Patents

Literature

341 results about "Porous oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

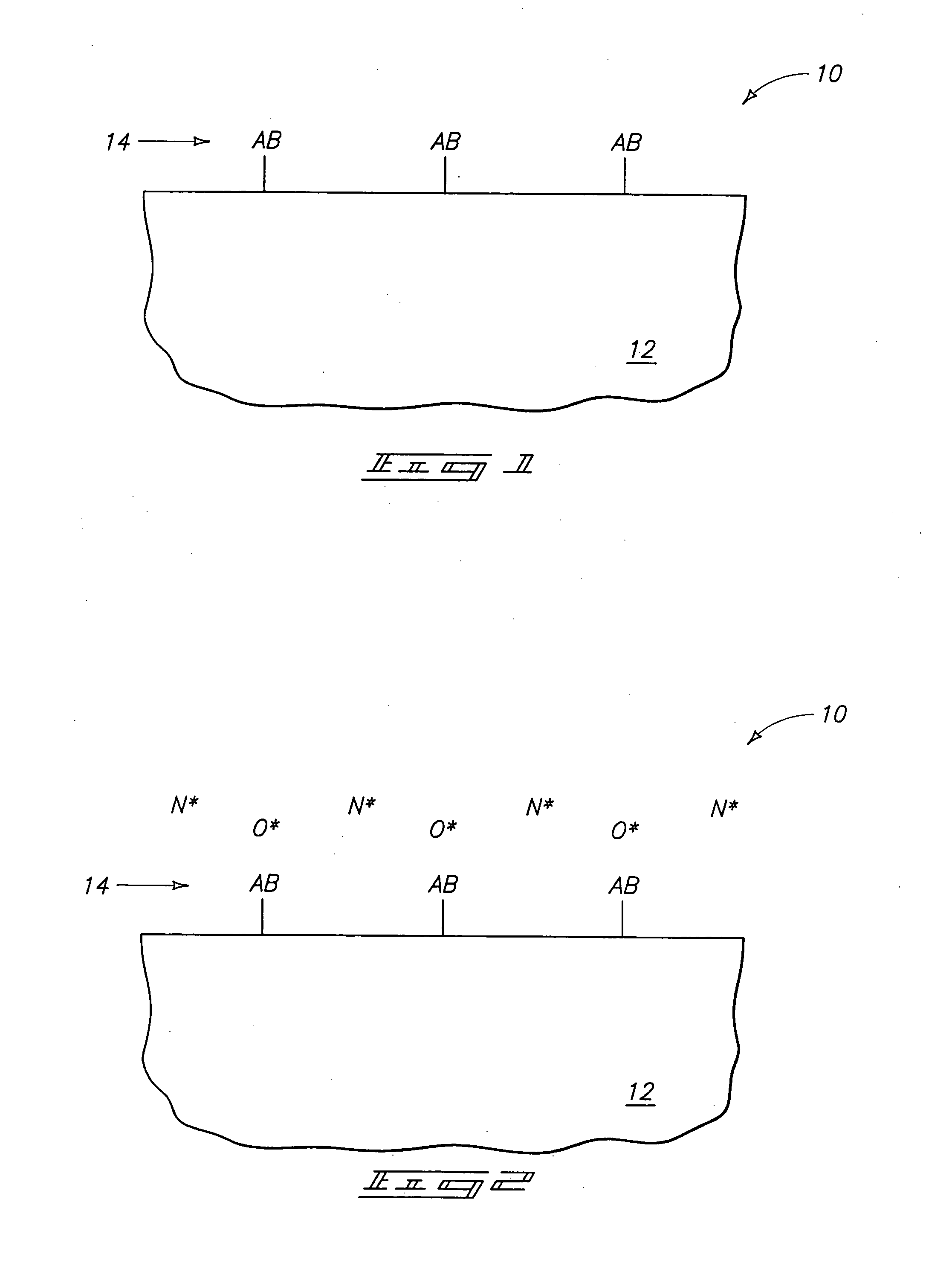

Atomic layer deposition method of depositing an oxide on a substrate

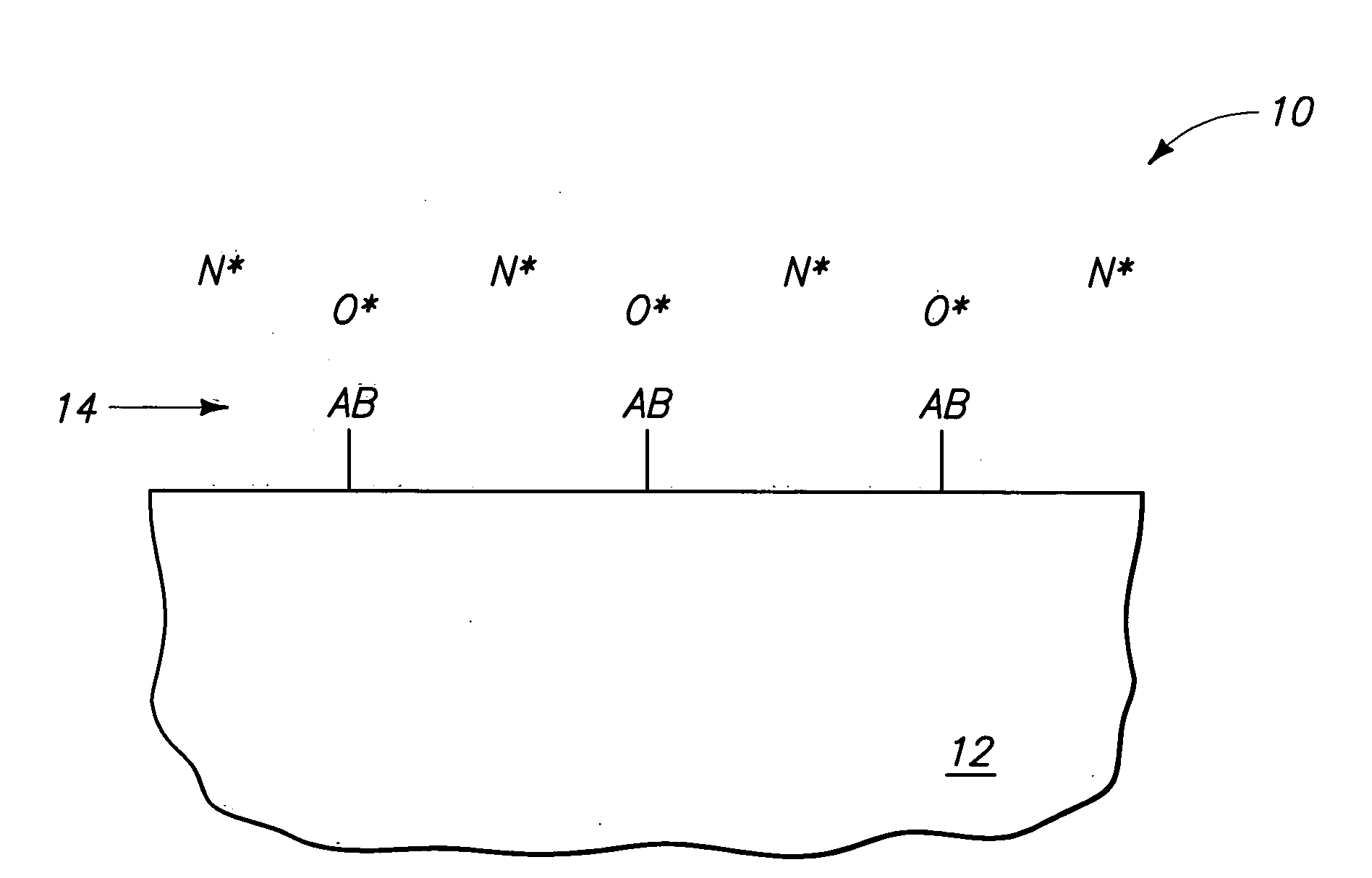

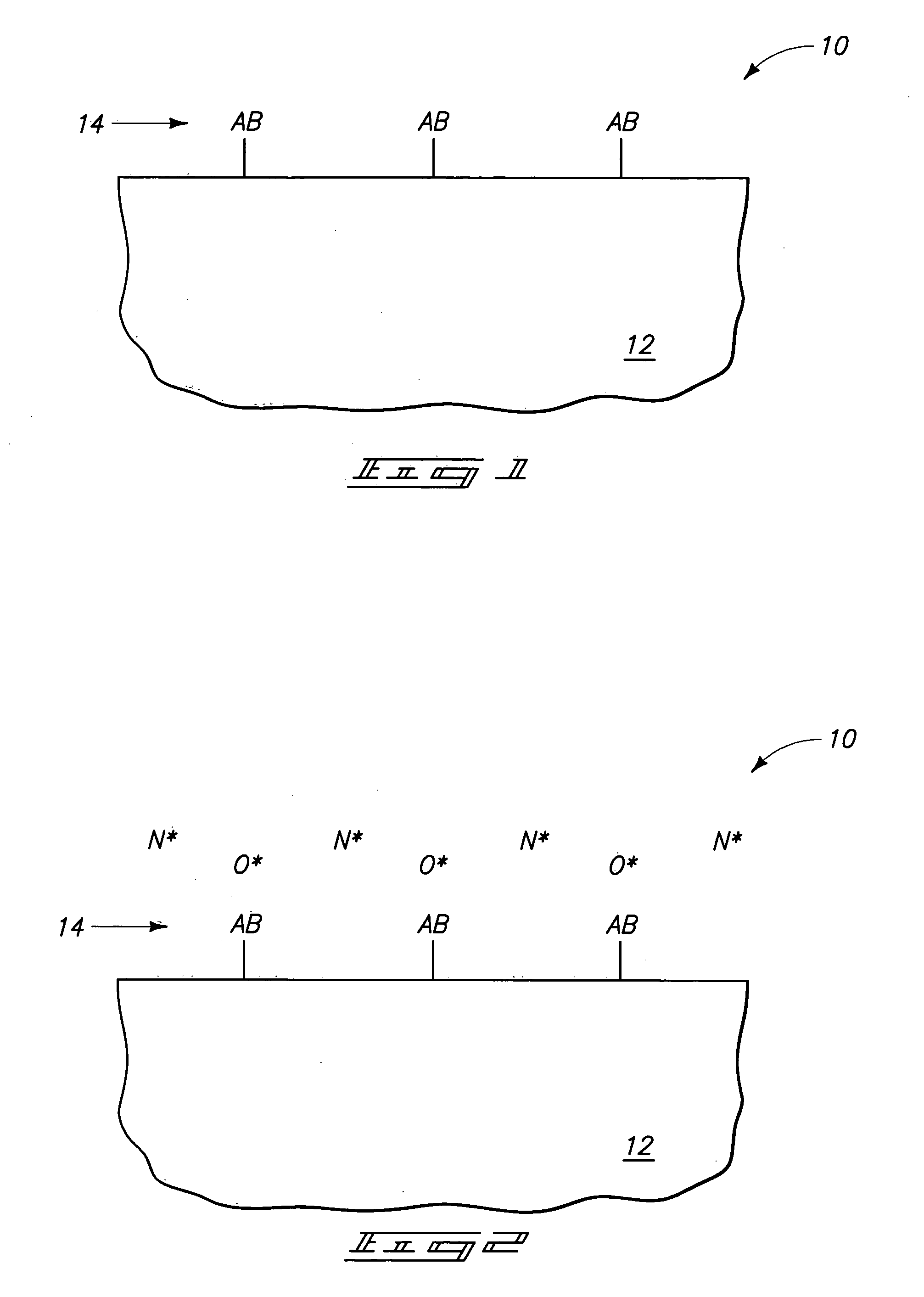

The invention includes atomic layer deposition methods of depositing an oxide on a substrate. In one implementation, a substrate is positioned within a deposition chamber. A first species is chemisorbed onto the substrate to form a first species monolayer within the deposition chamber from a gaseous precursor. The chemisorbed first species is contacted with remote plasma oxygen derived at least in part from at least one of O2 and O3 and with remote plasma nitrogen effective to react with the first species to form a monolayer comprising an oxide of a component of the first species monolayer. The chemisorbing and the contacting with remote plasma oxygen and with remote plasma nitrogen are successively repeated effective to form porous oxide on the substrate. Other aspects and implementations are contemplated.

Owner:MICRON TECH INC

Atomic layer deposition method of depositing an oxide on a substrate

The invention includes atomic layer deposition methods of depositing an oxide on a substrate. In one implementation, a substrate is positioned within a deposition chamber. A first species is chemisorbed onto the substrate to form a first species monolayer within the deposition chamber from a gaseous precursor. The chemisorbed first species is contacted with remote plasma oxygen derived at least in part from at least one of O2 and O3 and with remote plasma nitrogen effective to react with the first species to form a monolayer comprising an oxide of a component of the first species monolayer. The chemisorbing and the contacting with remote plasma oxygen and with remote plasma nitrogen are successively repeated effective to form porous oxide on the substrate. Other aspects and implementations are contemplated.

Owner:MICRON TECH INC

Method of increasing deposition rate of silicon dioxide on a catalyst

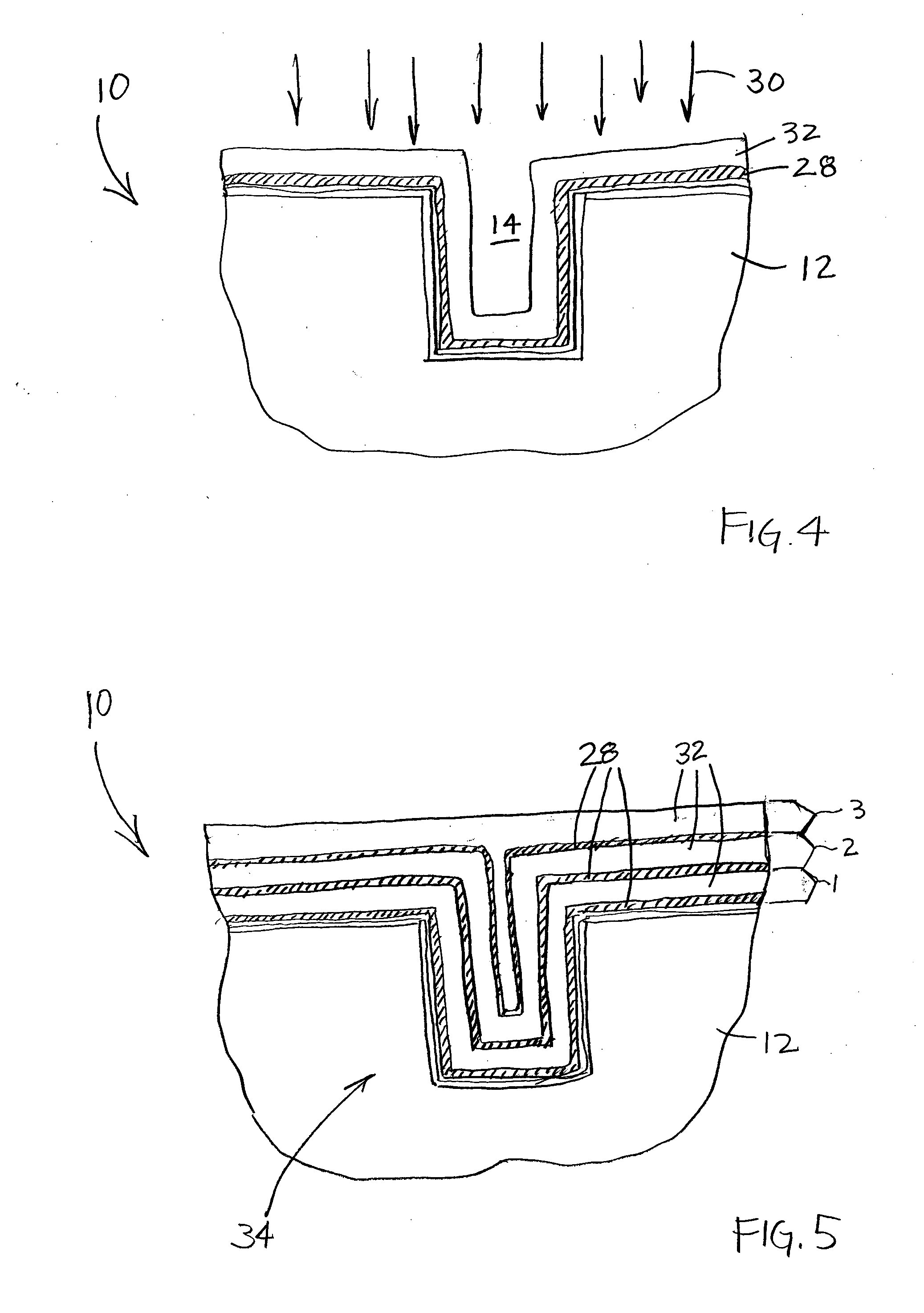

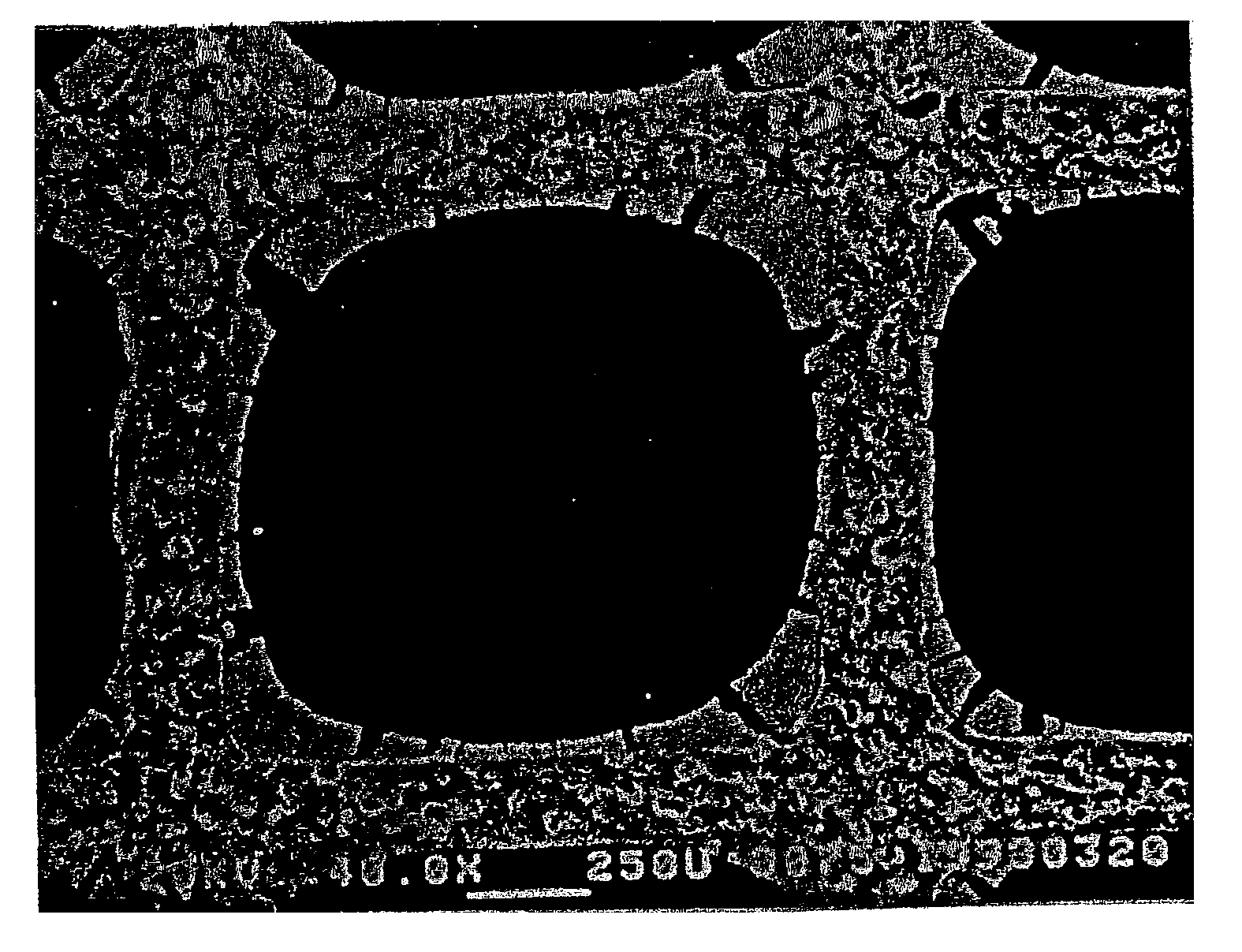

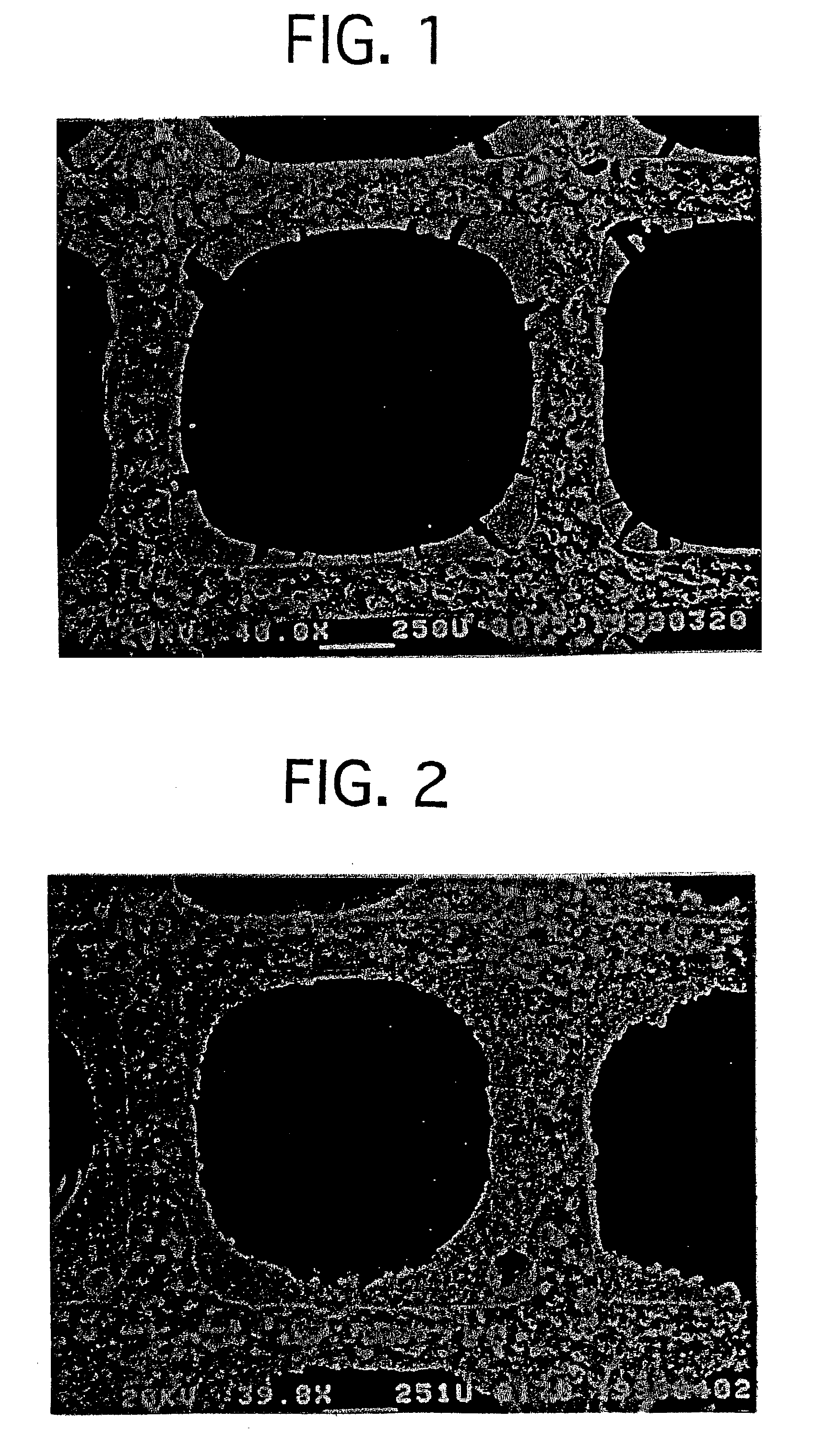

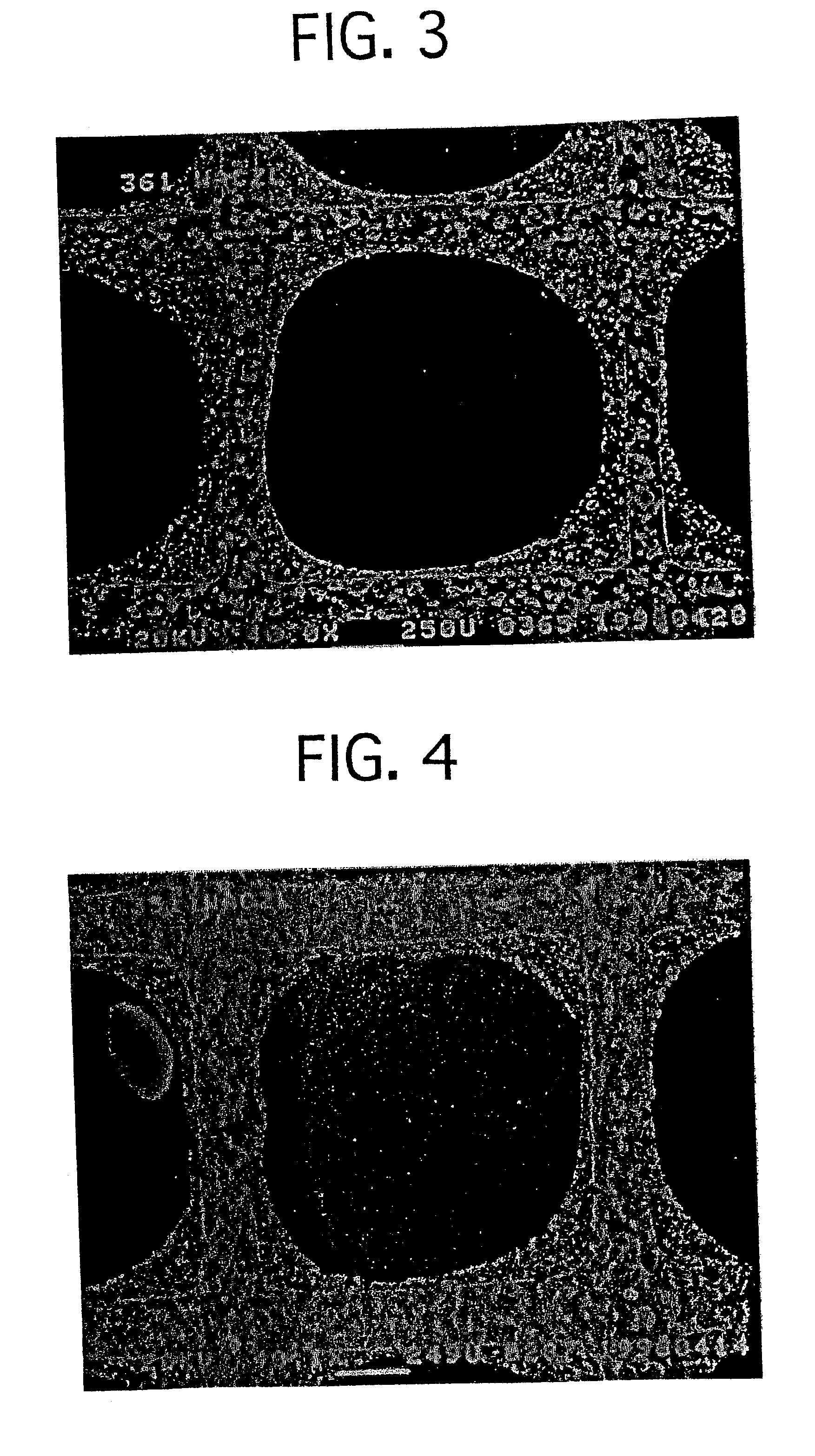

ActiveUS20060046518A1Good step coverageIncrease production outputSemiconductor/solid-state device manufacturingChemical vapor deposition coatingSilicon oxideOxygen

