Patents

Literature

1111 results about "Noble gas" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The noble gases (historically also the inert gases; sometimes referred to as aerogens) make up a group of chemical elements with similar properties; under standard conditions, they are all odorless, colorless, monatomic gases with very low chemical reactivity. The six naturally occurring noble gases are helium (He), neon (Ne), argon (Ar), krypton (Kr), xenon (Xe), and the radioactive radon (Rn). Oganesson (Og) is variously predicted to be a noble gas as well or to break the trend due to relativistic effects; its chemistry has not yet been investigated.

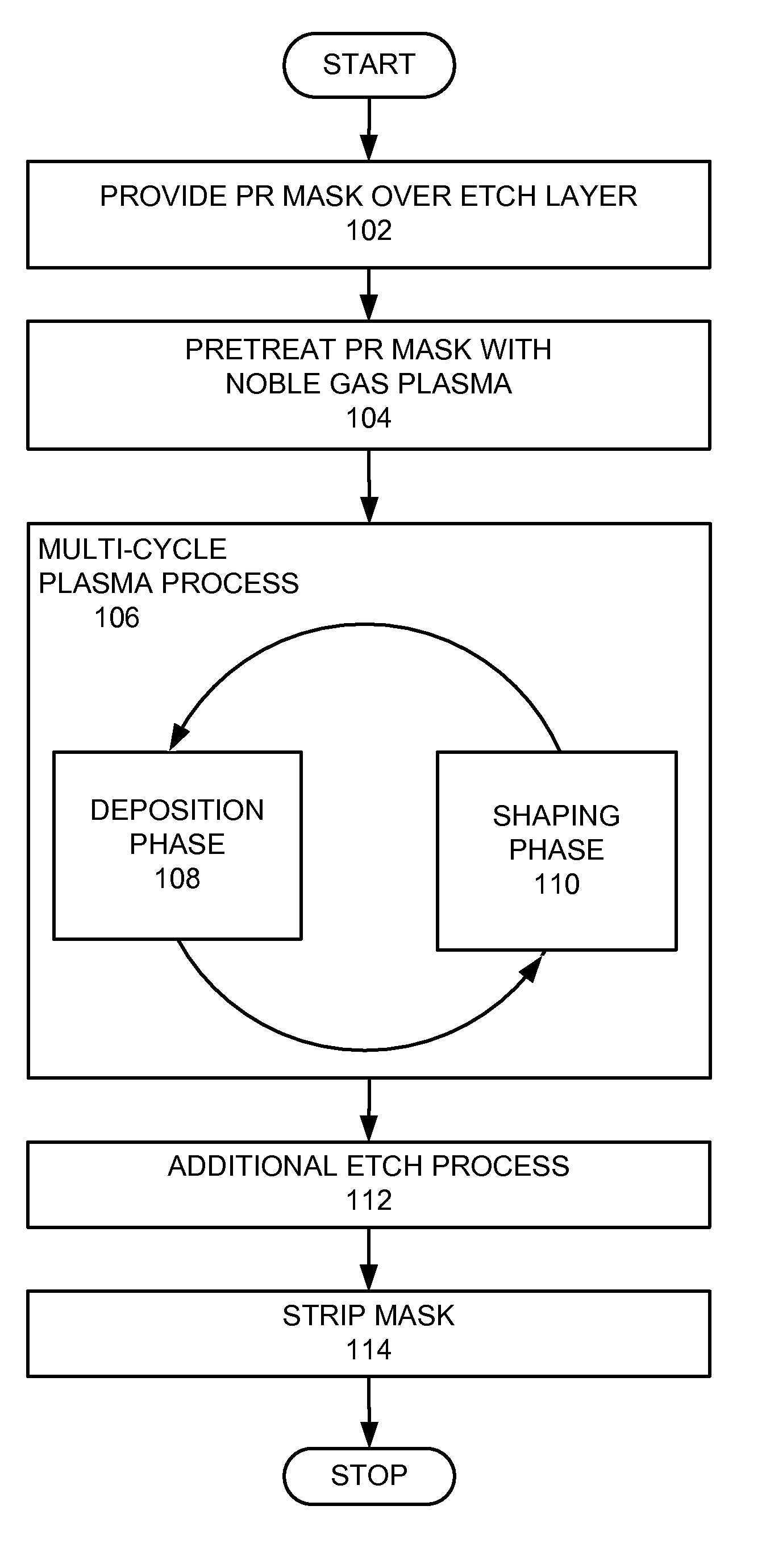

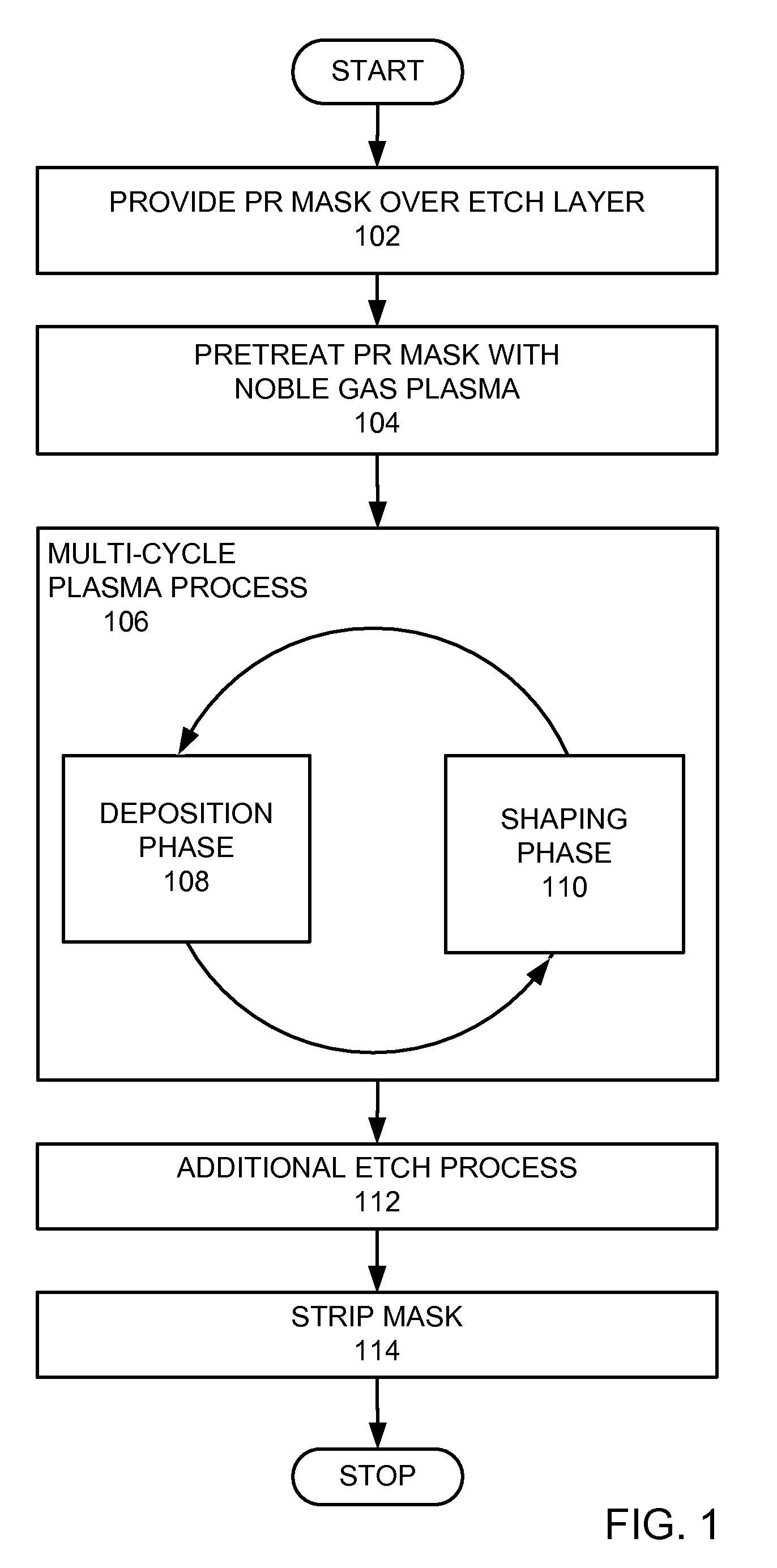

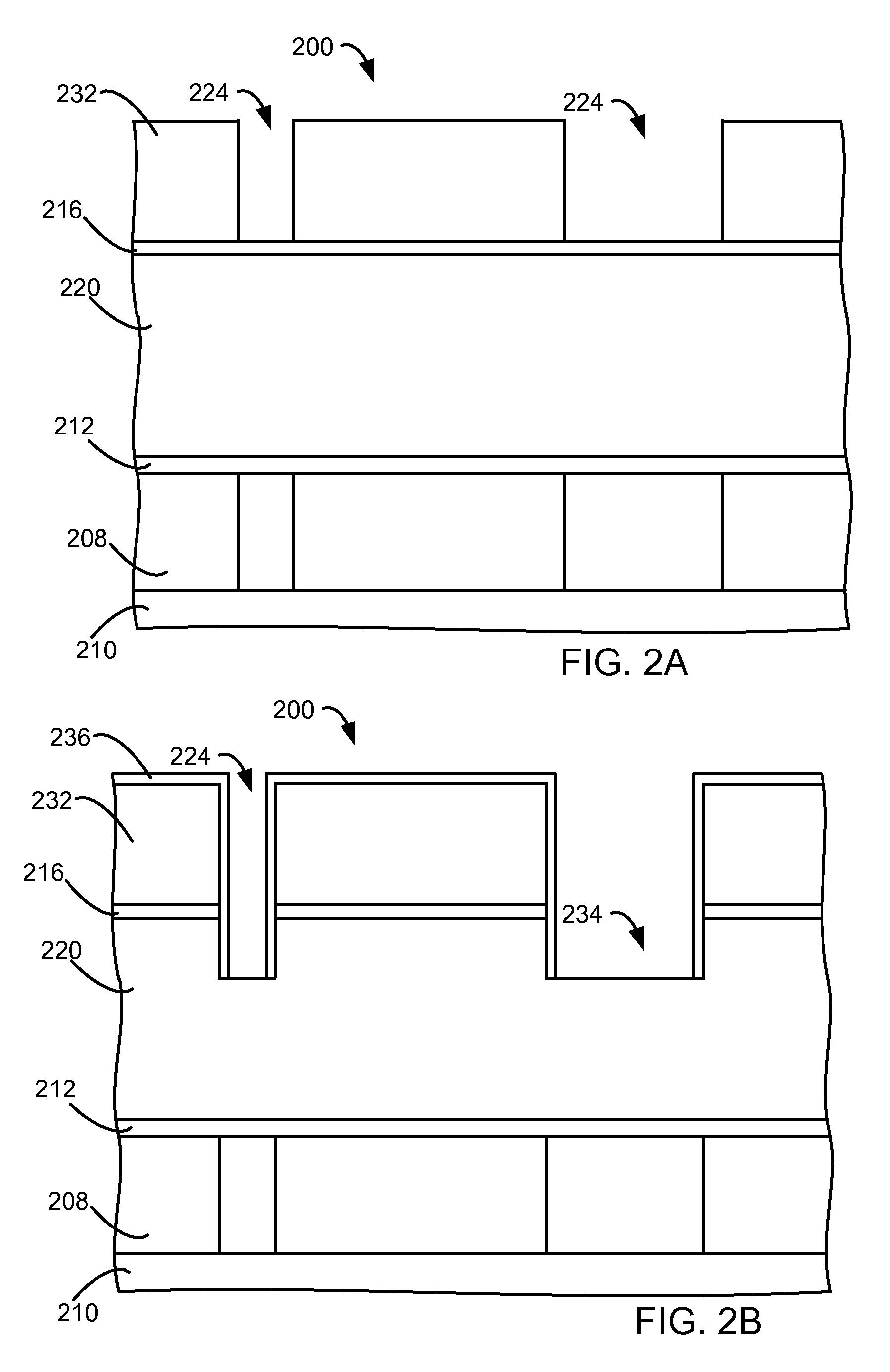

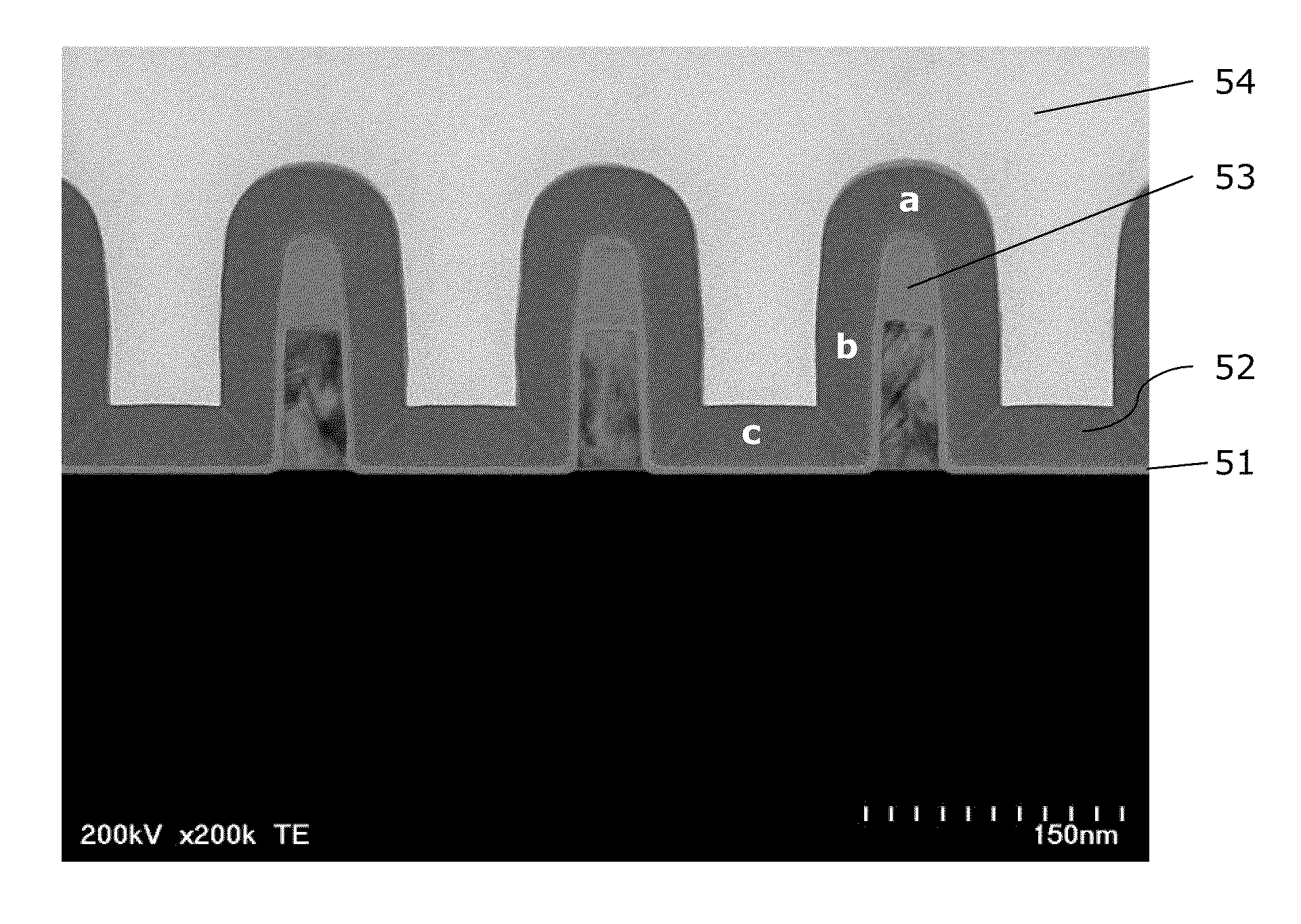

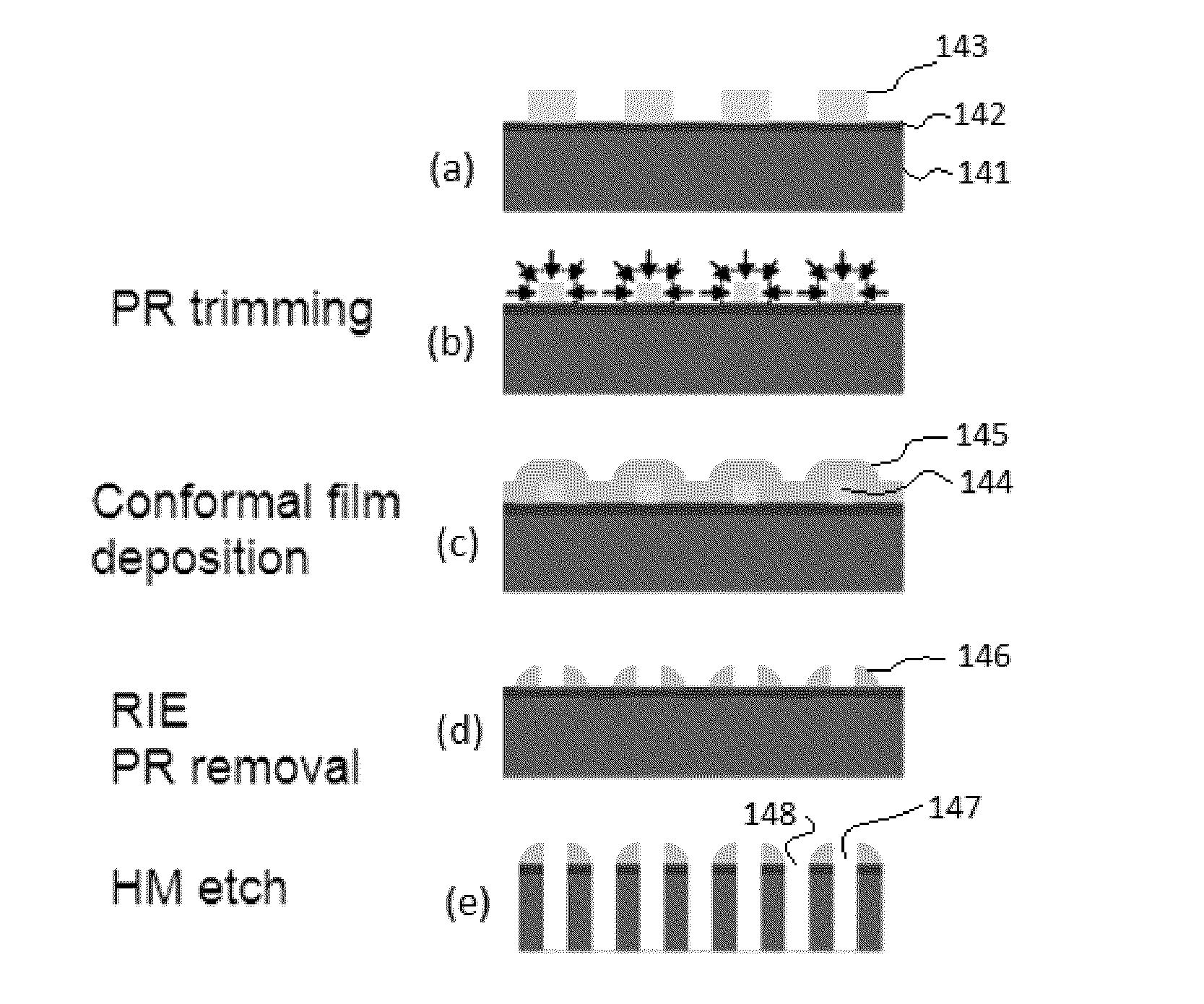

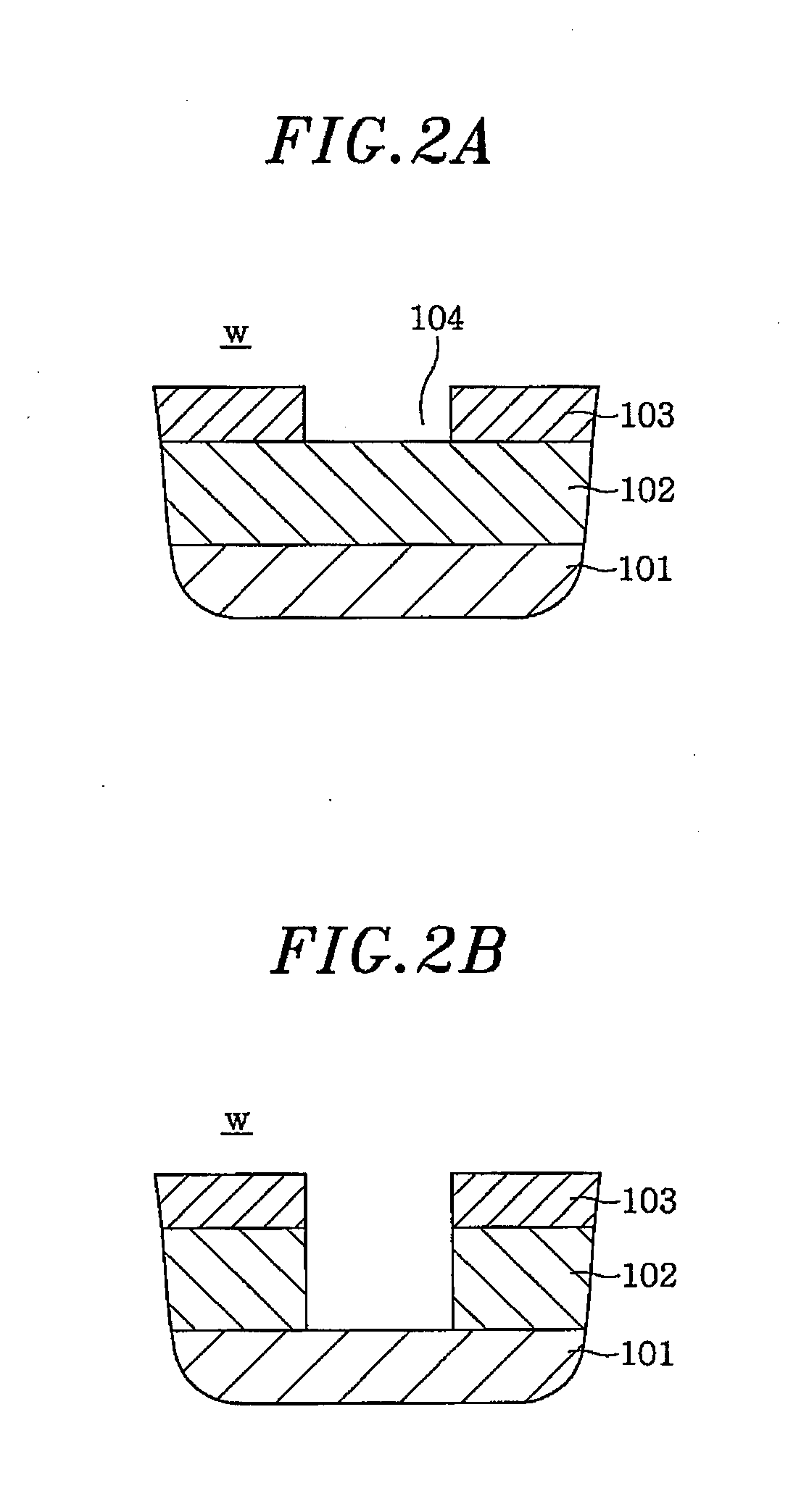

Plasma process with photoresist mask pretreatment

InactiveUS20090286400A1Decorative surface effectsSemiconductor/solid-state device manufacturingNoble gasLaser light

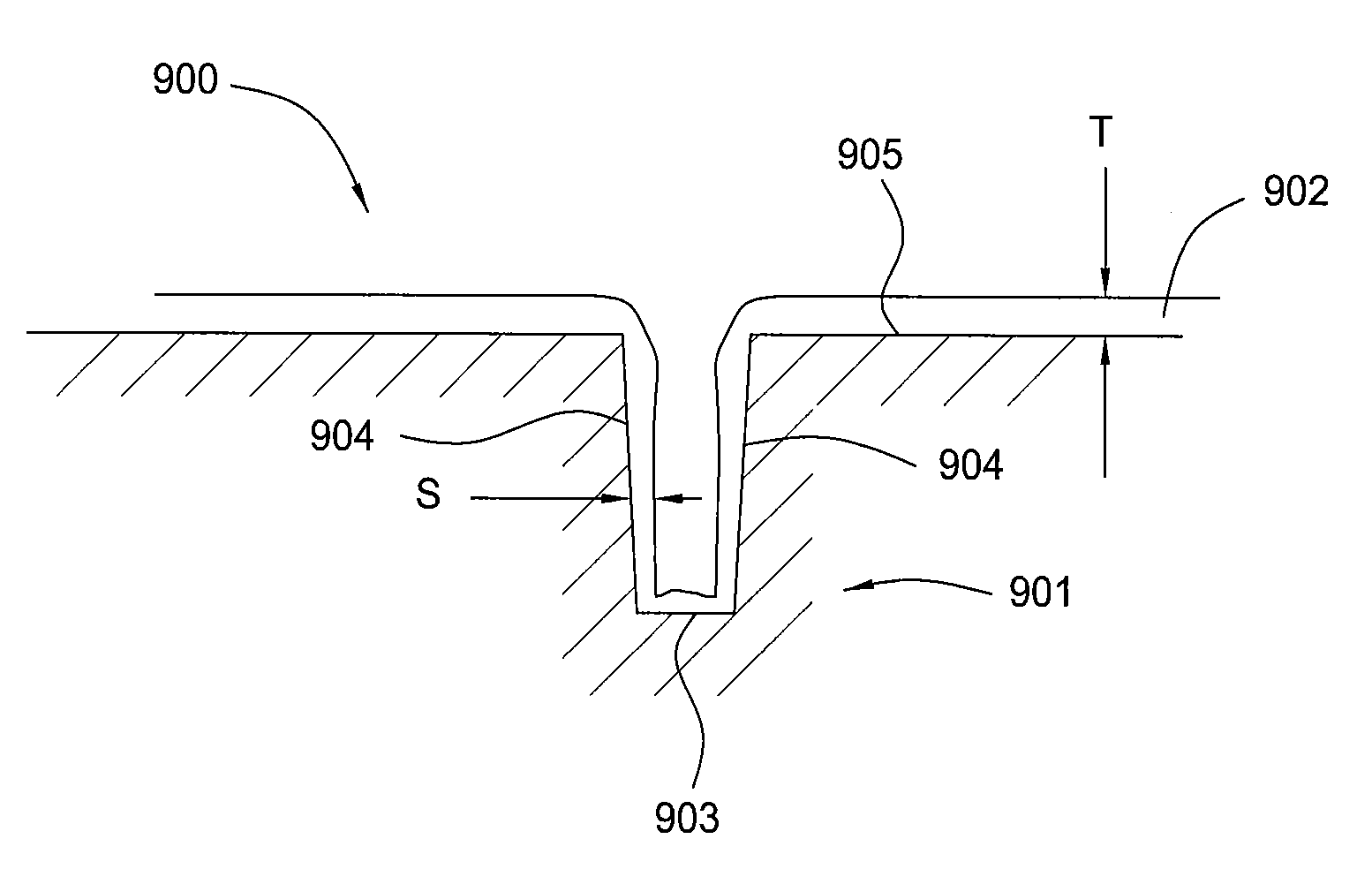

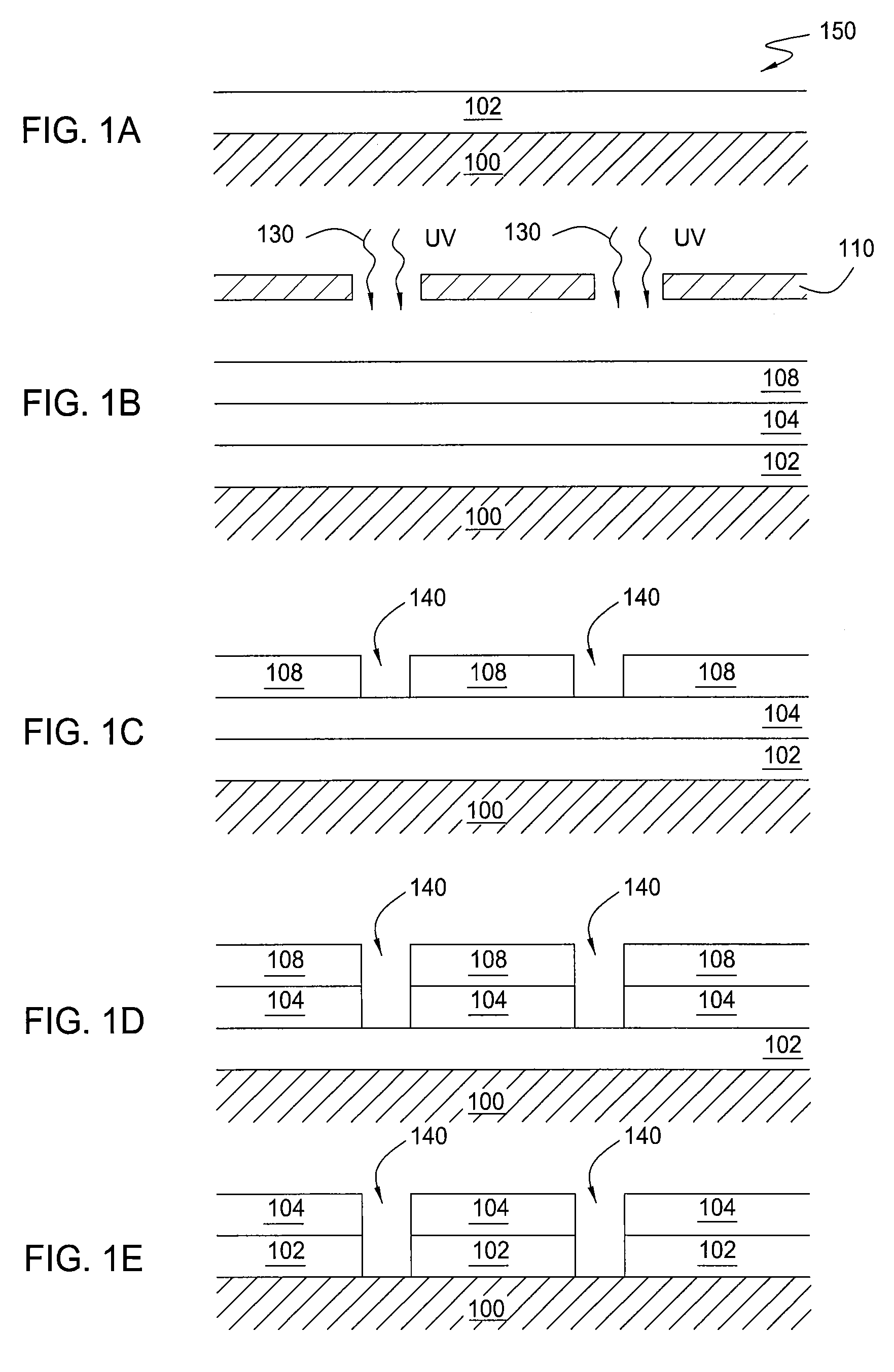

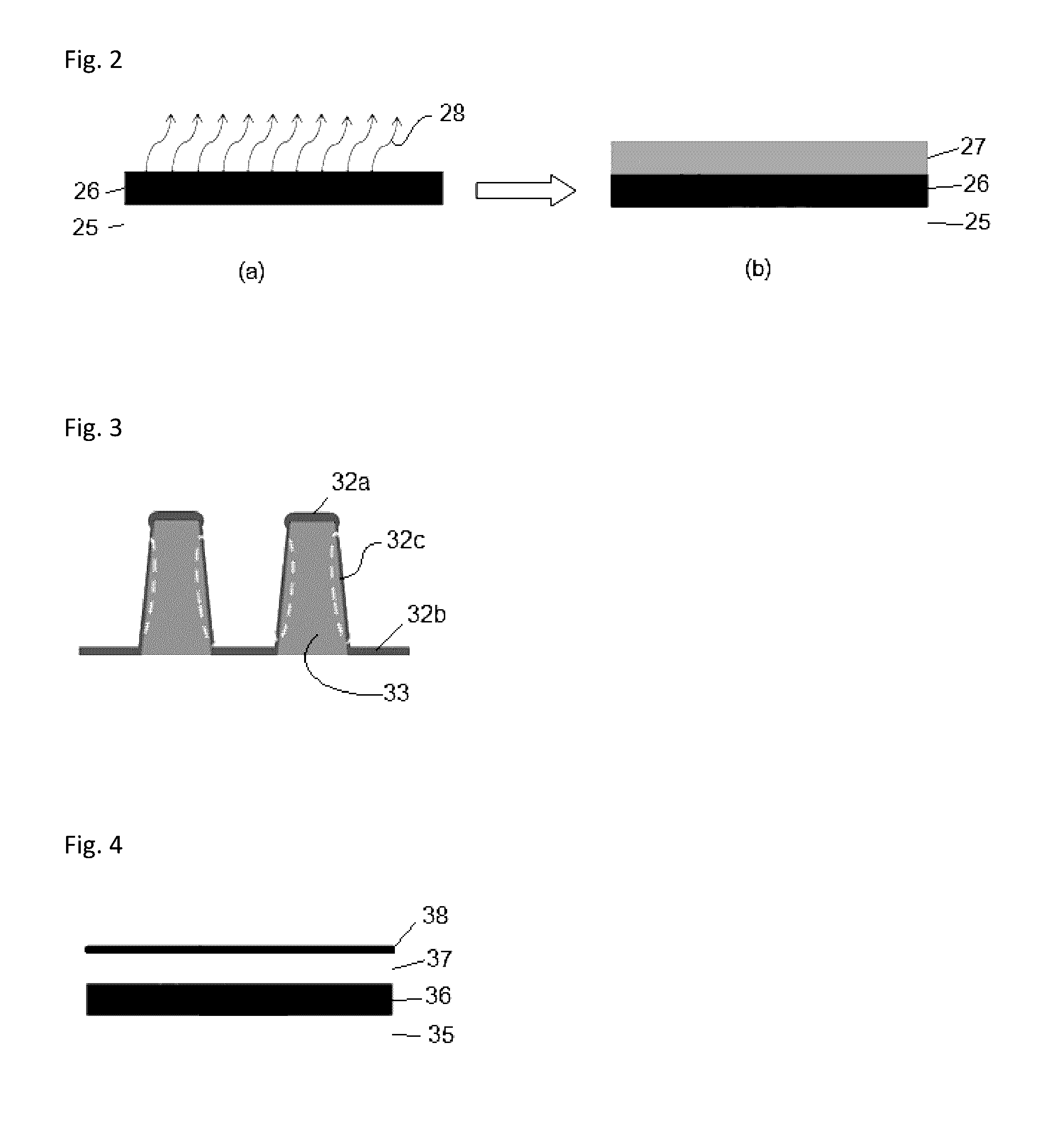

A method for etching features in a dielectric layer through a photoresist (PR) mask is provided. The PR mask is patterned using laser light having a wavelength not more than 193 nm. The PR mask is pre-treated with a noble gas plasma, and then a plurality of cycles of a plasma process is provided. Each cycle includes a deposition phase that deposits a deposition layer over the PR mask, the deposition layer covering a top and sidewalls of mask features of the PR mask, and a shaping phase that shapes the deposition layer deposited over the PR mask.

