Patents

Literature

7609 results about "Monolayer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A monolayer is a single, closely packed layer of atoms, molecules, or cells. In some cases it is referred to as a self-assembled monolayer. Monolayers of layered crystals like graphene and molybdenum disulfide are generally called 2D materials.

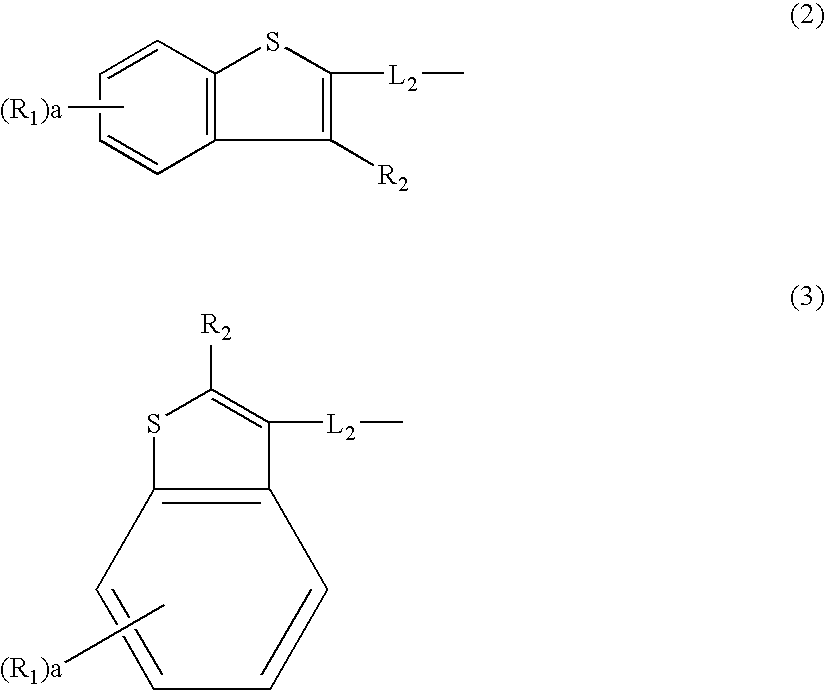

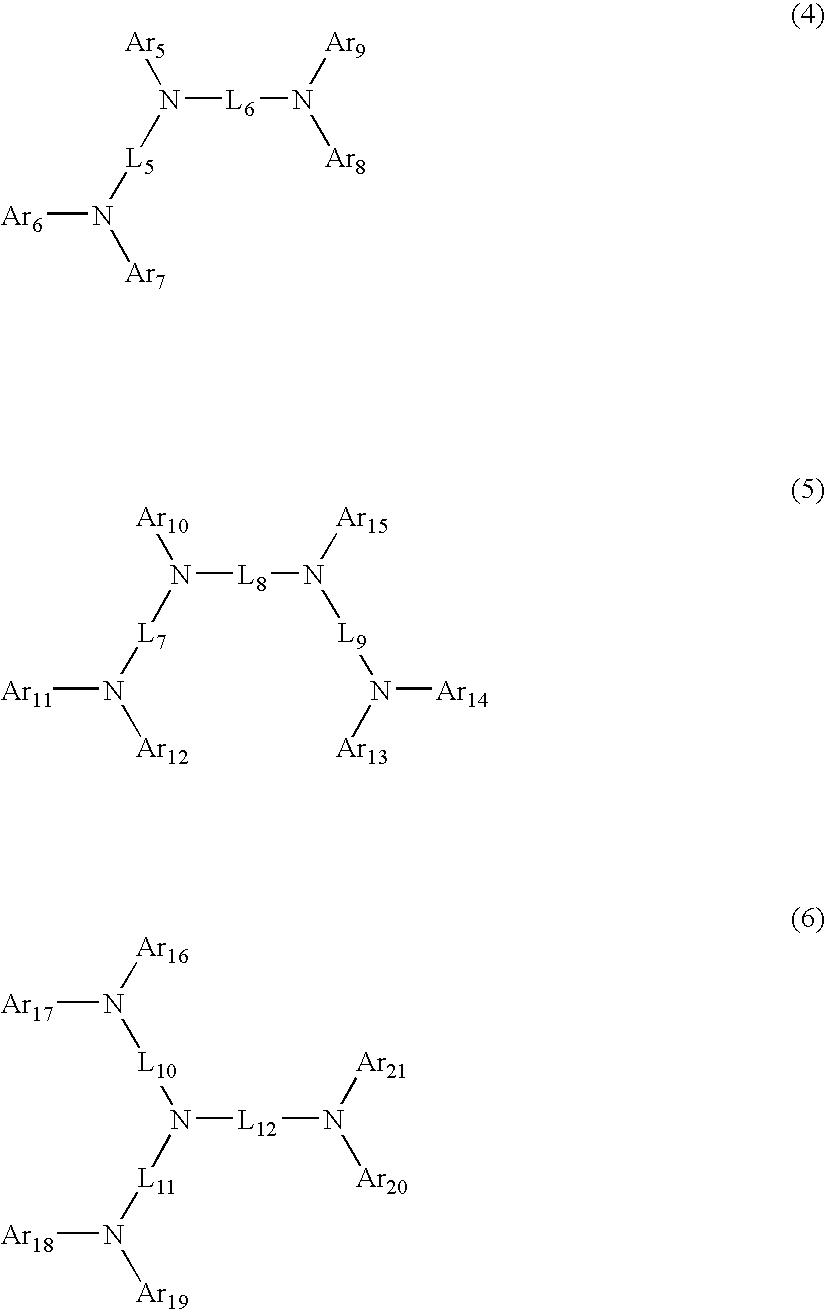

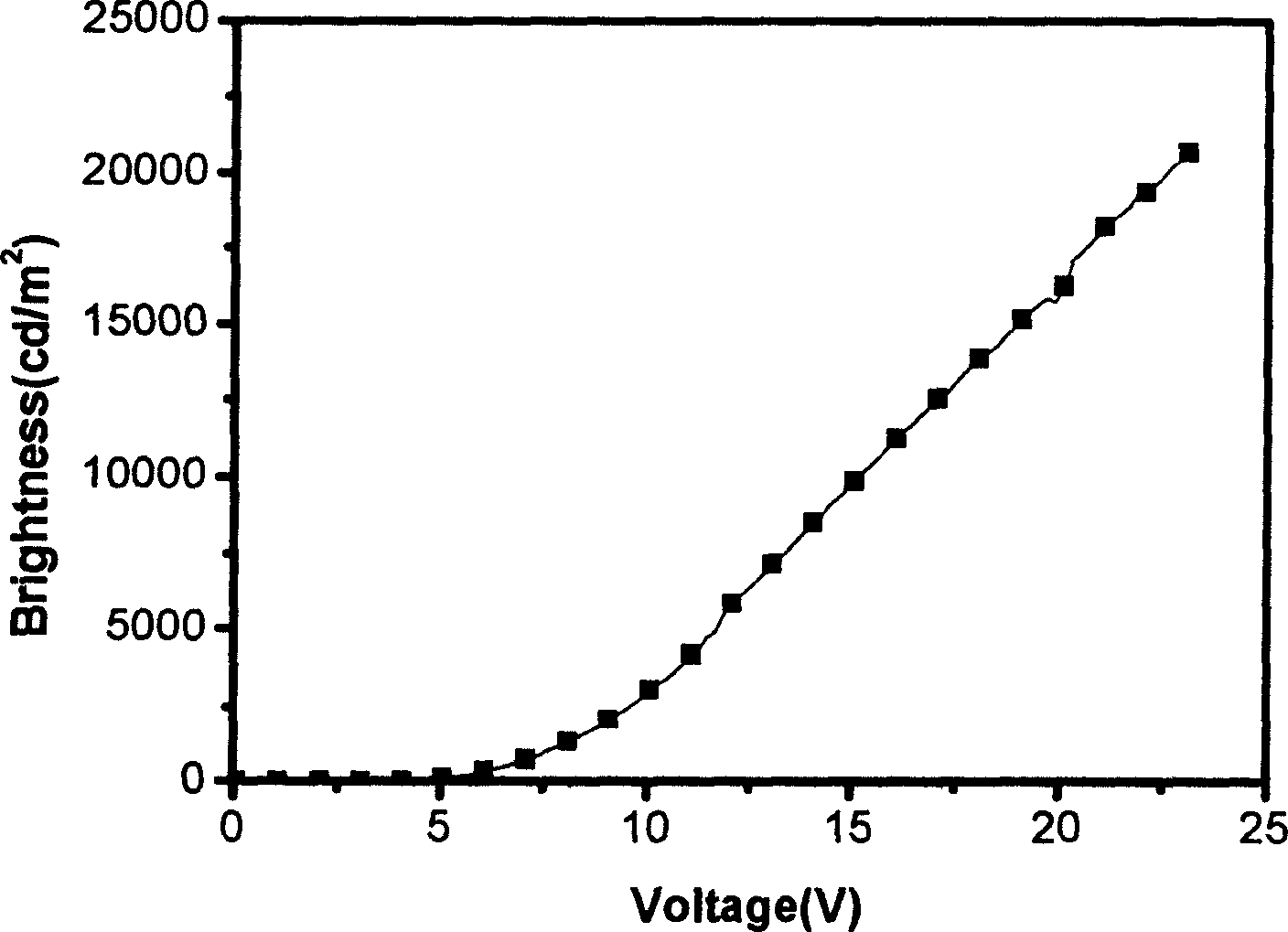

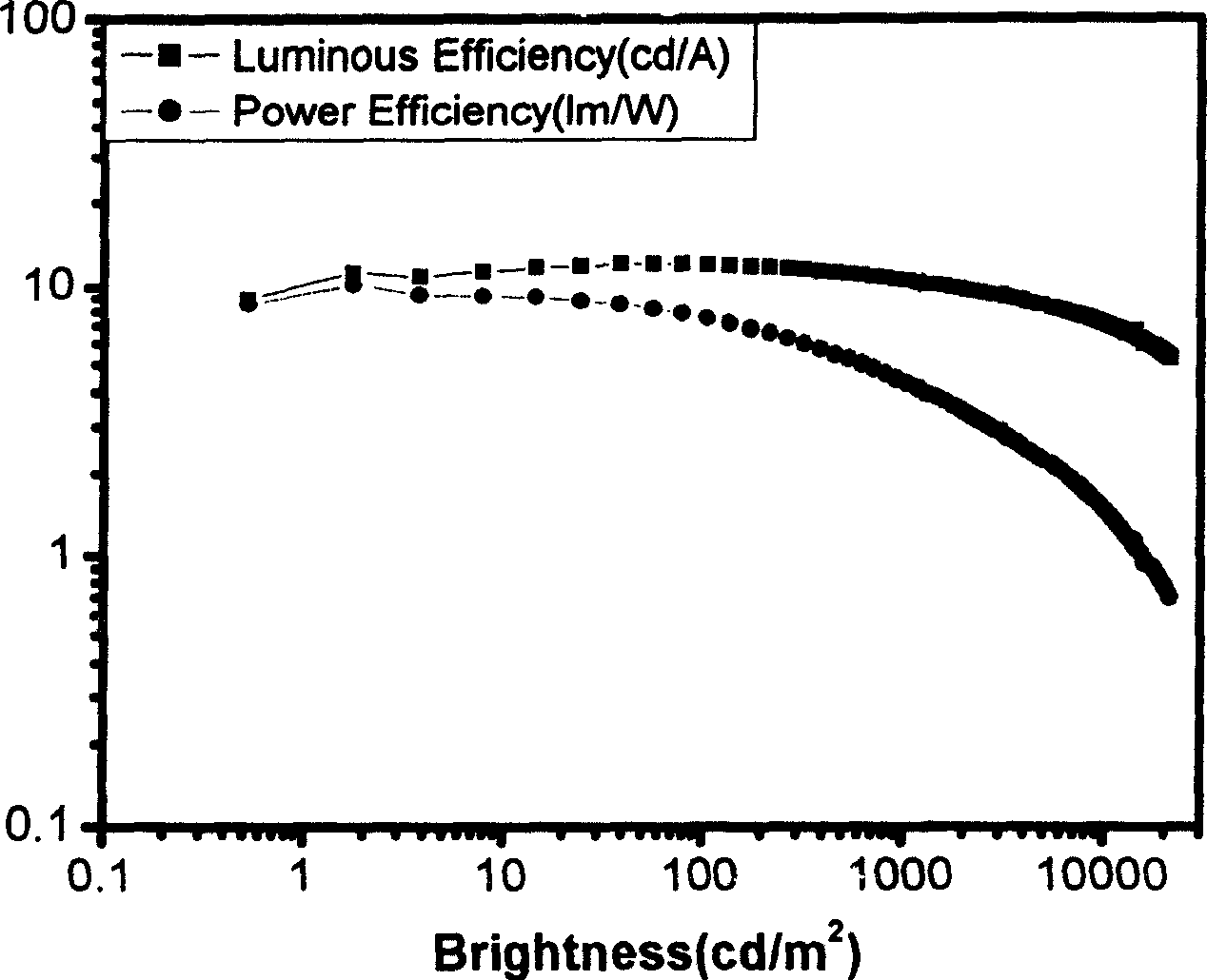

Aromatic amine derivatives and organic electroluminescent device using same

InactiveUS20080106190A1Less liableImproved in yield in producingOrganic chemistryDischarge tube luminescnet screensHole transport layerOrganic electroluminescence

The present invention provides a novel aromatic amine derivative having a specific structure and an organic electroluminescence device in which an organic thin film layer comprising a single layer or plural layers including at least a light emitting layer is interposed between a cathode and an anode, wherein at least one layer in the above organic thin film layer, particularly a hole transporting layer contains the aromatic amine derivative described above in the form of a single component or a mixed component. Use of the aromatic amine derivative described above materialize an organic electroluminescence device which reduces a driving voltage and makes molecules less liable to be crystallized and which enhances a yield in producing the organic EL device and has a long lifetime.

Owner:IDEMITSU KOSAN CO LTD

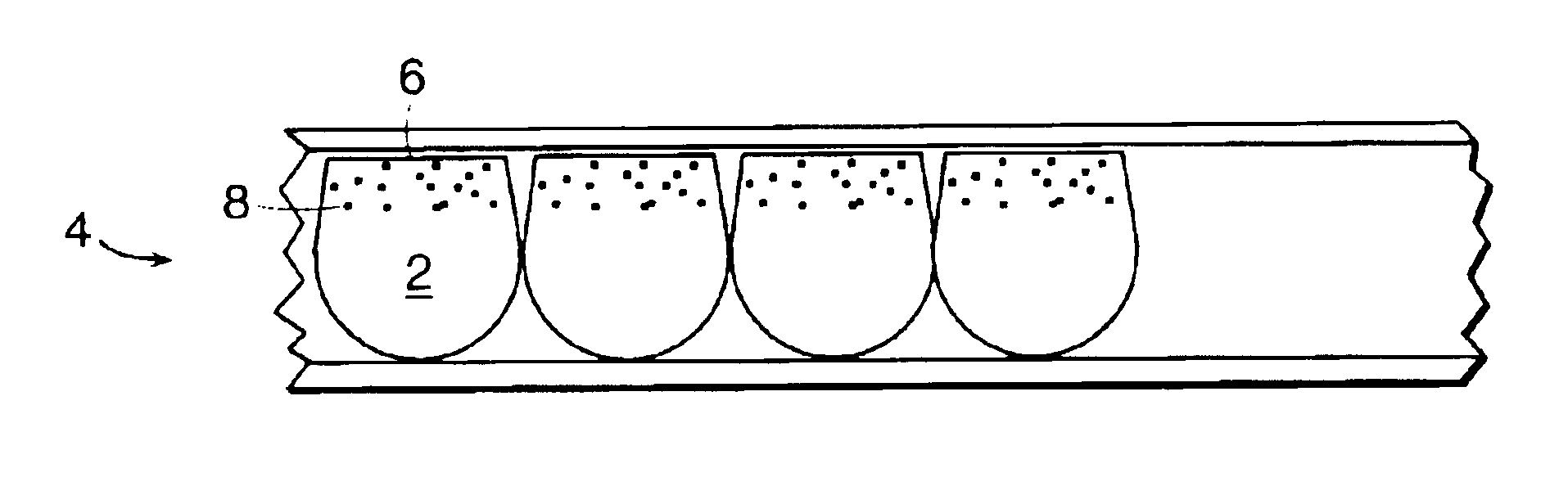

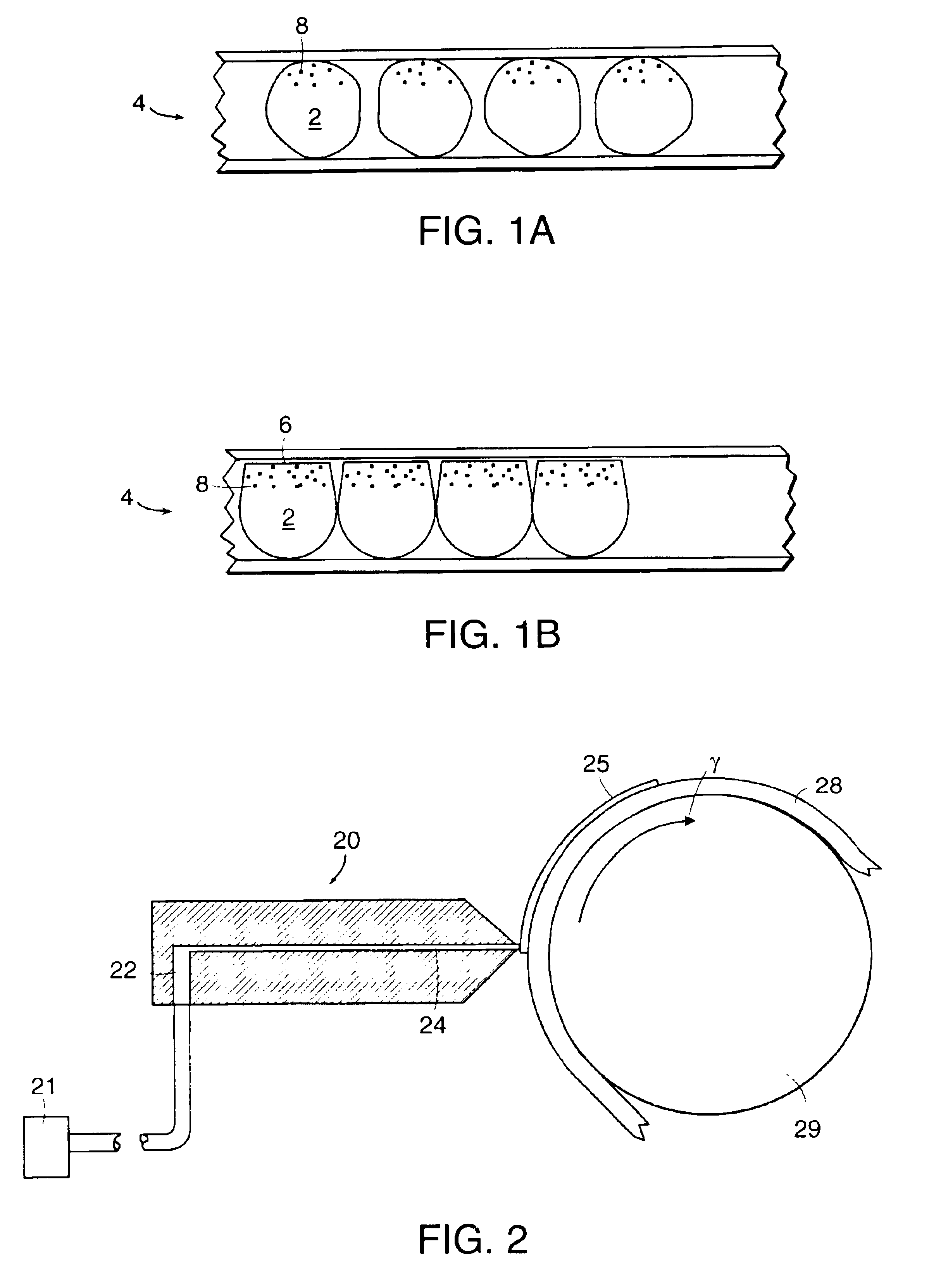

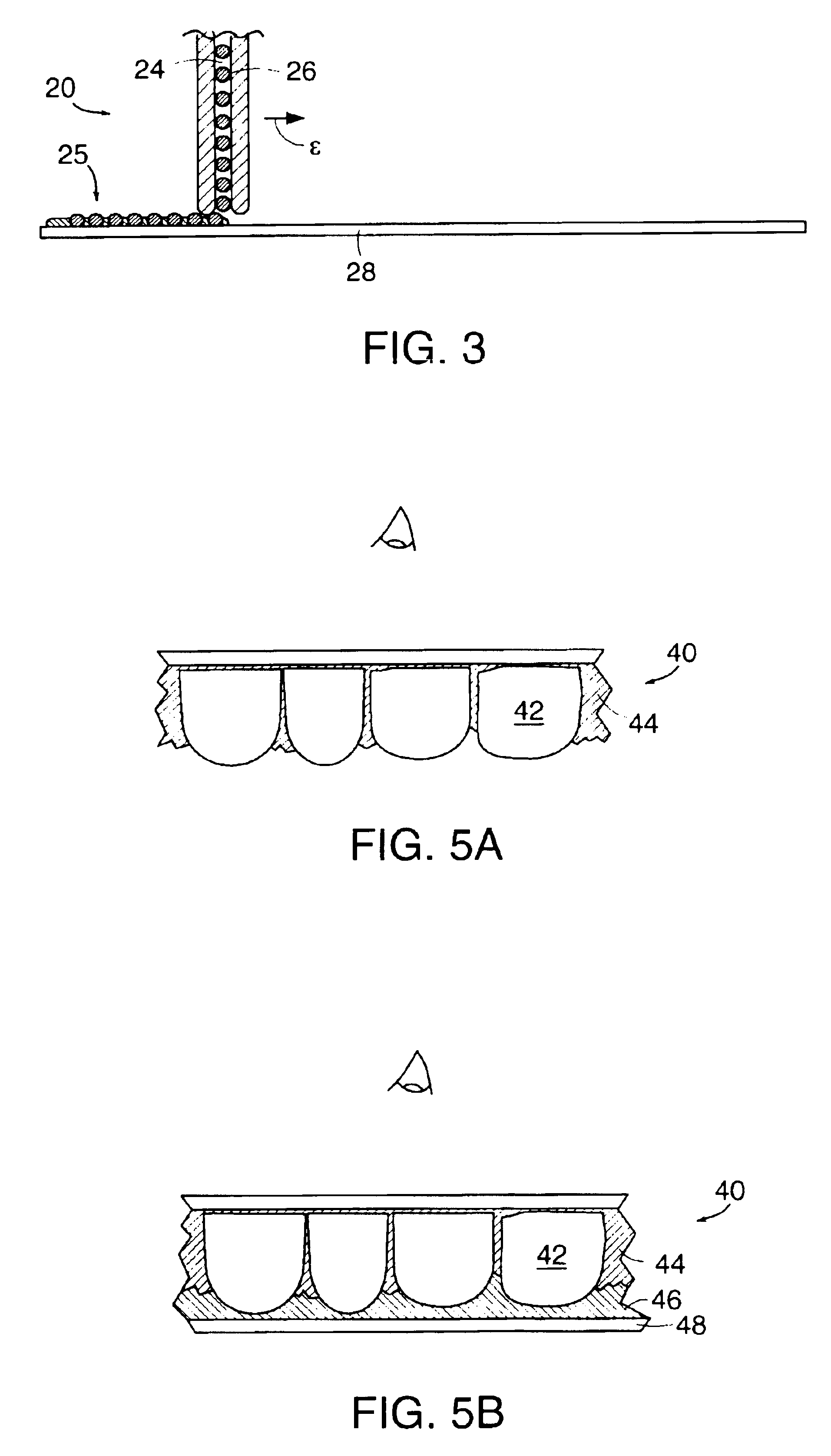

Encapsulated electrophoretic displays having a monolayer of capsules and materials and methods for making the same

InactiveUS6839158B2Static indicating devicesTime-pieces with integrated devicesElectrophoresisDisplay device

Owner:E INK CORPORATION

Methods and compositions for culturing a biological tooth

Tooth tissues include the pulp mesenchyme that forms the dentin and an epithelium that is responsible for enamel formation. Cells from these tissues were obtained from porcine third molars and were seeded onto a biodegradable scaffold composed of a polyglycolic acid—polylactic acid copolymer. Cell polymer constructs were then surgically implanted into the omentum of athymic nude rats so that the constructs would have a blood supply and these tissues were allowed to develop inside the rats. Infrequently, columnar epithelial cells were observed as a single layer on the outside of the dentin-like matrix similar to the actual arrangement of ameloblasts over dentin during early tooth development. Developing tooth tissues derived from such cell polymer constructs could eventually be surgically implanted into the gum of an edentulous recipient where the construct would receive a blood supply and develop to maturity, providing the recipient with a biological tooth replacement.

