Patents

Literature

59801results about "Chemical vapor deposition coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

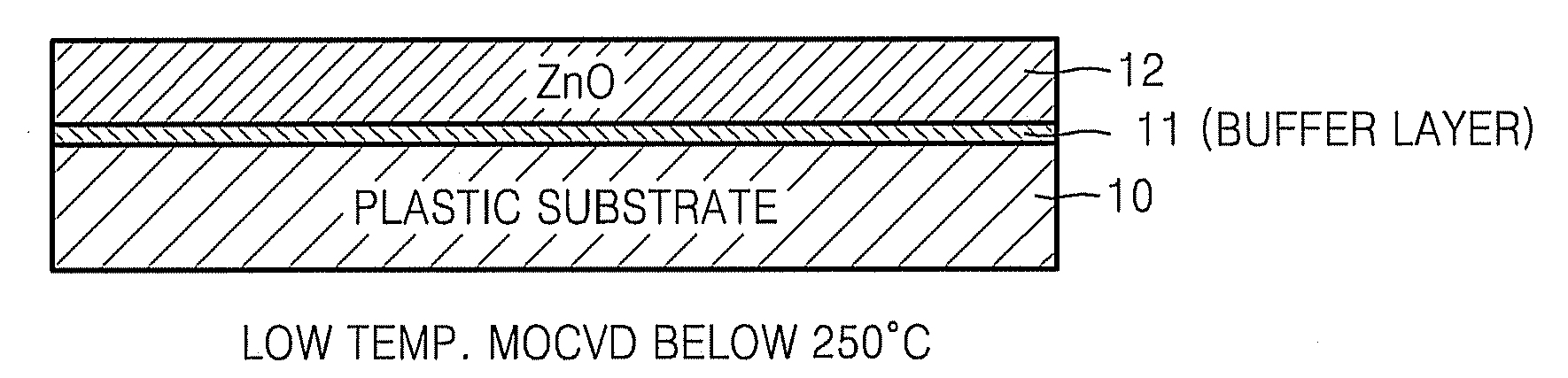

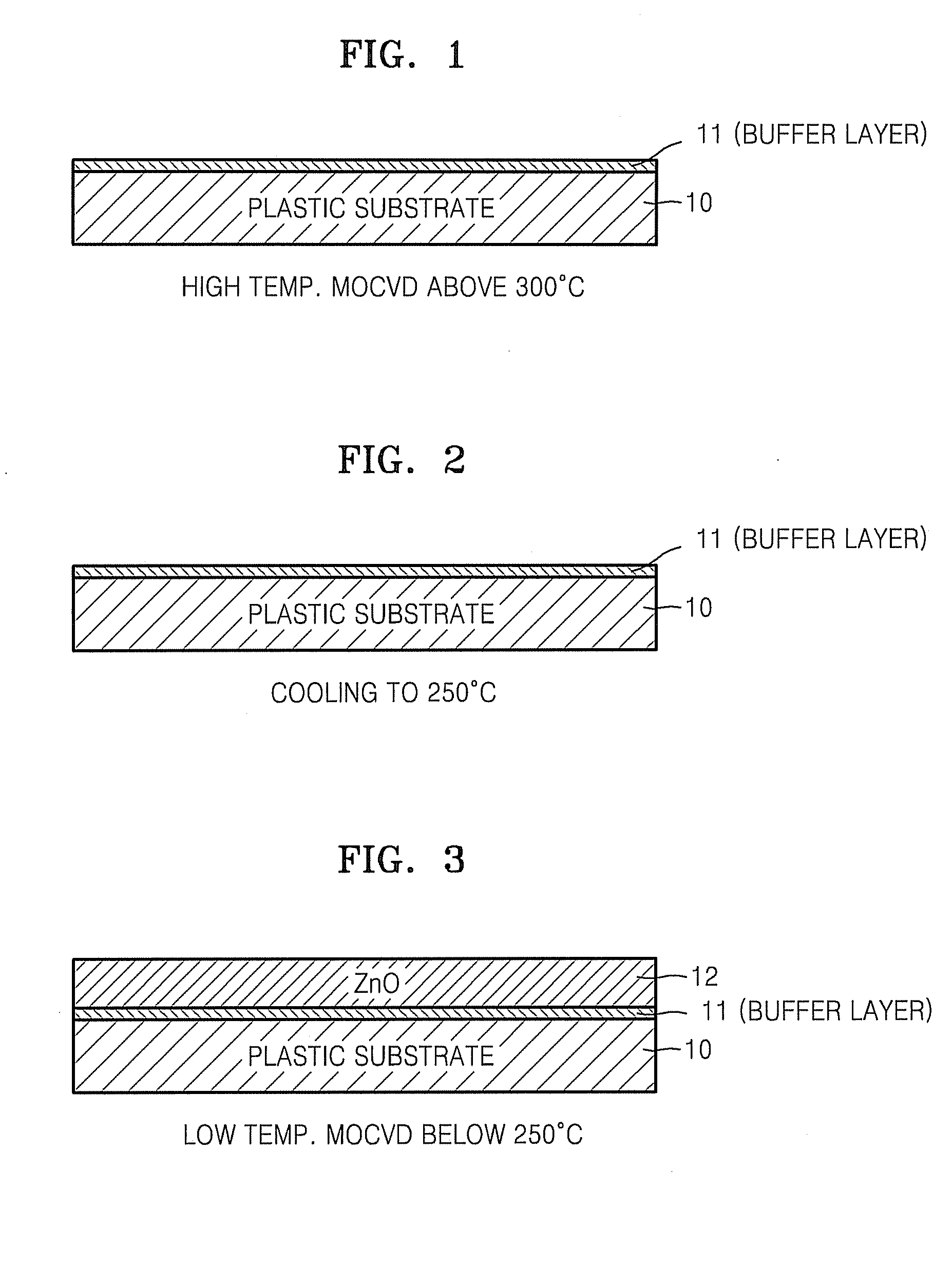

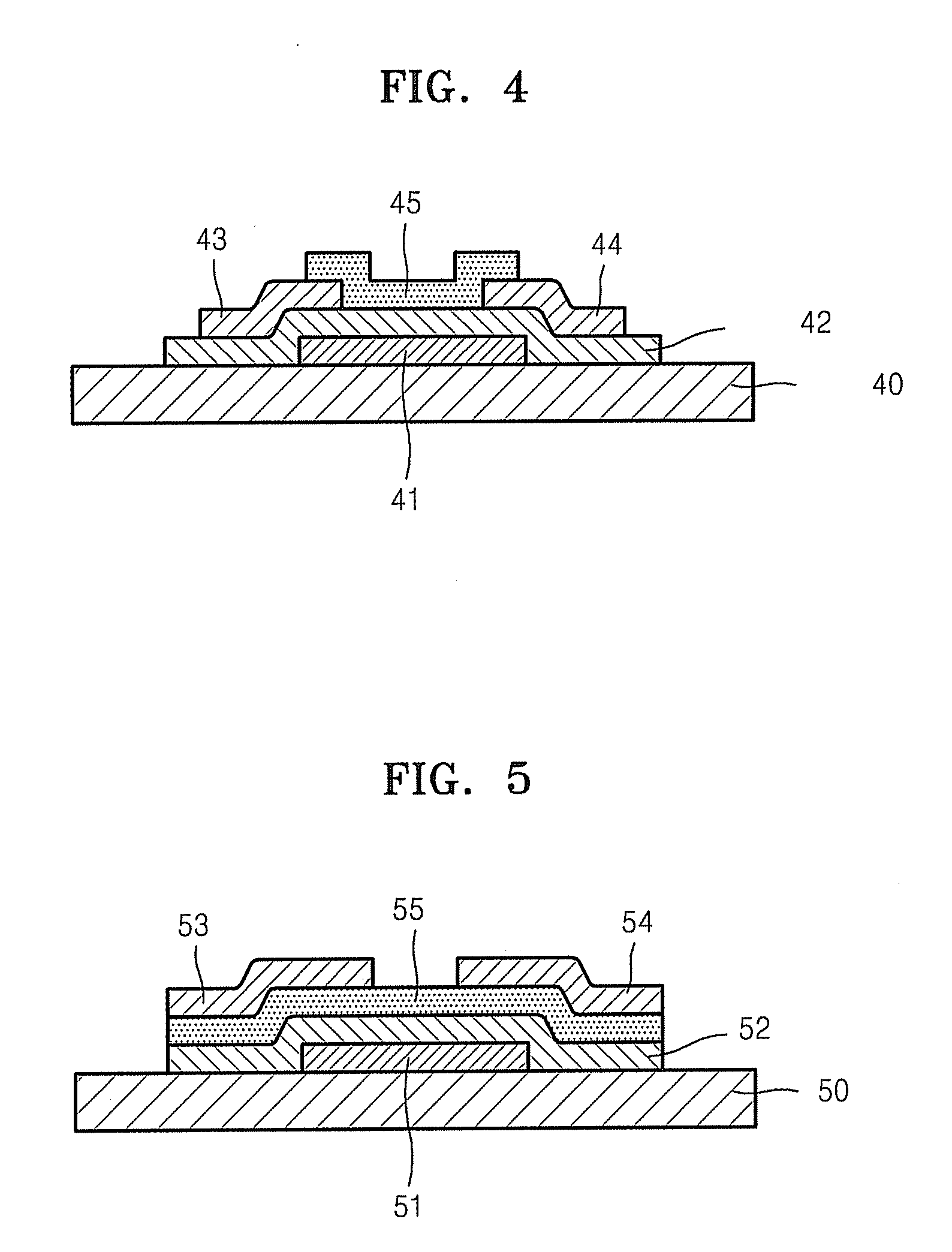

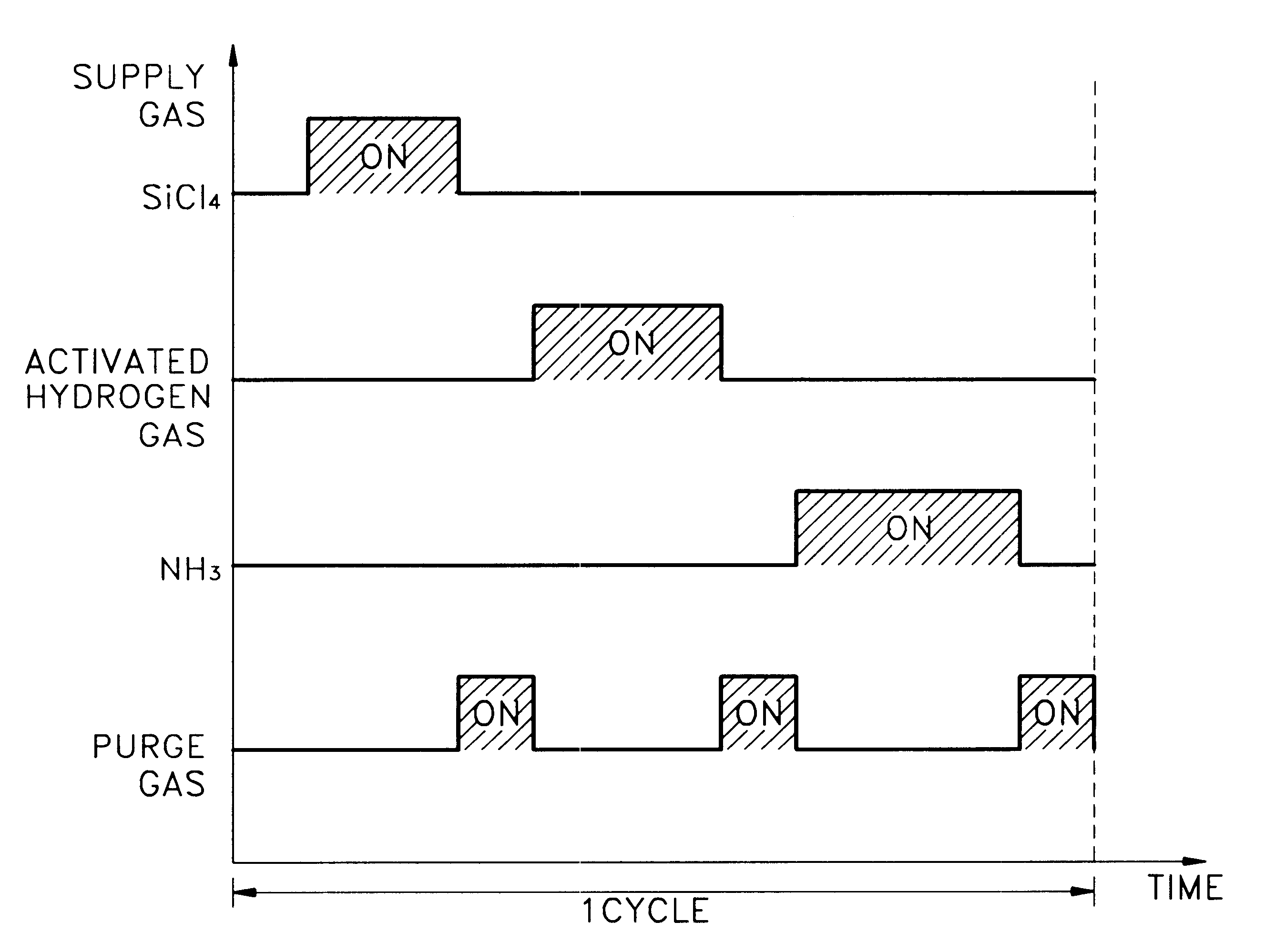

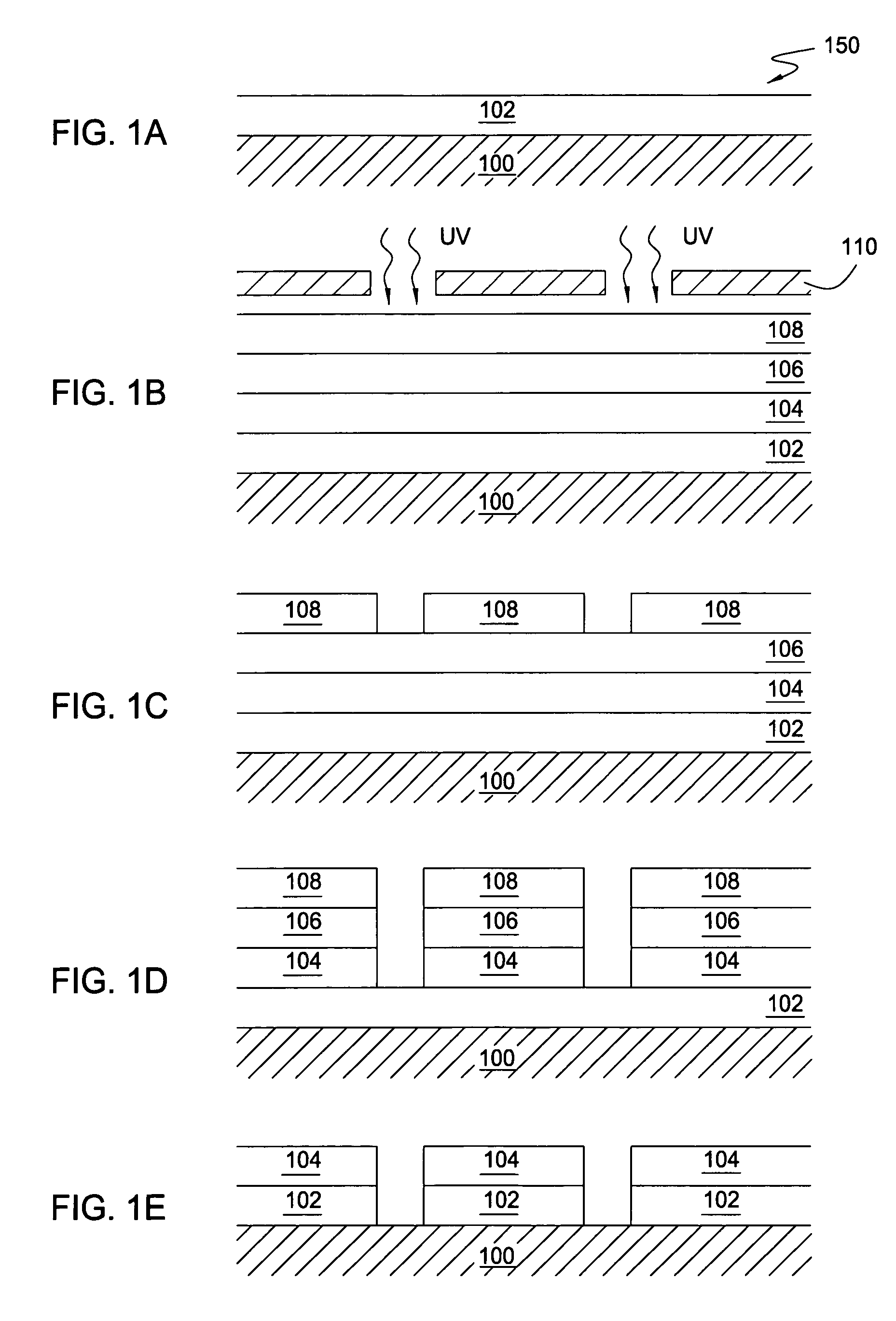

METHOD OF FABRICATING ZnO FILM AND THIN FILM TRANSISTOR ADOPTING THE ZnO FILM

InactiveUS20070172591A1Liquid surface applicatorsChemical vapor deposition coatingChemical vapor depositionMetal

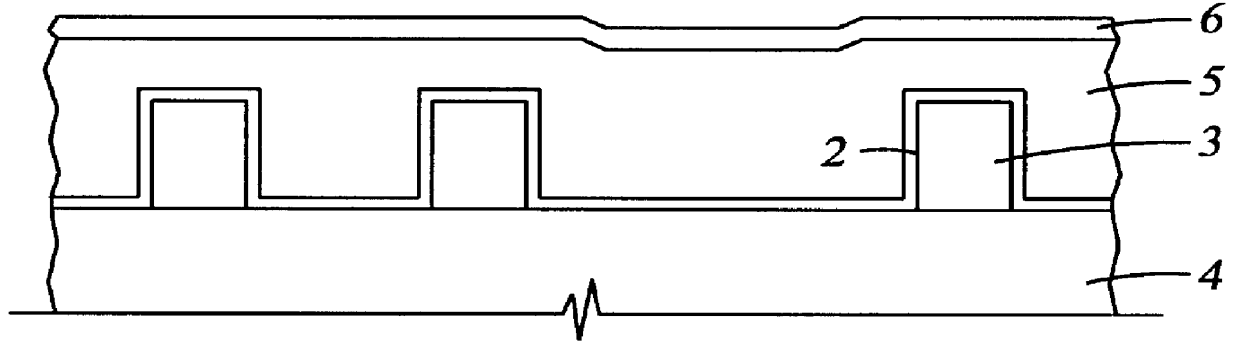

Provided is a method of fabricating a low temperature ZnO polycrystalline film and a thin film transistor (TFT) adopting the low temperature ZnO polycrystalline film. The method includes growing ZnO on a substrate at a first temperature for a first time using Metal Organic Chemical Vapor Deposition (MOCVD) to form a ZnO buffer layer, and heating the substrate at a temperature lower than the first temperature to grow ZnO on the ZnO buffer layer for a second time longer than the first time so as to form a ZnO film.

Owner:SAMSUNG ELECTRONICS CO LTD +1

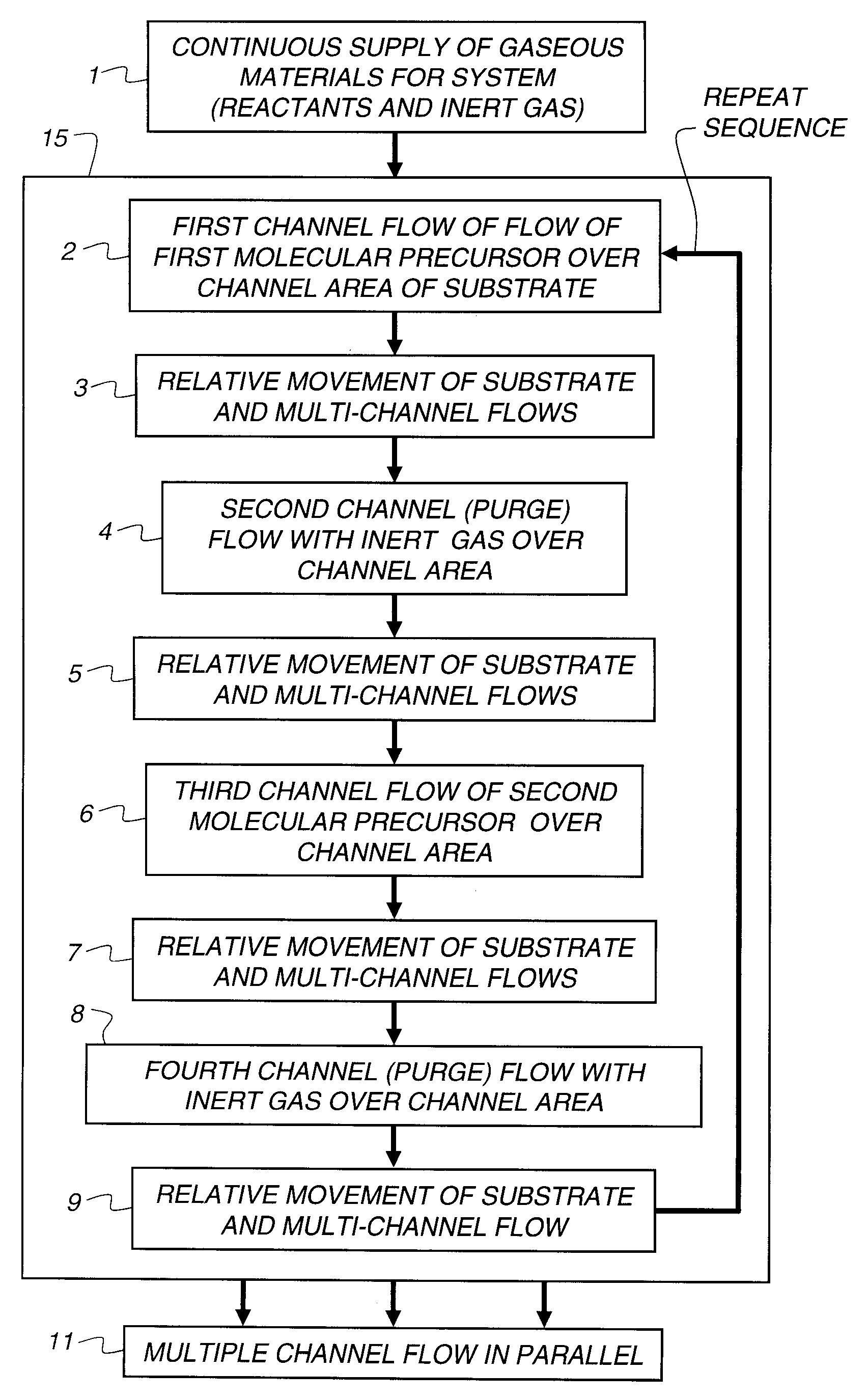

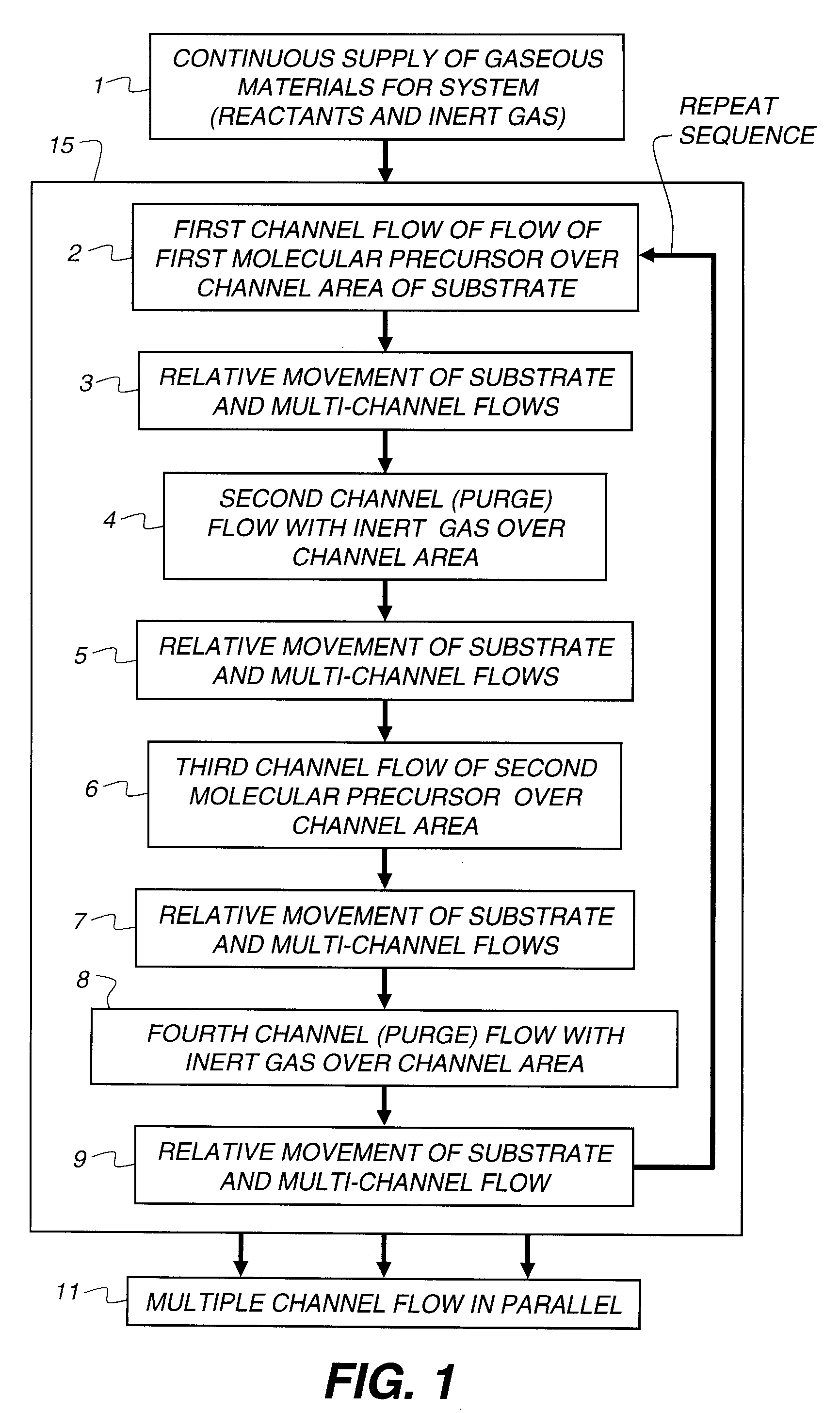

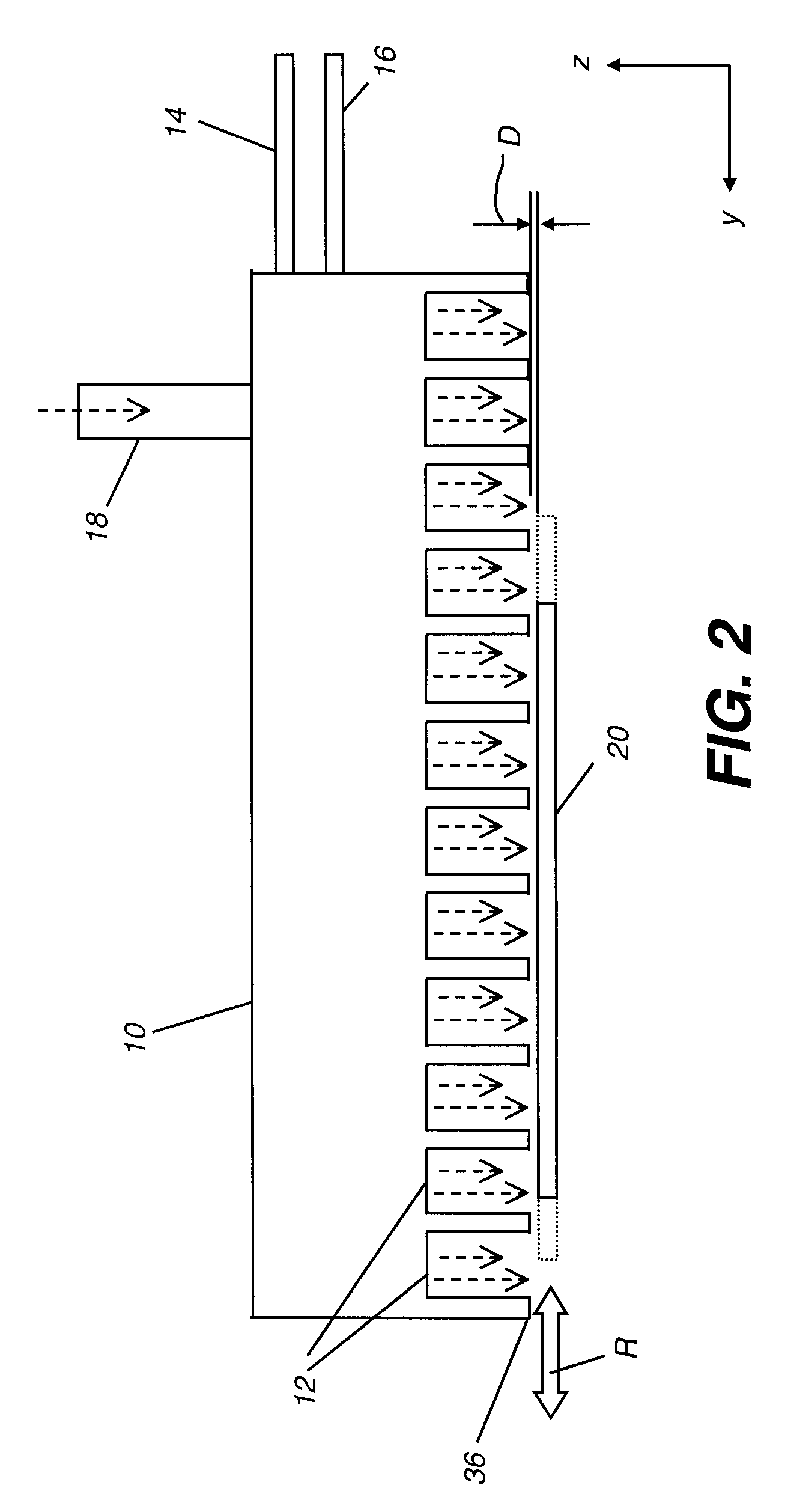

Process for atomic layer deposition

ActiveUS20080182358A1Suitable for processingAllowed to operateAdditive manufacturing apparatusSemiconductor/solid-state device manufacturingZincAtomic layer deposition

The present invention relates to a process of making a zinc-oxide-based thin film semiconductor, for use in a transistor, comprising thin film deposition onto a substrate comprising providing a plurality of gaseous materials comprising at least first, second, and third gaseous materials, wherein the first gaseous material is a zinc-containing volatile material and the second gaseous material is reactive therewith such that when one of the first or second gaseous materials are on the surface of the substrate the other of the first or second gaseous materials will react to deposit a layer of material on the substrate and wherein the third gaseous material is inert with respect to reacting with the first or second gaseous materials.

