Patents

Literature

13886 results about "Supporting system" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Support system. Formal or informal network of goods, services, personnel, and organizations that sustains an entity in its survival and growth.

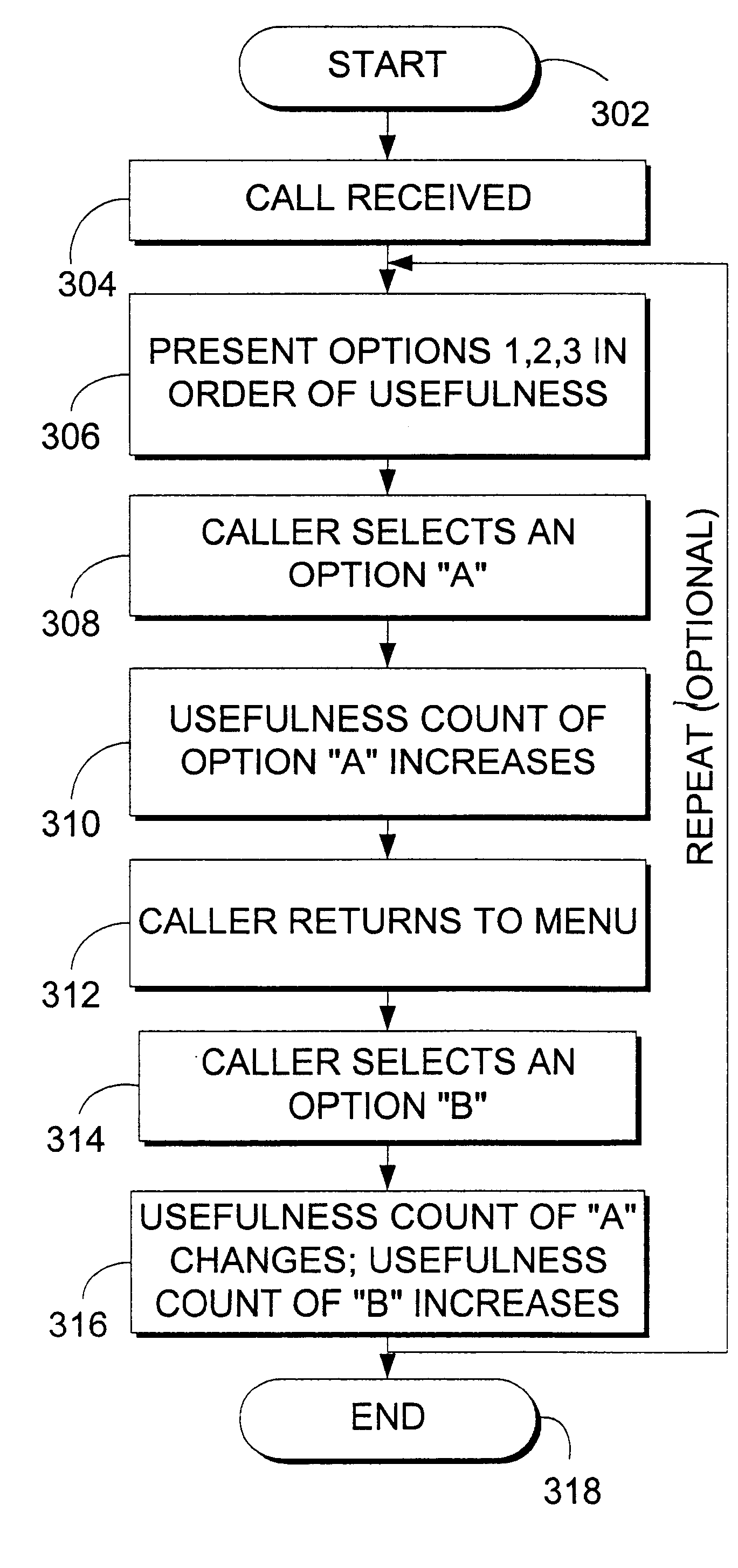

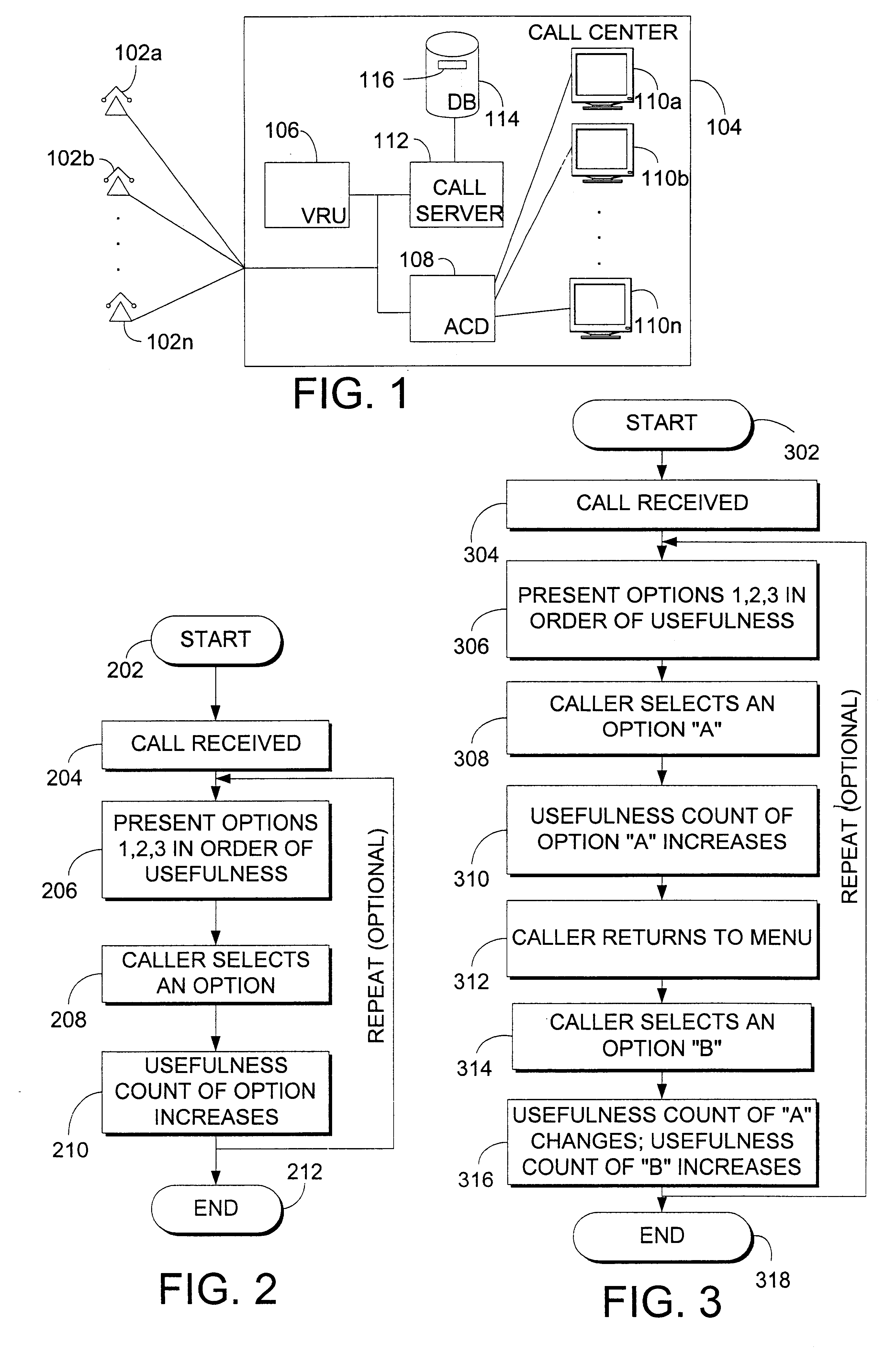

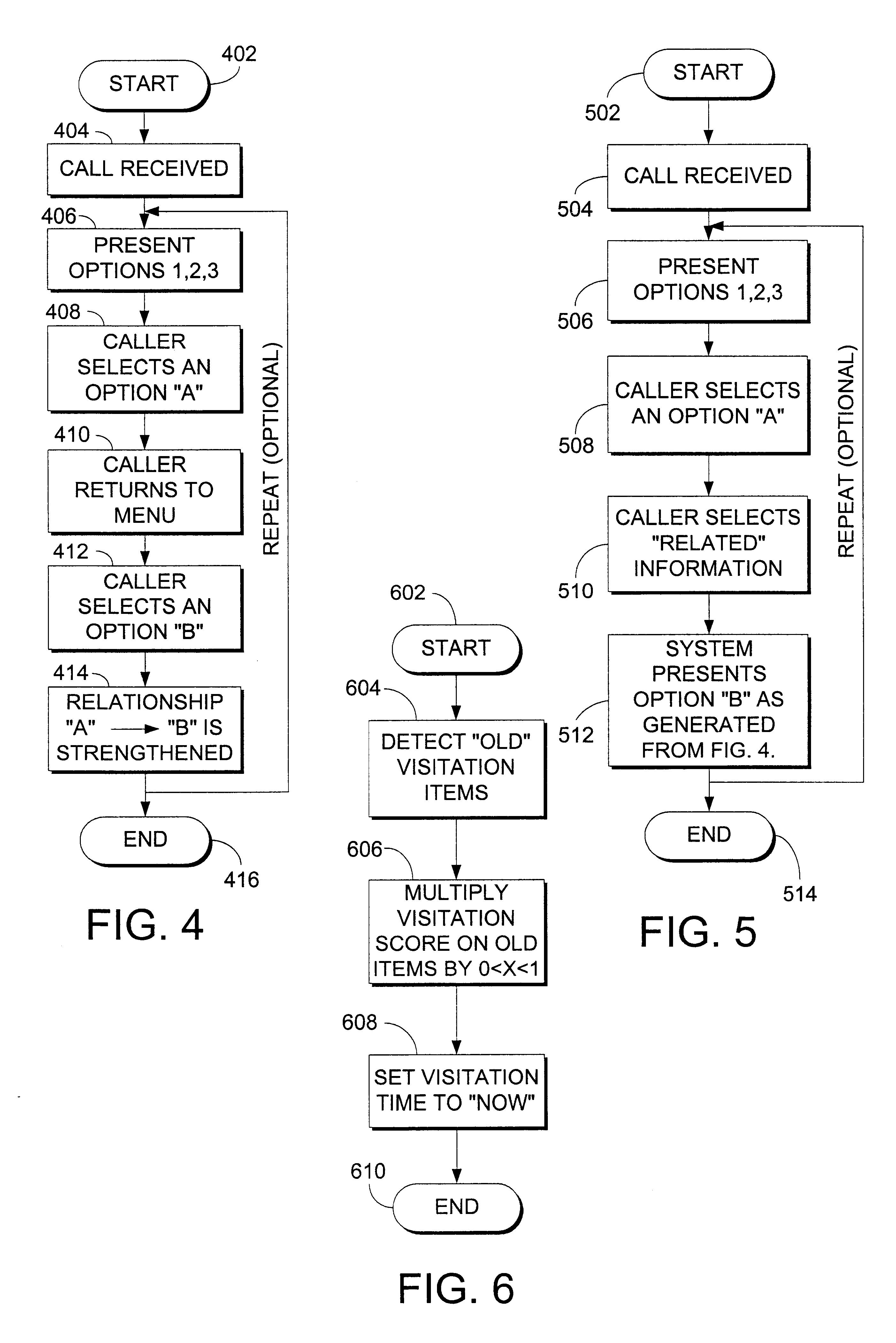

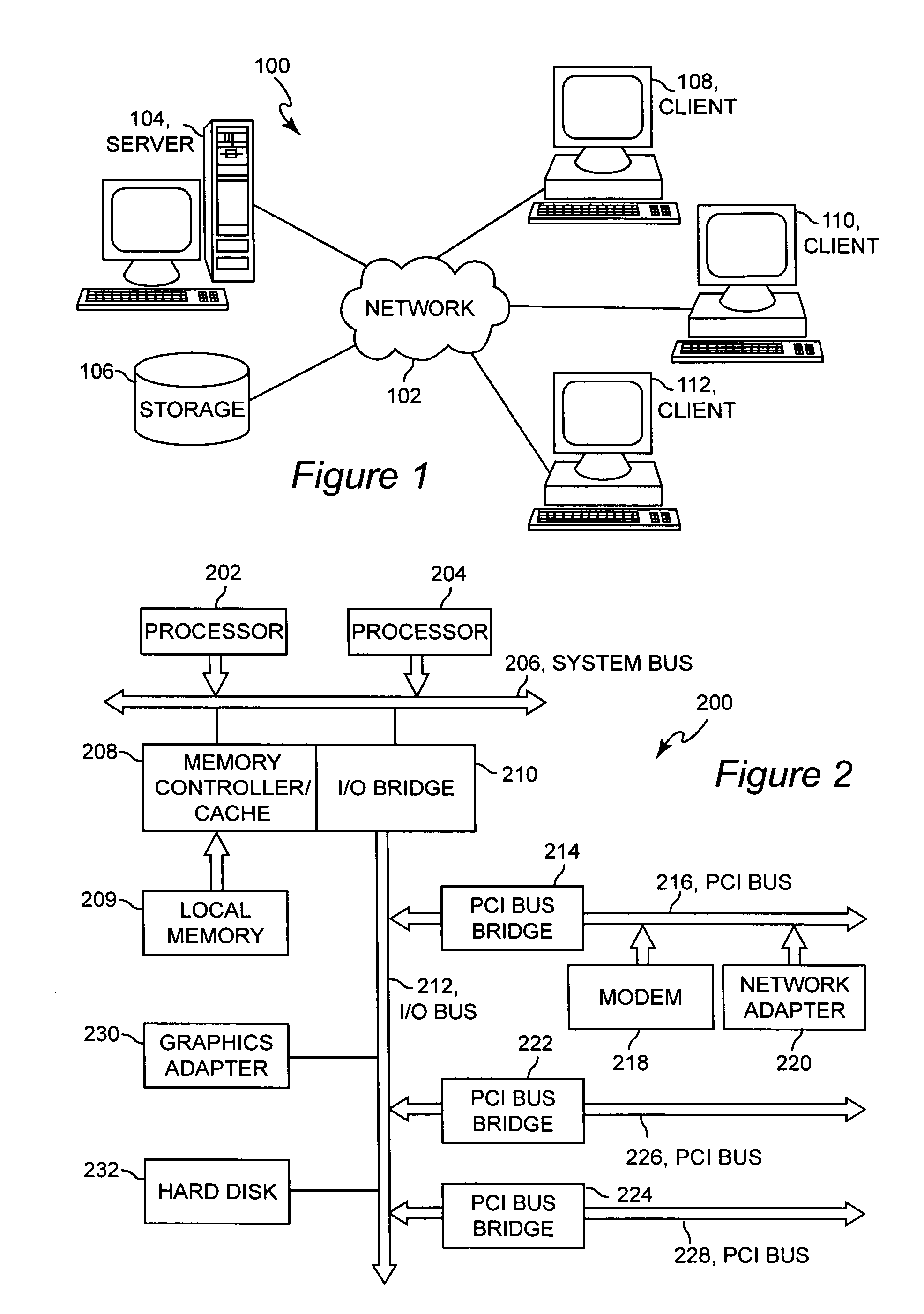

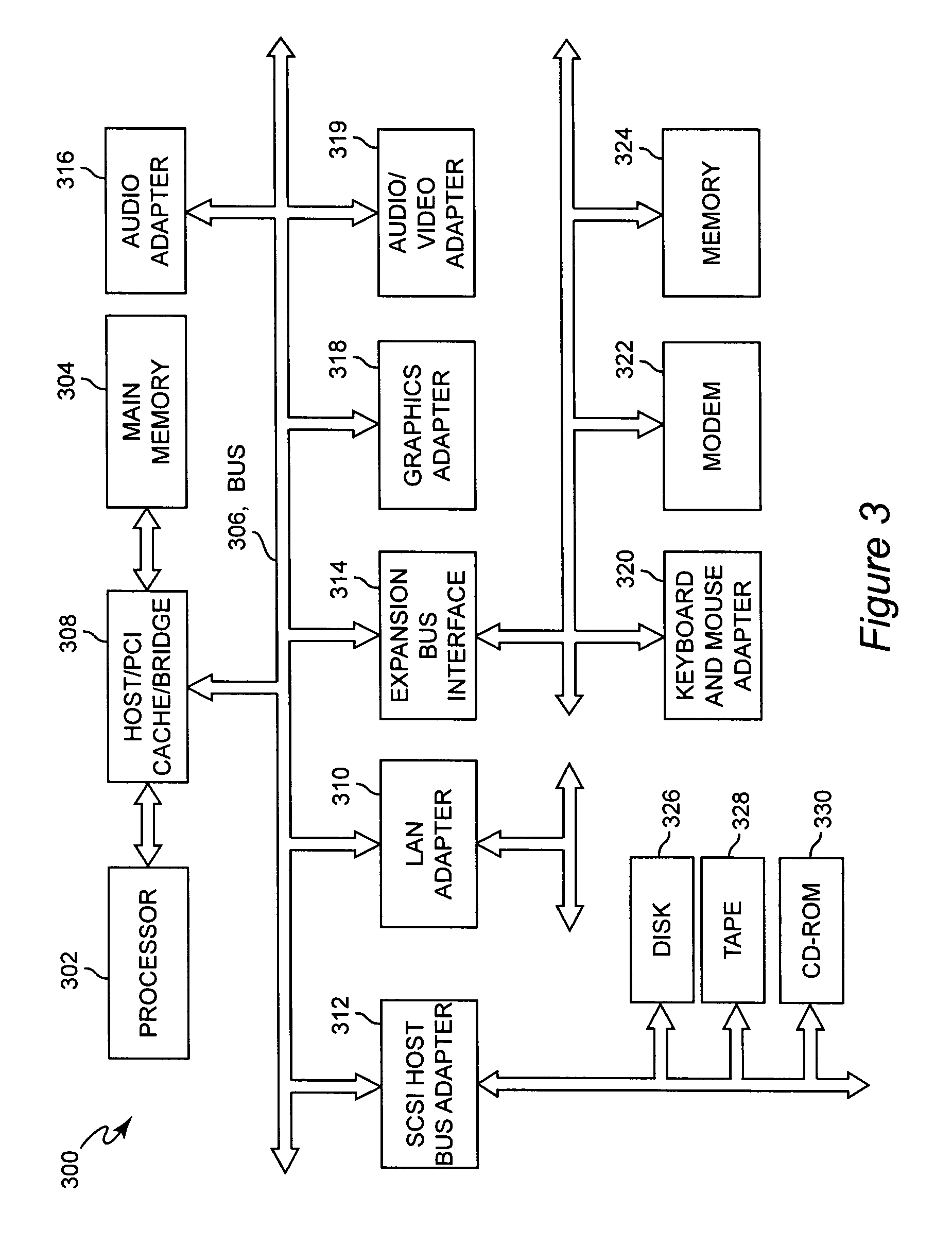

System and method for generating a dynamic interface via a communications network

InactiveUS6850949B2Prevent excessive inputIncrease administrative overheadData processing applicationsDigital data processing detailsSupporting systemNetwork generation

A system, method, and computer program product for dynamically adapting selections in an automatic phone support system is described. The invention may integrate a dynamic knowledge base of responses with the menu selections on an automated phone system or other response system to present the most frequently used items earlier in the option list, or otherwise order options and information. Call data may be captured from single callers or historical ensembles of callers. An automatically generated similarity relationship may be used to initialize the system without historical call data, based on textual similarity or other techniques. Prioritization of options provides a more enjoyable, efficient experience for callers without increasing administrative overhead.

