Patents

Literature

48138results about "Pretreated surfaces" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

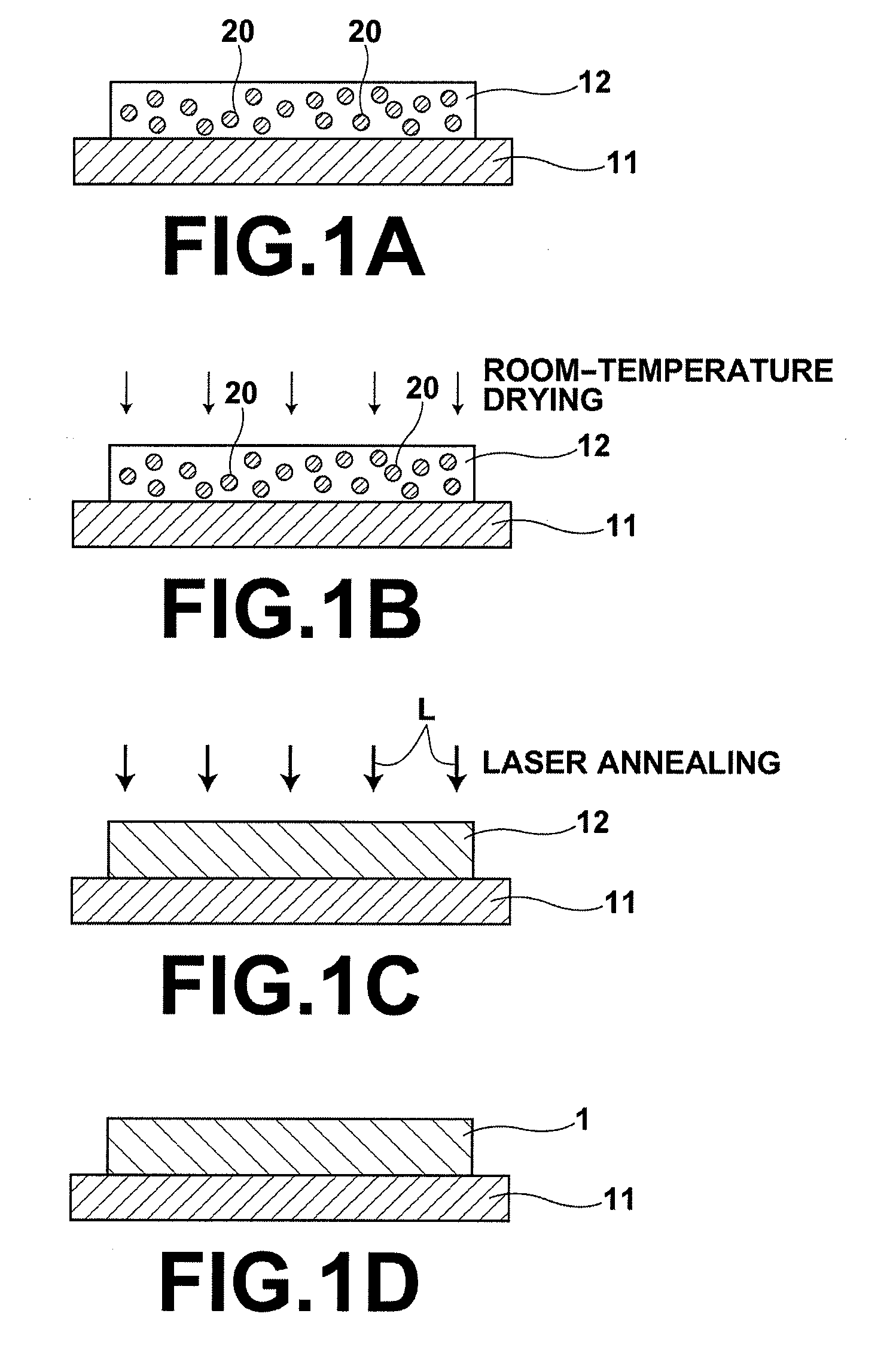

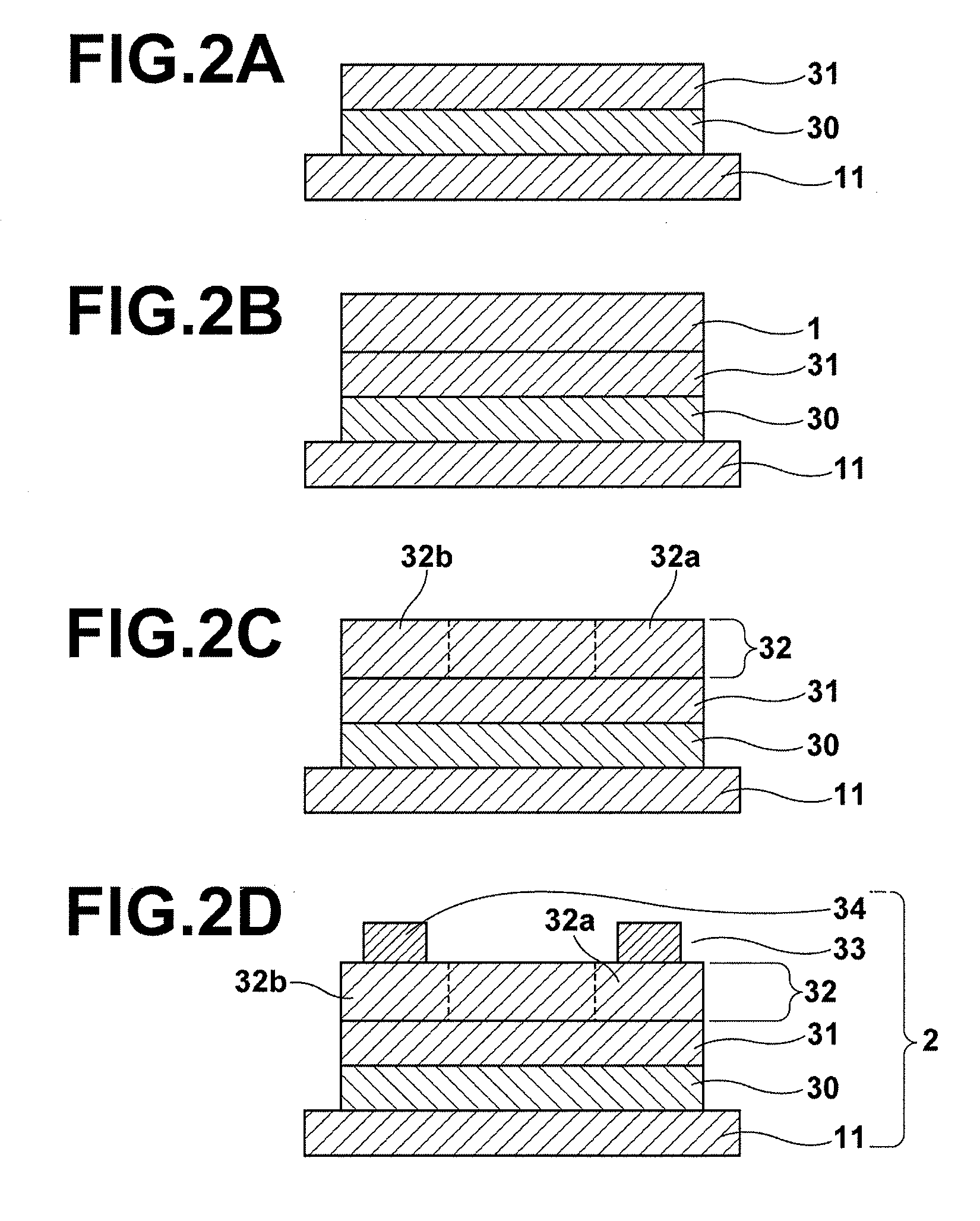

Process for producing oriented inorganic crystalline film, and semiconductor device using the oriented inorganic crystalline film

ActiveUS20090152506A1Orientation can be controlledLow costFrom gel stateFrom solid stateOrganic solventDevice material

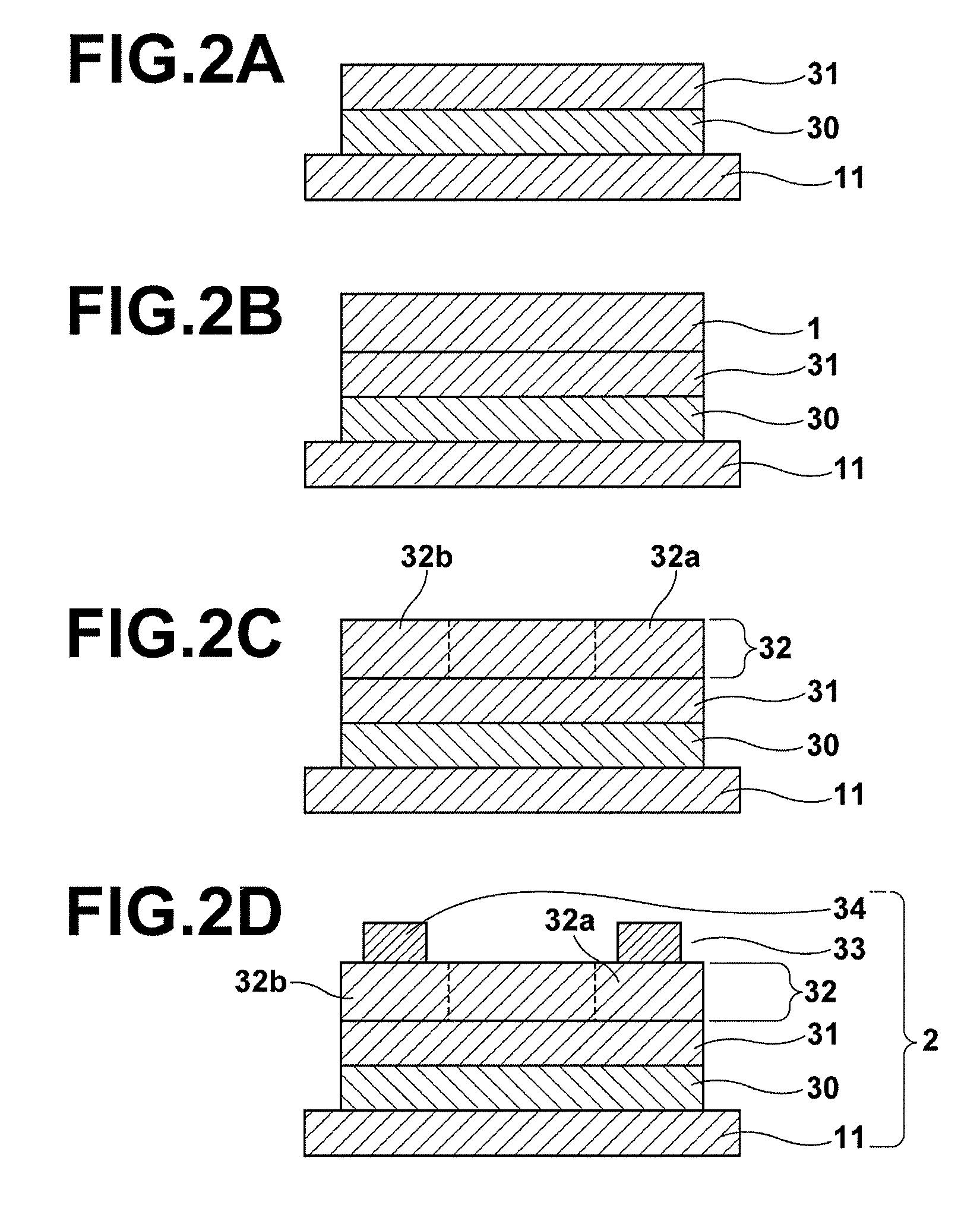

In a process for producing an oriented inorganic crystalline film, a non-monocrystalline film containing inorganic crystalline particles is formed on a substrate by a liquid phase technique using a raw-material solution which contains a raw material and an organic solvent, where the inorganic crystalline particles have a layered crystal structure and are contained in the raw material. Then, the non-monocrystalline film is crystallized by heating the non-monocrystalline film to a temperature equal to or higher than the crystallization temperature of the non-monocrystalline film so that part of the inorganic crystalline particles act as crystal nuclei.

Owner:FUJIFILM CORP

Silicone composition for biocompatible membrane

InactiveUS20050090607A1Microbiological testing/measurementSynthetic resin layered productsSensor materialsPolymer

Owner:DECOM

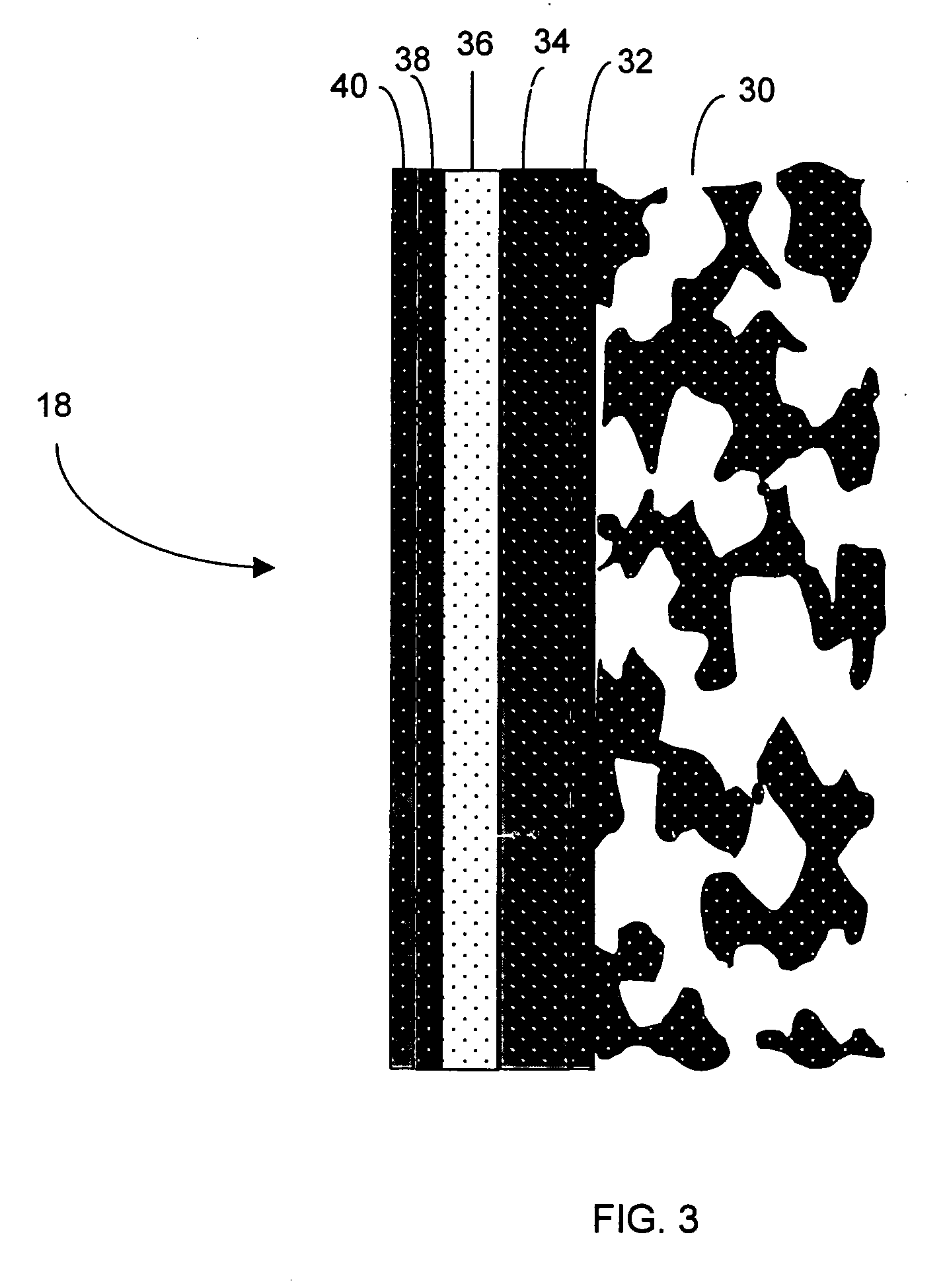

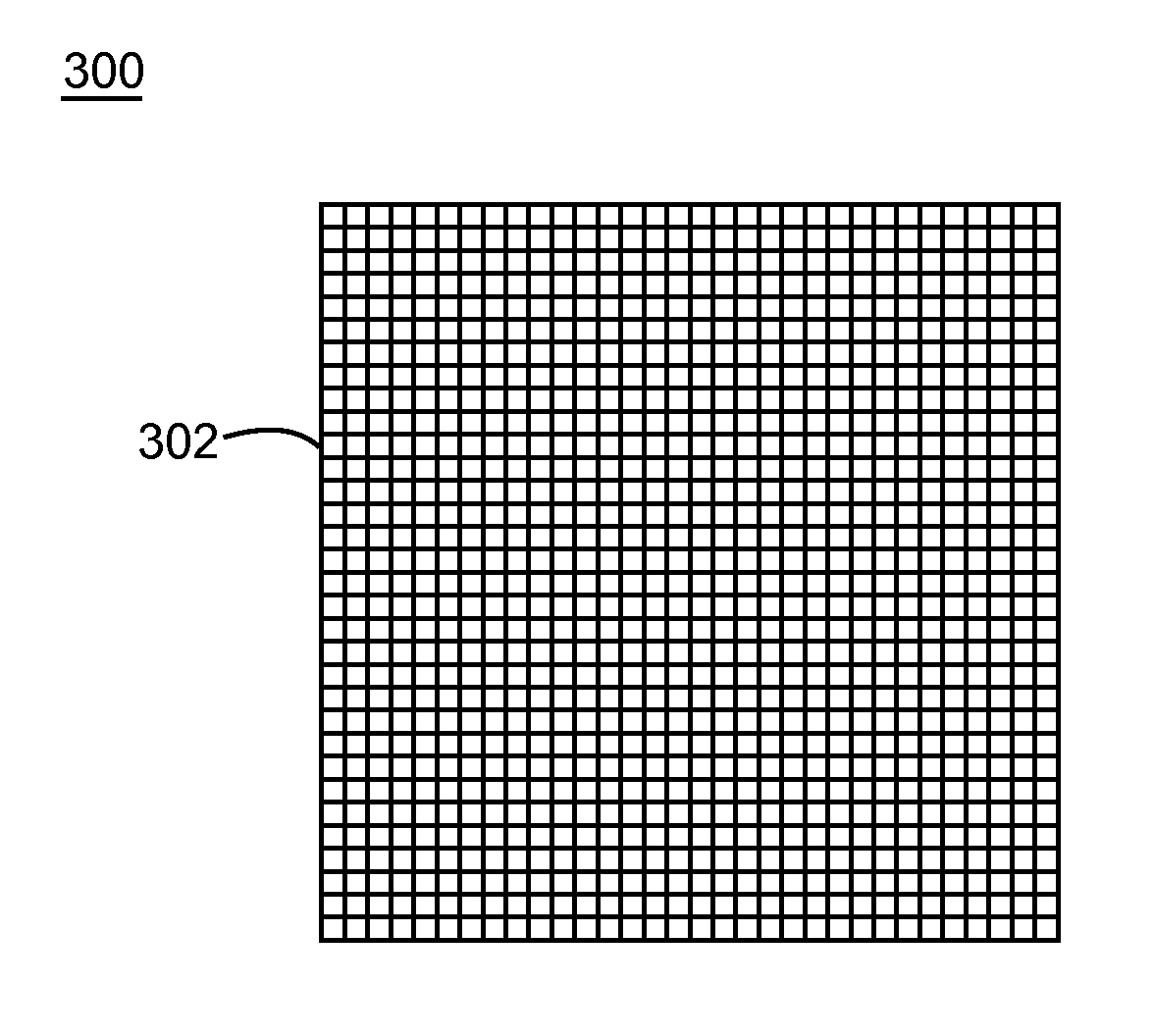

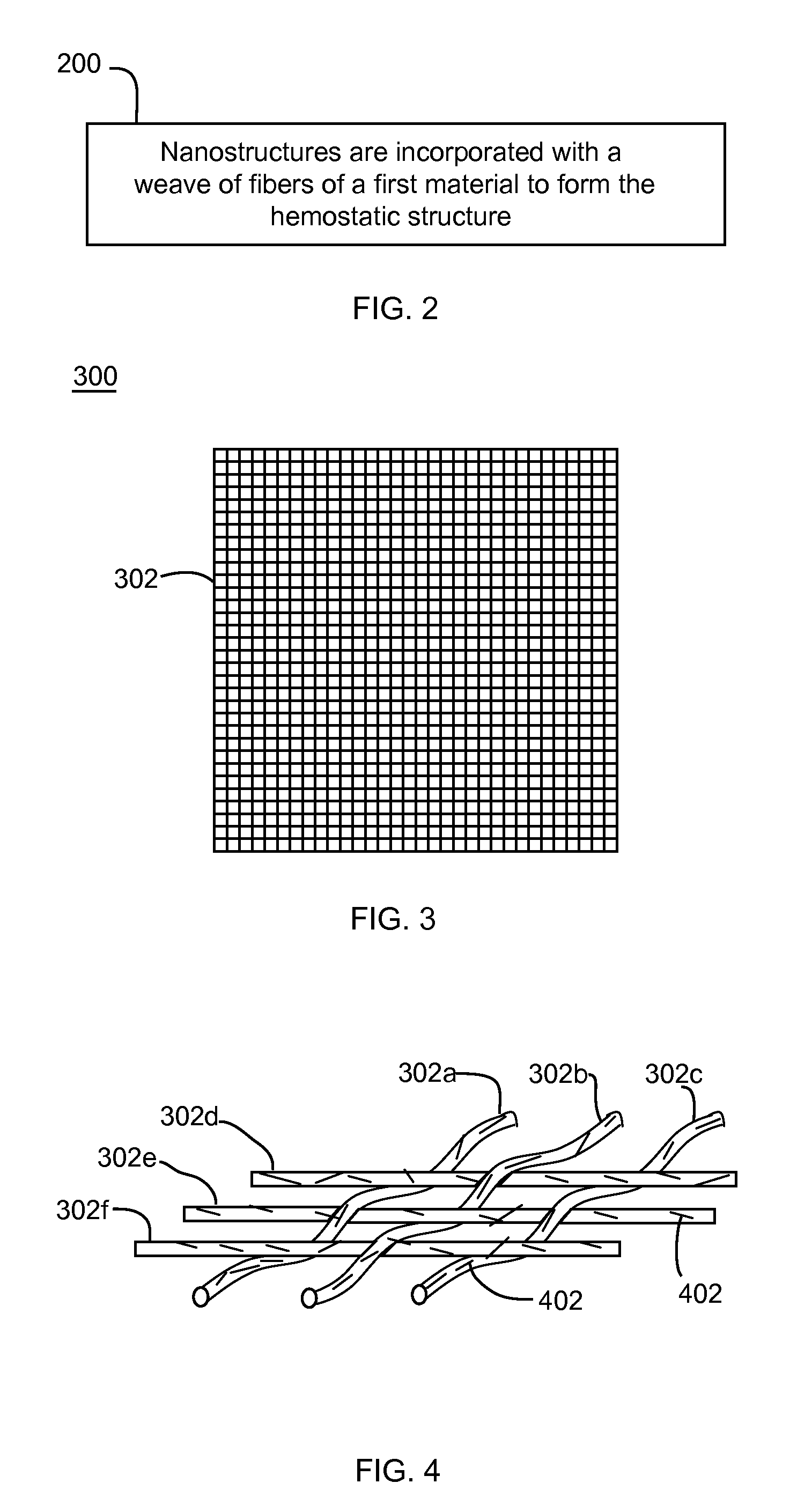

Nanostructure-enhanced platelet binding and hemostatic structures

InactiveUS8319002B2Enhancing overall rate and strengthInduce platelet binding and efficient hemostasisBiocideSurgical adhesivesPlateletNanofiber

Methods, systems, and apparatuses for nanomaterial-enhanced platelet binding and hemostatic medical devices are provided. Hemostatic materials and structures are provided that induce platelet binding, including platelet binding and the coagulation of blood at a wound / opening caused by trauma, a surgical procedure, ulceration, or other cause. Example embodiments include platelet binding devices, hemostatic bandages, hemostatic plugs, and hemostatic formulations. The hemostatic materials and structures may incorporate nanostructures and / or further hemostatic elements such as polymers, silicon nanofibers, silicon dioxide nanofibers, and / or glass beads into a highly absorbent, gelling scaffold. The hemostatic materials and structures may be resorbable.

Owner:NANOSYS INC

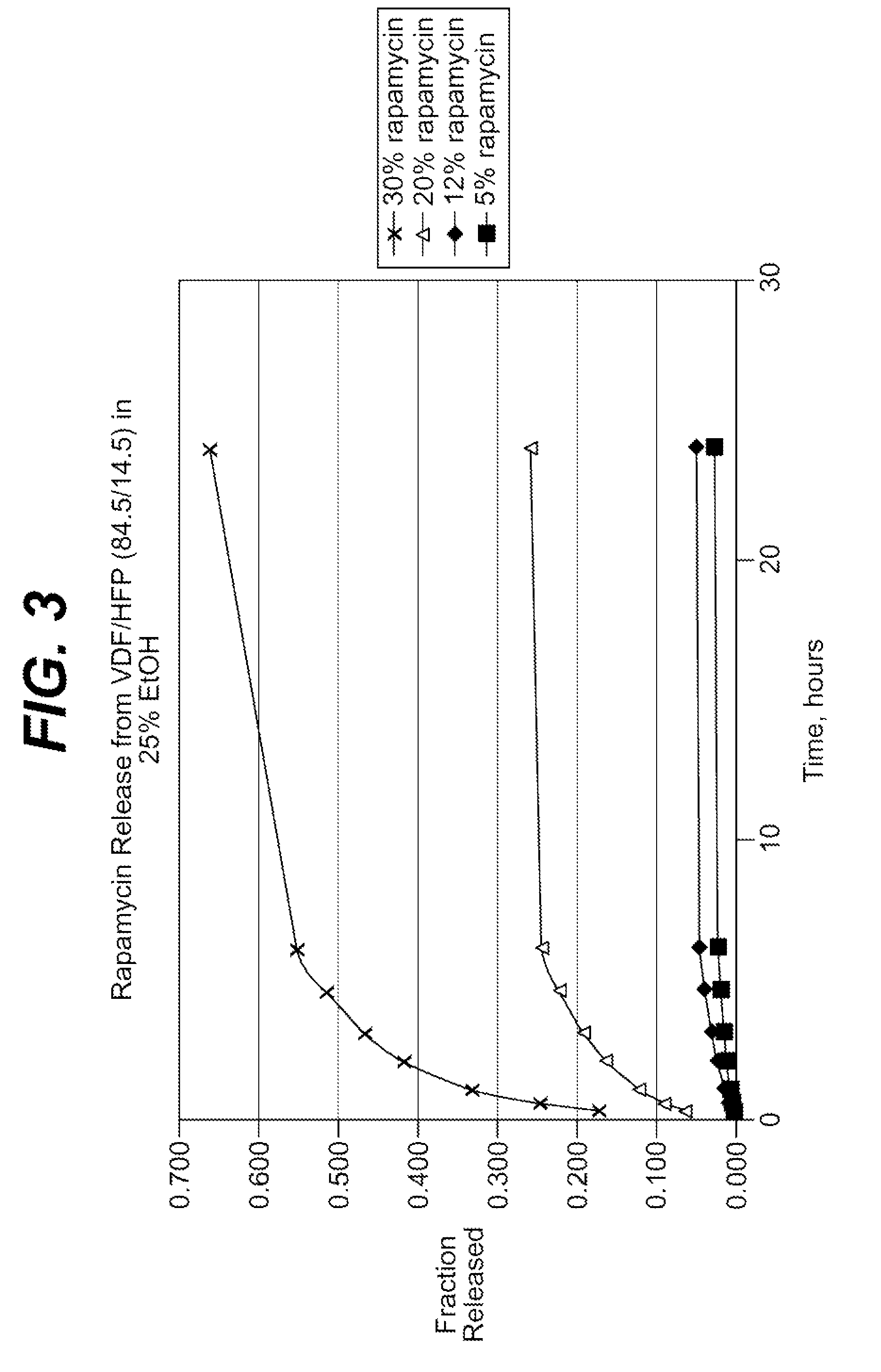

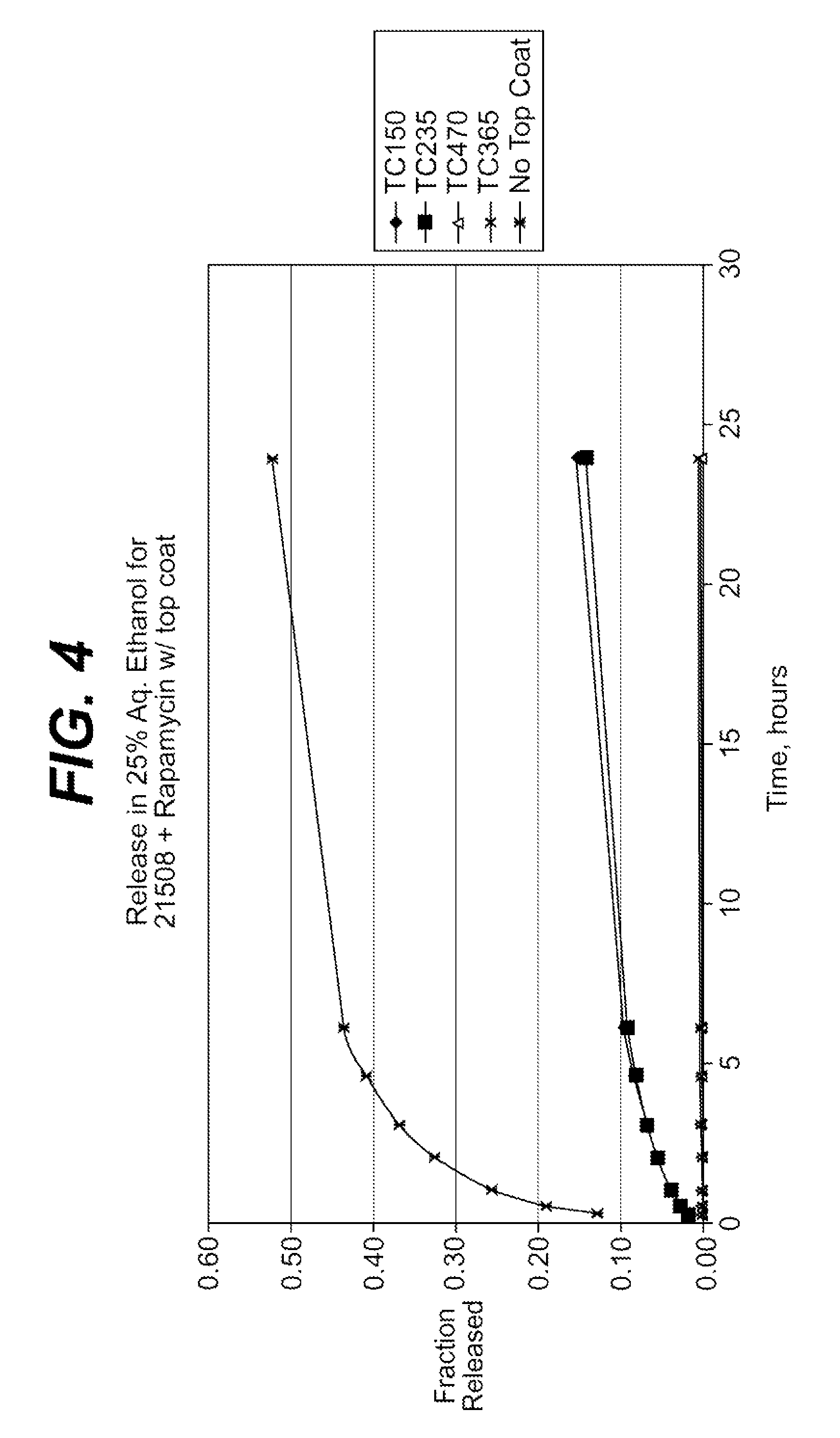

Extraction of solvents from drug containing polymer reservoirs

Owner:CARDINAL HEALTH SWITZERLAND 515 GMBH

Absorbent articles comprising nanoparticles

Owner:NANO MET ZERO

Silicone composition for biocompatible membrane

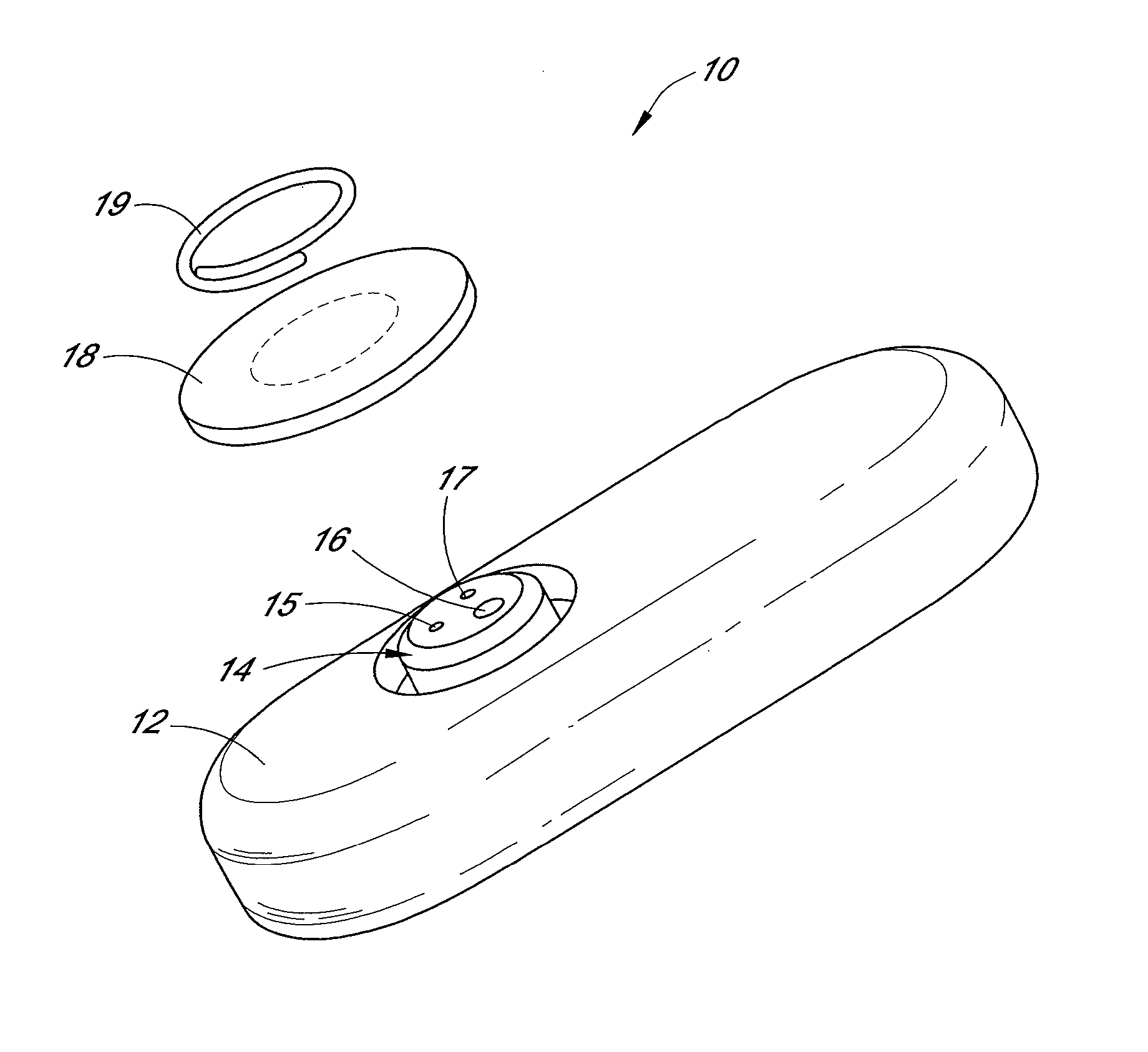

InactiveUS20080045824A1Prevent penetrationMicrobiological testing/measurementSynthetic resin layered productsSensor materialsBiosensor

