Patents

Literature

34results about How to "Increase production output" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

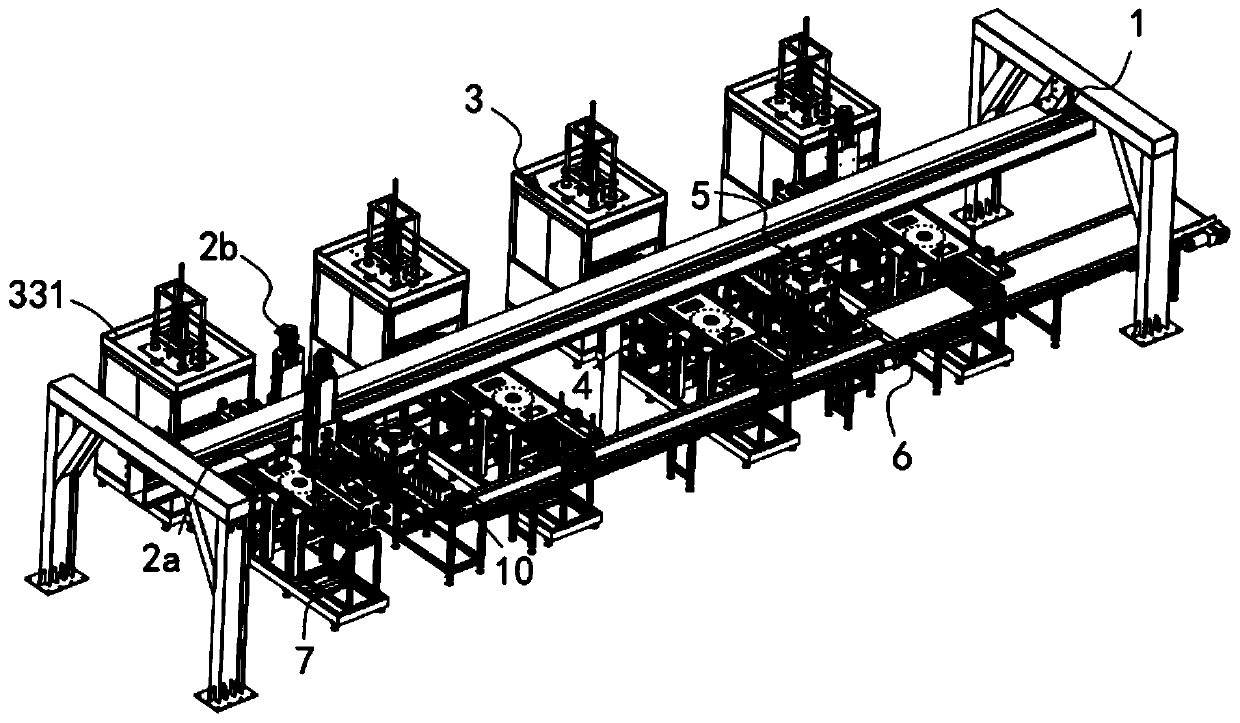

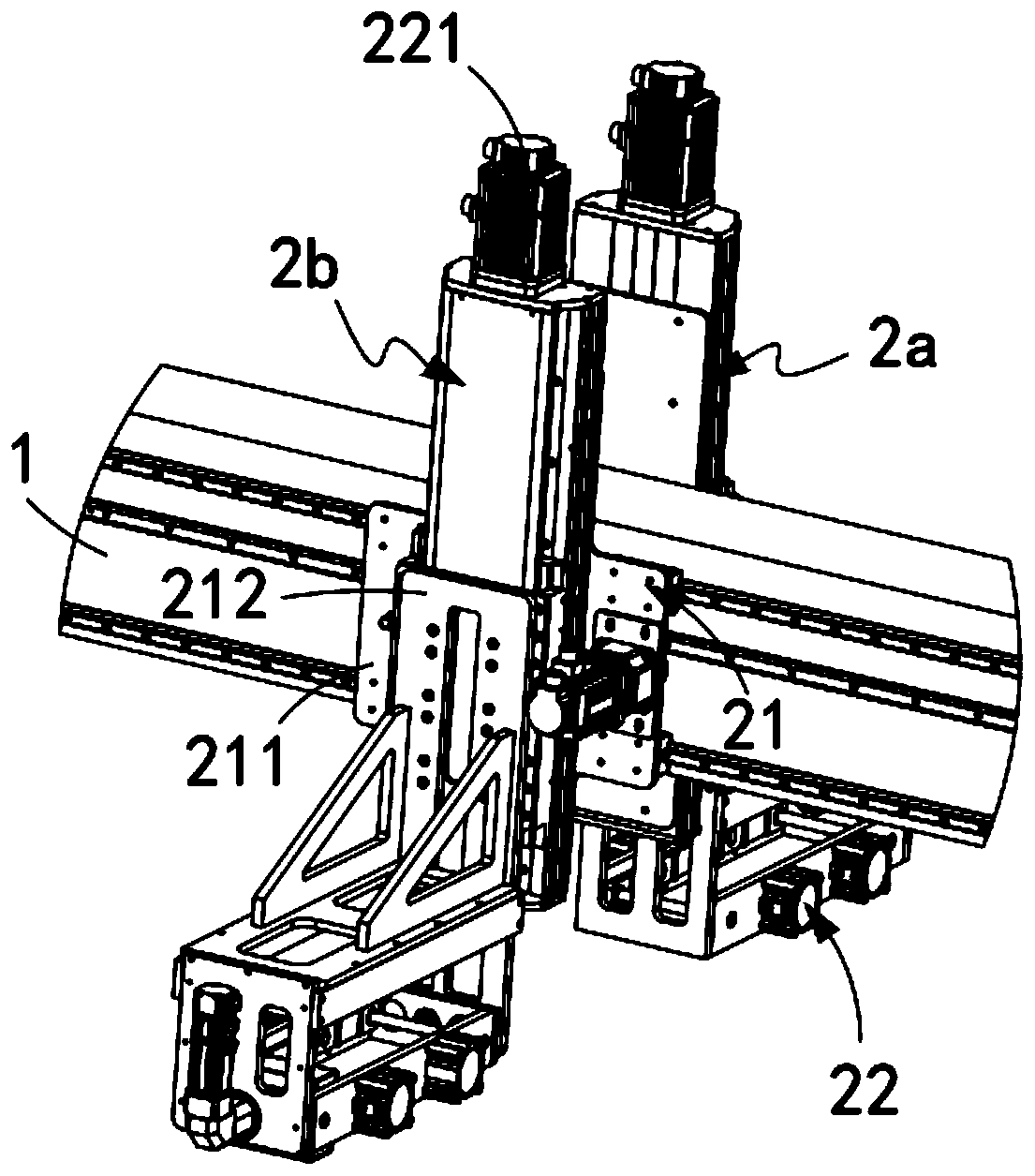

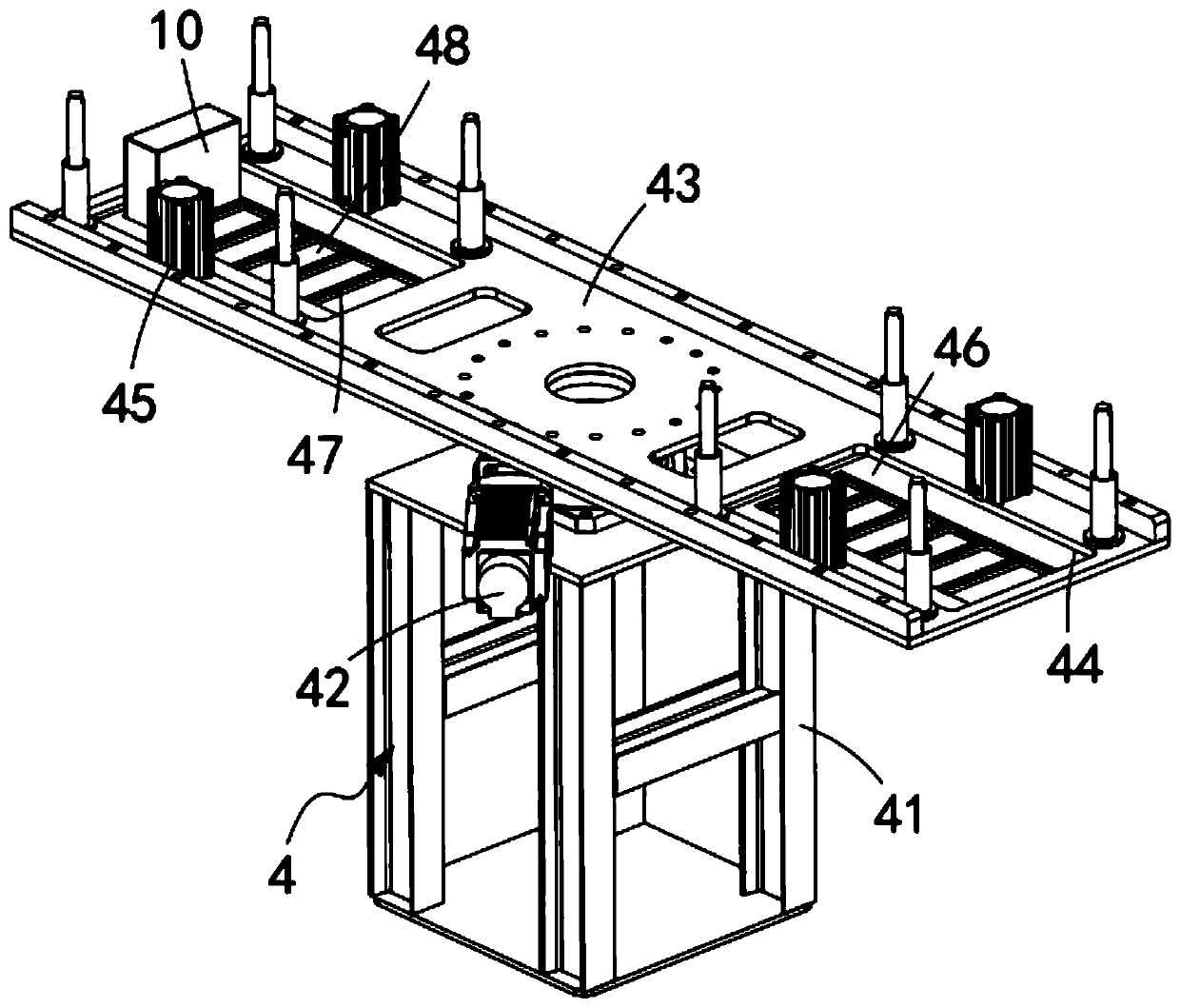

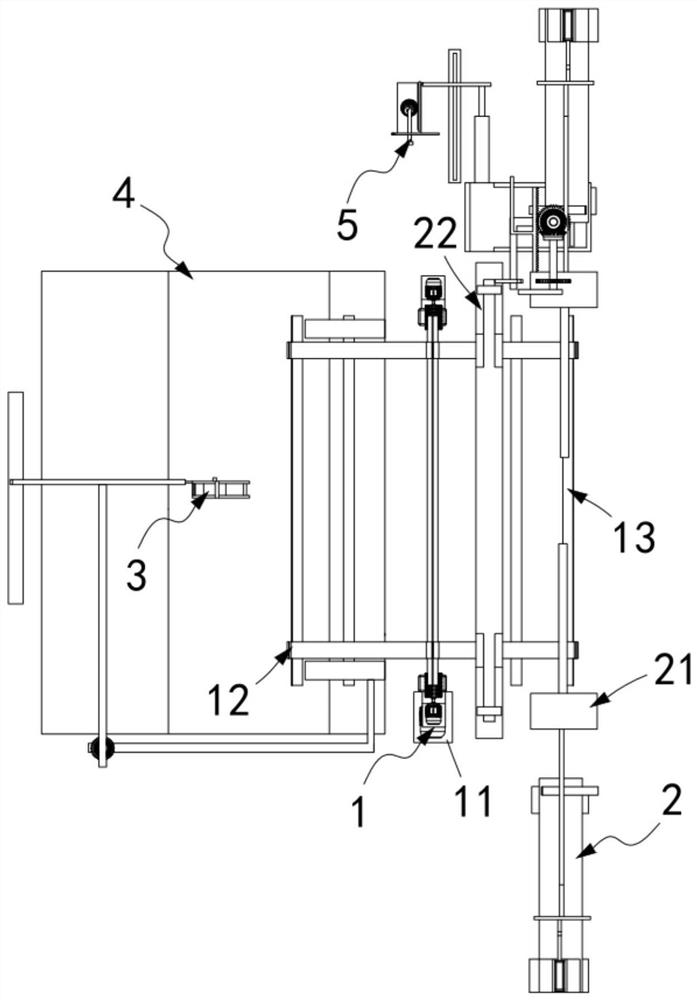

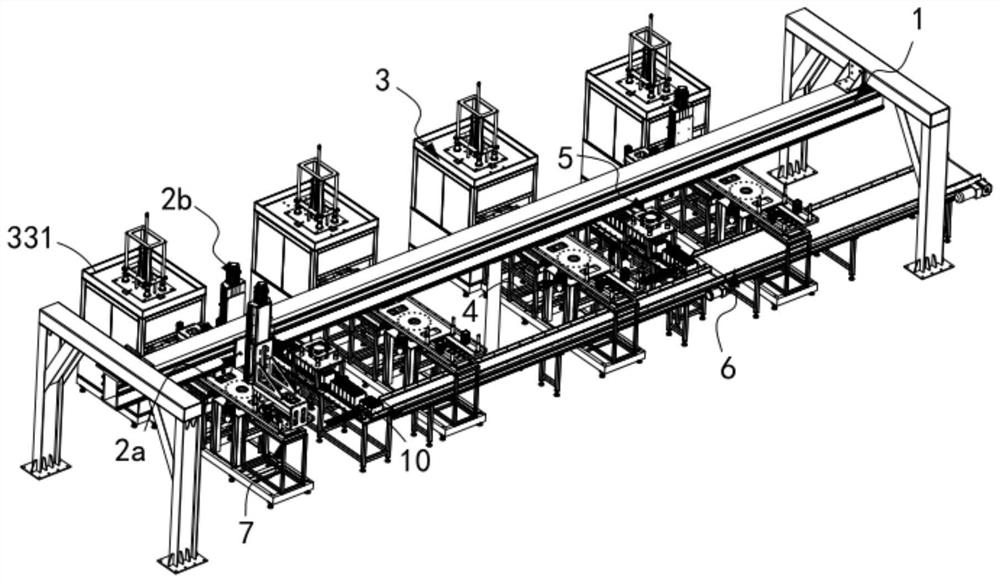

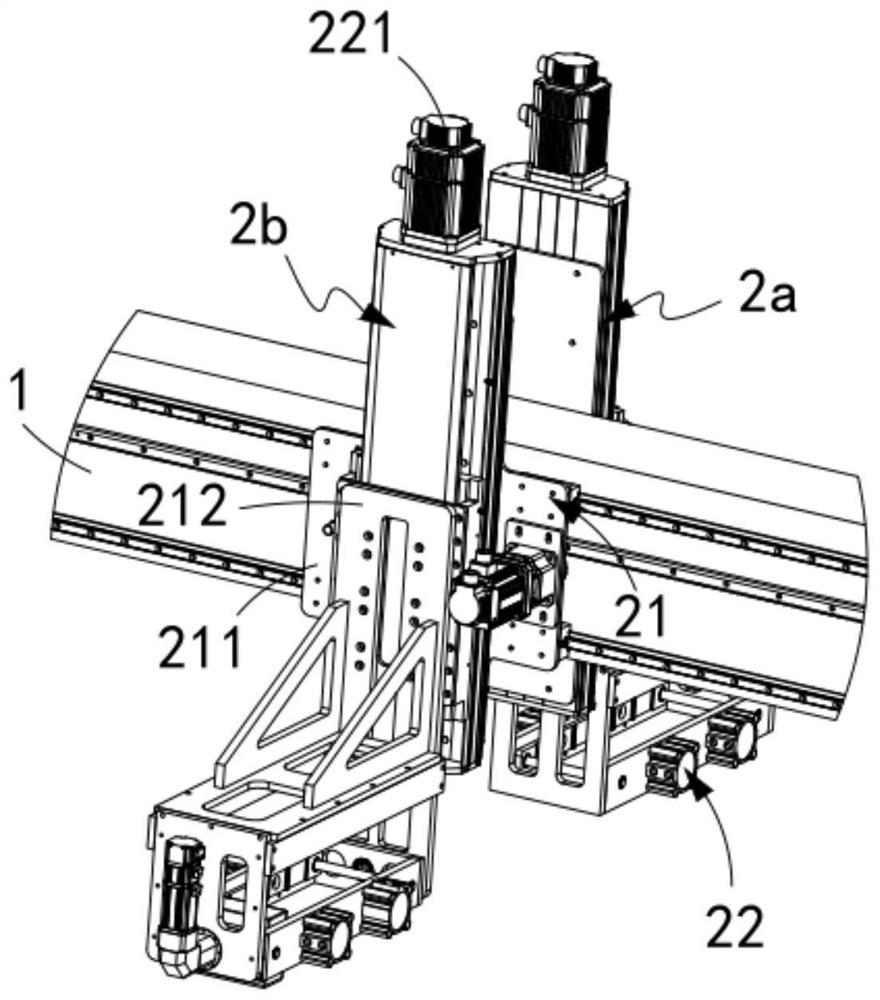

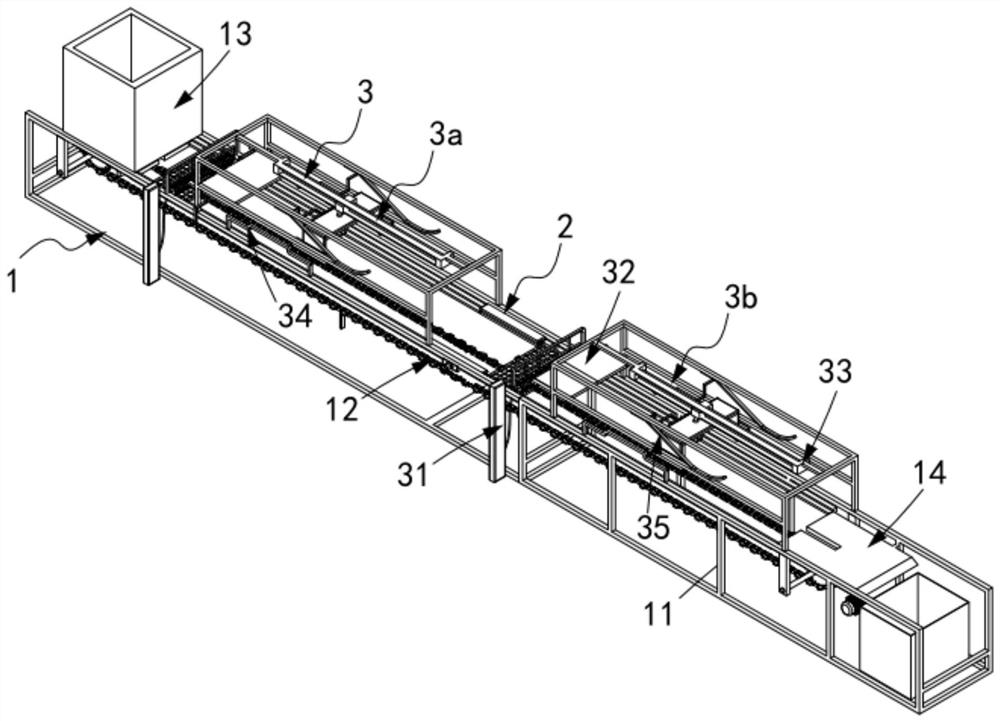

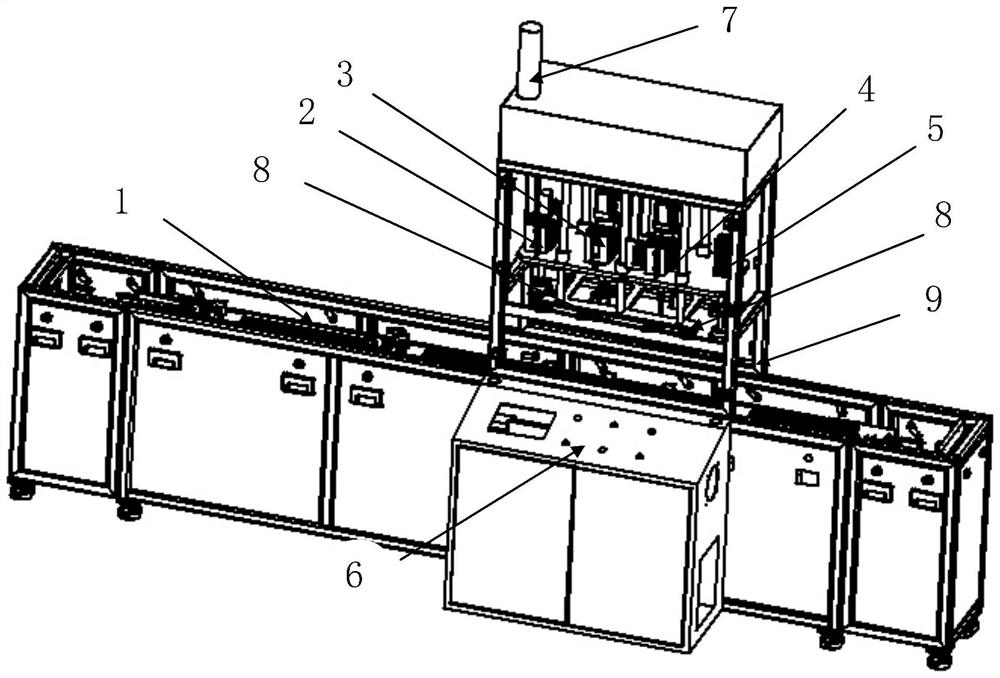

Full-automatic cast welding process and production line of lead-acid storage battery

ActiveCN111266556AConnection time is shortImprove work efficiencyCasting plantsProcess engineeringSoldering

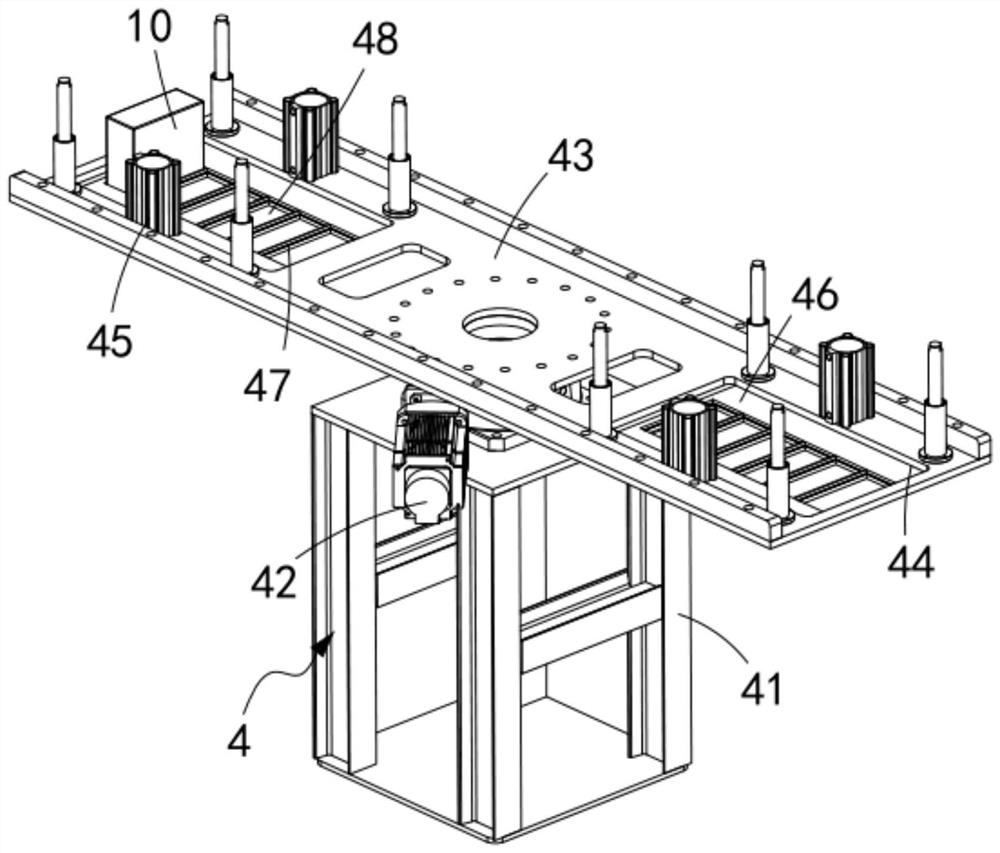

The invention relates to a full-automatic cast welding production line of a lead-acid storage battery. The full-automatic cast welding production line comprises a gantry frame, a feeding hand and a processing production line; the processing production line comprises a discharging hand, a cast welding machine, a station switching machine and a groove entering machine, the two ends of the station switching machine are provided with a feeding station and a processing station correspondingly, and the cast welding machine comprises a lead furnace, a cast welding die and a cooling assembly. The invention also provides a full-automatic cast welding process of the lead-acid storage battery. The process comprises the step: step 1, cutting and brushing work; step 2, feeding; step 3, soldering flux adhering; step 4, lead liquid containing; step 5, cast welding processing; step 6, groove entering; and step 7, outputting. The technical problems that feeding and discharging need to be carried out manually in the cast welding process, cannot be tightly connected with the cutting and brushing work, and connection production cannot be realized are solved.

