Patents

Literature

28941 results about "Metallic materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

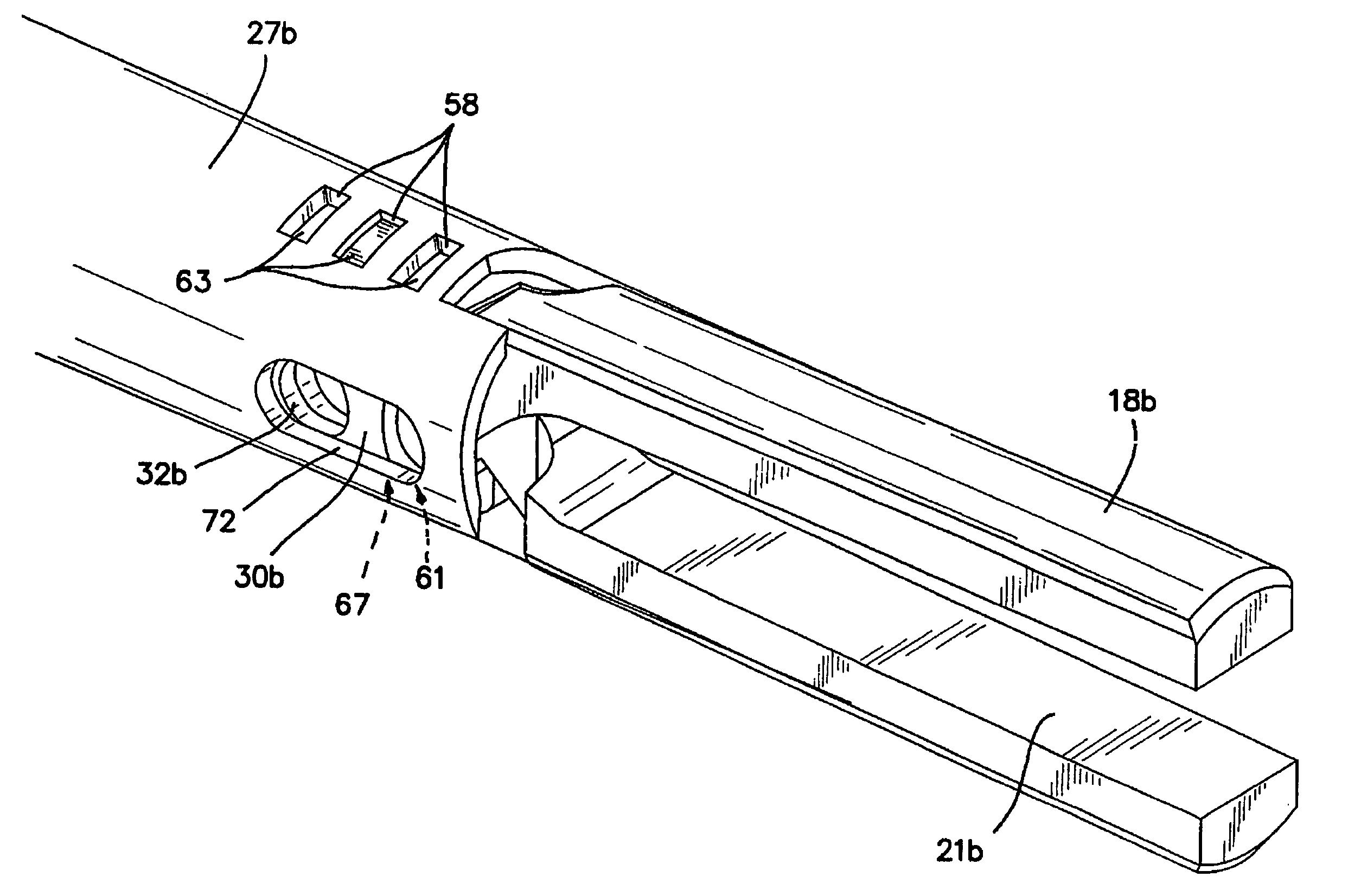

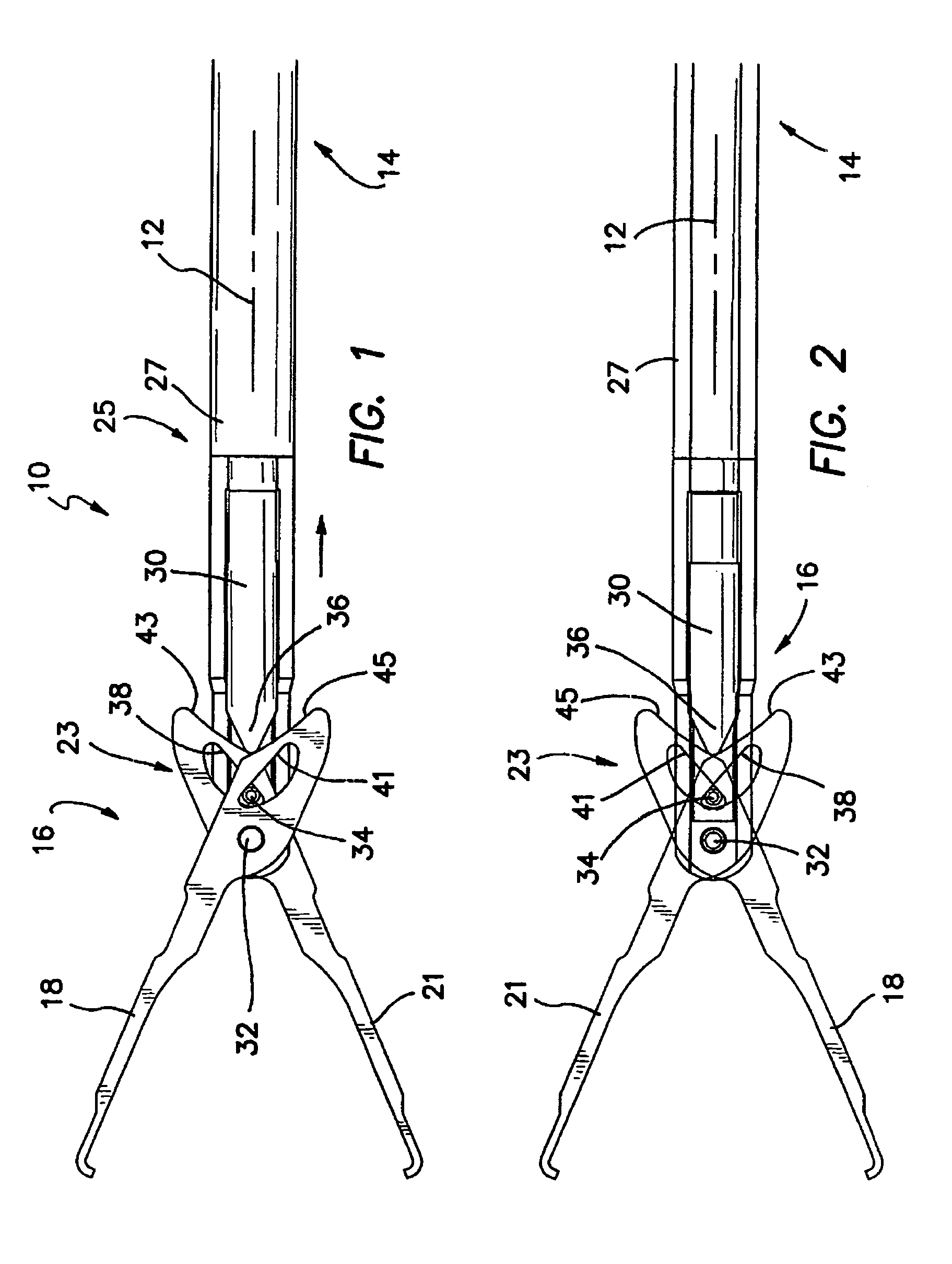

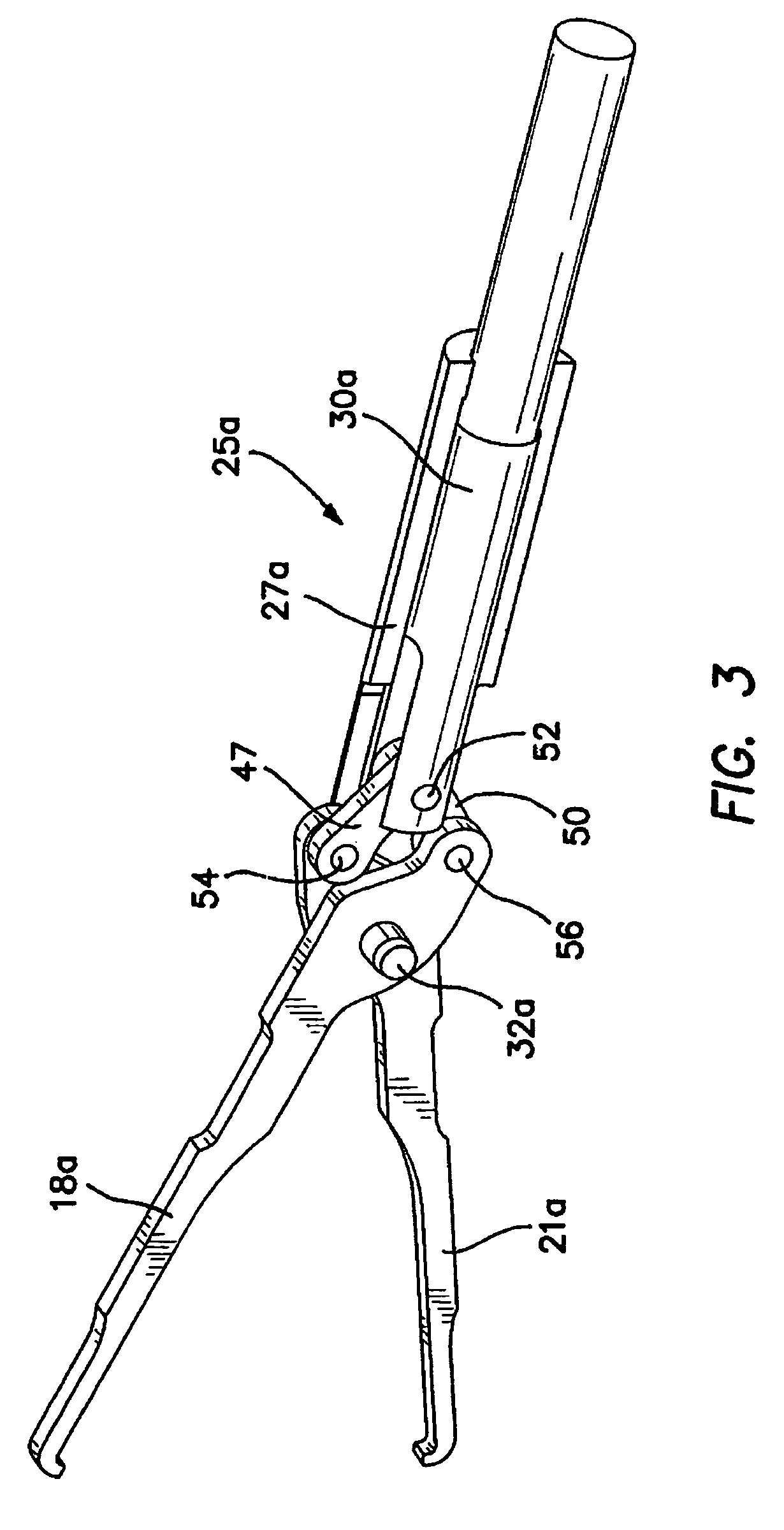

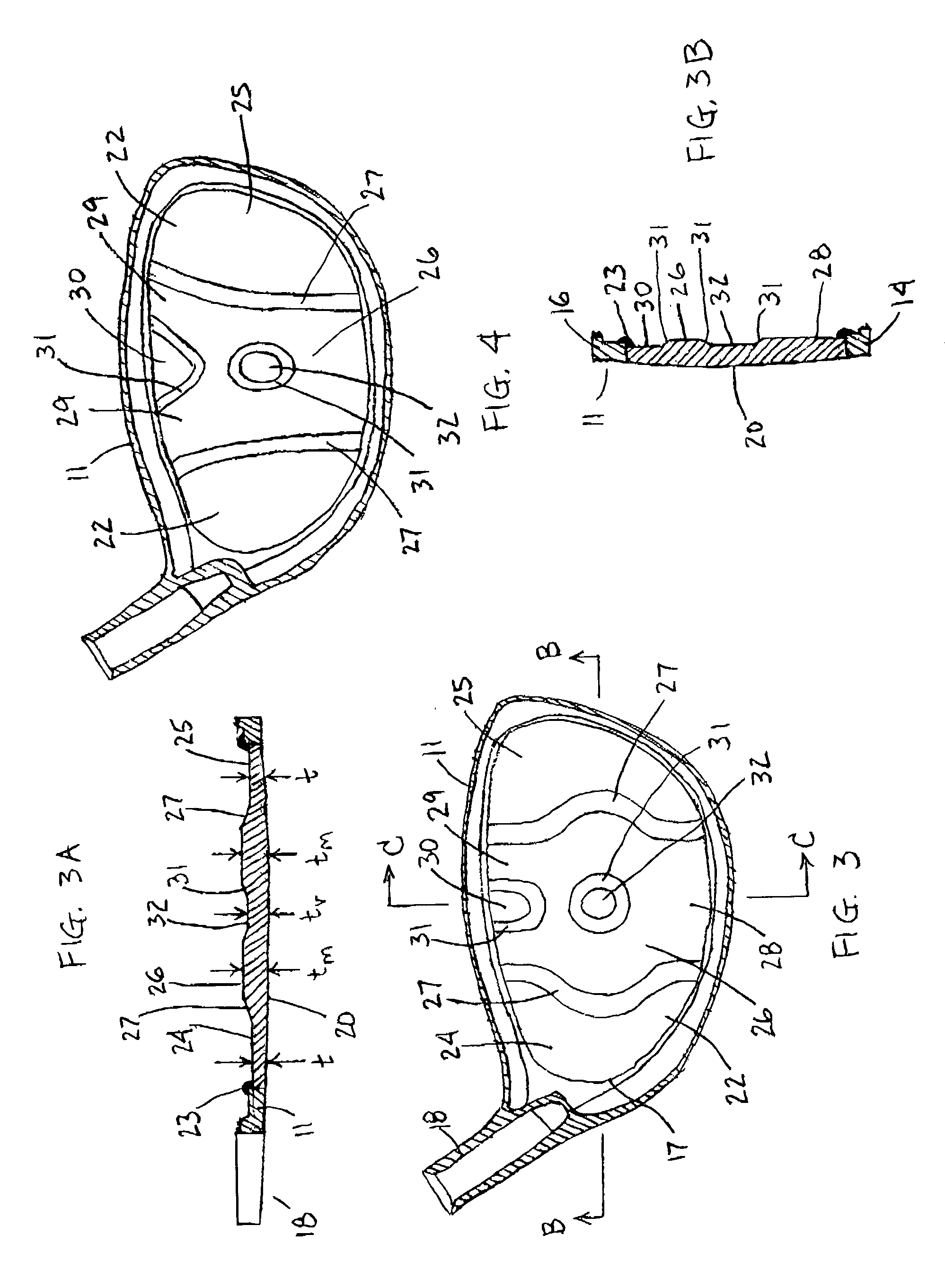

Overmolded grasper jaw

ActiveUS7494501B2Facilitate closing the jaw spinesEnhanced advantageSurgical forcepsPlastic materialsMetallic materials

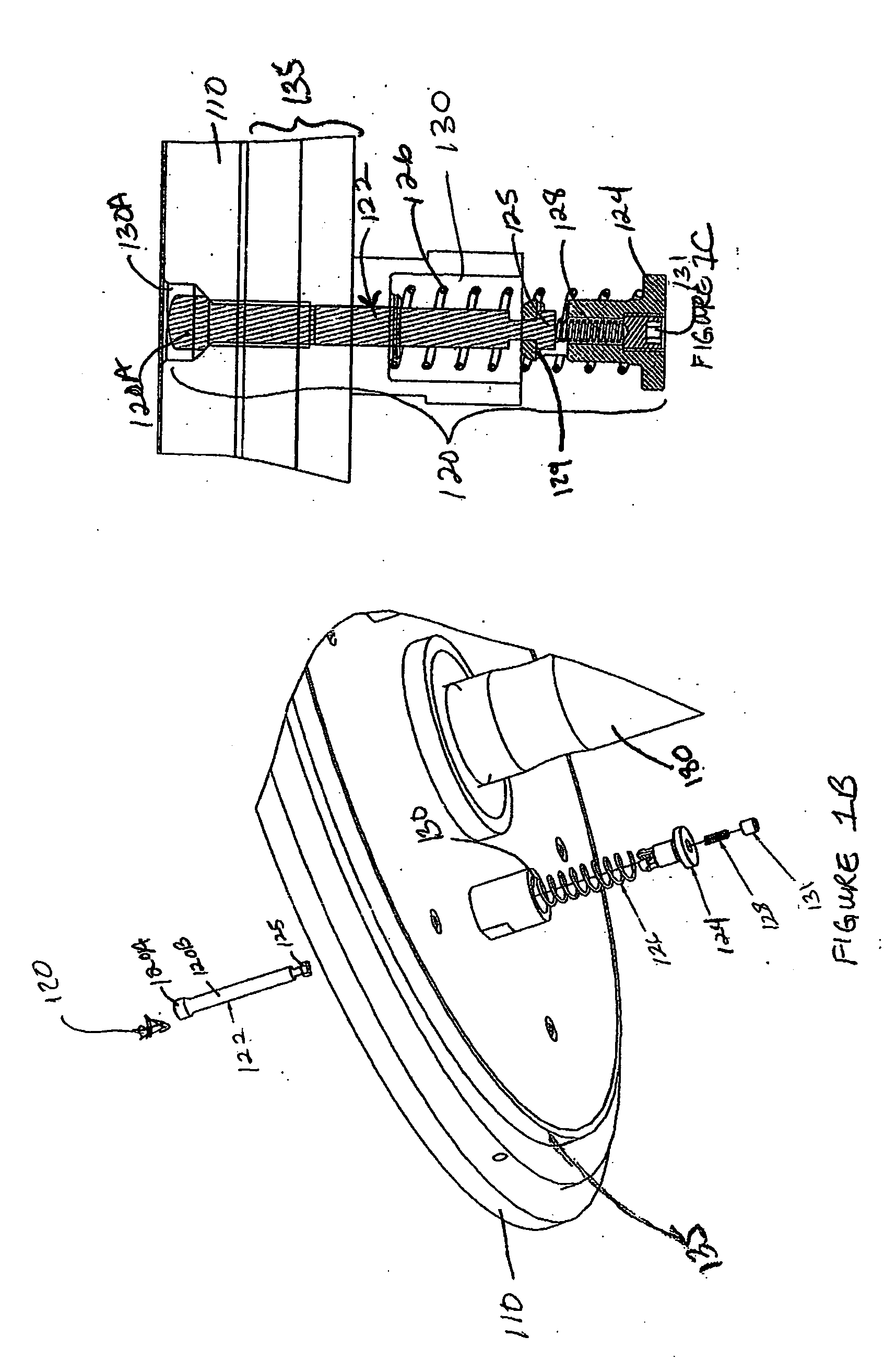

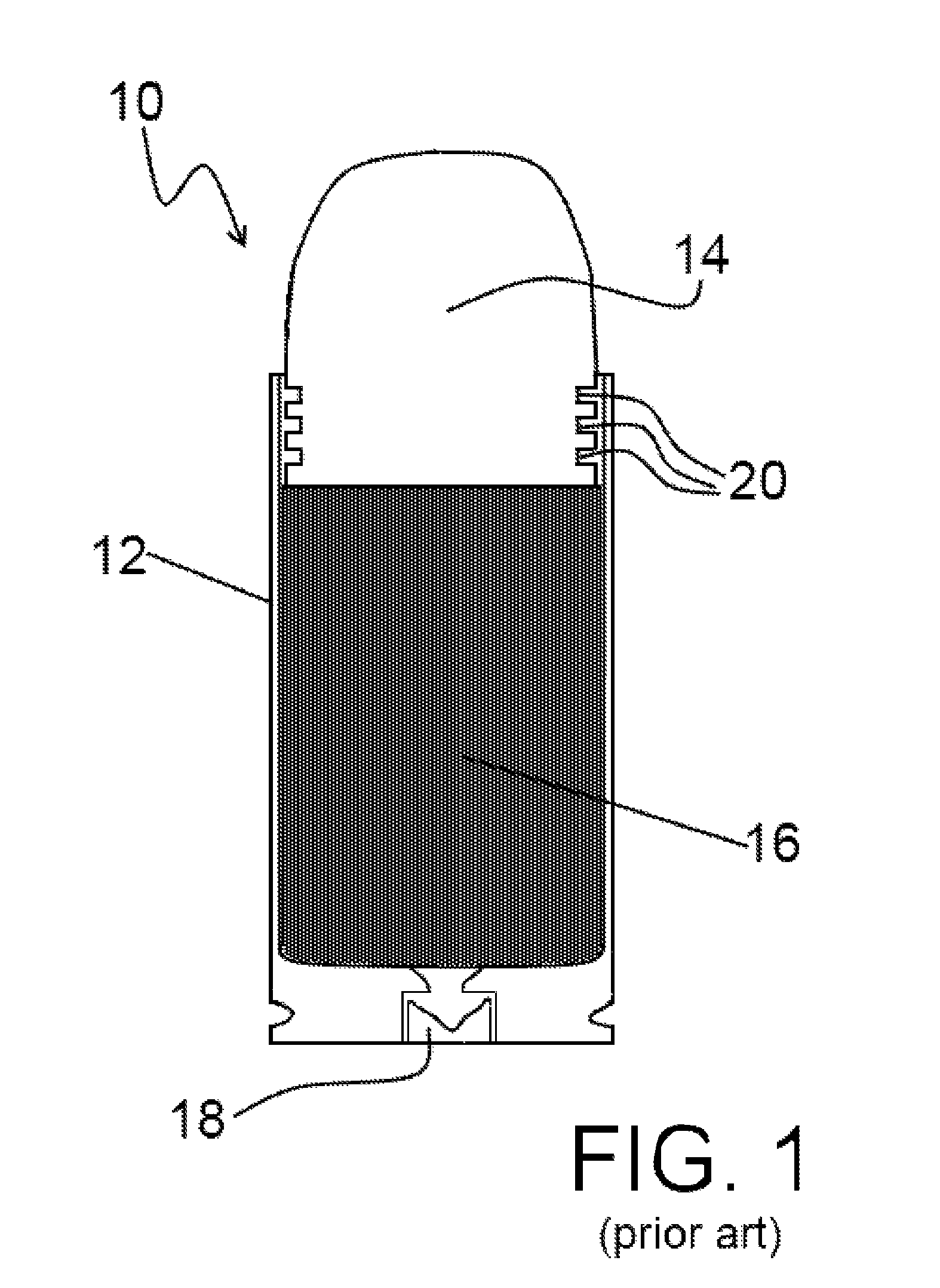

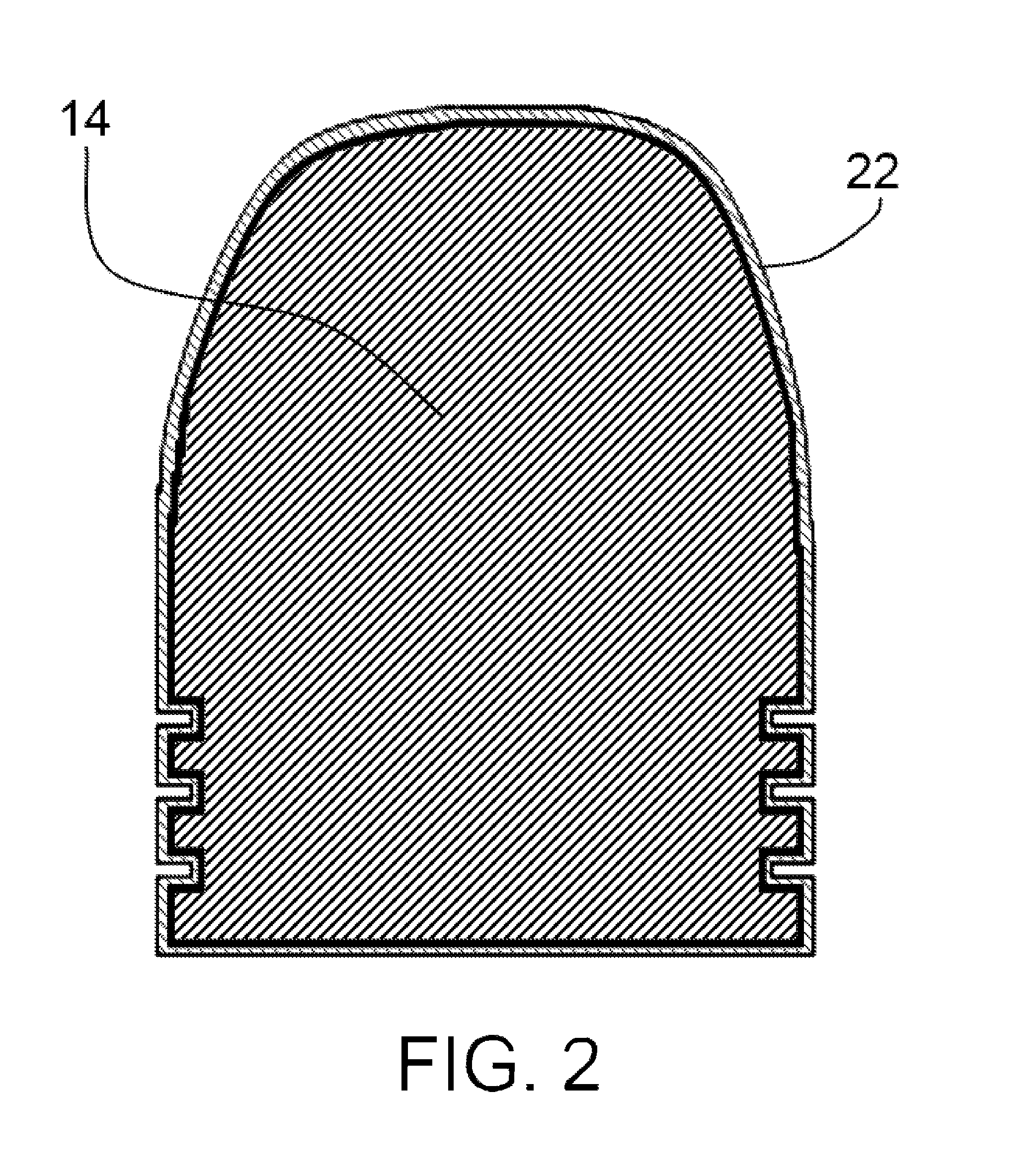

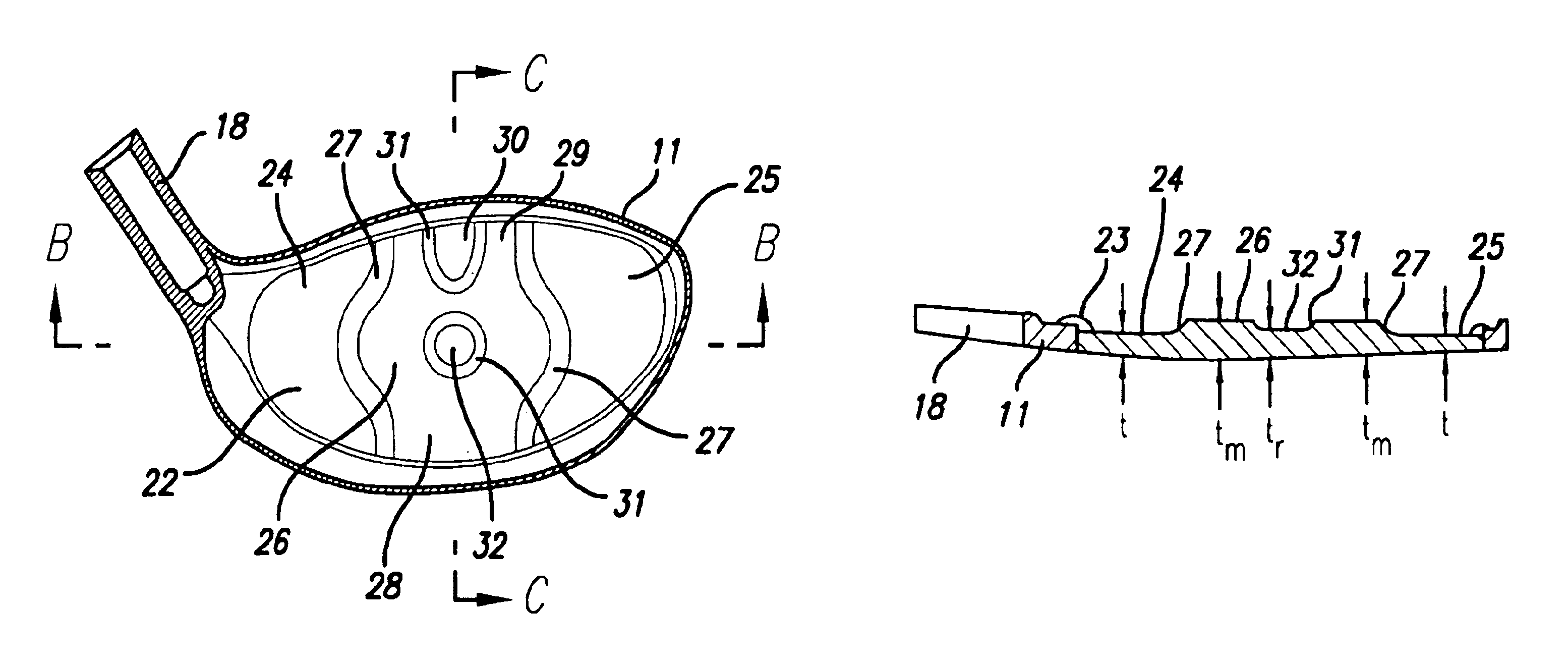

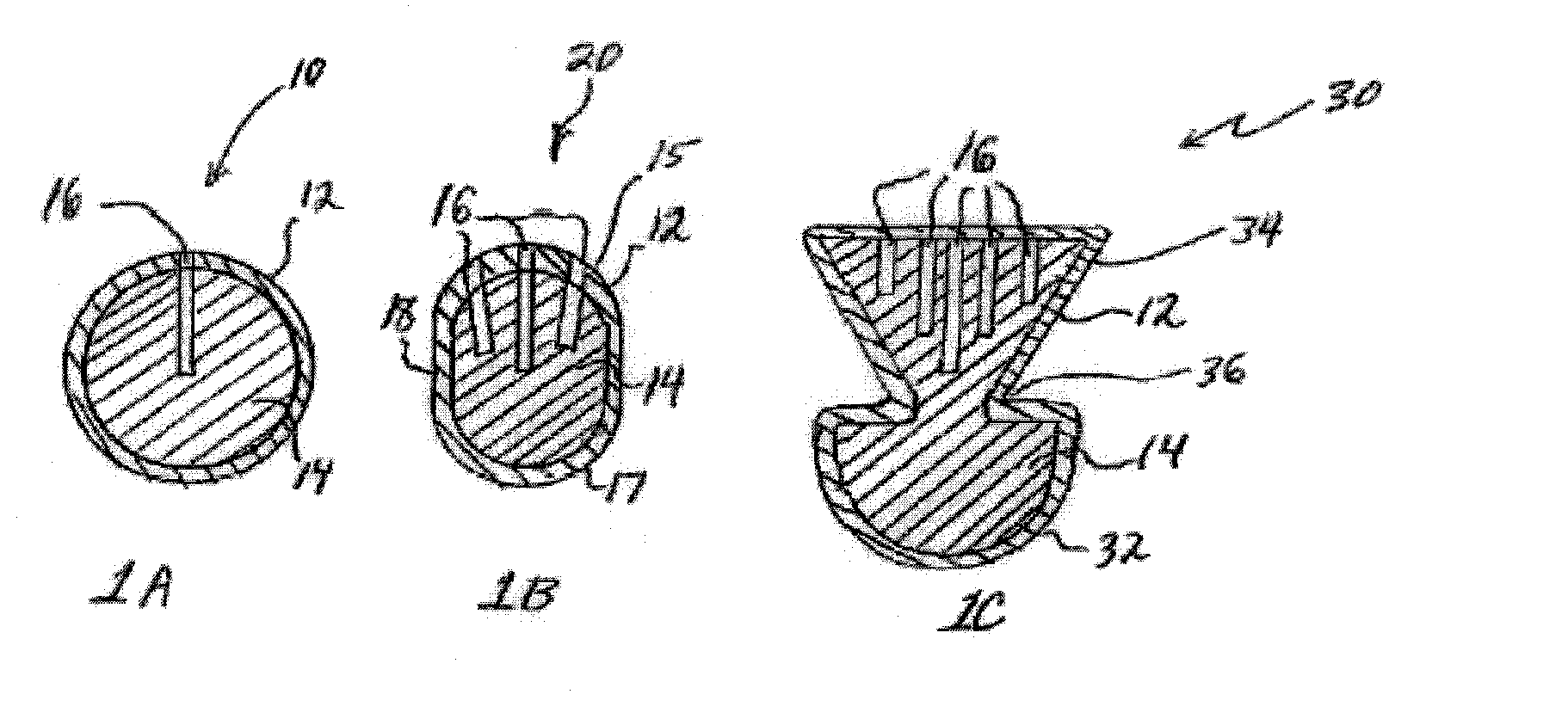

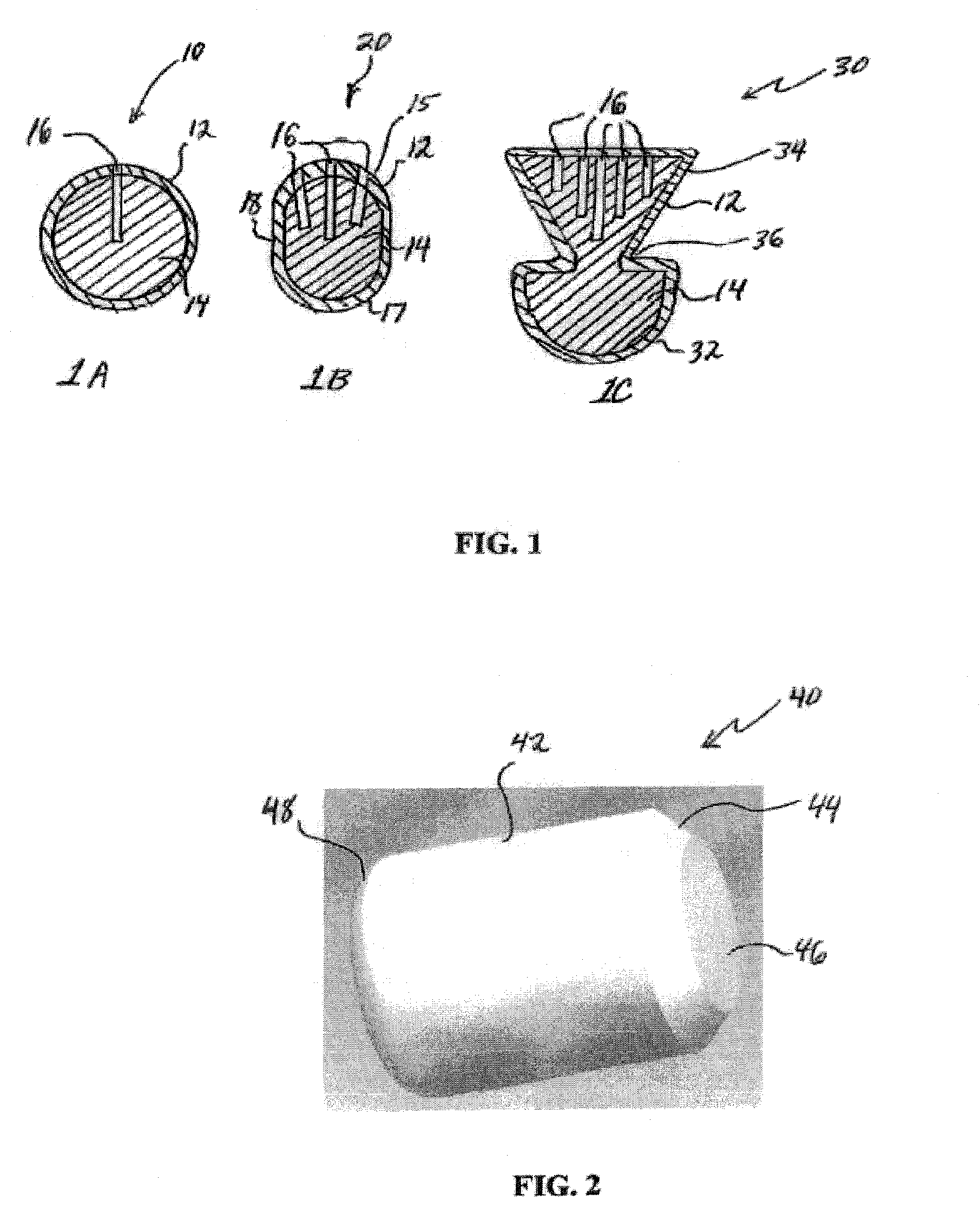

The invention is directed to a surgical instrument comprising an elongate tube extending along an axis including a camming rod and an actuation mechanism operably connected to the camming rod, the camming rod having a camming pin and a camming projection; a first jaw spine having a first cam slot, a first interior camming surface, and a first exterior camming surface; and a second jaw spine having a second cam slot, a second interior camming surface, and a second exterior camming surface, the second jaw spine pivotally connected to the first jaw spine at a common pivot pin operably connected to the elongate tube to open and close the jaw spines in response to movement of the actuation mechanism. The camming pin rides along the first and second interior camming surfaces and operates to close the jaw spines when the camming rod is moved proximally. When the camming rod moves distally, the camming projection rides on the first and second exterior camming surfaces formed on the proximal sides of the respective first and second jaw spines and operates to open the jaw spines. A feature of the invention is one camming surface on each jaw spine can facilitate closing the jaw spines while the other camming surface on each jaw spine can facilitate opening the jaw spines. These two camming surfaces on each jaw spine can be widely separated. The jaw spines can be formed of a metallic material and are overmolded with an atraumatic plastic material. By overmolding the plastic onto the metal spine, an atraumatic outer surface can be formed of the plastic material along with a high degree of detail.

