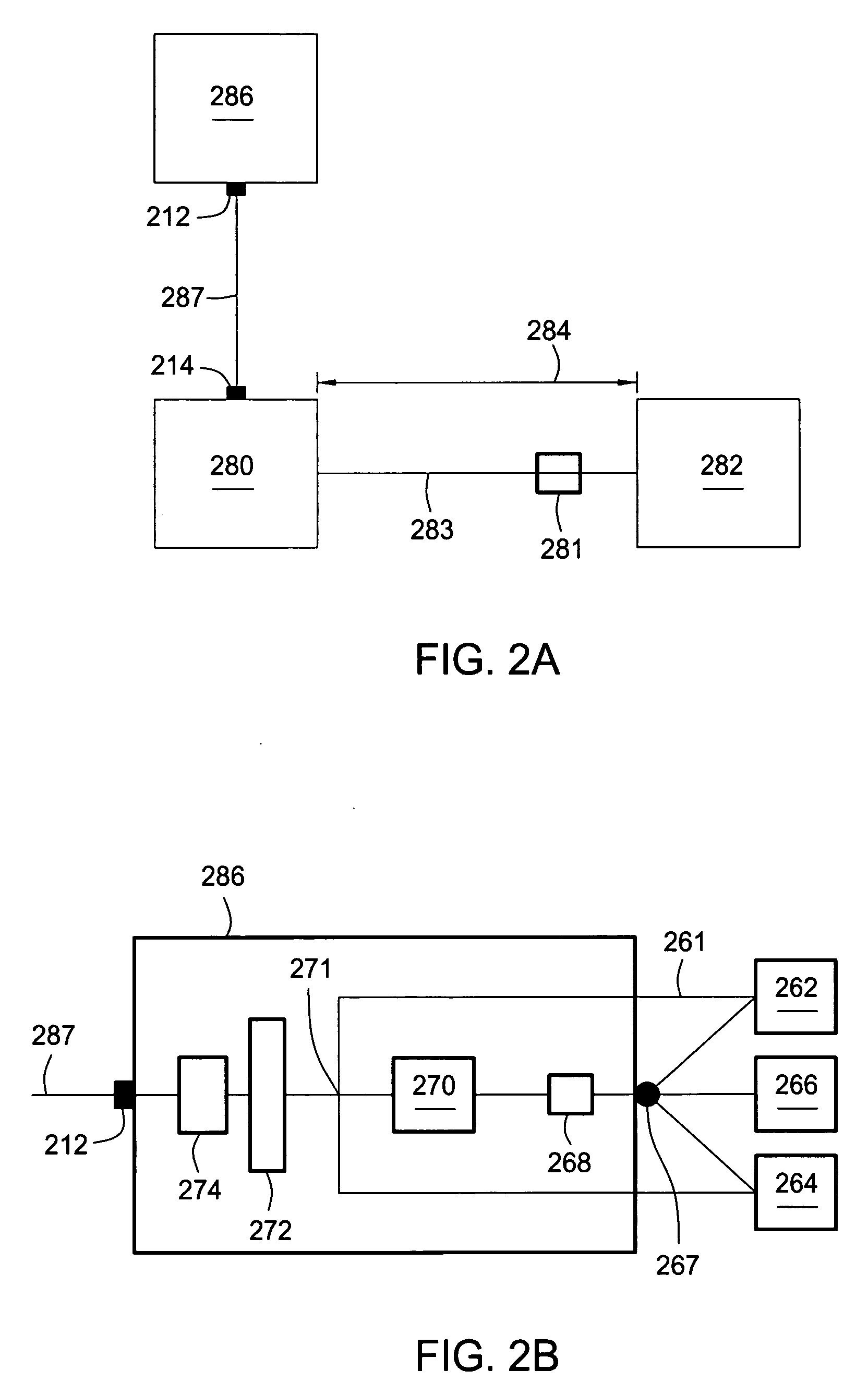

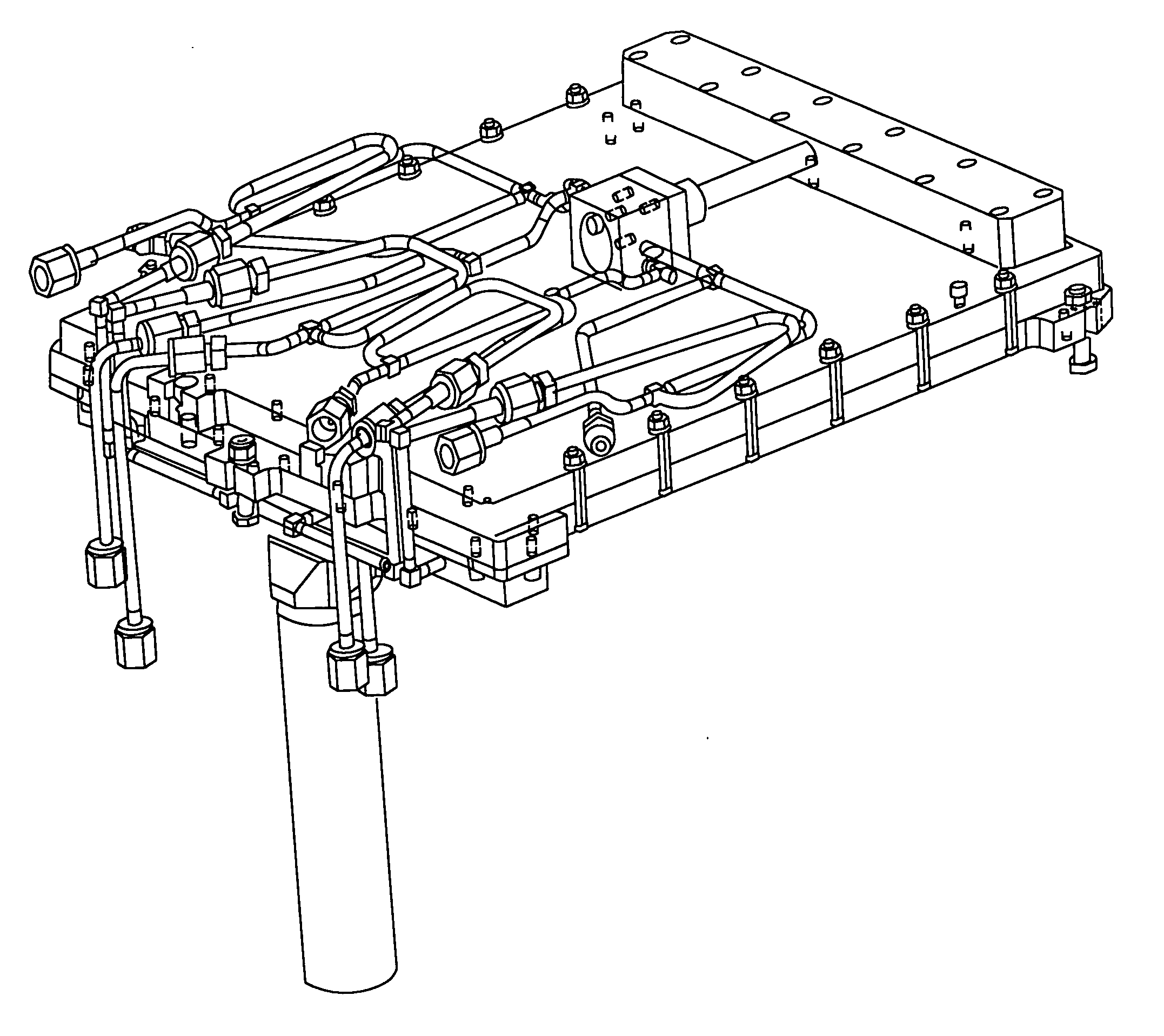

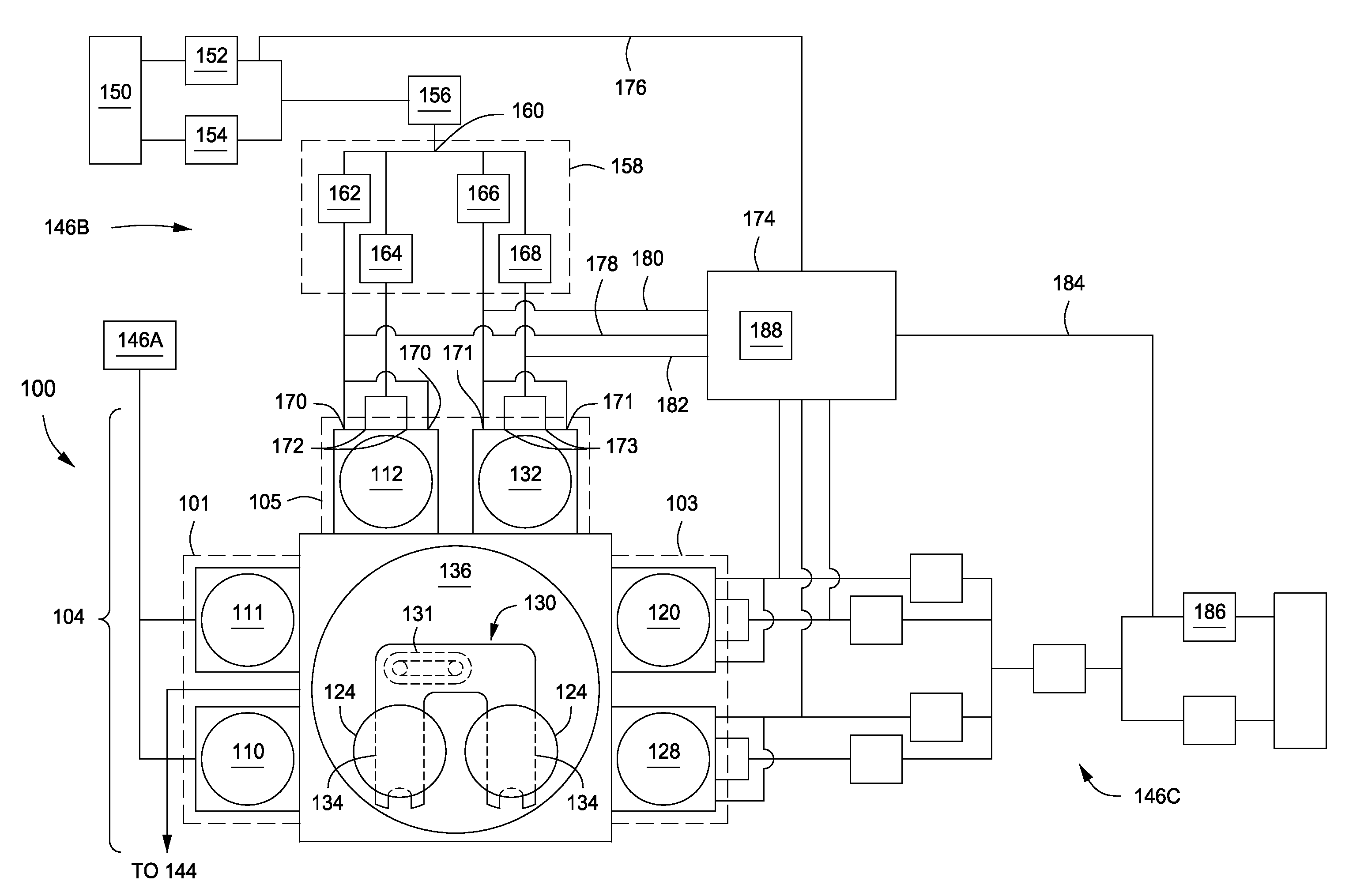

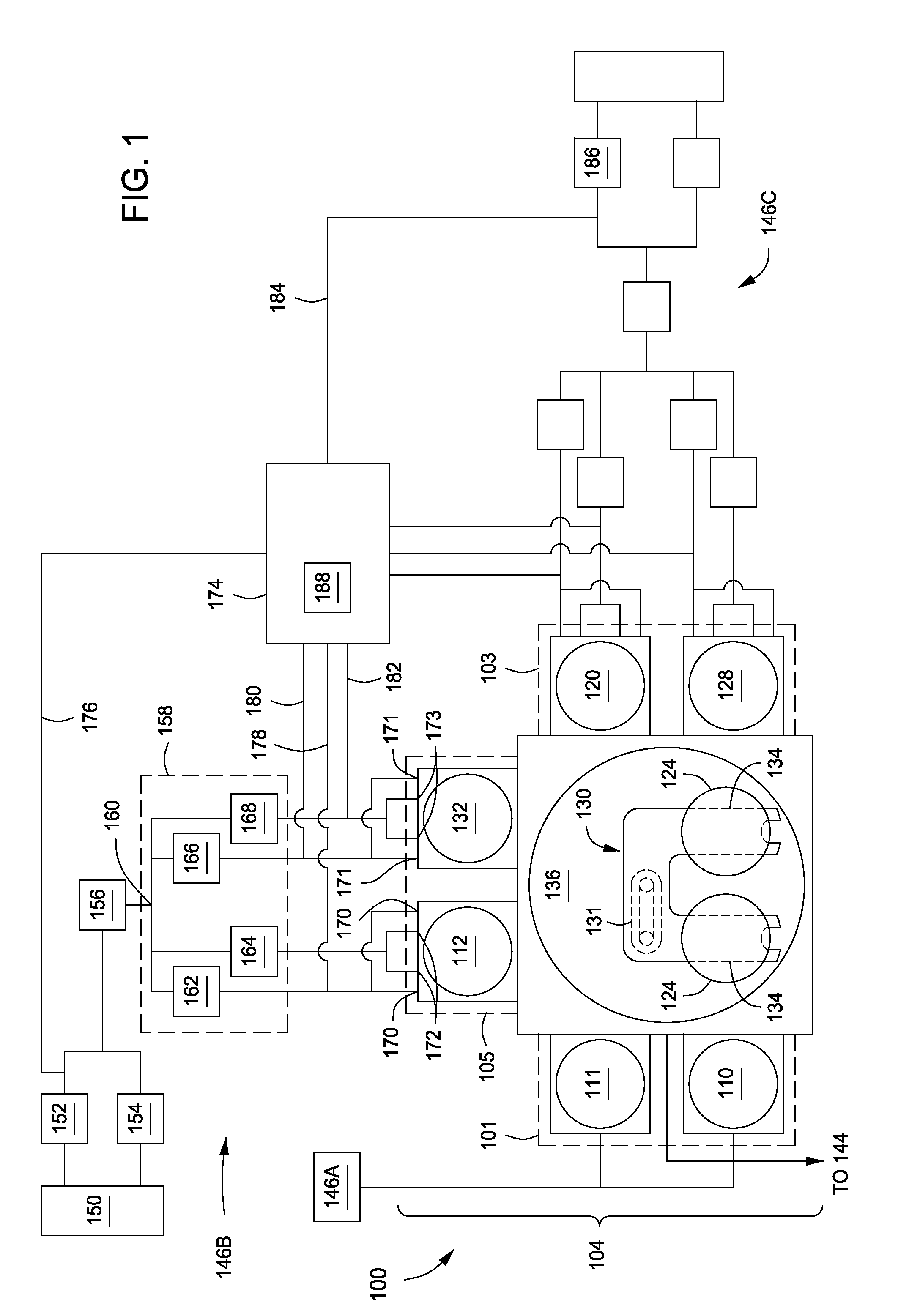

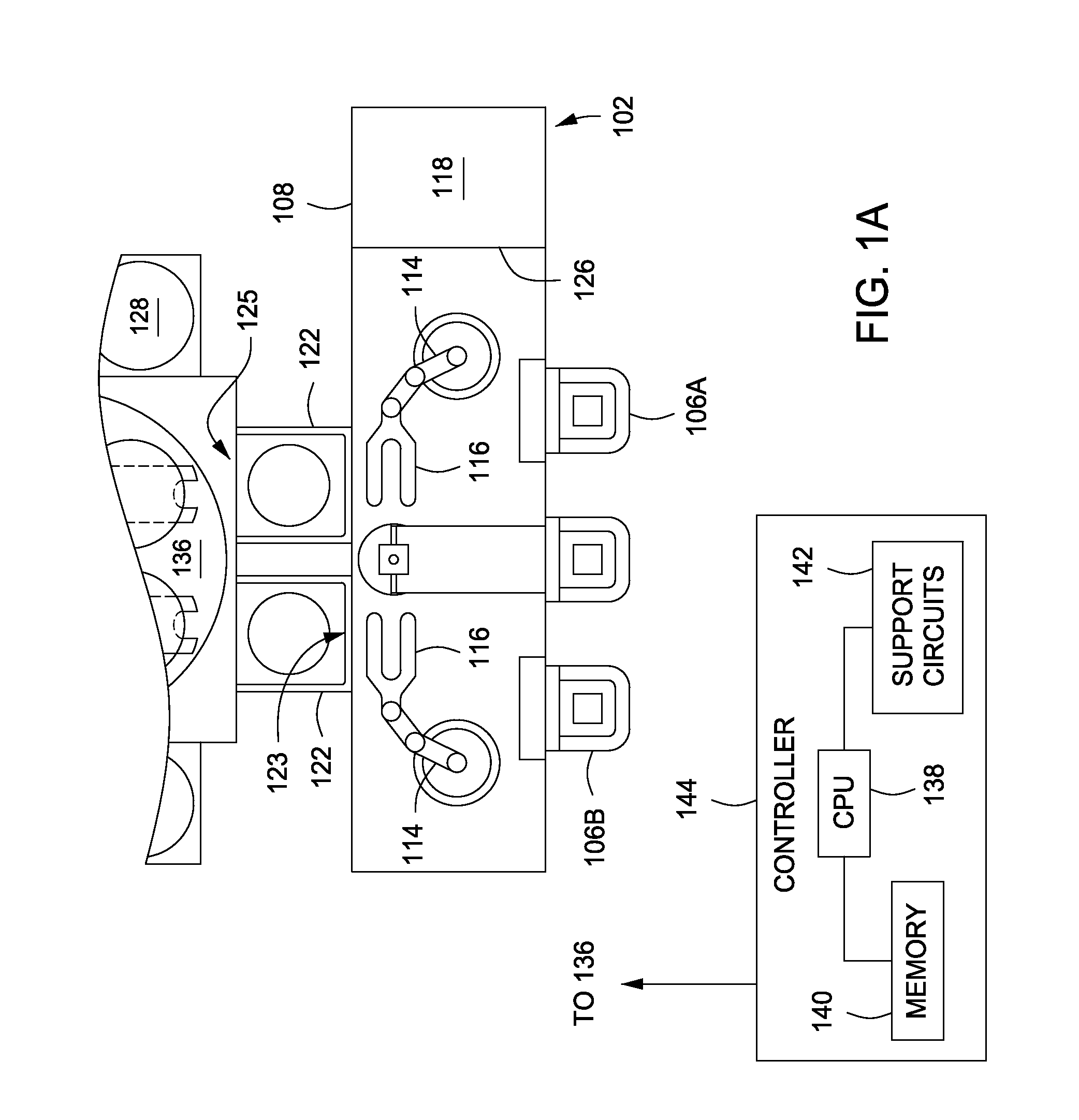

Methods and apparatus for calibrating flow