Owner:FORSYTH DENTAL INFARY FOR CHILDREN +2

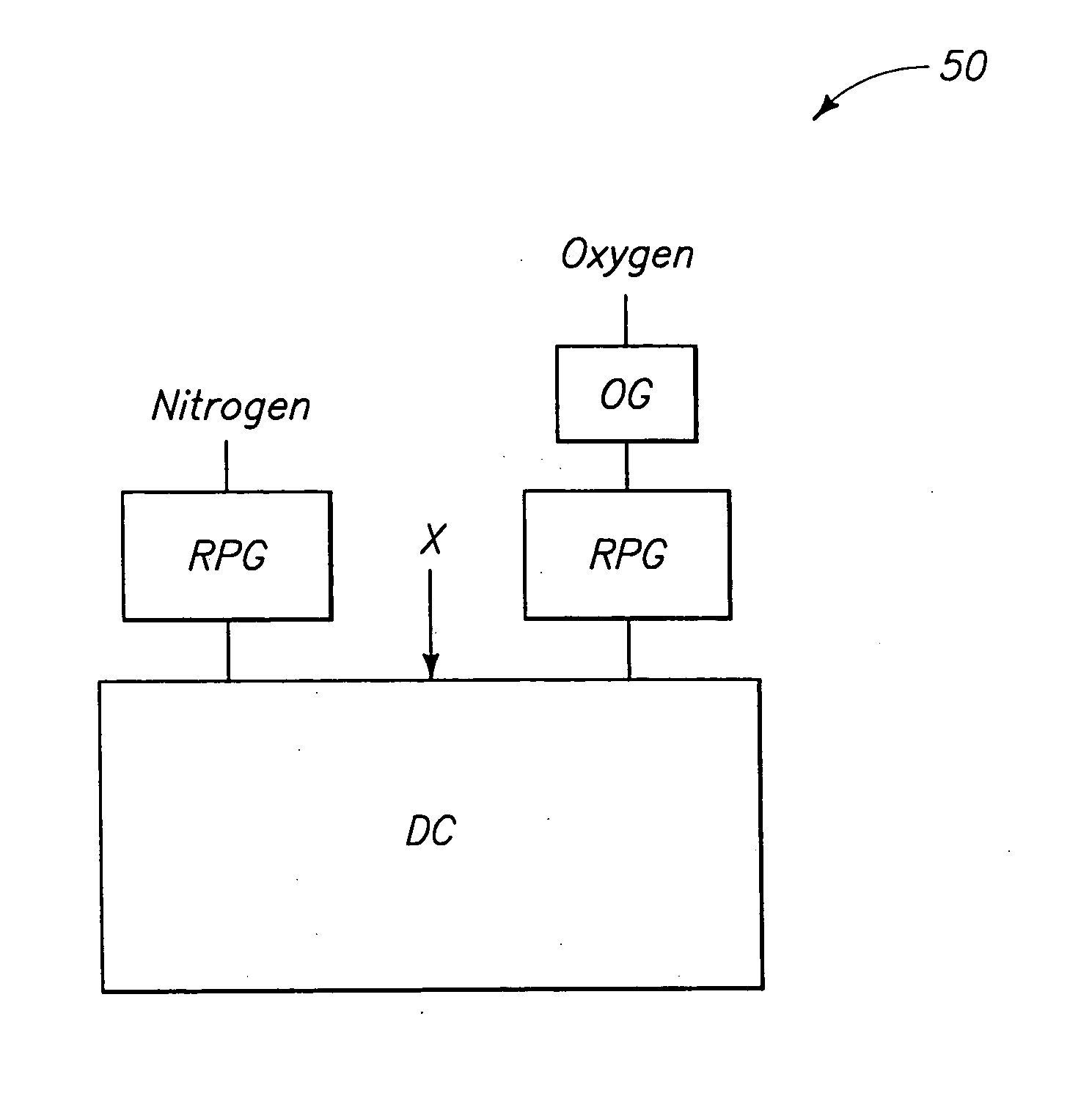

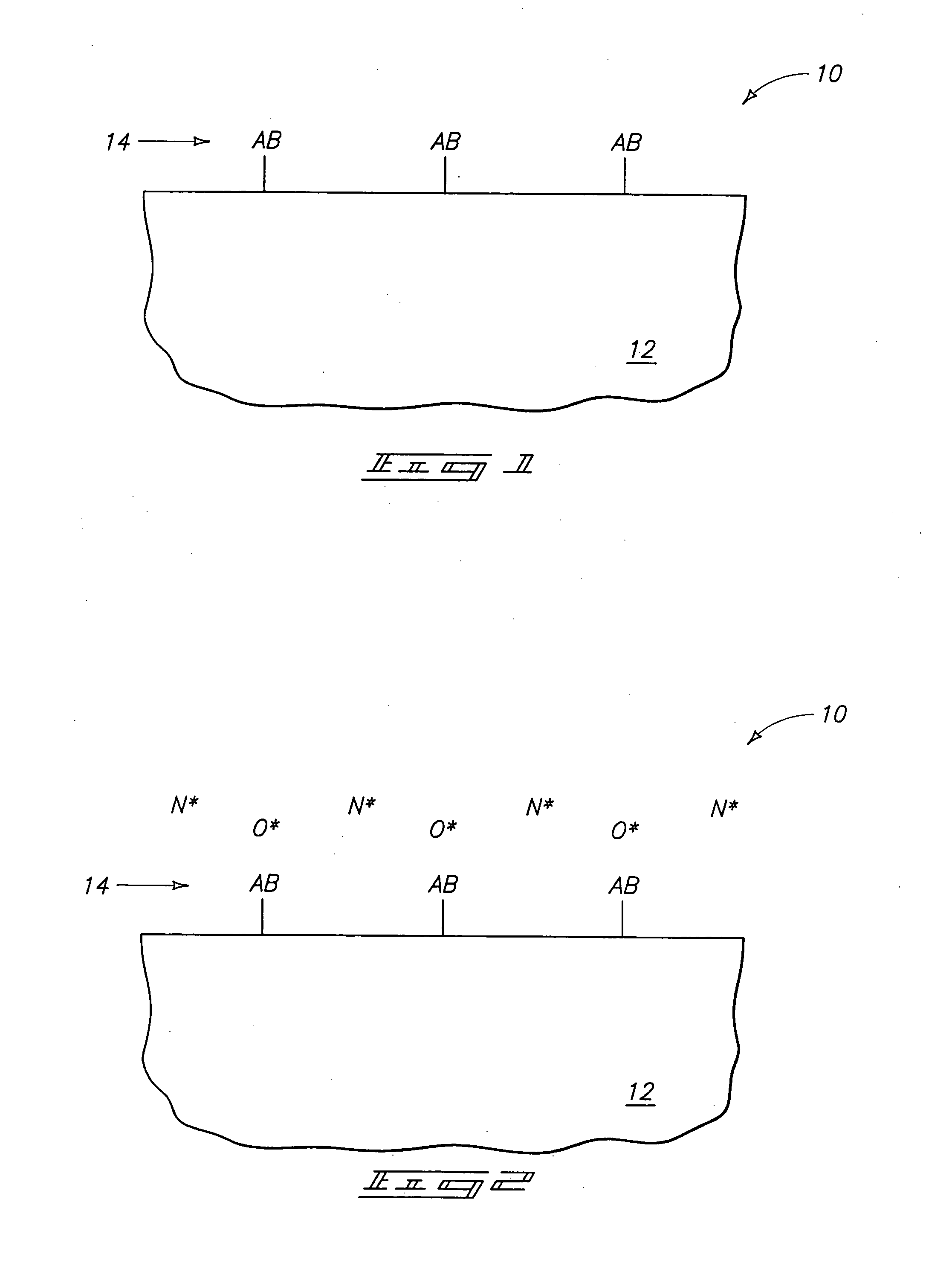

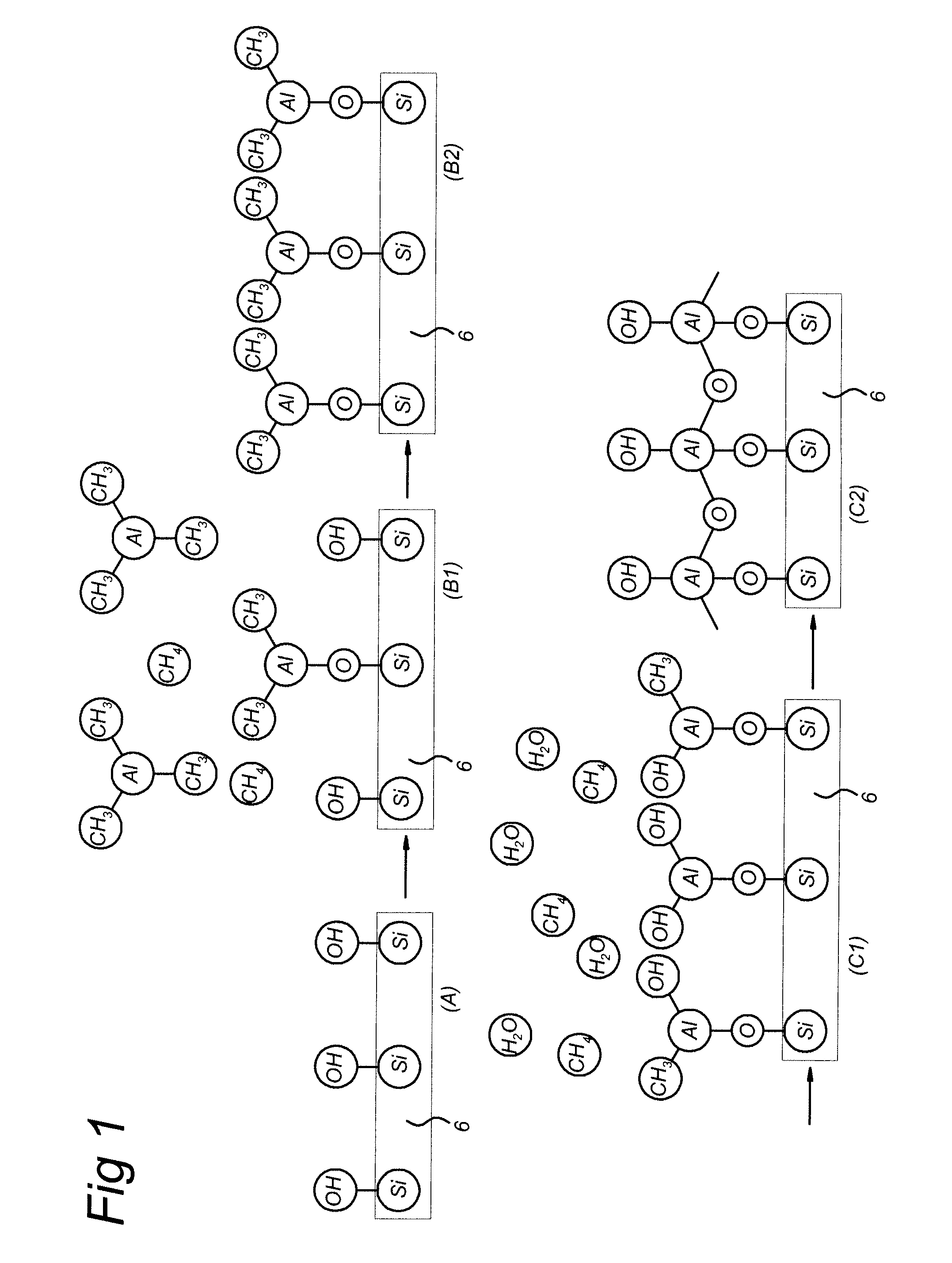

Atomic layer deposition method of depositing an oxide on a substrate

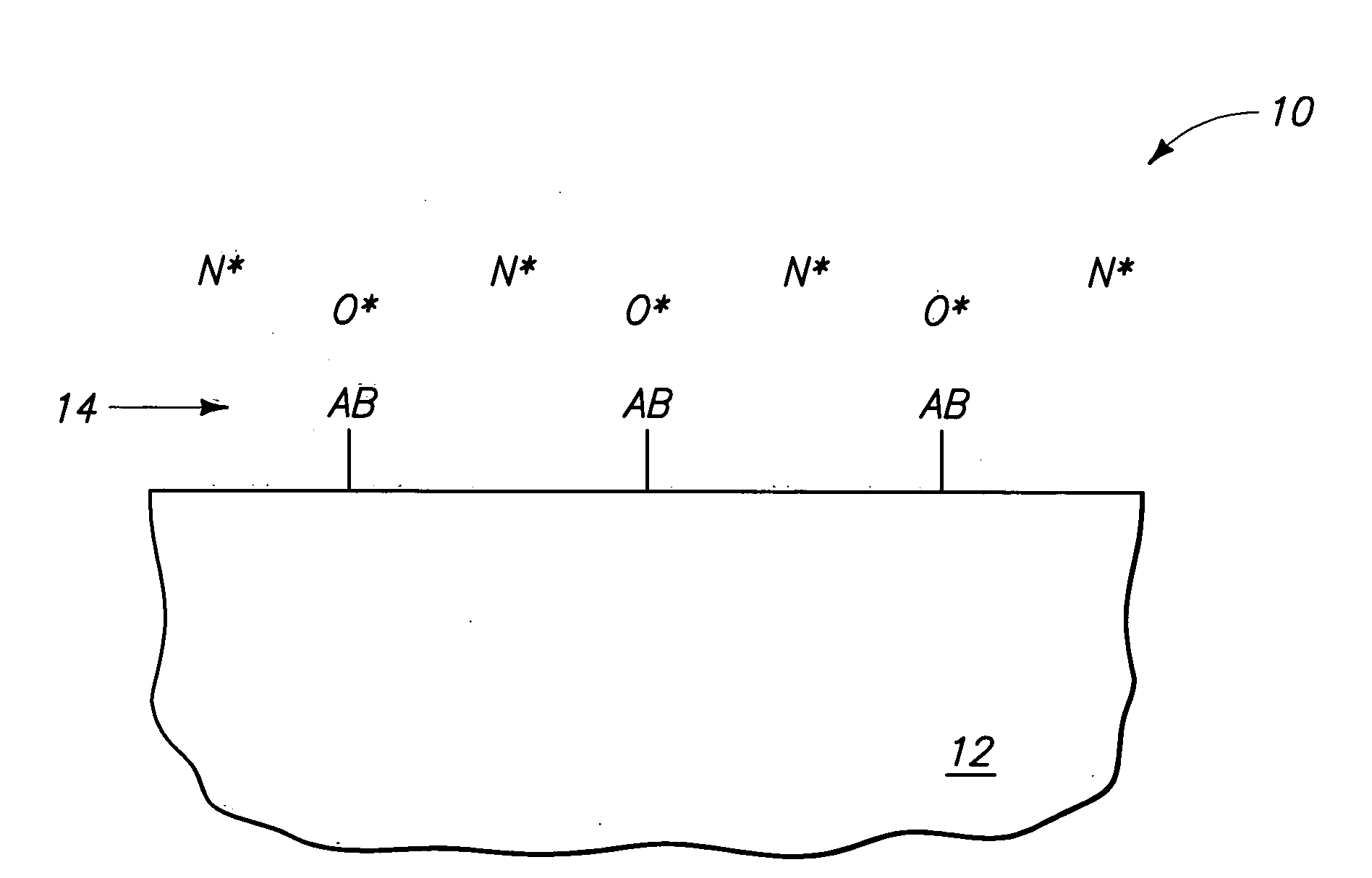

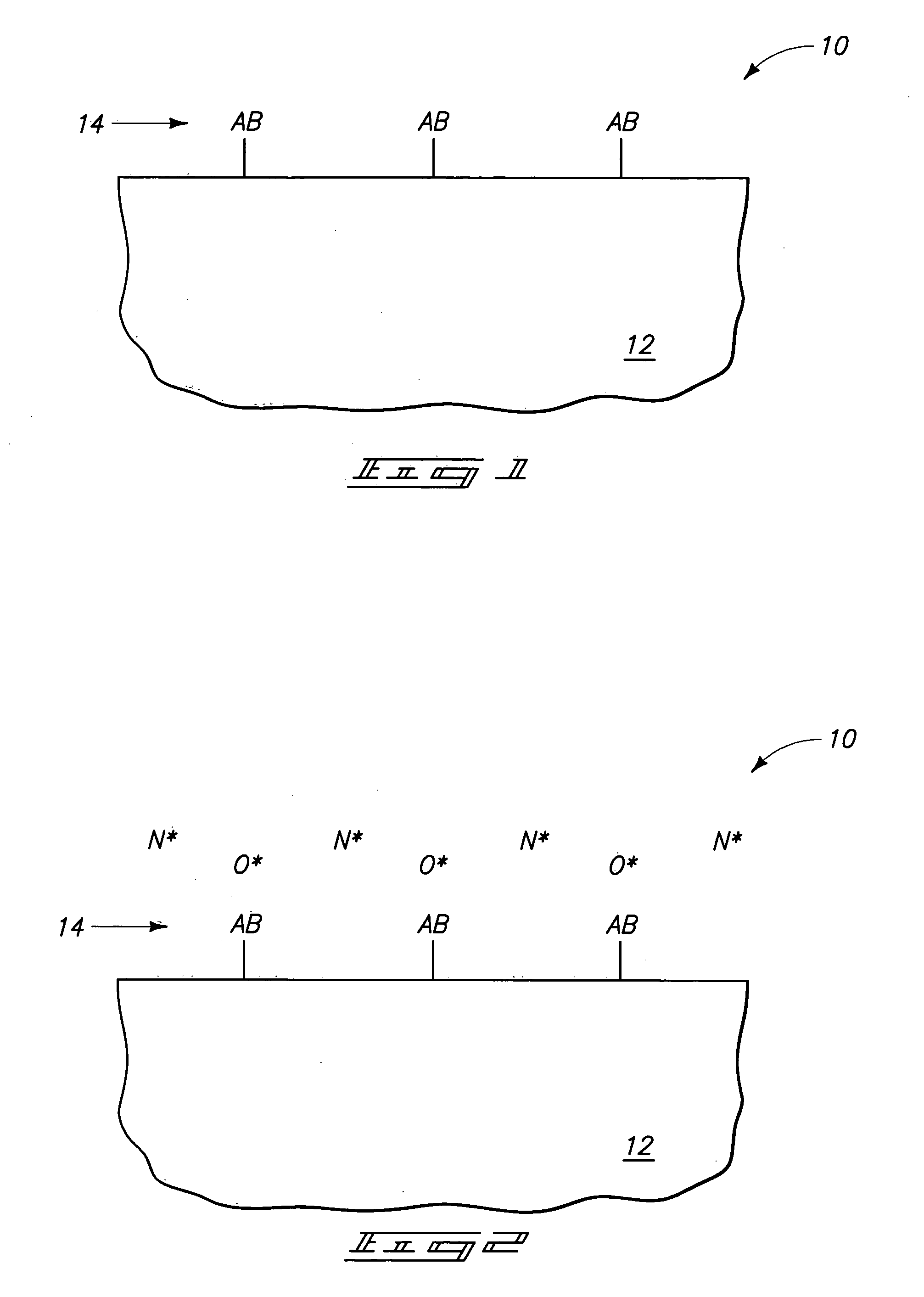

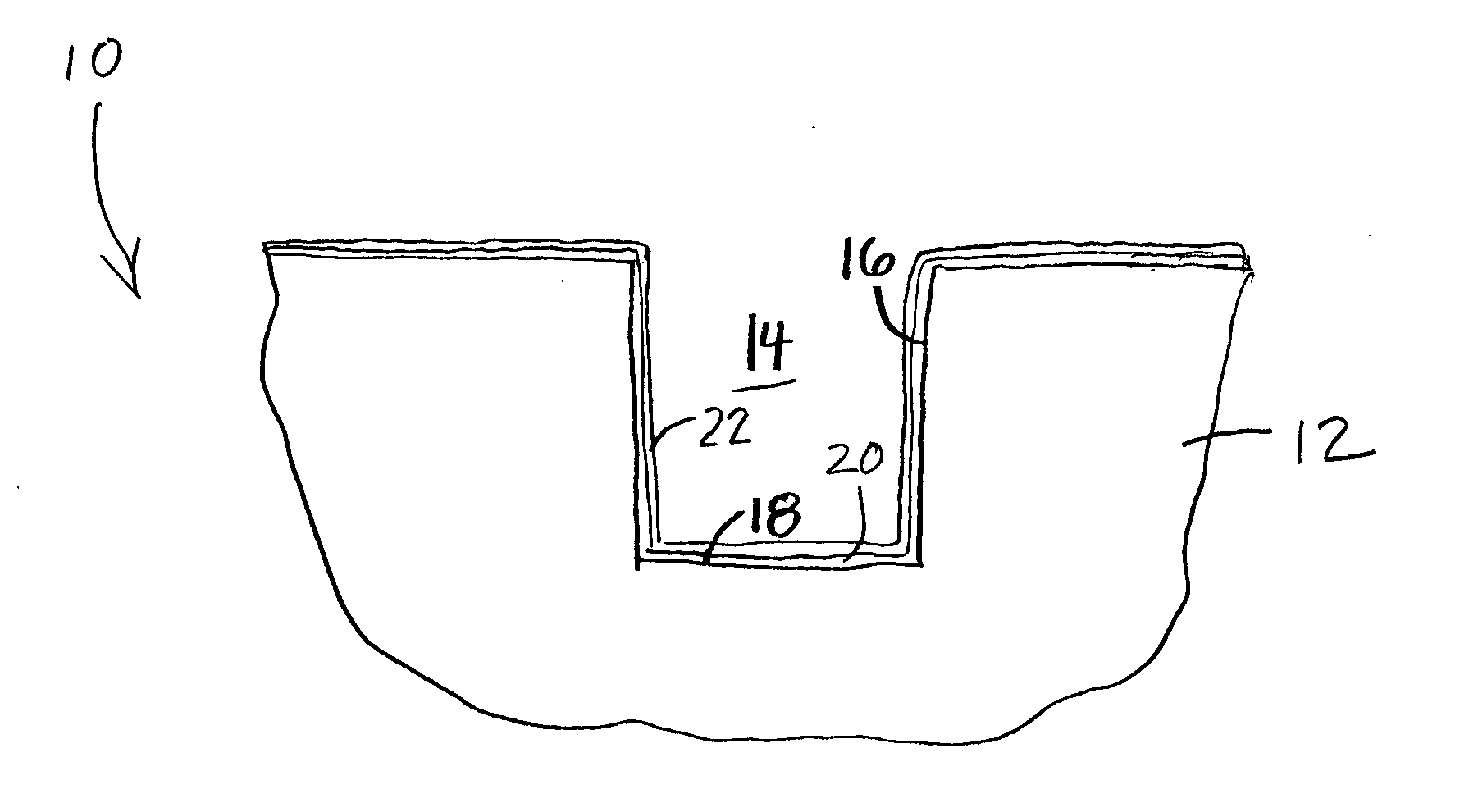

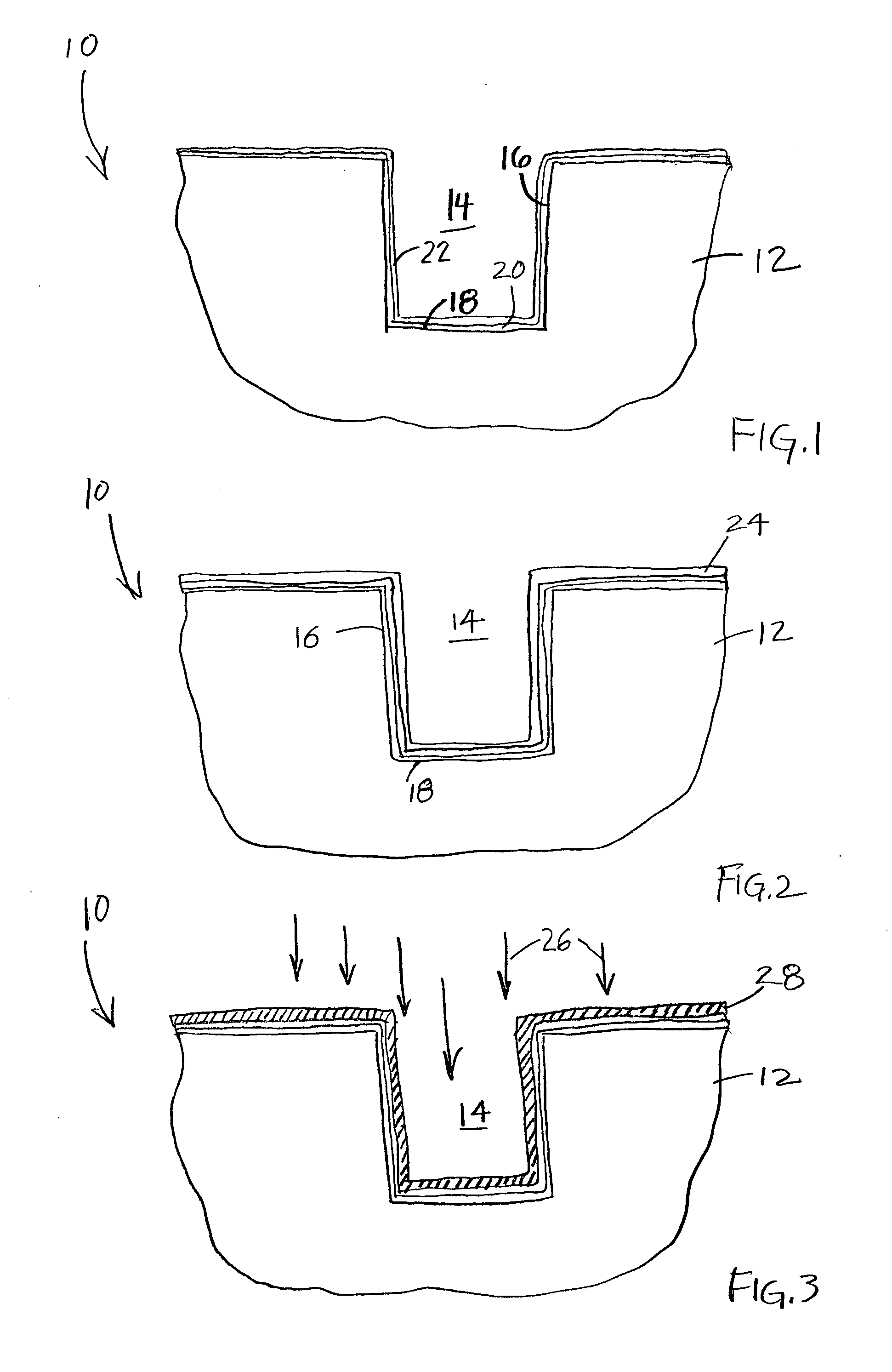

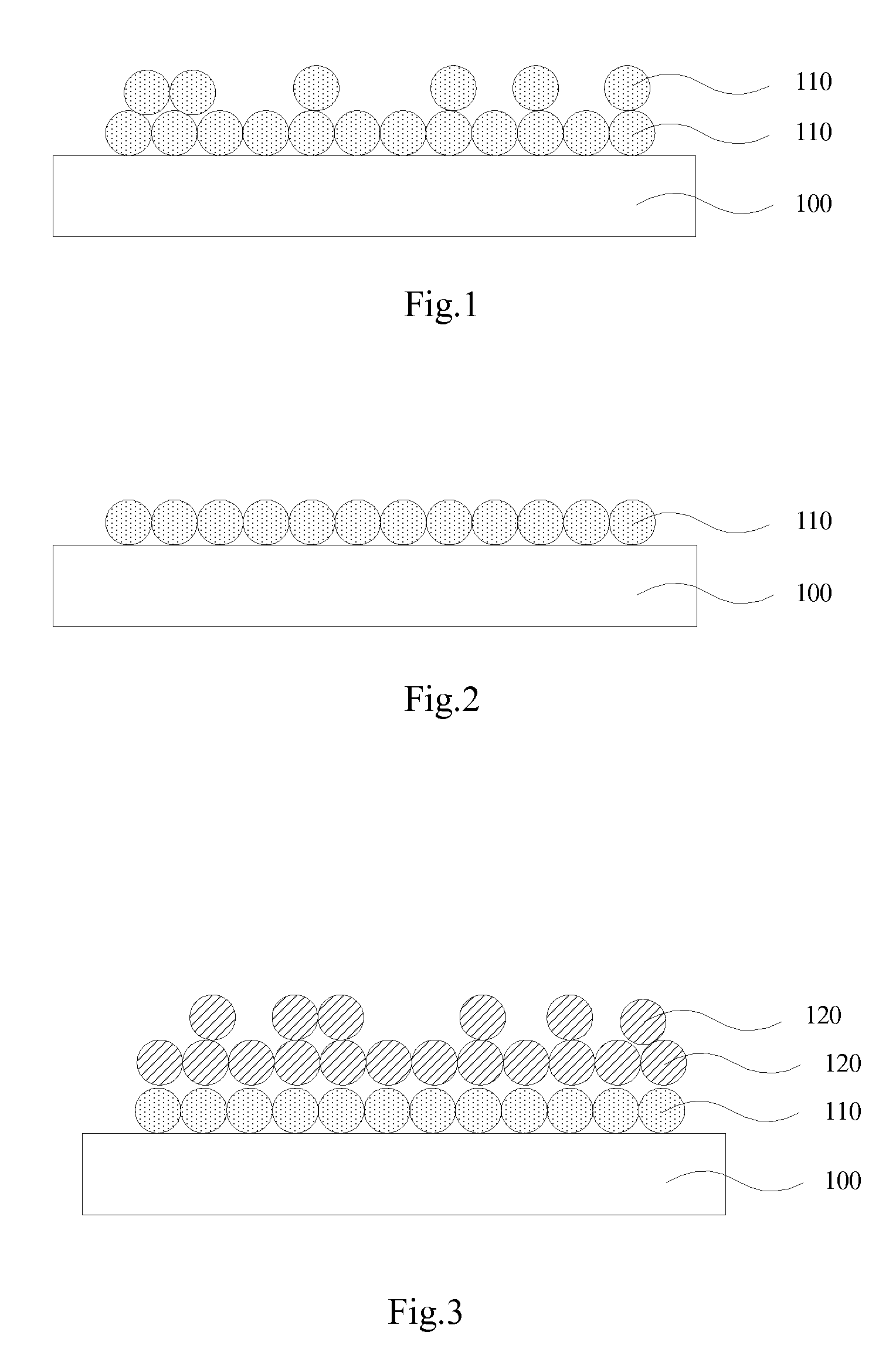

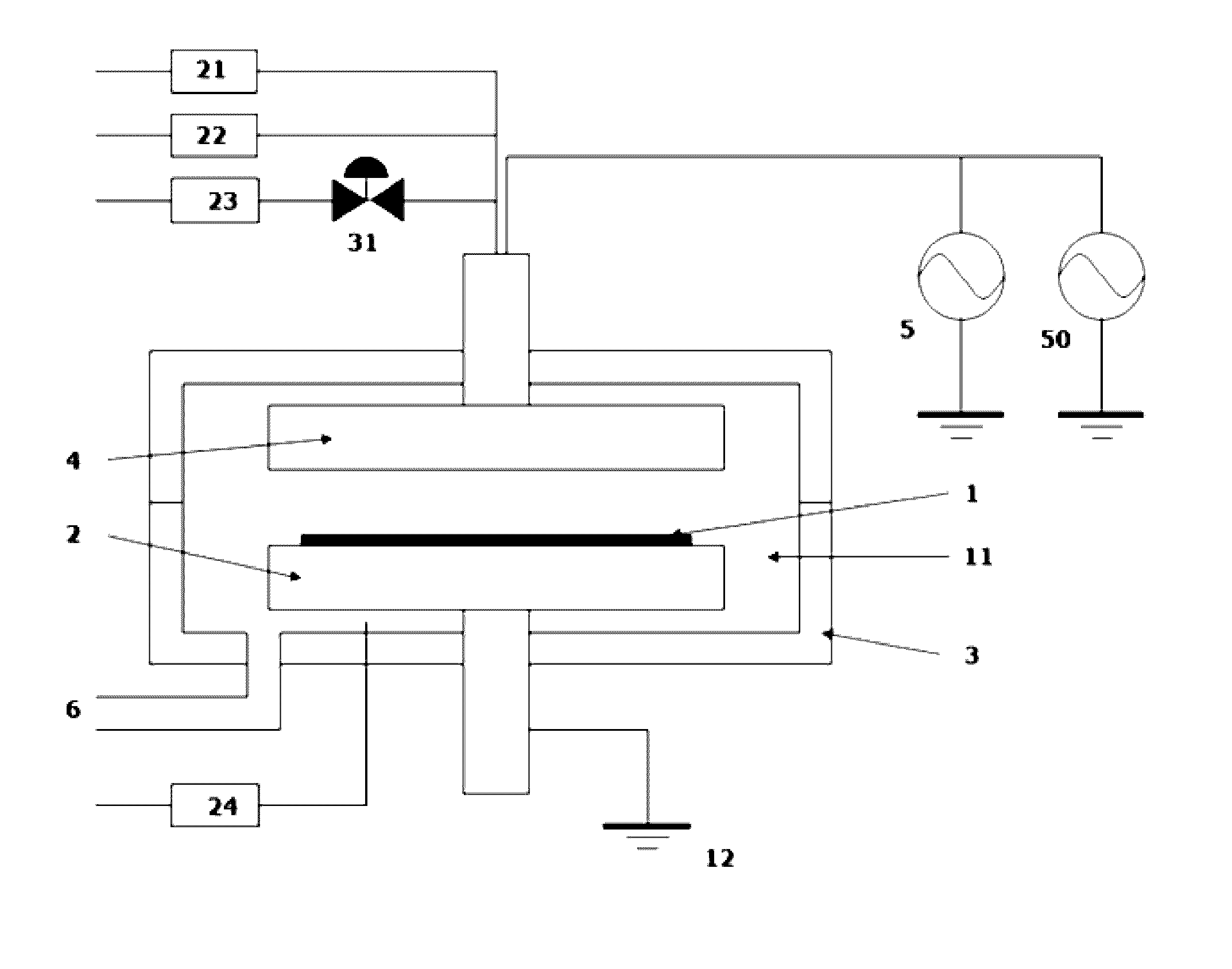

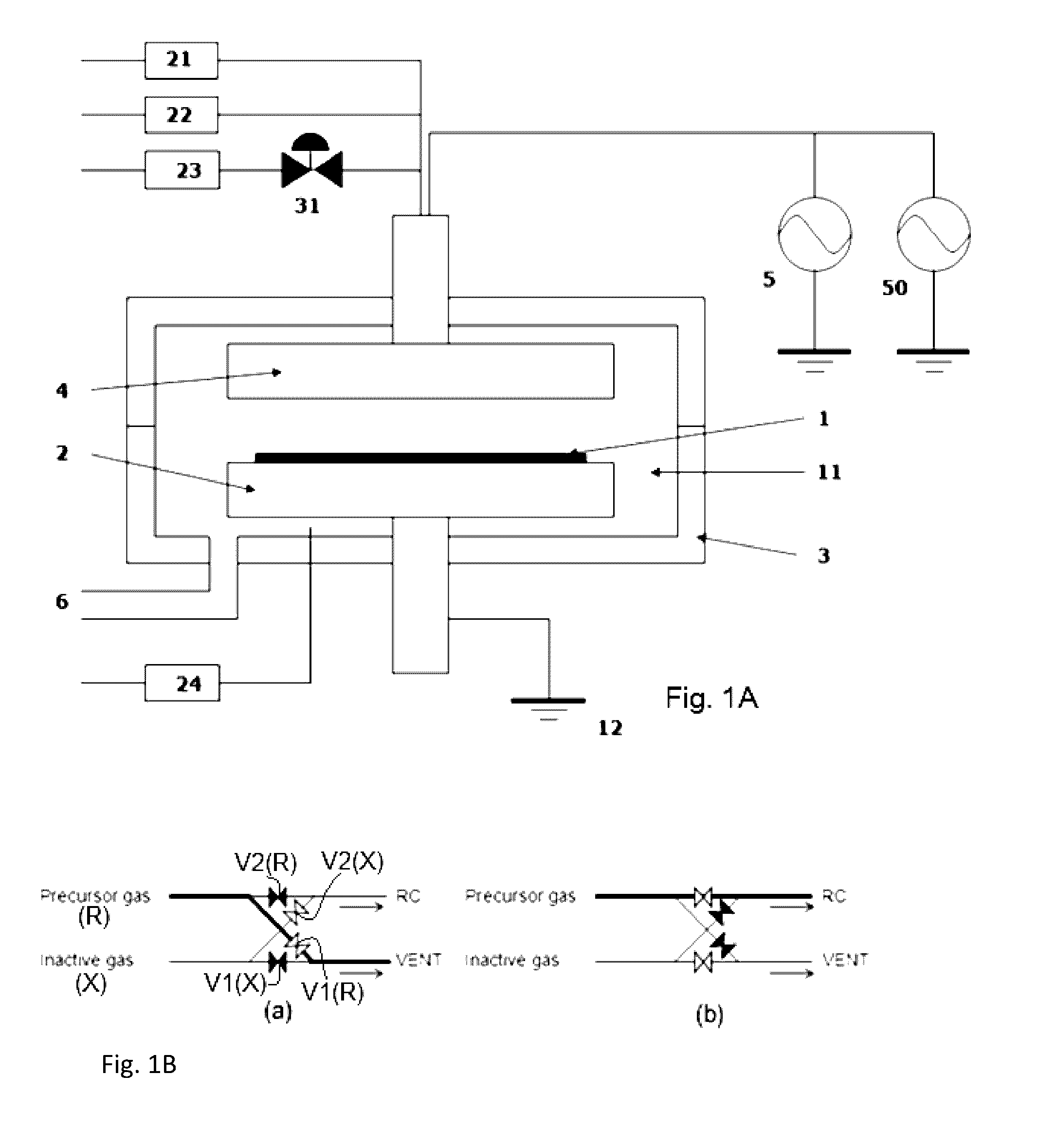

The invention includes atomic layer deposition methods of depositing an oxide on a substrate. In one implementation, a substrate is positioned within a deposition chamber. A first species is chemisorbed onto the substrate to form a first species monolayer within the deposition chamber from a gaseous precursor. The chemisorbed first species is contacted with remote plasma oxygen derived at least in part from at least one of O2 and O3 and with remote plasma nitrogen effective to react with the first species to form a monolayer comprising an oxide of a component of the first species monolayer. The chemisorbing and the contacting with remote plasma oxygen and with remote plasma nitrogen are successively repeated effective to form porous oxide on the substrate. Other aspects and implementations are contemplated.