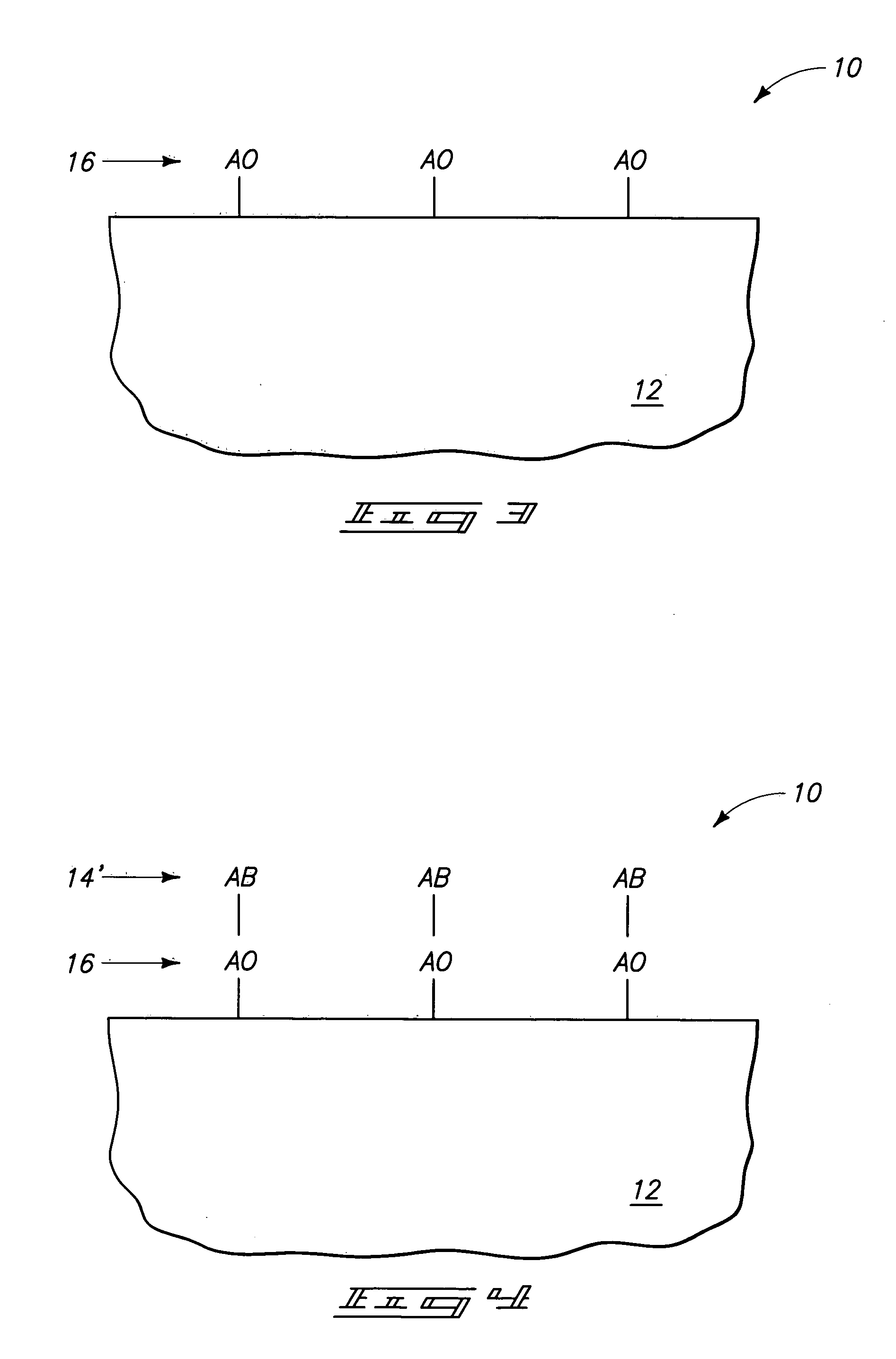

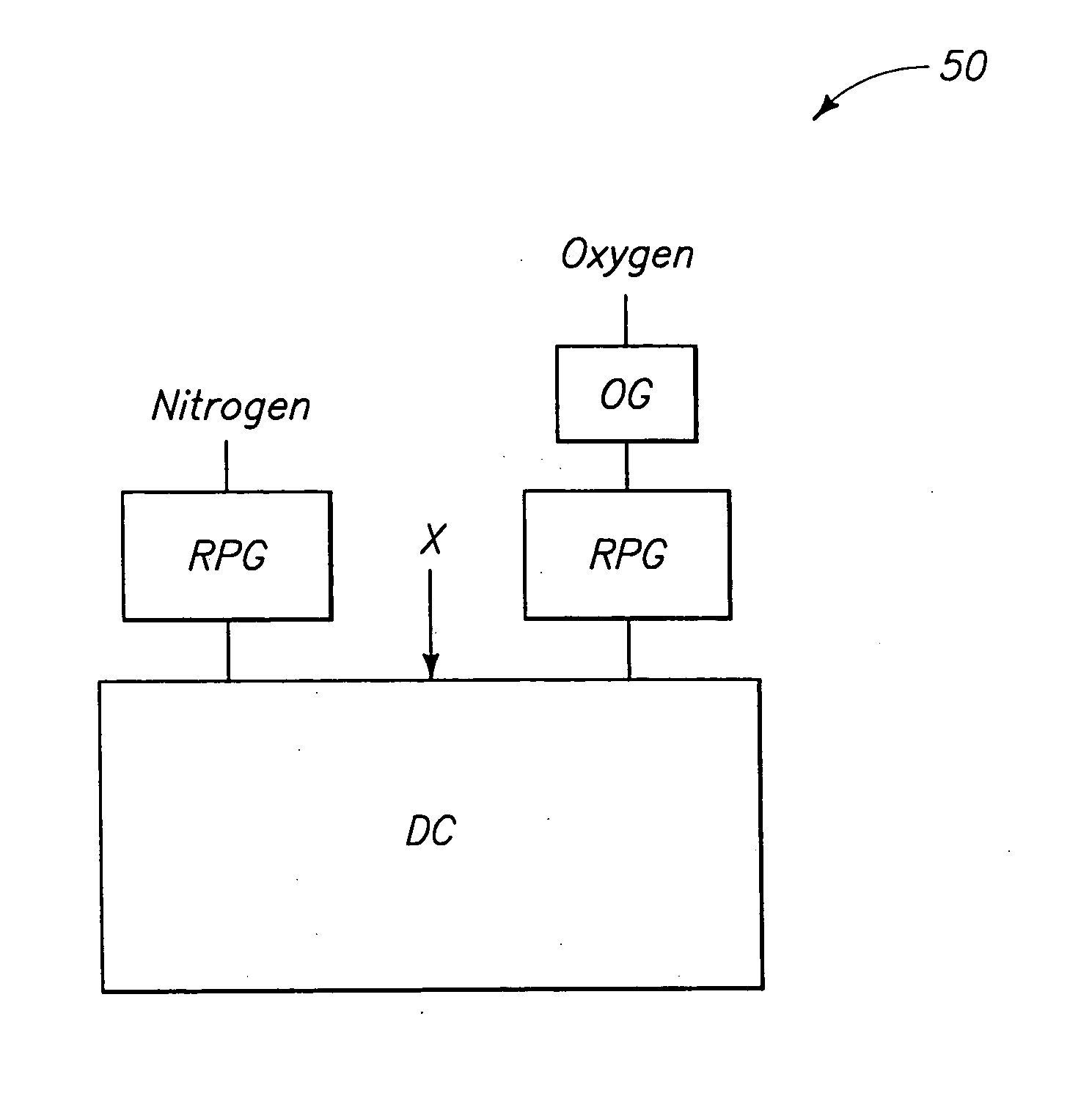

Methods for forming dielectric layers, and structures and devices resulting from such methods, and systems that incorporate the devices are provided. The invention provides an aluminum oxide / silicon oxide laminate film formed by sequentially exposing a substrate to an organoaluminum catalyst to form a monolayer over the surface, remote plasmas of oxygen and nitrogen to convert the organoaluminum layer to a porous aluminum oxide layer, and a silanol precursor to form a thick layer of silicon dioxide over the porous oxide layer. The process provides an increased rate of deposition of the silicon dioxide, with each cycle producing a thick layer of silicon dioxide of about 120 Å over the layer of porous aluminum oxide.

Owner:MICRON TECH INC

Catalyst for purifying exhaust gas

InactiveUS6335305B1Internal combustion piston enginesDispersed particle separationComposite oxideExhaust gas

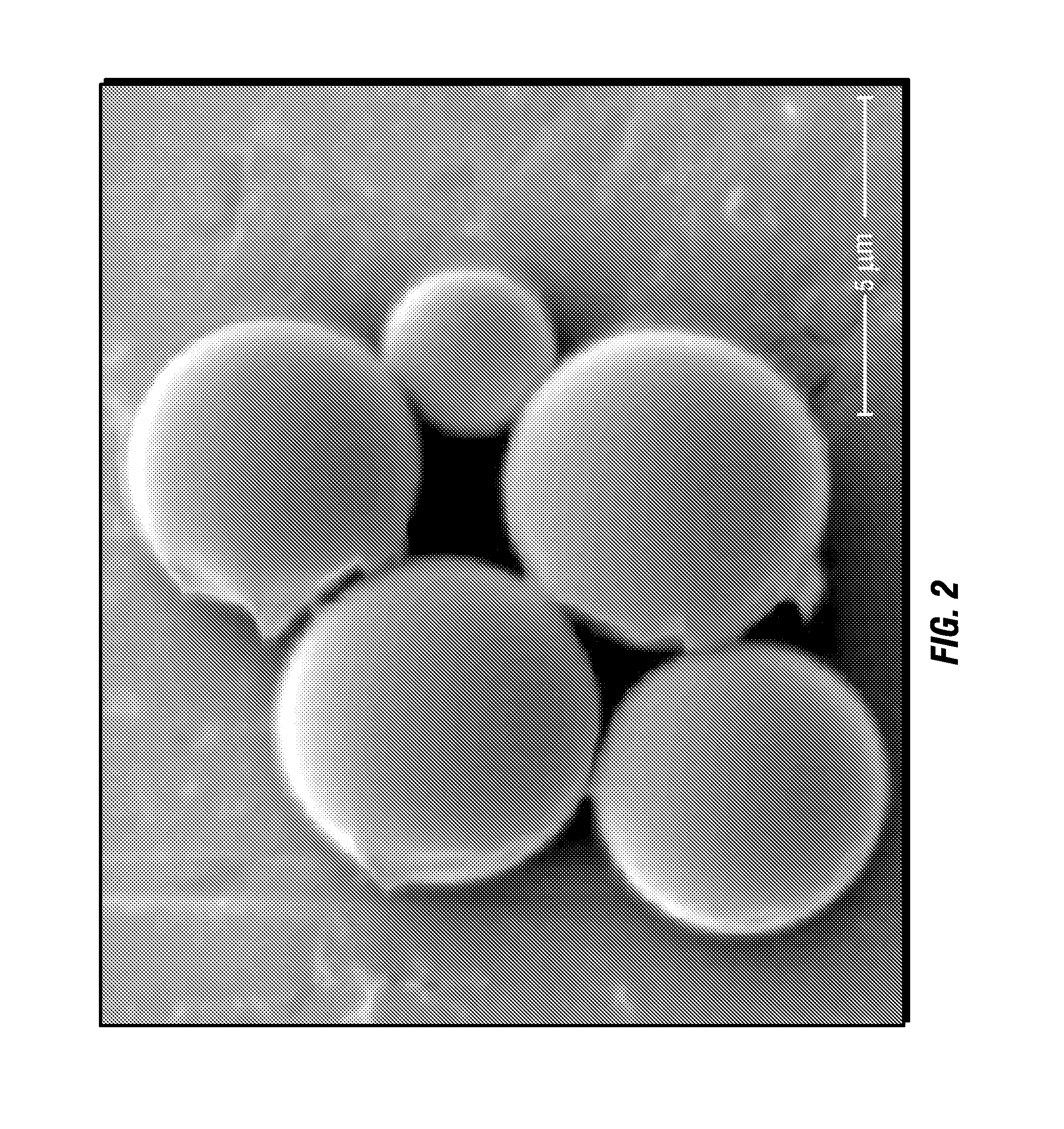

A catalyst for purifying an exhaust gas includes a support and a noble metal loaded on the support. The support includes a mixture containing a porous oxide and a composite oxide. The composite oxide is expressed by the following formula:in which the values "a" and "b" are molar ratios and the value "a" falls in a range of from 0.4 to 2.5 and the value "b" falls in a range of from 0.2 to 0.7. The support includes a particle having a particle diameter of 5 mum or more in an amount of 30% by volume or more. With the thus arranged support, even when the catalyst is subjected to such a severe durability test that it is heated at 1,000° C. for 10 to 20 hours, it exhibits a high purifying activity, and its coating layer is inhibited from cracking or coming off.

Owner:TOYOTA CENT RES & DEV LAB INC

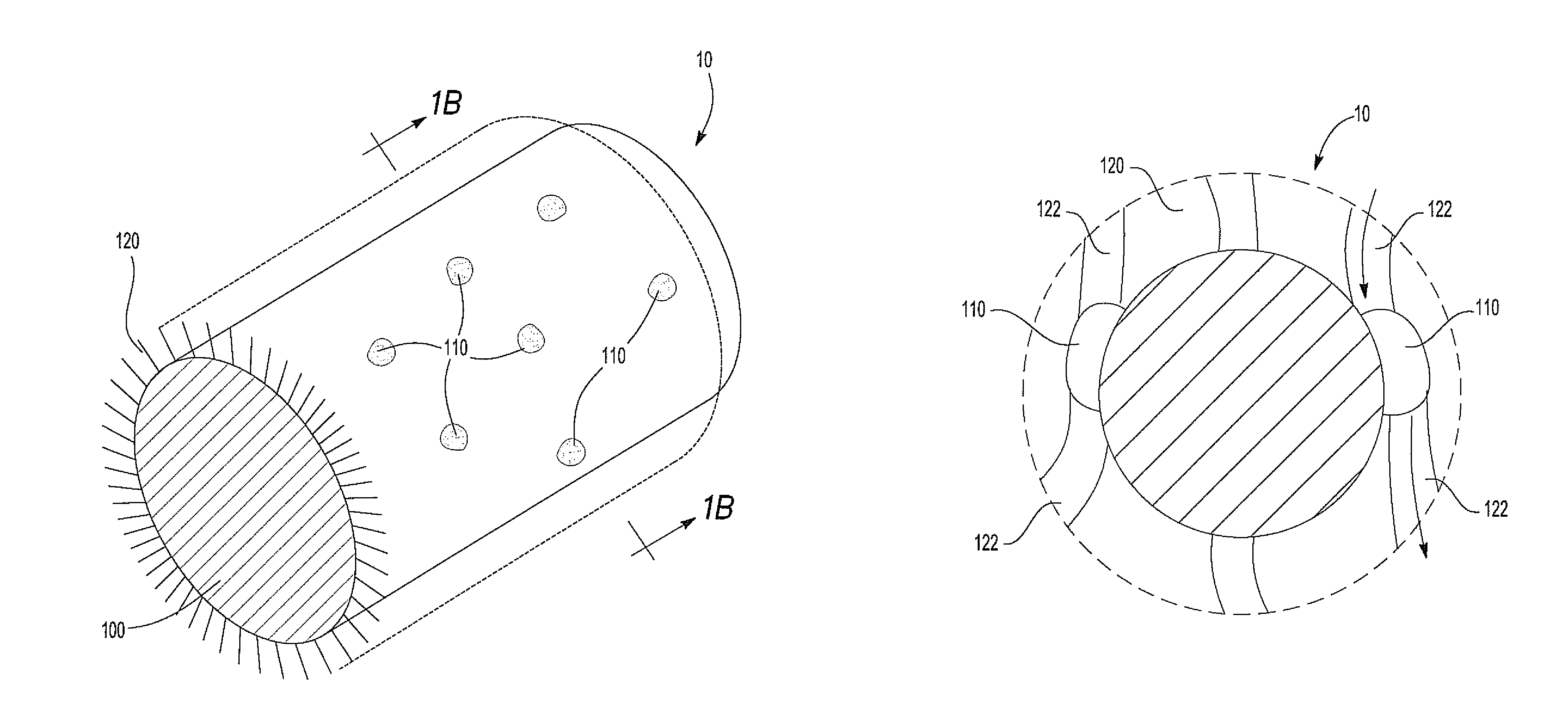

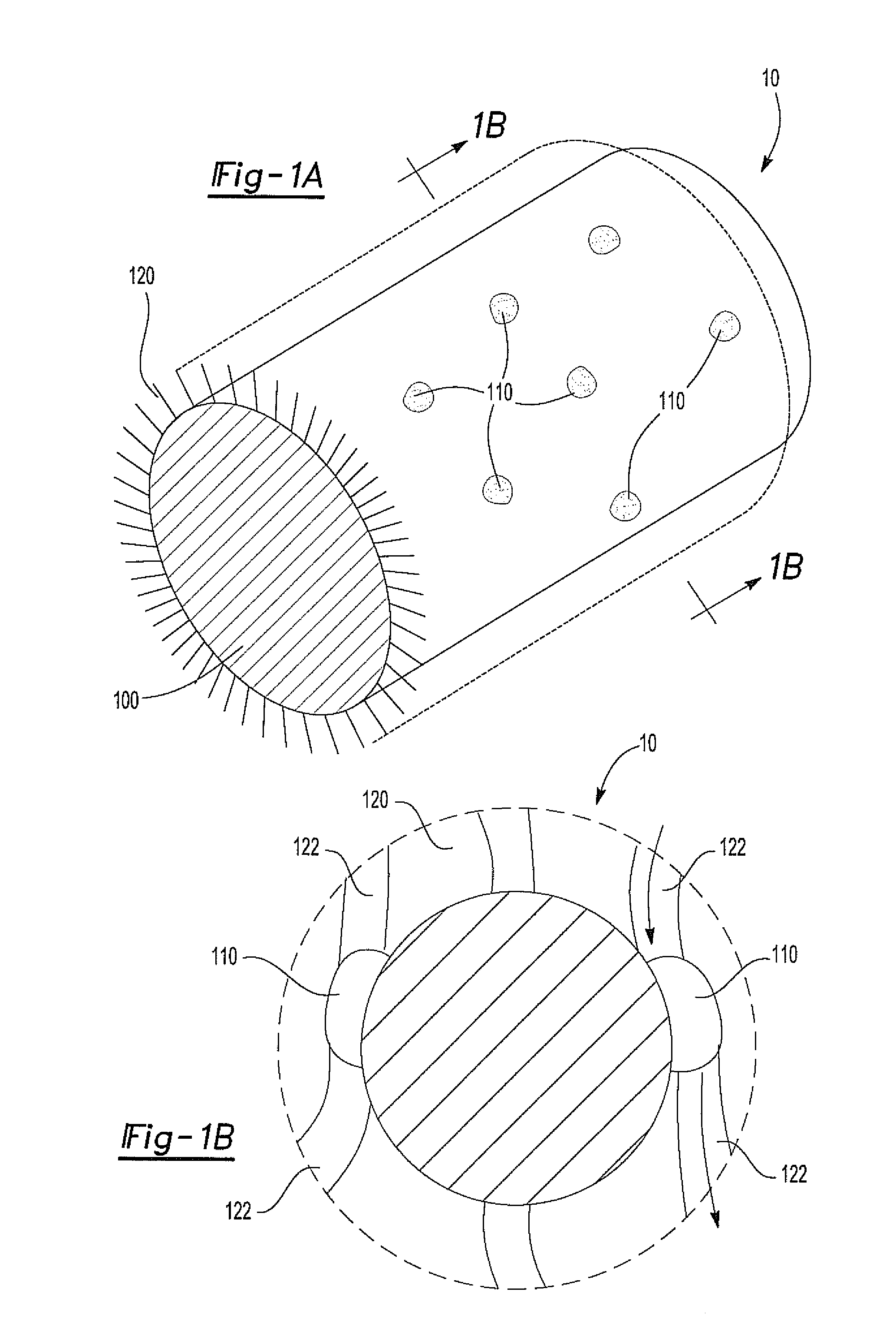

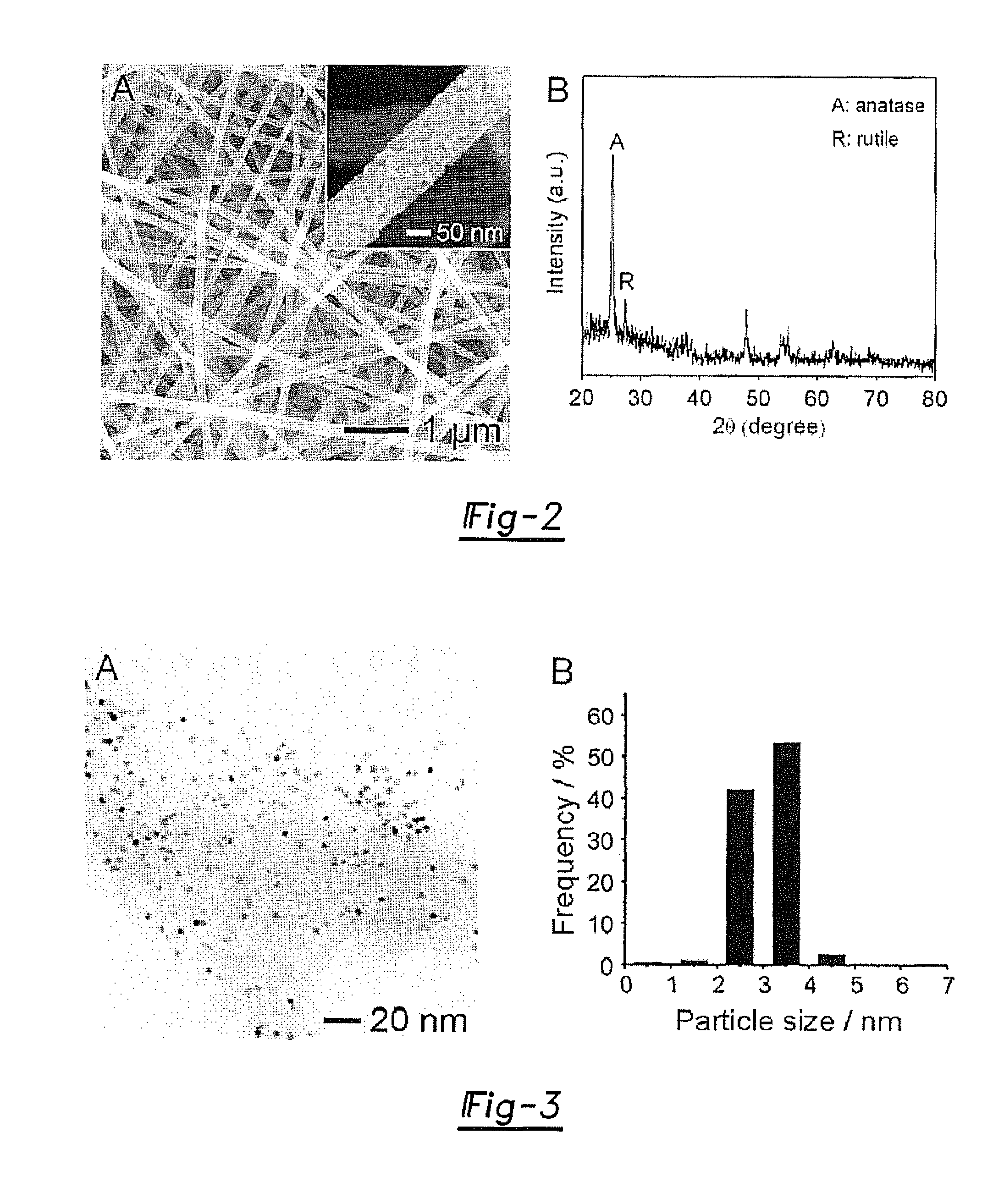

Dual-oxide sinter resistant catalyst

A catalyst material for use at elevated temperatures is provided. The material can include a plurality of fibers and a plurality of particles supported on the fibers. In addition, a porous layer can cover the plurality of particles and allow for process fluid to come into contact with the particles, and yet retard sintering of the particles at elevated temperatures is present. The plurality of fibers can be a plurality of nanofibers which may or may not be oxide nanofibers. The particles can be metallic nanoparticles and the porous layer can be a porous oxide layer.