Owner:APPL MEDICAL RESOURCES CORP

Bioabsorbable Polymer, Bioabsorbable Composite Stents

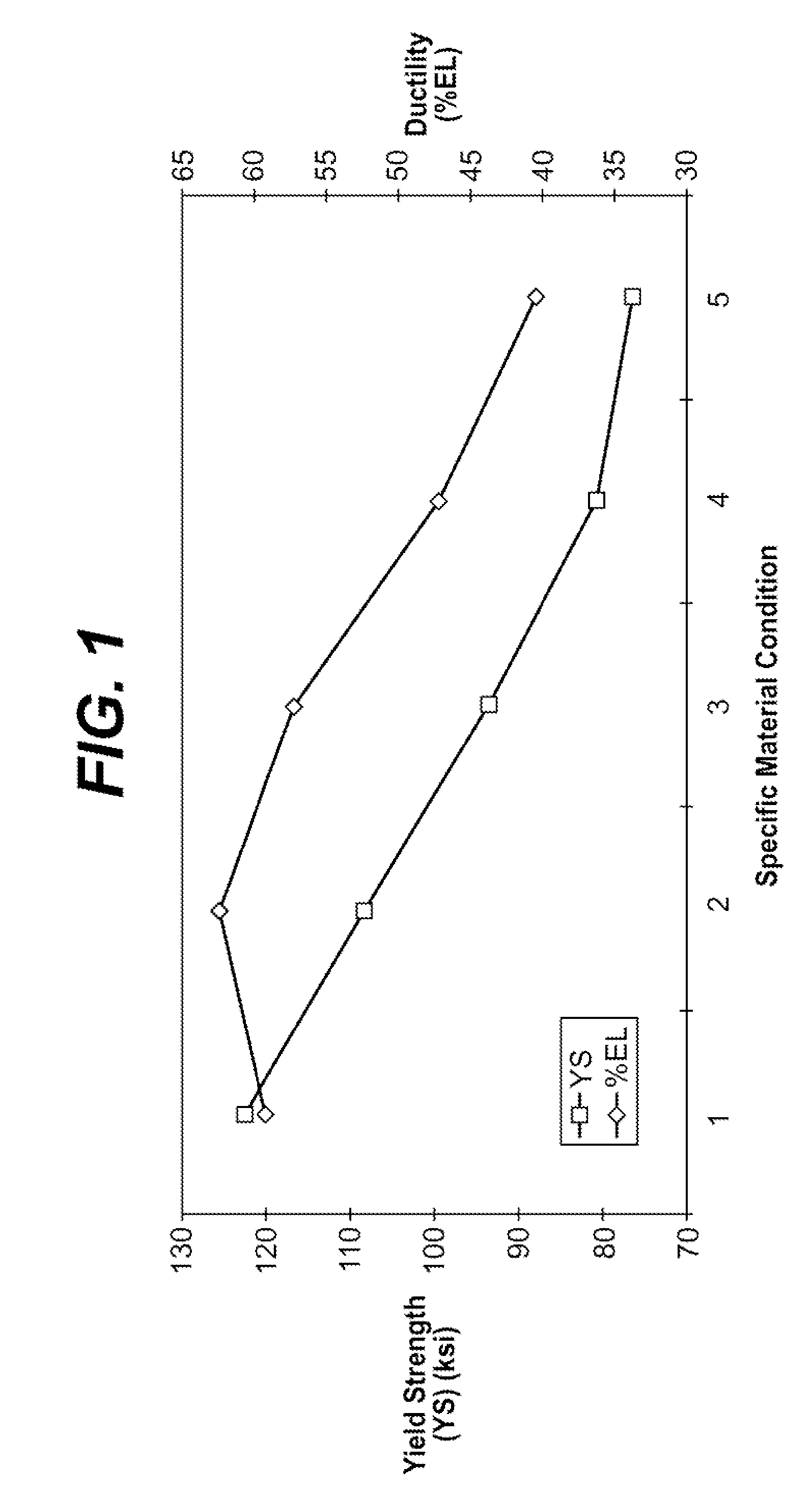

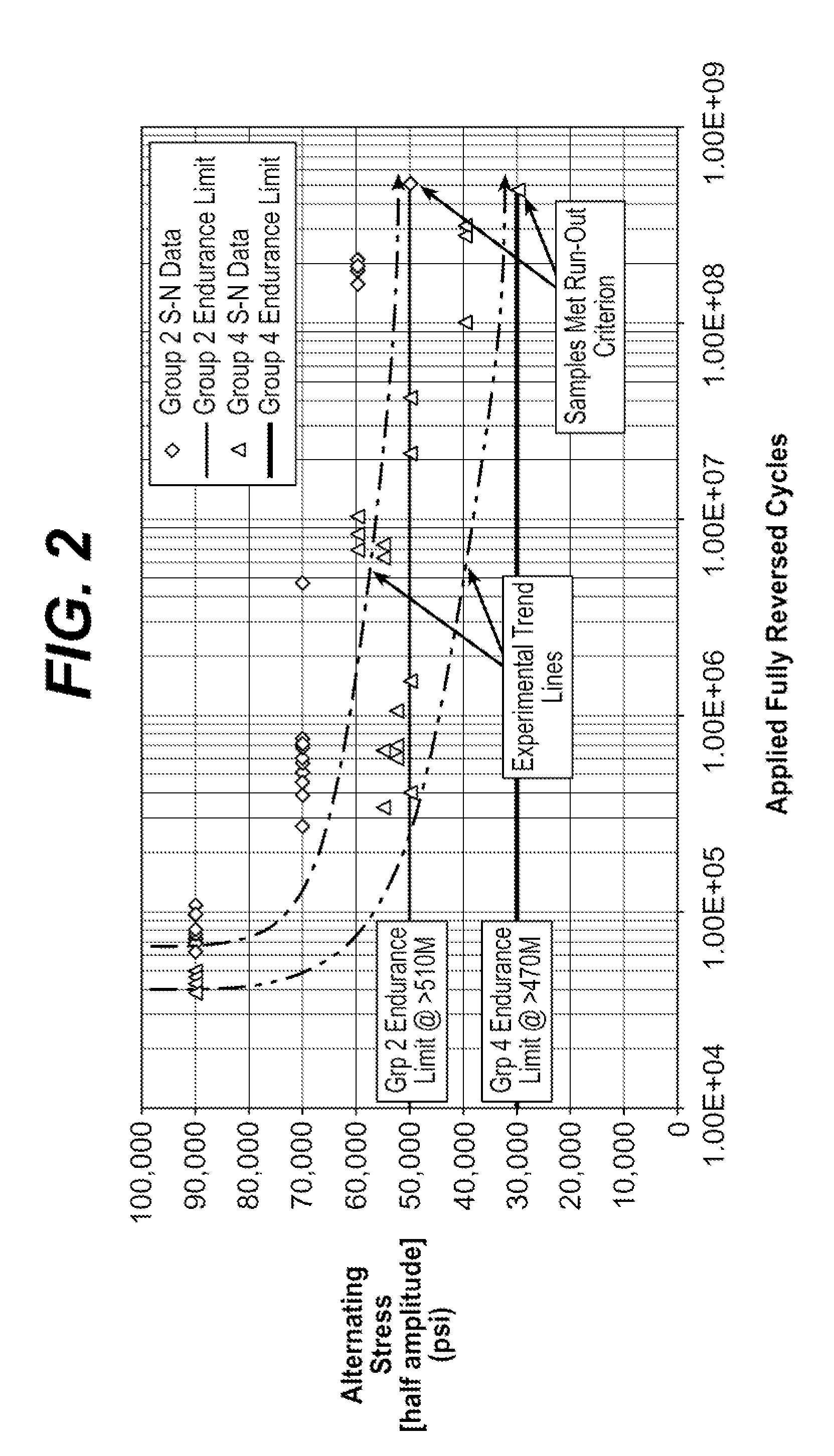

InactiveUS20080249608A1Simple and inexpensive to manufactureVarying of ductilityStentsSurgeryMetallic materialsMedical device

Biocompatible materials may be configured into any number of implantable medical devices including intraluminal stents. The biocompatible material may comprise metallic and non-metallic materials in hybrid structures. In one such structure, a device may be fabricated with one or more elements having an inner metallic core that is biodegradable with an outer shell formed from a polymeric material that is biodegradable. Additionally, therapeutic agents may be incorporated into the microstructure or the bulk material.

