Patents

Literature

5006 results about "Sodium benzoate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

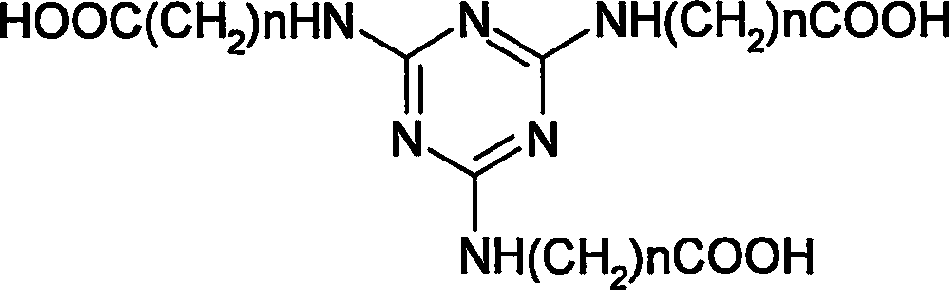

Sodium benzoate is a substance which has the chemical formula C₆H₅COONa. It is a widely used food preservative, with an E number of E211. It is the sodium salt of benzoic acid and exists in this form when dissolved in water. It can be produced by reacting sodium hydroxide with benzoic acid.

Articles derived from compositions containing modified polybutylene terephthalate (PBT) random copolymers derived from polyethylene terephthalate (PET)

ActiveUS20070275242A1Useful performance propertyPlastic recyclingSpecial tyresPolytetramethylene terephthalatePolyethylene terephthalate glycol

Compositions of matter including articles derived from (a) from 5 to 99.99 wt % of a modified polybutylene terephthalate random copolymer that (1) is derived from polyethylene terephthalate and (2) contains a at least one residue derived from polyethylene terephthalate selected from the group consisting of antimony, germanium, diethylene glycol groups, isophthalic acid groups, cis isomer of cyclohexane dimethanol, trans isomer of cyclohexane dimethanol, sodium benzoate, alkali salts, napthalane dicarboxylic acids, 1,3-propane diols, cobalt, cobalt-containing compounds, and combinations thereof, and (b) from 0.01 to 95 wt. % of a member selected from the group consisting of (1) fillers, (2) a carboxy reactive component, (3) polyethyelene terephthalate, (4) a component including a polycarbonate and an impact modifier. The articles may be derived from various conversion processes, e.g., injection molding processes, extrusion processes, thermoforming processes, melt-blown process.