Owner:LAM RES CORP

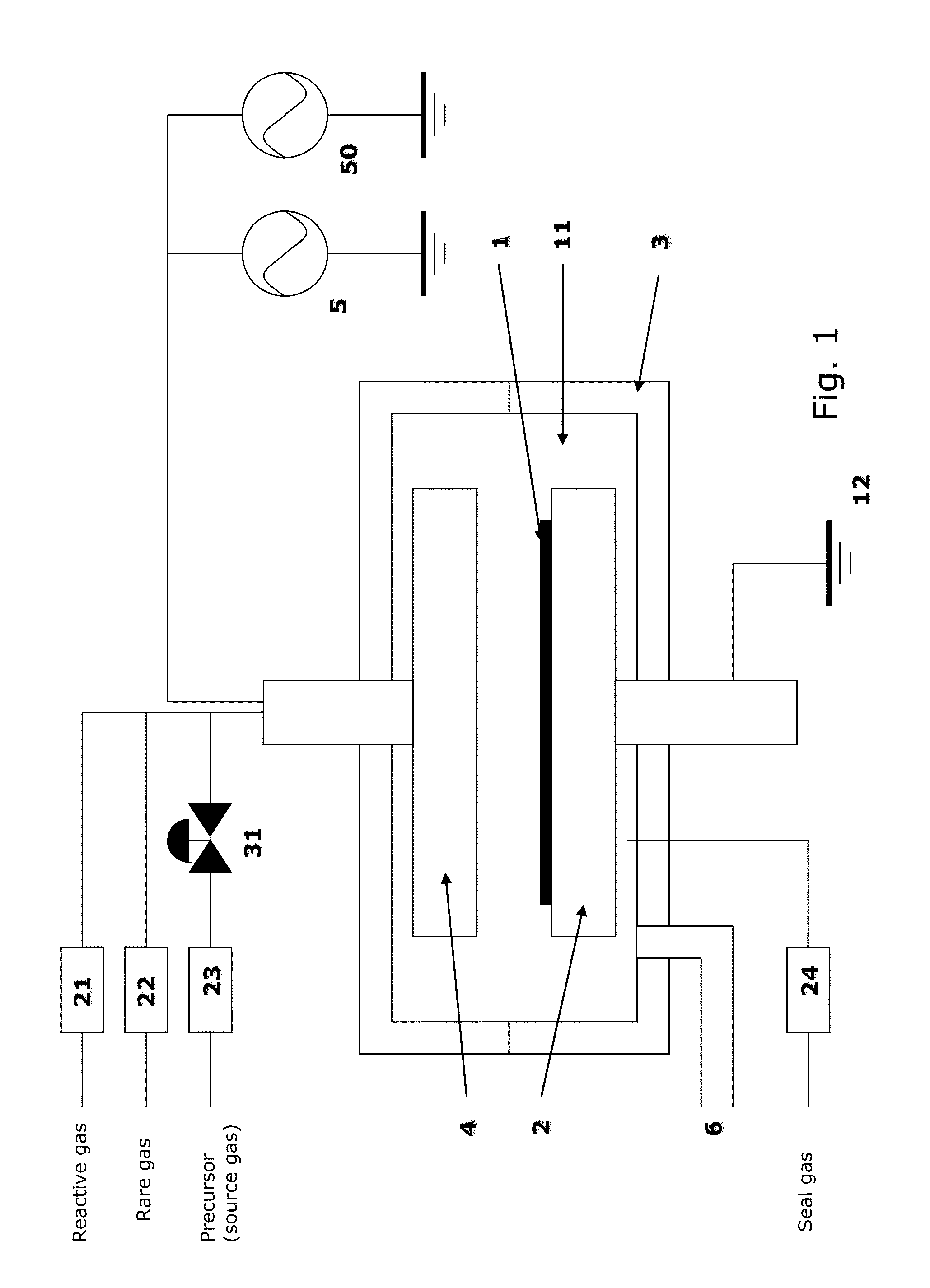

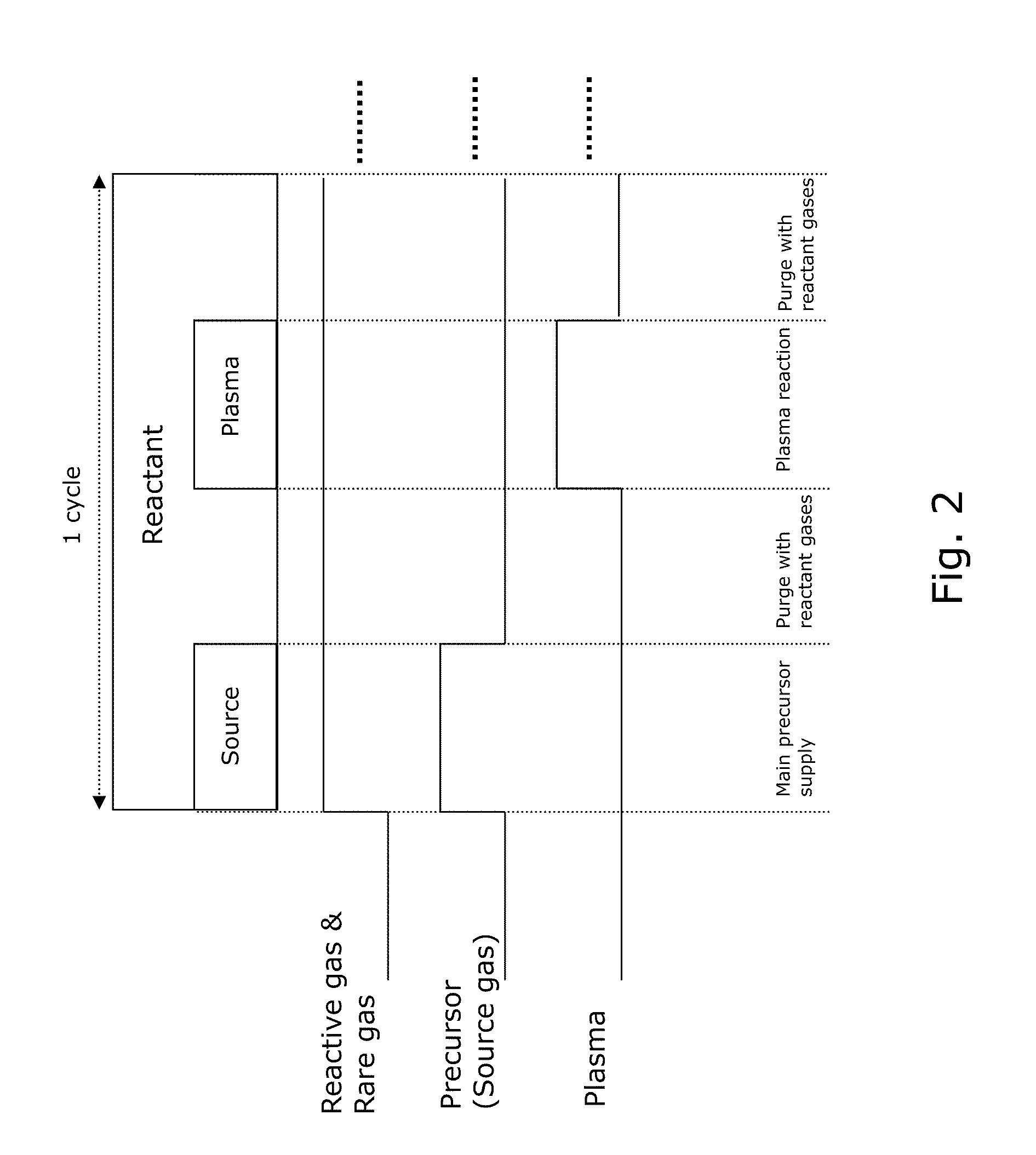

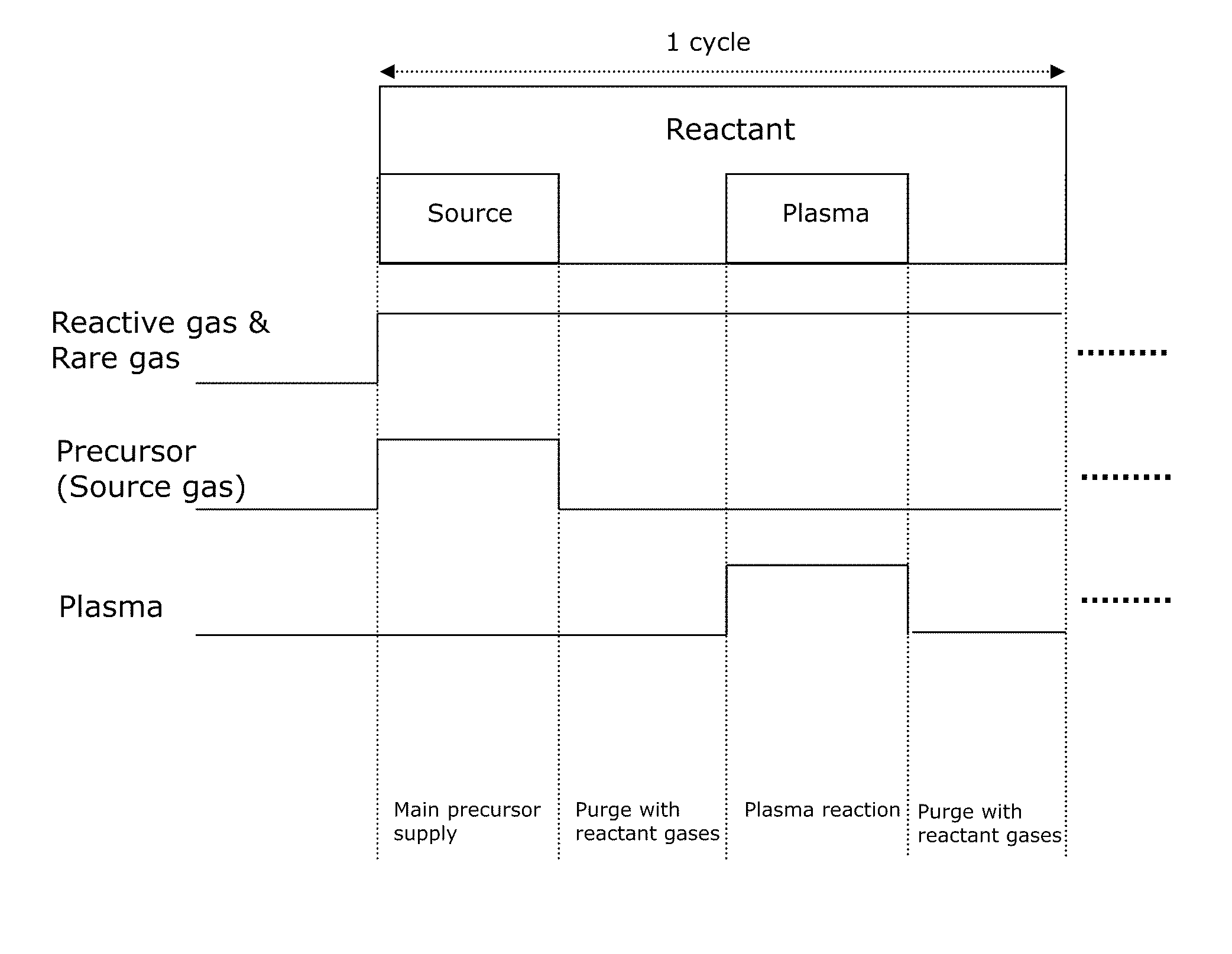

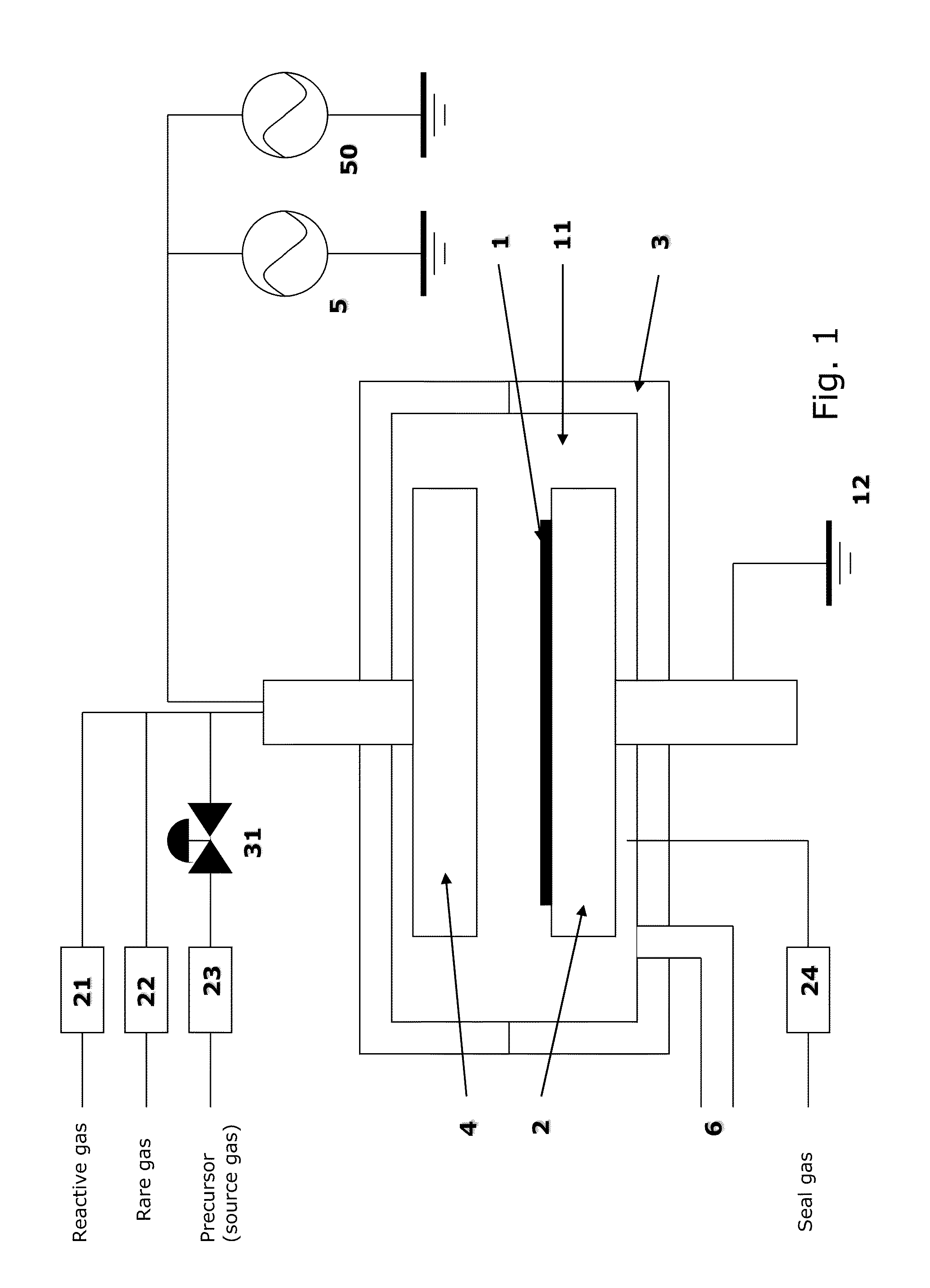

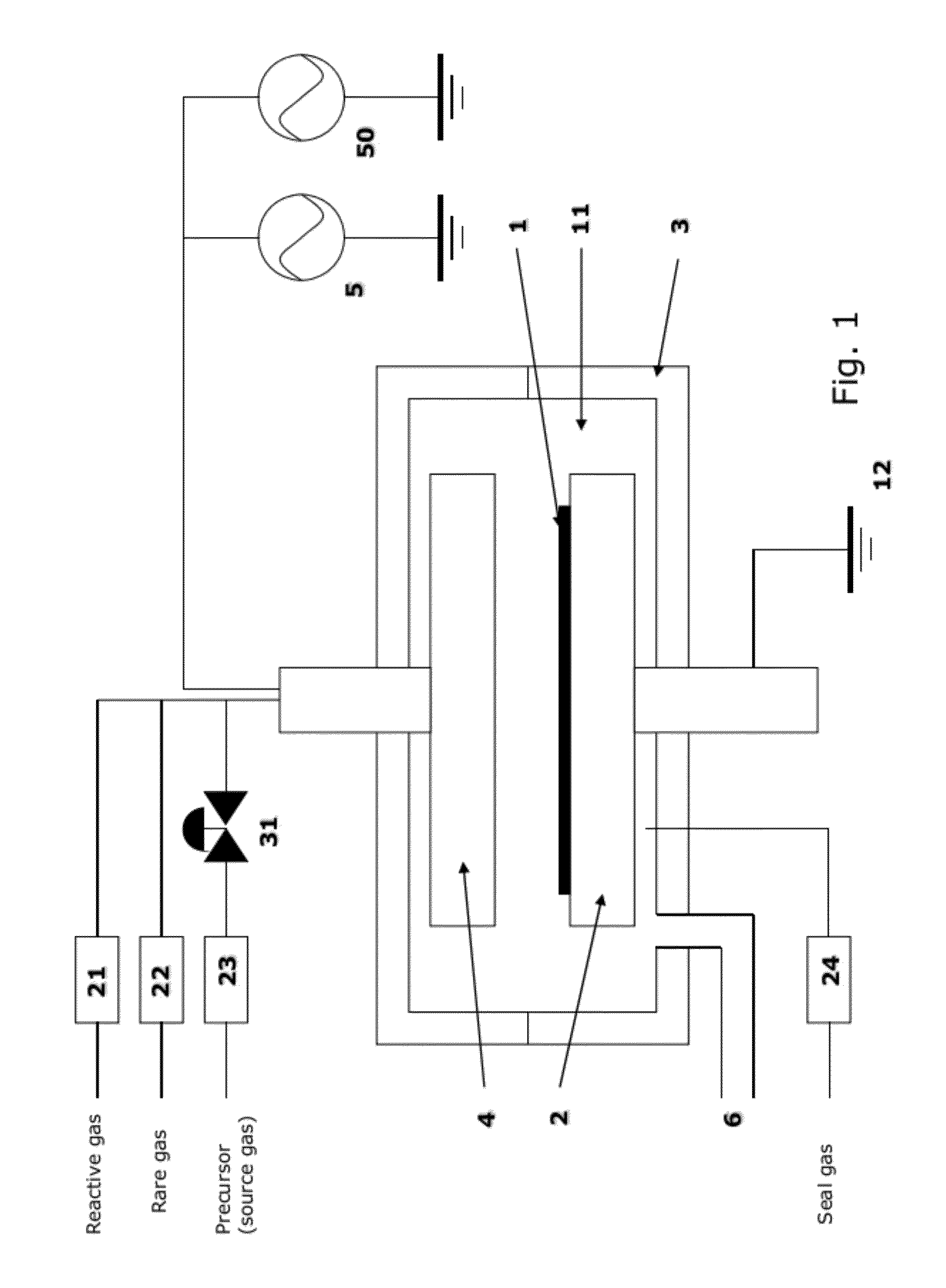

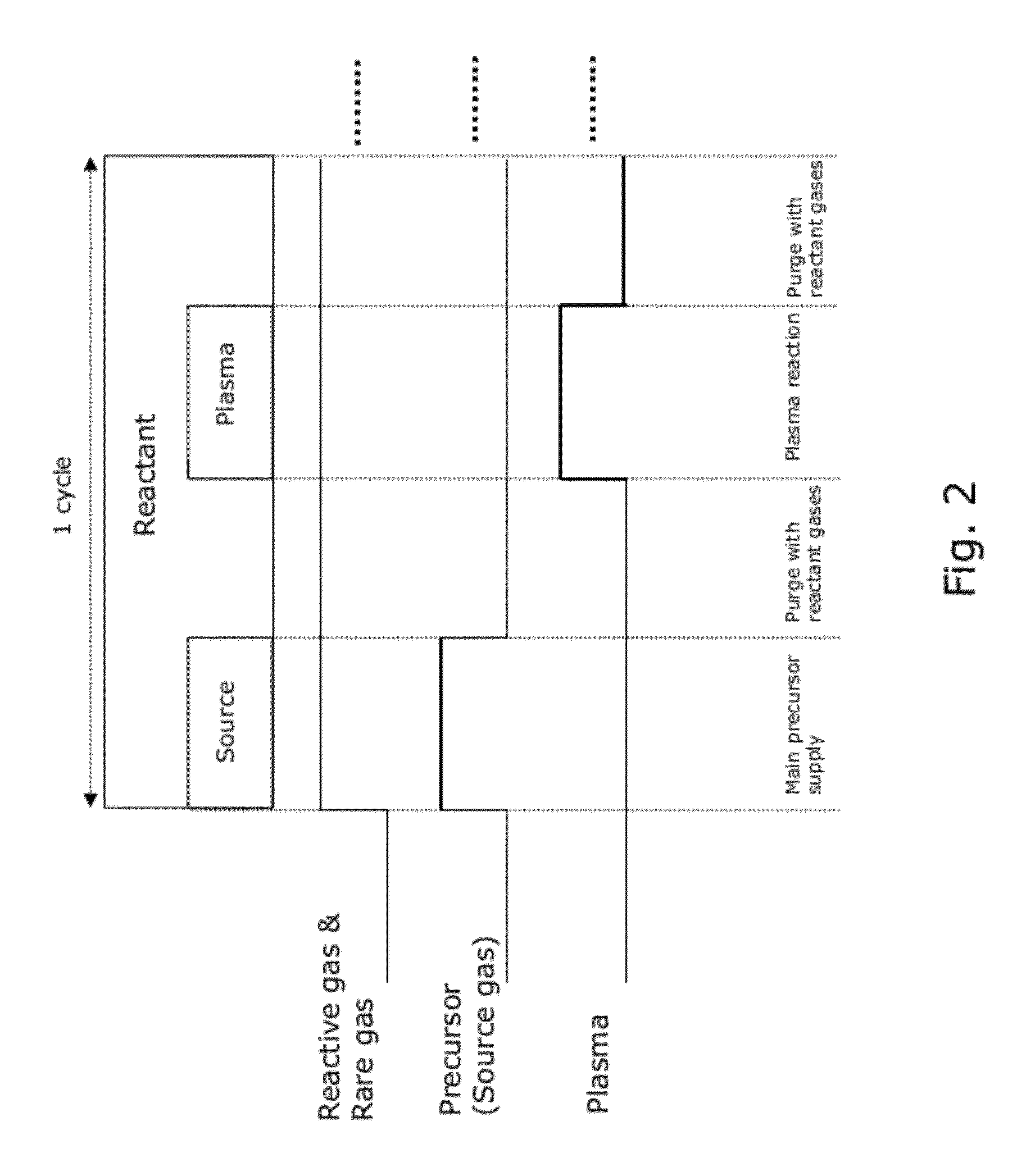

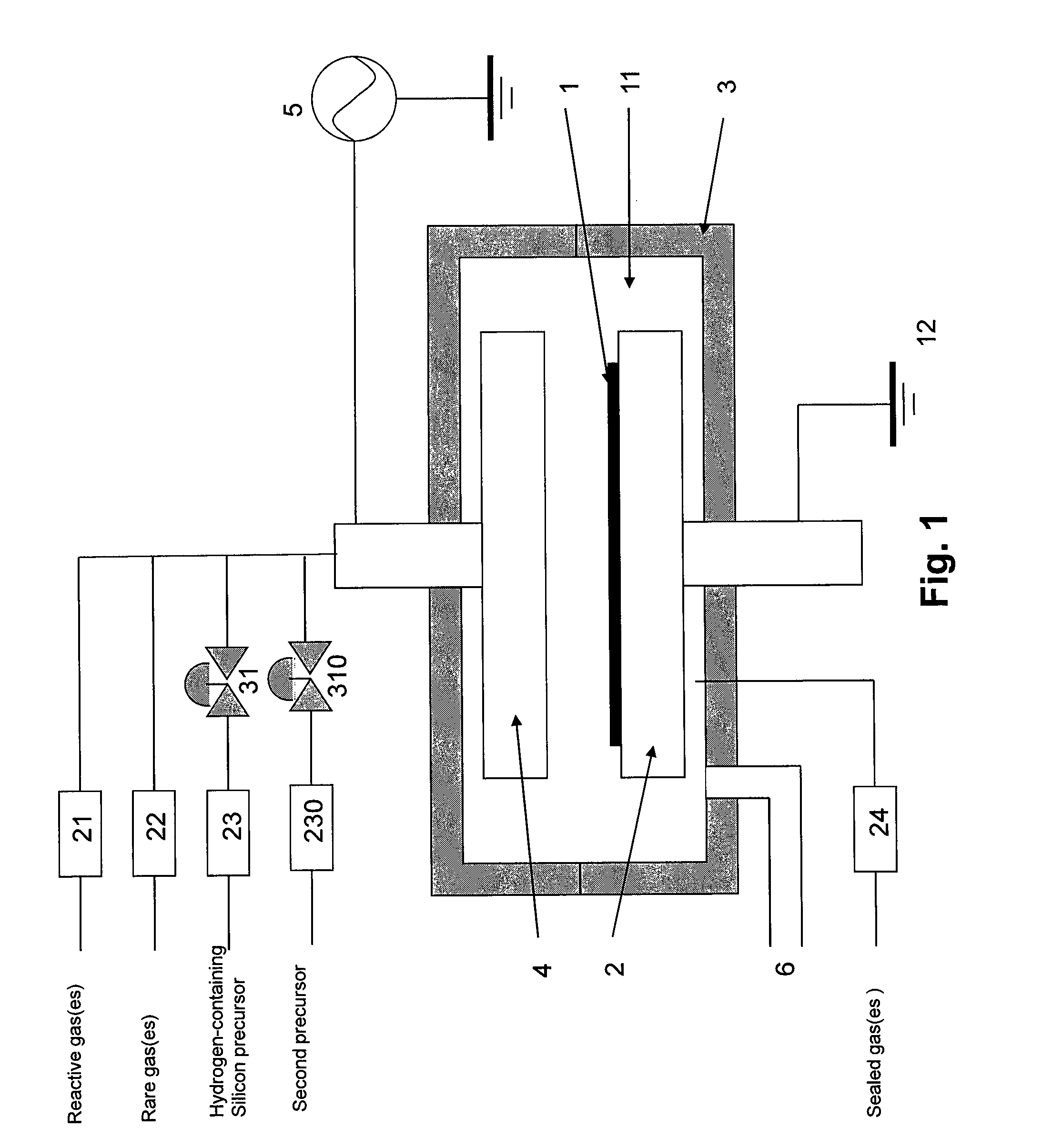

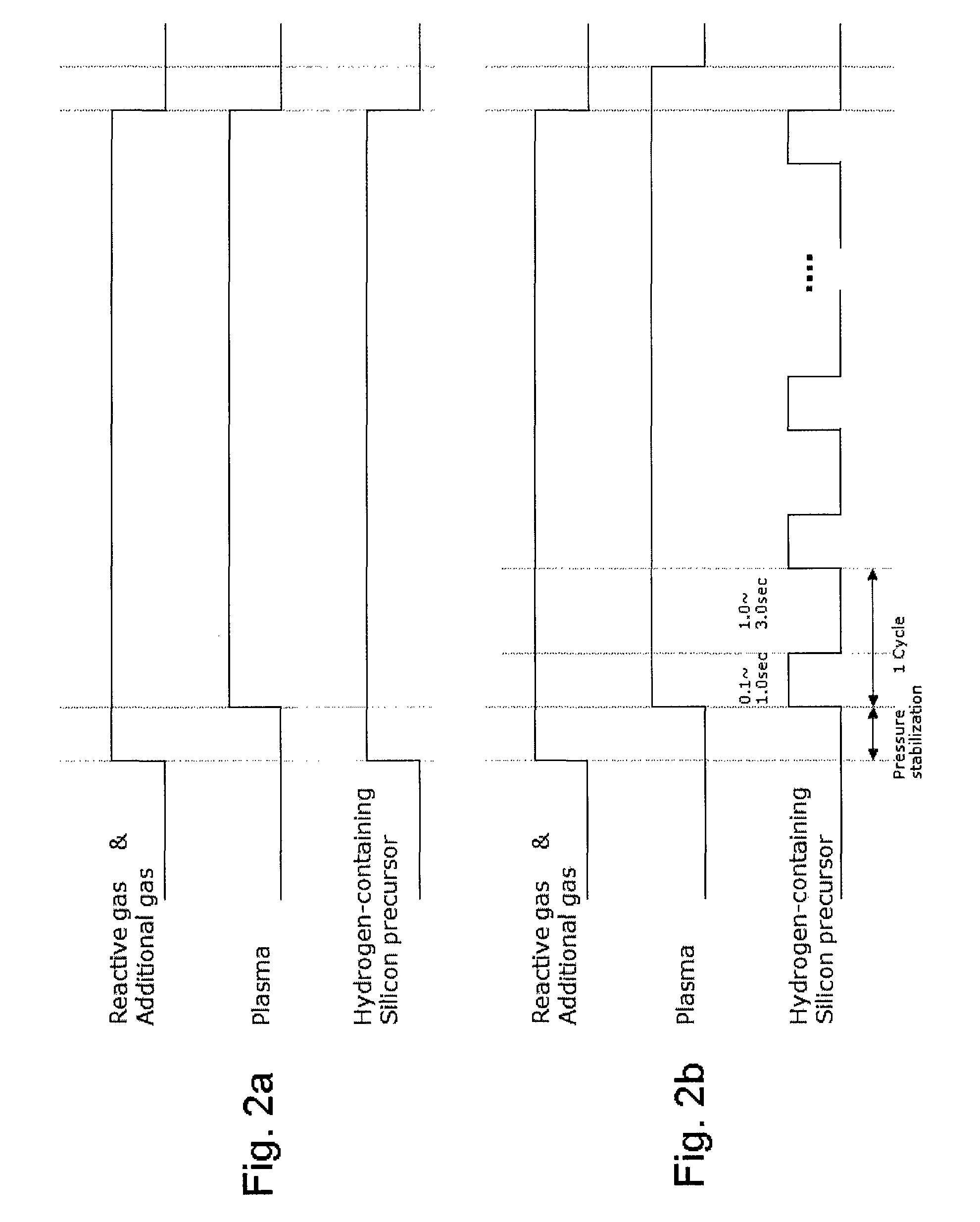

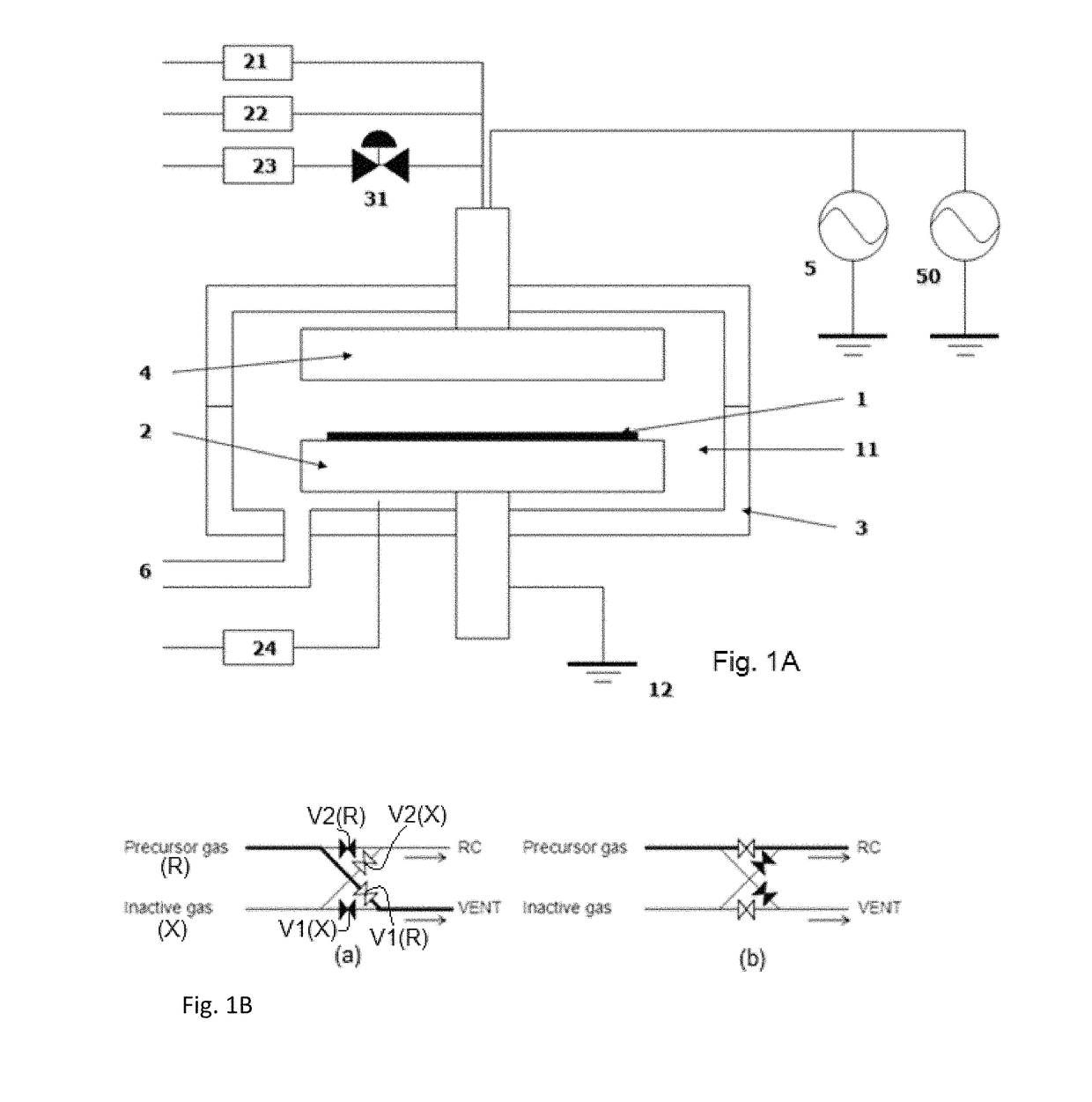

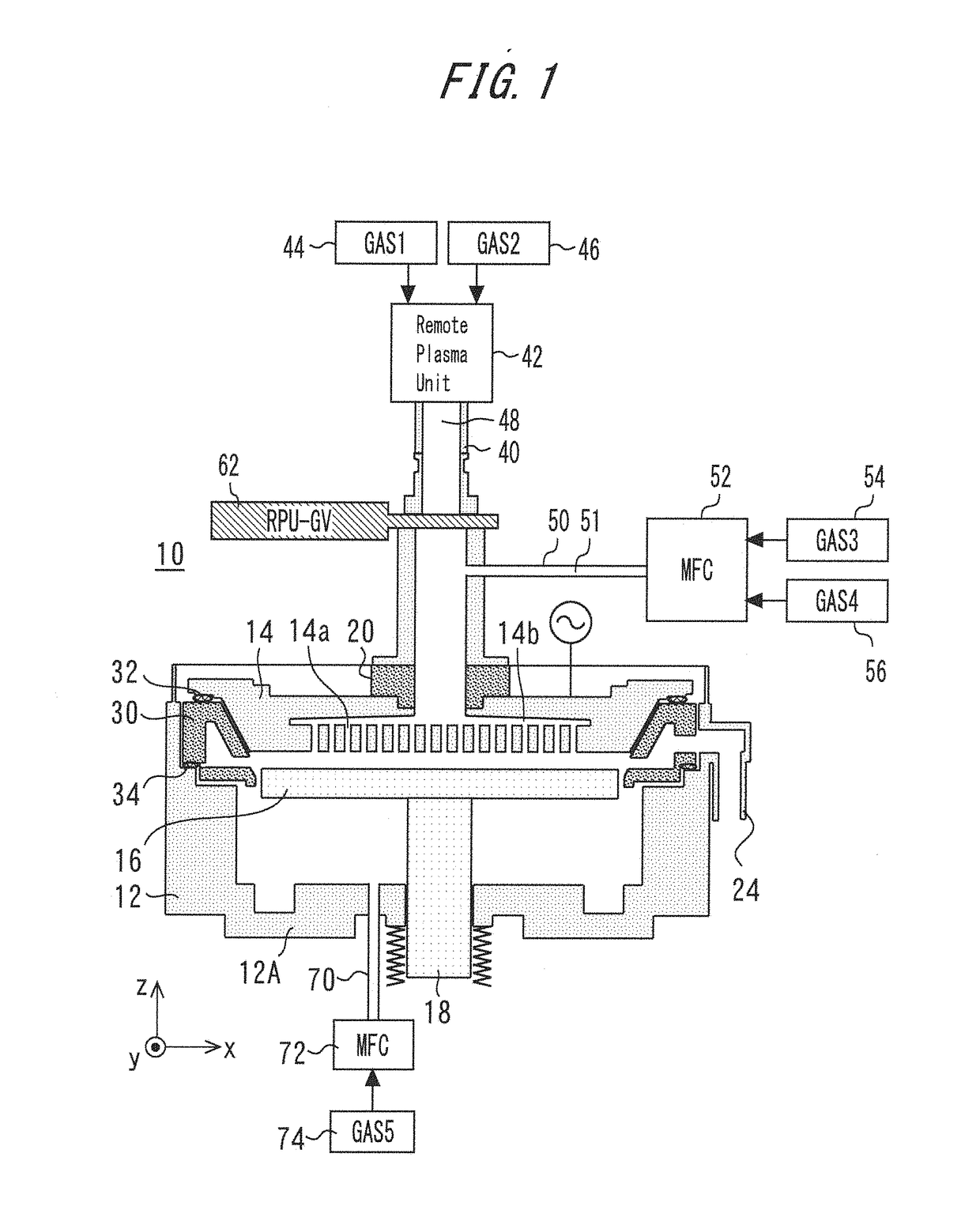

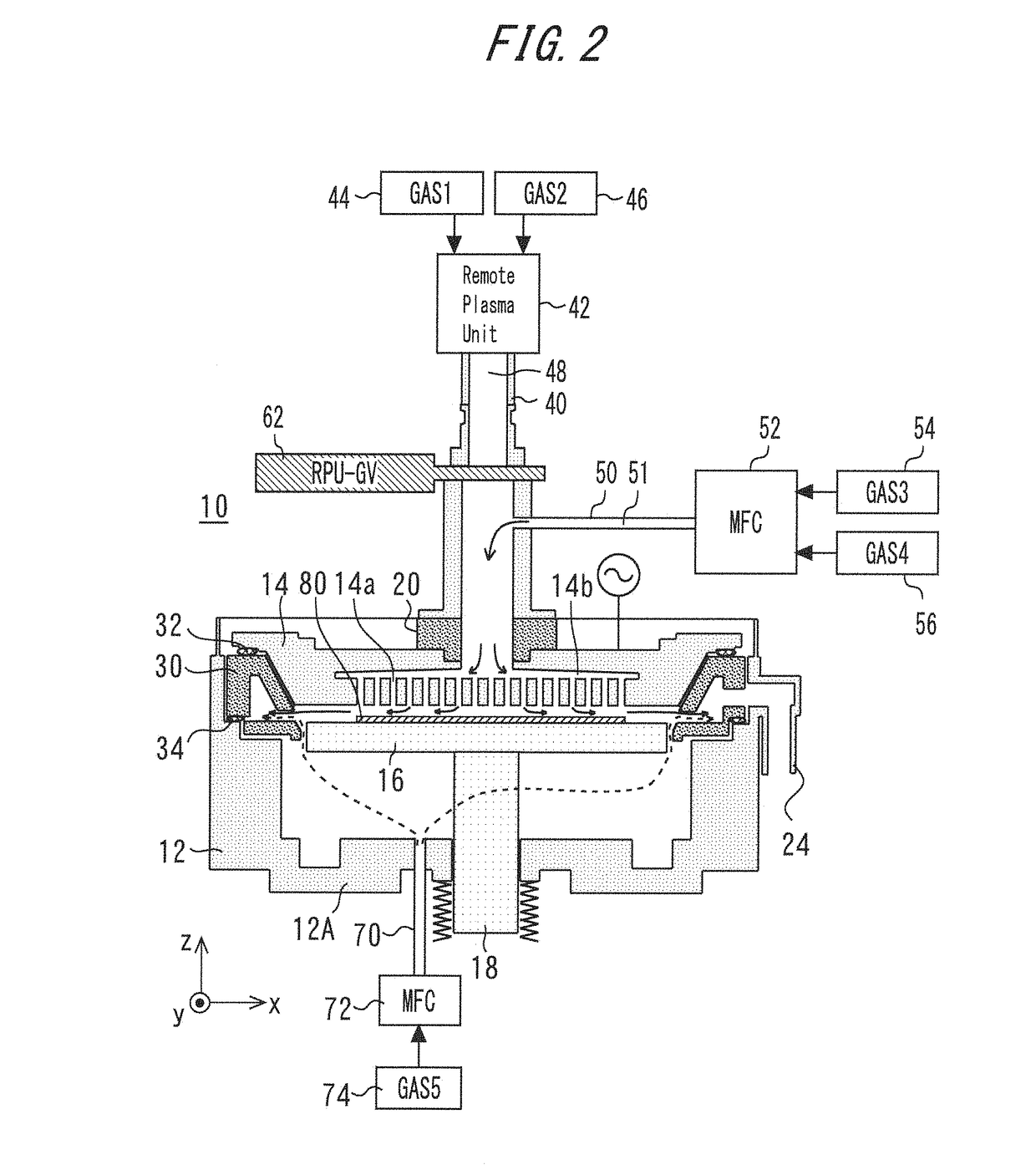

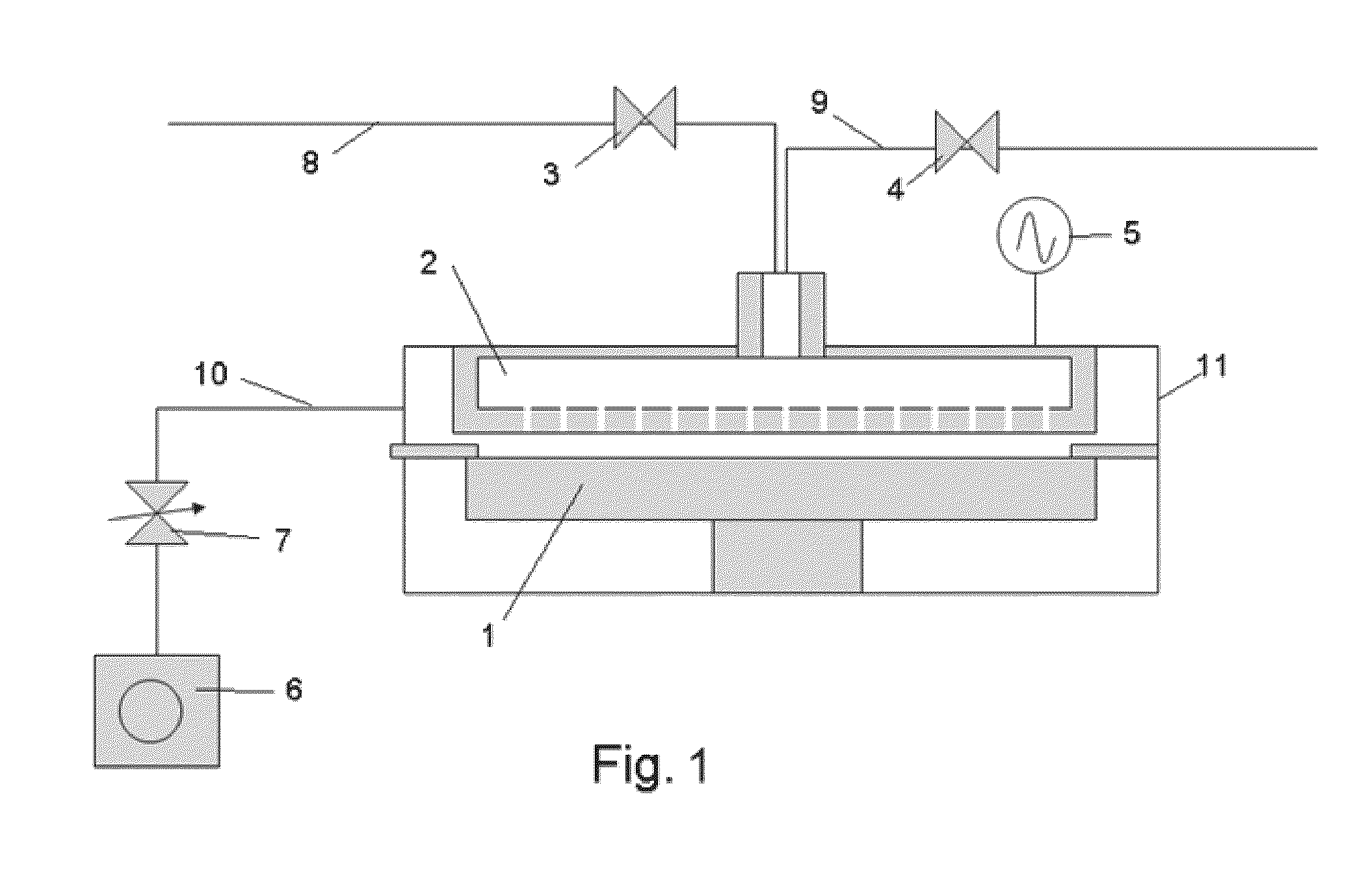

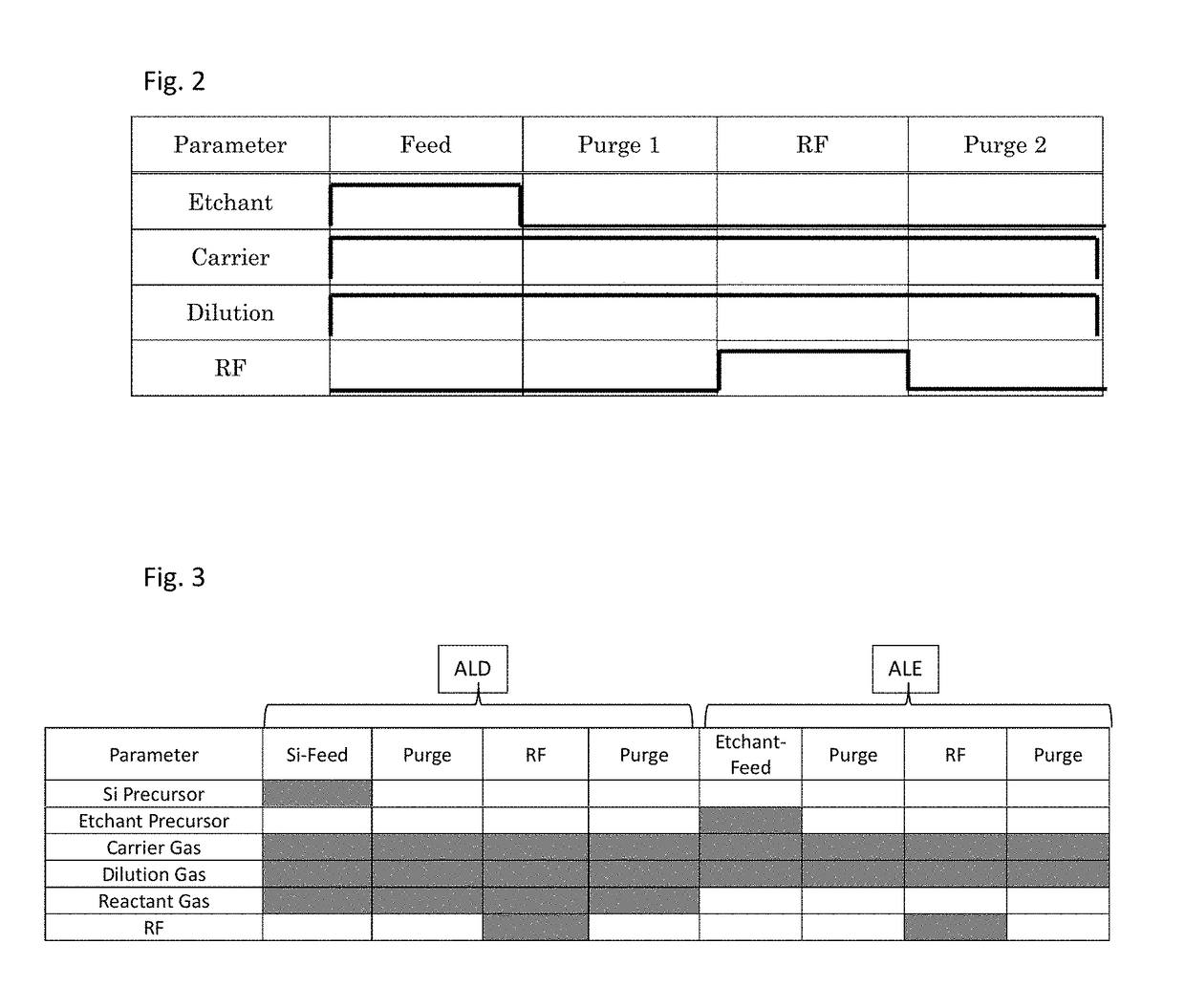

METHOD OF DEPOSITING DIELECTRIC FILM HAVING Si-N BONDS BY MODIFIED PEALD METHOD

ActiveUS20110086516A1High conformalityIncrease deposition rateSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDielectricNoble gas

