Patents

Literature

534results about How to "Low heat shrinkage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

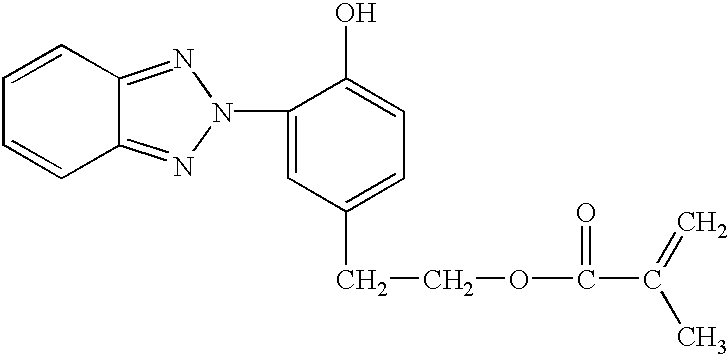

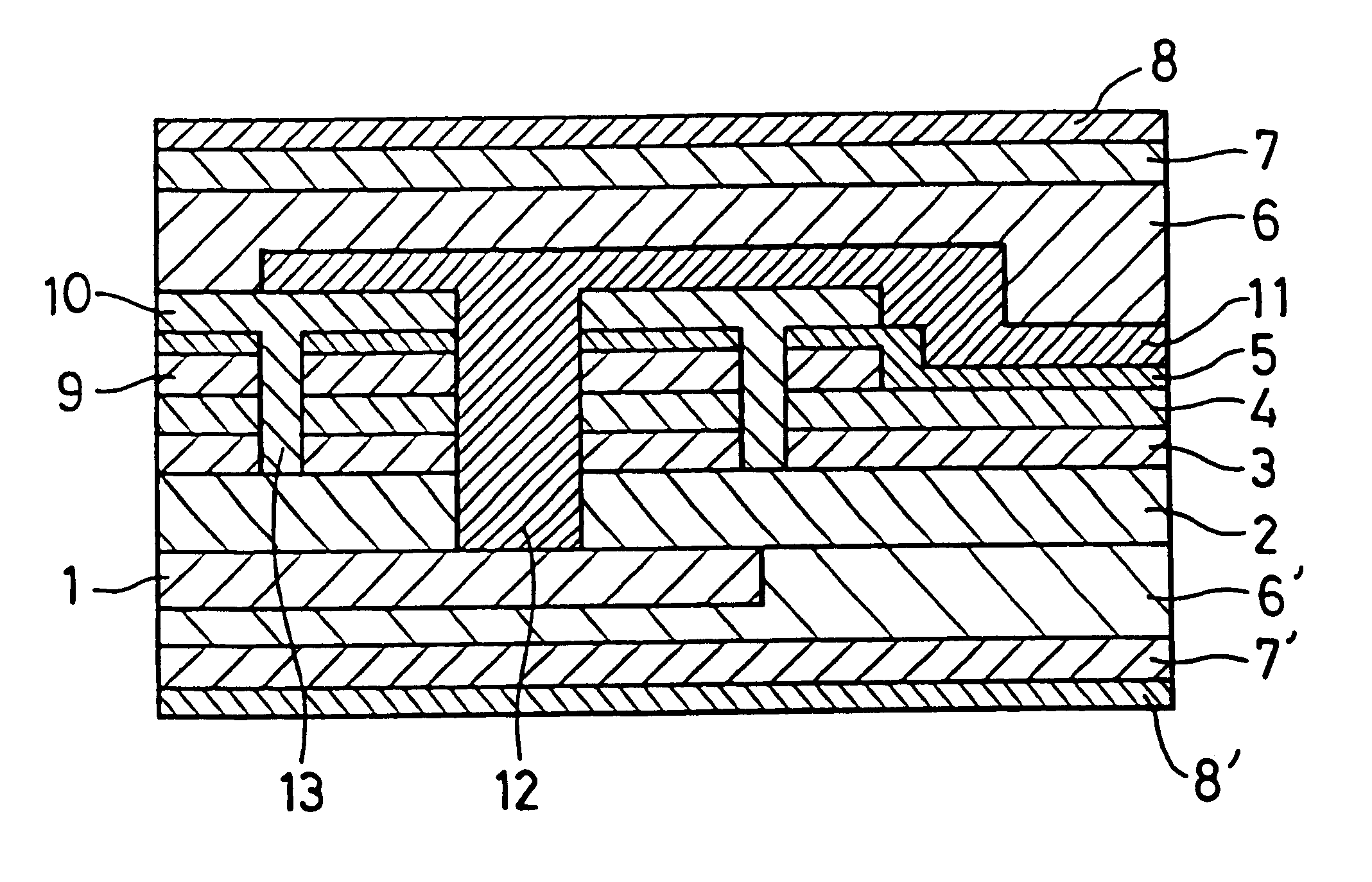

Coated article and solar battery module

InactiveUS6501014B1Small sizeLow heat shrinkagePV power plantsSolid-state devicesWeather resistanceSilica coating

An object of the invention is to provide a coated article having a protective member which is improved in light transparency, heat resistance, and weather resistance, and easy to manufacture, as typified by a solar battery module which experience no deterioration of performance during long-term outdoor installation; and to provide a coated article capable of protecting a functional film or device from water vapor and gases for dramatically improve the life of the functional film or device. These objects are achieved by a coated article having as a protective member a silica coating which is obtained by applying a polysilazane-containing coating solution on at least one surface of a resinous substrate having light transparency and heat resistance under atmospheric pressure, followed by steam oxidation and heat treatment.

Owner:TDK CORPARATION

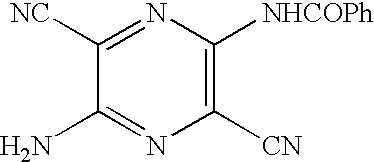

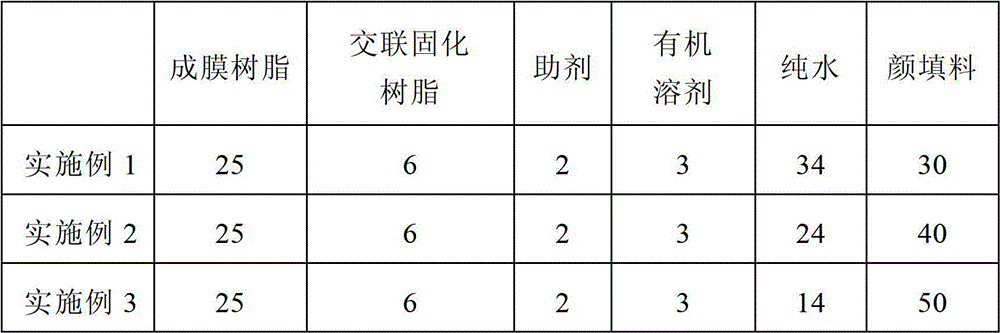

Silicon steel water-soluble environment-friendly super thick insulating coating and preparation method thereof

ActiveCN102746725AHigh solid contentGood heat resistancePolyurea/polyurethane coatingsEpoxy resin coatingsOrganic solventWater soluble

A silicon steel water-soluble environment-friendly super thick insulating coating and a preparation method thereof. The insulating coating comprises the following components, by weight percentage: 10-60% of organic resin containing film-forming resin and crosslinking curing resin; 0.1-5% of inorganic pigment; 28-60% of filler; additives including 0.1-4% of wetting agent, 0.1-4% of dispersing agent, 0.1-1% of defoaming agent in and 0.1-1% of pH regulator; 1-15% of organic solvent; and the balance of pure water. The present invention provides a chrome-free C6 water-soluble environment-friendly coating with low VOC emission. The coating has high solid content and inorganic filler content (solid no less than 60%, inorganic filler content no less than 40%, GB / T 1725-2007), excellent surface insulation performance no less than1500 ohm.cm<2> / tablet (ASTM A717), good attachment (grade class A, phi 10mm rod, GB / T 2522-2007), low lamination heat compression rate, and good corrosion resistance, and is suitable for silicon steel processed with clipping and stamping by large and medium-sized motors.