Owner:EASTMAN KODAK CO

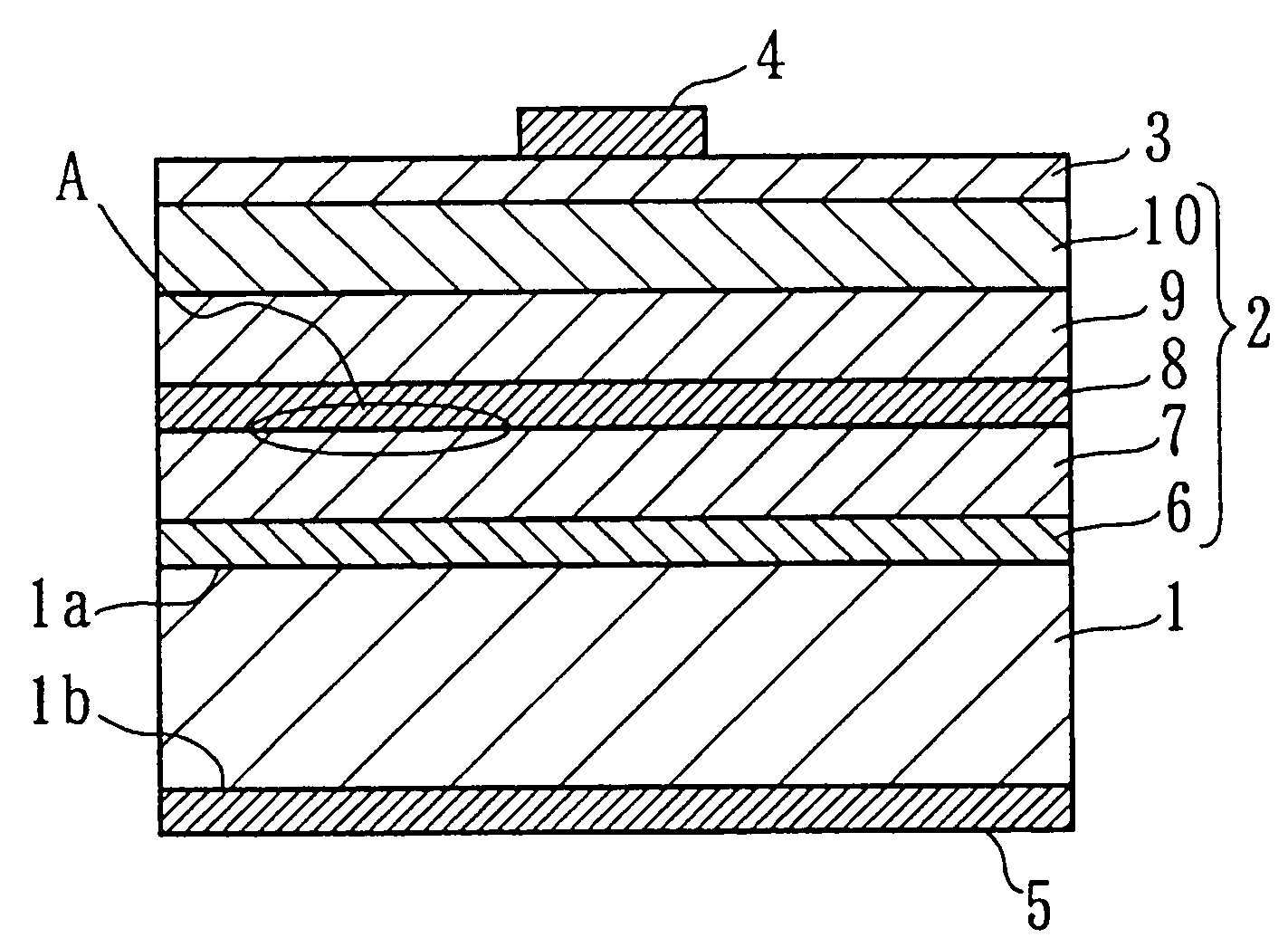

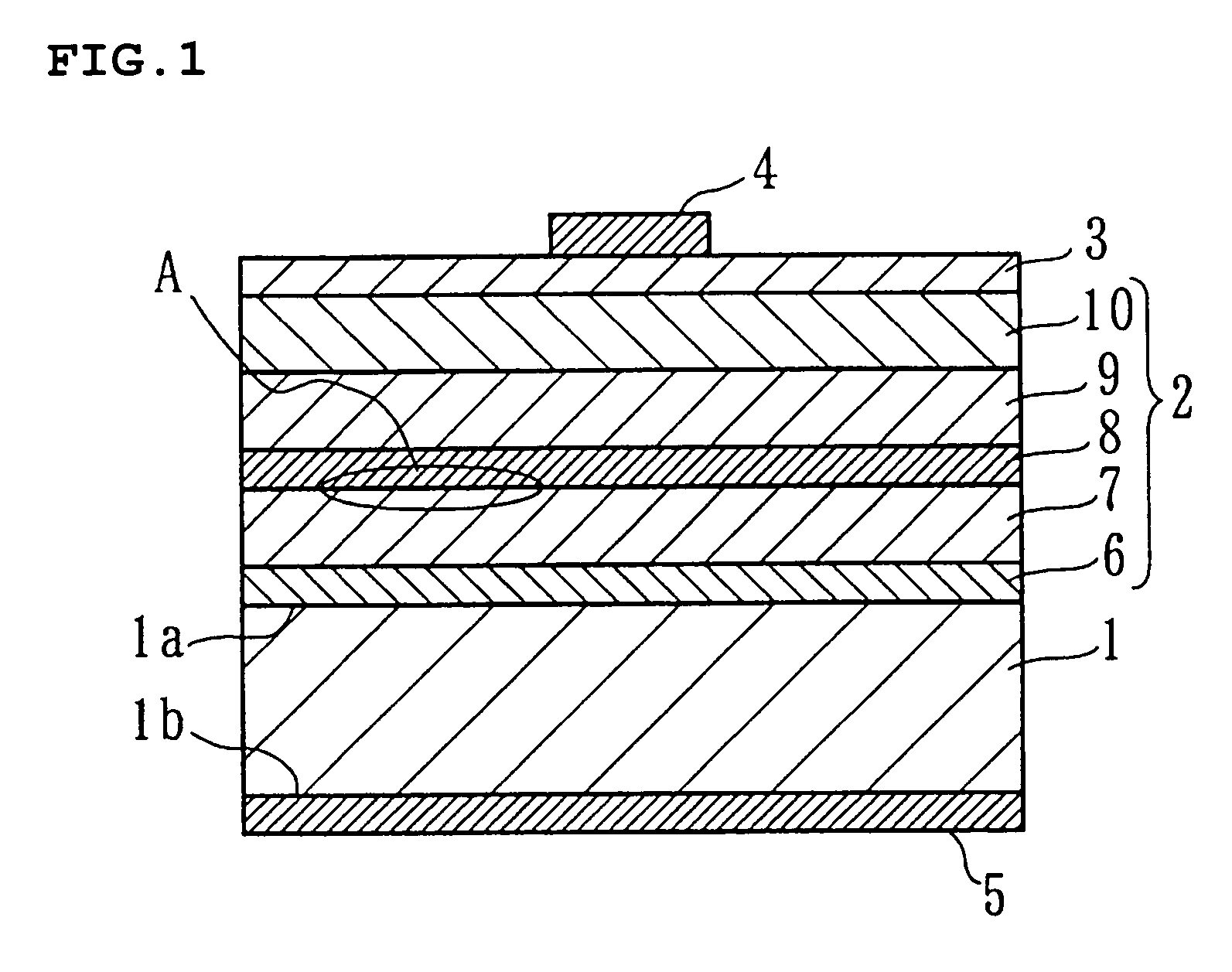

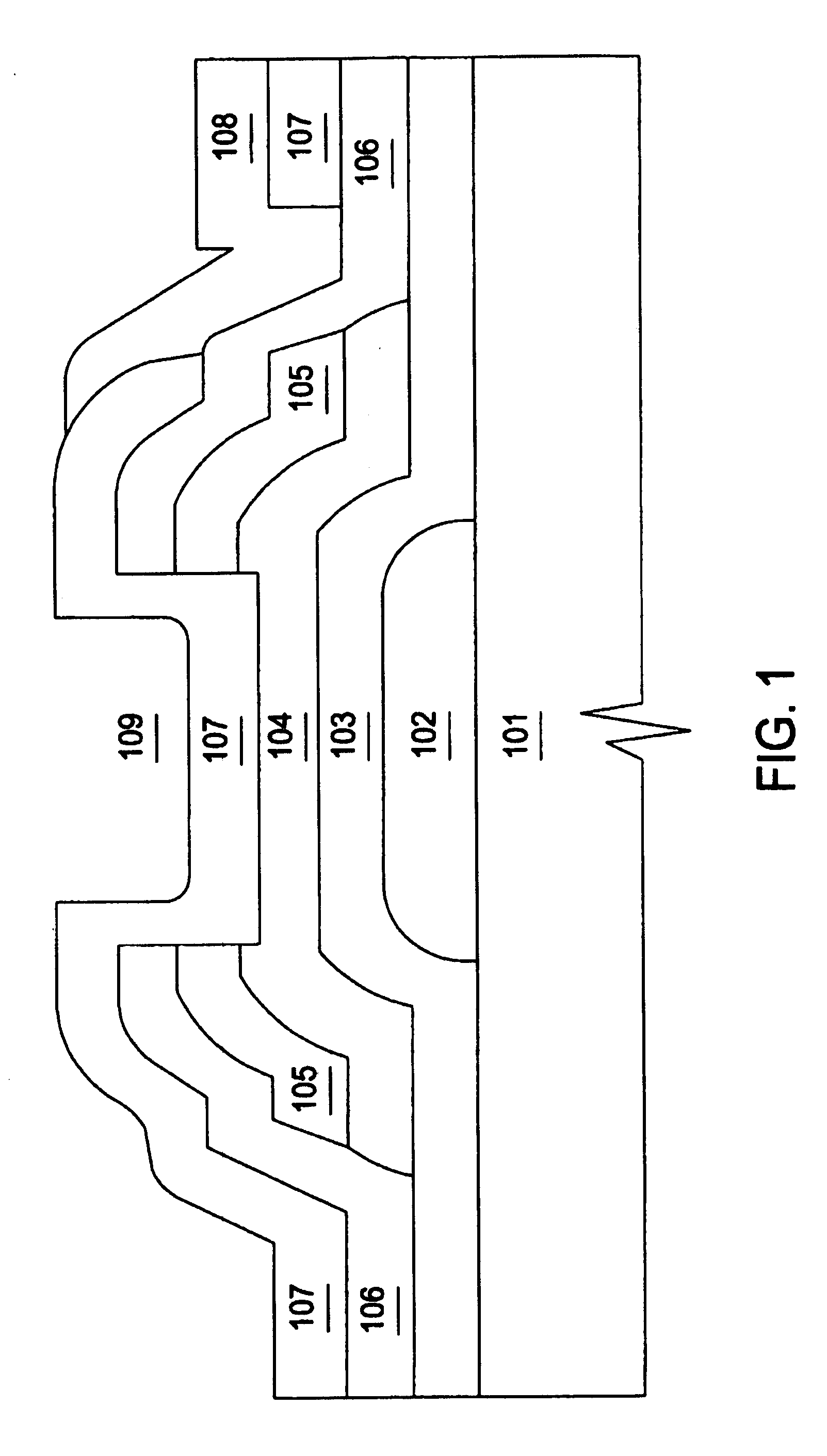

Semiconductor device in which zinc oxide is used as a semiconductor material and method for manufacturing the semiconductor device

ActiveUS7501293B2Improve surface smoothnessHigh crystallinityTransistorLaser detailsSemiconductor materialsDevice material

A semiconductor device having excellent crystallinity and excellent electric characteristics includes a ZnO thin film having excellent surface smoothness. ZnO-based thin films (an n-type contact layer, an n-type clad layer, an active layer, a p-type clad layer, and a p-type contact layer) primarily including ZnO are formed sequentially by an ECR sputtering method or other suitable method on a zinc-polar surface of a ZnO substrate. A transparent electrode and a p-side electrode are formed by an evaporation method or other suitable method on a surface of the p-type contact layer, and an n-side electrode is formed on an oxygen-polar surface of the ZnO substrate.

Owner:MURATA MFG CO LTD

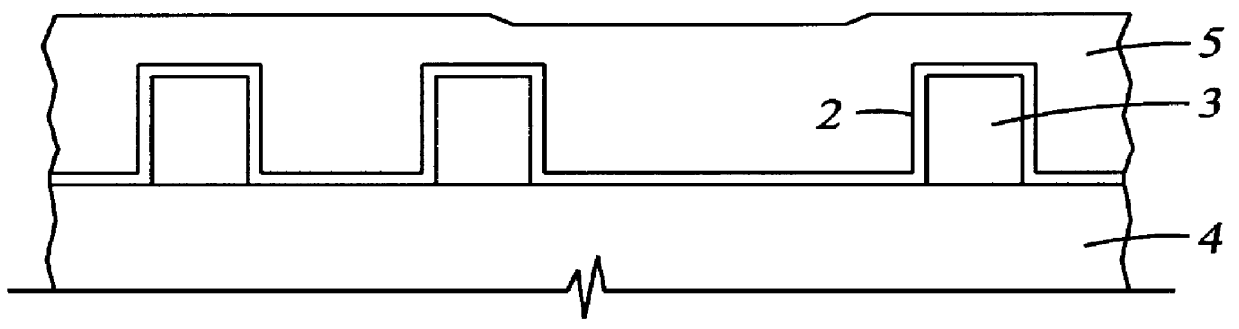

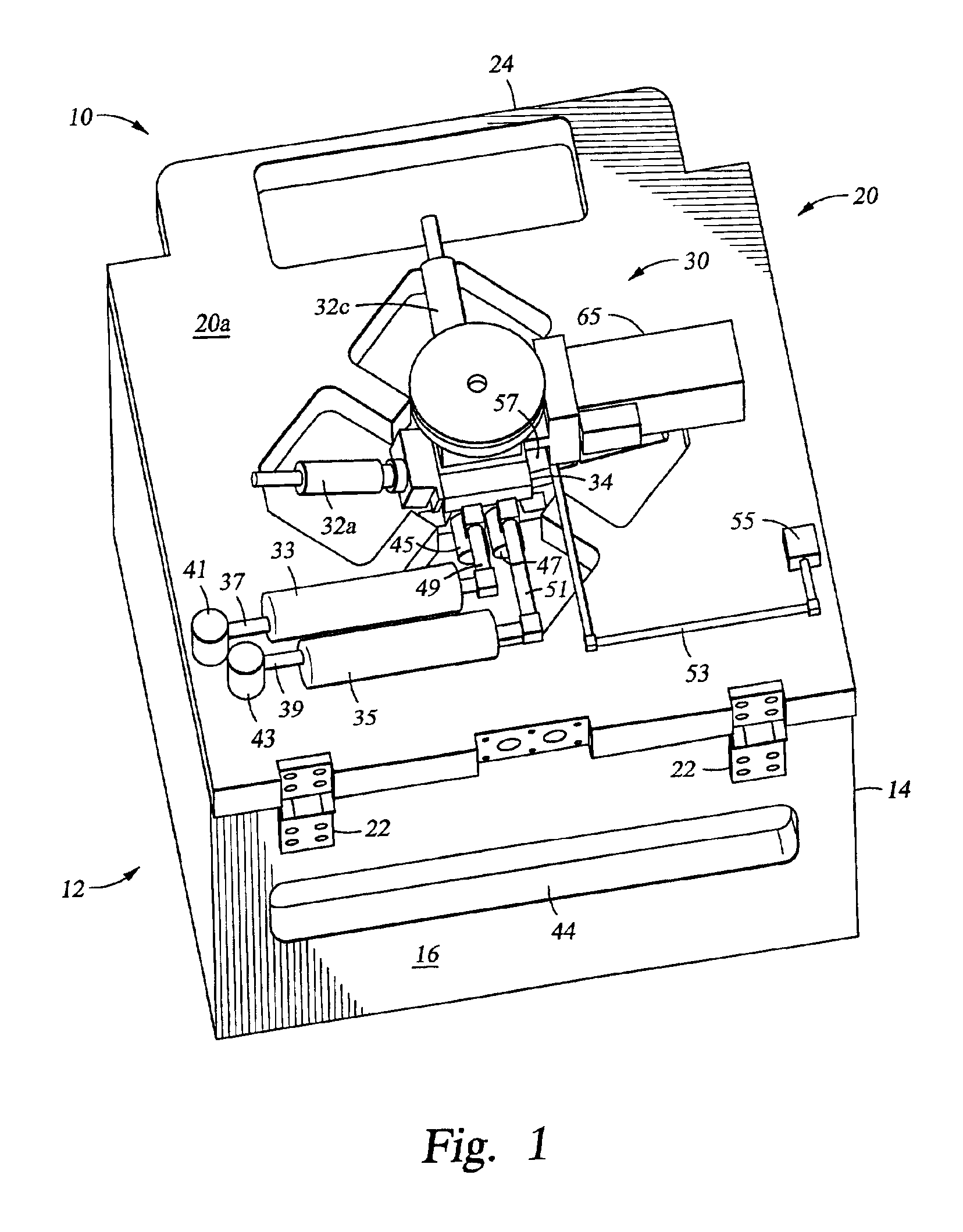

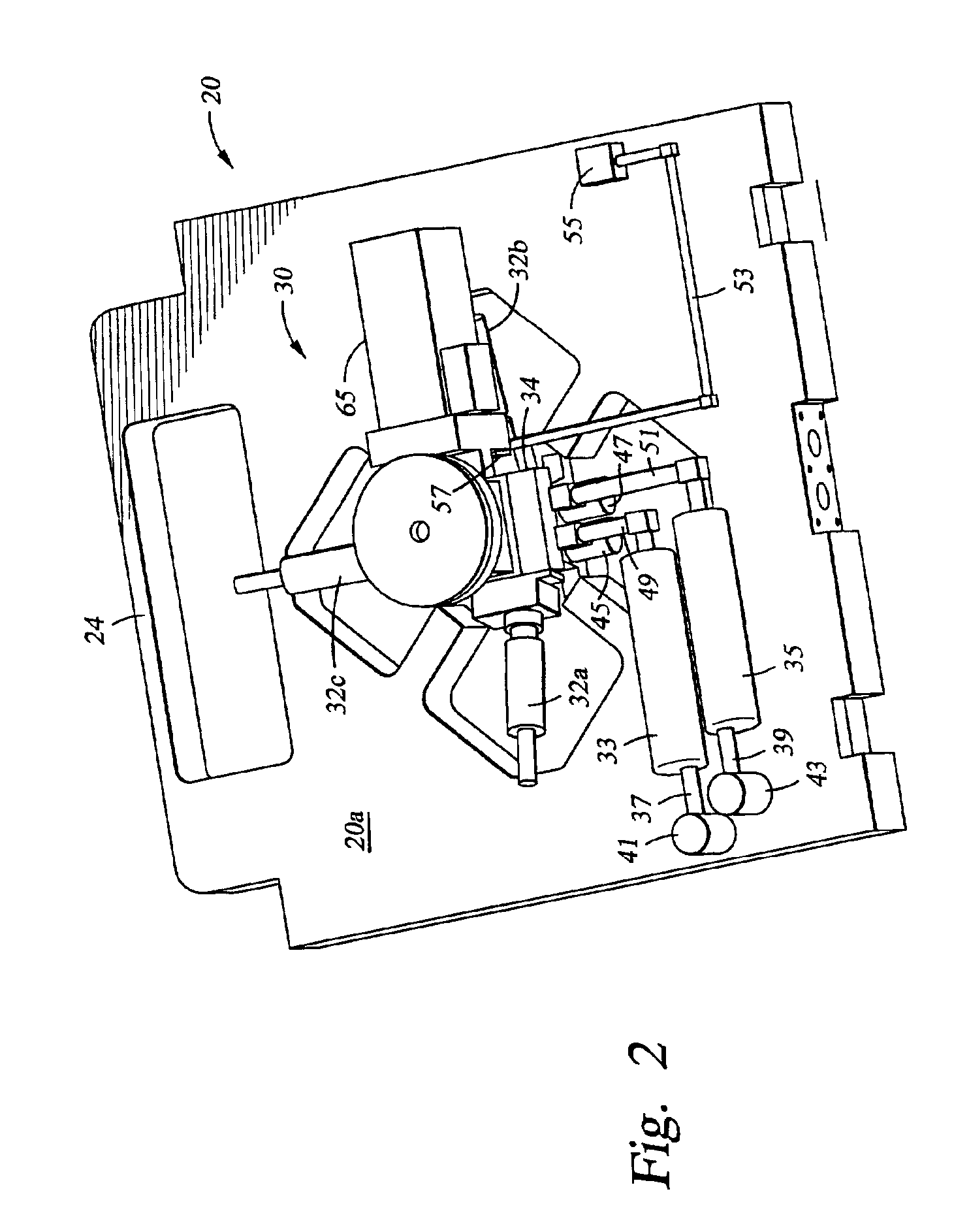

Process and apparatus for organic vapor jet deposition

ActiveUS7431968B1Good directionSharp pixelVacuum evaporation coatingSputtering coatingOrganic filmVacuum chamber

A method of fabricating an organic film is provided. A non-reactive carrier gas is used to transport an organic vapor. The organic vapor is ejected through a nozzle block onto a cooled substrate, to form a patterned organic film. A device for carrying out the method is also provided. The device includes a source of organic vapors, a source of carrier gas and a vacuum chamber. A heated nozzle block attached to the source of organic vapors and the source of carrier gas has at least one nozzle adapted to eject carrier gas and organic vapors onto a cooled substrate disposed within the vacuum chamber.