Owner:DEXCOM INC

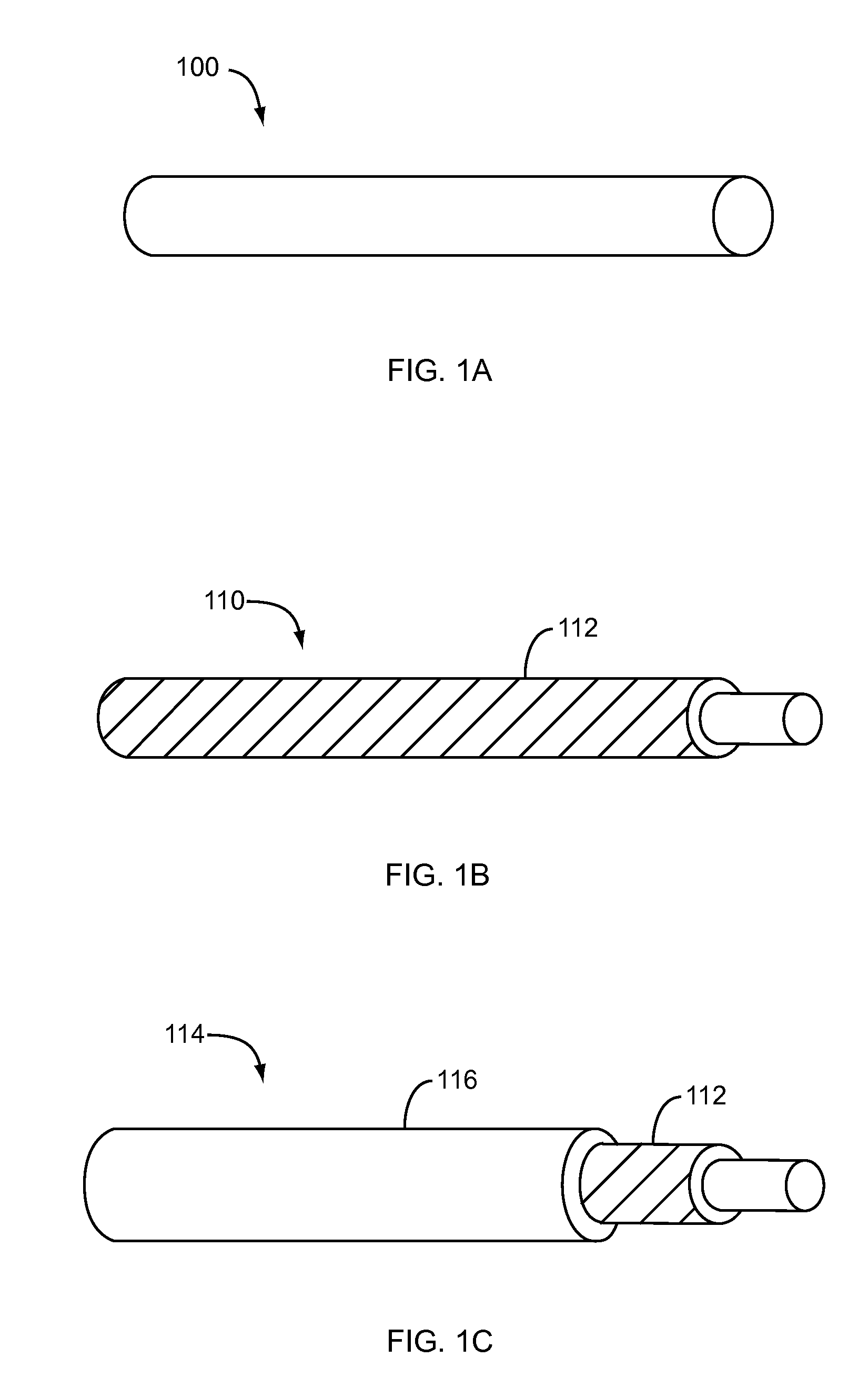

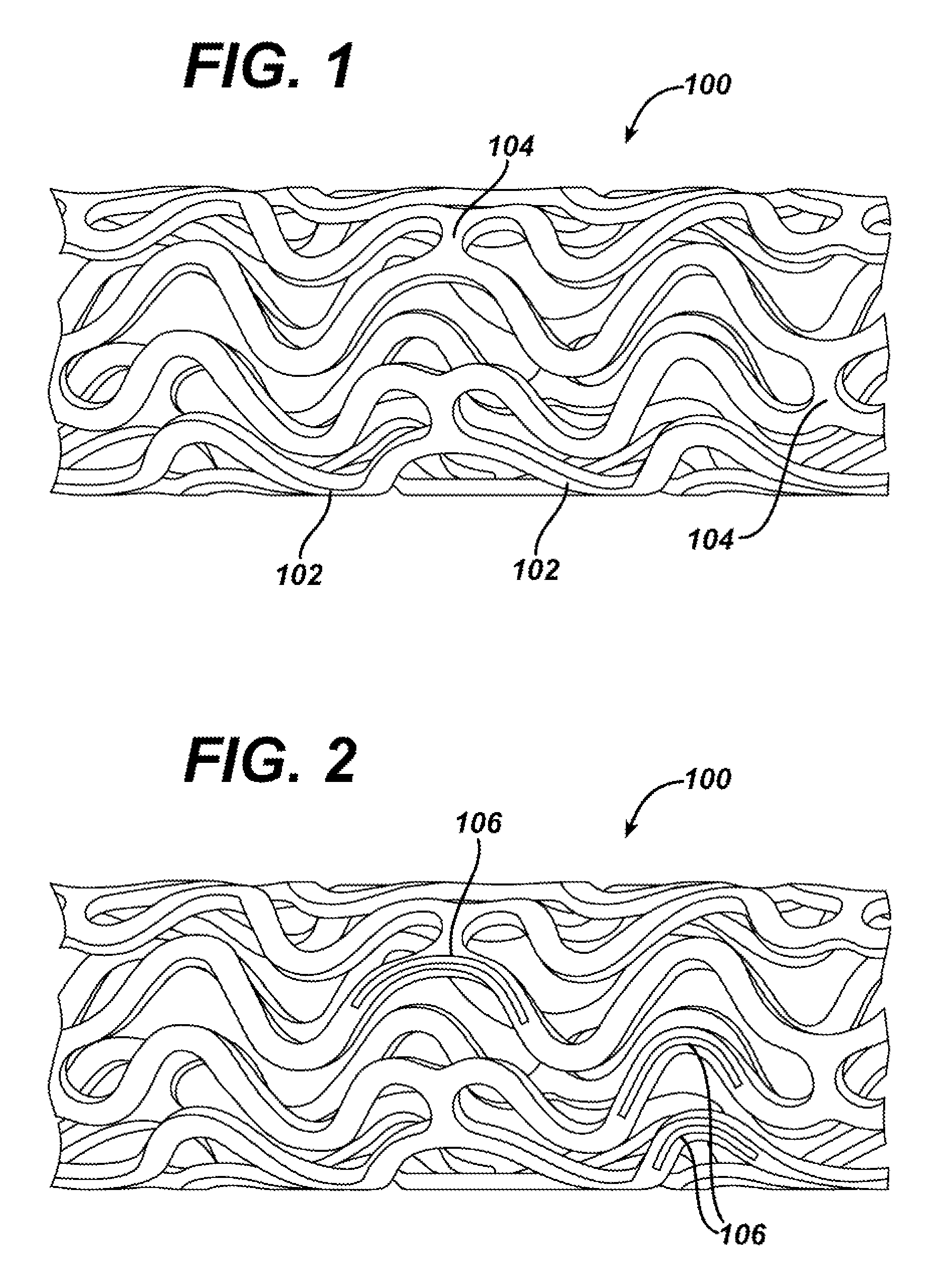

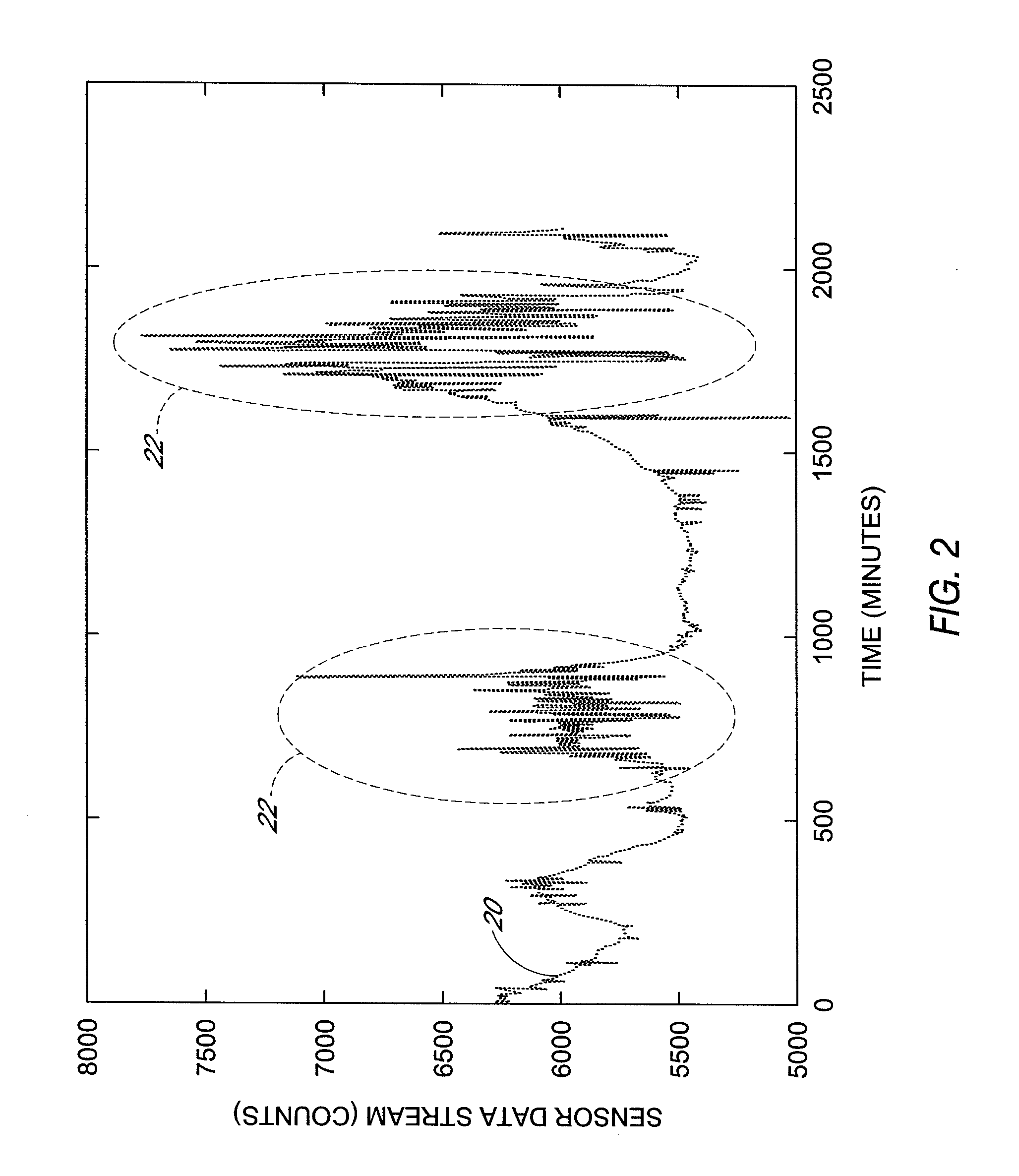

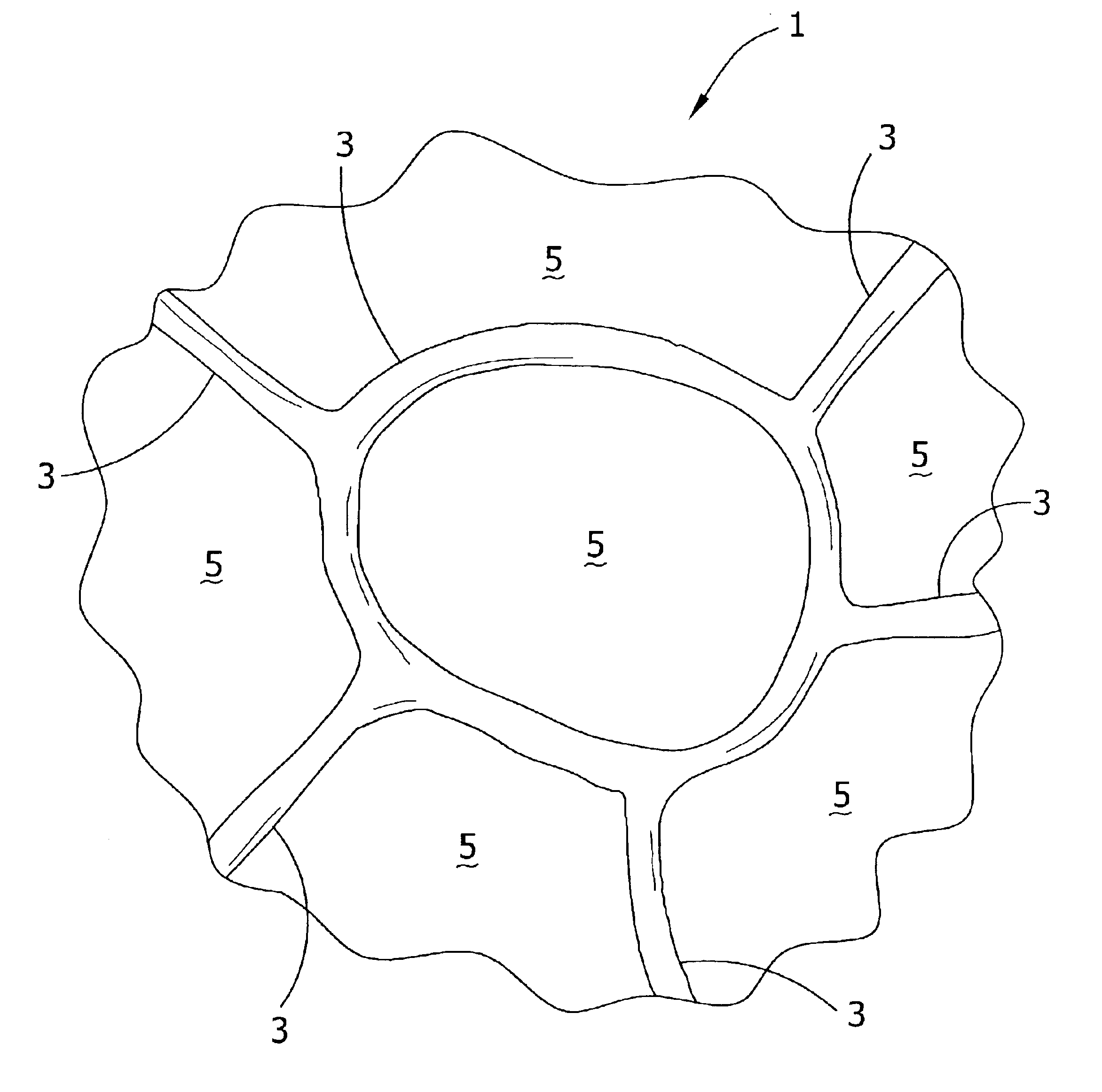

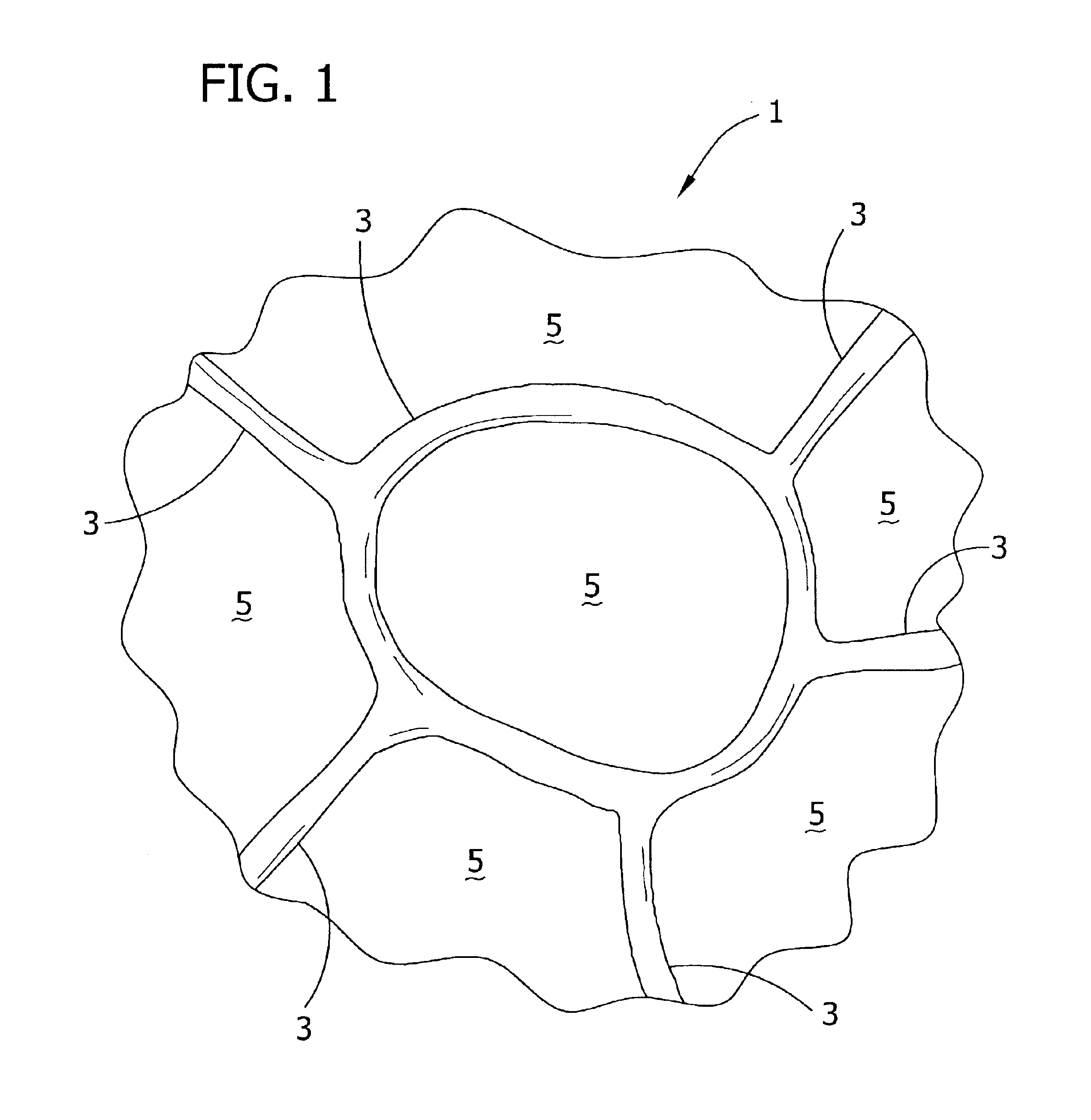

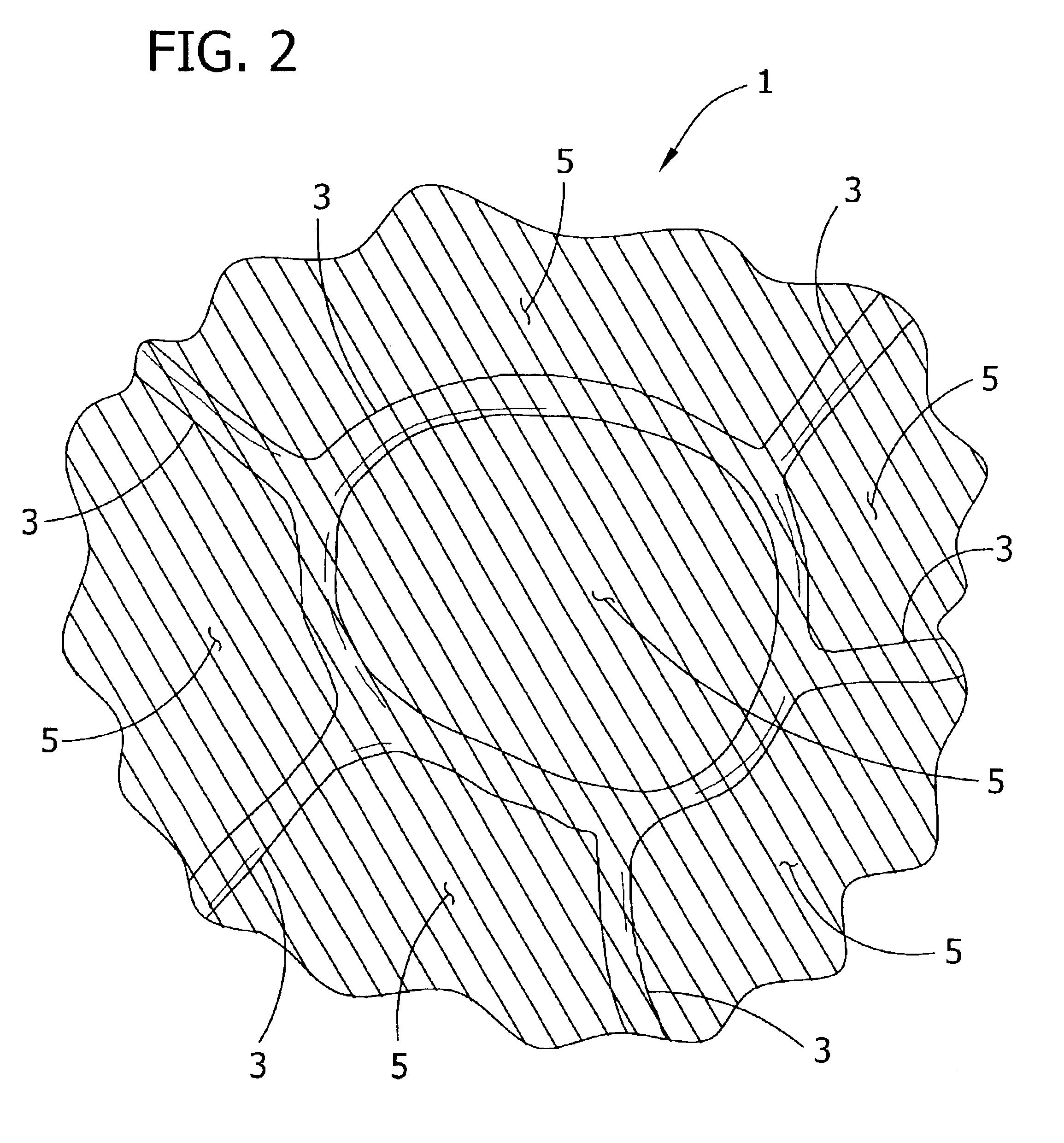

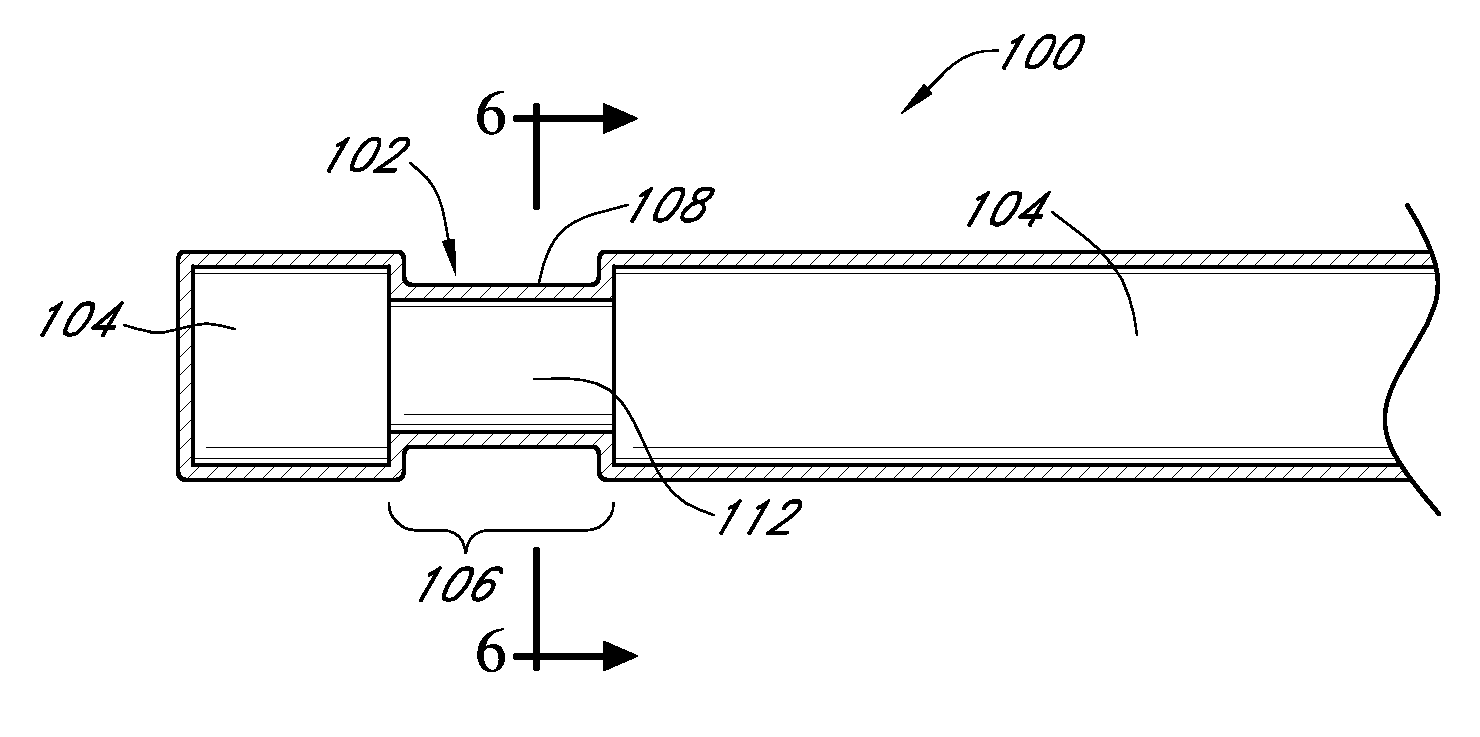

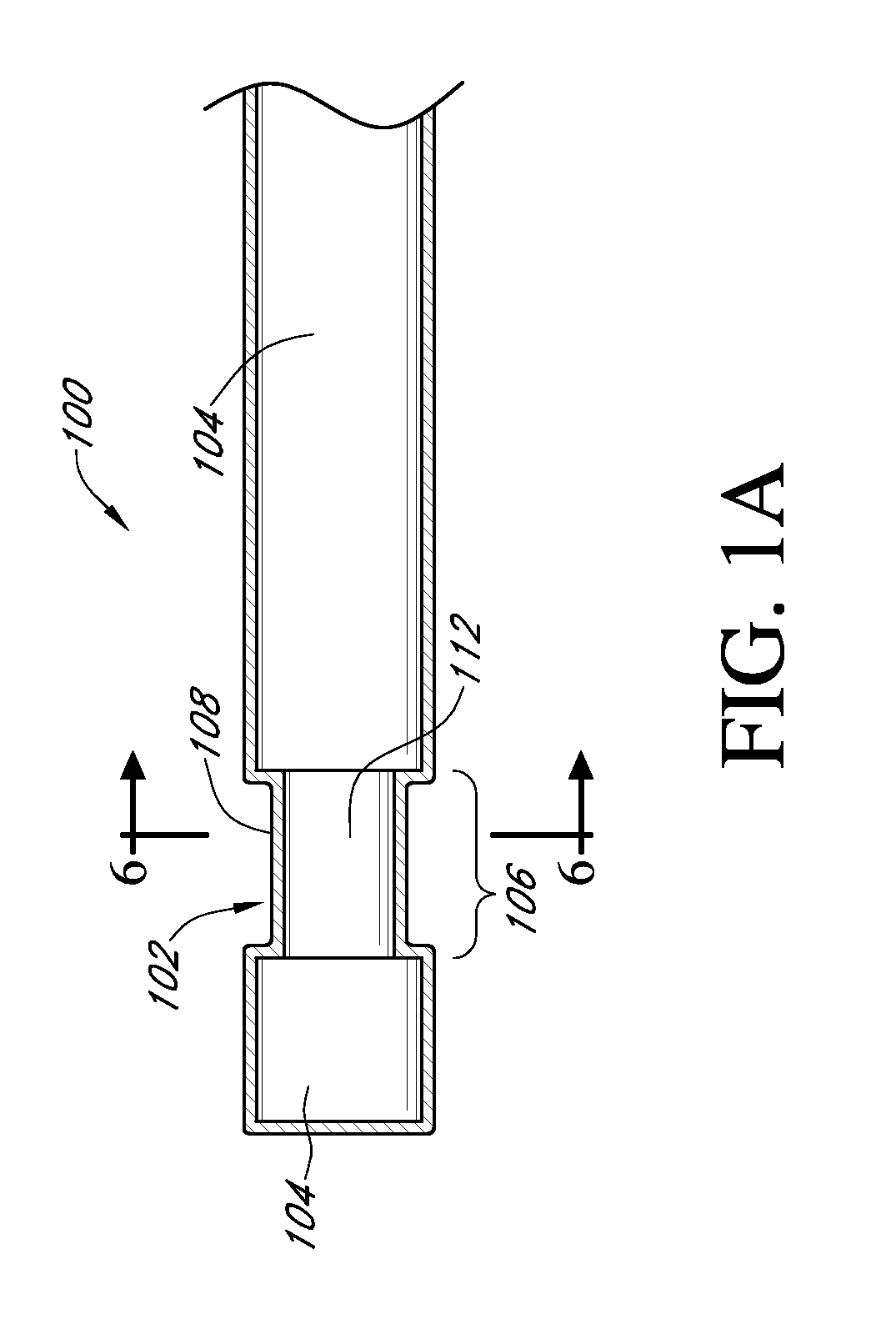

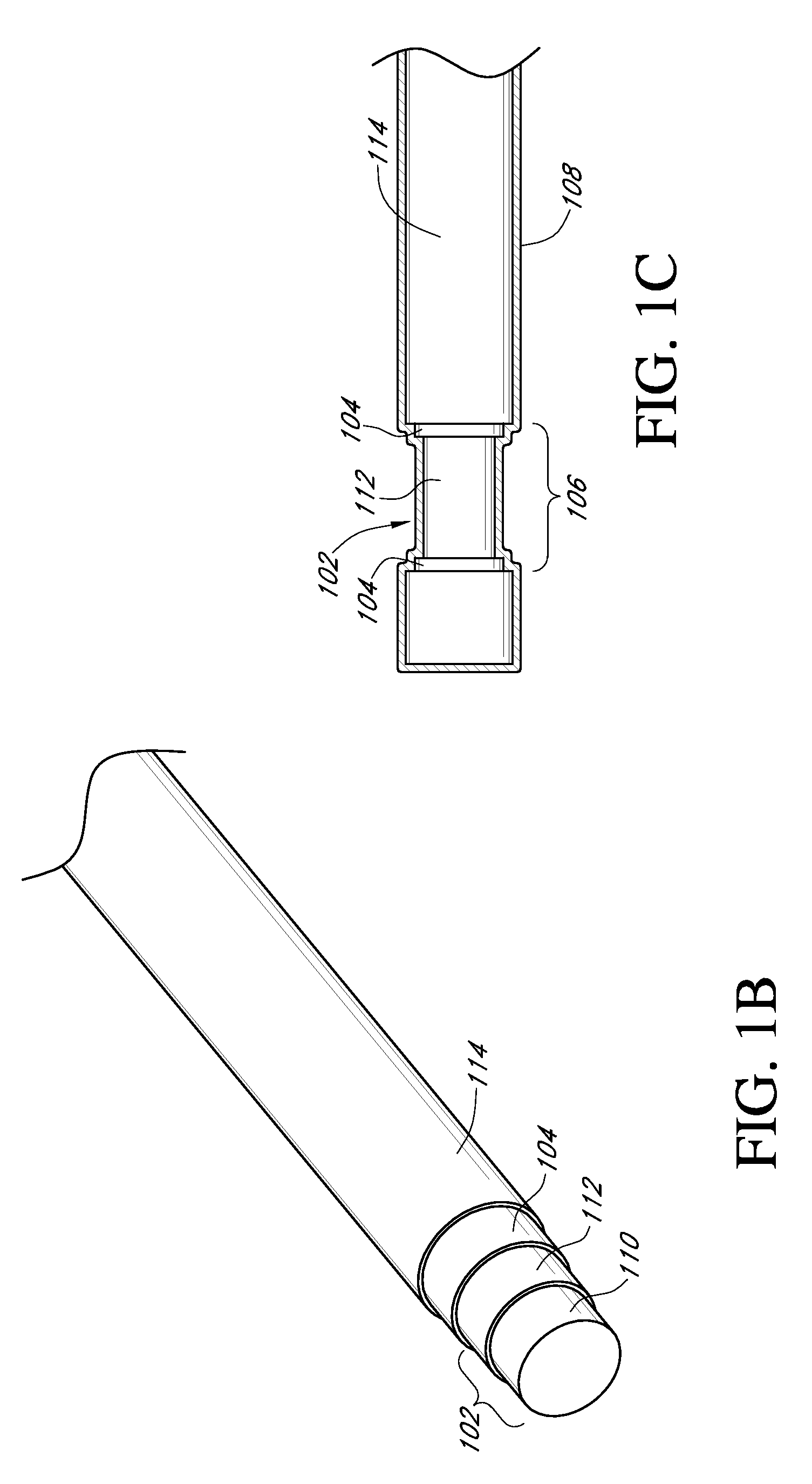

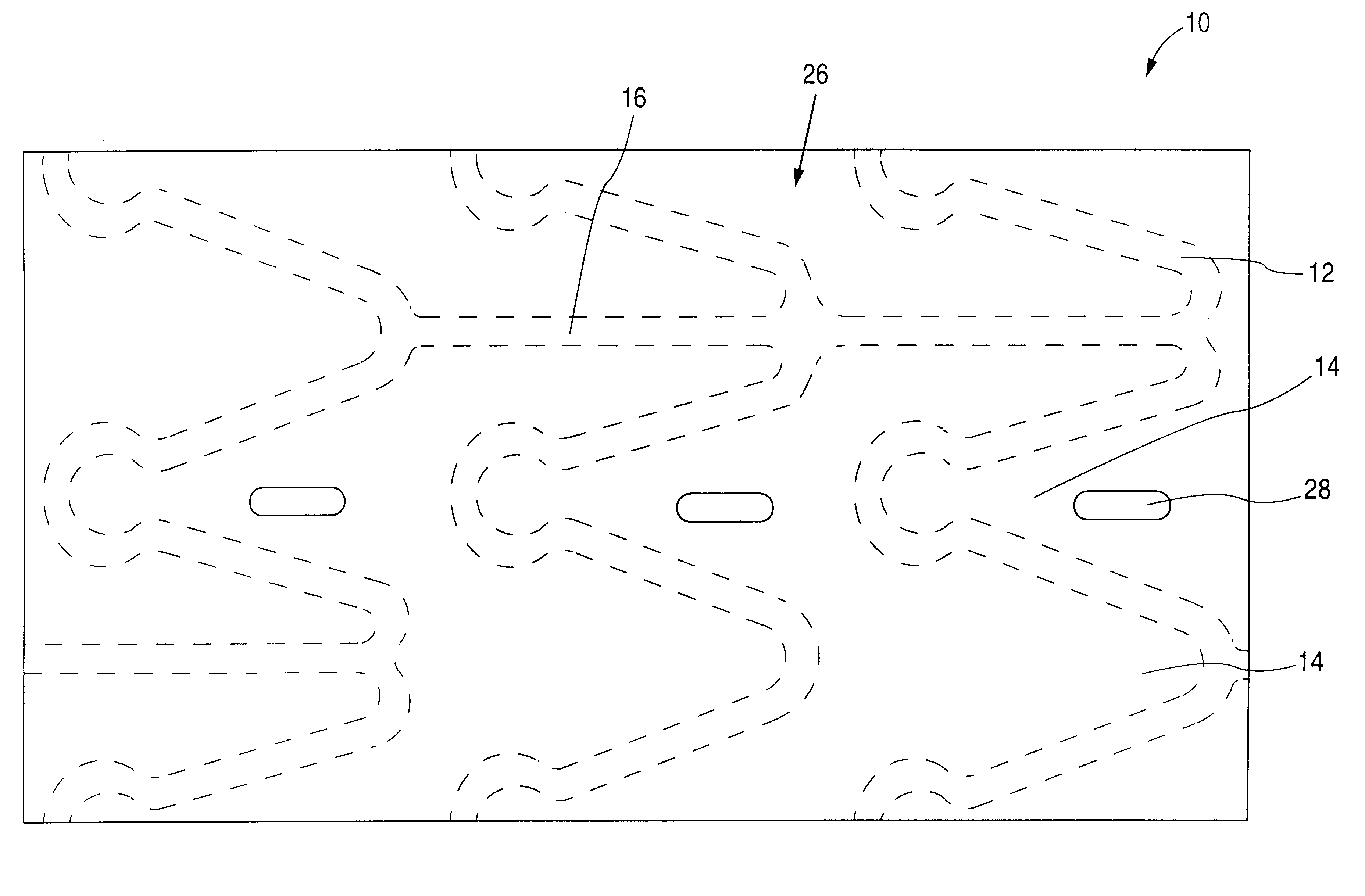

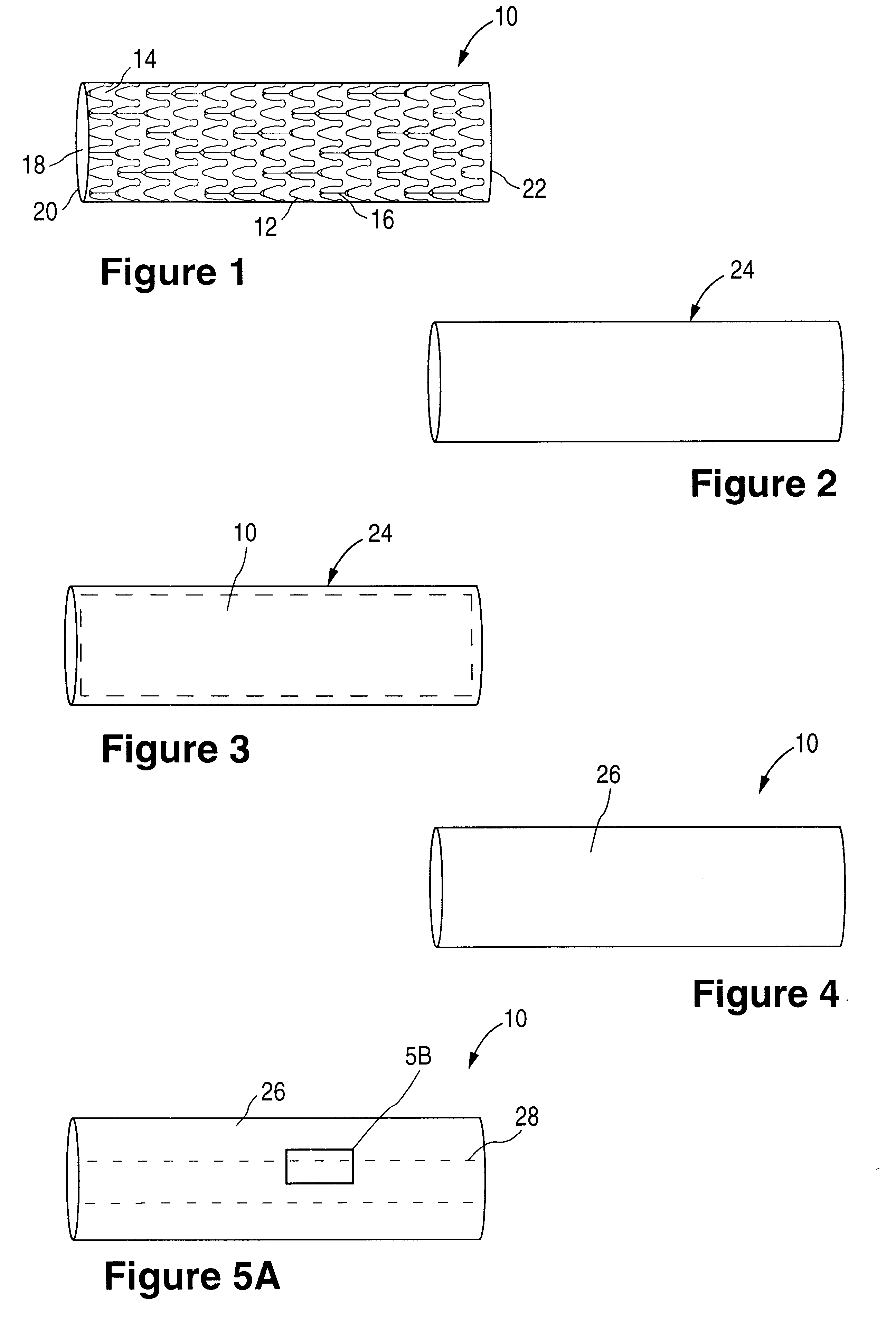

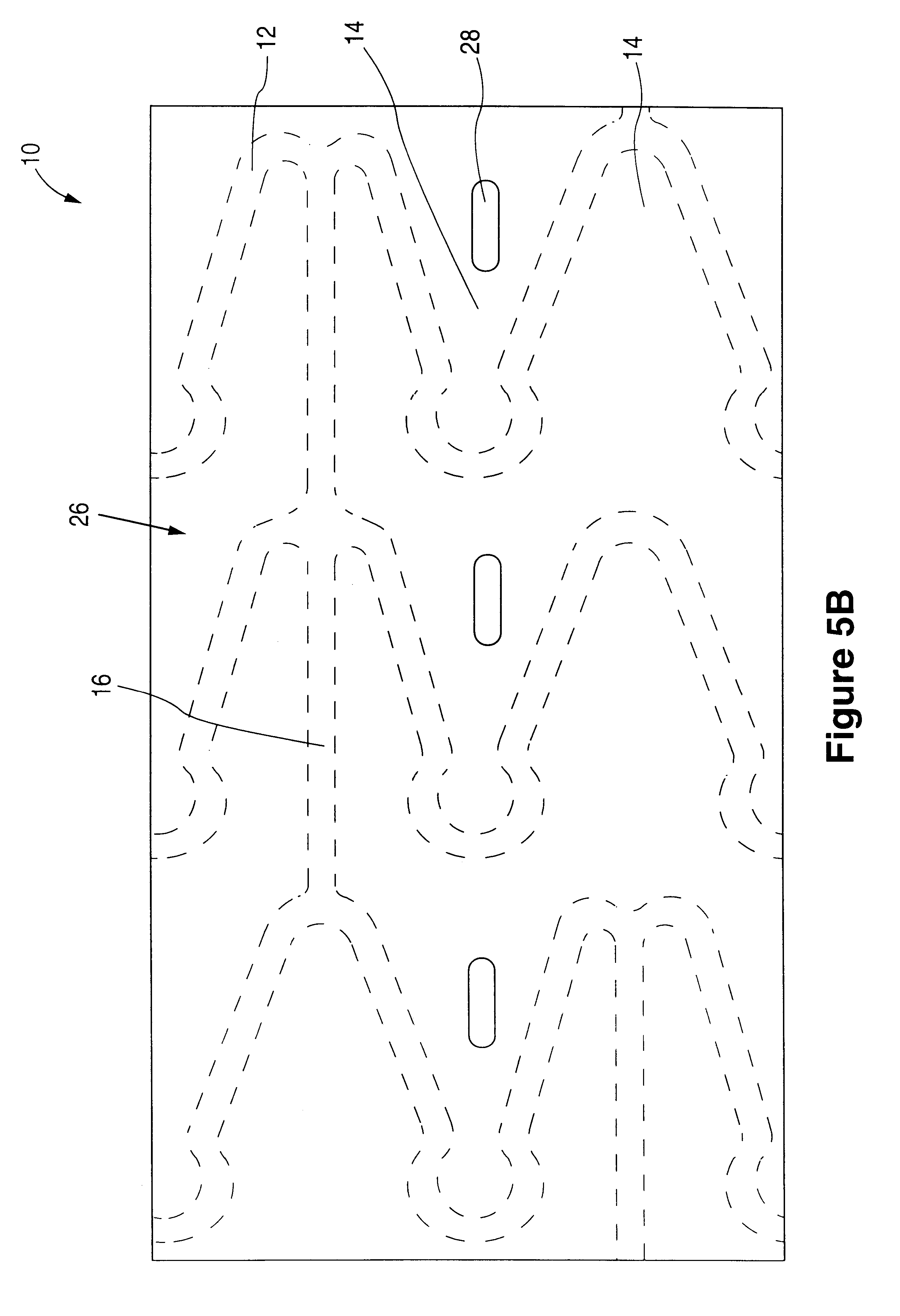

Fiber strand and implantable supporting body having a fiber strand

InactiveUS7997054B2Desired mechanical properties can be adjusted especially easilySignificant positive effectPowder deliveryStentsFiberBiomedical engineering

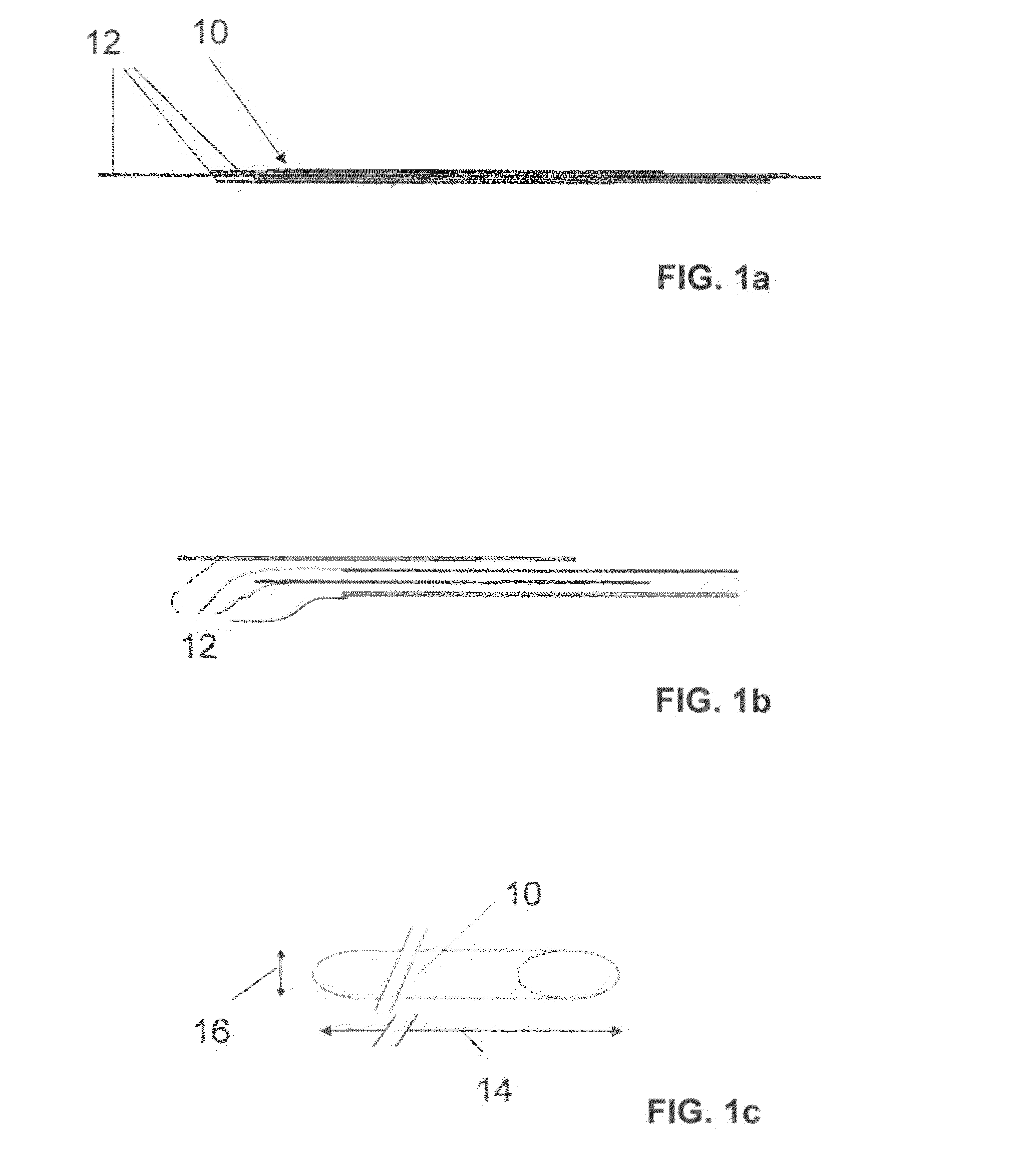

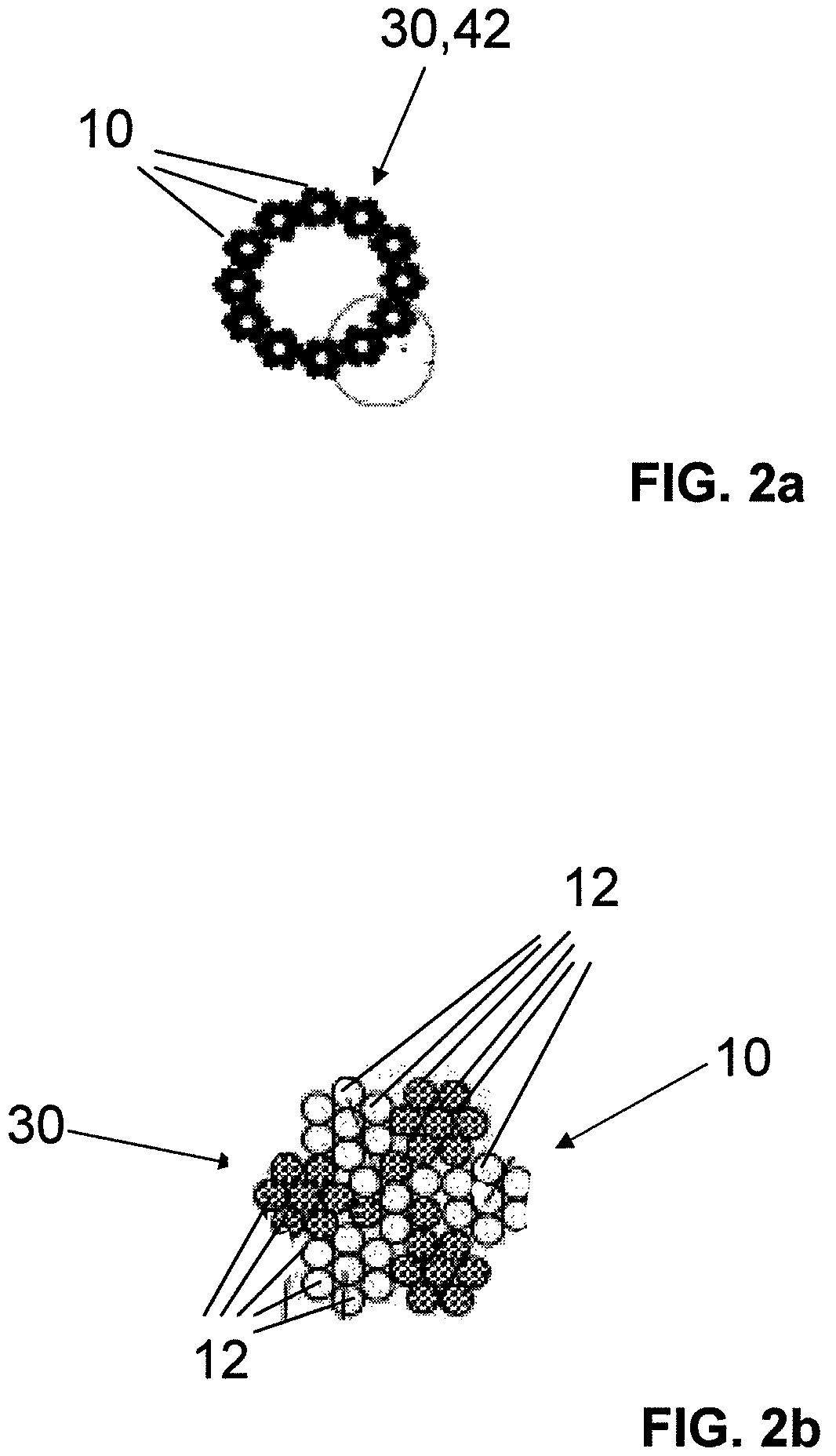

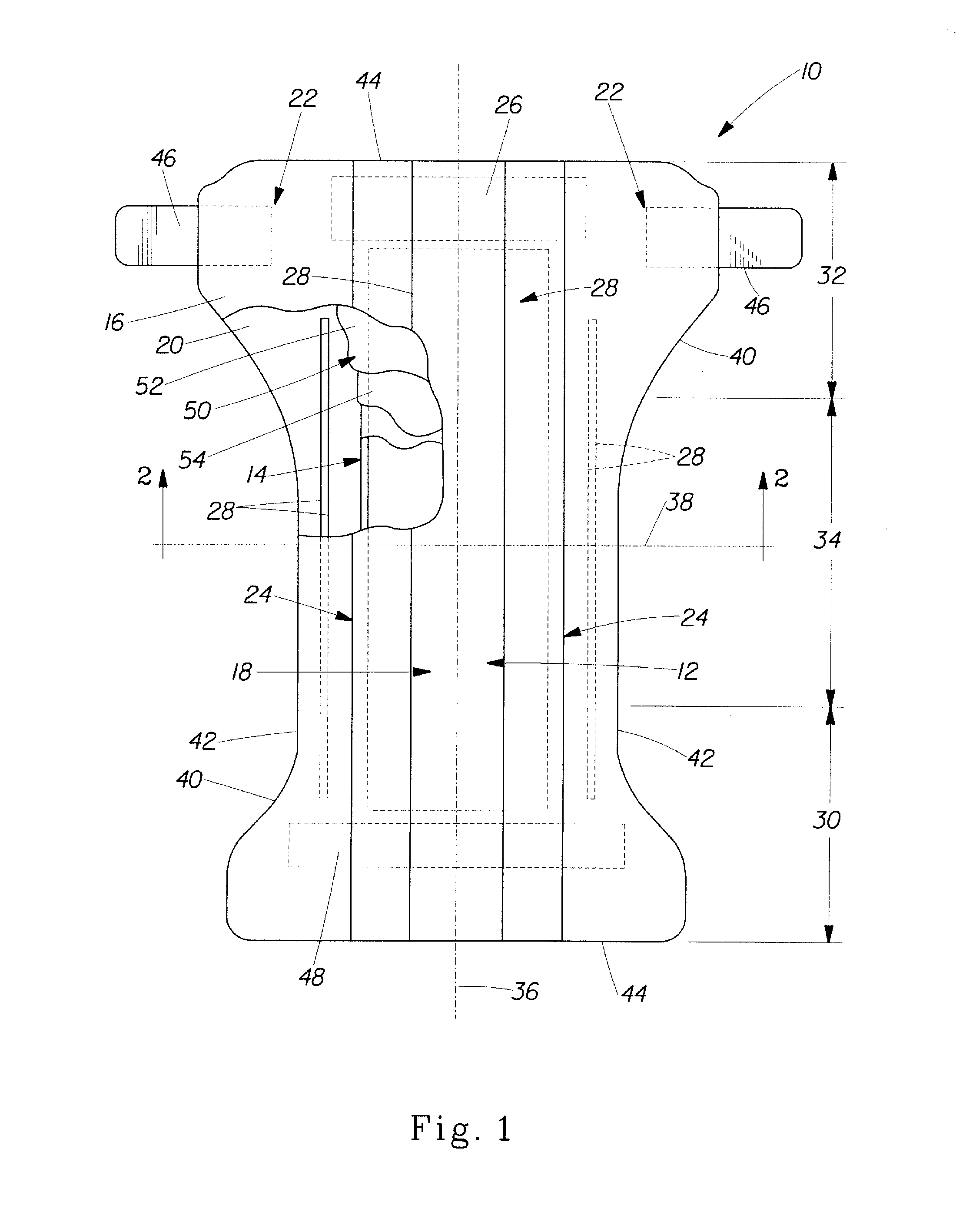

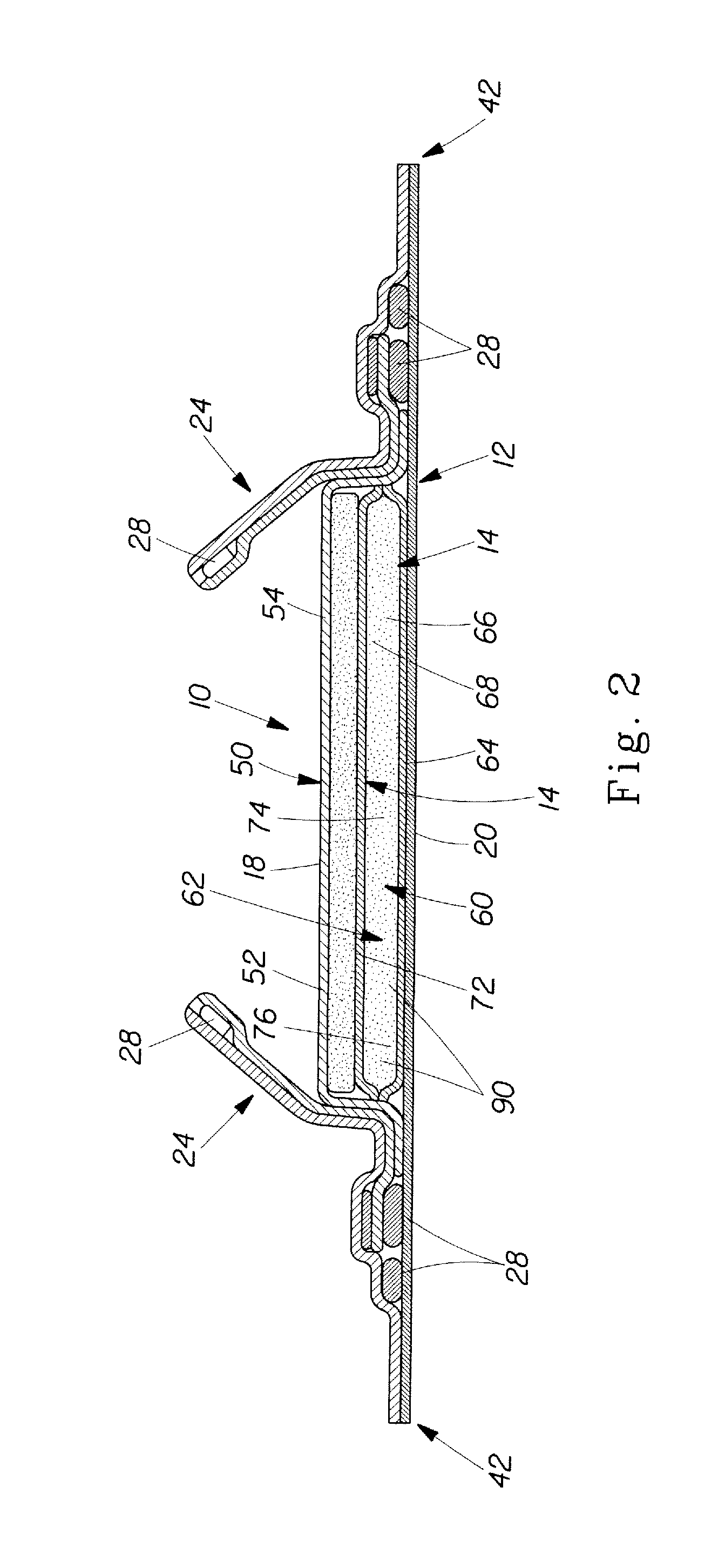

The invention relates to a fiber strand (10) for an implantable supporting body (100) comprising at least two individual fibers (12). The at least two individual fibers (12) are each shorter in their longitudinal extent than the longitudinal extent (14) of the fiber strand, and in their transverse extent they are each thinner than the transverse extent (16) of the fiber strand.

Owner:BIOTRONIK AG

Method of hydrophilizing materials

InactiveUS6863933B2Easy to controlGood removal effectInorganic/elemental detergent compounding agentsRadiation applicationsPolymer scienceNanoparticle

Coating compositions, methods and articles of manufacture comprising a nanoparticle system employing same to impart surface modifying benefits for all types of soft surfaces, and in some cases, hard surfaces, are disclosed. In some embodiments, dispersement of nanoparticles in a suitable carrier medium allows for the creation of coating compositions, methods and articles of manufacture that create multi-use benefits to the modified surfaces. These surface modifications can produce long lasting or semi-permanent multi-use benefits that, in some embodiments, may include