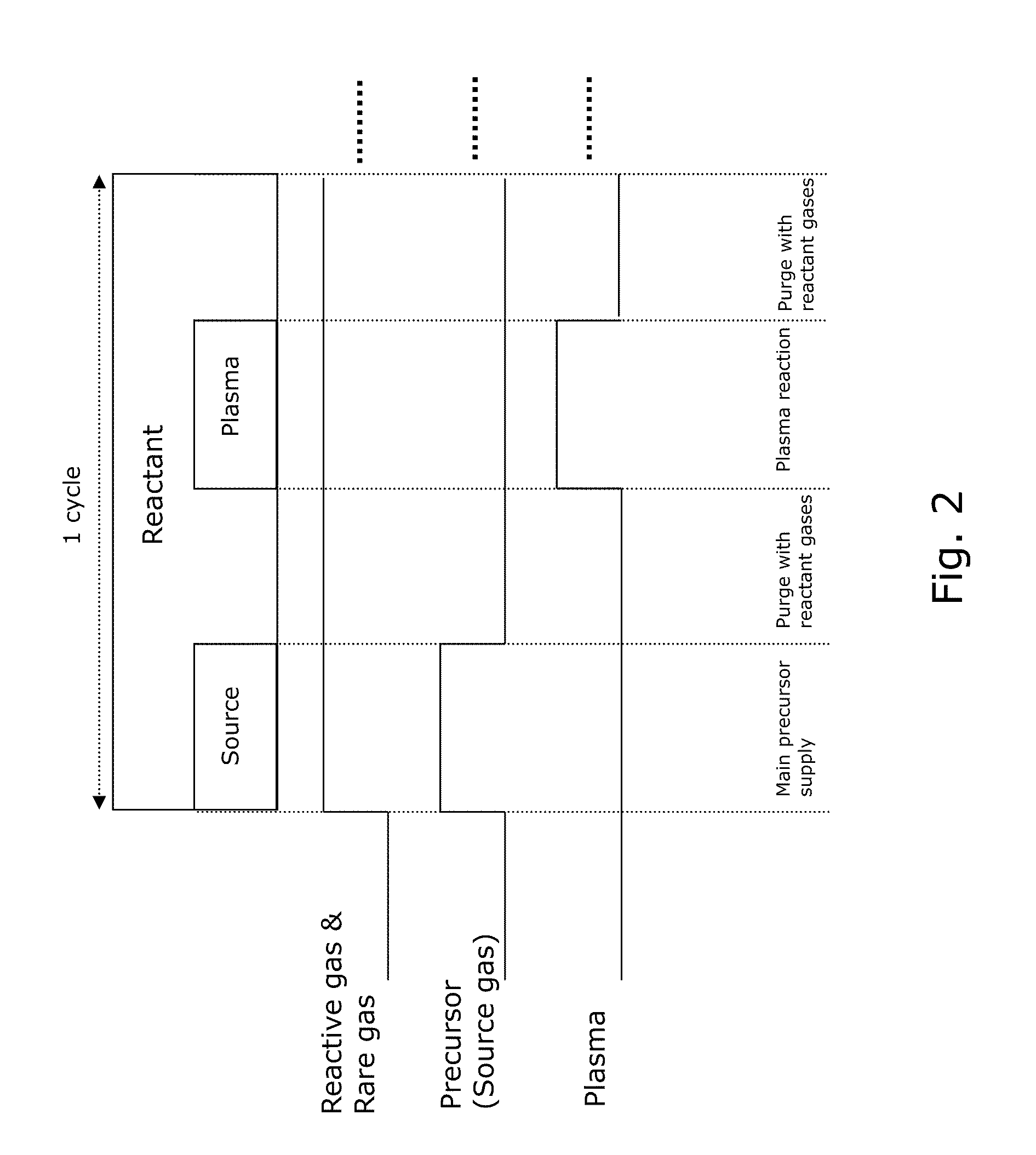

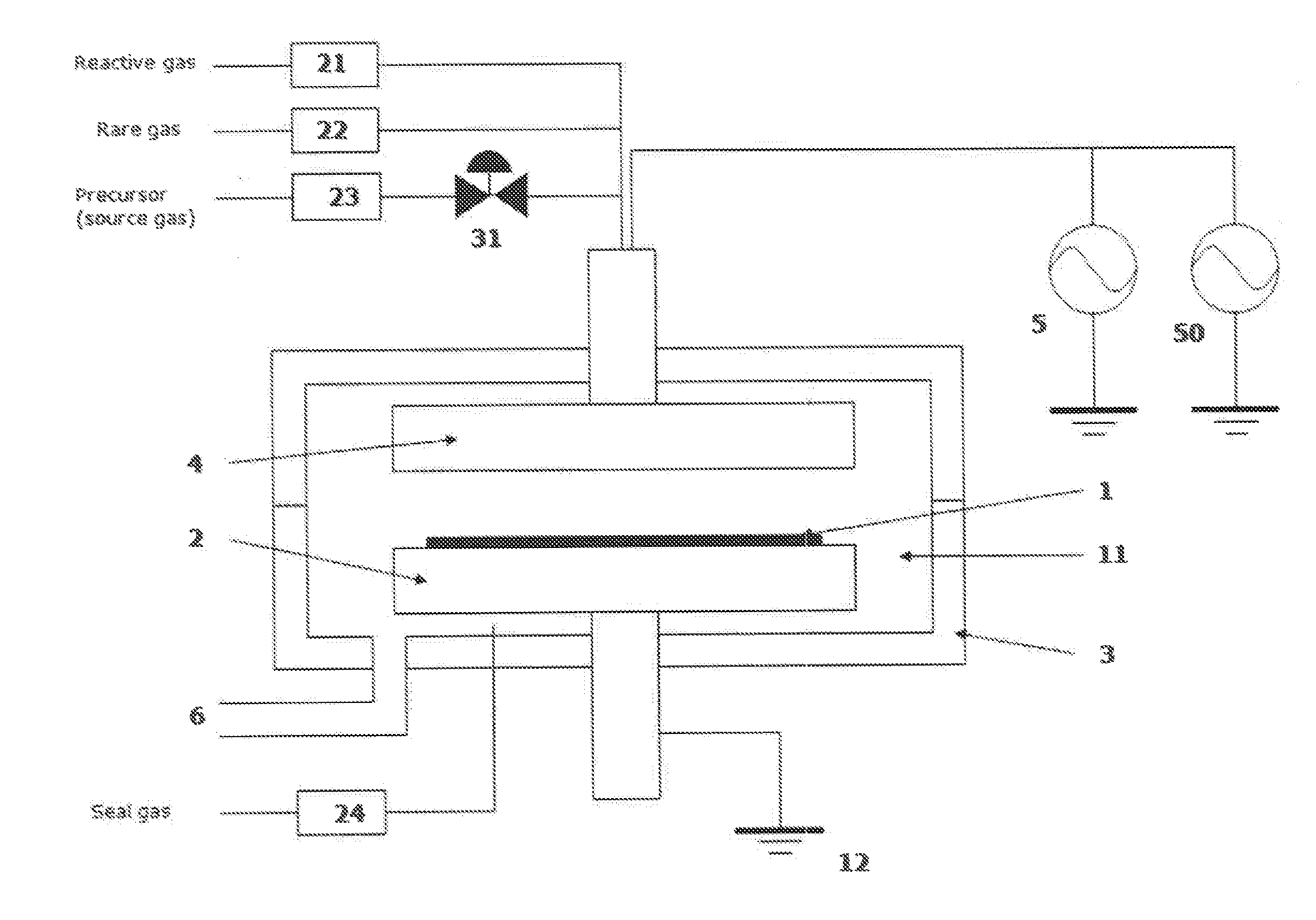

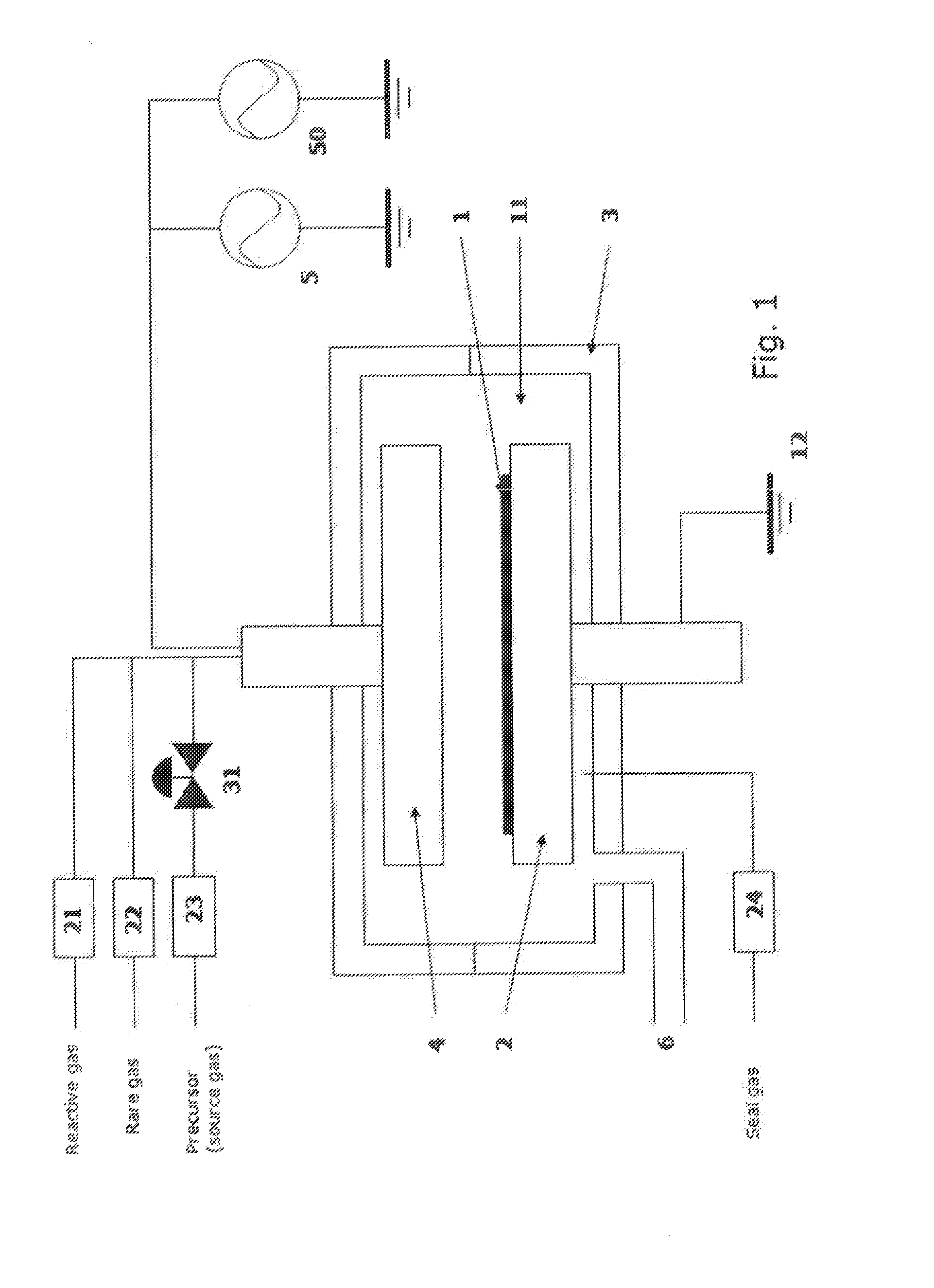

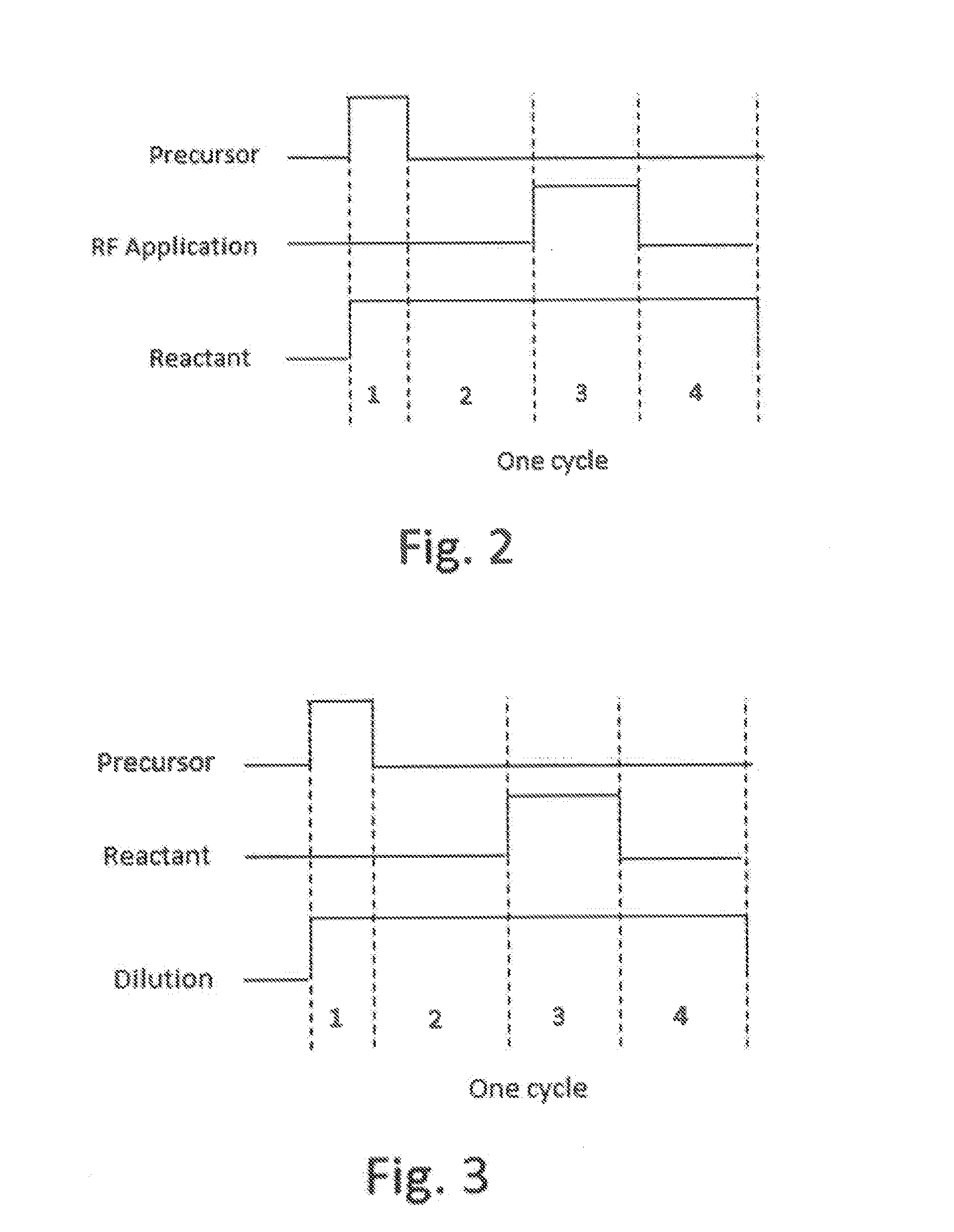

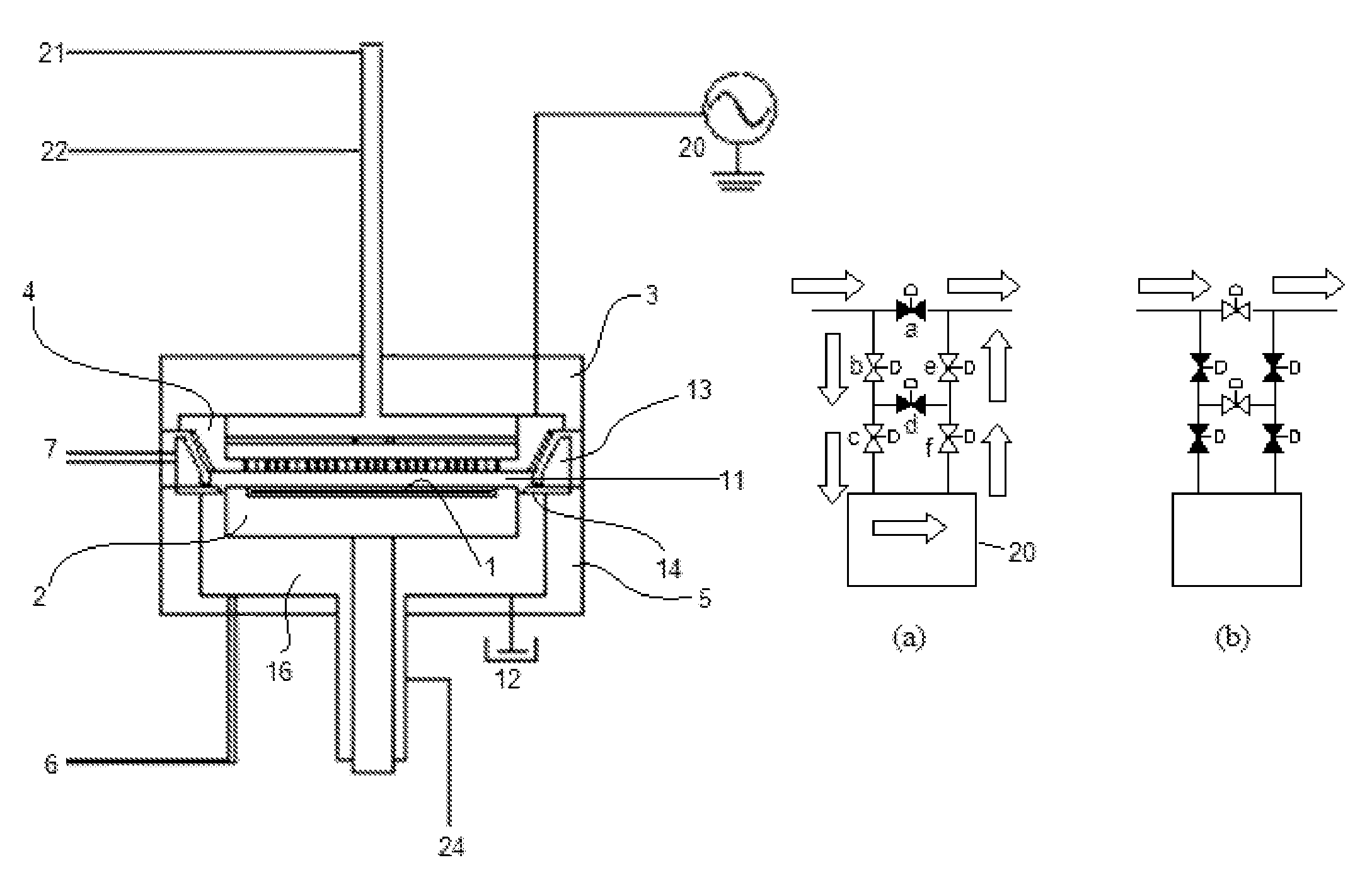

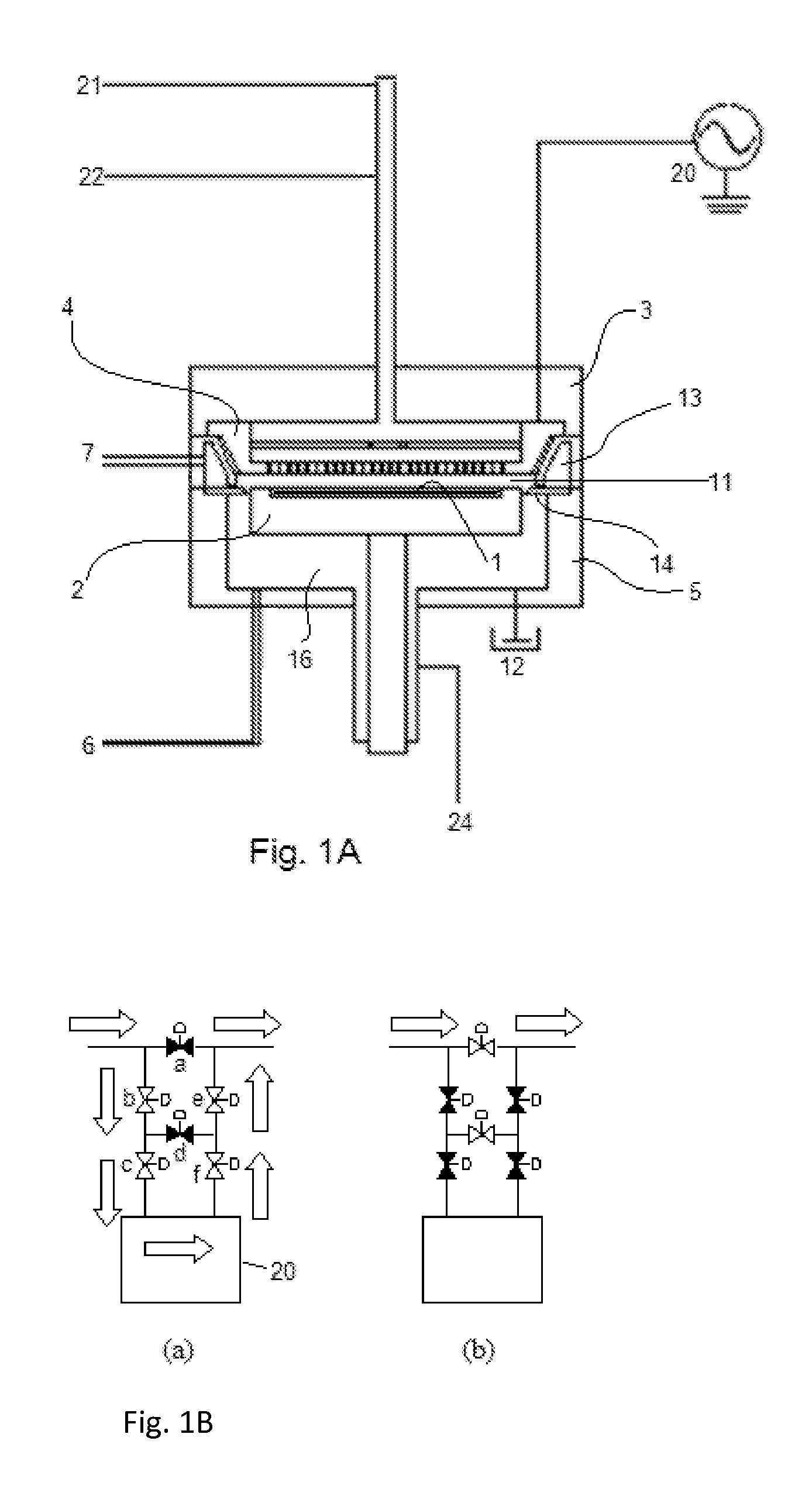

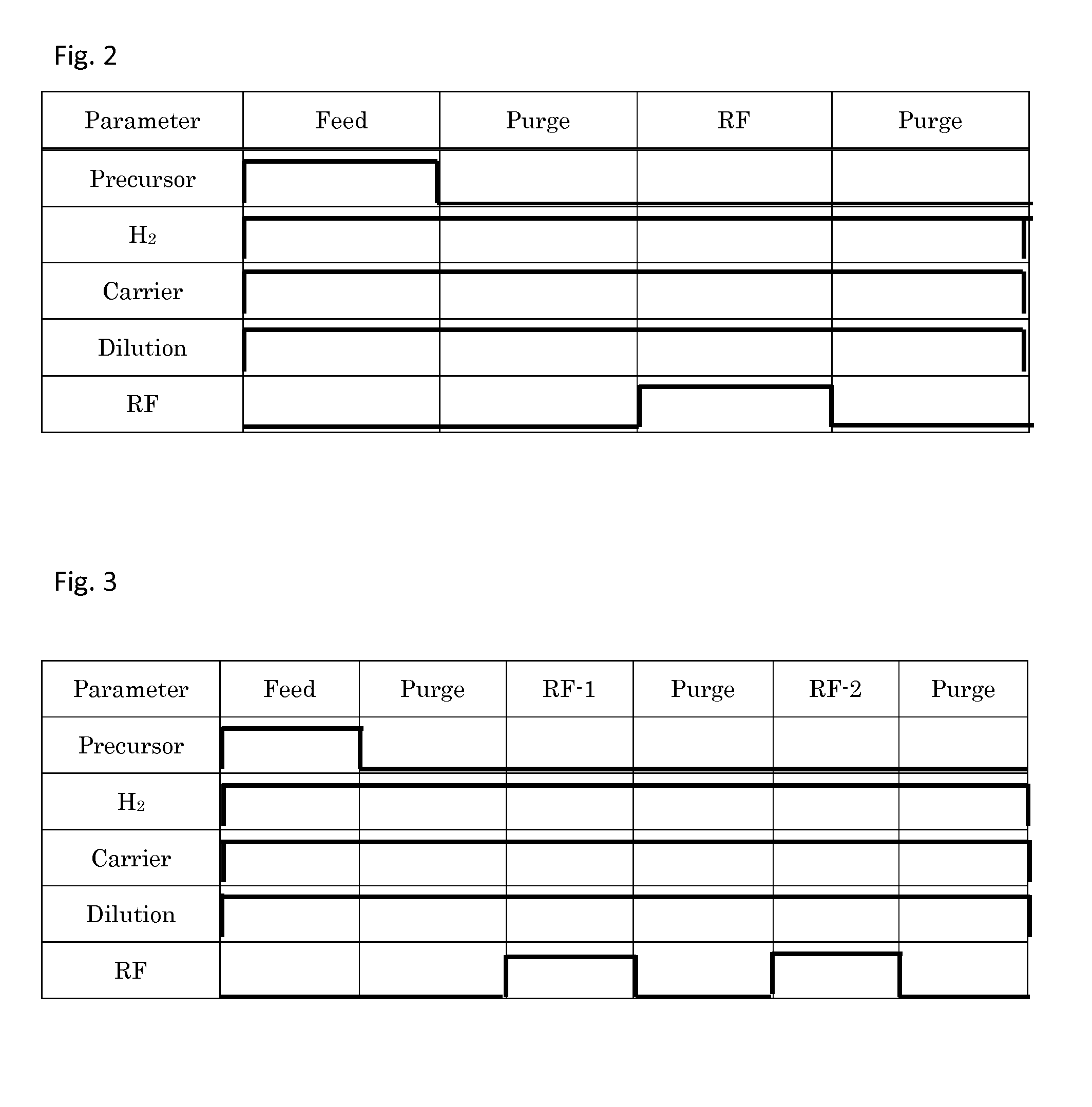

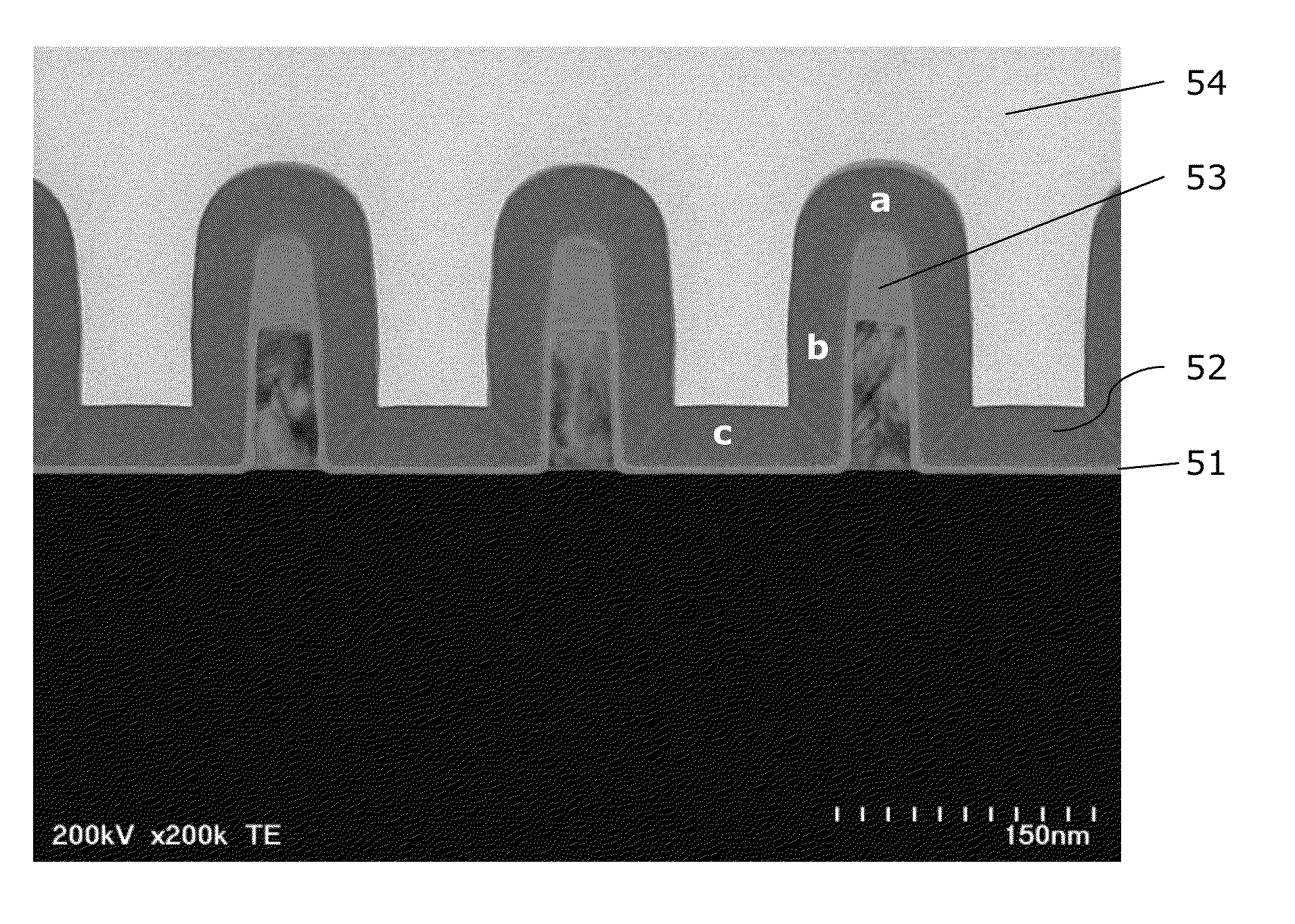

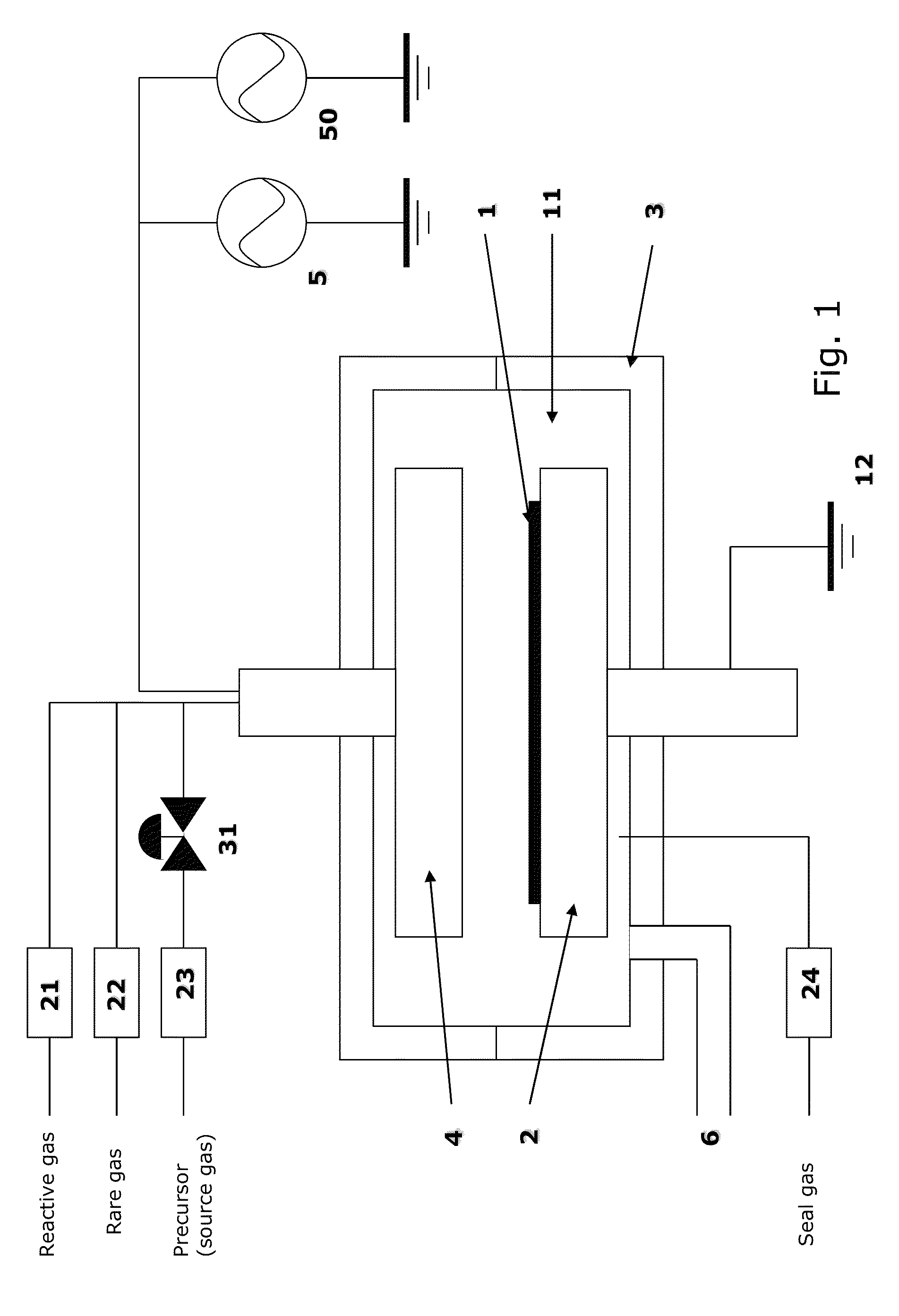

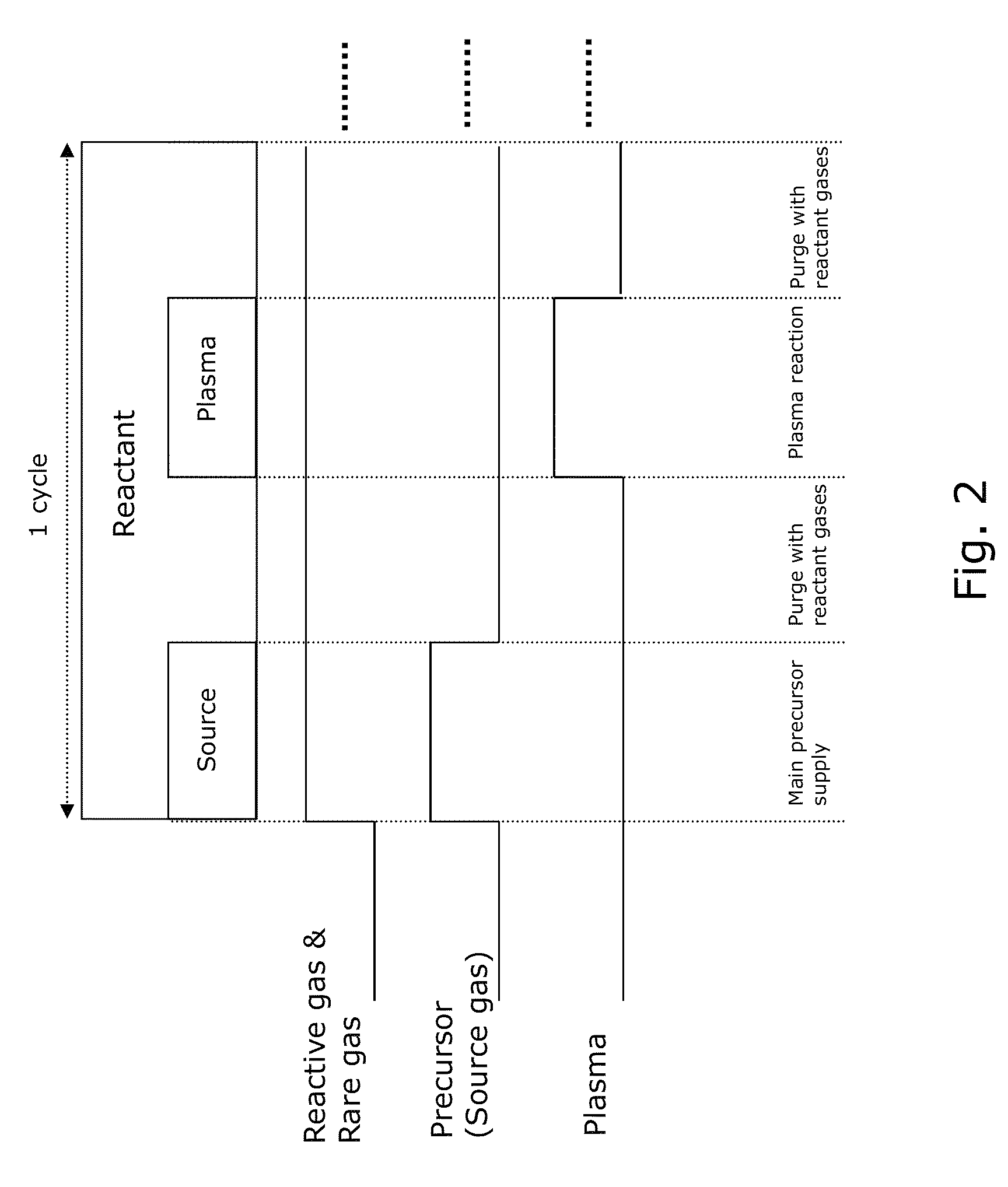

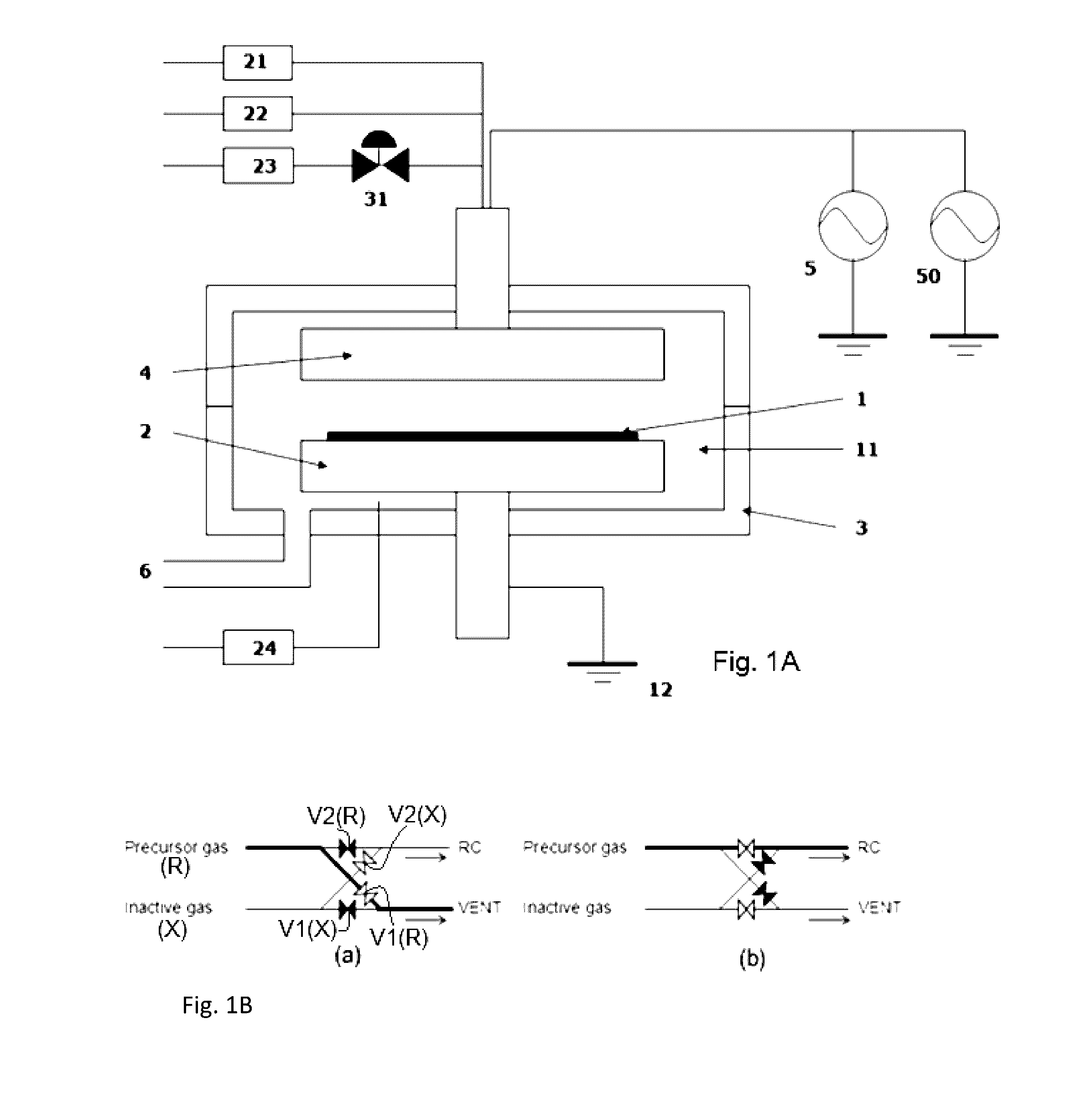

A method of forming dielectric film having Si—N bonds on a semiconductor substrate by plasma enhanced atomic layer deposition (PEALD), includes: introducing a nitrogen- and hydrogen-containing reactive gas and a rare gas into a reaction space inside which the semiconductor substrate is placed; introducing a hydrogen-containing silicon precursor in pulses of less than 1.0-second duration into the reaction space wherein the reactive gas and the rare gas are introduced; exiting a plasma in pulses of less than 1.0-second duration immediately after the silicon precursor is shut off; and maintaining the reactive gas and the rare gas as a purge of less than 2.0-second duration.