Owner:TOYOTA MOTOR CO LTD +2

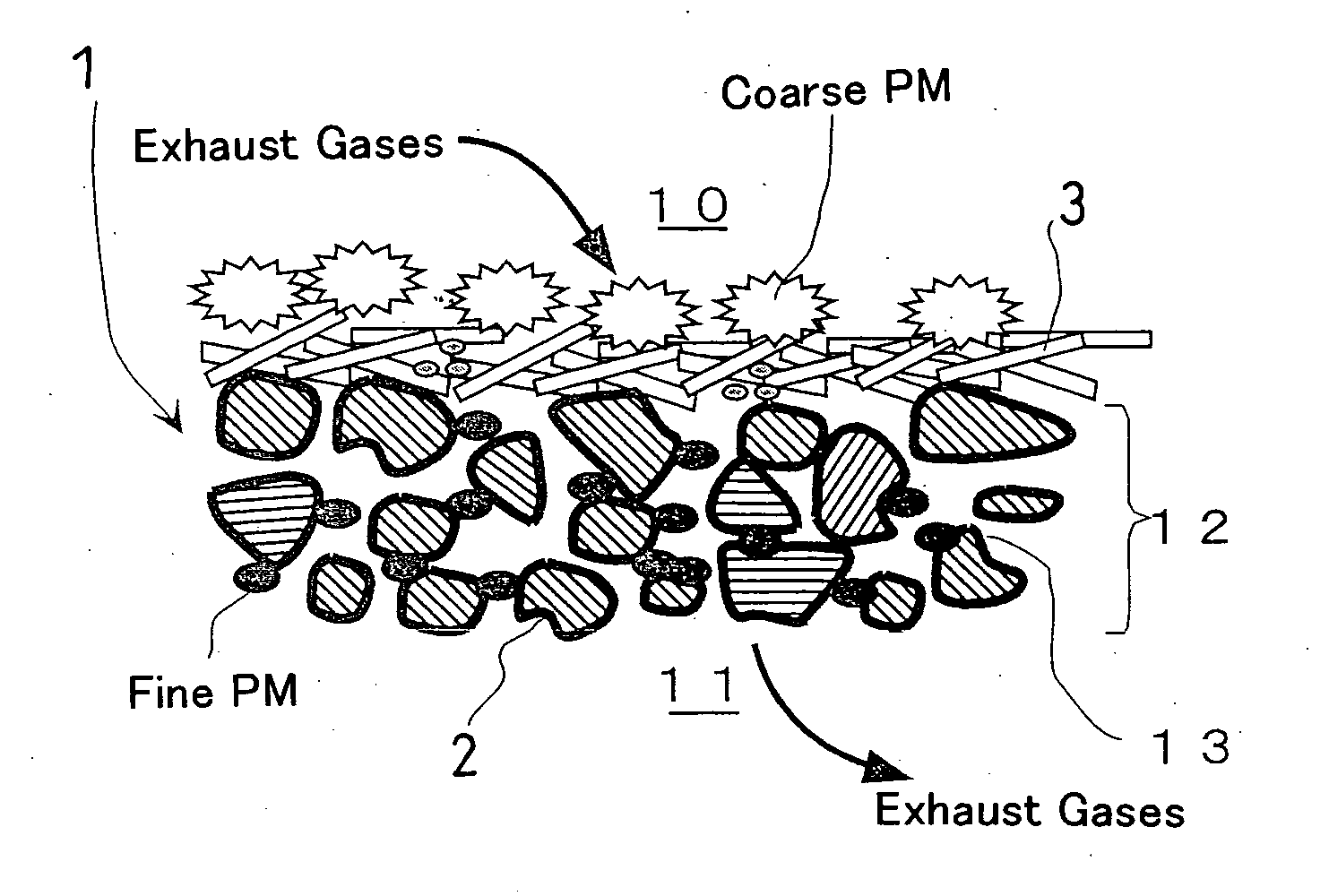

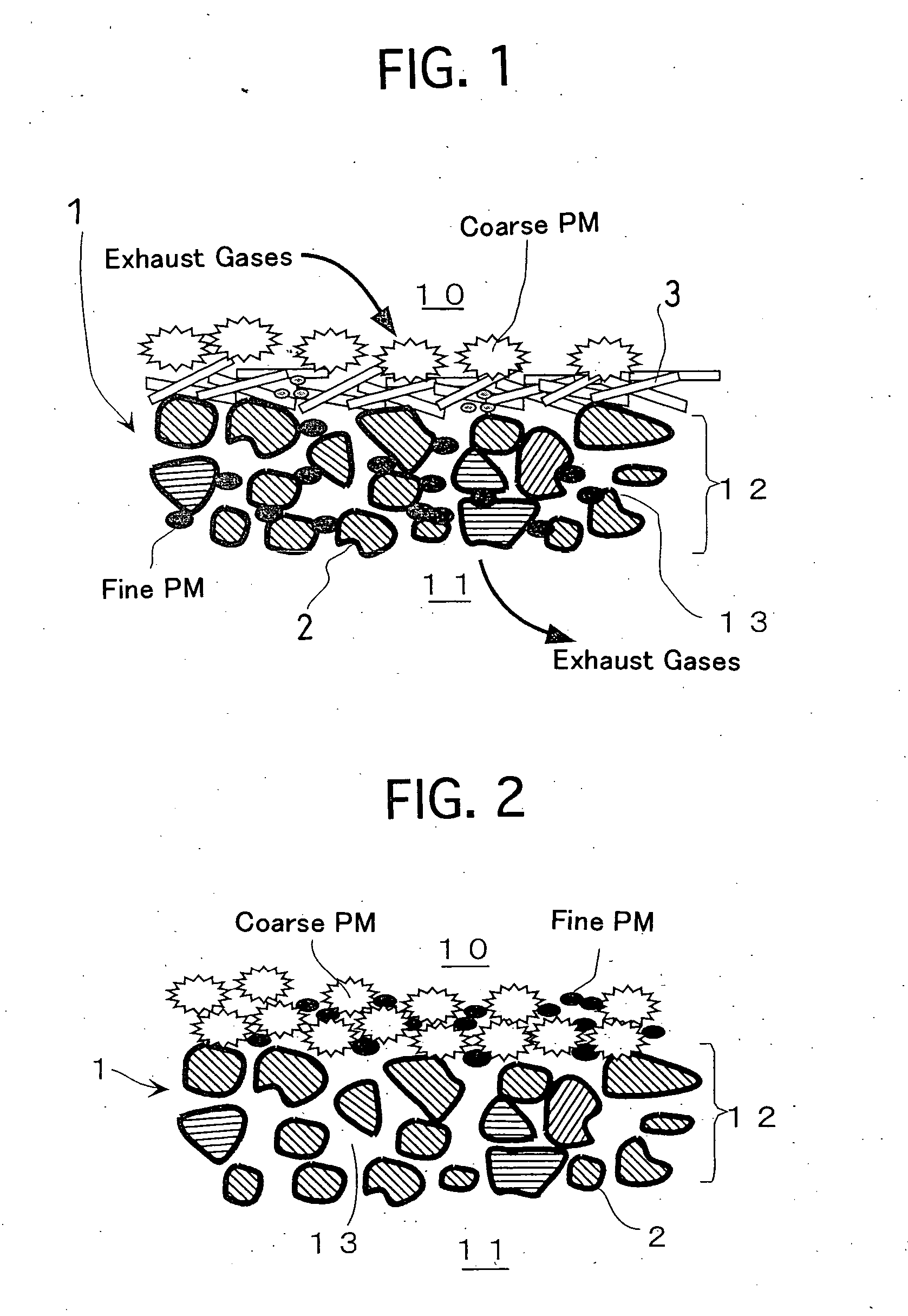

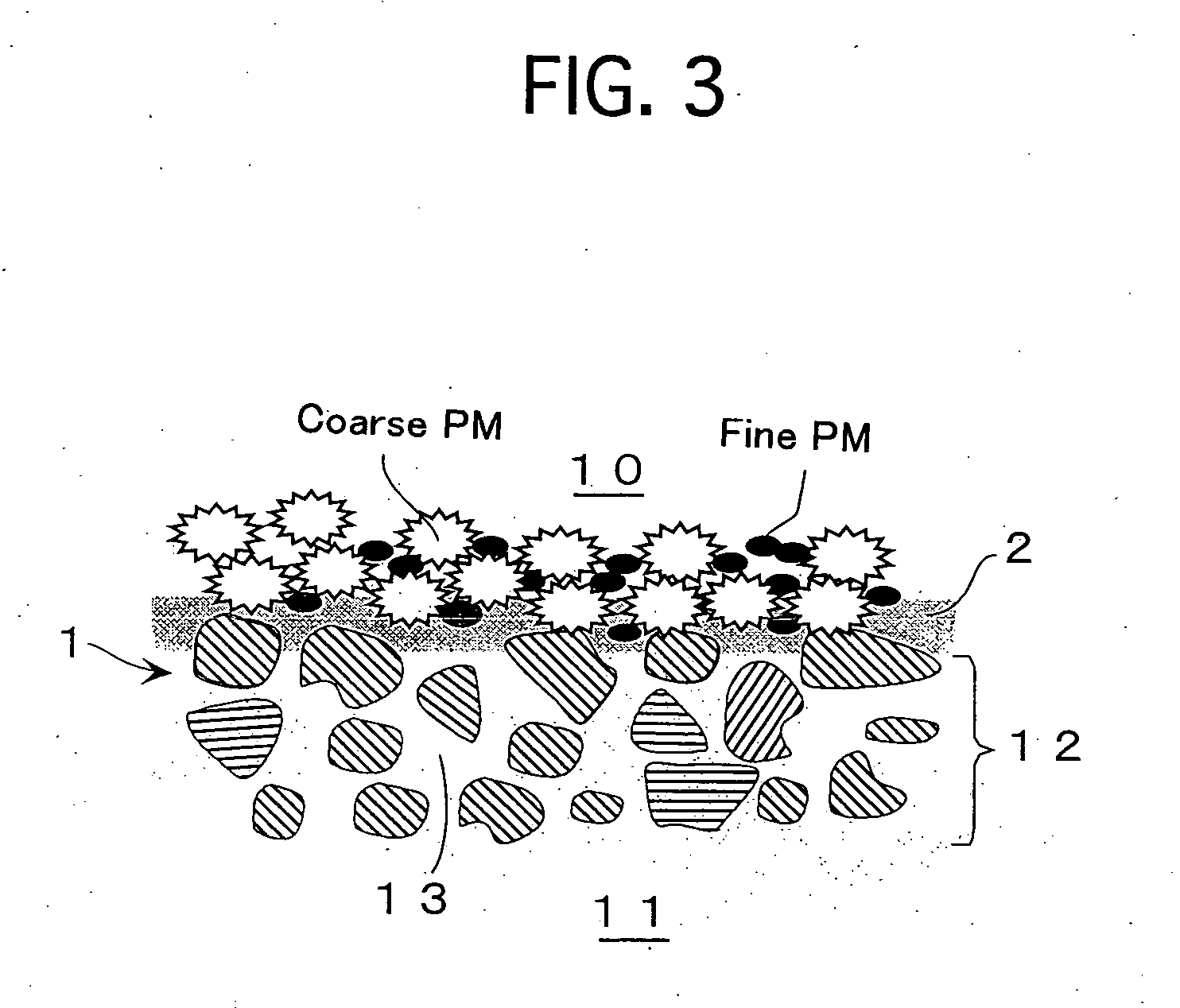

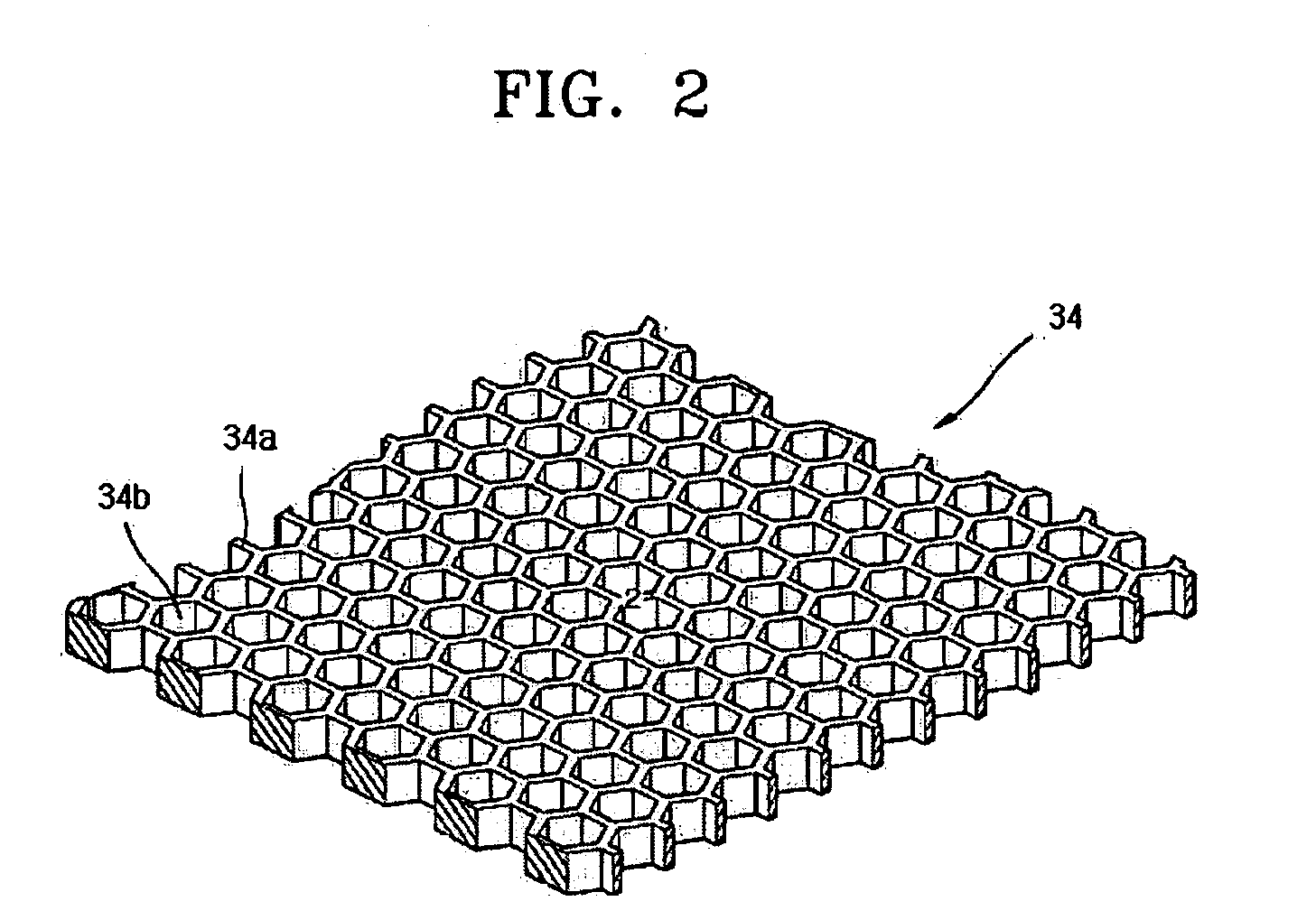

Filter catalyst for purifying exhaust gases

InactiveUS20050074374A1Oxidizing rateIncrease ratingsCombination devicesInternal combustion piston enginesAdditive ingredientExhaust fumes

A filter catalyst is for purifying exhaust gases, and comprises a honeycomb structure, a catalytic layer and a fibrous layer. The honeycomb structure comprises inlet cells clogged on a downstream side of a flow of the exhaust gases, outlet cells neighboring the inlet cells, and clogged on an upstream side of the flow of the exhaust gases, and cellular walls demarcating the inlet cells and the outlet cells, and having pores. The catalytic layer is formed on a surface of the cellular walls and an inner surface of the pores, and includes a porous oxide and a catalytic ingredient loaded on the porous oxide. The fibrous layer is formed on the outermost surface of the cellular walls of the inlet cells at least, and includes entangled fibrous substances composed of a heat-resistant material. The filter catalyst inhibits the pressure loss from increasing and upgrades the oxidizing rate of PMs greatly.

Owner:TOYOTA JIDOSHA KK

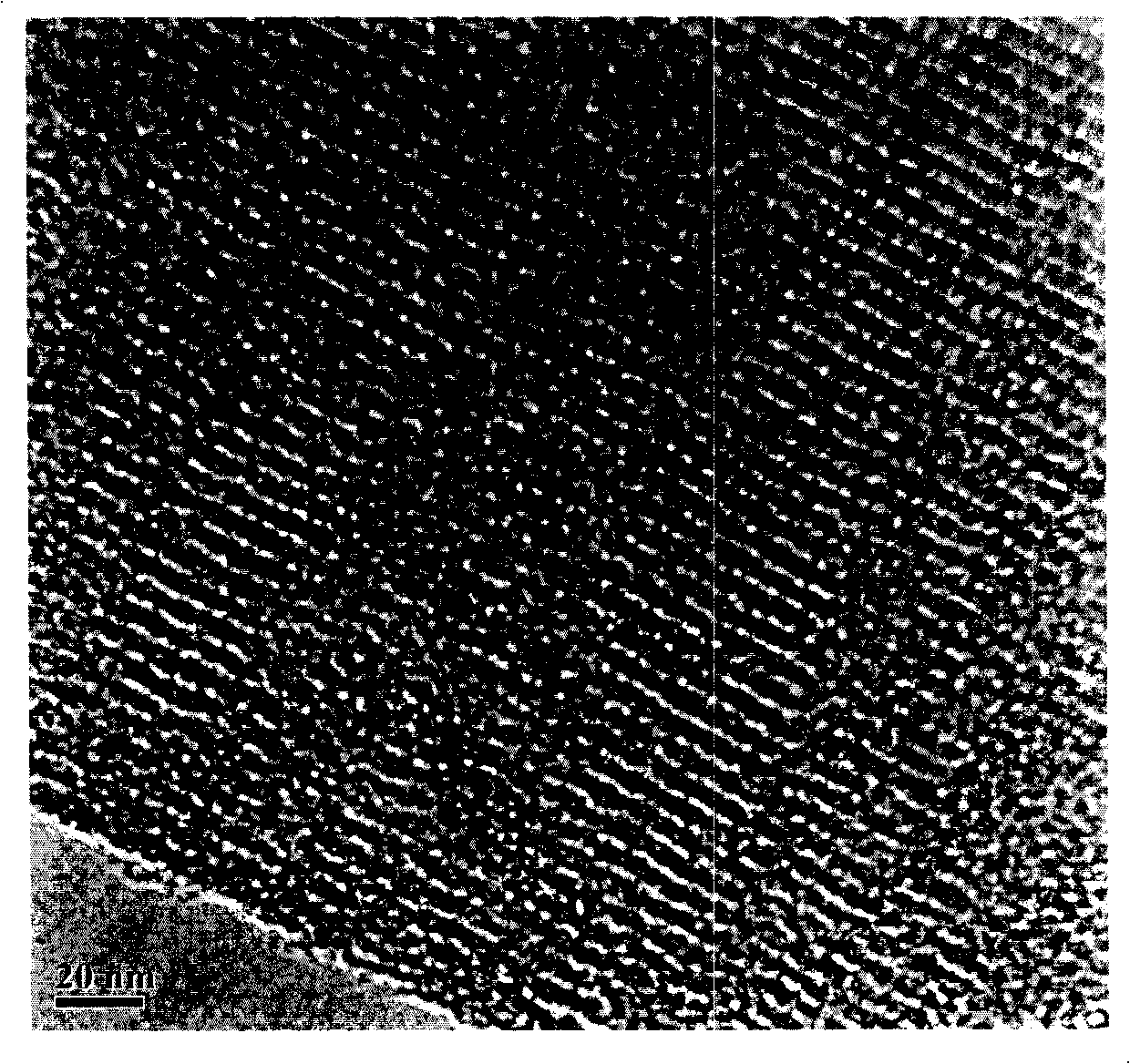

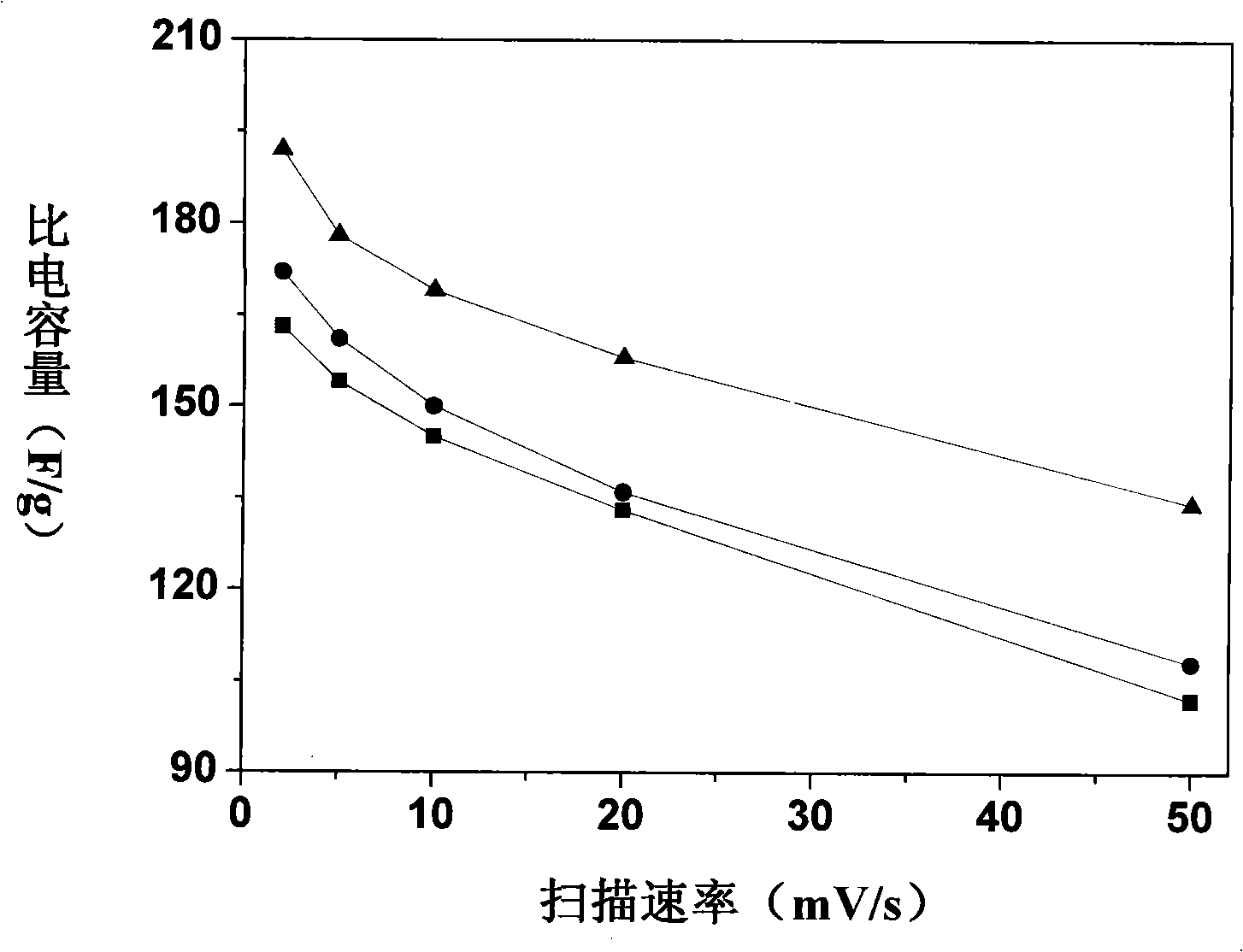

Stephanoporate carbon electrode material and preparation method thereof

InactiveCN101299397AFast deliveryExcellent electrochemical capacitance performanceHybrid capacitor electrodesElectrolytic capacitorsPorous carbonCarbonization

The invention relates to a porous carbon electrode materials and the preparation method, belonging to the electrochemistry and the novel energy source materials, wherein the porous carbon electrode materials adopt the template carbonization and the method combined with the CO2 post-processing using the meso-porous oxide silicon as the remplate, and the cane sugar, furfuryl alcohol, polyacrylonitrile and the like as the precursors, through the technology steps of the liquid phase impregnation, the high temperature carbonization and the template removal and the like, then combines high temperature process, obtaining the super capacitor porous carbon electrode materials. The porous carbon electrode materials prepared by the method has high surface area, large pore volume, adjustable pore structure and multilevel-microporous pore structure, wherein the pore channel is composed of a meso-porous of 2-5 nm and the microporous with the meso-porous wall of 0.1-2 nm, so the electrochemistry capacity of the prepared porous carbon electrode is marked increased, and the integral property of good.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Preparation method of continuous alumina fiber-reinforced aluminum oxide ceramic matrix composite material

The invention belongs to a continuous alumina fiber-reinforced aluminum oxide ceramic matrix composite material preparation technology and relates to a preparation method of a continuous alumina fiber-reinforced aluminum oxide ceramic matrix composite material. Firstly, an oxide organic polymer precursor is adopted as a raw material, a porous oxide ceramic coating is prepared through PIP process to serve as a fiber and matrix interface in the composite material, then a freeze drying process of aluminum oxide ceramic slurry is utilized to obtain a porous aluminum oxide matrix green body framework provided with three-dimensional network through holes, the oxide organic polymer precursor is utilized to repeatedly dip the porous aluminum oxide matrix green body framework to obtain a dense matrix green body, and finally the composite material green body is sintered to obtain the high-performance composite material. The freeze drying process is adopted in the matrix compactness process so that the high compactness matrix can be obtained, it can be also ensured that the interlayer layer does not crack before high-temperature heat treatment, obtaining of the porous oxide coating is ensured, so that a weak interface is formed between the fiber and the matrix of the composite material, and a toughness improving effect of the composite material is achieved.

Owner:AVIC COMPOSITES

Granular solid super strong acid catalyst and its preparing method

InactiveCN1425500AHigh catalytic activityHigh purityCatalyst activation/preparationSulfate radicalsStrong acids

The present invention provides a granular solid super strong acid catalyst and its preparation process. The active carrier is carried by granular basic carrier and contains oxide capable of binding with sulfate radical ion to form active catalyst layer; and the granular basic carrier contains porous oxide supporting the active catalyst layer and with certain strength and shape. During the preparation, granular basic carrier is first soaked into the salt solution of active carrier, ammonia water is added to regulate pH value greater than 8, the water solution is filtered out and filtered matter is washed and dried; and after soaking the dried granular carrier in sulfuric acid solution and filtering to eliminate sulfuric acid solution, the filtered matter is dried and roasted at 550-650 deg.c to obtain the catalyst.

Owner:曲阜市圣泉催化应用科技有限公司

Composite material and preparation method thereof

ActiveCN101768770ARich surface colorRetain glossAnodisationThin material handlingColor filmAnodic oxidation

The invention relates to a composite material and a preparation method thereof, which belong to the field of aluminum alloys. The invention provides the composite material against the defects of unevenness, no metal luster, easy scratch and easy abrasion of a gradient color film layer on the surface of the aluminum alloy, the composite material comprises a substrate, a porous anodic oxide film layer is arranged on the surface of the substrate, the substrate is aluminum or the aluminum alloy, at least one dye is filled in pores of the porous anodic oxide film layer, and the content of the same dye in part of the pores of the porous anodic oxide film layer is in gradient distribution. The preparation method of the composite material comprises the following steps: using the anodic oxidation method for forming the porous oxide film layer on the surface of the aluminum alloy; and dyeing the porous oxide film layer, wherein the dyeing method is to control the time of entering into the dye of different regions of the porous oxide film layer and further lead the content of the dye filled in the pores of the porous anodic oxide film layer to be in the gradient distribution. The composite material has the advantages of evenness, metal luster, difficult scratch and difficult abrasion of the film layer and is mainly applied on electronic products.

Owner:BYD CO LTD

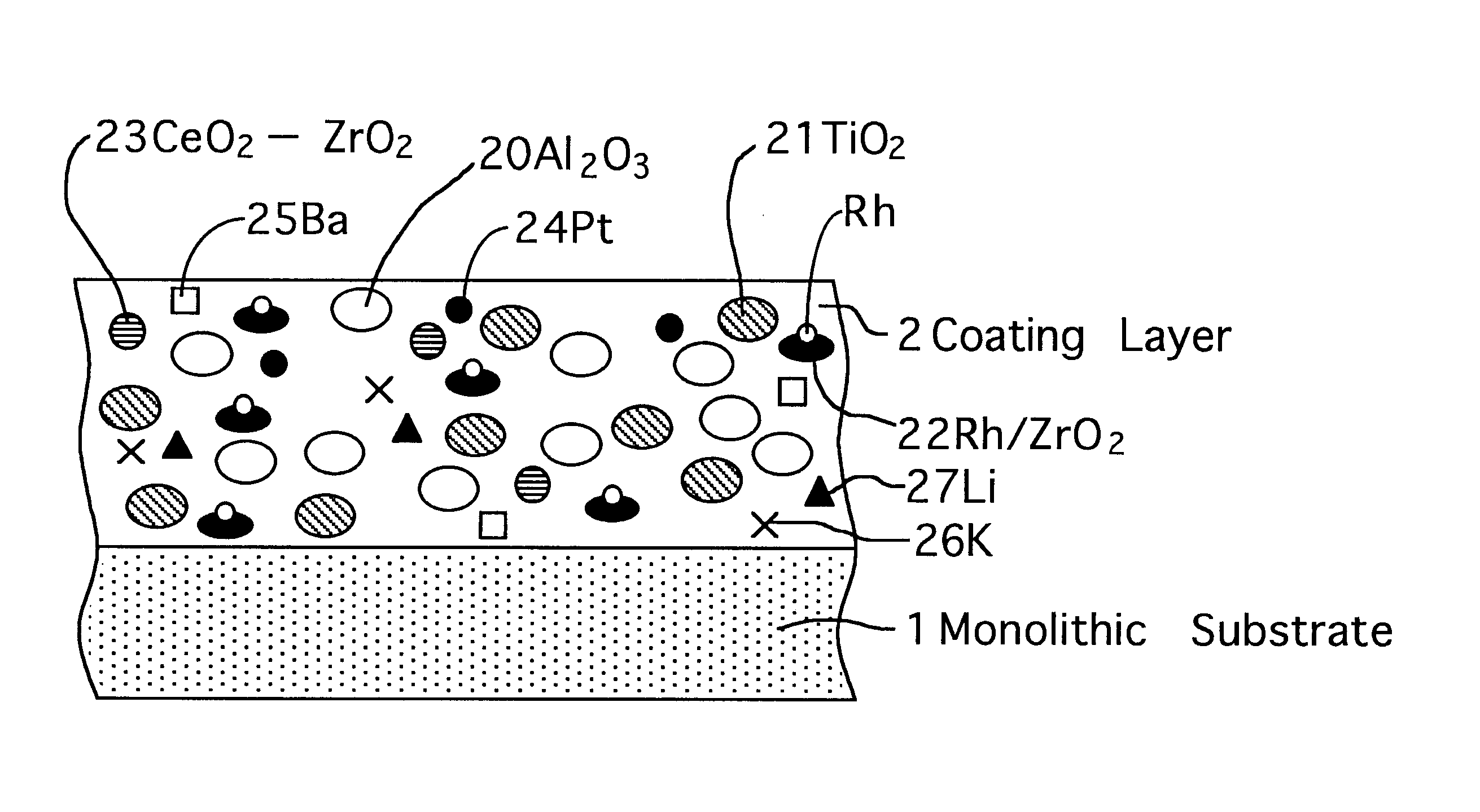

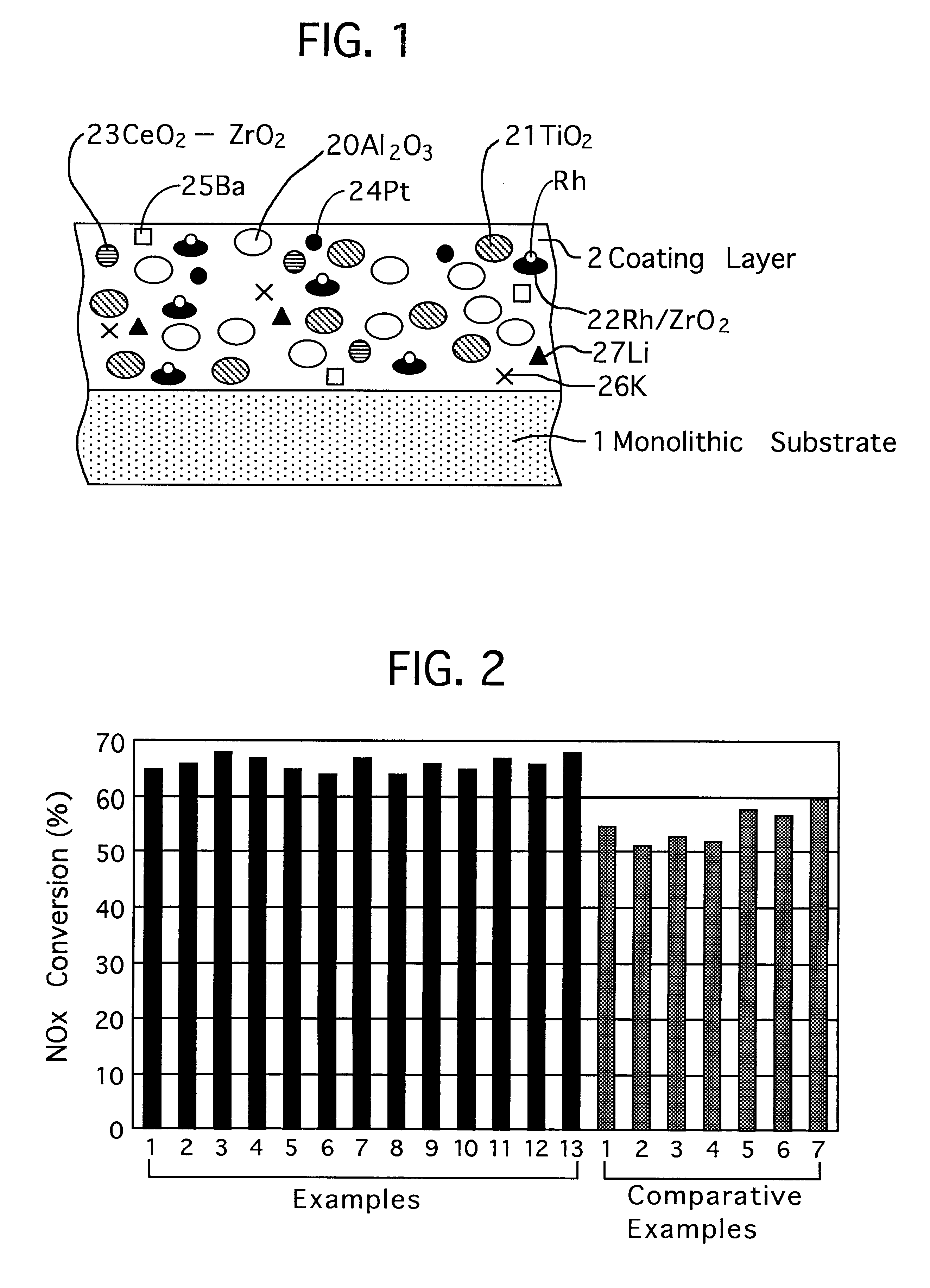

Catalyst for exhaust gas purification, process for producing the same, and method of purifying exhaust gas

InactiveUS6806225B1Lower performance requirementsPromote growthNitrogen compoundsInternal combustion piston enginesRare-earth elementAlkaline earth metal

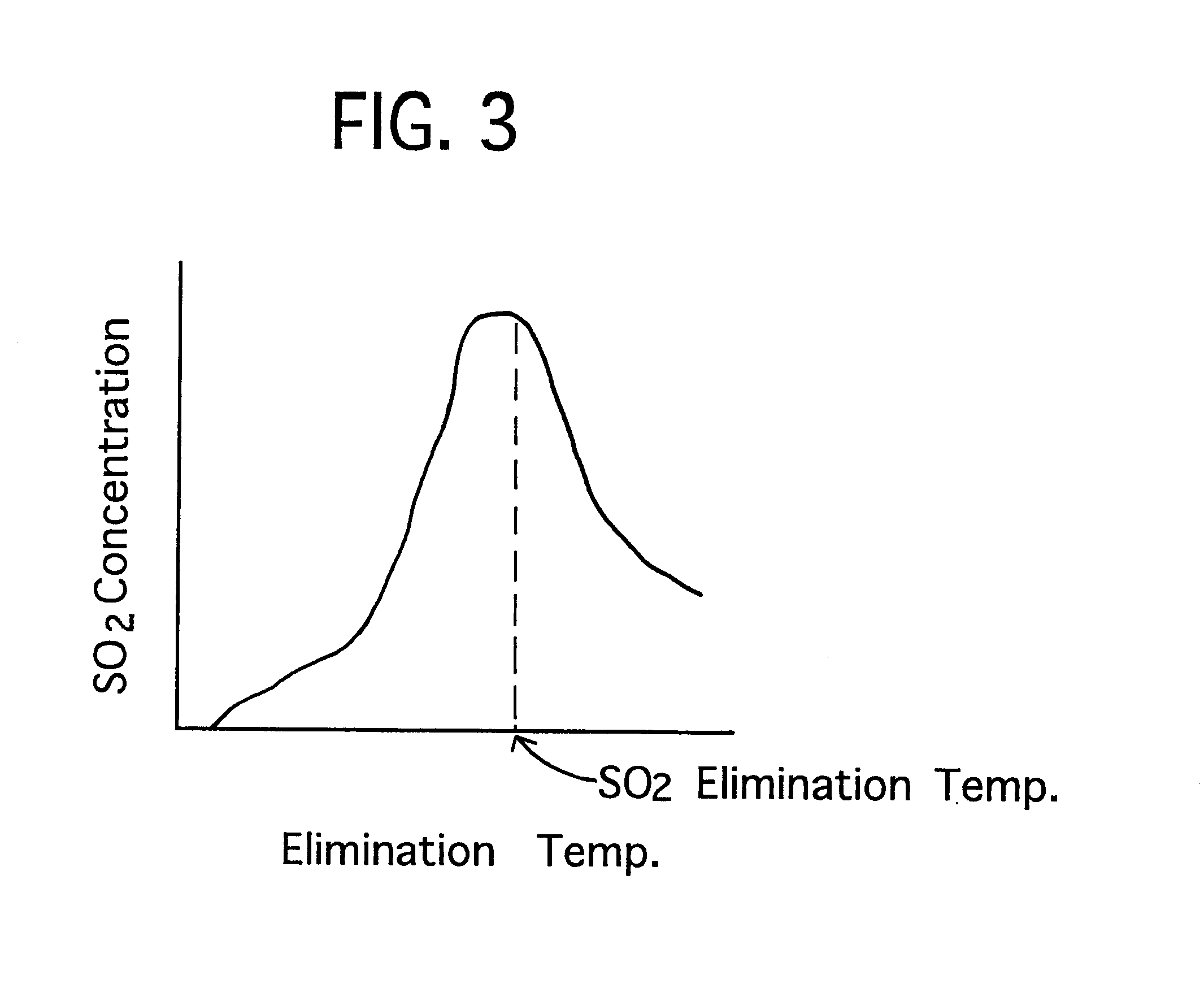

An NOx storage member including at least one member selected from the group consisting of alkali metals, alkaline-earth metals and rare-earth elements, and at least one noble metal selected from the group consisting of Pt, Pd and Rh are loaded on a support including a porous oxide including TiO2 at least and ZrO2 on which Rh is loaded in advance.H2, which is generated by Rh / ZrO2, inhibits the sulfur poisoning, and the support, which includes TiO2 at least, secures the initial NOx purifying capability, thereby further inhibiting the sulfur poisoning. Accordingly, it is possible to inhibit the NOx storage member from the sulfur poisoning, and to maintain a high NOx conversion even after a durability test.