Owner:MICRON TECH INC

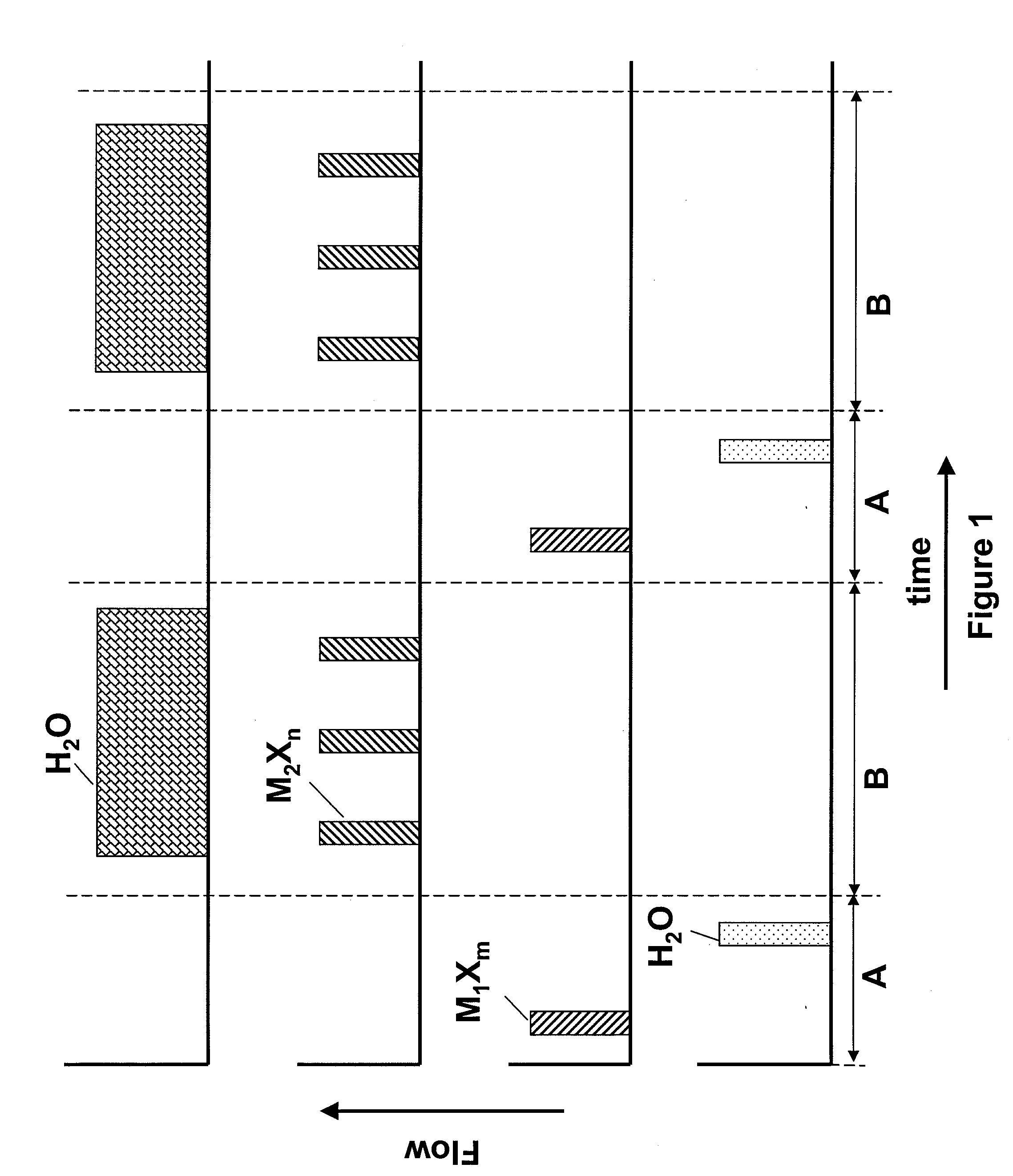

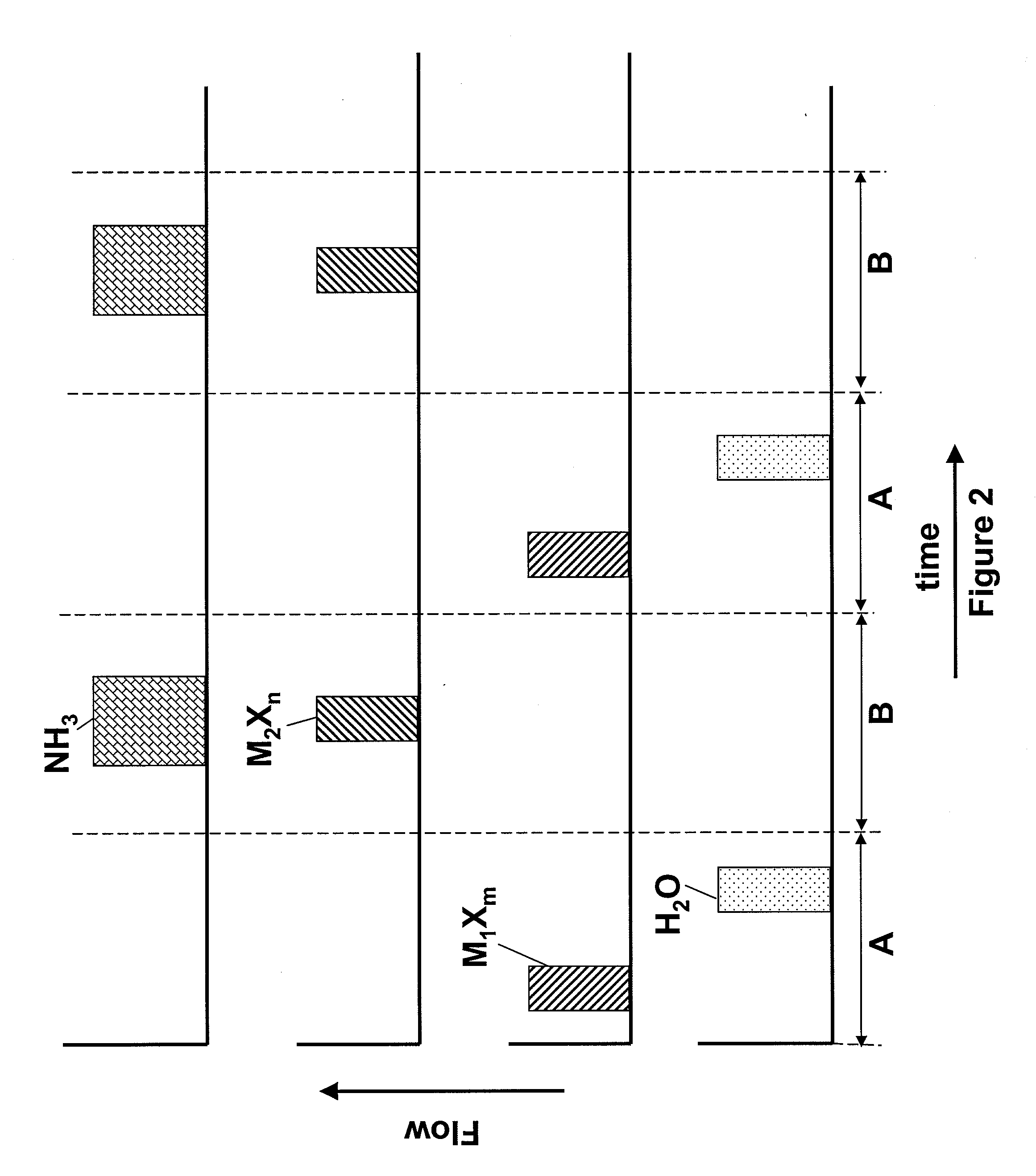

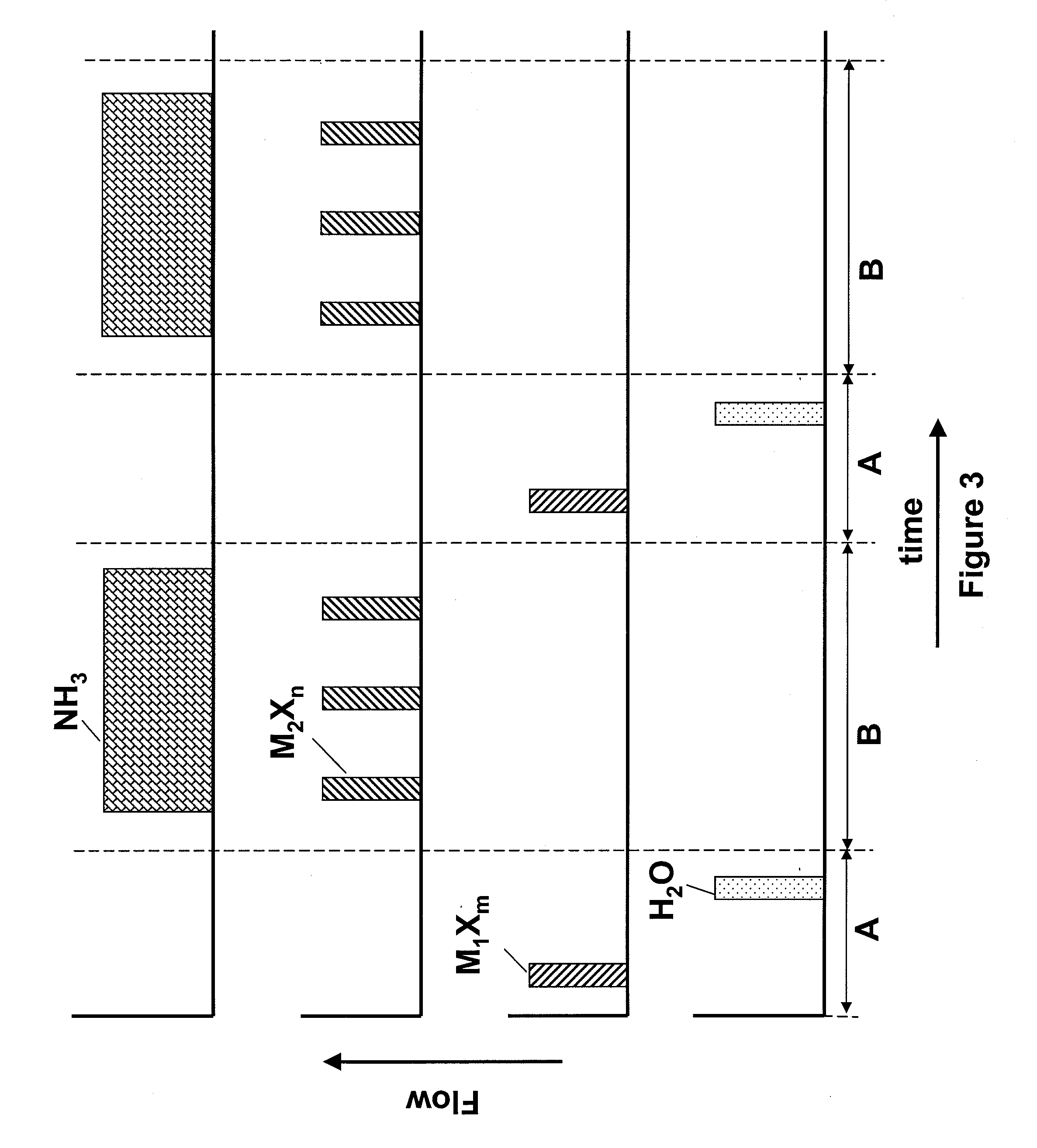

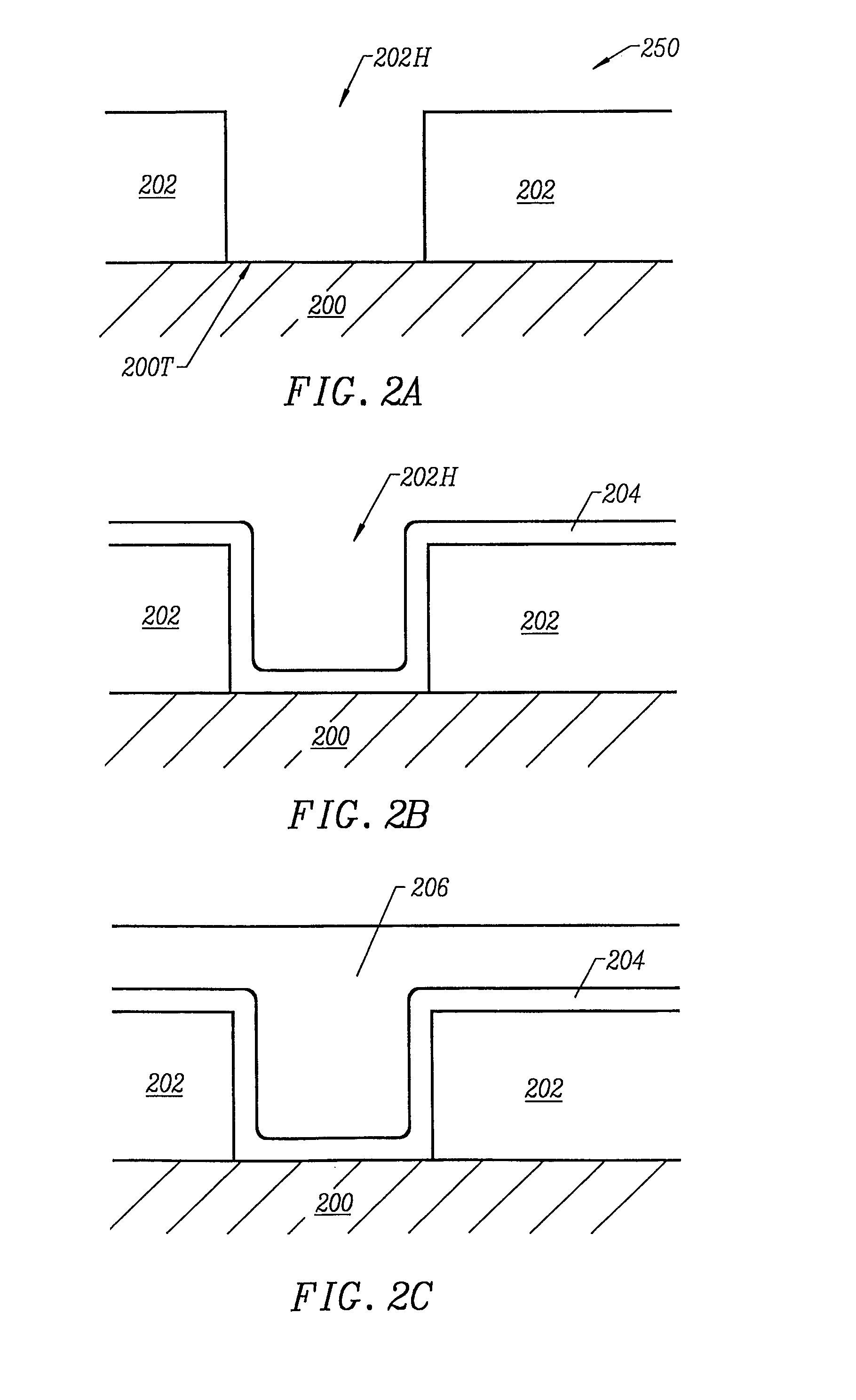

Method for depositing thin films by mixed pulsed CVD and ald

ActiveUS20080317972A1Easy to customizeImprove responseSemiconductor/solid-state device manufacturingChemical vapor deposition coatingChemical vapor depositionAtomic layer deposition

Films are deposited on a substrate by a process in which atomic layer deposition (ALD) is used to deposit one layer of the film and pulsed chemical vapor deposition (CVD) is used to deposit another layer of the film. During the ALD part of the process, a layer is formed by flowing sequential and alternating pulses of mutually reactive reactants that deposit self-limitingly on a substrate. During the pulsed CVD part of the process, another layer is deposited by flowing two CVD reactants into a reaction chamber, with at least a first of the CVD reactants flowed into the reaction chamber in pulses, with those pulses overlapping at least partially with the flow of a second of the CVD reactants. The ALD and CVD parts of the process ca be used to deposit layers with different compositions, thereby forming, e.g., nanolaminate films. Preferably, high quality layers are formed by flowing the second CVD reactant into the reaction chamber for a longer total duration than the first CVD reactant. In some embodiments, the pulses of the third reactant at separated by a duration at least about 1.75 times the length of the pulse. Preferably, less than about 8 monolayers of material are deposited per pulse of the first CVD reactant.

Owner:ASM INTERNATIONAL

Thin films

InactiveUS20050181555A1Quality improvementHigh dielectric constantSolid-state devicesSemiconductor/solid-state device manufacturingGate dielectricSilicon oxide

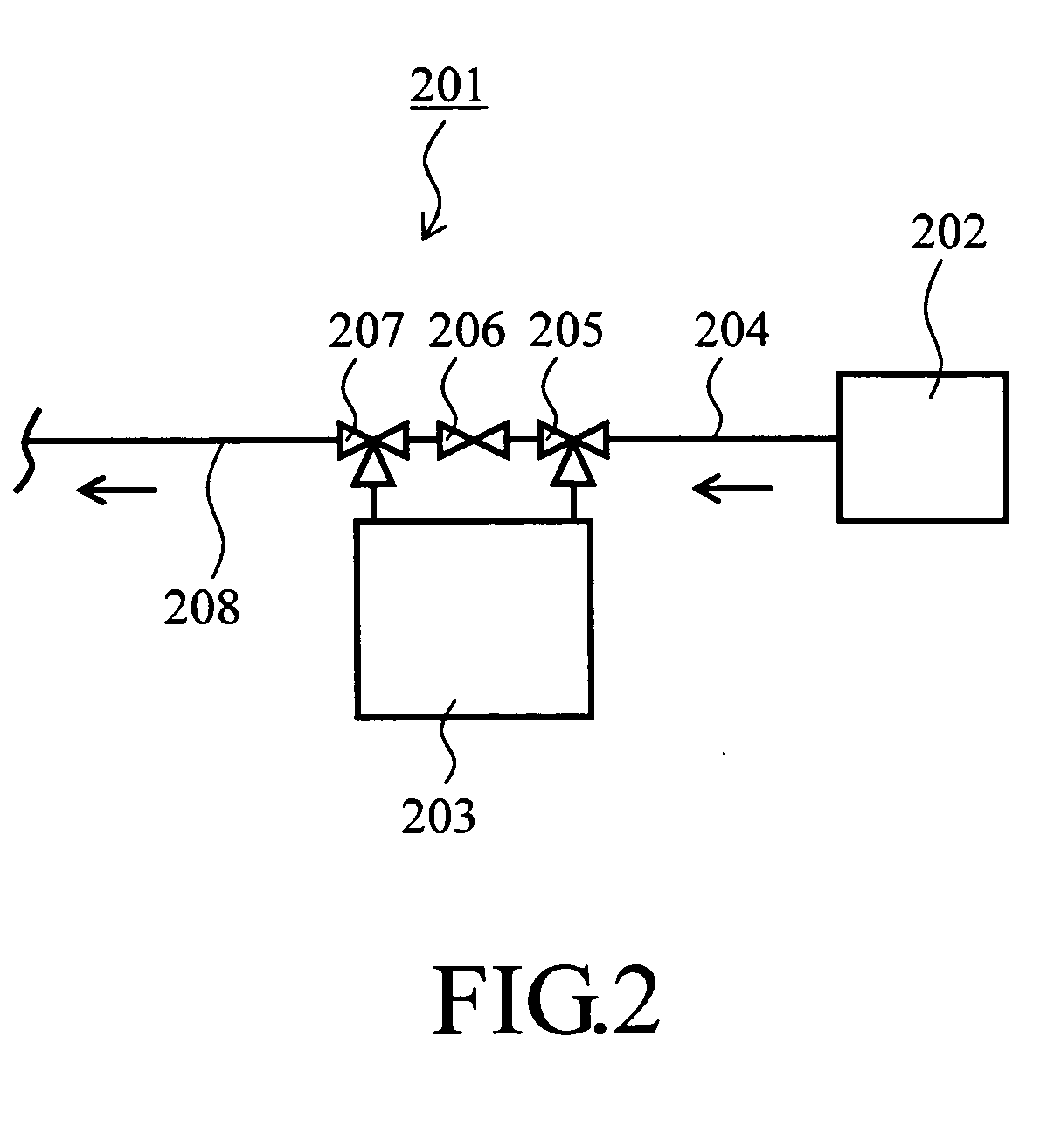

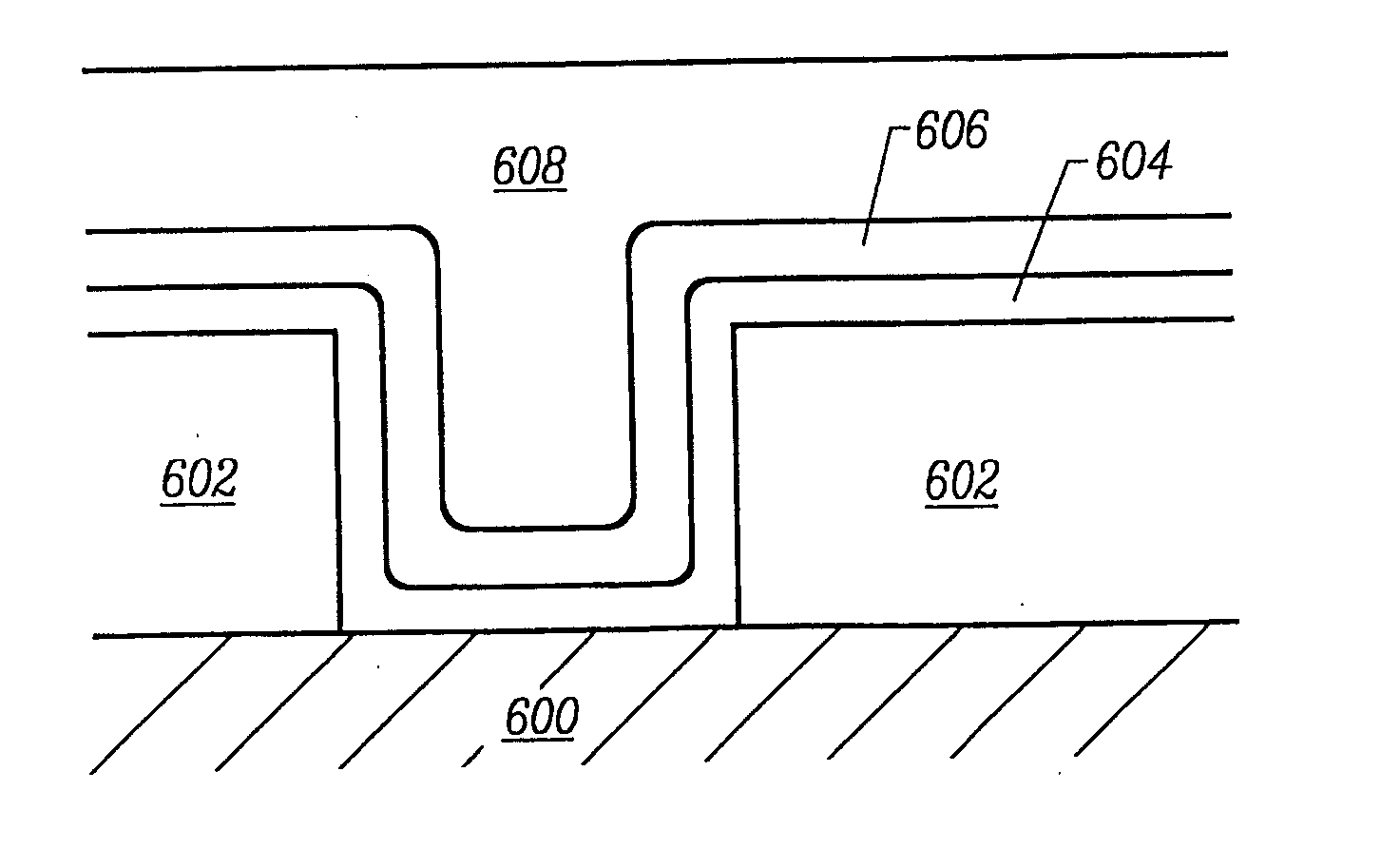

Thin films are formed by formed by atomic layer deposition, whereby the composition of the film can be varied from monolayer to monolayer during cycles including alternating pulses of self-limiting chemistries. In the illustrated embodiments, varying amounts of impurity sources are introduced during the cyclical process. A graded gate dielectric is thereby provided, even for extremely thin layers. The gate dielectric as thin as 2 nm can be varied from pure silicon oxide to oxynitride to silicon nitride. Similarly, the gate dielectric can be varied from aluminum oxide to mixtures of aluminum oxide and a higher dielectric material (e.g., ZrO2) to pure high k material and back to aluminum oxide. In another embodiment, metal nitride (e.g., WN) is first formed as a barrier for lining dual damascene trenches and vias. During the alternating deposition process, copper can be introduced, e.g., in separate pulses, and the copper source pulses can gradually increase in frequency, forming a transition region, until pure copper is formed at the upper surface. Advantageously, graded compositions in these and a variety of other contexts help to avoid such problems as etch rate control, electromigration and non-ohmic electrical contact that can occur at sharp material interfaces. In some embodiments additional seed layers or additional transition layers are provided.

Owner:ASM INTERNATIONAL

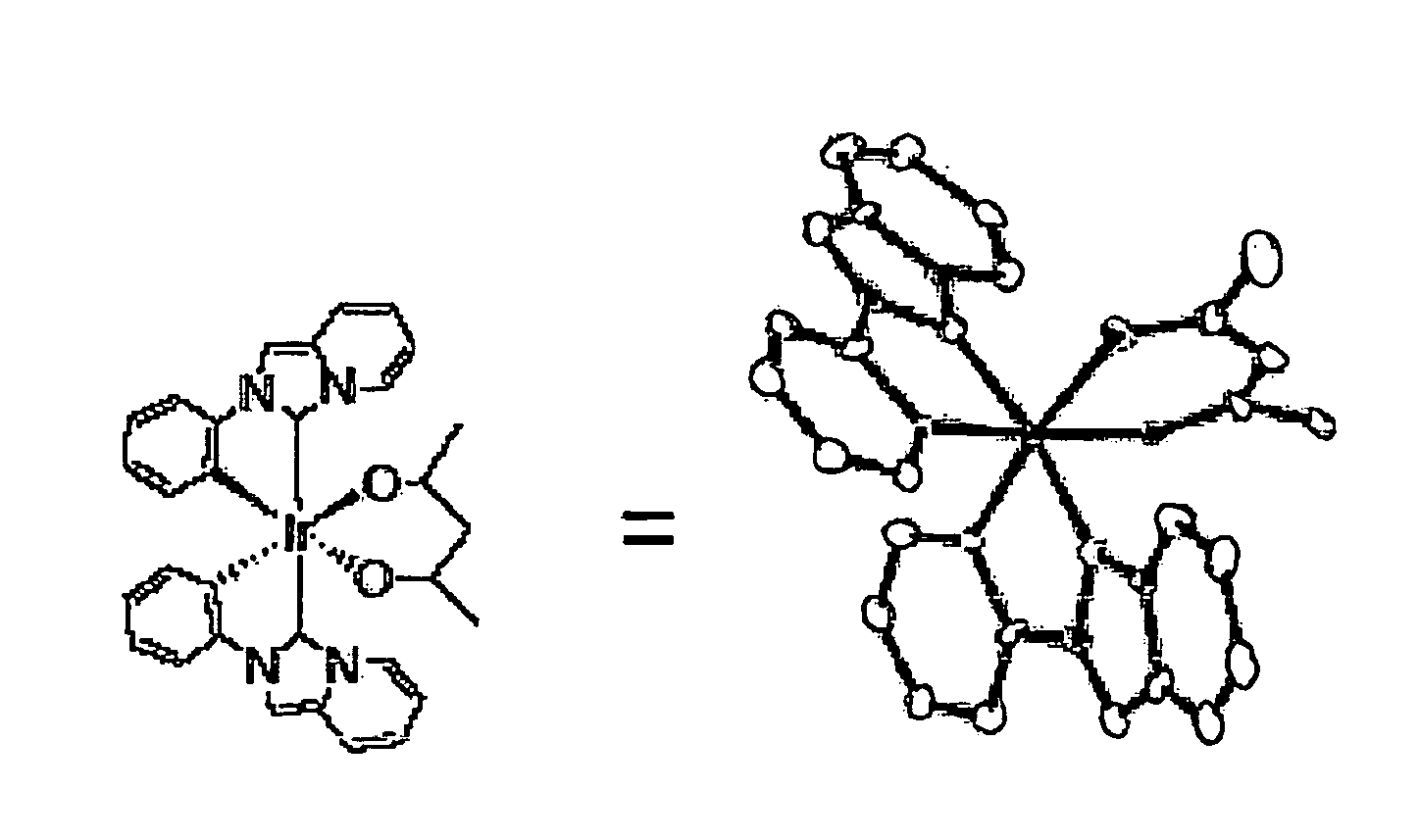

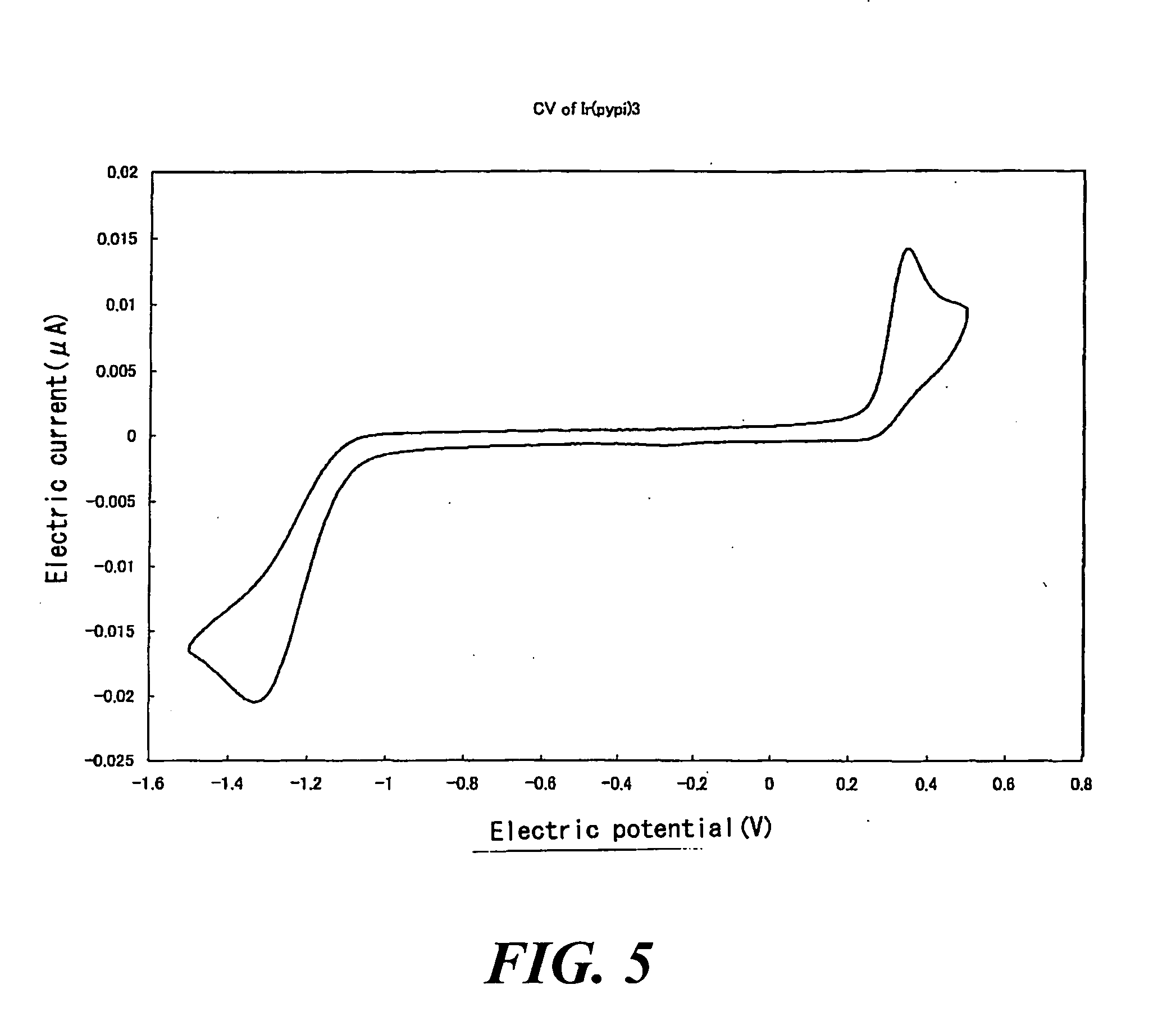

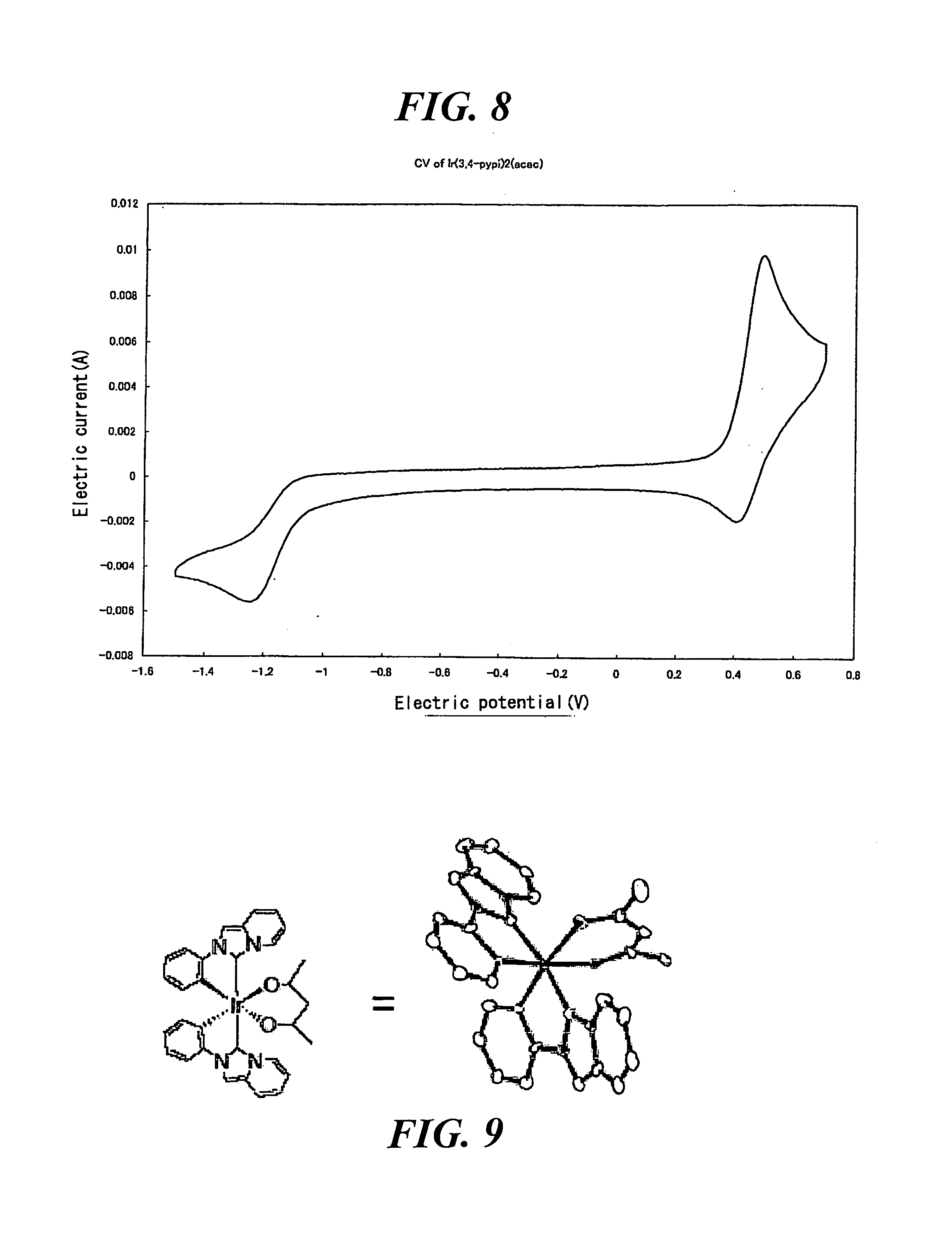

Transition metal complex compound

InactiveUS20080233410A1Solve low luminous efficiencyHigh luminous efficiencyIndium organic compoundsThin material handlingOrganic electroluminescenceMonolayer

The present invention provides a transition metal complex compound of a specific structure having a metal carbene bond, a production process for the same and an organic EL device in which an organic thin film layer comprising a single layer or plural layers having at least a luminescent layer is interposed between an anode and a cathode, wherein at least one layer in the above organic thin film layers contains the transition metal complex compound having a metal carbene bond described above. Provided are a novel transition metal complex compound having a metal carbene bond which has an electroluminescent characteristic and which can provide an organic electroluminescent device having a high luminous efficiency and a production process for a transition metal complex compound.

Owner:IDEMITSU KOSAN CO LTD +1

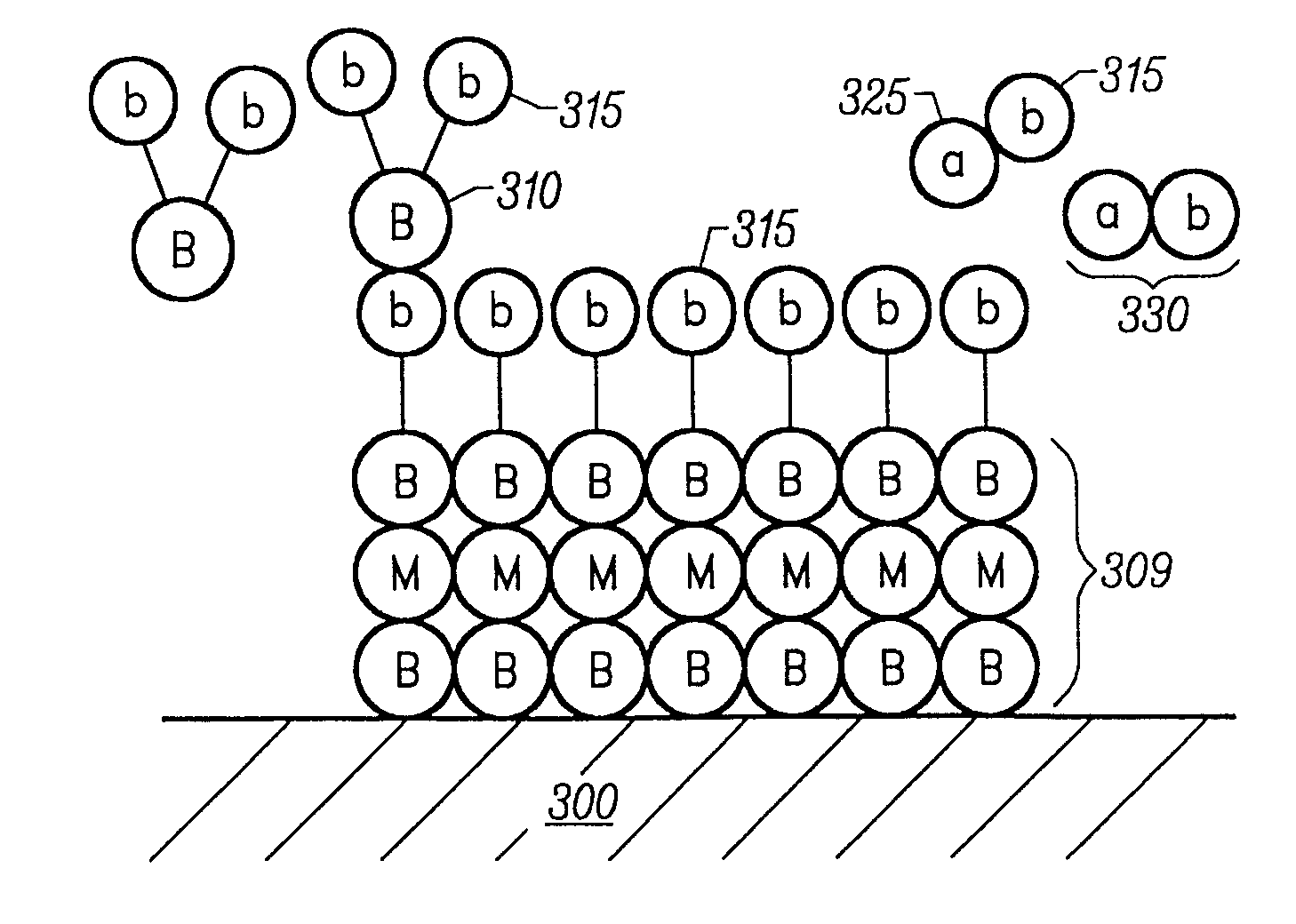

Formation of boride barrier layers using chemisorption techniques

InactiveUS7208413B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingBorideBoron containing

A method of forming a boride layer for integrated circuit fabrication is disclosed. In one embodiment, the boride layer is formed by chemisorbing monolayers of a boron-containing compound and one refractory metal compound onto a substrate. In an alternate embodiment, the boride layer has a composite structure. The composite boride layer structure comprises two or more refractory metals. The composite boride layer is formed by sequentially chemisorbing monolayers of a boron compound and two or more refractory metal compounds on a substrate.