Owner:ASM JAPAN

Method of depositing dielectric film having Si-N bonds by modified peald method

ActiveUS8173554B2Increase deposition rateHigh conformalitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingDielectricHydrogen

A method of forming dielectric film having Si—N bonds on a semiconductor substrate by plasma enhanced atomic layer deposition (PEALD), includes: introducing a nitrogen- and hydrogen-containing reactive gas and a rare gas into a reaction space inside which the semiconductor substrate is placed; introducing a hydrogen-containing silicon precursor in pulses of less than 1.0-second duration into the reaction space wherein the reactive gas and the rare gas are introduced; exiting a plasma in pulses of less than 1.0-second duration immediately after the silicon precursor is shut off; and maintaining the reactive gas and the rare gas as a purge of less than 2.0-second duration.

Owner:ASM JAPAN

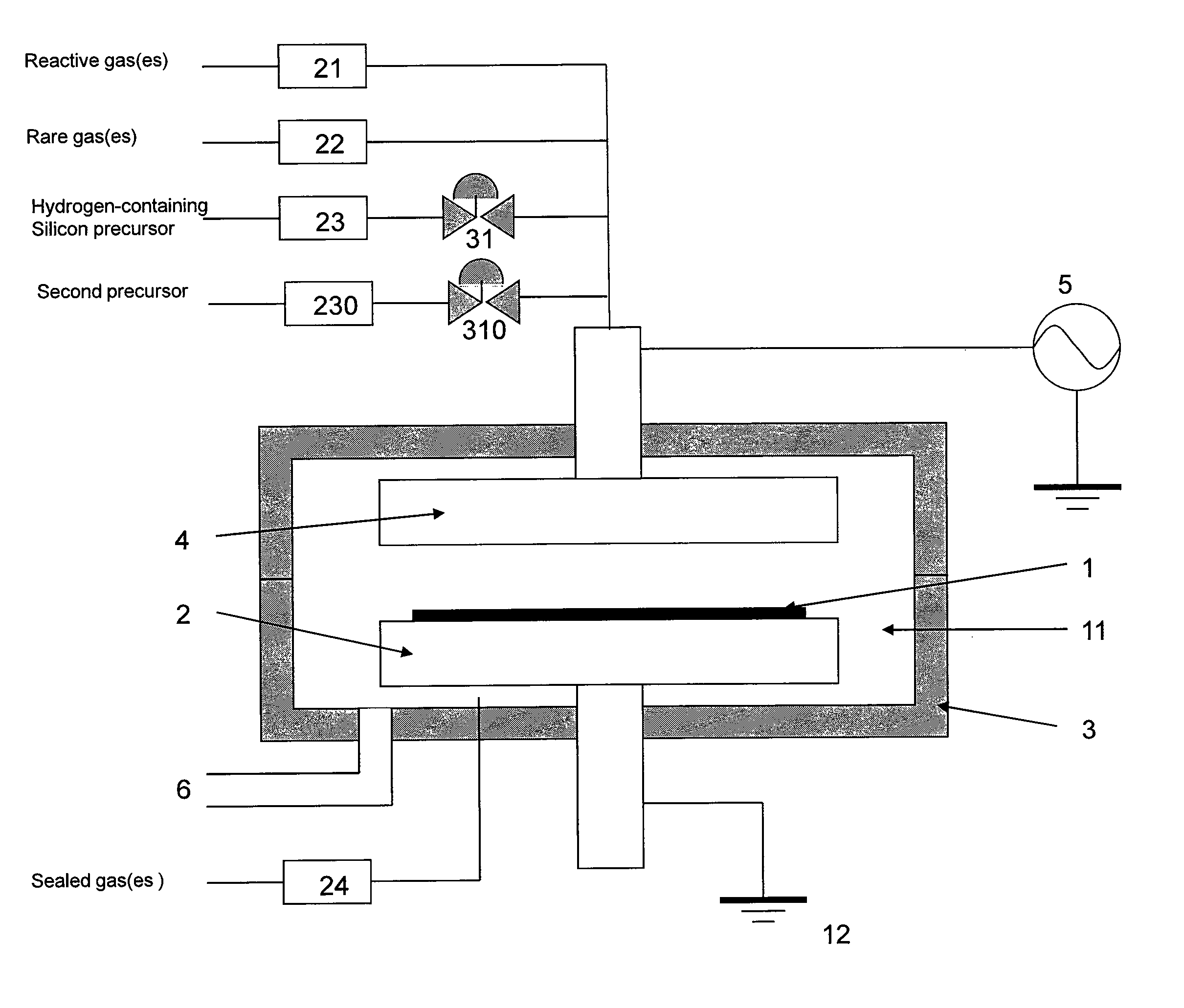

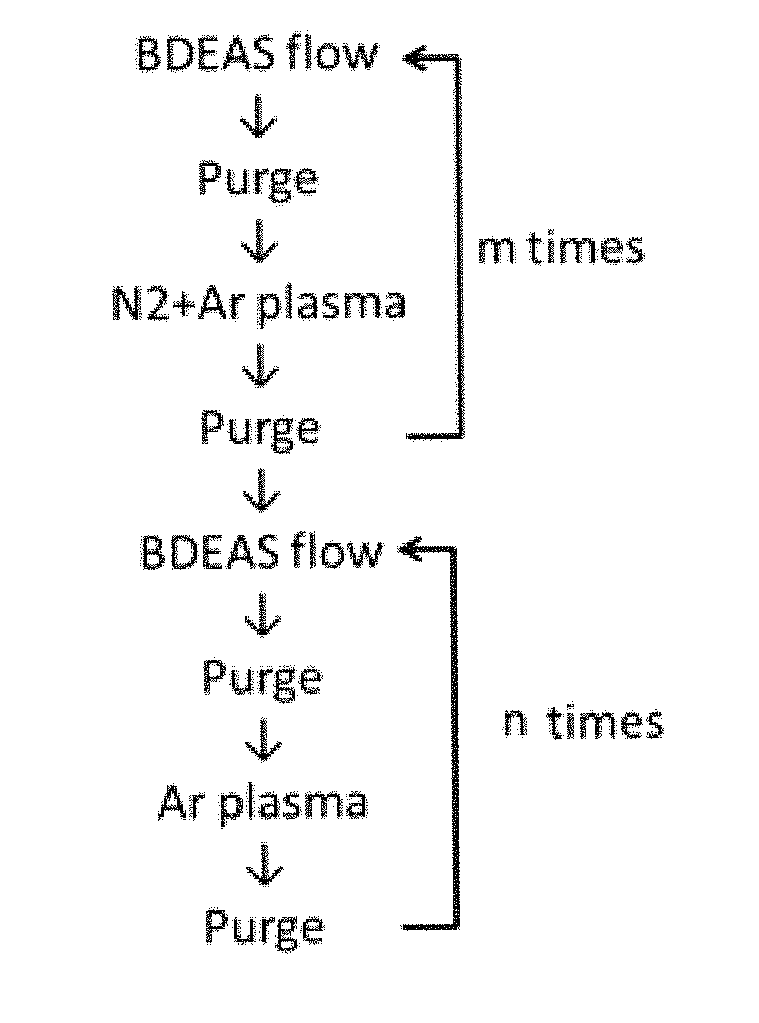

Method for Forming Dielectric Film Containing Si-C bonds by Atomic Layer Deposition Using Precursor Containing Si-C-Si bond

InactiveUS20130224964A1Good step coverageSemiconductor/solid-state device manufacturingChemical vapor deposition coatingNoble gasOxygen

A method of forming a dielectric film having Si—C bonds on a semiconductor substrate by atomic layer deposition (ALD), includes: (i) adsorbing a precursor on a surface of a substrate; (ii) reacting the adsorbed precursor and a reactant gas on the surface; and (iii) repeating steps (i) and (ii) to form a dielectric film having at least Si—C bonds on the substrate. The precursor has a Si—C—Si bond in its molecule, and the reactant gas is oxygen-free and halogen-free and is constituted by at least a rare gas.

Owner:ASM IP HLDG BV

Method of depositing dielectric film by modified peald method

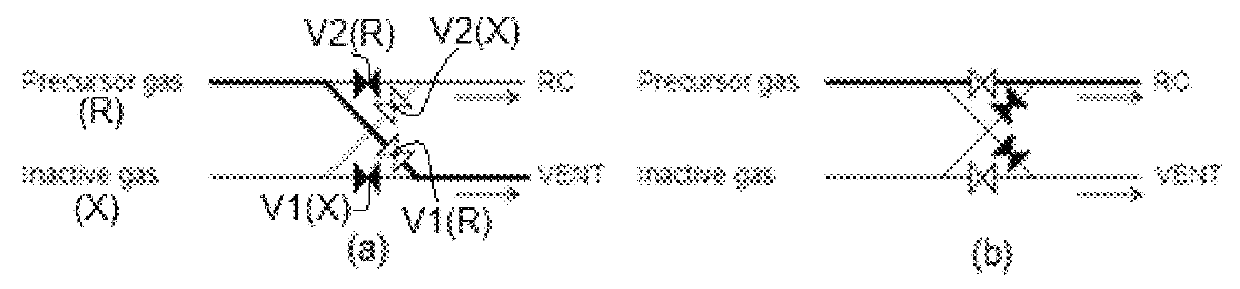

ActiveUS20120220139A1Increase deposition rateHigh conformalitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingNoble gasHydrogen

A method of forming a film on a semiconductor substrate by plasma enhanced atomic layer deposition (PEALD), includes: introducing a nitrogen- and hydrogen-containing reactive gas and a rare gas into a reaction space inside which the semiconductor substrate is placed; introducing a precursor in pulses of less than 1.0-second duration into the reaction space wherein the reactive gas and the rare gas are introduced; exiting a plasma in pulses of less than 1.0-second duration immediately after the precursor is shut off; and maintaining the reactive gas and the rare gas as a purge of less than 2.0-second duration.

Owner:ASM JAPAN

Method of forming conformal dielectric film having Si-N bonds by PECVD

ActiveUS7972980B2Increase deposition rateHigh conformalitySemiconductor/solid-state device detailsSolid-state devicesDielectricNoble gas

Owner:ASM JAPAN

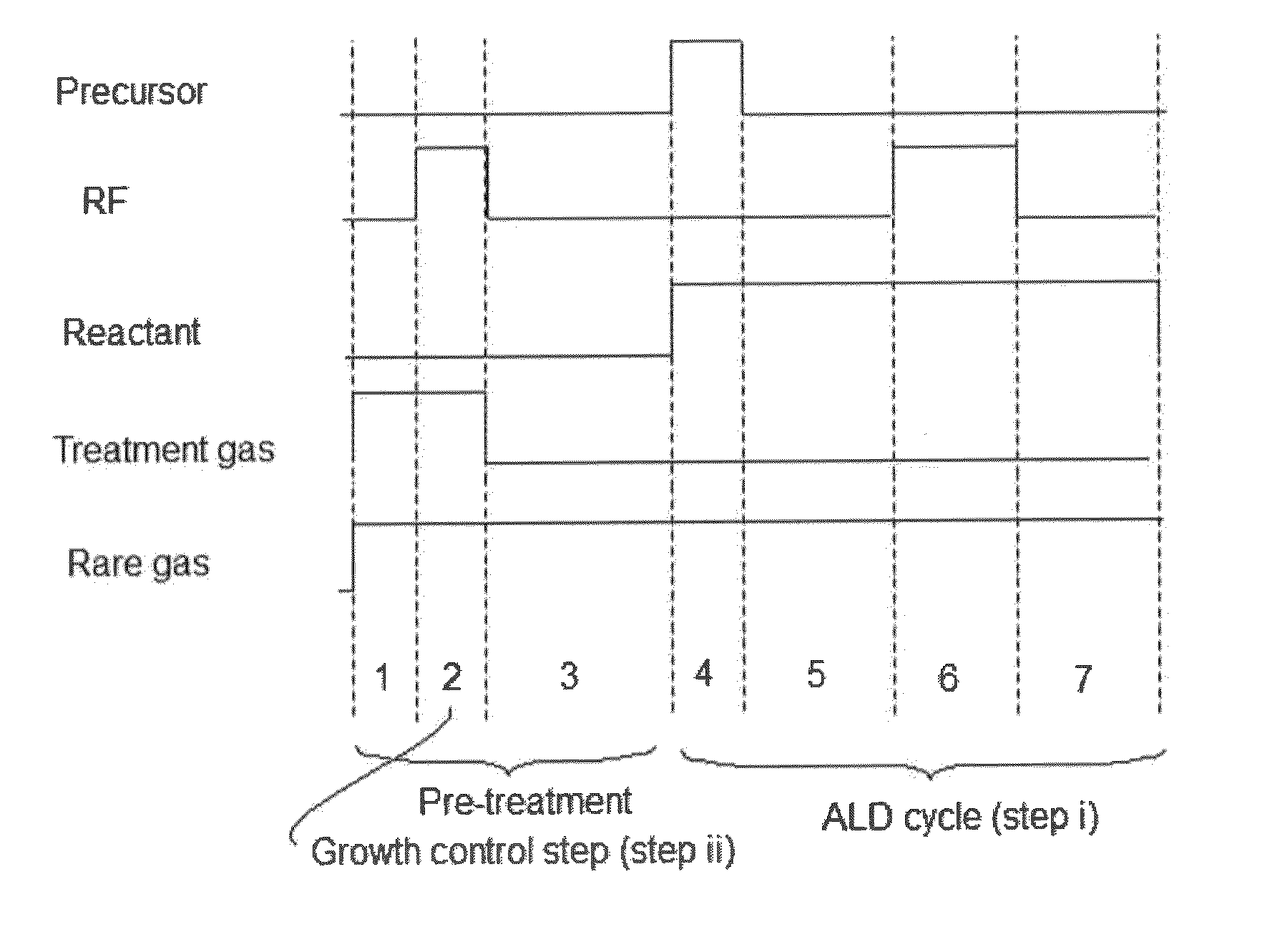

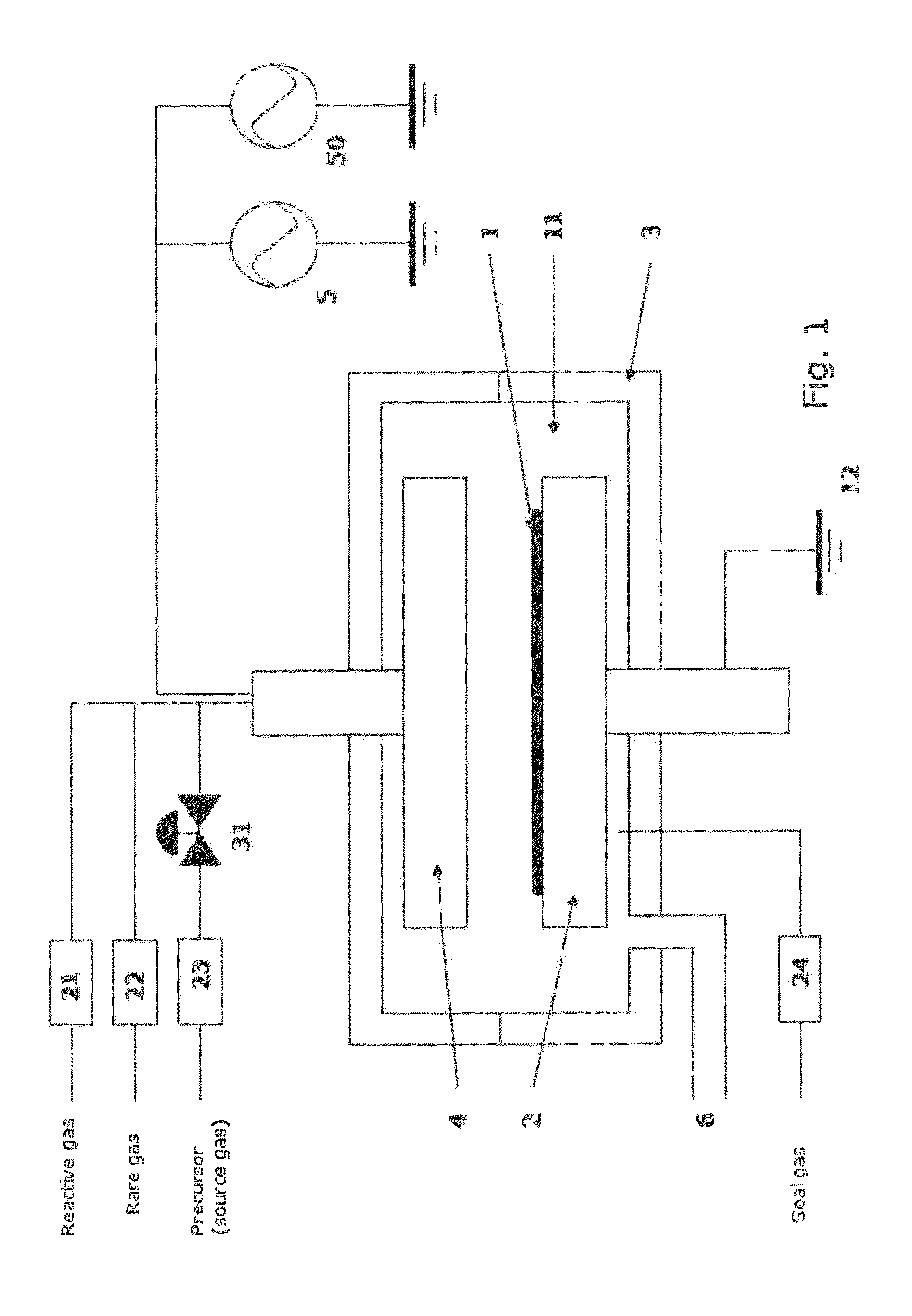

Method for forming silicon-containing dielectric film by cyclic deposition with side wall coverage control

ActiveUS8722546B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingDielectricNoble gas

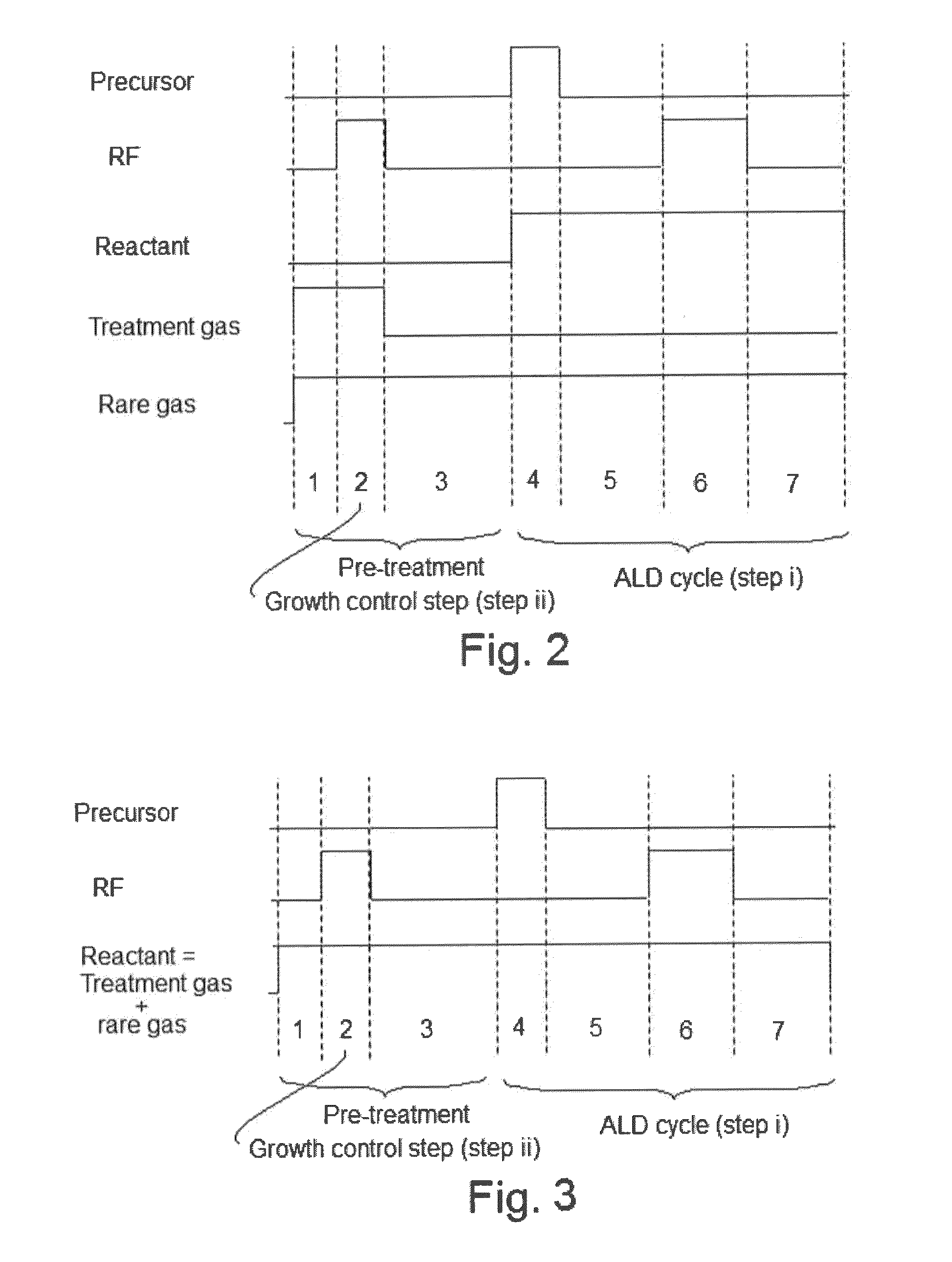

A method of forming a dielectric film having Si—C bonds and / or Si—N bonds on a semiconductor substrate by cyclic deposition, includes: (i) conducting one or more cycles of cyclic deposition in a reaction space wherein a semiconductor substrate is placed, using a Si-containing precursor and a reactant gas; and (ii) before or after step (i), applying a pulse of RF power to the reaction space while supplying a rare gas and a treatment gas without supplying a Si-containing precursor, whereby a dielectric film having Si—C bonds and / or Si—N bonds is formed on the semiconductor substrate.

Owner:ASM IP HLDG BV

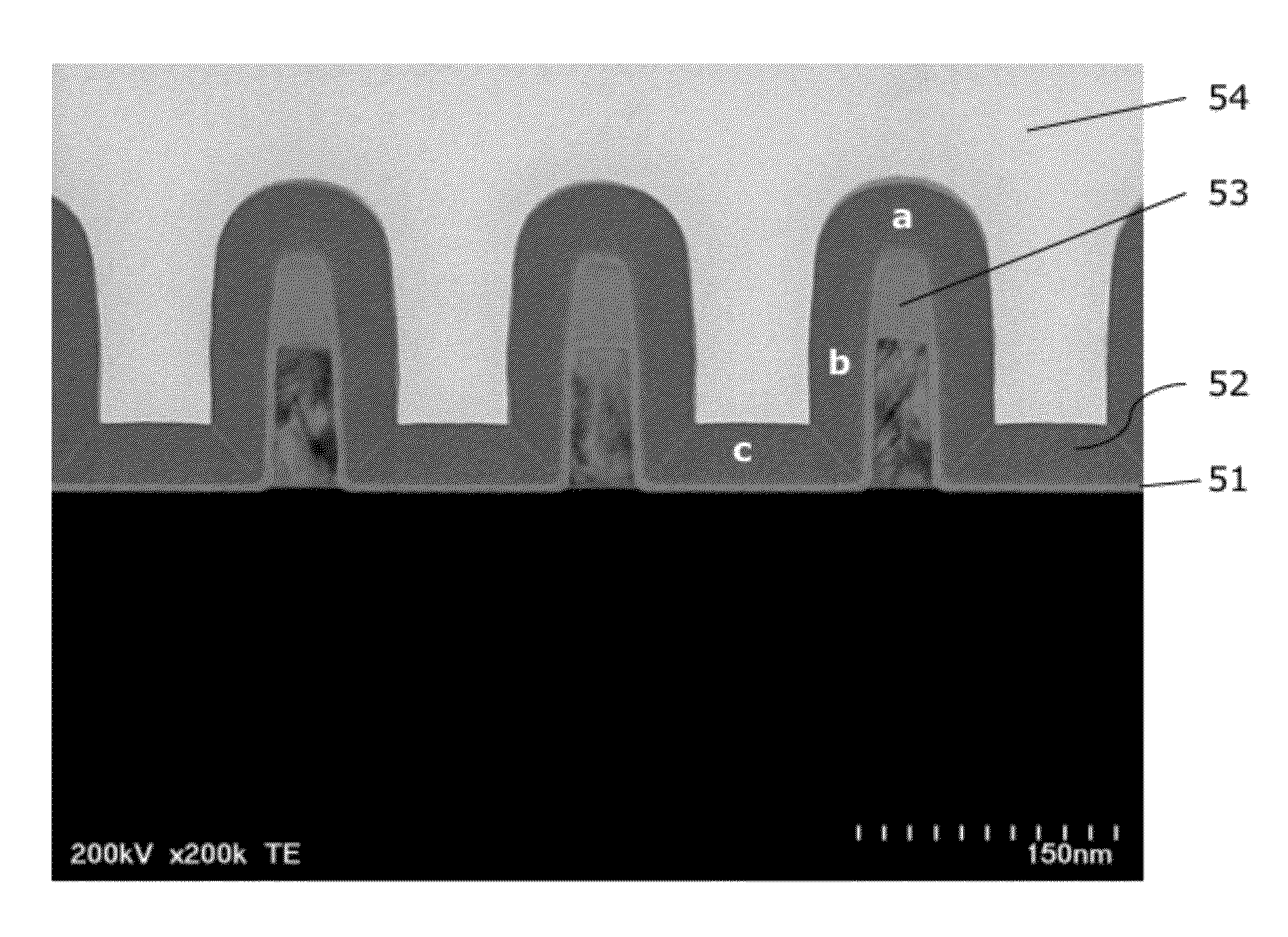

Method for forming dielectric film in trenches by PEALD using H-containing gas

ActiveUS9455138B1Increase deposition rateHigh film thicknessSemiconductor/solid-state device manufacturingChemical physicsNoble gas

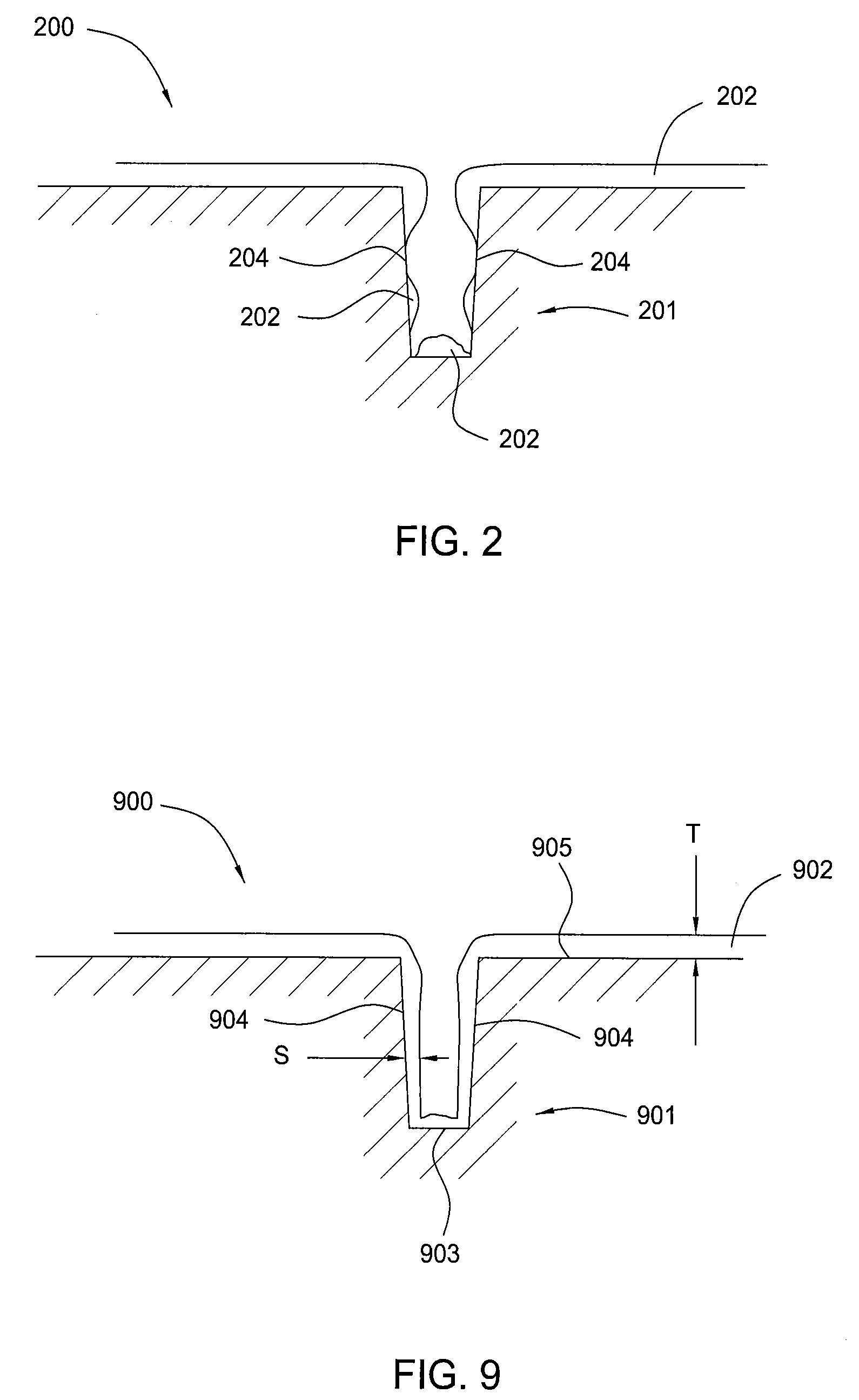

A method for forming a dielectric film in a trench on a substrate by plasma-enhanced atomic layer deposition (PEALD) performs one or more process cycles, each process cycle including: (i) feeding a silicon-containing precursor in a pulse; (ii) supplying a hydrogen-containing reactant gas at a flow rate of more than about 30 sccm but less than about 800 sccm in the absence of nitrogen-containing gas; (iii) supplying a noble gas to the reaction space; and (iv) applying RF power in the presence of the reactant gas and the noble gas and in the absence of any precursor in the reaction space, to form a monolayer constituting a dielectric film on a substrate at a growth rate of less than one atomic layer thickness per cycle.

Owner:ASM IP HLDG BV

Method For Depositing an Amorphous Carbon Film with Improved Density and Step Coverage

ActiveUS20080003824A1High densityLower thermal budgetPretreated surfacesSemiconductor/solid-state device manufacturingCarbon layerKrypton

A method for depositing an amorphous carbon layer on a substrate includes the steps of positioning a substrate in a chamber, introducing a hydrocarbon source into the processing chamber, introducing a heavy noble gas into the processing chamber, and generating a plasma in the processing chamber. The heavy noble gas is selected from the group consisting of argon, krypton, xenon, and combinations thereof and the molar flow rate of the noble gas is greater than the molar flow rate of the hydrocarbon source. A post-deposition termination step may be included, wherein the flow of the hydrocarbon source and the noble gas is stopped and a plasma is maintained in the chamber for a period of time to remove particles therefrom.

Owner:APPLIED MATERIALS INC

Method of depositing dielectric film by modified PEALD method

ActiveUS8415259B2Increase deposition rateHigh conformalitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingElectricityNoble gas

A method of forming a film on a semiconductor substrate by plasma enhanced atomic layer deposition (PEALD), includes: introducing a nitrogen- and hydrogen-containing reactive gas and a rare gas into a reaction space inside which the semiconductor substrate is placed; introducing a precursor in pulses of less than 1.0-second duration into the reaction space wherein the reactive gas and the rare gas are introduced; exiting a plasma in pulses of less than 1.0-second duration immediately after the precursor is shut off; and maintaining the reactive gas and the rare gas as a purge of less than 2.0-second duration.

