Patents

Literature

1267results about How to "Reduce carbon content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

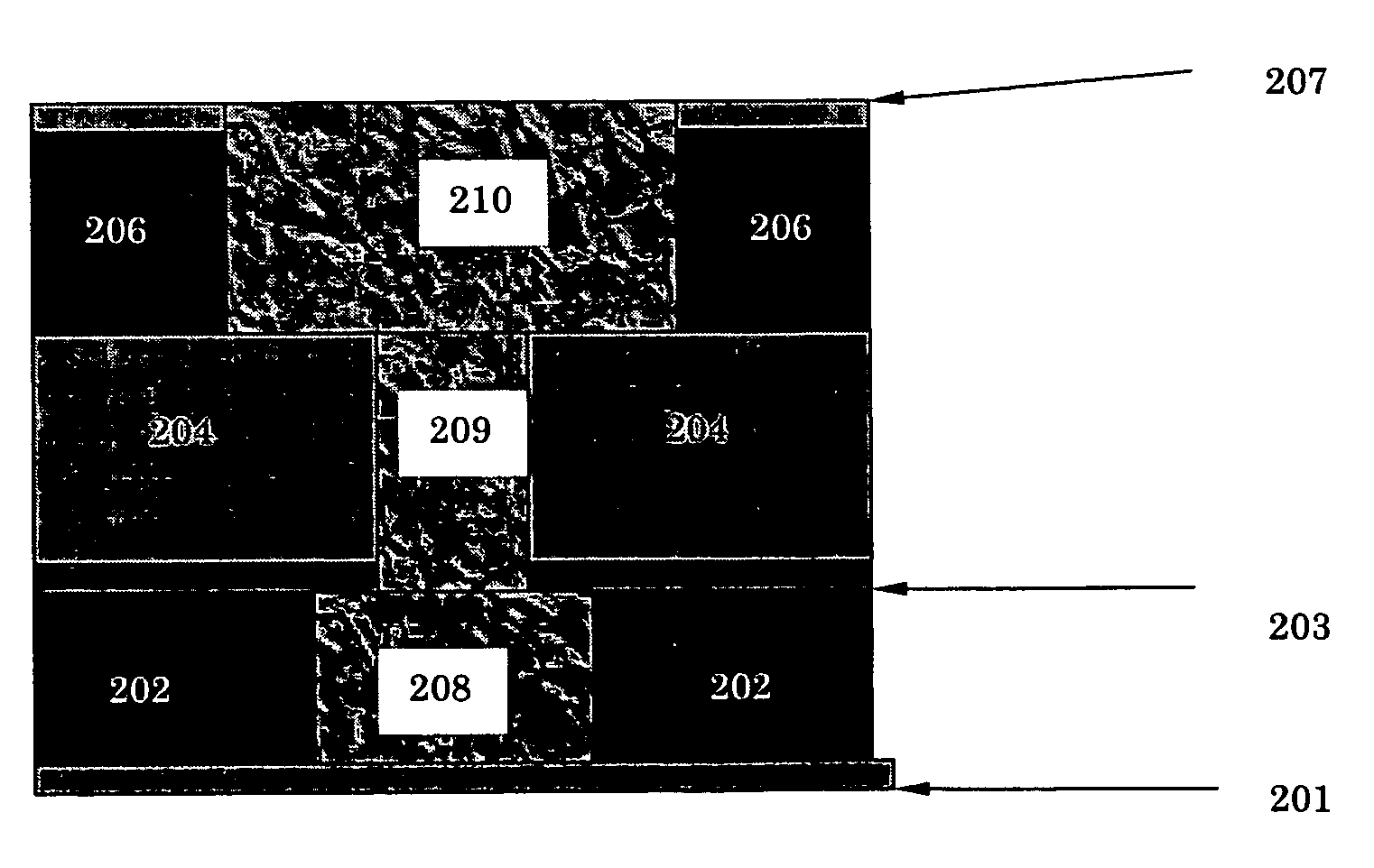

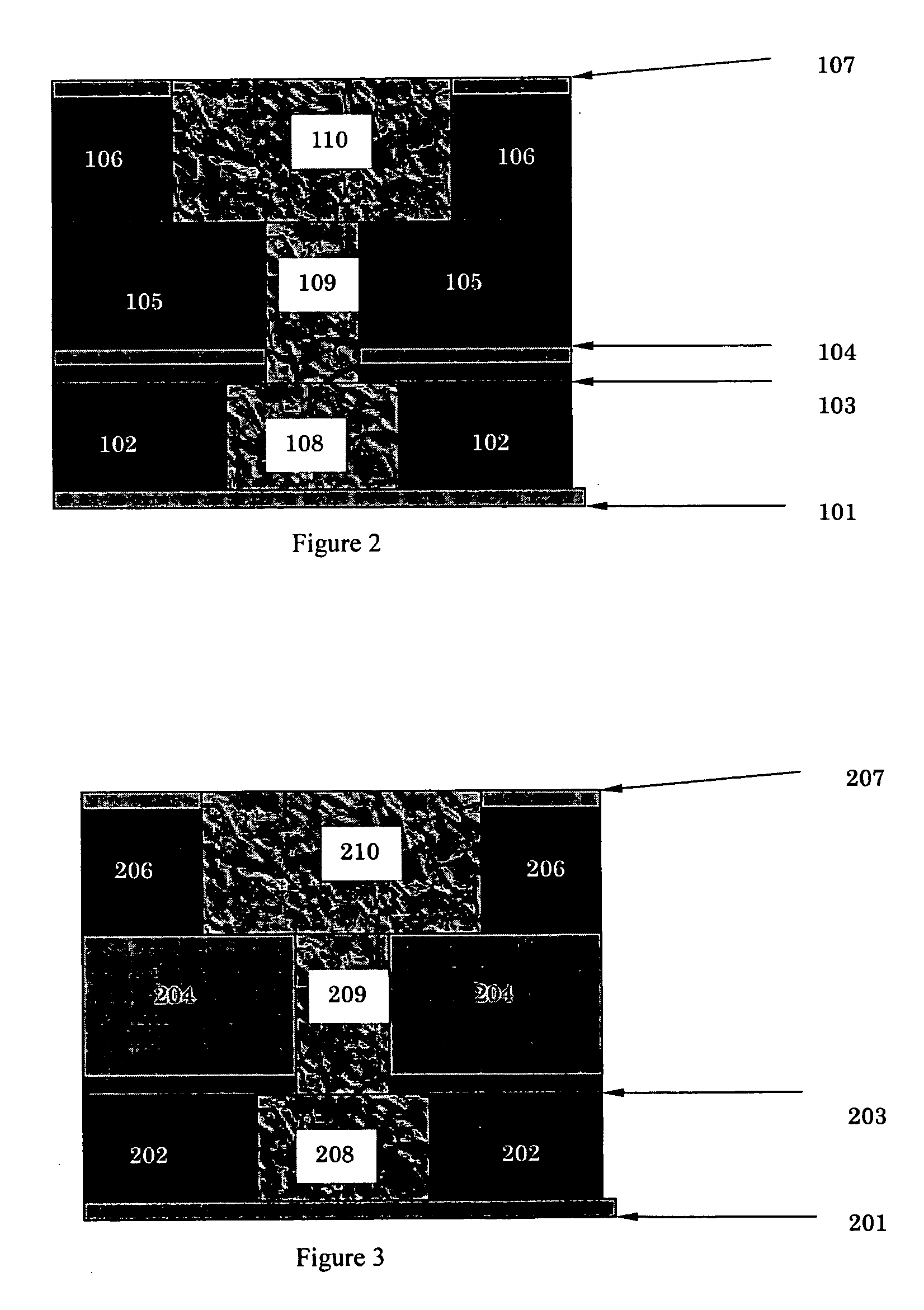

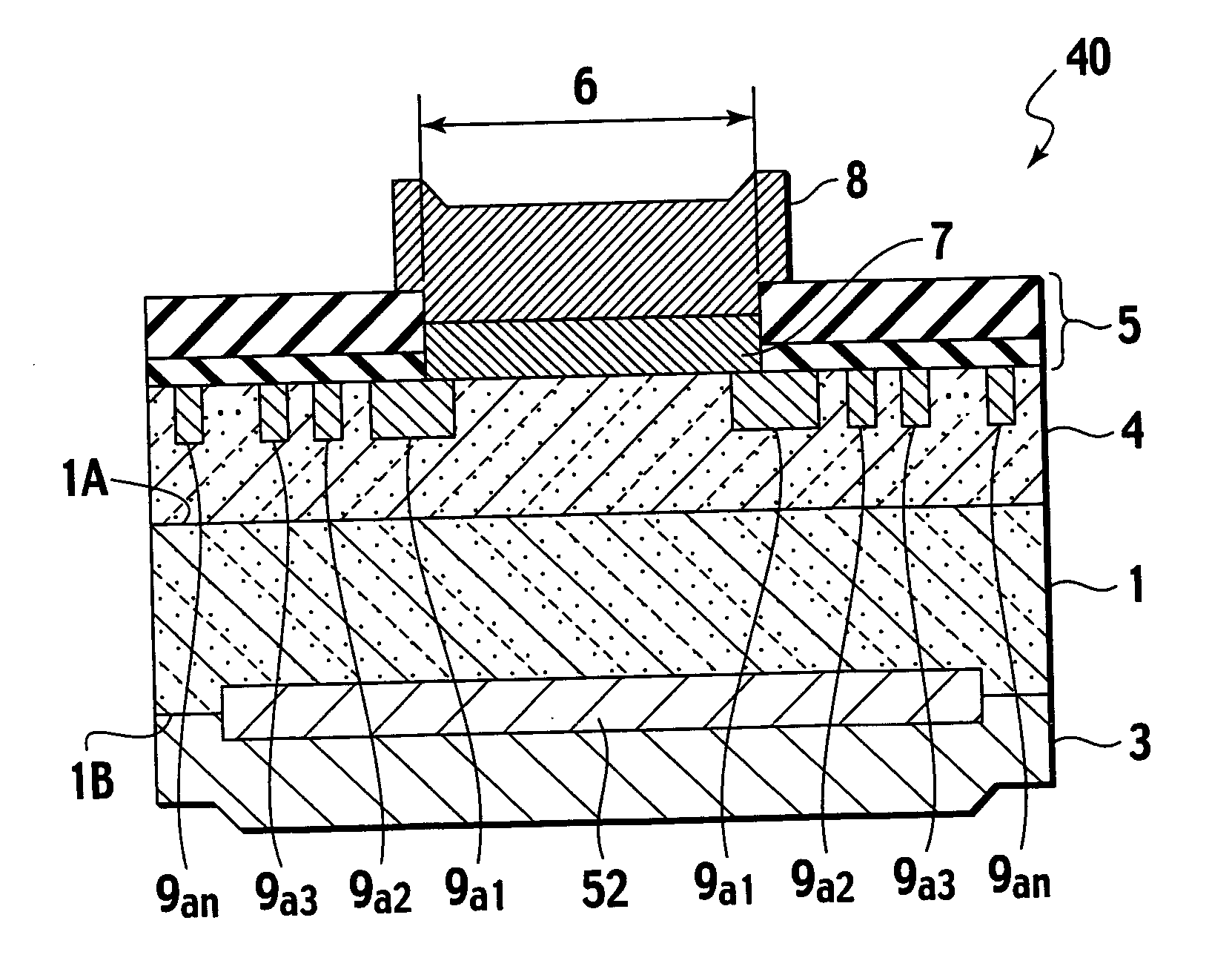

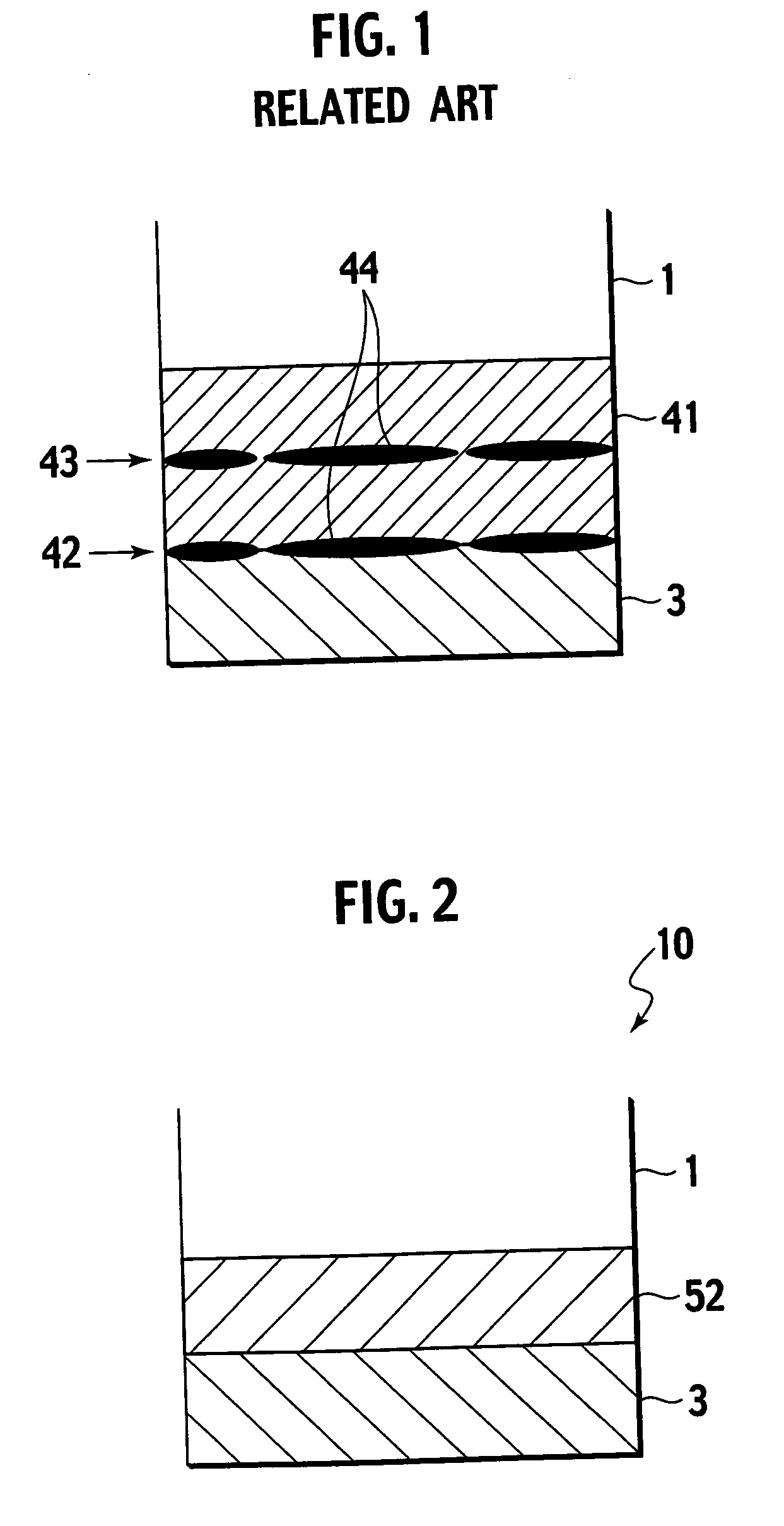

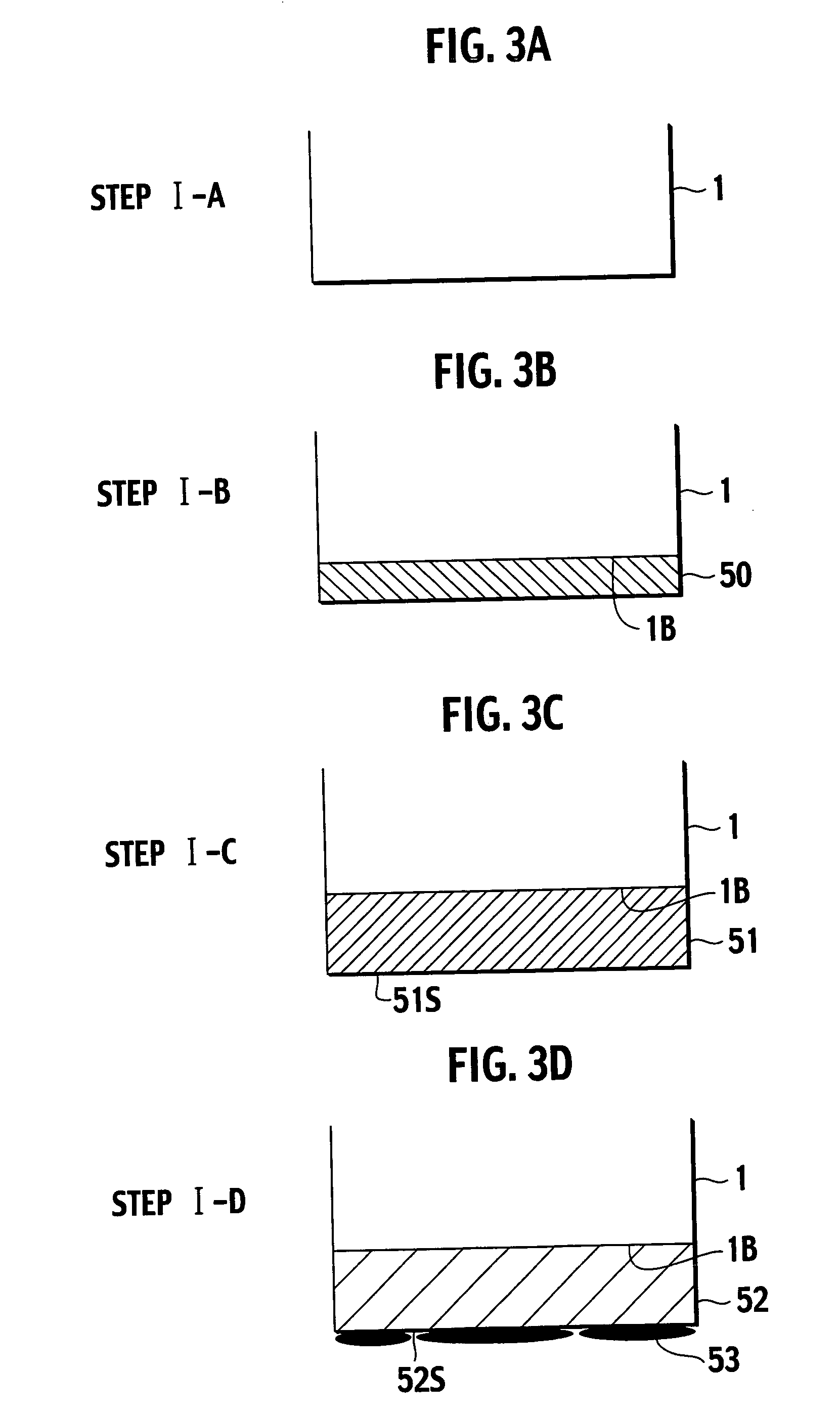

Low-carbon-doped silicon oxide film and damascene structure using same

ActiveUS20050260850A1Reduce electrical circuit lifetimeEnhance moisture intakeSemiconductor/solid-state device detailsSolid-state devicesMetal interconnectDevice material

A method of forming an interconnect for a semiconductor device using triple hard layers, comprises: forming a first hard layer serving as an etch stop layer on a metal interconnect-formed dielectric layer; forming a second hard layer on the first hard layer; forming a dielectric layer on the second hard layer; forming a third hard layer on the dielectric layer; forming a hole through the third and second hard layers, the dielectric layer, and the first hard layer; and filling the hole with metal to establish an interconnect. The second and third hard layers are each made of carbon-doped silicon oxide formed from a source gas and a redox gas, while controlling the carbon content in the second hard layer as a function of a flow rate of the redox gas.