Owner:SHPP GLOBAL TECH BV

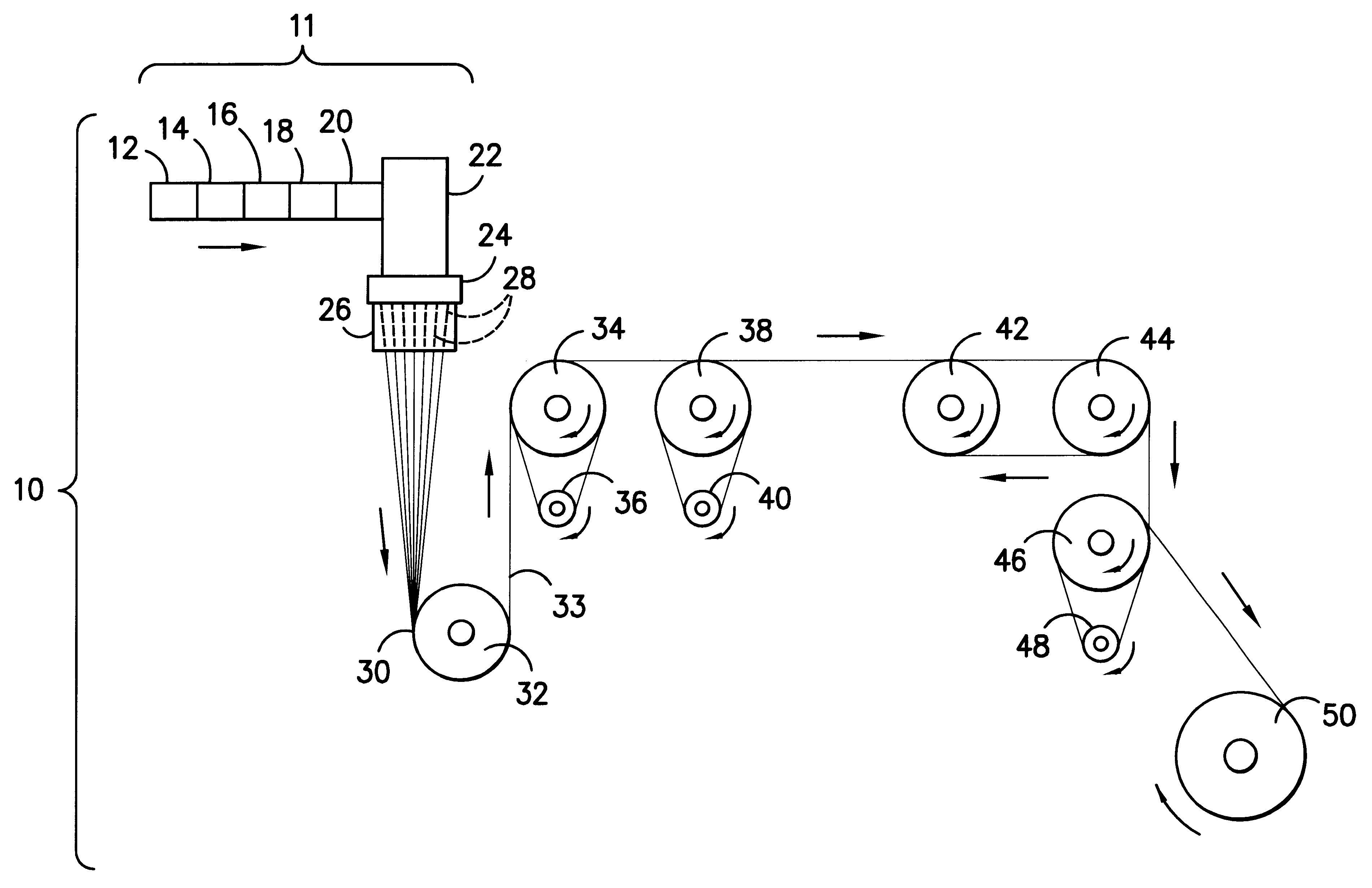

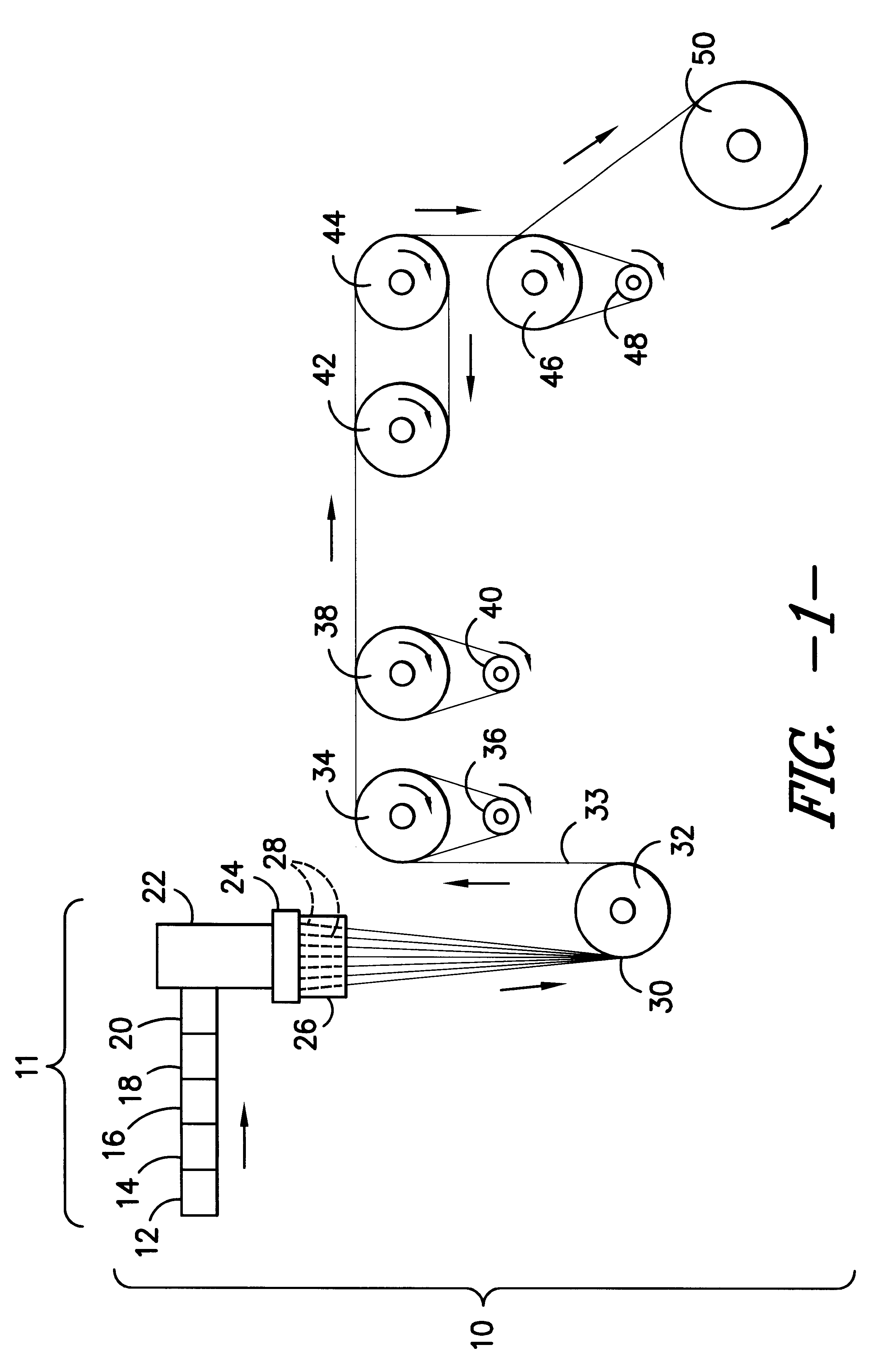

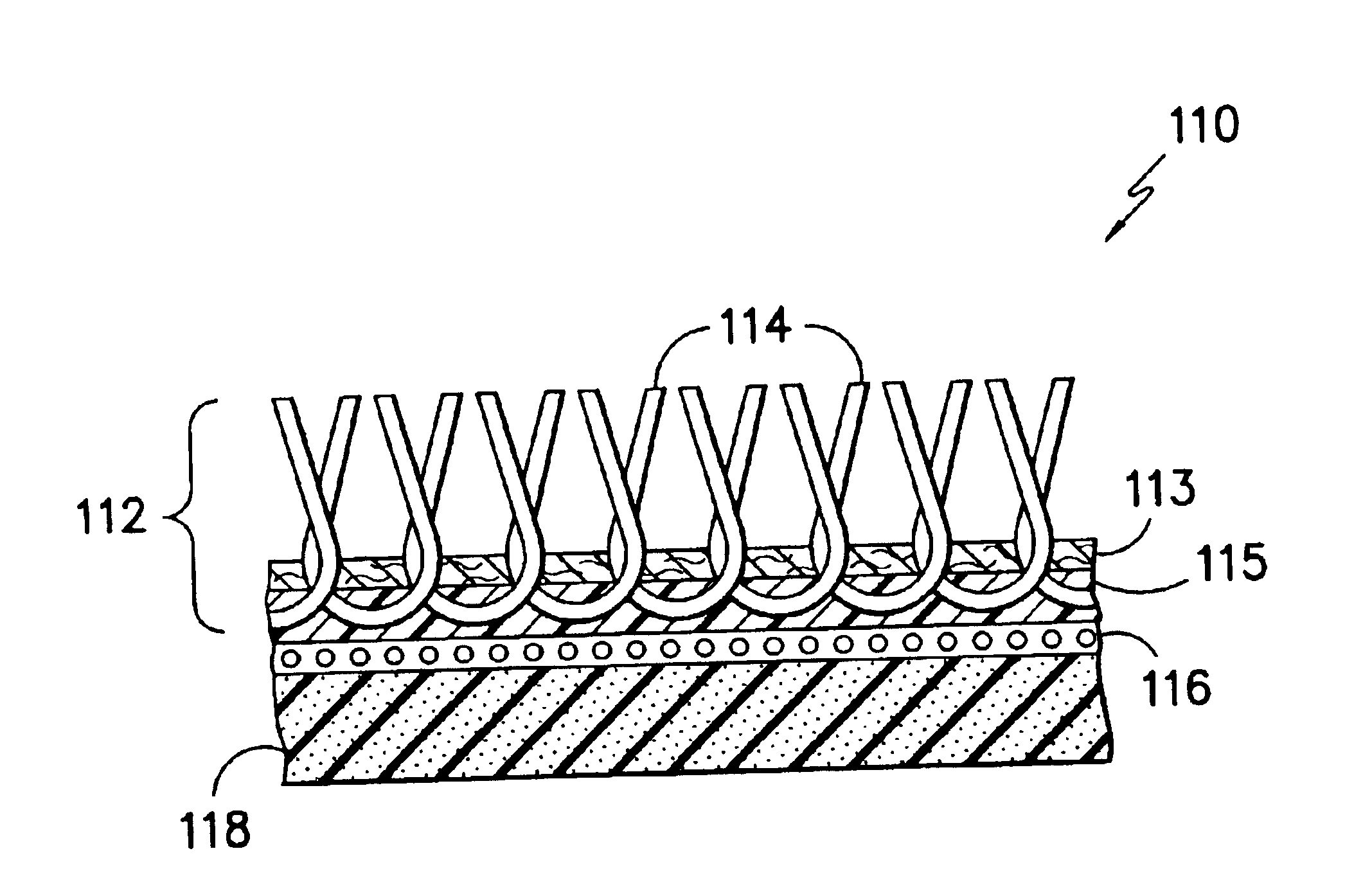

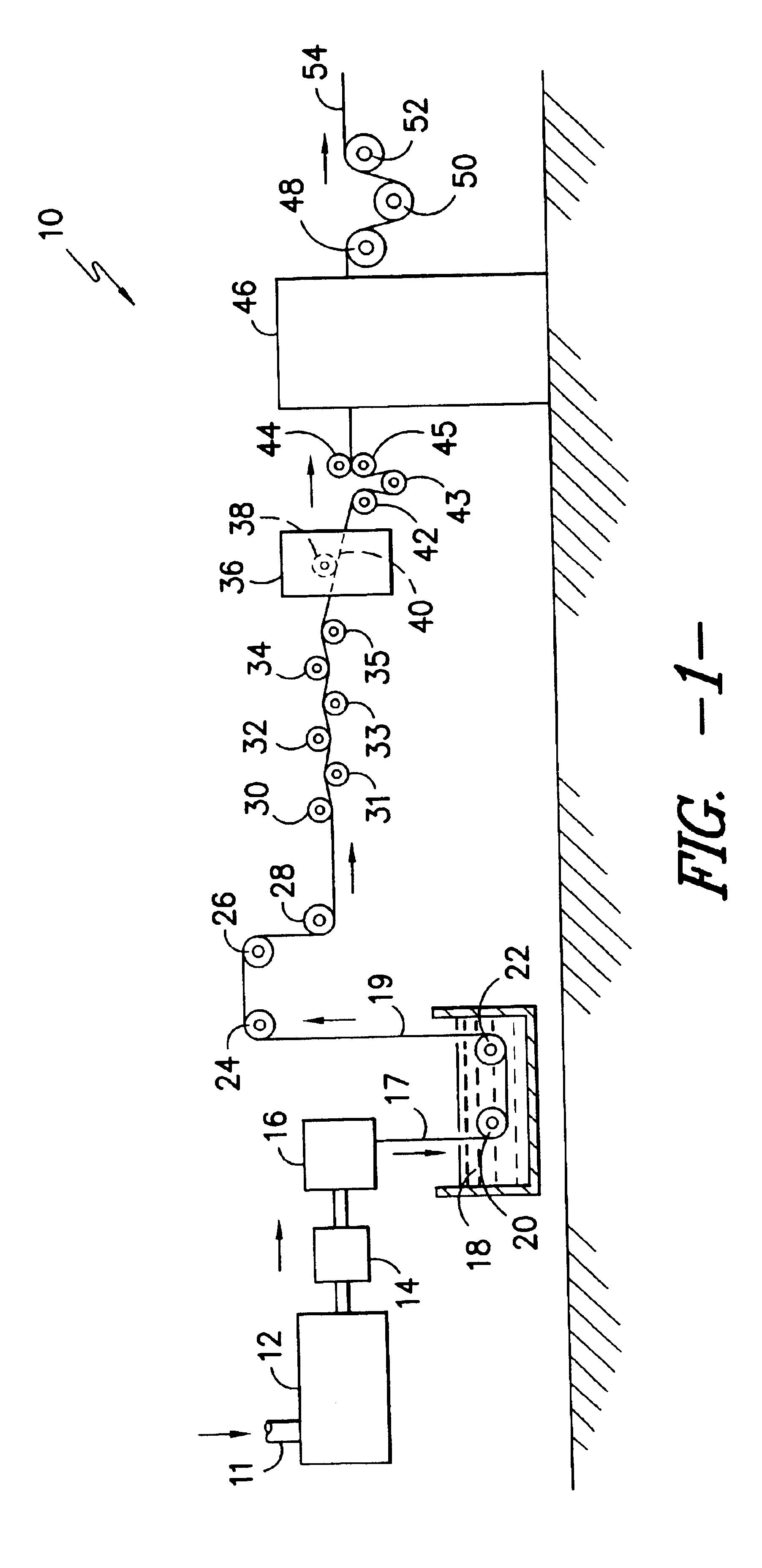

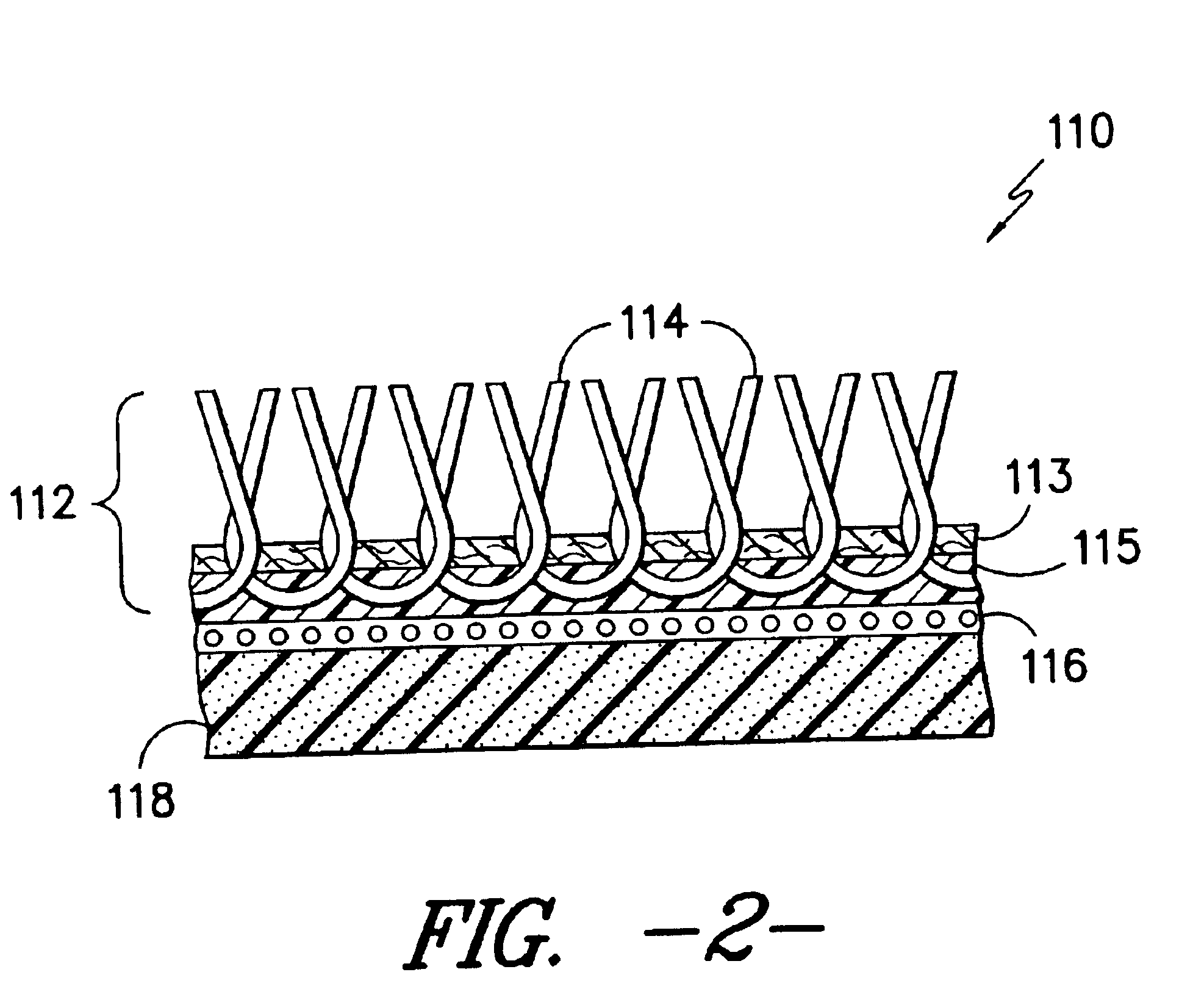

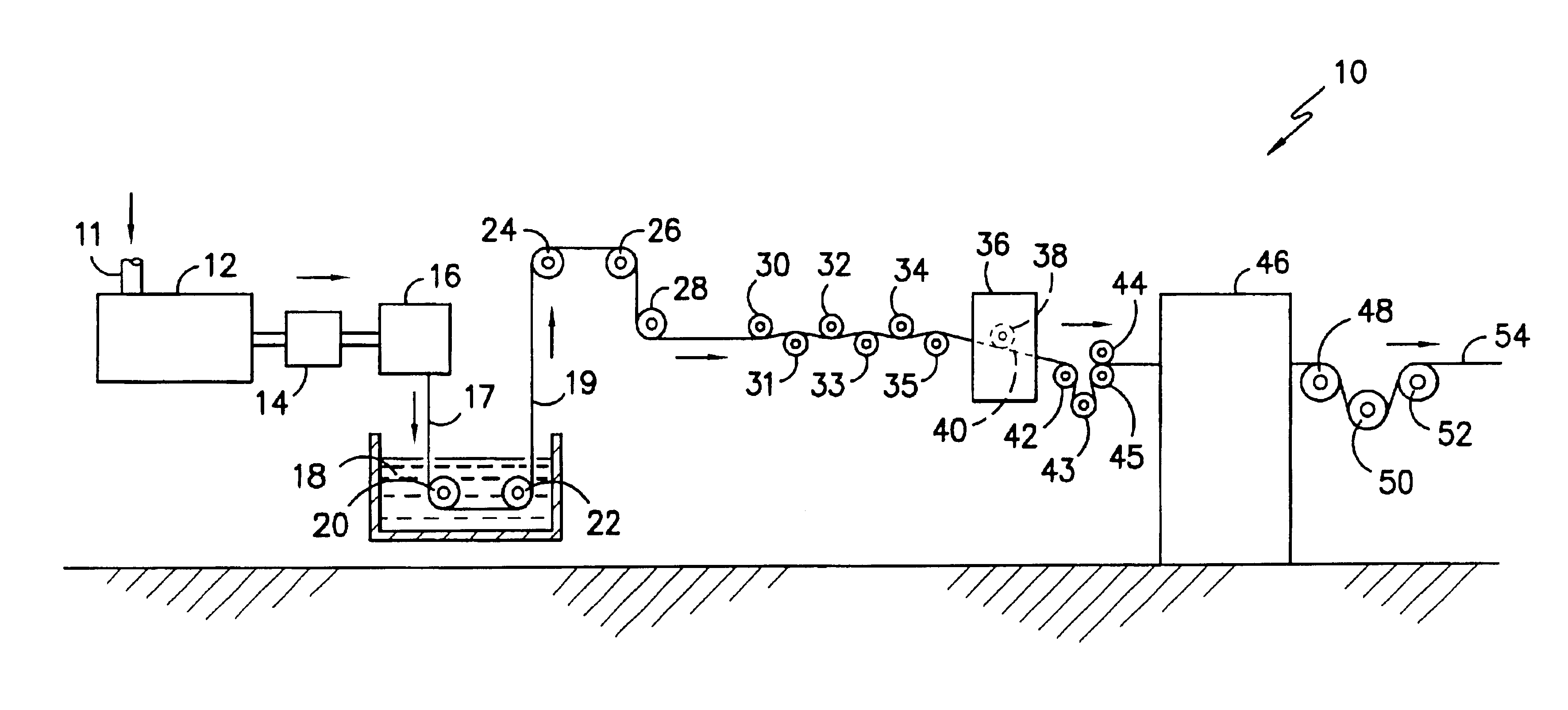

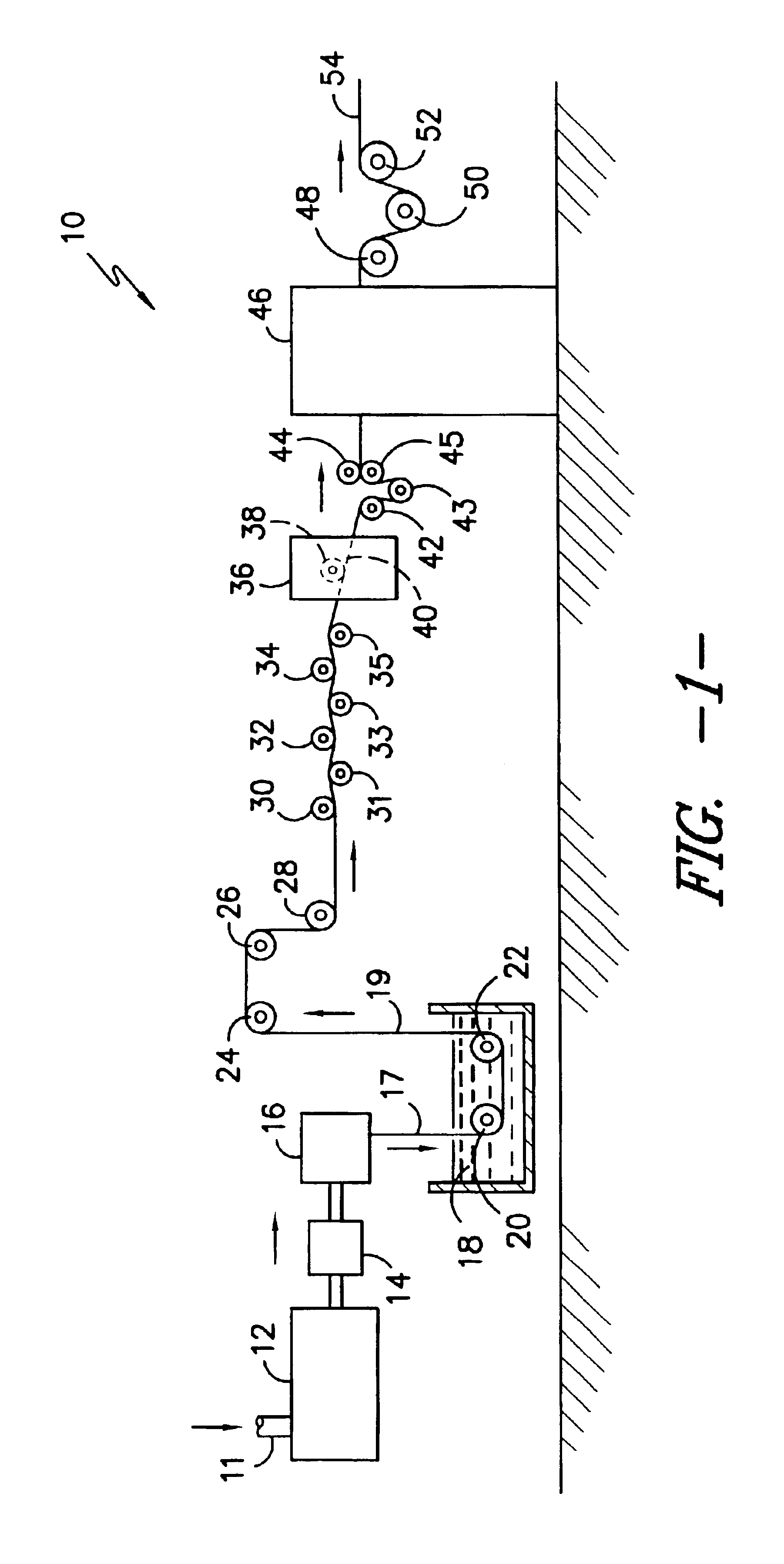

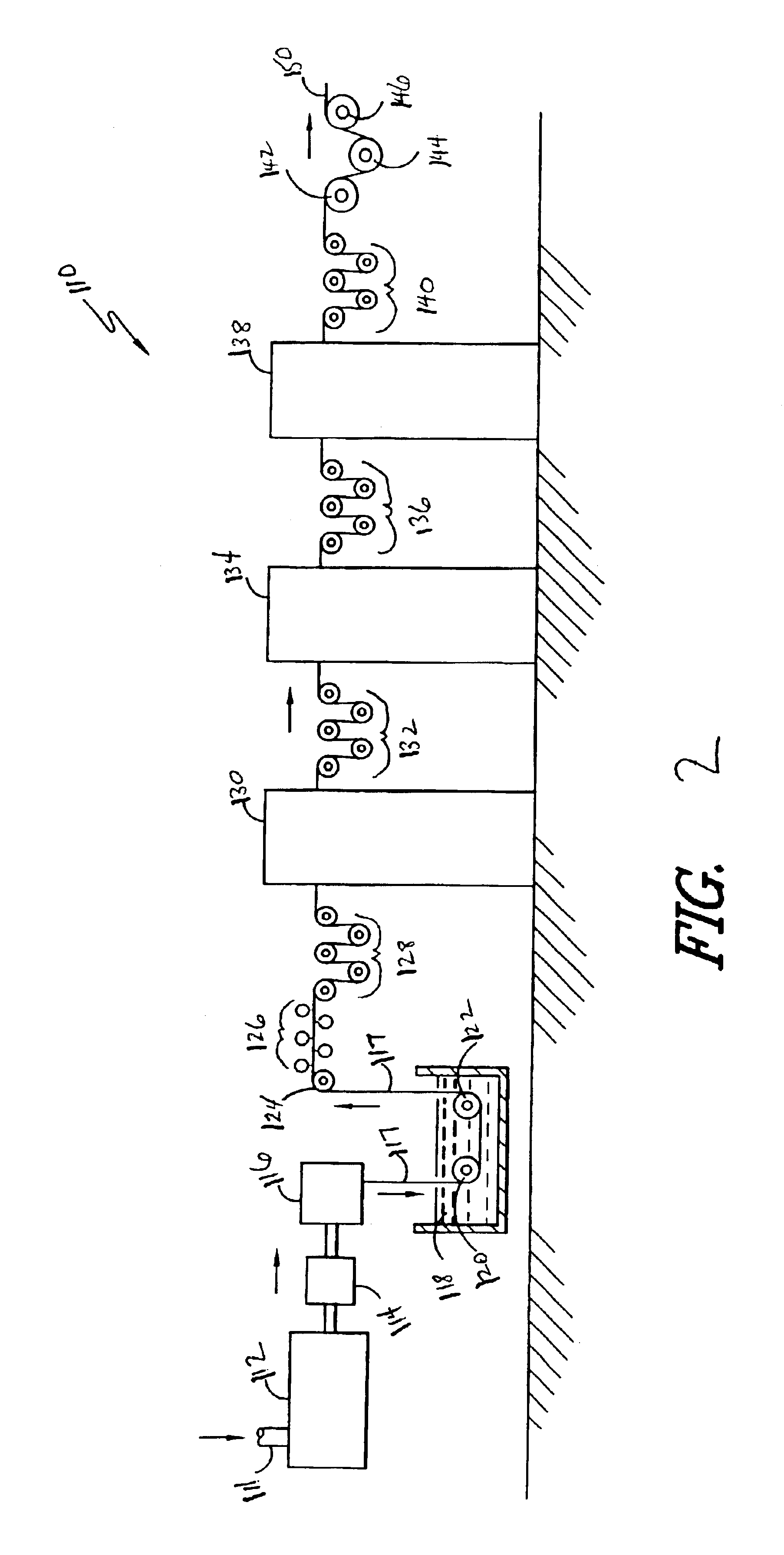

Thermoplastic monofilament fibers exhibiting low-shrink, high tenacity, and extremely high modulus levels