Owner:ASM JAPAN

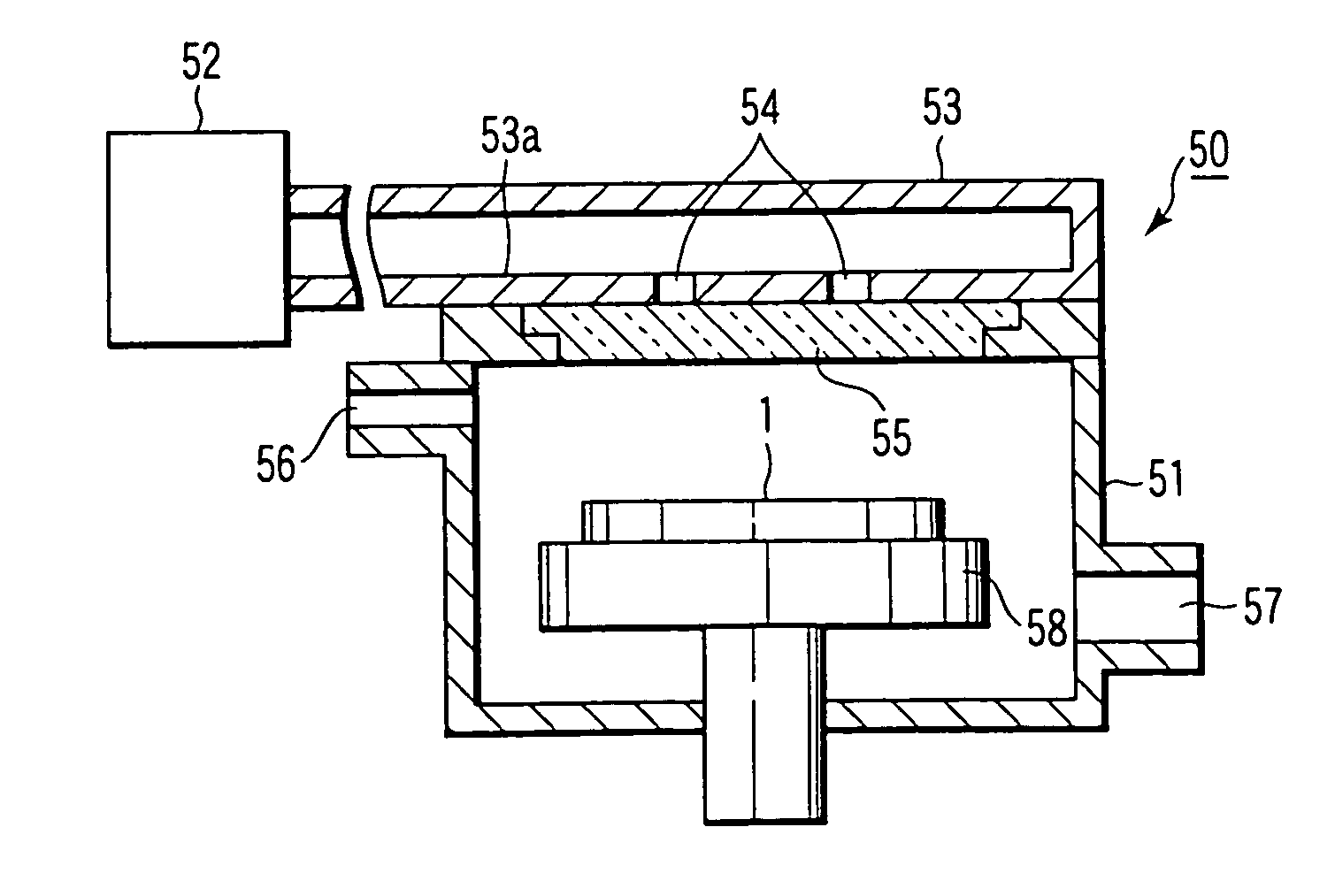

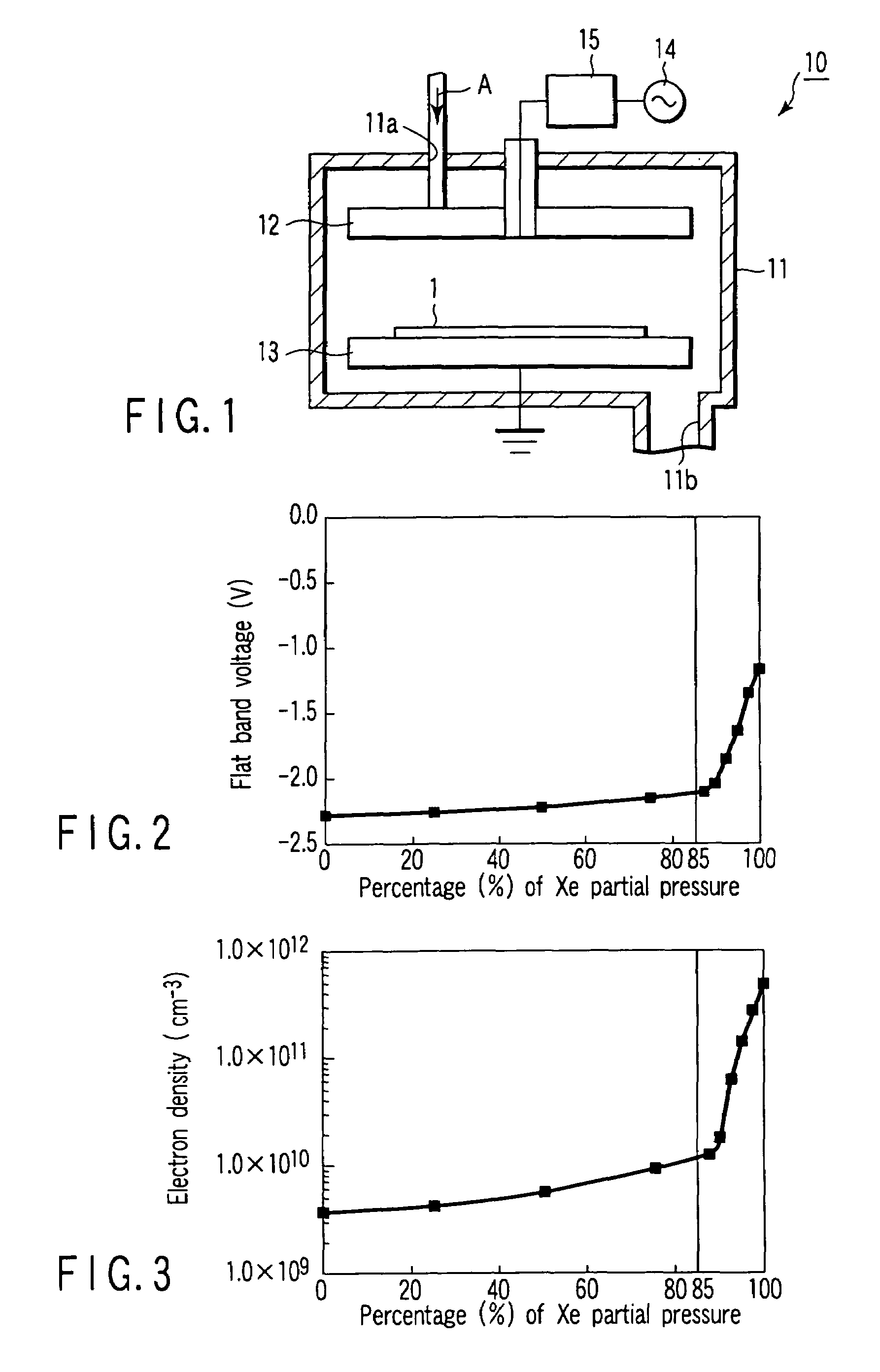

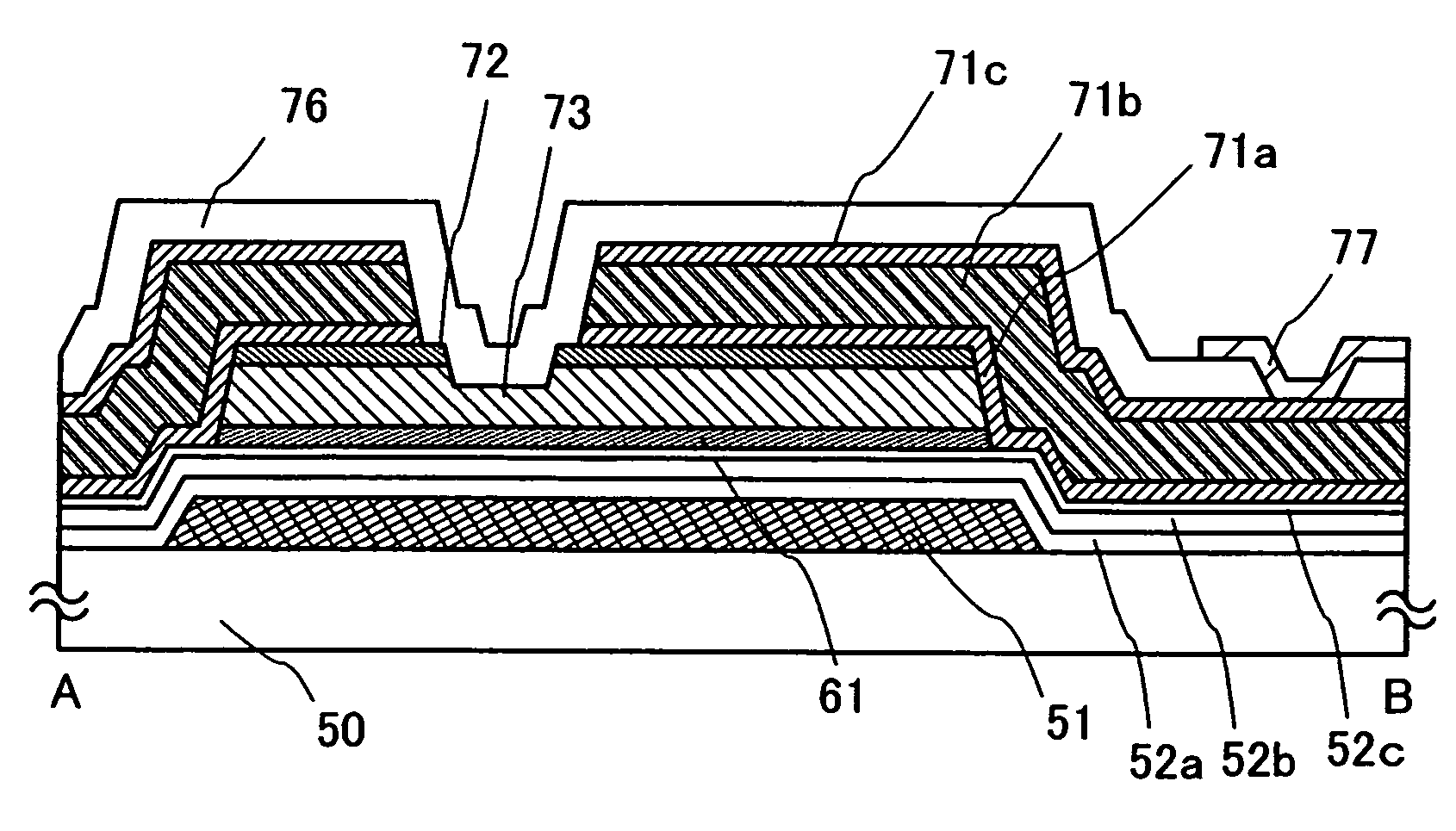

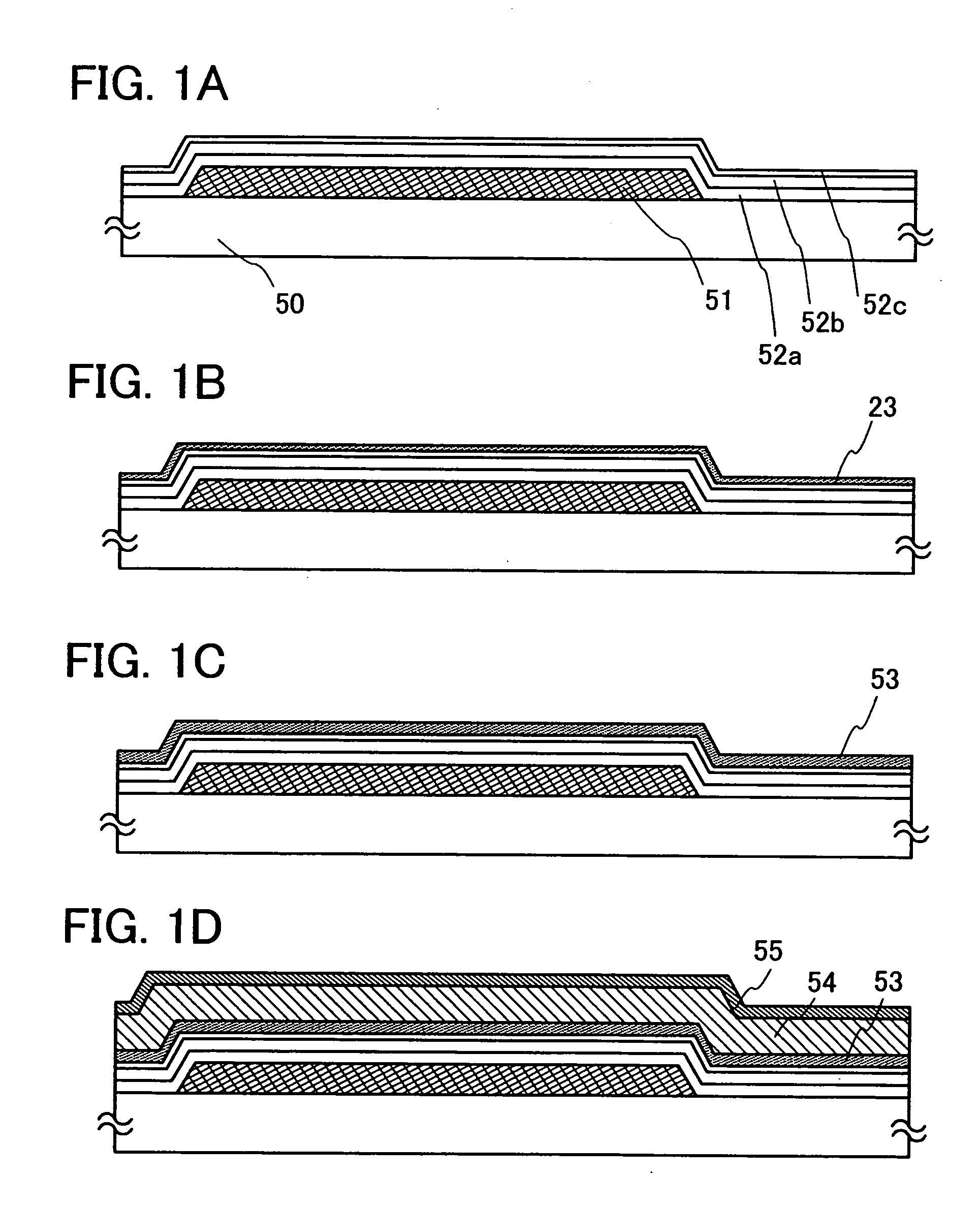

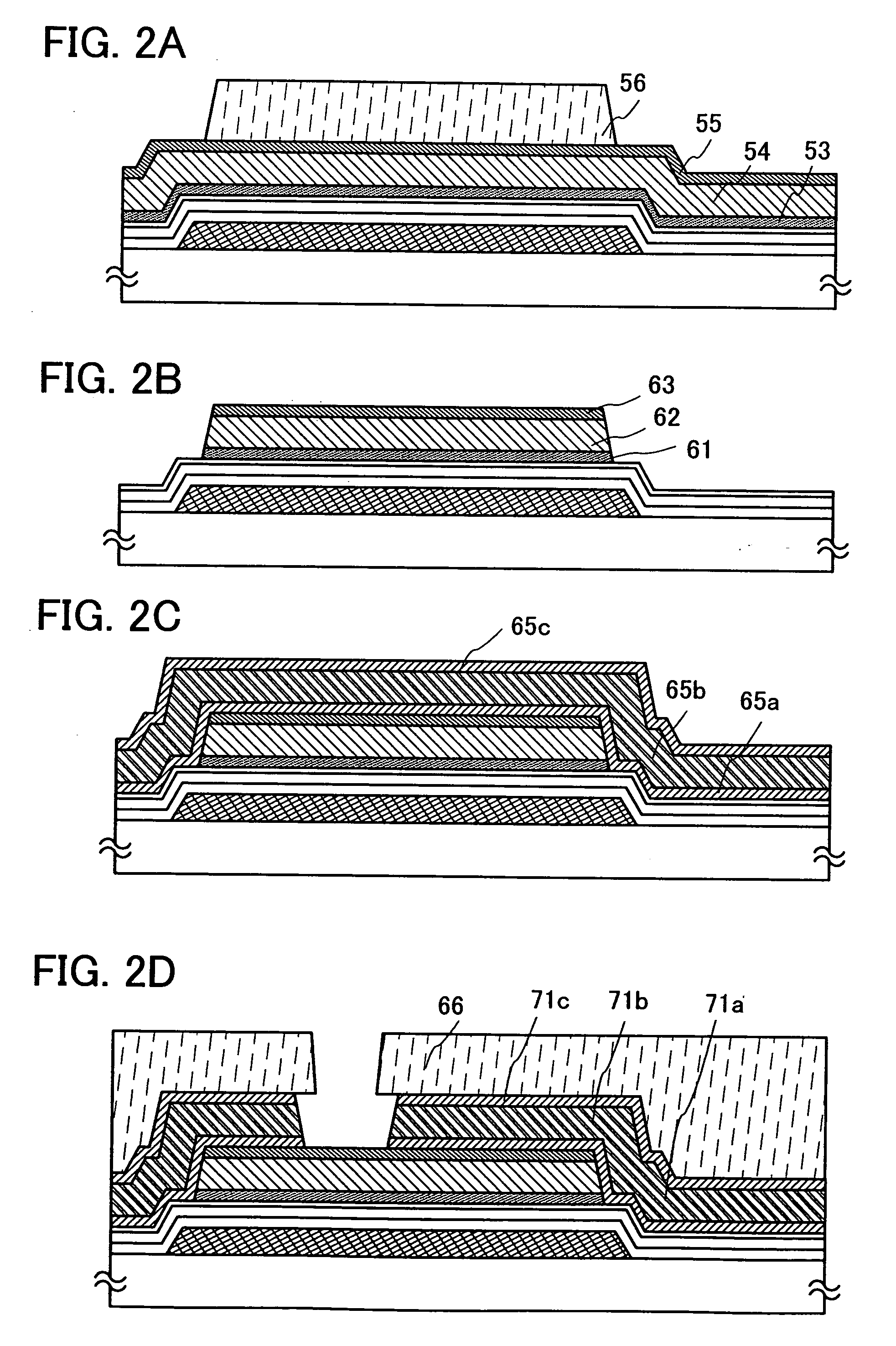

Film-forming method, method of manufacturing semiconductor device, semiconductor device, method of manufacturing display device, and display device

InactiveUS7307028B2Small currentTransistorSemiconductor/solid-state device manufacturingNoble gasDevice material

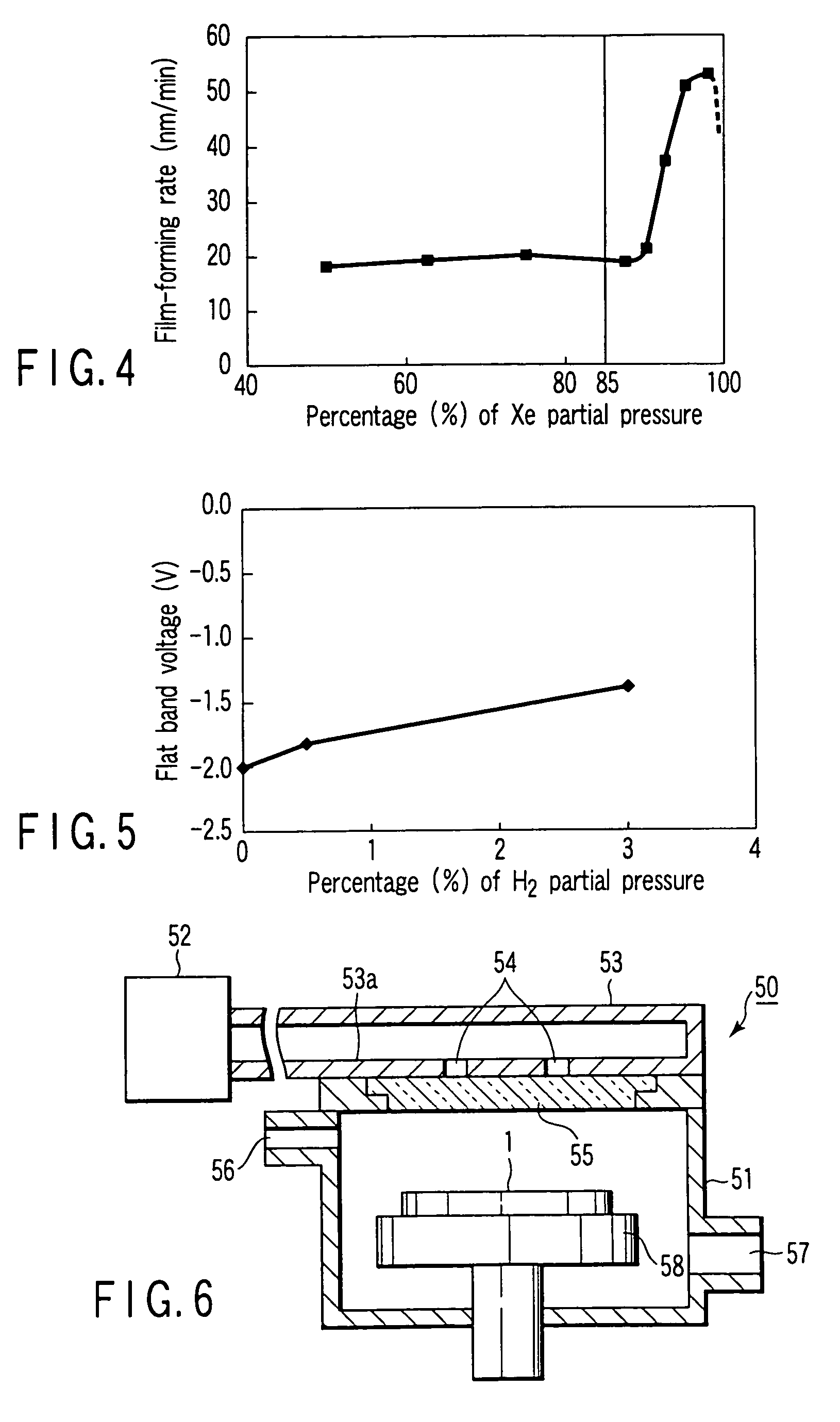

Disclosed is a film-forming method, comprising supplying into a plasma processing chamber at least three kinds of gases including a silicon compound gas, an oxidizing gas, and a rare gas, the percentage of the partial pressure of the rare gas (Pr) based on the total pressure being not smaller than 85%, i.e., 85%≦Pr<100%, and generating a plasma within the plasma processing chamber so as to form a film of silicon oxide on a substrate to be processed.

Owner:ADVANCED LCD TECH DEVMENT CENT

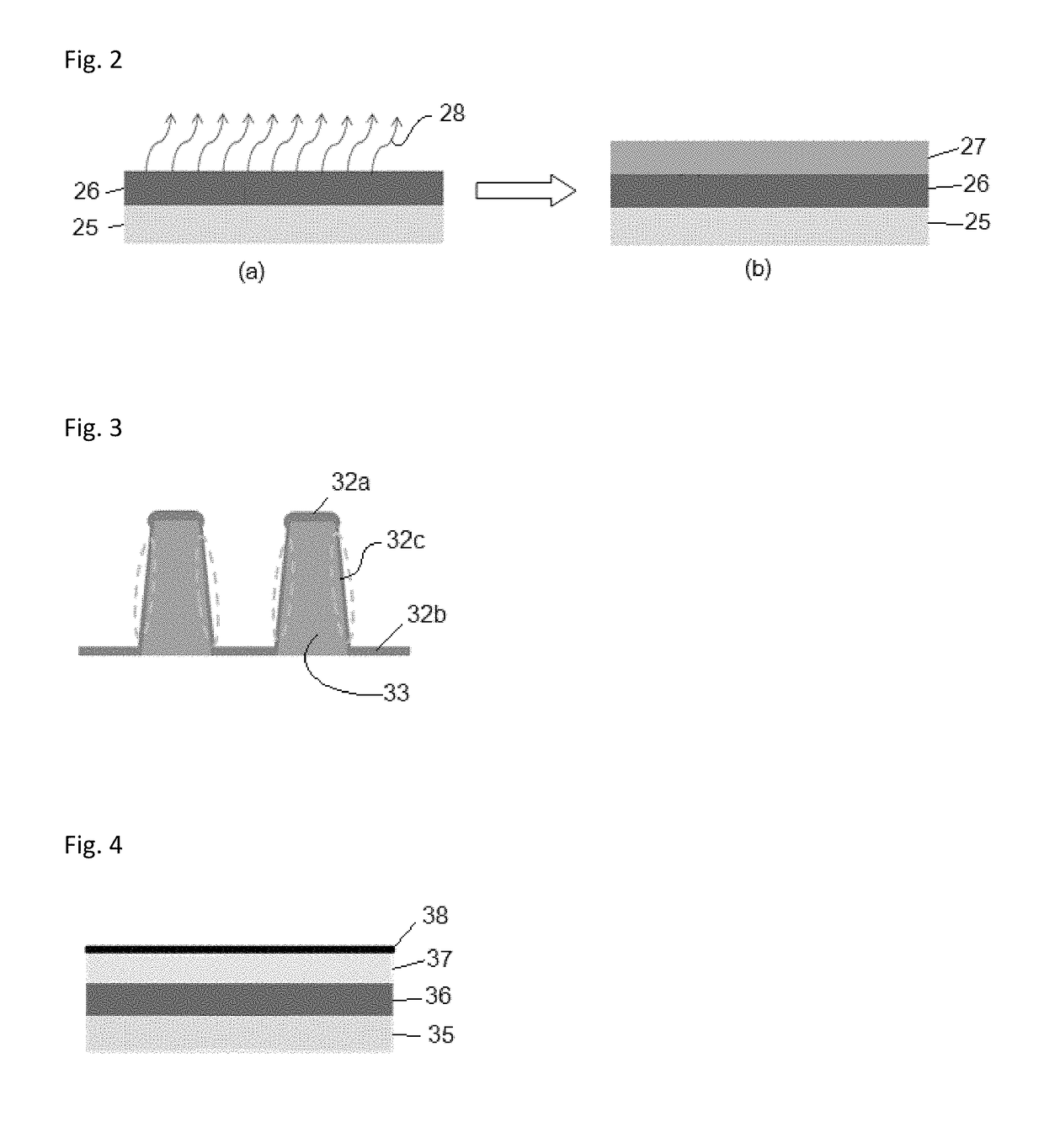

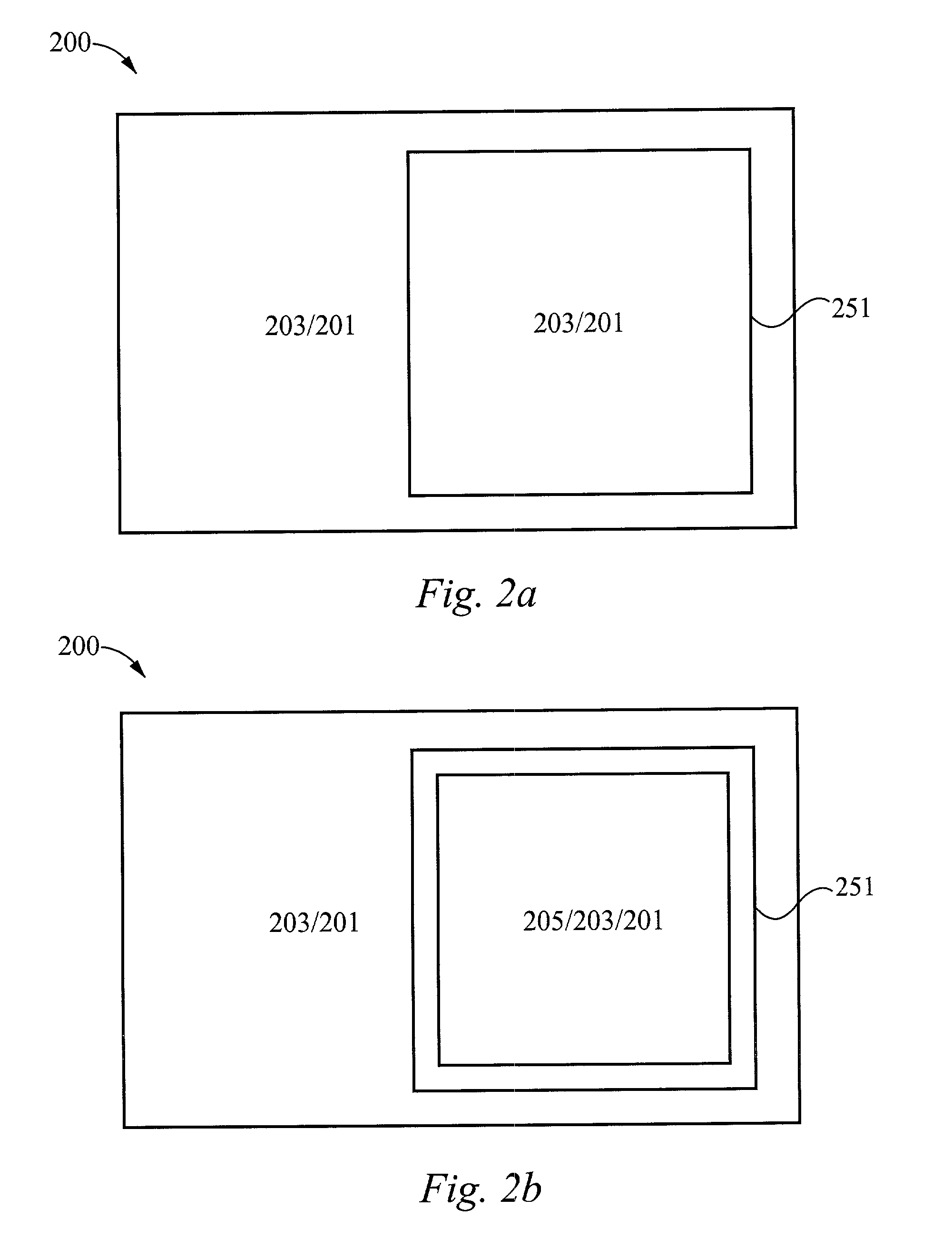

Method for protecting layer by forming hydrocarbon-based extremely thin film

ActiveUS20170018477A1Improve concentrationGood chemical resistanceSemiconductor/solid-state device detailsSolid-state devicesNoble gasProtection layer

A method for protecting a layer includes: providing a substrate having a target layer and forming a protective layer on the target layer, said protective layer contacting and covering the target layer and containing a hydrocarbon-based layer constituting at least an upper part of the protective layer, which hydrocarbon-based layer is formed by plasma-enhanced atomic layer deposition (PEALD) using an alkylaminosilane precursor and a noble gas without a reactant.

Owner:ASM IP HLDG BV

Method for protecting layer by forming hydrocarbon-based extremely thin film

ActiveUS9899291B2Improve concentrationGood chemical resistanceSemiconductor/solid-state device detailsSolid-state devicesNoble gasOptoelectronics

A method for protecting a layer includes: providing a substrate having a target layer and forming a protective layer on the target layer, said protective layer contacting and covering the target layer and containing a hydrocarbon-based layer constituting at least an upper part of the protective layer, which hydrocarbon-based layer is formed by plasma-enhanced atomic layer deposition (PEALD) using an alkylaminosilane precursor and a noble gas without a reactant.

Owner:ASM IP HLDG BV

Method for protecting layer by forming hydrocarbon-based extremely thin film

ActiveUS10043661B2Improve concentrationGood chemical resistanceSemiconductor/solid-state device manufacturingChemical vapor deposition coatingNoble gasProtection layer

A method for protecting a layer includes: providing a substrate having a target layer; depositing a protective layer on the target layer, which protective layer contacts and covers the target layer and is constituted by a hydrocarbon-based layer; and depositing an oxide layer on the protective layer so that the protective layer in contact with the oxide layer is oxidized. The hydrocarbon-based layer is formed by plasma-enhanced atomic layer deposition (PEALD) using an alkylaminosilane precursor and a noble gas without a reactant.