Owner:ASM JAPAN

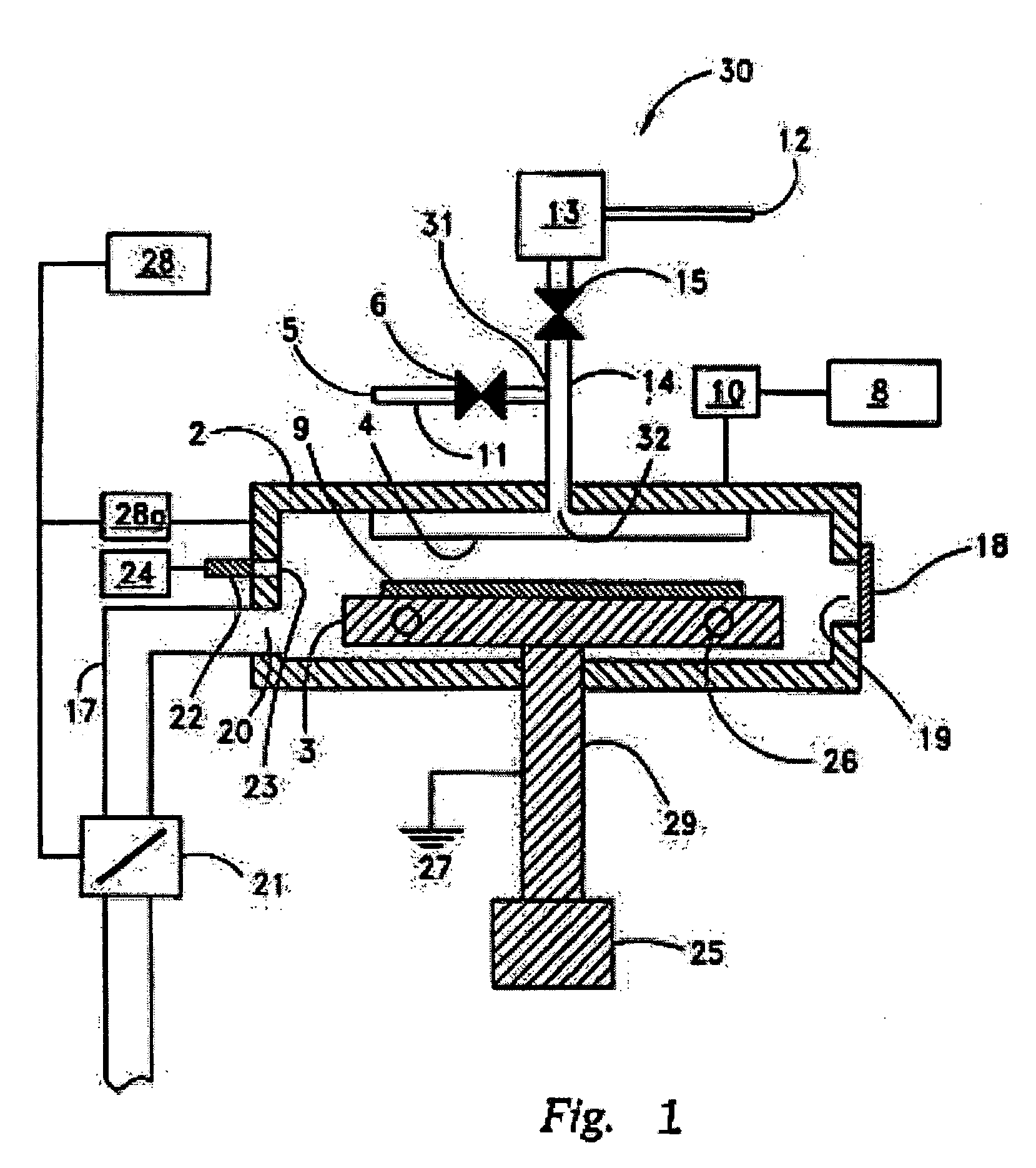

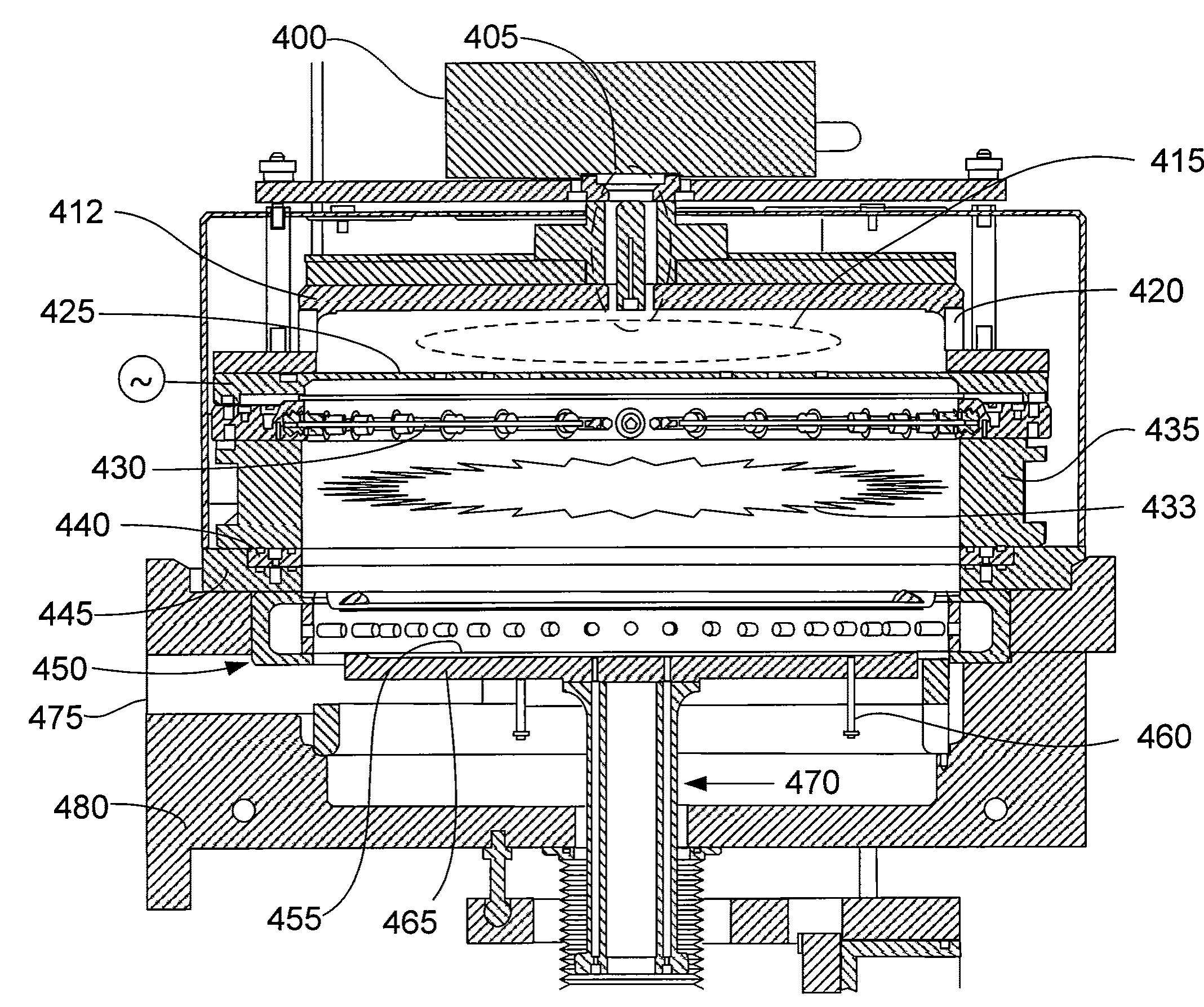

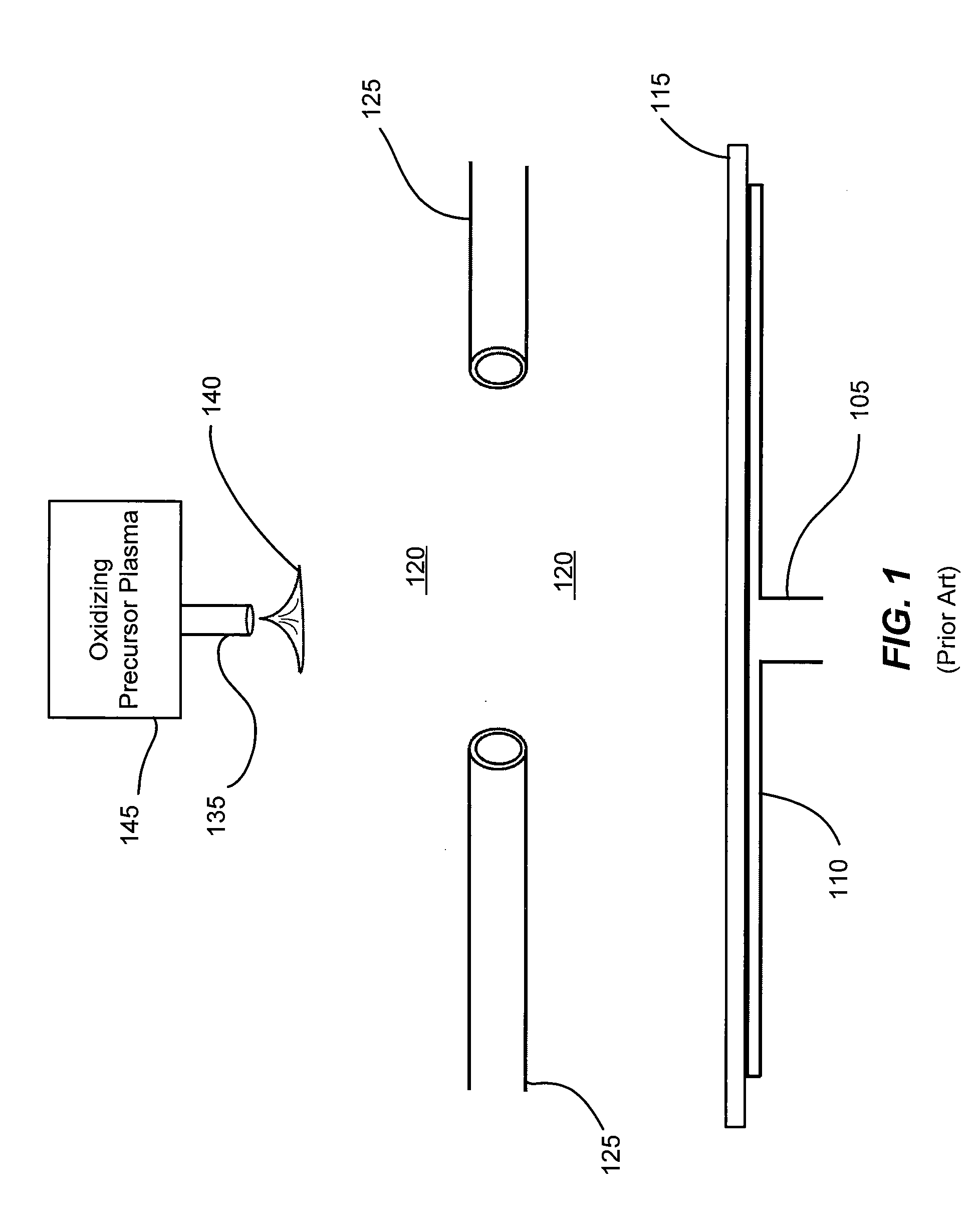

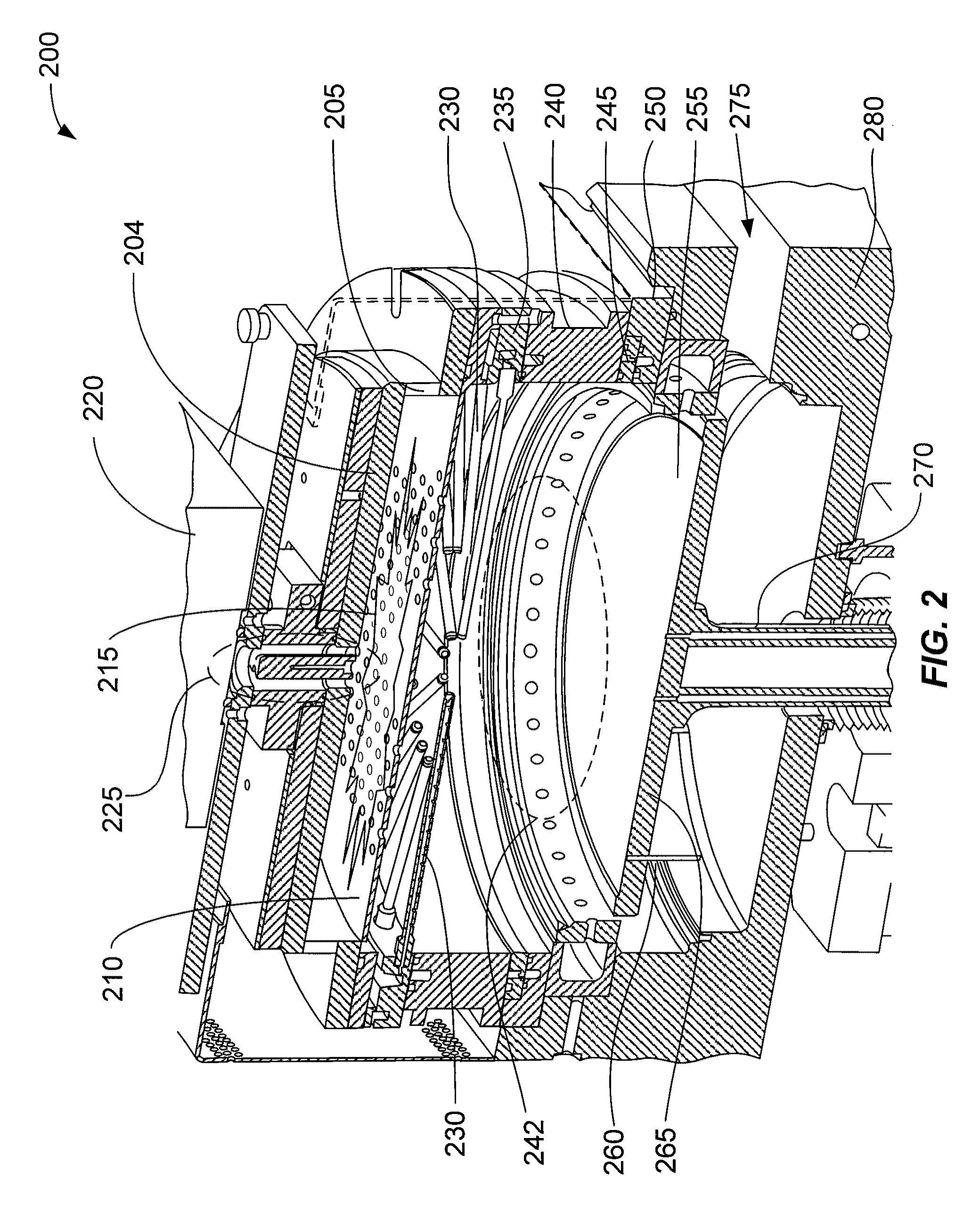

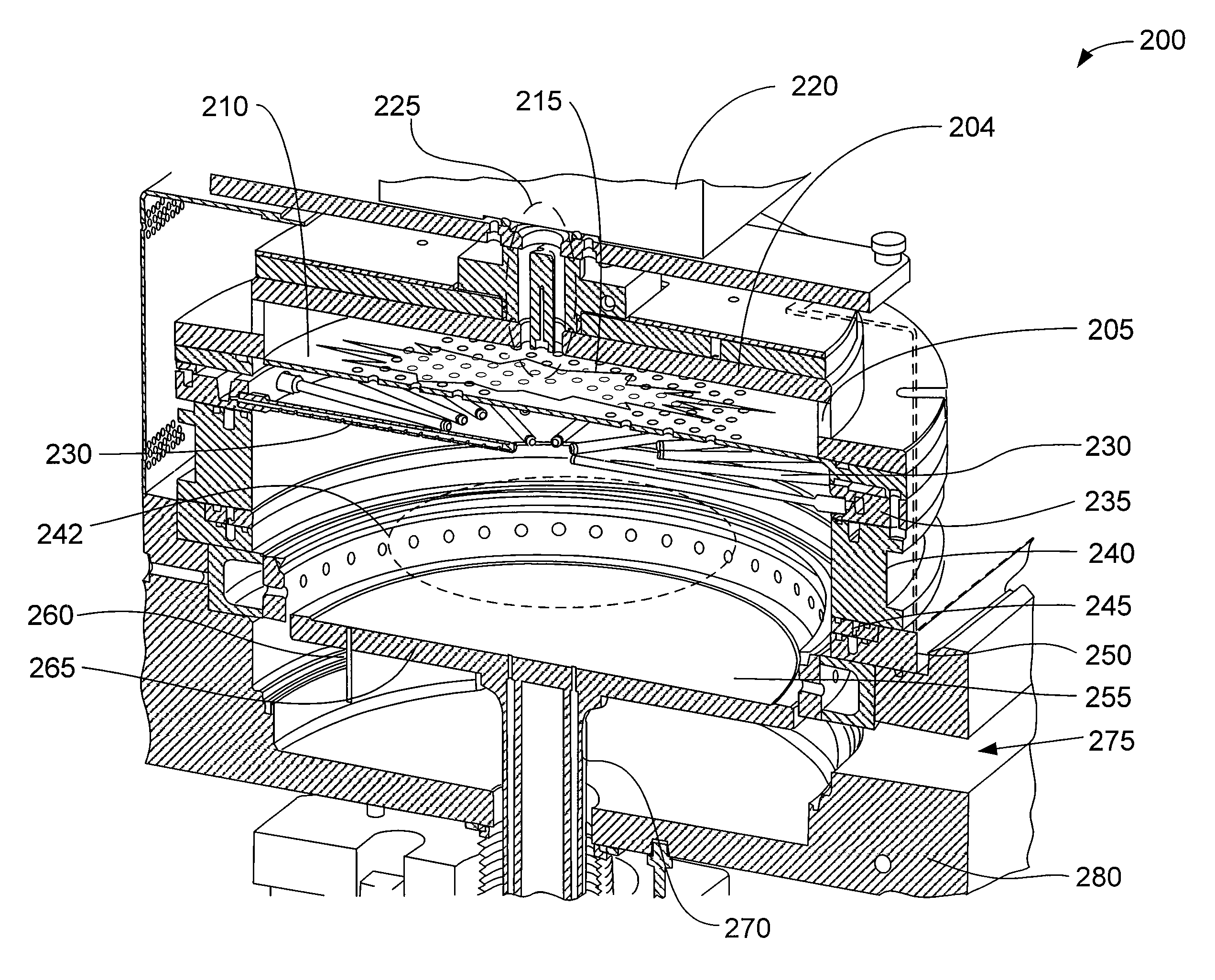

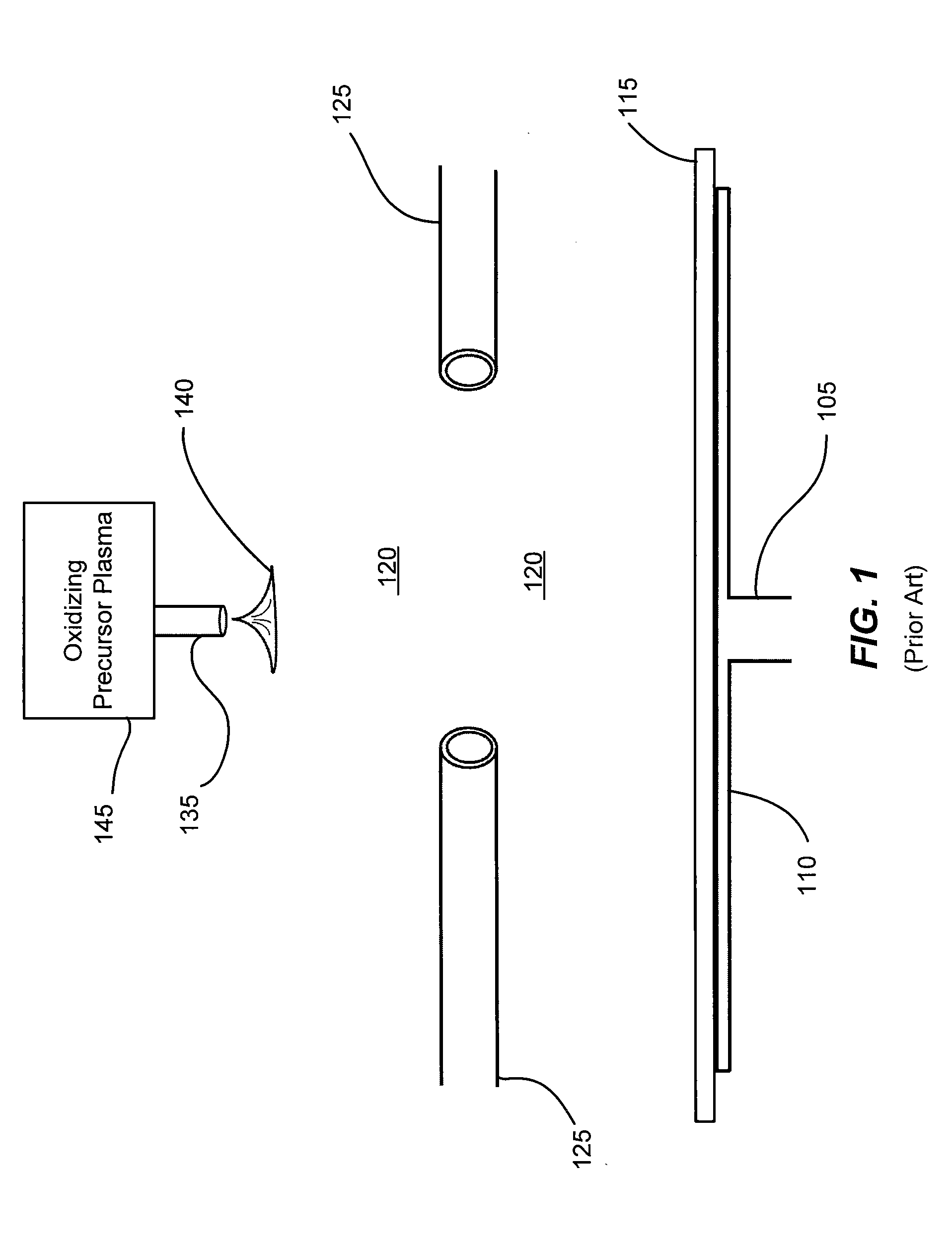

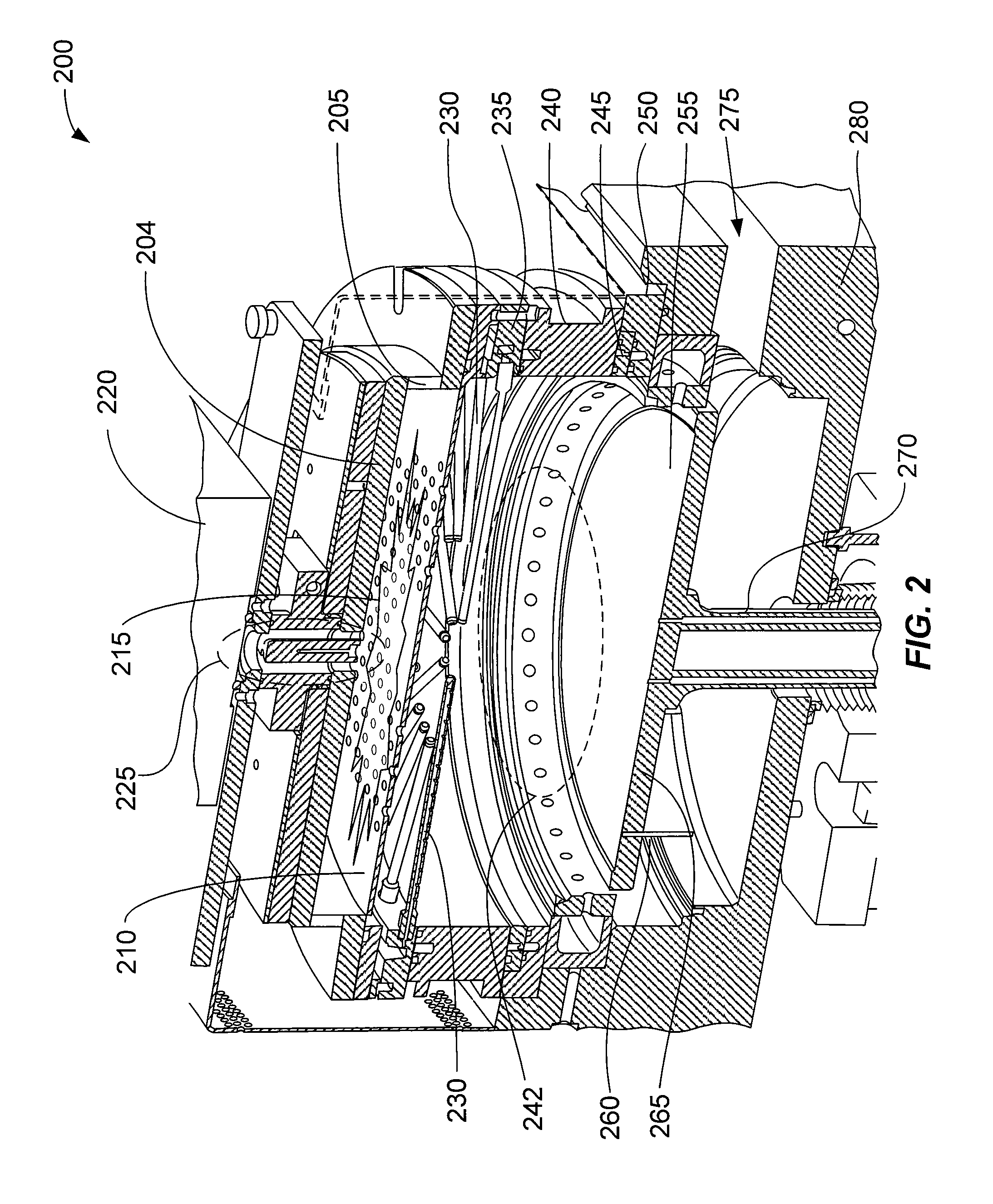

Flowable dielectric equipment and processes

ActiveUS20090280650A1Reduce carbon contentReduce fluorine contentElectric discharge tubesDecorative surface effectsDielectric layerMaterials science

Methods of depositing and curing a dielectric material on a substrate are described. The methods may include the steps of providing a processing chamber partitioned into a first plasma region and a second plasma region, and delivering the substrate to the processing chamber, where the substrate occupies a portion of the second plasma region. The methods may further include forming a first plasma in the first plasma region, where the first plasma does not directly contact with the substrate, and depositing the dielectric material on the substrate to form a dielectric layer. One or more reactants excited by the first plasma are used in the deposition of the dielectric material. The methods may additional include curing the dielectric layer by forming a second plasma in the second plasma region, where one or more carbon-containing species is removed from the dielectric layer.

Owner:APPLIED MATERIALS INC

Flowable dielectric equipment and processes

InactiveUS20090277587A1Reduce carbon contentReduce fluorine contentElectric discharge tubesSemiconductor/solid-state device manufacturingRemote plasmaProcess engineering

Substrate processing systems are described that may include a processing chamber having an interior capable of holding an internal chamber pressure different from an external chamber pressure. The systems may also include a remote plasma system operable to generate a plasma outside the interior of the processing chamber. In addition, the systems may include a first process gas channel operable to transport a first process gas from the remote plasma system to the interior of the processing chamber, and a second process gas channel operable to transport a second process gas that is not treated by the remote plasma system. The second process gas channel has a distal end that opens into the interior of the processing chamber, and that is at least partially surrounded by the first process gas channel.