InactiveUS6759124B2High tensile strengthLow shrinkageSynthetic resin layered productsFilament/thread formingThermoplasticYarn

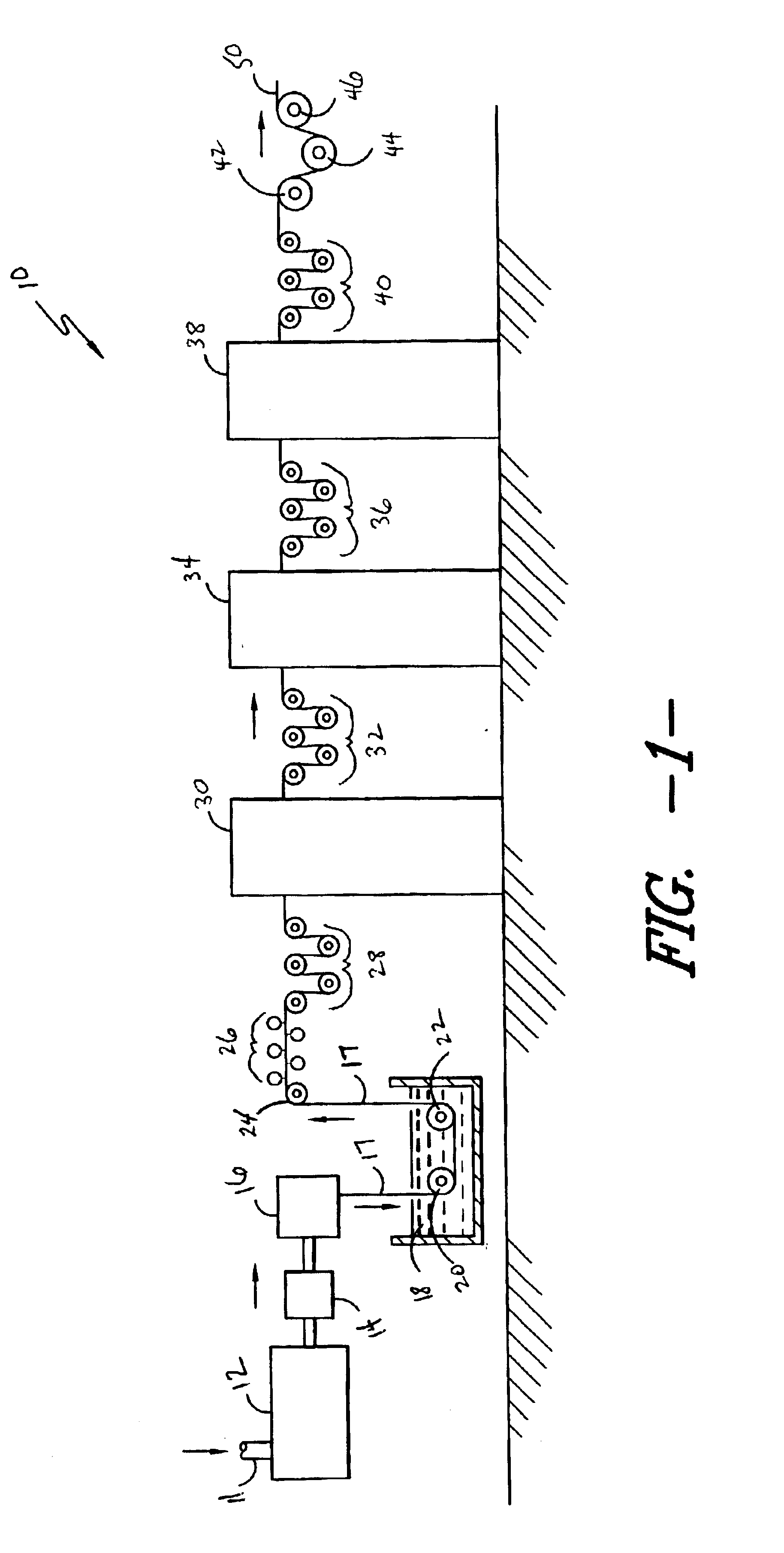

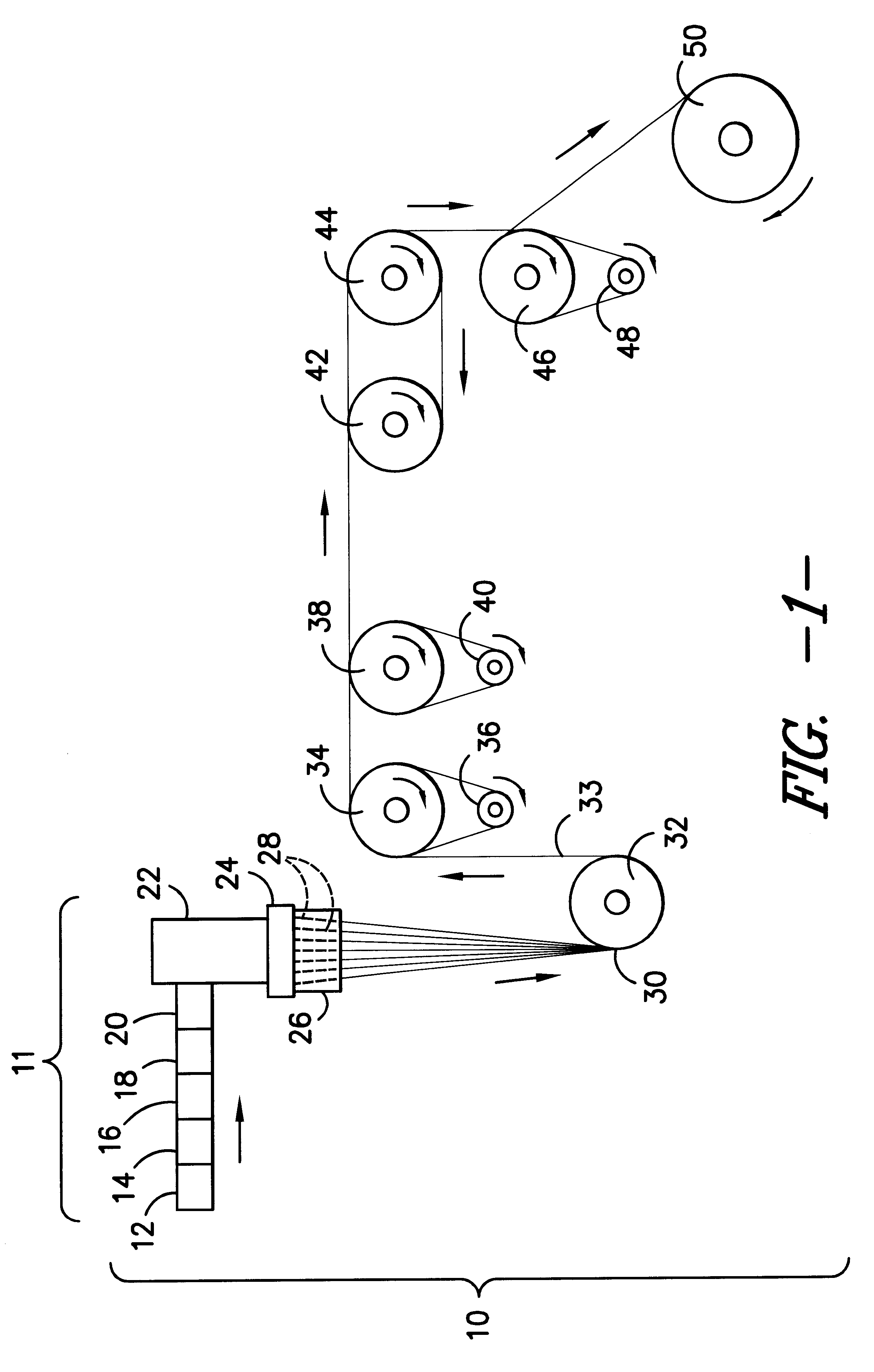

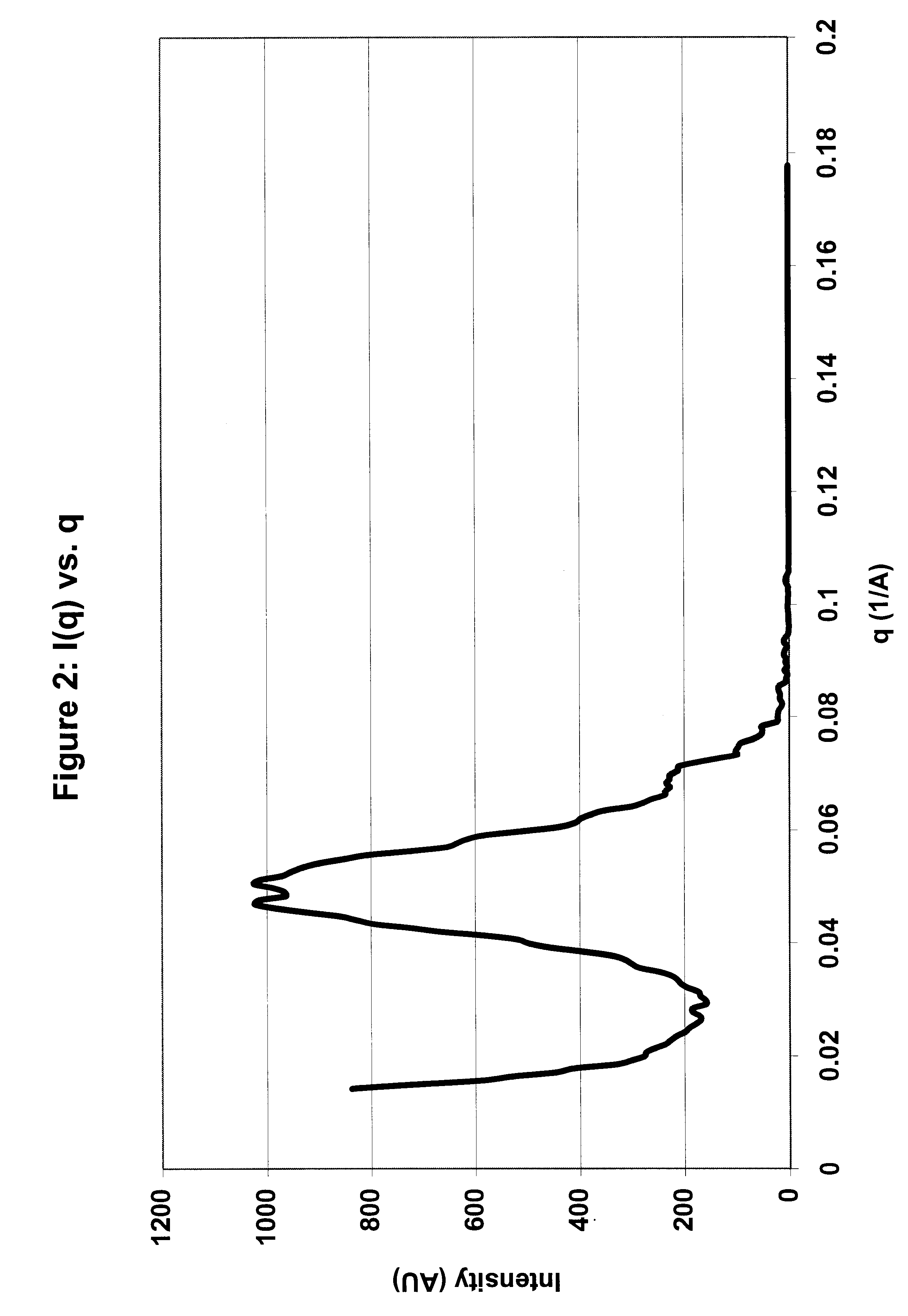

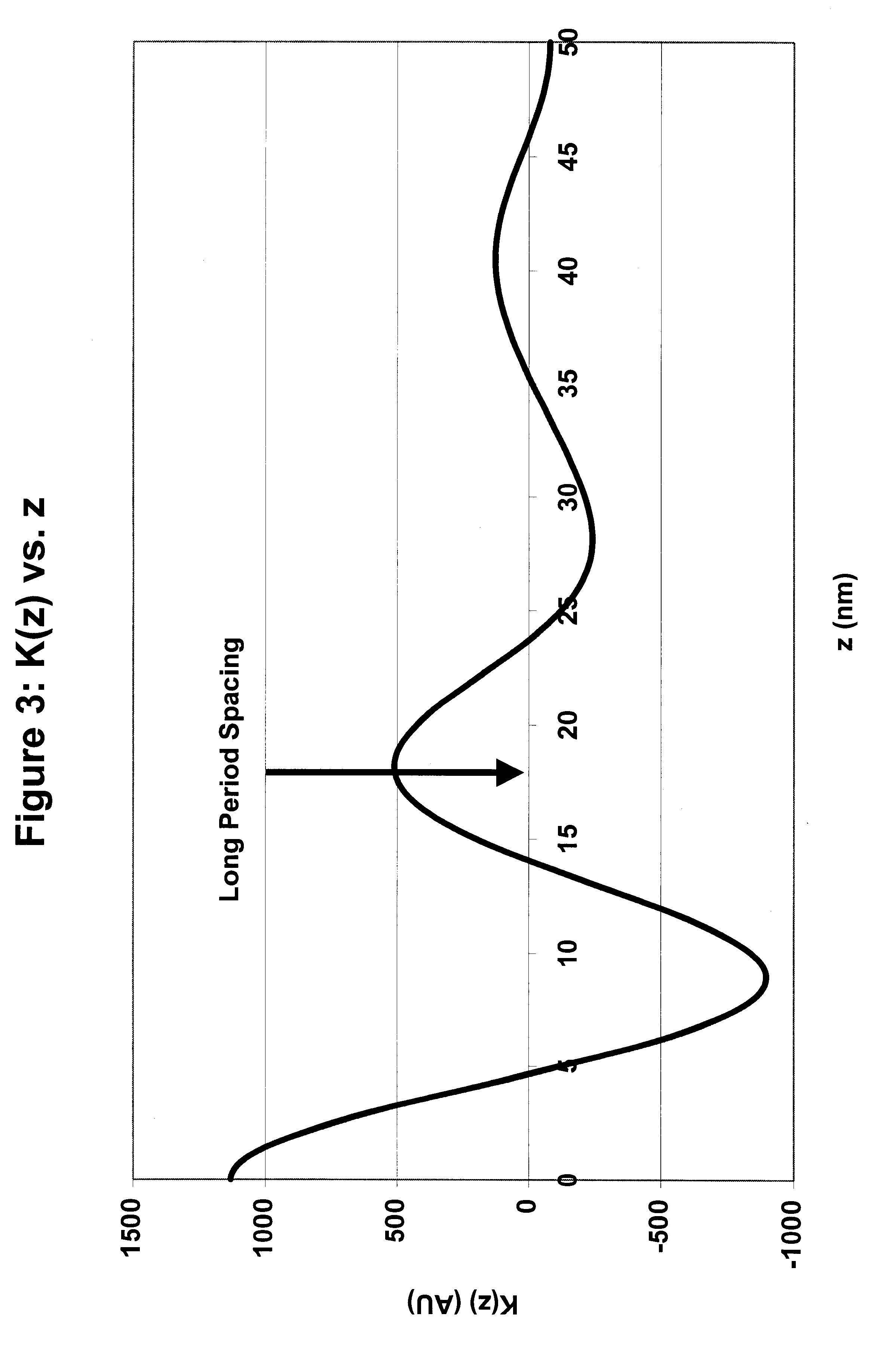

Unique thermoplastic monofilament fibers and yarns that exhibit heretofore unattained physical properties are provided. Such fibers are basically manufactured through the extrusion of thermoplastic resins that include a certain class of nucleating agent therein, and are able to be drawn at high ratios with such nucleating agents present that the tenacity and modulus strength are much higher than any other previously produced thermoplastic fibers, particularly those that also simultaneously exhibit extremely low shrinkage rates. Thus, such fibers require the presence of certain compounds that quickly and effectively provide rigidity to the target thermoplastic (for example, polypropylene), particularly after heat-setting. Generally, these compounds include any structure that nucleates polymer crystals within the target thermoplastic after exposure to sufficient heat to melt the initial pelletized polymer and allowing such an oriented polymer to cool. The compounds must nucleate polymer crystals at a higher temperature than the target thermoplastic without the nucleating agent during cooling. In such a manner, the "rigidifying" nucleator compounds provide nucleation sites for thermoplastic crystal growth. The preferred "rigidifying" compounds include dibenzylidene sorbitol based compounds, as well as less preferred compounds, such as [2.2.1]heptane-bicyclodicarboxylic acid, otherwise known as HPN-68, sodium benzoate, certain sodium and lithium phosphate salts [such as sodium 2,2'-methylene-bis-(4,6-di-tert-butylphenyl)phosphate, otherwise known as NA-11]. Specific methods of manufacture of such inventive thermoplastic fibers, as well as fabric articles made therefrom, are also encompassed within this invention.