Owner:THE TRUSTEES FOR PRINCETON UNIV

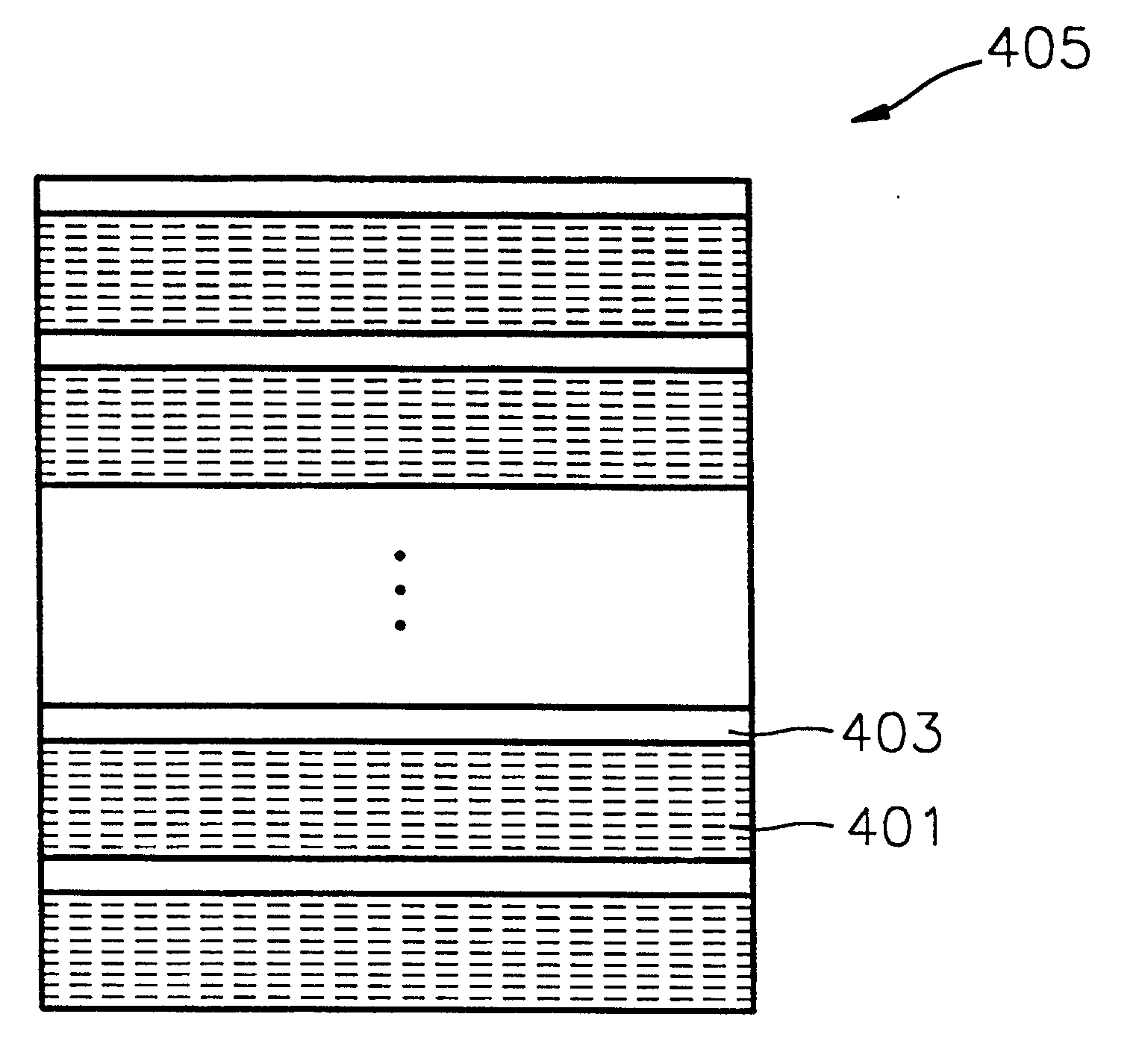

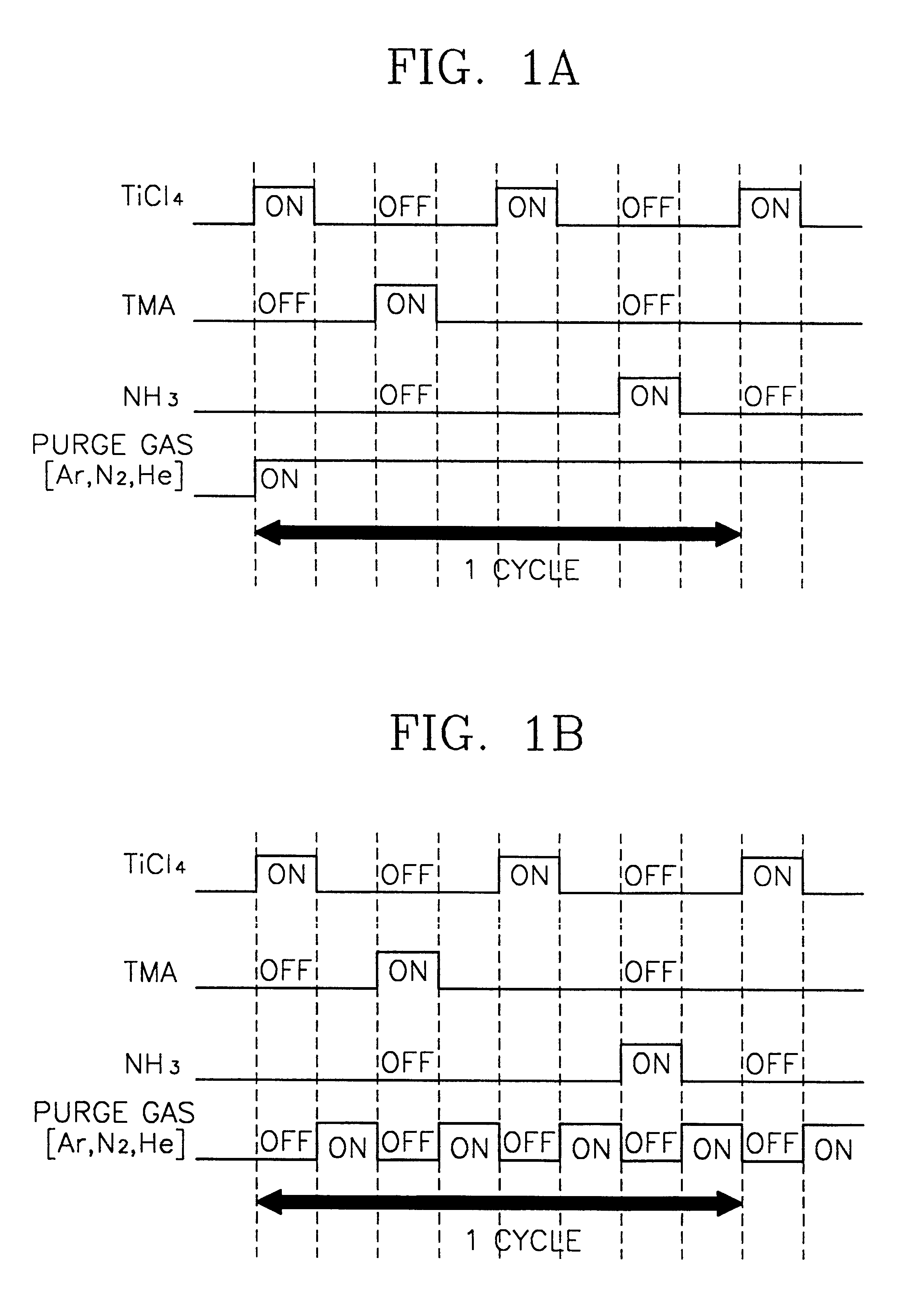

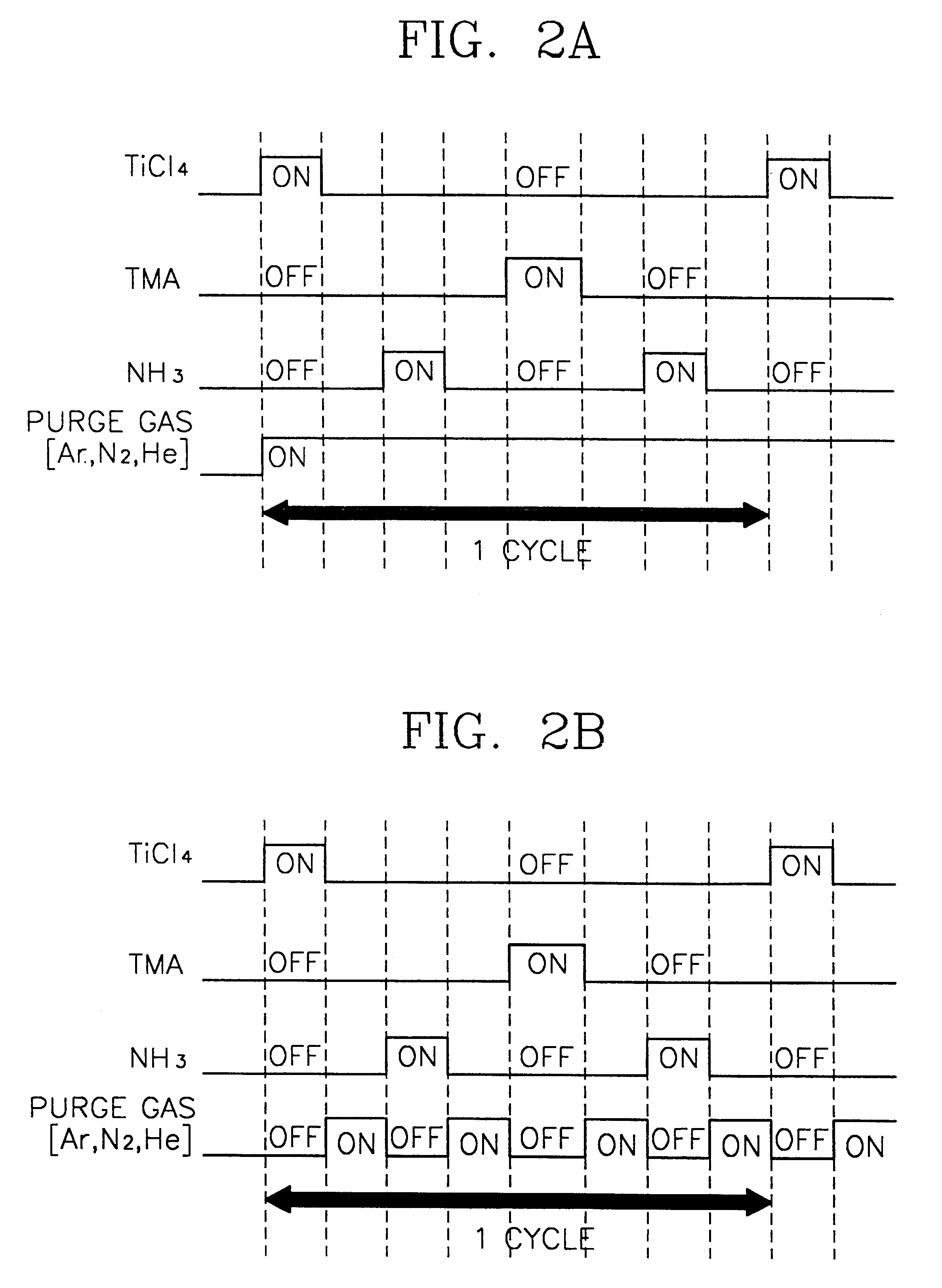

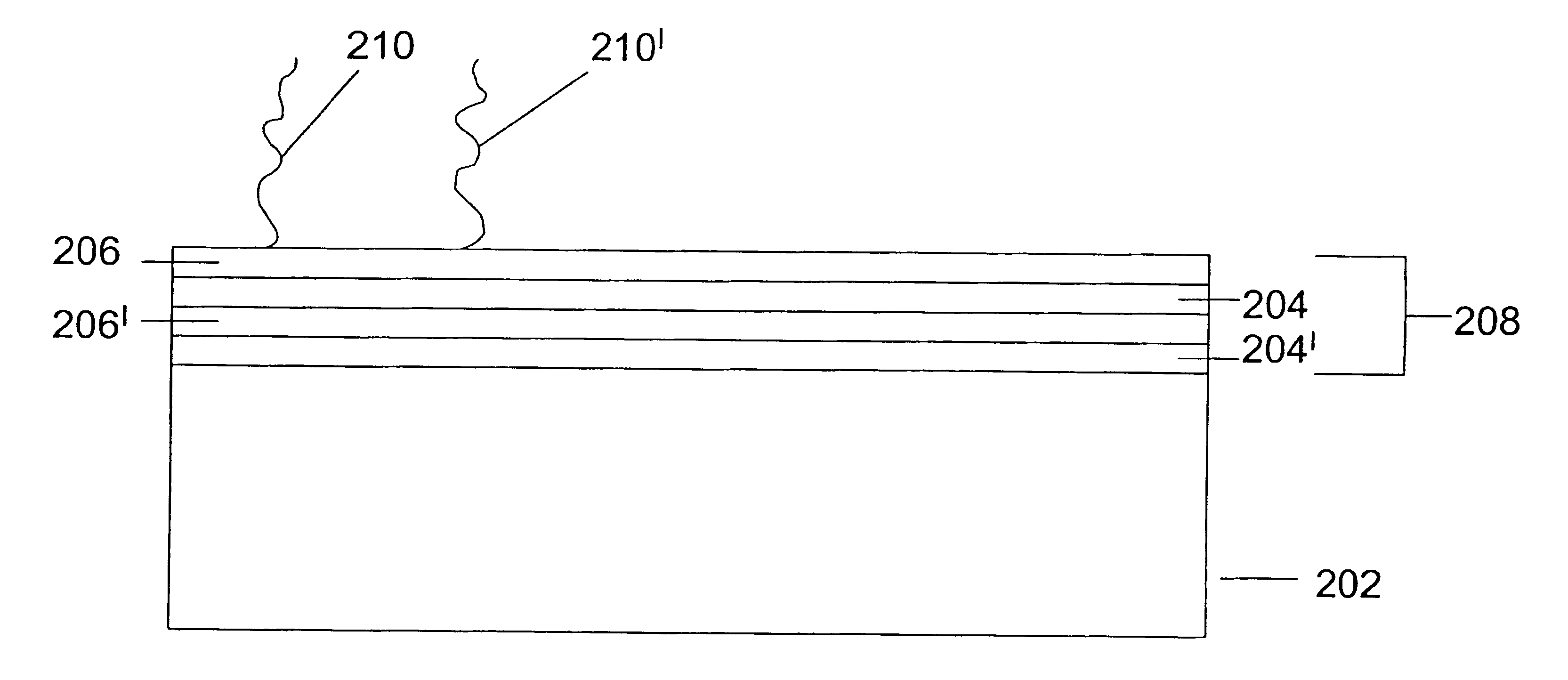

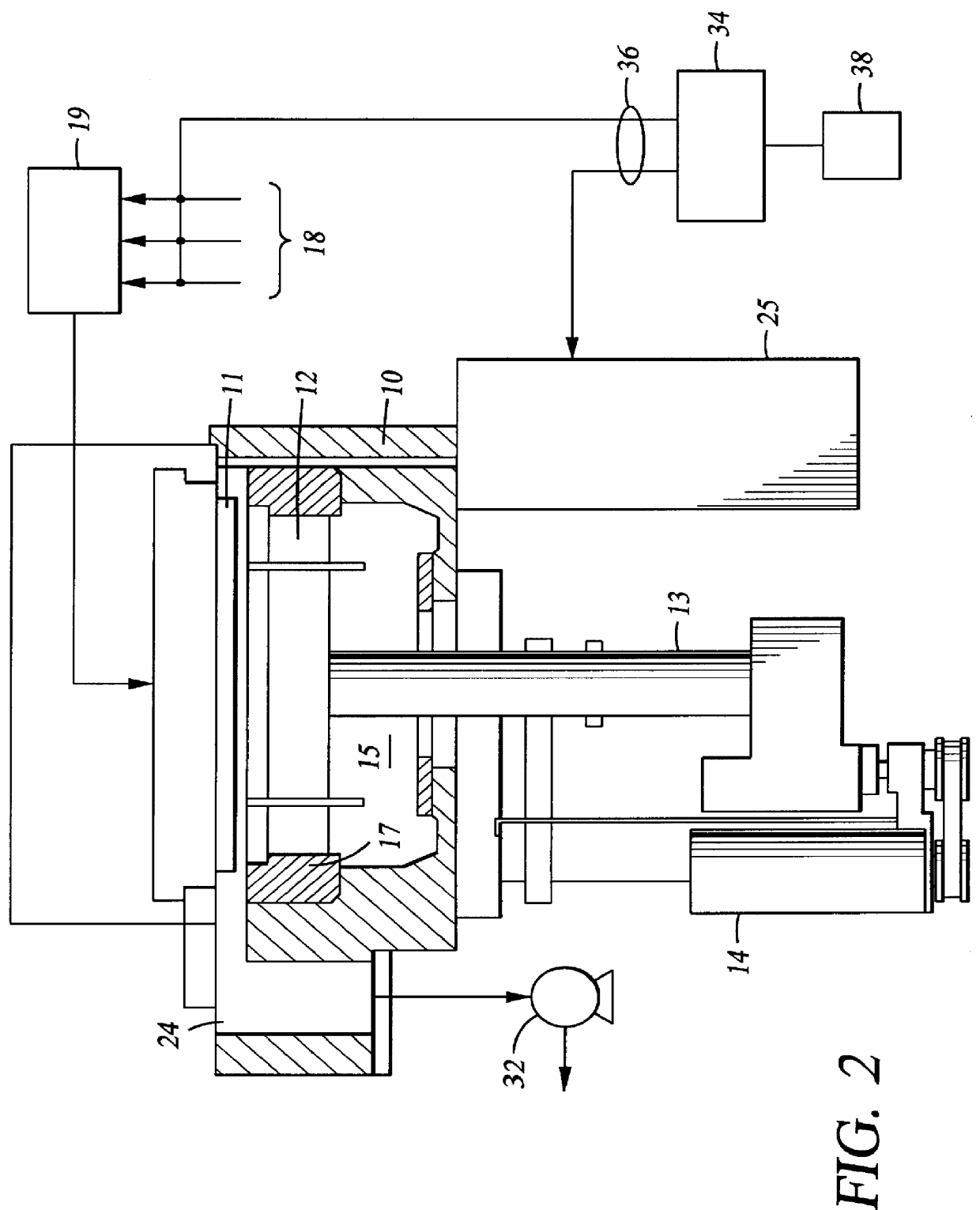

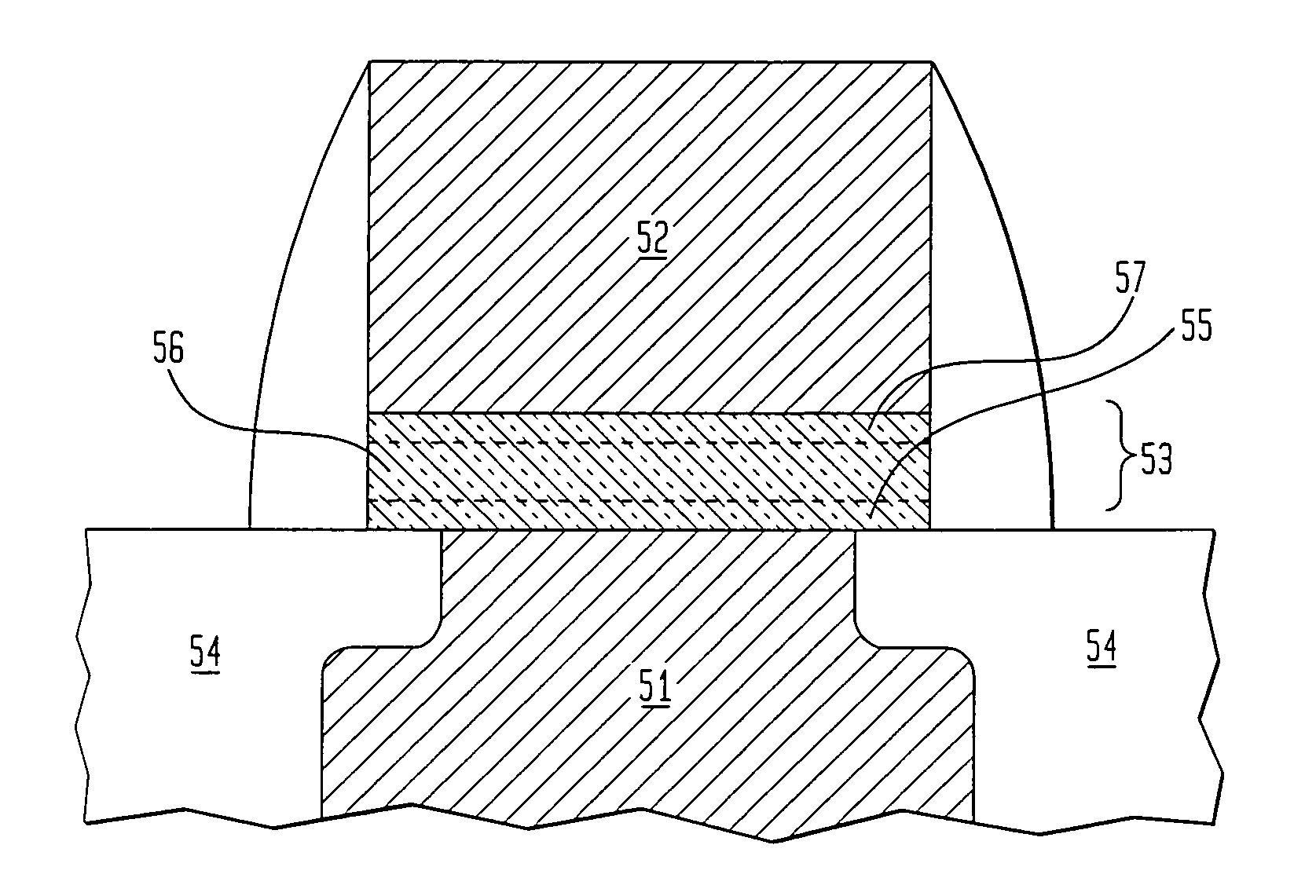

Method of forming metal layer using atomic layer deposition and semiconductor device having the metal layer as barrier metal layer or upper or lower electrode of capacitor

InactiveUS6287965B1High thermal resistantEasy to adjustSemiconductor/solid-state device manufacturingCapacitorsNiobiumDevice material

A method of forming a metal layer having excellent thermal and oxidation resistant characteristics using atomic layer deposition is provided. The metal layer includes a reactive metal (A), an element (B) for the amorphous combination between the reactive metal (A) and nitrogen (N), and nitrogen (N). The reactive metal (A) may be titanium (Ti), tantalum (Ta), tungsten (W), zirconium (Zr), hafnium (Hf), molybdenum (Mo) or niobium (Nb). The amorphous combination element (B) may be aluminum (Al), silicon (Si) or boron (B). The metal layer is formed by alternately injecting pulsed source gases for the elements (A, B and N) into a chamber according to atomic layer deposition to thereby alternately stack atomic layers. Accordingly, the composition ratio of a nitrogen compound (A-B-N) of the metal layer can be desirably adjusted just by appropriately determining the number of injection pulses of each source gas. According to the composition ratio, a desirable electrical conductivity and resistance of the metal layer can be accurately obtained. The atomic layers are individually deposited, thereby realizing excellent step coverage even in a complex and compact region. A metal layer formed by atomic layer deposition can be employed as a barrier metal layer, a lower electrode or an upper electrode in a semiconductor device.

Owner:SAMSUNG ELECTRONICS CO LTD

Methods and apparatus for analyzing polynucleotide sequences

The present invention provides an apparatus for analyzing the sequences of polynucleotides. The apparatus comprises (a) flow cell which has at least one microfabricated multilayer elastomeric synthesis channel; and (b) an inlet port and an outlet port. The inlet port and outlet ports are in fluid communication with the flow cell for flowing fluids into and through the flow cell.

Owner:CALIFORNIA INST OF TECH

Method of growing nitride semiconductors, nitride semiconductor substrate and nitride semiconductor device

InactiveUS6153010APolycrystalline material growthLaser detailsNitrogen sourceCrystallographic defect

PCT No. PCT / JP98 / 01640 Sec. 371 Date Dec. 9, 1998 Sec. 102(e) Date Dec. 9, 1998 PCT Filed Apr. 9, 1998 PCT Pub. No. WO98 / 47170 PCT Pub. Date Oct. 22, 1998A method of growing a nitride semiconductor crystal which has very few crystal defects and can be used as a substrate is disclosed. This invention includes the step of forming a first selective growth mask on a support member including a dissimilar substrate having a major surface and made of a material different from a nitride semiconductor, the first selective growth mask having a plurality of first windows for selectively exposing the upper surface of the support member, and the step of growing nitride semiconductor portions from the upper surface, of the support member, which is exposed from the windows, by using a gaseous Group 3 element source and a gaseous nitrogen source, until the nitride semiconductor portions grown in the adjacent windows combine with each other on the upper surface of the selective growth mask.

Owner:NICHIA CORP

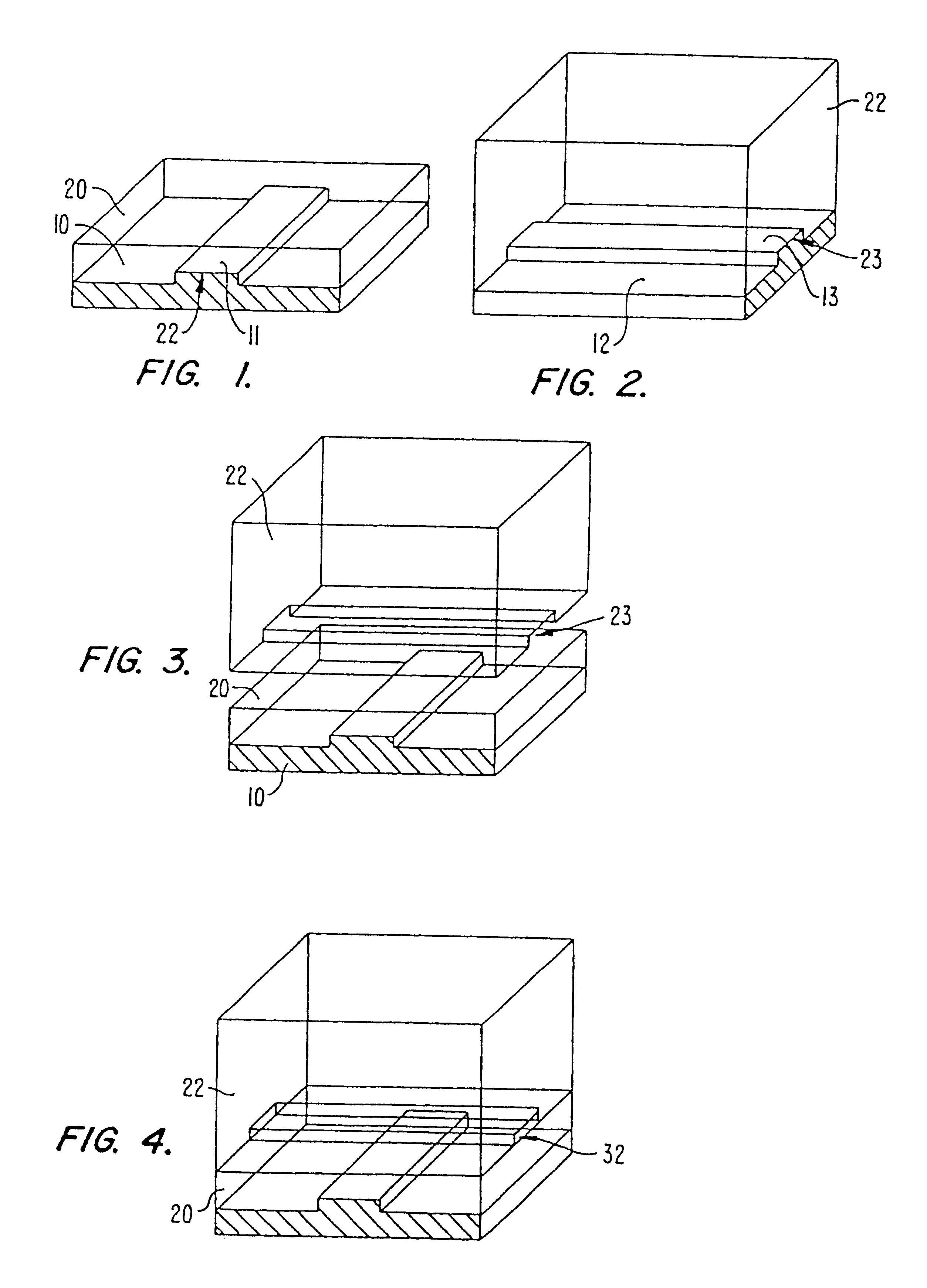

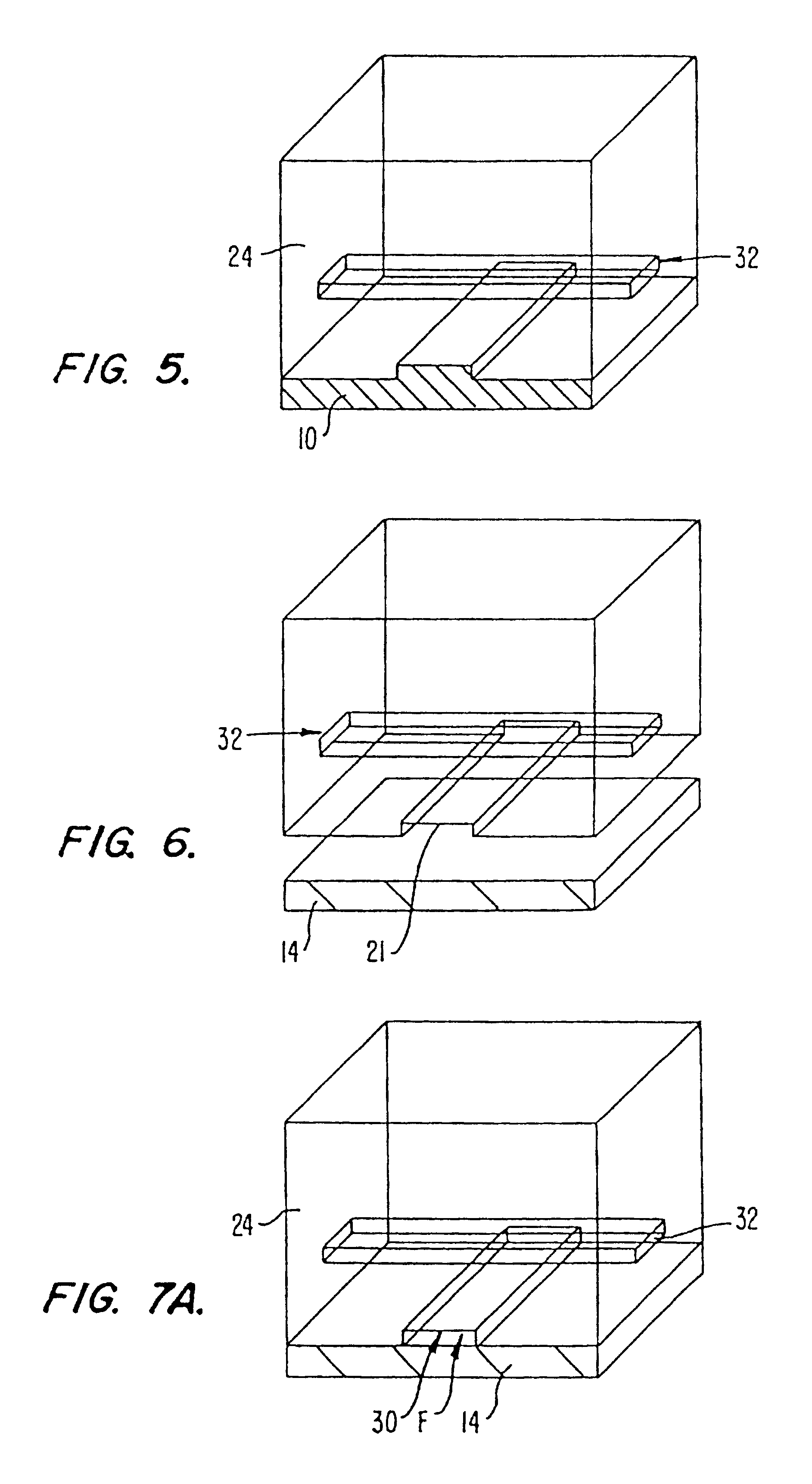

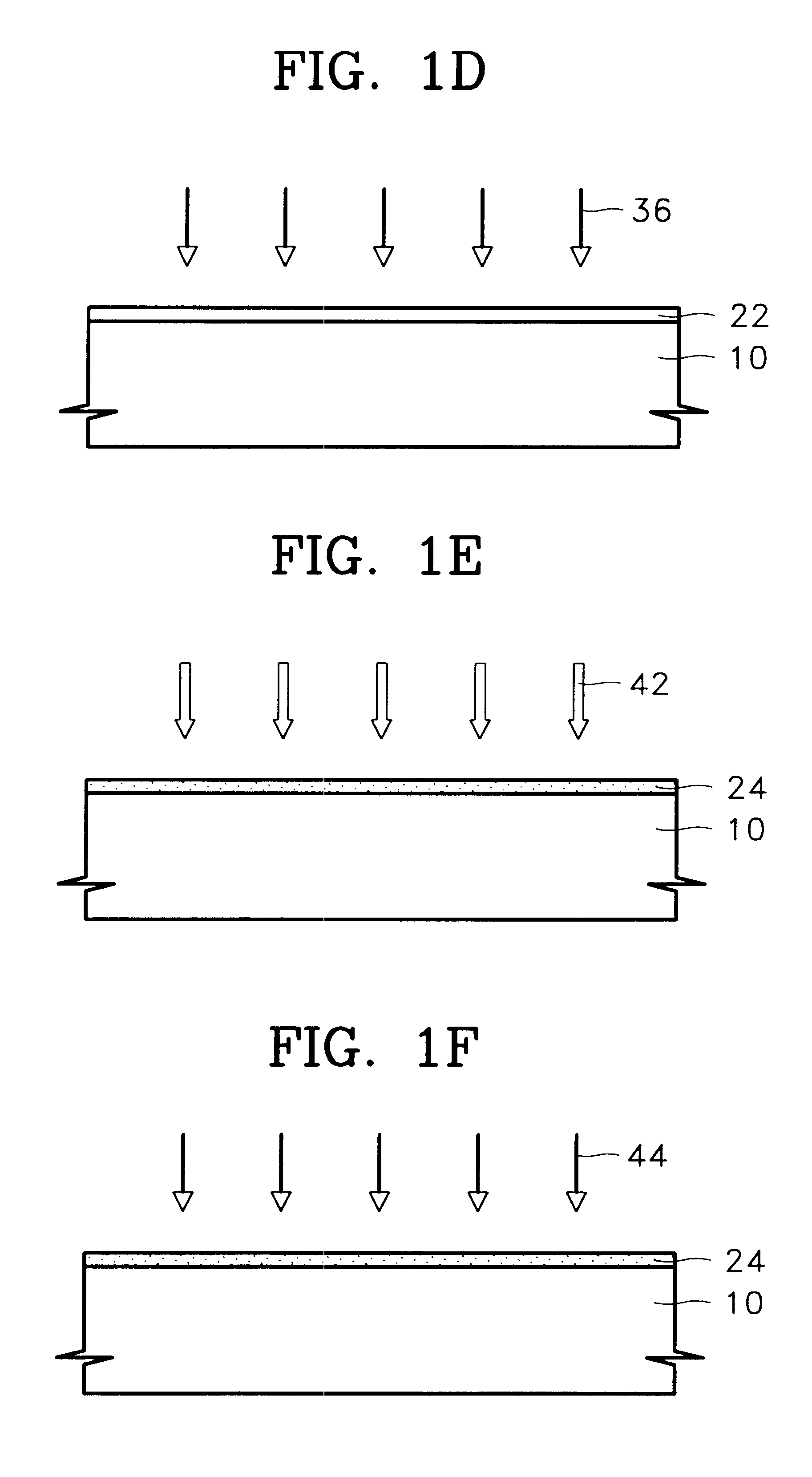

Methods of forming thin films by atomic layer deposition

InactiveUS6468924B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingHydrogenProduct gas

Methods of forming thin films include forming a first layer comprising a first element that is chemisorbed to a surface of a substrate, by exposing the surface to a first source gas having molecules therein that comprise the first element and a halogen. A step is then performed to expose the first layer to an activated hydrogen gas so that halogens associated with the first layer become bound to hydrogen provided by the activated hydrogen gas. The first layer may then be converted to a thin film comprising the first element and a second element, by exposing a surface of the first layer to a second source gas having molecules therein that comprise the second element.

Owner:SAMSUNG ELECTRONICS CO LTD

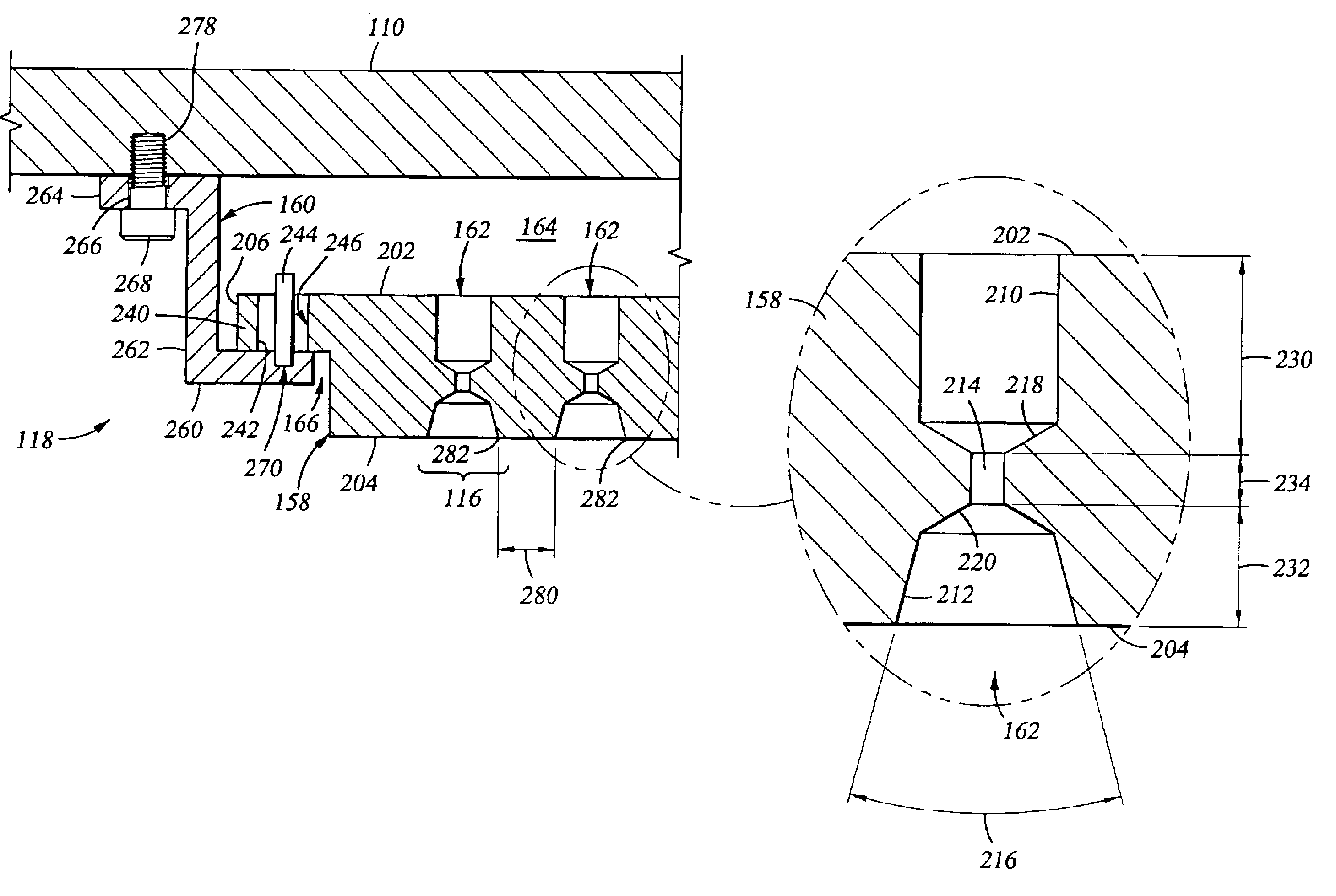

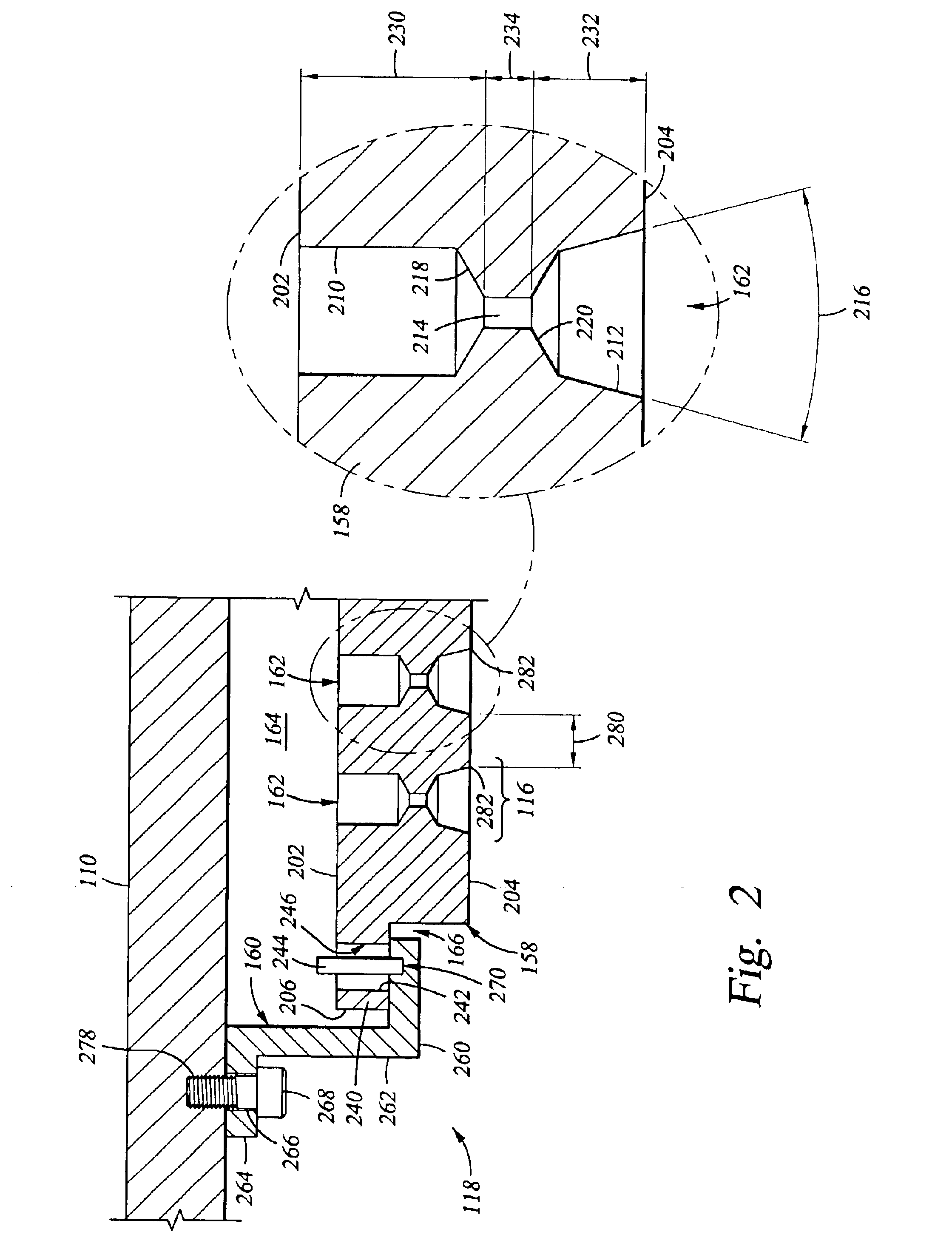

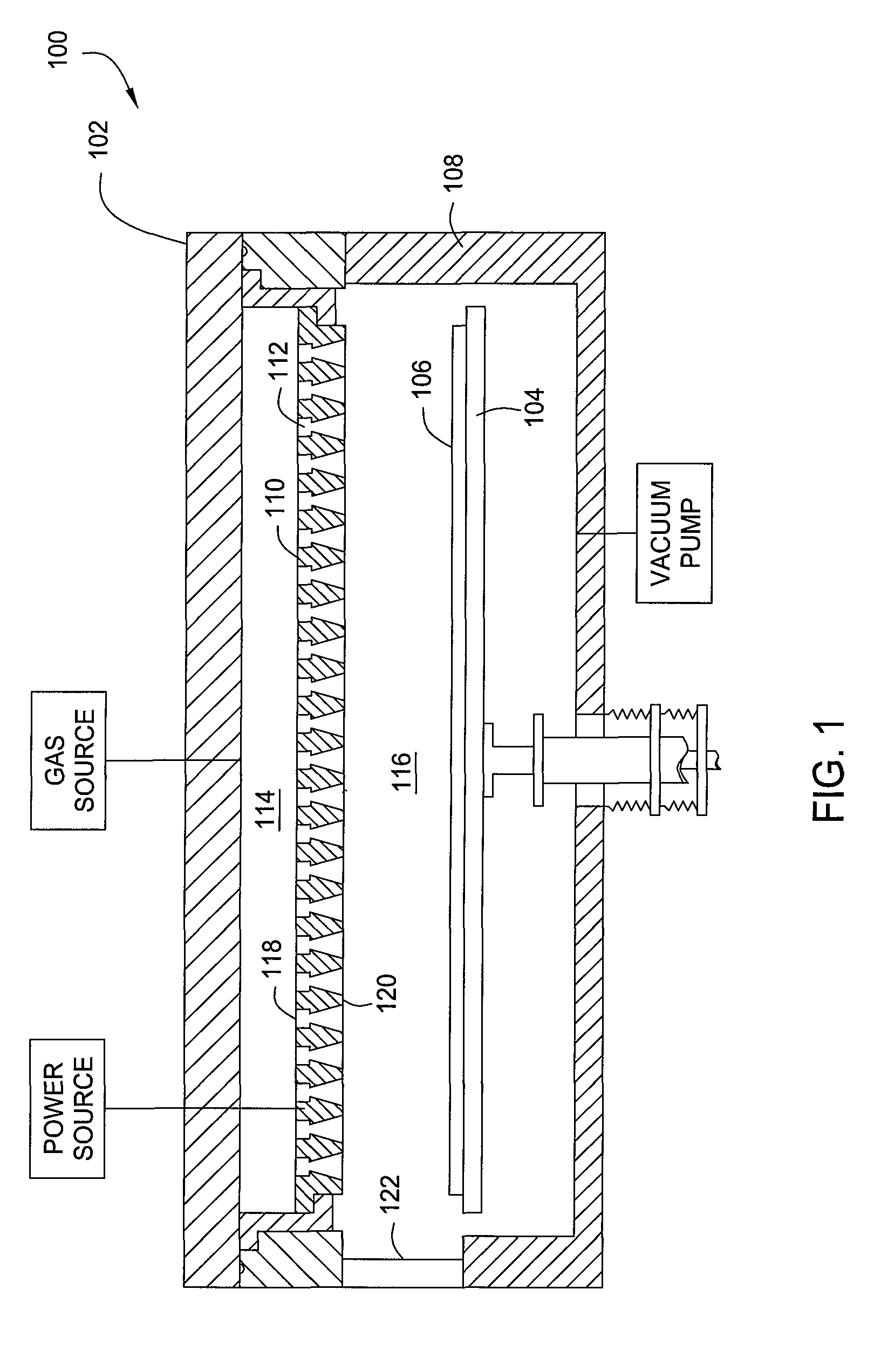

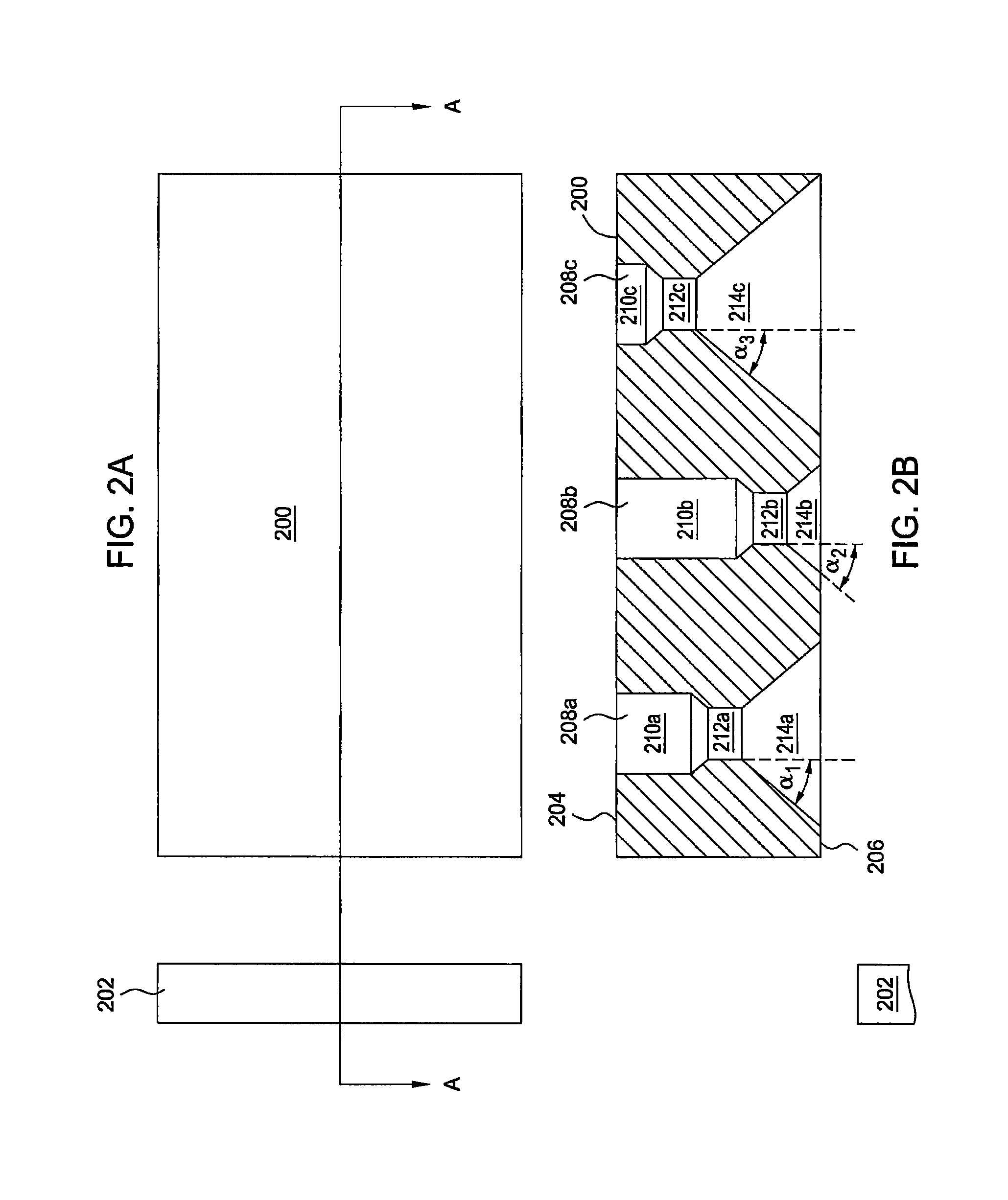

Plasma uniformity control by gas diffuser hole design

ActiveUS20050251990A1Electric discharge tubesSemiconductor/solid-state device manufacturingEngineeringVolumetric Mass Density

Embodiments of a gas diffuser plate for distributing gas in a processing chamber are provided. The gas distribution plate includes a diffuser plate having an upstream side and a downstream side, and a plurality of gas passages passing between the upstream and downstream sides of the diffuser plate. The gas passages include hollow cathode cavities at the downstream side to enhance plasma ionization. The depths, the diameters, the surface area and density of hollow cathode cavities of the gas passages that extend to the downstream end can be gradually increased from the center to the edge of the diffuser plate to improve the film thickness and property uniformity across the substrate. The increasing diameters, depths and surface areas from the center to the edge of the diffuser plate can be created by bending the diffuser plate toward downstream side, followed by machining out the convex downstream side. Bending the diffuser plate can be accomplished by a thermal process or a vacuum process. The increasing diameters, depths and surface areas from the center to the edge of the diffuser plate can also be created computer numerically controlled machining. Diffuser plates with gradually increasing diameters, depths and surface areas of the hollow cathode cavities from the center to the edge of the diffuser plate have been shown to produce improved uniformities of film thickness and film properties.