at least one of the following improved surface properties: cleaning, wettability, liquid strike-through, comfort, stain resistance, soil removal, malodor control, modification of surface friction, reduced damage to abrasion and color enhancement, relative to the surfaces unmodified with such nanoparticle systems.

Owner:THE PROCTER & GAMBLE COMPANY

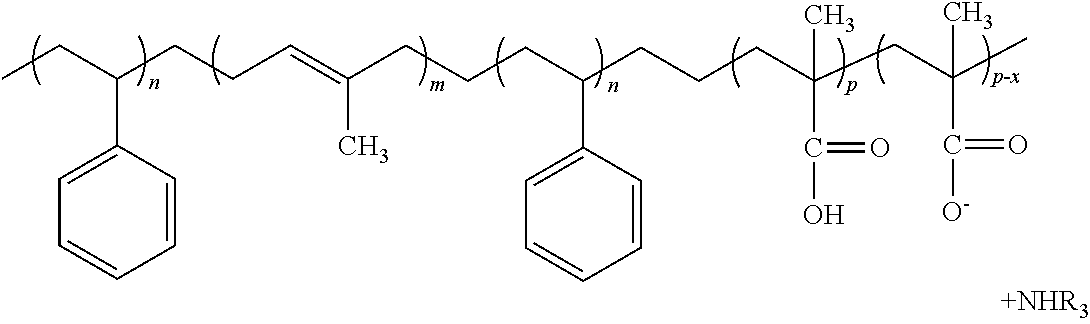

Method for hydrophilizing materials using hydrophilic polymeric materials with discrete charges

A method of rendering materials having hard and soft surfaces hydrophilic or more hydrophilic is disclosed. The method involves hydrophilizing such materials by applying a high energy treatment and charged particles and / or one or more hydrophilic polymeric materials with discrete charges to such materials.

Owner:THE PROCTER & GAMBLE COMPANY

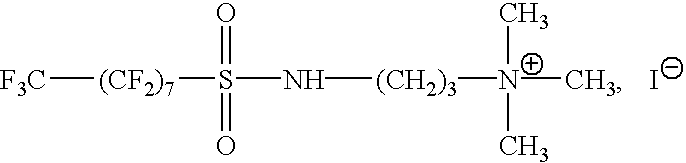

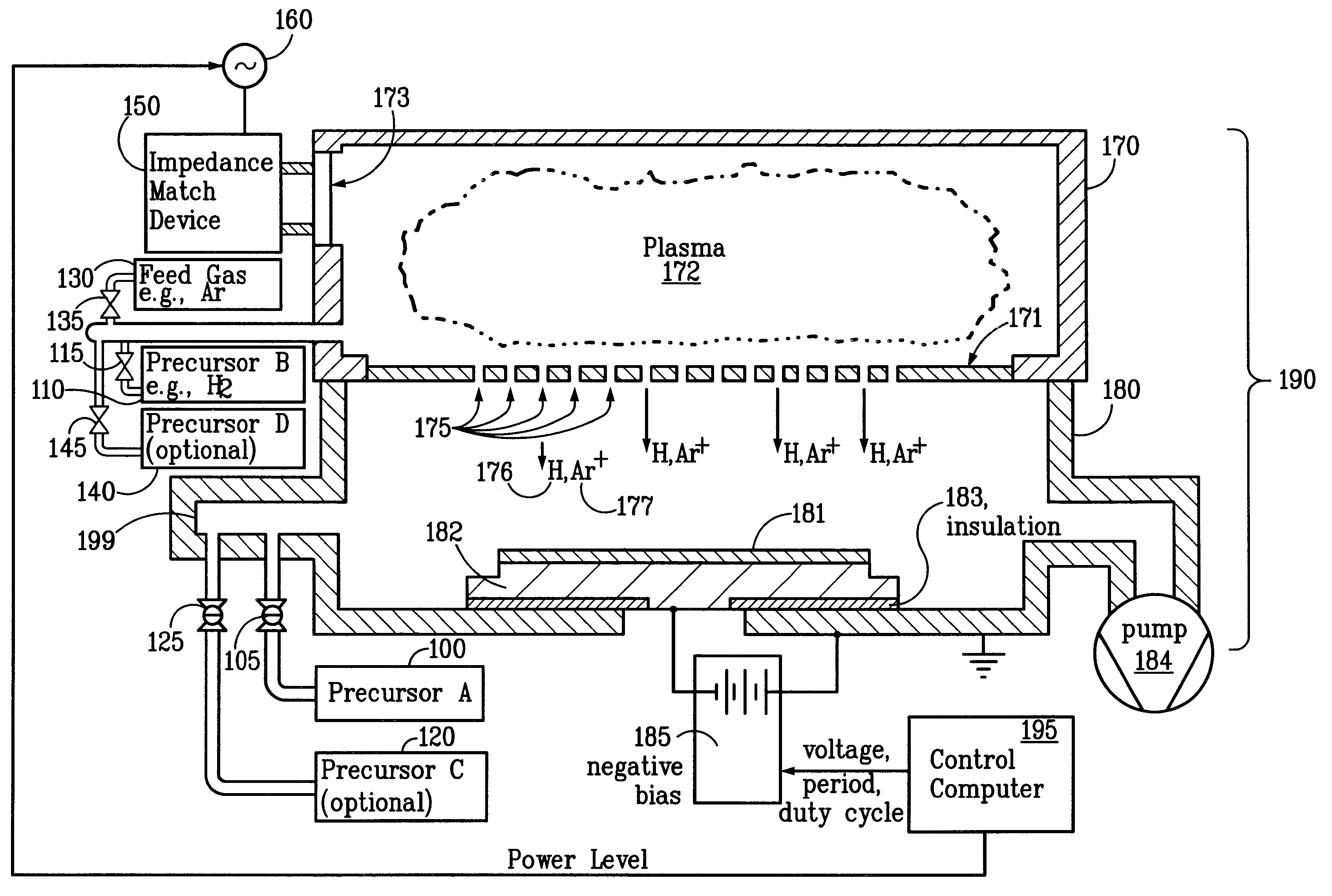

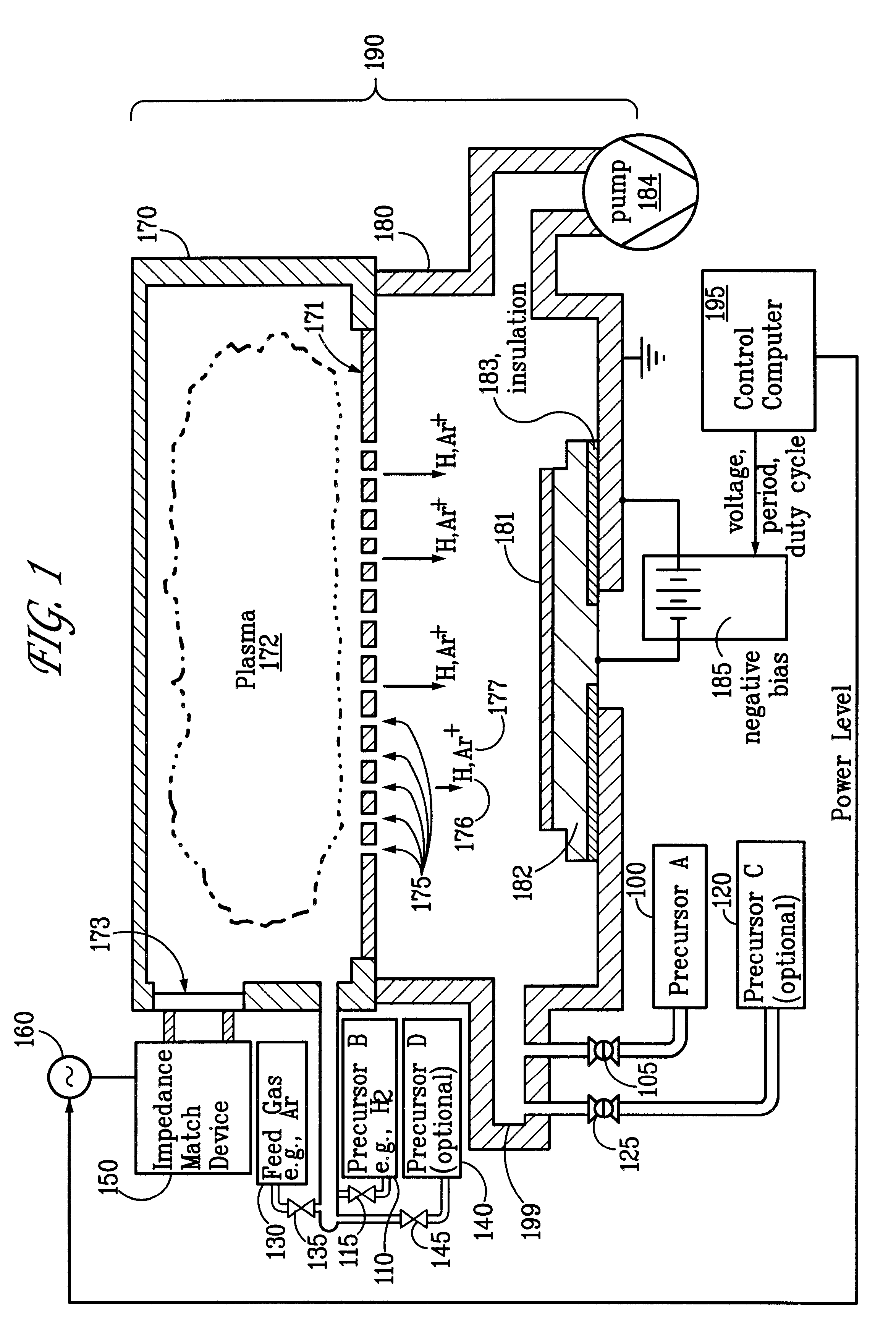

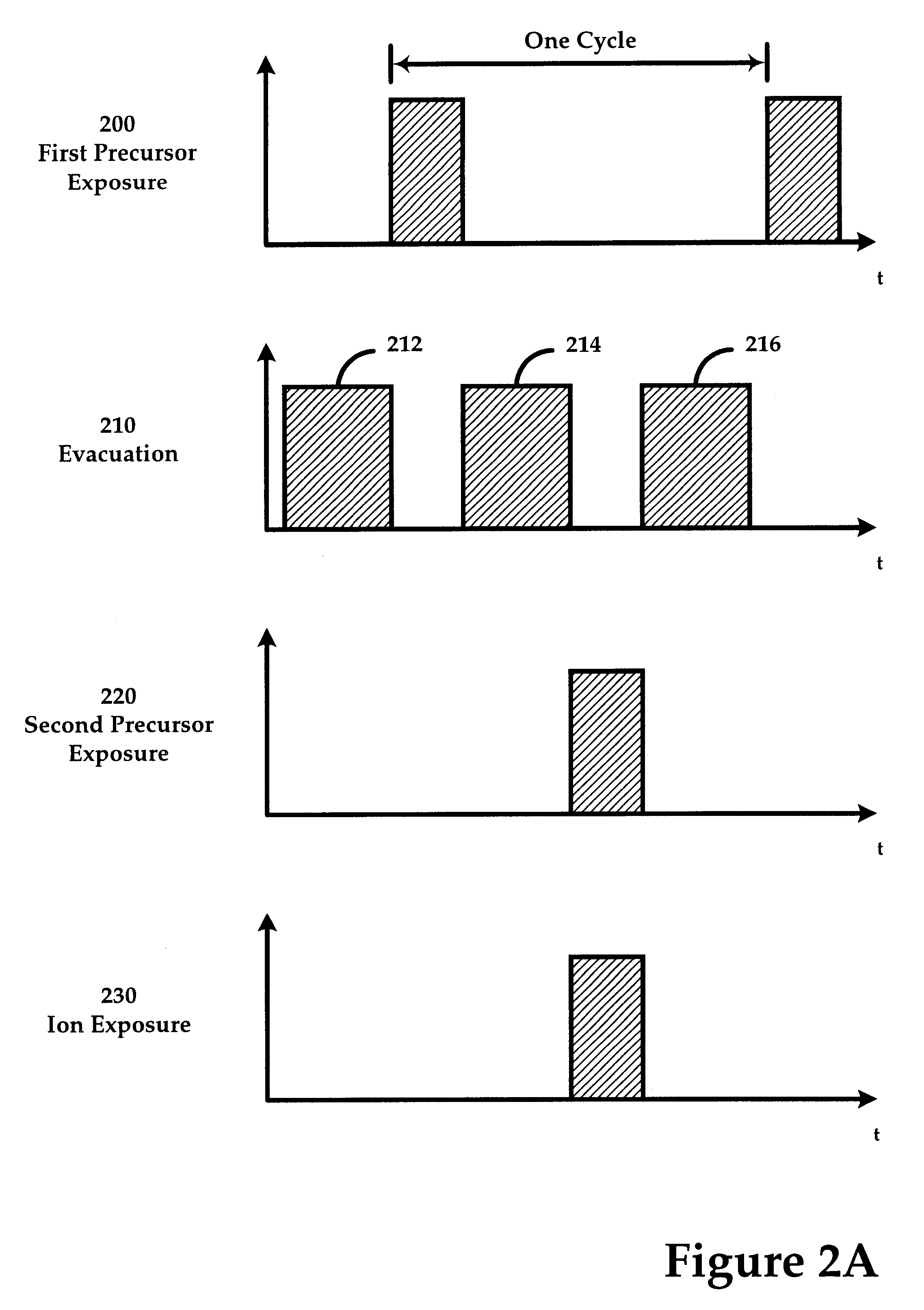

Sequential method for depositing a film by modulated ion-induced atomic layer deposition (MII-ALD)

InactiveUS6428859B1Faster efficient meanSimple methodVacuum evaporation coatingSputtering coatingSequential methodHigh density

The present invention relates to an enhanced sequential atomic layer deposition (ALD) technique suitable for deposition of barrier layers, adhesion layers, seed layers, low dielectric constant (low-k) films, high dielectric constant (high-k) films, and other conductive, semi-conductive, and non-conductive films. This is accomplished by 1) providing a non-thermal or non-pyrolytic means of triggering the deposition reaction; 2) providing a means of depositing a purer film of higher density at lower temperatures; and, 3) providing a faster and more efficient means of modulating the deposition sequence and hence the overall process rate resulting in an improved deposition method. It is emphasized that this abstract is provided to comply with the rules requiring an abstract that will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims.

