Medium-carbon ferrite-pearlite non-quenched and tempered steel and manufacturing method thereof

A technology of non-quenched and tempered steel and its manufacturing method, which is applied in the field of non-quenched and tempered steel and its manufacturing, can solve the problems of insufficient toughness of carbon ferrite-pearlite type non-quenched and tempered steel, and achieve good processing performance and economical efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

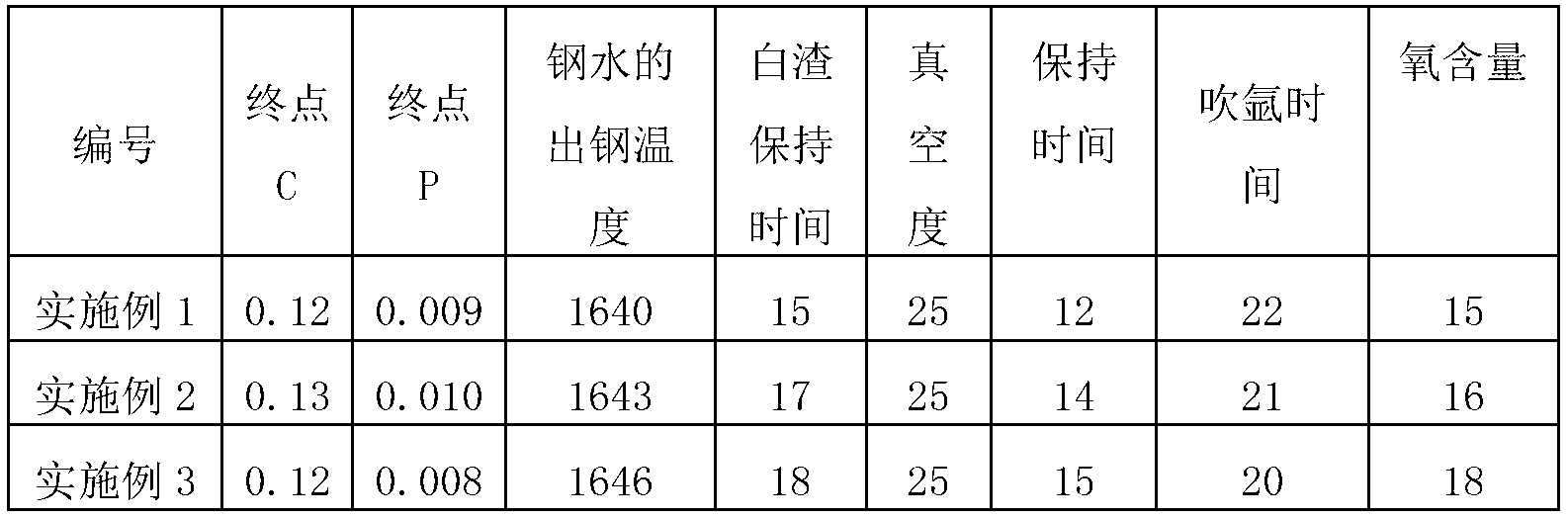

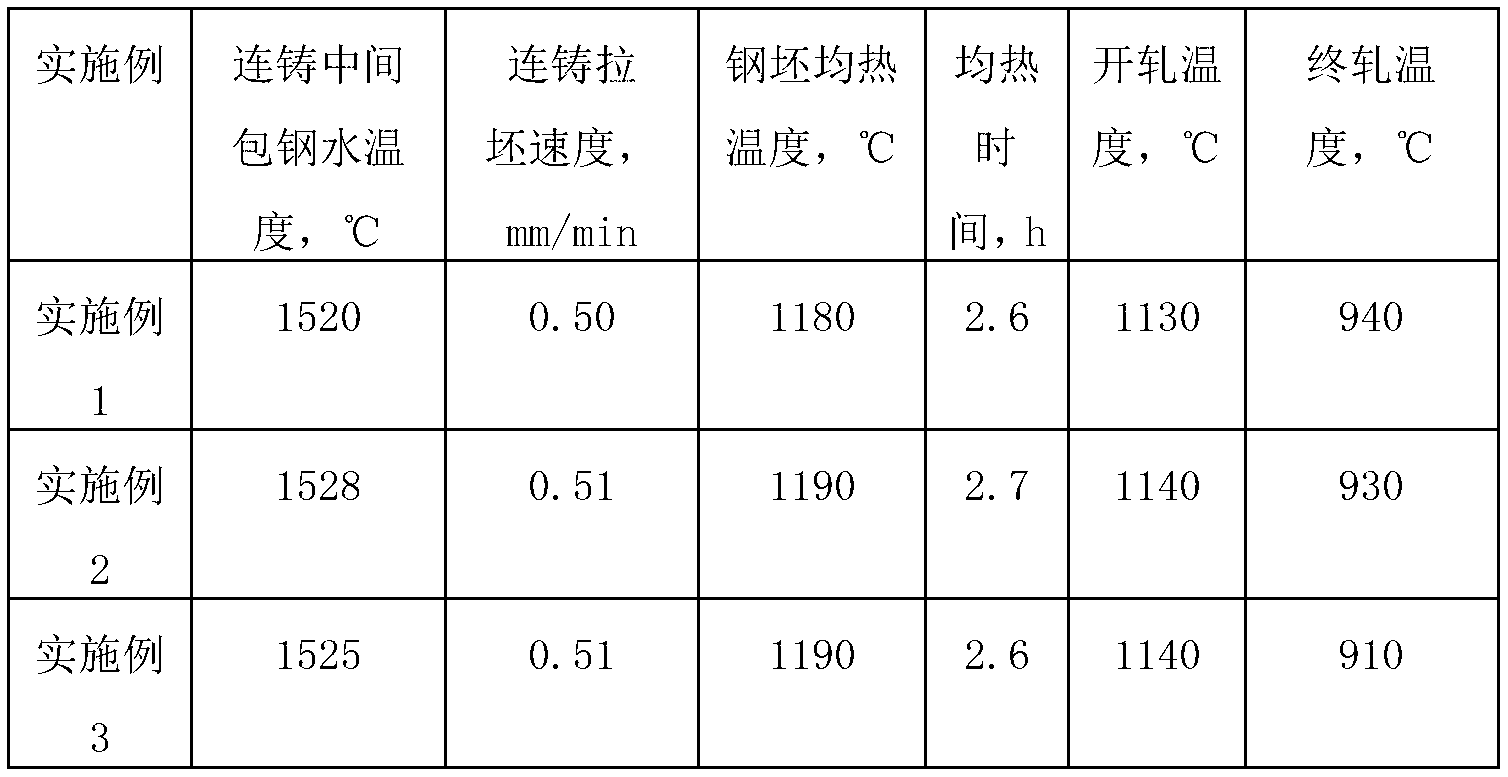

[0028] The present invention will be further described below in conjunction with embodiment.

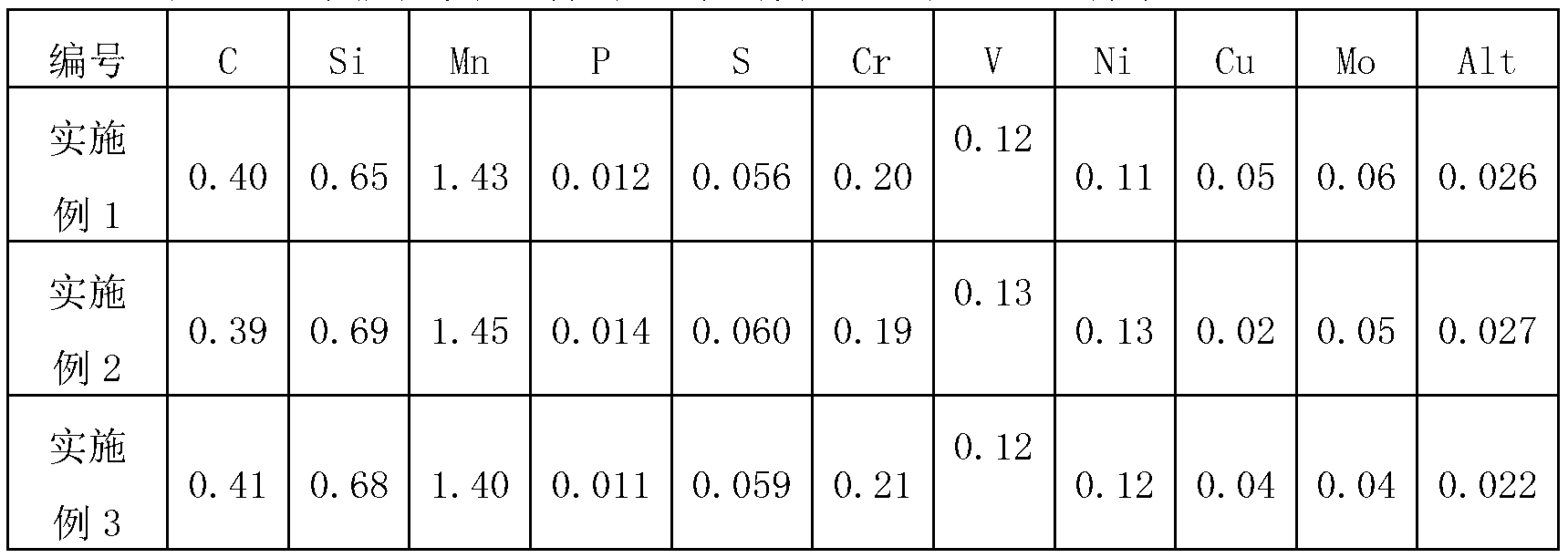

[0029] Table 3 shows the composition weight percentage of the medium carbon ferrite-pearlite non-quenched and tempered steel made in Examples 1 to 3 of the present invention; Mechanical properties of carbon-ferritic-pearlitic non-quenched and tempered steels. The test methods for the experimental data in Tables 3 and 4 all adopt international common methods.

[0030] Wherein, the weight percentages of the elements of the medium-carbon ferrite-pearlite non-quenched and tempered steel produced in Examples 1 to 3 of the present invention all fall within the following ranges:

[0031] C: 0.35-0.43% Si: 0.30-0.80%

[0032] Mn: 1.00-1.60% Cr: 0.10-0.30%

[0033] V: 0.06~0.20% Ni: 0.10~0.30%

[0034] P≤0.035% S: 0.040~0.075%

[0035] al t : 0.010~0.060% N: 100~200×10 -4 %

[0036] The remainder is Fe and unavoidable impurities.

[0037] Due to the reduction of C content in medium-c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com