Owner:APPLIED MATERIALS INC

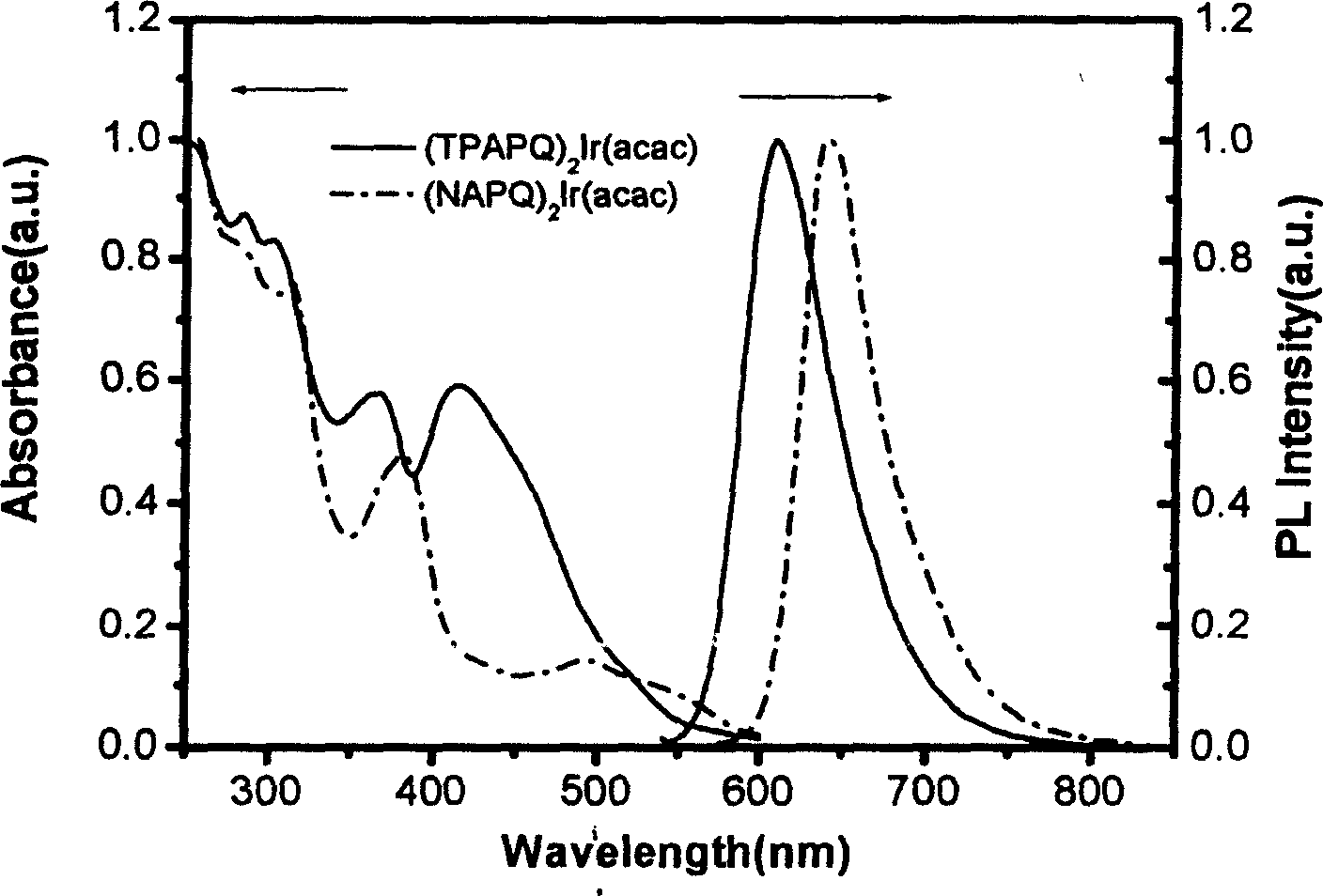

Complexes of red light iridium by using nitrogen heterocycles in quinoline as ligand, and application

ActiveCN1696137AShort lifeImprove efficiencyElectrical apparatusGroup 8/9/10/18 element organic compoundsIridiumNitrogen

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Atomic layer deposition method of depositing an oxide on a substrate

The invention includes atomic layer deposition methods of depositing an oxide on a substrate. In one implementation, a substrate is positioned within a deposition chamber. A first species is chemisorbed onto the substrate to form a first species monolayer within the deposition chamber from a gaseous precursor. The chemisorbed first species is contacted with remote plasma oxygen derived at least in part from at least one of O2 and O3 and with remote plasma nitrogen effective to react with the first species to form a monolayer comprising an oxide of a component of the first species monolayer. The chemisorbing and the contacting with remote plasma oxygen and with remote plasma nitrogen are successively repeated effective to form porous oxide on the substrate. Other aspects and implementations are contemplated.

Owner:MICRON TECH INC

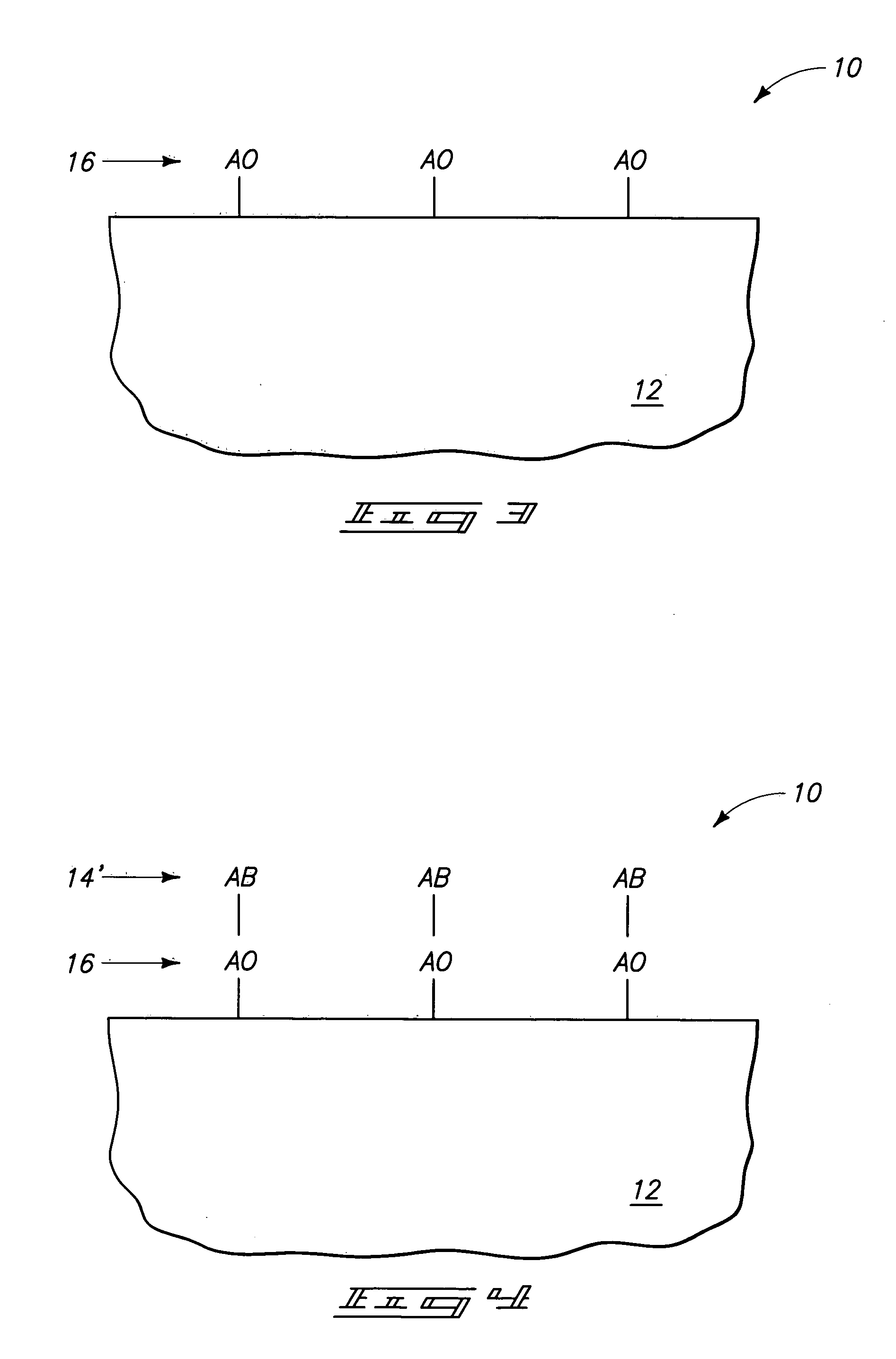

Method of increasing deposition rate of silicon dioxide on a catalyst

ActiveUS20060046518A1Good step coverageIncrease production outputSemiconductor/solid-state device manufacturingChemical vapor deposition coatingSilicon oxideOxygen

Methods for forming dielectric layers, and structures and devices resulting from such methods, and systems that incorporate the devices are provided. The invention provides an aluminum oxide / silicon oxide laminate film formed by sequentially exposing a substrate to an organoaluminum catalyst to form a monolayer over the surface, remote plasmas of oxygen and nitrogen to convert the organoaluminum layer to a porous aluminum oxide layer, and a silanol precursor to form a thick layer of silicon dioxide over the porous oxide layer. The process provides an increased rate of deposition of the silicon dioxide, with each cycle producing a thick layer of silicon dioxide of about 120 Å over the layer of porous aluminum oxide.