Owner:NOVELLUS SYSTEMS

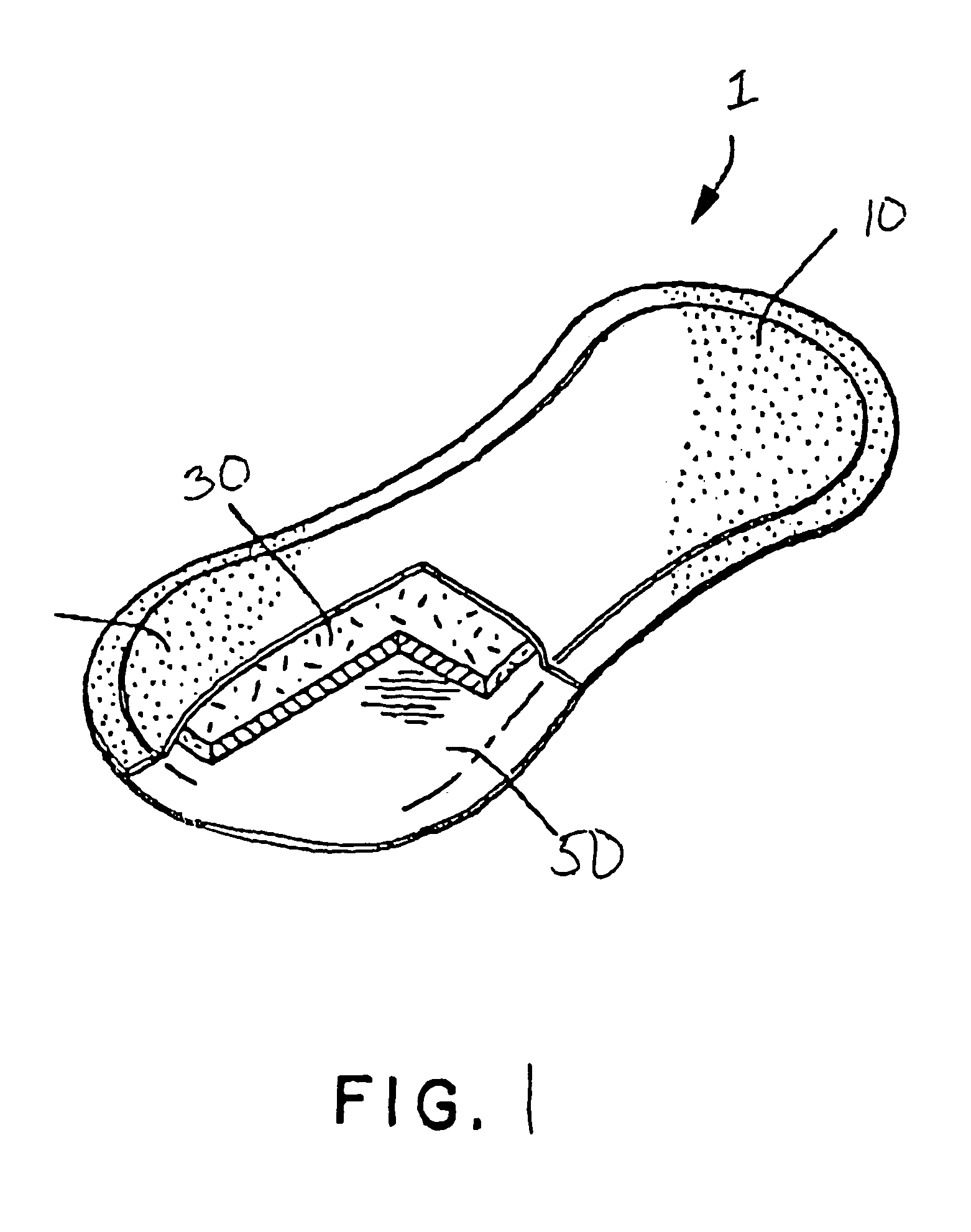

Method of making an absorbent composite

In a method of making an absorbent composite, a porous, stabilized structure is formed and impregnated with a flowable superabsorbent precursor. The flowable superabsorbent precursor is cross-linked to form a superabsorbent material within the stabilized structure. The surface area of one of the flowable superabsorbent precursor impregnated with the stabilized structure and the superabsorbent material formed within the structure is increased. In one embodiment, the surface is increased by freeze drying the impregnated structure.

Owner:KIMBERLY-CLARK WORLDWIDE INC

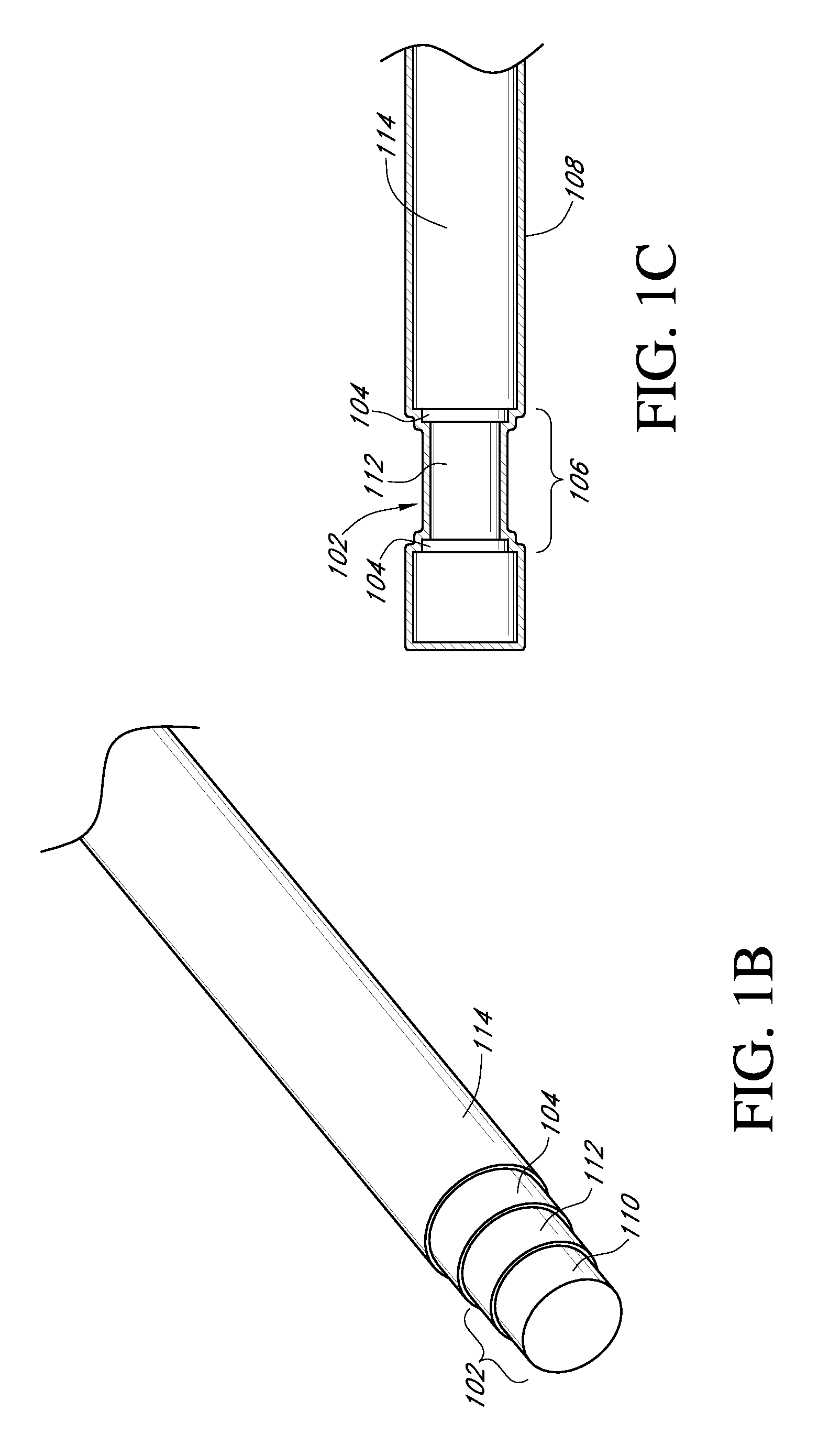

Analyte sensors and methods of manufacturing same

ActiveUS20110027127A1Hot-dipping/immersion processesMaterial analysis by electric/magnetic meansAnalyteEngineering

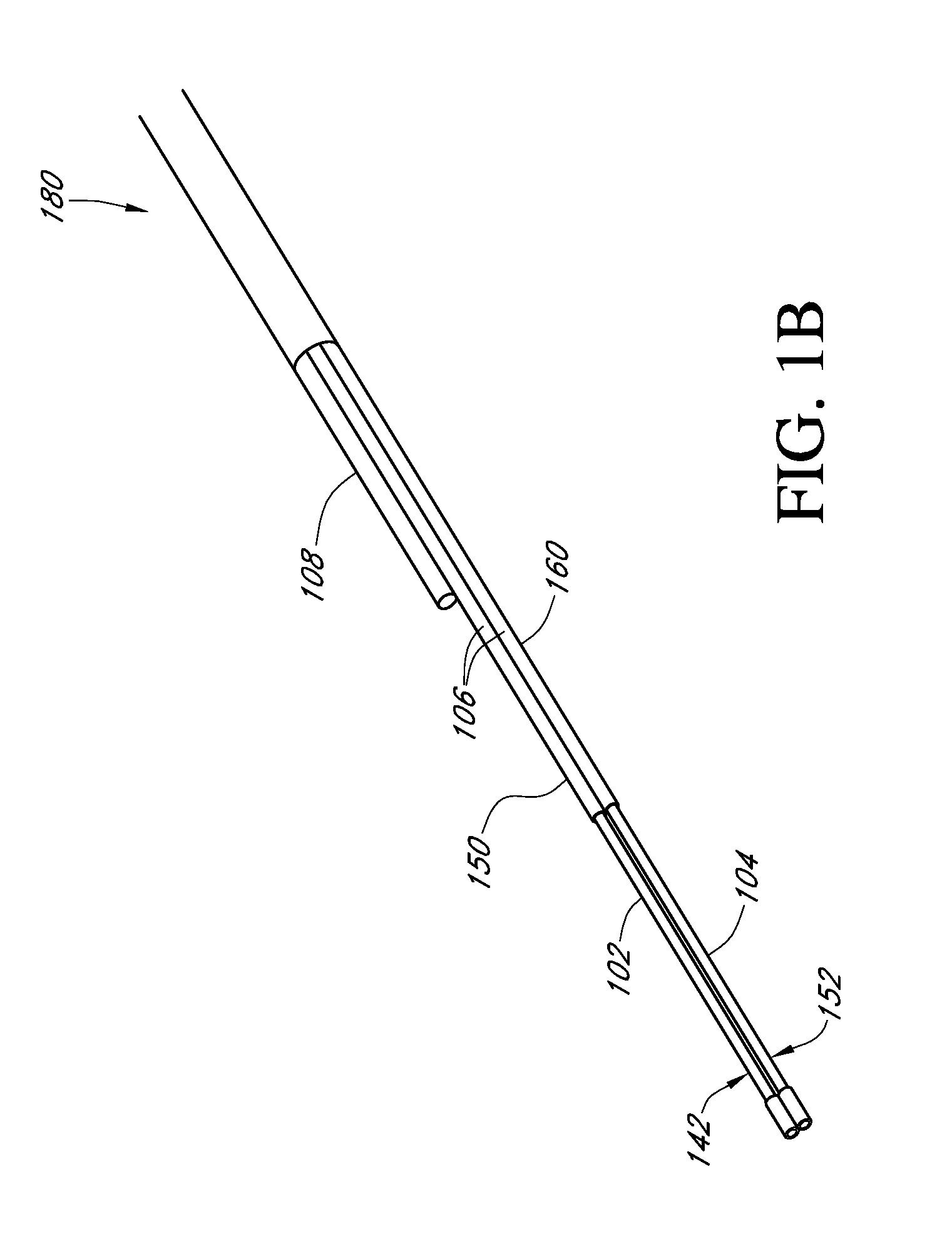

Analyte sensors and methods of manufacturing same are provided, including analyte sensors comprising multi-axis flexibility. For example, a multi-electrode sensor system 800 comprising two working electrodes and at least one reference / counter electrode is provided. The sensor system 800 comprises first and second elongated bodies E1, E2, each formed of a conductive core or of a core with a conductive layer deposited thereon, insulating layer 810 that separates the conductive layer 820 from the elongated body, a membrane layer deposited on top of the elongated bodies E1, E2, and working electrodes 802′, 802″ formed by removing portions of the conductive layer 820 and the insulating layer 810, thereby exposing electroactive surface of the elongated bodies E1, E2.

Owner:DEXCOM

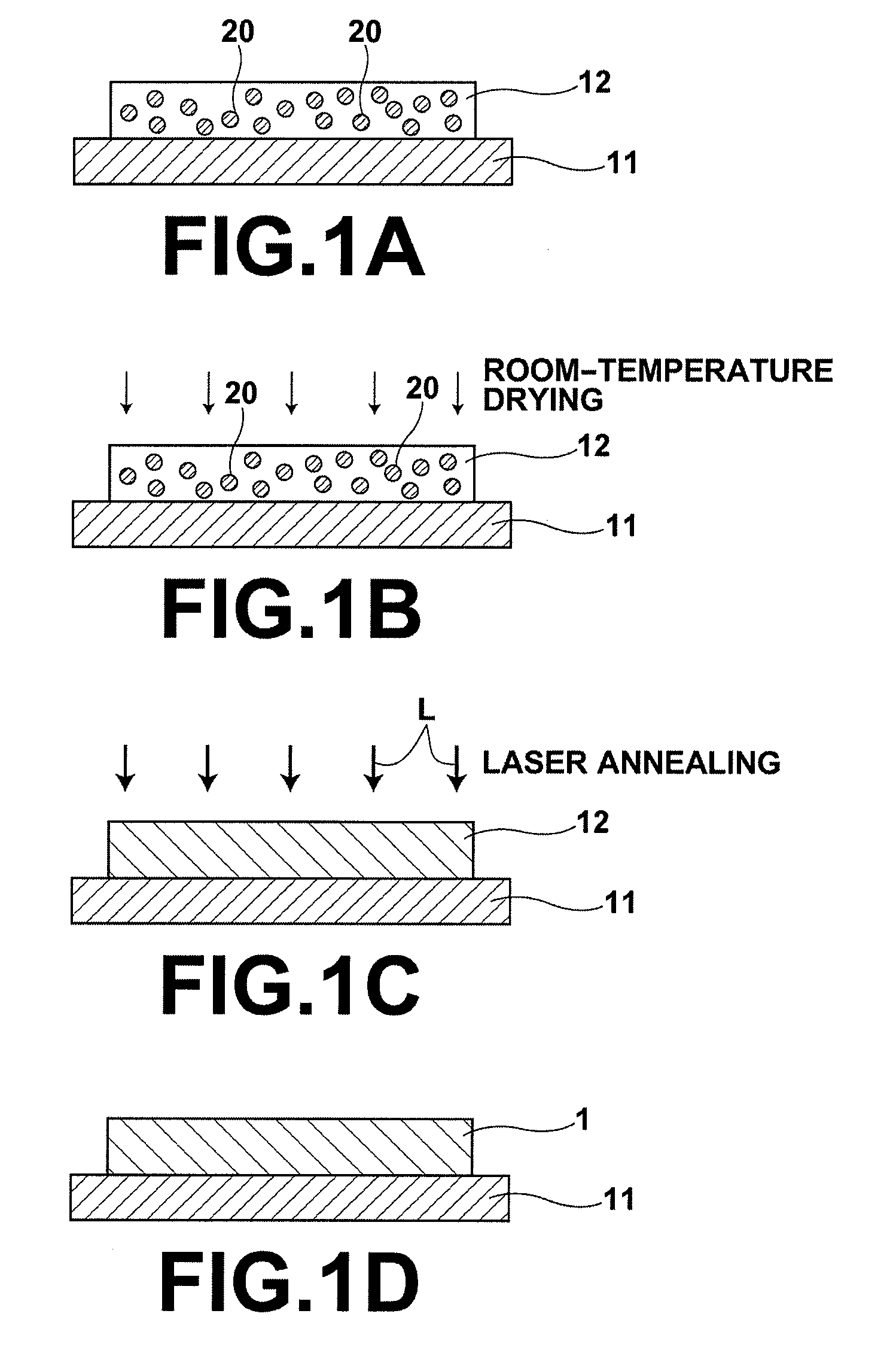

Process for producing oriented inorganic crystalline film, and semiconductor device using the oriented inorganic crystalline film

ActiveUS8202365B2Orientation can be controlledLow costFrom gel stateFrom solid stateOrganic solventCrystal structure

In a process for producing an oriented inorganic crystalline film, a non-monocrystalline film containing inorganic crystalline particles is formed on a substrate by a liquid phase technique using a raw-material solution which contains a raw material and an organic solvent, where the inorganic crystalline particles have a layered crystal structure and are contained in the raw material. Then, the non-monocrystalline film is crystallized by heating the non-monocrystalline film to a temperature equal to or higher than the crystallization temperature of the non-monocrystalline film so that part of the inorganic crystalline particles act as crystal nuclei.

Owner:FUJIFILM CORP

Modified Molecular Arrays

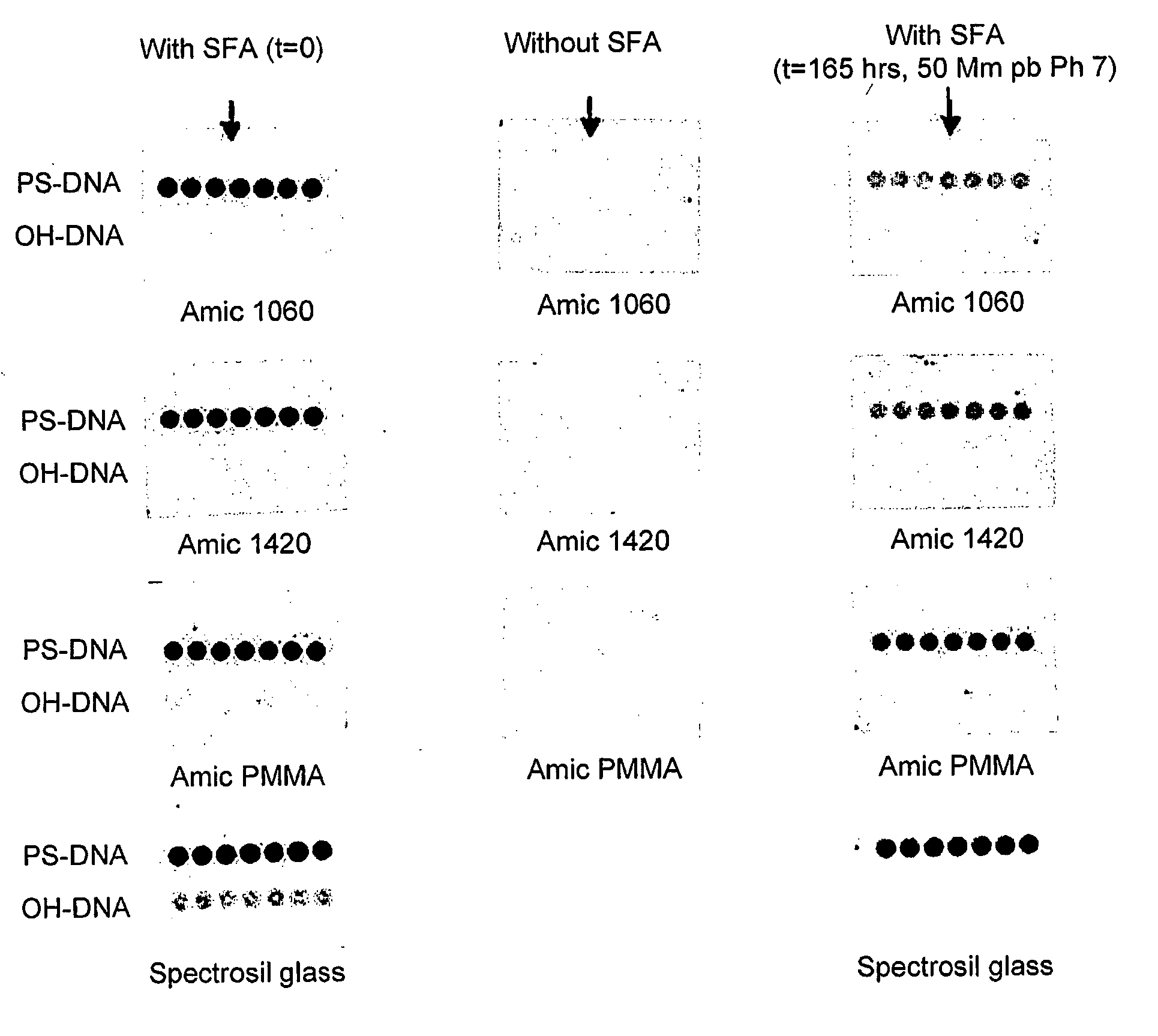

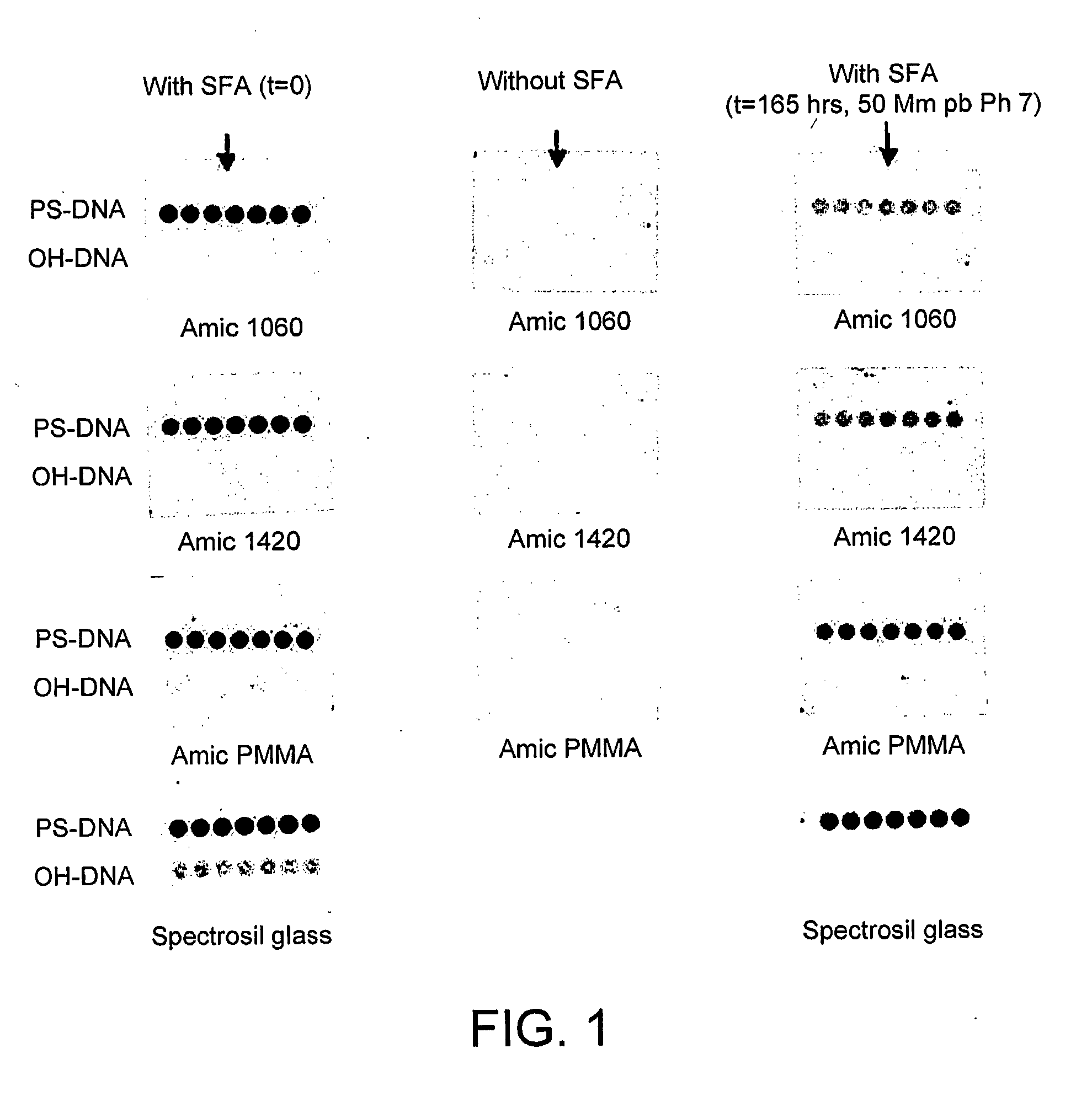

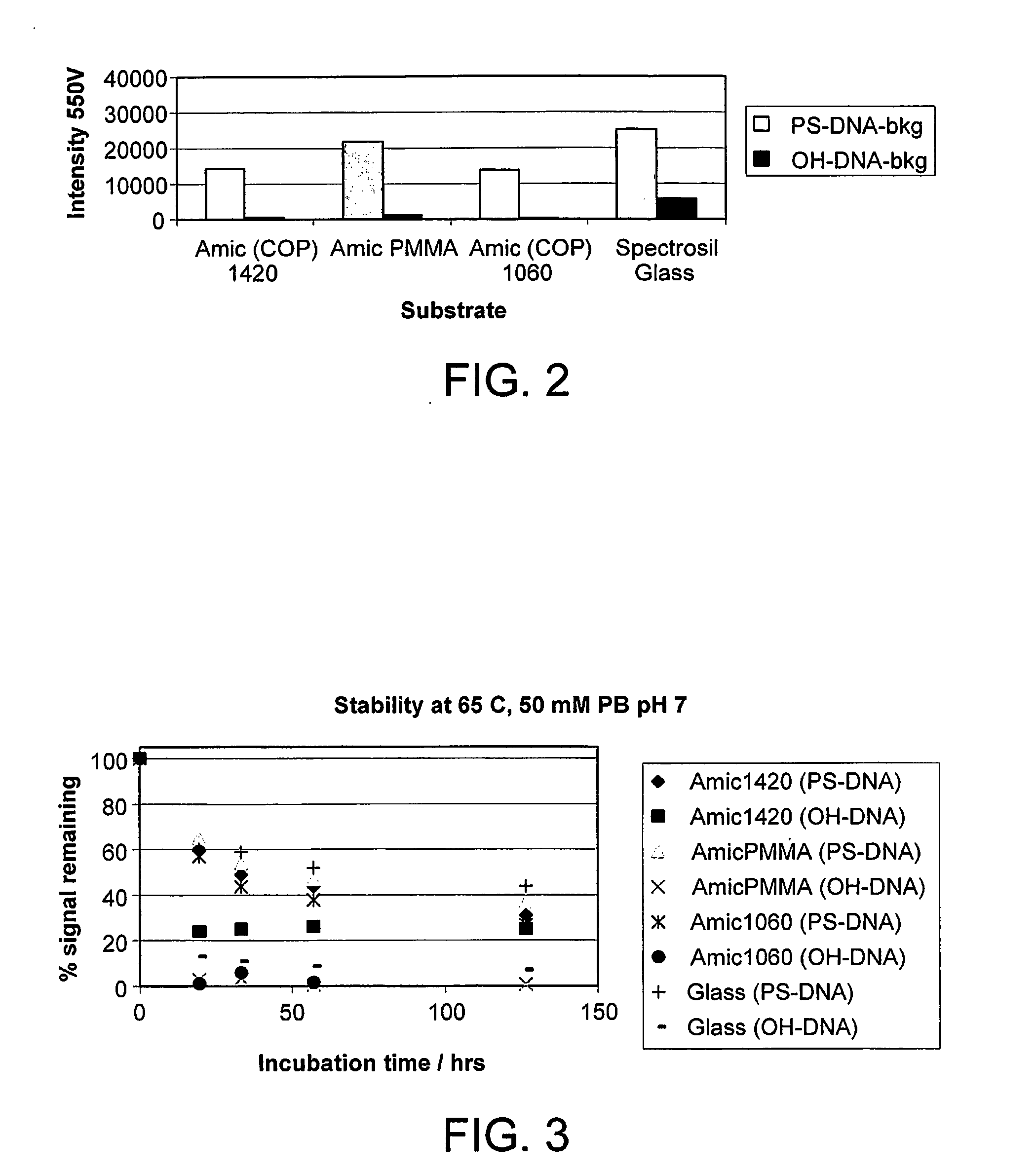

InactiveUS20110059865A1Less reactiveAccelerated programSequential/parallel process reactionsNucleotide librariesMolecular array(Hydroxyethyl)methacrylate

The invention relates to the preparation of a hydrogel surface useful in the formation and manipulation of arrays of molecules, particularly polynucleotides and to the chemical modification of these and other arrays. In particular, the invention relates to a method of preparing a hydrogel immobilised to a solid support comprising polymerising on the support a mixture of a first comonomer which is acrylamide, methacrylamide, hydroxyethyl methacrylate or N-vinyl pyrrolidinone and a second comonomer which is a functionalised acrylamide or acrylate.

Owner:ILLUMINA CAMBRIDGE LTD

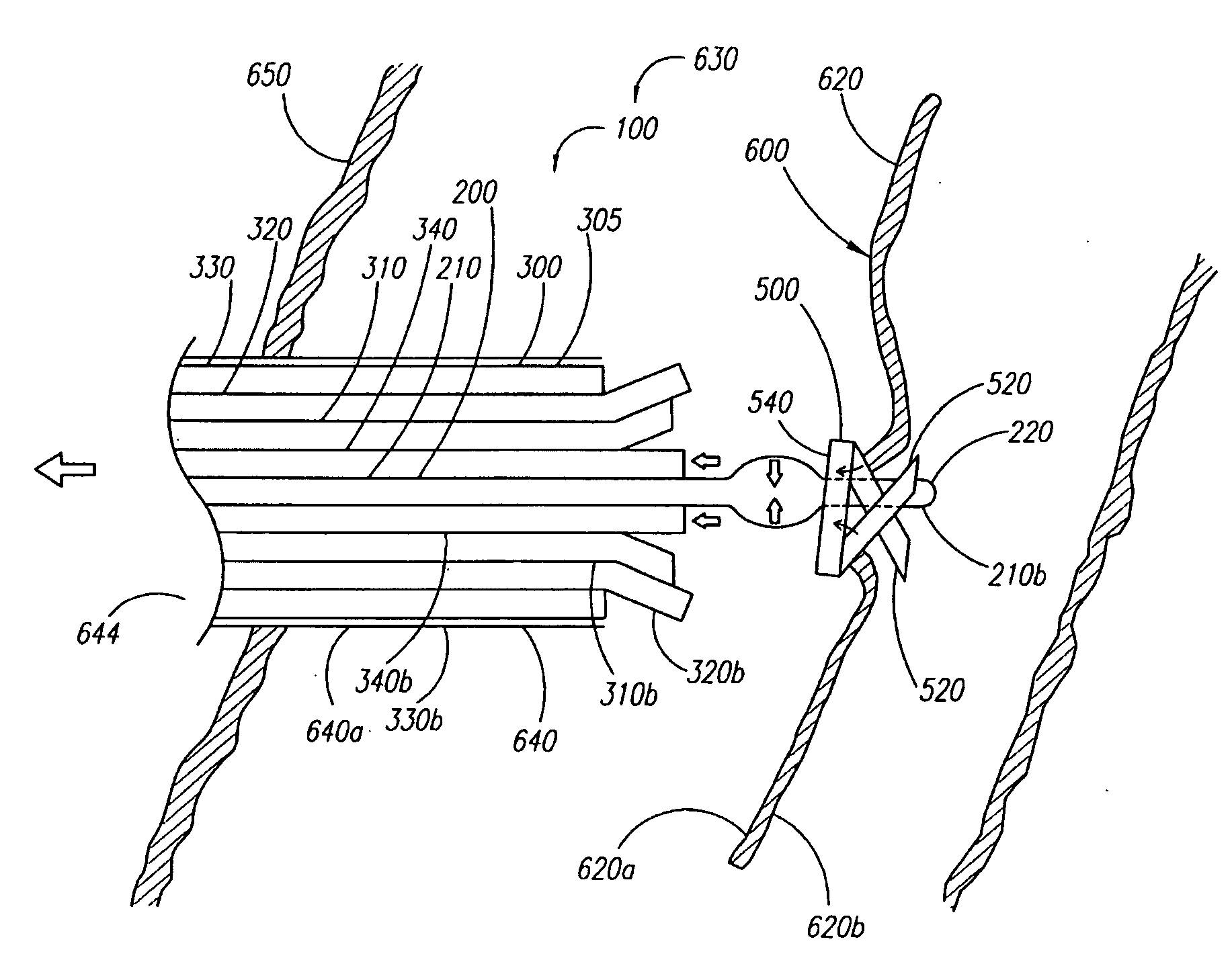

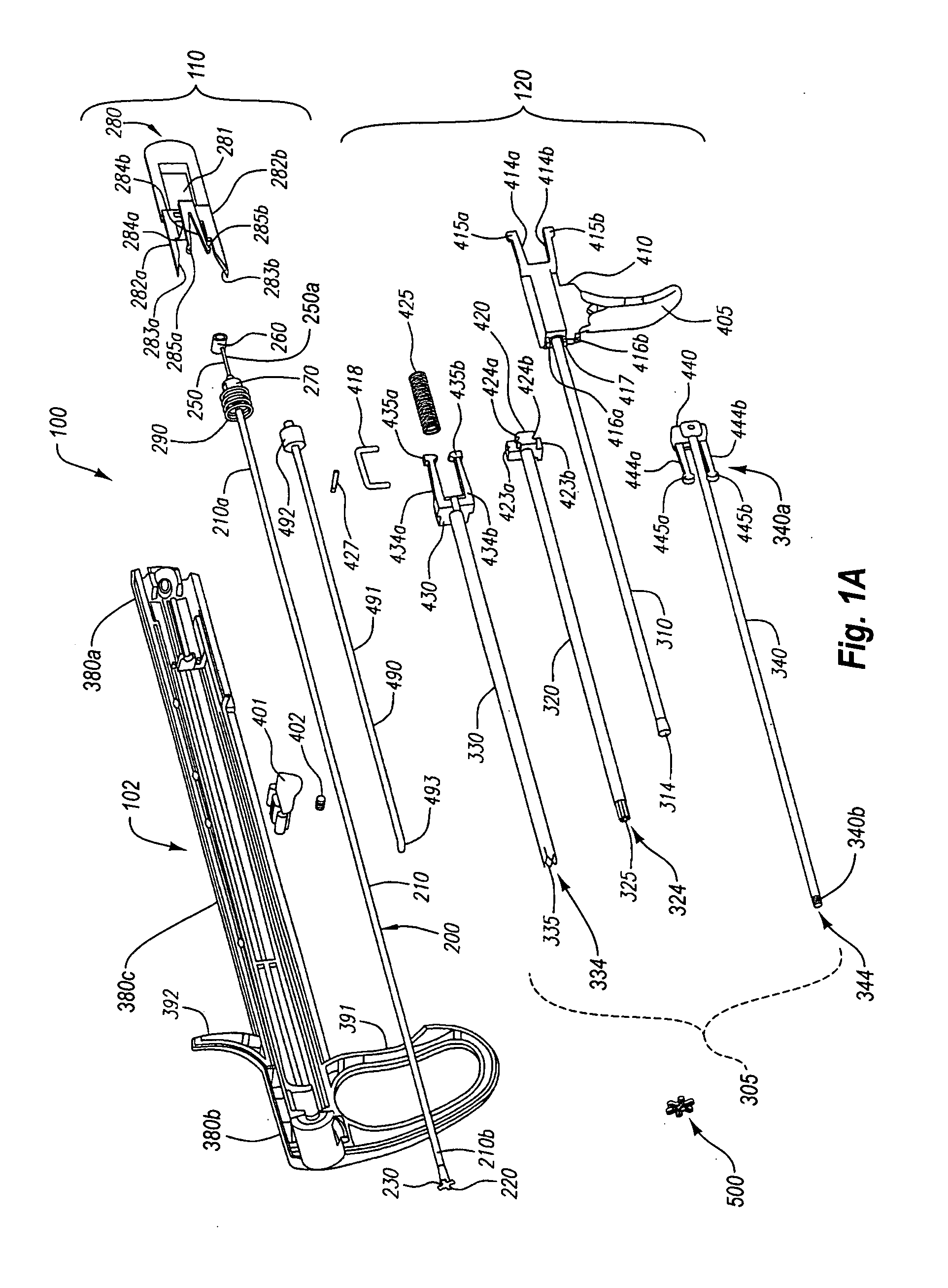

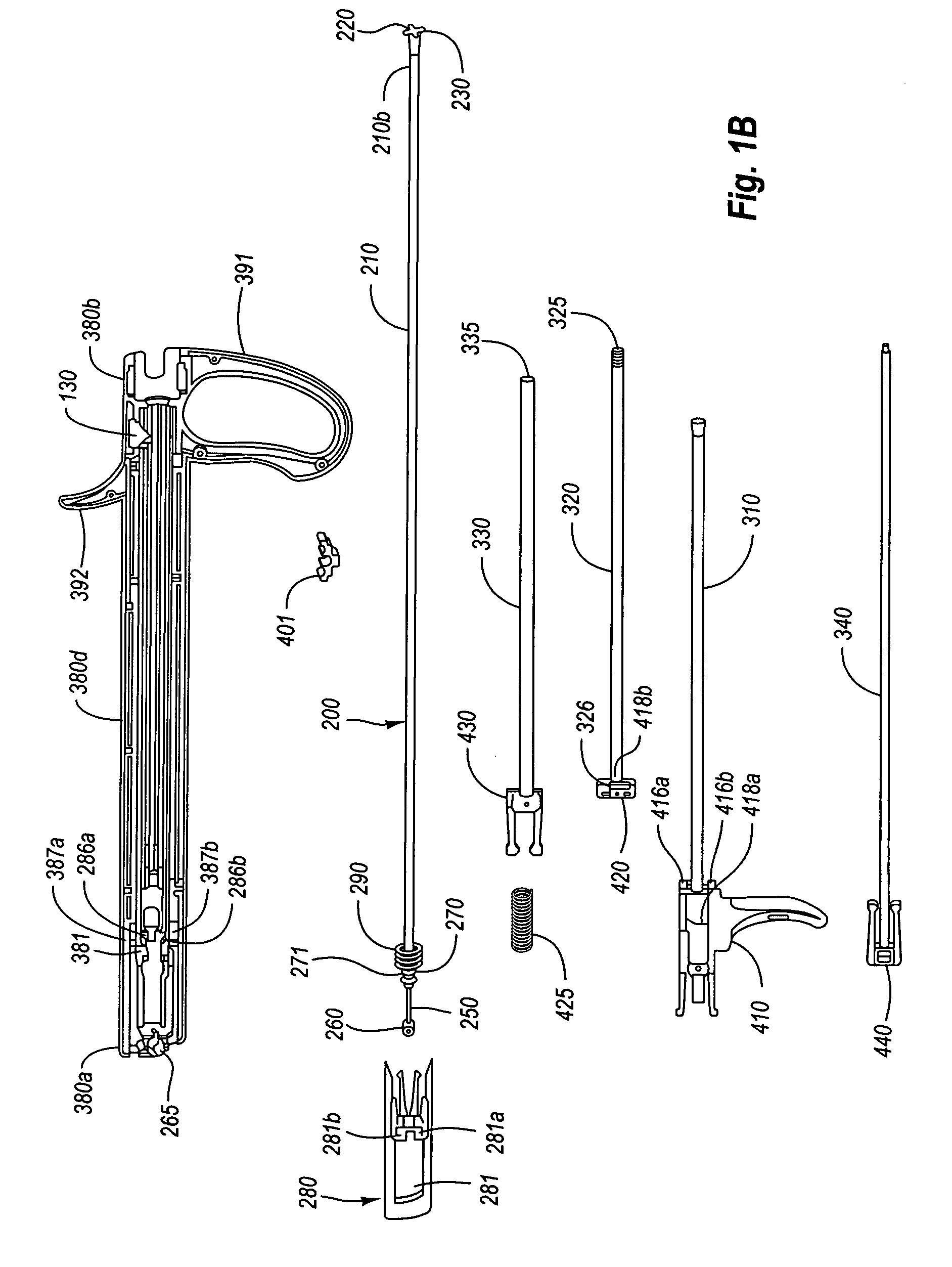

Antimicrobial closure element and closure element applier

A closure element is disclosed. The closure element includes a body. The body includes a plurality of tissue engaging portions extending from the body. The body is movable from a compressed state to a deployed state. The body includes a material. Silver or alloys thereof are included as a component of a coating over and / or a mixture with the material of at least a portion of the body.