Owner:APPLIED MATERIALS INC

Method of depositing a low k dielectric with organo silane

InactiveUS6054379ASemiconductor/solid-state device manufacturingChemical vapor deposition coatingSilane compoundsSilanes

A method and apparatus for depositing a low dielectric constant film by reaction of an organo silane compound and an oxidizing gas. The oxidized organo silane film has excellent barrier properties for use as a liner or cap layer adjacent other dielectric layers. The oxidized organo silane film can also be used as an etch stop or an intermetal dielectric layer for fabricating dual damascene structures. The oxidized organo silane films also provide excellent adhesion between different dielectric layers. A preferred oxidized organo silane film is produced by reaction of methyl silane, CH3SiH3, and N2O.

Owner:APPLIED MATERIALS INC

Liquid precursors for the CVD deposition of amorphous carbon films

ActiveUS20050287771A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingDual frequencyHydrogen

Methods are provided for depositing amorphous carbon materials. In one aspect, the invention provides a method for processing a substrate including positioning the substrate in a processing chamber, introducing a processing gas into the processing chamber, wherein the processing gas comprises a carrier gas, hydrogen, and one or more precursor compounds, generating a plasma of the processing gas by applying power from a dual-frequency RF source, and depositing an amorphous carbon layer on the substrate.

Owner:APPLIED MATERIALS INC

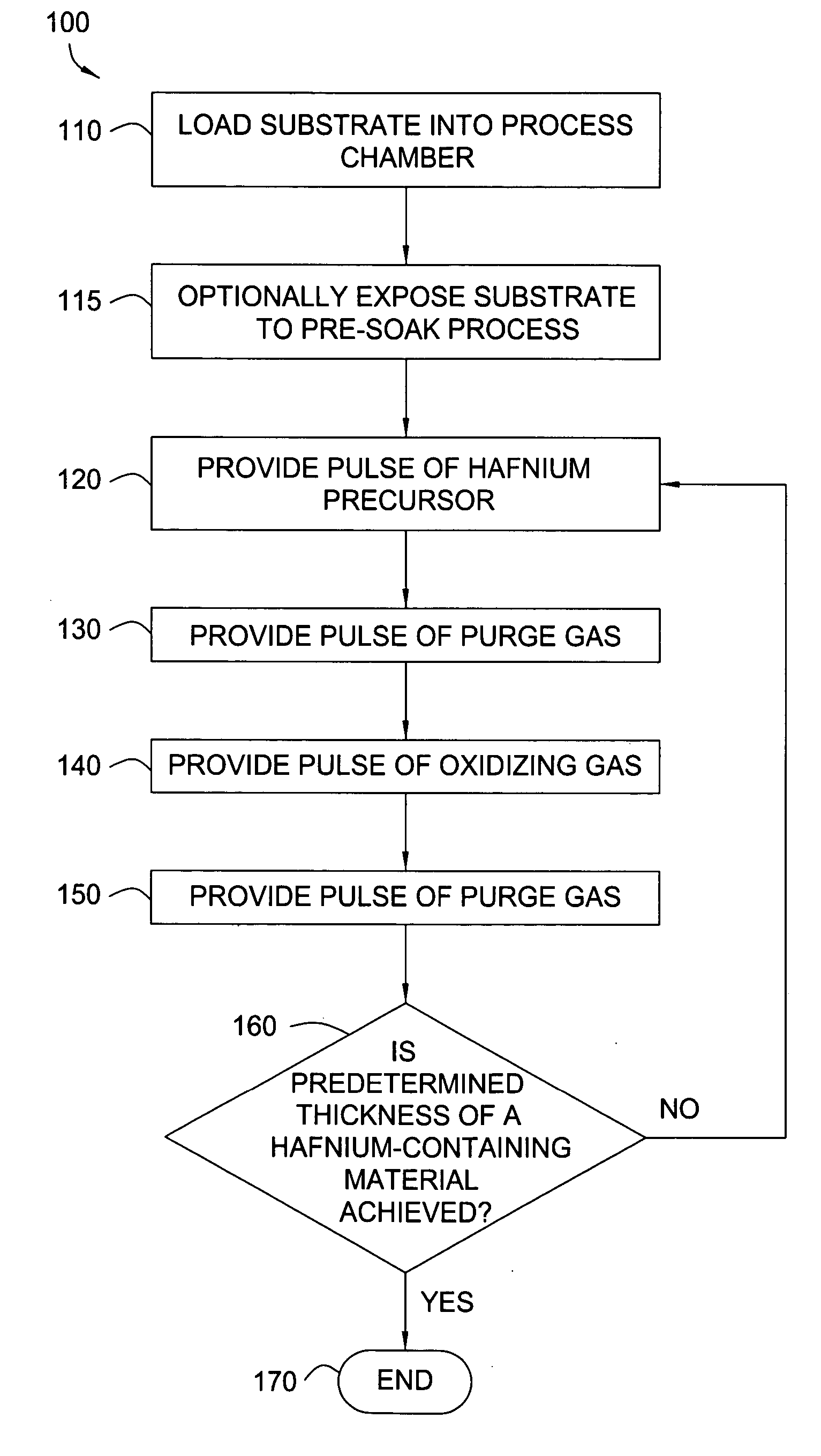

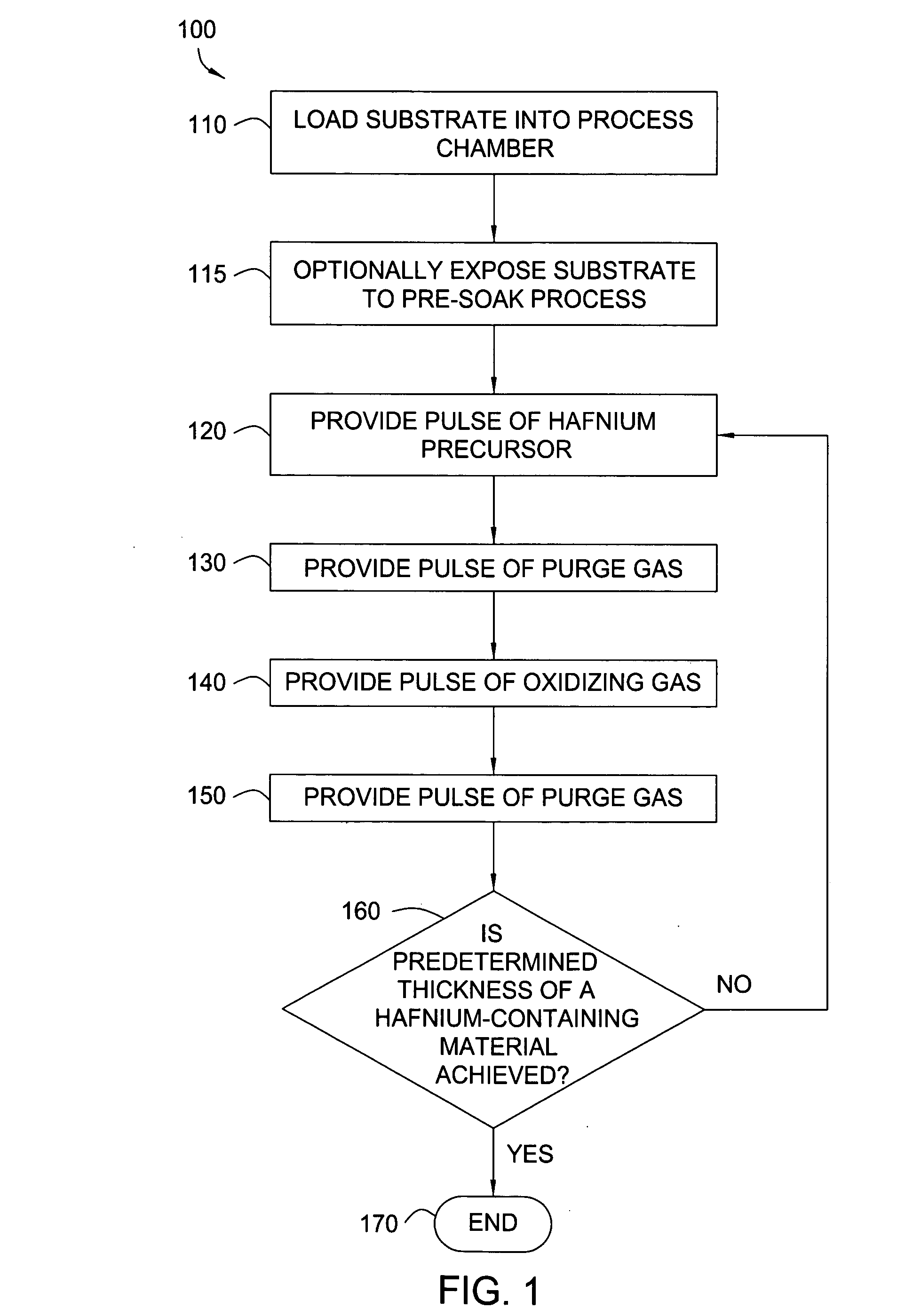

Apparatuses and methods for atomic layer deposition of hafnium-containing high-k dielectric materials

InactiveUS20050271813A1Steam generation heating methodsDecorative surface effectsGas phaseWater vapor

Embodiments of the invention provide methods for depositing dielectric materials on substrates during vapor deposition processes, such as atomic layer deposition (ALD). In one example, a method includes sequentially exposing a substrate to a hafnium precursor and an oxidizing gas to deposit a hafnium oxide material thereon. In another example, a hafnium silicate material is deposited by sequentially exposing a substrate to the oxidizing gas and a process gas containing a hafnium precursor and a silicon precursor. The oxidizing gas usually contains water vapor formed by flowing a hydrogen source gas and an oxygen source gas through a water vapor generator. In another example, a method includes sequentially exposing a substrate to the oxidizing gas and at least one precursor to deposit hafnium oxide, zirconium oxide, lanthanum oxide, tantalum oxide, titanium oxide, aluminum oxide, silicon oxide, aluminates thereof, silicates thereof, derivatives thereof or combinations thereof.