Owner:BAOSHAN IRON & STEEL CO LTD

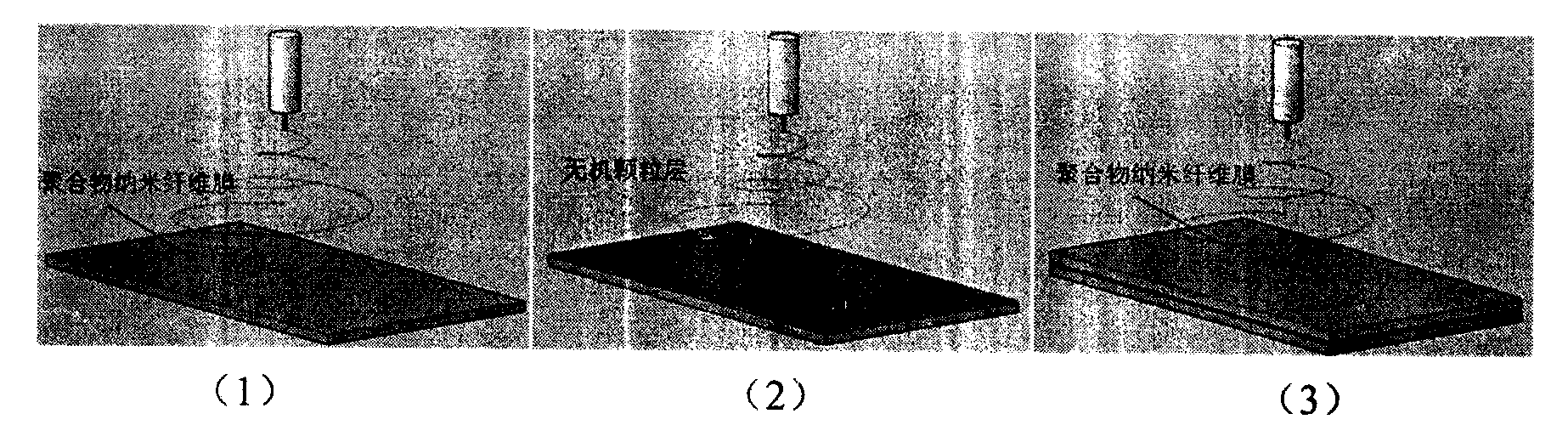

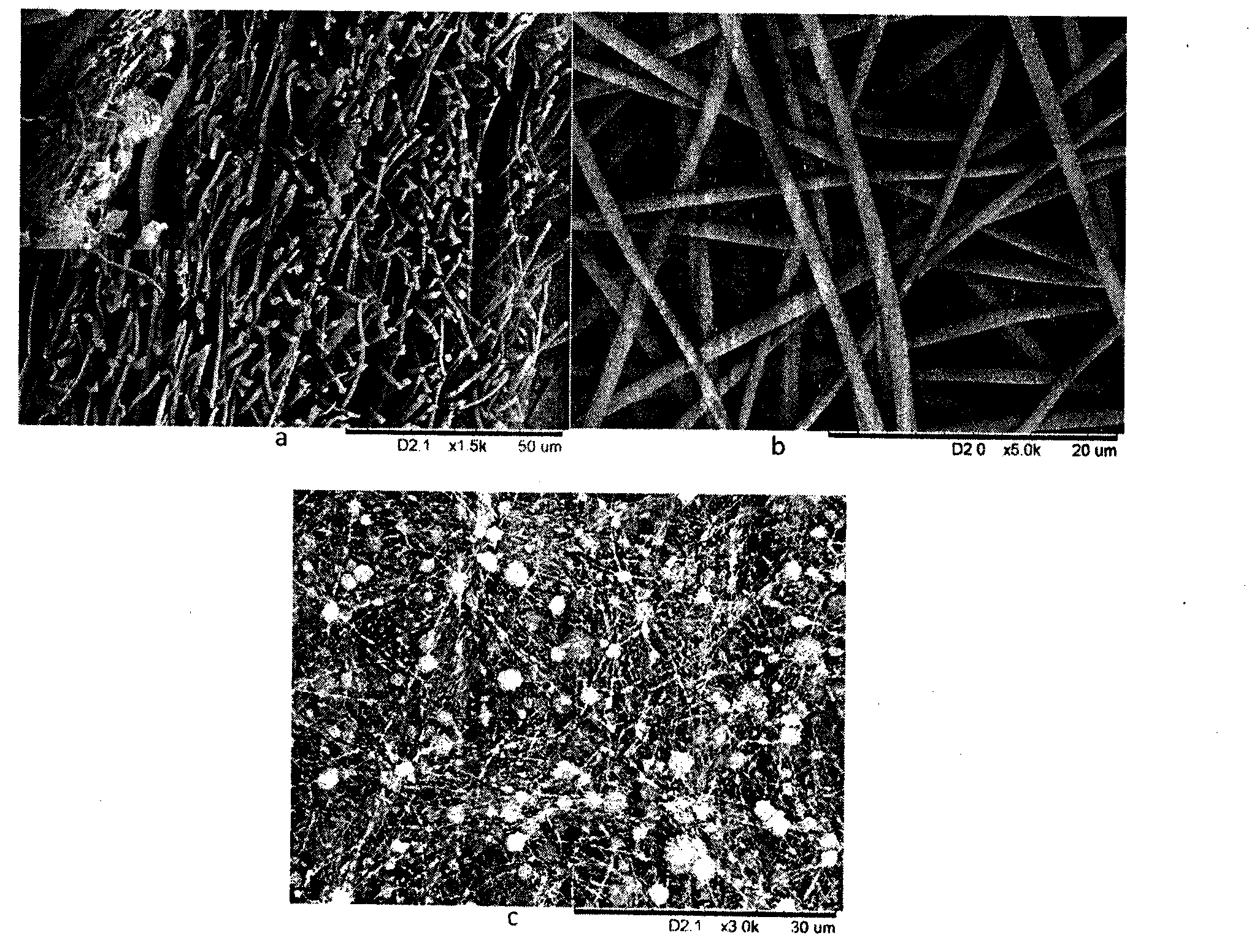

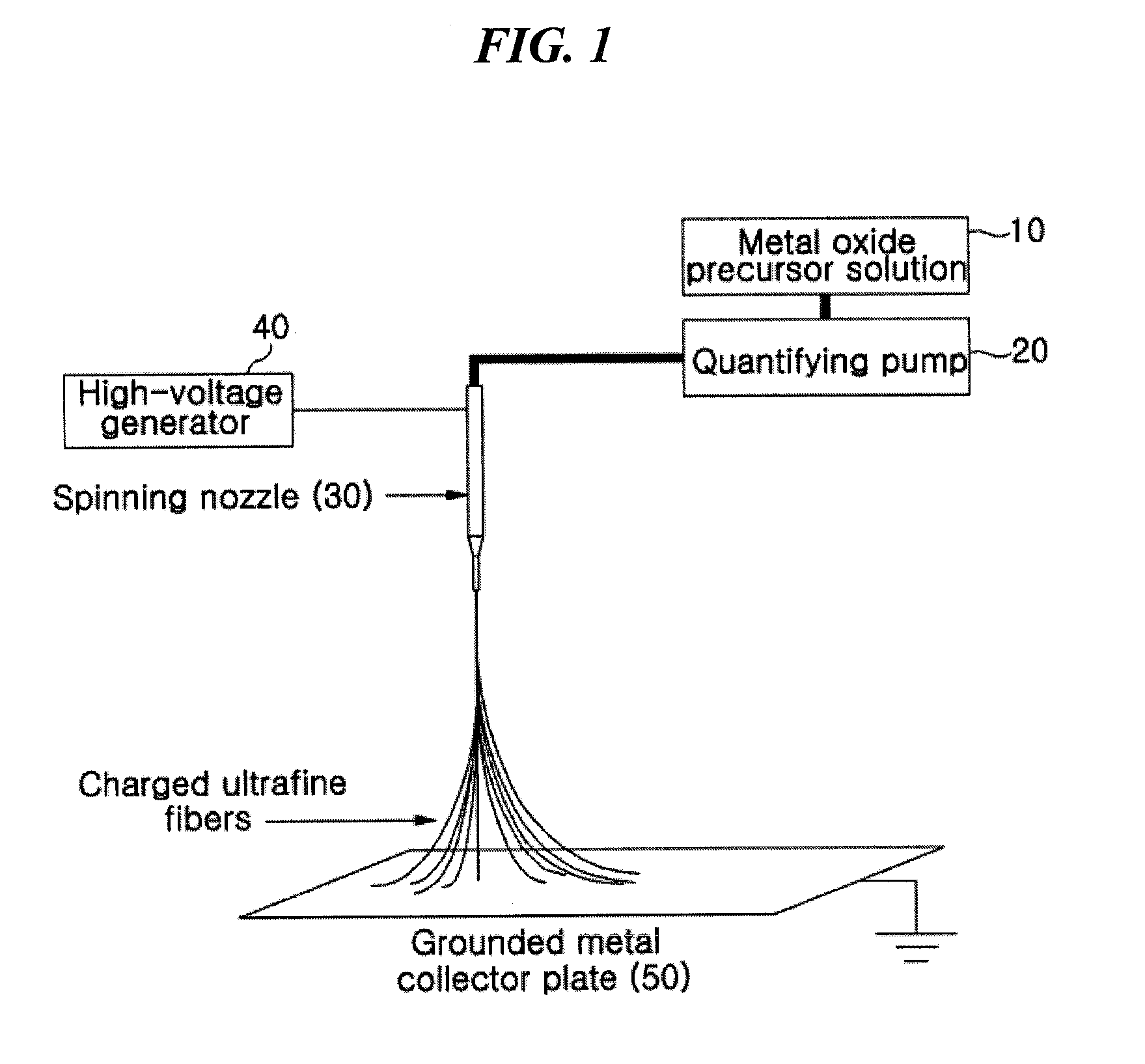

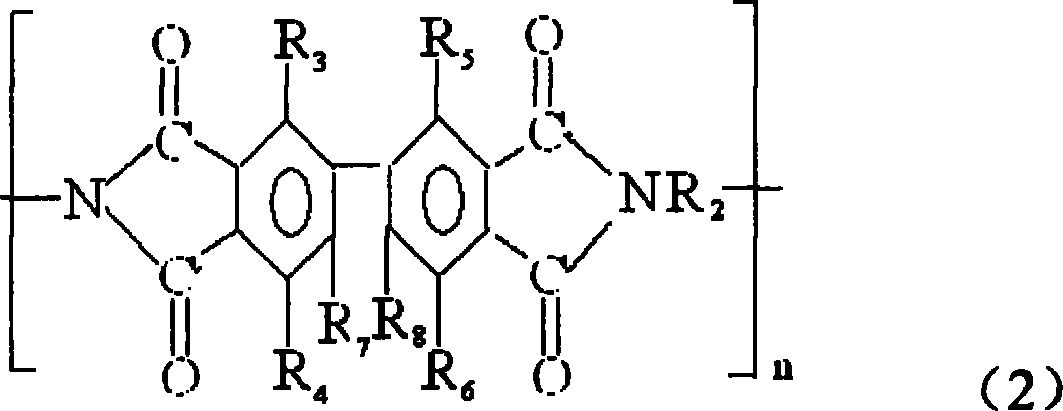

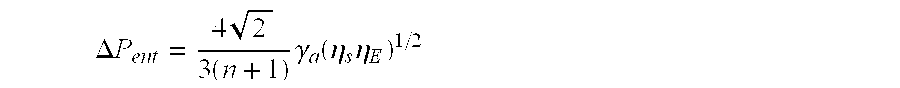

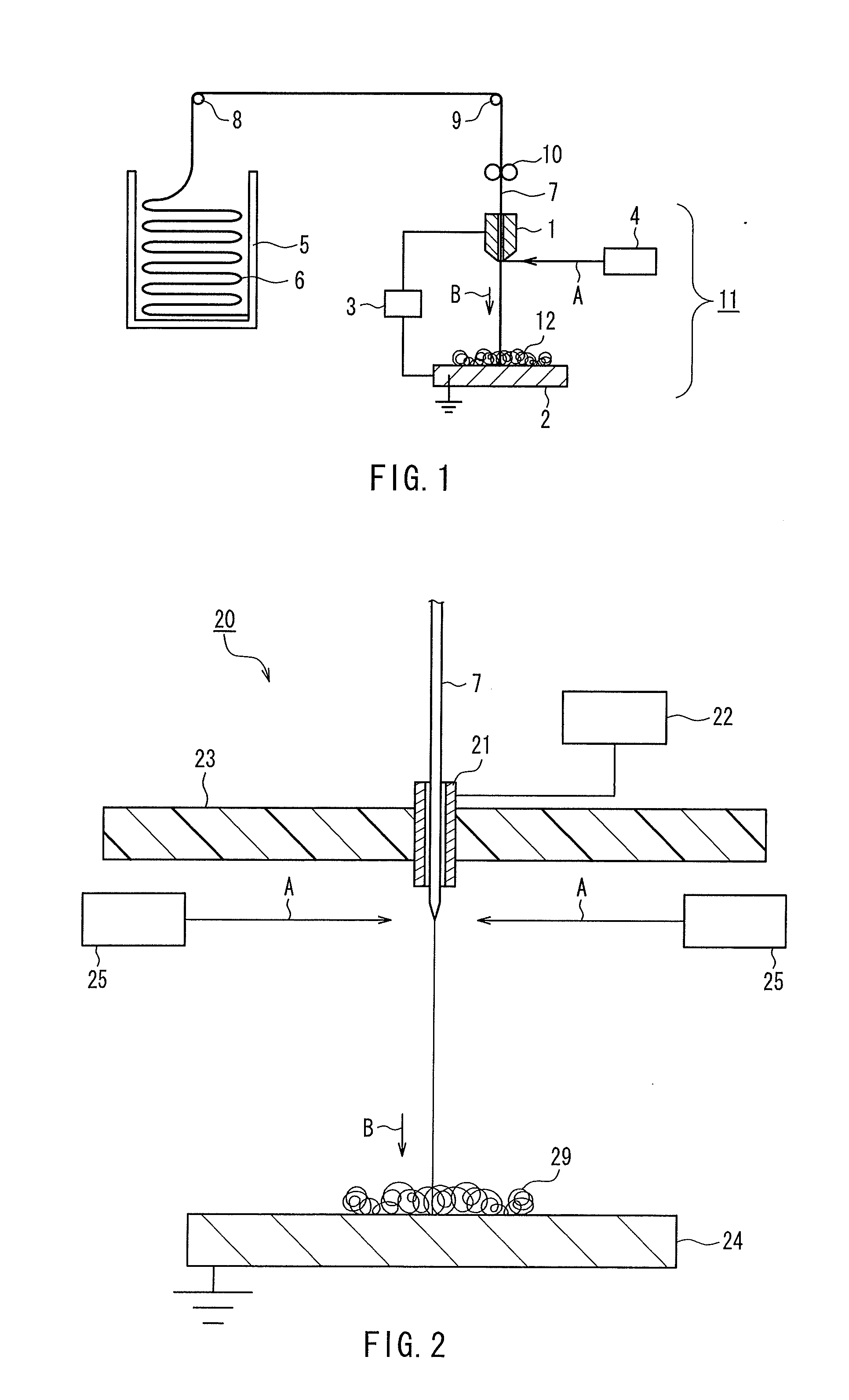

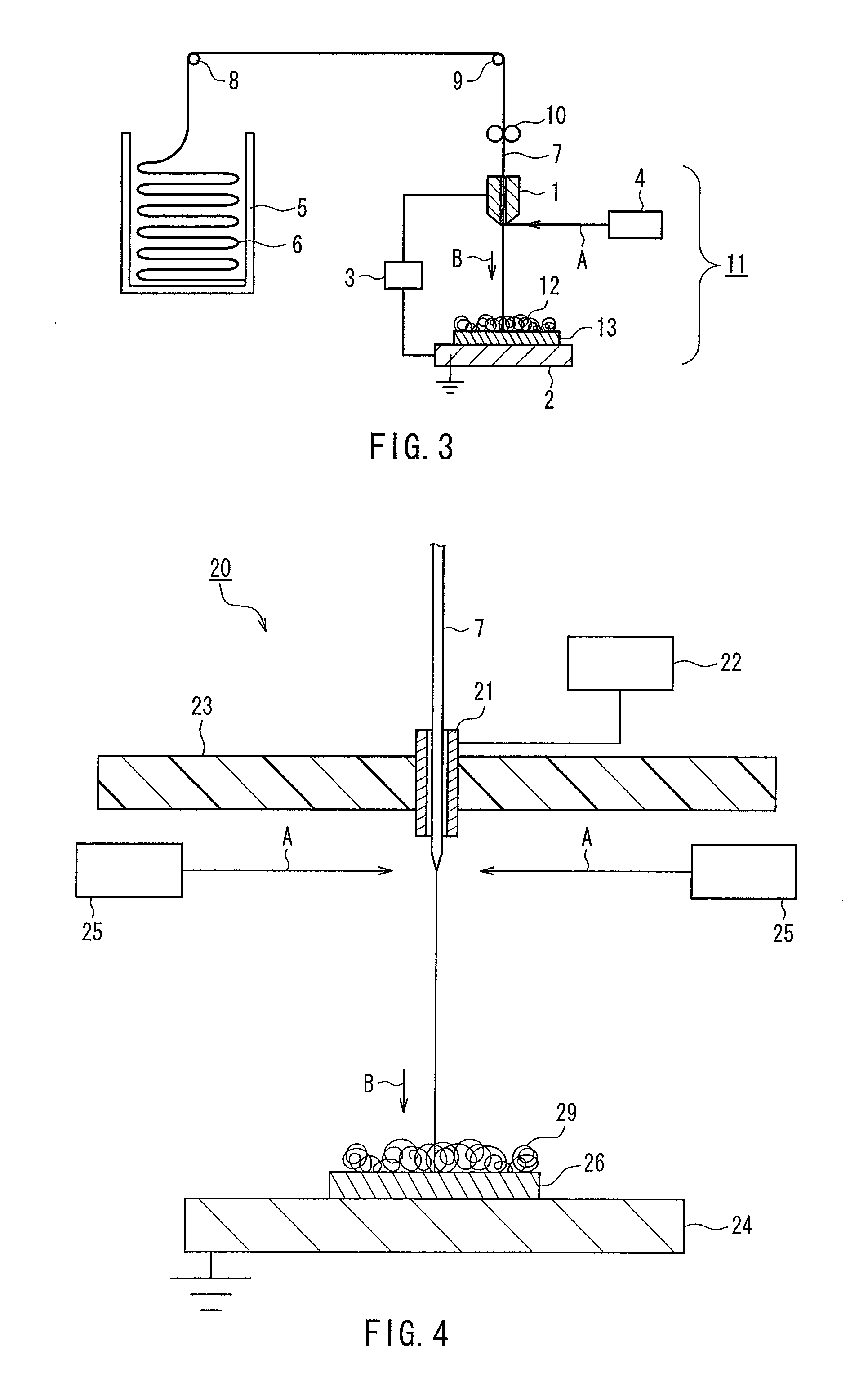

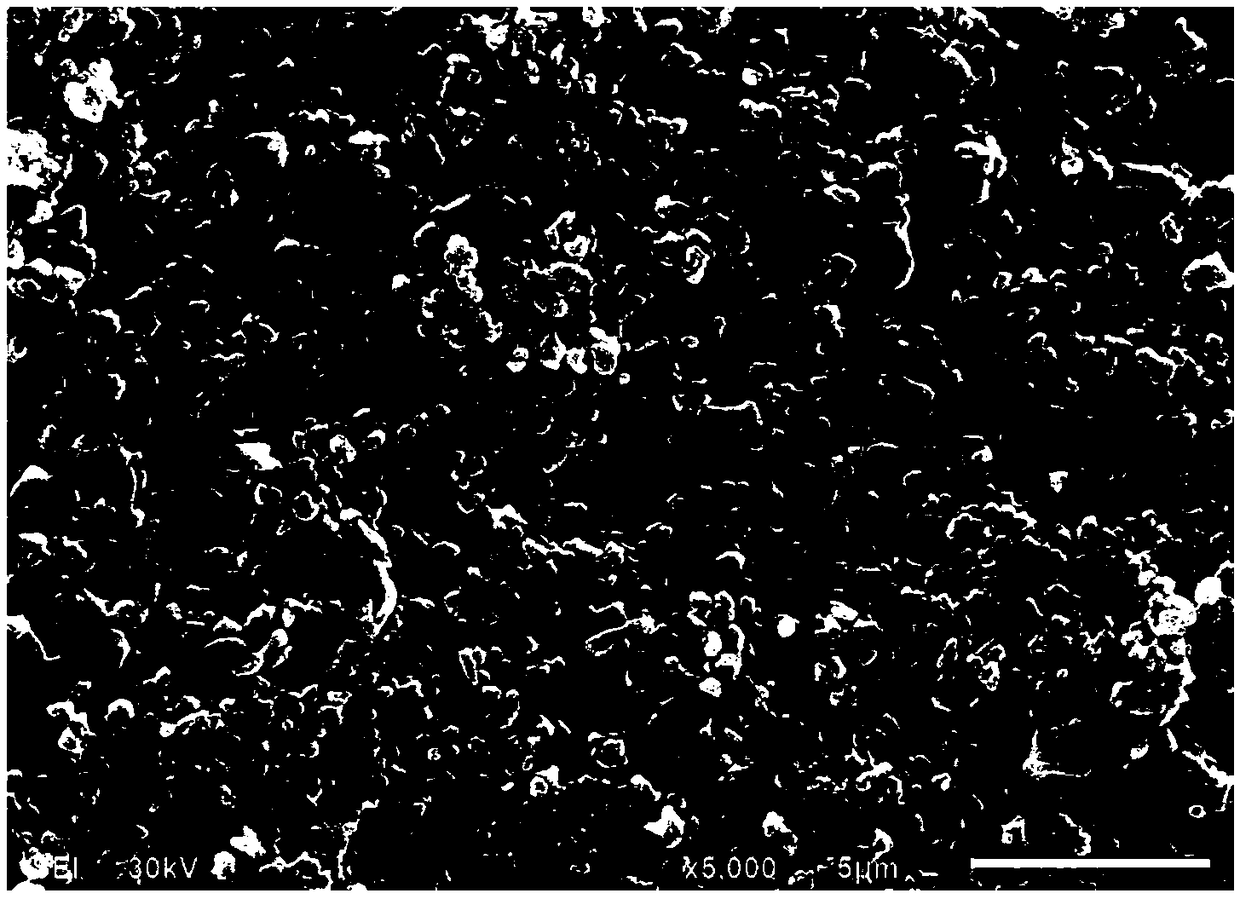

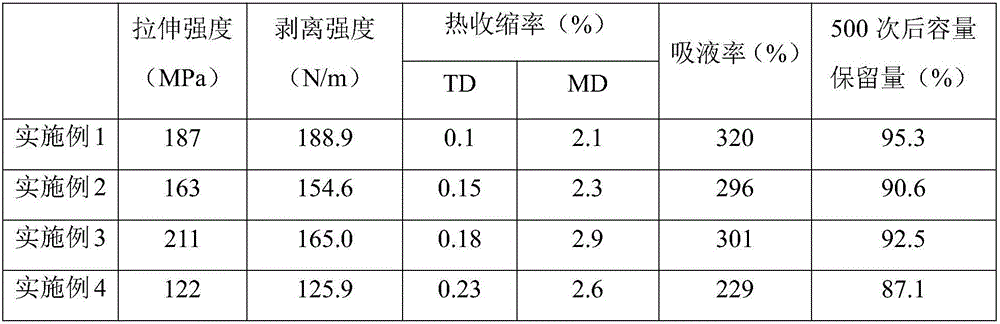

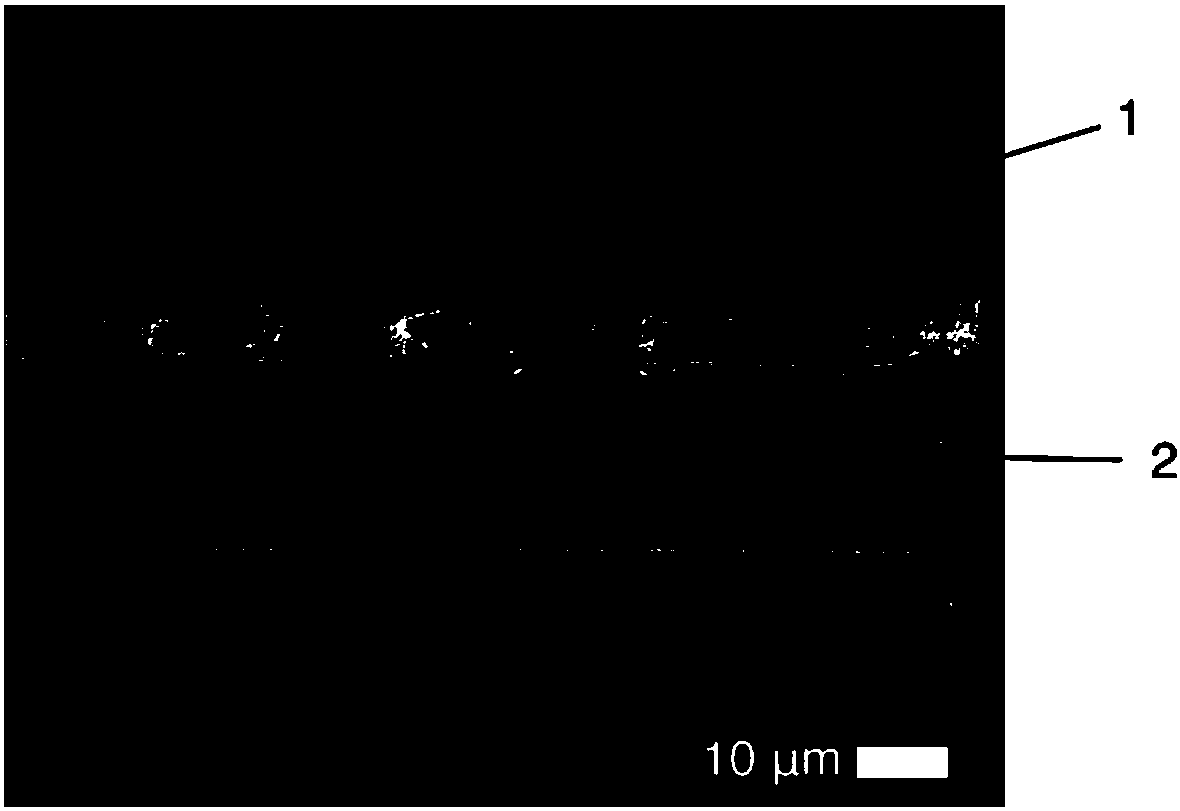

Method for preparing composite lithium-ion battery separator through electrostatic spinning/electrostatic spraying

InactiveCN103474610AExcellent heat shrinkage resistanceIncrease fluid retentionCell component detailsNon-woven fabricsFiberOrganic solvent

The invention relates to the field of lithium-ion batteries, in particular to a method for preparing a composite lithium-ion battery separator through electrostatic spinning / electrostatic spraying. The method specifically includes the steps of firstly, adding high molecular polymer into an organic solvent, dissolving the high molecular polymer through mechanical stirring to form a transparent solution, and obtaining an electrostatic spinning solution; secondly, mixing inorganic nanometer particles with the high molecular polymer and adding the mixture into the organic solvent, and conducting mechanical stirring to obtain inorganic nanometer particle suspension liquid; thirdly, conducting electrostatic spinning on the spinning solution prepared in the first step to prepare a lower layer nanometer fiber film, and enabling the inorganic nanometer particle suspension liquid prepared in the second step to be deposited on the lower layer nanometer fiber film through electrostatic spraying to obtain an interlayer; finally, receiving an electrostatic spun nanometer fiber layer on an inorganic particle layer to obtain the composite lithium-ion battery separator. The composite lithium-ion battery separator has the high imbibing rate and good electrochemical stability under the room temperature and has good heat shrinkage resistance performance at the same time.