Owner:TOYOTA JIDOSHA KK

Dye-sensitized solar cell module and the manufacturing method using carbon nanotube electrode

InactiveUS20080264482A1Highly practicalPractical utilityElectrolytic capacitorsFinal product manufactureElectrolysisCarbon nanotube

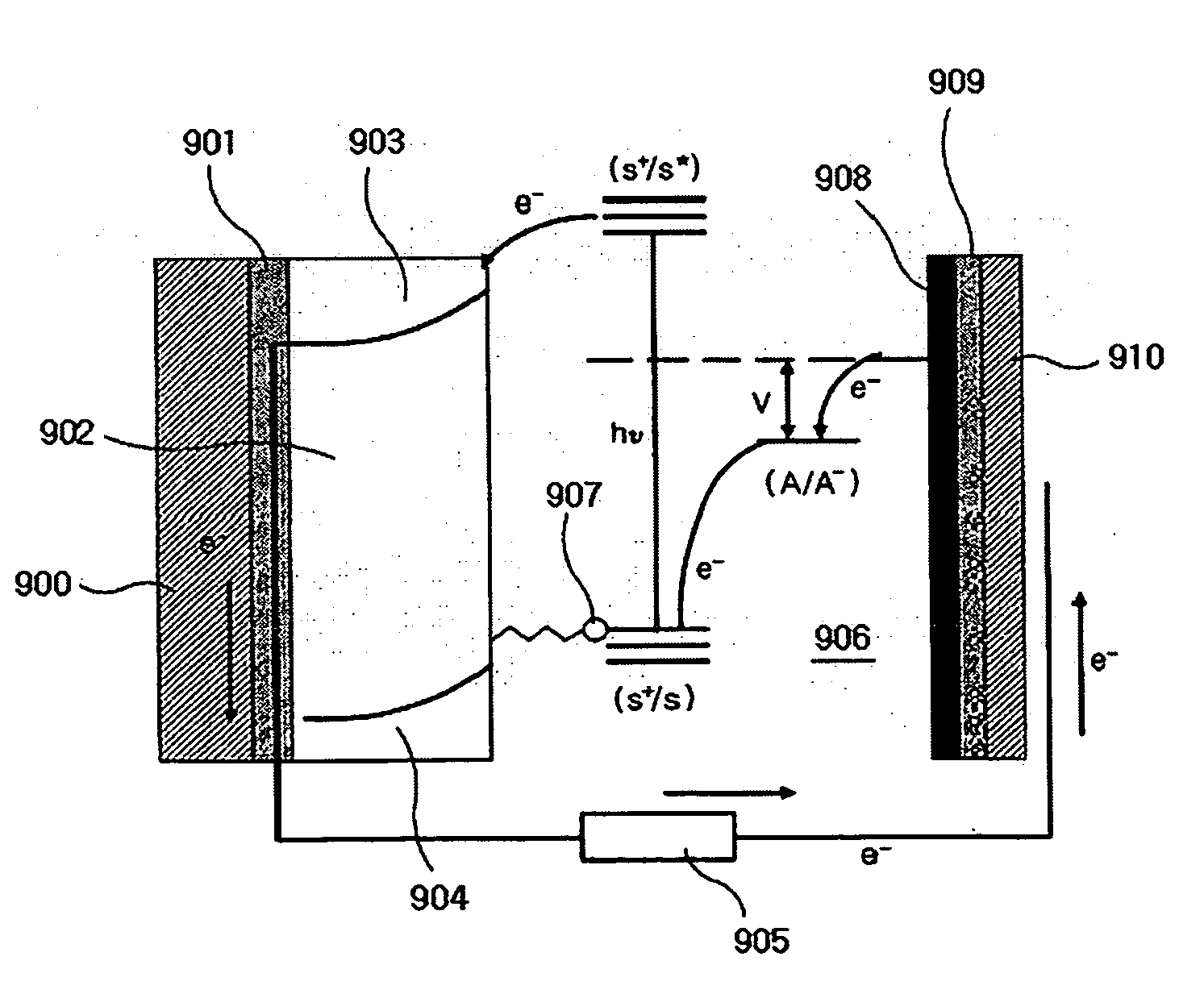

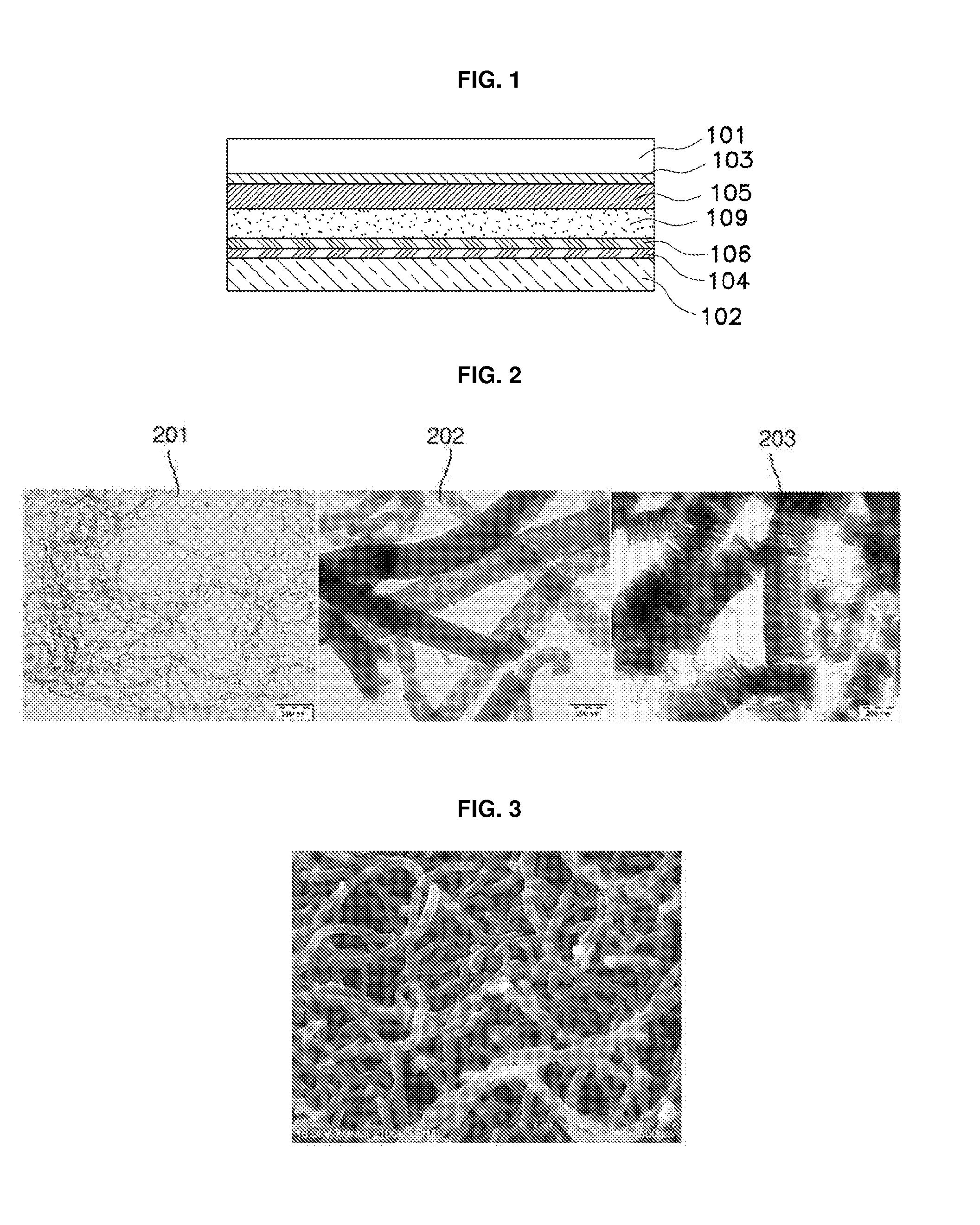

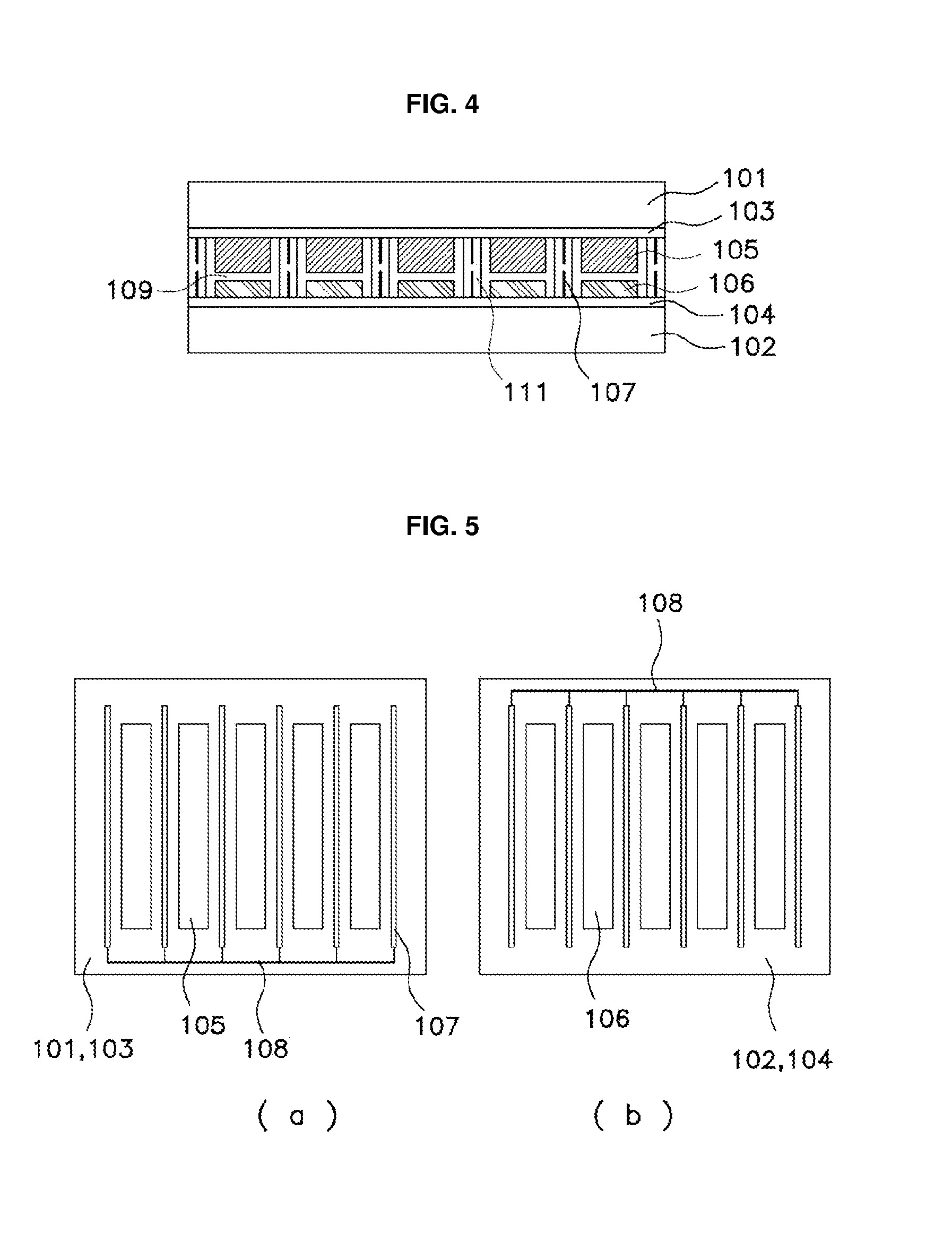

Disclosed herein is a dye-sensitized solar cell module having carbon nanotube electrodes, the solar cell module comprising: upper and lower transparent substrates; conductive transparent electrodes formed on the inner surfaces of the upper and lower transparent substrates; a plurality of porous oxide semiconductor negative electrodes formed on the upper conductive transparent electrode at a constant interval and having a dye adsorbed on the surface thereof; counter electrodes formed on the lower conductive transparent electrode in a thin film form and made of a carbon nanotube layer as a positive electrode portion corresponding to the negative electrodes; grid electrodes formed on the upper and lower conductive transparent electrodes between unit electrodes, each consisting of the negative electrode and the counter electrode corresponding thereto, the grid electrodes serving to collect electrons generated by photosensitization; connecting electrodes formed on the upper and lower conductive transparent electrodes and electrically connected with the grid electrode so as to transfer electrons moved from the grid electrodes to the outside; and electrolyte placed between the negative electrodes and the counter electrodes. Also disclosed is a method for manufacturing the solar cell module. According to the disclosed invention, a high-efficiency, large-area, dye-sensitized solar cell comprising carbon nanotubes is realized by forming a plurality of dye-sensitized solar cell units in a module arrangement, and forming grid electrodes and connection electrodes for the collection and movement of electrons. Thus, the disclosed invention has high practical utility.

Owner:KOREA ELECTROTECH RES INST

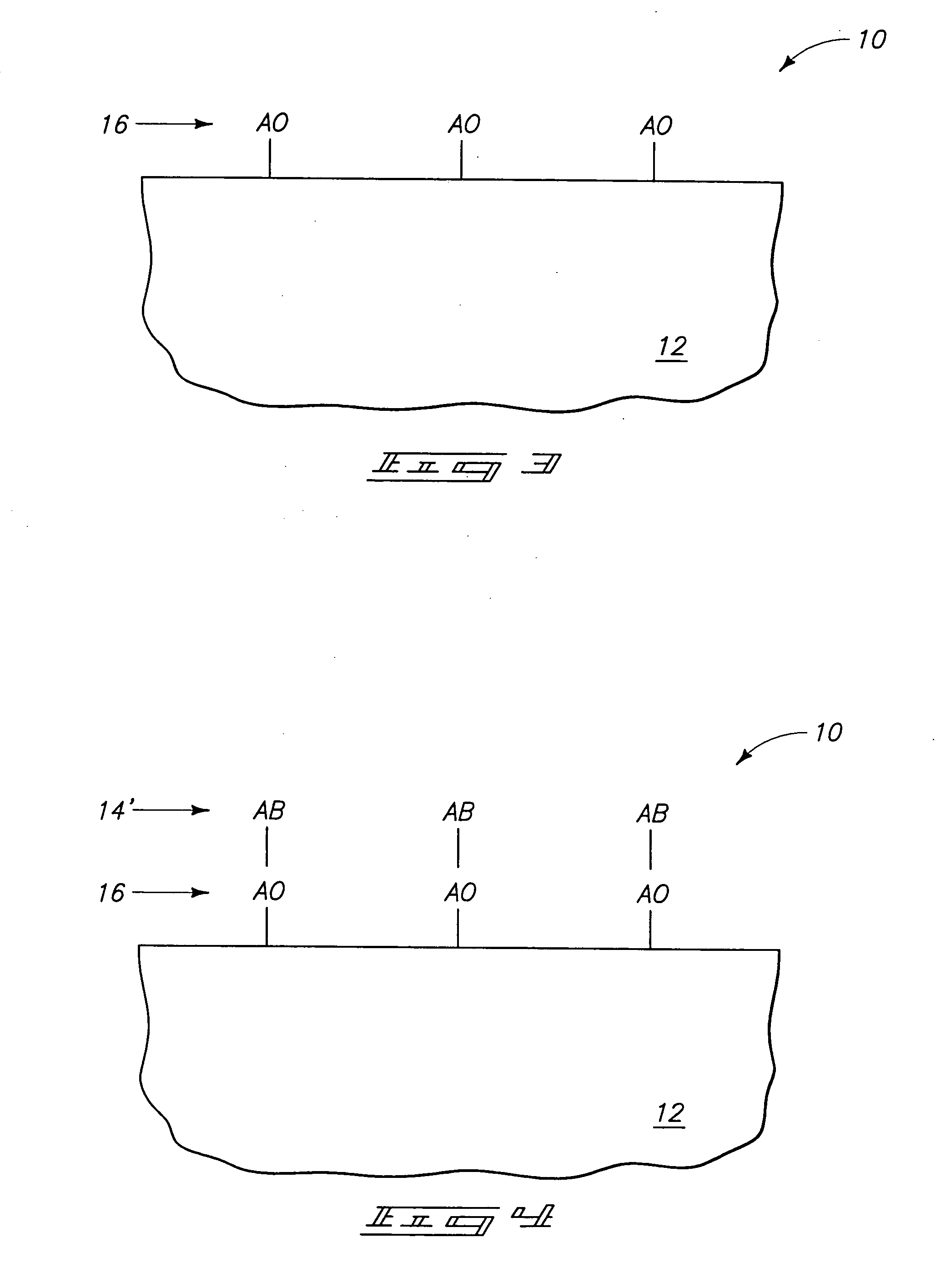

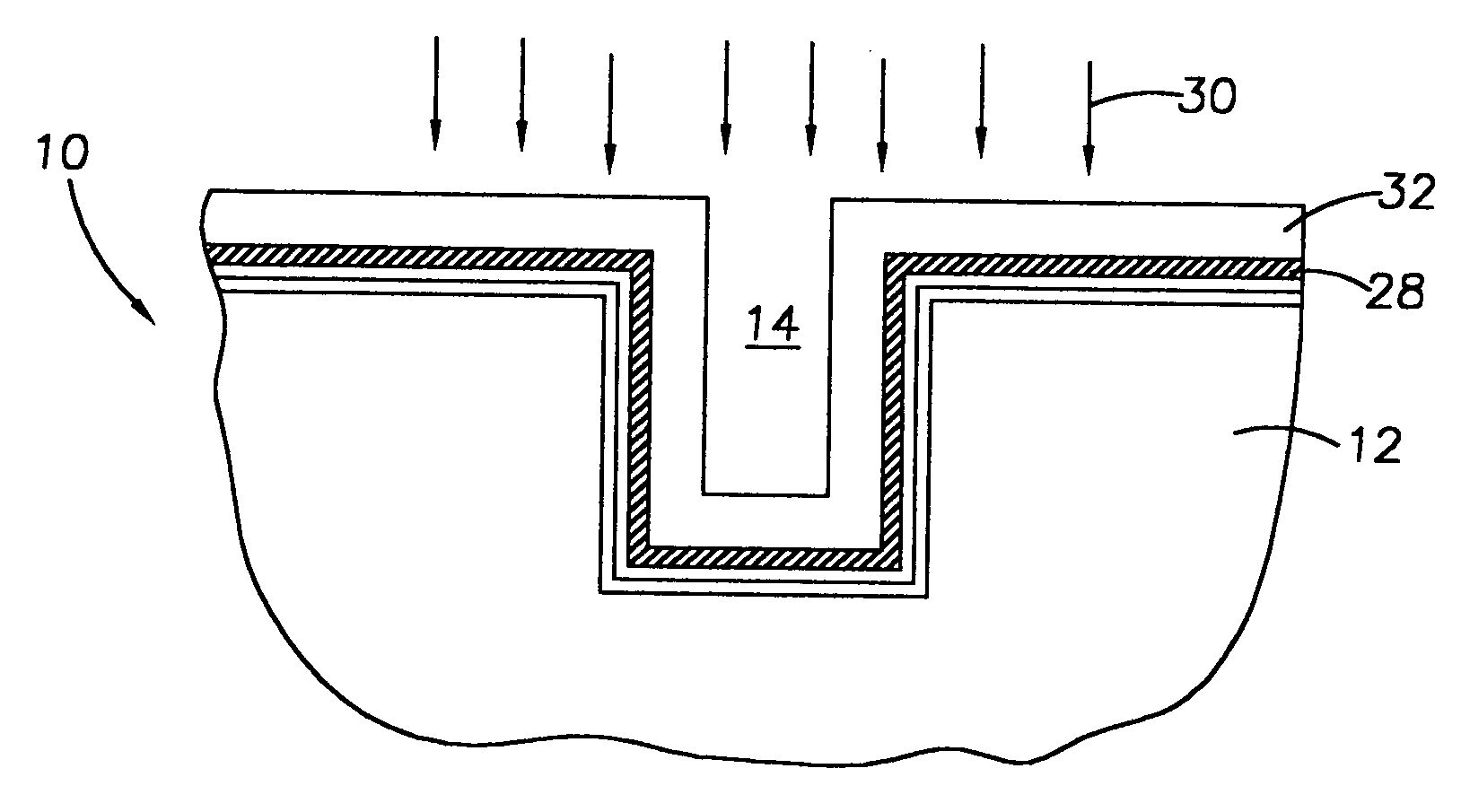

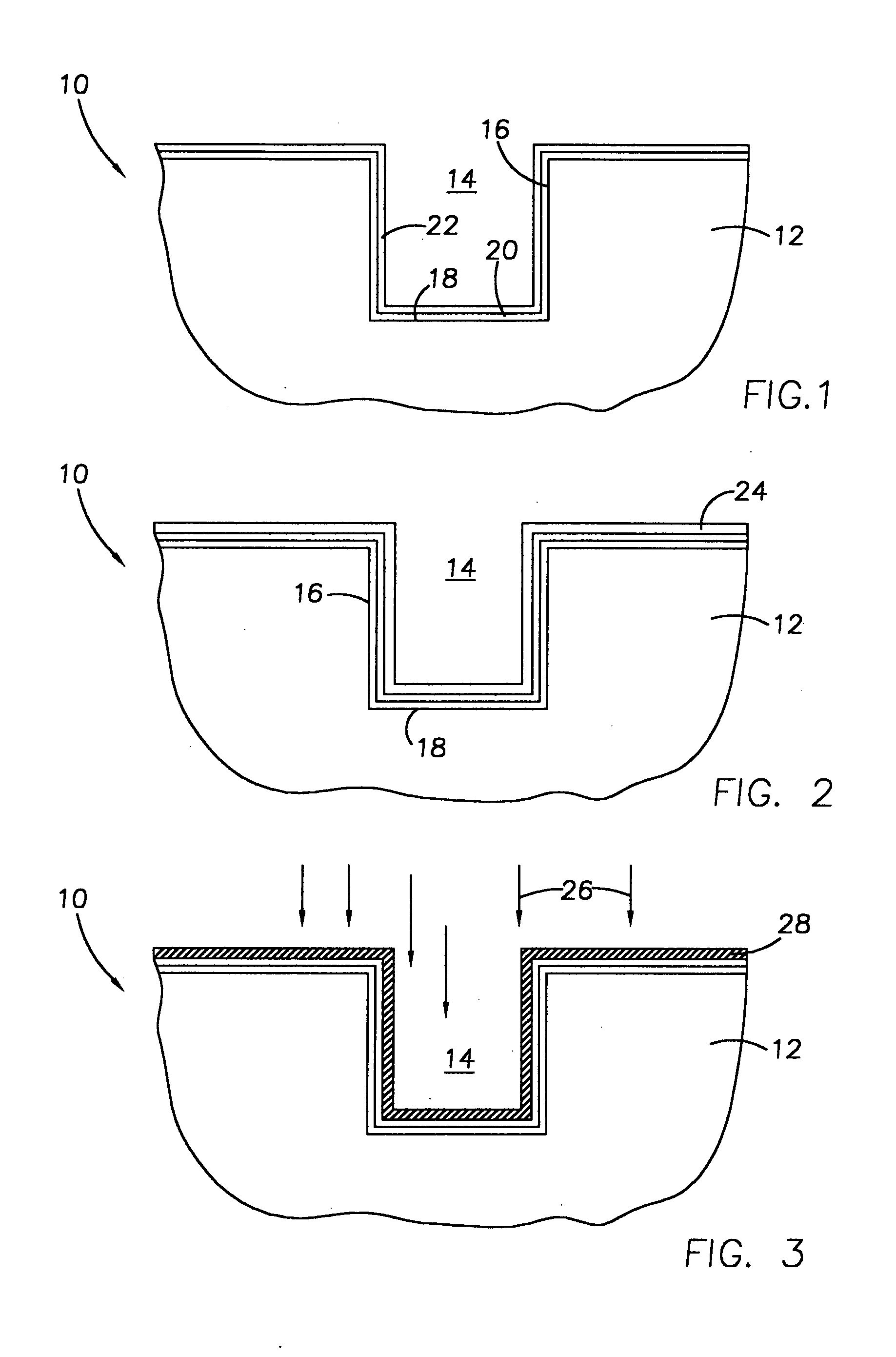

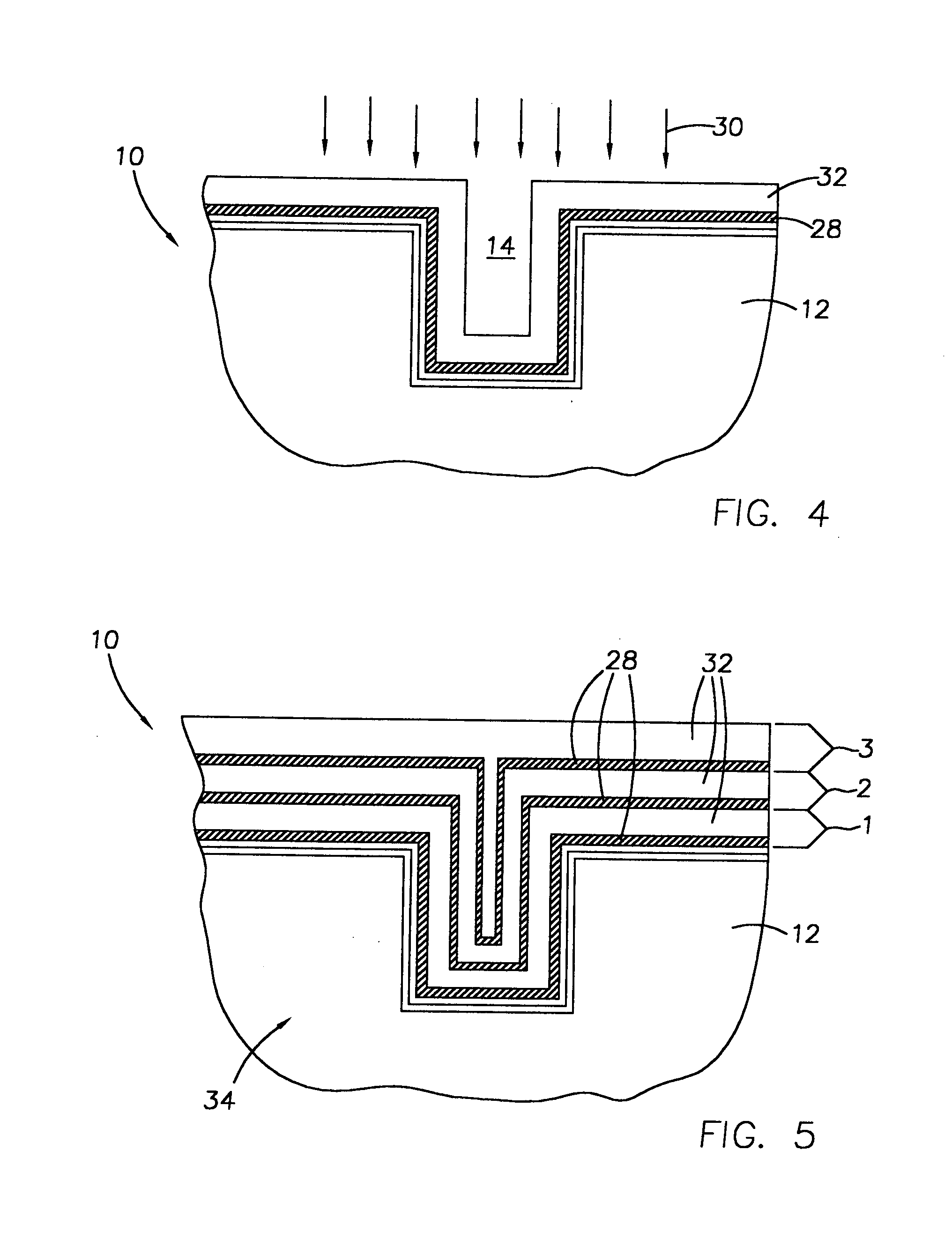

Method of increasing deposition rate of silicon dioxide on a catalyst

ActiveUS20060110936A1Good step coverageIncrease deposition rateSemiconductor/solid-state device manufacturingChemical vapor deposition coatingSilicon oxideOxygen

Methods for forming dielectric layers, and structures and devices resulting from such methods, and systems that incorporate the devices are provided. The invention provides an aluminum oxide / silicon oxide laminate film formed by sequentially exposing a substrate to an organoaluminum catalyst to form a monolayer over the surface, remote plasmas of oxygen and nitrogen to convert the organoaluminum layer to a porous aluminum oxide layer, and a silanol precursor to form a thick layer of silicon dioxide over the porous oxide layer. The process provides an increased rate of deposition of the silicon dioxide, with each cycle producing a thick layer of silicon dioxide of about 120 Å over the layer of porous aluminum oxide.