Owner:长兴玖佳机械股份有限公司

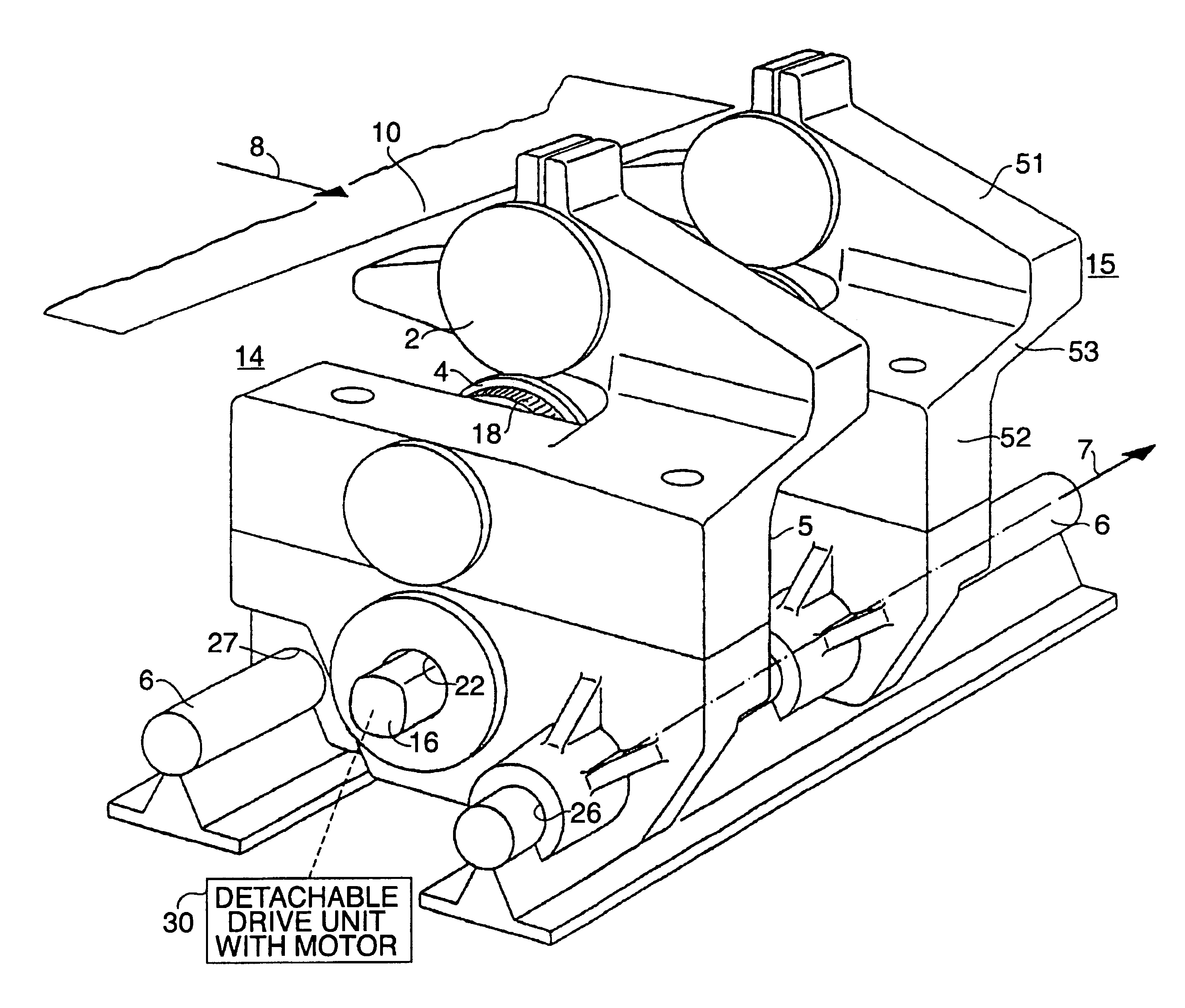

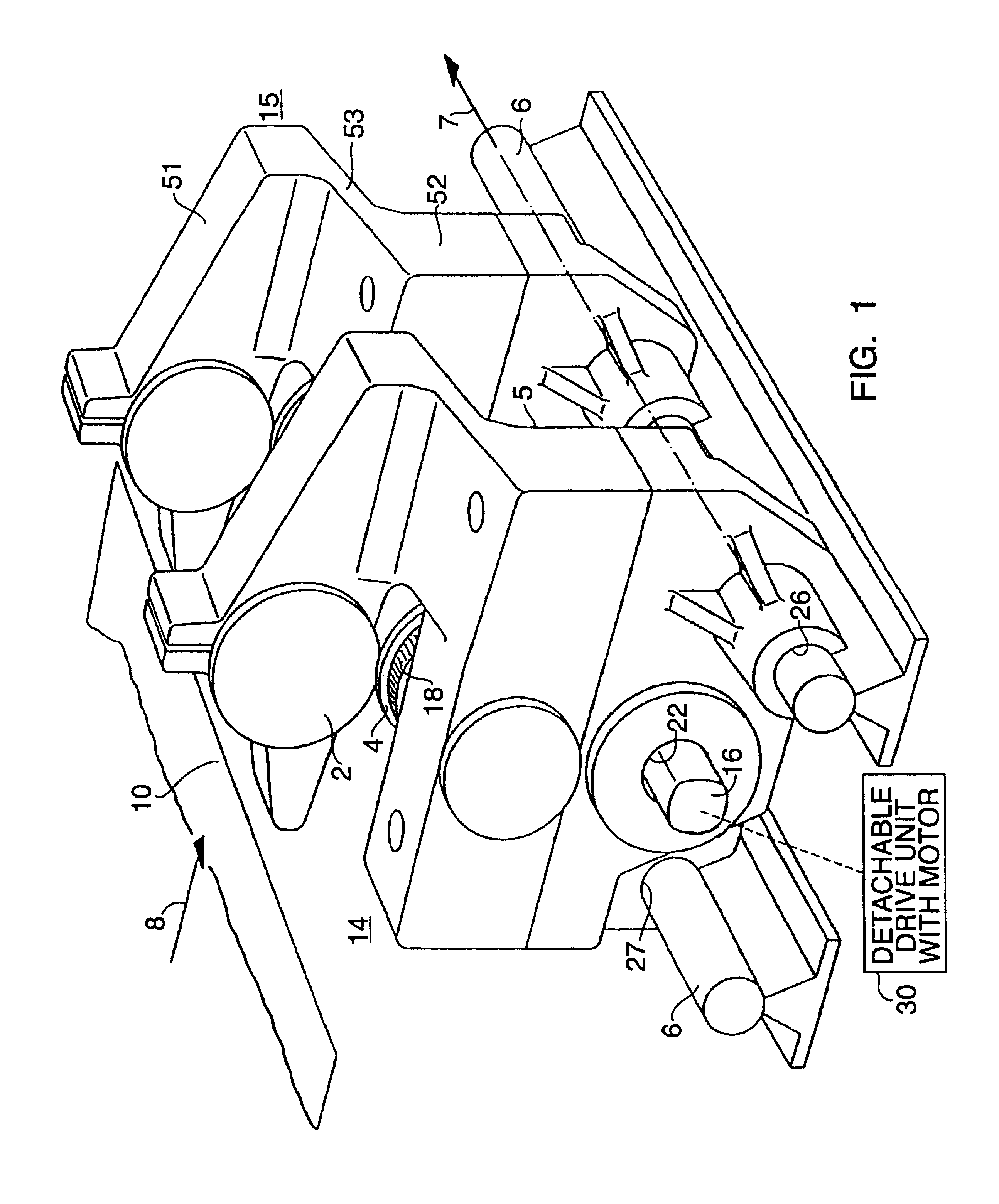

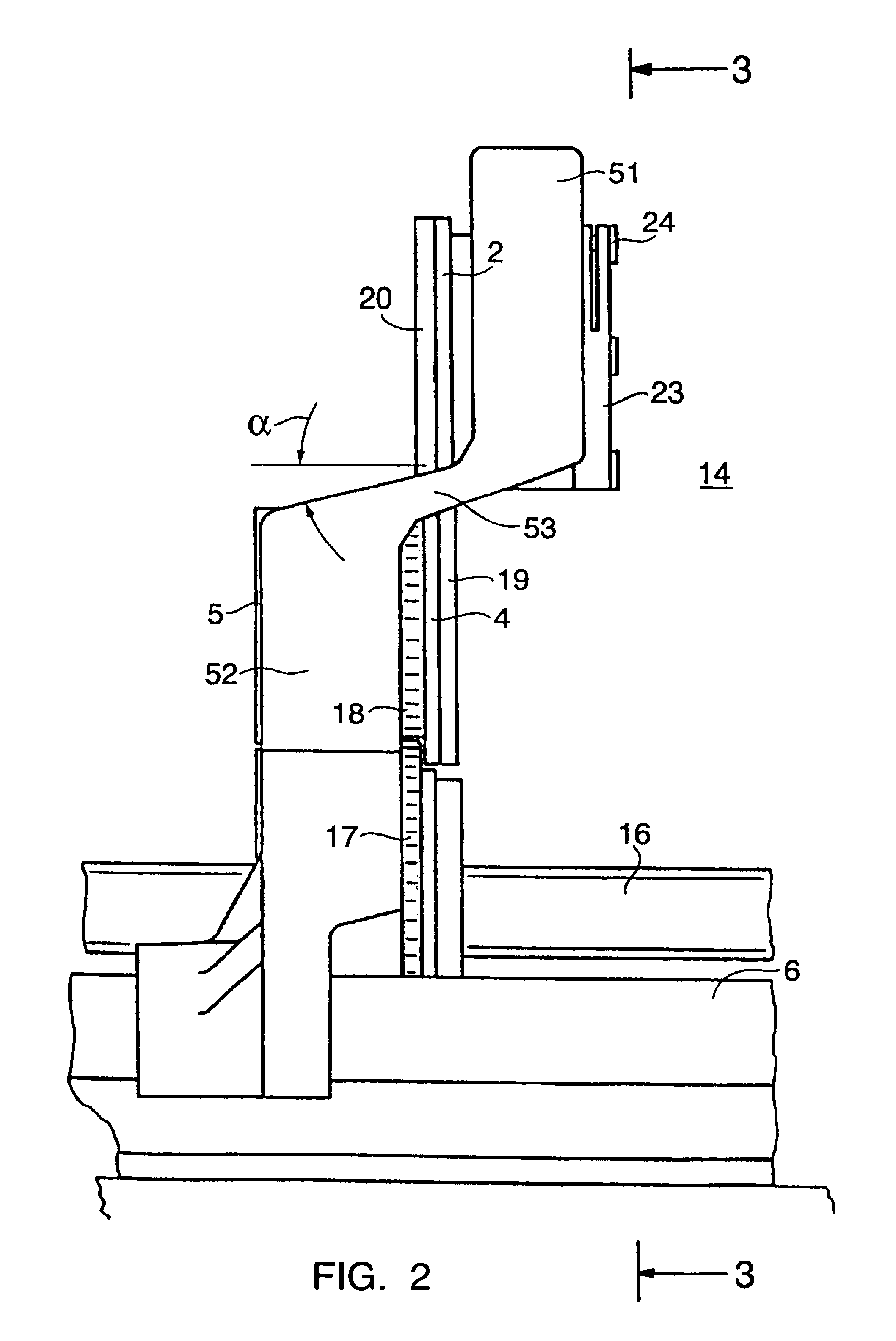

Rotary cutting unit

InactiveUS7028596B1Improve usabilityReduced conversion timeShearing machinesMetal working apparatusIn planeAcute angle

A circular-cutter unit for equipment cutting flat lengths of material and sheet metal in a horizontal plane has upper and a lower circular blades both in planes perpendicular to the horizontal plane and in a longitudinal direction, carried by an upper and lower blade shaft, respectively, which are parallel with the horizontal plane and perpendicular to the longitudinal direction. The two blade shafts are rigidly and rotatably mounted in a common frame. The frame is U-shaped with the upper and lower legs connected by a flat yoke intersecting the horizontal plane at an acute angle. Several cutter units are mounted in a single apparatus and driven by a common drive from which the units can be individually detached for servicing.