Owner:CORDIS CORP

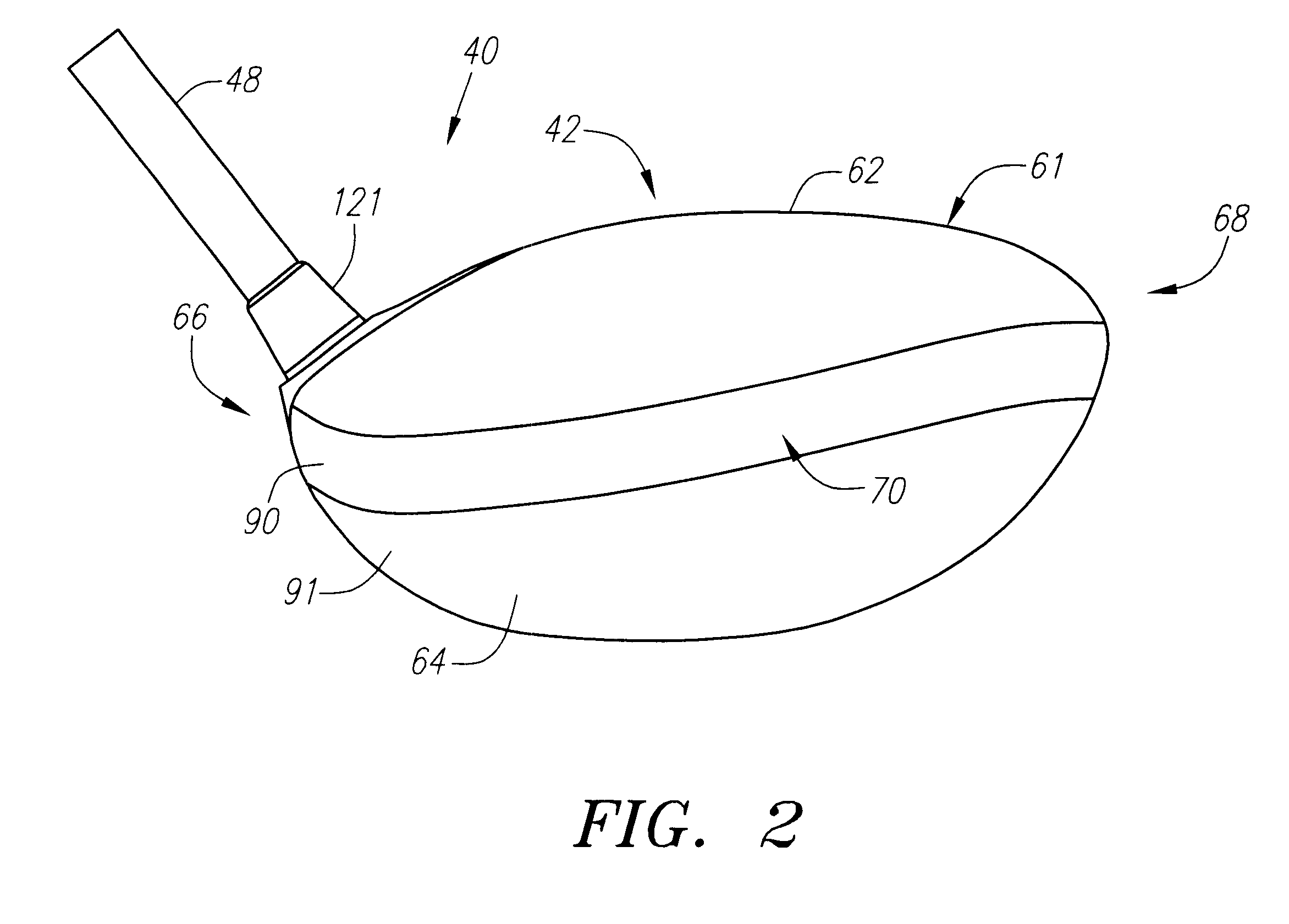

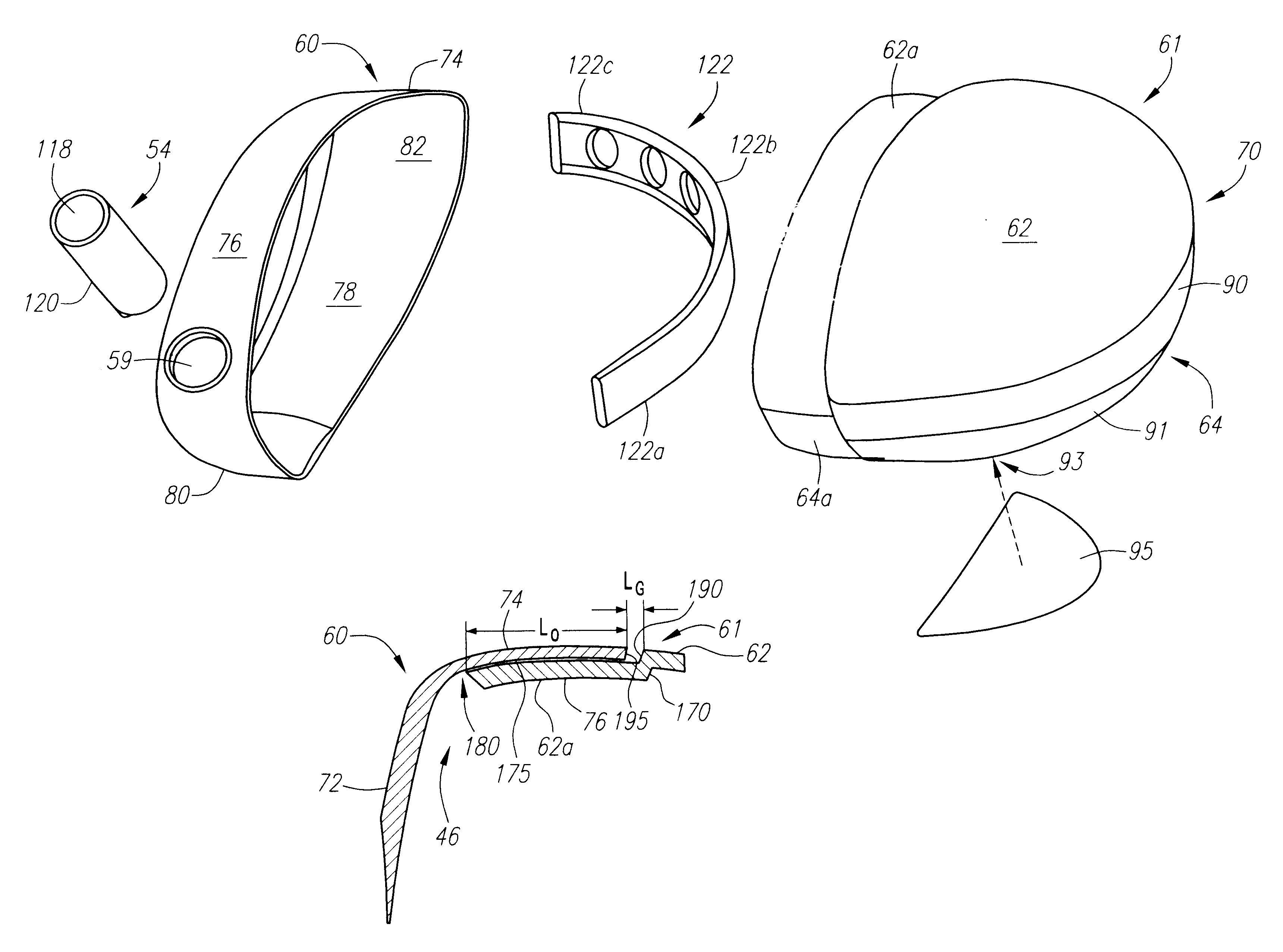

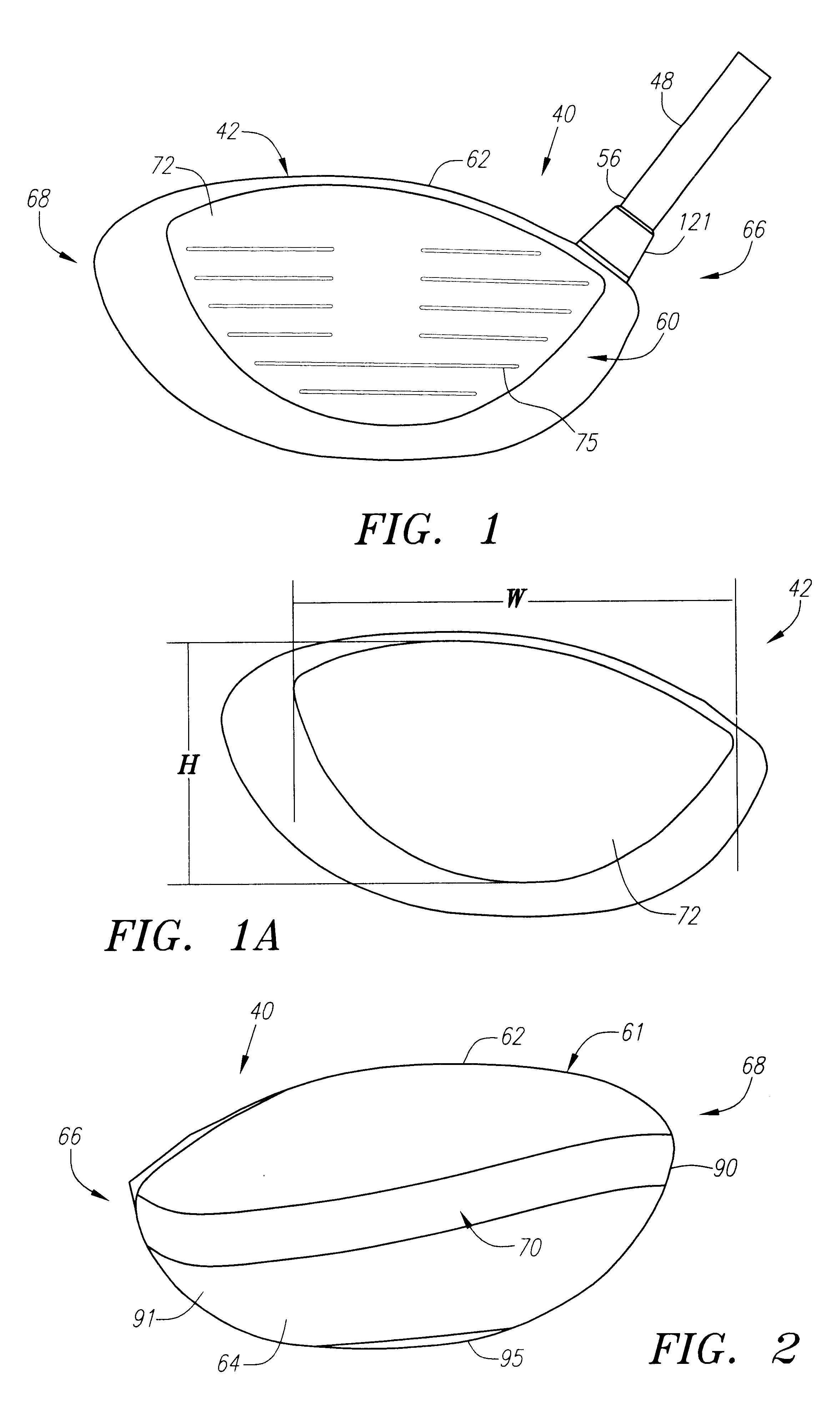

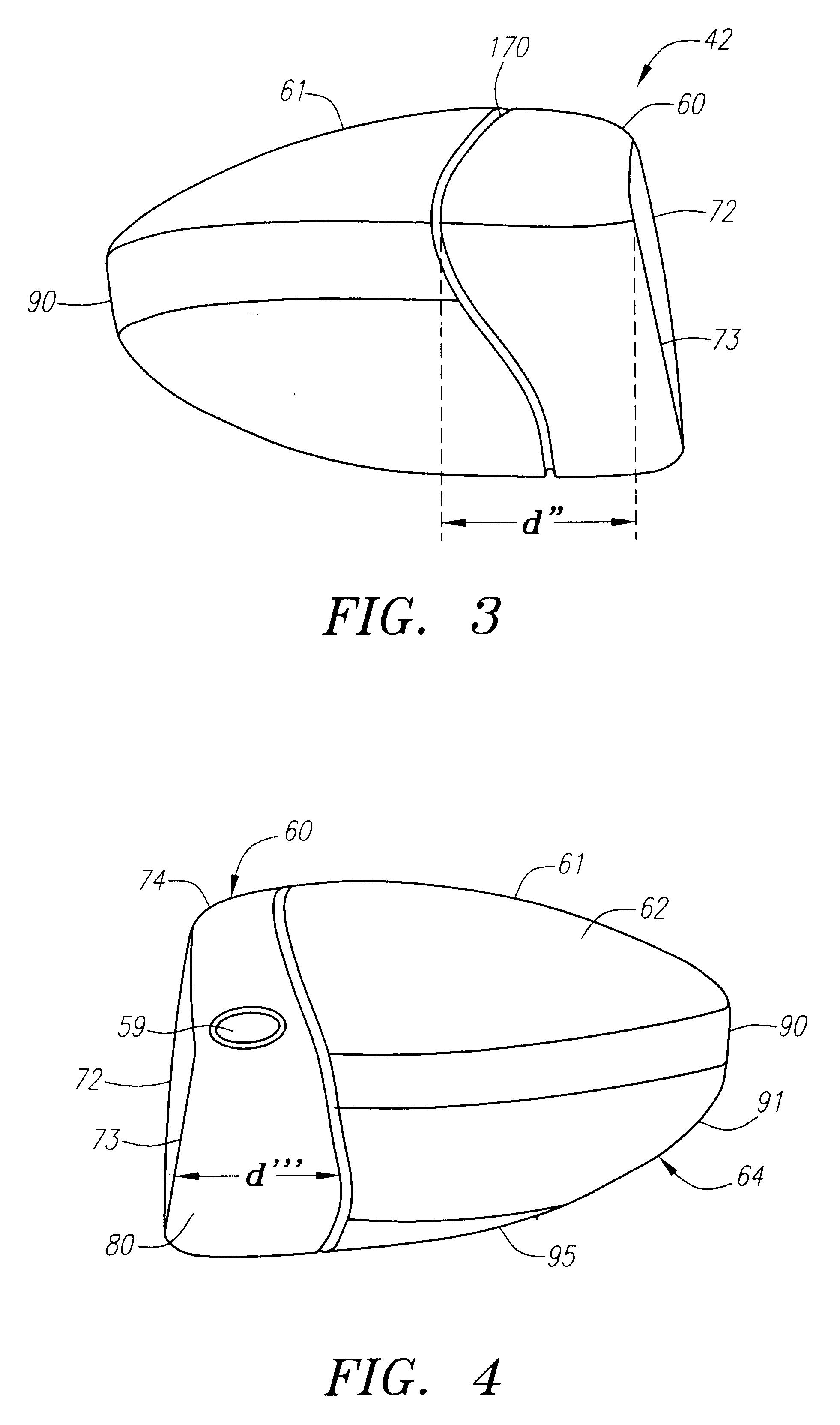

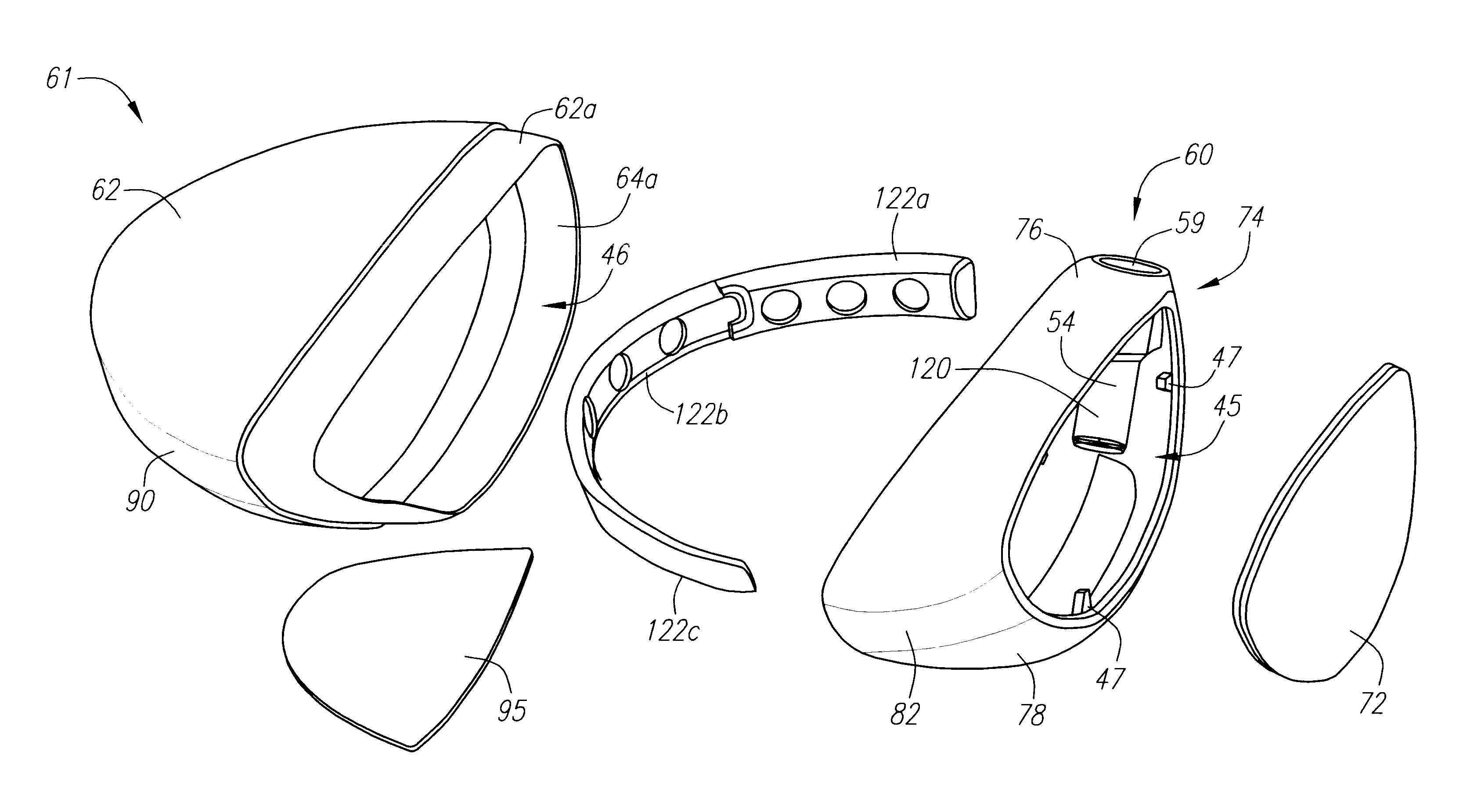

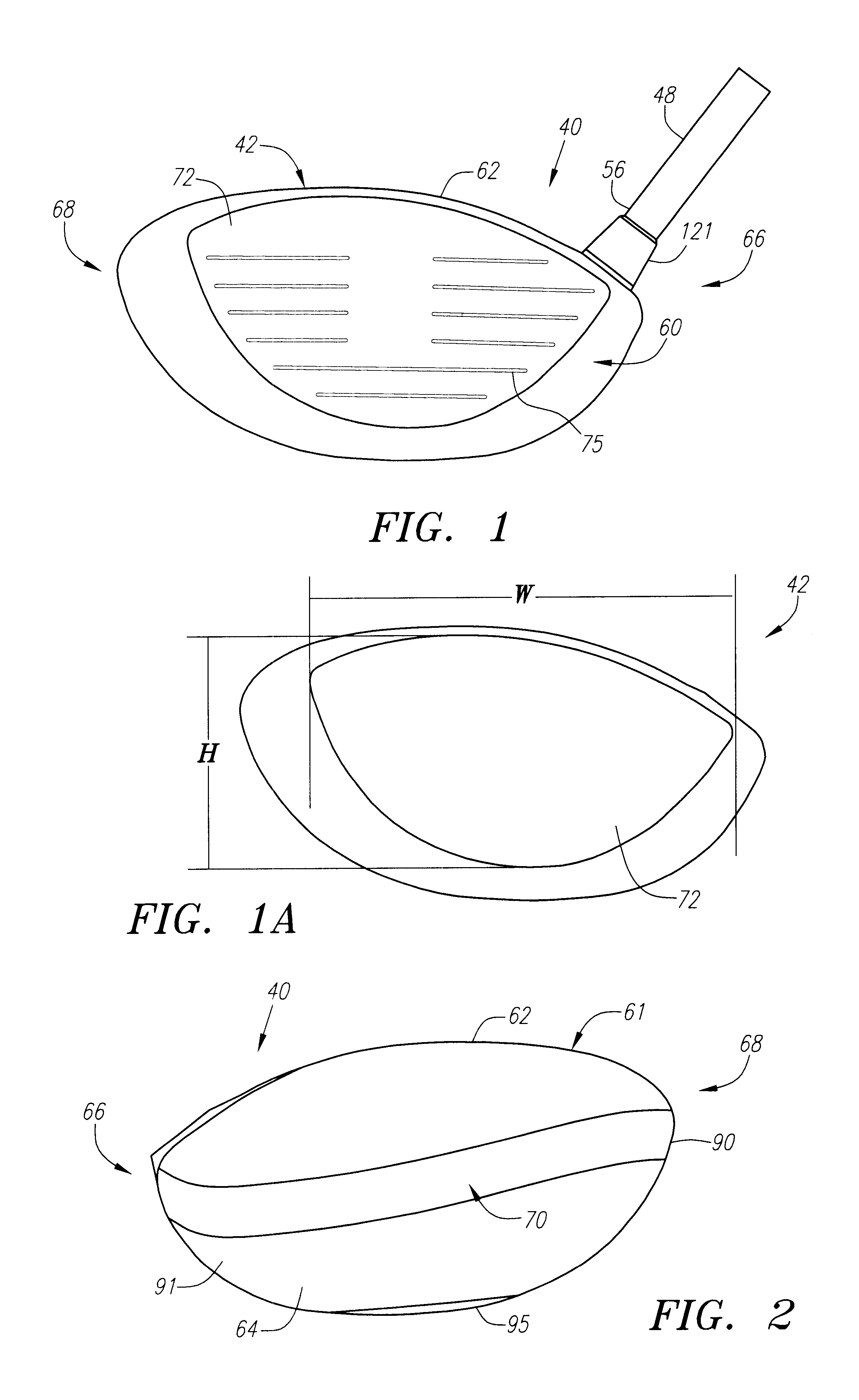

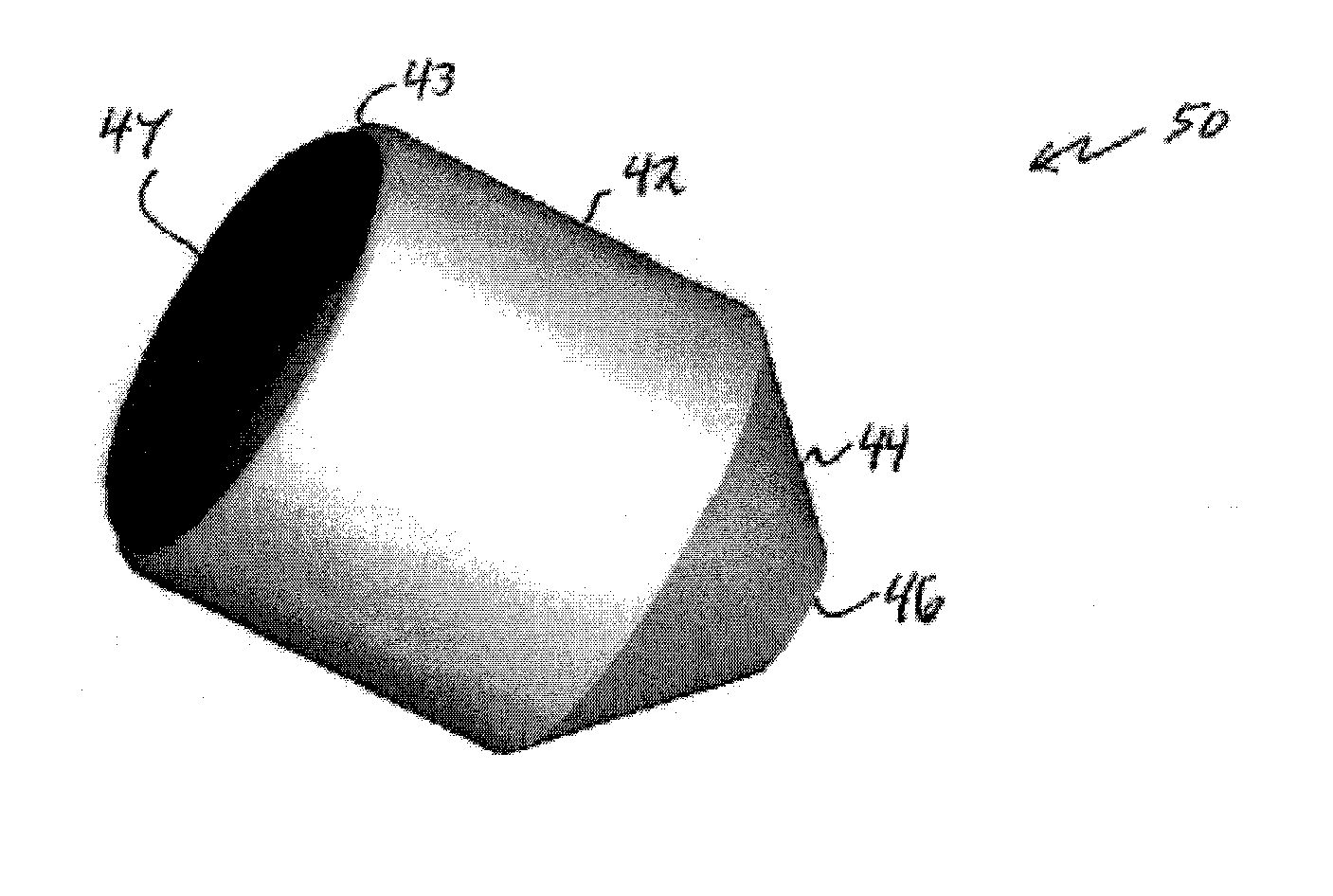

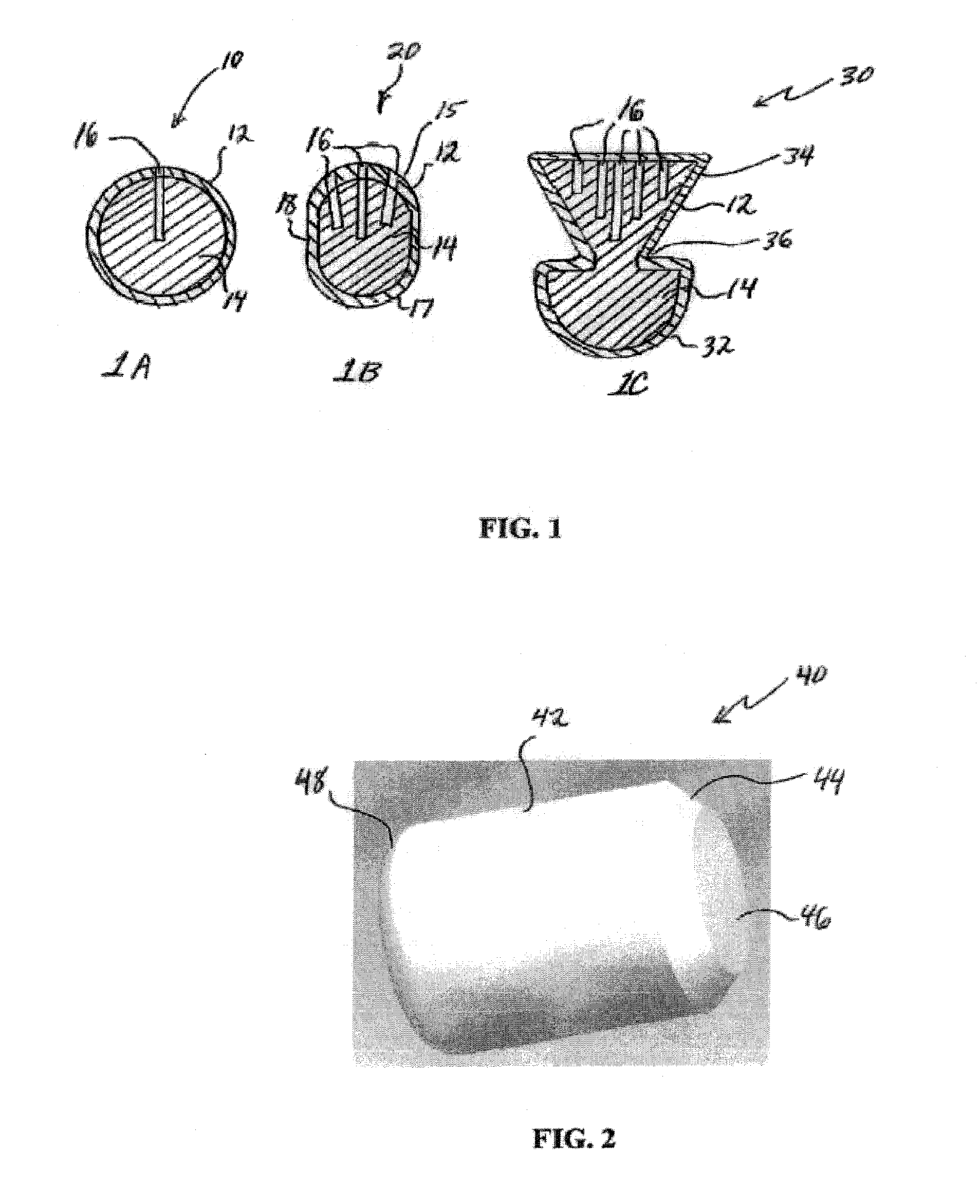

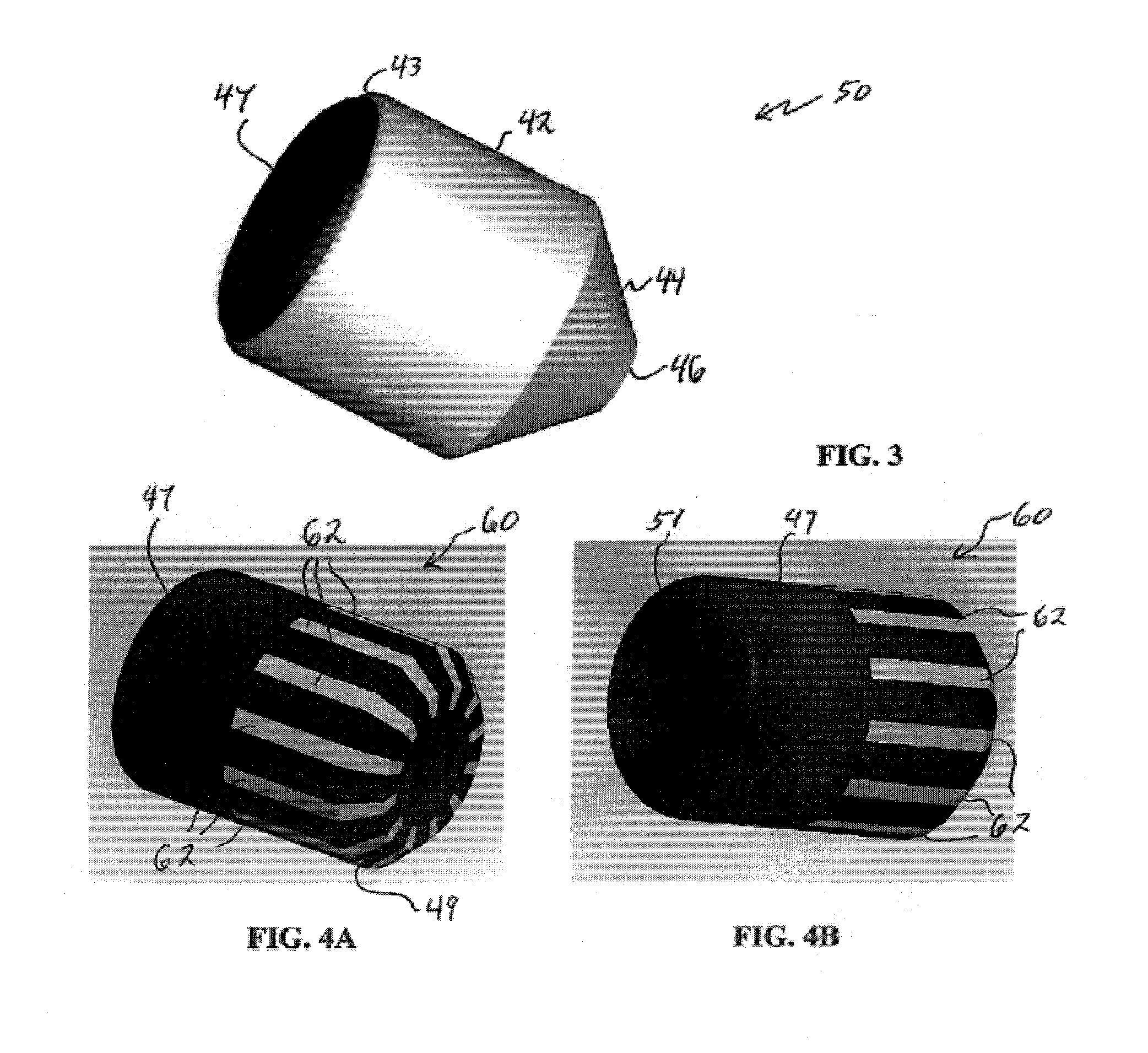

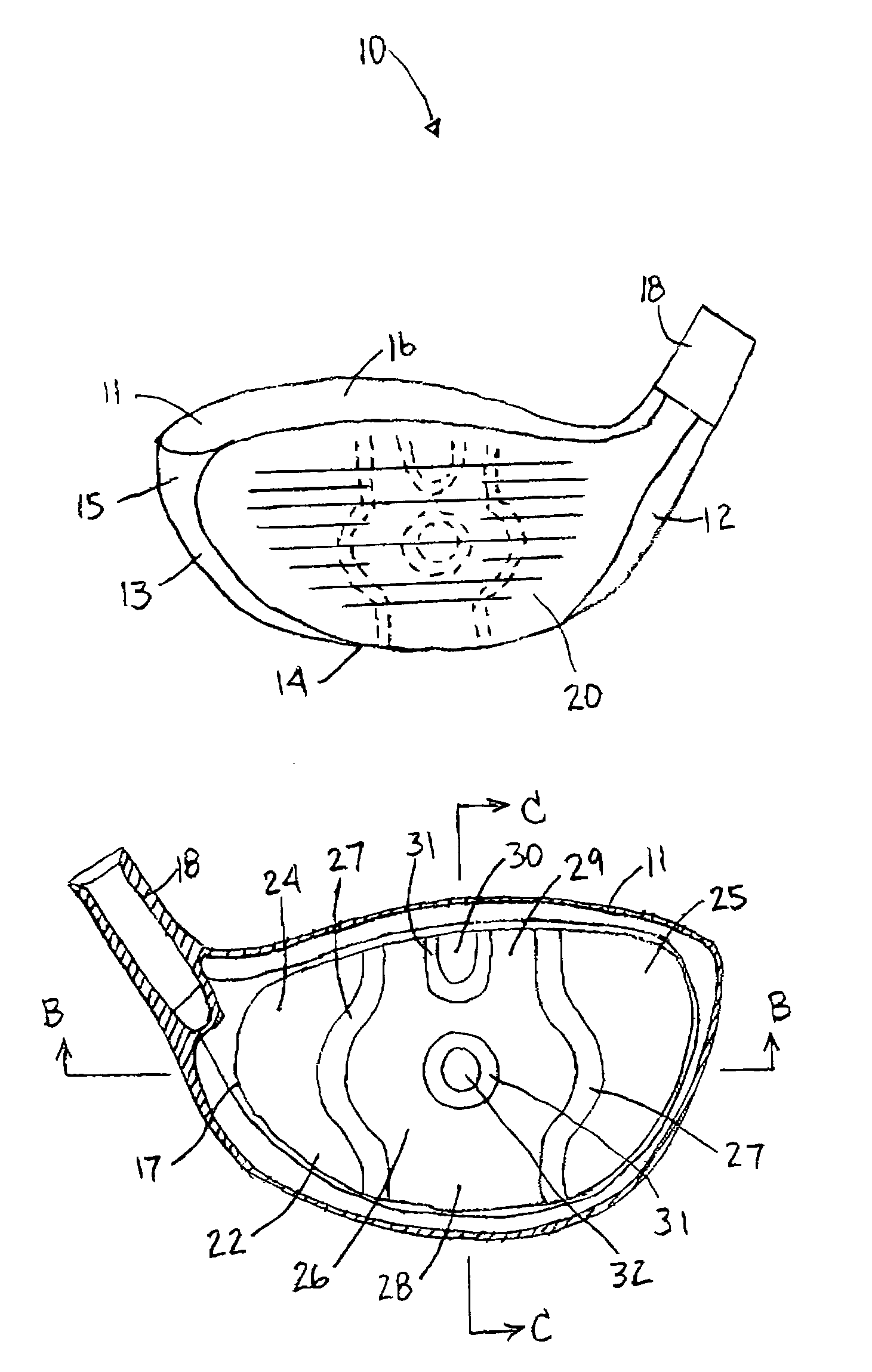

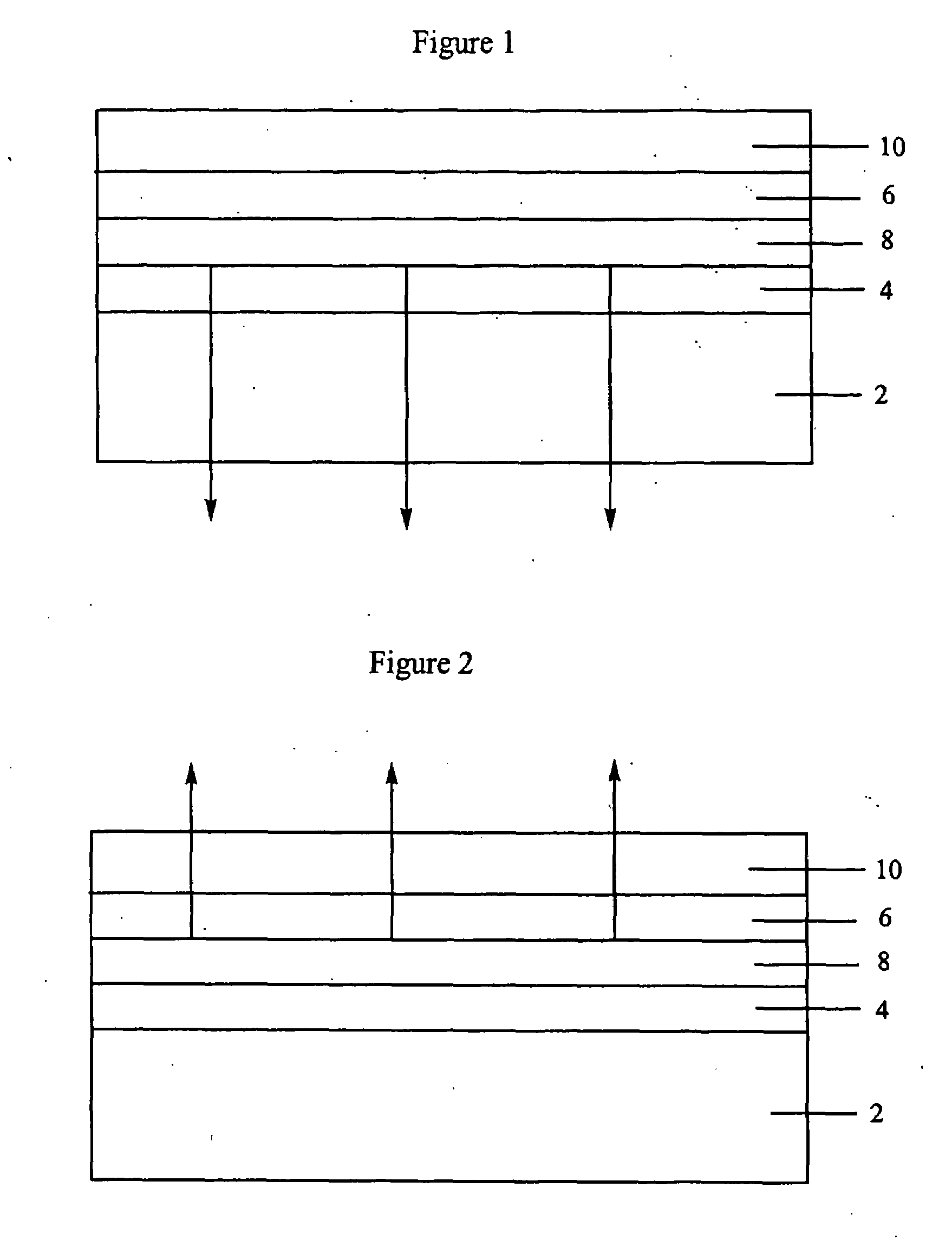

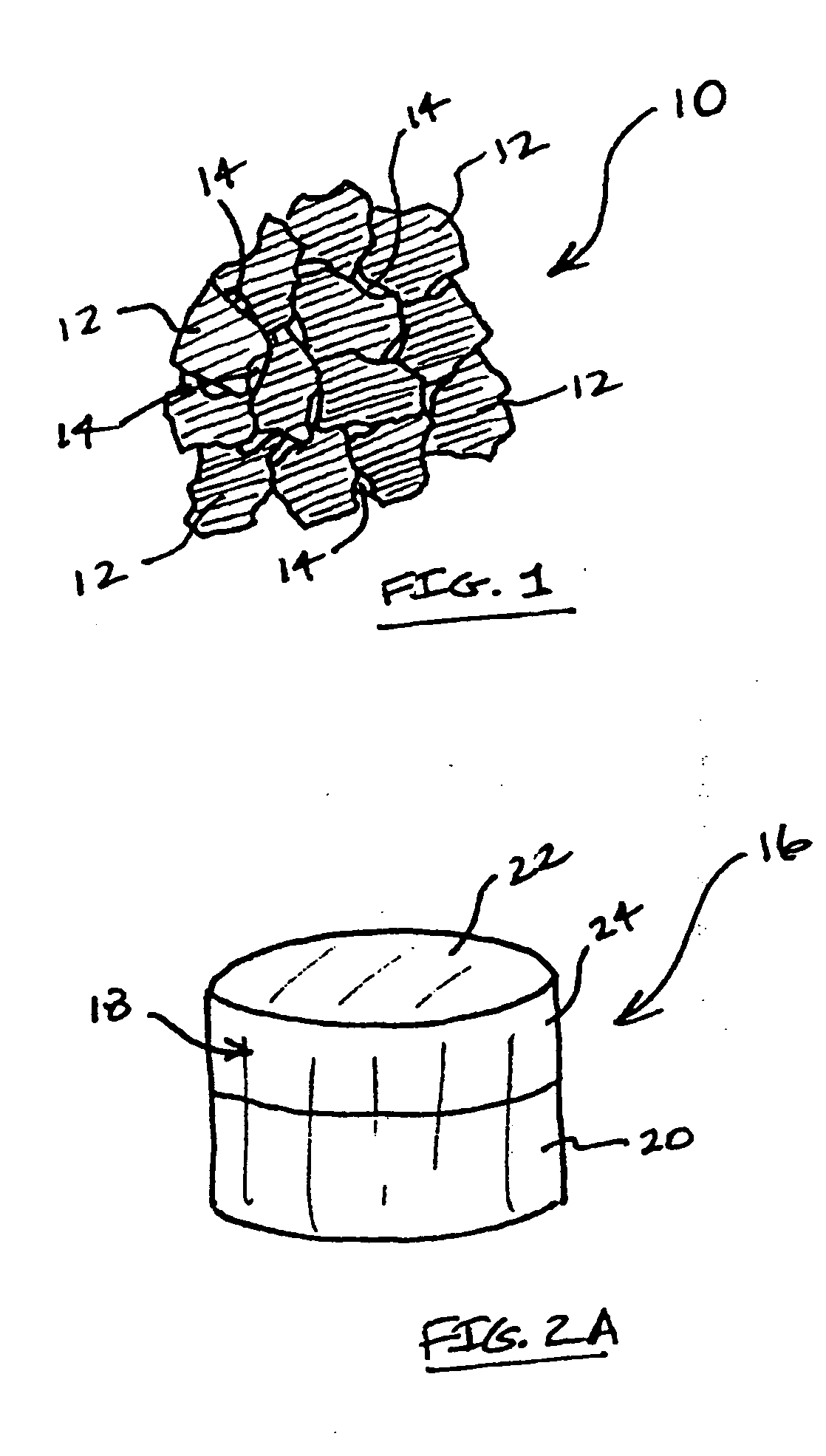

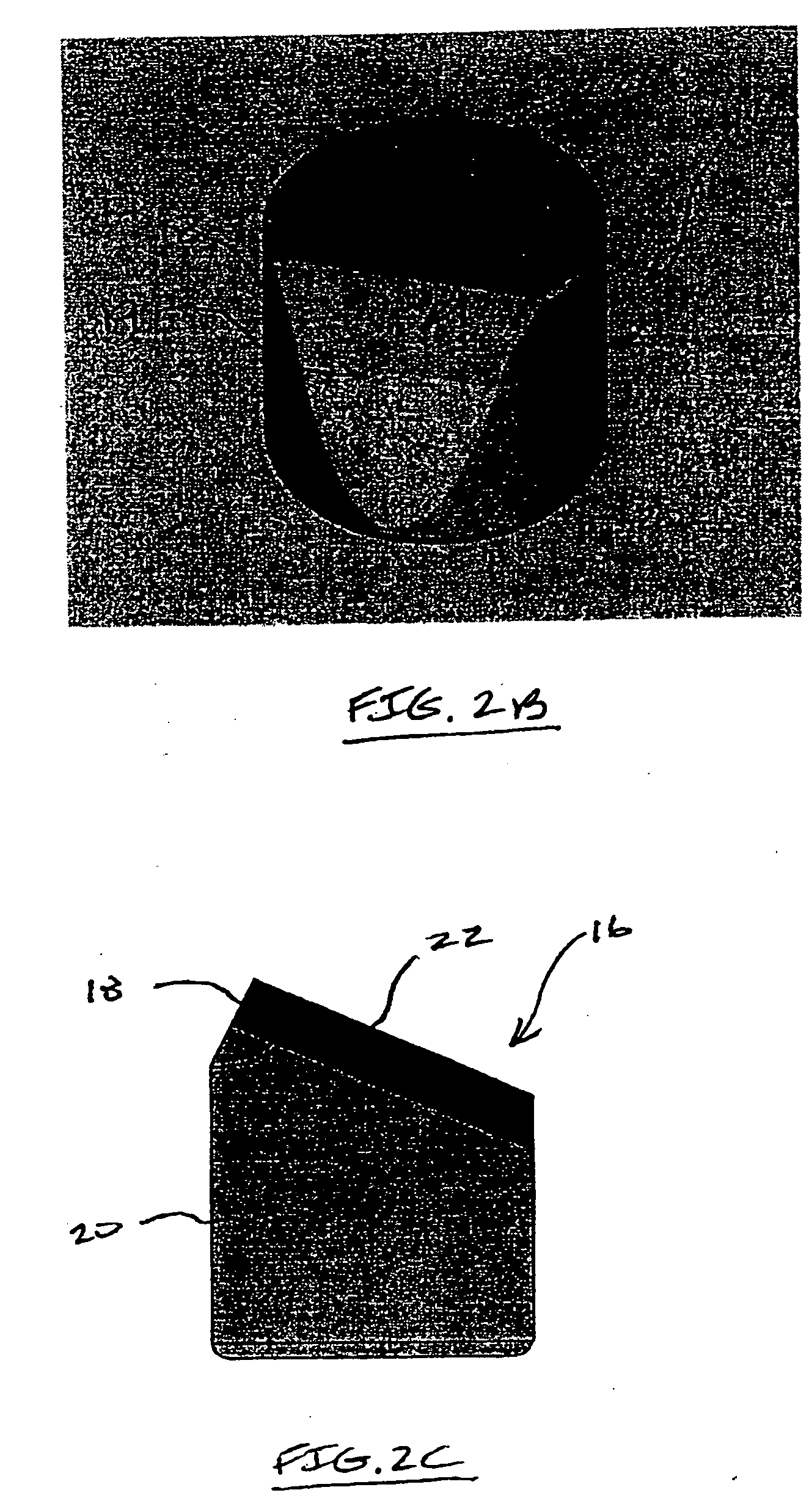

Multiple material golf club head

InactiveUS6491592B2Large coefficientImprove complianceMetal-working apparatusGolf clubsCoefficient of restitutionMetallic materials