Owner:ORACLE OTC SUBSIDIARY

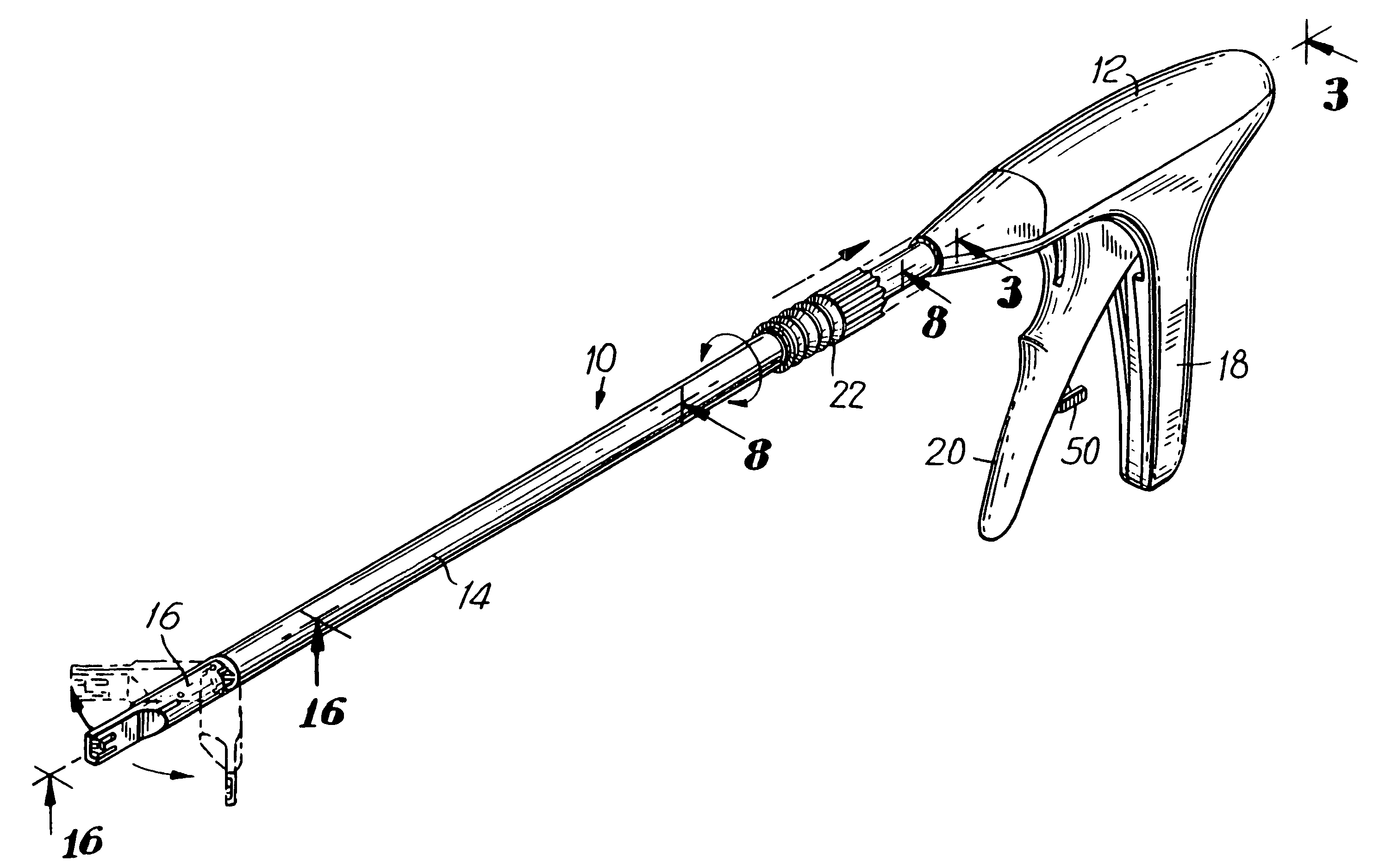

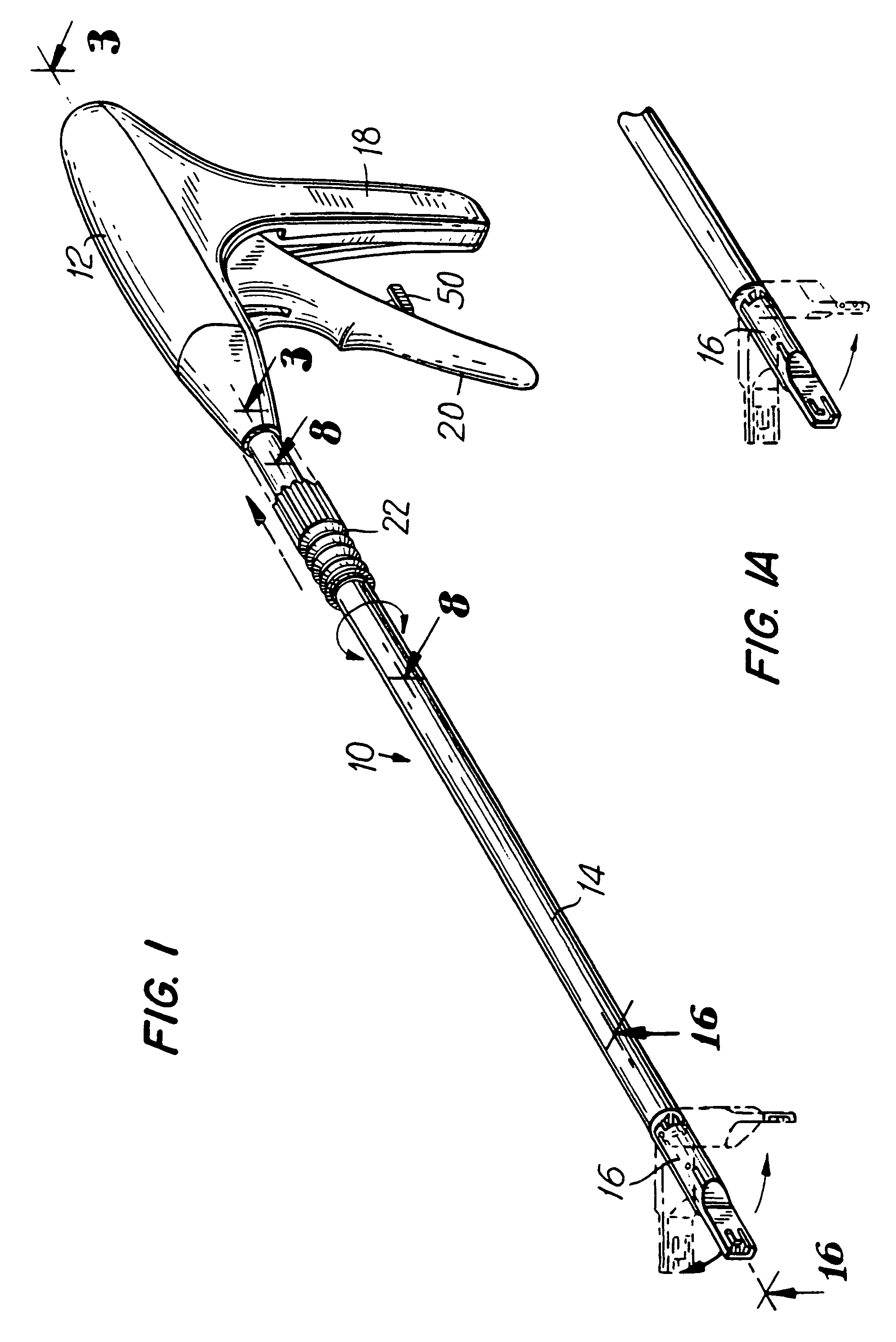

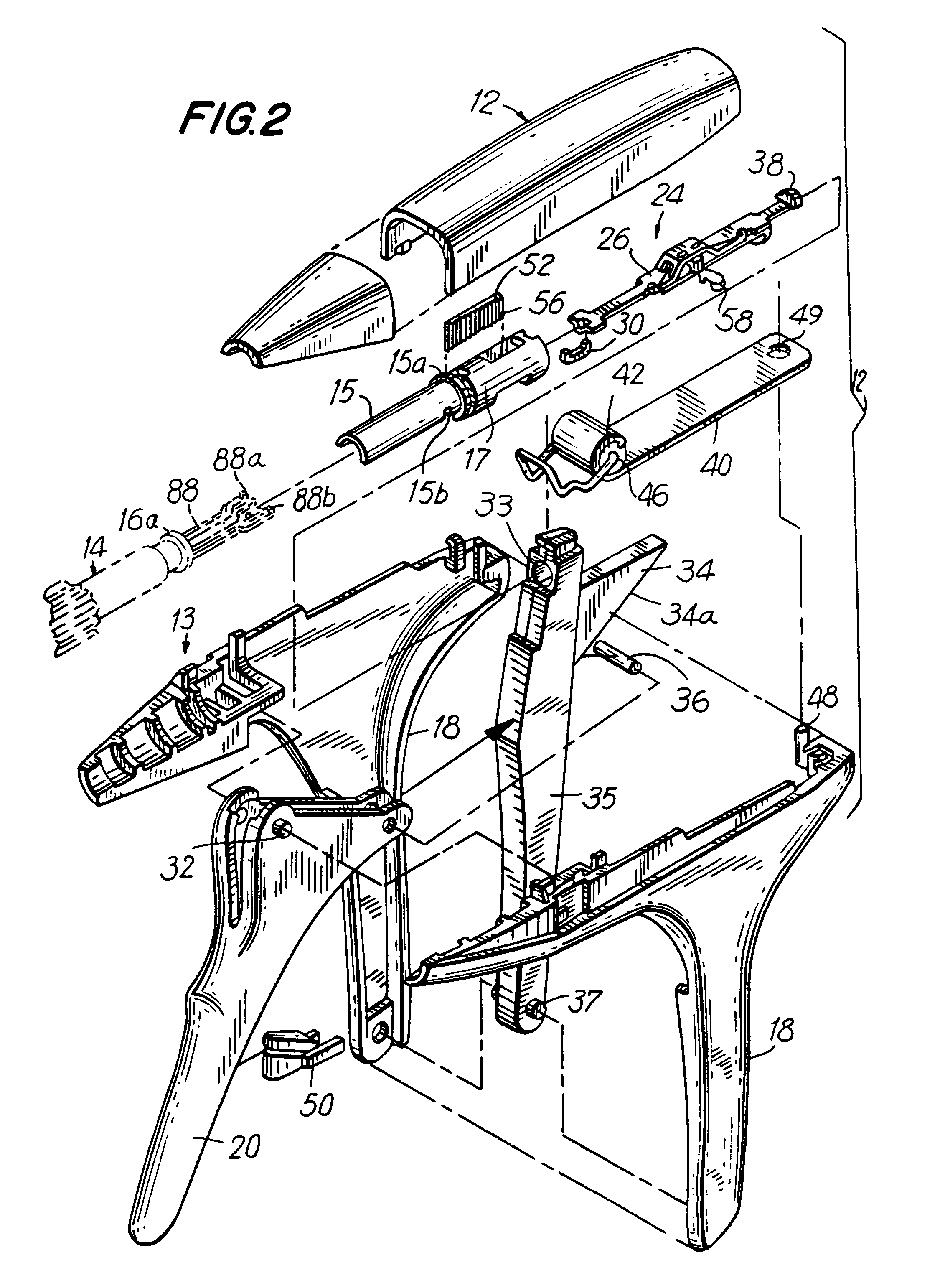

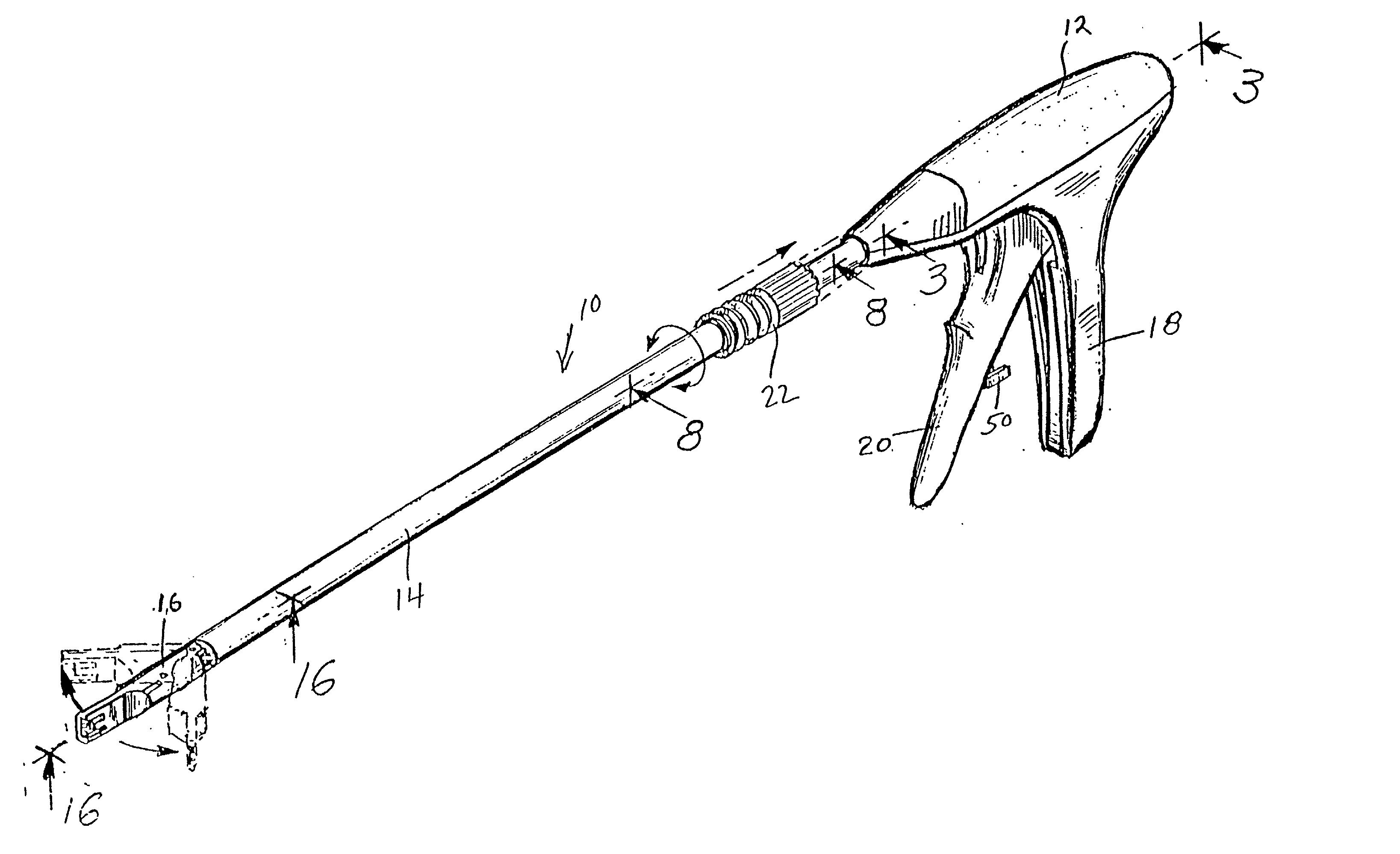

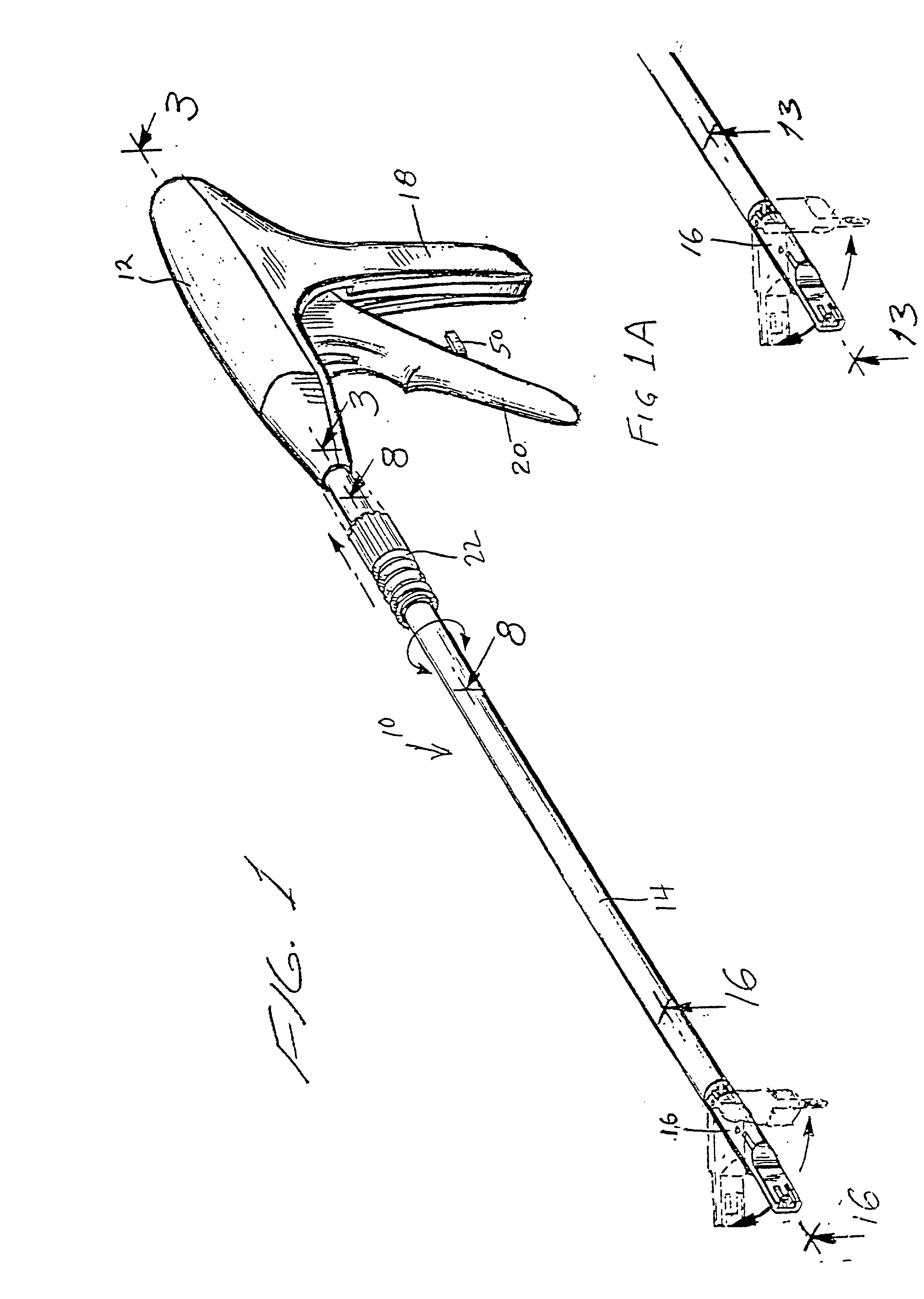

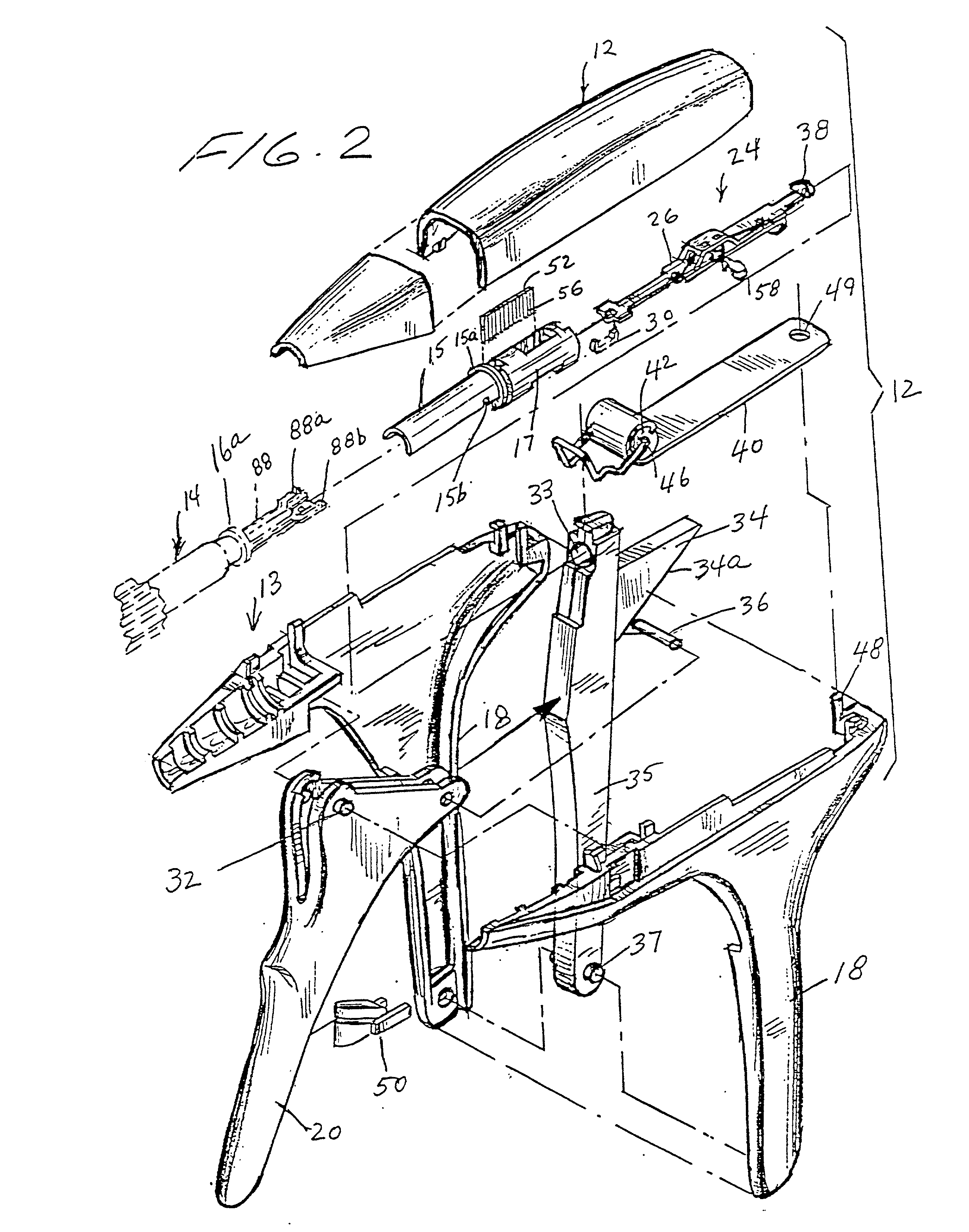

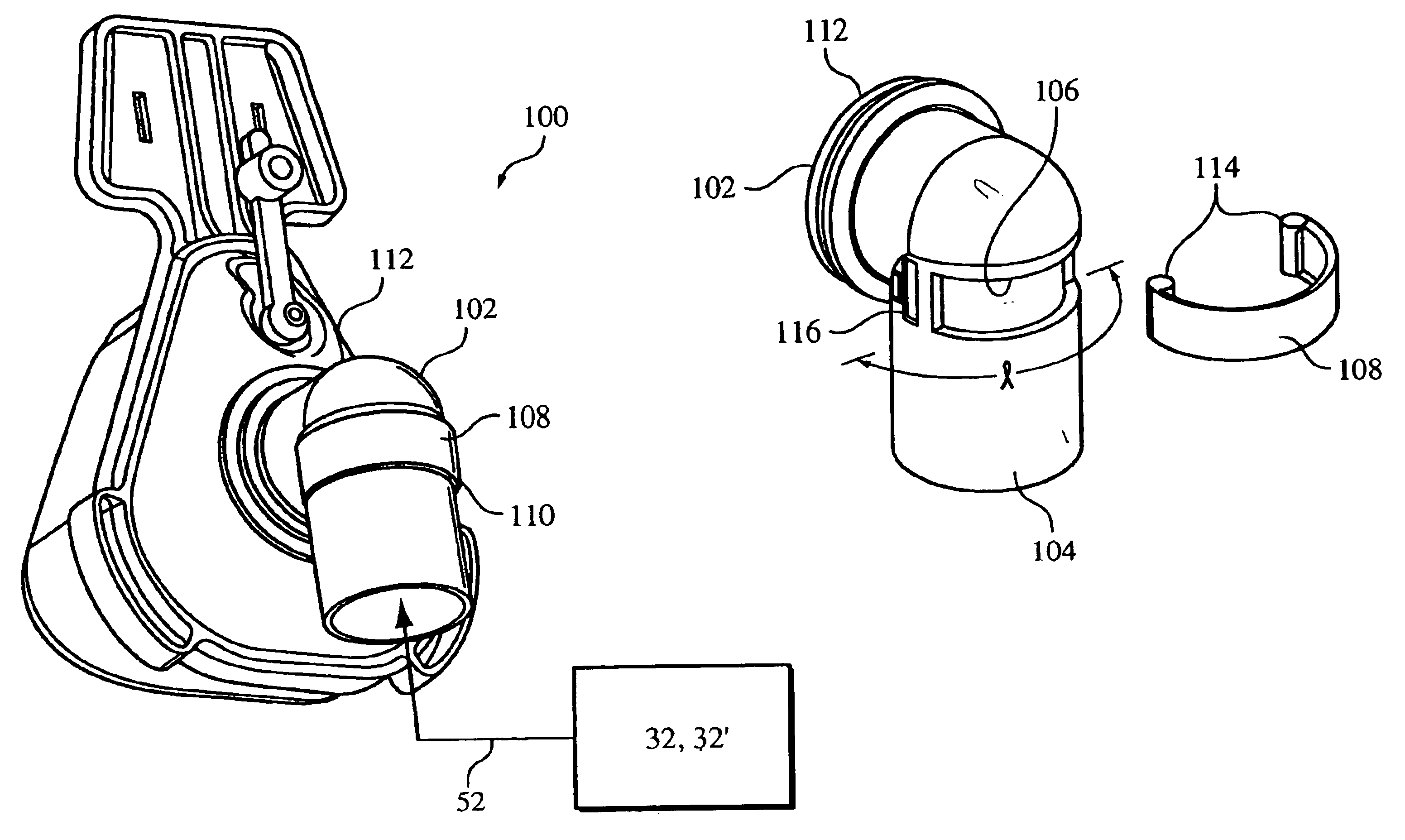

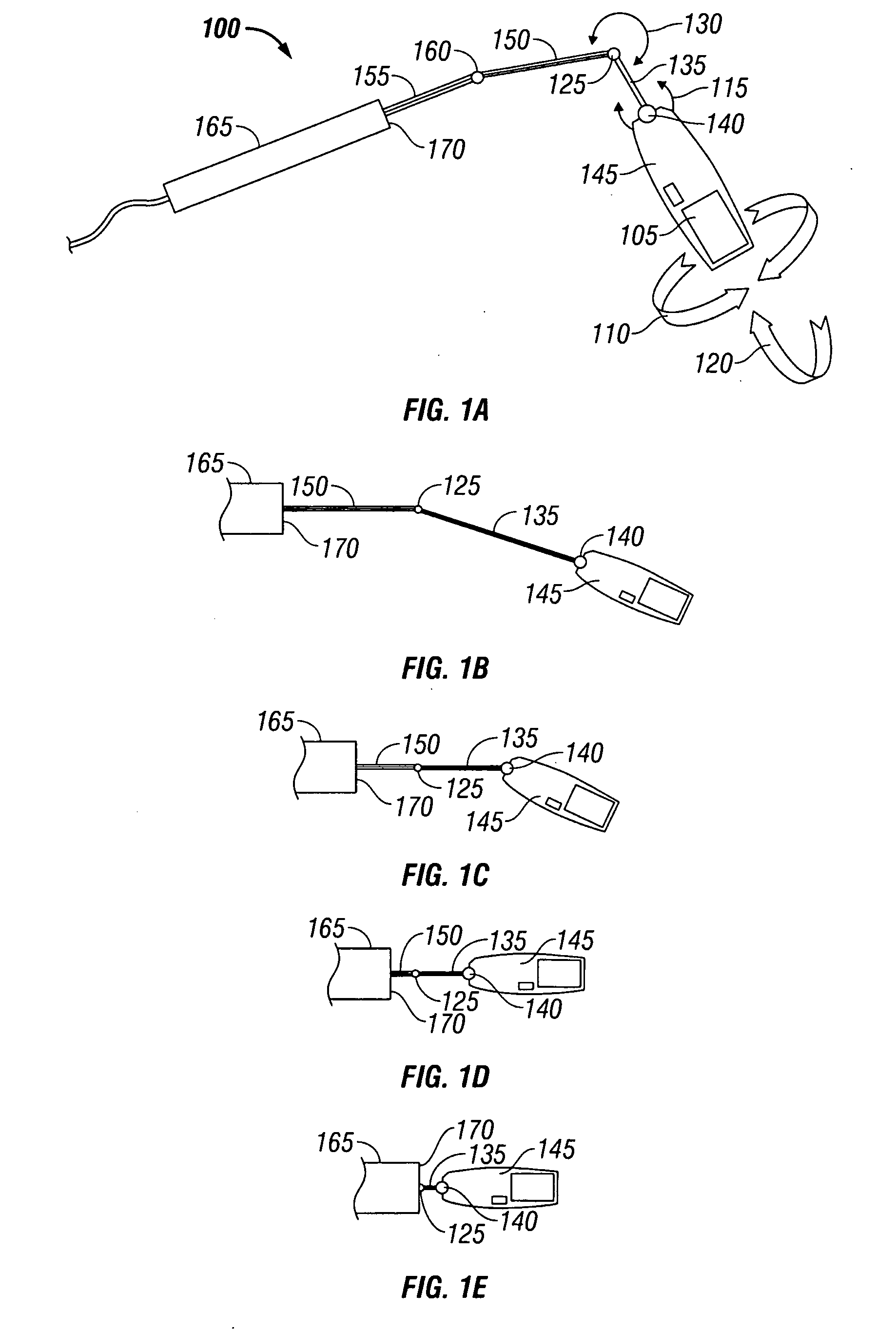

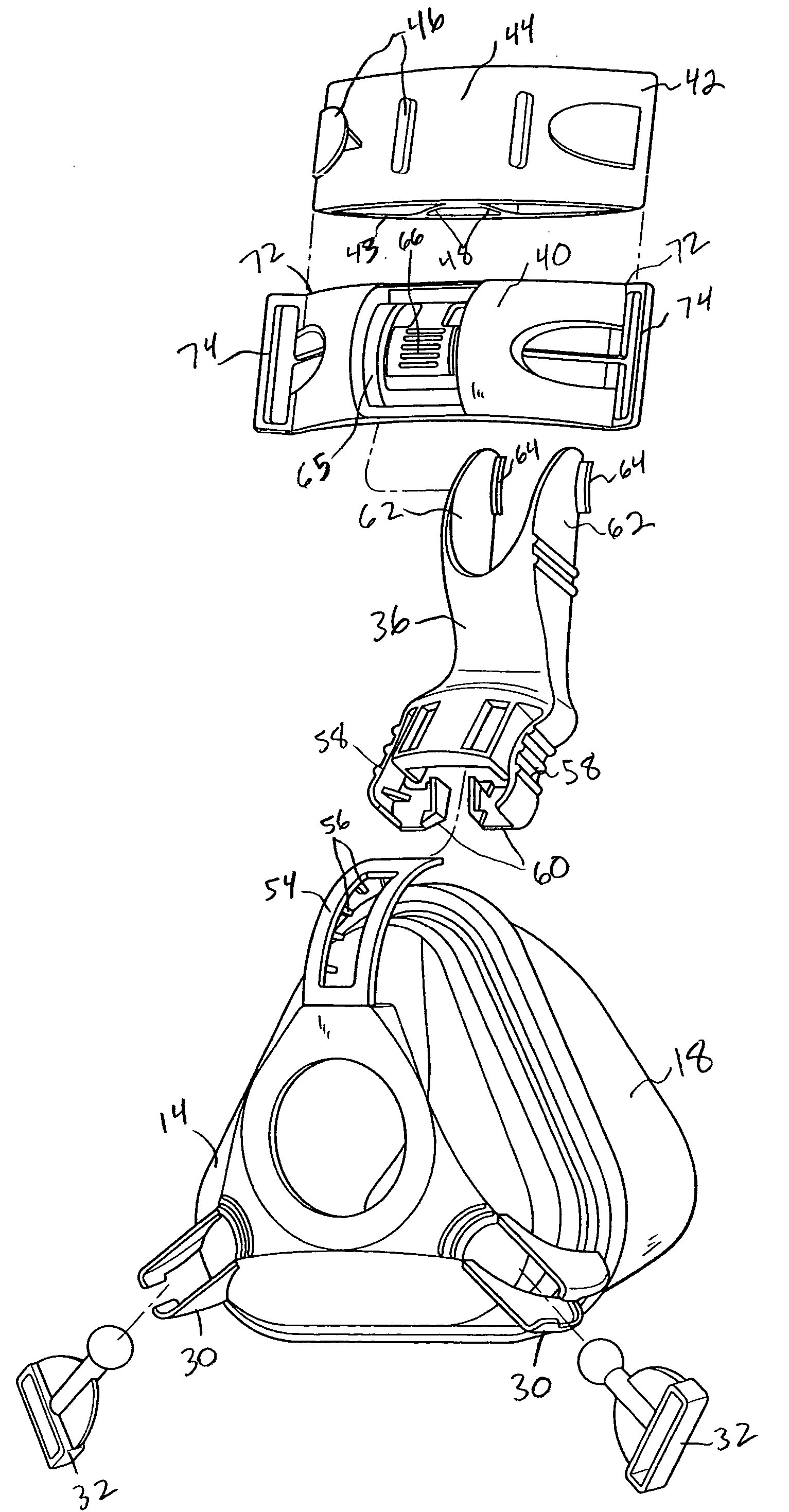

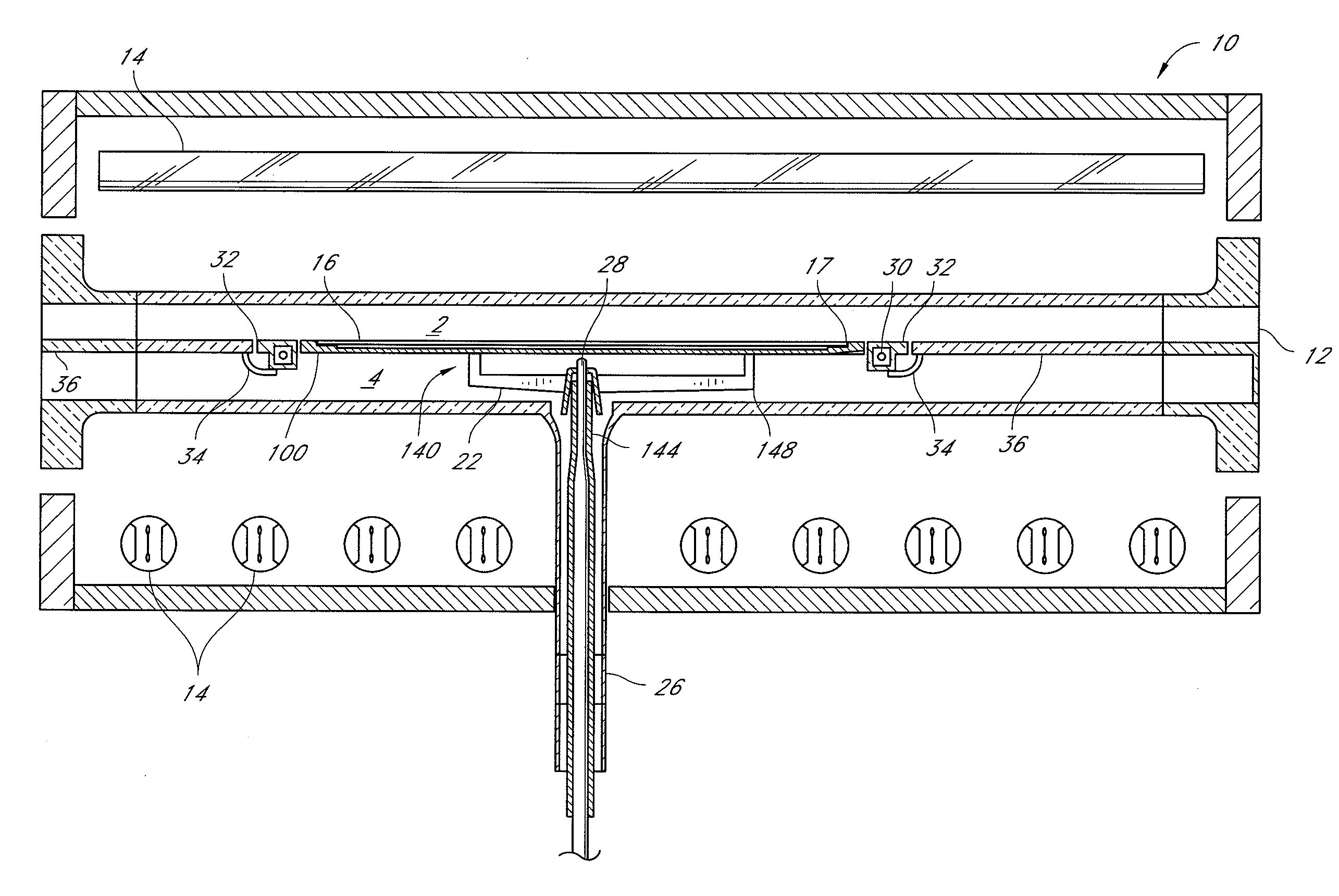

Apparatus for applying surgical fastners to body tissue

InactiveUS7624903B2Increase awarenessAvoid deformationSuture equipmentsStapling toolsSurgical stapleSupporting system

Owner:COVIDIEN LP

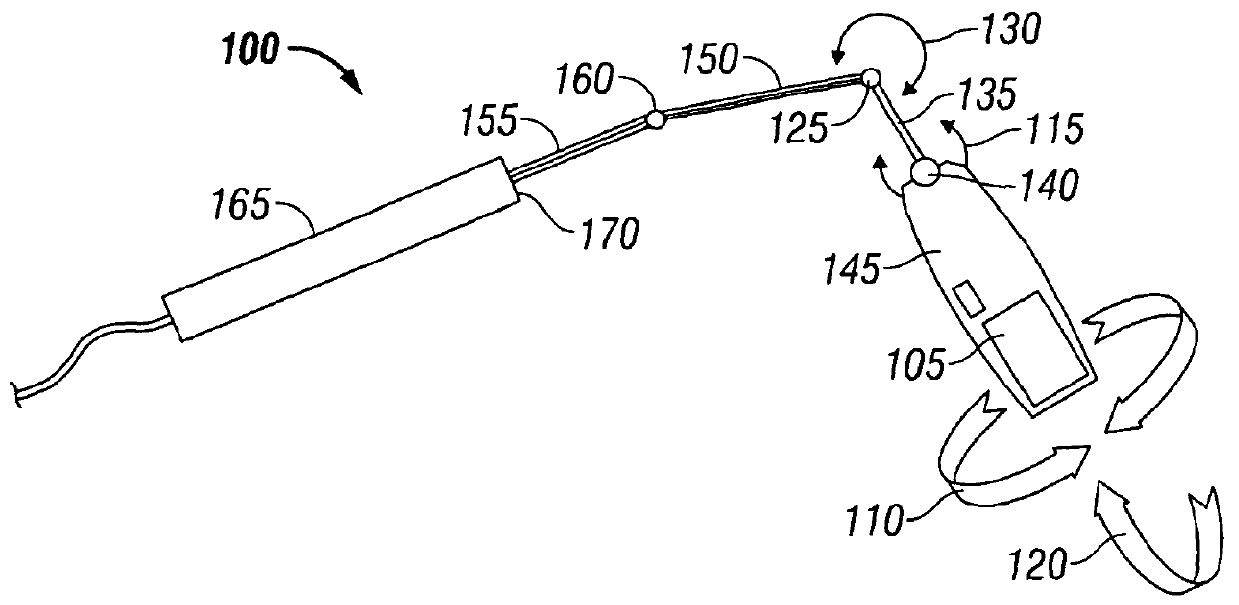

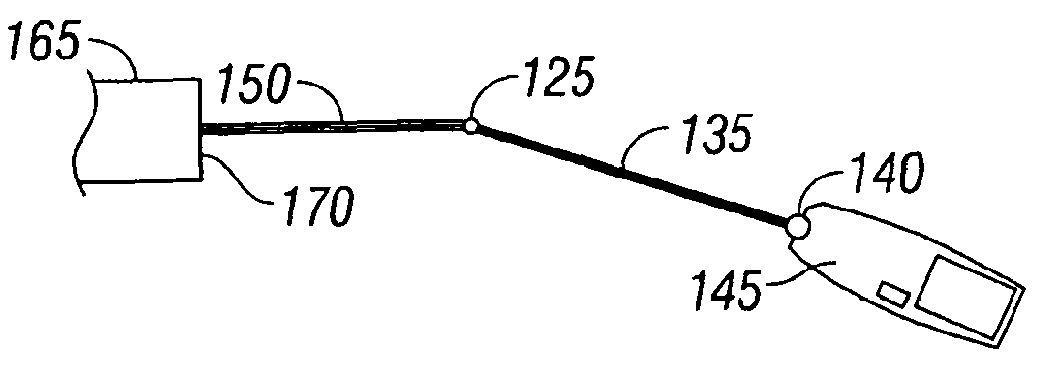

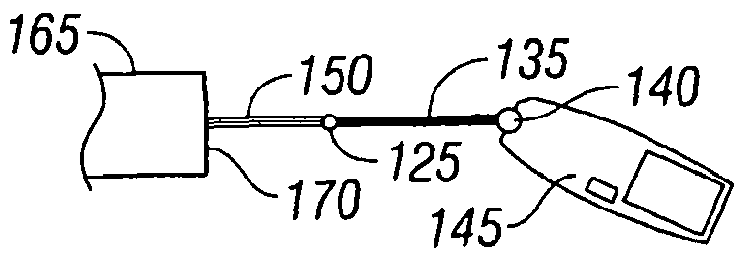

Apparatus and method for applying surgical staples to attach an object to body tissue

InactiveUS20020117534A1Avoid deformationSuture equipmentsStapling toolsSupporting systemSurgical staple

An apparatus is disclosed for endoscopic application of surgical staples adapted to attach surgical mesh to body tissue in laparoscopic hernia surgery. The apparatus includes a frame, and a generally elongated endoscopic section connected to the frame and extending distally therefrom. A staple storage cartridge is removably supported on a pivotal support system at the distal end portion of the endoscopic section with each staple being configured and adapted to attach the mesh to the body tissue. An elongated pusher system formed of several assembled components and extending from the frame to the endoscopic section is provided for individually advancing at least one staple at a time distally for positioning adjacent the surgical mesh and the body tissue. The pusher system also includes a trigger system to actuate the pusher. The trigger system is provided with perceptible tactile sensing means to indicate when the legs of the staple being advanced are exposed so as to be visible to the user for positioning and orientation purposes. Anvil means provides for individually closing each staple to encompass at least a portion of the surgical mesh and to penetrate the body tissue in a manner to attach the portion of the mesh to the body tissue. Projecting distally of the cartridge support system is a pair of legs which are dimensioned and configured to engage the staple during closure to prevent unwanted roll or deformation outside of the plane of the staple.

Owner:TYCO HEALTHCARE GRP LP

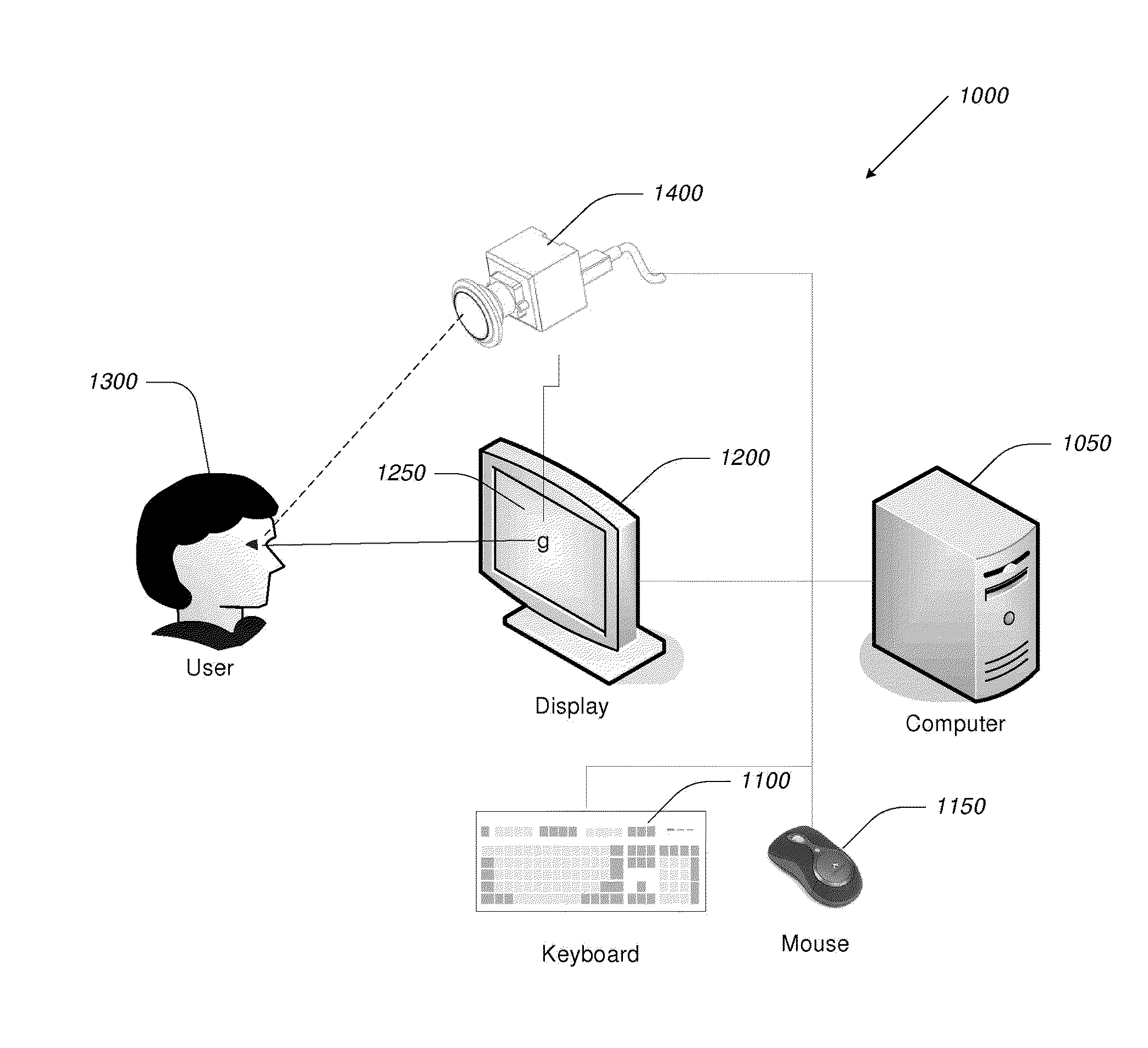

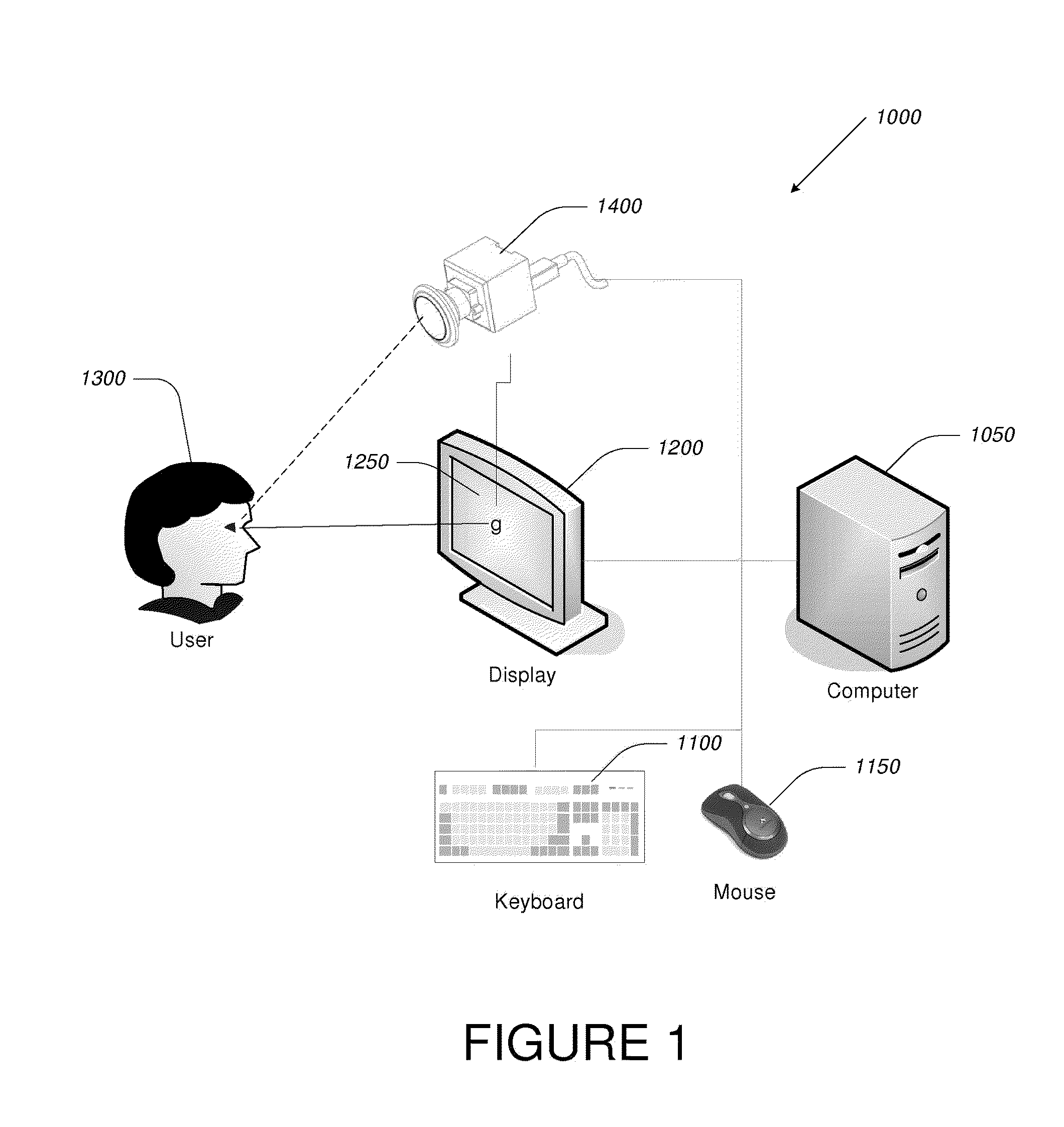

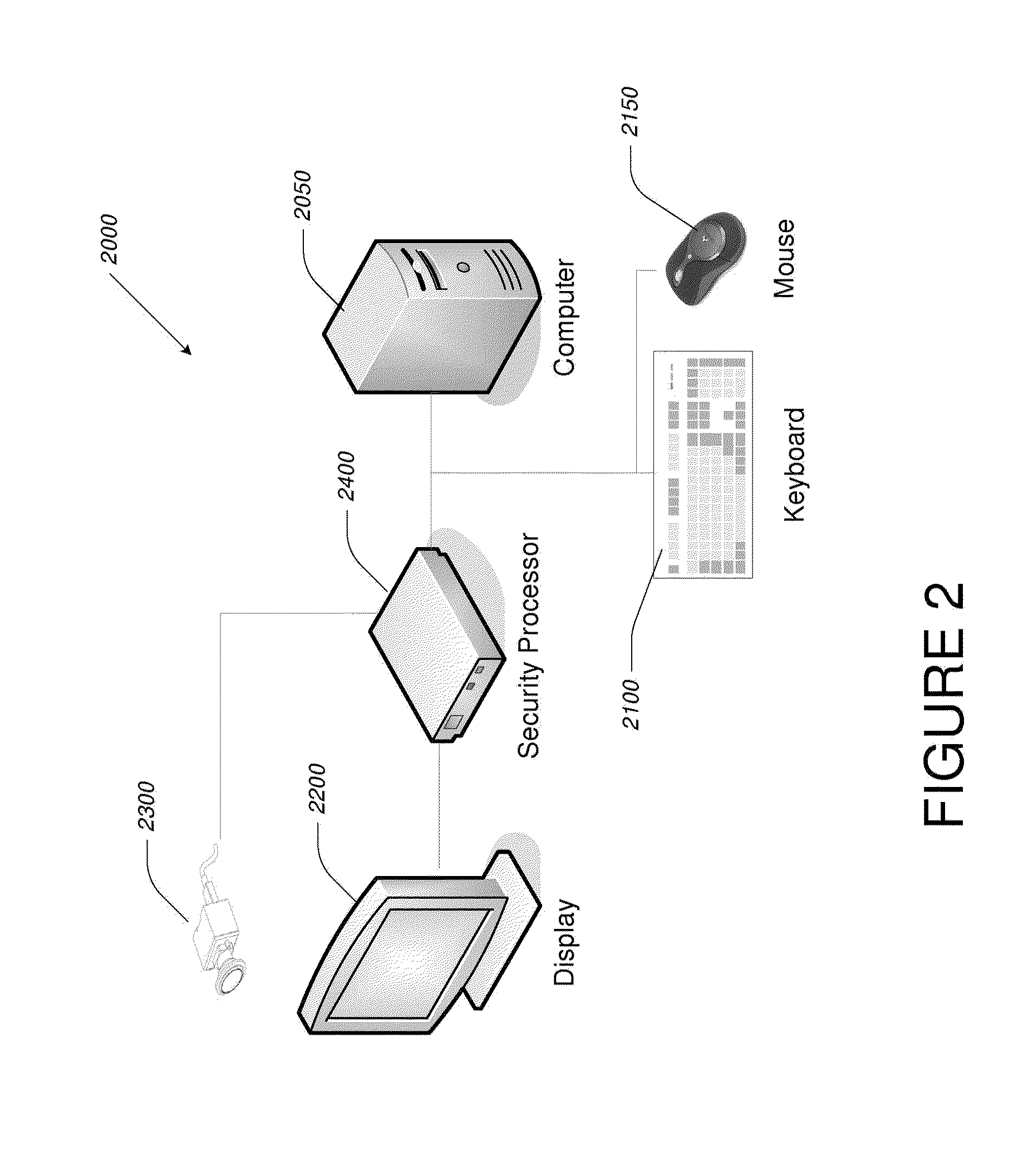

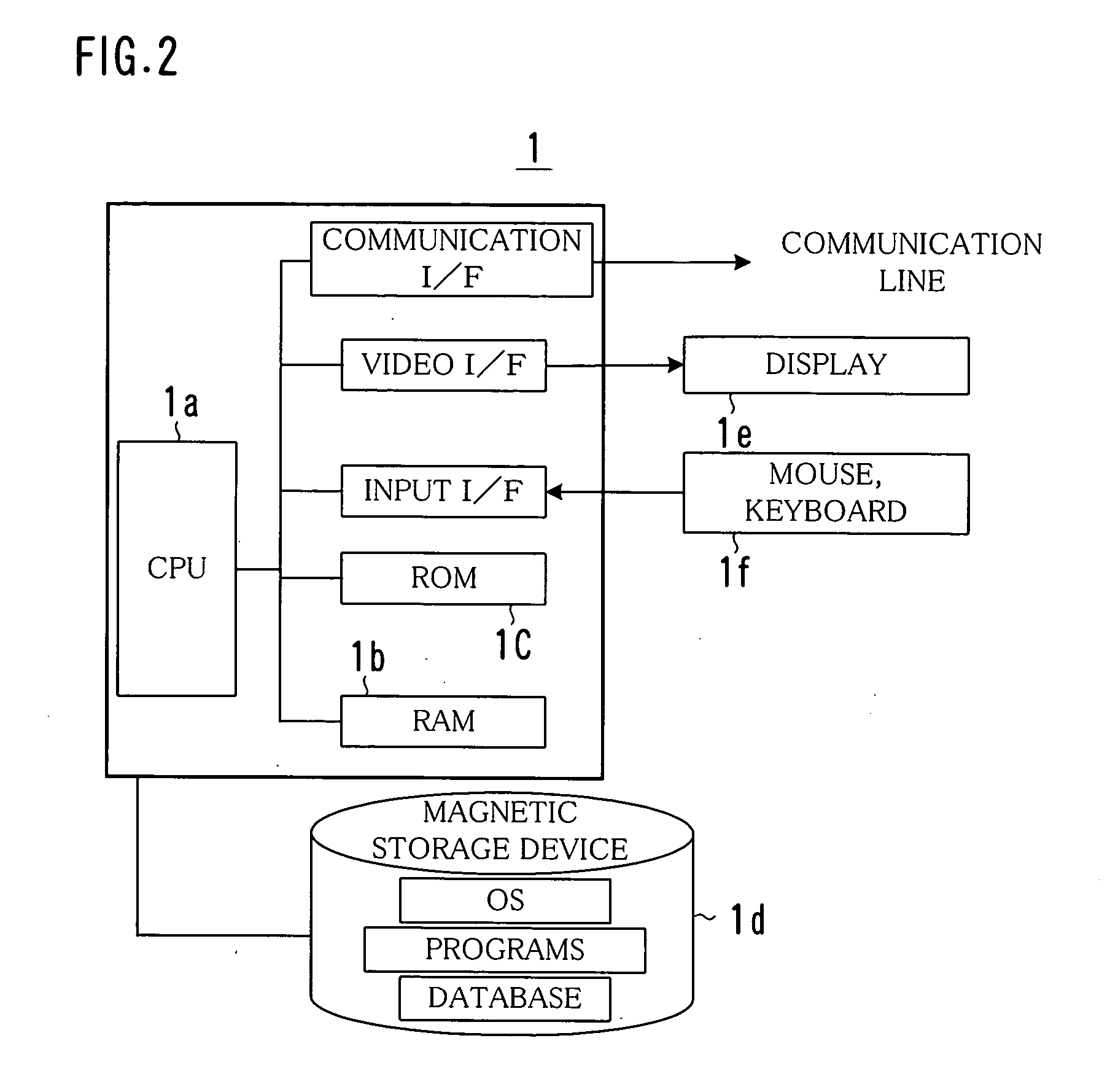

Video-Based Privacy Supporting System

ActiveUS20100205667A1Improve securityPrivacy protectionDigital data processing detailsUnauthorized memory use protectionDisplay deviceOutput device

Computer display privacy and security for computer systems. In one aspect, the invention provides a computer-controlled system for regulating the interaction between a computer and a user of the computer based on the environment of the computer and the user. For example, the computer-controlled system provided by the invention comprises an input-output device including an image sensor configured to collect facial recognition data proximate to the computer. The system also includes a user security parameter database encoding security parameters associated with the user; the database is also configured to communicate with the security processor. The security processor is configured to receive the facial recognition data and the security parameters associated with the user, and is further configured to at least partially control the operation of the data input device and the data output device in response to the facial recognition data and the security parameters associated with the user.

Owner:TOBII TECH AB

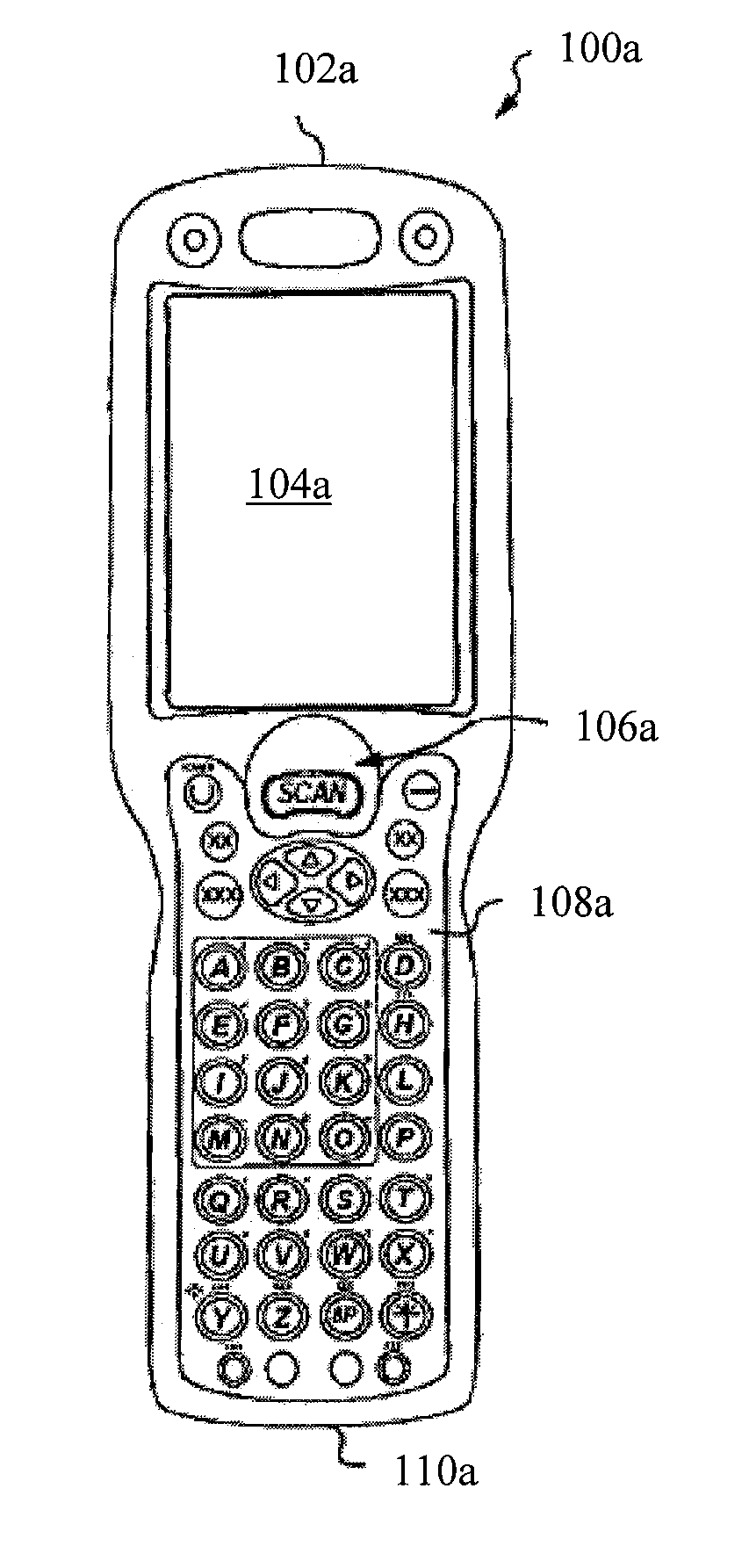

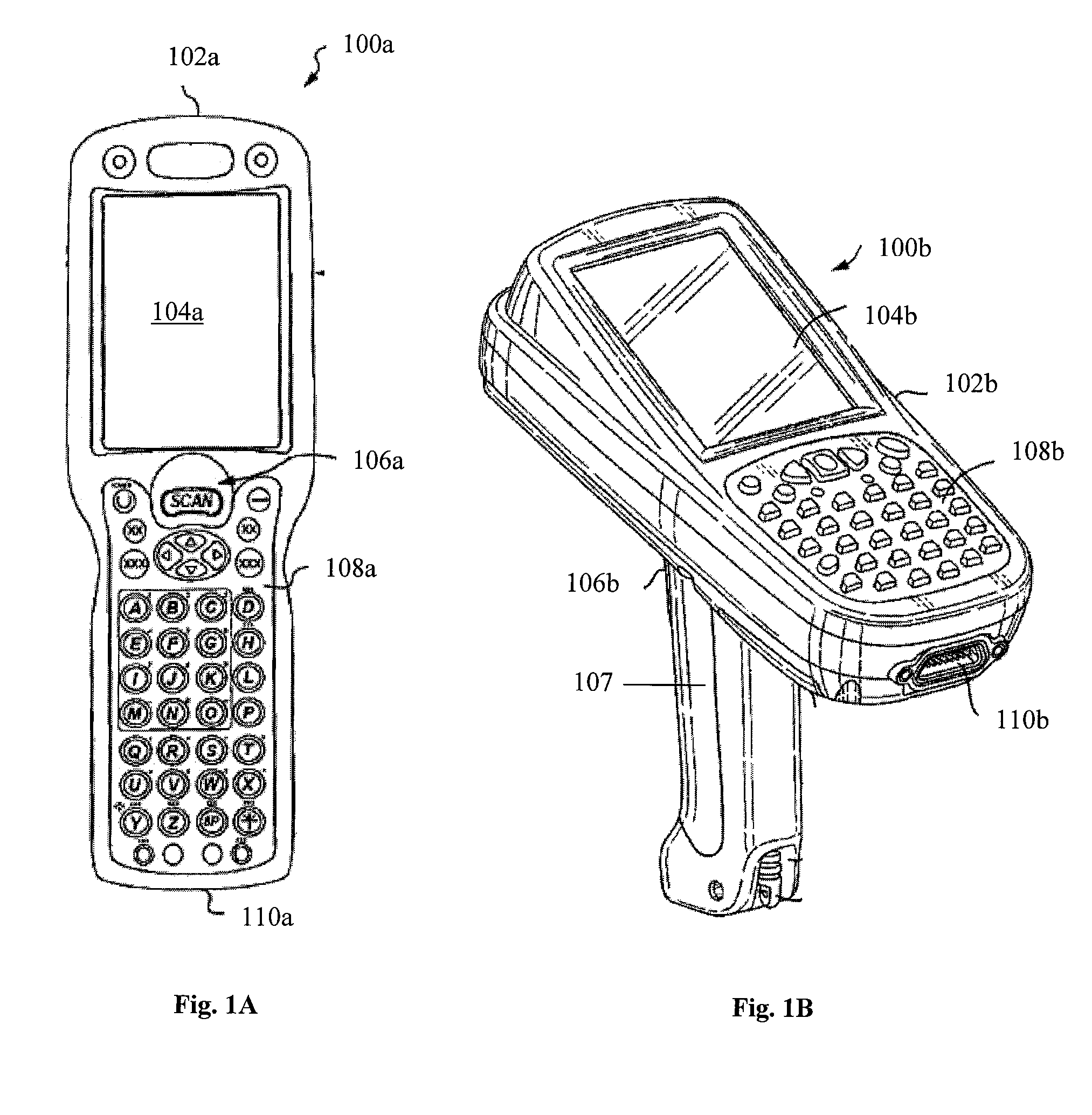

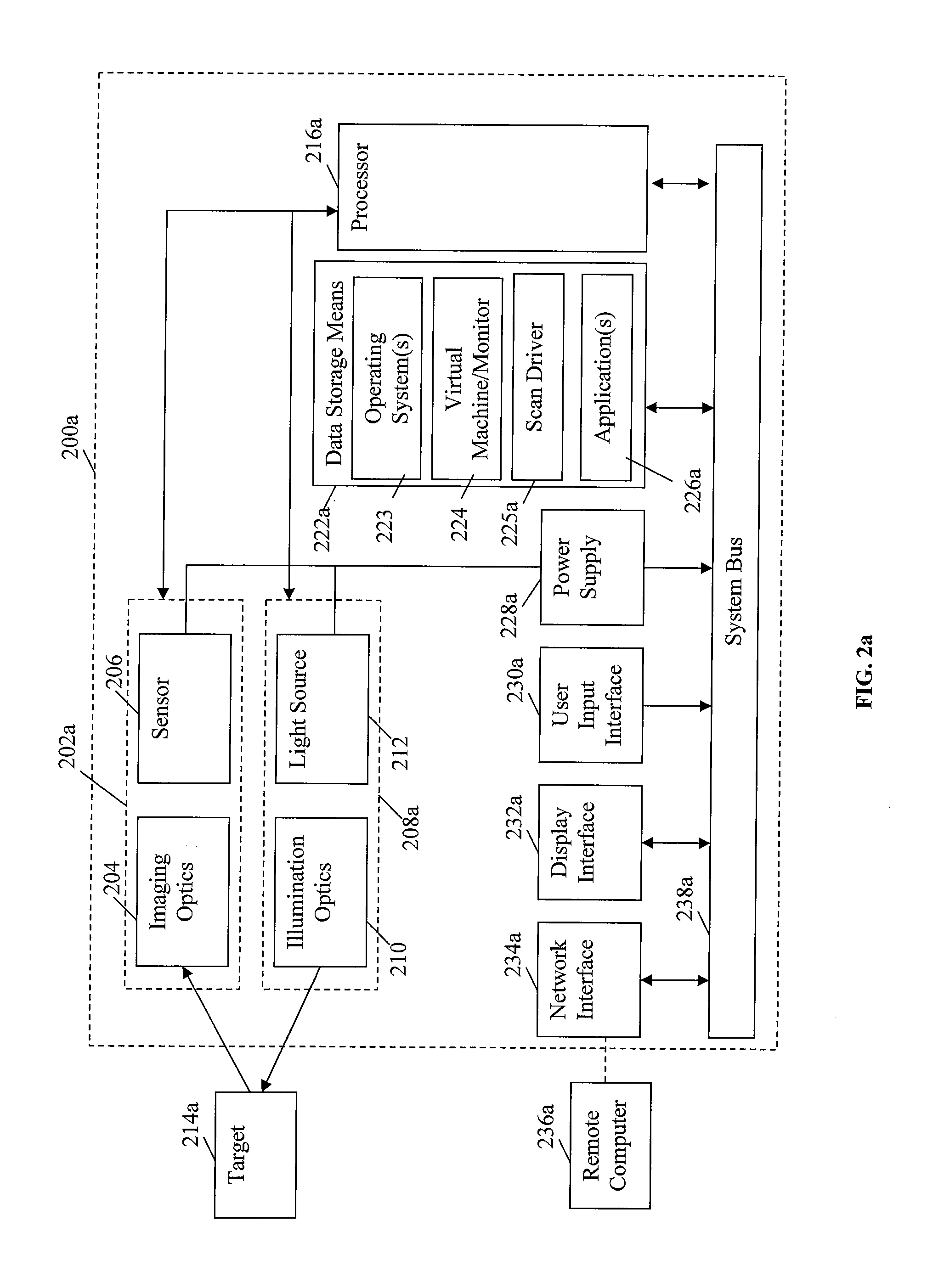

Multiple platform support system and method

InactiveUS9010641B2Software simulation/interpretation/emulationSpecial data processing applicationsSupporting systemData terminal

A portable data terminal including a processor having an instruction set architecture and data storage means configured to store a plurality of operating systems and a virtual machine monitor application program configured to receive at least one instruction from each operating system, communicate with the processor according to the instruction set architecture, and switch operating system access to the processor upon receipt of an electrical signal representing an event.