Owner:ELPATRONIC AG

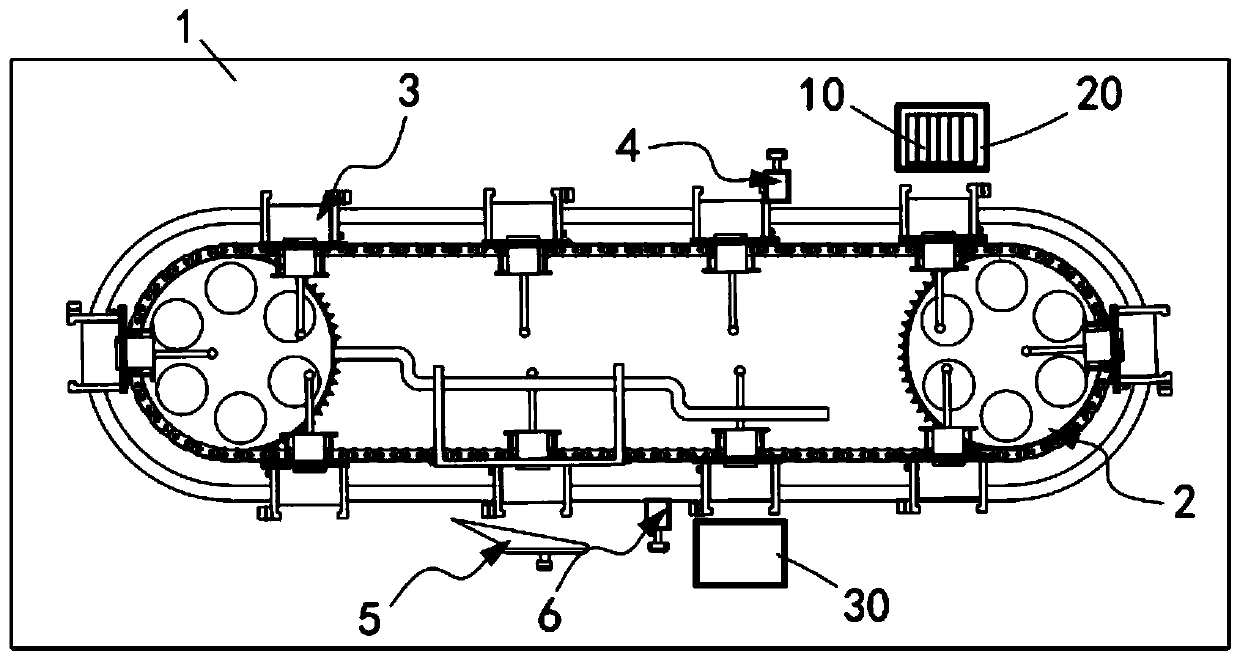

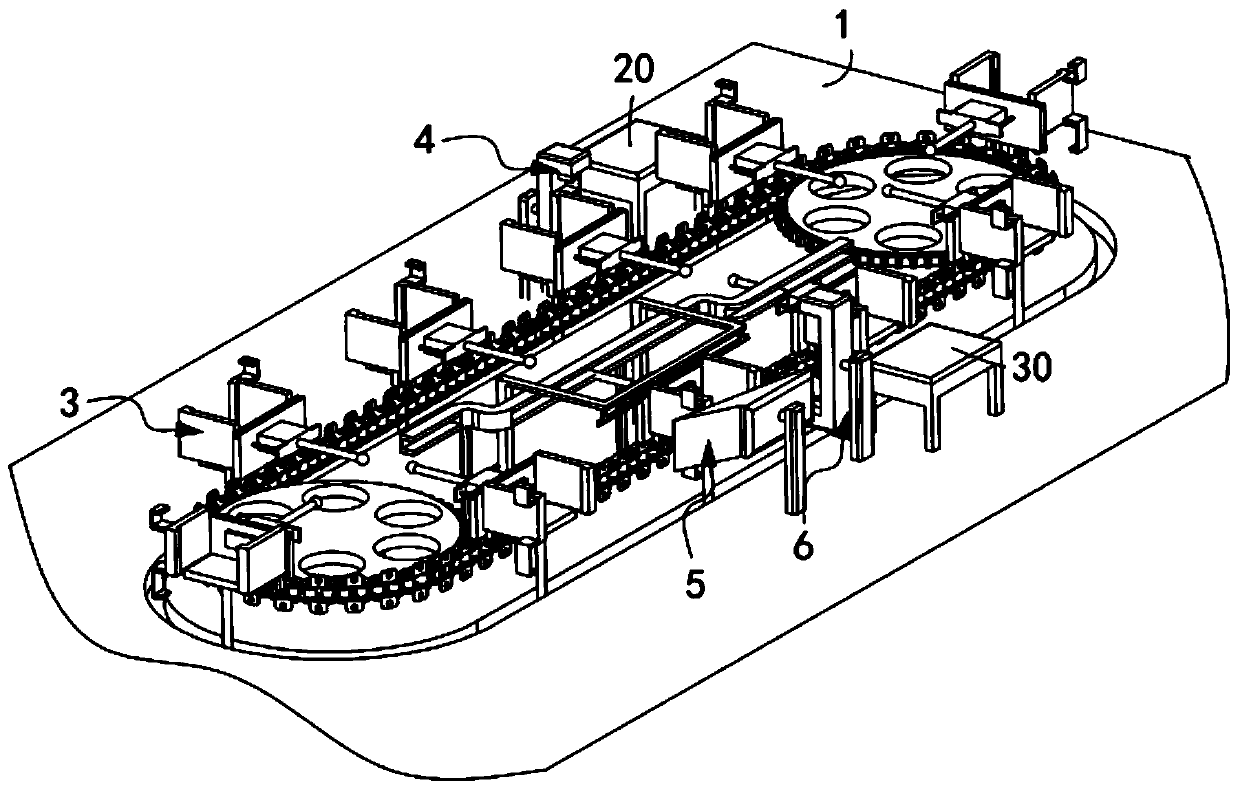

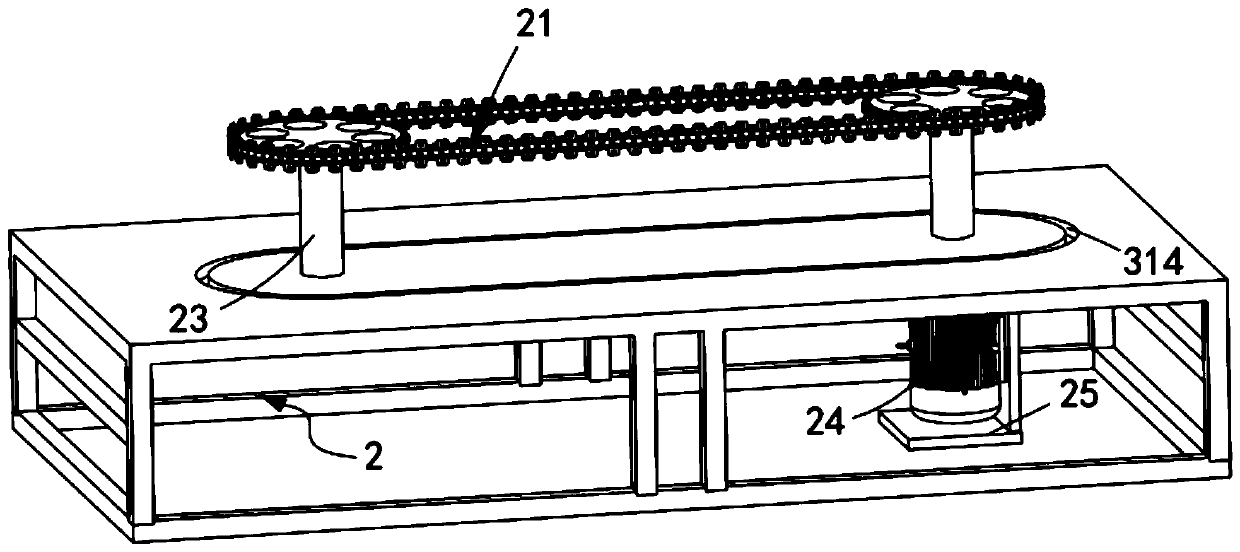

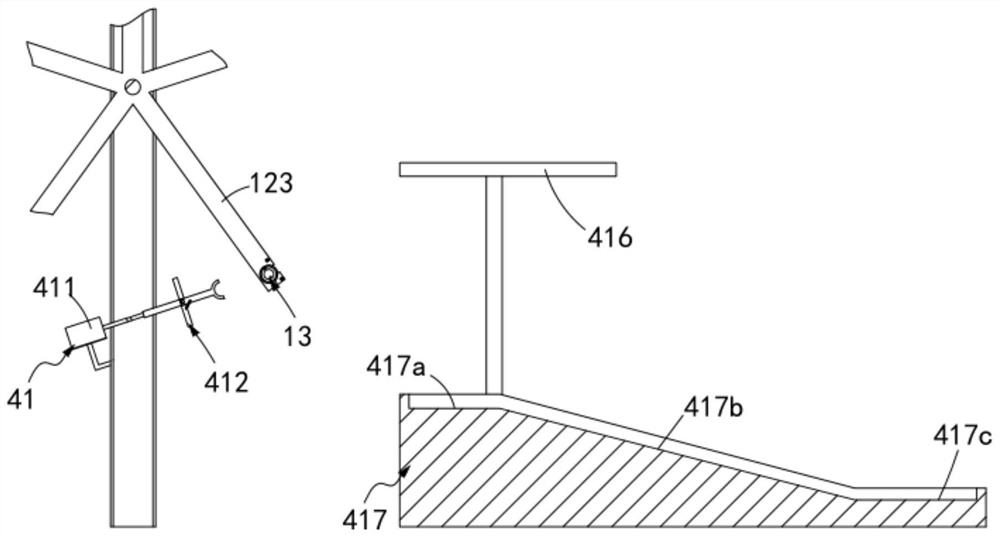

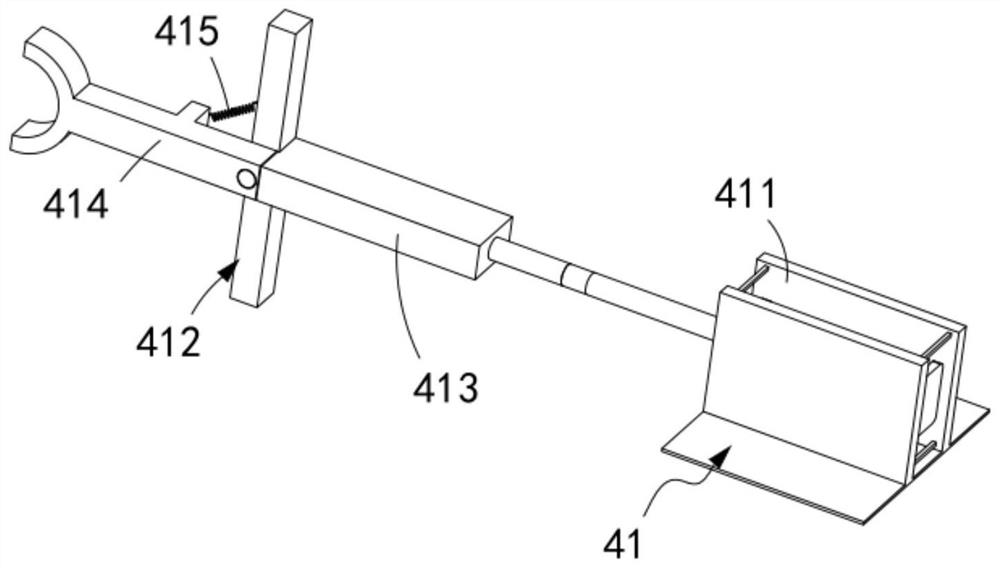

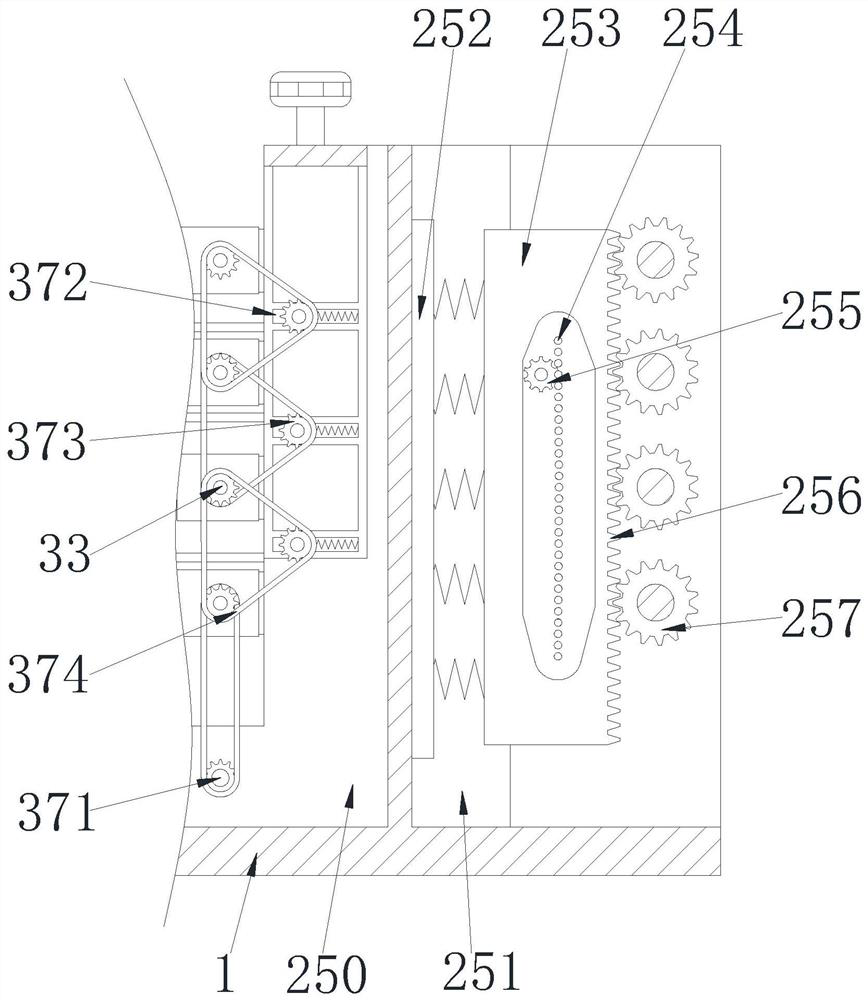

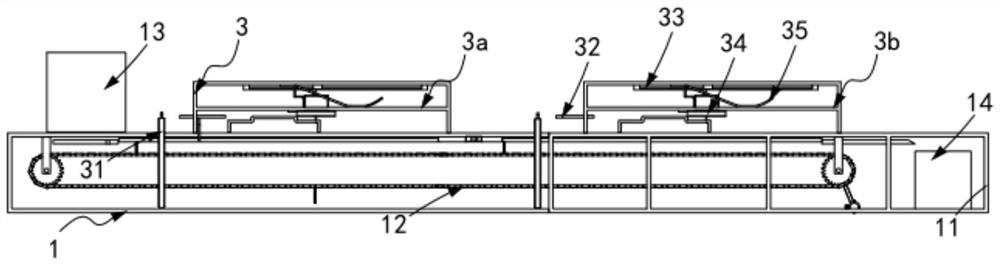

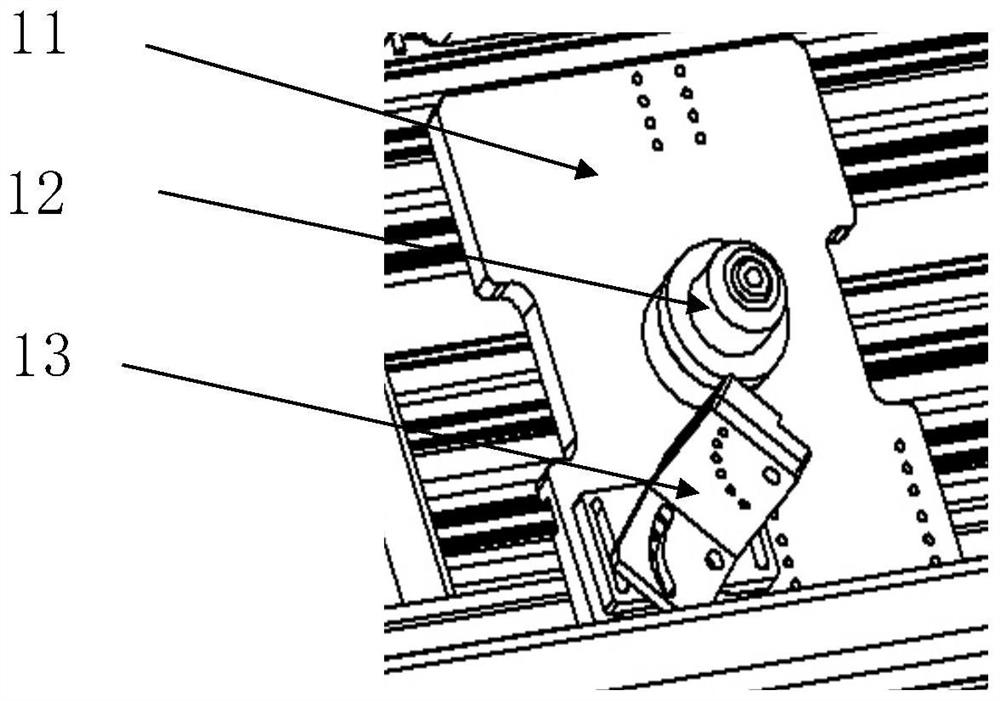

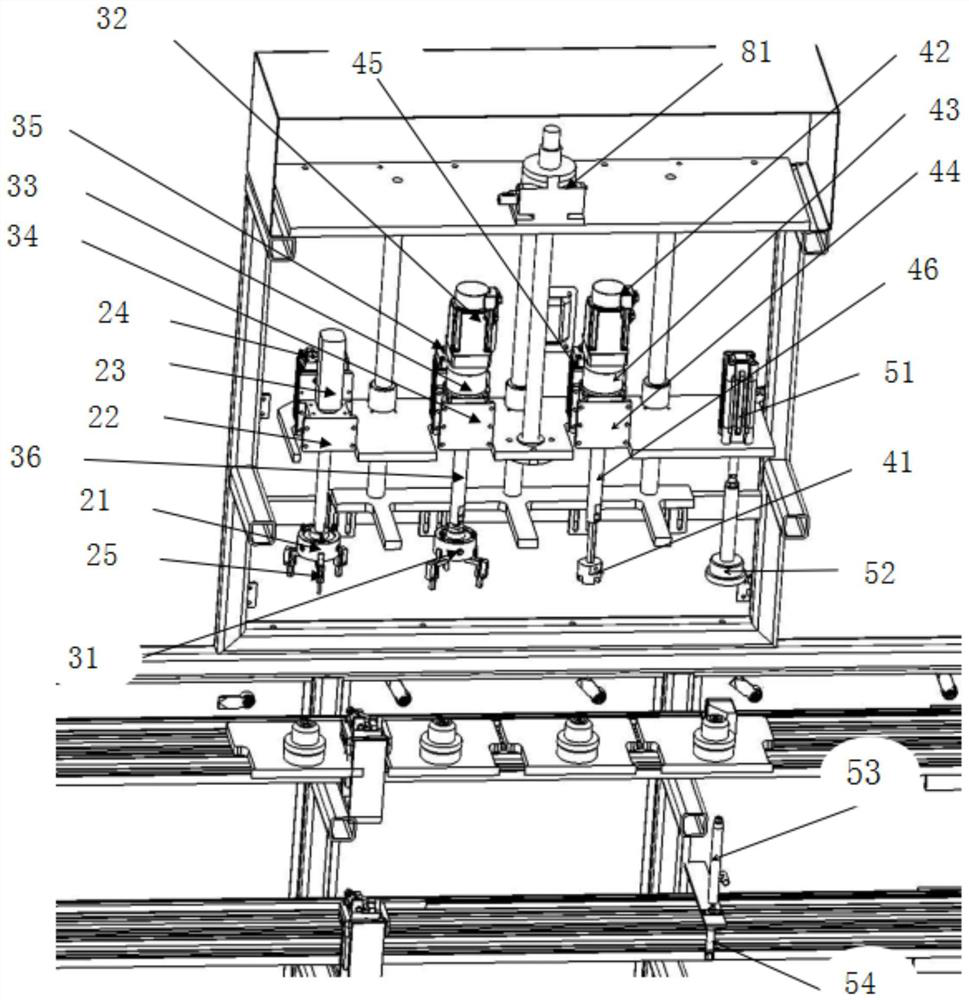

Burr machining equipment for plastic shell of storage battery

ActiveCN111168519AHigh degree of automationIncrease production outputEdge grinding machinesGrinding drivesEngineeringMechanical engineering

The invention relates to burr machining equipment for a plastic shell of a storage battery. The burr machining equipment for the plastic shell of the storage battery comprises a rack, a turnover mechanism installed on the rack, and a plurality of groups of clamping mechanisms which are equidistantly arranged in a transmission direction of the turnover mechanism, wherein a loading station, a cutting station and a discharge station are sequentially formed on the rack in a rotation direction of the turnover mechanism, a loading mechanism is arranged on the loading station, a cutting mechanism isarranged on the cutting station, and a discharge mechanism is arranged on the discharge station; and a shell body of the storage battery is loaded to the clamping mechanisms from the loading station through the loading mechanism, enter the cutting station under the driving of the turnover mechanism and is subjected to burr treatment working through the cutting mechanism, and then is transmitted tothe discharge station through the driving of the turnover mechanism, and meanwhile, automatic output is carried out by virtue of the discharge mechanism. According to the burr machining equipment forthe plastic shell of the storage battery, the technical problem that fixing location cannot be carried out on the shell body of the storage battery during deburring working, and then the accuracy ofthe deburring working is lowered, is solved.

Owner:湖南省金翼有色金属综合回收有限公司

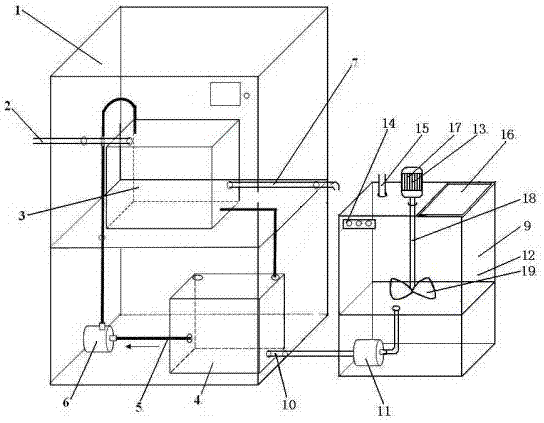

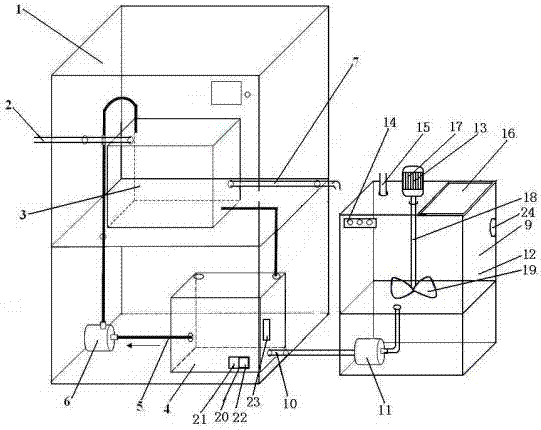

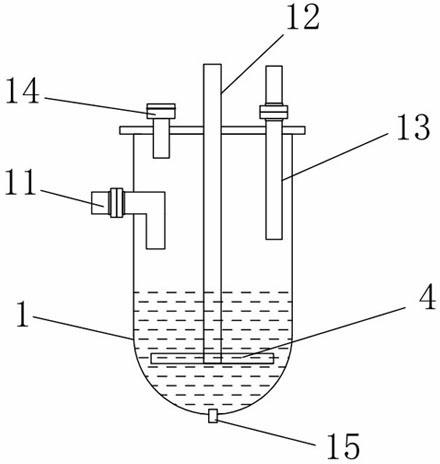

Strong basic electrolysis water generating device for controlling temperature of electrolyte

InactiveCN107055698AImprove production qualityIncrease production outputWater treatment parameter controlTreatment control/steeringEnvironmental chemistryElectrolysed water

The invention discloses a strong basic electrolysis water generating device for controlling the concentration of electrolyte and belongs to the technical field of electrolysis water production. The strong basic electrolysis water generating device is characterized in that an electrolyte solution concentration real-time replenishing device is arranged on an existing strong basic electrolysis water generating device and comprises a liquid replenishing pipe, a liquid replenishing pump, a liquid preparing tank and a stirrer; the stirrer is arranged in the liquid preparing tank and is used for stirring to enable the concentration of the electrolyte solution to be uniform; the liquid replenishing pump is arranged on the liquid replenishing pipe; the liquid preparing tank is communicated with an electrolyte solution storing tank by the liquid replenishing pipe. The strong basic electrolysis water generating device has the beneficial effects that the concentration of the electrolyte solution in the electrolysis process can be effectively controlled, the concentration of the electrolyte solution is enabled to meet the requirements, and the production quality of electrolysis water is improved; electrolysis equipment is enabled to continuously work, and production output of the electrolysis water is greatly increased; a concentration sensing device can be used for controlling and stabilizing the concentration of electrolyte in real time.

Owner:重庆七口泉生物医药科技有限公司

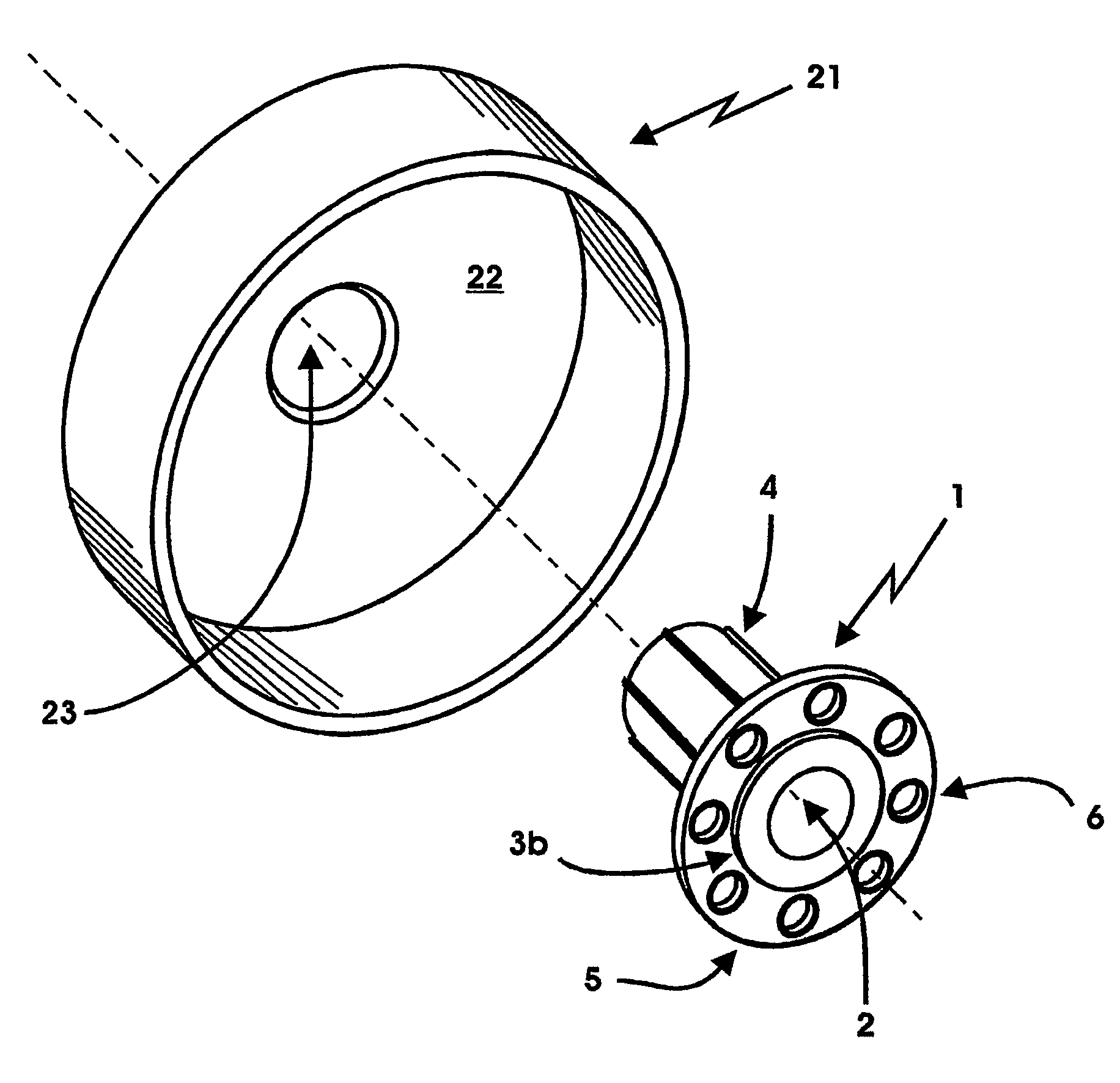

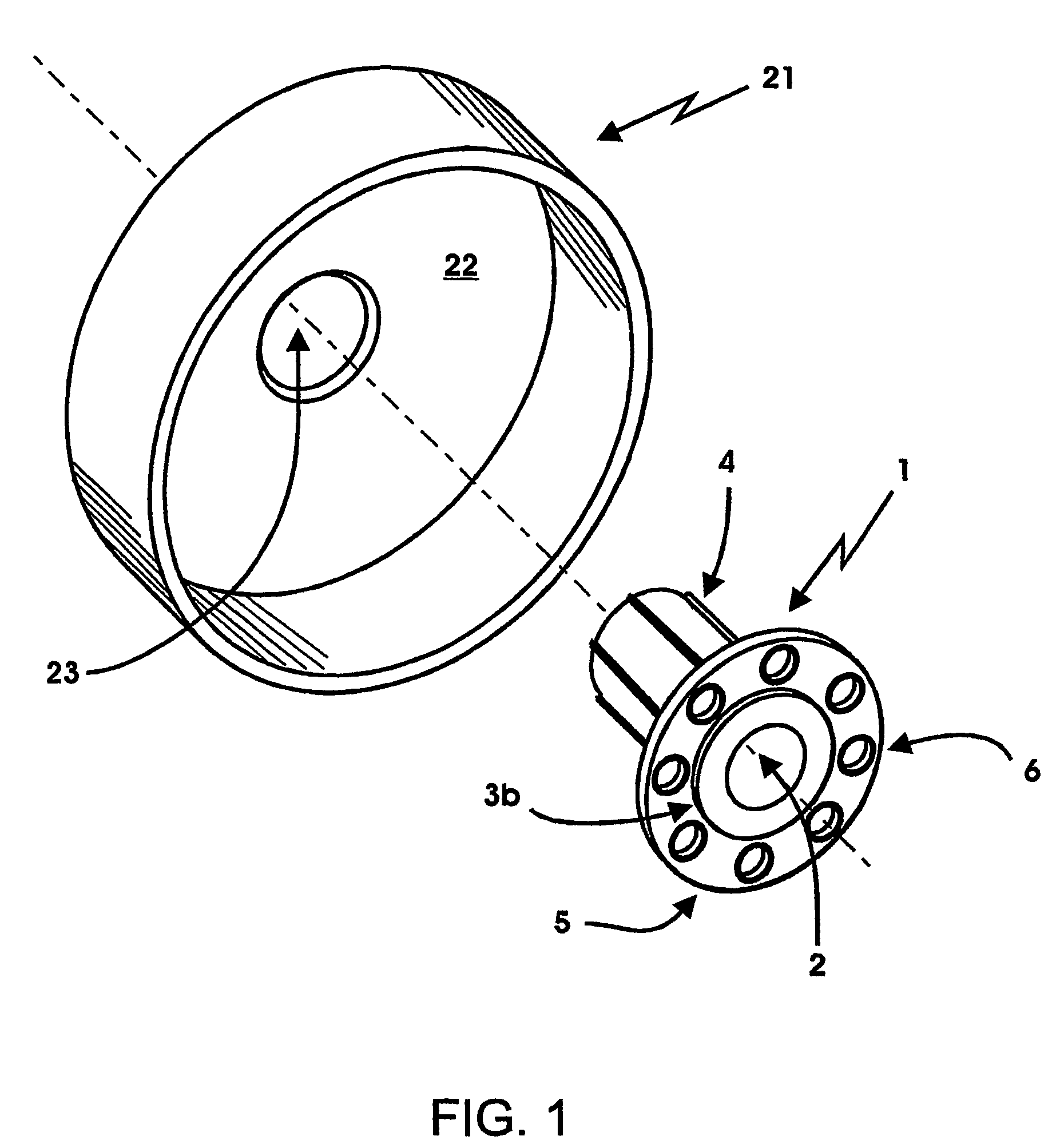

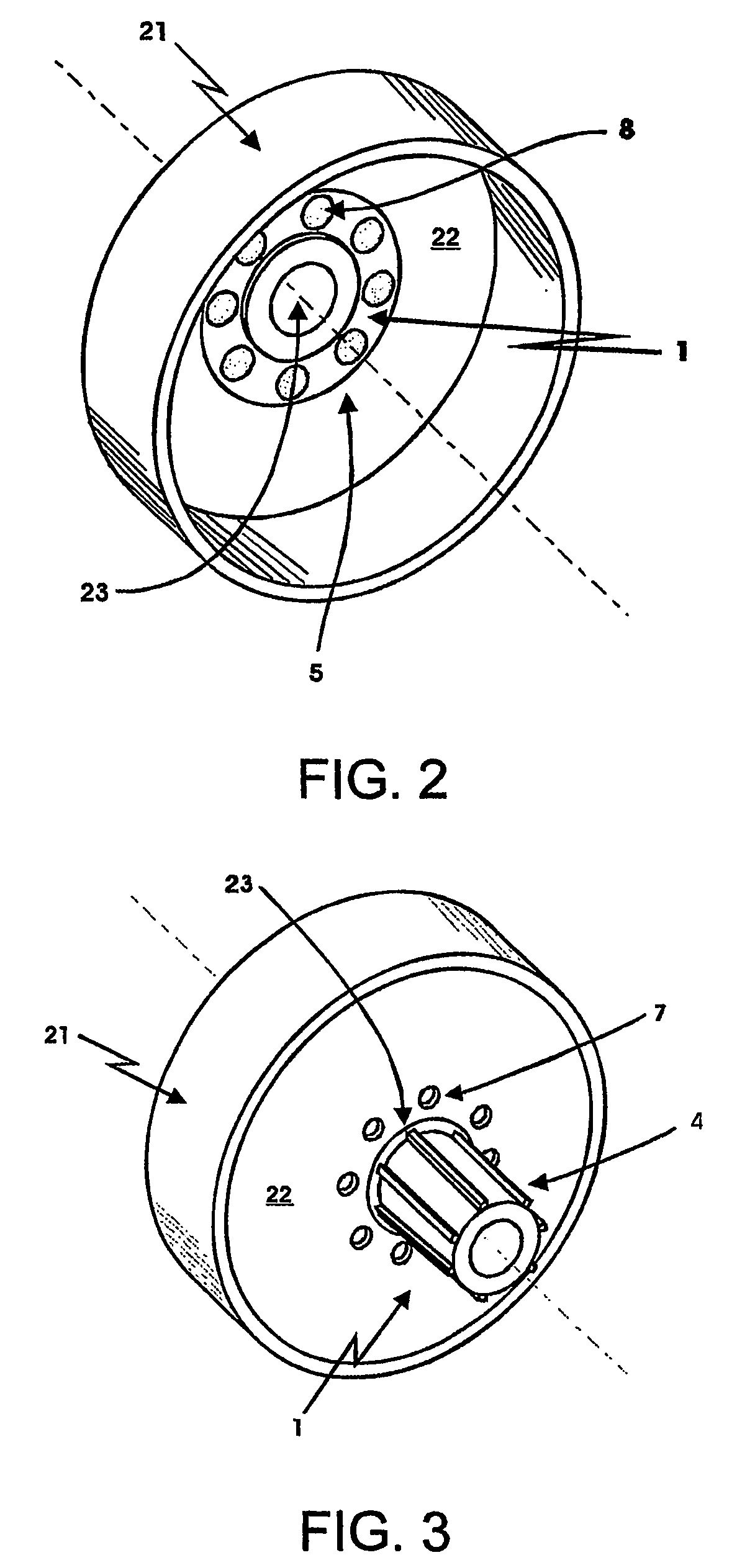

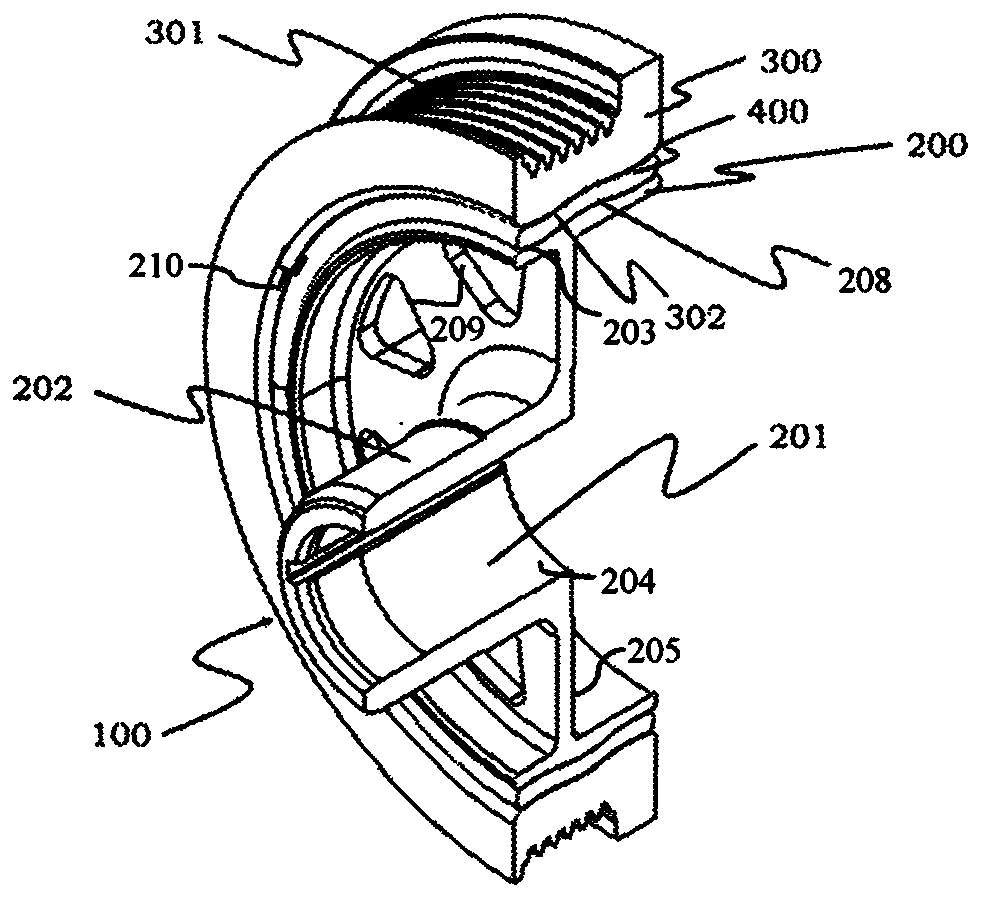

Centrifugal drum clutch assembly and method of manufacture

InactiveUS20060283684A1Increase production outputLow costBraking drumsFriction clutchesSprocketFlange

A clutch drum assembly comprising a clutch drum (21) and a drive means. The clutch drum (21) has an axis of rotation and includes an end wall (22). The drive means specifically a drive spline (1) or a fixed drive sprocket axially to one end of drive means, is a flange (5) with one or more radial evenly spaced minimally sized apertures (6) that have been counter sunk or counter bored to one side. Unitary axial motion of the two components is achieved via a mechanical connection between the two said components by tightly pressing metal from the outer surface of the end wall (22) clutch through each of the minimally sized apertures (6) in the drive means flange (5) against a die positioned proximate to each said aperture (6) forging the metal into the counter sunk or counter bored portion of the drive means flange (5).

Owner:BEERENS THOMAS

Cellulase solid fermentation large-scale production method and equipment thereof

InactiveCN1528890AIncrease production outputNo pollution in the processHydrolasesAmmonium sulfateSodium benzoate

The invention is a kind of large-scale producing method for cellulose solid yeast, it uses green trichoderma project strain, it is incubated through fungus cant tube, shaking bottle, the yeasting pot is expanded to the quantity of seeds needed by liquid, then carries on solid yeasting, they are transmitted to the asepsis inoculation room through asepsis channel, then they are placed in the plastic plate to be inoculated with incubation media, incubates for 72 hours, produces primary enzyme, condensates the liquid, and produces it into liquid enzyme through adding in sodium benzoate, the liquid enzyme is filtered and condensed adds in white ammonium sulfate, they are dried and produced into powder industry enzyme. The merit of the invention is that it realizes the solid yeasting large-scale producing, it has not contamination, the quality is high, the price is low.