Owner:TIANJIN POLYTECHNIC UNIV

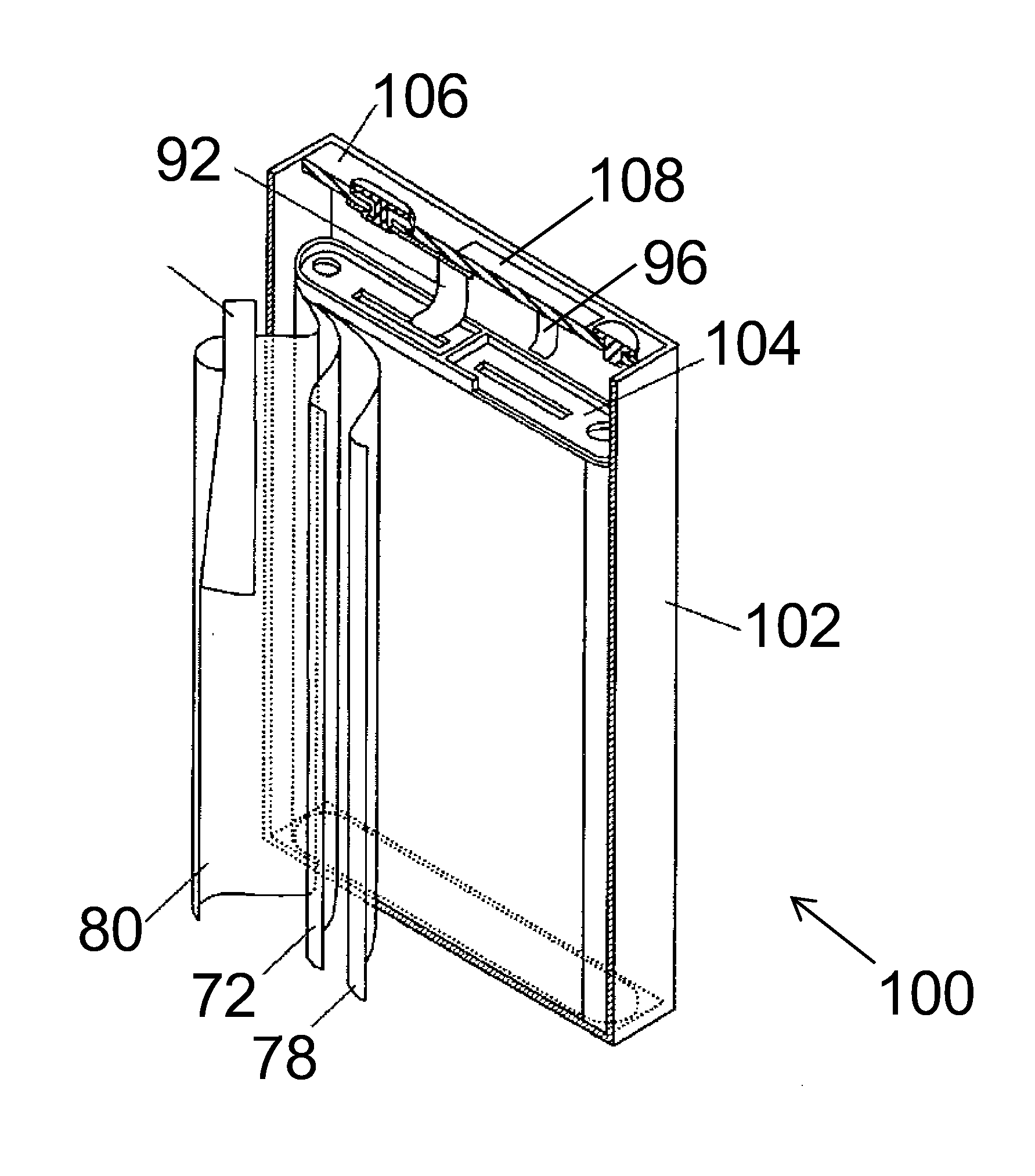

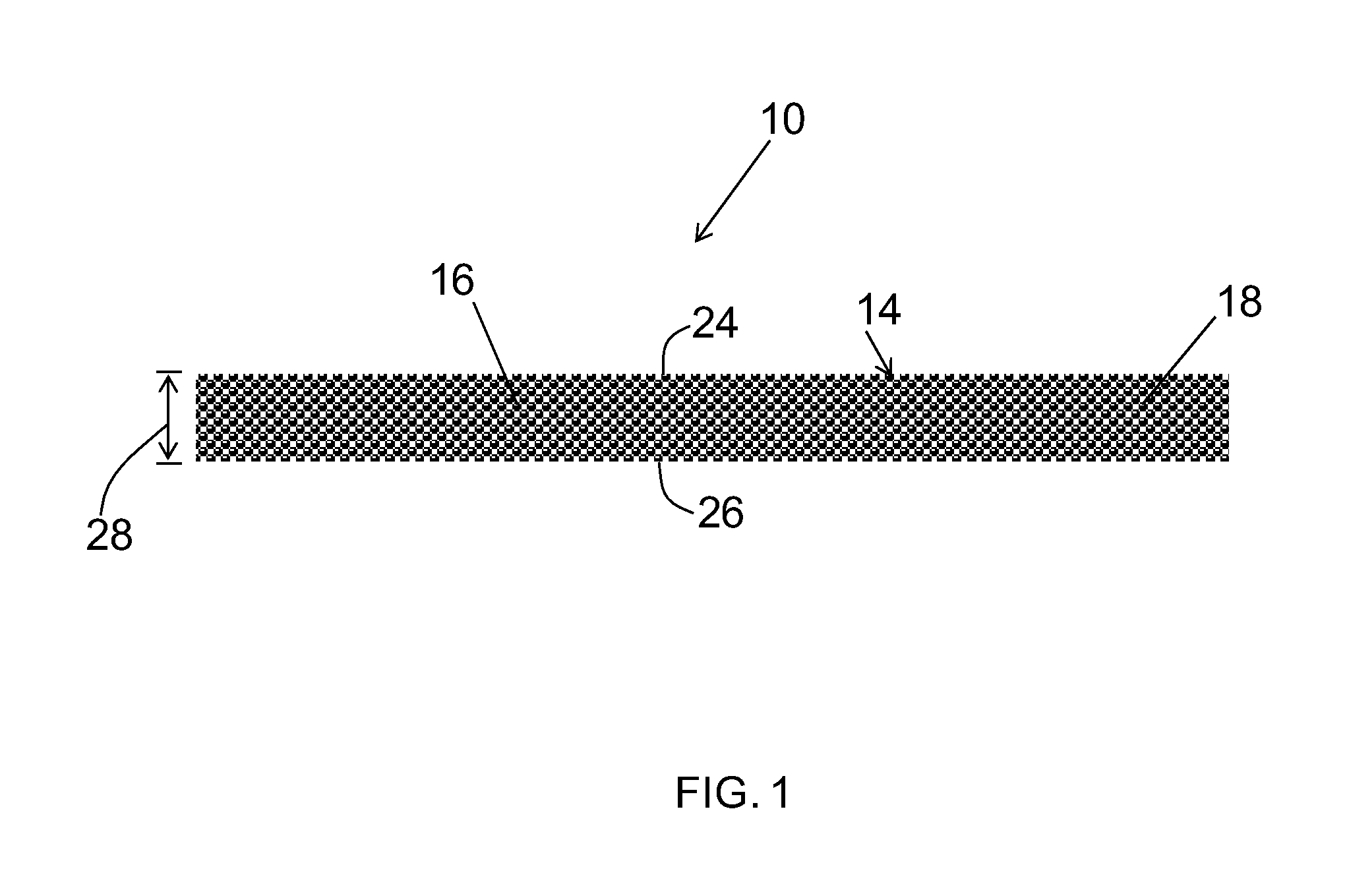

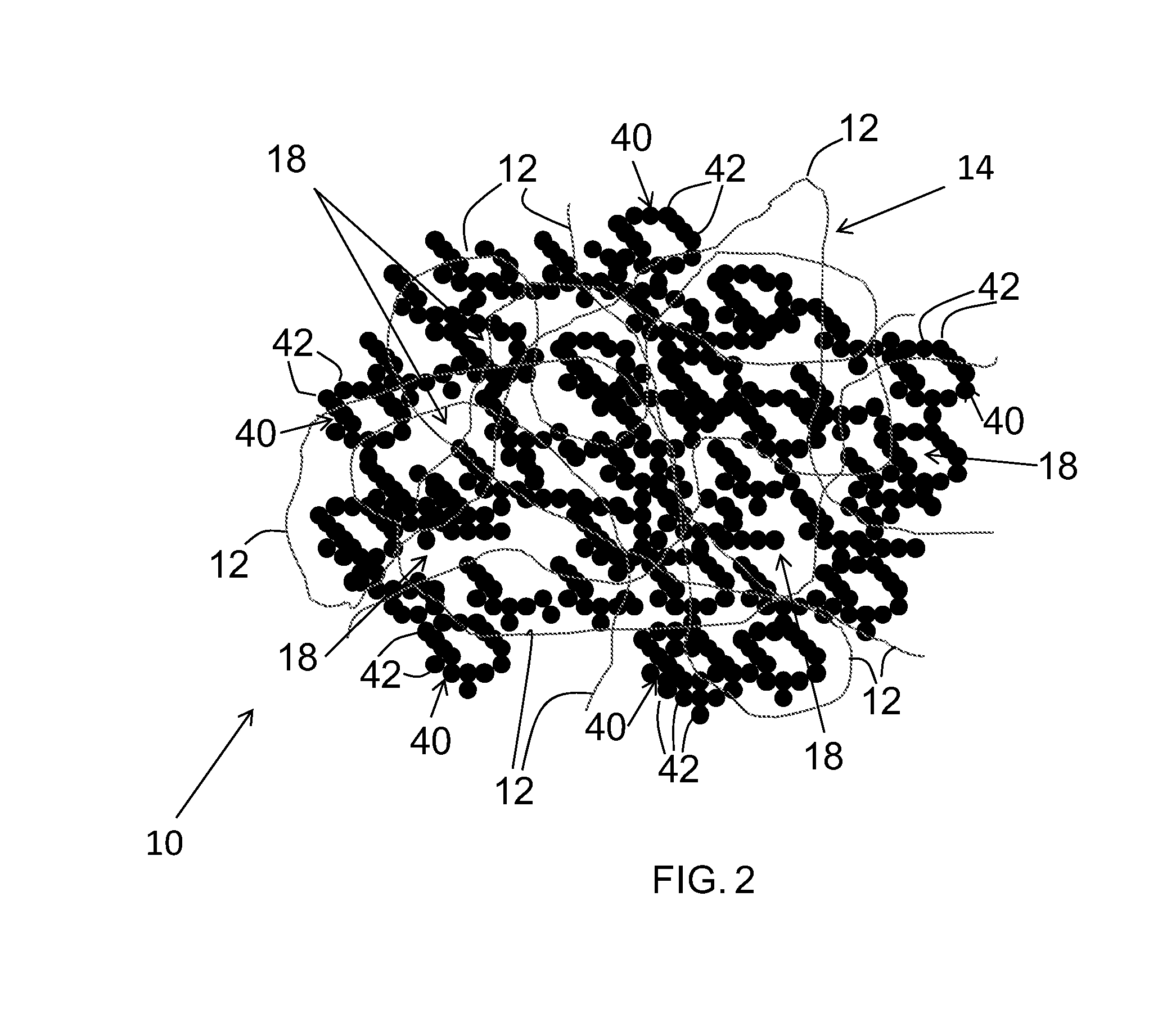

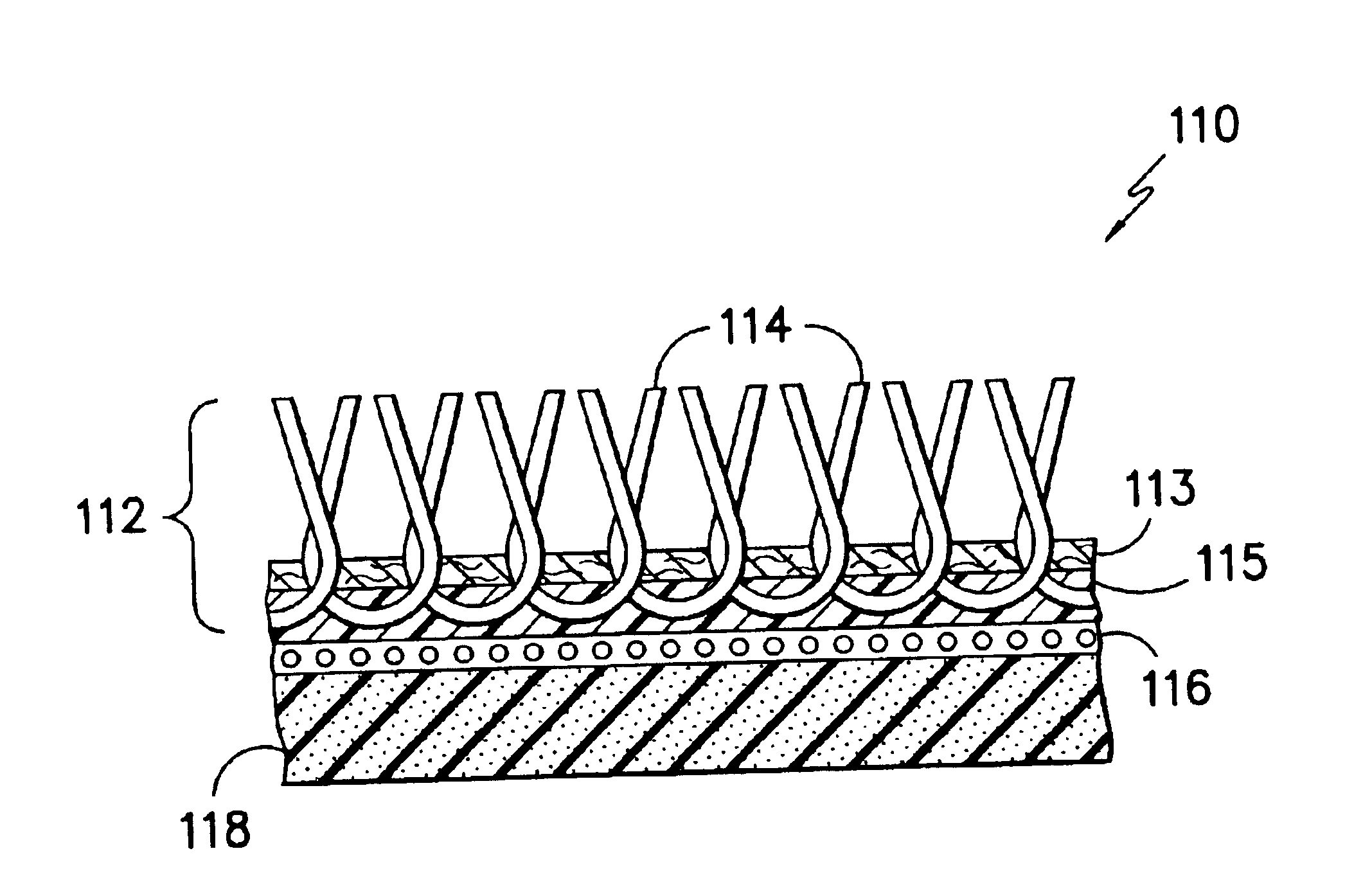

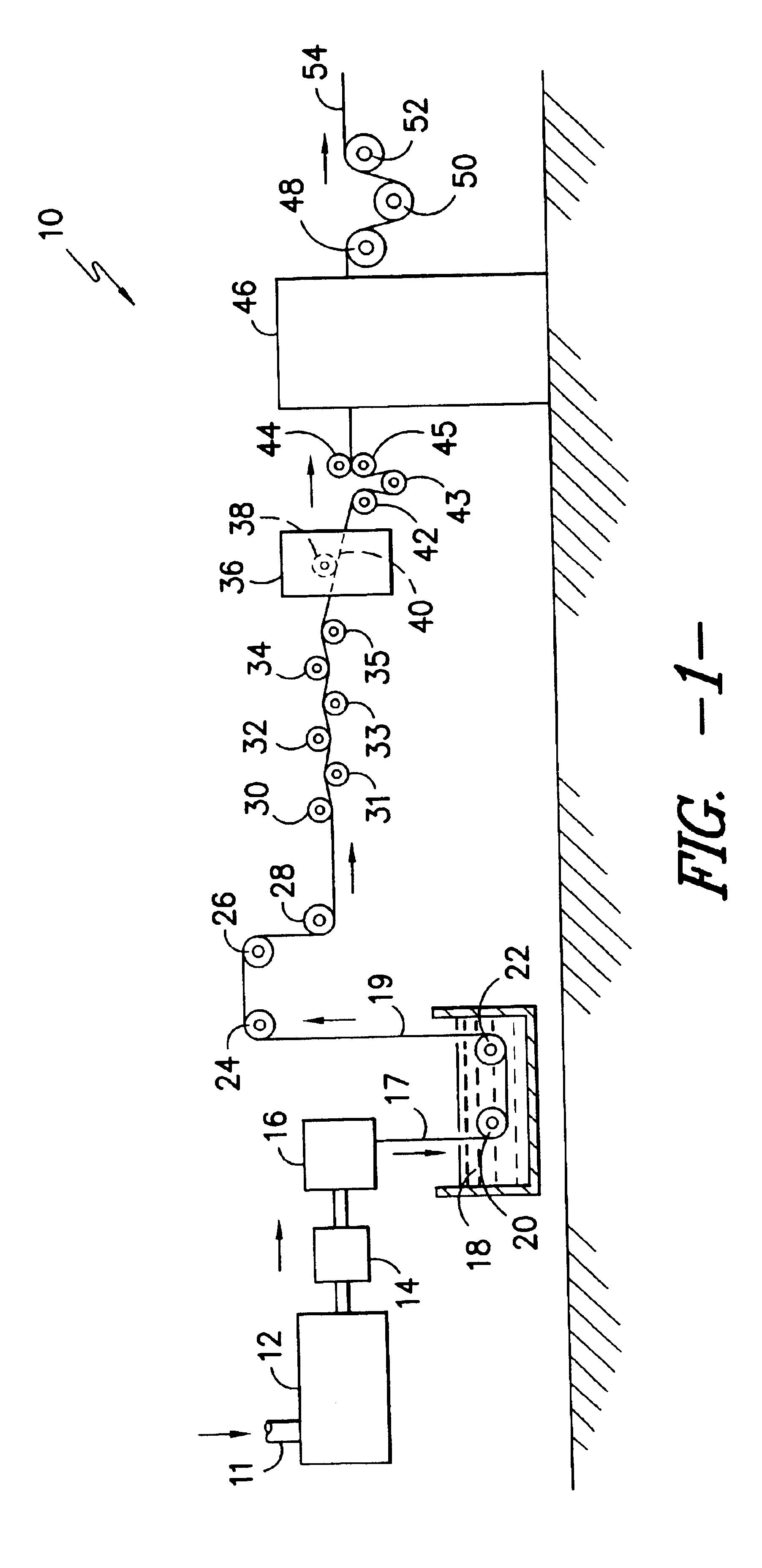

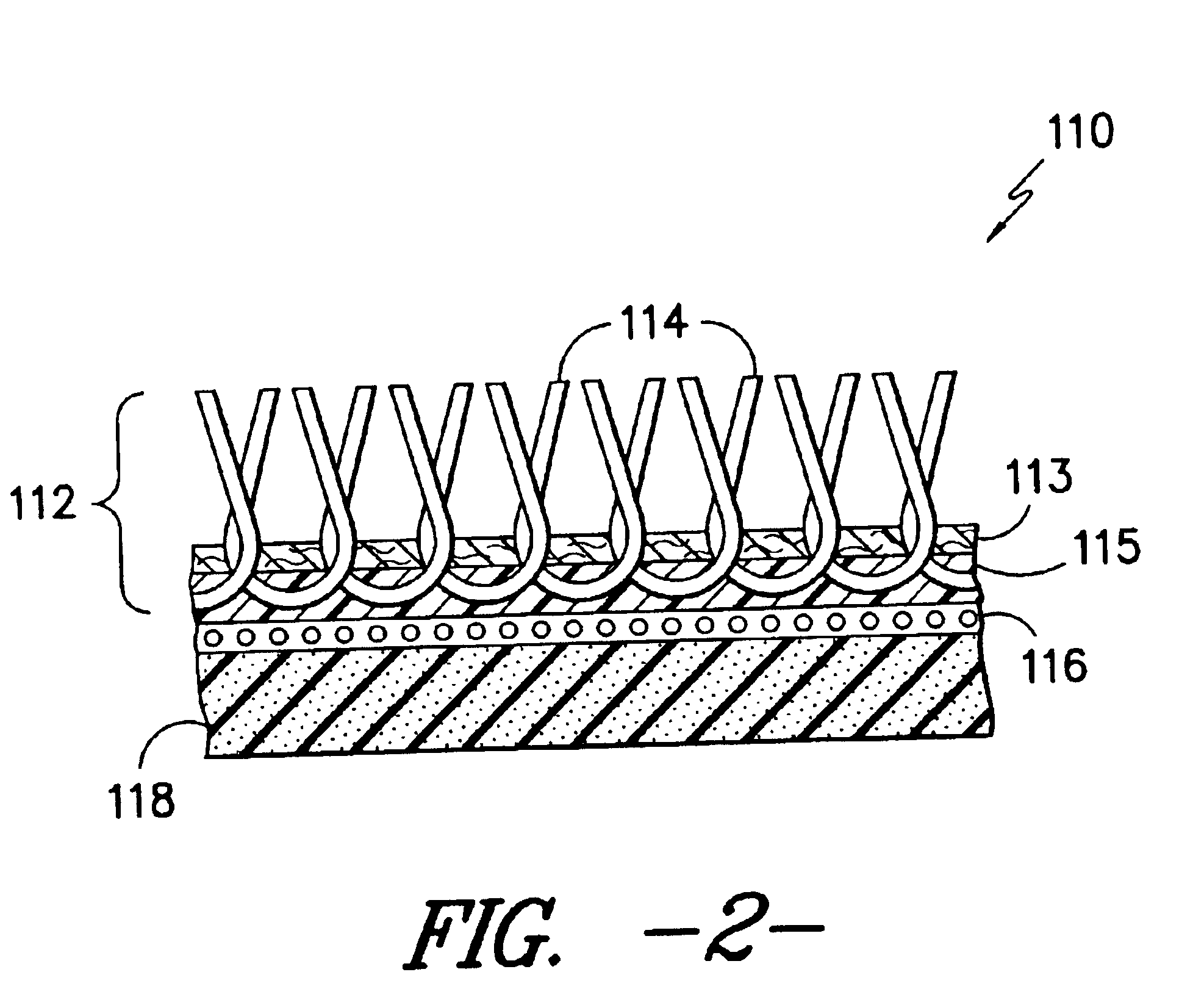

Freestanding, heat resistant microporous film for use in energy storage devices

ActiveUS20120145468A1Low thermal shrinkageHigh level of loadingPrimary cell to battery groupingAuxillary drivesCross-linked polyethyleneMelting Point Temperature

Preferred embodiments of a freestanding, heat resistant microporous polymer film (10) constructed for use in an energy storage device (70, 100) implements one or more of the following approaches to exhibit excellent high temperature mechanical and dimensional stability: incorporation into a porous polyolefin film of sufficiently high loading levels of inorganic or ceramic filler material (16) to maintain porosity (18) and achieve low thermal shrinkage; use of crosslinkable polyethylene to contribute to crosslinking the polymer matrix (14) in a highly inorganic material-filled polyolefin film; and heat treating or annealing of biaxially oriented, highly inorganic material-filled polyolefin film above the melting point temperature of the polymer matrix to reduce residual stress while maintaining high porosity. The freestanding, heat resistant microporous polymer film embodiments exhibit extremely low resistance, as evidenced by MacMullin numbers of less than 4.5.

Owner:AMTEK RES INT

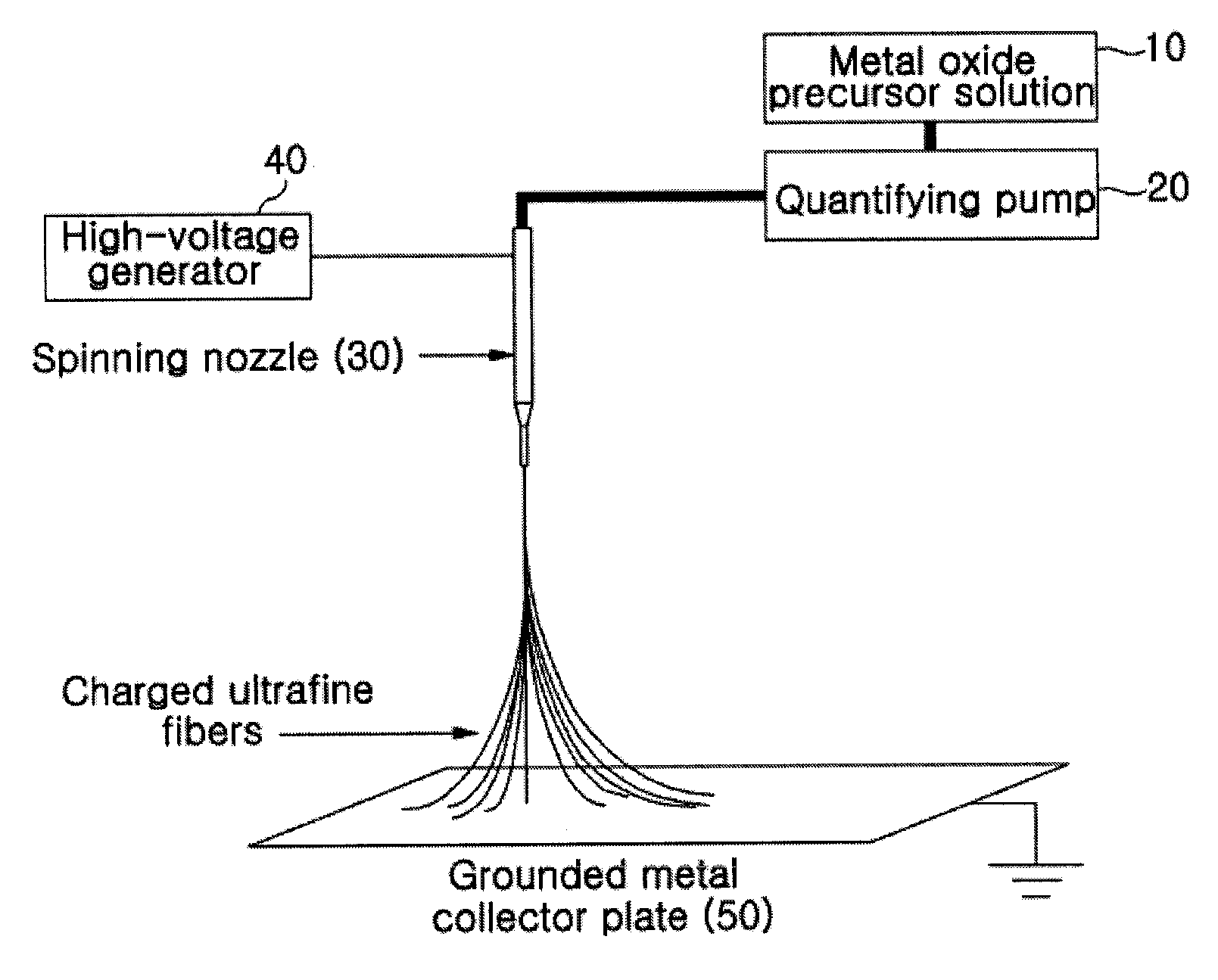

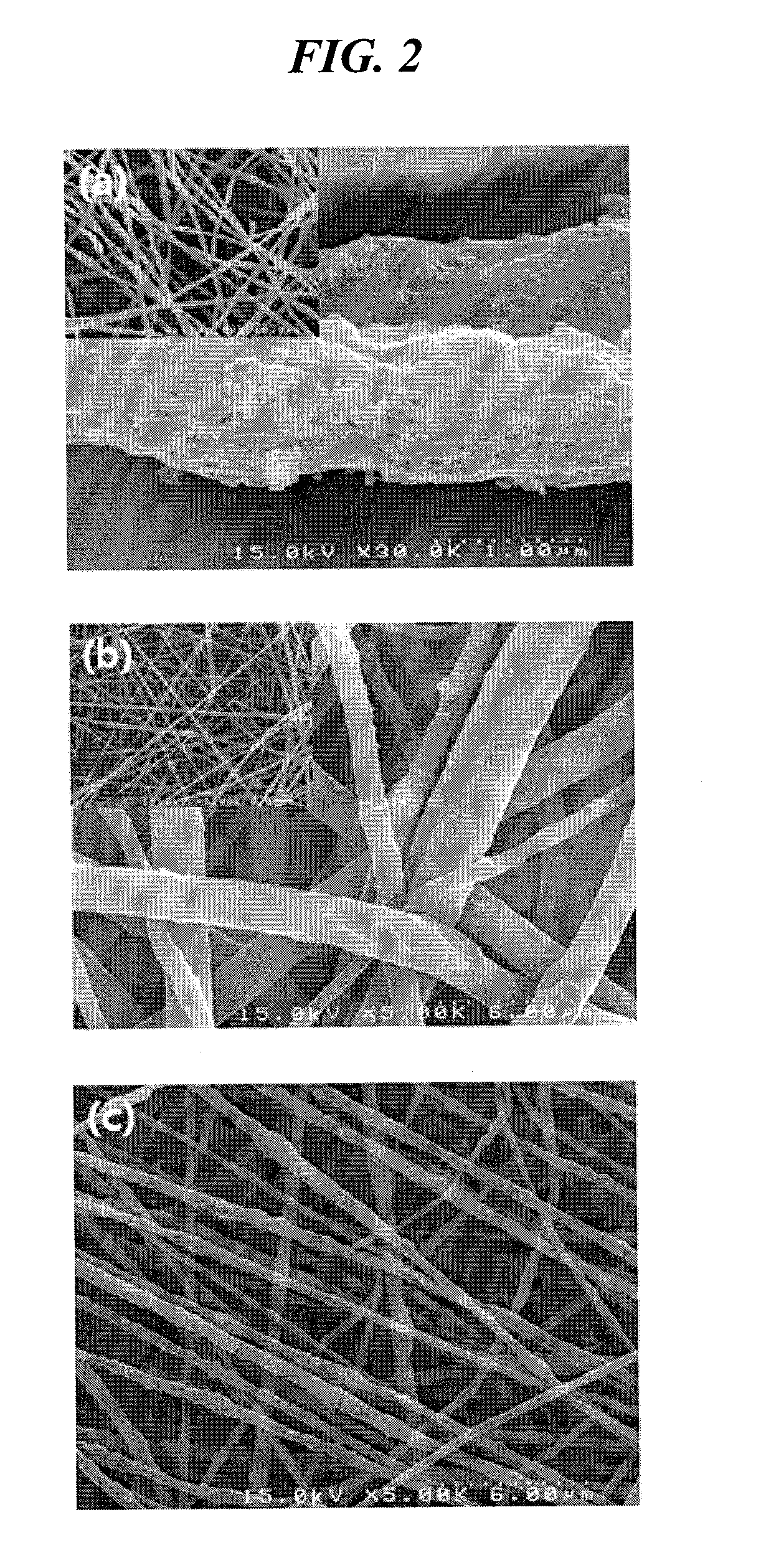

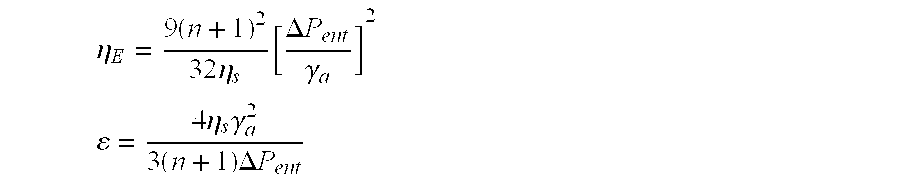

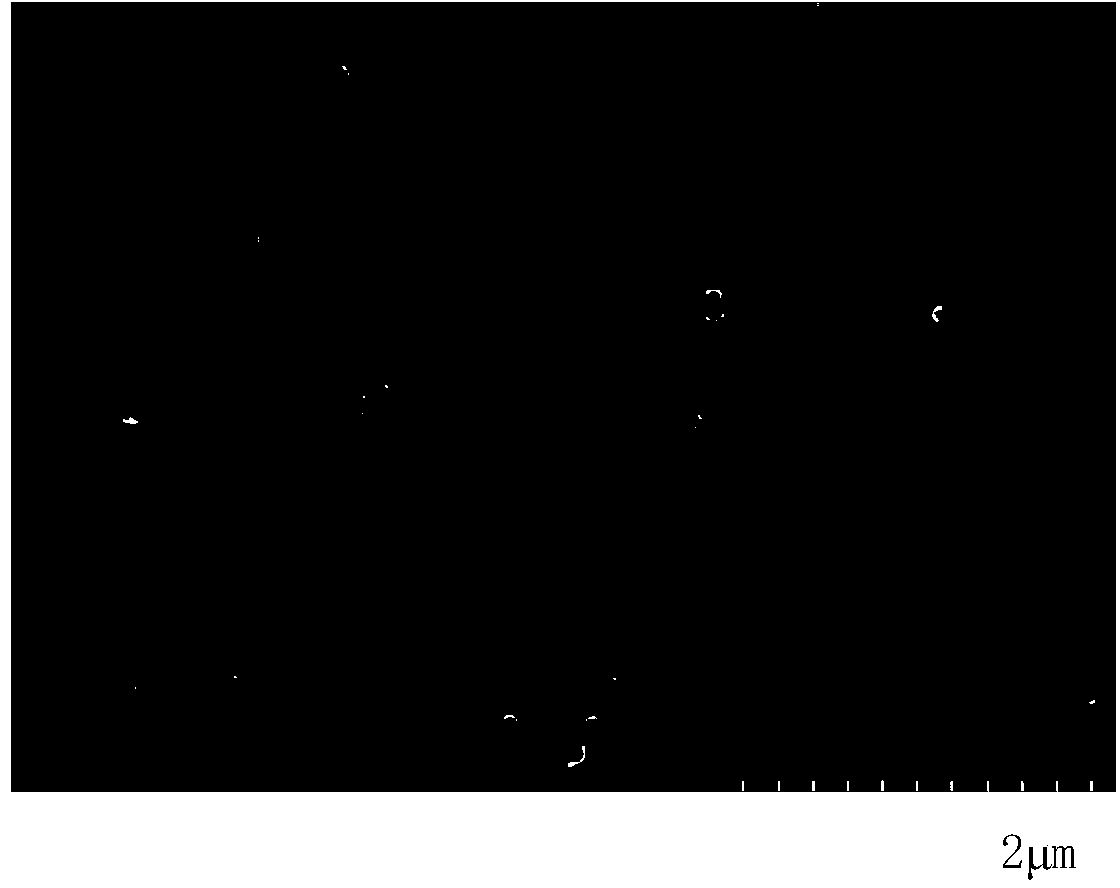

Metal oxide ultrafine fiber-based composite separator with heat resistance and secondary battery using same

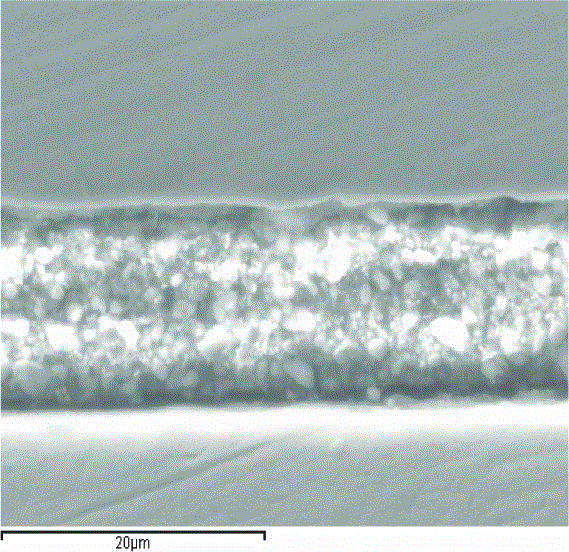