Owner:HAND HELD PRODS

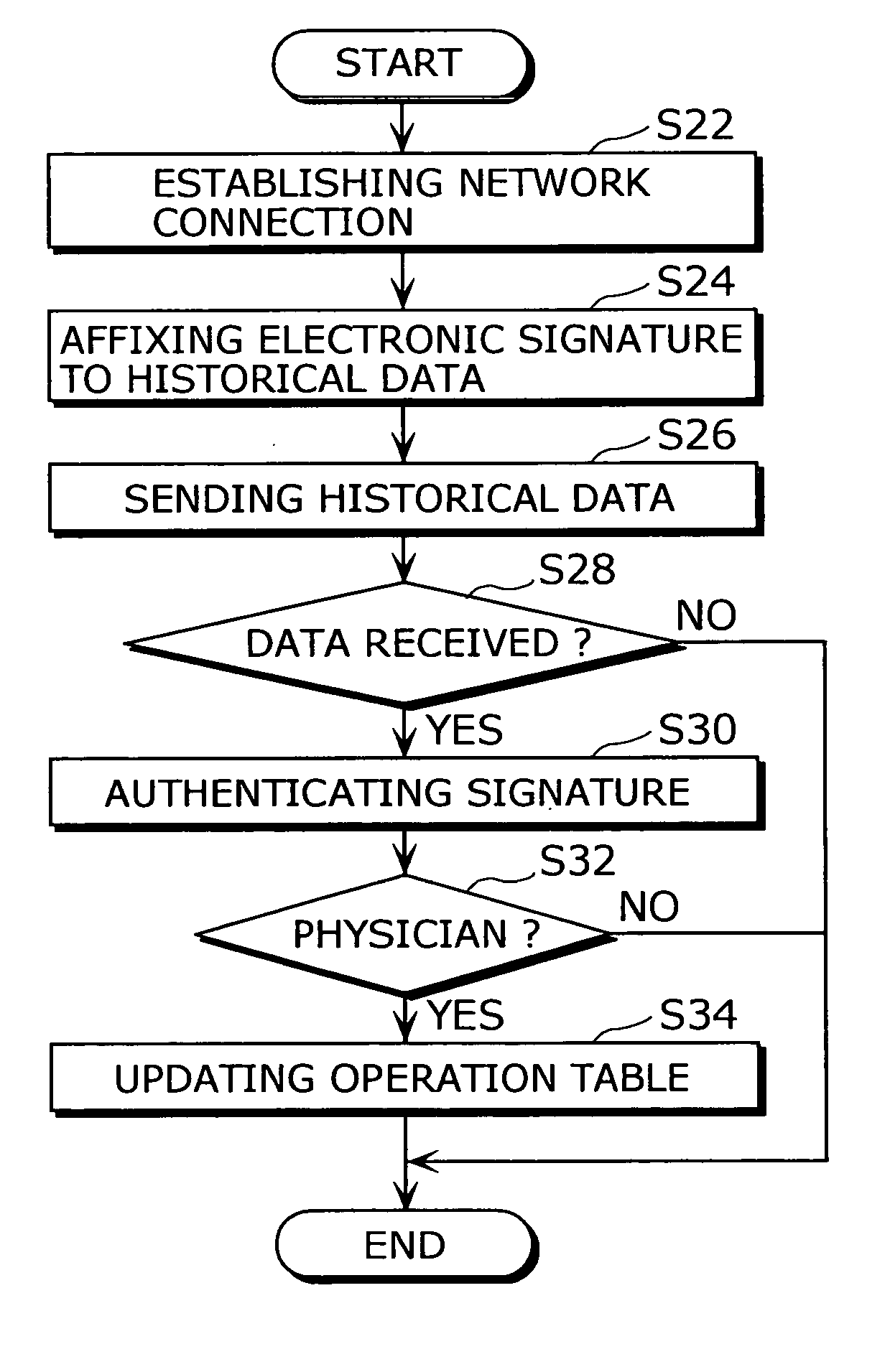

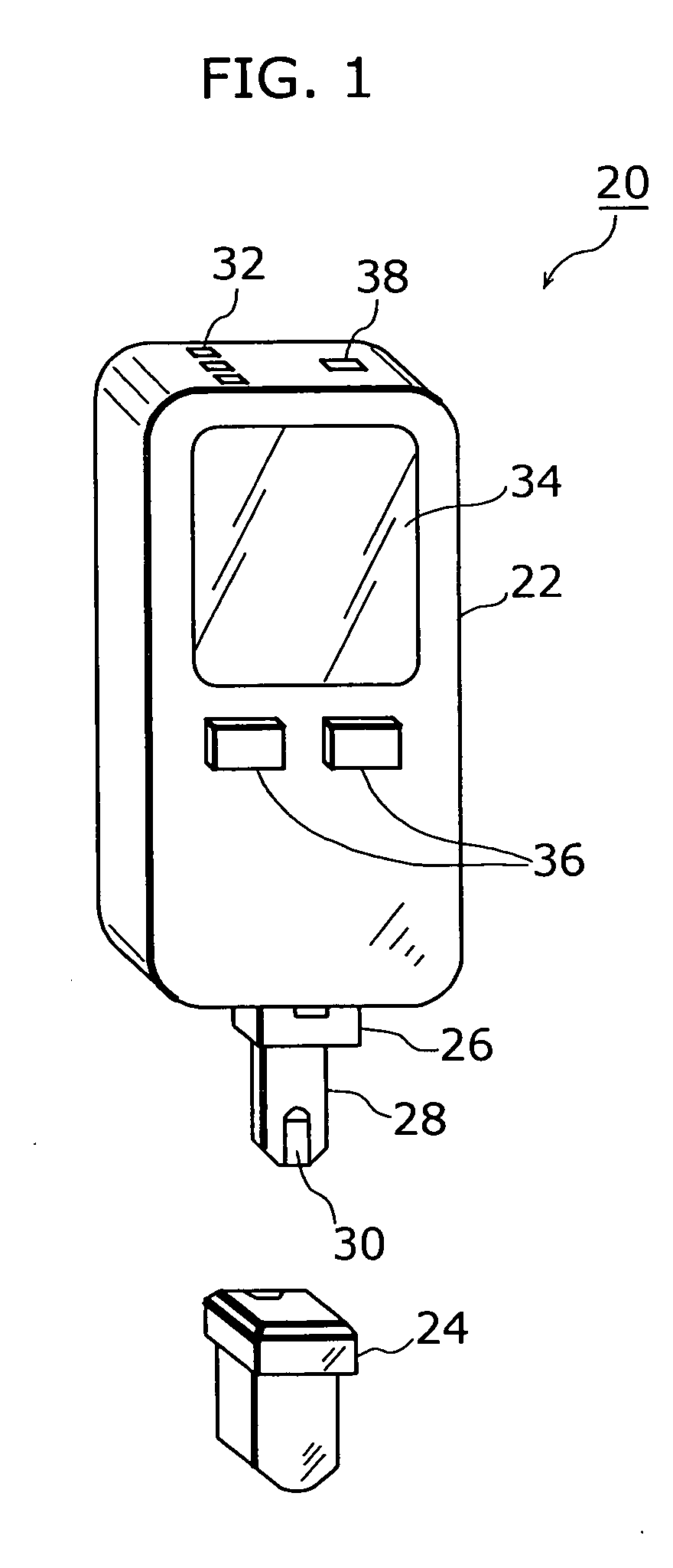

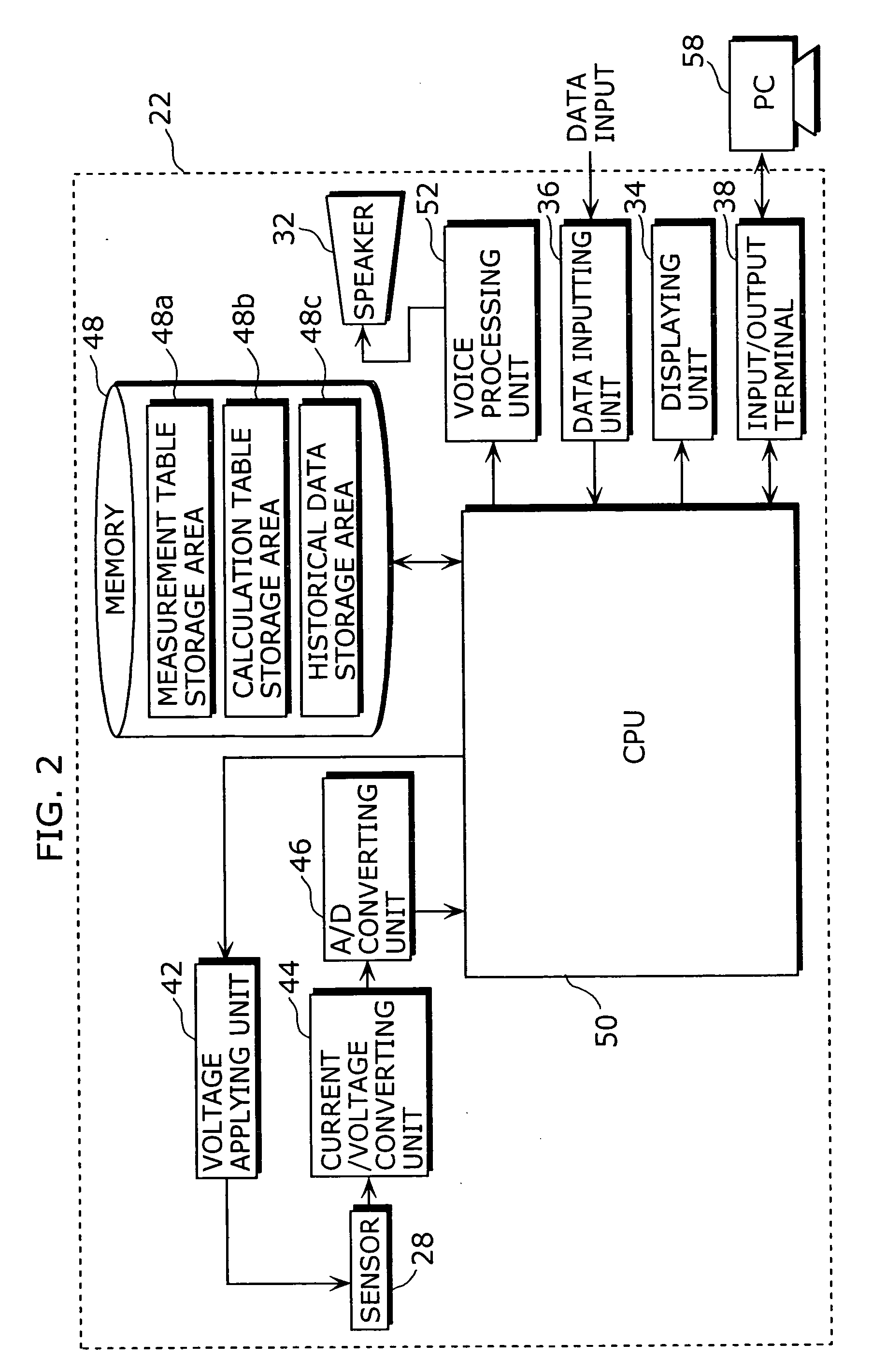

Dosage determination supporting device, injector, and health management supporting system

InactiveUS20050177398A1Improve reliabilityImprove portabilityData processing applicationsInfusion syringesSupporting systemMedicine

A dosage determination supporting apparatus, which is able to precisely determine a dosage in accordance with the health condition of a user, is provided with: a sensor (28) for measuring the blood sugar level obtained from the blood of the user; a memory (48) for storing an operation table showing a correspondence between the blood sugar level and the amount of insulin; a CPU (50) for calculating the amount of insulin corresponding to the blood sugar level, with reference to the operation table stored in the memory (48); a displaying unit (34) for displaying the amount of insulin; and a voice processing unit (52) for performing the voice processing on the amount of insulin and outputting the voice through a speaker (32).

Owner:PANASONIC CORP

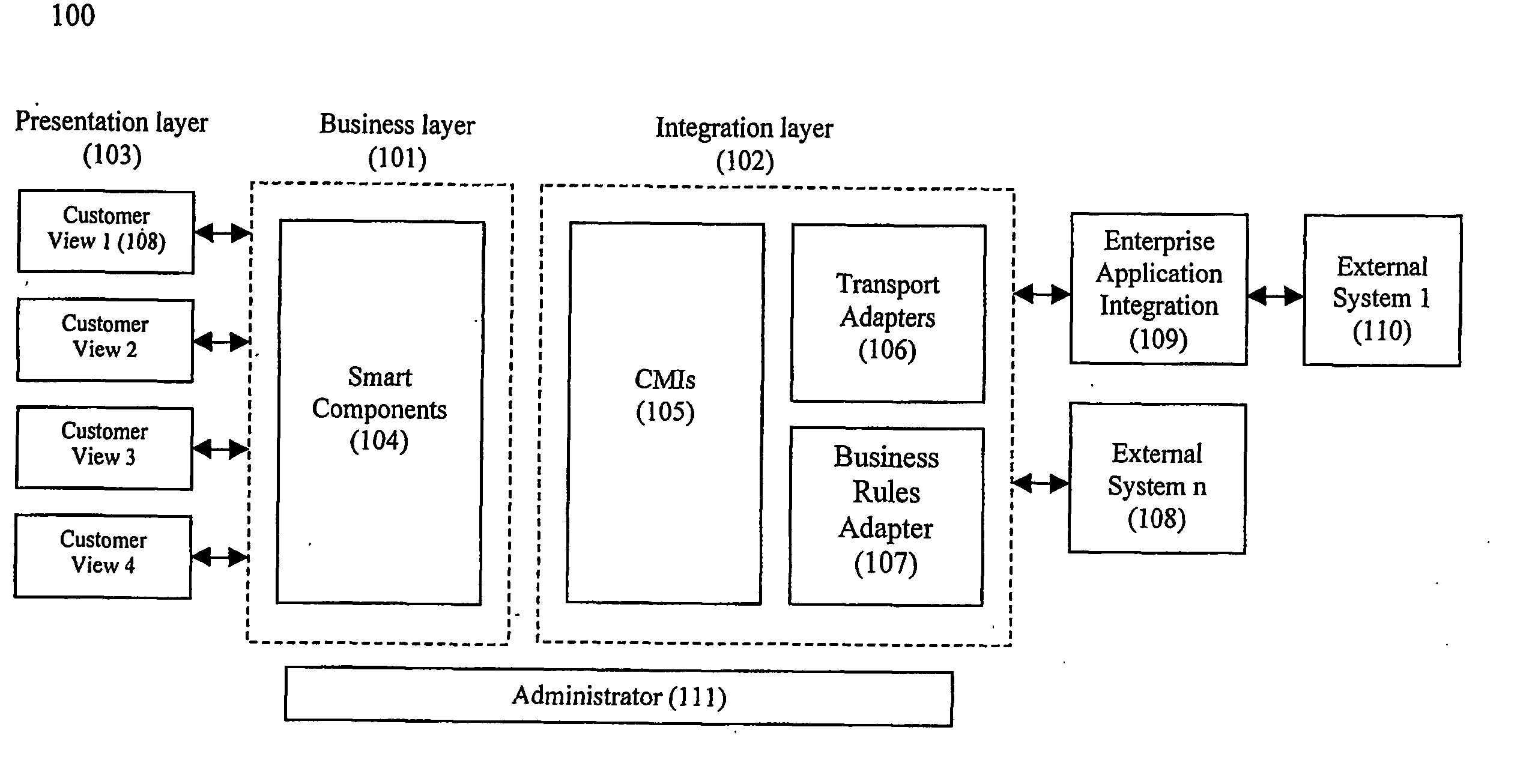

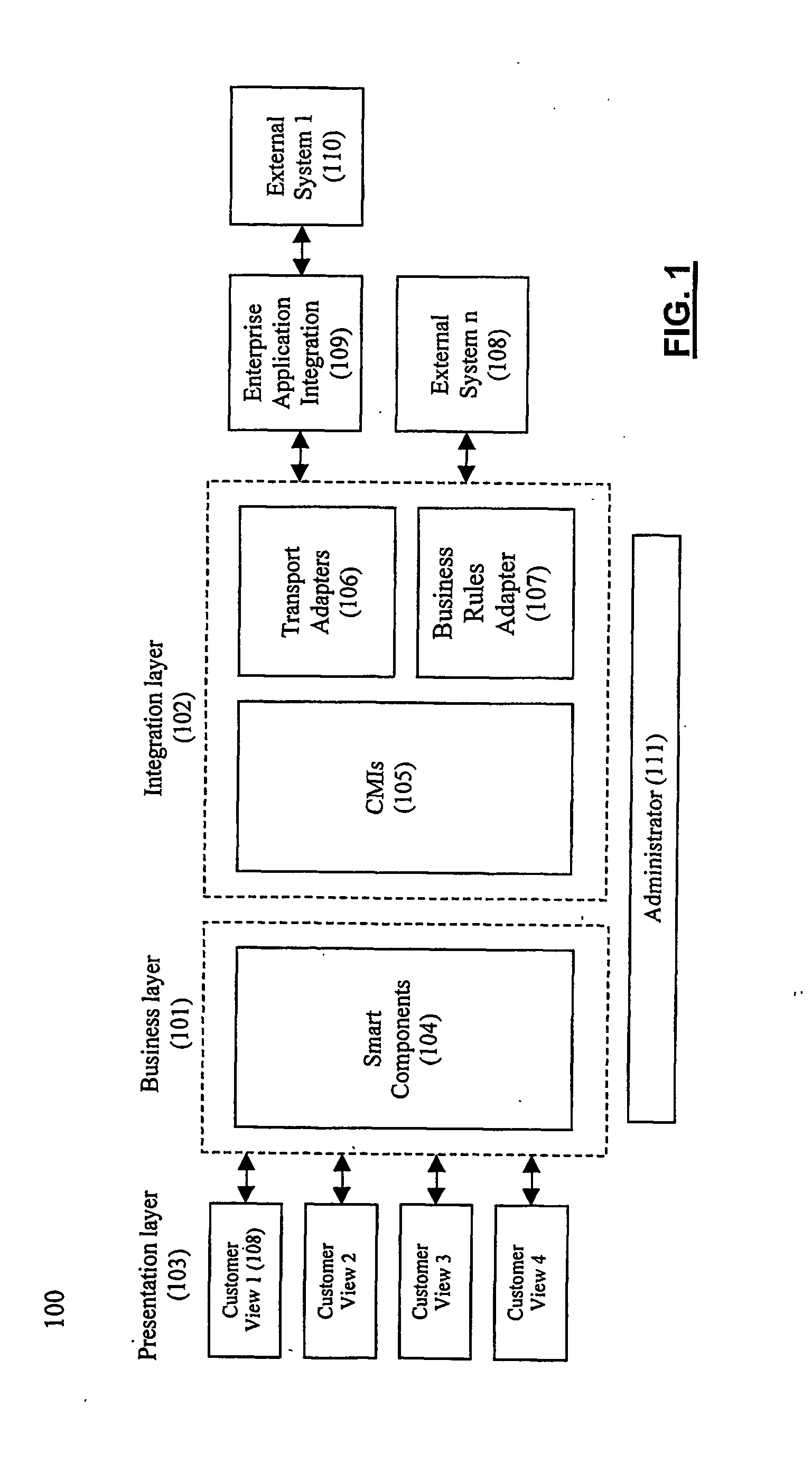

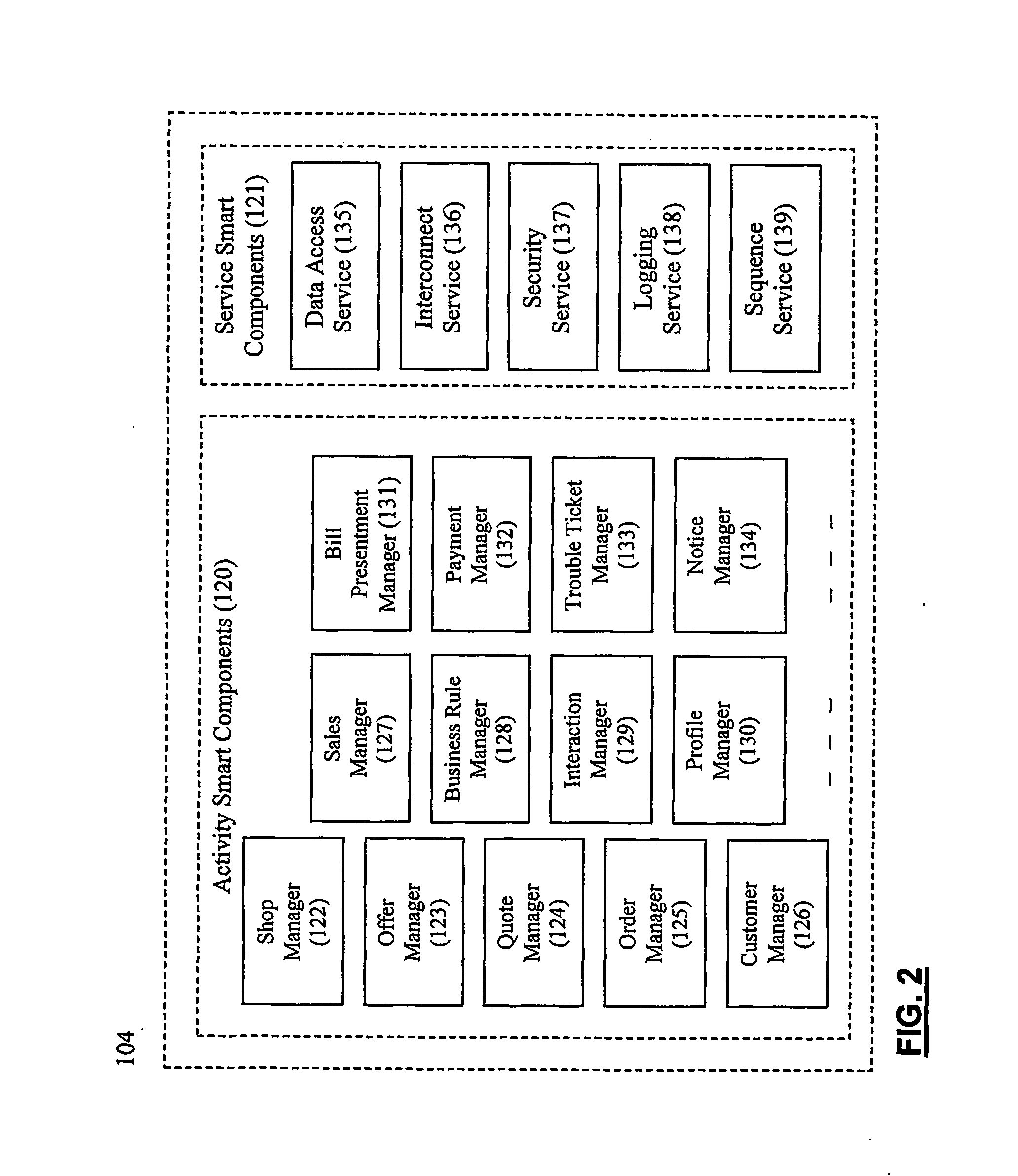

System and method for establishing eletronic business systems for supporting communications servuces commerce

ActiveUS20060059107A1Easy to addEasy to liftPayment protocolsBilling/invoicingEnterprise application integrationSupporting system