Owner:陈欣

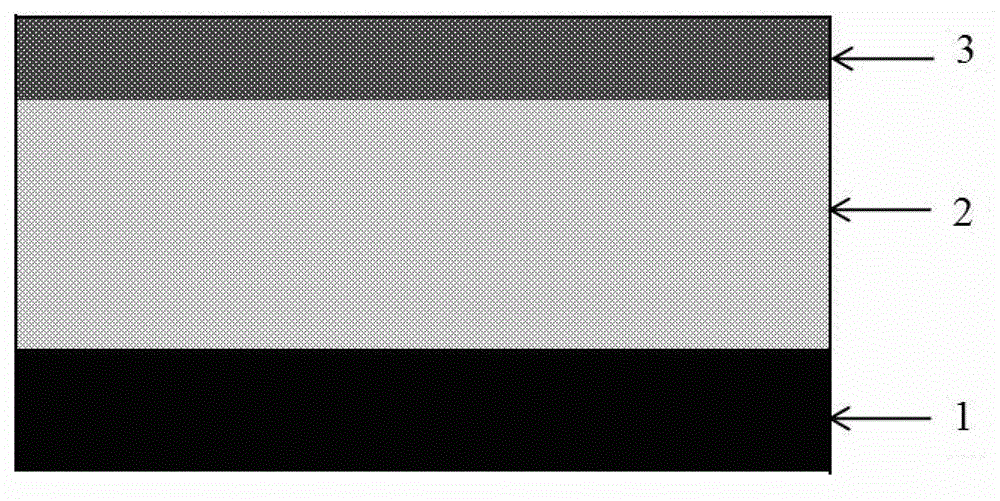

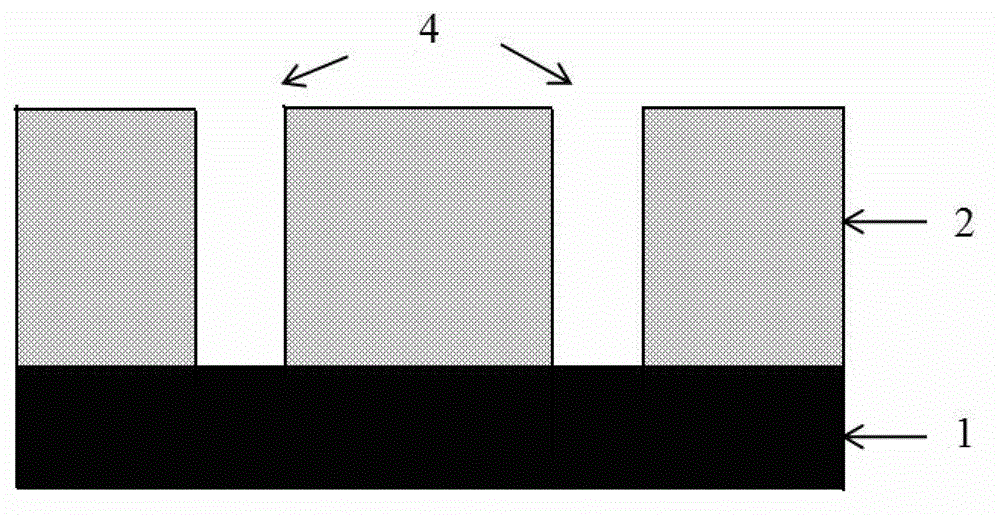

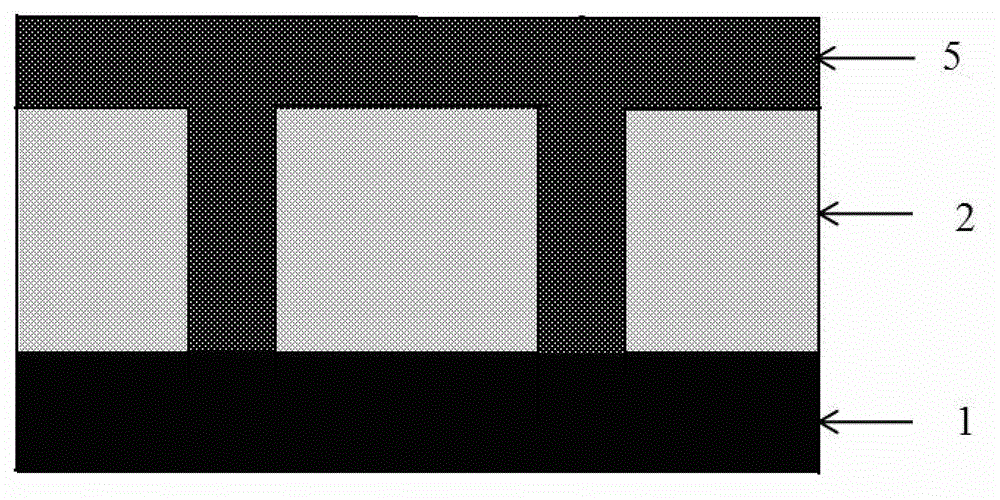

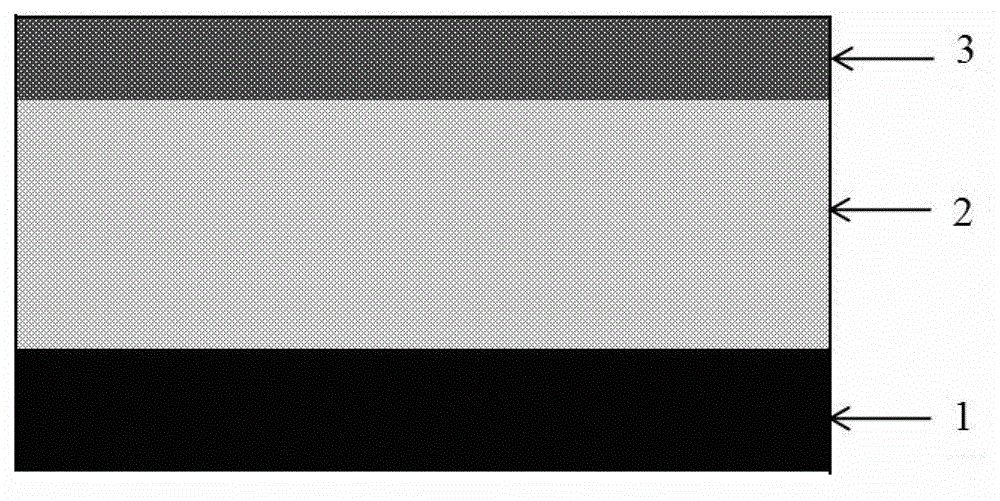

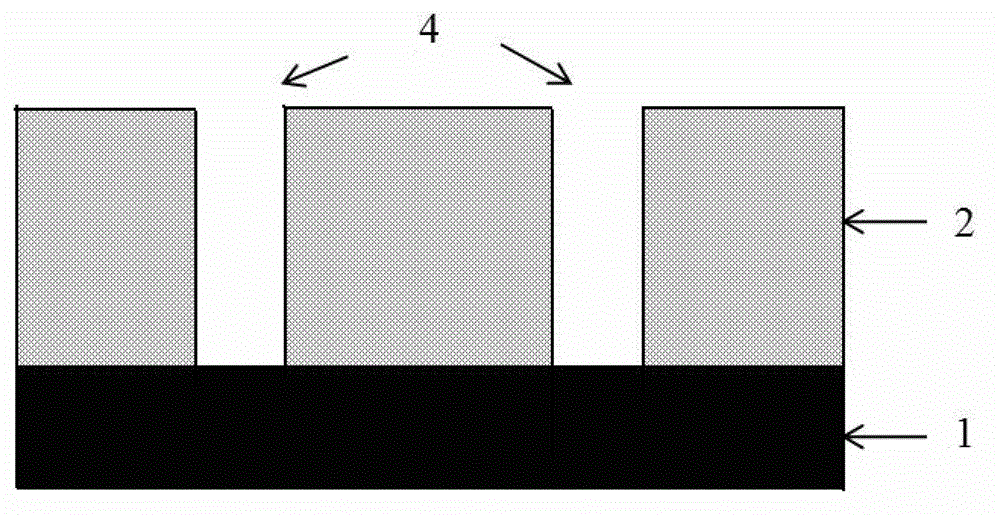

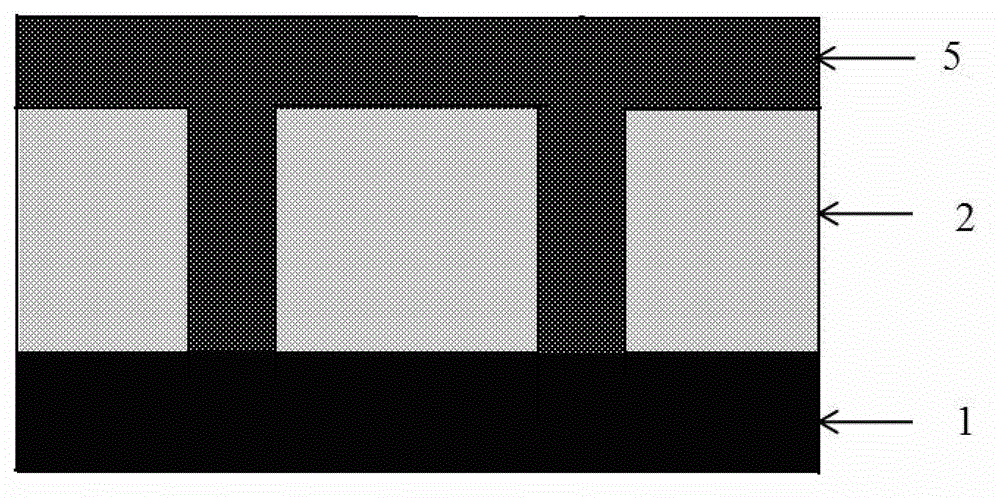

Method for manufacturing through-hole prior copper through interconnection

ActiveCN102881645ALow costIncrease production outputSemiconductor/solid-state device manufacturingSilicon chipPhotoresist

The invention provides a method for manufacturing a through-hole prior copper through interconnection. The manufacturing method comprises the following steps: firstly, depositing a medium layer on a substrate silicon chip, and coating first photoresist on the medium layer; secondly, completing exposure and development so as to form a through-hole structure in a photoresist film; thirdly, heating and curing the through-hole structure, then coating cross-linking materials on the first photoresist and curing a through-hole structure diaphragm in the first photoresist, forming an isolating membrane insoluble in second photoresist, and then removing the cross-linking materials; fourthly, coating the second photoresist on the first cured photoresist; fifthly, completing the exposure and development and forming a metal groove structure of the through-hole structure in the second photoresist film; sixthly, completing etching so as to transfer the through hole and the metal groove structure in the photoresist into the medium layer; and seventhly, carrying out metal deposition and metal chemical machinery grinding so as to complete the wire metal and through-hole metal filling.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

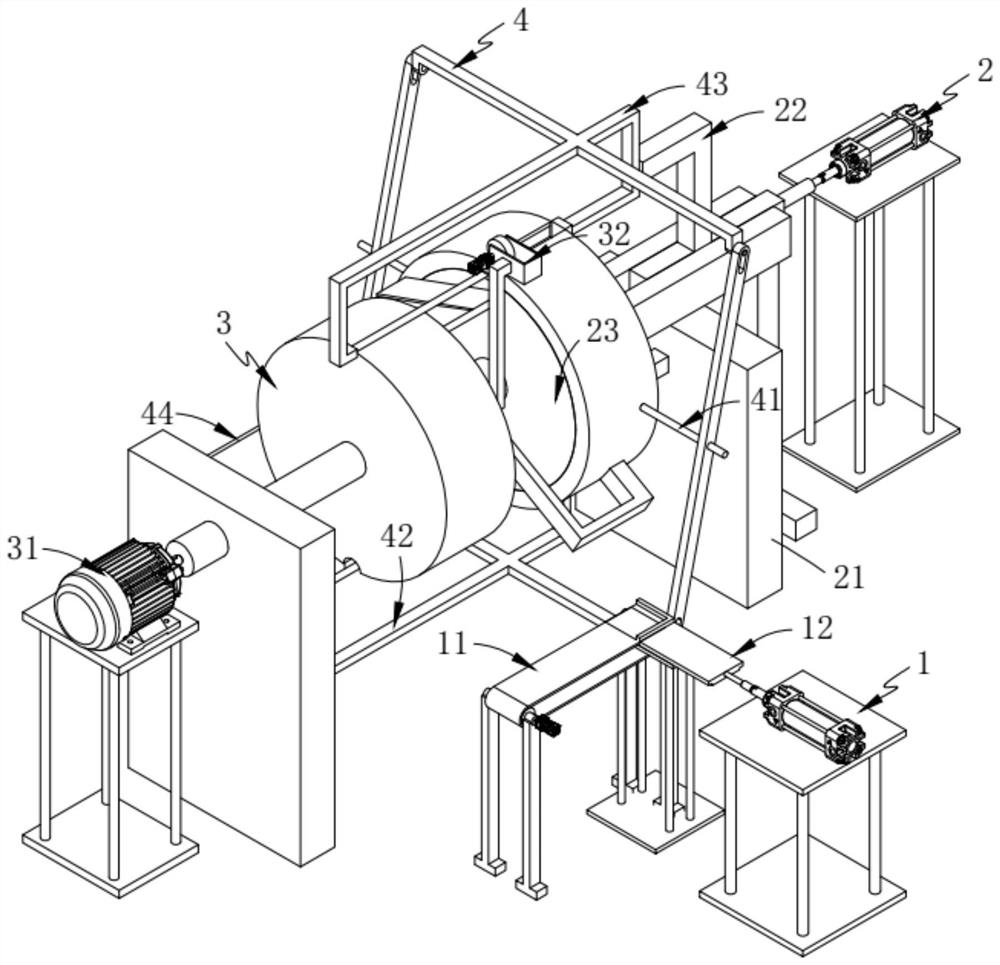

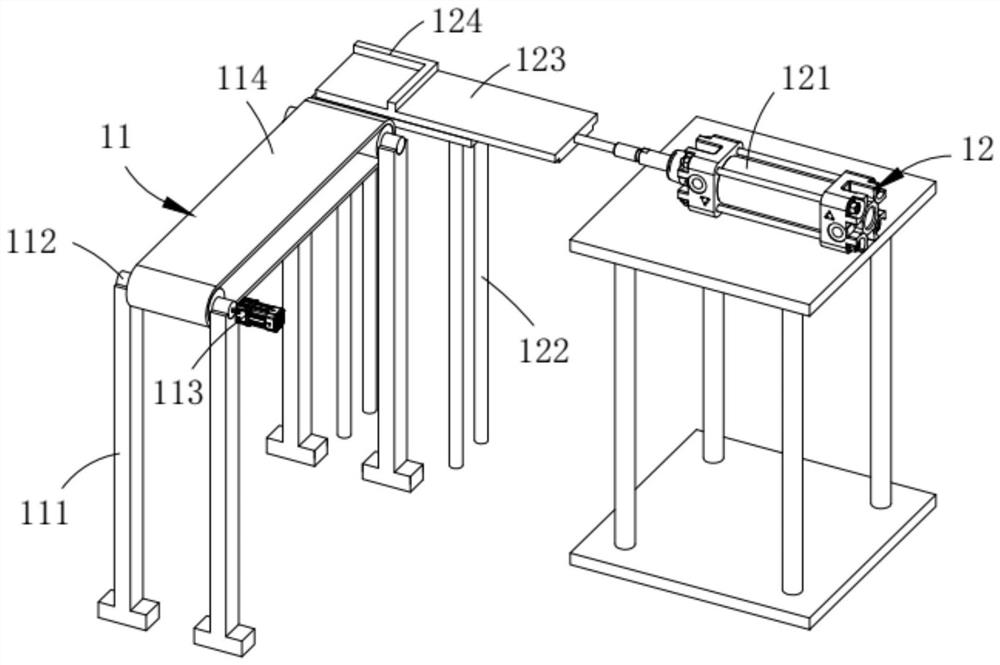

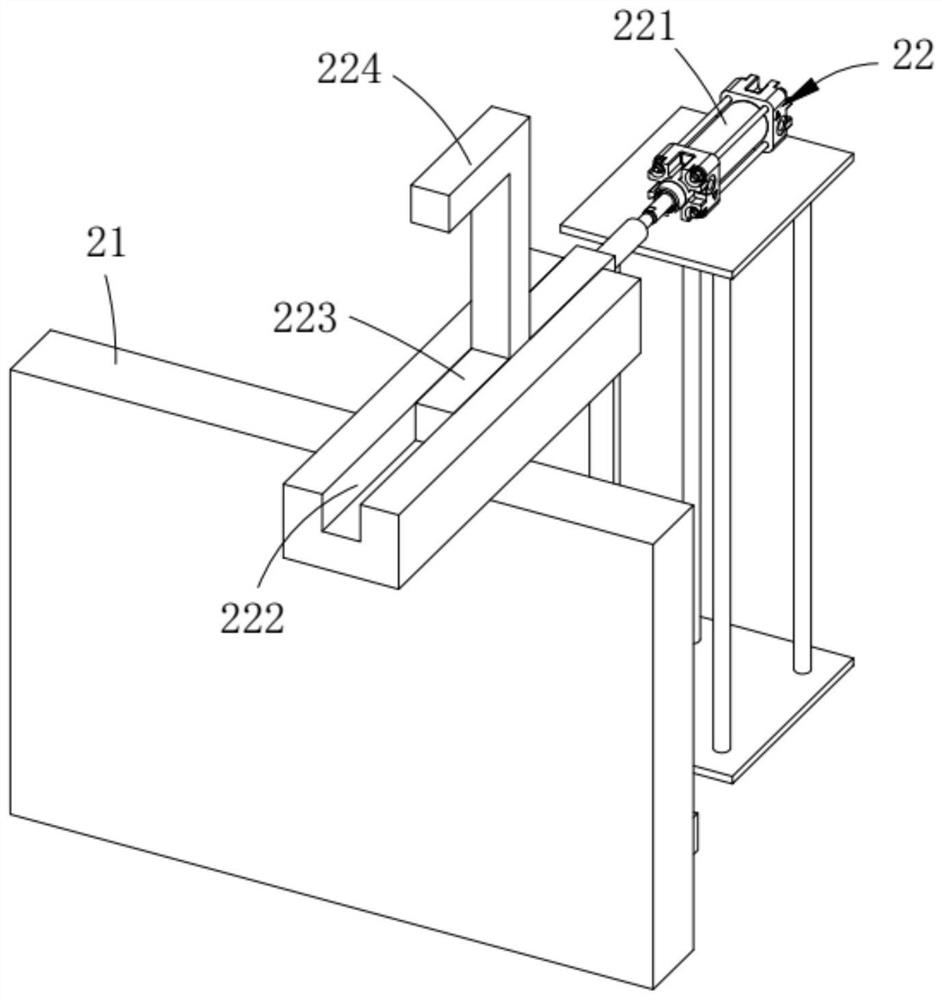

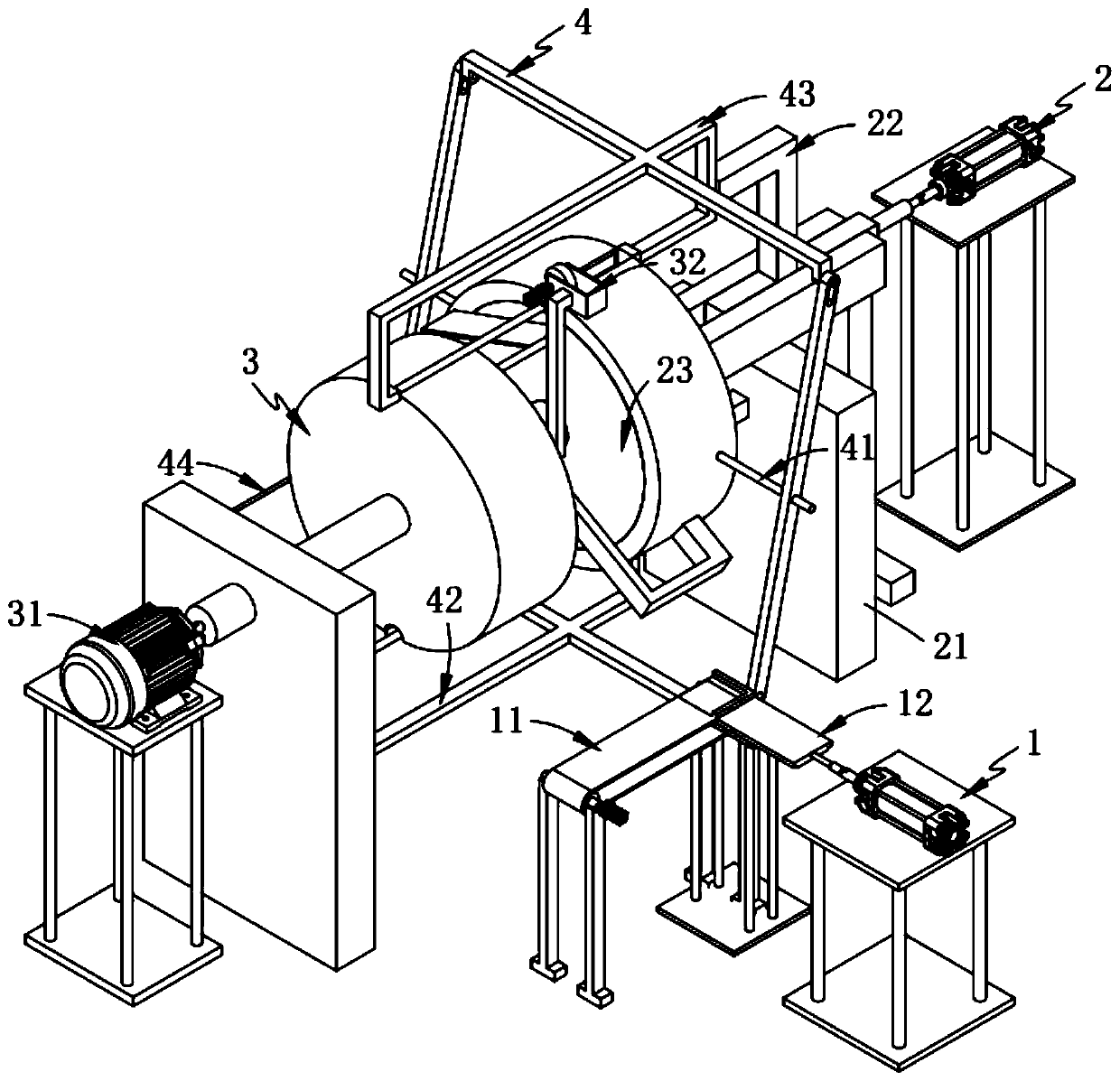

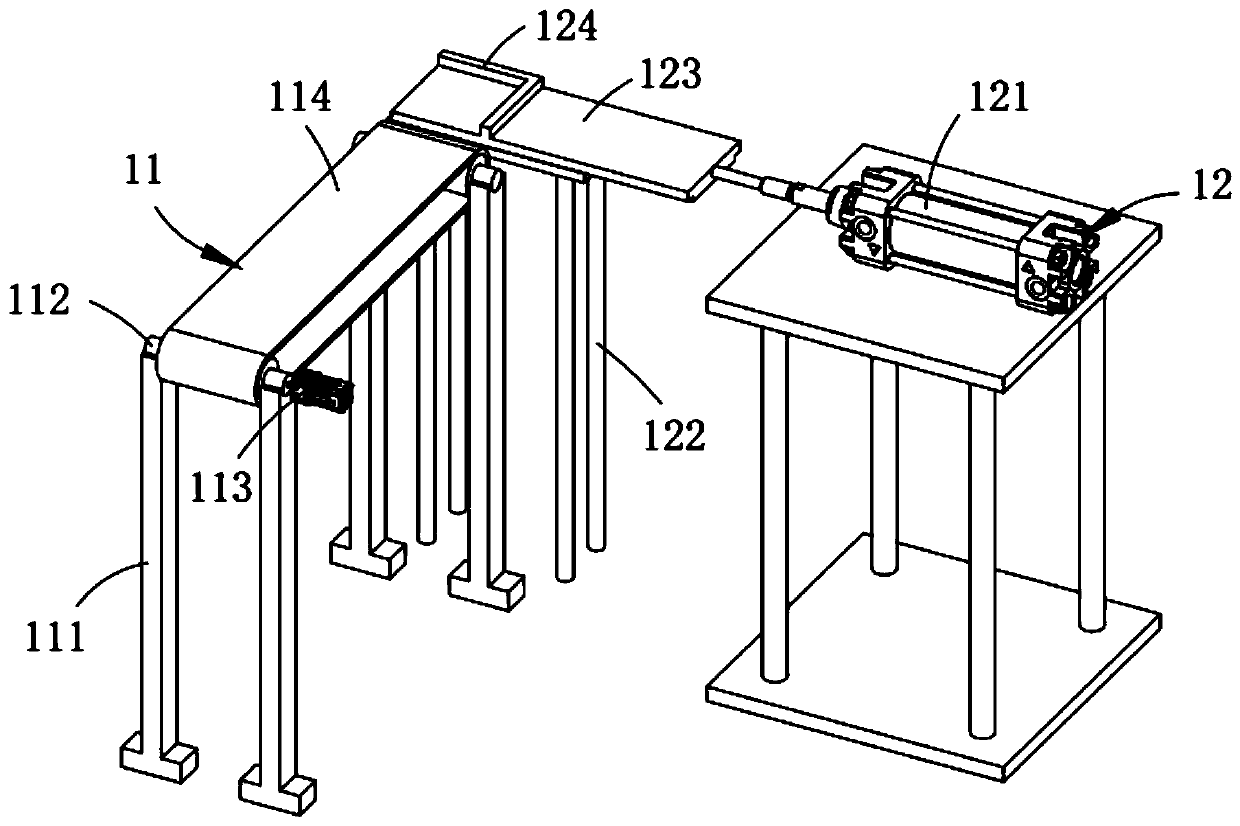

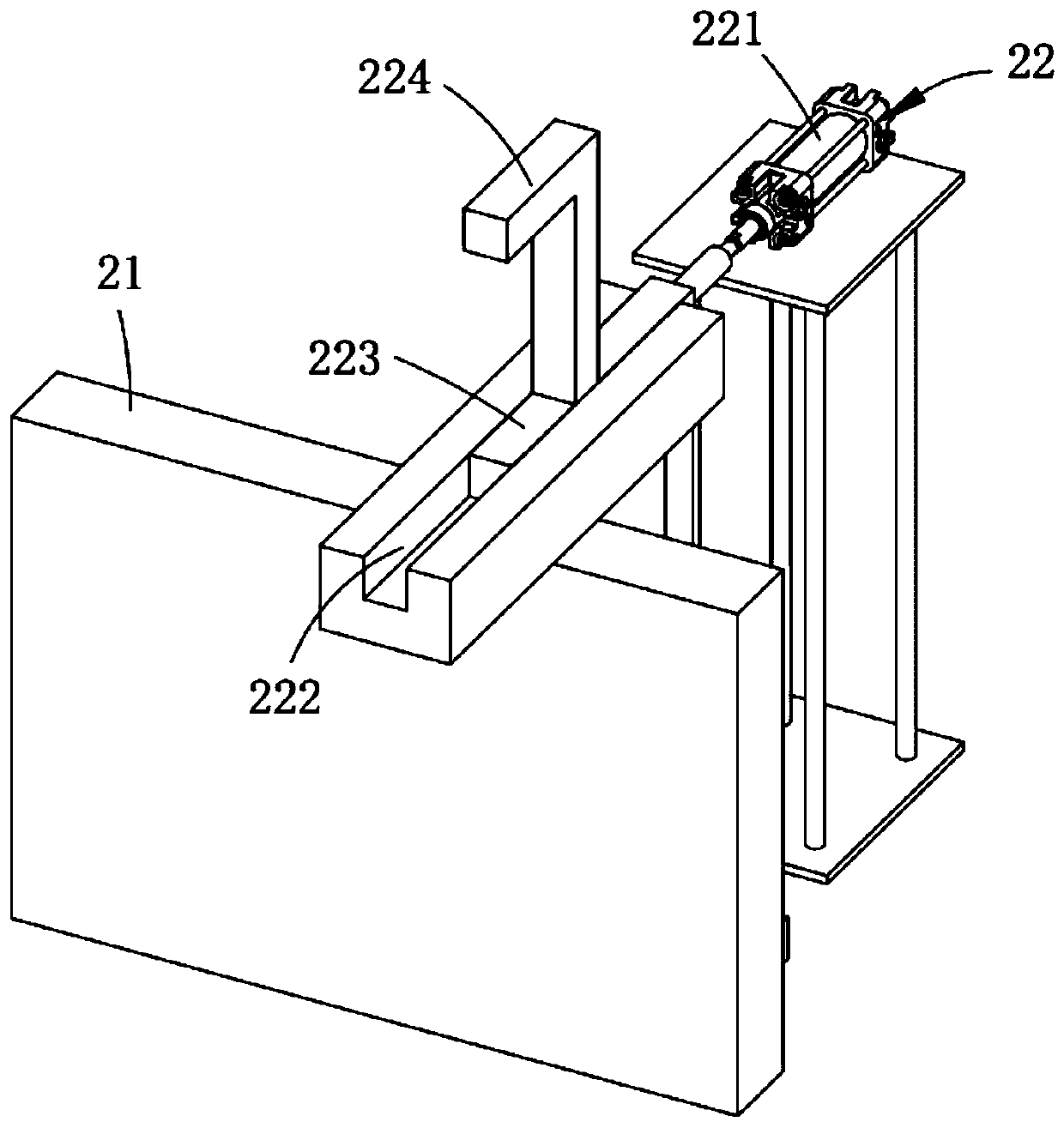

Automatic winding equipment for production of diversion net porous isolation film composite material