Owner:MICRON TECH INC

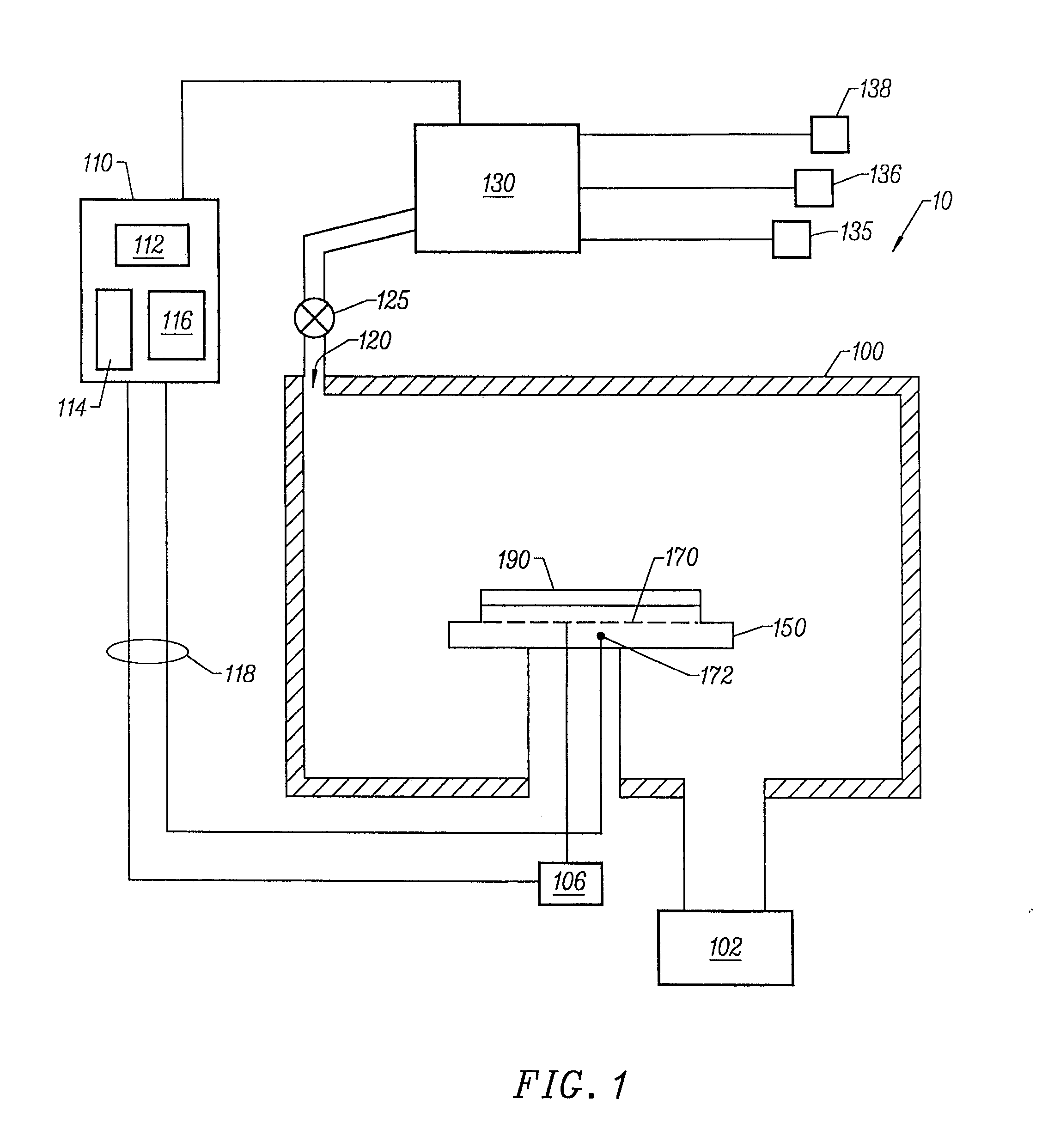

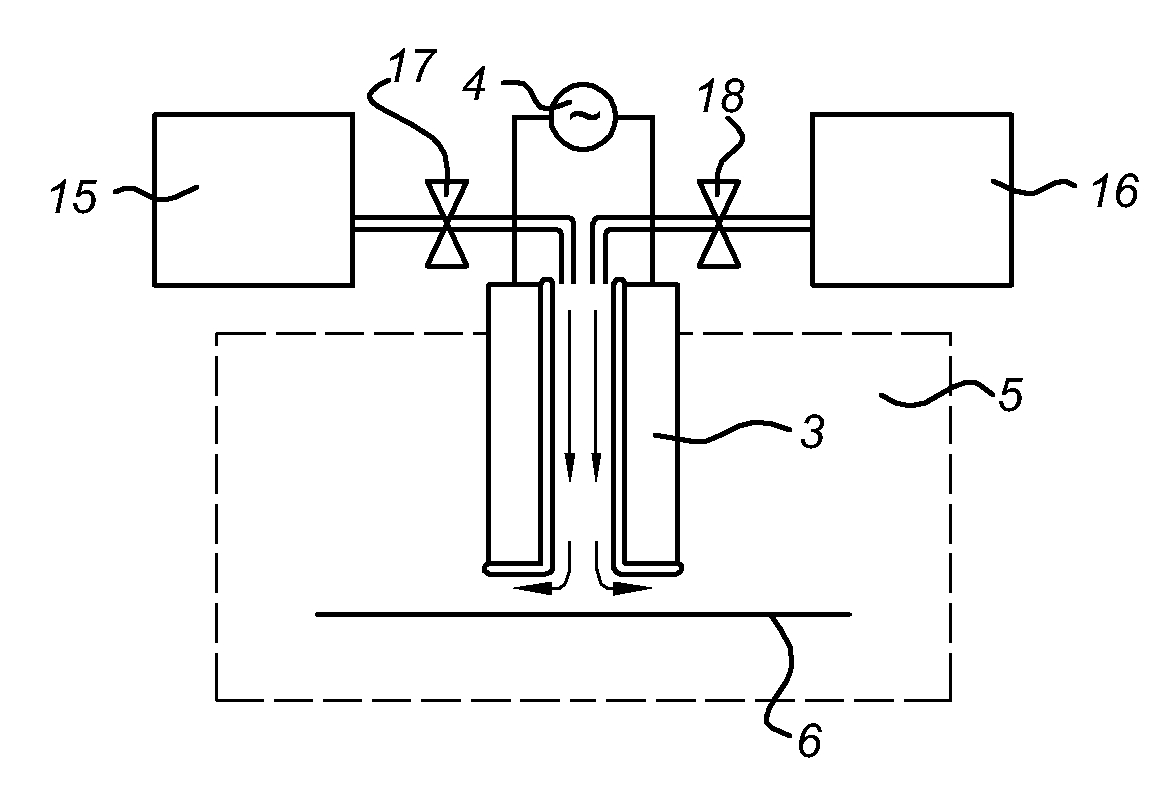

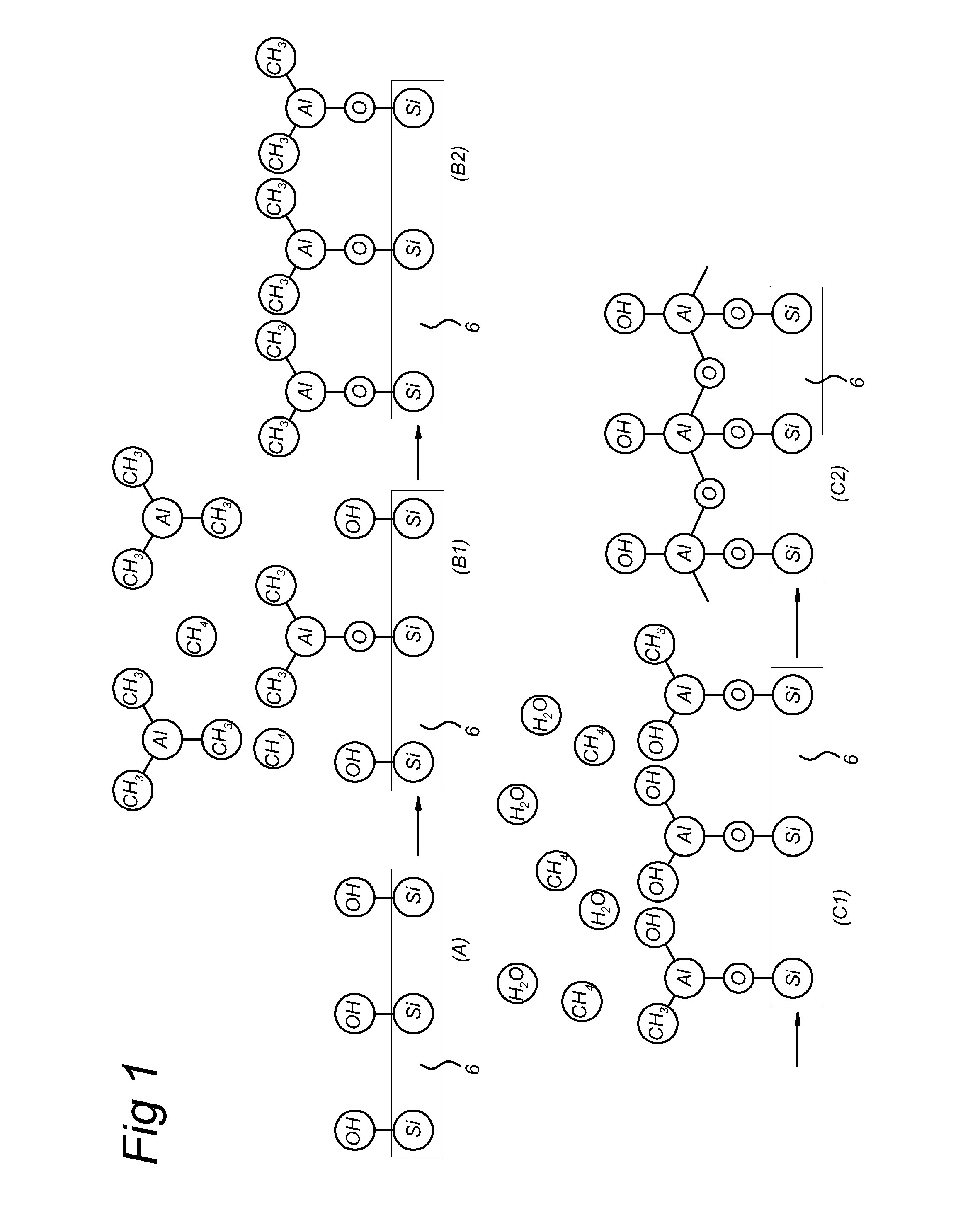

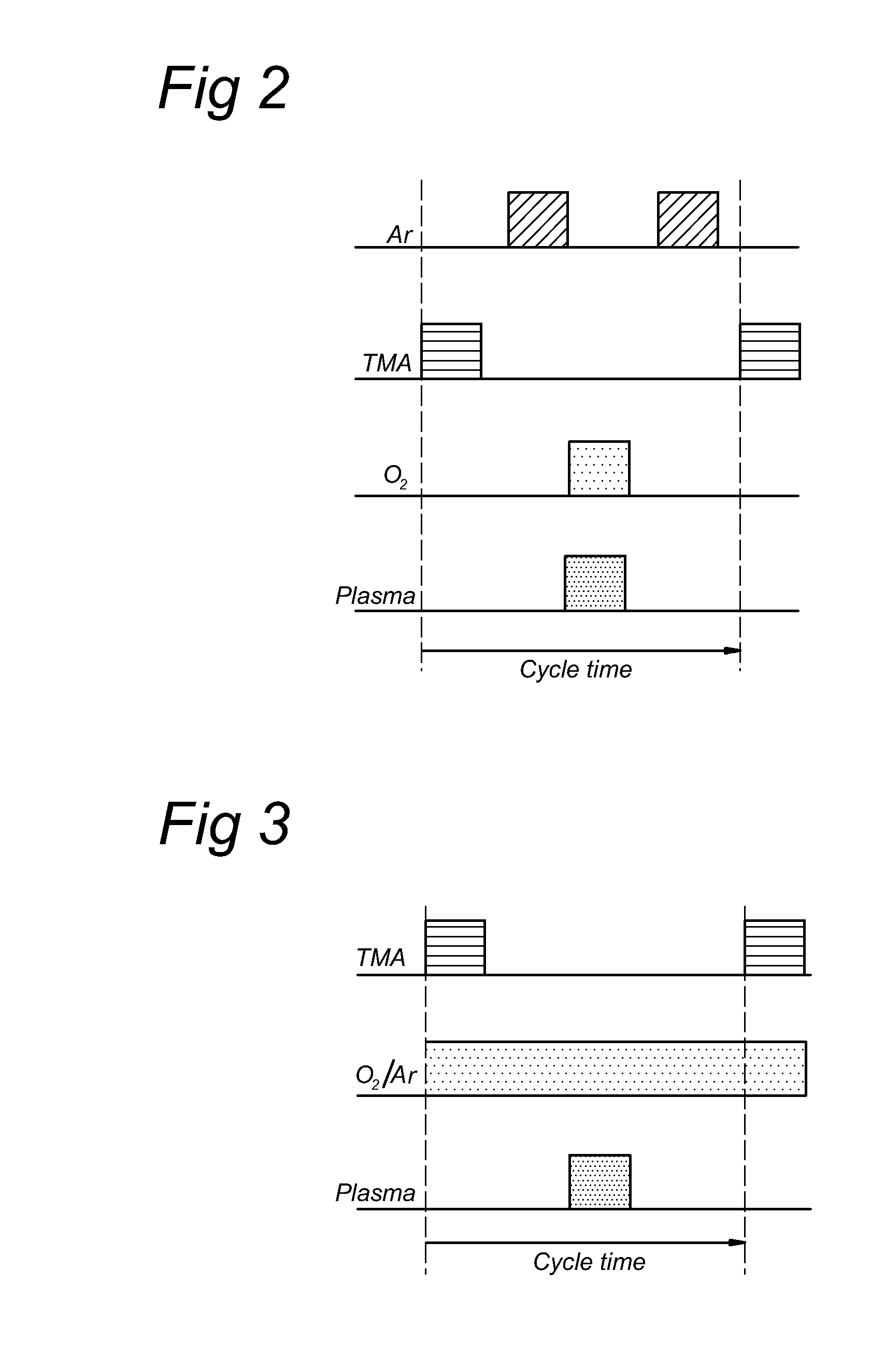

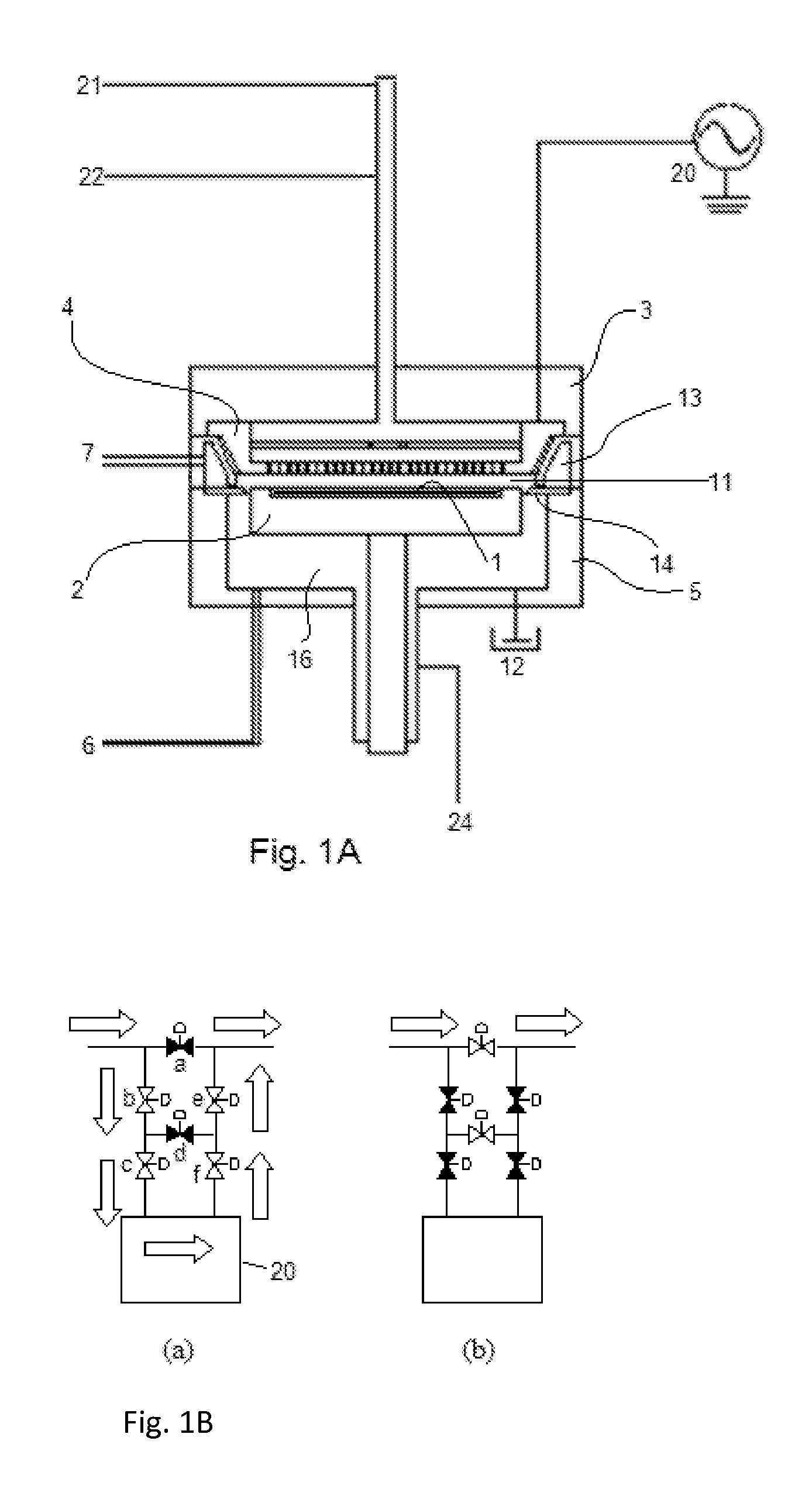

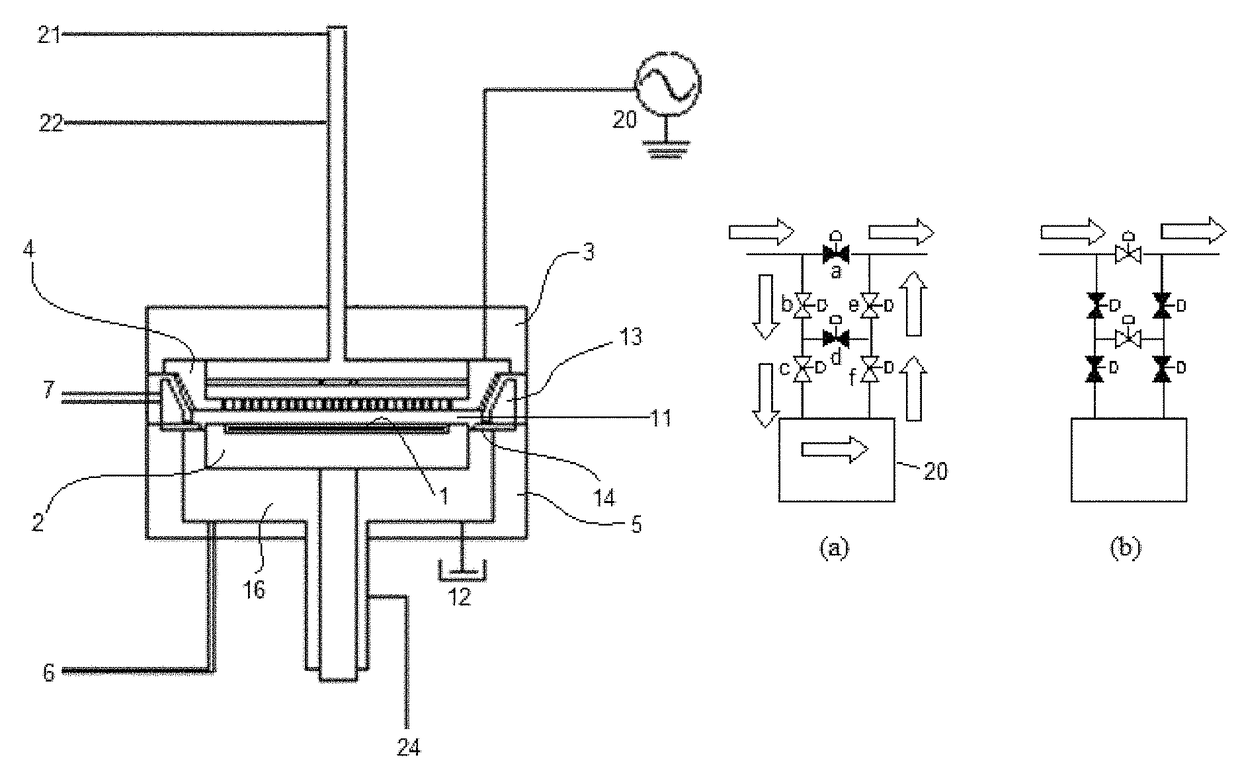

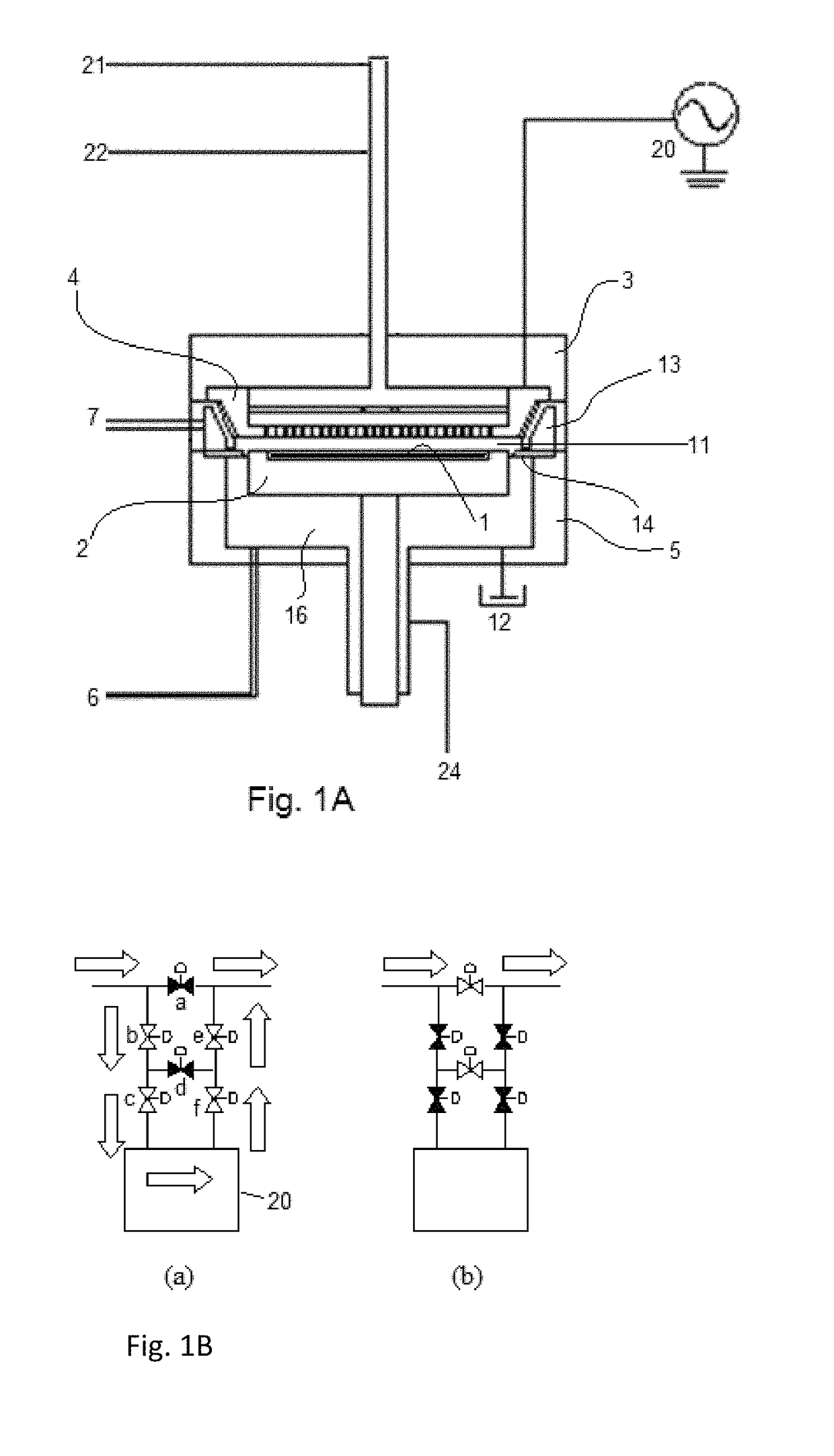

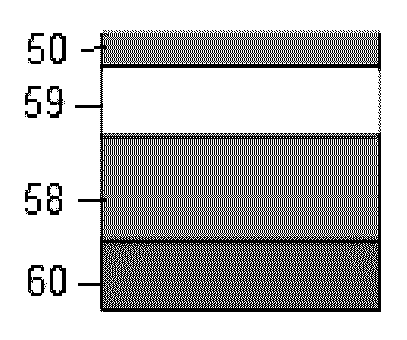

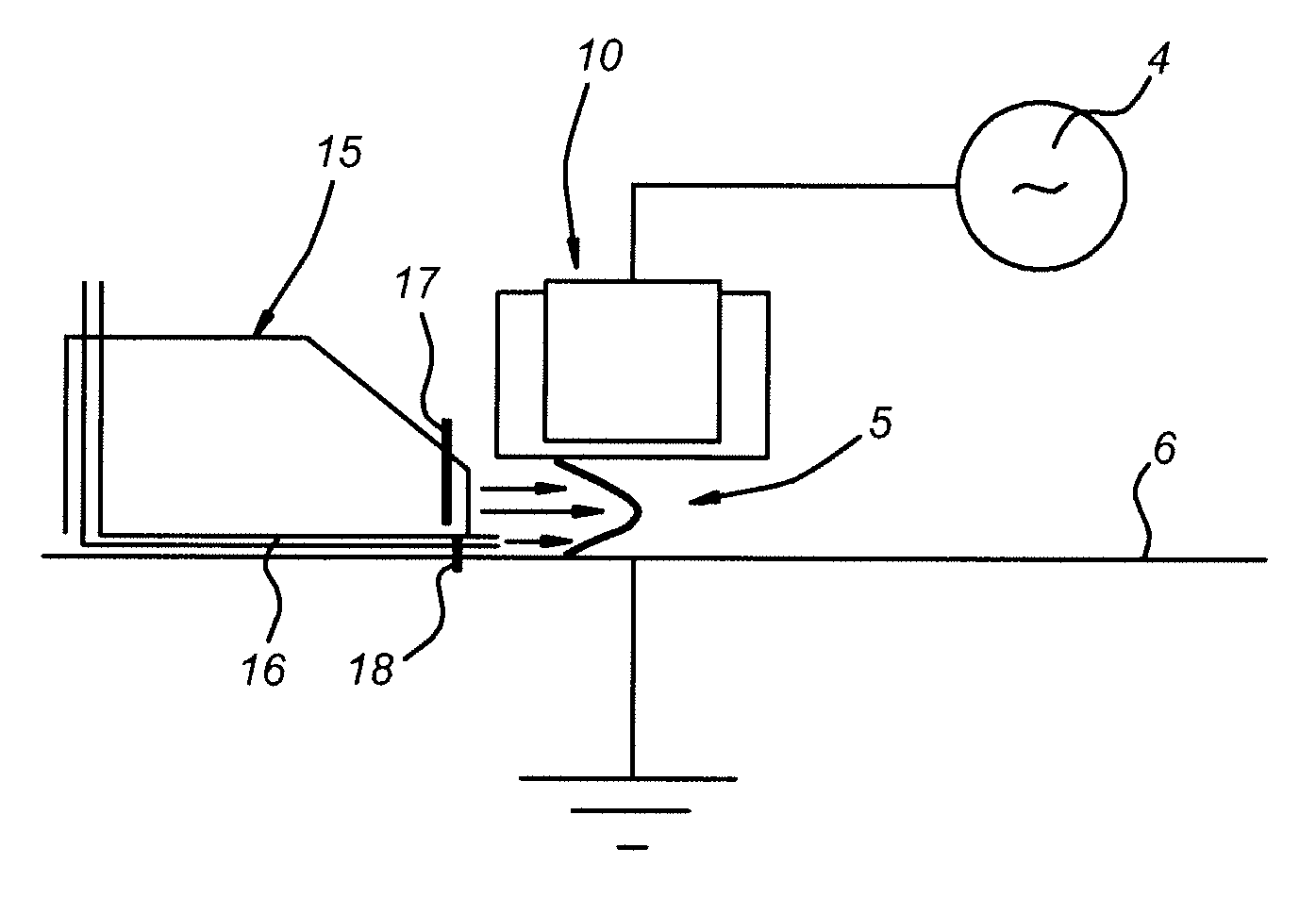

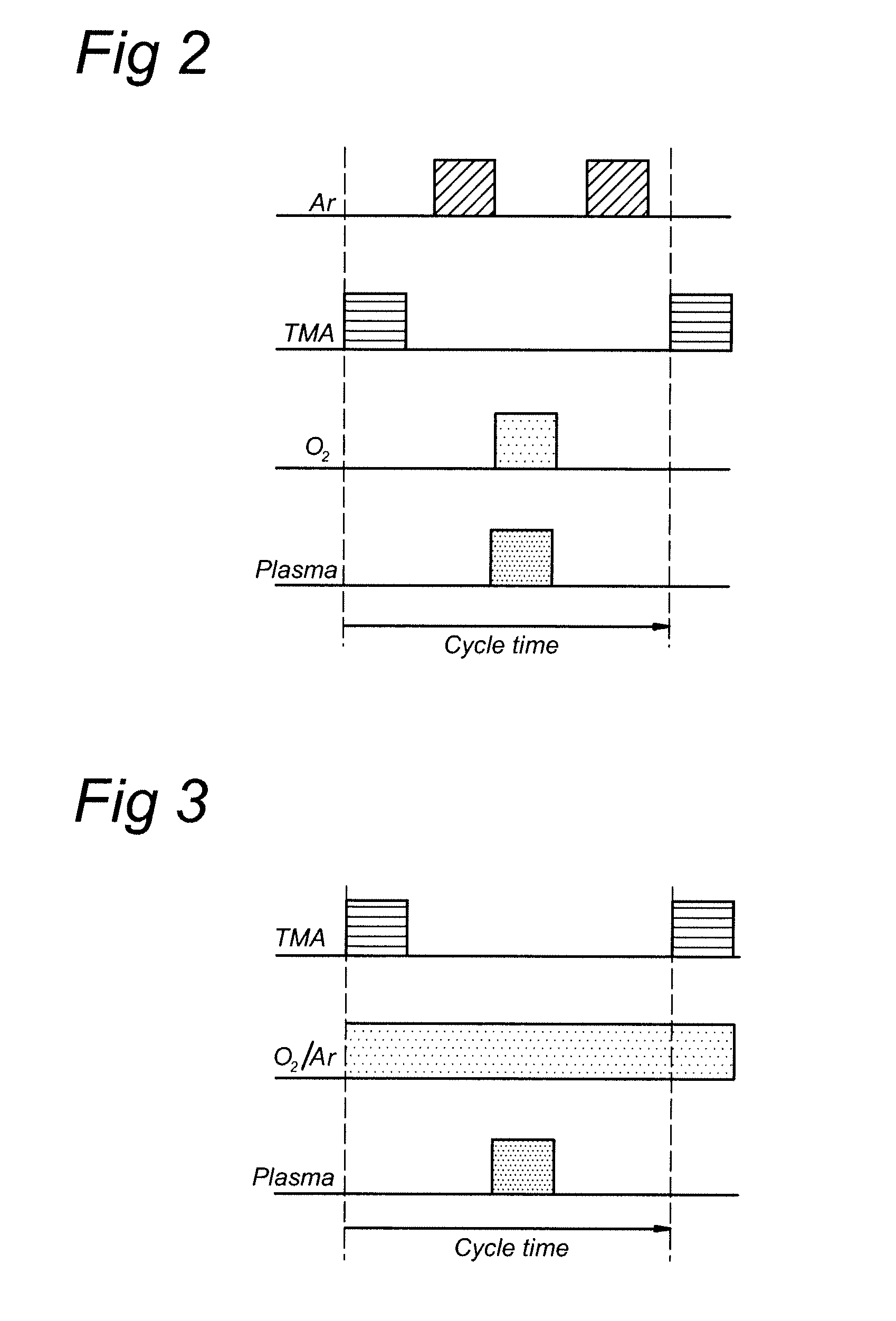

Method and apparatus for atomic layer deposition using an atmospheric pressure glow discharge plasma

InactiveUS20100255625A1Comparable and good performanceSemiconductor/solid-state device manufacturingChemical vapor deposition coatingPlasma generatorProduct gas

Apparatus and method for atomic layer deposition on a surface of a substrate (6) in a treatment space. A gas supply device (15, 16) is present for providing various gas mixtures to the treatment space (1, 2). The gas supply device (15, 16) is arranged to provide a gas mixture with a precursor material to the treatment space for allowing reactive surface sites to react with precursor material molecules to give a surface covered by a monolayer of precursor molecules attached via the reactive sites to the surface of the substrate. Subsequently, a gas mixture comprising a reactive agent capable to convert the attached precursor molecules to active precursor sites is provided. A plasma generator (10) is present for generating an atmospheric pressure plasma in the gas mixture comprising the reactive agent, the plasma generator being arranged remote from the treatment space (1, 2).

Owner:FUJIFILM MFG EURO

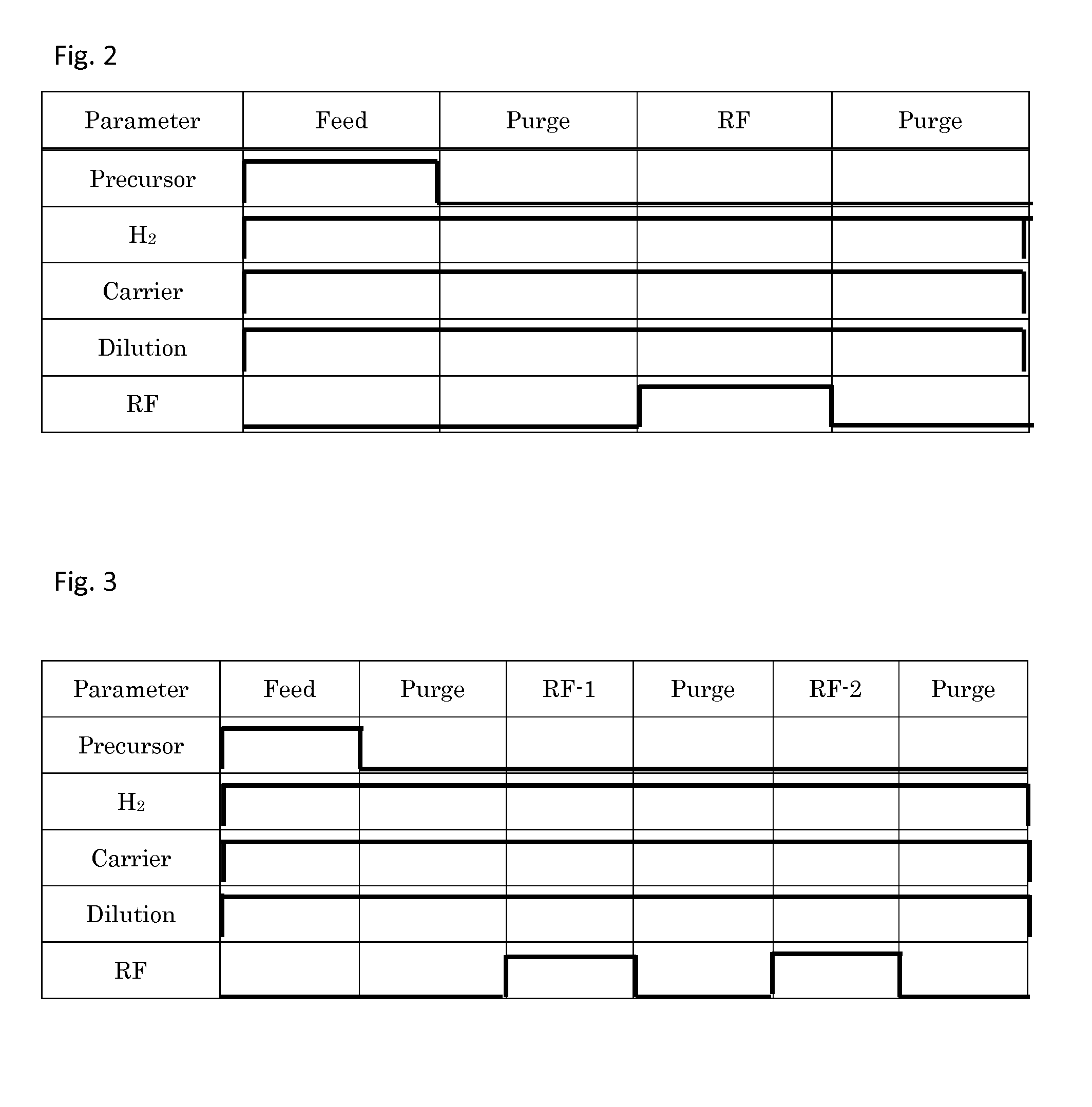

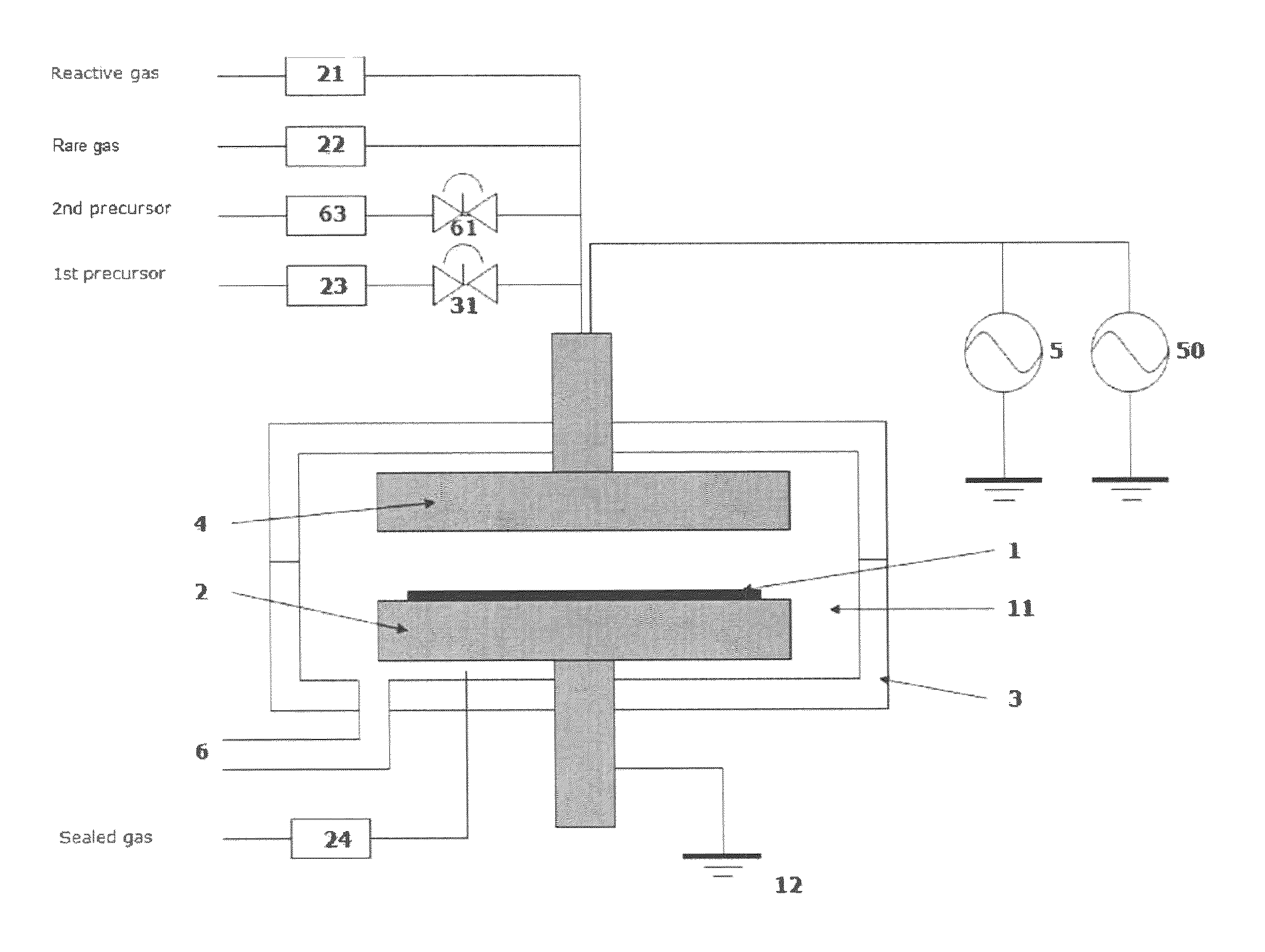

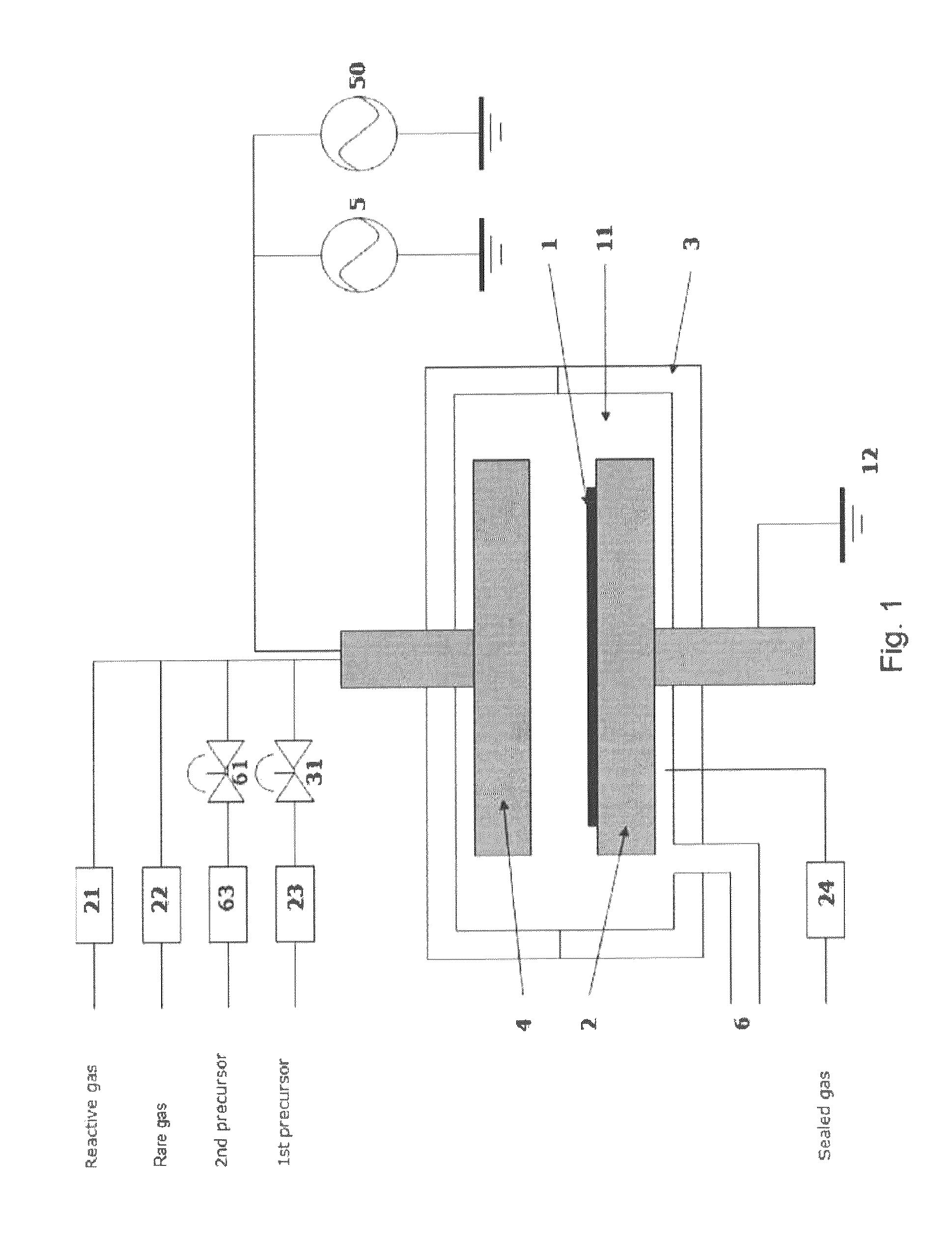

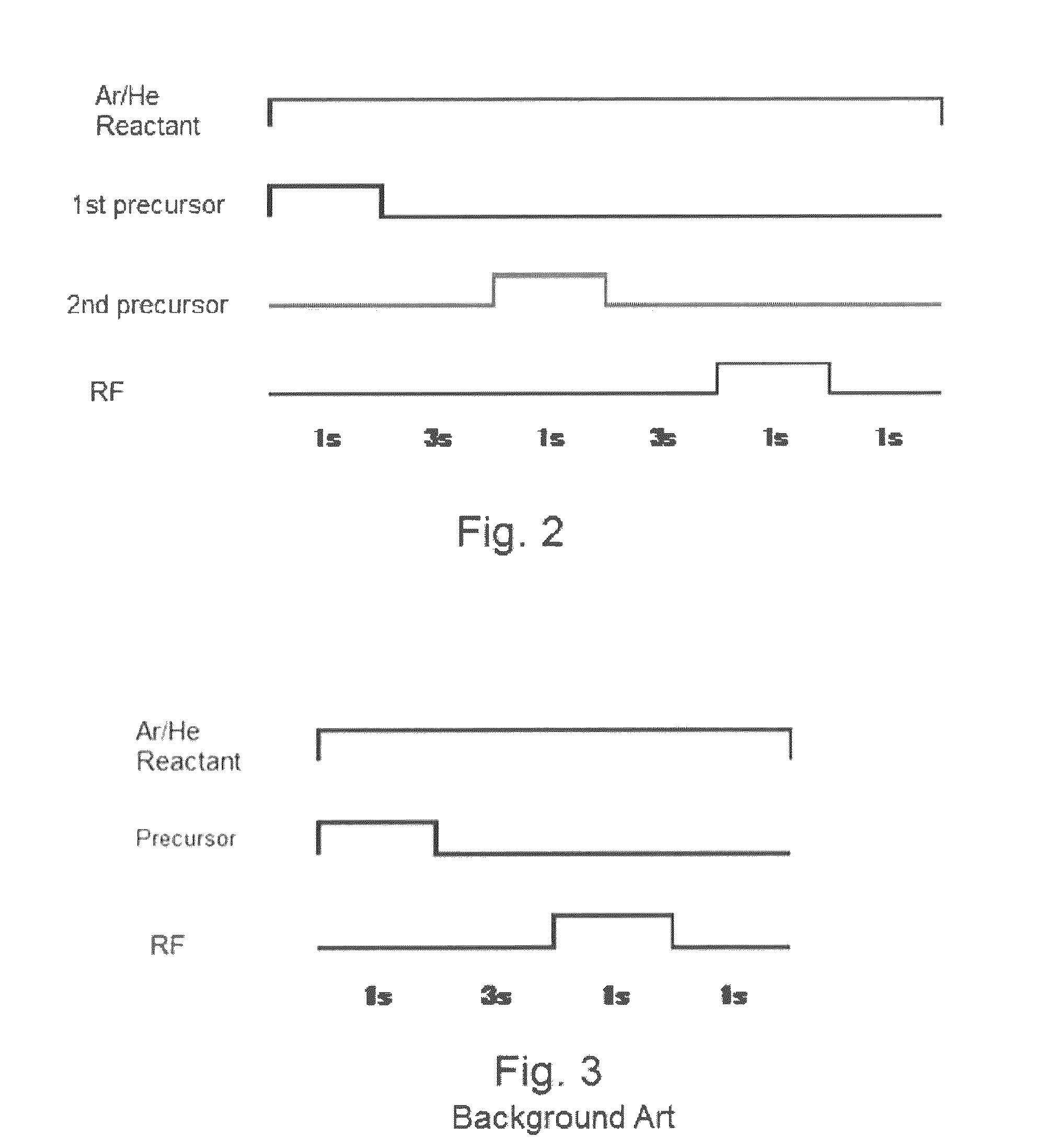

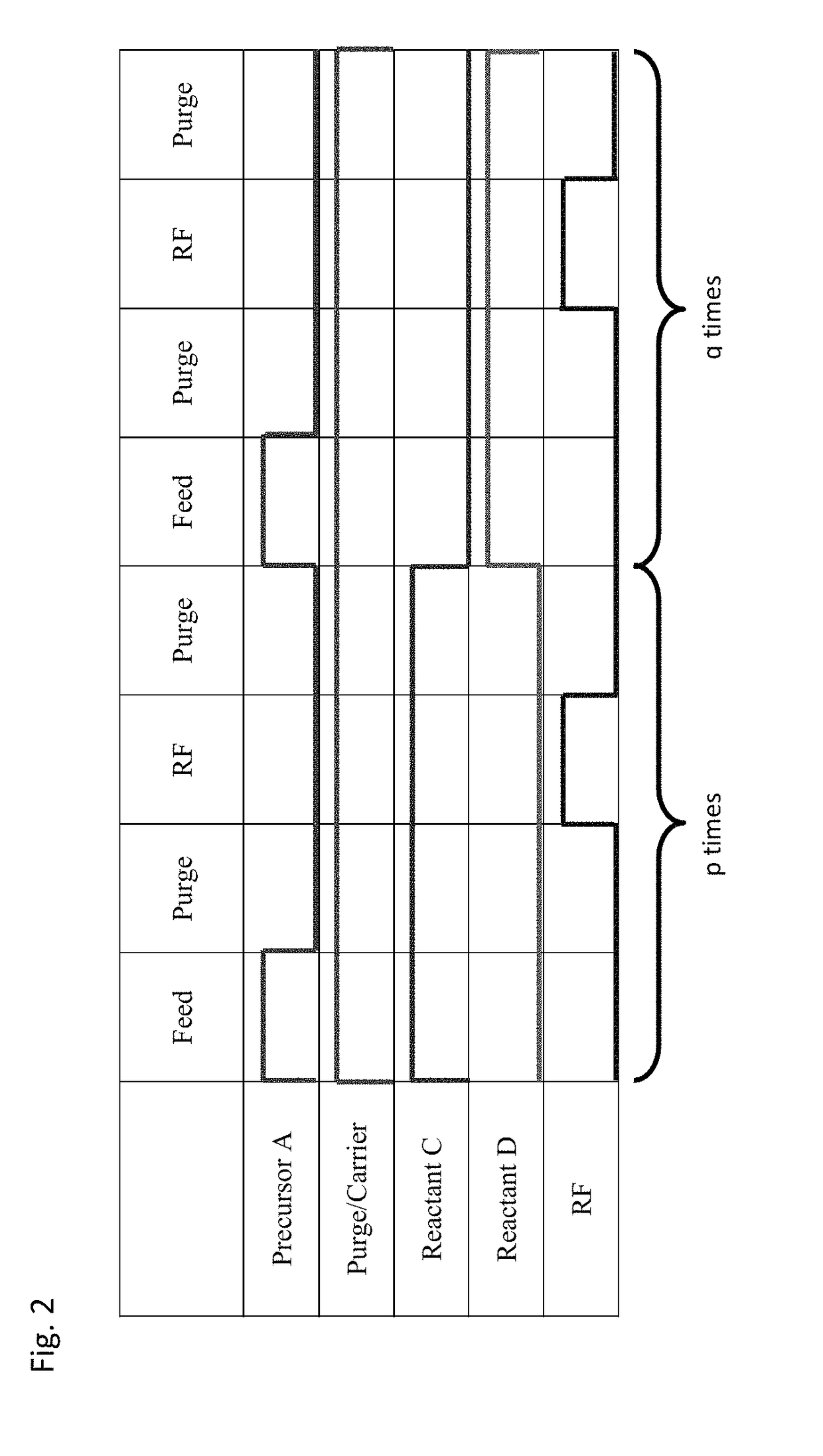

Method for forming dielectric film in trenches by PEALD using H-containing gas

ActiveUS9455138B1Increase deposition rateHigh film thicknessSemiconductor/solid-state device manufacturingChemical physicsNoble gas

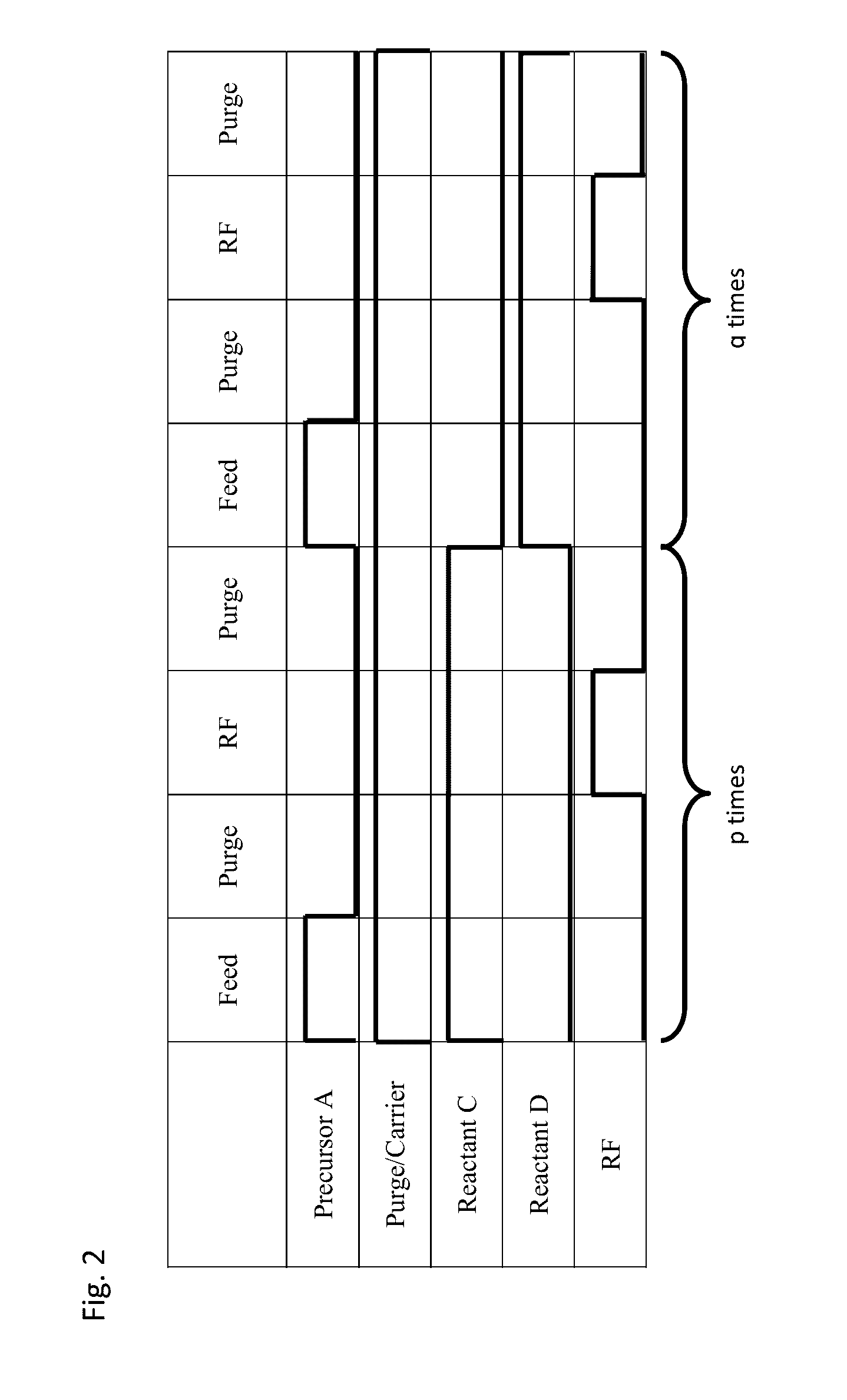

A method for forming a dielectric film in a trench on a substrate by plasma-enhanced atomic layer deposition (PEALD) performs one or more process cycles, each process cycle including: (i) feeding a silicon-containing precursor in a pulse; (ii) supplying a hydrogen-containing reactant gas at a flow rate of more than about 30 sccm but less than about 800 sccm in the absence of nitrogen-containing gas; (iii) supplying a noble gas to the reaction space; and (iv) applying RF power in the presence of the reactant gas and the noble gas and in the absence of any precursor in the reaction space, to form a monolayer constituting a dielectric film on a substrate at a growth rate of less than one atomic layer thickness per cycle.

Owner:ASM IP HLDG BV

Atomic layer deposition of metal oxynitride layers as gate dielectrics

InactiveUS20060051925A1Semiconductor/solid-state device manufacturingSemiconductor devicesGate dielectricHafnium

A metal oxynitride layer formed by atomic layer deposition of a plurality of reacted monolayers, the monolayers comprising at least one each of a metal, an oxide and a nitride. The metal oxynitride layer is formed from zirconium oxynitride, hafnium oxynitride, tantalum oxynitride, or mixtures thereof. The metal oxynitride layer is used in gate dielectrics as a replacement material for silicon dioxide. A semiconductor device structure having a gate dielectric formed from a metal oxynitride layer is also disclosed.