Owner:ABBOTT LAB INC

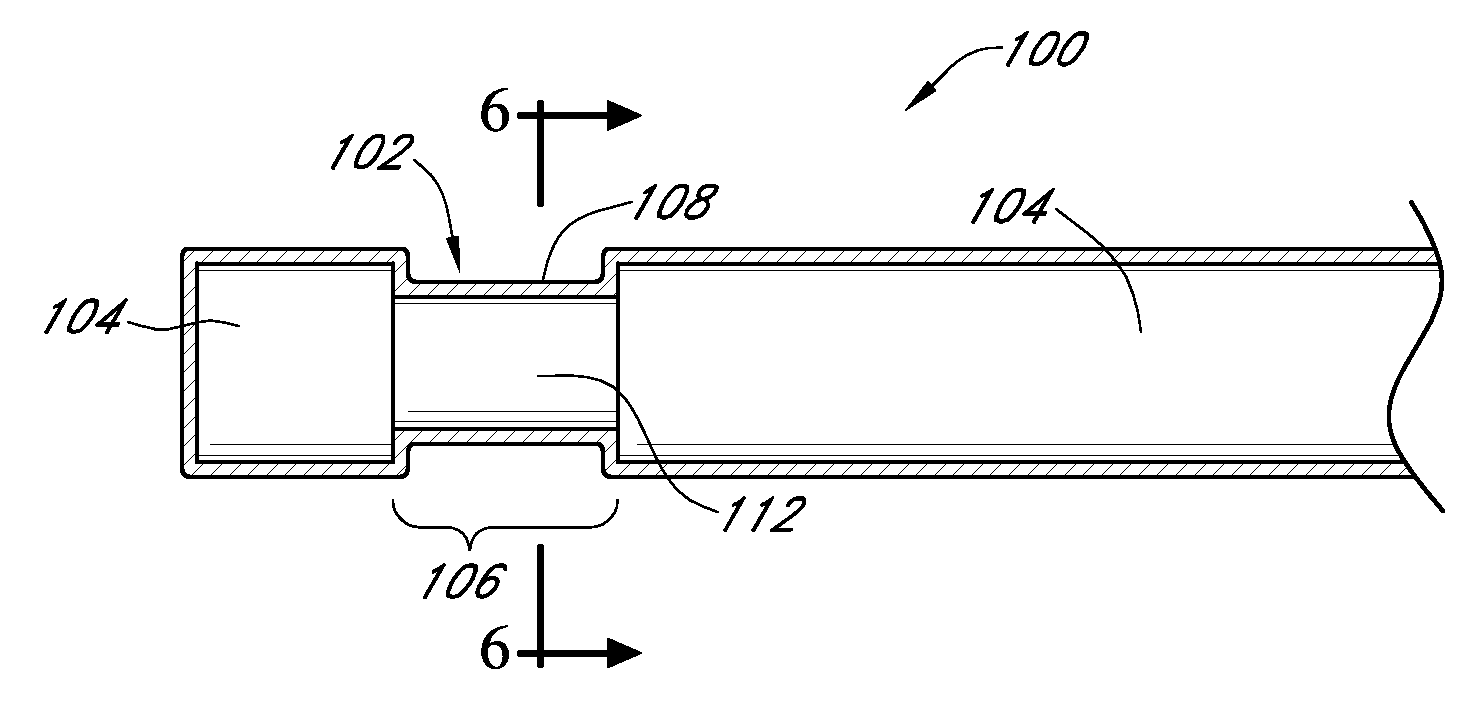

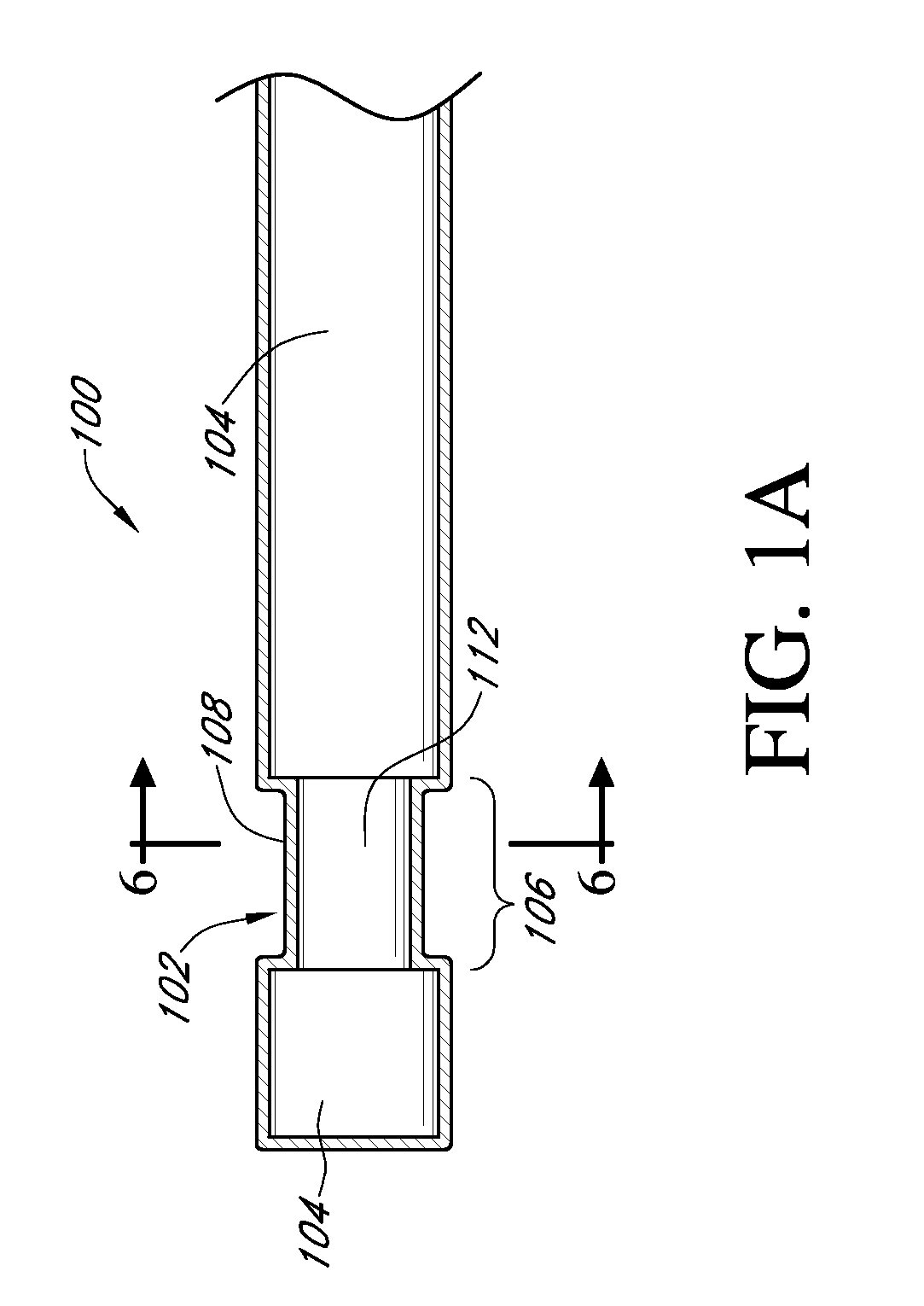

Methods of forming a coating for a prosthesis

InactiveUS6503556B2Increase the amount addedIncrease the number ofRadiation applicationsGlovesProsthesisImplanted device

Methods of forming a coating onto an implantable device or endoluminal prosthesis, such as a stent, are provided. The coating may be used for the delivery of an active ingredient. The coating may have a selected pattern of interstices for allowing a fluid to seep through the coating in the direction of the pattern created.

Owner:ABBOTT CARDIOVASCULAR

Analyte sensors and methods of manufacturing same

Analyte sensors and methods of manufacturing same are provided, including analyte sensors comprising multi-axis flexibility. For example, a multi-electrode sensor system 800 comprising two working electrodes and at least one reference / counter electrode is provided. The sensor system 800 comprises first and second elongated bodies E1, E2, each formed of a conductive core or of a core with a conductive layer deposited thereon, insulating layer 810 that separates the conductive layer 820 from the elongated body, a membrane layer deposited on top of the elongated bodies E1, E2, and working electrodes 802′, 802″ formed by removing portions of the conductive layer 820 and the insulating layer 810, thereby exposing electroactive surface of the elongated bodies E1, E2.

Owner:DEXCOM

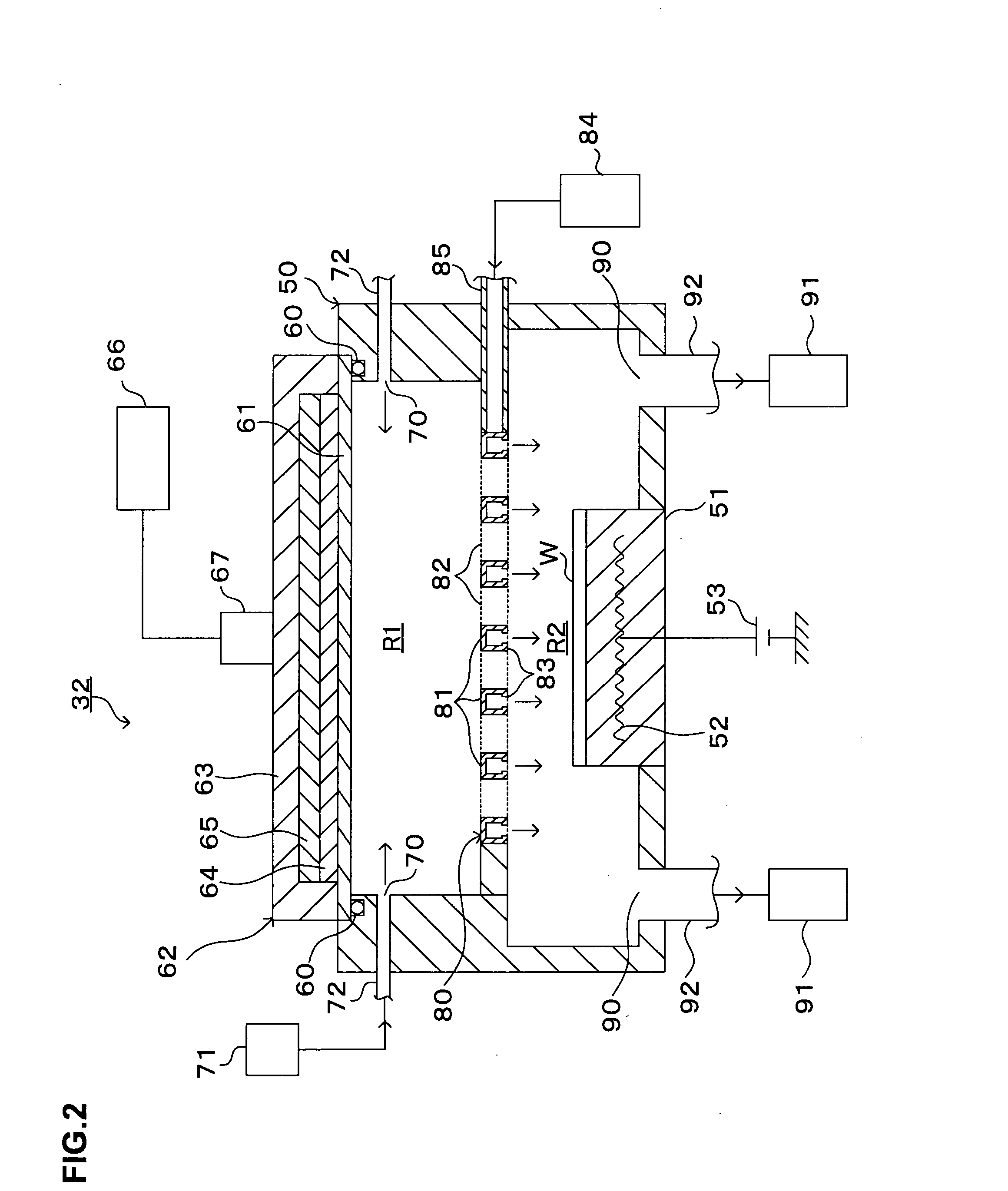

Substrate processing method, computer readable recording medium and substrate processing apparatus

InactiveUS20070062453A1Low dielectric constantImprove heat resistanceElectric discharge tubesSemiconductor/solid-state device detailsMicrowaveEngineering

In the present invention, Ar gas for plasma generation is supplied to a plasma generation region and butyne gas having a multiple bond is supplied to a film formation region at a substrate side as source gas, inside of a process vessel in an insulating film forming apparatus. A microwave is supplied inside of the process vessel from a radial line slot antenna under a state in which a bias voltage is not applied to a substrate W. A plasma is thereby generated in the plasma generation region, the butyne gas in the film formation region is activated by the plasma, and an insulating film of amorphous carbon is formed on the substrate.

Owner:TOKYO ELECTRON LTD

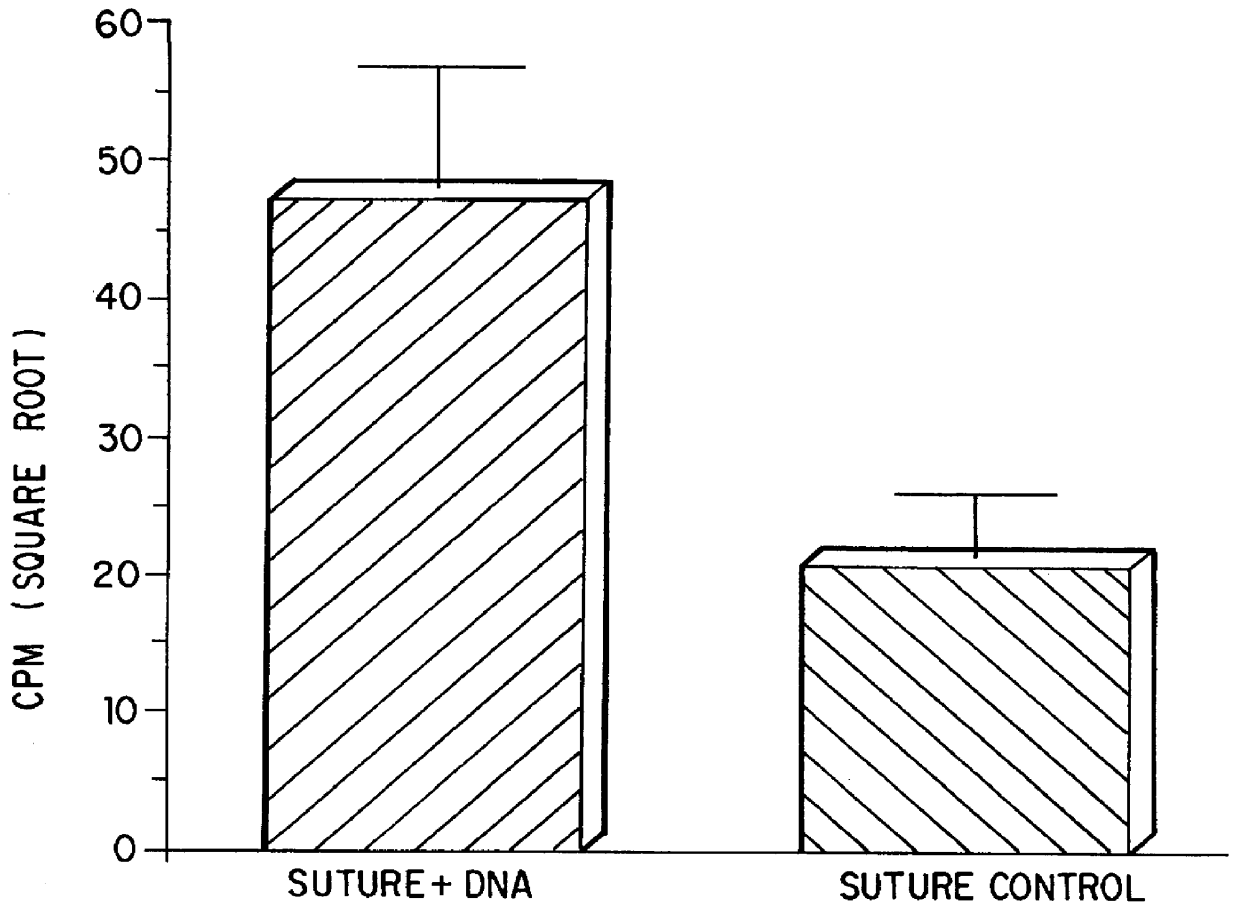

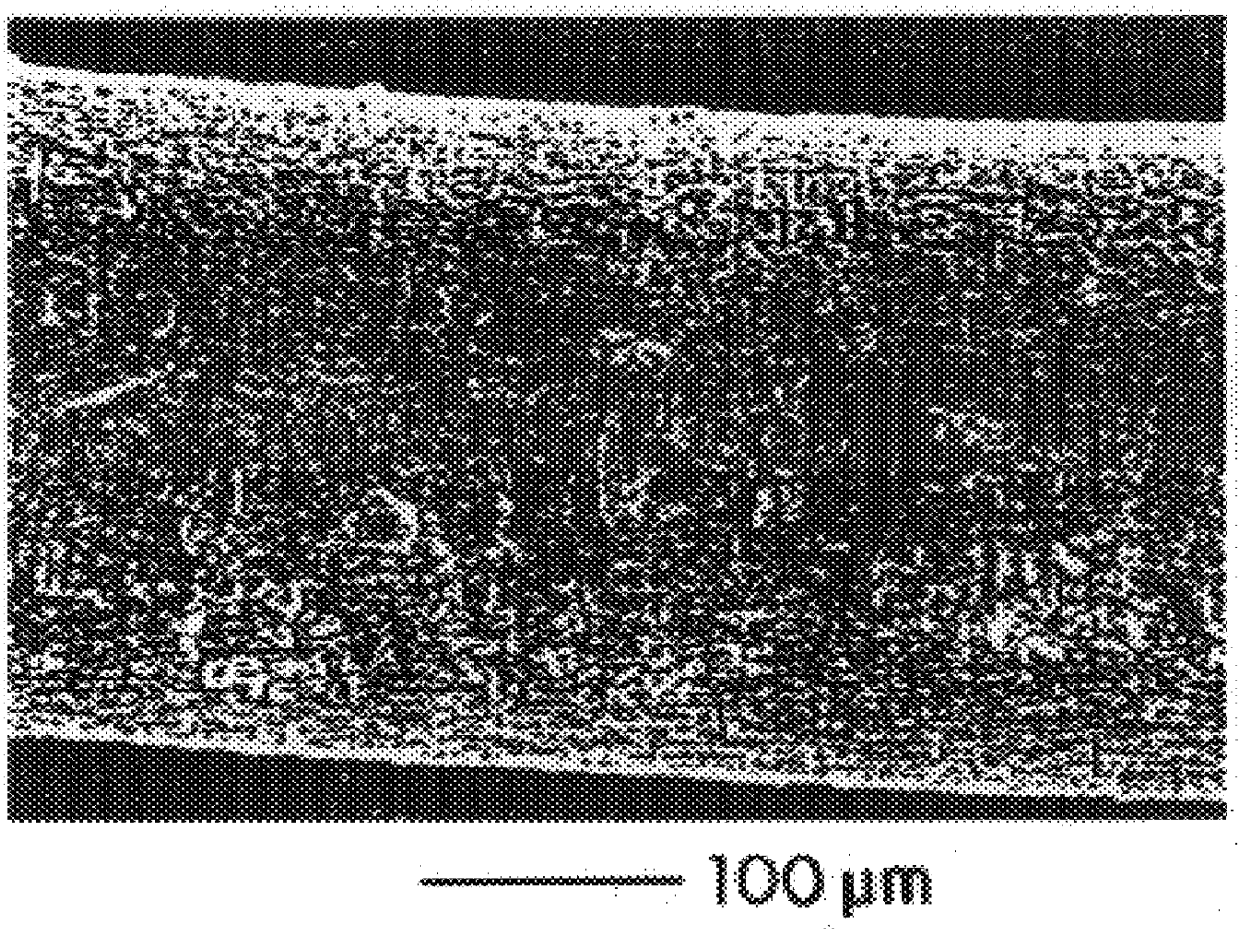

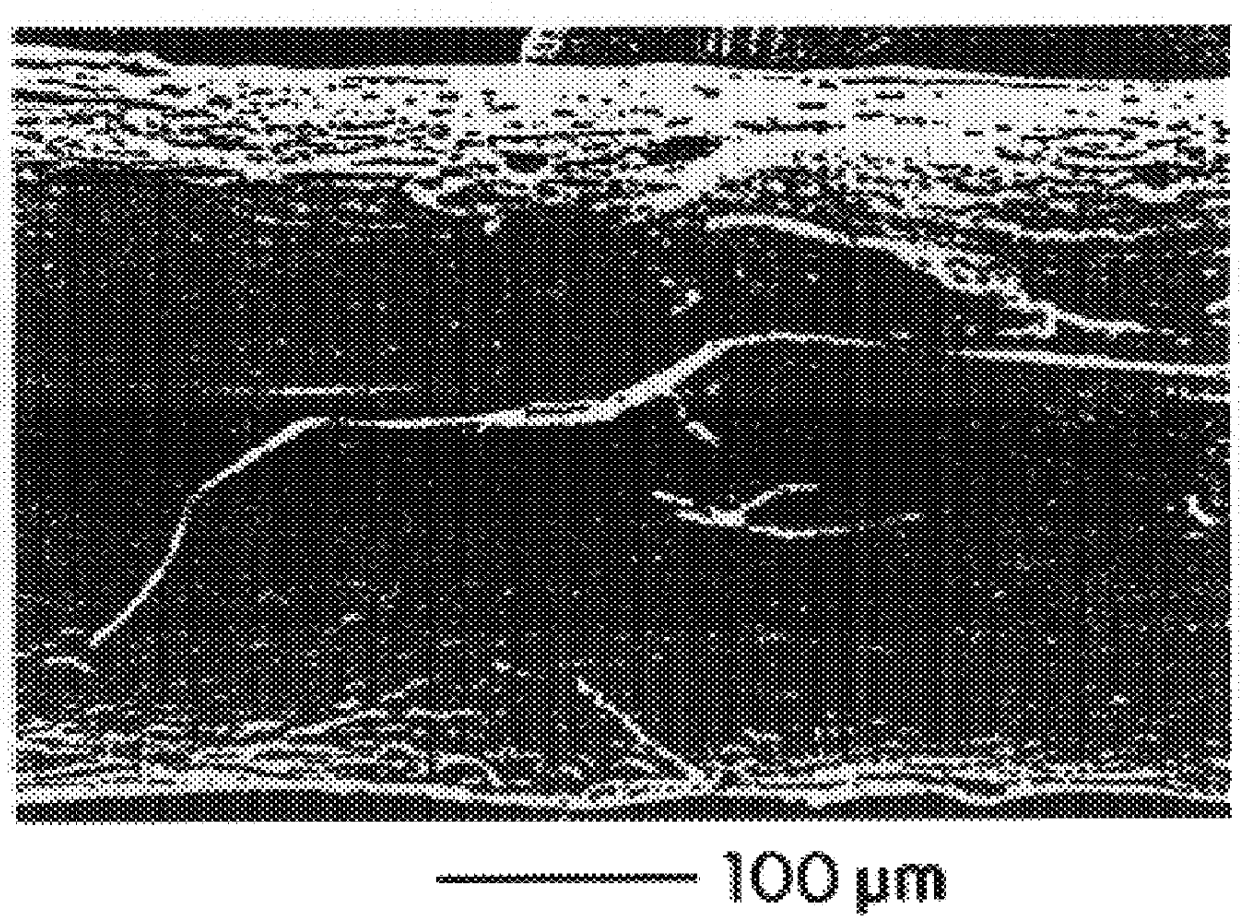

Compositions and methods for coating medical devices

InactiveUS6143037AStimulates and promotesImproved wound healing characteristicSuture equipmentsInternal osteosythesisDiseaseMedical device

Owner:MICHIGAN REGENTS THE UNIV OF

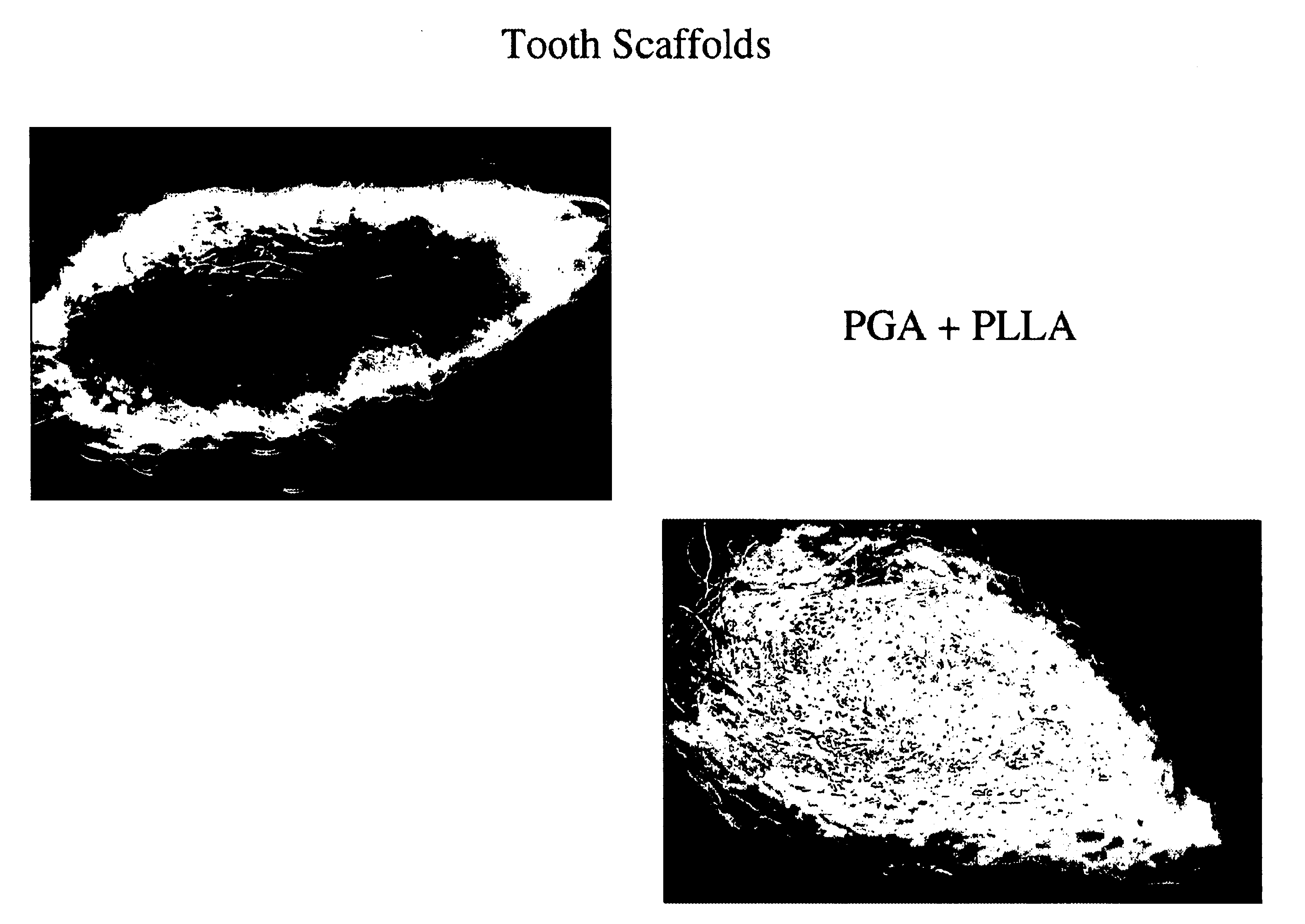

Methods and compositions for culturing a biological tooth

Tooth tissues include the pulp mesenchyme that forms the dentin and an epithelium that is responsible for enamel formation. Cells from these tissues were obtained from porcine third molars and were seeded onto a biodegradable scaffold composed of a polyglycolic acid—polylactic acid copolymer. Cell polymer constructs were then surgically implanted into the omentum of athymic nude rats so that the constructs would have a blood supply and these tissues were allowed to develop inside the rats. Infrequently, columnar epithelial cells were observed as a single layer on the outside of the dentin-like matrix similar to the actual arrangement of ameloblasts over dentin during early tooth development. Developing tooth tissues derived from such cell polymer constructs could eventually be surgically implanted into the gum of an edentulous recipient where the construct would receive a blood supply and develop to maturity, providing the recipient with a biological tooth replacement.