Owner:APPLIED MATERIALS INC

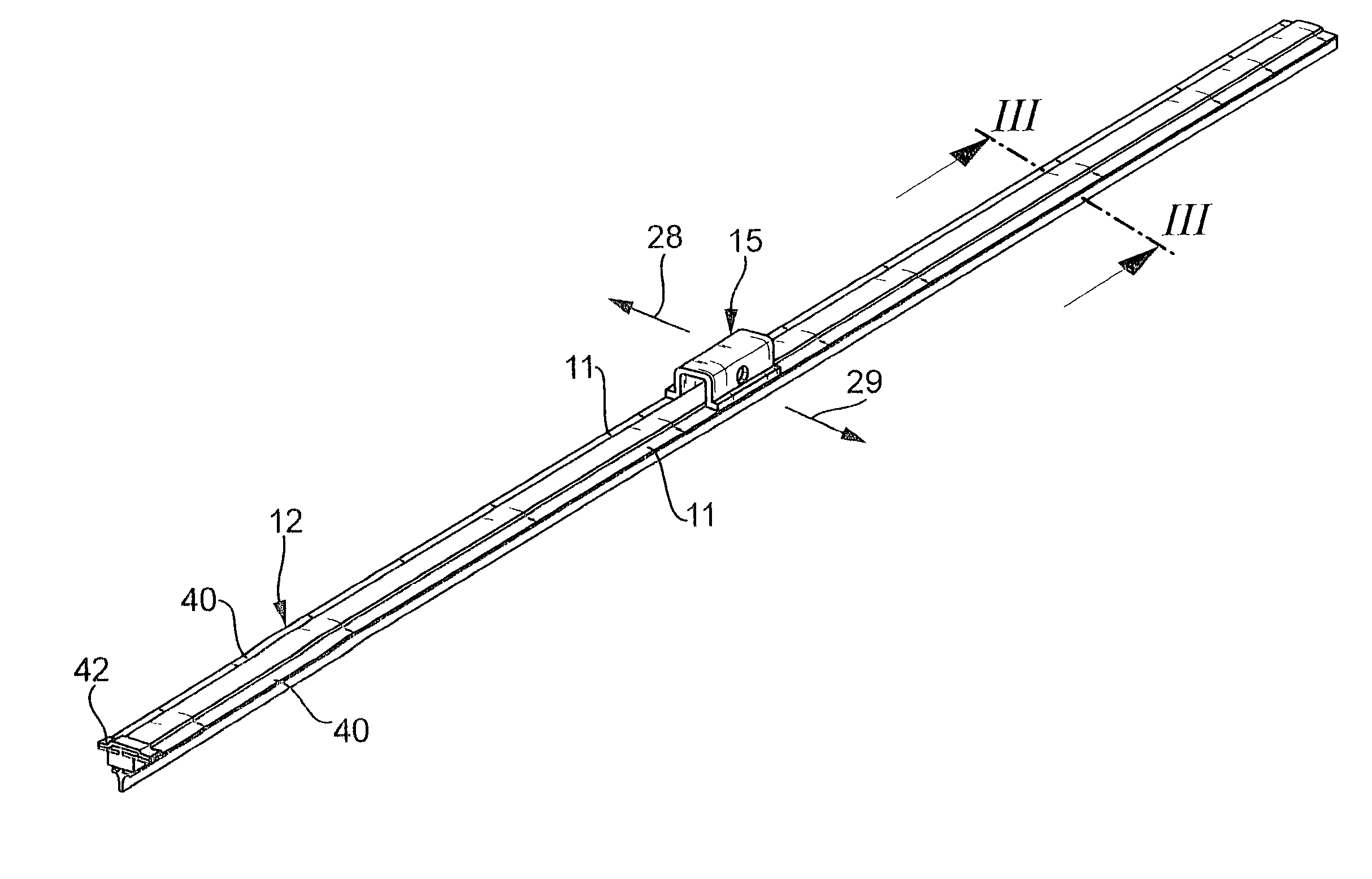

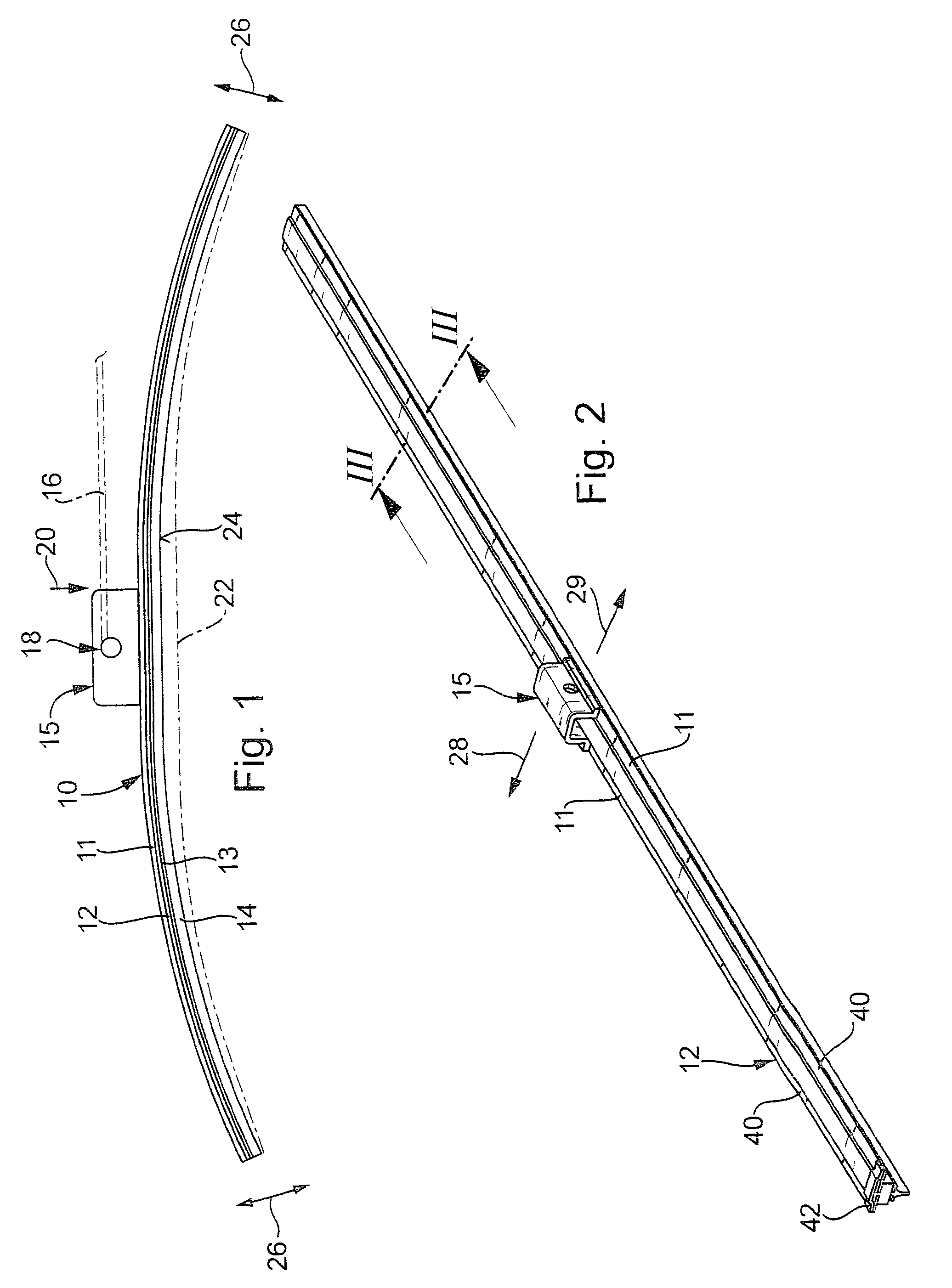

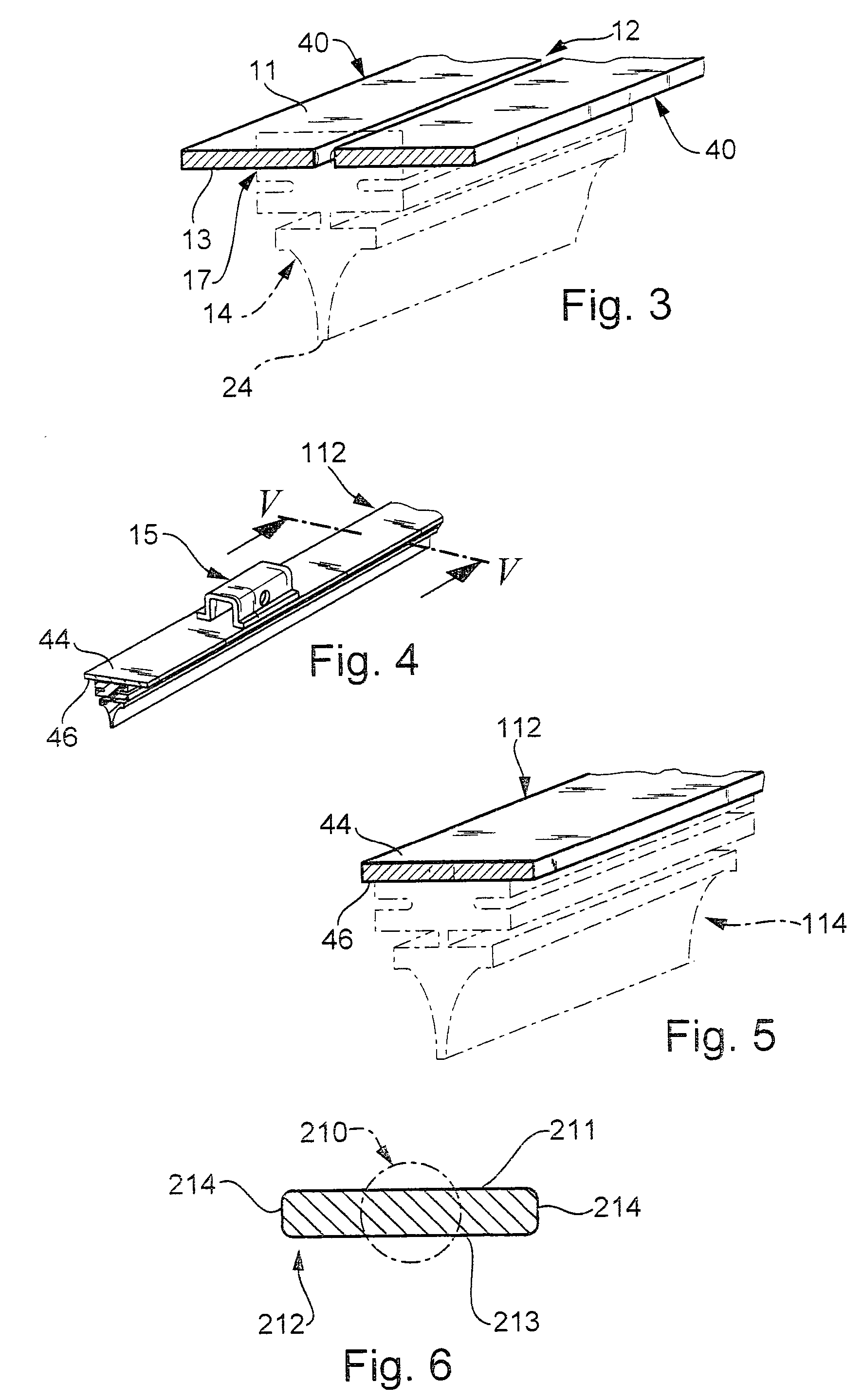

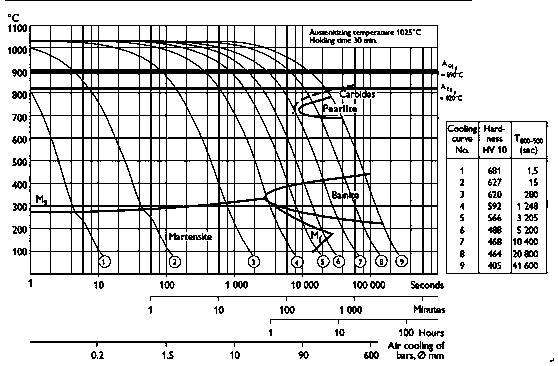

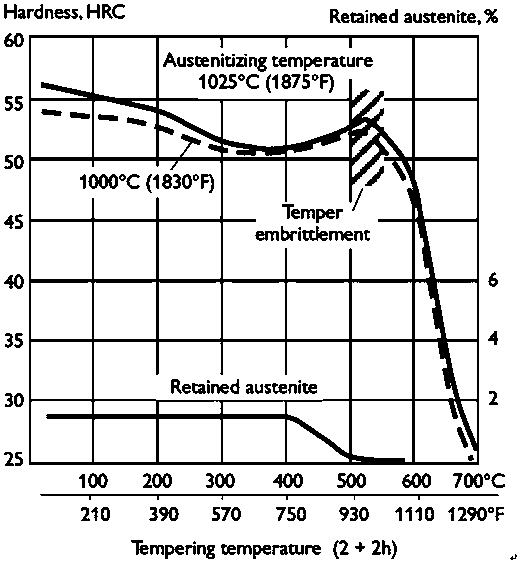

Wiper blade for cleaning glass panes, especially of motor vehicles, and method for the production of said wiper blade

InactiveUS20040025280A1Reduce adverse effectsImprove hardenabilityWindow cleanersVehicle cleaningMobile vehicleSulfur

A wiper blade is proposed for cleaning windows, especially of motor vehicles, is proposed, which is provided with an elongated, rubber-elastic wiper strip that can be placed against the window, which wiper strip is disposed on the lower band face (13), oriented toward the window, of a bandlike-elongated support element (12) made from a spring-elastic steel, on whose other, upper band face (11) facing away from the middle, particularly in the middle portion of the support element, a device (15) for connecting the wiper blade to the free end, urged toward the window, of a driven wiper arm (16) guided on the motor vehicle is welded. It has proved particularly advantageous, in view of the demands made of the support element, if the support element is made from an alloyed quenched and tempered steel, which has the following alloy components: carbon (C), 0.18% to 0.36%; silicon (Si), 0.40% to 0.50 %; manganese (Mn), 1.10 % to 1.80%; phosphorus (P), 0.015% to 0.035%; and sulfur (S), 0.035% to 0.04%.

Owner:ROBERT BOSCH GMBH

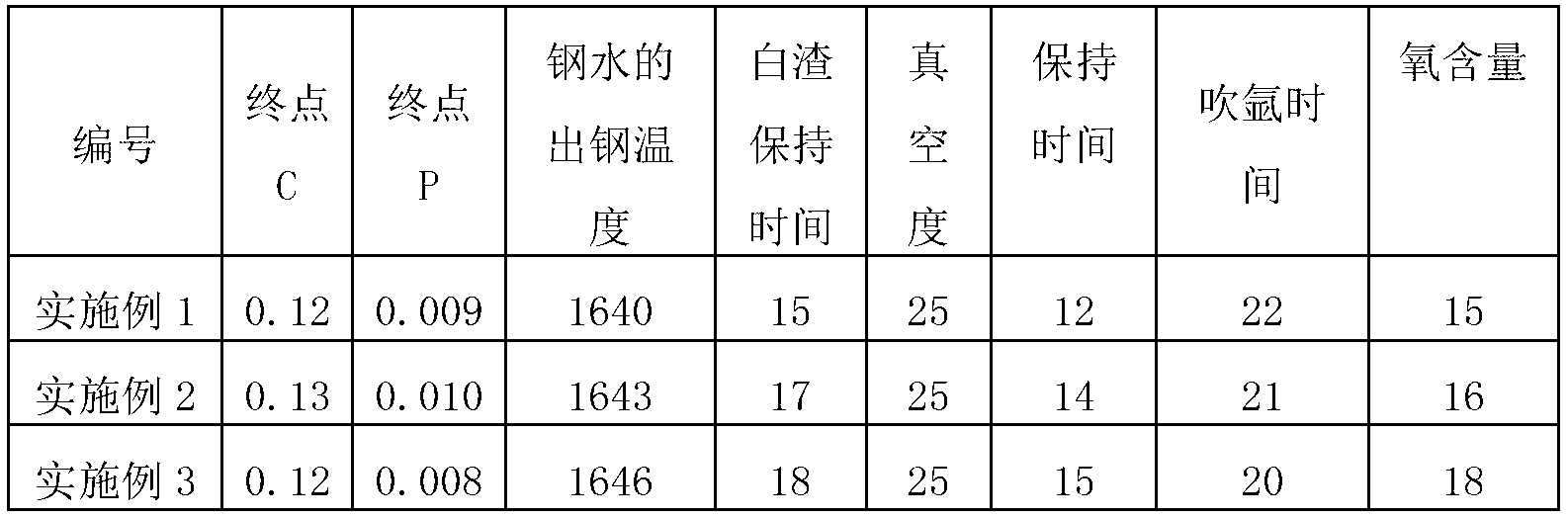

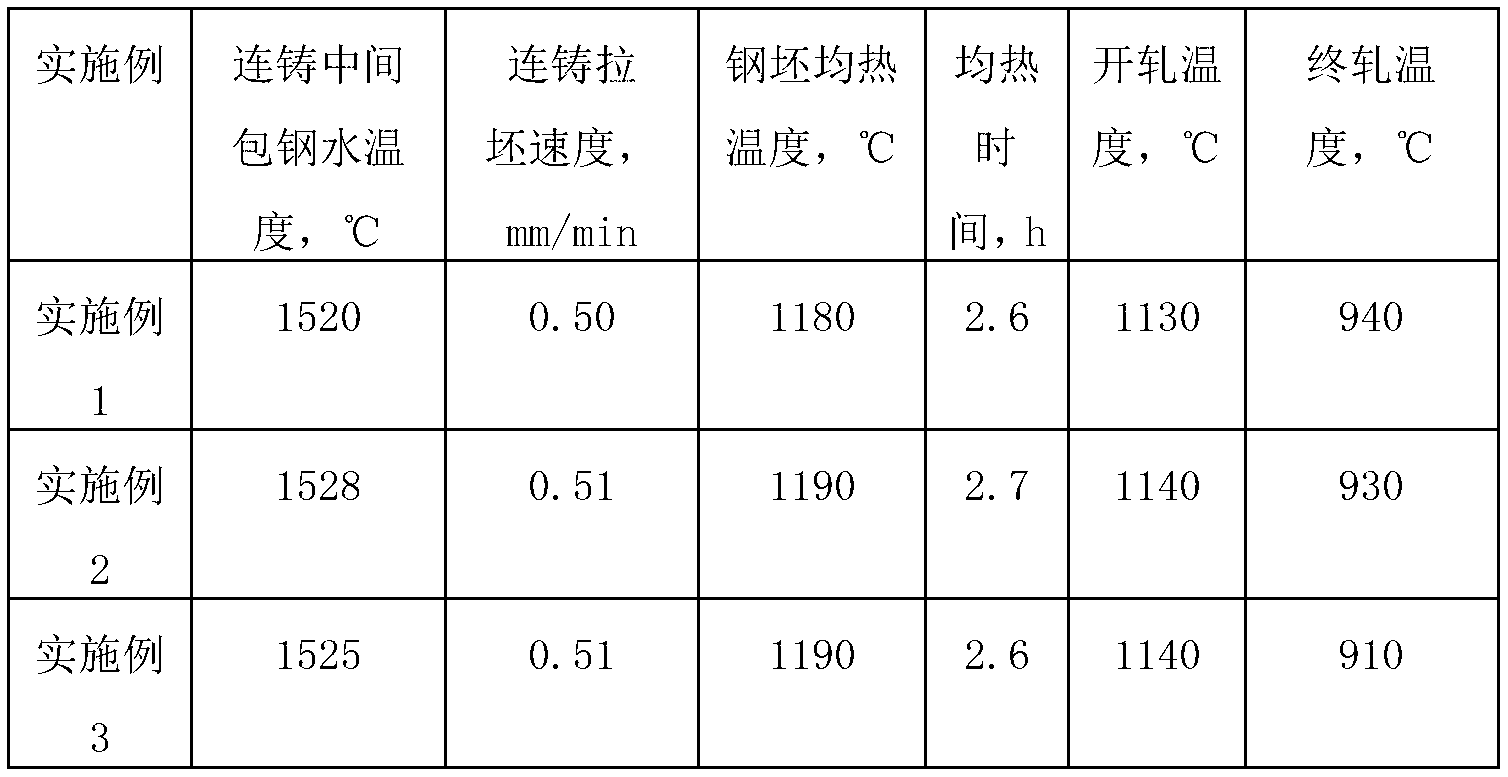

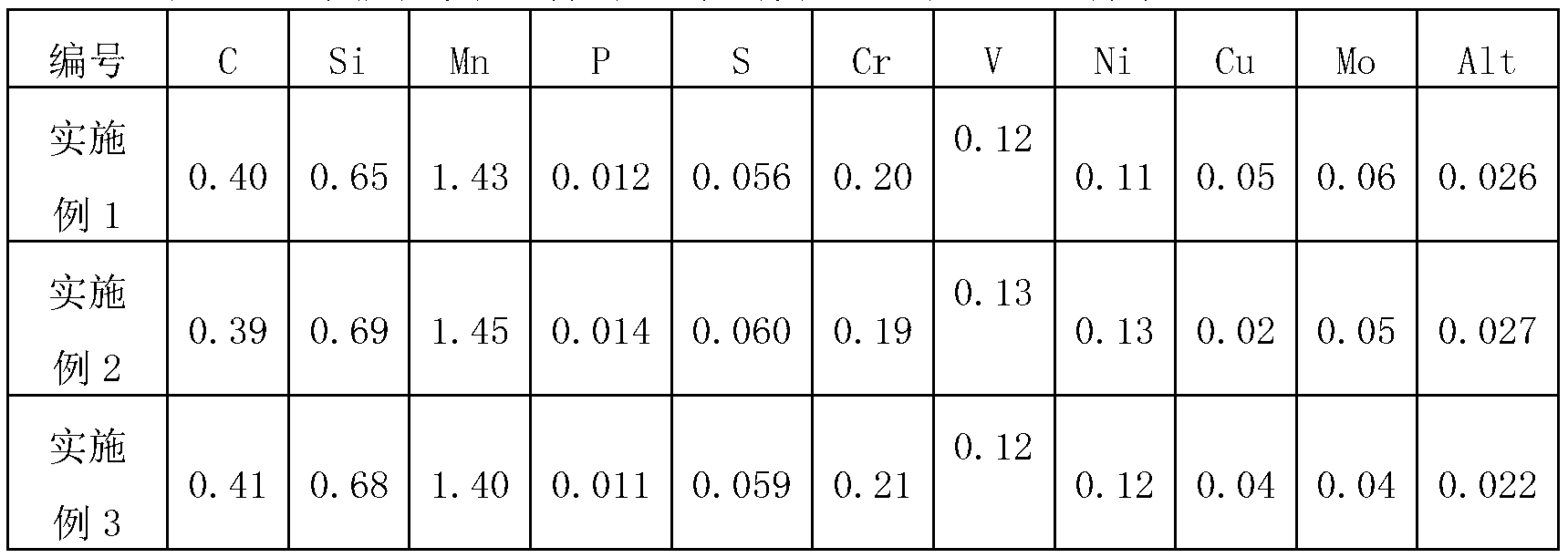

Medium-carbon ferrite-pearlite non-quenched and tempered steel and manufacturing method thereof

ActiveCN103266287AHigh strengthImprove toughnessTemperature control deviceProcess efficiency improvementQuenchingToughness

The invention relates to a medium-carbon ferrite-pearlite non-quenched and tempered steel which comprises the following components in percentage by weight: 0.35-0.43% of C, 0.30-0.80% of Si, 1.00-1.60% of Mn, 0.10-0.30% of Cr, 0.06-0.20% of V, 0.10-0.30% of Ni, at most 0.035% of P, 0.040-0.075% of S, 0.010-0.060% of Alt, 100-200*10<-4>% of N, and the balance of Fe and inevitable impurities. The medium-carbon ferrite-pearlite non-quenched and tempered steel has the characteristics of high strength and high toughness, and the plasticity of the hot rolled steel can still achieve the level of 40Cr or 40MnB quenched and tempered steel under the condition of no quenching and tempering treatment. The invention also relates to a manufacturing method of the medium-carbon ferrite-pearlite non-quenched and tempered steel.

Owner:LAIWU IRON & STEEL GRP

Method for smelting ultra-low carbon steel

ActiveCN102719593AHigh carbon contentReduce carbon contentManufacturing convertersProcess efficiency improvementHigh carbonSlag

The invention provides a method for melting ultra-low carbon steel. The method adopts a desulfuration of molten iron-converter-RH-continuous casting process, wherein a sulfur content in the molten iron is 0.002%-0.006% after desulphurization; converter smelting controls oxygen blowing time, an oxygen gun flow, a bottom-blowing intensity and a smelting period, adopts slag-stopping tapping, steel tapping with a content of C being 0.06%-0.08% and with a temperature of 1650-1680 DEG C, and an oxygen content in the molten iron is 0.03%-0.05%; an RH adopts forced decarburization with a highest vacuum degree of 67-100 MPa and decarburization time of 15-27 min, and a carbon content in the molten iron is 0.0010%-0.0020% and a dissolved oxygen content in the molten iron is 0.025%-0.040% after the decarburization; the molten iron is recycled for 3-5 min after deoxidation by adding aluminium and recycled for another 3-5 min after adding other alloys; a nitrogen content in the molten iron is 0.0015%-0.0035%, and the temperature is 1590-1640 DEG C; and killed steel treatment is carried out for 10-30 min. The method adopts converter tapping with a high carbon and low oxygen content, can use less or not use slag modified agents during the tapping process, accelerates the production rhythm, makes the molten steel cleaner, and reduces the production cost.