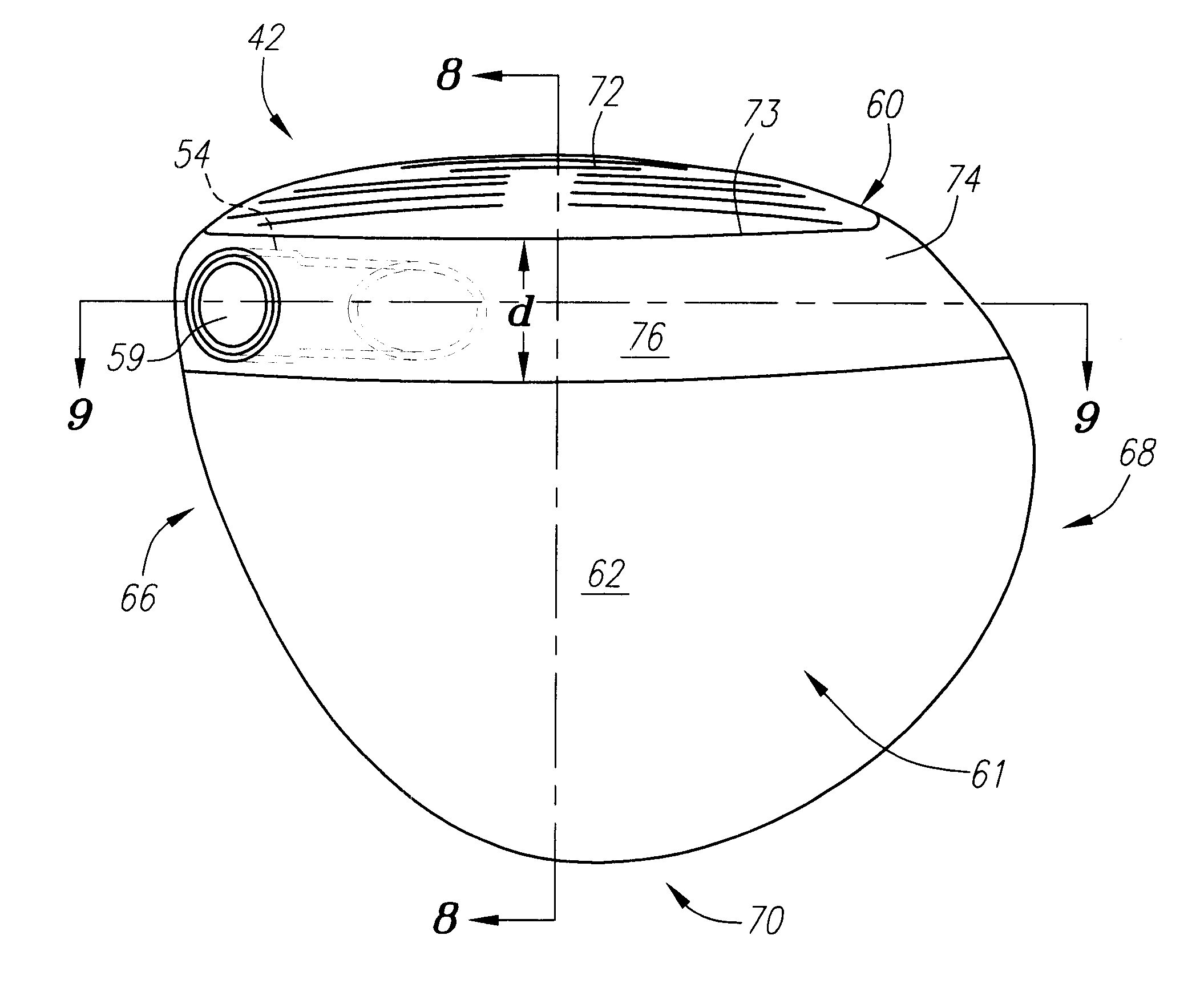

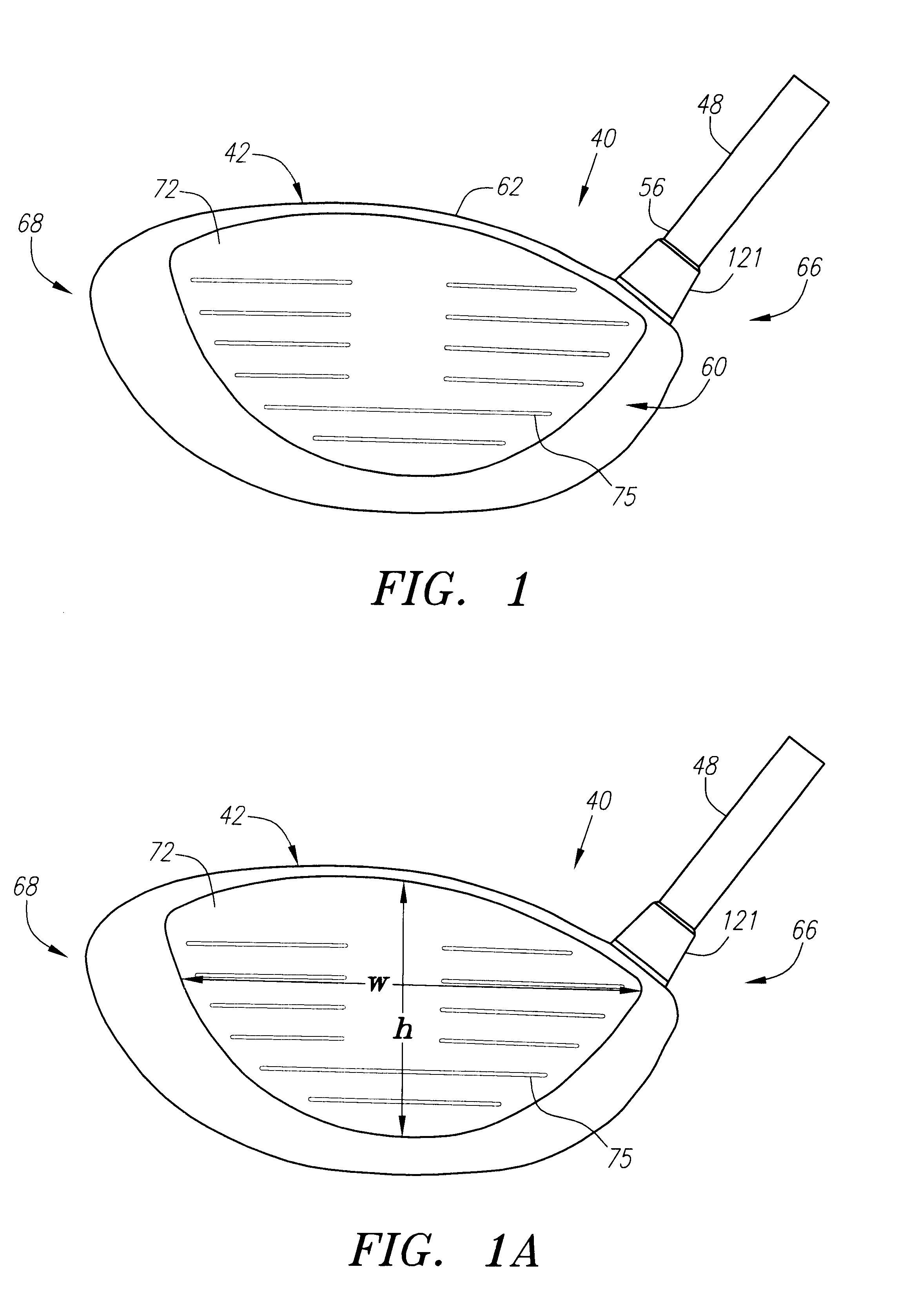

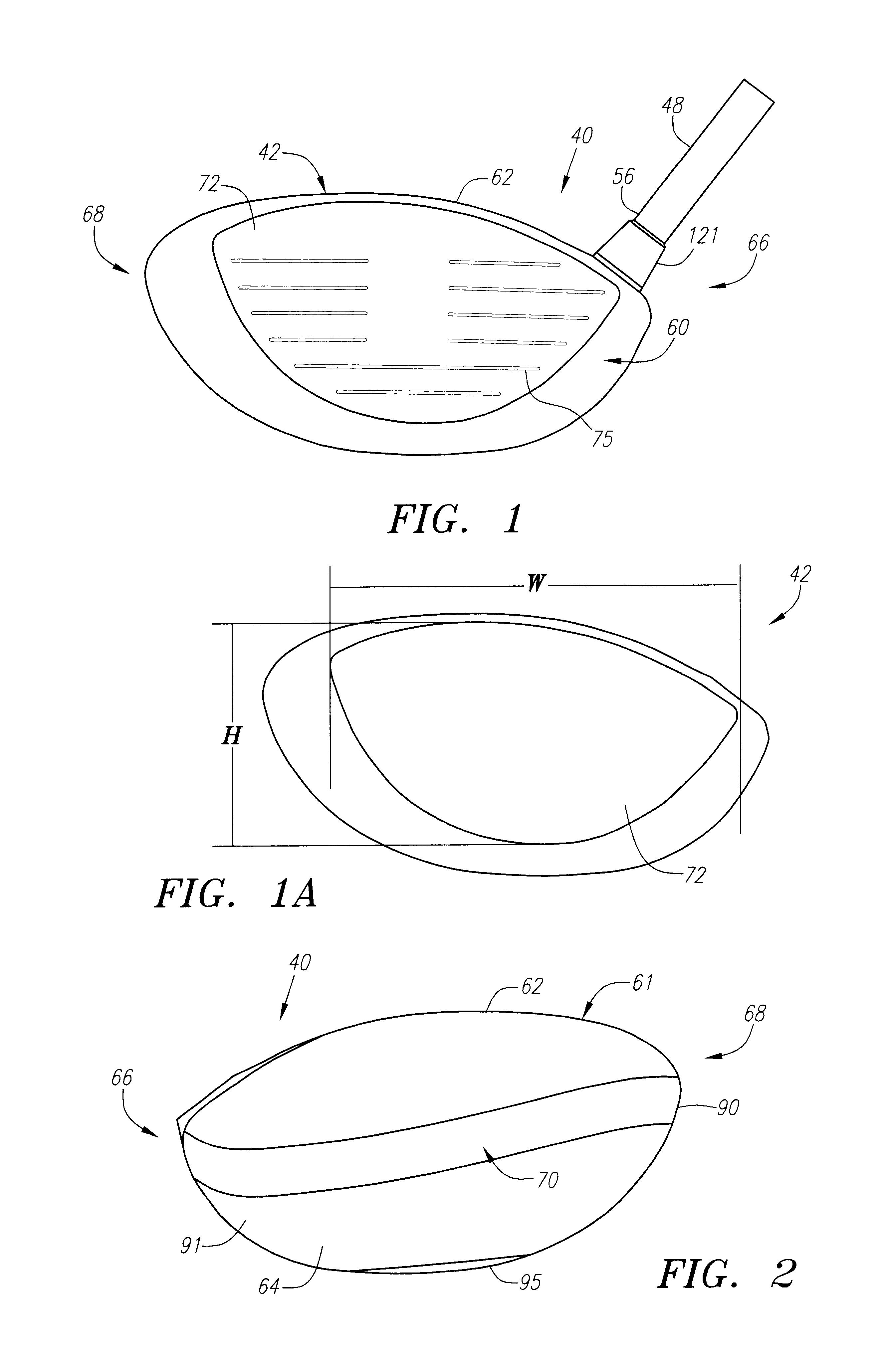

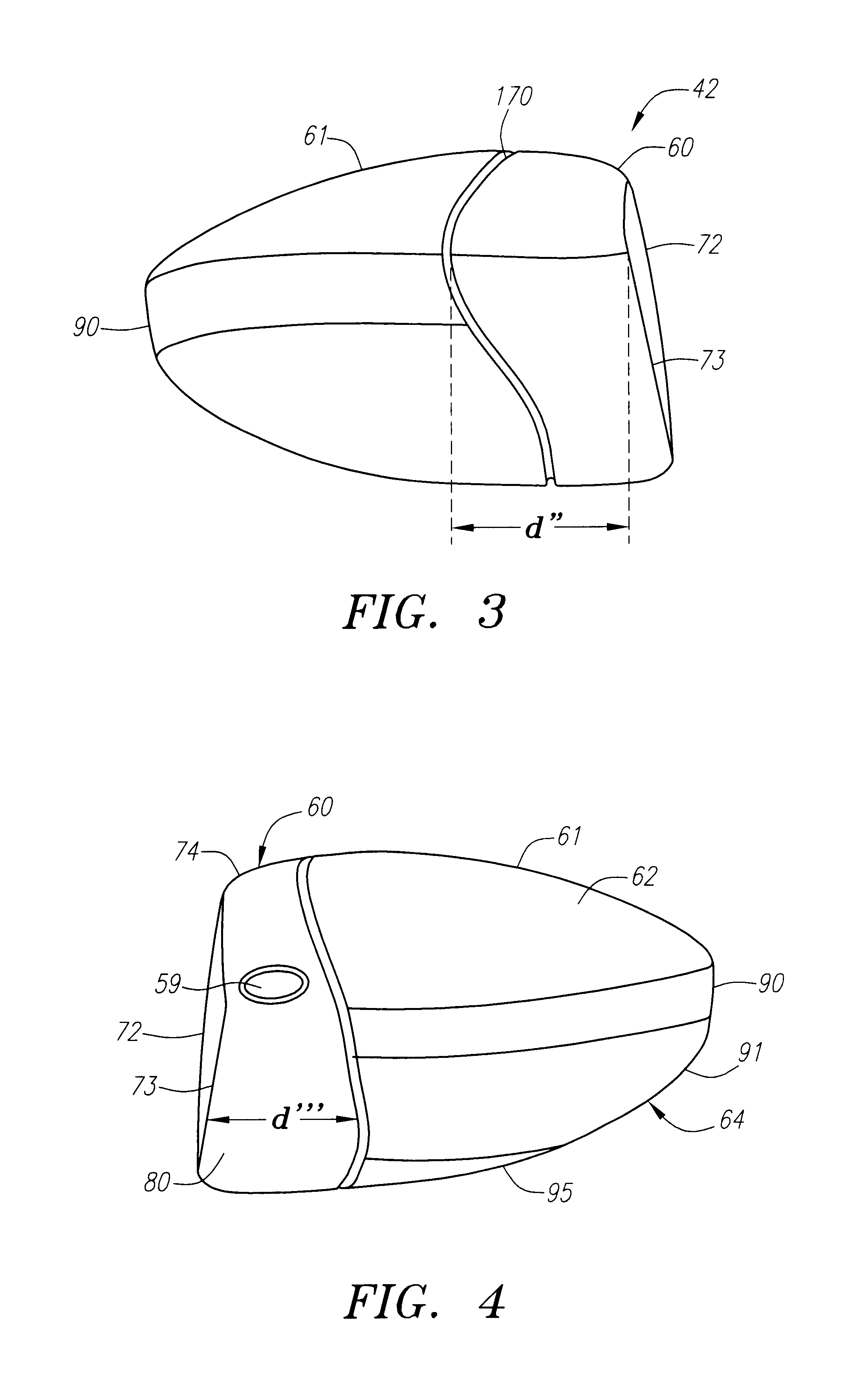

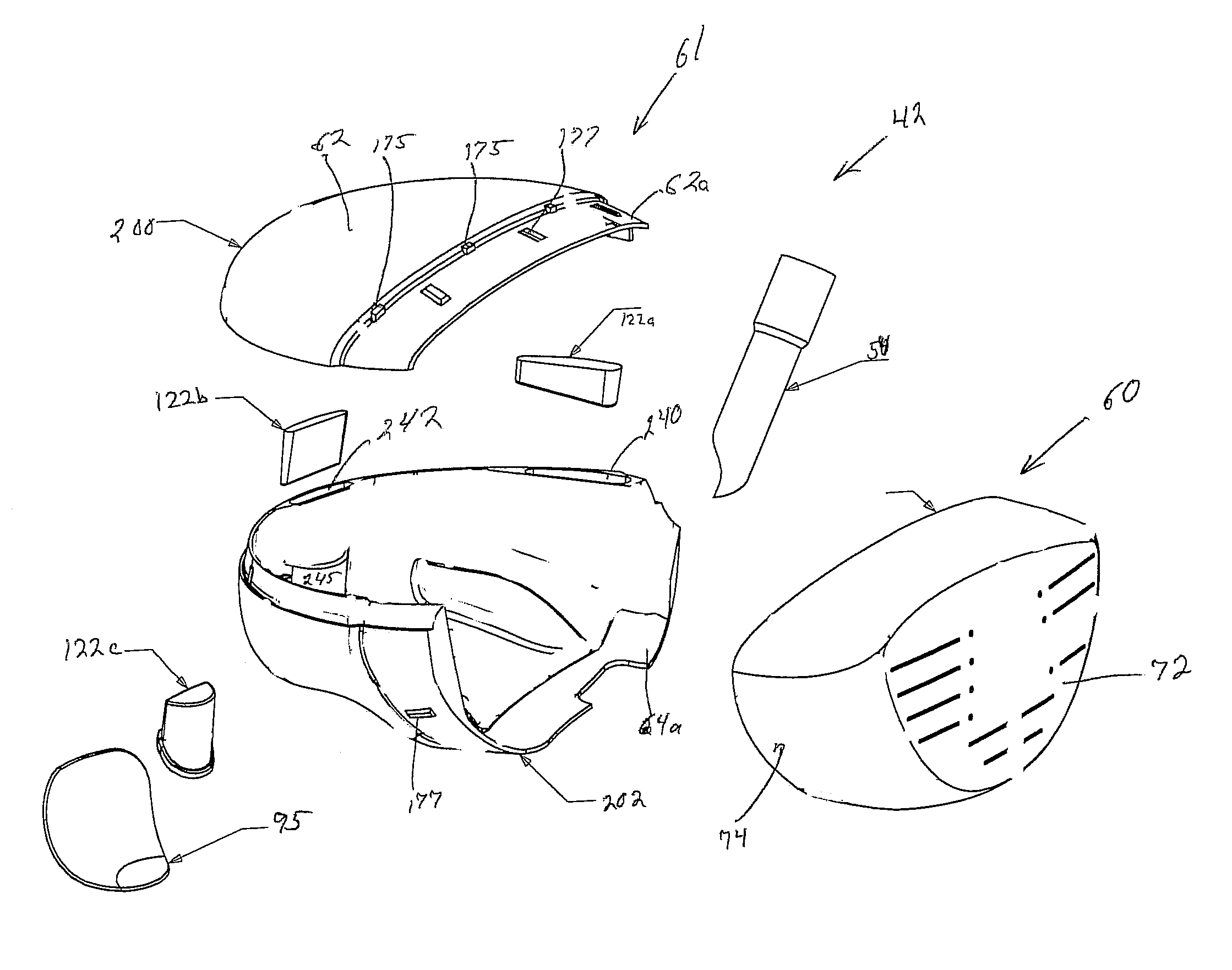

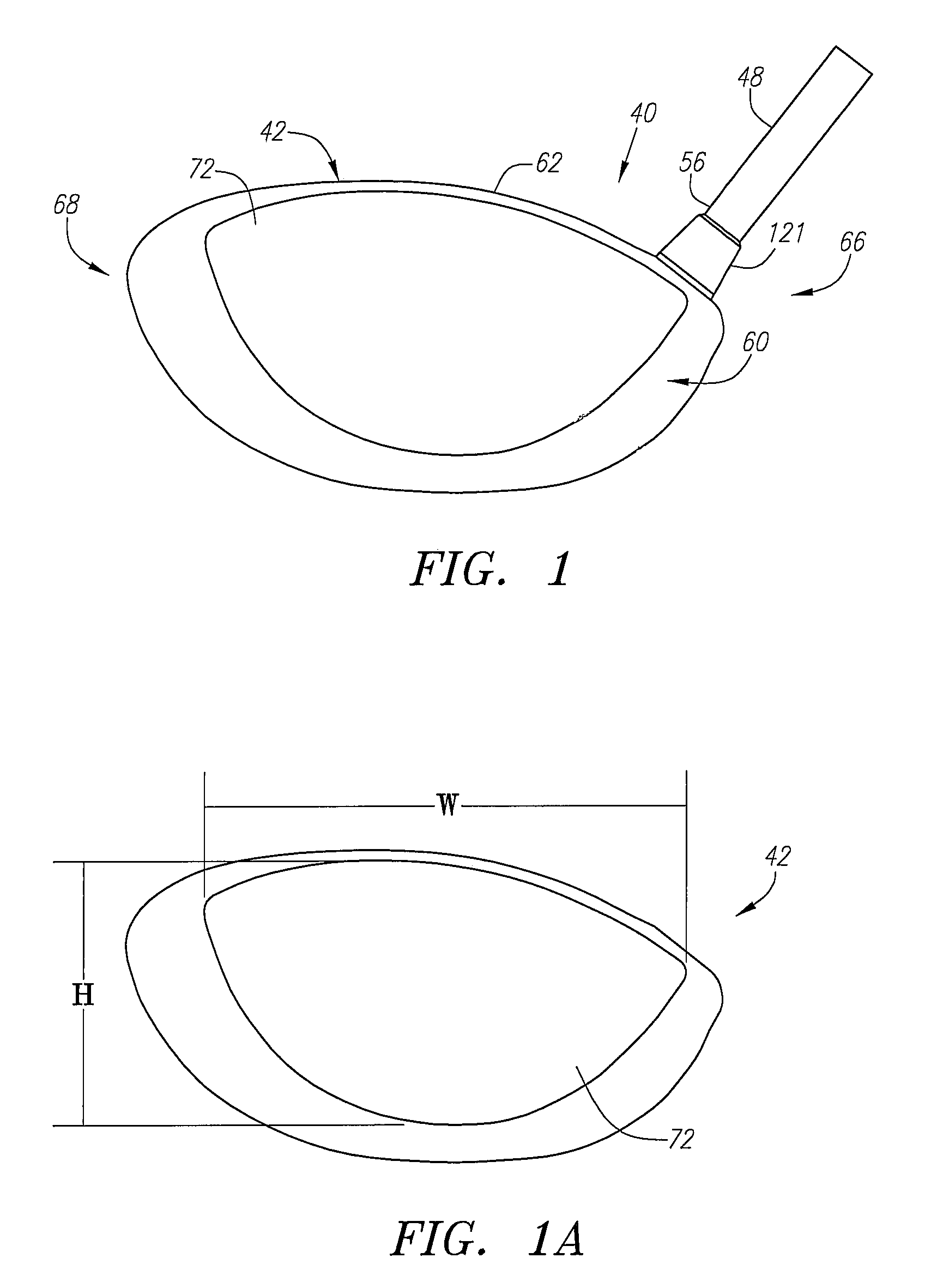

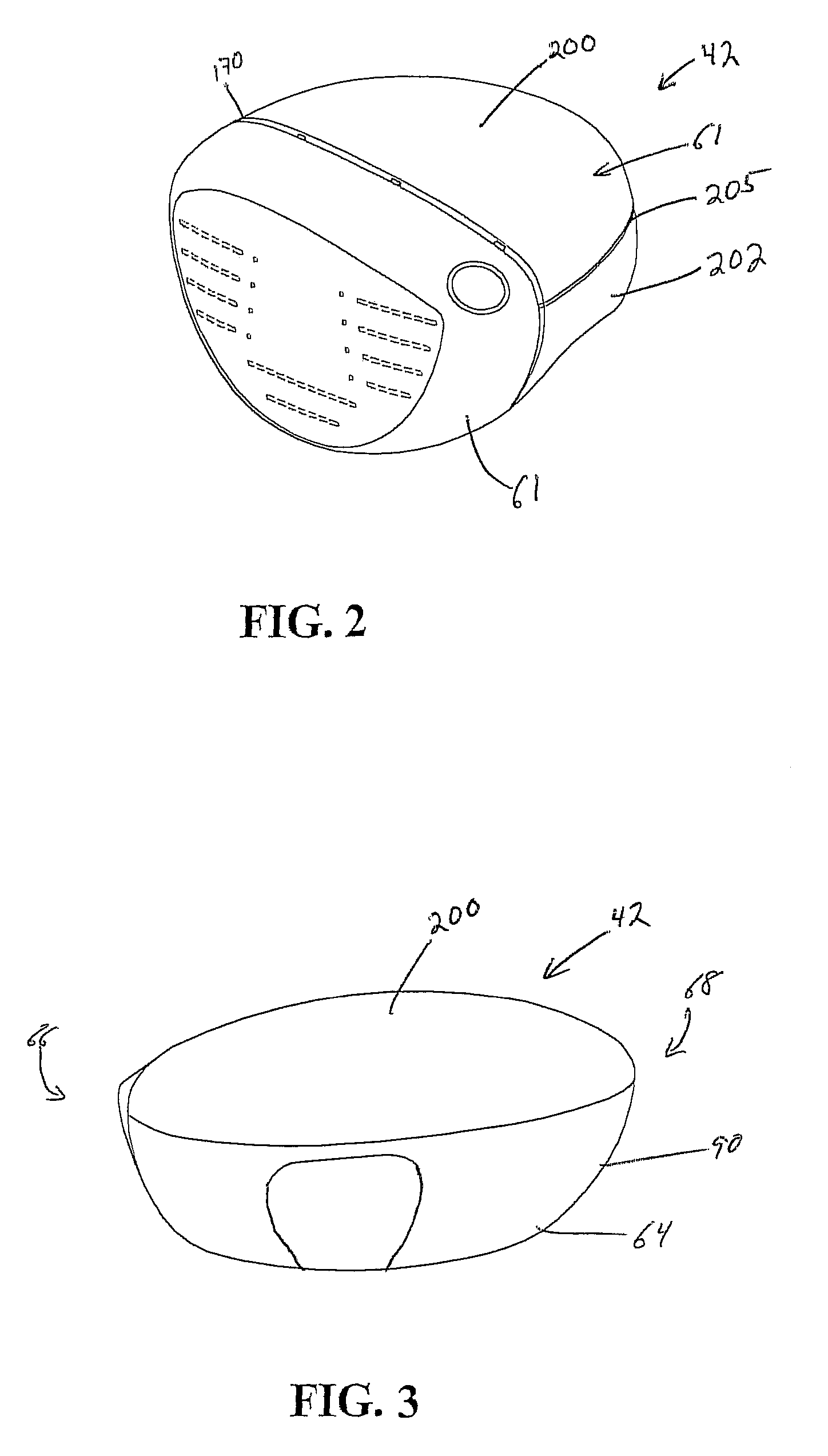

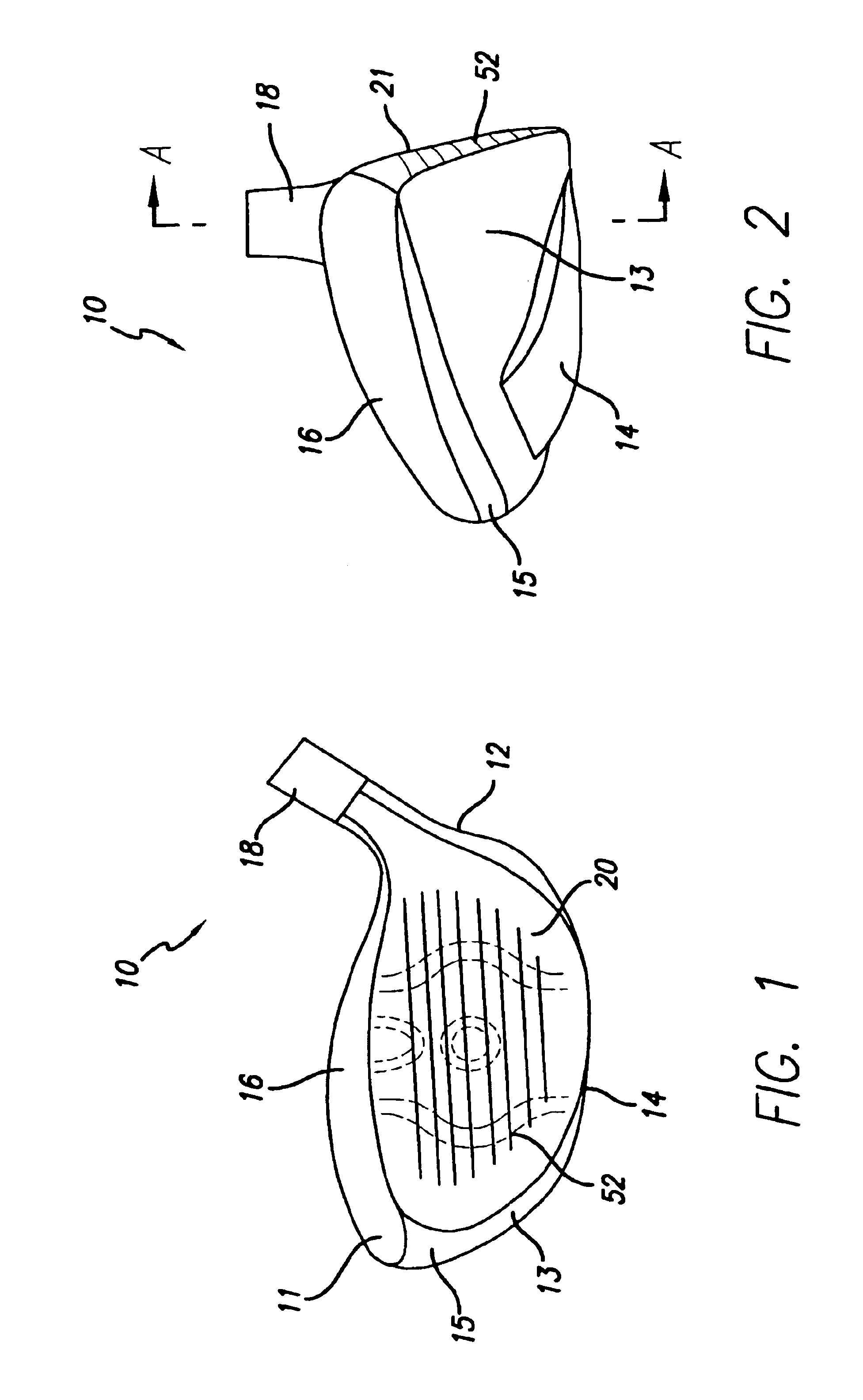

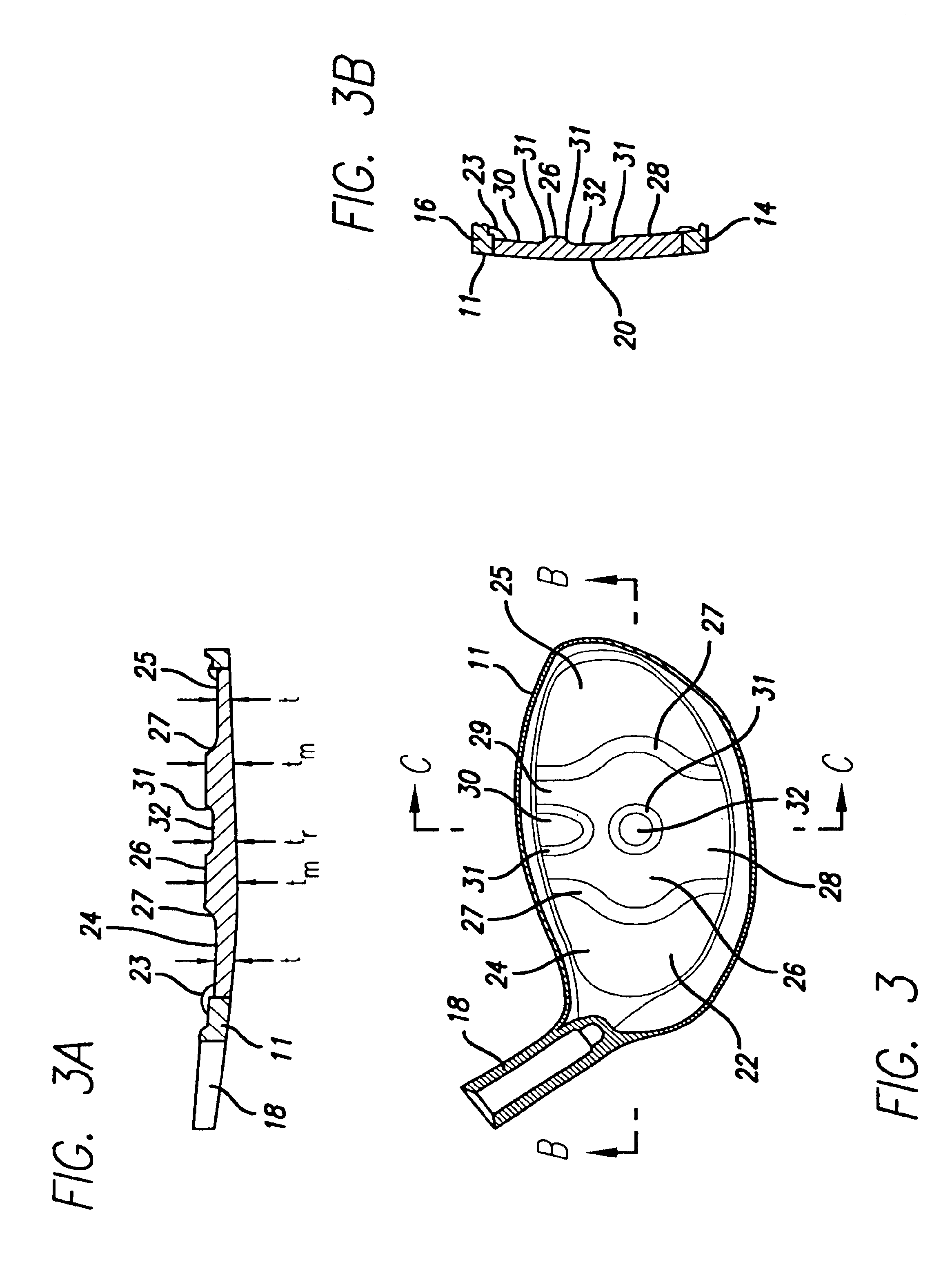

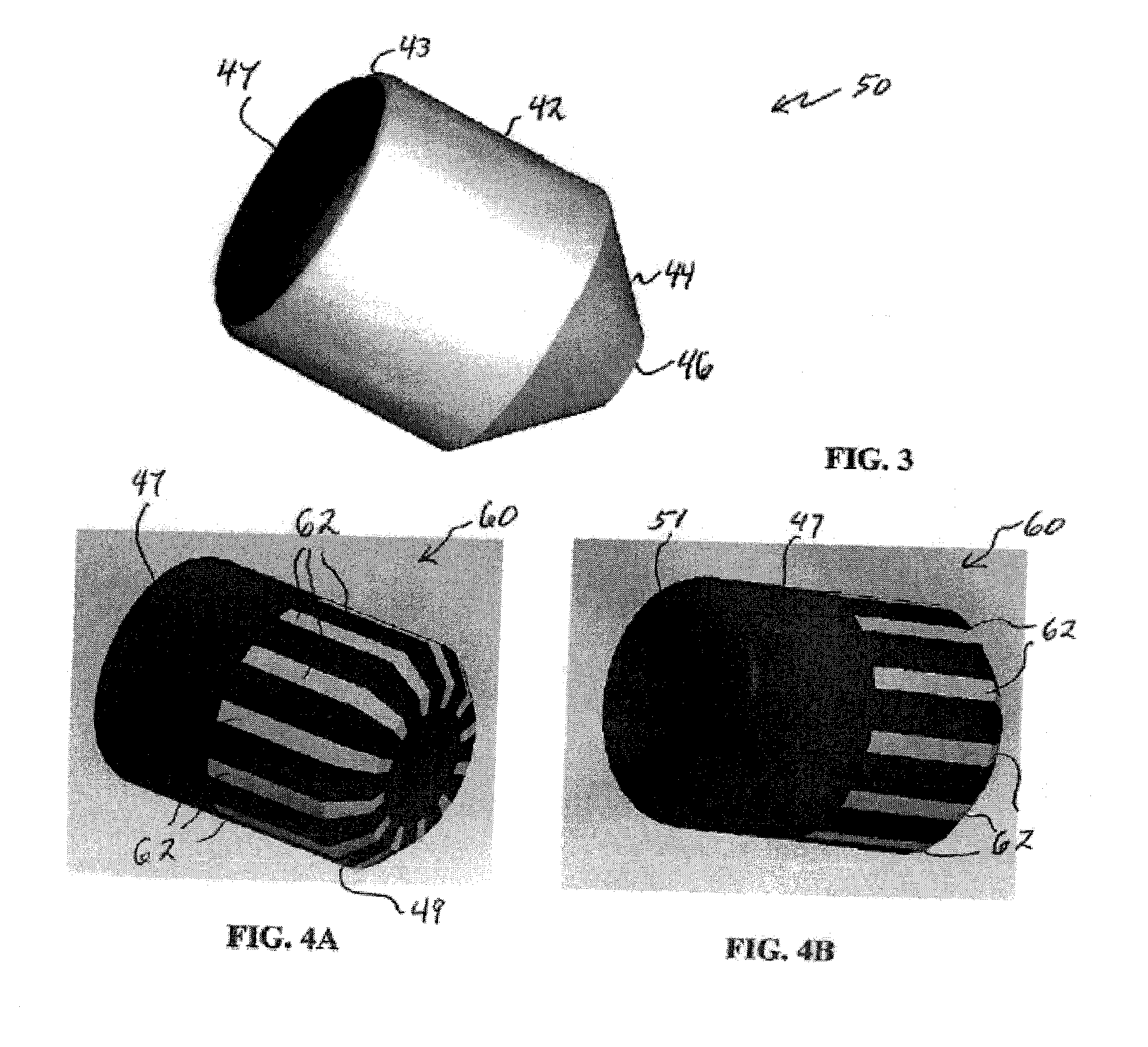

A golf club (40) having a club head (42) with a face component (60) and an aft-body (61) is disclosed herein. The face component (60) has a striking plate portion (72) and a return portion (74). The aft-body (61) is composed of a crown portion (62), a sole portion (64) and optionally a ribbon section (90). The face component (60) is composed of a metal material, and the aft-body (61) is composed of a non-metal material such as a composite material or a thermoplastic material. The striking plate portion (72) preferably has an aspect ratio less than 1.7. The striking plate portion (72) preferably has concentric regions of thickness with the thickness portion in the center (102). The club head (42) has a volume in the range of 300 cubic centimeters to 600 cubic centimeters, a weight in the range of 165 grams to 300 grams, and a striking plate portion (72) surface area in the range of 4.00 square inches to 7.50 square inches. The golf club head (42) has a coefficient of restitution greater than 0.81 under test such as the USGA test conditions specified pursuant to Rule 4-1e, Appendix II, of the Rules of Golf for 1998-1999.

Owner:TOPGOLF CALLAWAY BRANDS CORP

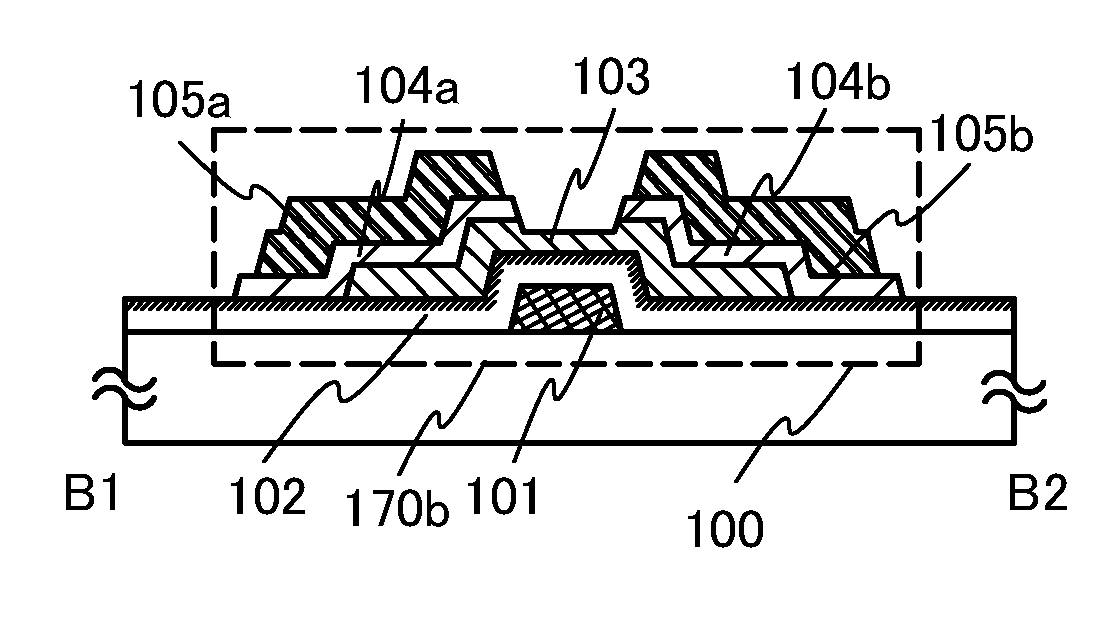

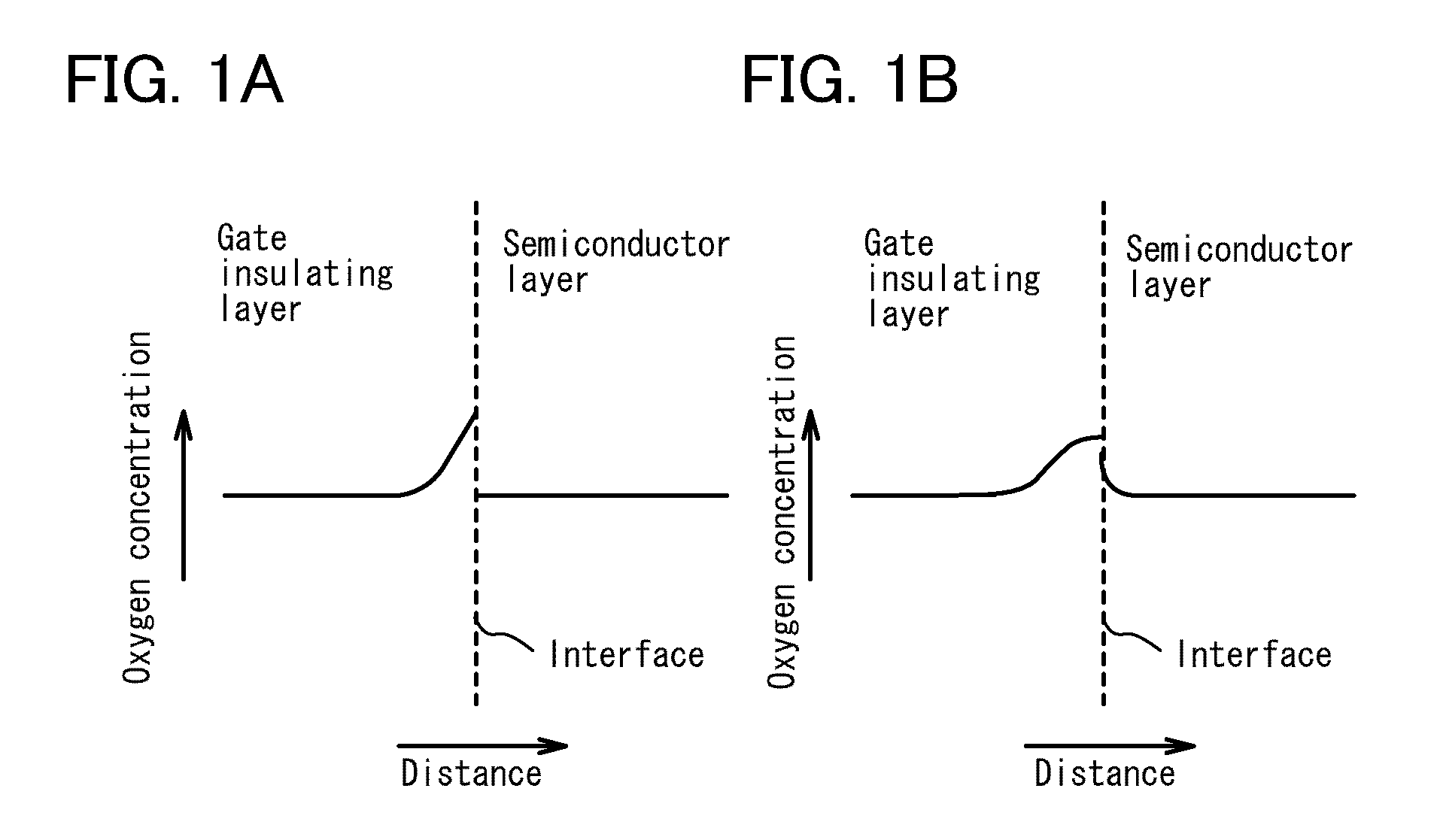

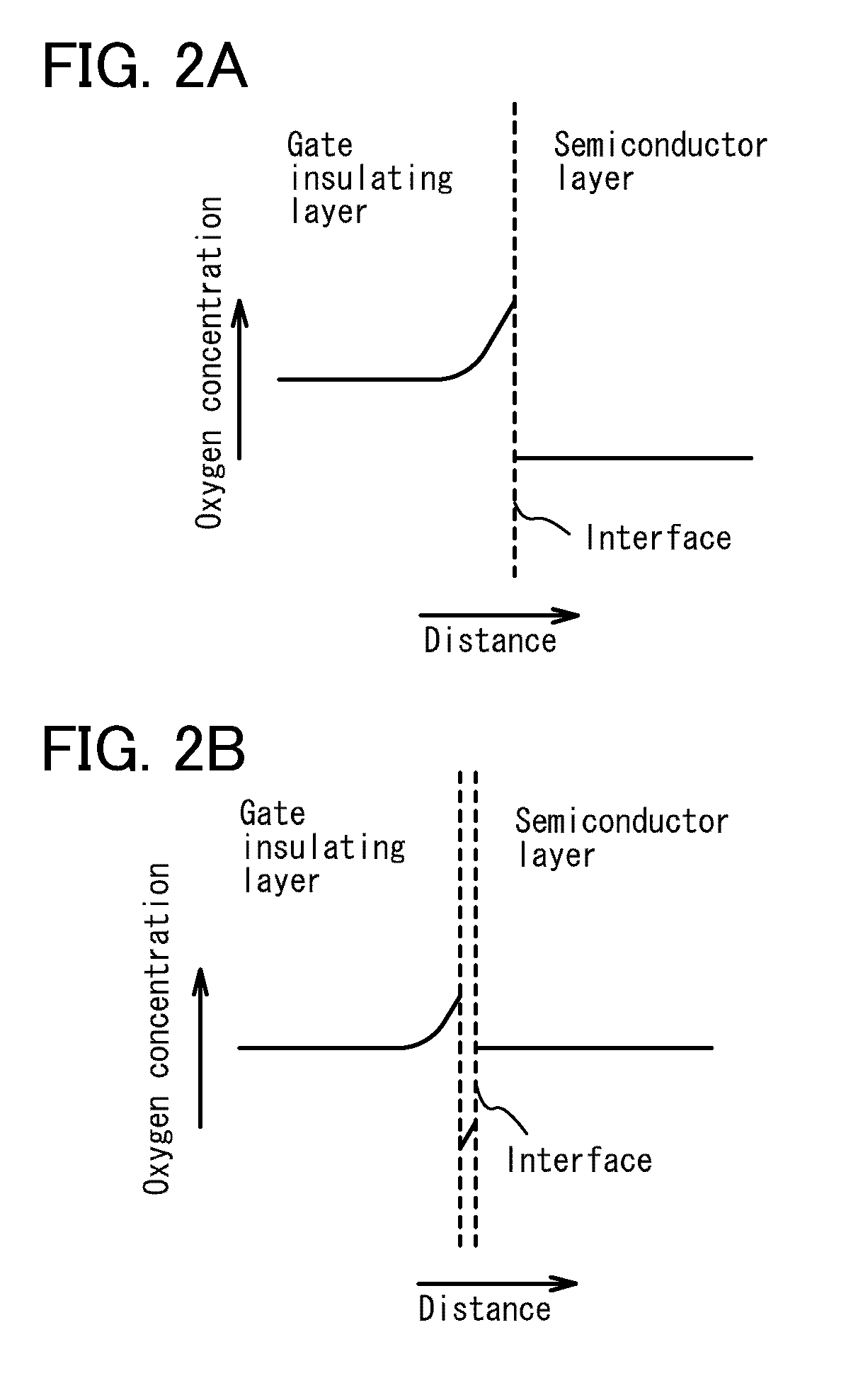

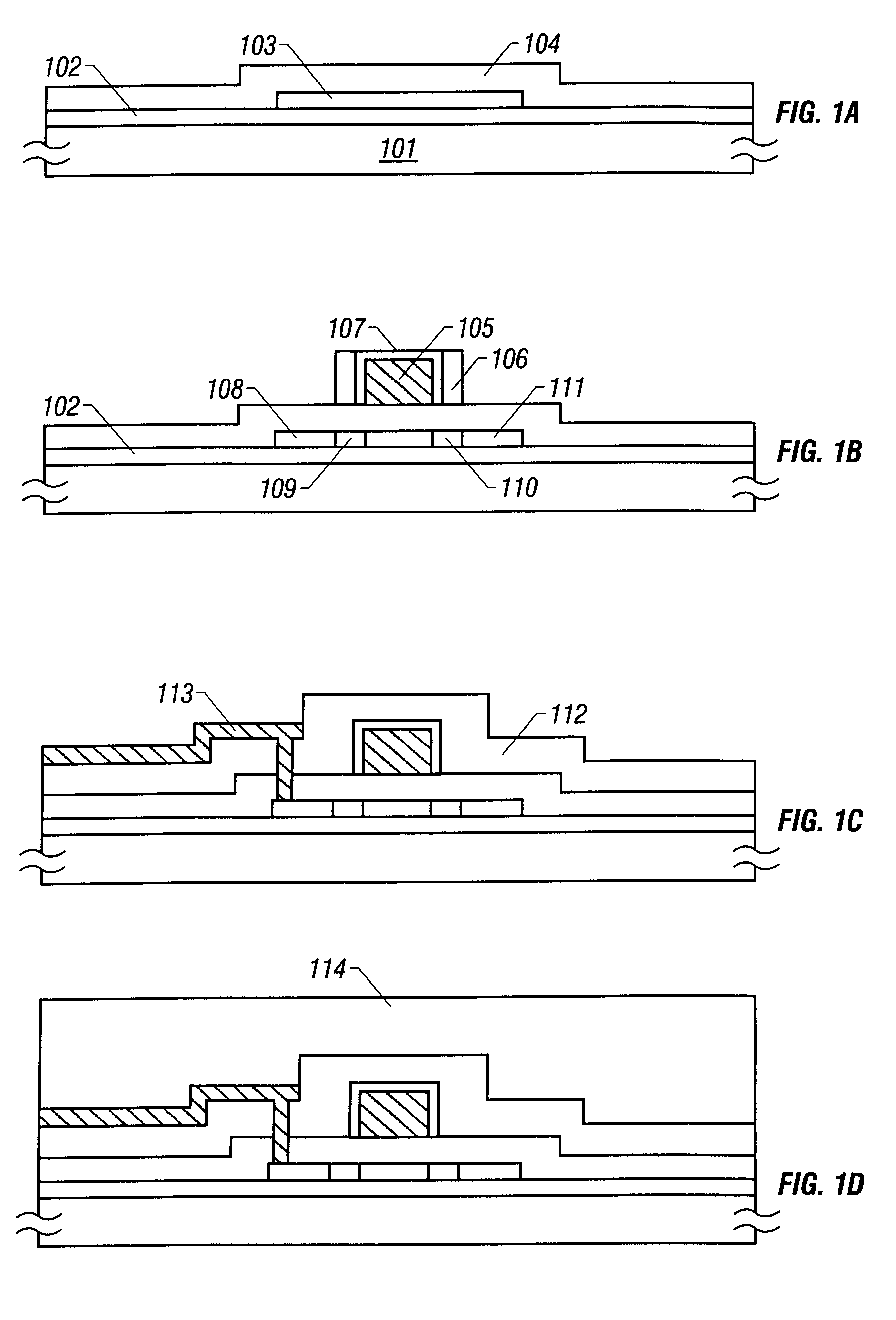

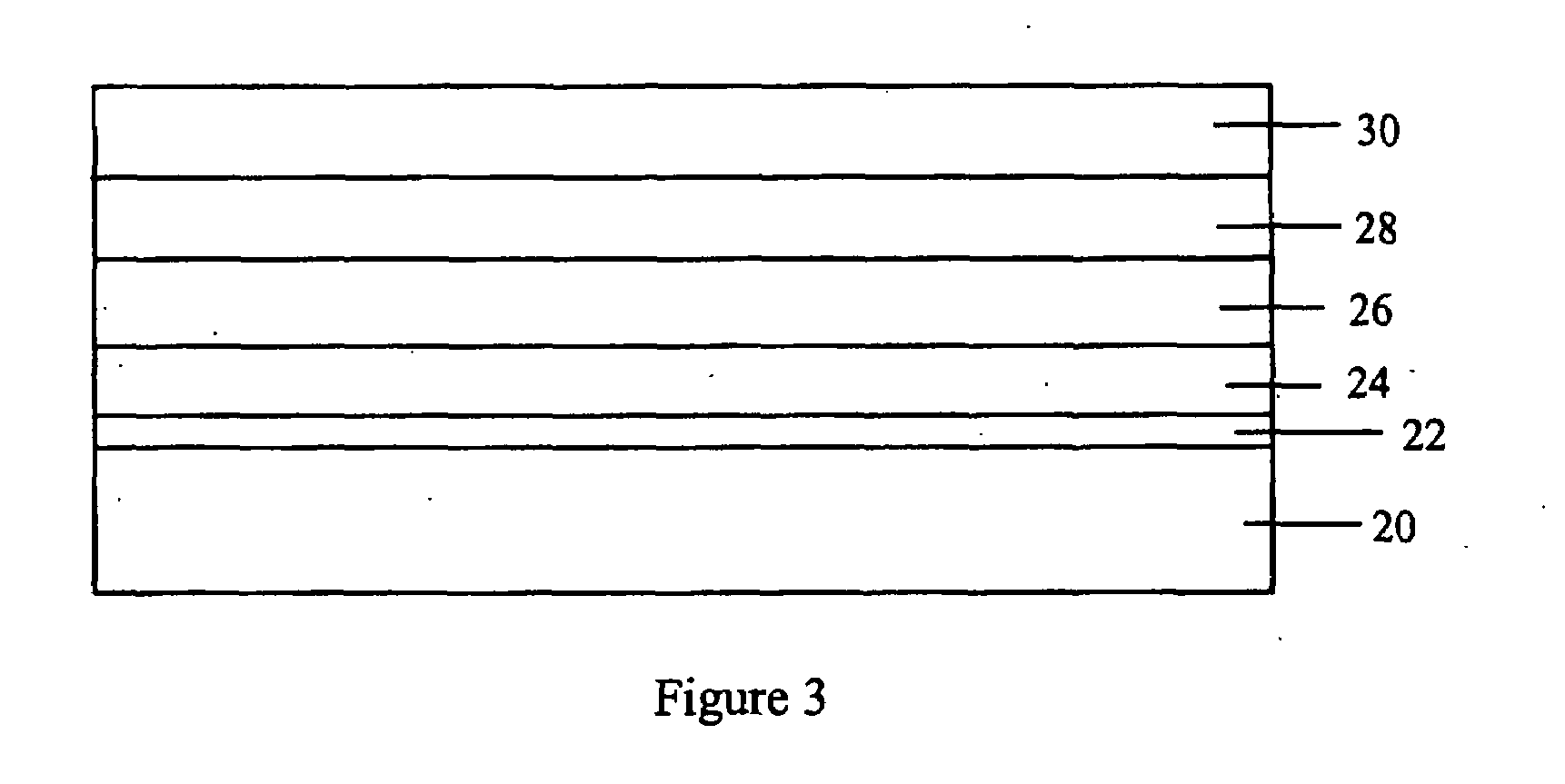

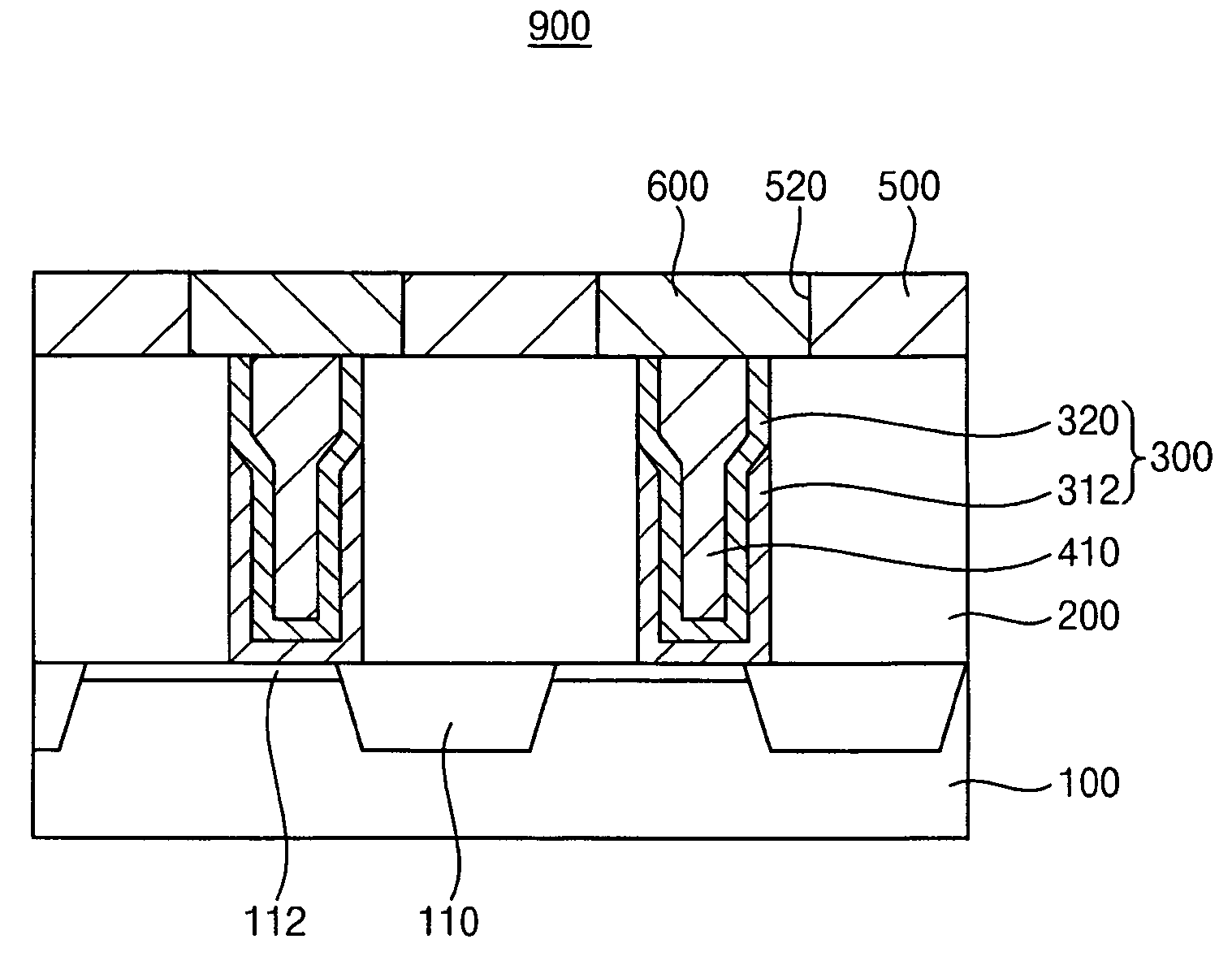

Semiconductor device and method for manufacturing the same

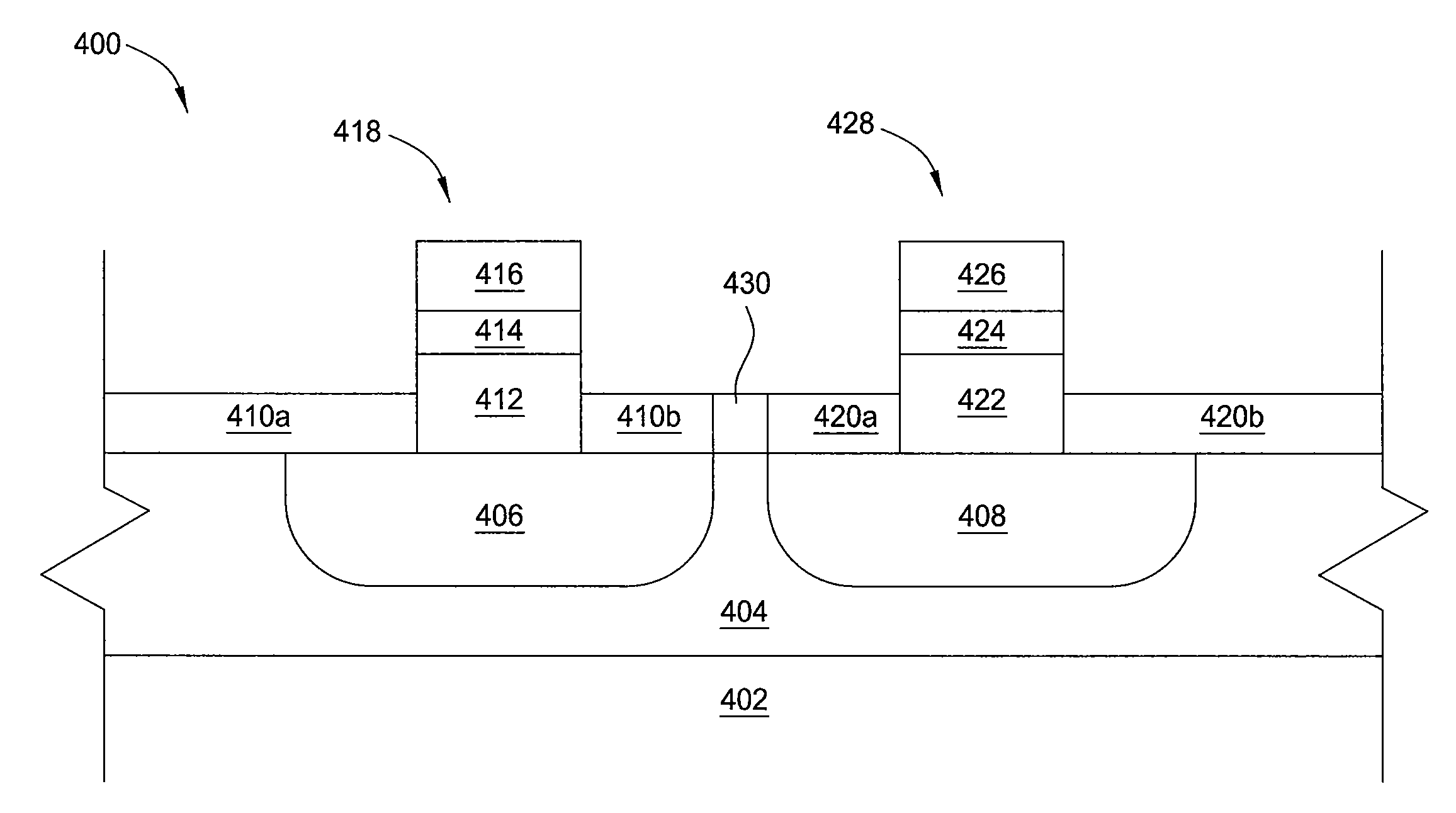

ActiveUS20100051949A1Small currentHigh on-off ratioTransistorStatic indicating devicesMetallic materialsOxygen deficient

A thin film transistor structure in which a source electrode and a drain electrode formed from a metal material are in direct contact with an oxide semiconductor film may lead to high contact resistance. One cause of high contact resistance is that a Schottky junction is formed at a contact plane between the source and drain electrodes and the oxide semiconductor film. An oxygen-deficient oxide semiconductor layer which includes crystal grains with a size of 1 nm to 10 nm and has a higher carrier concentration than the oxide semiconductor film serving as a channel formation region is provided between the oxide semiconductor film and the source and drain electrodes.