Owner:FORSYTH DENTAL INFARY FOR CHILDREN +2

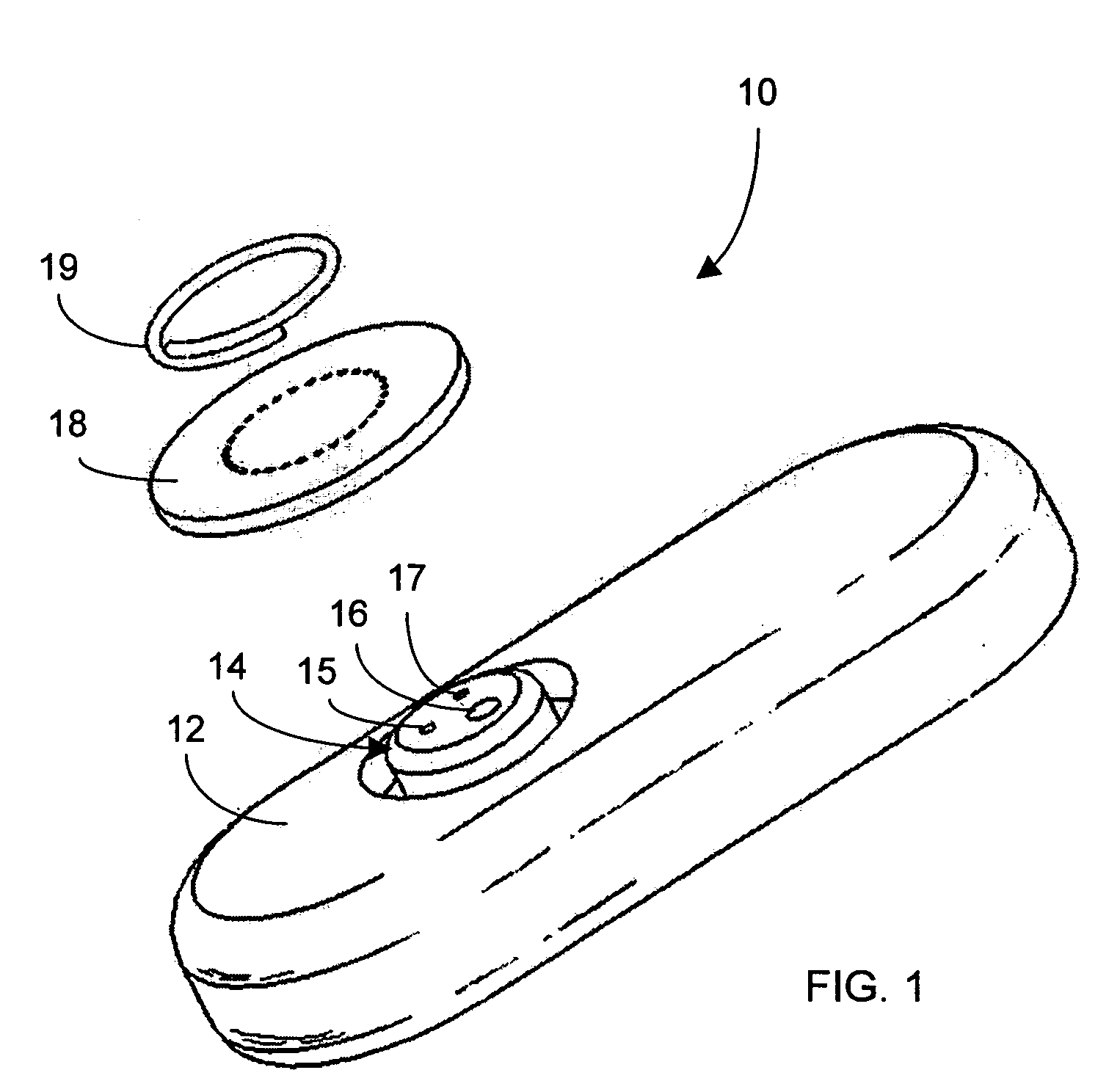

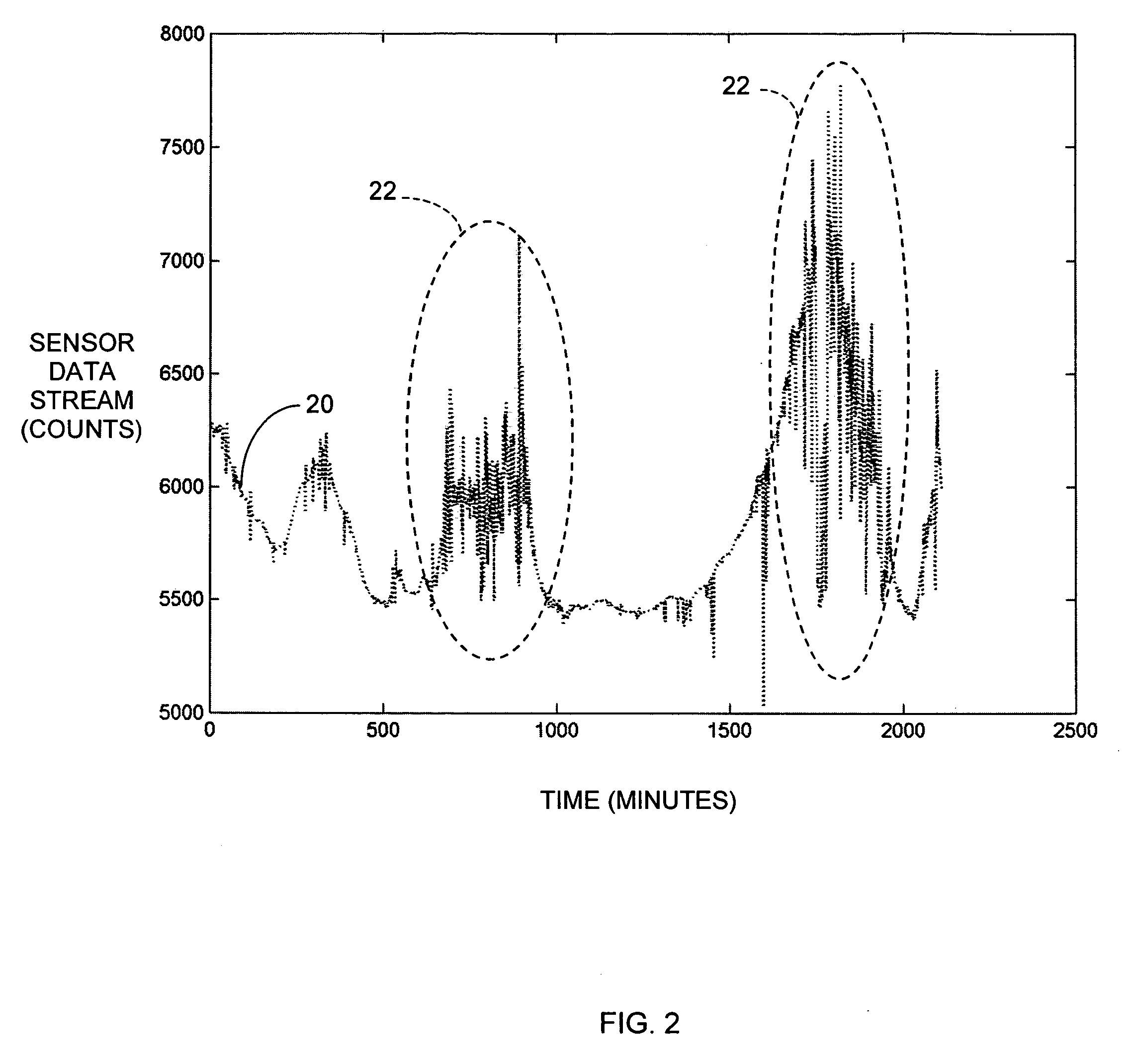

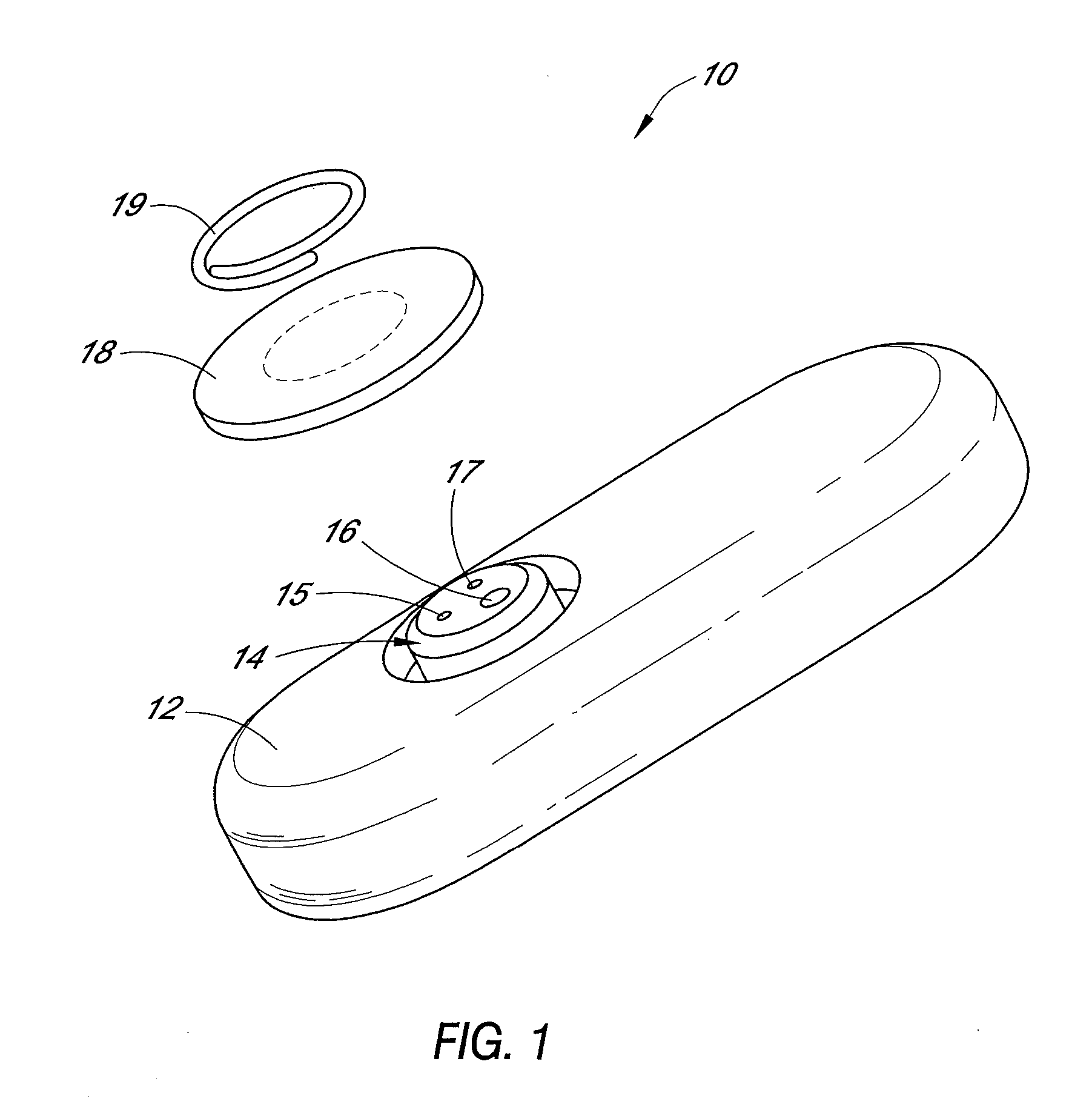

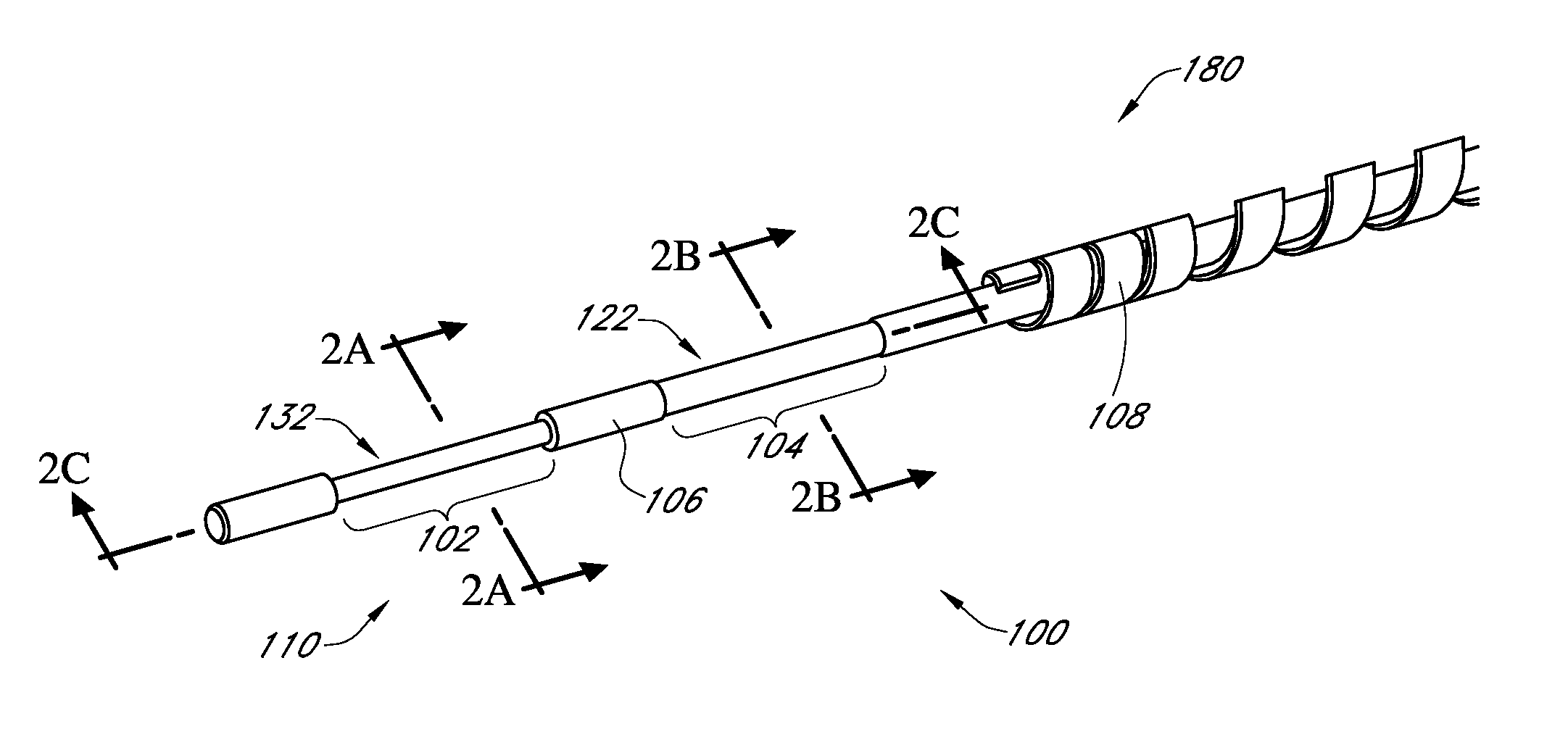

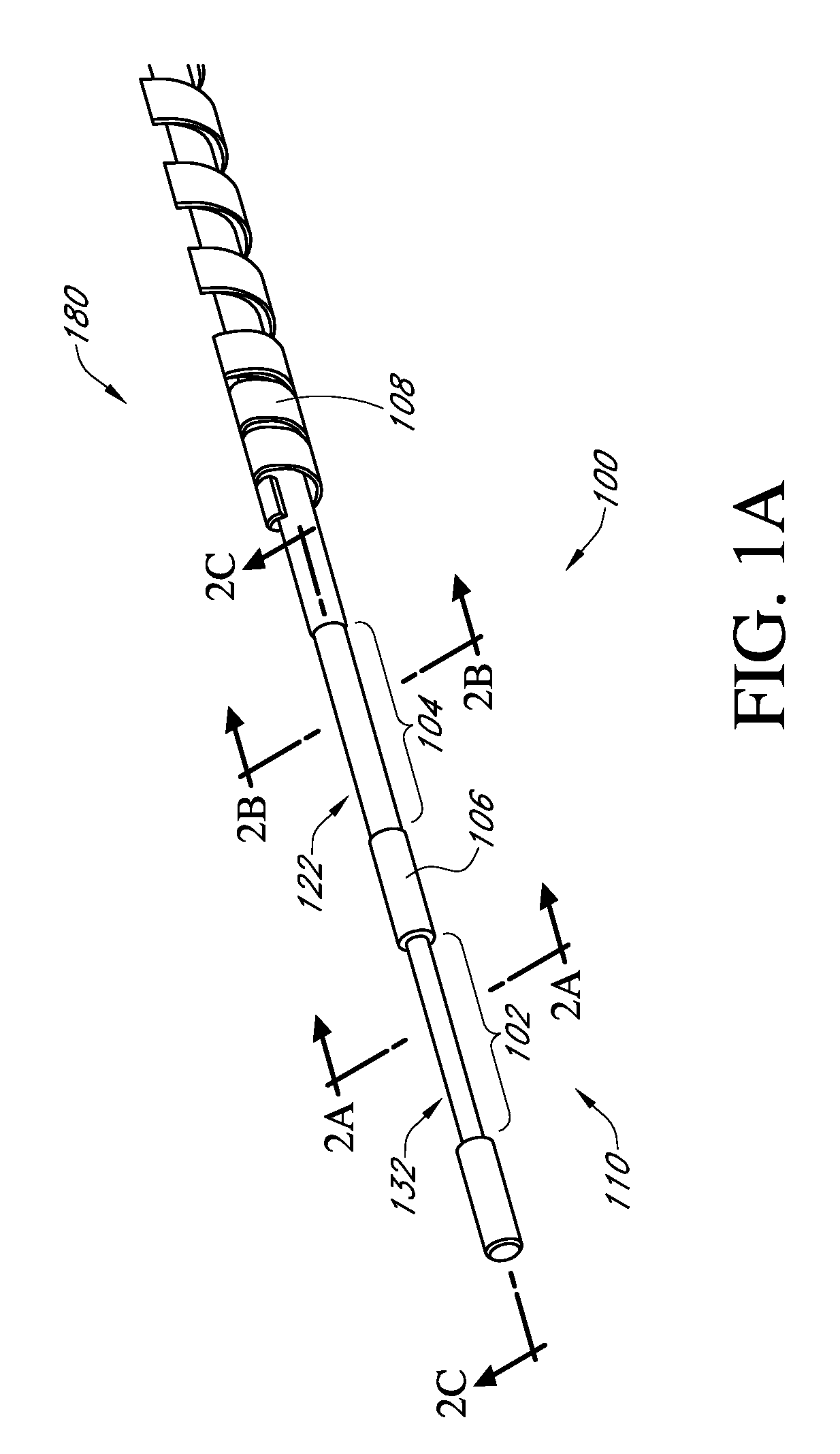

Analyte sensor

InactiveUS20110024307A1Substantial linearityImmobilised enzymesHot-dipping/immersion processesContinuous measurementAnalyte

Devices and methods are provided for continuous measurement of an analyte concentration. The device can include a sensor having a plurality of sensor elements, each having at least one characteristic that is different from other sensor(s) of the device. In some embodiments, the plurality of sensor elements are each tuned to measure a different range of analyte concentration, thereby providing the device with the capability of achieving a substantially consistent level of measurement accuracy across a physiologically relevant range. In other embodiments, the device includes a plurality of sensor elements each tuned to measure during different time periods after insertion or implantation, thereby providing the sensor with the capability to continuously and accurately measure analyte concentrations across a wide range of time periods. For example, a sensor system 180 is provided having a first working electrode 150 comprising a first sensor element 102 and a second working electrode 160 comprising a second sensor element 104, and a reference electrode 108 for providing a reference value for measuring the working electrode potential of the sensor elements 102, 104.

Owner:DEXCOM

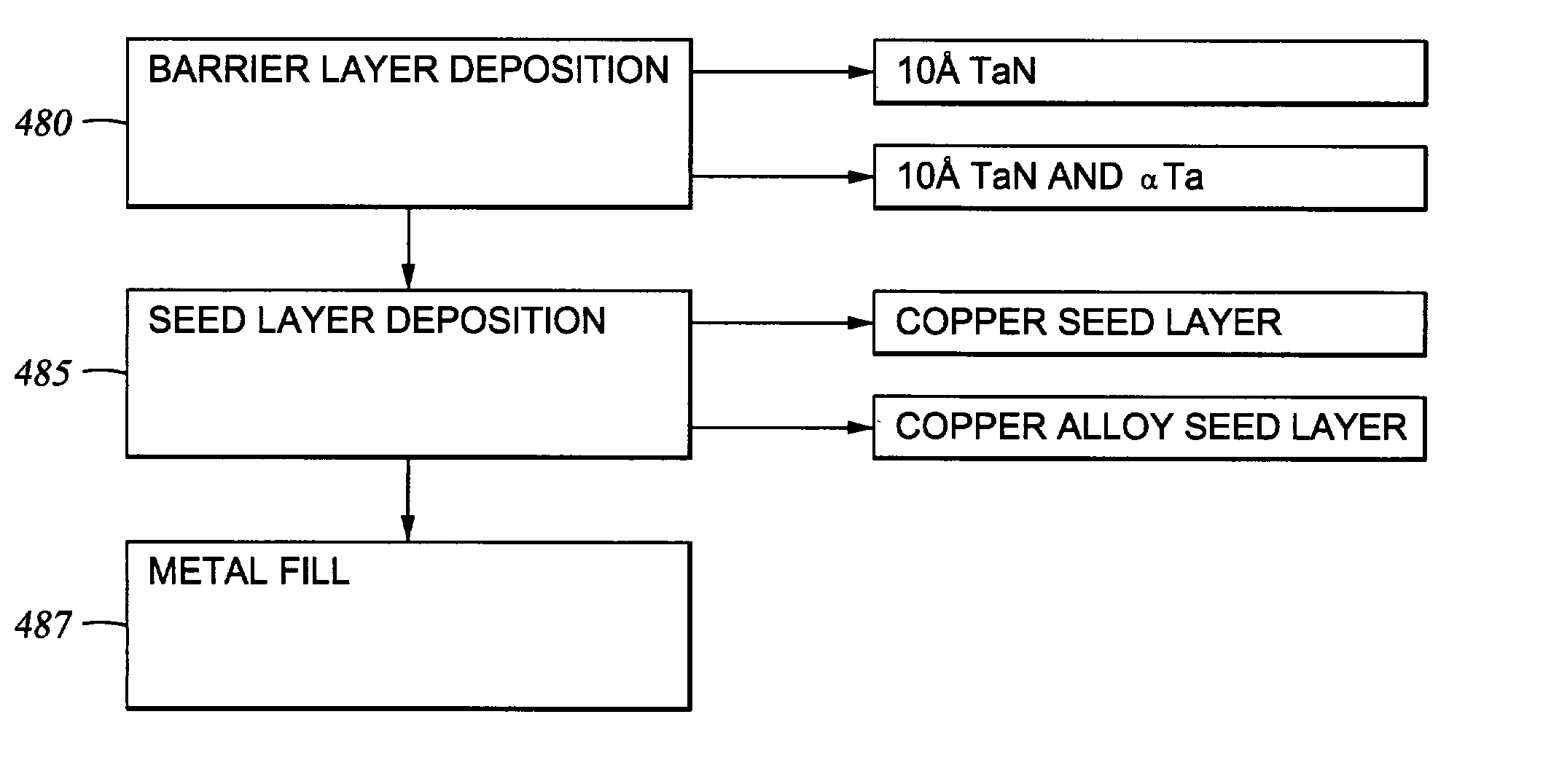

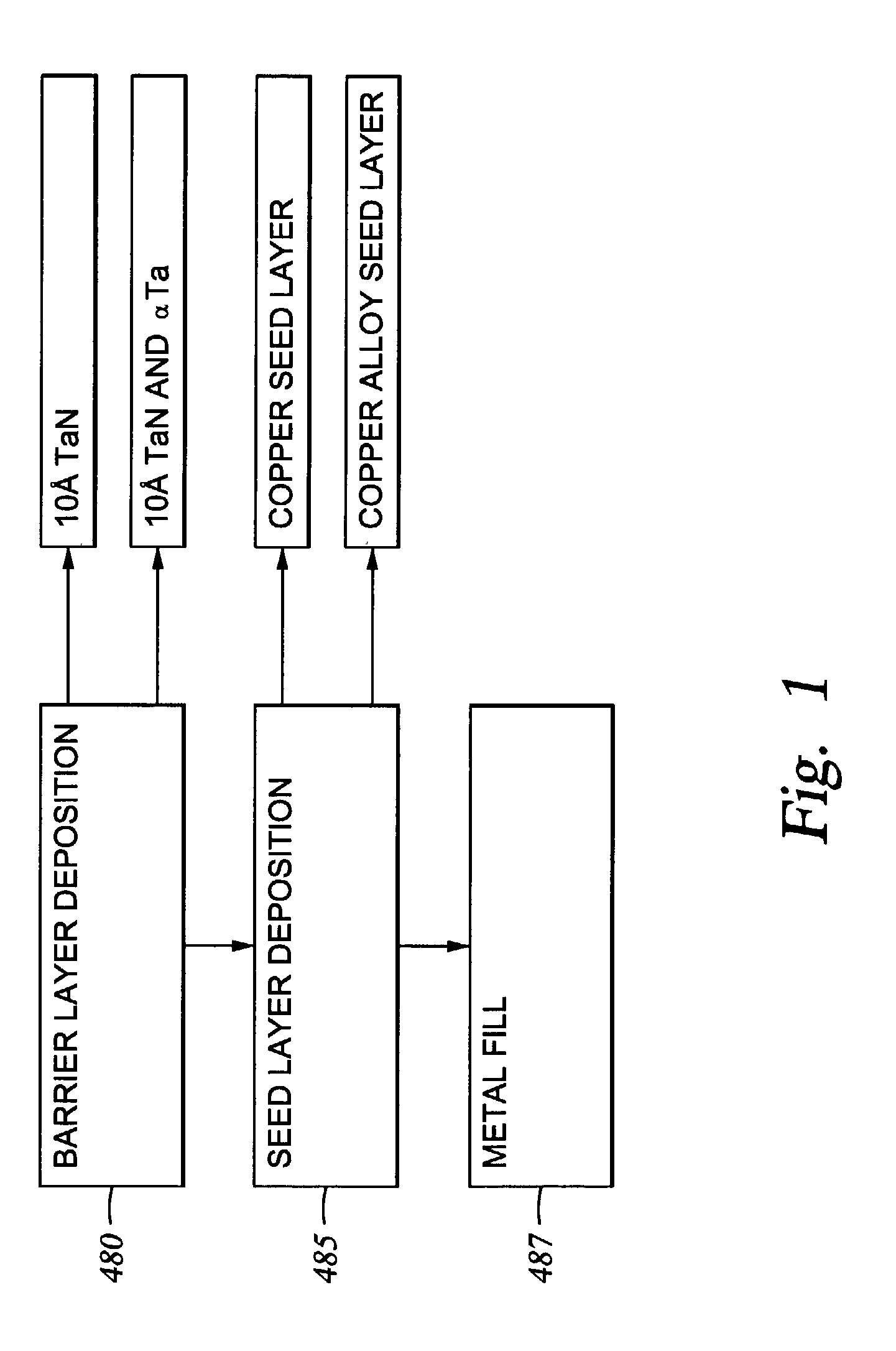

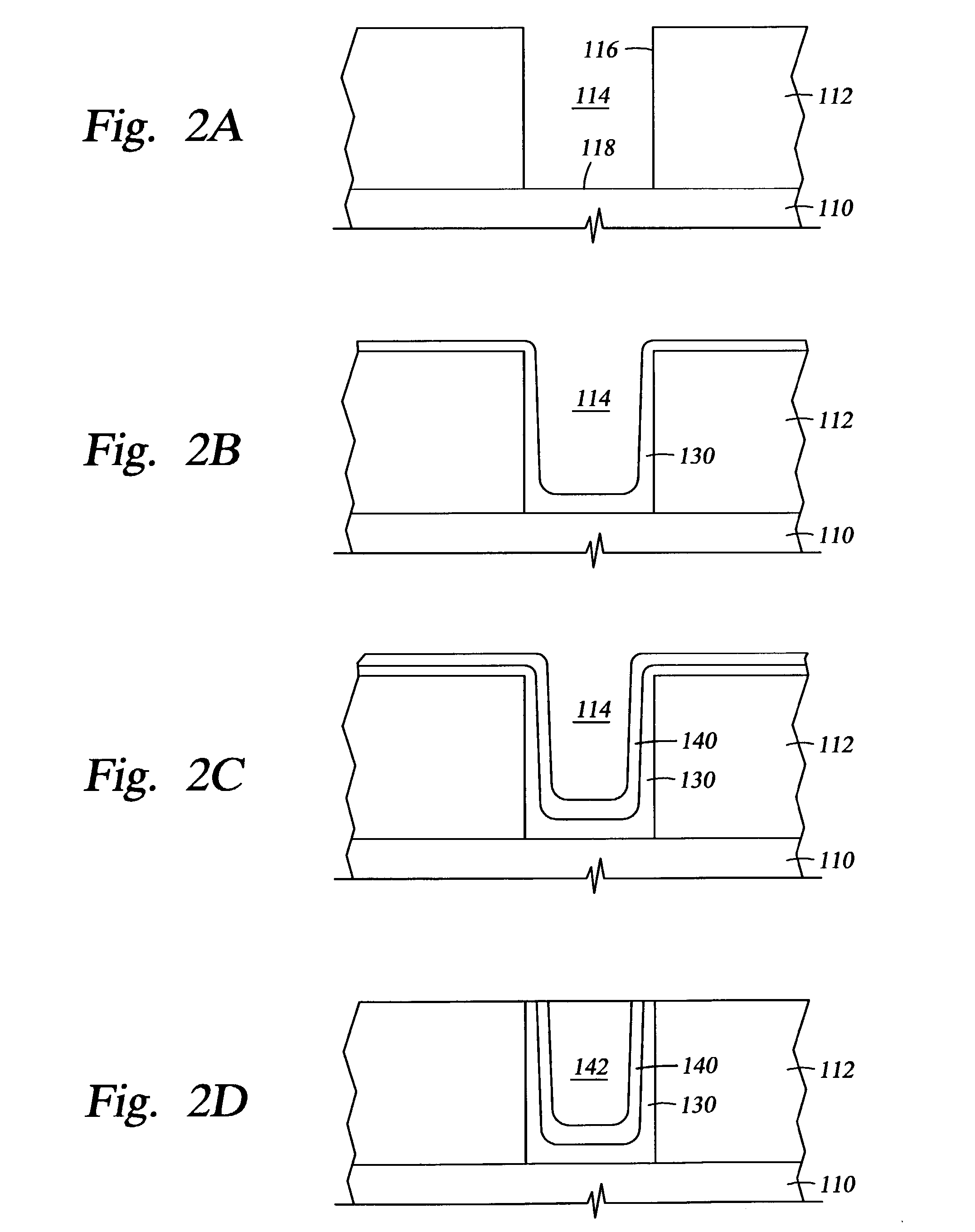

Integration of ALD tantalum nitride and alpha-phase tantalum for copper metallization application

InactiveUS20030082307A1Pretreated surfacesSemiconductor/solid-state device manufacturingMetal interconnectTantalum nitride

A method for forming a metal interconnect on a substrate is provided. The method includes depositing a refractory metal-containing barrier layer having a thickness less than about 20 angstroms on at least a portion of a metal layer by alternately introducing one or more pulses of a metal-containing compound and one or more pulses of a nitrogen-containing compound. The method also includes depositing a seed layer on at least a portion of the barrier layer, and depositing a second metal layer on at least a portion of the seed layer. The barrier layer provides adequate barrier properties and allows the grain growth of the metal layer to continue across the barrier layer into the second metal layer thereby enhancing the electrical performance of the interconnect.