Owner:ANGANG STEEL CO LTD

Low carbon magnesia carbon brick and preparation method thereof

The invention relates to the technical field of magnesia carbon brick refractory materials, in particular to a low carbon magnesia carbon brick and a preparation method thereof. The technical proposal comprises the following steps: mixing 58 to 70 weight percent of magnesite grains, 20 to 28 weight percent of magnesite fine powder, 0.5 to 5 weight percent of expansion graphite, 0 to 6 weight percent of crystalline flake graphite, 1 to 5 weight percent of antioxidant, 0.1 to 5 weight percent of metal fibre and 1.5 to 4.5 weight percent of phenolic resin; and molding and drying the mixture to prepare a low carbon magnesia carbon brick of which carbon content is between 2 and 7 percent. The low carbon magnesia carbon brick prepared by the invention has the advantages of low heat expansion rate, good scale resistant performance, good high temperature strengthen, good thermal shock resistant performance, good toughness and corrosion resistance, and the brick is not easy to fracture when using.

Owner:JINAN LUDONG REFRACTORY CO LTD

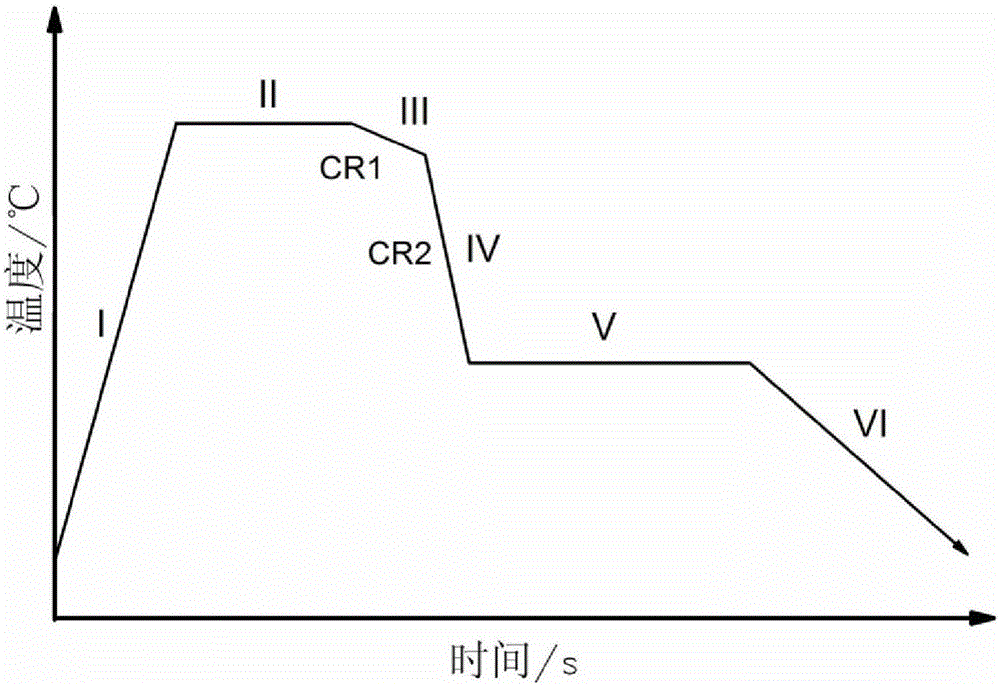

Method for smelting nickel-based high temperature alloy in vacuum induction furnace

The invention relates to a method for smelting a nickel-based high temperature alloy in a vacuum induction furnace. The method sequentially comprises the following steps of: I, putting alloy raw materials into the furnace in a ratio; II, closing a furnace cover, vacuumizing, and performing power transmission to melt furnace burden; III, melting at the speed of less than or equal to 1 / 2 maximum furnace capacity / hour; IV, after the furnace burden is completely melted, starting performing bottom argon blowing, and refining for 20 to 25 minutes; V, stopping argon blowing, adding Al and Ti, and alloying; VI, after Al and Ti are completely melted, performing bottom argon blowing, and refining; VII, after refining is finished, closing a vacuum pump, and filling argon into the furnace and an ingot mold; VIII, alloying at the finishing point, namely adding B, Zr and a rare earth element, and adding a Ni-Mg alloy; and IX, performing electrified tapping after 3 to 4 minutes, and casting into an alloy ingot. By the method for smelting the nickel-based high temperature alloy in the vacuum induction furnace, refining time is 35 to 40 minutes, and the nickel-based high temperature alloy with very low carbon content can be obtained.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

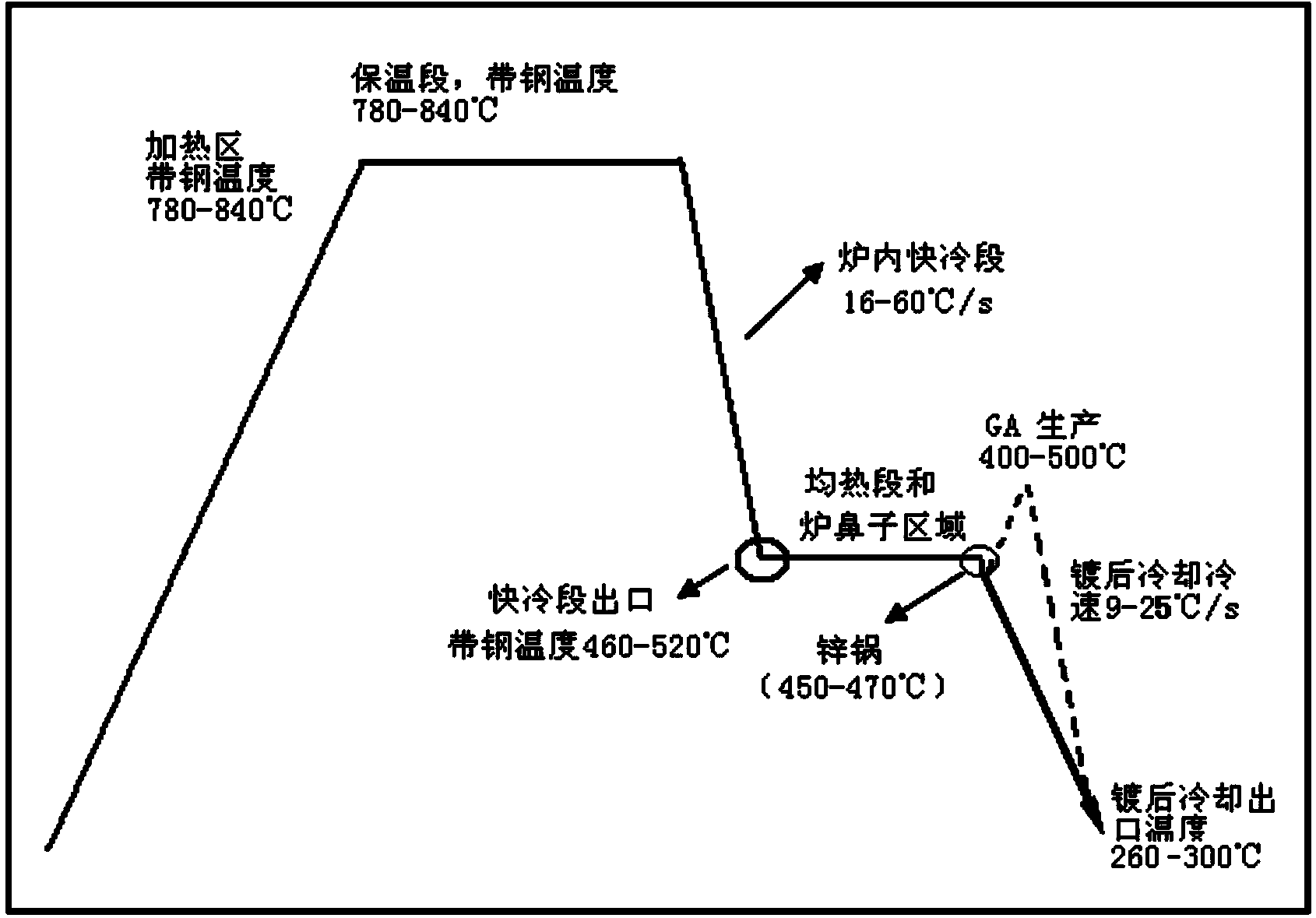

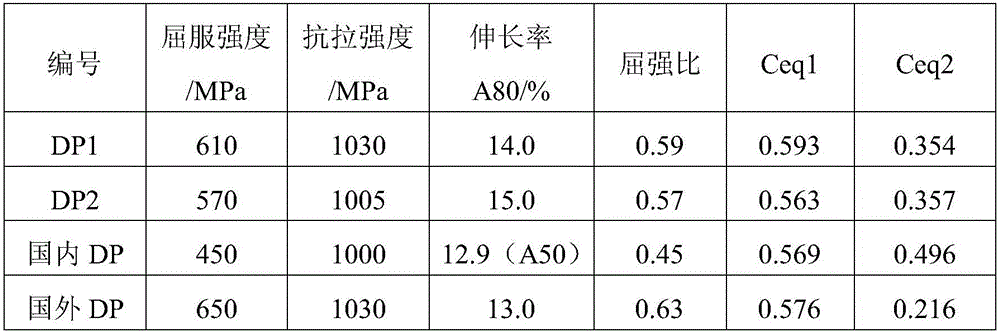

Cold-rolled hot-galvanized dual-phase steel plate with flanging property and manufacturing method thereof

The invention relates to a cold-rolled hot-galvanized dual-phase steel plate with a flanging property and a manufacturing method thereof. The steel plate comprises the following chemical components by weight percent: 0.06% to 0.095% of C, 0.3% to 0.6% of Si, 1.4% to 1.8% of Mn, greater than 0% and less than or equal to 0.02% of P, greater than 0% and less than or equal to 0.01% of S, 0.02% to 0.05% of Al, 0.35% to 0.55% of Cr, 0.02% to 0.04% of Nb, greater than 0% and less than or equal to 0.005% of N and the balance of Fe. According to the steel plate provided by the invention, the austenite is dispersedly distributed in a ferrite matrix via the refining of austenite grains by adding the Nb element and controlling temperatures during hot rolling and finish rolling and a rolling temperature; the amount of the austenite after annealing is increased by limiting the content of C and carrying out high-temperature annealing in a continuous hot-galvanized annealing furnace, so that tissues in low-C martensite are obtained after quenching. Thus, the hardness of the martensite is decreased. As a result, a hardness difference between the martensite phase and the ferrite phase is reduced.