Owner:MILLIKEN & CO

Anti-emulsification water-soluble metal washing agent

The invention relates to an anti-emulsification water-soluble metal washing agent. Every 100 parts of the anti-emulsification water-soluble metal washing agent include the following components according to parts by weight: 3-7 non-ionic surfactant, 3-7 bi-ion active agent, 1-5 chelator, 1-5 rust preventive, 5-10 inorganic builder and the balance water, wherein the non-ionic surfactant is any one of fatty amine polyoxypropylene ether, alkylphenol ether and fatty amine polyoxyethylene alkyl ether ammonium sulfate, the bi-ion active agent is any one of alkyl dimethylin acetic acid betaine, lauramidopropyl betaine and cocamidopropyl betaine, the chelator is any one of sodium citrate, ethylenediaminetetraacetic acid tetrasodium salt and nitrilotriacetic acid sodium salt, the rust preventive is any one of sodium borate, sodium nitrite, sodium benzoate and long carbon chain carboxylic acid amine, and the inorganic builder is any one of trisodium phosphate, sodium metasillcate, sodium carbonate, sodium bicarbonate and sodium hydroxide. The anti-emulsification water-soluble metal washing agent has the advantage of higher cleaning capacity and reutilization capacity.

Owner:NANJING KERUN LUBRICANTS

Soil improvement type straw compound organic fertilizer and preparation method of soil improvement type straw compound organic fertilizer

InactiveCN105777429AImprove physical and chemical propertiesImprove qualityCalcareous fertilisersBio-organic fraction processingCompound organicPhosphate

The invention provides a soil improvement type straw compound organic fertilizer and a preparation method of the soil improvement type straw compound organic fertilizer. The soil improvement type straw compound organic fertilizer is prepared from the following raw materials in parts by weight: 30 to 35 parts of rice straw, 25 to 30 parts of animal excrement, 20 to 25 parts of biological charcoal, 10 to 15 parts of soybean meal, 5 to 10 parts of cassava residue, 5 to 10 parts of diatom ooze, 2 to 2.5 parts of plant ash, 2 to 2.5 parts of turfy soil, 2 to 3 parts of zeolite powder, 3 to 4 parts of a microorganism bacterium agent, 2 to 3 parts of sodium benzoate, 2 to 3 parts of ammonium monohydrogen phosphate, 1 to 2 parts of calcium chloride, 1 to 2 parts of amino acid, 1 to 2 parts of starch, 1 to 2 parts of molasses powder and 1 to 2 parts of humic acid. The soil improvement type straw compound organic fertilizer takes plant wastes as raw materials; the quality of soil can be easily improved and the production cost can also be reduced, so that the physicochemical properties of the soil are improved, and the structure of the soil is comprehensively improved, and furthermore, the soil quality has the effects of softness, air permeability, water retention and fertilizer conservation; the aim of producing an environment-friendly high-quality organic fertilizer through preferably selecting heavy metal capable of being passivated, the biological charcoal capable of improving the fertilizer efficiency of the organic fertilizer, and conversion products of organic wastes including the biological humic acid and the like as composting base materials, and optimizing a composting process.

Owner:JIXI YUANDAO AGRI IND TECH

Low-shrink polypropylene fibers

This invention relates to improvements in preventing heat- and moisture-shrink problems in specific polypropylene fibers. Such fibers require the presence of certain compounds that quickly and effectively provide rigidity to the target polypropylene fiber after heat-setting. Generally, these compounds include any structure that nucleates polymer crystals within the target polypropylene after exposure to sufficient heat to melt the initial pelletized polymer and upon allowing such a melt to cool. The compounds must nucleate polymer crystals at a higher temperature than the target polypropylene without the nucleating agent during cooling. In such a manner, the "rigidifying" nucleator compounds provide nucleation sites for polypropylene crystal growth. After drawing the nucleated composition into fiber form, the fiber is then exposed to sufficient heat to grow the crystalline network, thus holding the fiber in a desired position. The preferred "rigidifying" compounds include dibenzylidene sorbitol based compounds, as well as less preferred compounds, such as sodium benzoate, certain sodium and lithium phosphate salts (such as sodium 2,2'-methylene-bis-(4,6-di-tert-butylphenyl)phosphate, otherwise known as NA-11). Specific methods of manufacture of such fibers, as well as fabric articles made therefrom, are also encompassed within this invention.

Owner:MILLIKEN & CO

Methods of making low-shrink polypropylene fibers

InactiveUS6656404B2Monocomponent polypropylene artificial filamentWoven fabricsPhosphateLITHIUM PHOSPHATE

Improved polypropylene fibers exhibiting greatly reduced heat- and moisture-shrink problems and including certain compounds that quickly and effectively provide rigidity to the target polypropylene fiber after heat-setting are disclosed herein. In such a manner, the "rigidifying" compounds provide nucleation sites for polypropylene crystal growth. After drawing the nucleated composition into fiber form, the fiber is then exposed to sufficient heat to grow the crystalline network, thus holding the fiber in a desired position. The preferred "rigidifying" compounds include dibenzylidene sorbitol based compounds, as well as less preferred compounds, such as sodium beuzoate, certain sodium and lithium phosphate salts (such as sodium 2,2'-methylene-bis-(4,6-di-tert-butylphenyl)phosphate, otherwise known as NA-11).

Owner:MILLIKEN & CO

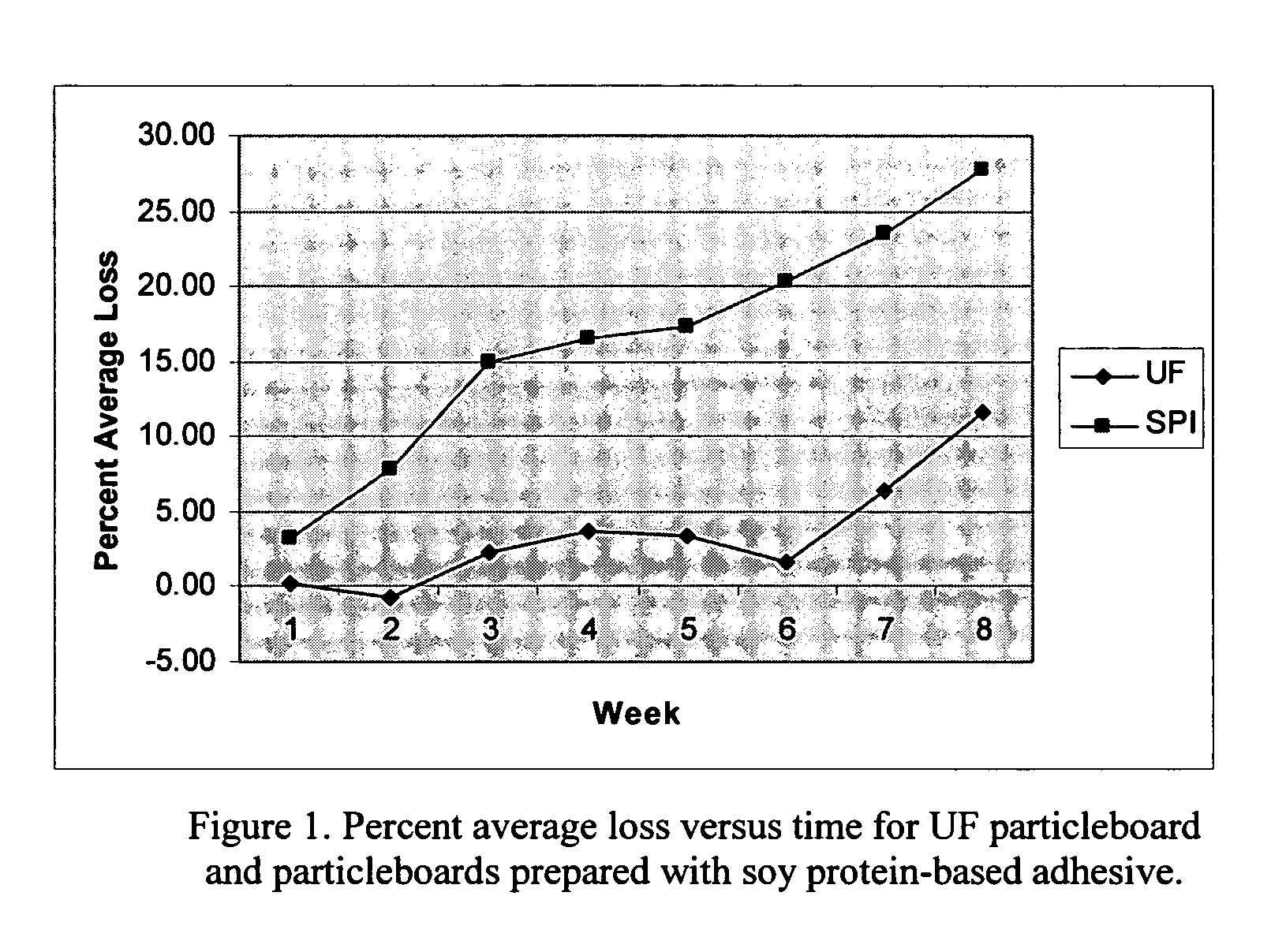

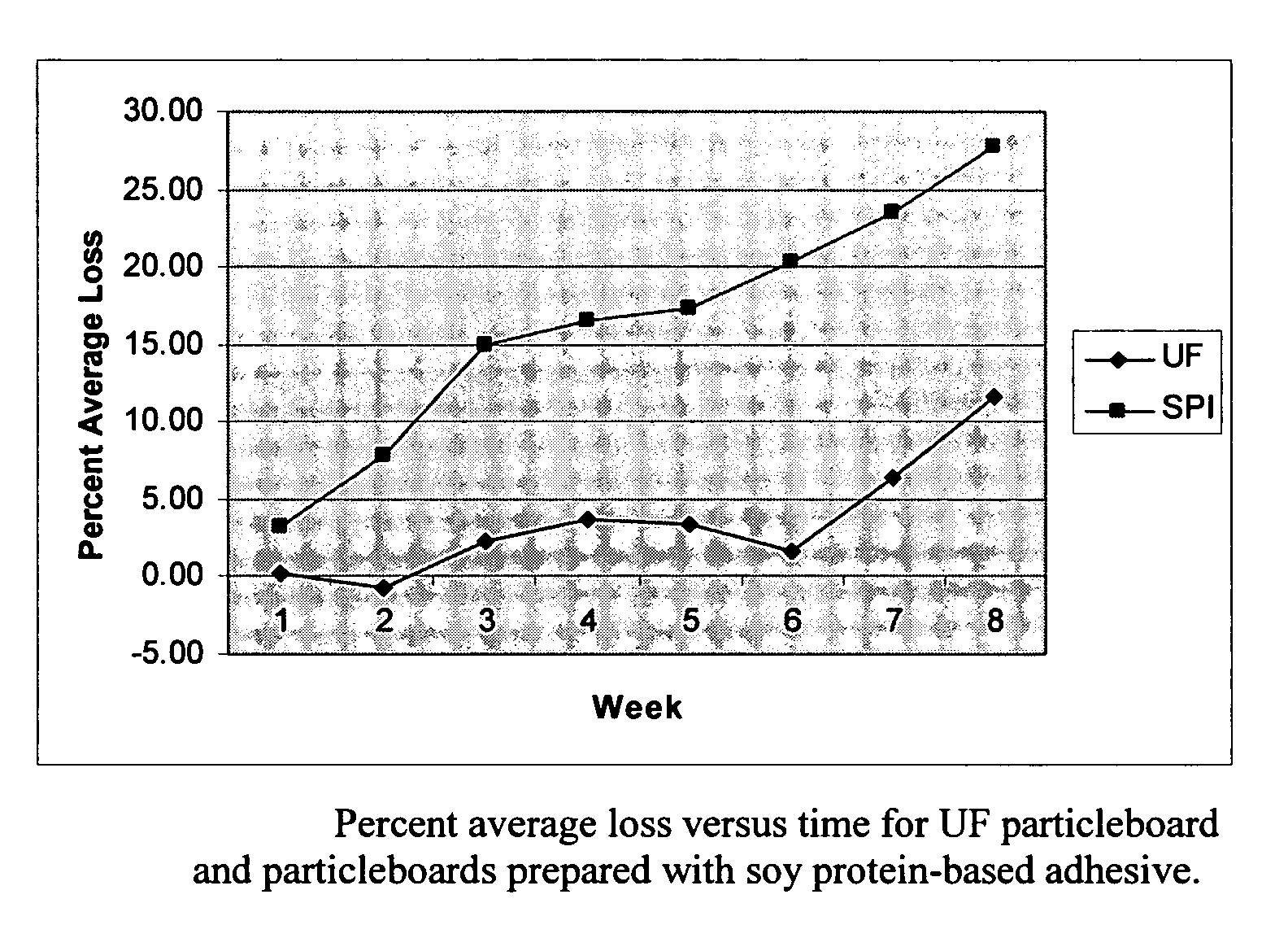

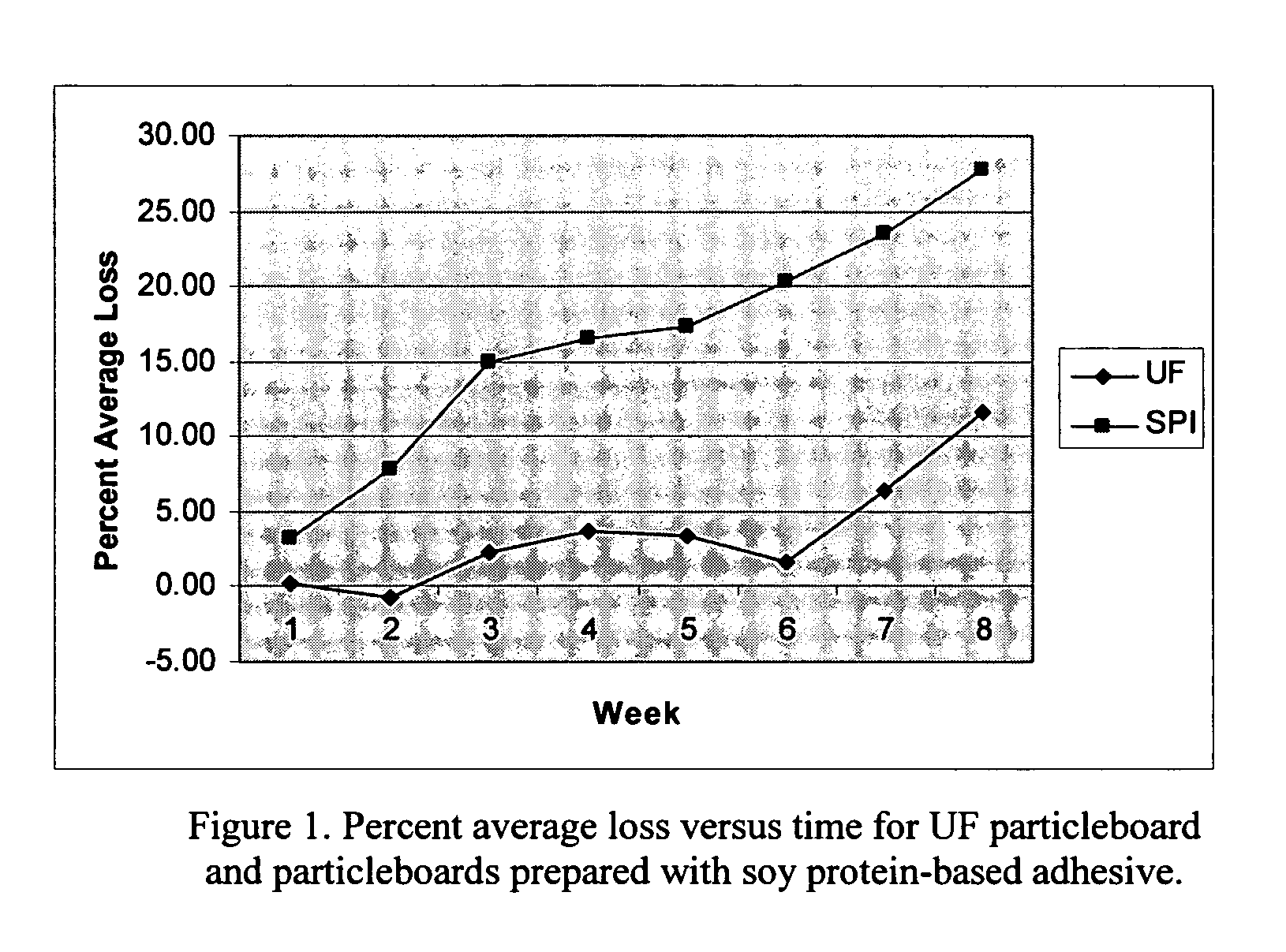

Soy protein based adhesive and particleboard

An adhesive composition that can be used in particleboards and other composites is formed from an aqueous mixture of soy protein, zinc sulfate heptahydrate, calcium oxide, sodium benzoate, pine oil, wax emulsion and non-sulfonated kraft lignin. In a second embodiment the composition further includes an acid.