Owner:MICRON TECH INC

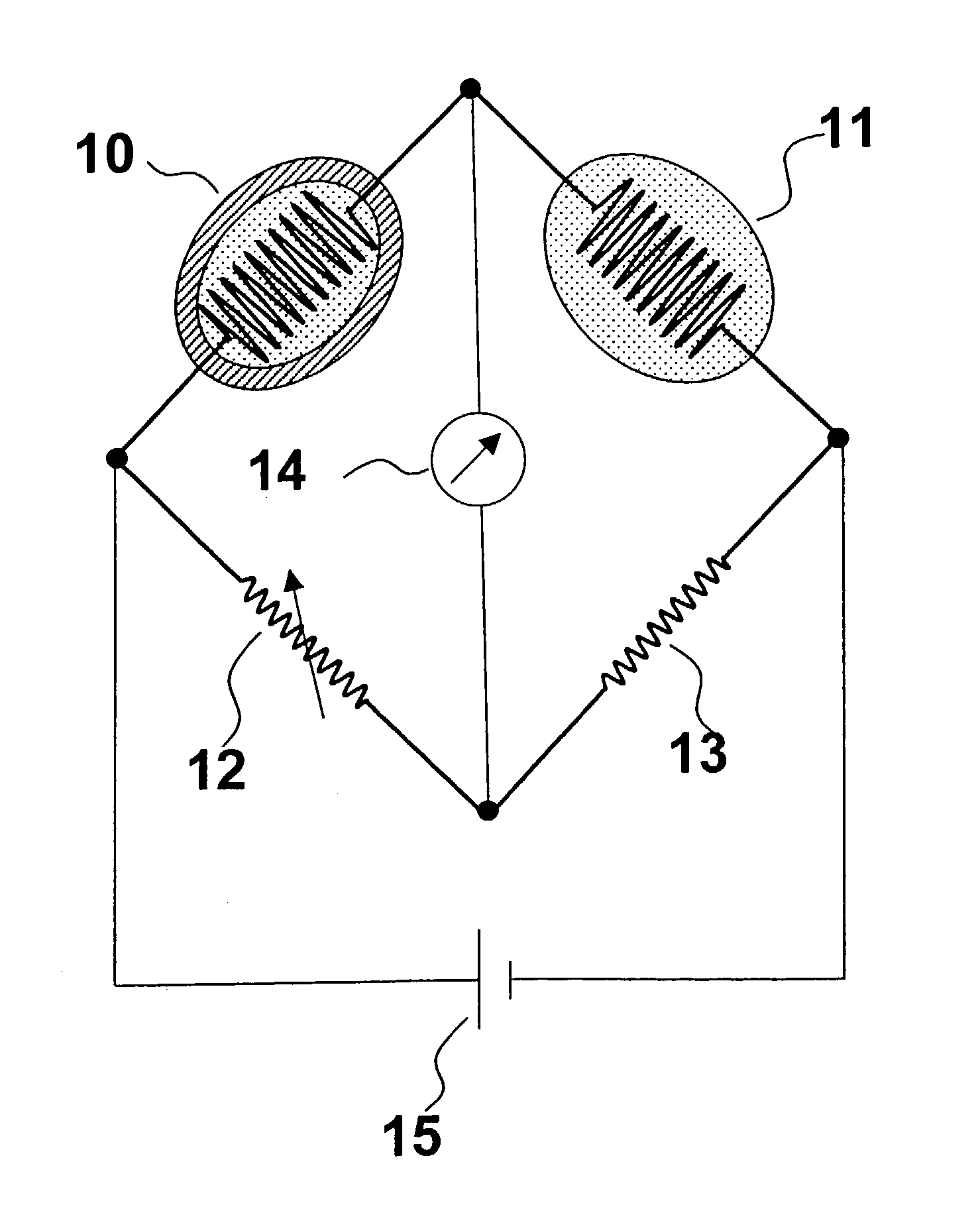

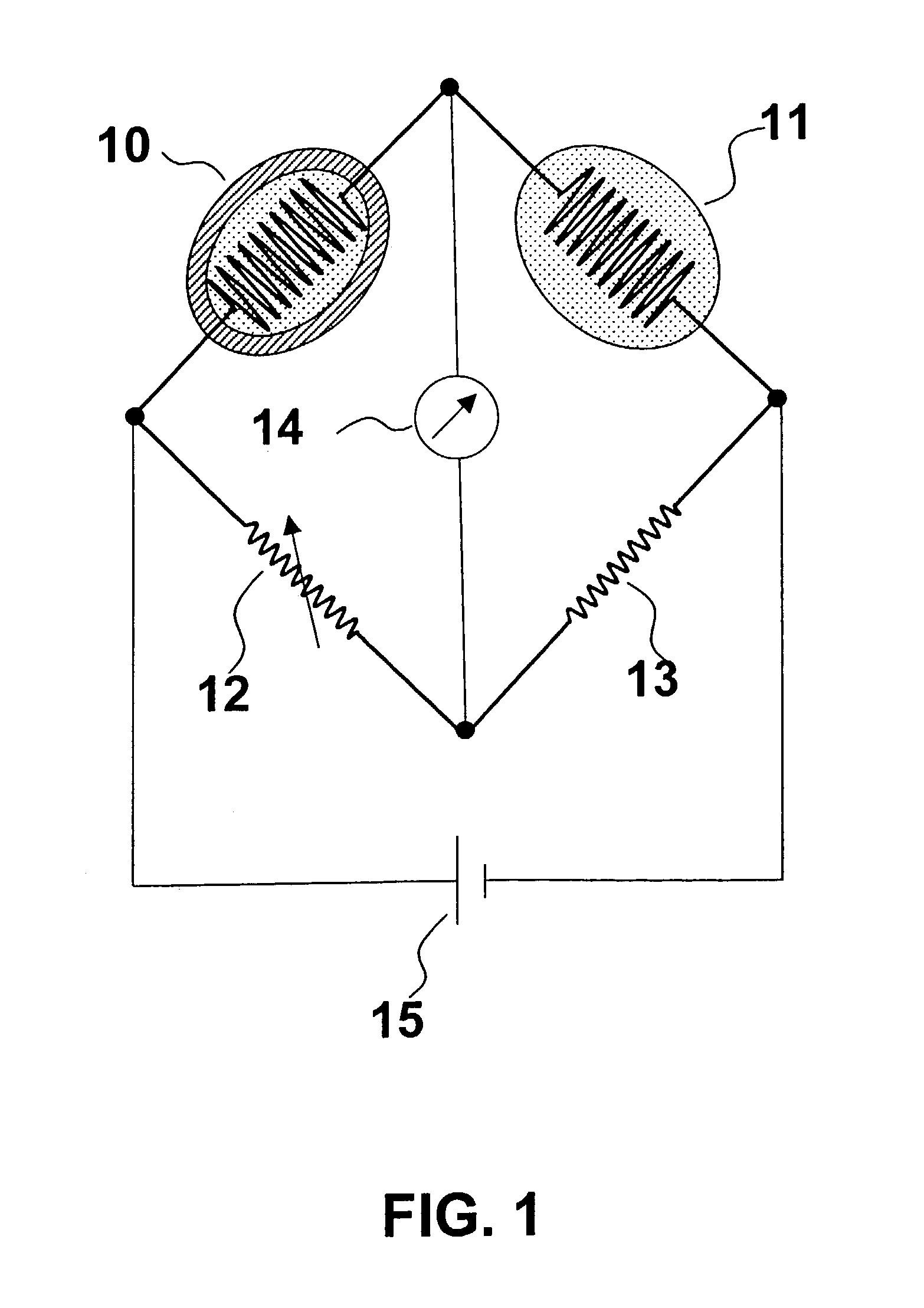

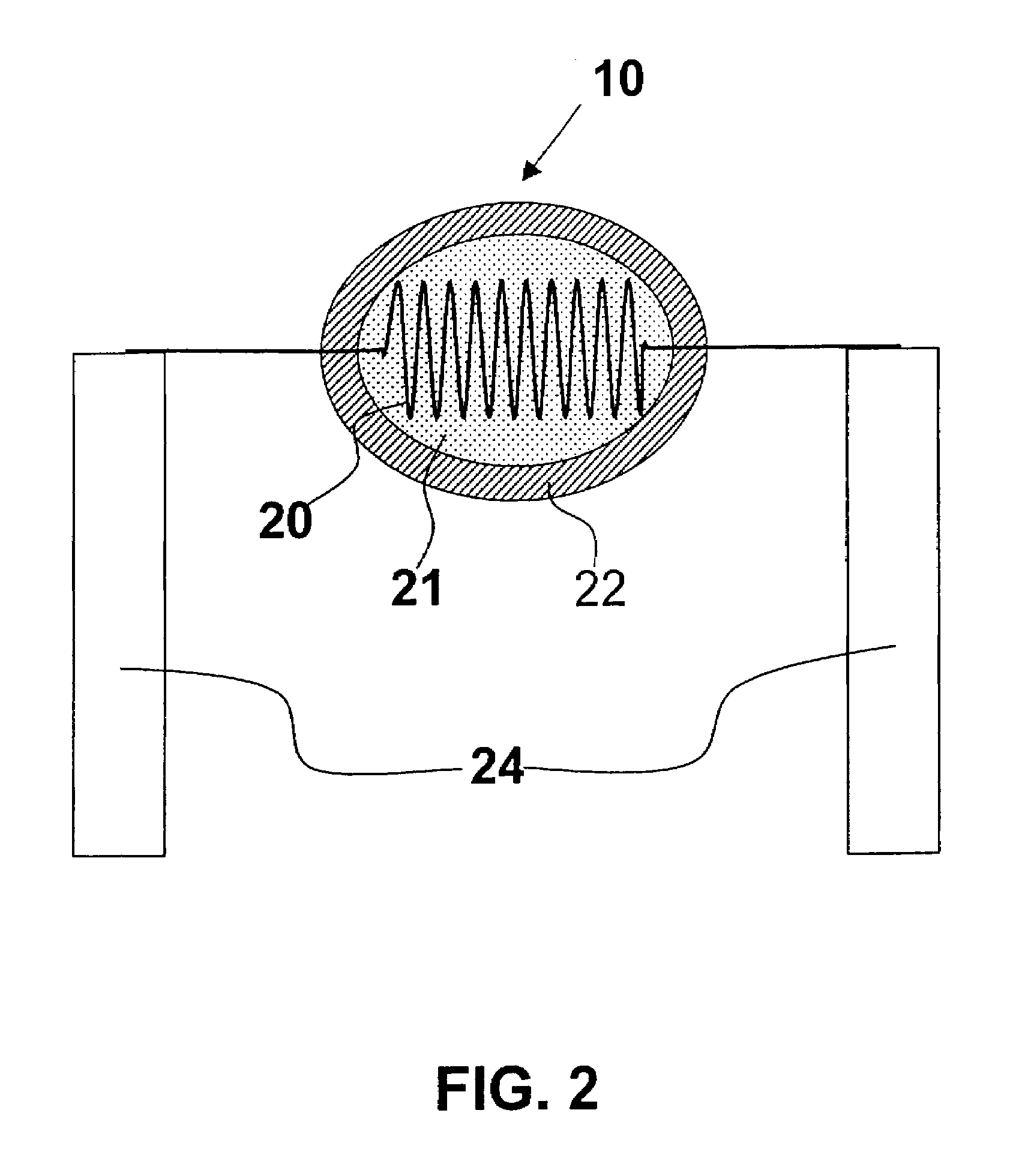

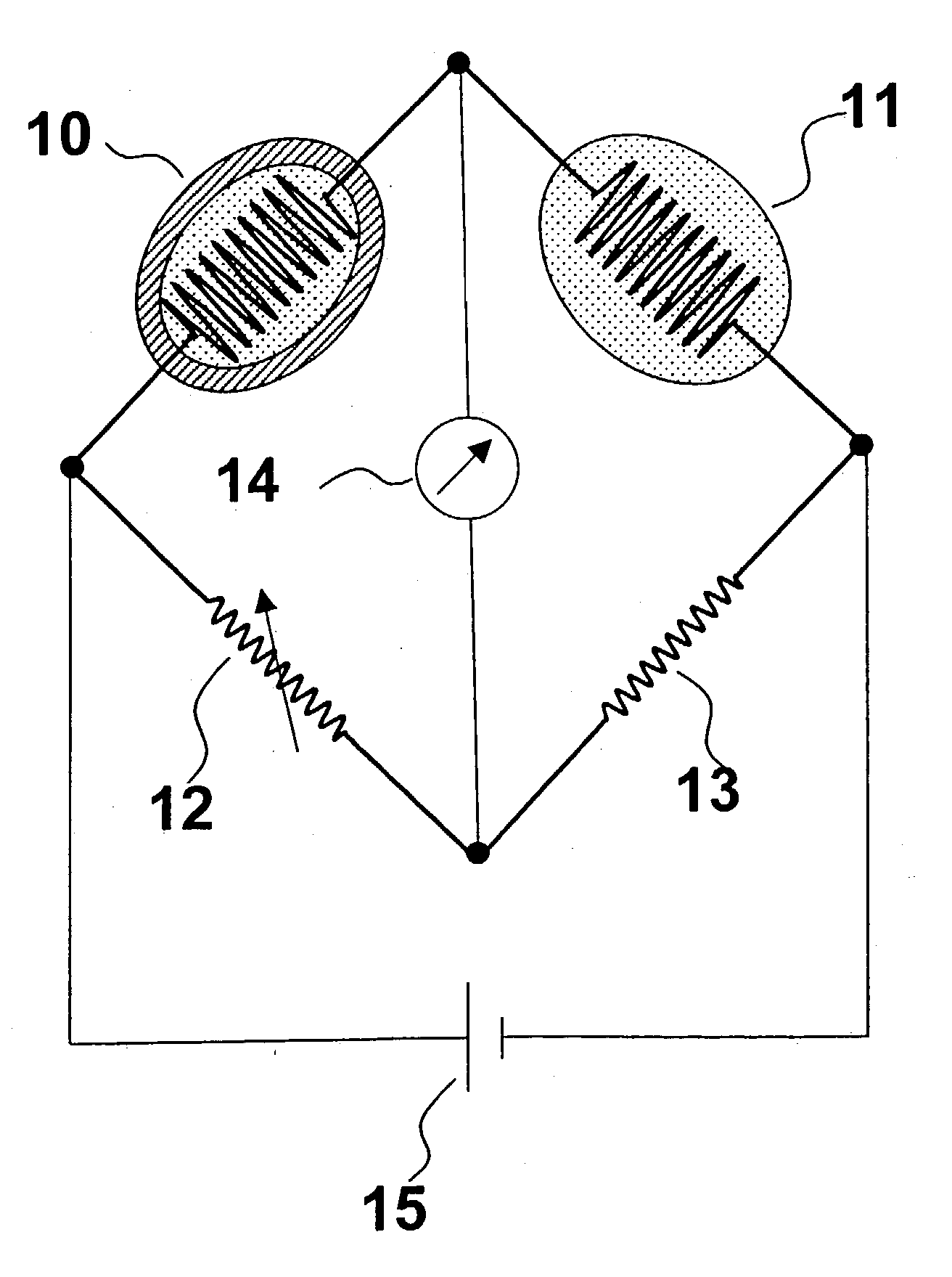

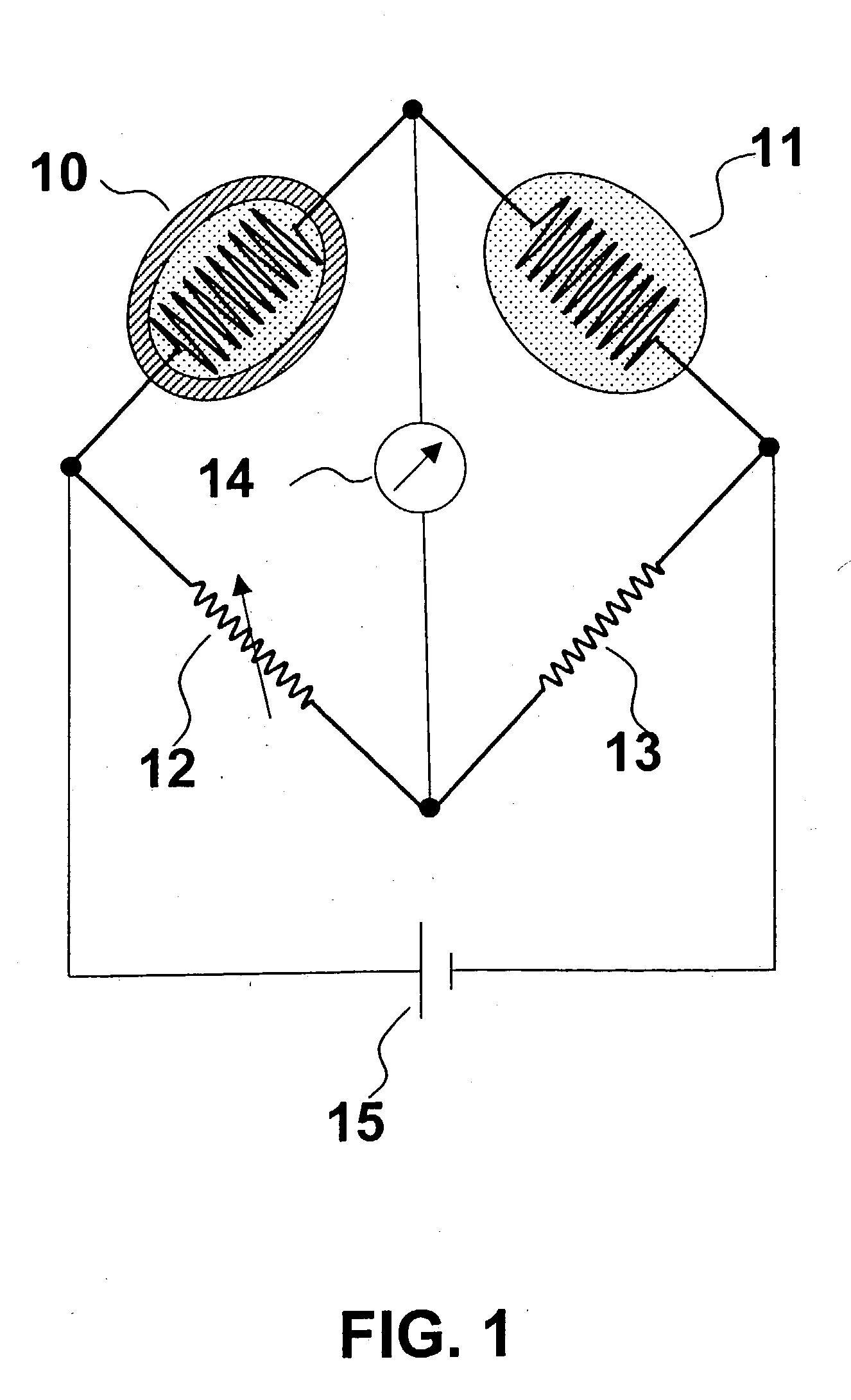

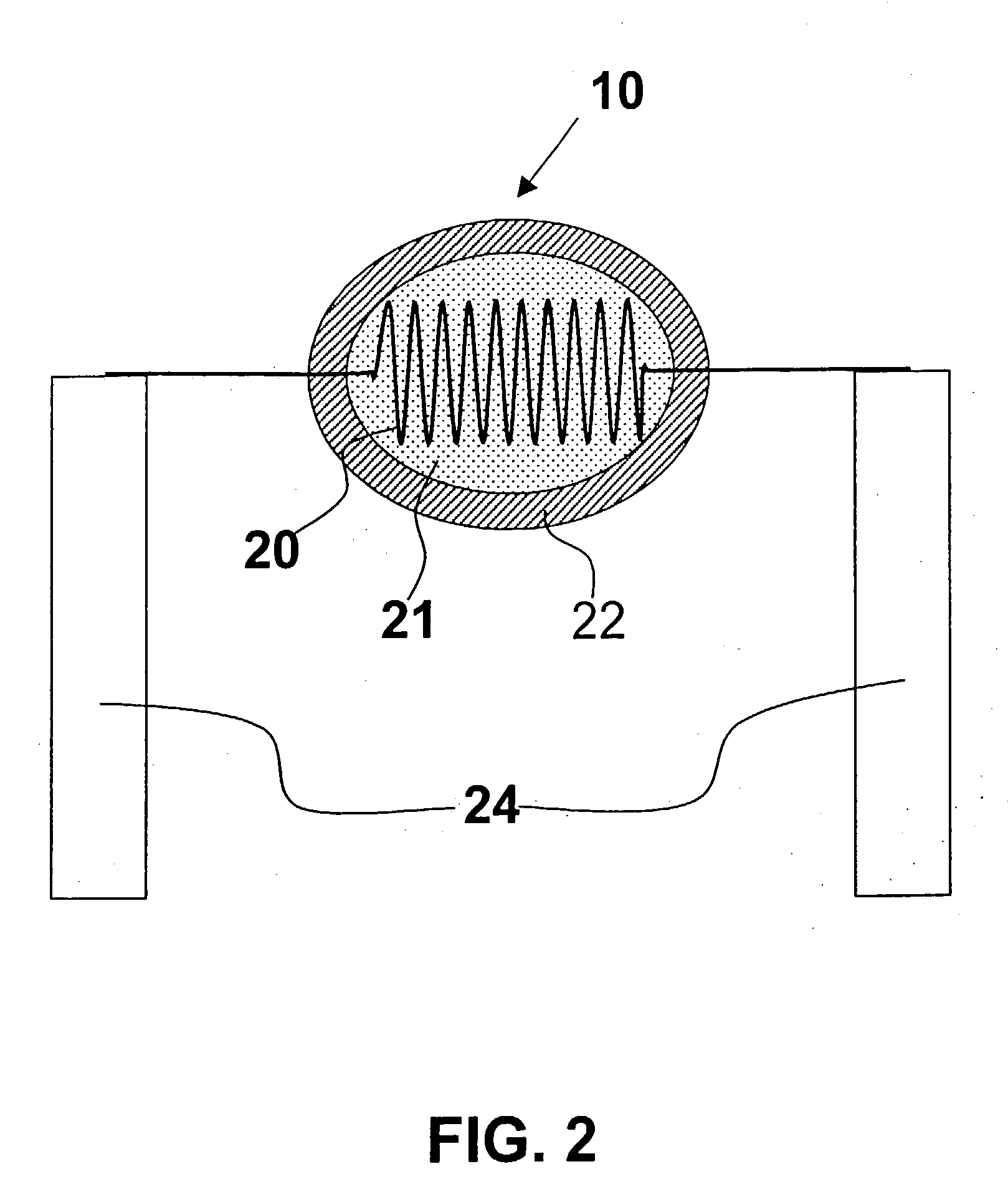

Method of warning of poisoning in poison resistant combustible gas sensors

InactiveUS7007542B2Sure easySimple and cost-effective diagnosticAnalysing fluids using sonic/ultrasonic/infrasonic wavesWave amplification devicesTrappingCombustible gas

A poison resistant combustible gas sensing element, a method for its production and a method for determining poisoning of the element. The element includes an electric heating element, an inner layer coated on the electric heating element and containing a precious metal catalyst supported on a porous oxide, the precious metal catalyst catalyzing combustion of a combustible gas to be detected by the element, and an outer layer overlaying the first layer, and containing a catalytic compound capable of trapping gases which poison the precious metal catalyst, the catalytic compound being supported on a porous oxide.

Owner:INDUSTRIAL SCIENTIFIC CORPORATION

Method for preparing self-doping nitrogen grading porous oxide by using biomass template

InactiveCN101249952AWide variety of sourcesSelf-doping is effectively achievedOxide/hydroxide preparationDistilled waterHierarchical porous

Disclosed is a process for preparing nitrogen self-doped hierarchical porous oxide in the technical field of functional material by employing biological templates, steps of which comprises 1) selecting fresh biomaterial to fix in glutaraldehyde PBS stationary liquid, 2) soaking the biomaterial, after being rinsed by pure water and fixed, in HCl, then rinsing the biomaterial by distilled water for a plurality of times, soaking the biomaterial in salt solution of metal M, 3) rinsing the biomaterial obtained from step 2) by pure water, soaking in the salt solution of metal M, 4) rinsing the obtained biomaterial from step 3) to obtain biomaterial which is naturally dried, then heating within the range of 500-1000 DEG C in an oxygen atmosphere and insulating to obtain the nitrogen-doped porous oxide N-MxOy. The nitrogen self-doped porous oxide prepared by the invention not only is provided with a biological porous structure, but also effectively realizes nitrogen self-doping, and has the obviously strengthened advantage of capturing and absorbing light wave with different wave ranges.