Owner:ANSC TKS GALVANIZING

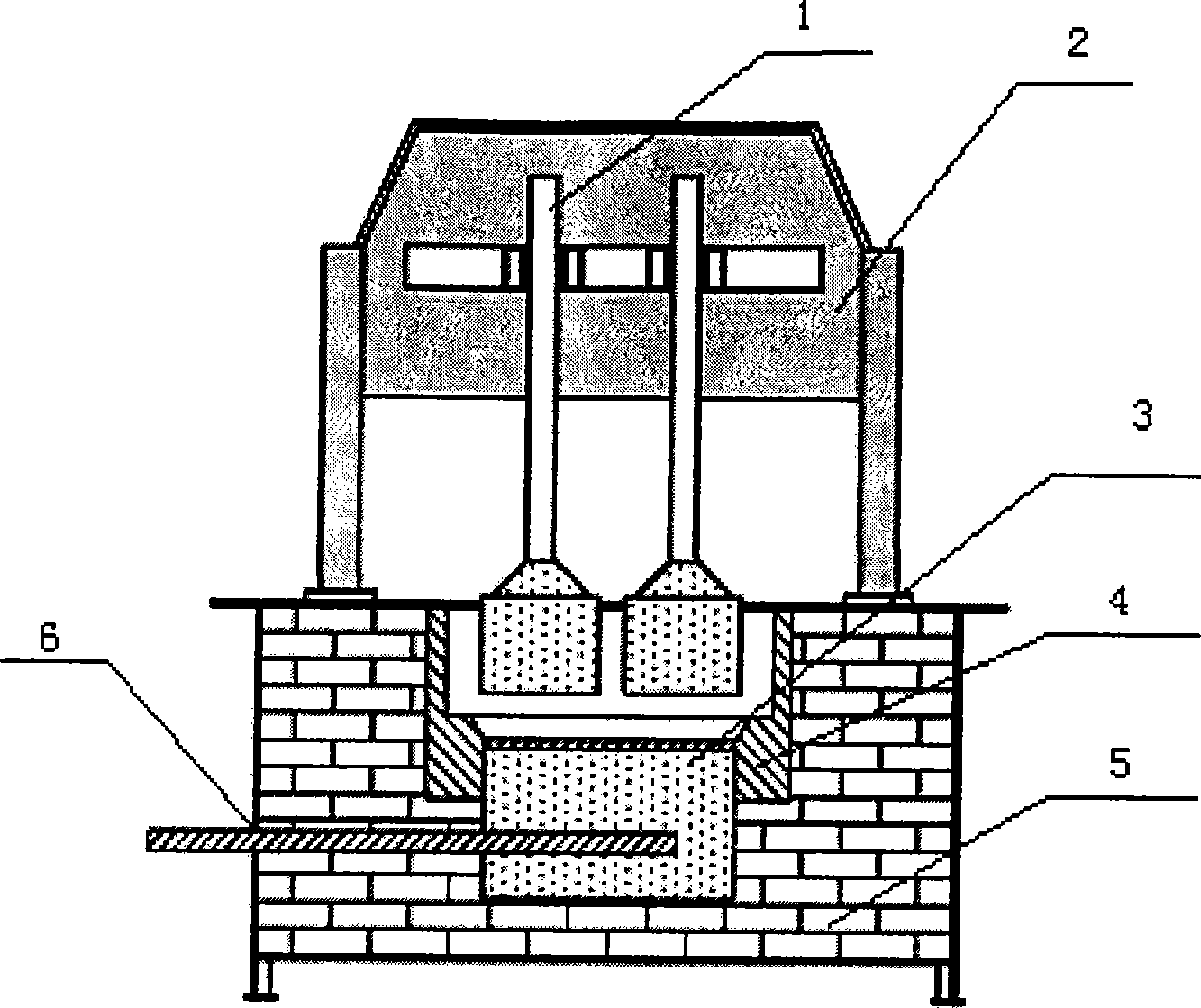

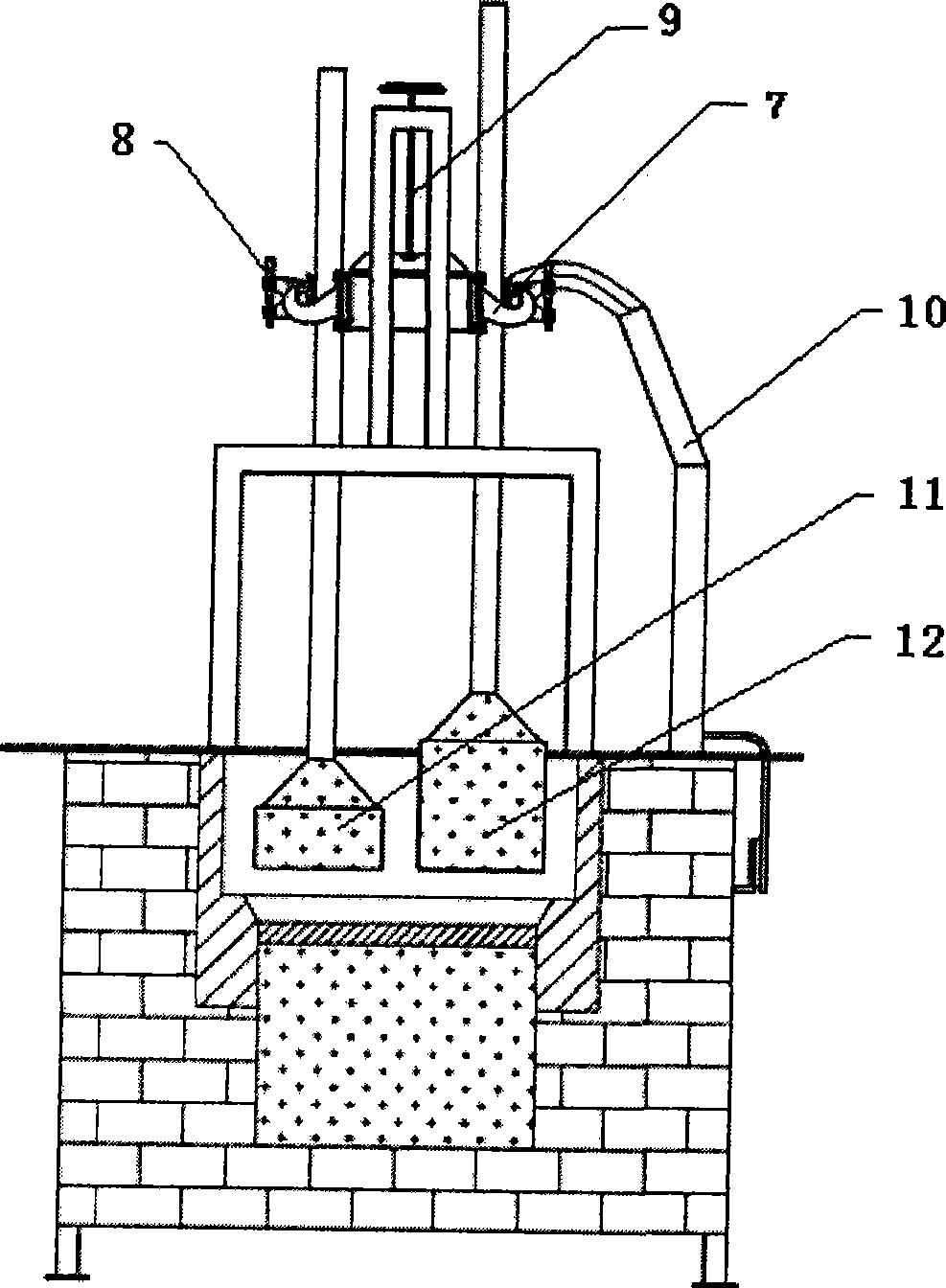

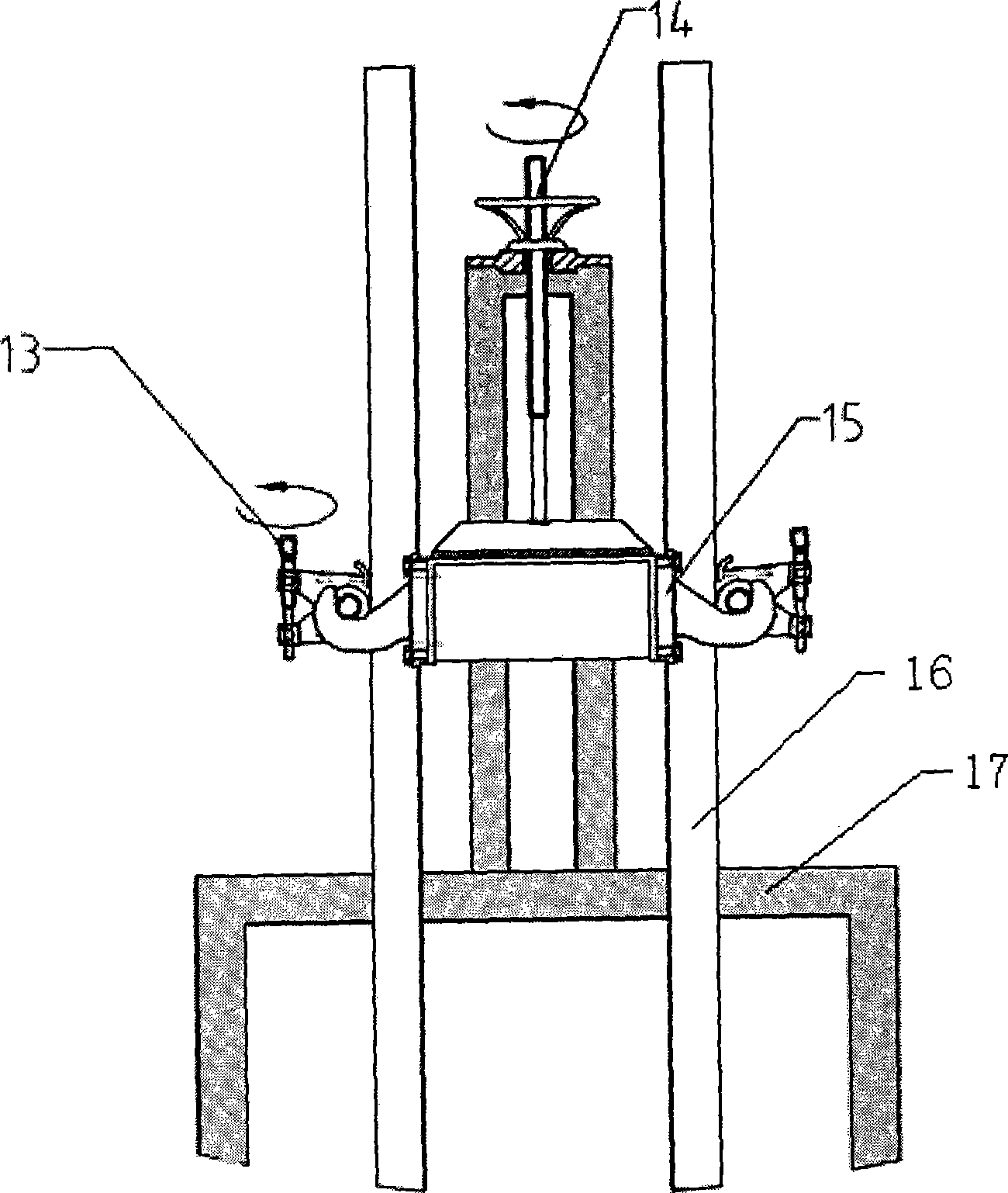

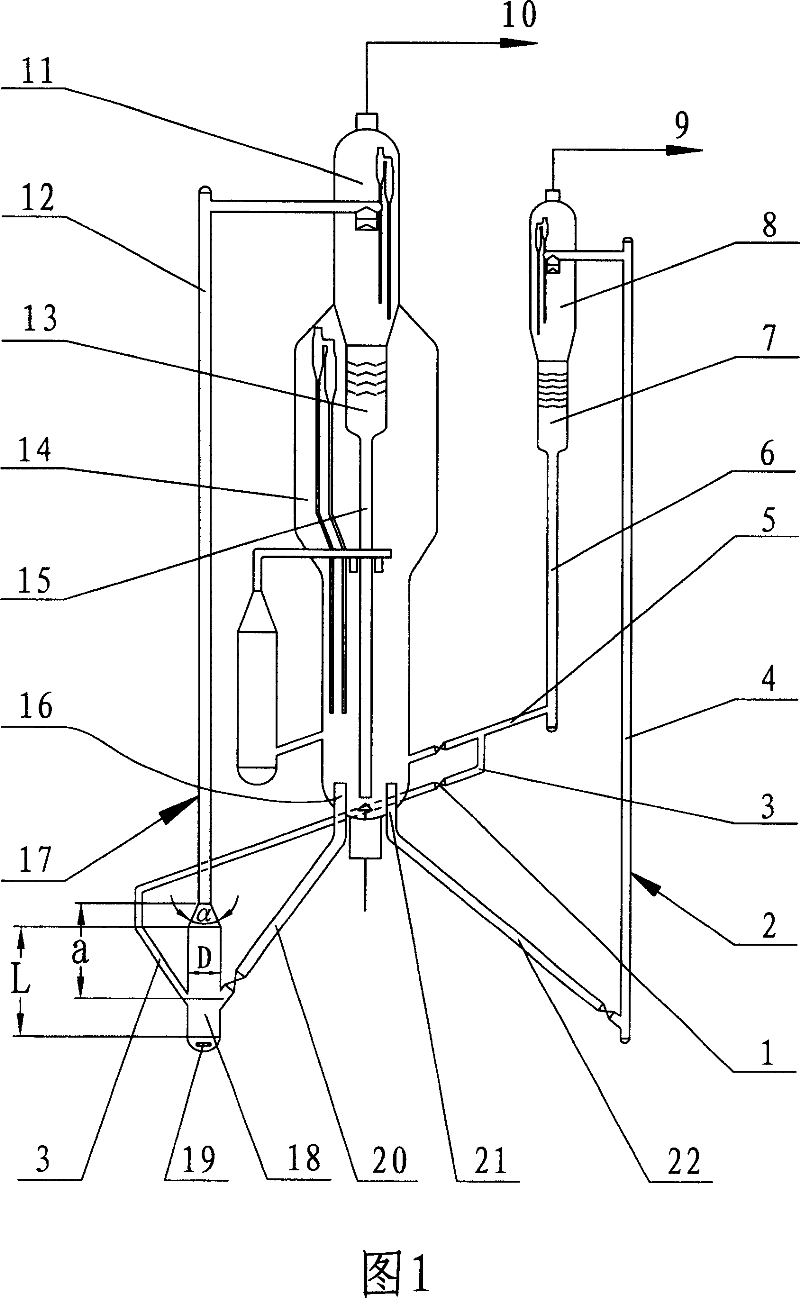

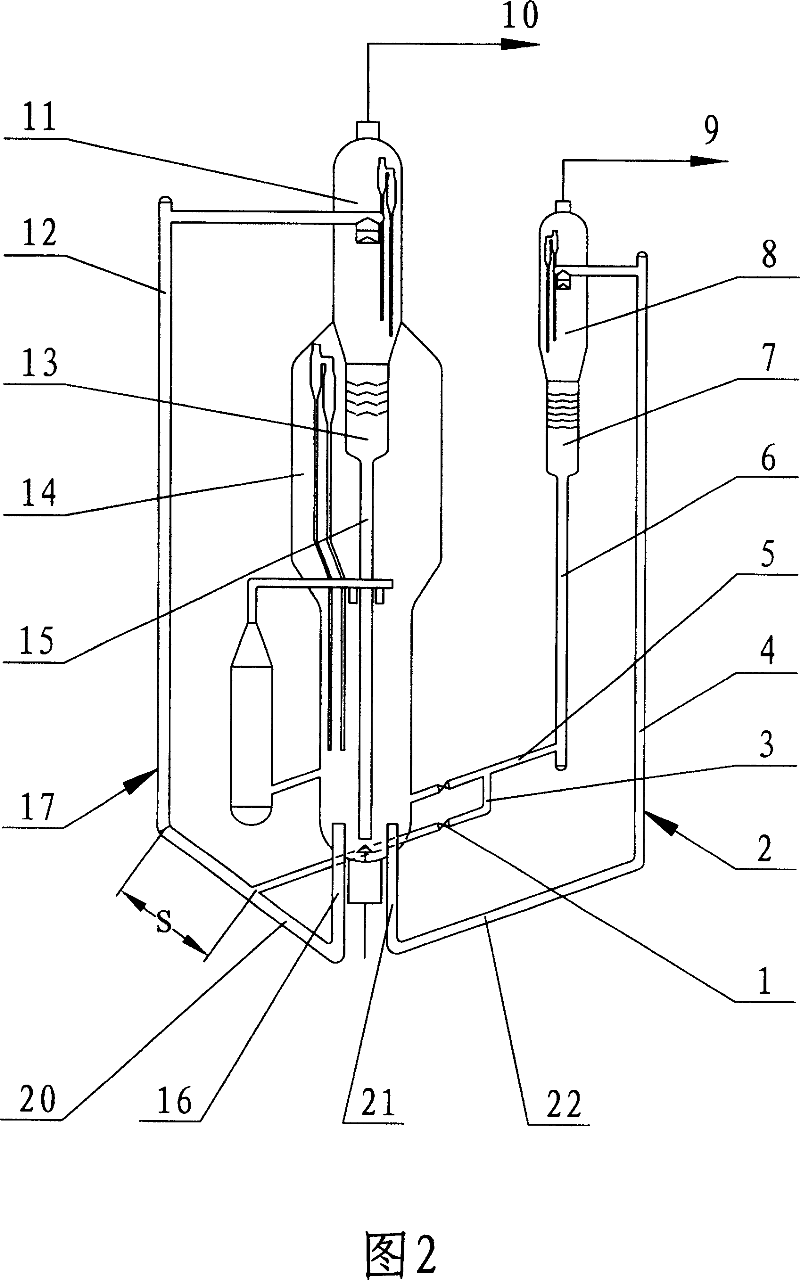

Lower cathode rare earth metal electrolytic tank and electrolysis technique adopting the same

The invention provides a cathode rare earth metal electrobath and an electrolysis technique for using the electrobath. The electrobath comprises an anode and a cathode. The cathode is arranged at the bottom part of the electrobath; the electrolyzed single or mixed metals are collected on the cathode; a liquid metal surface is used as the surface of the cathode; the anode arranged above the cathode is connected with a transmission mechanism; the transmission mechanism adjusts the distance between the cathode and the anode. The electrobath is suitable for electrolyzing in a fluoride electrolyzing system to generate the rare earth elements which include generating single rare earth metals of La, Ce, Pr and Nd as well as the mixed rare earth metals between the elements. The distance between the anode and the cathode can be adjusted at any time; the power operating factor and the current efficiency of the electrobath are high; the effective operating factor of an auxiliary material is high; the service life of the electrobath is longer than that of the prior electrobath; the electrobath is suitable for developing on the aspect of large capacity.

Owner:GRIREM ADVANCED MATERIALS CO LTD

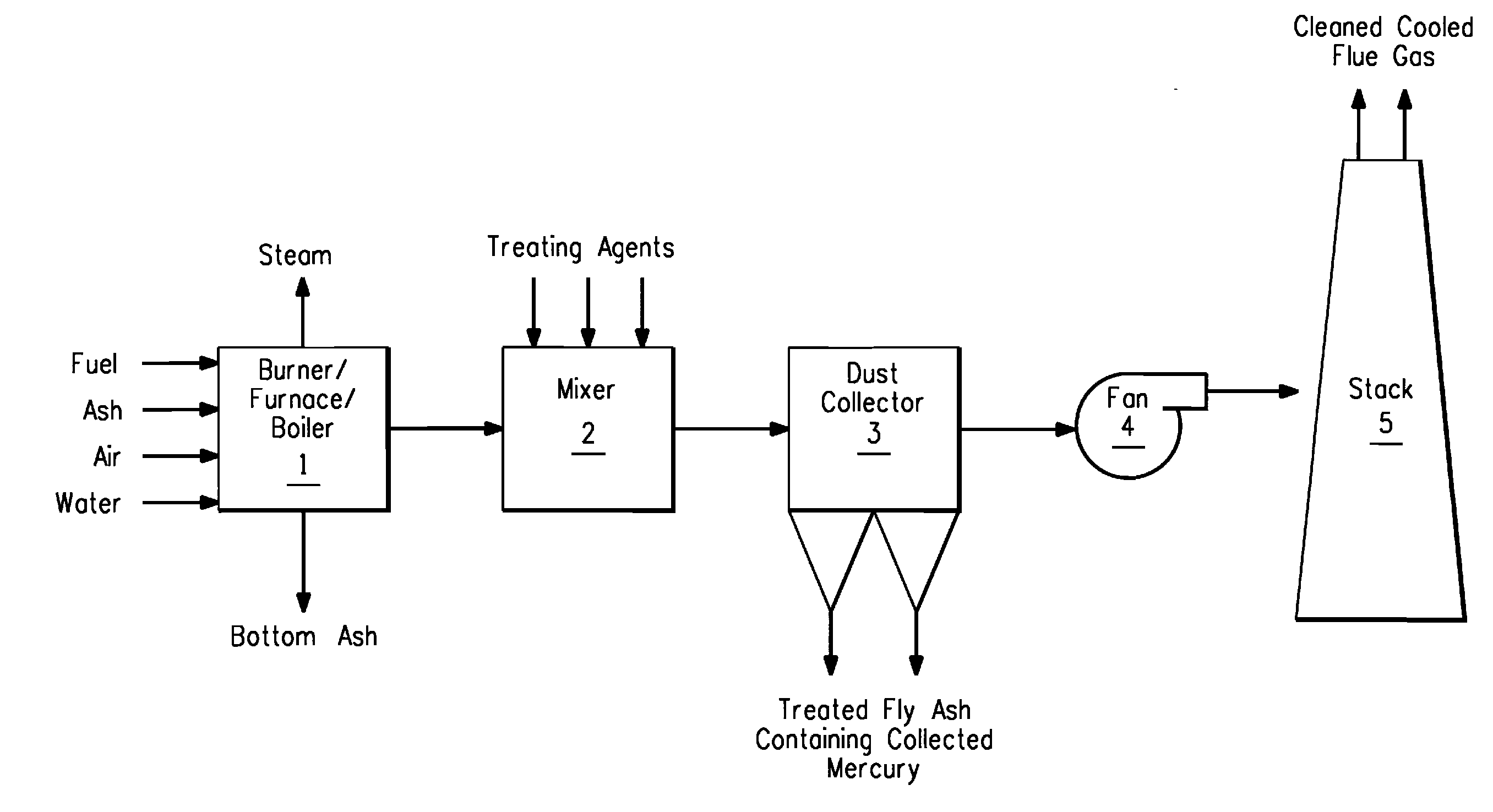

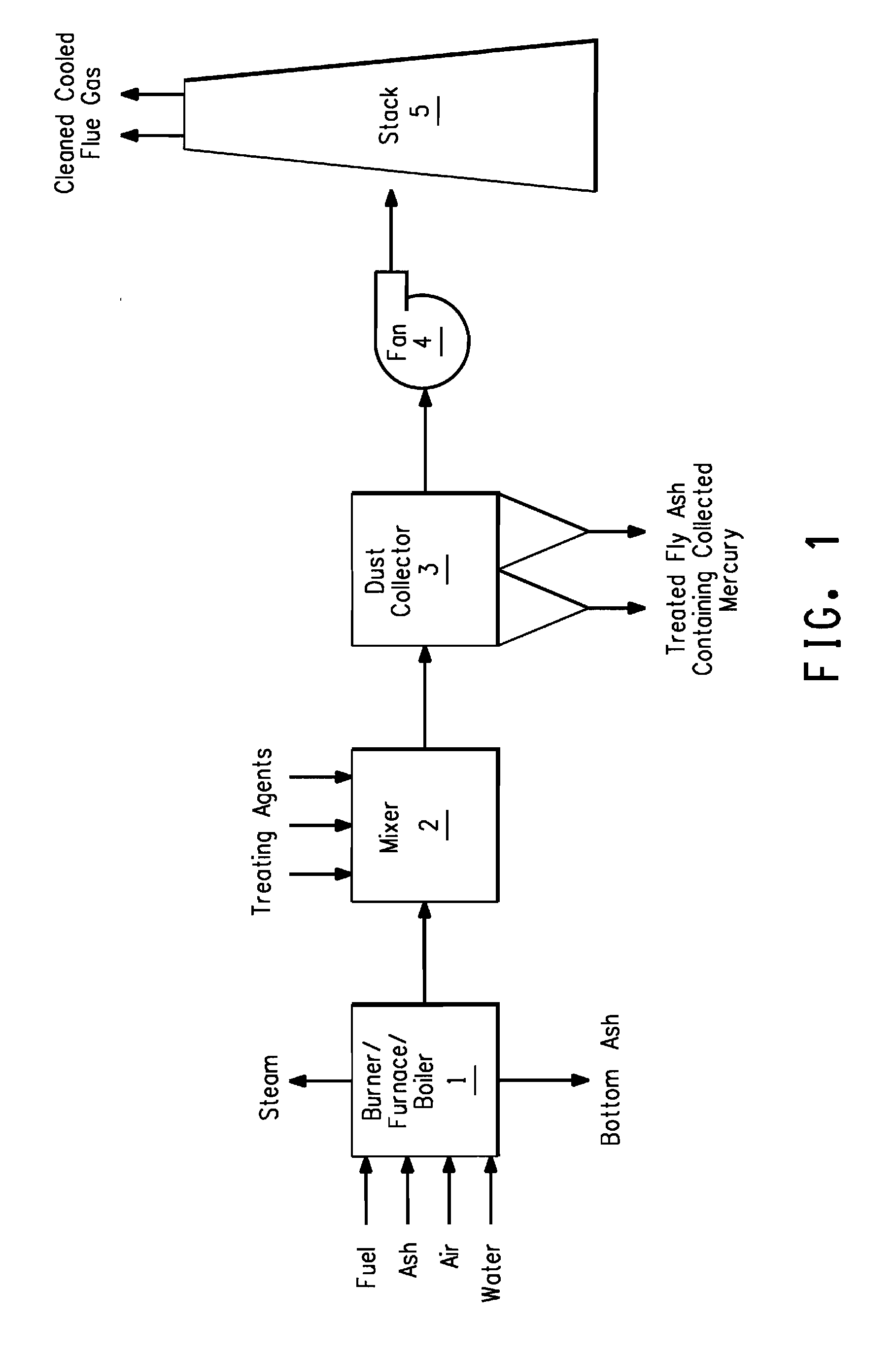

Mercury removal from a gas stream

InactiveUS20090104097A1Reduce LeachabilityReduce carbon contentGas treatmentDispersed particle filtrationOxygenBoric acid

This invention is a novel process for removing volatile mercury from a gas stream to produce a filtered solid. The gas stream is contacted with treating agents which comprise a semivolatile acidic vitrifying compound such as boric acid, water, oxygen-containing gas and a chlorine source. The filtered solids produced in the process have low mercury leachability thereby allowing the solids to be used, for example in flyash-containing concrete.

Owner:EI DU PONT DE NEMOURS & CO

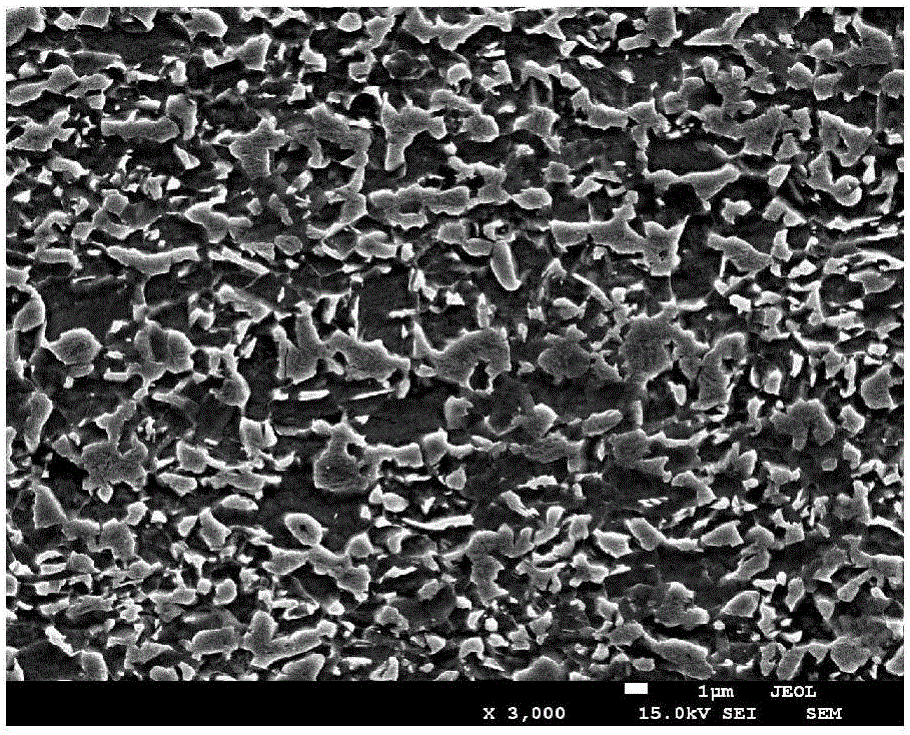

980 MPa-level vanadium-contained ultrafine grain cold rolled dual-phase steel and preparing method thereof

The invention provides 980 MPa-level vanadium-contained ultrafine grain cold rolled dual-phase steel and a preparing method, and belongs to the technical field of cold rolling ultrahigh strength steel for an automobile. The 980 MPa-level vanadium-contained ultrafine grain cold rolled dual-phase steel is composed of, by weight percent, 0.10% to 0.20% of C, 0.30% to 1.00% of Si, 1.50% to 2.50% of Mn, 0.20% to 0.80% of Cr, 0.01% to 0.06% of Al, 0.05% to 0.15% of V, not larger than 0.020% of P, not larger than 0.015% of S, not larger than 0.006% of N and the balance Fe and inevitable impurities. Ferrite and martensite grains are refined through the micro amount of V; and meanwhile, VC dispersed precipitation plays a role in strengthening sedimentation, and the production cost is obviously reduced. The prepared cold rolled dual-phase steel is excellent in mechanical property, forming property and welding property, the cost advantages are obvious, and the obvious economic benefits and social benefits are achieved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Flux-cored wire for austenitic stainless steel welding

ActiveCN102451961AReduce carbon contentImprove oxidation capacityArc welding apparatusWelding/cutting media/materialsManganeseRutile

The invention discloses a flux-cored wire for austenitic stainless steel welding. The flux-cored wire consists of a flux core and an external steel belt; the external steel belt is an austenitic stainless steel belt of which the carbon content is less than 0.025 percent; the carbon content of the flux core is not greater than 0.04 percent and carbon accounts for 18.0 to 24.0 percent based on the total weight of the flux-cored wire; the flux core comprises the following components in percentage by weight: 18.5 to 25.0 percent of metal chromium powder, 8.0 to 10.0 percent of metal nickel powder, 2.0 to 5.0 percent of electrolytic manganese metal, 1.0 to 3.0 percent of aluminum magnesium alloy, 28.0 to 35.0 percent of rutile, 3.0 to 5.0 percent of quartz, 2.0 to 5.0 percent of zircon sand, 2.0 to 5.0 percent of feldspar, 1.0 to 2.0 percent of cryolite, 2.0 to 5.0 percent of arc stabilizer and the balance of iron powder; and the arc stabilizer consists of K2O, Na2O and TiO2 in a weight ratio of (6.0-8.0):(8.0-10.0):(68.0-70.0), and the water content is not greater than 400 ppm.

Owner:CHINA JINGYE ENG TECH CO LTD +1

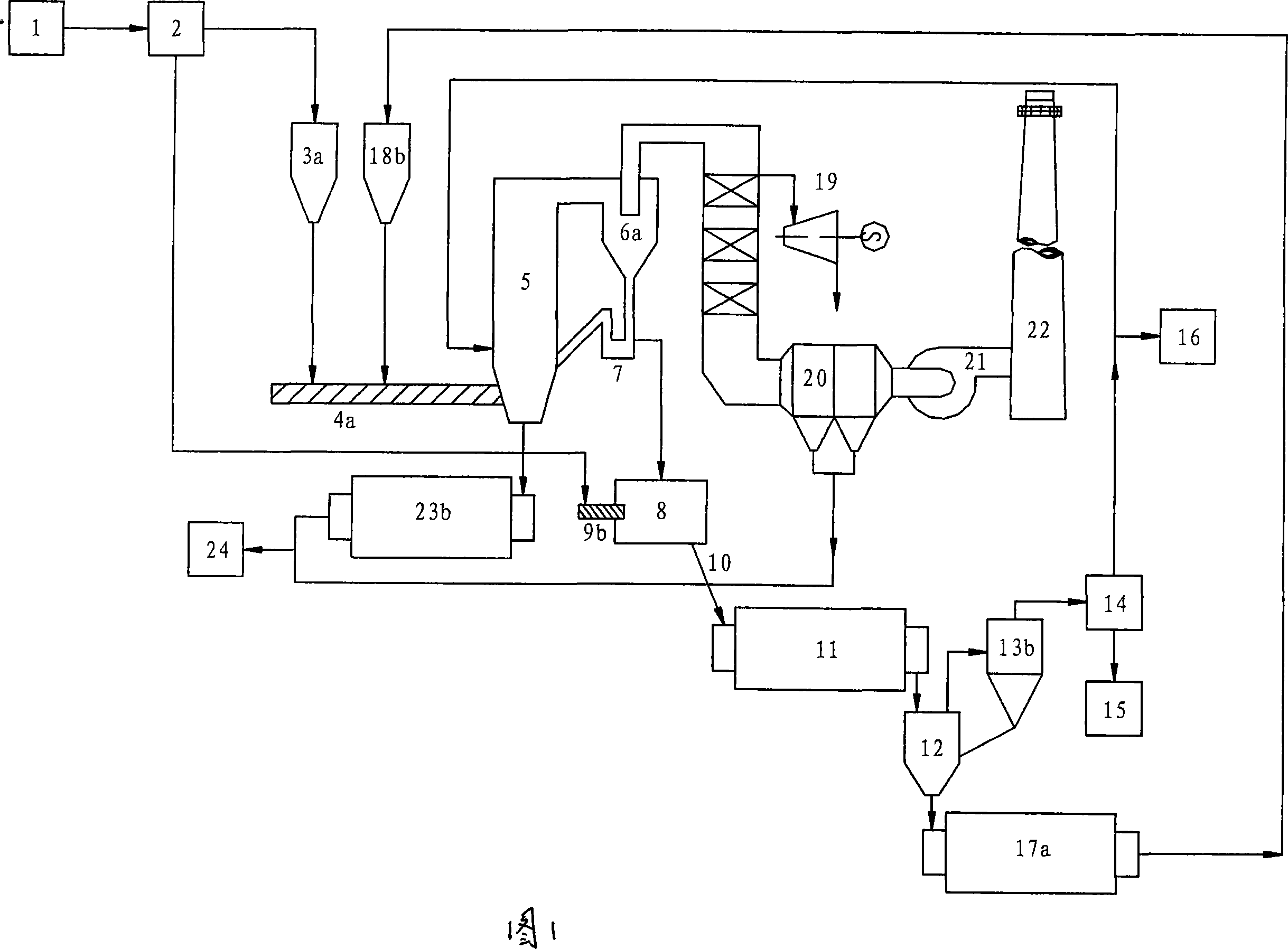

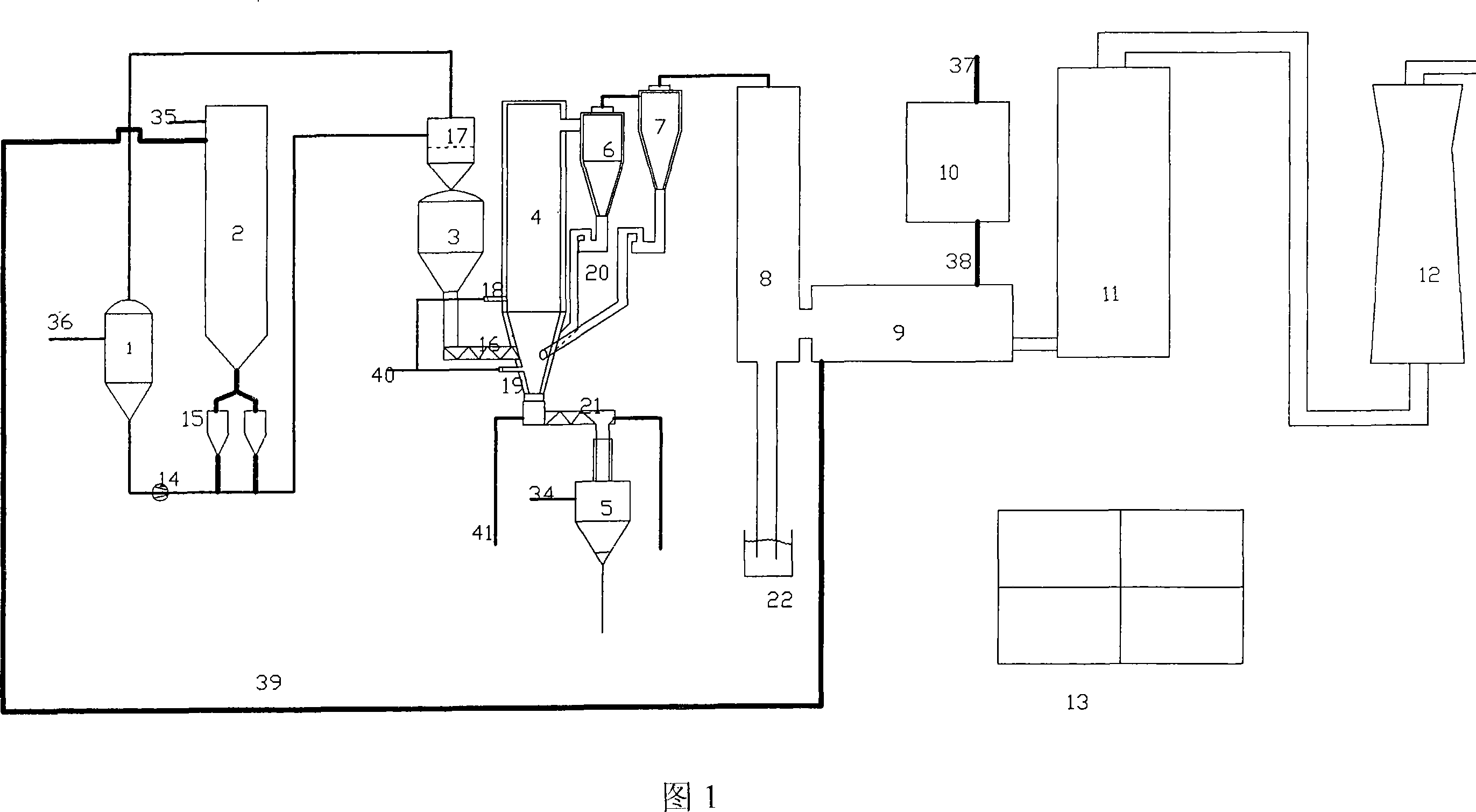

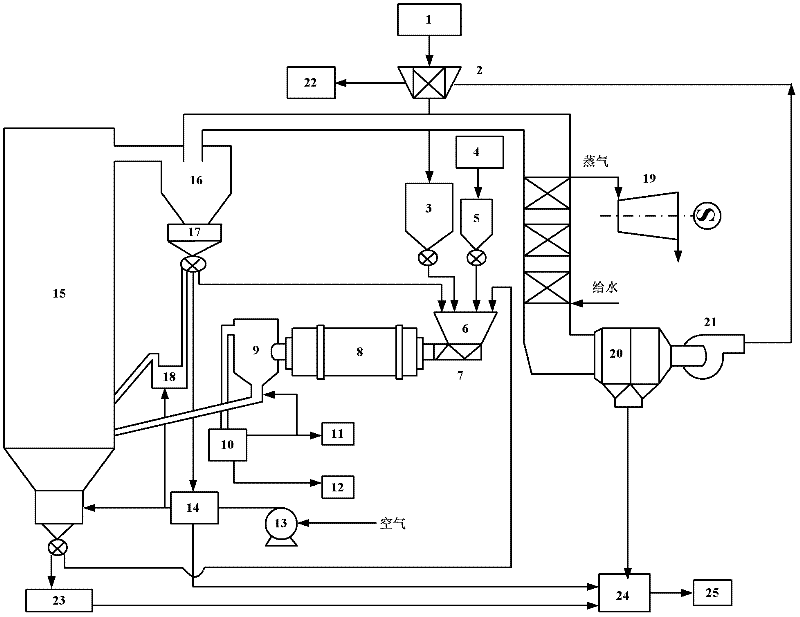

Integral process for oil shale retorting oil refining and coal-char combustion power generation