InactiveCN111634730AClose working relationshipHigh degree of automationWebs handlingMachineIsolation membrane

The invention relates to automatic winding equipment for production of a diversion net porous isolation film composite material. The equipment comprises a switching mechanism, a replacement mechanism,a glue sealing mechanism, an output mechanism and an input mechanism, wherein the switching mechanism comprises a machine frame, a revolving assembly and a winding roller element, and a winding station, a packaging station, an output station, an upper roller station and a station to be replaced are sequentially arranged on the revolving assembly in the circumferential direction; the replacementmechanism comprises a winding mechanism and a cutting mechanism, and the winding mechanism cooperates with the winding roller element to complete the clamping work of a finished product; the glue sealing mechanism is used for automatic finishing touches of composite diversion net tail after cutting on the winding roller element; the output mechanism comprises an outgoing assembly and a first linkage assembly; and the input mechanism comprises an installation assembly and a second linkage assembly. According to the equipment, the technical problems that manual automatic installation of new winding rollers after replacing rollers and manual discharging work of old winding rollers after the completion of the winding work are required, the work efficiency is low, and additional manual labor output is required are solved.

Owner:潘利斌

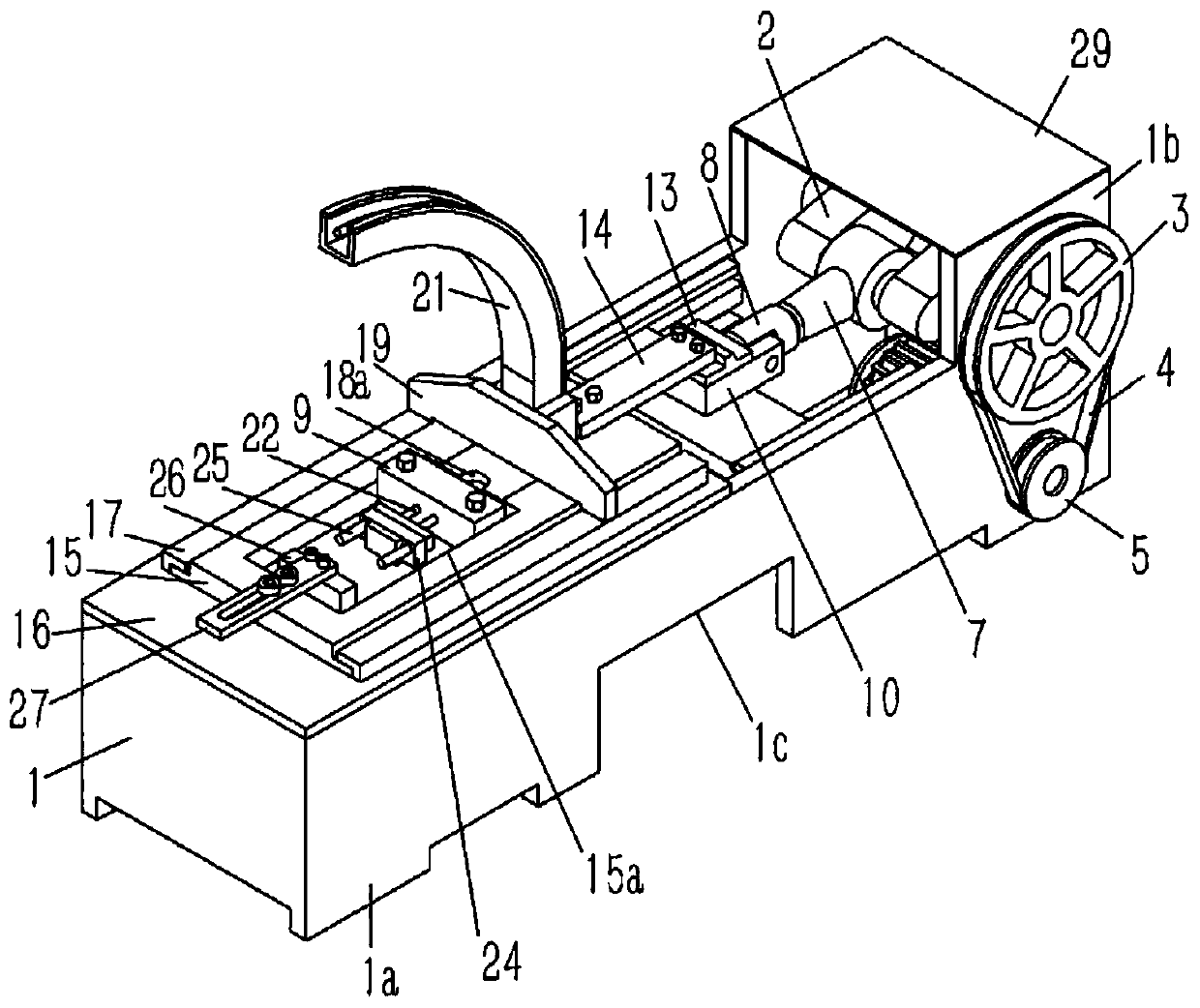

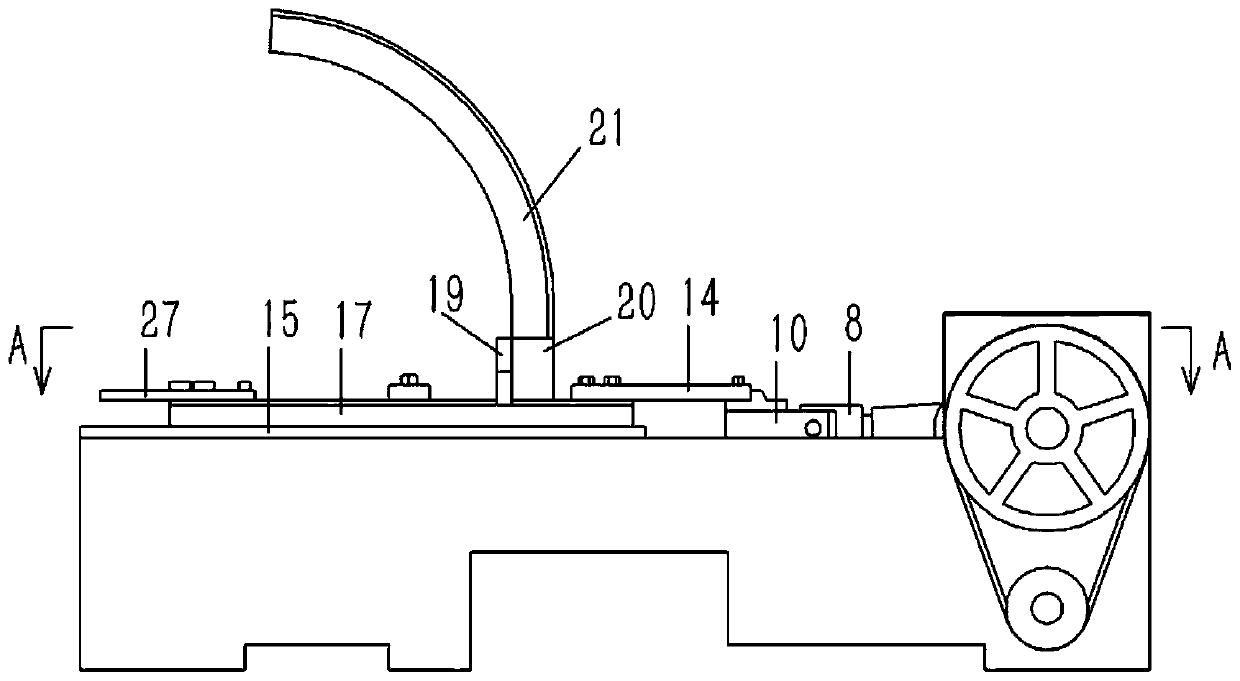

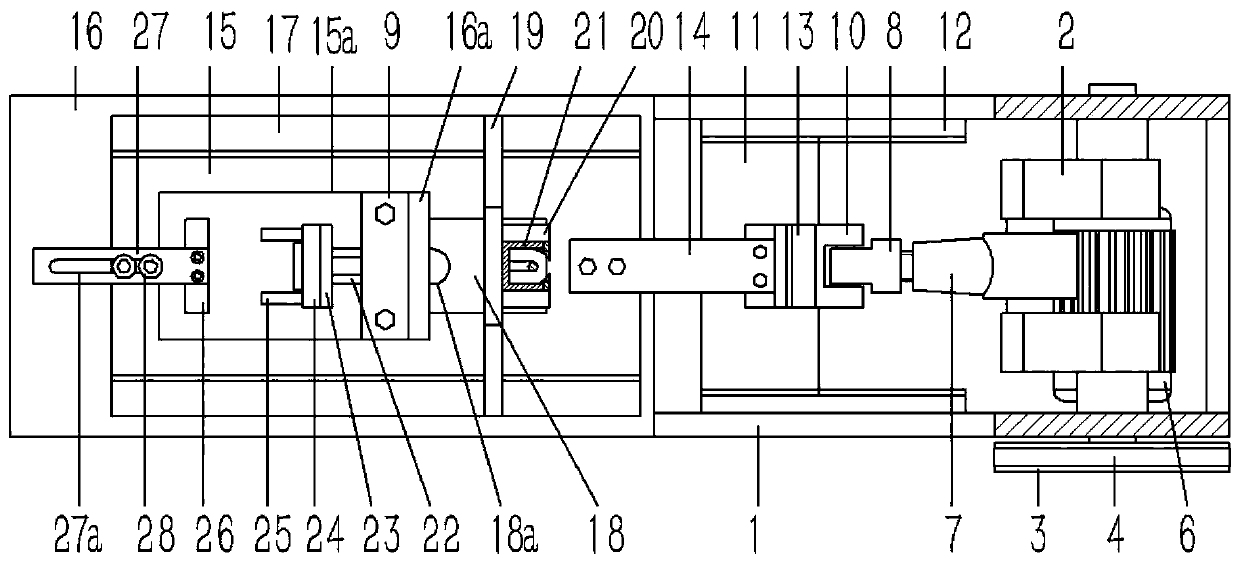

Full-automatic pipe mouth shaping machine for U-shaped copper pipe

A full-automatic pipe mouth shaping machine for a U-shaped copper pipe comprises a rack. The rack is composed of a rectangular frame body. Support plates extending upwards are formed on the frames ofthe two sides of the right end of the rack. A crankshaft is arranged between the support plates. The two ends of the crankshaft are hinged to the support plates of the rack through bearings. One end of the crankshaft penetrates the support plates and is fixedly sleeved with a driven pulley. The driven pulley is connected with a driving pulley through a transmission belt. A rotating shaft of a motor is fixedly sleeved with the driving pulley. The motor is fixed to the rack. By the adoption of the full-automatic pipe mouth shaping machine for the U-shaped copper pipe, an upper pipe mouth in theU-shaped copper pipe can be automatically shaped, the shaping efficiency is improved effectively, the production yield can be indirectly increased, and the personnel cost is reduced.

Owner:绍兴市凯杰铜业有限公司

Process for producing composite zinc-coated steel pipe with inner stainless steel lining

InactiveCN1409041ASimple production processIncrease production outputLayered productsRigid pipesSteel tubeMetalworking

The production process of composite zinc-coated steel pipe with stainless steel lining belongs to the field of metal processing technology. The production process includes trimming inside wall of thezinc-coated steel pipe, painting adhesive to outer wall of the stainless steel pipe, inserting the stainless steel pipe into the zinc-coated steel pipe, hemming and sealing two ends, leading steam into the stainless steel pipe to heat and pressurize, heating the zinc-coated steel pipe from outside electrically to combine two layers of steel pipe firmly. The composite pipe may be used in city water supply to raise water quality and used to replace stainless steel pipe or copper pipe as industrial conveyance pipe.

Owner:郑阿松

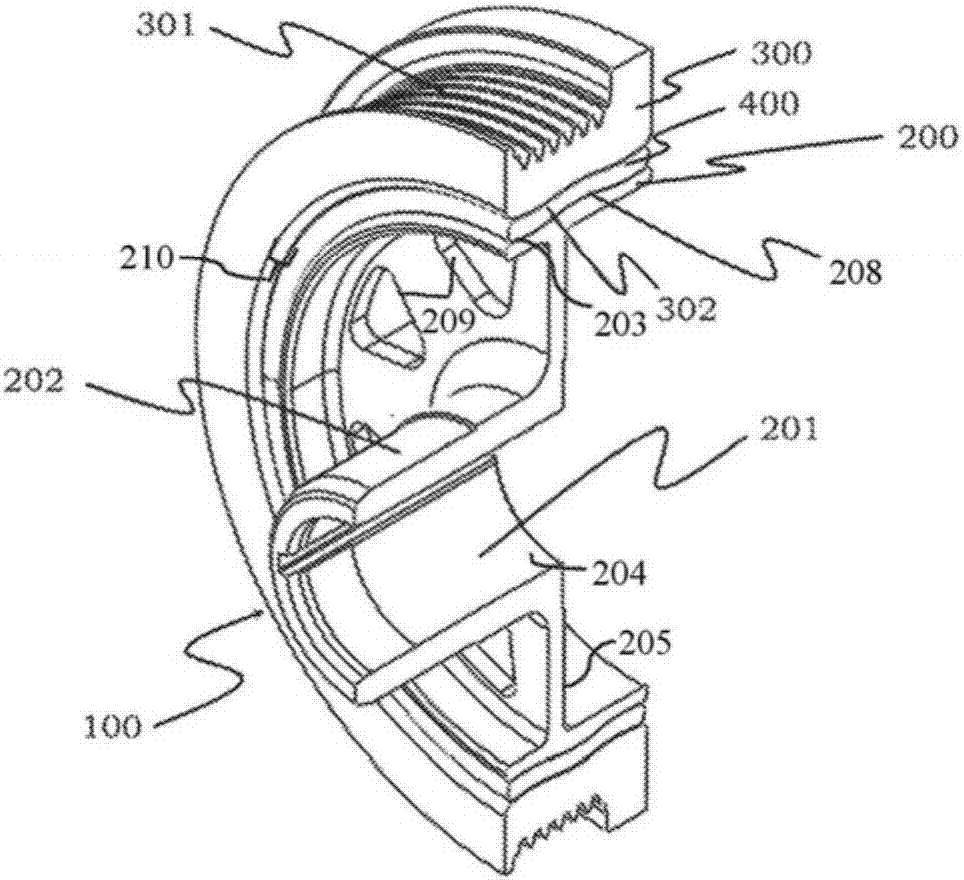

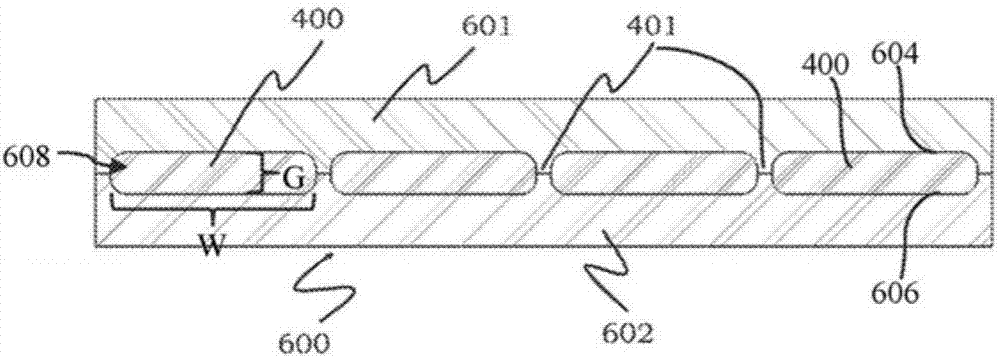

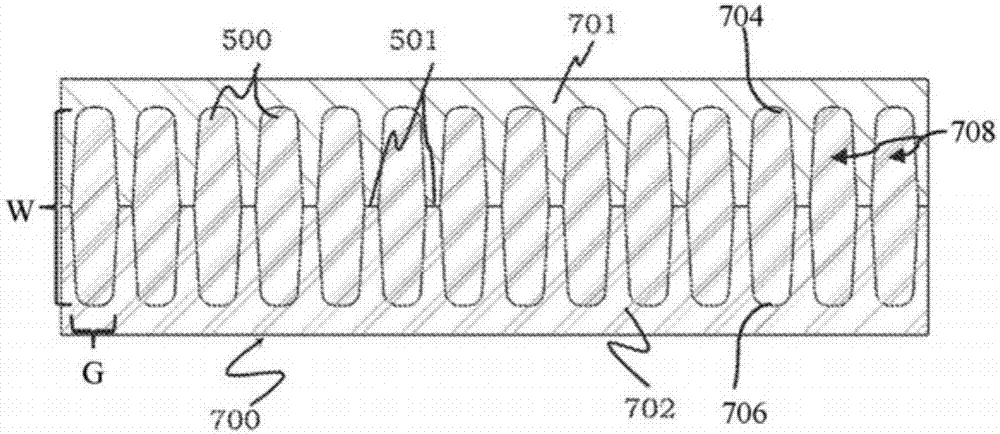

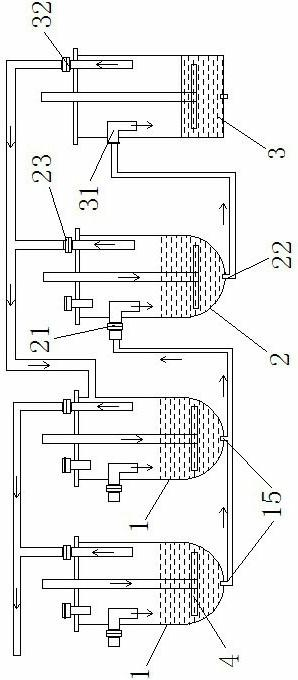

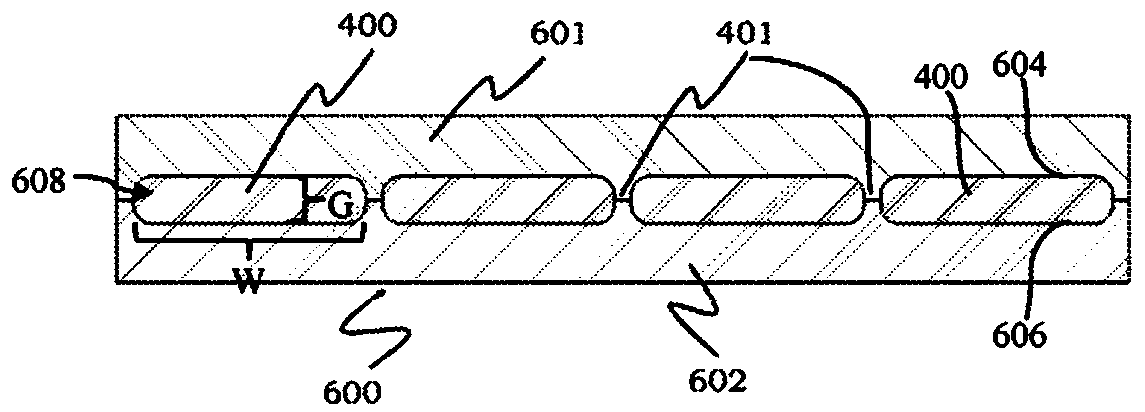

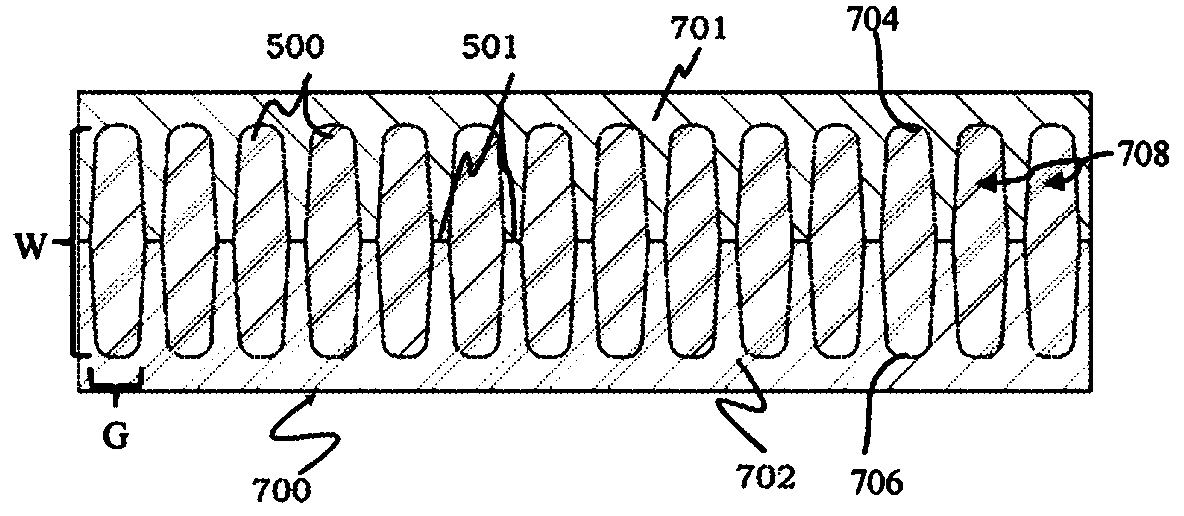

Elastomer strip design for torsional vibration dampers and torsional vibration dampers having same

InactiveCN107208691AIncreased slip torque capacityImprove fatigue lifeSpringsShaftsTransverse planeEngineering

Elastomer members for a torsional vibration damper, methods of making the same, and torsional vibration dampers having the elastomer members are disclosed. The elastomer members have a first major surface and an opposing second major surface with opposing side joining the first major surface to the second major surface, have a median sagittal plane extending parallel to the first major surface and the second major surface, and a transverse plane perpendicular to the median sagittal plane. In a cross-sectional geometry in a plane bisecting the median sagittal plane and the transverse plane, a thickness of the elastomer member changes along the median sagittal plane in a direction parallel to the transverse plane with a first thickness at both opposing sides and a second thickness at the transverse plane, where the second thickness is greater than the first thicknesses.