Owner:ASM IP HLDG BV

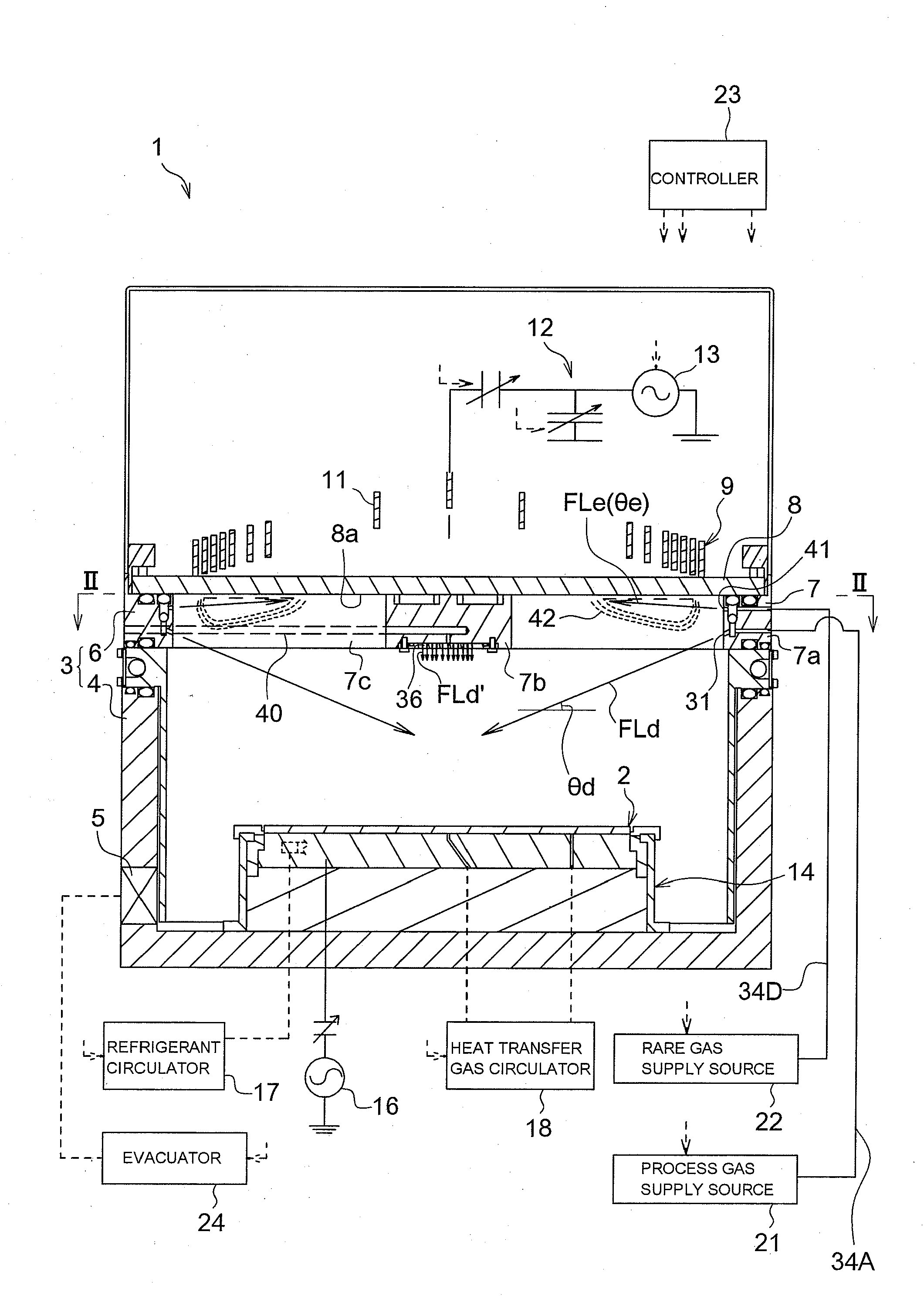

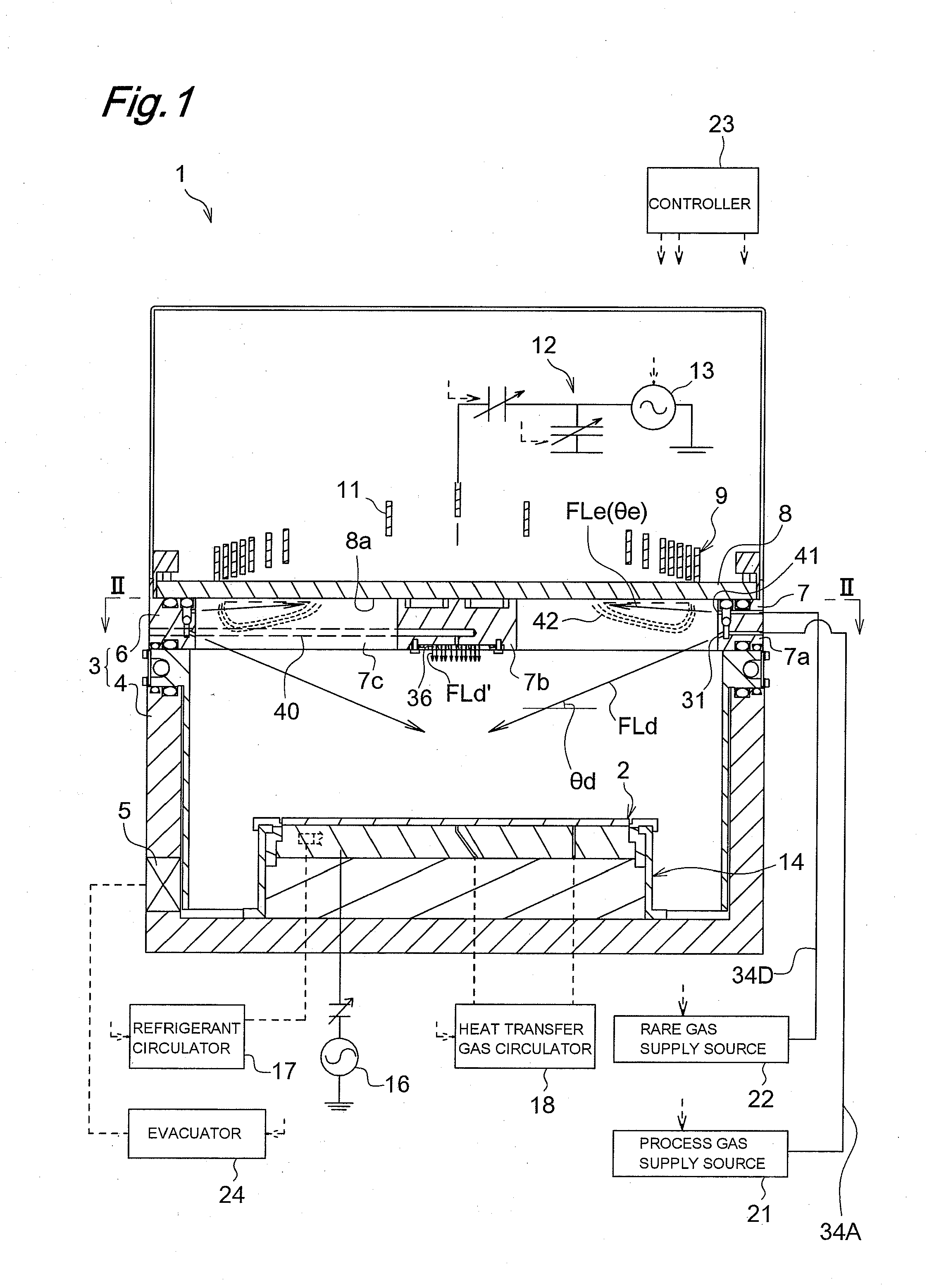

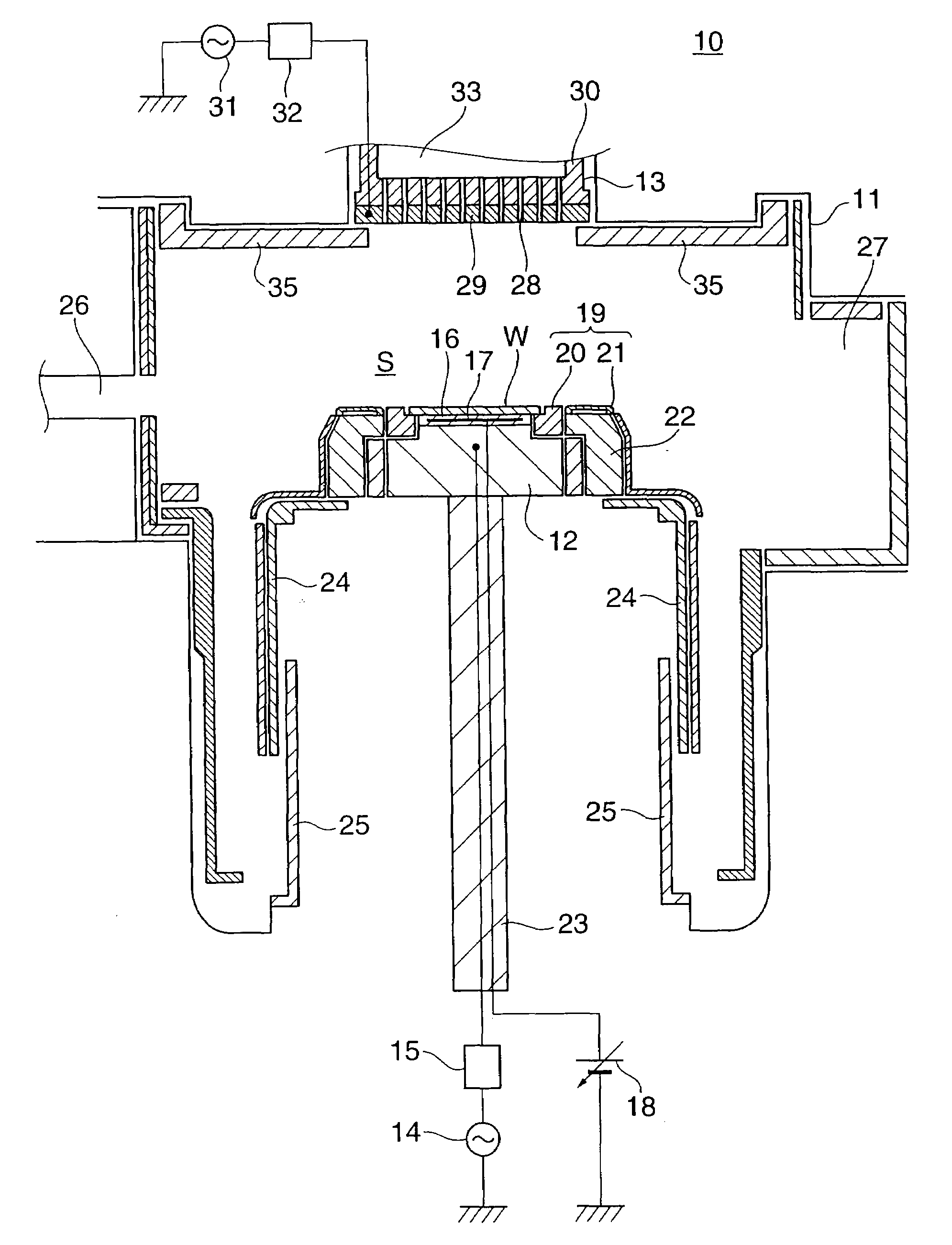

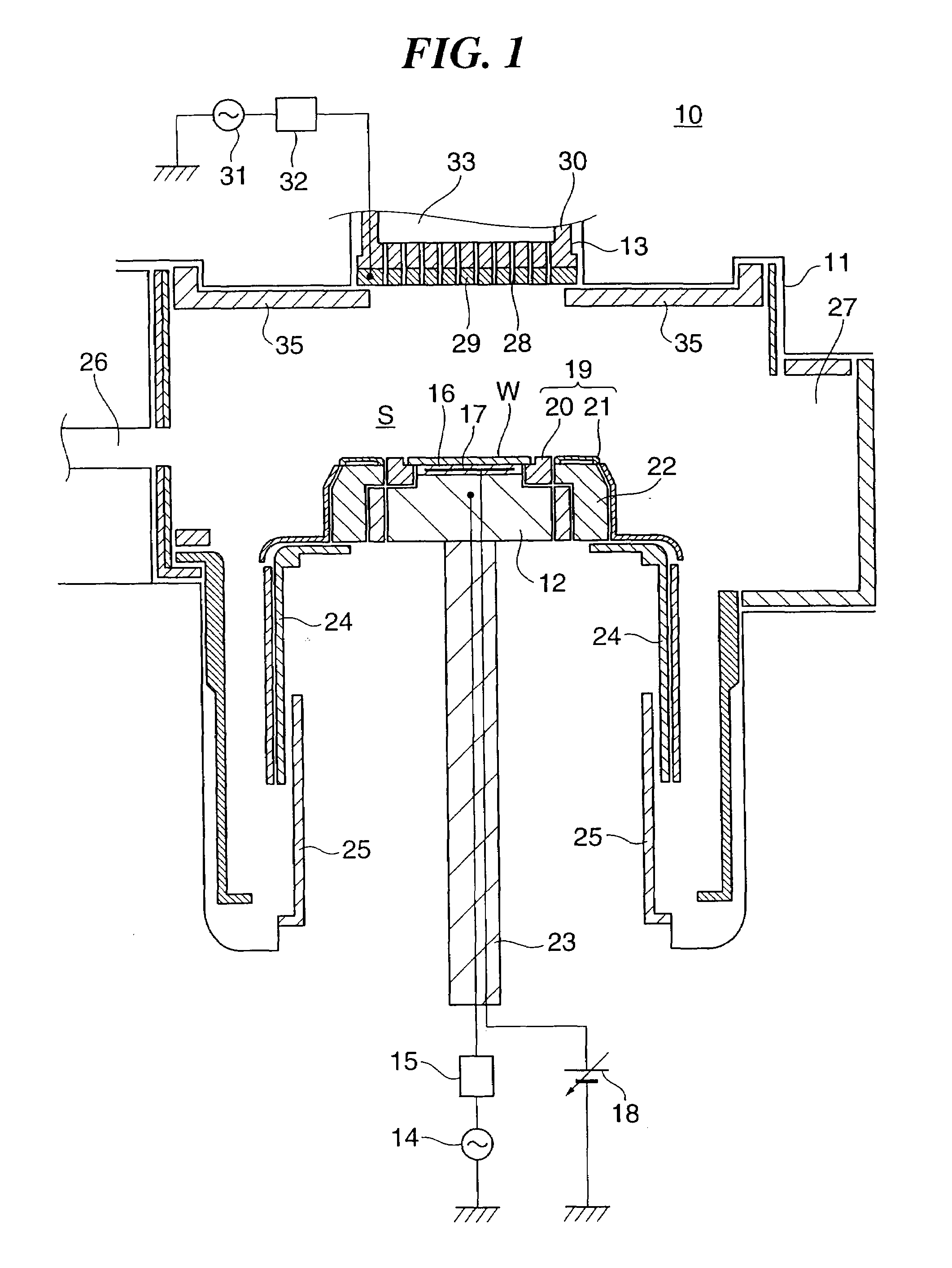

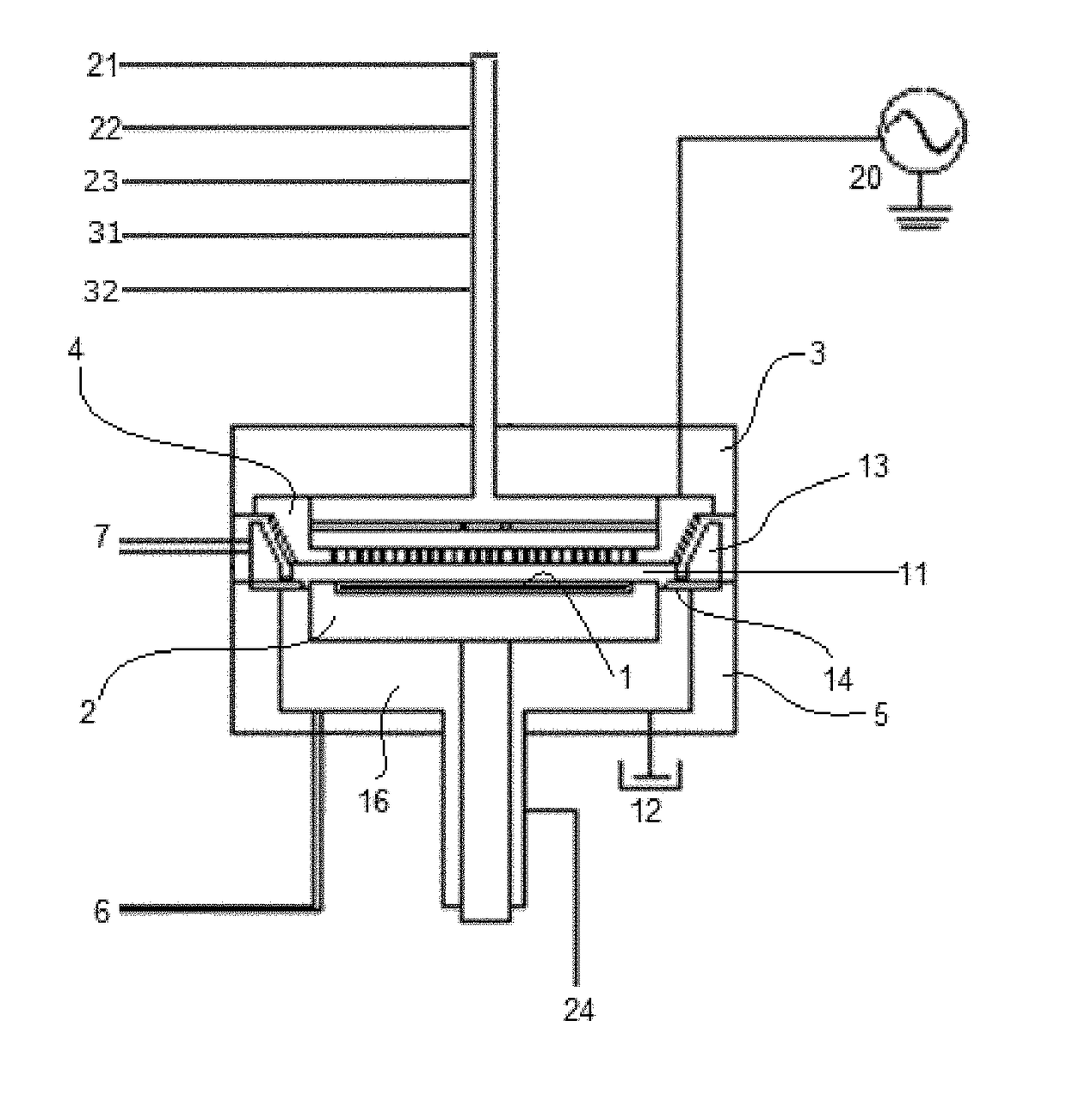

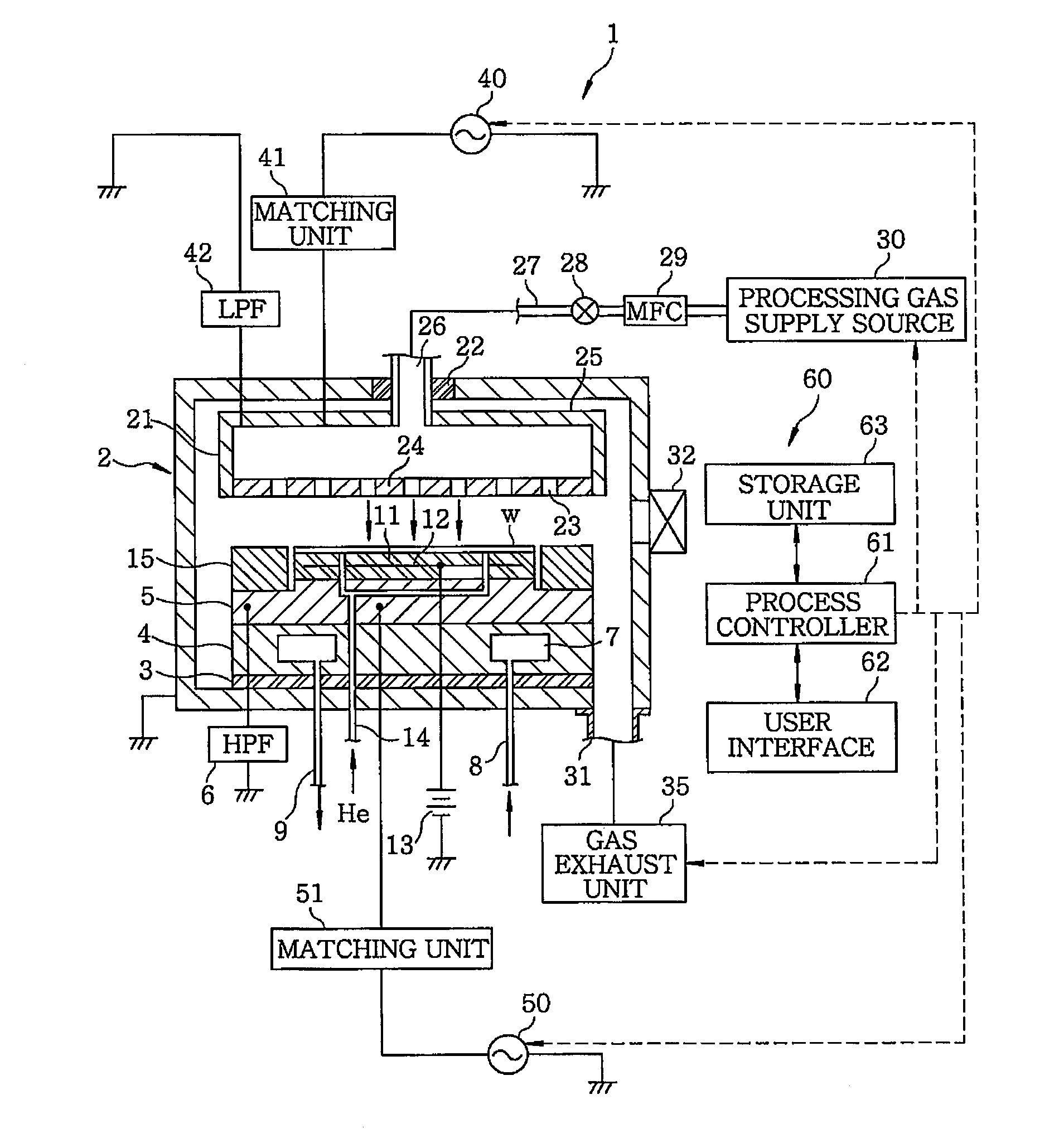

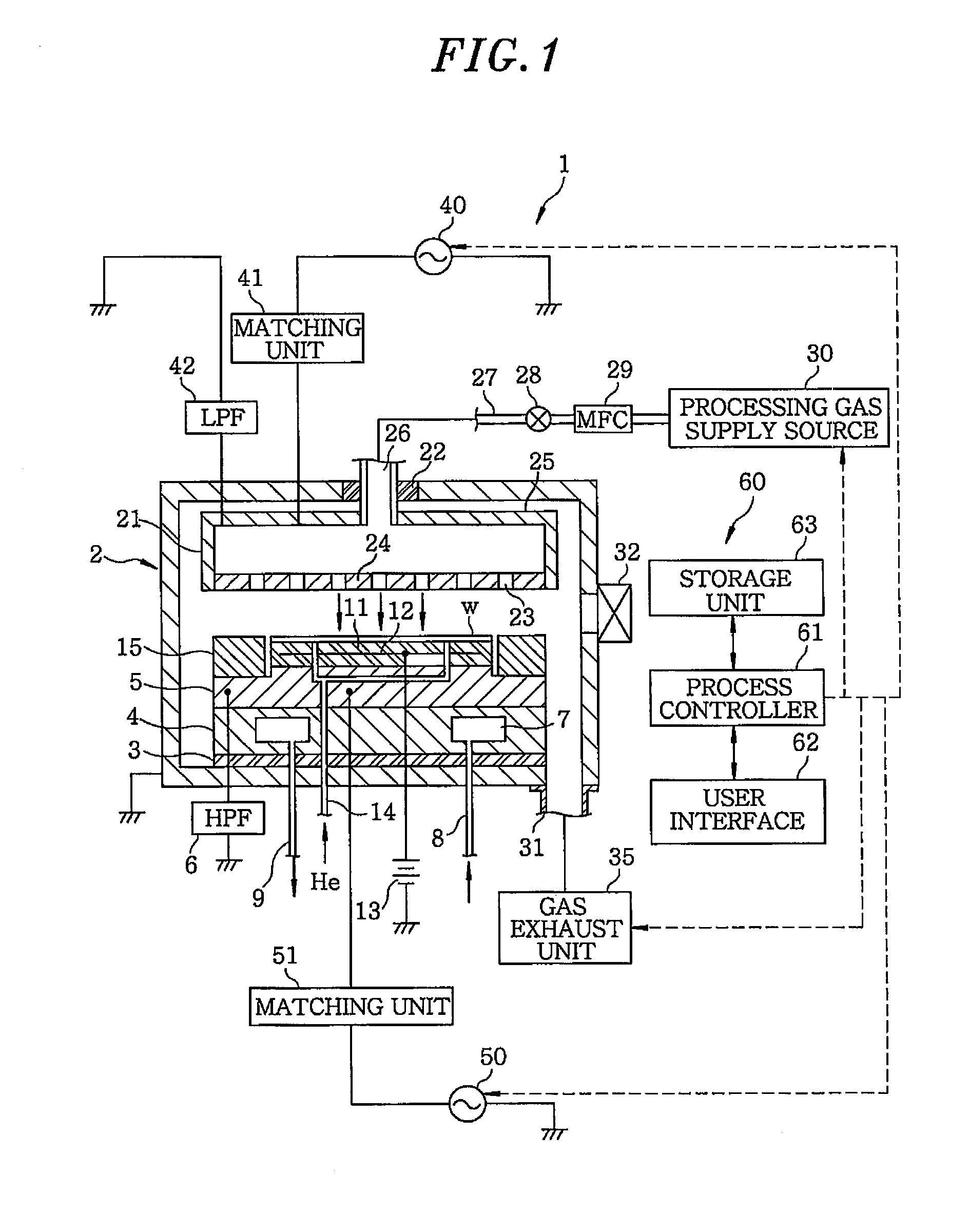

Plasma processing apparatus and plasma processing method

ActiveUS20100089870A1Improve processing speedEffective suppression of wearElectric discharge tubesDecorative surface effectsElevation angleNoble gas

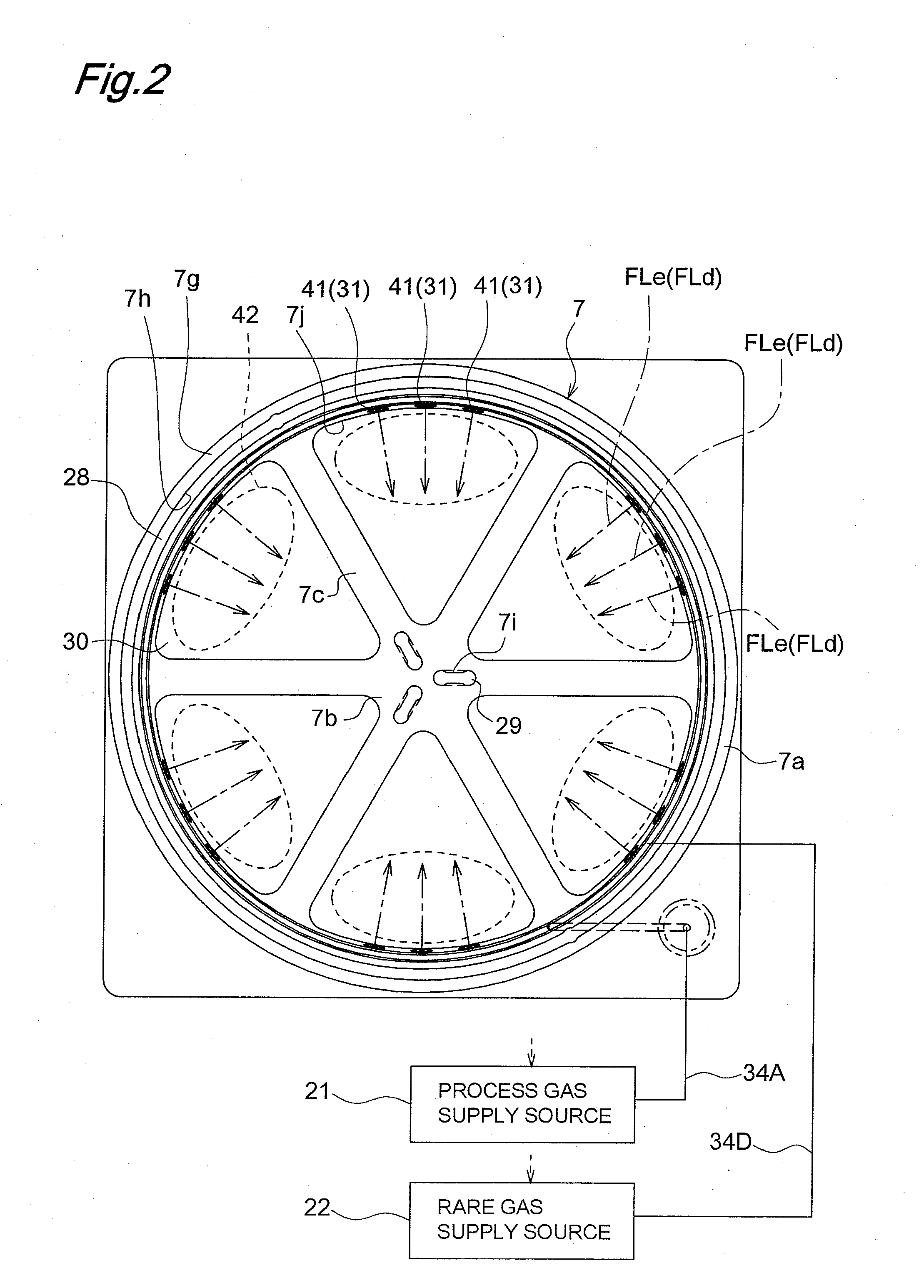

A plasma processing apparatus includes a beam-shaped spacer 7 which is placed at an upper opening of a chamber 3 opposed to a substrate 2 to support a dielectric plate 8. The dielectric plate 8 is supported by the beam-shaped spacer 7. In the beam-shaped spacer 7 are provided a plurality of process gas introducing ports 31, 36 which have a depression angle θd and which are provided downward and directed toward the substrate 2, as well as a plurality of rare gas introducing ports 41 having a elevation angle θe directed toward the dielectric plate 8. Improvement of processing rates such as etching rate as well as effective suppression of wear of the dielectric plate 8 can be achieved.

Owner:PANASONIC CORP

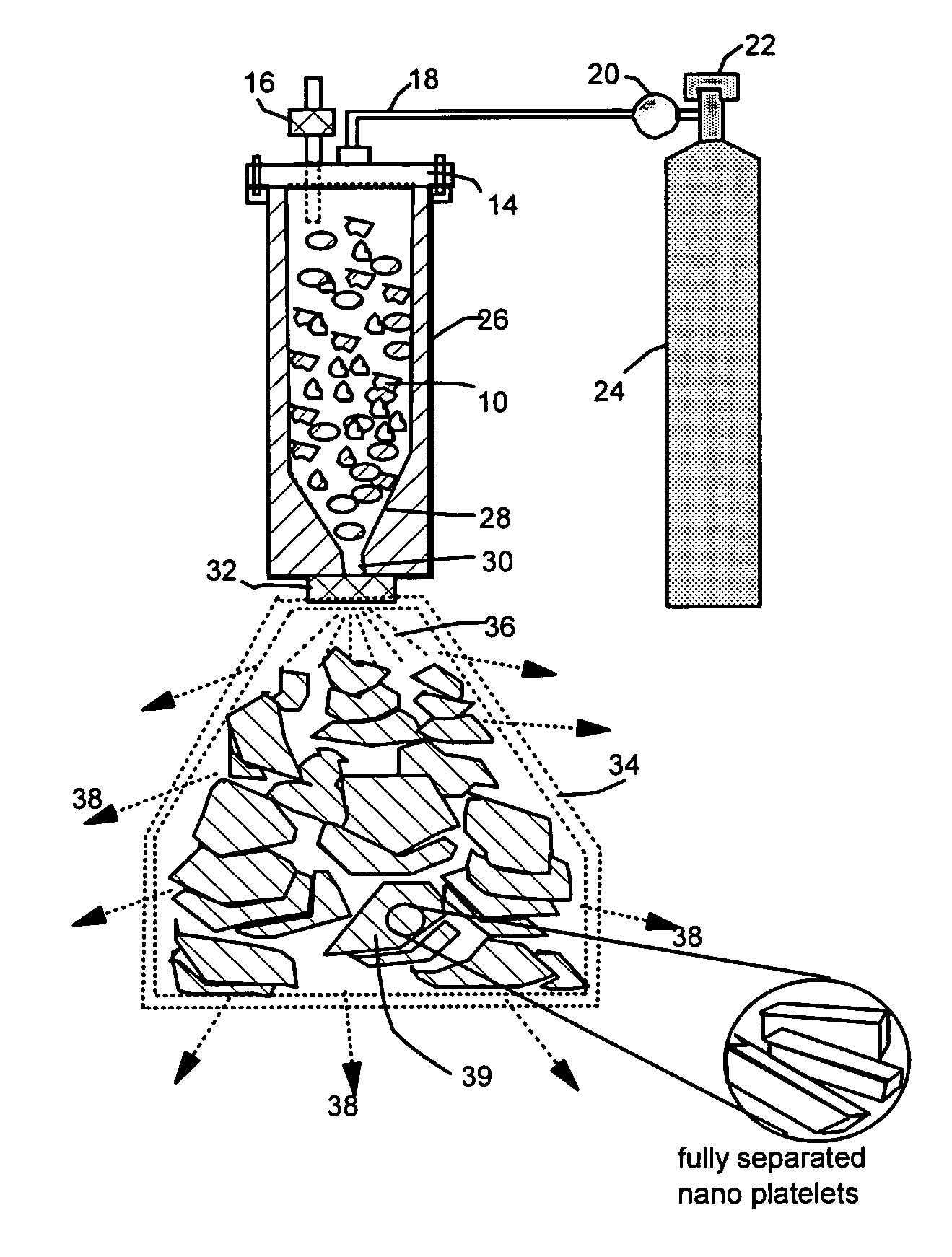

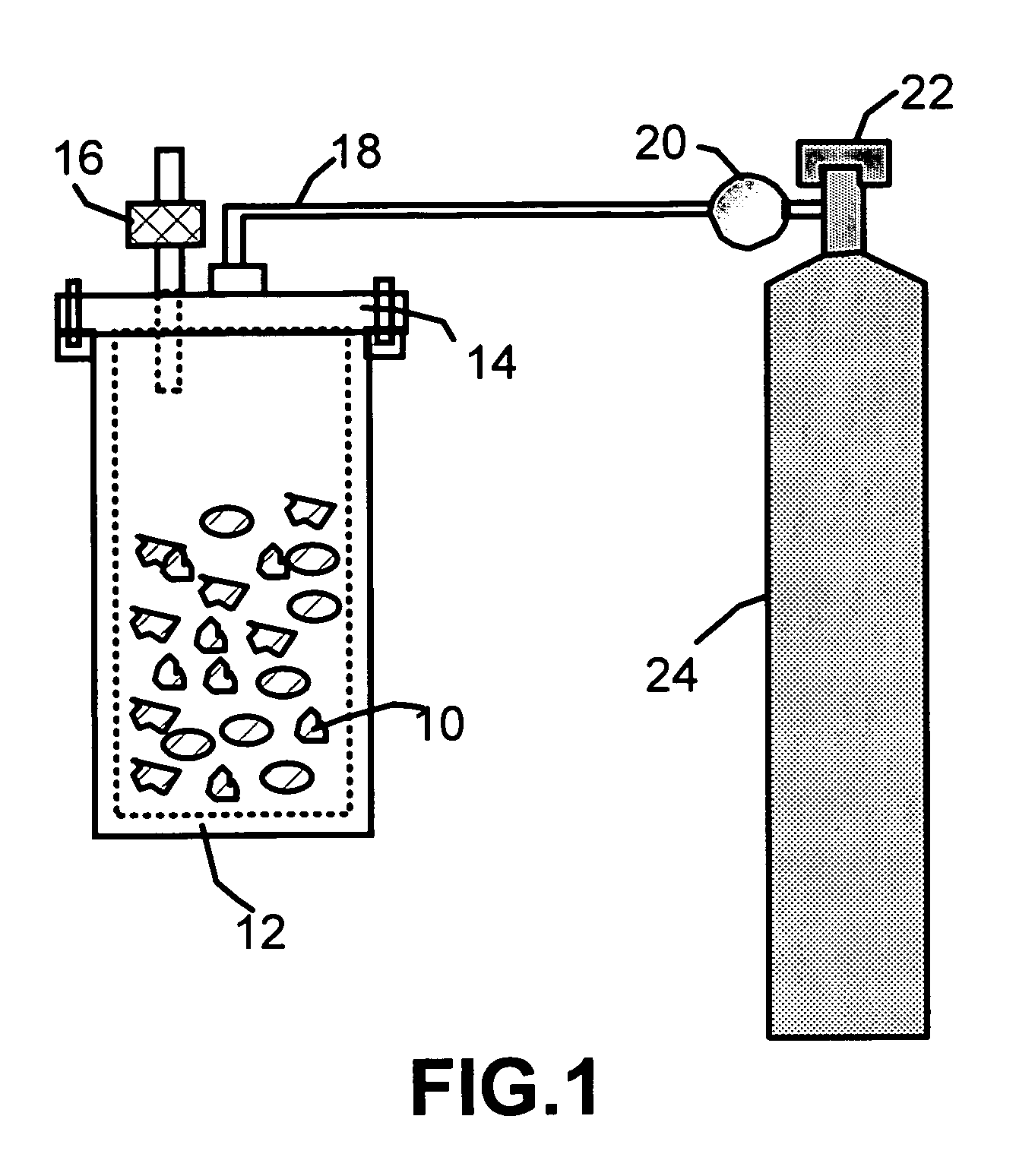

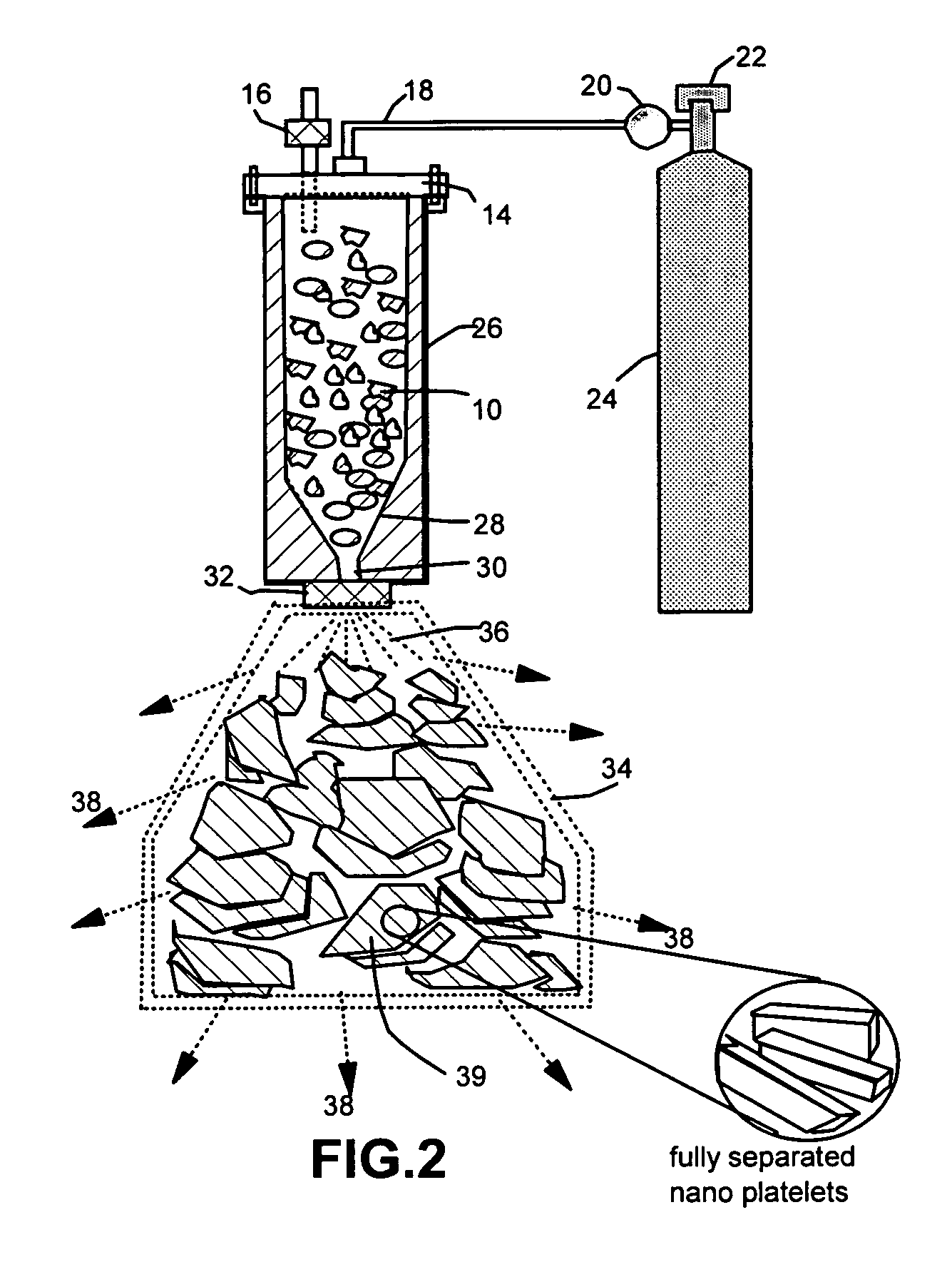

Process for producing nano-scaled platelets and nanocompsites

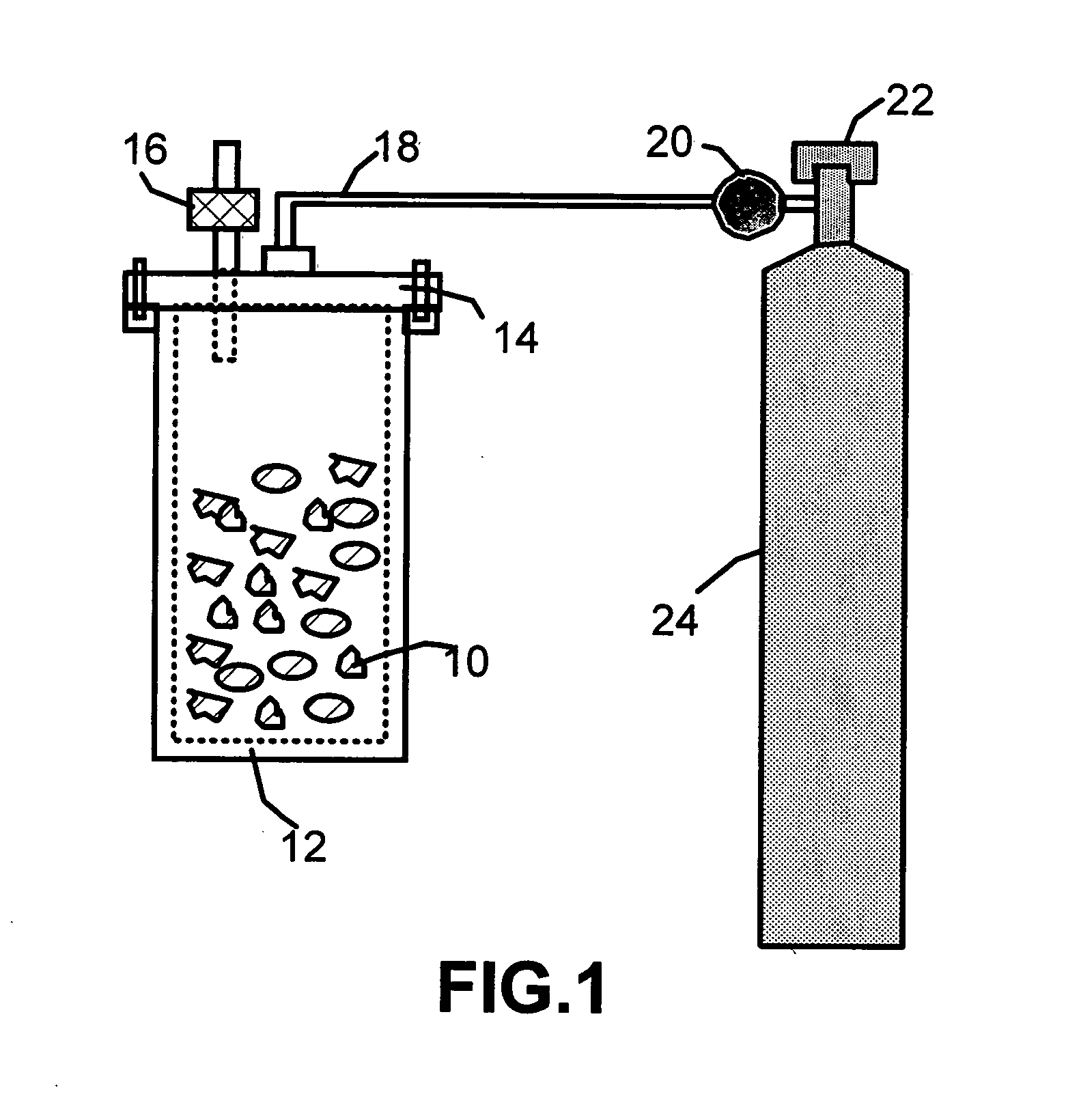

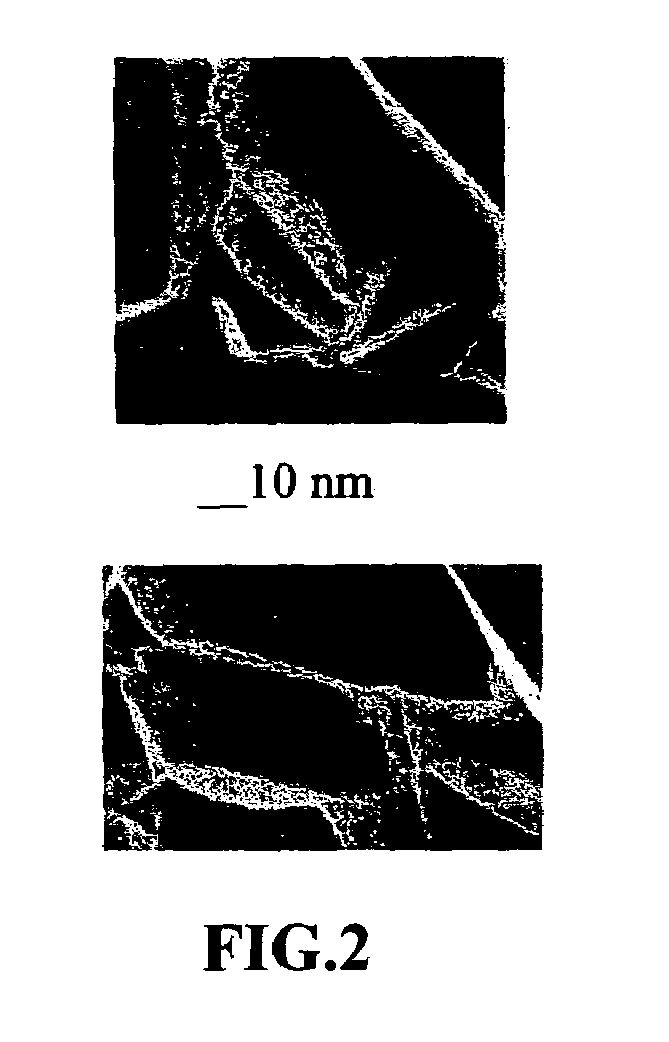

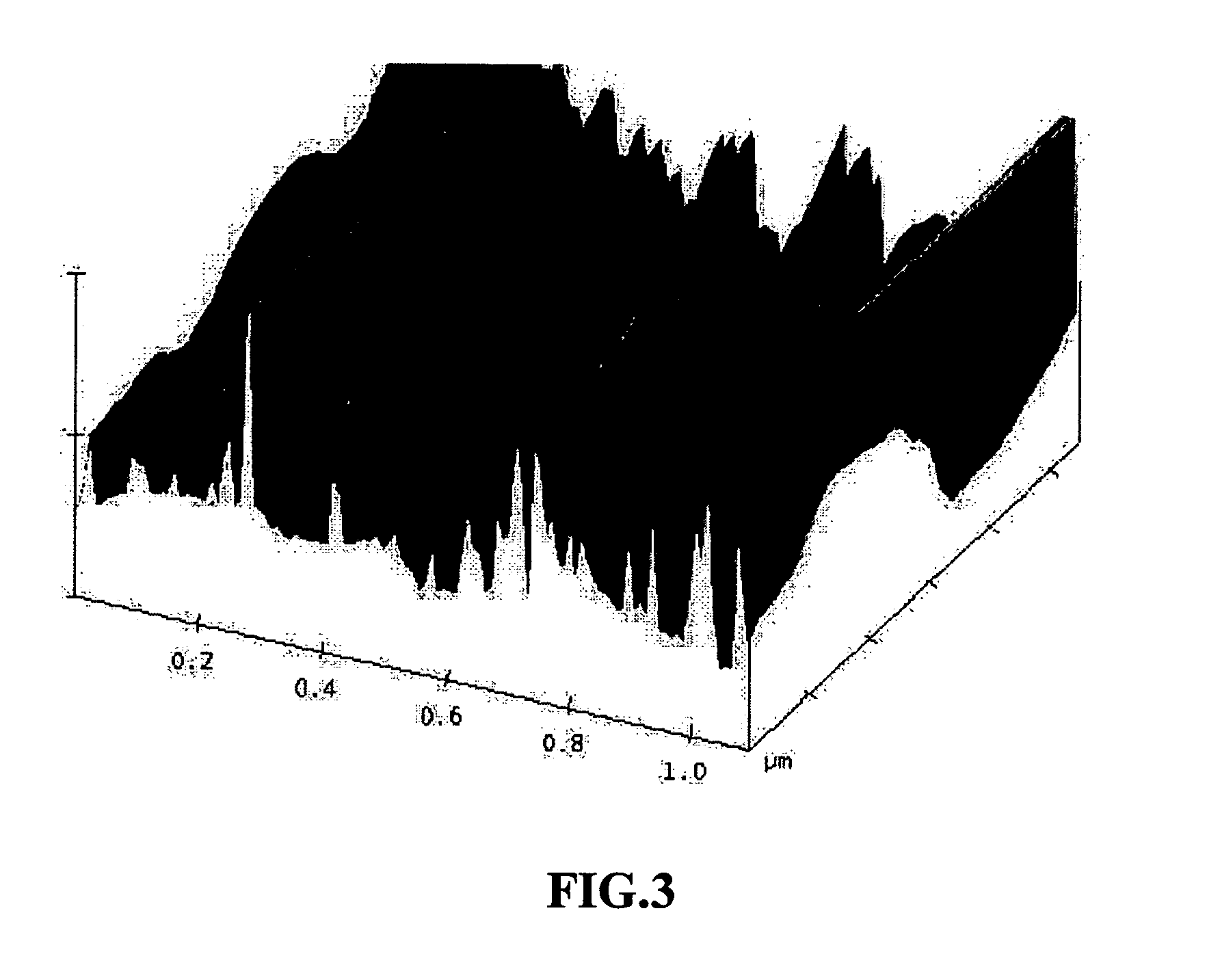

Disclosed is a process for exfoliating a layered material to produce nano-scaled platelets having a thickness smaller than 100 nm, typically smaller than 10 nm, and often between 0.34 nm and 1.02 nm. The process comprises: (a) subjecting a layered material to a gaseous environment at a first temperature and first pressure sufficient to cause gas species to penetrate between layers of the layered material, forming a gas-intercalated layered material; and (b) subjecting the gas-intercalated layered material to a second pressure, or a second pressure and a second temperature, allowing gas species to partially or completely escape from the layered material and thereby exfoliating the layered material to produce partially delaminated or totally separated platelets. The gaseous environment preferably contains only environmentally benign gases that are reactive (e.g., oxygen) or non-reactive (e.g., noble gases) with the layered material. The process can also include dispersing the platelets in a matrix material to form a nanocomposite.

Owner:GLOBAL GRAPHENE GRP INC

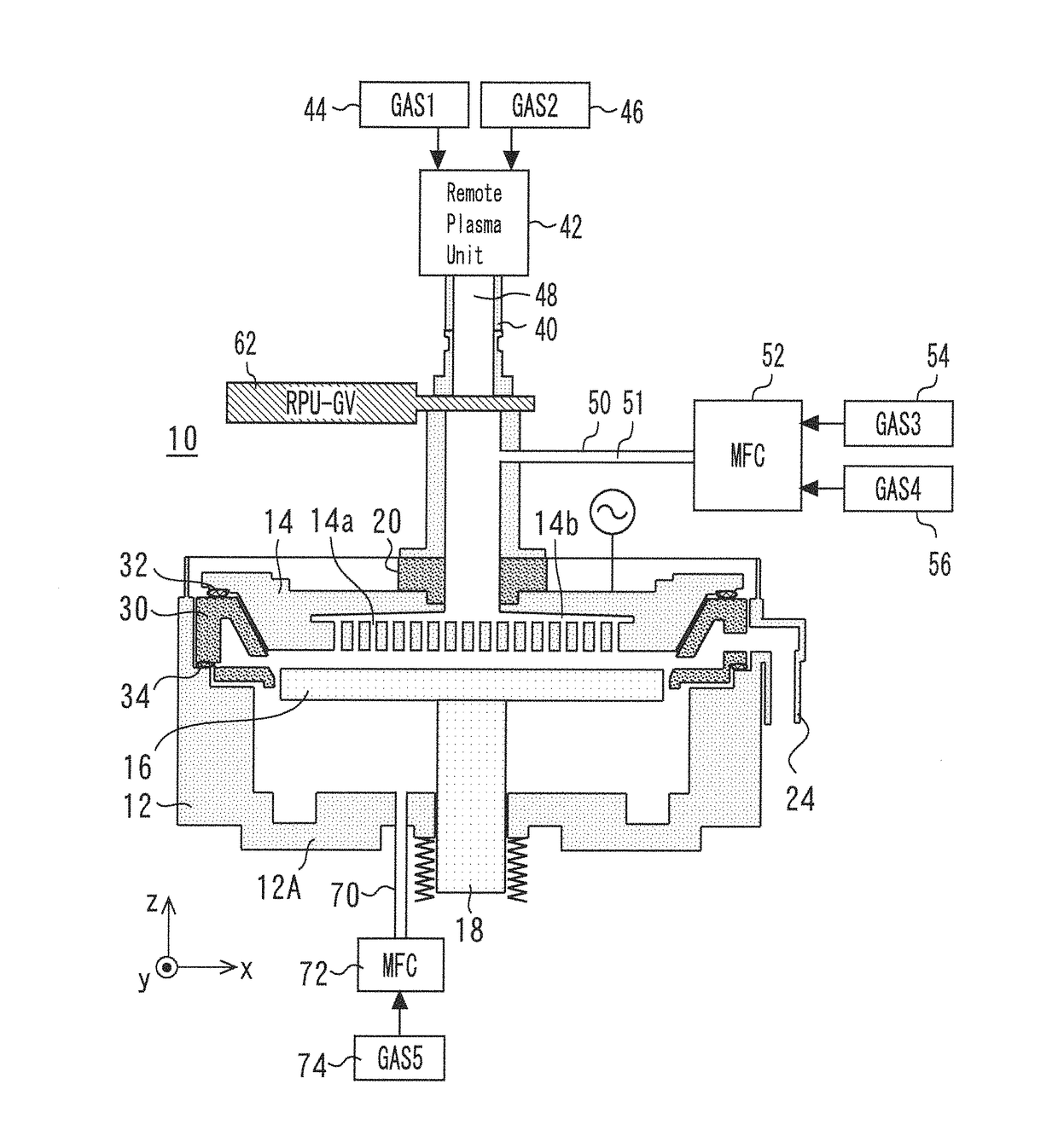

Substrate processing apparatus and method of processing substrate

PendingUS20180155836A1Avoid dischargeElectric discharge tubesSemiconductor/solid-state device manufacturingNoble gasProduct gas

A substrate processing apparatus includes a stage provided in a chamber, a shower head in which a plurality of slits are formed and which is opposed to the stage, a first gas supply part which supplies a first gas to a space between the stage and the shower head via the plurality of slits, and a second gas supply part which supplies a second gas which is not a noble gas to a region below the stage, wherein the second gas is the same gas as one of a plurality of kinds of gases constituting the first gas in a case where the first gas is a mixture gas constituted of the plurality of kinds of gases, and the second gas is the same gas as the first gas in a case where the first gas is a single kind of gas.

Owner:ASM IP HLDG BV

Method of making semiconductor device

InactiveUS20080261404A1Improve controllabilityGood etchingElectric discharge tubesSemiconductor/solid-state device manufacturingNoble gasControllability

A plasma processing method, which enables the etching controllability for a high-dielectric-constant insulating film to be improved. A substrate having a high-dielectric-constant gate insulating film and a hard mask formed thereon is subjected to etching processing using a plasma of a processing gas containing a noble gas and a reducing gas.