Owner:AHN KIE Y +1

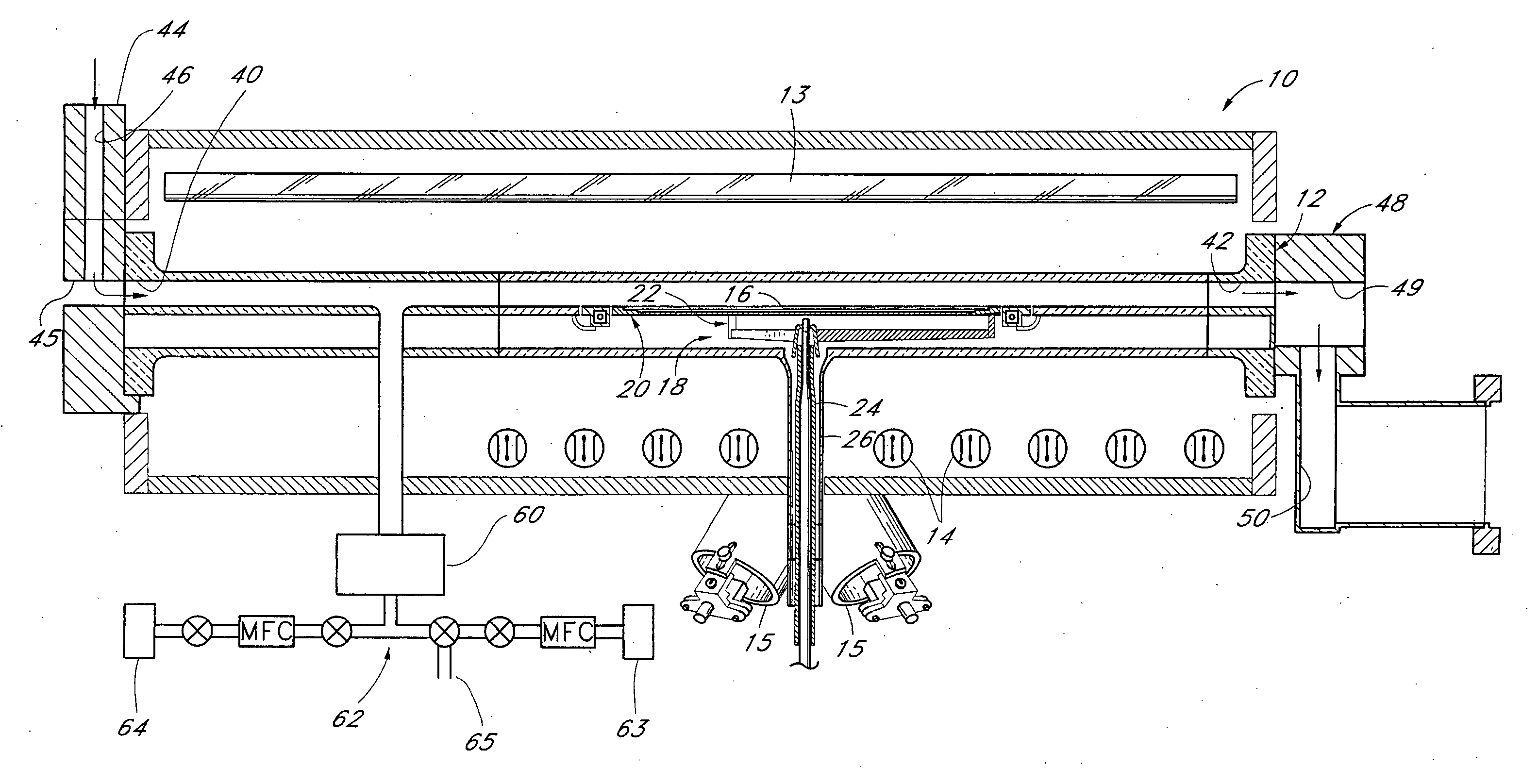

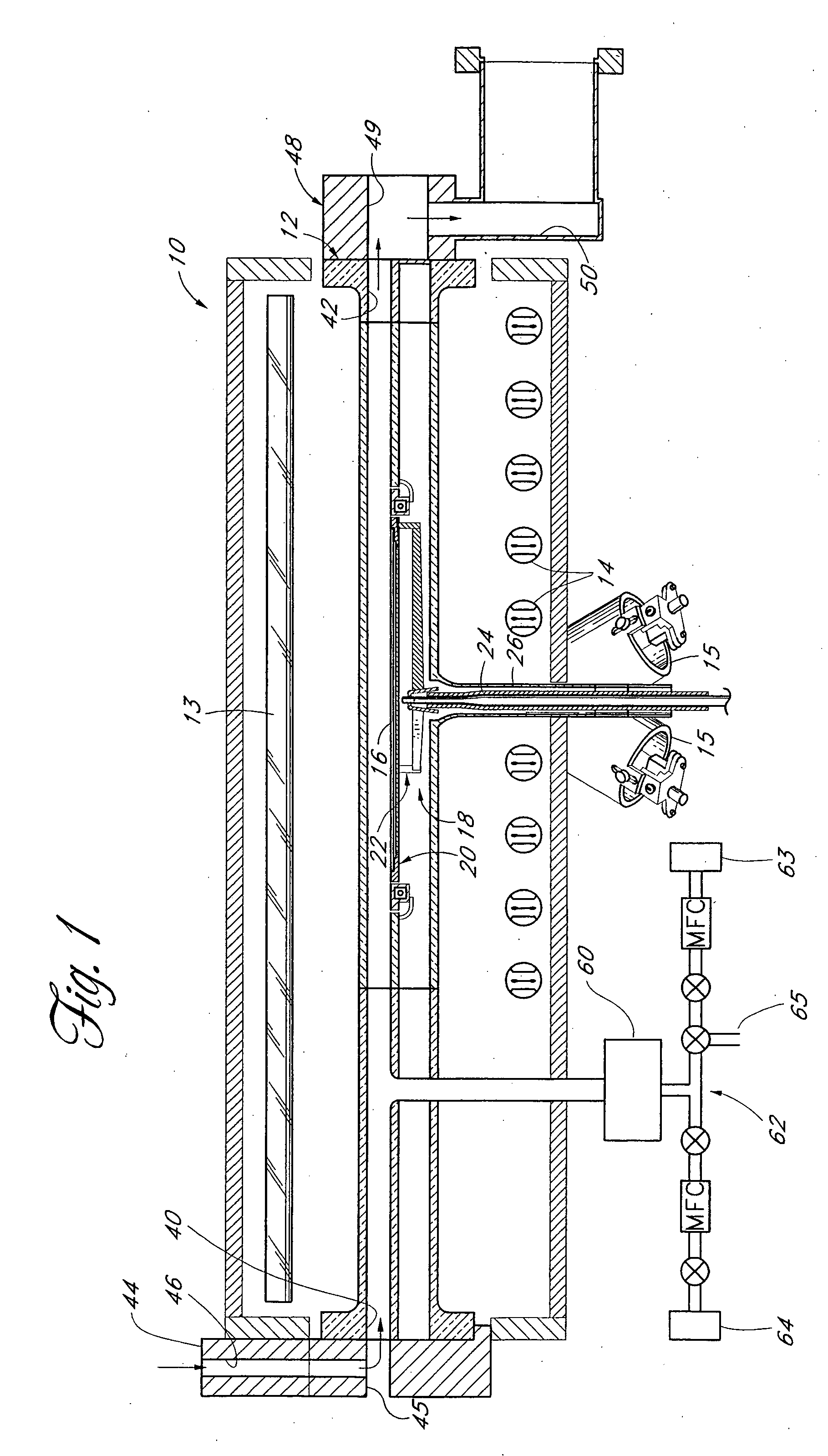

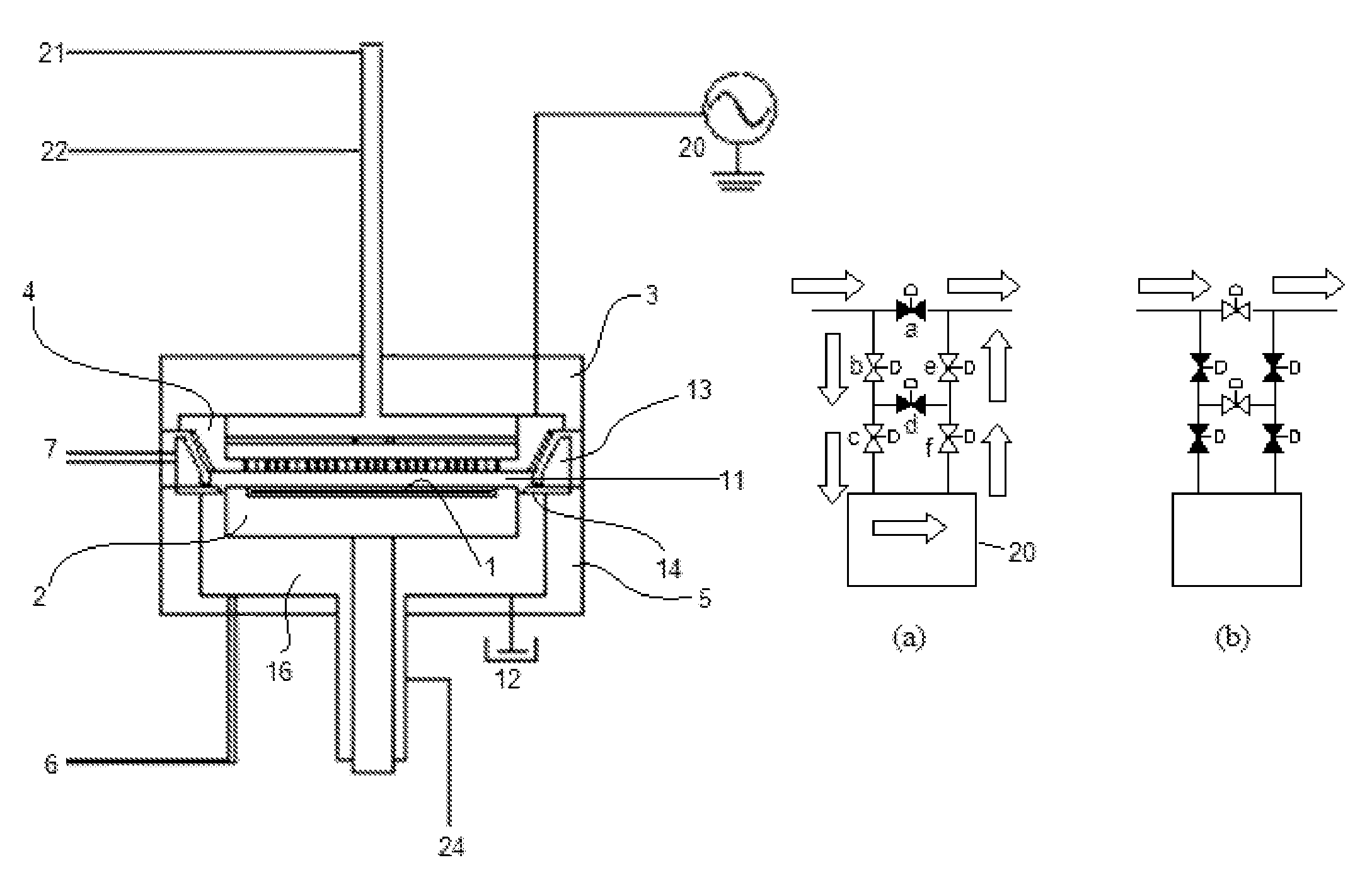

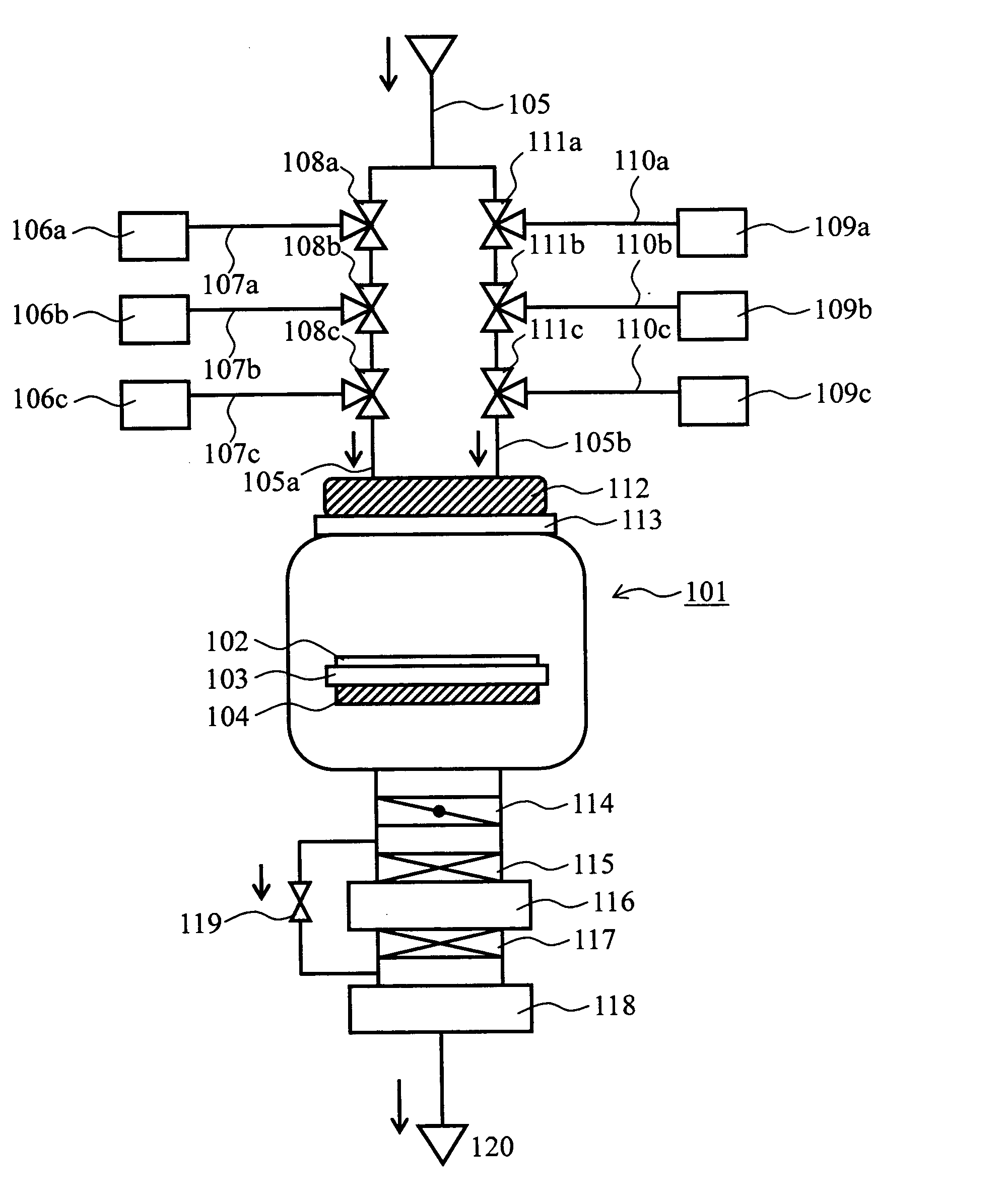

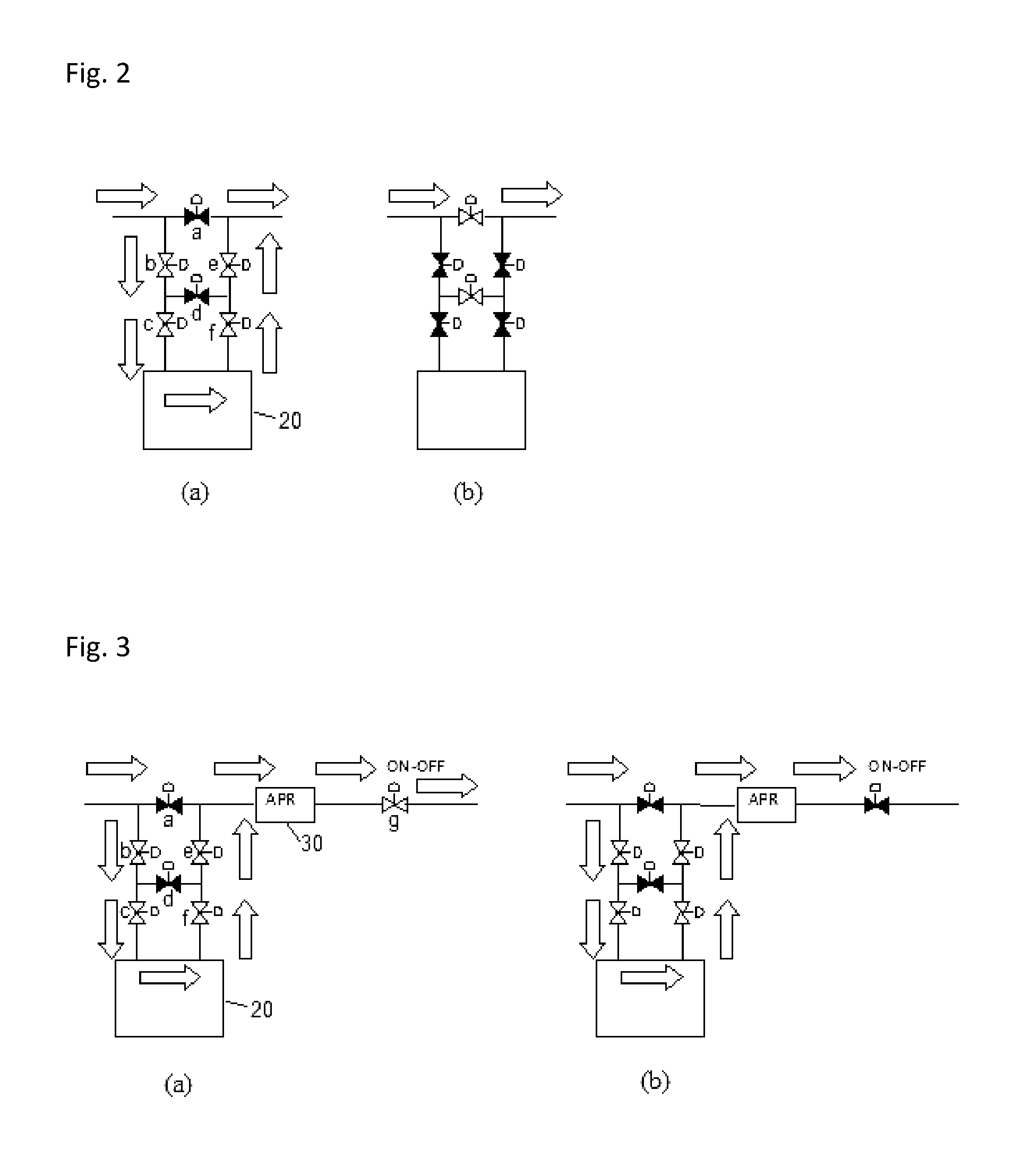

Film forming apparatus and method

InactiveUS20050249876A1Ameliorating the in-plane uniformity of an ALD filmTransistorSemiconductor/solid-state device manufacturingEngineeringReducer

An atomic layer deposition (ALD) apparatus capable of forming a conformal ultrathin-film layer with enhanced step coverage is disclosed. The apparatus includes an ALD reactor supporting therein a wafer, and a main pipe coupled thereto for constant supply of a carrier gas. This pipe has two parallel branch pipes. Raw material sources are connected by three-way valves to one branch pipe through separate pipes, respectively. Similarly, oxidant / reducer sources are coupled by three-way valves to the other branch pipe via independent pipes. ALD works by introducing one reactant gas at a time into the reactor while being combined with the carrier gas. The gas is “chemisorped” onto the wafer surface, creating a monolayer deposited. During the supply of a presently selected material gas from its source to a corresponding branch pipe, this gas passes through its own pipe independently of the others. An ALD method is also disclosed.

Owner:RENESAS TECH CORP

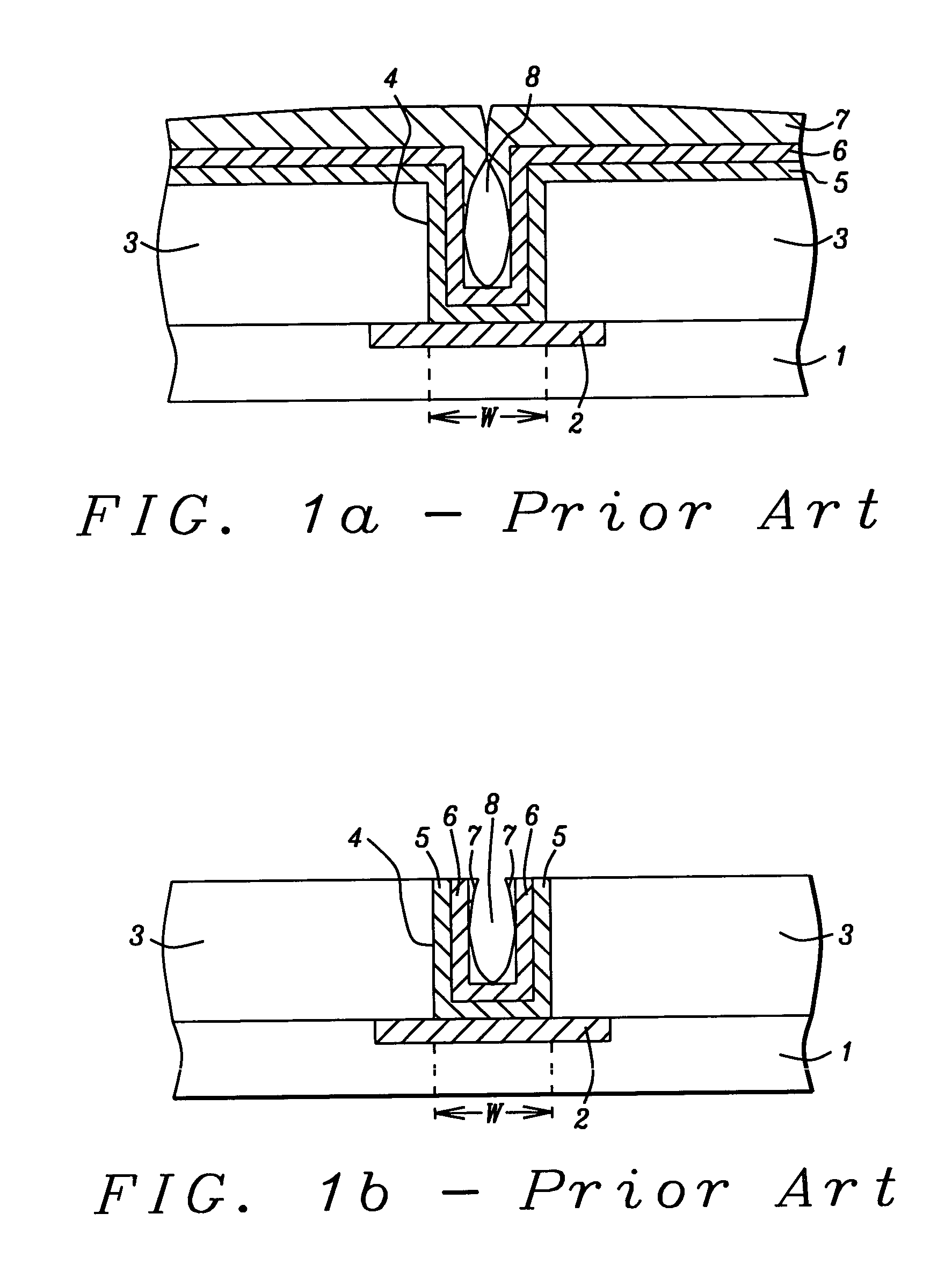

Method of manufacturing a contact interconnection layer containing a metal and nitrogen by atomic layer deposition for deep sub-micron semiconductor technology

ActiveUS7235482B2Good step coverageSafe handlingSemiconductor/solid-state device detailsSolid-state devicesAtomic layer depositionContamination

An atomic layer deposition method is used to deposit a TiN or TiSiN film having a thickness of about 50 nm or less on a substrat. A titanium precursor which is tetrakis(dimethylamido)titanium (TDMAT), tetrakis(diethylamido)titanium (TDEAT), or Ti{OCH(CH3)2}4 avoids halide contamination from a titanium halide precursor and is safer to handle than a titanium nitrate. After a monolayer of the titanium precursor is deposited on a substrate, a nitrogen containing reactant is introduced to form a TiN monolayer which is followed by a second purge. For TiSiN, a silicon source gas is fed into the process chamber after the TiN monolayer formation. The process is repeated several times to produce a composite layer comprised of a plurality of monolayers that fills a contact hole. The ALD method is cost effective and affords an interconnect with lower impurity levels and better step coverage than conventional PECVD or CVD processes.

Owner:TAIWAN SEMICON MFG CO LTD

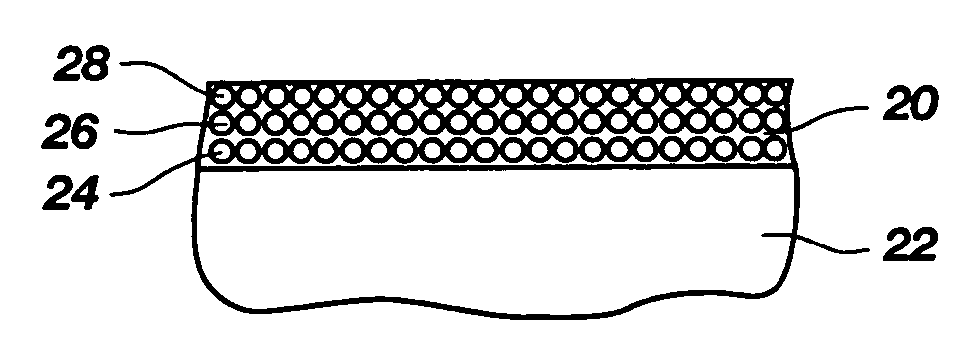

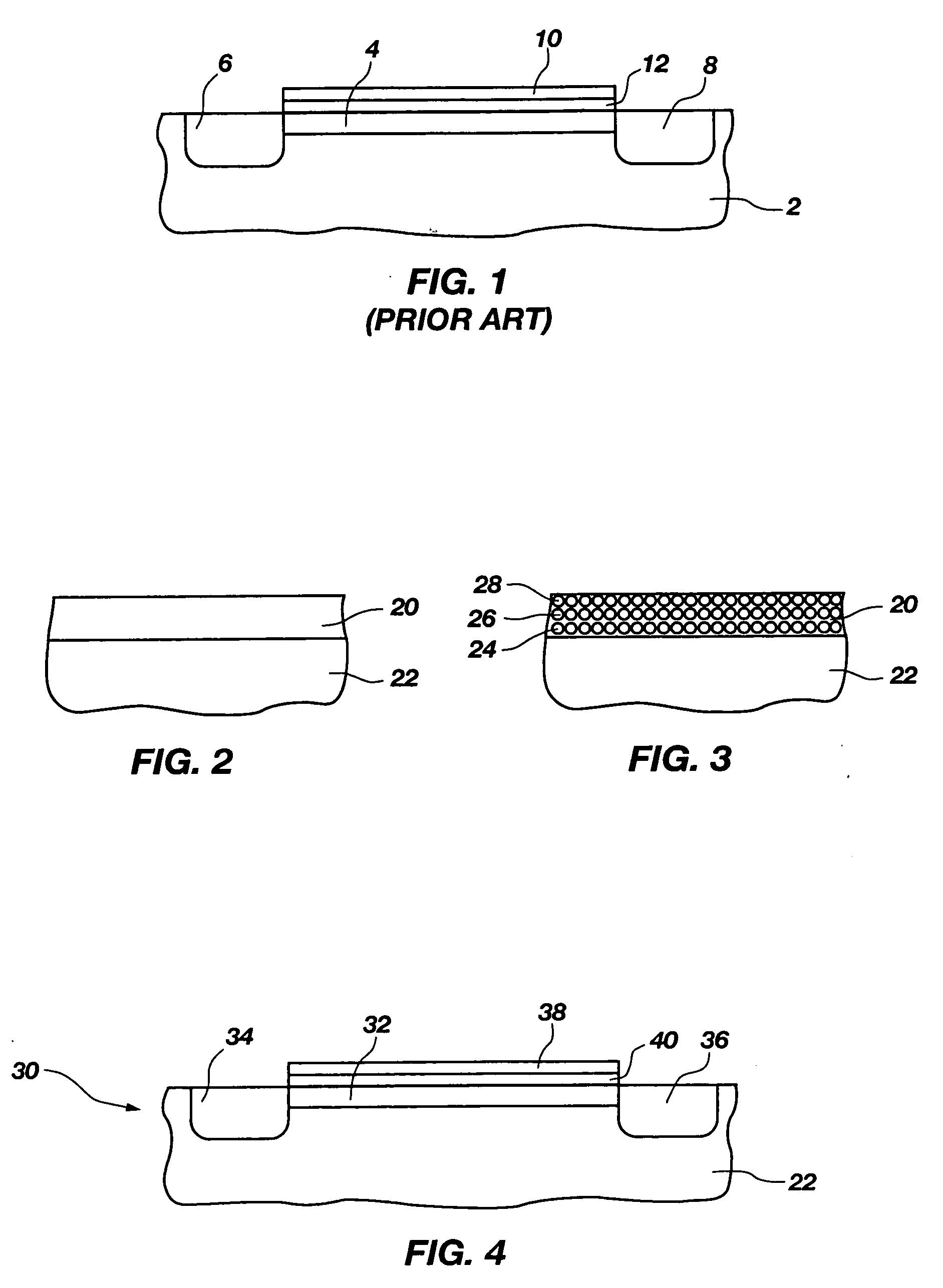

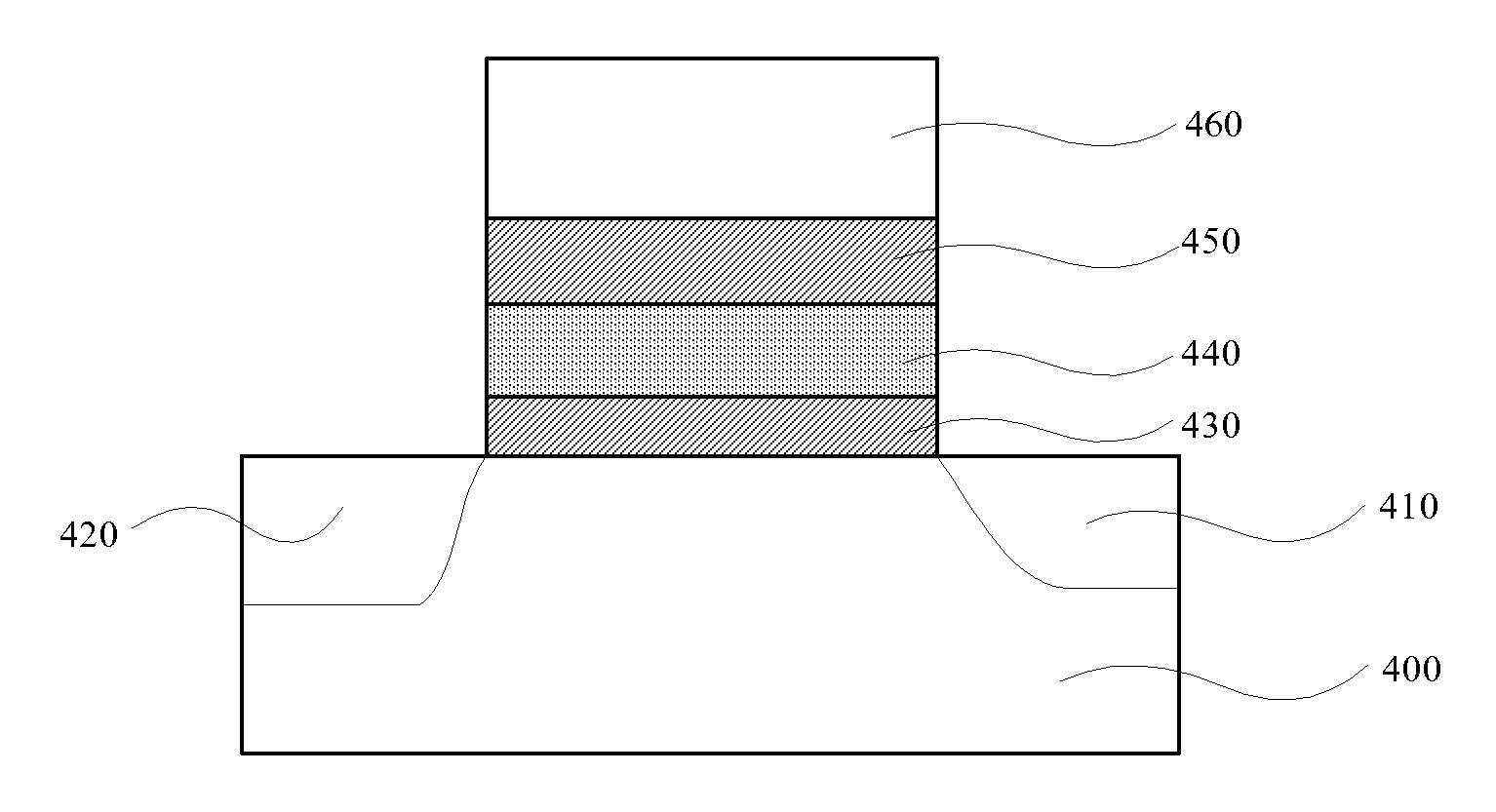

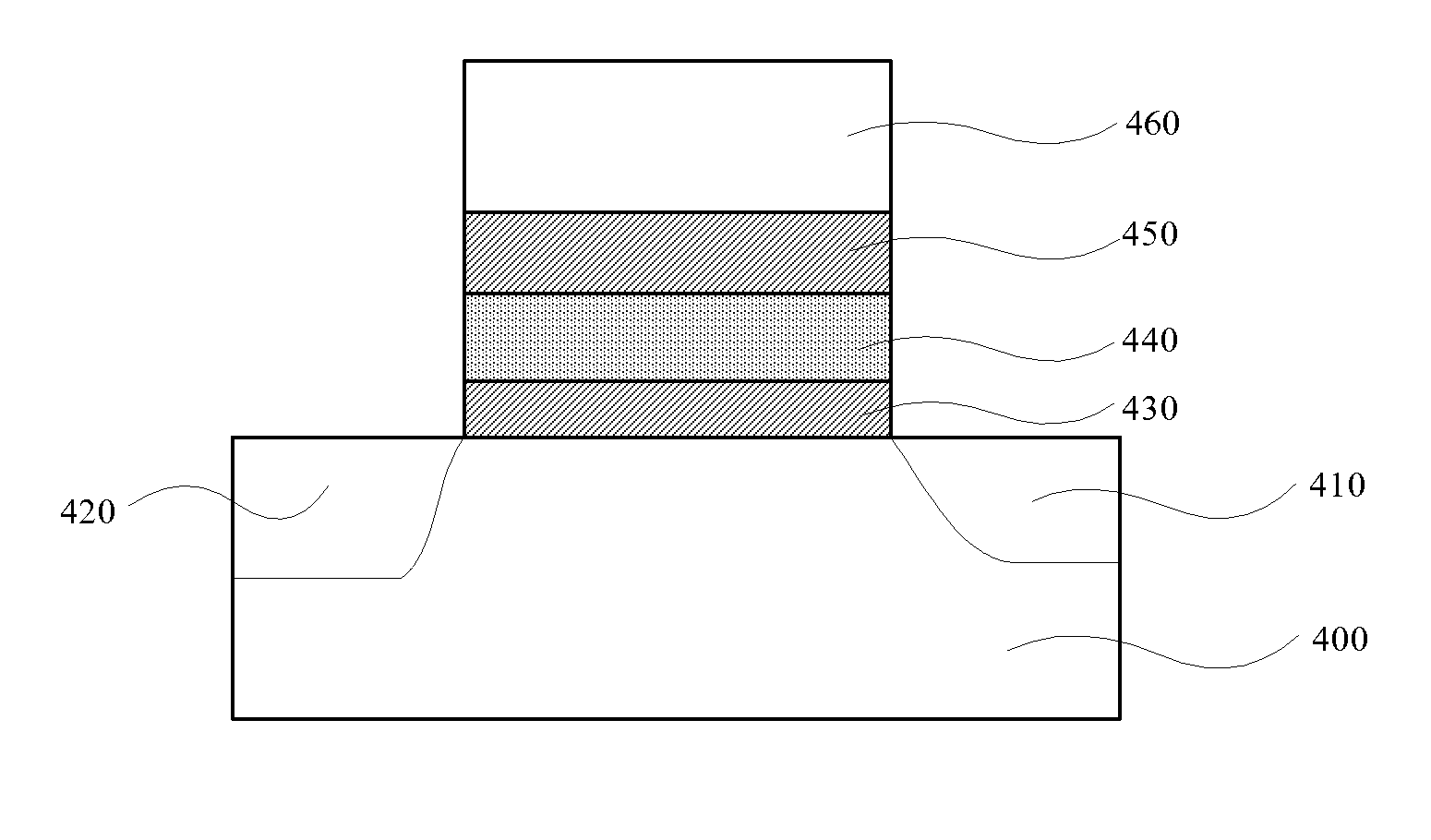

Atomic Layer Deposition Method and Semiconductor Device Formed by the Same

ActiveUS20080315292A1Improve storage capability capabilityImprove capability memory isolation capabilitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingAtomic layer depositionDielectric layer