Owner:UNIVERSITY OF SOUTHERN MISSISSIPPI

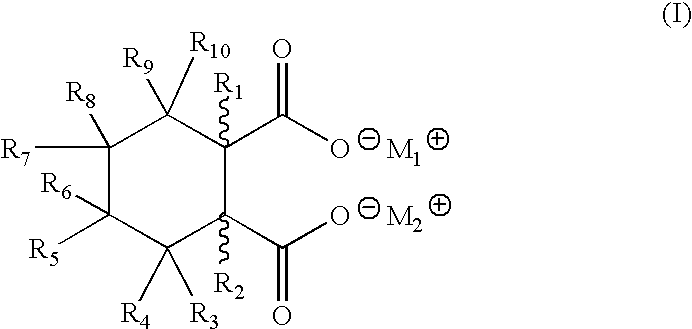

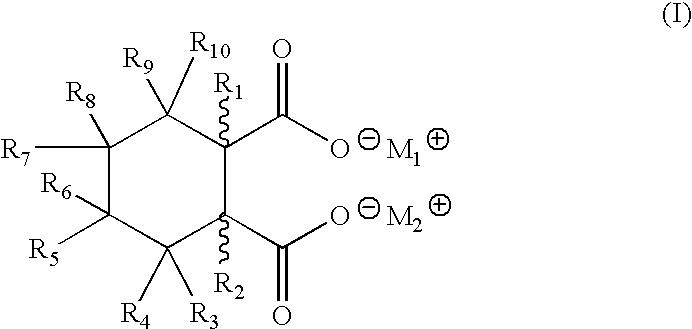

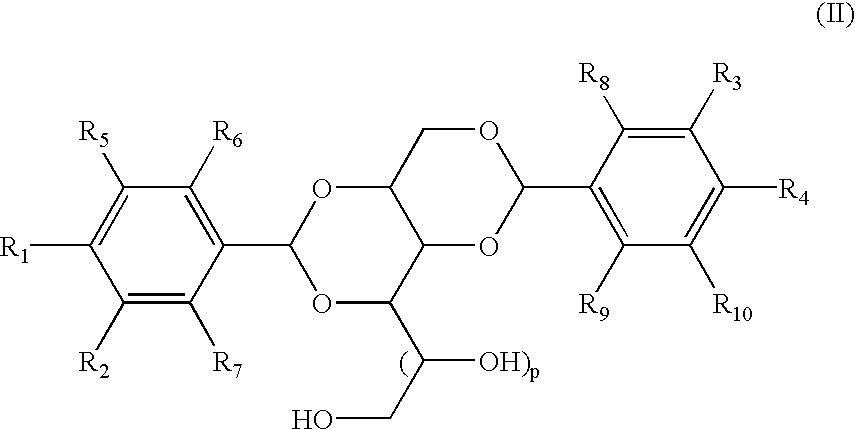

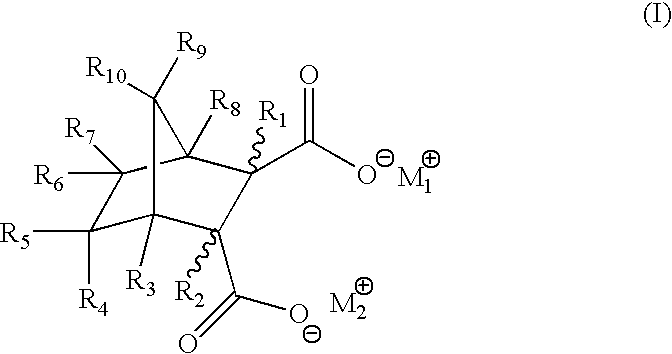

Disodium hexahydrophthalate salt compositions and nucleated polymers comprising such compositions

InactiveUS6562890B2Improve compatibilityExcellent high peak crystallization temperatureChemical/physical processesScavengerPolyolefin

Compositions comprising specific disodium hexahydrophthalate(HHPA) salts in combination with acid scavengers (such as organic calcium salts or dihydrotalcite complexes) that provide highly desirable and effective nucleating properties within polymer articles (such as polyolefins) are provided. Surprisingly, such a combination of HHPA salt and acid scavenger provides high crystallization temperatures, low haze, and / or high flexural modulus to the finished polymer product. Other sodium salt polymer nucleators (such as sodium benzoate) deleteriously react with calcium organic salt acid scavengers such that characteristically high crystallization temperatures are drastically reduced when in combination with calcium salts (such as calcium stearate). Also, sodium benzoate when combined with dihydrotalcite acid scavengers produce extremely high haze levels in the finished target polymer article, whereas the inventive compositions surprisingly reduce haze. The finished polymer articles comprising such an inventive composition are also contemplated within this invention.

Owner:MILLIKEN & CO

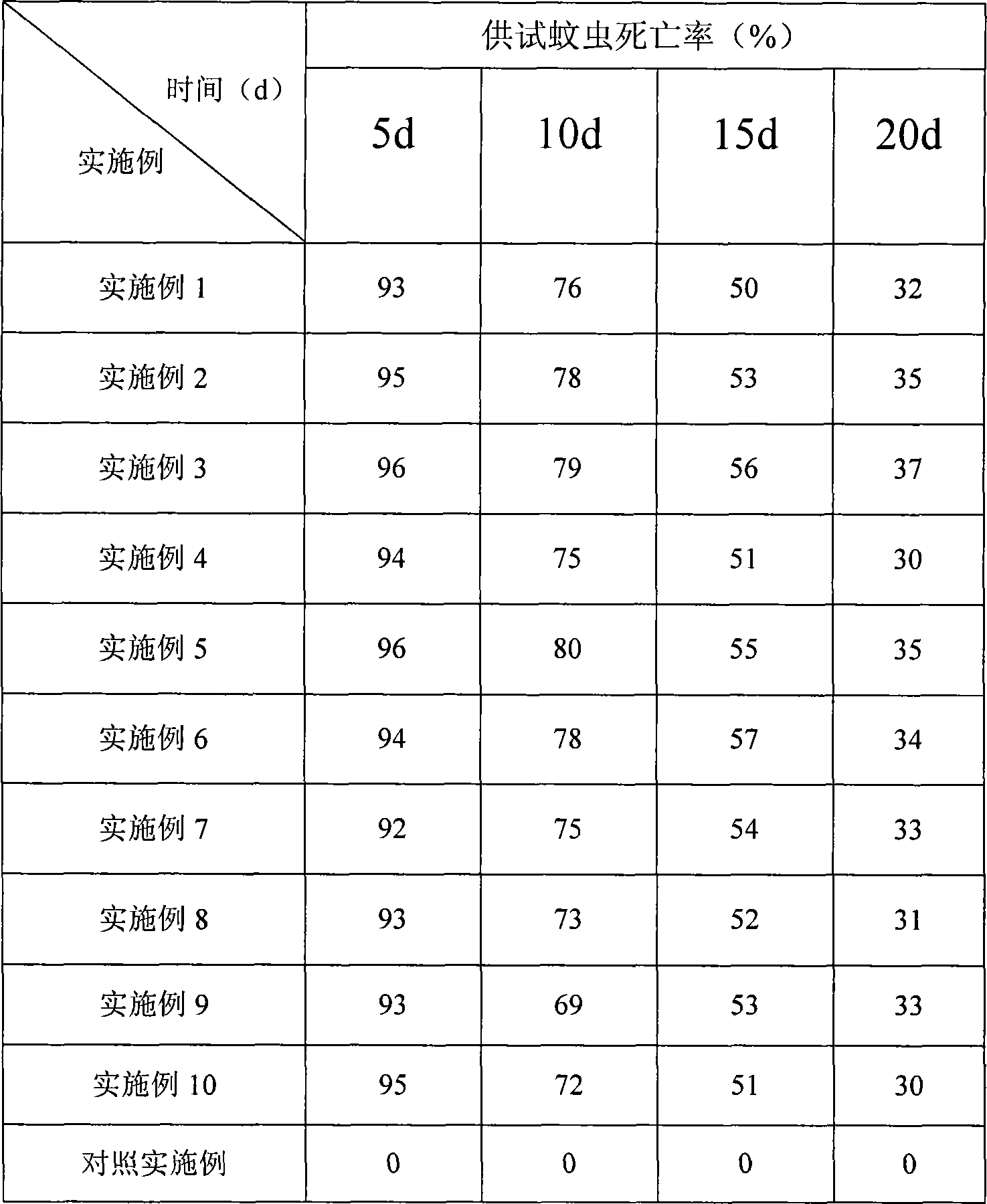

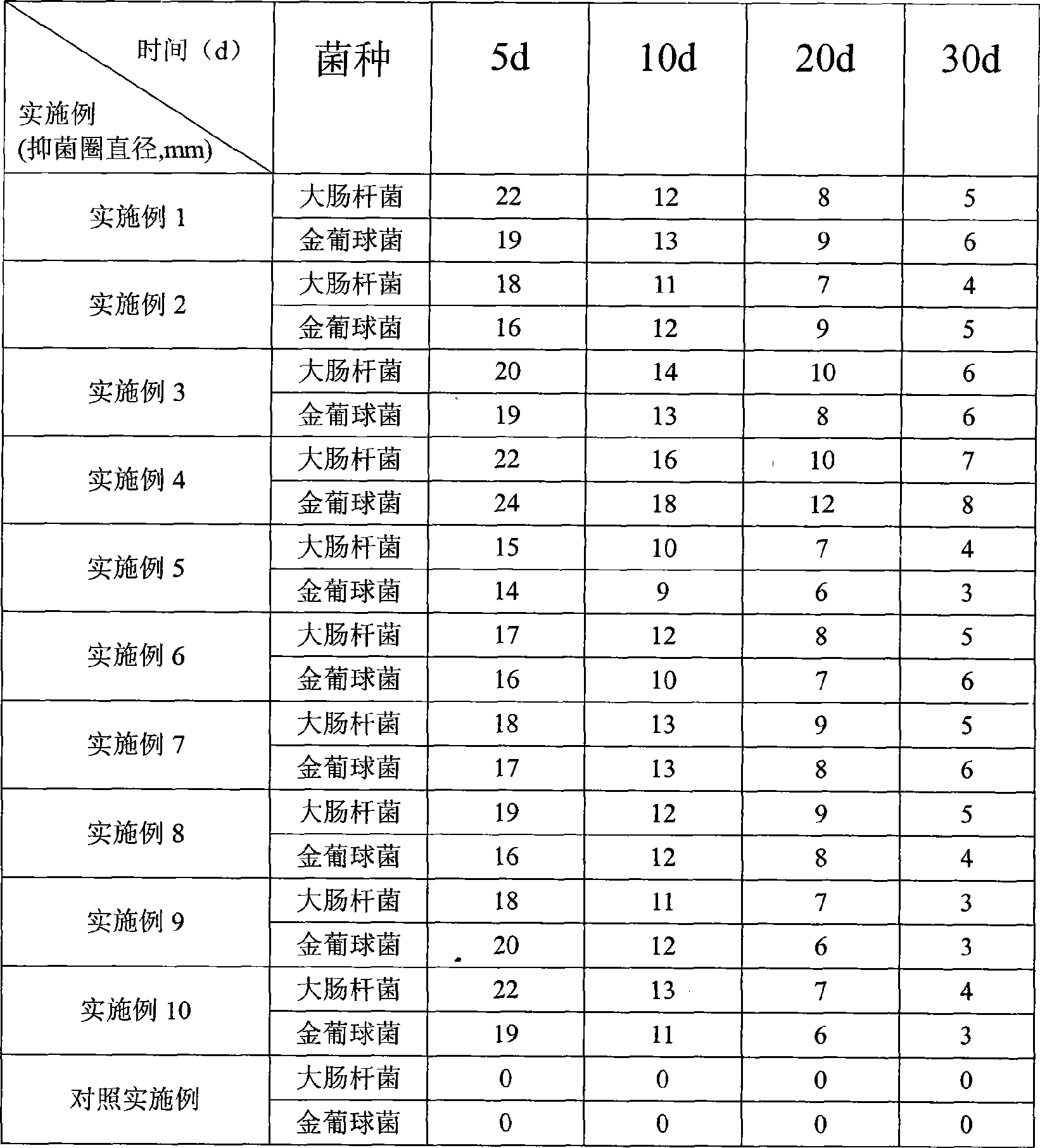

Traditional Chinese medicine mosquito-repelling air-sterilizing air refreshing agent

The invention provides an air refreshing agent of traditional Chinese medicine for dispelling mosquito and sterilizing. The prescription of the invention, which is calculated according to the weight percentage, is 1 percent to 3 percent of essential oil of southernwood, 1 percent to 3 percent of essential oil of eucalyptus leaf, 2 percent to 3 percent of excipient, 1 percent to 3 percent of solubilizer, 0.5 percent to 1 percent of preservative, 0.5 percent to 1 percent of coagulant, 50 percent to 80 percent of solvent, 5 percent to 10 percent of essence and 0.5 percent to 1 percent of pigment, wherein the excipient is sodium alginate, gelatin and agar; the solubilizer is the tween series (40, 60 and 80); the preservative is sodium benzoate and potassium sorbate; the coagulant is calcium carbonate or calcium chloride; the solvent is water. The invention uses the traditional Chinese medicinal materials of the essential oil of southernwood and the essential oil of eucalyptus leaf as the main component for dispelling mosquito and sterilizing to replace a traditional chemical mosquito-dispelling and sterilizing agent with toxic and side effect, and the invention is nontoxic and innoxious to human body and is a green and environmental protective product and can be applied widely.

Owner:CHONGQING UNIV

Cooling fluid of engine

This invention discloses an engine cooling liquid, which comprises: ethylene glycol, fatty acid and its alkali metal salts, polytricarboxylic sodium silicate, silicate stabilizer, azole compound, antifoamer and deionized water. The cooling liquid does not comprise toxic or pollutive matters such as amine, nitrite, phosphate and imidazole, thus can effectively prevent corrosion to metal and nonmetal materials, especially soldering tin, aluminum and their alloys. Besides, the cooling liquid can avoid gelation or precipitation, and can maintain the stability at a low concentration and a large pH value variation.