Owner:TOKYO ELECTRON LTD

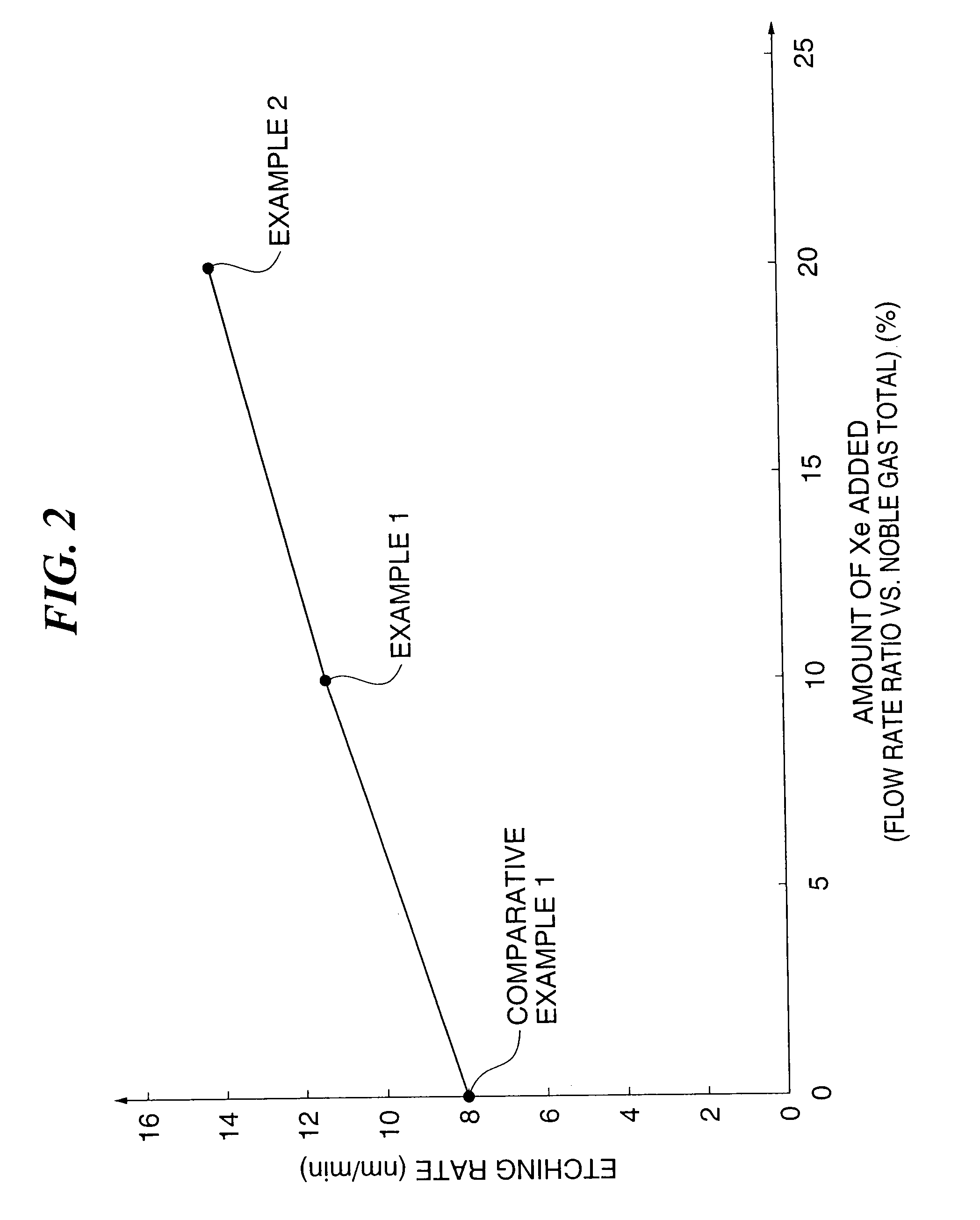

Method For Trimming Carbon-Containing Film At Reduced Trimming Rate

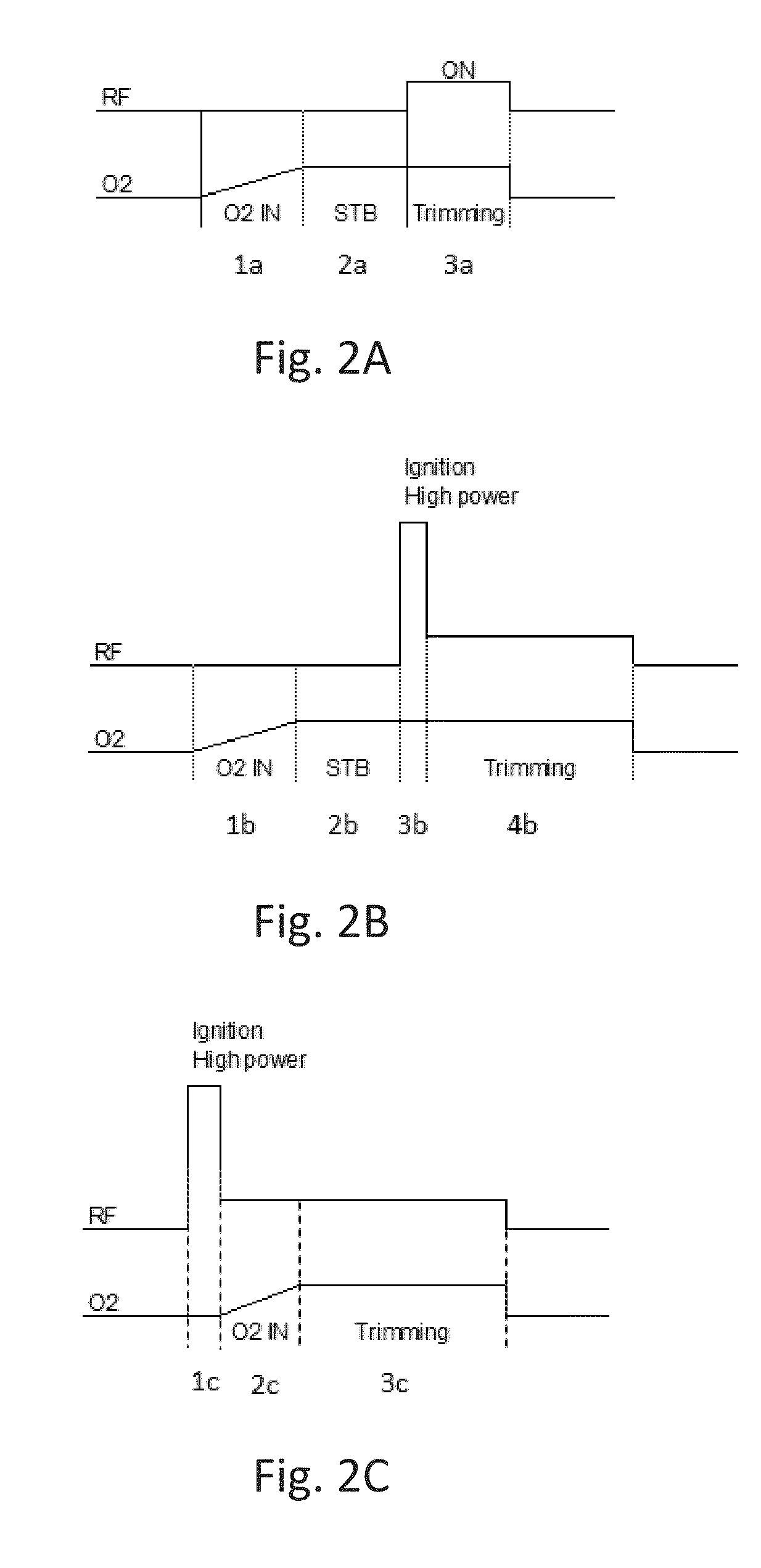

ActiveUS20150118846A1Reduce trimming rateReducing trimming rateElectric discharge tubesSemiconductor/solid-state device manufacturingNoble gasNitrogen

A method for trimming a carbon-containing film includes: (i) providing a substrate having a carbon-containing film formed thereon; (ii) supplying a trimming gas and a rare gas to the reaction space, which trimming gas includes an oxygen-containing gas; and (iii) applying RF power between the electrodes to generate a plasma using the trimming gas and the rare gas and to thereby trim the carbon-containing film while controlling a trimming rate at 55 nm / min or less as a function of at least one parameter selected from the group consisting of a flow rate of an oxygen-containing gas, a flow rate of nitrogen-containing gas to be added to the oxygen-containing gas, pressure in the reaction space, RF power, a duty cycle of RF power, a distance between the electrodes, and a temperature of a susceptor on which the substrate is placed.

Owner:ASM IP HLDG BV

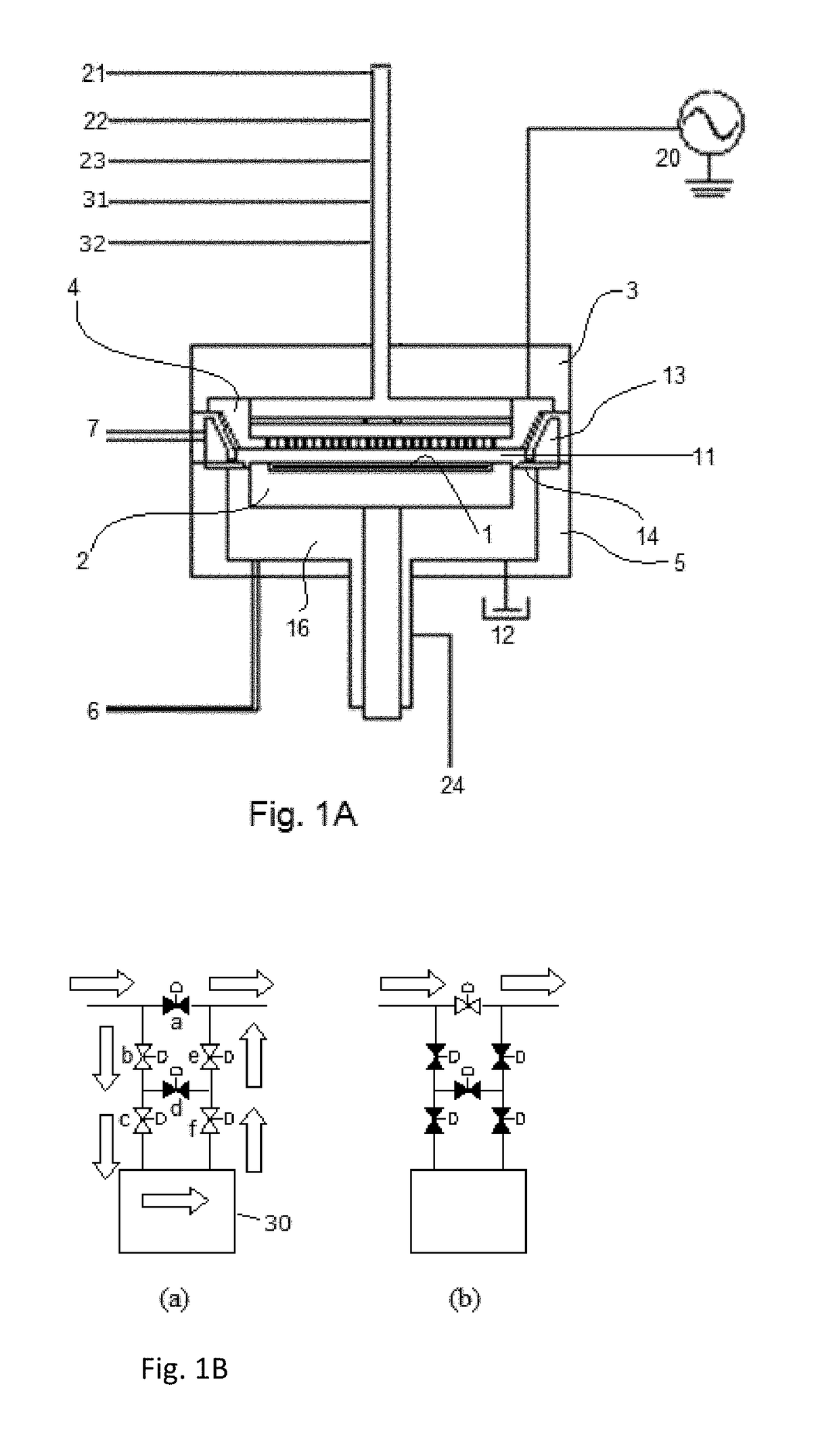

Method of atomic layer etching using functional group-containing fluorocarbon

ActiveUS20170186621A1Improve in-plane uniformityElectric discharge tubesSemiconductor/solid-state device manufacturingSelf limitingNoble gas

Owner:ASM IP HLDG BV

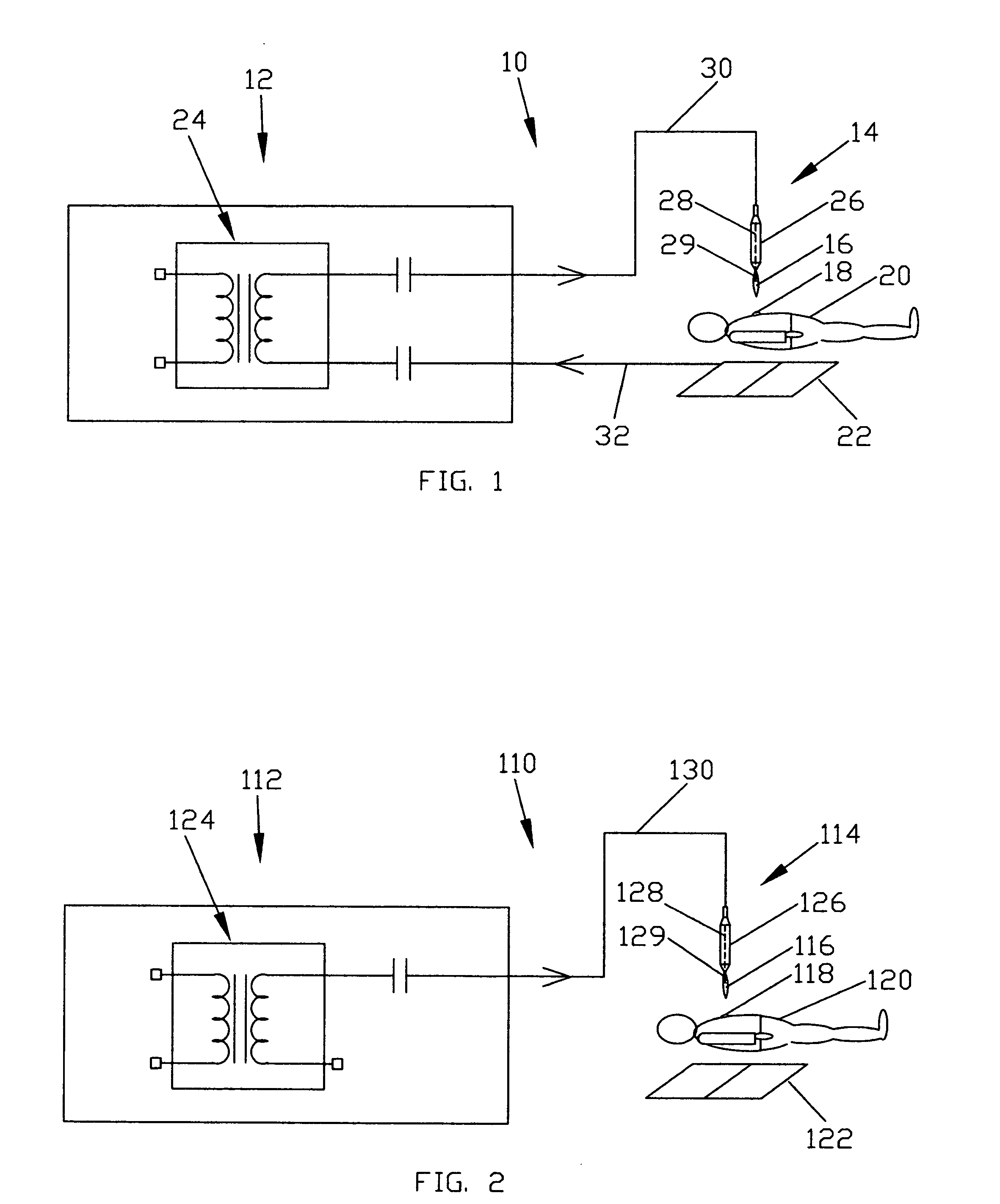

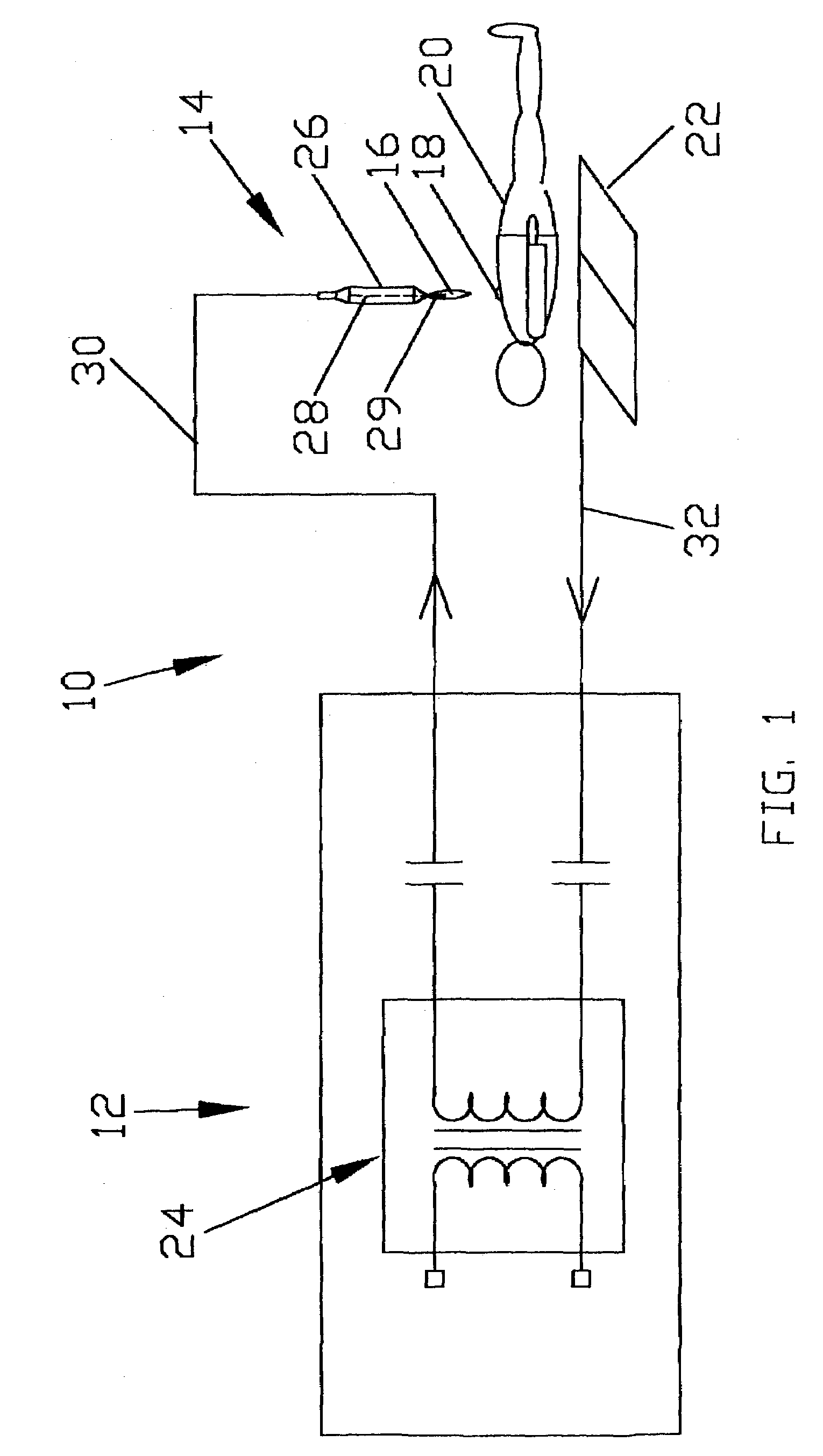

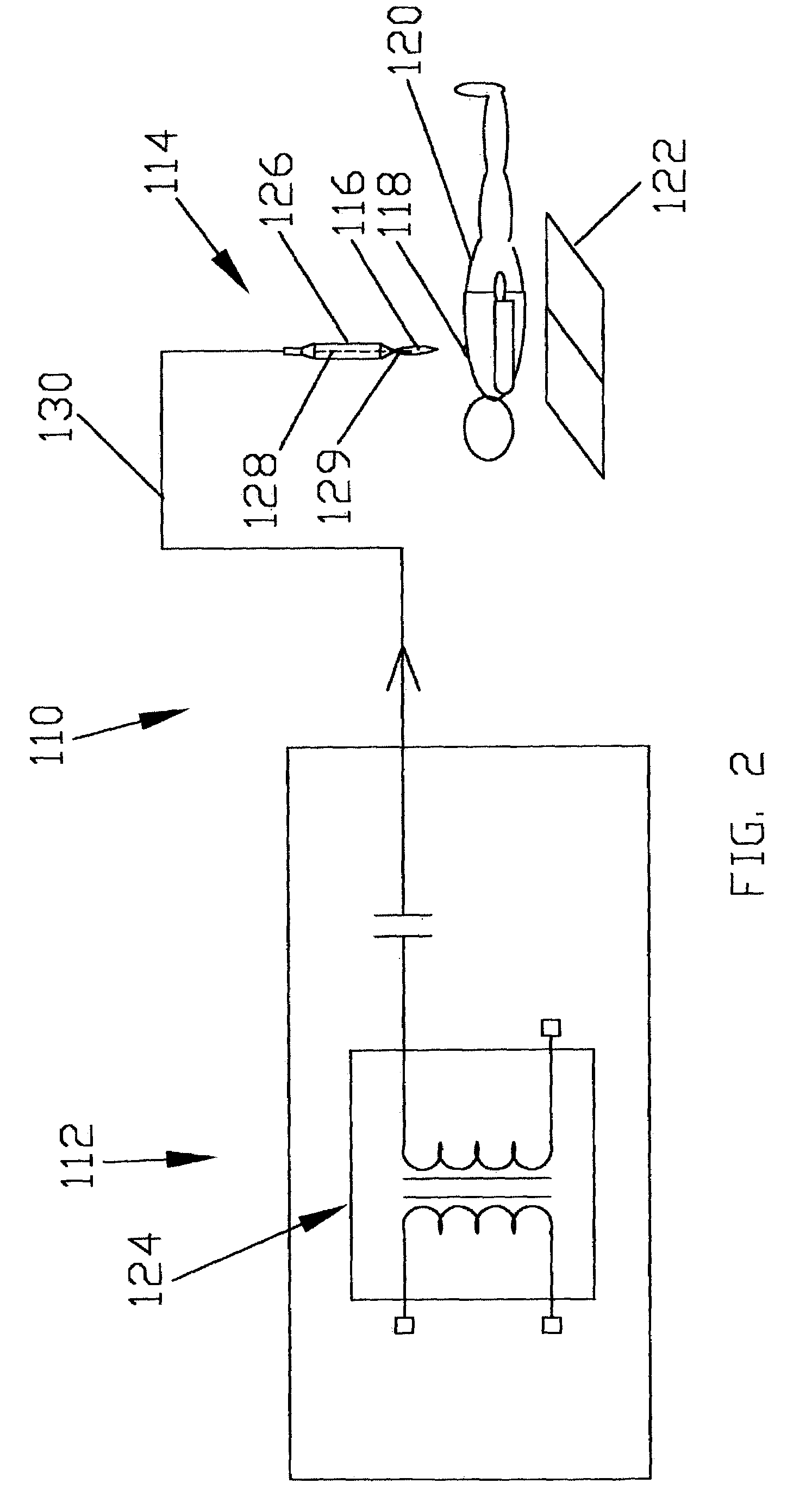

Method to generate a plasma stream for performing electrosurgery

InactiveUS8057468B2Control areaEnhance flow-assisted removalSurgical instruments for heatingSurgical instruments for aspiration of substancesNoble gasSurgical site

Owner:BOVIE MEDICAL CORP

Dry etching method for metal film

ActiveUS20130098868A1Decorative surface effectsSemiconductor/solid-state device manufacturingHalogenNoble gas

A method for performing dry etching on a metal film containing Pt via a mask layer includes performing dry etching on the metal film by generating a plasma of an etching gas including a gaseous mixture of H2 gas, CO2 gas, methane gas and rare gas. With the dry etching method, it is possible to make a vertical sidewall of a hole or trench more vertical without using a halogen gas.

Owner:TOKYO ELECTRON LTD

Microelectronic mechanical system and methods

InactiveUS20040053434A1Decorative surface effectsSemiconductor/solid-state device detailsNoble gasSilicon oxide

The current invention provides for encapsulated release structures, intermediates thereof and methods for their fabrication. The multi-layer structure has a capping layer, that preferably comprises silicon oxide and / or silicon nitride, and which is formed over an etch resistant substrate. A patterned device layer, preferably comprising silicon nitride, is embedded in a sacrificial material, preferably comprising polysilicon, and is disposed between the etch resistant substrate and the capping layer. Access trenches or holes are formed in to capping layer and the sacrificial material are selectively etched through the access trenches, such that portions of the device layer are release from sacrificial material. The etchant preferably comprises a noble gas fluoride NGF2x (wherein Ng=Xe, Kr or Ar: and where x=1, 2 or 3). After etching that sacrificial material, the access trenches are sealed to encapsulate released portions the device layer between the etch resistant substrate and the capping layer. The current invention is particularly useful for fabricating MEMS devices, multiple cavity devices and devices with multiple release features.

Owner:SILICON LIGHT MACHINES CORP

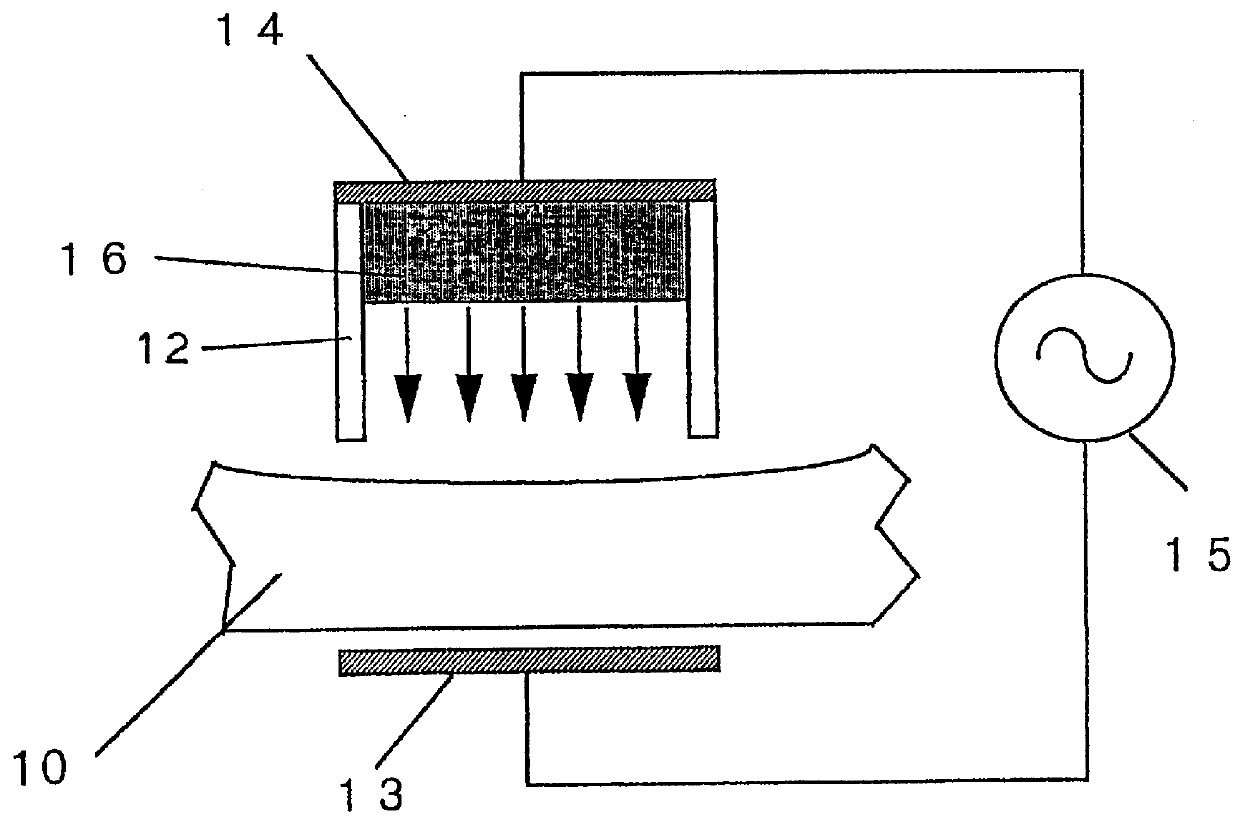

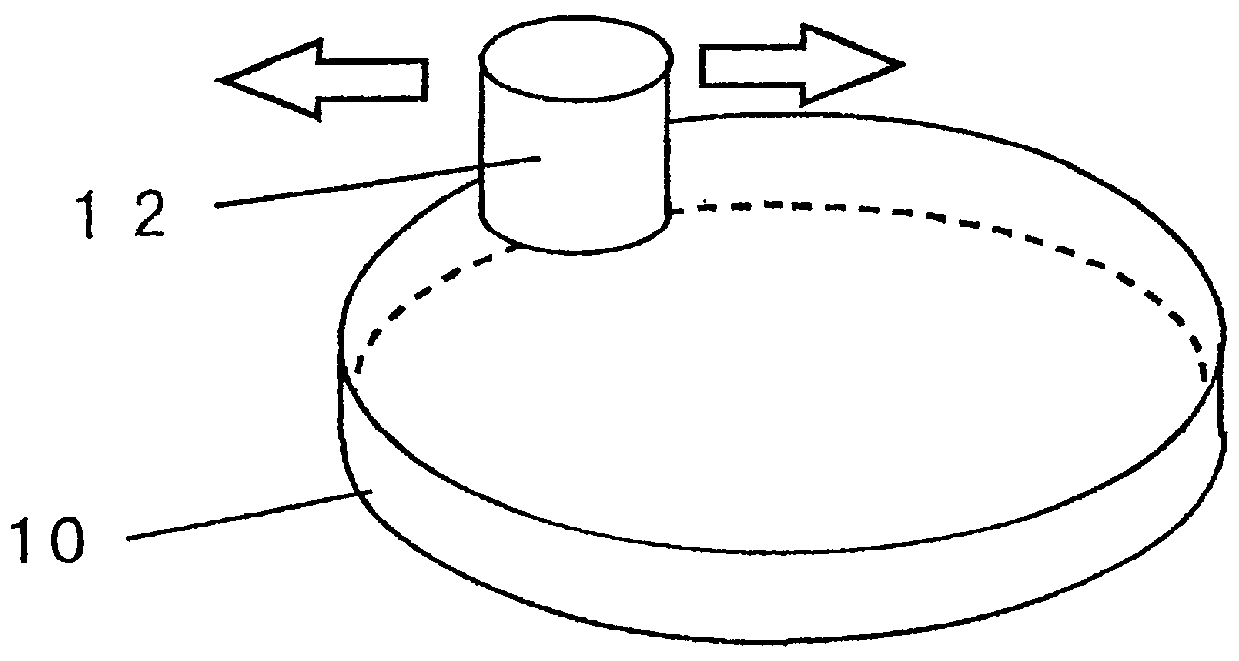

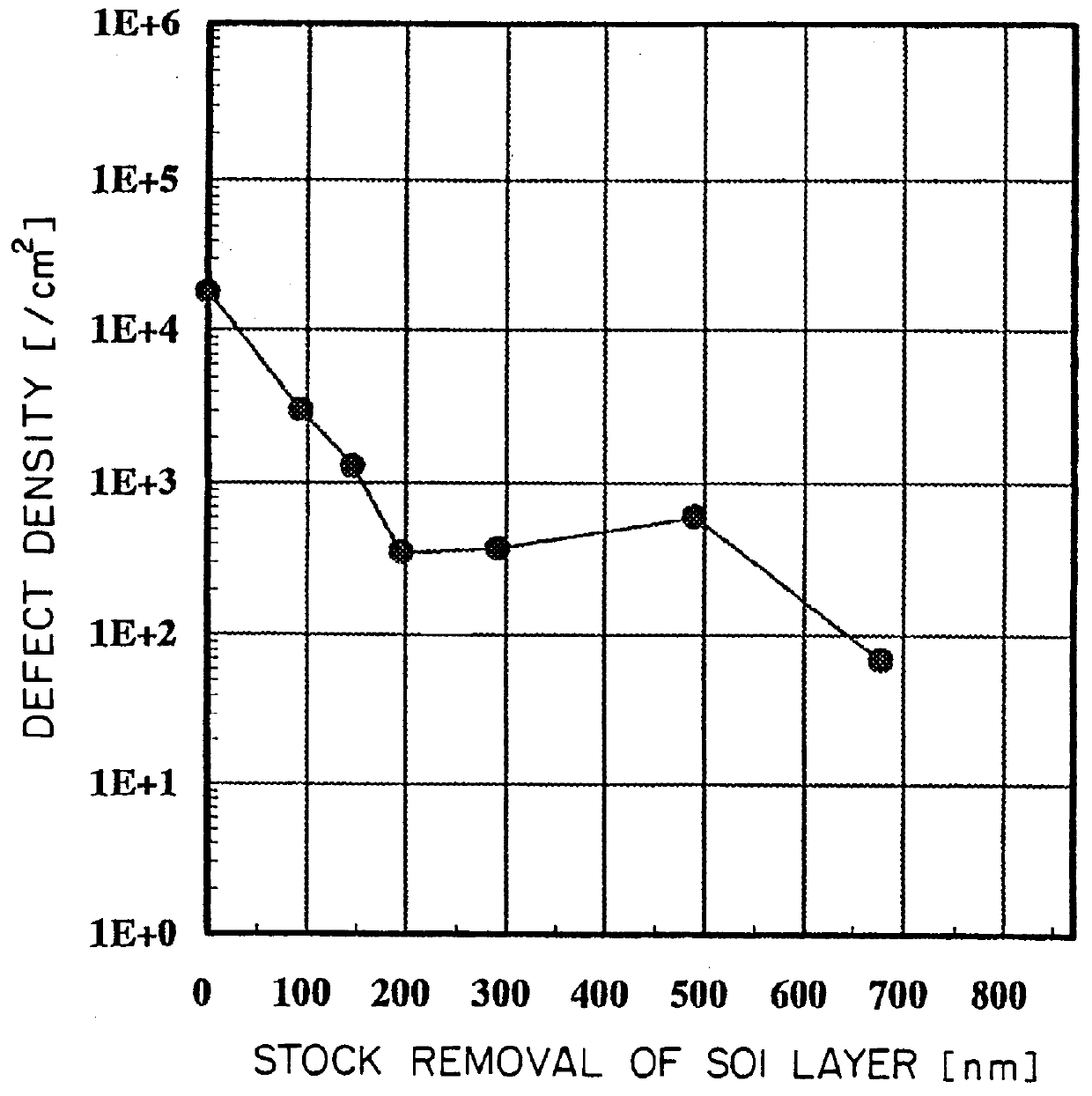

Method of fabricating an SOI wafer and SOI wafer fabricated thereby

InactiveUS6140210AReliably removedUniform thicknessSolid-state devicesSemiconductor/solid-state device manufacturingNoble gasEtching

In a method of fabricating an SOI wafer, an oxide film is formed on the surface of at least one of two silicon wafers; hydrogen ions or rare gas ions are implanted into the upper surface of one of the two silicon wafers in order to form a fine bubble layer (enclosed layer) within the wafer; the ion-implanted silicon wafer is superposed on the other silicon wafer such that the ion-implanted surface comes into close contact with the surface of the other silicon wafer via the oxide film; heat treatment is performed in order to delaminate a portion of the ion-implanted wafer while the fine bubble layer is used as a delaminating plane, in order to form a thin film to thereby obtain an SOI wafer. In the method, a defect layer at the delaminated surface of the thus-obtained SOI wafer is removed to a depth of 200 nm or more through vapor-phase etching, and then mirror polishing is performed. Therefore, the obtained SOI wafer has an extremely low level of defects and a high thickness uniformity.