Owner:APPLIED MATERIALS INC

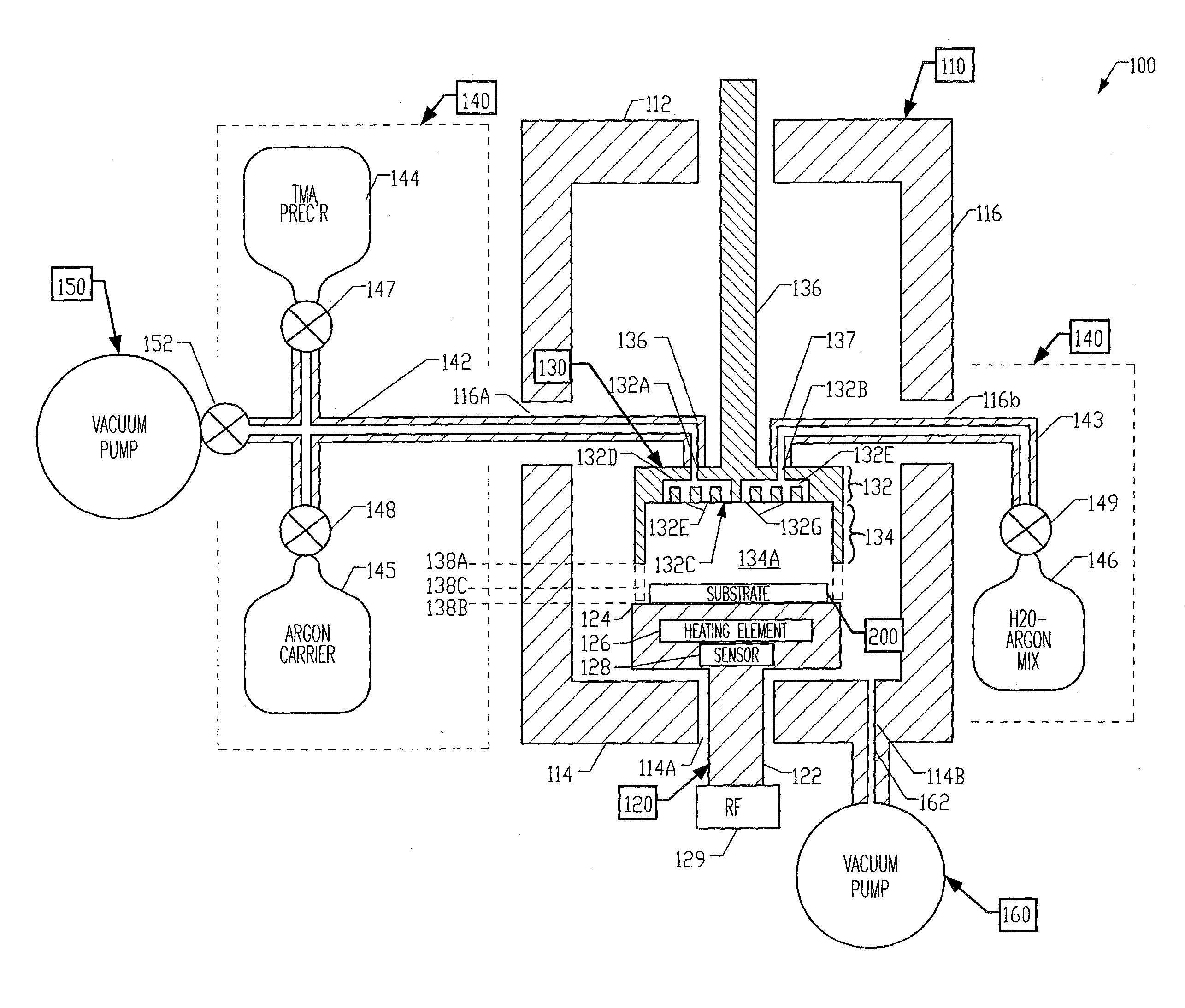

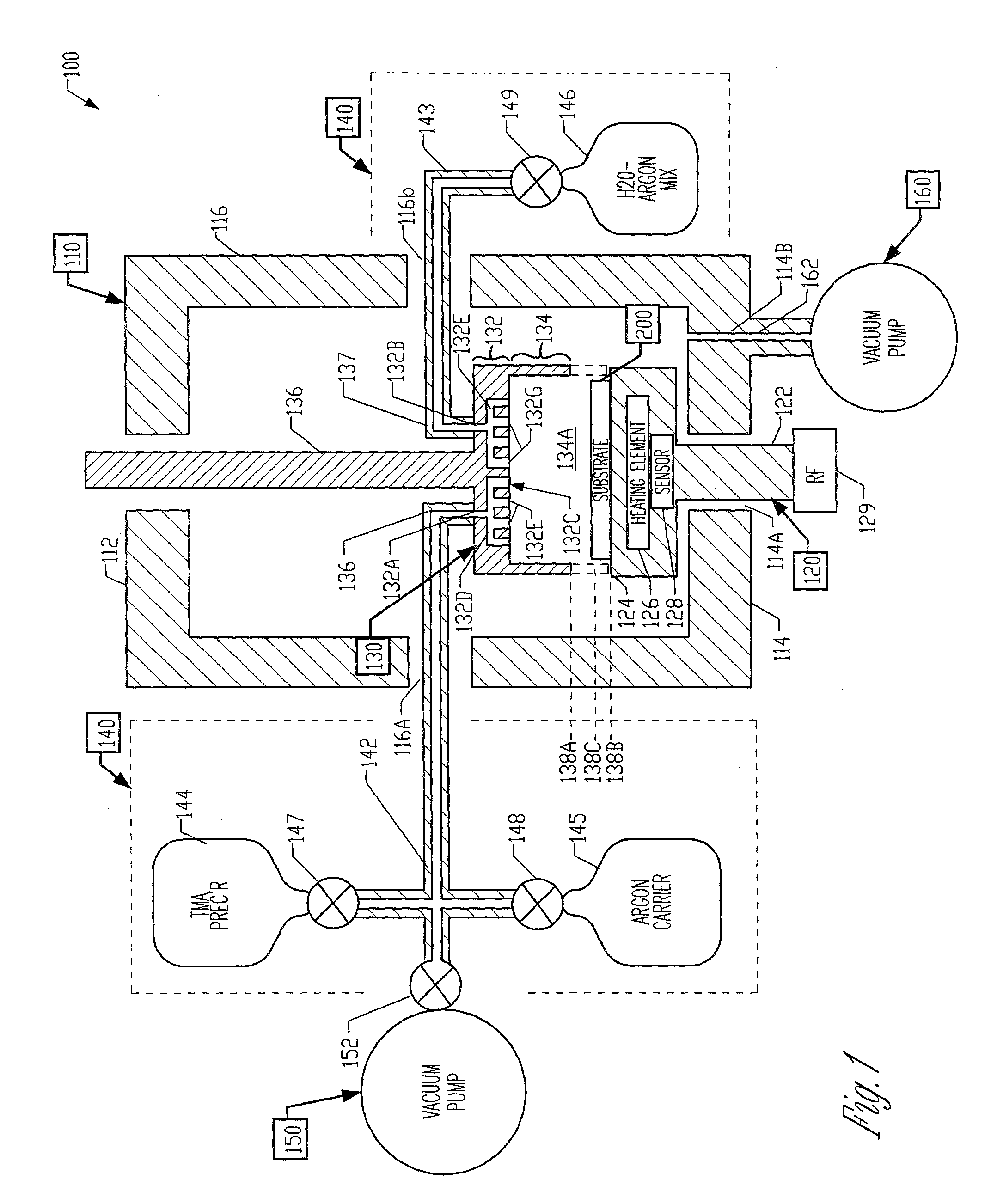

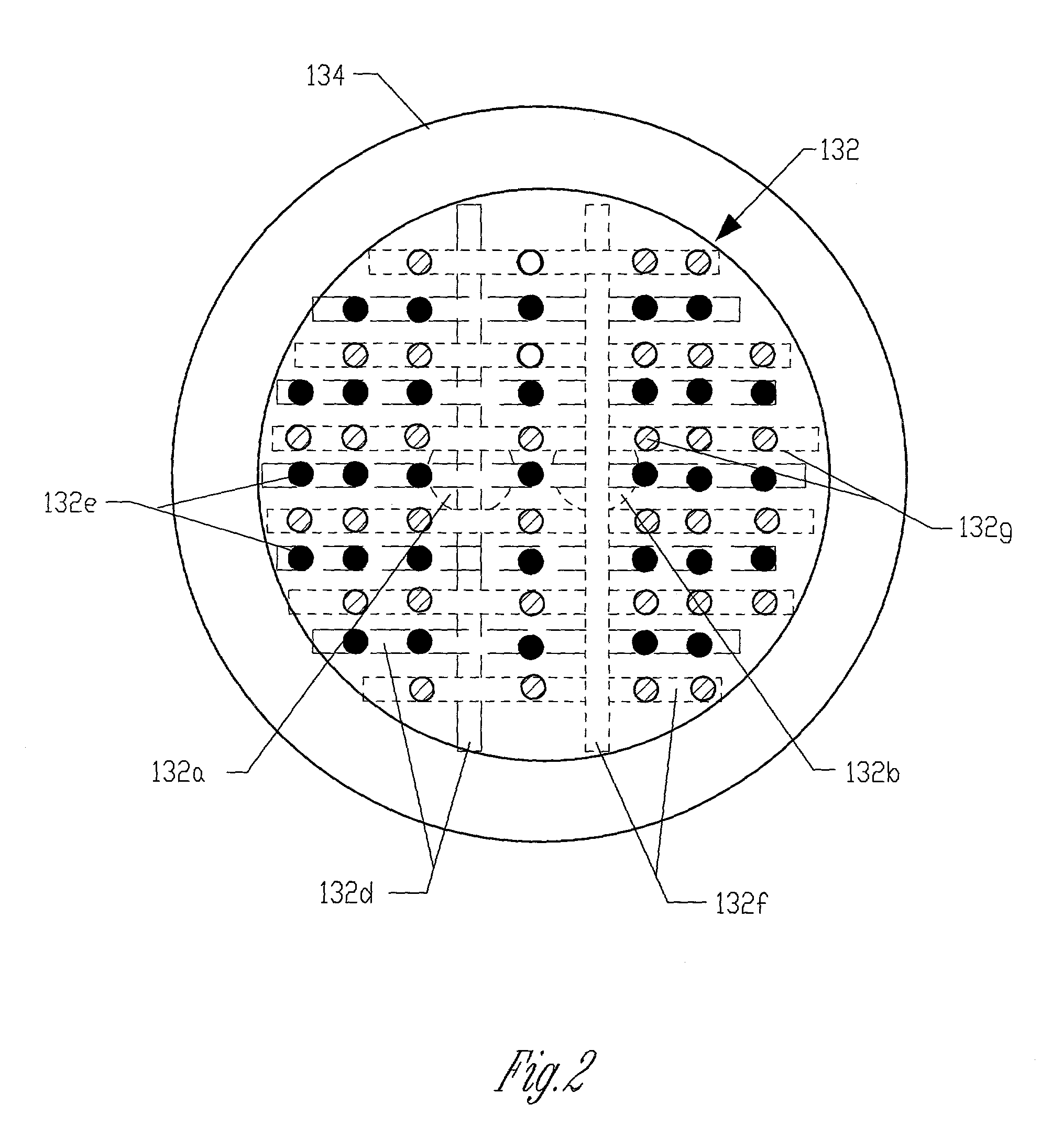

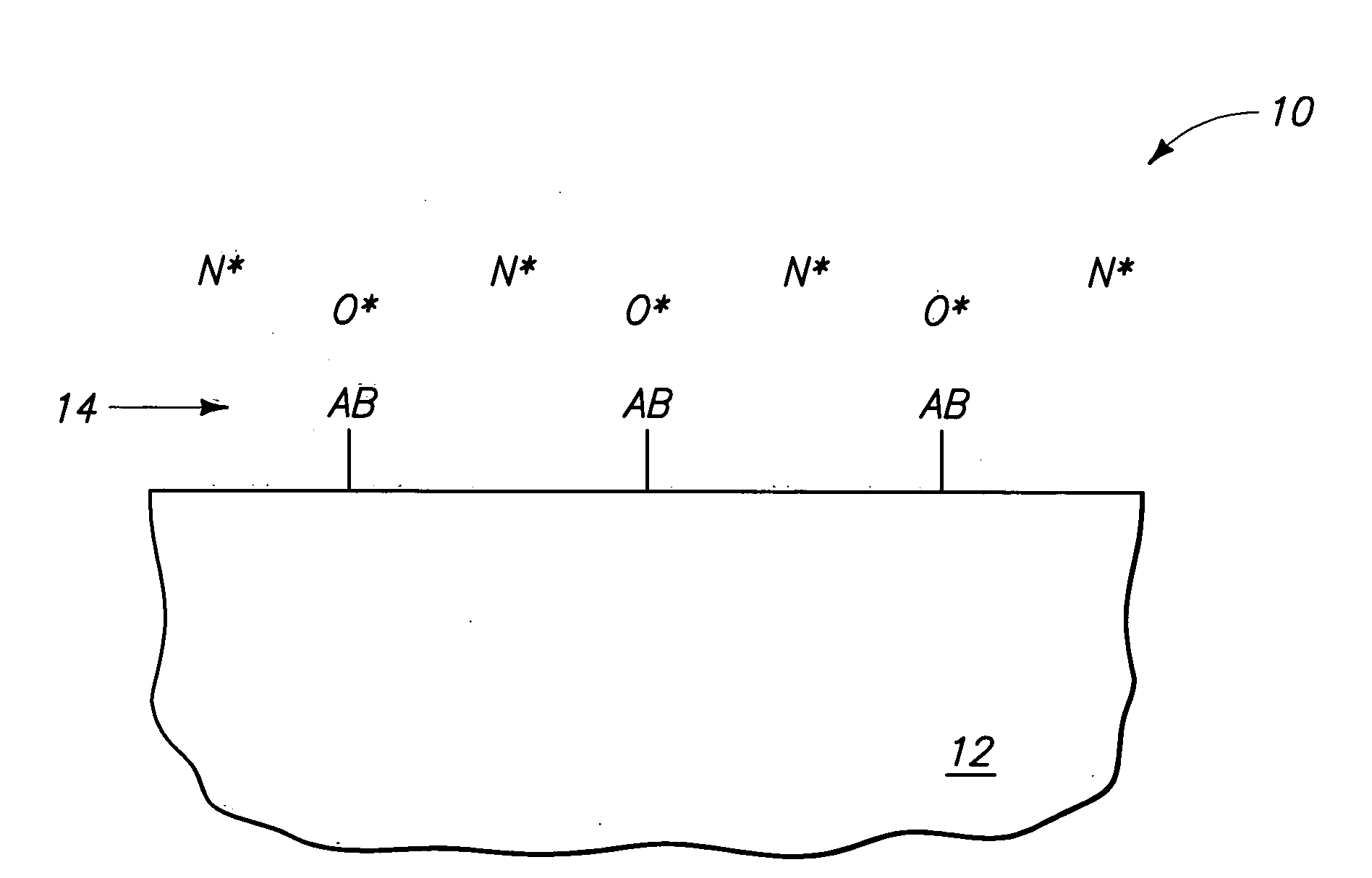

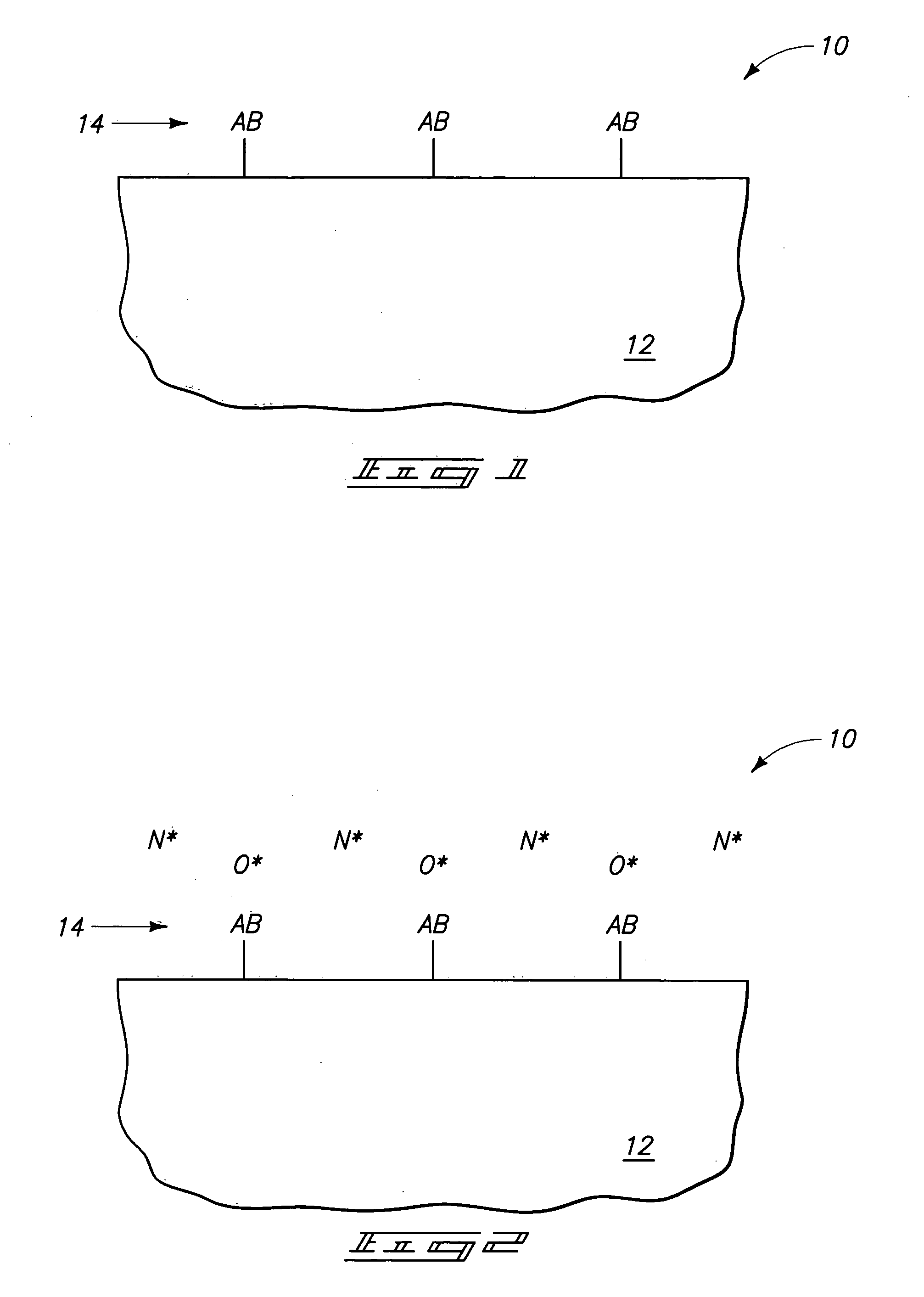

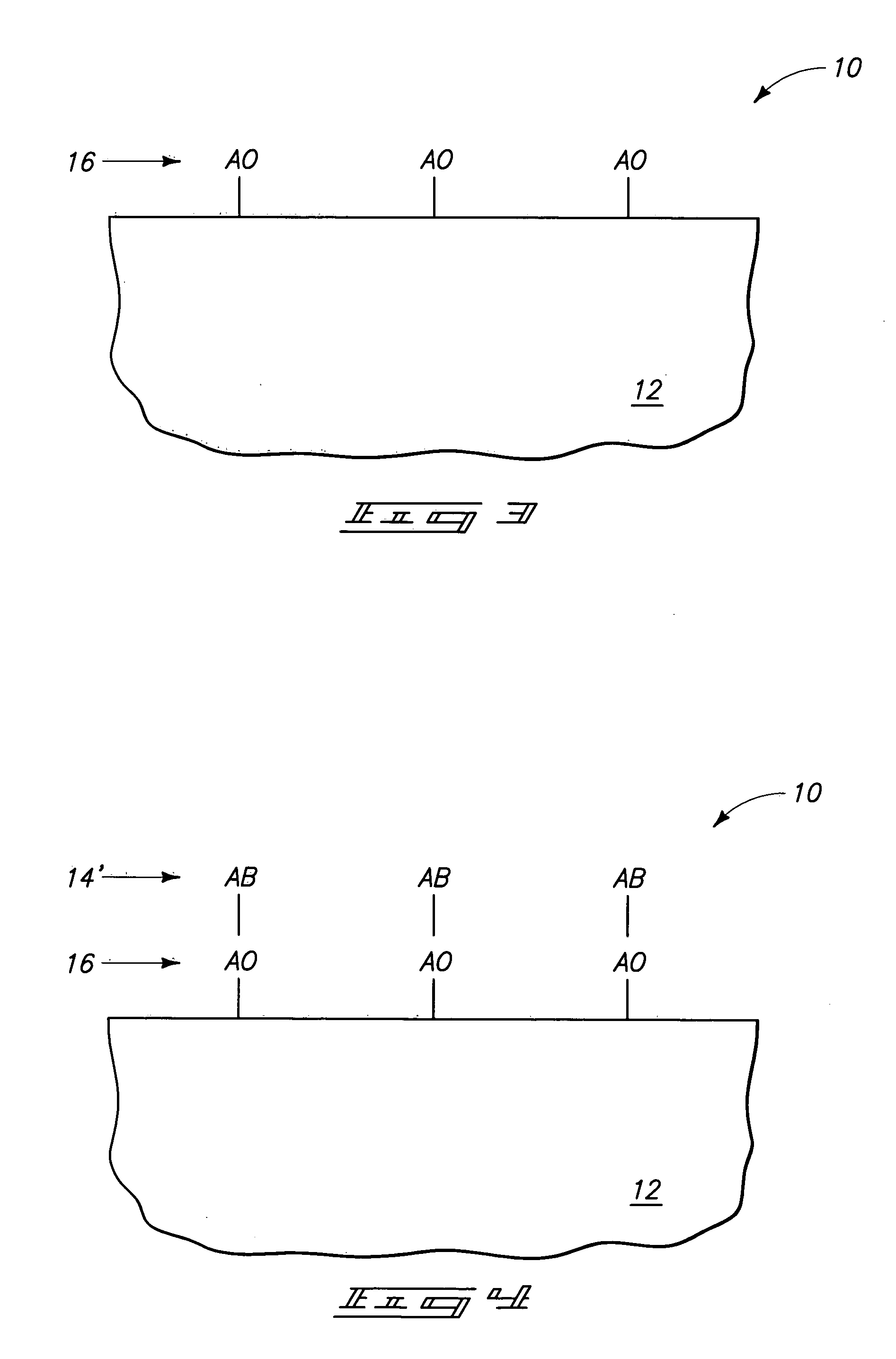

Methods, systems, and apparatus for atomic-layer deposition of aluminum oxides in integrated circuits

InactiveUS20030207032A1Small volumeConsumes less gasPretreated surfacesChemical vapor deposition coatingProduct gasIntegrated circuit layout

Integrated circuits, the key components in thousands of electronic and computer products, are generally built layer by layer on a silicon substrate. One common layer-formation technique, known as chemical-vapor deposition (CVD), produces uneven layers and covers vertical surfaces poorly. An emergent technique, atomic-layer deposition, overcomes these shortcomings, but has others, such as slow deposition rates and longer than desirable cycle times, particularly as applied to deposition of aluminum oxide. Accordingly, the inventors devised unique atomic-layer deposition systems, methods, and apparatus suitable for aluminum-oxide deposition. One exemplary system includes an outer chamber, a substrate holder, and a gas-distribution fixture that engages or cooperates with the substrate holder to form an inner chamber within the outer chamber. The inner chamber has a smaller volume than the outer chamber, which ultimately requires less time to fill and purge and thus promises to reduce cycle times for deposition of materials, such as aluminum oxide.

Owner:MICRON TECH INC

Substrate Coated With A Hydrophilic Elastomer

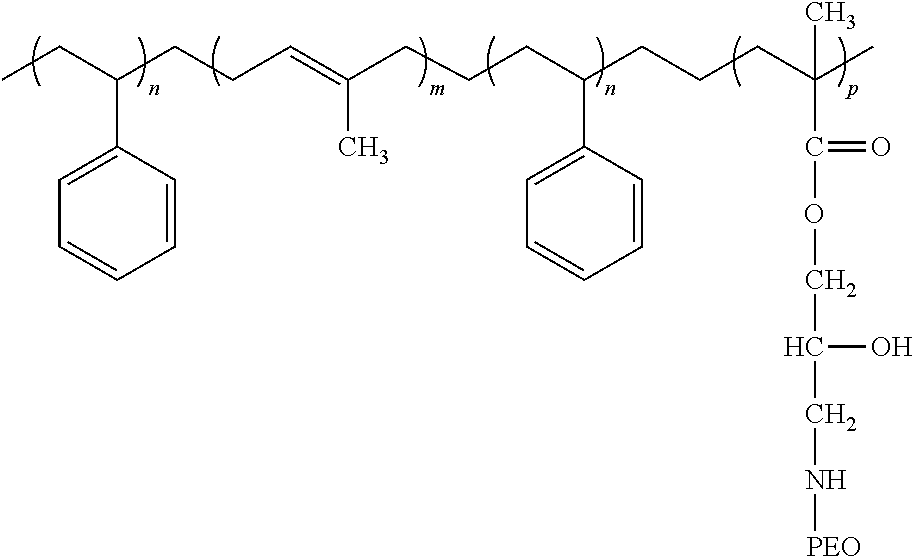

ActiveUS20110319848A1Improve hydrophilicityGood coating stabilitySynthetic resin layered productsPretreated surfacesElastomerPolymer science

Substrates, coated with a block copolymer comprising at least four blocks being at least two hard blocks, one soft block and one hydrophilic block, wherein a the soft block is sandwiched between the hard blocks.

Owner:THE PROCTER & GAMBLE COMPANY

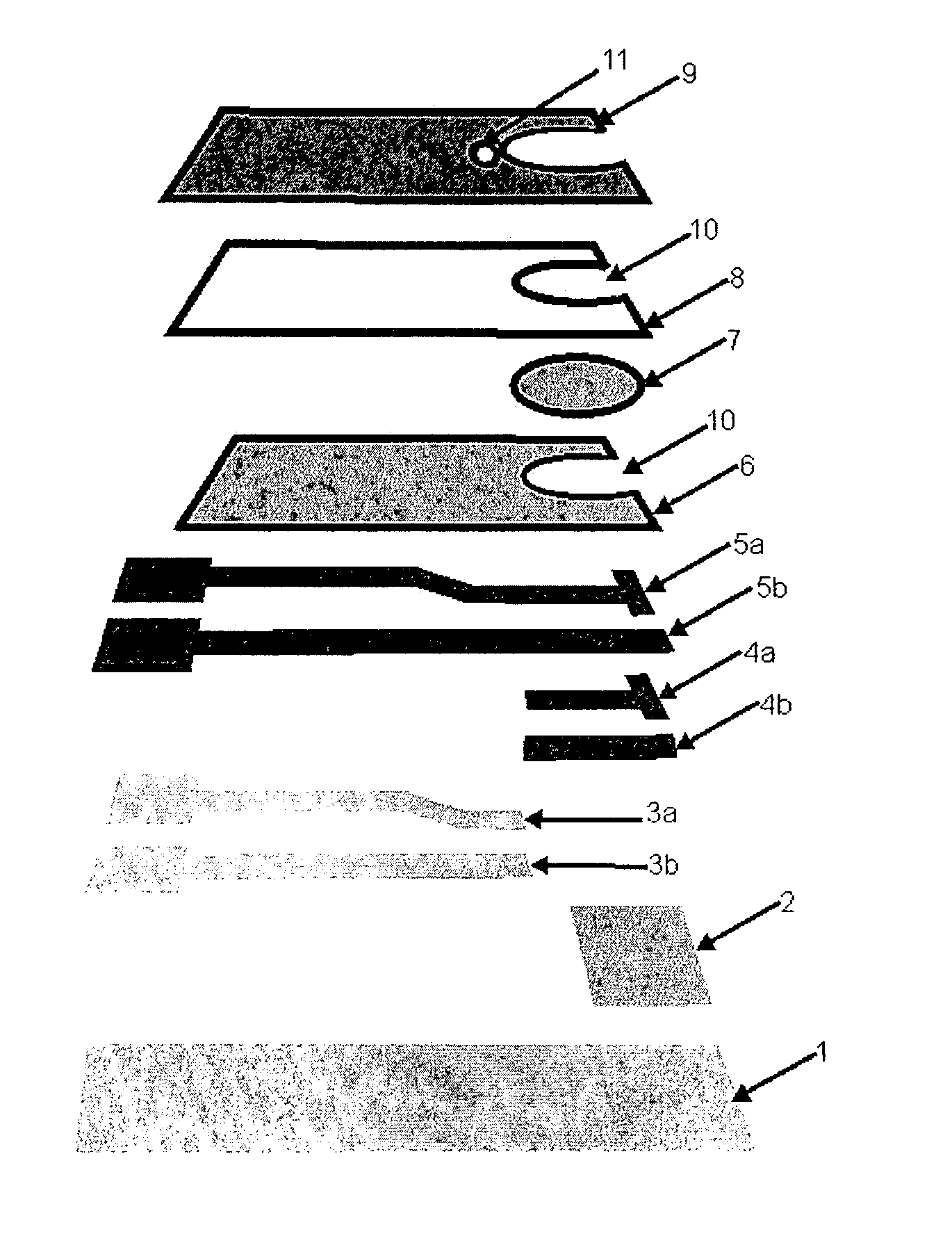

Biosensors having improved sample application and uses thereof

InactiveUS7118667B2Improve distributionEnhance introductionImmobilised enzymesBioreactor/fermenter combinationsAnalyteEnzyme

The present invention relates to biosensors having improved sample application and measuring properties and their uses for detection, preferably, quantitative measurement, of analyte in a liquid sample. In particular, the invention provides for a biosensor having a sample application, reaction area and liquid soluble hydrophilic material facilitating the speed and uniformity of sample application, especially small volume sample application, via capillary flow. Methods for assaying analytes or enzymes using the biosensors are further provided.

Owner:LEE JIN PO

Continuous analyte sensors and methods of making same

InactiveUS20110027458A1Low production costMinimize changesHot-dipping/immersion processesVacuum evaporation coatingAnalyteSolvent

Owner:DEXCOM

Atomic layer deposition method of depositing an oxide on a substrate

The invention includes atomic layer deposition methods of depositing an oxide on a substrate. In one implementation, a substrate is positioned within a deposition chamber. A first species is chemisorbed onto the substrate to form a first species monolayer within the deposition chamber from a gaseous precursor. The chemisorbed first species is contacted with remote plasma oxygen derived at least in part from at least one of O2 and O3 and with remote plasma nitrogen effective to react with the first species to form a monolayer comprising an oxide of a component of the first species monolayer. The chemisorbing and the contacting with remote plasma oxygen and with remote plasma nitrogen are successively repeated effective to form porous oxide on the substrate. Other aspects and implementations are contemplated.

Owner:MICRON TECH INC

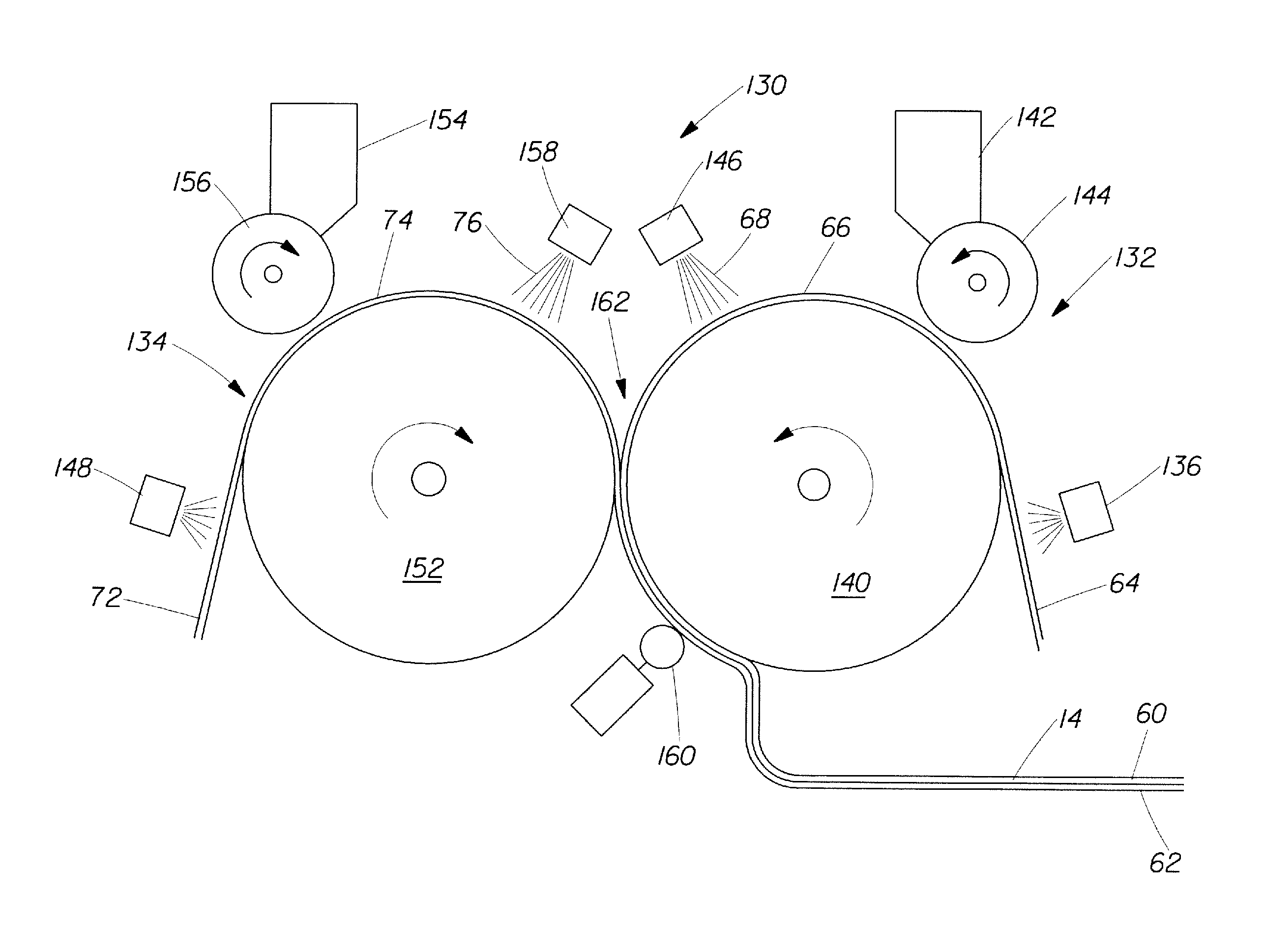

Method And Apparatus For Making Disposable Absorbent Article With Absorbent Particulate Polymer Material And Article Made Therewith

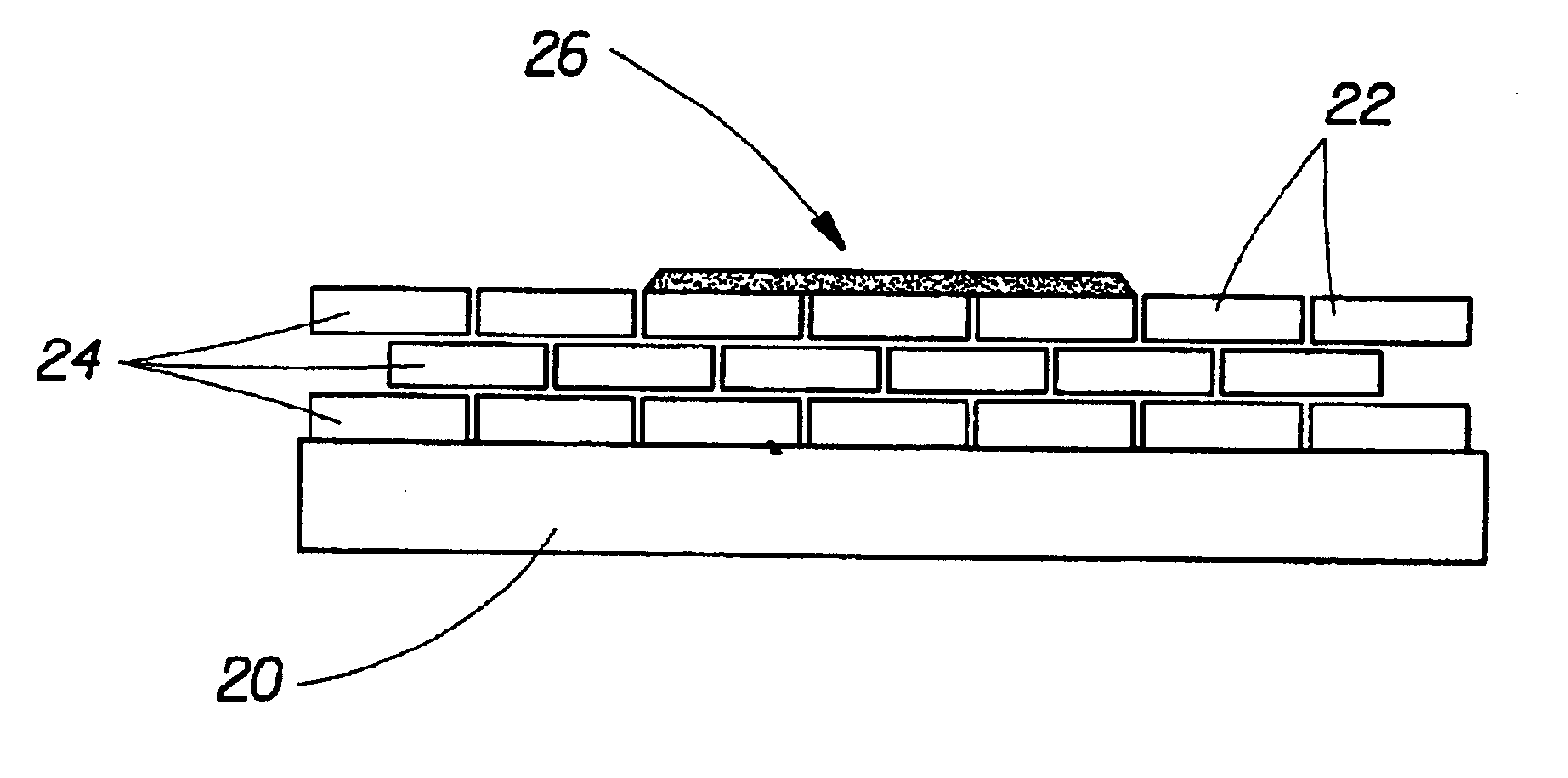

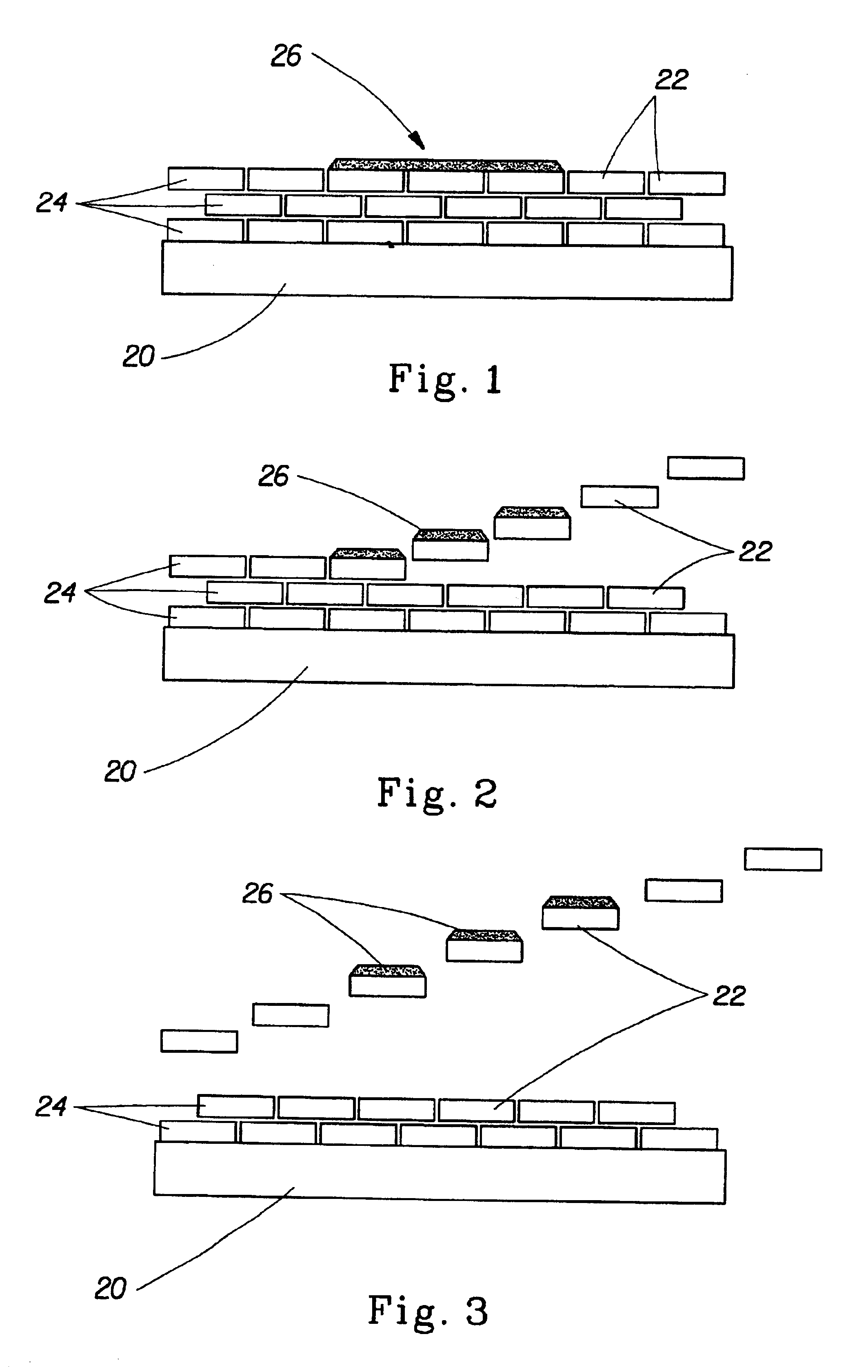

A method for making a disposable absorbent core comprises depositing absorbent particulate polymer material from a plurality of reservoirs in a printing roll onto a substrate disposed on a grid of a support which includes a plurality of cross bars extending substantially parallel to and spaced from one another so as to form channels extending between the plurality of cross bars. The plurality of reservoirs in the first peripheral surface are arranged in an array comprising rows extending substantially parallel to and spaced from one another. The support and printing roll are arranged such that the plurality of cross bars are substantially parallel to the rows of the plurality of reservoirs and the absorbent particulate polymer material is deposited on the substrate in a pattern such that the absorbent particulate polymer material collects in rows on the first substrate formed between the first plurality of cross bars. A thermoplastic adhesive material is deposited on the absorbent particulate polymer material and the substrate to cover the absorbent particulate polymer material on the substrate and form an absorbent layer. A disposable absorbent article and apparatus for making an absorbent article are also disclosed.