Owner:SHANGHAI JIAO TONG UNIV

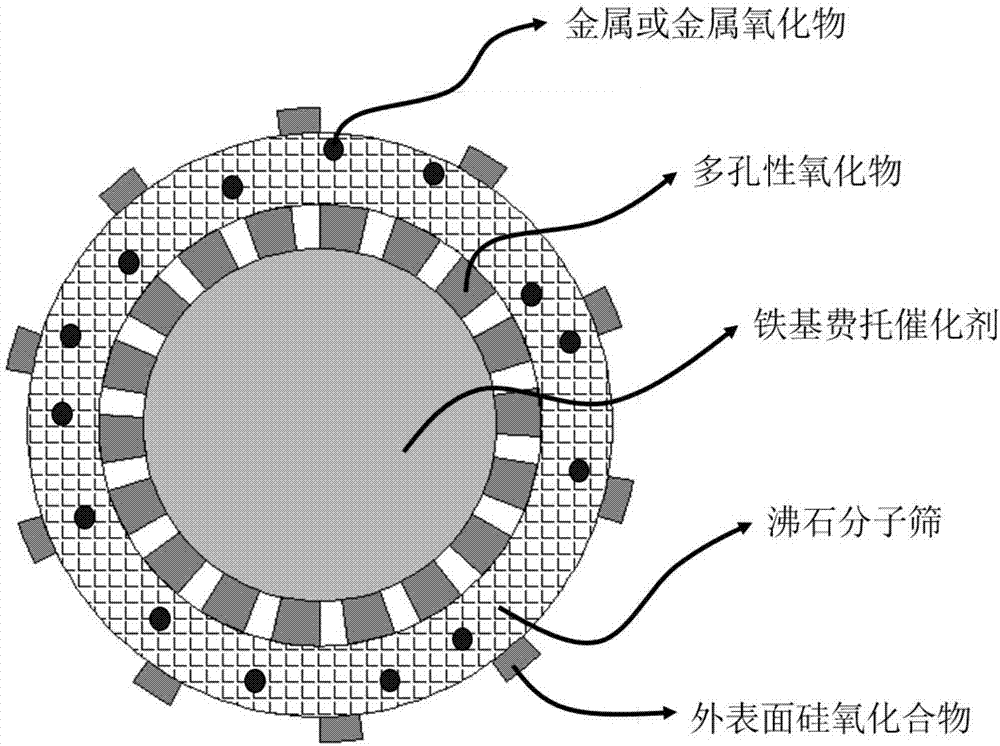

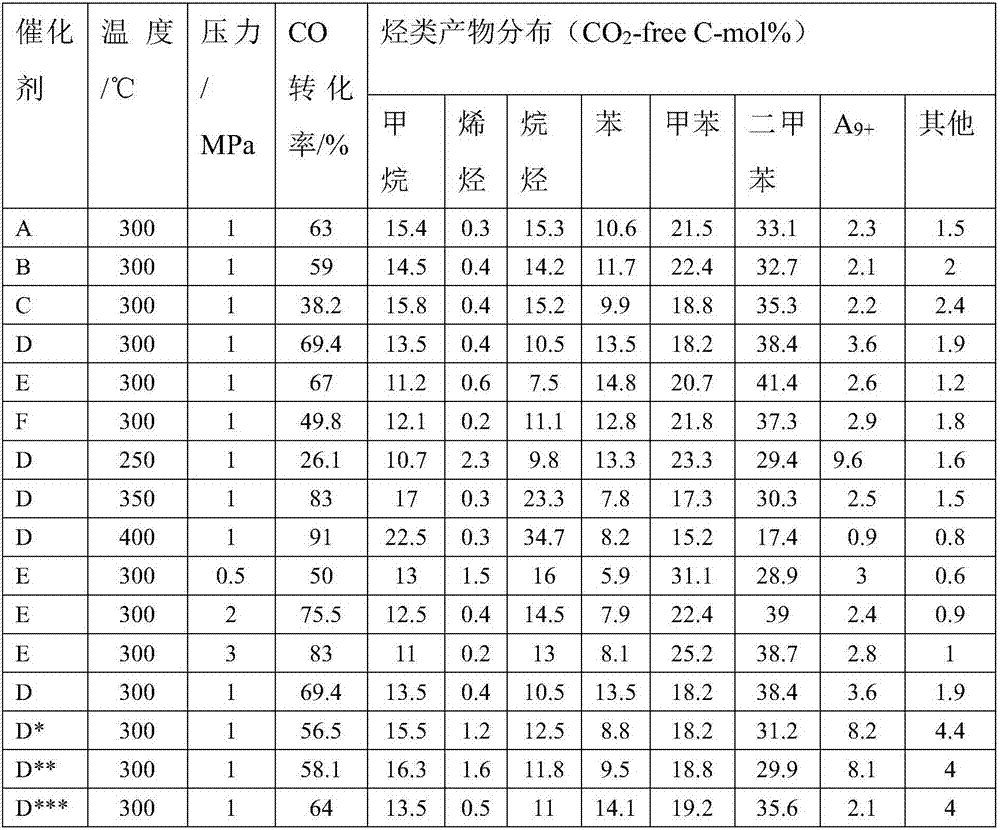

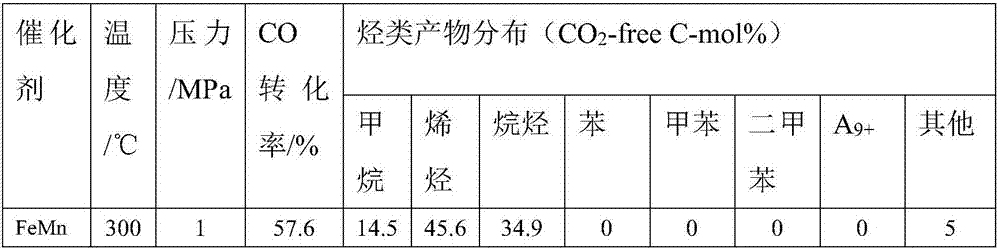

Multistage nano-reactor catalyst for direct preparation of aromatic compounds from synthetic gas, and preparation method and application thereof

ActiveCN107349954AAvoid influenceImprove conversion rateHydrocarbon from carbon oxidesMolecular sieve catalystsNanoreactorPorous carbon

The invention discloses a multistage nano-reactor catalyst for one-step direct preparation of aromatic hydrocarbons from synthetic gas, and a preparation method and an application thereof. The catalyst comprises a core layer iron-based Fischer-Tropsch catalyst, a porous oxide or porous carbon material transition layer and a molecular sieve shell layer having an aromatization function, wherein the shell layer molecular sieve can be further modified with a metal element or a nonmetal element, and the external surface of the molecular sieve is further modified with a silicon-oxygen compound to adjust the acidic site of the external surface and the aperture of the molecular sieve in order to inhibit the formation of heavy aromatic hydrocarbons. The preparation method of the multistage nano-reactor catalyst is characterized in that the transition shell layer can be prepared from the Fischer-Tropsch catalyst through multiple steps, the shell layer contains or does not contain an assistant, and the shell layer molecular sieve undergoes or does not undergo surface modification. The catalyst can be used for the direct preparation of the aromatic compounds, especially lightweight aromatic hydrocarbons, from the synthetic gas; the selectivity of the lightweight aromatic hydrocarbons in the hydrocarbons can reach 75% or more, and the content of the aromatic hydrocarbons aromatic hydrocarbons in a liquid phase product is not less than 95%; and the catalyst has a good stability and has a very good industrial application prospect.

Owner:JIANGNAN UNIV

Nanometer catalyst with adsorbing and virus killing activity

InactiveCN1552205AGood for absorbing virusesImprove efficiencyBiocideMolecular sieve catalystsNano catalystSilica gel

A nanocatalyst for adsorbing and deactivating virus (influenza virus, adenovirus, etc) is composed of the carrier chosen from natural zeolite, synthetic molecular sieve, porous silica gel, aluminium oxide and titanium oxide, and the active component chosen from the nanoparticles of Ag, Cu, Zn, Au and Pt. Its advantage is high effect.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method of warning of poisoning in poison resistant combustible gas sensors

InactiveUS20060019402A1Sure easySimple and cost-effective diagnosticAnalysing fluids using sonic/ultrasonic/infrasonic wavesChemical analysis using combustionTrappingCombustible gas

A poison resistant combustible gas sensing element, a method for its production and a method for determining poisoning of the element. The element includes an electric heating element, an inner layer coated on the electric heating element and containing a precious metal catalyst supported on a porous oxide, the precious metal catalyst catalyzing combustion of a combustible gas to be detected by the element, and an outer layer overlaying the first layer, and containing a catalytic compound capable of trapping gases which poison the precious metal catalyst, the catalytic compound being supported on a porous oxide.

Owner:INDUSTRIAL SCIENTIFIC CORPORATION

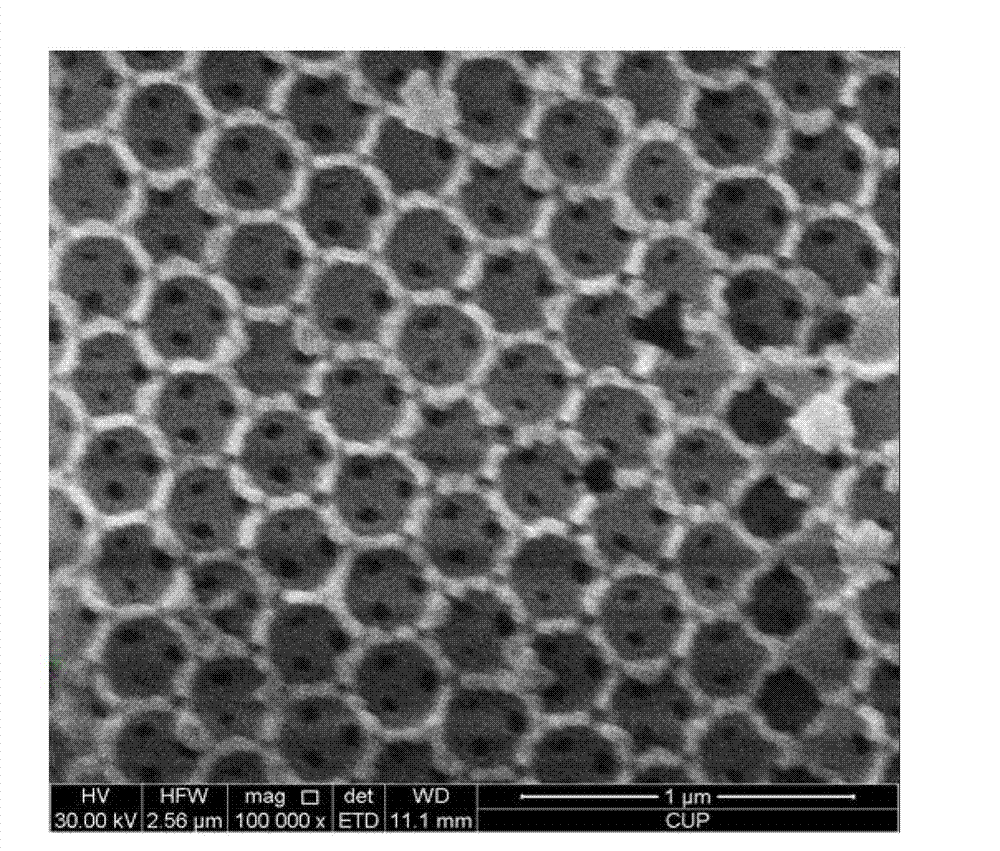

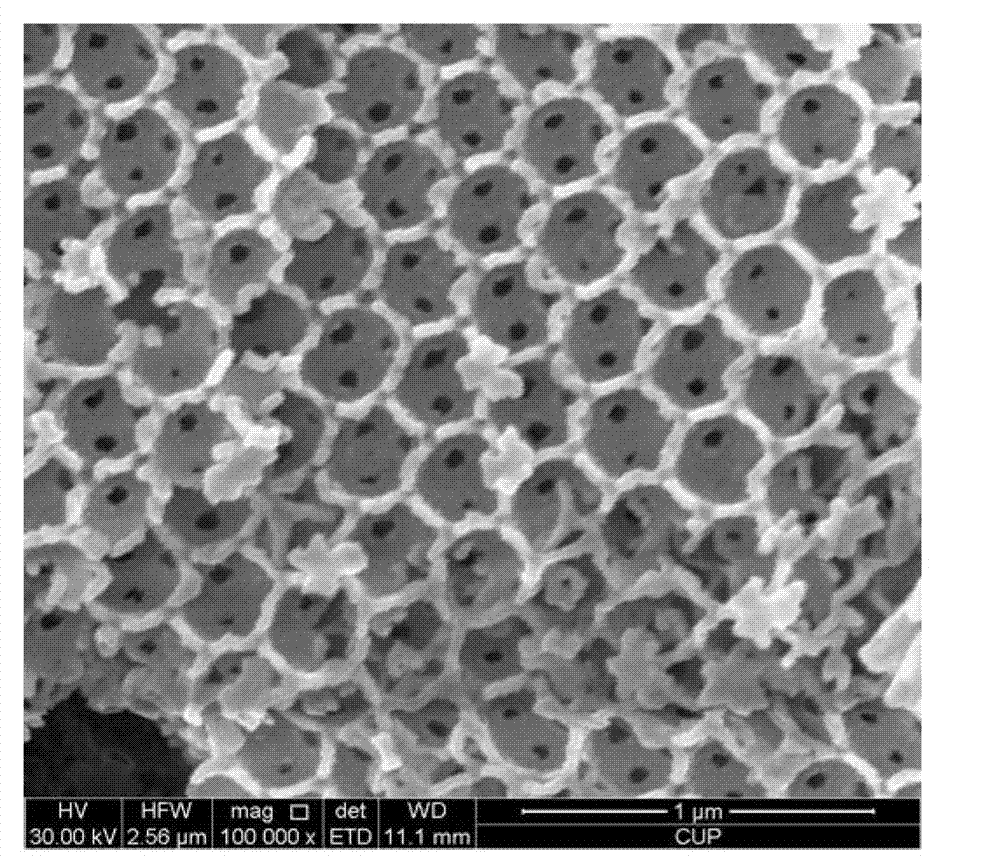

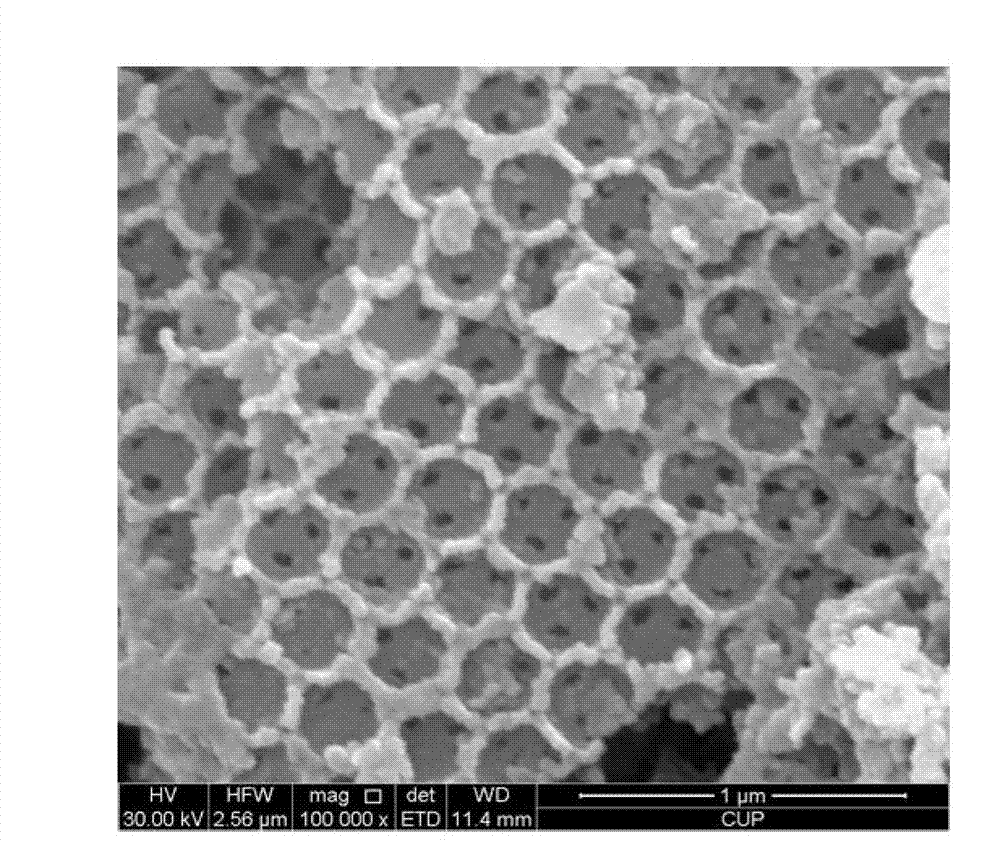

Catalyst for macro-porous oxide supported core-shell structure nanoparticles and preparation method of catalyst

InactiveCN103240088AIncrease contactImprove adsorption capacityDispersed particle separationCatalyst activation/preparationRare-earth elementActive component

The invention relates to a catalyst for macro-porous oxide supported core-shell structure nanoparticles and a preparation method of the catalyst. The catalyst for the macro-porous oxide supported core-shell structure nanoparticles is obtained by using a simple oxide with a three-dimensional macro-porous structure as a supporter to support the core-shell structure nanoparticles; the core of the core-shell structure nanoparticles is noble metal; the shell material of the core-shell structure nanoparticles is one or combination of more selected from rare earth elements and transitional metal elements; the simple oxide is the catalytically inactive oxide; the average pore size of the macro-pore of the supporter is 50nm to 1mu m. The invention also provides a preparation method of the catalyst. Compared with a corresponding general catalyst, a nanoparticle catalyst and a three-dimensional ordered macro-porous oxide catalyst, the oxidation catalyst, prepared by supporting noble metal (core)-rare earth element or transitional metal element (shell) active component by the simple oxide with a three-dimensional ordered macro-porous structure, has higher catalytic activity.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

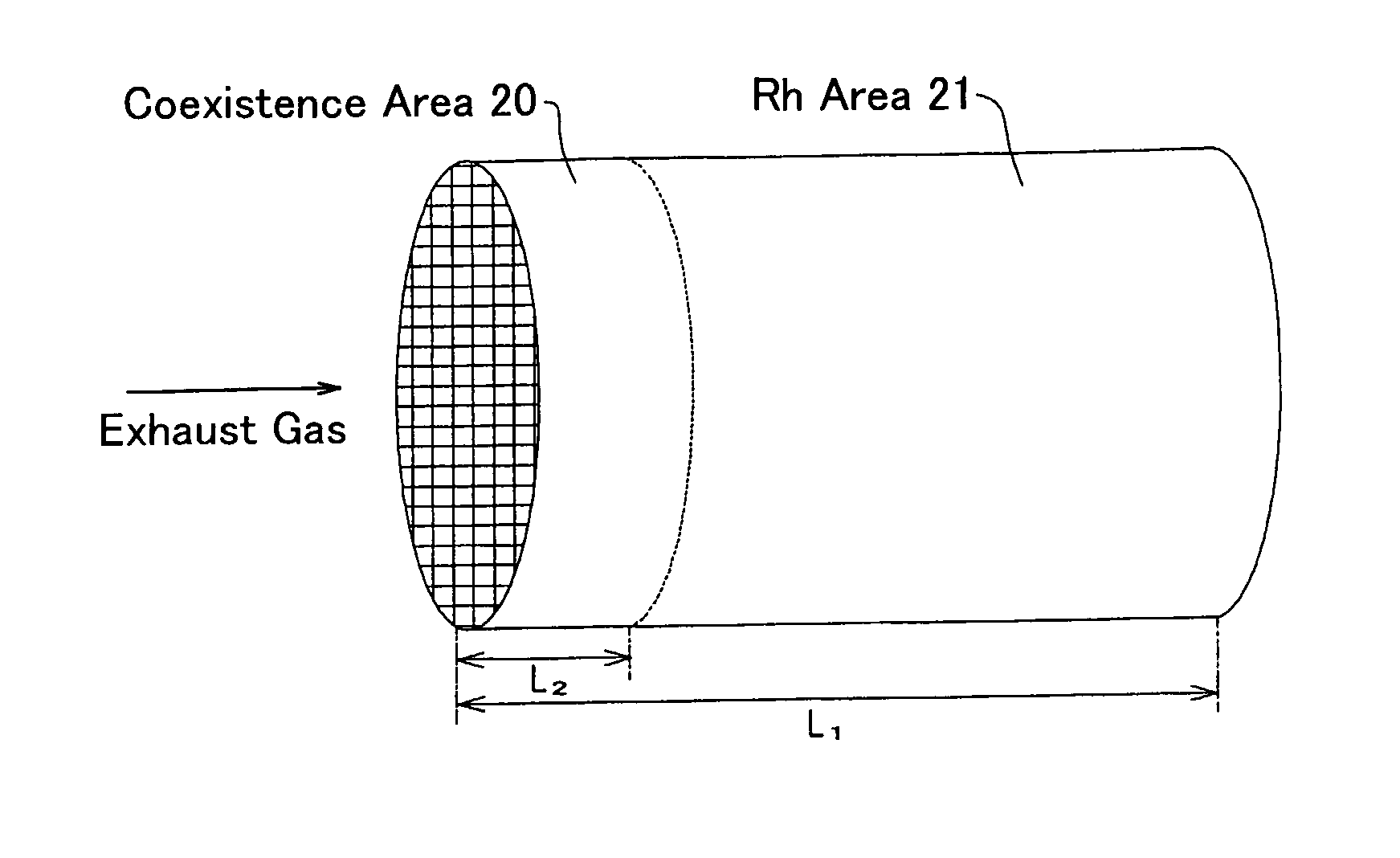

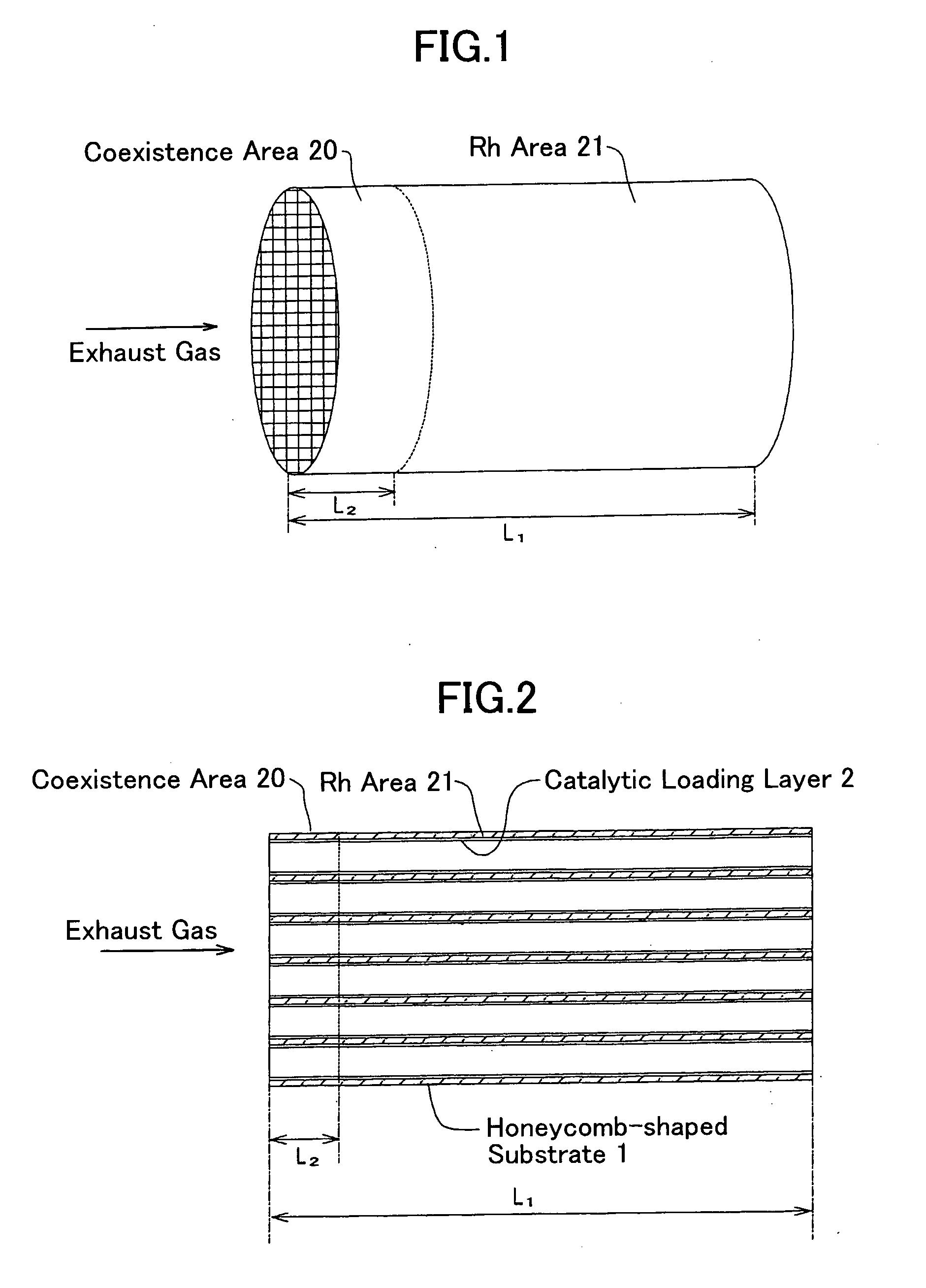

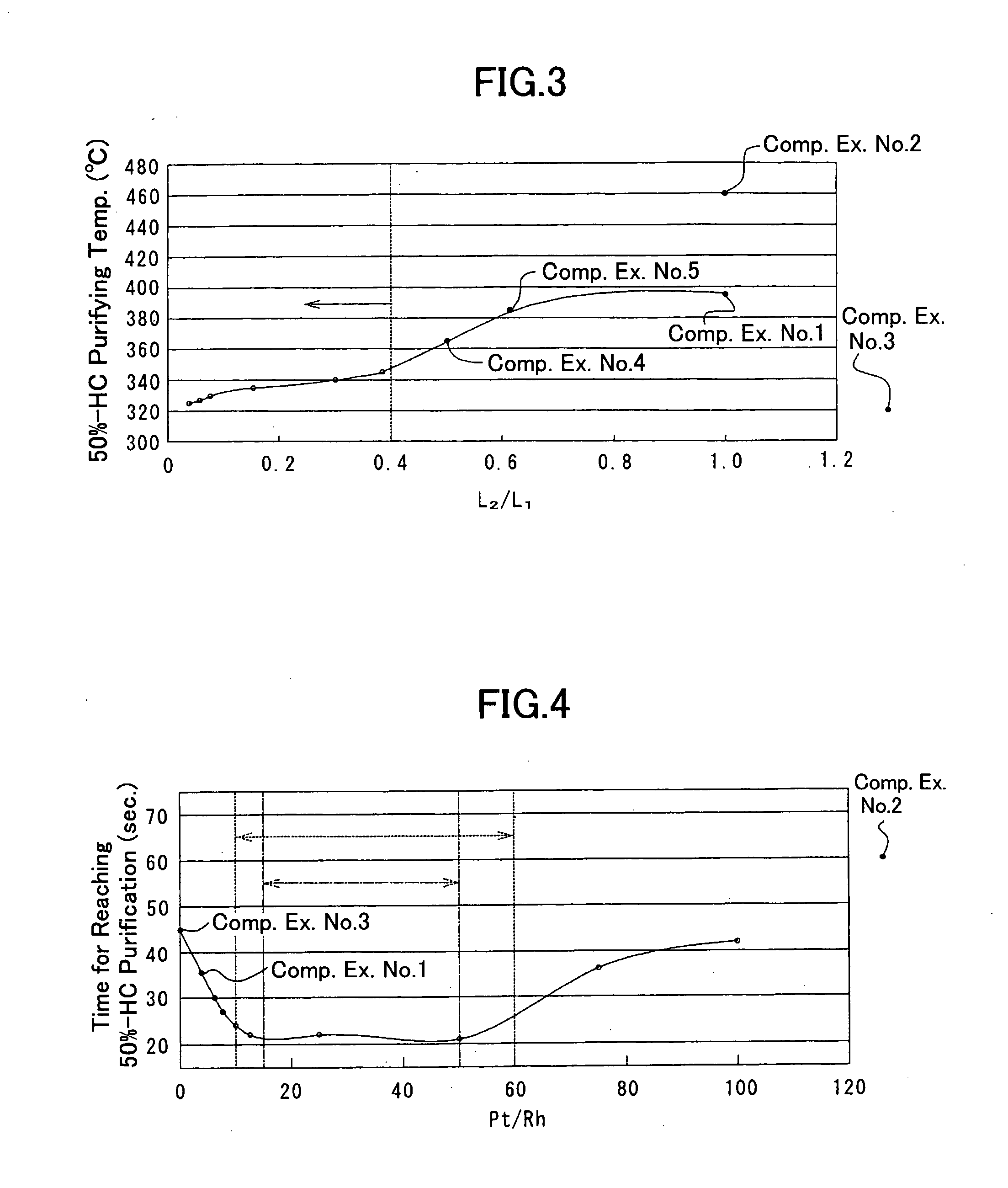

Catalyst for Purifying Exhaust Gases

InactiveUS20080081761A1Efficient use ofMaximally inhibiting deteriorationInternal combustion piston enginesDispersed particle separationPlatinumExhaust fumes

A catalyst for purifying exhaust gases includes a support substrate, and a catalytic loading layer. The support substrate demarcates an exhaust-gas flow passage, an exhaust-gas inlet end and an exhaust-gas outlet end, and has an overall length between the exhaust-gas inlet end and the exhaust-gas outlet end. The catalytic loading layer is formed on a surface of the exhaust-gas flow passage, and is composed of a porous oxide support and a noble metal. The catalytic loading layer includes a coexistence area, and a rhodium area. The coexistence area occupies the overall length of the support substrate by a factor of 4 / 10 or less from the exhaust-gas inlet end, and is composed of rhodium and platinum loaded thereon. The rhodium area is formed toward the exhaust-gas outlet end from the coexistence area, and is composed of rhodium loaded uniformly thereon in a flow direction of the exhaust gases.

Owner:TOYOTA JIDOSHA KK

Active bio piezoelectric ceramic coating layer and method of preparing said coating layer on titanium base body surface

InactiveCN1785439AReduce bond strengthHigh bonding strengthAnodisationImpression capsPlasma electrolytic oxidationMicro arc oxidation

A coated active biologic piezoelectric layer on Ti substrate is prepared from fluorohydroxy apatite (FHA) and barium titanate (BT) through cleaning the surface of Ti substrate, microarc oxidizing to form a porous oxide film layer, and electrophoretic deposition to form a FHABT layer on the surface of Ti substrate. Its advantages are easy control to content of F, high implantation stability, binding power to interface, biocompatibility and bioactivity, and high effect to promote generation of biologic bone and taking part energy conversion in human body.