ActiveUS20120003524A1Low heat shrinkage rateSuperior heat resistance and ionic conductivityMembranesSemi-permeable membranesIonElectrospinning

An ultrafine fiber-based composite separator comprising a fibrous porous body which comprises ultrafine metal oxide / polymer composite fibers, or ultrafine metal oxide fibers and a polymer resin coating layer formed on the surface thereof, the ultrafine fibers being continuously randomly arranged and layered, and obtained by electrospinning a metal oxide precursor sol-gel solution or a mixture of a metal oxide precursor sol-gel solution and a polymer resin solution, wherein the surface of the metal oxide / polymer composite fibers has a uniform mixing composition of the metal oxide and the polymer resin, in which the separator has a heat shrinkage rate at 150˜250° C. of 10% or less and does not break down due to melting at a temperature of 200° C. or lower, has low heat shrinkage rate, and superior heat resistance and ionic conductivity, being capable of providing improved cycle and power properties when used in manufacturing a battery.

Owner:KOREA INST OF SCI & TECH

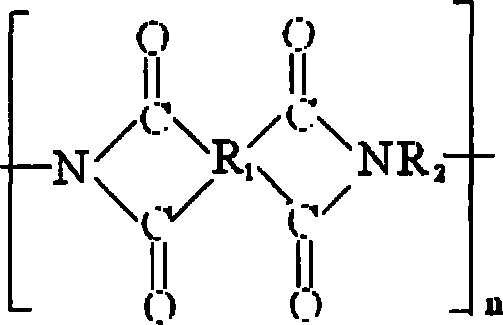

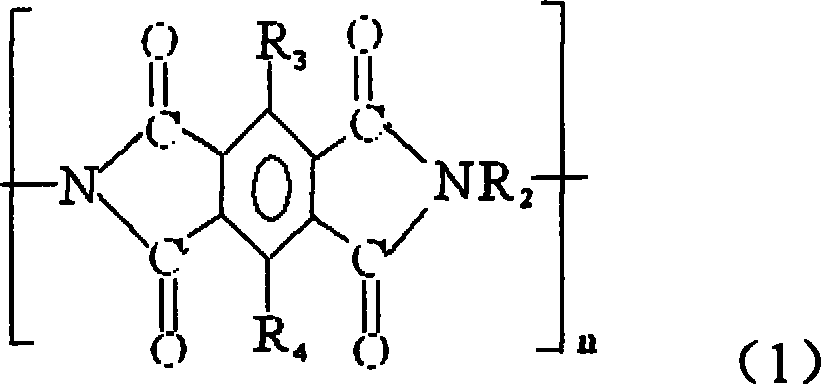

Battery diaphragm and its preparation method and lithium ion secondary battery containing the diaphragm

InactiveCN101000951AGood chemical stabilityNo ruptureSecondary cellsCell component detailsLithiumPower battery

A battery separator includes the substrate and holes distributed on it, in which, the substrate contains polyimide. The battery separator of this invention uses polyimide which is a new material bearing high temperature as substrate, so that it has excellent chemical stability, high temperature, good permeability and high mechanical strength. The lithium-ion rechargeable batteries using this invention don't appear short circuit even in 150 deg. C, thus this battery separator can be used for high-capacity and power batteries.