Owner:NETCRACKER TECH SOLUTIONS

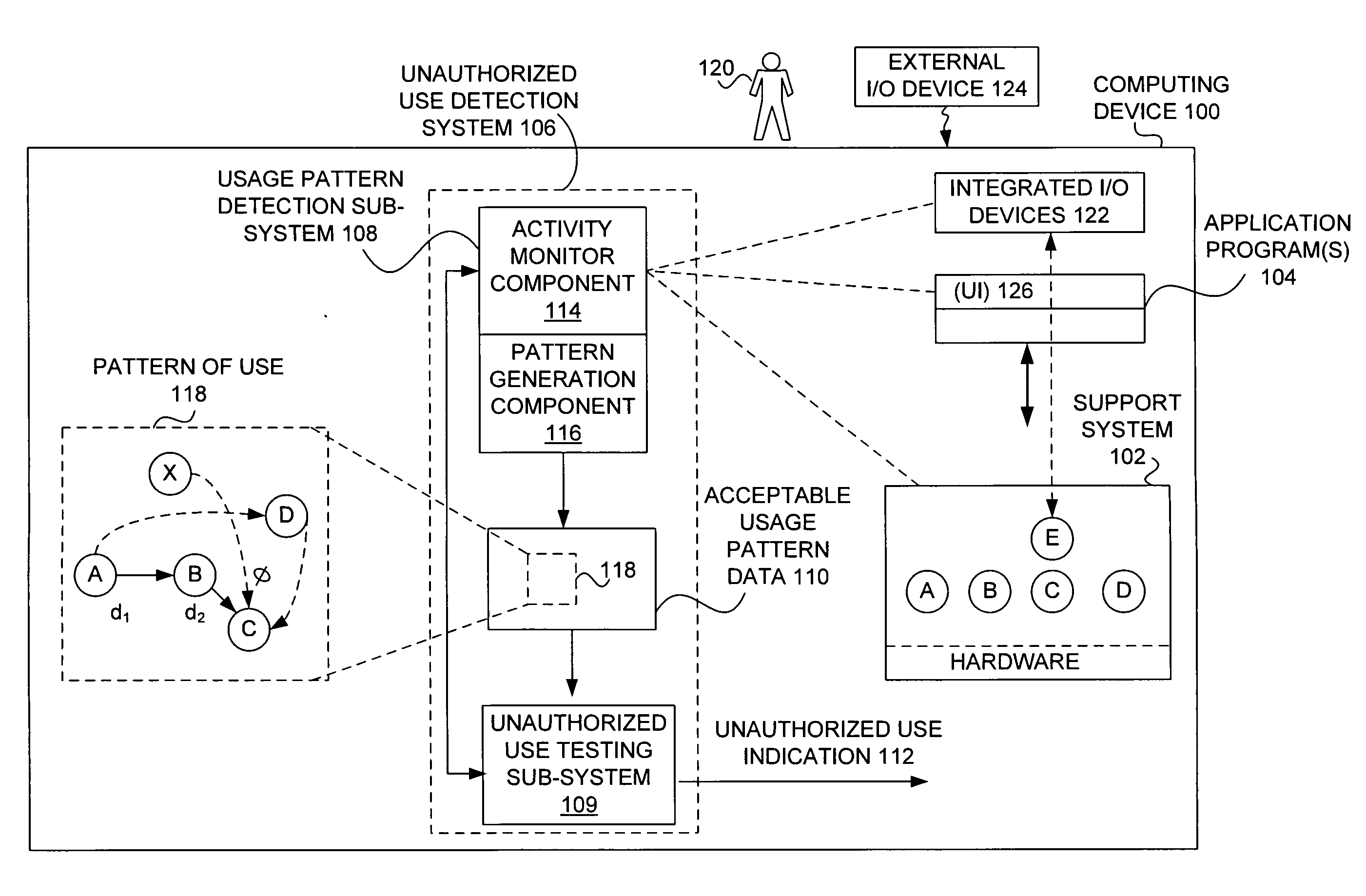

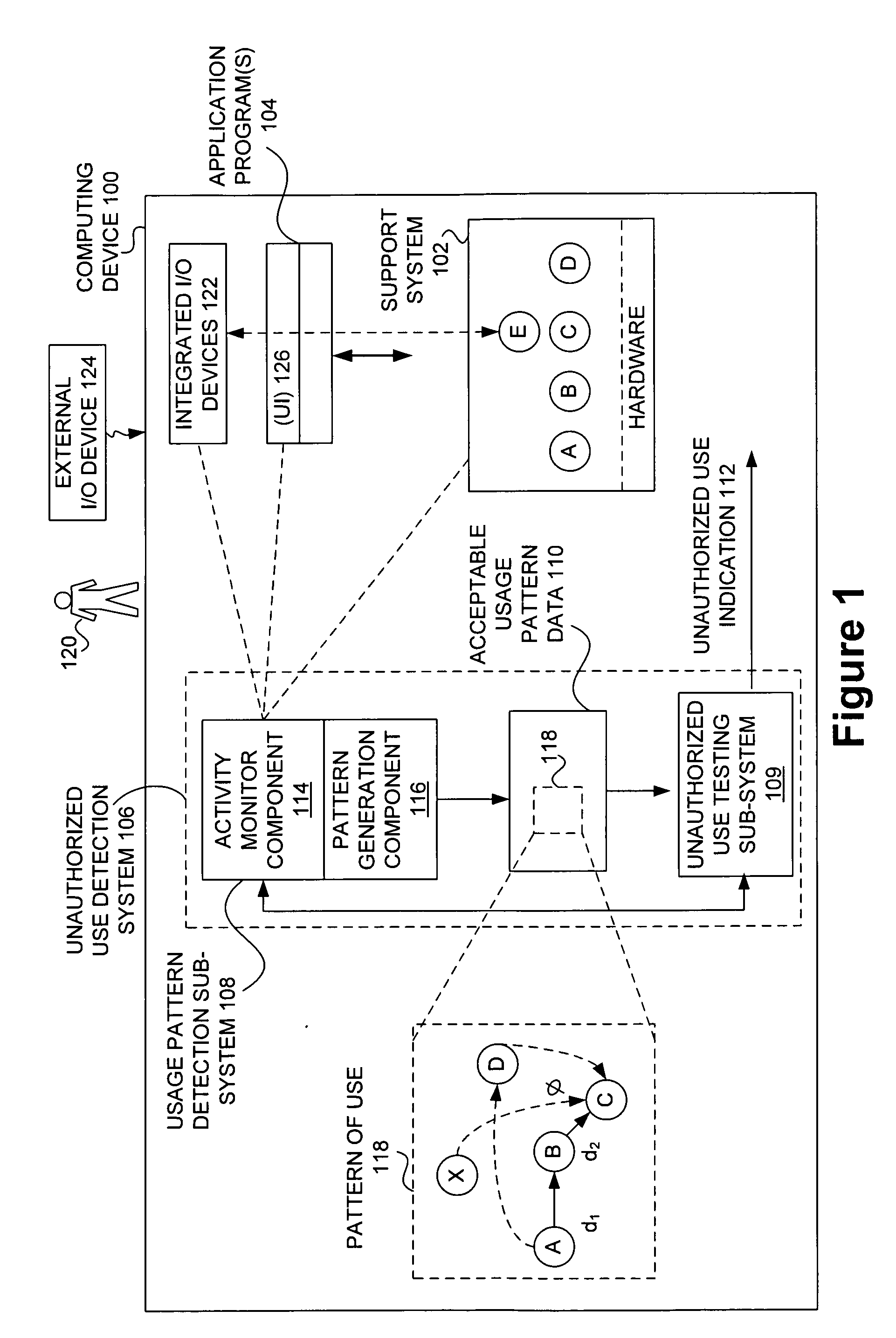

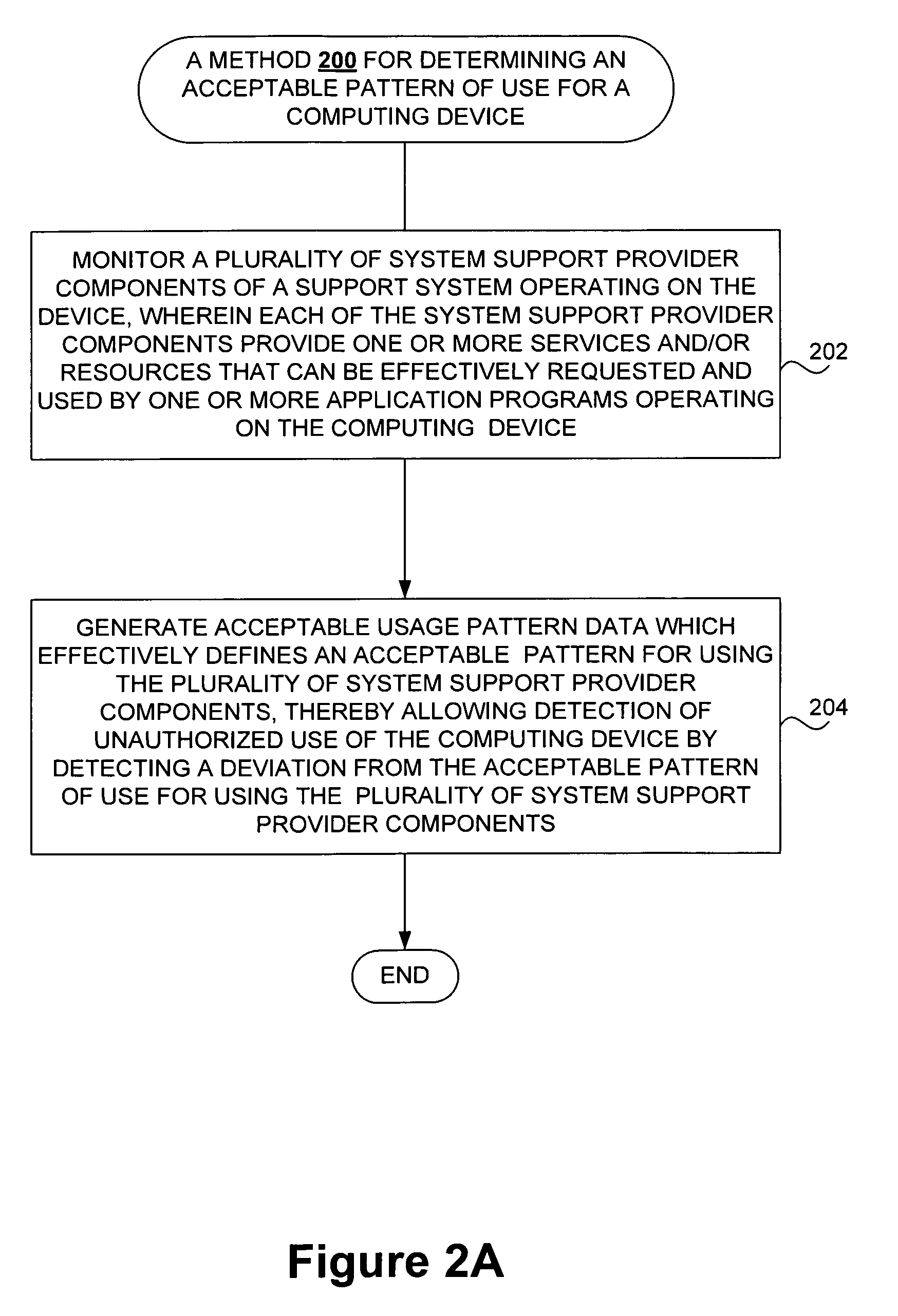

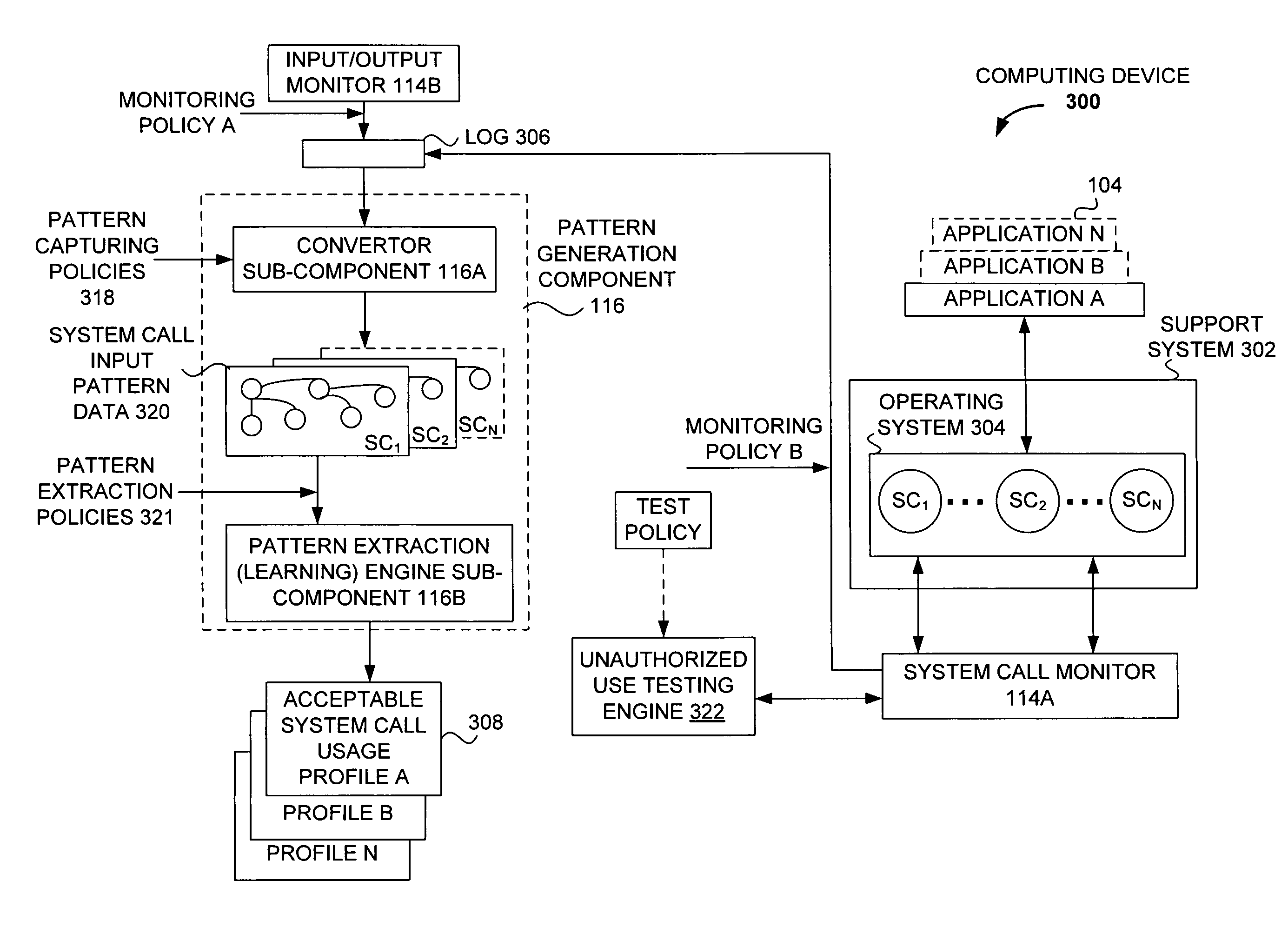

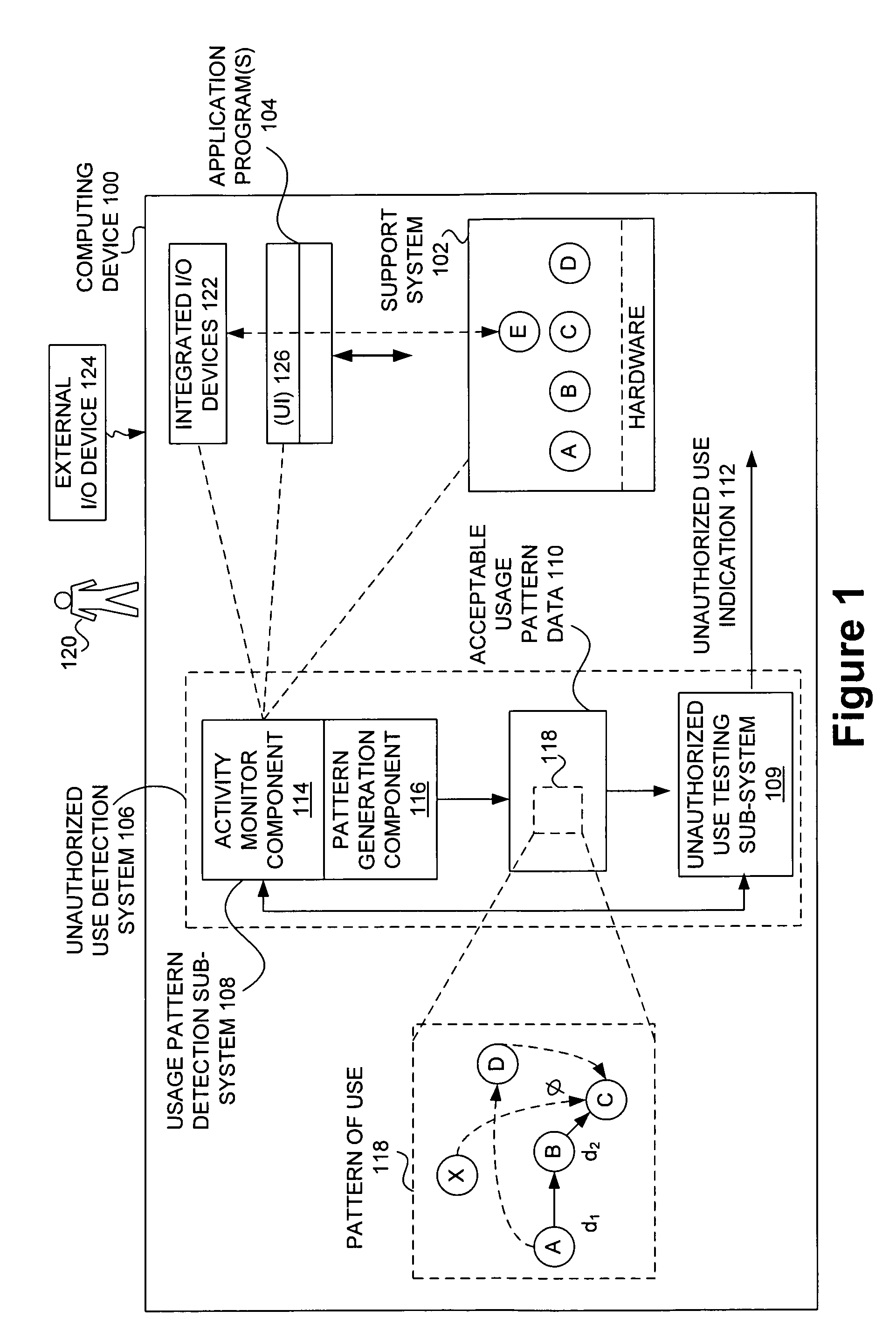

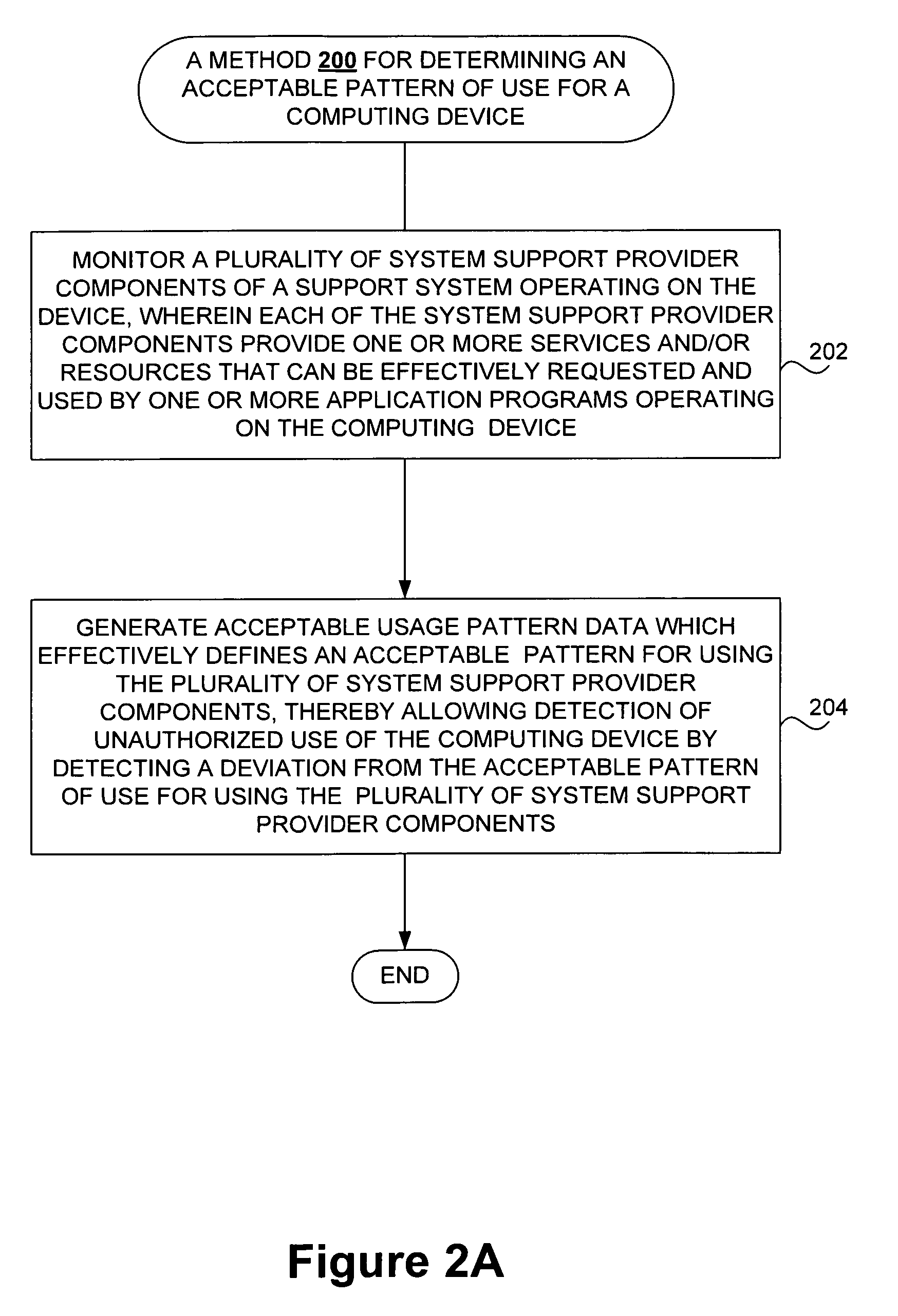

Detecting unauthorized use of computing devices based on behavioral patterns

InactiveUS20090199296A1Efficiently definedMemory loss protectionError detection/correctionSupporting systemOperational system

Techniques for detecting unauthorized use (e.g., malicious attacks) of the computing systems (e.g., computing devices) are disclosed. Unauthorized use can be detected based on patterns of use (e.g., behavioral patterns of use typically associated with a human being) of the computing systems. Acceptable behavioral pattern data can be generated for a computing system by monitoring the use of a support system (e.g., an operating system, a virtual environment) operating on the computing system. For example, a plurality of system support provider components of a support system (e.g., system calls, device drivers) can be monitored in order to generate the acceptable behavioral pattern data in a form which effectively defines an acceptable pattern of use (usage pattern) for the monitored system support provider components, thereby allowing detection of unauthorized use of a computing system by detecting any deviation from the acceptable pattern of use of the monitored system support provider components.

Owner:SAMSUNG ELECTRONICS CO LTD

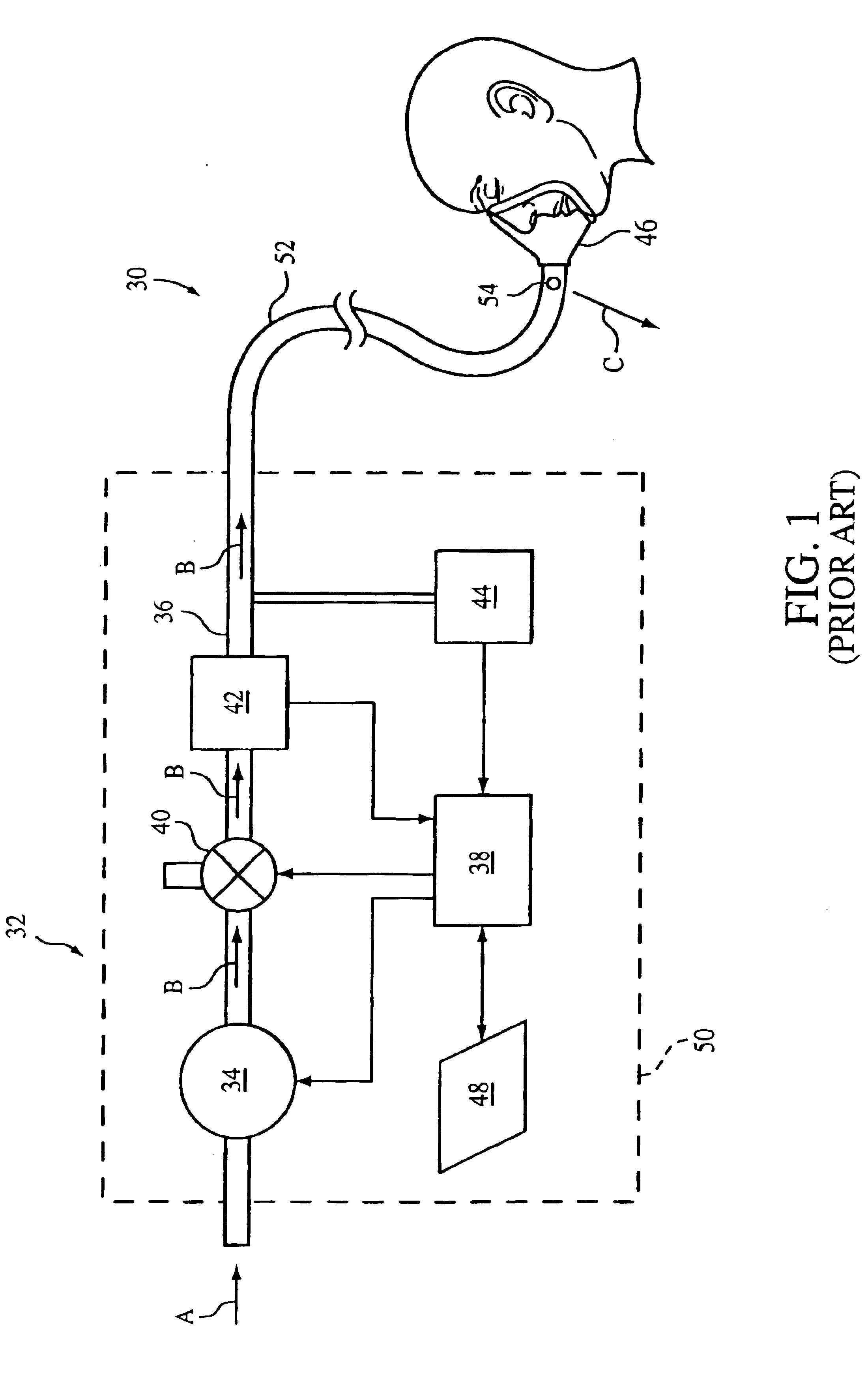

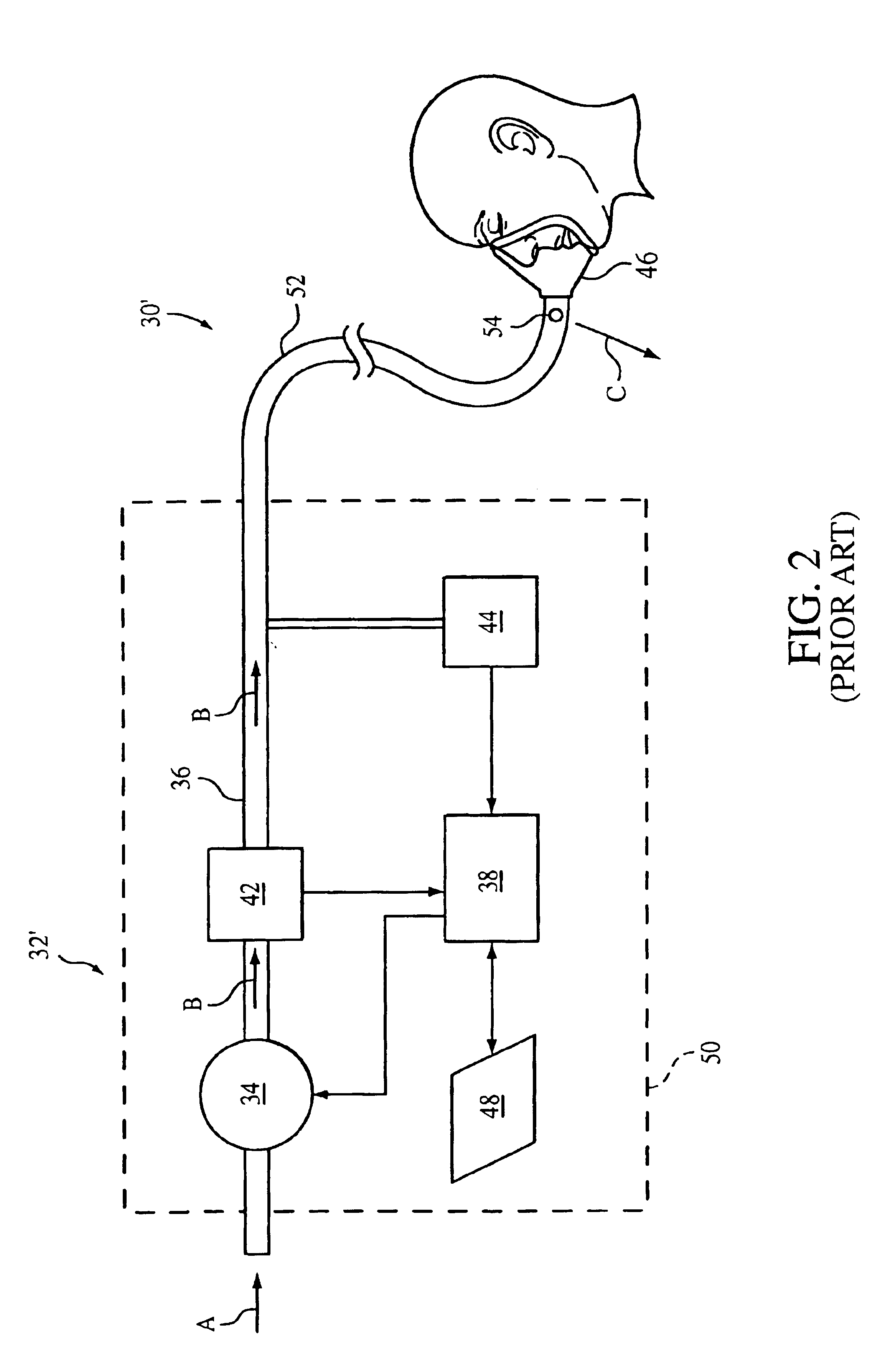

Exhaust port assembly for a pressure support system

InactiveUS6851425B2Noise minimizationArea minimizationBreathing masksRespiratory masksSupporting systemAtmospheric air

An exhaust port assembly comprising a conduit carries a flow of gas. A vent assembly having a fixed exhaust area is provided on the conduit for venting a flow of exhaust gas from within the conduit to ambient atmosphere. The vent assembly is configured so as to minimize noise associated with the flow of exhaust gas passing to atmosphere, diffuse the flow of exhaust gas passing to ambient atmosphere over a relatively large area, and minimize the area occupied by the venting assembly on the conduit.

Owner:RIC INVESTMENTS LLC

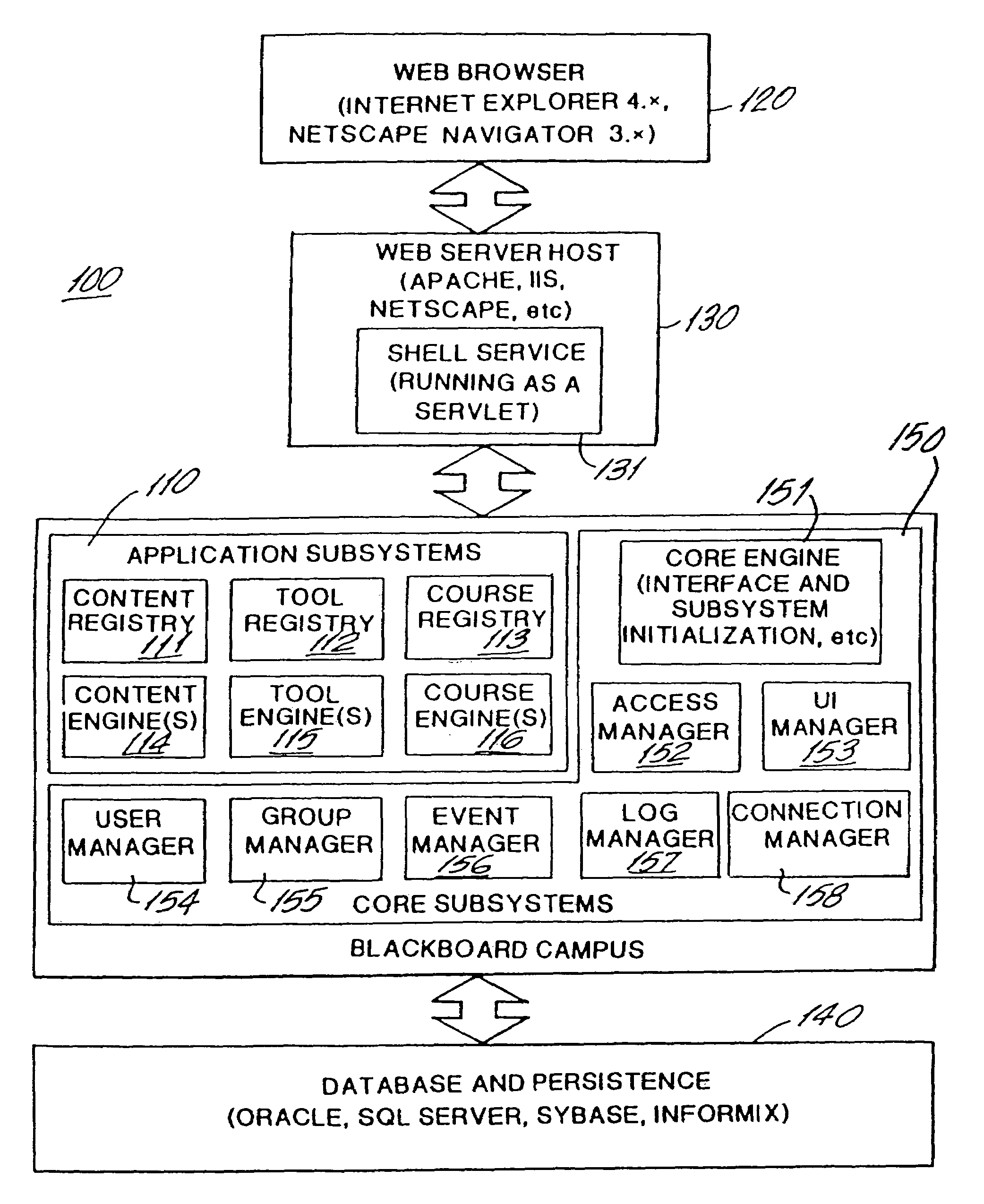

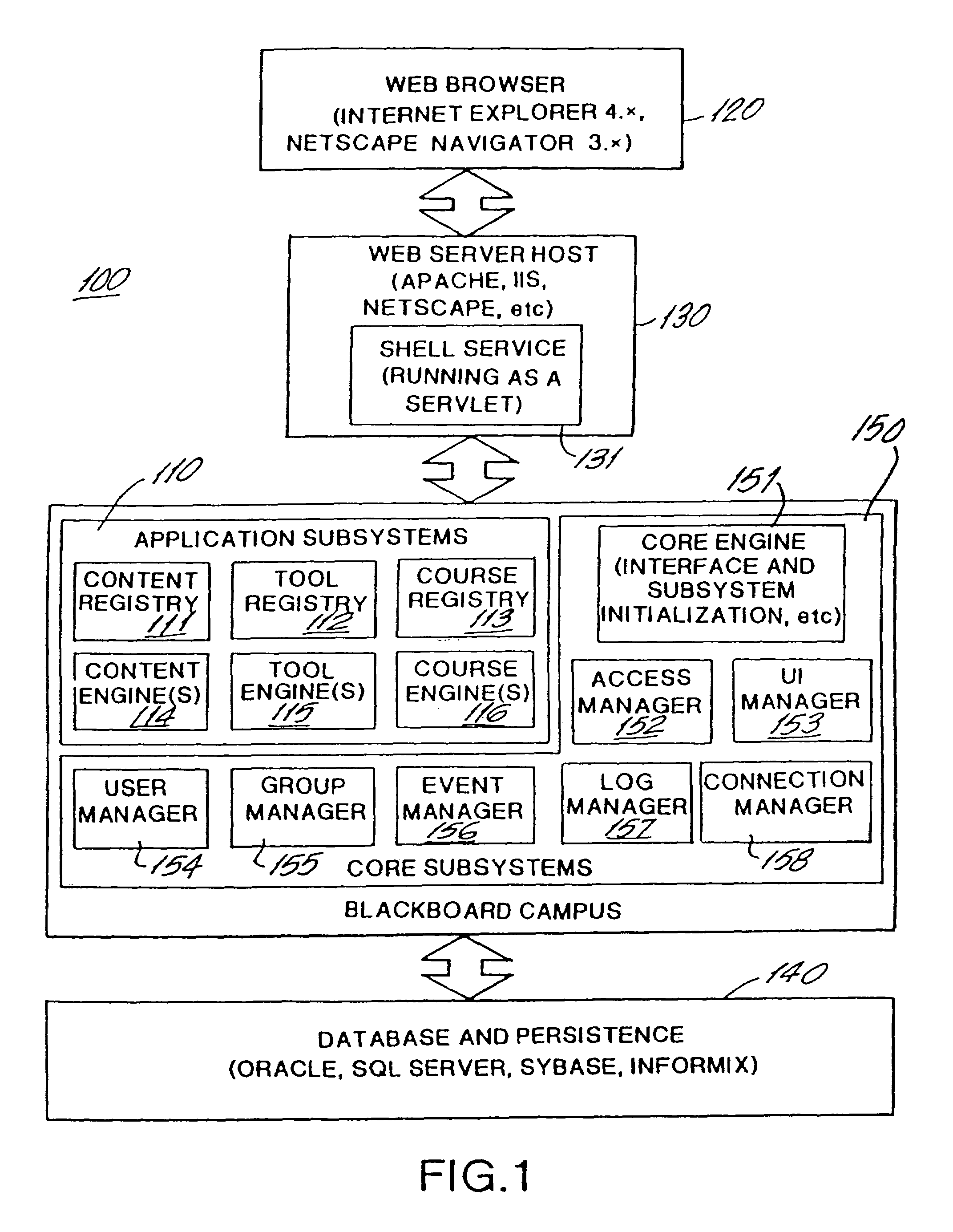

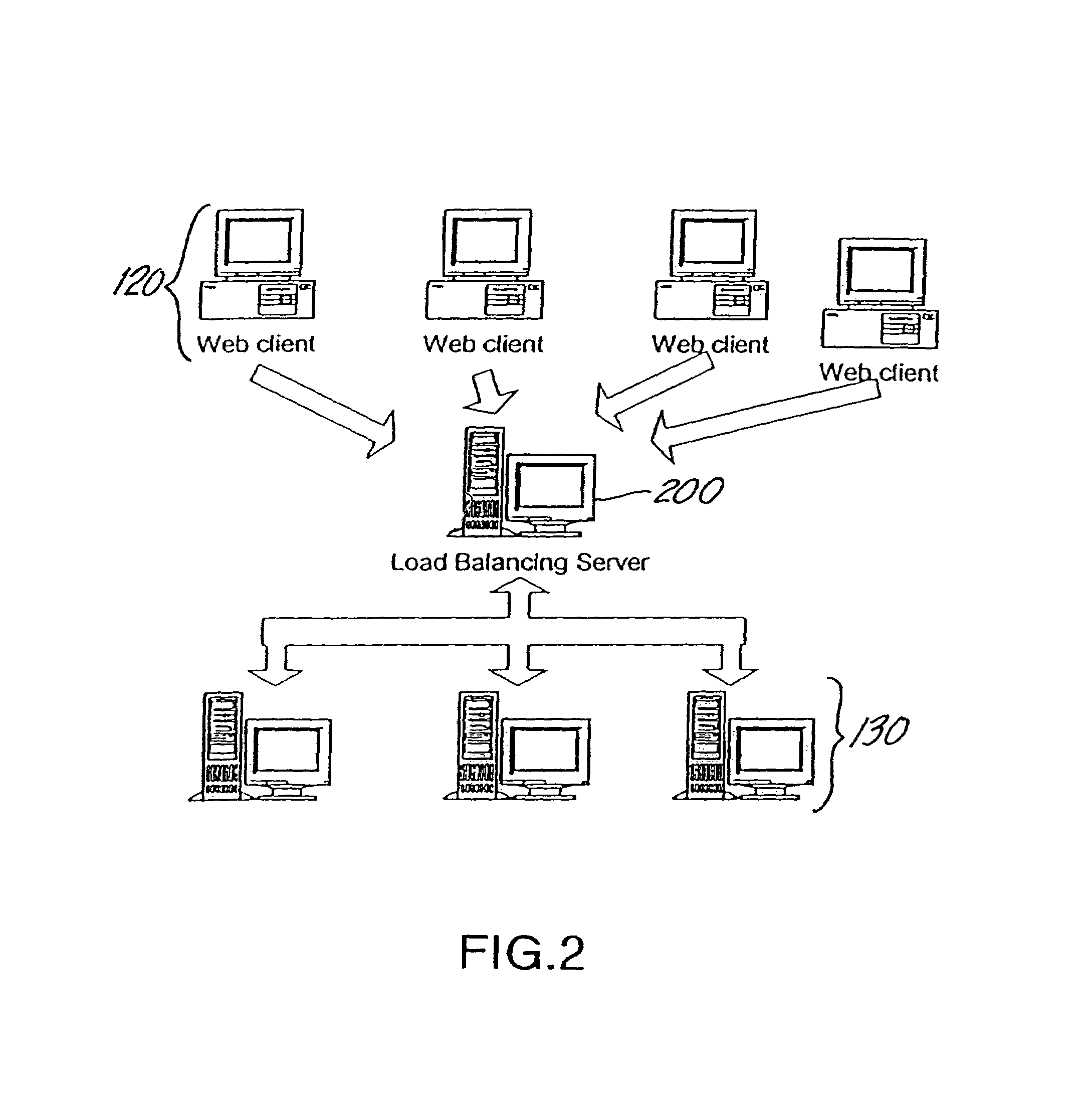

Internet-based education support system and methods

InactiveUS6988138B1Easily interfaceEasy transitionMultiple digital computer combinationsElectrical appliancesSupporting systemWhiteboard

A system and methods for implementing education online by providing institutions with the means for allowing the creation of courses to be taken by students online, the courses including assignments, announcements, course materials, chat and whiteboard facilities, and the like, all of which are available to the students over a network such as the Internet. Various levels of functionality are provided through a three-tiered licensing program that suits the needs of the institution offering the program. In addition, an open platform system is provided such that anyone with access to the Internet can create, manage, and offer a course to anyone else with access to the Internet without the need for an affiliation with an institution, thus enabling the virtual classroom to extend worldwide.

Owner:BLACKBOARD INC

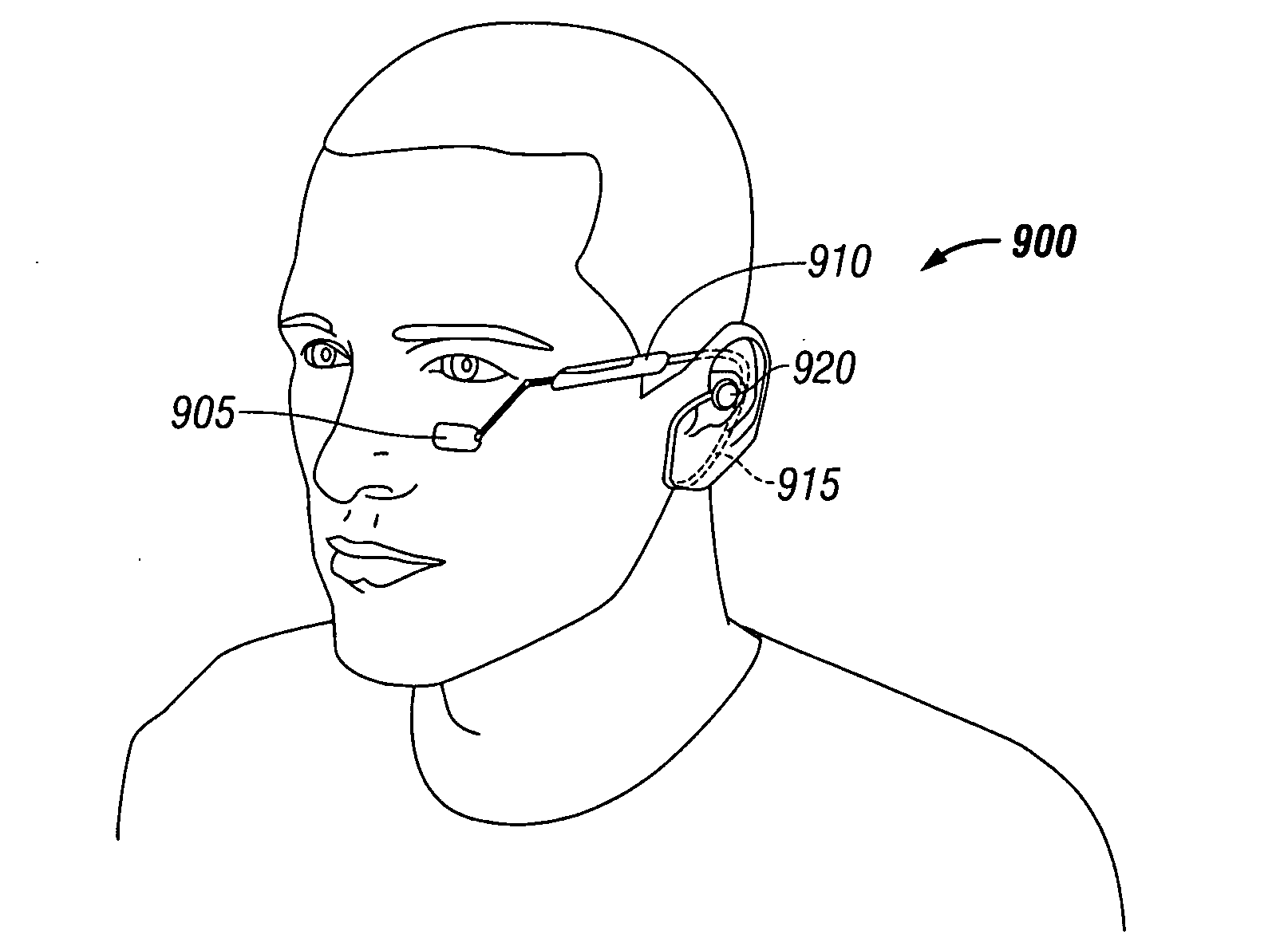

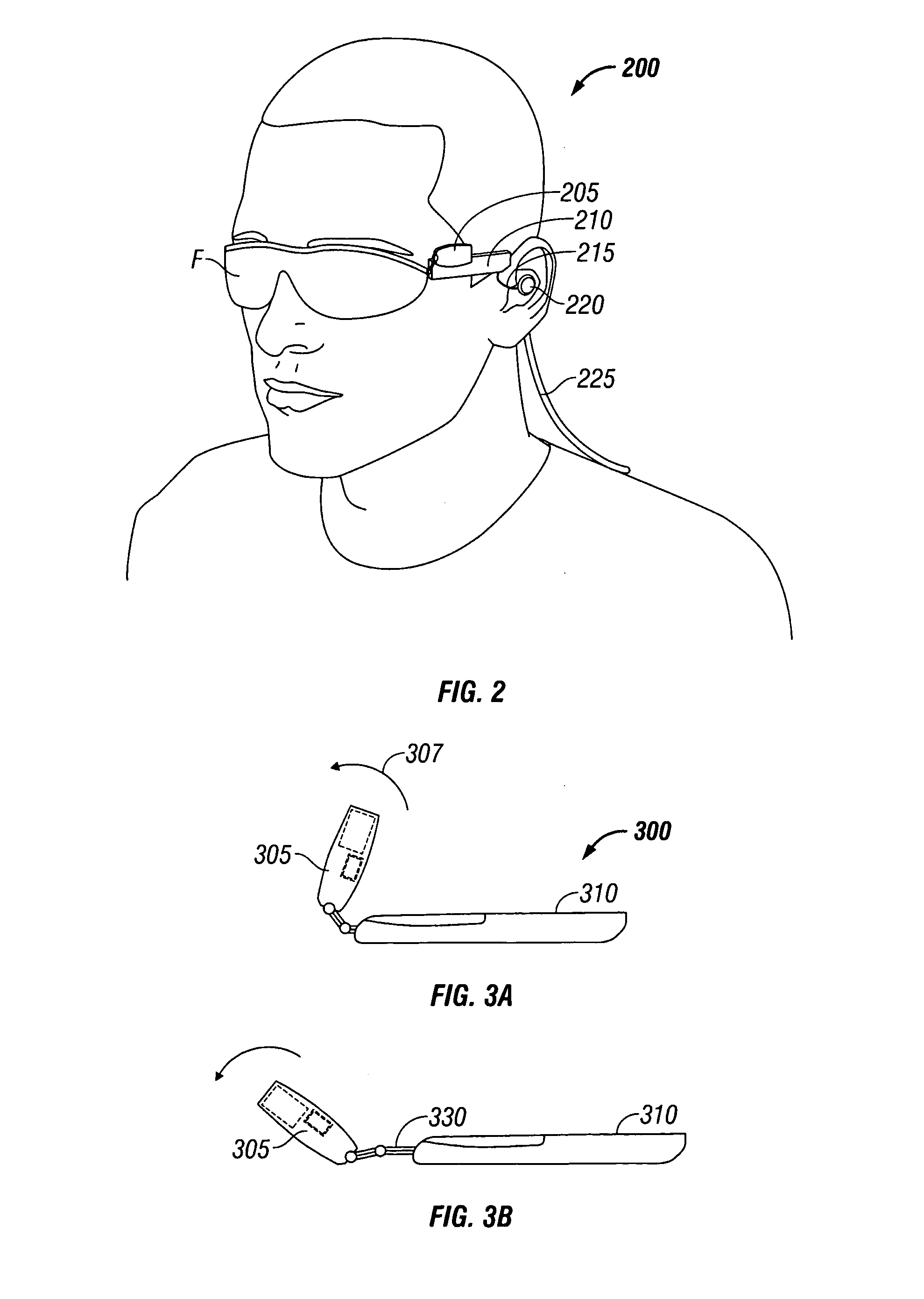

Monocular display device

ActiveUS20080291277A1Equally distributedTelevision system detailsTravelling sacksCommunication interfaceSupporting system

A head mounted support system for a head mounted apparatus. The apparatus includes a monocular display with a wireless communications interface, a user input device, a transmitter, receiver and a controller. The controller is configured to control the transmitter for sending and receiving control signals to and from an external device via the wireless interface. The monocular display is positioned relative to the user's dominant eye to display images to the user while occluding less than half of the user's maximum viewing space, while enabling the user to send and receive audible information or music. The head mounted support system may include an ear loop, and a housing for storing one or more functional components of the apparatus.