Owner:HARBIN ENG UNIV

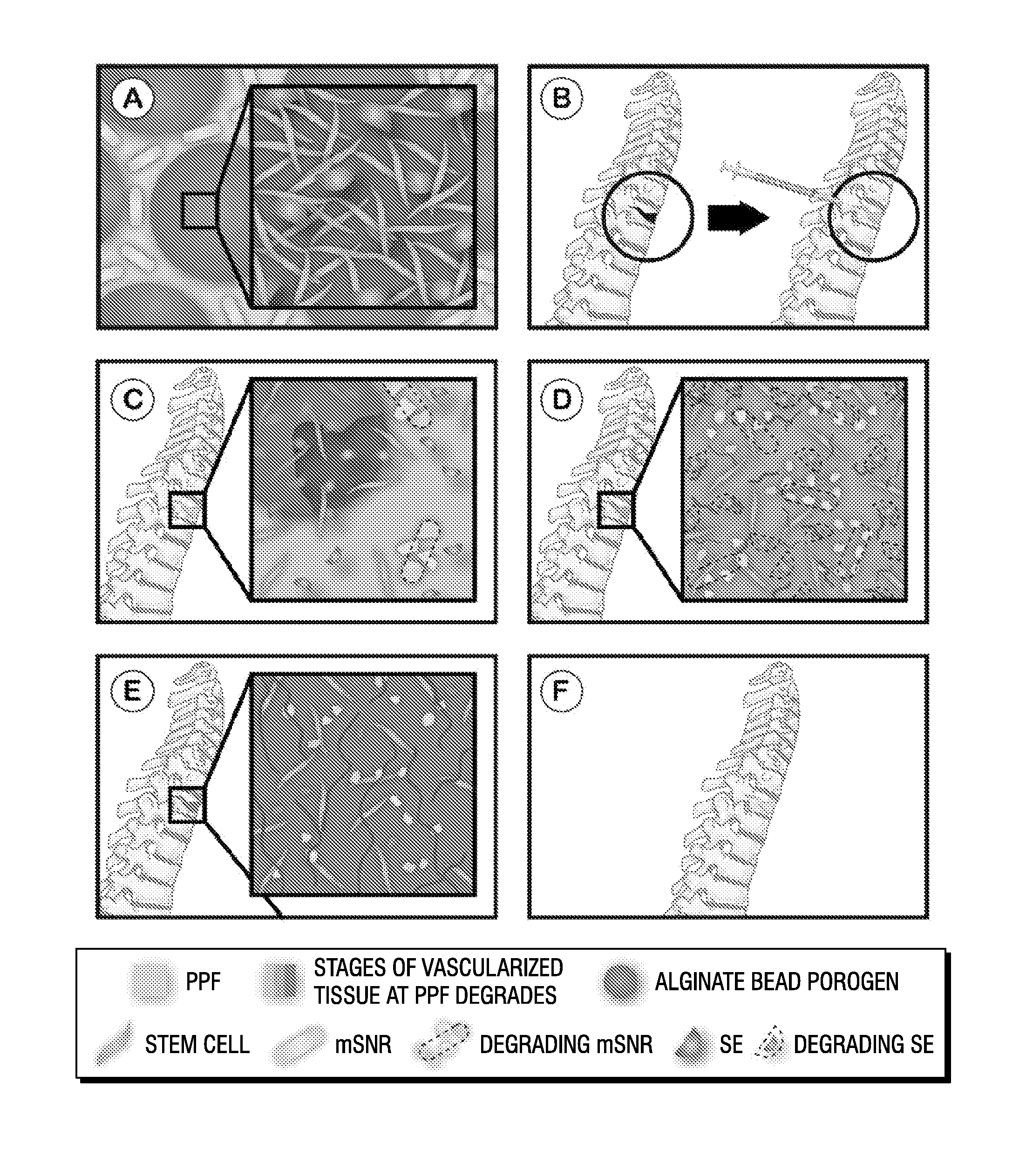

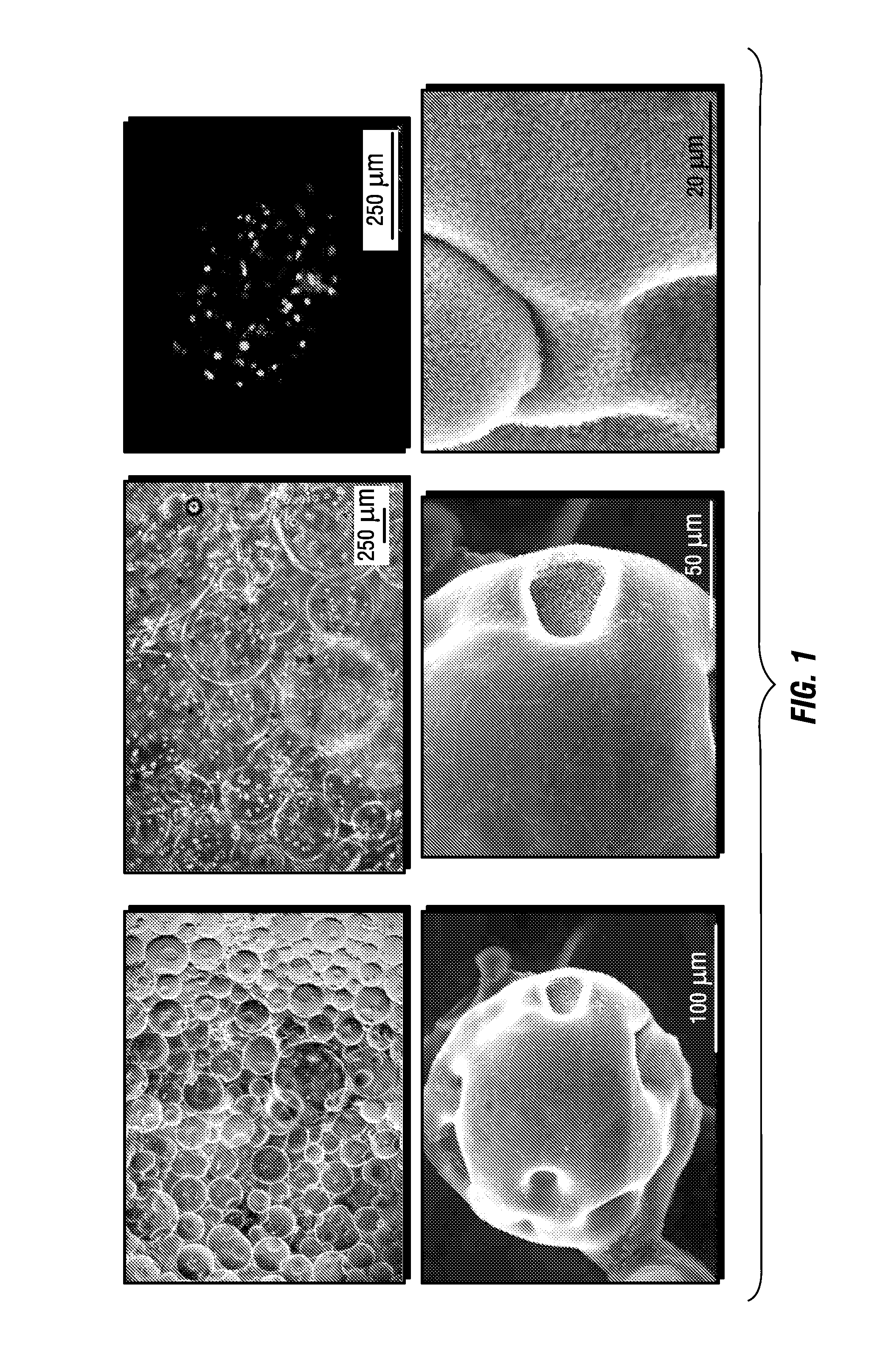

Biodegradable scaffolds

InactiveUS20130184835A1Optimal mechanical characteristicEnhance healing processBiocidePowder deliveryActive agentBiodegradable scaffold

In some embodiments, the present invention provides compositions that comprise: (1) a biodegradable polymer matrix; and (2) at least one biodegradable reinforcing particle that is dispersed in the matrix. In some embodiments, the biodegradable reinforcing particle is selected from the group consisting of porous oxide particles and porous semiconductor particles. In additional embodiments, the compositions of the present invention further comprise a (3) porogen particle that is also dispersed in the matrix. In further embodiments, the compositions of the present invention are also associated with one or more active agents. In various embodiments, the active agents are associated with the biodegradable polymer matrix, the biodegradable reinforcing particle, and / or the porogen particle. In various embodiments, the compositions of the present invention may be utilized as scaffolds, such as scaffolds for treating bone defects. Further embodiments of the present invention pertain to methods of making the compositions of the present invention.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Catalyst for catalytic conversion of biological cellulose and preparation method and applications of catalyst

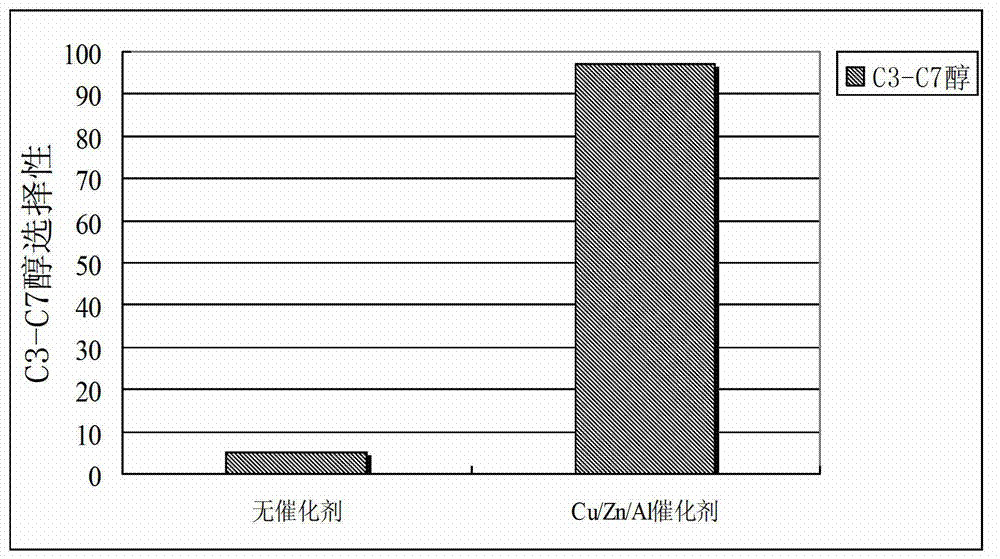

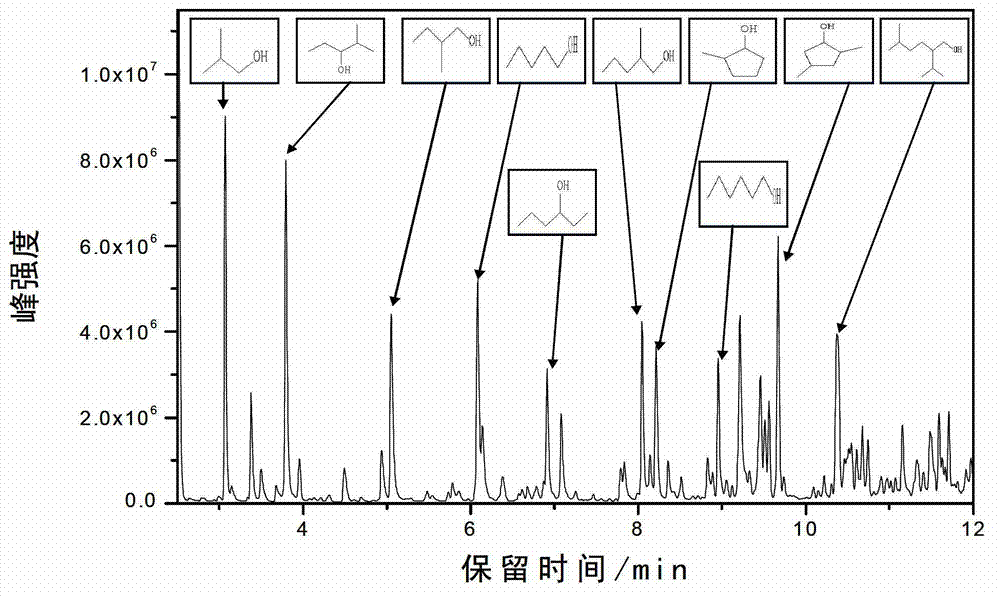

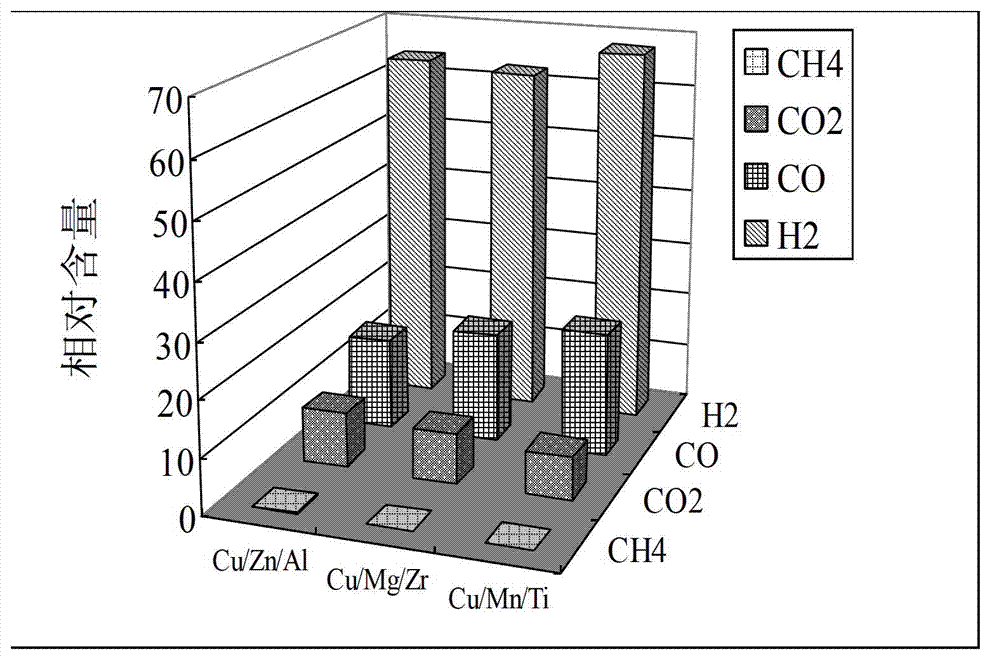

ActiveCN102921426ALow costThe synthesis method is simpleOrganic compound preparationHydroxy compound preparationCelluloseCopper oxide

The invention relates to a catalyst for catalytic conversion of biological cellulose. The catalyst is composed of active components, assistants and carries, the active components include copper oxide and / or nickel oxide, the assistants include alkaline earth oxides and / or transition metal oxides, and the carries are porous oxides. The invention further relates to a preparation method of the catalyst and a method for catalytic conversion of alcohol reforming coupling biological cellulose. The method for catalytic conversion of the alcohol reforming coupling biological cellulose has the advantages that reaction conditions are mild, external hydrogen is not needed to be fed, the conversion efficiency is high, and the like. The utilized catalyst has the advantages of being simple in synthesis, low in cost, high in catalytic conversion activity on alcohol reforming and biological cellulose and good in catalytic recycling stability.

Owner:JIANGXI INST OF RARE EARTHS CHINESE ACAD OF SCI

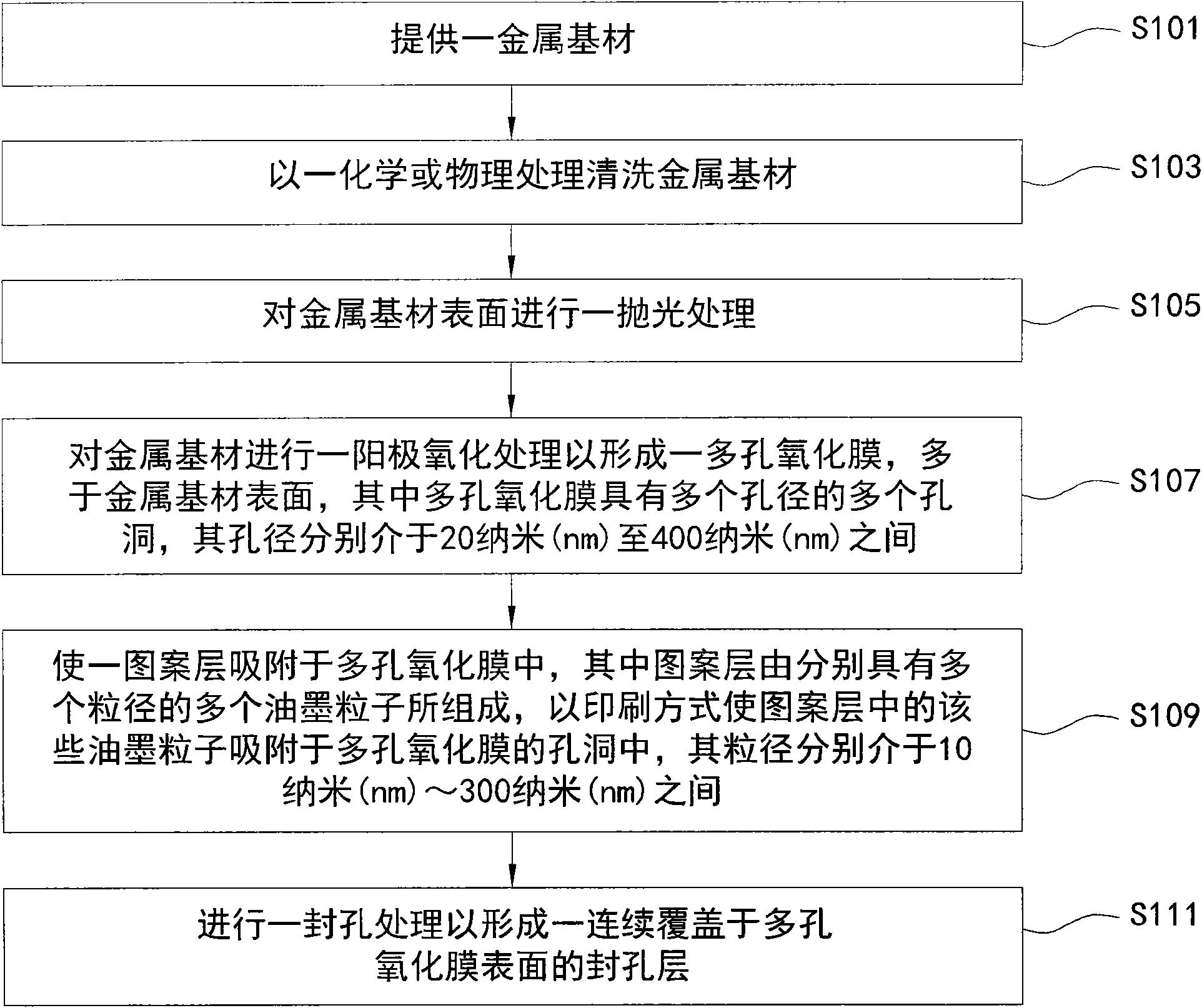

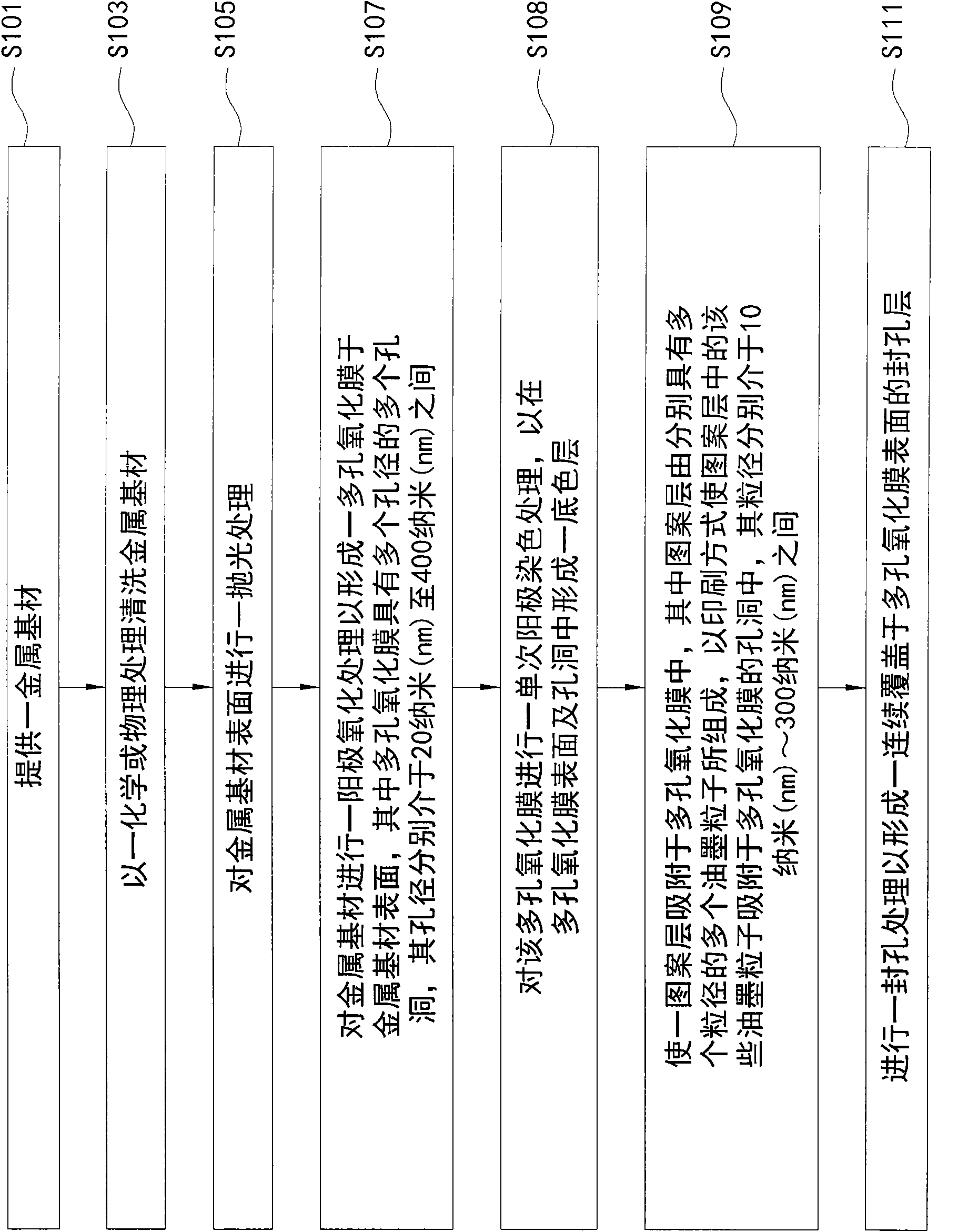

Method and structure for patterning metal surface

InactiveCN102071447AImprove metallic textureWear-resistantSurface reaction electrolytic coatingPore diameterParticle adsorption

The invention provides a method for patterning a metal surface. The method comprises the following steps of: firstly, cleaning a metal substrate by chemical or physical treatment and polishing the metal substrate; secondly, performing anodic oxidation treatment on the metal substrate so as to form a porous oxide film on the surface of the metal substrate, wherein the porous oxide film is provided with a plurality of pores with the pore diameters of between 20 and 400 nanometers; thirdly, providing a pattern layer and absorbing ink particles into the pores of the porous oxide film in a printing mode, wherein the particle sizes of the ink particles are between 10 and 300 nanometers; and lastly, sealing the pores so as to form a pore sealing layer which is continuously covered on the surface of the porous oxide film.

Owner:BIN CHUAN ENTERPRISE

Electrochemical preparation method for medical external use aluminum alloy multifunctional coating

The invention discloses an electrochemical preparation method for a medical external use aluminum alloy multifunctional coating. The medical external use aluminum alloy multifunctional coating prepared by the method has multifunctional purposes of decoration, corrosion resistance, sterilization, self cleaning and the like. According to the electrochemical preparation method, an aluminum alloy base material is subjected to anodic oxidation treatment and electrolytic coloring, so that a porous oxide film is formed on the surface of the aluminum alloy and contains certain metals such as silver, copper, zinc and the like; and the surface of the oxide film has self-cleaning nanometer titanium dioxide, so that the aluminum alloy has the functions of decoration, corrosion resistance, sterilization and self cleaning. The medical external use aluminum alloy multifunctional coating prepared by the electrochemical preparation method has the effects of decoration, corrosion resistance, sterilization and self cleaning, has the advantages of simple process, environmental protection, no toxicity, high stability of film layers and high practicability, meets various requirements on the aluminum alloy in the aspects of medical external use, and expands the application range of the aluminum alloy. According to the multifunctional coating obtained by the method, the aluminum alloy can be used in various fields of medical instruments such as disabled person stair handrails, medical carts, wheelchairs, stretchers, supports, intelligent call and the like.