Owner:APPLIED MATERIALS INC

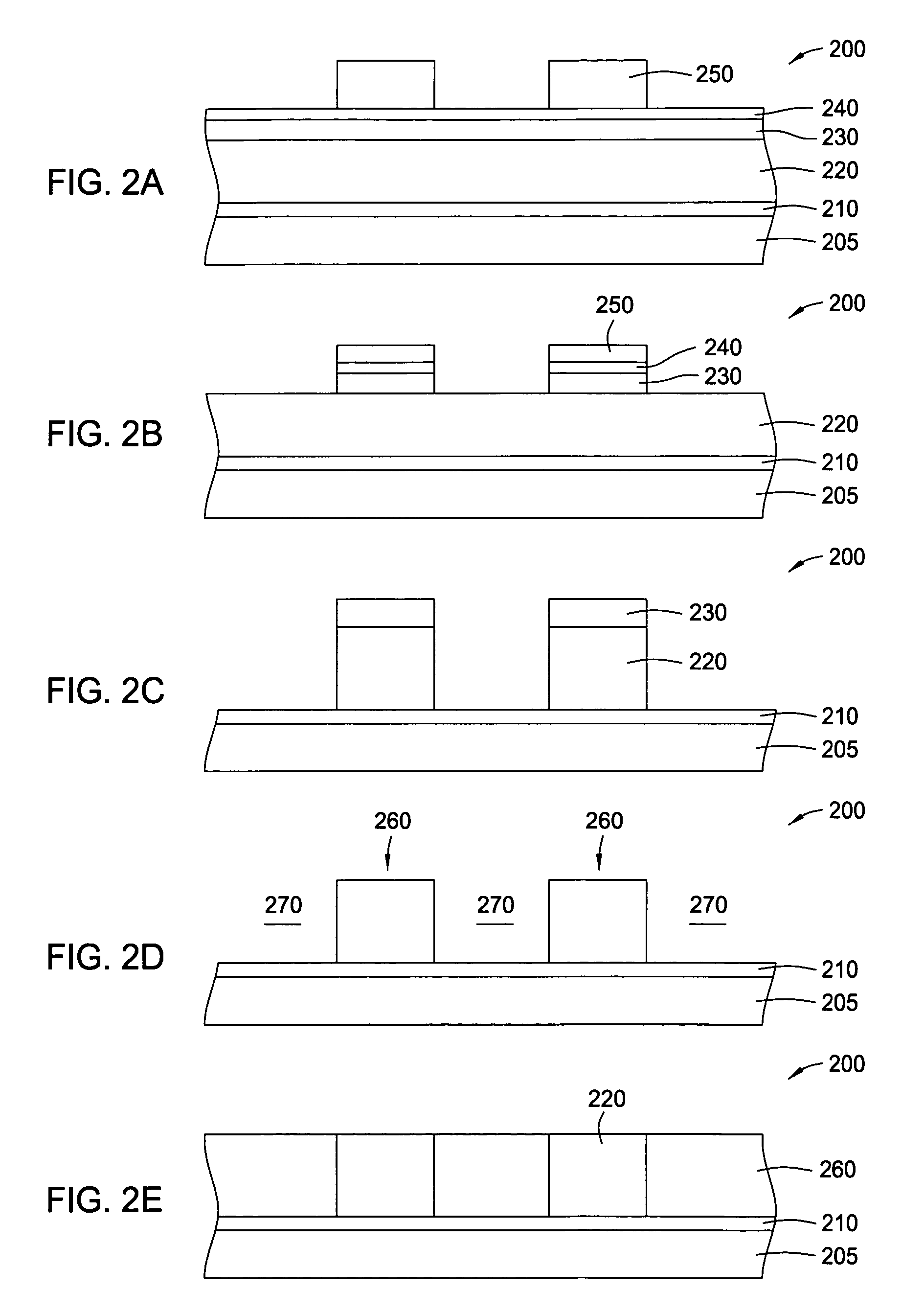

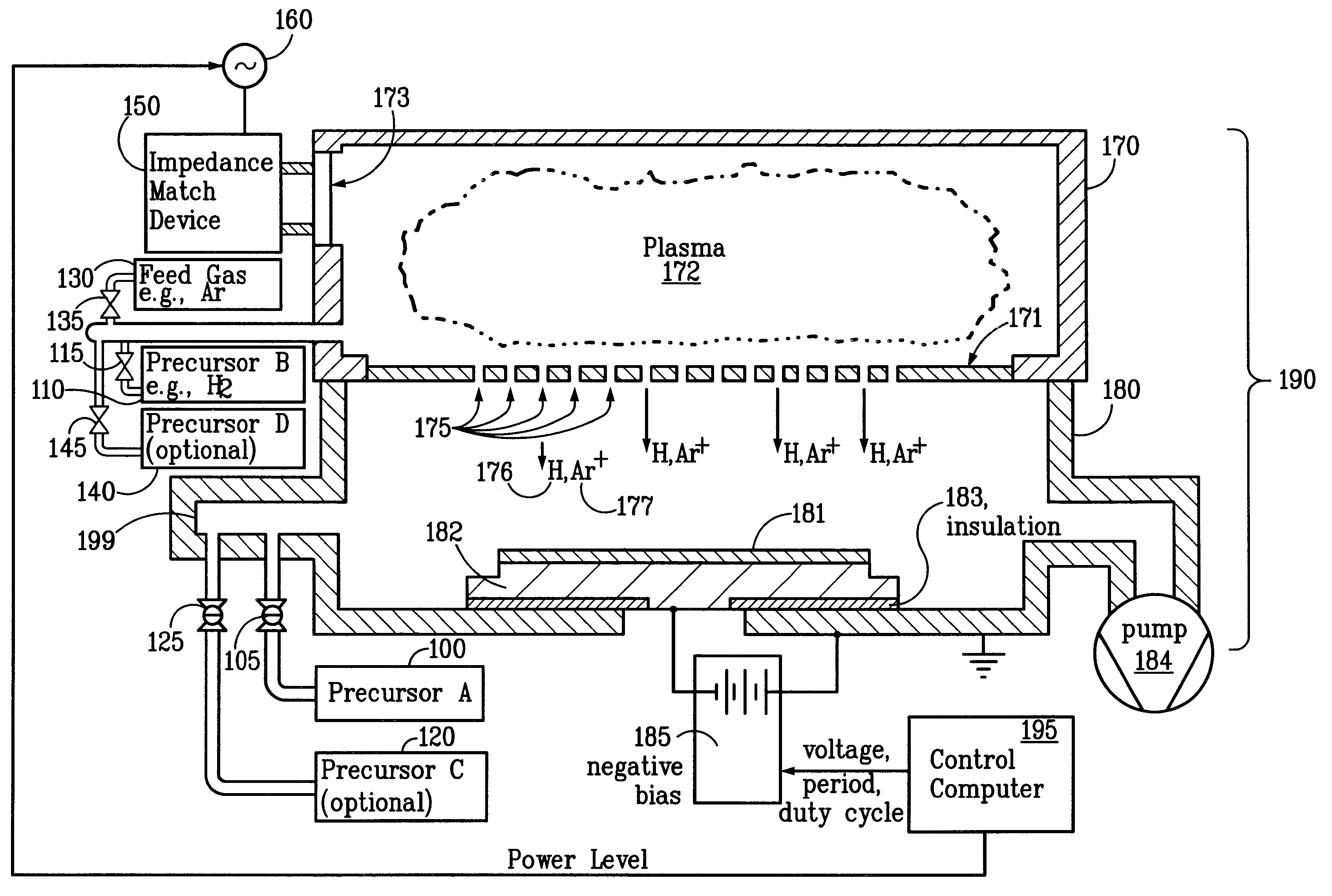

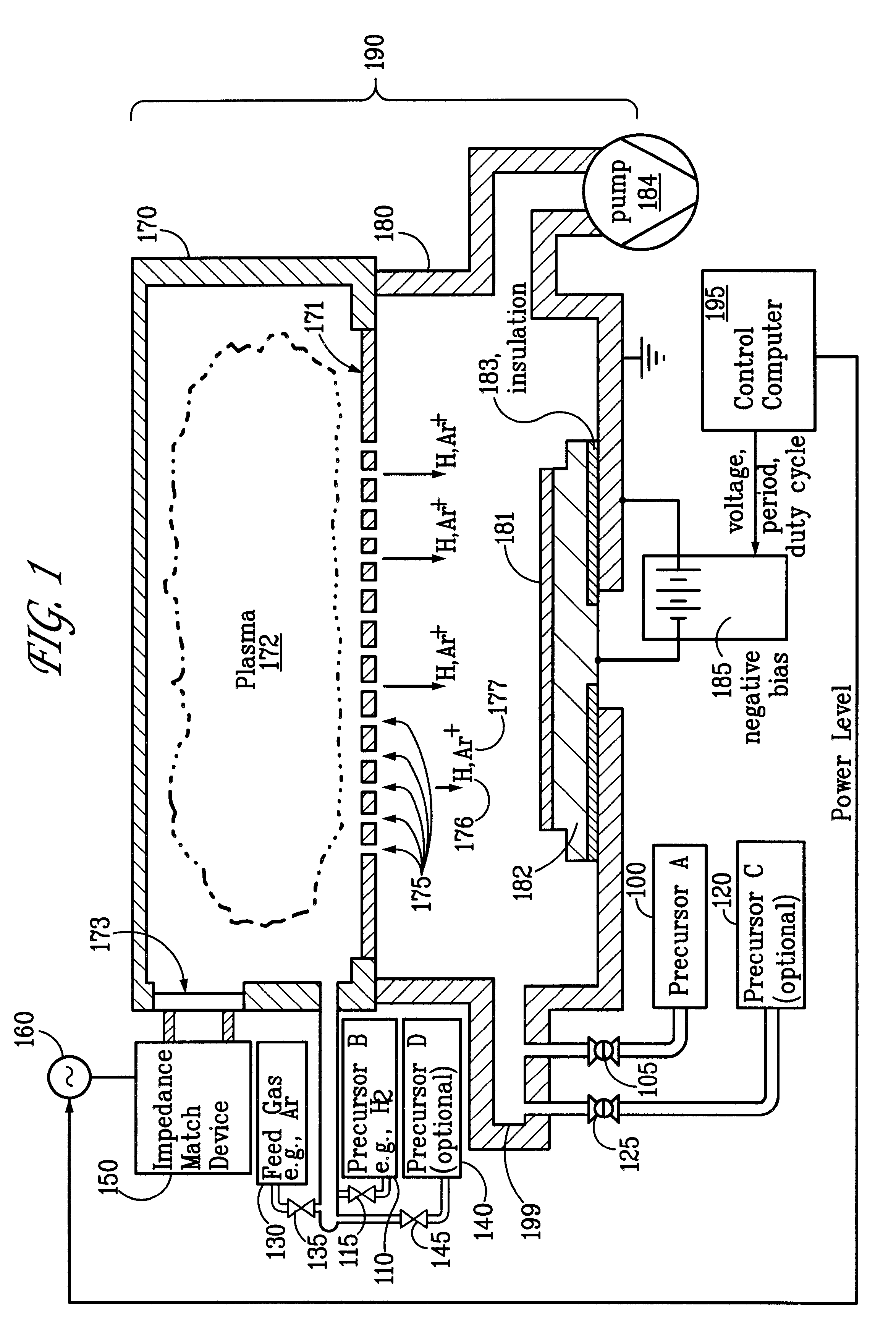

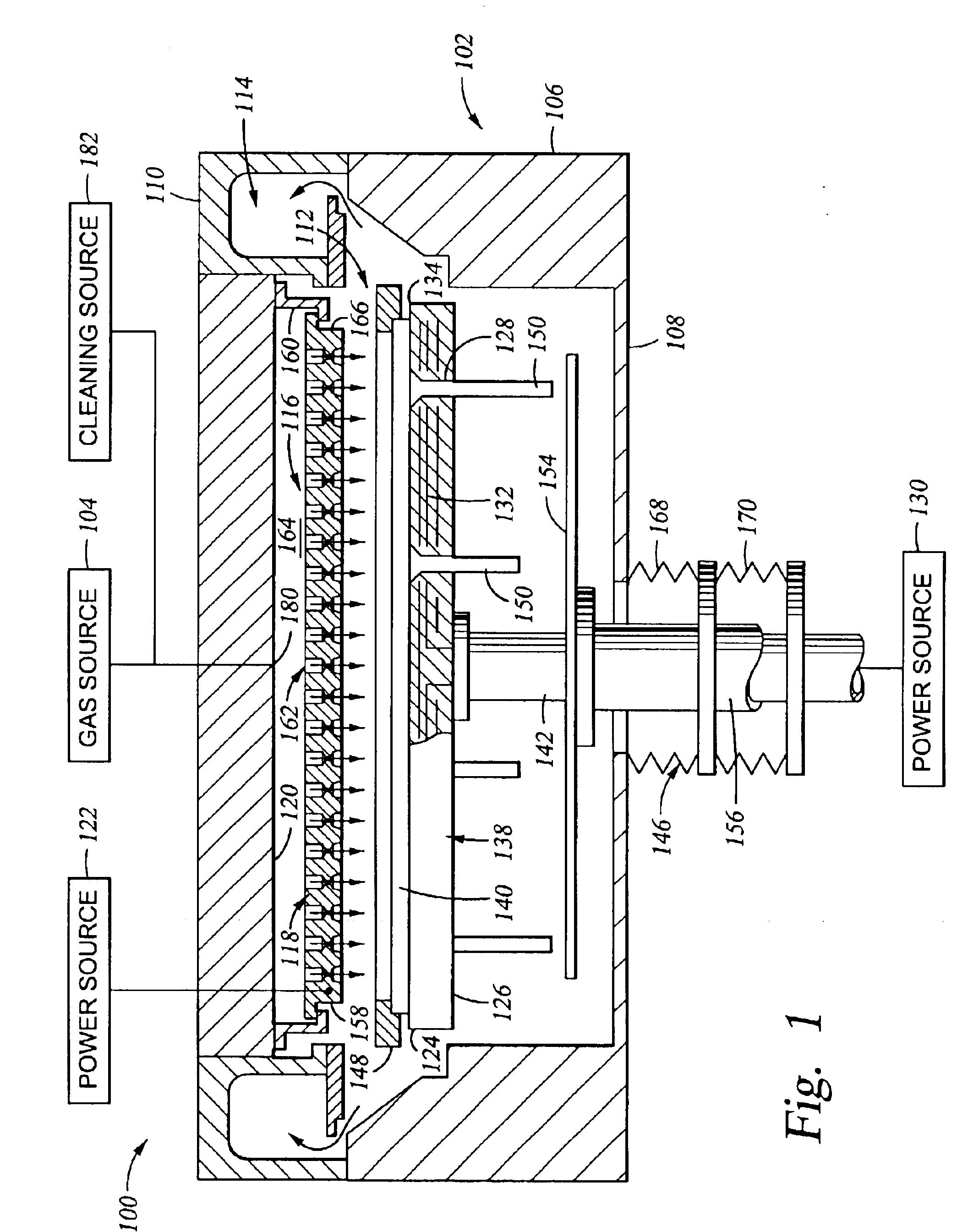

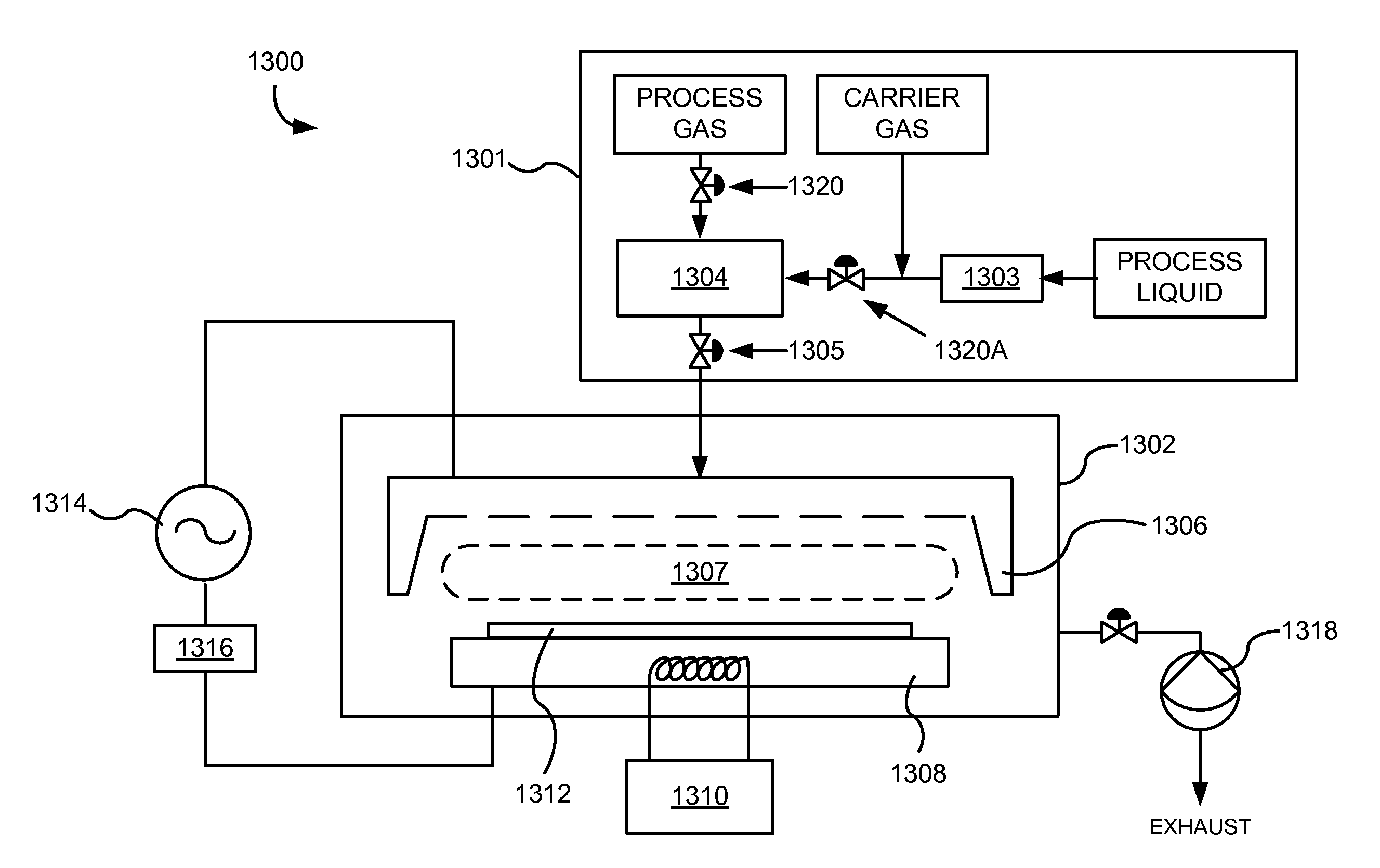

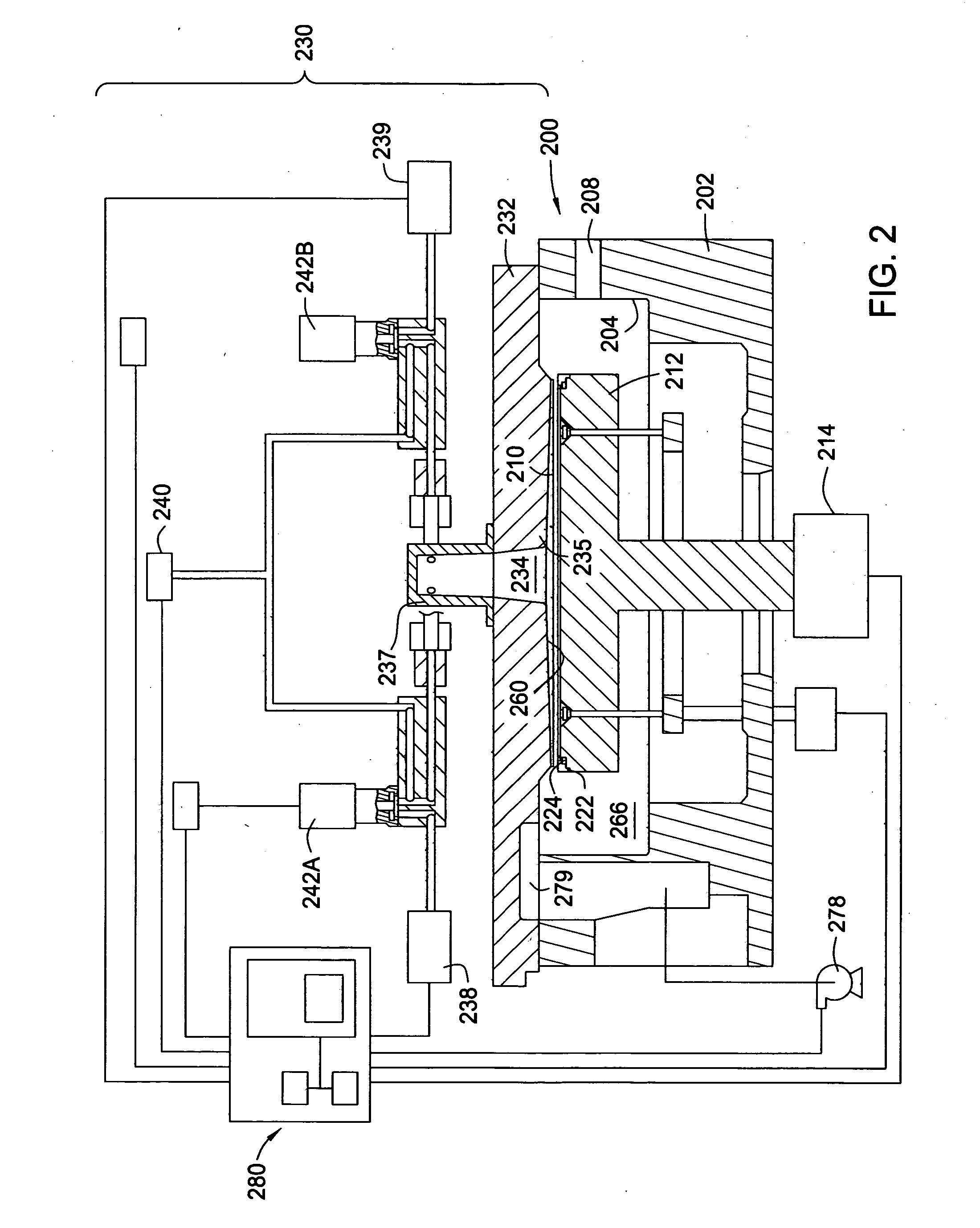

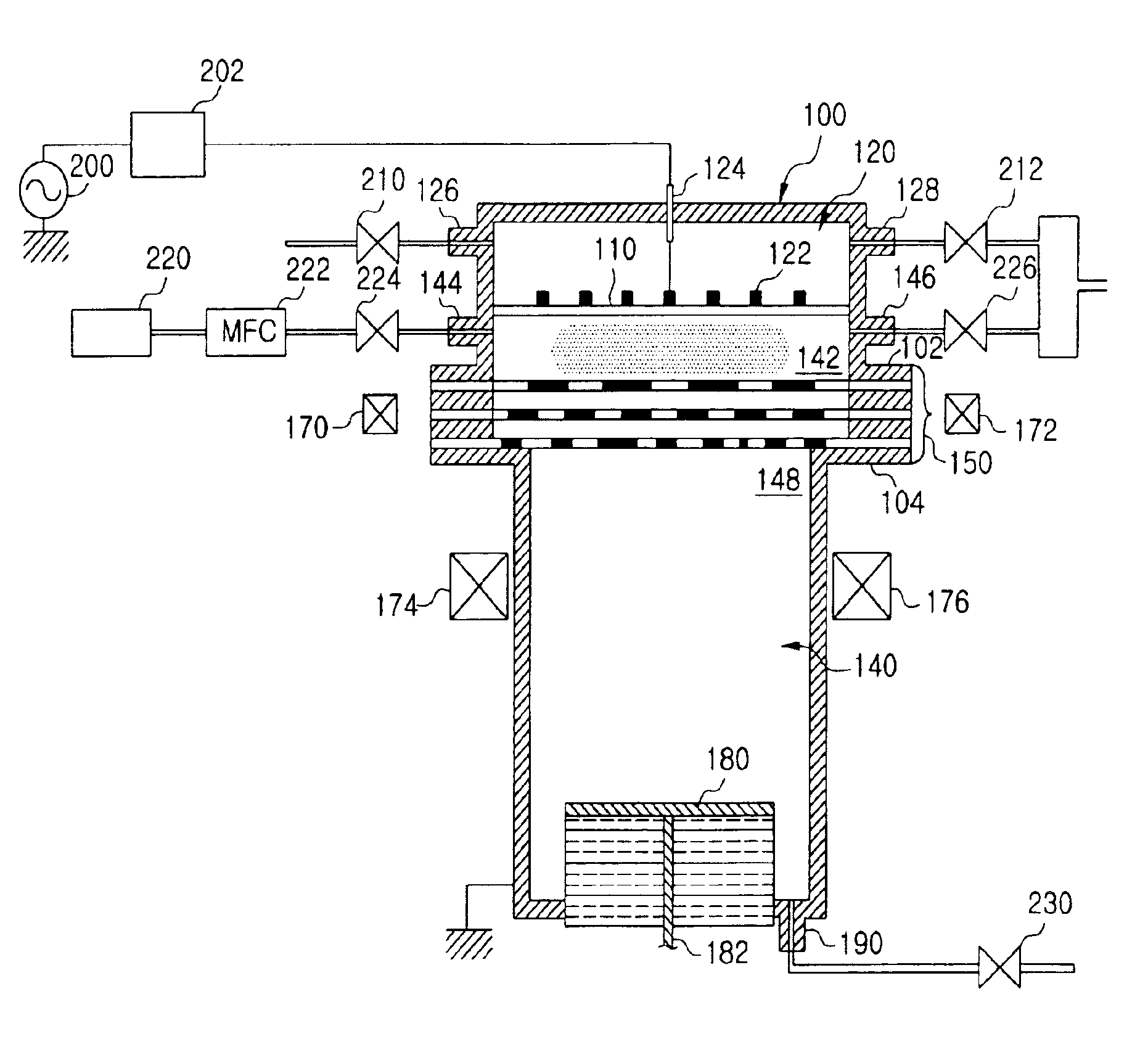

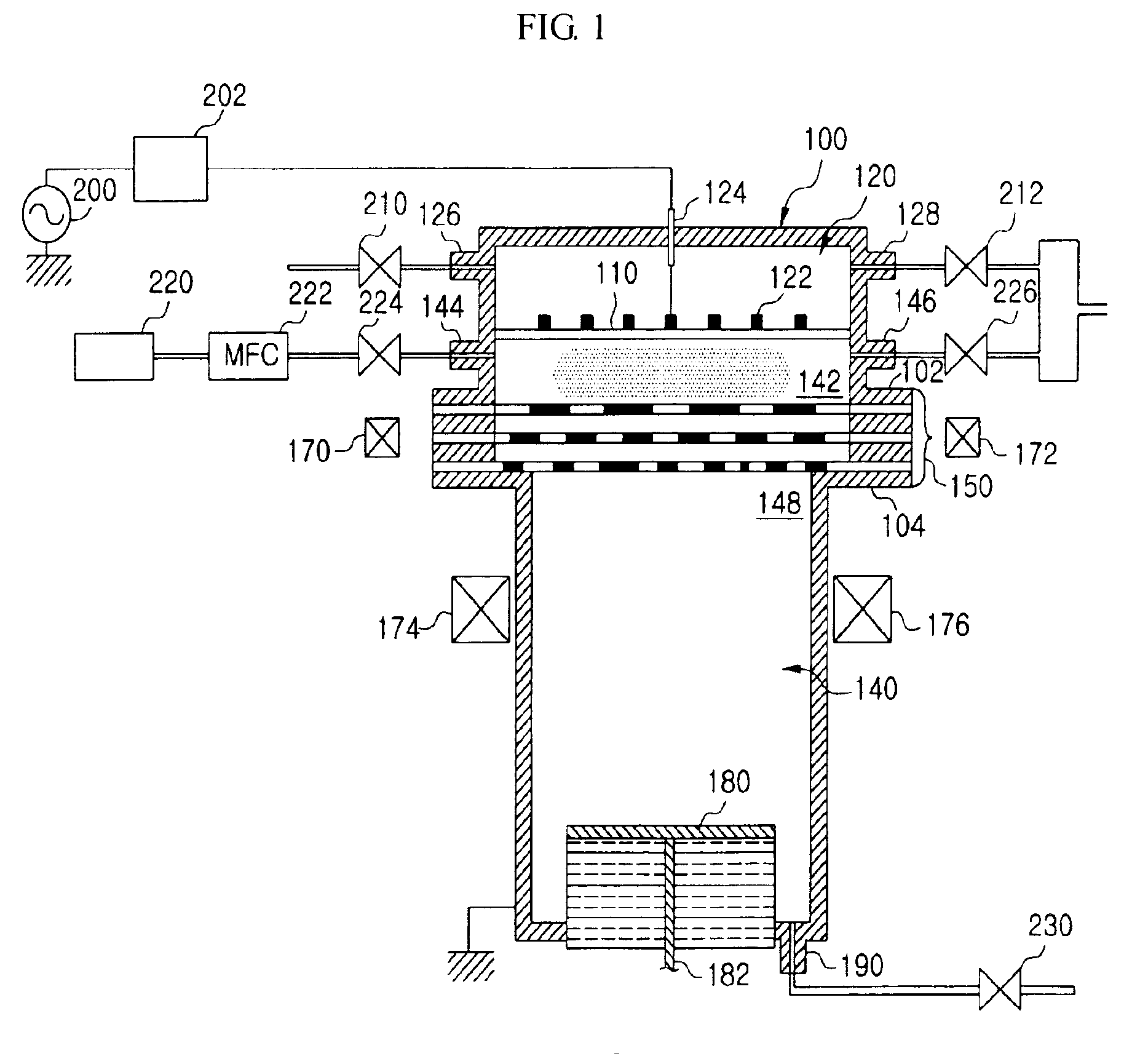

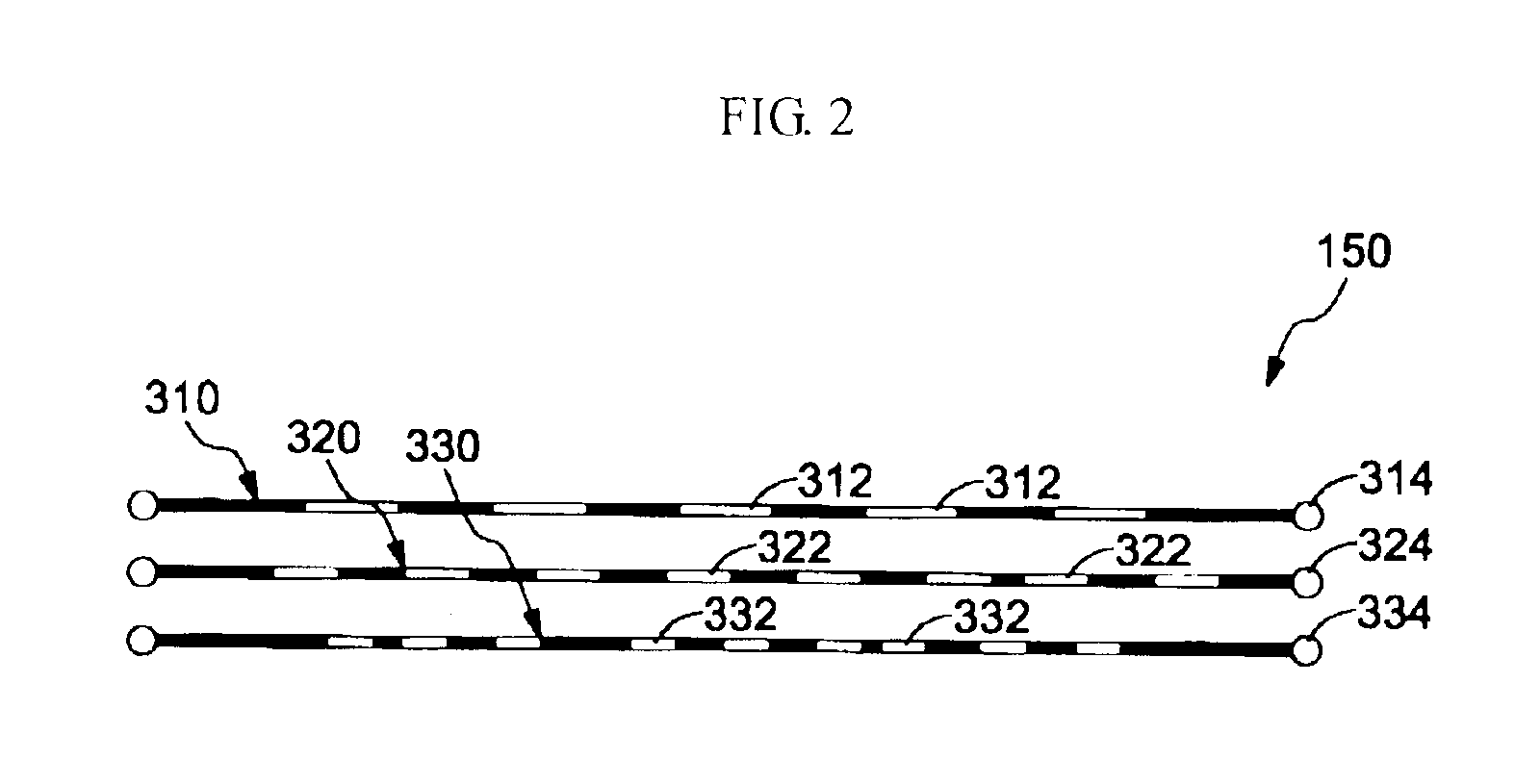

Apparatus and process for plasma-enhanced atomic layer deposition

Embodiments of the invention provide an apparatus configured to form a material during an atomic layer deposition (ALD) process, such as a plasma-enhanced ALD (PE-ALD) process. In one embodiment, a process chamber is configured to expose a substrate to a sequence of gases and plasmas during a PE-ALD process. The process chamber comprises components that are capable of being electrically insulated, electrically grounded or RF energized. In one example, a chamber body and a gas manifold assembly are grounded and separated by electrically insulated components, such as an insulation cap, a plasma screen insert and an isolation ring. A showerhead, a plasma baffle and a water box are positioned between the insulated components and become RF hot when activated by a plasma generator. Other embodiments of the invention provide deposition processes to form layers of materials within the process chamber.

Owner:APPLIED MATERIALS INC

Gas separation type showerhead

InactiveUS20070163440A1Minimize hydrogen contentIncrease diversityElectric discharge tubesExternal electric electrostatic seperatorEngineeringProcess engineering

Provided is a gas separation type showerhead for effective energy supply. The gas separation type showerhead includes: a gas supply module to which a first gas and a second gas are separately supplied; a gas separation module in which the supplied first and second gases are separately dispersed; and a gas injection module which is a multi-hollow cathode having a plurality of holes and in which the first and second gases separately dispersed are ionized in the holes to be commonly dispersed.

Owner:ATO

Precursor source mixtures

A precursor source mixture useful for CVD or ALD of a film comprising: at least one precursor composed of an element selected from the group consisting of Li, Na, K, Rb, Cs, Fr, Be, Mg, Ti, Zr, Hf, Sc, Y, La, V, Nb, Ta, Cr, Mo, W, Mn, Re, Fe, Ru, Os, Co, Rh, Ir, Ni, Pd, Pt, Cu, Ag, Au, Zn, Cd, Hg, B, Al, Ga, In, Tl, Si, Ge, Sn, Pb, As, P, Sb and Bi, to which is bound at least one ligand selected from the group consisting of hydride, alkyl, alkenyl, cycloalkenyl, aryl, alkyne, carbonyl, amido, imido, hydrazido, phosphido, nitrosyl, nitryl, nitrate, nitrile, halide, azide, alkoxy, siloxy, silyl, and halogenated, sulfonated or silyated derivatives thereof, which is dissolved, emulsified or suspended in an inert liquid selected from the group consisting of aliphatic hydrocarbons, aromatic hydrocarbons, alcohols, ethers, aldehydes, ketones, acids, phenols, esters, amines, alkylnitrile, halogenated hydrocarbons, silyated hydrocarbons, thioethers, amines, cyanates, isocyanates, thiocyanates, silicone oils, nitroalkyl, alkylnitrate, and mixtures thereof. The precursor source mixture may be a solution, emulsion or suspension and may consist of a mixture of solid, liquid and gas phases which are distributed throughout the mixture.

Owner:GLOBALFOUNDRIES INC

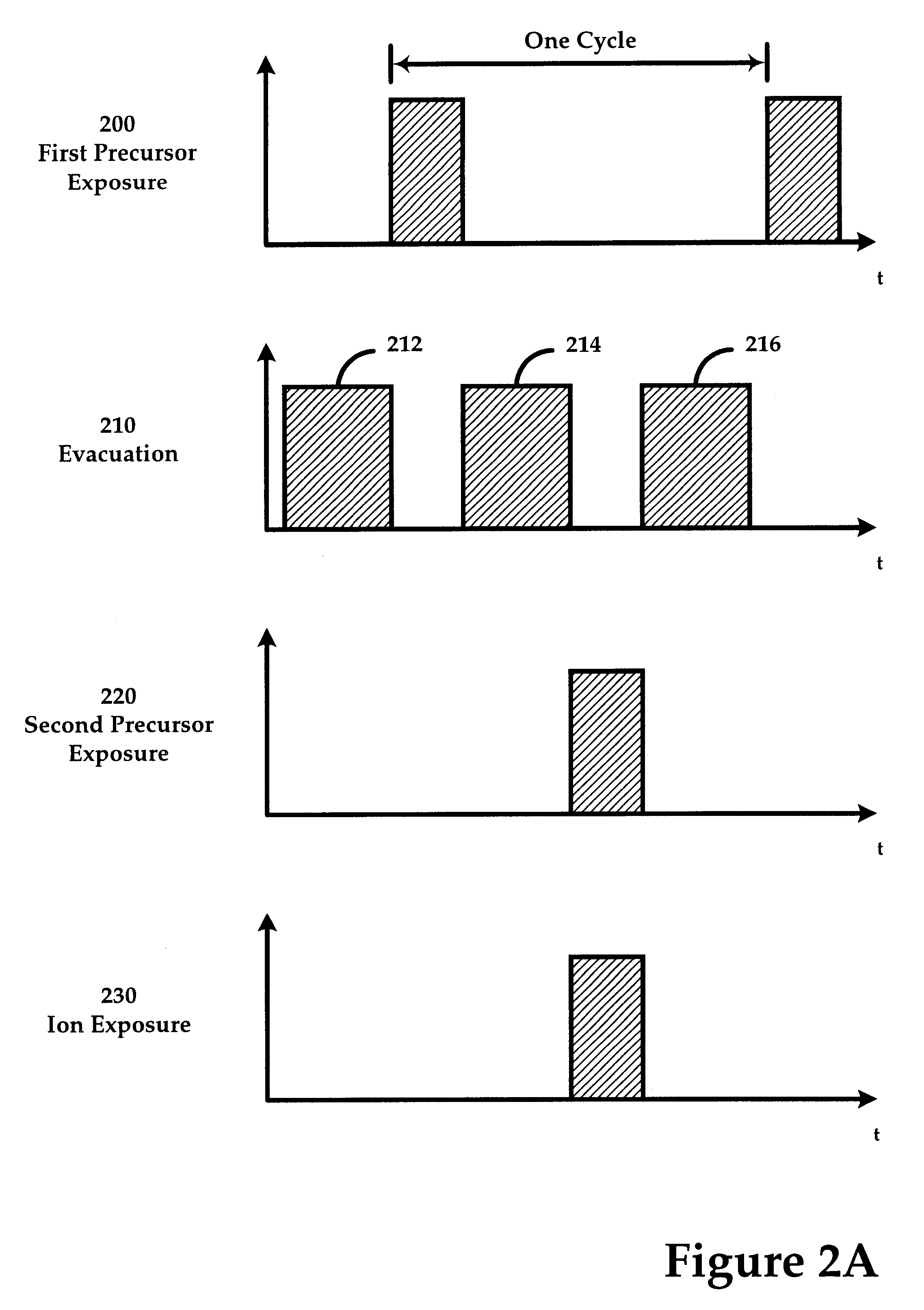

Sequential method for depositing a film by modulated ion-induced atomic layer deposition (MII-ALD)

InactiveUS6428859B1Faster efficient meanSimple methodVacuum evaporation coatingSputtering coatingSequential methodHigh density

The present invention relates to an enhanced sequential atomic layer deposition (ALD) technique suitable for deposition of barrier layers, adhesion layers, seed layers, low dielectric constant (low-k) films, high dielectric constant (high-k) films, and other conductive, semi-conductive, and non-conductive films. This is accomplished by 1) providing a non-thermal or non-pyrolytic means of triggering the deposition reaction; 2) providing a means of depositing a purer film of higher density at lower temperatures; and, 3) providing a faster and more efficient means of modulating the deposition sequence and hence the overall process rate resulting in an improved deposition method. It is emphasized that this abstract is provided to comply with the rules requiring an abstract that will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims.

Owner:NOVELLUS SYSTEMS

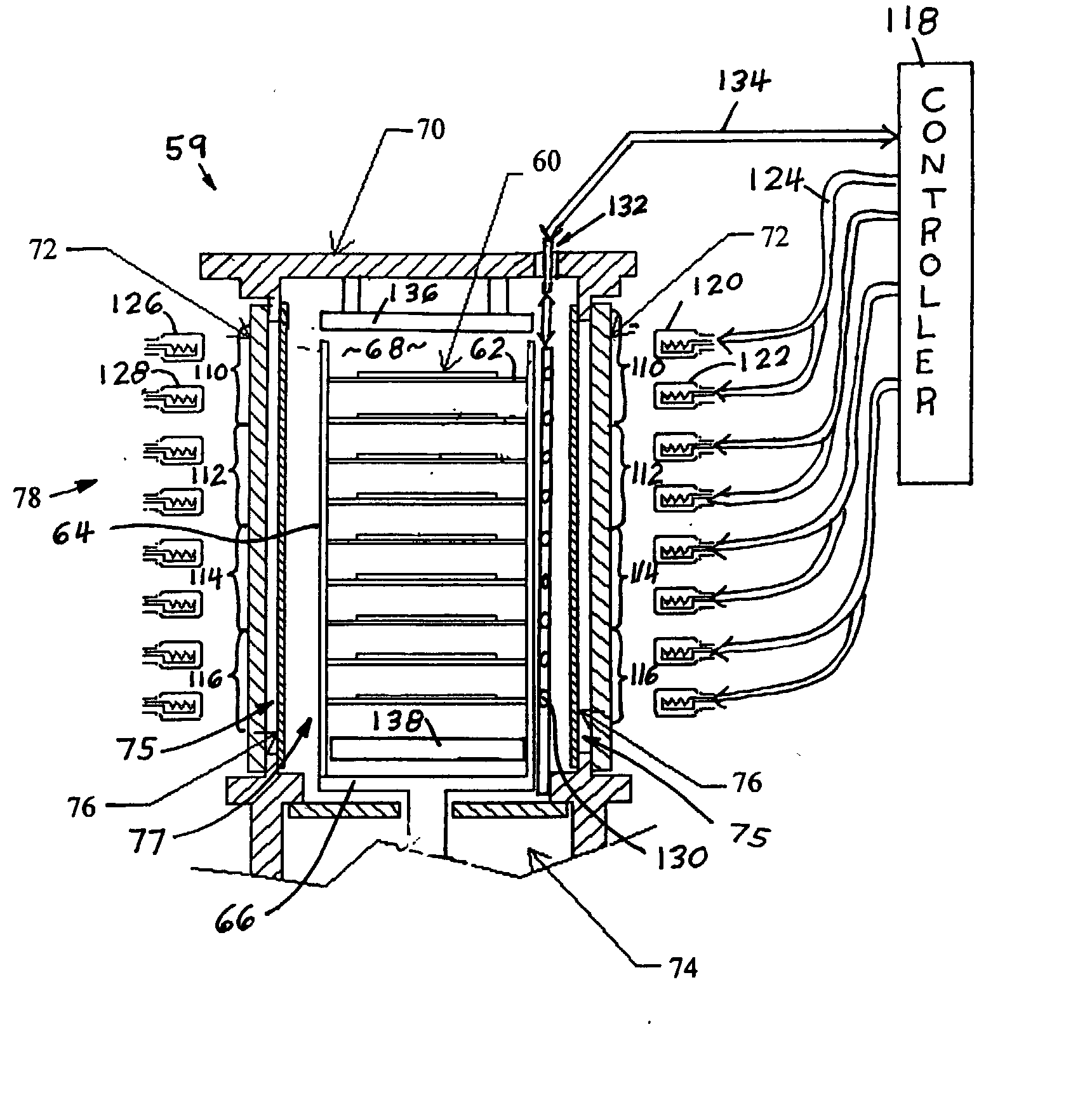

High rate deposition at low pressures in a small batch reactor

InactiveUS20030049372A1Increase ratingsRapid and uniform deposition of materialElectric discharge tubesSemiconductor/solid-state device manufacturingHigh rateSusceptor

A chemical vapor deposition reactor including a wafer boat with a vertical stack of horizontally oriented susceptors serving as thermal plates and each having pins extending upward for suspending a wafer between a pair of susceptors. Reactant gas injector and exhaust apparatus are positioned to concentrate a forceful supply of reactant gas across each wafer at a speed in excess of 10 cm / sec. The pressure is held in the range of 0.1 to 5,000 mTorr. The forceful gas flow avoids gas depletion effects, thinning the boundary layer and resulting in faster delivery of reactants to substrate surfaces, resulting in surface rate reaction limited operation. A plurality of individually controllable heaters are spaced vertically around the sides of the boat. Temperature sensors monitor the temperature along the boat height and provide input to a controller for adjusting the heater drive to optimize the temperature uniformity.

Owner:APPLIED MATERIALS INC

Gas distribution plate assembly for large area plasma enhanced chemical vapor deposition

InactiveUS6942753B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingGas phaseProduct gas

Embodiments of a gas distribution plate for distributing gas in a processing chamber are provided. In one embodiment, a gas distribution plate includes a diffuser plate having a plurality of gas passages passing between an upstream side and a downstream side of the diffuser plate. At least one of the gas passages includes a first hole and a second hole coupled by an orifice hole. The first hole extends from the upstream side of the diffuser plate while the second hole extends from the downstream side. The orifice hole has a diameter less than the respective diameters of the first and second holes.

Owner:APPLIED MATERIALS INC

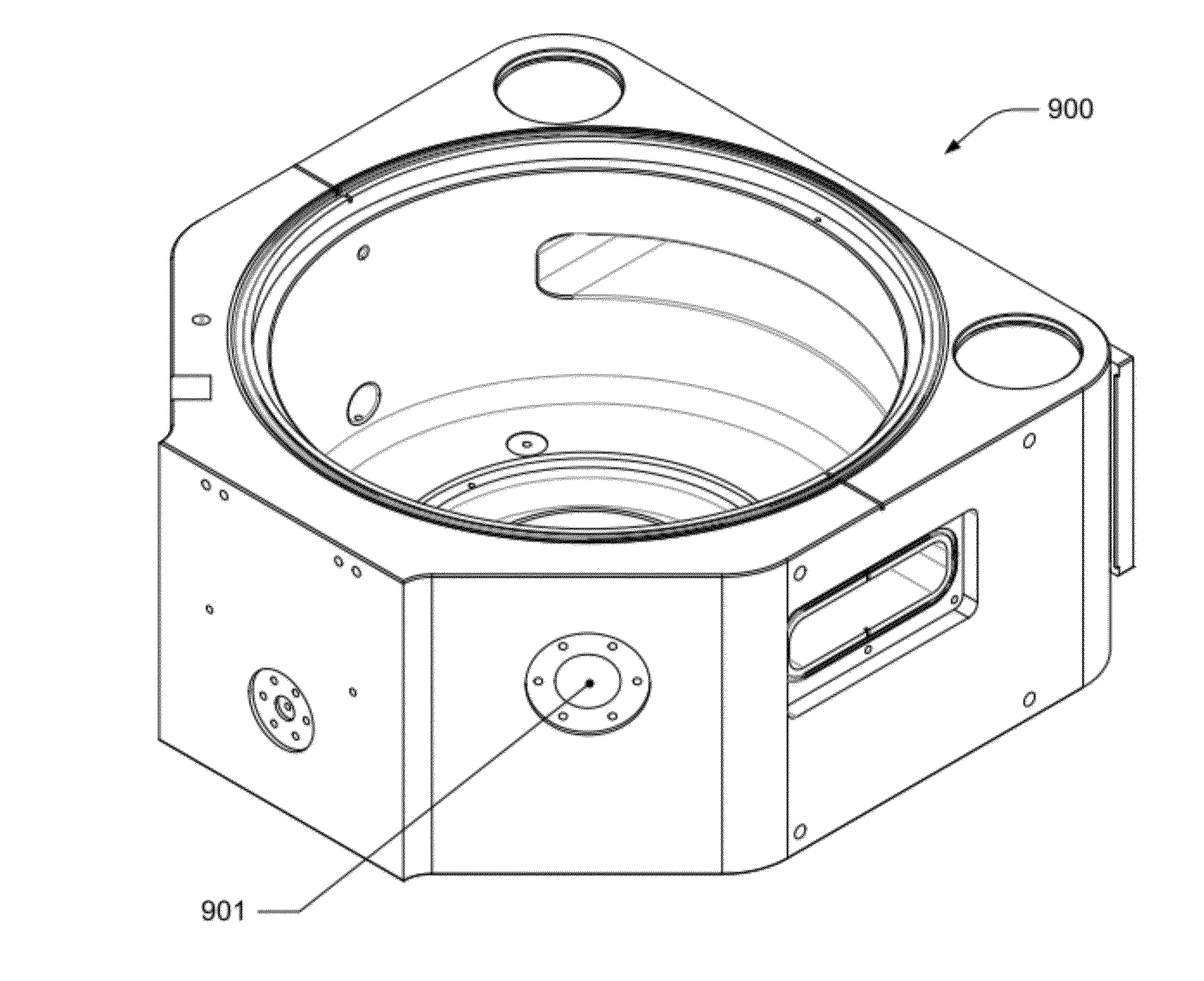

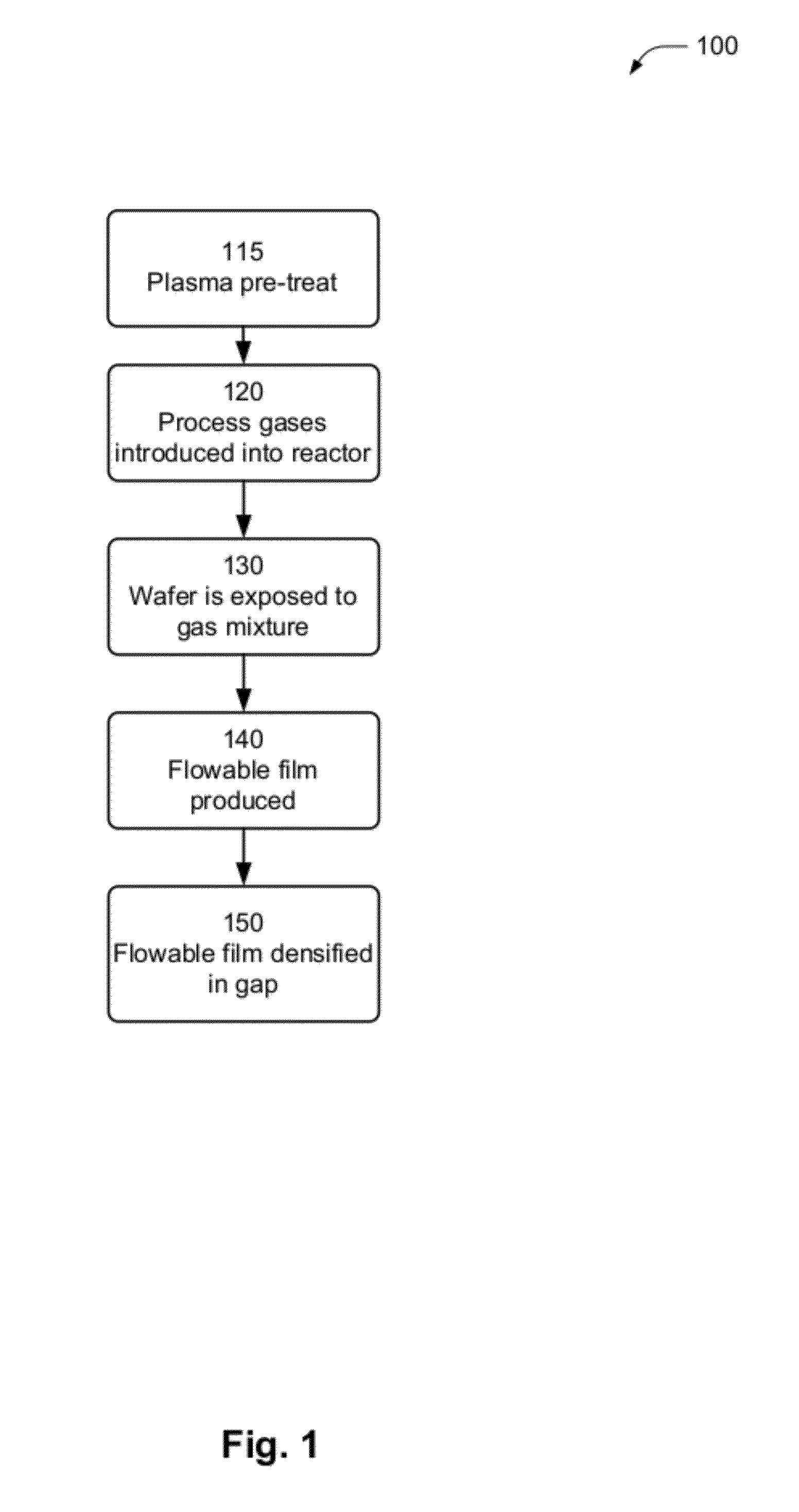

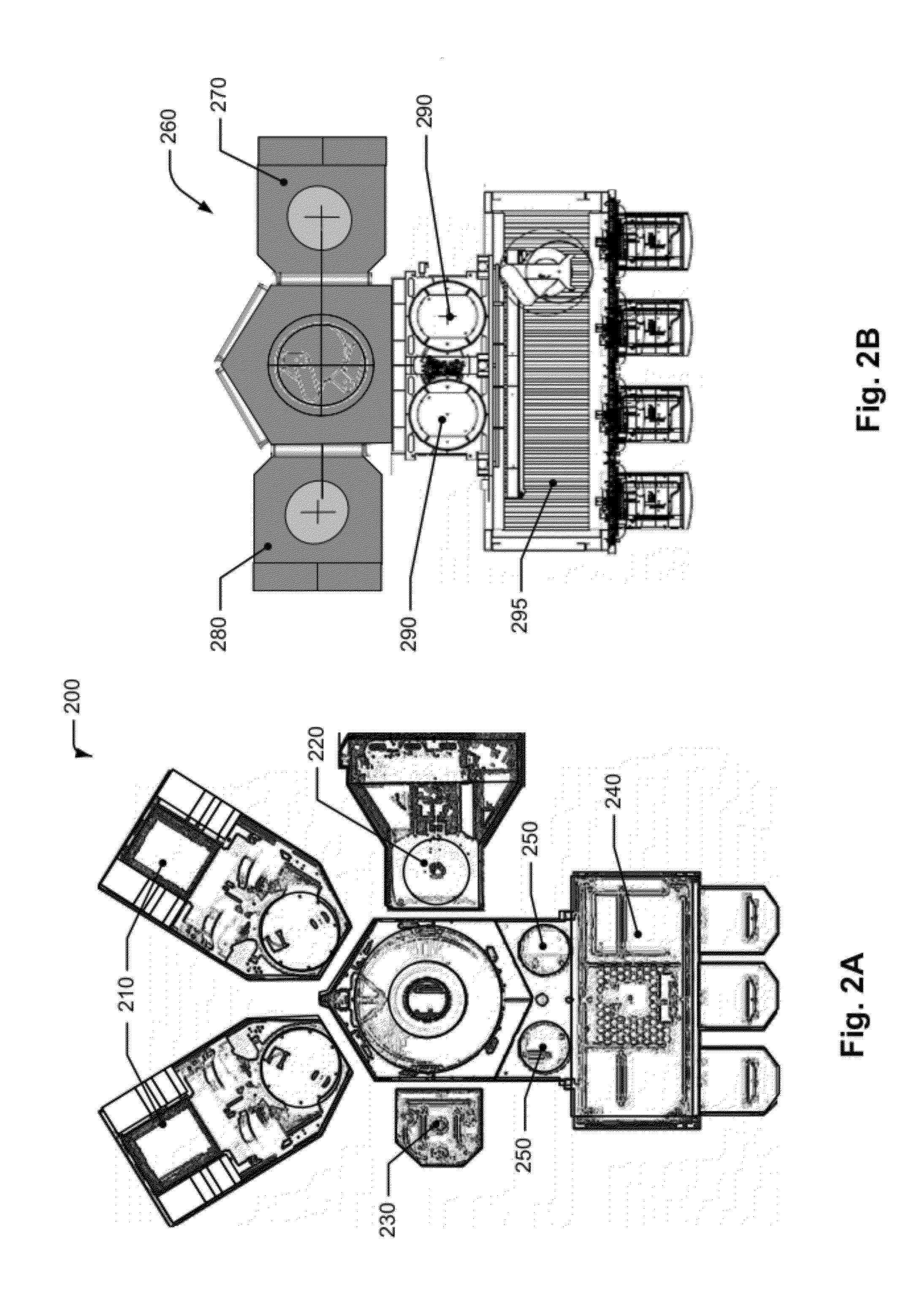

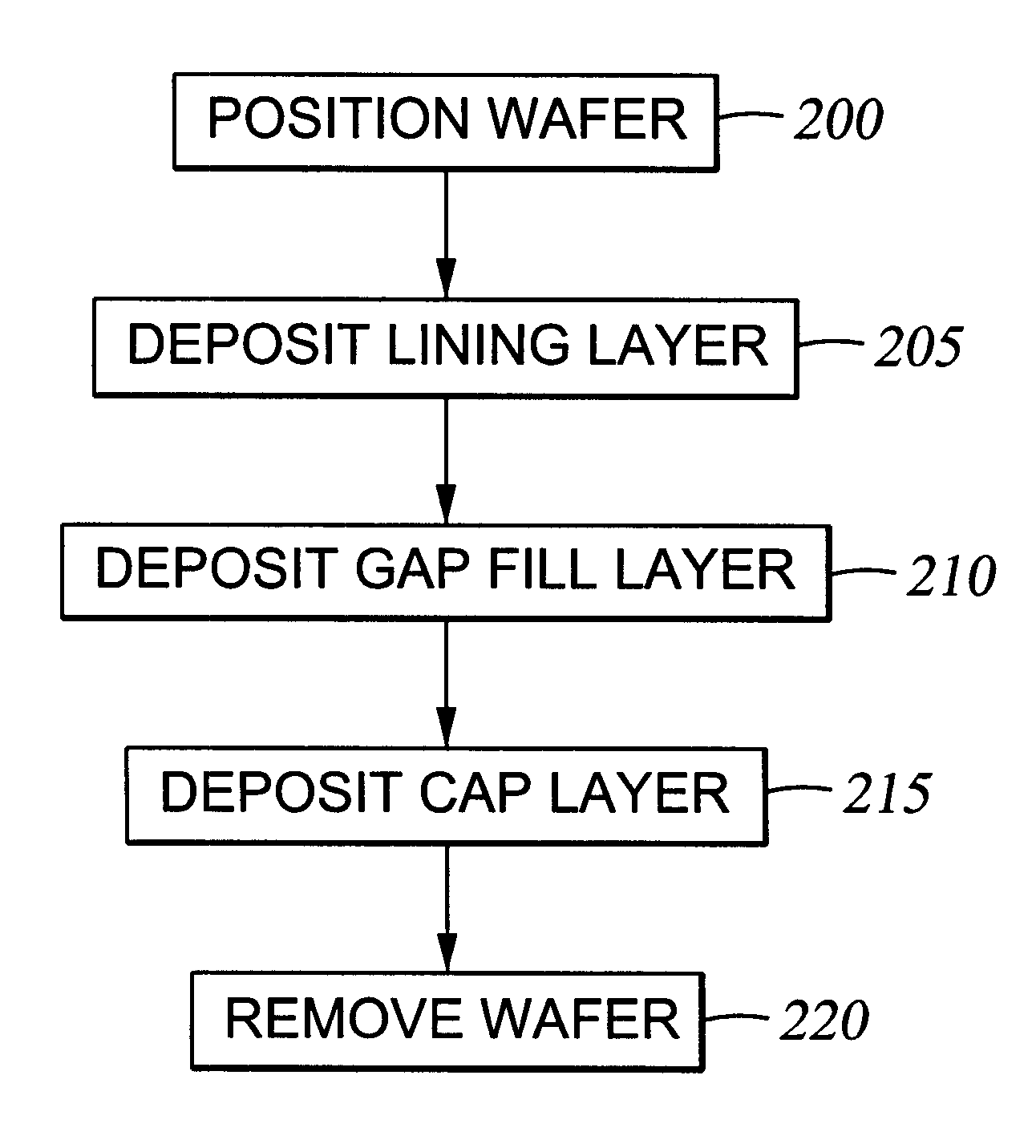

System and apparatus for flowable deposition in semiconductor fabrication

ActiveUS20120161405A1Sleeve/socket jointsSemiconductor/solid-state device manufacturingEngineeringElectron

Electronic device fabrication processes, apparatuses and systems for flowable gap fill or flowable deposition techniques are described. In some implementations, a semiconductor fabrication chamber is described which is configured to maintain a semiconductor wafer at a temperature near 0° C. while maintaining most other components within the fabrication chamber at temperatures on the order of 5-10° C. or higher than the wafer temperature.