Owner:SEMICON ENERGY LAB CO LTD

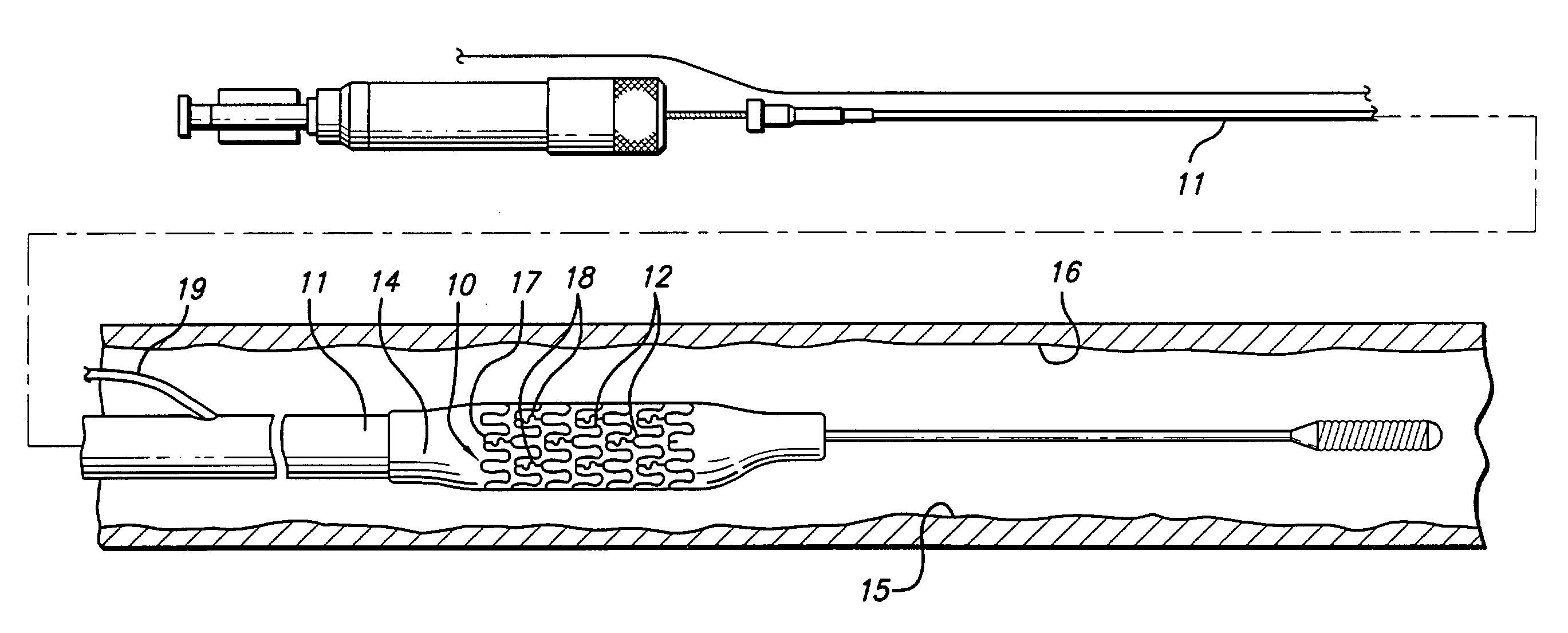

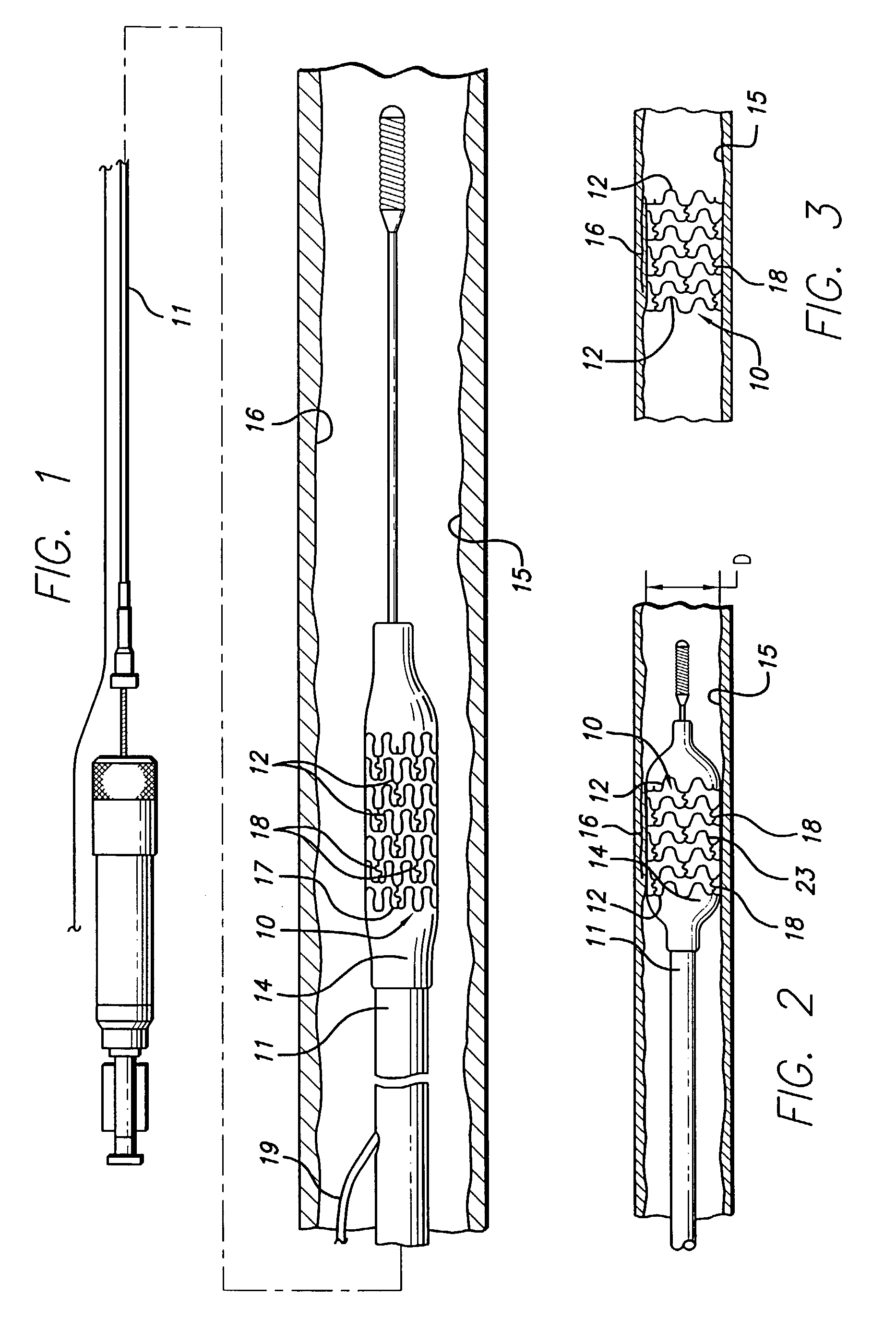

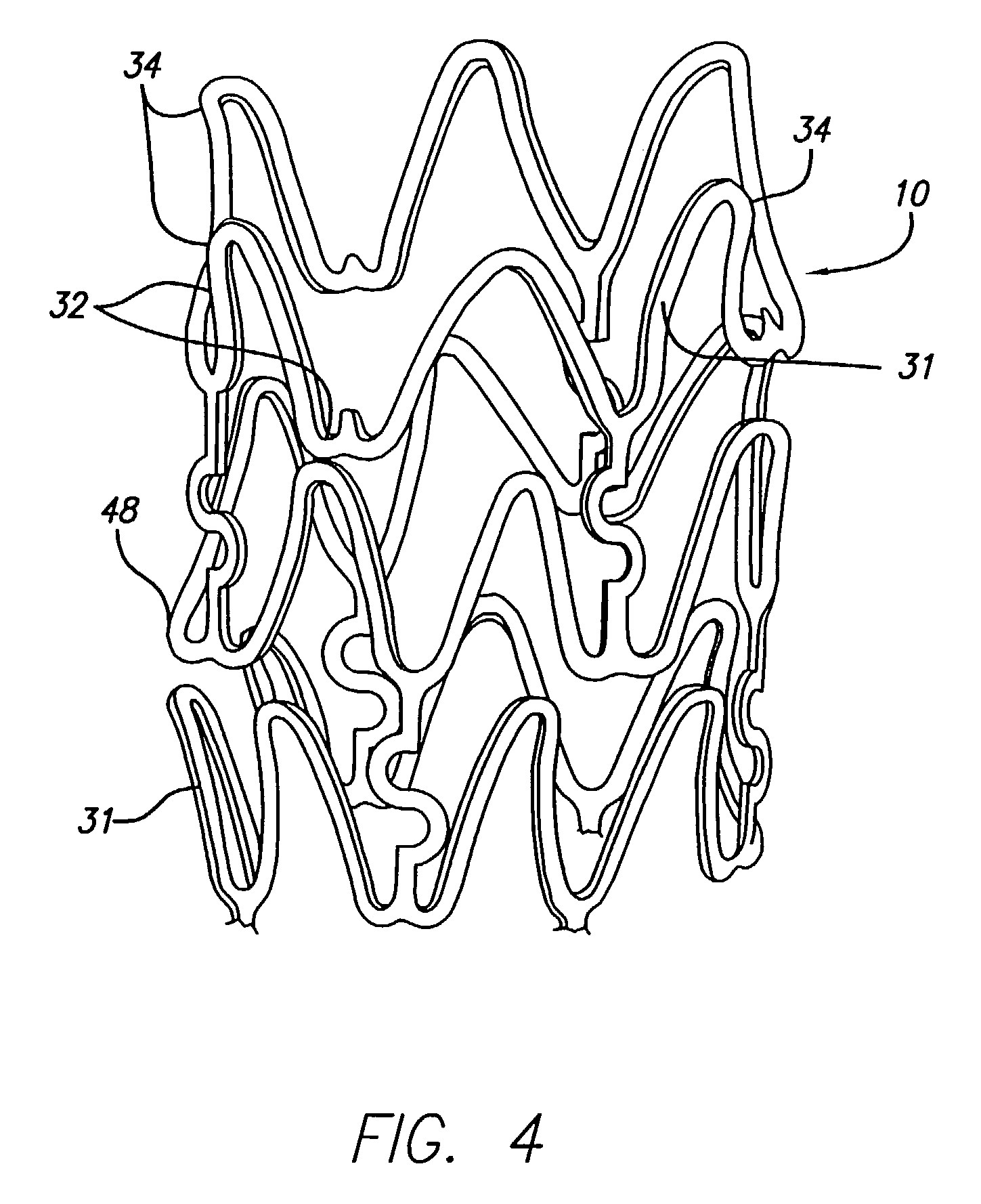

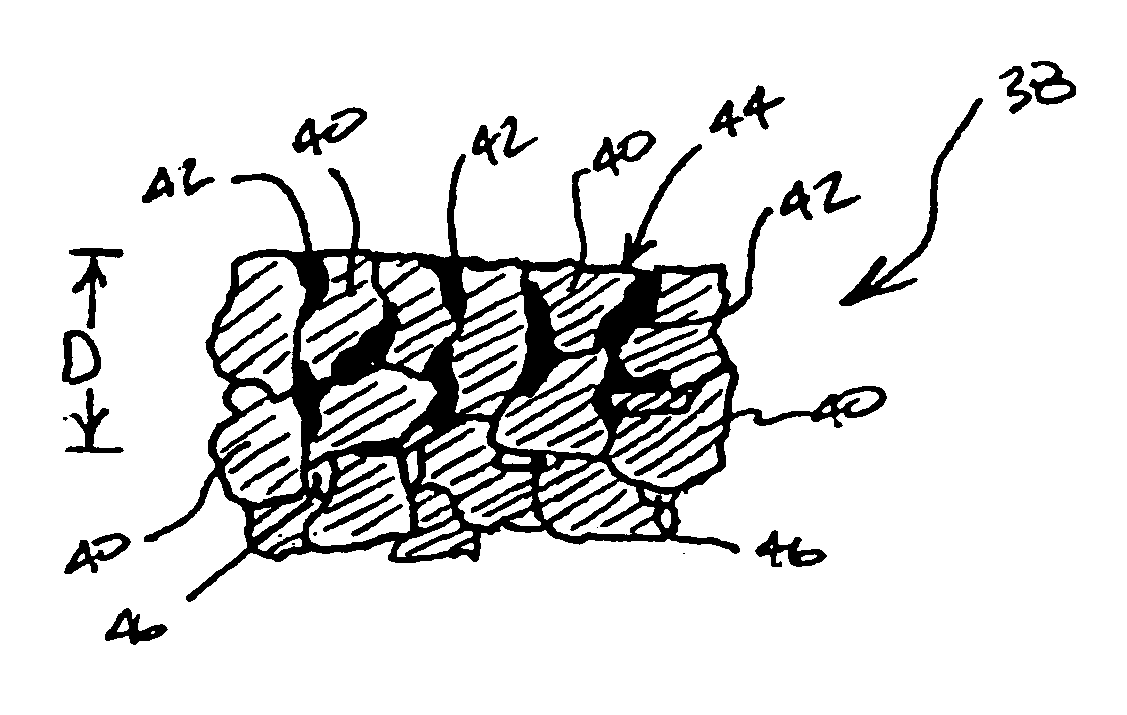

Polymer link hybrid stent

InactiveUS7455687B2Improve column strengthHigh strengthStentsSurgeryCoronary arteriesMetallic materials

The present invention is directed to an expandable polymer link hybrid stent for implantation in a body lumen, such as a coronary artery along with a method of making the stent. The stent generally includes a series of metallic cylindrical rings longitudinally aligned on a common axis of the stent and interconnected by a series of polymeric links. The polymer links are formed by applying polymer layers between the rings and laser ablating the excess material. The polymeric material forming the polymeric links, provides longitudinal and flexural flexibility to the stent while maintaining sufficient column strength to space the cylindrical rings along the longitudinal axis. The metallic material forming the rings provides the necessary radial stiffness.

Owner:ABBOTT CARDIOVASCULAR

Bonded joint design for a golf club head

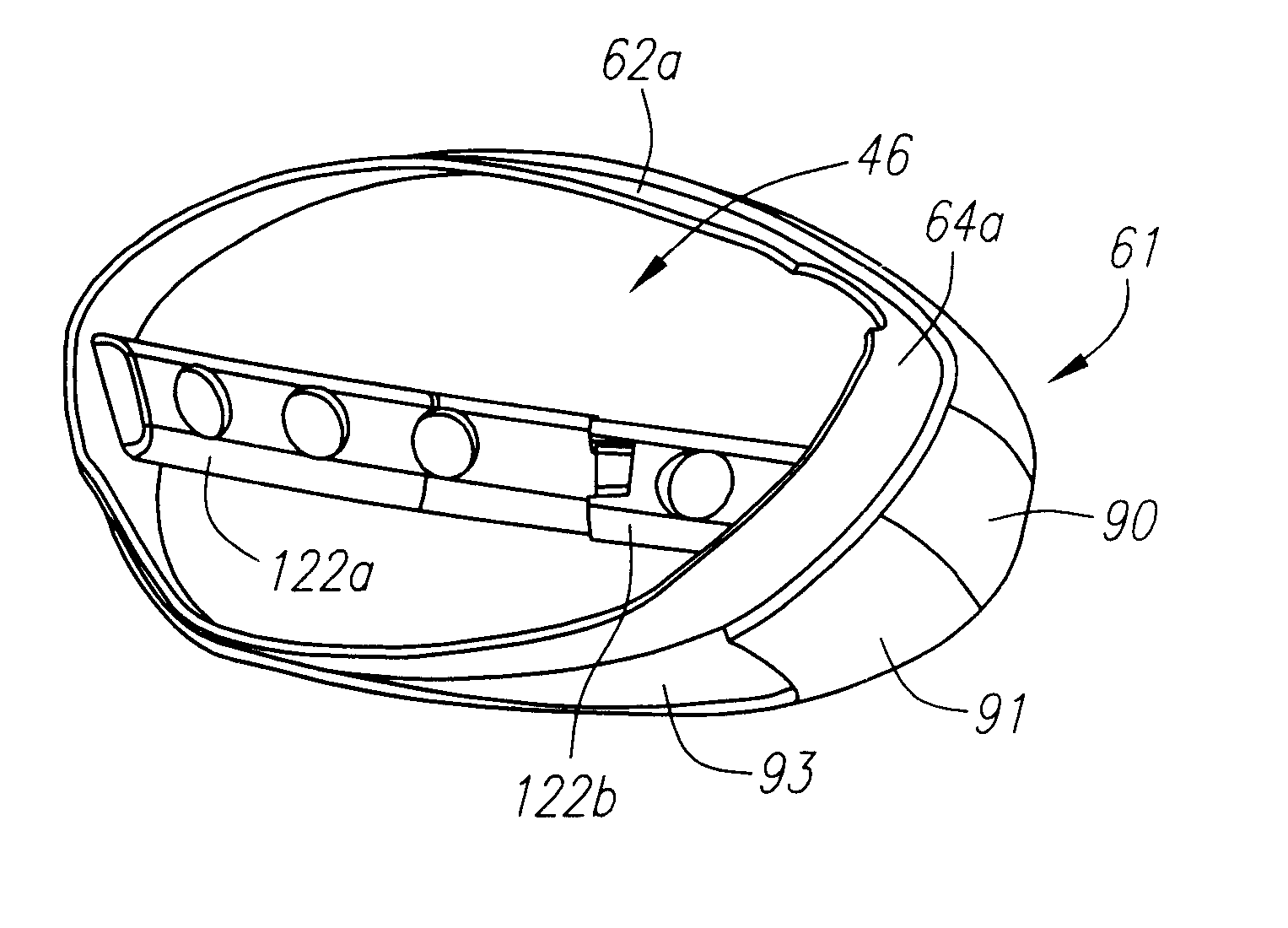

A golf club (40) having a club head (42) with a face component (60) and an aft body (61) is disclosed herein. The face component (60) has a striking plate port ion (72) and a return portion (74). The aft-body (61) is composed of a crown portion (62), a sole portion (64) and optionally a ribbon section (90). The face component (60) is composed of a metal material, and the aft-body (61) is preferably composed of a non-metal material such as a composite material or a thermoplastic material. The face component (60) is bonded to the aft-body (61) with a leading edge (180) of an undercut portion (62a and 64a) of the aft-body positioned a distance of 0.100 inch to 0.500 inch from the interior surface (60a) of the face component (60) in order to reduce the stress on the bonded joint of between the face component (60) and the aft-body (61). The club head (42) has a volume in the range of 290 cubic centimeters to 600 cubic centimeters, a weight in the range of 165 grams to 300 grams, and a striking plate portion (72) surface area in the range of 4.00 square inches to 7.50 square inches.

Owner:TOPGOLF CALLAWAY BRANDS CORP

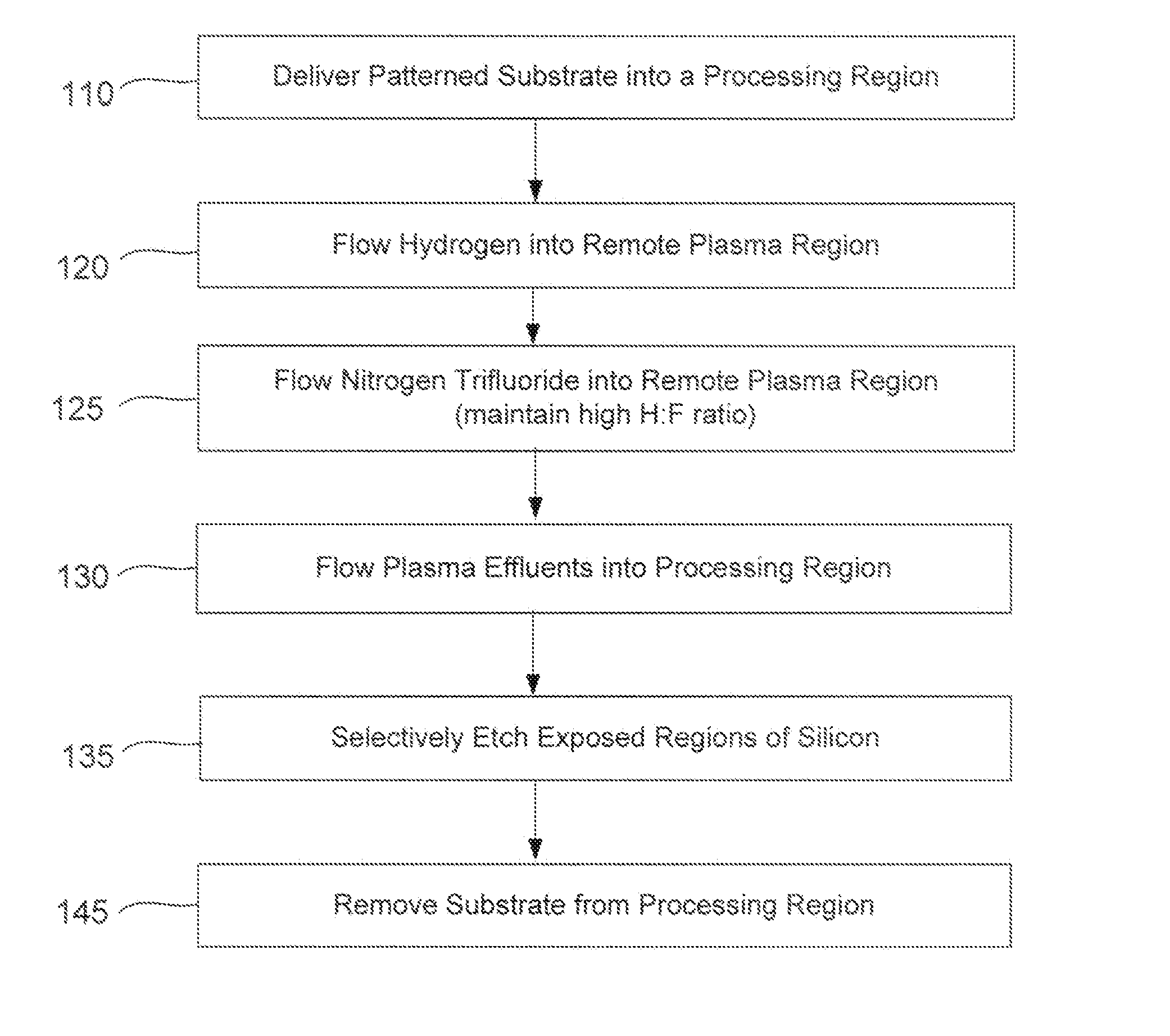

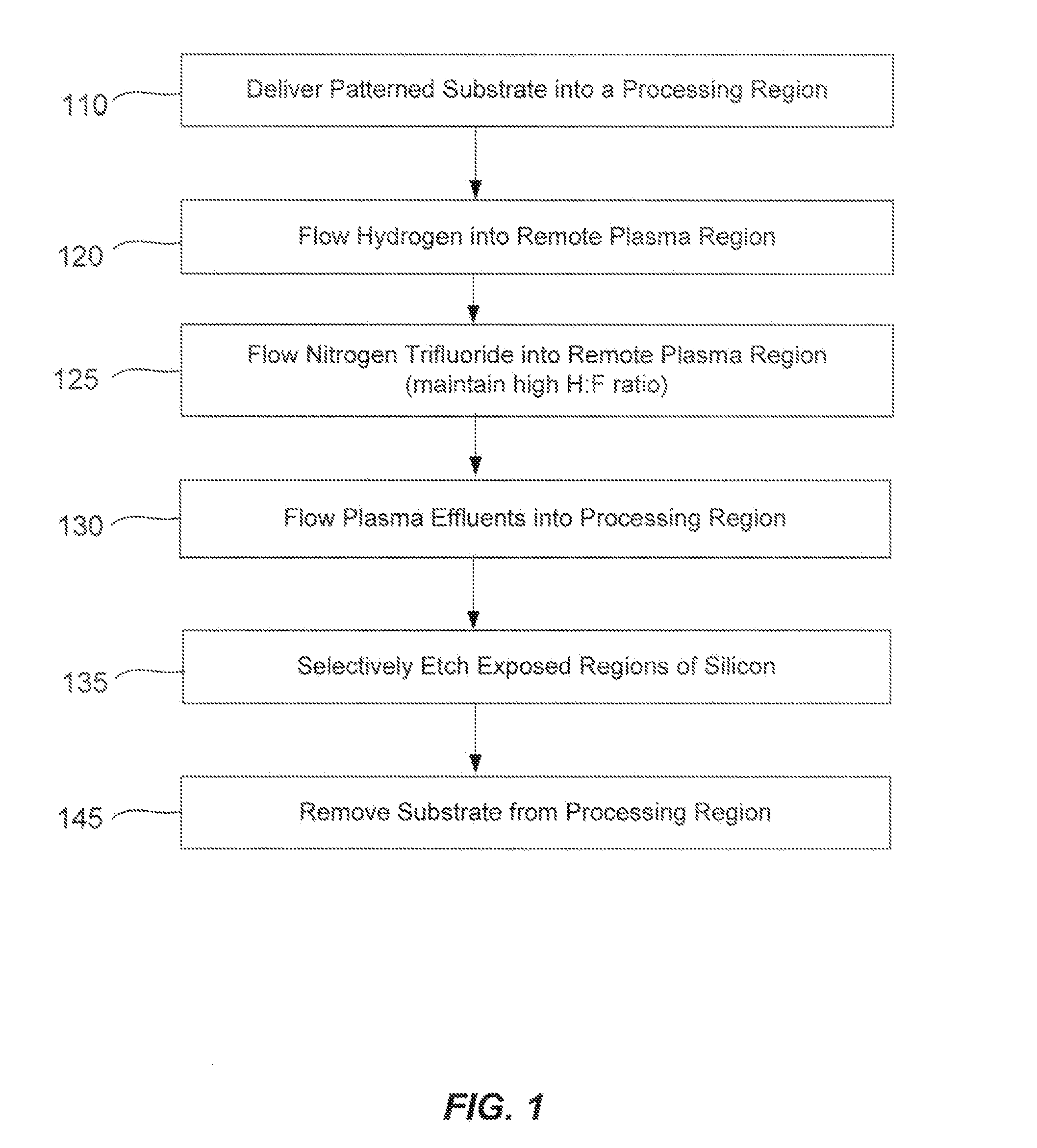

Selective etch of silicon by way of metastable hydrogen termination

ActiveUS20130089988A1Easy to disassembleReduces and substantially eliminates numberElectric discharge tubesSemiconductor/solid-state device manufacturingRemote plasmaHydrogen

Methods of etching exposed silicon on patterned heterogeneous structures is described and includes a remote plasma etch formed from a fluorine-containing precursor and a hydrogen-containing precursor. Plasma effluents from the remote plasma are flowed into a substrate processing region where the plasma effluents react with the exposed regions of silicon. The plasmas effluents react with the patterned heterogeneous structures to selectively remove silicon while very slowly removing other exposed materials. The silicon selectivity results, in part, from a preponderance of hydrogen-containing precursor in the remote plasma which hydrogen terminates surfaces on the patterned heterogeneous structures. A much lower flow of the fluorine-containing precursor progressively substitutes fluorine for hydrogen on the hydrogen-terminated silicon thereby selectively removing silicon from exposed regions of silicon. The methods may be used to selectively remove silicon far faster than silicon oxide, silicon nitride and a variety of metal-containing materials.

Owner:APPLIED MATERIALS INC

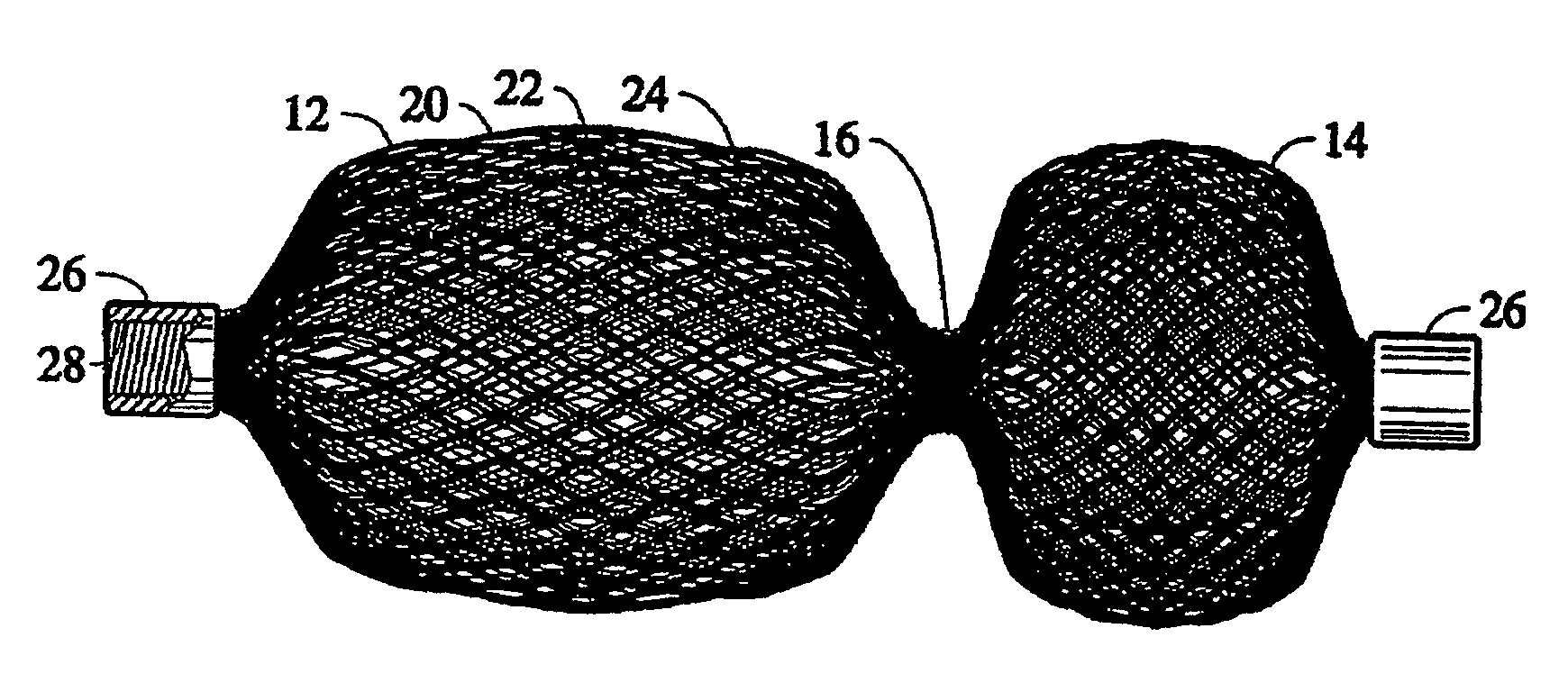

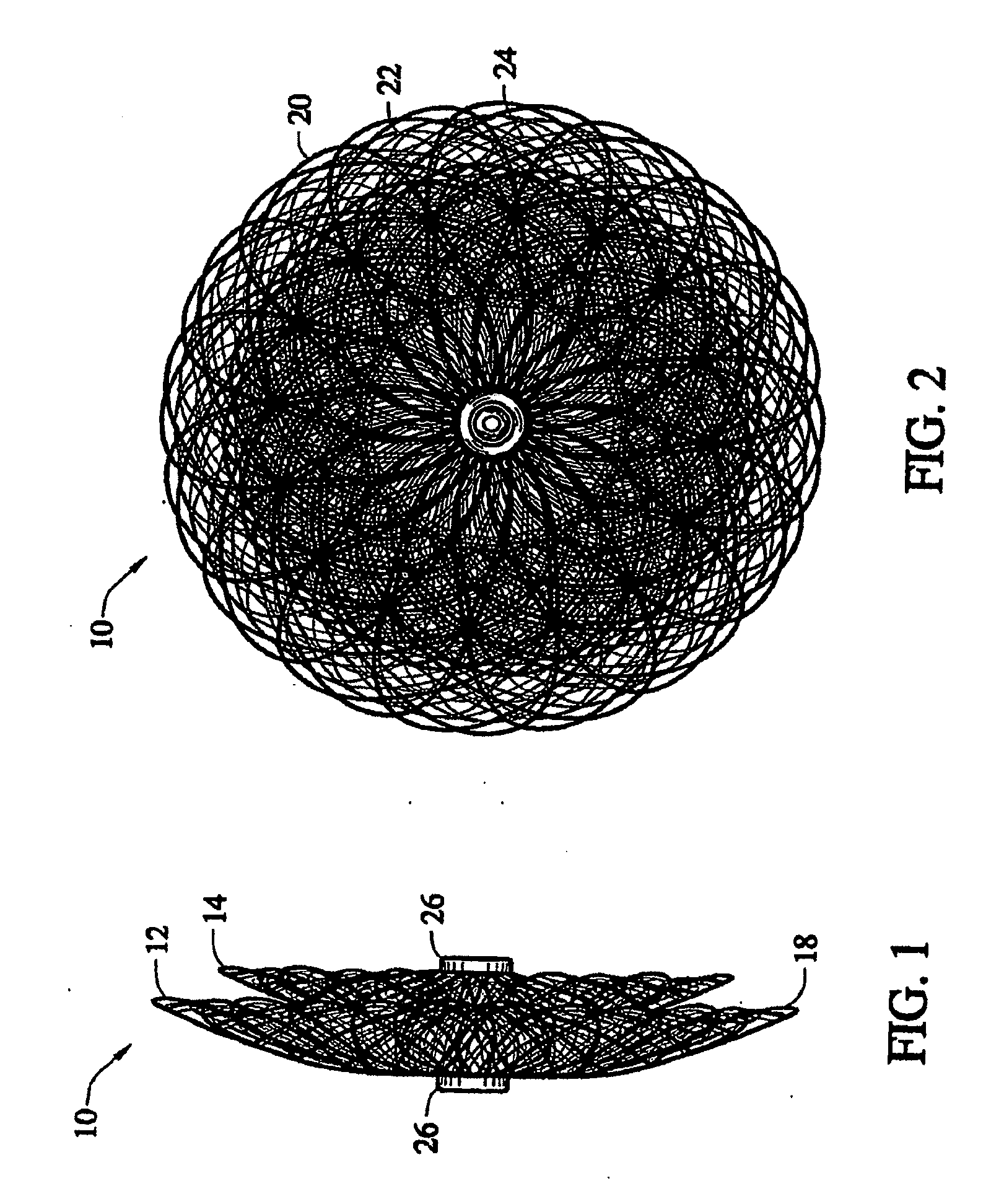

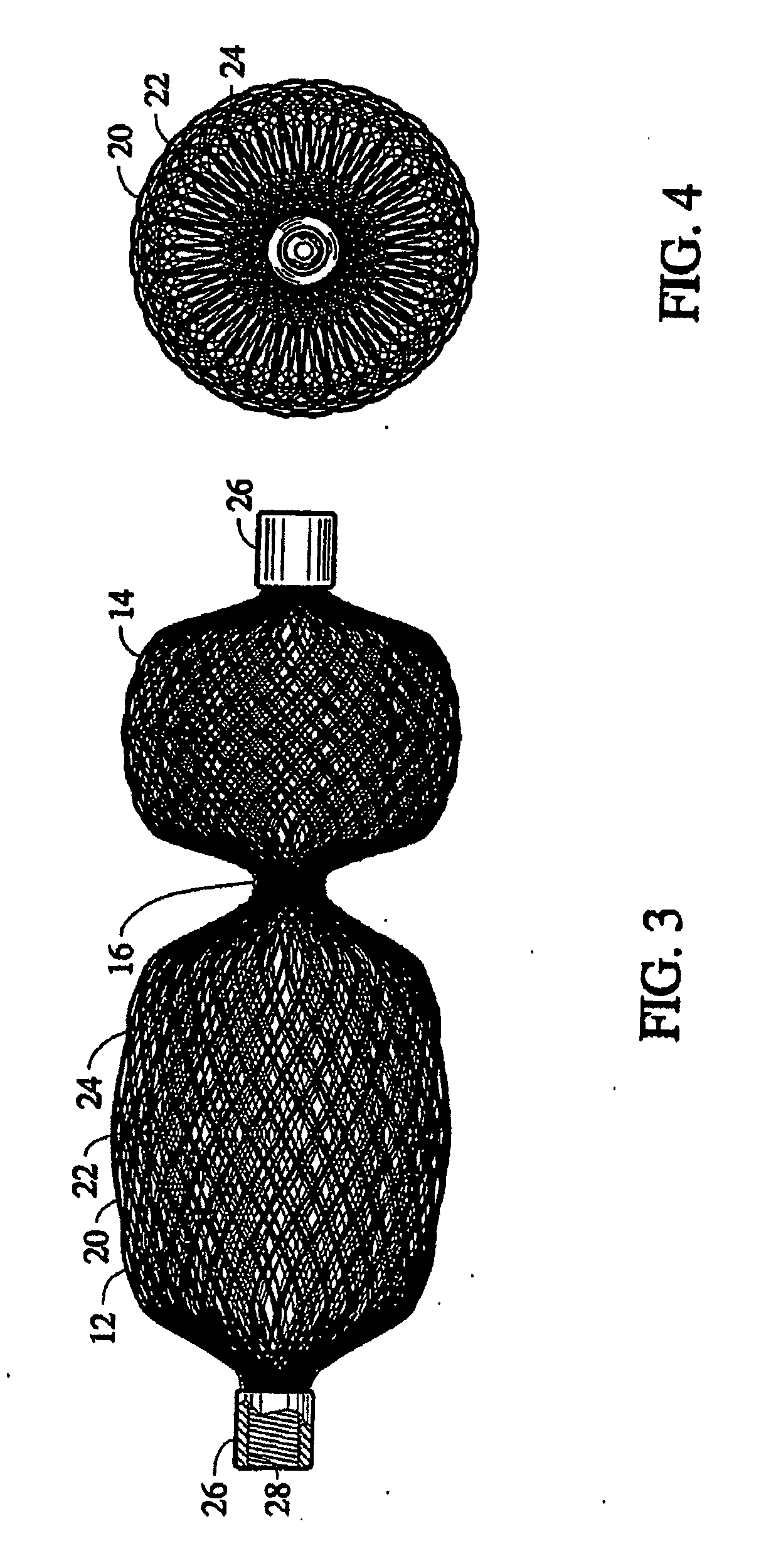

Device for occluding vascular defects

A multi-layer occluder for treating a target site within the body is provided. The occluder may include first and second layers. For example, the first layer may include braided strands of metallic material, and the second layer may include braided strands of polymeric material. At least one of the first or second layers may be configured to facilitate thrombosis.

Owner:ST JUDE MEDICAL CARDILOGY DIV INC

Multiple material golf club head with face insert

A golf club (40) having a club head (42) with a face component (60) and an aft body (61) is disclosed herein. The face component (60) has a striking plate insert (72) within an opening (45) of a return portion (74). The aft-body (61) is composed of a crown portion (62), a sole portion (64) and optionally a ribbon section (90). The return portion (74) is preferably composed of a cast metal material, the striking plate insert (72) is preferably composed of a formed or forged metal material, and the aft-body (61) is preferably composed of a non-metal material such as a composite material or a thermoplastic material. The golf club head (42) preferably has a volume in the range of 250 cubic centimeters to 600 cubic centimeters and a weight in the range of 165 grams to 300 grams.

Owner:TOPGOLF CALLAWAY BRANDS CORP

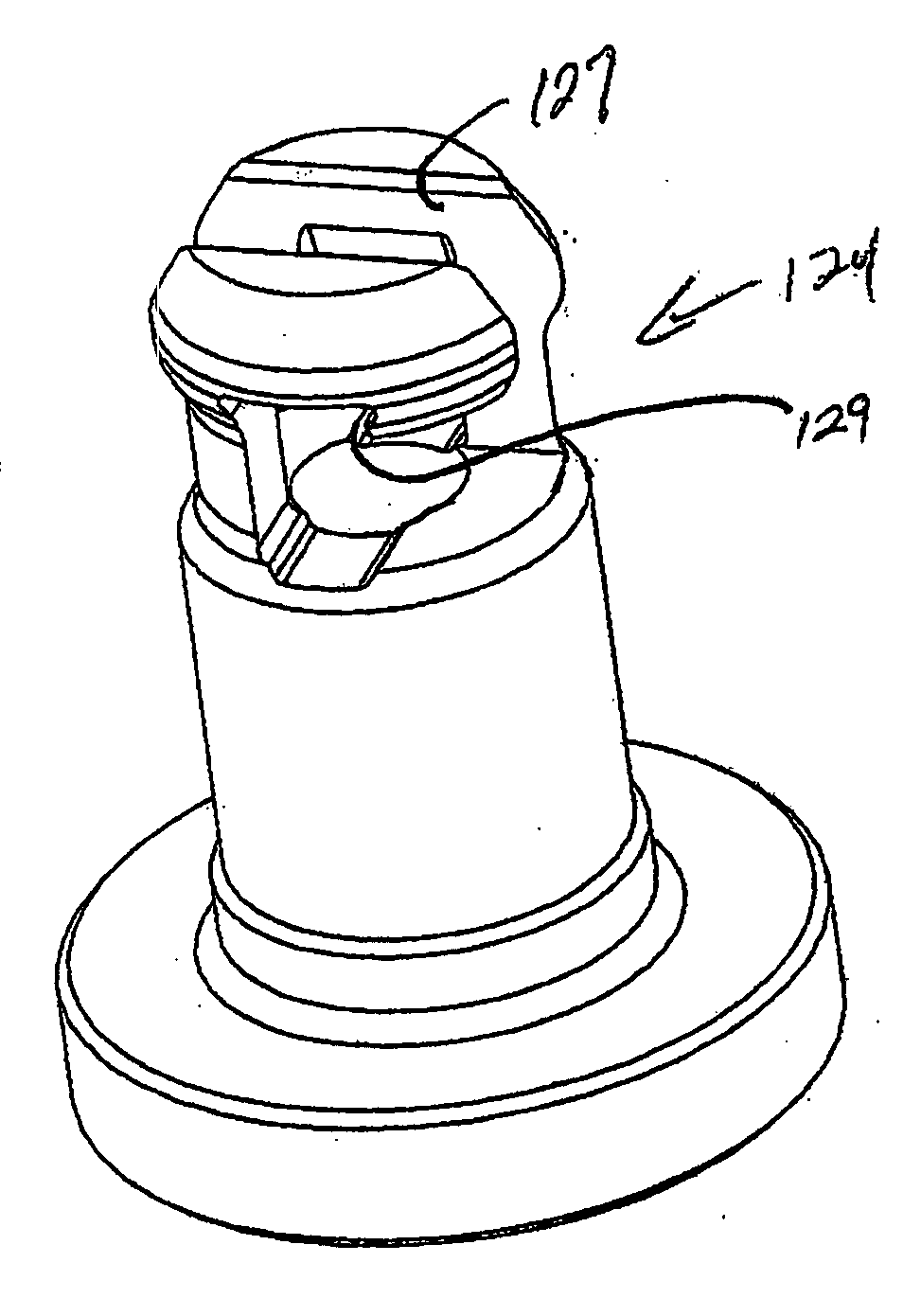

Wafer support pin assembly

InactiveUS20060156981A1After-treatment apparatusSemiconductor/solid-state device manufacturingSusceptorFast release

A semiconductor wafer support pin assembly. A susceptor has at least three support pins configured to raise a wafer above the top surface of the susceptor. Each support pin includes and upper pin and a lower pin, which lock together by means of a quick-release mechanism in the form of a bayonet mount. The upper pin is made of a non-metallic material, such as polybenzimidazole. The susceptor is driven up and down by a lifting mechanism, driven by an electric motor or pneumatic cylinder. The susceptor moves up and down, relative to the support pins.