Owner:DAYCO IP HLDG

A fully automatic casting and welding process and production line for lead-acid batteries

ActiveCN111266556BConnection time is shortImprove work efficiencyCasting plantsProcess engineeringSoldering

Owner:长兴玖佳机械股份有限公司

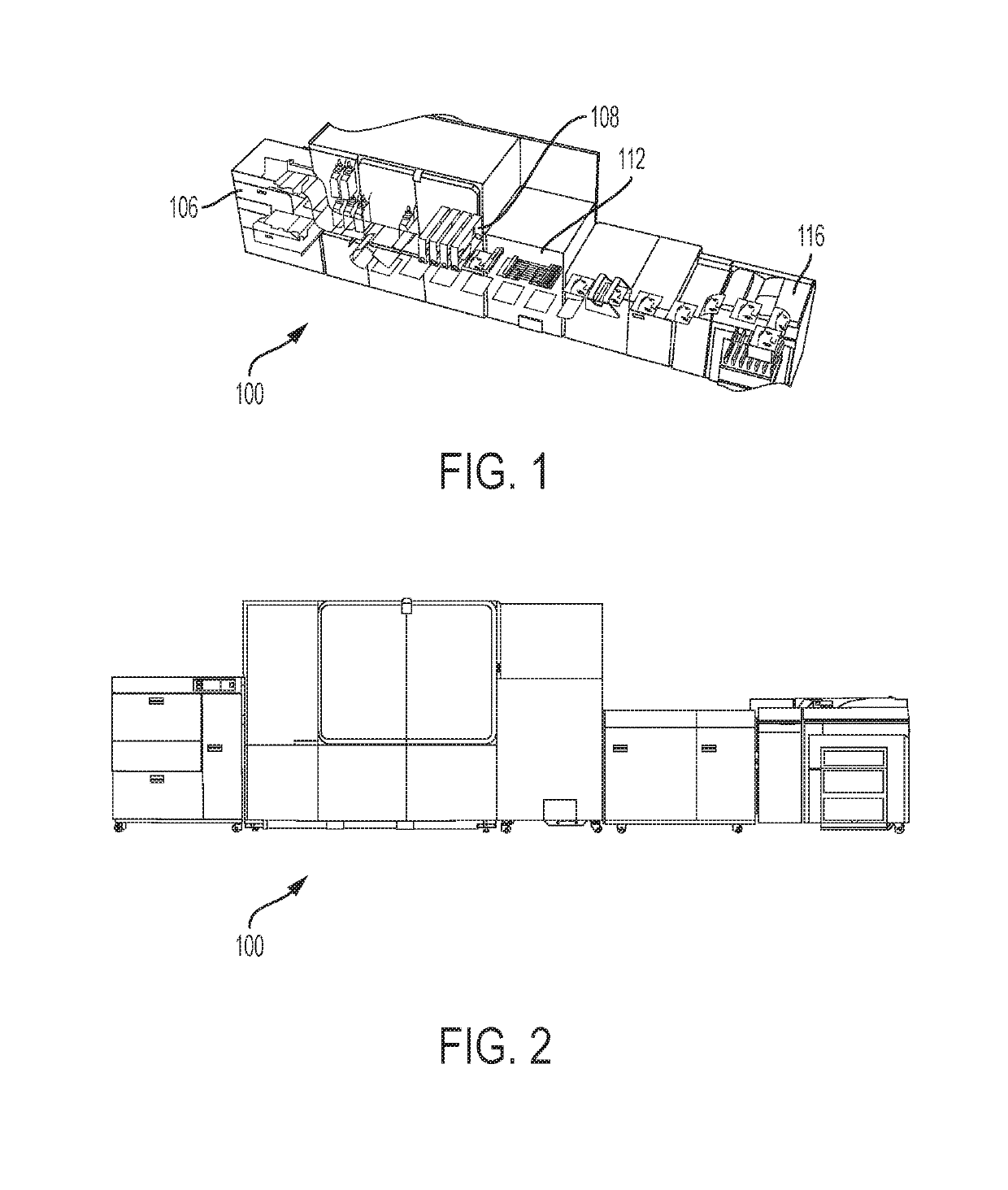

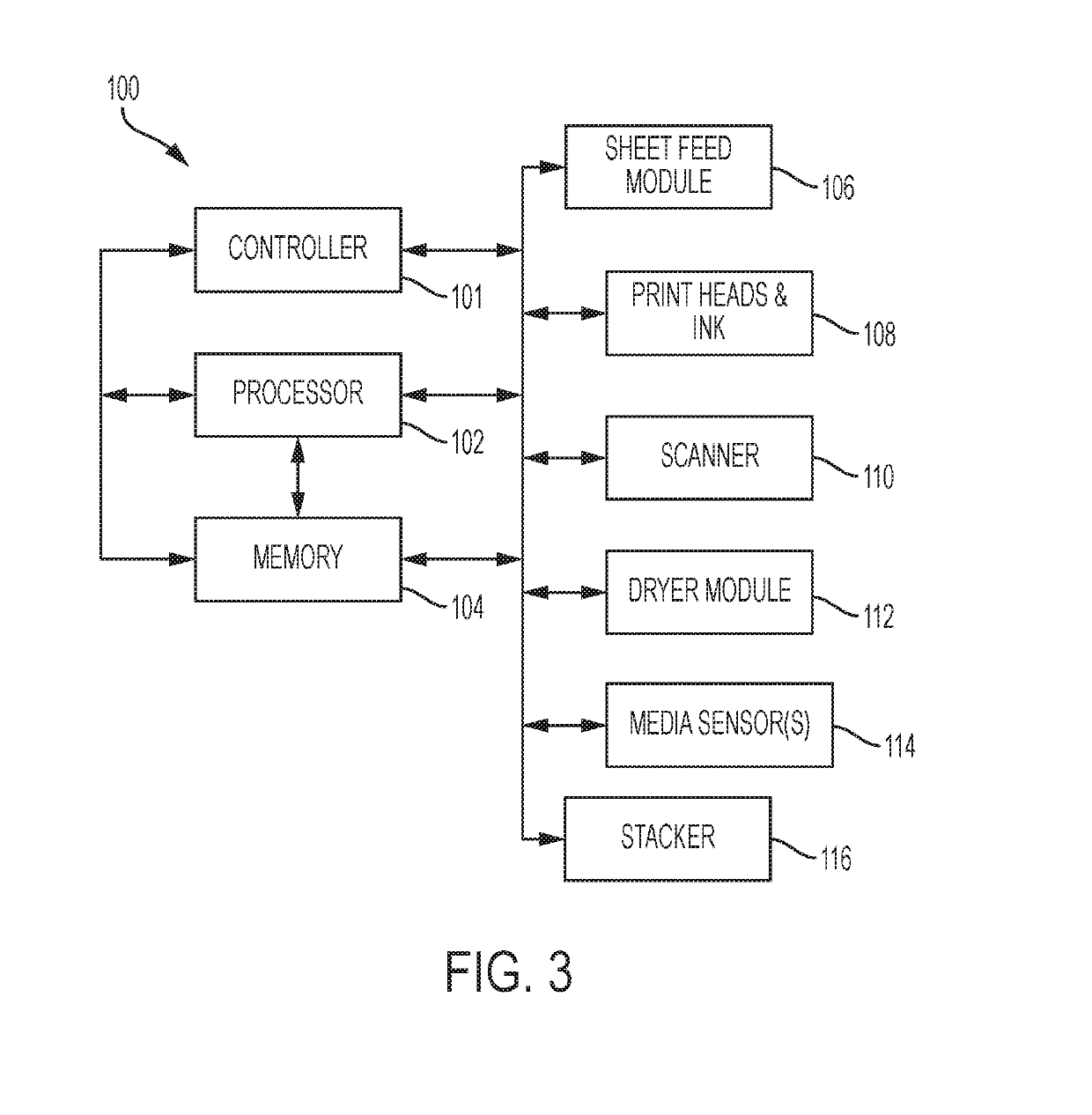

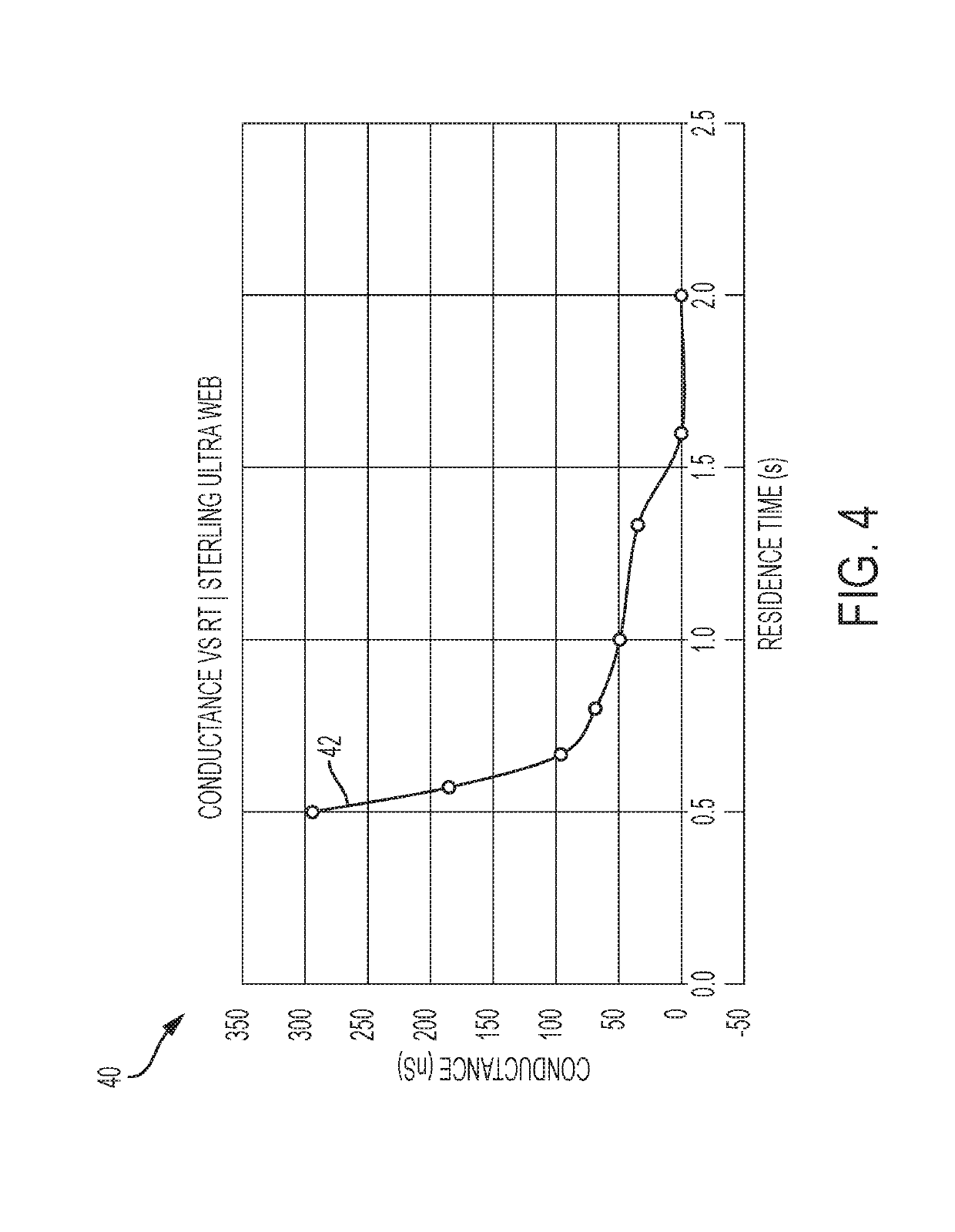

Method and system for intelligent drying in cut-sheet aqueous ink jet printing systems

InactiveUS20190337310A1Low running costEnhanced printer performanceDuplicating/marking methodsOther printing apparatusEngineeringMoisture

Methods and systems for facilitating drying of media in a high-speed digital printer (e.g., a cut-sheet aqueous ink jet printing system). The high-speed digital printer includes a dryer module composed of a group of dryers that dry media including the test media. In an example embodiment, a series of test media can be printed at increasingly higher ink loading. The moisture content of the test media is monitored at each exit of each dryer to generate data indicative of the threshold at which the dryer module is no longer able to effectively dry the test media. Data resulting from such moisture content monitoring is fed to a marking engine and / or image path of the high-speed digital printer to generate a linearization profile in-situ. Such a linearization profile includes ink volume limiting linearization data that is used to ensure that media exiting the dryer module are dry.

Owner:XEROX CORP

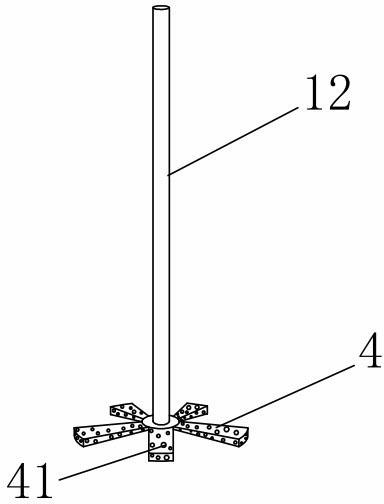

Chlorine dioxide reaction device

InactiveCN102583251AIncrease production outputIncrease productivityChlorine oxidesChemical reactionChemical engineering

The invention relates to a chemical reaction device, in particular to a chlorine dioxide reaction device. The problems that the conversion efficiency is low and the structure is complicated at preset are solved. The chlorine dioxide reaction device comprises two primary reaction kettles (1) and a secondary reaction kettle (2) and is characterized in that the two primary reaction kettles (1) are connected in parallel to form first-stage reaction; the secondary reaction kettle (2) and the two primary reaction kettles (1) connected in parallel are connected in series to form second-stage reaction; the secondary reaction kettle (2) and a gas-liquid blower (3) are connected in series to form third-stage reaction; an escape pipe (21) of the secondary reaction kettle (2) and an escape pipe (32) of the gas-liquid blower (3) are connected into one of the two primary reaction kettles (1) after being communicated each other; and the escape pipes connected in parallel of the two primary reaction kettles (1) are connected into a gathering tank. The chlorine dioxide reaction device has the advantages that the structure is more optimized and the chlorine dioxide conversion rate is higher.

Owner:云南玉溪滇豫化工科技有限公司

Torsional vibration damper, elastomer member therefor, and manufacturing method thereof

InactiveCN107208691BIncreased slip torque capacityImprove fatigue lifeSpringsShaftsElastomerTransverse plane

An elastic body member for a torsional vibration damper and a method of manufacturing the same are disclosed, as well as a torsional vibration damper having the elastic body member. The elastomeric member has a first major surface and an opposing second major surface, the first major surface and the opposing second major surface having opposing sides joining the first major surface and the second major surface, having A midsagittal plane extending parallel to the first and second major surfaces, and a transverse plane perpendicular to the midsagittal plane. The cross-sectional geometry in a plane bisects the midsagittal plane and the transverse plane, the thickness of the elastomeric member varies along a direction in which the midsagittal plane is parallel to the transverse plane, a first thickness at the opposite and a second thickness substantially at said transverse plane, wherein said second thickness is greater than said first thickness.

Owner:DAYCO IP HLDG

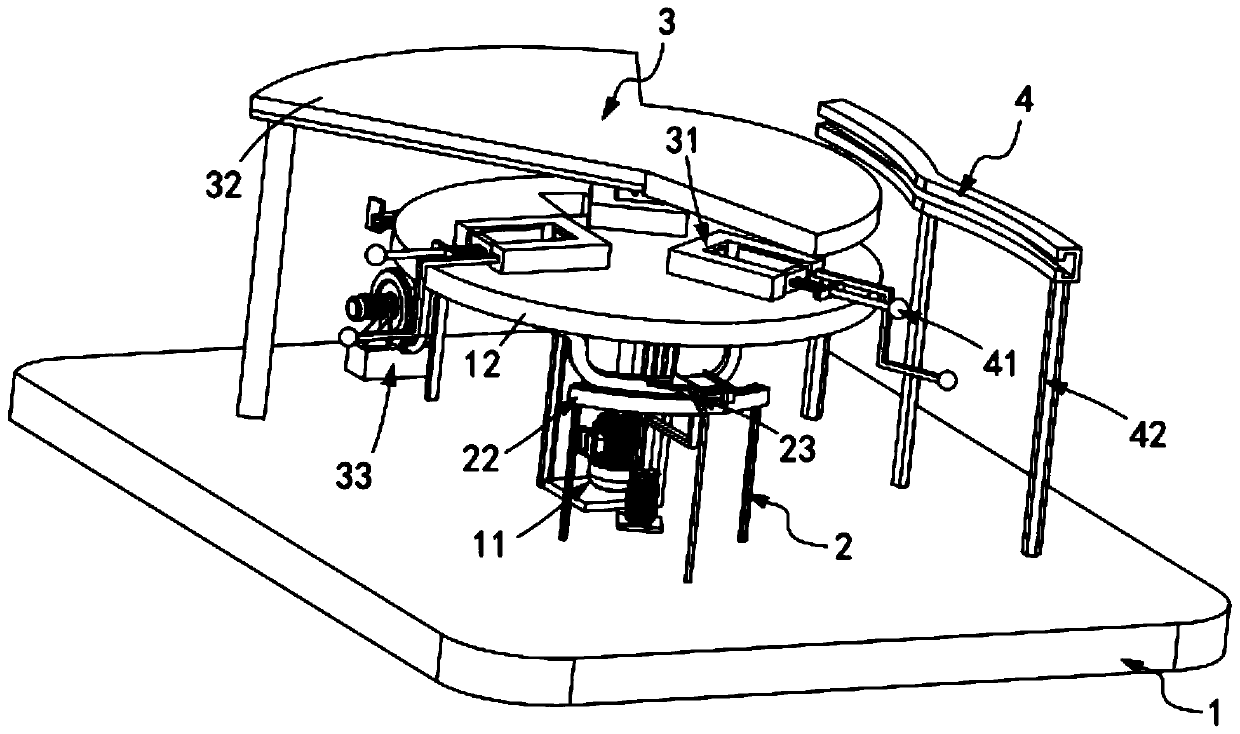

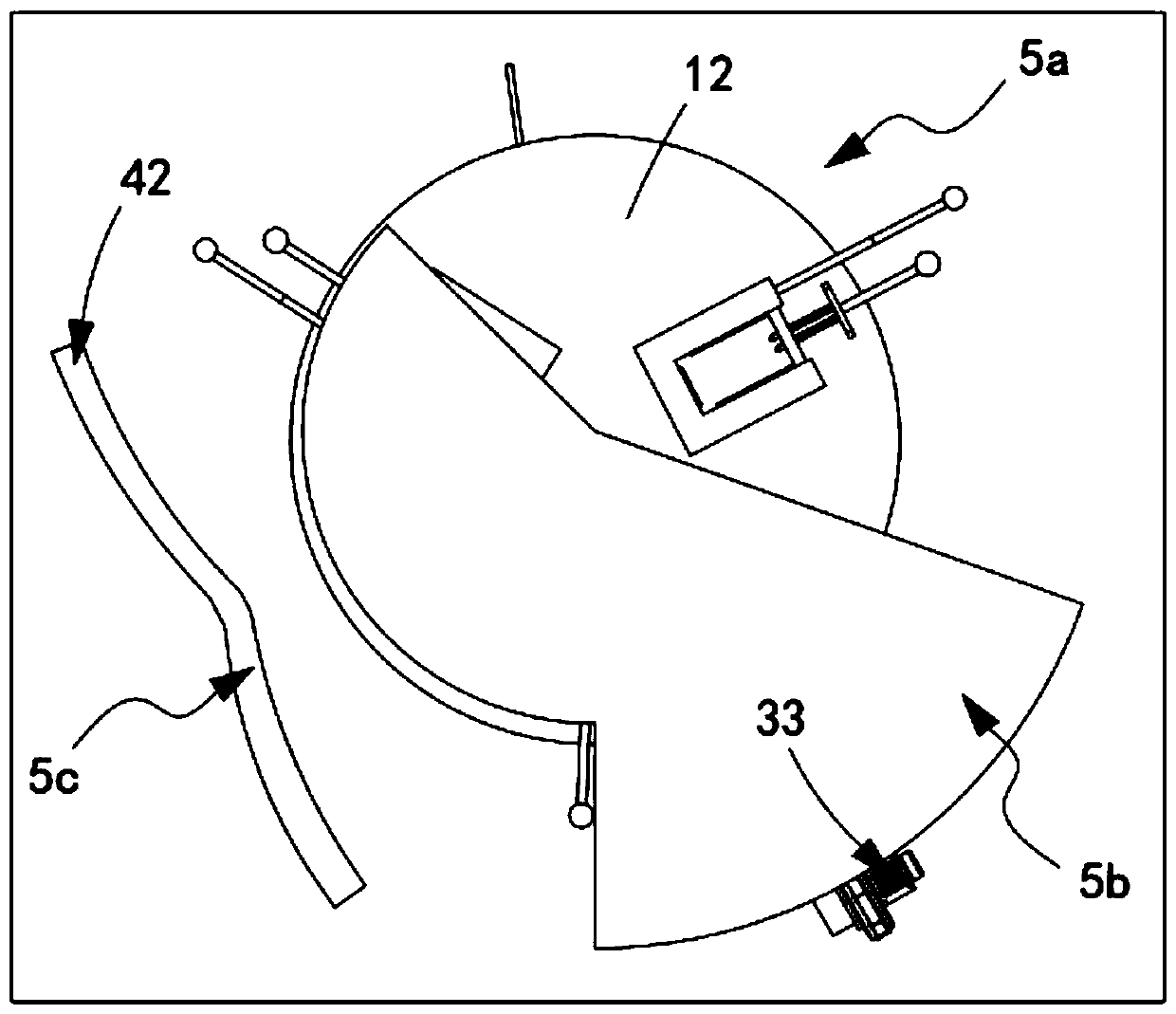

Perforating machine applied to preparation of medical dressings

InactiveCN111098355AEasy piercingEasy in and outMetal working apparatusSurgeryMechanical engineering

The invention relates to a perforating machine applied to preparation of medical dressings. The perforating machine applied to preparation of the medical dressings comprises a station switching mechanism, a dressing loading mechanism, a dressing positioning mechanism and a dressing perforating mechanism, wherein the station switching mechanism comprises a driving assembly and a rotating disk; multiple groups of positioning grooves matched with the dressings are formed on the rotating disk equidistantly along a circumferential direction of the rotating disk; the dressing loading mechanism comprises a lifting assembly, a guide assembly, a feeding assembly and a discharging assembly; the dressing positioning mechanism comprises a pressing assembly, a limiting plate and an inflating assembly for driving the pressing assembly to limit the dressings; the pressing assembly is elastically connected with the lifting assembly; the dressing perforating mechanism comprises a perforating assembly and an action limiting assembly; the perforating assembly is arranged corresponding to and matched with the pressing assembly and is arranged on the rotating disk in a sliding way; the action limitingassembly drives the perforating assembly to perform perforation work on the dressings; and the technical problems that continuous input and output of the dressing cannot be realized through mechanicalaction during manual dressing loading and discharging work, the working efficiency is low and the yield is low are solved.

Owner:韩惠

Arrangement scheme of high-speed wire cutting production process

PendingCN114789196AIncrease production outputReduce production processWork treatment devicesMetal rolling arrangementsWire cuttingManufacturing engineering

Owner:HEFEI ORIENT METALLURGICAL EQUIP

A green and harmless planting method of citrus citrus seedlings

The invention discloses a green and harmless planting method of Or citrus seedlings, which comprises the steps of seedling selection, seedling planting, seedling warm keeping, seedling nutrient supply, pruning in the growing process of the seedlings and pest and disease control. Cultivation for the Or citrus seedlings is carried out through using the method disclosed by the invention, the growth speed of the Or citrus seedlings is enabled to be improved by 30%-45%, the death rate of the Or citrus seedlings is enabled to be reduced by 15%-20%, the cultivation cost of the Or citrus seedlings is greatly reduced, the use of pesticides is reduced, and the yield output is increased. Meanwhile, the cultivated Or citrus seedlings are rich in branch and leaf and well in growth, and the survival rate after transplantation is close to 88%.