Owner:KOPIN CORPORATION

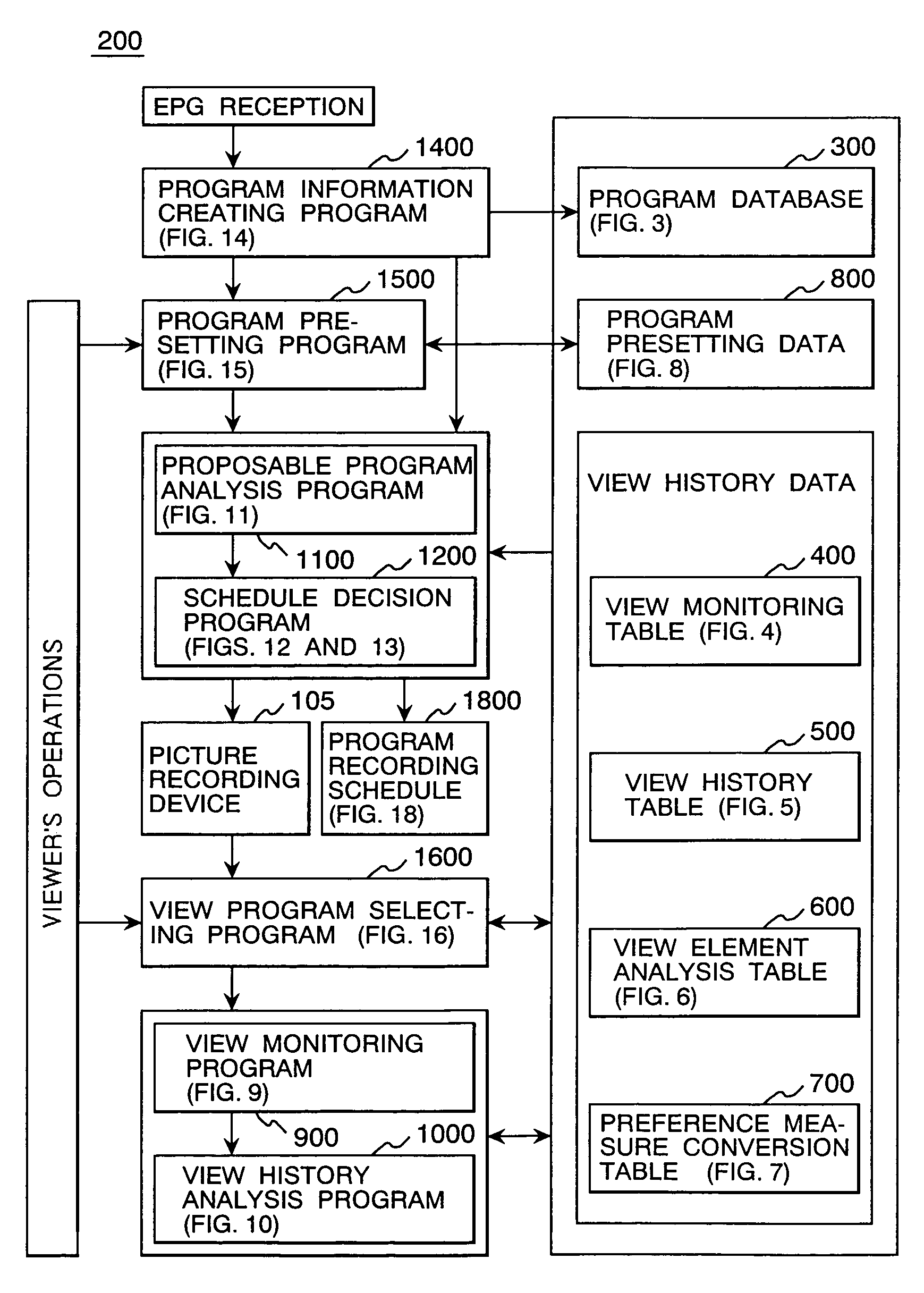

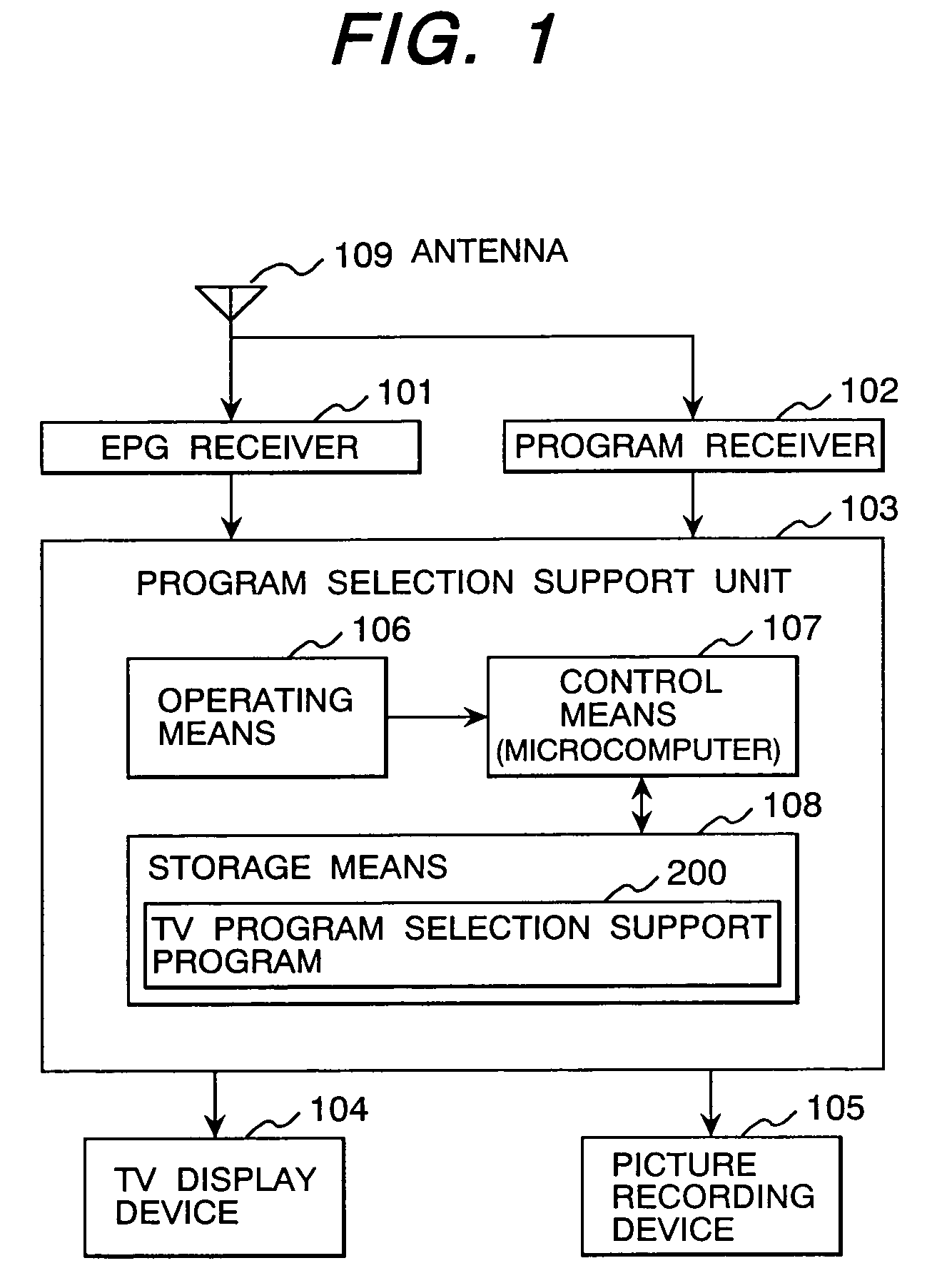

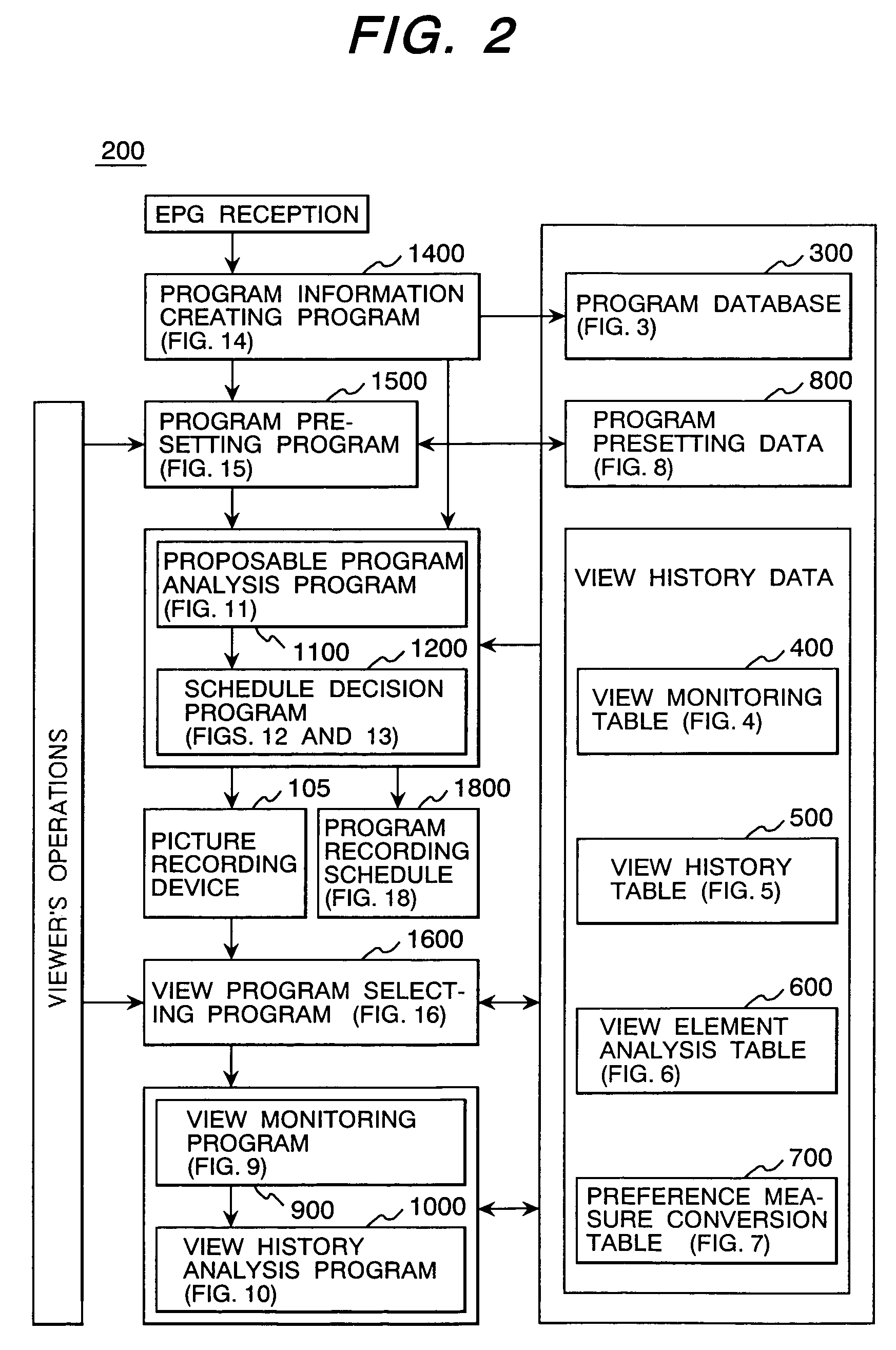

TV program selection support system

InactiveUS7096486B1Television system detailsColor television detailsSupporting systemElectronic program guide

A TV program selection support system selects only programs suiting viewer's preference or necessary for a viewer from a large number of programs to be broadcast and proposes the selected programs to the viewer. The TV program selection support system comprises a program receiver for receiving broadcast TV programs, an EPG receiver for receiving an electronic program table listing TV programs, an EPG storage device for storing an EPG received by the EPG receiver, an operating means to be operated by the viewer to select a program from the stored electronic program table, a program selection support program for determining viewer's view tendency by analyzing the operation made by the viewer, creating an electronic program table on the basis of the view tendency and displaying the created electronic program table.

Owner:HITACHI CONSUMER ELECTRONICS CORP +1

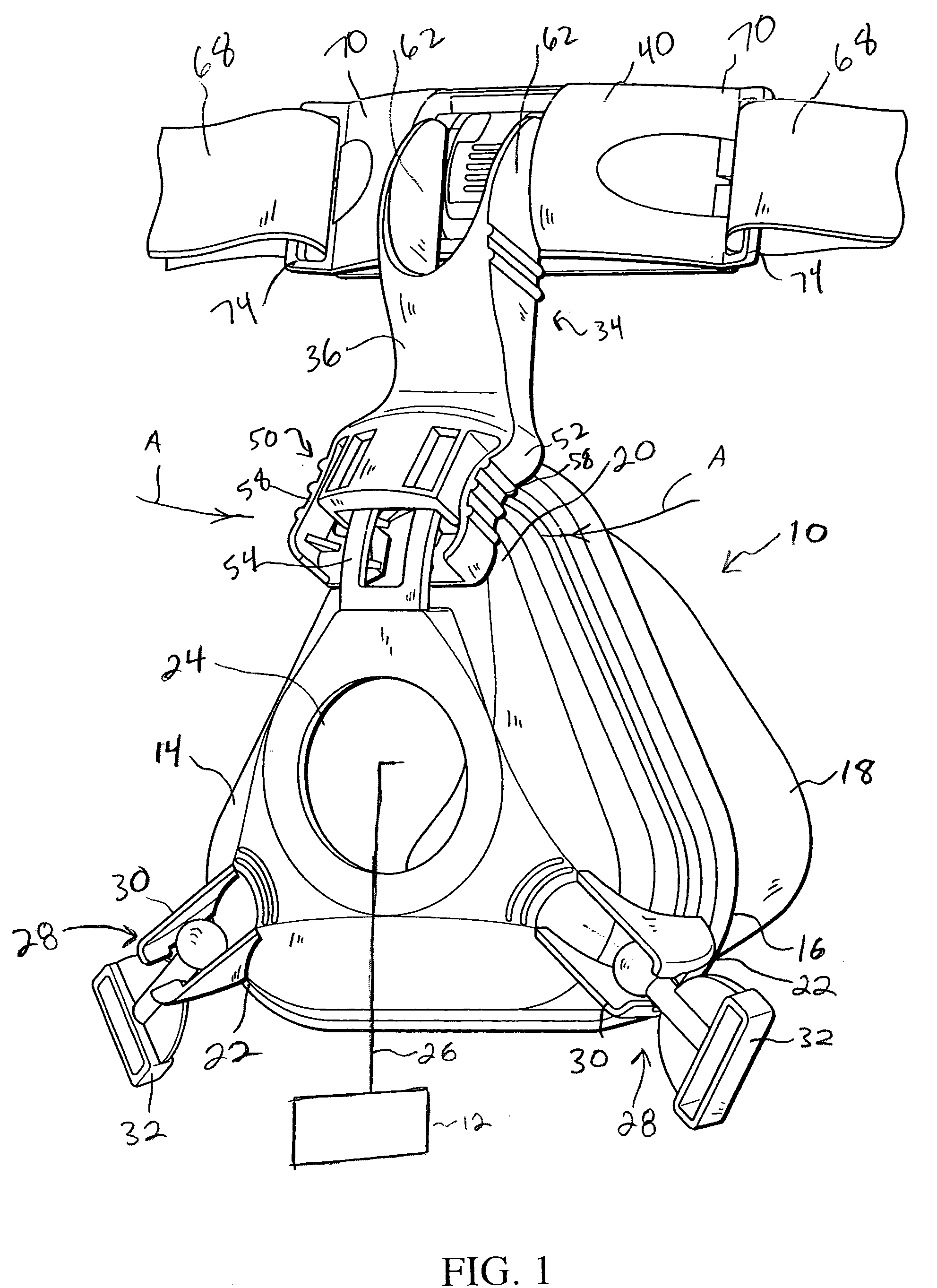

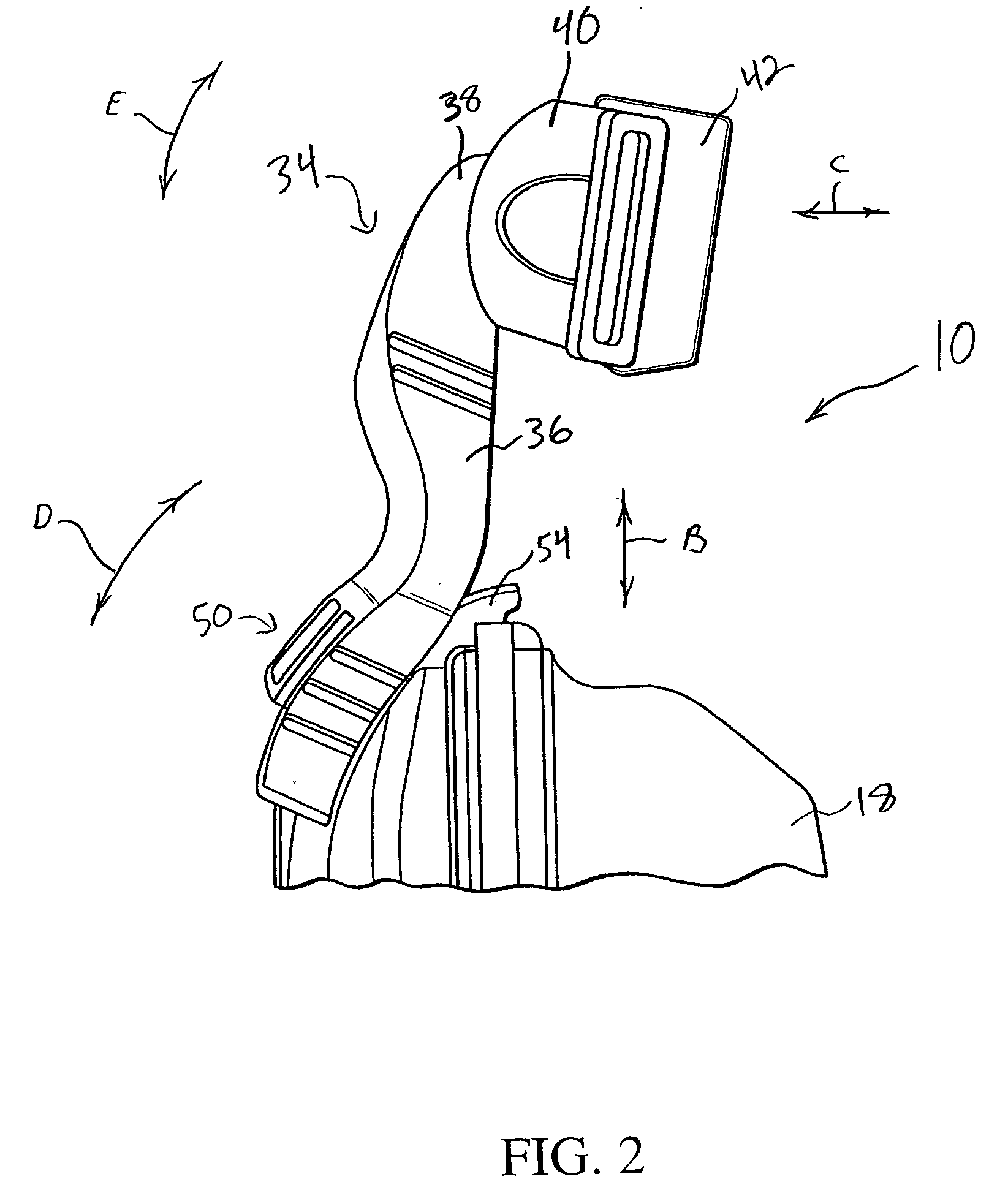

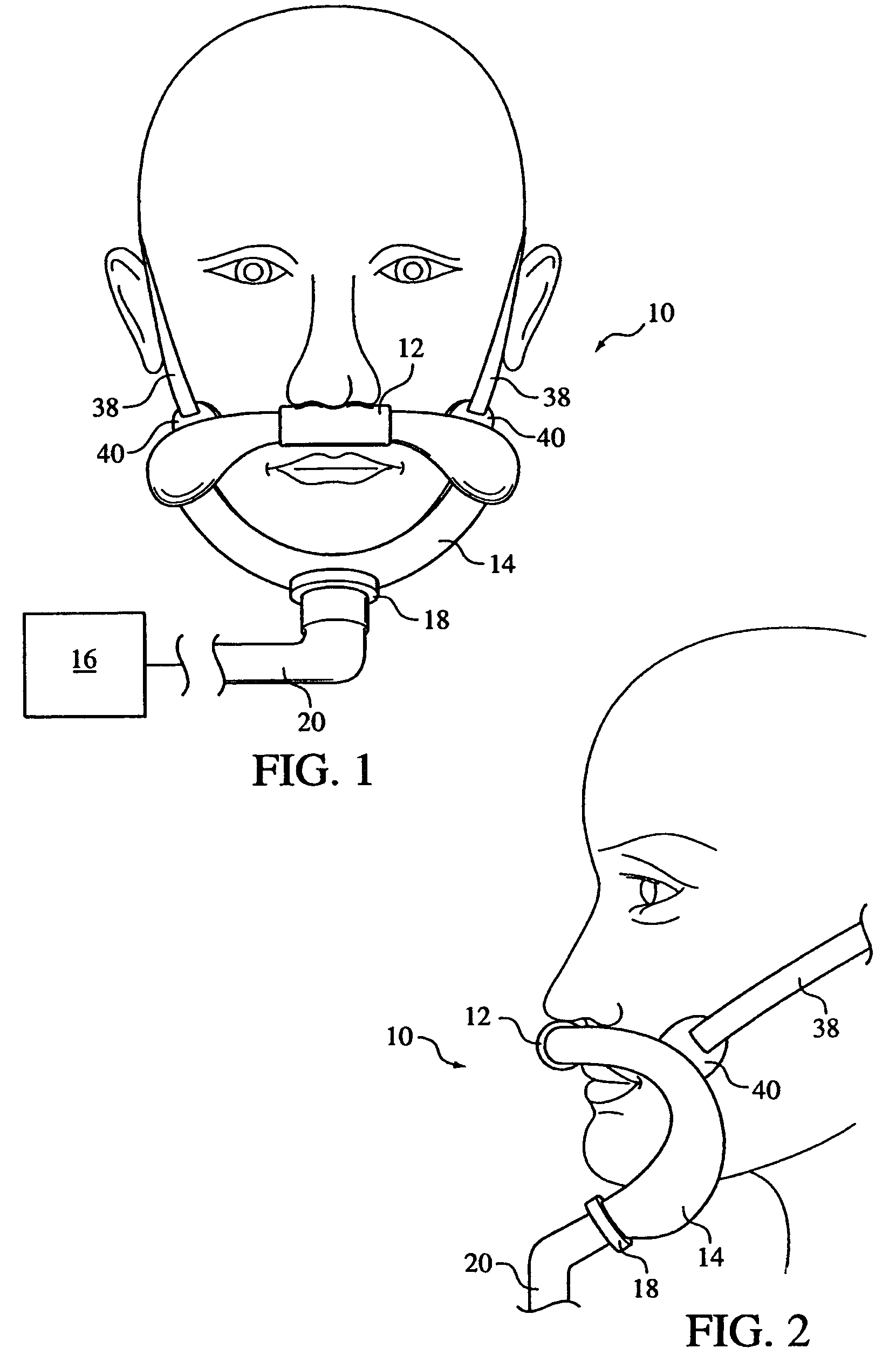

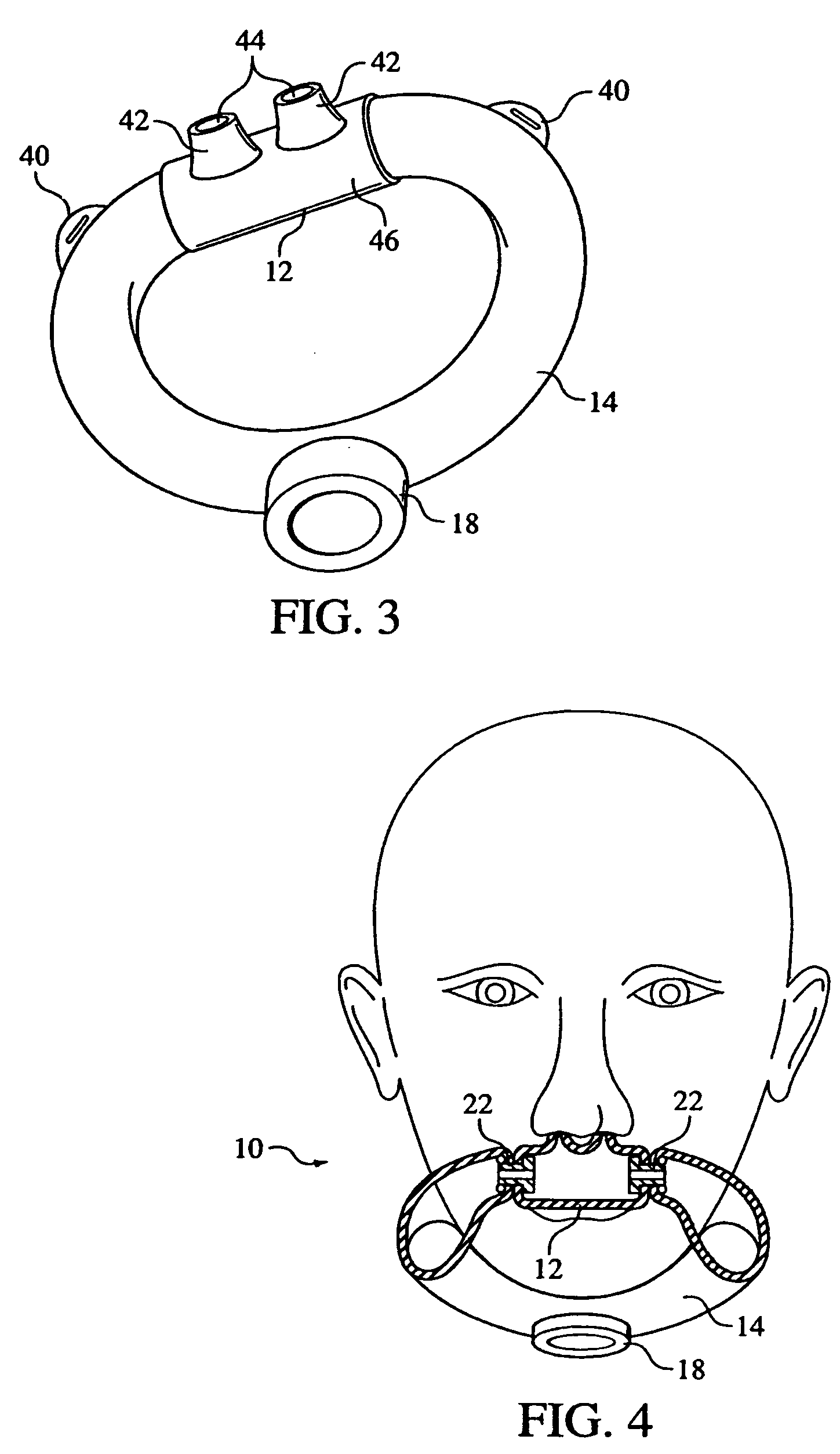

Patient interface with forehead support system

ActiveUS20040045551A1Easy to disassembleImprove stabilityPhysical therapyBreathing masksSupporting systemForehead

A patient interface having a forehead support adjustably. The forehead support assembly includes a support arm that is adjustably mounted to the mask shell, thereby allowing the adjustment of the distance between the forehead support bracket and the mask shell in order to adjust for patient's of different sizes. A forehead support bracket is pivotally connected to the support arm. The pivoting forehead support bracket is self-aligning to allow the forehead pad to remain parallel to the patient's forehead at all times, thus enhancing comfort and stability. The forehead support bracket is removable from the support arm, allowing the headgear (with support bracket attached) to be donned separately from the mask and support arm. The forehead support bracket in one embodiment has a forehead pad formed from the headgear itself.

Owner:RIC INVESTMENTS LLC

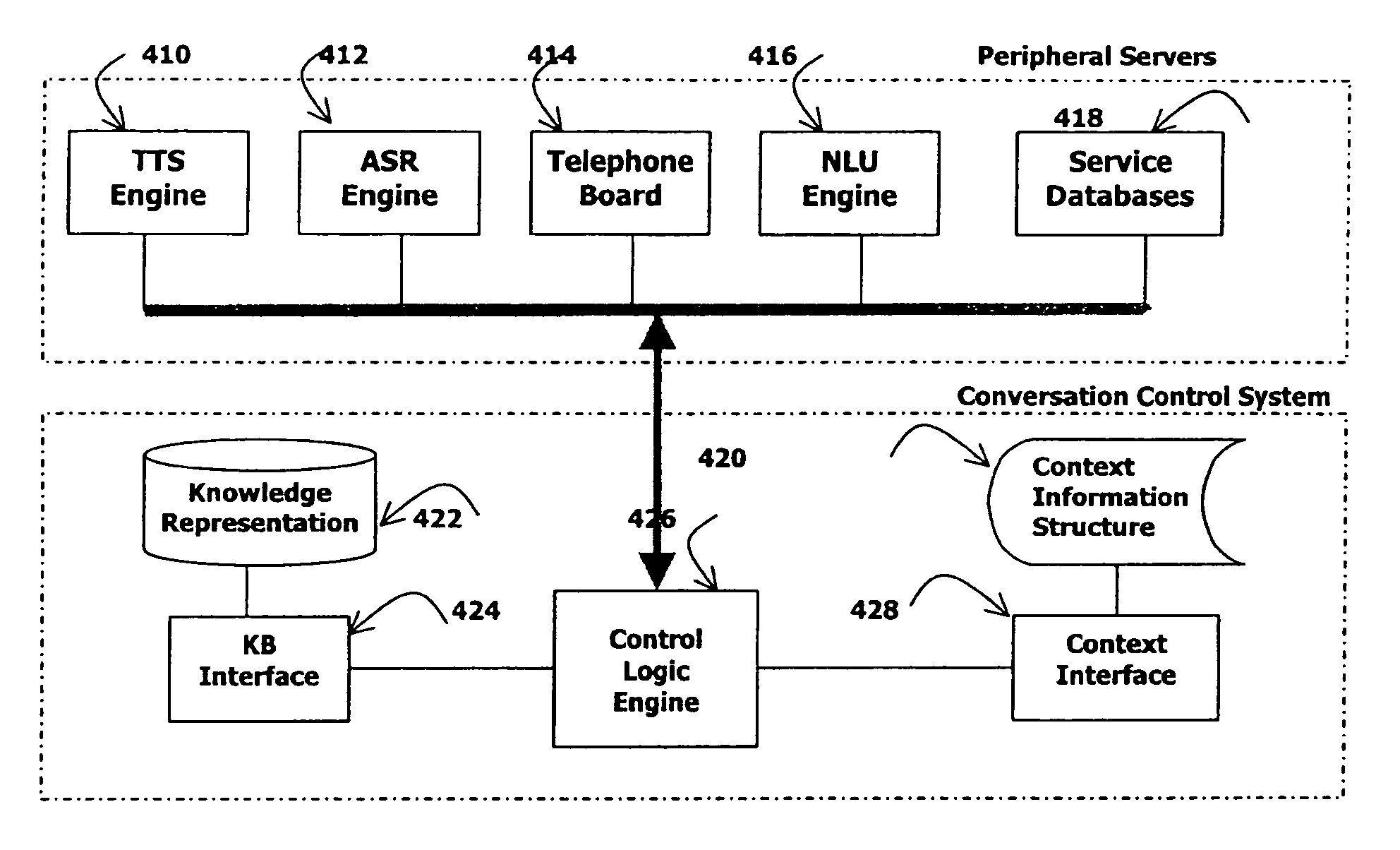

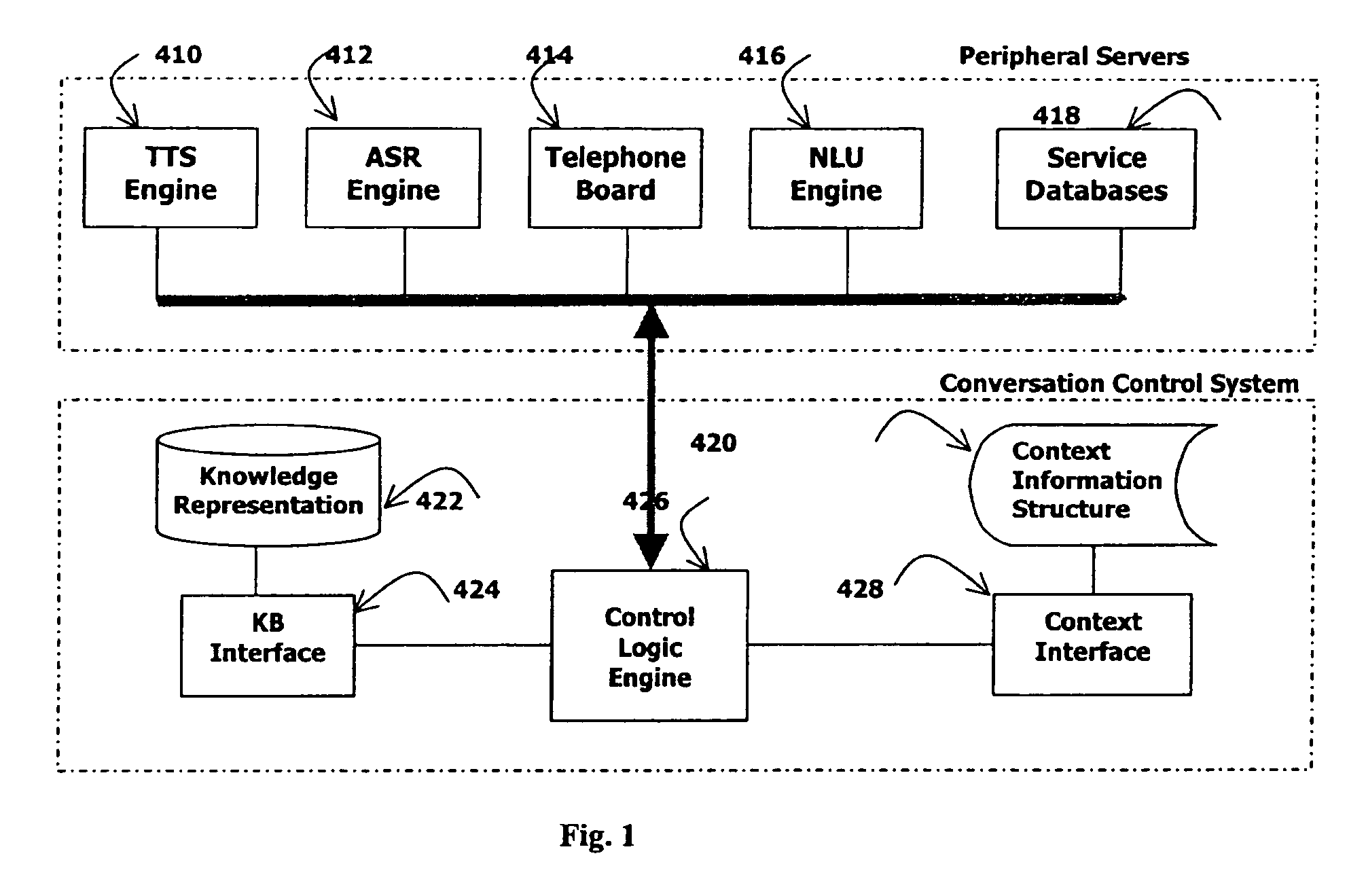

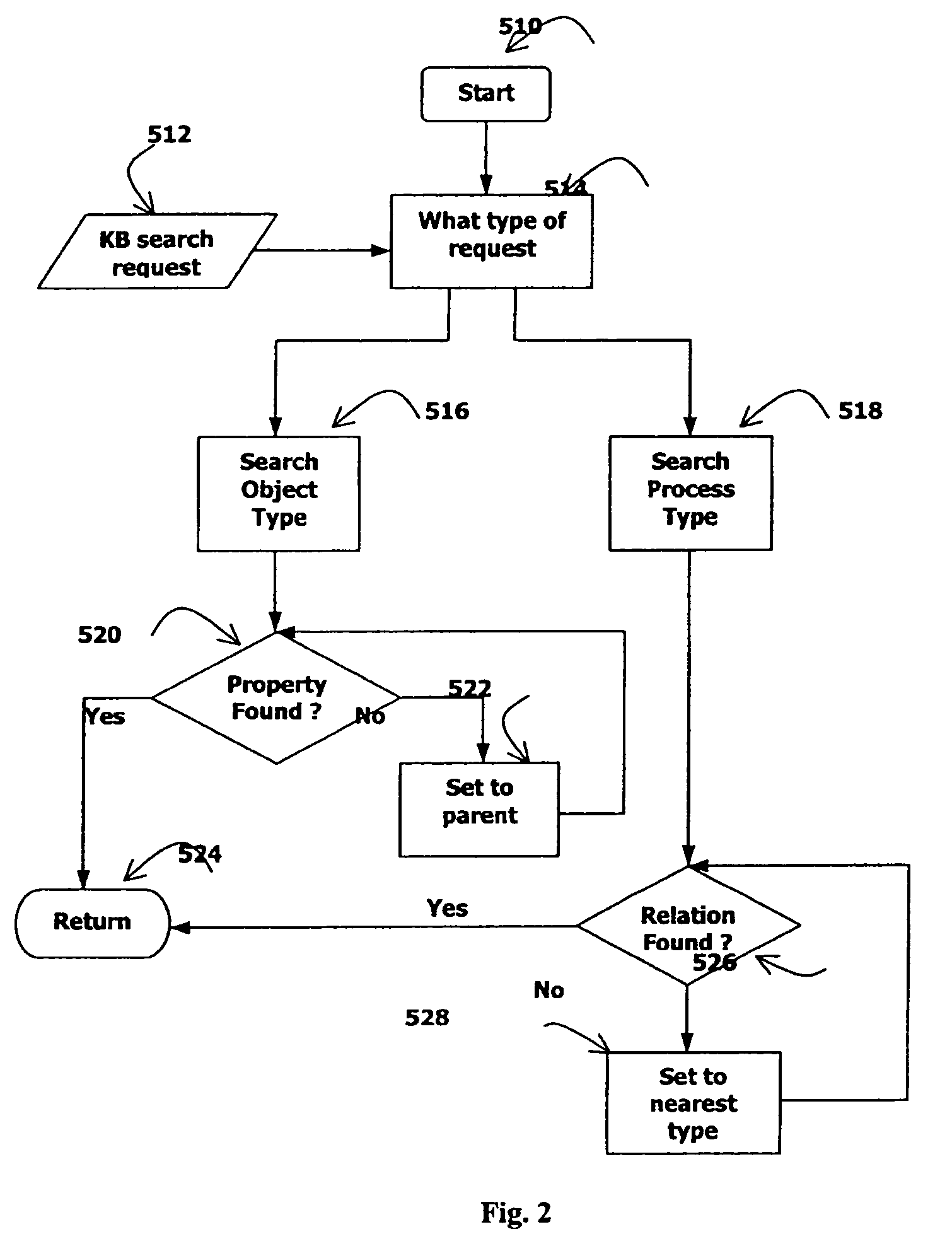

Knowledge-based flexible natural speech dialogue system

InactiveUS7386449B2Speech recognitionSpecial data processing applicationsHuman–computer interactionFixed position

A knowledge-based natural speech dialogue system includes: (i) a knowledge support system, (ii) a flexible dialogue control system, and (iii) a context information system. Flexibilities of the conversation structure, inherent in mixed-initiative mode for dealing with complex user request, are managed because the knowledge structures involved are represented by additional, powerful knowledge representation tools, and because the context information is retained by more specific data structures, which covers larger temporal scopes by the logic of the conversation, rather than by a fixed locality of the grammar flow. This system provides a simple yet reliable method to compensate for these factors to enable more powerful conversation engines with mixed-initiative capabilities.

Owner:VOICE ENABLING SYST TECH

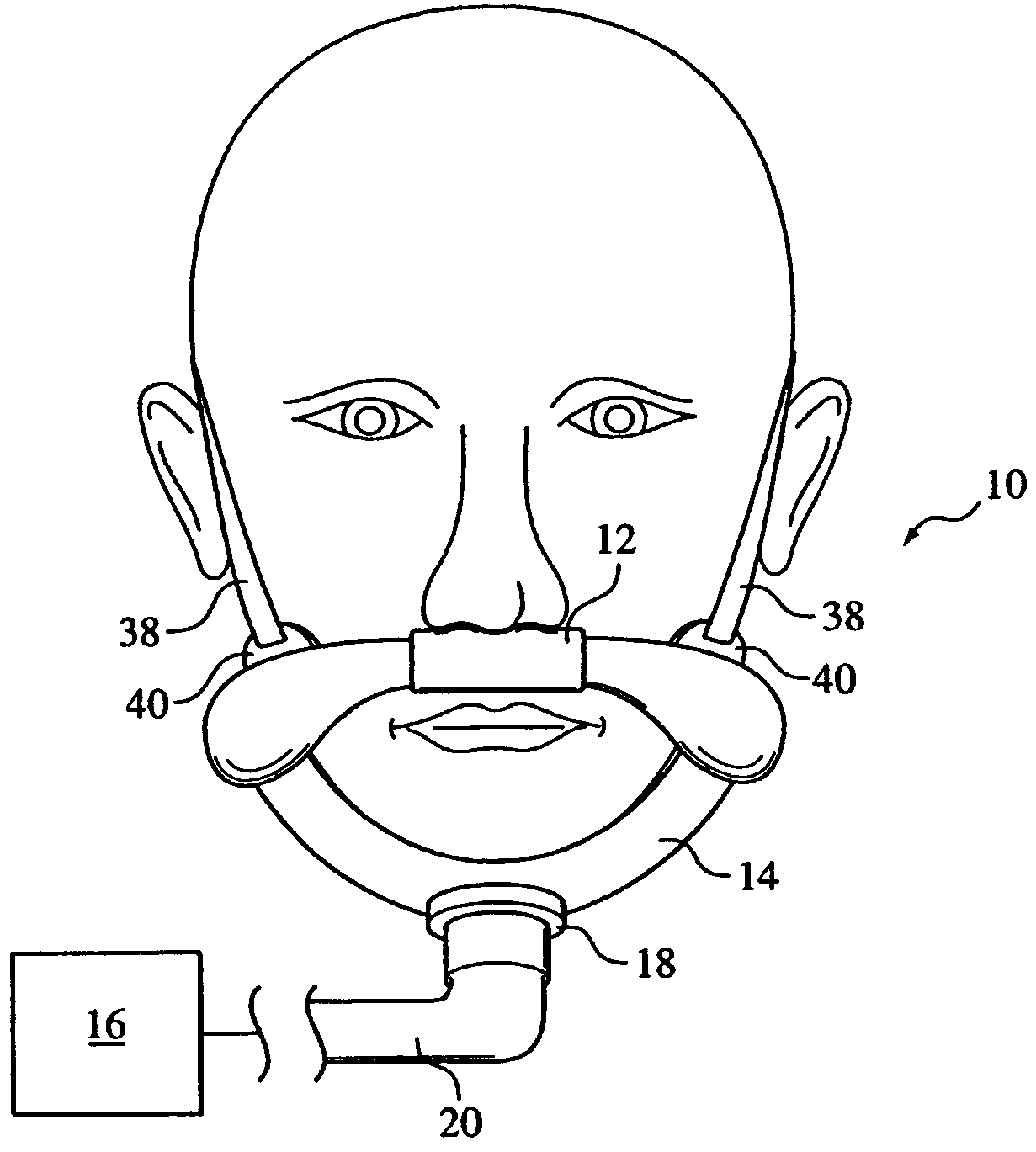

Patient interface assembly supported under the mandible

ActiveUS7178525B2Obstruction in may takeAllow useBreathing masksRespiratory masksChinSupporting system

A patient interface system having a patient interface and chin support system for supporting the patient interface on the patient and for supplying a flow of gas from a patient circuit to the patient interface. In one embodiment, the chin support is formed from flexible hollow chambered support and extends from either side of the patient interface curving downwardly in front of the patient's cheeks, around the outside of the patient's mouth, to a position beneath the patient's mandible. In another embodiment, the chin support is coupled to a conduit that is coupled to the patient interface. The chin support includes at least a portion that is disposed under the patient's mandible.

Owner:PHILIPS RS NORTH AMERICA LLC

Monocular display device

ActiveUS8378924B2Equally distributedCathode-ray tube indicatorsOptical partsSupporting systemCommunication interface

A head mounted support system for a head mounted apparatus. The apparatus includes a monocular display with a wireless communications interface, a user input device, a transmitter, receiver and a controller. The controller is configured to control the transmitter for sending and receiving control signals to and from an external device via the wireless interface. The monocular display is positioned relative to the user's dominant eye to display images to the user while occluding less than half of the user's maximum viewing space, while enabling the user to send and receive audible information or music. The head mounted support system may include an ear loop, and a housing for storing one or more functional components of the apparatus.