Owner:ASM AMERICA INC

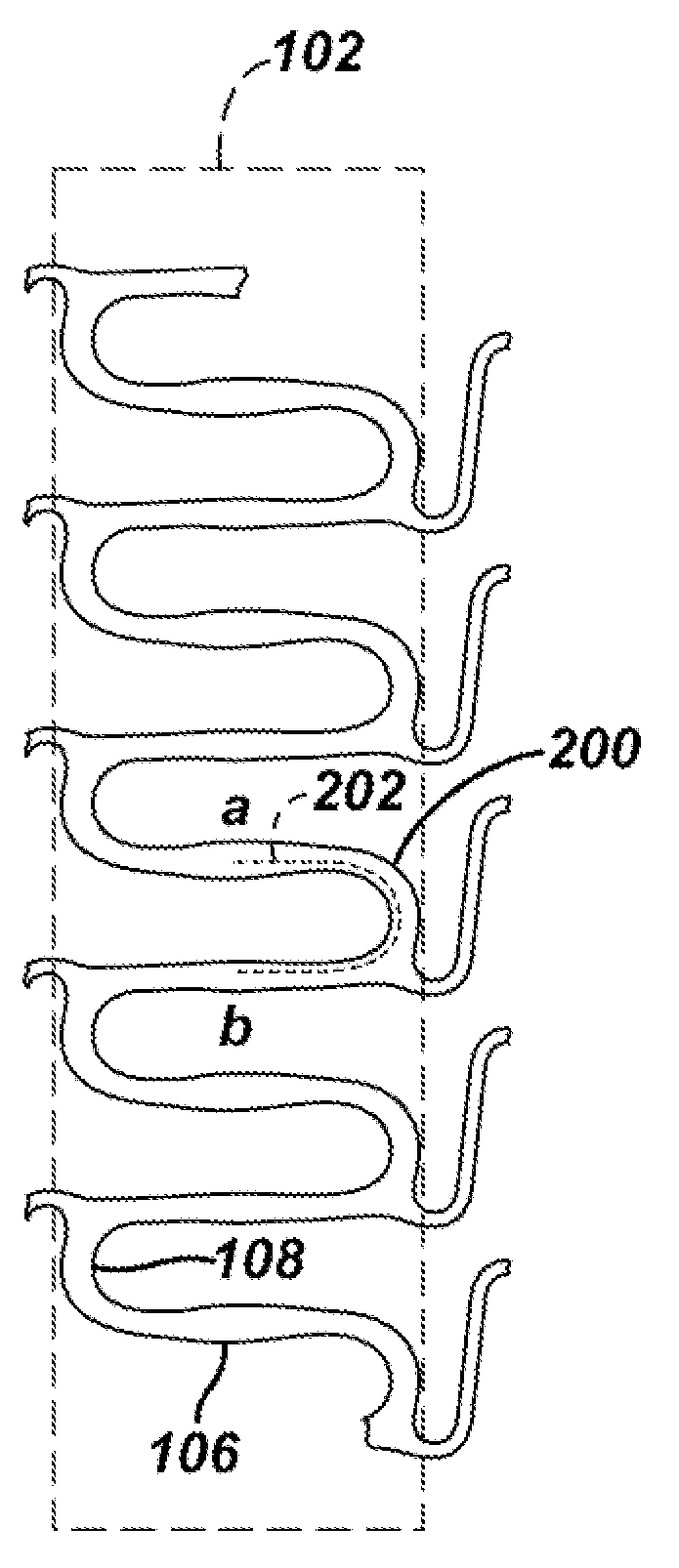

Multiple material golf club head

InactiveUS6582323B2Increase flexibilityGood coefficientMetal-working apparatusGolf clubsGramMetallic materials

A golf club (40) having a club head (42) with a face component (60) and an aft body (61) is disclosed herein. The face component (60) has a striking plate portion (72) and a return portion (74). The aft-body (61) is composed of a crown portion (62), a sole portion (64) and optionally a ribbon section (90). The face component (60) is composed of a metal material, and the aft-body (61) is composed of a non-metal material such as a composite material or a thermoplastic material. The striking plate portion (72) preferably has an aspect ratio less than 1.7. The striking plate portion (72) preferably has concentric regions of thickness with the thickness portion in the center (102). The club head (42) has a volume in the range of 290 cubic centimeters to 600 cubic centimeters, a weight in the range of 165 grams to 300 grams, and a striking plate portion (72) surface area in the range of 4.00 square inches to 7.50 square inches. The golf club head (42) has a coefficient of restitution greater than 0.81 under test conditions such as the USGA test conditions specified pursuant to Rule 4-1e, Appendix II, of the Rules of Golf for 1998-1999.

Owner:TOPGOLF CALLAWAY BRANDS CORP

Multiple material golf club head

Owner:TOPGOLF CALLAWAY BRANDS CORP

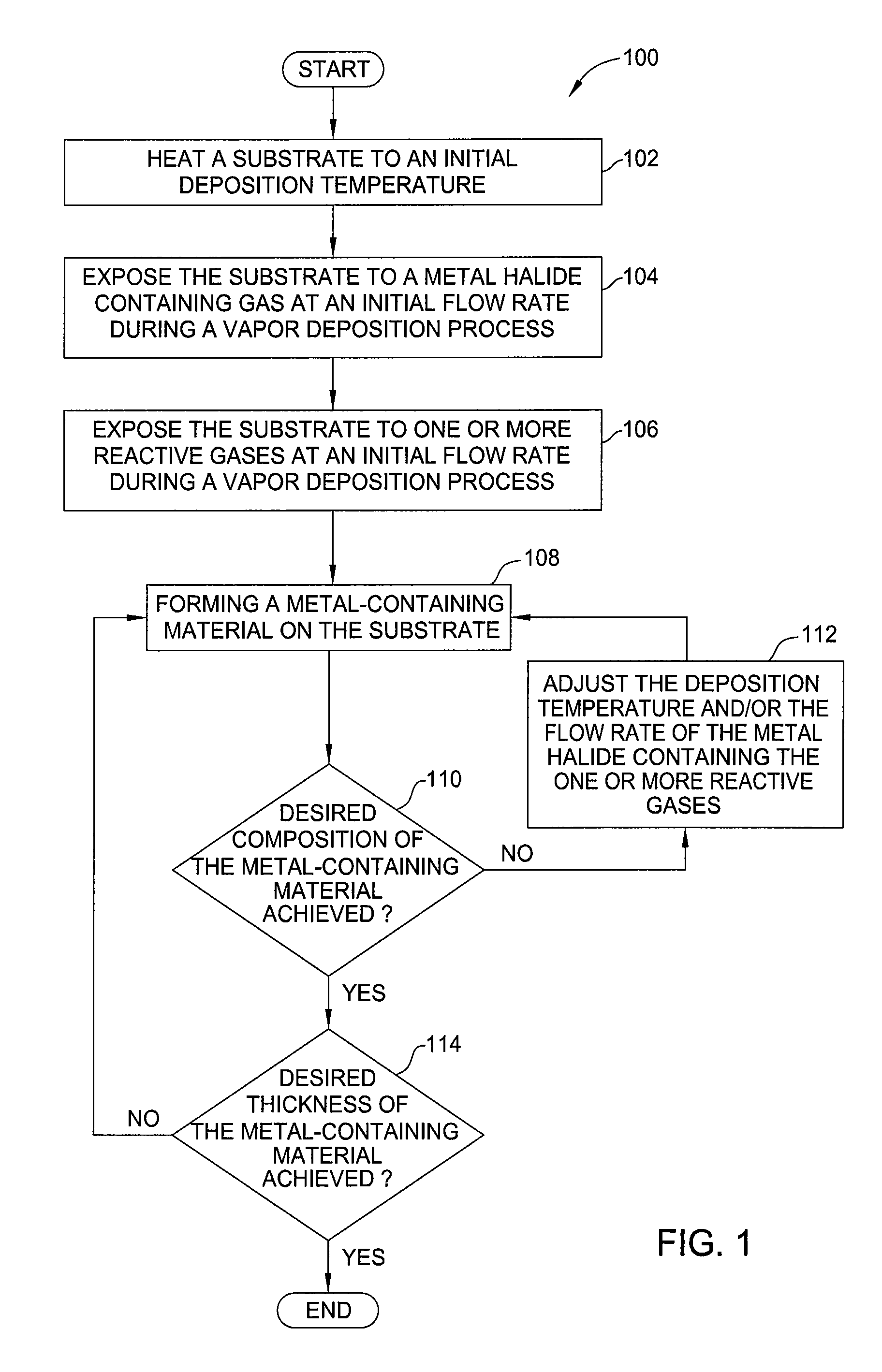

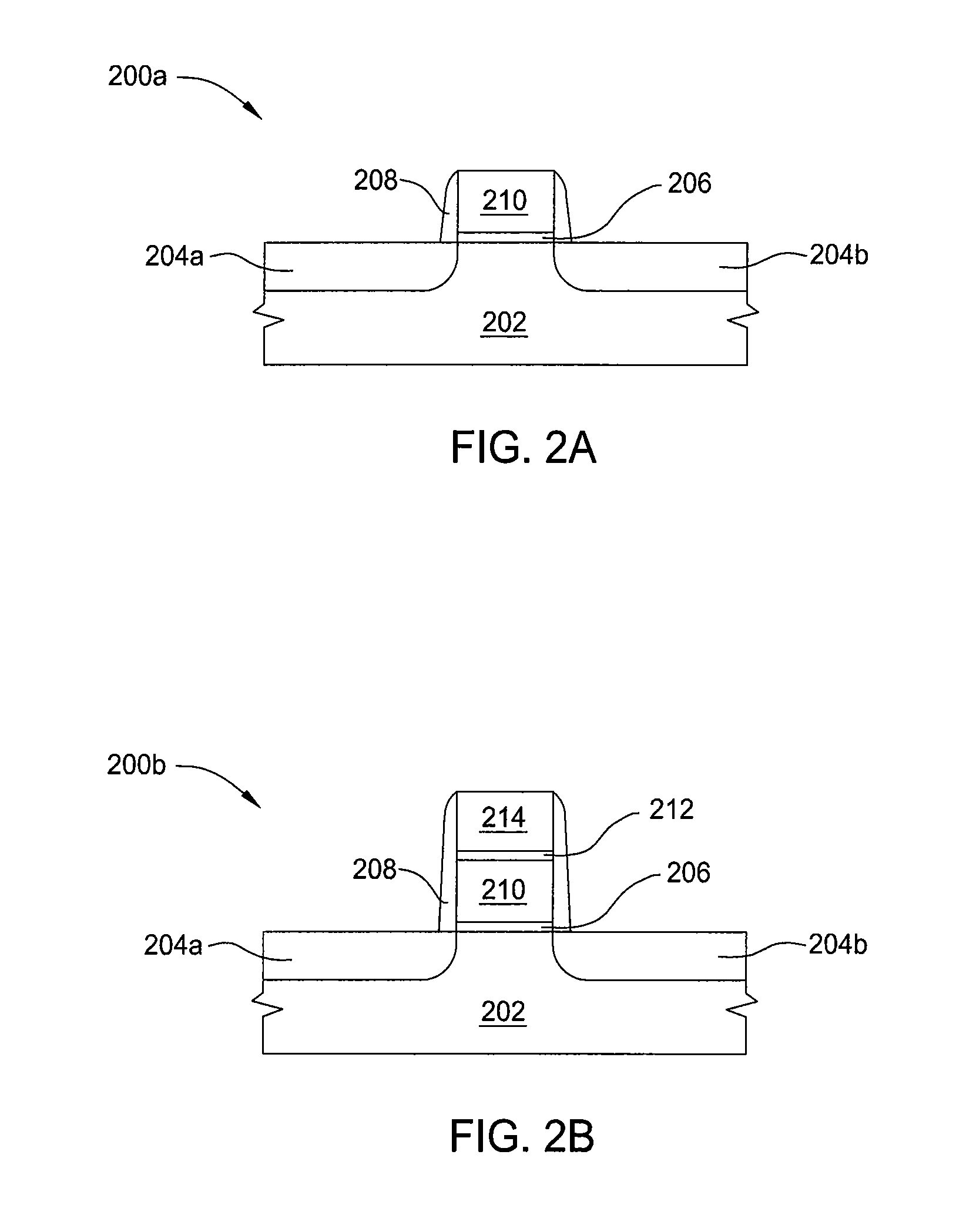

Nmos metal gate materials, manufacturing methods, and equipment using CVD and ald processes with metal based precursors

ActiveUS20110263115A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingGas phaseMetallic materials

Embodiments of the invention generally provide methods for depositing metal-containing materials and compositions thereof. The methods include deposition processes that form metal, metal carbide, metal silicide, metal nitride, and metal carbide derivatives by a vapor deposition process, including thermal decomposition, CVD, pulsed-CVD, or ALD. In one embodiment, a method for processing a substrate is provided which includes depositing a dielectric material having a dielectric constant greater than 10, forming a feature definition in the dielectric material, depositing a work function material conformally on the sidewalls and bottom of the feature definition, and depositing a metal gate fill material on the work function material to fill the feature definition, wherein the work function material is deposited by reacting at least one metal-halide precursor having the formula MXY, wherein M is tantalum, hafnium, titanium, and lanthanum, X is a halide selected from the group of fluorine, chlorine, bromine, or iodine, and y is from 3 to 5.

Owner:APPLIED MATERIALS INC

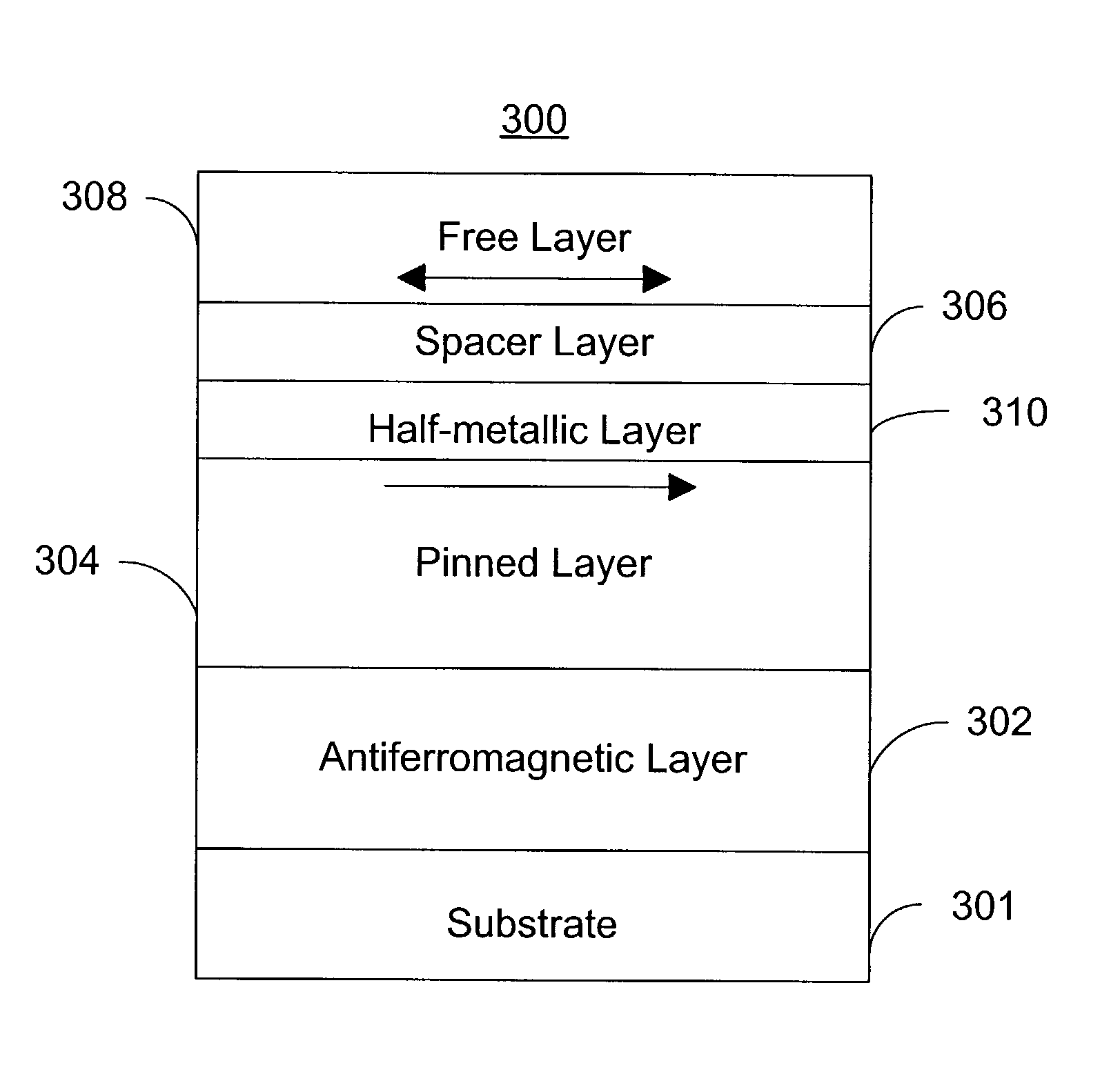

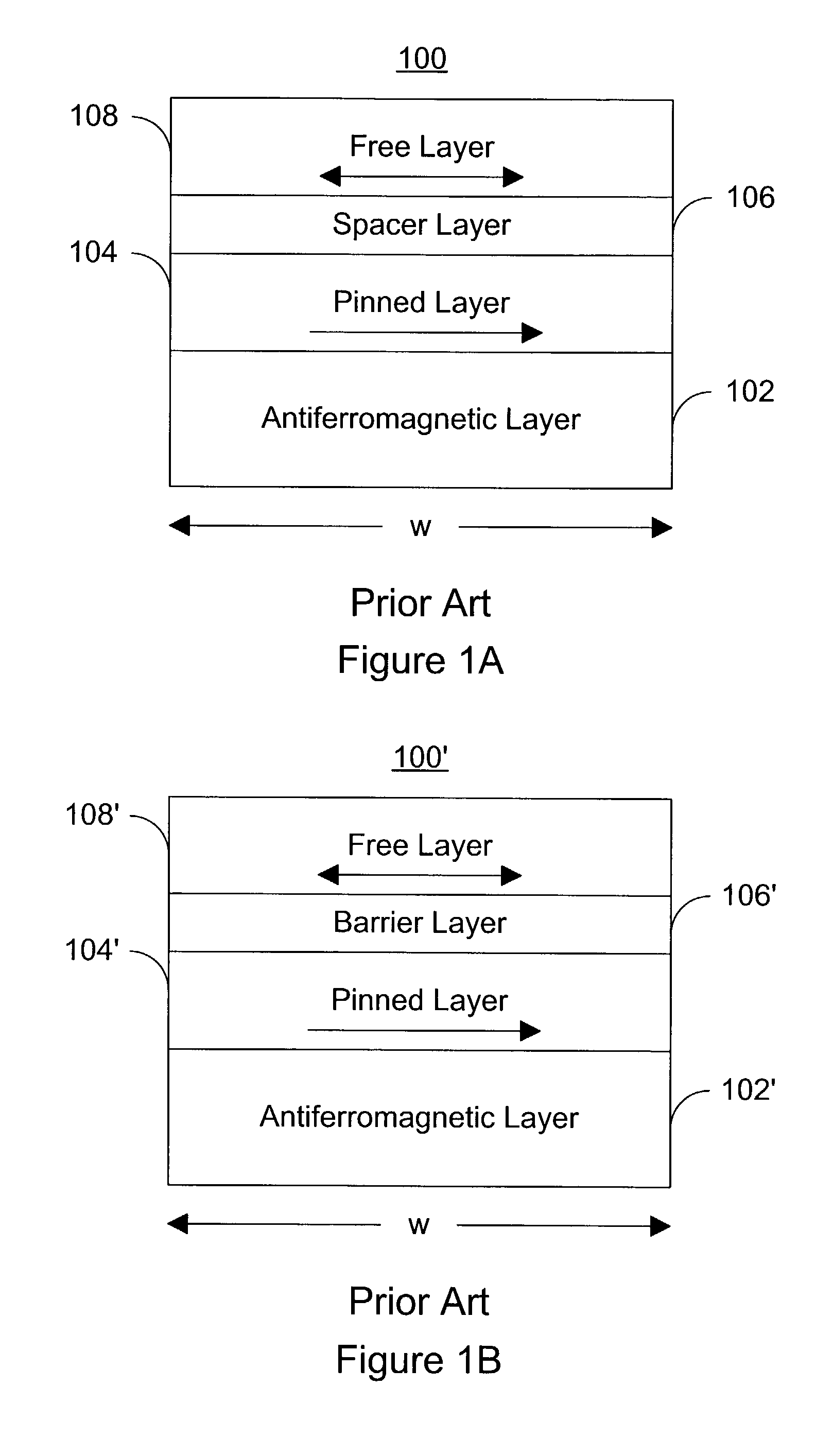

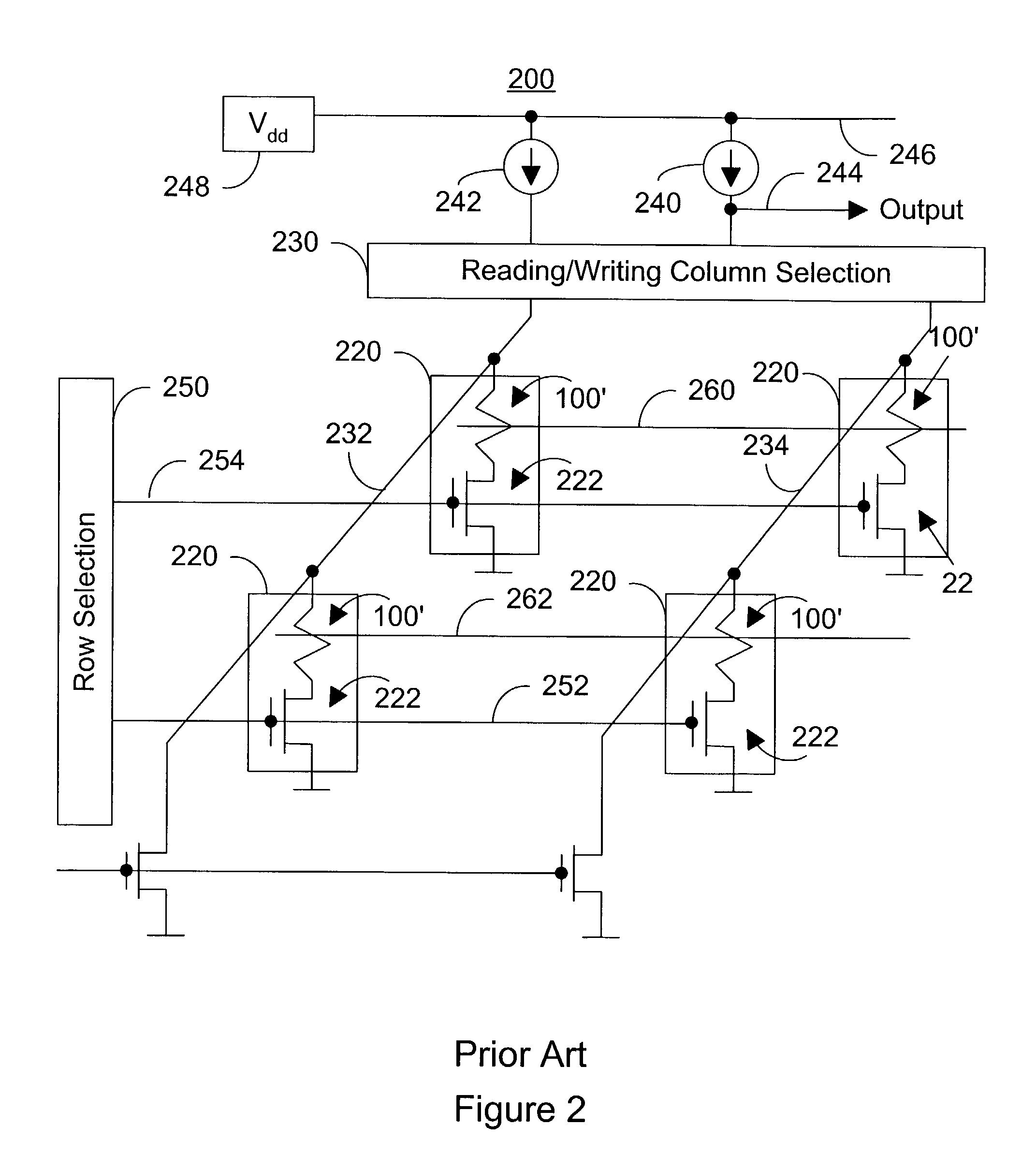

Magnetic element utilizing spin-transfer and half-metals and an MRAM device using the magnetic element

InactiveUS6958927B1Reduce high switching currentReduce power consumptionMagnetic-field-controlled resistorsSemiconductor/solid-state device manufacturingHigh densityHalf-metal

A magnetic element that can be used in a memory array having high density includes a pinned layer, a half-metallic material layer, a spacer (or a barrier) layer and a free layer. The half-metallic material layer is formed on the pinned layer and preferably has a thickness that is less than about 100 Å. The half-metallic material layer can be formed to be a continuous layer or a discontinuous on the pinned layer. The spacer (or barrier) layer is formed on the half-metallic material layer, such that the spacer (or barrier) layer is nonmagnetic and conductive (or insulating). The free layer is formed on the spacer (or barrier) layer and has a second magnetization that changes direction based on the spin-transfer effect when a write current passes through the magnetic element.

Owner:SAMSUNG SEMICON

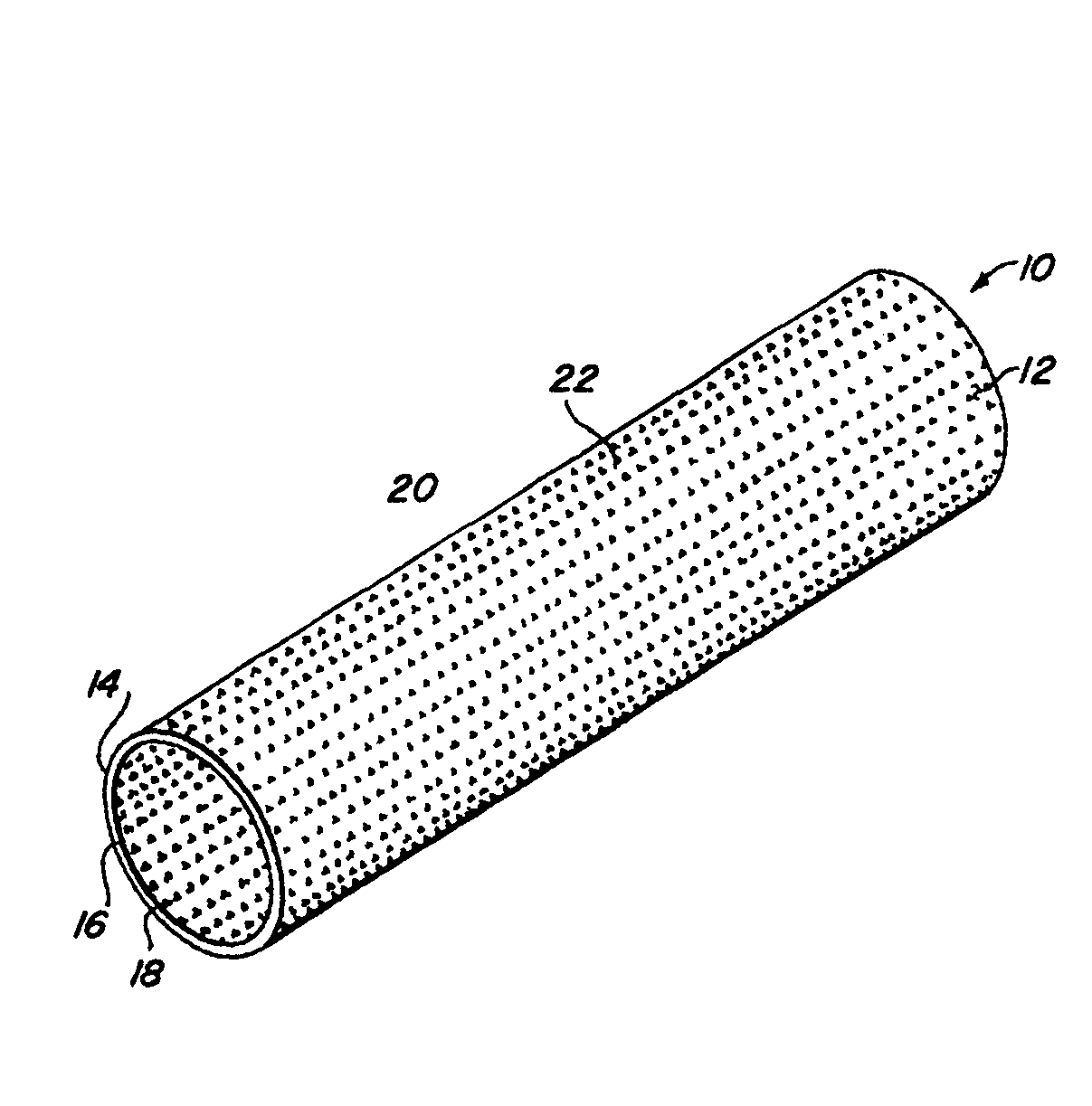

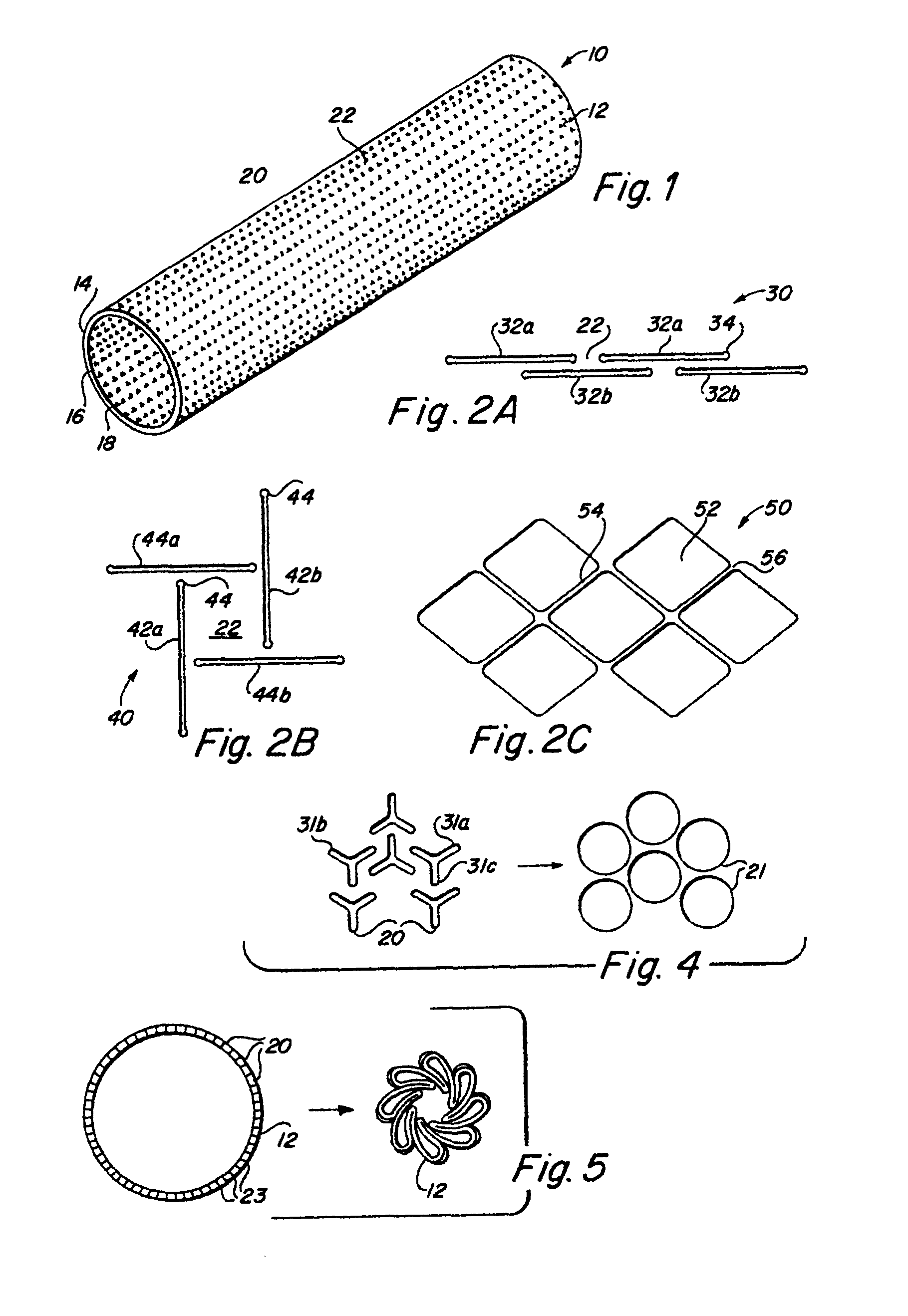

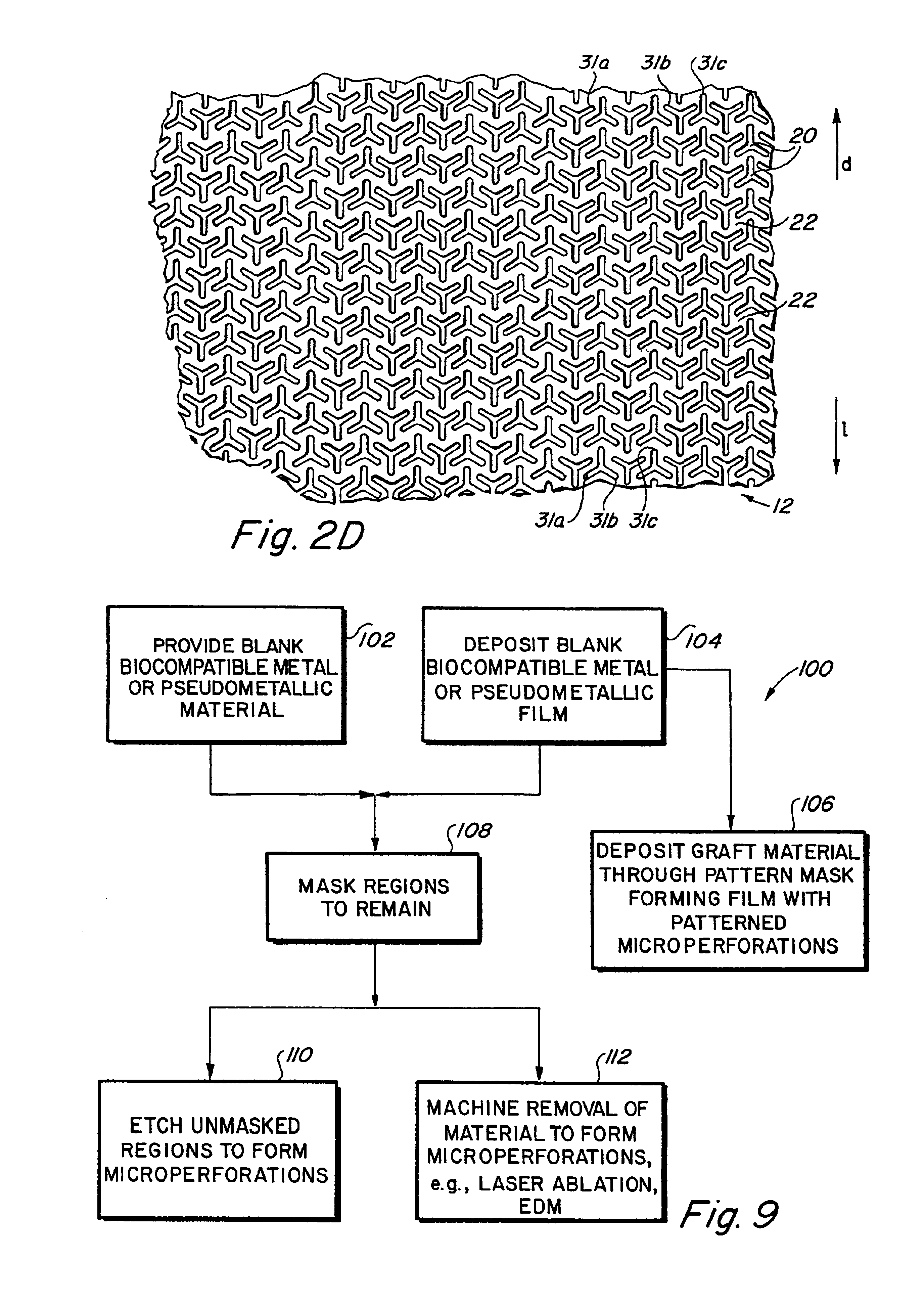

Complaint implantable medical devices and methods of making same

InactiveUS6936066B2Give flexibilityFacilitating transmural endothelializationStentsHeart valvesSurgical GraftMetallic materials

Implantable medical grafts fabricated of metallic or pseudometallic films of biocompatible materials having a plurality of microperforations passing through the film in a pattern that imparts fabric-like qualities to the graft or permits the geometric deformation of the graft. The implantable graft is preferably fabricated by vacuum deposition of metallic and / or pseudometallic materials into either single or multi-layered structures with the plurality of microperforations either being formed during deposition or after deposition by selective removal of sections of the deposited film. The implantable medical grafts are suitable for use as endoluminal or surgical grafts and may be used as vascular grafts, stent-grafts, skin grafts, shunts, bone grafts, surgical patches, non-vascular conduits, valvular leaflets, filters, occlusion membranes, artificial sphincters, tendons and ligaments.

Owner:VACTRONIX SCI LLC

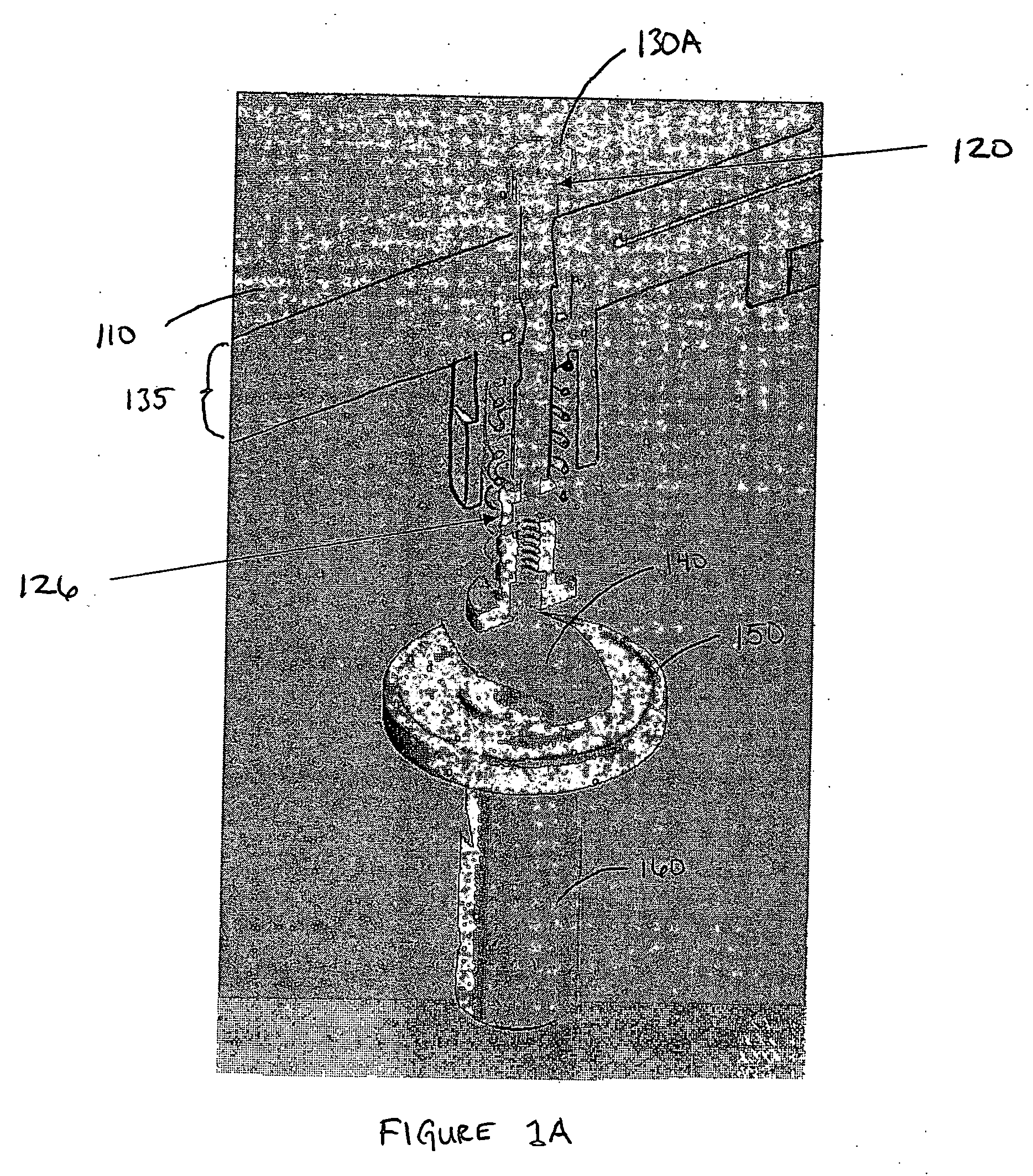

Oilfield Elements Having Controlled Solubility and Methods of Use

ActiveUS20070107908A1Ease of the element traversingFluid removalDrilling compositionPolyamideSubject matter

Oilfield elements are described, one embodiment comprising a combination of a normally insoluble metal with an element selected from a second metal, a semi-metallic material, and non-metallic materials; and one or more solubility-modified high strength and / or high-toughness polymeric materials selected from polyamides, polyethers, and liquid crystal polymers. Methods of using the oilfield elements in oilfield operations are also described. This abstract allows a searcher or other reader to quickly ascertain the subject matter of the disclosure. It will not be used to interpret or limit the scope or meaning of the claims. 37 CFR 1.72(b).