Owner:BYD CO LTD

Biaxially oriented polypropylene film

InactiveUS20040053064A1Low heat shrinkageGood dimensional stabilityFixed capacitor dielectricSynthetic resin layered productsFiberHigh stiffness

A biaxially stretched polypropylene film of the present invention has high stiffness in the film longitudinal direction and can be manufactured by a conventional longitudinal-transverse sequential biaxial stretching method, since the biaxially stretched polypropylene film comprises a polypropylene which comprises a polypropylene having controlled specific values of a melt strength (MS) and a melt flow rate (MFR) at 230° C. or consists of a polypropylene having controlled specific values of a melt strength (MS) and a melt flow rate (MFR) at 230° C. and / or a Trouton ratio of the polypropylene is controlled at a specific value, moreover, the biaxially stretched polypropylene film contains regulated longitudinal fibrils.

Owner:TORAY IND INC

Fiber assembly, composite of electro conductive substrate and fiber assembly, and production methods thereof

InactiveUS20110177395A1Improve puncture strengthHigh tensile strengthElectric discharge heatingLayered productsFiberElectrospinning

The present invention relates to a fiber assembly obtained by electrifying a resin in a melted state by application of voltage between a supply-side electrode and a collection-side electrode so as to extend the resin into an ultrafine composite fiber by electrospinning, and accumulating the ultrafine composite fiber, wherein the ultrafine composite fiber includes at least two polymeric components and the ultrafine composite fiber includes at least one type of composite fiber selected from a sea-island structure composite fiber and a core-sheath structure composite fiber as viewed in fiber cross section, at least one selected from an island component and a core component has a volume specific resistance of 1015Ω·cm or less, and at least one selected from a sea component and a sheath component has a volume specific resistance exceeding 1015Ω·cm. Thereby, the present invention provides a fiber assembly obtained by accumulating an ultrafine composite fiber obtained by electrospinning without the use of any solvent or water as a spinning solution, a composite of an electro conductive substrate and such a fiber assembly, and production methods thereof.

Owner:DAIWABO HLDG +1

Waterborne ceramic coated membrane for lithium ion battery and preparation method thereof

InactiveCN105789539AHigh porosityImprove thermal stabilityCell component detailsCoatingsCoated membraneAdhesive

The invention discloses a waterborne ceramic coated membrane for a lithium ion battery and a preparation method thereof. The waterborne ceramic coated membrane comprises a microporous membrane and a ceramic coating, the ceramic coating is arranged on one side or two sides of the microporous membrane and prepared from, by weight, 40-70 wt% of water and 30-60 wt% of base materials, and the base materials include, by weight, 65-98 parts of boehmite powder, 1-15 parts of waterborne wetting agent, 1-15 parts of waterborne adhesive and 1-5 parts of waterborne dispersant. The waterborne ceramic coated membrane is good in conduction effect and high in thermostability and safety.

Owner:CANGZHOU MINGZHU SEPARATOR TECH CO LTD

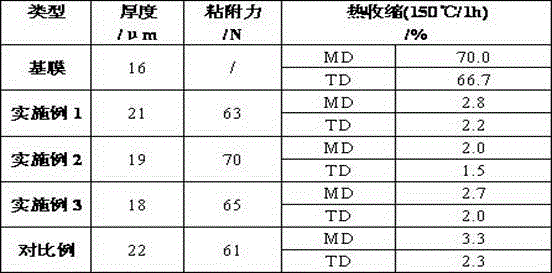

Composite diaphragm as well as preparation method and application thereof

InactiveCN104064713ALarge specific surface areaImprove thermal stabilitySecondary cellsCell component detailsSolventWater soluble

The invention provides a composite diaphragm as well as a preparation method and application thereof, and relates to a lithium ion battery. The composite diaphragm comprises a base diaphragm material; a protective layer coats the surface of the base diaphragm material and adopts a water-soluble bonding agent; a solvent used by slurry of the protective layer is water. The preparation method of the composite diaphragm comprises the steps of (1) evenly mixing inorganic particle powder, the water-soluble bonding agent and the solvent to obtain mixed powder; and (2) coating the single or double surfaces of a common commercially available diaphragm with the mixed powder obtained in the step (1) by a film applicator, carrying out vacuum drying, and removing the solvent to obtain the composite diaphragm, wherein the thickness of the composite diaphragm can be adjusted by controlling the concentration of the slurry and the parameters of the film applicator. The composite diaphragm can be applied to the preparation of a secondary battery and can be used for replacing an existing ceramic diaphragm, wherein the secondary battery comprises but not limited to a lithium ion battery.

Owner:XIAMEN UNIV +1

Low-shrink polypropylene tape fibers comprising high amounts of nucleating agents

InactiveUS6794033B2Low shrinkageLow heat shrinkageSynthetic resin layered productsFilament/thread formingFiberPolymer science

Owner:MILLIKEN & CO

Lithium ion battery ceramic diaphragm paste

InactiveCN105489819ALow costAdjustable viscosityCell seperators/membranes/diaphragms/spacersInorganic particleShrinkage rate

The invention discloses paste for a lithium ion battery ceramic diaphragm. The lithium ion battery ceramic diaphragm comprises a basic membrane and a coating coated on a single side or double sides of the basic membrane. Paste adopted for the coating is paste which is formed in the mode that inorganic nanoparticles and whiskers are composited with a basic material and water. The inorganic nanoparticles are prepared from one of alumina, boehmite, silicon dioxide and barium sulfate, the whiskers are prepared from one of alumina and boehmite, and the basic material is prepared from a thickening agent, a dispersing agent and an adhering agent. The paste can continuously form a uniform inorganic nanometer and whisker coating on PE / PP in a roller painting mode, and the composite diaphragm with the ultra-thin coating and high adhesive force is obtained through drying. The composite diaphragm can effectively reduce the heat-shrinkage rate of the lithium ion battery ceramic diaphragm, and compared with a traditional composite diaphragm prepared from single inorganic particle paste, the ultrathin coating is favorable for increase of air permeability and ionic conductivity, and space in a battery and paste cost are saved.

Owner:EAST CHINA UNIV OF SCI & TECH

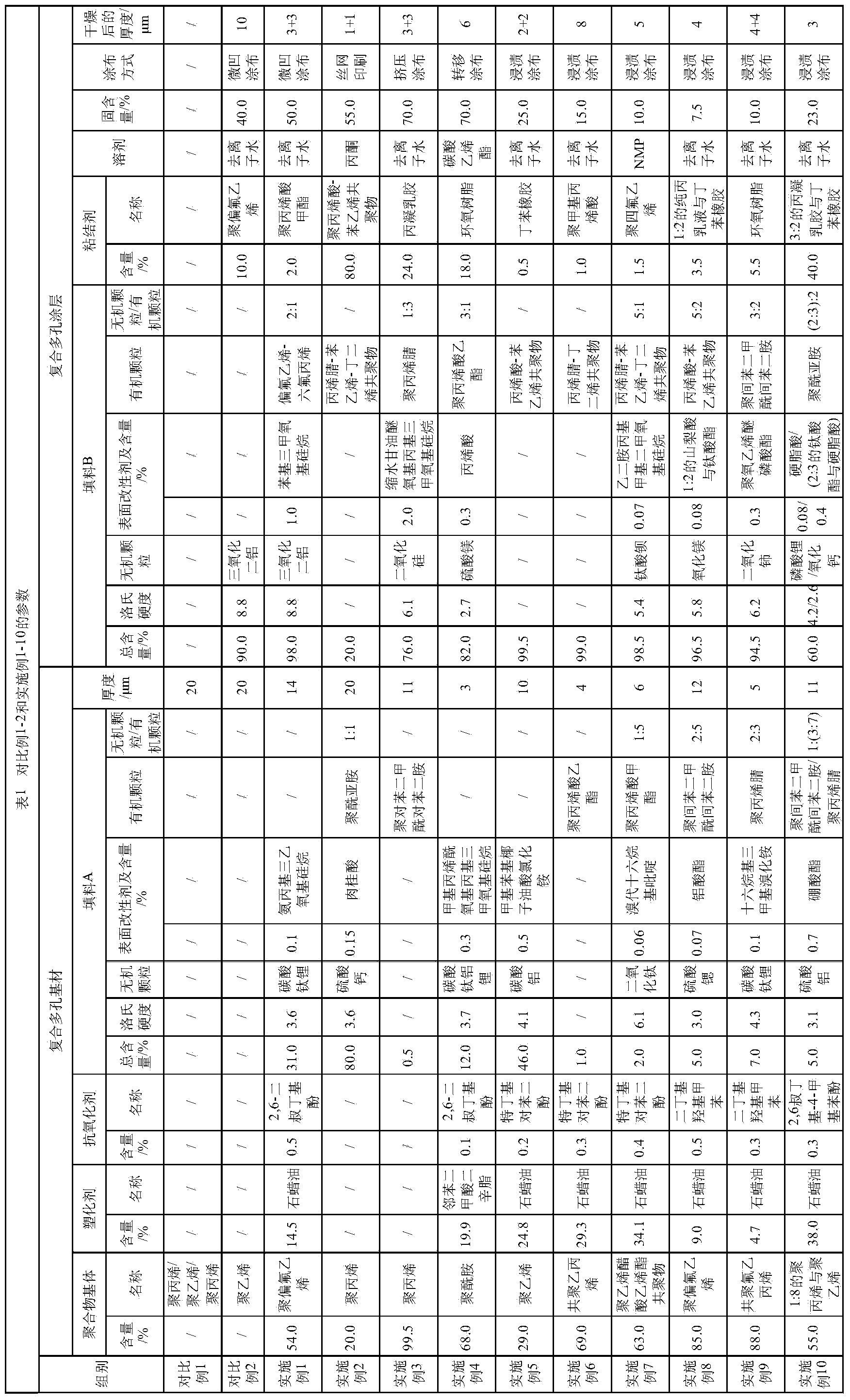

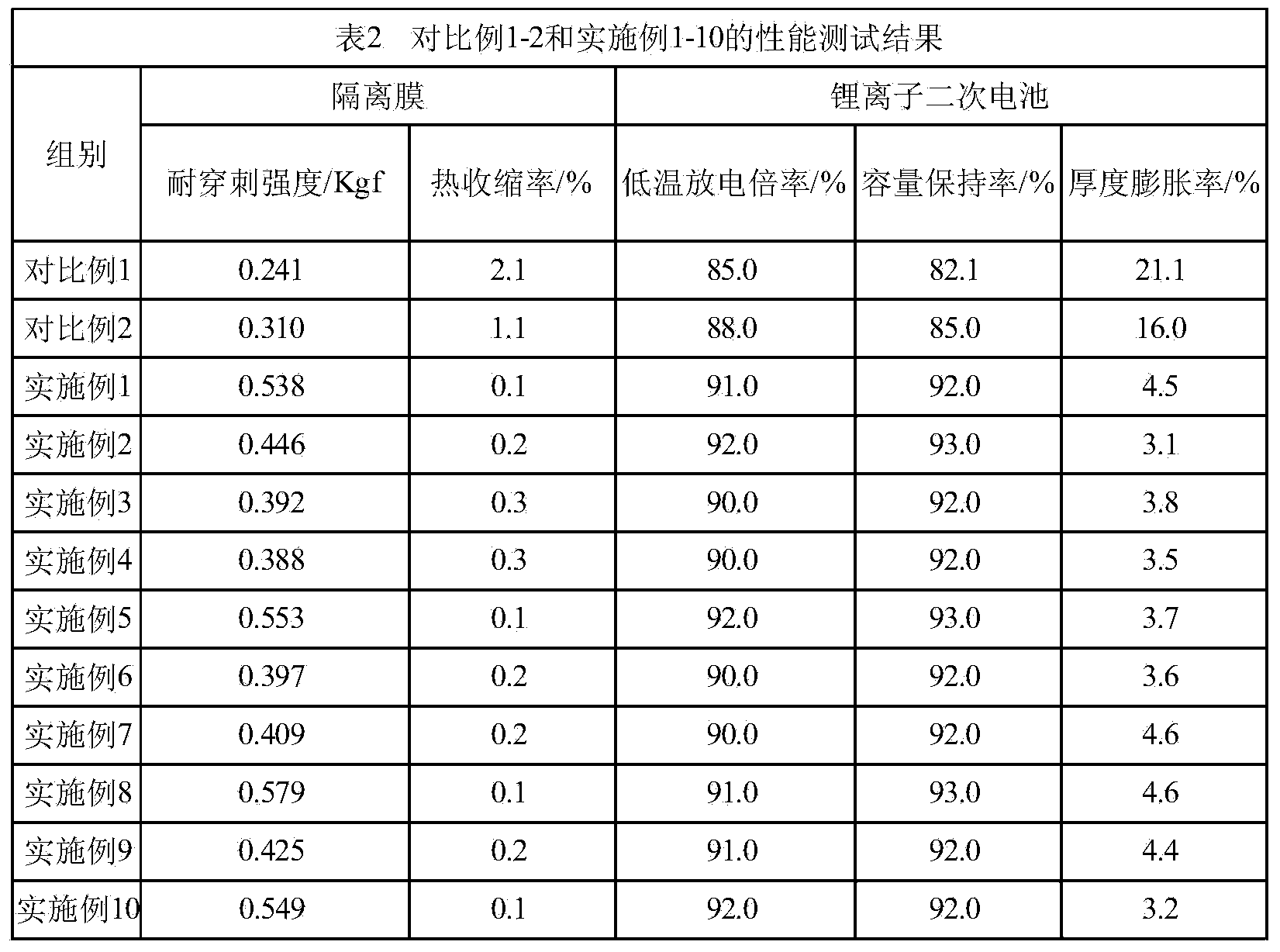

Composite porous isolating film and electrochemical device

ActiveCN103904276AImprove puncture strengthImprove thermal stabilitySecondary cellsCell component detailsPorous substratePorous coating

The invention provides a composite porous isolating film and an electrochemical device. The composite porous isolating film comprises a composite porous base material and a composite porous coating which is coated on at least one surface of the composite porous base material. The composite porous base material comprises filler A and a polymer substrate, and the filler A is selected from at least one of inorganic particles and organic particles; the composite porous coating comprises filler B and an adhesive, and the filler B is selected from at least one of inorganic particles and organic particles. The electrochemical device has a composite porous isolating film. By adopting the composite porous isolating film, the heat stability of the composite porous isolating film is improved, the deformation resistance and the capacity maintaining rate of the electrochemical device can be improved, and the cycling performance and low-temperature kinetic performance of the electrochemical device can be improved.

Owner:DONGGUAN AMPEREX TECH

Polyester film and method for producing same, backsheet for solar cell, and solar cell module

InactiveUS20110306747A1Good long-term durabilityGood planar surface stateSynthetic resin layered productsCoatingsWeather resistancePolyester resin

A polyester film containing a polyester resin having an intrinsic viscosity IV of from 0.73 to 0.9 dL / g in which the polyester film has a specific heat change at 85° C. to 135° C. (ΔCp) of from 0.06 to 0.1 J / g, has an excellent weather resistance, a good planar surface state and a low thermal shrinkage.

Owner:FUJIFILM CORP

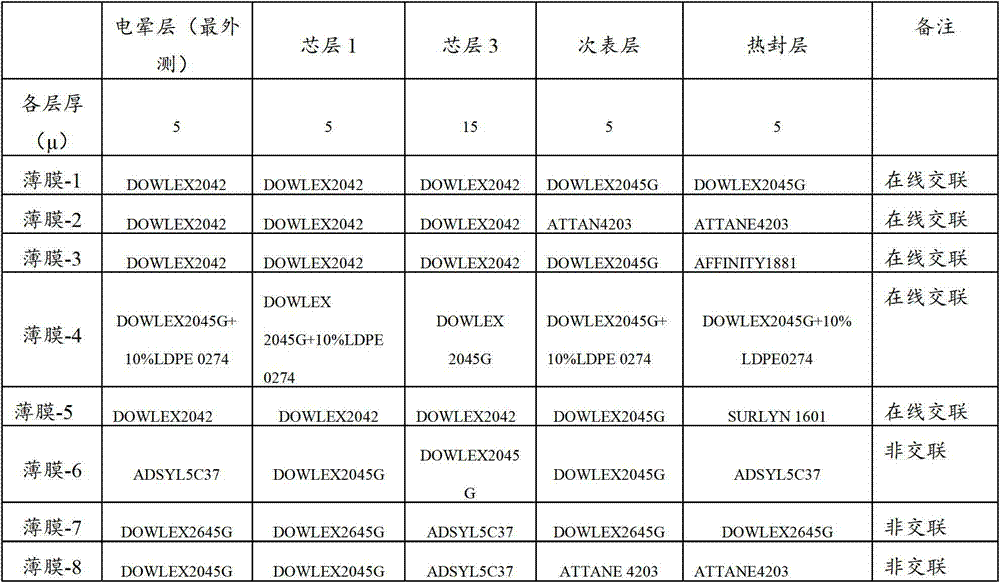

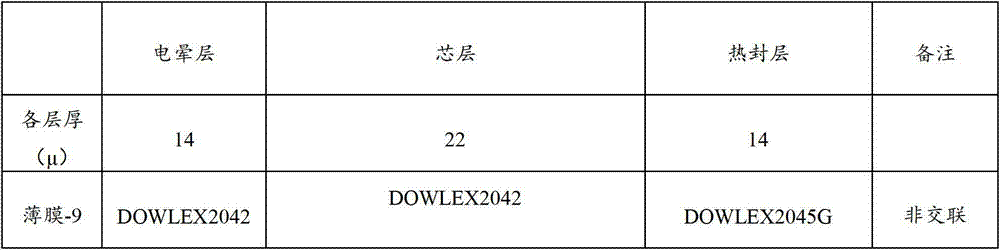

Packaging polyolefin film and preparation method thereof

ActiveCN103085415ALow heat shrinkageLow shrinkageSynthetic resin layered productsPolymer sciencePolyolefin

The invention provides a coextruded biaxially-oriented polyolefin film. The coextruded biaxially-oriented polyolefin film comprises a composite layer, an intermediate layer and an heat sealing layer, wherein the composite layer, the intermediate layer and the heat sealing layer are in coextruded structures and contain propylene polymer, ethylene polymer and the blend or mixture of the propylene polymer and the ethylene polymer respectively. The ratio of the longitudinal elongation of the biaxially-oriented polyolefin film to the transverse elongation is less than 1:6, and the ratio of the longitudinal elongation to the transverse elongation is less than 8% at the temperature of 90 DEG C. The invention further provides a composite packaging structure with a substrate and the biaxially-oriented polyolefin film and a method for preparing the biaxially-oriented polyolefin film.