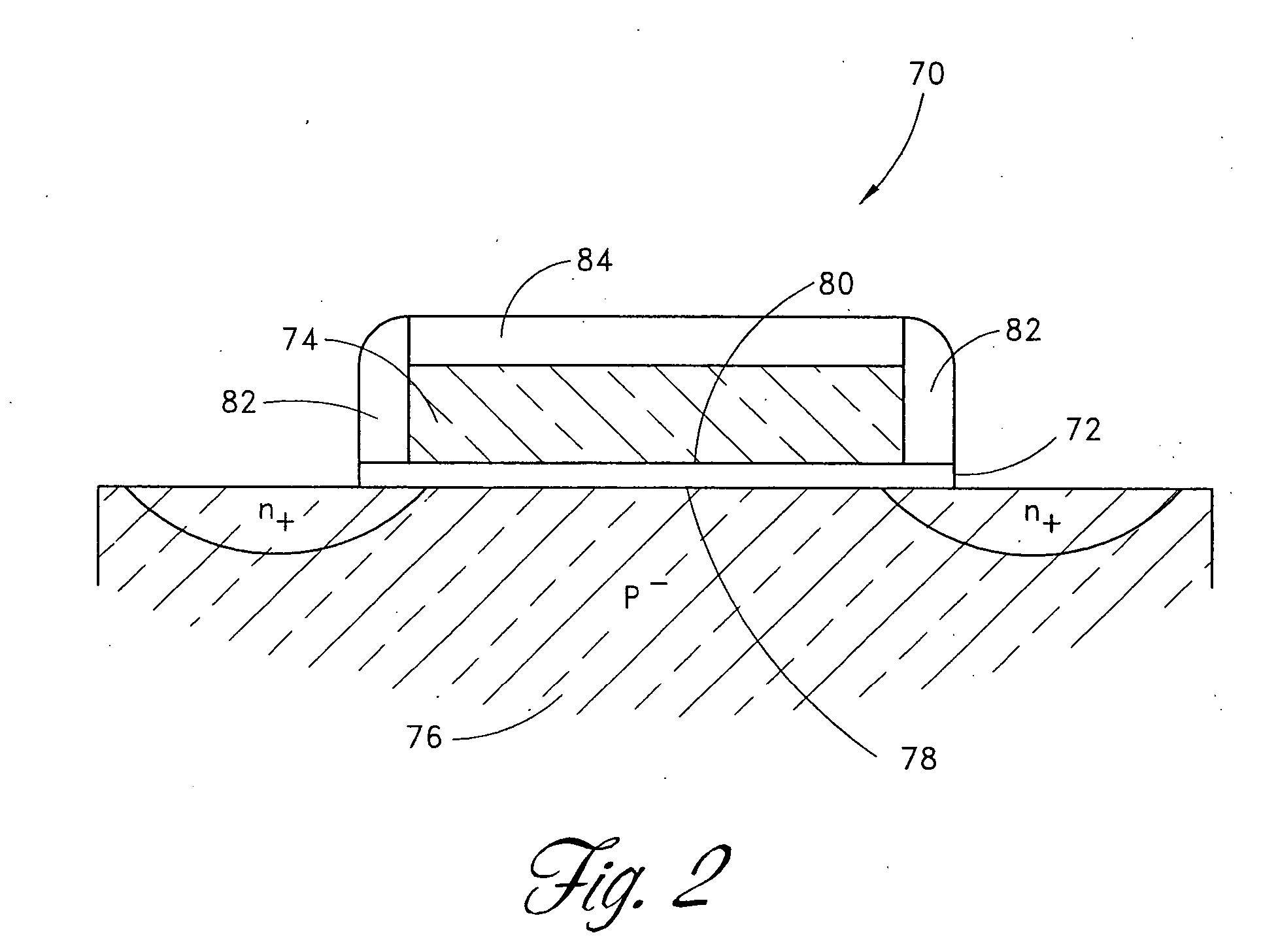

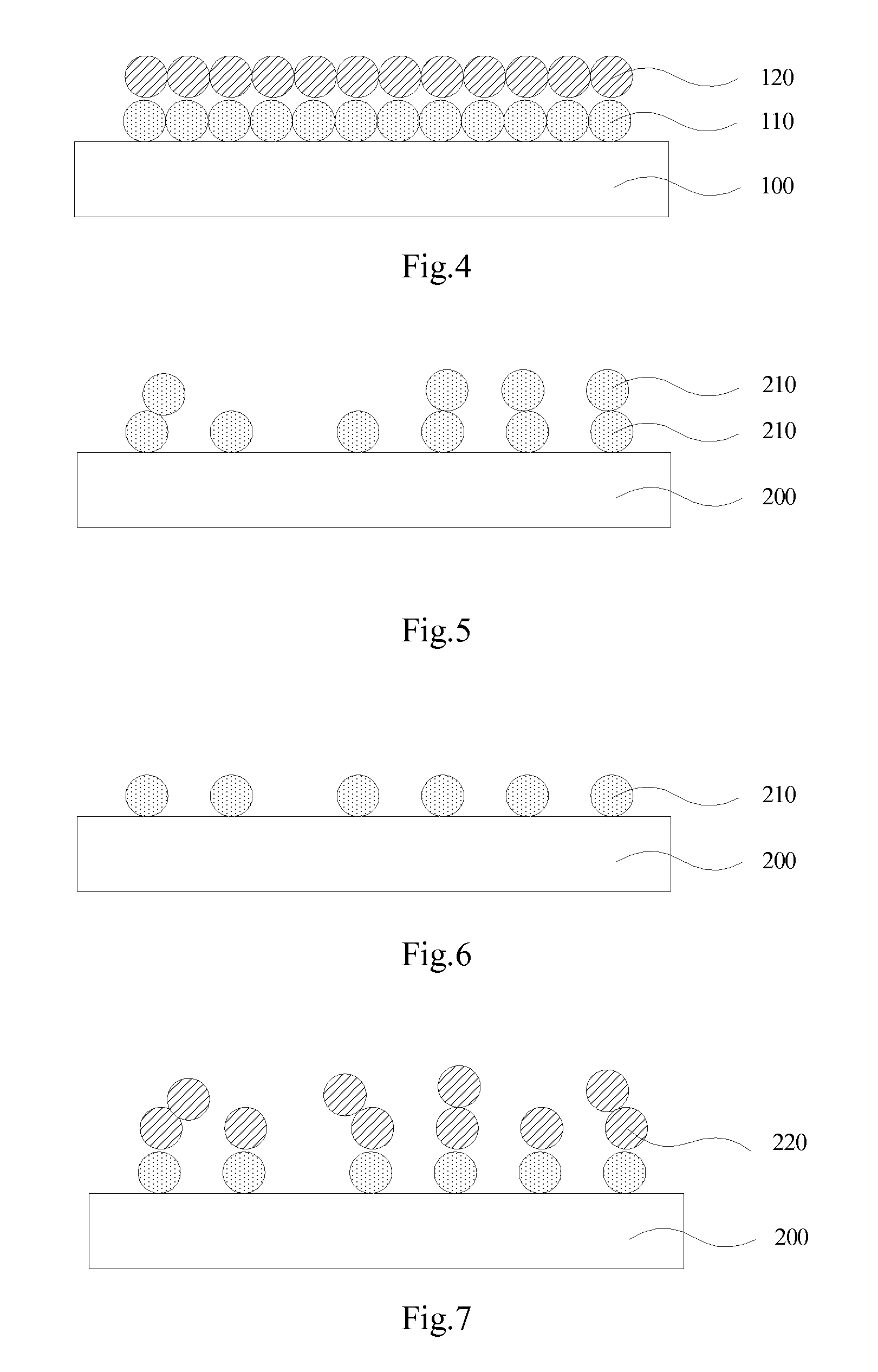

There is provided a method of manufacturing a semiconductor device, including the following steps: flowing a first precursor gas to the semiconductor substrate within a ALD chamber to form a first discrete monolayer on the semiconductor substrate; flowing an inert purge gas to the semiconductor substrate within the ALD chamber; flowing a second precursor gas to the ALD chamber to react with the first precursor gas which has formed the first monolayer, thereby forming a first discrete compound monolayer; and flowing an inert purge gas; forming a first dielectric layer to cover the discrete compound monolayer; forming a second third monolayer above first dielectric layer; and forming a second discrete compound monolayer; and forming a second dielectric layer to cover the second discrete compound monolayer above the first dielectric layer. There is also provided a semiconductor device formed by the ALD method.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Method for forming Si-containing film using two precursors by ALD

ActiveUS8912101B2Increase probabilitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingSurface reactionHalogen

A method for forming a silicon-containing dielectric film on a substrate by atomic layer deposition (ALD) includes: providing two precursors, one precursor containing a halogen in its molecule, another precursor containing a silicon but no halogen in its molecule, adsorbing a first precursor, which is one of the two precursors onto a substrate to deposit a monolayer of the first precursor; adsorbing a second precursor, which is the other of the two precursors onto the monolayer of the first precursor to deposit a monolayer of the second precursor; and exposing the monolayer of the second precursor to radicals of a reactant to cause surface reaction with the radicals to form a compound monolayer of a silicon-containing film.

Owner:ASM IP HLDG BV

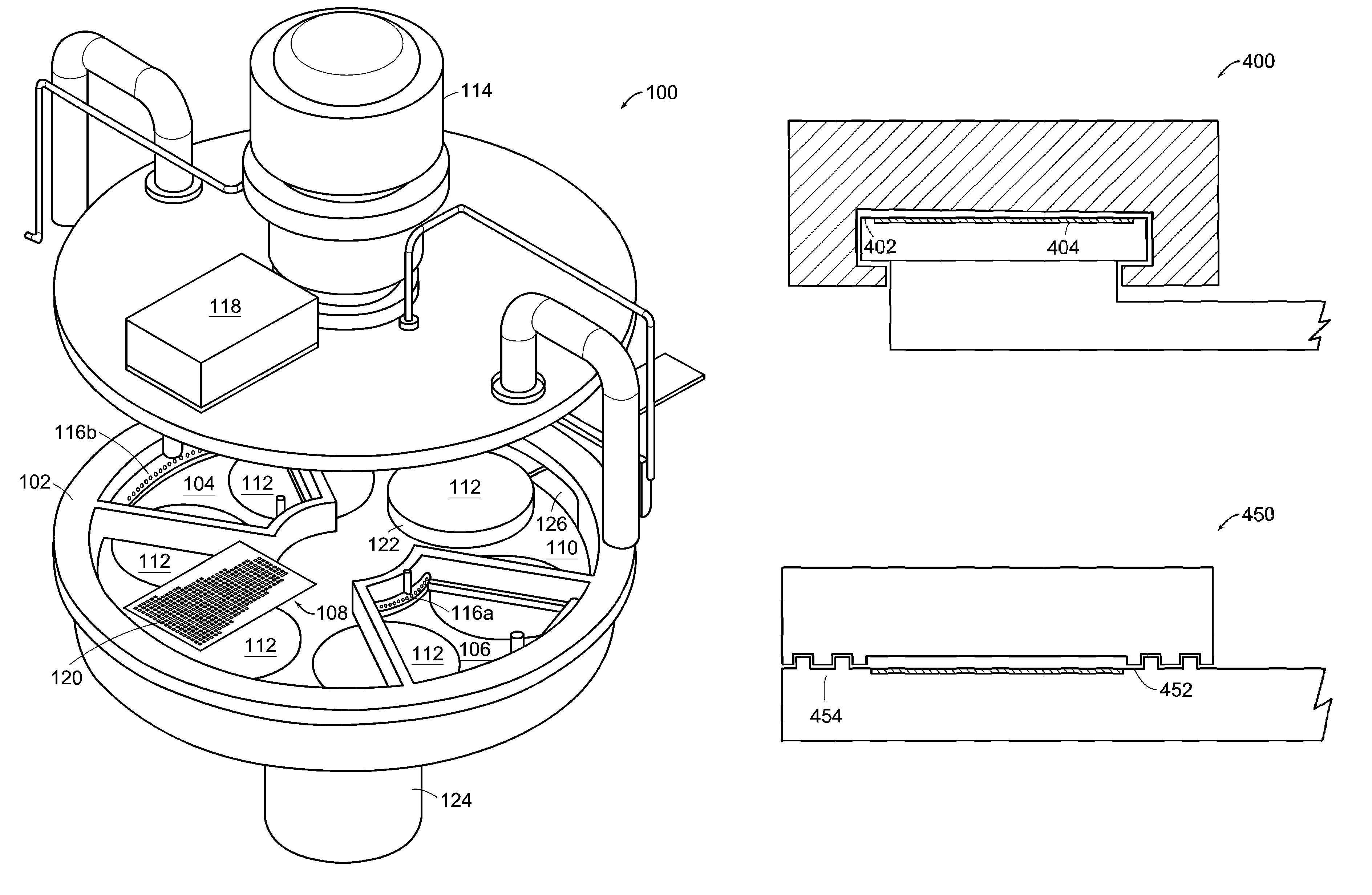

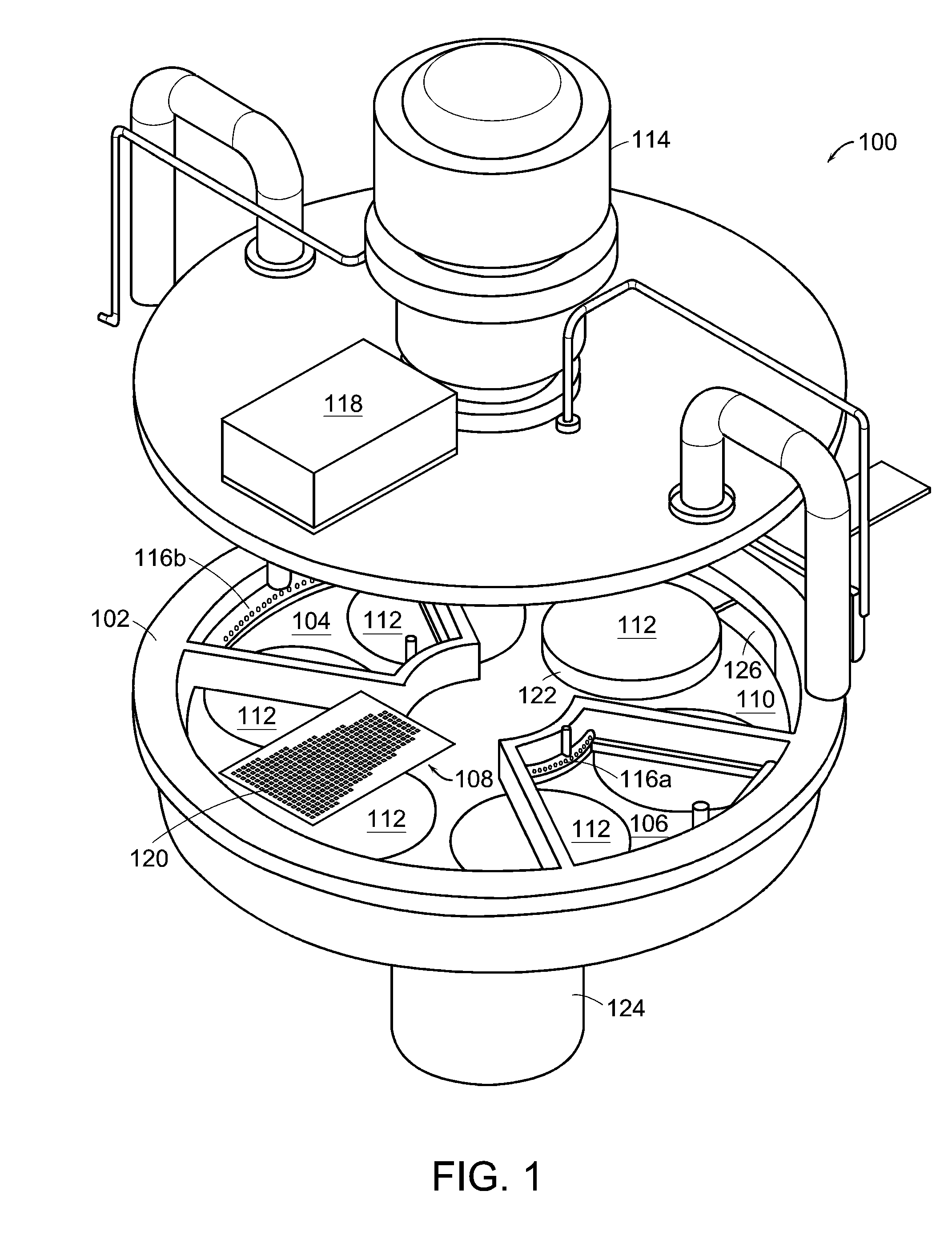

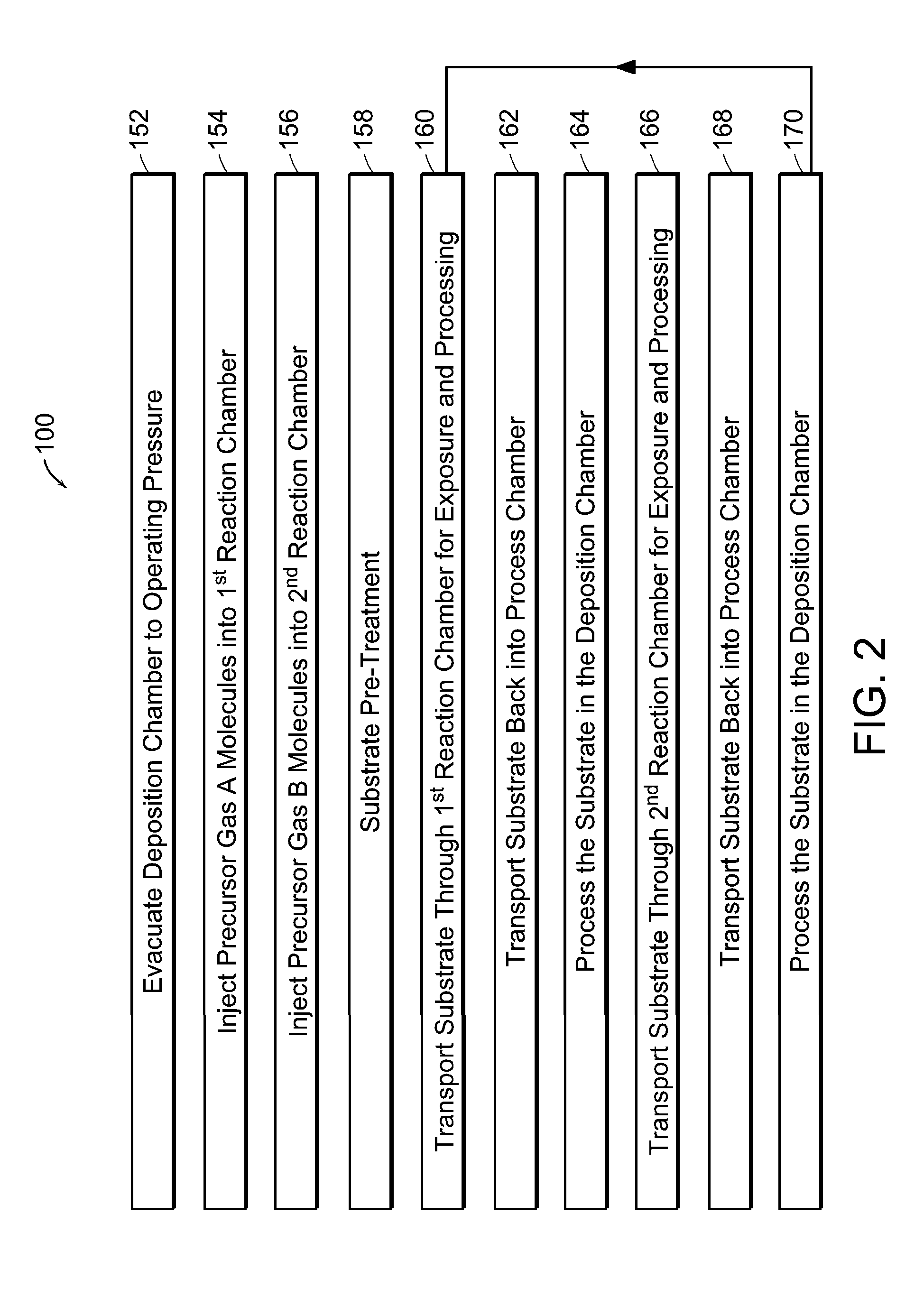

Continuous flow deposition system

An atomic layer deposition system is described that includes a deposition chamber. A first and second reaction chamber are positioned in the deposition chamber and contain a first and a second reactant species, respectively. A monolayer of the first reactant species is deposited on a substrate passing through the first reaction chamber. A monolayer of the second reactant species is deposited on a substrate passing through the second reaction chamber. A transport mechanism transports a substrate in a path through the first reaction chamber and through the second reaction chamber, thereby depositing a film on the substrate by atomic layer deposition. The shape of the first and the second reaction chambers are chosen to achieve a constant exposure of the substrate to reactant species when the transport mechanism transports the substrate in the path through the respective reaction chambers at the constant transport rate.

Owner:VEECON INSTR

Formation of boride barrier layers using chemisorption techniques

InactiveUS20050118804A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingBorideChemisorption

A method of forming a boride layer for integrated circuit fabrication is disclosed. In one embodiment, the boride layer is formed by chemisorbing monolayers of a boron-containing compound and one refractory metal compound onto a substrate. In an alternate embodiment, the boride layer has a composite structure. The composite boride layer structure comprises two or more refractory metals. The composite boride layer is formed by sequentially chemisorbing monolayers of a boron compound and two or more refractory metal compounds on a substrate.

Owner:APPLIED MATERIALS INC

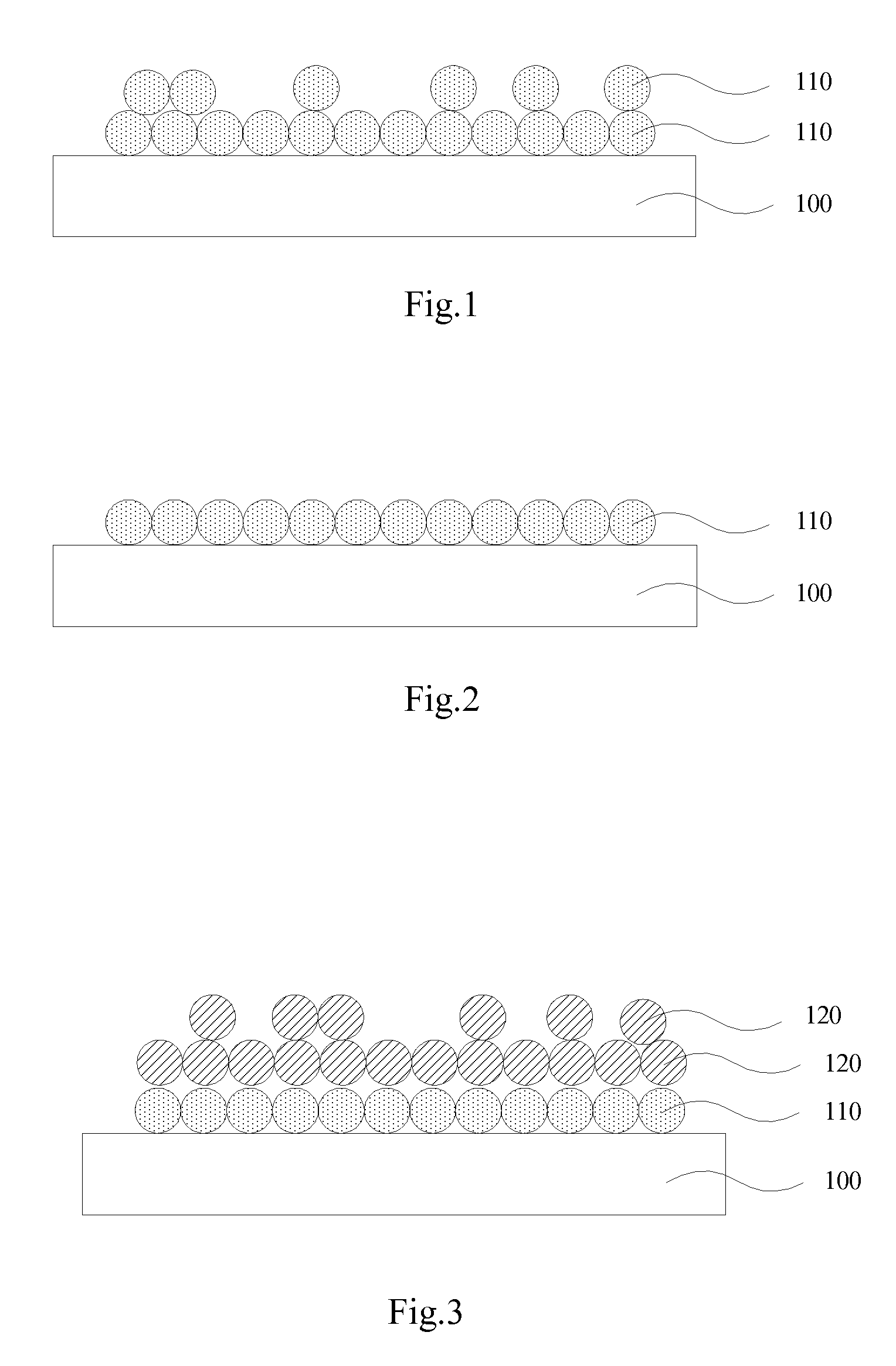

Use of adipose tissue-derived stromal cells for chondrocyte differentiation and cartilage repair

Methods and compositions for directing adipose-derived stromal cells cultivated in vitro to differentiate into cells of the chondrocyte lineage are disclosed. The invention further provides a variety of chondroinductive agents which can be used singly or in combination with other nutrient components to induce chondrogenesis in adipose-derived stromal cells either in cultivating monolayers or in a biocompatible lattice or matrix in a three-dimensional configuration. Use of the differentiated chondrocytes for the therapeutic treatment of a number of human conditions and diseases including repair of cartilage in vivo is disclosed.

Owner:COGNATE BIOSERVICES

Compositions for the electronic detection of analytes utilizing monolayers

Owner:OSMETECH TECH +2

Method for forming aluminum nitride-based film by PEALD

ActiveUS9711345B2Improve leakage currentSemiconductor/solid-state device detailsSolid-state devicesPhysical chemistryThin membrane

Owner:ASM IP HLDG BV

Atomic layer deposition method and semiconductor device formed by the same

ActiveUS8158512B2Improve abilitiesTotal current dropSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDielectric layerAtomic layer deposition

There is provided a method of manufacturing a semiconductor device, including the following steps: flowing a first precursor gas to the semiconductor substrate within a ALD chamber to form a first discrete monolayer on the semiconductor substrate; flowing an inert purge gas to the semiconductor substrate within the ALD chamber; flowing a second precursor gas to the ALD chamber to react with the first precursor gas which has formed the first monolayer, thereby forming a first discrete compound monolayer; and flowing an inert purge gas; forming a first dielectric layer to cover the discrete compound monolayer; forming a second third monolayer above first dielectric layer; and forming a second discrete compound monolayer; and forming a second dielectric layer to cover the second discrete compound monolayer above the first dielectric layer. There is also provided a semiconductor device formed by the ALD method.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Method for forming aluminum nitride-based film by peald

ActiveUS20170062209A1Improve leakage currentSemiconductor/solid-state device detailsSolid-state devicesPhysical chemistryThin membrane

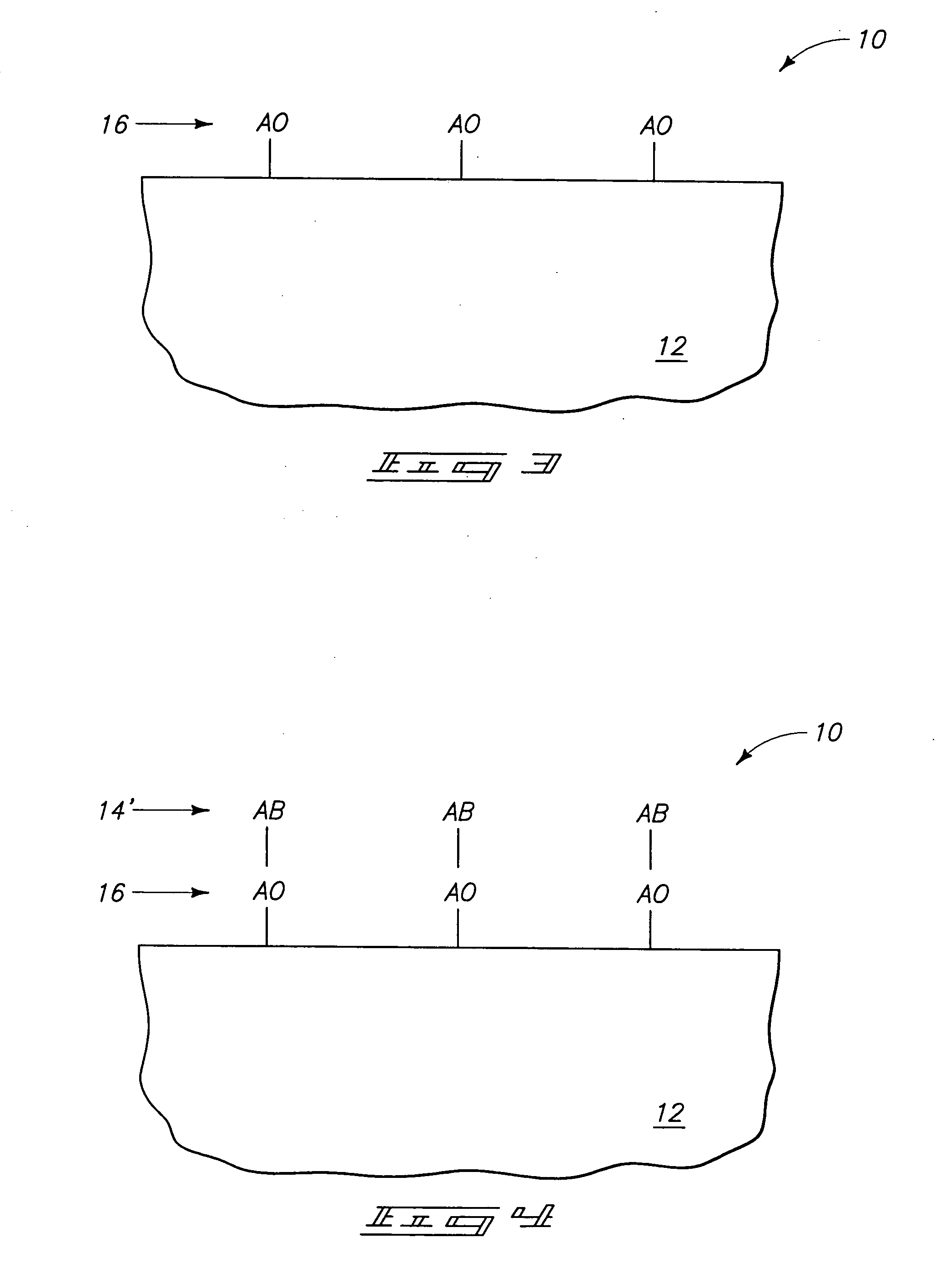

A method for forming an aluminum nitride-based film on a substrate by plasma-enhanced atomic layer deposition (PEALD) includes: (a) forming at least one aluminum nitride (AlN) monolayer and (b) forming at least one aluminum oxide (AlO) monolayer, wherein steps (a) and (b) are alternately conducted continuously to form a laminate. Steps (a) and (b) are discontinued before a total thickness of the laminate exceeds 10 nm, preferably 5 nm.

Owner:ASM IP HLDG BV

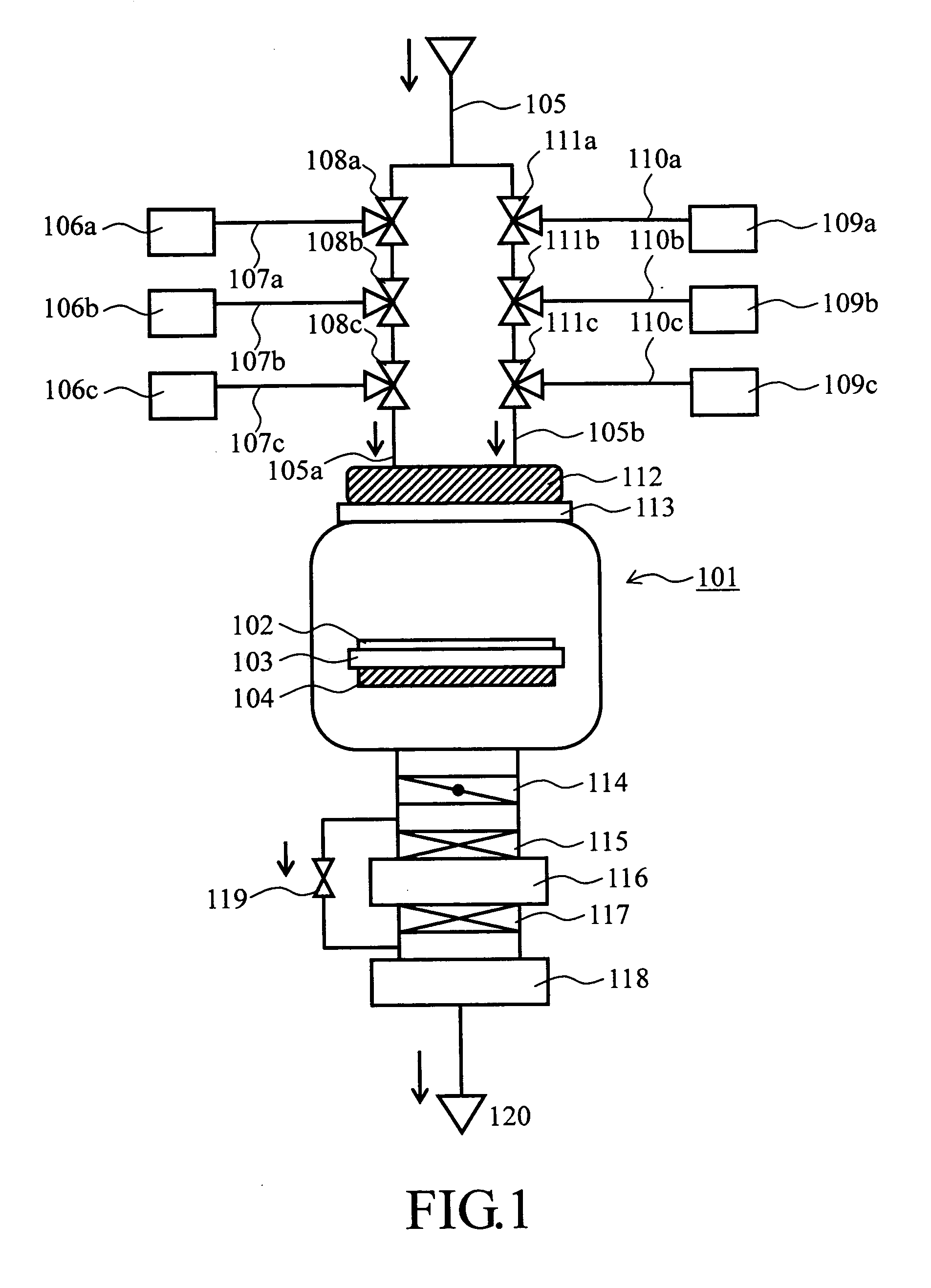

Method and apparatus for atomic layer deposition using an atmospheric pressure glow discharge plasma

InactiveUS20090324971A1Increase response rateImprove productivitySynthetic resin layered productsChemical vapor deposition coatingPlasma generatorProduct gas

Apparatus and method for atomic layer deposition on a surface of a substrate (6) in a treatment space. A gas supply device (15, 16) is present for providing various gas mixtures to the treatment space. The gas supply device (15, 16) is arranged to provide a gas mixture with a precursor material to the treatment space for allowing reactive surface sites to react with precursor material molecules to give a surface covered by a monolayer of precursor molecules attached via the reactive sites to the surface of the substrate. Subsequently, a gas mixture comprising a reactive agent capable to convert the attached precursor molecules to active precursor sites is provided. A plasma generator (10) is present for generating an atmospheric pressure plasma in the gas mixture comprising the reactive agent.