Owner:KOPIN CORPORATION

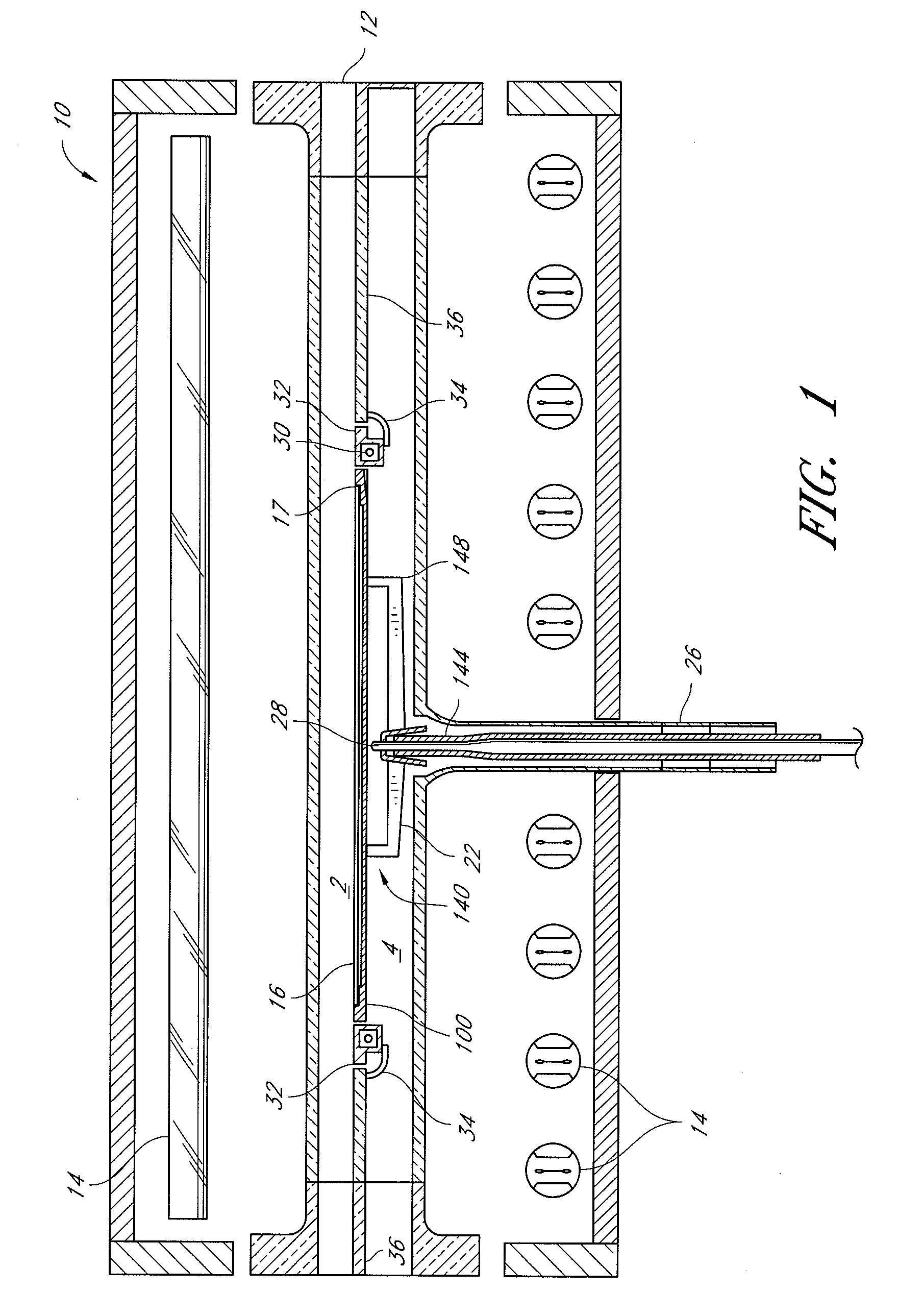

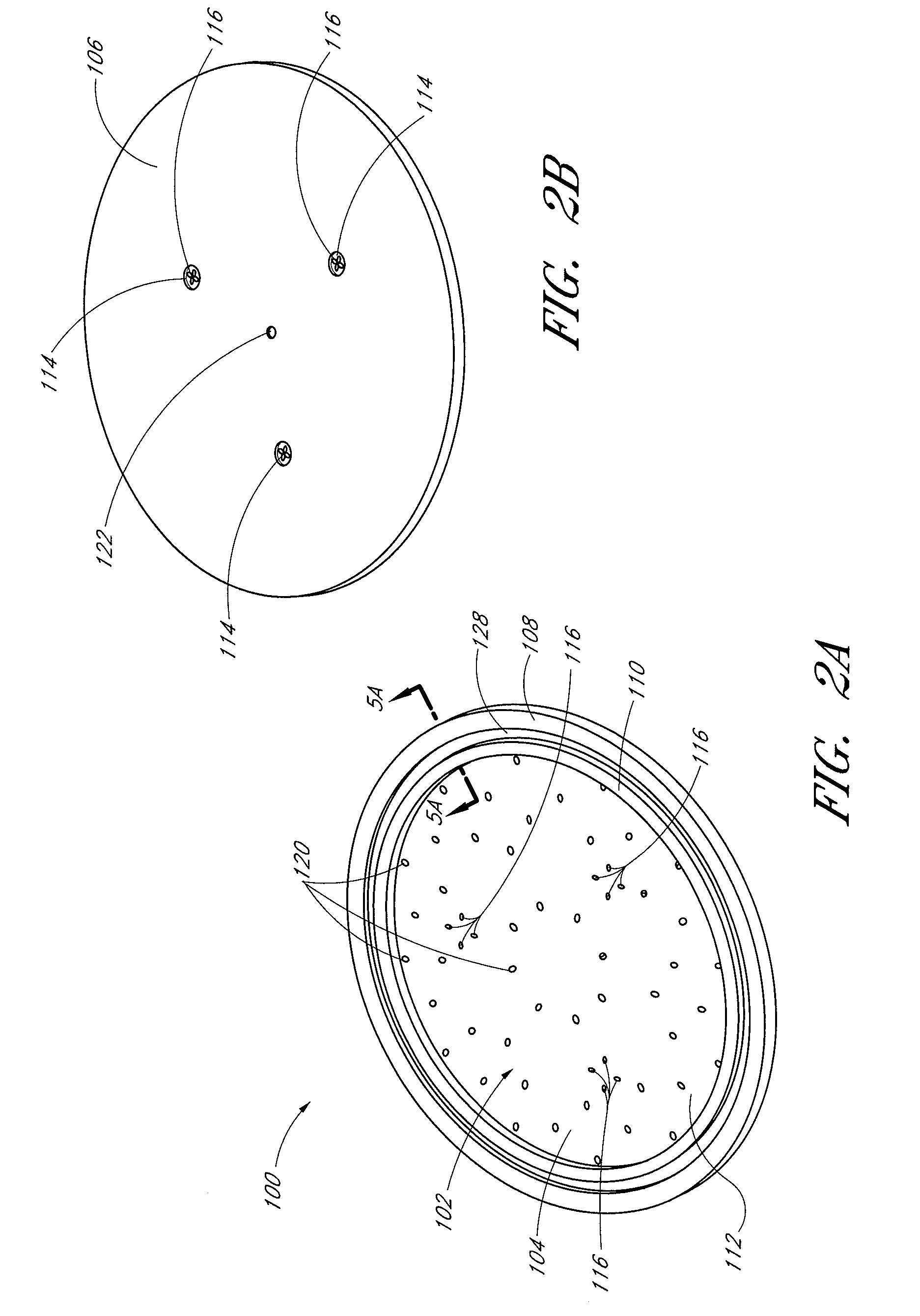

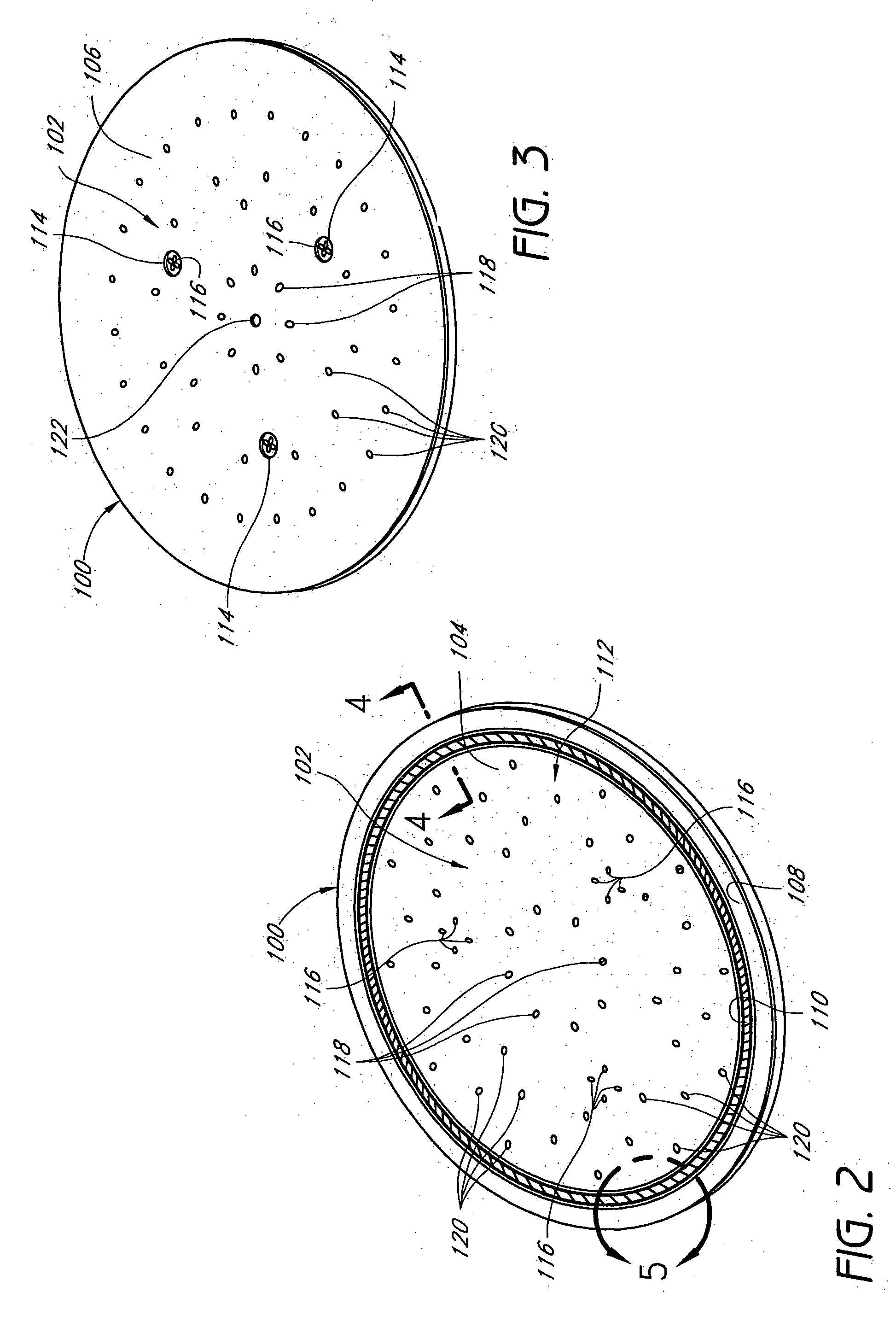

Porous substrate holder with thinned portions

InactiveUS20090280248A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingPorous substrateSupporting system

A substrate support system comprises a substrate holder for supporting a substrate. The substrate holder comprises a central portion sized and shaped to extend beneath most or all of a substrate supported on the substrate holder. The central portion has one or more recesses defining thinned portions of the central portion. The one or more thinned portions may comprise at least about 10% of an upper or lower surface of the central portion. The central portion is formed of a porous material, such as a material having a porosity between about 10-40%, configured to allow gas flow therethrough.

Owner:ASM AMERICA INC

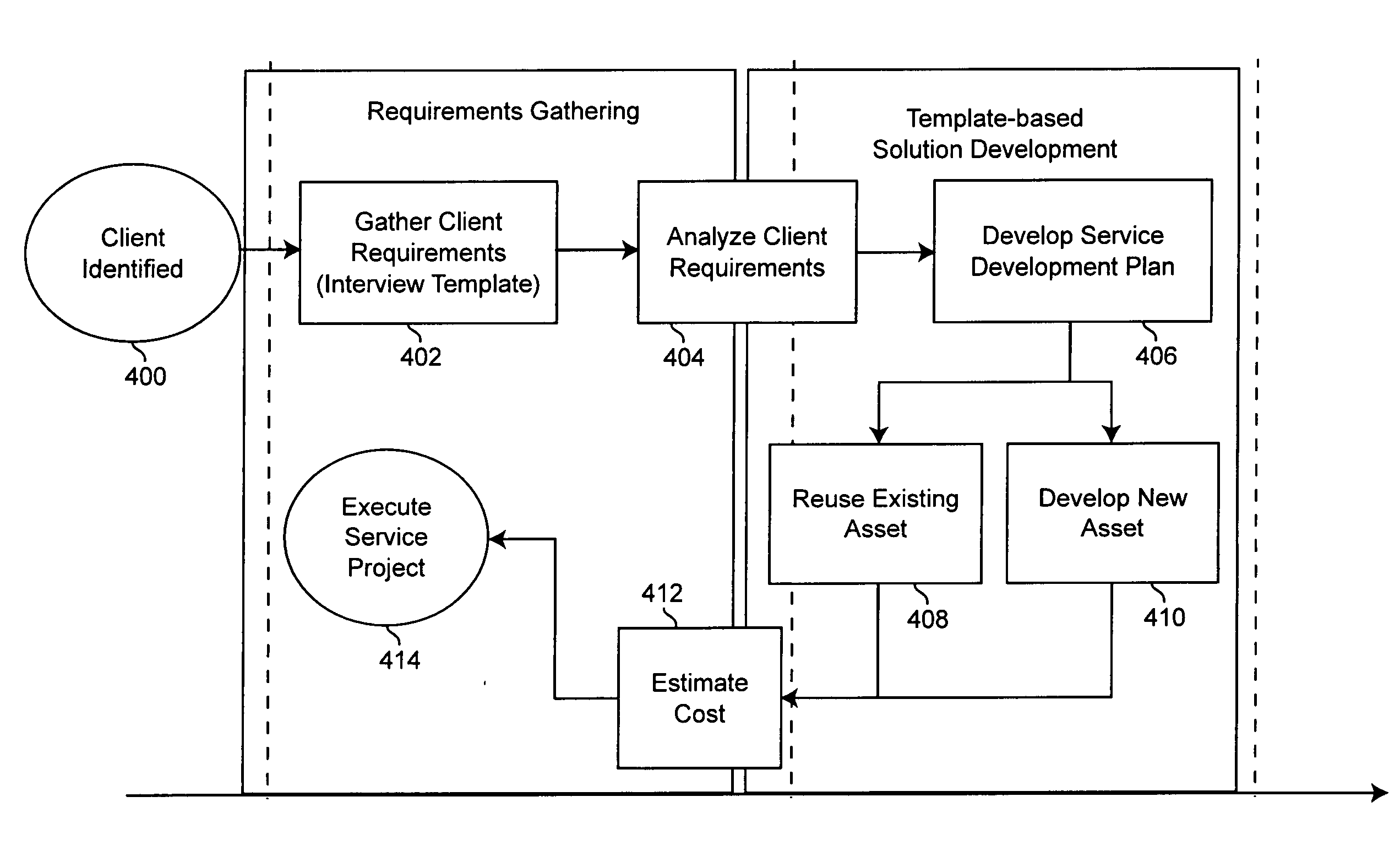

Method and apparatus for model-driven managed business services

InactiveUS20070179793A1Avoid longerAvoid costly service implementationMarket predictionsResourcesSupporting systemTemplate based

A mechanism provides a model-driven solution template-based approach for managed business services. Key assets of the business services are templatized and made configurable. The mechanism implements a metamodel describing standard service offerings that can be configured to meet specific business and operational requirements at a level of business process and system components. A cost and pricing model of service offerings helps assess the service costs and resource requirements based on a client's selection of standard and customized processes and system components. A supporting system solution is developed based upon underlying solution templates and solution artifacts as well as client-specific requirements.

Owner:IBM CORP

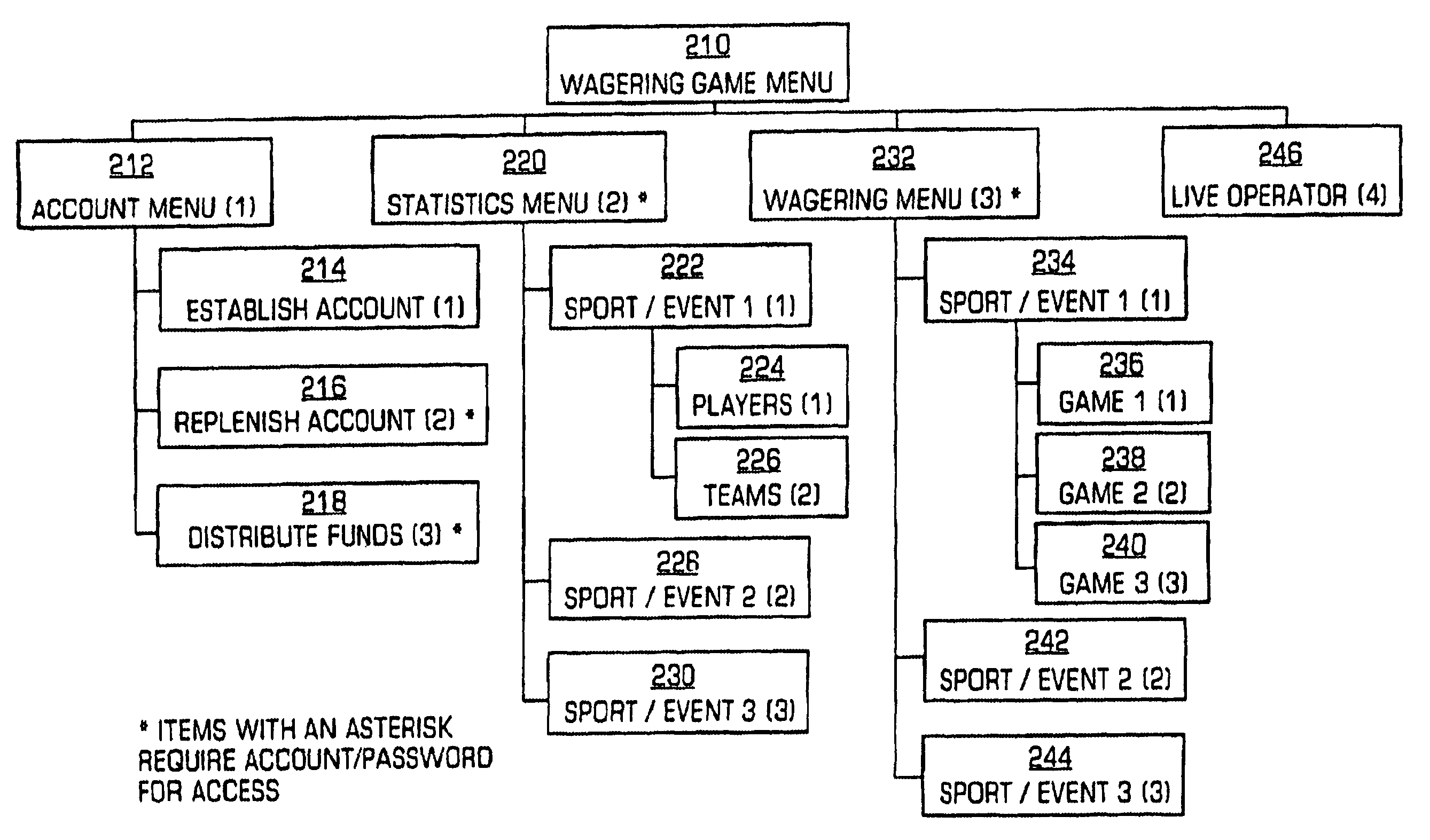

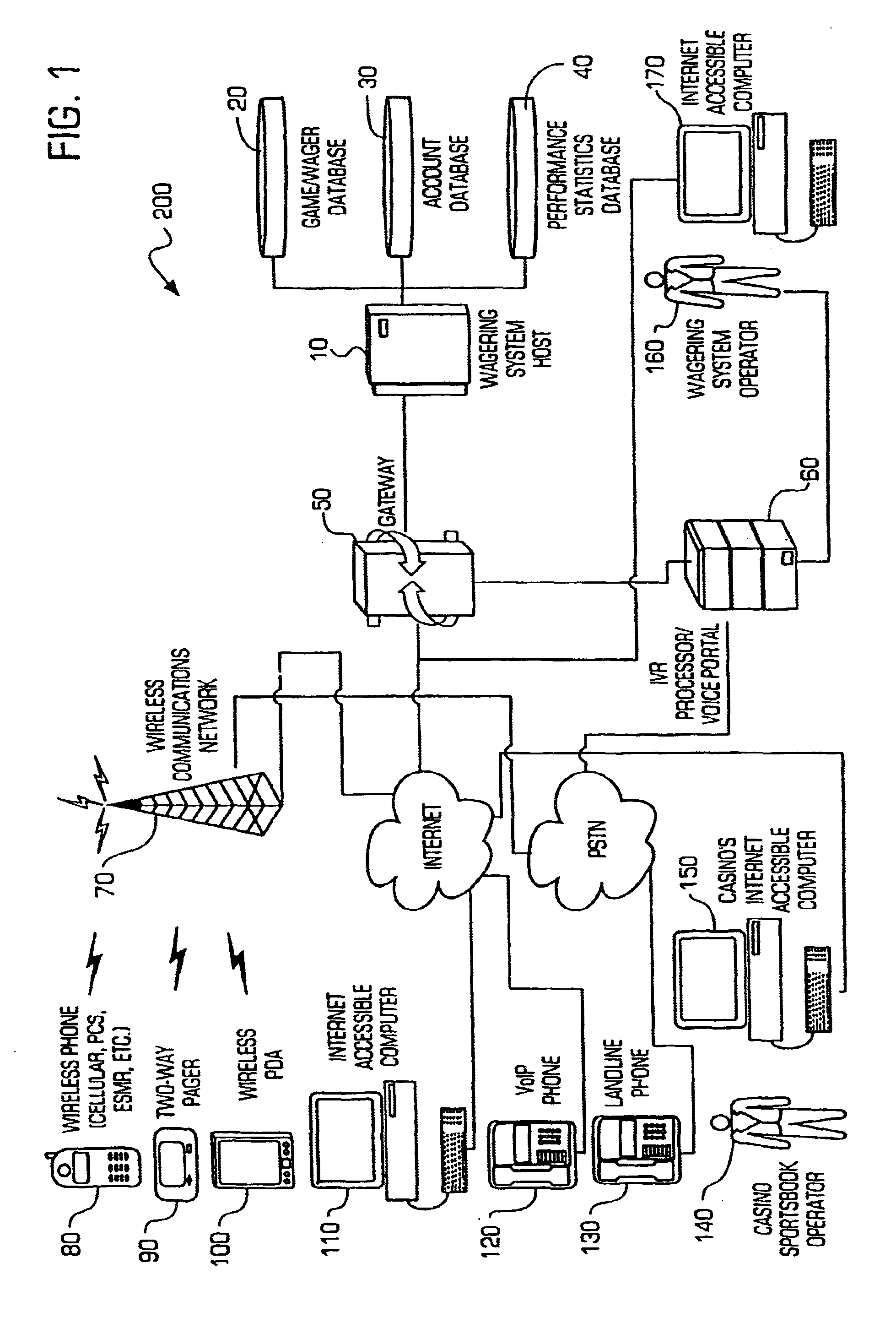

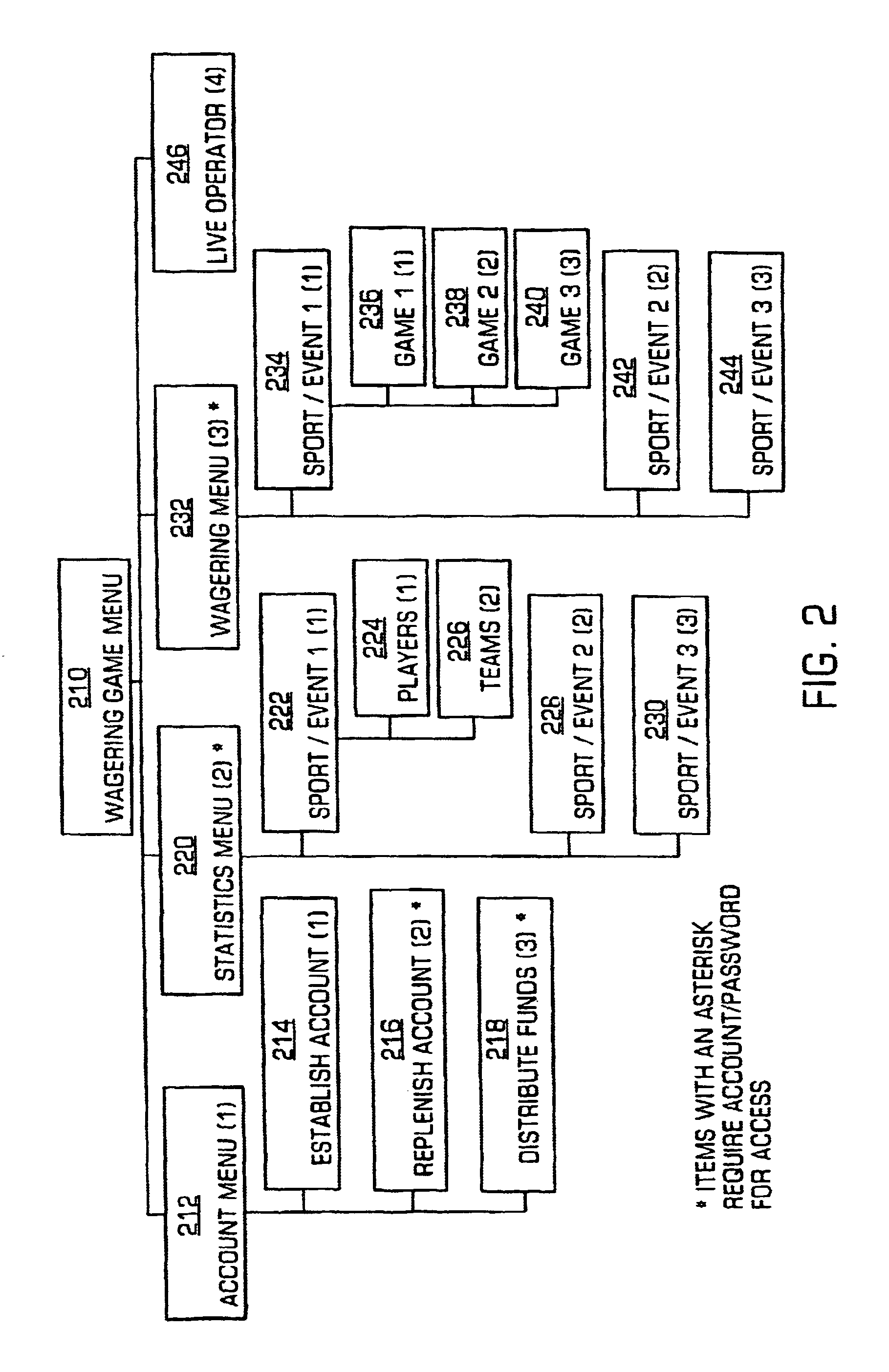

Pari-mutuel sports wagering system

InactiveUS6910965B2Effectively bettingReduce riskApparatus for meter-controlled dispensingVideo gamesSupporting systemElectronic systems

This invention relates to sports and event wagering, particularly to a new sport and event wagering game and system. This game and supporting system allows pari-mutuel wagering with respect to new areas other than horse or dog racing, which will expand the sports wagering industry to encompass new areas of interest and enjoyment to bettors. Specifically, pari-mutuel wagering is enabled with respect to the performance statistics of individual sport or event participants, combinations of sport participants, combinations of event participants, and sport teams. This wagering game is supported by an electronic system, which allows interaction with the game via various communications methods, remotely or in-person, which can allow or restrict wagering activity based upon bettor location.

Owner:DOWNES DAVID W

Pivot/ratchet assembly and support system

Multi-jointed and pivoted mounting systems for support of a flat panel video display and / or keyboard tray, incorporating a plurality of pivot points providing for pivotal motion of one or more components about a plurality of vertical and horizontal axes. Support arms having elevational pivot assemblies, including plastic friction washers and gas springs, offer elevational arm control requiring constant and predetermined positioning effort on the part of the video display operator and keyboard operator.

Owner:ERGOTRON

Detecting unauthorized use of computing devices based on behavioral patterns

InactiveUS8595834B2Memory loss protectionError detection/correctionSupporting systemMonitoring system

Techniques for detecting unauthorized use (e.g., malicious attacks) of the computing systems (e.g., computing devices) are disclosed. Unauthorized use can be detected based on patterns of use (e.g., behavioral patterns of use typically associated with a human being) of the computing systems. Acceptable behavioral pattern data can be generated for a computing system by monitoring the use of a support system (e.g., an operating system, a virtual environment) operating on the computing system. For example, a plurality of system support provider components of a support system (e.g., system calls, device drivers) can be monitored in order to generate the acceptable behavioral pattern data in a form which effectively defines an acceptable pattern of use (usage pattern) for the monitored system support provider components, thereby allowing detection of unauthorized use of a computing system by detecting any deviation from the acceptable pattern of use of the monitored system support provider components.

Owner:SAMSUNG ELECTRONICS CO LTD

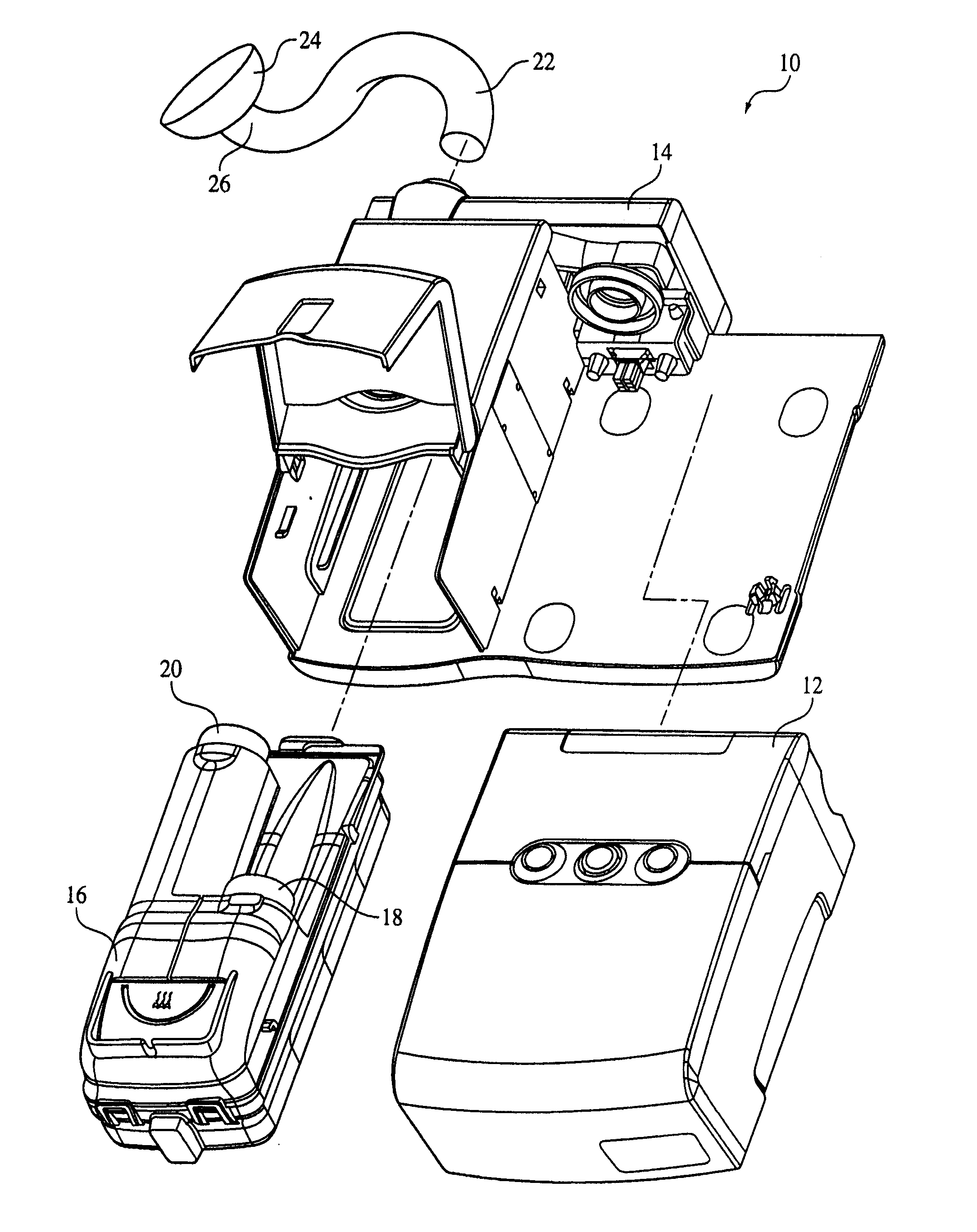

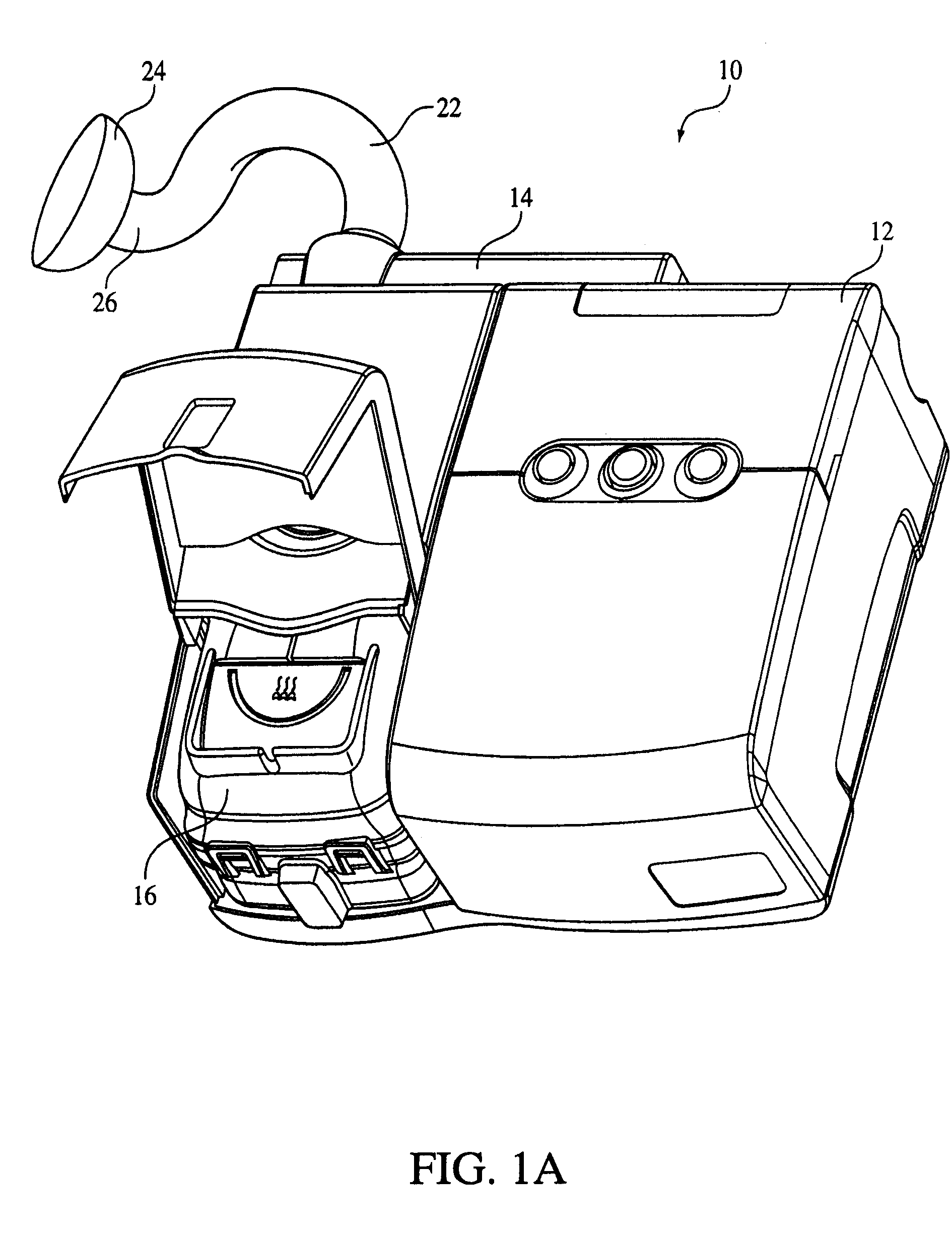

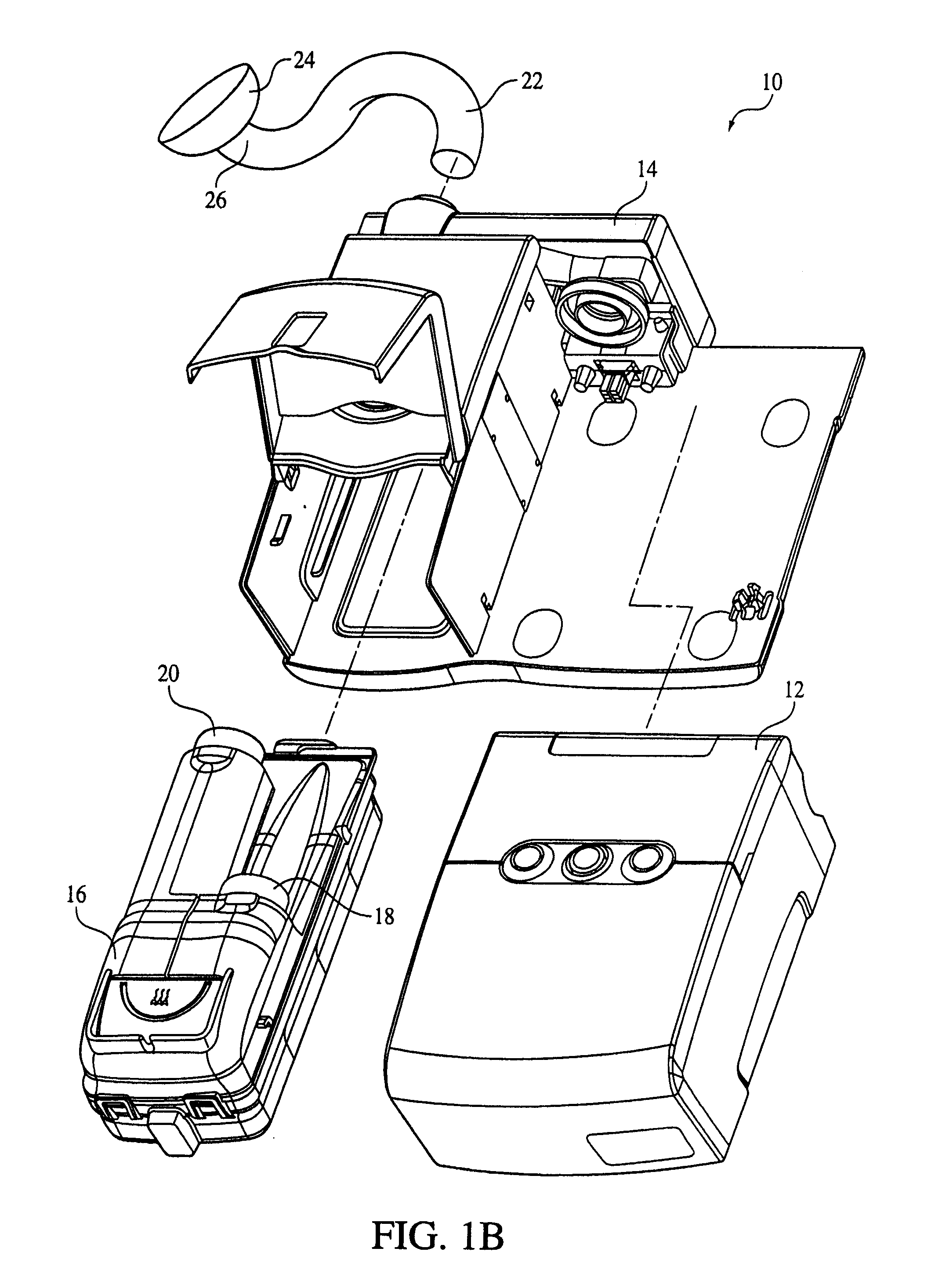

Modular pressure support system

A pressure support system that comprises a patient circuit, a docking assembly, and a tank. The patient circuit delivers a pressurized flow of breathable gas to a patient. The docking assembly has an inlet and an outlet that is adapted to receive the pressurized flow of breathable gas, and is also adapted to be connected with the patient circuit. The tank is constructed and arranged to be removably connected with the docking assembly, and enables the pressurized flow of breathable gas to pass therethrough. The tank is also adapted to contain a liquid such that a humidity level of the pressurized flow of breathable gas is elevated as the pressurized flow of breathable gas passes therethrough.