Owner:北京蓝星清洗有限公司

Articles derived from compositions containing modified polybutylene terephthalate (PBT) random copolymers derived from polyethylene terephthalate (PET)

Compositions of matter including articles derived from (a) from 5 to 99.99 wt % of a modified polybutylene terephthalate random copolymer that (1) is derived from polyethylene terephthalate and (2) contains a at least one residue derived from polyethylene terephthalate selected from the group consisting of antimony, germanium, diethylene glycol groups, isophthalic acid groups, cis isomer of cyclohexane dimethanol, trans isomer of cyclohexane dimethanol, sodium benzoate, alkali salts, napthalane dicarboxylic acids, 1,3-propane diols, cobalt, cobalt-containing compounds, and combinations thereof, and (b) from 0.01 to 95 wt. % of a member selected from the group consisting of (1) fillers, (2) a carboxy reactive component, (3) polyethyelene terephthalate, (4) a component including a polycarbonate and an impact modifier. The articles may be derived from various conversion processes, e.g., injection molding processes, extrusion processes, thermoforming processes, melt-blown process.

Owner:SHPP GLOBAL TECH BV

Multiple-effect type water-based synthesized cutting solution and preparation thereof

InactiveCN101323813AExtended service lifeImprove extreme pressure and anti-wearLubricant compositionWater basedCleansing Agents

The invention relates to a multi-effect water-based composite cutting / grinding fluid which consists of water-soluble oil, cleaning agent, extreme pressure antiwear agent, antirust, antibacterial agent, complexant, solubilizer and anstatic agent. The water-soluble oil is the mixture of aminoethyl alcohol and triethanolamine oleate, the cleaning agent is anionic surfactant or nonionic surfactant, the extreme pressure antiwear agent is one or two of additives A, B, C, D, E and F, the antirust is benzotriazole and sodium benzoate, the antibacterial agent is boric acid and borax, the complexant is EDTA and the solubilizer is urea. The cutting / grinding fluid with various improved performances is non-toxic and tasteless, is an environment-friendly product and has no harm to human body and the skin of users; the operating cycle is normally more than 6 months.

Owner:大连弘瑞化工有限公司

Soy protein based adhesive and particleboard

Owner:UNIVERSITY OF SOUTHERN MISSISSIPPI

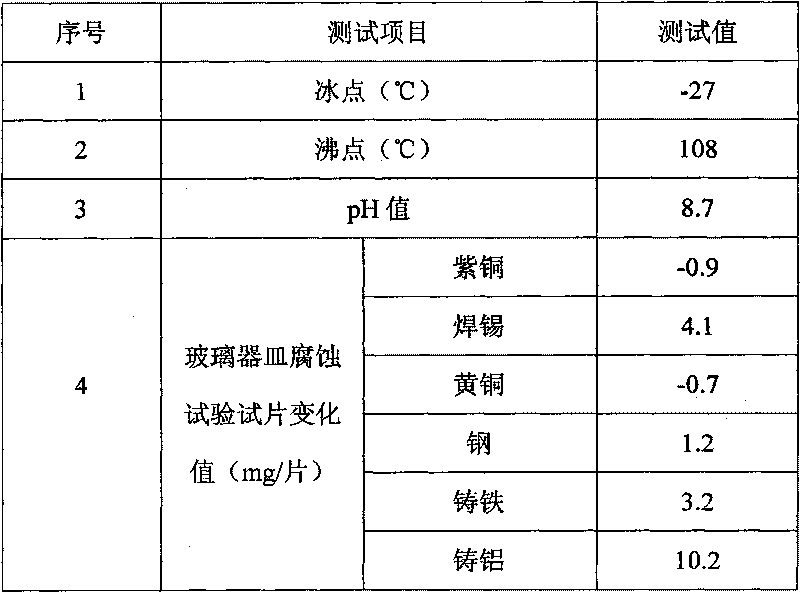

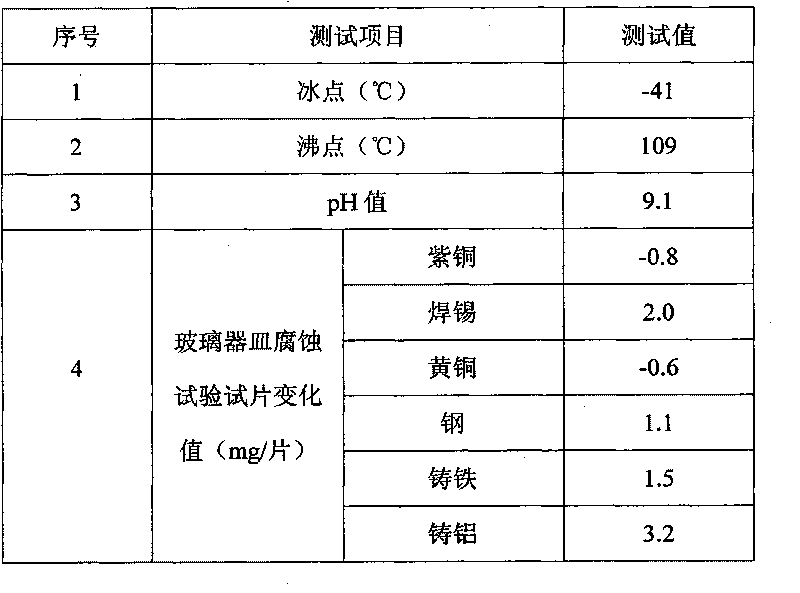

Engine antifreezing solution

ActiveCN101691484AAvoid the disadvantages of instabilityWith boiling suppressionHeat-exchange elementsCooperative interactionSebacic acid

The invention relates to an engine antifreezing solution which is prepared by mixing the following components to react: glycol, sodium molybdate, sodium hydroxide, isooctanoic acid, sebacic acid, sodium benzoate, benzotriazole, sodium 2-mercaptobenzothiazole, dye and deionized water. The invention adopts a new formula which uses organic matter as main component and inorganic matter as auxiliary component to reach the aim of controlled release on the basis of conventional inorganic and all-organic engine antifreezing solution technologies, wherein the organic acid uses the combination of monoacid and binary acid. The invention does not contain sodium borate and silicate so as to avoid the defect that precipitate is easy to generate due to the existence of sodium borate and silicate in glycol series antifreezing solution and the antifreezing solution is unstable; and the engine antifreezing solution of the invention does not contain amine, nitrate, phosphate and other substances which are harmful to the environment and human body. The researched antifreezing solution has good performances of stability, freeze-proofing, boil-proofing, corrosion-proofing and scale prevention through the cooperative interaction of components so as to perform multi-level anticorrosion protection for the cooling system of the vehicle.