Owner:ZHEJIANG ZHONGCHENG PACKING MATERIAL

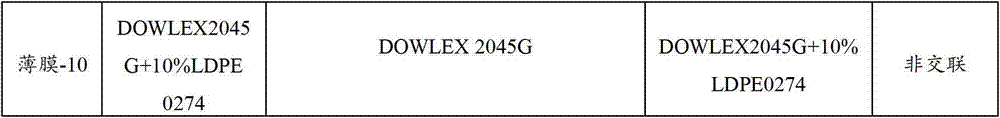

Material special for polyvinylidene fluoride film

The invention discloses a material special for a polyvinylidene fluoride film. The material comprises the following components in part by weight: 60 to 75 parts of polyvinylidene fluoride, 5 to 10 parts of nanoscale filler, 0.5 to 3.5 parts of mobility modifier, and 10 to 20 parts of reinforced resin; and the material can further comprise 5 to 10 weight parts of inorganic filler and / or 0.1 to 2 weight parts of thermal stability auxiliary agent. The mobility of the polyvinylidene fluoride is greatly improved by the mobility modifier in the special material, so that melt extrusion and film forming can be easily performed; the reinforced resin has the functions of plasticization and toughening at the same time, so that the tear strength of the film is increased; under the strong shearing action of a double-screw extruder, the nanometer filler can be uniformly distributed, and the introduction of nanometer particles facilitates the reduction of the light transmittance and the water and vapor penetration rates of the film; the nanometer filler and the inorganic filler facilitate the improvement of the dimension stability of the film under the heated condition; and the polyvinylidene fluoride film prepared from the special material has the advantages of high mechanical strength, weather resistance and water and vapor barrier properties, low thermal shrinkage and the like.

Owner:HANGZHOU FUMO NEW MATERIAL TECH

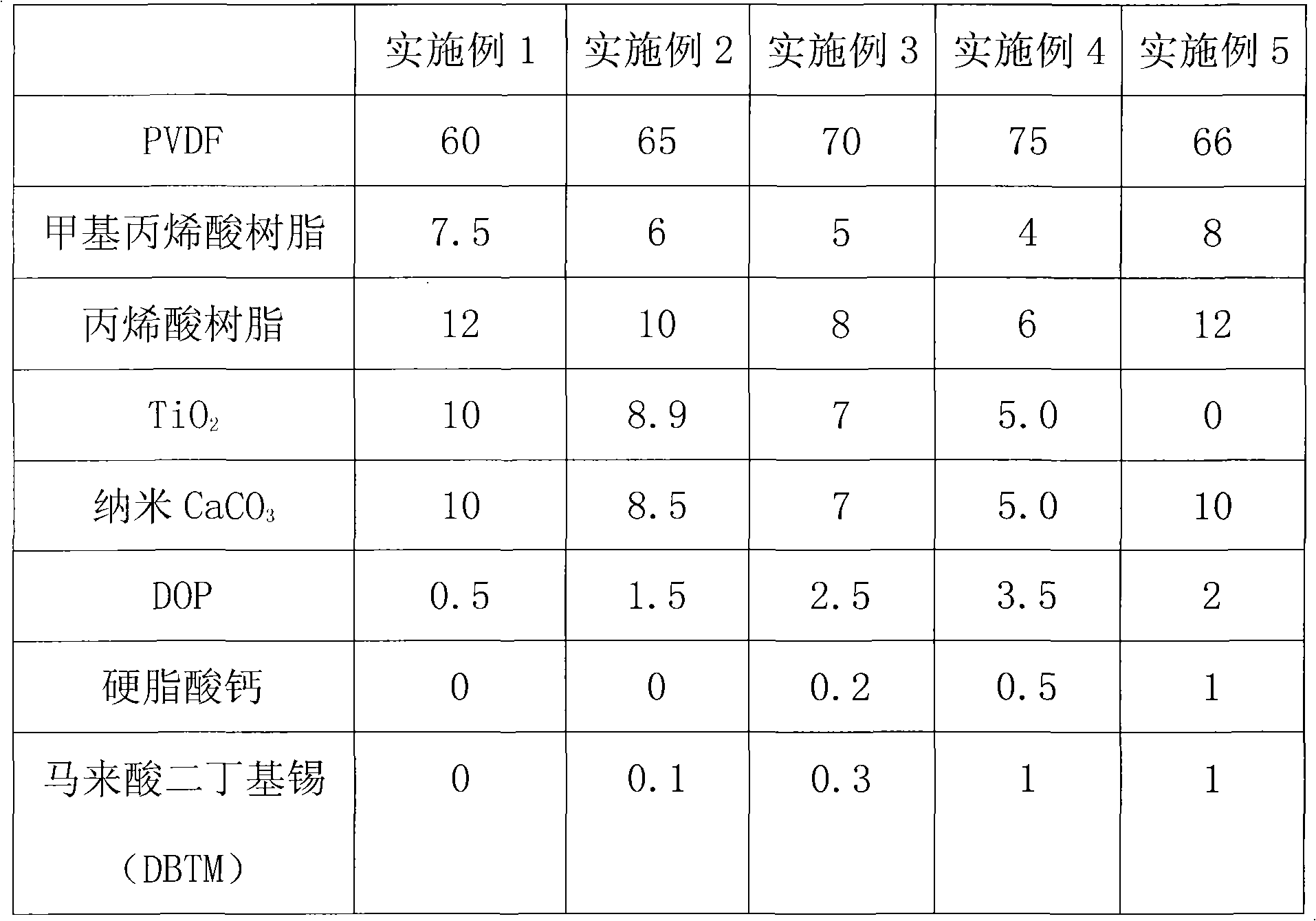

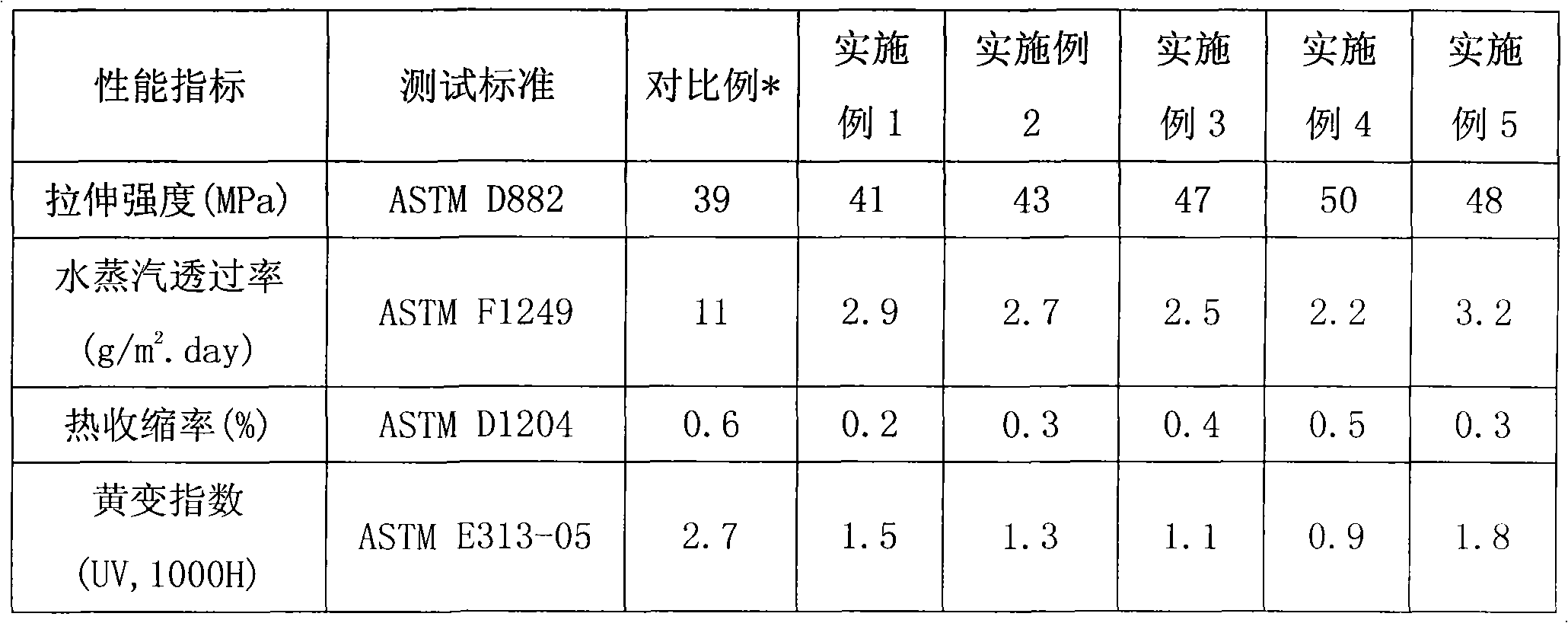

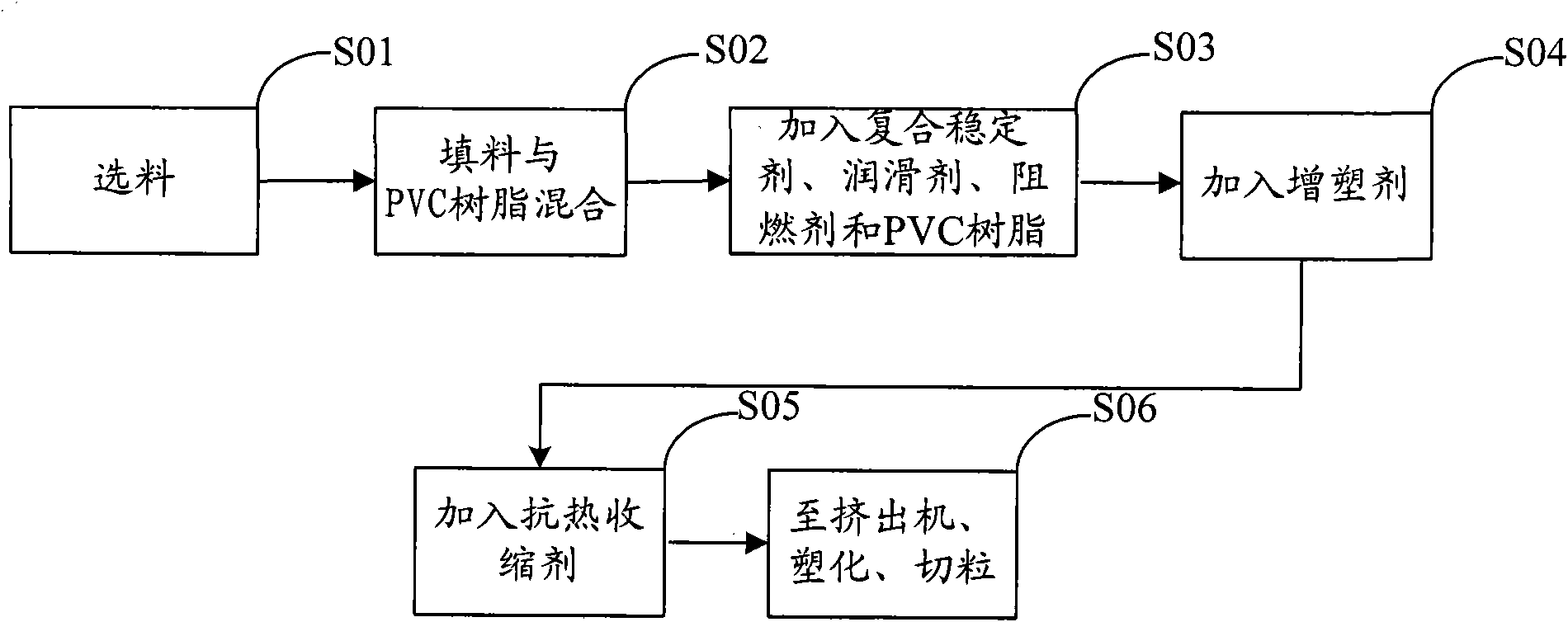

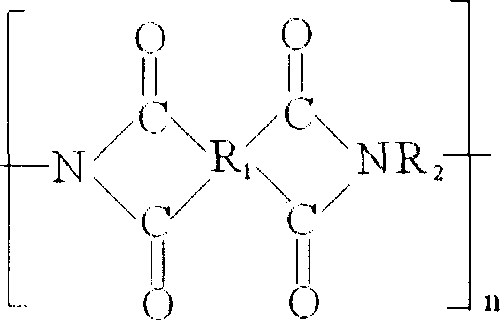

Nontoxic, anti-heat shrinkable polyvinyl chloride material and manufacturing technology thereof

The invention provides a nontoxic, anti-heat shrinkable polyvinyl chloride material, comprising the following components in parts by weight: 100 parts of polyvinyl chloride resin, 20-30 parts of filling, 10-60 parts of plasticizer, 1-2 parts of lubricating agent, 2-12 parts of compound stabilizer, 3-10 parts of fire retardant and 10-15 parts of anti-heat shrinkable agent. The invention also provides a manufacturing technology of the nontoxic, anti-heat shrinkable polyvinyl chloride material. The nontoxic compound stabilizer and the anti-heat shrinkable agent are added to the nontoxic, anti-heat shrinkable polyvinyl chloride material, which dramatically improves various thermostabilization performances of the polyvinylchloride material, especially the anti-heat shrinkable performances. The raw material of the invention has low cost and is environment friendly, thus having wide application prospect.

Owner:深圳市帝源新材料科技股份有限公司

Battery isolating film and method for producing the same

The invention provides a battery diaphragm. The diaphragm comprises a substrate; the substrate is provided with a via, wherein, the substrate has polyimide; the channel of the via has polyolefin. The battery diaphragm obtained from the embodiment of the invention has an excellent high temperature resistance and burst can not be happened by heating to 400 DEG C; all the heat shrinkage are not more than 1.3 percent at 400 DEG C, which is far less than the heat shrinkage of 5 percent in prior art; the average diameter of pores and porosity all meet the demand of conductivity; a suitable and fine air permeability is provided; the heat shrinkage is also far less than the battery diaphragm in prior art. The battery made by the battery diaphragm provided by the invention has excellent high temperature resistance that unsafe phenomena of explosion, smoking, firing and liquid leaking can not happen even under a high temperature of 150 DEG C.

Owner:BYD CO LTD

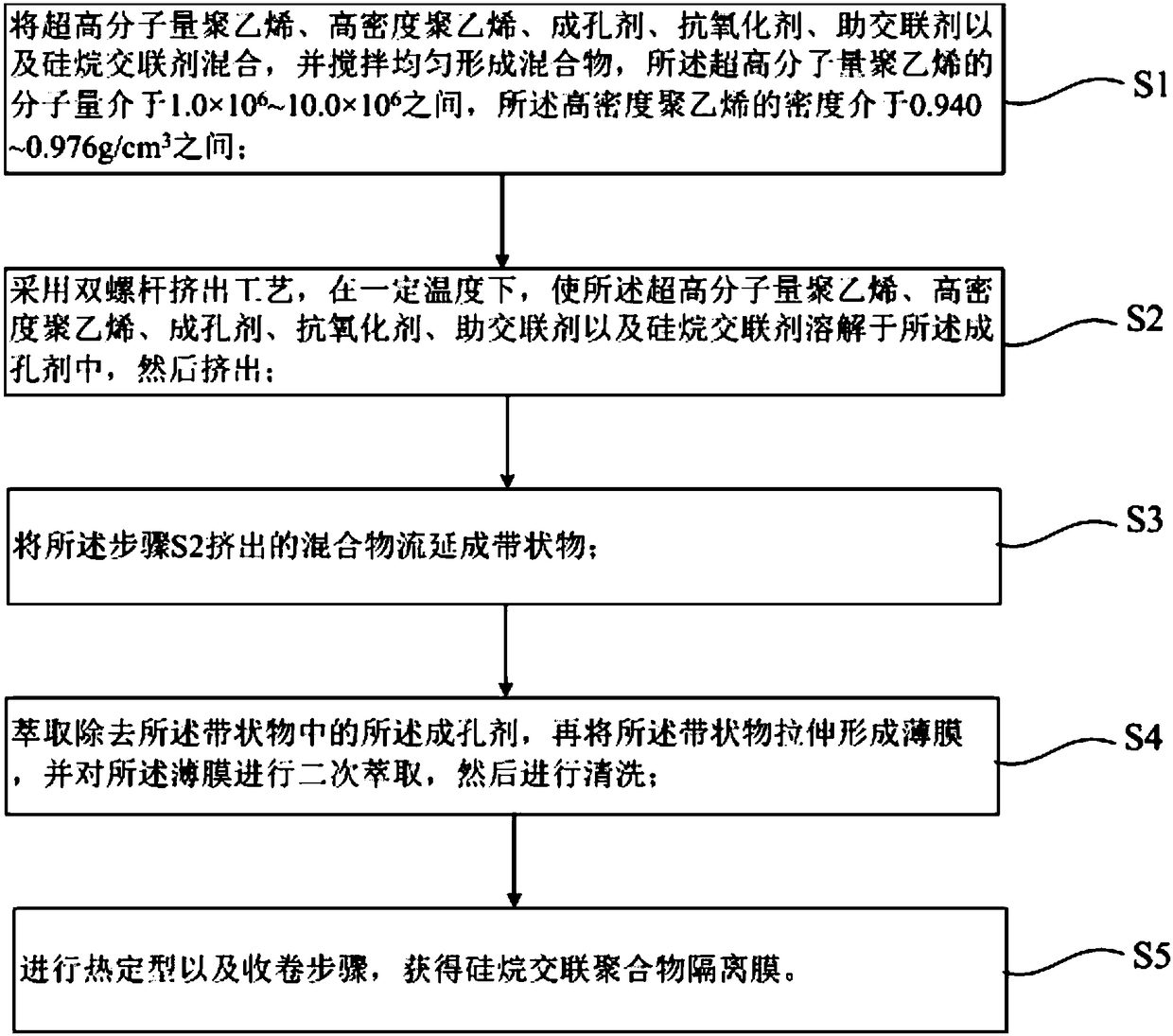

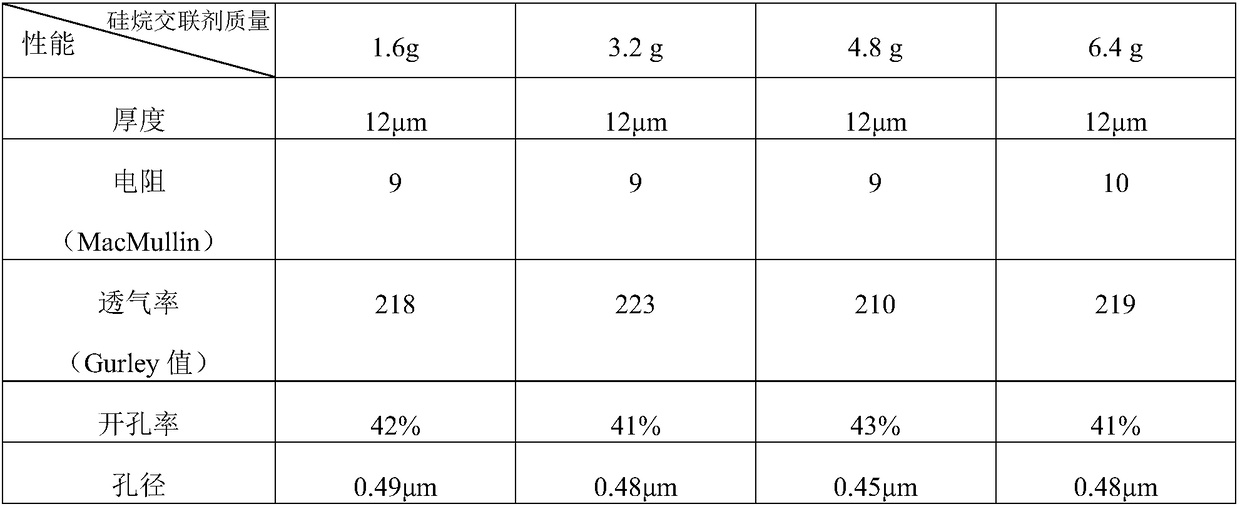

Silane crosslinked polymer separation film and preparation method thereof

InactiveCN108198986AReduce processing costsLow heat shrinkageCell seperators/membranes/diaphragms/spacersHigh densityAntioxidant