Owner:PHILIPS RS NORTH AMERICA LLC

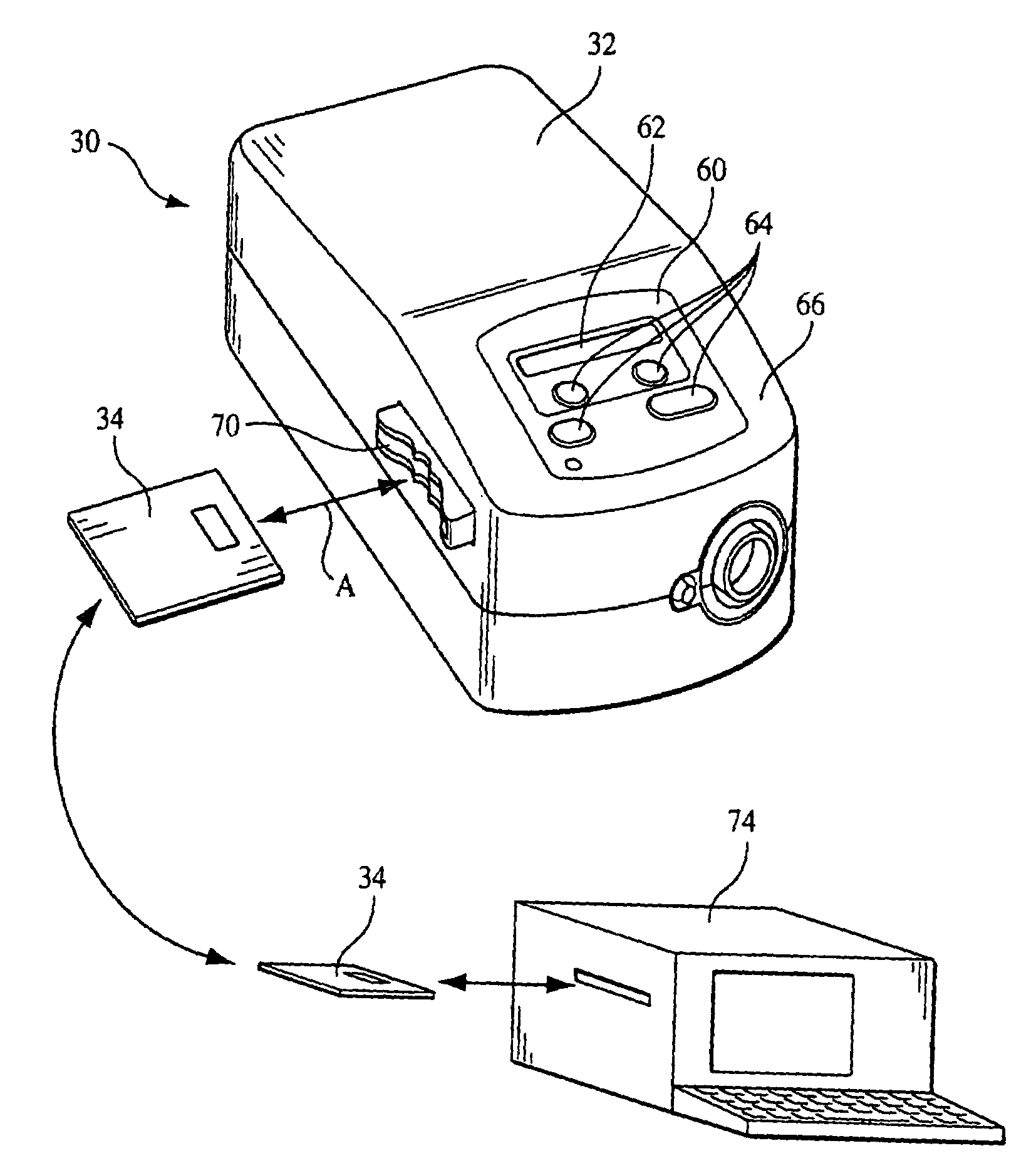

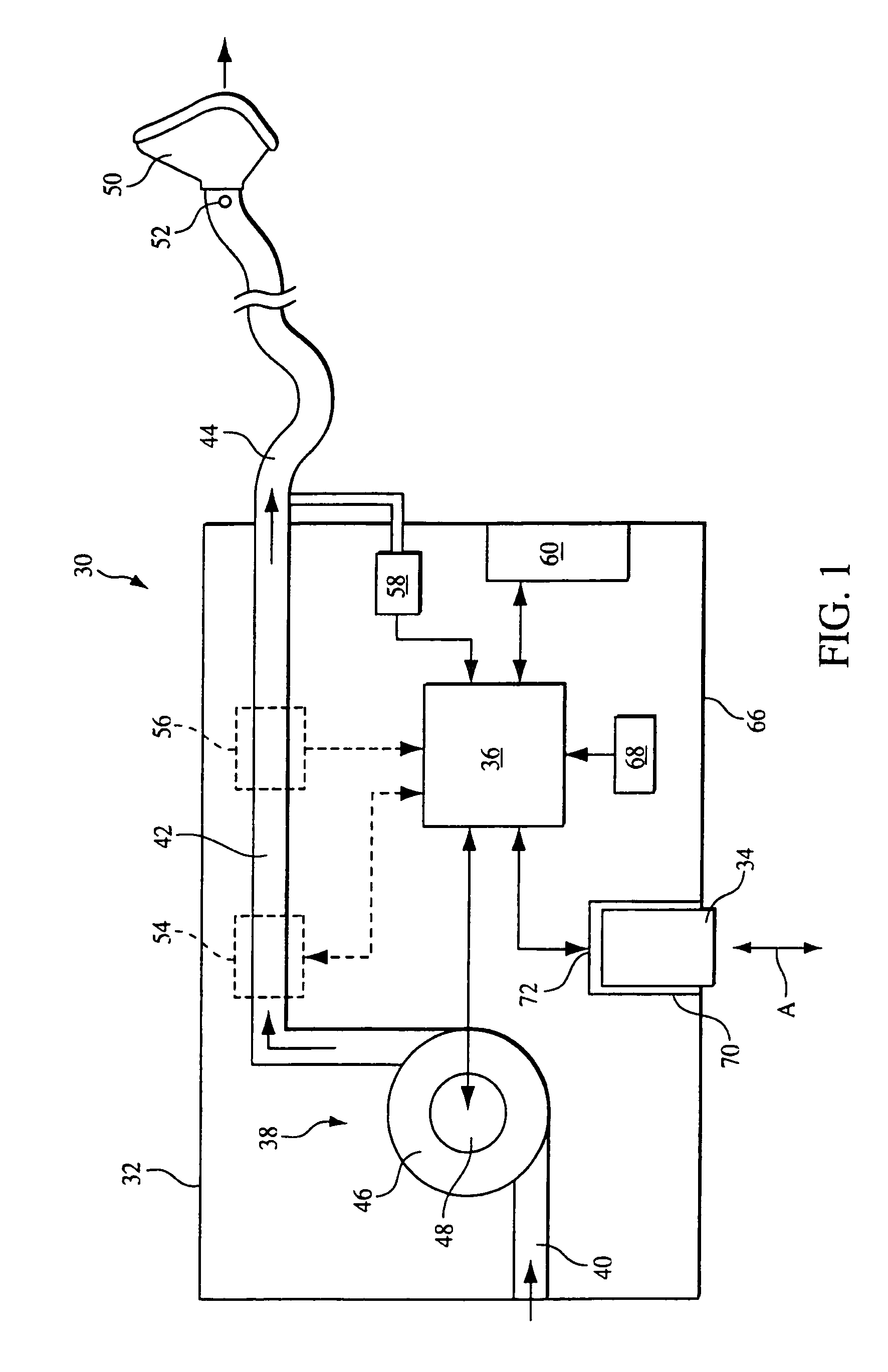

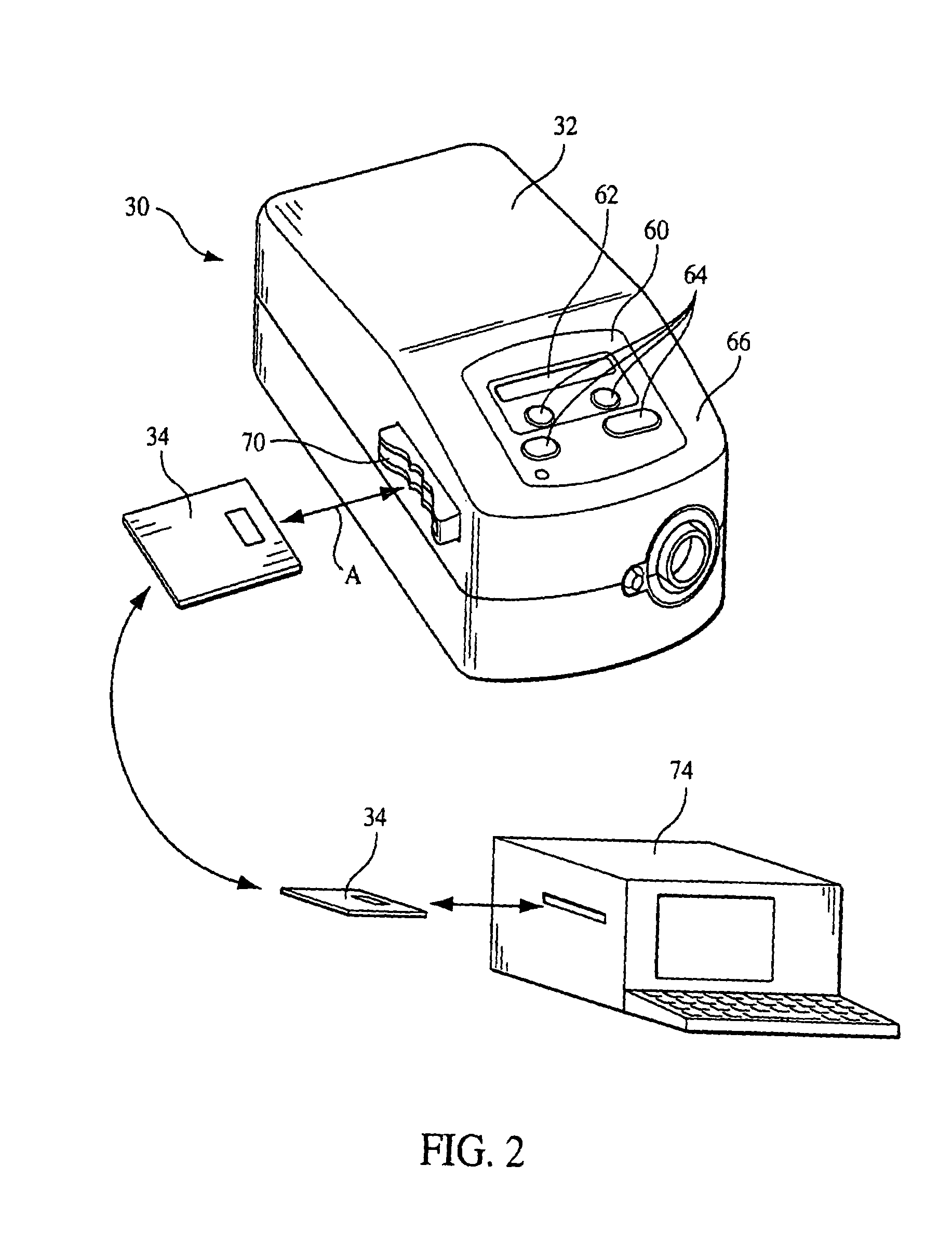

Method and apparatus for monitoring and controlling a medical device

InactiveUS7225809B1Easy to transportLight weightRespiratorsOperating means/releasing devices for valvesSupporting systemMedical device

A medical device, such as pressure support system, and a method of communicating with such a device using an information storage device. The information storage device, in one embodiment, is adapted to be provided in a slot in the medical device so that information for controlling the operating of the pressure support device can be read from the information storage device, information regarding the usage and / or operation of the pressure support device can be written to the information storage device, or both operations can be performed.

Owner:RIC INVESTMENTS LLC

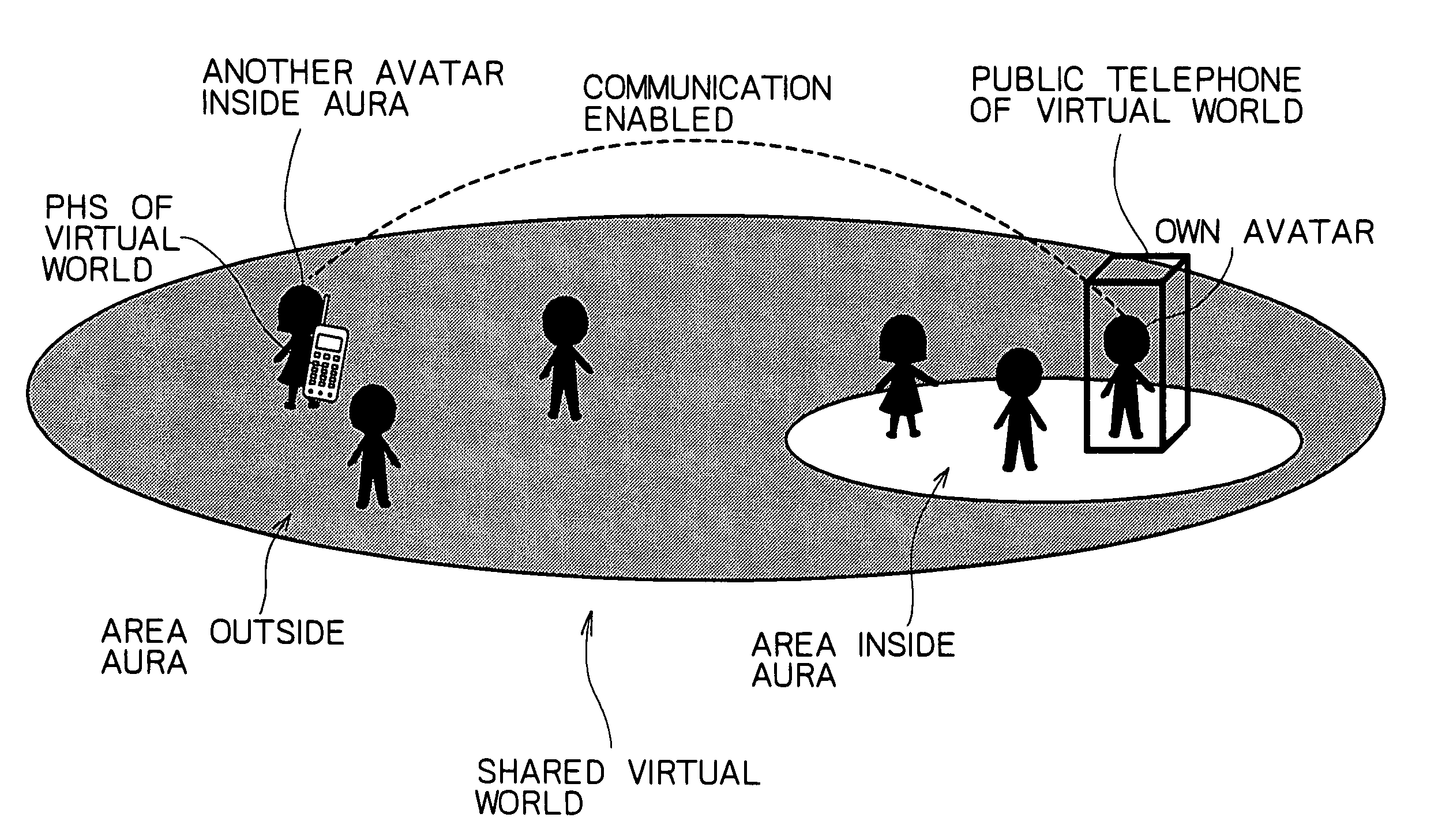

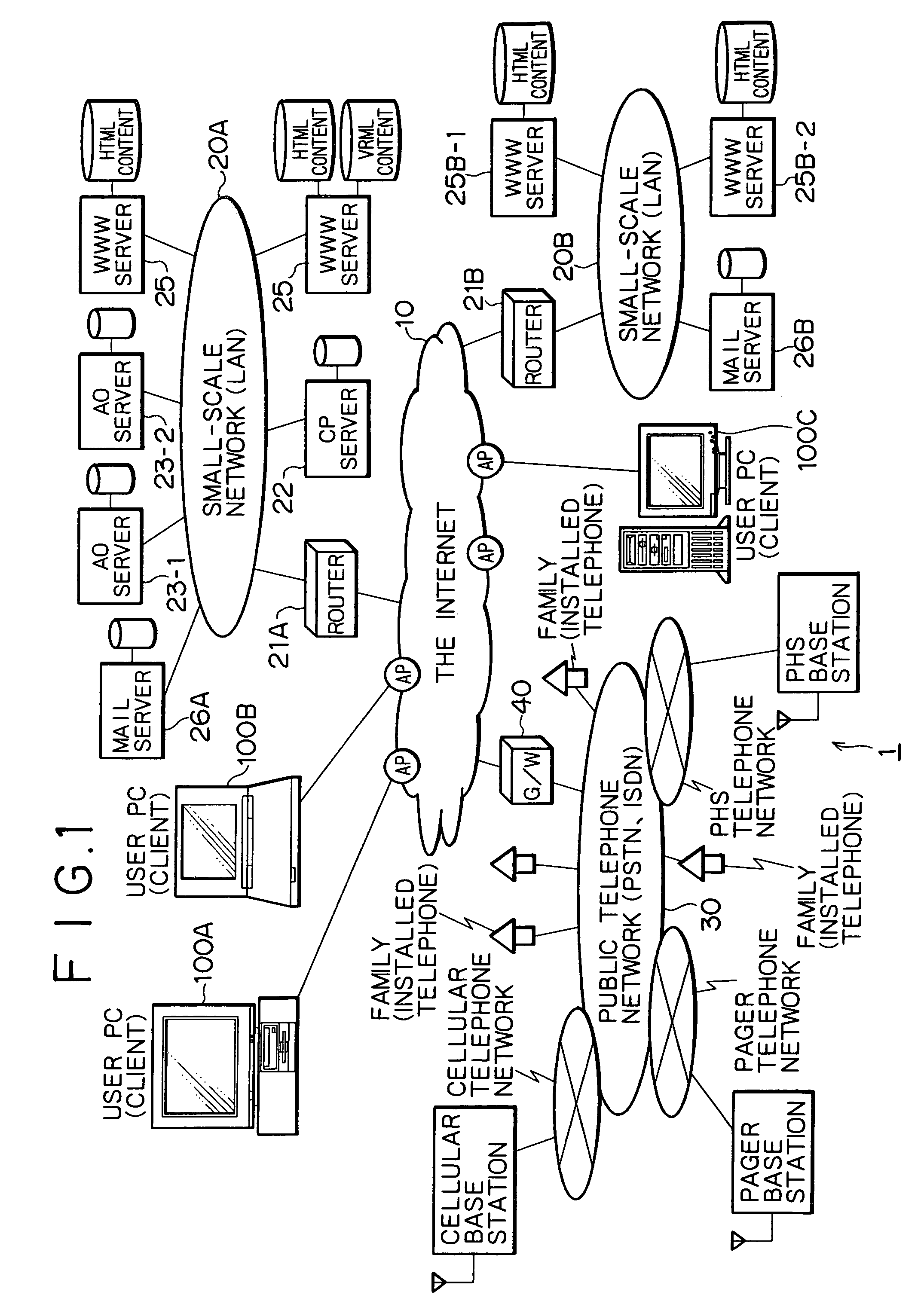

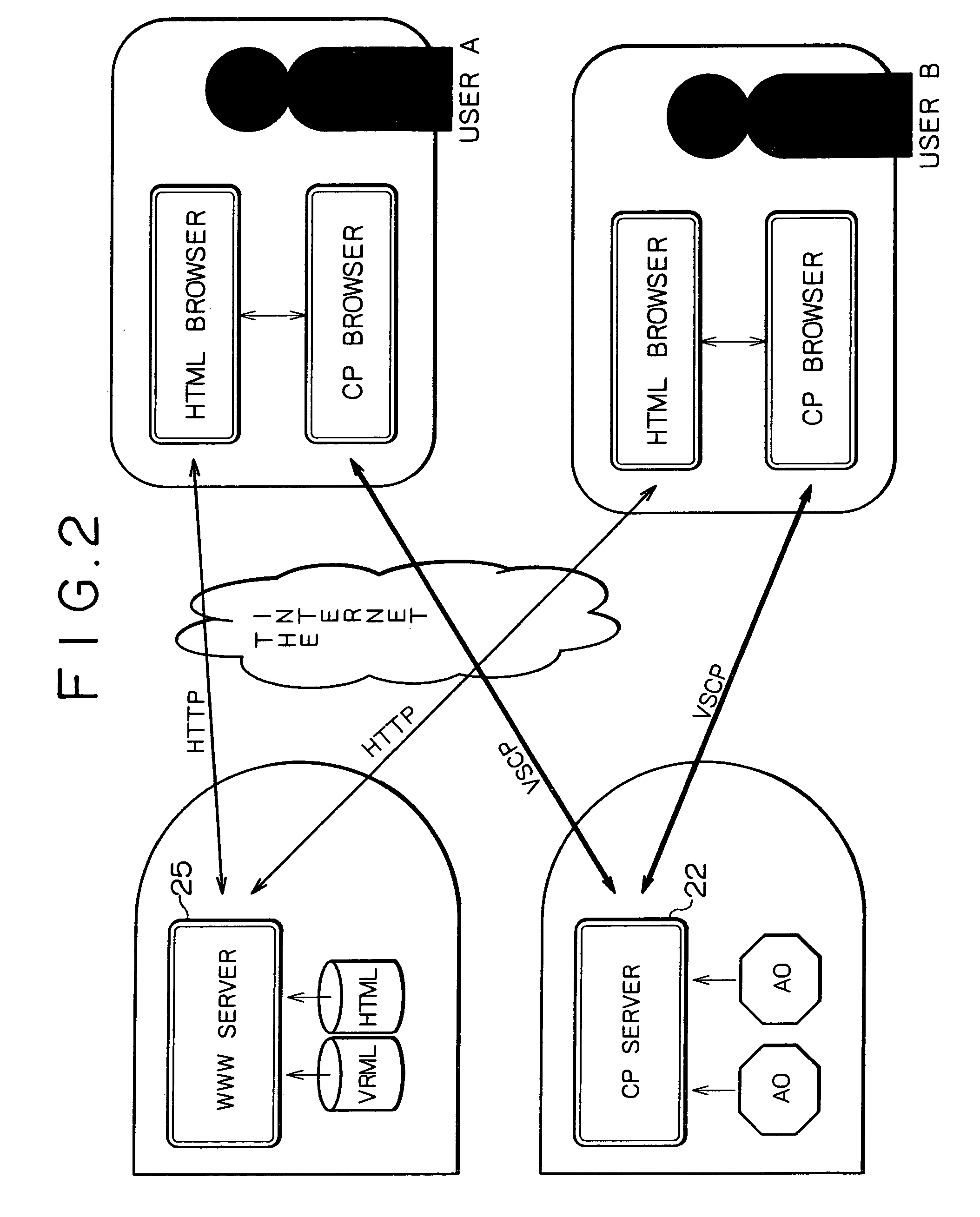

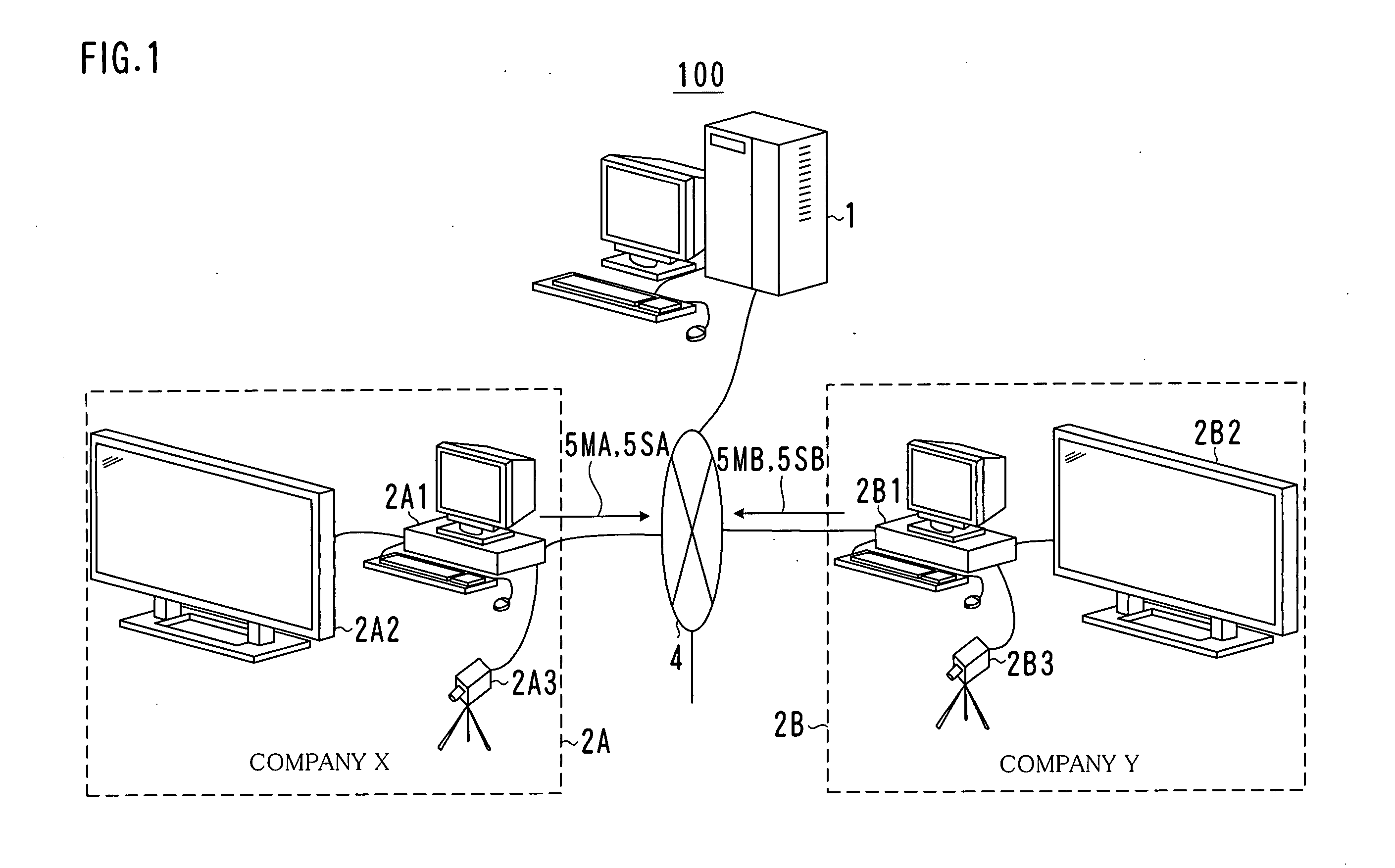

Shared virtual space conversation support system using virtual telephones

A conversation support system and a conversation support method for providing a realtime communications environment in which a plurality of users simultaneously participate in a virtual world built and provided on a computer network for realtime talking. A shared virtual space accommodates remote communications infrastructures such as mobile telephone, PHS, and public telephone. Avatars can have a talk with each other by use of these infrastructures regardless of the locations of the communicating avatars, namely regardless of whether each avatar is inside or outside its aura. Namely, the avatars can communicate each other beyond a single shared virtual world. The PHS owned by each avatar can communicate with any PHS in another virtual world or even in the real world.

Owner:SONY CORP

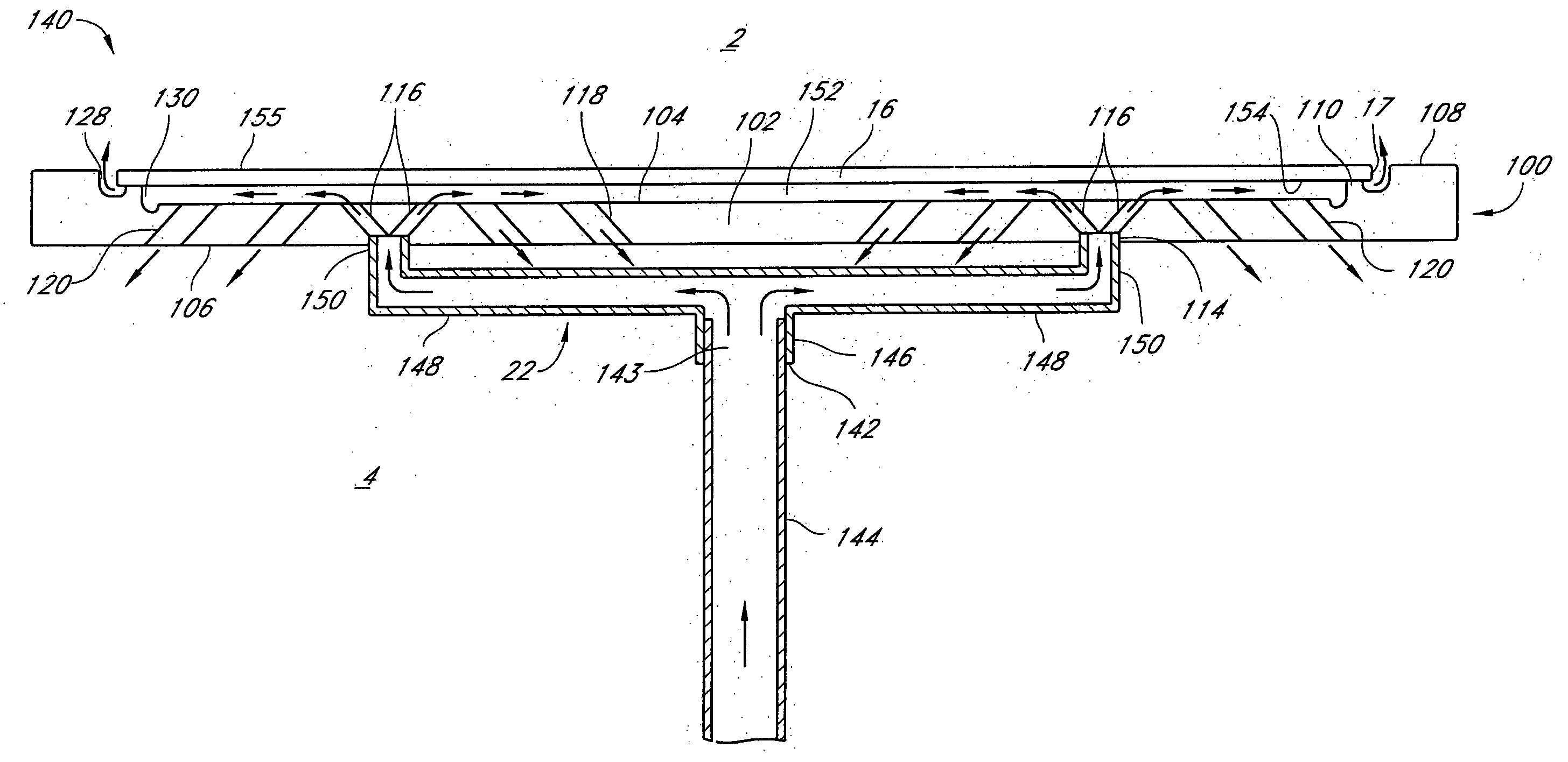

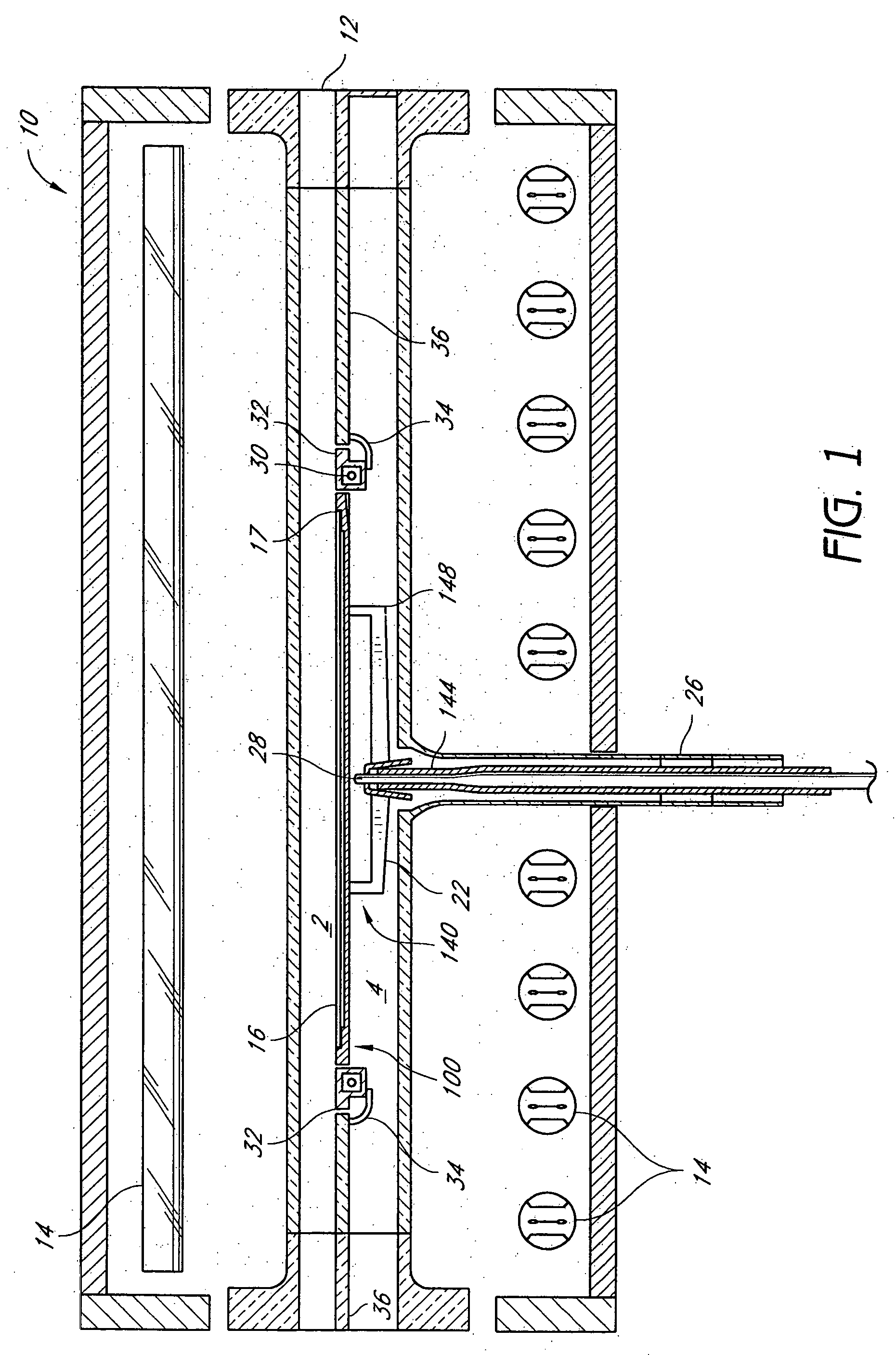

Substrate support system for reduced autodoping and backside deposition

ActiveUS20050193952A1Speed up gas flowAvoid flowLiquid surface applicatorsElectric discharge tubesSupporting systemEngineering

A substrate support system comprises a relatively thin circular substrate holder having a plurality of passages extending between top and bottom surfaces thereof. The substrate holder includes a single substrate support ledge or a plurality of substrate support spacer vanes configured to support a peripheral portion of the substrate backside so that a thin gap is formed between the substrate and the substrate holder. The vanes can be angled to resist backside deposition of reactant gases as the substrate holder is rotated. A hollow support member provides support to an underside of the substrate holder. The hollow support member is configured to convey gas (e.g., inert gas or cleaning gas) upward into one or more of the passages of the substrate holder. The upwardly conveyed gas flows into the gap between the substrate and the substrate holder. Depending upon the embodiment of the invention, the gas in the gap can then flow either (1) outward and upward around the substrate edge or (2) downward through passages of the substrate holder, if any, that do not lead back into the hollow support member. The gas that flows outward and upward around the substrate edge inhibits backside deposition of reactant gases above the substrate. The gas that flows downward through the passages that do not lead back to the support member advantageously inhibits autodoping by sweeping out-diffused dopant atoms away from the substrate front side. In one embodiment, the support member comprises a hollow multi-armed support spider that conveys gas into selected ones of the passages. In another embodiment, the support member comprises a bowl- or cup-shaped structure that conveys gas upward into all of the passages. In yet another embodiment, the support member comprises a bowl- or cup-shaped structure that conveys gas upward into all but one or more of the passages.

Owner:ASM IP HLDG BV

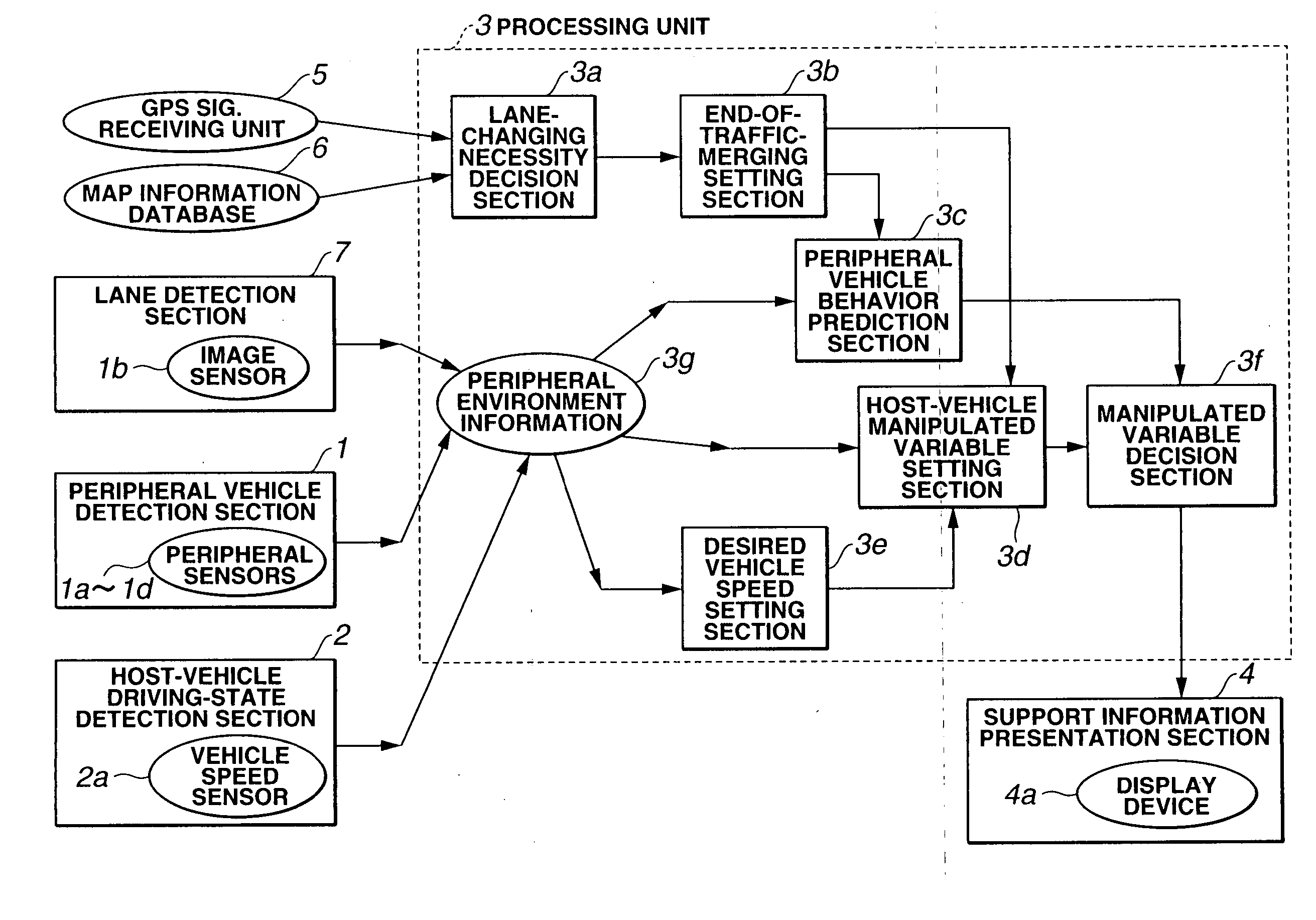

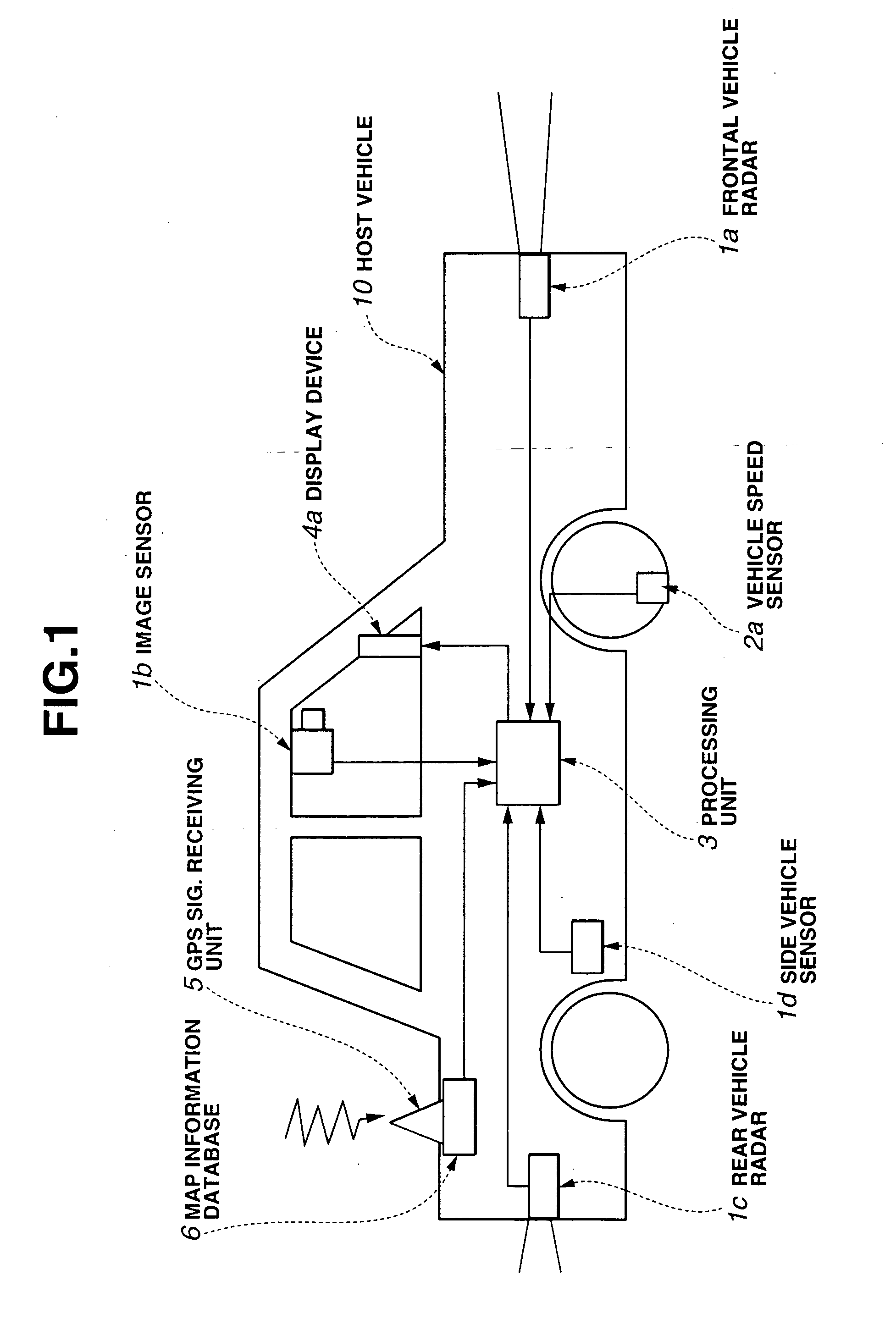

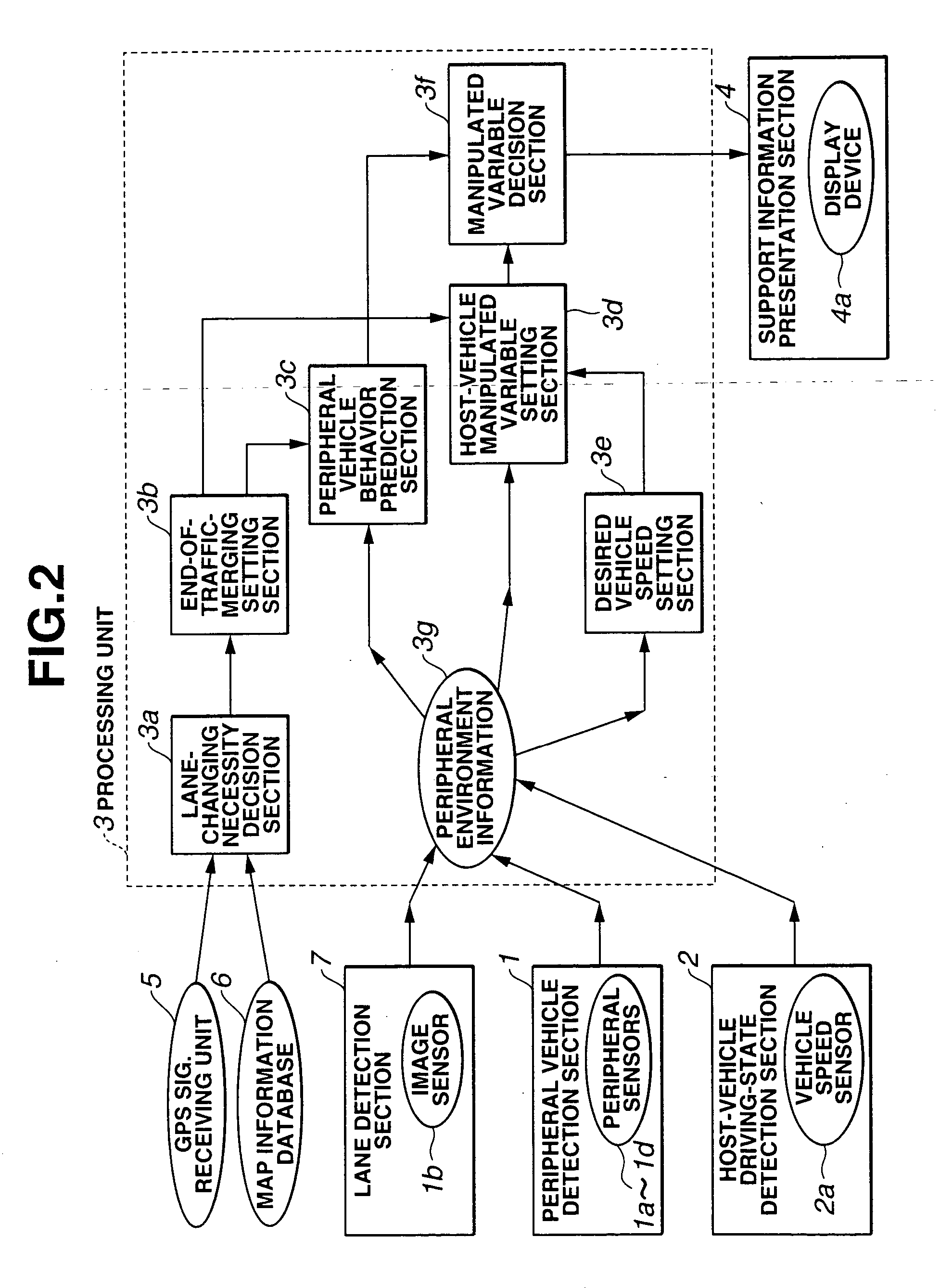

Lane-changing support system

InactiveUS20050015203A1Arrangements for variable traffic instructionsPedestrian/occupant safety arrangementSupporting systemProcessing element

A lane-changing support system includes a processing unit sets an assumed traffic-merging end, predicts a driving behavior of each peripheral vehicle, and generates at least one host vehicle's manipulated-variable time series to be executed until the host vehicle reaches the assumed traffic-merging end. The processing unit determines whether the host vehicle's lane change is appropriately achievable when executing the manipulated-variable time series, and additionally determines which of gaps defined between the peripheral-vehicles traveling on a traffic lane of destination of lane-changing should be suited for an entry of the host vehicle in case of a decision result that the appropriate lane change is achievable by execution of the manipulated-variable time series. The processing unit transmits information regarding a correspondence between a current host vehicle's manipulated variable on the manipulated-variable time series and at least one lane-changing enabling gap to the driver.