Owner:湖南迈迪科新材有限公司

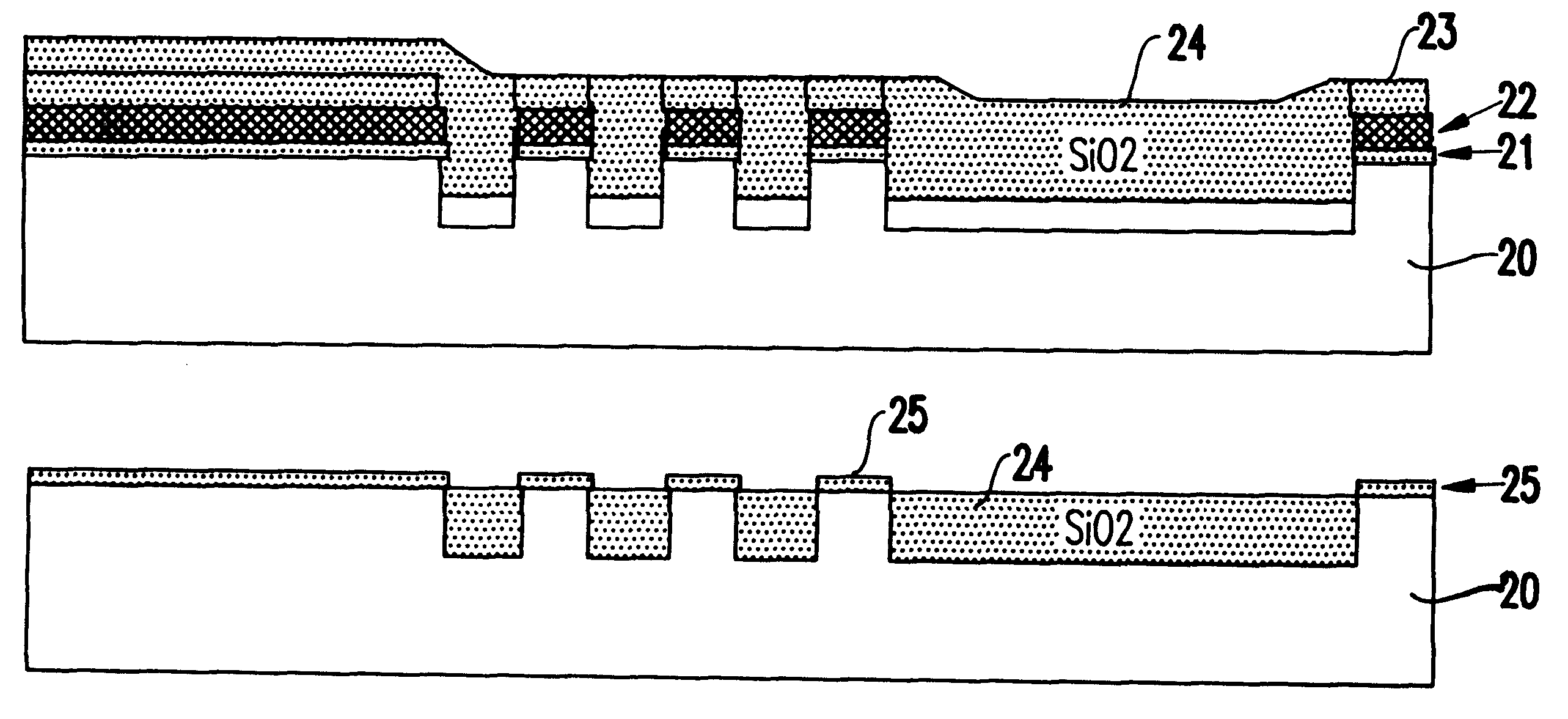

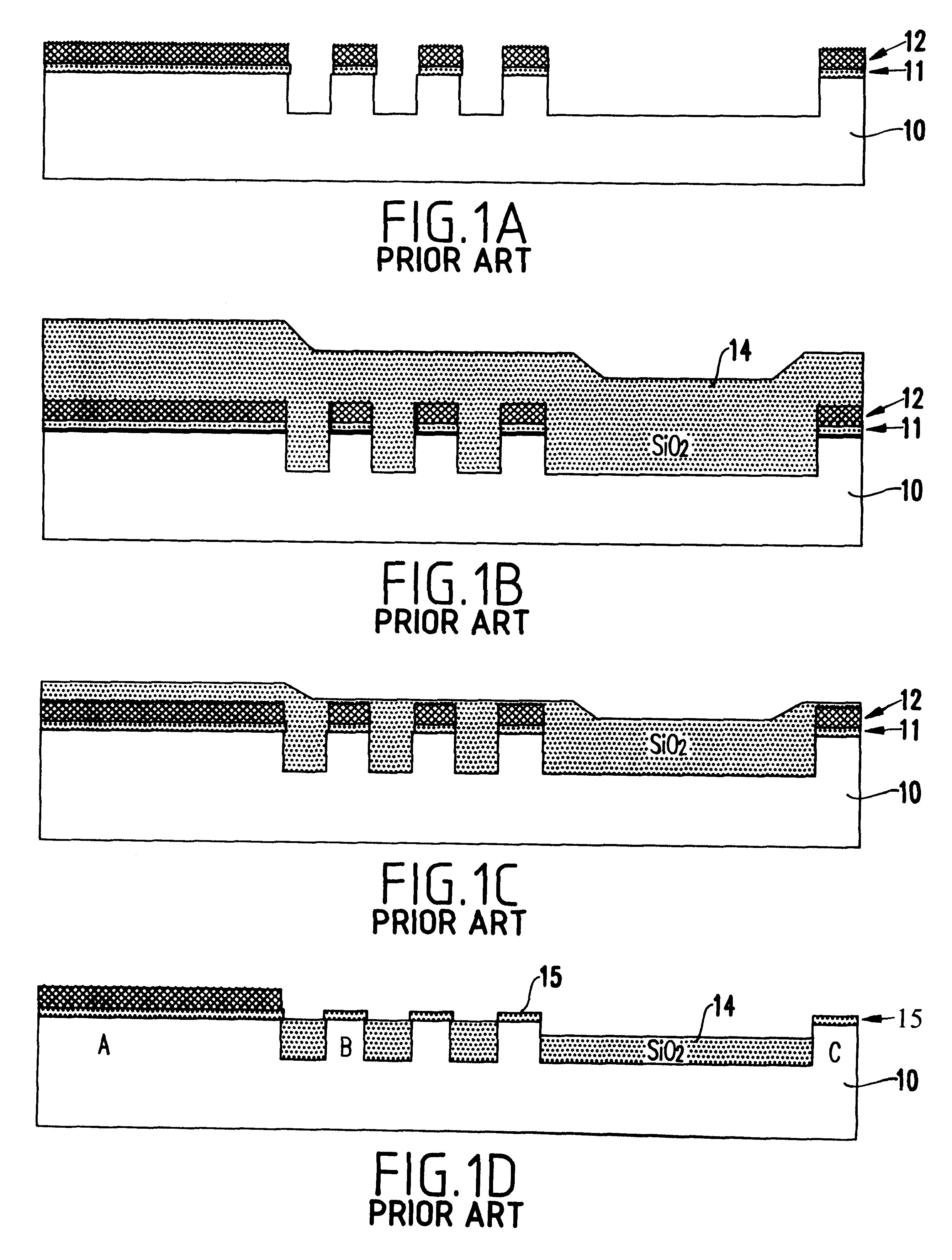

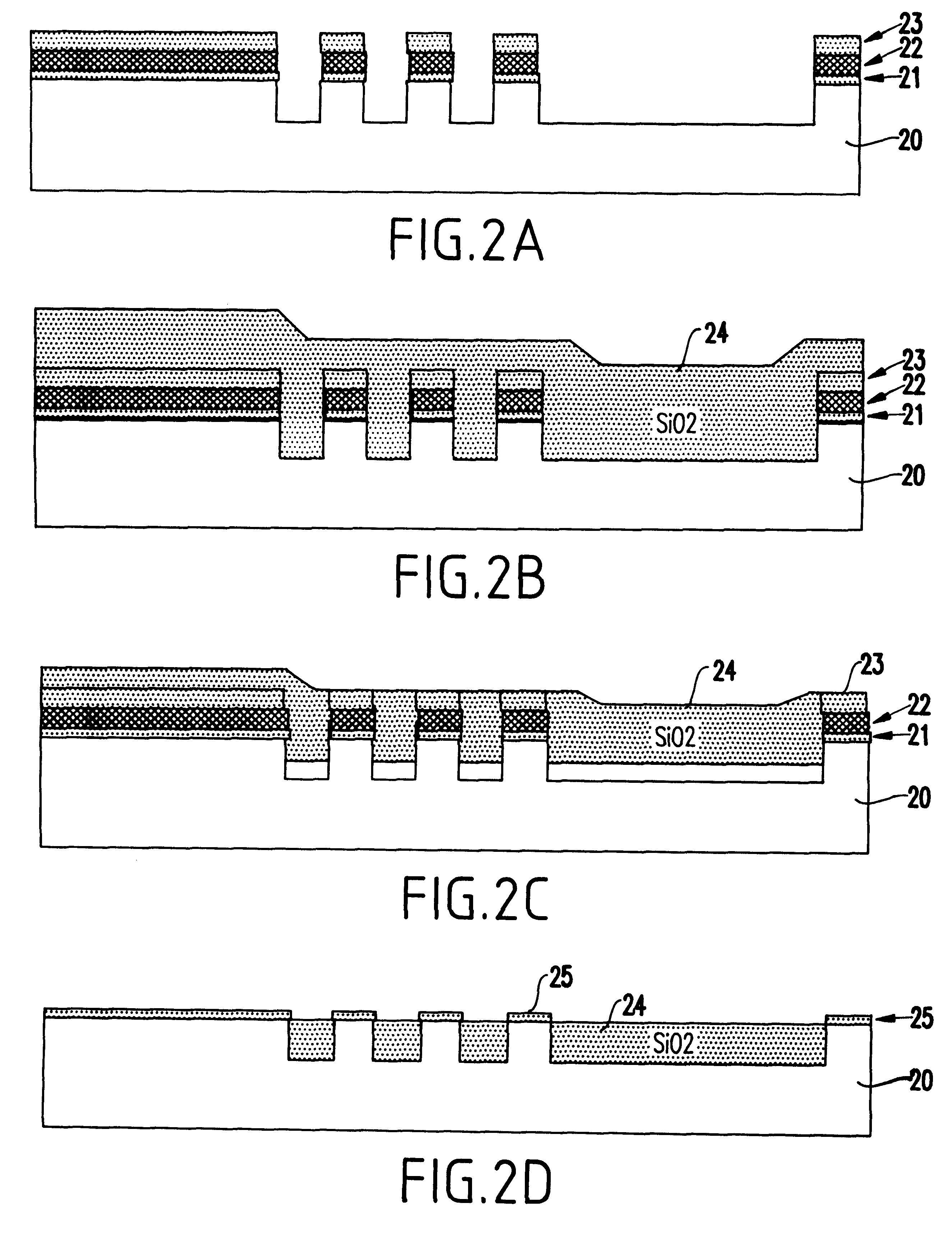

Process for improving local uniformity of chemical mechanical polishing using a self-aligned polish rate enhancement layer

A method for making a semiconductor device, includes forming an oxide layer on a silicon substrate, forming a nitride layer over the oxide layer; depositing one of a doped oxide layer and an undoped porous oxide layer on the nitride layer, etching trenches through the one of the doped layer and the undoped porous oxide layer, the nitride layer, and the oxide layer, depositing an undoped oxide layer to fill the trenches, and patterning the undoped oxide by chemical mechanical polishing (CMP).

Owner:IBM CORP

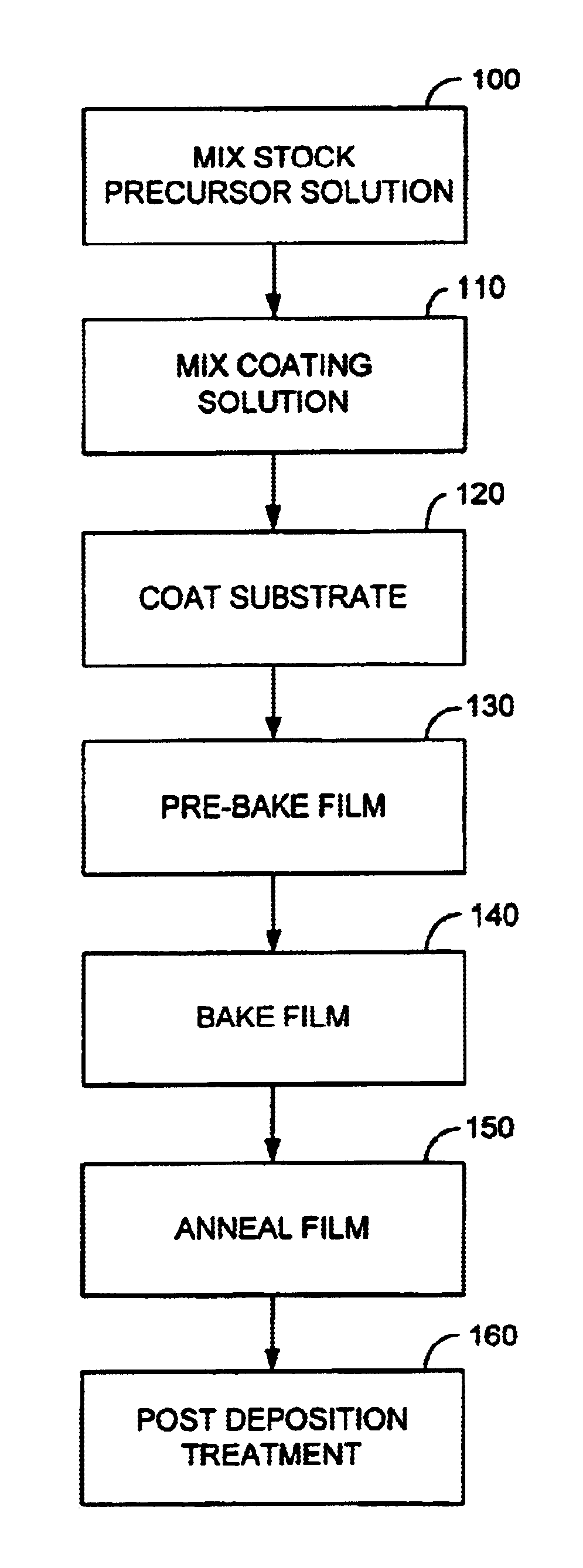

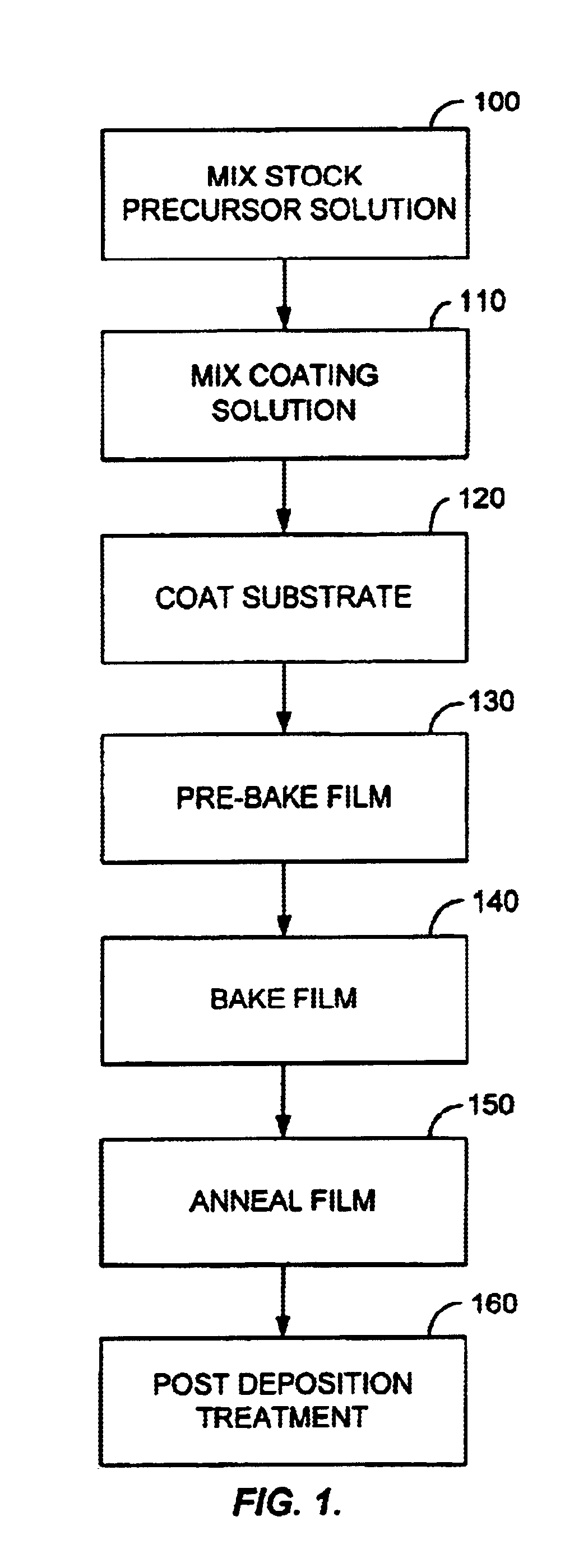

Ionic additives for extreme low dielectric constant chemical formulations

InactiveUS6896955B2Minimal levelSufficient mechanical propertySilicaLayered productsAlkali ionsPhosphate

A process for depositing porous silicon oxide-based films using a sol-gel approach utilizing a precursor solution formulation which includes a purified nonionic surfactant and an additive among other components, where the additive is either an ionic additive or an amine additive which forms an ionic ammonium type salt in the acidic precursor solution. Using this precursor solution formulation enables formation of a film having a dielectric constant less than 2.5, appropriate mechanical properties, and minimal levels of alkali metal impurities. In one embodiment, this is achieved by purifying the surfactant and adding ionic or amine additives such as tetraalkylammonium salts and amines to the stock precursor solution. In some embodiments, the ionic additive is a compound chosen from a group of cationic additives of the general composition [NR(CH3)3]+A−, where R is a hydrophobic ligand of chain length 1 to 24, including tetramethylammonium and cetyltrimethylammonium, and A− is an anion, which may be chosen from the group consisting essentially of formate, nitrate, oxalate, acetate, phosphate, carbonate, and hydroxide and combinations thereof. Tetramethylammonium salts, or more generally tetraalkylammonium salts, or tetraorganoammonium salts or organoamines in acidic media are added to surfactant templated porous oxide precursor formulations to increase the ionic content, replacing alkali ion impurities (sodium and potassium) removed during surfactant purification, but which are found to exhibit beneficial effects in promoting the formation of the resulting dielectric.

Owner:VERSUM MATERIALS US LLC

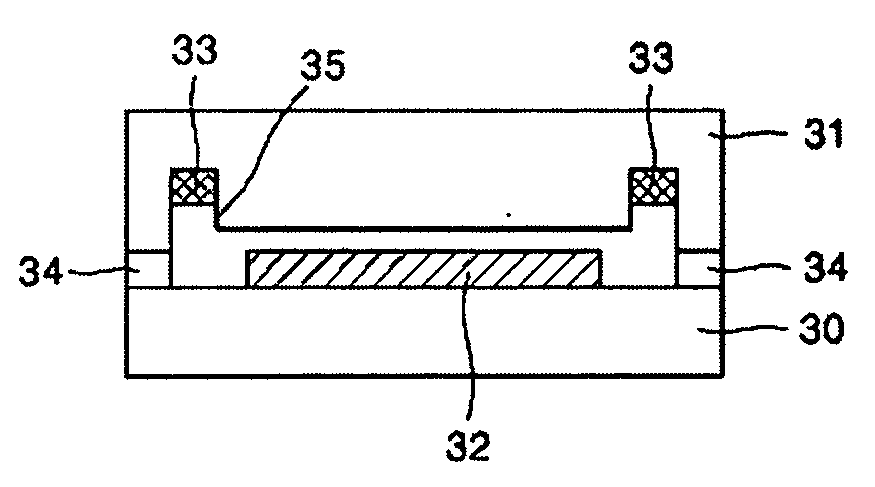

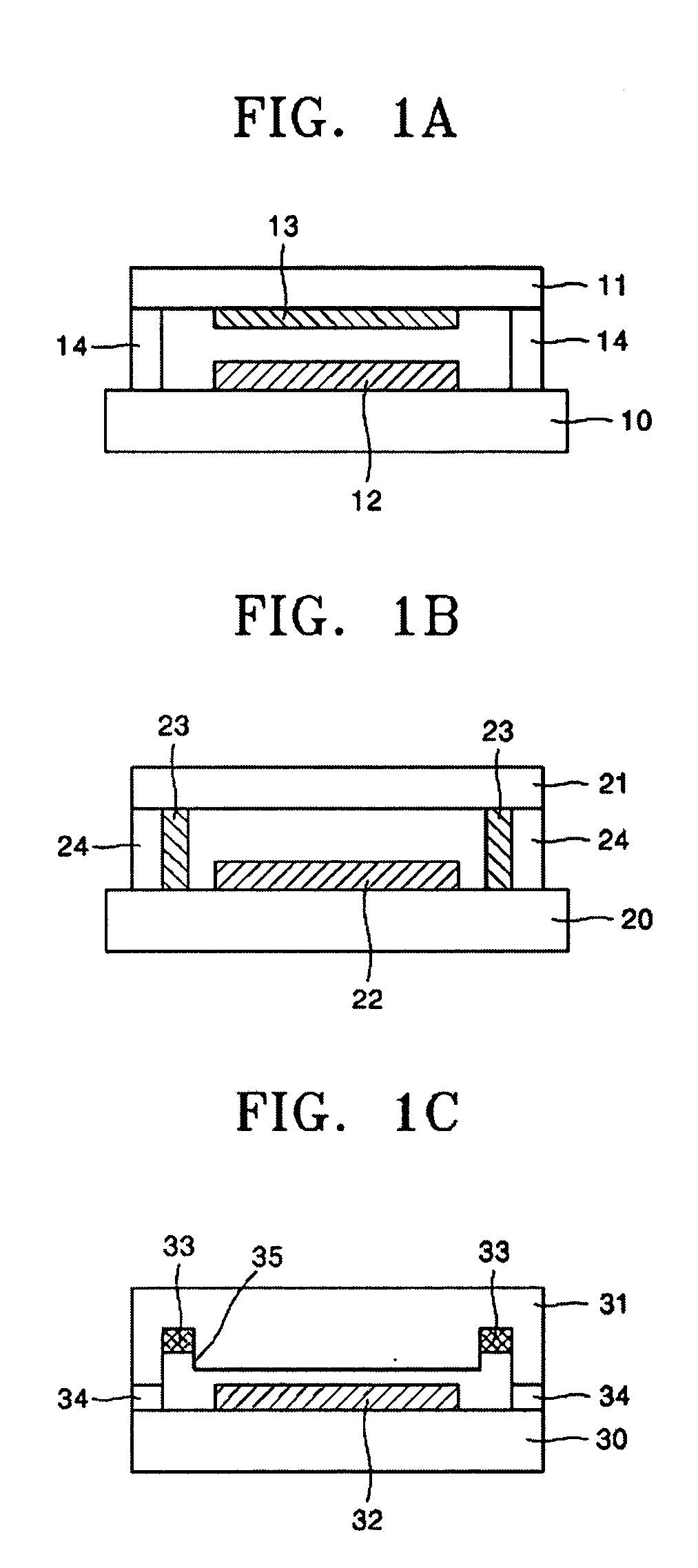

Organic electroluminescent device and method of manufacturing the same

ActiveUS20050046344A1Discharge tube luminescnet screensElectroluminescent light sourcesOrganic filmCompound (substance)

An organic electroluminescent device and its method of manufacturing are provided. The organic electroluminescent device may include a rear substrate, an organic electroluminescent unit including a first electrode, an organic film, and a second electrode stacked on a surface of the rear substrate. It may also include a front substrate joined to the rear substrate to seal an internal space in which the organic electroluminescent unit is disposed. It may also include a porous oxide layer composed of a porous silica and a metal compound on a lower surface thereof. A device constructed according to the present invention may have excellent adsorption of moisture and oxygen, thereby increasing the life span of the device.

Owner:SAMSUNG DISPLAY CO LTD

Bioelectrode formed by three-dimensional ordered porous oxide modified conductive film and preparation method of bioelectrode

InactiveCN103412019AGood biocompatibilityReduced Diffusion ResistanceMaterial analysis by electric/magnetic meansThin film electrodeMembrane surface

The invention relates to a bioelectrode formed by a three-dimensional ordered porous oxide modified conductive film and a preparation method of the bioelectrode. The bioelectrode comprises a conductive film electrode which is formed on an insulation substrate, wherein the film electrode is formed on the insulation substrate in a deposition manner through a physical vapor deposition process; a three-dimensional ordered porous oxide layer containing redox proteins is prepared in situ on the surface of the film electrode; the redox proteins are fixed in pores of the three-dimensional ordered porous oxide layer by adopting an adsorption way, a crosslink way or a covalent bonding way. The pores in the three-dimensional ordered porous oxide layer of the bioelectrode are communicated with one another, so that the dispersion of analyte in an ordered porous material modified layer on the surface of the conductive film can be favored, the dispersion capacity of the analyte can be improved, a mesoporous structure which can be matched with different enzyme molecules can be obtained by utilizing different mesoporous structure guiding agents, and the fixation of the enzyme molecules can be favored. The bioelectrode has good biological compatibility, the fixing effect of the redox proteins is good, the dispersion resistance of the analyte is small, and the electron transmission efficiency is high, so that a biological sensor with high sensitivity can be provided.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

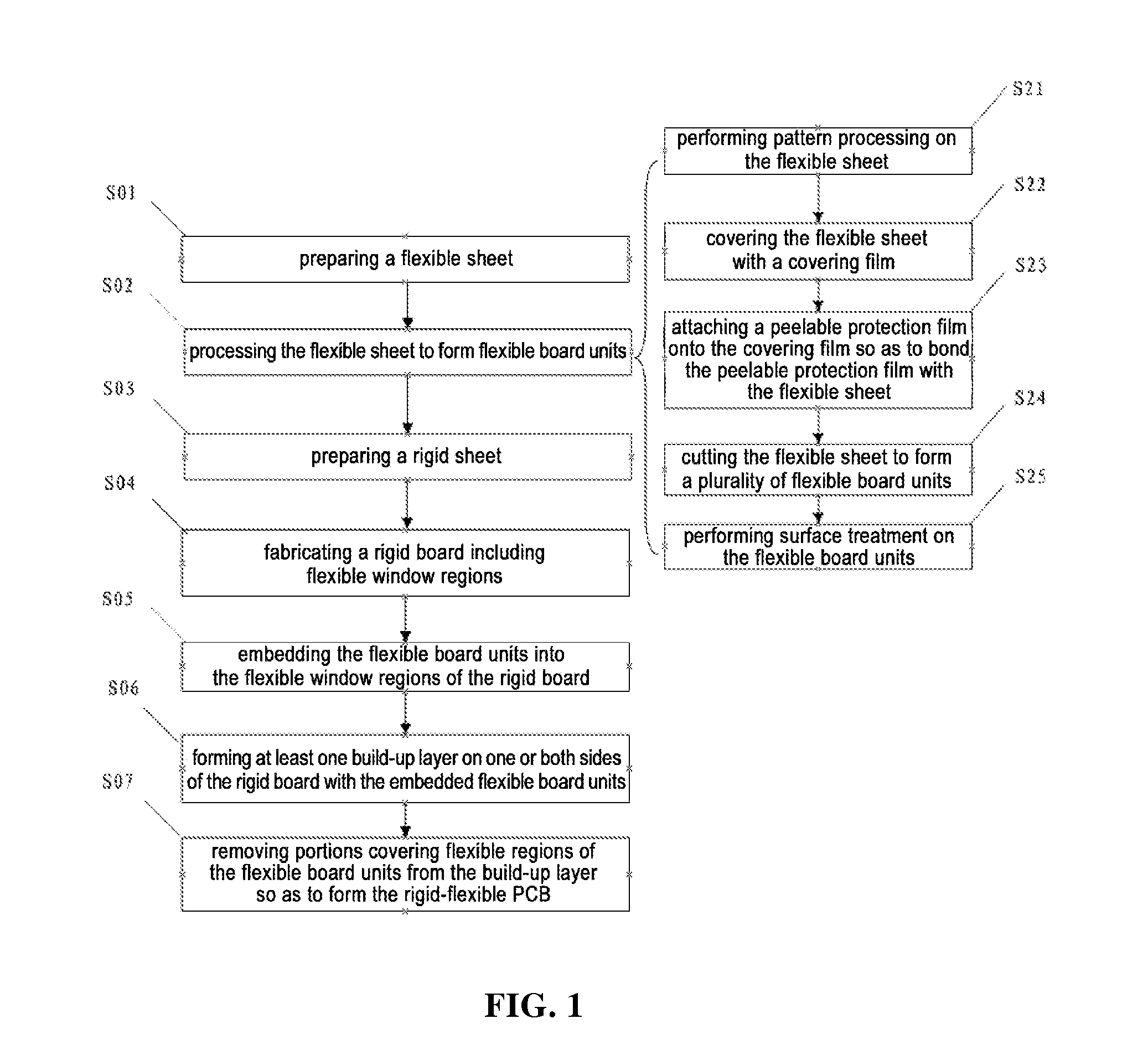

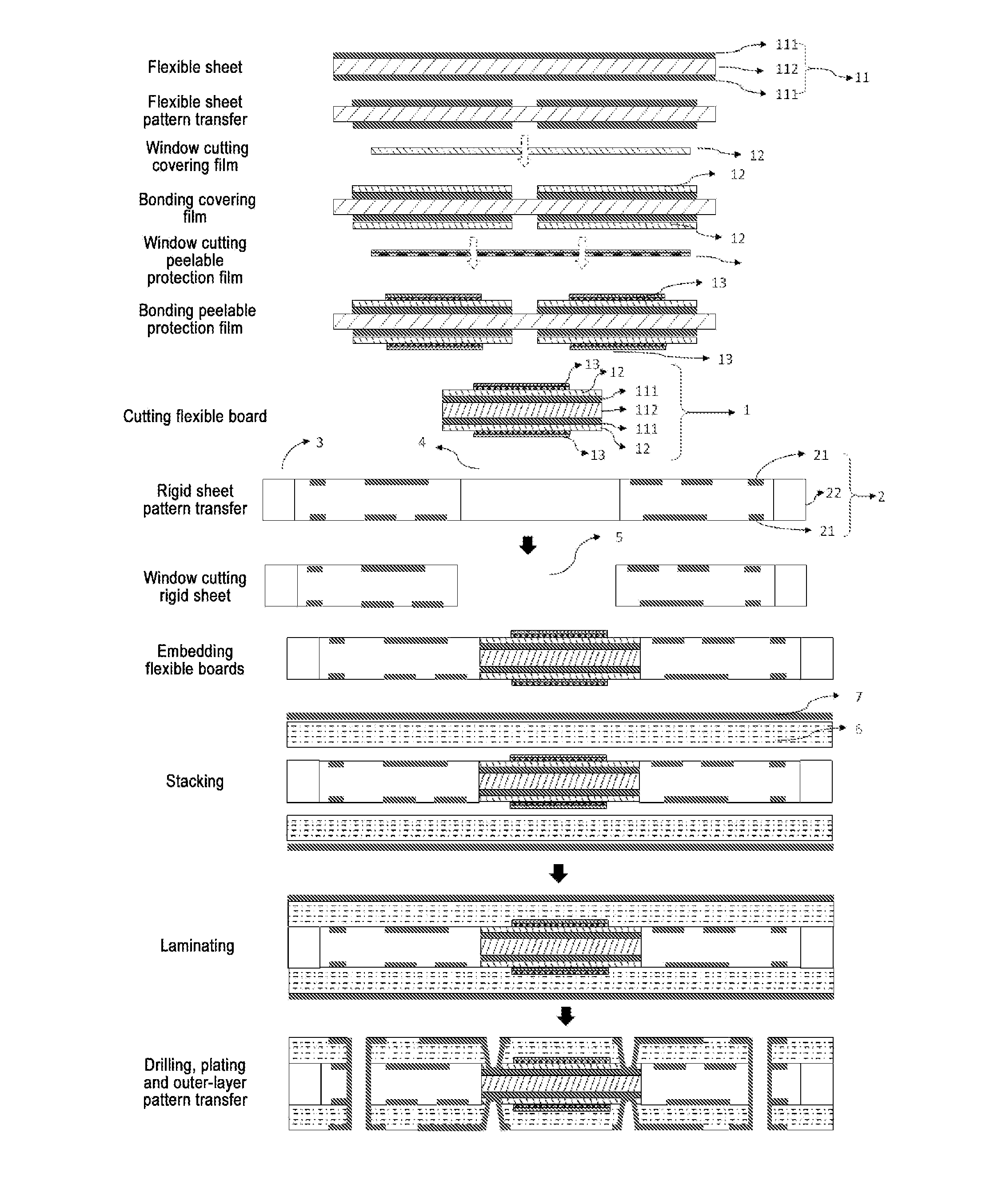

Fabrication method of a rigid-flexible circuit board and rigid-flexible printed circuit board

InactiveUS20140318832A1Low costHigh fabrication costPrinted circuit assemblingPrinted circuit detailsFlexible circuitsUltra high voltage

A manufacturing method of an anode foil for an aluminum electrolytic capacitor is provided, which comprises a first step of forming a porous oxide film, i.e. subjecting an etched foil having etched holes thereon to an anodic oxidation process to form a porous oxide film on both the outer surface of the etched foil and the inner surface of etched holes, and a second step of forming a dense oxide film, i.e. converting the porous oxide film into the dense oxide film. The method can be used to manufacture an anode foil for various voltage ranges, e.g. an ultra-high voltage anode foil whose voltage is more than 800 vf, and the method can increase specific capacity, reduce power consumption, simplify the process, and increase production efficiency.

Owner:PEKING UNIV FOUNDER GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com