controllers in substrate processing systems

Methods and apparatus for calibrating a plurality of gas flows in a substrate processing system are provided herein. In some embodiments, a substrate processing system may include a cluster tool comprising a first process chamber and a second process chamber coupled to a central vacuum transfer chamber; a first flow controller to provide a process gas to the first process chamber; a second flow controller to provide the process gas to the second process chamber; a mass flow verifier to verify a flow rate from each of the first and second flow controllers; a first conduit to selectively couple the first flow controller to the mass flow verifier; and a second conduit to selectively couple the second flow controller to the mass flow verifier.

Owner:APPLIED MATERIALS INC

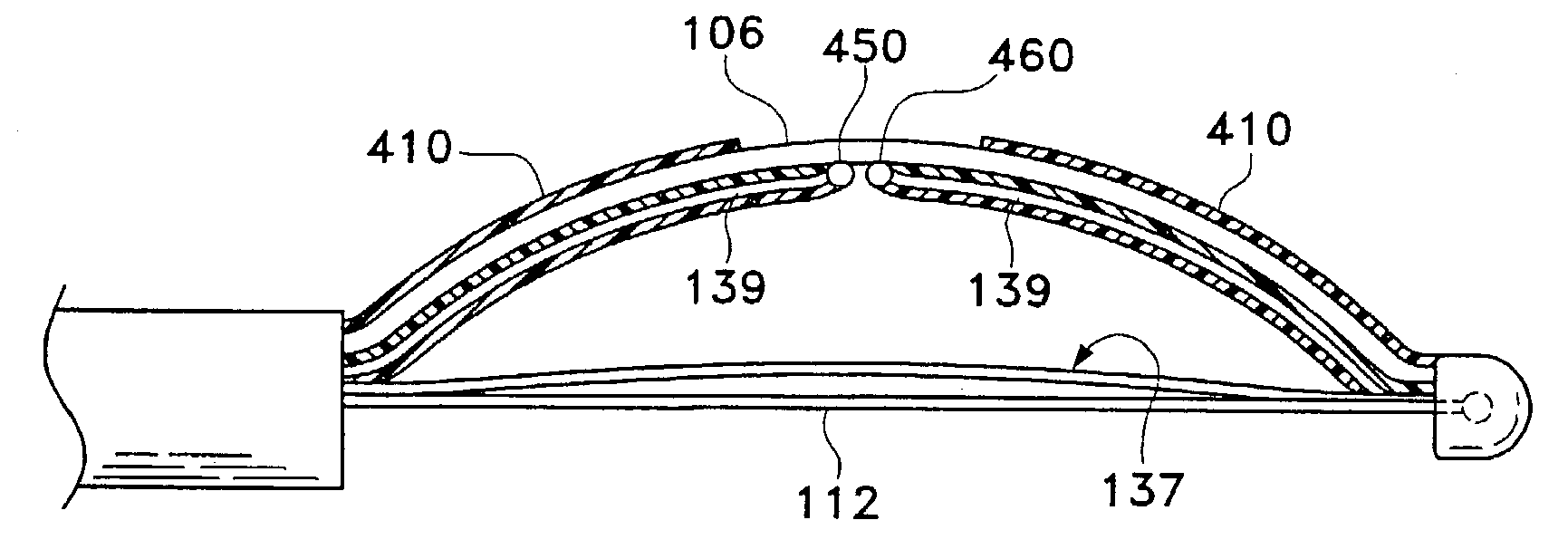

Humidifier for respiratory apparatus

ActiveUS20080105257A1Increasing patient comfortElectrocardiographyRespiratory masksWater vaporBreathing gas