Owner:SHAANXI DADI IND CO LTD OF CHINA NAT NUCLEAR

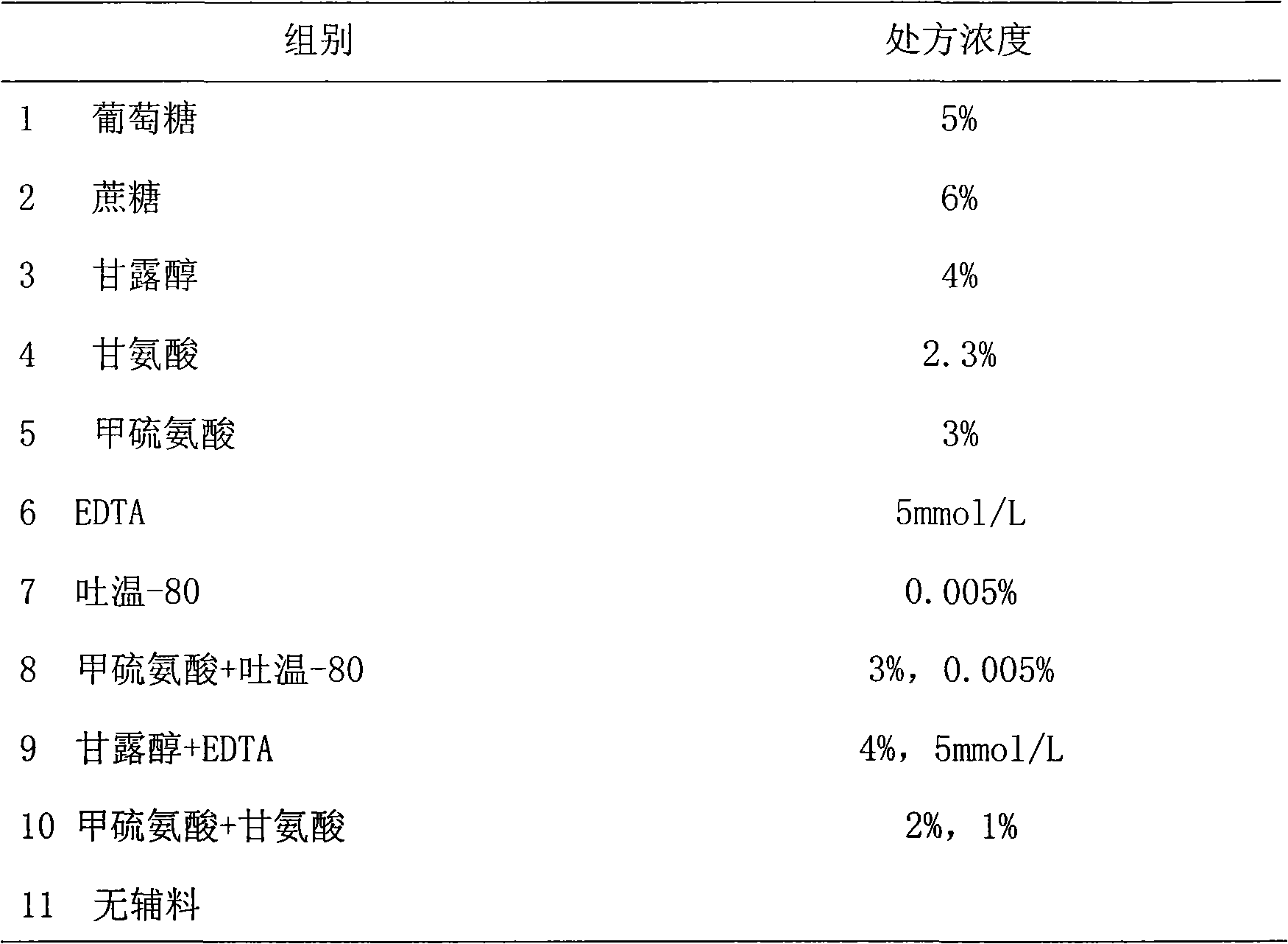

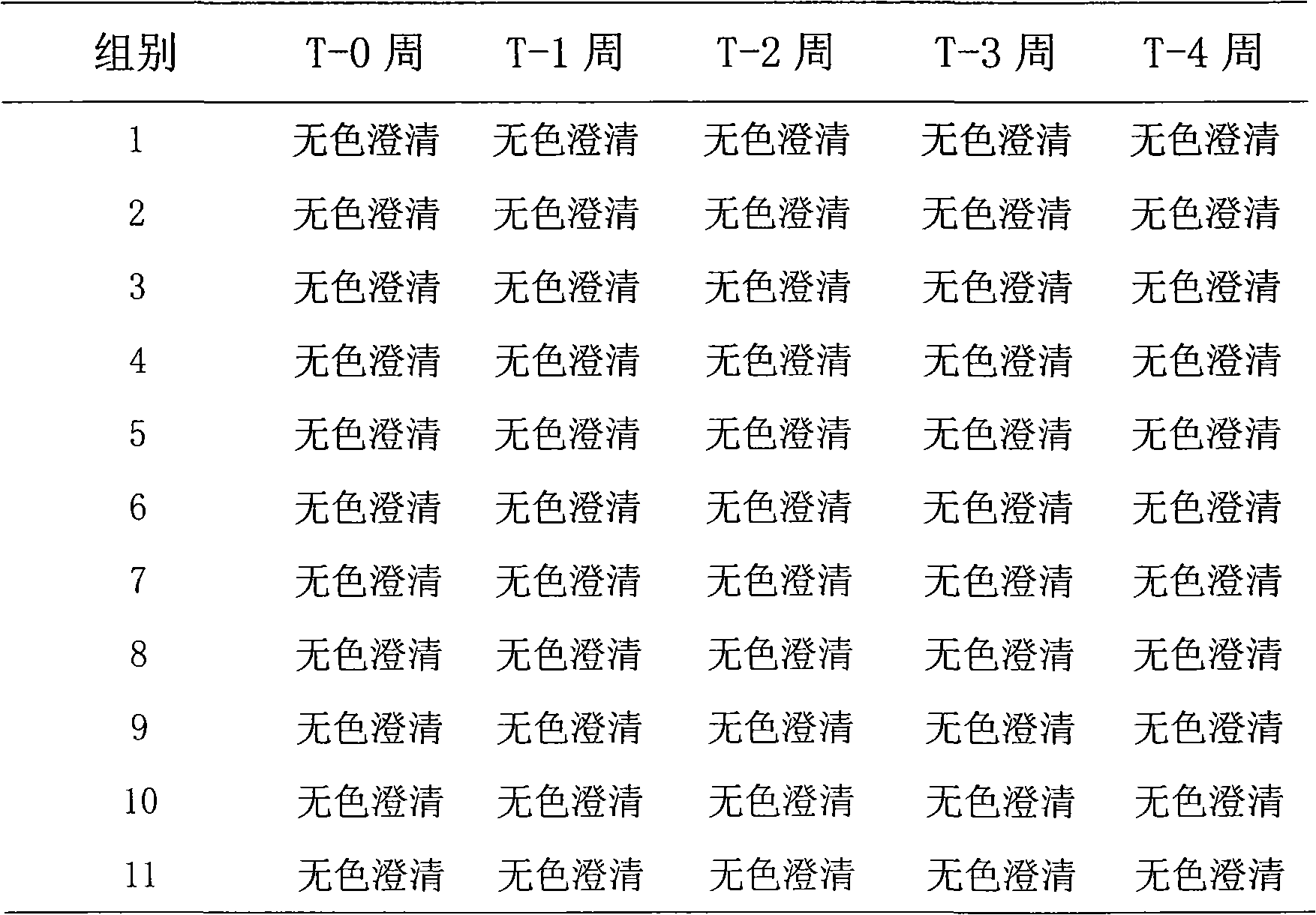

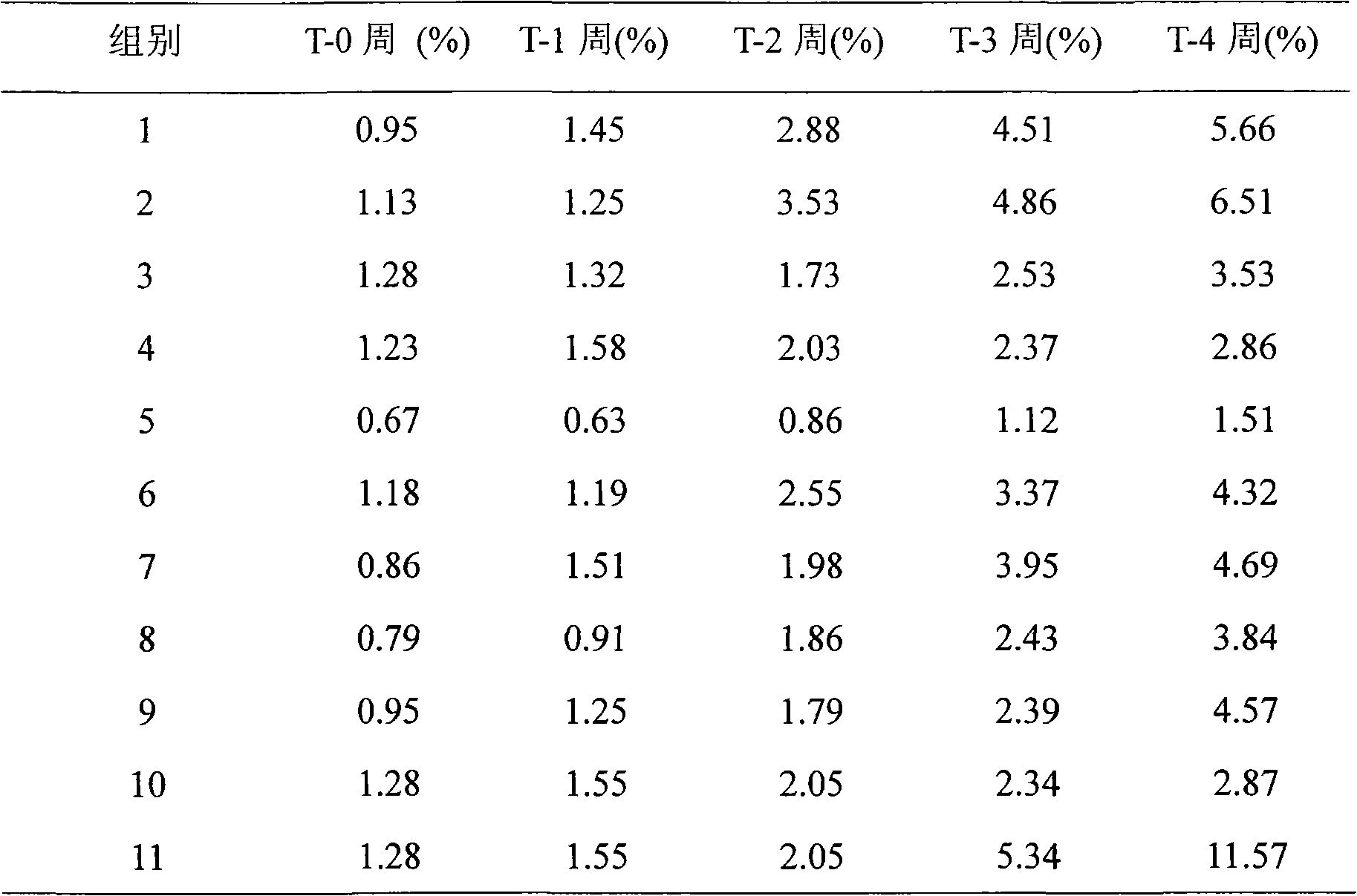

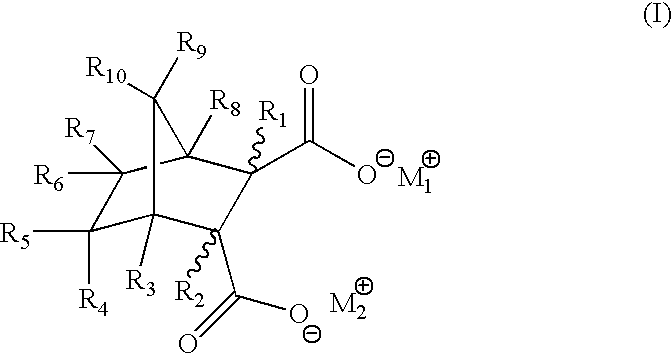

Medicinal preparation containing exenatide

The invention provides a medicinal preparation containing exenatide suitable for multi-administration, which contains exenatide, buffer solution, pharmaceutically acceptable accessory and preservative, wherein the buffer solution can keep the pH value of the preparation in an aqueous solution state at 3.0 to 7.0; the accessory may be one or combination of glucose, sucrose, methionine, mannitol or glycine; and the preservative is selected from benzoic acid, sodium benzoate, potassium sorbate or acetone chloroform. The medicinal preparation has the advantages that the stability of physicochemical and biological activities of the exenatide is enhanced by adding a few components capable of being accepted by the human body, and then a preparation suitable for clinical use, particularly injection use is prepared.

Owner:HANGZHOU JIUYUAN GENE ENG

Stainless steel degreasing agent

InactiveCN101979711AImprove solubilityImproves the properties of uniform corrosionActive agentBrominated hydrocarbon

The invention provides a stainless steel degreasing agent, which comprises the following components in percentage by weight: 5 to 25 percent of organic solvent, 2 to 5 percent of corrosion inhibitor, 10 to 25 percent of surfactant, 5 to 10 percent of inorganic salt, 1 to 3 percent of defoaming agent and the balance of deionized water, wherein the organic solvent is bromohydrocarbon; the corrosion inhibitor is sodium benzoate, ammonium benzoate, triethanolamine, ethanolamine or benzotriazole; the surfactant is one or more of alkylphenol polyoxyethylene ether and fatty alcohol-polyoxyethylene ether; the inorganic salt is alkaline salt; and the defoaming agent is tributyl phosphate, organic silicon, oleic acid or sodium oleate. The stainless steel degreasing agent can replace the currently used ODS cleaning agents, can achieve the cleaning effect of the ODS cleaning agents, does not damage the surface of the stainless steel, has obvious cleaning effect, can clean a large number of products, and does not harm a human body; and the preparation method is simple, safe, and environment-friendly.

Owner:JIANGSU TIANHENG NANO SCI & TECH

Clarified thermoplastics exhibiting very high nucleation efficacy

Owner:MILLIKEN & CO

Multi-element co-polymerization oil well cement fluid loss additive and preparation method thereof

ActiveCN101397491ASimple preparation processDrilling compositionPotassium persulfateSodium hydroxide

The invention relates to a multicomponent copolymerization oil well cement fluid loss additive and a preparation method thereof. The method comprises: 10-120 portions of 2-acrylamide-2-methyl-1-AMPSA, 1-5 portions of acrylic acid and 15-50 portions of deionized water are added, stirred and then added with sodium hydroxide aqueous solution with the mass fraction of 5-10 percent for neutralizing to pH equal to 3-11; then 10 portions of acrylamide, 0.1-1 portion of complexing agent EDTA and 0.01-1 portion of chain transfer agent are added, the chain transfer agent is isopropyl alcohol or sodium benzoate, the temperature is controlled between 30 DEG C and 60 DEG C and N2 is introduced for 30 minutes; 2-10 portions of N-vinyl pyrrolidone and 0.01-0.5 portion of initiator are added, the initiator is potassium persulfate or ammonium persulfate, and the reaction is carried out for 4-12 hours. The solution keeps still for 5 hours at the temperature of 180 DEG C, and is cooled through flowing water after being taken out, without sedimentation or water separating; and the water loss is zero at the temperature of 180 DEG C according to the standards of drilling fluid, and the water loss is 48ml according to the standards of cement.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

Semi-hard dentifrice

InactiveUS20050152851A1Extended shelf lifeHigh melting pointCosmetic preparationsToilet preparationsSodium bicarbonateSodium stearate

The invention comprises a formulation for a semi-hard stick-type dentifrice optimally for use in an oral hygiene device which utilizes such semi-hard stick-type dentifrice, most often used when traveling. The dentifrice includes a primary base material such as glycerin. Sodium benzoate is included as a preservative. Sodium coco-sulfate and a mixture of wheat gluten proteins and potassium cocoate provide a foaming material. Cleansers are included and the dentifrice is strengthened by vegetal-based sodium stearate and vegetal-based stearyl alcohol. Whitening materials are included, as is an absorption material and sodium bicarbonate as an abrasive.

Owner:KAMINSKI BASIA

Composition of composite potassium peroxymonosulfate disinfection tablet and preparation method thereof

ActiveCN101828550AEasy to useDisintegrates quicklyBiocideDisinfectantsSodium bicarbonateFiller Excipient

The invention discloses acomposite potassium peroxymonosulfate disinfection tablet which comprises 10.0-70.0 parts by weight of potassium monopersulfate, 1.0-65.0 parts by weight of fillers, 1.0-20.0 parts by weight of adhesives and 0.01-10.0 parts by weight of lubricant, wherein the fillers is formed by one or more then one of sodium sulfate, sodium chloride, potassium chloride, sodium carbonate, sodium bicarbonate, phosphate, inorganic acid, organic acid, starch, dextrin, glucose, solid emulsifier, xylitol and a metal ion complexing agent, the adhesives comprise cellulose, polyvinylpyrrolidone and gelatin; the lubricant is formed by one or more than one of magnesium stearate, talcum powder, micro-powder silica gel, sodium benzoate and polyethylene glycol; in addition, sodium percarbonate, calcium percarbonate, sodium perborate or calcium peroxide 1-2 are added. The invention is convenient to use, has the advantages of quick disintegration and dissolution, can significantly increase the effect of the disinfection tablet and can adjust pH value.

Owner:镇江威特药业有限责任公司 +1

Low-shrink polypropylene tape fibers comprising high amounts of nucleating agents

InactiveUS6794033B2Low shrinkageLow heat shrinkageSynthetic resin layered productsFilament/thread formingFiberPolymer science

Owner:MILLIKEN & CO

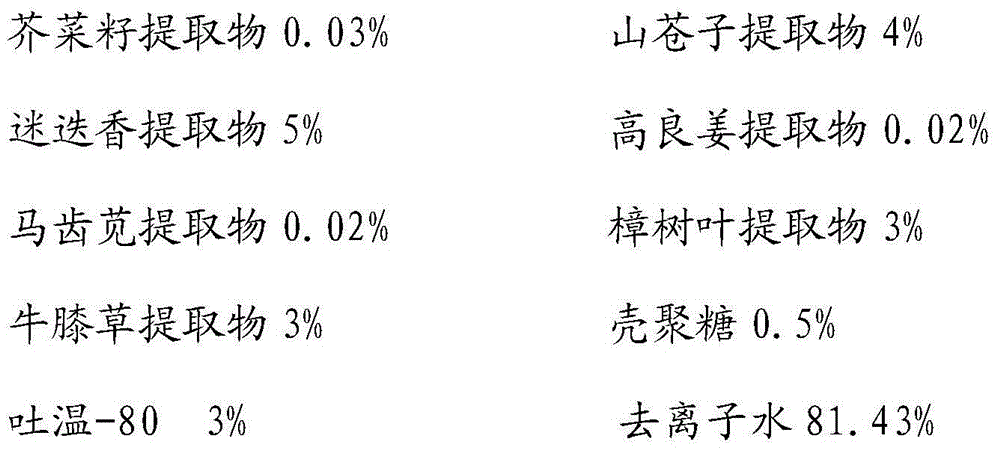

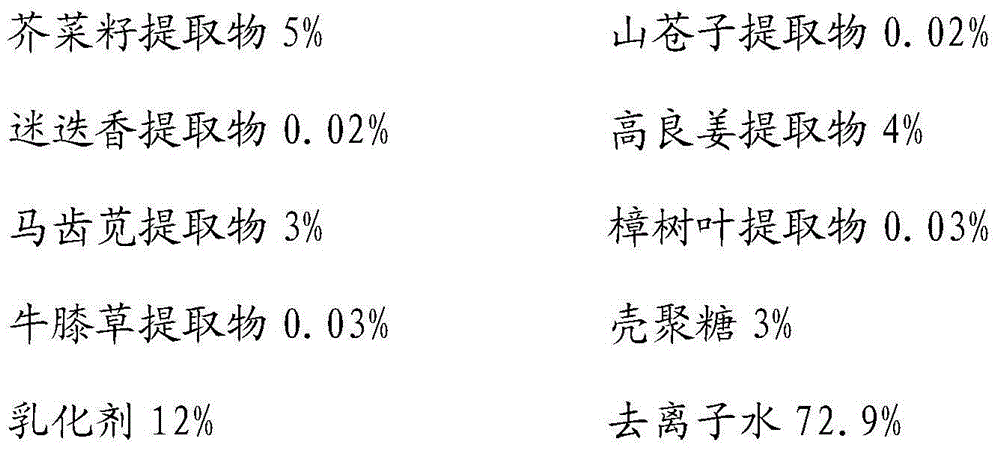

Seed coating and preparation method thereof

The invention discloses a seed coating and a preparation method thereof, which relates to a preparation used for treating crop seeds and belongs to plant seed coating technology in the field of agriculture and forestry. Raw materials of the seed coating disclosed by the invention are composed of biological protein, humic acid, seaweed gel, sodium benzoate, ethylene glycol, Twain 80, a bacteriostatic agent, a nutritional agent and water. The beneficial effects of the seed coating are as follows: slurry and crop seeds are fully stirred according to a proportion of 1: (30-80) until the liquid medicine is uniformly distributed on the surfaces of the seeds, and the seeds can be planted after being dried. As shown in a large amount of experiments, the physical and chemical properties of a novel biological seed coating completely meet general requirements of the seed coating, the film forming property is good, the coating can quickly cure to a film under natural conditions without dropping, connecting or agglomerating, and meanwhile, the experiments prove that the seed coating can obviously promote the growth of paddy rice, corn, wheat, soybean, cotton and pepper and improve the germination rate and seedling rate and has a significant effect of preventing and treating diseases and insect pests of crops.

Owner:何诚慧

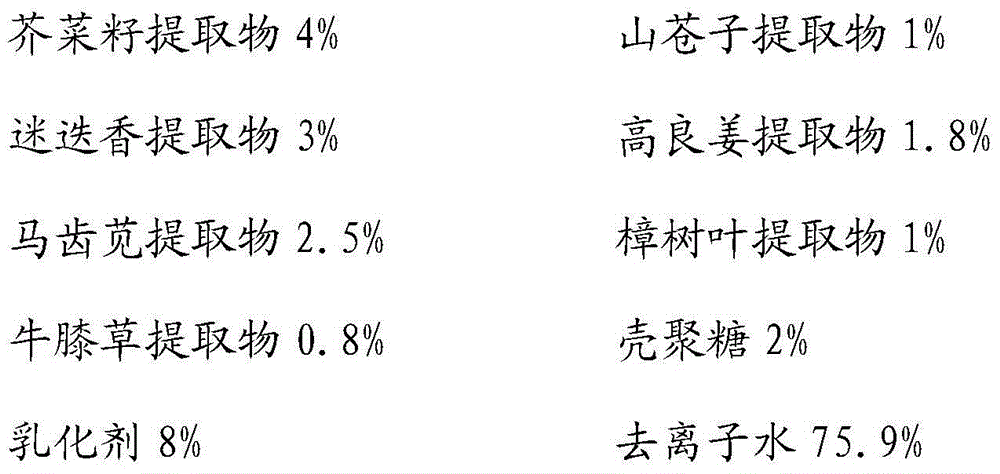

Plant source fruit and vegetable preservative

InactiveCN104146055AReduce rotEnhanced inhibitory effectFruit and vegetables preservationChemical synthesisHyssopus officinalis extract

The invention discloses a plant source fruit and vegetable preservative, belonging to the technical field of fruit and vegetable preservation. The plant source fruit and vegetable preservative is characterized by being composed of following components in percentage by weight: 0.03-5% of mustard seed extract, 0.02-4% of litsea cubeba extract, 0.02-5% of rosemary extract, 0.02-4% of alpinia officinarum hance extract, 0.02-3% of portulaca oleracea extract, 0.03-3% of camphortree leaf extract, 0.03-3% of hyssopus officinalis extract, 0.5-3% of chitosan, 3-12% of emulsifying agent and the balance of de-ionized water. The main antibacterial components of the plant source fruit and vegetable preservative are extracted from medicine and food homology plants; raw materials are natural and non-toxic and do not contain common chemically-synthesized preservatives including sodium benzoate and the like, thus the plant source fruit and vegetable preservative is very safe to a human body; and the synergic antibacterial effect of plant extracts with good antibacterial effect is utilized so that the preservation effect is good and the shelf life of fruits and vegetables can be prolonged.