InactiveCN101117584AGood heat transfer effectImprove heat utilizationInternal combustion piston enginesPowdered engine fuelsHeat carrierCirculating fluidized bed boiler

The present invention discloses an oil shale carbonization oil refining, carbocoal burning electricity generating integrated technology. The present invention is characterized in that green ore oil shale is crushed into 0 to 15mm grains by a crusher, through that circulating fluid bed boiler circulating ash is used as a solid heat carrier, the mixture of the oil shale and the circulating ash is fed into a roller retort to form oil shale oil refining, carbocoal and the oil shale are mixed, fluidized and burned to generate electricity as a whole, separated non-condensation carbonization coal gas is fed into the circulating fluid bed boiler and the both are burned with the carbocoal and the oil shale together or is fed into a gas engine for direct-fired power generation; the carbon content of the clinker after burned on the circulating fluid bed is less than 2 percent, thus no further roasting is necessary, and the present invention can be directly used as building raw material; the thermal value of produced carbonization coal gas which can be directly used as fuel to feed into the boiler for burning is high, the quantity of heat released through burning can be transferred to the water through the heated surface of the boiler, the water is heated into a overheat steam to be used as out-supplied working substance and / or to be fed into a steam turbine for power and electricity generating. The present invention has the advantages that the comprehensive utilization degree is high, the cost is low, the technology is scientific and reasonable, etc.

Owner:NORTHEAST DIANLI UNIVERSITY +1

Silicon carbide semiconductor device and method for producing the same

InactiveUS20070138482A1Reduce carbon contentSemiconductor/solid-state device manufacturingSemiconductor devicesParent materialElectrical conductor

A silicon carbide semiconductor device, includes: 1) a silicon carbide substrate; 2) a silicide electrode configured to be formed by depositing a contact parent material on the silicon carbide substrate in such a manner as to cause a solid phase reaction, the silicide electrode being a lower carbon content silicide electrode including: i) silicon, and ii) carbon smaller than the silicon in mol number; and 3) an upper conductor film deposited to the silicide electrode.

Owner:NISSAN MOTOR CO LTD +1

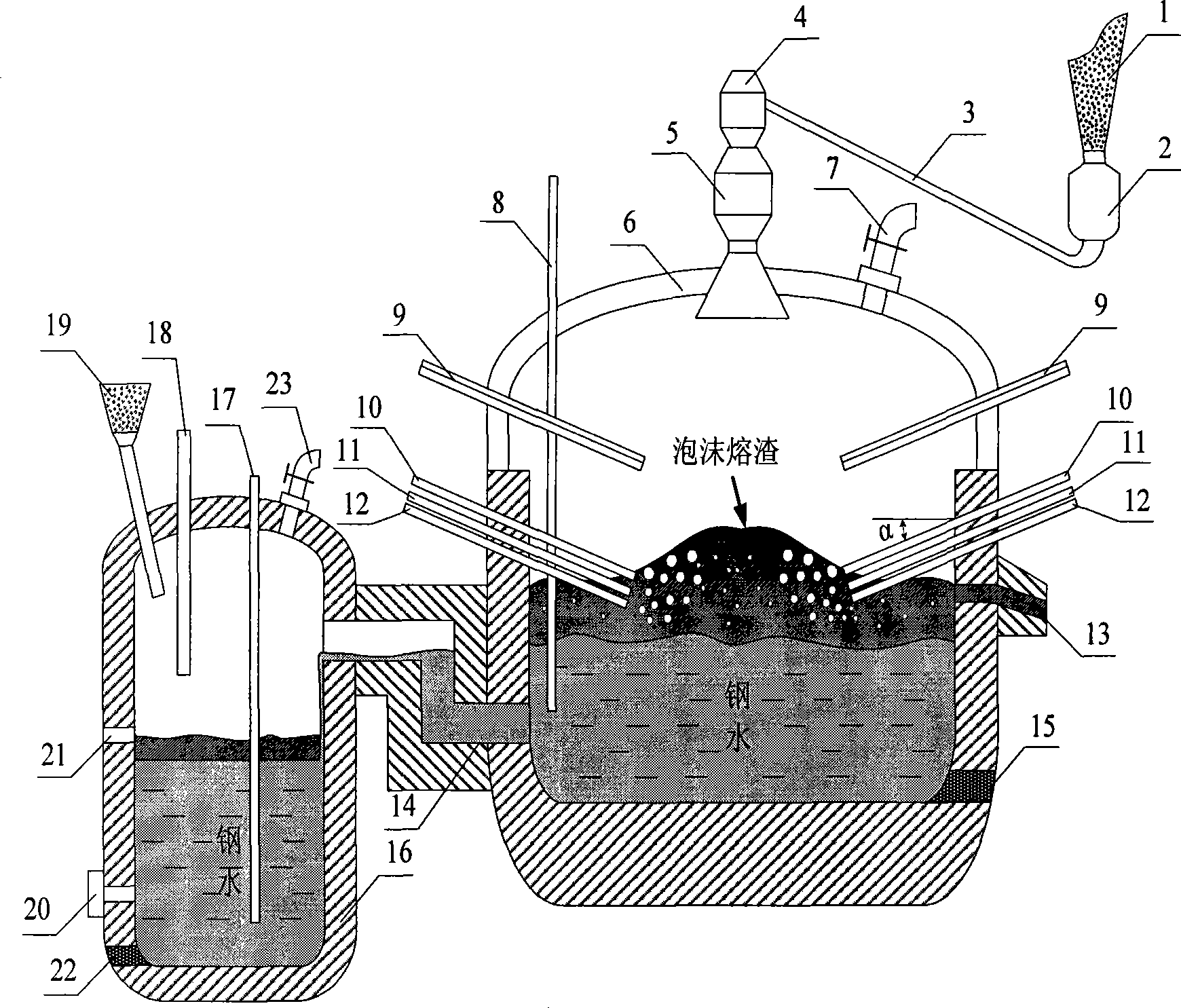

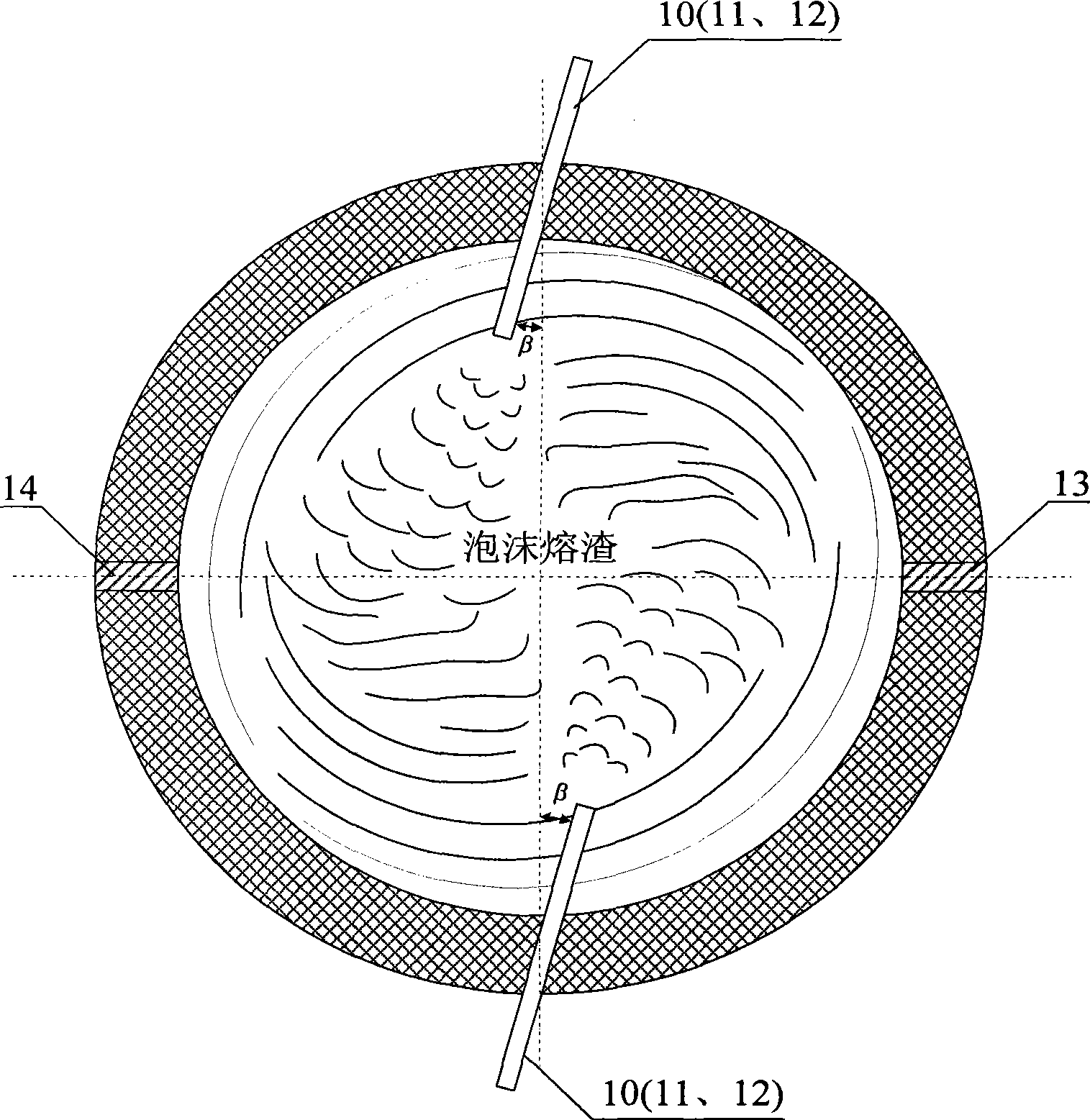

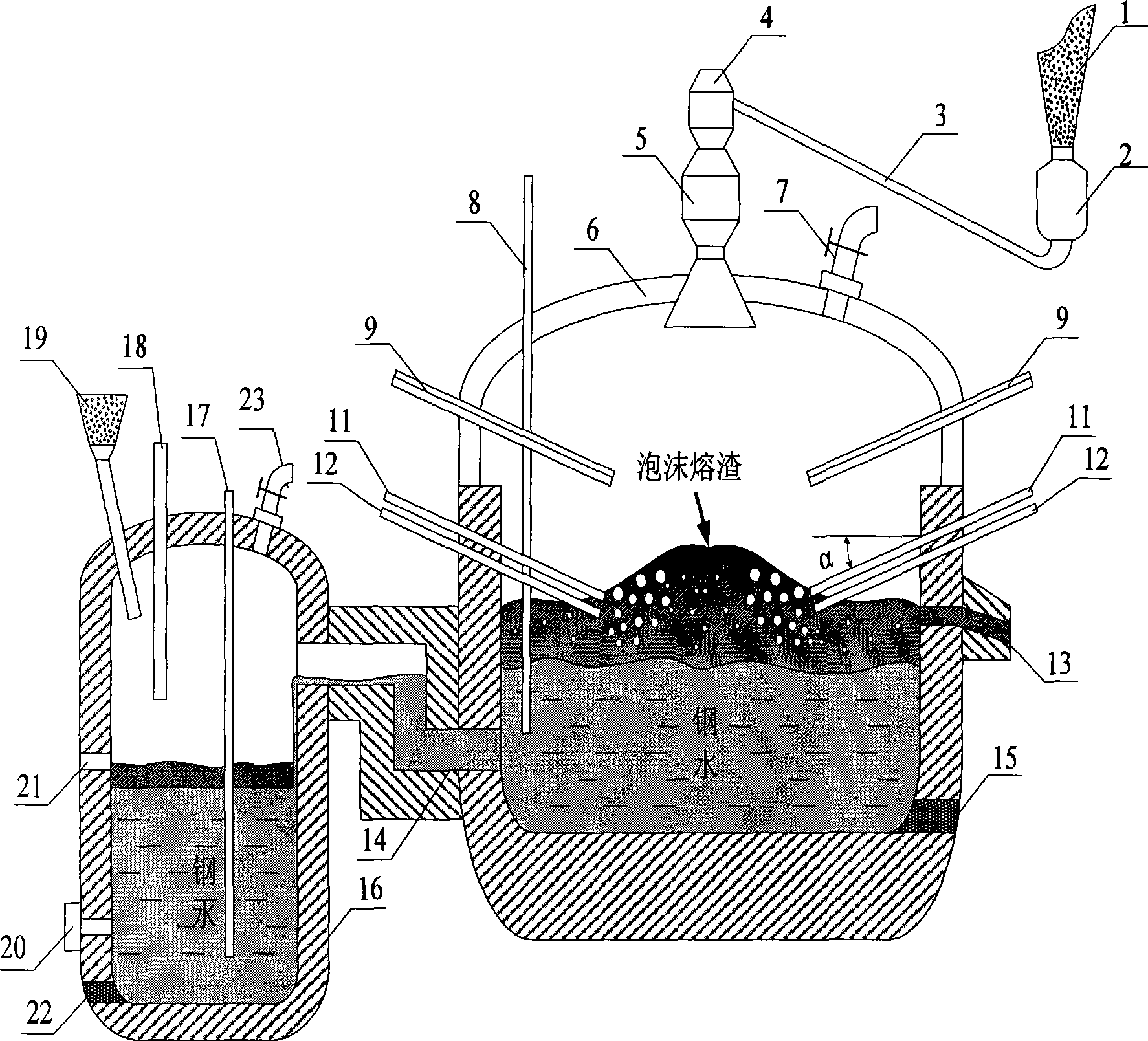

Process and device for continuous steelmaking from ferriferous material

ActiveCN101445848AReduce carbon contentIncrease temperatureFurnace typesProcess efficiency improvementSteelmakingMelting tank

The invention relates to a process for continuous steelmaking from a ferriferous material. A molten pool is formed in a steel-smelting furnace at first, and carbonic material and oxygen are insufflated to form foaming slag; the ferriferous material and a fluxing agent are added into the smelting furnace to be molten and reduced, oxygen is insufflated into the molten steel so as to reduce the carbon content in the molten steel, the temperature of the molten steel is risen, and the molten steel is stirred with the generated CO gas; high temperature oxygen or oxygen-enriched air is insufflated and burns with CO gas generated in the smelting furnace; and the molten steel continuously flows into an oxygen blowing furnace through a siphon nozzle, and a small quantity of the fluxing agent is added into the oxygen blowing furnace so that slag formation, desulfurization and dephosphorization are performed, the C content and the temperature in the molten steel are further adjusted through blowing oxygen by an insertion oxygen lance, therefore, the obtained molten steel is directly supplied for an LF refining furnace or an RH refining furnace. The invention has the advantages that the productivity equipment including a suspended pre-reduction furnace, the smelting furnace and the oxygen blowing furnace, the investment for devices and capital construction is saved, the land is saved, the physical distribution is simplified, and the continuous production and the automatic control are facilitated.

Owner:LAIWU IRON & STEEL GRP

Method for removing contaminants from fluid streams

InactiveUS20050155934A1Increase valueReduce carbon contentGas treatmentOther chemical processesPresent methodSorbent

A method and recyclable magnetic adsorbent are provided for removing contaminants from a fluid stream that has by-products. The method includes providing an adsorbent material that has incorporated at least one ferromagnetic material. Contacting the ferromagnetic adsorbent material to at least a portion of contaminated stream to adsorb the contaminant. The contaminated adsorbent is then separated from the by-products using a magnetic separation process. The adsorbent is recovered from the solid by-products and reusable in the present method.

Owner:CALGON CARBON

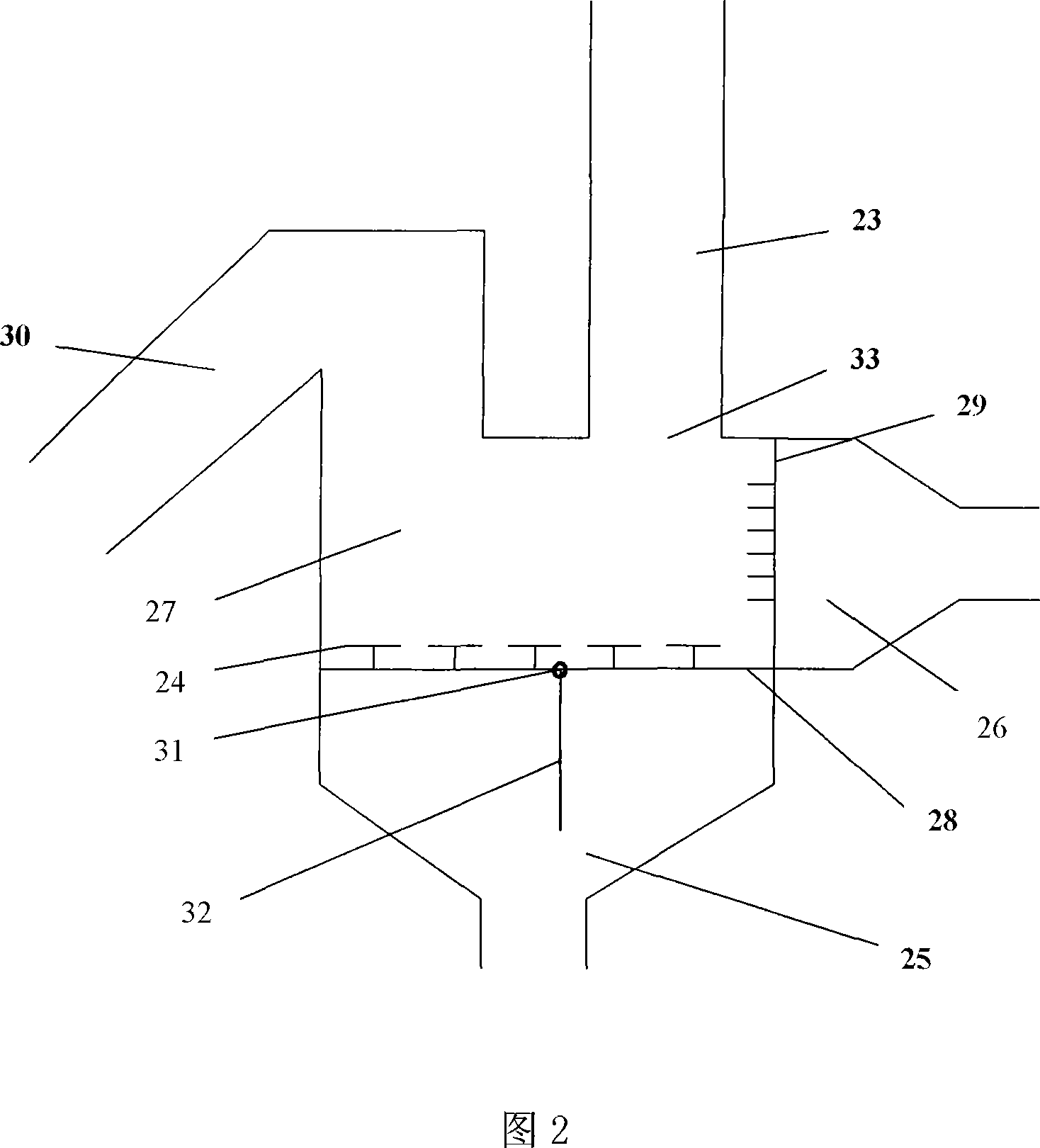

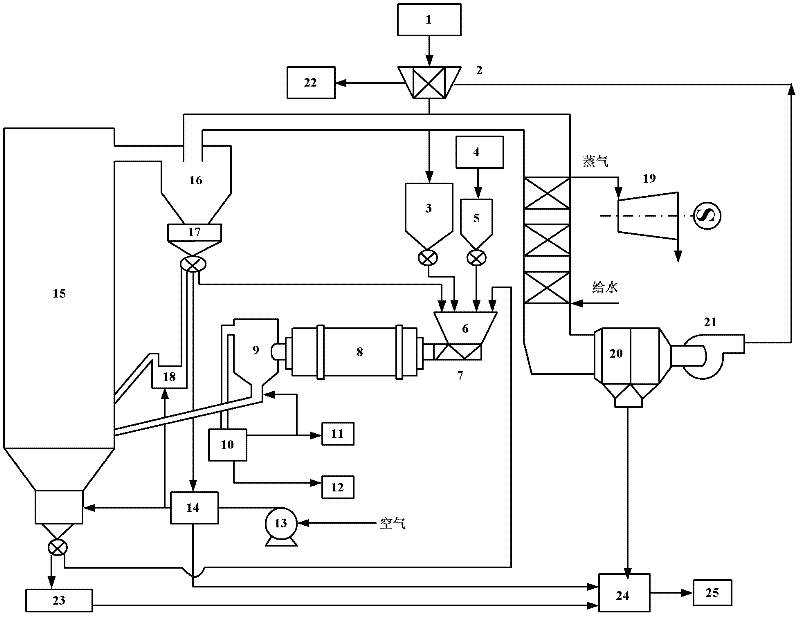

Coal gasification device for circulating fluidized bed and manufacturing method thereof

InactiveCN101054536AImprove gasification efficiencyReduce outputEnergy inputGranular/pulverulent flues gasificationCycloneHearth

A circulating fluidized bed coal gasification apparatus includes coal blending system, generator, cyclone dust collector, exhaust-heat boiler, water-cooling tower and Venturi scrubber, wherein the generator has up-and-down two rows of gasifying agent nozzles, helix dust collector and storage groove. The gas pipe which communicates to the cyclone dust collector is set on the top. A feed back pipe which communicates to the generator is set at the bottom of the cyclone dust collector. The cyclone dust collector communicates to the exhaust-heat boiler by gas pipe. The exhaust-heat boiler communicates to the water-cooling tower by gas pipe and communicates to the Venturi scrubber by gas pipe. The characteristics are: the feed back pipe facing to the generator hearth of the cyclone dust collector is a feed back machine with small-sized fluid bed; the cyclone dust collector is composed of at least two tandem dust collector; coal blending system has wind feeding and dust coal drier. The invention achieves the transition of the boiling bed to the circulating fluidized bed and increases the system gasification efficiency.