Owner:NOVELLUS SYSTEMS

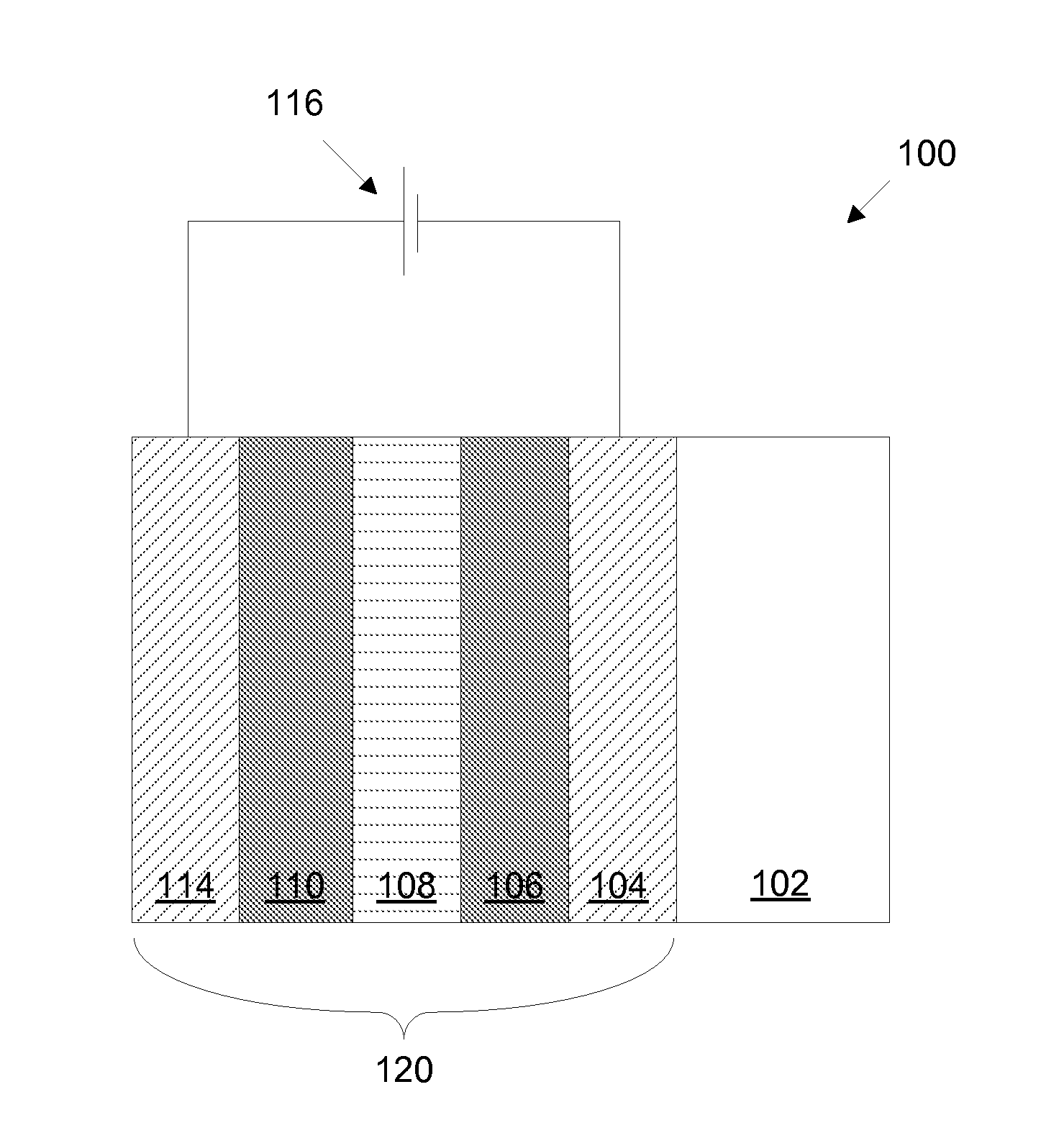

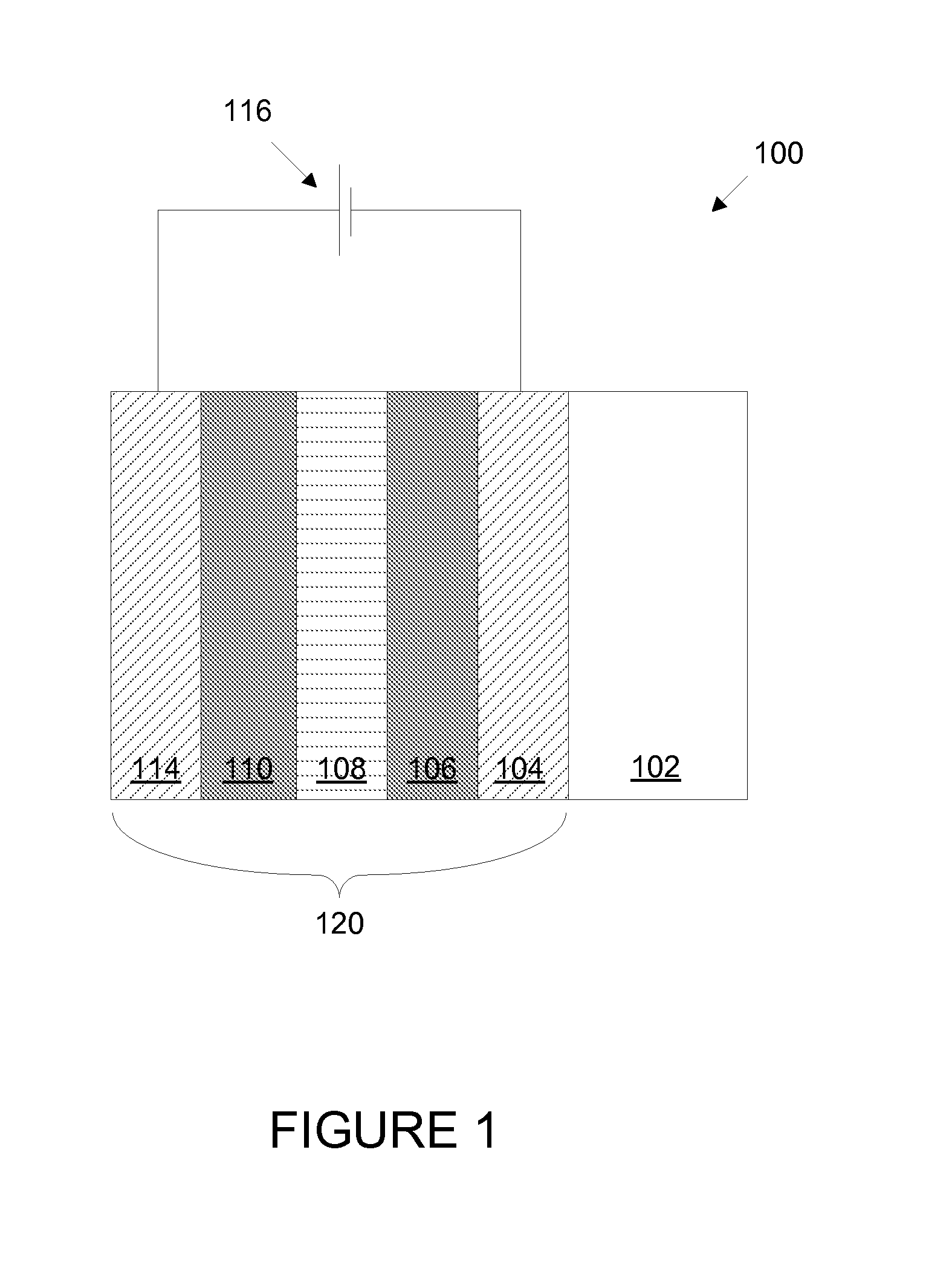

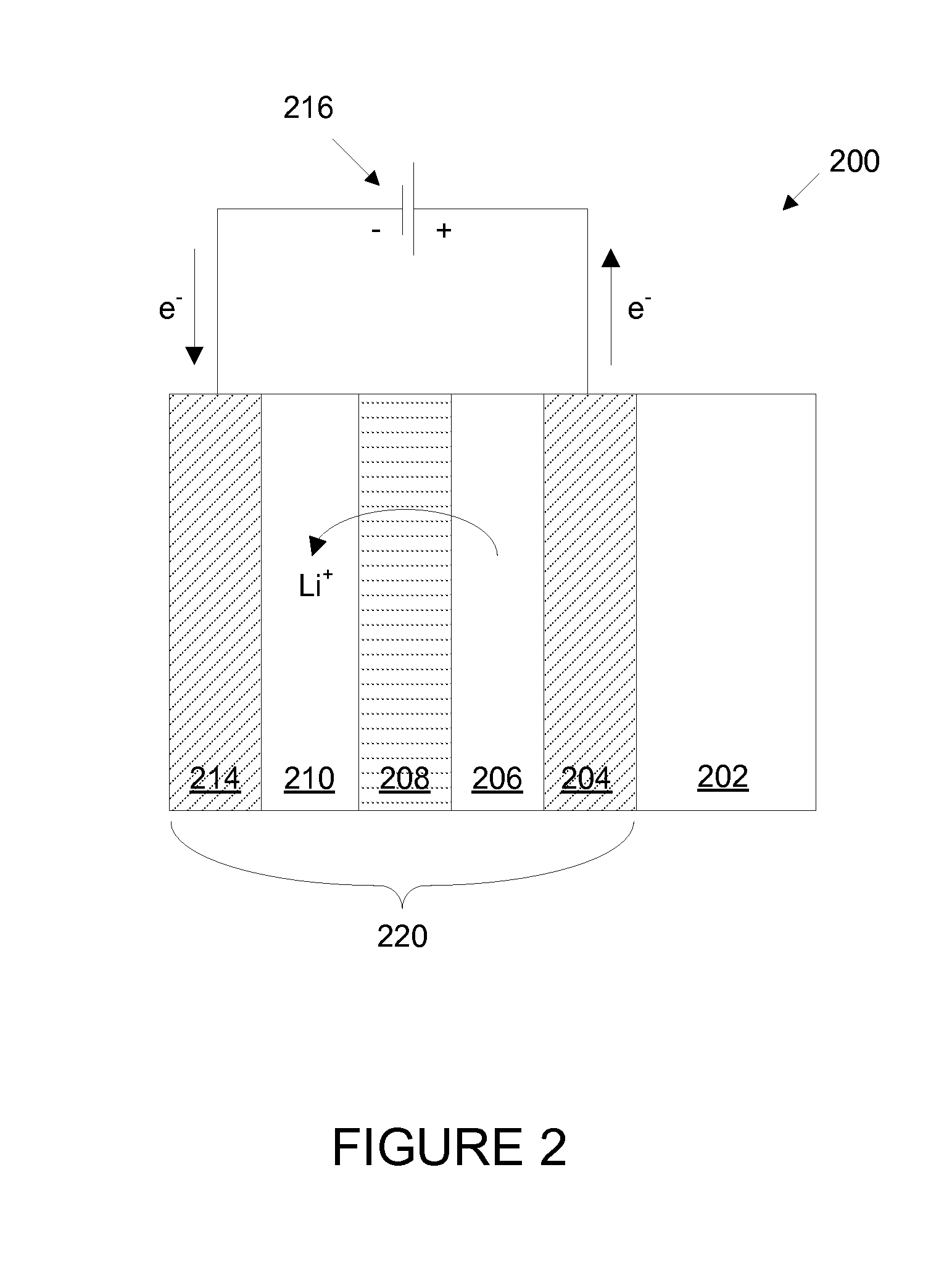

Fabrication of low defectivity electrochromic devices

ActiveUS20100243427A1High level of defectivityVacuum evaporation coatingSputtering coatingArchitectural glassGas phase

Prior electrochromic devices frequently suffer from high levels of defectivity. The defects may be manifest as pin holes or spots where the electrochromic transition is impaired. This is unacceptable for many applications such as electrochromic architectural glass. Improved electrochromic devices with low defectivity can be fabricated by depositing certain layered components of the electrochromic device in a single integrated deposition system. While these layers are being deposited and / or treated on a substrate, for example a glass window, the substrate never leaves a controlled ambient environment, for example a low pressure controlled atmosphere having very low levels of particles. These layers may be deposited using physical vapor deposition.

Owner:VIEW INC

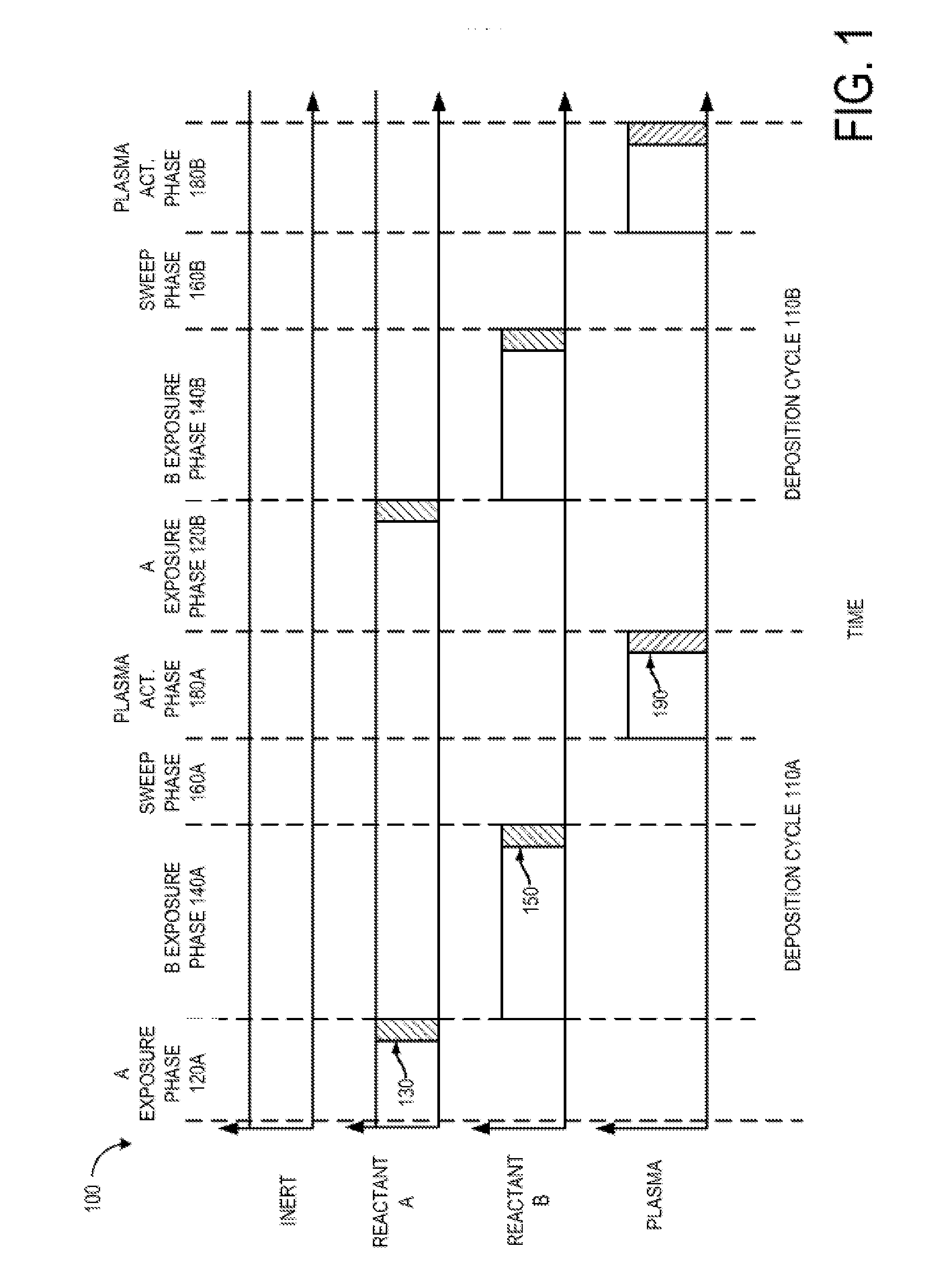

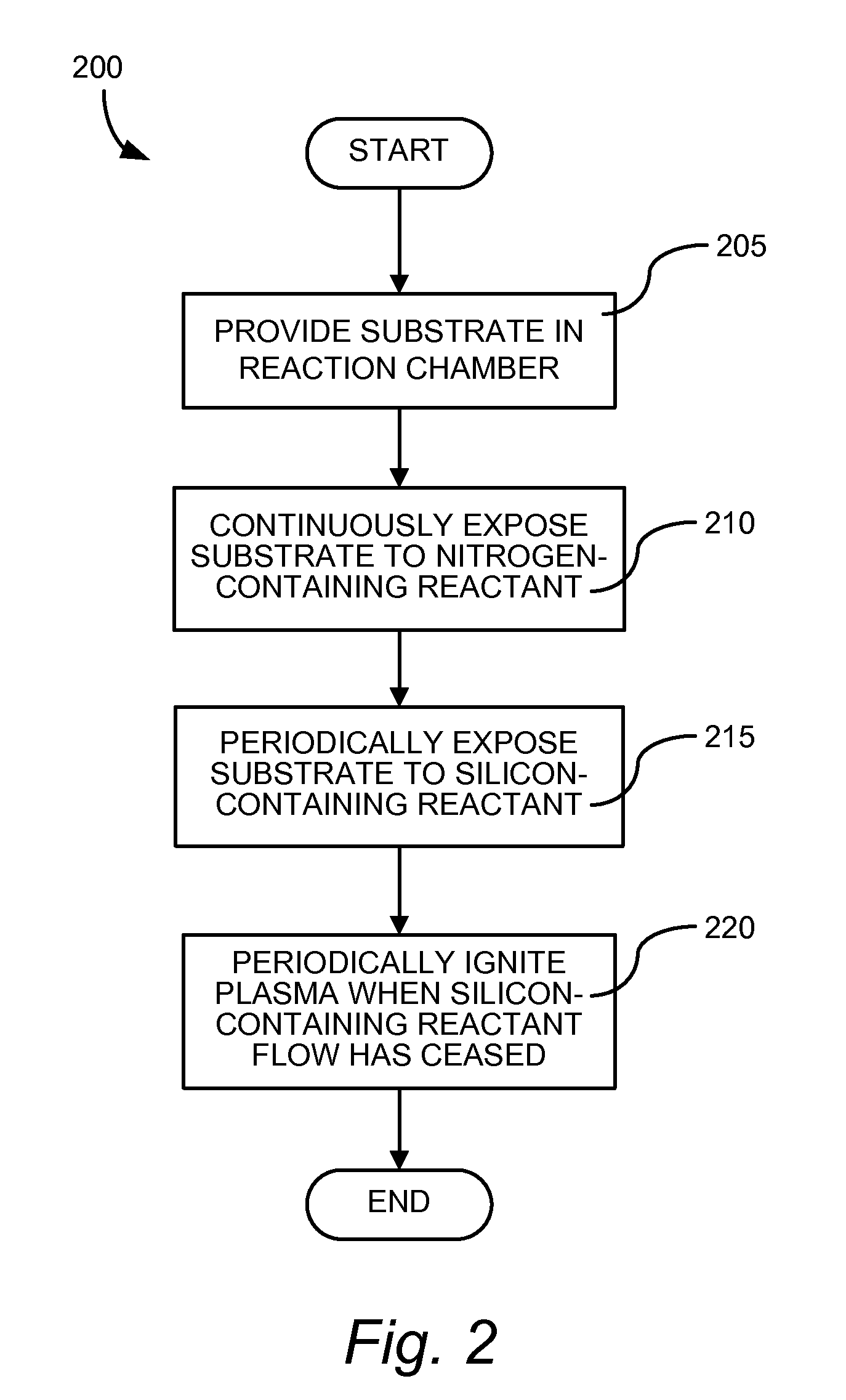

Silicon nitride films and methods

InactiveUS20110256734A1Reduce carbon contentSemiconductor/solid-state device manufacturingChemical vapor deposition coatingOptoelectronicsSemiconductor

Described are methods of making SiN materials on substrates, particularly SiN thin films on semiconductor substrates. Improved SiN films made by the methods are also included.

Owner:NOVELLUS SYSTEMS

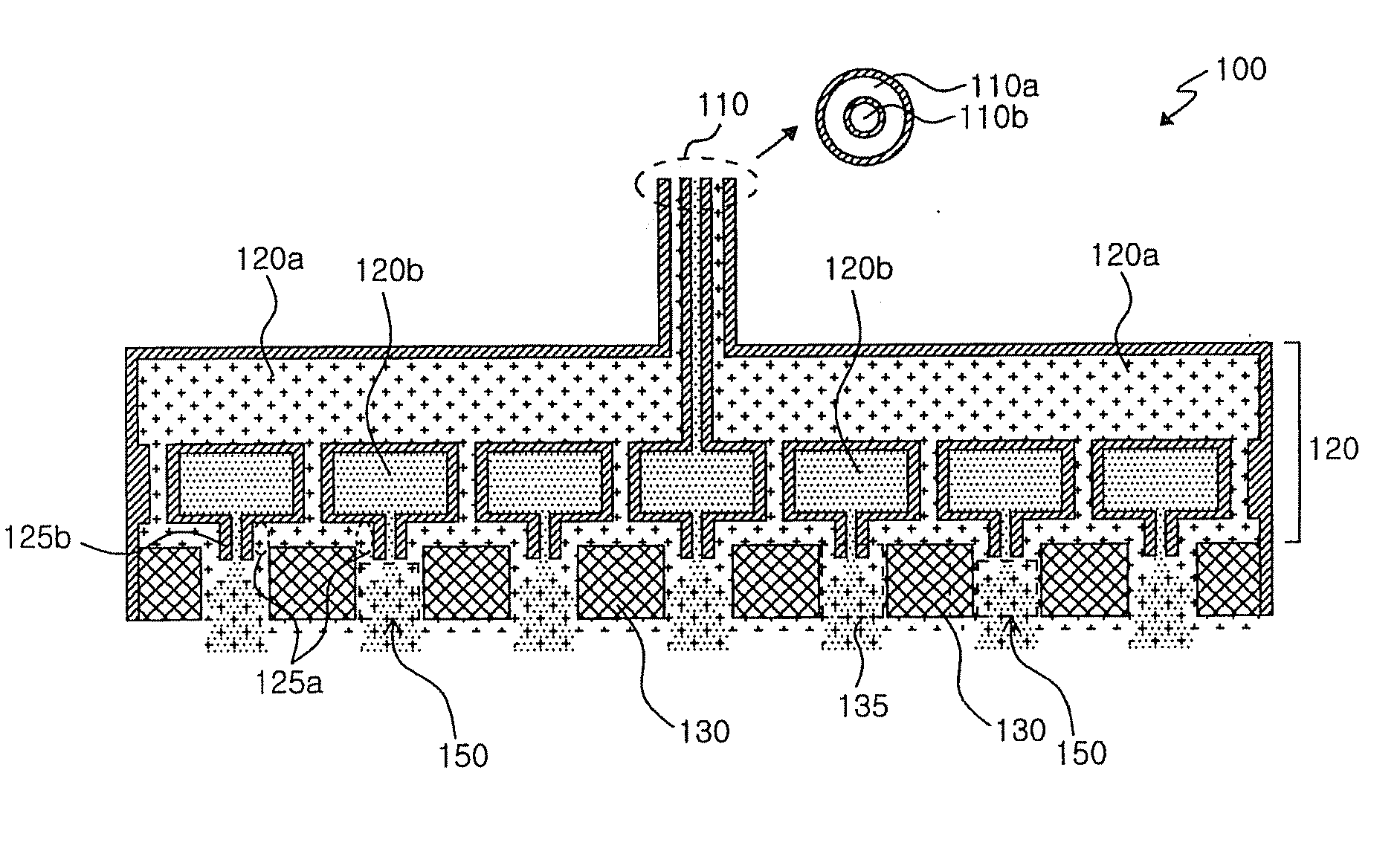

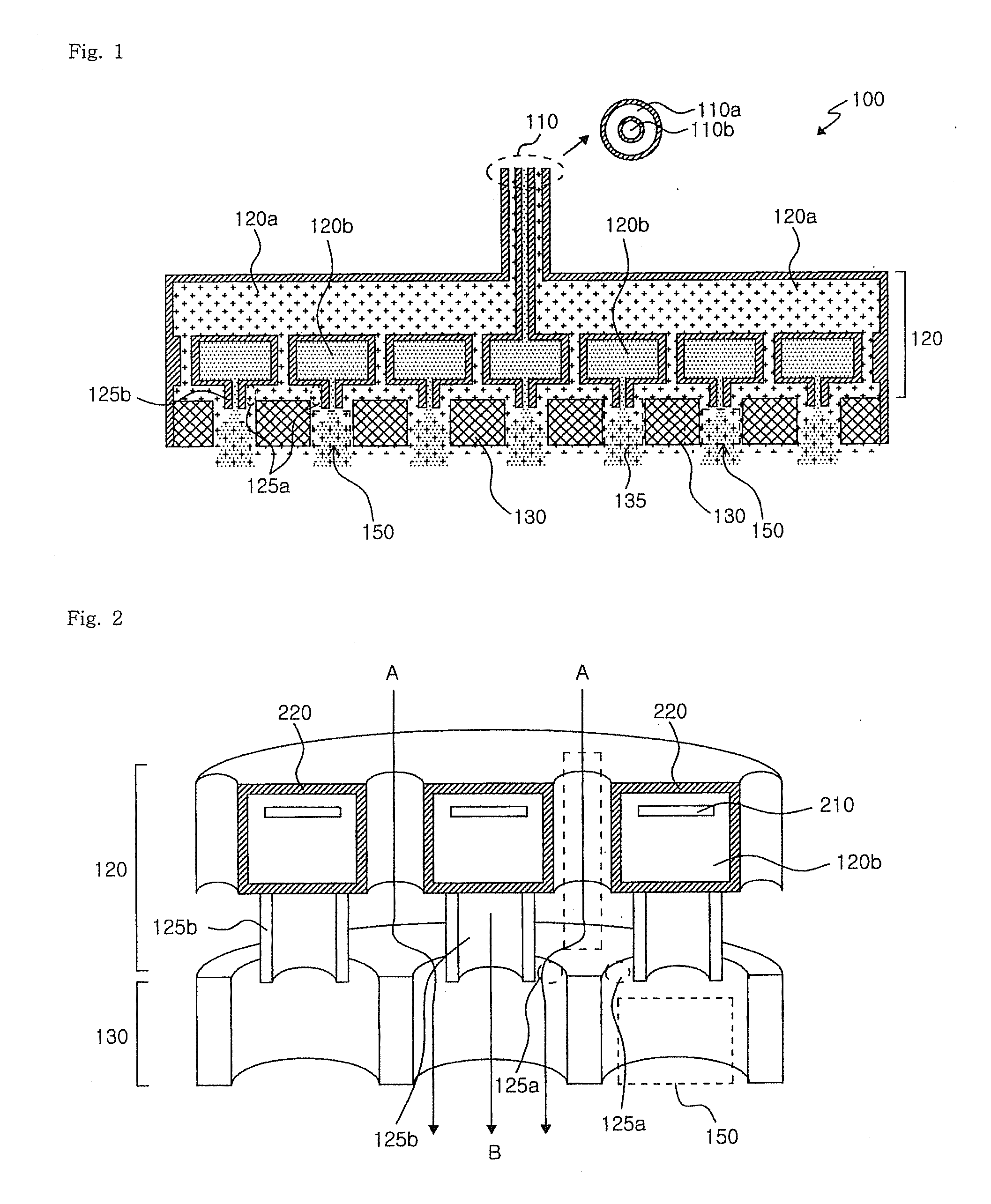

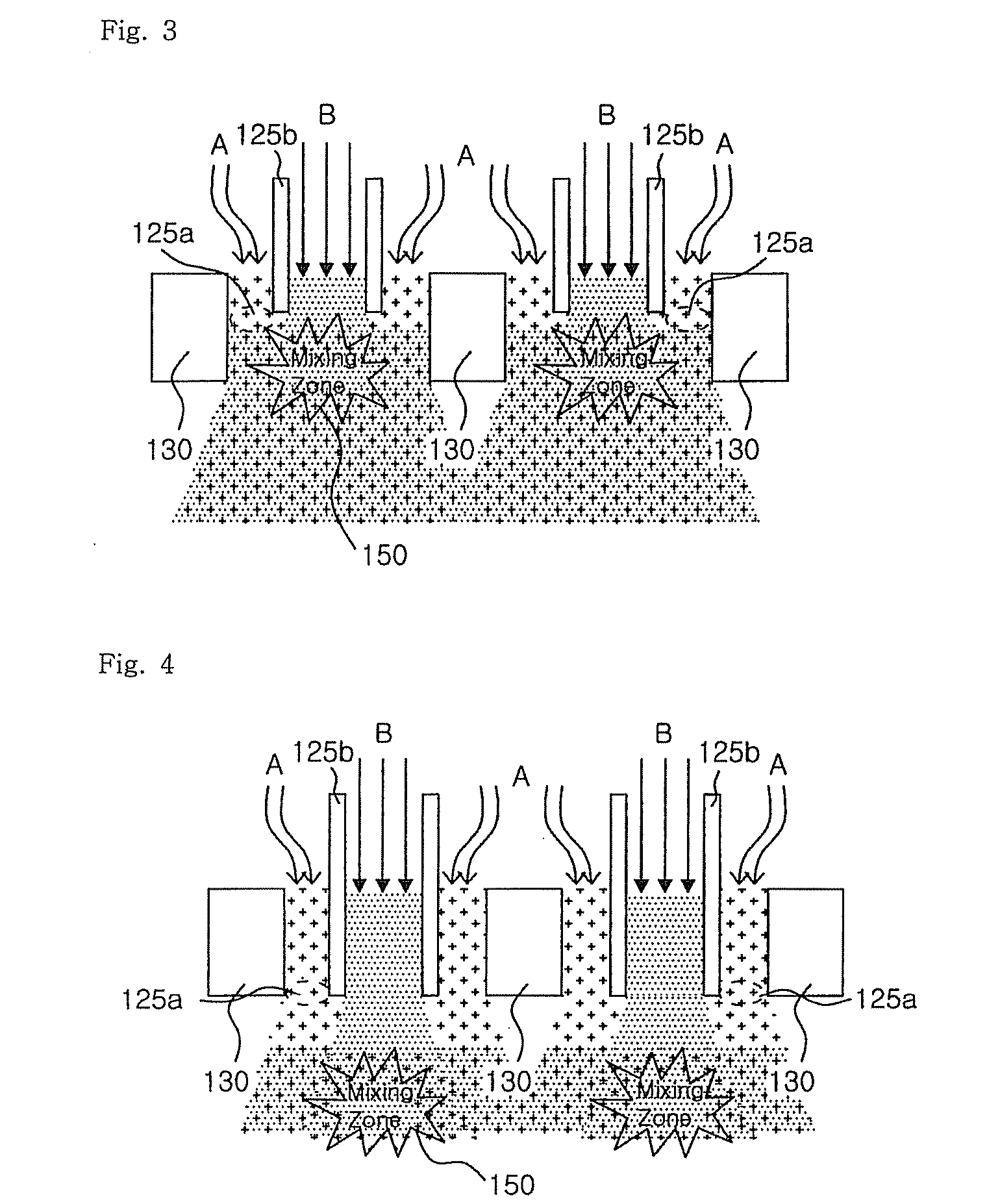

Film deposition apparatus and film deposition method

ActiveUS8506713B2Efficient solutionImprove uniformitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringDeposition process

Owner:TOKYO ELECTRON LTD

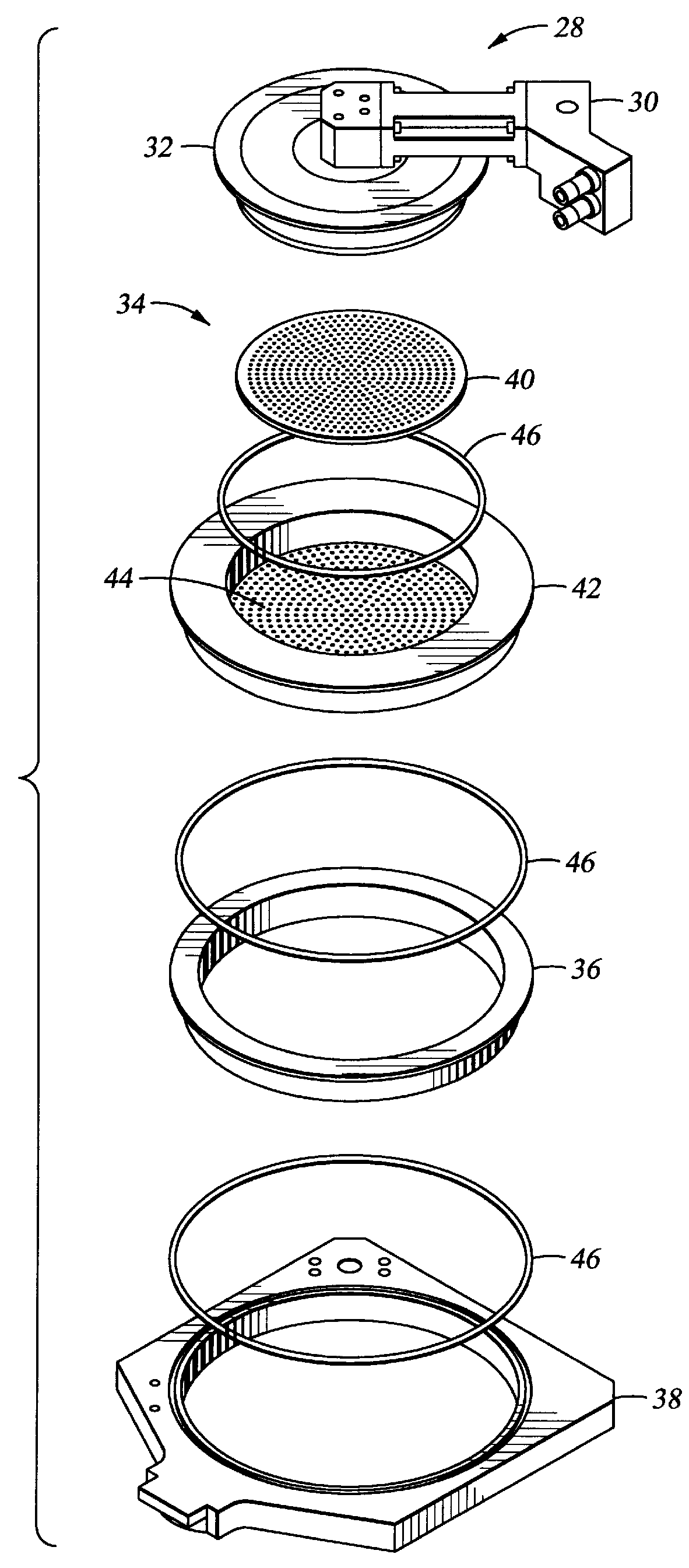

Diffuser plate with slit valve compensation

InactiveUS8328939B2Uniform plasma distributionUniform film thicknessLiquid surface applicatorsMolten spray coatingEngineeringMechanical engineering

The present invention generally comprises a diffuser plate for a PECVD chamber. The diffuser plate comprises a plurality of hollow cathode cavities. The edge of the diffuser plate that will reside closest to a slit valve within a processing chamber may have the shape and / or size of the hollow cathode cavities adjusted to compensate for the proximity to the slit valve. By adjusting the shape and / or size of the hollow cathode cavities closest to the slit valve, the diffuser plate may permit a uniform plasma distribution across the processing chamber and thus, a uniform film thickness upon a substrate during a PECVD process.