Owner:GUANGXI UNIV

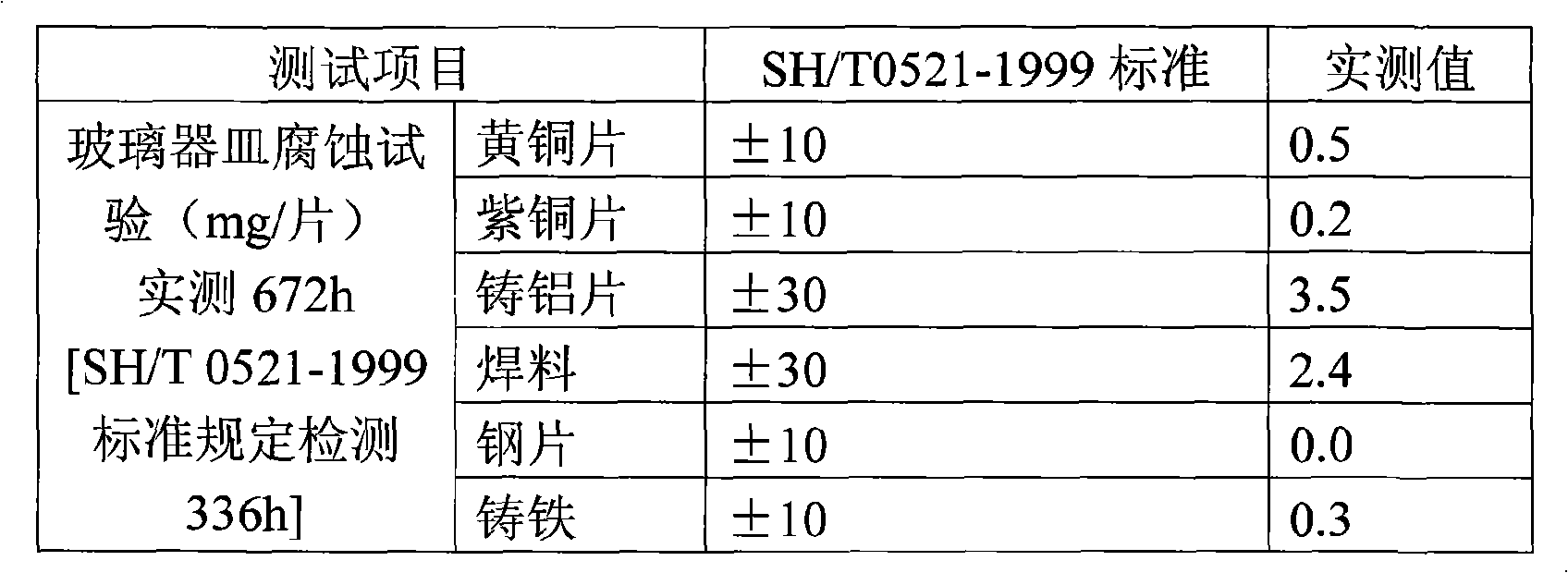

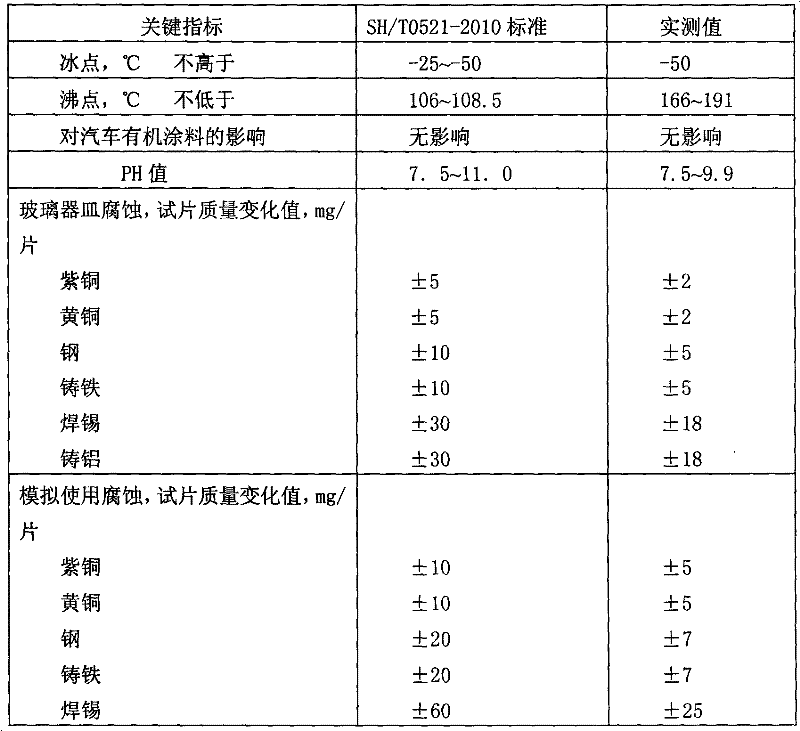

Engine coolant

ActiveCN101629070APrevent precipitationGuaranteed anti-corrosion performanceHeat-exchange elementsSodium nitrateDefoaming Agents

The invention relates to an engine coolant, which comprises the following compositions in portion by weight: 100 portions of glycol, 60 to 160 portions of deionized water, 1.0 to 1.6 portion of sodium benzoate, 1.0 to 1.4 portion of sodium tetraborate, 0.1 to 0.5 portion of sodium nitrate, 0.5 to 0.9 portion of phthalic acid, 0.3 to 0.6 portion of sodium silicate, 0.03 to 0.06 portion of silicate stabilizer, 0.3 to 0.4 portion of sodium hydroxide, 0.1 to 0.3 portion of pyrrodiazole, 0.01 to 0.06 portion of defoaming agent and 0.005 to 0.02 portion of coloring agent; the engine coolant is characterized in that: the coolant does not contain molybdate, amine, nitrite, phosphate and other substances which are harmful to the environment and human body and has excellent anticorrosive and protective function on red copper, brass, steel, cast iron, soldering tin, cast aluminum and other metals of a cooling system and magnesium alloy adopted in an engine; and the coolant has strong anti-hard water capacity and low cost, meets the requirement of SH / T0521-1999 standard and is applicable to industrialized production.

Owner:PETROCHINA CO LTD

Anti-freezing fluid

ActiveCN101302424ATo achieve long-term goalsTo achieve the characteristics of green environmental protectionHeat-exchange elementsSodium molybdateAnti freezing

The invention discloses anti-freeze fluid. The compositions by weight percentage of the anti-freeze fluid are: 35 to 85 percent of glycol, 0.25 to 0.06 percent of sodium molybdate, 0.4 to 0.1 percent of sodium nitrate, 3.5 to 0.8 percent of potassium hydroxide, 1.2 to 0.2 percent of 85 percent phosphoric acid, 0.3 to 0.02 percent of metyl benzotriazole, 0.5 to 0.05 percent of benzotriazole, 3.5 to 0.8 percent of sebacic acid, 1.0 to 0.25 percent of undecanedioic acid, 1.0 to 0.2 percent of octanoic acid, 3.0 to 0.8 percent of sodium benzoate, 0.2 to 0.05 percent of hydrolytic-polymeric maleic anhydride, 0.003 to 0.01 percent of antifoaming agent, the balance being deionized water. The anti-freeze fluid is characterized by long effect and environmental protection, and can perform all-around multi-layer protection on an automobile cooling system.

Owner:张家港迪克汽车化学品有限公司

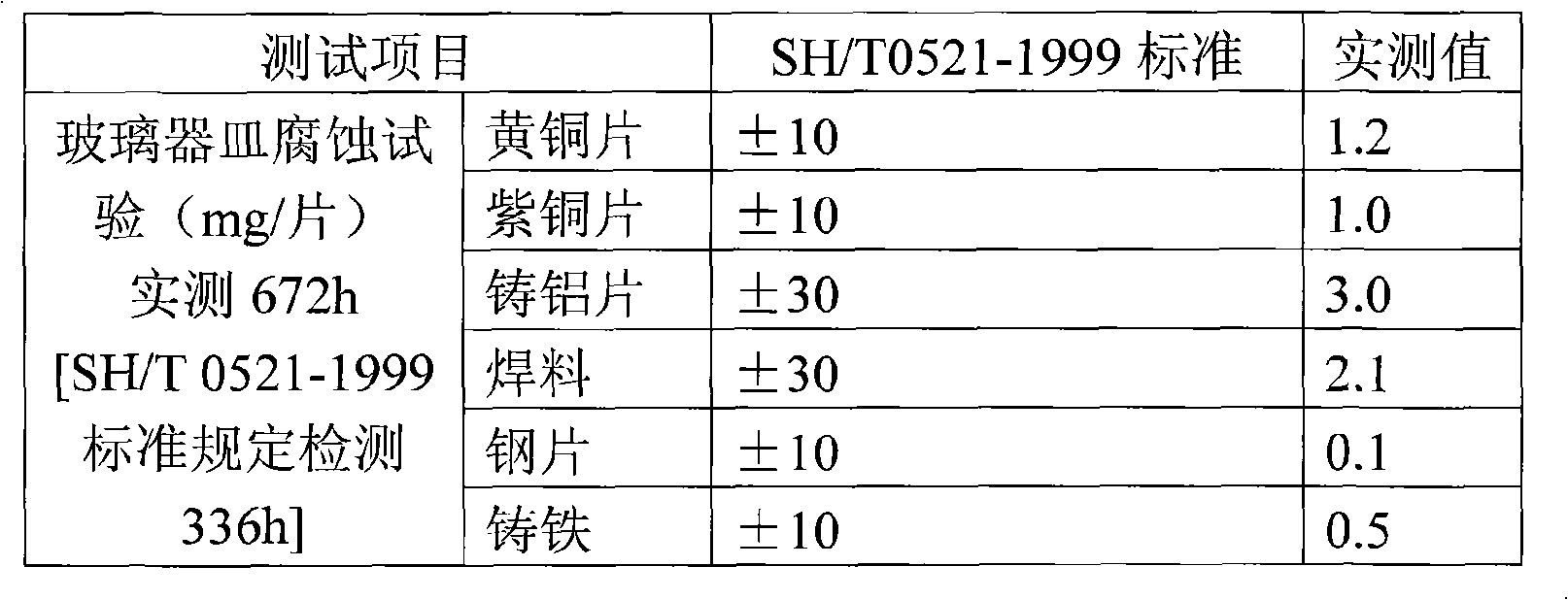

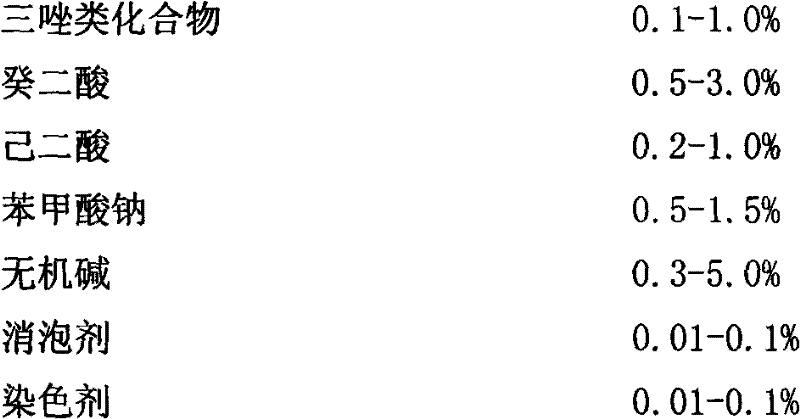

Life-cycle water-free cooling solution

The invention relates to a life-cycle water-free cooling solution which is characterized by comprising the following components in percent by weight: 10-50 percent of propylene glycol, 50-80 percent of ethylene glycol, 0.1-10 percent of triazole compounds, 0.5-3.0 percent of sebacic acid, 0.2-1.0 percent of adipic acid, 0.5-1.5 percent of sodium benzoate, 0.3-5 percent of inorganic base, 0.01-0.1 percent of antifoaming agent and 0.01-0.1 percent of colouring agent. The cooling solution has a freezing point of below -50 DEG C and a boiling point of 166-191 DEG C; and because the cooling solution does not contain water, problems of boiling, gas etching, evaporating, scaling, rusting and the like caused by water existing in the cooling solution are thoroughly eliminated, a steam air resistance layer seriously influencing heat radiation is avoided from generating, power of an engine can be effectively improved and fuel is saved. Because the cooling solution does not contain water and has a reasonable corrosion inhibition system, the problem of corrosion is thoroughly solved; and the cooling solution has a service life of reaching up to 8 hundred thousand kilometers, is added once without replacement, is a life-cycle cooling solution, is especially suitable for military vehicles, high-end vehicles and high-power heavy-loading trucks and passenger cars, and can ensure that the vehicles safely run under extremely hot weather, severe cold weather, and severe environments such as desert, plateau, snowfield and the like.

Owner:JIANGXI CHEPU IND CO LTD

Full mold casing coating

ActiveCN102397983AImprove performanceIncrease stiffnessFoundry mouldsFoundry coresSodium BentonitePolyvinyl alcohol

The invention discloses a full mold casting coating, which consists of the lower components in part by weight: 70-80 parts of quartz powder, 10-15 parts of olivine powder, 10-15 parts of alundum powder, 4-6 parts of sodium bentonite, 1-2 parts of lignosulfonic acid, 2-3 parts of dextrin powder, 0.8-1.5 parts of sodium carboxymethylcellulose, 0.4-0.6 part of sodium benzoate, 1-2 parts of hollow glass microsphere, 7-9 parts of aluminum sulfate, 4-6 parts of polyvinyl alcohol, 5-6 parts of silica sol, 0.5-0.8 part of brown iron oxide, 0.04-0.06 part of n-octyl alcohol and 15-25 parts of water.

Owner:南通市通州区俊朗建筑工程有限公司

Fruit and evgetable fresh-keeping agent and its production method

InactiveCN1476764AStrong adsorption and degradationSlow postharvest ripeningFruit and vegetables preservationSorbentOxygen

The fruit and vegetable fresh-keeping agent is placed in the paper bag or cloth bag. Its composition includes (1) active adsorbent, 0.5-5 portions, it is active carbon in which the potassium permanganate is adsorbed, active clay, attapulgite or diatoms; (2) oxygen absorbent, 0.5-5 portions, it is iron powder, (3) ethylene absorbent, 0.5-5 portions, it is zeolite or bentonite; (4). CO2 adsorbent, 0.5-5 portions, it is lime hydrate or coke molecular sieve; (5) antimicrobial agent, 1 portion, it is sodium benzoate; and (6) auxiliary agent, 1-10 portions, it is mixture formed from equi-mass sodium chloride and crystal sodium carbonate or mixture formed from equi-mass calcium chloride and crystal sodium carbonate. The adoption of said fresh-keeping agent can obtain obvious fresh-keeping effect.

Owner:NANJING UNIV

Deformed steel bar compound corrosion-inhibited quenching agent and usage method thereof

The invention discloses a deformed steel bar compound corrosion-inhibited quenching agent and a usage method thereof. The compound corrosion-inhibited quenching agent is obtained by mixing the following compositions in parts by weight: 0-1 part of sodium carboxy methyl cellulose, 0-1 part of sodium polyacrylate, 0.1-1 part of sodium benzoate, 0.1-2 parts of triethanolamine, 0-0.1 part of sodium molybdate, 0-5 parts of sodium hydroxide, 0-10 parts of sodium carbonate, 5-15 parts of sodium silicate, and 70-90 parts of water. In use, the non-rusted deformed steel bar is subjected to quenching treatment in the corrosion-inhibited quenching agent for 1-2s at 100-200 DEG C, thereby being capable of slowing down the corrosion of the deformed steel bar under the atmosphere. The corrosion-inhibited quenching agent does not contain nitrite and chromate, has no S and P atoms, and is green and environment-friendly, low in cost, and recyclable.

Owner:HEFEI UNIV OF TECH

Polypropylene monofilament and tape fibers exhibiting certain creep-strain characteristics and corresponding crystalline configurations

InactiveUS6863976B2High tensile strengthLow shrinkageSynthetic resin layered productsFilament/thread formingYarnThermoplastic

Unique thermoplastic (polypropylene, specifically) monofilament and / or tape fibers and yarns that exhibit heretofore unattained physical properties are provided. Such fibers are basically manufactured through the extrusion of thermoplastic resins that include a certain class of nucleating agent therein, and are able to be drawn at high ratios with such nucleating agents present, that the tenacity and modulus strength are much higher than other previously produced thermoplastic fibers (particularly those produced under commercial conditions), particularly those that also simultaneously exhibit extremely low shrinkage rates. Thus, such fibers require the presence of certain compounds that quickly and effectively provide rigidity to the target thermoplastic (for example, polypropylene), particularly after heat-setting. Generally, these compounds include any structure that nucleates polymer crystals within the target thermoplastic after exposure to sufficient heat to melt the initial pelletized polymer and allowing such an oriented polymer to cool. The compounds must nucleate polymer crystals at a higher temperature than the target thermoplastic without the nucleating agent during cooling. In such a manner, the “rigidifying” nucleator compounds provide nucleation sites for thermoplastic crystal growth. The preferred “rigidifying” compounds include dibenzylidene sorbitol based compounds, as well as less preferred compounds, such as [2.2.1]heptane-bicyclodicarboxylic acid, otherwise known as HPN-68, sodium benzoate, talc, certain sodium and lithium phosphate salts [such as sodium 2,2′-methylene-bis-(4,6-di-tert-butylphenyl)phosphate, otherwise known as NA-11]. Specific methods of manufacture of such inventive thermoplastic fibers, as well as fabric articles made therefrom, are also encompassed within this invention.

Owner:MILLIKEN & CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com