Owner:SHIN-ETSU HANDOTAI CO LTD

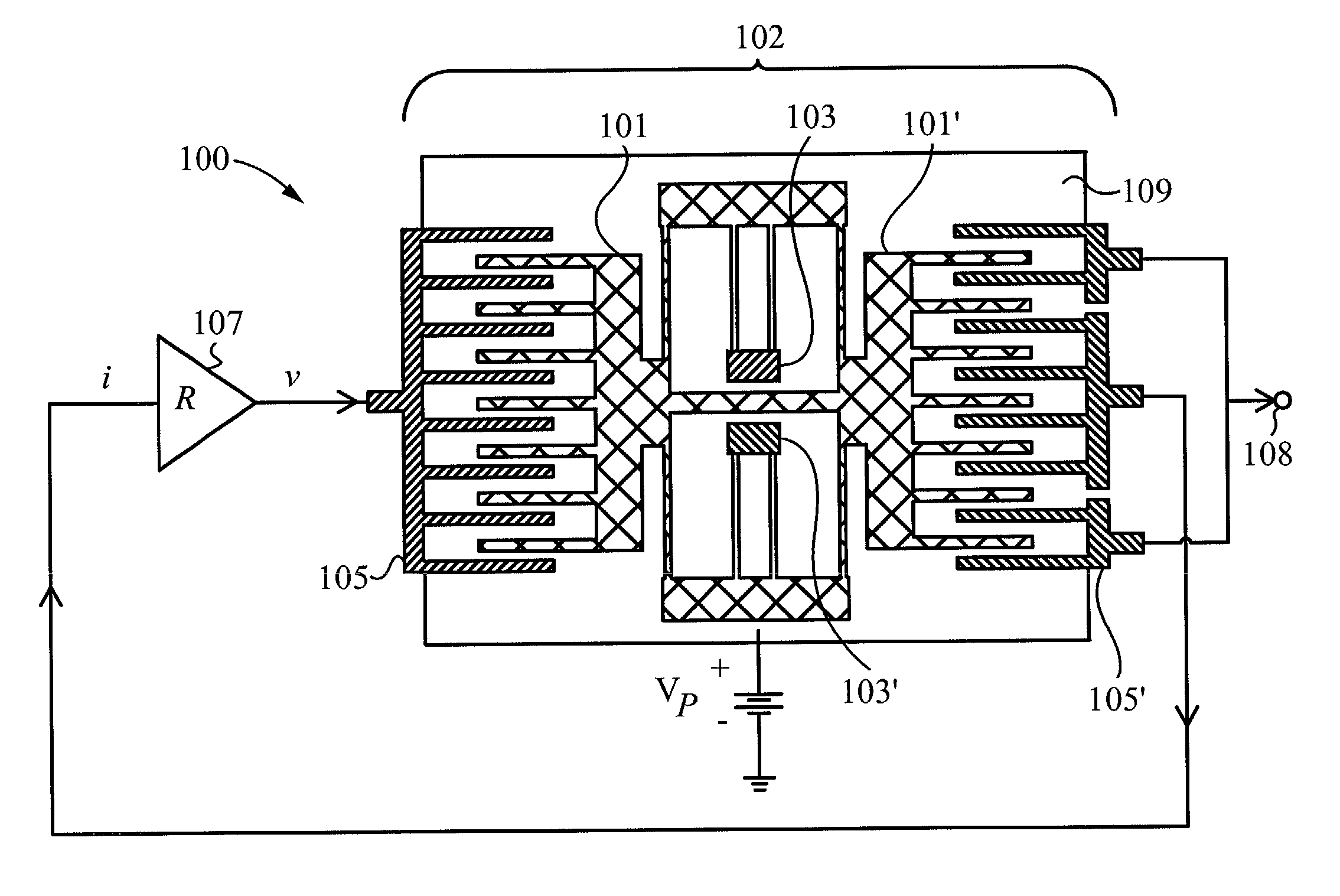

Low-field MRI

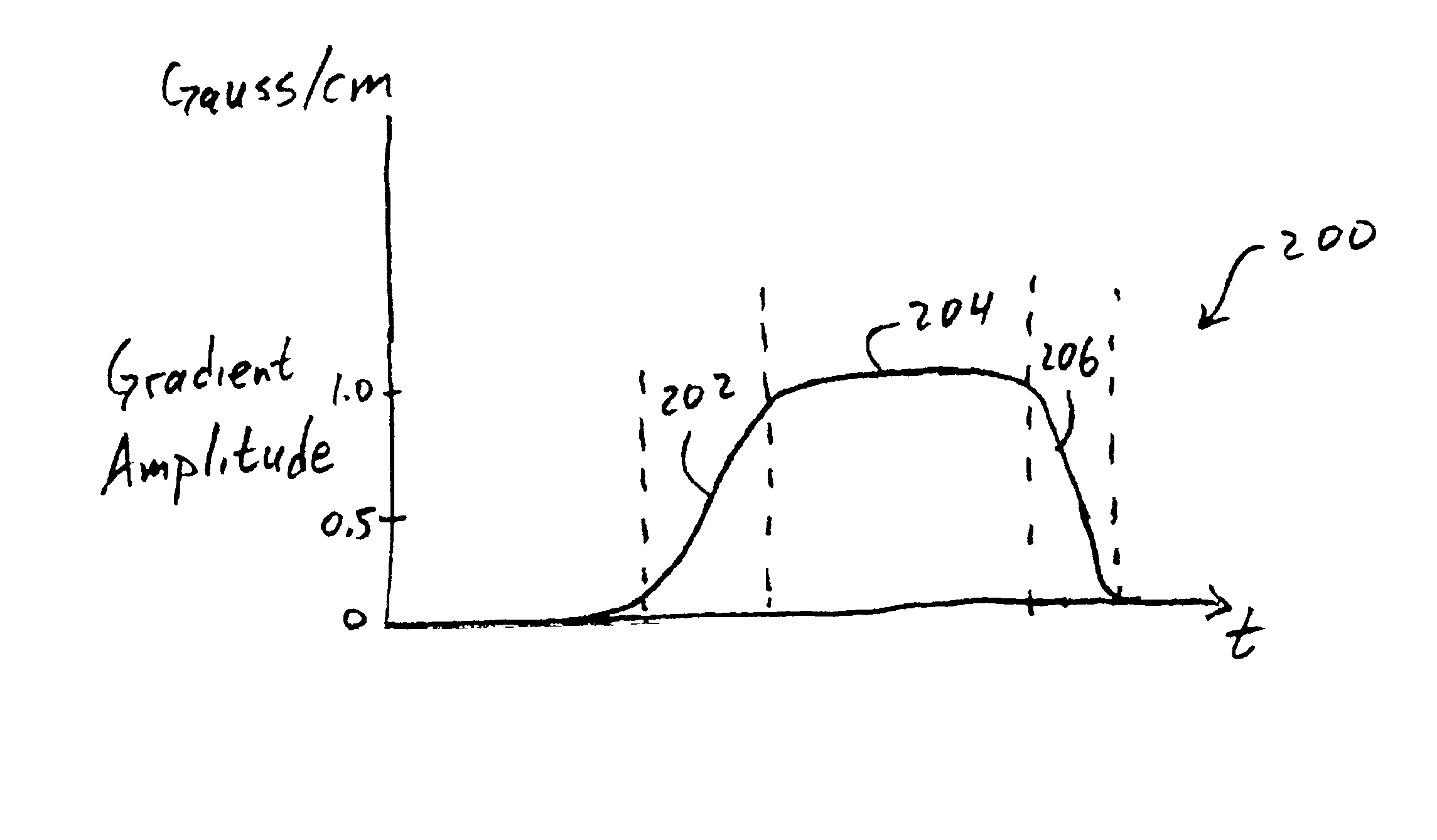

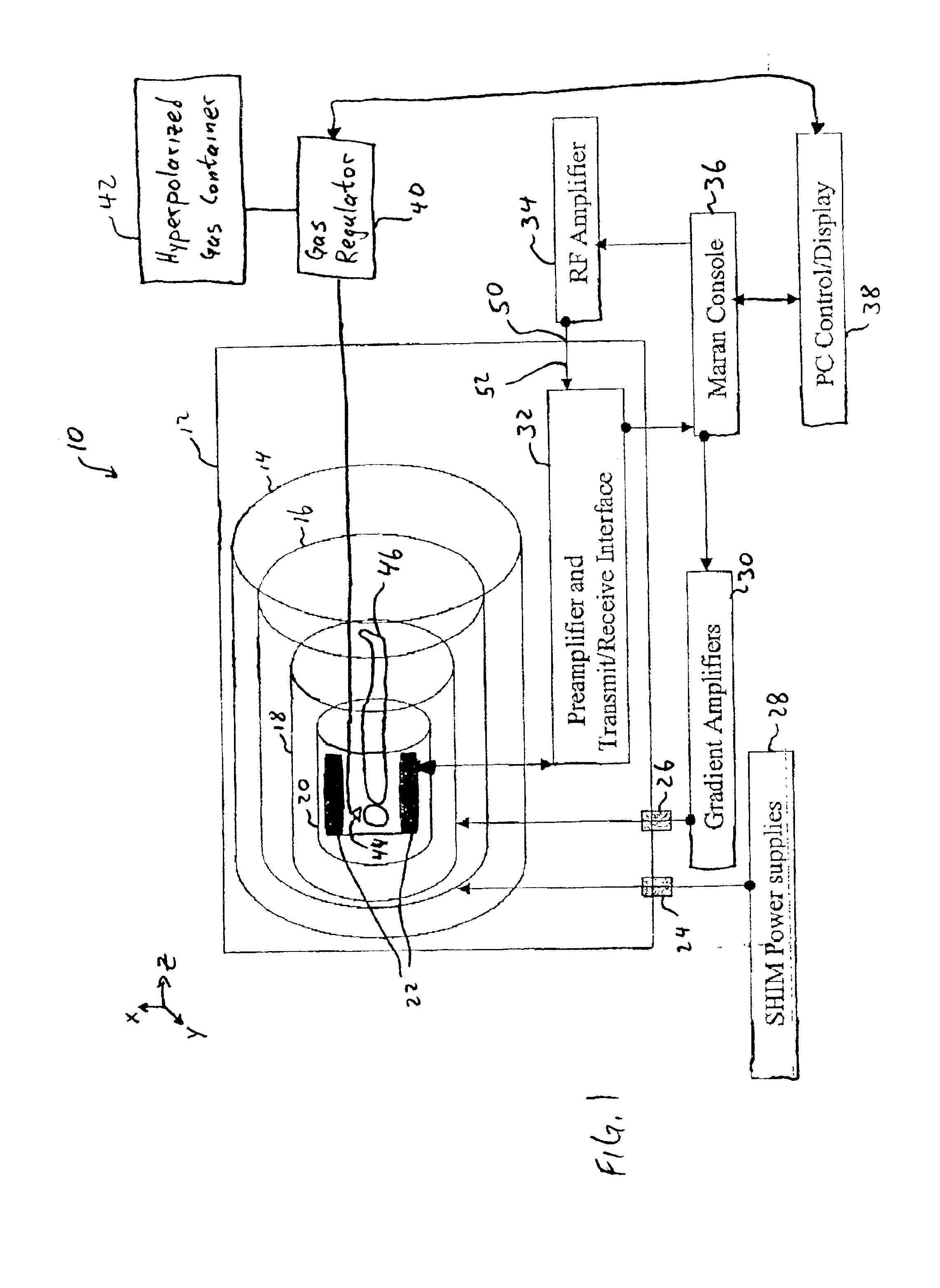

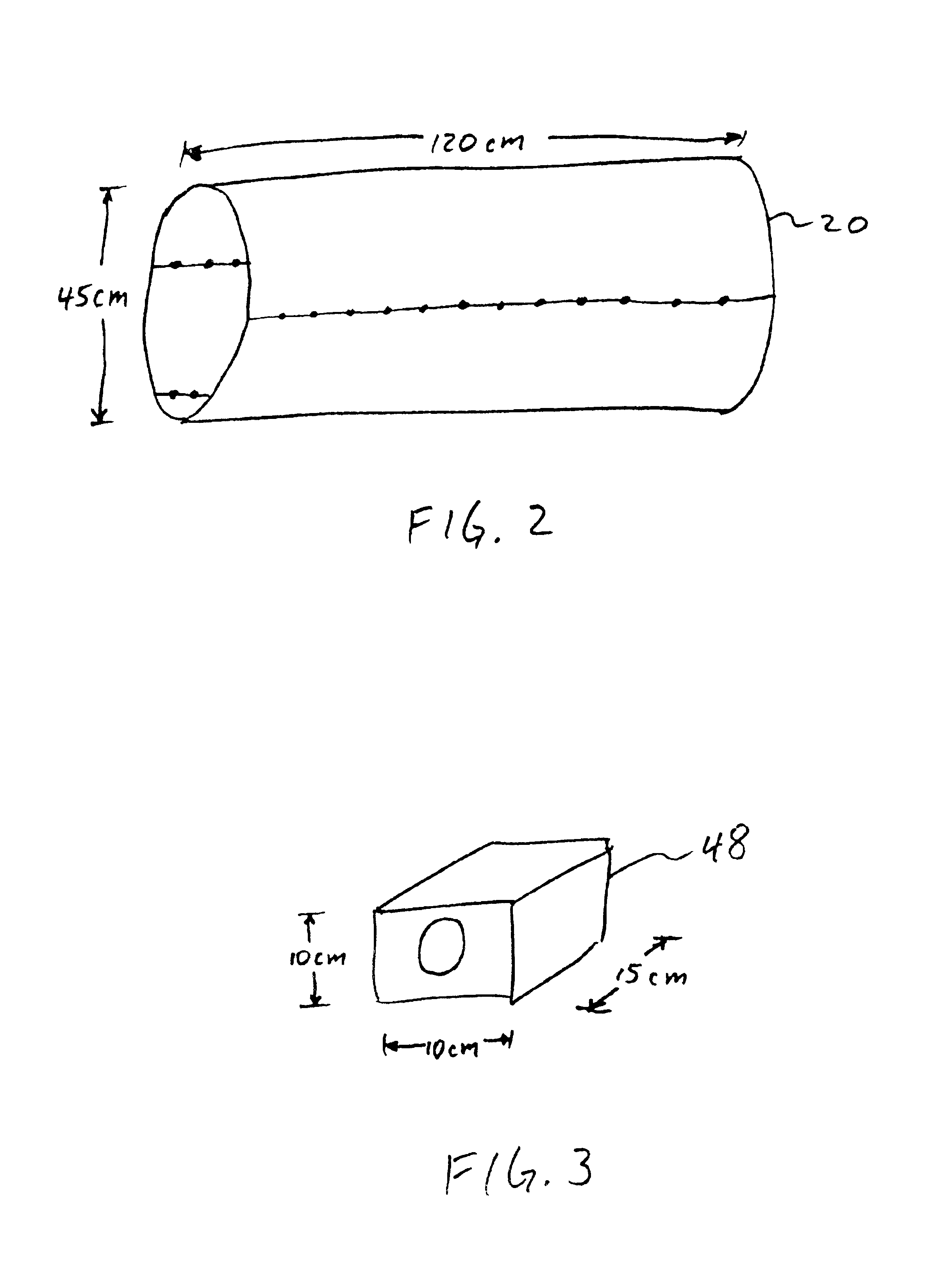

InactiveUS6845262B2Convenient clinical diagnosisReduce artifactsDiagnostic recording/measuringMeasurements using NMR imaging systemsNoble gasMethod of images

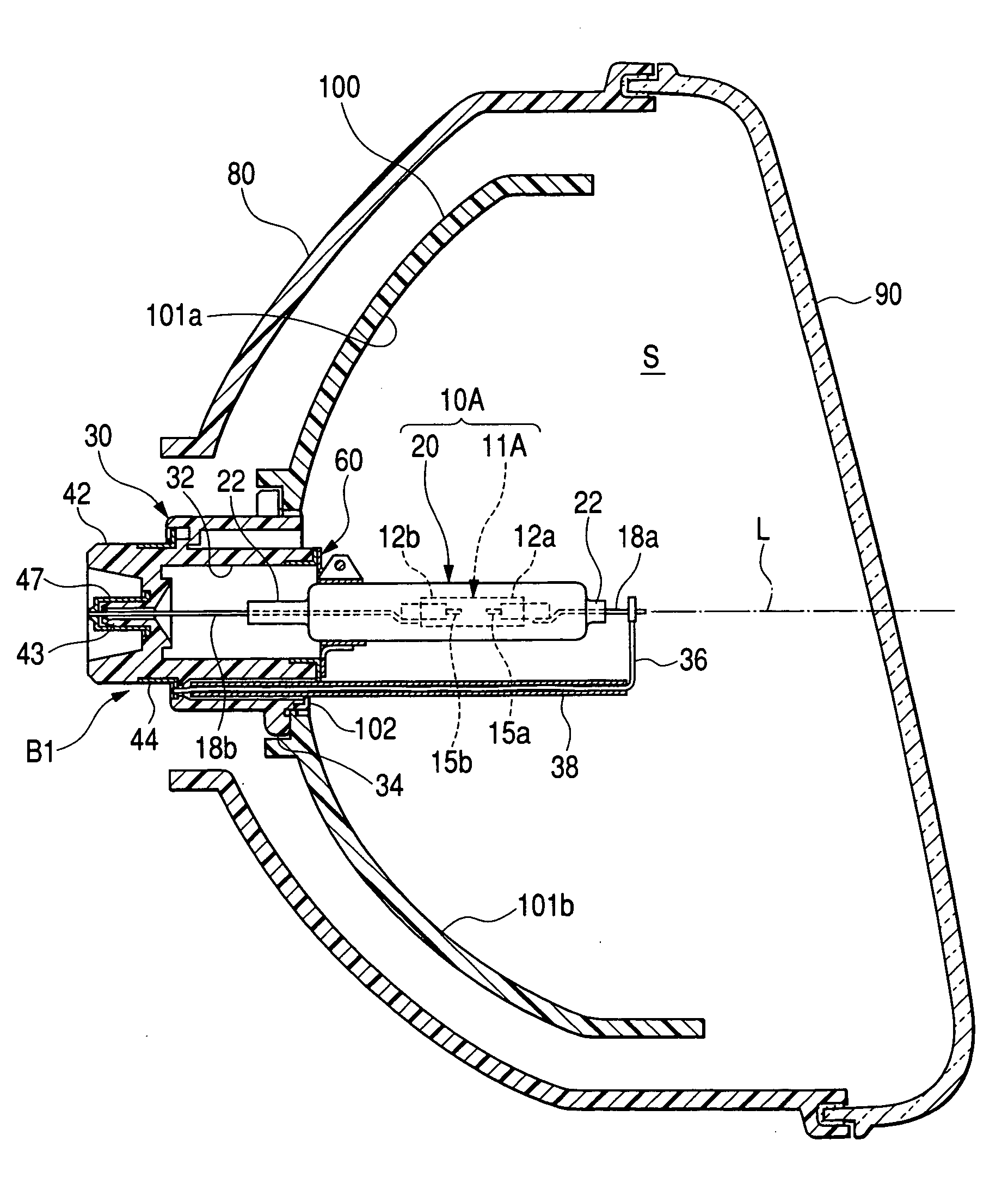

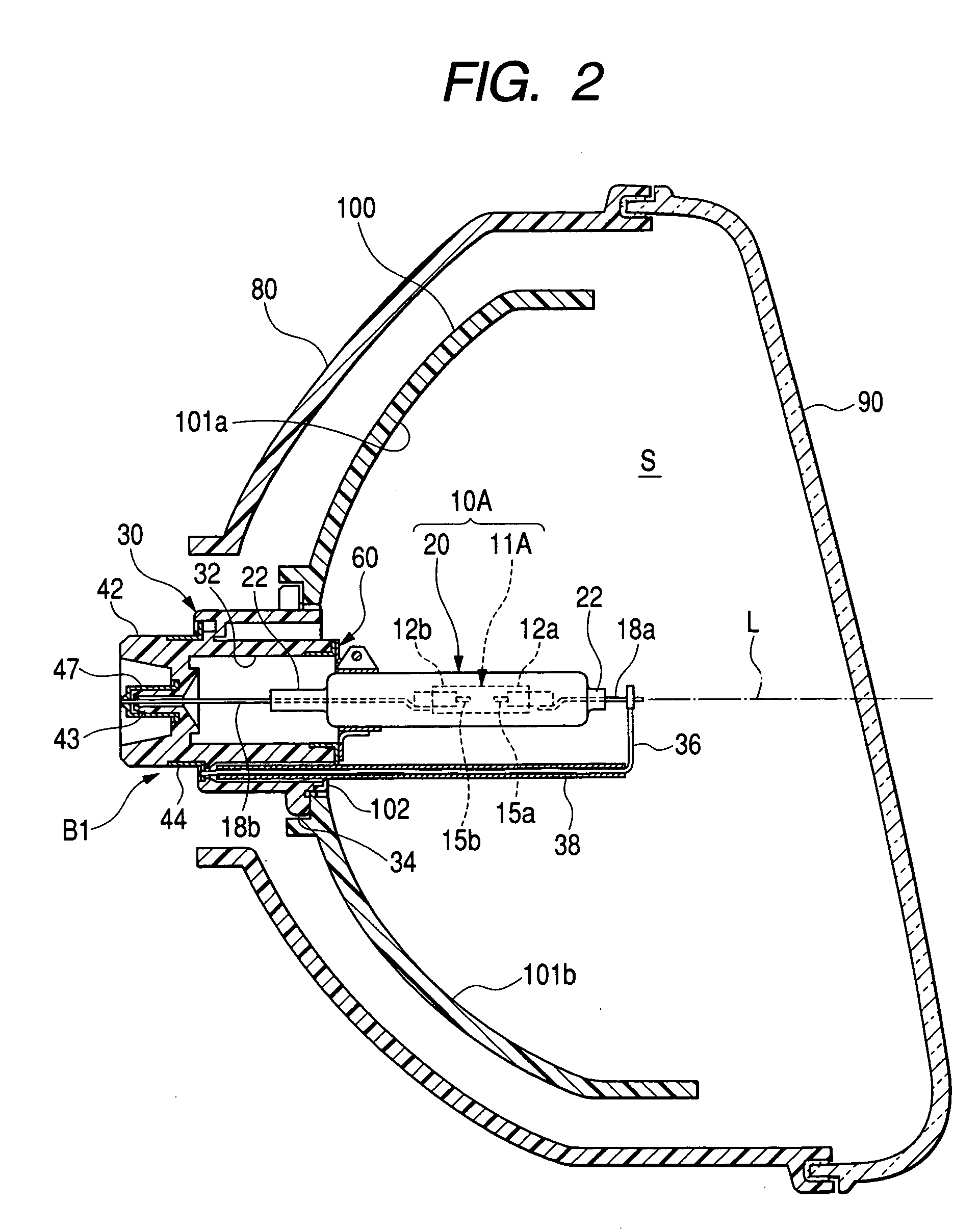

A method of imaging using magnetic resonance includes administering hyperpolarized noble gas to a subject in a region to be imaged, applying a magnetic field of a magnitude between about 0.0001 Tesla and about 0.1 Tesla to the subject at least in the region of the subject to be imaged, detecting a spatial distribution of magnetic resonance signals of the hyperpolarized noble gas in the subject, and producing a representation of the spatial distribution.

Owner:THE BRIGHAM & WOMEN S HOSPITAL INC

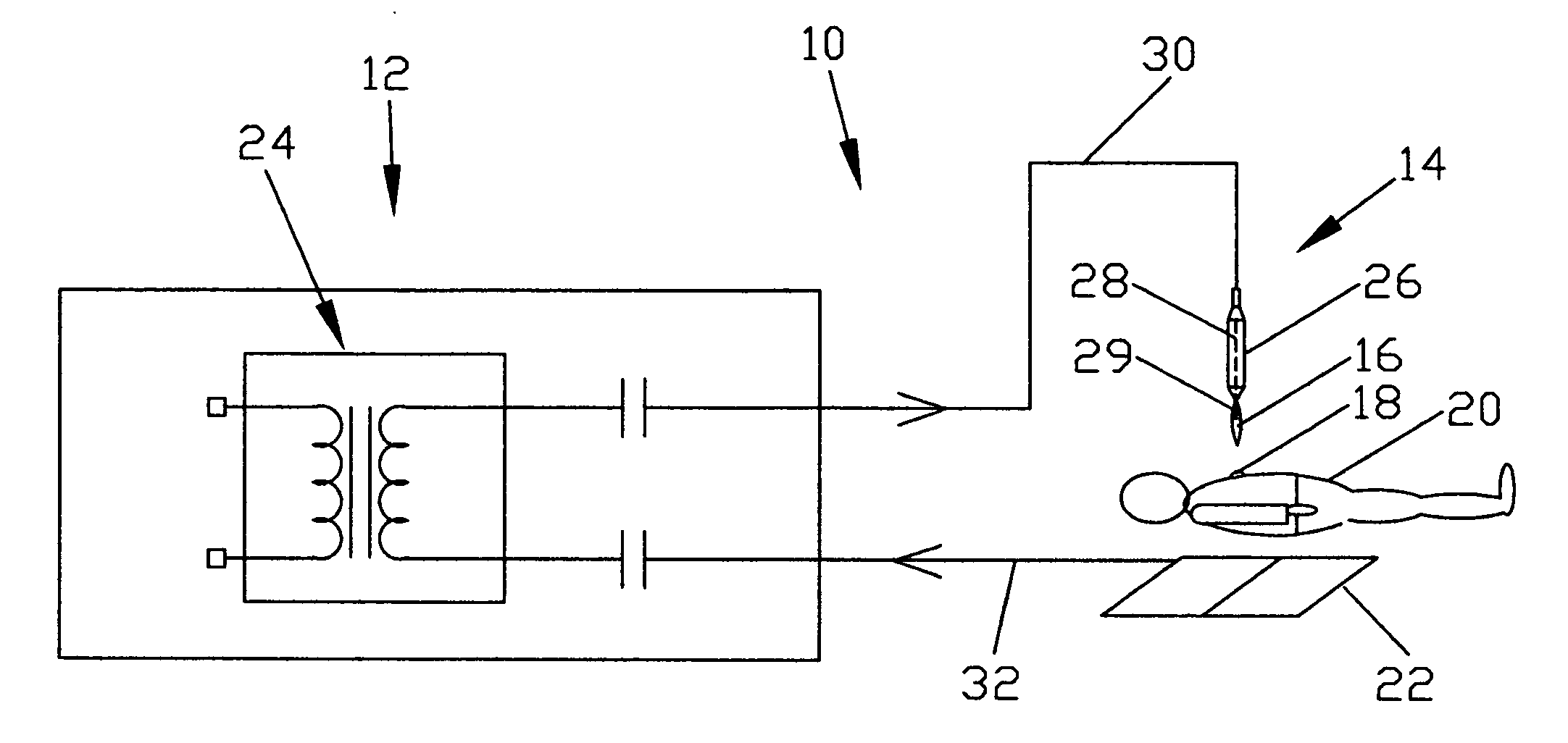

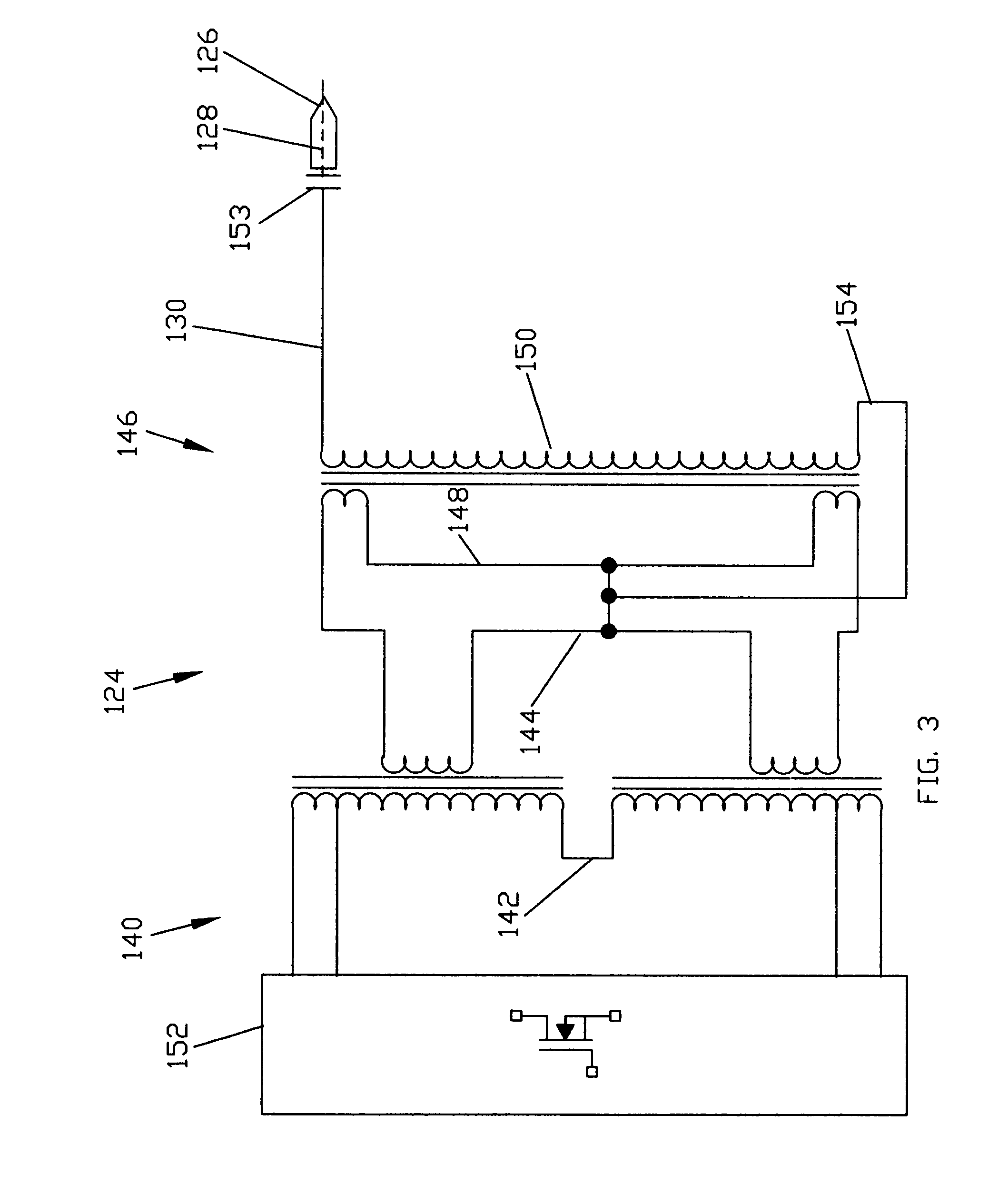

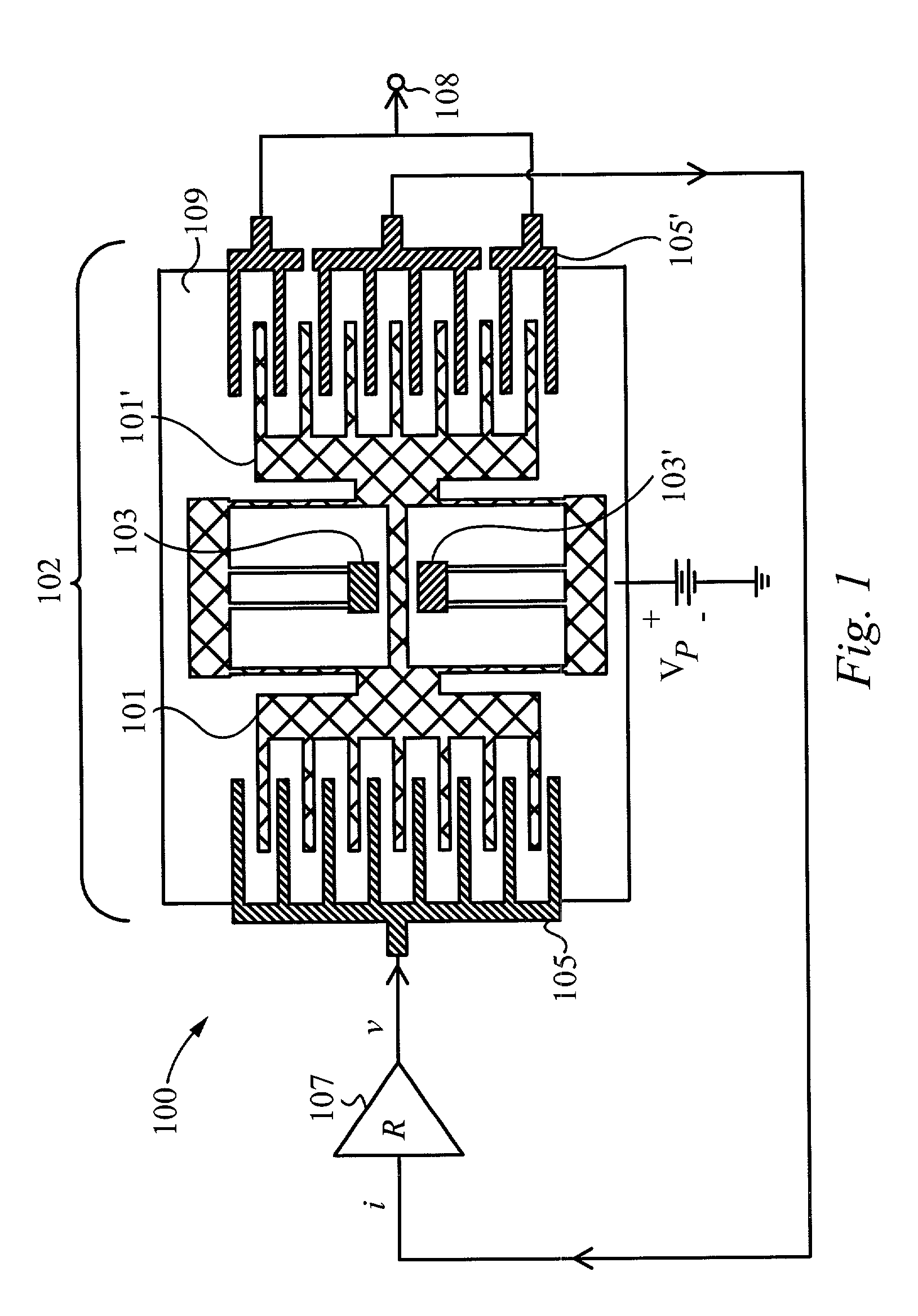

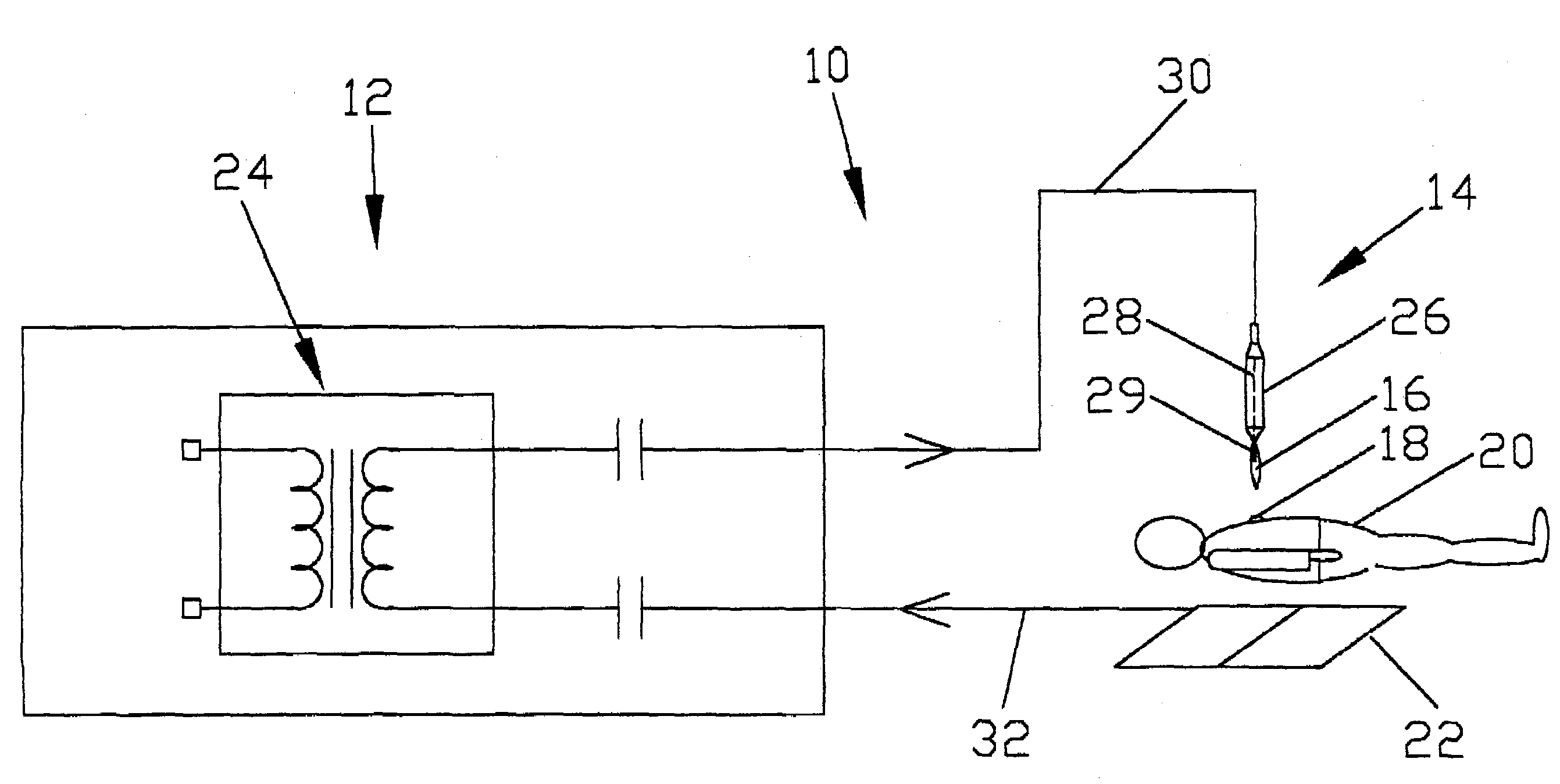

Electrosurgical device to generate a plasma stream

ActiveUS7316682B2Enhance flow-assisted removalSurgical instruments for heatingSurgical instruments for aspiration of substancesElectricityNoble gas

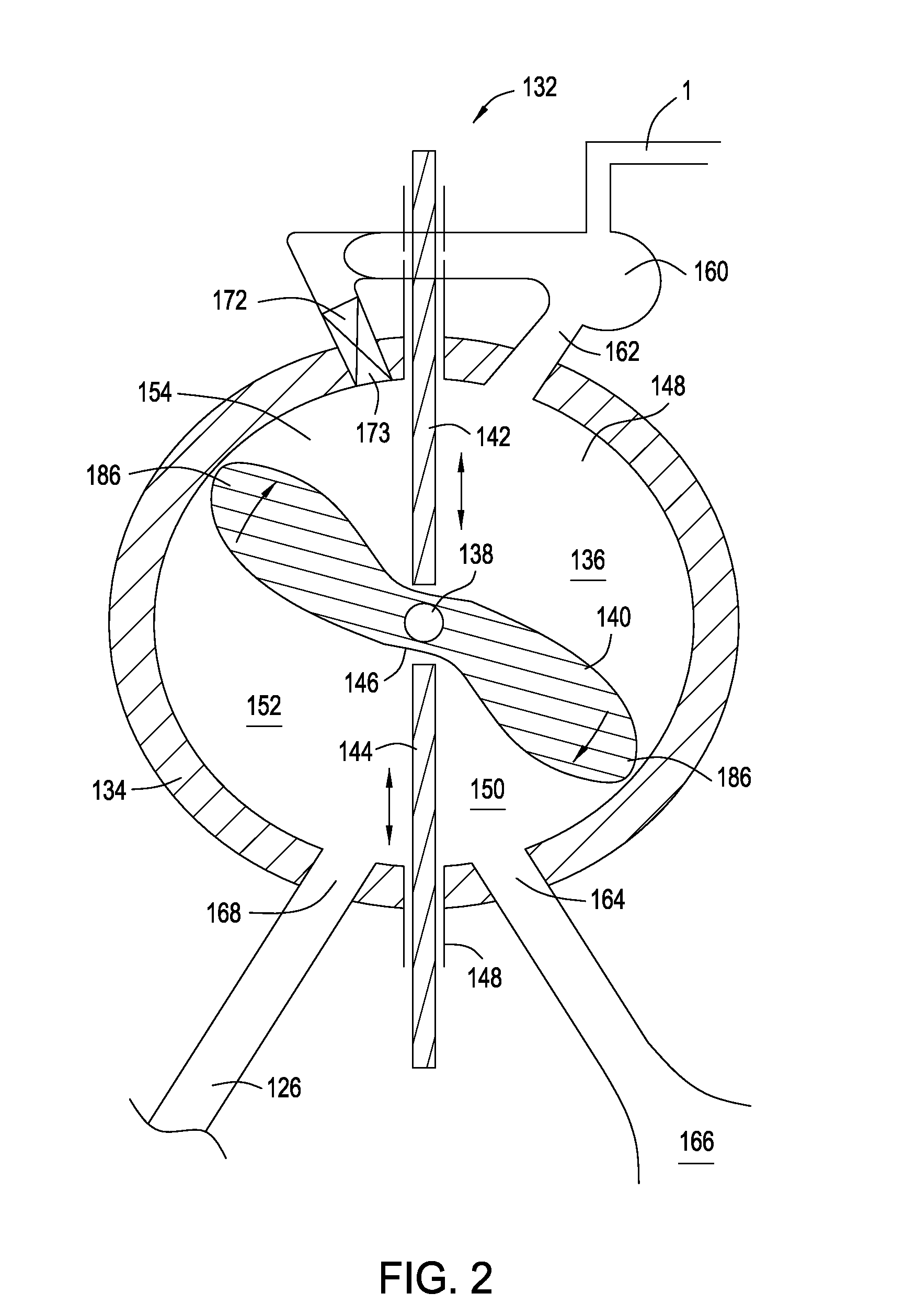

An electrosurgical device to generate a plasma stream for performing electrosurgery on a surgical site on a patient comprising an electrosurgical generator coupled to a electrical power source to supply power to the electrosurgical device and a plasma generator including an electrode operatively coupled to the electrosurgical generator to receive electrical energy therefrom and concentrically disposed within an inner noble gas conduit to form a plasma channel coupled to a noble gas source to feed noble gas to the inner noble gas conduct, an intermediate electronegative gas conduit disposed in surrounding coaxial relation relative to the noble gas conduit to cooperatively form an electronegative gas channel therebetween coupled to a gas source to feed electronegative gas to the electronegative gas channel and an outer aspiration conduit disposed in surrounding coaxial relation relative to the intermediate electronegative gas conduit to cooperatively form an aspiration channel therebetween coupled to a negative pressure source such that the electrode heats the noble gas to at least partially ionize the noble gas to generate the plasma stream to be directed to the surgical site to perform the surgical procedure while the electronegative gas maintains or sustains the plasma stream and the negative pressure source removes fluid and solid debris from the surgical site.

Owner:BOVIE MEDICAL CORPORATION

Low emission energy source

Owner:BRIGHTSOURCE ENERGY

Automotive discharge bulb and automotive headlamp

InactiveUS20050007020A1Wasteful consumption can be reducedReduce the ratioDischarge tube luminescnet screensPoint-like light sourceNoble gasLuminous flux

An automotive discharge bulb having a light emitting tube includes a ceramic tube with paired electrodes oppositely placed, and contains a light emitting material and starting rare gas. A transversal section of the ceramic tube is longitudinally elongated. Because the capacity of an enclosed space of the ceramic tube is small, after discharging begins, the enclosed space temperature increases. Consequently, the ceramic tube has a good luminous flux rising characteristic. Because of the small surface area of the ceramic tube, the load imposed on the wall surface increases. Consequently, the ceramic tube has good luminous efficiency. In the ceramic tube having a longitudinally elongated transversal section, an arc generated into an upwardly convex shape and the tube wall do not make contact. Thermal shock resistance required of the ceramic tube is alleviated, durability is enhanced, and the ceramic tube is made of a ceramic material hitherto unusable.

Owner:KOITO MFG CO LTD

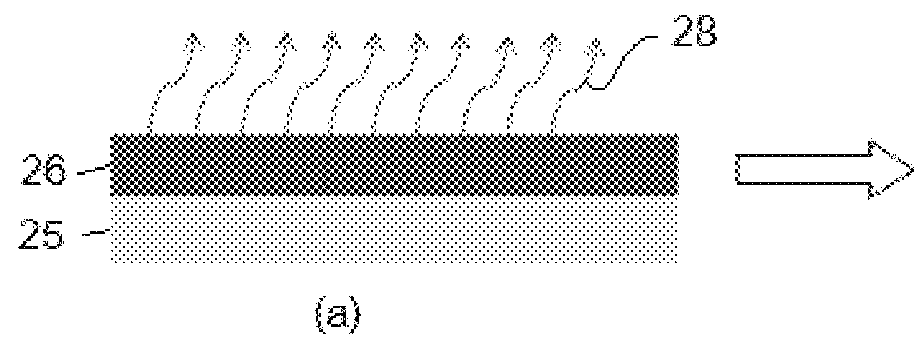

Mass production of nano-scaled platelets and products

ActiveUS7785492B1Reduce necessary intercalation timeSmall thicknessMaterial nanotechnologyGraphiteNoble gasGraphite

Disclosed is a process for exfoliating a layered material to produce nano-scaled platelets having a thickness smaller than 100 nm, typically smaller than 10 nm, and often between 0.34 nm and 1.02 nm. The process comprises: (a) charging a layered material to an intercalation chamber comprising a gaseous environment at a first temperature and a first pressure sufficient to cause gas species to penetrate into the interstitial space between layers of the layered material, forming a gas-intercalated layered material; and (b) operating a discharge valve to rapidly eject the gas-intercalated layered material through a nozzle into an exfoliation zone at a second pressure and a second temperature, allowing gas species residing in the interstitial space to exfoliate the layered material to produce the platelets. The gaseous environment preferably contains only environmentally benign gases that are reactive (e.g., oxygen) or non-reactive (e.g., noble gases) with the layered material. The process can additionally include dispersing the platelets in a matrix material to form a nanocomposite. The process also can include an additional process of re-compressing the nana-scaled platelets into a product such as a flexible graphite sheet.

Owner:GLOBAL GRAPHENE GRP INC

Method for manufacturing semiconductor device

InactiveUS20090047759A1Increase display contrastQuality improvementSolid-state devicesSemiconductor/solid-state device manufacturingNoble gasHydrogen

After a gate insulating film is formed over a gate electrode, in order to improve the quality of a microcrystalline semiconductor film which is formed in an early stage of deposition, a film near an interface with the gate insulating film is formed under a first deposition condition in which a deposition rate is low but the quality of a film to be formed is high, and then, a film is further deposited under a second deposition condition in which a deposition rate is high. Then, a buffer layer is formed to be in contact with the microcrystalline semiconductor film. Further, plasma treatment with a rare gas such as argon or hydrogen plasma treatment is performed before formation of the film under the first deposition condition for removing adsorbed water on a substrate.

Owner:SEMICON ENERGY LAB CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com