Owner:广西中欧鲜农电子商务有限责任公司

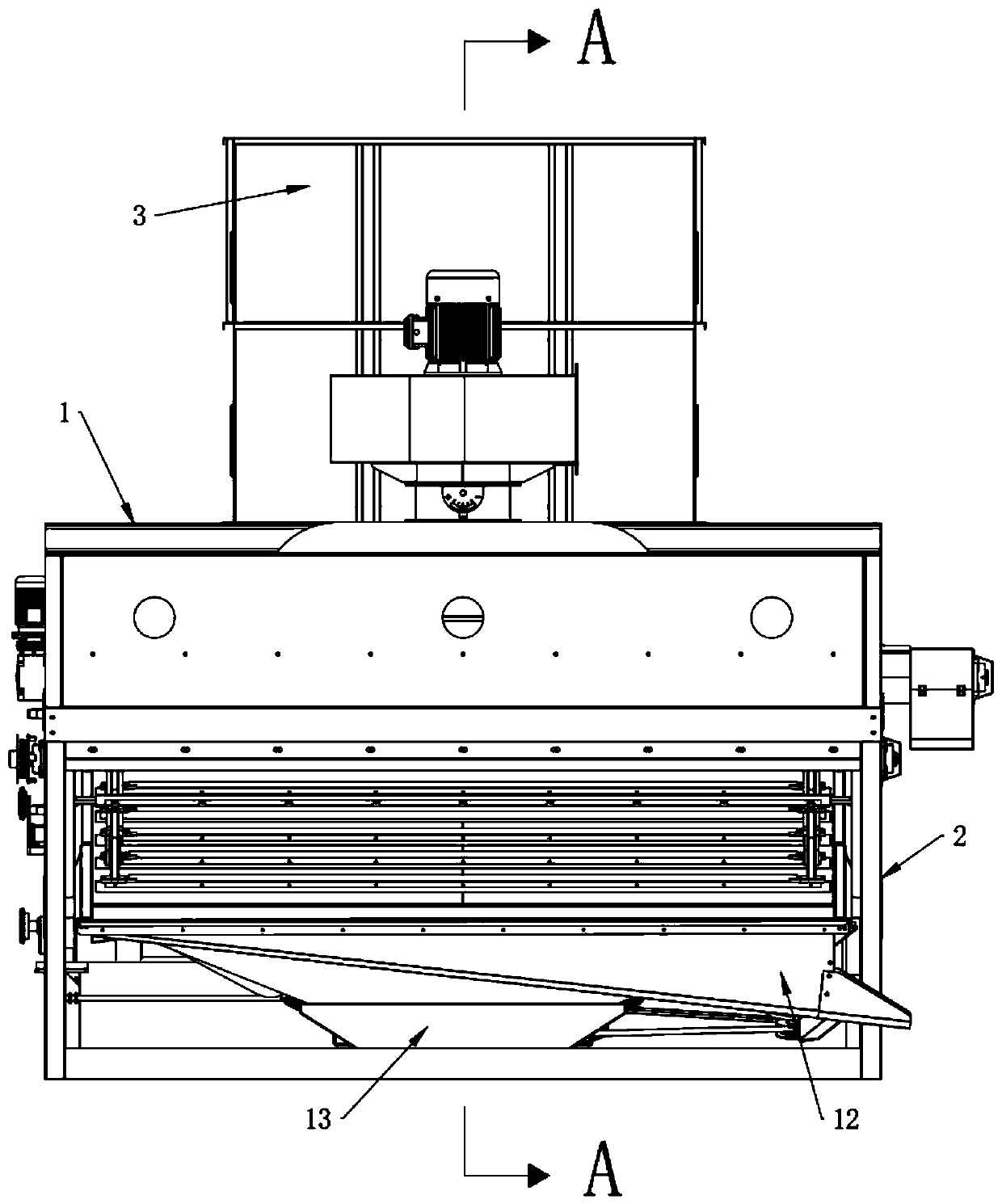

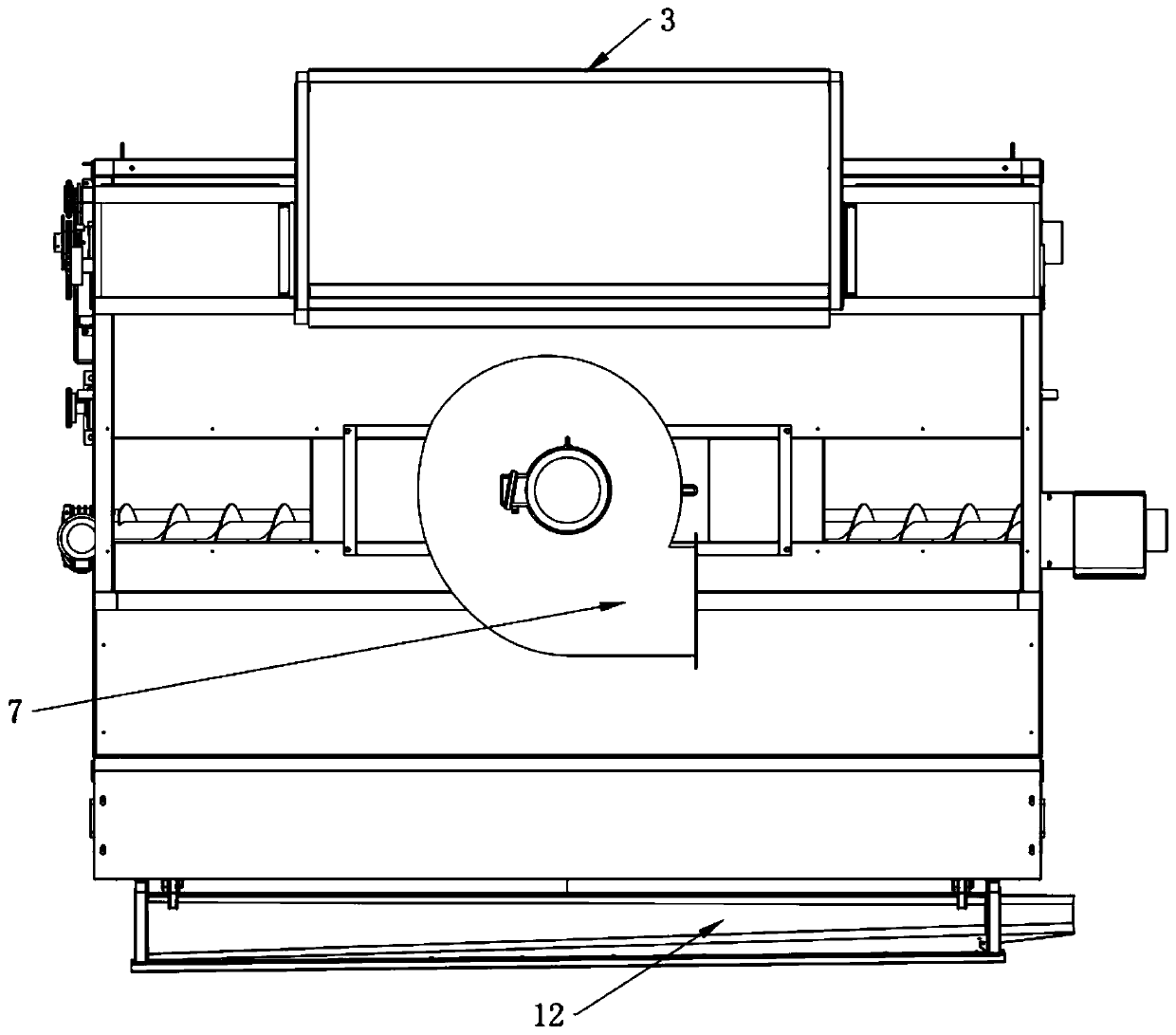

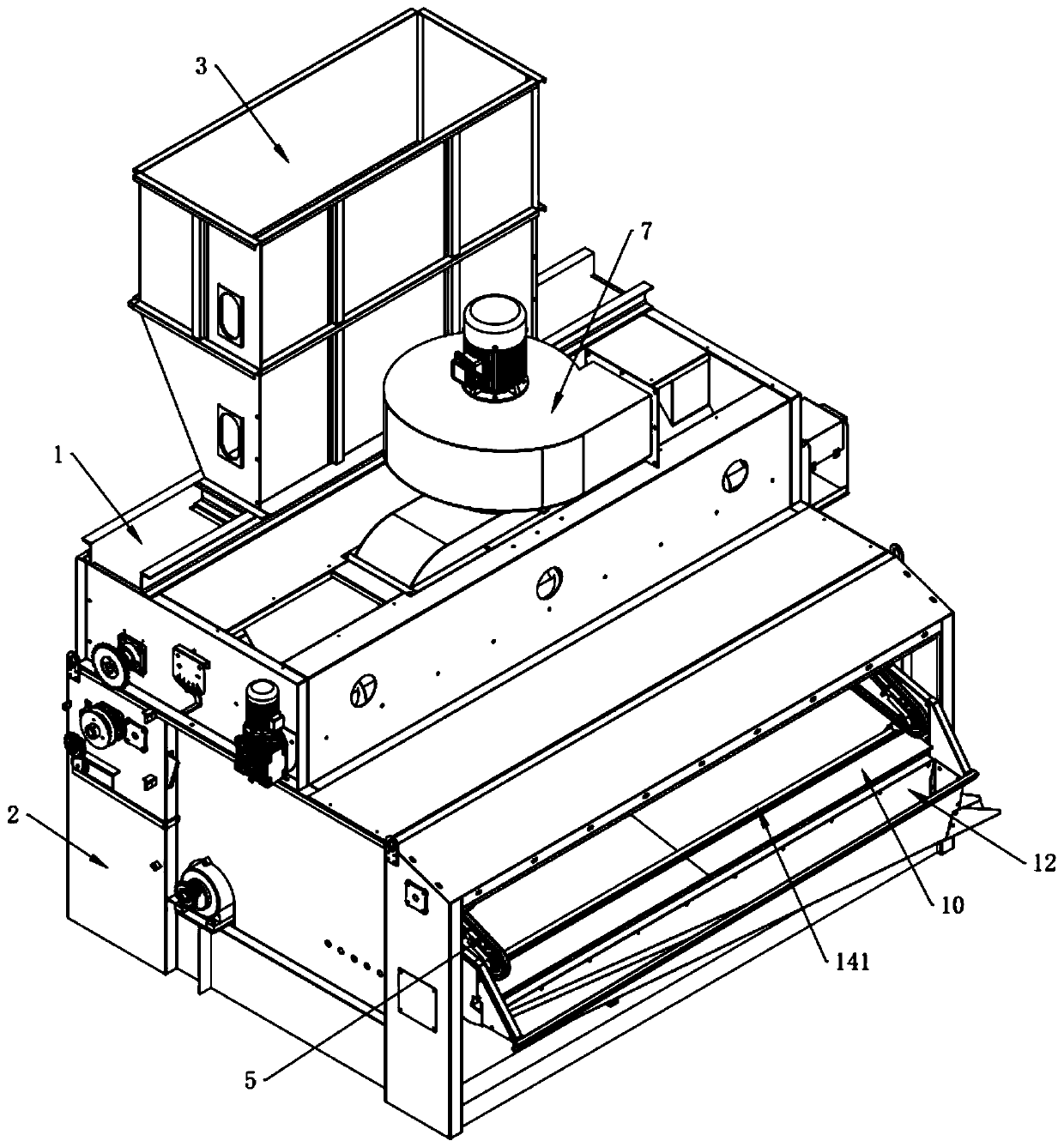

Grain screening machine with scraping plate impurity removing structure

PendingCN109939939ALabor savingIncrease production outputSievingGas current separationAgricultural engineeringMaterial storage

The invention discloses a grain screening machine with scraping plates impurities removing structure. The machine comprises a feeding box, an impurities removing box and a material storage hopper, wherein a grain stirring wheel is arranged in the feeding box, a discharging pipe is arranged on one side of the grain stirring wheel, a light impurities outputting opening is formed in one side, far away from the grain stirring wheel, of the discharging pipe, and a fan is fixedly arranged above the light impurities outputting opening; and the chain is sequentially and fixedly connected with a nylonscraping plate device, a brush scraping plate device and a PVC scraping plate device, wherein the nylon scraping plate device comprises an installing mechanism and a nylon scraping plate, the brush scraping plate device comprises an installing mechanism and a brush scraping plate, the PVC scraping plate device comprises an installing mechanism and a PVC scraping plate. According to the machine, the impurities which cannot be removed on the existing machine can be well removed by comprehensively using the scraping plates of three different materials, labor is saved, and meanwhile, the production yield is greatly improved under the condition that the size of an original screening net surface is not changed, the practicability is strong, and the machine is worthy of popularizing.

Owner:ANHUI VISION OPTOELECTRONICS TECH

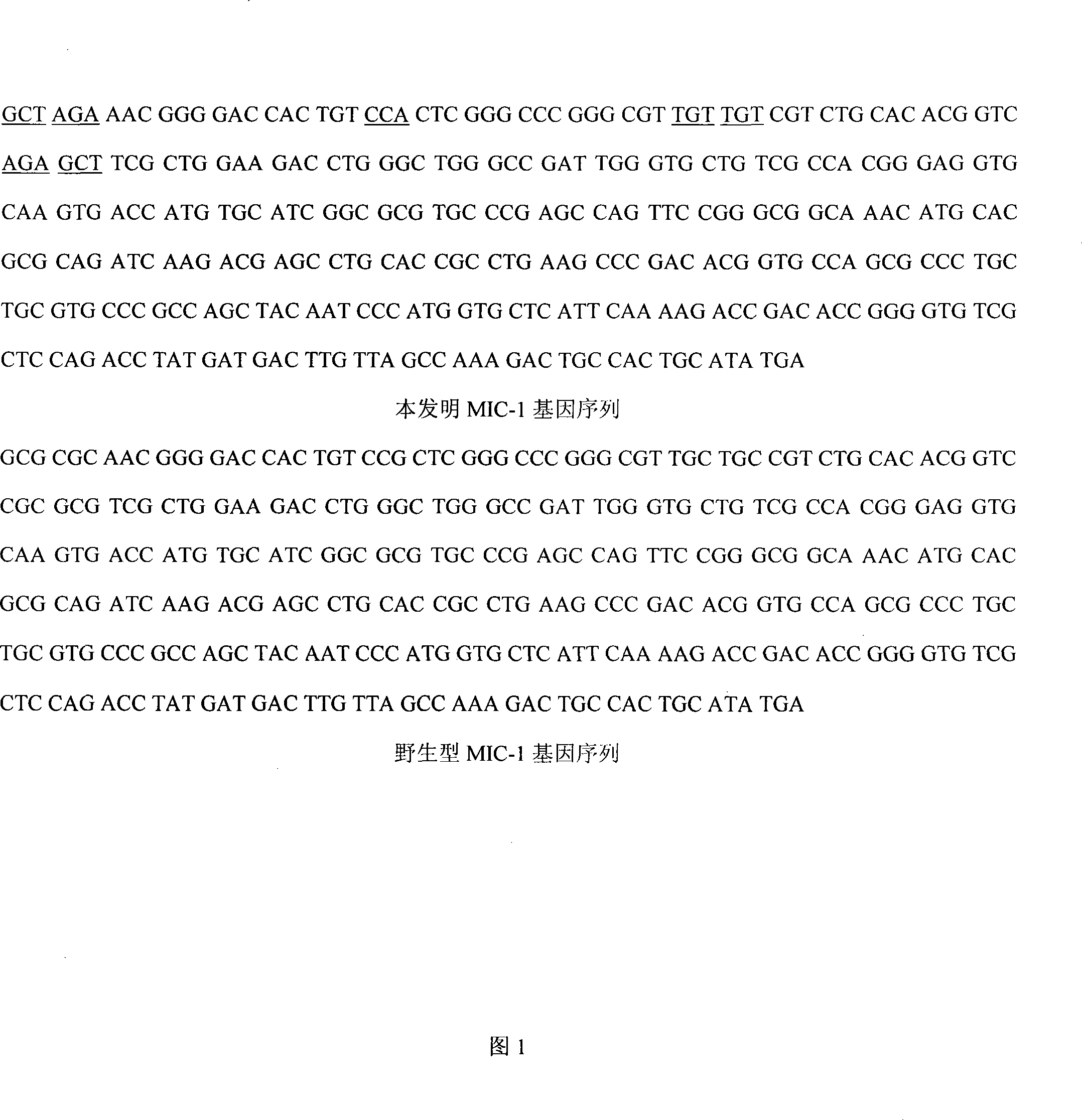

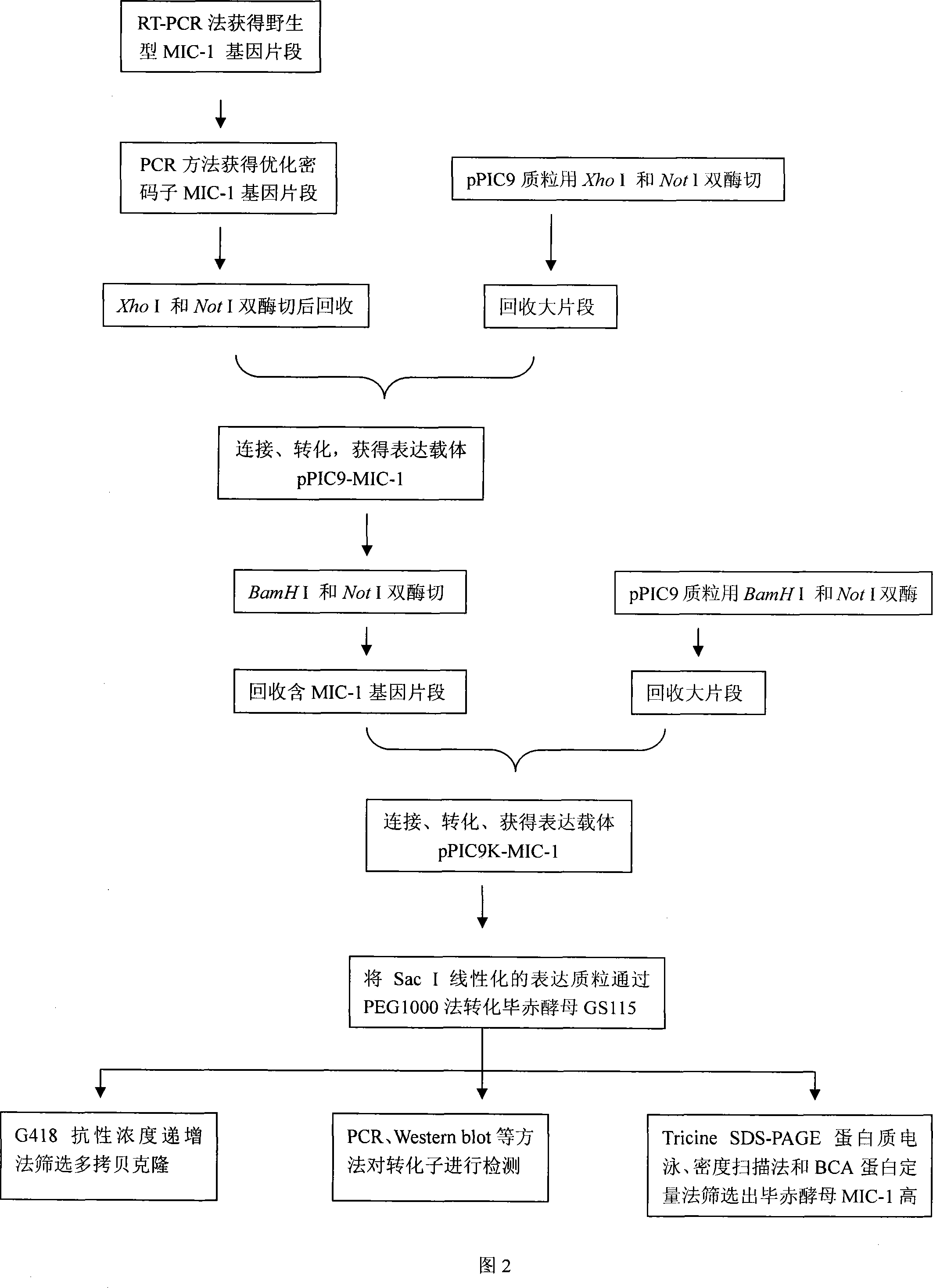

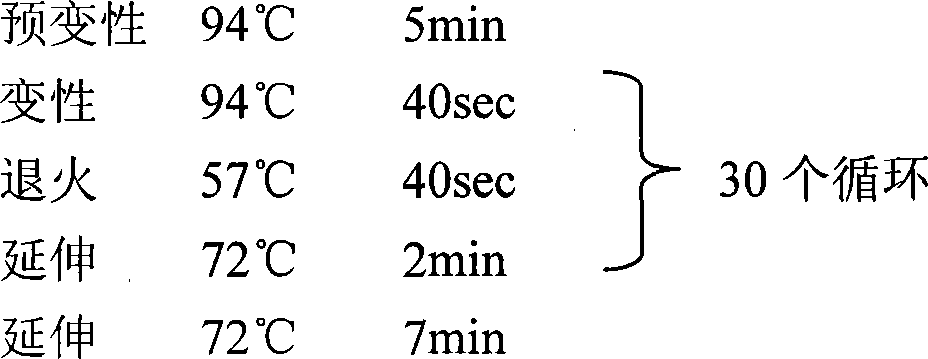

Method for improving expression of recombinant human macrophage inhibitor-1(MIC-1) in pichia yeast

InactiveCN101225400AIncrease production outputSimple processFermentationVector-based foreign material introductionAntigenAntibody

The invention relates to a method for improving expression of recombination human macrophage inhibitory factor in pichia yeast, which is characterized in that gene sequence of the recombination human macrophage inhibitory factor is modified by molecular biological method, facilitating the expression thereof in the pichia yeast; external secretion expression vector containing the recombination human macrophage inhibitory factor is constructed, GS115 pichia yeast is transformed through PEG1000 method, multi-copy clone is screened through G418 resistance concentration increasing method, and high expression pichia yeast engineering bacteria GS115 / pPIC9K-MIC-1 is obtained; the macrophage inhibitory factor pichia yeast engineering bacteria is expressed through methanol induction, and the expression product is directly secreted outside the cell; the obtained supernatant is subject to centrifugation, and then the recombinant protein expression product-macrophage inhibitory factor is contained in the supernatant. The method for improving expression of recombination human macrophage inhibitory factor in pichia yeast has the advantages of simple purification process, low cost, and large-scale expression, and lays the foundation for function research and antibody preparation through antigen in the future.

Owner:张伟

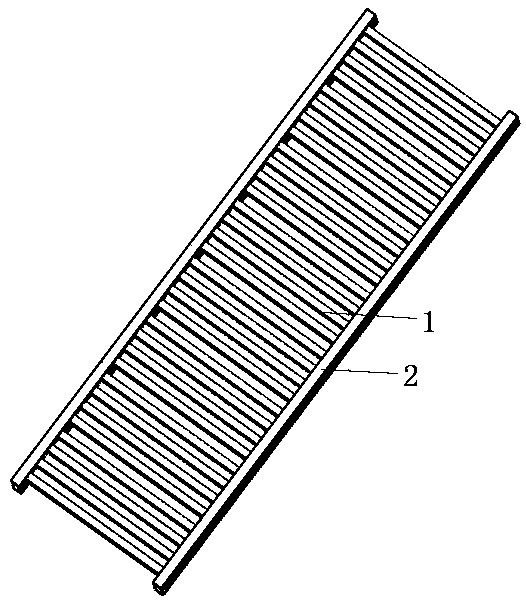

Novel water-cooled cooling device

InactiveCN109014033AImprove cooling efficiencyIncrease production outputMould handling/dressing devicesEngineeringWater cool

The invention creatively provides a novel water-cooled cooling device, and belongs to the technical field of casting. The novel water-cooled cooling device comprises ladder frames and cold water pipelines, wherein the two ladder frames are arranged in parallel; the multiple cold water pipelines are perpendicularly connected between the two ladder frames; each ladder frame is in a rectangular thinplate shape; each cold water pipeline is in a long cylindrical hollow pipe shape; the cold water pipelines are arranged on the ladder frames row by row; and the upper row and the lower row of the coldwater pipelines are arranged on the ladder frames side by side. When the novel water-cooled cooling device is in use, cold water flows into a hollow pipeline and the cooling pipelines from the ladderframes so as to play a role in circulating cooling, so that the cooling efficiency is improved, the production capacity in the unit time is improved, the working efficiency is high, energy conservation and emission reduction are realized, and the adaptability is good.

Owner:YUZHOU KUNLUN MOLD CO LTD

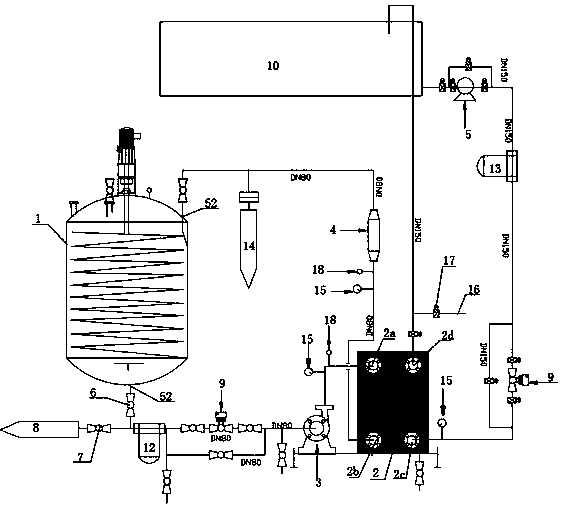

Circulation flow reactor

PendingCN108607491AIncrease production outputImprove product qualityOrganic chemistryTransportation and packagingWater circulationWater pipe

The invention discloses a circulation flow reactor which comprises a reaction kettle, a heat exchanger, an oil transfer pump, a static mixer and a cooling water pump. The reaction kettle, the oil transfer pump, the heat exchanger and the static mixer are connected through a pipeline to form a material circulation loop; the heat exchanger, the cooling water pump and a workshop water feeding tank are connected through a water pipe to form a cooling water circulation loop; materials in the material circulation loop and cooling water in the cooling water circulation loop exchange heat in the heatexchanger. By the aid of the circulation flow reactor, production and product quality are improved, and safety coefficient is improved.