Owner:APPLIED MATERIALS INC

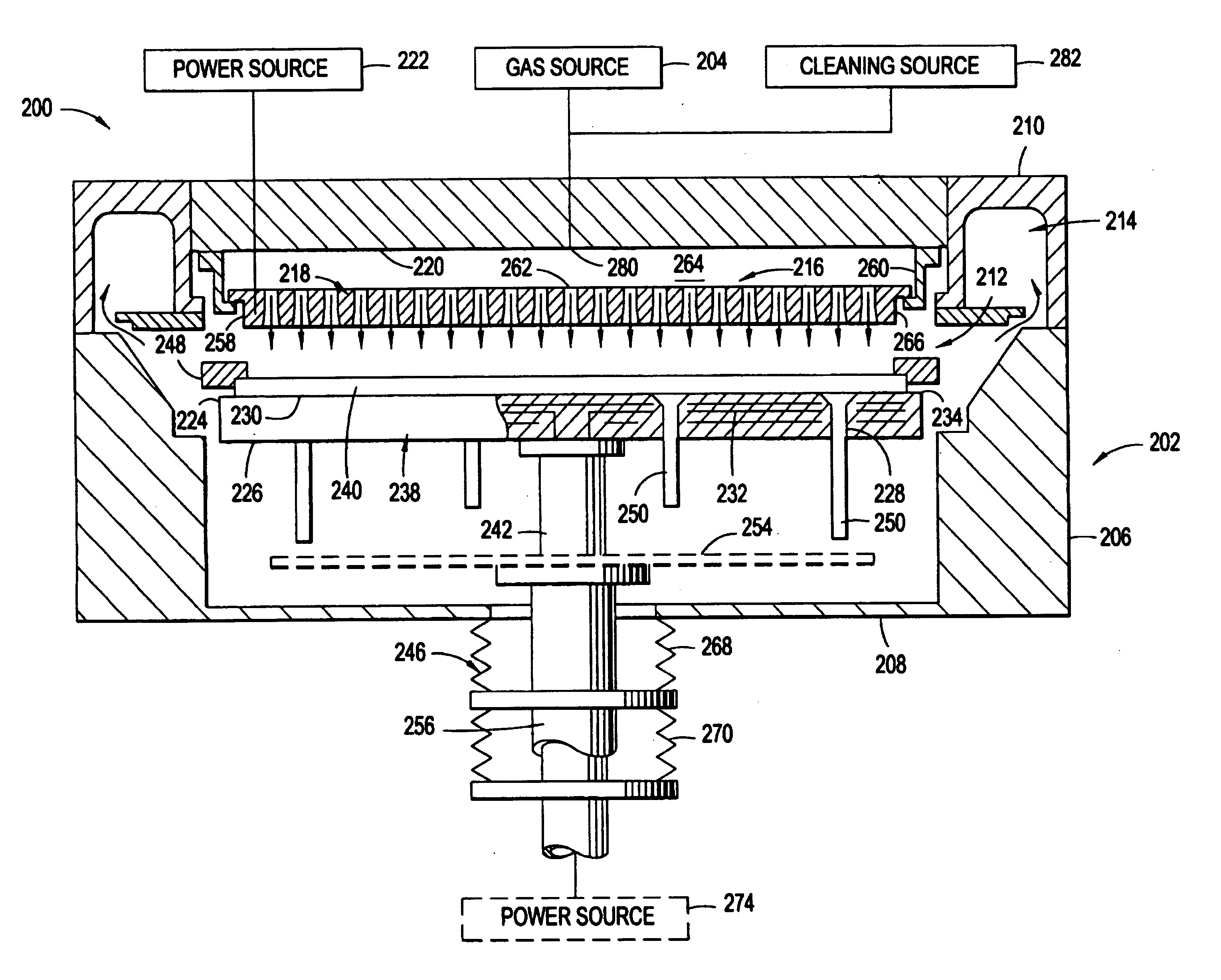

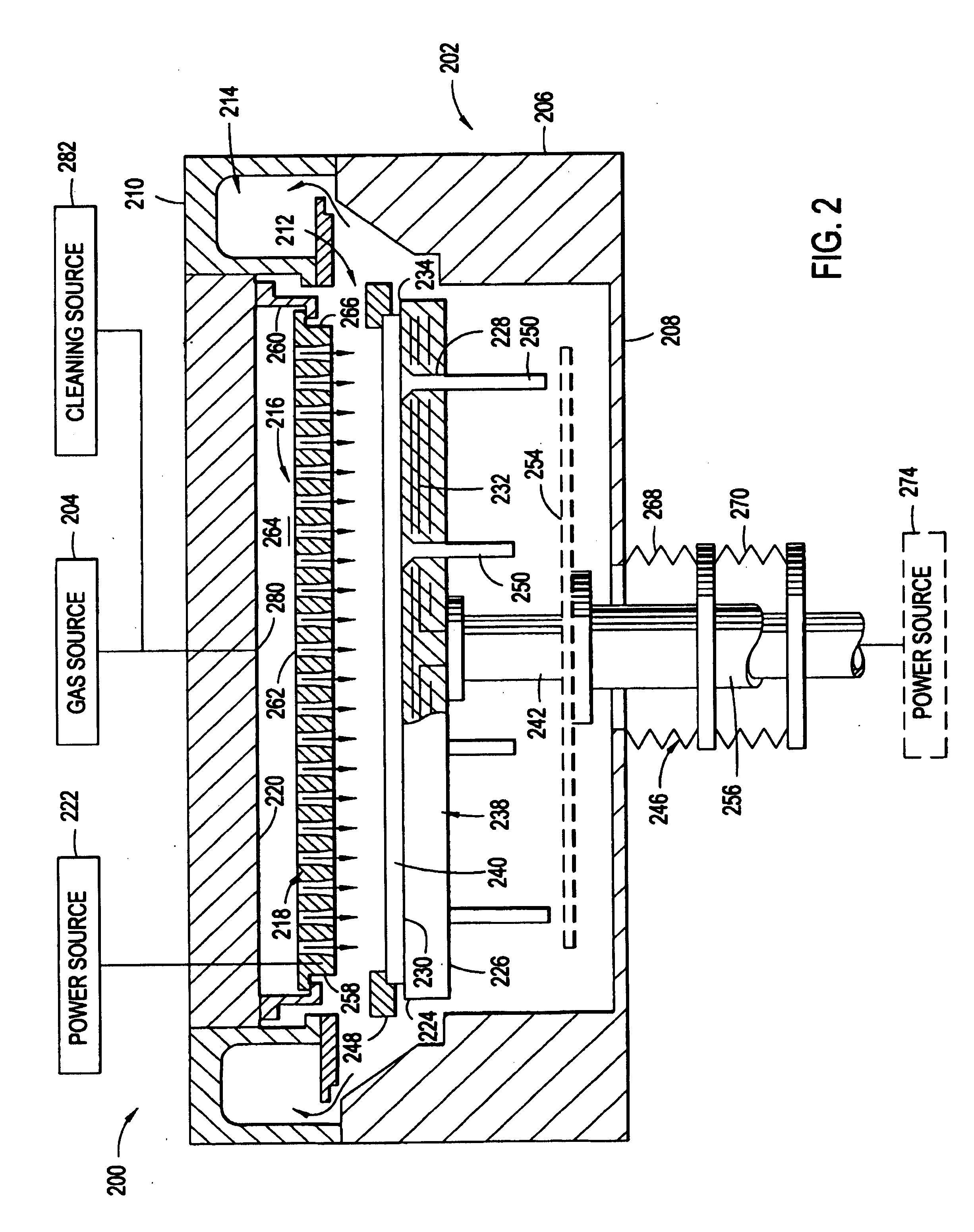

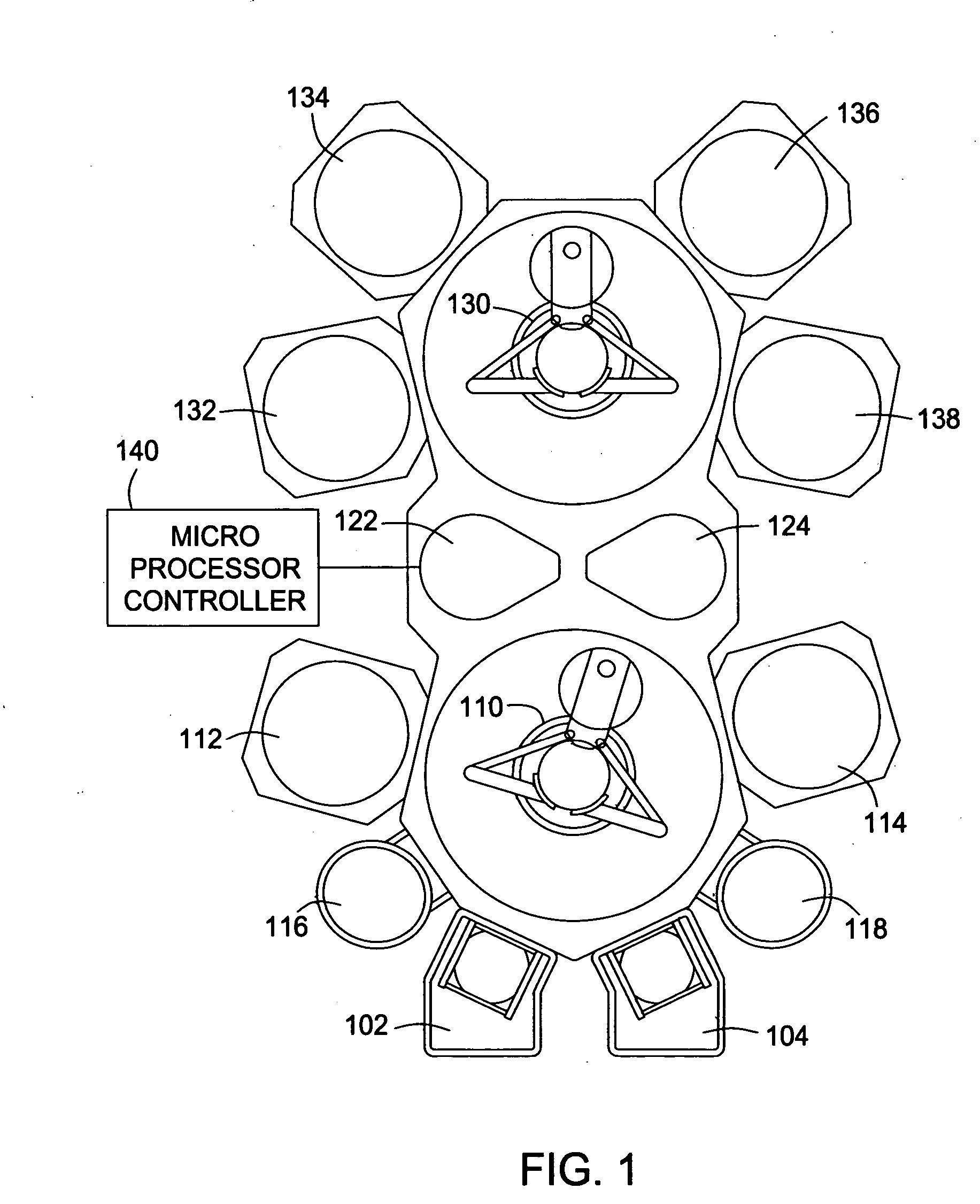

Lid assembly for a processing system to facilitate sequential deposition techniques

InactiveUS6878206B2Easy to controlIncrease ratingsSemiconductor/solid-state device manufacturingChemical vapor deposition coatingHandling systemSequential deposition

A lid assembly for a semiconductor processing system is provided. The lid assembly generally includes a lid having a gas manifold mounted on a first side and a baffle plate mounted on a second side. The gas manifold is configured to deliver a plurality of gases to a plenum defined between the baffle plate and the lid. The gases are mixed within a recess formed in the baffle plate before exiting into the processing system through a singular passage.

Owner:APPLIED MATERIALS INC

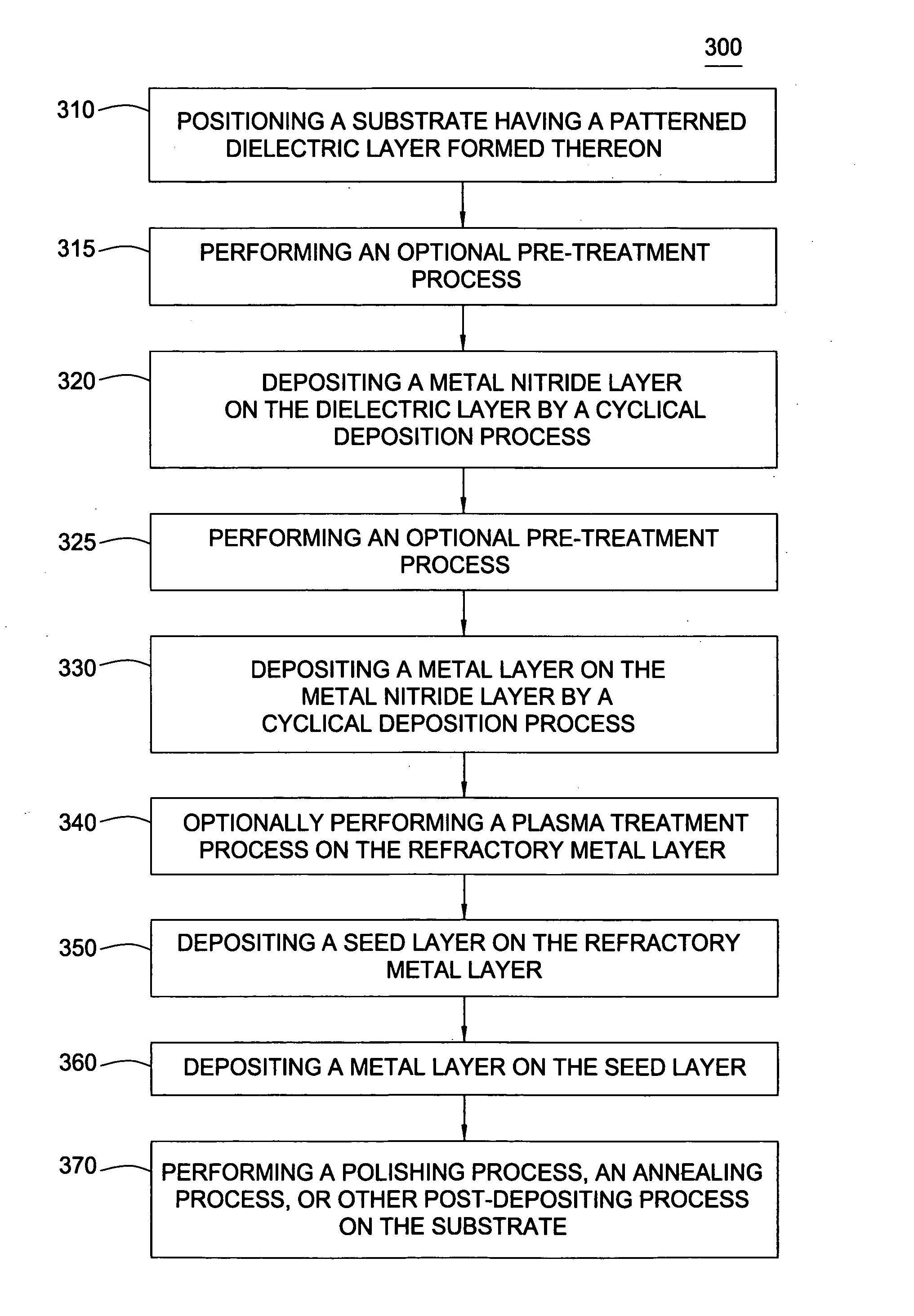

Atomic layer deposition of barrier materials

InactiveUS20050009325A1Material nanotechnologySemiconductor/solid-state device manufacturingNitrogenNitride

Methods for processing substrate to deposit barrier layers of one or more material layers by atomic layer deposition are provided. In one aspect, a method is provided for processing a substrate including depositing a metal nitride barrier layer on at least a portion of a substrate surface by alternately introducing one or more pulses of a metal containing compound and one or more pulses of a nitrogen containing compound and depositing a metal barrier layer on at least a portion of the metal nitride barrier layer by alternately introducing one or more pulses of a metal containing compound and one or more pulses of a reductant. A soak process may be performed on the substrate surface before deposition of the metal nitride barrier layer and / or metal barrier layer.