Owner:FUJIFILM MFG EURO

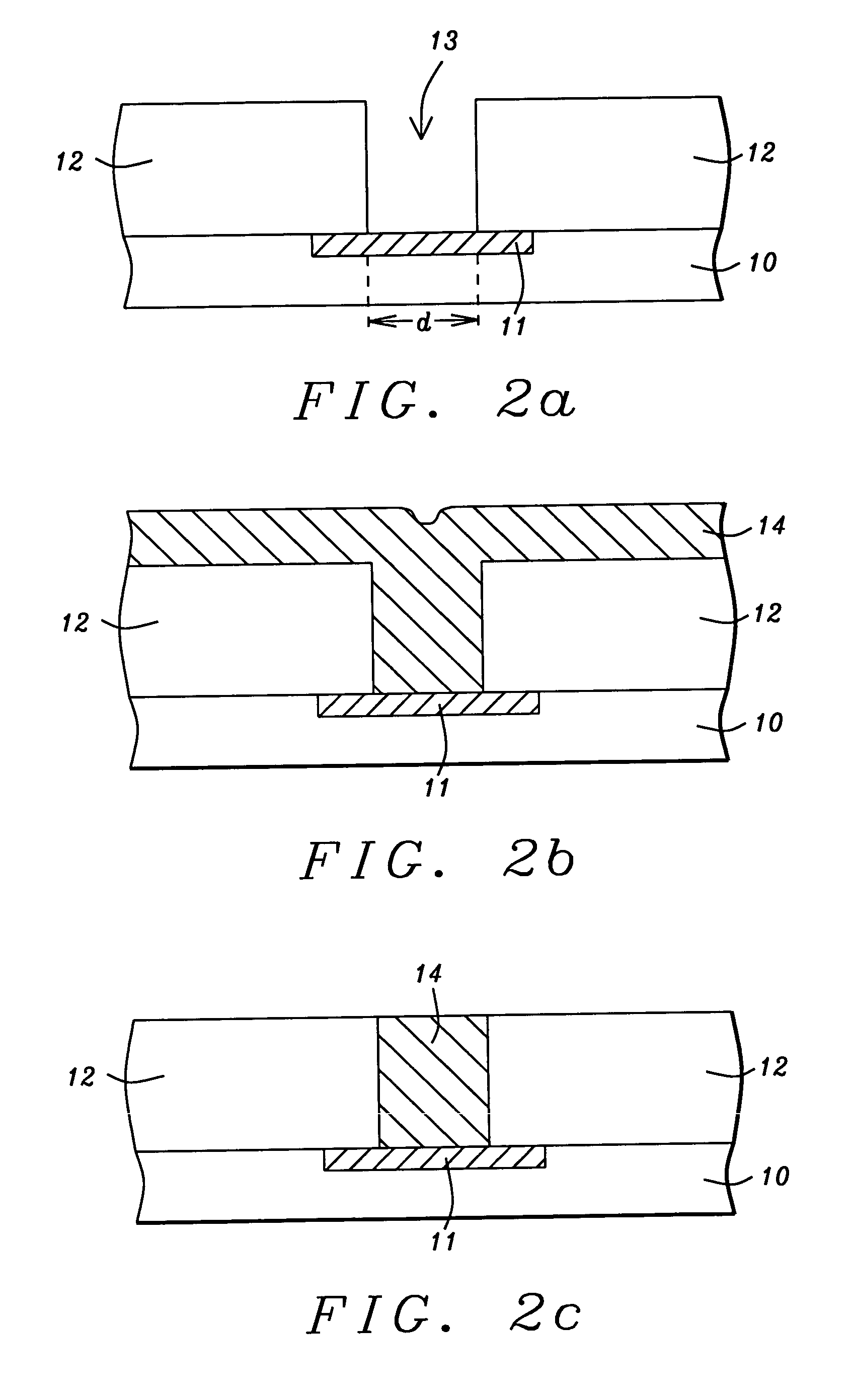

Methods for forming arrays of a small, closely spaced features

ActiveUS20060263699A1Solid-state devicesSemiconductor/solid-state device manufacturingCombined useEngineering

Methods of forming arrays of small, densely spaced holes or pillars for use in integrated circuits are disclosed. Various pattern transfer and etching steps can be used, in combination with pitch-reduction techniques, to create densely-packed features. Conventional photolithography steps can be used in combination with pitch-reduction techniques to form sumperimposed, pitch-reduced patterns of crossing elongate features that can be consolidated into a single layer.

Owner:MICRON TECH INC

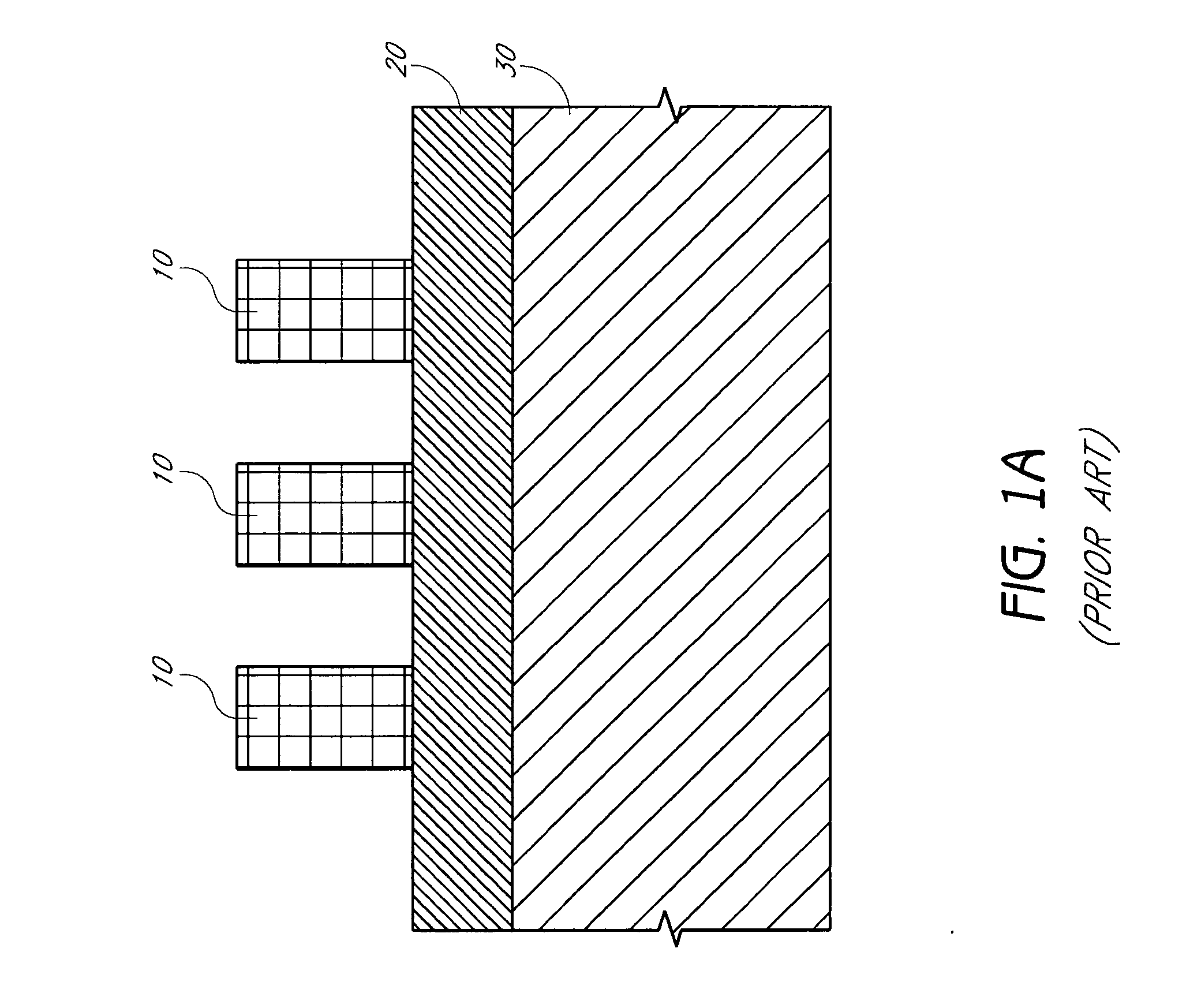

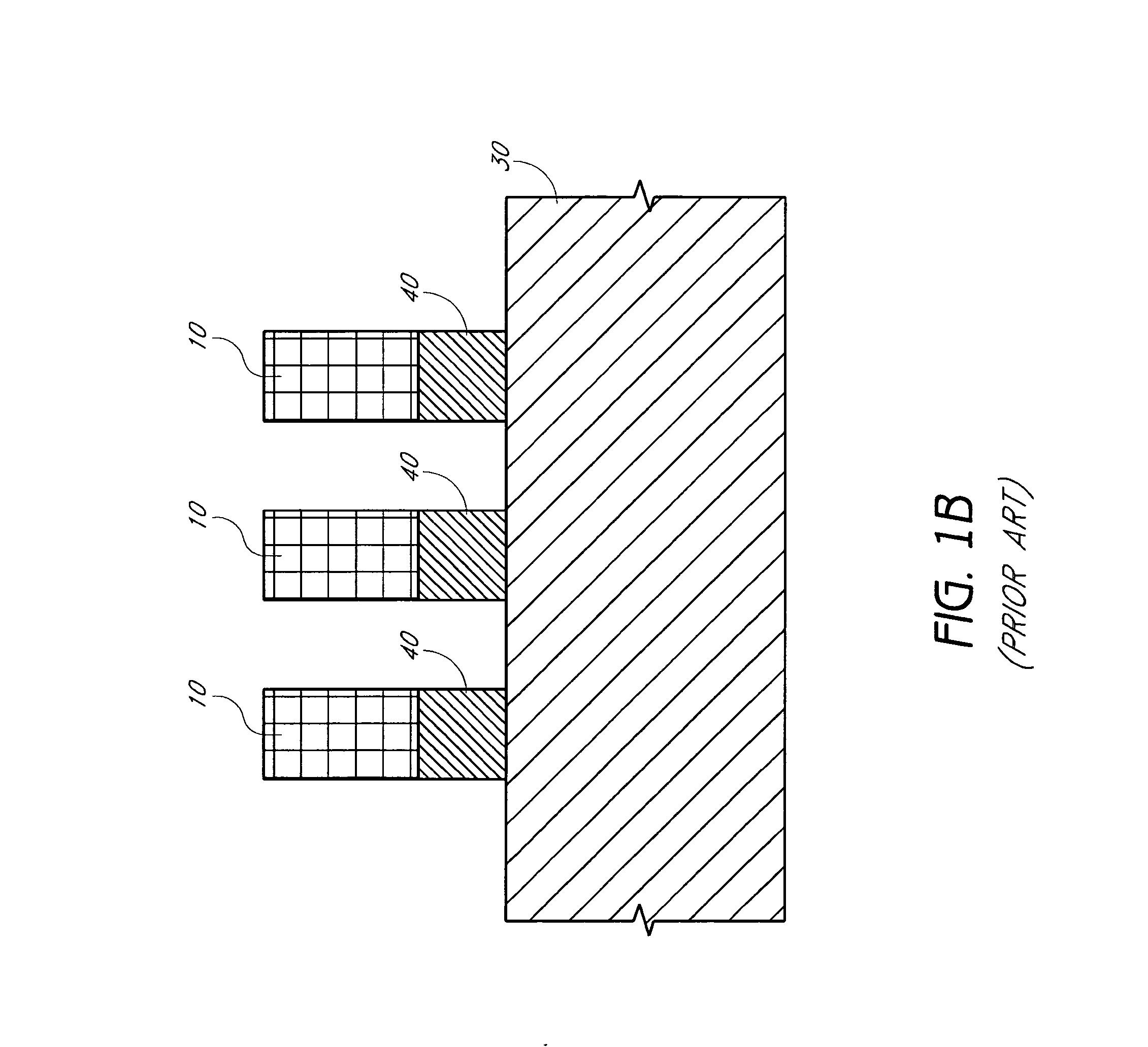

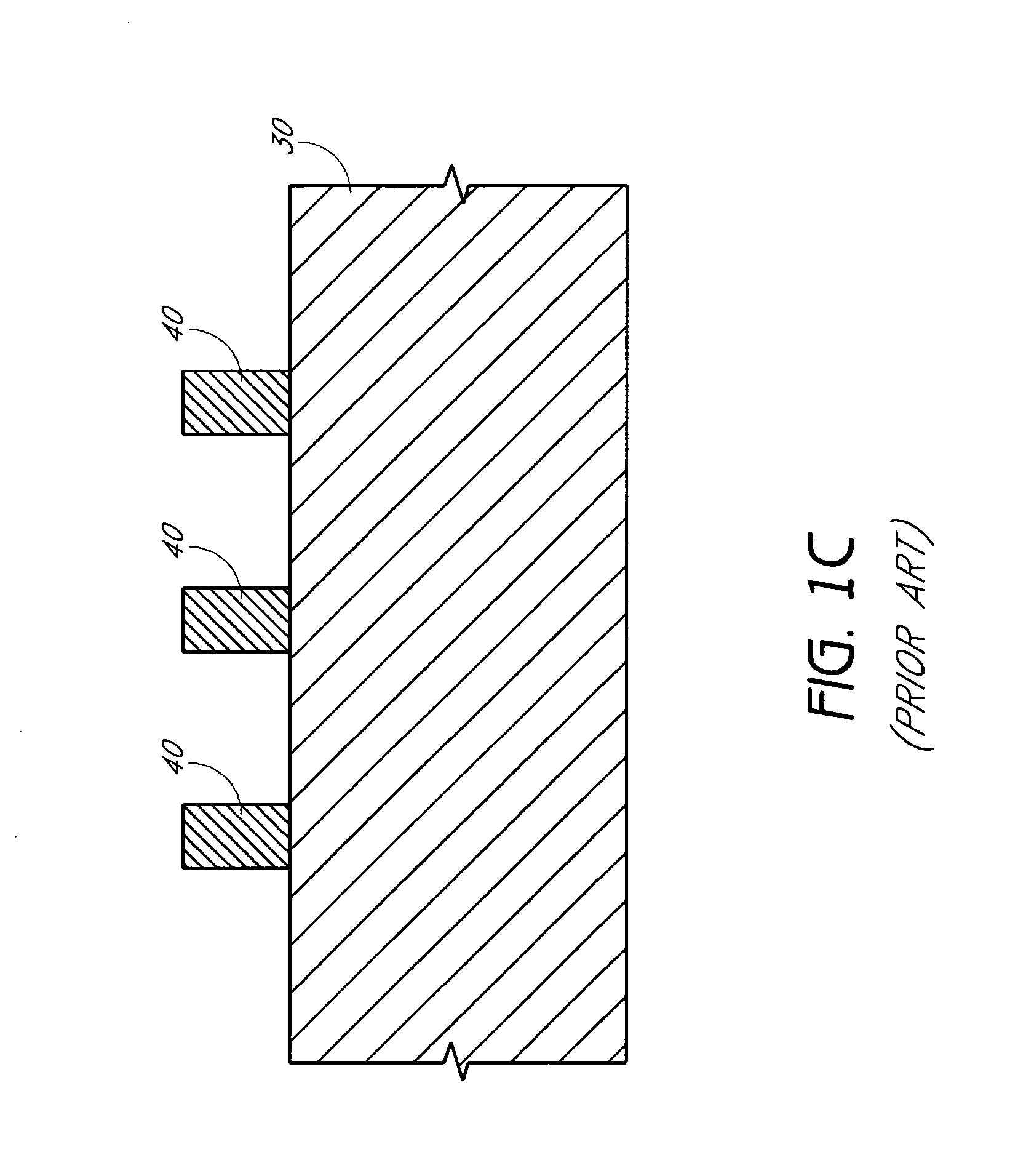

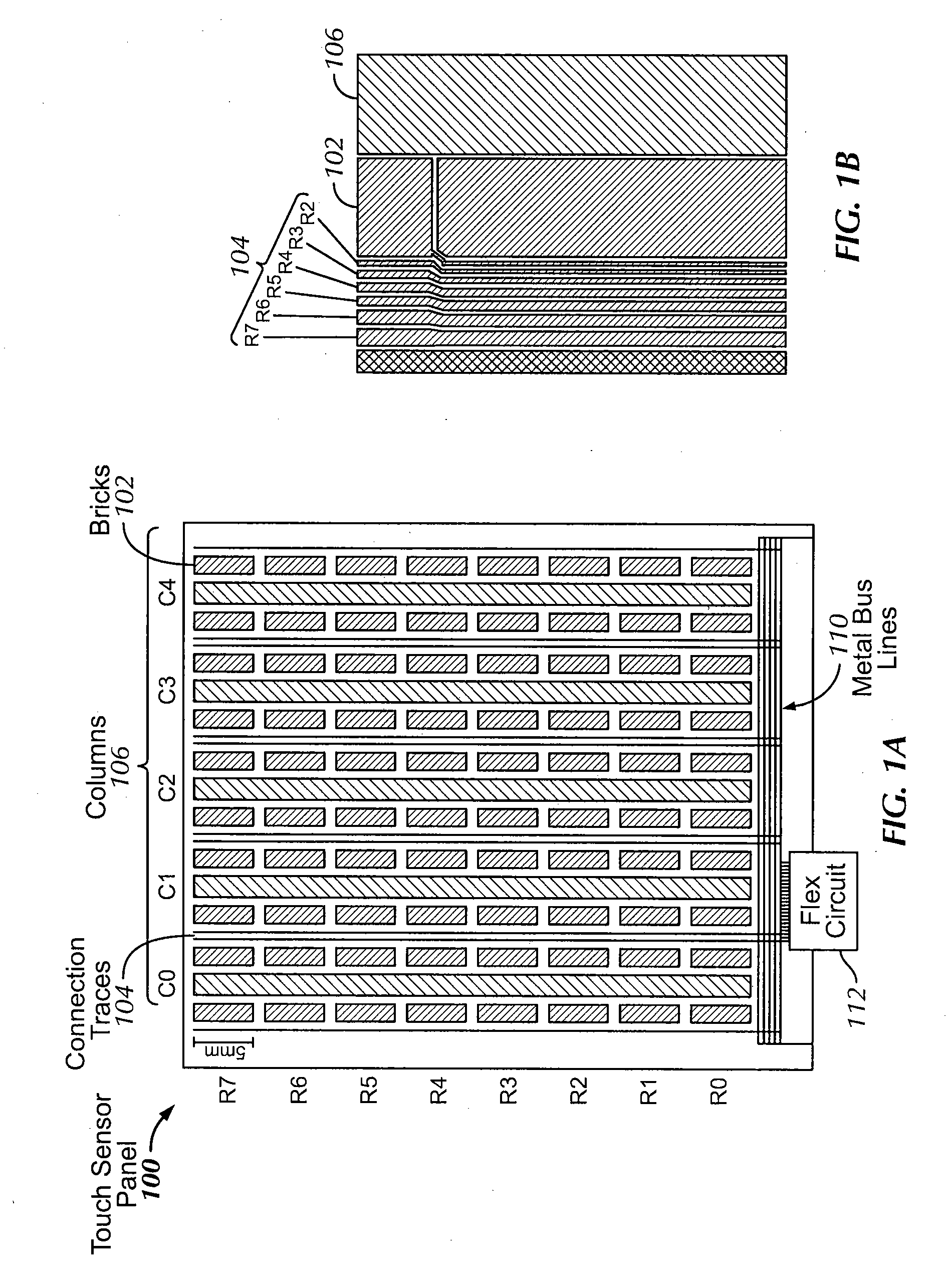

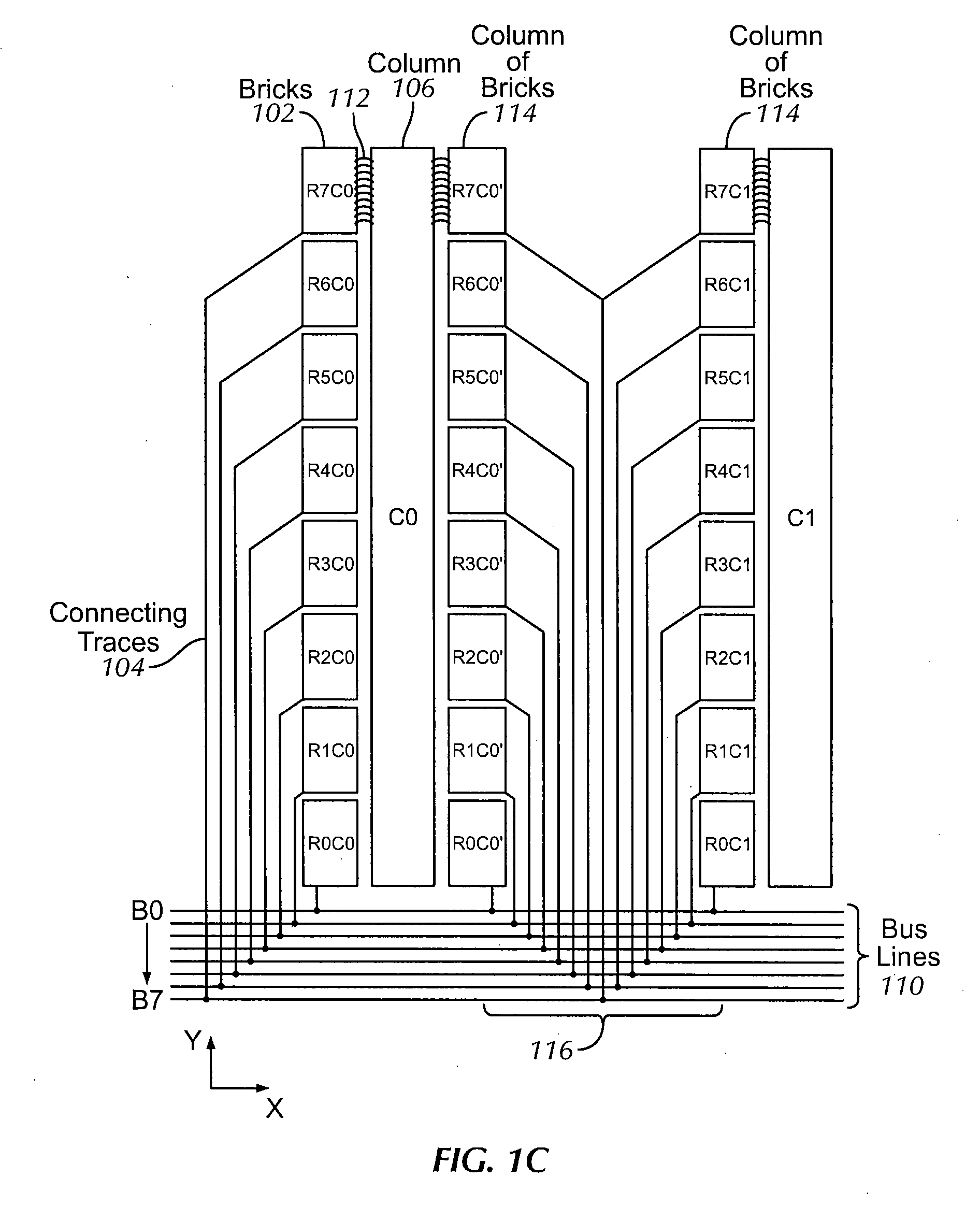

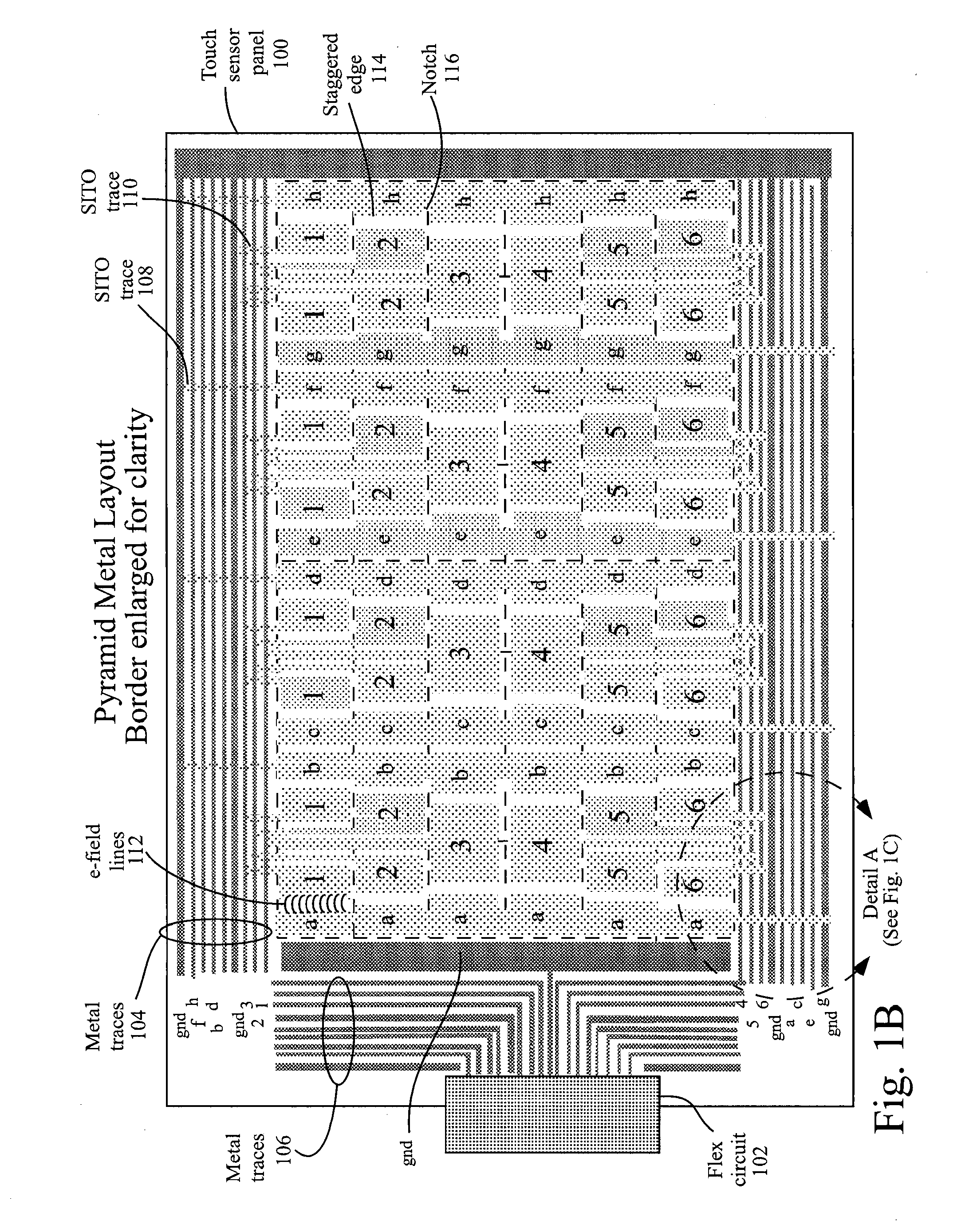

Single layer touch panel with segmented drive and sense electrodes

ActiveUS20100149108A1Less spaceUniform sensitivityInput/output processes for data processingTouch SensesEngineering

A touch sensor panels having segmented electrodes for both the drive and sense lines. The touch sensor panel may include a number of columns of sense electrodes and a number of rows of drive electrodes. Each of the drive and sense electrodes are connected to one of the metal bus lines using a connecting trace. Pixels on the touch sensor panel are formed by the unique pairings of individual drive electrodes and their adjacent sense electrodes. Electrically, the mutual capacitance of one touch-sensing pixel can be distinguished from the mutual capacitance of another touch sensing pixel because the two mutual capacitances are formed with combinations of different drive electrodes and sense electrodes. In one embodiment, the drive electrodes and sense electrodes in adjacent columns are staggered horizontally with respect to each other by half a Y-pitch of the electrodes.

Owner:APPLE INC

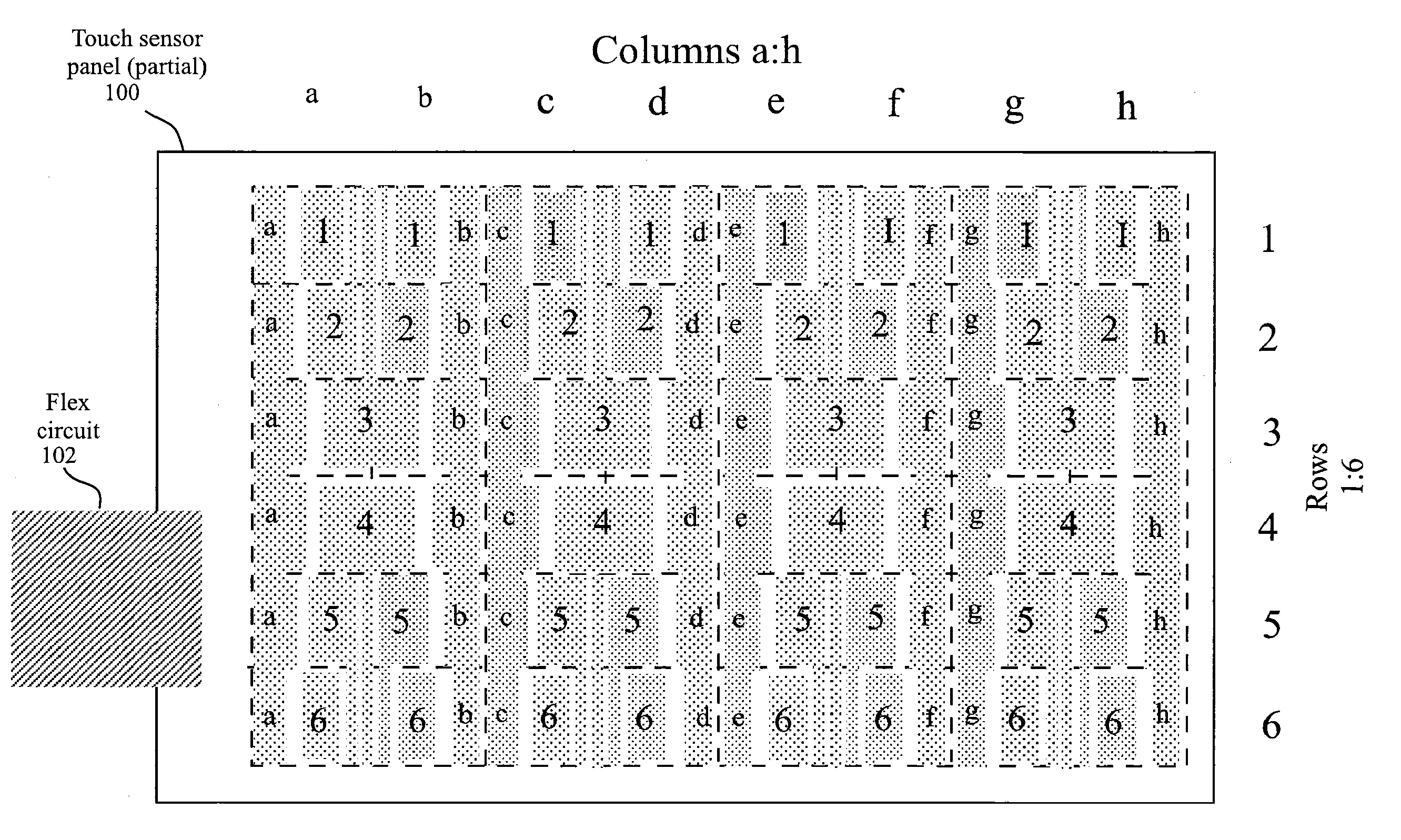

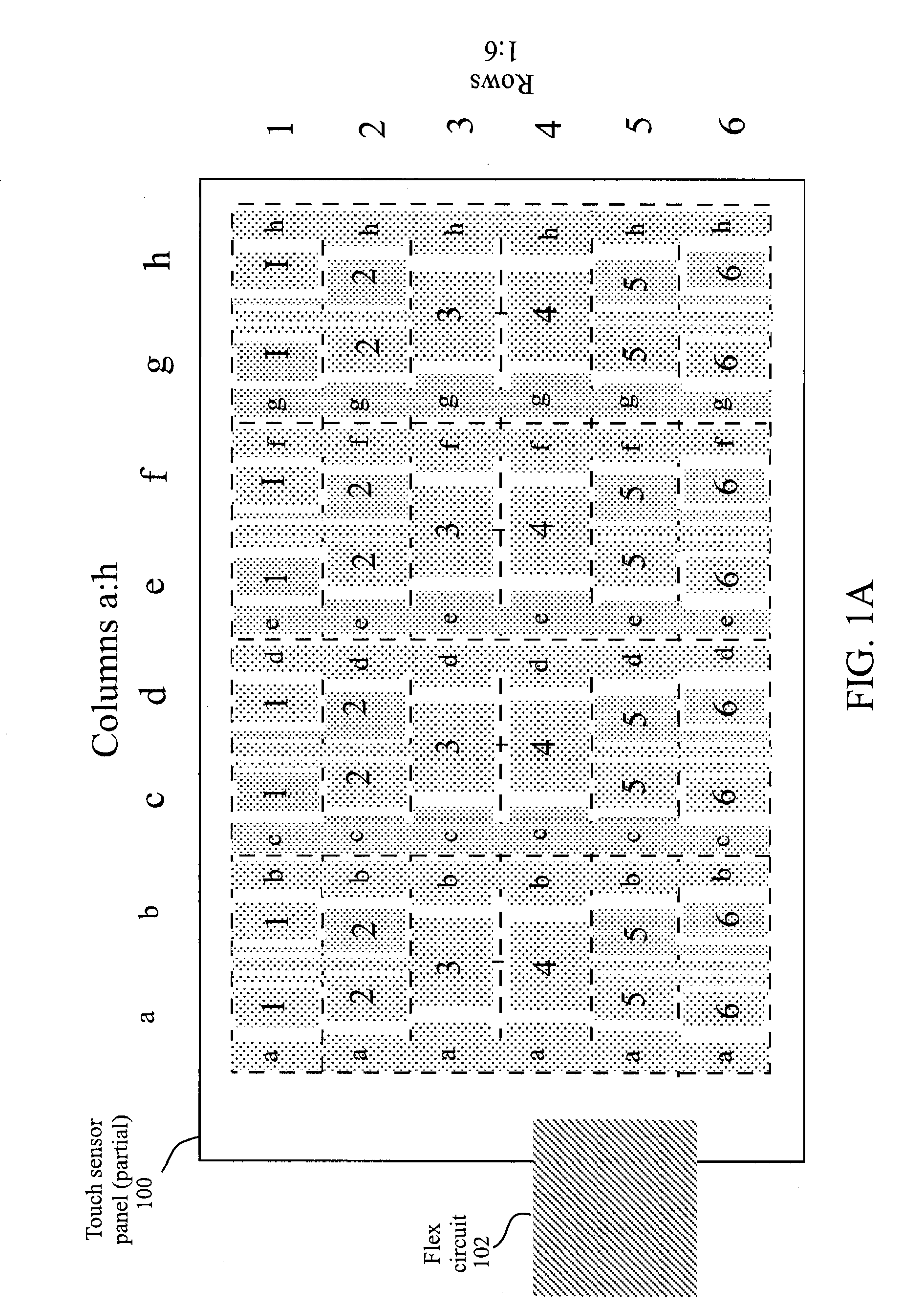

Single-layer touch-sensitive display

A touch sensor panel having co-planar single-layer touch sensors fabricated on a single side of a substrate is disclosed. The drive and sense lines can be fabricated as column-like patterns in a first orientation and patches in a second orientation, where each column-like pattern in the first orientation is connected to a separate metal trace in the border area of the touch sensor panel, and all patches in each of multiple rows in the second orientation are connected together using a separate metal trace in the border area of the touch sensor panel. The metal traces in the border areas can be formed on the same side of the substrate as the patches and columns, but separated from the patches and column-like patterns by a dielectric layer.

Owner:APPLE INC

Method for forming sin or sicn film in trenches by peald

InactiveUS20170051405A1Step-coverage is poorImprove responseChemical vapor deposition coatingHalogenAtomic layer deposition

A method for forming a SiN or SiCN film in a trench on a substrate by plasma-enhanced atomic layer deposition (PEALD) conducts one or more process cycles, each process cycle including: (i) feeding a precursor in a pulse to a reaction space where the substrate is place, said precursor having a Si—N—Si bond in its skeletal structure to which at least one halogen group is attached; and (ii) applying RF power to the reaction space in the presence of a reactant gas and in the absence of any precursor to form a monolayer constituting a SiN or SiCN film.

Owner:ASM IP HLDG BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com