The invention provides a silane crosslinked polymer separation film, which comprises crosslinked polymerized ultrahigh molecular weight polyethylene, high-density polyethylene, an antioxidant, an assistant crosslinker and a silane crosslinking agent, wherein the molecular weight of the ultrahigh molecular weight polyethylene is 1.0*10<6> to 10.0*10<6>; the density of the high-density polyethyleneis 0.940-0.976g / cm<3>; and on the basis of 100 parts by weight of a mixture of the ultrahigh molecular weight polyethylene and the high-density polyethylene, the weight of the antioxidant is 0.5-20 parts, the weight of the assistant crosslinker is 0.1-10 parts and the weight of the silane crosslinking agent is 0.1-10 parts. The separation film is prepared through a chemical crosslinking method, sothat a difference value between the film rupture temperature and the obturator temperature of the prepared silane crosslinked polymer separation film and the hot shrinkage rate are improved and the safety performance of a battery is higher.

Owner:SHANGHAI ENERGY NEW MATERIALS TECH CO LTD

Battery isolating membrane preparation method

InactiveCN106450112AImprove performanceHigh membrane rupture temperatureCell component detailsHigh densityAntioxidant

The invention discloses a battery isolating membrane preparation method. Mixed raw materials are extruded, cooled, formed, extracted, stretched and heat-set to obtain a battery isolating membrane. The raw materials include ultra-high molecular weight polyethylene, high-density polyethylene, antioxidants and pore-forming agents, the molecular weight of the ultra-high molecular weight polyethylene is 1.0*10<6>-10.0*10<6>, the density of the high-density polyethylene ranges from 0.940g / cm<3> to 0.976g / cm<3>, and the method includes cross-linking.

Owner:SHANGHAI ENERGY NEW MATERIALS TECH CO LTD

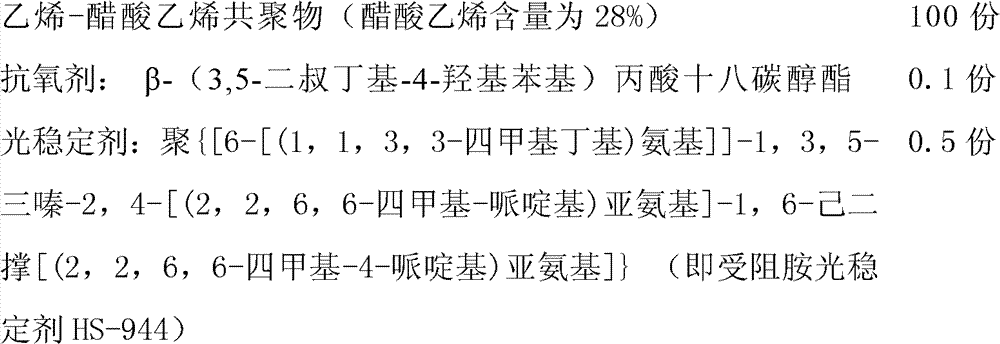

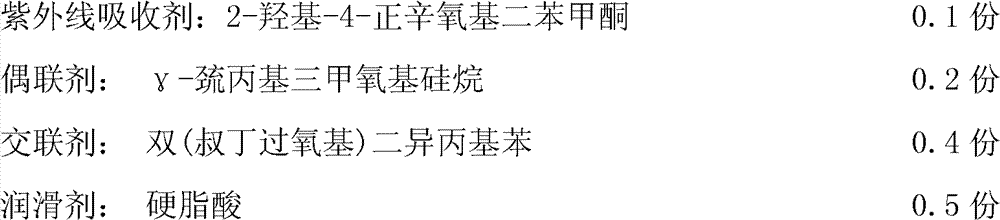

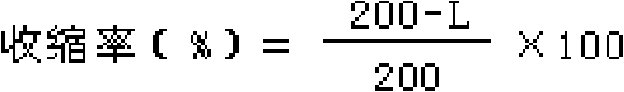

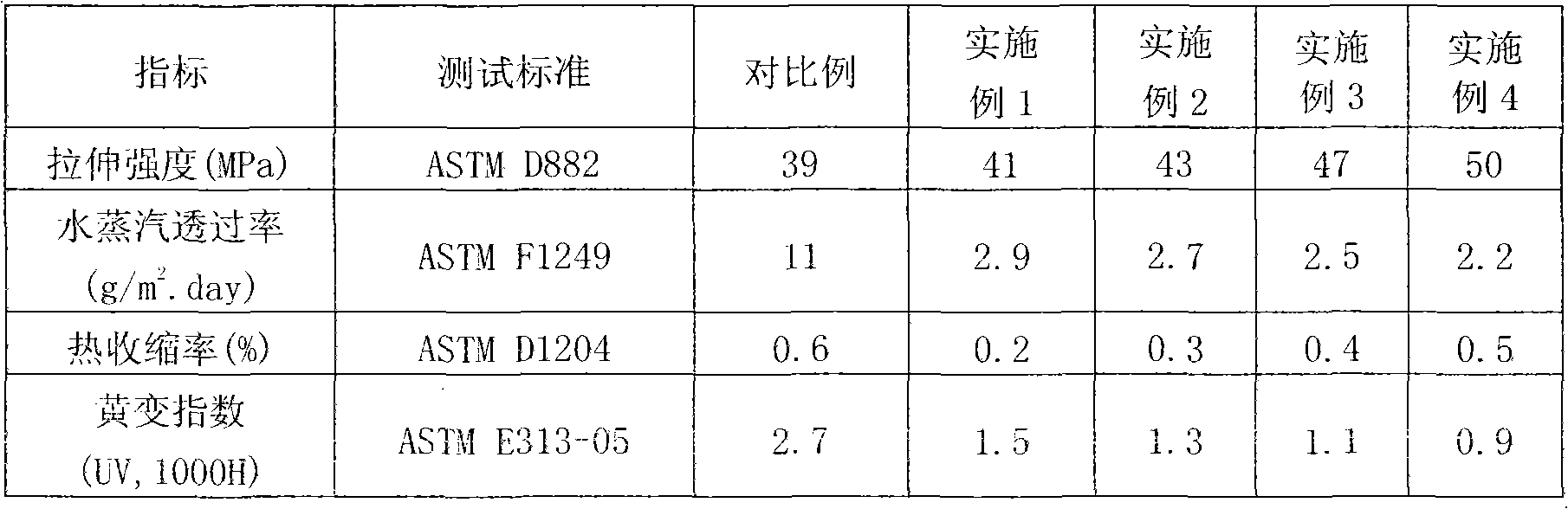

EVA film for packaging solar photovoltaic module and preparation method thereof

ActiveCN103087643ALow heat shrinkageReduce frictionNon-macromolecular adhesive additivesFilm/foil adhesivesUltraviolet lightsSmall footprint

The invention discloses an EVA film for packaging a solar photovoltaic module and a preparation method thereof. The preparation method comprises the following steps of adding an anti-oxidant, a light stabilizer, an ultraviolet light absorber, a coupling agent, a crosslinking agent and a lubricant into an ethylene-vinyl acetate copolymer, uniformly mixing to obtain a mixture, putting the mixture into an extruder, heating and mixing the mixture in the extruder to obtain melt, extruding the melt by a mold, and carrying out molding treatment to obtain the EVA film. The EVA film has the advantages of small internal stress, low shrinking percentage, fast production line speed, high production efficiency, small land occupation area, and low energy and raw material consumption.

Owner:TIANJIN CAIDA NEW MATERIALS TECH CO LTD

Ceramic slurry, ceramic composite diaphragm and lithium ion battery

InactiveCN109449354AEvenly dispersedNo settlementSecondary cellsCell component detailsCeramic compositeCeramic coating

The invention relates to the technical field of lithium ion battery diaphragm preparation, and discloses ceramic slurry, a ceramic composite diaphragm and a lithium ion battery. The slurry comprises deionized water, ceramic particles, a thickening agent, a binder, a dispersing agent and a wetting agent, wherein the dispersing agent is an amphiphilic high-molecular compound with a comb structure. The ceramic composite diaphragm prepared from the slurry is high in thermal stability, puncture resistance and liquid absorption capacity, and the ceramic coating is not easy to fall off in an electrolyte when being used in the lithium ion battery, so that the cycling life of the battery can be prolonged, and the consistency of cells and the safety of the battery can be improved.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

Preparation method of special material for fluorine-containing plastic film

InactiveCN102336992AHigh tear strengthGood weather resistancePhotovoltaic energy generationSemiconductor devicesSolar cellProtection layer

The invention relates to a preparation method of a special material for a fluorine-containing plastic film. The formula of the special material is: 50-85 weight portions of polyvinylidene fluoride, 5-30 weight portions of reinforced resin, 5-15 weight portions of inorganic filler, 5-15 weight portions of nano filler, 0.5-5 weight portion(s) of mobile modifier, and 0.1-2 portion(s) of thermal stability additive. Particles of the special material can be prepared via adding of the raw materials into a mixing and blending machine, mixing for 10-40 minutes at the speed of 50-1000 rounds per minute at the room temperature, melting and extrusion at the temperature of 170-230 DEG C through a double-screw extruder, cooling, drying and pelletization. The follow-up film processing with the special material as a raw material has the advantages of good melt mobility, high production yield, high equipment applicability and the like. Meanwhile, the produced fluorine-containing plastic film has excellent vapor blocking performance, high tear strength, good weathering resistance and good acid resistance and alkali resistance and can completely meet the performance requirements of films on protective layers in packaging backplanes of solar cells.

Owner:刘波

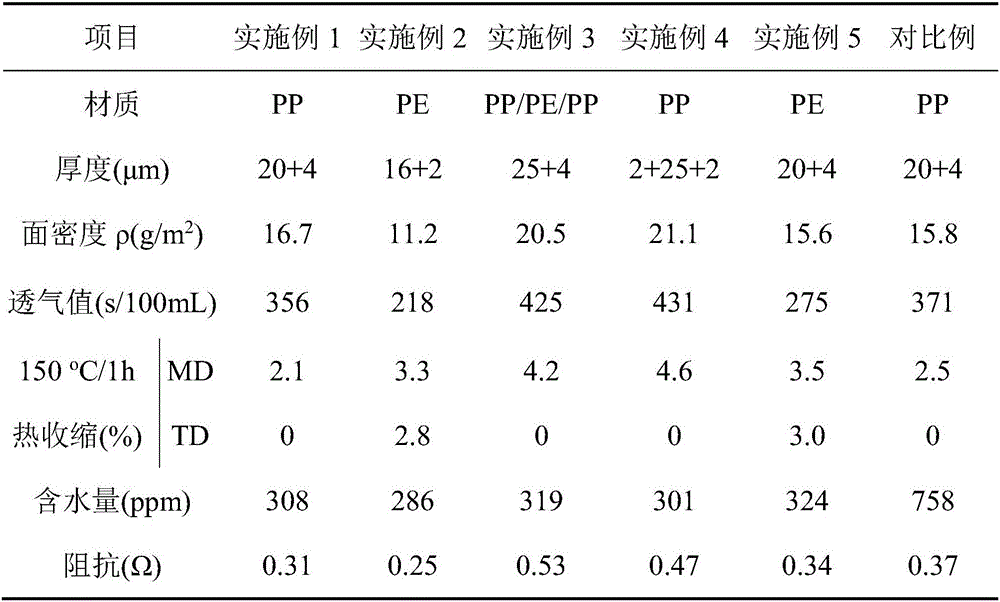

Composite diaphragm for lithium ion batteries, production method thereof, and lithium ion battery

InactiveCN107437603AImprove mechanical propertiesInhibit powder dropCell seperators/membranes/diaphragms/spacersSecondary cellsFiberCellulose

The invention relates to the technical field of lithium ion batteries, and discloses a composite diaphragm for lithium ion batteries, a production method thereof, and a lithium ion battery. The composite diaphragm for lithium ion batteries includes a polymer matrix and a ceramic film coated on the surface of the polymer matrix, the ceramic film is made of a ceramic slurry, the ceramic slurry contains a dispersant, a binder and a powder, and the powder contains ceramic particles, ceramic whiskers and cellulose. The addition of ceramic fibers to the ceramic slurry increases the mechanical properties of the composite film, so the composite film does not shed from the polymer matrix, maintains a good adhesion, and inhibits dry linting of the ceramic diaphragm; and the addition of the cellulose increases the electrolyte absorption and retention ability of the diaphragm, and also effectively reduces the thermal shrinkage rate of the diaphragm at a high temperature.

Owner:WINNERWAY MOTORS CO LTD

Isolating membrane and lithium ion secondary battery

ActiveCN103956448AIncrease liquid absorptionImprove ionic conductivityCell seperators/membranes/diaphragms/spacersLi-accumulatorsLithiumHigh absorption

The invention provides an isolating membrane and a lithium ion secondary battery. The isolating membrane comprises a microporous membrane with micropores and a coating arranged on the surface of the microporous membrane, wherein the coating comprises polymer particles and binder particles, the polymer particles are of empty shell structures, each empty shell structure comprises a shell and a cavity formed inside the shell, nanopores communicated with the cavity are distributed on the outer surface of the shell, and the diameters of the polymer particles are more than the bore diameter of the micropore of the microporous membrane; the diameters of the binder particles are more than the bore diameter of the micropore of the microporous membrane; the lithium ion secondary battery comprises a positive electrode piece, a negative electrode piece, the isolating membrane interlaid between the positive electrode piece and the negative electrode piece, and electrolyte. The isolating membrane has high absorption amount, high ionic electrical conductivity and low heat shrinkage, and the lithium ion secondary battery has good-normal temperature cycle performance, low-temperature discharge performance, rate capability and safety performance.