A respiratory apparatus for delivering breathable gas to a patient includes a flow generator that generates a supply of pressurised gas to be delivered to the patient; a humidifier for vaporising water and delivering water vapor to humidify the gas; a gas flow path leading from the flow generator to the humidifier and from the humidifier to a patient interface; and a heater in thermal contact with the gas and / or the water, wherein the heater comprises an elongate heating filament in the form of a tape. A humidifier for respiratory apparatus includes a first respiratory gas passage for receiving gas from a flow generator, a humidifier chamber, a second respiratory gas passage for delivering humidified gas to a patient interface, and a heater in thermal contact with the gas and / or the water, wherein the heater comprises an elongate heating filament extending along at least part of both said first and second respiratory gas passages. A conduit for use in a respiratory apparatus for delivering breathable gas to a patient includes a tube; a helical rib on an outer surface of the tube; and a plurality of wires supported by the helical rib in contact with the outer surface of the tube.

Owner:RESMED LTD

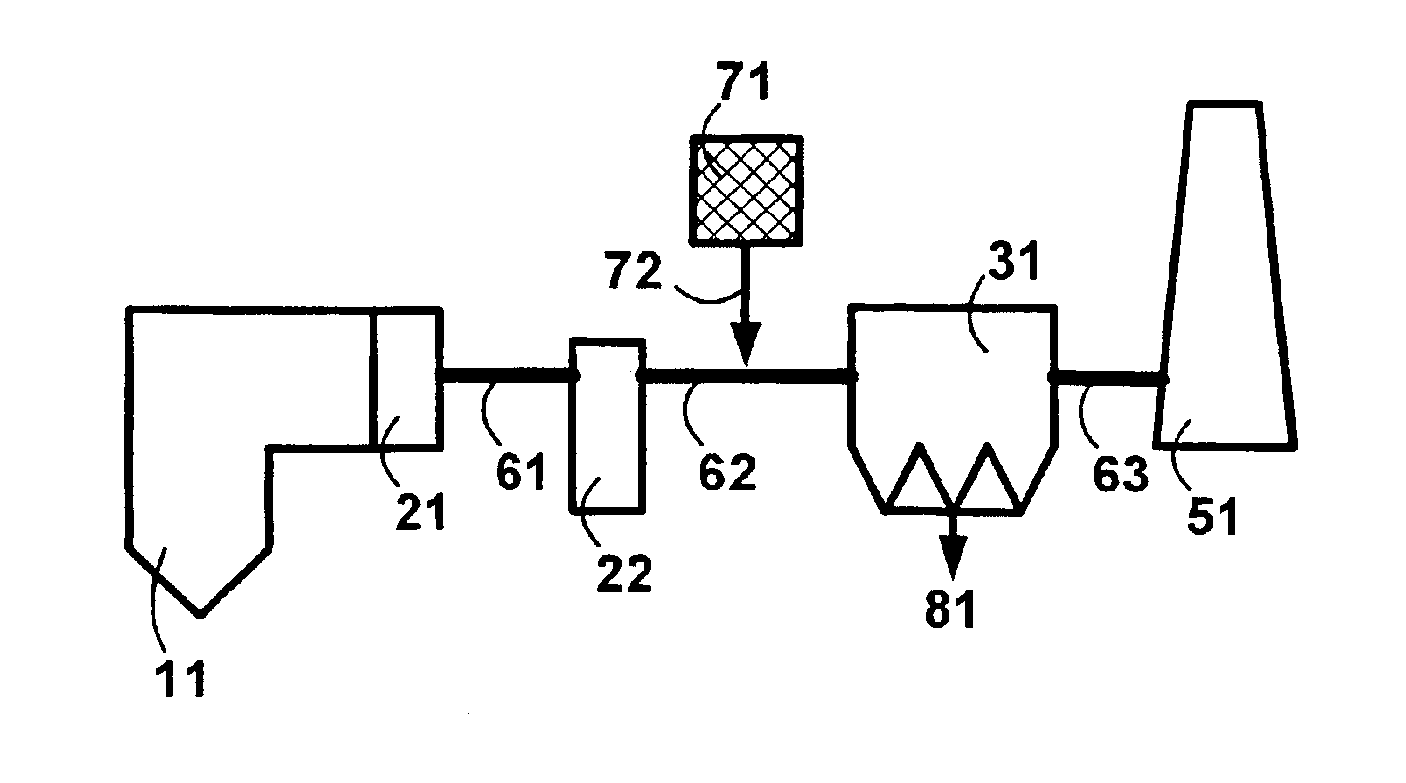

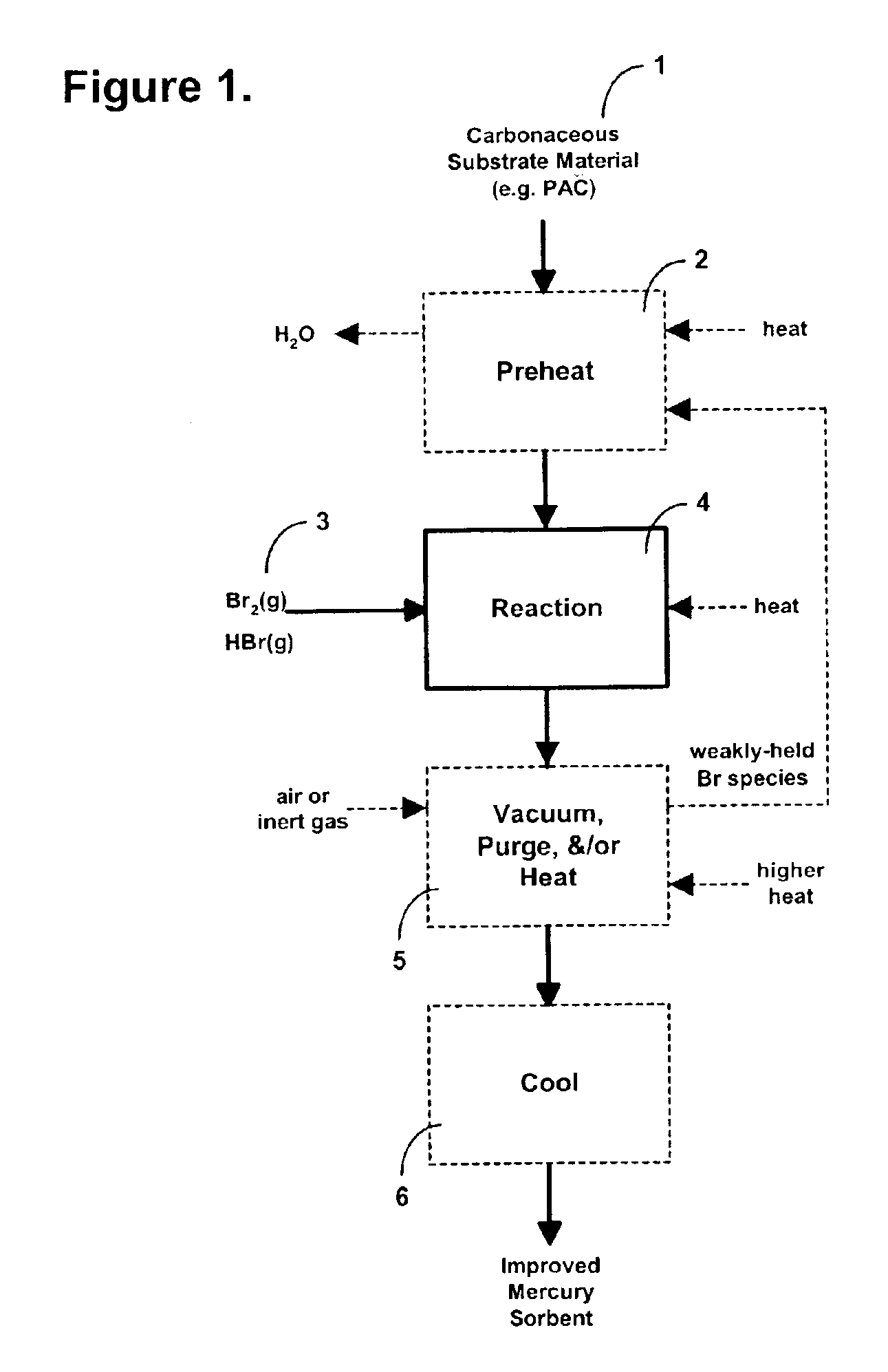

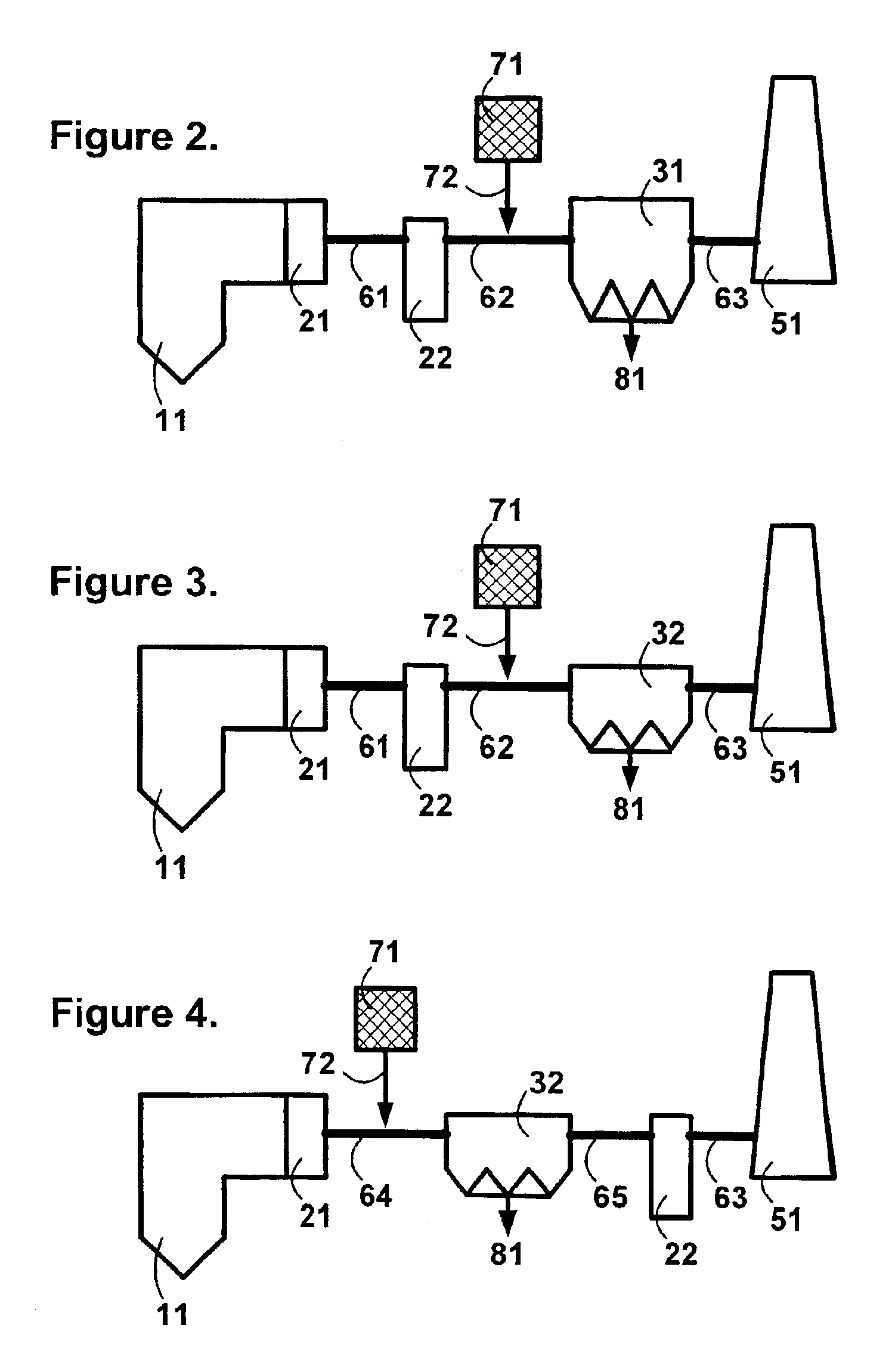

Sorbents and methods for the removal of mercury from combustion gases

InactiveUS6953494B2Improve abilitiesUnified processingGas treatmentOther chemical processesSufficient timeCombustion

A method for removing mercury and mercury-containing compounds from a combustion gas in an exhaust gas system has the steps of providing a mercury sorbent; injecting the mercury sorbent into a stream of the mercury-containing combustion gas for a sufficient time to allow at least an effective amount of the mercury and mercury-containing compounds in the combustion gas to adsorb onto the mercury sorbent, and collecting and removing the mercury sorbent from the combustion gas stream. The mercury sorbent is prepared by treating a carbonaceous substrate with an effective amount of a bromine-containing gas, especially one containing elemental bromine or hydrogen bromide, for a time sufficient to increase the ability of the carbonaceous substrate to adsorb mercury and mercury-containing compounds. The points of injecting and collecting and removing the mercury sorbent may be varied, depending upon the exact configuration of the exhaust gas system.

Owner:SORBENT TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com