Owner:THE PROCTER & GAMBLE COMPANY

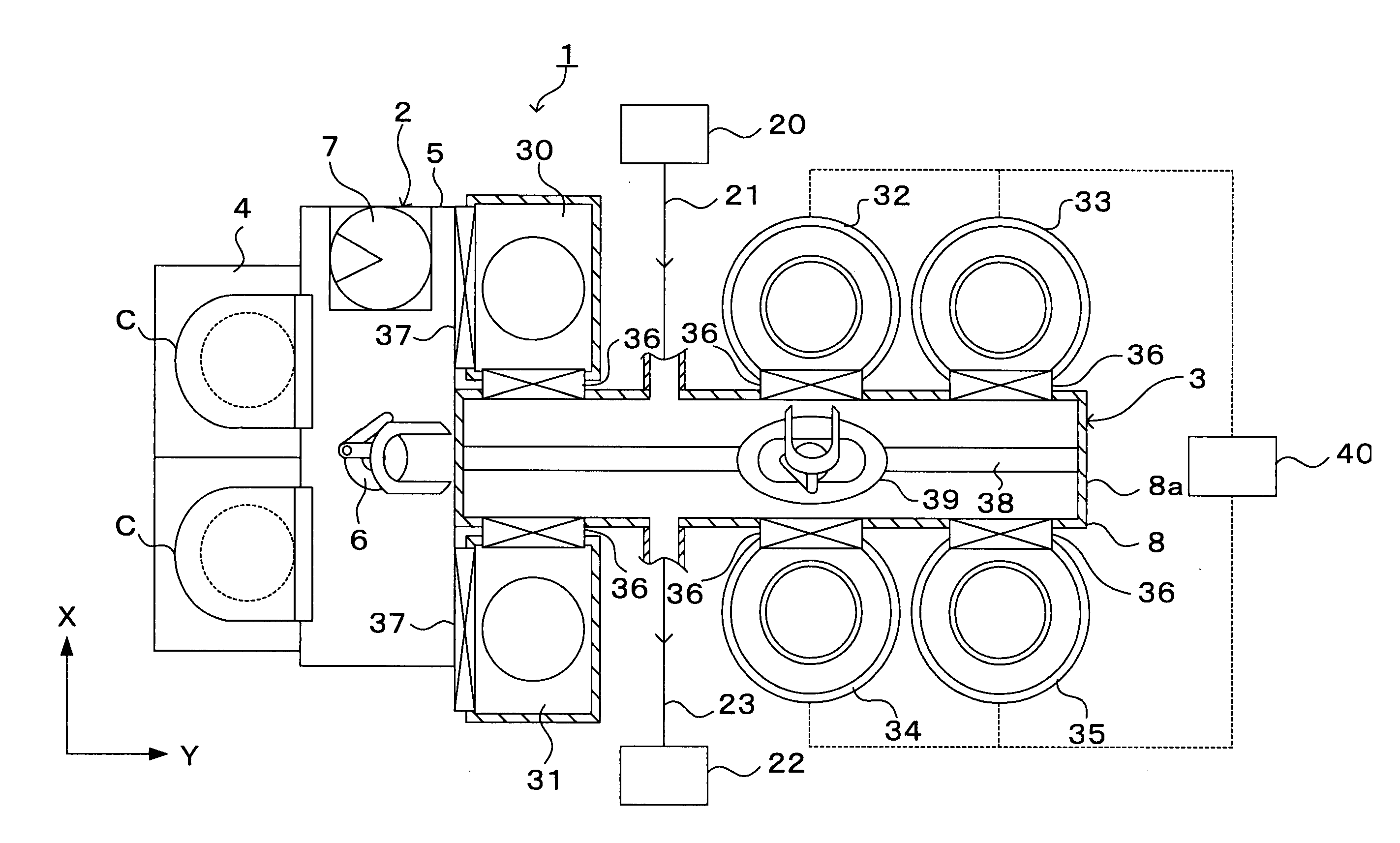

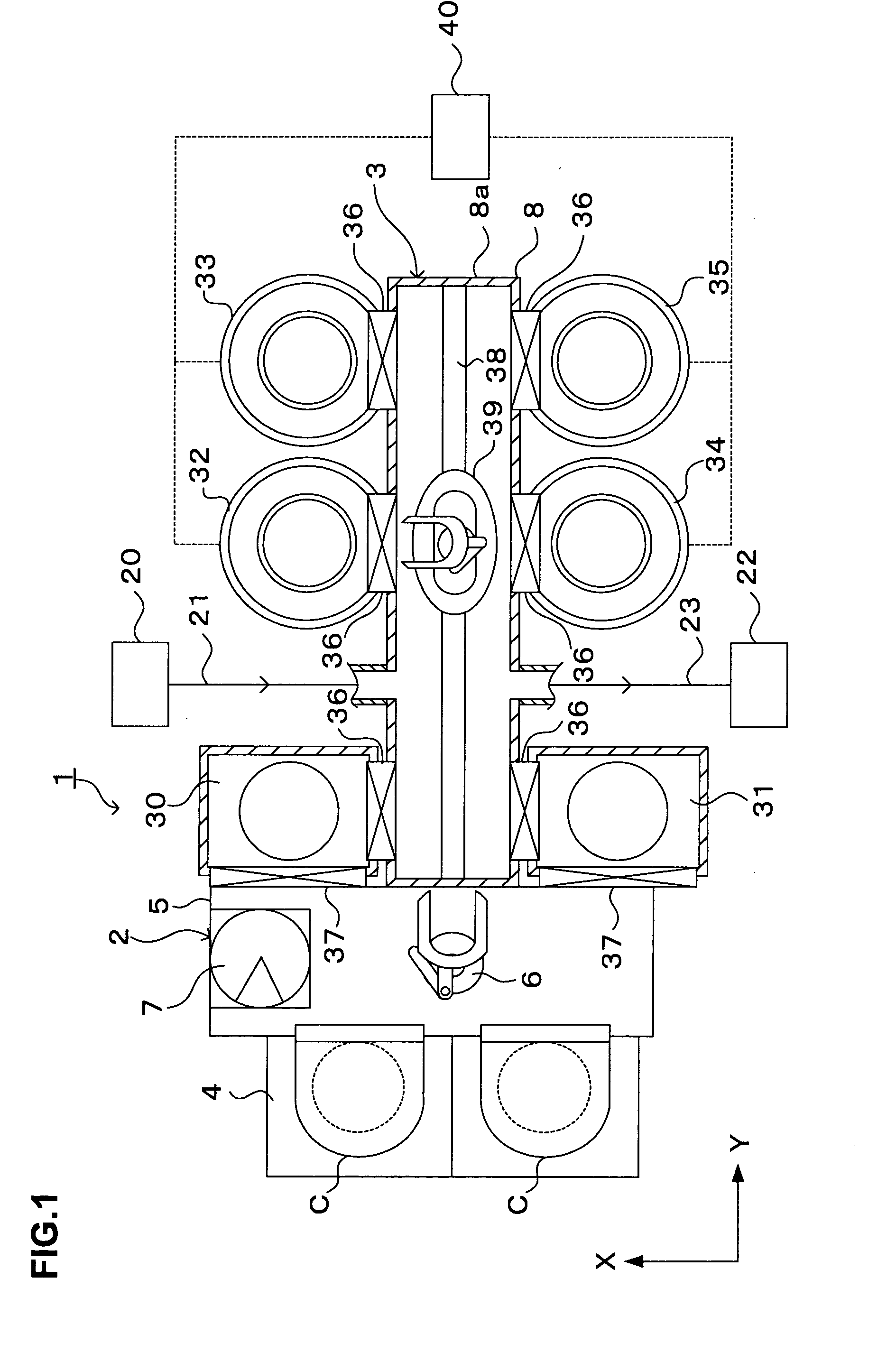

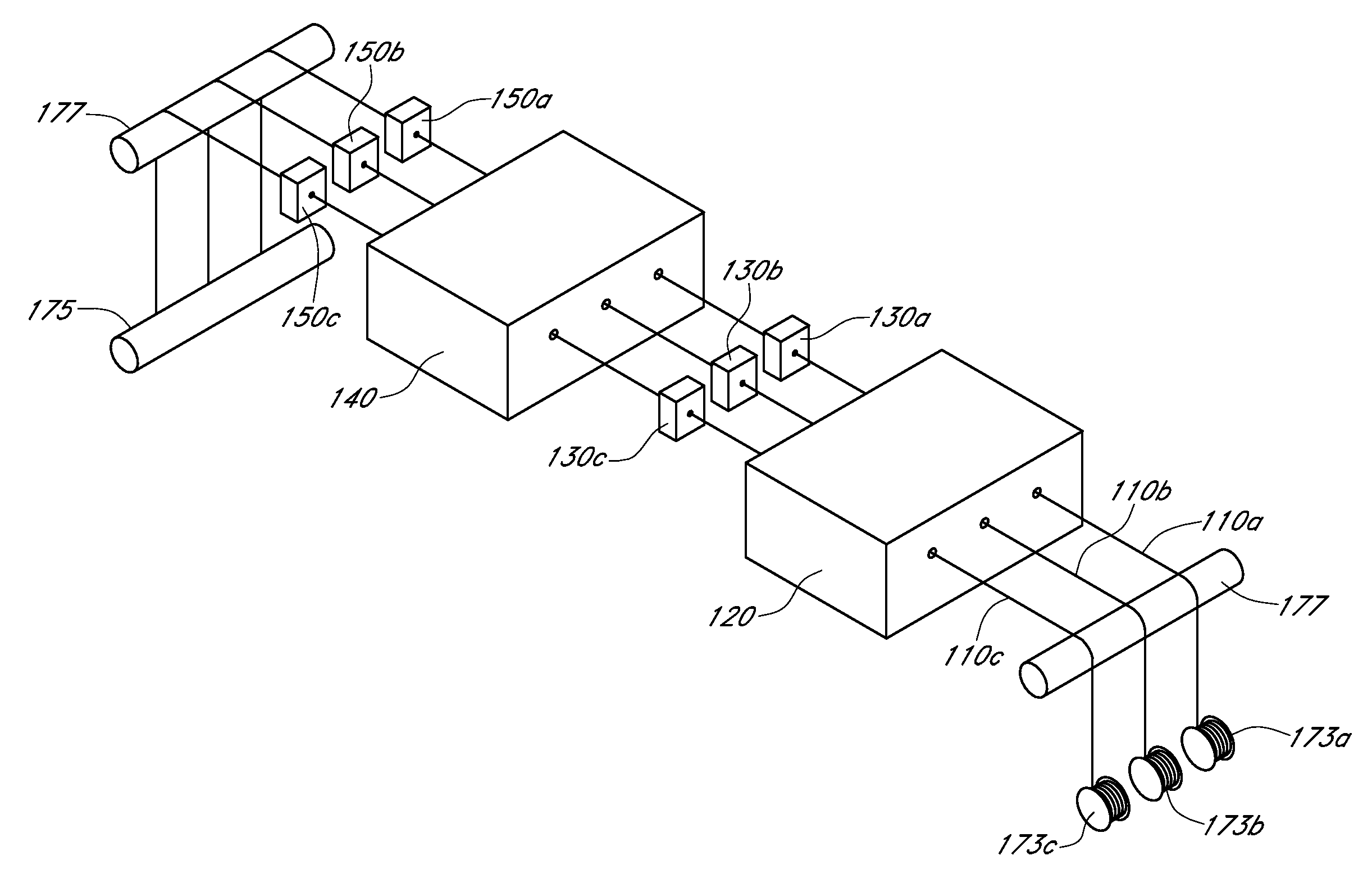

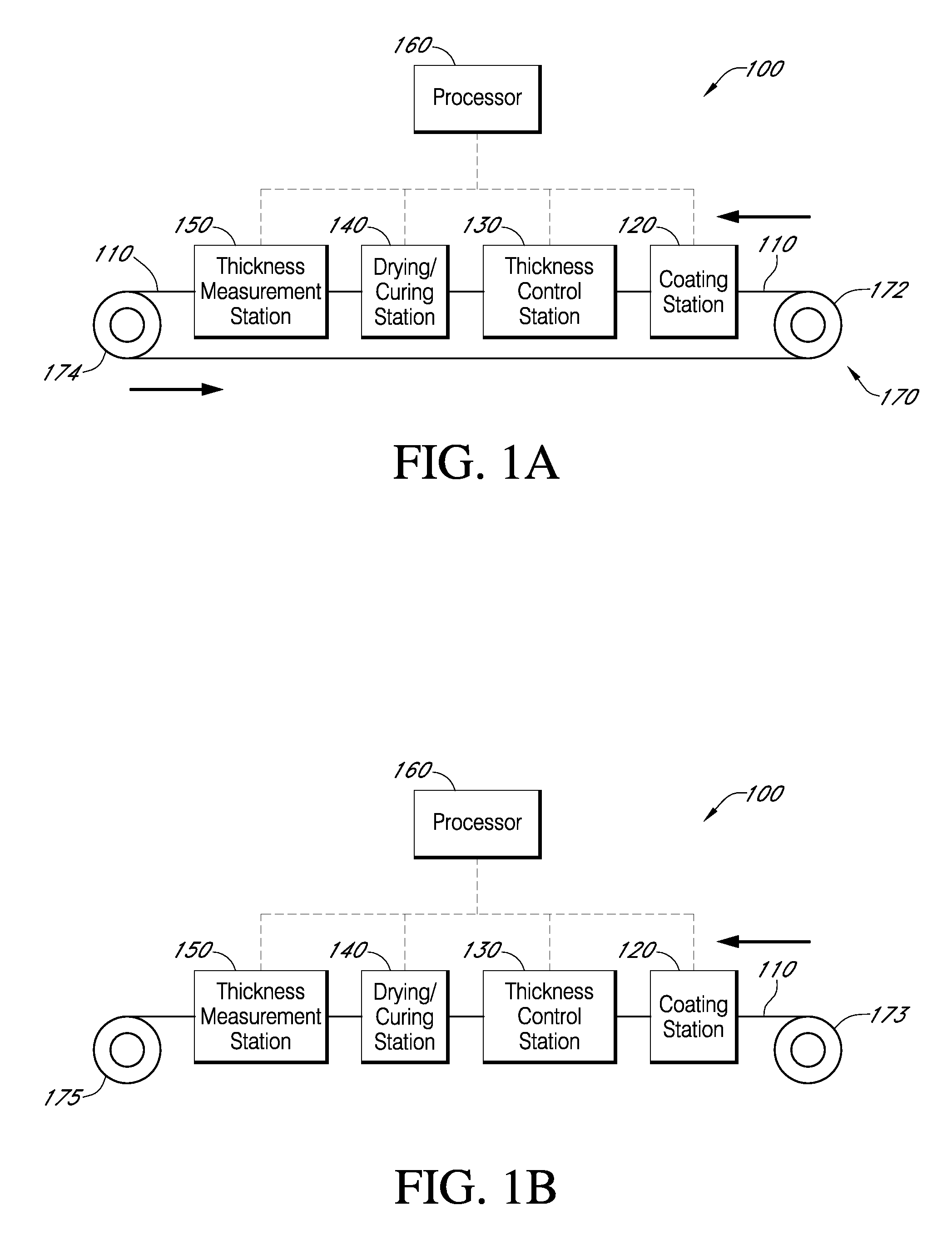

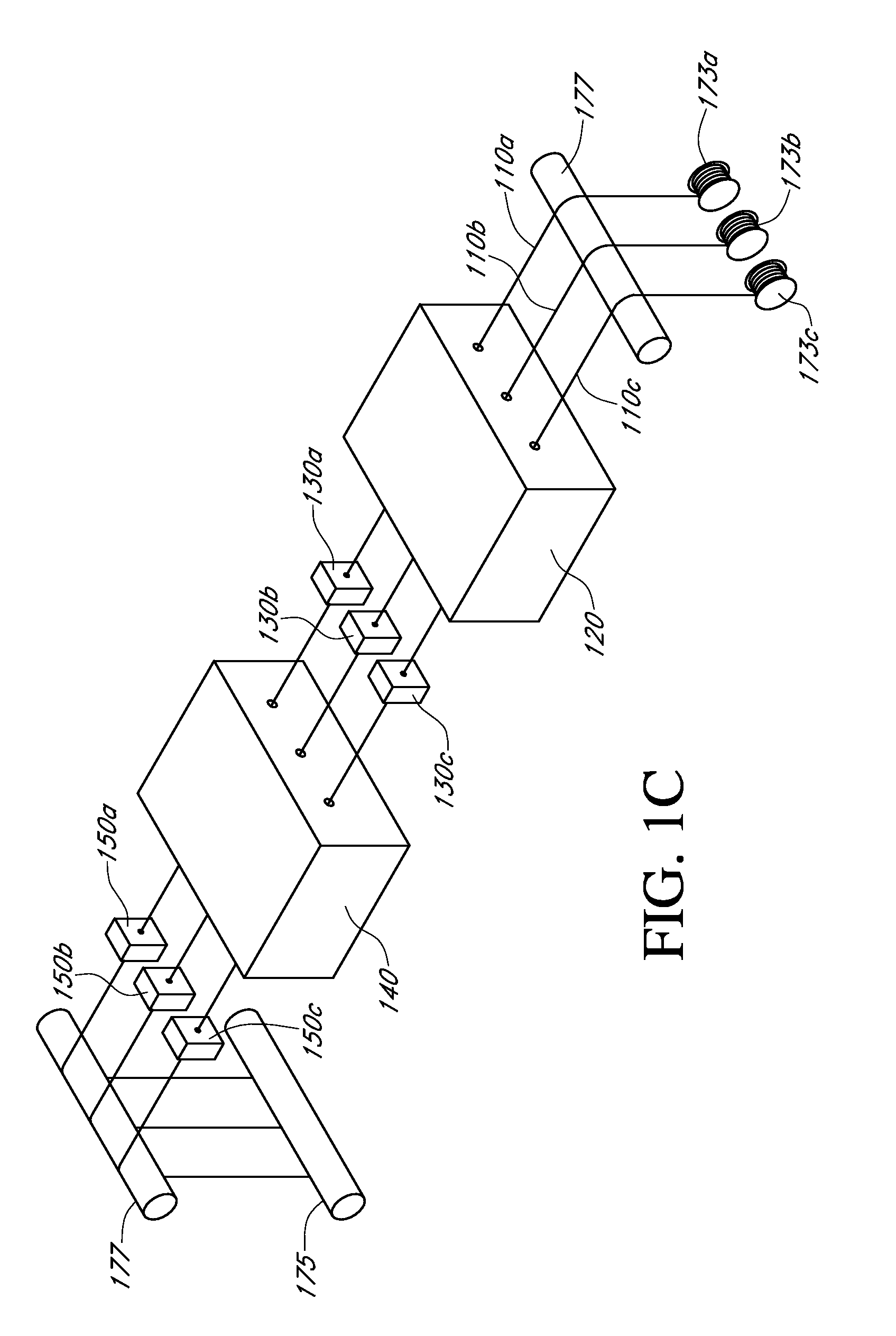

Continuous analyte sensors and methods of making same

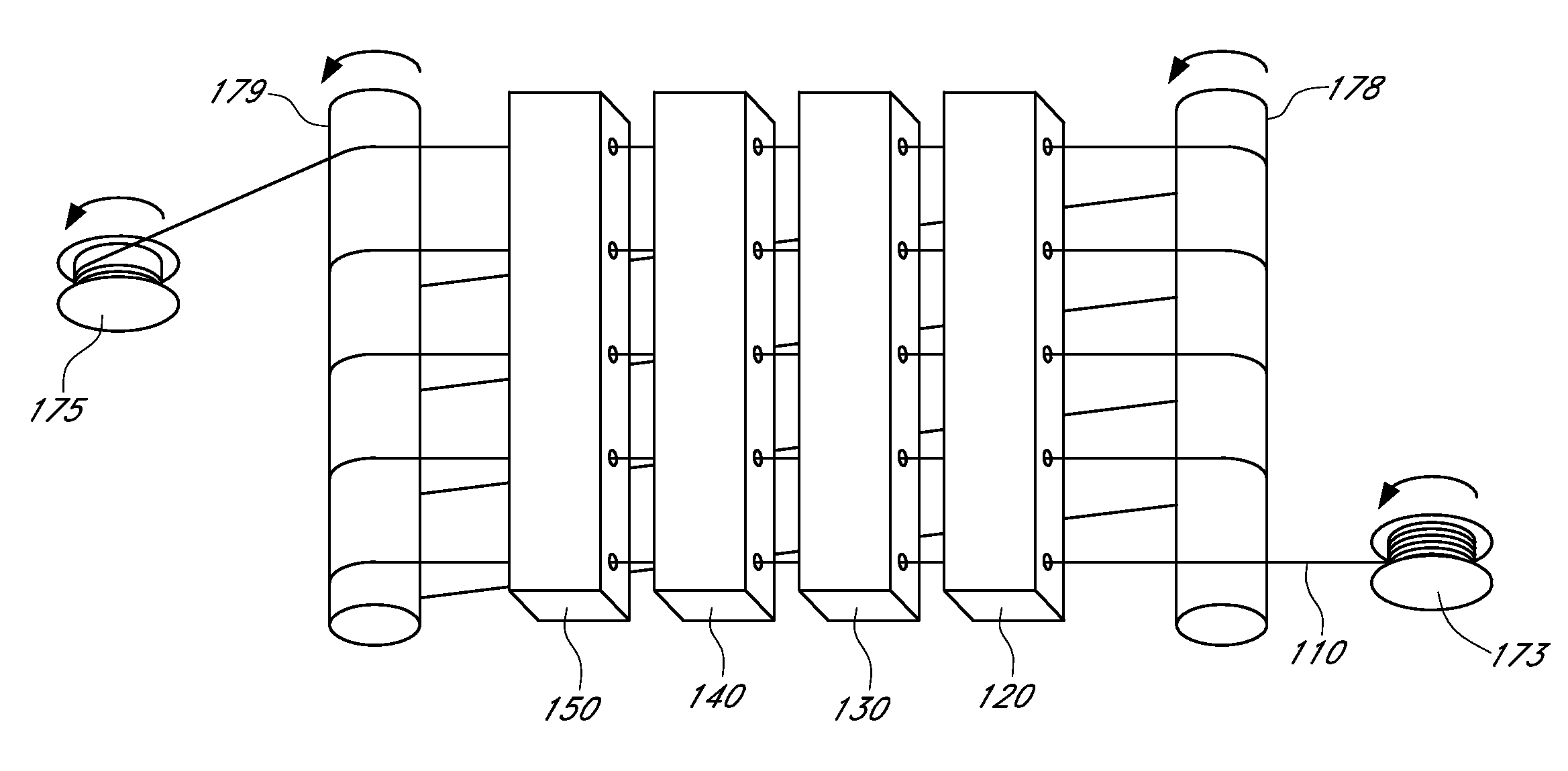

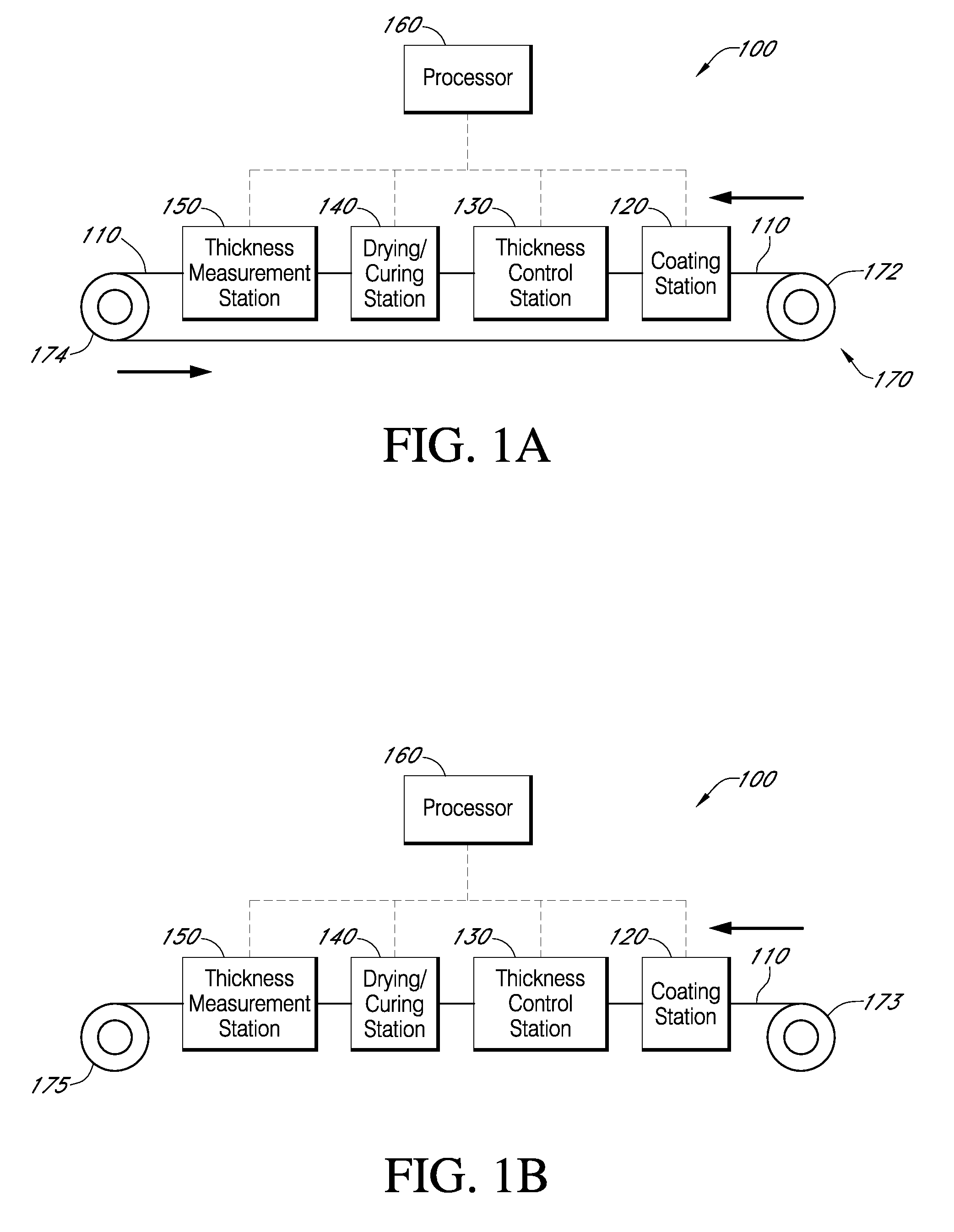

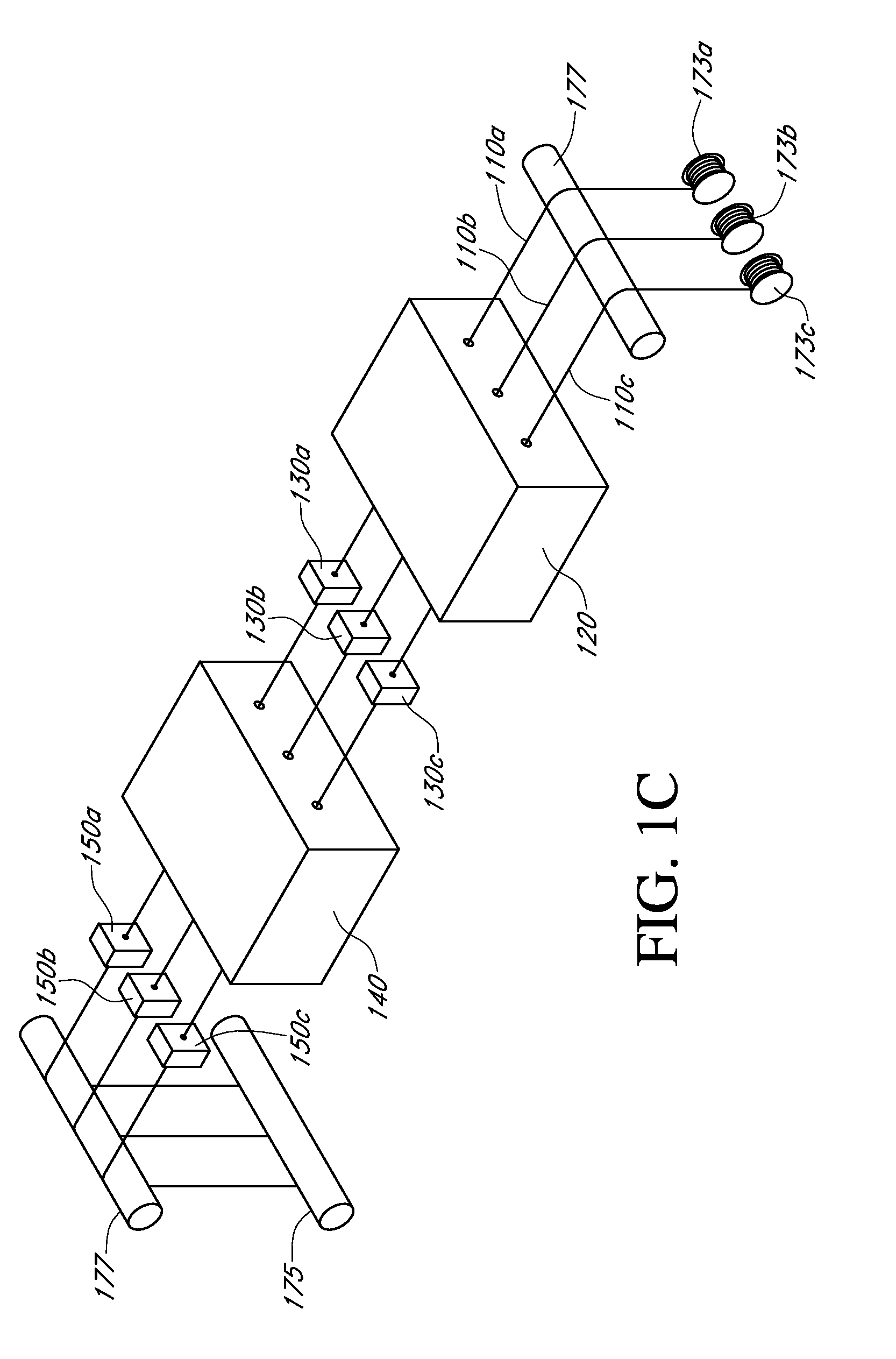

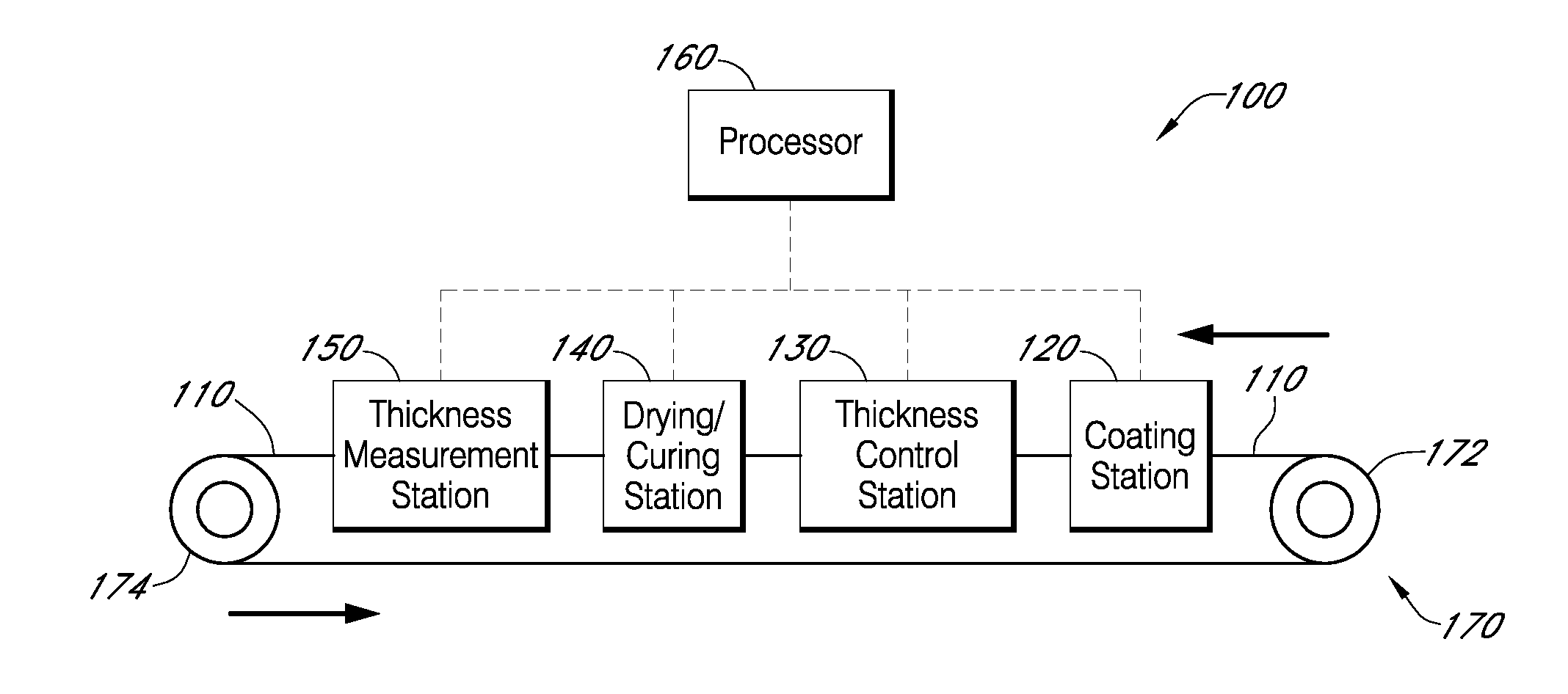

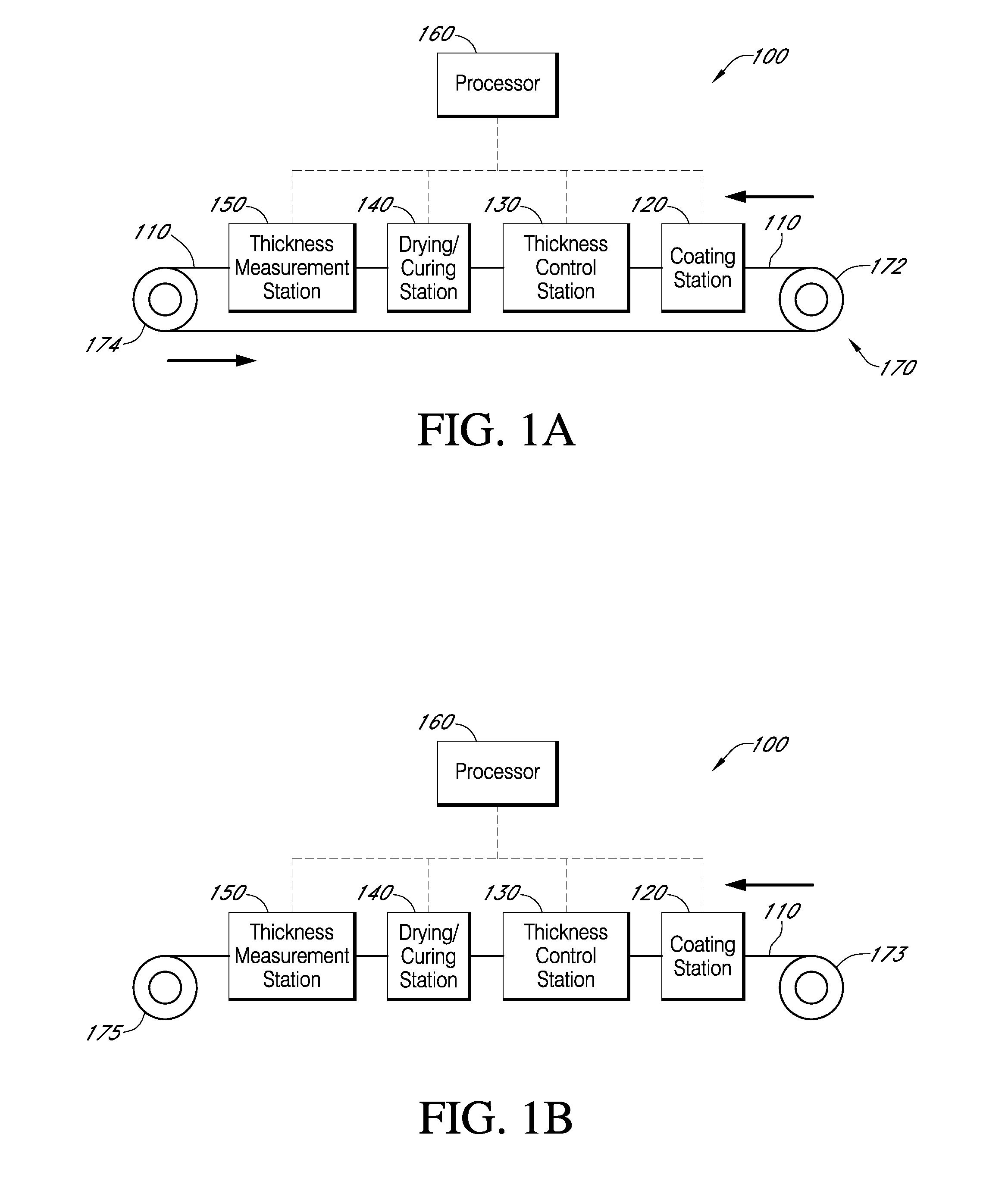

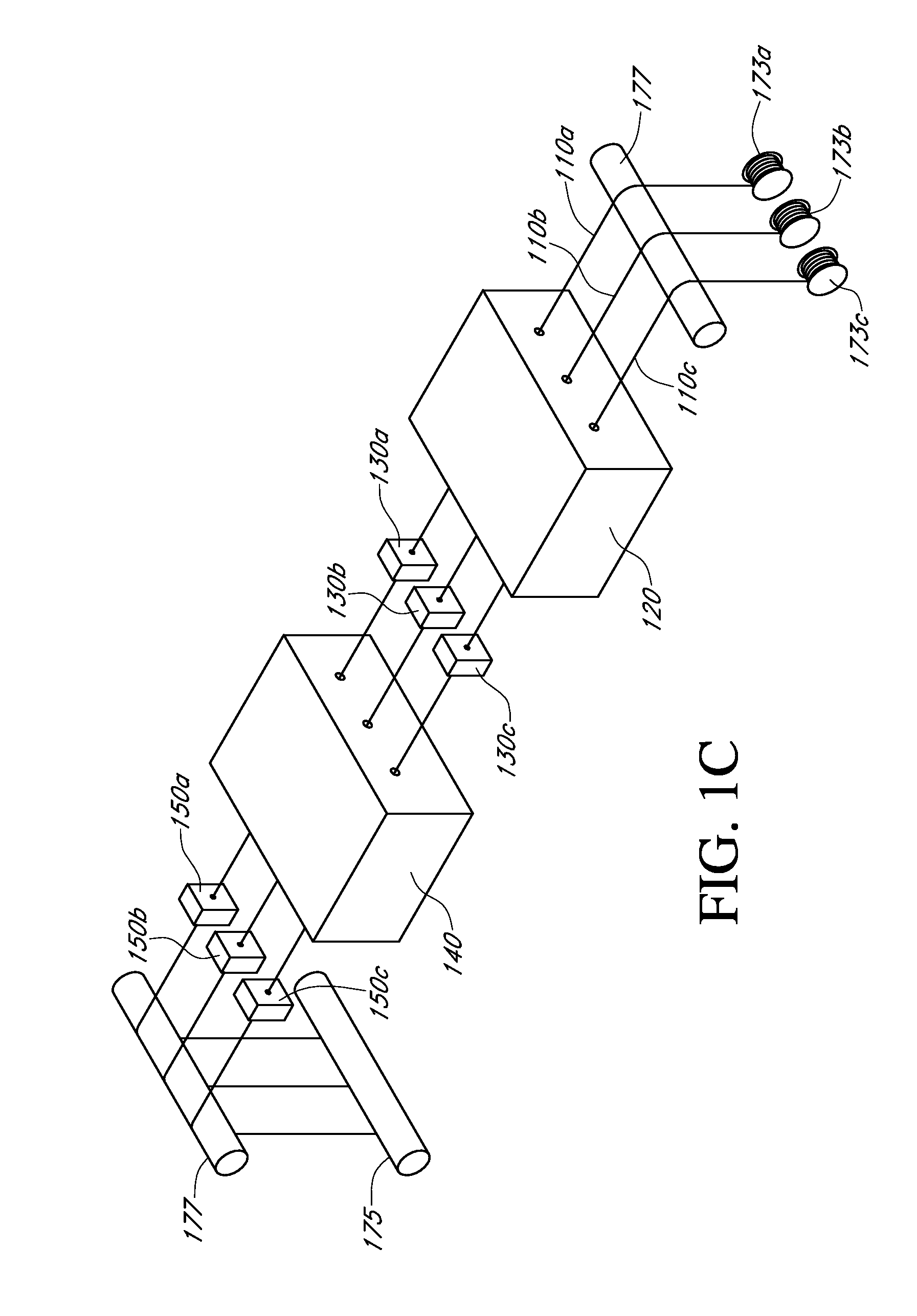

InactiveUS20110024043A1Low production costMinimize changesHot-dipping/immersion processesPretreated surfacesAnalyteSolvent

Described here are embodiments of processes and systems for the continuous manufacturing of implantable continuous analyte sensors. In some embodiments, a method is provided for sequentially advancing an elongated conductive body through a plurality of stations, each configured to treat the elongated conductive body. In some of these embodiments, one or more of the stations is configured to coat the elongated conductive body using a meniscus coating process, whereby a solution formed of a polymer and a solvent is prepared, the solution is continuously circulated to provide a meniscus on a top portion of a vessel holding the solution, and the elongated conductive body is advanced through the meniscus. The method may also comprise the step of removing excess coating material from the elongated conductive body by advancing the elongated conductive body through a die orifice. For example, a provided elongated conductive body 510 is advanced through a pre-coating treatment station 520, through a coating station 530, through a thickness control station 540, through a drying or curing station 550, through a thickness measurement station 560, and through a post-coating treatment station 570.

Owner:DEXCOM

Continuous analyte sensors and methods of making same

InactiveUS20110027453A1Low production costMinimize changesHot-dipping/immersion processesPharmaceutical containersAnalyteSolvent

Described here are embodiments of processes and systems for the continuous manufacturing of implantable continuous analyte sensors. In some embodiments, a method is provided for sequentially advancing an elongated conductive body through a plurality of stations, each configured to treat the elongated conductive body. In some of these embodiments, one or more of the stations is configured to coat the elongated conductive body using a meniscus coating process, whereby a solution formed of a polymer and a solvent is prepared, the solution is continuously circulated to provide a meniscus on a top portion of a vessel holding the solution, and the elongated conductive body is advanced through the meniscus. The method may also comprise the step of removing excess coating material from the elongated conductive body by advancing the elongated conductive body through a die orifice. For example, a provided elongated conductive body 510 is advanced through a pre-coating treatment station 520, through a coating station 530, through a thickness control station 540, through a drying or curing station 550, through a thickness measurement station 560, and through a post-coating treatment station 570.

Owner:DEXCOM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com