Owner:SCHLUMBERGER TECH CORP

Tool with a molybdenum sulfide containing coating and method for its production

InactiveUS6528171B1Improve wear resistanceRecord information storageMagnetic recordingMetallic materialsMonolayer

The invention relates to a tool, especially a cutting insert for cutting metallic materials, which consist of a hard metal, cermet ceramics or steel base, especially of a high speed steel base, and at least one layer deposited thereon. The single layer, or in the case of several layers the outer layer or the layer underneath the outer layer, contains molybdenum sulfide. The aim of the invention is to improve the resistance to wear of the friction-reducing, molybdenum sulfide containing layer even at high pressures. To this end, the molybdenum sulfide containing layer consists of an alternating sequence of two layer that are different from one another. The first layer contains 51 to 100% by weight of metallic molybdenum and the second layer contains 21 to 100% by weight of MoS2 which substantially consists of hexagonal crystals that are at least substantially oriented in a plane parallel to the tool surface.

Owner:WIDIA

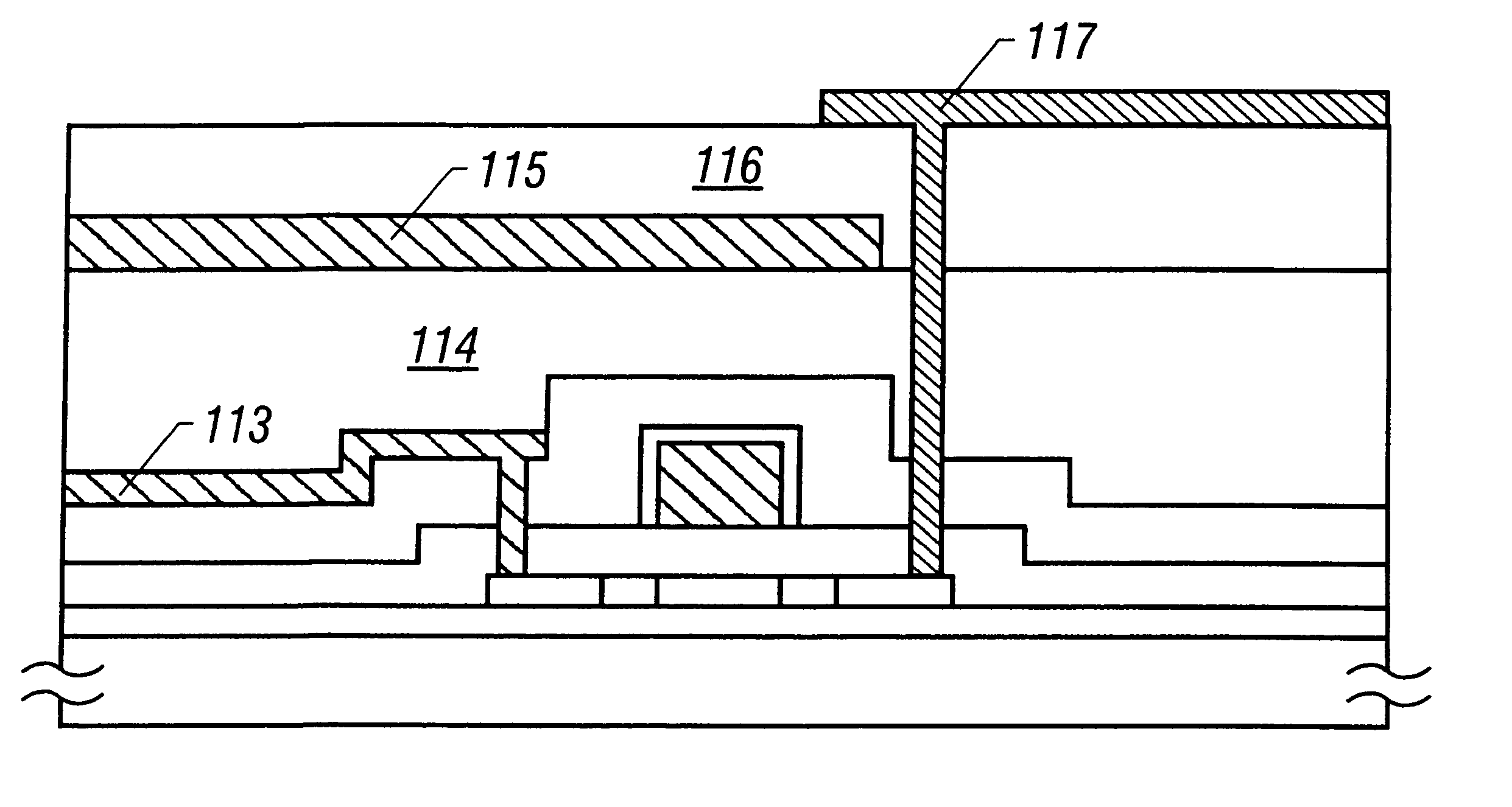

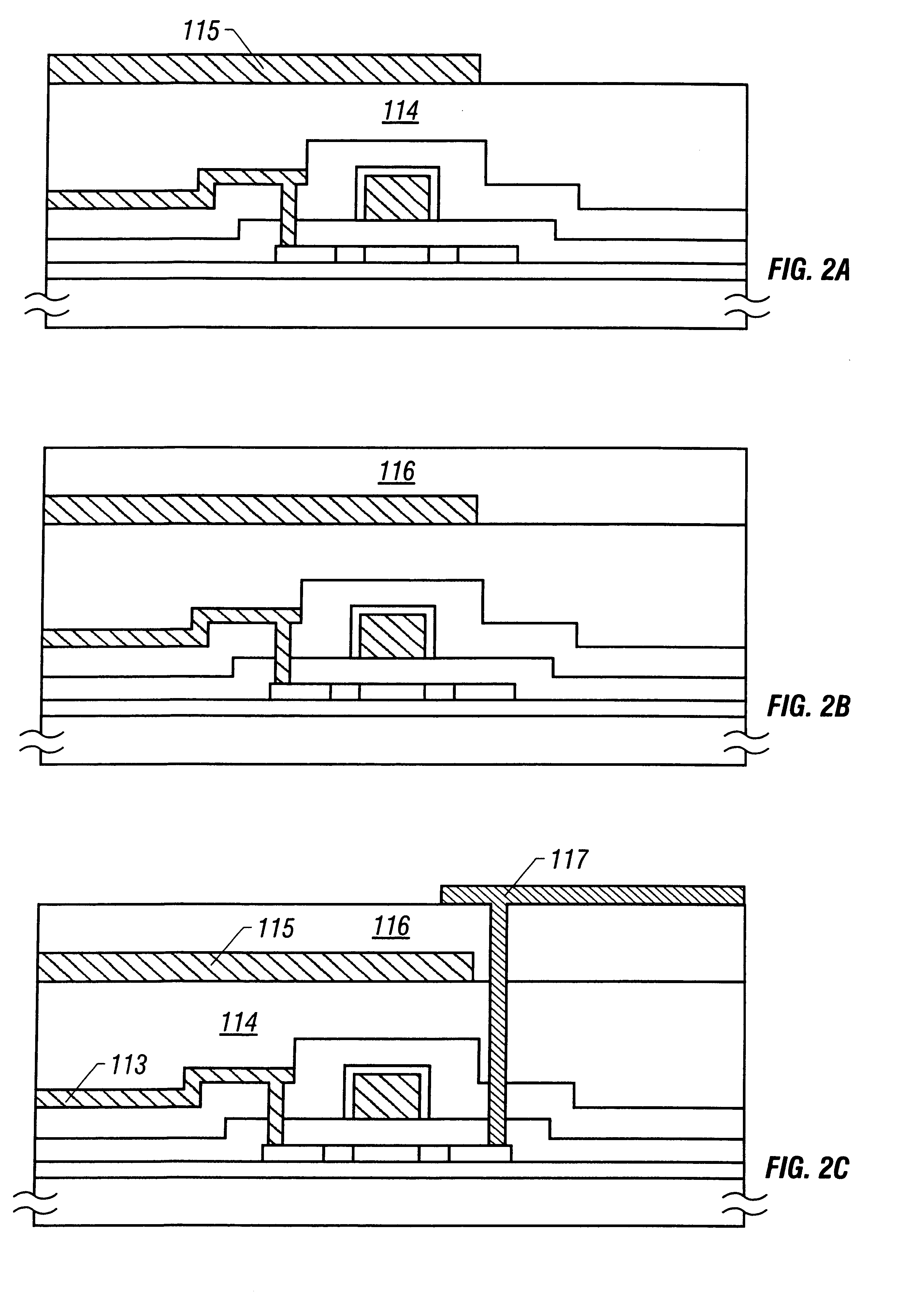

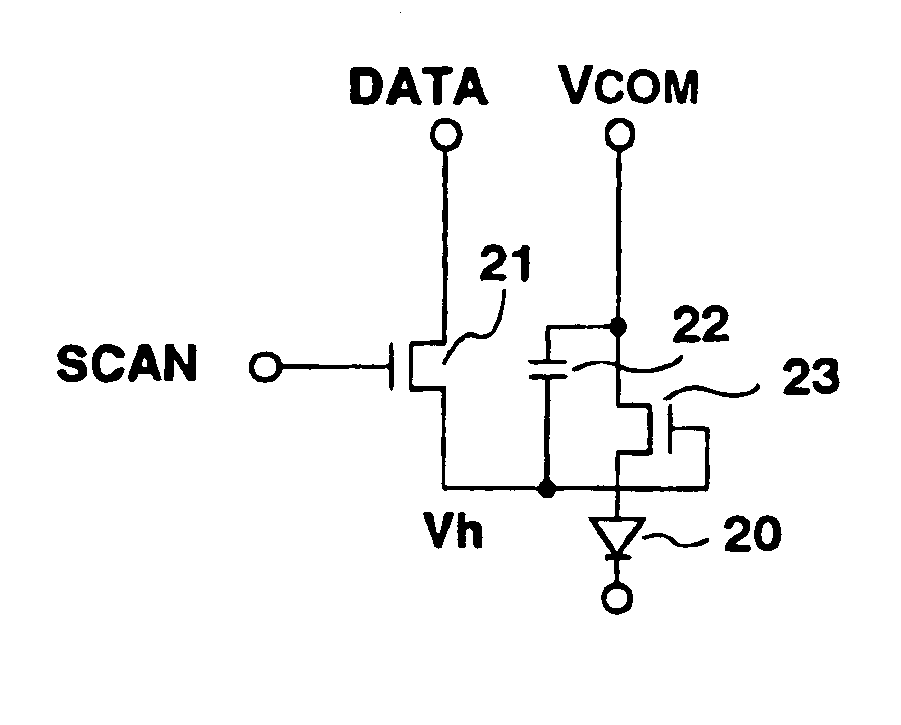

Active matrix electro-luminescent display thin film transistor

InactiveUS6239470B1Improve performanceSolve the real problemTransistorSemiconductor/solid-state device detailsCapacitanceActive matrix

A resin material having a small relative dielectric constant is used as a layer insulation film 114. The resin material has a flat surface. A black matrix or masking film for thin film transistors is formed thereon using a metal material. Such a configuration prevents the problem of a capacity generated between the masking film and a thin film transistor.

Owner:SEMICON ENERGY LAB CO LTD

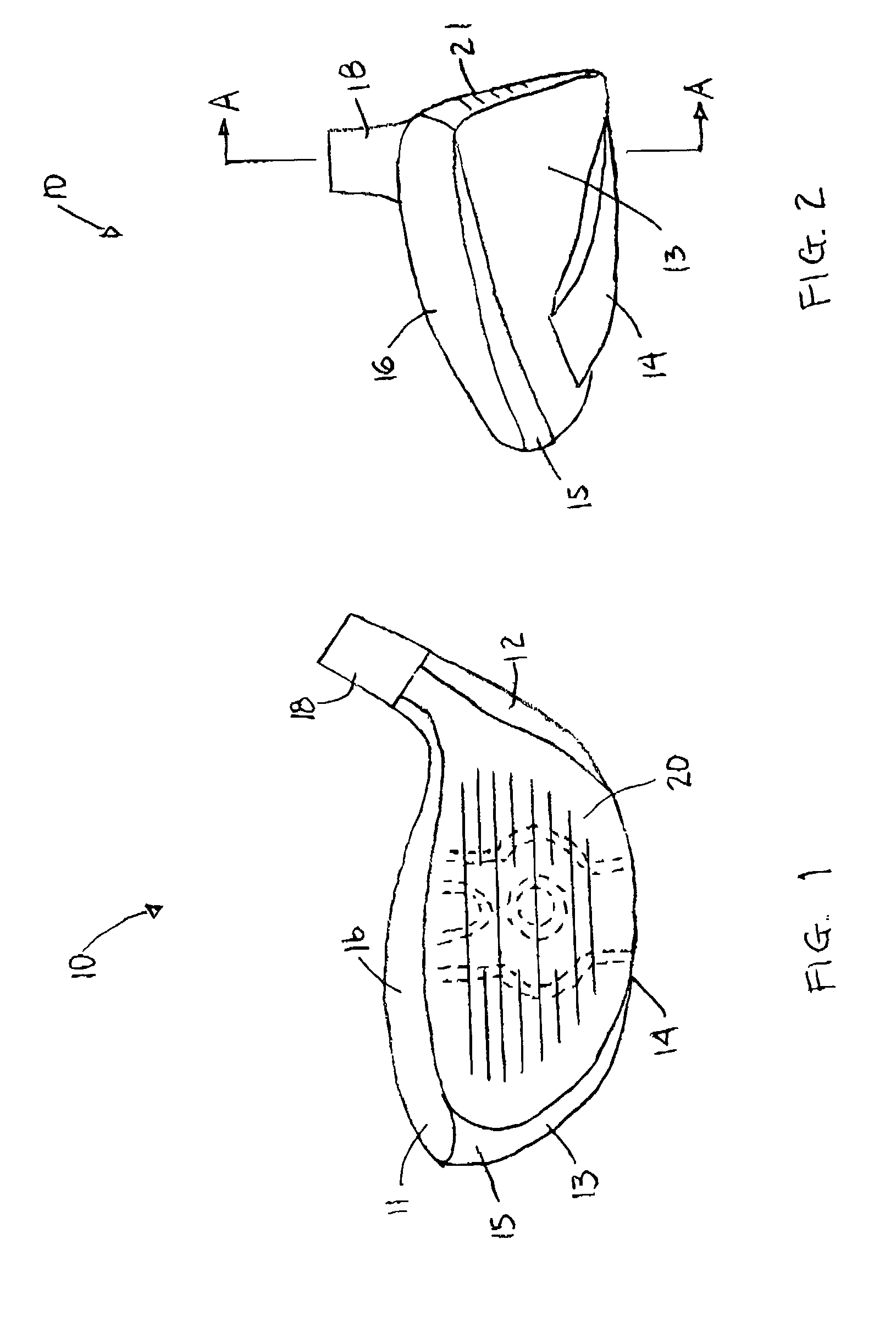

Golf club having an improved face plate

InactiveUS6997820B2Increasing the thicknessReduce thicknessGolf clubsRacket sportsEngineeringMetallic materials

A golf club head is provided having an increased sweet spot across its club face. A preferred construction includes a face plate having vertical zone of increased thickness and a central region having a reduced thickness. An upward extension of the vertical zone comprises divergent segments separated by an upper region of reduced thickness. The face plate material is preferably metallic, but in alternative embodiments may be formed of a composite or non-metal material. Methods for manufacturing a golf club head having a face plate with the thicknesses of the present invention include forging and machining techniques. The club head may be a wood-type or iron.

Owner:TAYLOR MADE GOLF

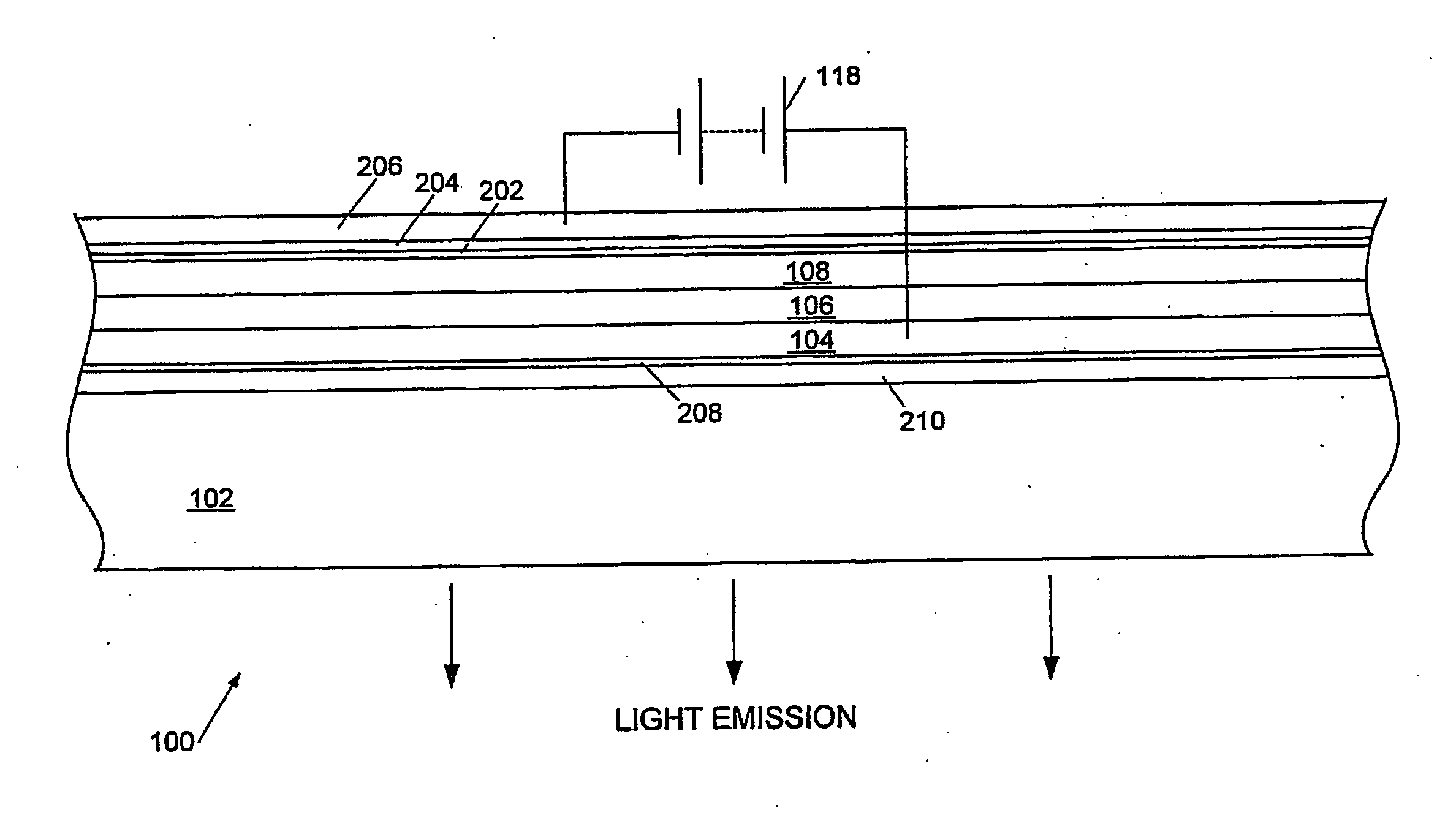

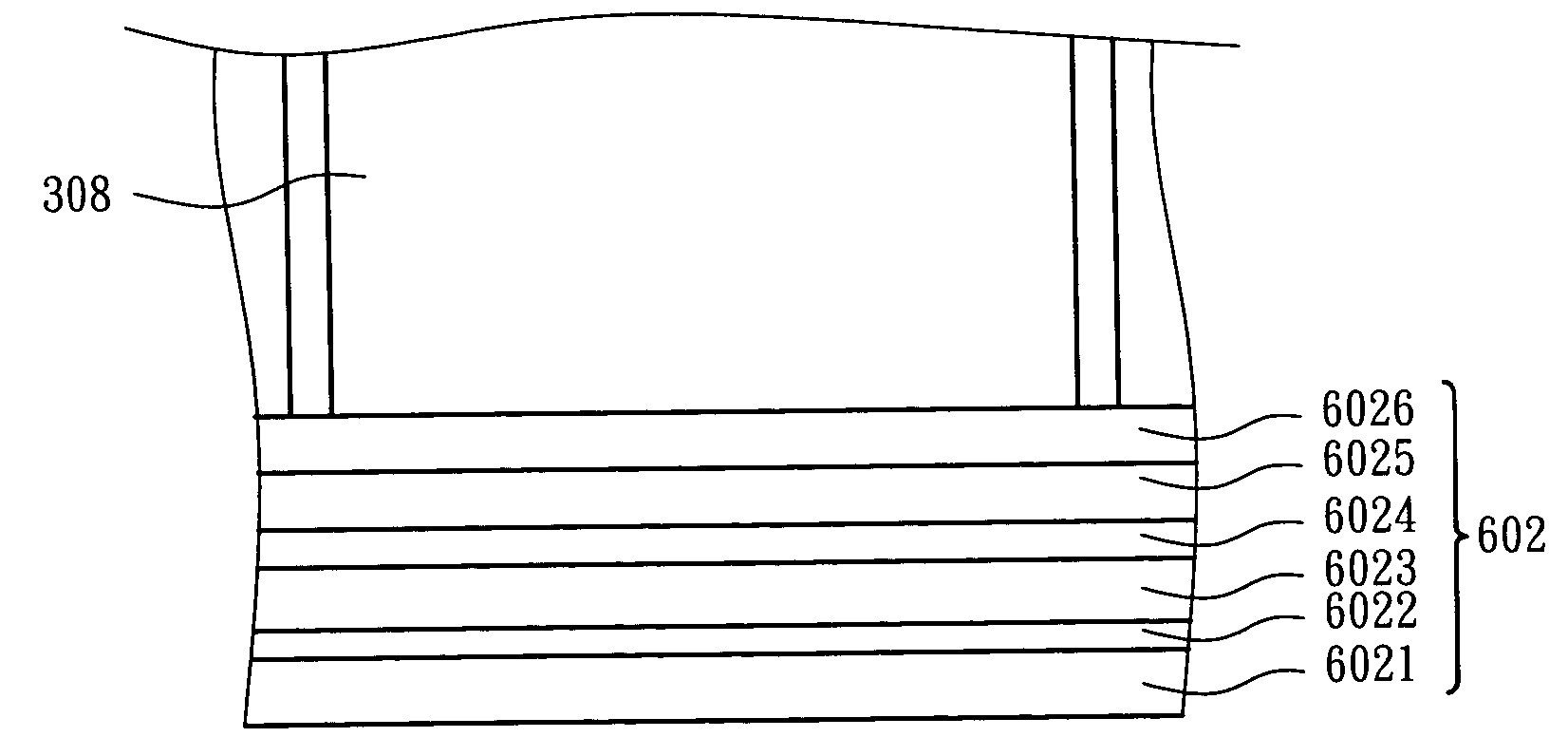

Organic Electroluminescent Device

ActiveUS20110042696A1Improve light outcoupling efficiencyHigh color puritySolid-state devicesVacuum evaporation coatingInter layerRefractive index

An organic electroluminescent device cfomprising: a transparent substrate; a first electrode disposed over the substrate for injecting charge of a first polarity; a second electrode disposed over the first electrode for injecting charge of a second polarity opposite to said first polarity; an organic light-emitting layer disposed between the first and the second electrode, wherein the second electrode is reflective, the first electrode is transparent or semi-transparent, and one or more intermediate layers of dielectric material with a refractive index greater than 1.8 or a metal material is disposed between the substrate and the first electrode forming a semi-transparent mirror whereby a microcavity is provided between the reflective second electrode and the semi-transparent mirror, all the intermediate layers disposed between the substrate and the first electrode having a surface nearest the organic light-emitting layer not more than 150 nm from a surface of the first electrode nearest the organic light-emitting layer.

Owner:CAMBRIDGE DISPLAY TECH LTD

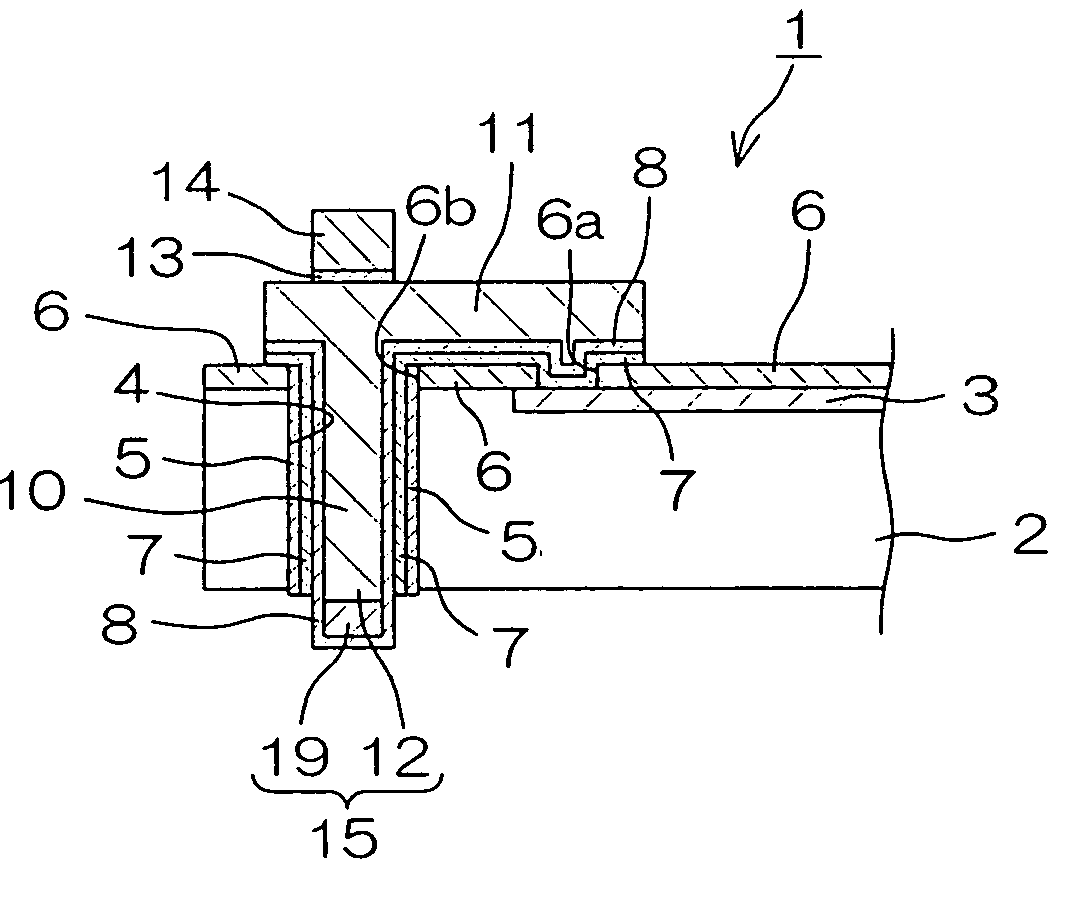

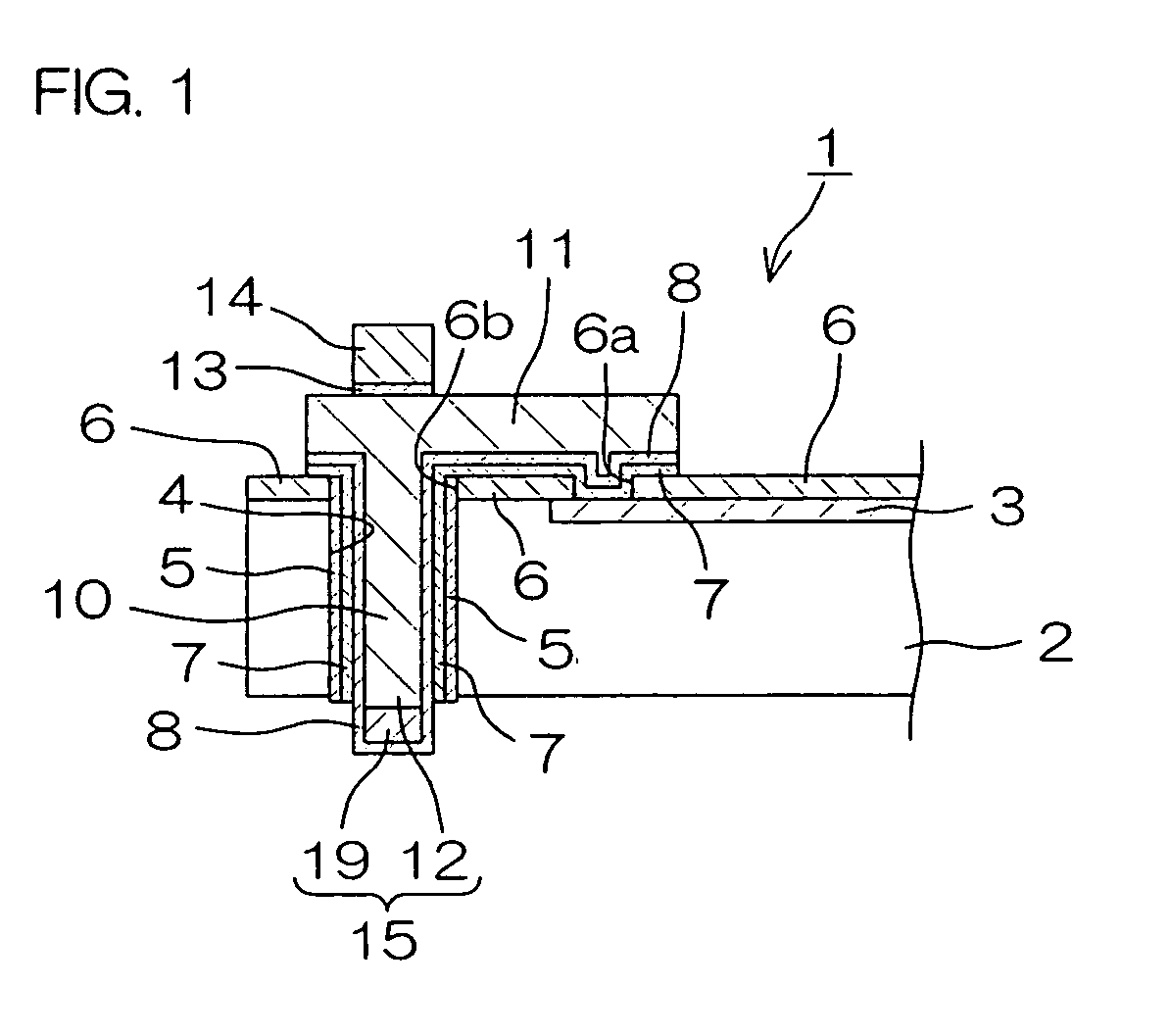

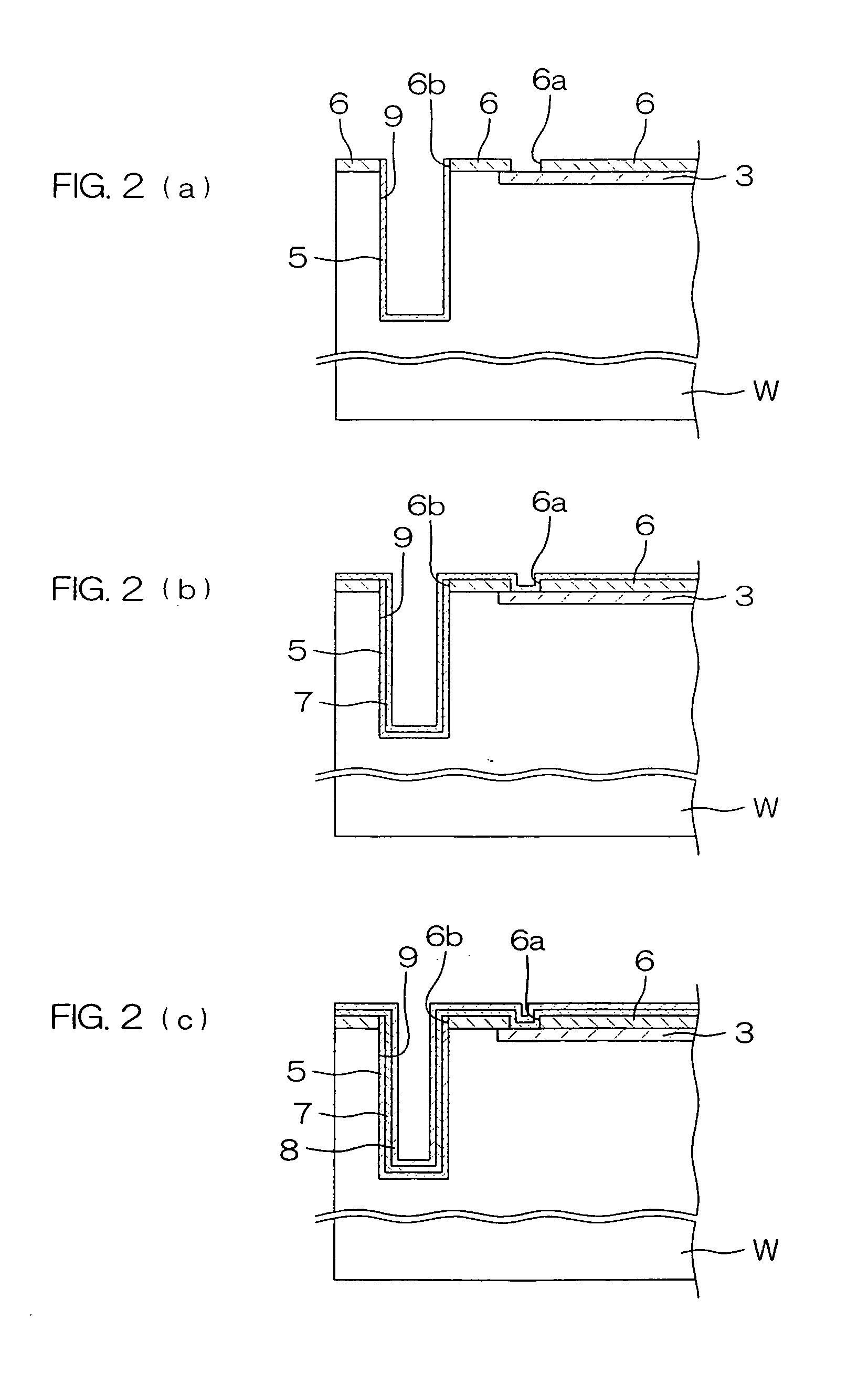

Semiconductor chip and manufacturing method for the same, and semiconductor device

ActiveUS20050151228A1Improve reliabilityThe connection is tight and firmSemiconductor/solid-state device detailsSolid-state devicesDevice formSemiconductor chip

The invention provides a semiconductor chip manufacturing method including the steps of: forming a concave portion extended in the thickness direction of a semiconductor substrate which has a front surface and a rear surface and has a function device formed on the front surface, from the front surface; forming an oxidation preventive film made of an inert first metal material by supplying the first metal material onto the inner wall surface of the concave portion; supplying a second metal material containing a metal which is oxidized more easily than the first metal material to the inside of the concave portion after the step of forming the oxidation preventive film; electrically connecting the second metal material supplied to the inside of the concave portion and the function device; and thinning the semiconductor substrate so that the thickness thereof becomes thinner than the depth of the concave portion by removing the semiconductor substrate from the rear surface while leaving the oxidation preventive film.

Owner:KIOXIA CORP +3

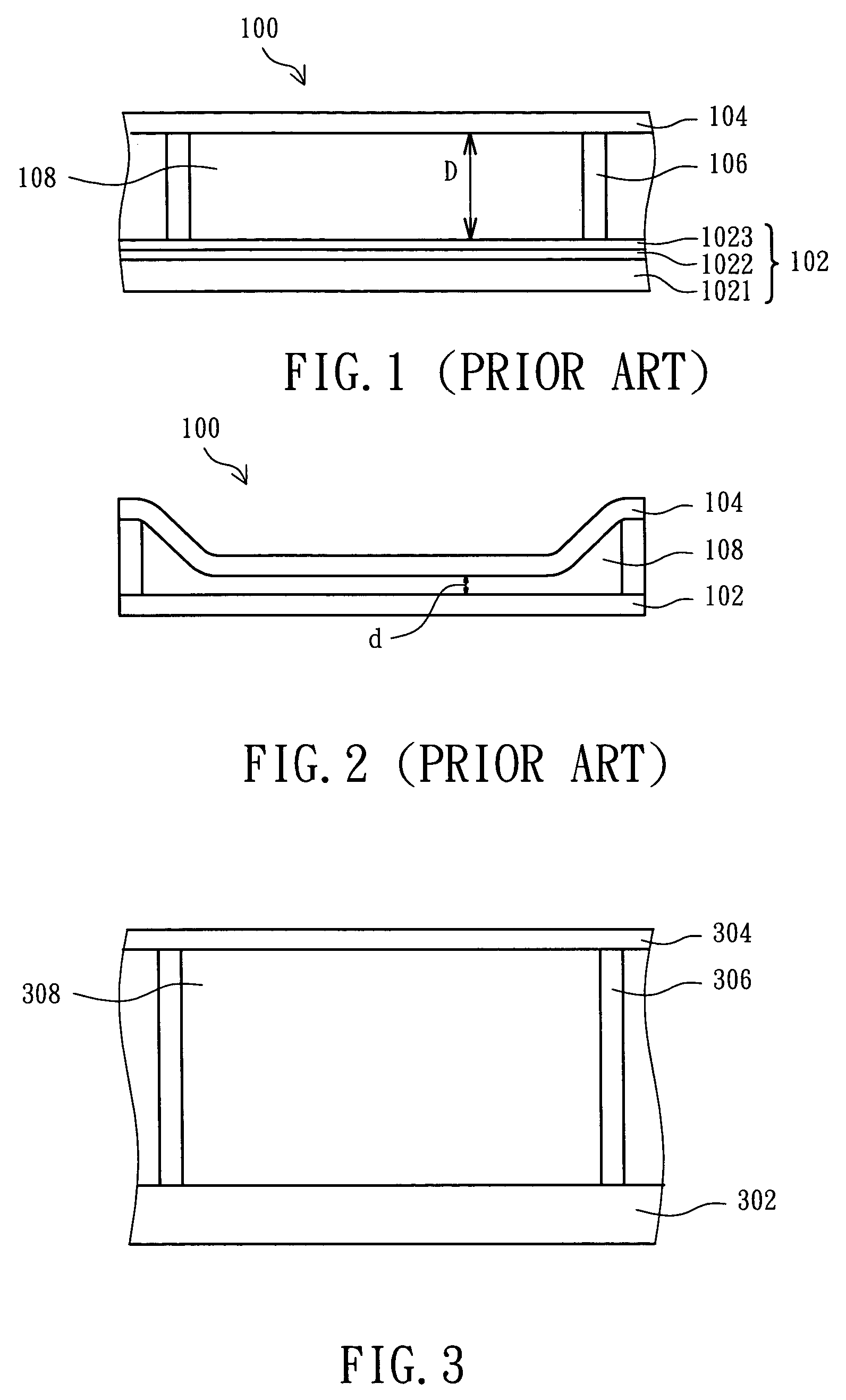

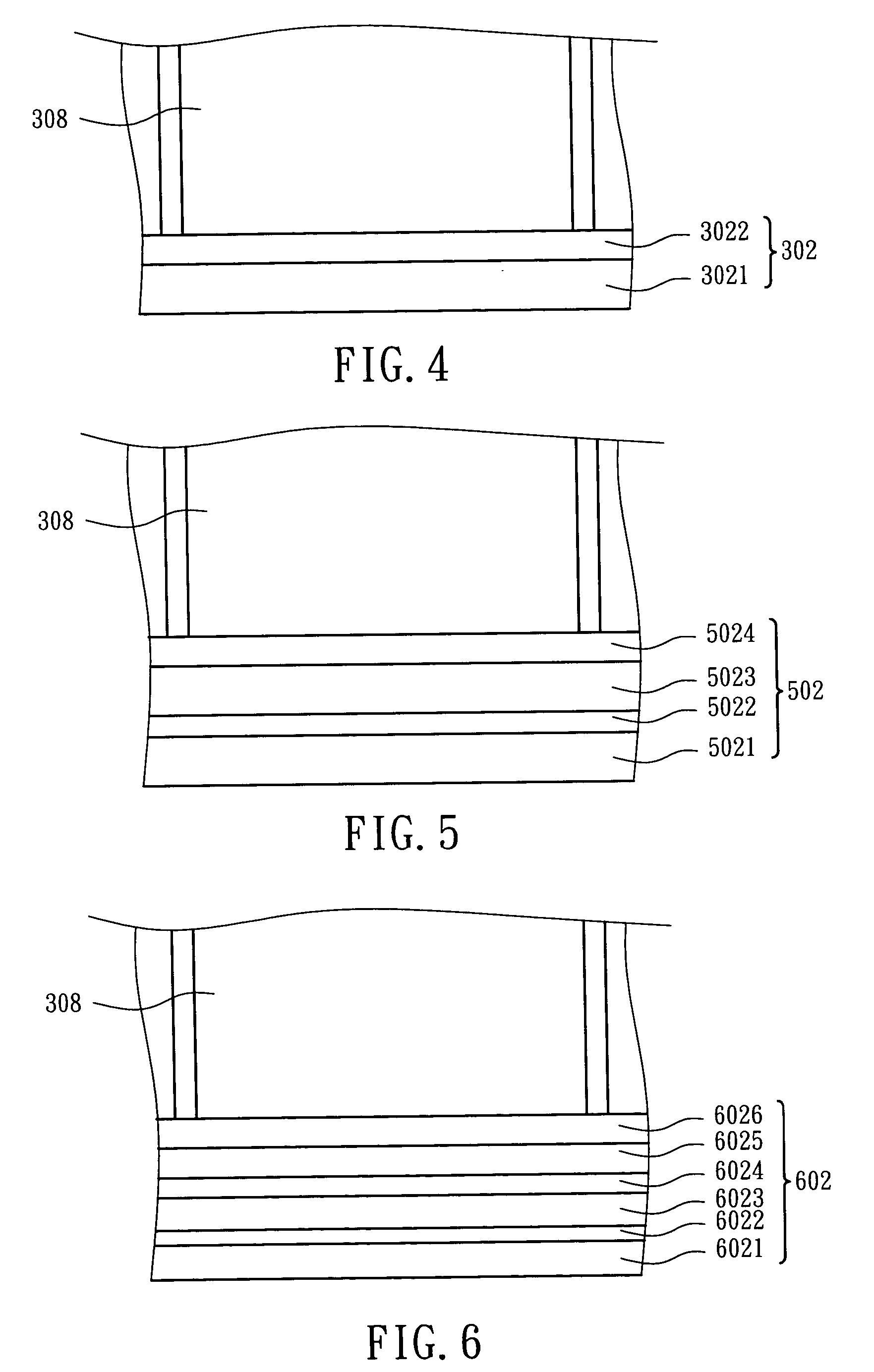

Structure of a light-incidence electrode of an optical interference display plate

InactiveUS20040175577A1Glass/slag layered productsNon-linear opticsLight reflectionMetallic materials

An optical interference display plate at least comprises a light-incidence electrode and a light-reflection electrode. The light-incidence electrode at least comprises an absorption layer and a dielectric layer. A material of the absorption layer does not comprises metallic material.