Owner:APPLIED MATERIALS INC

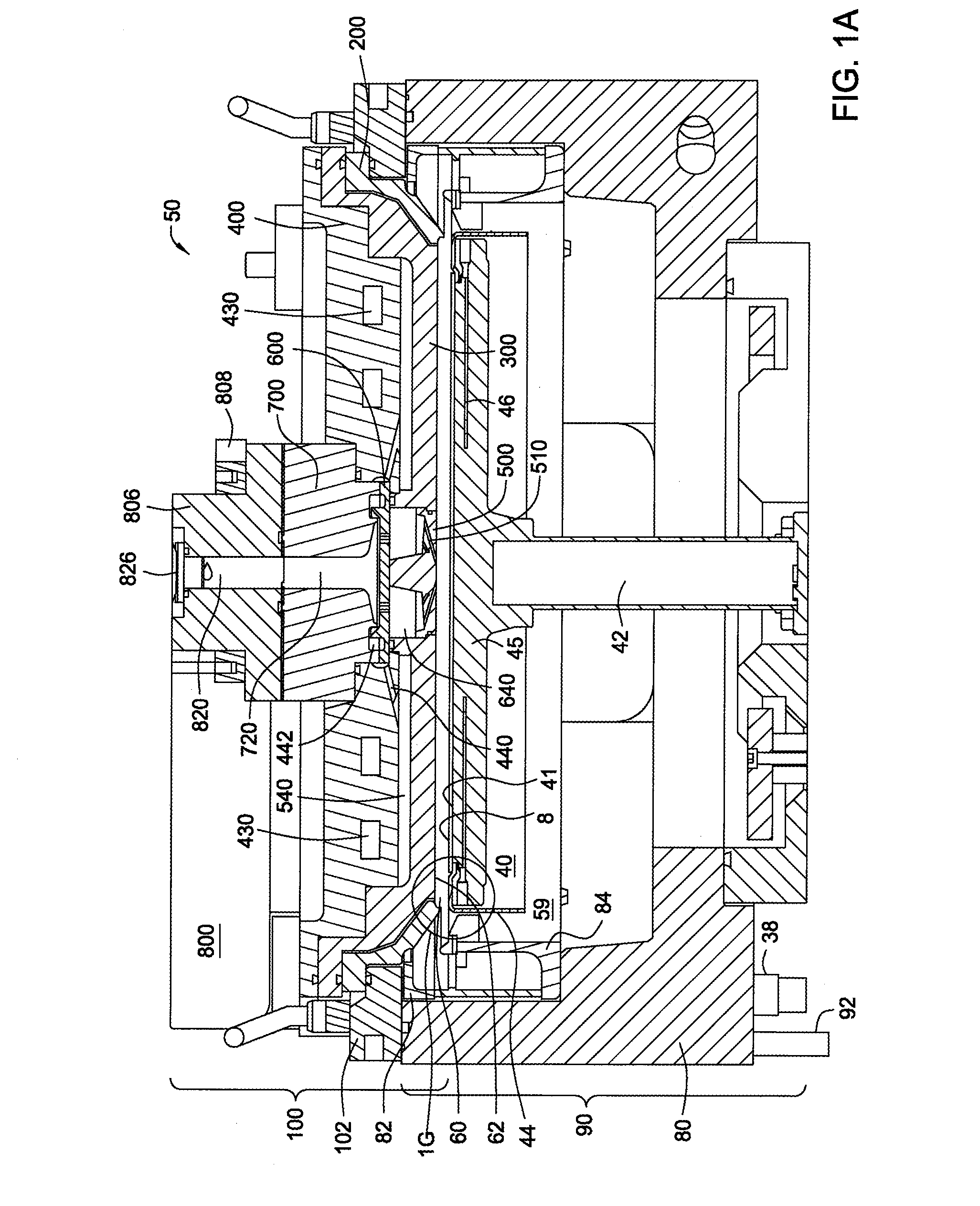

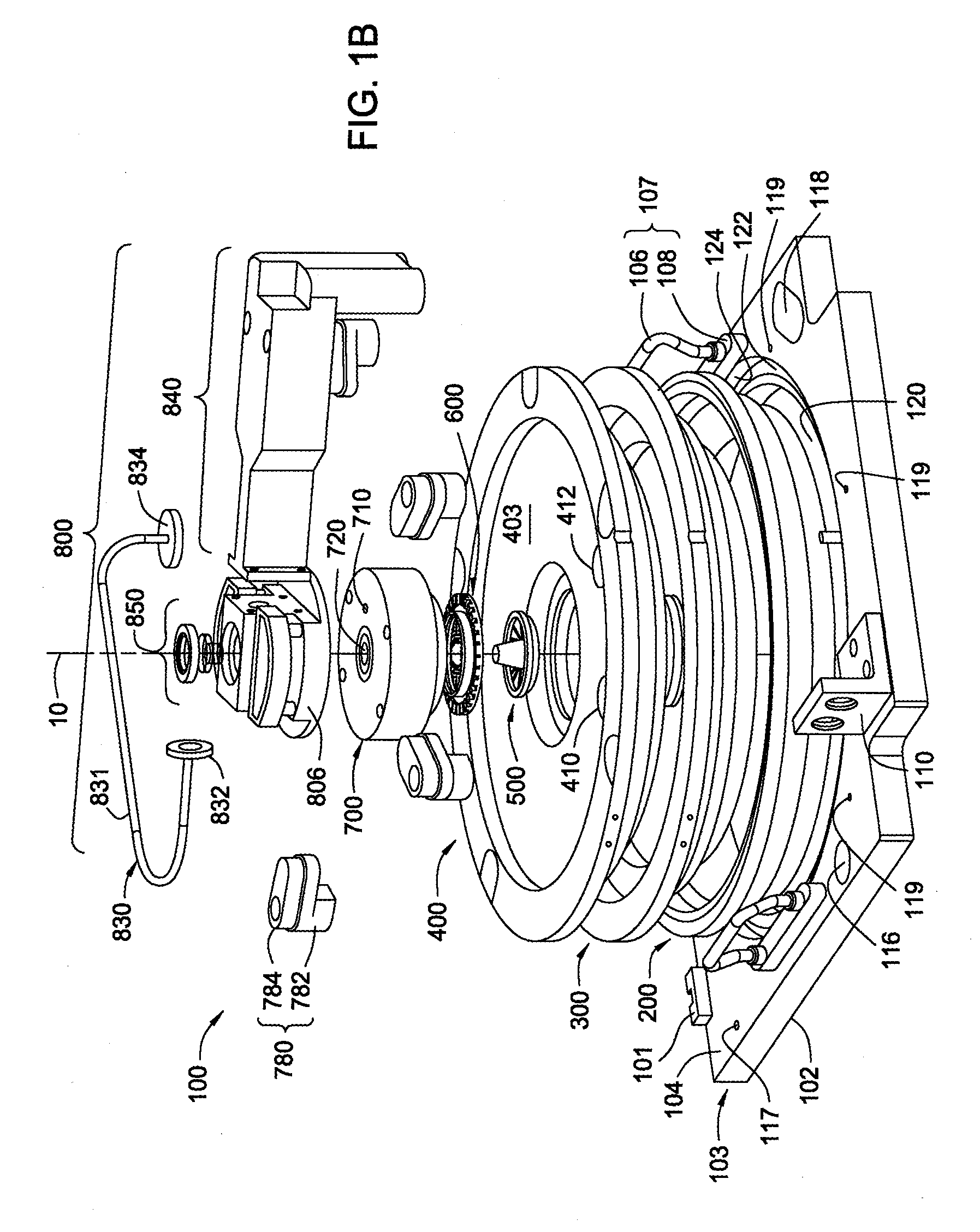

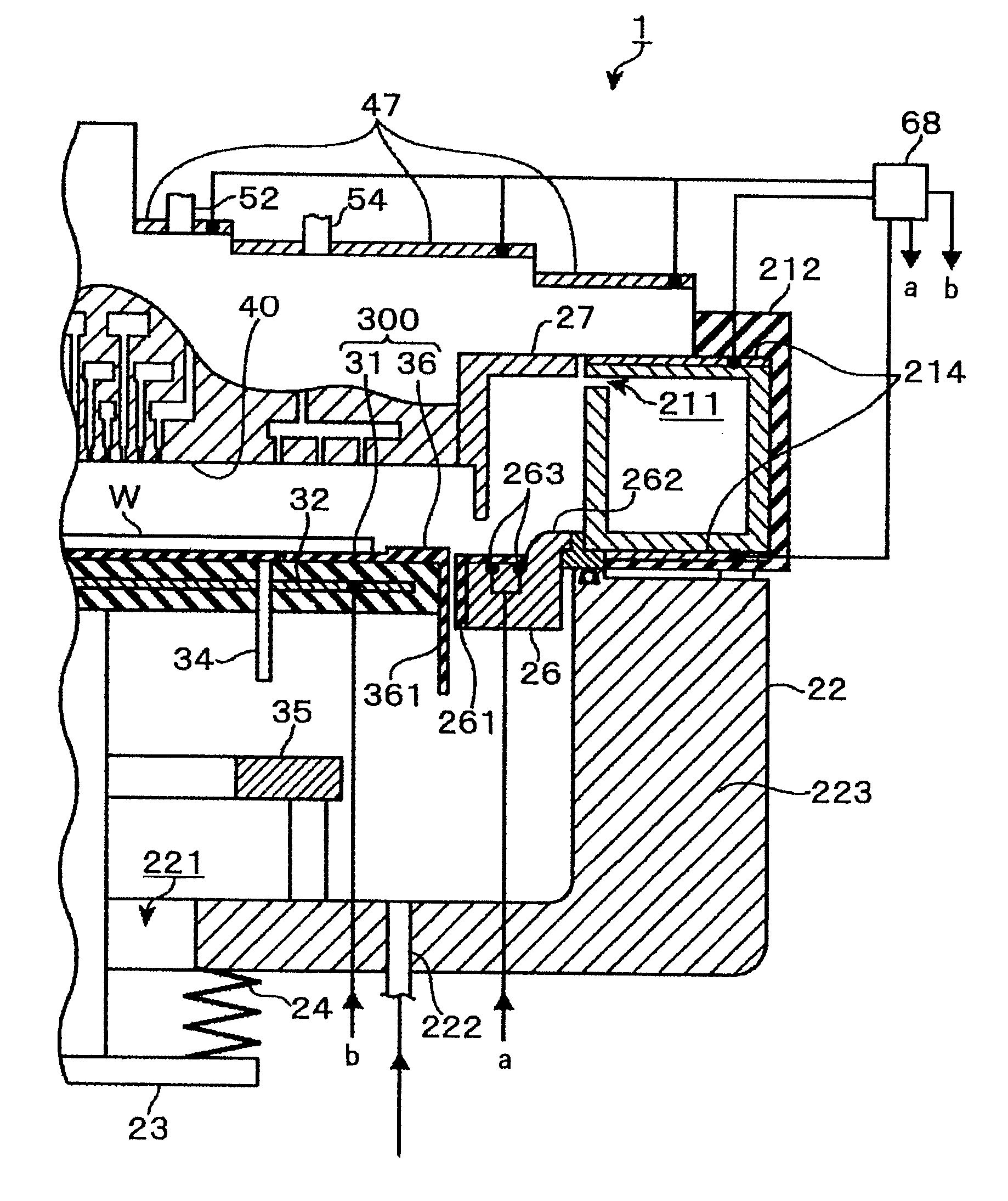

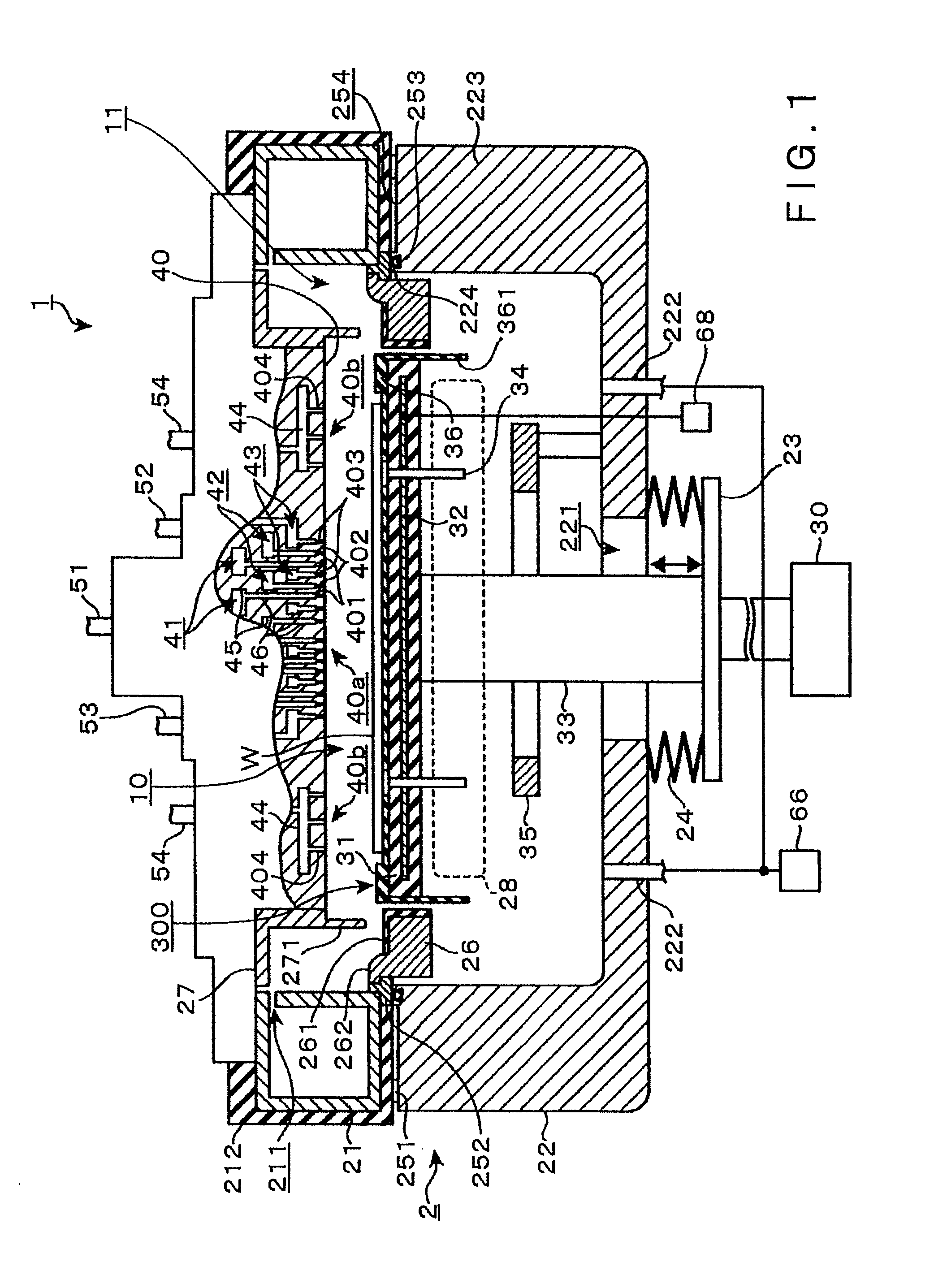

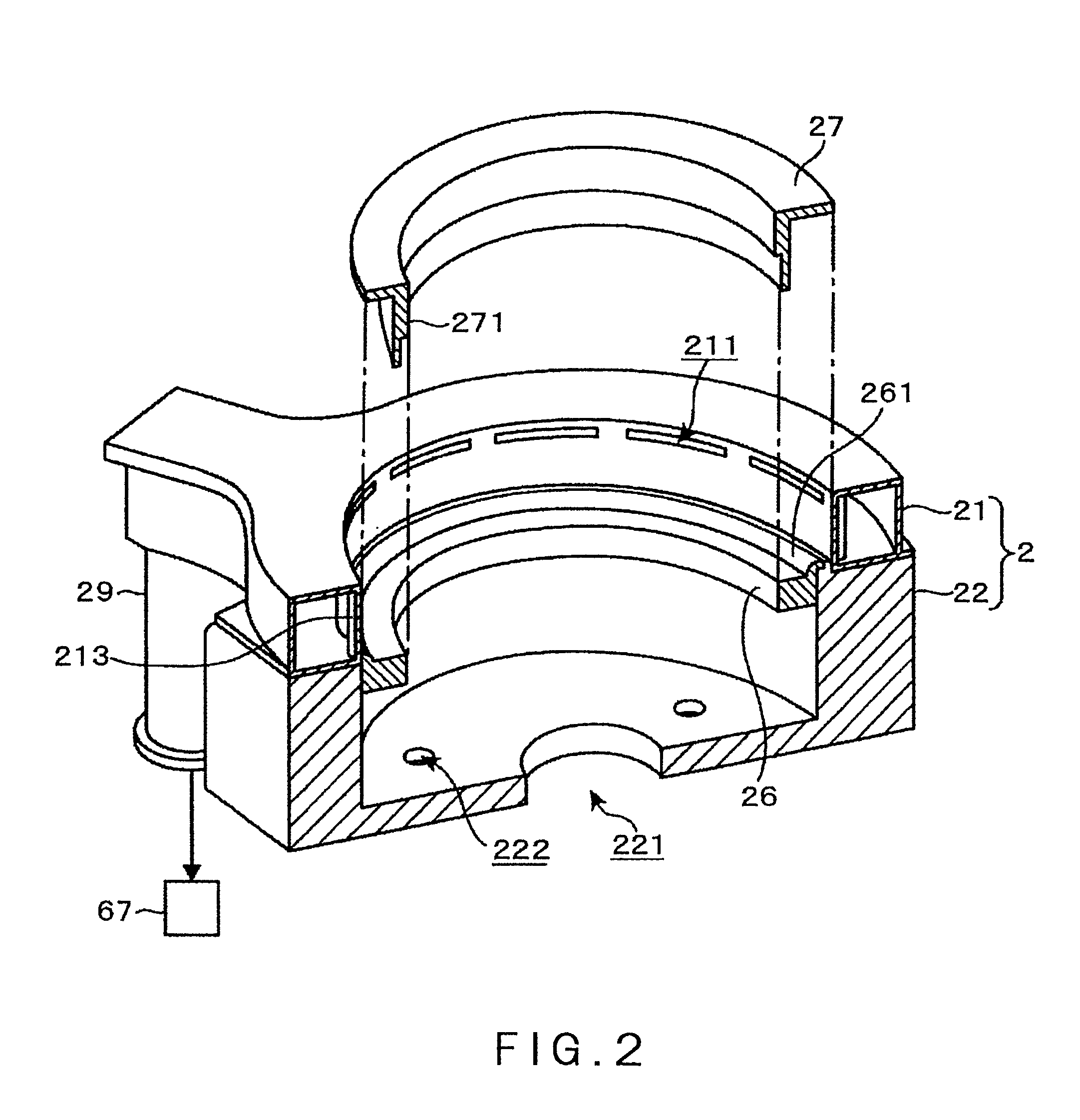

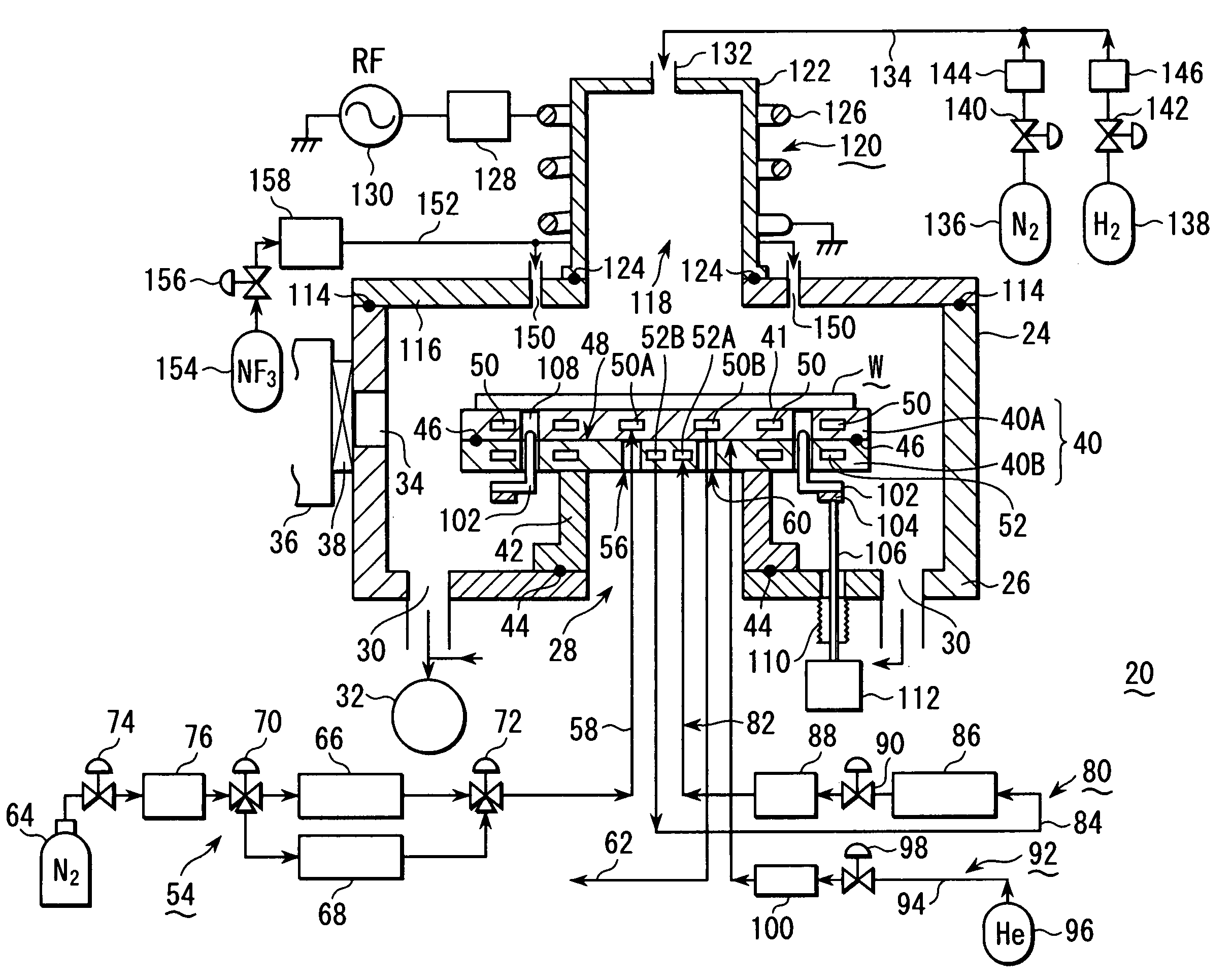

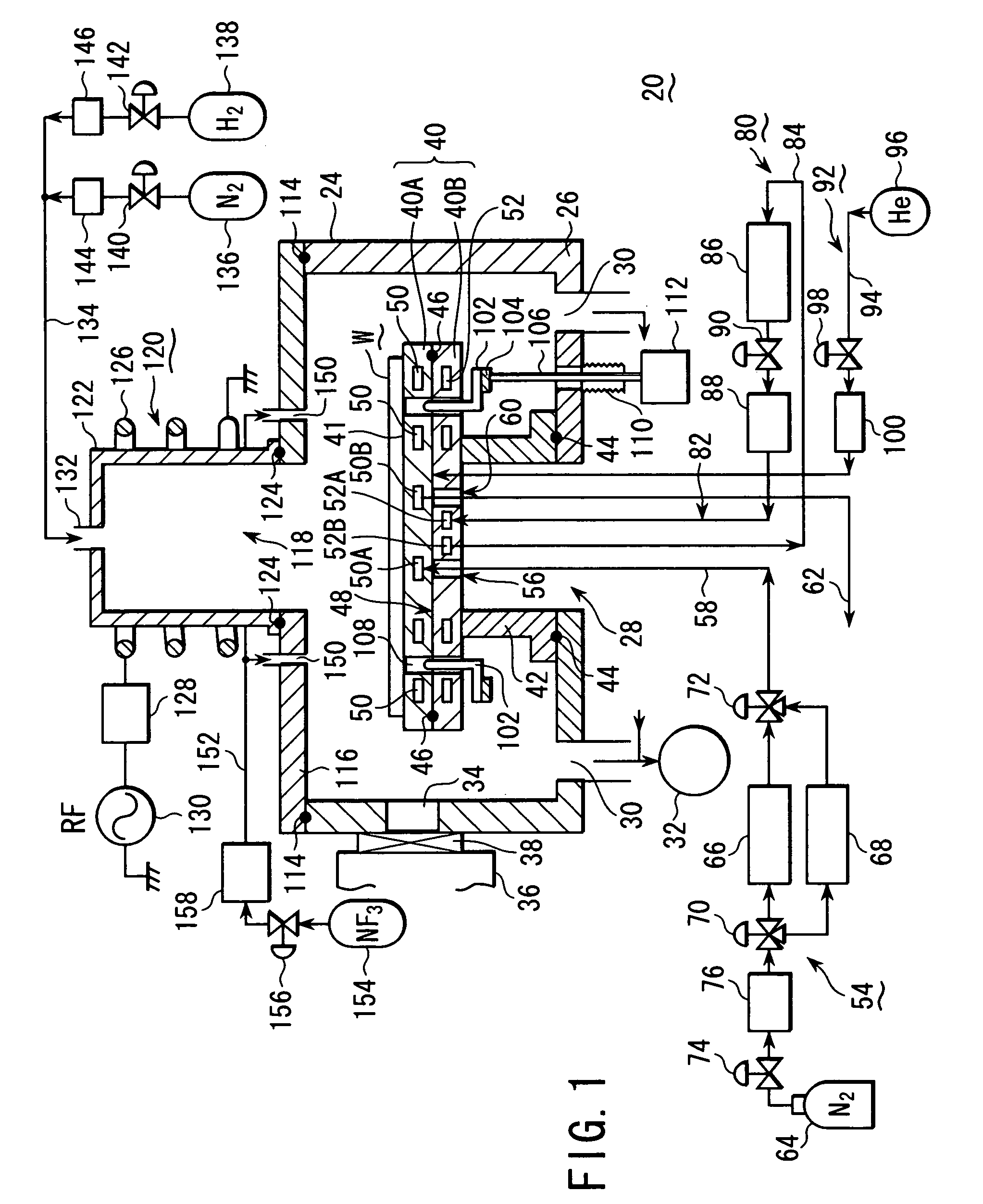

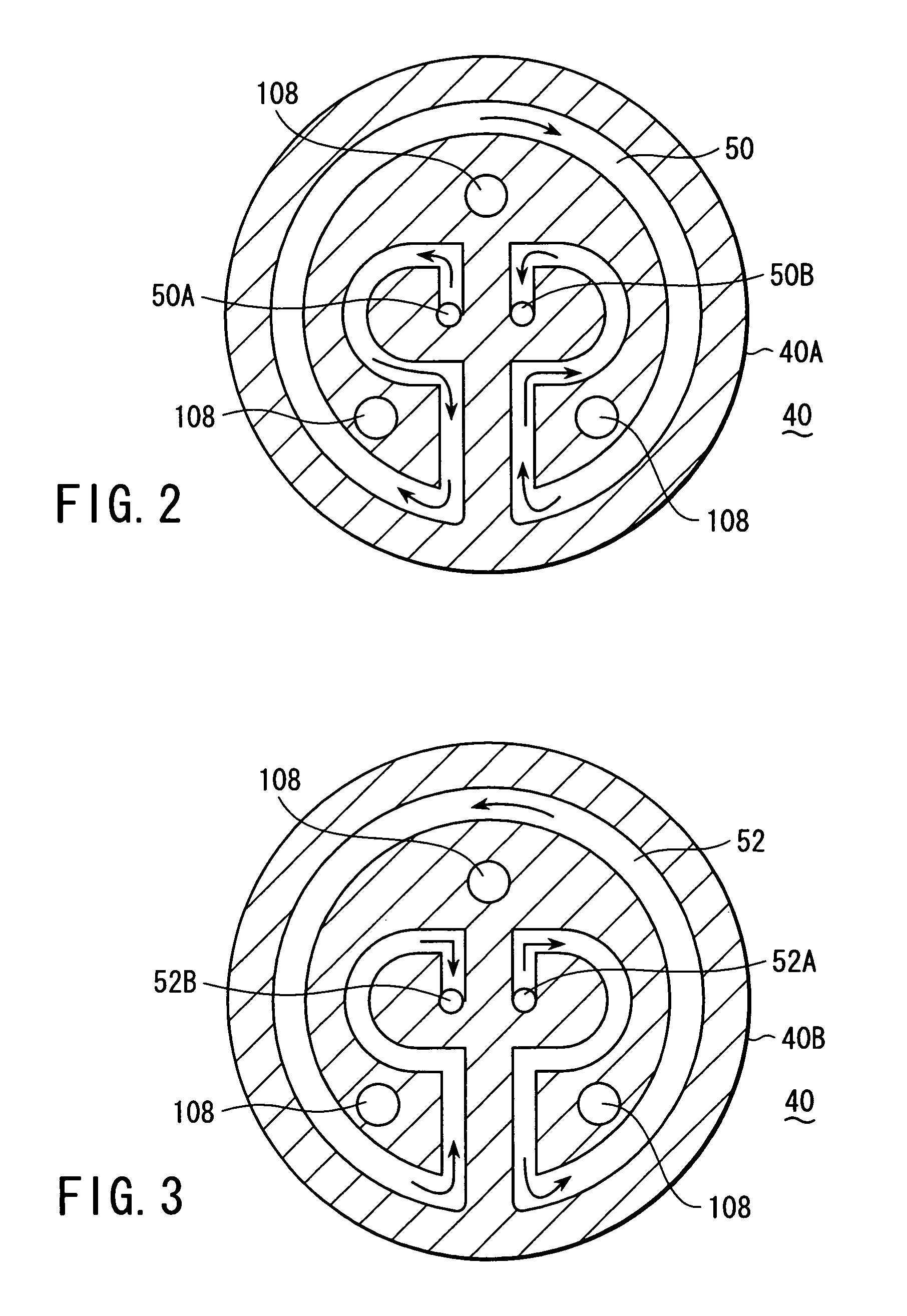

Conductor treating single-wafer type treating device and method for semi-conductor treating

InactiveUS7235137B2High processing temperatureLiquid surface applicatorsDecorative surface effectsElectrical conductorEngineering

A single-substrate processing apparatus (20) has a worktable (40) disposed in a process chamber (24), which accommodates a target substrate (W). The worktable (40) has a thermally conductive mount surface (41) to place the target substrate (W) thereon. The worktable (40) is provided with a flow passage (50) formed therein, in which a thermal medium flows for adjusting temperature of the target substrate (W) through the mount surface (41). The flow passage (50) is connected to a thermal medium supply system (54), which selectively supplies a cooling medium and a heating medium.

Owner:TOKYO ELECTRON LTD

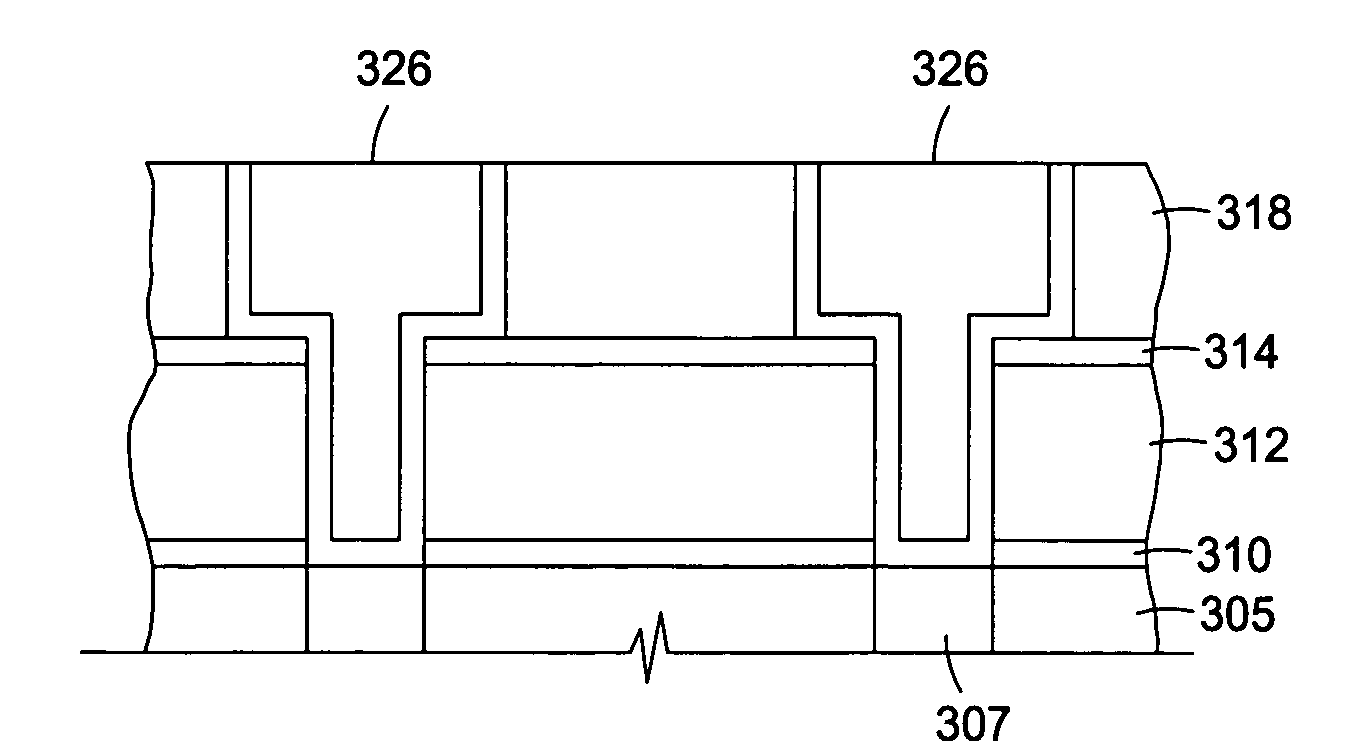

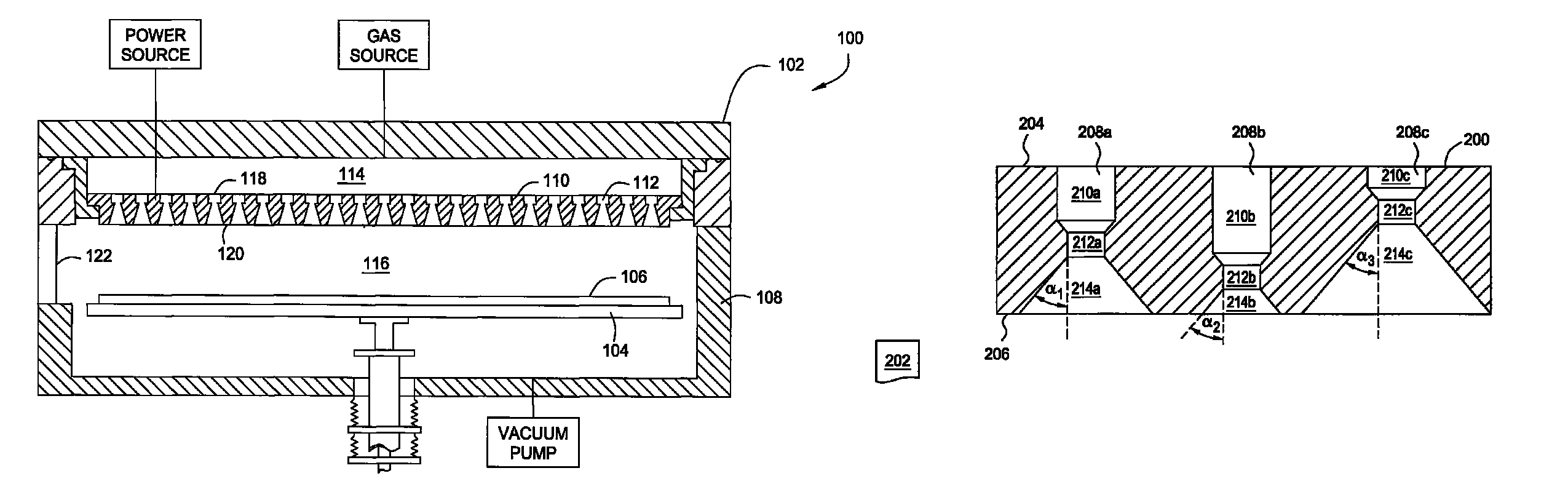

Dual channel gas distribution plate

InactiveUS6148761ASemiconductor/solid-state device manufacturingChemical vapor deposition coatingVertical channelDelivery system

A multi-channel faceplate 200, that in some embodiments is monolithic, is provided as a portion of a gas delivery system to a process chamber 100. At least two sets of gas pathways are disposed through a faceplate and allow for independent delivery of separate gases into a process chamber 100. In one embodiment, a first gas pathway, which includes a first set of vertical channels 226, is formed through the faceplate 200. A second gas pathway includes a second set of vertical channels 228, which is formed through a portion of the faceplate and connected to a set of interconnecting horizontal channels 222 in the faceplate 200, where the second gas pathway maintains fluidic separation from the first gas pathway, prior to the gases entering the process chamber 100.

Owner:APPLIED MATERIALS INC

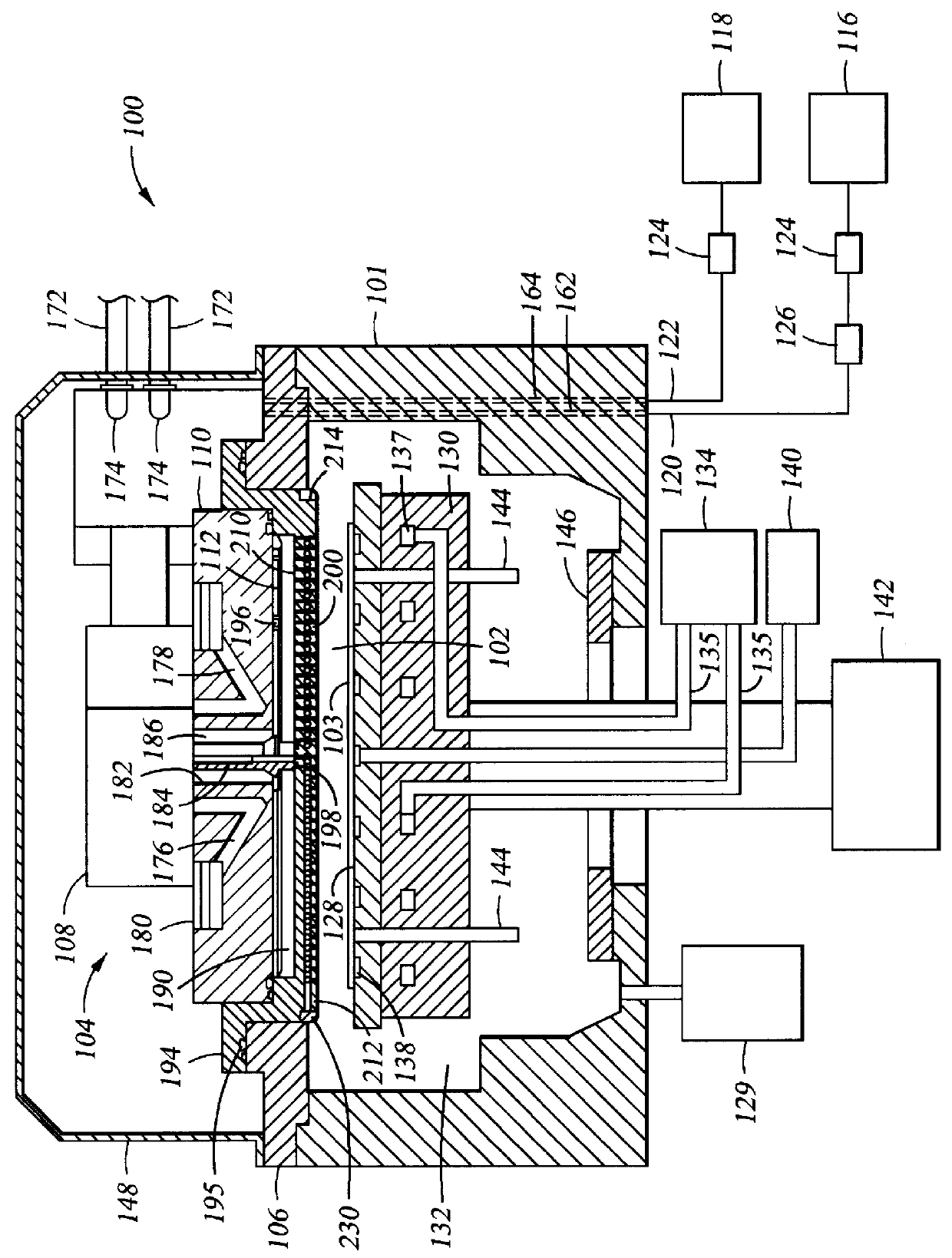

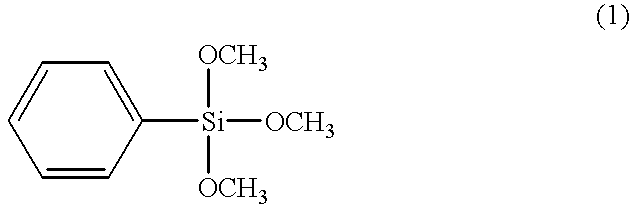

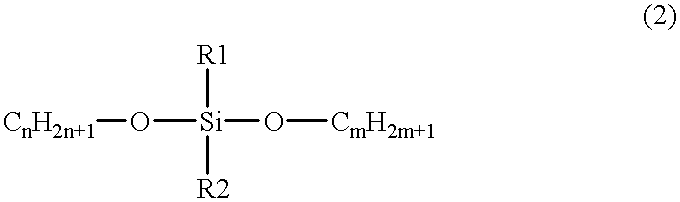

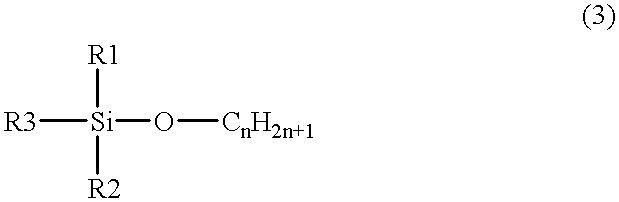

Silicone polymer insulation film on semiconductor substrate and method for forming the film

InactiveUS6352945B1Low dielectric constantImprove thermal stabilityLiquid surface applicatorsSemiconductor/solid-state device detailsPolymer scienceHigh humidity

A method for forming a silicone polymer insulation film having a low relative dielectric constant, high thermal stability and high humidity-resistance on a semiconductor substrate is applied to a plasma CVD apparatus. The first step is introducing a silicon-containing hydrocarbon compound expressed by the general formula SialphaObetaCxHy (alpha, beta, x, and y are integers) to the reaction chamber of the plasma CVD apparatus. The silicon-containing hydrocarbon compound has at most two O-CnH2n+1 bonds and at least two hydrocarbon radicals bonded to the silicon. The residence time of the material gas is lengthened by, for example, reducing the total flow of the reaction gas, in such a way as to form a silicone polymer film having a micropore porous structure with a low relative dielectric constant.

Owner:ASM JAPAN

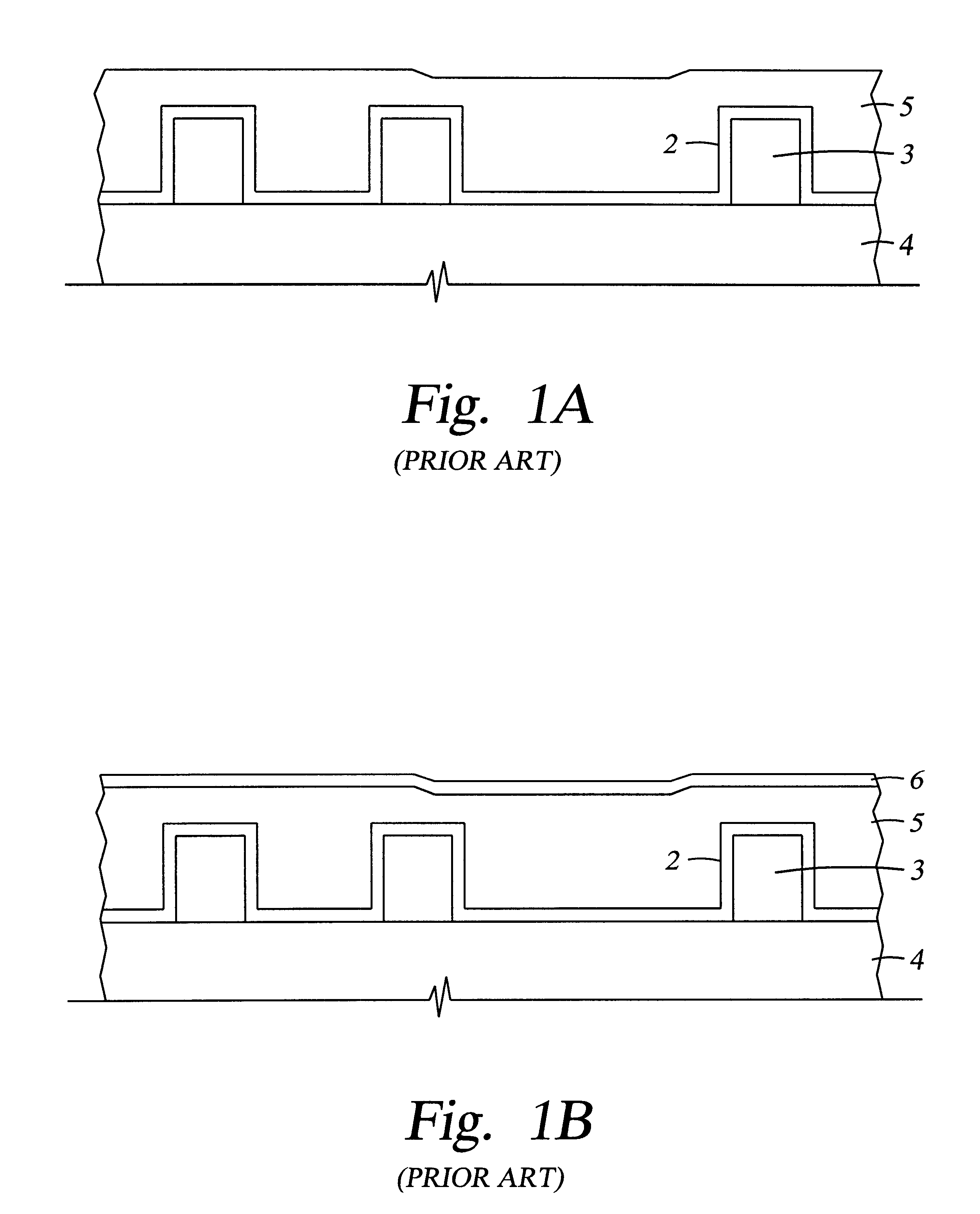

Formation of a liquid-like silica layer by reaction of an organosilicon compound and a hydroxyl forming compound

InactiveUS6413583B1Semiconductor/solid-state device detailsSolid-state devicesSilicon oxideSilicon dioxide

A method for depositing silicon oxide layers having a low dielectric constant by reaction of an organosilicon compound and a hydroxyl forming compound at a substrate temperature less than about 400° C. The low dielectric constant films contain residual carbon and are useful for gap fill layers, pre-metal dielectric layers, inter-metal dielectric layers, and shallow trench isolation dielectric layers in sub-micron devices. The hydroxyl compound can be prepared prior to deposition from water or an organic compound. The silicon oxide layers are preferably deposited at a substrate temperature less than about 40° C. onto a liner layer produced from the organosilicon compound to provide gap fill layers having a dielectric constant less than about 3.0.

Owner:APPLIED MATERIALS INC

Apparatus for treating the surface with neutral particle beams

InactiveUS6935269B2Wide effective cross sectionImprove throughputRadiation/particle handlingElectric discharge tubesTarget surfaceMetal

The present invention relates to an apparatus for treating the surface with neutral particle beams comprising an antenna container, a plasma generating part, a neutral particle beam generating part and a treating part, wherein the antenna container comprises antennas connected to high frequency electric power supply through which high frequency electric power supplies, the plasma generating part transfers gases from a gas injector into plasmas with the supplied power, the neutral particle beam generating part reverts the obtained plasmas to neutral particle beams via the collision thereof with metal plates, and the treating part treats the surface of a target with the neutral particle beams.

Owner:SEM TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com