Owner:宋建元

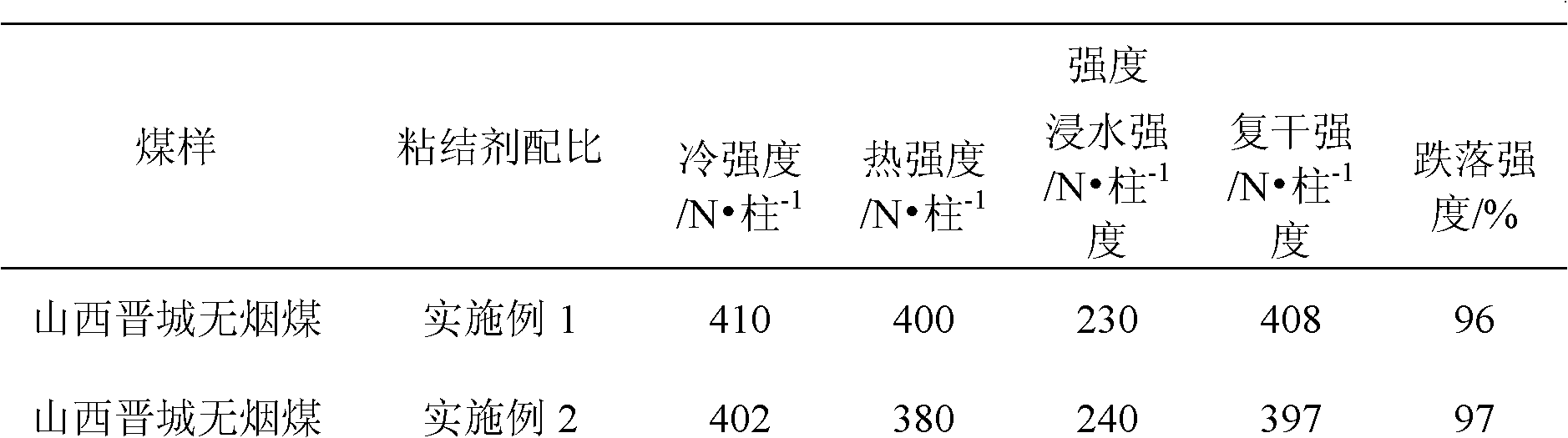

Briquette binder and briquette preparation method based on binder

The invention provides a briquette binder and a briquette preparation method based on the binder. The binder comprises 45 to 75 mass percent of humic acid, 8 to 20 mass percent of bentonite, 5 to 18 mass percent of kaolin, 1 to 5 mass percent of quartz sand, 2 to 8 mass percent of quicklime, 0.1 to 2 mass percent of sodium chloride, 0.1 to 2 mass percent of potassium permanganate and 0.05 to 0.1 mass percent of polyacrylamide. The binder has a simple preparation process, low cost, convenient use and no any secondary pollution and is applicable to various types of coal. The process for preparing the briquette by using the binder comprises the following steps of: only making little pretreatment on raw material coal and the binder, mixing the raw material coal and the binder in proportion, adding water into the mixture, uniformly stirring, pressing the mixture into a cylindrical briquette by using a press machine, and air-drying or drying the cylindrical briquette. The briquette prepared by using the binder of the invention has the characteristics of high cold strength, high water resistance, low cost, low ash increment, high thermal strength, high sulfur retention rate and wide source of raw materials.

Owner:SHAANXI UNIV OF SCI & TECH

Petroleum casing pipe with high strength and high toughness and preparing method thereof

InactiveCN101586450ALow alloy contentLow costDrilling rodsProcess efficiency improvementAlloyMechanical property

The present invention provides a petroleum casing pipe with high strength and high toughness, wherein the weight of the component element of the casing pipe steel is characterized proportionally. The invention also provides a preparing method for preparing the petroleum casing pipe with high strength and high toughness, wherein the method comprises the following steps: 1. smelting the ingredients and casting the tube blank; 2. punching and tandem rolling of the steel tube; and 3. heat treating. The invention has the following beneficial effects: the performance of the petroleum casing pipe obtained by the method is the performance of the steel with lower content of alloy and the cost is low; a low carbon content is adopted so that the lath martensite tissue is obtained after heat treatment, the high toughness is provided after tempering and a delayed fracture resistance is provided; the complex micro-alloying processing techniques of V, Nb, Ti, B, etc. are adopted for strengthening the matrix, strengthening the grain-boundary strength, increasing the tempering resistance, reducing the content of manganese element, reducing the content of the impurity elements and improving the shape of the inclusion. The rolling ratio is optimized so that the aeolotropism of the material is remarkably reduced and the horizontal and vertical impact toughness of the material is larger than 0.8. The casing pipe of the invention far exceeds the prior highest steel grade requirement of the API standard.

Owner:TIANJIN PIPE GROUP CORP

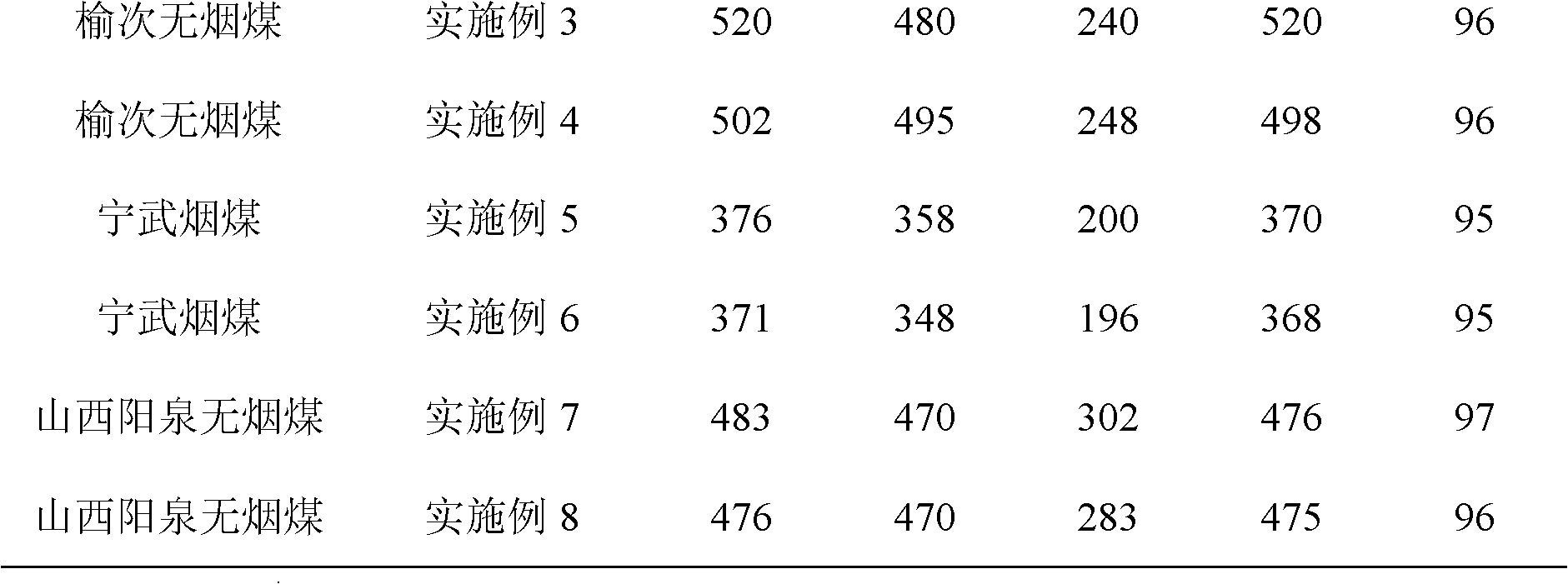

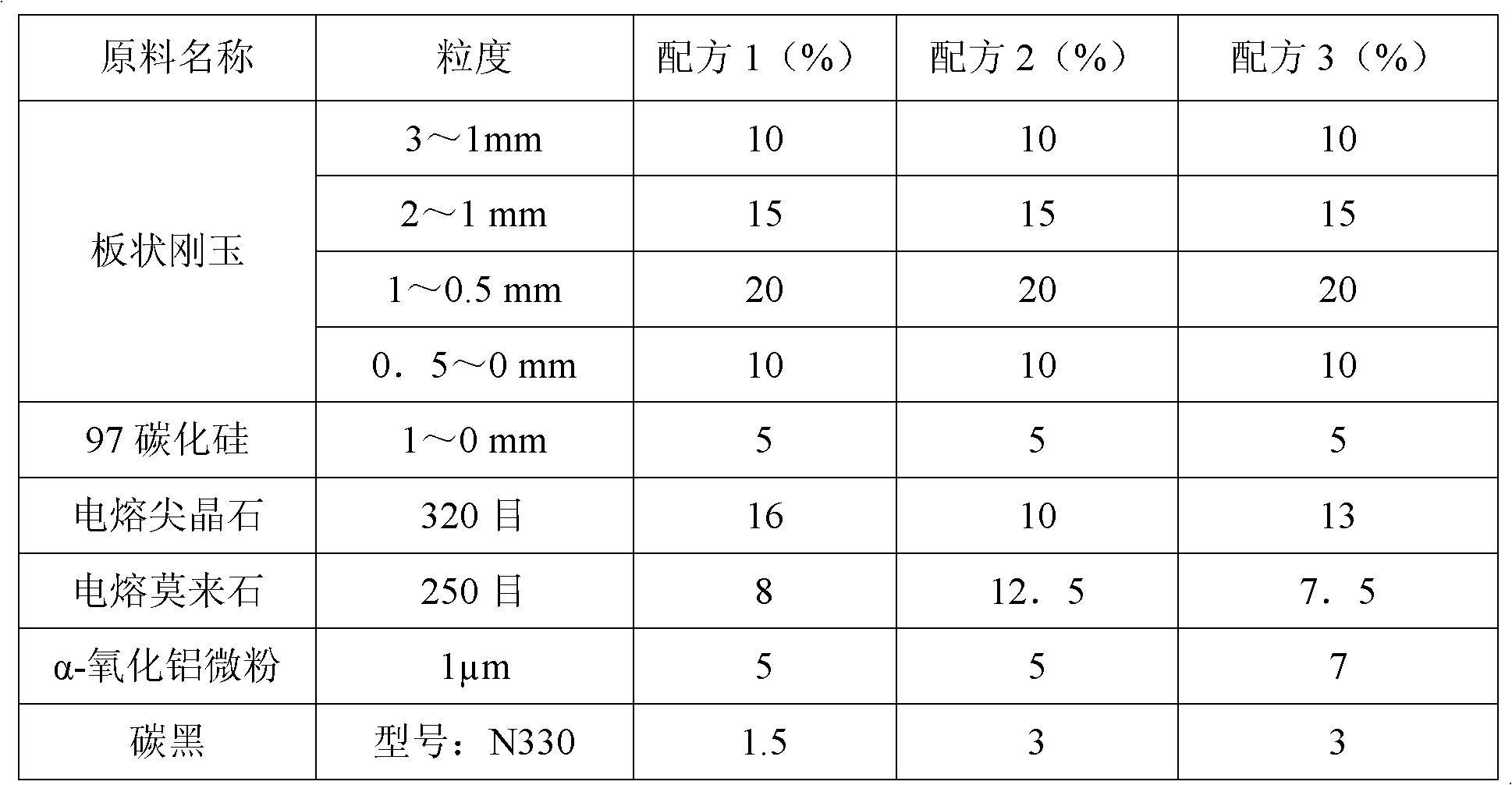

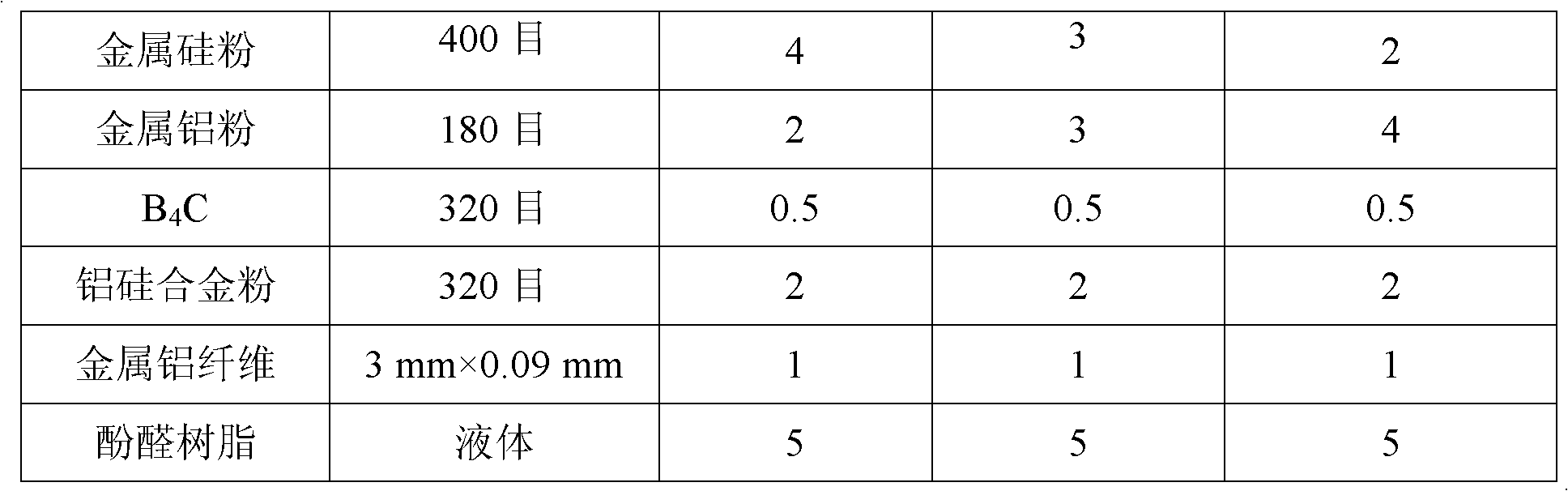

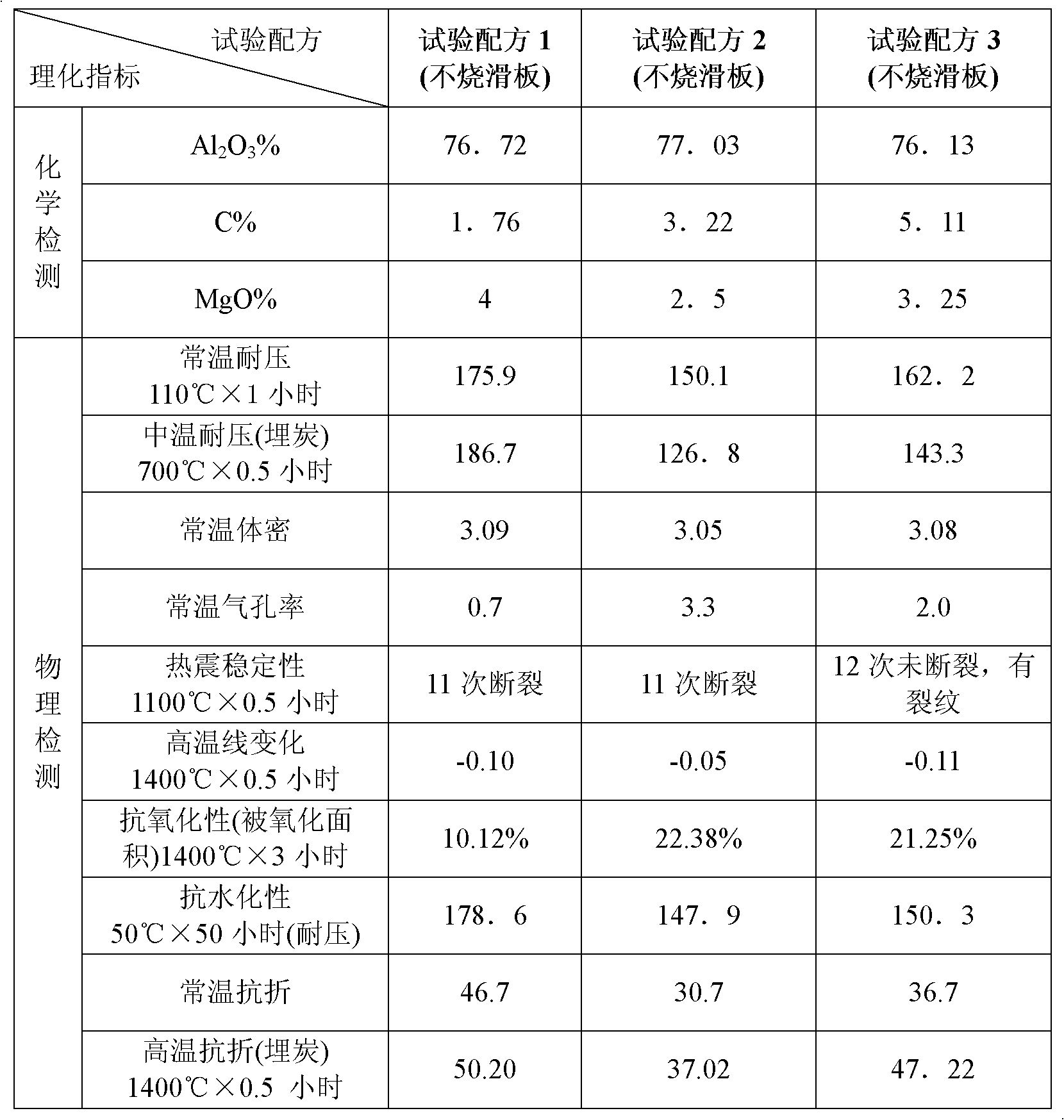

Metal ceramic combination sintering free low carbon sliding plate brick and preparation method thereof

The invention discloses a metal ceramic combination sintering free low carbon sliding plate brick and a preparation method thereof. The sliding plate brick comprises the following components according to weight percentage: 50%-60% of sintered plate shape alundum, 10%-25% of electric melting akerite, 5%-15% of electric melting mullite, 1%-3% of soot carbon, 3%-8% of Alpha- aluminum oxide micropowder, 5%-10% of silicon carbide, 2%-5% of metallic silicon powder,1%-5% of metallic aluminium powder, 0.5%-1% of boron carbide, 1%-3% of aluminum-silicon alloy powder, and 0.5%-2% of metallic aluminium fiber. In the invention, the product has low carbon, high thermal state strength, thermal shock resistance and good oxidation resistance, hole reaming is uniform, galling is less and the crack is verysmall; the process of the invention is characterized in that drying is carried out at a low temperature, the production cycle is shortened from 30 days originally to 7 days, the natural gas consumption is reduced to 2.5% of original technology, and the sintering free low carbon sliding plate brick is indeed belongs to the environmental protective and energy-saving and environmental material resistance product.