Owner:SNAPTRACK

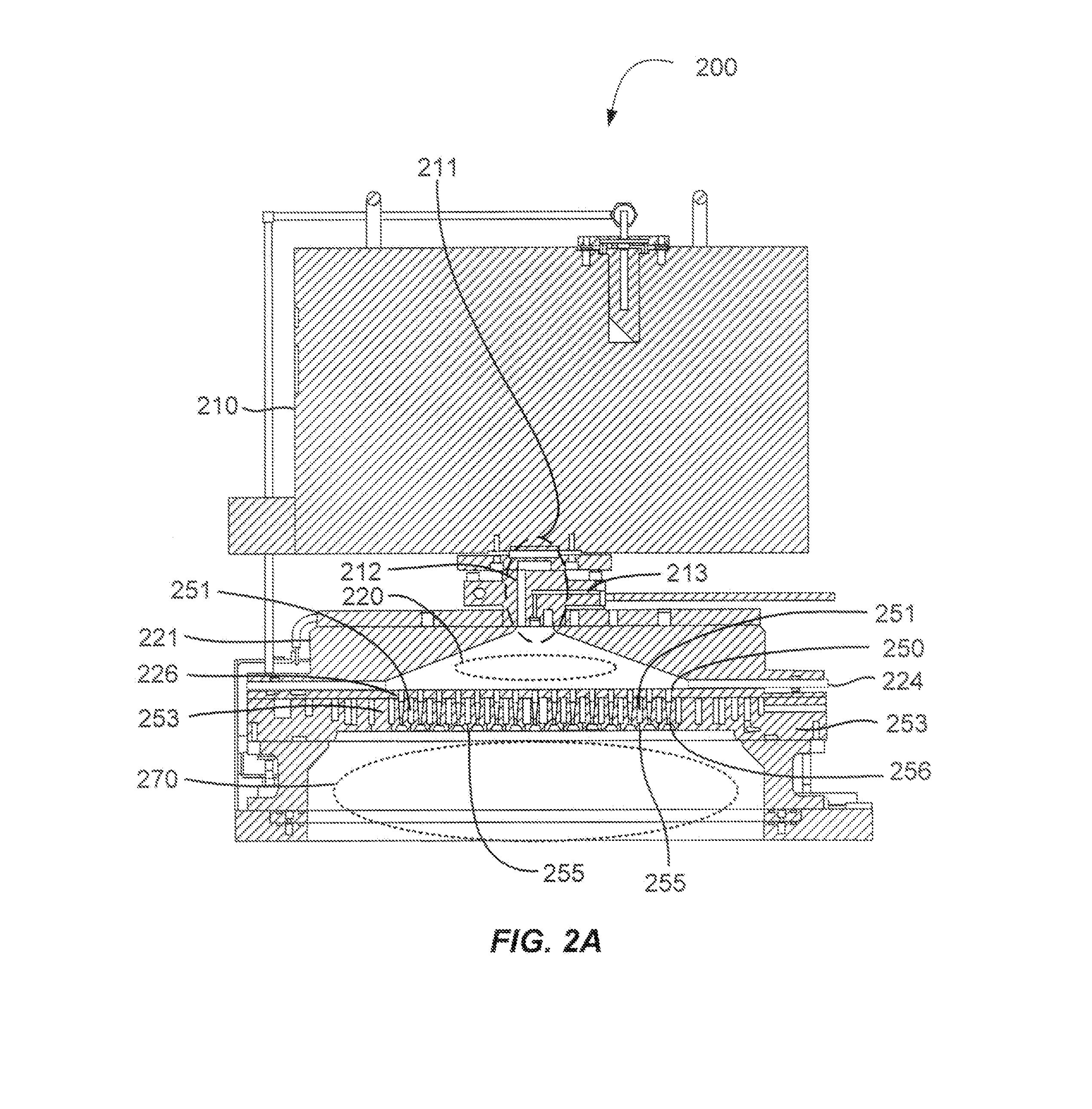

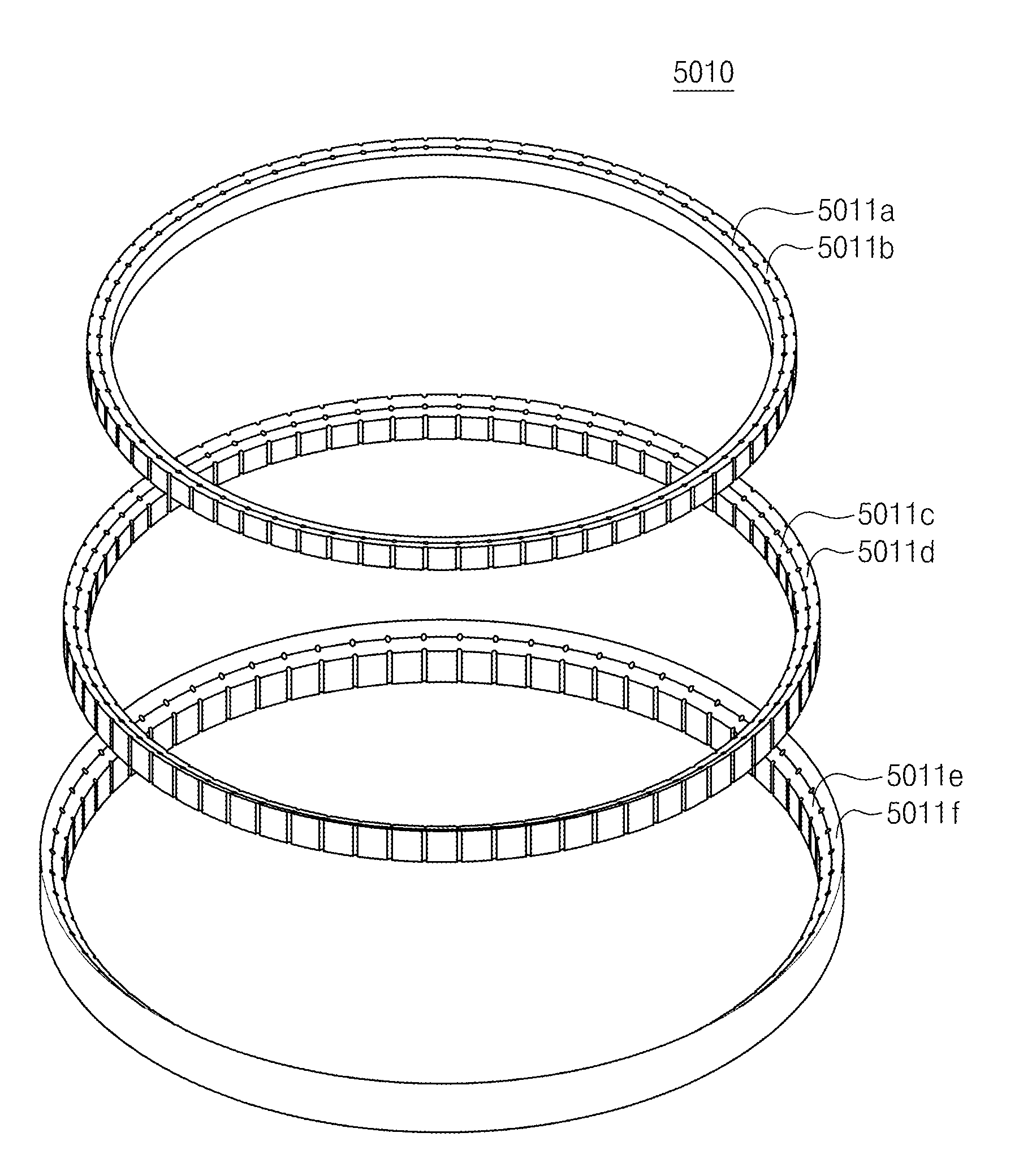

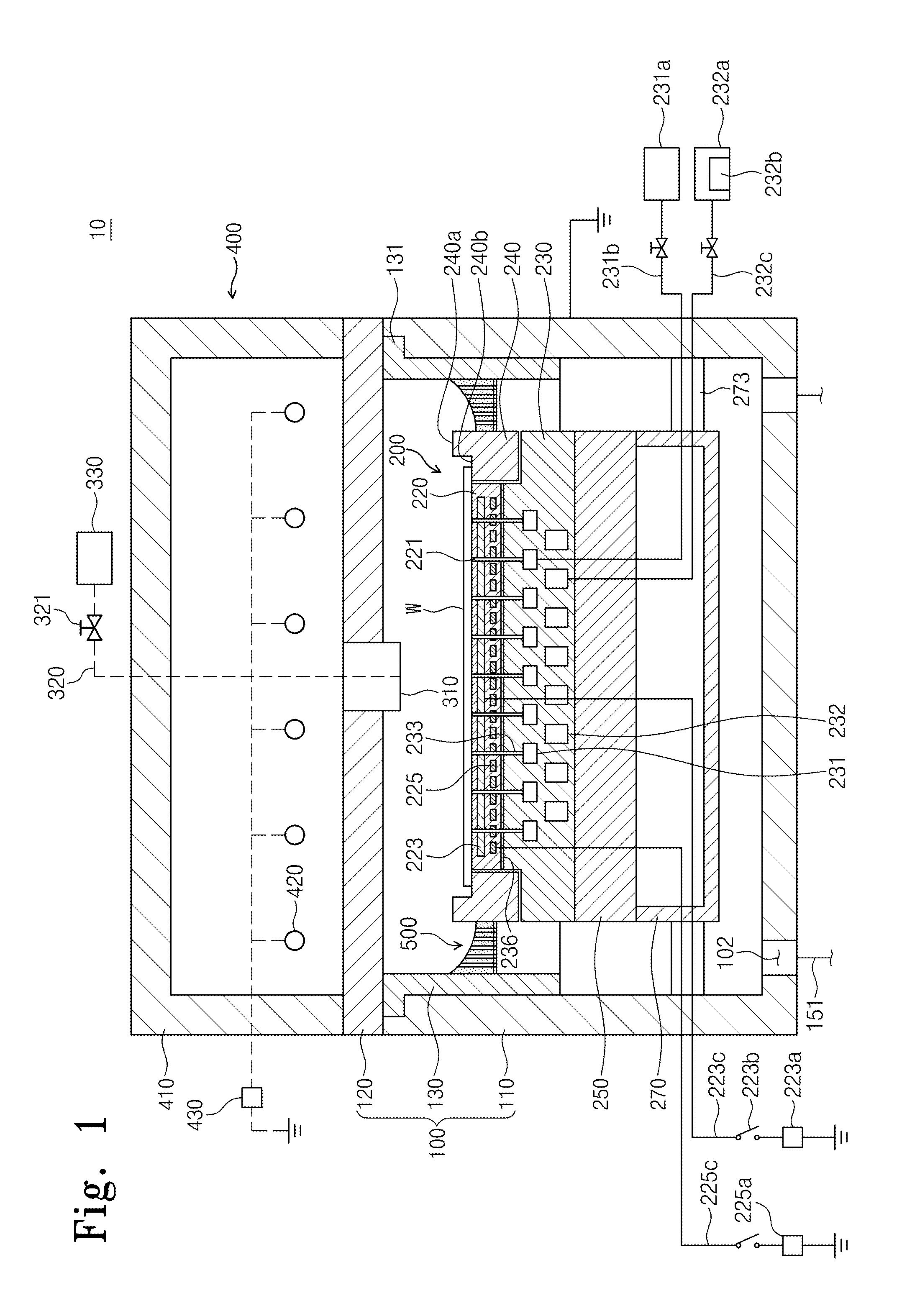

Apparatus for treating substrate

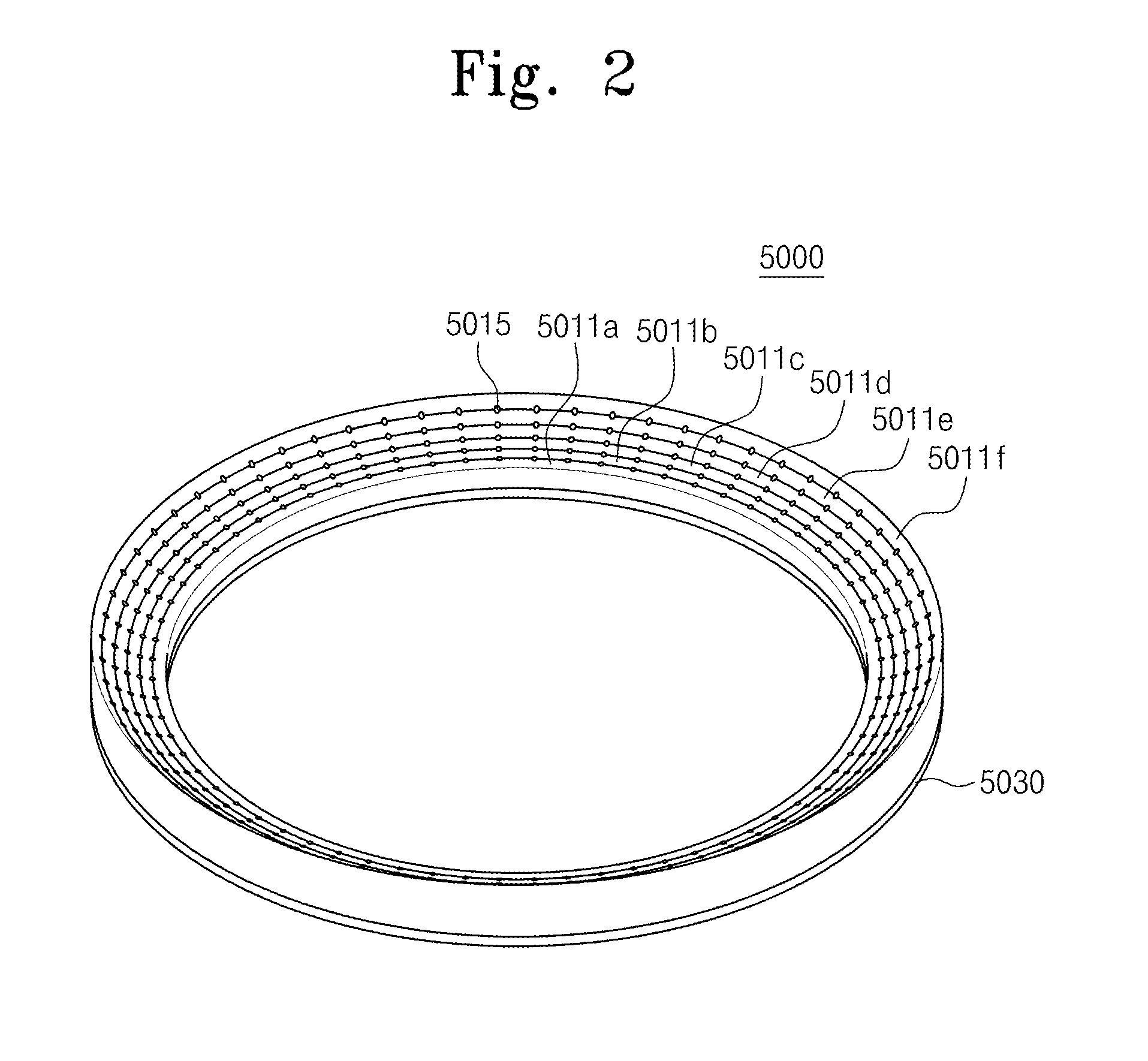

ActiveUS20140034240A1Prevent archingElectric discharge tubesSemiconductor/solid-state device manufacturingInterior spaceMetallic materials

Provided is a substrate treatment apparatus using plasma. The substrate treatment apparatus includes a housing having an inner space in which a substrate is treated, a support member disposed within the housing to support the substrate, a gas supply unit supplying a gas into the housing, a plasma source generating plasma from the gas supplied into the housing, and a baffle unit disposed to surround the support member within the housing, the baffle unit including a baffle in which through holes for exhausting the gas into the inner space of the housing are defined. The baffle is divided into a plurality of areas when viewed from an upper side, and each of portions of the plurality of areas is formed of a metallic material, and each of the other portions of the plurality of areas is formed of a nonmetallic material.

Owner:SEMES CO LTD

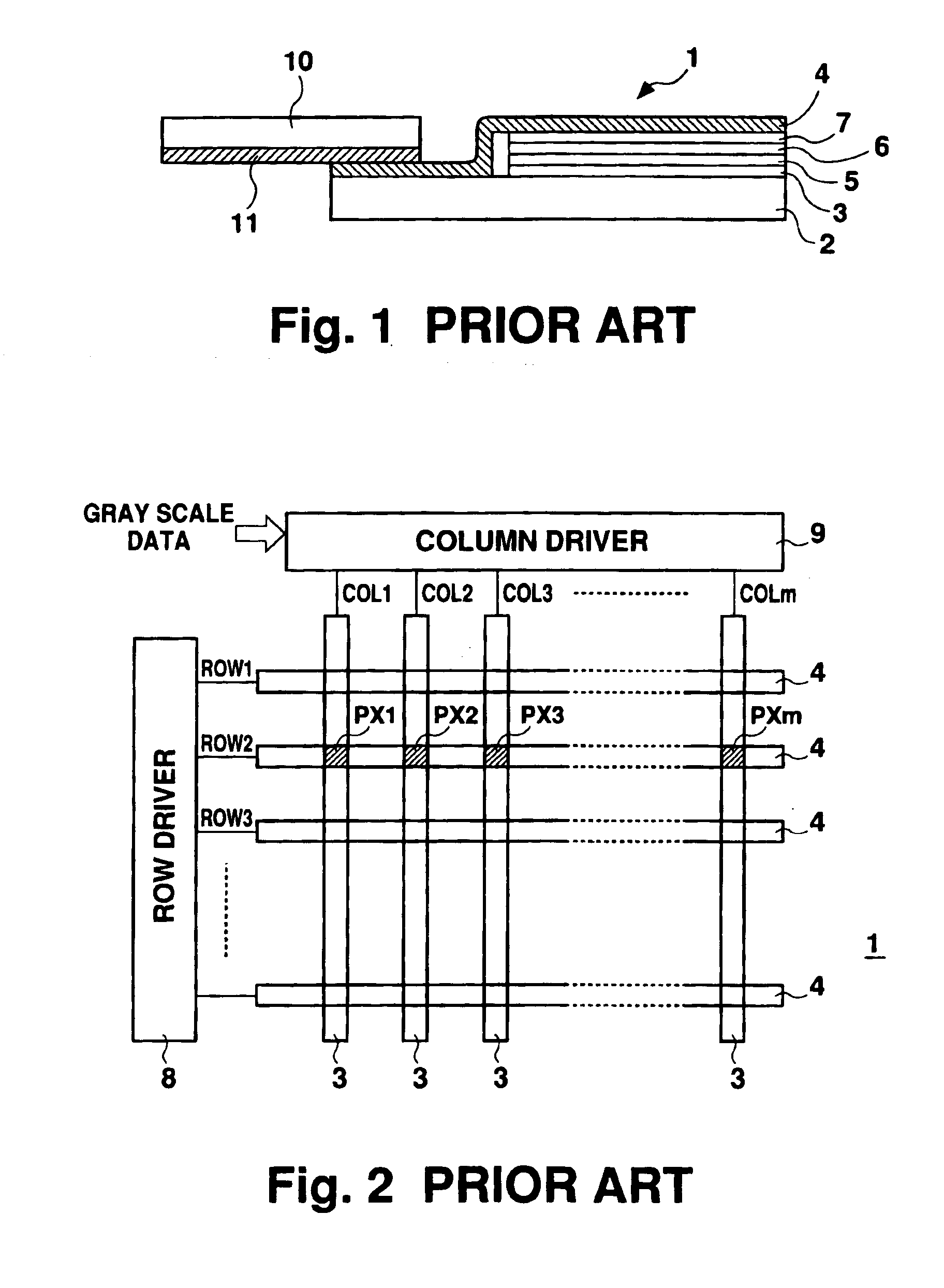

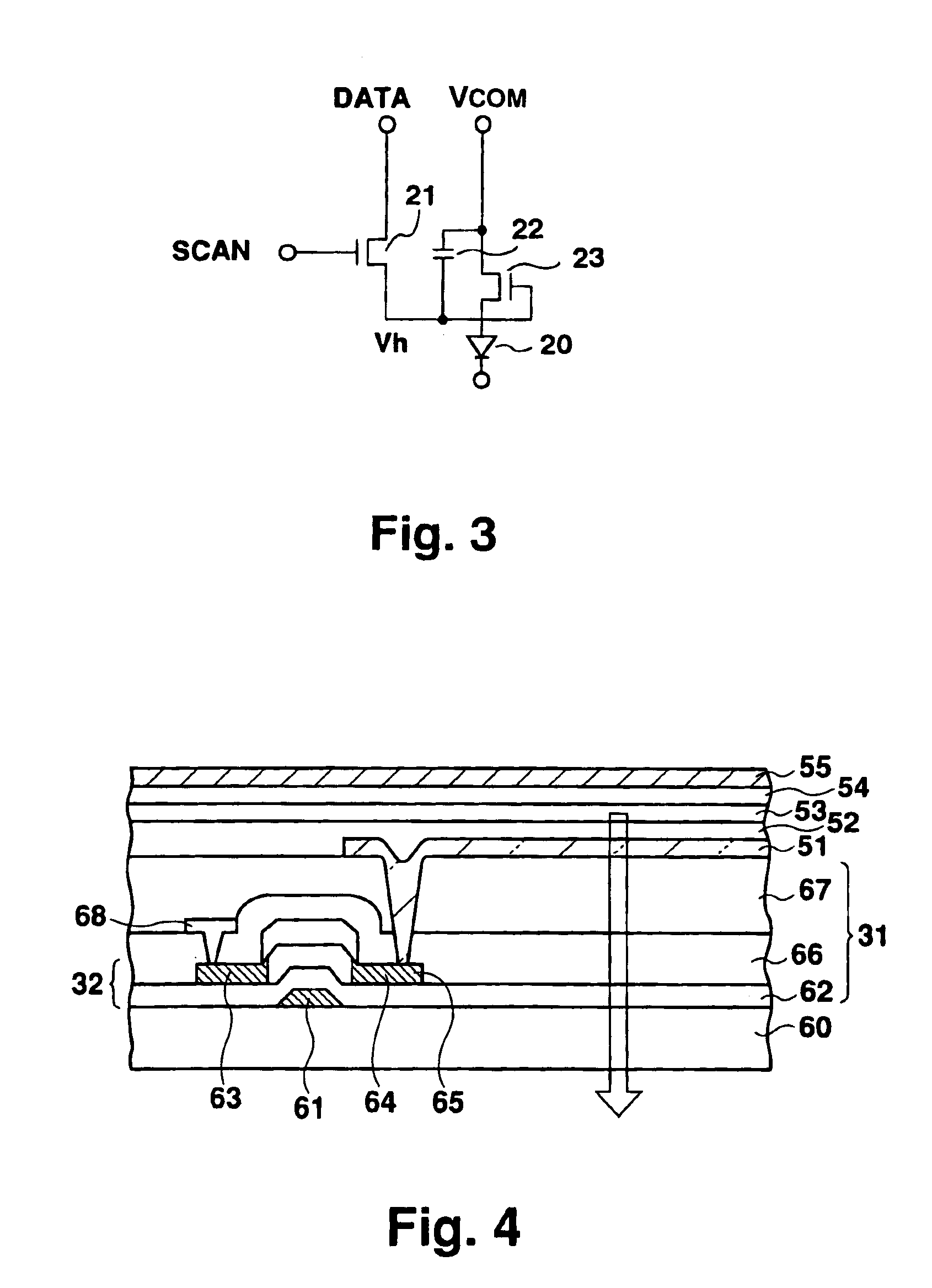

Active-type electroluminescent display

InactiveUS6911960B1Reduce conductor resistanceReduce light intensityDischarge tube luminescnet screensStatic indicating devicesElectrical resistance and conductanceMetallic materials

In an active-type electroluminescent (EL) display, a conductor interconnecting a cathode (55) of an EL panel (30, 40) and a connection terminal of a signal input substrate (35) has a multilayer structure formed of a cathode material and a conductive material used in a thin-film transistor forming step. The conductor may be formed of a conductive material used in a thin film transistor forming step. A metal material for a gate electrode or drain electrode is preferably used as the conductive material. The connection conductor structure can reduce the electrical resistance of the connection conductor, thus preventing a decrease in display intensity of an EL display.

Owner:SANYO ELECTRIC CO LTD

Thermally stable diamond polycrystalline diamond constructions

ActiveUS20060060392A1Improve thermal stabilityGood adhesionDrill bitsConstructionsDiamond crystalPolycrystalline diamond

Thermally stable diamond constructions comprise a diamond body having a plurality of bonded diamond crystals and interstitial regions disposed among the crystals. A metallic substrate is attached to the body. The body includes a first region substantially free of a catalyst material that extends a partial depth from a surface into the body, and a second region that includes the catalyst material. The body can include natural diamond grains and / or a blend of natural and synthetic diamond grains, and is treated to form the first region. Before treatment, a portion of the body to be treated is finished to an approximate final dimension so that the depth of the first region of the finished product is substantially the same as when treated. During treatment, catalyst materials as well as non-catalyst metallic materials are removed from the diamond body to provide a further enhanced degree of thermal stability.

Owner:SMITH INT INC

Semiconductor device and method of manufacturing the same

ActiveUS20090014879A1Semiconductor/solid-state device detailsSolid-state devicesInsulation layerDevice material

In a method of forming a wiring structure for a semiconductor device, an insulation layer is formed on a semiconductor substrate on which a plurality of conductive structures is positioned. An upper surface of the insulation layer is planarized and spaces between the conductive structures are filled with the insulation layer. The insulation layer is partially removed from the substrate to form at least one opening through which the substrate is partially exposed. A residual metal layer is formed on a bottom and a lower portion of the sidewall of the at least one opening and a metal nitride layer is formed on the residual metal layer and an upper sidewall of the opening with a metal material. Accordingly, an upper portion of the barrier layer can be prevented from being removed in a planarization process for forming the metal plug.

Owner:SAMSUNG ELECTRONICS CO LTD

Enamel coated bullet, method of making an enamel coated bullet

ActiveUS9254503B2Reduces barrel depositsLess expensiveAmmunition projectilesLiquid surface applicatorsSufficient timeLacquer thinner

Owner:WARD TYLER

Method for manufacturing a golf club face

InactiveUS6904663B2Large thickness variationImprove performanceGolf clubsRacket sportsVariable thicknessAsymmetric face

A method of manufacturing a face plate for a golf club head is presented to provide face having substantial thickness variation for enhanced performance. The method includes the steps of providing a rolled sheet of metal material having an initial thickness and forming a blank having a prescribed outer shape from the material. The method also includes machining a second side of the blank such that the resulting face plate has a variable thickness. The machining is such that the plate has a first thickness less than or equal to the initial thickness, a second thickness less than the first thickness and a third thickness less than the second thickness. The machining is performed over a substantial portion of the surface area of the second side. Either a CNC lathe or milling machine may be used; however, for an axisymmetric face thickness a CNC lathe is preferred and for an asymmetric face thickness a CNC end mill is preferred. The club head may be a wood-type or iron, and titanium or steel alloys may be used.

Owner:TAYLOR MADE GOLF

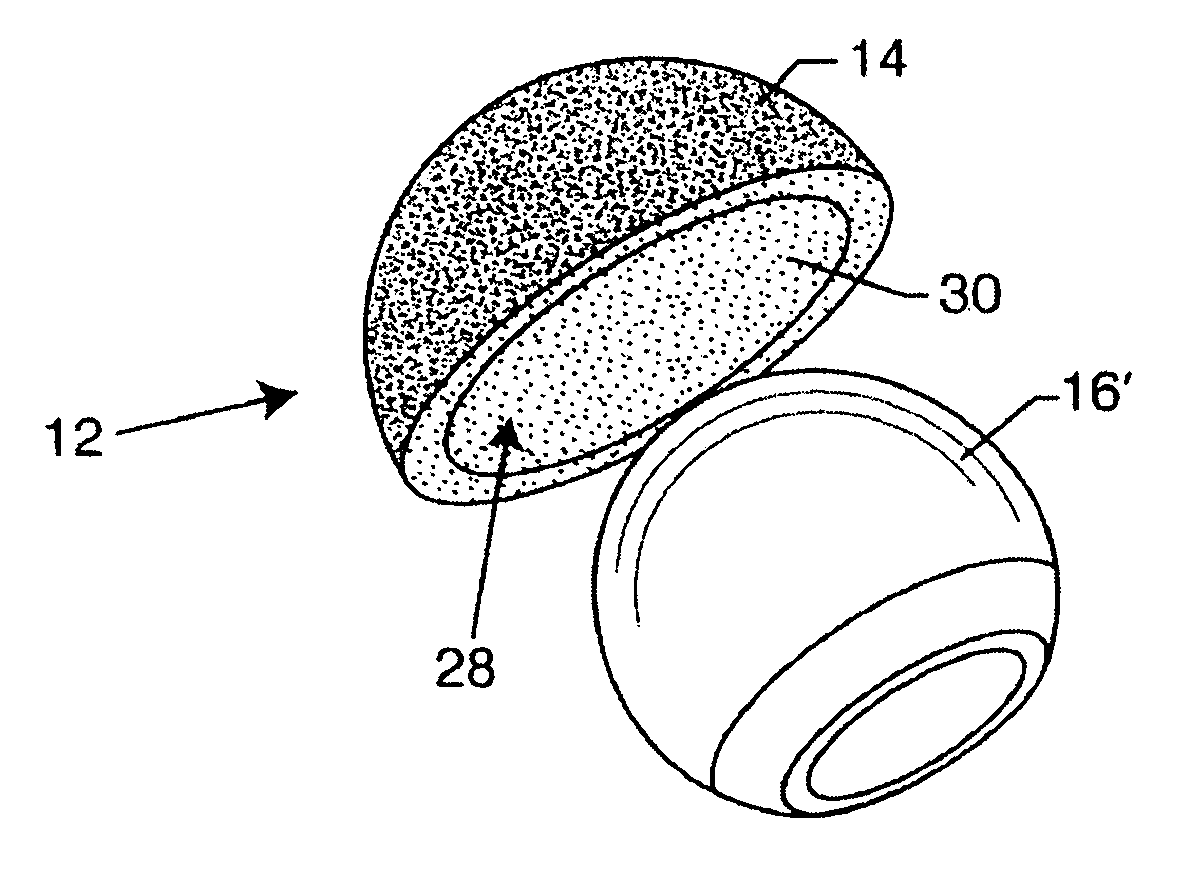

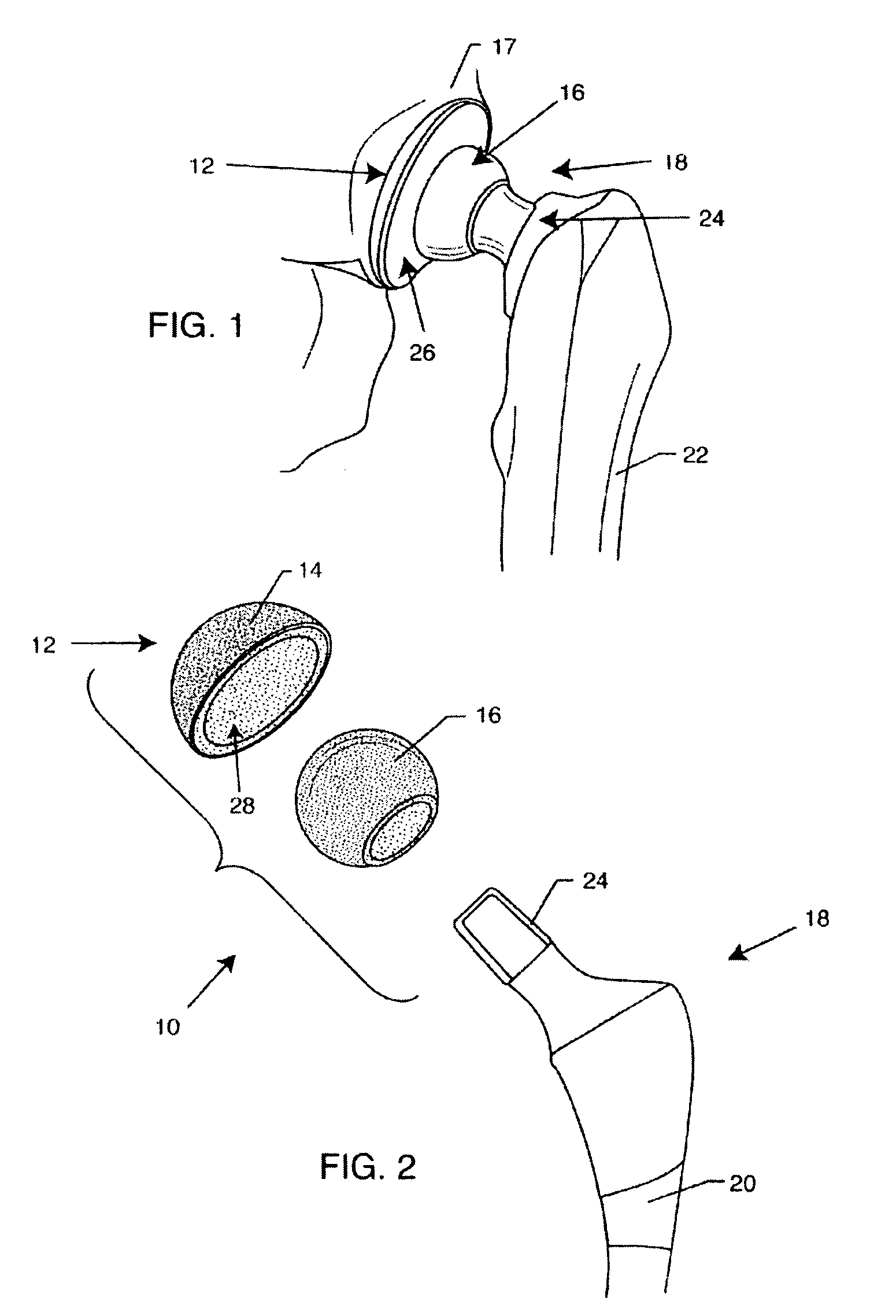

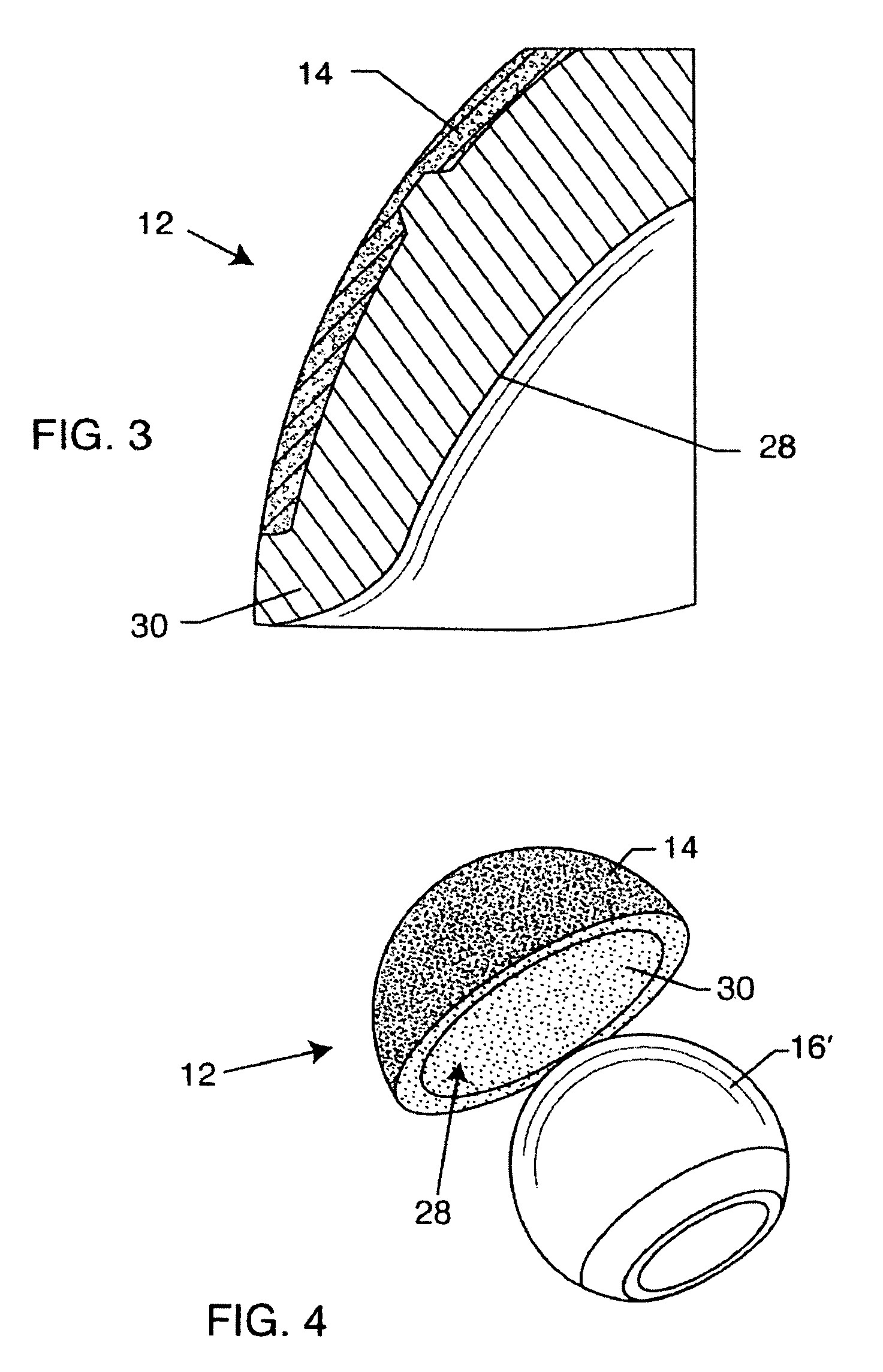

Hip prosthesis with monoblock ceramic acetabular cup

InactiveUS7695521B2High strengthImprove toughnessBone implantJoint implantsRight femoral headMetallic materials

An improved hip prosthesis includes an acetabular cup bearing component constructed from a relatively hard and high strength ceramic material for articulation with a ball-shaped femoral head component which may be constructed from a compatible ceramic or metal material. In one form, the acetabular cup further includes a ceramic porous bone ingrowth surface adhered thereto for secure ingrowth attachment to natural patient bone.

Owner:AMEDICA A DELAWARE

Oilfield elements having controlled solubility and methods of use

ActiveUS8231947B2Ease of the element traversingEnvelopes/bags making machineryLayered productsSolubilityPolyamide

Oilfield elements are described, one embodiment comprising a combination of a normally insoluble metal with an element selected from a second metal, a semi-metallic material, and non-metallic materials; and one or more solubility-modified high strength and / or high-toughness polymeric materials selected from polyamides, polyethers, and liquid crystal polymers. Methods of using the oilfield elements in oilfield operations are also described. This abstract allows a searcher or other reader to quickly ascertain the subject matter of the disclosure. It will not be used to interpret or limit the scope or meaning of the claims.

Owner:SCHLUMBERGER TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com