Owner:DONGGUAN AMPEREX TECH

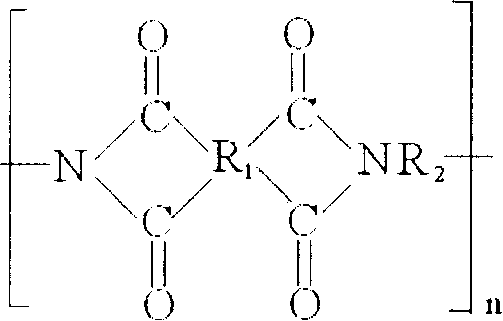

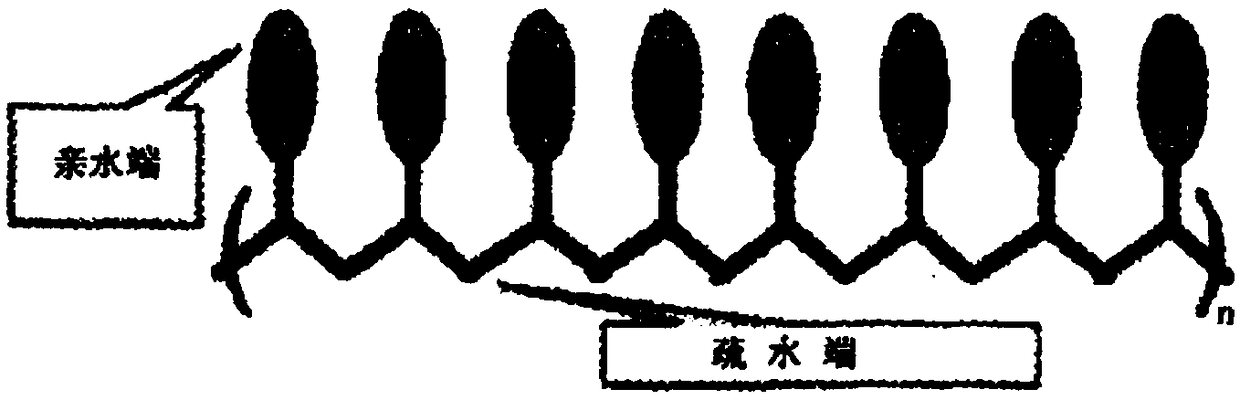

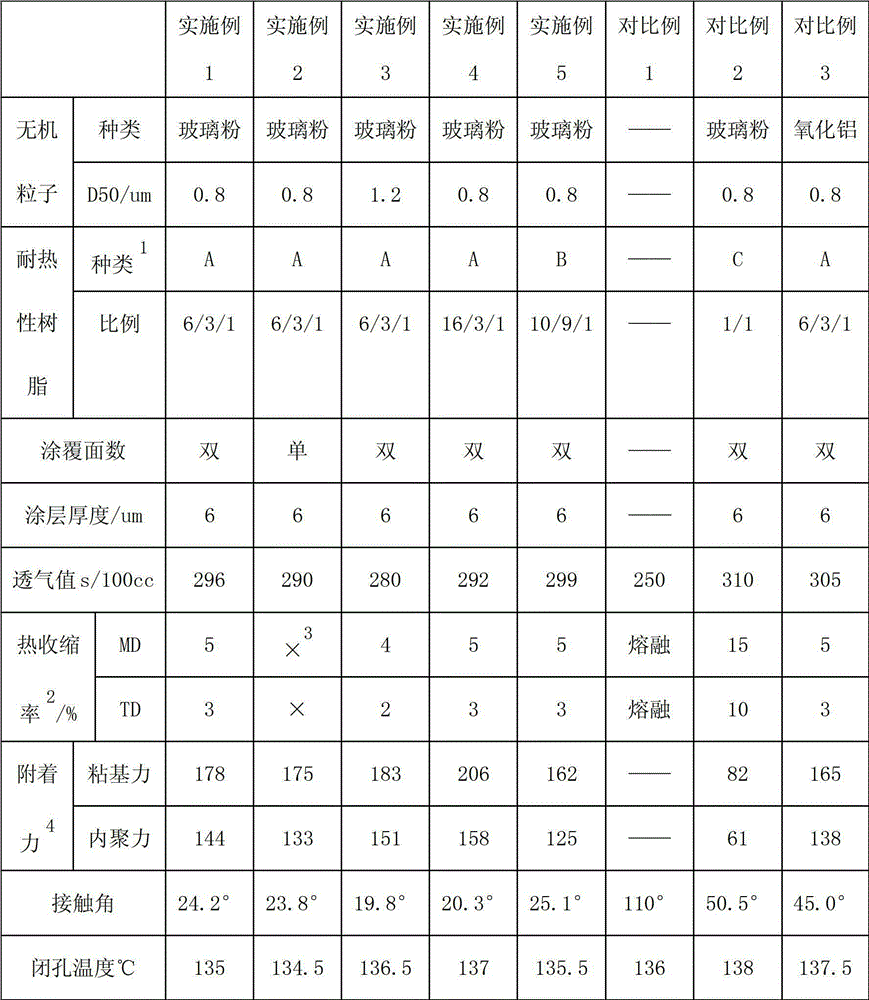

Coating composite for lithium ion secondary battery membrane and method for manufacturing membrane

ActiveCN102942831AHigh temperature resistantLow densityCell seperators/membranes/diaphragms/spacersSecondary cellsCoated surfaceLithium

The invention discloses a coating composite for a lithium ion secondary battery membrane and a method for manufacturing the membrane. The coating composite comprises heat resistant resins and inorganic non-conducting insulation particles, molecular chains of the heat resistant resins comprise oleophylic structural units, hydrophilic structural units and functional group structural units, and a thermal decomposition temperature is larger than 250 DEG C. The inorganic non-conducting insulation particles have the advantages of being high temperature resistant, low in density, rigidity and water absorption and the like; composite micro porous membranes prepared through the coating composite has the advantages of being low in hole closing temperature, high in membrane breaking temperature, low in thermal shrinkage rate, high in combining force between a heat resistant coating and a substrate, good in wettability of the heat resistant coating surface and the like simultaneously; and the membrane used for manufacturing a lithium ion secondary battery has good comprehensive properties and reliable safety performances.

Owner:河南惠强新能源材料科技股份有限公司

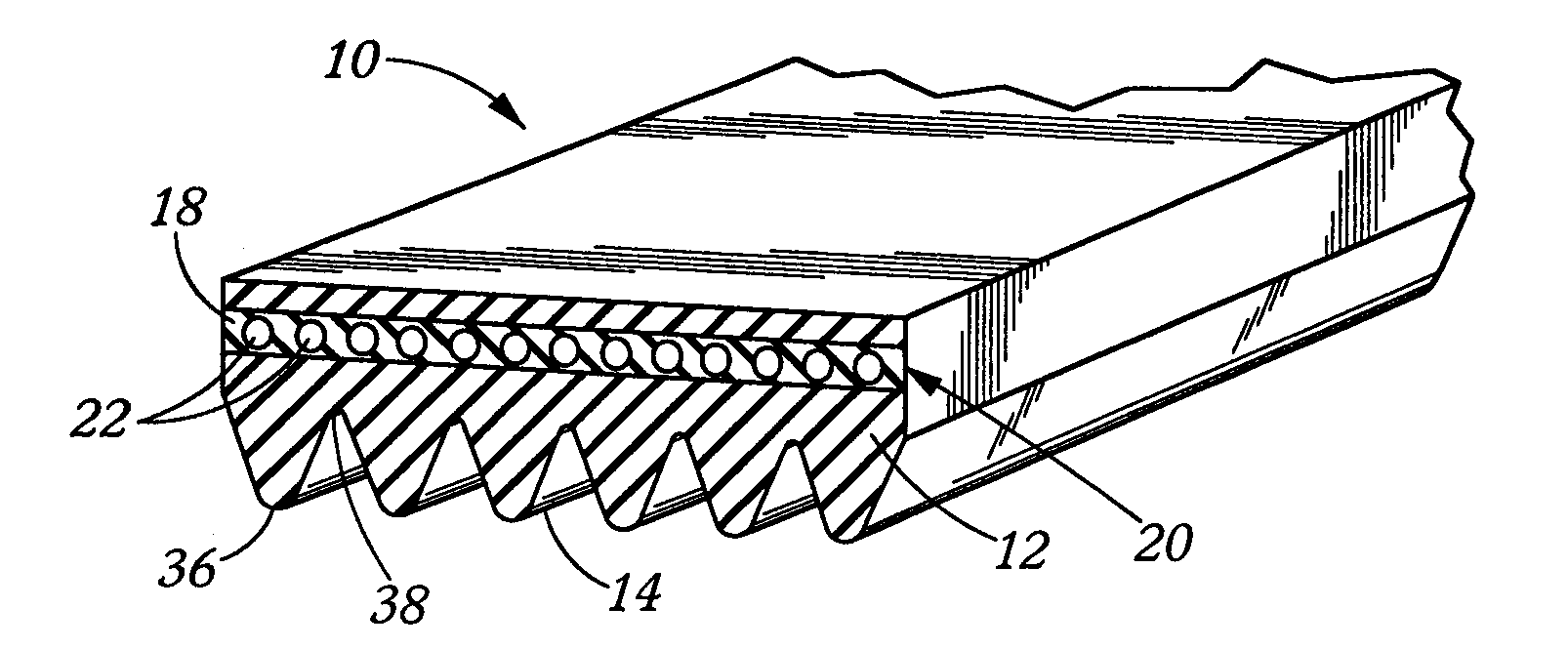

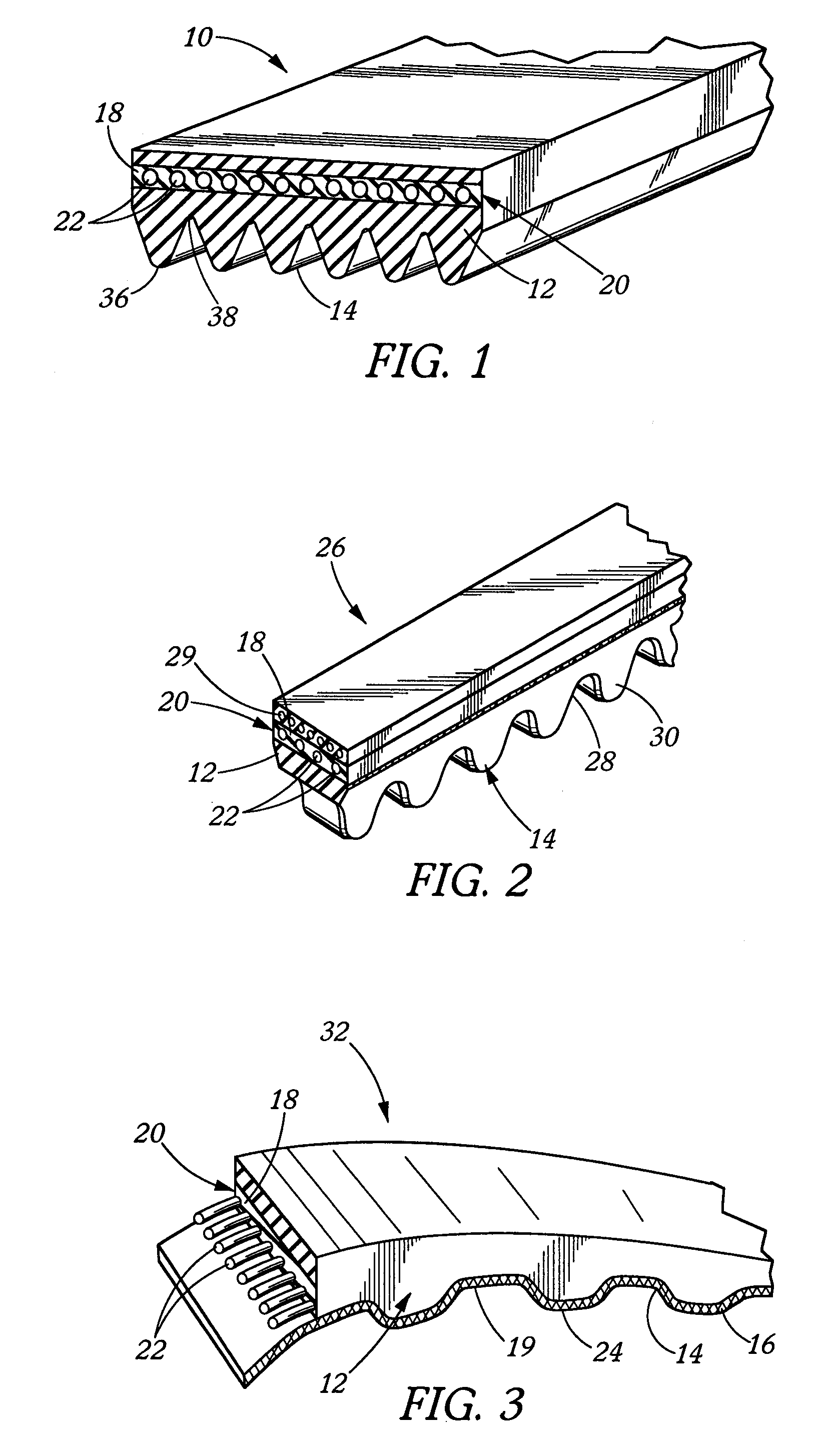

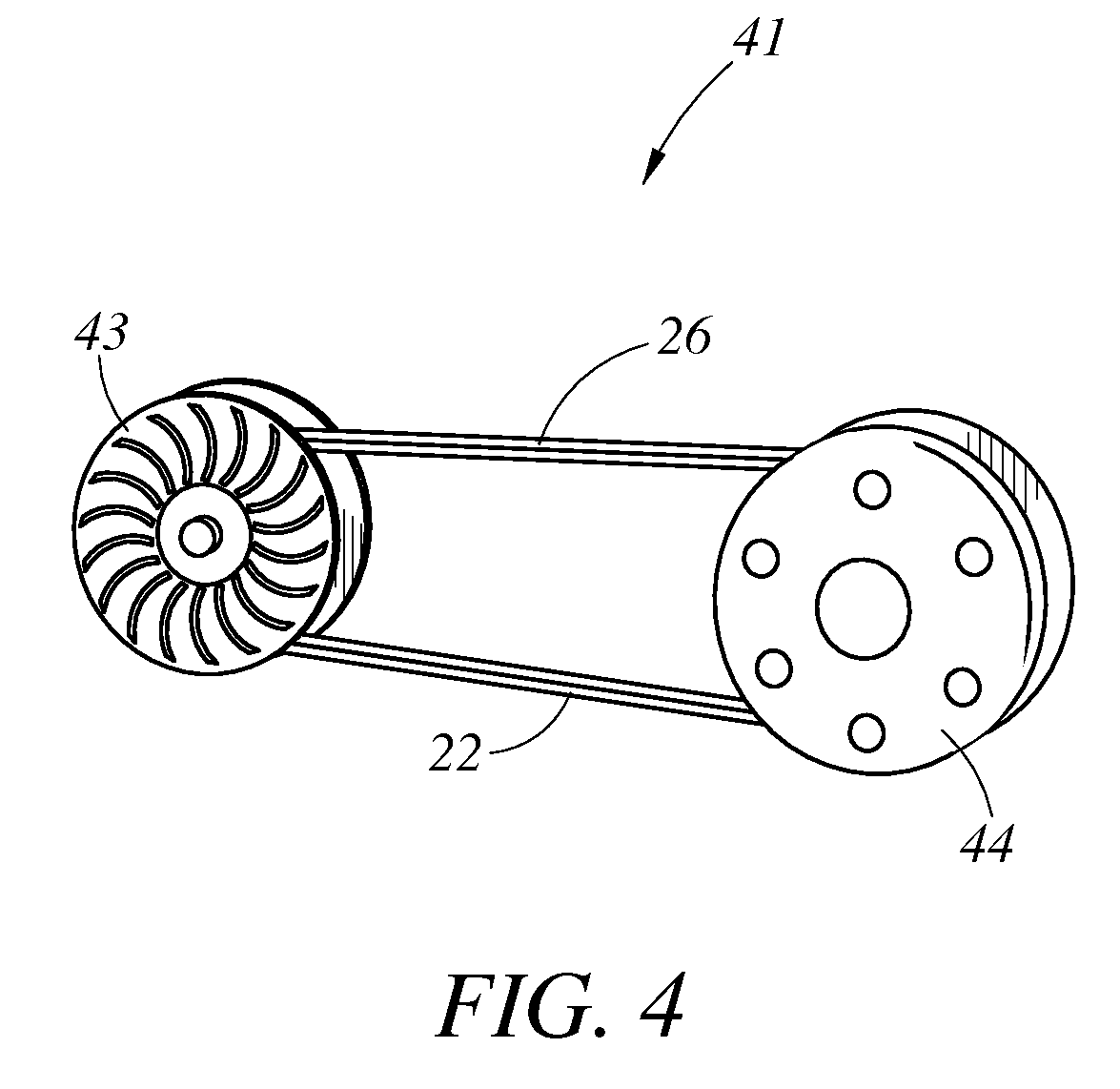

Power Transmission Belt

ActiveUS20090011883A1Low heat shrinkageHigh modulusEnvelopes/bags making machineryV-beltsPolyesterStability index

A power transmission belt comprising a polyester tensile cord having a heat shrinkage at 100° C. of less than 1% and / or a heat shrinkage at 150° C. of less than about 1.5% and / or a dimensional stability index of less than about 6%. The belt has a heat shrinkage after 24 hours at 100° C. of less than 1%. The polyester may be that sold under the trade name A360 or A363 by Performance Fibers, Inc. or equivalent polyethylene terephthalate. The tensile cord is particularly suited for use in V-belts for variable speed drives.

Owner:THE GATES CORP

Water-based self-drying/quick-drying sand type casting coating and preparation method thereof

ActiveCN103878302AHigh refractorinessLow heat shrinkageFoundry mouldsFoundry coresCast ironEnvironmental geology

The invention provides a water-based self-drying / quick-drying sand type casting coating and a preparation method thereof, wherein the water-based self-drying / quick-drying sand type casting coating is high in drying speed, little in pollution / pollution-free, safe to use, low in manufacture cost and high in sintering and stripping rate. The preparation method takes natural fireproof materials which are not calcined or electrically molten, such as zircon powder, chromite powder or zirconic composite silicate mineral powder, as basic materials, adopts a normal-temperature cured-type modified macromoleclar polymer as a main normal-temperature self-drying / low-temperature quick-drying binder, takes a quick-drying type silicate binder as a main high-temperature binder, adopts an efficient composite suspension dispersant high in fire-resistant degree and low in hot shrinkage rate and is added with proper amounts of efficient water reducing agents and defoaming agents to prepare a steel-iron casting water-based self-drying / quick-drying coating which is high in content of solid (nonvolatile matter) and low in permeability. The water-based self-drying / quick-drying sand type casting coating is excellent in thixotropy, brushing property and quick-drying function, thereby achieving the aim of saving energy, improving the environment and improving the quality of castings. The water-based self-drying / quick-drying sand type casting coating is applicable to the field of casting coatings.

Owner:广东省铸力铸材科技有限公司 +1

Composite separator for lithium battery

ActiveCN108365152AEvenly distributedGrowth inhibitionCell component detailsSecondary cells servicing/maintenanceElectrical conductorIon distribution

The invention discloses a composite separator for a lithium battery. The composite separator is applicable to a lithium ion battery or a metal lithium battery. The composite separator is formed by combining a substrate layer and an inorganic lithium ion conductor layer, wherein the inorganic lithium ion conductor layer employs an inorganic lithium ion conductor material with lithium ion conductivity larger than 1.0*10<-8>S cm<-1> under a temperature of 20-120 DEG C, the inorganic lithium ion conductor material exists in the substrate layer in a form of one or more of particle, cylinder, pipe and line, the substrate layer provides a basic separator framework, lithium ions can be induced to be uniformly deposited by the lithium ion conductor layer, and the mechanical property and the thermalstability of the separator are improved. The composite separator is simple in preparation method, lithium dendrites growth caused by non-uniform lithium ion distribution can be effectively suppressed, and the cycle efficiency and the safety of the battery within a wide temperature range are greatly improved; and by matching a high-capacity positive / negative electrode material, the cycle lifetimeof the lithium battery can be prolonged, the energy density and the safety of the lithium battery can be improved, and the industrial process is promoted.

Owner:TSINGHUA UNIV

High-stability lithium ion battery diaphragm, preparation method thereof and lithium ion battery

ActiveCN107342387AImprove breathabilityImprove stabilitySecondary cellsCell component detailsFiberAdhesive

The invention relates to the technical field of a lithium ion battery and discloses a high-stability lithium ion battery diaphragm, a preparation method thereof and the lithium ion battery. The high-stability lithium ion battery diaphragm comprises a polymer substrate and ceramic film coated on the surface of the polymer substrate. The ceramic film is prepared by ceramic slurry. The ceramic slurry comprises dispersant, adhesive and powder. The power comprises the following substances of ceramic particles and fibers. The ceramic particles comprise ceramic particles A with a particle size range of 80nm-200nm and the ceramic particles B with the particle size range of 10nm-50nm. The high-stability lithium ion battery diaphragm provided by the invention has excellent absorption and electrolyte holding capability; a hot-shrinkage rate of the diaphragm at the high temperature can be reduced; and the stability and service life of the battery can be improved.

Owner:WINNERWAY MOTORS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com