Owner:NISSAN MOTOR CO LTD

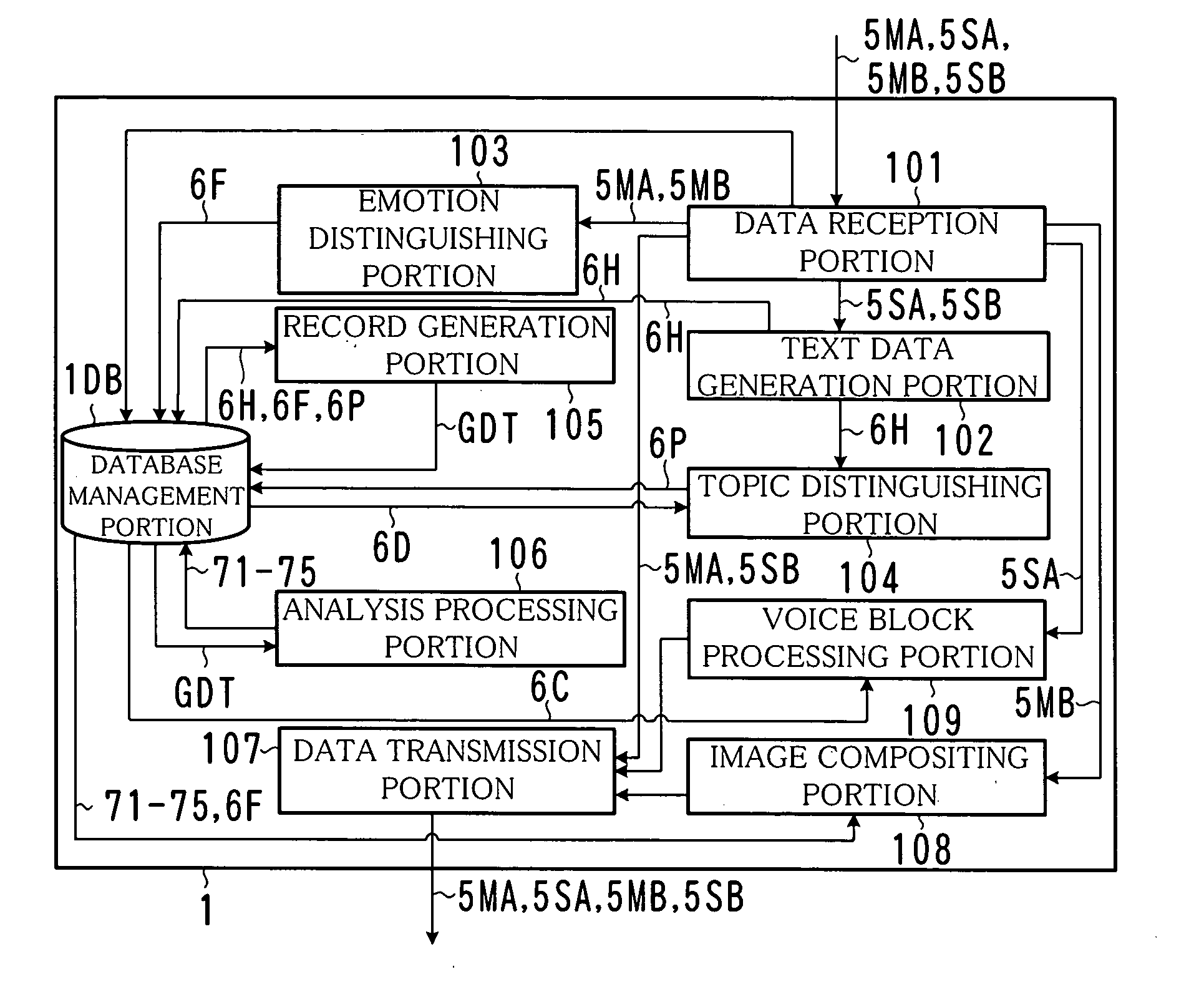

Conference support system, record generation method and a computer program product

InactiveUS20050209848A1Special service provision for substationTelevision conference systemsSupporting systemSpeech sound

A conference support system includes a data reception portion for receiving image data of attendants in a conference and voice data, an emotion distinguishing portion for distinguishing emotions of attendants in accordance with the image data, a text data generation portion for generating comment text data that indicate contents of speeches of the attendants in accordance with the voice data, and a record generation portion for generating record data that include contents of a speech of an attendant and emotions of attendants when the speech was made, in accordance with emotion data that indicate a result of distinguishing made by the emotion distinguishing portion and the comment text data.

Owner:FUJITSU LTD

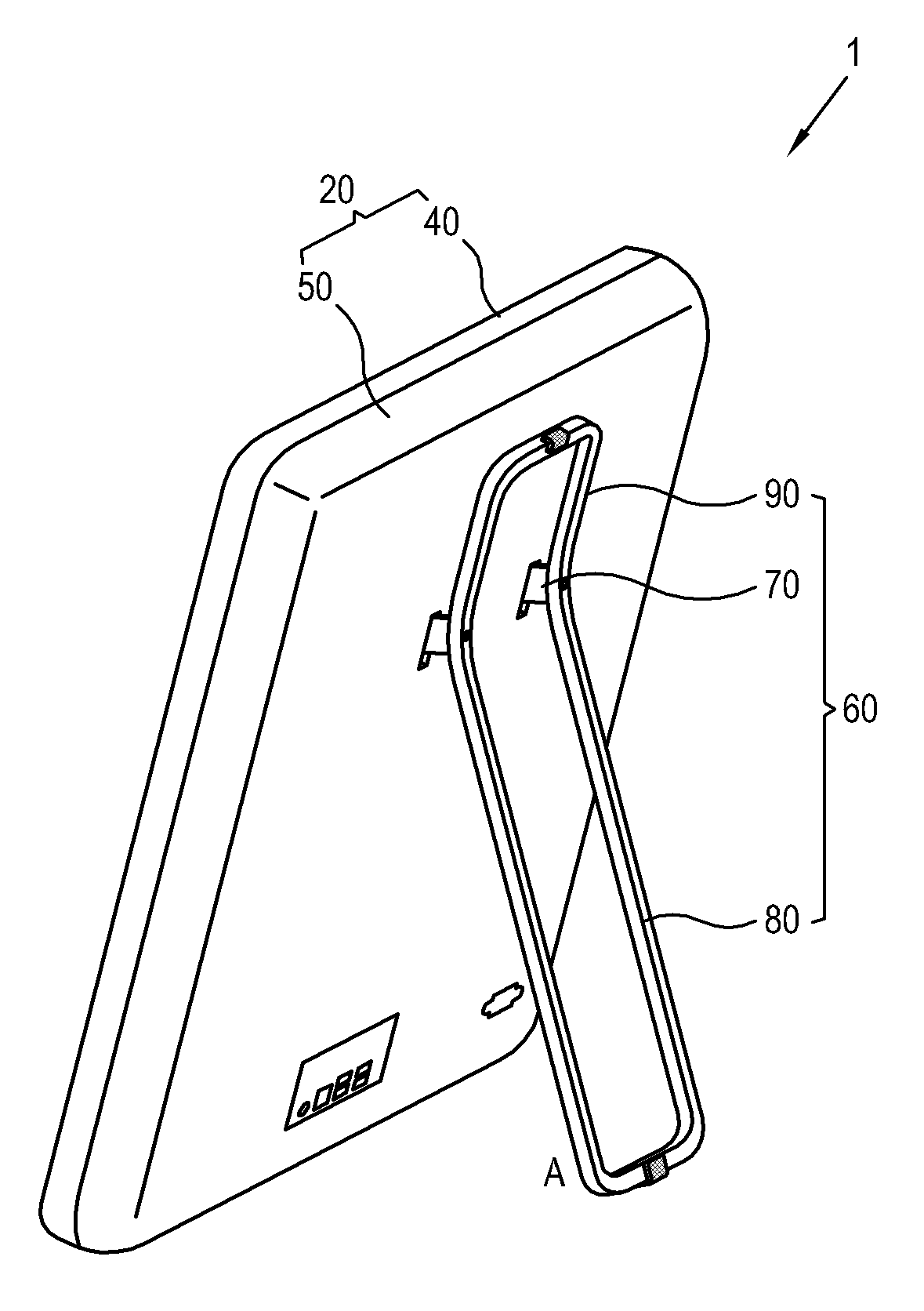

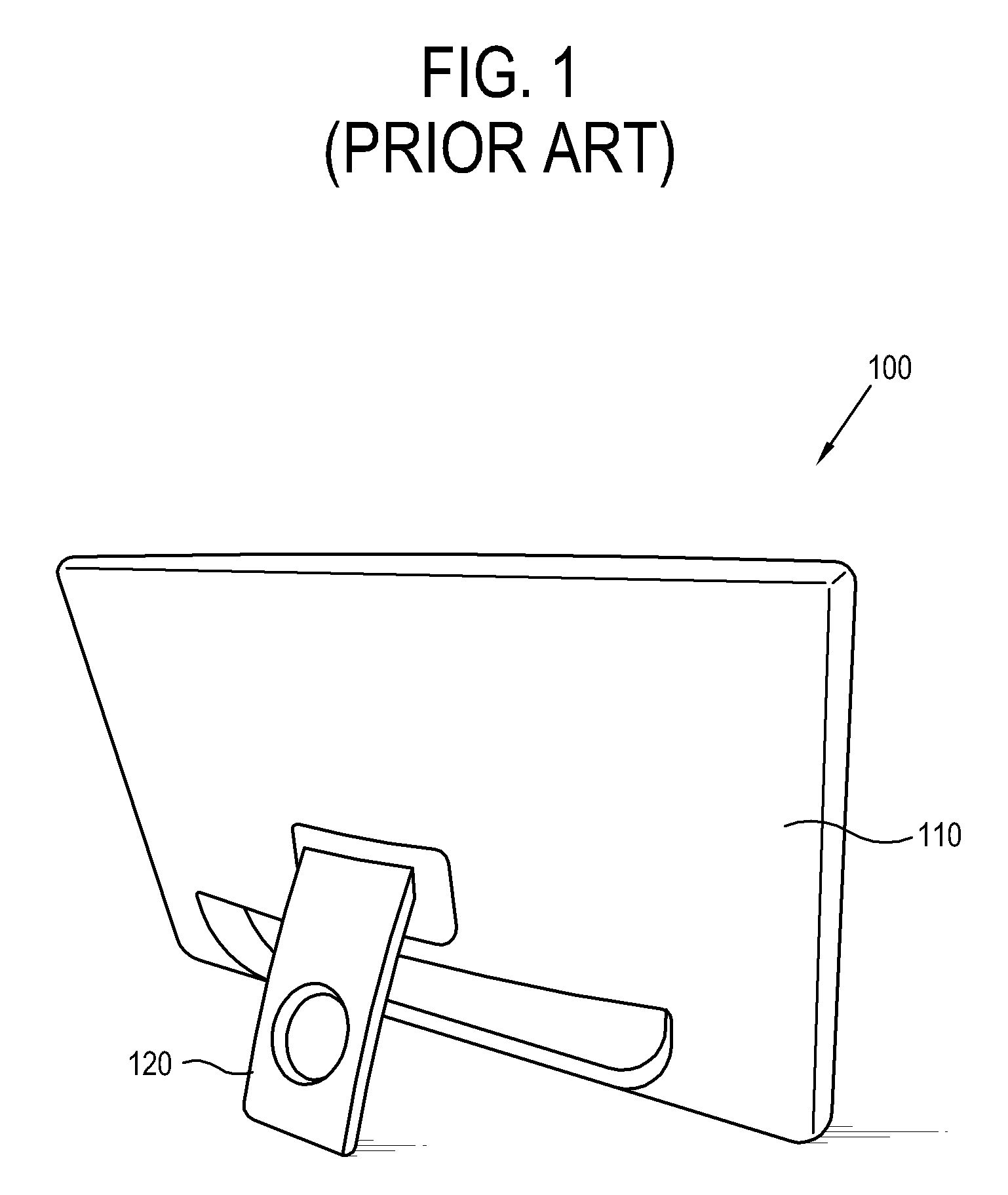

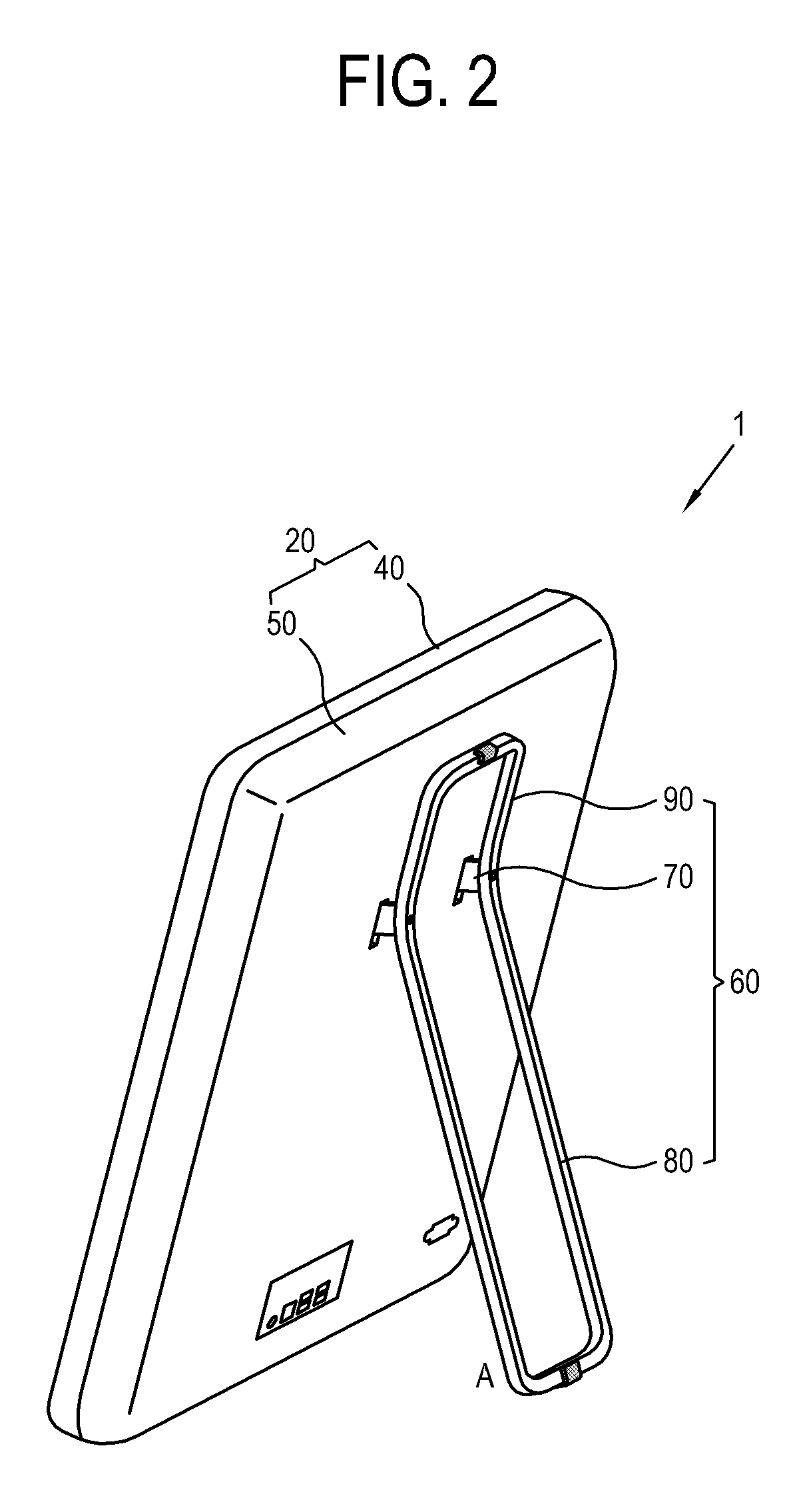

Electronic apparatus with stable support member system

InactiveUS8400767B2Television system detailsDigital data processing detailsSupporting systemEngineering

An electronic apparatus includes a display panel which displays an image; a cover unit which covers the display panel; and support system including a support member. The support member which includes a hinge unit which is rotably formed in the forward and backward directions in the rear side of the cover unit, a first support which is downwardly bent and extends from the hinge unit, and a second support which is upwardly bent and extends from the hinge unit. The configuration of the support system on the electronic apparatus permits a stable support at a variety of angles on an installation plane.

Owner:SAMSUNG ELECTRONICS CO LTD

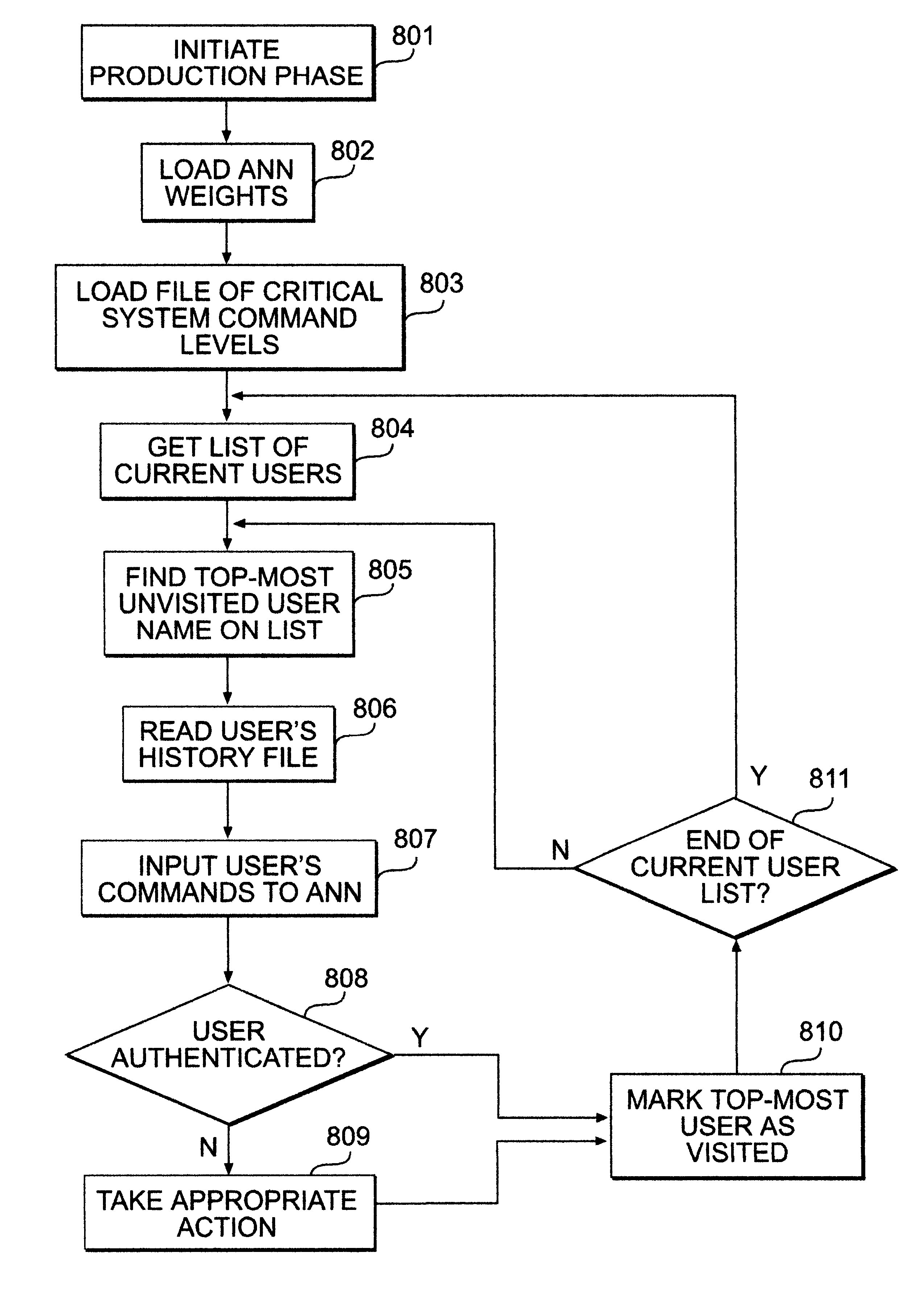

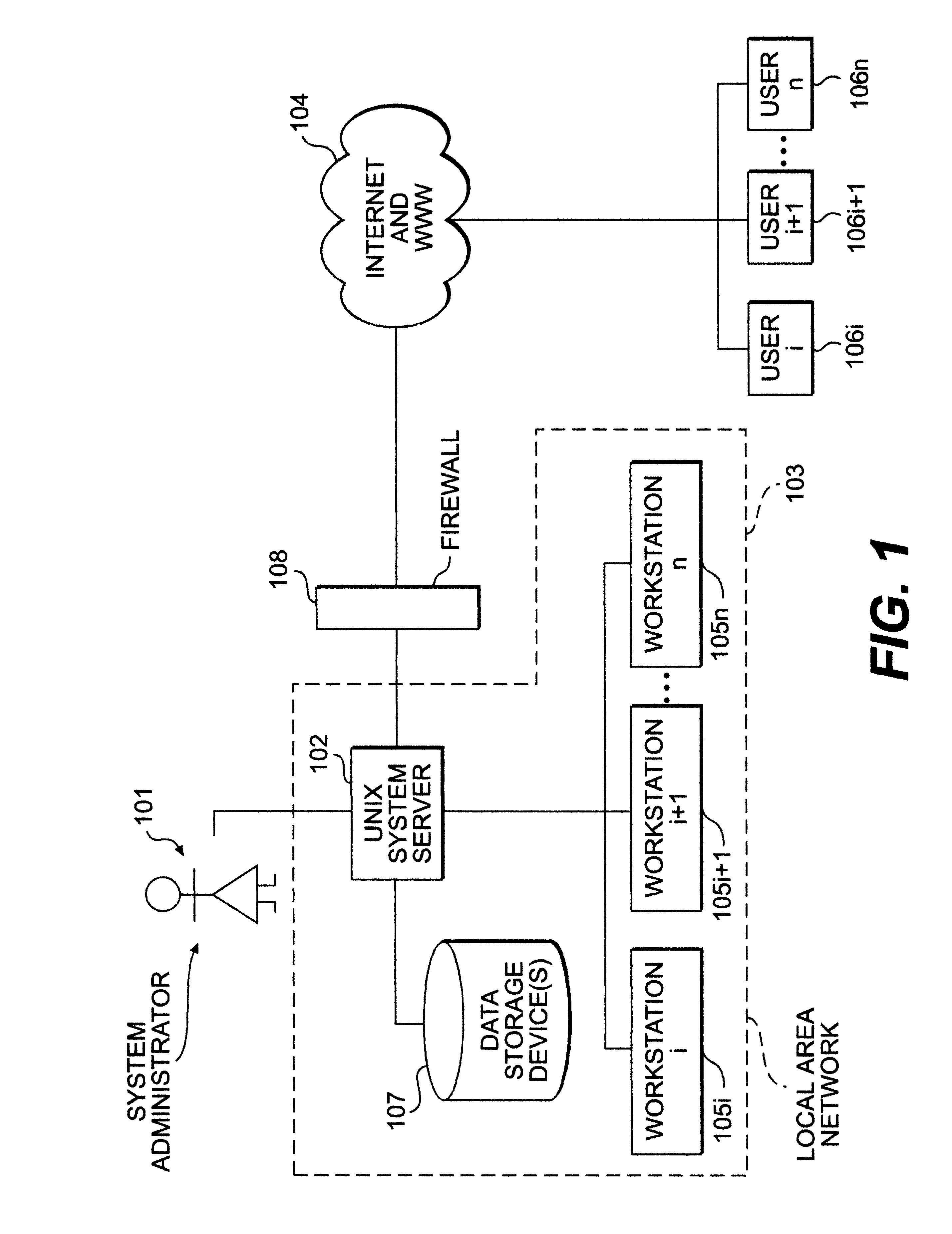

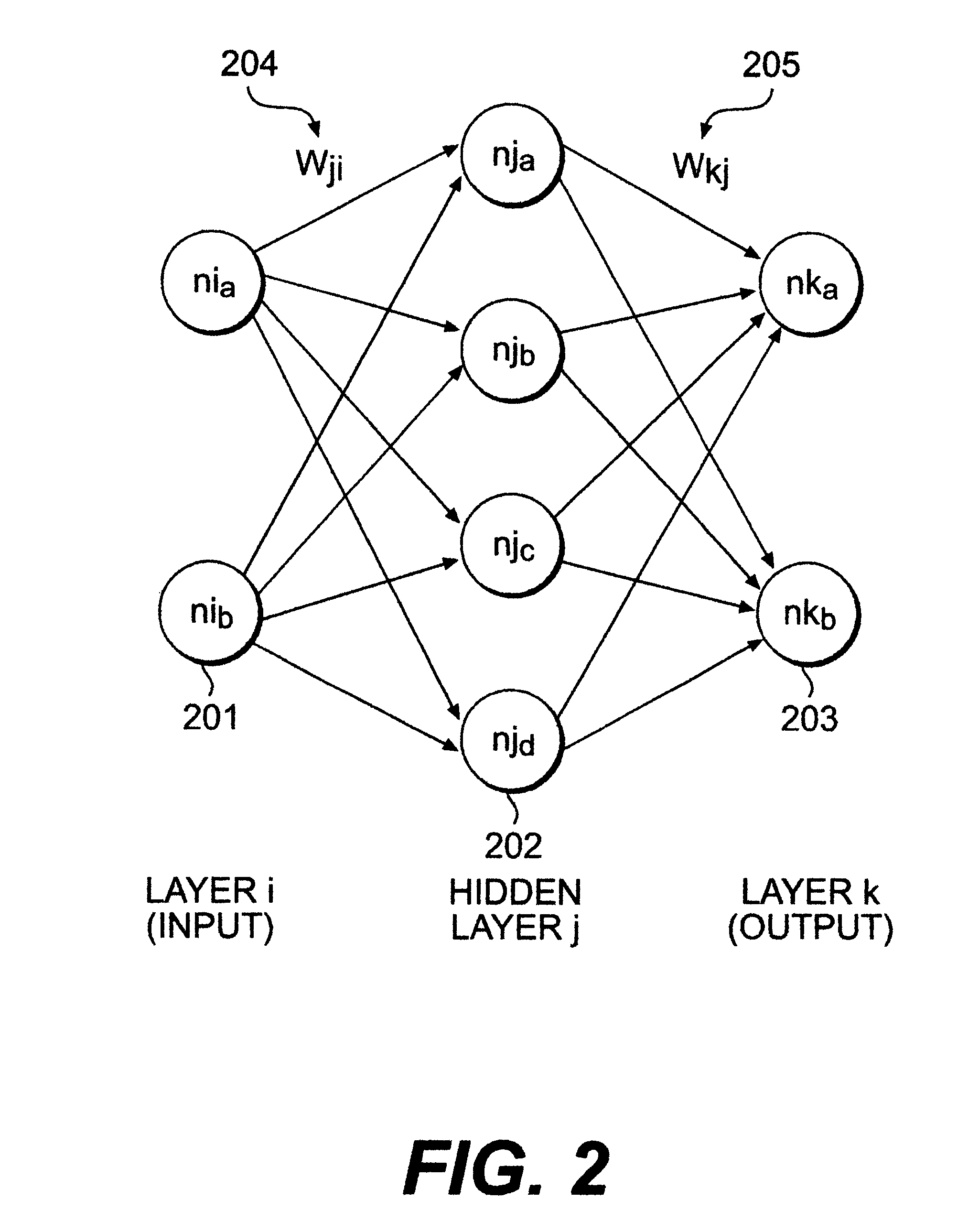

Usage pattern based user authenticator

InactiveUS6334121B1Control damagePreventing executionDigital computer detailsComputer security arrangementsOperational systemOperating system level

A usage based pattern authenticator for monitoring and reporting on user usage patterns in an operating system using a set of security rules and user usage patterns. This computer system security tool authenticates users at the operating system level in multi-user operating systems. It supports system administrators in limiting the ability of unauthorized users to disrupt system operations using a neural network and set of rules to track usage patterns and flag suspicious activity on the system. The data collection mode collects and stores usage patterns of authenticated users. The training mode trains an artificial neural network and sets the interconnection weights of the network. The production mode monitors and reports on usage patterns, and optionally performs automatic responses when confronted with non-authenticated users.

Owner:VIRGINIA COMMONWEALTH UNIV

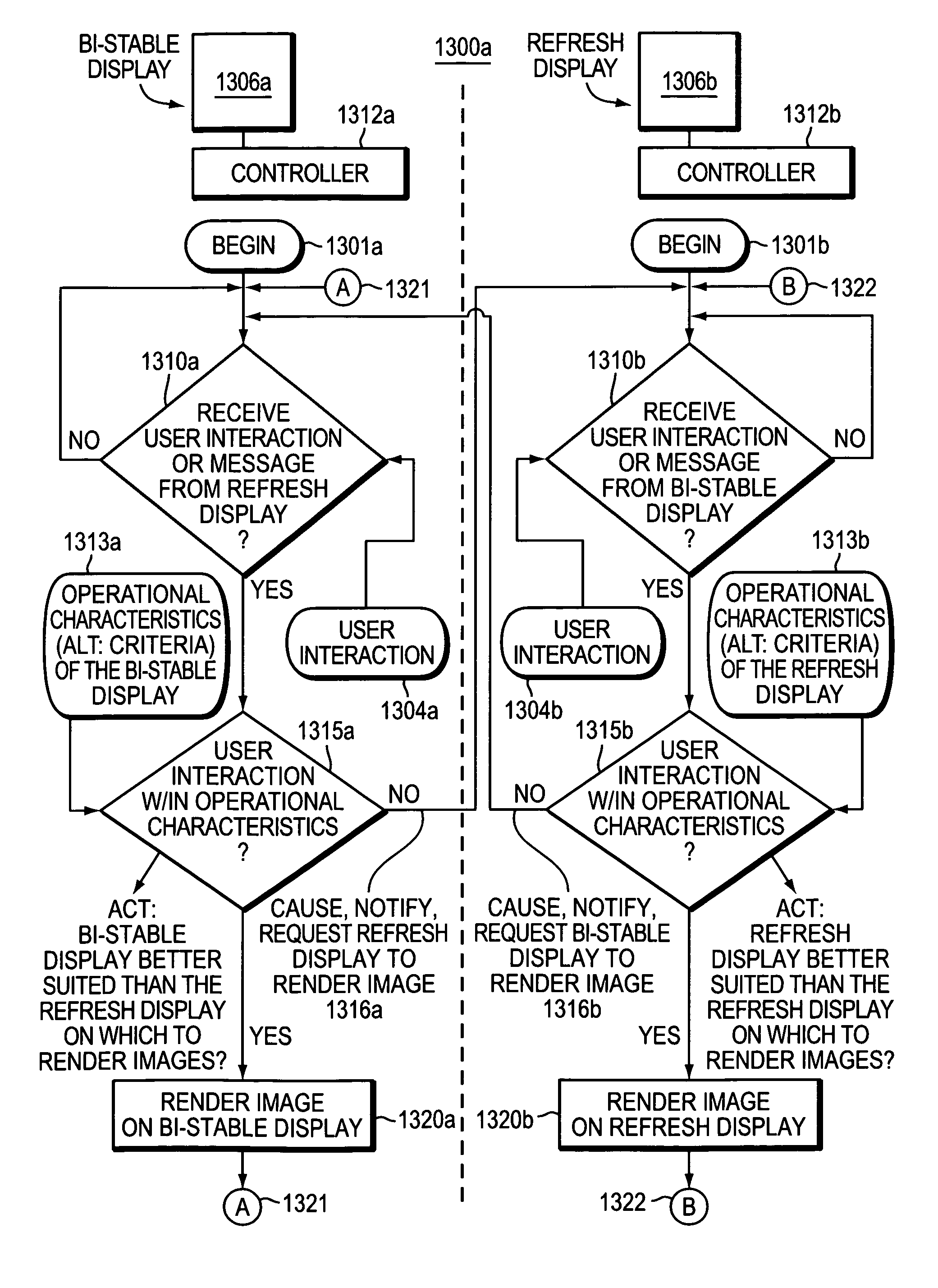

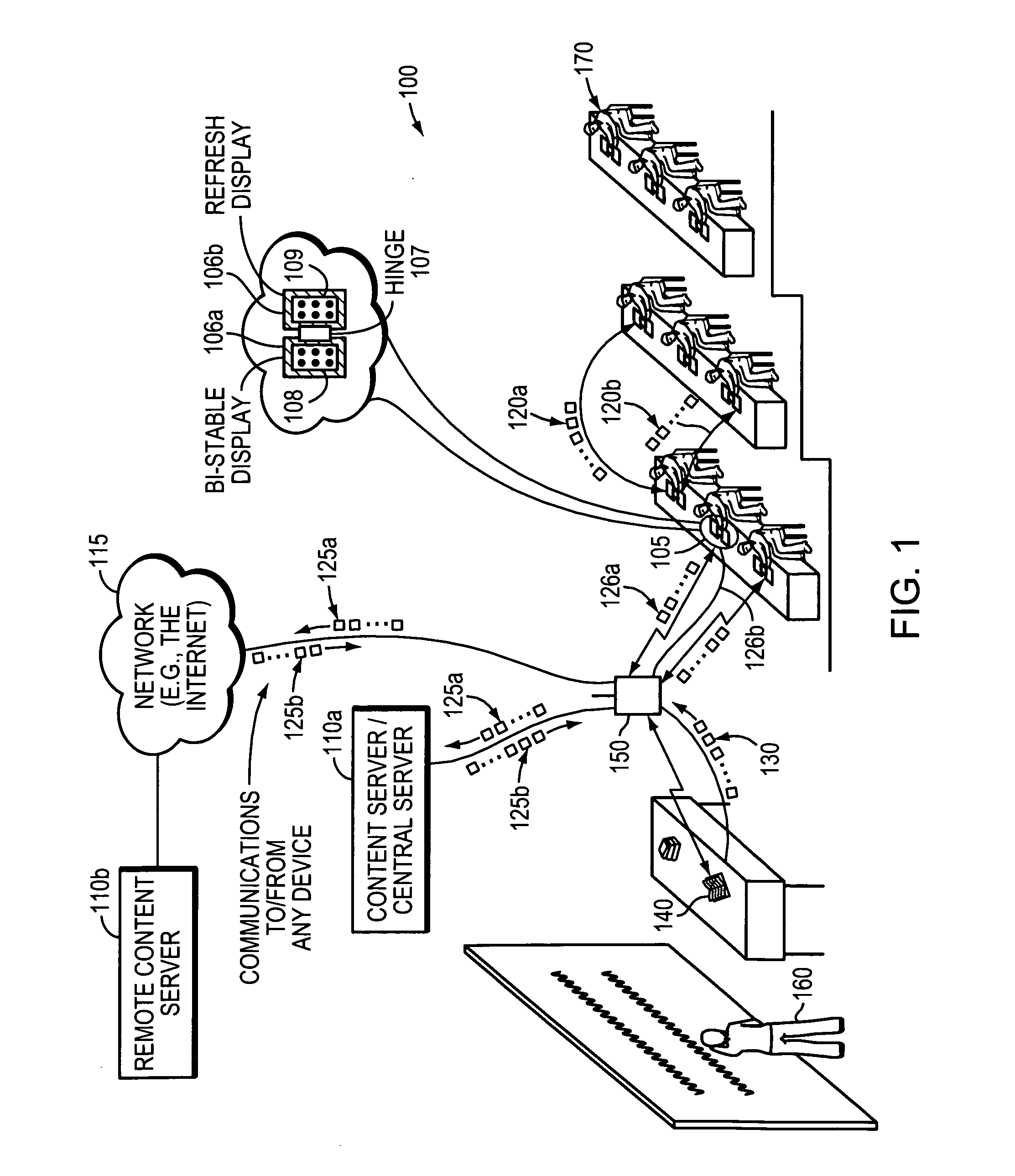

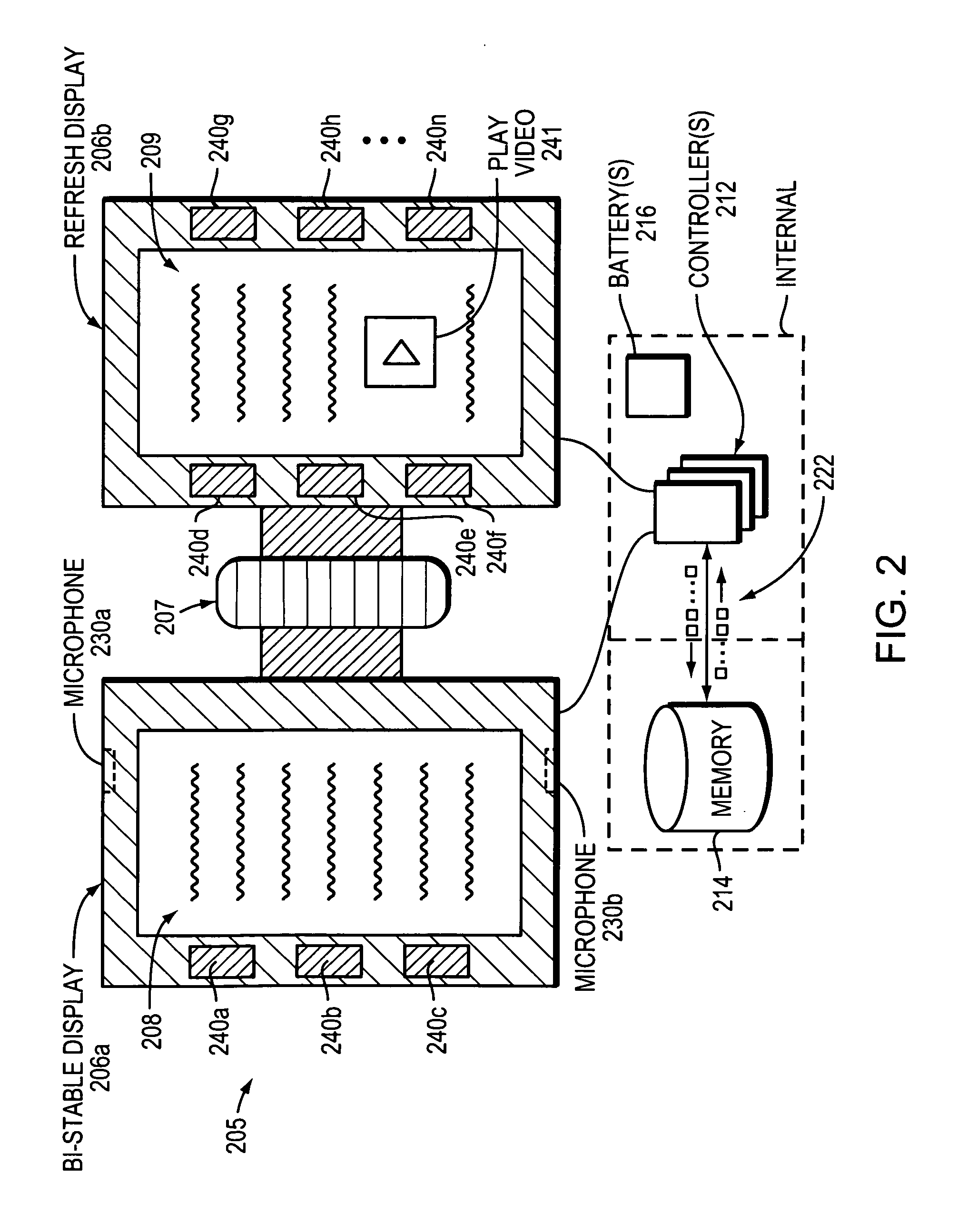

Multi-display handheld device and supporting system

InactiveUS20100156913A1Static indicating devicesInput/output processes for data processingSupporting systemDisplay device

Current approaches to paperless books use single screen laptop computers or electronic paper display (EPD)-based book readers. Laptop computers consume too much power and cannot be used for extended periods of time, such as an entire school day, without recharging its battery. EPD devices are limited in functionality due to their slow refresh rate and grey-scale only images. An embodiment of the present invention integrates bi-stable display technology and refresh display technology into a single device and manages the use of these technologies to achieve power savings while providing a rich set of display functionalities to support user interaction with content in a synergistic manner. The power savings functionality enables the device to have a battery operating life between charges of many hours of operation, such as eight hours or more, while the display functionality enables users to access, display, and interact with content in ways users have become accustomed and in ways not before possible.

Owner:PLEIADES PUBLISHING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com