Owner:NANTONG HAIERMA TECH CO LTD

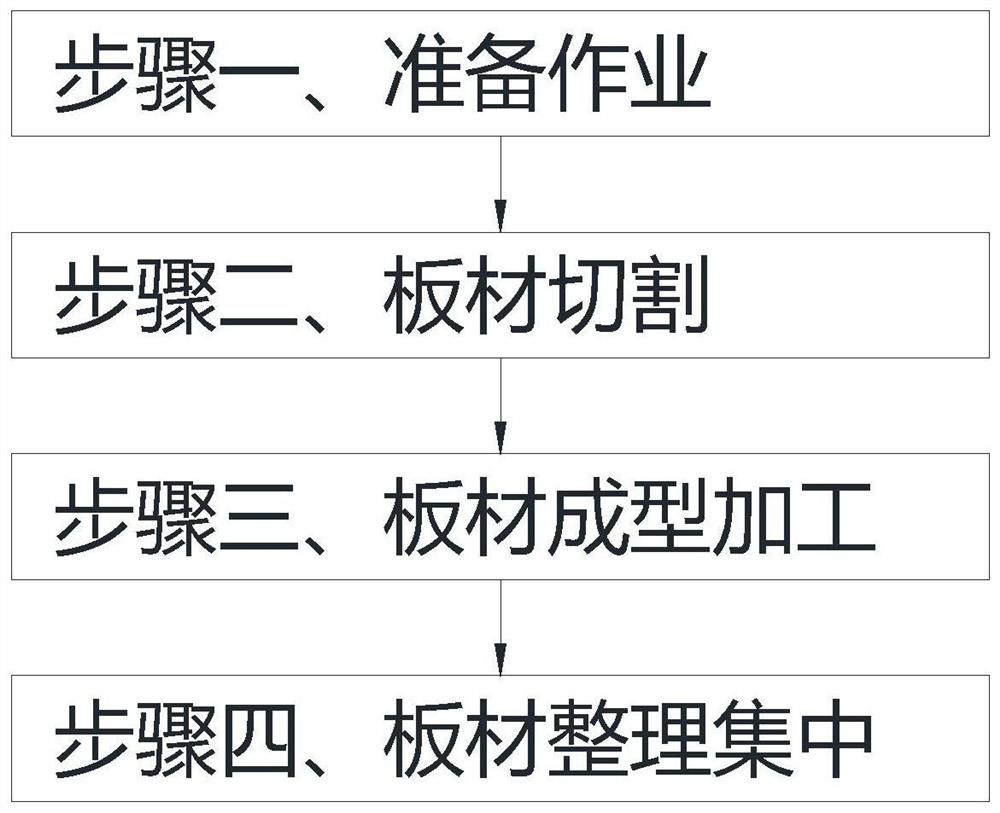

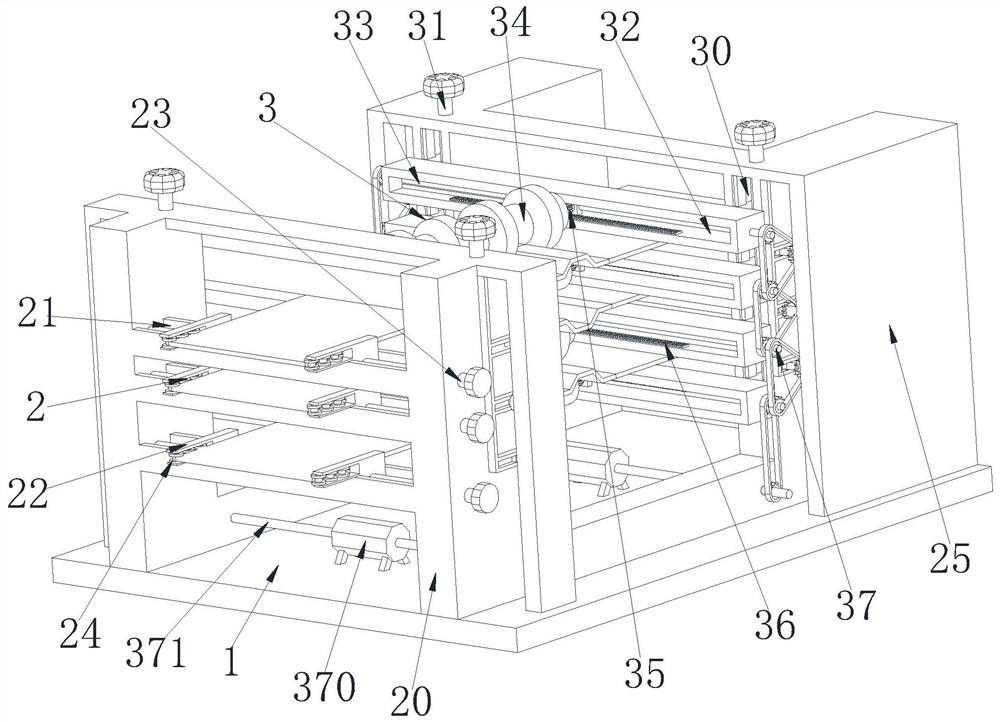

Manufacturing and machining technology of automobile container

InactiveCN111992600AImprove molding efficiencyIncrease production outputShaping toolsMetal-working feeding devicesMoulding deviceManufacturing efficiency

The invention relates to a manufacturing and machining technology of an automobile container. The manufacturing and machining technology of the automobile container uses an automobile container manufacturing and machining device. The automobile container manufacturing and machining device comprises a base, a conveying device and a forming device. The conveying device is arranged on the upper surface of the base. The forming device is arranged in the middle of the conveying device. The manufacturing and machining technology of the automobile container can solve the following problems that at present, when the automobile container is manufactured and machined, rolling formation can only be conducted on one cut plate every time when an existing container forming machine conducts forming and machining on plates for container manufacturing, so that the container producing and manufacturing efficiency is low, when the angle of the rolling formation conducted on some plates needs adjustment,a forming roller needs to be replaced, the time consumed by replacing a whole set of forming rollers is long in this way, the angle adjusting manner is not a good choice for rolling formation production of the plates of the container, and the container producing and manufacturing efficiency can be also lowered.

Owner:崔路飞

Method for manufacturing through-hole prior copper through interconnection

ActiveCN102881645BLow costIncrease production outputSemiconductor/solid-state device manufacturingCross-linkInterconnection

The invention provides a method for manufacturing a through-hole prior copper through interconnection. The manufacturing method comprises the following steps: firstly, depositing a medium layer on a substrate silicon chip, and coating first photoresist on the medium layer; secondly, completing exposure and development so as to form a through-hole structure in a photoresist film; thirdly, heating and curing the through-hole structure, then coating cross-linking materials on the first photoresist and curing a through-hole structure diaphragm in the first photoresist, forming an isolating membrane insoluble in second photoresist, and then removing the cross-linking materials; fourthly, coating the second photoresist on the first cured photoresist; fifthly, completing the exposure and development and forming a metal groove structure of the through-hole structure in the second photoresist film; sixthly, completing etching so as to transfer the through hole and the metal groove structure in the photoresist into the medium layer; and seventhly, carrying out metal deposition and metal chemical machinery grinding so as to complete the wire metal and through-hole metal filling.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

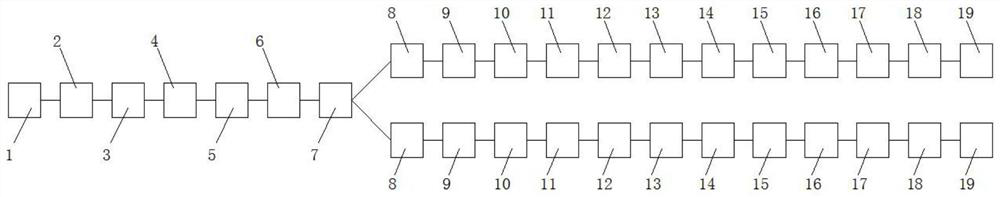

An automatic conveying line for processing molded wire-wound inductors

ActiveCN109994307BHigh degree of work automationIncrease production outputInductances/transformers/magnets manufactureEngineeringInductor

The invention relates to an automatic conveying line for molded winding inductor processing, which comprises a first feeding mechanism, a second feeding mechanism, a circulation mechanism and a transmission mechanism. The first feeding mechanism comprises a transmission component and a pneumatic component (a). The second feeding mechanism comprises a frame, a pneumatic component (b) and a storagecomponent. The circulation mechanism comprises a turnover component arranged on the storage component, and a gluing component fixedly arranged on the storage component and located above the turnover component. The transmission mechanism comprises linkage components fixedly arranged on the turnover component and symmetrically arranged along the lengthwise direction of the frame, a reciprocating component (a) articulated with the linkage components and arranged in a sliding manner on the turnover component, a reciprocating component (b), and an output component arranged below the gluing component, wherein the reciprocating component (a) and the reciprocating component (b) are symmetrically arranged along the middle line of the length of the linkage component. The technical problems of low working efficiency and low productivity due to the need of one-by-one manual operation in the bonding forming process are solved.

Owner:耒阳市铭博电子有限公司

A continuous processing and production process of composite geotechnical drainage net

ActiveCN110978544BAvoid empty spaceClose working relationshipDomestic netsEnvironmental resource managementAdhesive

Owner:SHANDONG FEICHENG LIANYI ENG PLASTICS CO LTD

Automatic bottom rotating device and process for heat preservation container product

PendingCN114074250AImprove running accuracy and stabilityIncrease production outputFluid-tightness measurementMetal working apparatusProcess engineeringHeat conservation

The invention discloses an automatic bottom rotating device and process for a heat preservation container product. The automatic bottom rotating device comprises a speed chain assembly line, a pre-rotating positioning mechanism, an outsole rotating mechanism, a bottom screw rotating mechanism, a sealing performance detection mechanism and an electric appliance control system, wherein the pre-rotating positioning mechanism, the outsole rotating mechanism and the bottom screw rotating mechanism are each provided with a clamping claw, a rotating base, a servo motor, an air cylinder and a bearing base, and operate according to preset data by the electric appliance control system. The process comprises the following steps of: feeding a to-be-processed product online; pre-rotating and positioning the to-be-processed product; rotating an outsole; screwing bottom screws; detecting the sealing performance; and turning to a next procedure after processing, and circulating the production line. The automatic bottom rotating device has the advantages that the automatic bottom rotating and bottom screw rotating process of the product is completed through multi-station cooperation, enables the torsion of an outsole rotating base and a bottom screw rotating base which are connected with the machine to reache a preset torsion value, and solves the problems that fastening torsion is not stable, positioning is not accurate and the bottom is prone to being wiped due to manual operation.

Owner:SHANGHAI WANSHENG VACUUM FLASK & VESSEL

Automatic conveying line for molded winding inductor processing

ActiveCN109994307AHigh degree of work automationIncrease production outputInductances/transformers/magnets manufactureInductorEngineering

The invention relates to an automatic conveying line for molded winding inductor processing, which comprises a first feeding mechanism, a second feeding mechanism, a circulation mechanism and a transmission mechanism. The first feeding mechanism comprises a transmission component and a pneumatic component (a). The second feeding mechanism comprises a frame, a pneumatic component (b) and a storagecomponent. The circulation mechanism comprises a turnover component arranged on the storage component, and a gluing component fixedly arranged on the storage component and located above the turnover component. The transmission mechanism comprises linkage components fixedly arranged on the turnover component and symmetrically arranged along the lengthwise direction of the frame, a reciprocating component (a) articulated with the linkage components and arranged in a sliding manner on the turnover component, a reciprocating component (b), and an output component arranged below the gluing component, wherein the reciprocating component (a) and the reciprocating component (b) are symmetrically arranged along the middle line of the length of the linkage component. The technical problems of low working efficiency and low productivity due to the need of one-by-one manual operation in the bonding forming process are solved.

Owner:耒阳市铭博电子有限公司

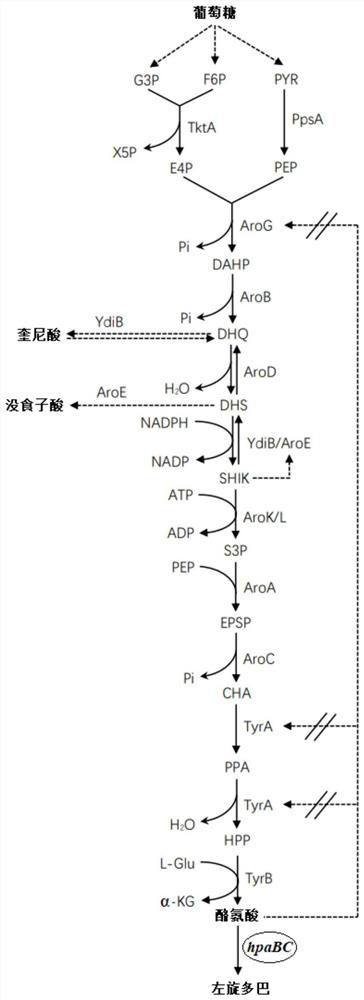

Method for producing levodopa through microbial fermentation and application

PendingCN114395590AIncrease glucose fluxIncrease production outputBacteriaMicroorganism based processesLevodopaPhenylacetic acid

The invention discloses a method for producing levodopa through microbial fermentation. According to the method, levodopa is produced with higher efficiency and higher yield mainly by improving the effect of 4-hydroxyphenylacetic acid 3-monooxygenase B (hpaB) in microorganisms.

Owner:NANJING SHOUBAI BIOTECH CO

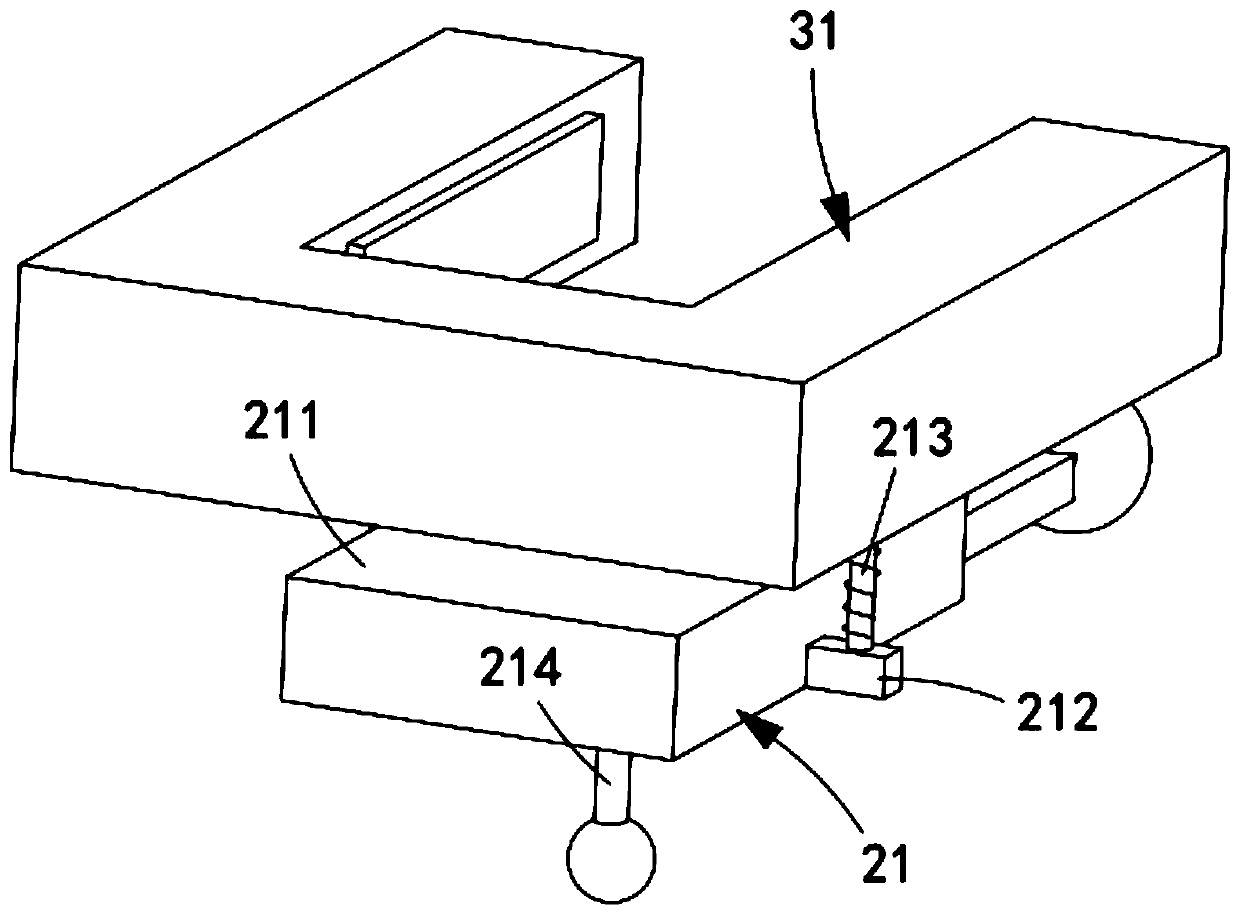

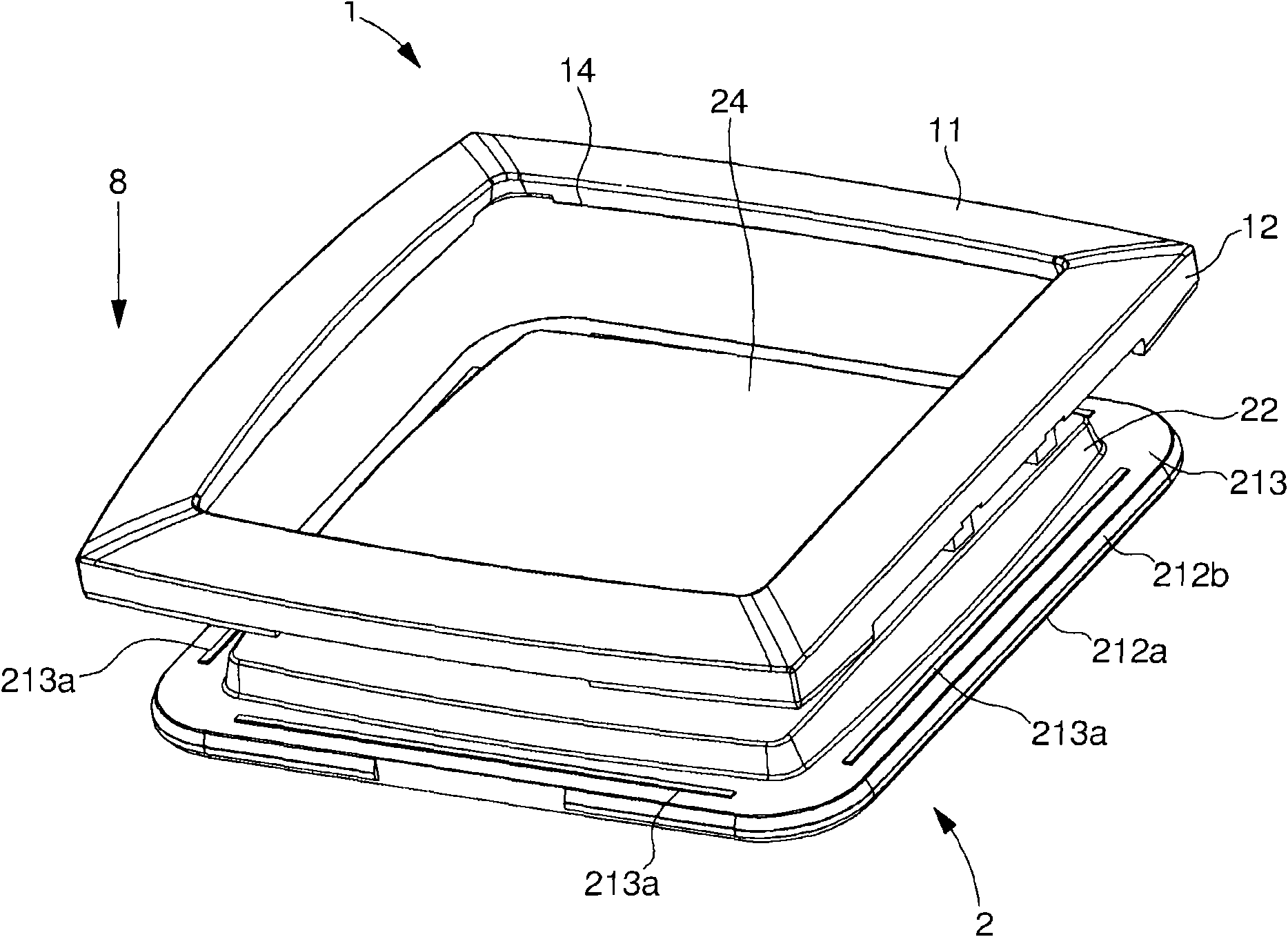

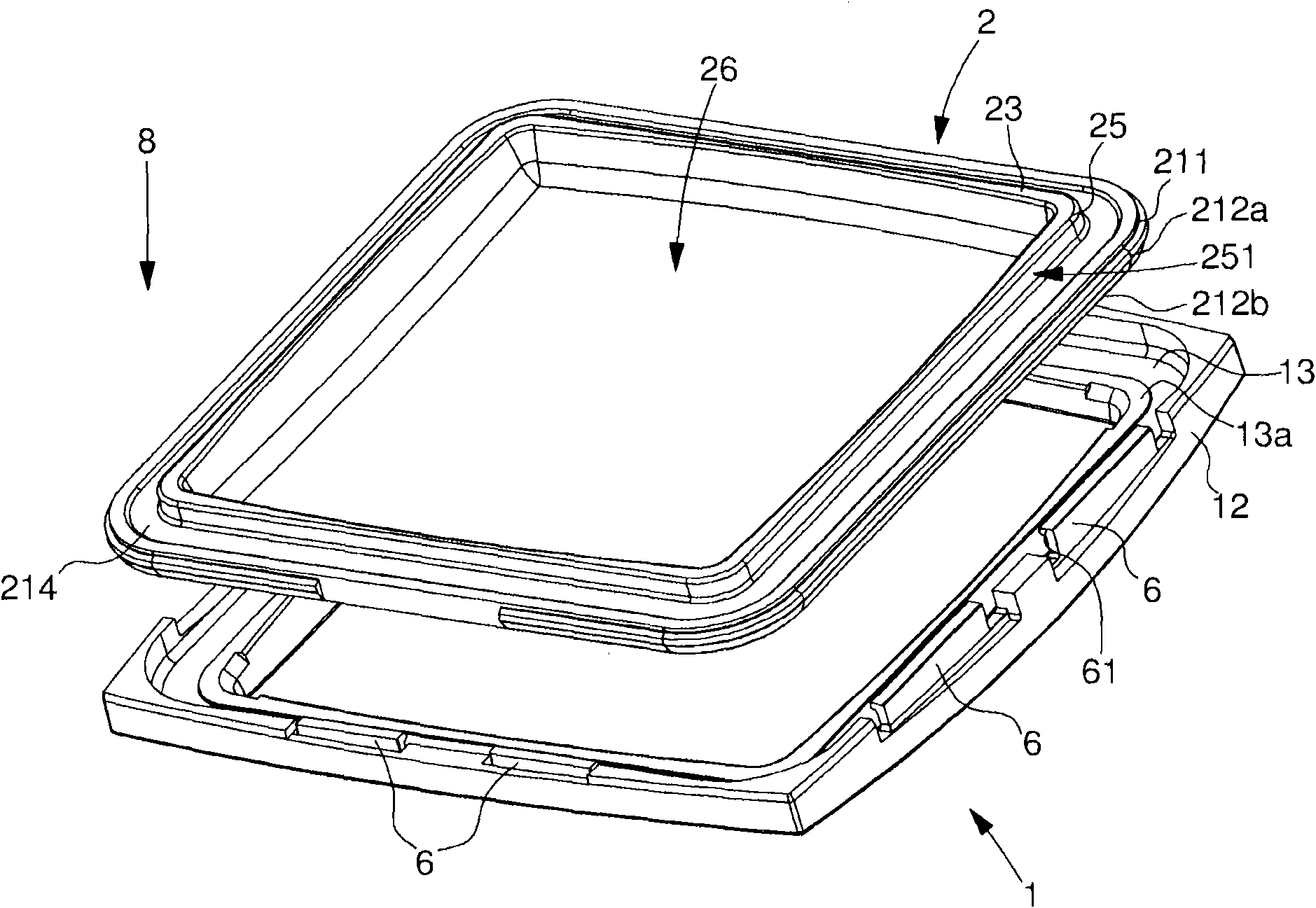

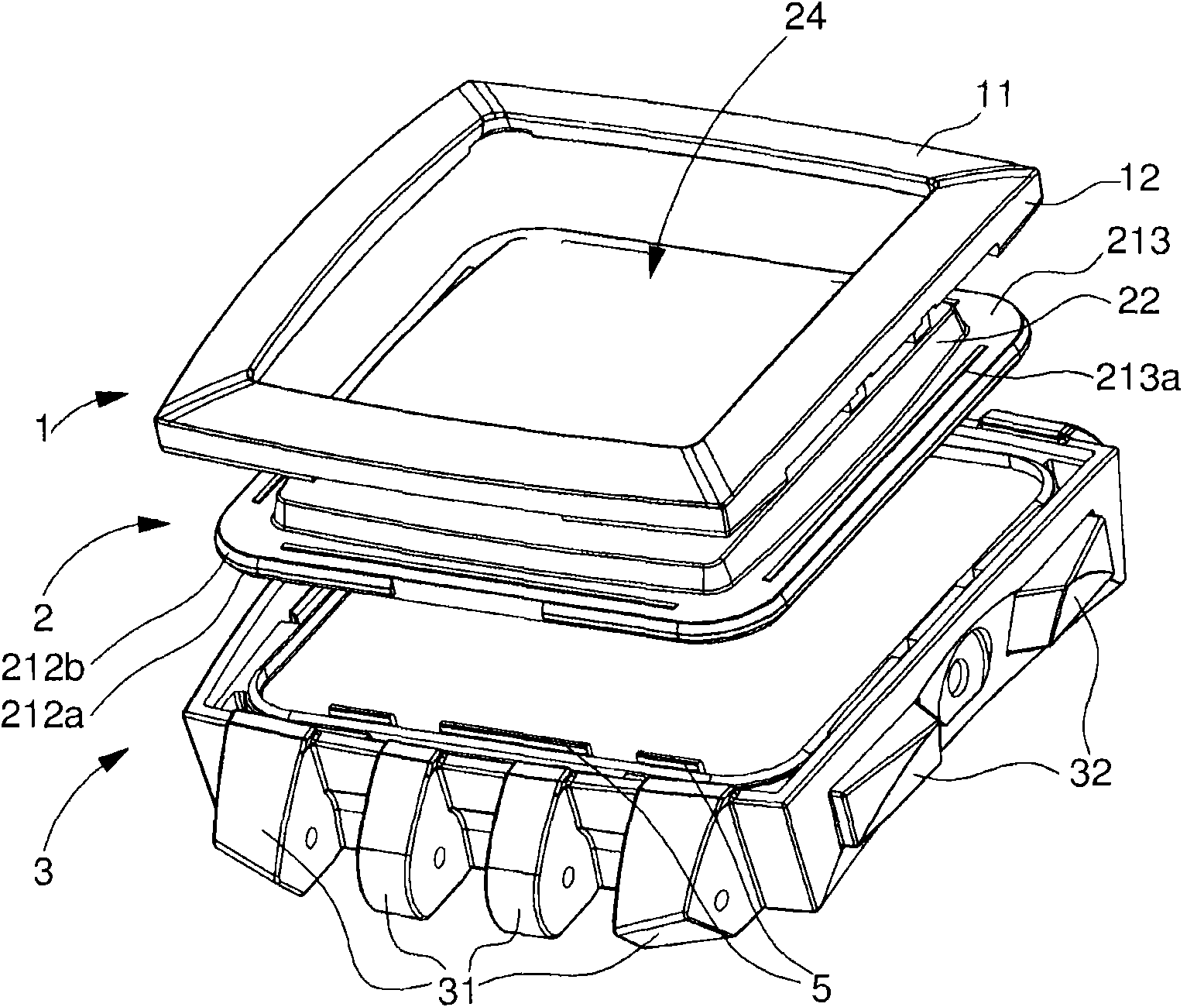

Method and device for fixing a sheet of glass with counter-blade

ActiveCN102200755BEasy to fixImprove sturdinessDoors/windowsRepair toolsElectrical and Electronics engineeringCrystal

The method involves snap fitting a watch bezel (1) on a crystal (2), where the bezel includes a snap fit unit that is guided by a guide unit (5) installed on a case (3). The snap fit unit is located against the crystal by the guide unit. The crystal is secured to the case. Axial positioning of the crystal relative to the bezel is ensured by axial positioning unit arranged on an internal face of the bezel and a top face (213) of peripheral edge of the bezel. A snap fit surface of the snap fit unit is formed underneath a snap fit surface of the crystal located on peripheral edge of the crystal. An independent claim is also included for a device for securing a watch bezel, comprising an axial positioning unit.

Owner:ETA SA MFG HORLOGERE SUISSE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com