Owner:无锡市南方耐材有限公司

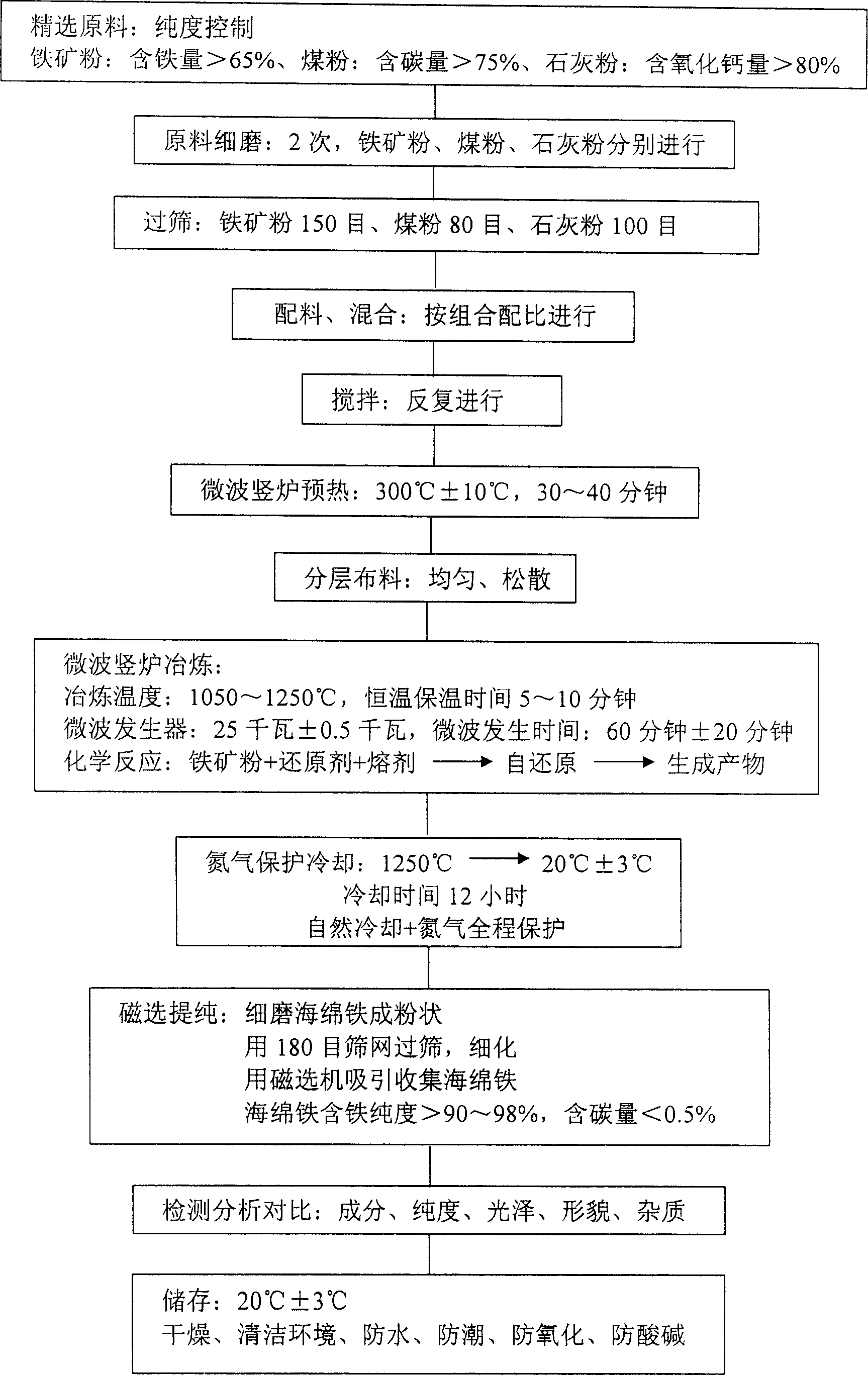

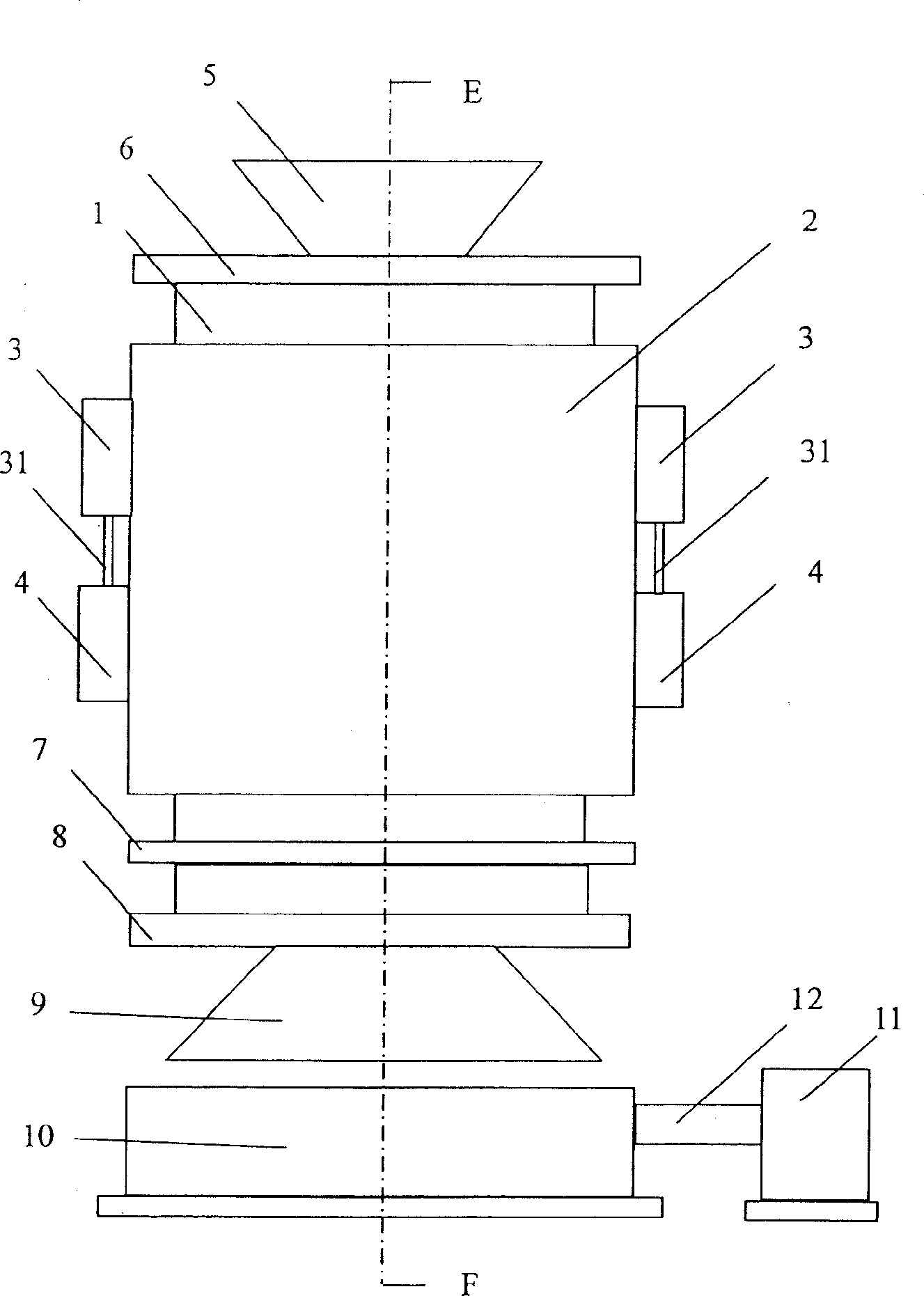

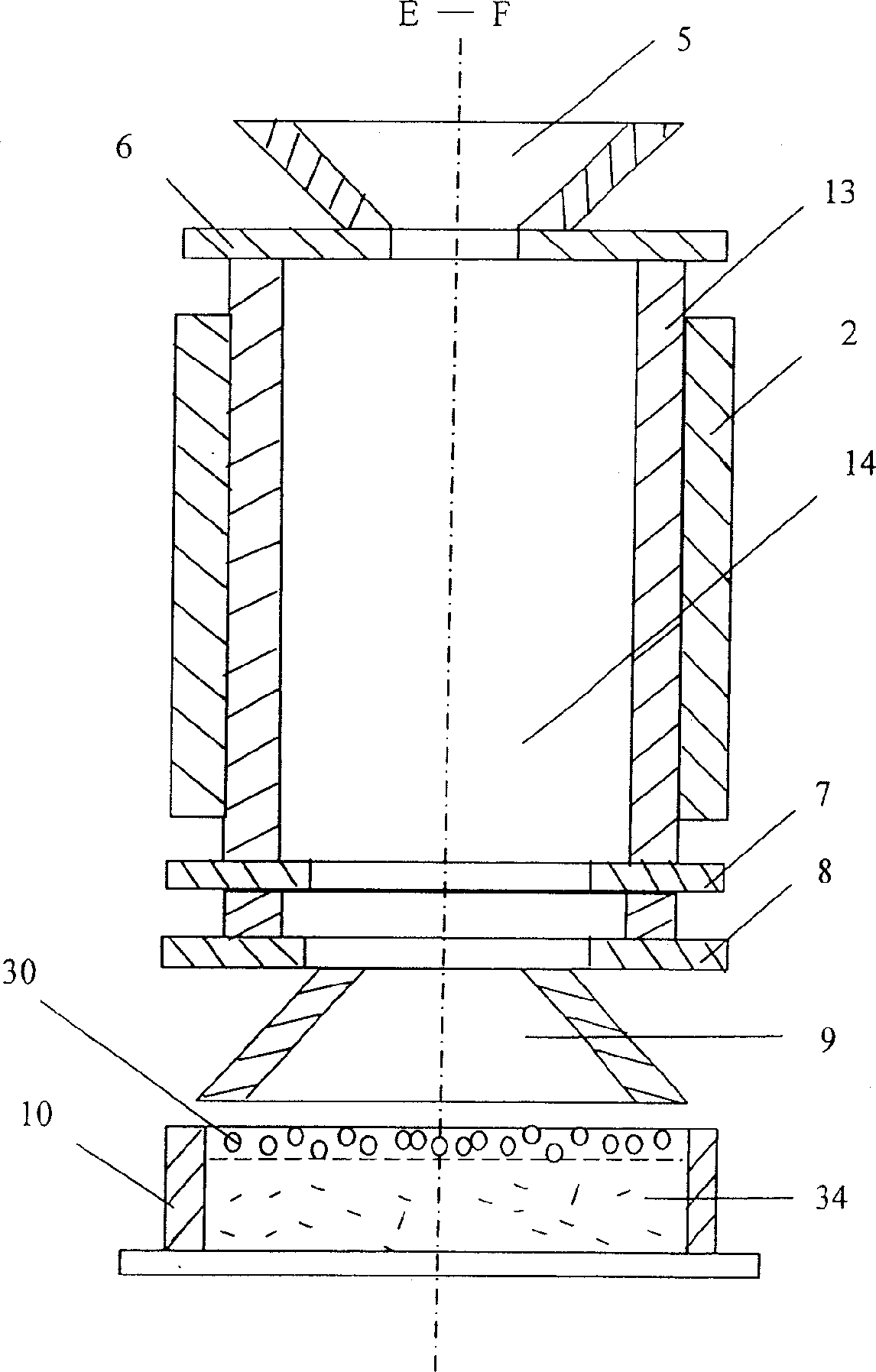

Method of manufacturing low carbon sponge iron using microwave vertical furnace

The invention relates to a method to make low carbon sponge iron by microwave shaft furnace. It adopts iron ore powder as raw material, common soft coal dust or anthracite dust as reducer to gain high quality low carbon sponge. It uses the feature that the iron ore powder, carbon powder, and lime powder has selective absorbing to microwave. Under the condition of sealing and high temperature, and under the effect of microwave generator, heater, and adjustor, it would take carbon heat self-reduction by absorbing the heat produced by microwave generator to gain low carbon sponge iron. The method has simple technology, shortens the reduction time period, saves coking coal and coke resource, and reduces environment pollution. The degree of metallization could reach 90-98%, and the carbon content could be lower than 0.5%. It is the ideal method to make low carbon sponge iron.

Owner:TAIYUAN UNIV OF TECH

Water gap lining layer material for continuous casting

The invention discloses a water gap lining layer material for continuous casting. The material is prepared from the following components in percent by weight: 20-60 percent of corundum, 0-30 percent of electrofusion zirconium mullite, 0-40 percent of fused silica, 3-40 percent of ceramic hollow sphere, 1-10 percent of light burning alumina, 2-6 percent of sintering assistant, 2-6 percent of phosphate bonding agent and 4-8 percent of solid phenolic resin bonding agent. A water gap for continuous casting produced by adopting the material is suitable for cold casting, and a lining basically has no nodule blocking phenomenon; the lining has high strength and does not have phenomena of chambering and abnormal erosion; a water gap has long service life; and the continuous casting production efficiency is improved.

Owner:SHANGHAI BAOMING REFRACTORIES CO LTD

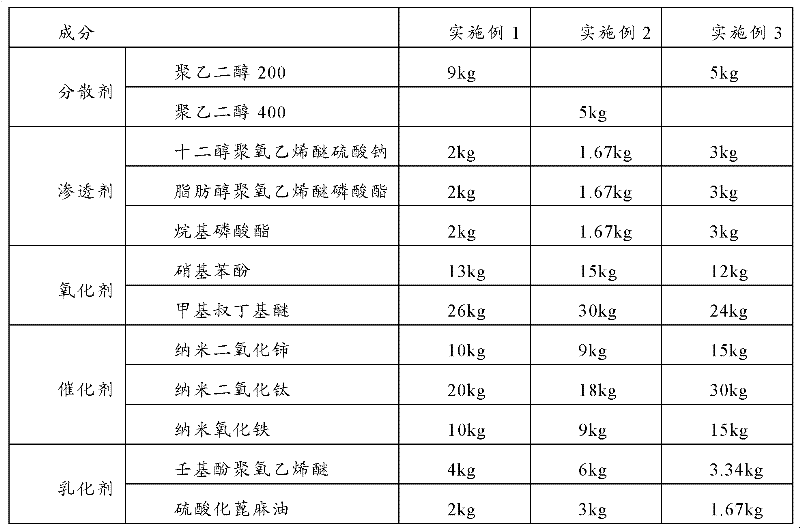

A kind of coal combustion accelerant

The invention provides a coal combustion improver which comprises 5 to 10 percent of dispersing agent, 5 to 10 percent of penetrant, 35 to 50 percent of oxidizing agent, 35 to 50 percent of catalyst and 5 to 10 percent of emulsifying agent, wherein the oxidizing agent is a mixture of nitrophenol and methyl tertiary butyl ether; and the catalyst is nano-scale metallic oxide. The coal combustion improver provided by the invention has high combustion improving efficiency and is safe and environmental-friendly. The invention also provides a method for preparing the coal combustion improver.

Owner:安徽海螺材料科技股份有限公司

High-performance hot-working die steel for large die-casting die and manufacturing technology of high-performance hot-working die steel

The invention relates to high-performance hot-working die steel for a large die-casting die and a manufacturing technology of the high-performance hot-working die steel. The high-performance hot-working die steel is prepared from, by mass, 0.20%-0.30% of C, smaller than or equal to 0.40% of Si, 0.30%-0.60% of Mn, 4.10%-4.50% of Cr, 2.10%-2.30% of Mo, 0.10%-0.20% of W, 0.40%-0.80% of V, smaller than 0.01% of P, smaller than 0.005% of S, 0.02%-0.04% of Nb and the balance Fe. The manufacturing method of the die steel comprises the following manufacturing process that material mixing, smelting andcasting are conducted, and then electroslag remelting is conducted; high-temperature diffusion heat treatment is conducted, multi-directional forging hot working is conducted, and cooling controllingafter forging is conducted; secondary carbide refining heat treatment and isothermal annealing treatment are conducted; and finally quenching and tempering heat treatment is conducted. The hot-working die steel has the advantages that the hardenability, the heat stability, the impact toughness and the thermal fatigue property are superior to those of H13 steel, the hot-working die steel can be machined into a single large die-casting die with the weight reaching 5 tons or above, and the good using performance is achieved.

Owner:ZHANGJIAGANG CITY GUANGDA MACHINERY FORGING

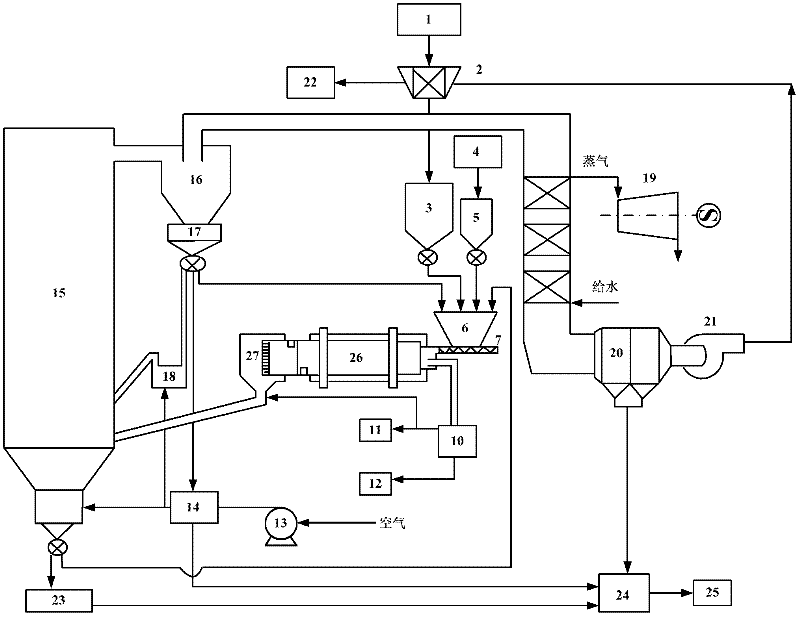

Oil shale rotary kiln dry distillation and circulating fluidized bed combustion process

InactiveCN102533296AImprove combustion efficiencyControl generationDirect heating destructive distillationBiofuelsBottom ashInternal combustion engine

An oil shale rotary kiln dry distillation and circulating fluidized bed combustion process makes organic combination of a rotary kiln dry distillation with a circulating fluidized bed; oil shale particles are mixed with thermal-cycle ash from a circulating fluidized bed boiler and part of circulating fluidized bed boiler bottom ash, and then are sent into a rotary kiln for dry distillation to prepare shale oil and dry distillation coal gas; the dry distillation coal gas has a high calorific value; a part of the coal gas is used as recycle wind of a semicoke material recycle device, and enters the circulating fluidized bed boiler with oil shale semicoke particles for combustion, and the residual part is delivered into an internal combustion engine for combustion generation. The invention can increase shale oil and coal gas quality, reduce energy loss and environment pollution, and improve the comprehensive utilization degree.

Owner:SHANGHAI JIAO TONG UNIV

Catalytic cracking method and apparatus

ActiveCN100338185CReduce carbon contentHigh activityCatalytic crackingChemical industryControl valves

The invention discloses a kind of catalysis crack method and its device in petroleum chemical industry, to solve the problems as the whole activeness reduction of mixed catalysts and the flexibility lack of adjusting the agent-oil proportion of heavy oil riser reactor caused by the mixing wise of the spend catalyst and regenerating catalyst of the present two-riser catalysis crack device. The main characteristics of the invention method are: part of the spent catalyst from the light hydrocarbon riser reactor (4) gets into catalyst mixer through the spent catalyst duct (3) set flow control valve (1) after water vapour stripped in the stripping section (7) of the second settler, and gets into heavy oil riser reactor (12) to react after mixed by the effect of water vapour with the regenerating catalyst form regenerator (14) in catalyst mixer. The method of the invention is suitable to be used in the two-riser catalysis crack craft and the three-riser catalyst crack craft set heavy oil riser reactor; the invention has disclosed related devices.

Owner:SINOPEC LUOYANG PETROCHEM ENG CORP

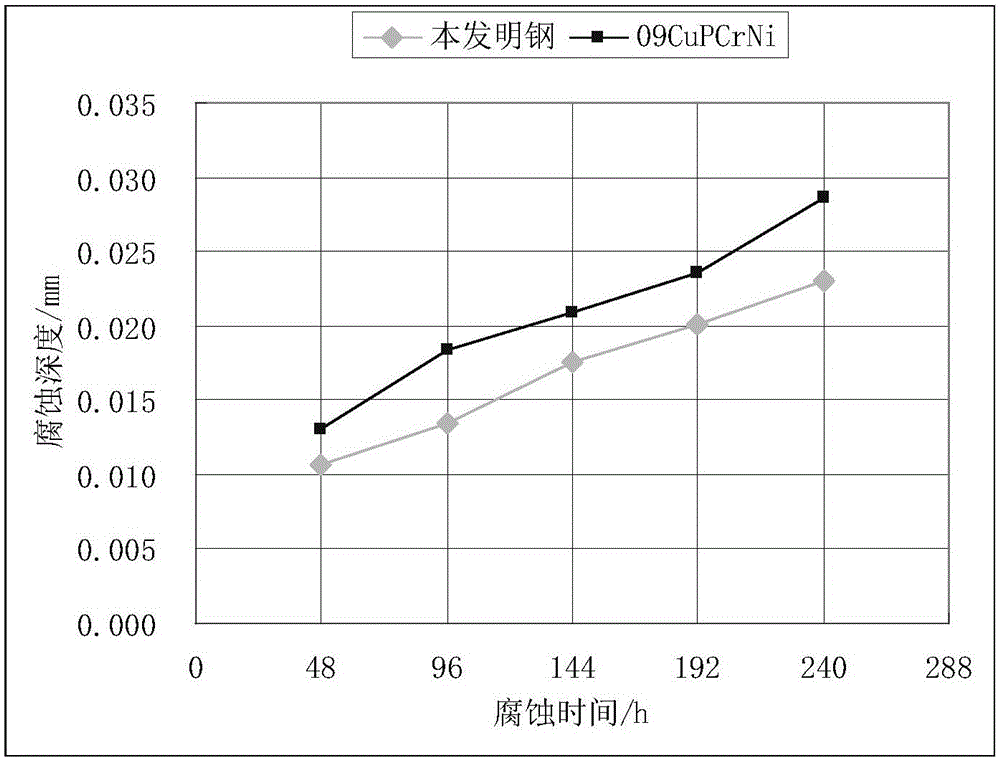

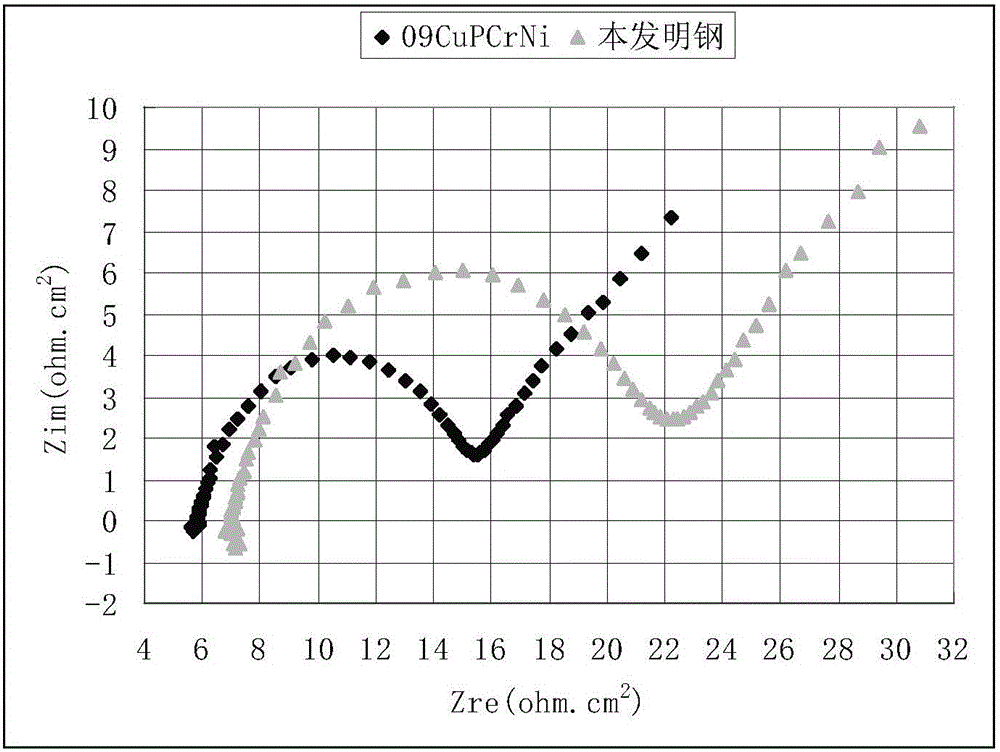

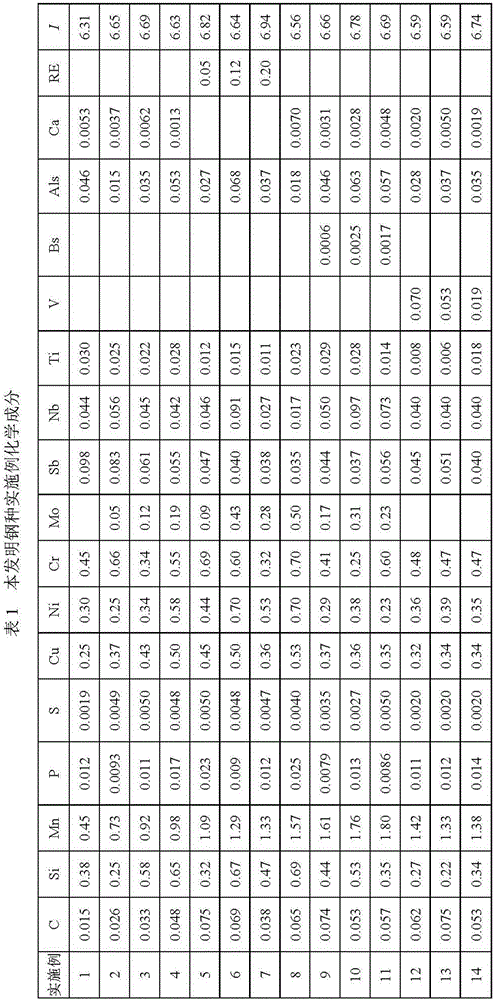

High-performance hot-rolled H profile steel resisting atmosphere corrosion and preparation method thereof

The invention aims to solve the defects of welding and strength performances in traditional weather-resistant H profile steel, and provides high-performance hot-rolled H profile steel resisting atmosphere corrosion and a preparation method thereof. The H profile steel comprises the following chemical components: C, Si, Mn, Cr, Cu, Ni, Mo, Sb, Als, not more than 0.025% of P, not more than 0.010% of S, not more than 0.0080% of N, Bs, Nb, Ti, V, Ca, and the balance of Fe and inevitable impurities; and the required atmosphere corrosion resisting index I is not less than 6.30. The preparation method is to perform air cooling or rapid cooling for a forging blank of the components after secondary rolling. The product reduces the carbon content, adds the microalloying elements of Nb and Ti, adds Ni, Mo, Cu and Cr, and also adds Sb to greatly improve the corrosion resistance in industrial-polluted atmosphere environment containing such higher pollutants as SO2; the steel structure of the product mainly adopts ferrite and ferrite+bainite; and the product has the yield strength of 235-500 MPa grade, is excellent in toughness and plasticity, is excellent in industrial-polluted atmosphere environment corrosion resistance, and can be used without coating in the industrial-polluted atmosphere environment.

Owner:蒋南宁

Method for directly reducing ferronickel by tunnel kiln using laterite-nickel ore as raw material

InactiveCN101037713AReduce carbon contentIncrease concentrationRetort furnacesTunnel kilnLow dissipation

A method of using nickeliferous laterite to reduce ferronickel directly in tunnel kiln relates to a method of reducing ferronickel. Comparing with high furnace smelting ferronickel and electric furnace smelting ferronickel having problems such as great invest, high manufacturing cost and produced ferronickel with high carbon content, the method of the invention is finished as: selecting nickeliferous laterite as material, the nickeliferous laterite contains 0.75-2.60% by weight of nickel, 8.00-55.0% by weght of iron; adding weight ratio of nickeliferous laterite and reductant as 1.00:0.25-0.55 into reducing pot, then putting the reducing pot in tunnel kiln, through preheating and stoving, heating reducing, cooling, taking off to get qualified reduced directly nickeliferous laterite. The invention selects natural nickeliferous laterite as material to reduce nickeliferous laterite, having advantages such as technology which easy to control, simple operation, low dissipation of energy, environment protection without pollution, low manufacturing cost, low installion cost and produced ferronickel with low carbon content.

Owner:章宇

Method for removing contaminants from fluid streams

InactiveUS7429330B2Increase valueReduce carbon contentGas treatmentOther chemical processesPresent methodSorbent

A method and recyclable magnetic adsorbent are provided for removing contaminants from a fluid stream that has by-products. The method includes providing an adsorbent material that has incorporated at least one ferromagnetic material. Contacting the ferromagnetic adsorbent material to at least a portion of contaminated stream to adsorb the contaminant. The contaminated adsorbent is then separated from the by-products using a magnetic separation process. The adsorbent is recovered from the solid by-products and reusable in the present method.

Owner:CALGON CARBON

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com